Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

670 results about "Maintenance strategy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical equipment state maintenance system

InactiveCN103914791AImprove data transfer efficiencyImprove transmission efficiencyData processing applicationsEnergy industryMaintenance strategyPower grid

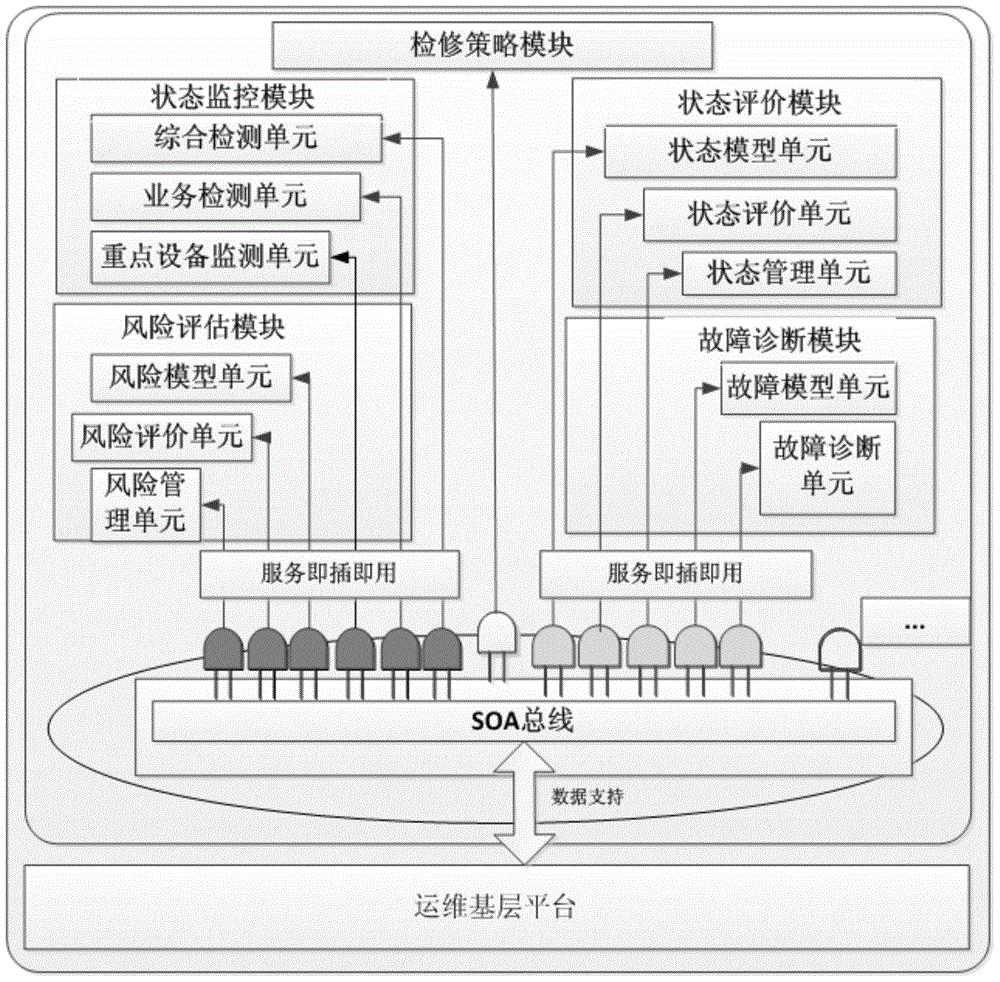

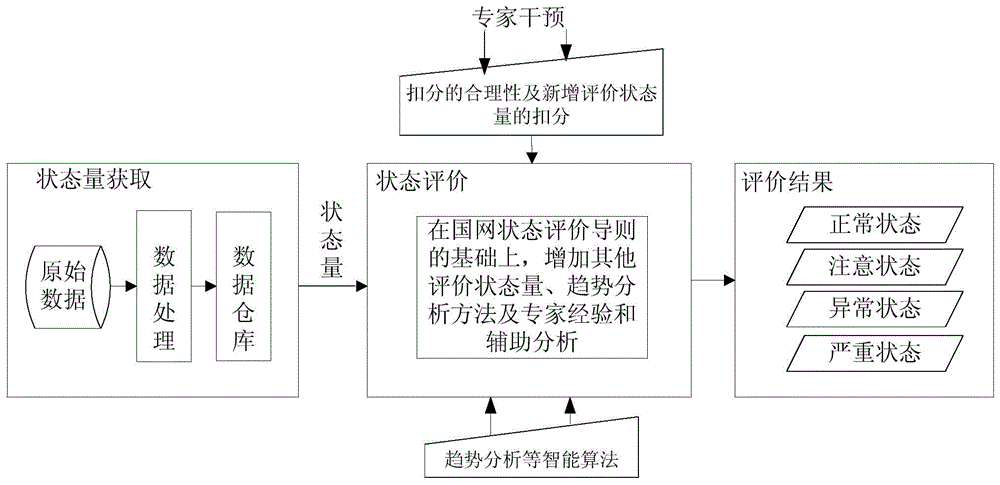

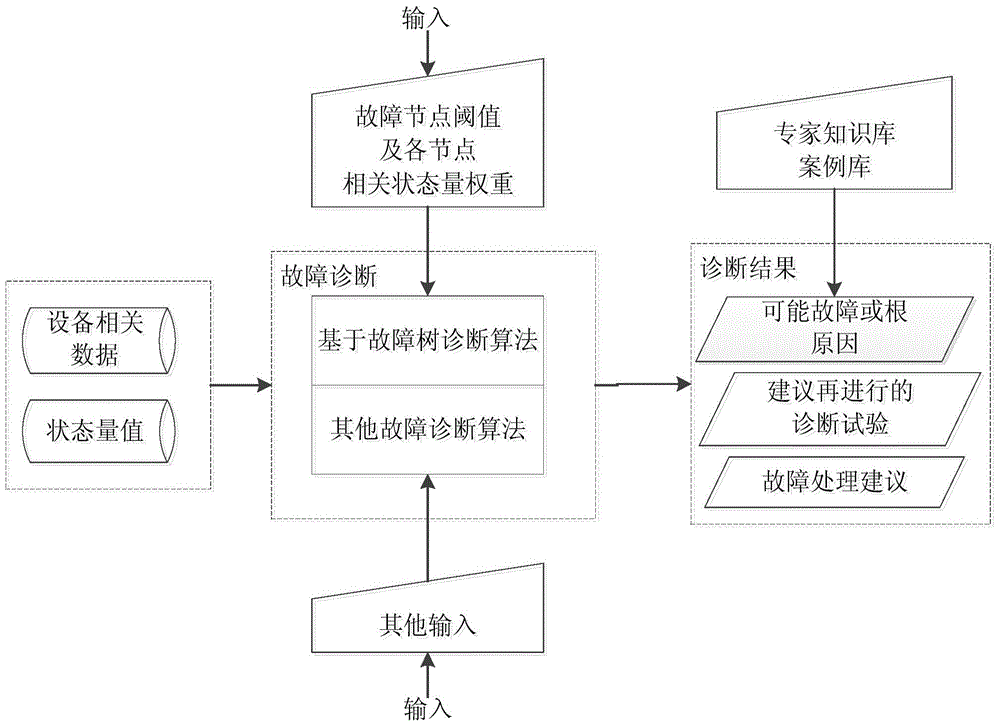

The invention provides an electrical equipment state maintenance system. The electrical equipment state maintenance system comprises an operation and maintenance base layer platform, a state monitoring module, a state evaluation module, a risk assessment module, a fault diagnosis module and a maintenance strategy module, wherein production area I data of a power grid system and production area III data of the power grid system are integrated on the operation and maintenance base layer platform, the state monitoring module is used for collecting on-line monitoring data of electrical equipment and operating environment information of the electrical equipment through the operation and maintenance base layer platform, the state evaluation module is used for evaluating the on-line monitoring data according to state evaluation standards of the electrical equipment to acquire an electrical equipment health state represented by the on-line monitoring data, the risk assessment module is used for calculating the risk index of the electrical equipment according to risk assessment standards of the electrical equipment, the fault diagnosis module is used for diagnosing faults of the electrical equipment and generating a fault diagnosis report according to the health state and the risk index of the electrical equipment, and the maintenance strategy module is used for generating maintenance strategy information of the electrical equipment according to the health state, the risk index and the fault diagnosis report of the electrical equipment. By means of the electrical equipment state maintenance system, evaluation, assessment and predication are automatically carried out on the power grid system, and therefore the automation level and the intelligentization level of the power grid system are improved.

