Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8761results about "Engine testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

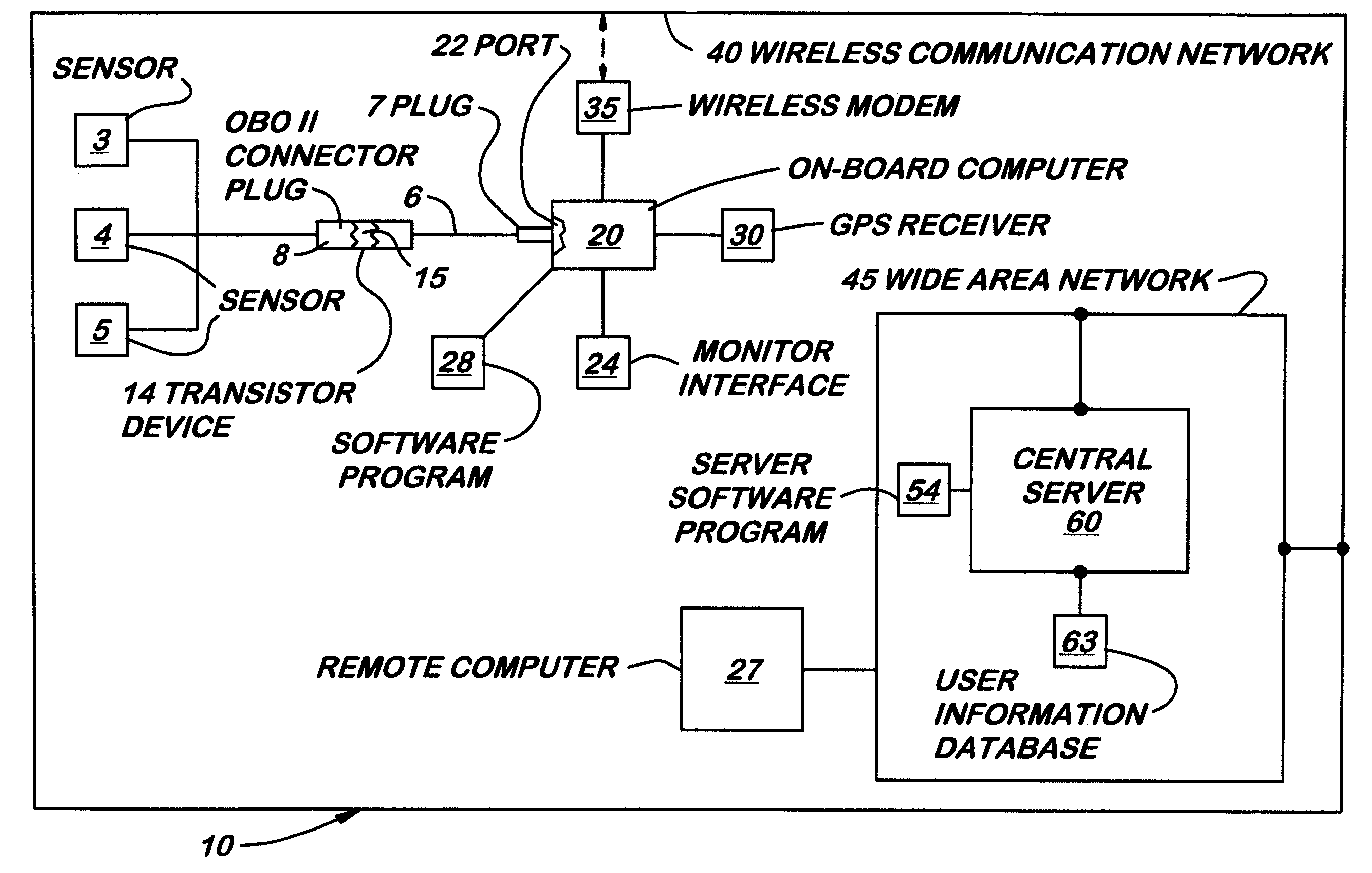

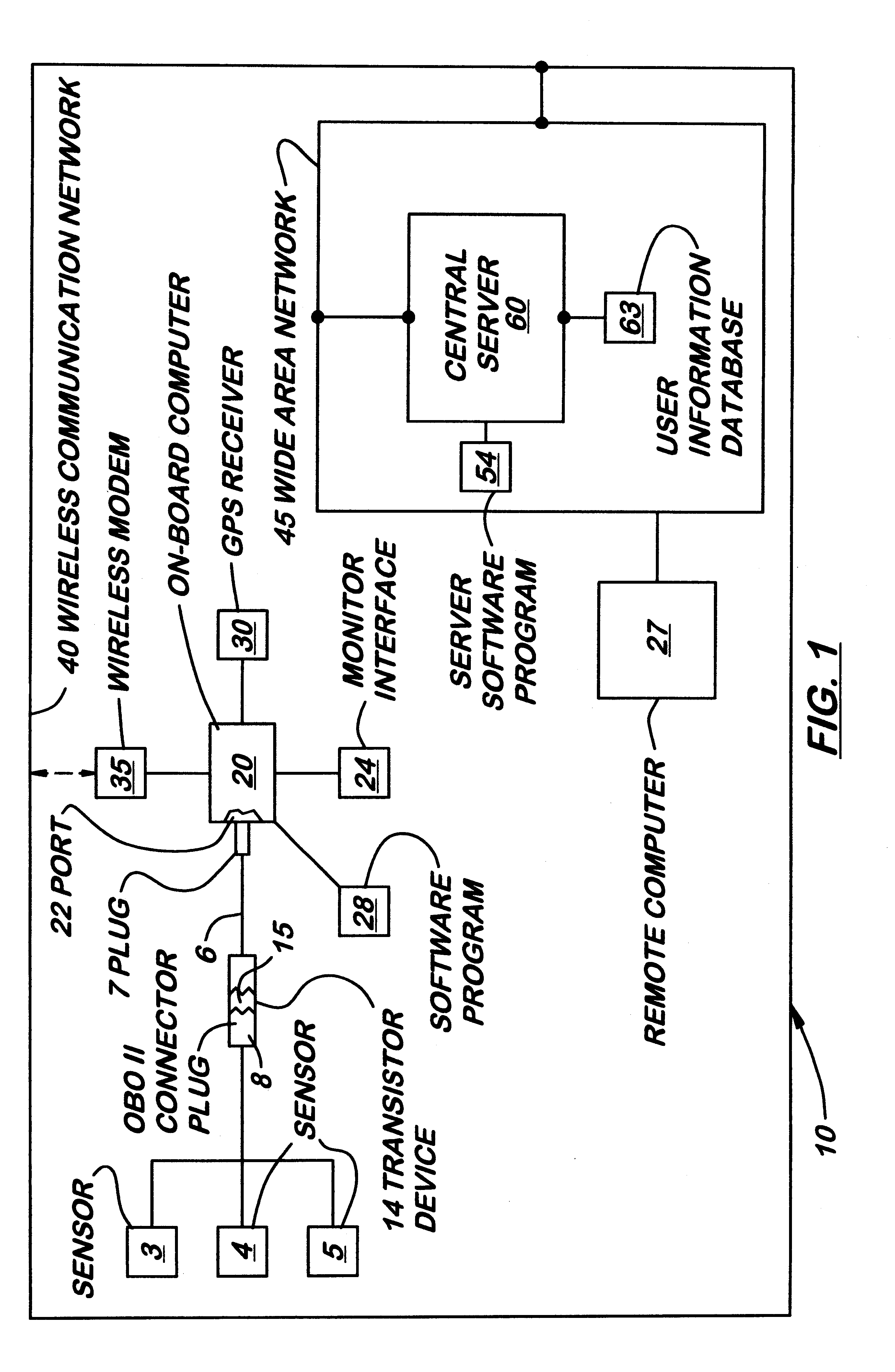

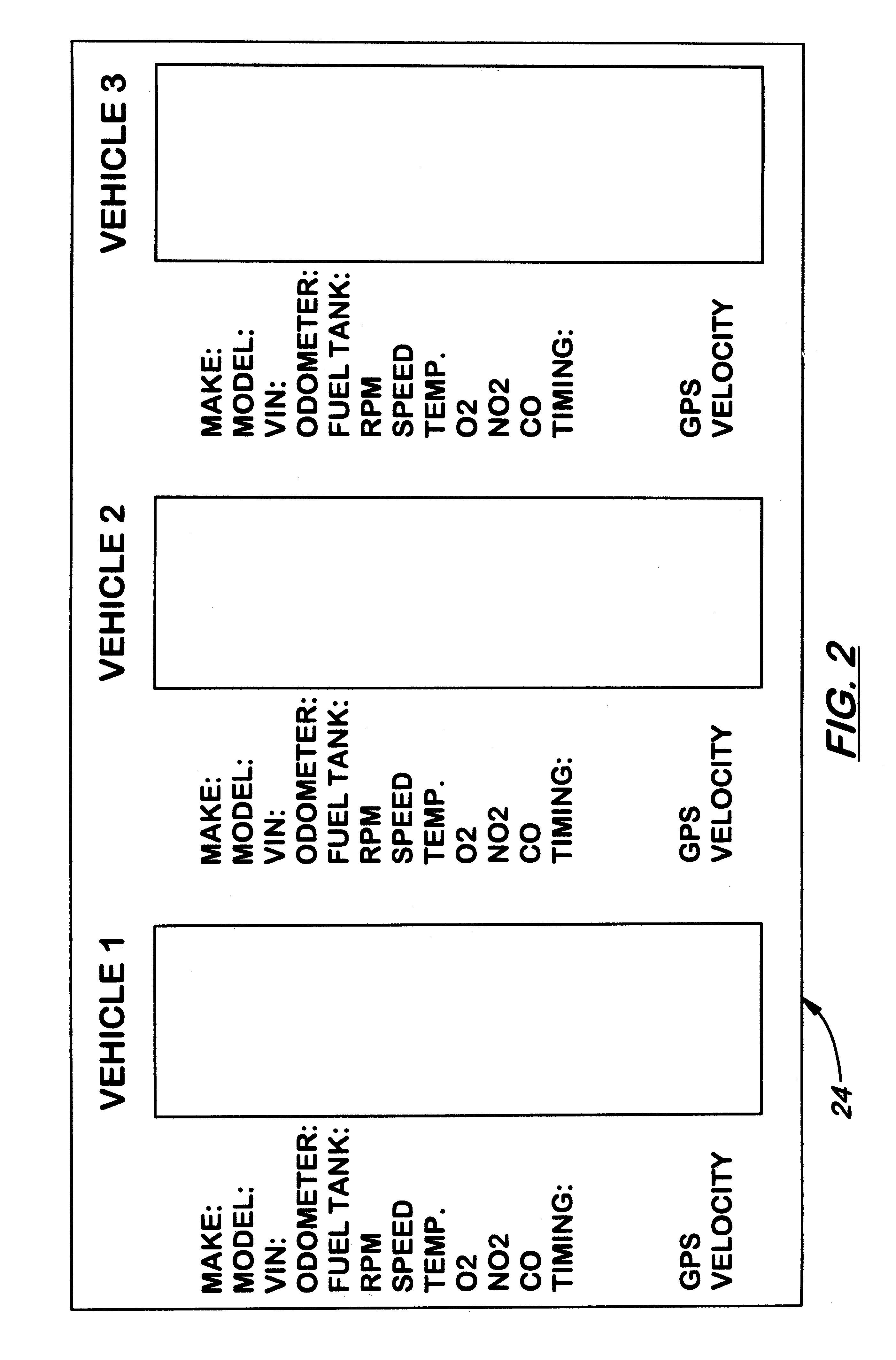

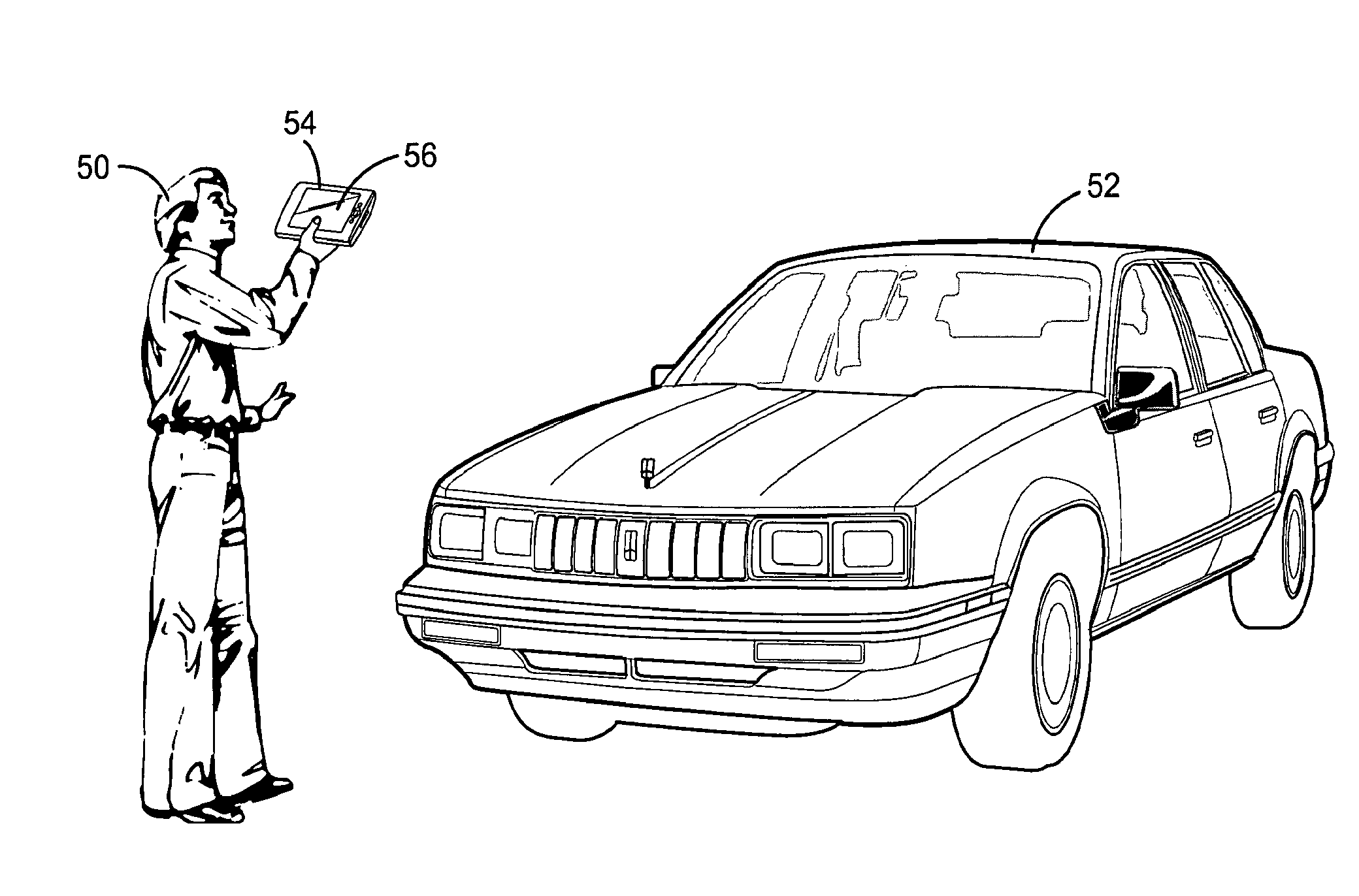

System for transmitting and displaying multiple, motor vehicle information

InactiveUS6295492B1Vehicle testingRegistering/indicating working of vehiclesMobile vehicleSystems design

A system for transmitting, collecting and displaying diagnostic and operational information from one or more motor vehicles to a central server connected to a wide area network. The system is designed to be used with an existing on-board diagnostic system found in most motor vehicles manufactured today. The system includes a translator device capable of translating the codes from an on-board diagnostic connector into computer readable files such as ASCII files. The translator device may be connected to an on-board computer that includes a wireless modem capable of connecting to a wireless communication network and eventually to a wide area network. A central server is connected to the wide area network which receives and stores information from the on-board computer. Authorized users may connect to central server via the wide area network and request information therefrom regarding selected motor vehicles. All of the information may be presented in a single interface.

Owner:VERIZON PATENT & LICENSING INC

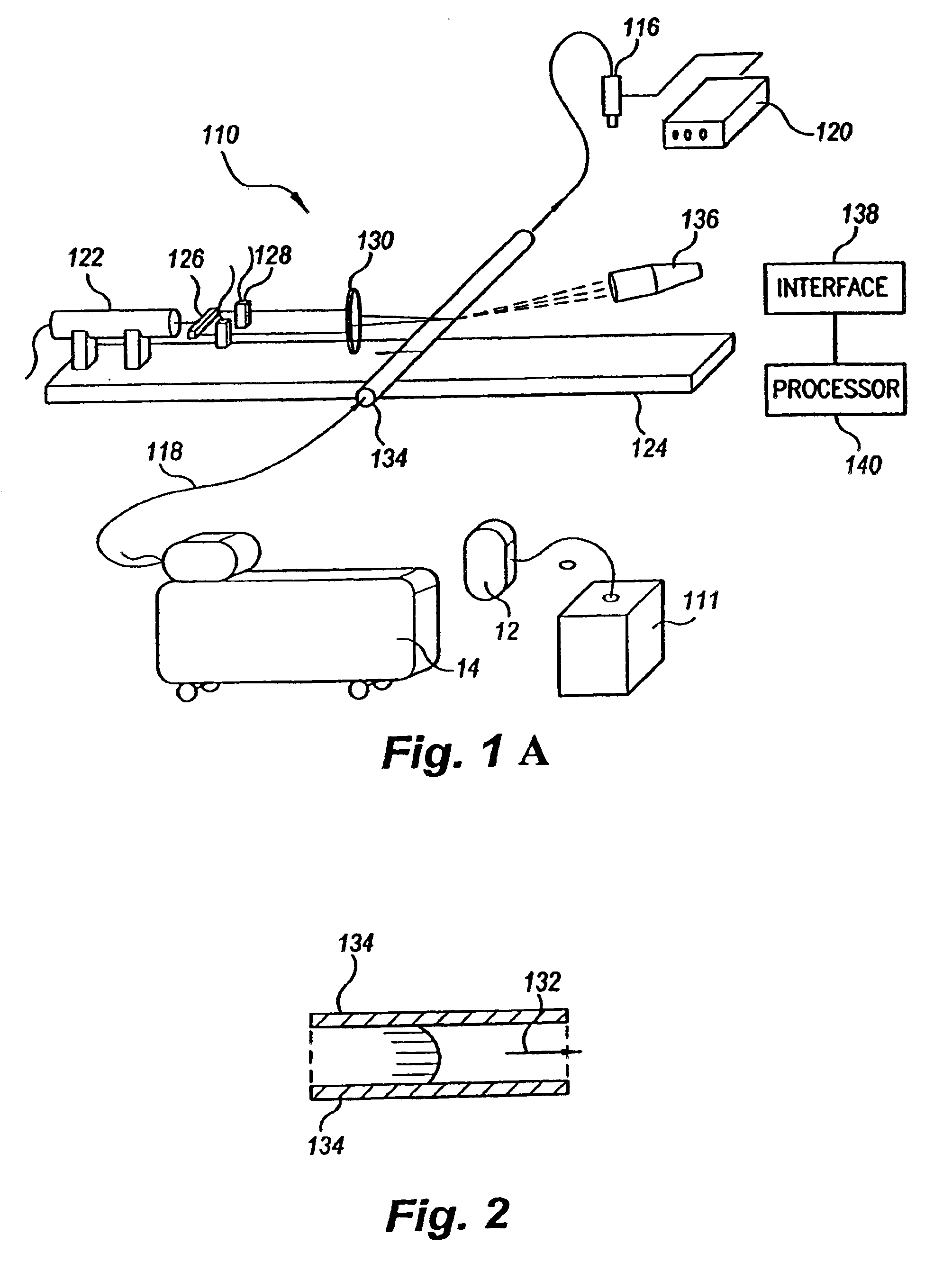

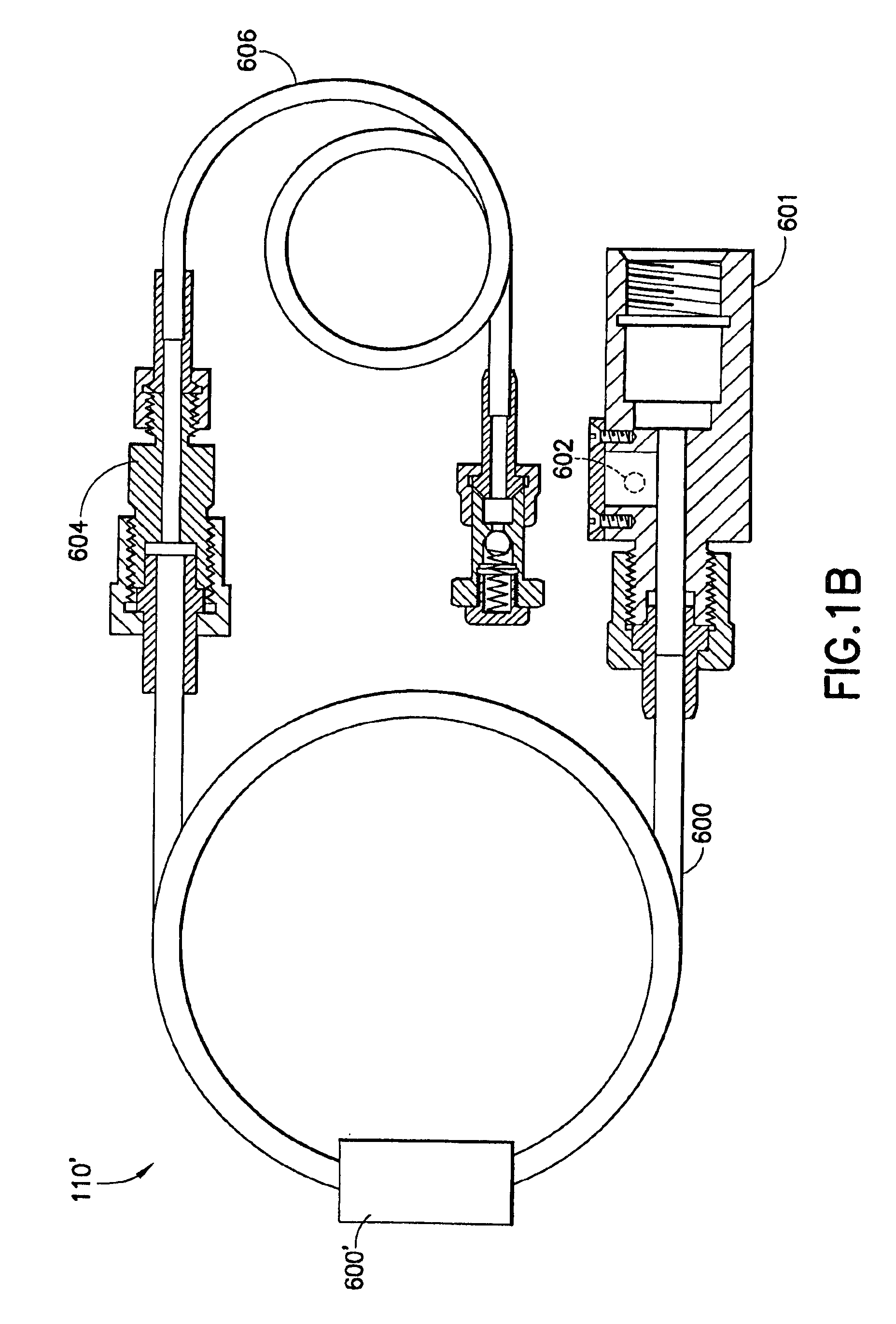

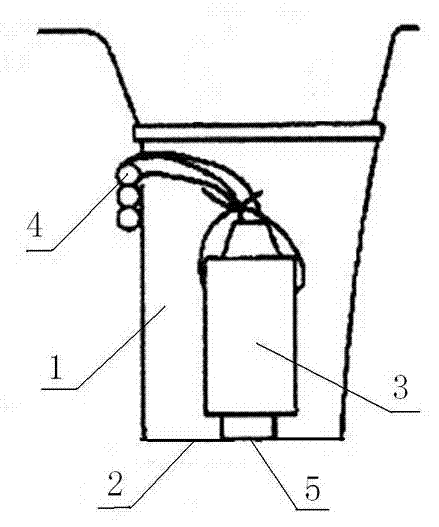

Flow meter

Various embodiments of the present invention provide a flow meter device having a laser Doppler anemometer (LDA) which measures the instantaneous center line velocity of fluid flow in a pipe. The flow meter may process the instantaneous velocity so obtained to compute the volumetric flow rate, mass rate, and / or other flow characteristics (e.g., as instantaneous quantities and / or integrated over a time interval) The flow meter may use an electronic processing method. The electronic processing method may provide essentially an exact solution to the Navier-Stokes equations for any periodically oscillating flow.

Owner:COMBUSTION DYNAMICS

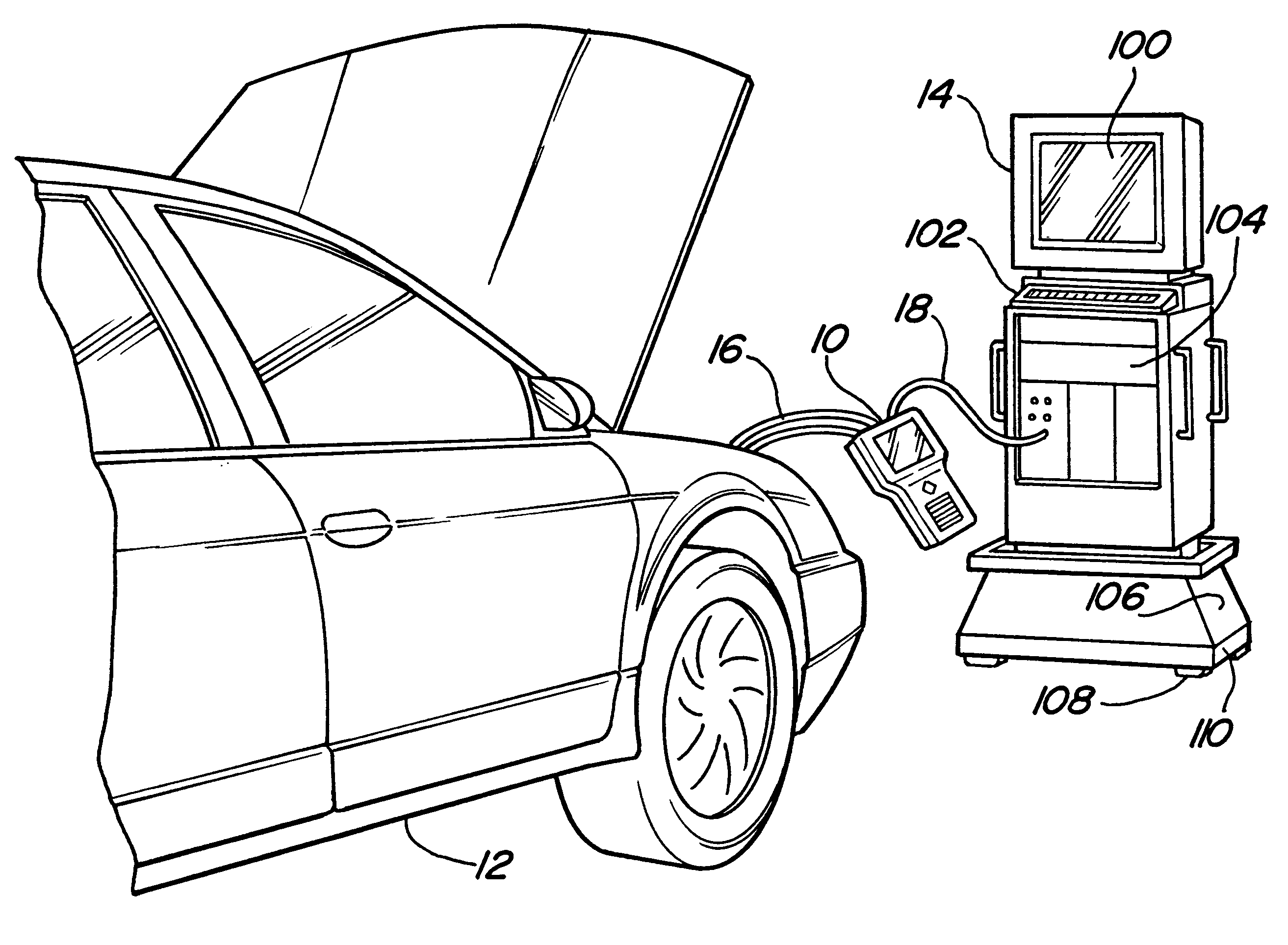

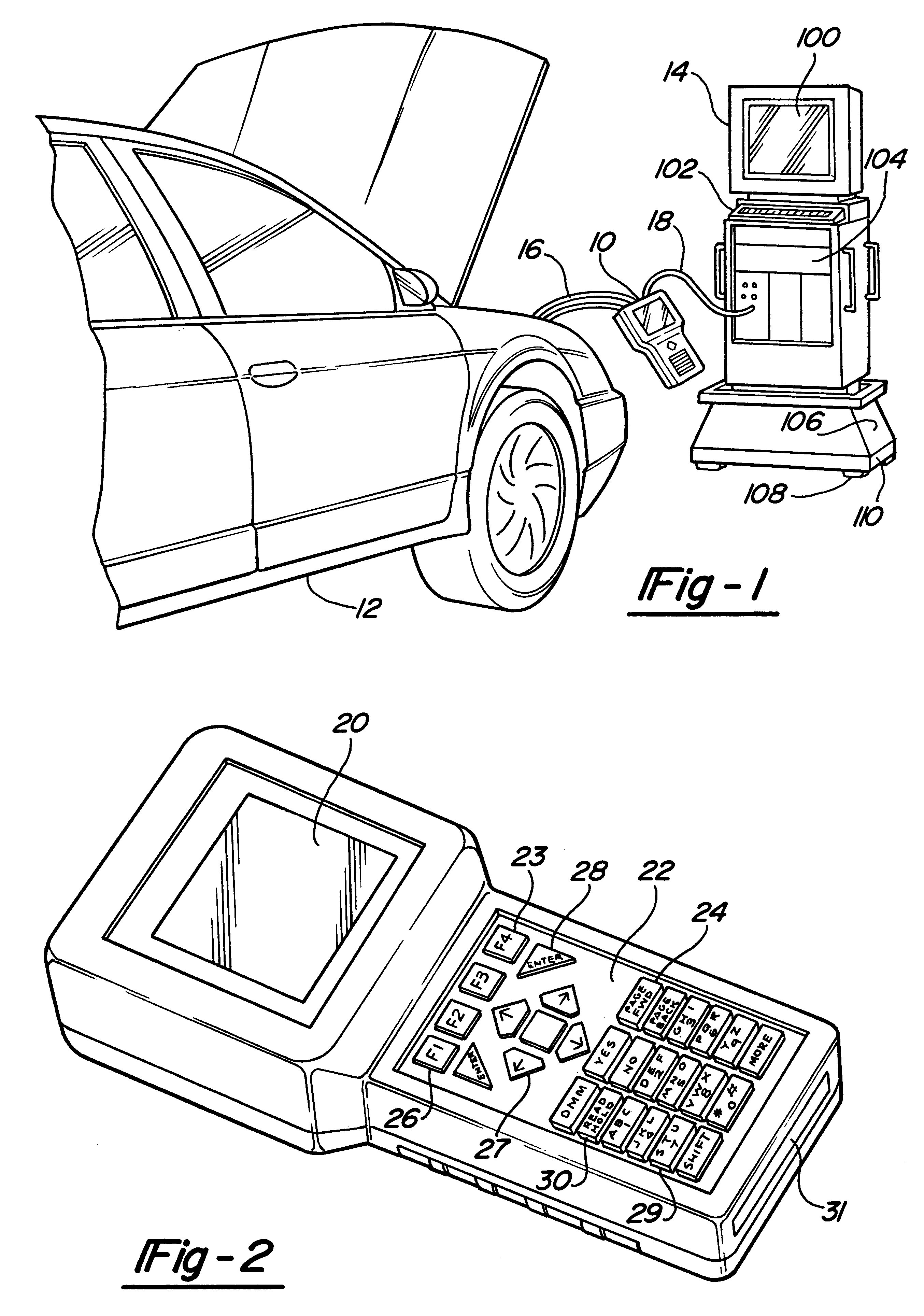

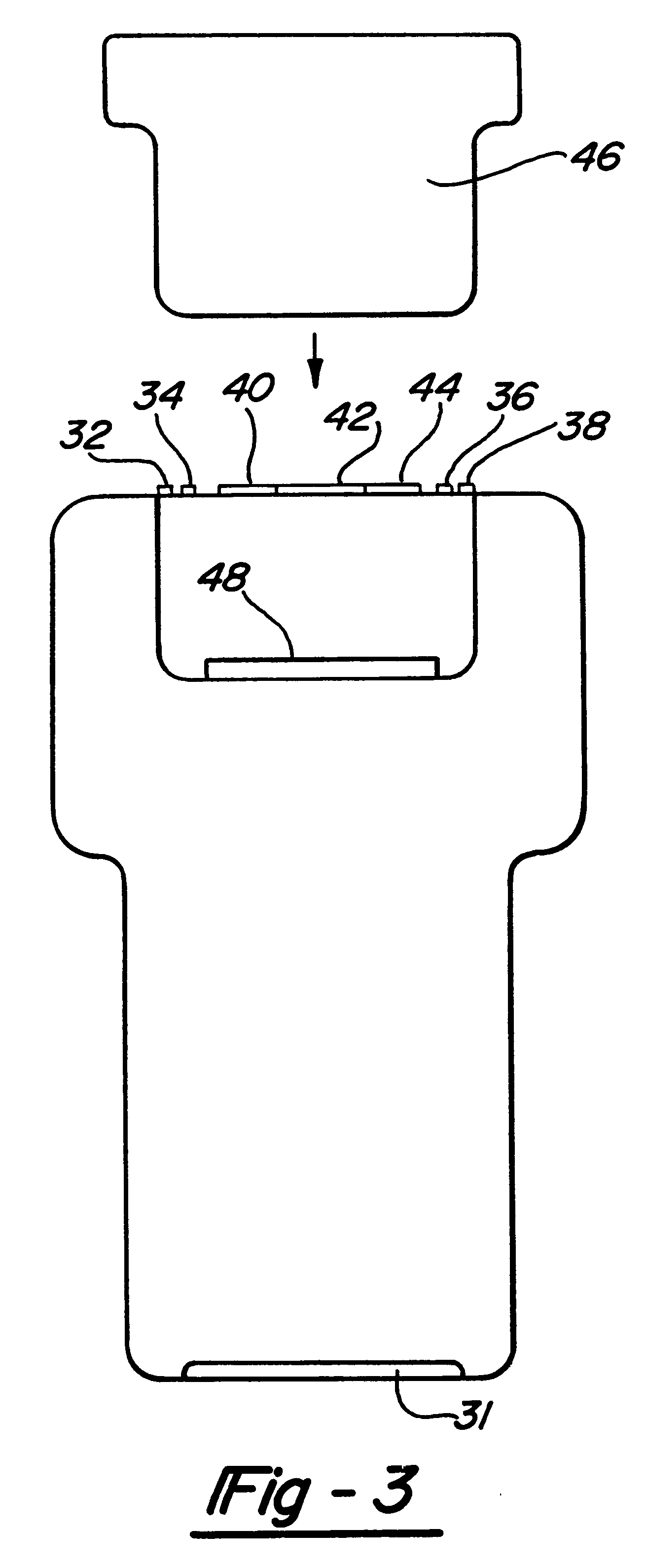

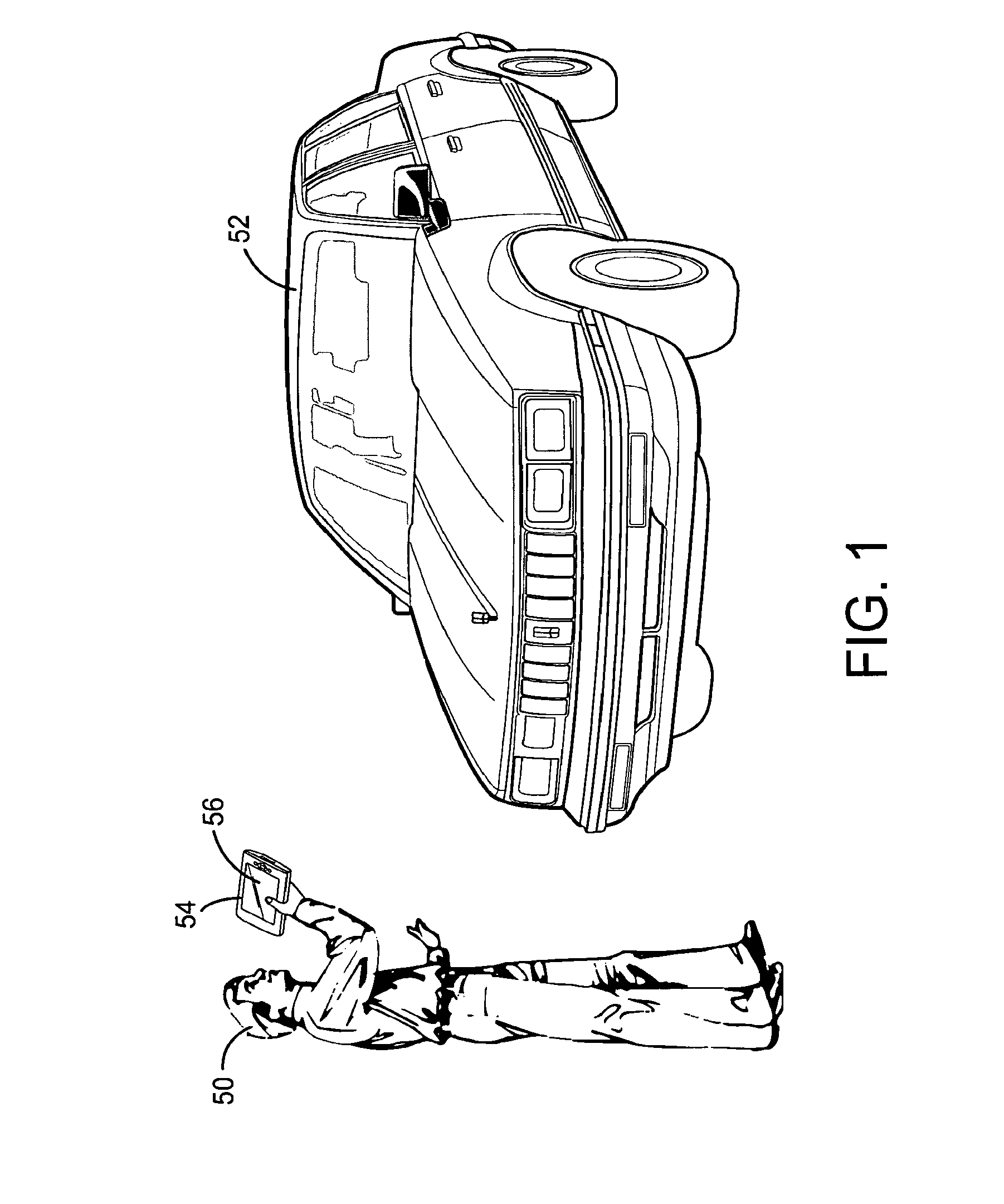

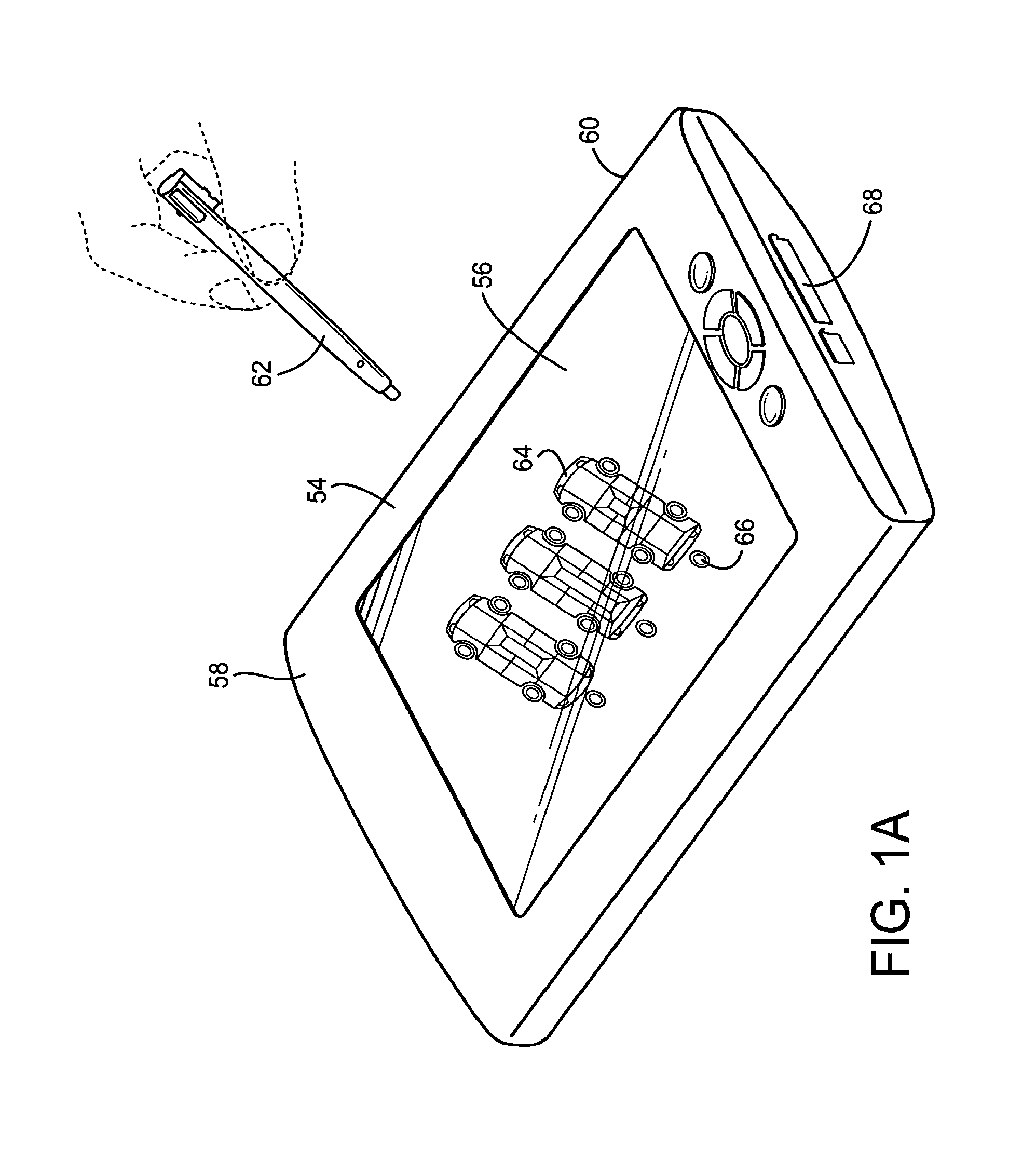

Automotive diagnostic service tool with hand held tool and master controller

InactiveUS6181992B1Reduce needQuick updateVehicle testingRegistering/indicating working of vehiclesOn boardMaster station

The present invention relates to a system and method for diagnosing and isolating problems and for monitoring operting conditions on an automobile. The system includes a hand held unit and a master station which can operate alone or in unison to accomplish functions such as logging and displaying data on a real-time basis, logging data remotely and displaying the data at a later time, diagnosing fault conditions, monitoring operating parameters, reprogramming on-board vehicle controllers, displaying service manual and service bulletin pages and ordering parts on-line.

