Optimal selective maintenance optimization method and device for multi-stage task multi-state system

A multi-state system and multi-stage technology, applied in data processing applications, forecasting, computing, etc., can solve problems that can only be carried out at a specific time, affect the operation of multiple task stages, and task failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

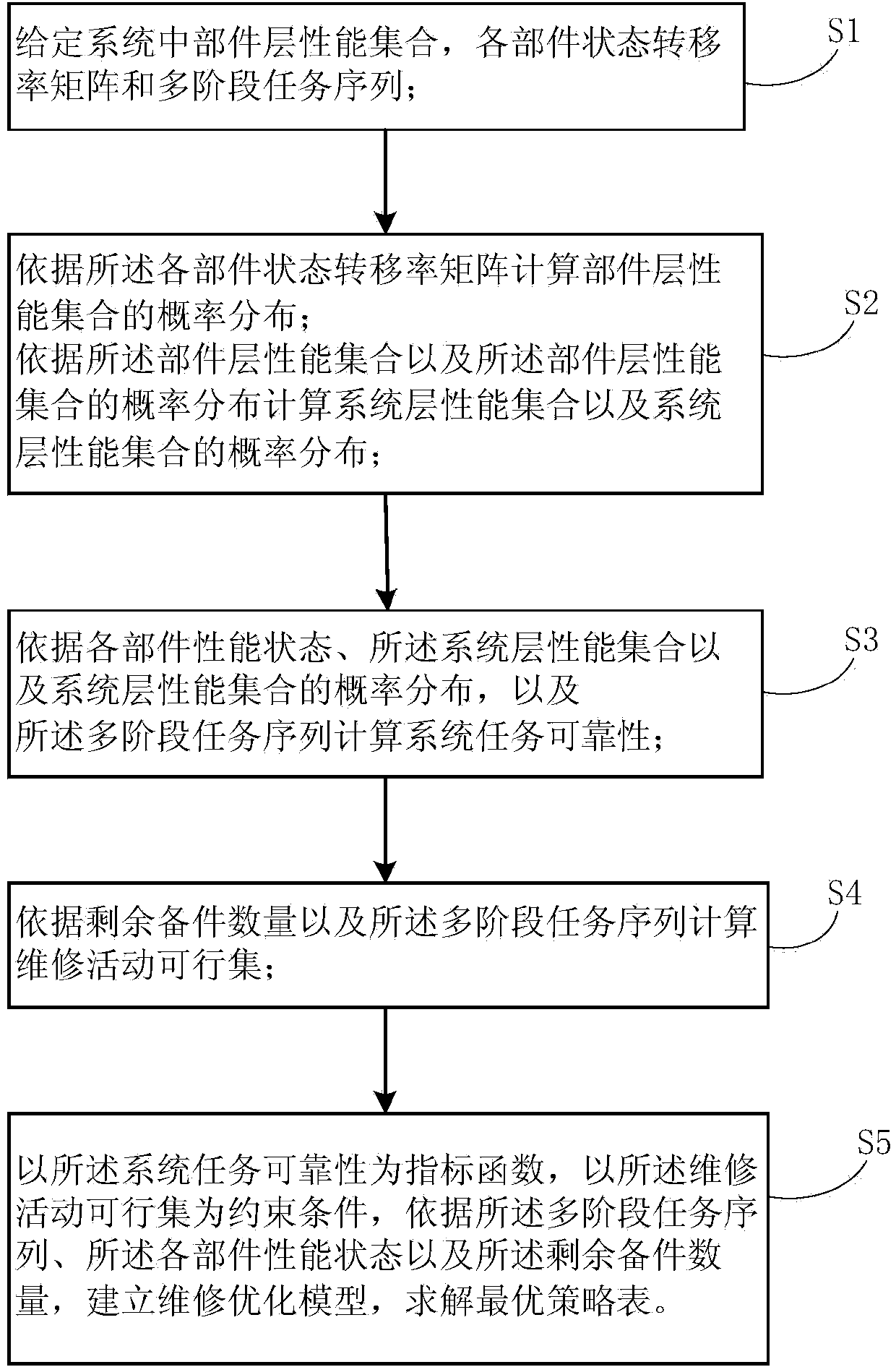

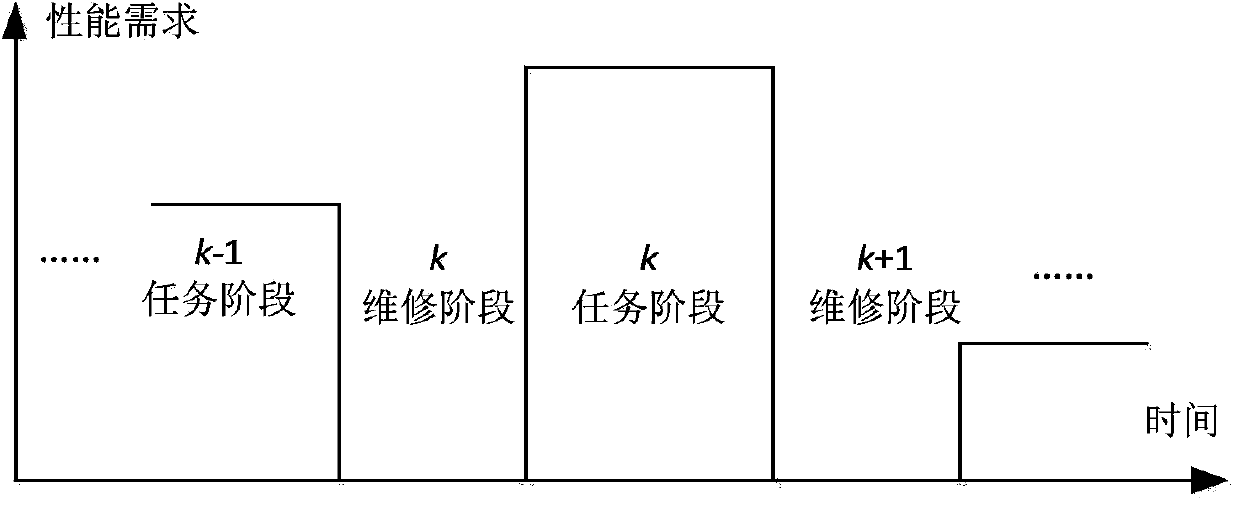

[0066] Refer below figure 1 A method for optimal selective maintenance optimization of a multi-stage task and multi-state system according to an embodiment of the present invention will be described in detail. Based on the information of the component layer, the performance set and the corresponding probability distribution of the system layer are calculated, combined with the sequence model of the multi-stage task, the reliability of the system task is calculated, and the maintenance optimization model is established by using the dynamic programming method, and the following The number of task stages, the performance status of each component, and the remaining amount of spare parts are the input optimal strategy tables.

[0067] In this embodiment, the method includes the following steps:

[0068] Step S1, given the component layer performance set in the system, the state transition rate matrix of each component in the system and the multi-stage task sequence.

[0069] Spec...

no. 2 example

[0128] Refer below image 3 To describe in detail the application of the optimal selective maintenance optimization method of the multi-stage task multi-state system in the commonly used water pipe hydraulic system according to the present invention, image 3 It is the