Owner:EXAMING & EXPERIMENTAL CENT OF ULTRAHIGH VOLTAGE POWER TRANSMISSION COMPANY CHINA SOUTHEN POWER GRID +1

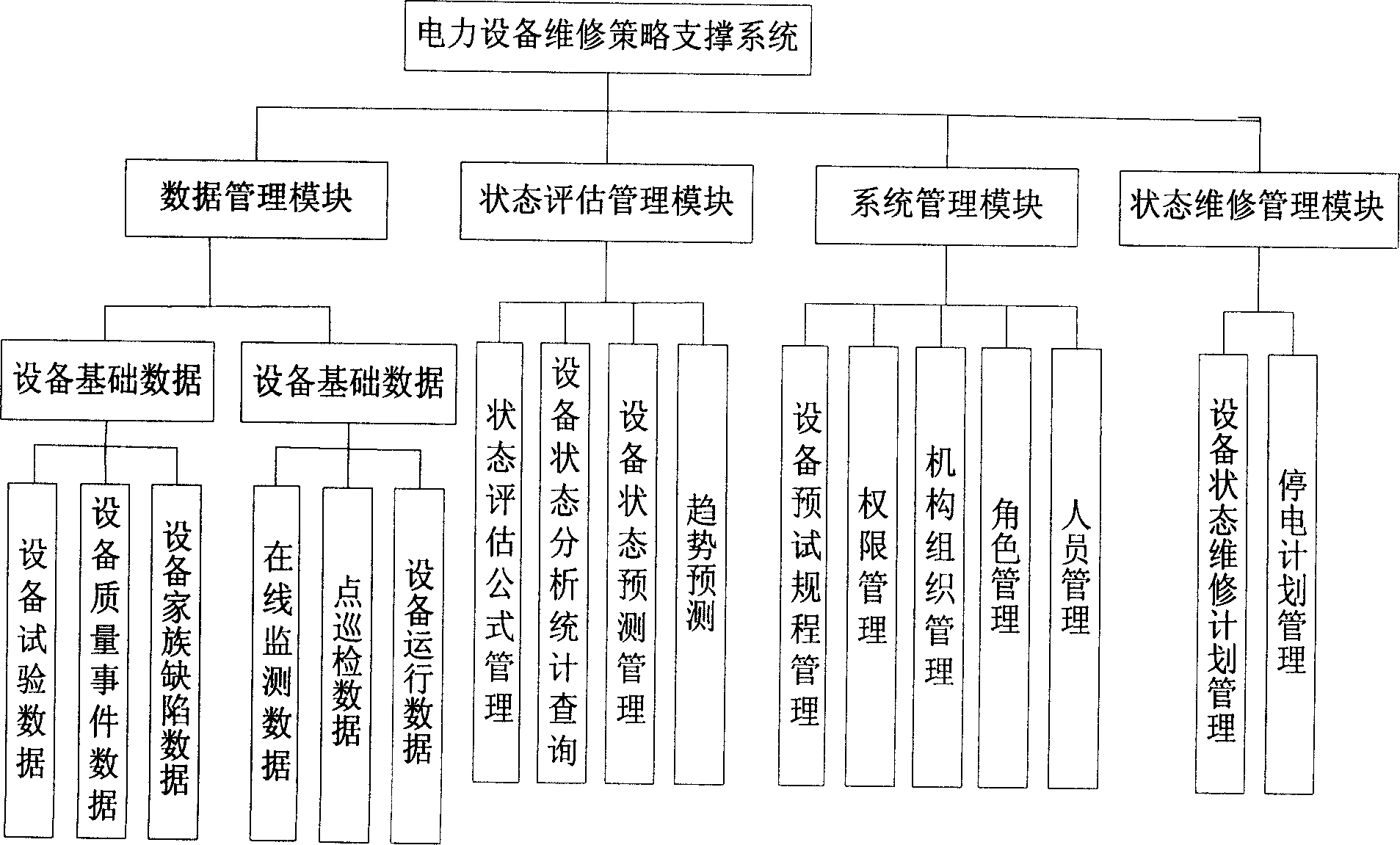

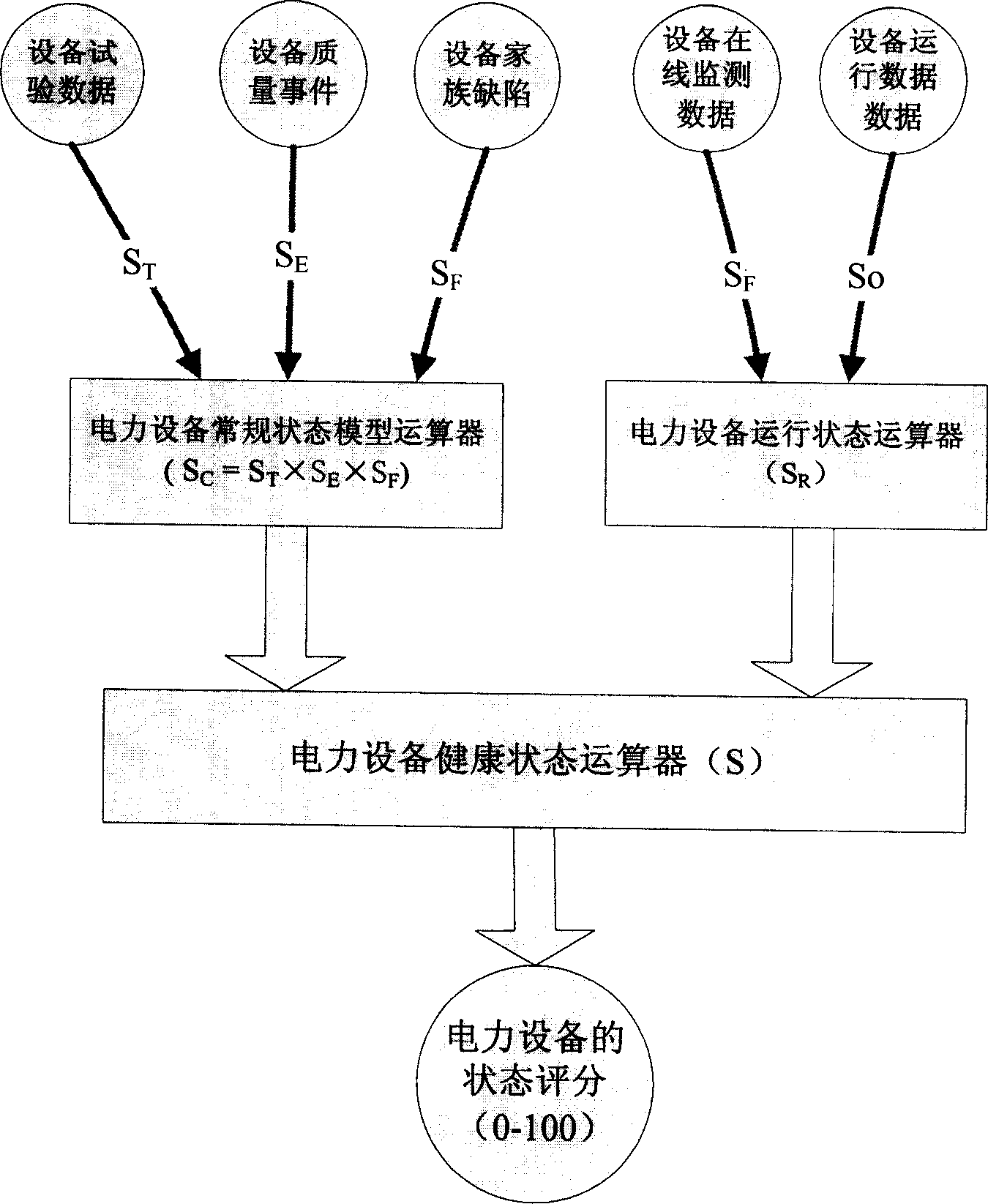

Support system for evaluating status of electric power equipments, and maintaining strategy

InactiveCN1916949AMeet more sub-level requirementsEasy to manage digitallyResourcesSystems managementElectric power equipment

