Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143 results about "Maintenance actions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Maintenance actions, historically referred to as socio-emotive actions, are those leadership actions taken by one or more members of a group to enhance the social relationships among group members. They tend to increase the overall effectiveness of the group and create a more positive atmosphere of interaction within the group.

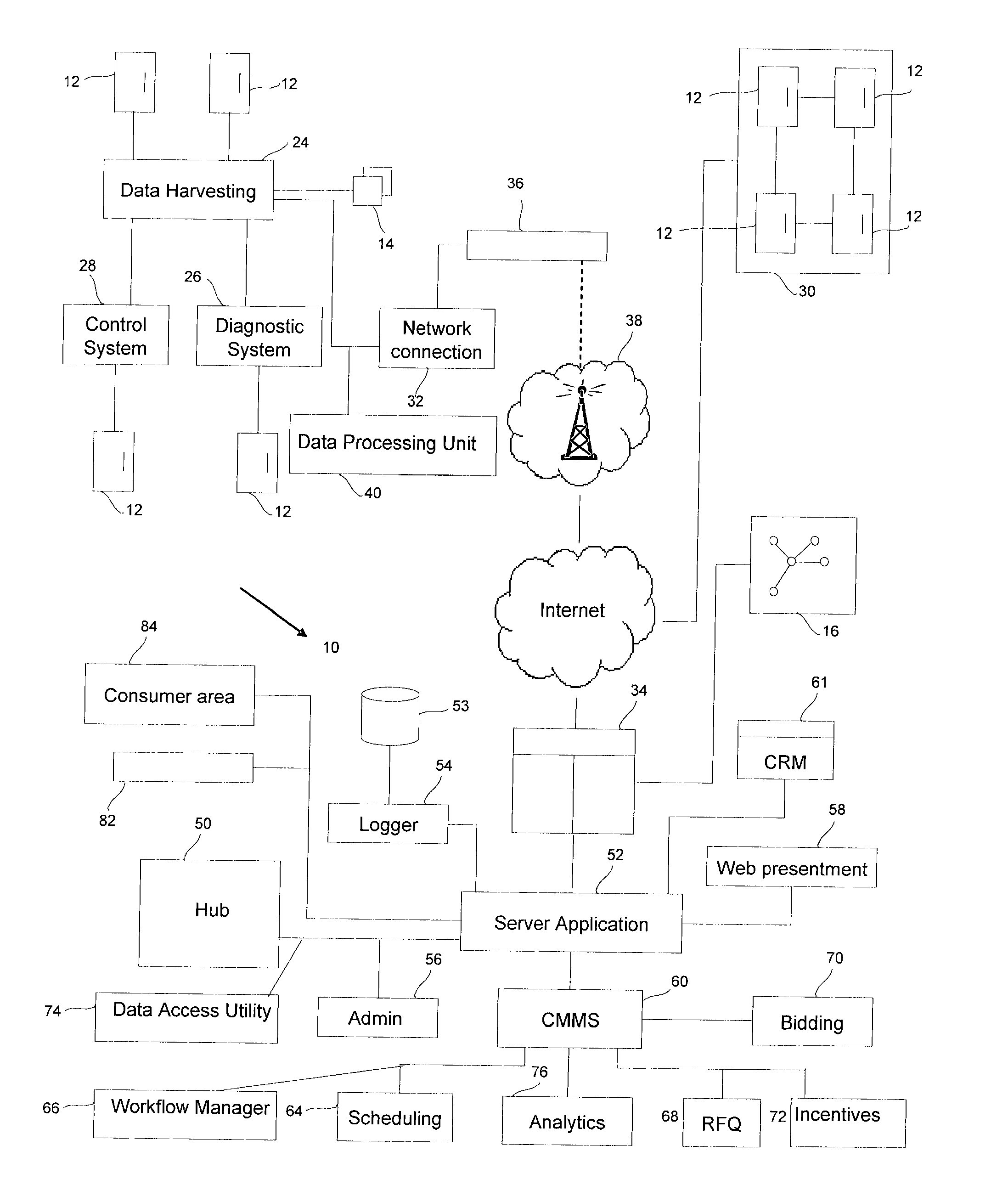

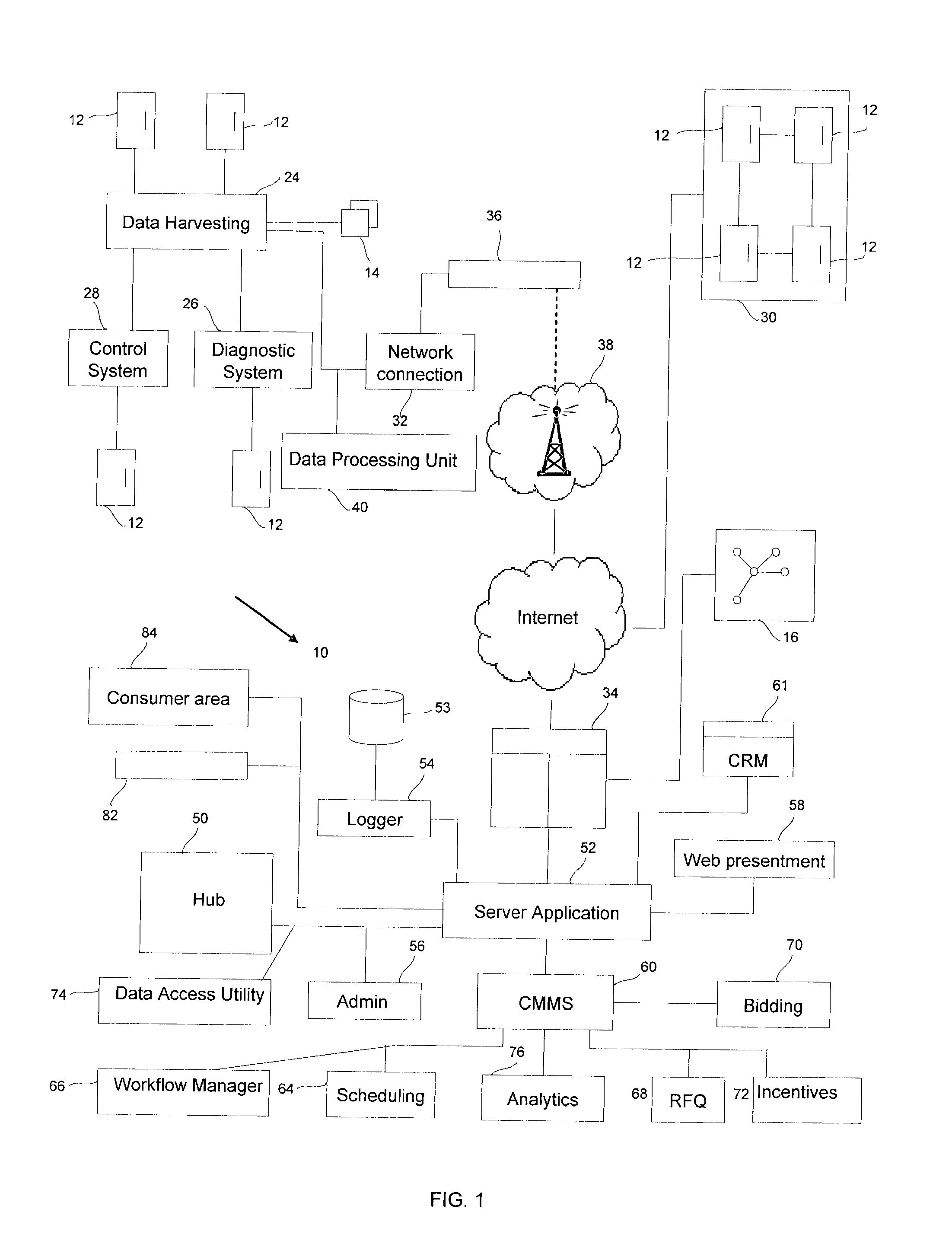

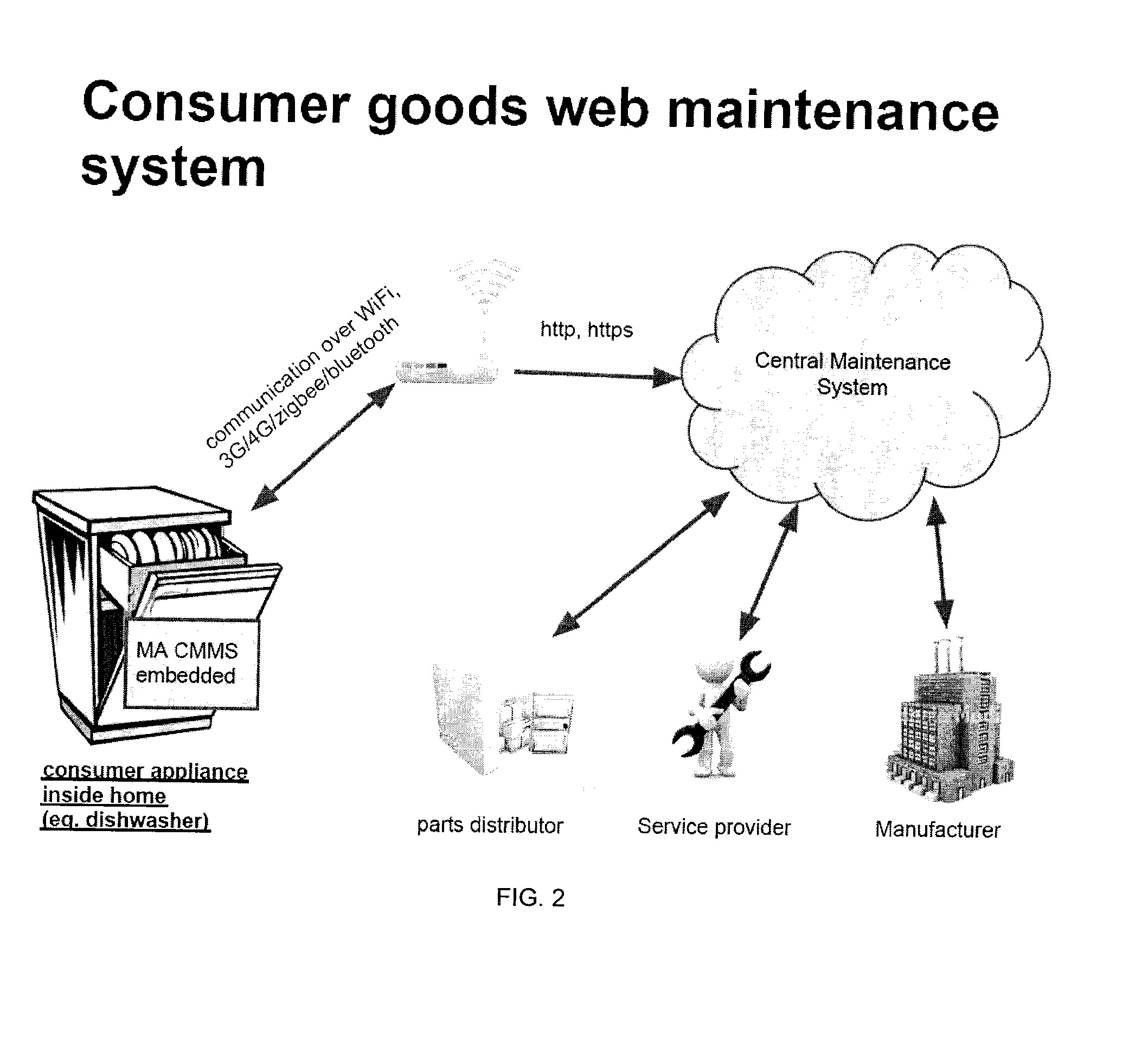

System and method for providing consumer side maintenance

A computer system is provided that is connected to the Internet and enables a plurality of network connected devices to access a novel and innovative resource management platform. The computer system includes an Internet enabled computer platform that implements a multi-tenant architecture that enables multiple platform clients to populate the platform with various information regarding their maintenance service requirements. The computer system includes one or more tools that (i) track activities of consumers in connection with their appliances or other consumer resource, (ii) extracts insights from such activities, and / or (iii) enables service businesses or manufacturers to upload information or documents related to maintenance services, such tools enabling the automated suggestion of maintenance actions and / or product or service requirements of consumers. A range of different intelligent features are provided. The computer system may include a CMMS with intelligent features. A number of related computer implemented methods for managing maintenance in an intelligent way is also provided.

Owner:FIIX INC

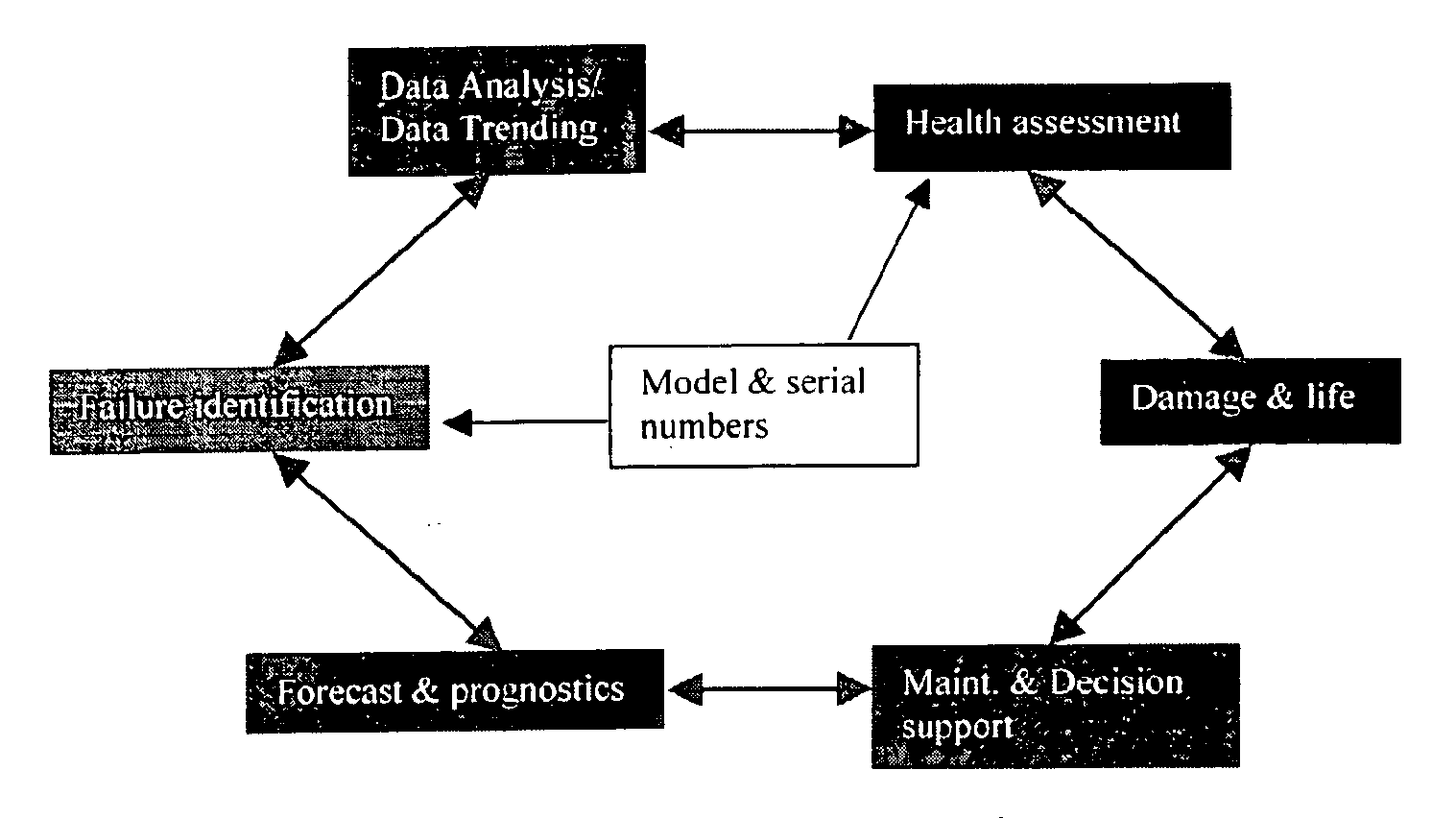

Intelligent condition-based engine/equipment management system

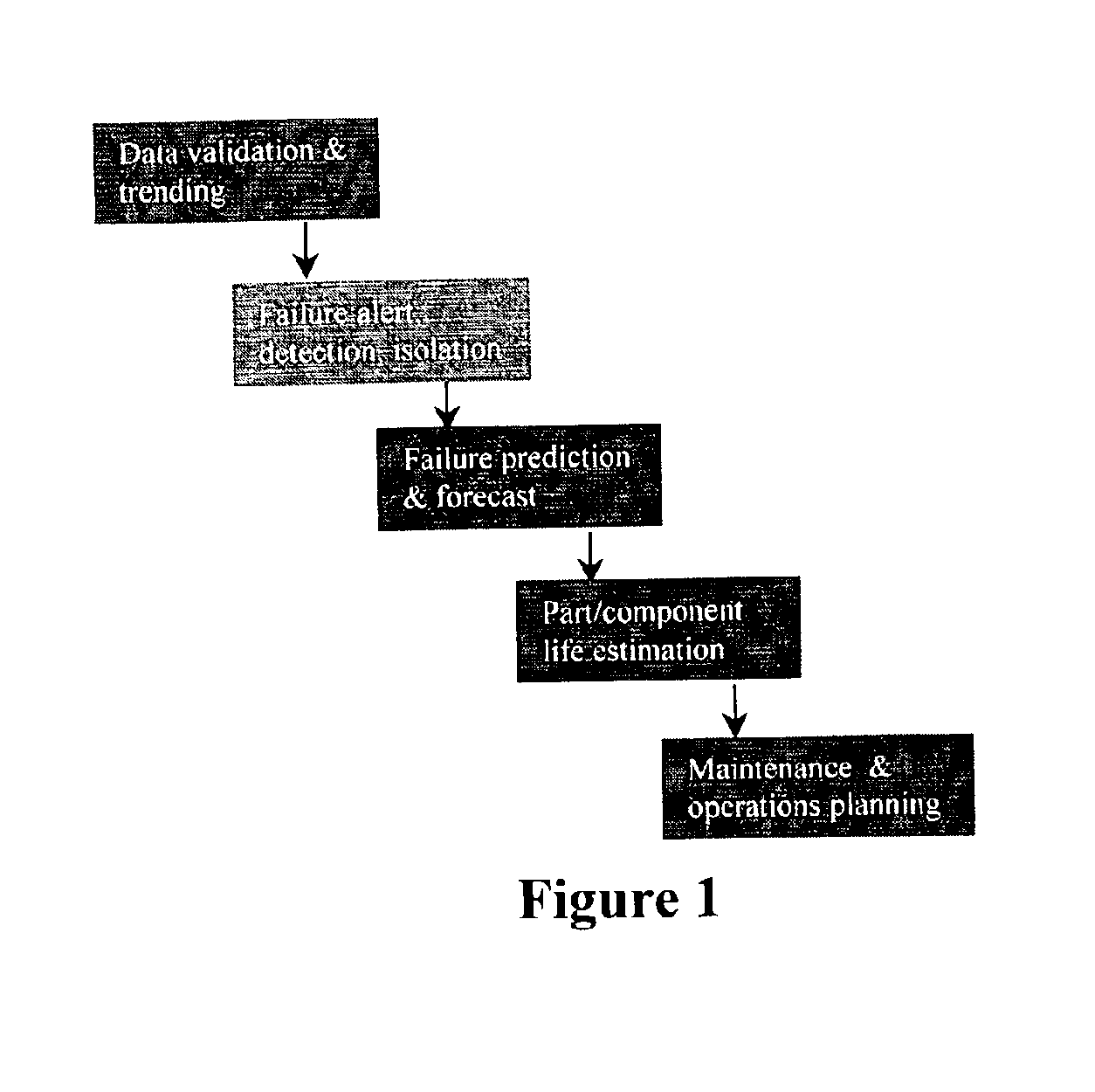

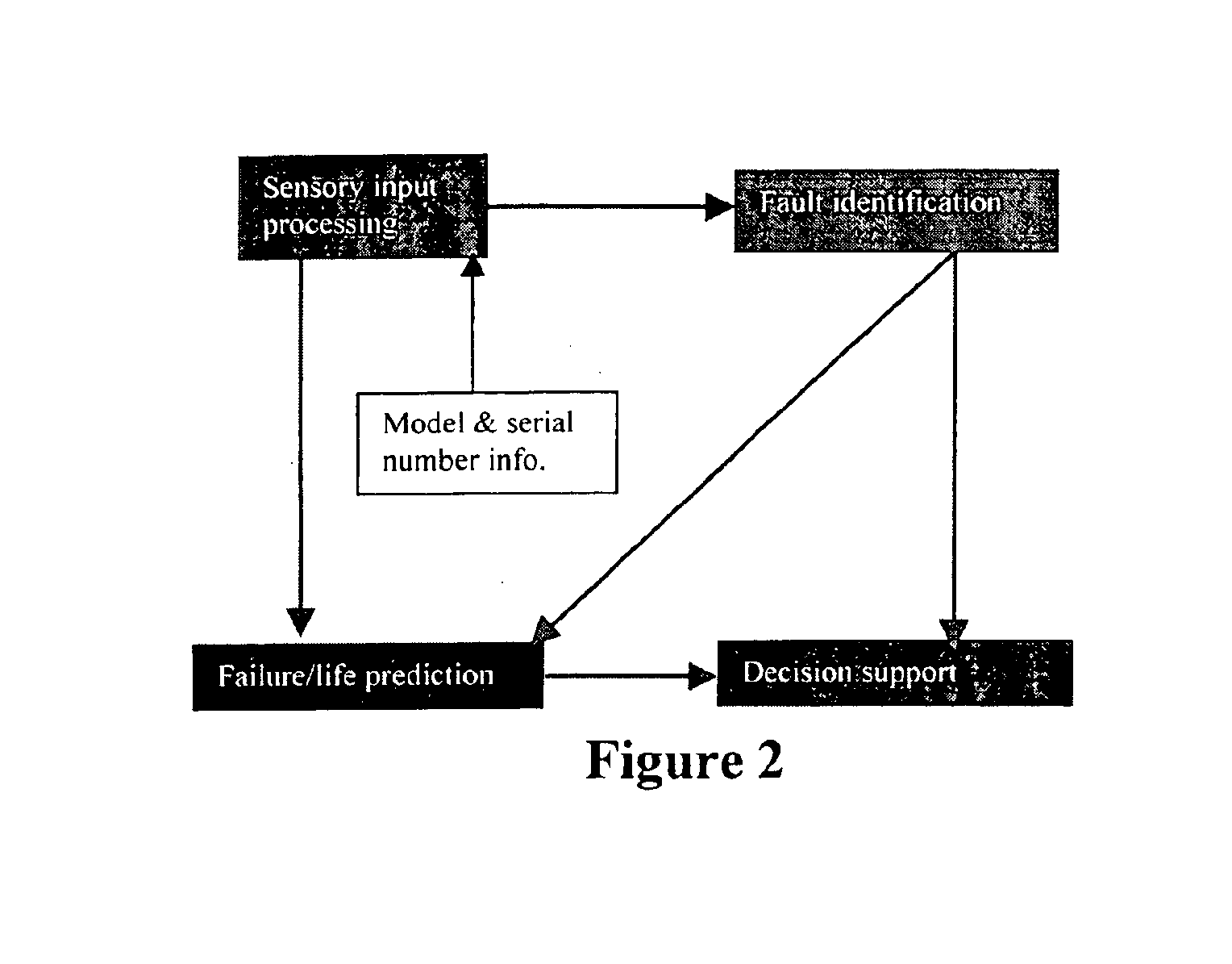

Health management of machines, such as gas turbine engines and industrial equipment, offers the potential benefits of efficient operations and reduced cost of ownership. Machine health management goes beyond monitoring operating conditions, it assimilates available information and makes the most favorable decisions to maximize the value of the machine. These decisions are usually related to predicted failure modes and their corresponding failure time, recommended corrective actions, repair / maintenance actions, and planning and scheduling options. Hence machine health management provides a number of functions that are interconnected and cooperative to form a comprehensive health management system. While these interconnected functions may have different names (or terminology) in different industries, an effective health management system should include four primary functions: sensory input processing, fault identification, failure / life prediction, planning and scheduling. These four functions form the foundation of the method of ICEMS (Intelligent Condition-based Engine / Equipment Management System). To facilitate information processing and decision making, these four functions may be repartitioned and regrouped, such as for network based computer software designed for health management of sophisticated machinery.

Owner:INTEL CORP

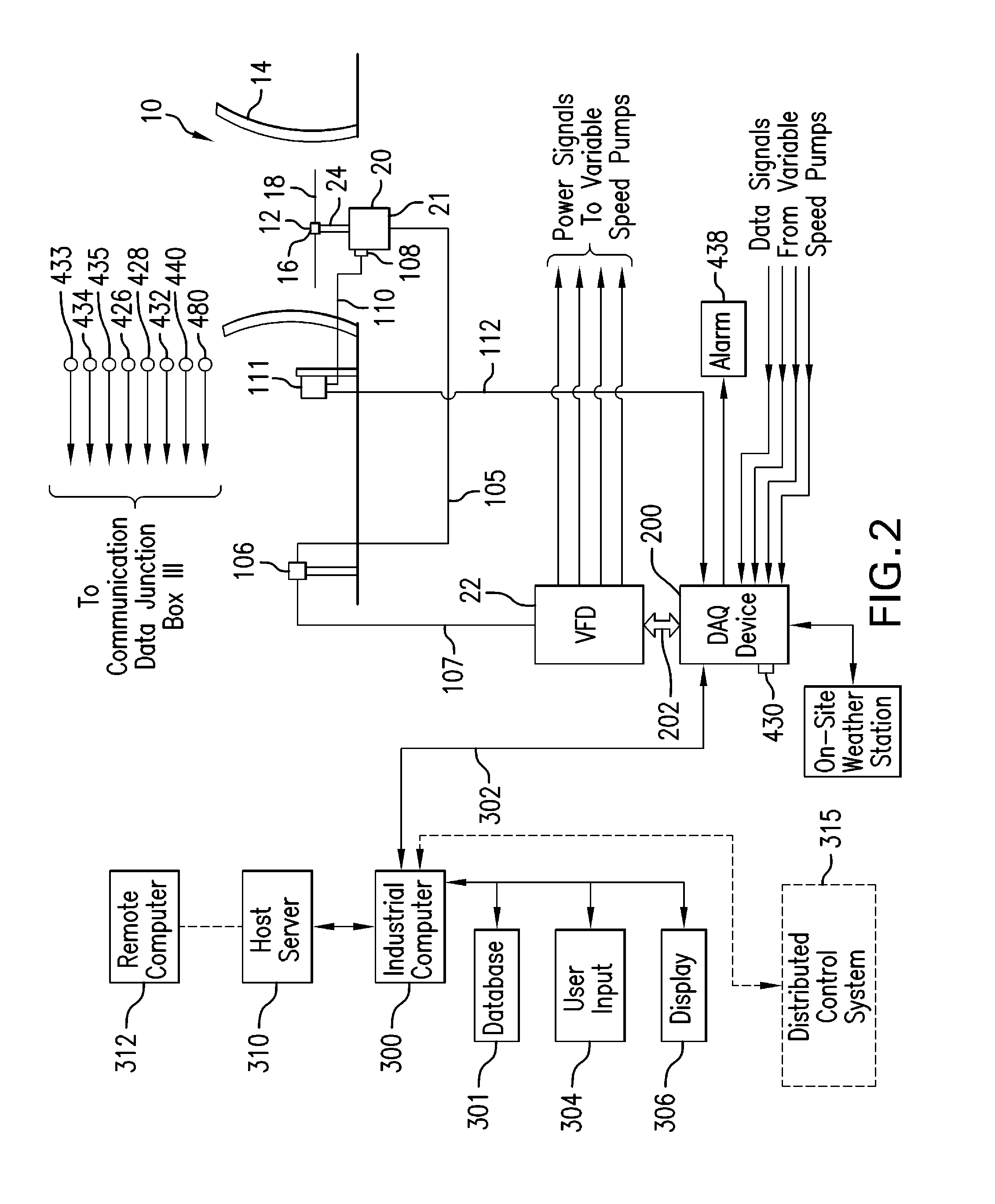

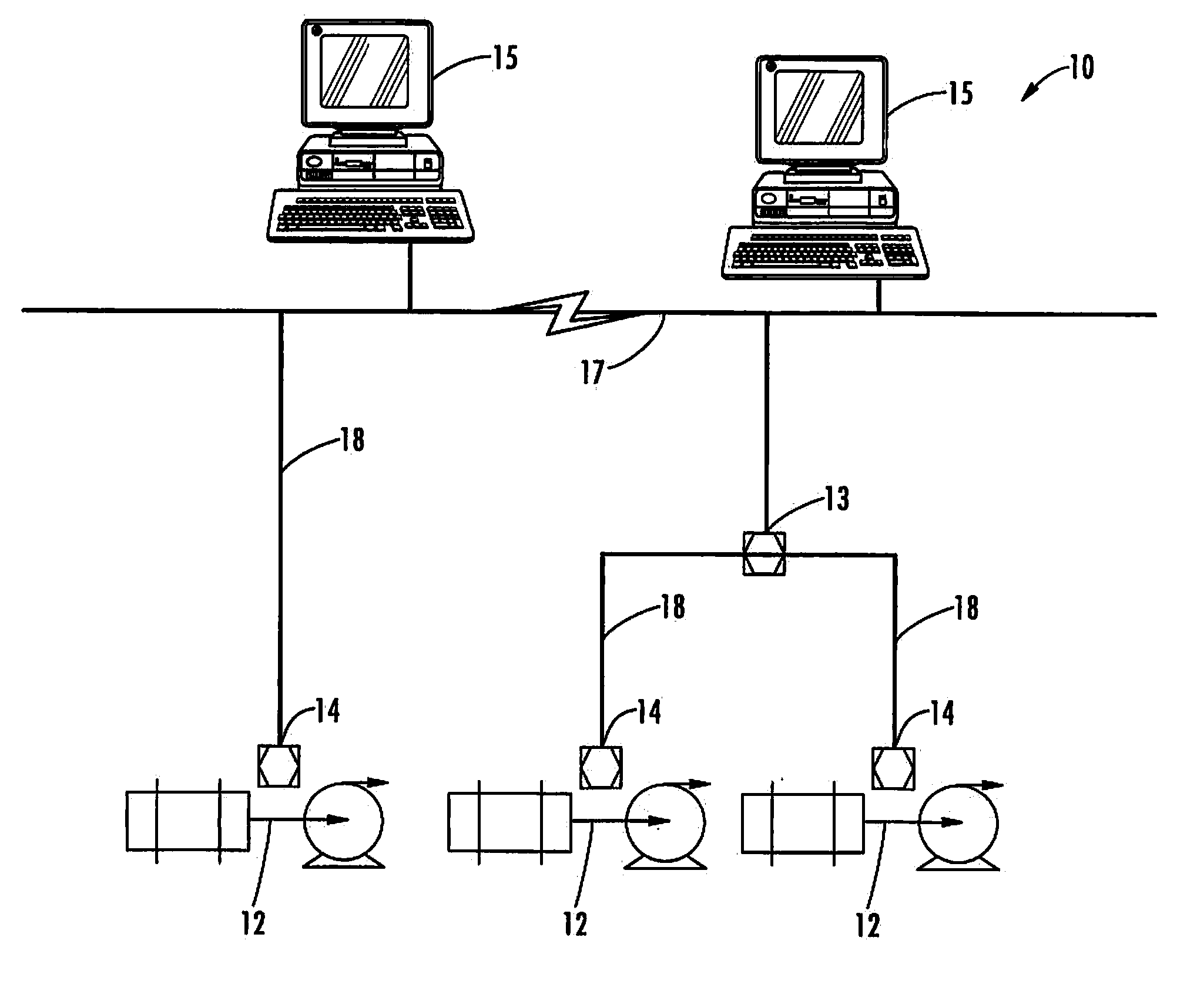

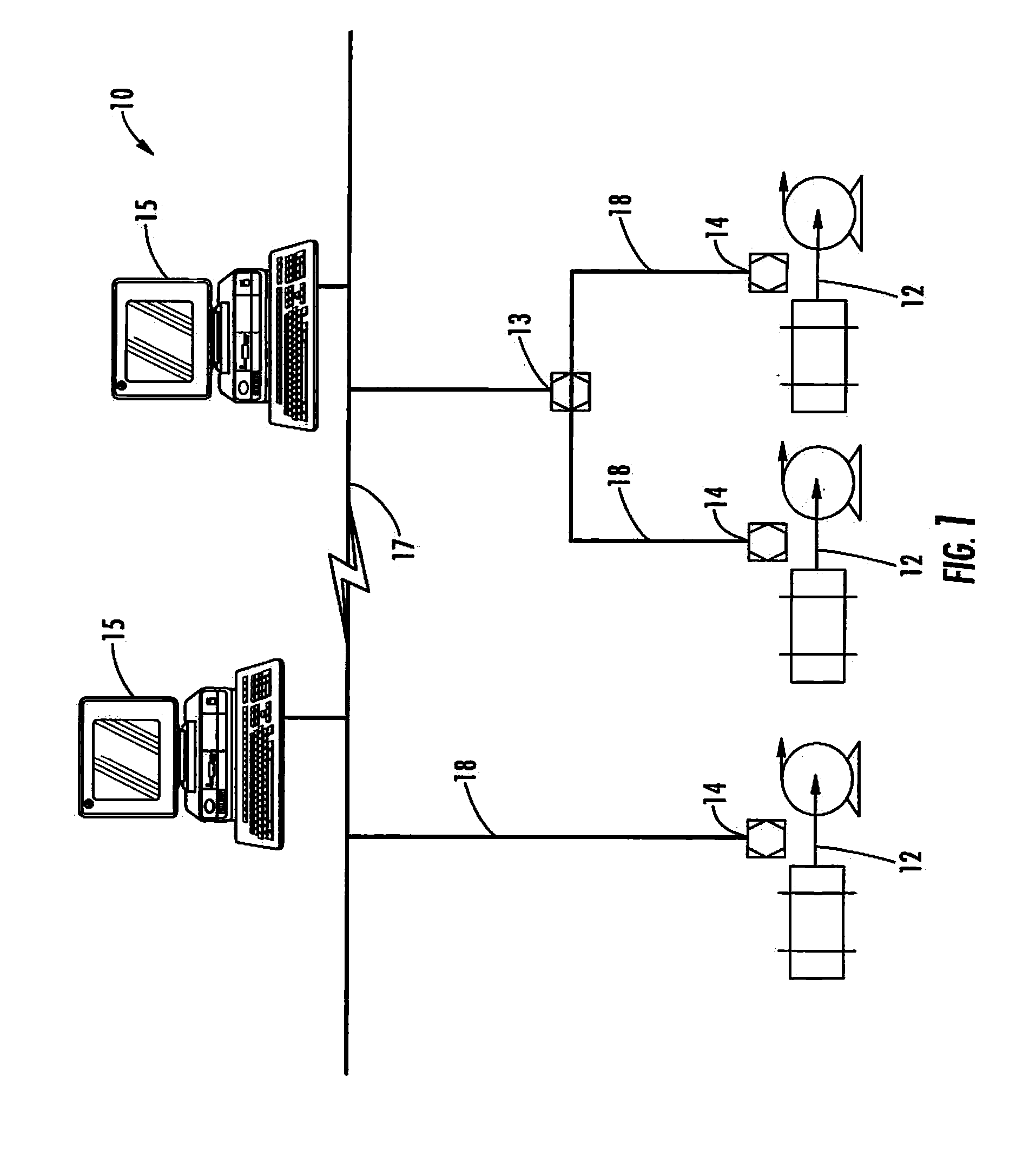

Direct drive fan system with variable process control

ActiveUS20140244051A1System smoothReduce vibrationTransportation and packagingEngine fuctionsCooling towerHigh torque

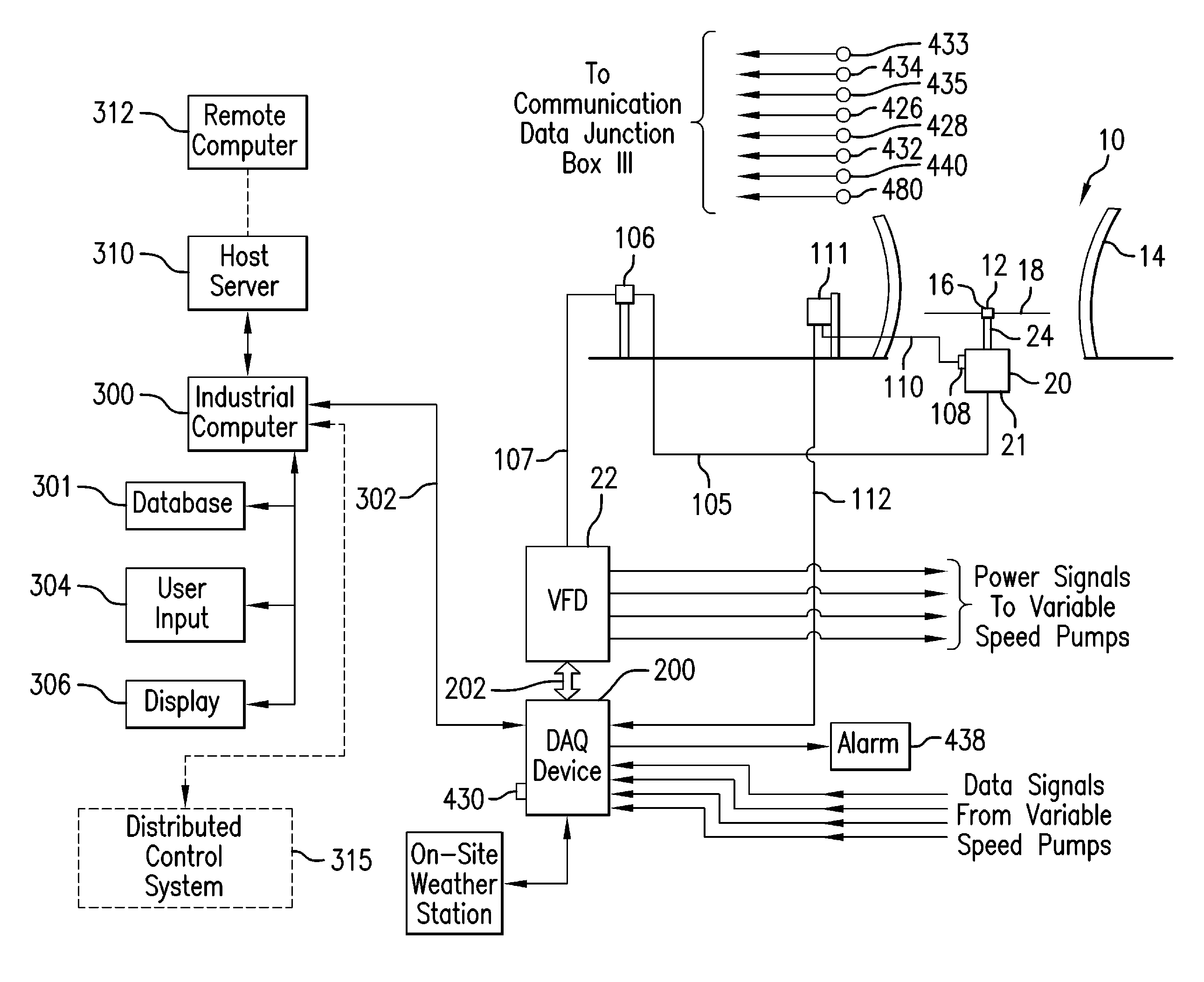

The present invention is directed to a direct-drive fan system and a variable process control system for efficiently managing the operation of fans in a cooling system such a as wet-cooling tower or air-cooled heat exchanger (ACHE), HVAC systems, mechanical towers or chiller systems. The present invention is based on the integration of key features and characteristics such as tower thermal performance, fan speed and airflow, motor torque, fan pitch, fan speed, fan aerodynamic properties, and pump flow. The variable process control system processes feedback signals from multiple locations in order control a high torque, variable speed, permanent magnet motor to drive the fan. Such feedback signals represent certain operating conditions including motor temperature, basin temperature, vibrations, and pump flow rates. Other data processed by the variable process control system in order to control the motor include turbine back pressure set-point, condenser temperature set-point and plant part-load setting. The variable process control system processes this data and the aforesaid feedback signals to optimize the operation of the cooling system in order to prevent disruption of the industrial process and prevent equipment (turbine) failure or trip. The variable process control system alerts the operators for the need to conduct maintenance actions to remedy deficient operating conditions such as condenser fouling. The variable process control system increases cooling for cracking crude and also adjusts the motor RPM, and hence the fan RPM, accordingly during plant part-load conditions in order to save energy.