Owner:FCA US

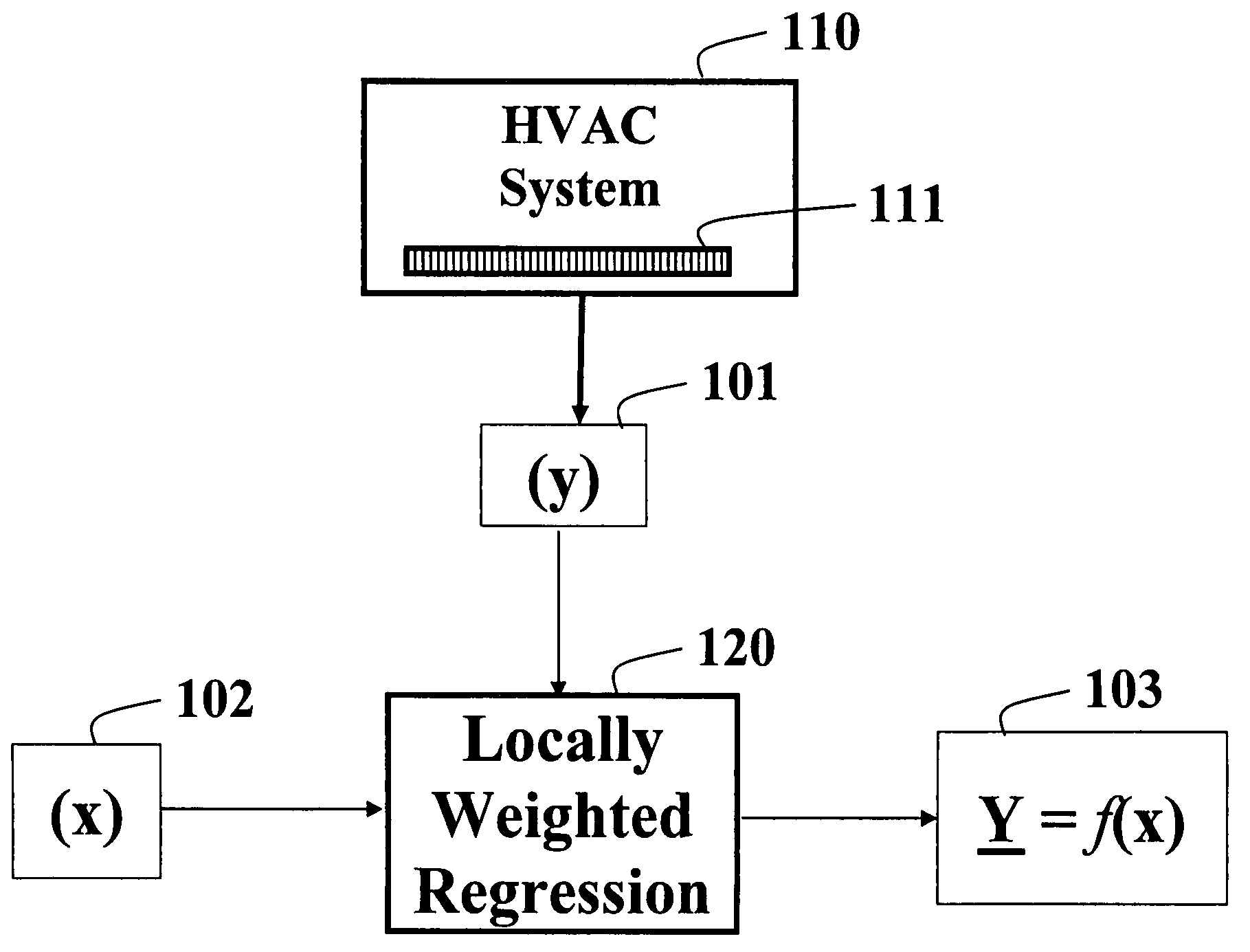

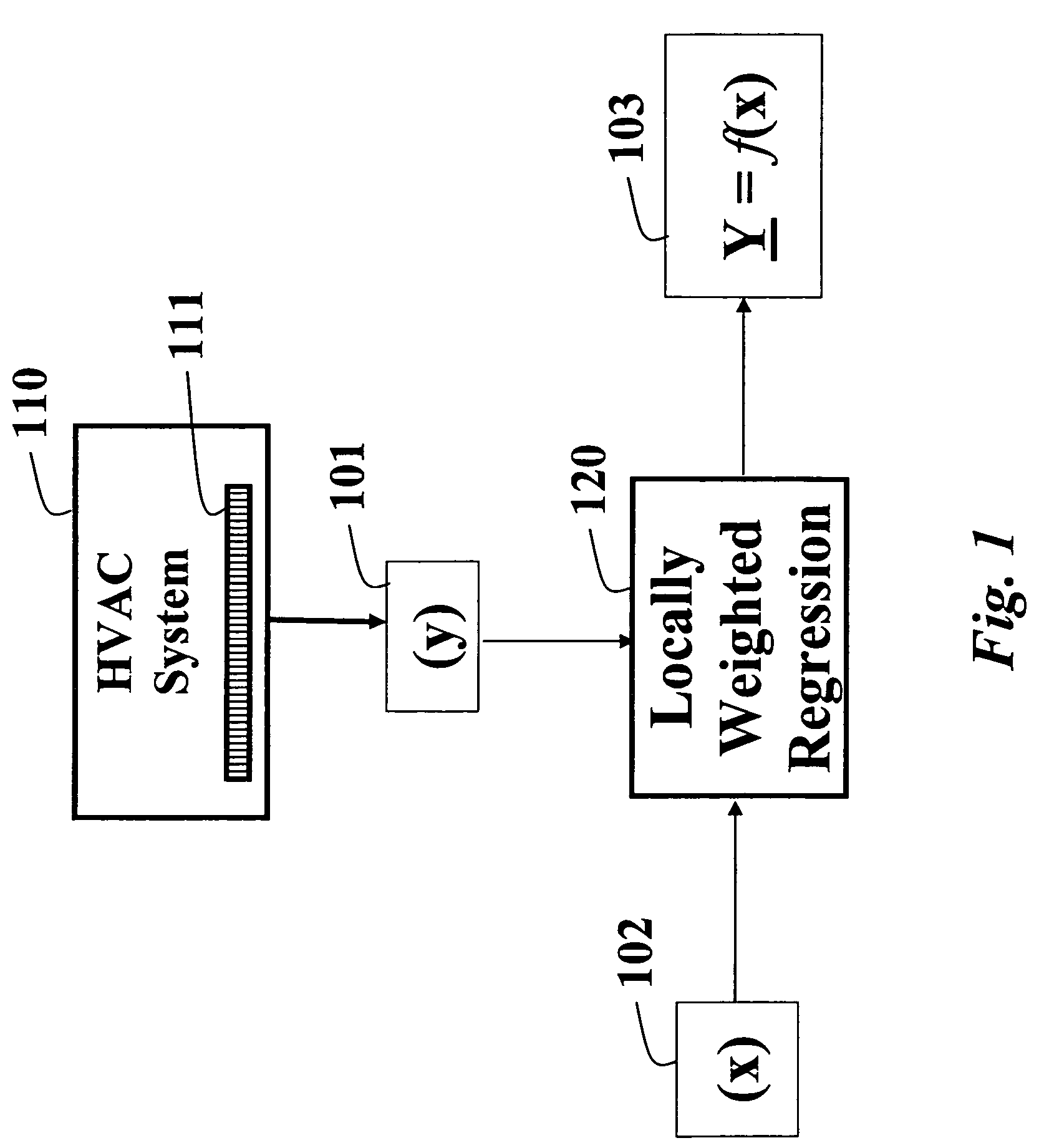

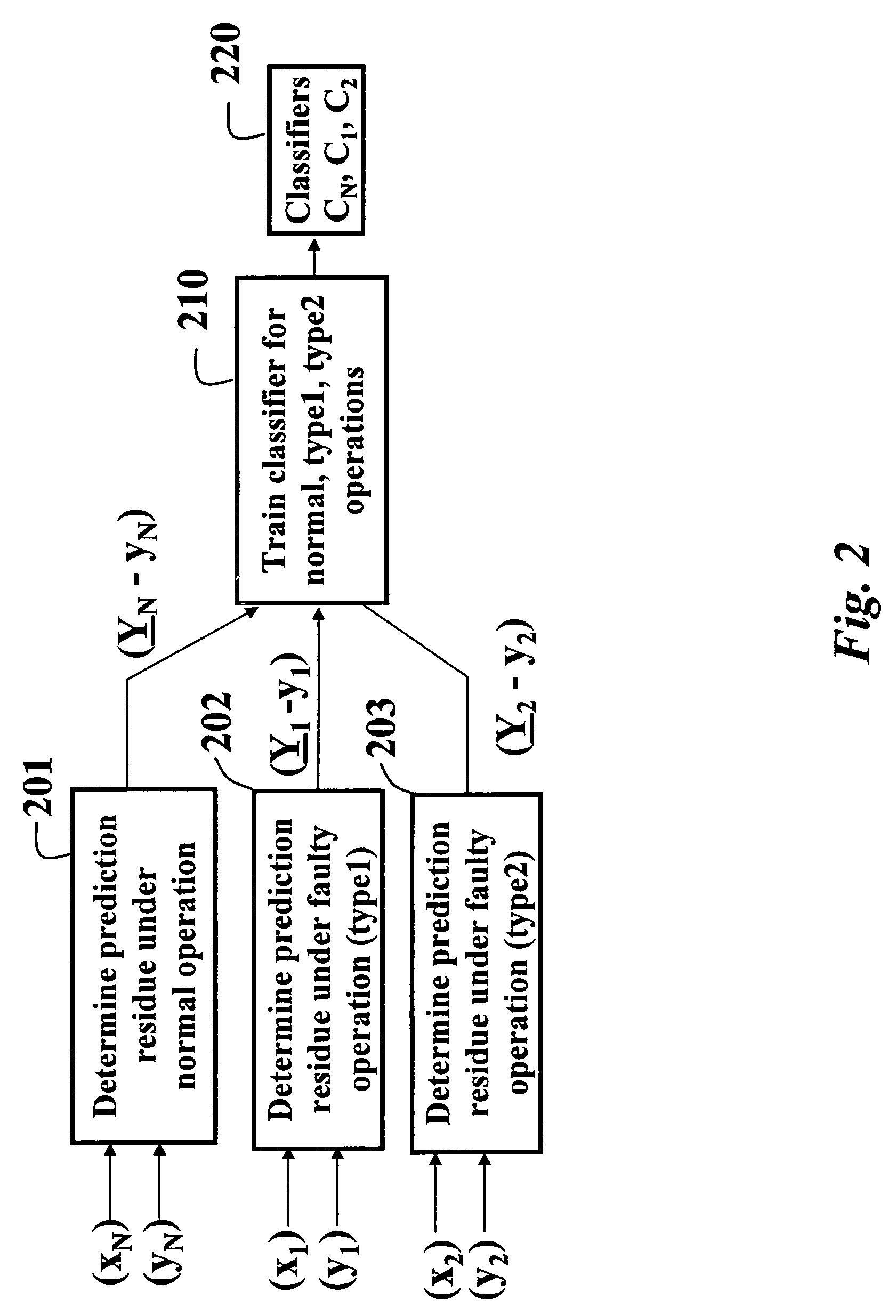

Detecting and diagnosing faults in HVAC equipment

A method and system detects and diagnoses faults in heating, ventilating and air conditioning (HVAC) equipment. Internal state variables of the HVAC equipment are measured under external driving conditions. Expected internal state variables are predicted for the HVAC equipment operating under the external driving conditions using a locally weighted regression model. Features are determined of the HVAC based on differences between the measured and predicted state variables. The features are classified to determine a condition of the HVAC equipment.

Owner:MITSUBISHI ELECTRIC RES LAB INC

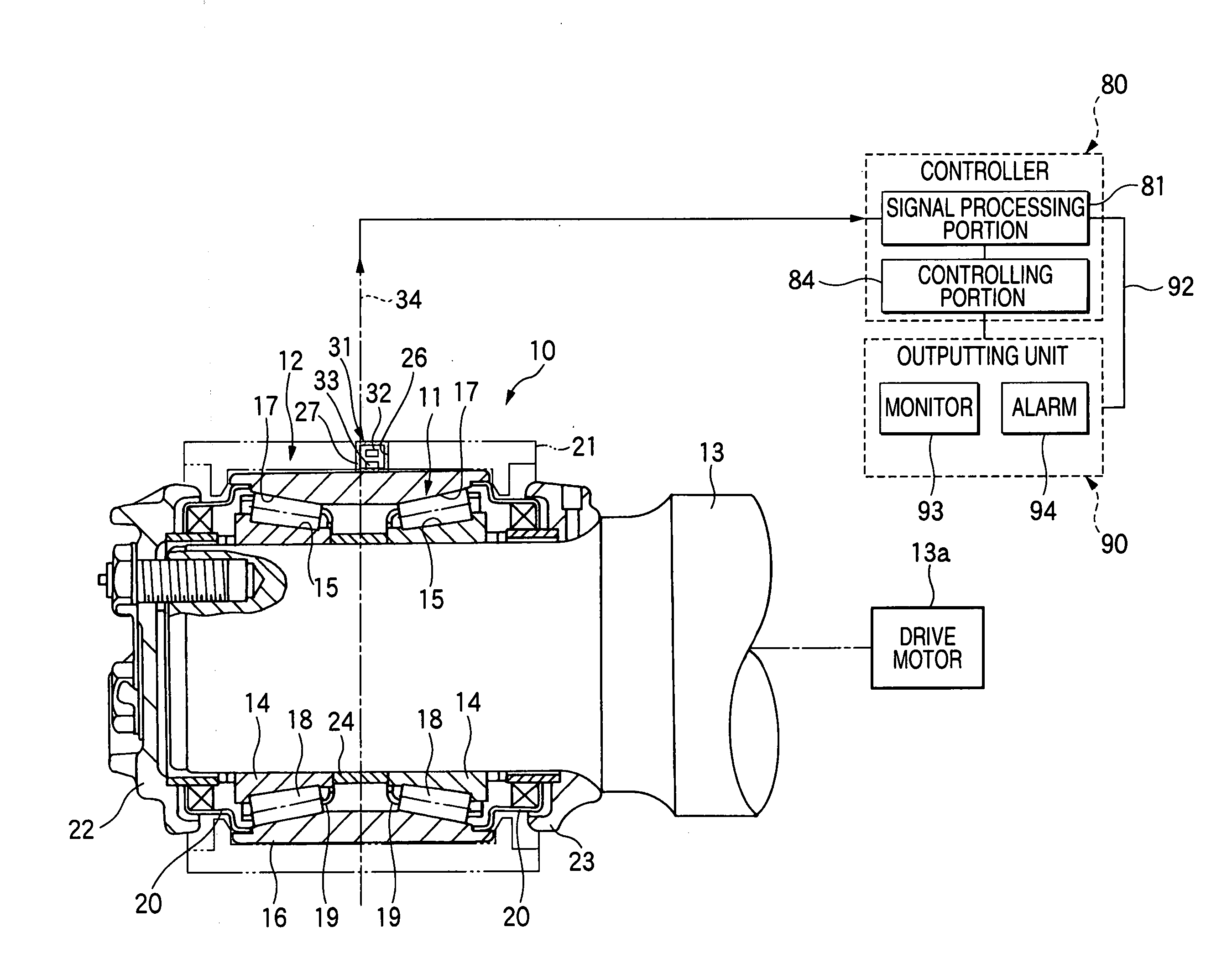

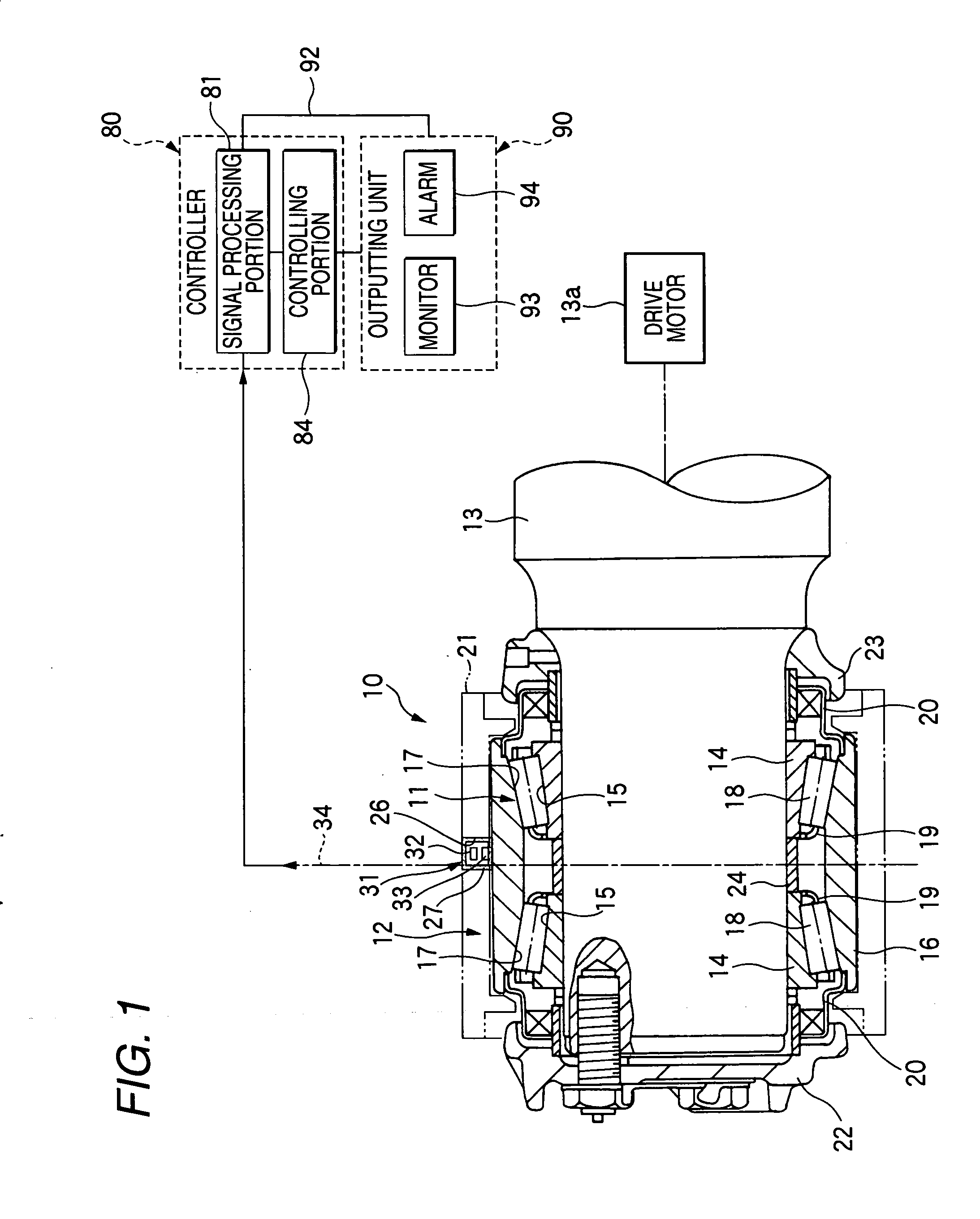

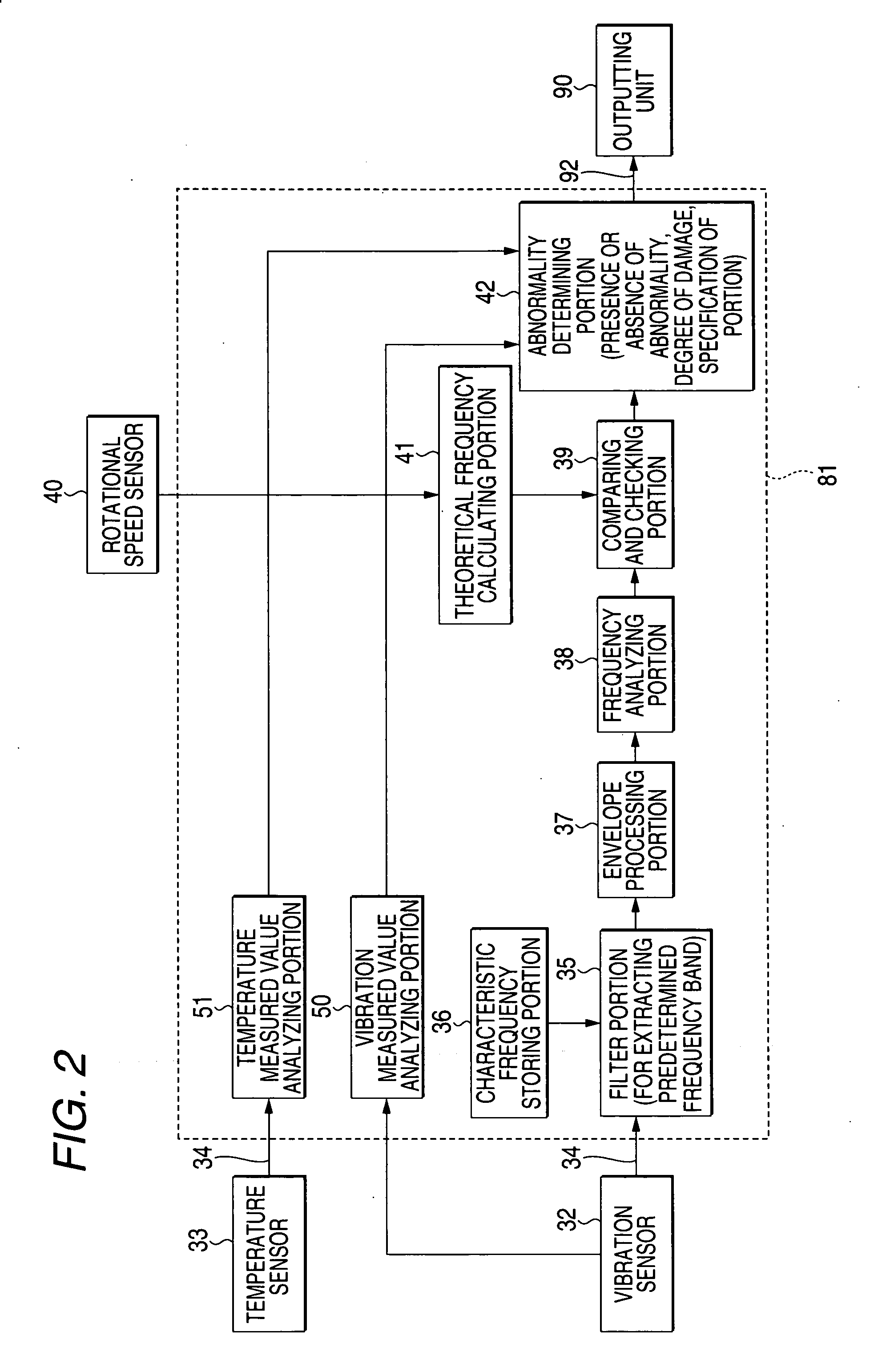

Abnormality Diagnosing Apparatus and Abnormality Diagnosing Method

ActiveUS20080234964A1Improve reliabilityEffective maintenanceVibration measurement in solidsVehicle testingEngineeringSignal processing

A abnormality diagnosing apparatus used in a machine equipment including a rotating or sliding part relative to a stationary member includes a detecting portion 31 fixed to the rotating or sliding part or the stationary member and including a vibration sensor 32 and a temperature sensor 33, and a signal processing portion 81 for determining a state of the part from a detecting signal outputted by the detecting portion 31. The signal processing portion 81 determines presence or absence of a abnormality, or presence or absence of the abnormality and a degree of a damage of the part based on a combination of a measured result by the vibration sensor 32 and a measured result by the temperature sensor 33.