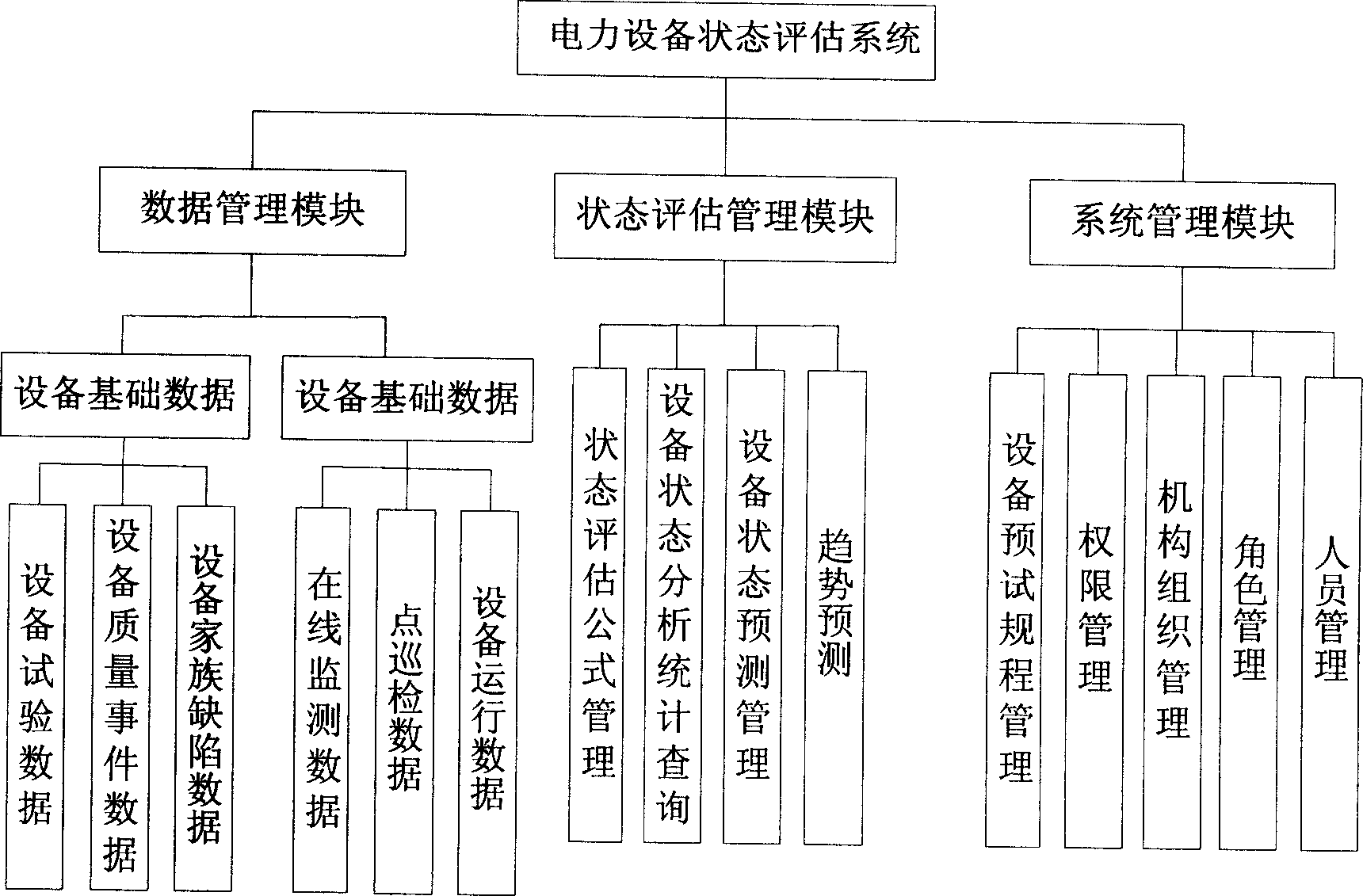

An evaluation and support system of electric power device state comprises system management module for managing test process, authority, organization and personnel; data management module for classifying and managing device data such as device type, device parts, device parameter, weight ant test parameter; state evaluation management module for obtaining healthy state result of electric power device by calculating and analyzing means.