Owner:PRIME DATUM

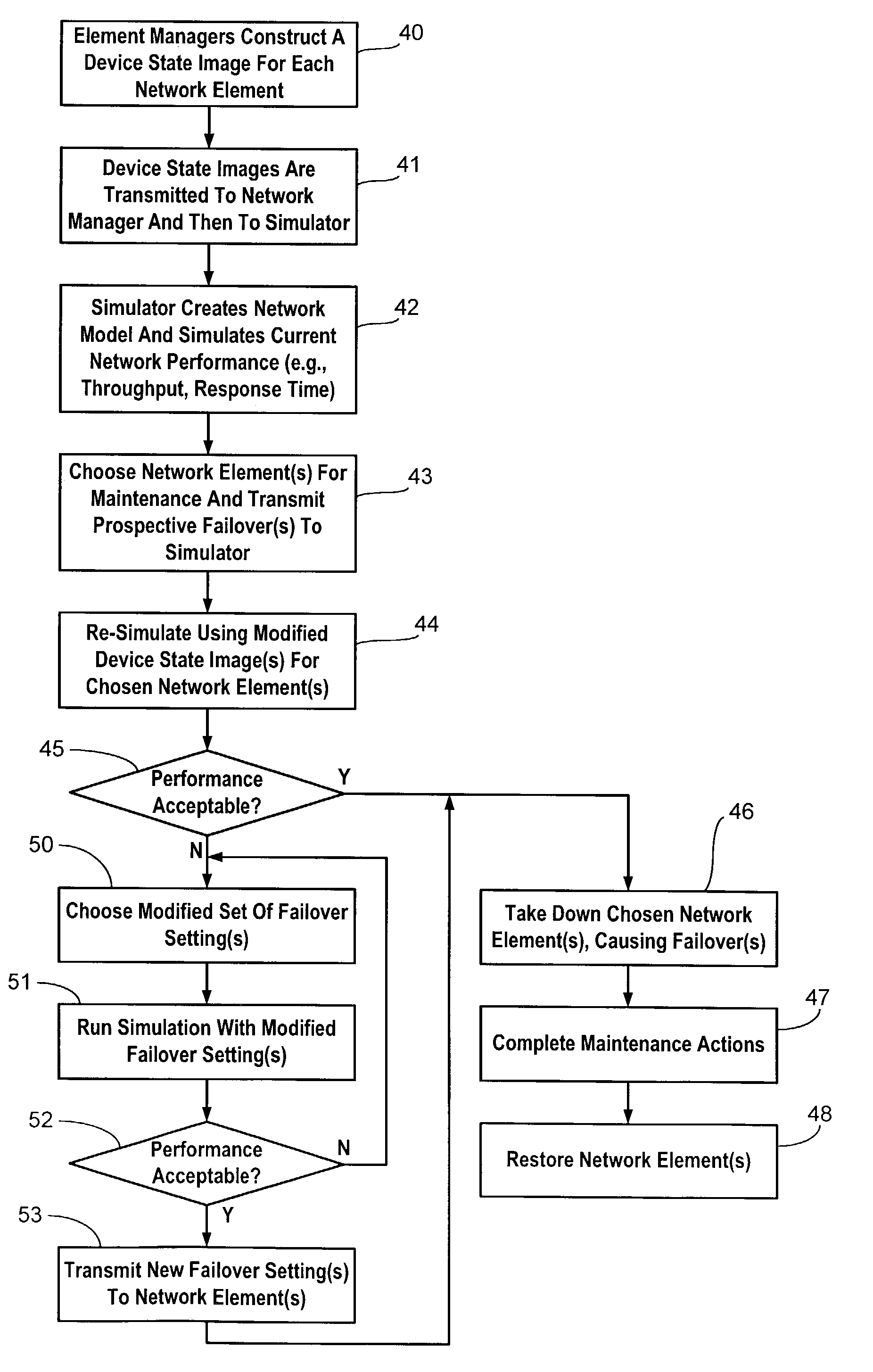

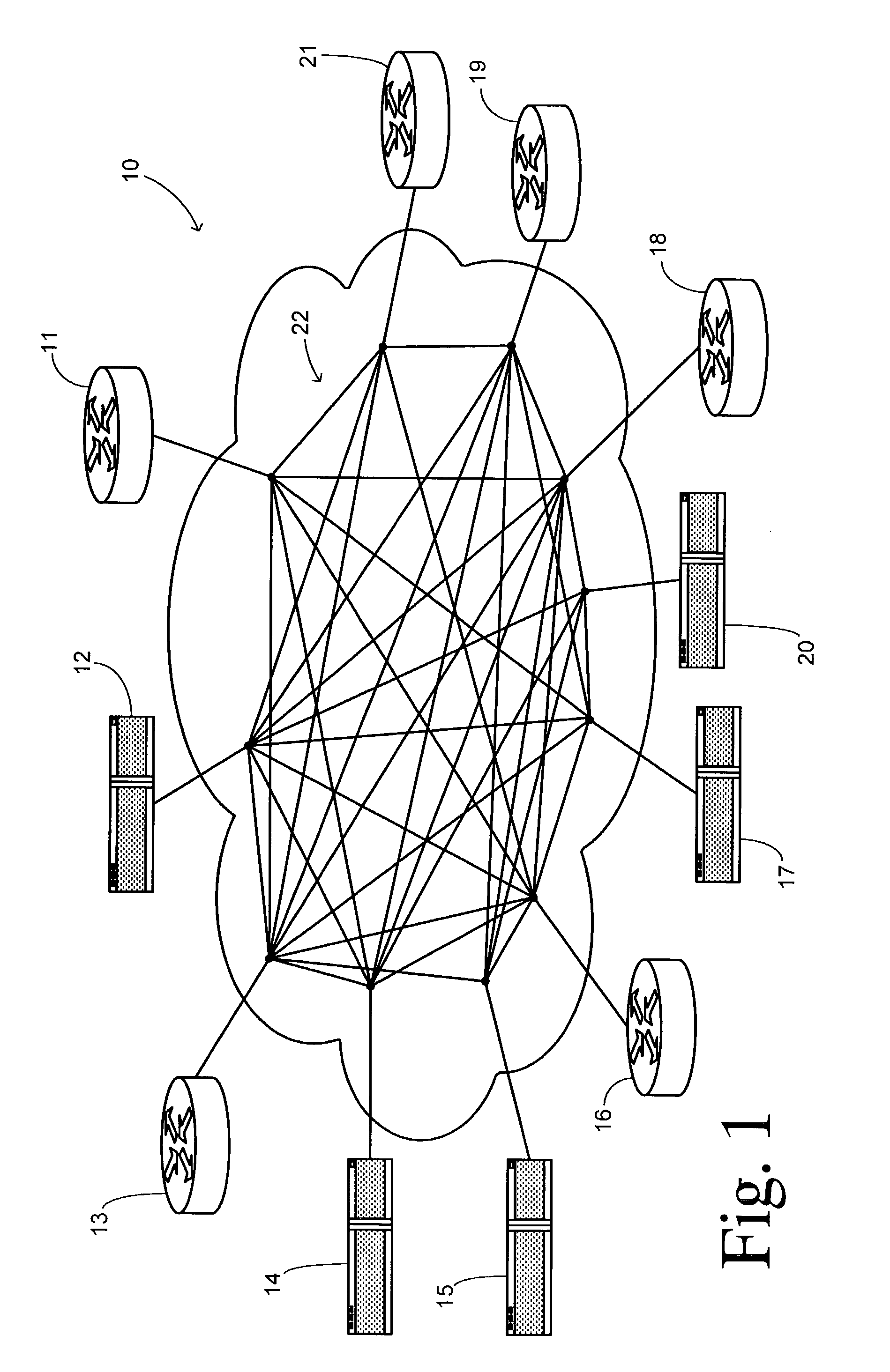

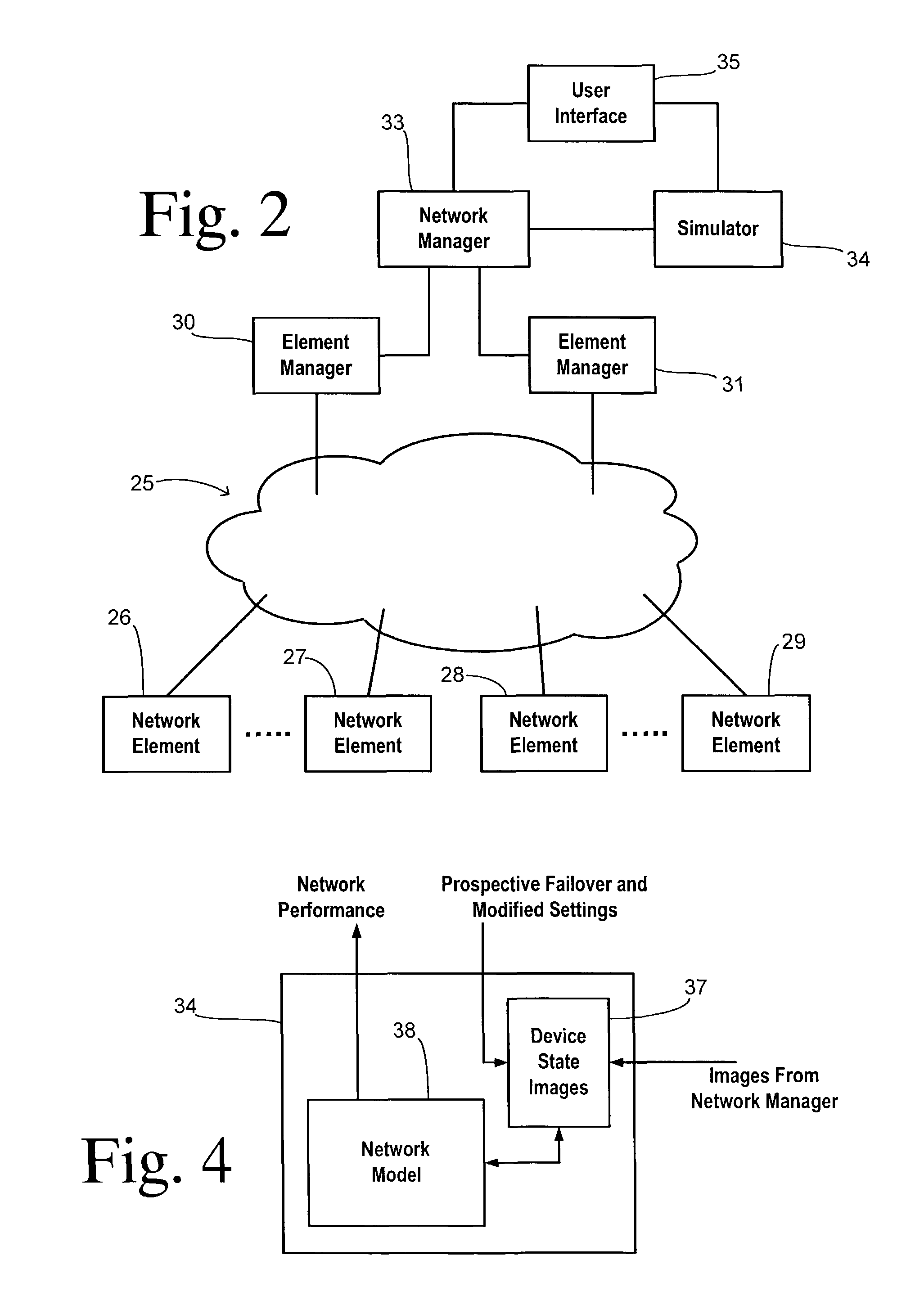

Network maintenance simulator with path re-route prediction

InactiveUS8018860B1Avoid power outagesFacilitate actionError preventionTransmission systemsFailoverDevice status

Re-routing interactions are predicted for a communications network including a plurality of network elements. A respective device state image is constructed for each of the plurality of network elements, with each of the device state images including a failover setting of a respective one of the network elements. The device state images are transmitted to a network simulator. The performance of the communications network is simulated in response to the device state images. A prospective network element failover of a predetermined one of the network elements is transmitted to the network simulator. A performance of the communications network is simulated in response to the device state images modified by the prospective network element failover. It is then detected whether an acceptable performance is maintained in view of the prospective network element failover in order to identify whether is will be permissible to perform a maintenance action on the network element which makes it unavailable to the network.

Owner:SPRINT CORPORATION

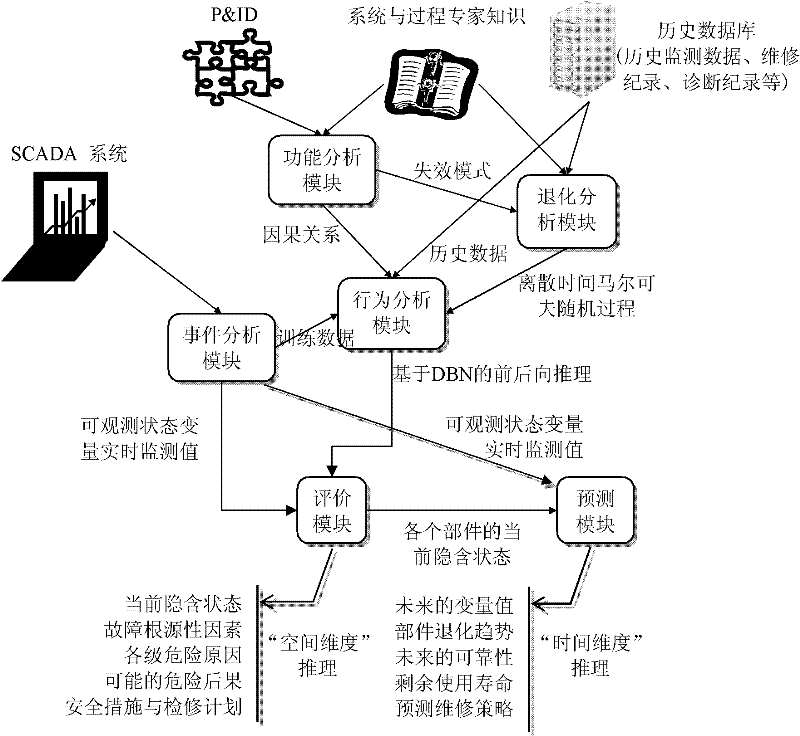

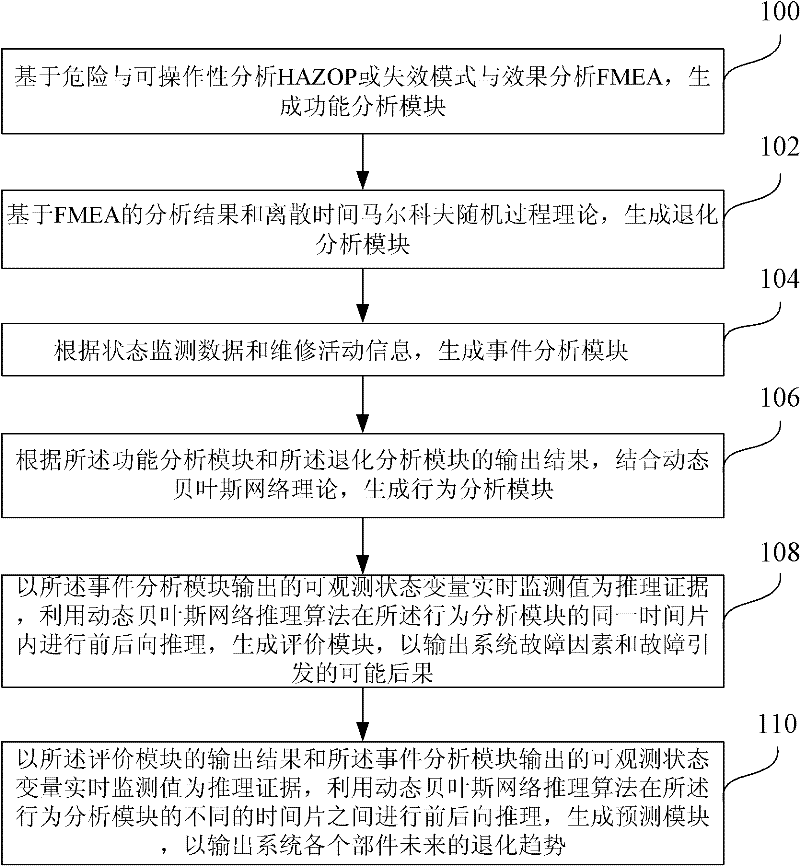

A modeling method of hybrid fault early warning model and hybrid fault early warning model

InactiveCN102262690AGuarantee intrinsic safetySpecial data processing applicationsOperabilitySystem failure

The embodiment of the invention provides a modeling method of an early warning model of mixed failures and a modeling system. The modeling method provided by the invention comprises the following steps of: generating a function analyzing module on the basis of HAZOP (Hazard and Operability Analysis) or FMEA (Failure Mode and Effects Analysis); generating a degeneration analyzing module on the basis of FMEA analyzing results and a theory of stochastic processes; generating an accident analyzing module according to state monitoring data and maintenance action information; generating an action analyzing module according to output results of the function analyzing module and the degeneration analyzing module through combining a DBN (Dynamic Bayesian Network) theory; taking the output of the accident analyzing module as an inference evidence and utilizing a DBN inference algorithm to process forward and backward inferences in the same time period to generate an evaluating module for outputting factors and consequences of system failures; taking the output results of the evaluating module and the accident analyzing module as the inference evidence and utilizing the DBN inference algorithm to process forward and backward inferences in the different time periods to generate a predicating module for outputting prospective degeneration tendencies of each member of the system. The model provided by the invention can be used for tracking the failure factors of the system and inferring possible failure consequences and probability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

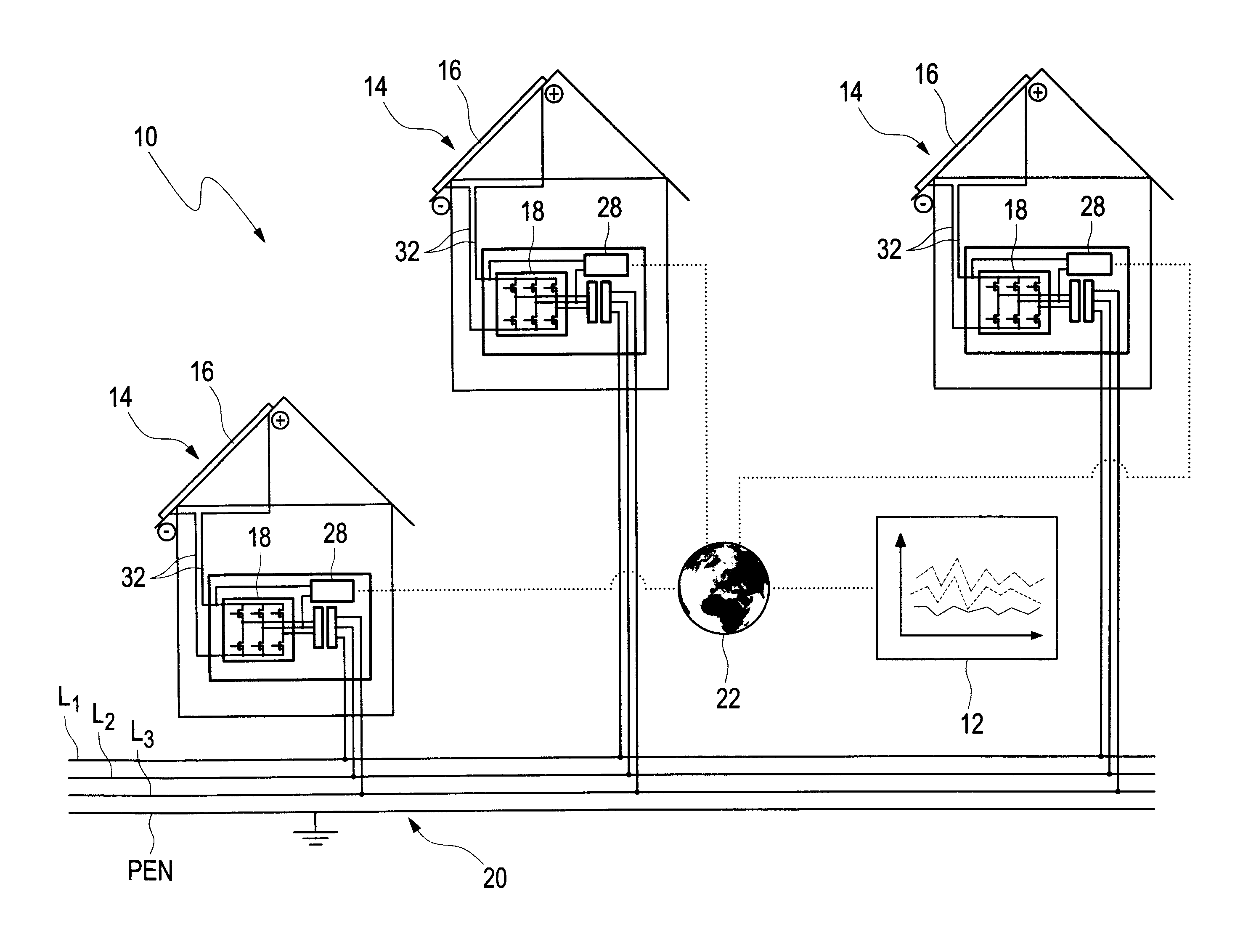

Monitoring System for Power Grid Distributed Power Generation Devices

InactiveUS20110130982A1Restoring power performance of powerReducing false alarmElectric devicesPower measurement by current/voltageData acquisitionData interface

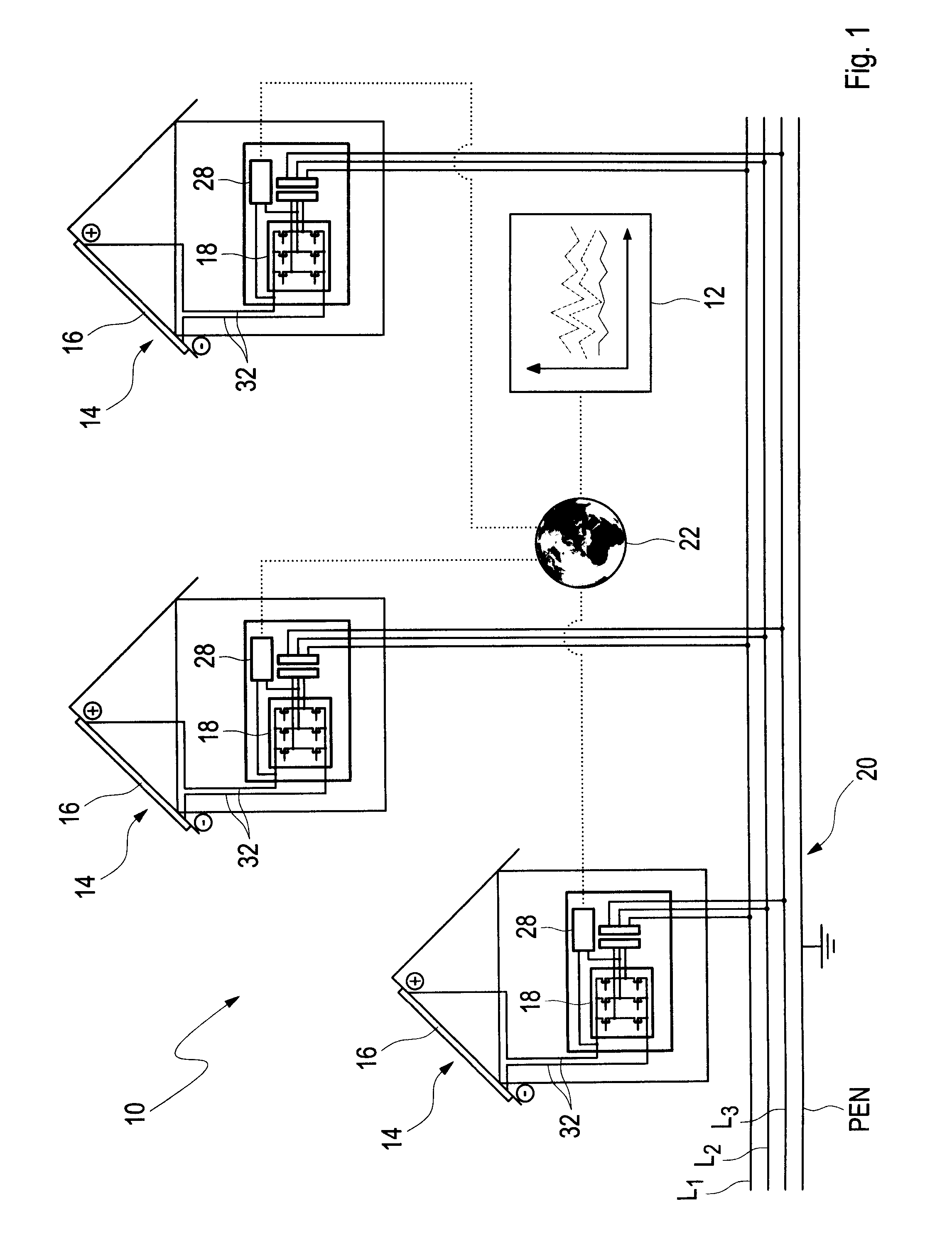

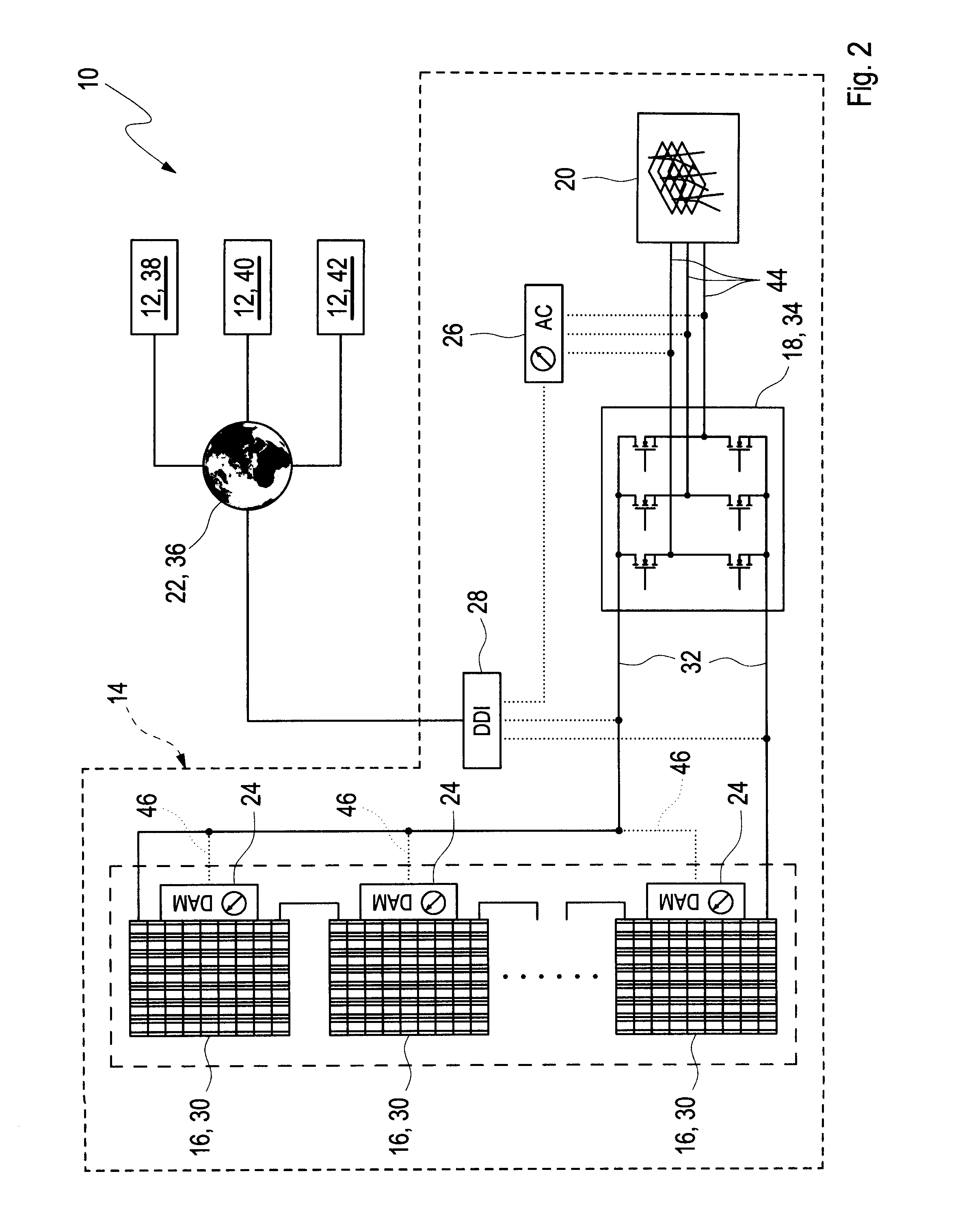

The invention relates to an autonomously working monitoring system (10), a method for monitoring and maintenance of power grid distributed power generation devices (14) and a related computer program product. The system comprises at least one power performance monitoring unit (12) for monitoring, analyzing and storing at least power performance data (70) of at least one power generation device (14);at least one power generation device (14) comprising at least one power generation module (16) for generation of electric power and at least one inverter module (18) for feeding in electric power of said power generation module (16) to a power grid (20);and an external network (22) connecting one or more power generation devices (14) with said power performance monitoring unit (12).The power generation device (14) further comprisesat least one data acquisition module (24) for measuring of power output of each power generation module (16);at least one inverter measuring module (26) for measuring of power output of said inverter (18) to the power grid (20);a data interface module (28) in power line communication with said data acquisition module (24), and in communication with said inverter measuring module (26) and said external network (22) for sending power performance data (70) of said power generation device (14) to said power performance monitoring unit (12) including power generation module ID (66) and inverter ID (68), and / or for autonomously sending a maintenance notice for requesting a maintenance action based on at least a specific power performance pattern.