Owner:NSK LTD

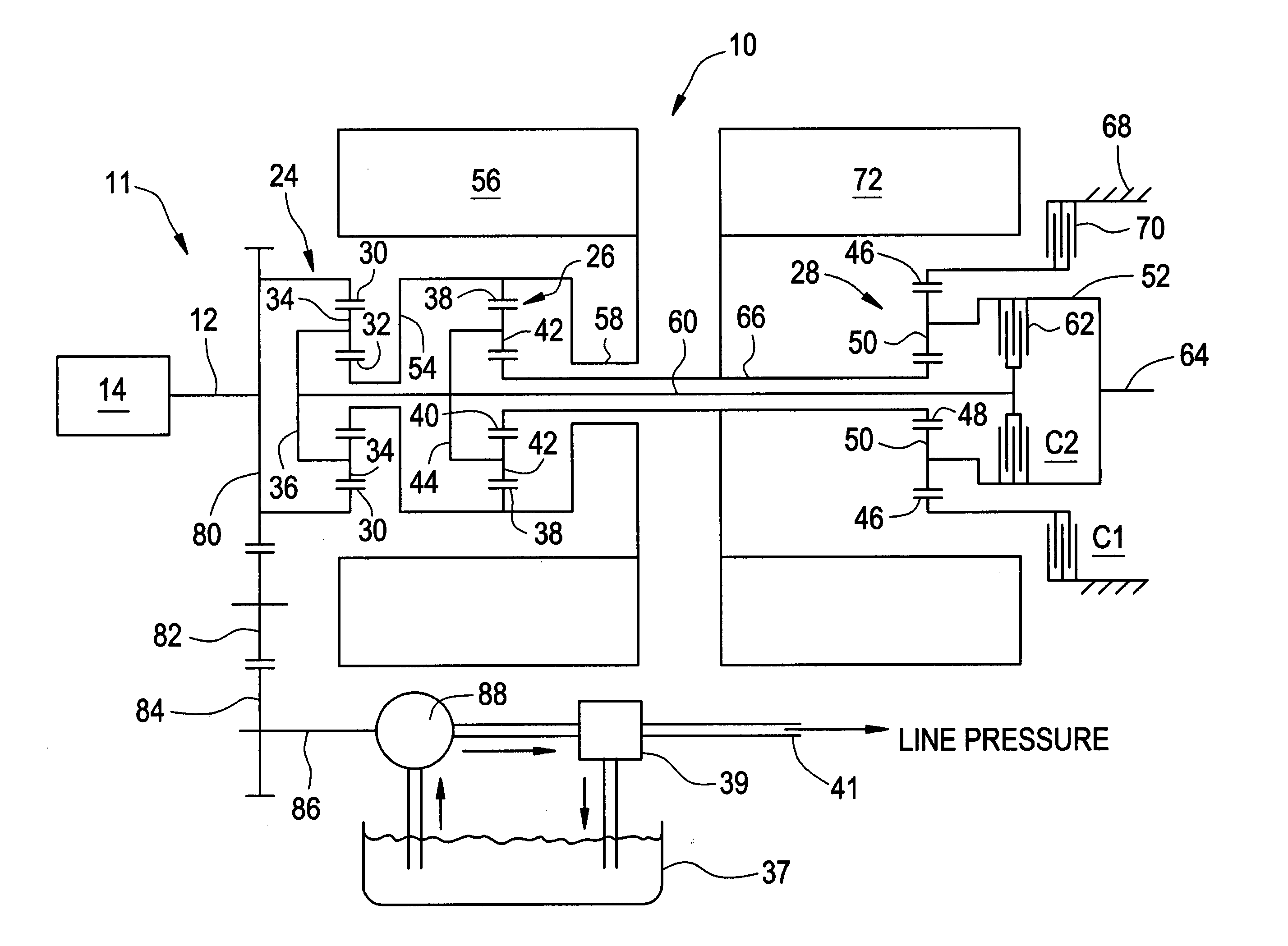

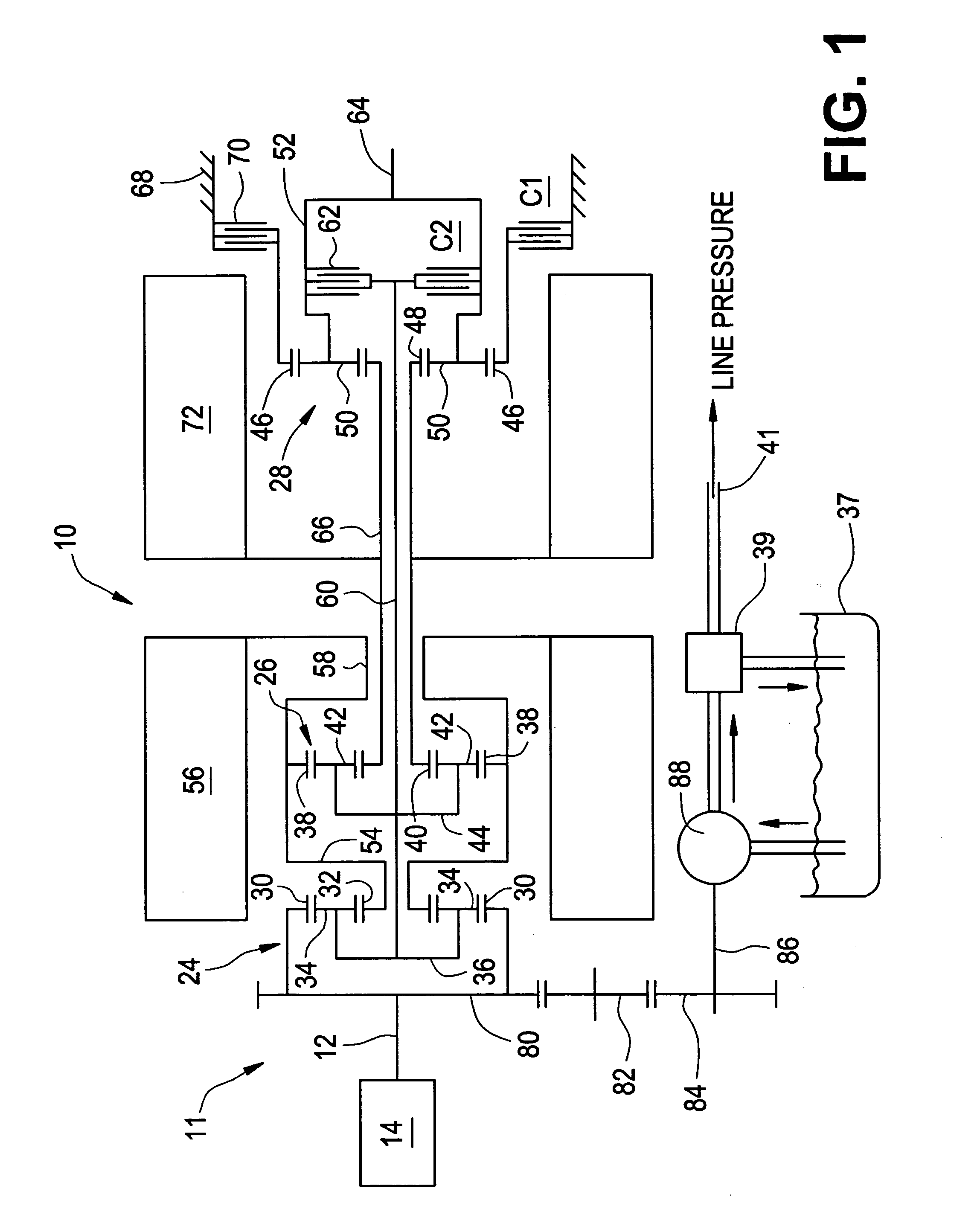

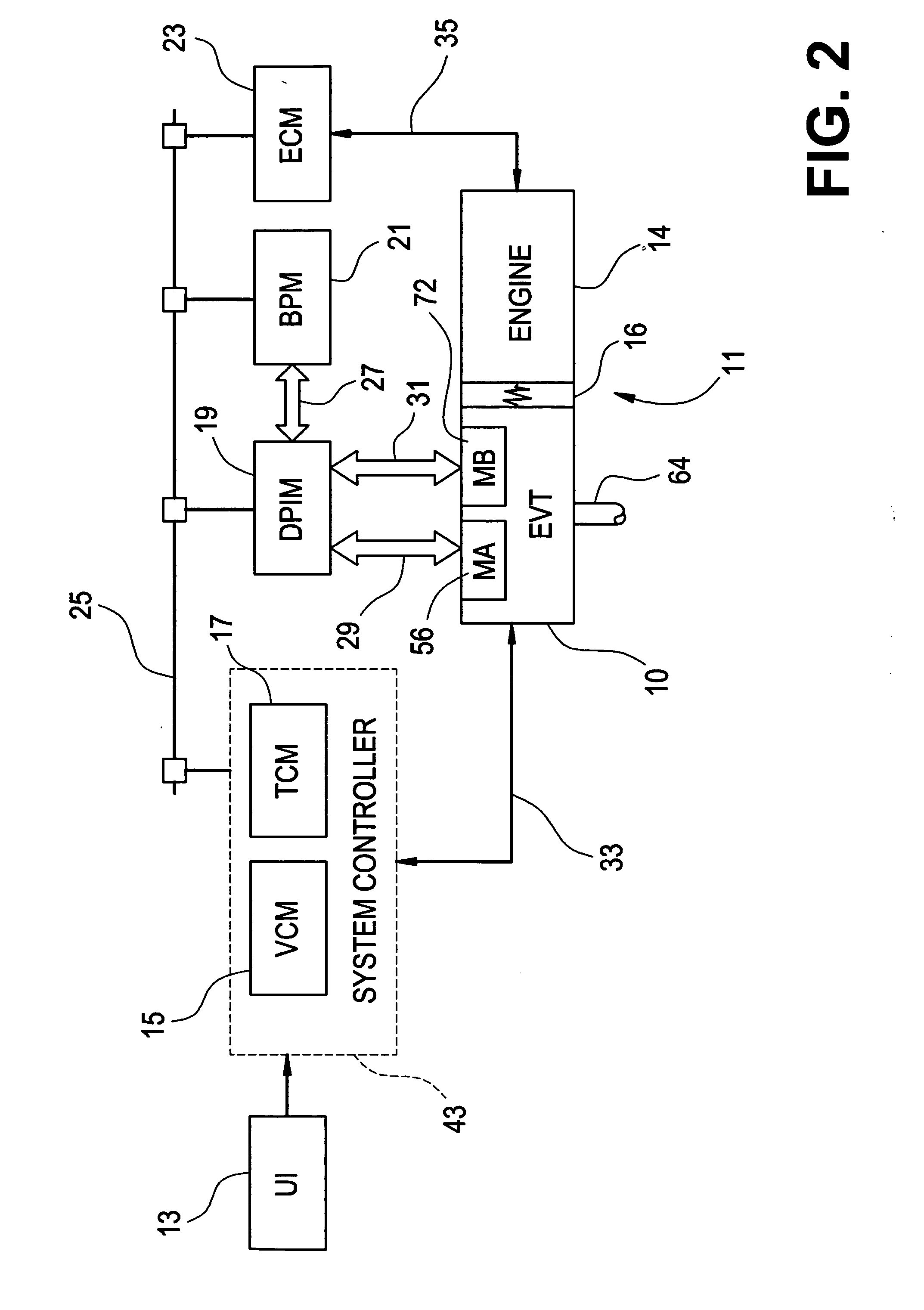

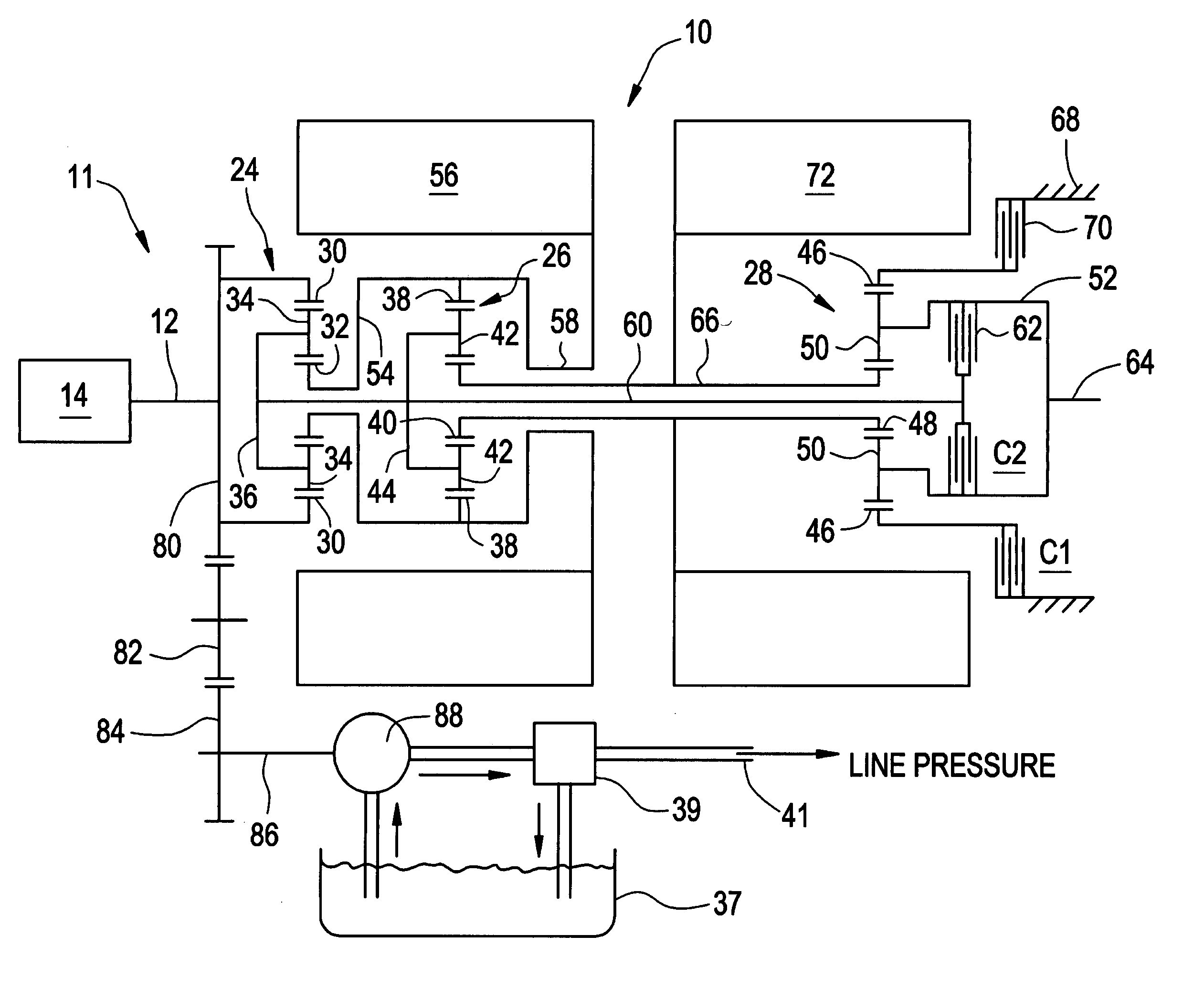

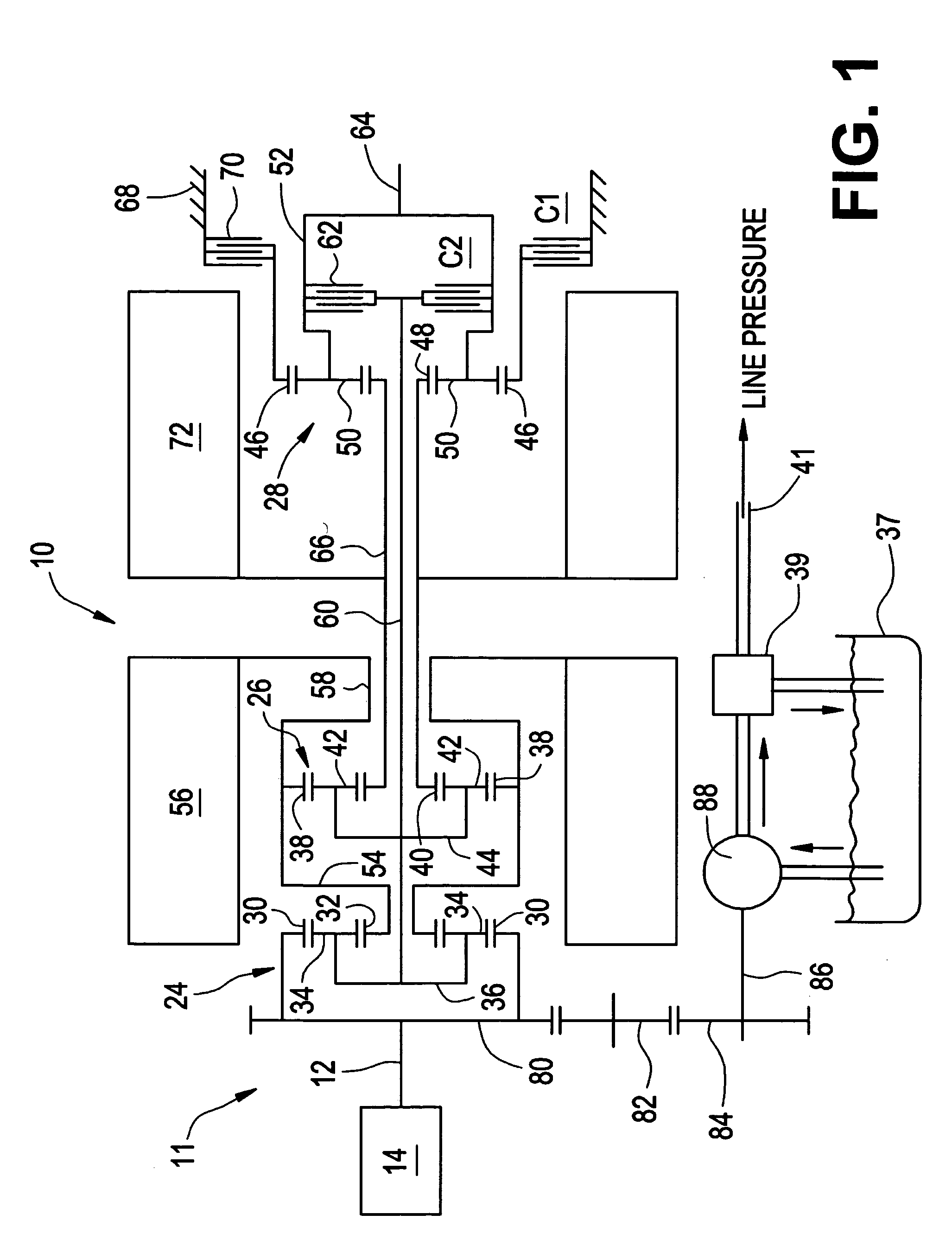

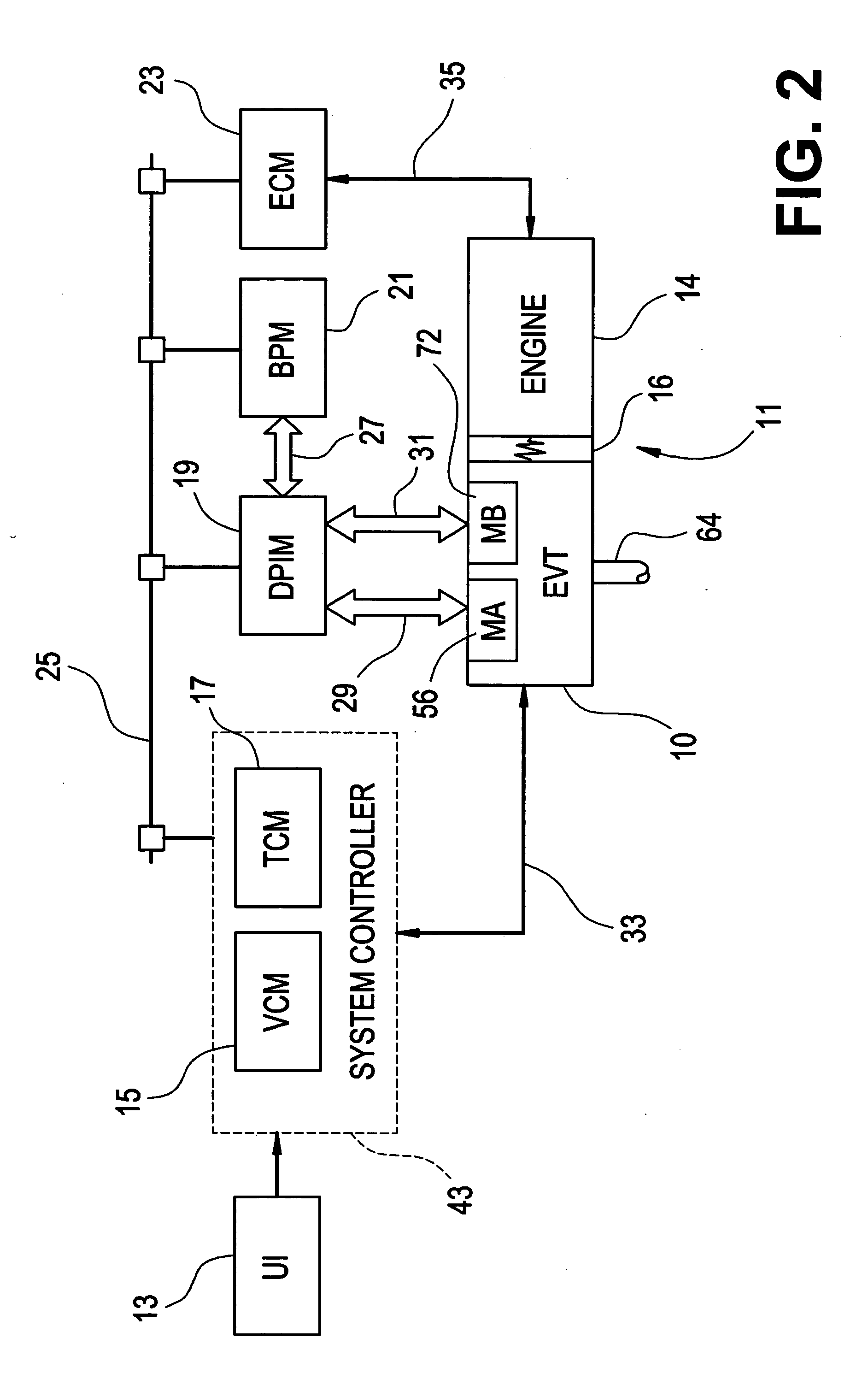

Method for dynamically determining peak output torque in an electrically variable transmission

A method for determining output torque limits of a powertrain including an electrically variable transmission relies upon a model of the electrically variable transmission. Transmission operating space is defined by combined electric machine torque constraints and engine torque constraints. Output torque limits are determined at the limits of the transmission operating space.

Owner:GM GLOBAL TECH OPERATIONS LLC

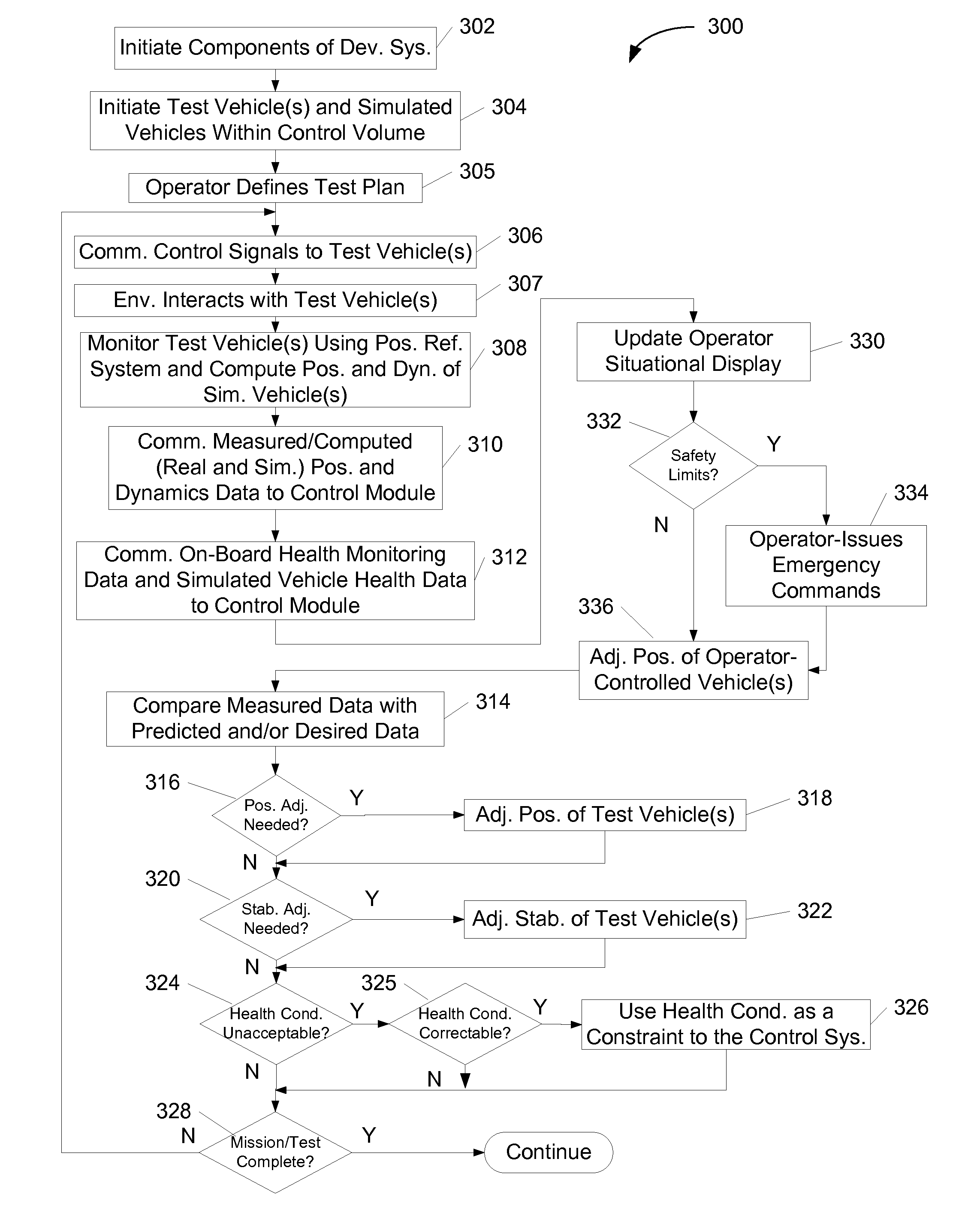

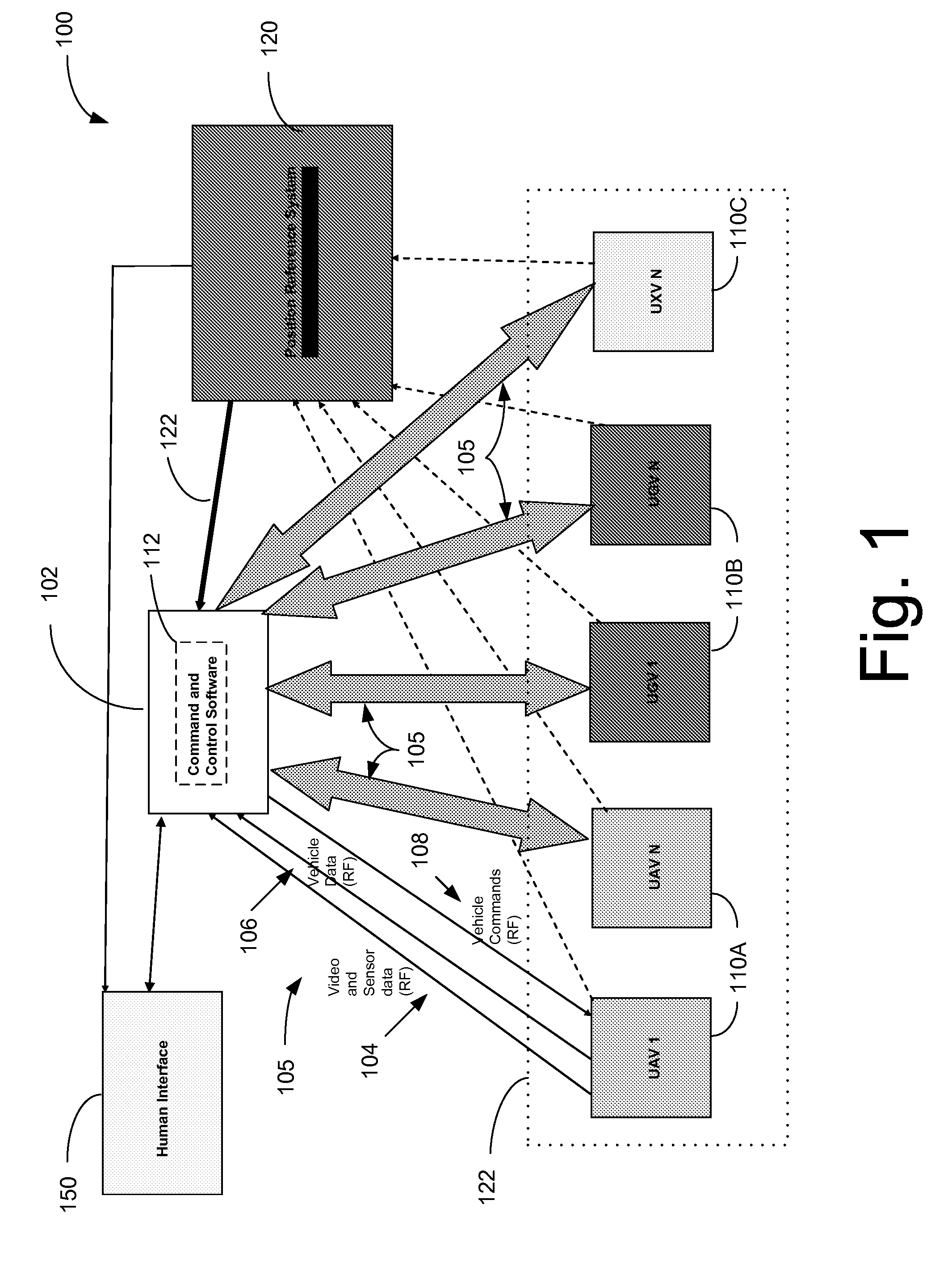

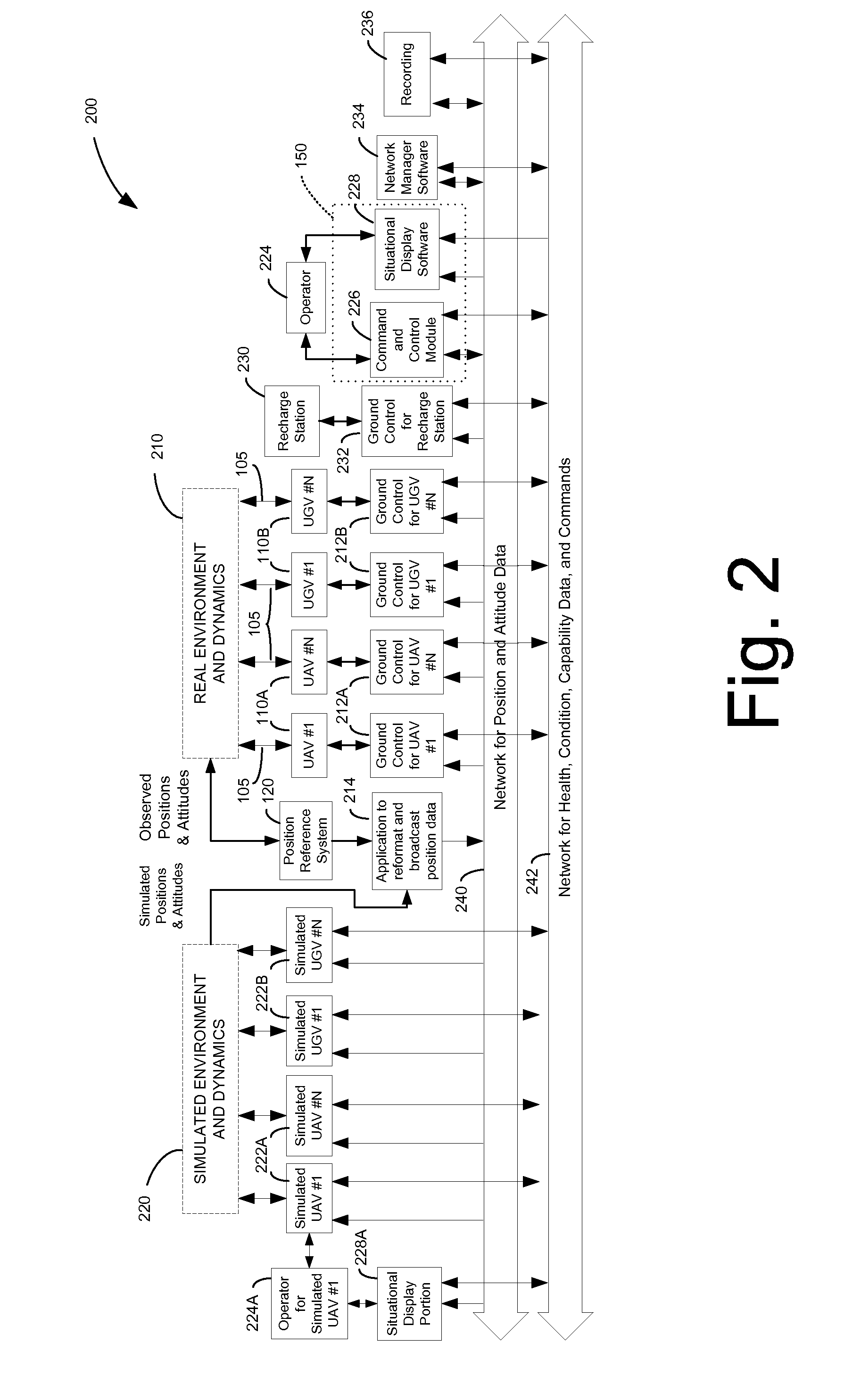

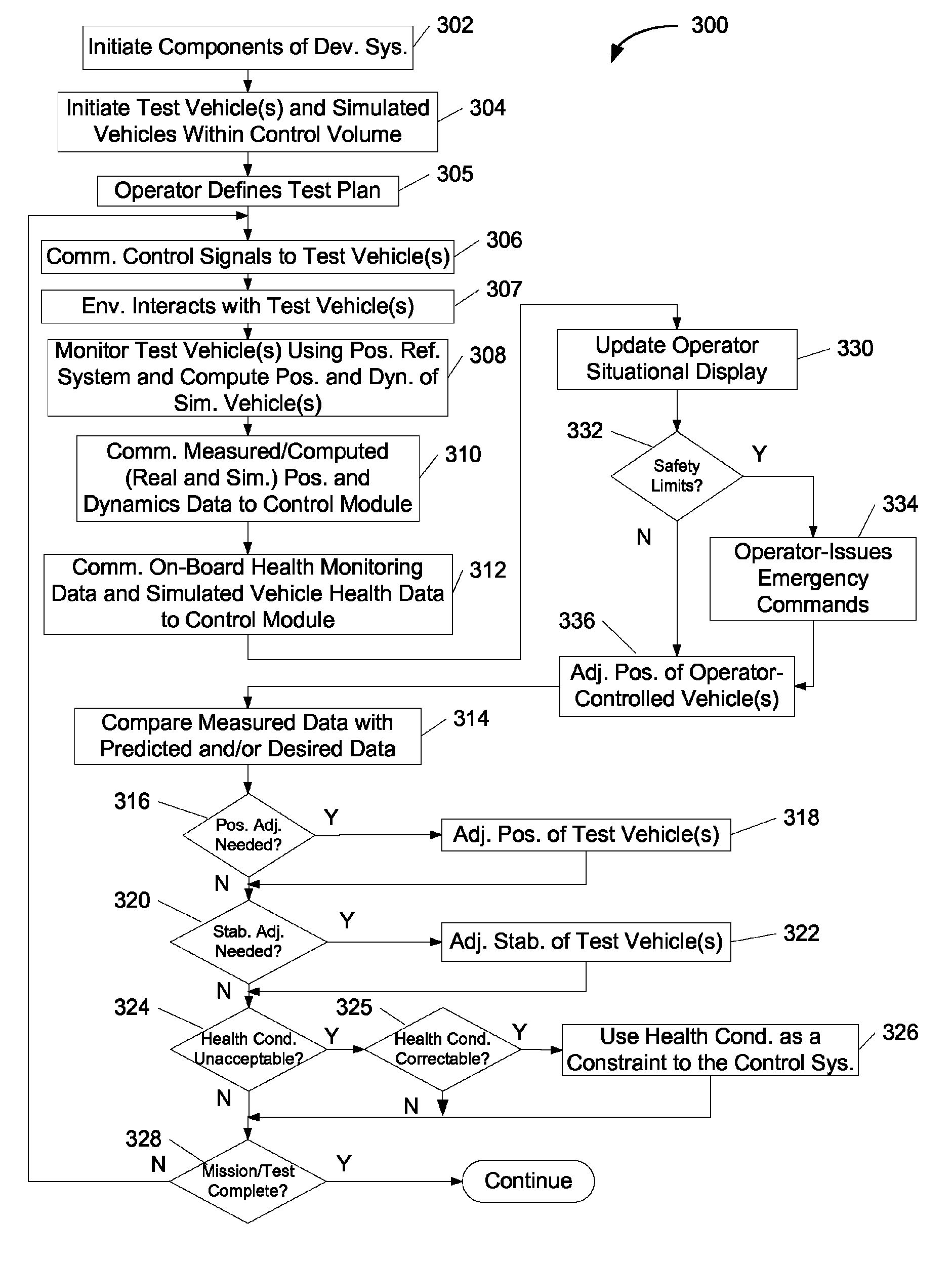

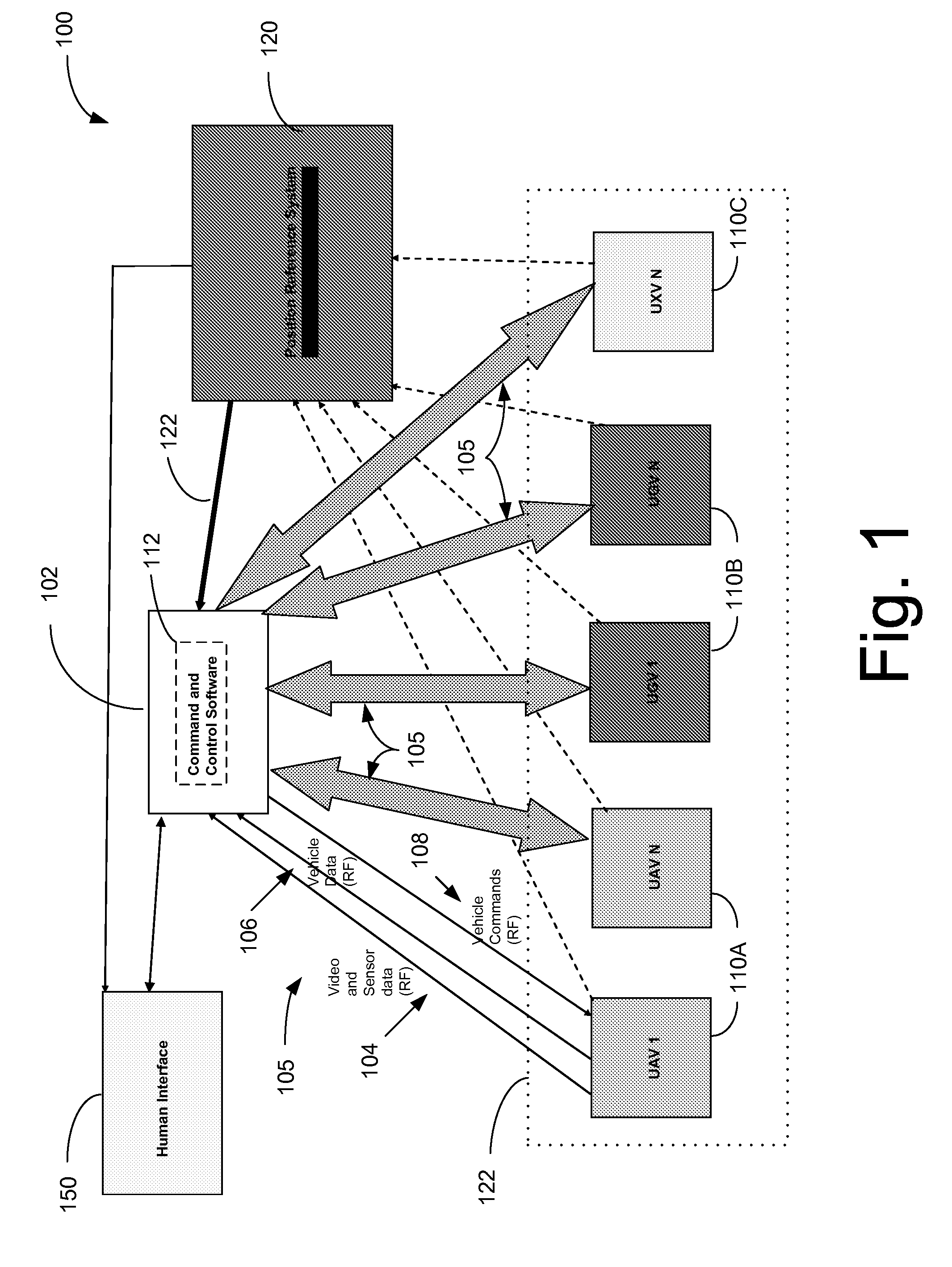

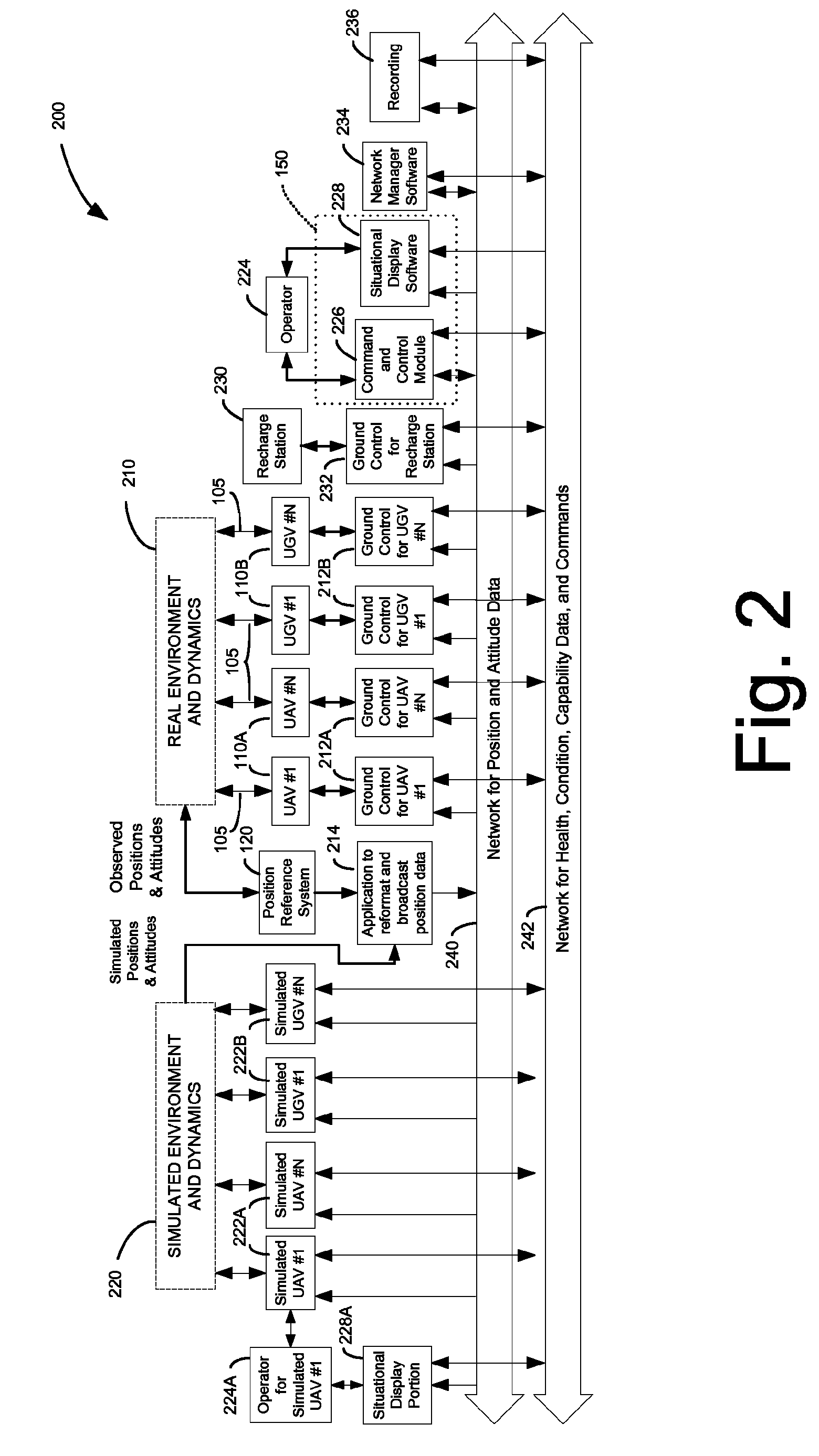

Autonomous Vehicle Rapid Development Testbed Systems and Methods

ActiveUS20080033684A1Easy to detectRapid development and testingVehicle testingDigital data processing detailsCommand and controlControl signal

Systems and methods for development testing of vehicles and components are disclosed. In one embodiment, a system includes a position reference system and a command and control architecture. The position reference system is configured to repetitively measure one or more position and motion characteristics of one or more vehicles operating within a control volume. The command and control architecture is configured to receive the repetitively measured characteristics from the position reference system, and to determine corresponding control signals based thereon. The control signals are then transmitted to the one or more vehicles to control at least one of position, movement, and stabilization of the one or more vehicles in a closed-loop feedback manner. The system may further include a health monitoring component configured to monitor health conditions of the one or more vehicles, the control signals being determined at least in part on the health conditions.

Owner:THE BOEING CO

Autonomous vehicle rapid development testbed systems and methods

ActiveUS7813888B2Rapid development and testingEasy to detectVehicle testingElectrical measurementsControl signalCommand and control

Systems and methods for development testing of vehicles and components are disclosed. In one embodiment, a system includes a position reference system and a command and control architecture. The position reference system is configured to repetitively measure one or more position and motion characteristics of one or more vehicles operating within a control volume. The command and control architecture is configured to receive the repetitively measured characteristics from the position reference system, and to determine corresponding control signals based thereon. The control signals are then transmitted to the one or more vehicles to control at least one of position, movement, and stabilization of the one or more vehicles in a closed-loop feedback manner. The system may further include a health monitoring component configured to monitor health conditions of the one or more vehicles, the control signals being determined at least in part on the health conditions.

Owner:THE BOEING CO

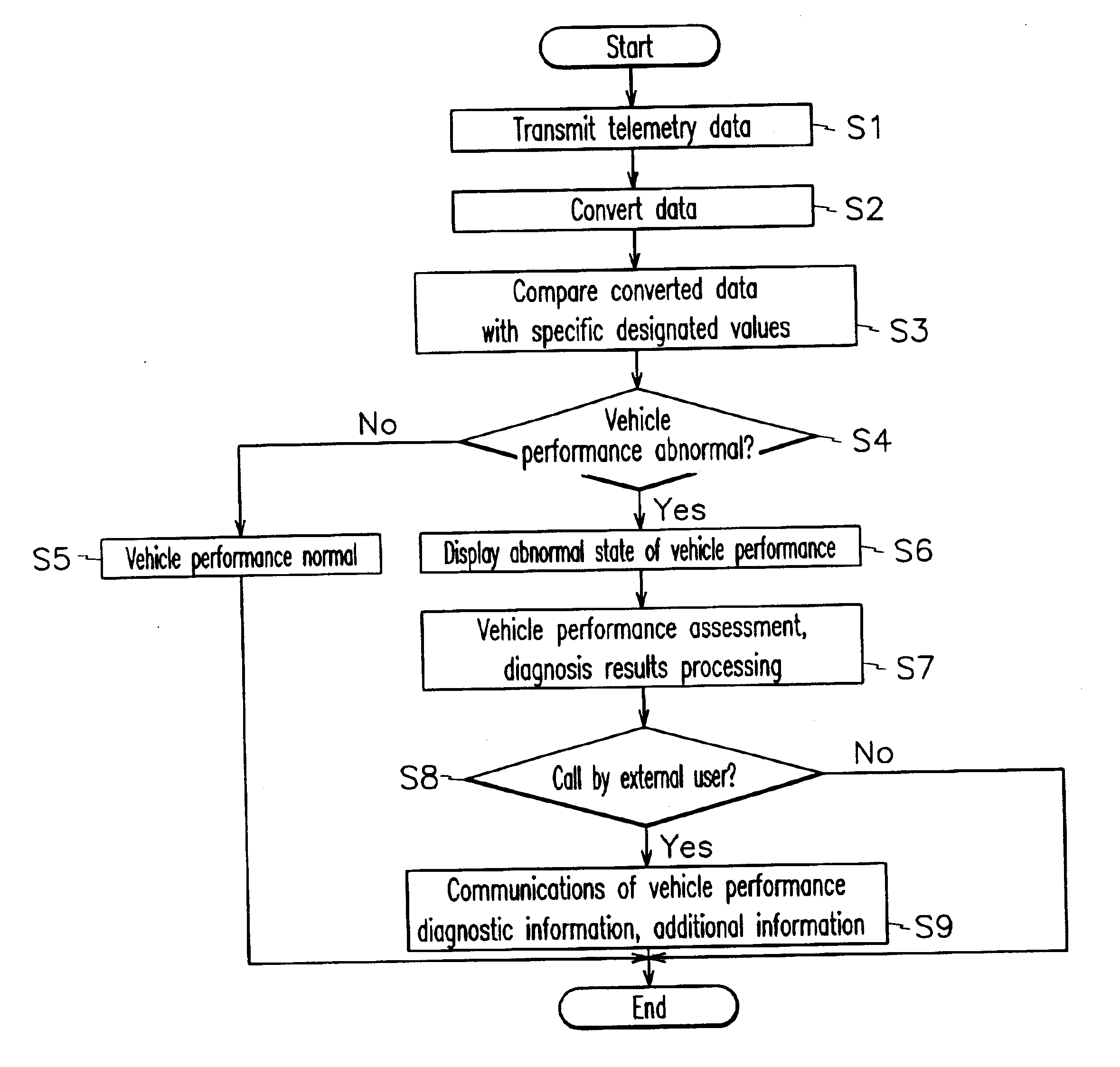

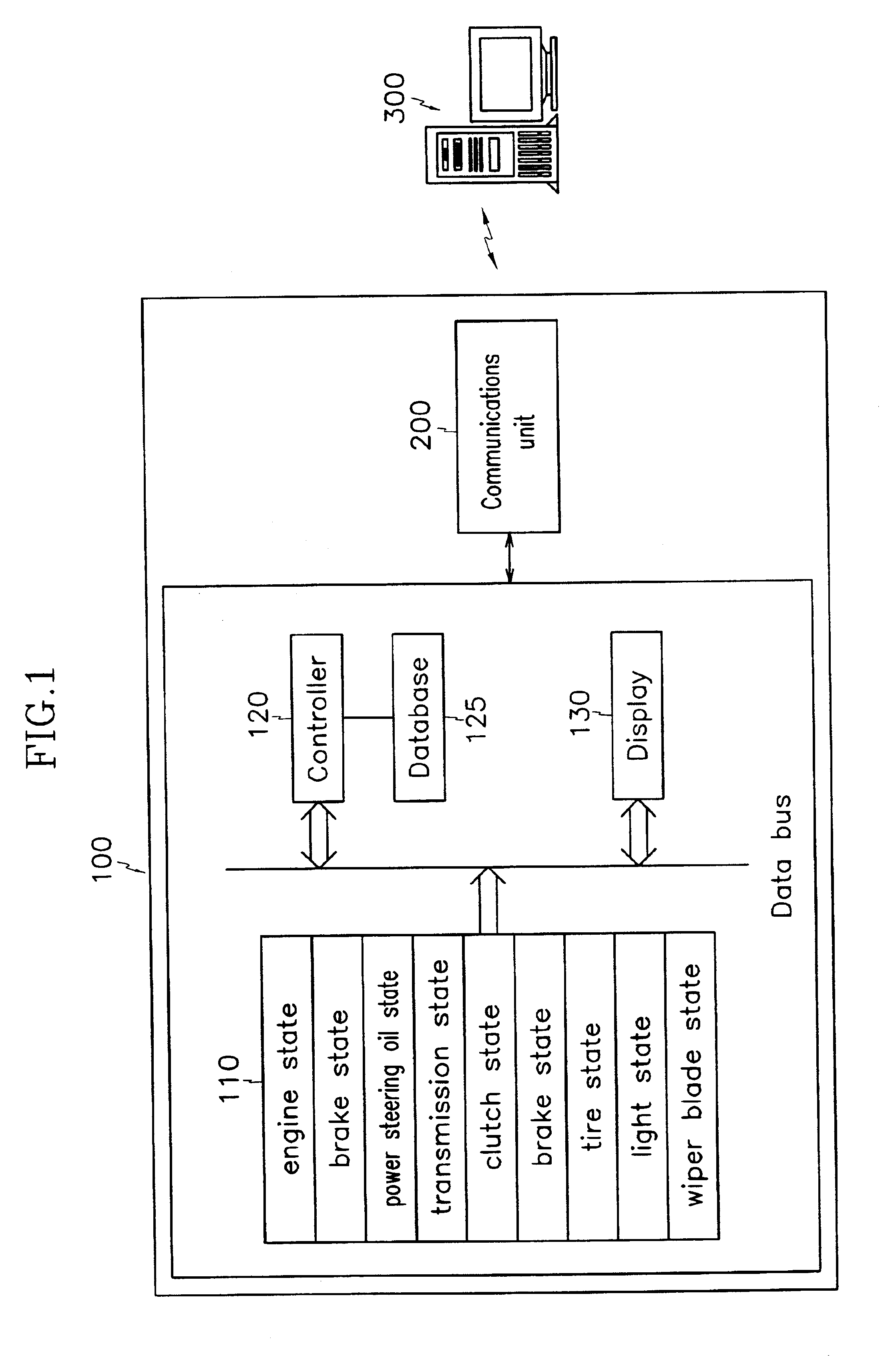

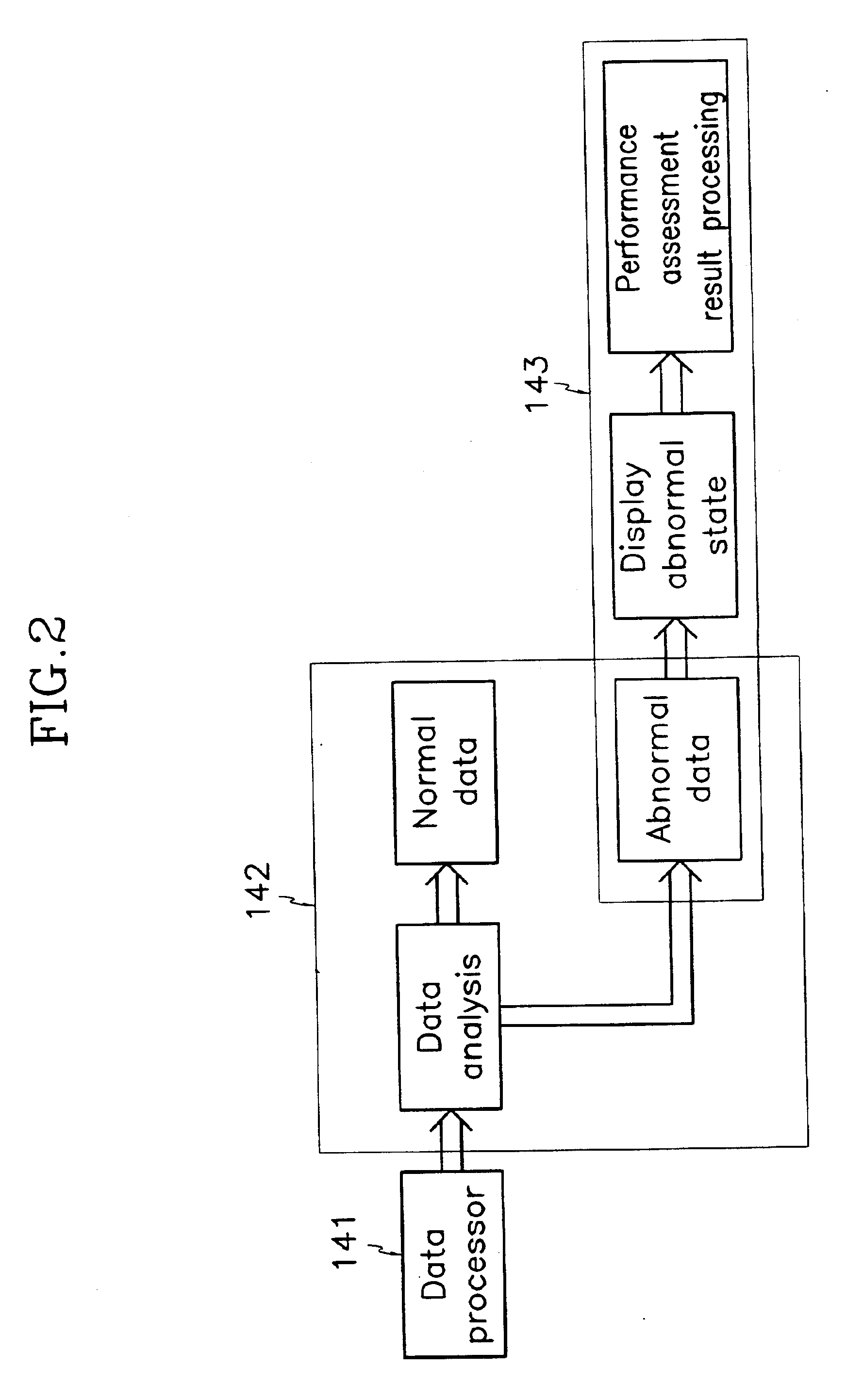

System and method for executing diagnosis of vehicle performance

InactiveUS6850823B2Sure easyVehicle testingRegistering/indicating working of vehiclesDriver/operatorCommunication unit

A system for executing diagnosis of vehicle performance using satellite telemetry technology includes a diagnostic unit for compiling telemetry data, transmitted in real-time, of an engine and various parts of a vehicle, comparing the telemetry data with specific values of the engine and various parts to determine if there are any abnormalities in vehicle performance, and monitoring diagnostic results of vehicle performance; and a communications unit for performing communications in real-time through a network with an external user requesting vehicle performance diagnostic results of the diagnostic unit. Accordingly, the driver or external user may easily determine if there are abnormalities in vehicle performance, take steps to cope with vehicle malfunctions before they occur, and know the precise location of any abnormal areas of vehicle performance.

