Combined loading system for static strength tests of solid motors

A solid engine and combined loading technology, which is applied in the direction of engine testing, strength characteristics, machine/structural component testing, etc., can solve the problems of low coordination control accuracy and insufficient consideration of test safety factors, etc., so as to facilitate detection and maintenance, Ease of installation and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

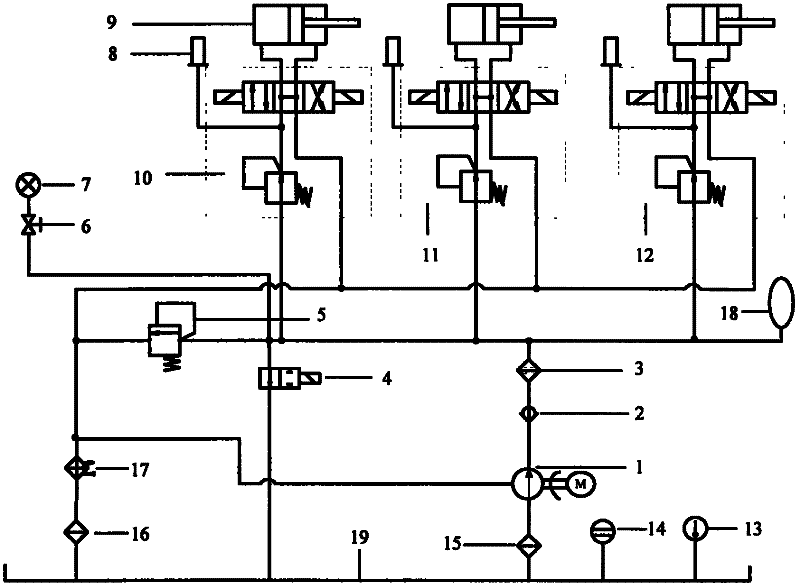

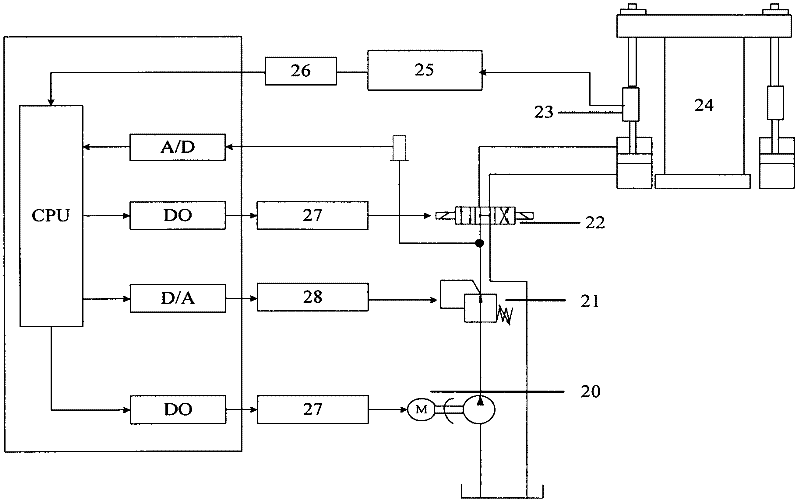

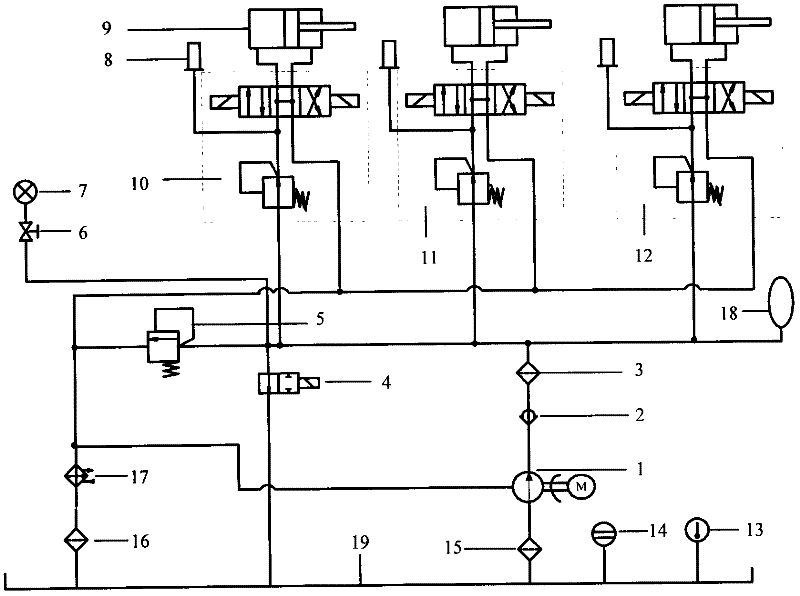

[0030] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0031] Such as figure 1 As shown, the hydraulic energy part of the present invention includes hydraulic pump 1, model A2F12; check valve 2, model CIT-06A1; unloading valve 4, model DHI-0631 / 2 / A-24DC; proportional overflow valve 5, model RZMO--033 / 315; pressure transmitter, actuator, model ZDT-31.5MPa; high pressure proportional pressure reducing valve group 10, model RZGO-033 / 315; medium pressure proportional pressure reducing valve group 11, model RZGO-010 / 210; low pressure proportional pressure reducing valve group 12, model RZGO-010 / 100); water cooler 17, model LQ-3.1; accumulator 18, model NXQA-2.5 / 31.5; oil tank 19, model BU630LVW; and connecting pipes ; The hydraulic pump 1 connected to the oil tank 19 is connected to the input end of the high pressure proportional pressure reducing valve group 10, the medium pressure proportional pressure reducing valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com