Owner:IBM CORP

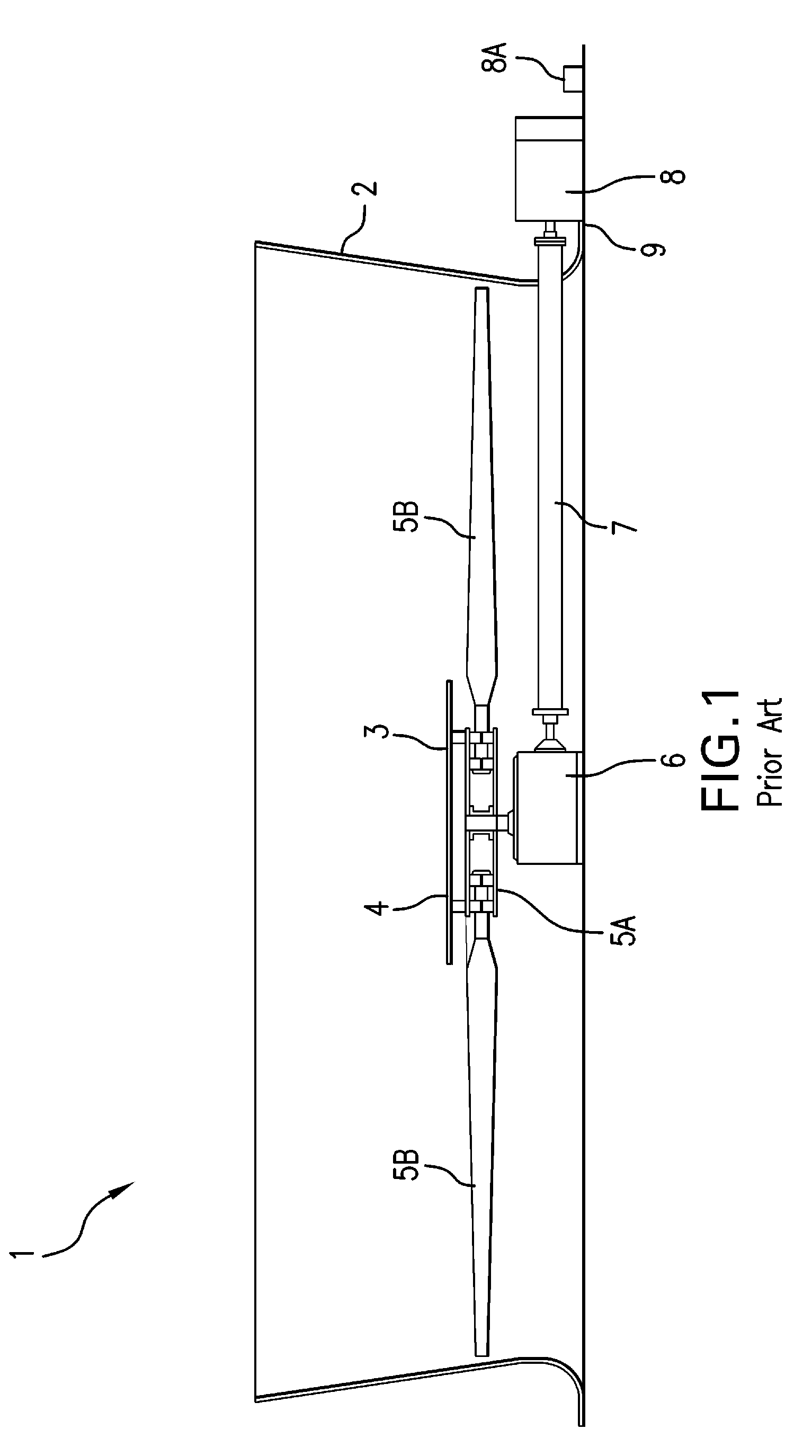

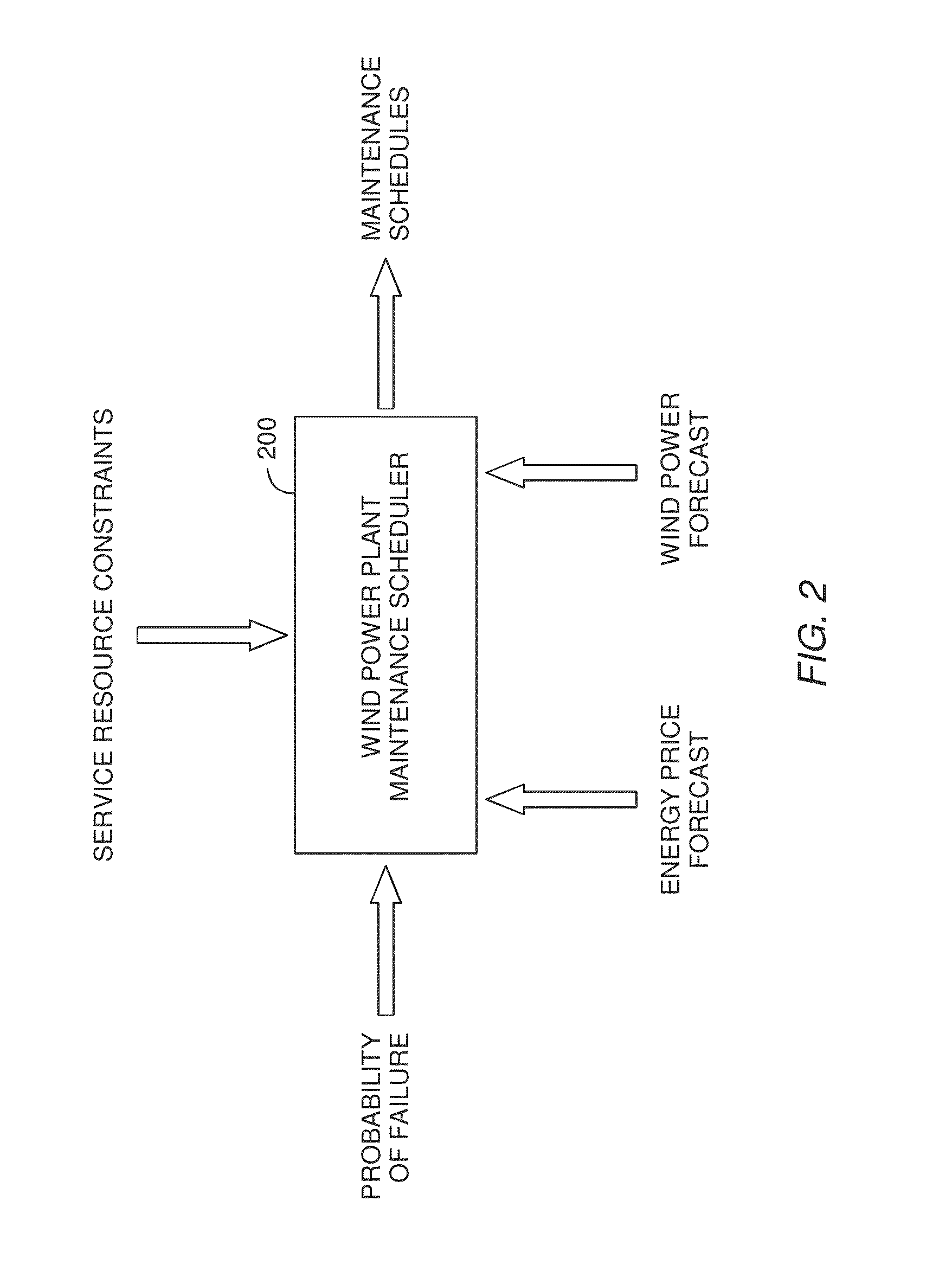

Wind turbine maintenance optimizer

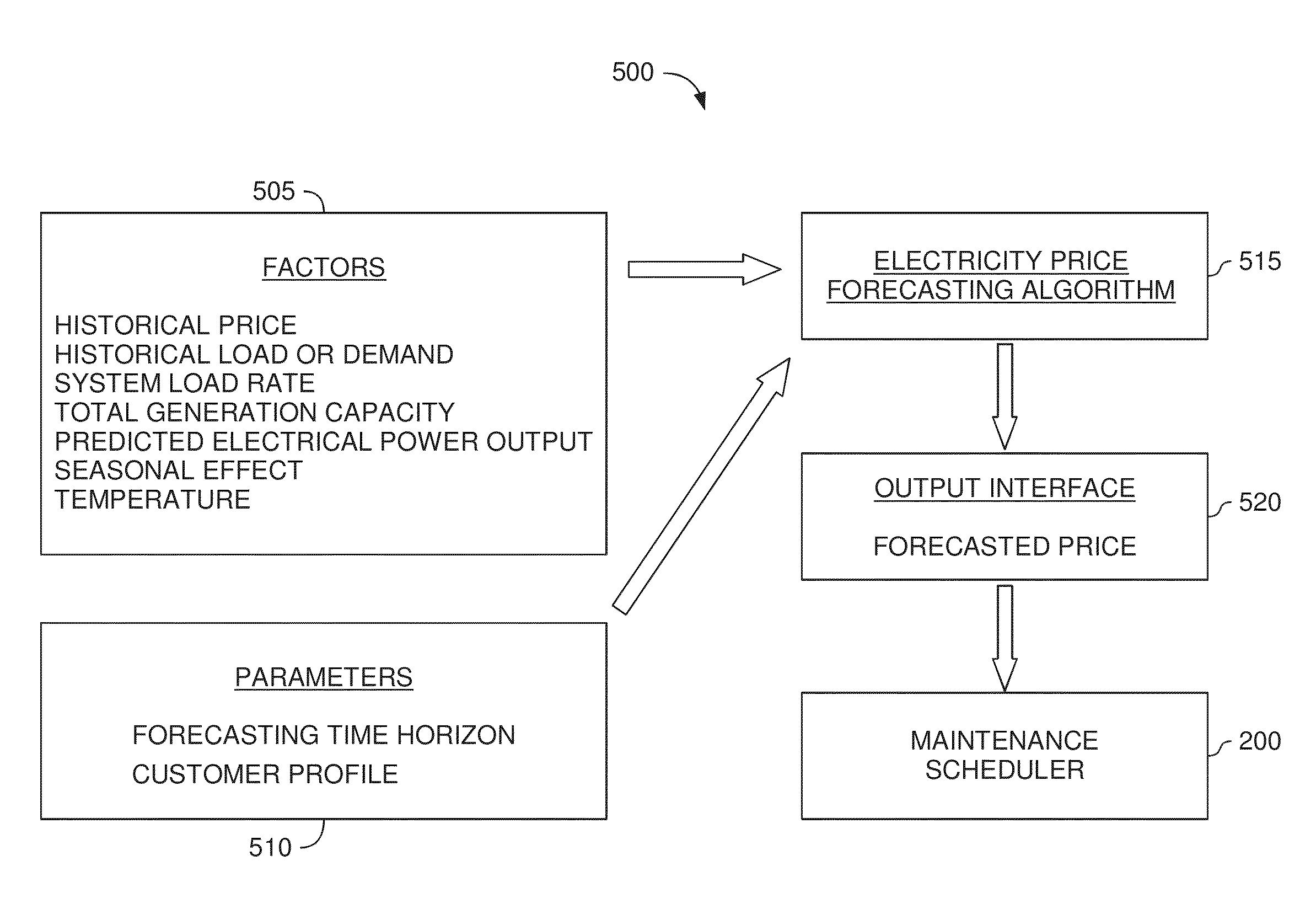

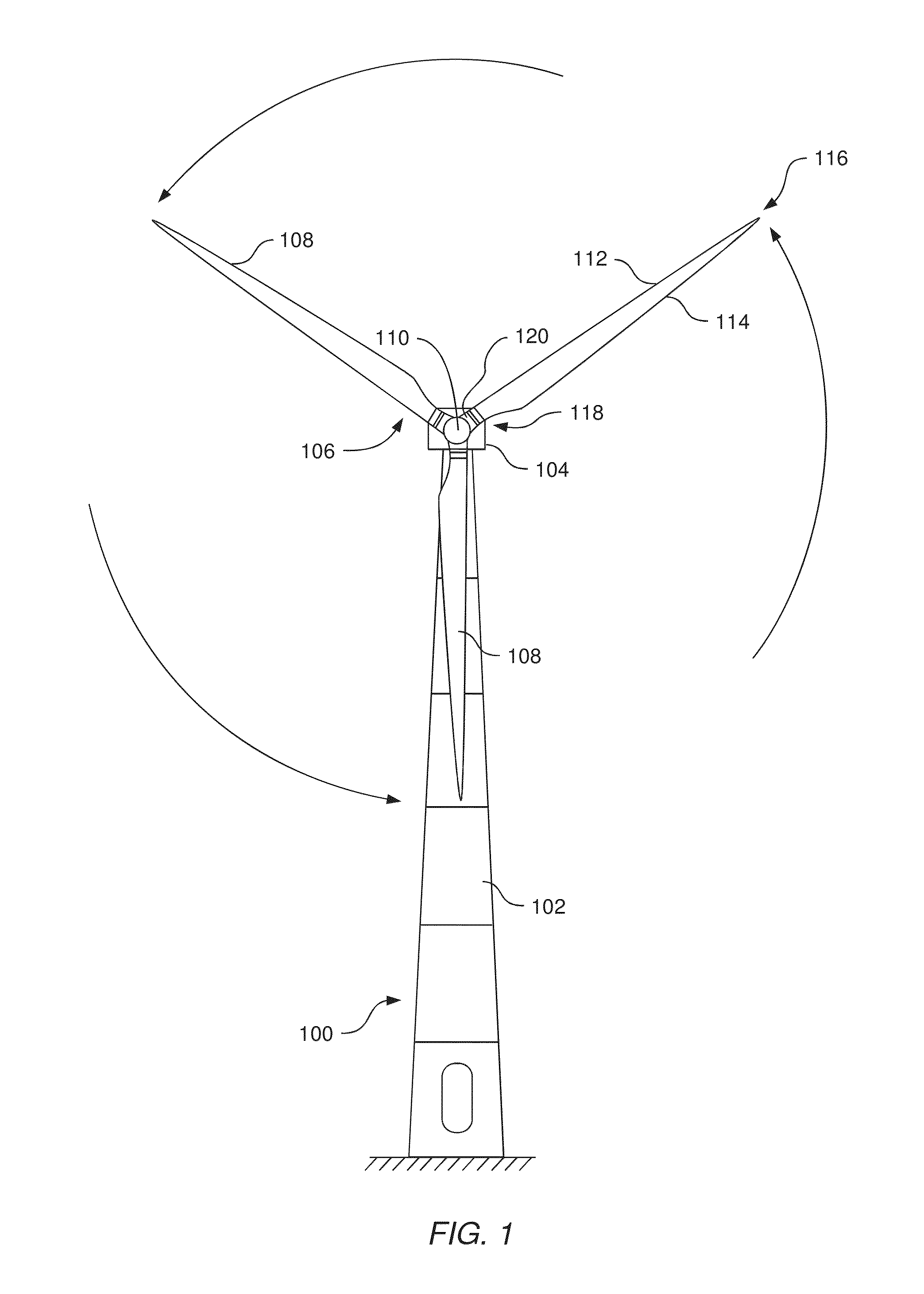

Determining when to perform preventative maintenance is an important consideration for maximizing the revenue of a wind turbine. For example, performing preventative maintenance may be cheaper than replacing turbine components when they fail. When determining to perform preventative maintenance, a maintenance scheduler may consider multiple factors. These factors may include the probability of failure, the predicted price of energy, predicted wind power production, resource constraints, and the like. Specifically, the maintenance scheduler may predict the future values of these factors which are then integrated into a net present value (NPV) for each of the components. Based on the respective NPVs, the maintenance scheduler may determine which maintenance actions to perform and in what order.

Owner:VESTAS WIND SYST AS

Fault-tolerant IS-IS routing system, and a corresponding method

The invention provides a high availability control method for a router in an autonomous system, the router being in communication with other routers using an IS-IS protocol via interfaces and presenting both an active IS-IS protocol engine and a standby IS-IS protocol engine. The method comprises steps of storing data concerning adjacency, the state of links, and interfaces in a memory of the active protocol engine, updating the data stored in a memory of the standby protocol engine, and activating the standby protocol engine using the updated data. The invention also provides a router implementing the method. The invention serves to increase router availability in the event of a failure or of maintenance actions.

Owner:ALCATEL LUCENT SAS

Real time asset optimization

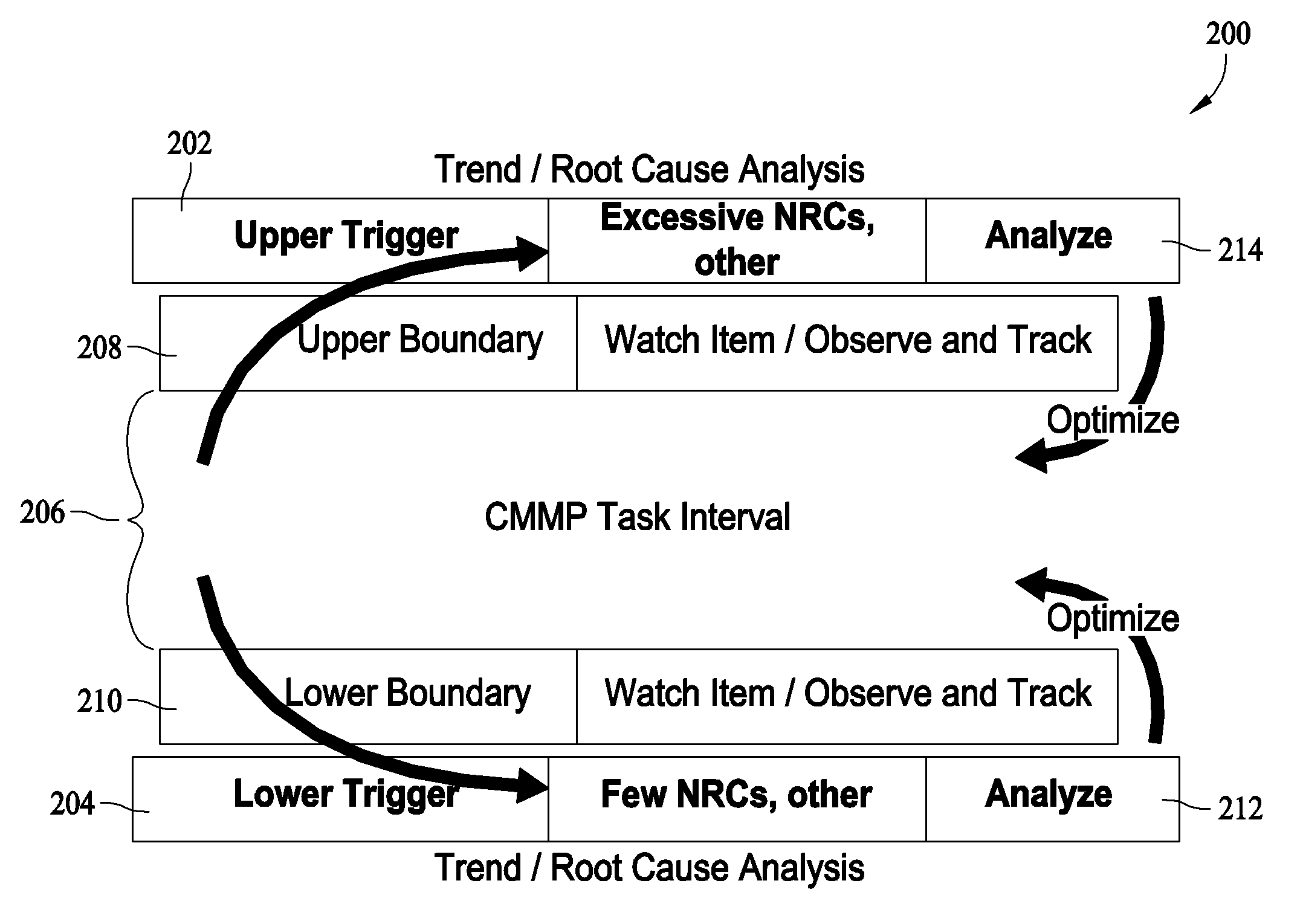

InactiveUS20030130755A1Technology managementResourcesComputerized maintenance management systemEngineering

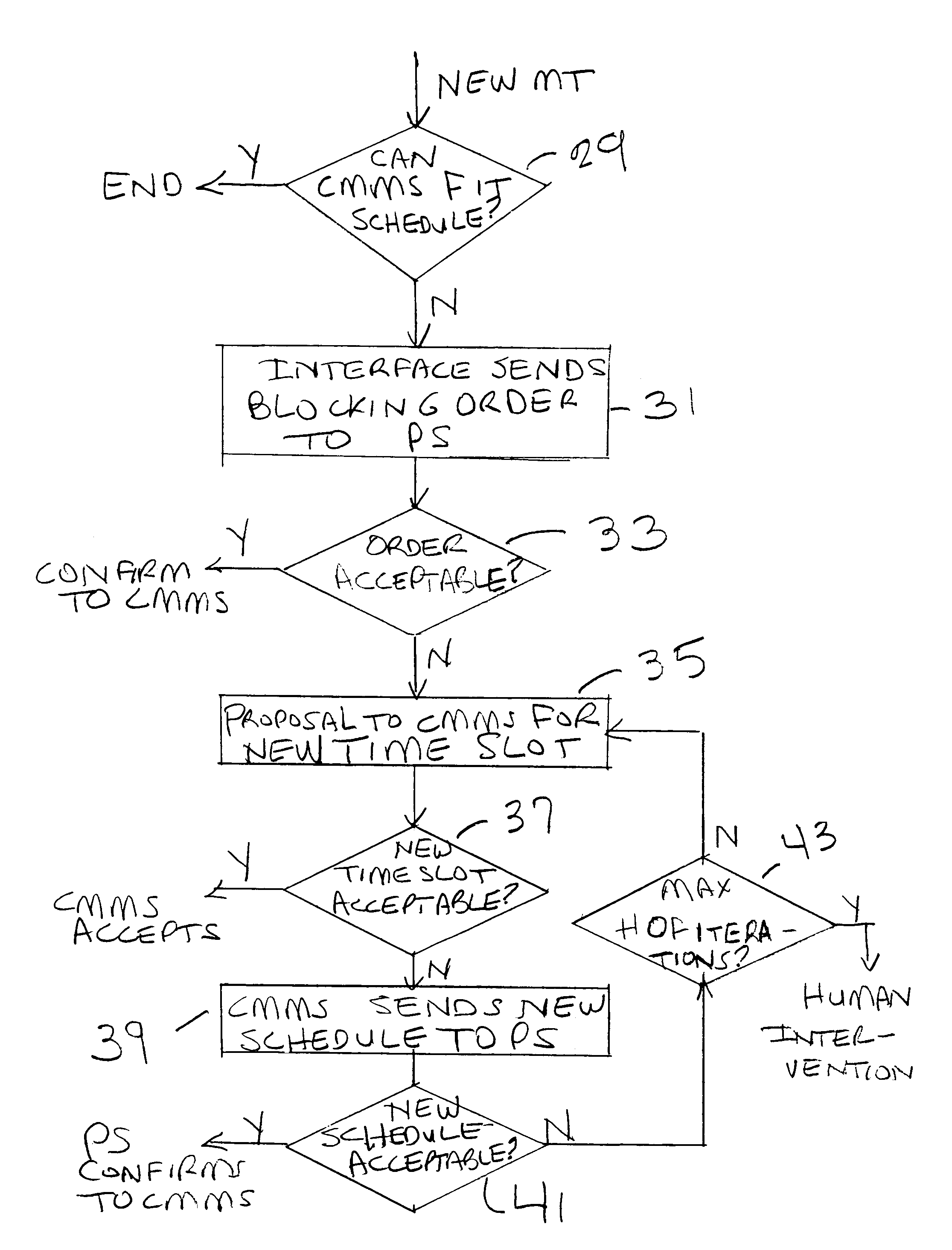

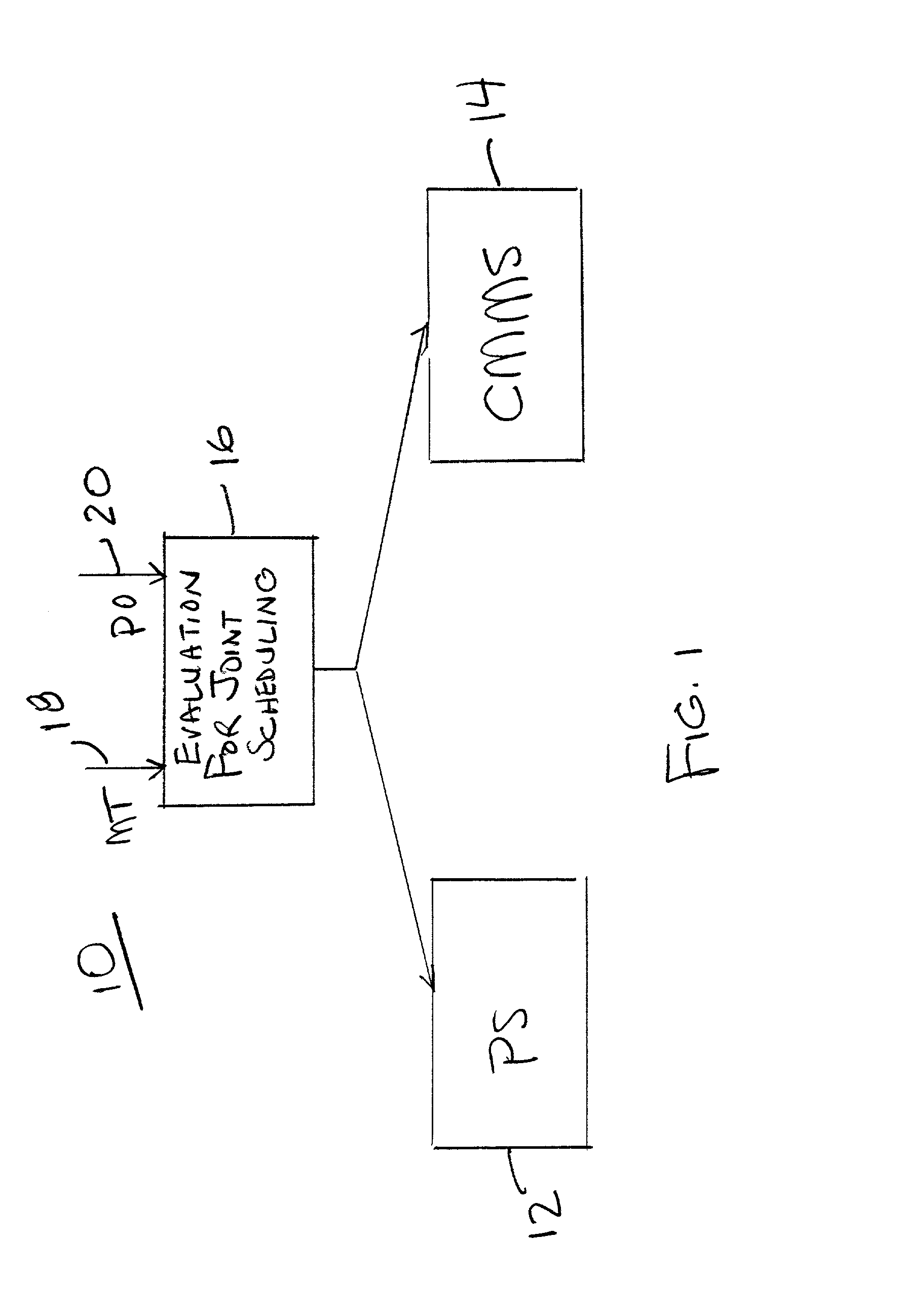

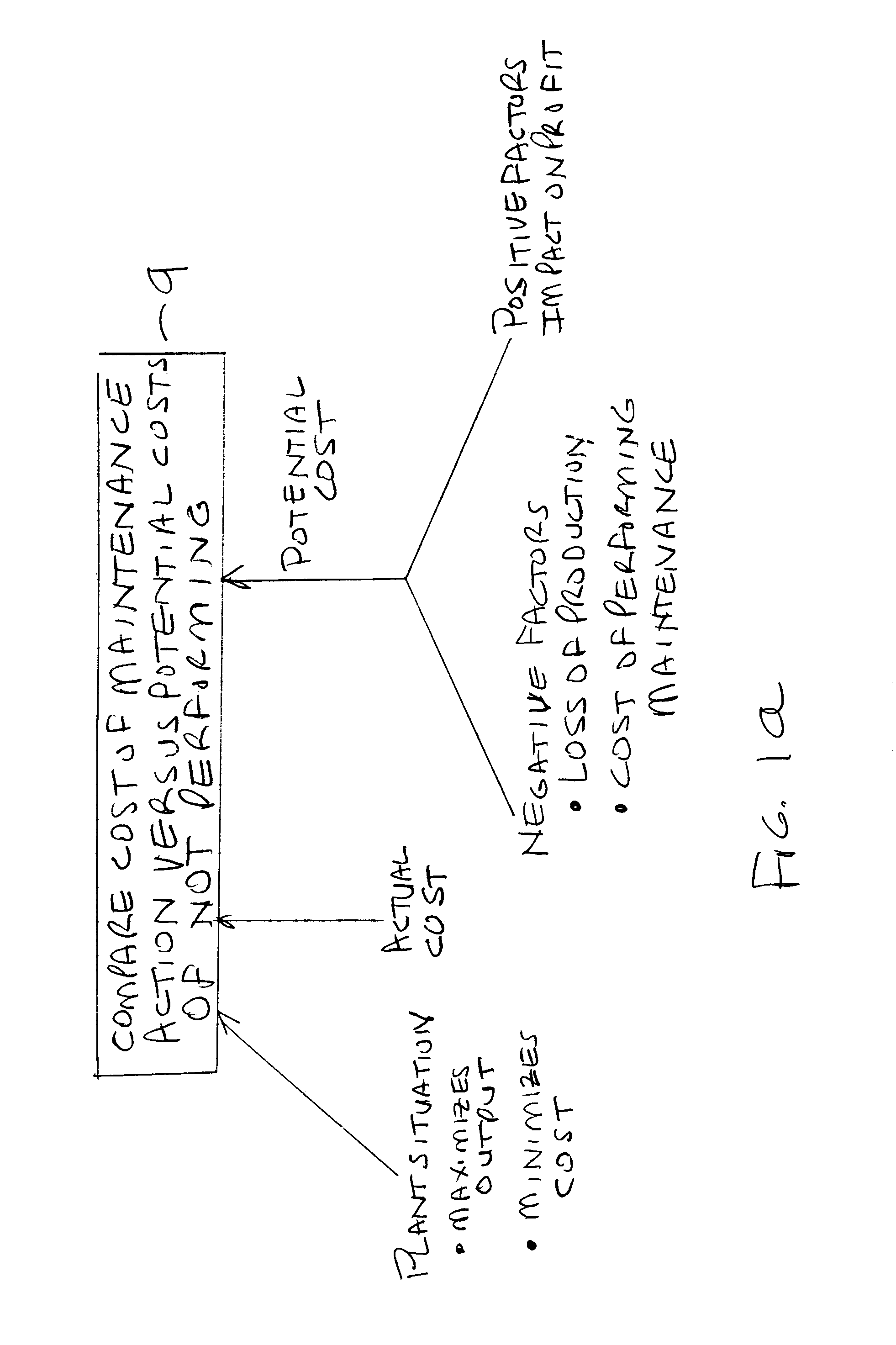

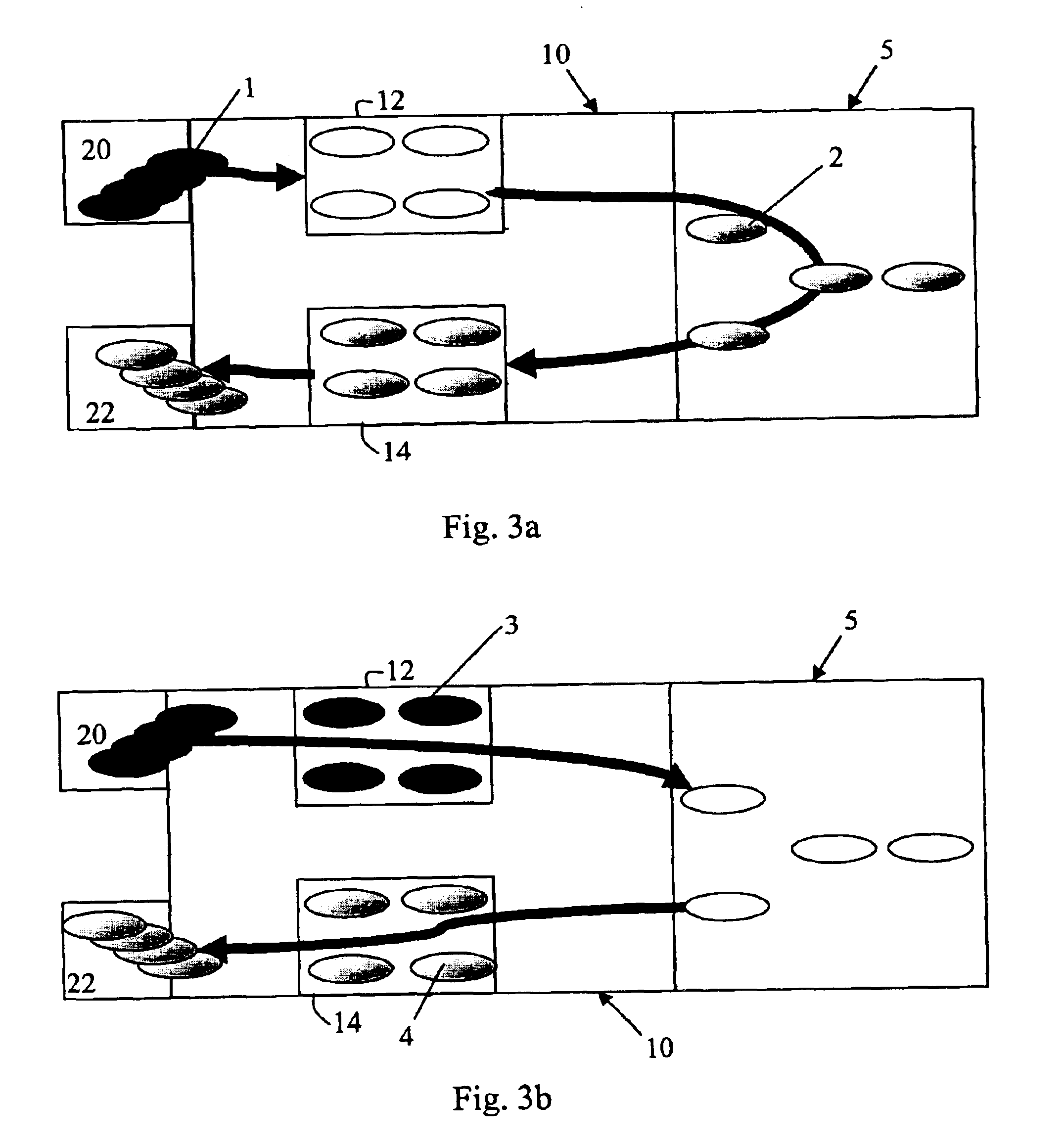

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

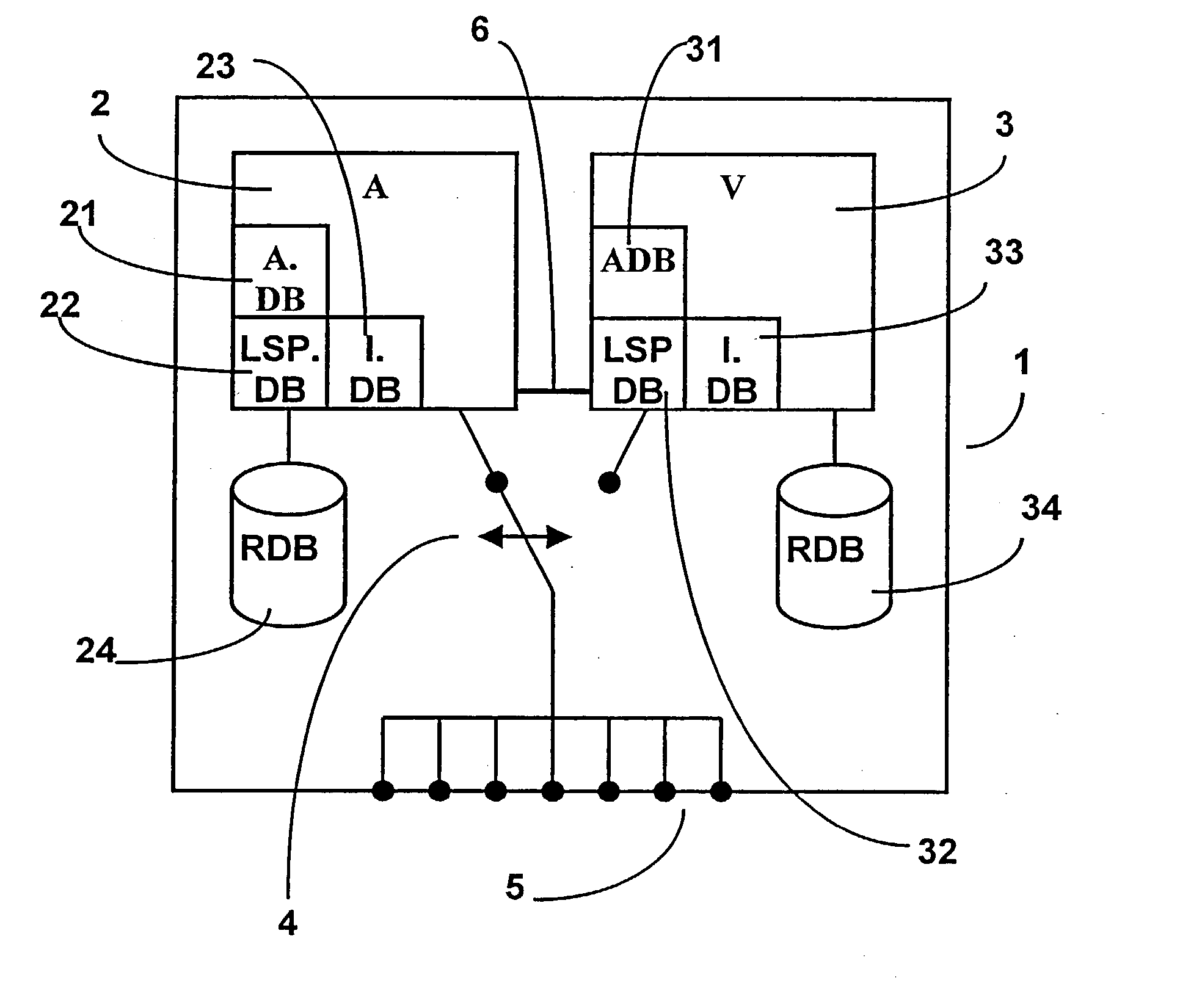

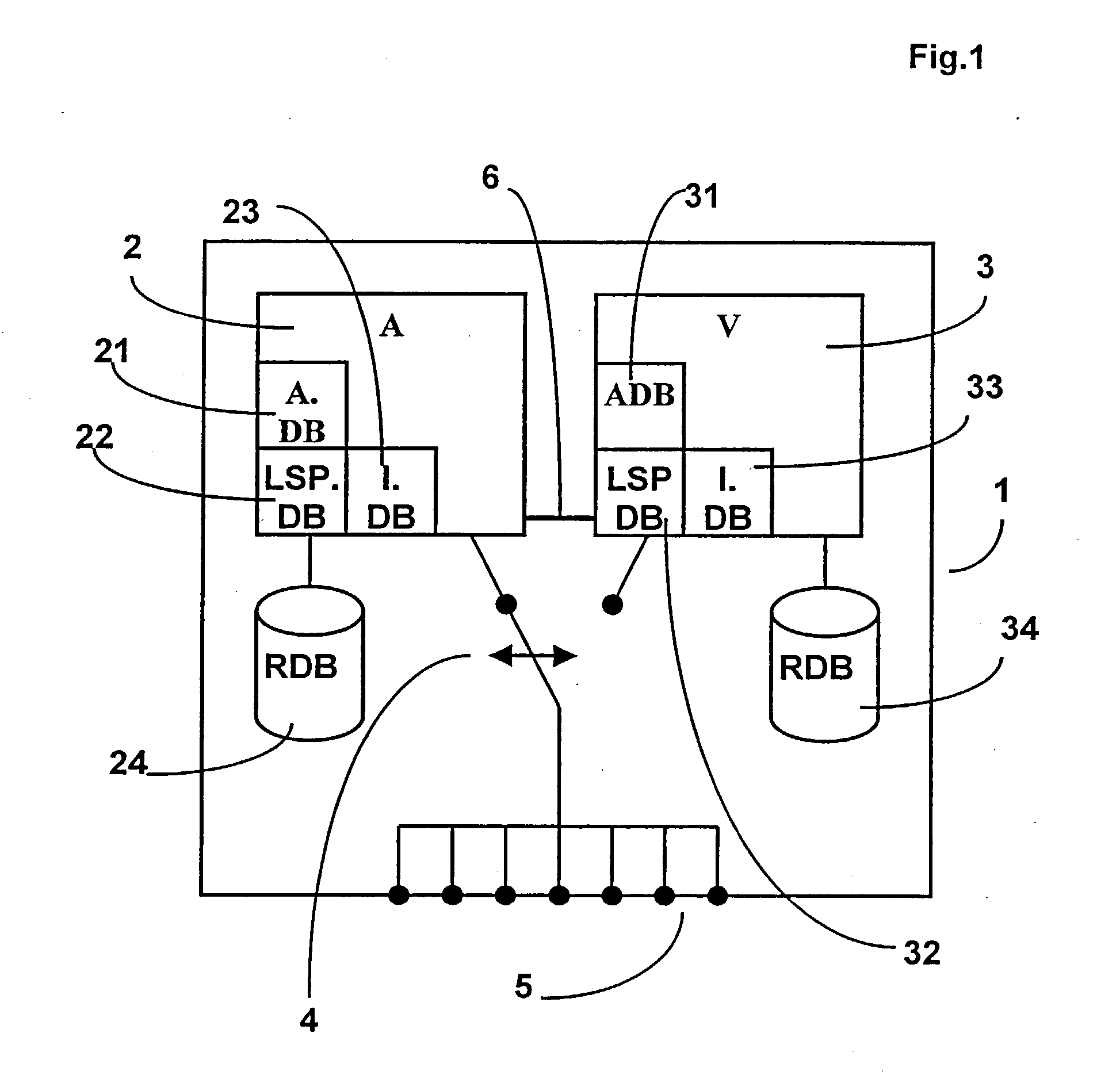

Real time asset optimization

InactiveUS6999829B2Technology managementResourcesComputerized maintenance management systemTechnology assessment

A technique to optimize both the production schedule and the maintenance of plant assets based on predetermined criteria which may be economic or otherwise. In one embodiment the technique receives at least one maintenance trigger (MT) and one production order and evaluates those inputs to propose one or more solutions for the joint scheduling of the asset maintenance and required plant production. In another embodiment a computerized maintenance management system (CMMS) acquires a new MT and proposes a new maintenance schedule. The technique transmits a blocking order to a production scheduling (PS) system for converting the maintenance request into a production schedule. In another embodiment, a CMMS acquires a new MT and asks for confirmation of a time slot to perform the maintenance action. The technique evaluates the priorities and finds based on the predetermined criteria the right time slot and communicates a request for that slot to the PS.