Owner:WI LAN TECH INC

Diagnostic method for a torque control of an electrically variable transmission

ActiveUS20050252283A1Impaired speed controlImpaired torque controlVehicle testingRegistering/indicating working of vehiclesLoop controlLow speed

A condition of impaired speed and torque control of a parallel electrically variable transmission due to factors beyond nominal modeling and estimation errors is diagnosed under low speed operation. The transmission includes at least one electric machine and a motor torque controller for regulating the transmission input speed and output torque. The motor torque controller includes an open-loop control path based on predetermined torques and accelerations and a closed loop control path based on input speed error. The presence of a larger than expected closed-loop correction magnitude, combined with low output speed and one or more other conditions is used to diagnose a condition of potential torque error, in which case the transmission control is altered to prevent unwanted operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

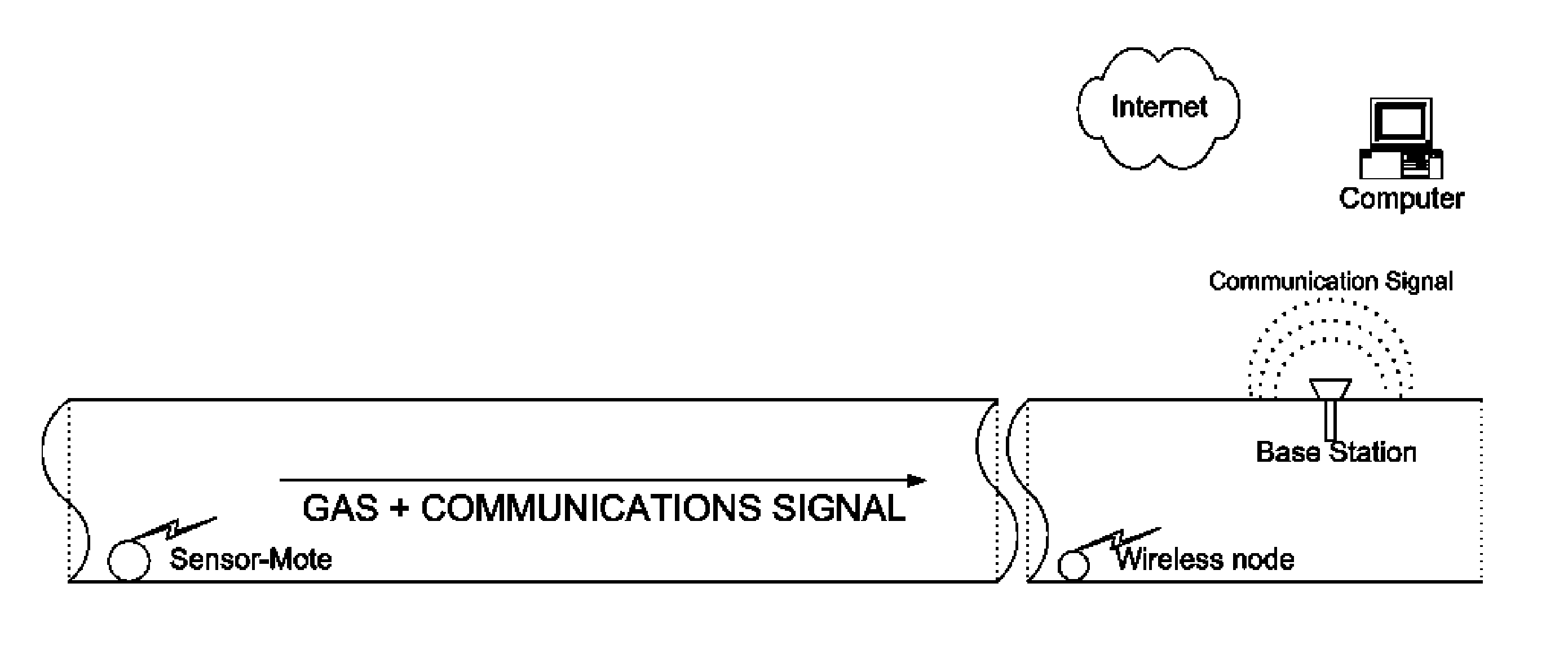

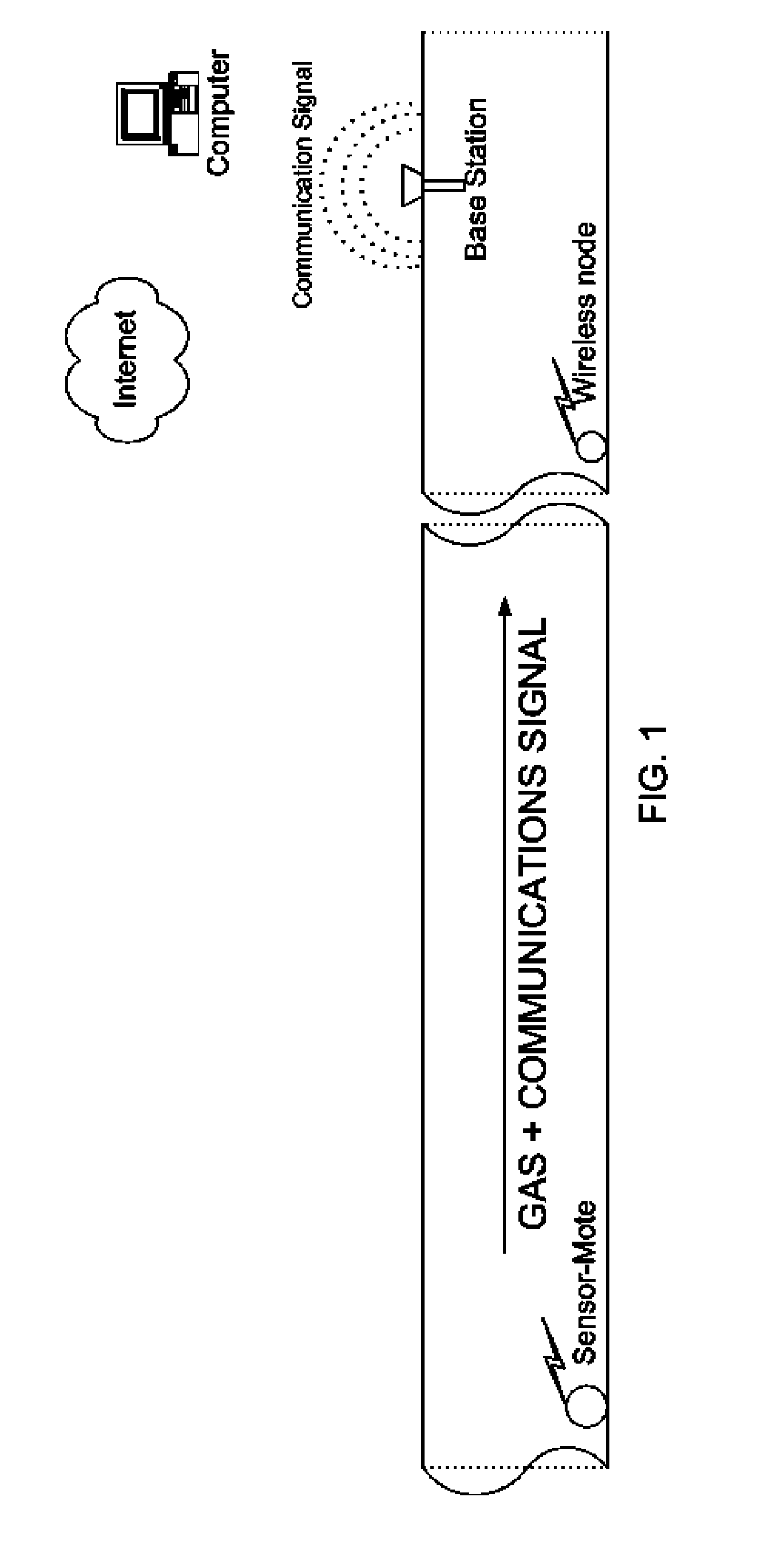

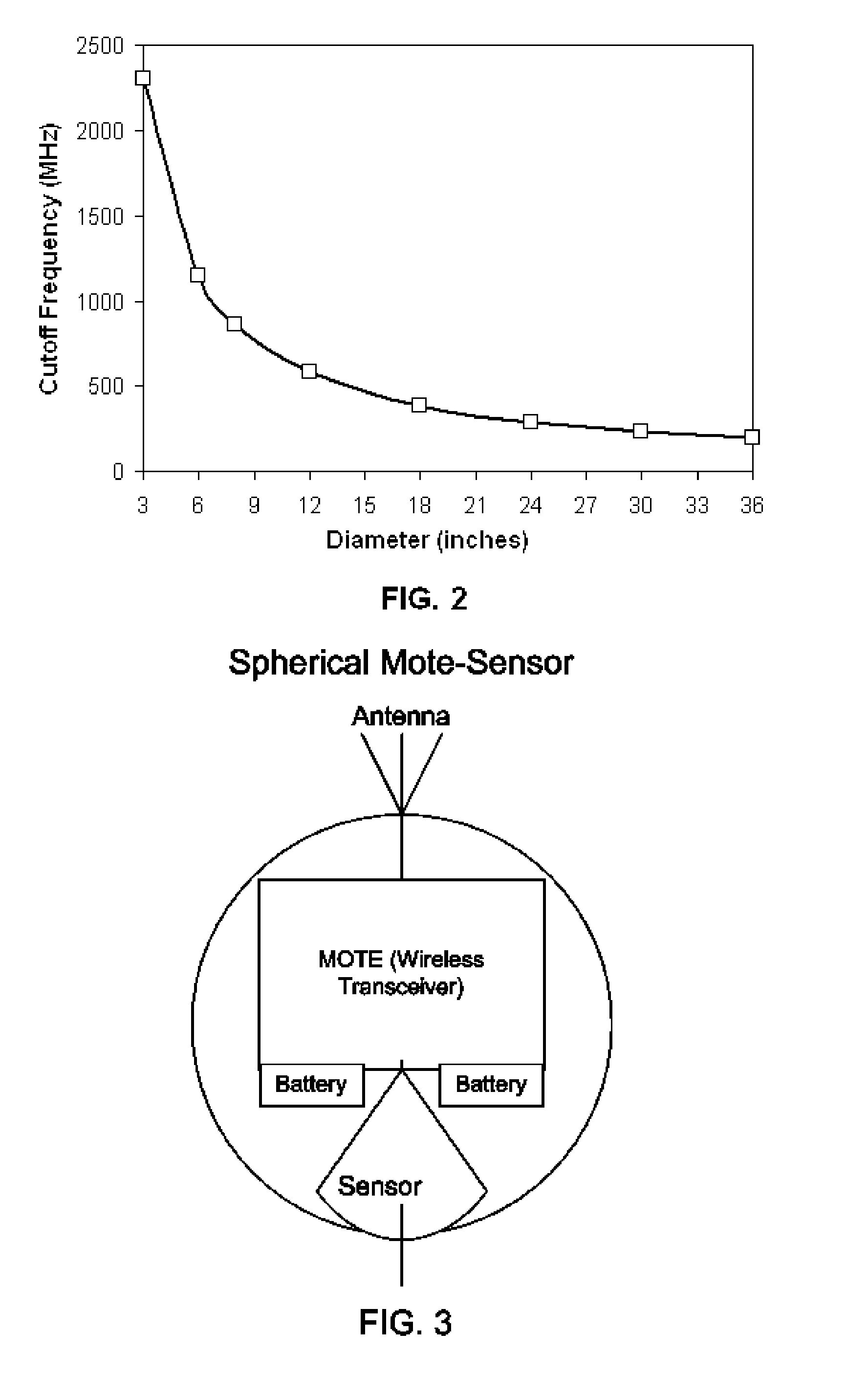

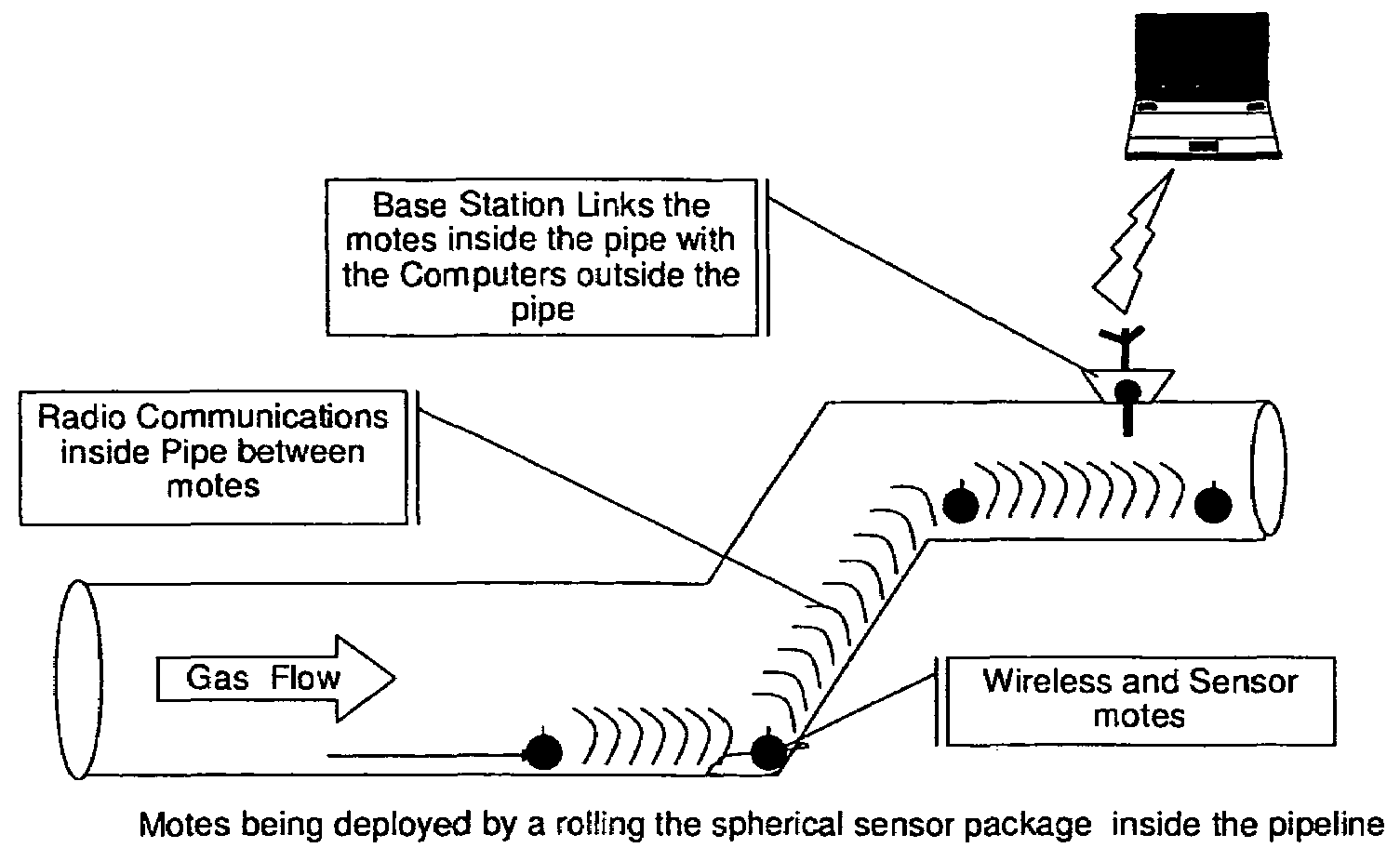

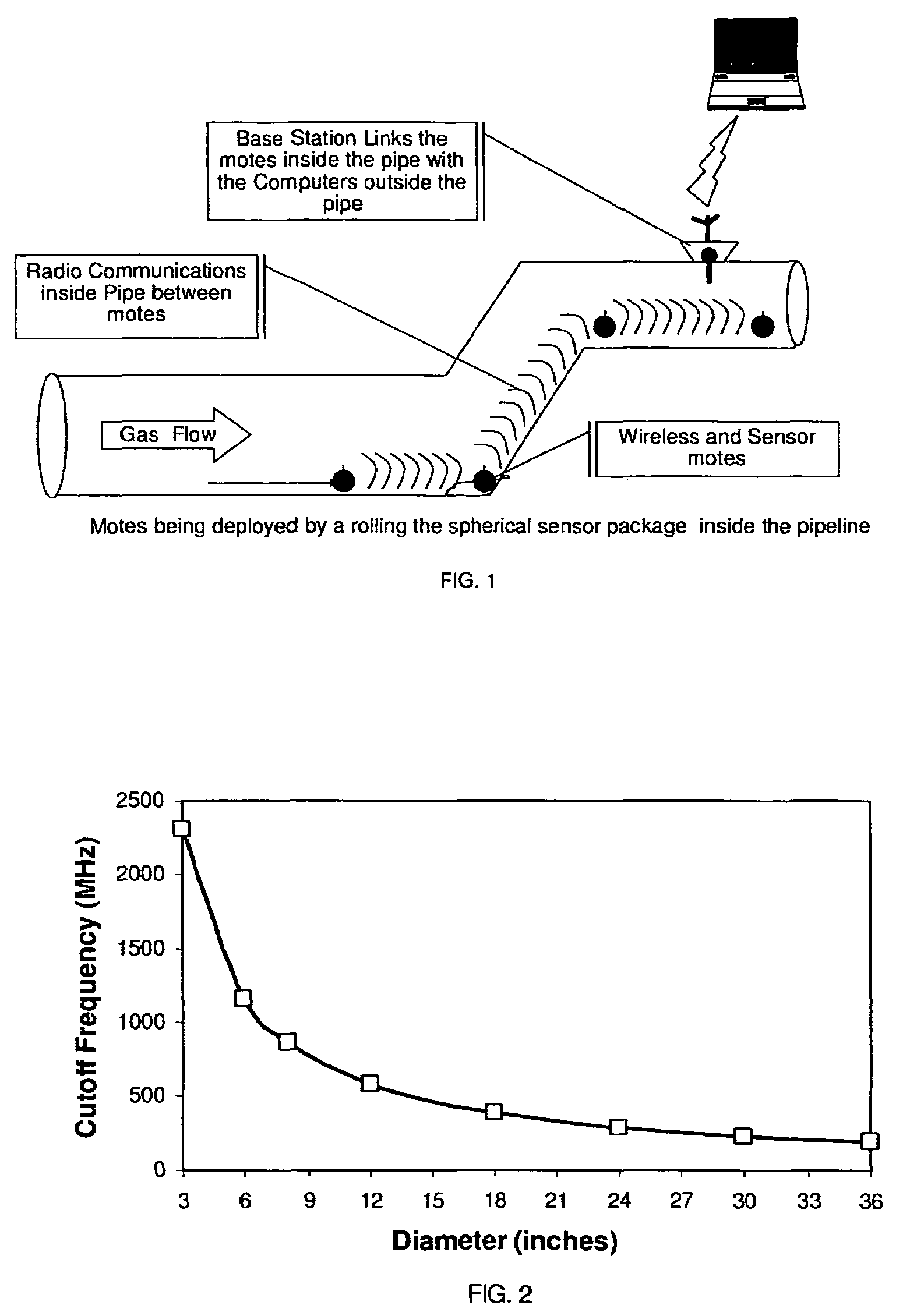

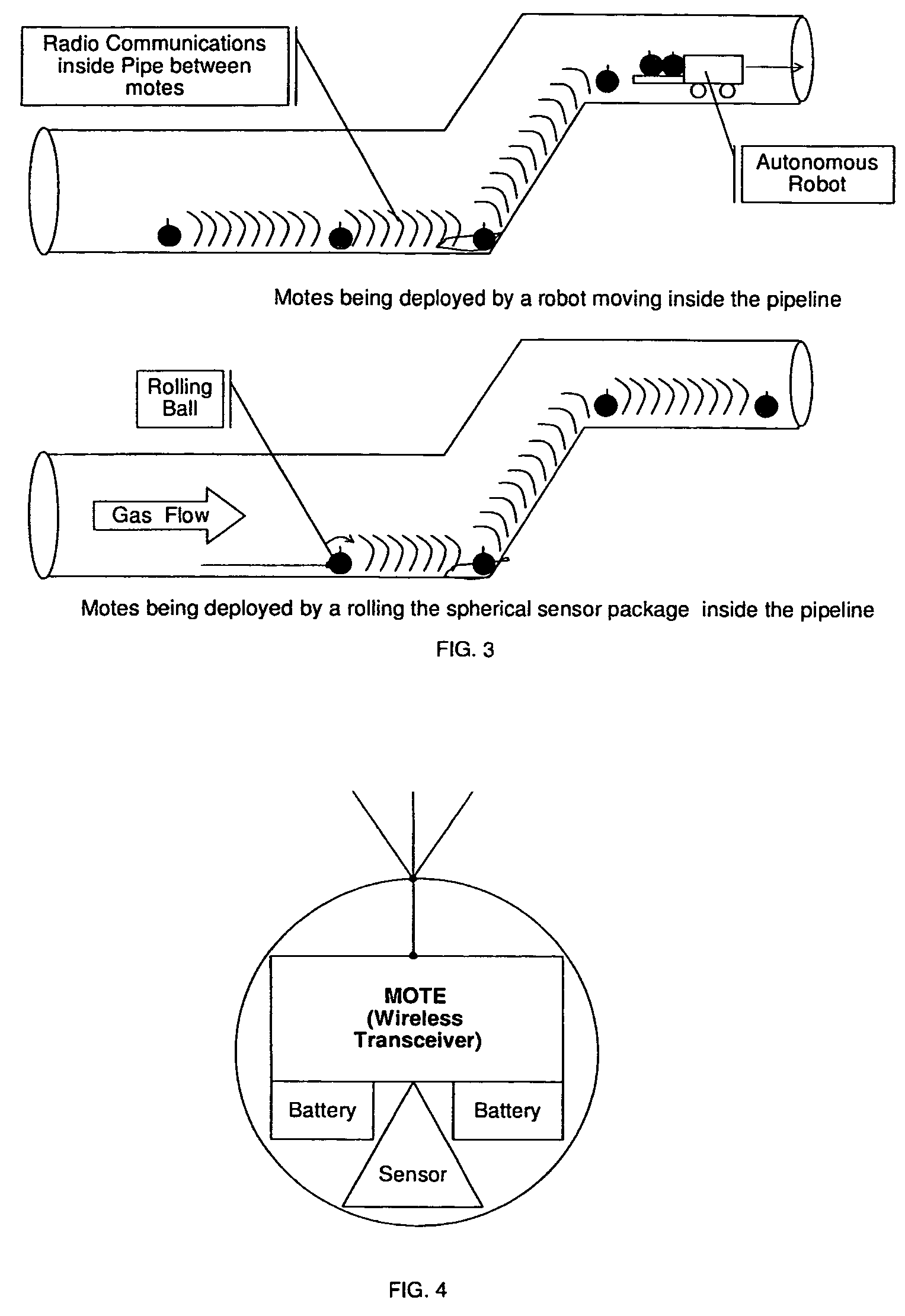

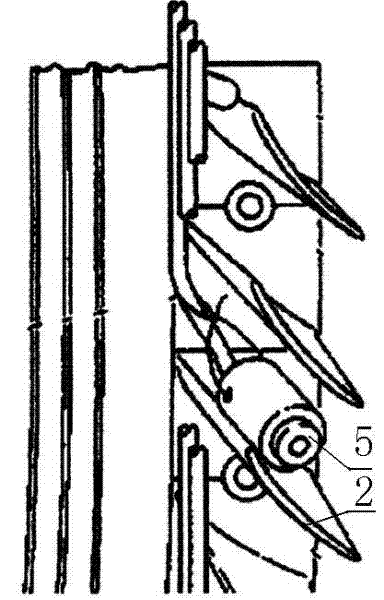

Remote Monitoring of Pipelines using Wireless Sensor Network

InactiveUS20050145018A1Low costLittle powerVehicle testingDetection of fluid at leakage pointLine sensorWireless transceiver

A wireless sensor system is installed inside pipelines using sensors and wireless transceivers that are small, low-cost, and rugged. The objective is monitoring the pipeline and recommending maintenance and repair at specific locations in the pipeline. Maintenance includes detection of leaks and prevention of catastrophic failures as a result of internal corrosion or other damage, such as third party mechanical damage, using multitude of sensors. After establishing the wireless sensor network the network is activated so the sensor can make measurements periodically or continuously using instructions transmitted via the base station. The sensor data from the various sensors are transmitted inside the pipe and extracted to access points in the pipeline to a remote computer that stores the data within the computer memory. The sensed information can be used for monitoring as well as analysis using a recommendation engine to provide maintenance and repair alerts.

Owner:SOUTHWEST RES INST

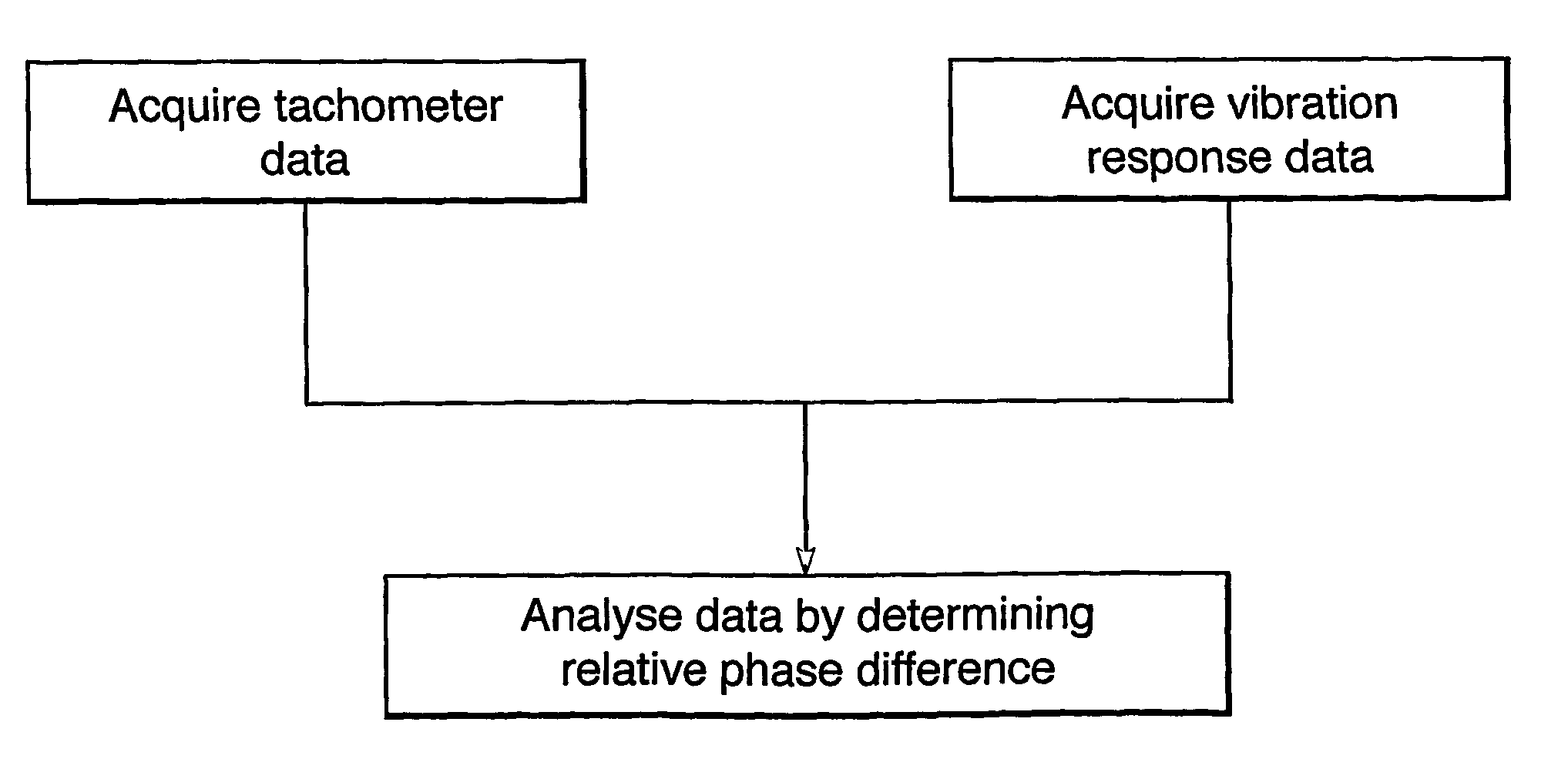

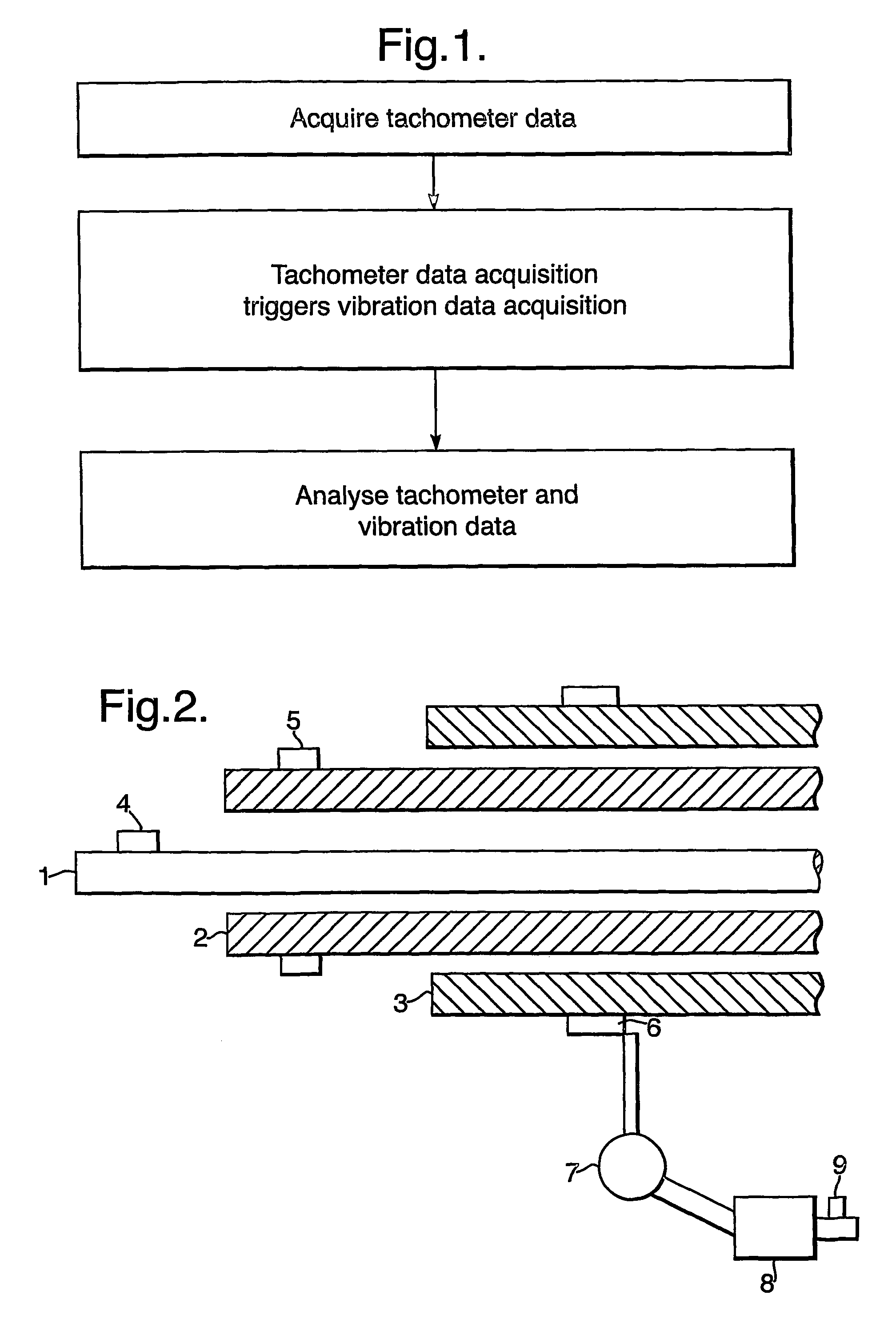

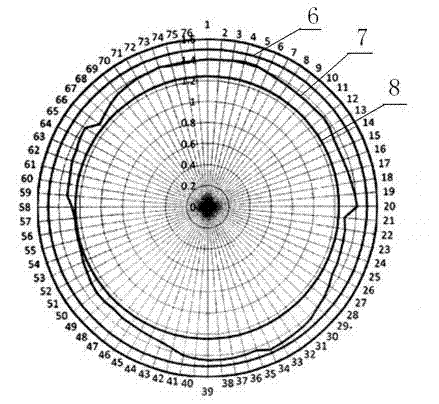

Method and system for analysing tachometer and vibration data from an apparatus having one or more rotary components

ActiveUS7640802B2Avoid problemsEasy to getVibration measurement in solidsVehicle testingForce frequencyVibration amplitude

A method of analysing tachometer and vibration response data from an apparatus having one or more rotary components is provided. The method comprises the steps of: providing vibration response data and corresponding tachometer data from the apparatus for a period over which a rotary component of the apparatus varies in rotational speed, the tachometer data being for that component; repeatedly performing at intervals throughout the period the sub-steps of: determining a forcing frequency of the component from the tachometer data and a corresponding vibration response frequency of the apparatus from the vibration response data, comparing the forcing and vibration response frequencies to determine the relative phase difference between the frequencies, and determining the corresponding amplitude of the vibration response from the vibration response data; and plotting the relative phase differences and vibration amplitudes on a polar diagram. The plot trajectory is characteristic of the behavior of the apparatus over the period.

Owner:ROLLS ROYCE PLC +1

Method and system for analysing tachometer and vibration data from an apparatus having one or more rotary components

ActiveUS20070006636A1Avoid problemsEasy to getVehicle testingVibration measurement in solidsForce frequencyVibration amplitude

A method of analysing tachometer and vibration response data from an apparatus having one or more rotary components is provided. The method comprises the steps of: providing vibration response data and corresponding tachometer data from the apparatus for a period over which a rotary component of the apparatus varies in rotational speed, the tachometer data being for that component; repeatedly performing at intervals throughout the period the sub-steps of: determining a forcing frequency of the component from the tachometer data and a corresponding vibration response frequency of the apparatus from the vibration response data, comparing the forcing and vibration response frequencies to determine the relative phase difference between the frequencies, and determining the corresponding amplitude of the vibration response from the vibration response data; and plotting the relative phase differences and vibration amplitudes on a polar diagram. The plot trajectory is characteristic of the behaviour of the apparatus over the period.