structural diagram of the water pipe hydraulic system, and the relevant performance parameters of each component are shown in Table 1. Multi-stage task sequence is O 1 ={[w 1 ,τ 1 ],[w 2 ,τ 2 ],[w 3 ,τ 3 ]}={[1.5,1 / 120],[1.8,1 / 120],[3.5,1 / 120]}. The specific values in the task sequence are given according to the actual usage requirements of the managers, and are considered as known quantities here.

[0129] Table 1

[0130]

[0131] In this embodiment, the method includes the following steps:

[0132] Step S1, given the component layer performance set in the system The state transition rate matrix of each component and the multi-stage task sequence, the state transition rate matrix Q i (i=1,......

Embodiment 3

[0173] According to another aspect of the present invention, an optimal selective maintenance optimization device for a multi-stage task and multi-state system is proposed. Such as Figure 5 Shown is a structural diagram of an optimal selective maintenance optimization device for a multi-state system under a multi-stage task in an embodiment of the present invention.

[0174] In this embodiment, the optimal selective maintenance optimization device 500 for a multi-stage task multi-state system includes an initialization module 501, a system layer parameter generation module 502, a system task reliability generation module 503, a maintenance activity feasible set generation module 504, a maintenance Policy generation module 505 .

[0175] Among them, the initialization module 501 is used to set the component layer performance set in the given system, the state transition rate matrix of each component and the multi-stage task sequence; the system layer parameter generation modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com