Owner:ABB INC +1

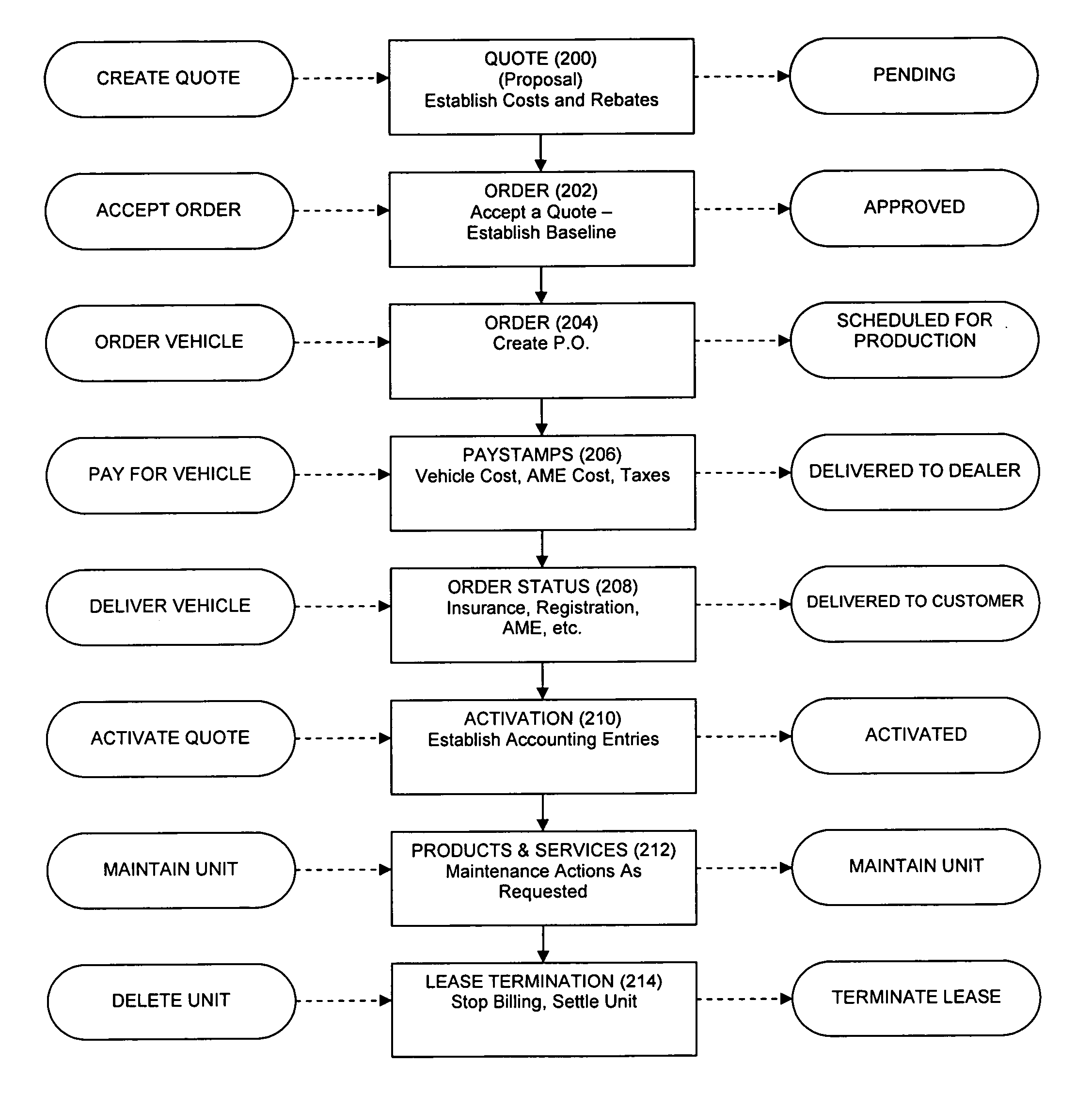

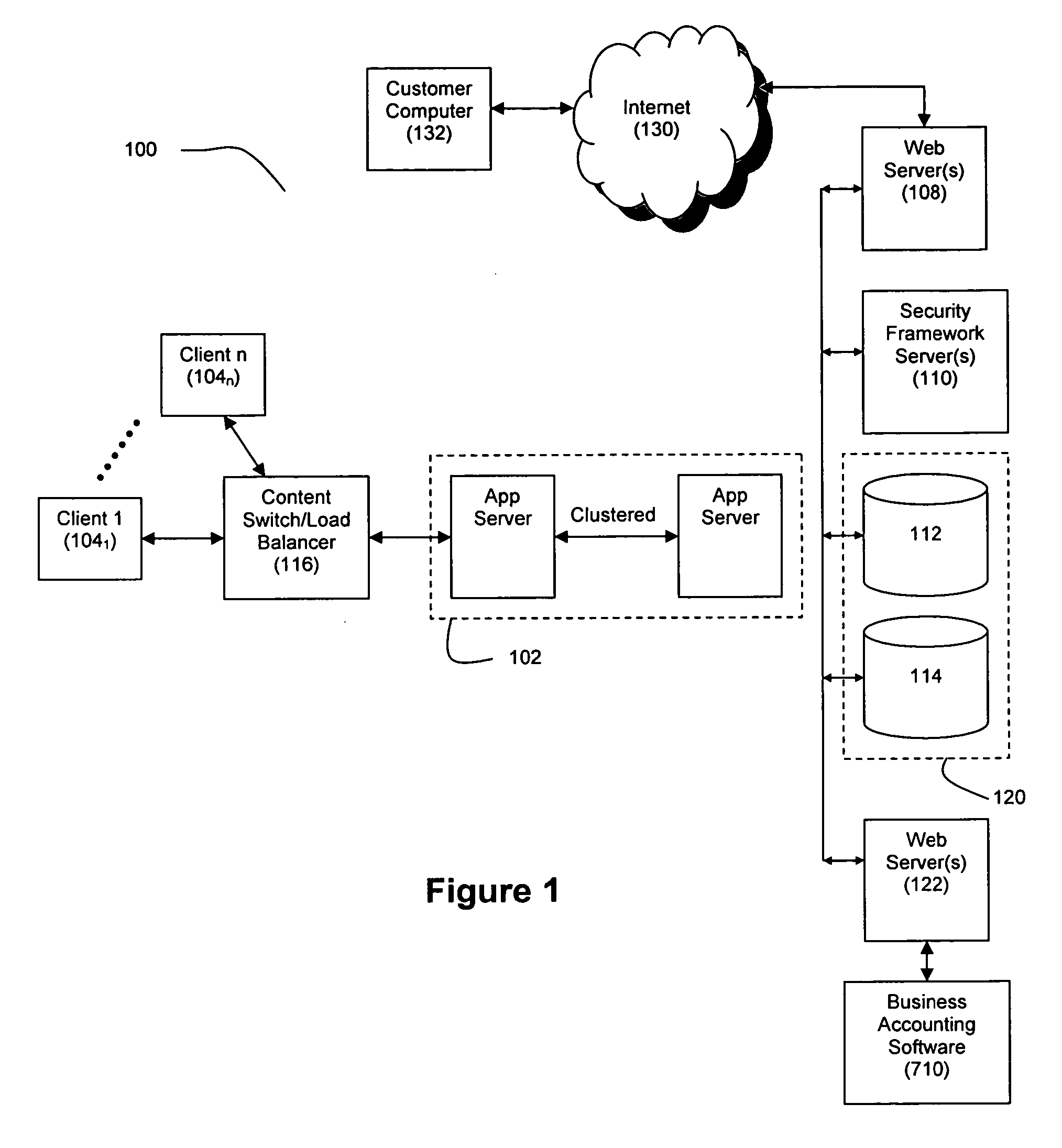

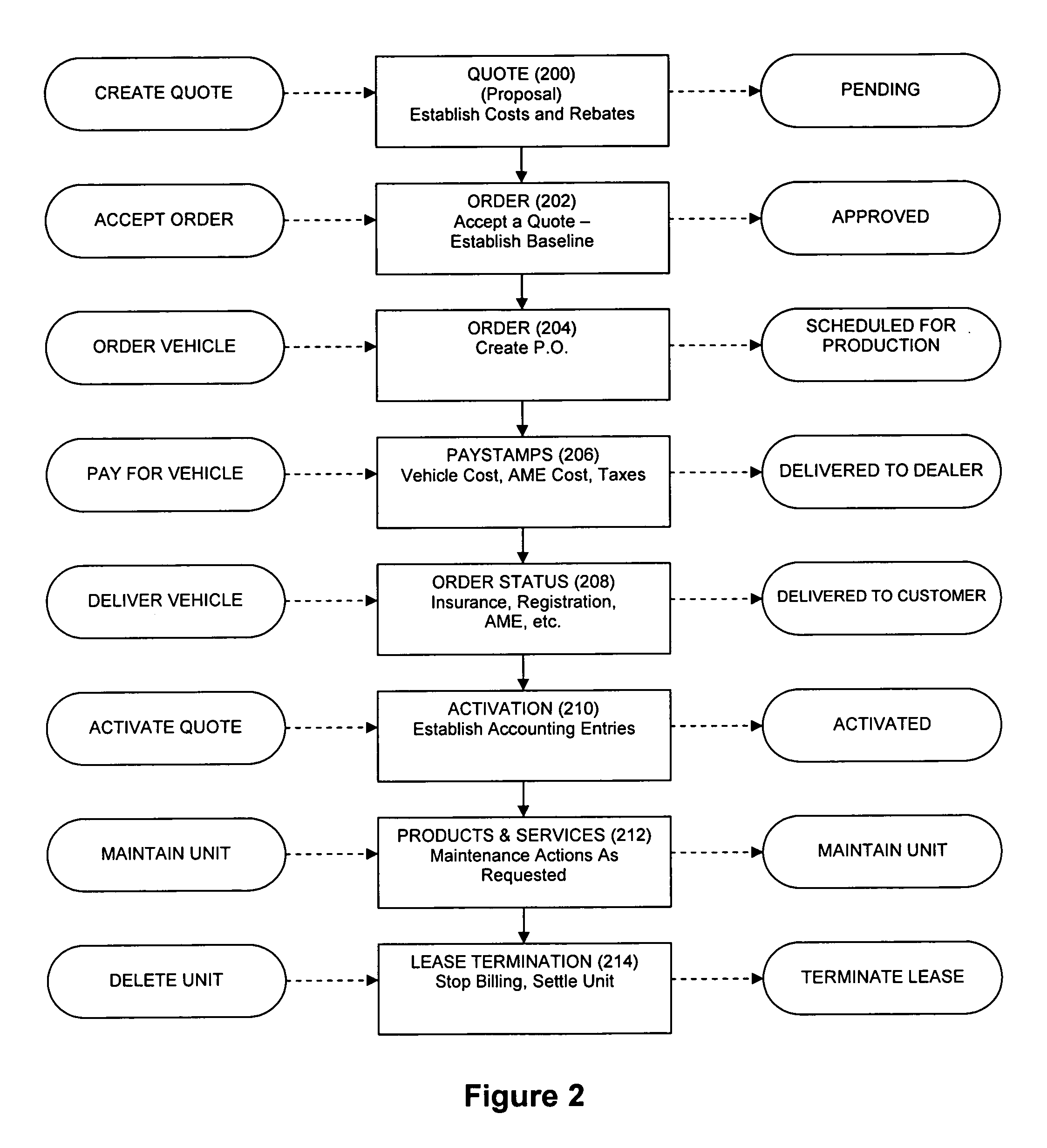

Method and system for managing vehicle leases

InactiveUS20060265235A1Great ability to determineRisk minimizationOffice automationCommerceGraphicsFleet management

An improved lease management system is disclosed herein for use by fleet managers to manage customer vehicle leases for a variety of management issues that arise throughout the lifecycle of a lease. According to one aspect, the system comprises a system for management of a plurality of vehicle leases, the system comprising: (1) at least one user computer; (2) a memory storing a database, the database being configured to store vehicle lease data for each of a plurality of vehicle leases; and (3) a server in communication with the user computer and the memory, the server being configured to execute a lease management software program, the lease management software program being configured to provide lease management functionality for each of said vehicle leases throughout a vehicle lease lifecycle via a plurality of interrelated graphical user interfaces (GUIs), the lease management functionality including a plurality of user selectable maintenance actions for an activated one of said customer vehicle leases, and wherein the lease management software program is further configured to update the stored vehicle lease data in the database in response to a user selection of at least one of said plurality of selectable maintenance actions.

Owner:THE CRAWFORD GROUP

System for maintenance recommendation based on maintenance effectiveness estimation

ActiveUS20170309094A1Labor savingImprove usabilityRegistering/indicating working of vehiclesTesting/monitoring control systemsDecision takingSystem usage

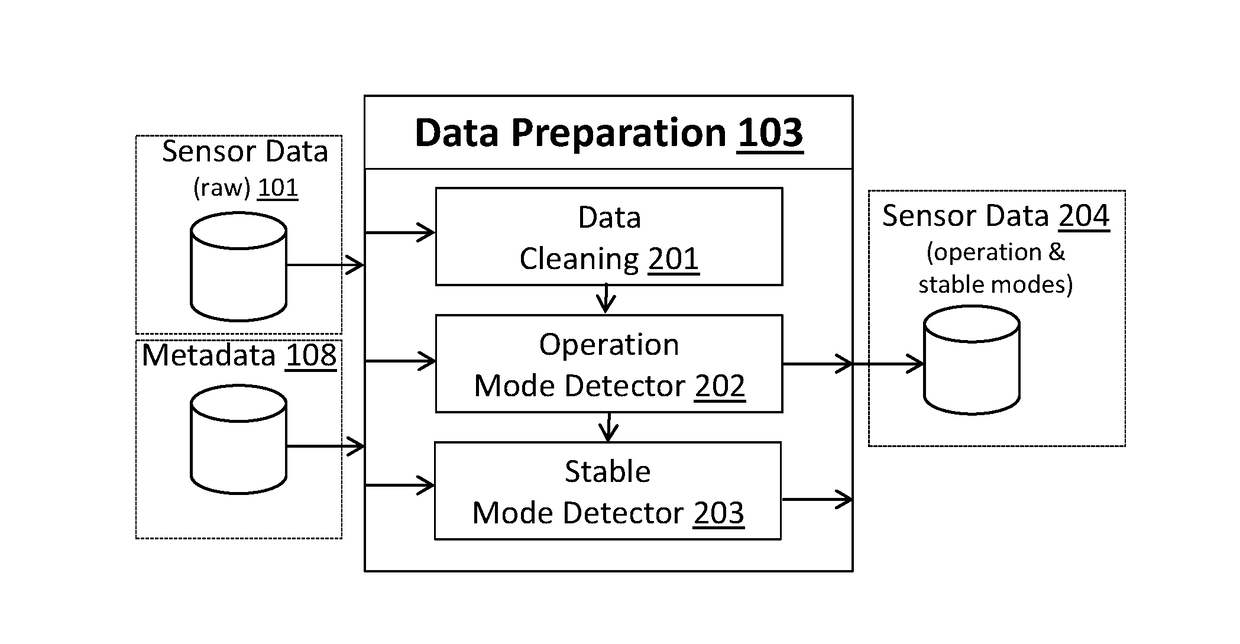

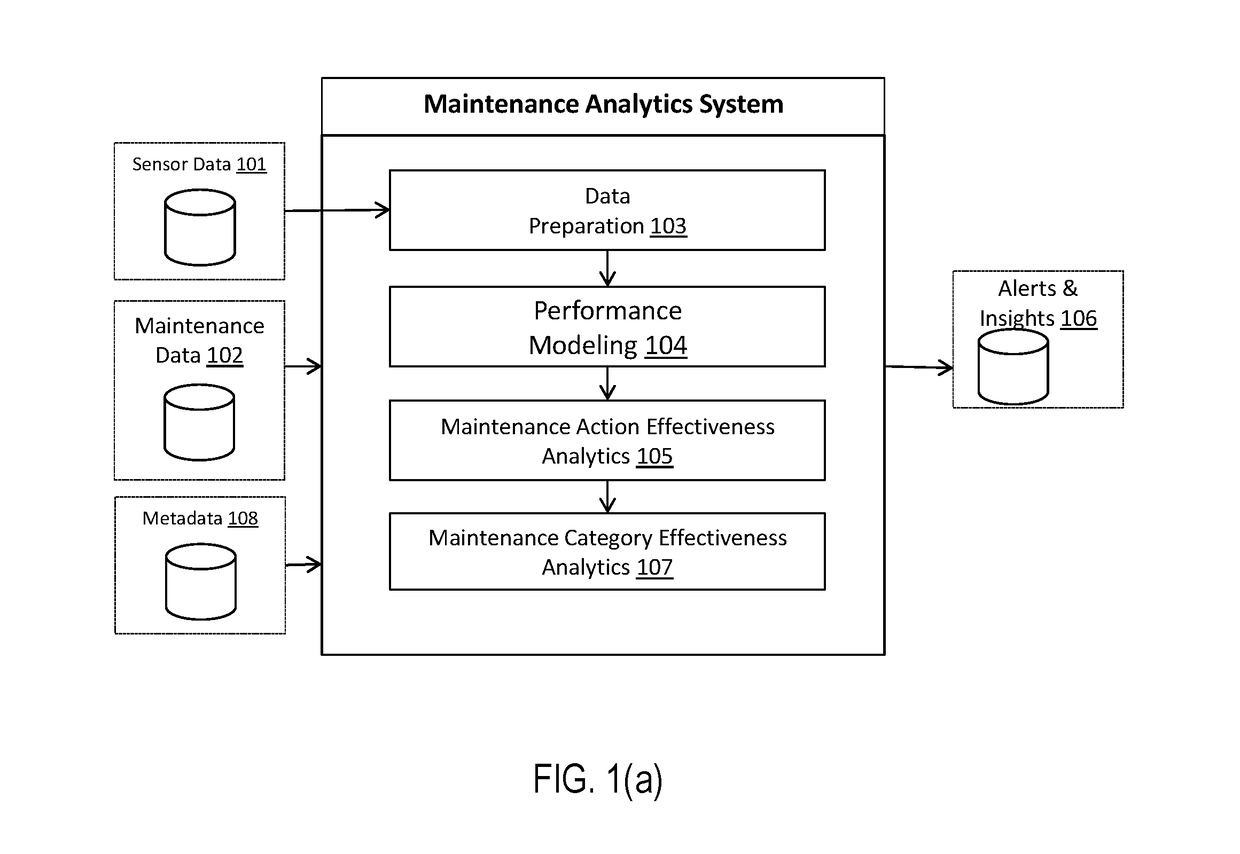

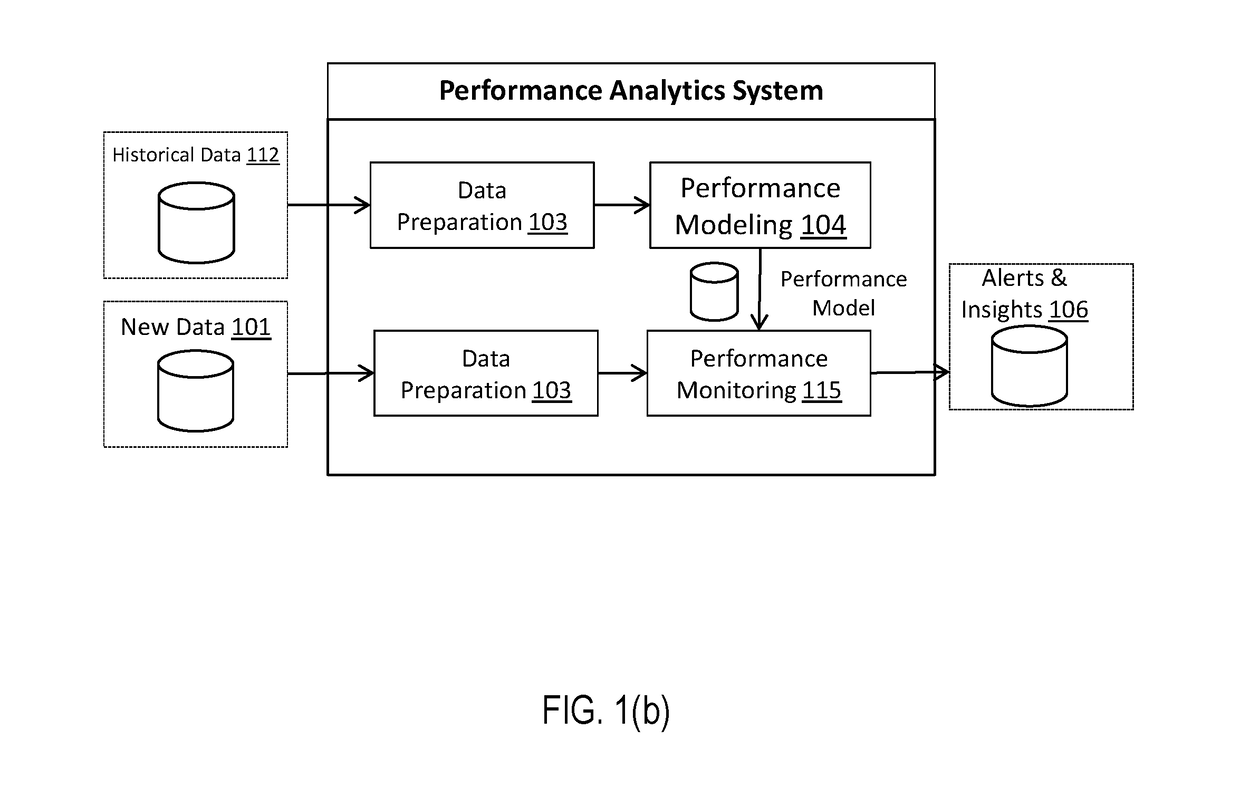

Example implementations described herein are directed to a decision-support system for maintenance recommendation that uses analytics technology to evaluate the effectiveness of a maintenance action or a group of actions in improving the performance of equipment and its components, and provide recommendations on which maintenance actions or a group of maintenance actions should be pursued and which should be avoided.