Owner:ROLLS ROYCE PLC +1

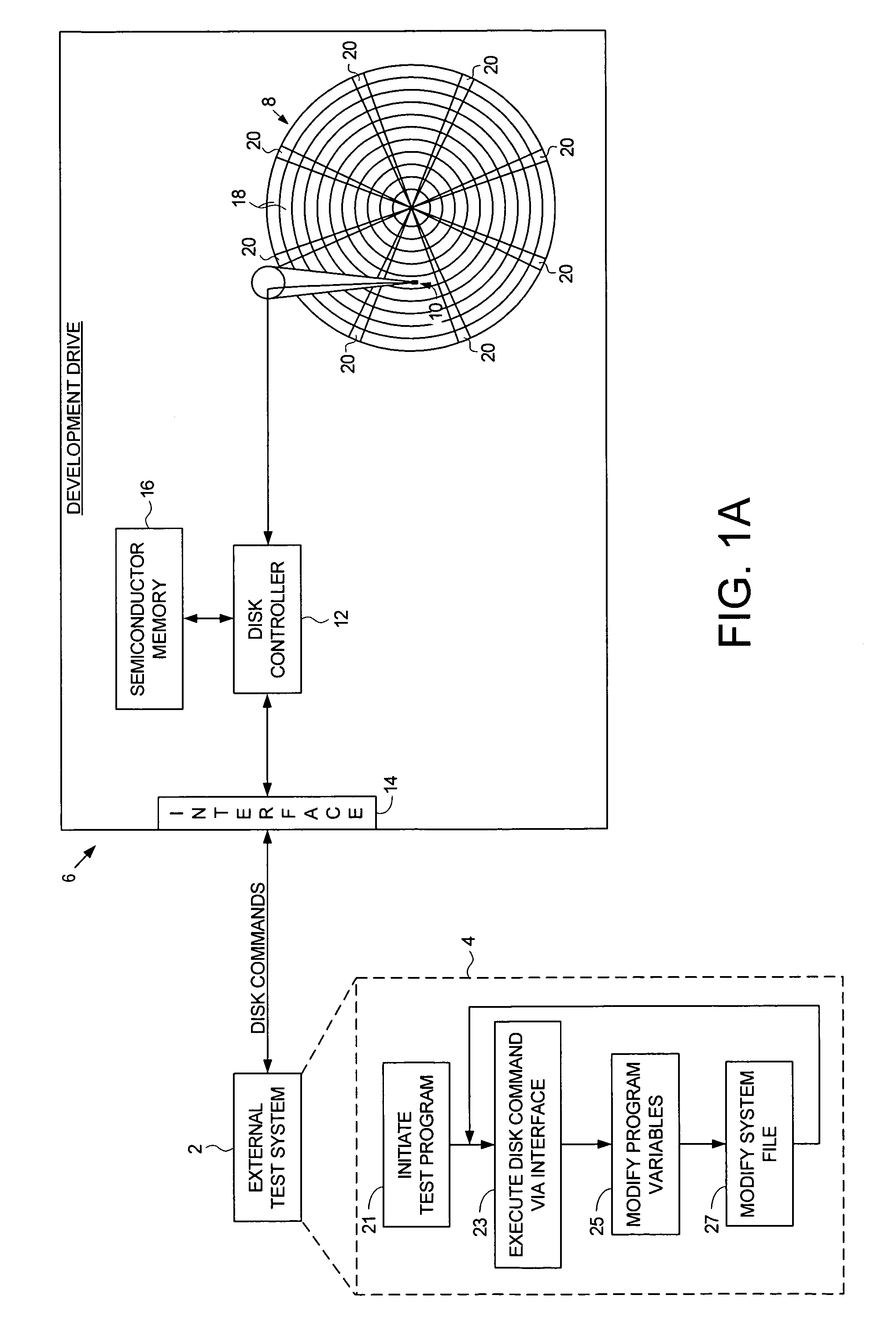

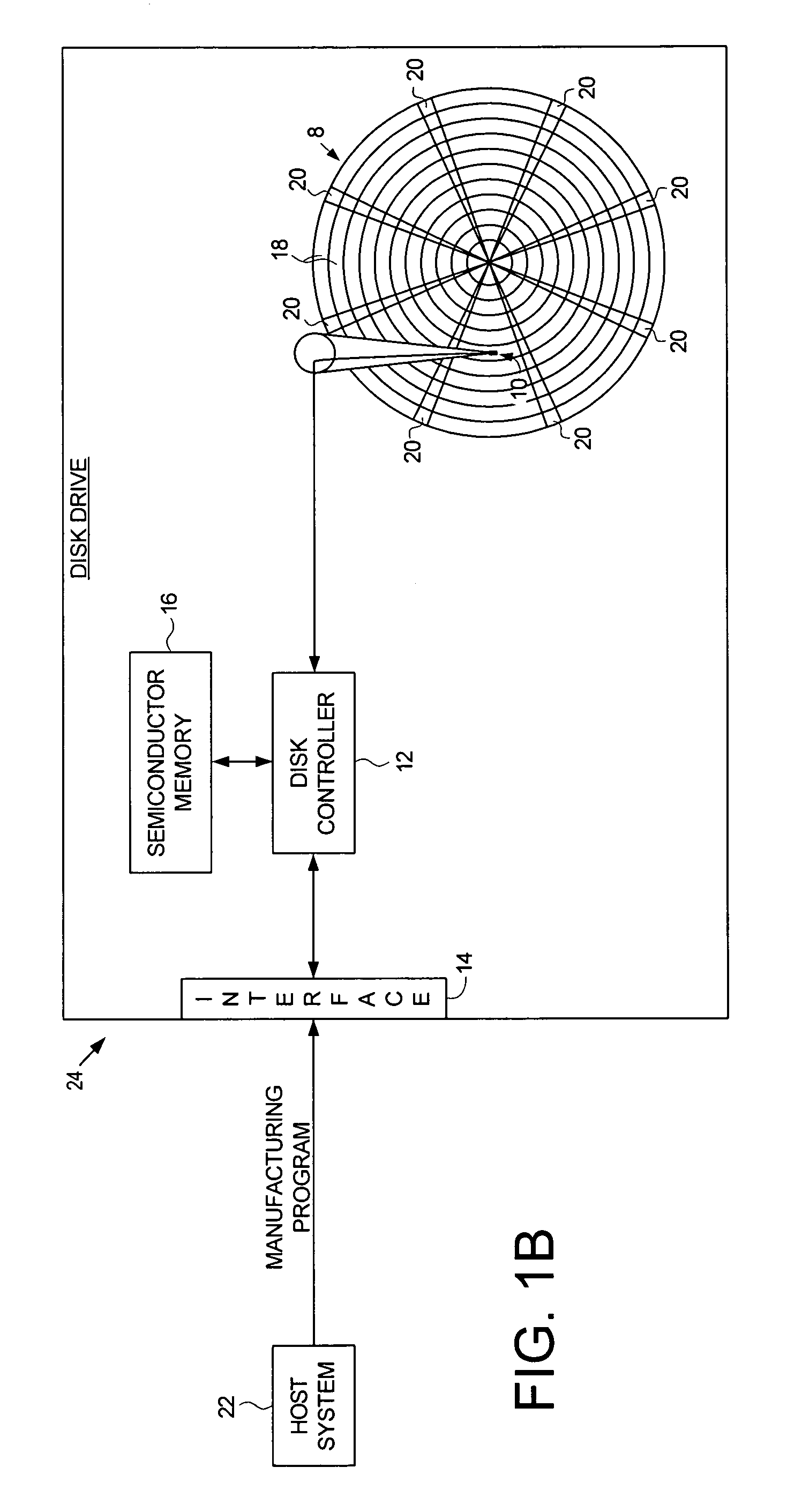

Developing a disk drive manufacturing program by executing the manufacturing program on an external test system

A method of manufacturing a disk drive is disclosed. The disk drive comprising a disk, a head actuated radially over the disk, a host interface for receiving disk commands from a host system, and a semiconductor memory for storing a drive operating program and a manufacturing program. The drive operating program comprising a disk access procedure for processing disk commands and a disk access vector for calling the disk access procedure. During a development stage, the manufacturing program is executed by an external test system that sends disk commands to a development drive. During a manufacturing stage, the manufacturing program is executed internally on each disk drive being manufactured by calling the disk access procedure of the drive operating program through the disk access vector.

Owner:WESTERN DIGITAL TECH INC

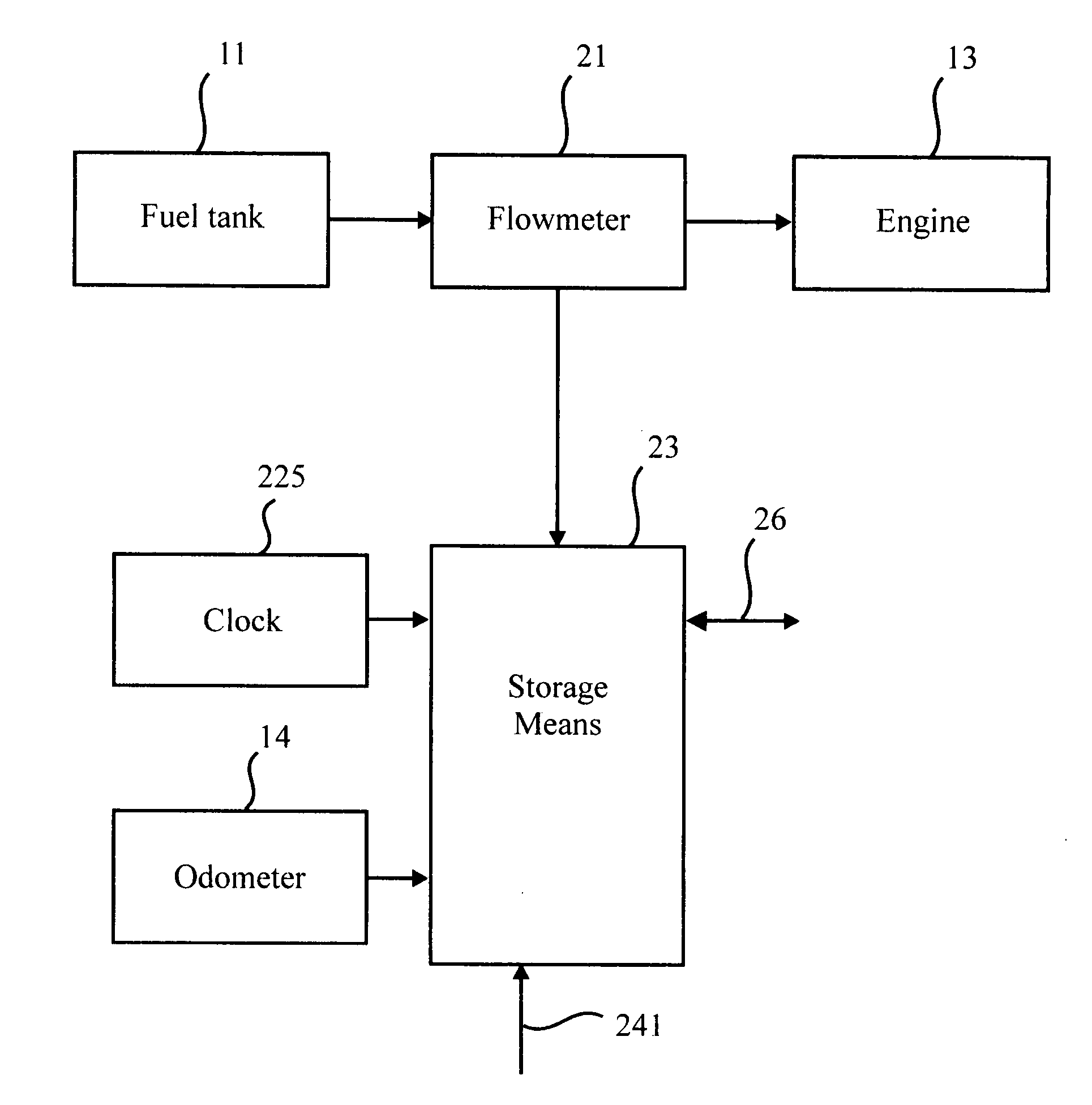

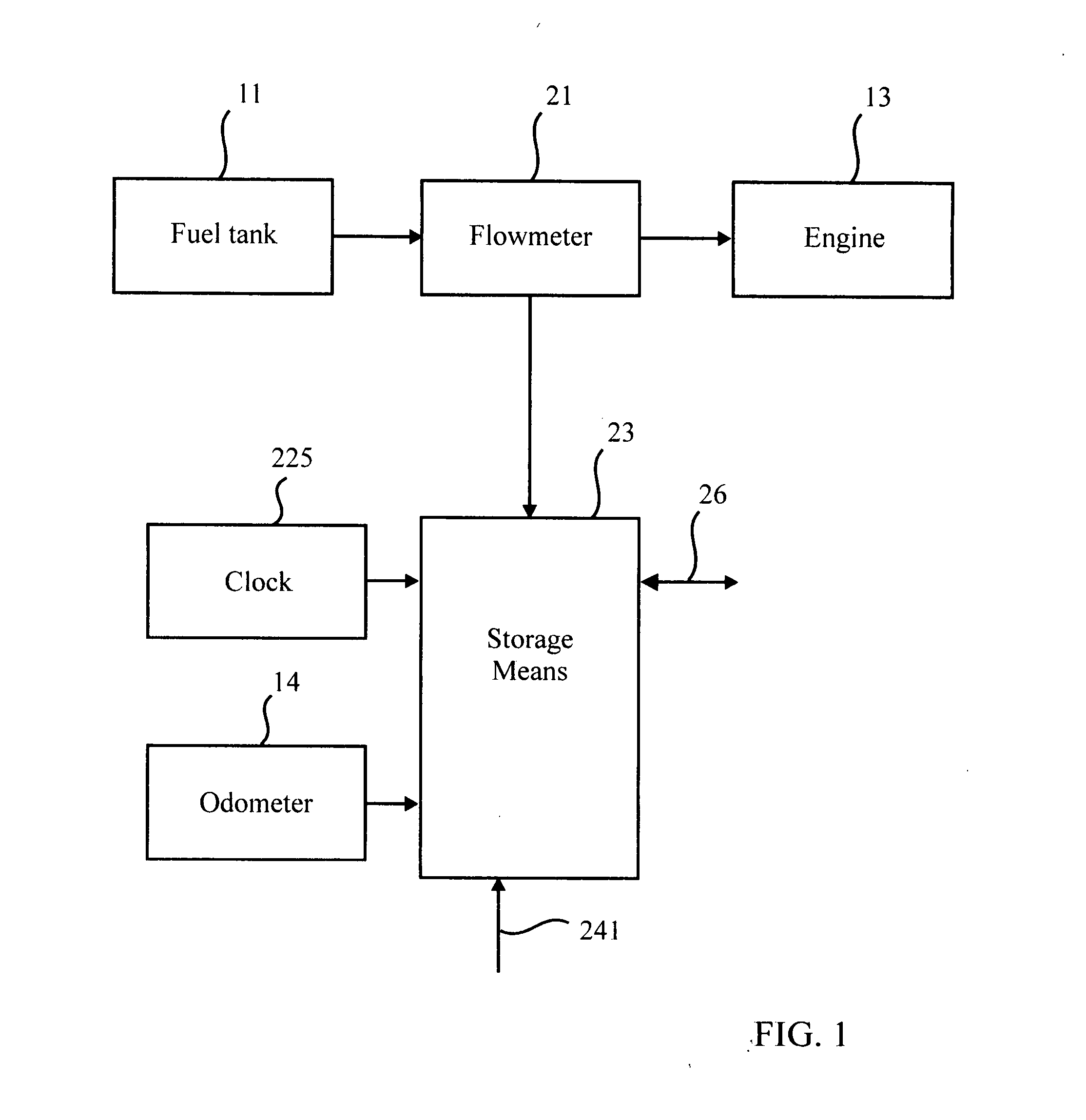

Measuring system and method

InactiveUS20070262855A1Cutting costsLow costRoad vehicles traffic controlEngine testingReal time analysisMeasurement device

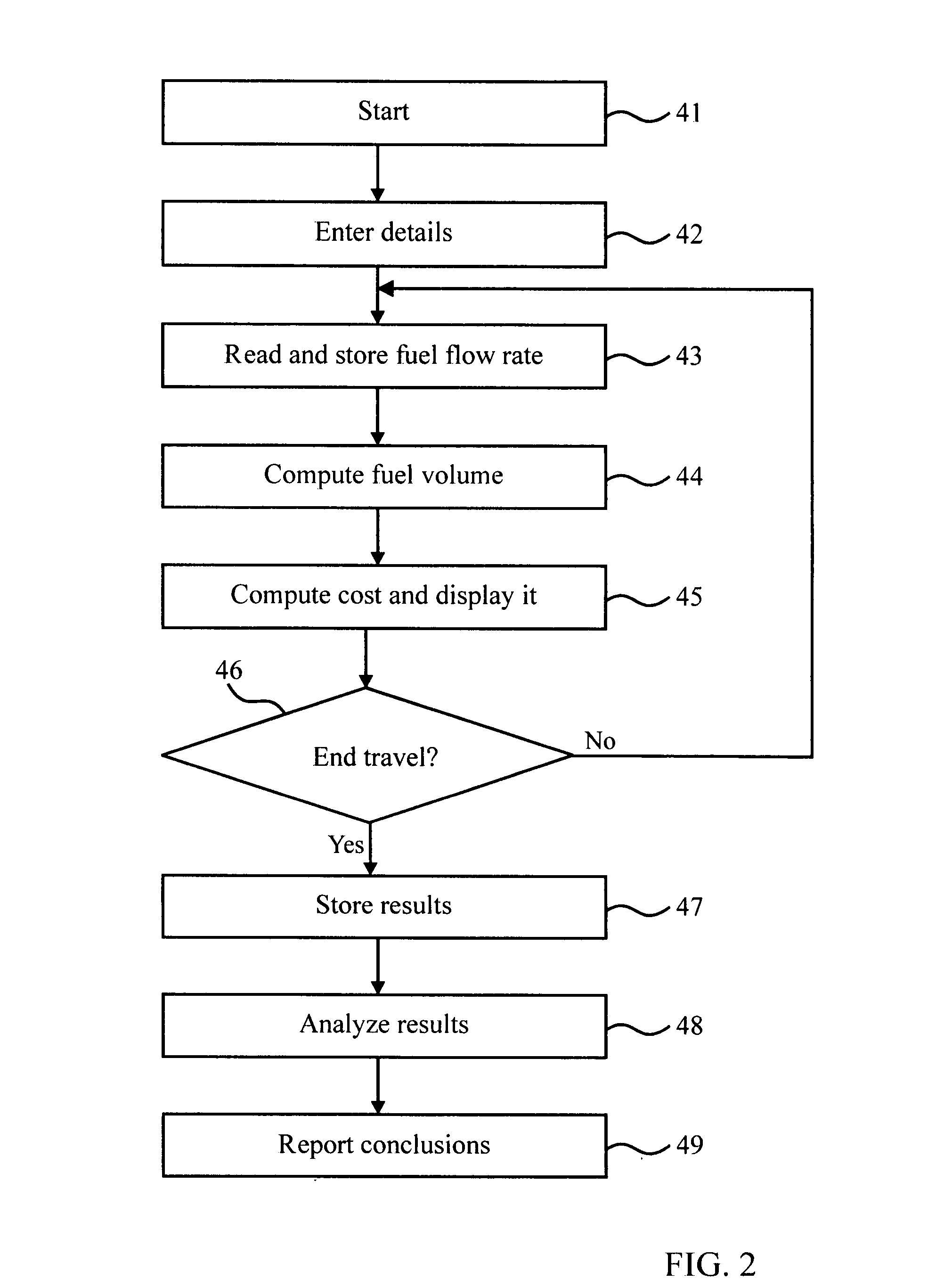

In a motor vehicle, a fuel consumption measurement system comprising: measuring device for the vehicle's fuel consumption as first data; measuring device for second data for variables which may affect the fuel consumption, the second data including at least locations traveled by the vehicle, and wherein vehicle's location is measured in real time using a global positioning system or using info provided by a cellular wireless supplier; c. storage for storing samples of the first data with the second data; d. computing device for analyzing in real time the stored first and second data for reaching conclusions relating to ways for reducing the fuel consumption, wherein the conclusions include at least the cost of fuel used; e. display for presenting the conclusions in real time to a vehicle's driver.

Owner:ZUTA MARC +1

Intelligent condition-based engine/equipment management system

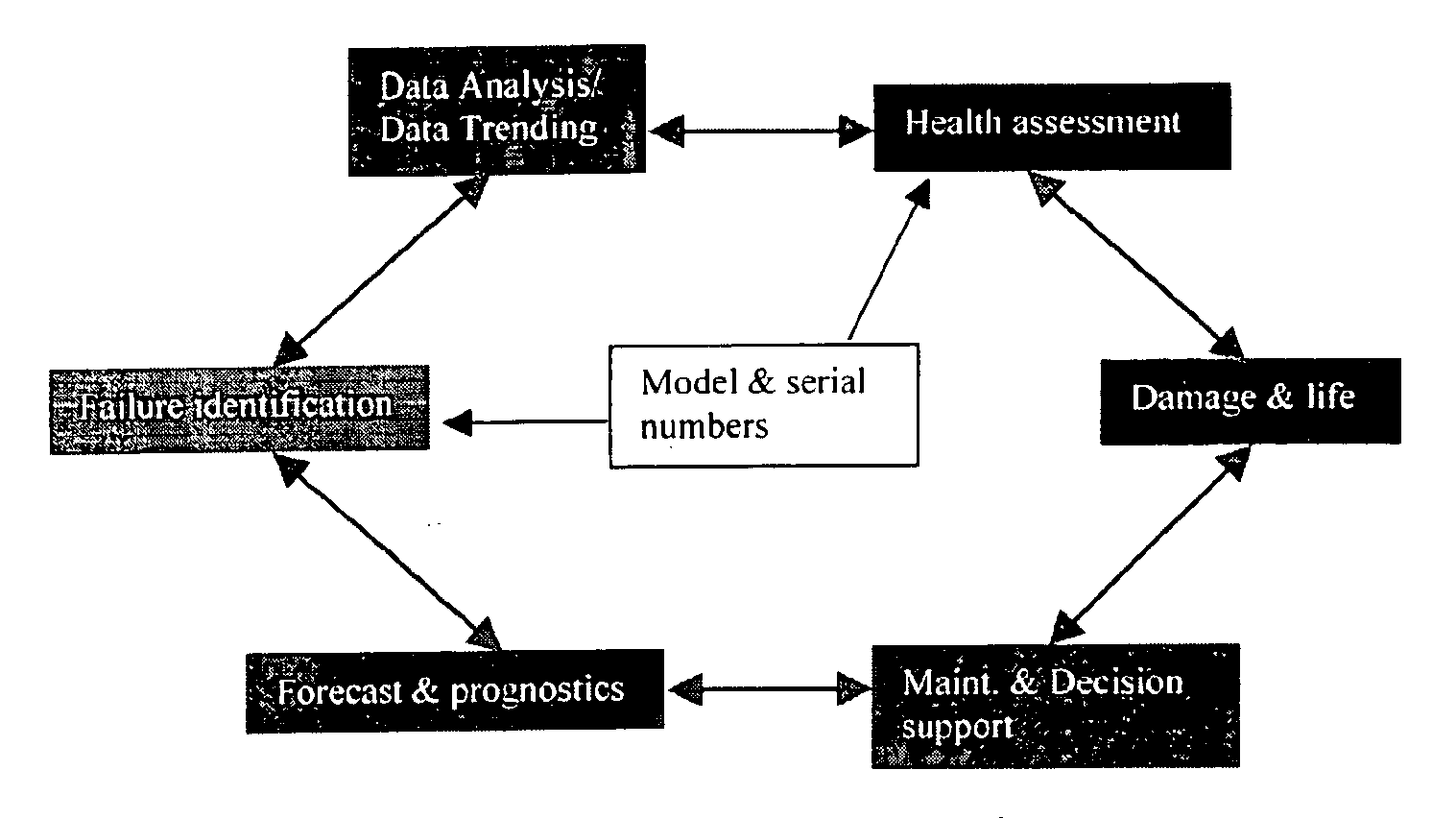

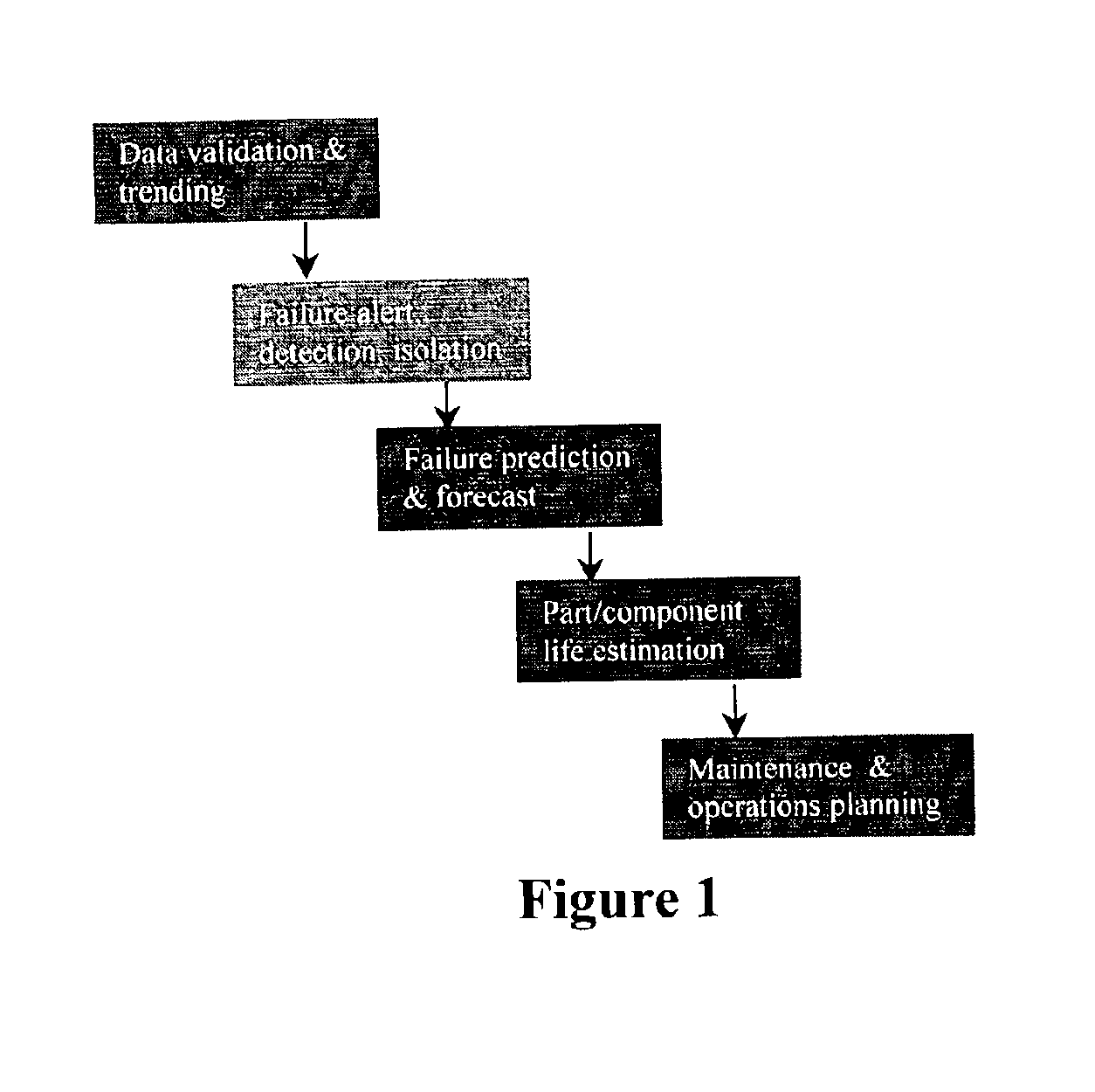

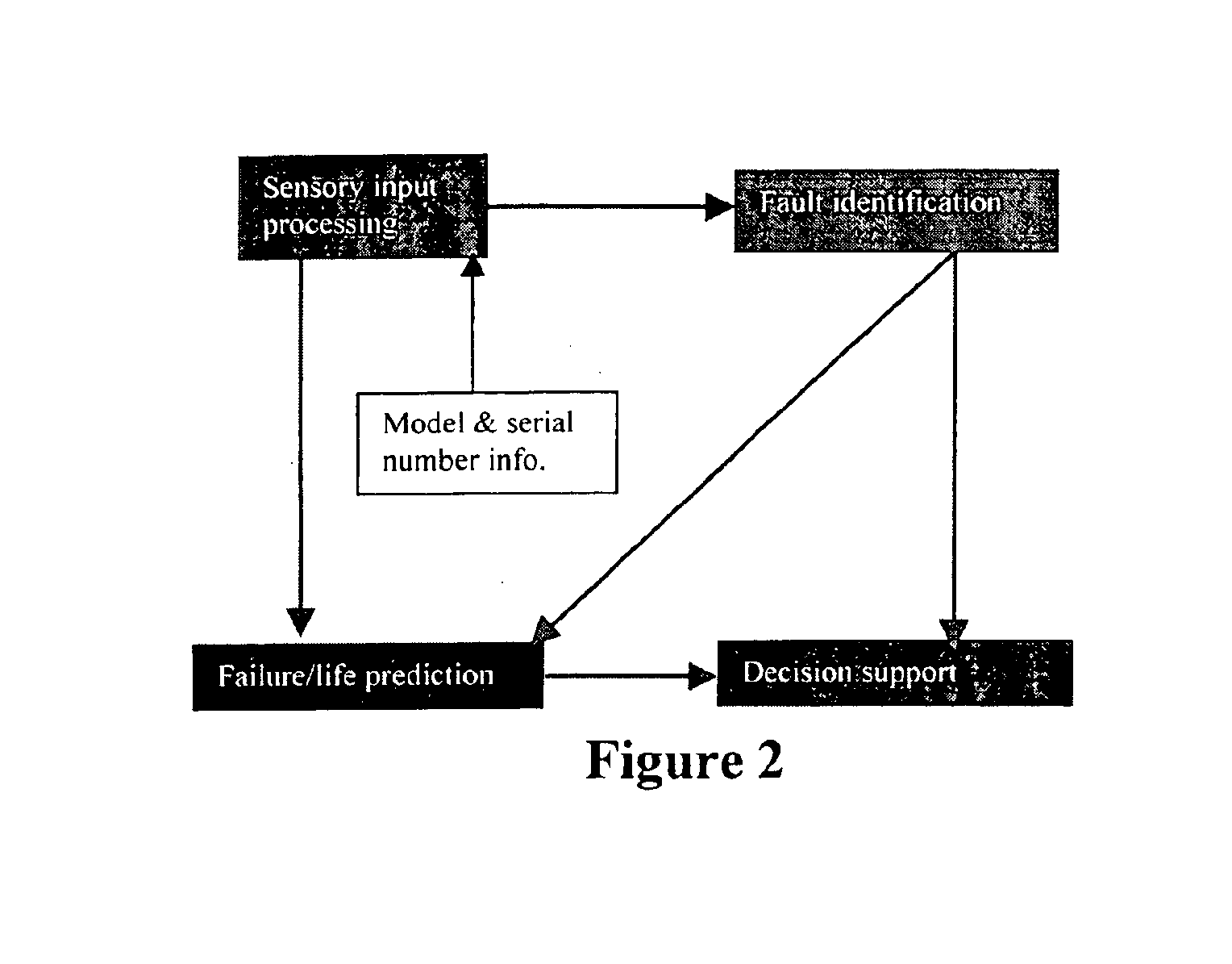

Health management of machines, such as gas turbine engines and industrial equipment, offers the potential benefits of efficient operations and reduced cost of ownership. Machine health management goes beyond monitoring operating conditions, it assimilates available information and makes the most favorable decisions to maximize the value of the machine. These decisions are usually related to predicted failure modes and their corresponding failure time, recommended corrective actions, repair / maintenance actions, and planning and scheduling options. Hence machine health management provides a number of functions that are interconnected and cooperative to form a comprehensive health management system. While these interconnected functions may have different names (or terminology) in different industries, an effective health management system should include four primary functions: sensory input processing, fault identification, failure / life prediction, planning and scheduling. These four functions form the foundation of the method of ICEMS (Intelligent Condition-based Engine / Equipment Management System). To facilitate information processing and decision making, these four functions may be repartitioned and regrouped, such as for network based computer software designed for health management of sophisticated machinery.

Owner:INTEL CORP

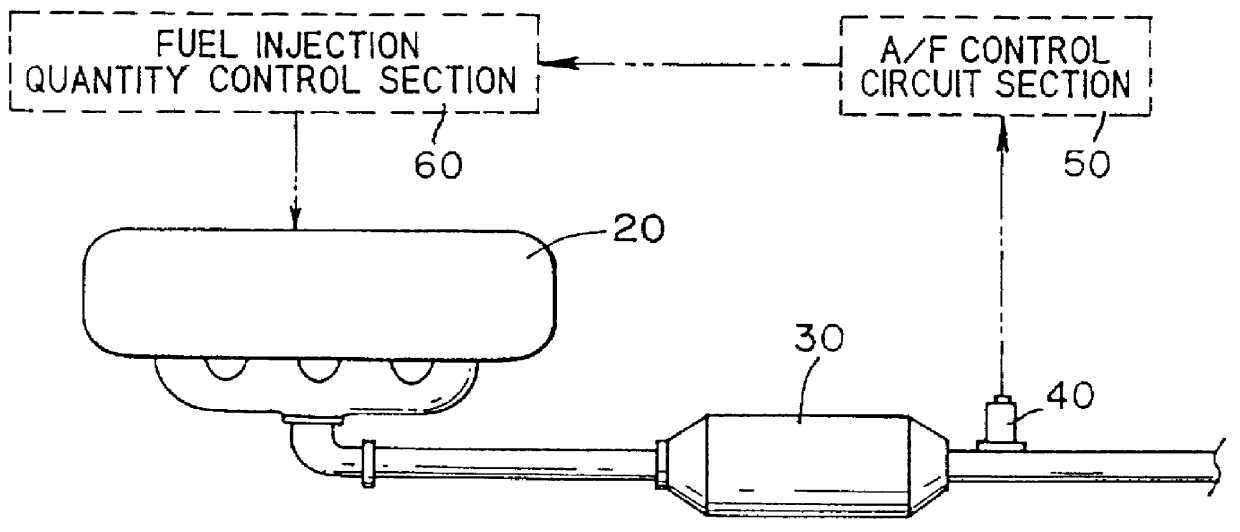

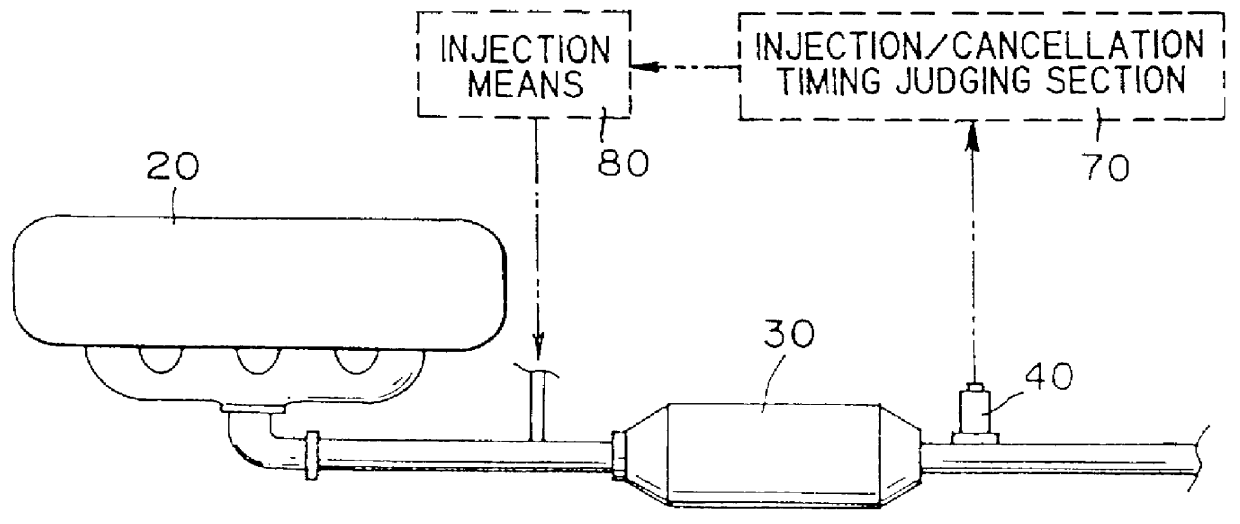

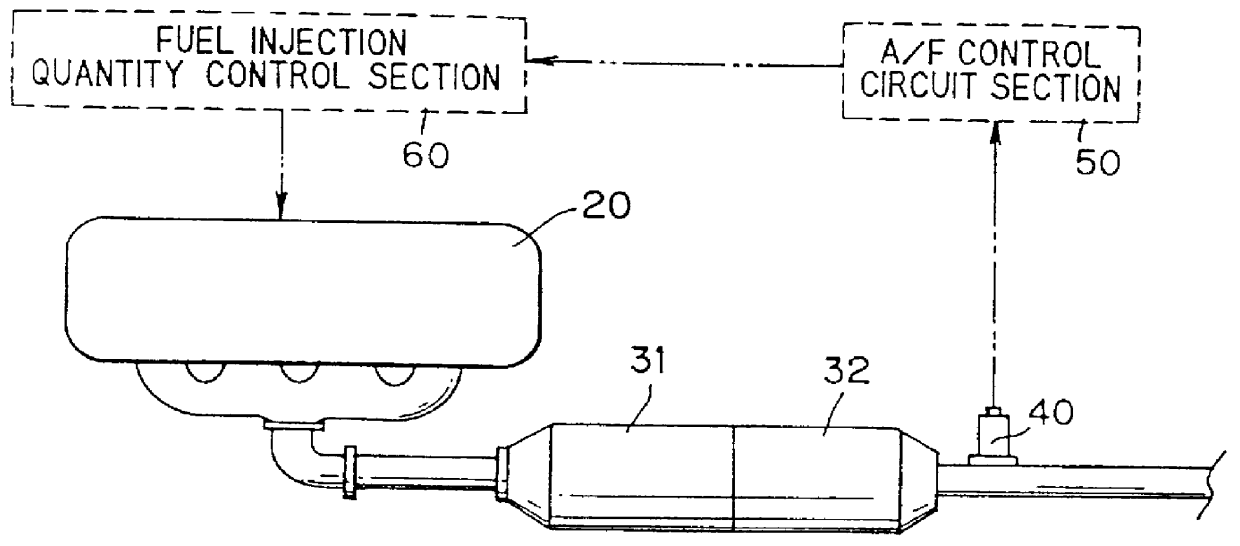

Method of controlling an engine exhaust gas system and method of detecting deterioration of catalyst/adsorbing means

InactiveUS6134883AAccurate detectionElectrical controlInternal combustion piston enginesNitrogen oxide sensorInternal combustion engine

In a method of controlling an exhaust gas system of an internal combustion engine including a nitrogen oxide reducing catalyst capable of adsorbing nitrogen oxide under a lean atmosphere and a nitrogen oxide sensor disposed downstream of the nitrogen oxide reducing catalyst, the nitrogen oxide reducing catalyst and the nitrogen oxide sensor are disposed in the exhaust gas system operated mainly under a lean condition, respectively. An output value of the nitrogen oxide sensor is compared with a predetermined value, and an operation condition of the internal combustion engine is temporarily changed into a stoichiometric condition or a rich condition, or a fuel is injected upstream of the nitrogen oxide reducing catalyst, so that the nitrogen oxide adsorbed to the nitrogen oxide reducing catalyst is detached or decomposed, and again the internal combustion engine is operated under the lean condition. Deterioration of the catalyst is determined based on Nox amount which is calculated from the sensor output, exhaust has flow amount and vehicle running distance.