Owner:四川赛康智能科技股份有限公司

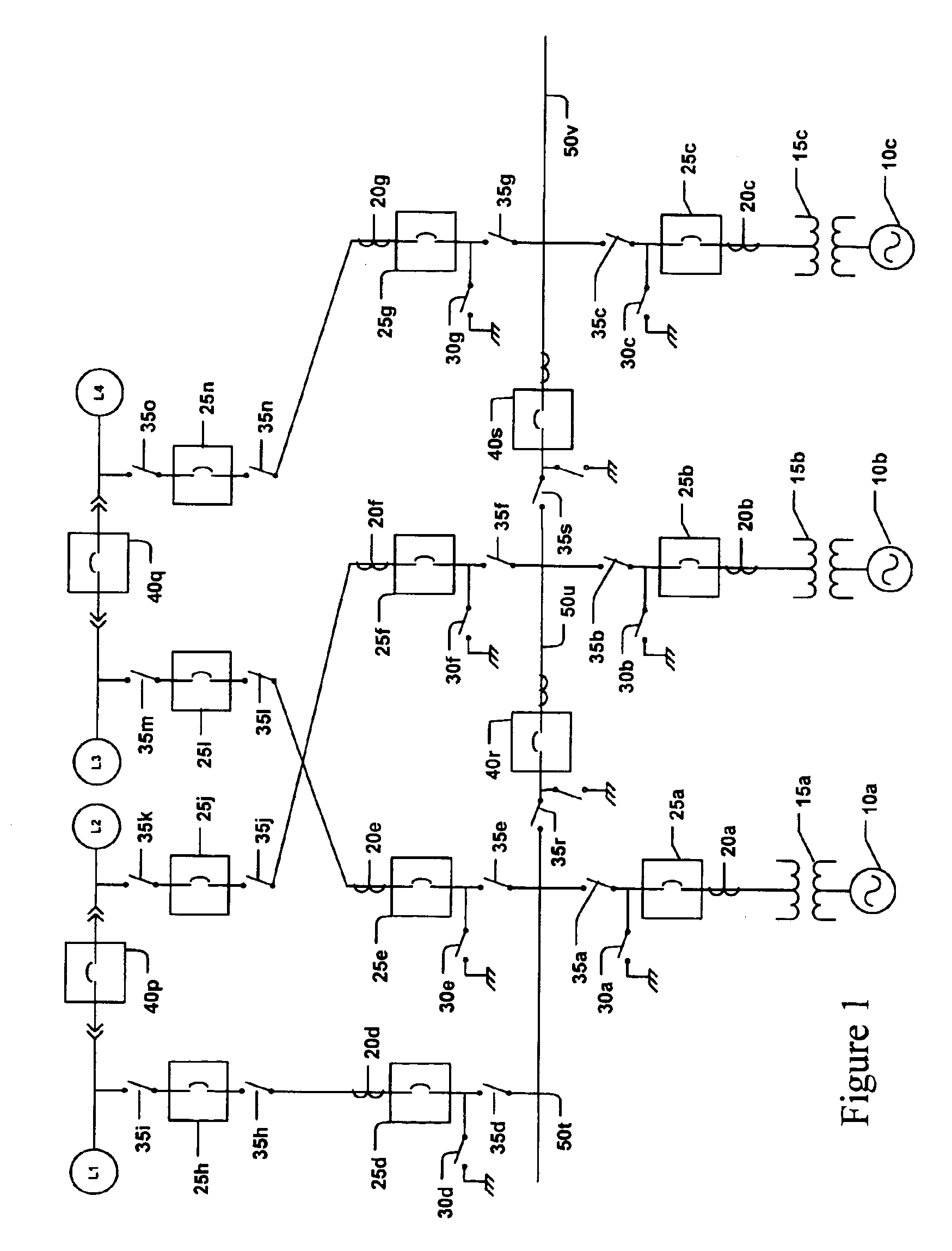

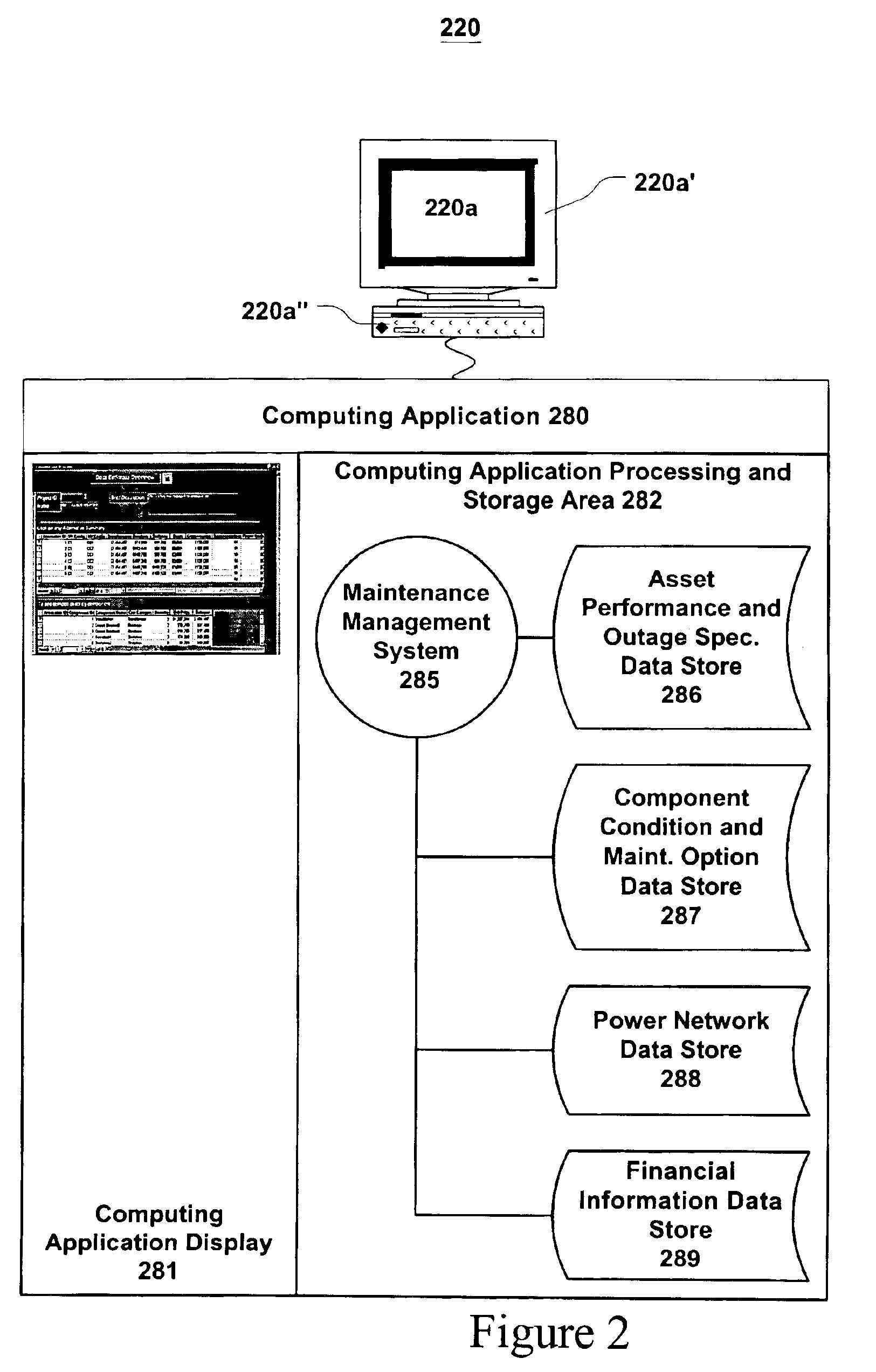

Value-based transmission asset maintenance management of electric power networks

A systematic approach is presented for the development and implementation of cost-effective transmission asset maintenance strategies. The overall concept and methodology are based on transmission reliability and risk management and address the value of preventive maintenance activities. This may help electric network utilities conduct maintenance policy assessment, region-wide criticality analysis, and optimal maintenance resource allocation and task scheduling.