Owner:HITACHI LTD

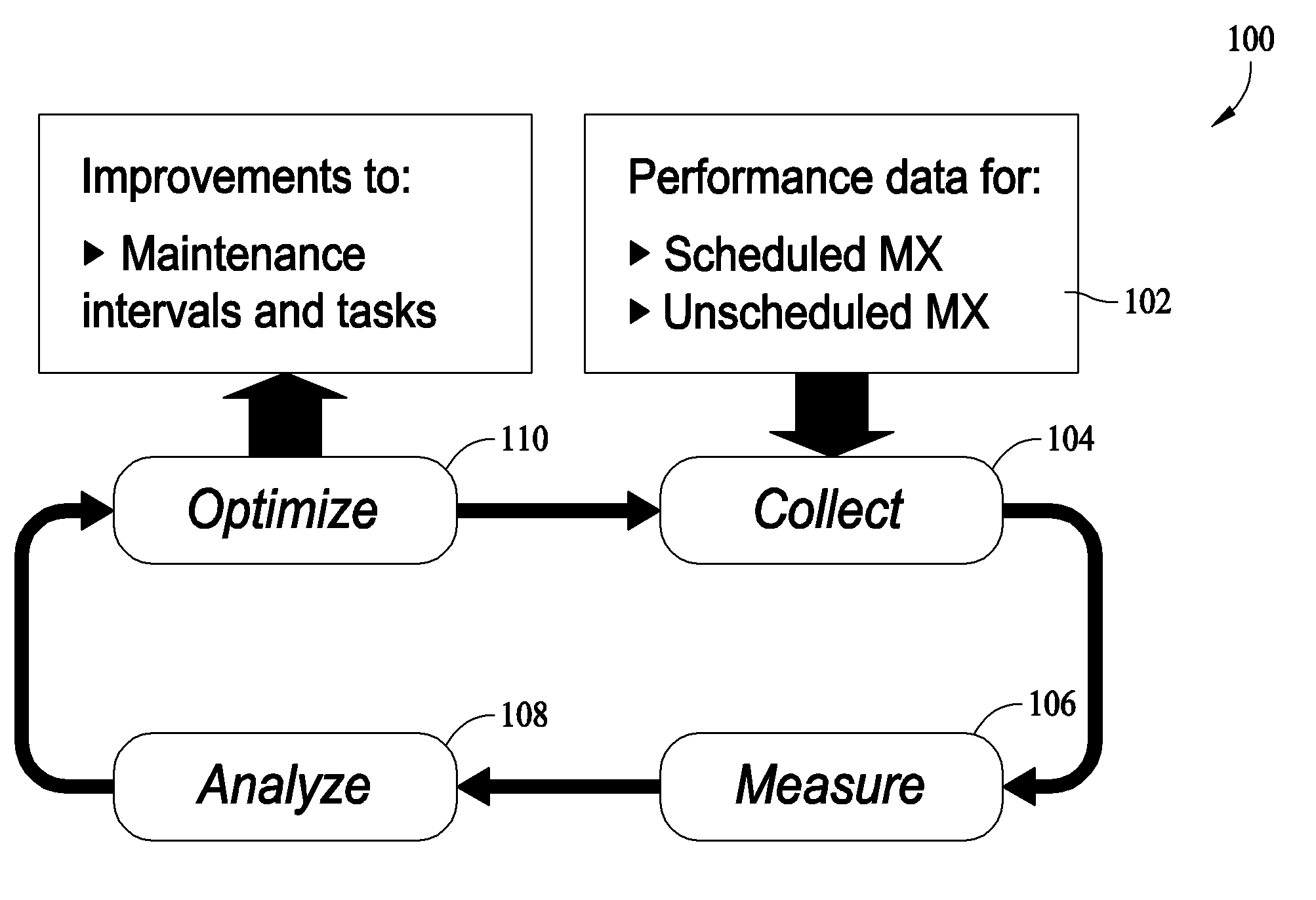

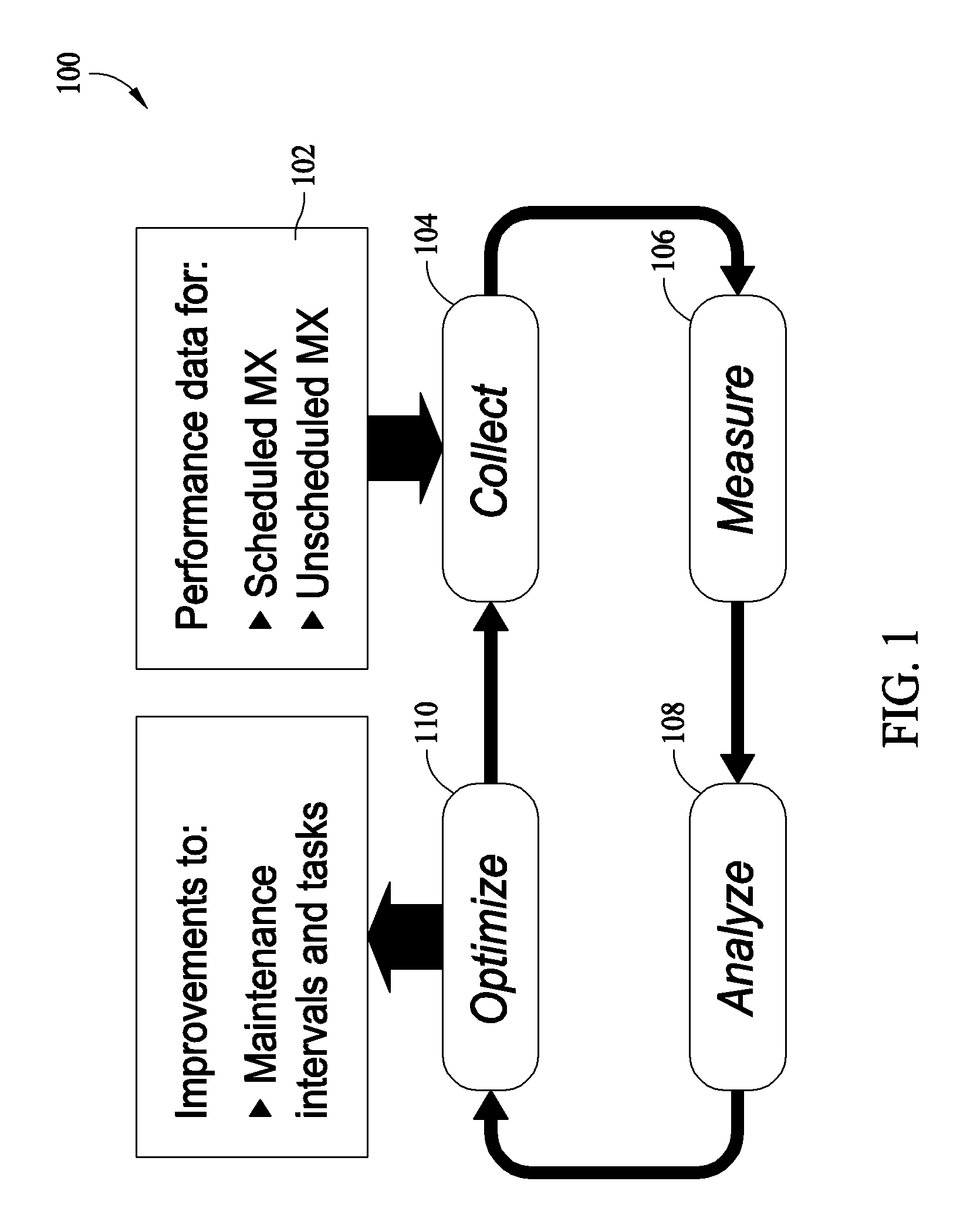

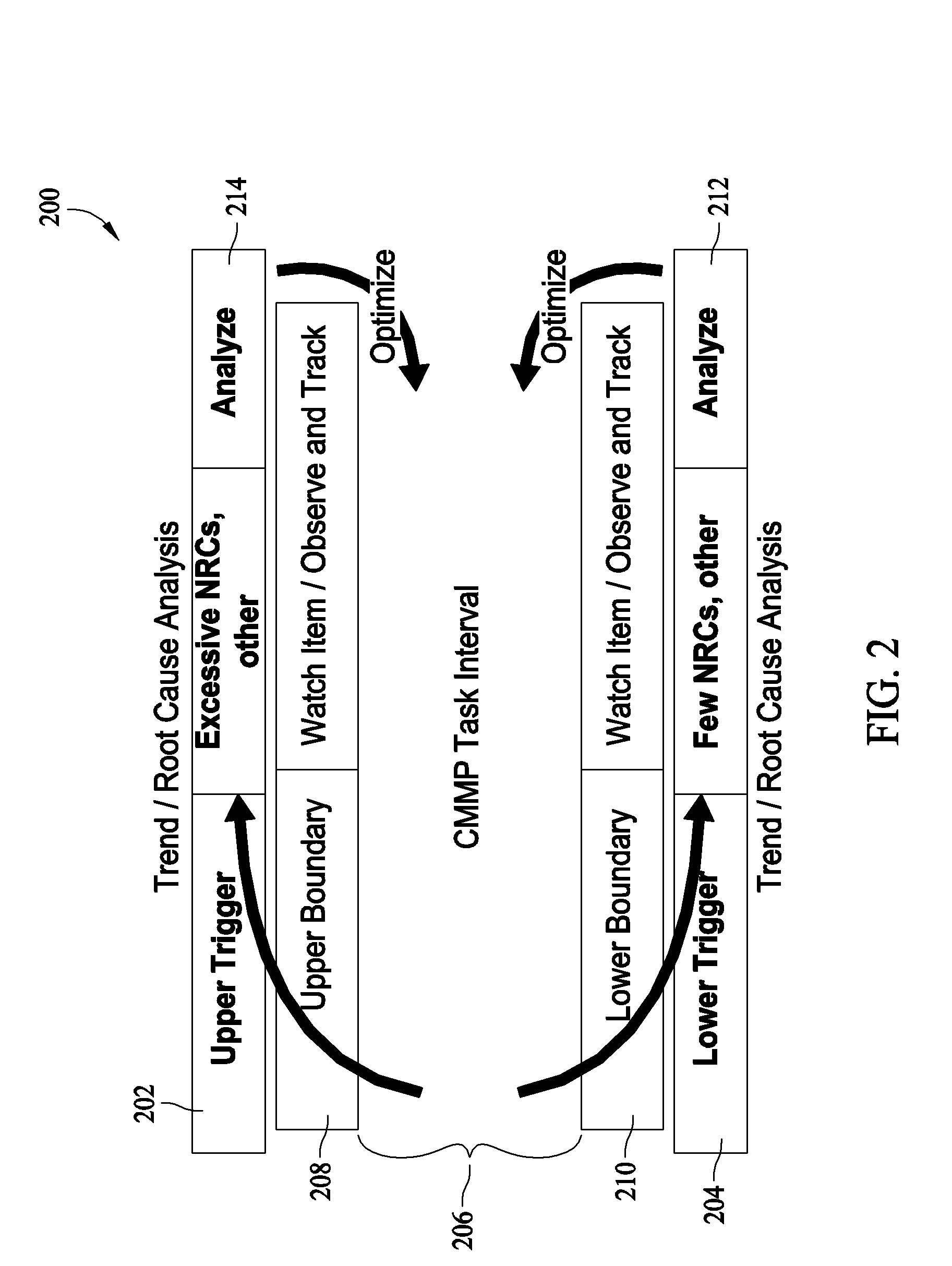

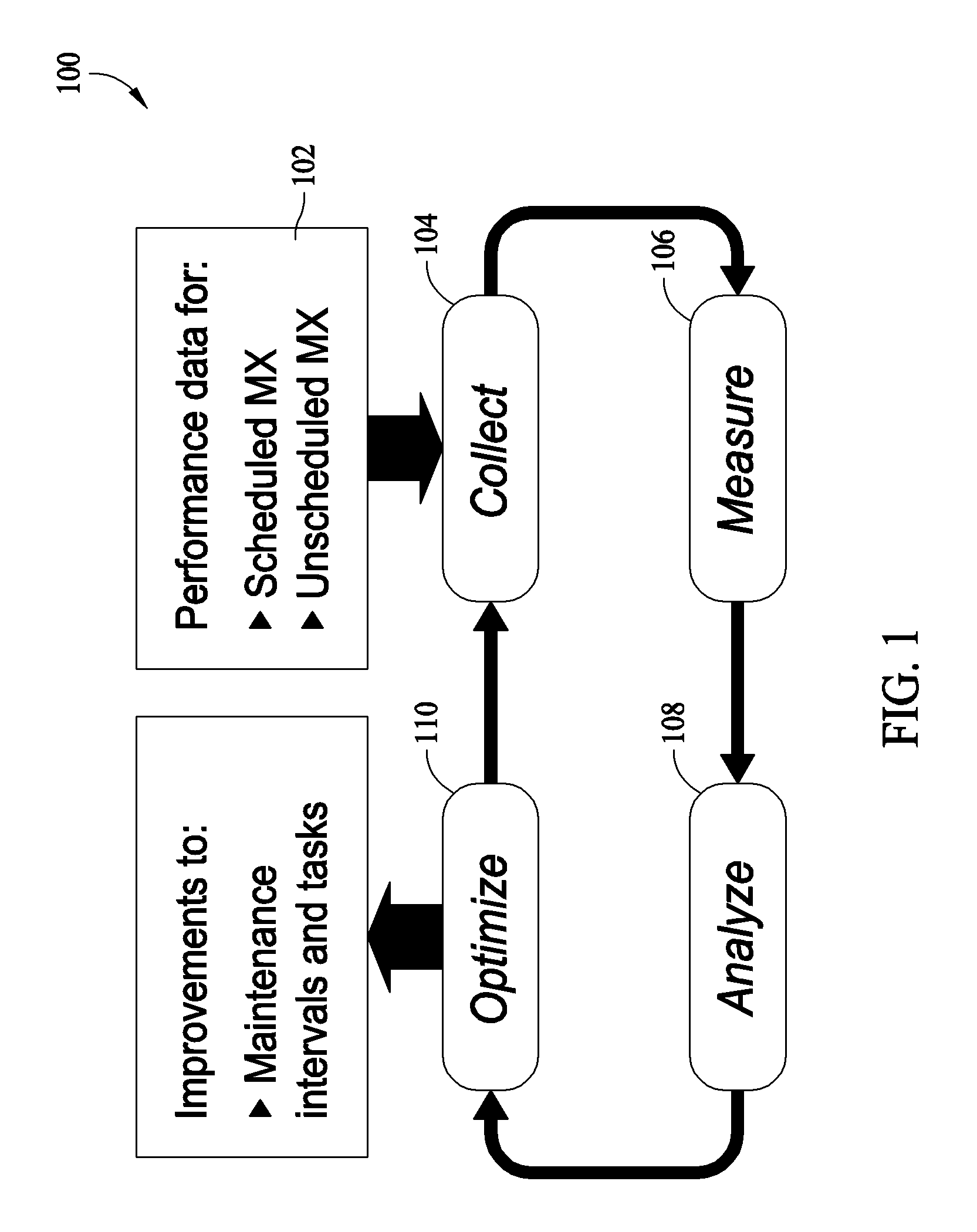

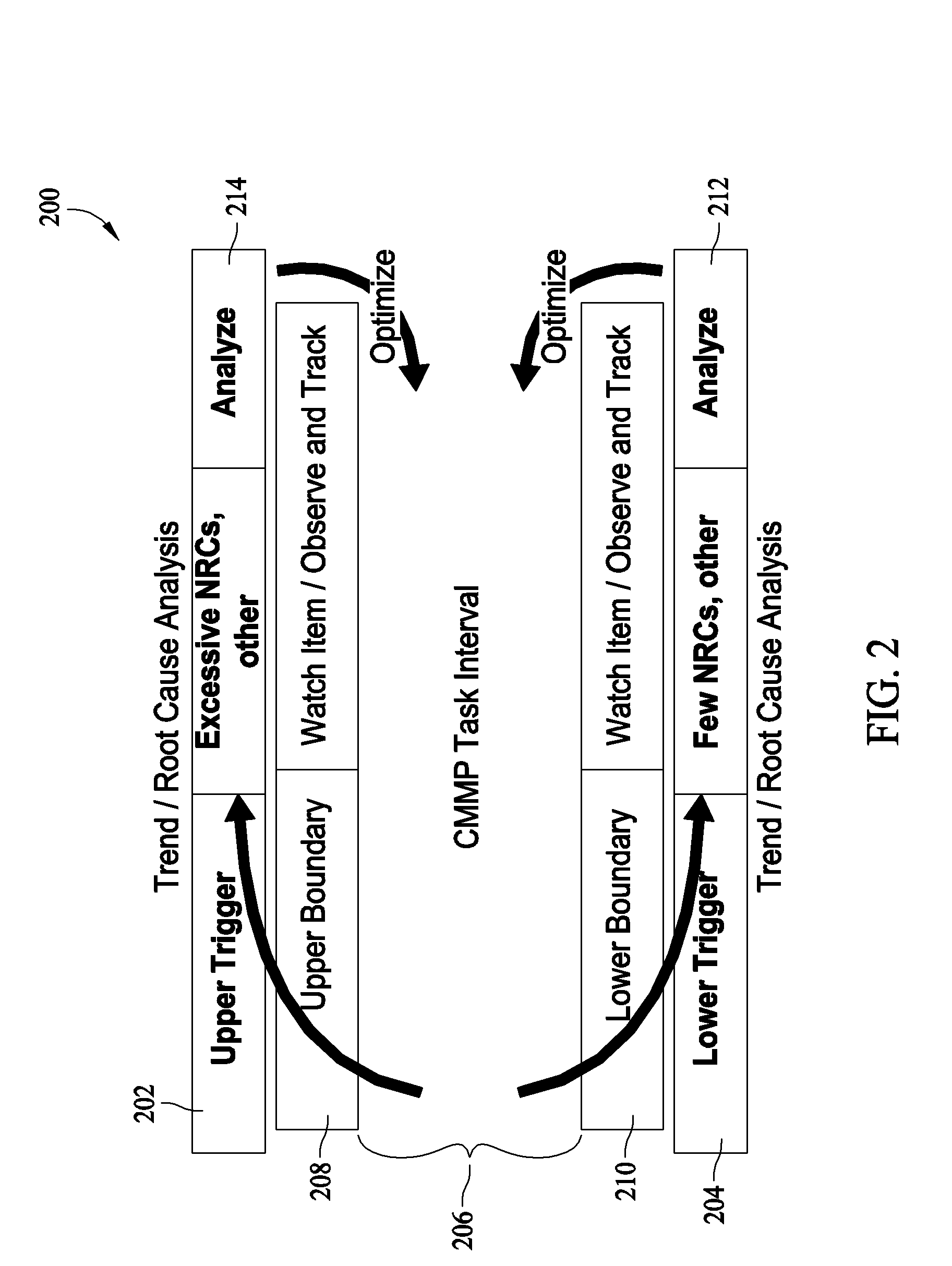

Methods and systems for centrally managed maintenance program for aircraft fleets

ActiveUS20080147264A1Reduce in quantityFacilitate numberVehicle testingAnalogue computers for trafficCentralized managementAirplane

Methods and systems for managing maintenance of a fleet of aircraft are provided. The method includes collecting data from at least one aircraft in each of the fleets related to the operation of the aircraft, determining a range of acceptable values of performance parameters associated with the collected data and based on the collected data, analyzing the collected data having values outside the range of acceptable values, and modifying at least one of a maintenance requirement and an interval between maintenance actions to facilitate reducing the number of performance parameters values that are outside the range of acceptable values during future operation of the aircraft.

Owner:THE BOEING CO

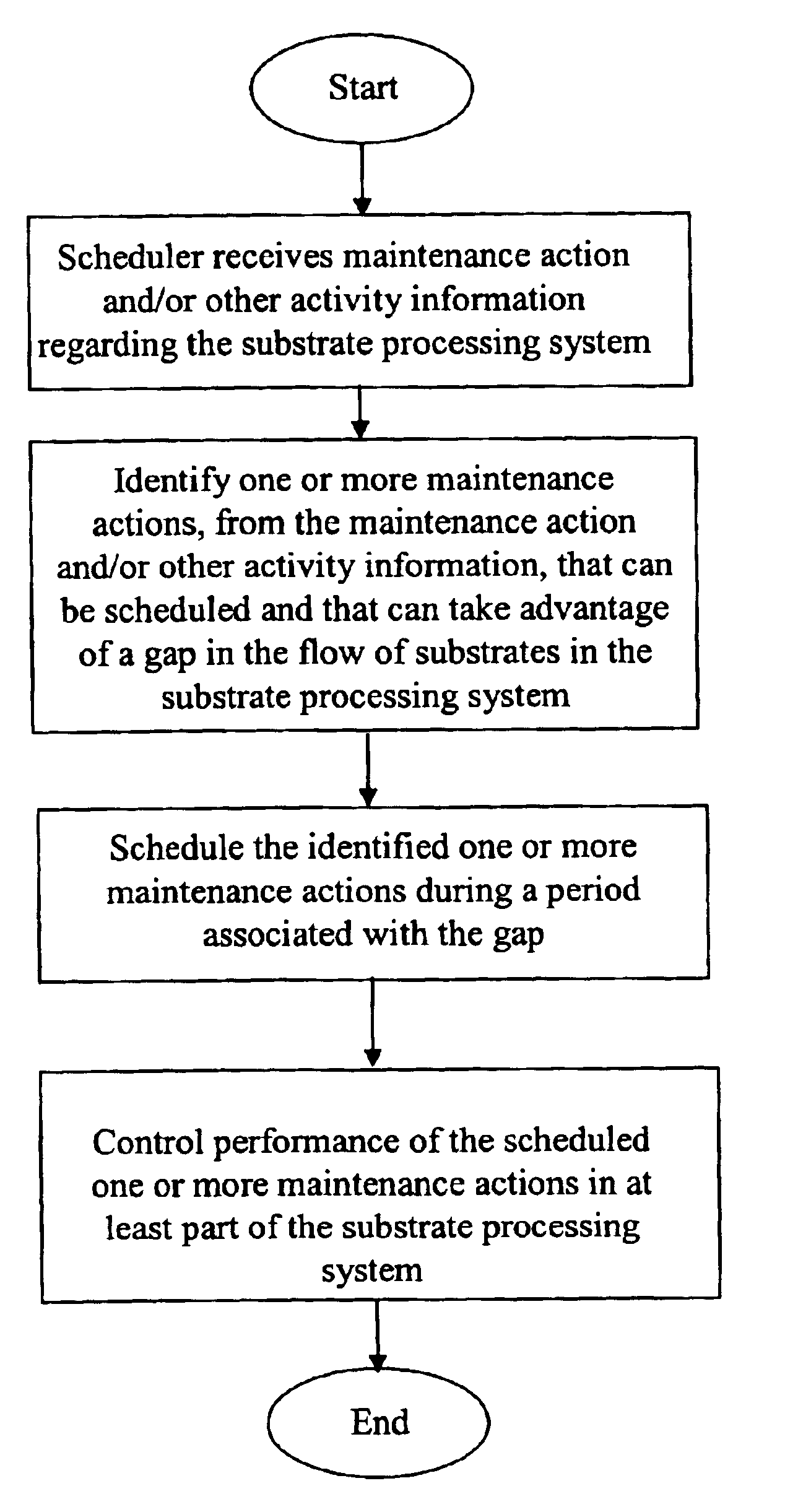

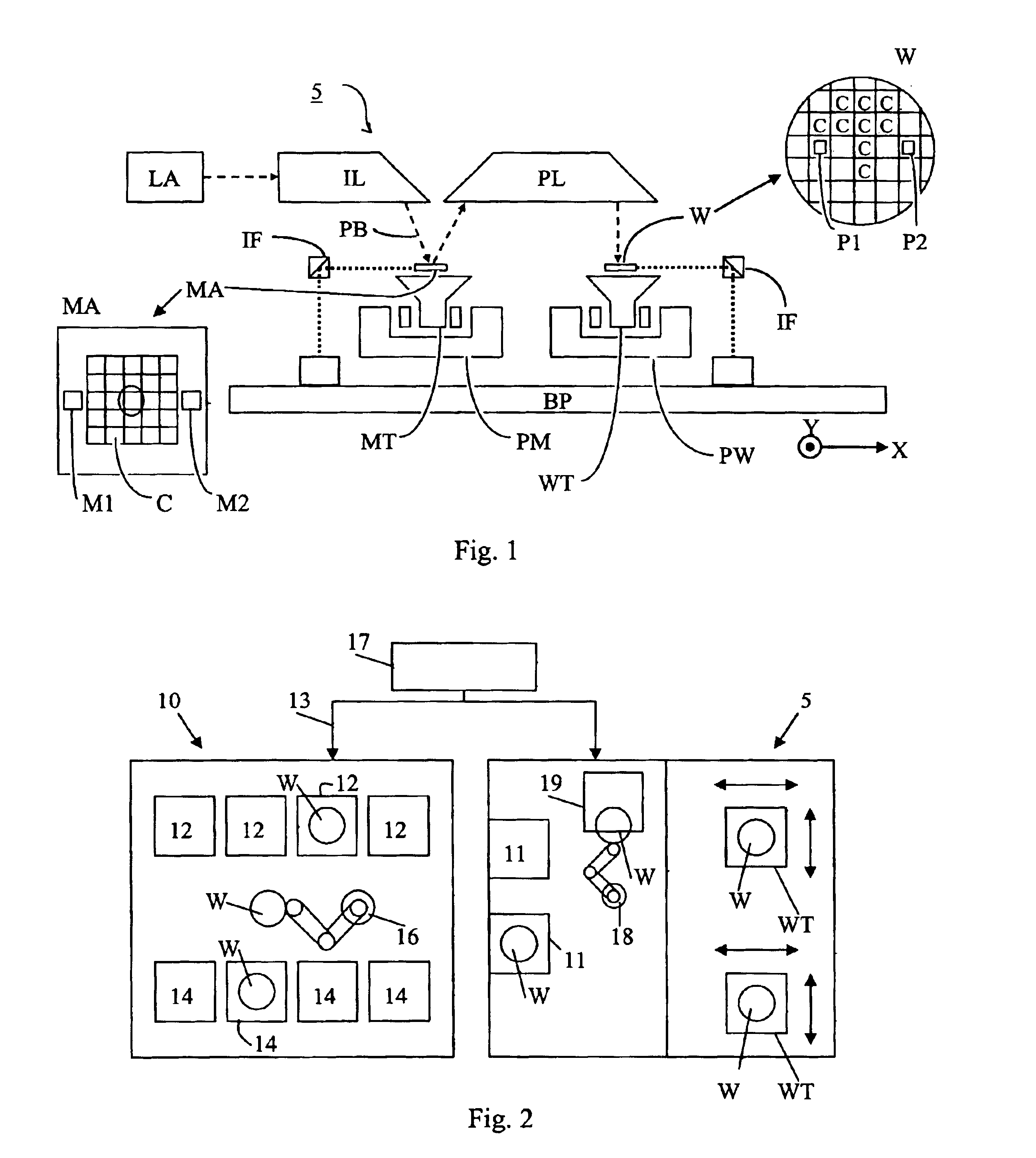

Method, computer program product and apparatus for scheduling maintenance actions in a substrate processing system

Owner:ASML NETHERLANDS BV

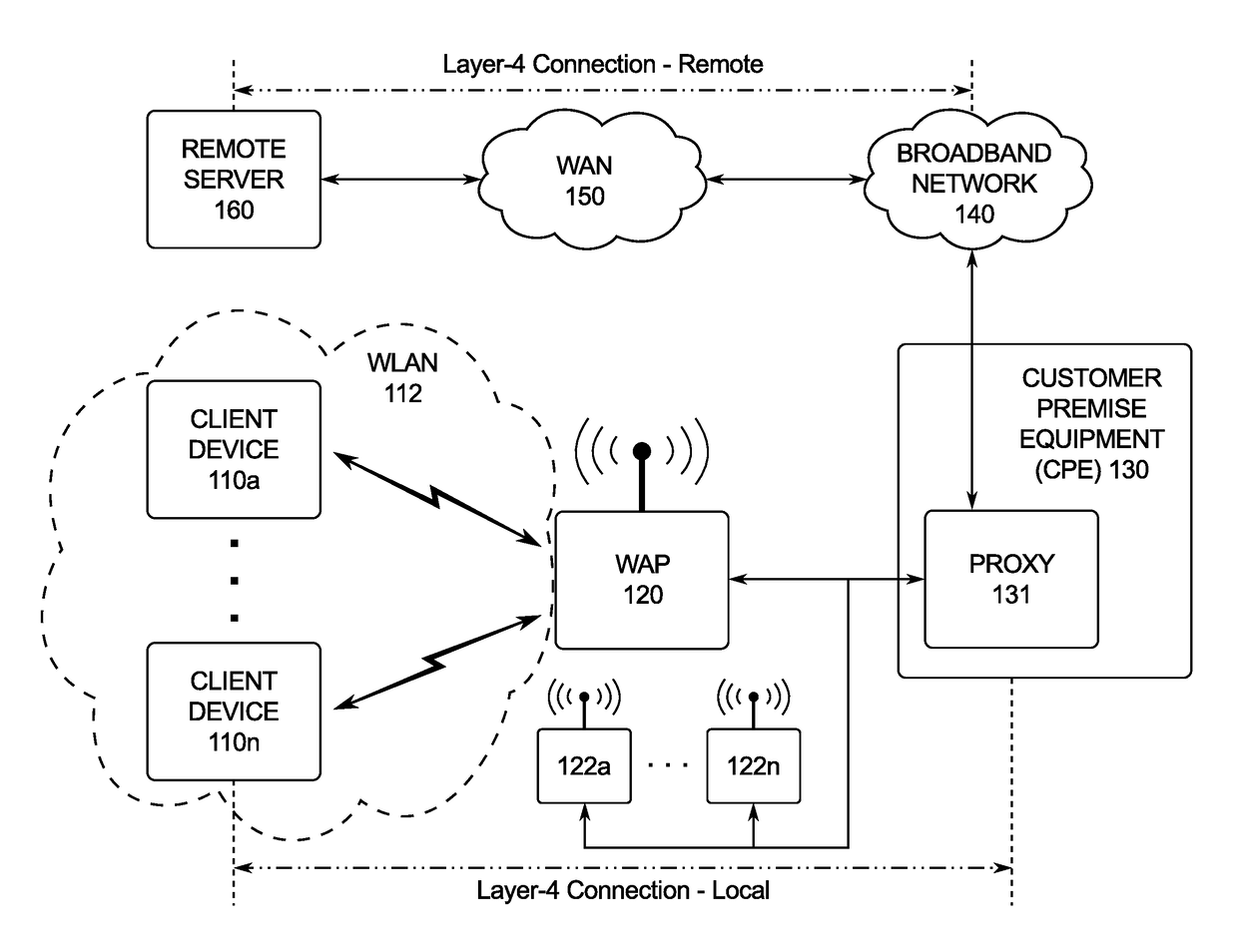

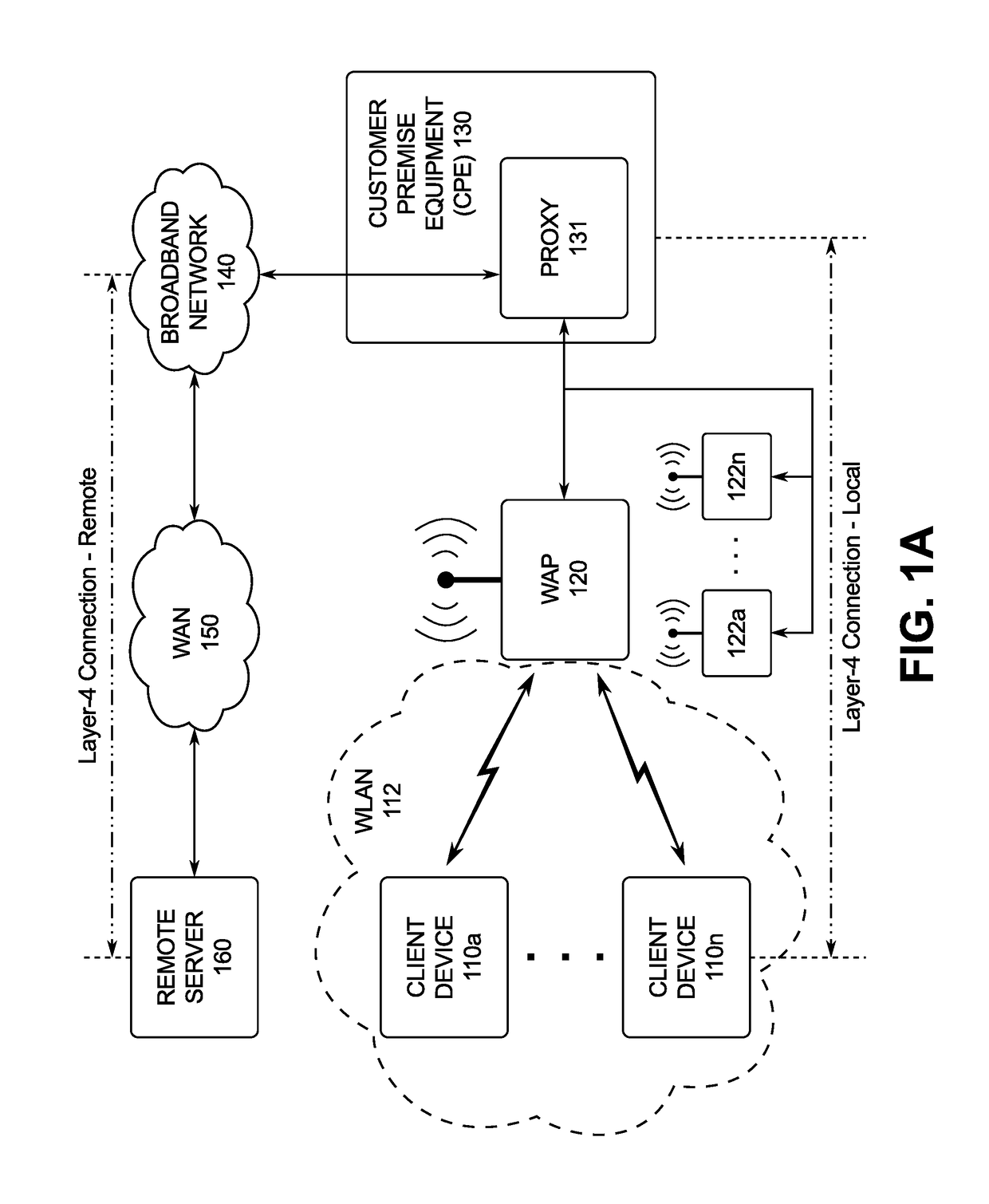

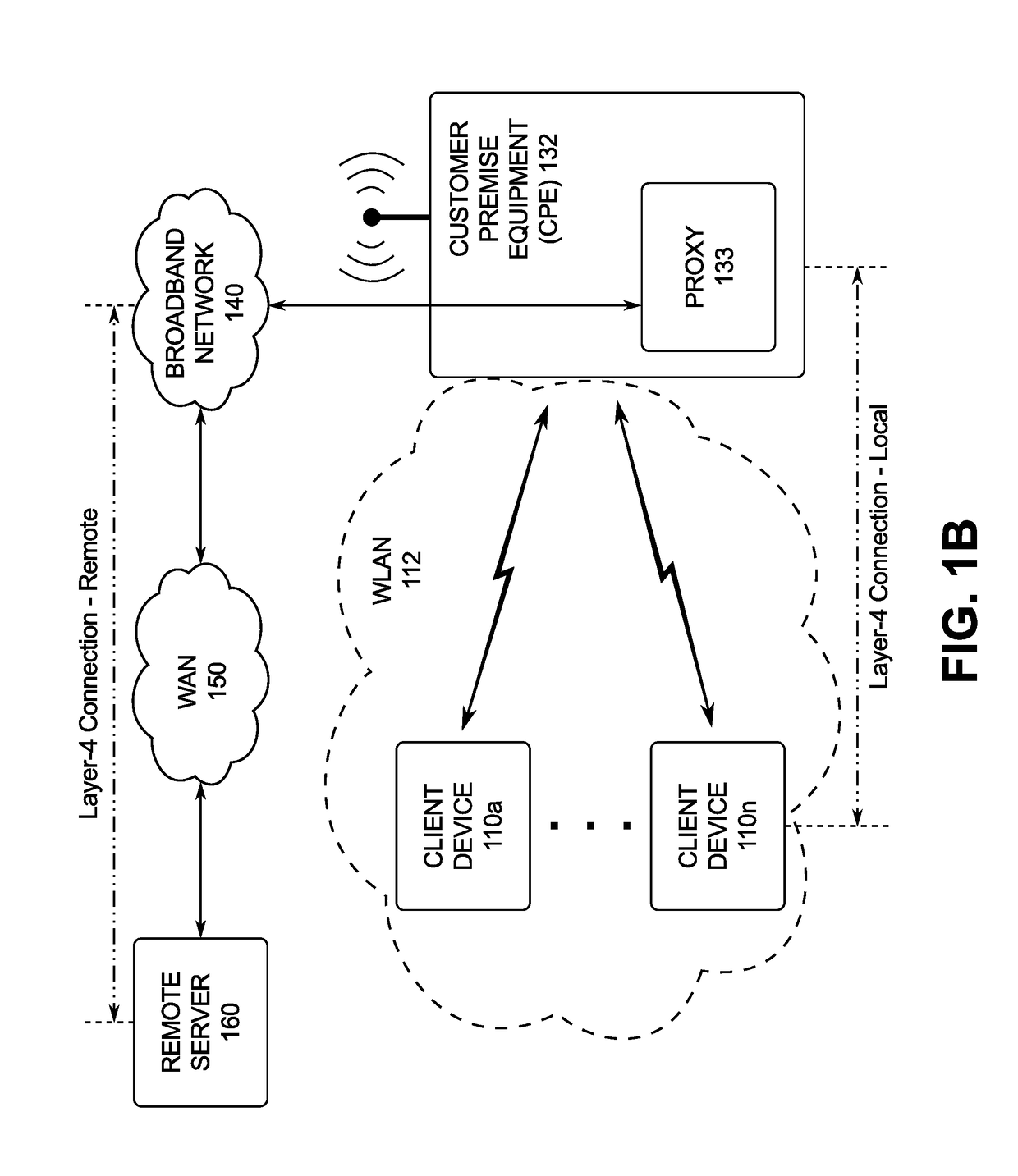

Automated network diagnostic techniques

Automatically diagnosing operation of a communication network, including collecting, during a plurality of time periods, a plurality of Layer-4 and / or Layer-1 / -2 statistics for network activity on the communication network; determining a network performance indicator, based on the statistics collected during a first time period included in the time periods and the statistics collected during a second time period included in the time periods and neither overlapping nor consecutive with the first time period; determining whether the communication network has experienced a performance issue based on the network performance indicator; and causing a diagnostic action, a corrective action, or a maintenance action to be performed based on the determination whether the communication network has experienced a performance issue.

Owner:HUGHES NETWORK SYST

Machine condition indication system

ActiveUS20080106424A1Programme controlTesting/monitoring control systemsState parameterIndustrial communication

A machine condition monitor resides in close proximity to a machine train, such as an AC inductive electric motor coupled to a driven unit such as a centrifugal pump or fan. A plurality of sensing devices are connected to the machine and the machine condition monitor. Machine state and condition parameters sensed by these devices are utilized by the machine condition monitor to derive machine condition values for each component and for the machine train as a whole. These derived condition values are transmitted via an industrial communications network to a control center where they can be trended and monitored. With no particular knowledge of machine analysis techniques or severity of specific machine faults, and no special training, Operators and Production Planners can use the condition values to plan production schedules, adjust process parameters, and request appropriate maintenance action.

Owner:COMPUTATIONAL SYST

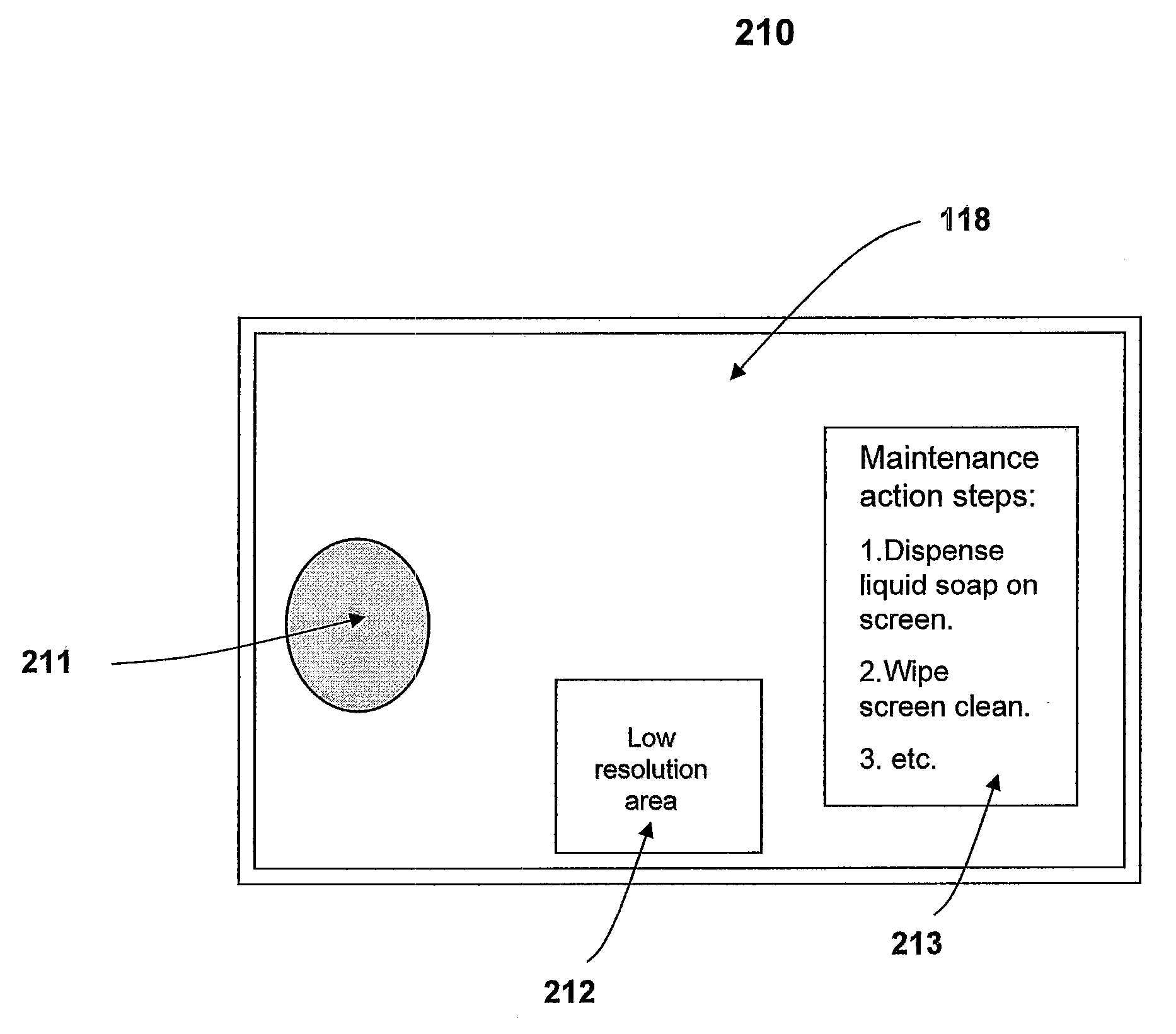

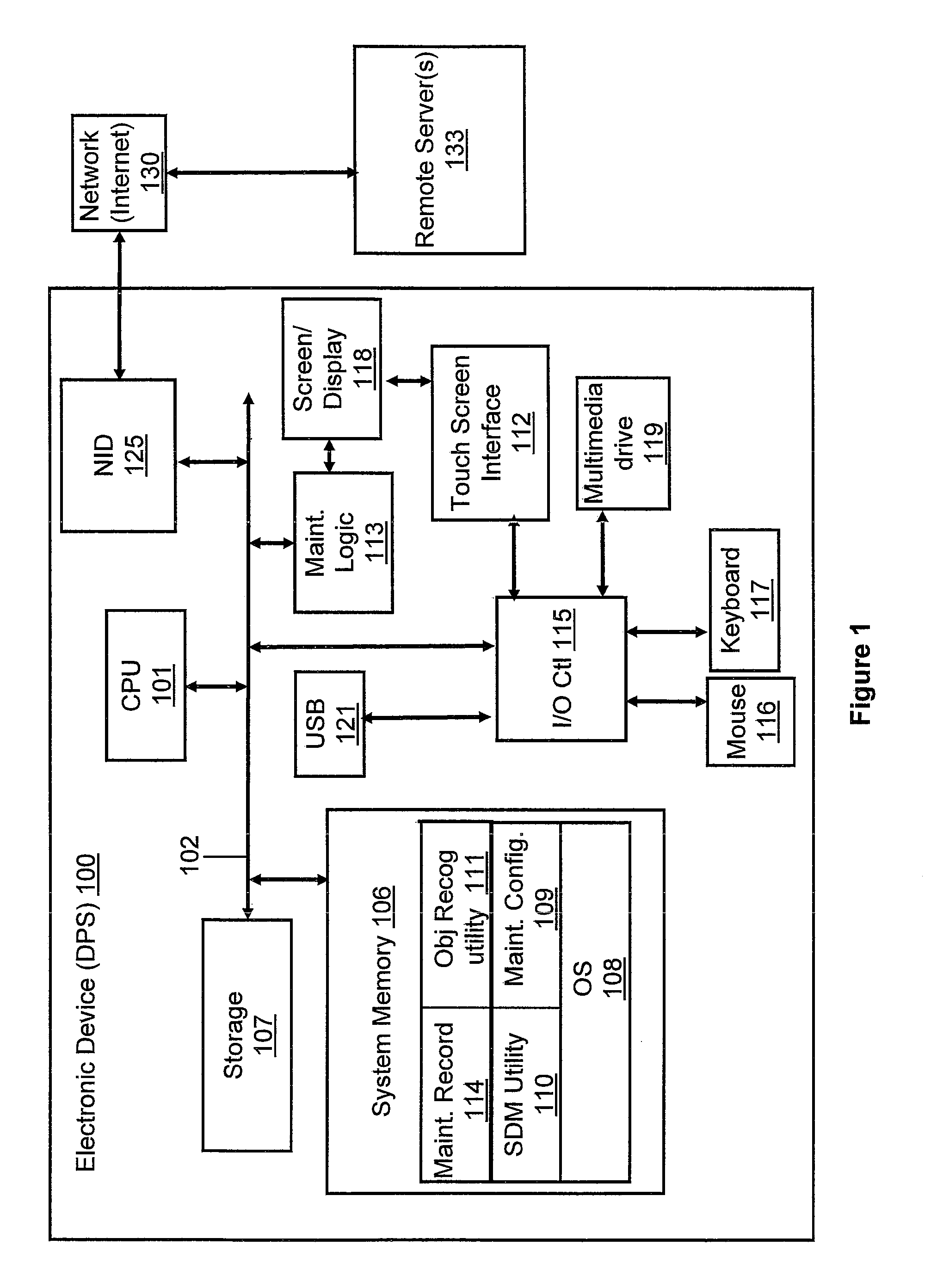

Self-healing and diagnostic screen

A method, system, and computer program product for determining a level of cleanliness of a multi-touch screen display, characterizing objects that make contact with the screen, and initiating a specific maintenance action on the screen, based on screen cleanliness and the object(s) characterization(s). A screen diagnostic and maintenance (SDM) utility initiates a number of procedures to determine the type of object(s) and a set of characteristics of object(s) that make contact with the touch screen. Based on the results of the procedures, the SDM utility characterizes / identifies the object(s). In addition, the SDM utility initiates maintenance screen check(s) based on information stored in maintenance configuration file(s). Based on the results of the maintenance check(s), configuration file(s) data and type and characterization of the object(s) that have made contact with the screen, the SDM utility determines the type of maintenance that is performed and the timing / schedule of the maintenance action(s).