Owner:NGK INSULATORS LTD

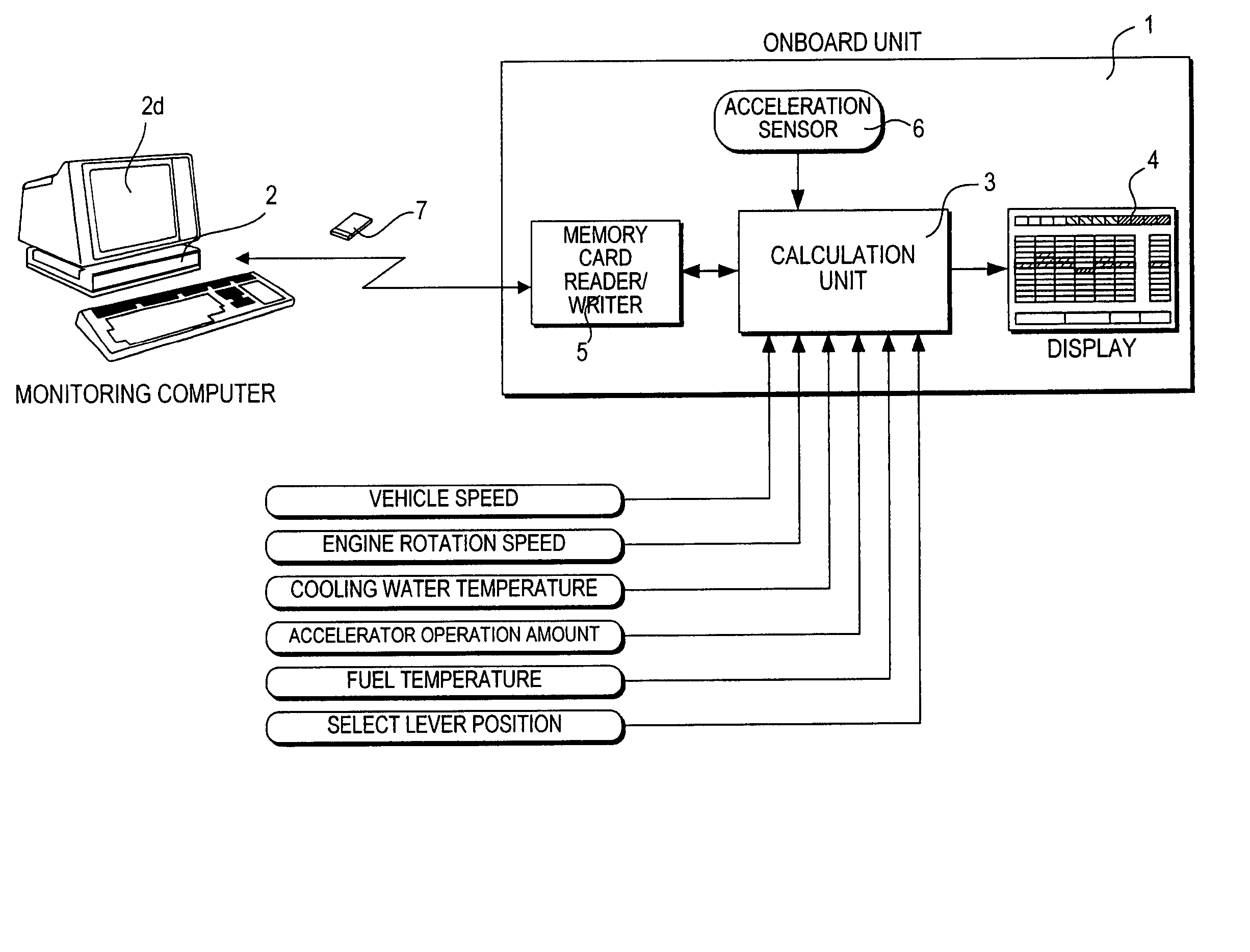

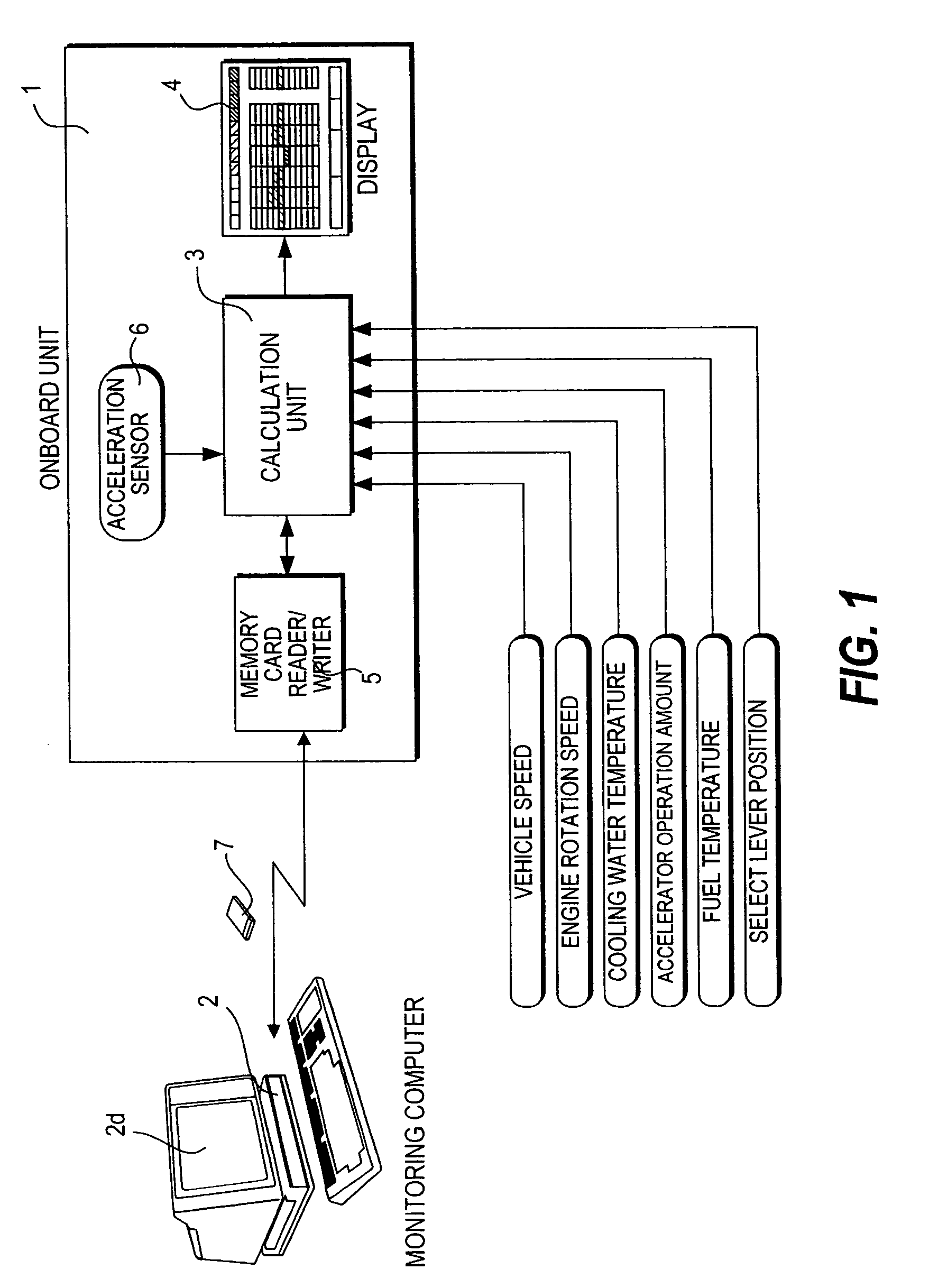

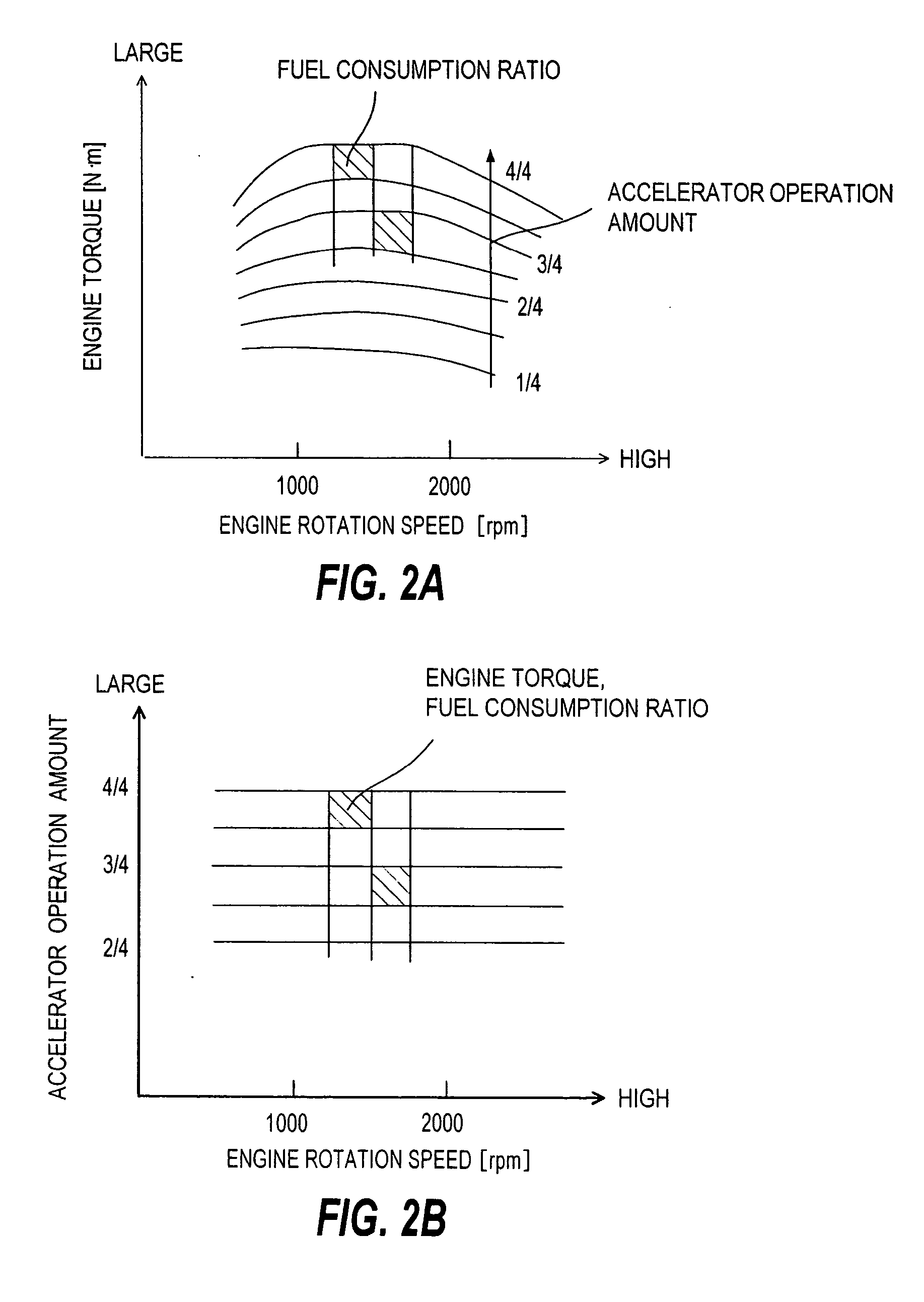

Evaluation system for vehicle operating conditions and evaluation method thereof

InactiveUS20050021222A1Improve fuel economyImprove economyVehicle testingAnalogue computers for vehiclesDisplay deviceEvaluation system

Owner:MIYAMA

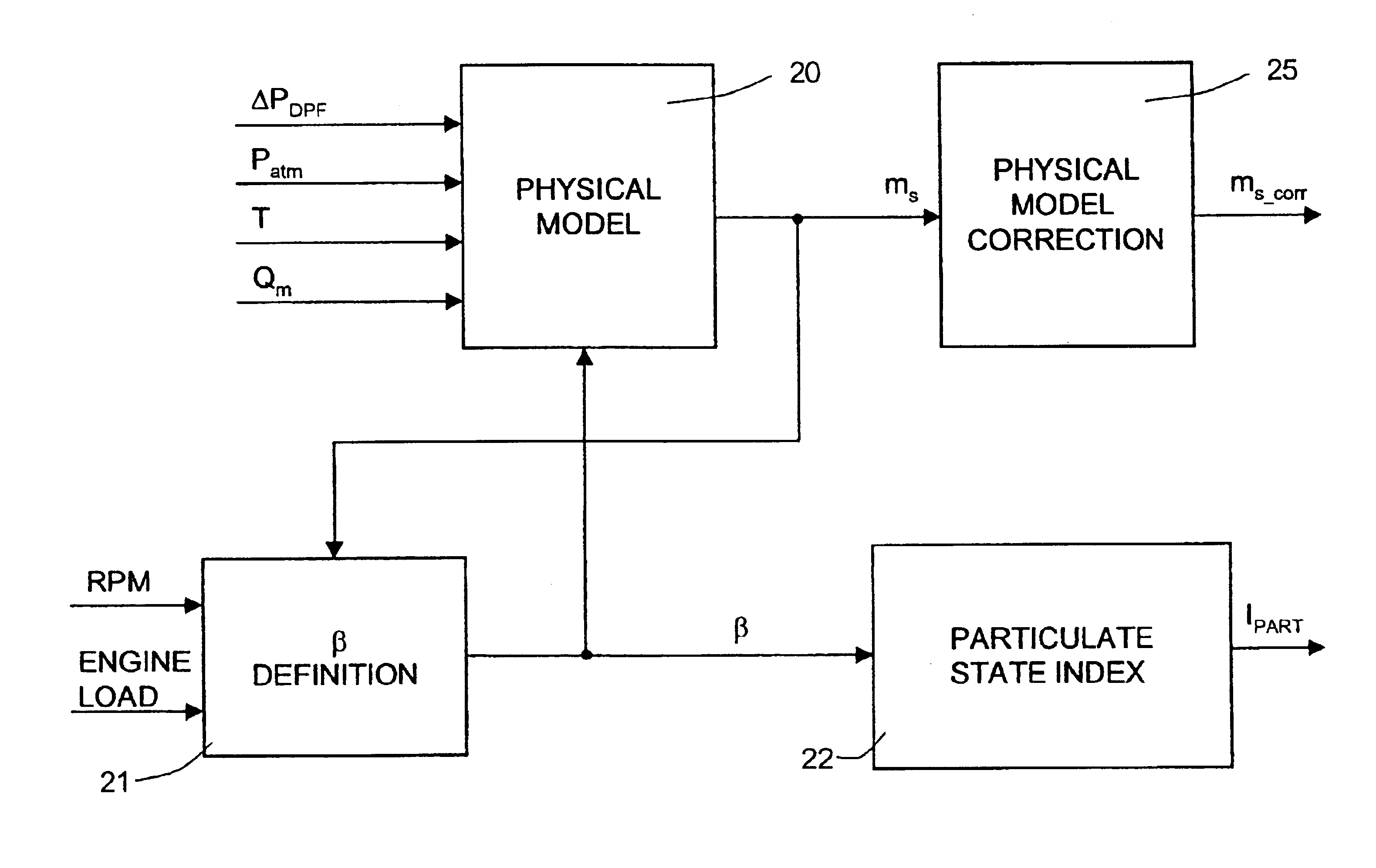

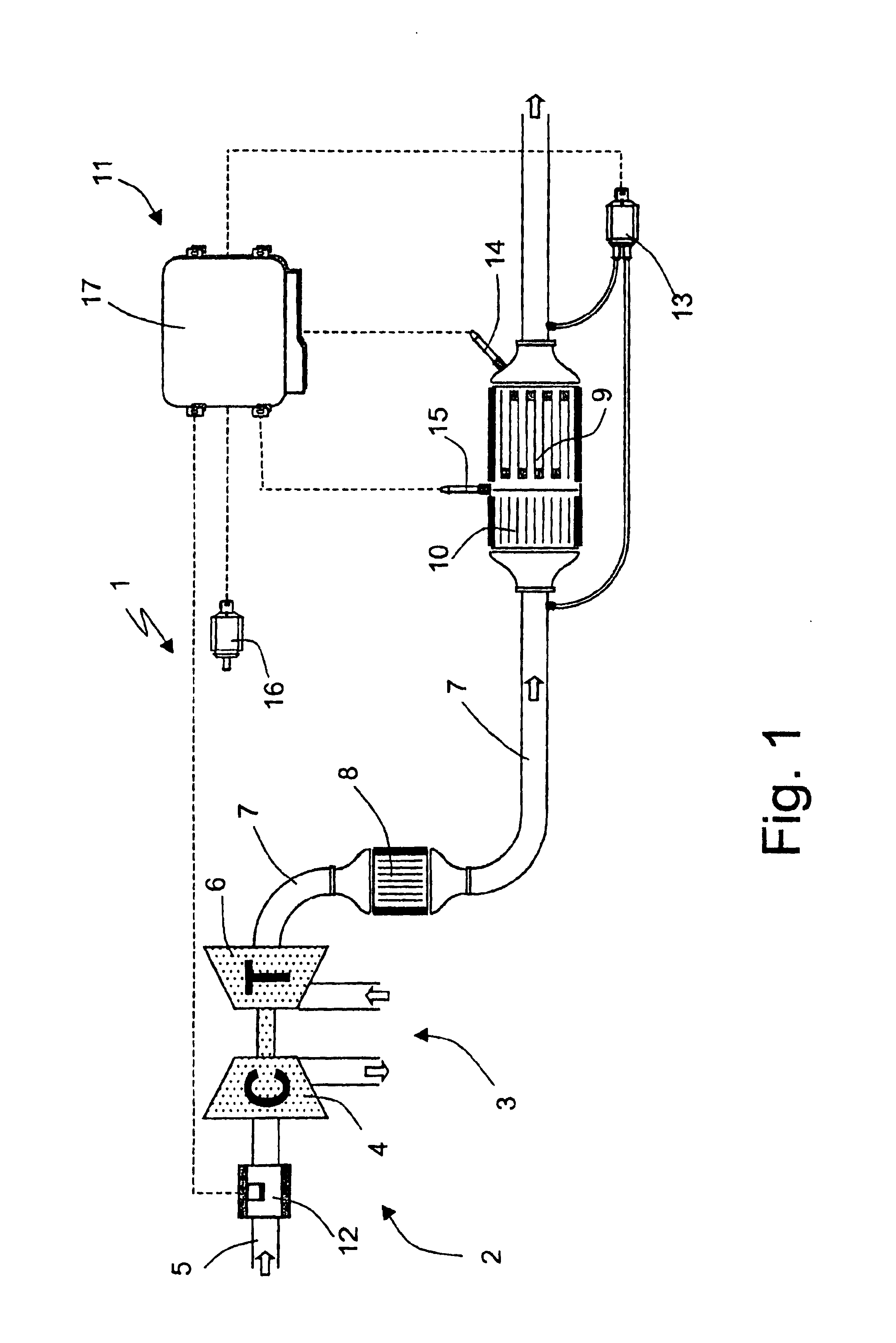

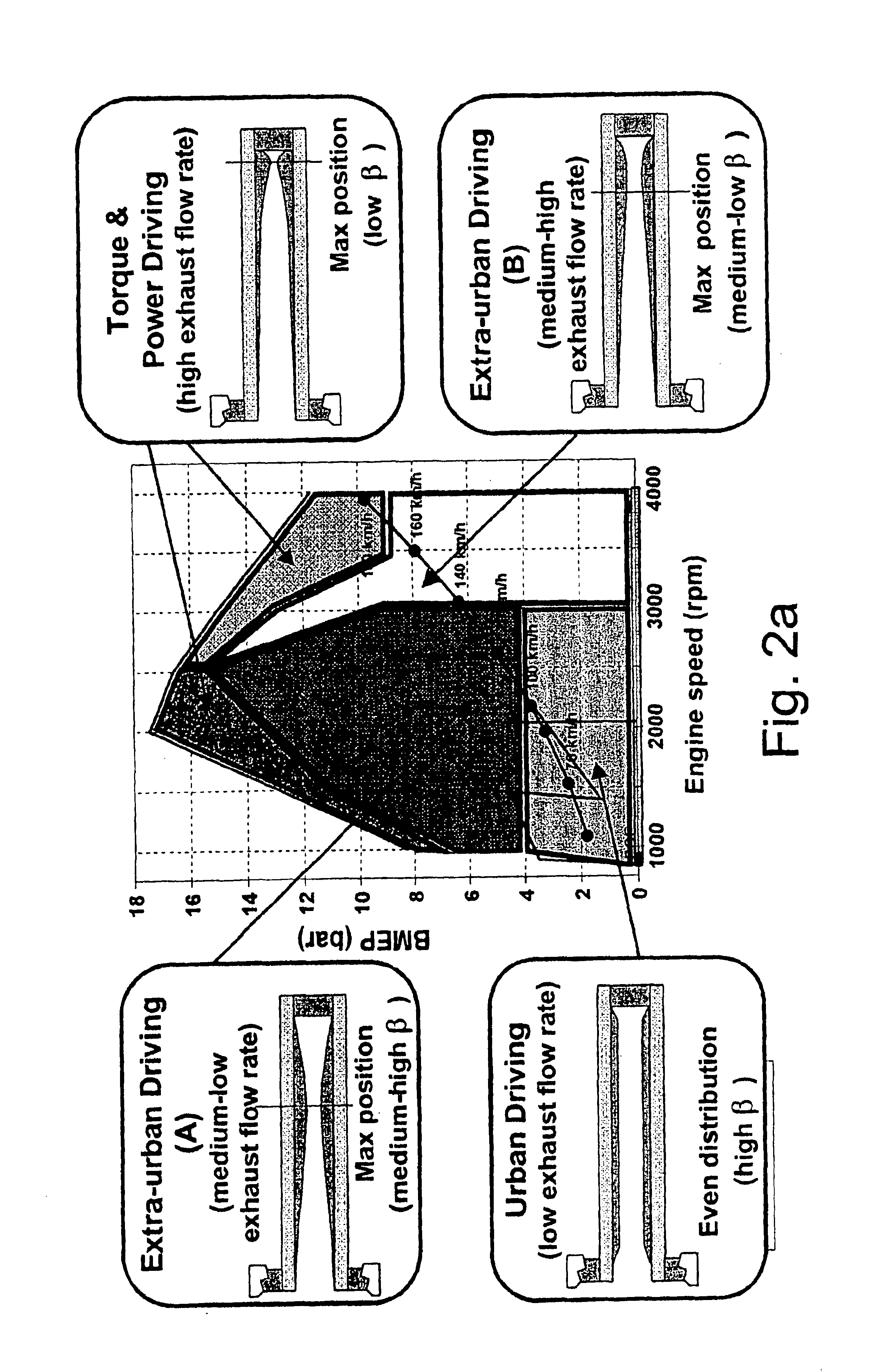

Method of determining the amount of particulate accumulated in a particulate filter

InactiveUS6941750B2Drawback can be obviatedElectrical controlInternal combustion piston enginesParticulatesEngineering

A method of determining the amount of particulate accumulated in a particulate filter, is based on determining possible variations in the spatial distribution and / or physical-chemical properties of the particulate as a function of engine operating conditions and past particulate accumulation in the particulate filter. A number of reference values defining a relationship between the amount of particulate accumulated in the particulate filter and the pressure drop across the particulate filter are mapped, each of the reference values relating to a respective steady engine operating condition in which particulate is accumulated in the particulate filter. In a given engine operating condition, an operating value of the parameter is then determined as a function of the reference value of the parameter relative to the same steady engine operating condition, and of past particulate accumulation in the particulate filter.

Owner:CENT RICERCHE FIAT SCPA

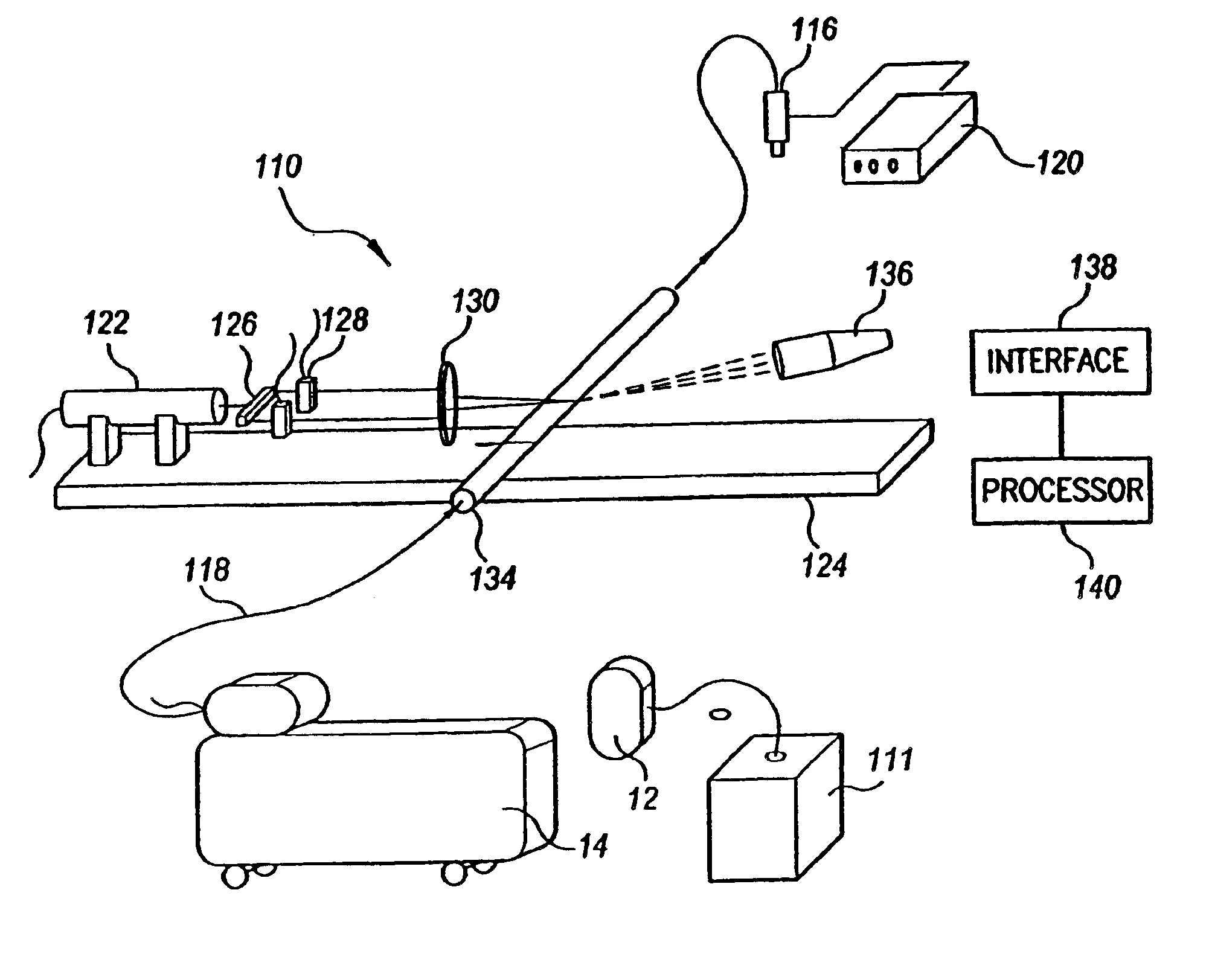

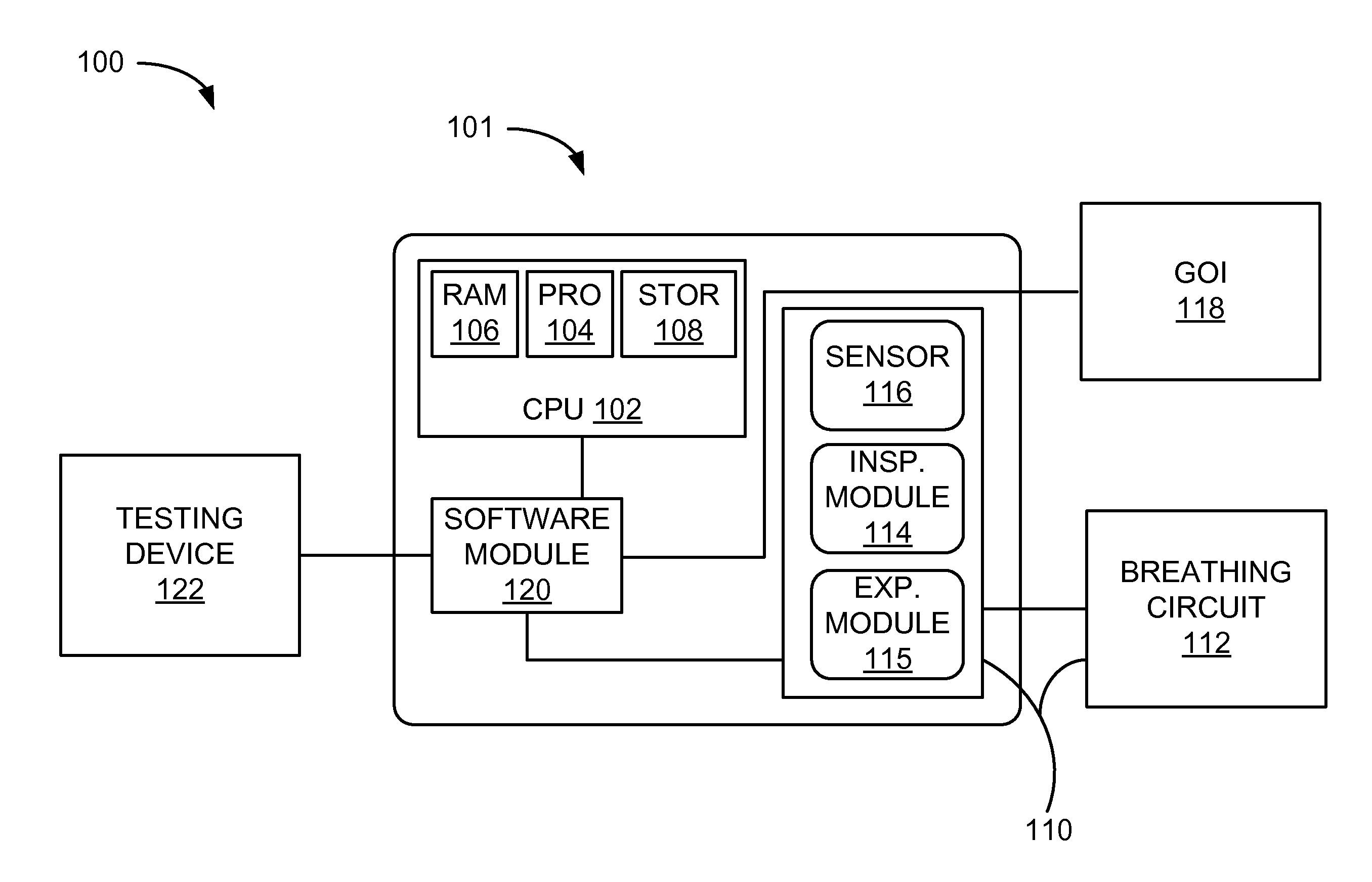

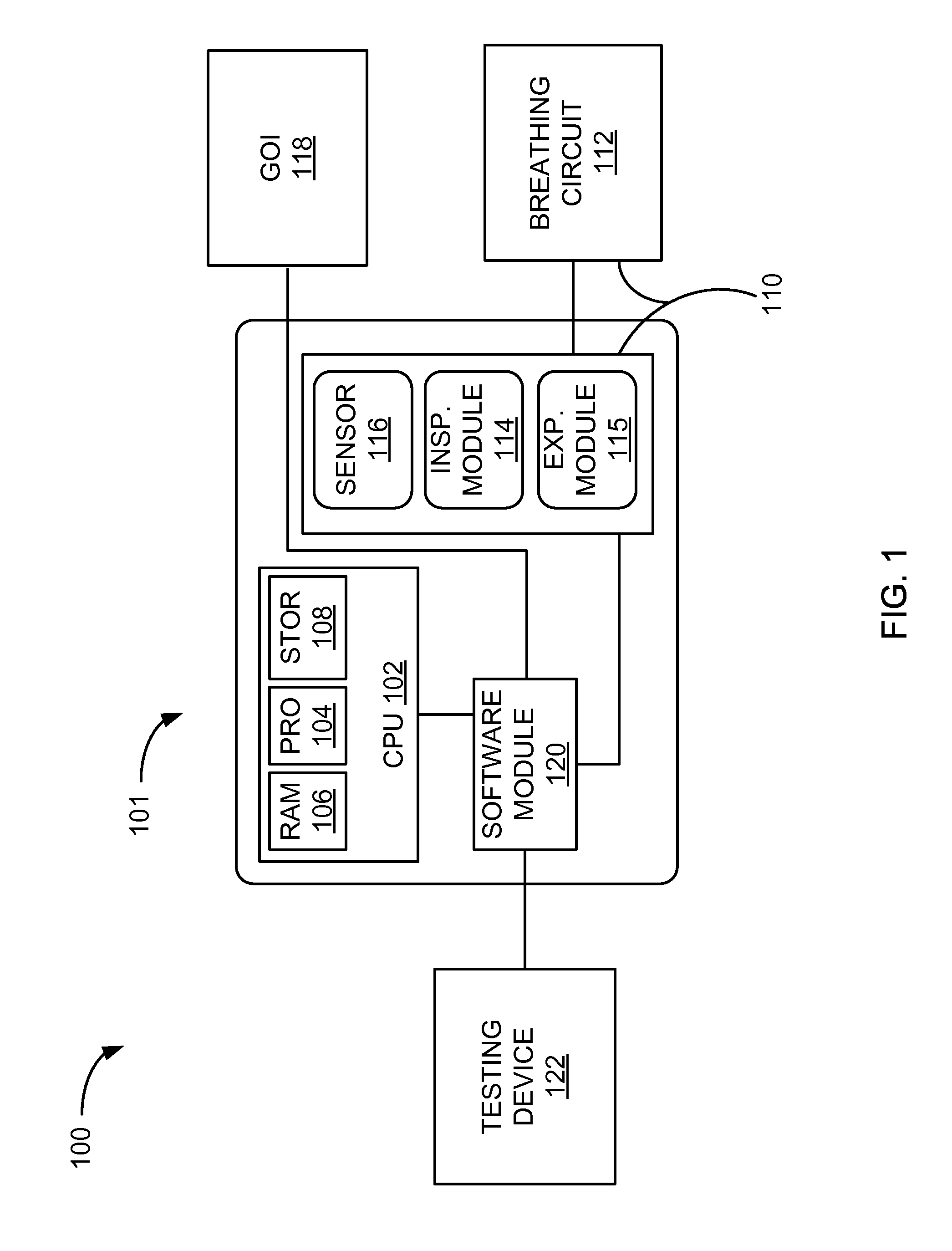

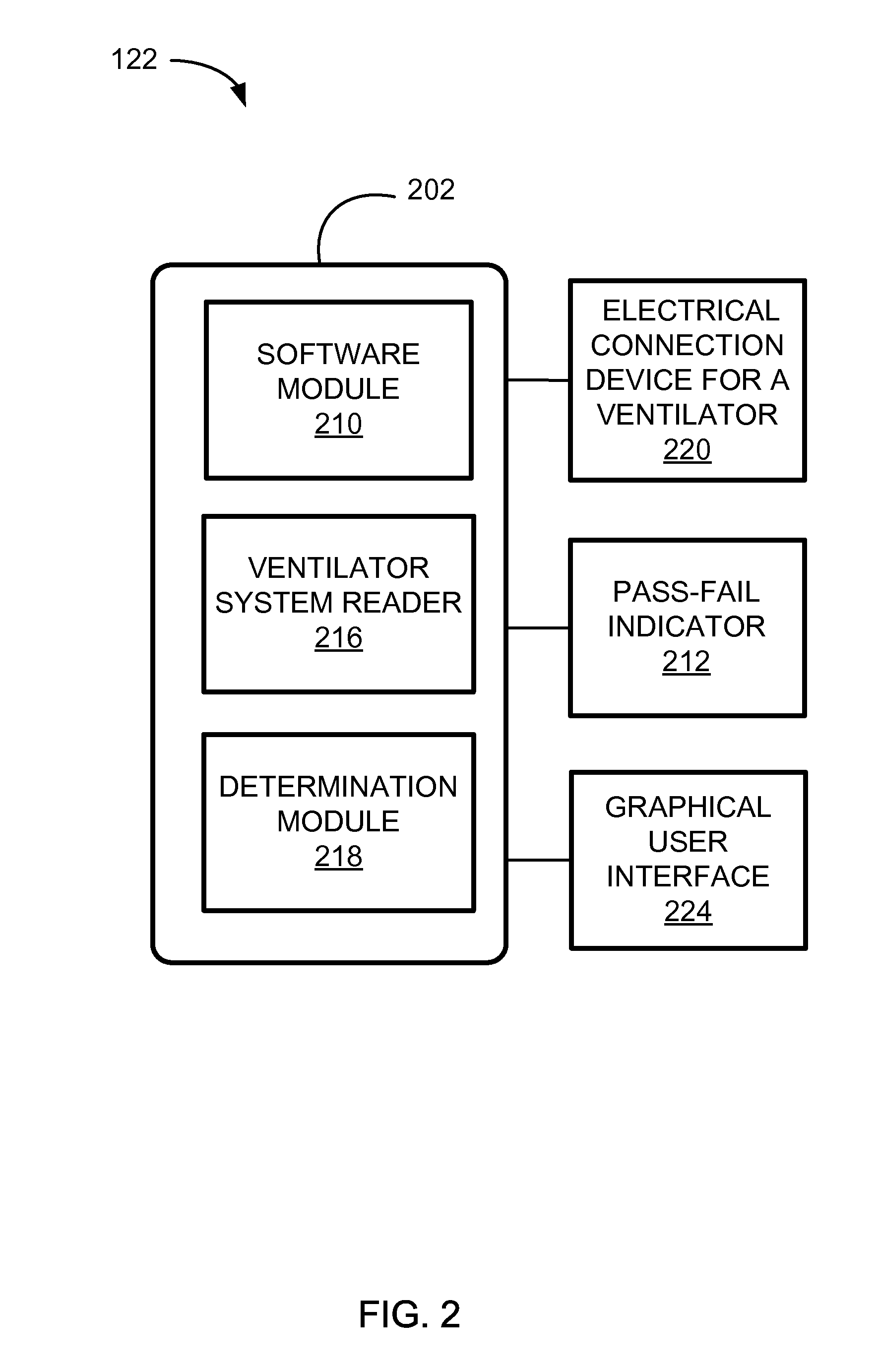

Systems And Methods For Medical Device Testing

ActiveUS20120197580A1Guaranteed functionVehicle testingRespiratory device testingMedicineMedical testing

This disclosure describes systems and methods for testing a medical device. The disclosure describes a novel approach determining if the ventilator system is functioning properly without having to connect the medical device to a patient.