Owner:ABB (SCHWEIZ) AG

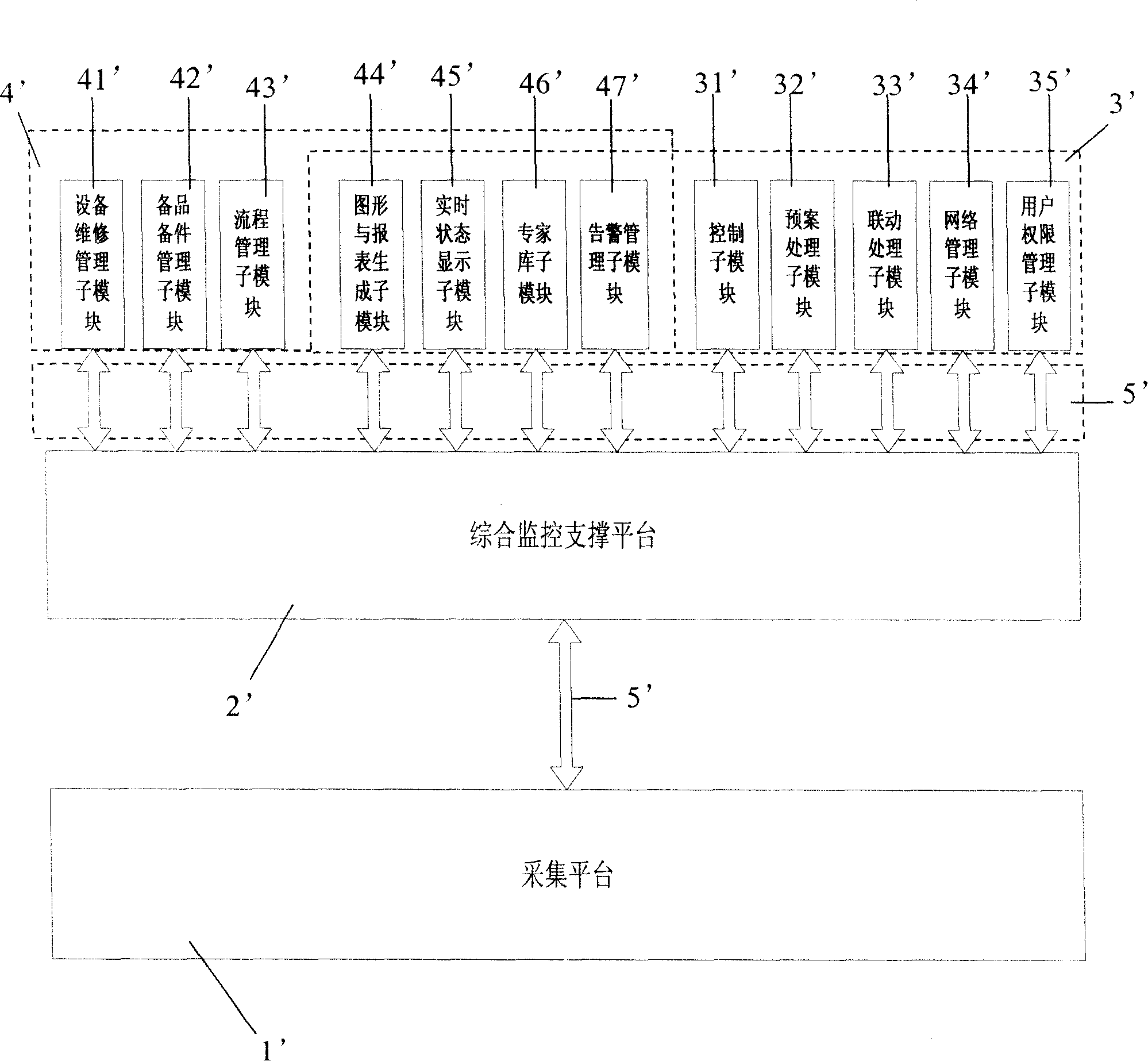

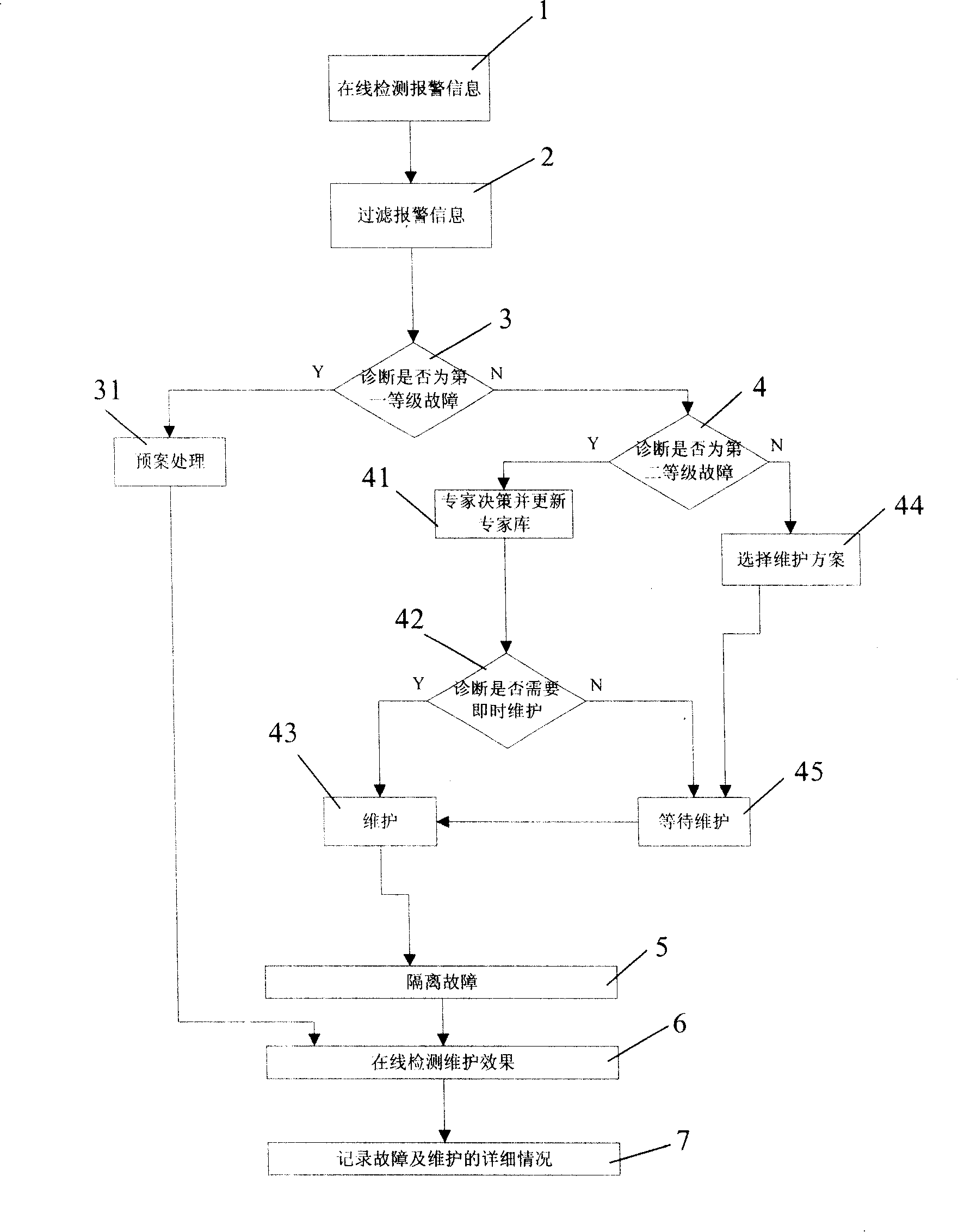

Track traffic synthetic monitoring system and method

The invention discloses a rail traffic comprehensive monitoring system and a method thereof, comprising a collecting platform, a comprehensive monitoring supporting platform and a monitoring control module which are sequentially connected through application interfaces. The invention also comprises a maintenance management module which is connected with the comprehensive monitoring supporting platform through the application interface. The method comprises online detection, filtration and malfunction grade judgement. The disposal is carried out according to different grades and different situations; a preparedness disposal is carried out if the disposal belongs to the first grade and, for the residual disposals, the maintenance strategy is determined and the expert database sub-module is updated according to the decision of experts; the equipment which is required to be maintained at once is maintained or waits to be maintained; a nominal disposal is firstly carried out during the maintenance and then malfunctions are isolated; the maintenance result is detected finally and the malfunction and maintenance condition are recorded. The invention can effectively reflects the healthy condition of equipment and gives out maintenance strategy in the comprehensive monitoring system, which leads the maintenance and operation scheduling to be integrated for management, implements high integration, transparence and informationization of maintenance operation, and effectively reduces construction cost.

Owner:SHANGHAI AUTOMATION INSTRAION CO LTD

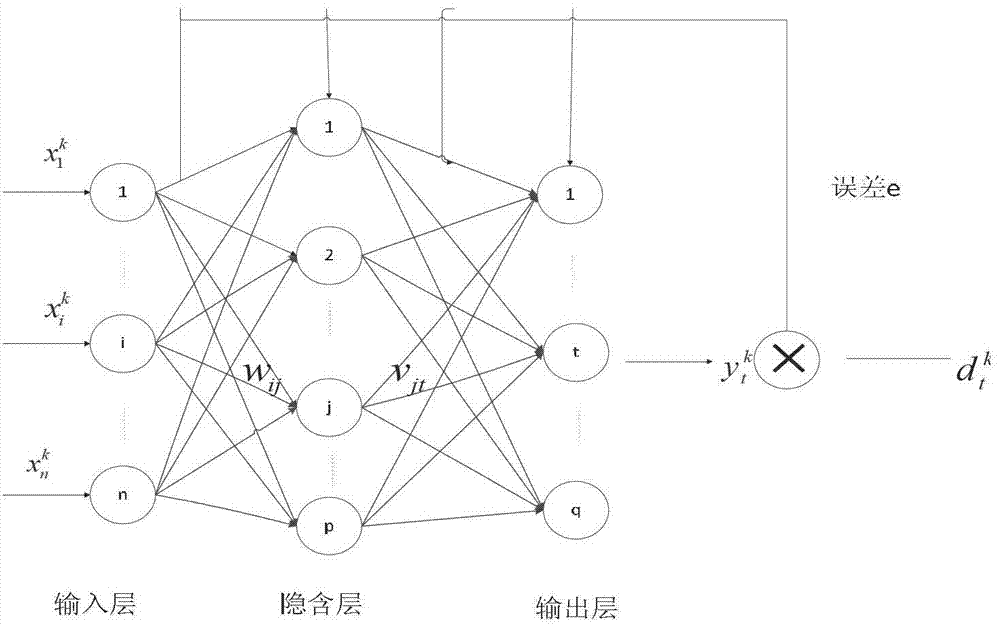

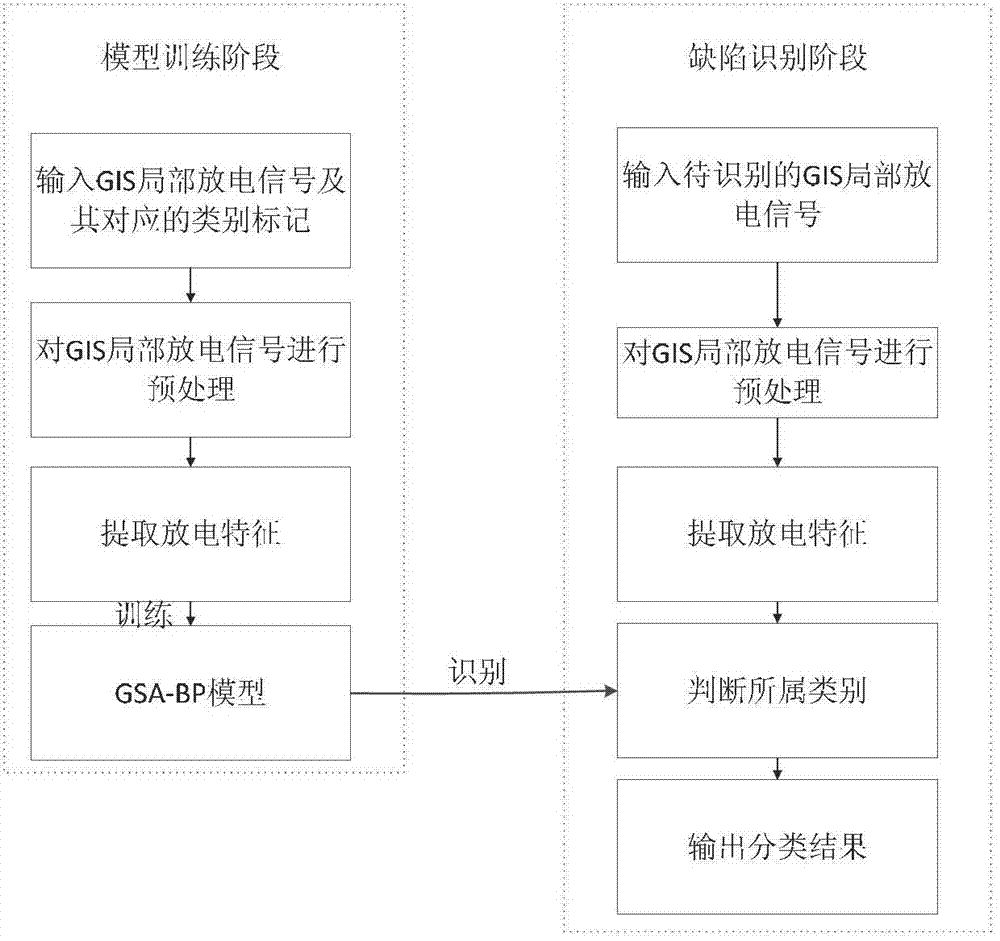

Ultra-high-frequency partial discharge signal identification method for gas insulated switchgear (GIS)

InactiveCN102809718AImprove operational efficiencyImprove running qualityTesting dielectric strengthMaintenance strategyEngineering