Owner:IBM CORP

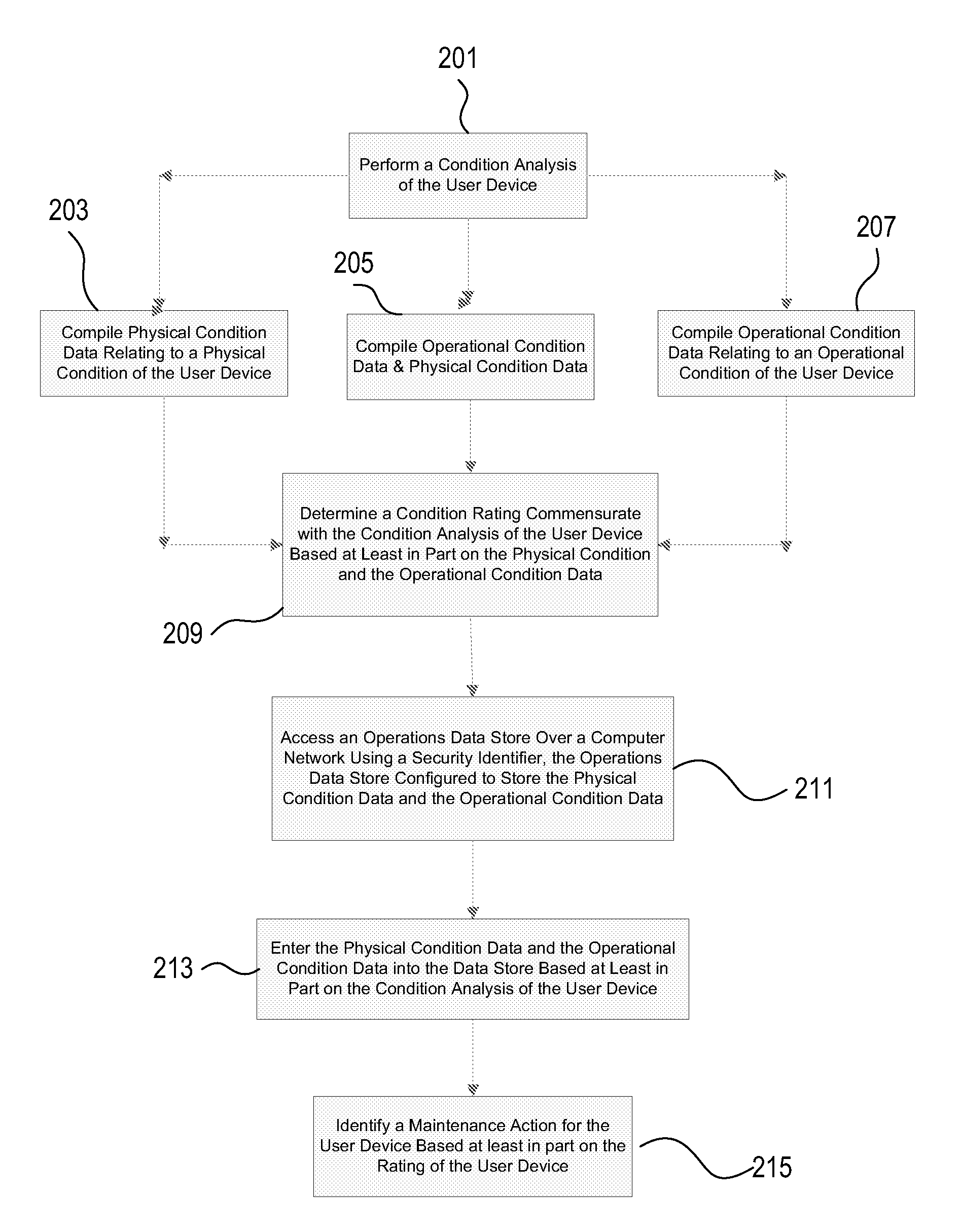

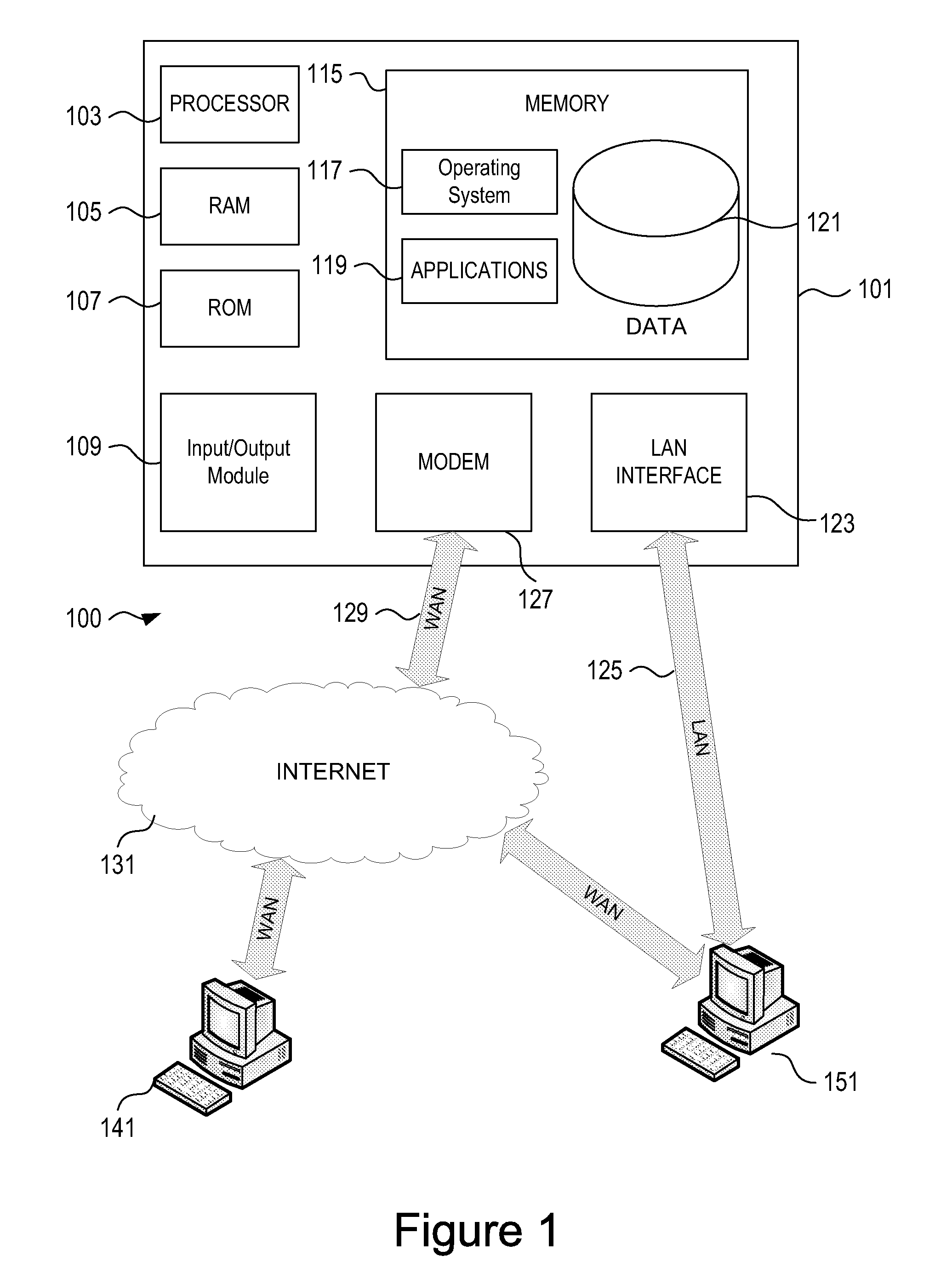

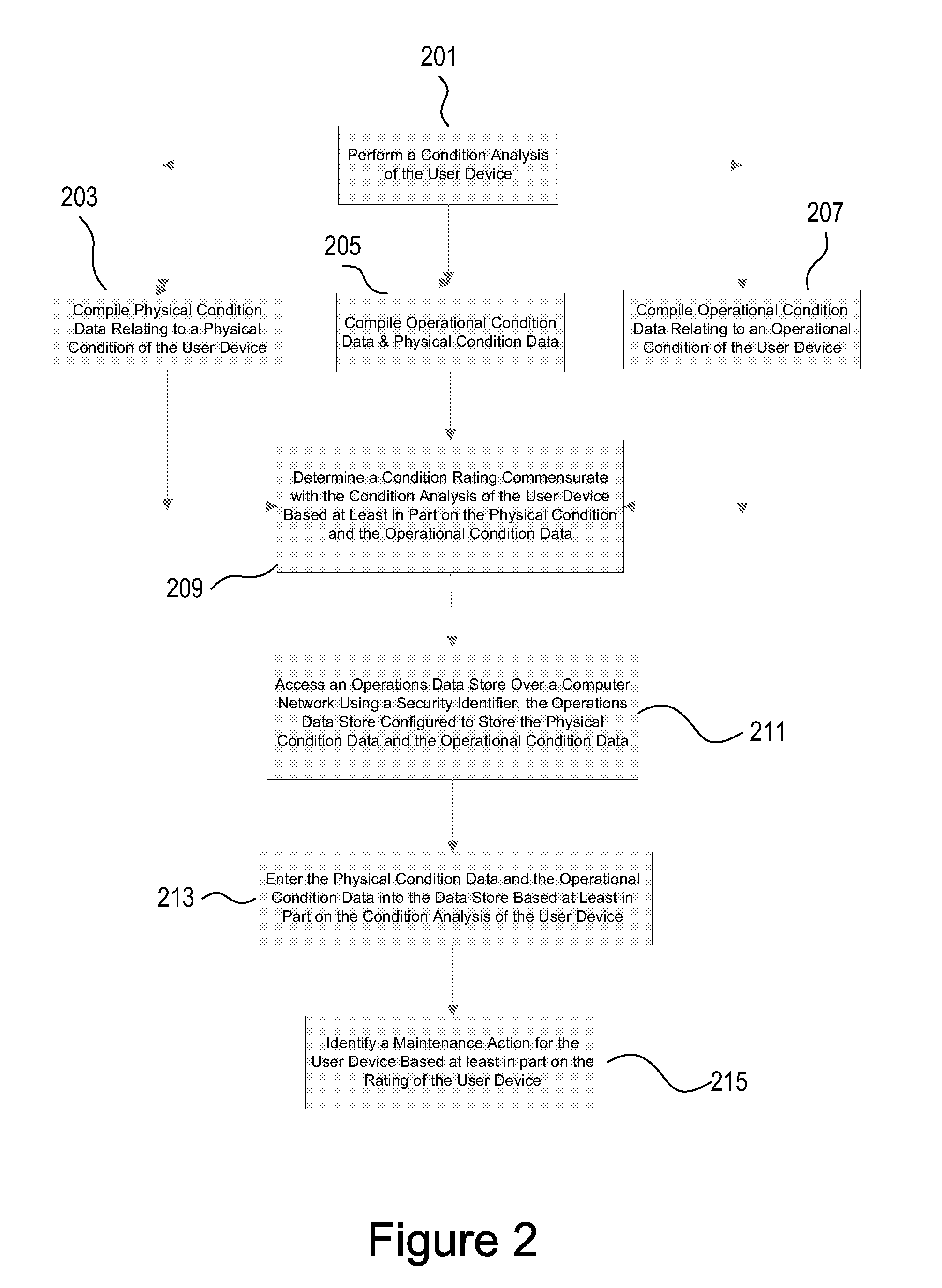

Services portal

A user device may be capable of providing a service portal and feedback on the condition of the user device, such as a user device. A condition analysis of the user device may be performed by a user, such as a person or a computing device. A condition analysis may be performed to determine the physical condition and the operational condition of the user device. A condition rating may be assigned to the user device that may be commensurate with the condition analysis. The condition data and condition analysis may be entered into and stored in a data store. A maintenance action may be performed based at least in part on the condition rating. The user device may be a user device that may be operated by a financial institution or other business entity. A user may be a customer and / or an employee, vendor, or contractor of the financial institution or other business entity.

Owner:BANK OF AMERICA CORP +1

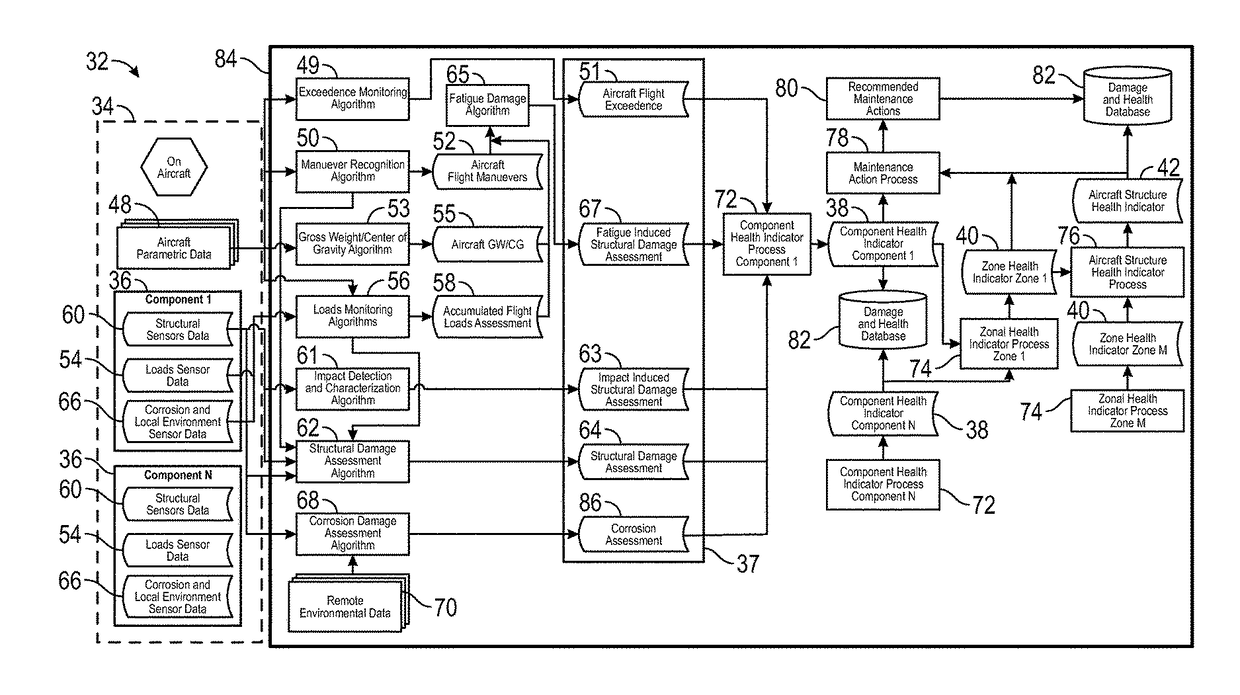

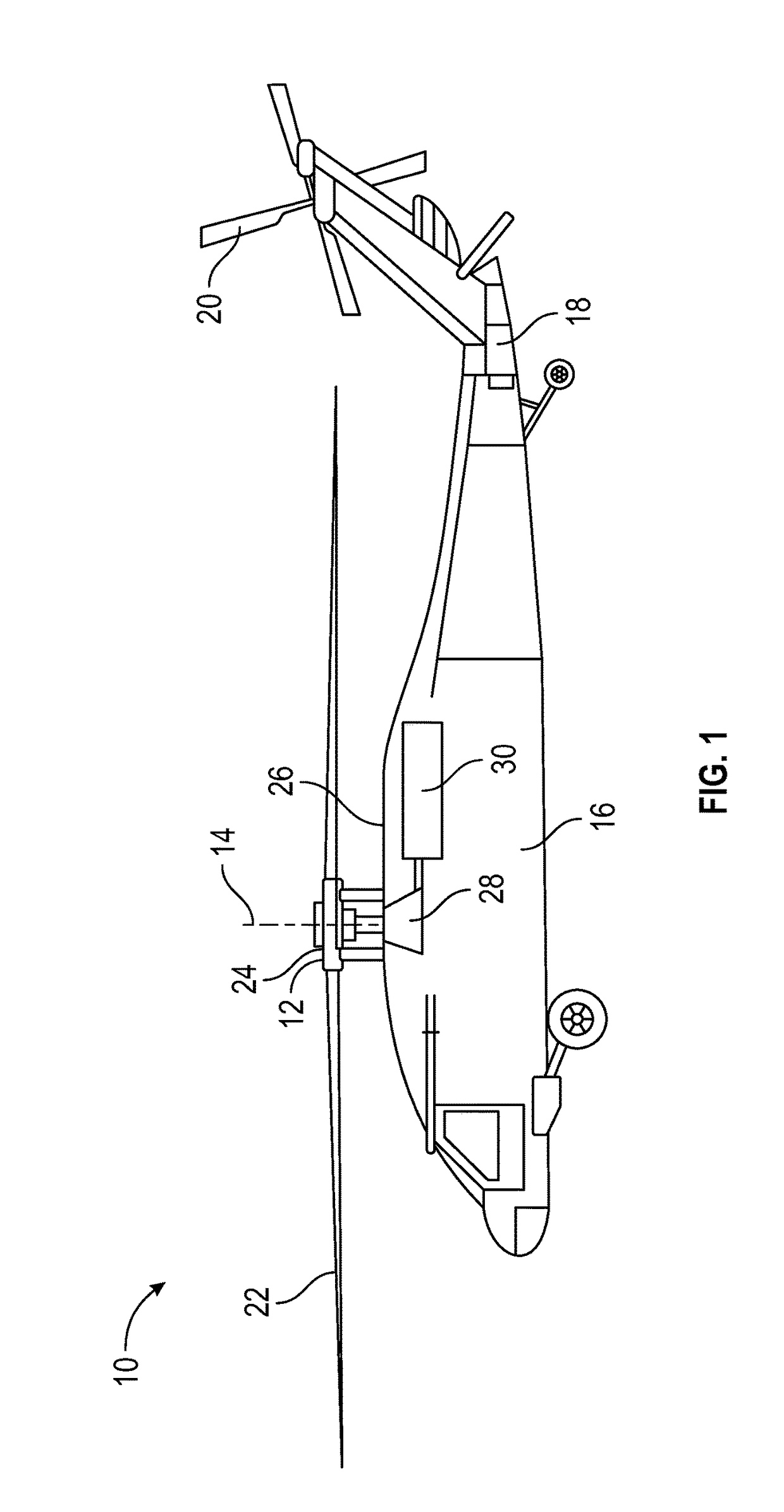

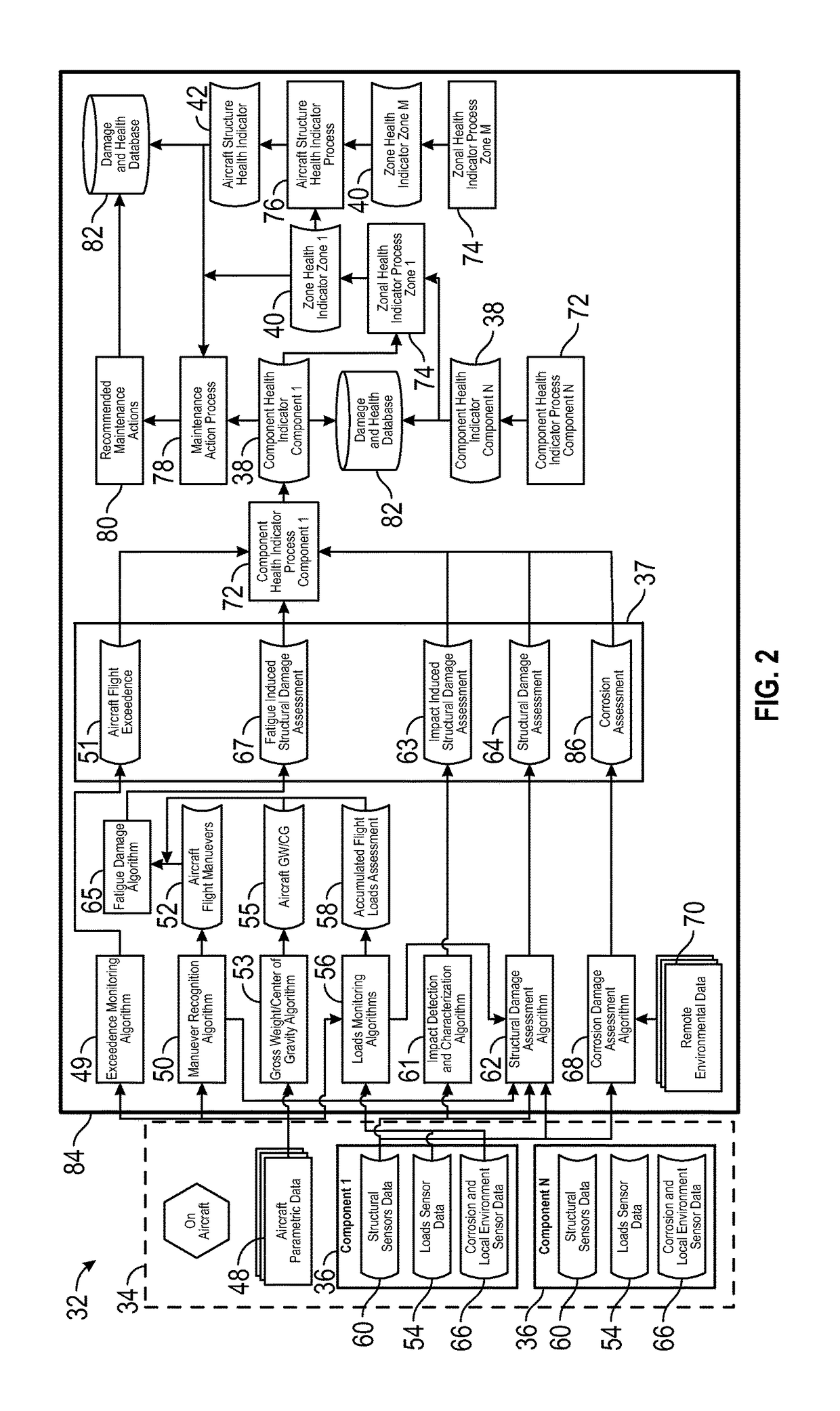

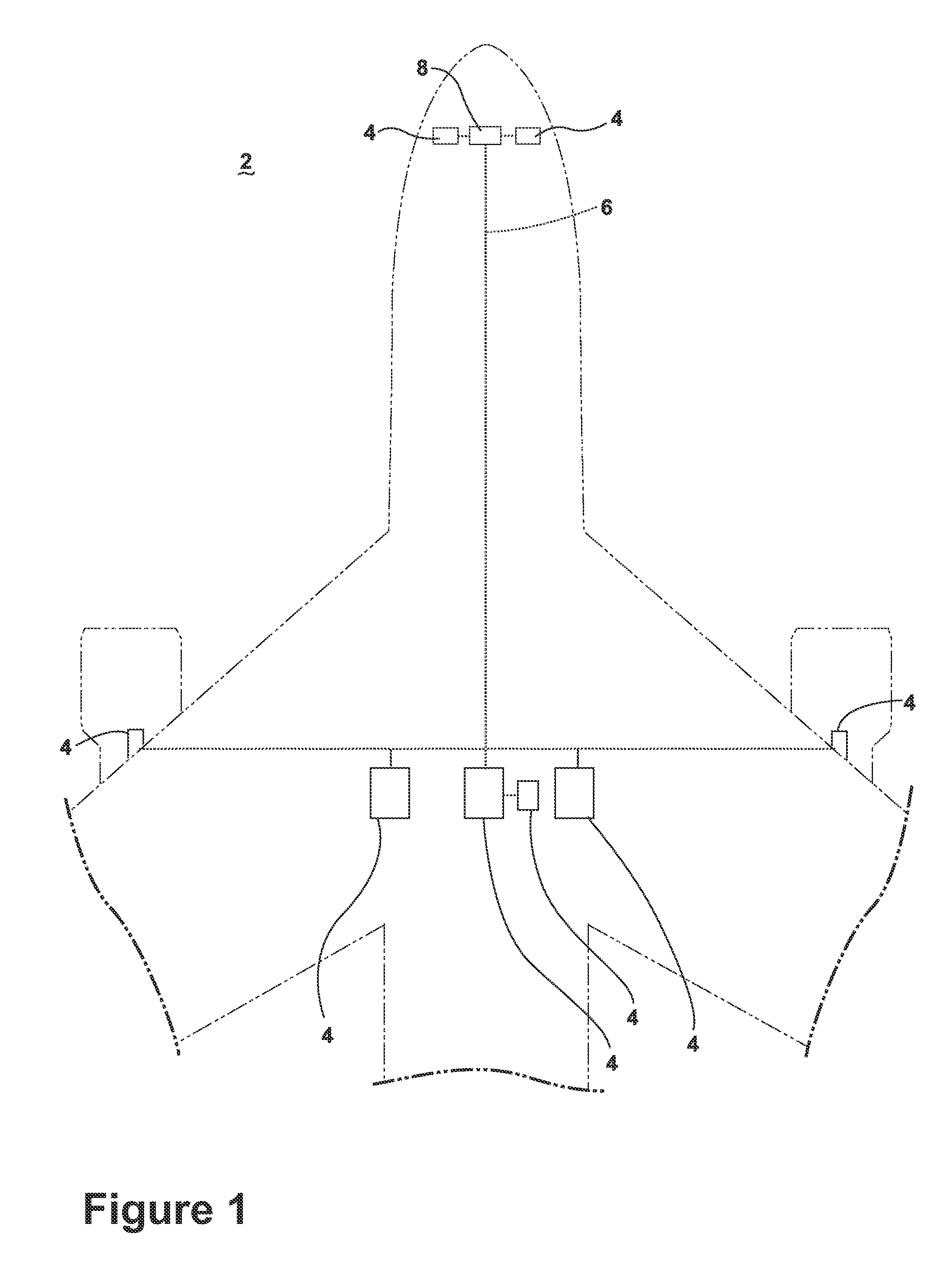

System and method for health assessment of aircraft structure

InactiveUS20170183107A1Aircraft health monitoring devicesRegistering/indicating working of vehiclesStructural conditionHealth indicator

A method of health monitoring and assessment of an aircraft structure includes collecting data from a plurality of sensors located at one or more components of the aircraft. The sensors assess a physical condition of the components and are arrayed in one or more aircraft zones. The data is communicated to a health assessment module, which calculates one or more component structural condition indicators of each component. The component structural condition indicators are compiled and one or more component structural health indicators are calculated. The component structural health indicators are compiled by aircraft zone and a zone structural health indicator is calculated based on the component structural health indicators of components residing in the particular aircraft zone. An aircraft level health indicator is calculated based on the zone structural health indicators and one or more maintenance actions are recommended based on the structural condition and health indicators.

Owner:SIKORSKY AIRCRAFT CORP

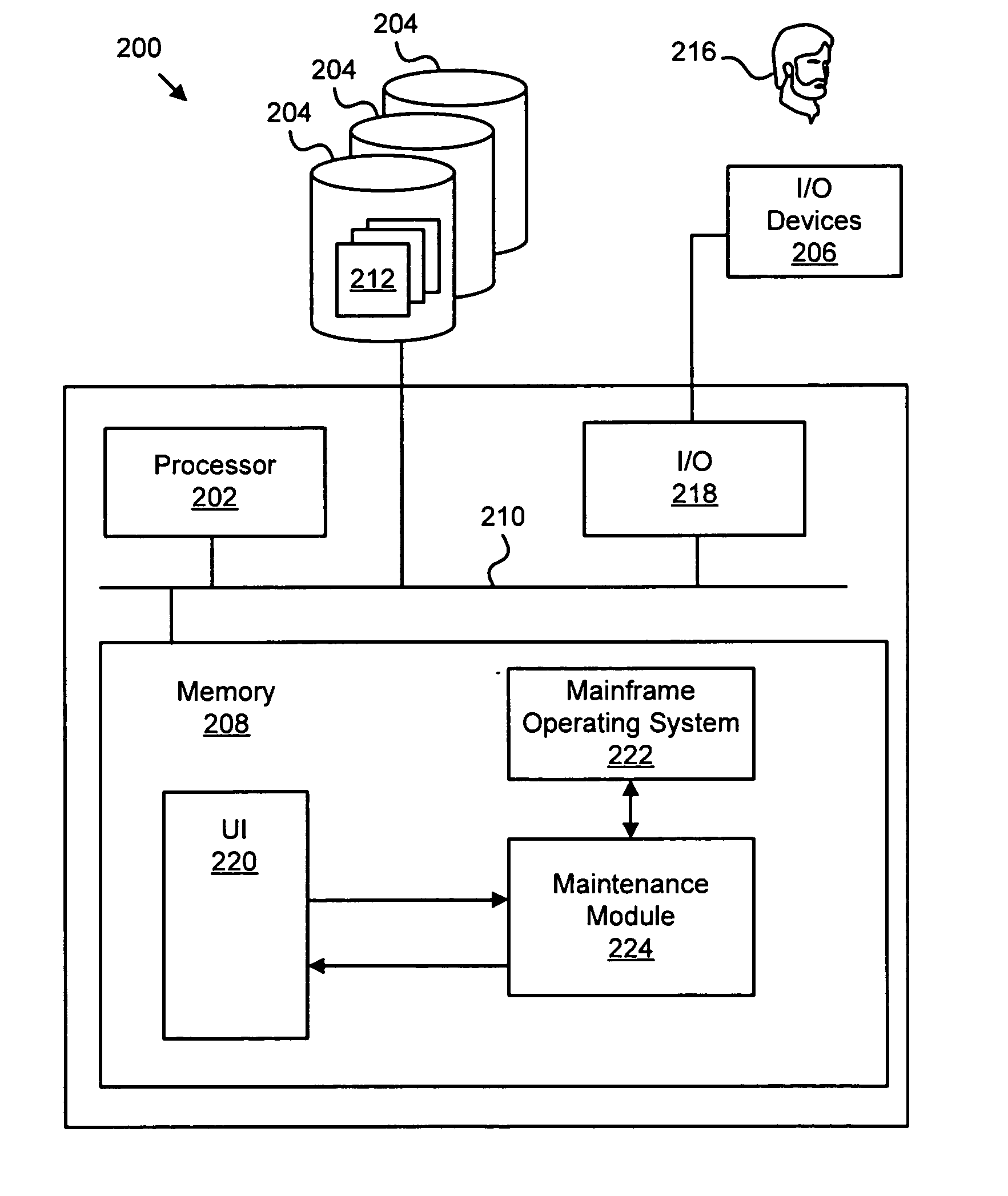

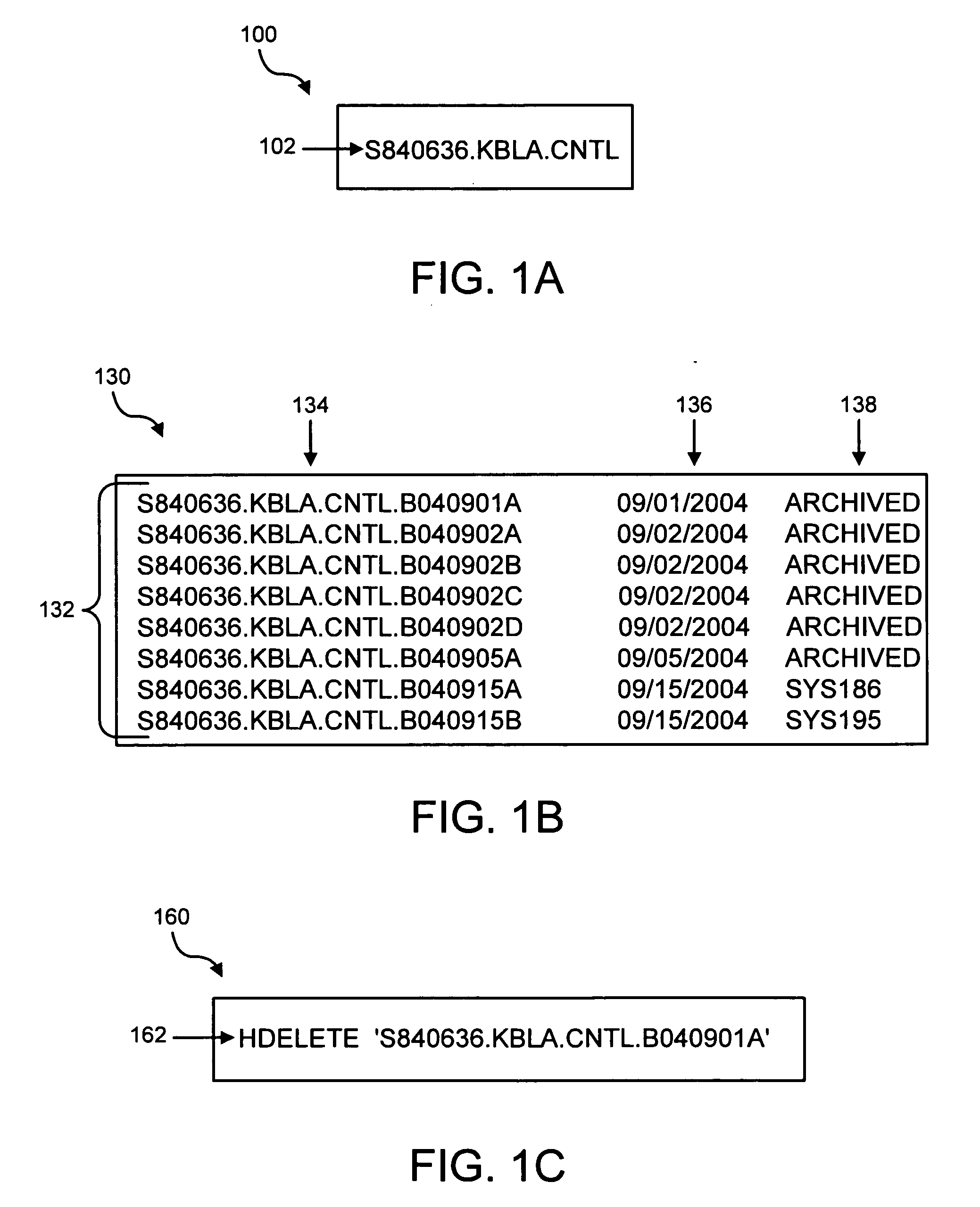

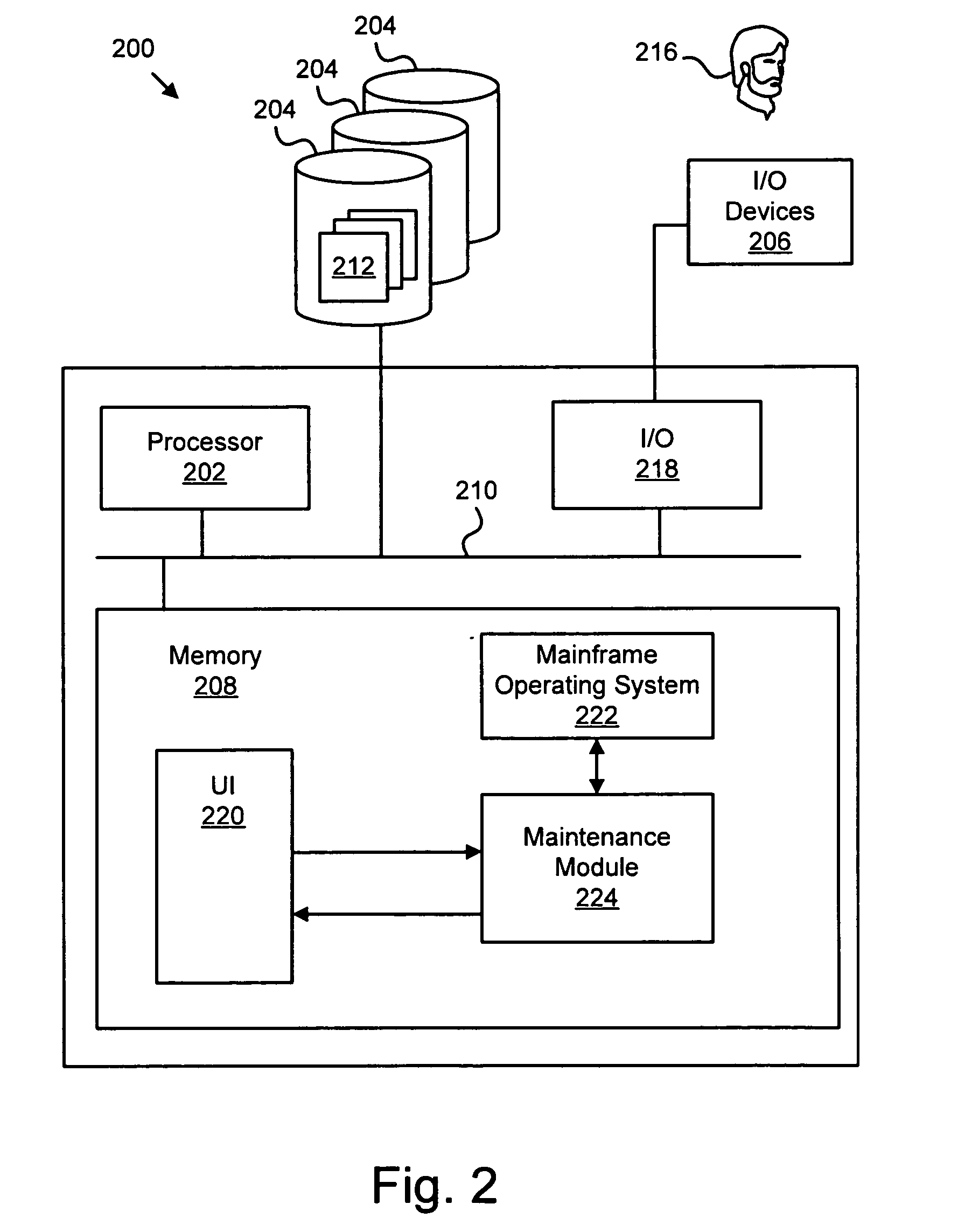

Apparatus, system, and method for performing semi-automatic dataset maintenance

InactiveUS20070011208A1Data processing applicationsDigital data information retrievalData setOperational system

An apparatus, system, and method are disclosed for performing semi-automatic dataset maintenance. The apparatus includes an input module that receives a dataset qualifier. The dataset qualifier describes a collection of datasets. The input module also receives a desired maintenance action to be applied to the datasets. A retrieval module retrieves a set of dataset identifiers that satisfy the dataset qualifier from a mainframe operating system. A command module constructs a set of mainframe operating system commands to fulfill the desired maintenance action. The set of commands includes at least one command for each dataset.