Owner:TYCO HEALTHCARE GRP LP

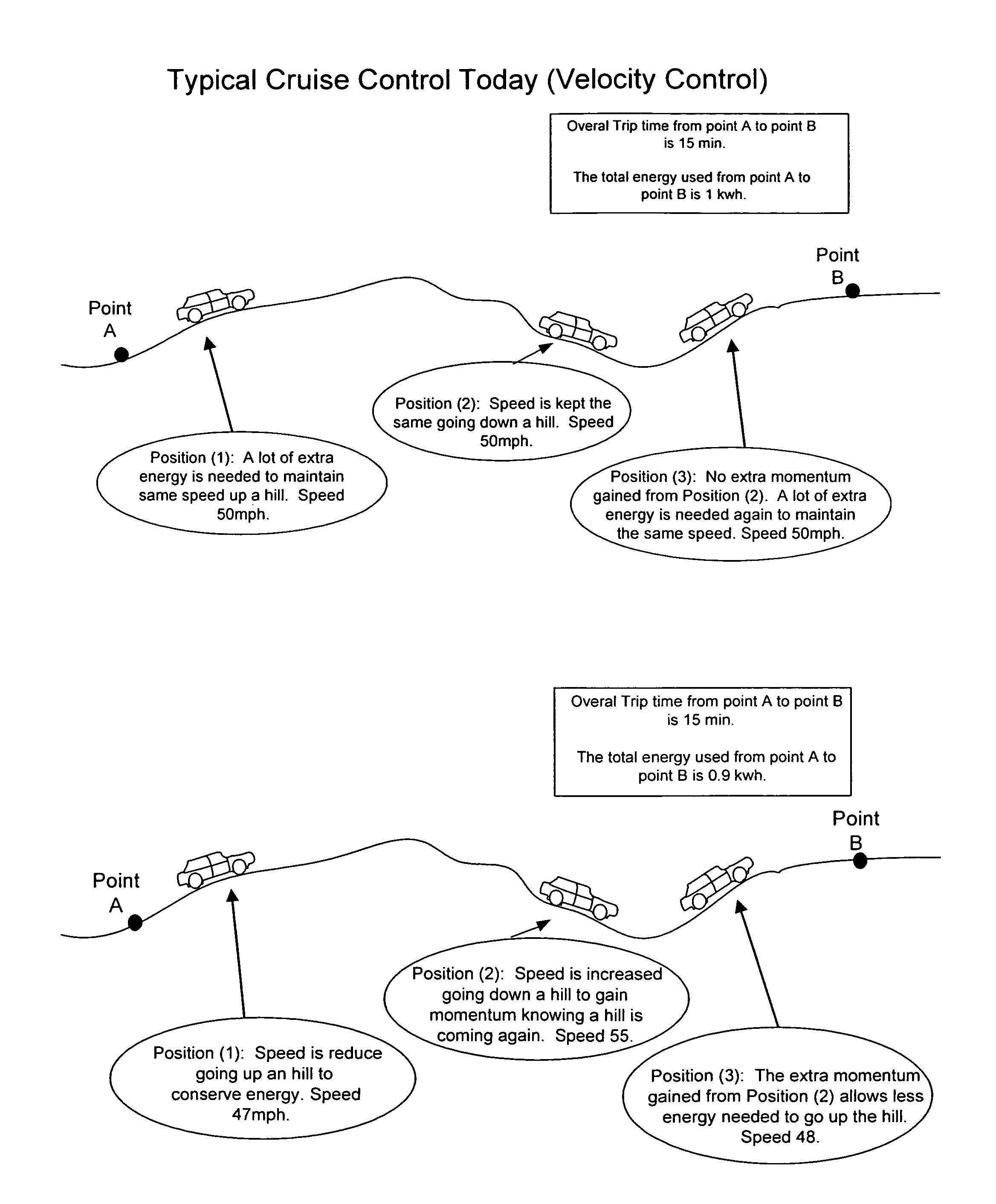

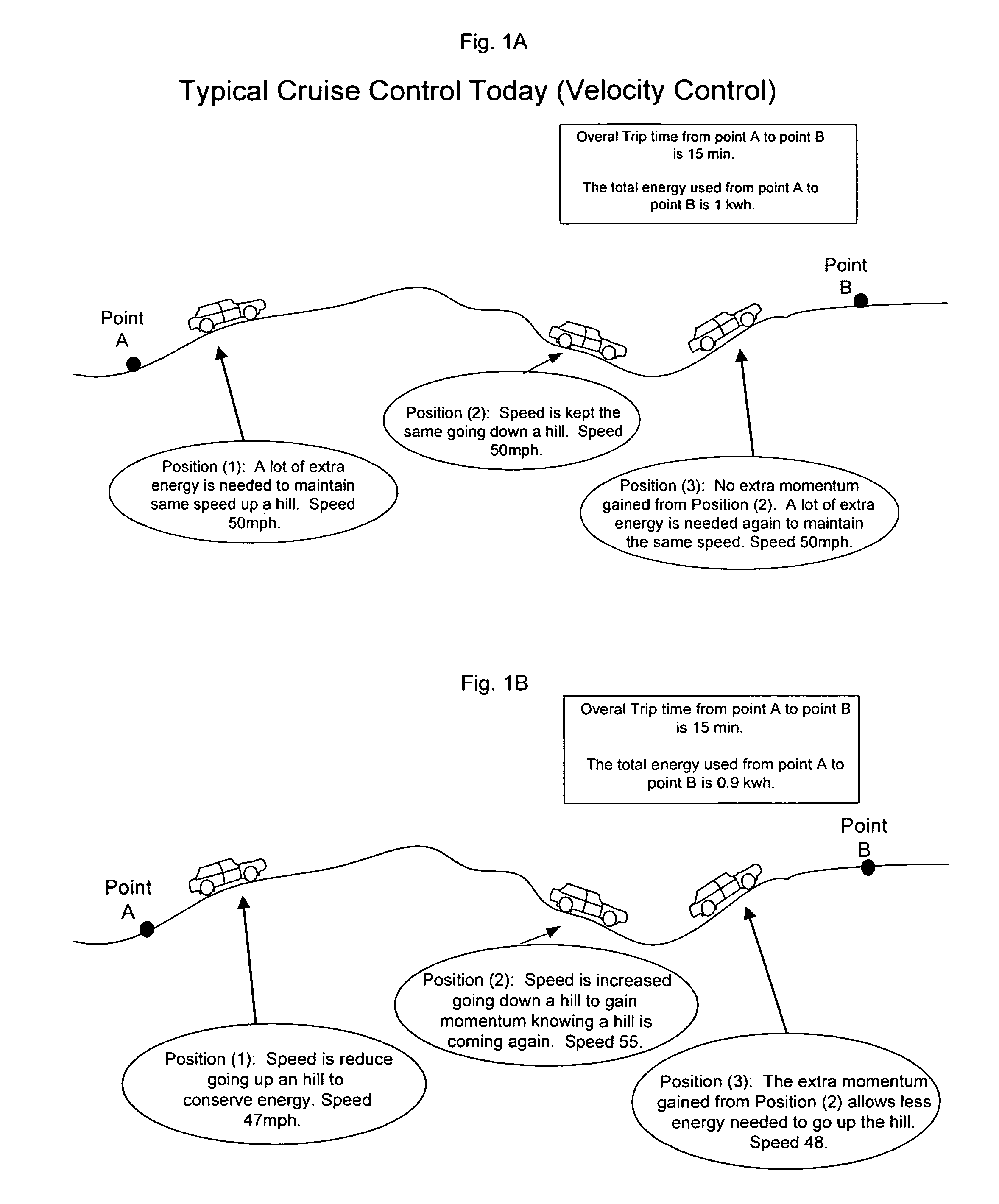

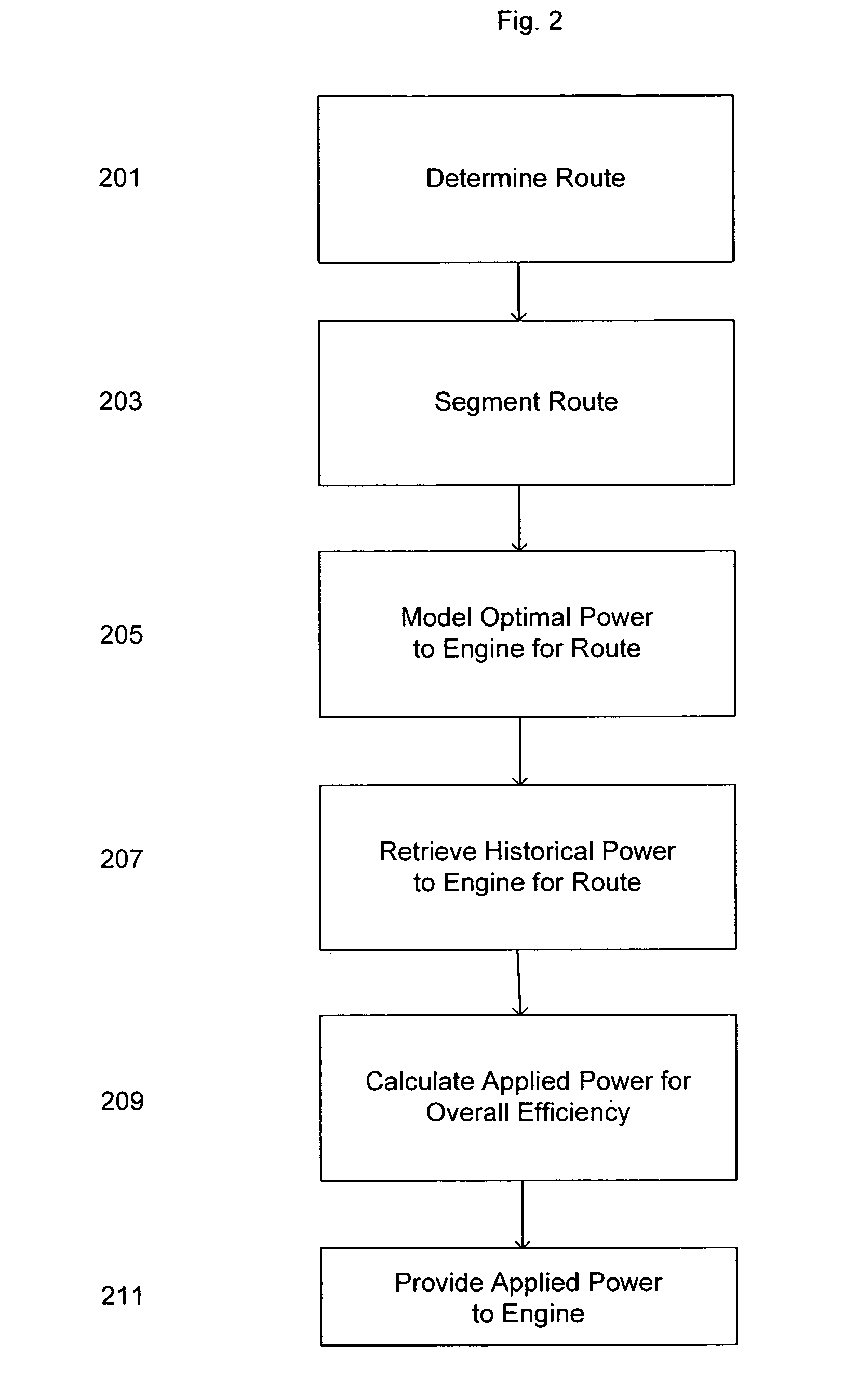

Power management systems and devices

ActiveUS7925426B2Registering/indicating working of vehiclesDigital data processing detailsDriver/operatorManagement system

Described herein are devices, systems, and methods for managing the power consumption of an automotive vehicle, and thereby for optimizing the power consumption of the vehicle. The devices and systems for managing the power consumption of the vehicle typically include power management logic that can calculate an applied power for the vehicle engine based on information provided from the external environment of the vehicle, the operational status of the vehicle, one or more command inputs from a driver, and one or more operational parameters of the vehicle.

Owner:IQAR INC

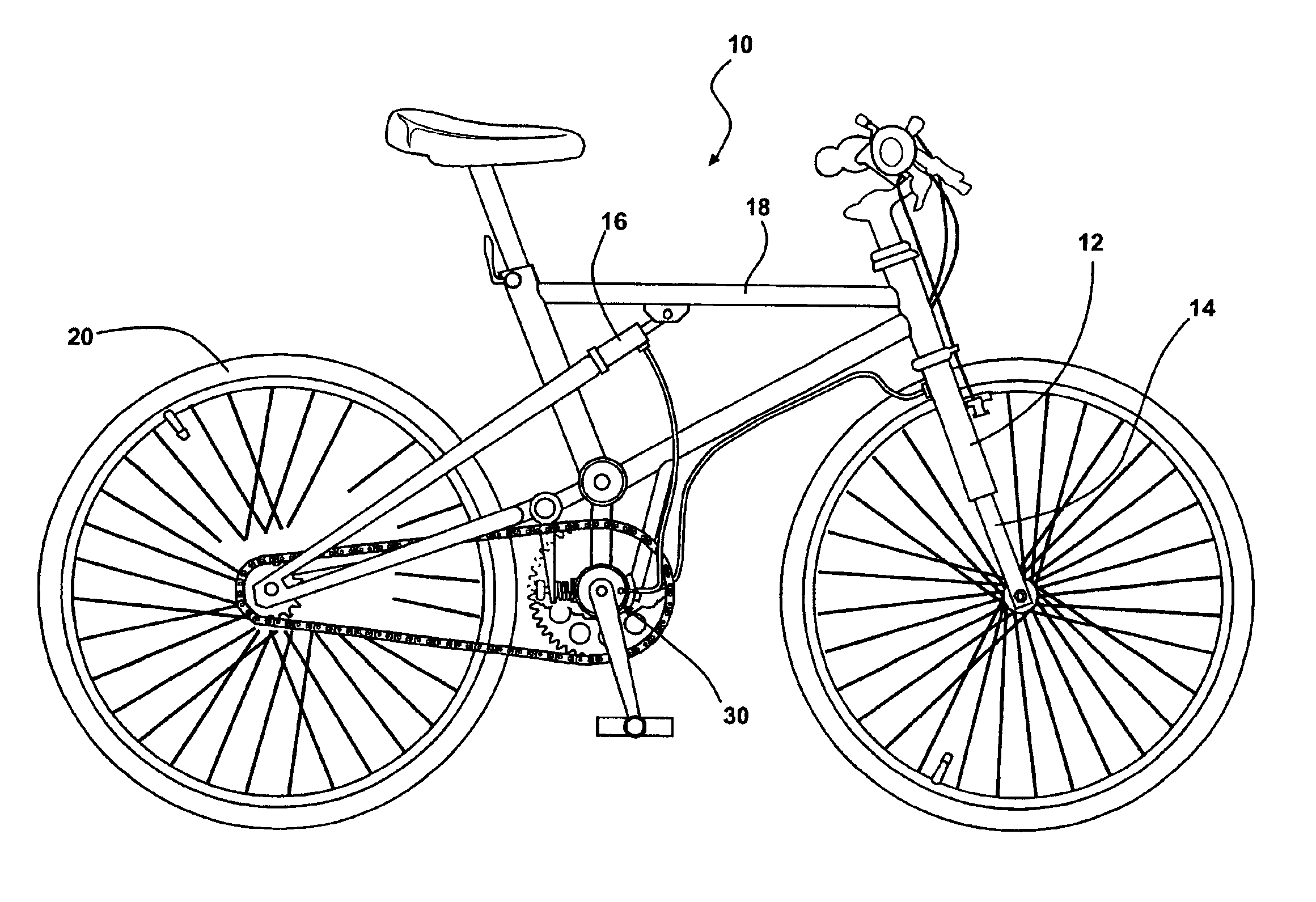

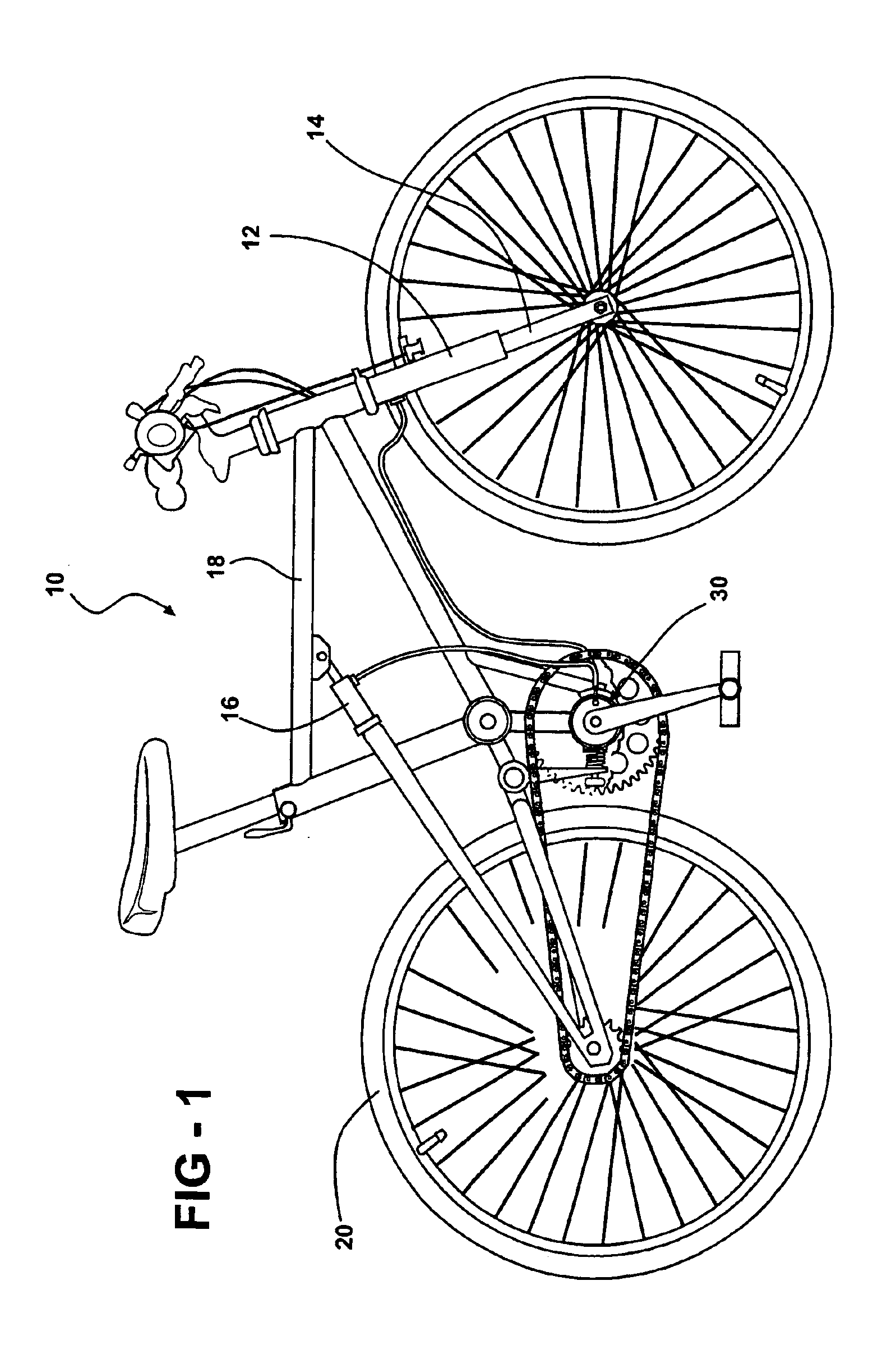

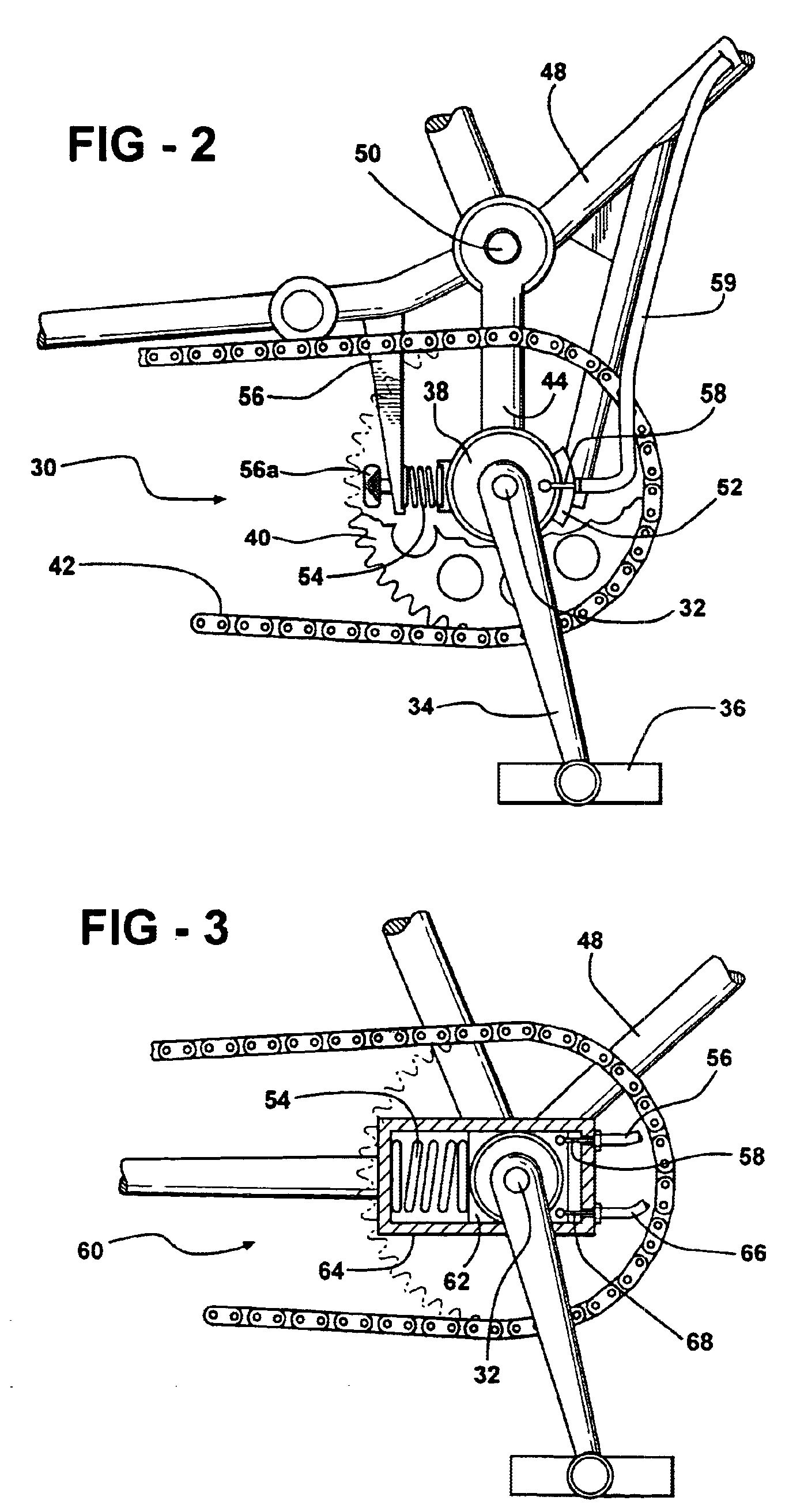

Anti-bob system for cycles

A control system is operable to selectably activate shock damping devices associated with a bicycle so as to eliminate bobbing encountered under extreme pedaling conditions. The system includes a crank axle torque detector which operates to detect a level of torque applied to a crank axle and provide a control signal corresponding to the level of torque. A shock damping device is coupled to the frame of the cycle, and functions to absorb and dampen mechanical shocks communicated to the frame. The shock damping device includes an activator for controlling its damping function. The activator is operable to receive the control signal from the crank axle torque detector and control the shock damping device in response thereto. The control signal may be an electrical or a mechanical signal.

Owner:THE LARRY D MILLER TRUST LARRY D MILLER & MARY L MILLER TRUSTEES DTD 06 12 98

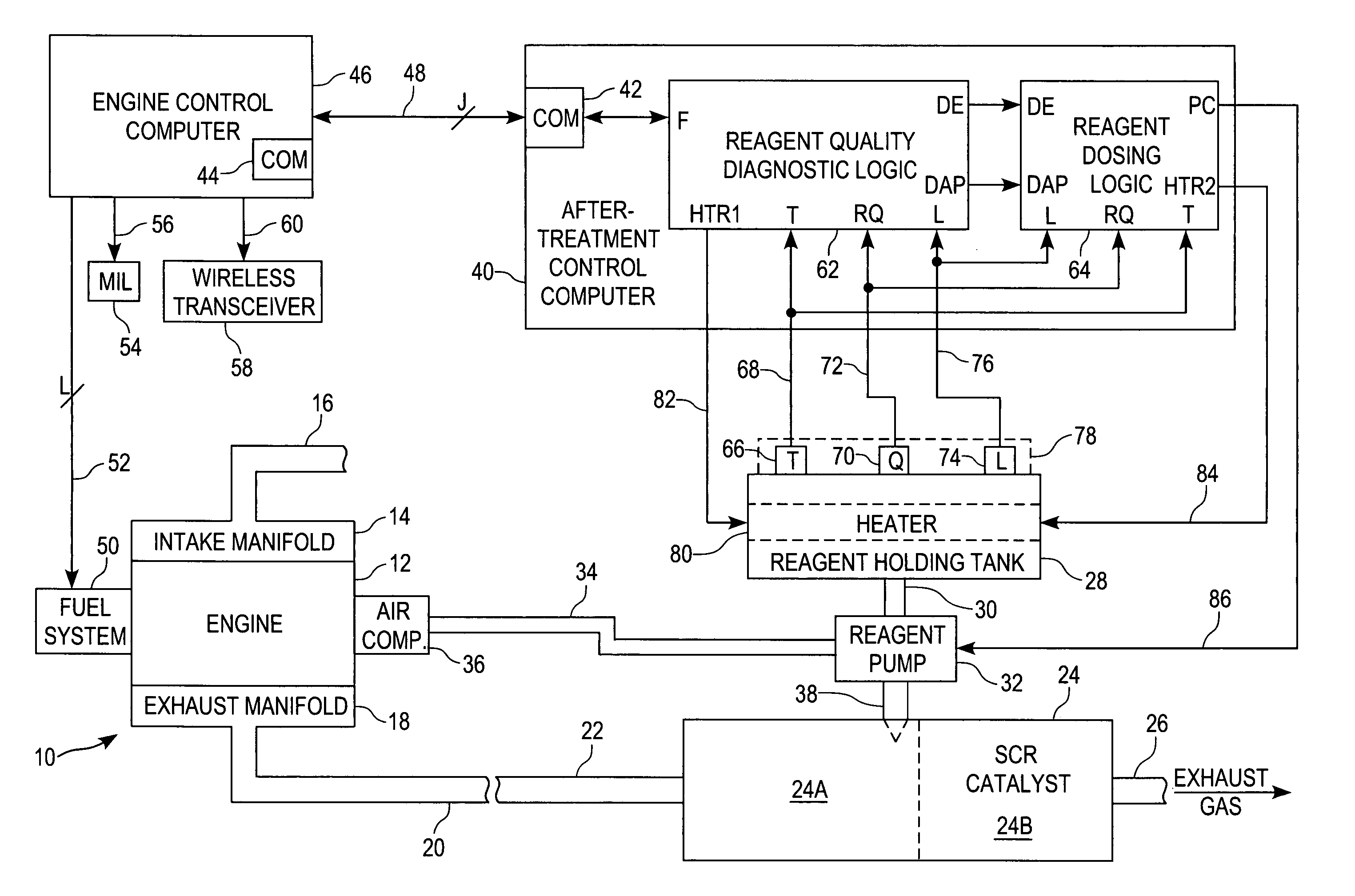

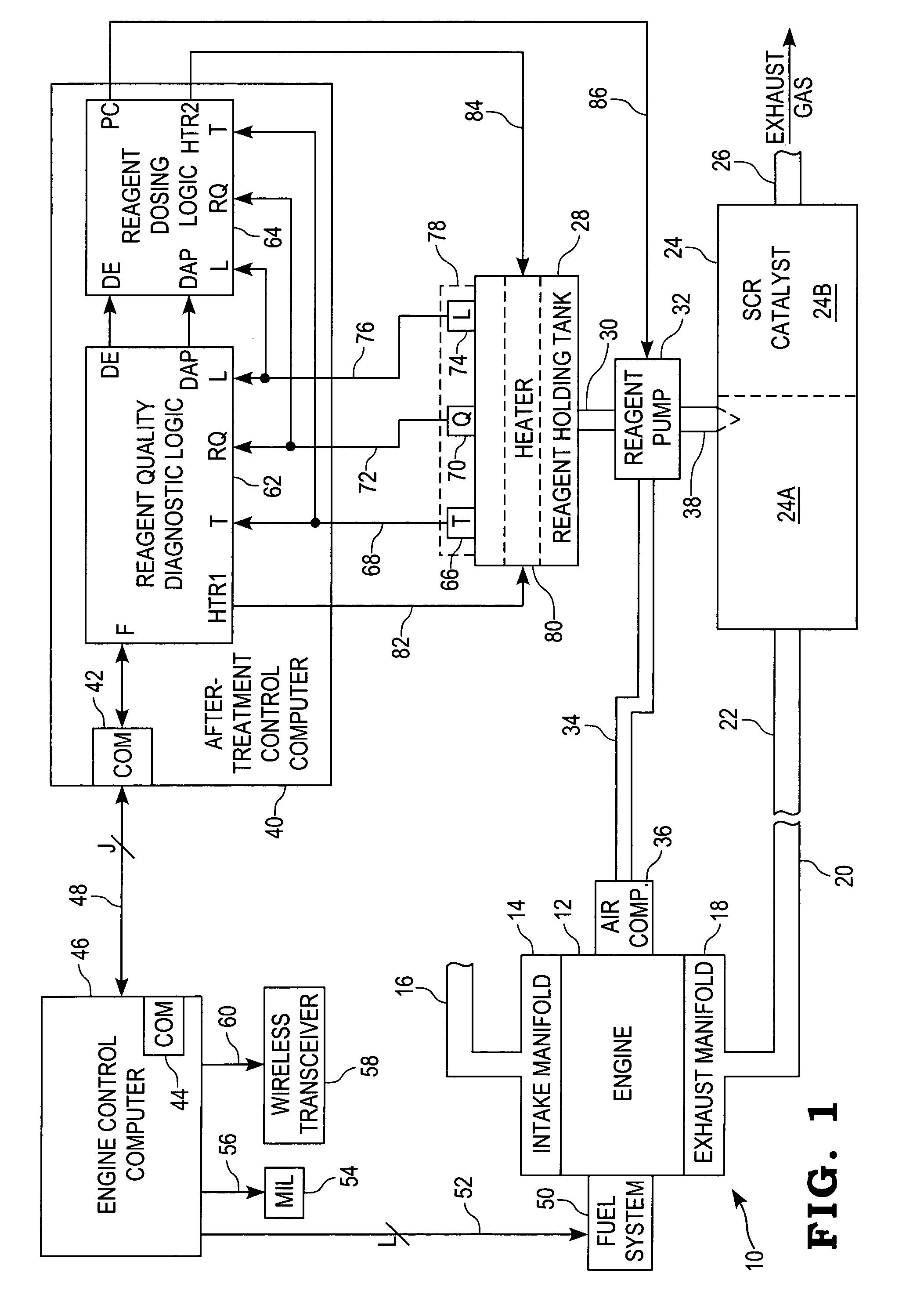

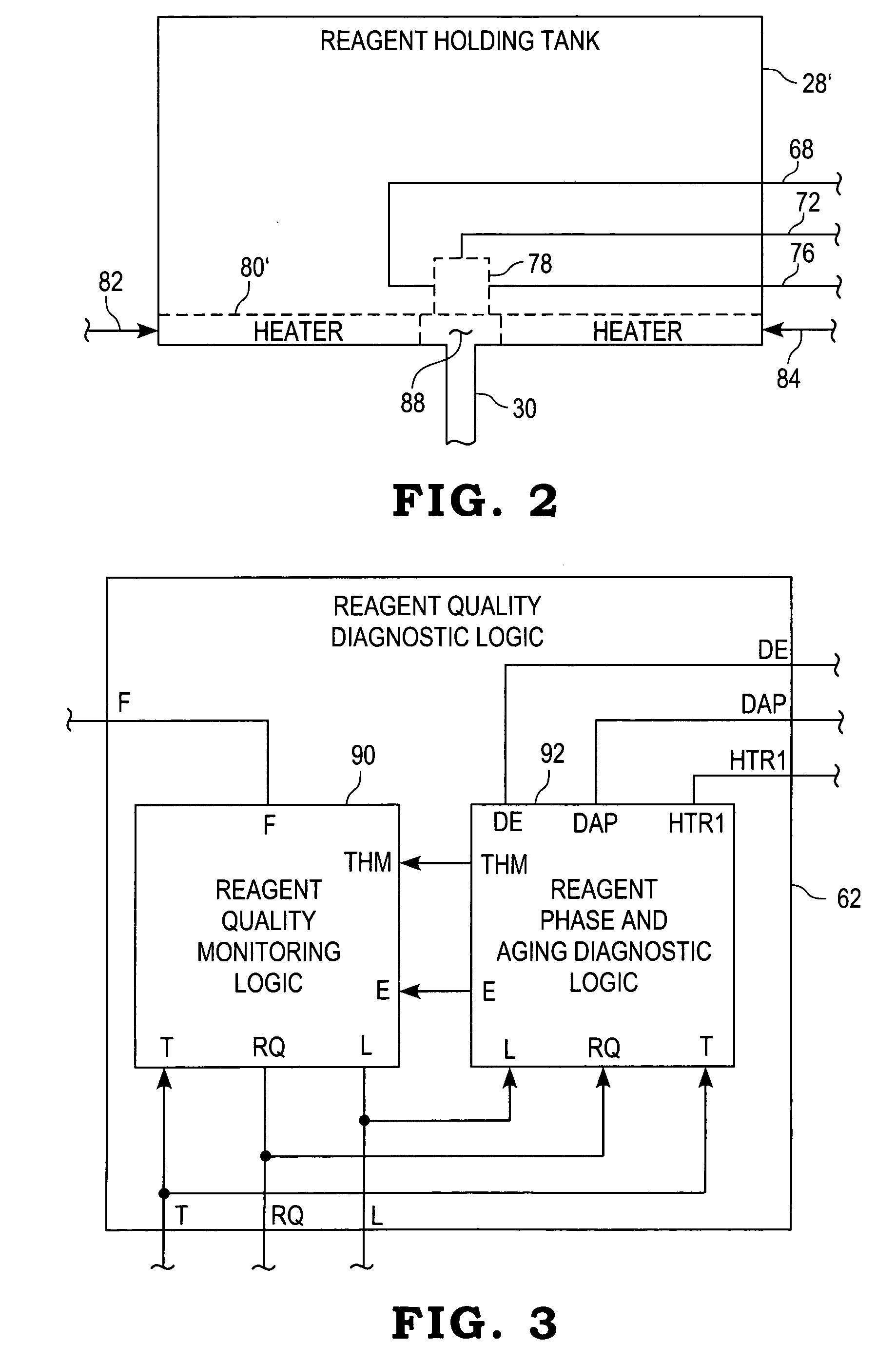

System for diagnosing reagent solution quality

ActiveUS20050207936A1Electrical controlInternal combustion piston enginesInternal combustion engineComparator

A system for diagnosing the quality of a reagent solution may comprise a reagent solution source for supplying the reagent solution to an emissions catalyst of an internal combustion engine. Means may be provided for determining a quality value corresponding to the quality of the reagent solution. A first filter may receive the quality value and produce a first filtered quality value, and a first comparator may compare the filtered quality value to a threshold and produce a fault value if the first filtered quality value crosses the threshold. Alternatively or additionally, a second filter may receive the quality value and produce a second filtered quality value. A second comparator may compare a difference between the first and second filtered quality values to another threshold and produce another fault value if the difference crosses that threshold.

Owner:CUMMINS FILTRATION IP INC

Remote monitoring of pipelines using wireless sensor network

InactiveUS7526944B2Low powerLow costVehicle testingDetection of fluid at leakage pointWireless transceiverWireless mesh network

A wireless sensor network is installed inside pipelines using sensors and wireless transceivers that are small, low-cost, and rugged. The objective is monitoring the pipeline and recommending maintenance and repair at specific locations in the pipeline. Maintenance includes detection of internal corrosion using sensors that can result in leaks. Furthermore detection of leaks for prevention of catastrophic failures as a result of damage, such as third party mechanical damage. After establishing the wireless sensor network, the network is activated so the sensors can make measurements periodically or continuously using instructions transmitted via a base station. The sensor data from the various sensors are transmitted inside the pipe and extracted to access points in the pipeline to a remote computer that stores the data within the computer. The sensed information can be used for monitoring as well as analysis using a recommendation engine to provide maintenance and repair alerts.

Owner:SOUTHWEST RES INST

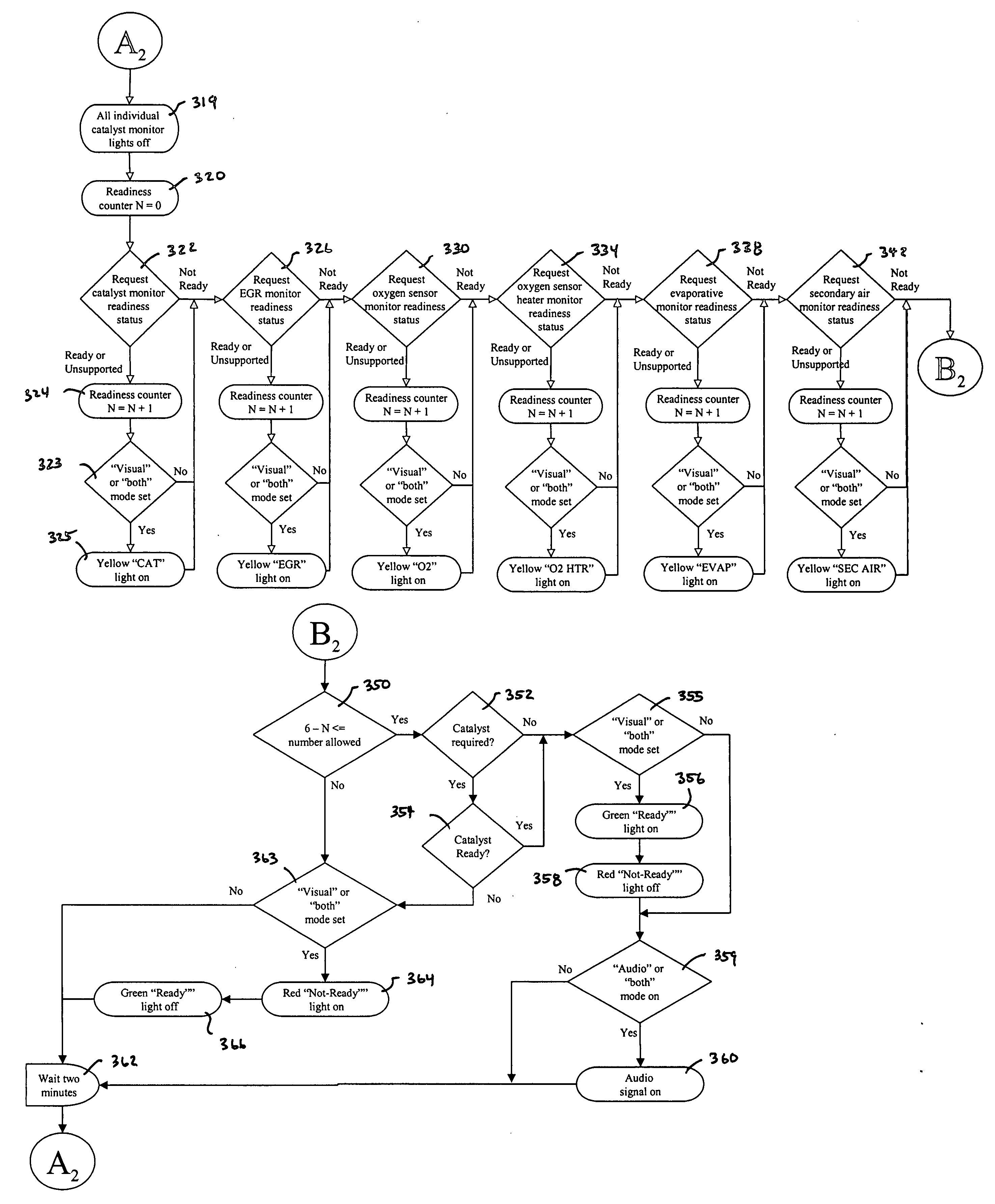

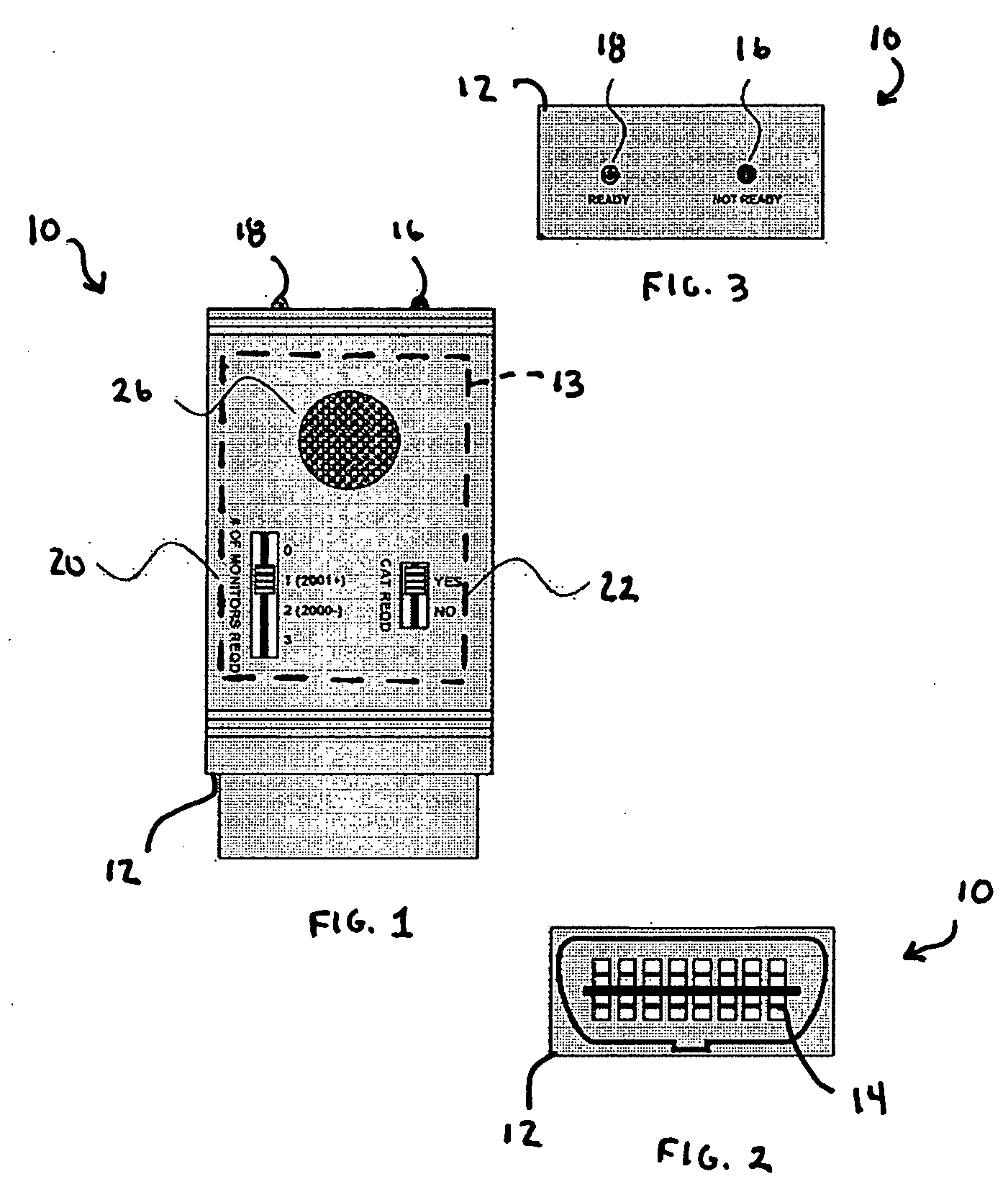

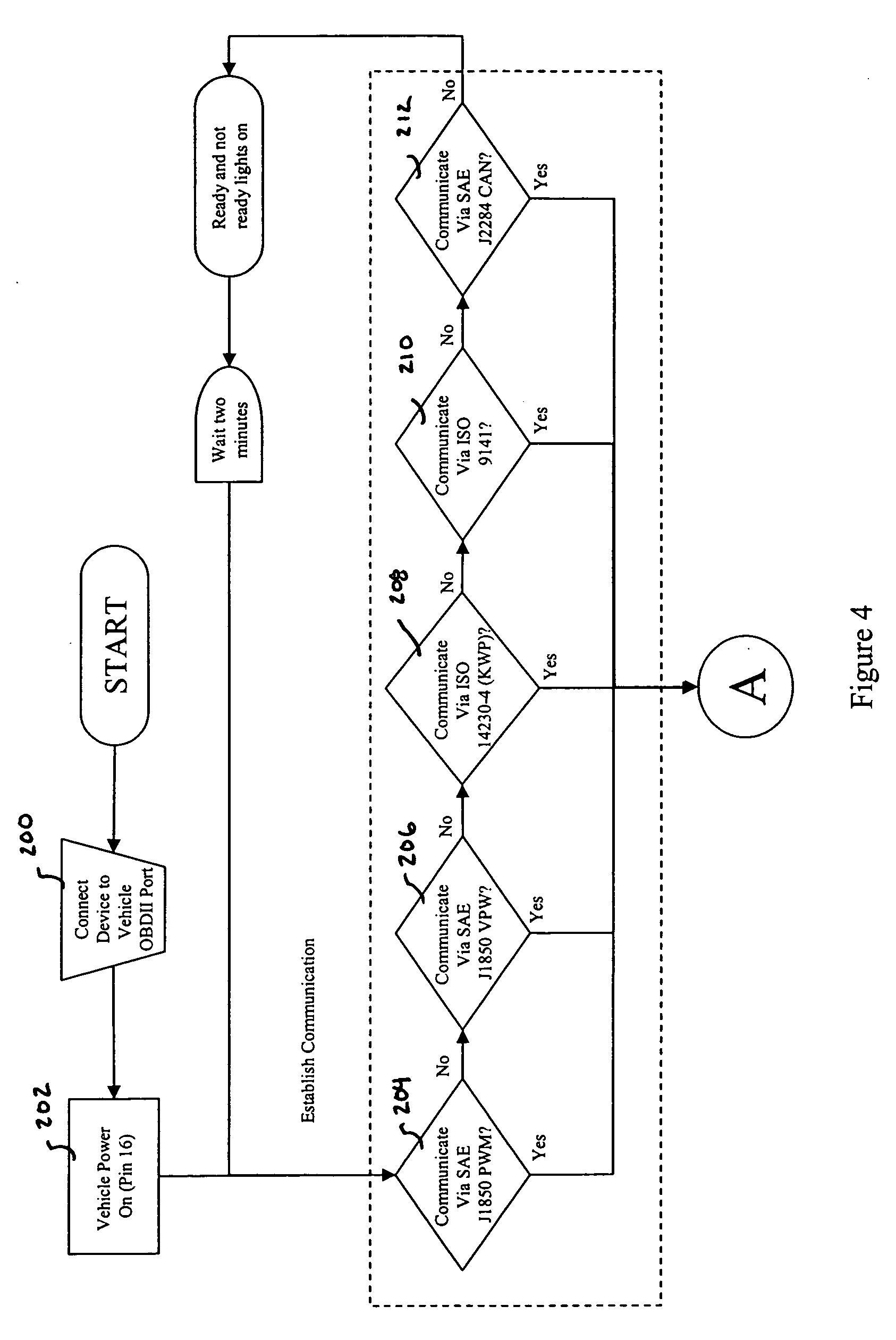

OBDII readiness status notification device

InactiveUS20060030980A1Vehicle testingRegistering/indicating working of vehiclesEngineeringControl logic

A device for notifying an operator of the readiness of a vehicle for emissions testing includes a control logic for evaluating the status of each of a plurality of the monitors of an on-board diagnostics (OBDII) system of the vehicle. Once the vehicle is determined to be ready for emissions testing based on the status of each evaluated monitor of the OBDII system, an indicator light is illuminated and / or an audio signal is emitted to notify the operator.