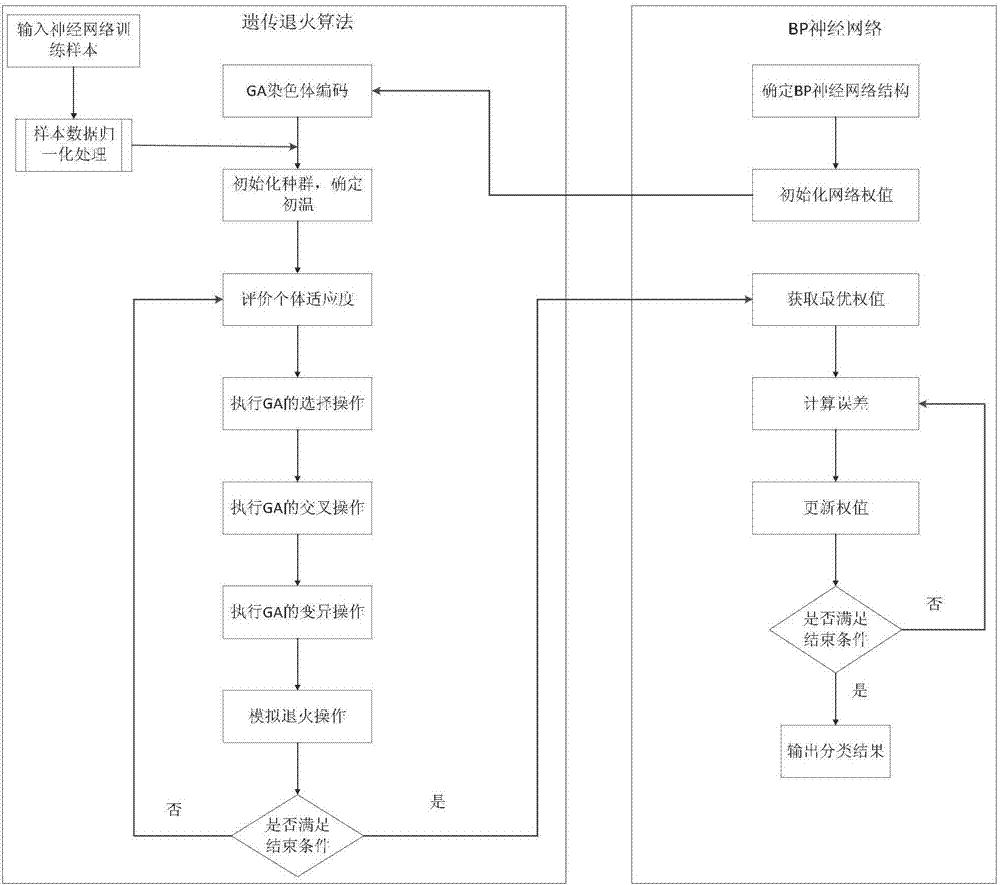

The invention discloses an ultra-high-frequency partial discharge signal identification method for gas insulated switchgear (GIS). The method comprises a model training process and a defect identification process, and specifically comprises the following steps of: reprocessing partial discharge signals of the GIS; extracting discharge characteristic parameters such as average discharge amplitude, discharge amplitude standard deviation, discharge phase distribution, discharge polarity, discharge time interval mean, discharge time interval standard deviation; optimizing a weight and a threshold value of a back propagation (BP) neural network by utilizing a genetic simulated annealing tool; training samples by utilizing a BP neural network tool; establishing a corresponding gas statistic algorithm (GSA)-BP model; preprocessing the partial discharge signals to be identified of the GIS; and identifying the samples to be measured in a classified way according to the GSA-BP model after extracting the corresponding characteristic parameters. By the method, the efficiency and the accuracy of partial discharge fault diagnosis of the GIS are improved effectively; and the method is critical to evaluate the insulation state of the GIS and formulate a reasonable maintenance strategy.

Owner:SOUTH CHINA UNIV OF TECH

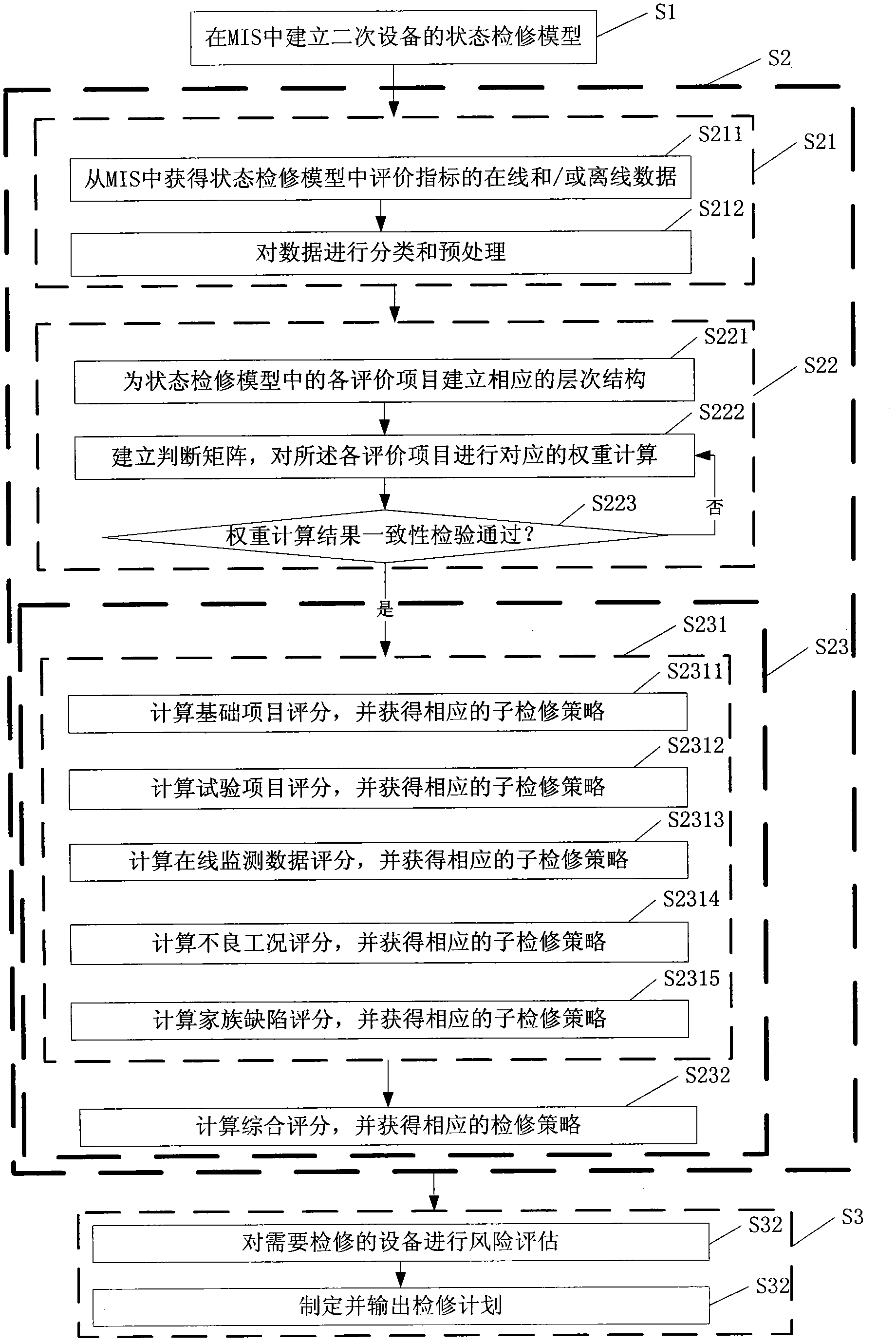

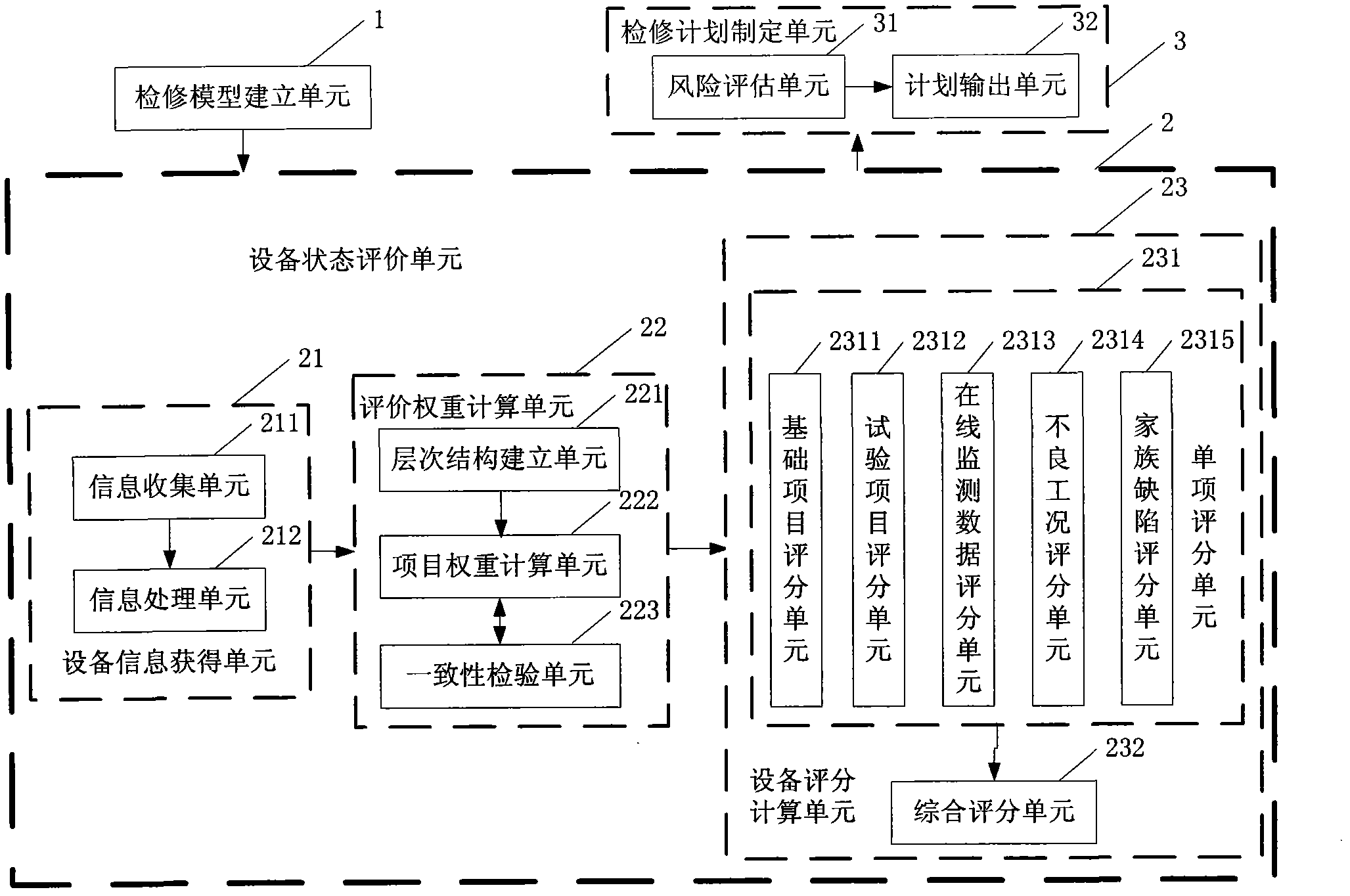

State maintenance method and device for secondary equipment of power grid

ActiveCN102222276ALow investment costReduce maintenance costsData processing applicationsSwitchgearEvaluation resultMaintenance strategy