Owner:IBM CORP

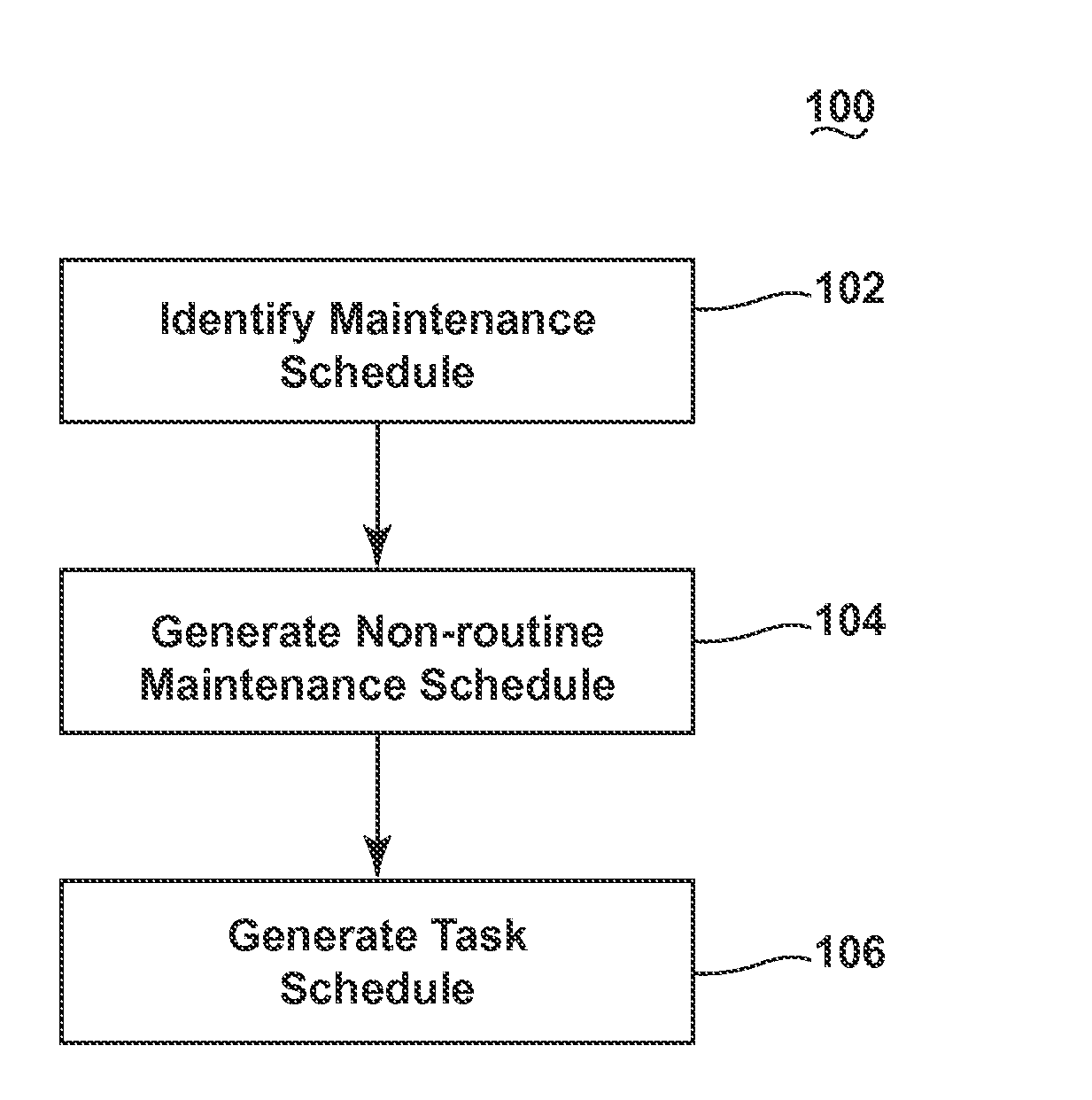

Maintenance system for aircraft fleet and method for planning maintenance

ActiveUS20140121885A1Vehicle testingRegistering/indicating working of vehiclesAirplaneMaintenance actions

A maintenance system for a fleet of aircraft and a method of planning maintenance for a fleet of aircraft that includes identifying a maintenance schedule having at least one routine maintenance action for an aircraft to be maintained, generating a non-routine maintenance task schedule comprising non-routine maintenance tasks, and generating a combined schedule comprising a combination of the maintenance schedule and the non-routine maintenance task schedule.

Owner:GE AVIATION SYST LLC

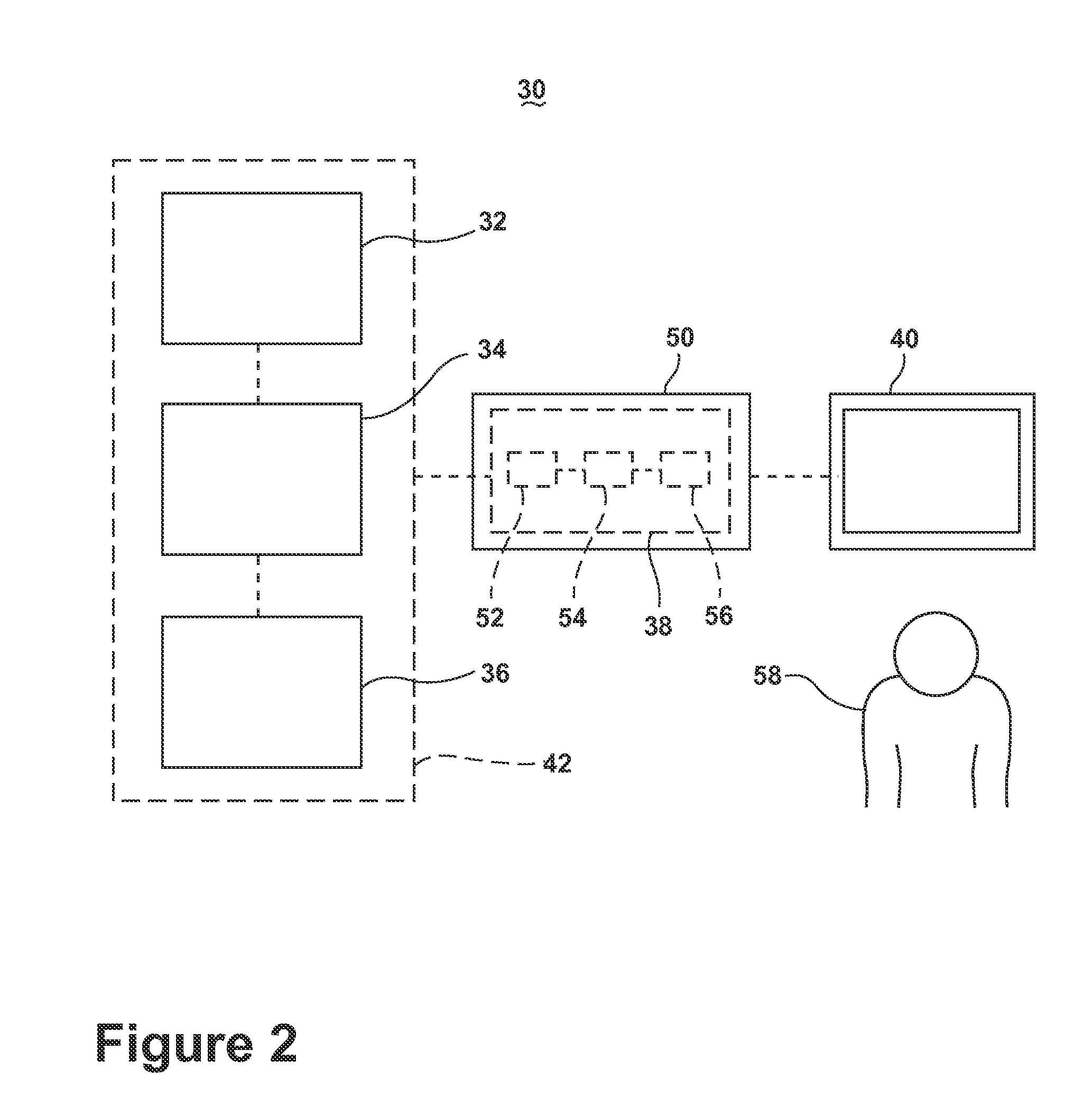

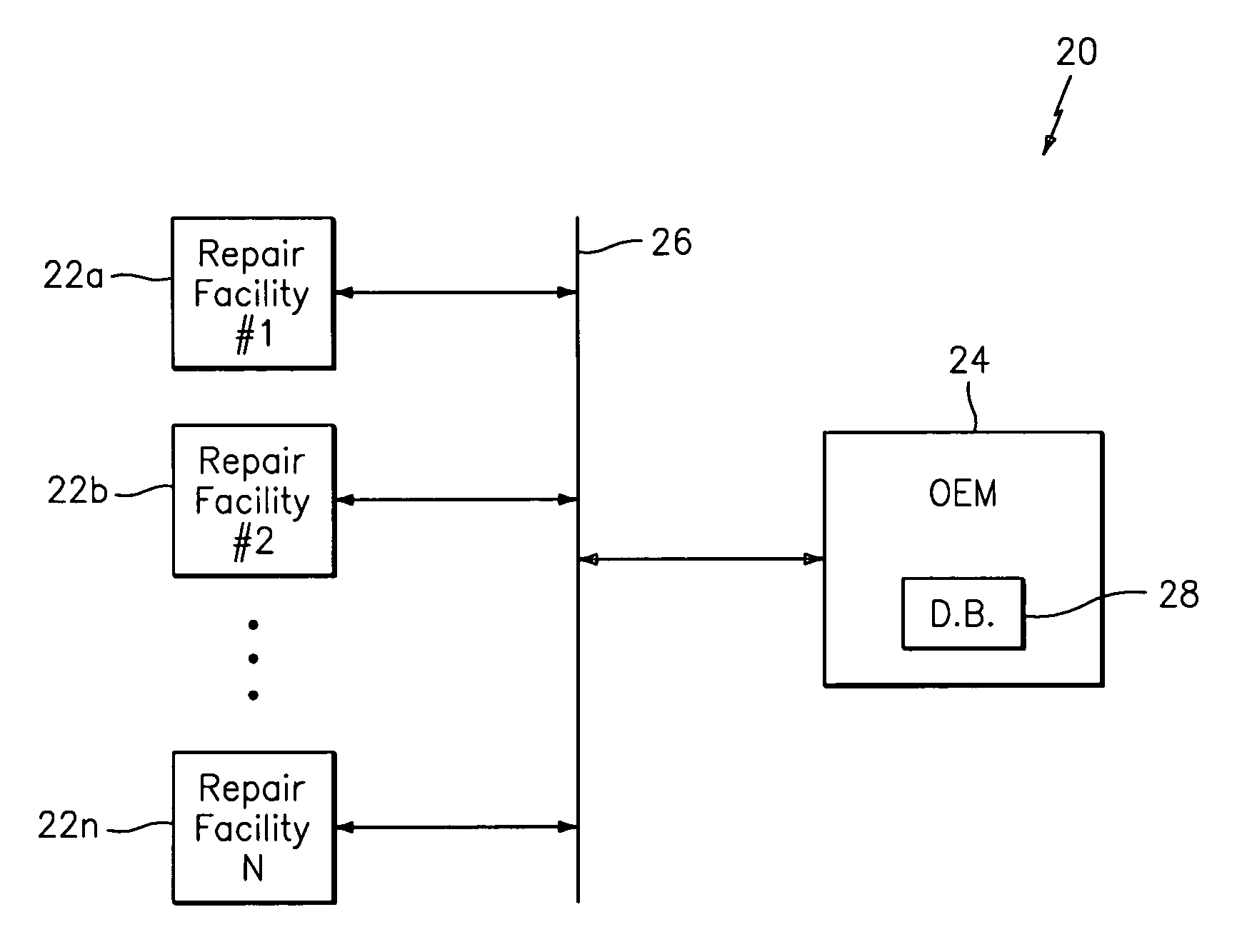

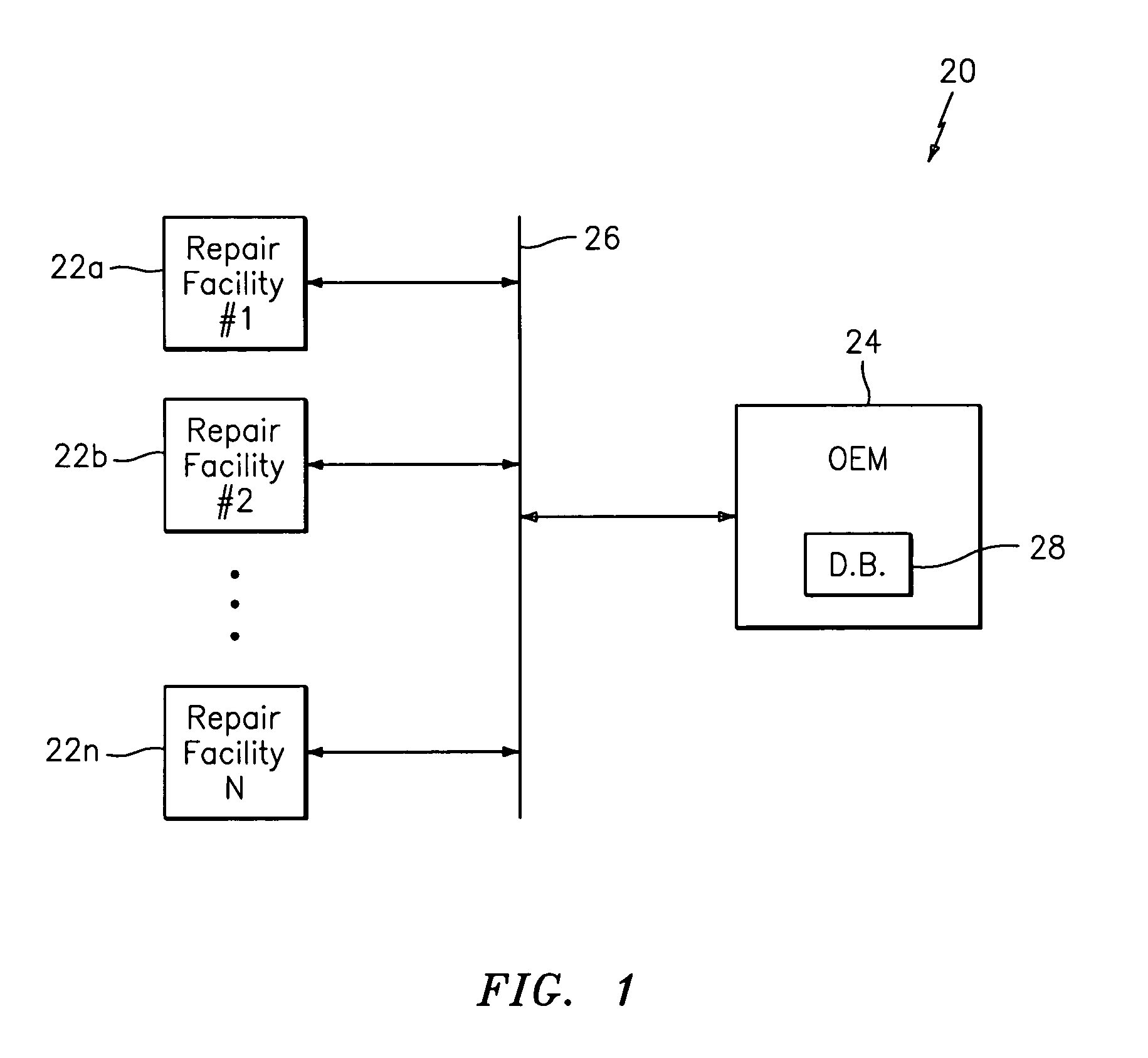

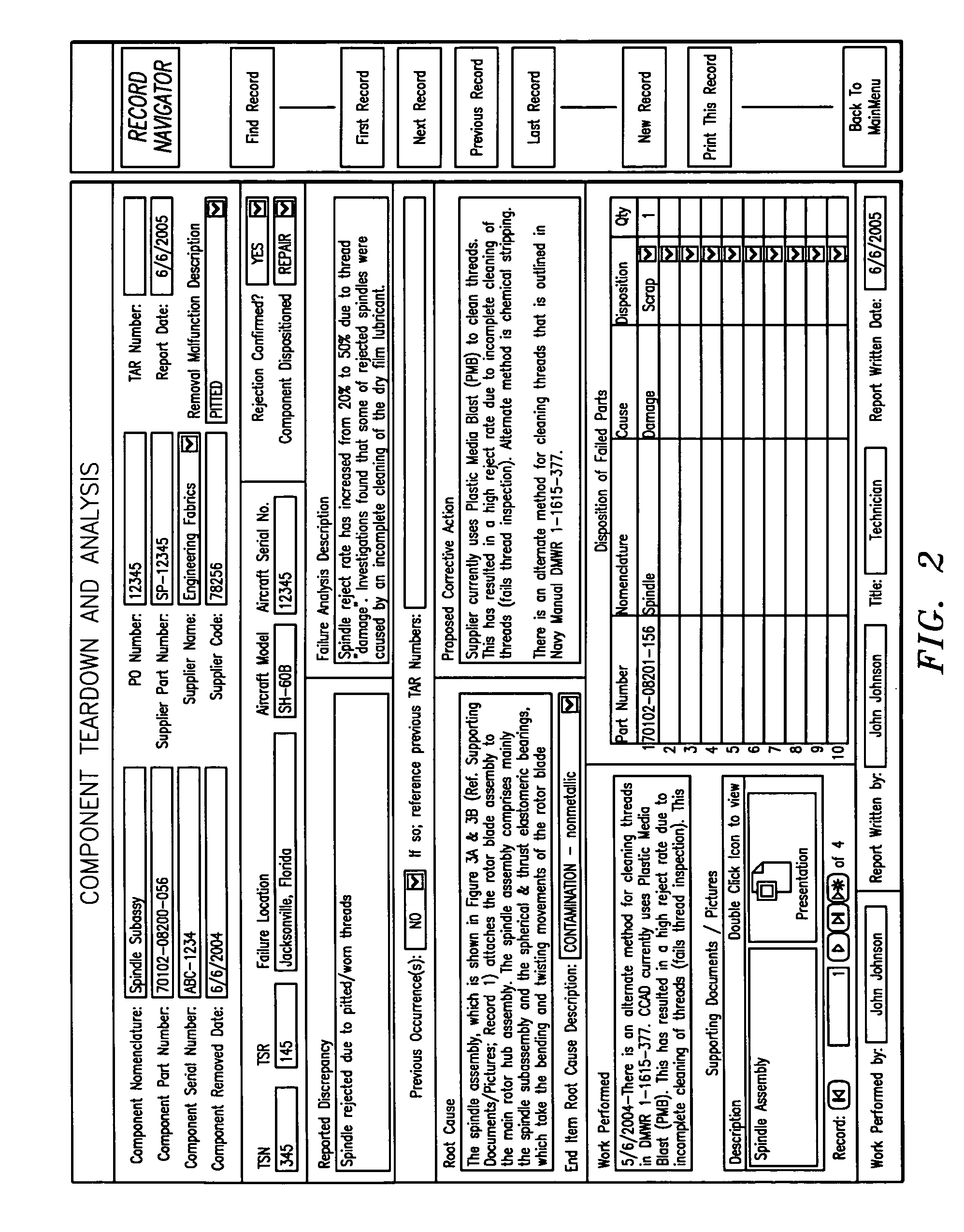

Supplier teardown & analysis reporting system

InactiveUS20070294052A1Facilitates design engineer understandingFailed analysisPlug gaugesAmplifier modifications to reduce noise influenceProgram planningAction plan

A Supplier Teardown and Analysis Reporting System (STARS) captures information pertaining to component removals or failures that caused an unscheduled maintenance action. The detailed data facilitates design engineers understanding of failure drivers and propose improvements and commence implementation of a Corrective Action Plan at the earliest practicable time.

Owner:SIKORSKY AIRCRAFT CORP

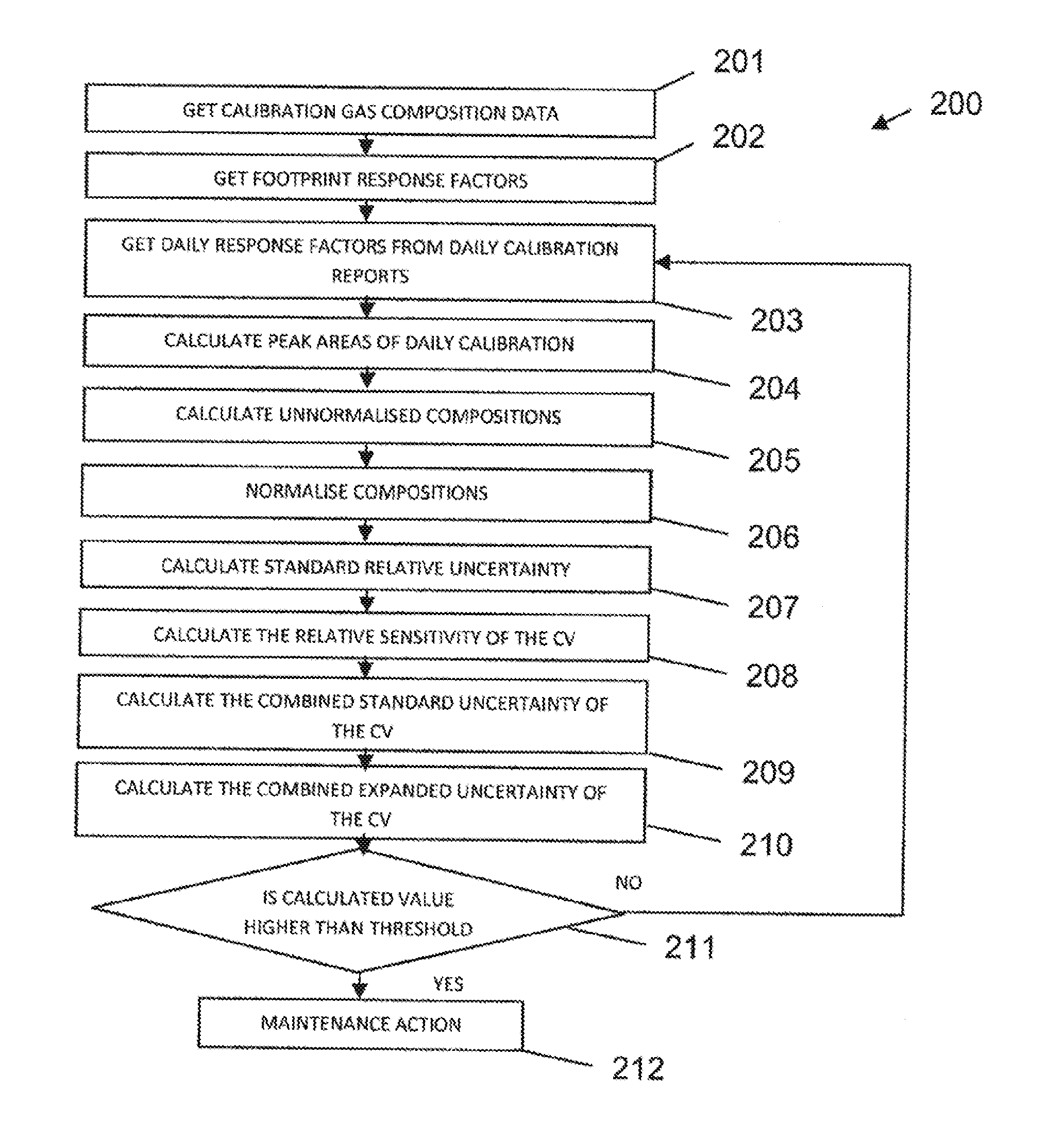

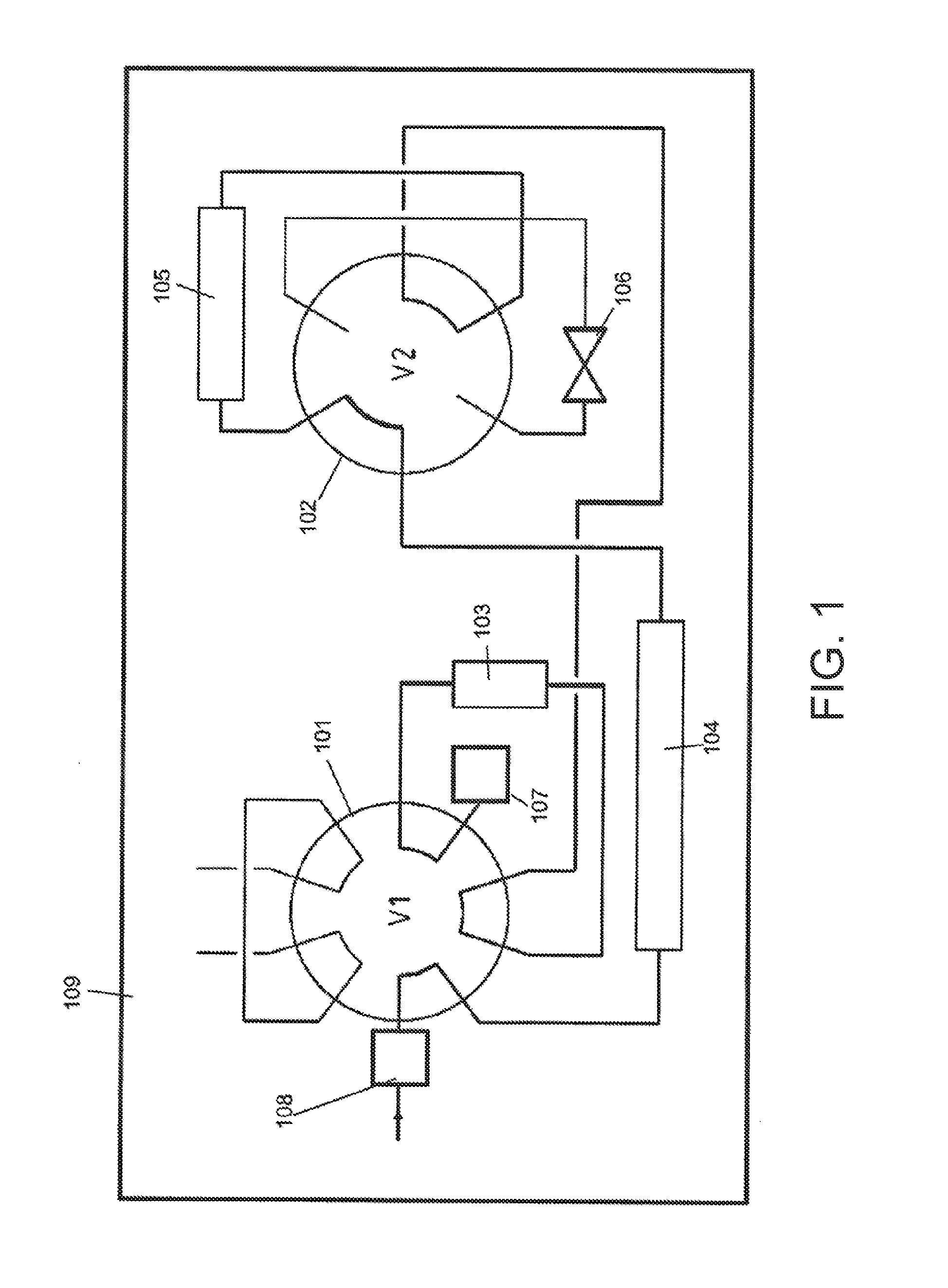

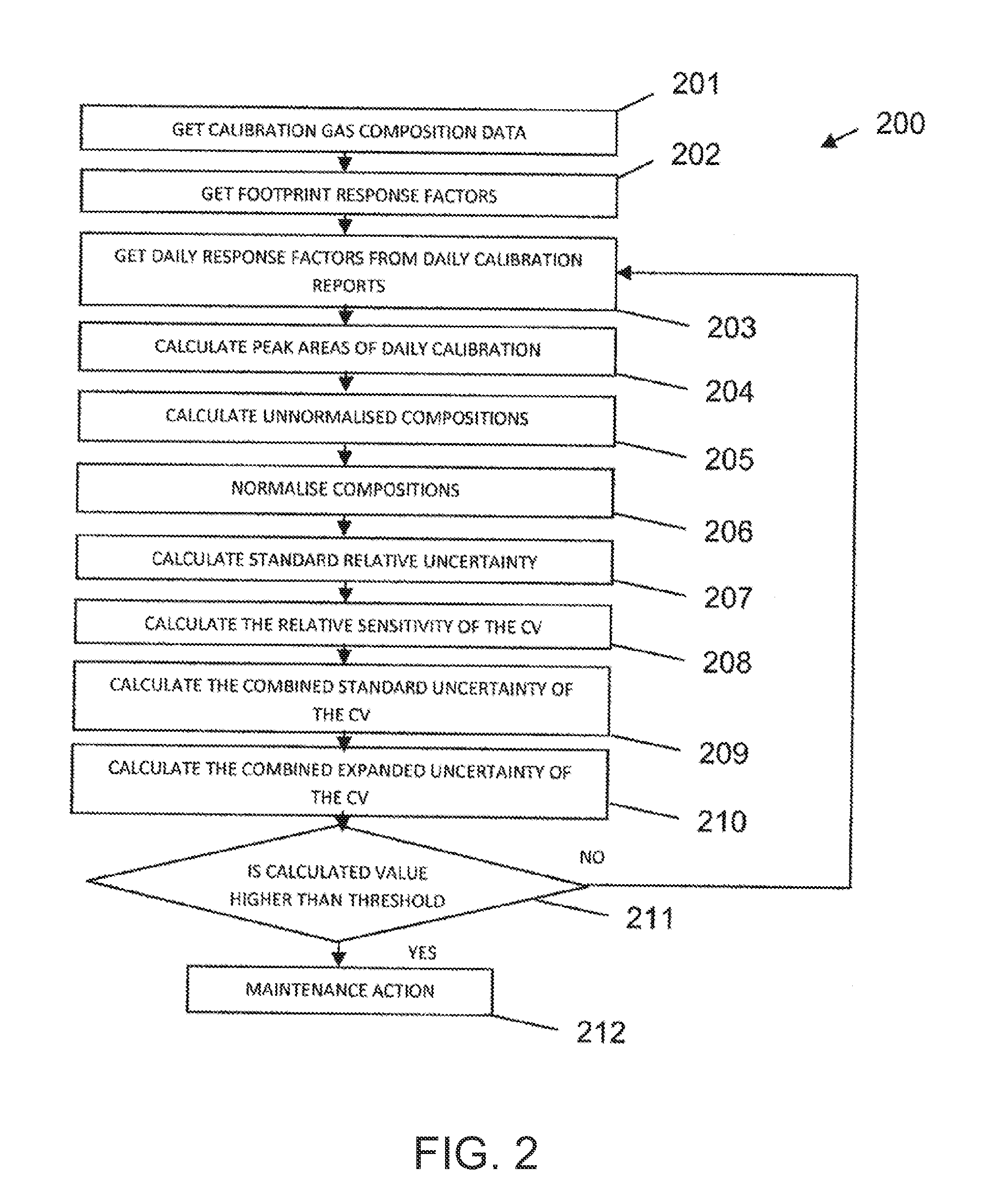

Improved method of analysing gas chromatography data

ActiveUS20130304393A1Economical resourceWaste of time economicalComponent separationSpecial data processing applicationsResponse factorData set

A method of analysing gas chromatography data is described. The method, a first response factor data set acquired from a gas chromatograph (GC) apparatus during a procedure on a calibration or reference gas sample at a first time is received. One or more additional response factor data sets acquired from the gas chromatograph apparatus during a procedure on a calibration or reference gas sample from one or more later times are received. The method comprises calculating a measure of uncertainty for at least one compound of the reference gas sample from the first and additional response factor data sets. The one or more later times are during an operational period of the gas chromatograph apparatus. The measure of uncertainty may be used to, for example, identify the necessity to perform a maintenance action in the GC or to assess whether the GC is in a healthy or unhealthy condition.

Owner:I VIGILANT TECH

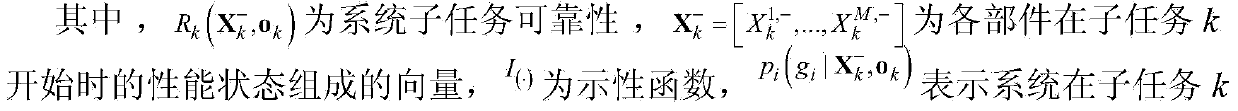

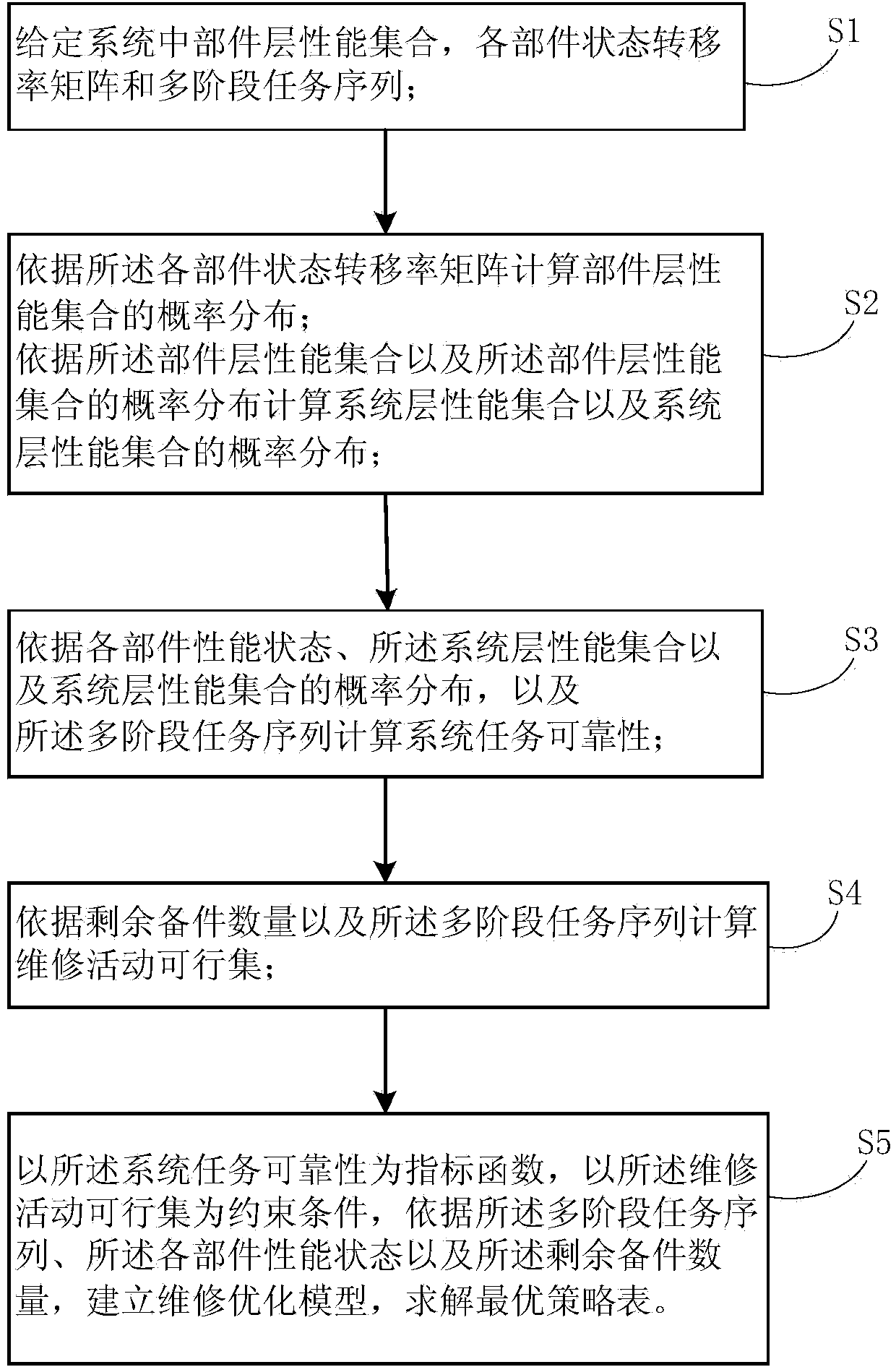

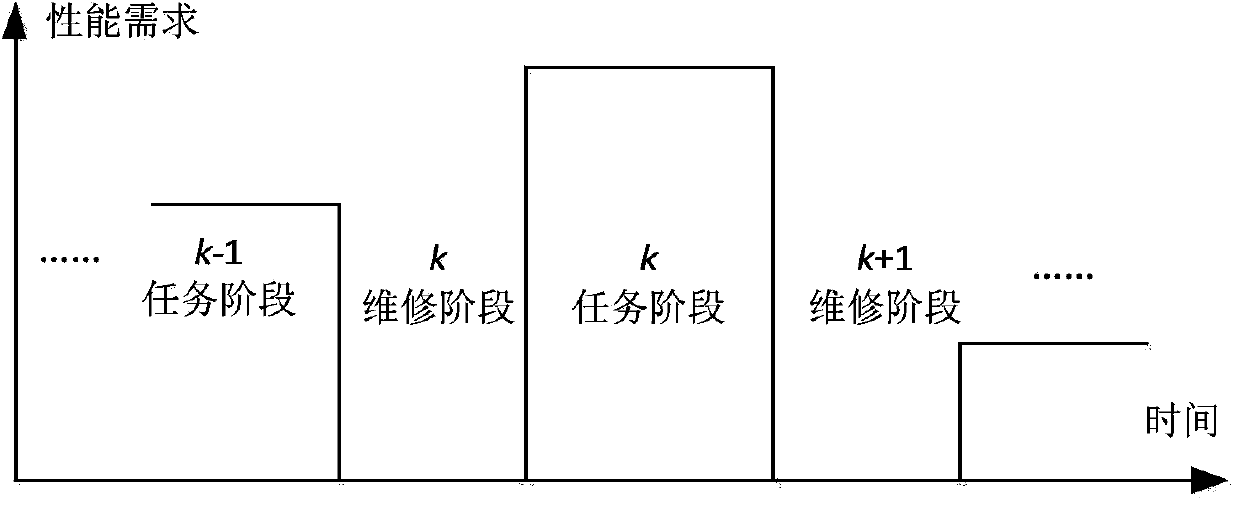

Optimal selective maintenance optimization method and device for multi-stage task multi-state system

ActiveCN103714397AAvoid the risk of overuseEasy to implementForecastingDependabilityComputer science

The invention discloses an optimal selective maintenance optimization method and device for a multi-stage task multi-state system. The method comprises the steps that a component layer performance set, a state transition rate matrix of each component and a multi-stage task sequence in the system are given; according to the state transition rate matrix of each component, probability distribution of the component layer performance set is calculated; according to the component layer performance set and the probability distribution of the component layer performance set, a system layer performance set and probability distribution of the system layer performance set are calculated; according to the performance state of each component, the system layer performance set, the probability distribution of the system layer performance set and the multi-stage task sequence, system reliability is calculated; according to the residual number of replacement components, a maintenance action feasible set is calculated; the system task reliability is taken as an indicator function, and the maintenance action feasible set is taken as constraint conditions; according to the multi-stage task sequence, the performance state of each component and the residual number of the replacement components, a maintenance optimization model is built, and an optimal strategy table is solved.