Owner:ST DENIS INNOVATIONS

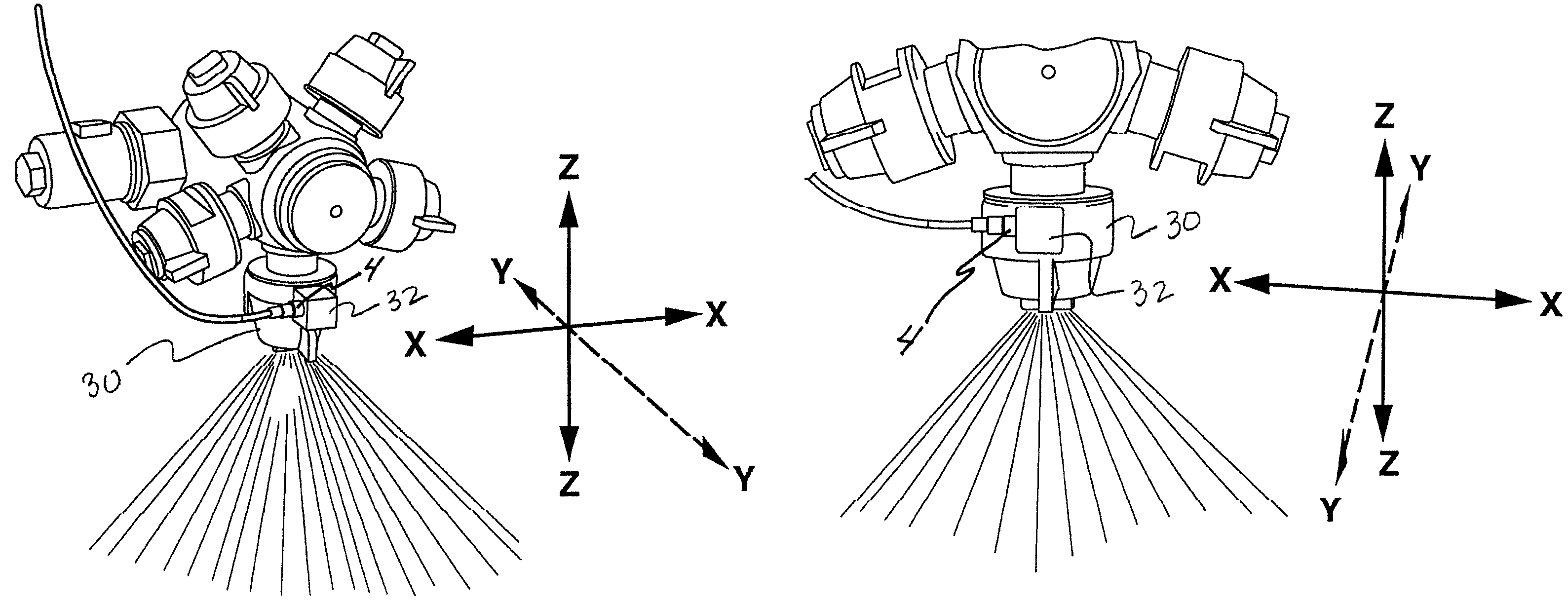

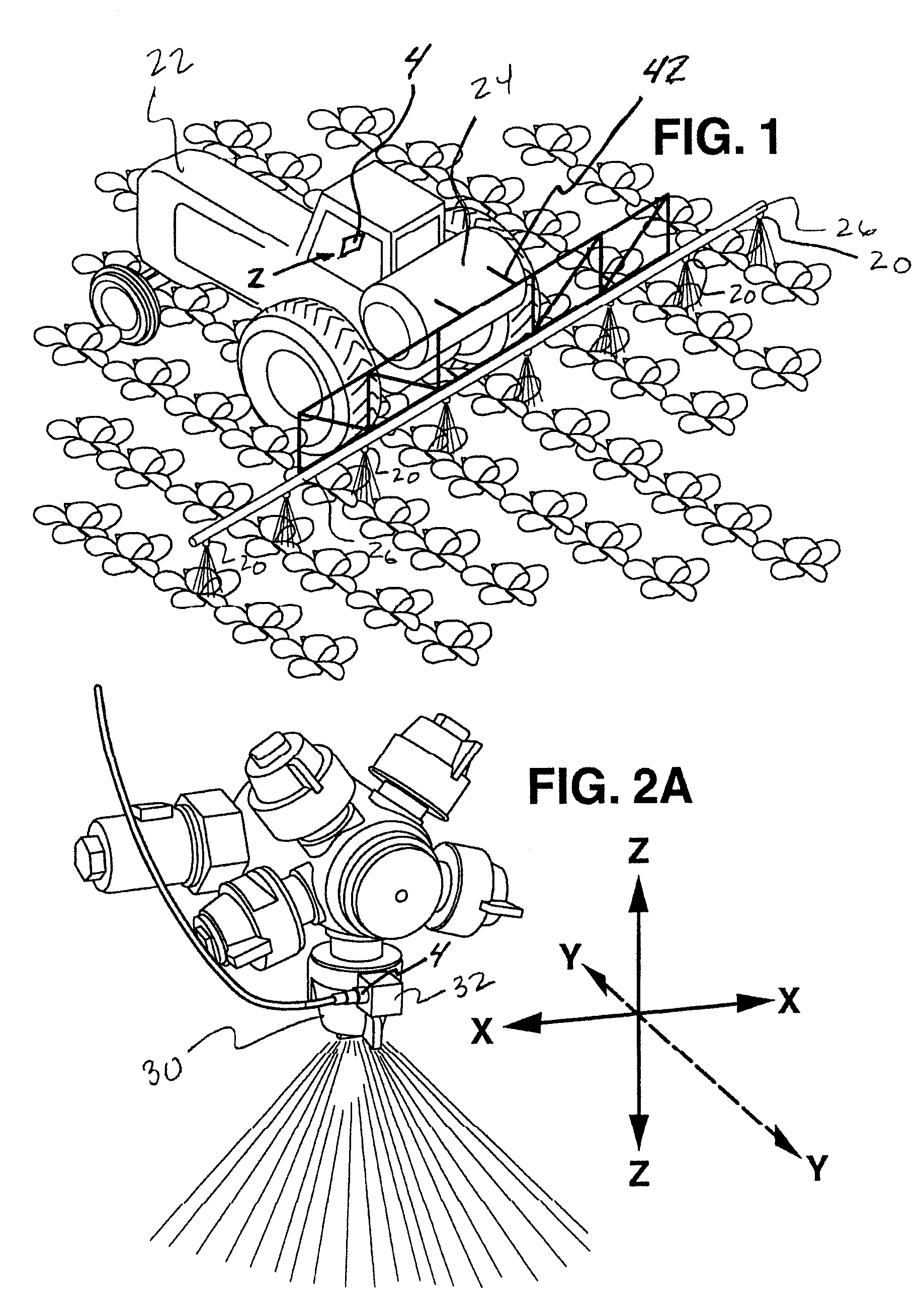

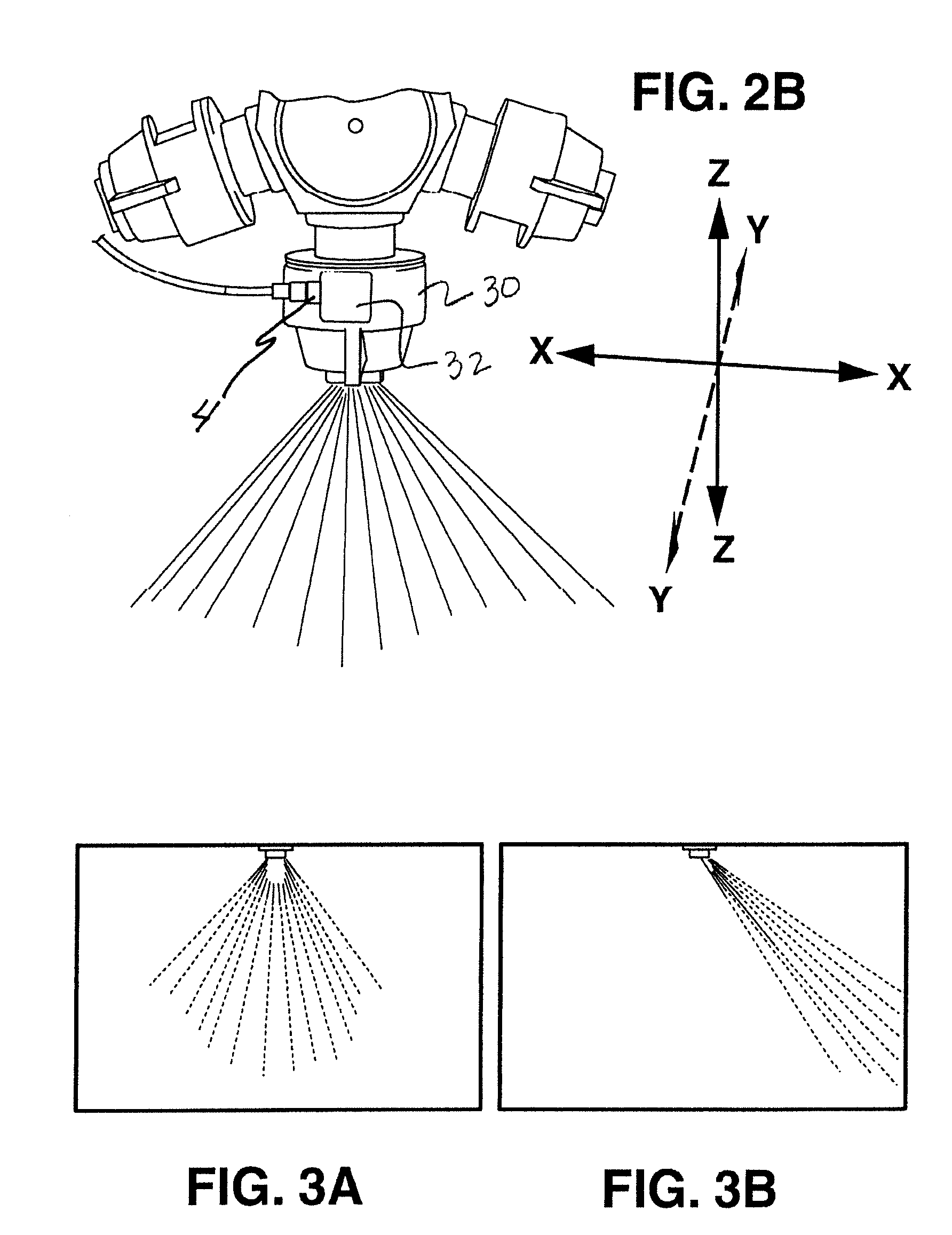

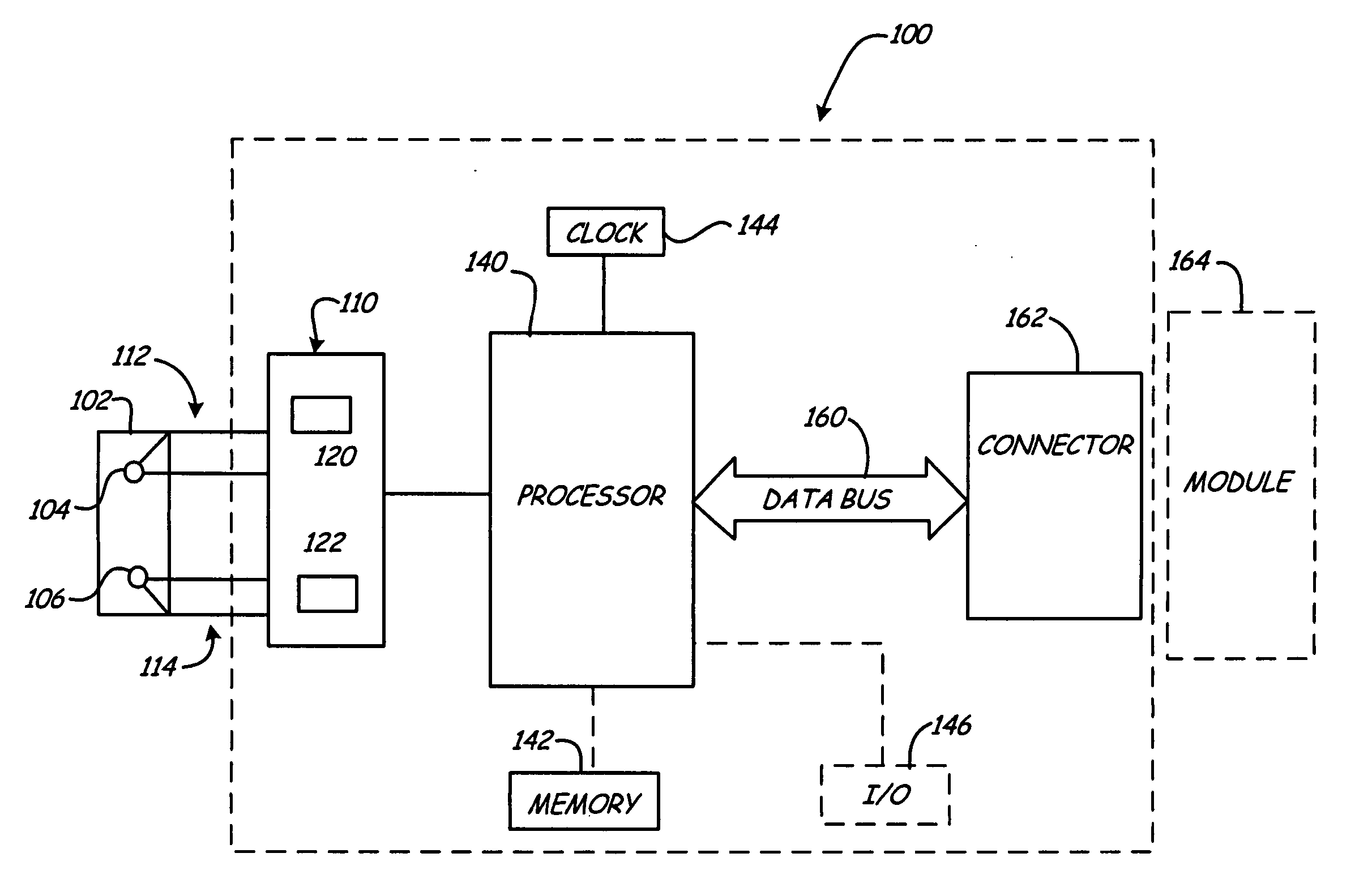

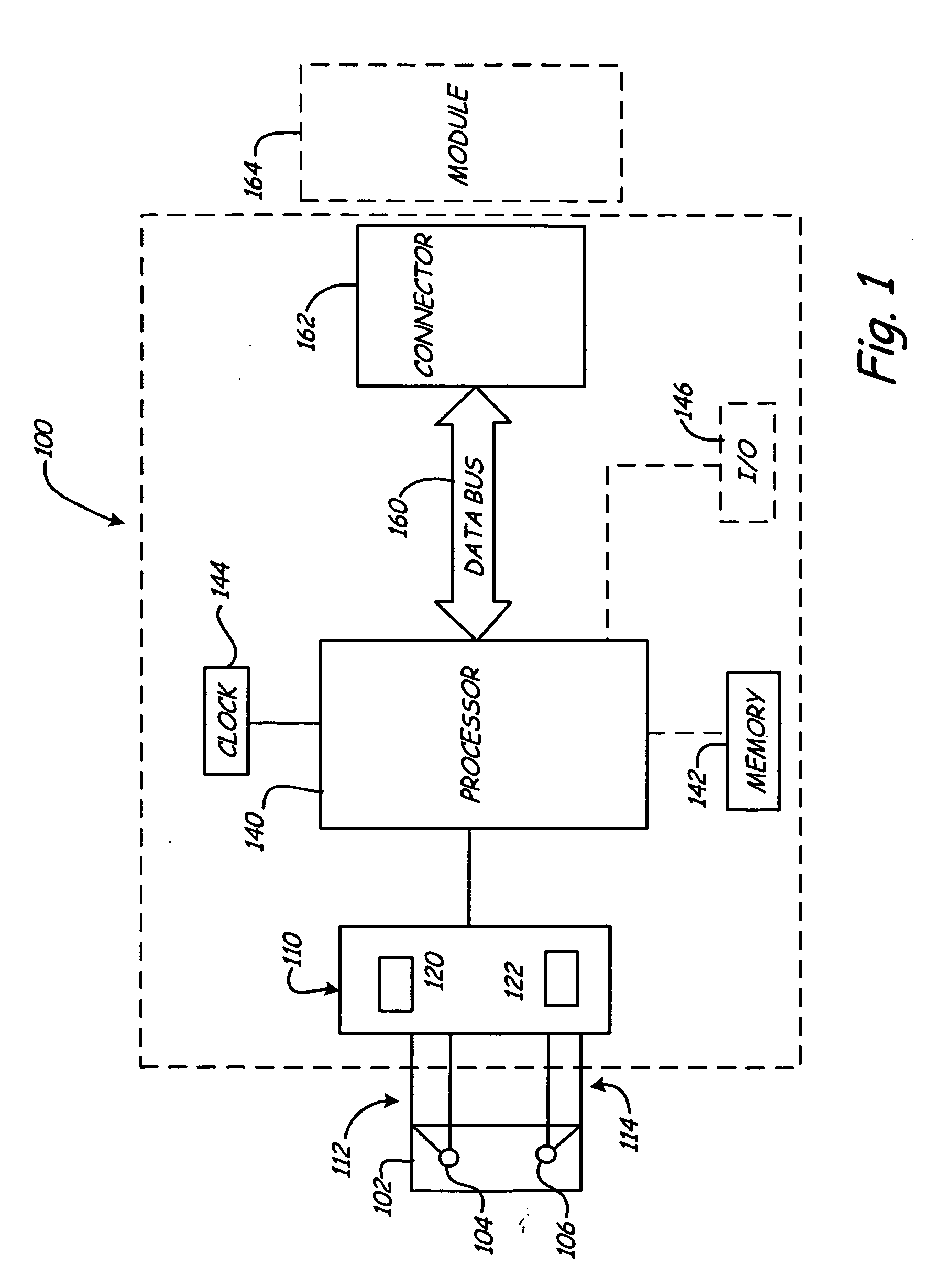

Flow control and operation monitoring system for individual spray nozzles

ActiveUS7311004B2Vibration measurement in solidsVibration measurement in fluidAccelerometerMonitoring system

An apparatus and process for monitoring fluid flow through a nozzle is disclosed. A vibration sensor, such as an accelerometer, is mounted to a nozzle. The vibration output received from the sensor is then analyzed to determine whether or not the nozzle is operating properly. Through the present invention, information can be obtained regarding variations in flow rate, and / or variations in spray pattern and droplet size spectra. If the nozzle flow pulsates, the vibration sensor may also provide information regarding whether the nozzle is pulsating according to a desired frequency duty cycle or waveform.

Owner:CAPSTAN

Battery testers with secondary functionality

InactiveUS20060217914A1Vehicle testingInflated body pressure measurementElectrical batteryTester device

An electronic vehicle tester includes a battery tester configured to measure a parameter of a battery of a vehicle. A tire tester is configured to receive a parameter of a tire of the vehicle. A wireless receiver can be configured to receive pressure information from a transmitter associated with a tire of a vehicle.

Owner:MIDTRONICS

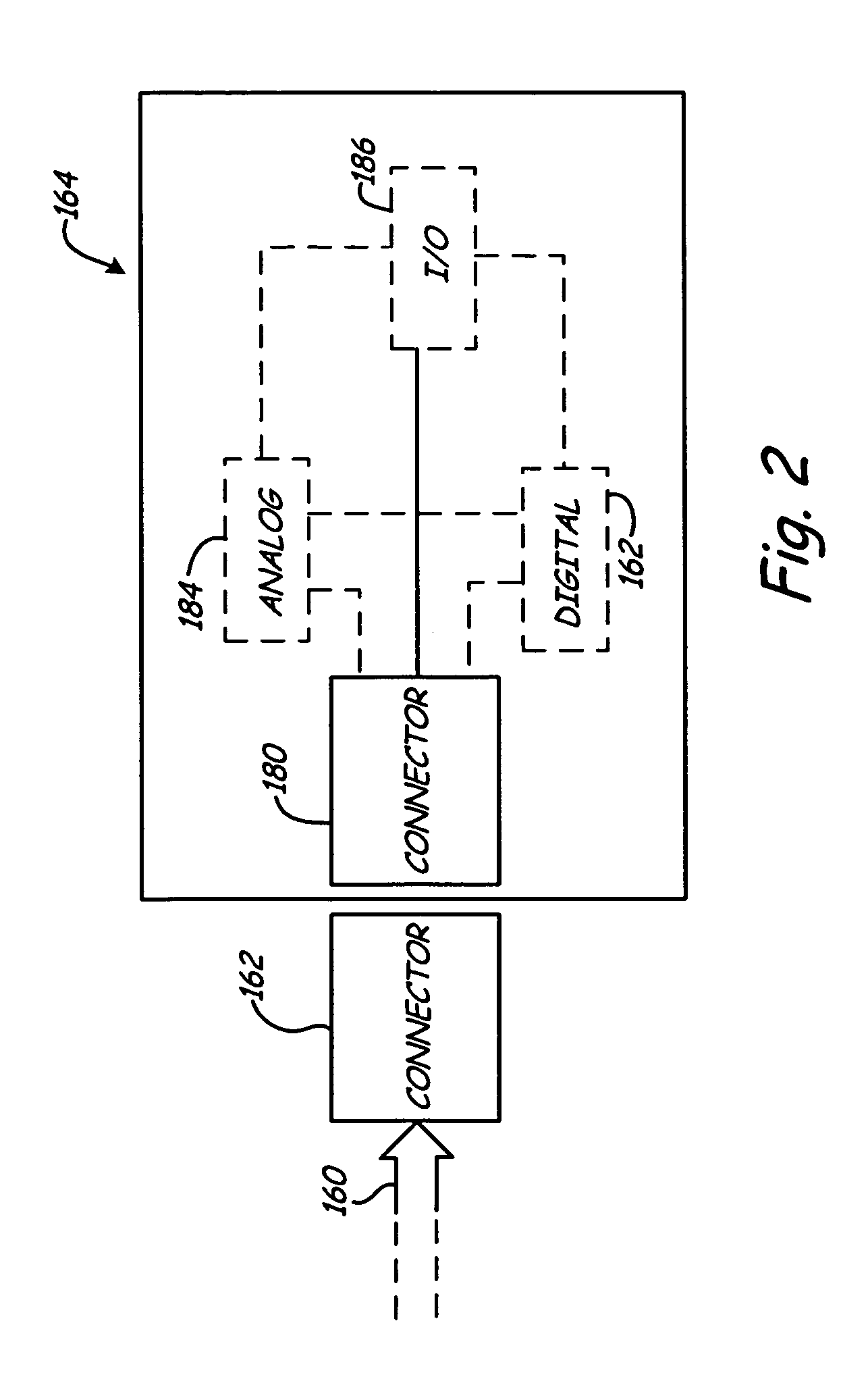

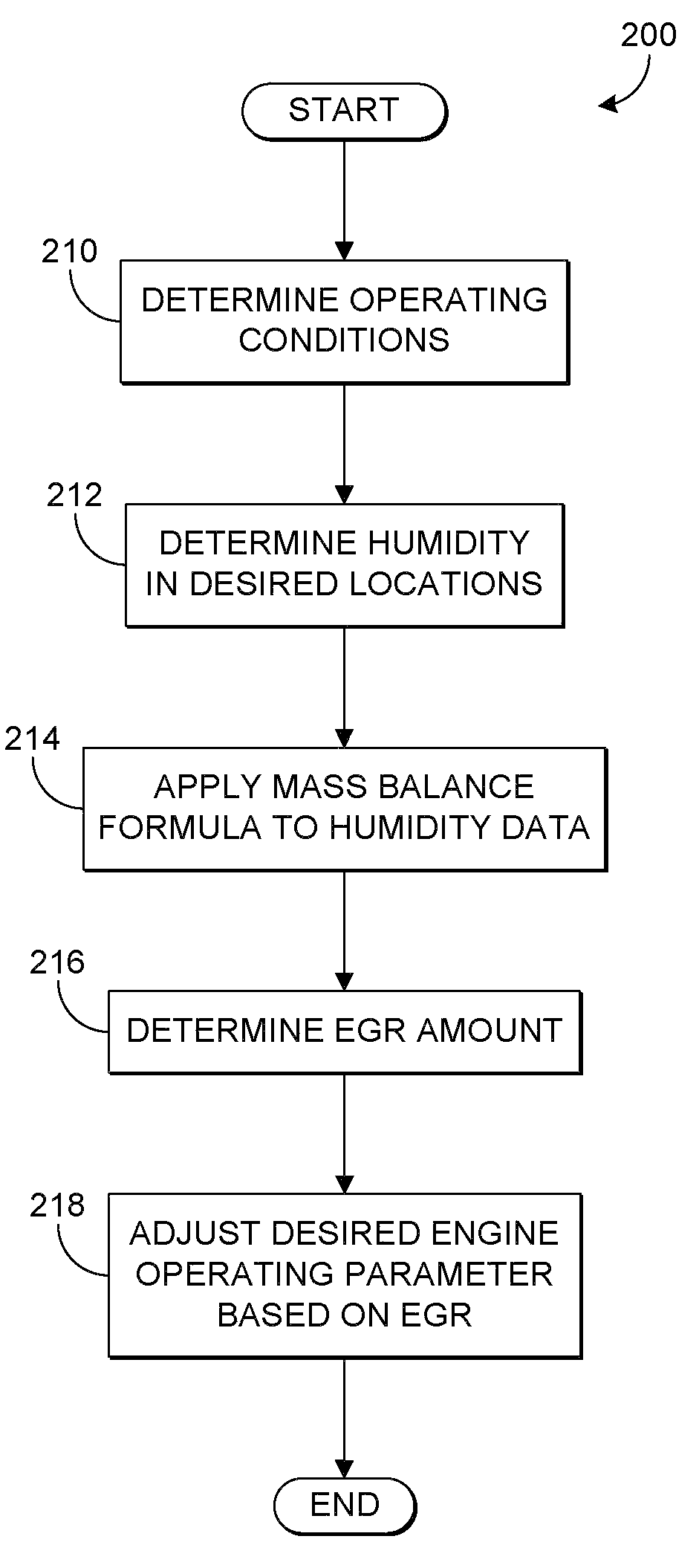

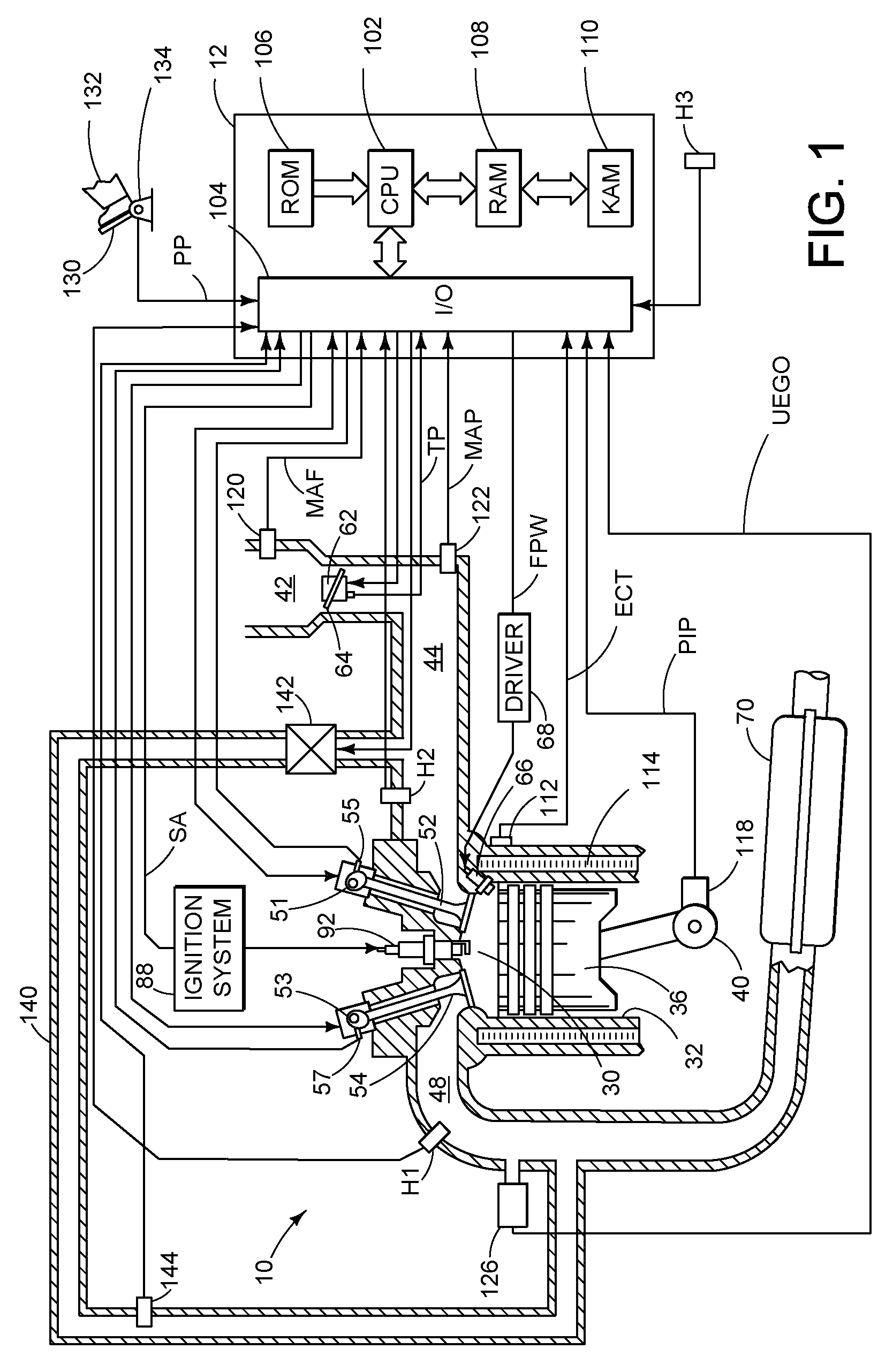

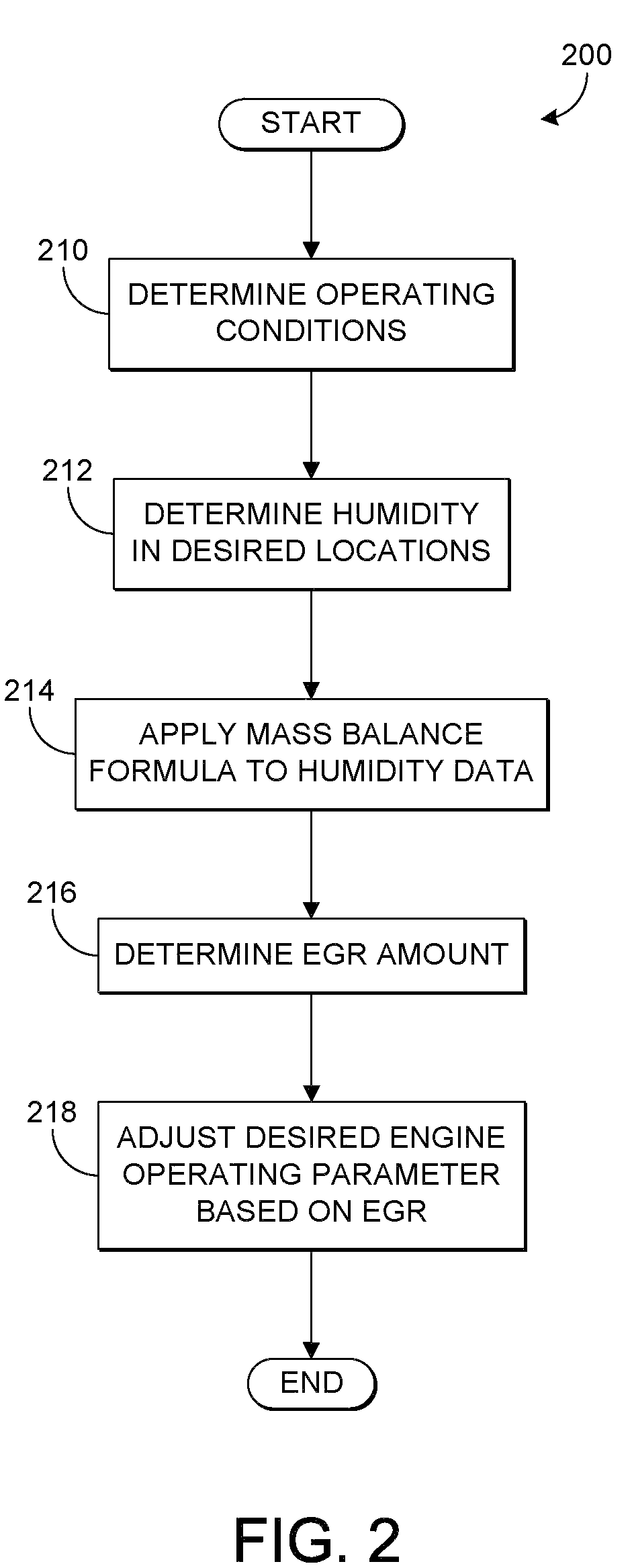

EGR detection via humidity detection

InactiveUS7715976B1Amount of EGRAccurately determineElectrical controlInternal combustion piston enginesExhaust gas recirculationMoisture sensor

Various systems and methods are described for controlling an engine in a vehicle which includes an exhaust passage and an exhaust gas recirculation system. One example method comprises adjusting an engine operating parameter based on an exhaust gas recirculation amount, the exhaust gas recirculation amount based on a first humidity and a second humidity, the first humidity generated from a first humidity sensor at a first location and the second humidity generated from a second humidity sensor located in the exhaust passage of the engine.

Owner:FORD GLOBAL TECH LLC

Non-contact measuring method for leaf apex radial clearance of engine rotor

InactiveCN102175135AImprove assembly qualityReduce disassemblyEngine testingUsing electrical meansCapacitanceFailure rate

The invention relates to a non-contact measuring method for a leaf apex radial clearance of an engine rotor, and the method comprises the following steps: 1) assembling a measuring system, calibrating a sensor and determining the relation between the radial clearance and voltage of a leaf apex; 2) preparing before measuring; and 3) measuring the leaf apex radial clearance of the engine rotor. In the measuring method provided by the invention, a measurement technique based on a capacitance method is adopted; the measuring course and the assembling are synchronously carried out; the once cartridge disassembly and assembly is reduced; the measuring time is shortened; the production efficiency is improved; and the measuring accuracy is improved, thereby improving the assembly quality of an engine and reducing the failure rate of the engine. The non-contact measuring method provided by the invention is mainly used for measuring the leaf apex radial clearance of the rotors of parts such as an engine, a high-pressure compressor, a low-pressure compressor, a high-pressure turbine, a low-pressure turbine and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Computer-assisted and/or enabled systems, methods, techniques, services and user interfaces for conducting motor vehicle and other inspections

A computer-assisted inspection system provides customized workflow based on different types of inspections and other factors. The system can provide different rules that can be activated in response to valuation / pricing, rule-based validation and automatic grading. Features include flat car part picking, easy to use, inspectors can be geographically separated, and system is installable over the internet to provide efficient installation to far-flung install sites.

Owner:MANHEIM INVESTMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com