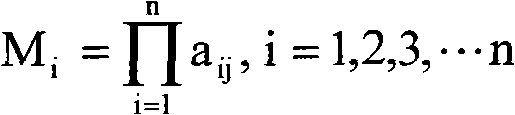

The invention discloses a state maintenance method for secondary equipment of a power grid. The method comprises the following steps of: establishing a maintenance model: establishing a state maintenance model comprising a plurality of assessment items and a maintenance strategy for the secondary equipment in a management information system, wherein each assessment item comprises at least one assessment index; evaluating an equipment state: acquiring online and / or offline data information of the assessment index of each assessment item in the state assessment model of the secondary equipment to be detected from the management information system and evaluating the state of the equipment according to the data information; and making a maintenance scheme: making a maintenance scheme of the equipment according to a state evaluation result of the equipment and the maintenance strategy in the state maintenance model. The invention further discloses a corresponding state maintenance device for the secondary equipment of the power grid. According to the method and the method, the investment and maintenance costs of the secondary equipment of the power grid can be reduced greatly.

Owner:SHENZHEN POWER SUPPLY BUREAU

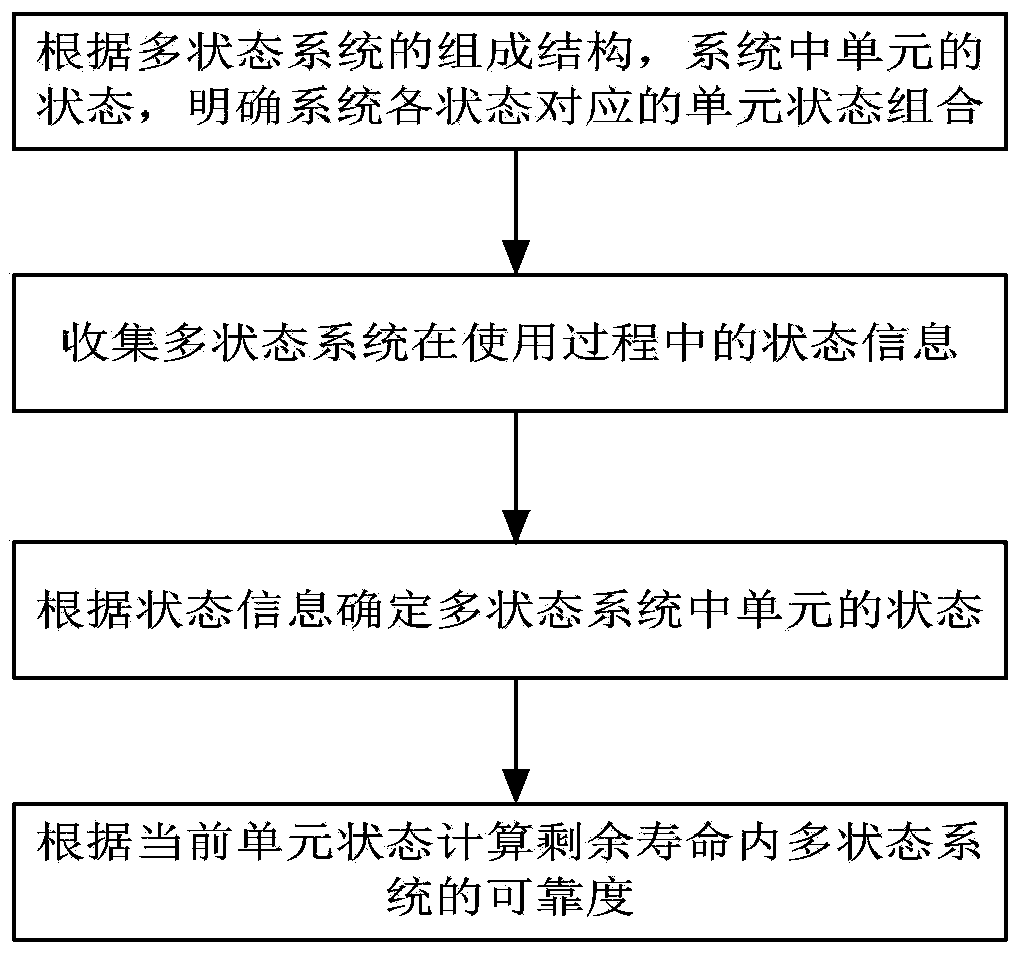

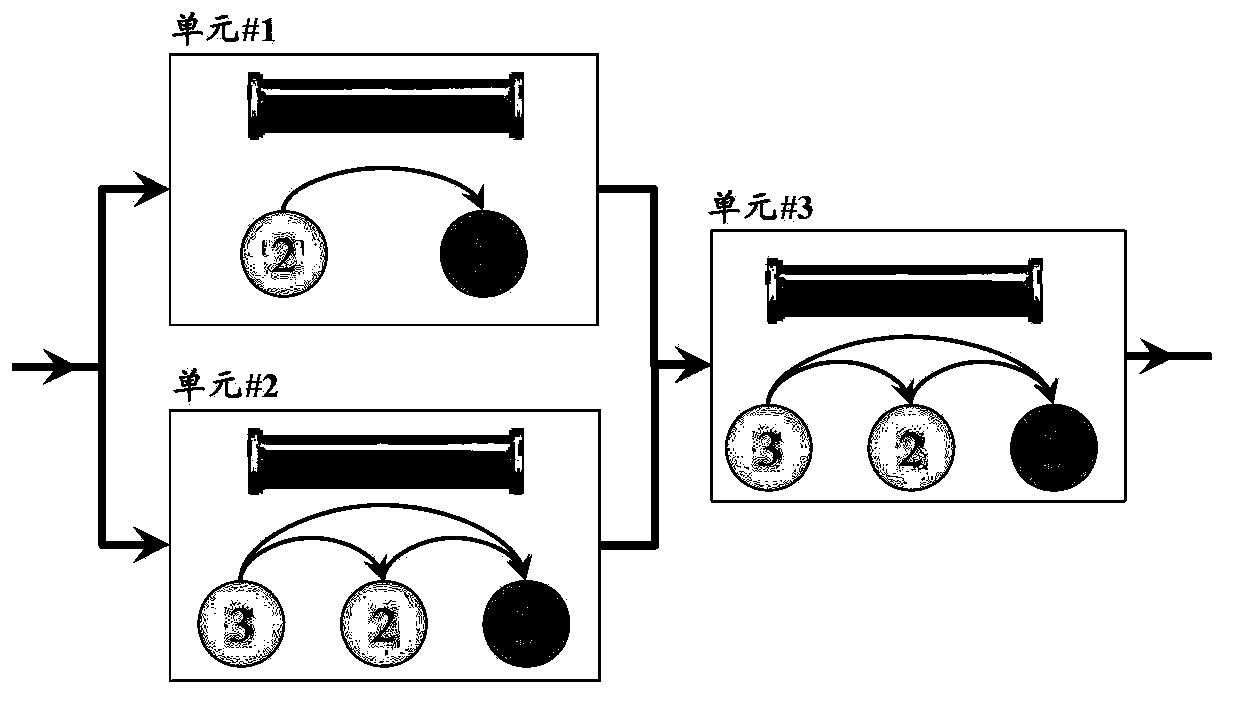

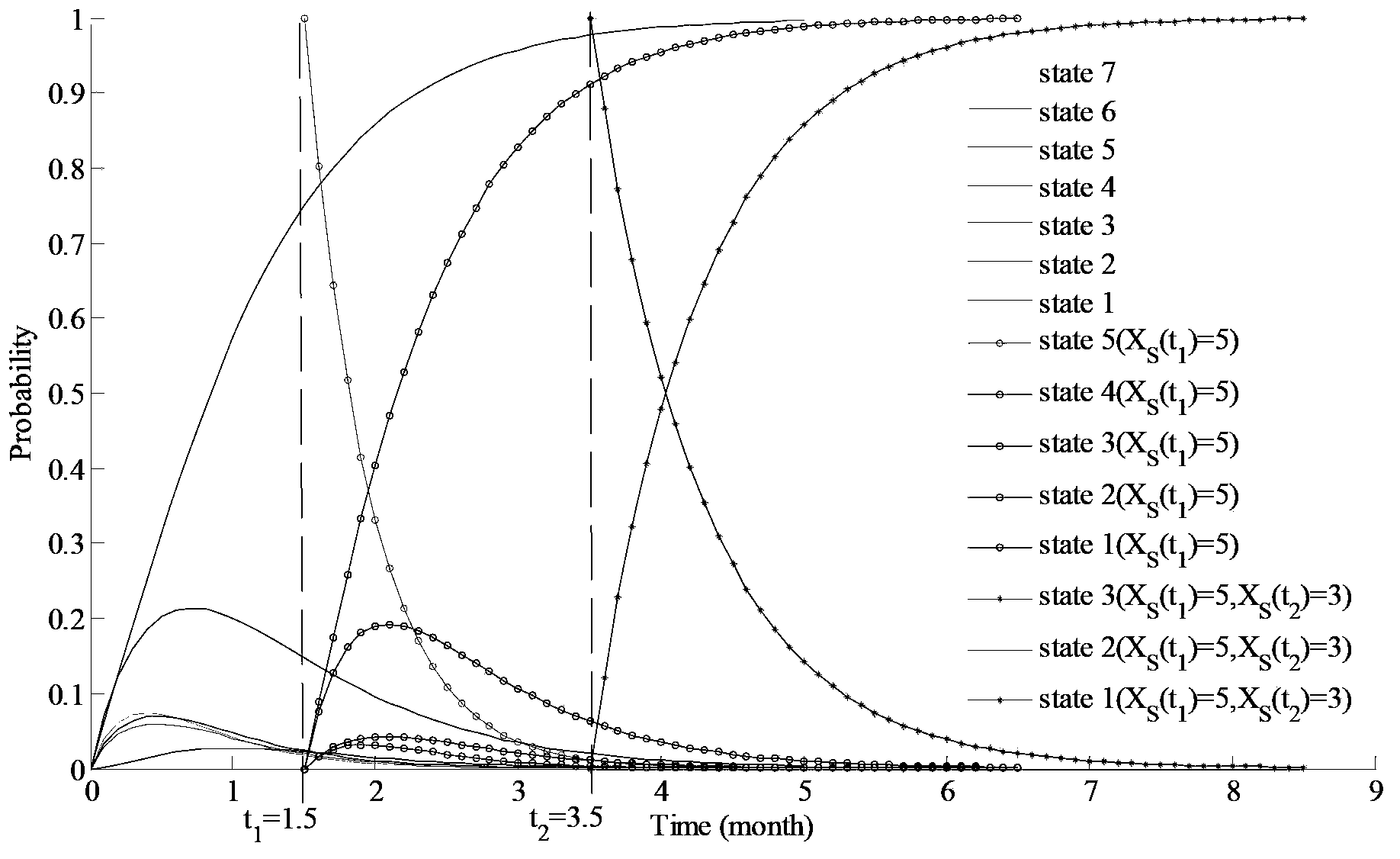

Multi-state system dynamic reliability assessment method

InactiveCN103413023AAccurate Reliability EstimateAvoid failureSpecial data processing applicationsRecursive modelMaintenance strategy

The invention discloses a multi-state system dynamic reliability assessment method. According to state information monitored by multi-state systems and constitution logic of units in the multi-state systems, current state probabilities of the units in the multi-state systems are calculated by building a Bayes recursive model, and therefore the state probabilities and reliability of the multi-state systems in the surplus