Owner:TSINGHUA UNIV

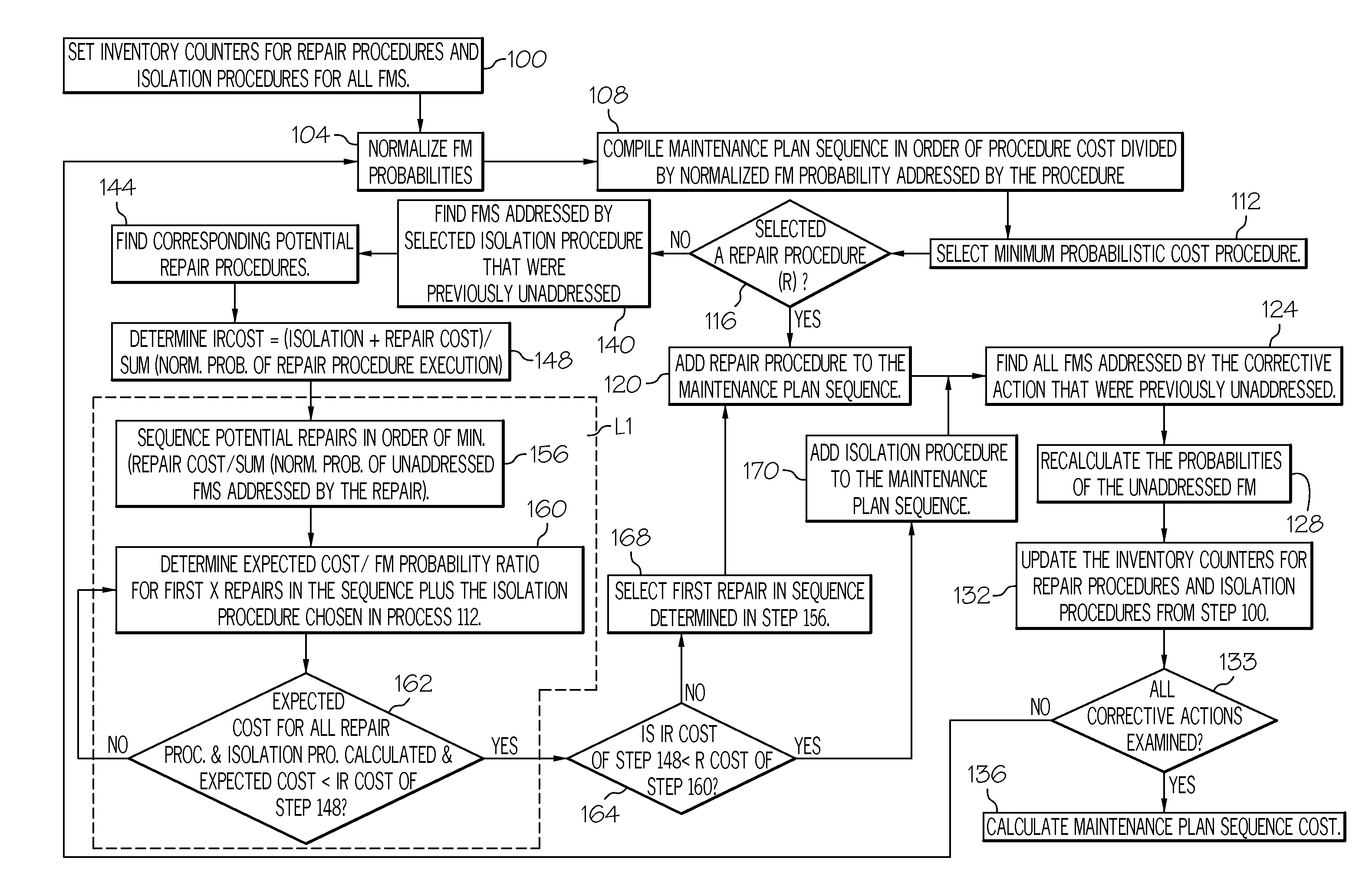

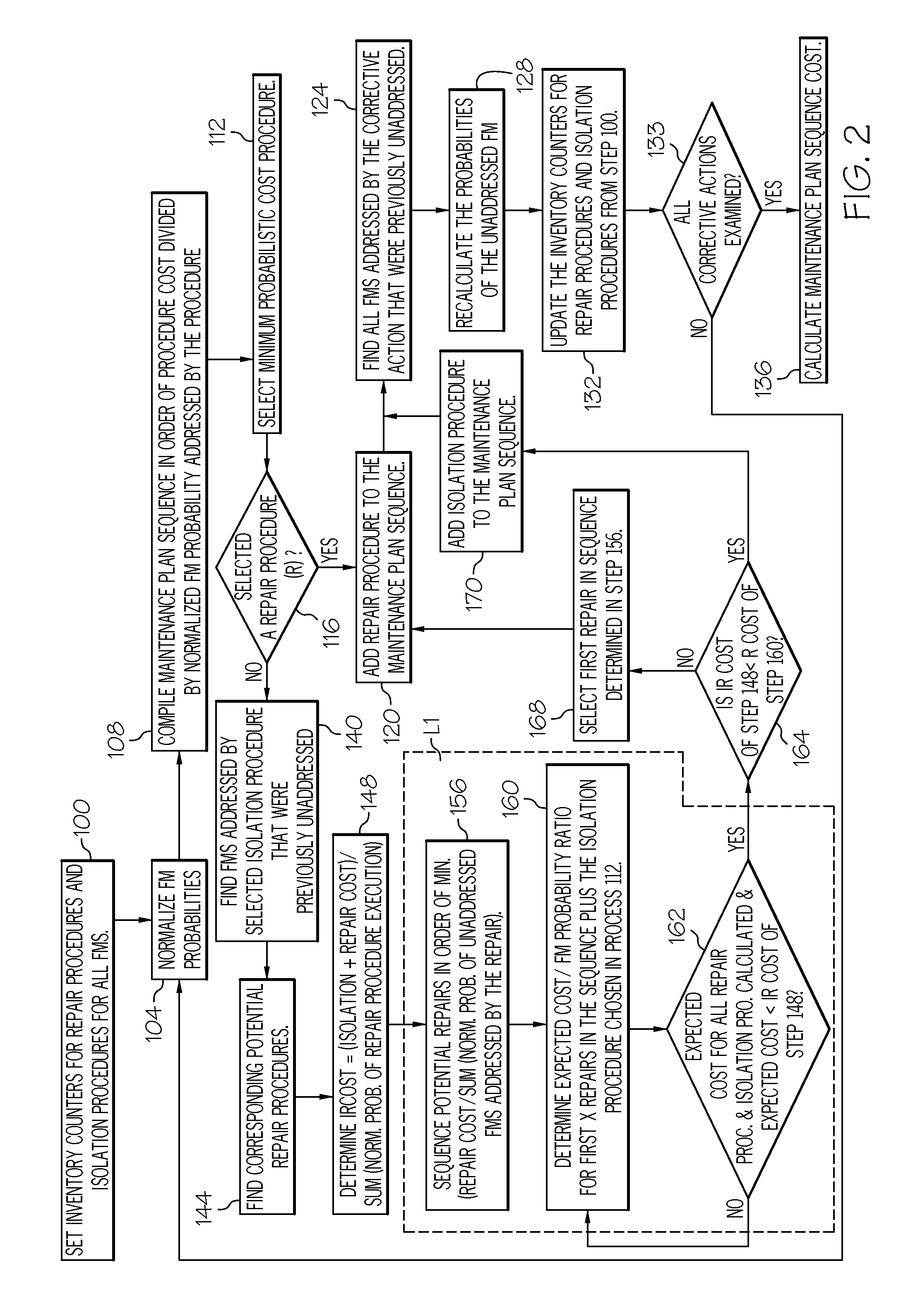

Systems and methods for creating a near optimal maintenance plan

Methods and apparatus are provided for determining a lowest total cost maintenance plan. The method comprises receiving a sequence of maintenance actions in an order of a waiting time for each maintenance action, wherein one of the maintenance actions is likely to repair the failure mode. Each maintenance action has an associated cost equal to a waiting time cost, an execution time cost and a material cost, wherein the waiting time of each maintenance action is the time required to requisition and receive material required to perform the maintenance action. The method also constructs a maintenance plan comprising a primary requisition and a secondary requisition by assigning each of the sequence of maintenance actions to one of the primary and secondary requisition.

Owner:HONEYWELL INT INC

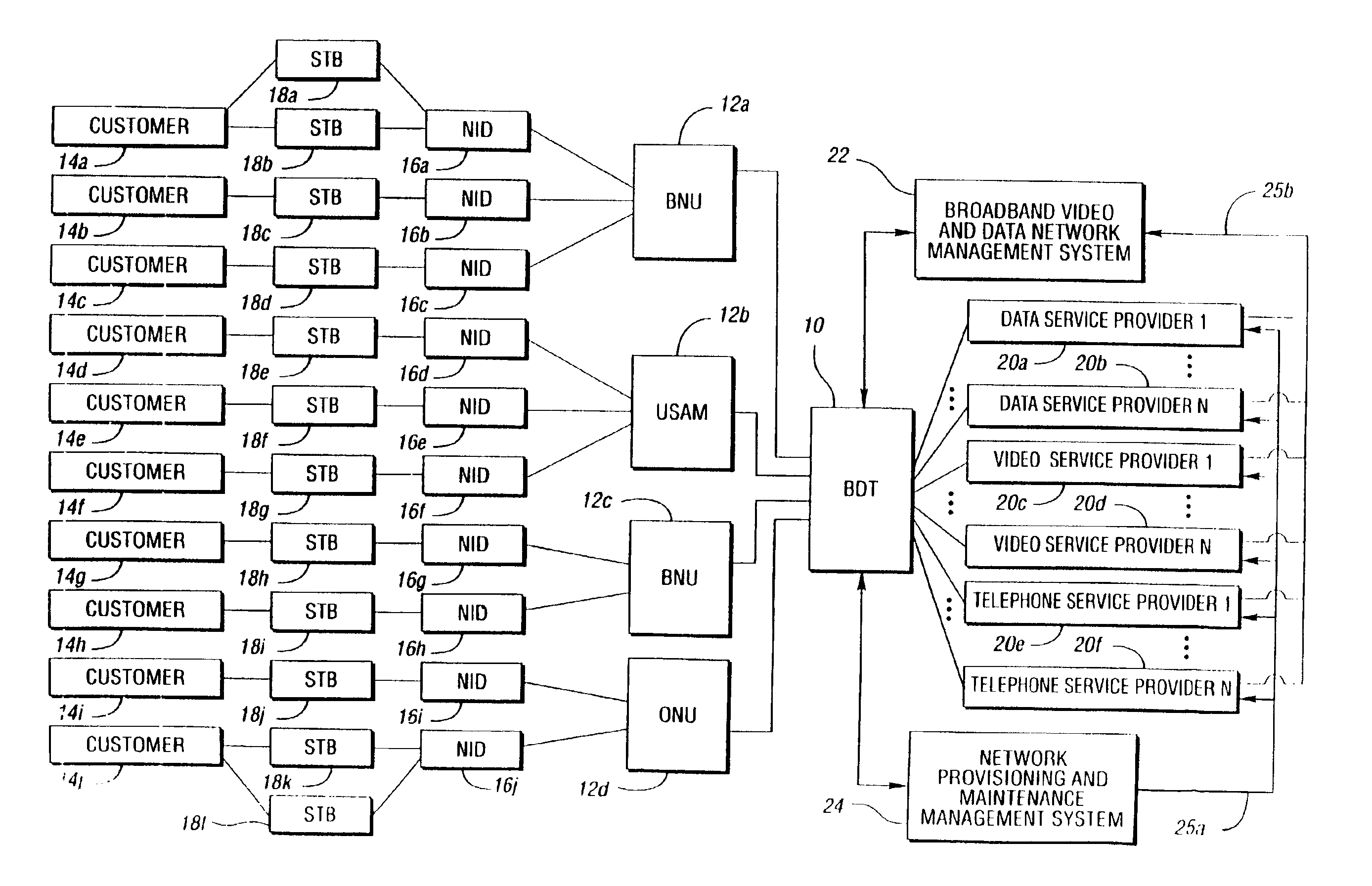

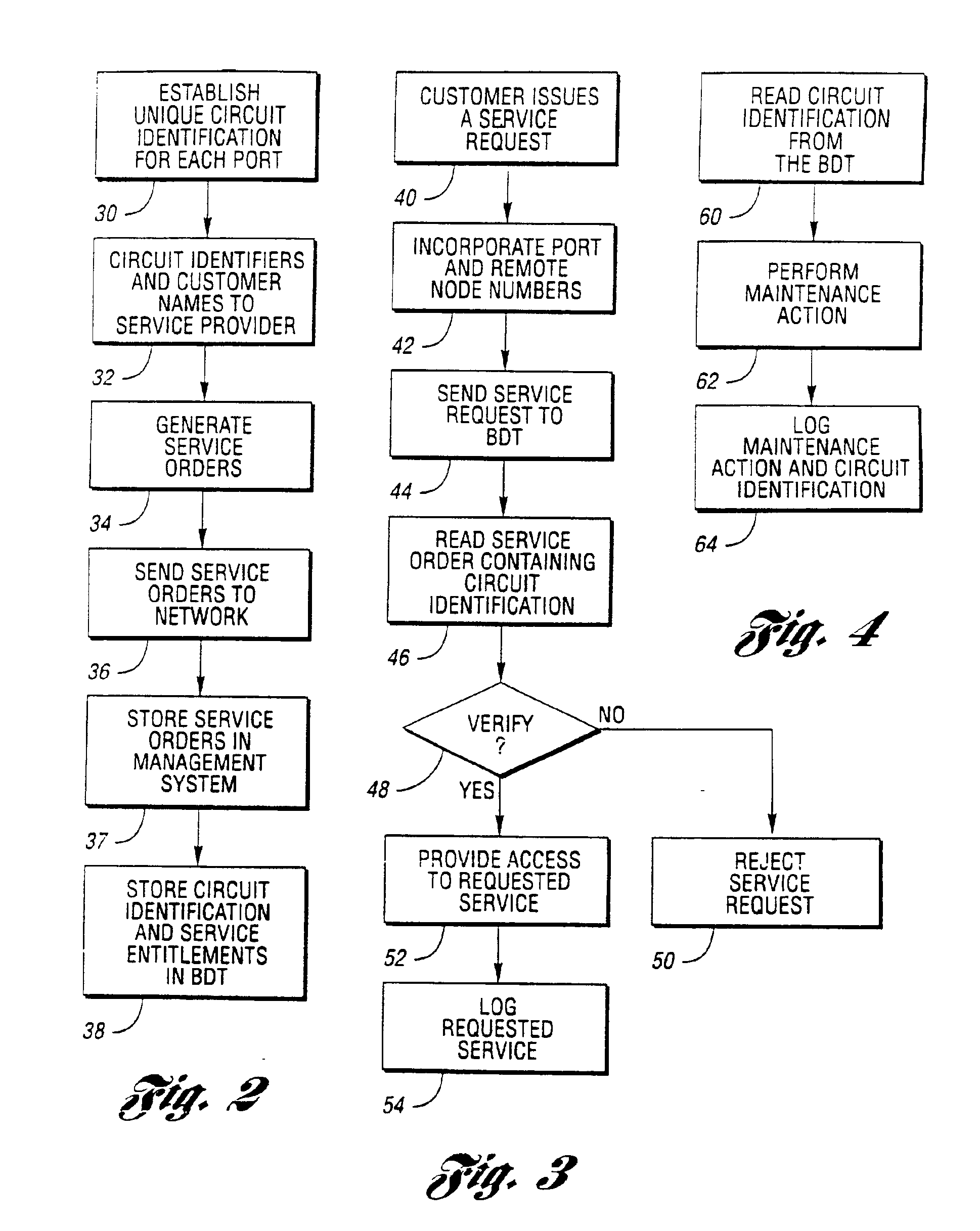

Broadband circuit identification method for controlling service access

InactiveUS6873622B1Facilitate service access controlBroadband local area networksBroadcast transmission systemsPayment service providerData bank

A method for controlling customers' access to services on a broadband network. The method uses a circuit identifier, unique to each customer, to compare service requests with service entitlements. The network provider flows the circuit identifiers to the service providers where relationship between the circuit identifiers and the service entitlements is established in service orders. Service providers flow the service orders back to the broadband network though a standard business system interface. The relationship between the circuit identifiers and the service requests is accomplished at the Broadband Digital Terminal that interface the customers to the broadband network. The circuit identifiers also permit sorting of data bases containing logs of service requests and logs of maintenance actions.

Owner:QWEST

Methods and systems for centrally managed maintenance program for aircraft fleets

ActiveUS8340854B2Reduce in quantityFacilitate numberVehicle testingAnalogue computers for trafficCentralized managementAirplane

Methods and systems for managing maintenance of a fleet of aircraft are provided. The method includes collecting data from at least one aircraft in each of the fleets related to the operation of the aircraft, determining a range of acceptable values of performance parameters associated with the collected data and based on the collected data, analyzing the collected data having values outside the range of acceptable values, and modifying at least one of a maintenance requirement and an interval between maintenance actions to facilitate reducing the number of performance parameters values that are outside the range of acceptable values during future operation of the aircraft.

Owner:THE BOEING CO

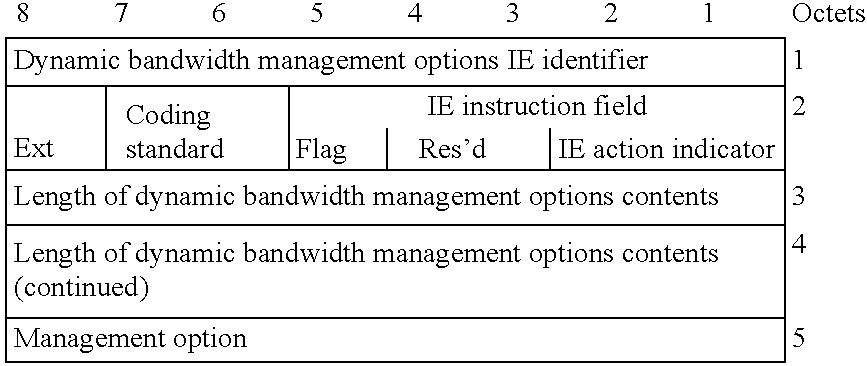

Dynamic bandwidth management and rerouting

InactiveUS6735176B1Multiplex system selection arrangementsError preventionDynamic resourceBandwidth management

A communications network performs a variety of maintenance actions. One of those actions is rerouting of a connection path. A feature called "dynamic resource management option" allows the network or the called party of an active connection to initiate a resource change procedure when needs arises. The resource change can also be achieved by rerouting the existing path of the active connection. However a maintenance action taken in one network domain is only effected within the same domain, because a different domain may have different maintenance procedures. Telecommunication connections often span more than one domain and a request for resource adjustment must be considered differently for a proper maintenance action. A resource change indication message includes a flag to indicate the message originated within or outside the domain. By observing the flag, it is possible to decide on a proper maintenance procedure.

Owner:NORTEL NETWORKS LTD

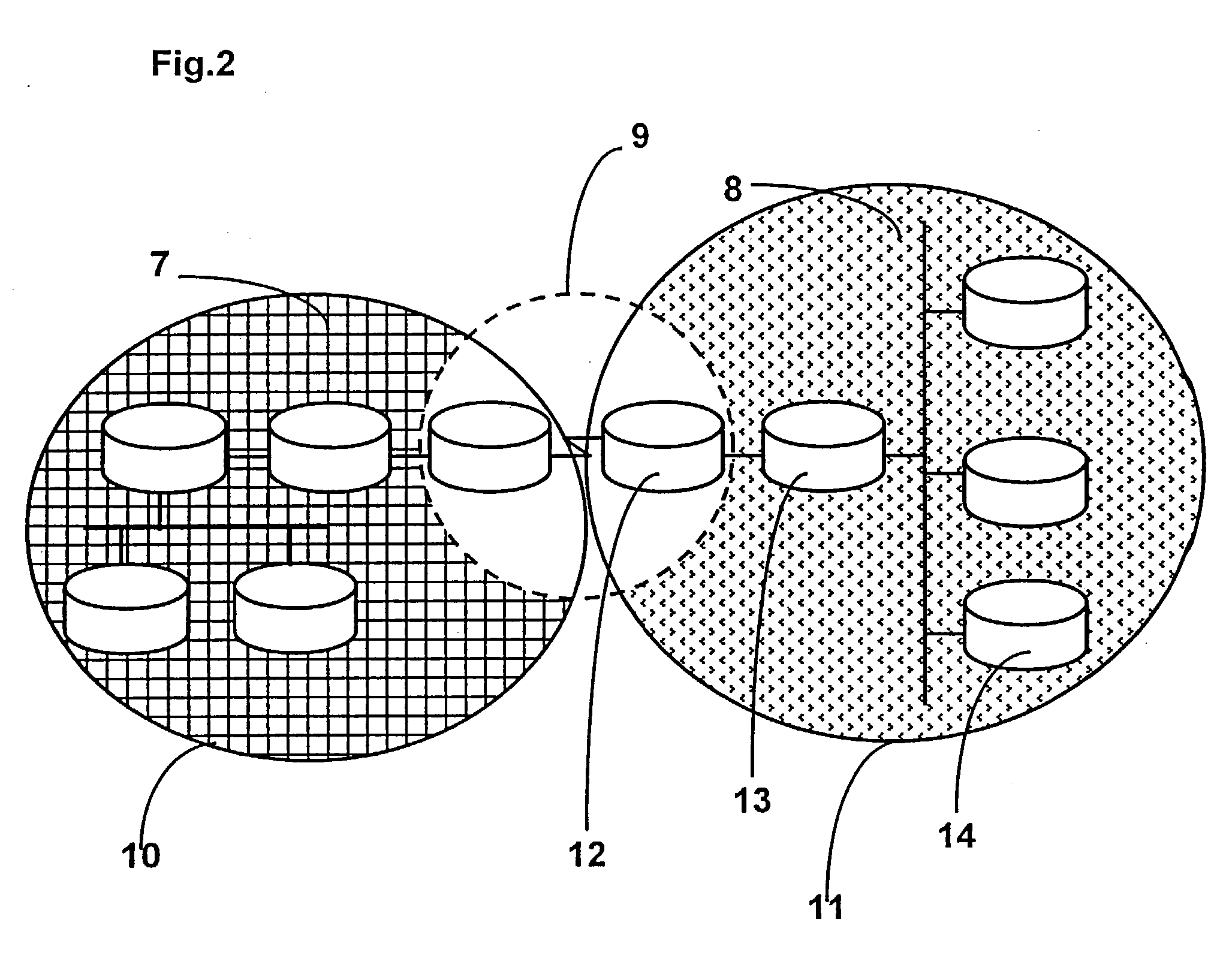

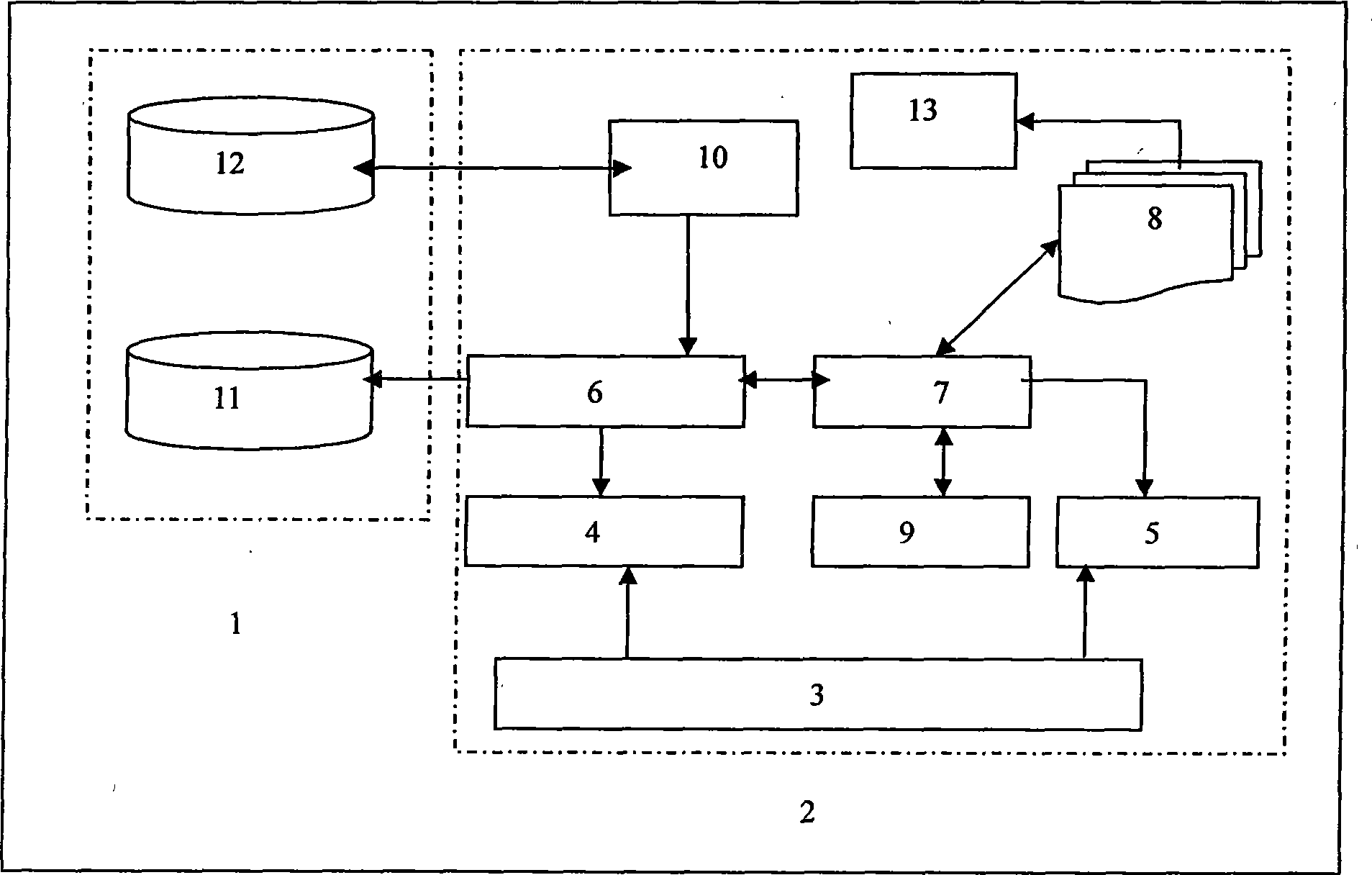

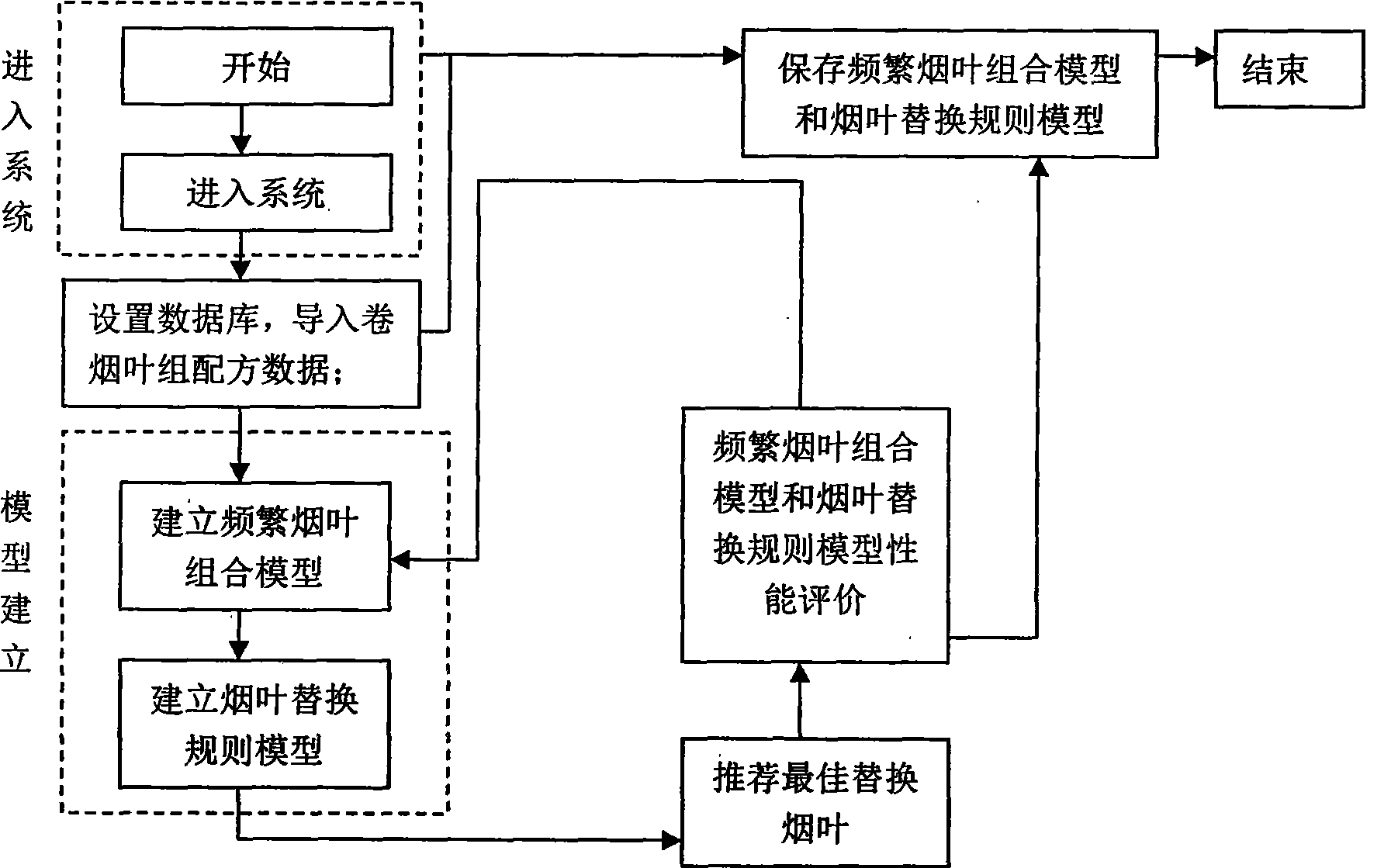

Cigarette composition maintenance action digging system based on associations ruler and method thereof

ActiveCN101419627AAutomatic replacementAchieve substitutionSpecial data processing applicationsData connectionPassword

The invention discloses a cigarette formulating maintenance behavior mining system based on association roles and a method thereof. The cigarette formulating maintenance behavior mining system comprises a database server and a data mining client, wherein, the data mining client comprises a visual displaying tool which is connected with a data displaying and processing module and a result displaying module; the data displaying and processing module is connected with a data connecting module which provides connection of data sources with different data type formats, a database generating a mining algorithm and also interfaces through which a data object performs accessing; the result displaying module is connected with a mining and processing module which is respectively connected with a pattern storage module, a pattern evaluating module and a data connecting module; the data connecting module is connected with the data resources in an authentication processing module and the database server, and simultaneously, the authentication processing module is connected with a permission database in the database server, and the authentication processing module verifies the user validity through a user name and a password.

Owner:CHINA TOBACCO SHANDONG IND +1

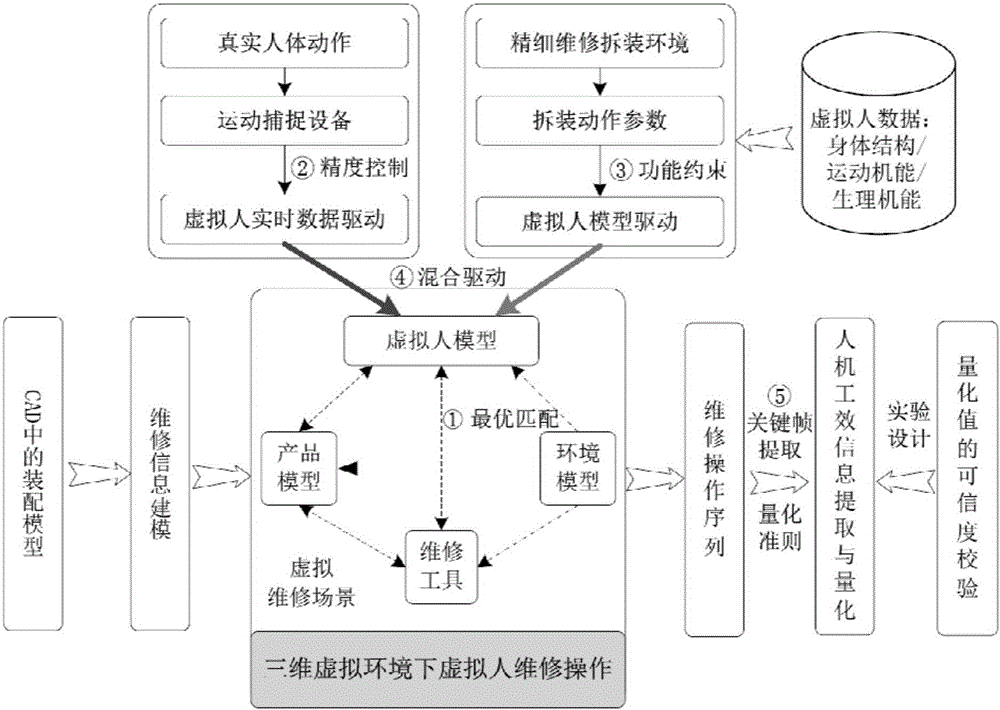

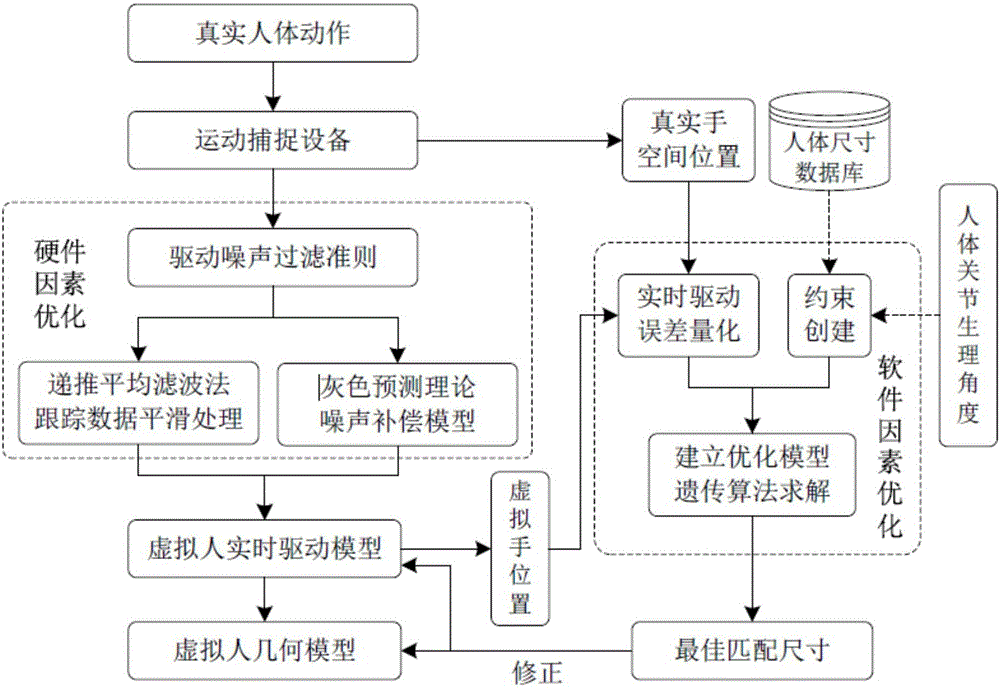

Hybrid driving method for virtual human maintenance actions

ActiveCN105160139AAccessibility Quick JudgmentSolve efficiency problemsSpecial data processing applicationsReal Time KinematicSimulation

The invention discloses a hybrid driving method for virtual human maintenance actions. The hybrid driving method comprises the following steps: realizing maintenance information modeling through an assembly module in CAD; virtualizing human maintenance operations in a three-dimensional virtual environment according to the maintenance information model; performing hybrid driving on the virtual human actions by use of real-time motion capture data and a model algorithm; driving local maintenance actions and transitional maintenance actions by use of the real-time motion capture data, and automatically switching the driving to model algorithm driving and improving the efficiency and accuracy of virtual human action driving by an attitude constraint machine when fine maintenance action constraint recognition and matching are performed by a virtual hand or a maintenance tool or a dismantlement tool, and meanwhile, performing evaluation according to a user-defined quantification criterion by automatically extracting the human-machine efficacy information of key frames in the maintenance process, and designing an experiment to perform dependability evaluation on a quantification result.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com