service period are deduced. The method makes full use of the state information monitored by each system to update a reliability assessment model. Compared with an existing reliability assessment method, the multi-state system dynamic reliability assessment method can achieve the fact that more accurate and dynamically updated reliability assessment values of each system can be obtained, and therefore each system can be effectively prevented from losing efficacy, and more accurate maintaining strategies are generated in a guided mode.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

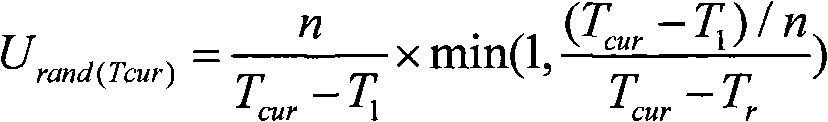

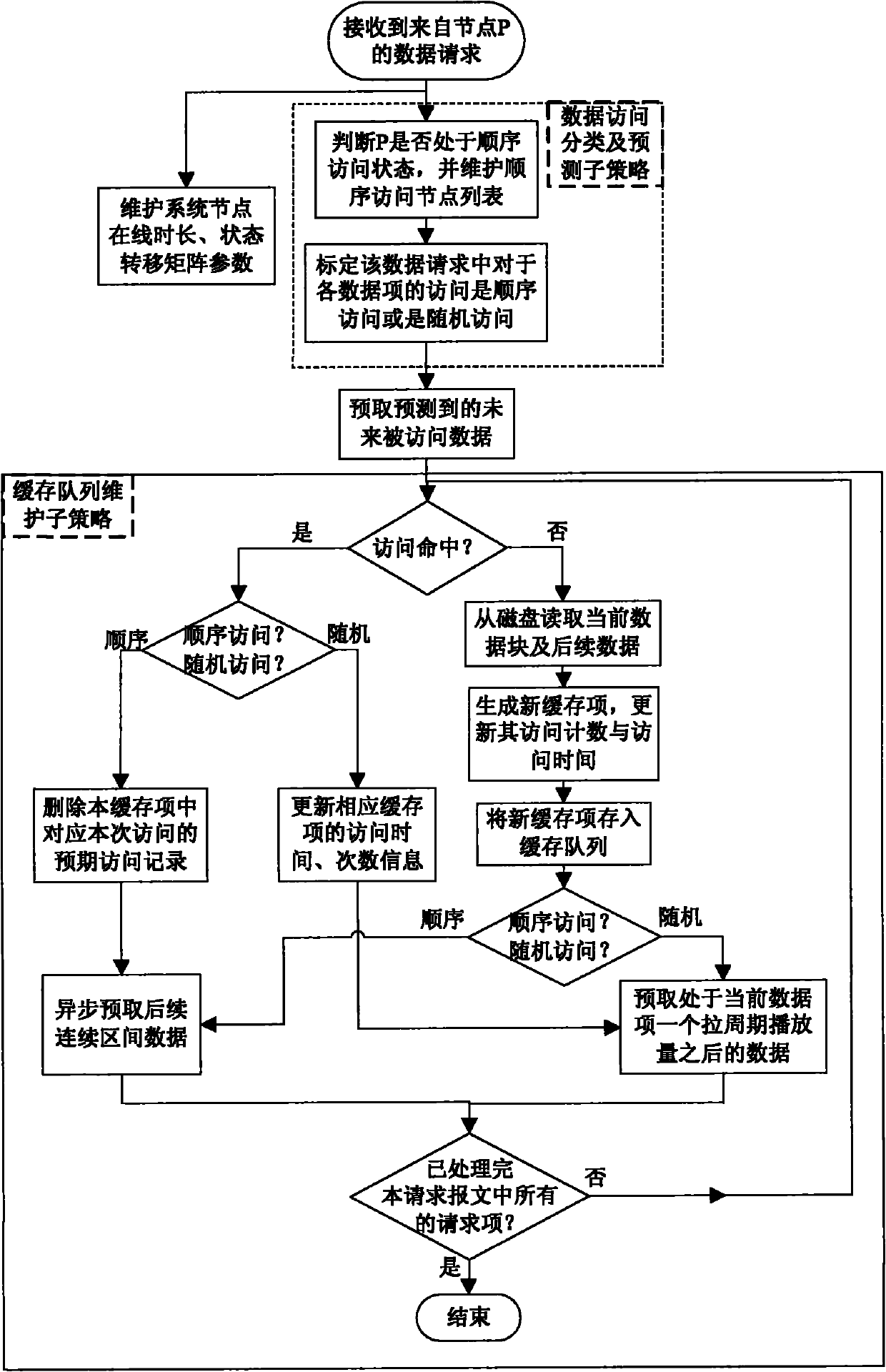

Access prediction-based data cache strategy for P2P Video-on-Demand (VoD) system server

ActiveCN101951395ASpend less timeIncrease concurrent service capabilitiesTransmissionMaintenance strategyData access

The invention relates to an access prediction-based data cache strategy for a P2P Video-on-Demand (VoD) system server. The strategy comprises a data access classification and prediction strategy, a data prefetching strategy and a cache queue maintenance strategy, wherein the data access classification and prediction strategy is in charge of classifying data requests of the server, performing access prediction on different types of requests by different methods according to the application characteristics of the VoD, and predicting data access targets of nodes, which perform the data requests, in the future; a cache queue maintenance sub-strategy is in charge of maintaining a fixed-length cache queue and performing inserting, deleting and replacing operation of the cache queue by a future access frequency-based cache replacement algorithm; and the calculation of the future access frequency synthesizes the probability of the cache item accessed sequentially and randomly in the future and takes consideration on the influence factors of data access stability such as on-off line of the nodes in the P2P VoD system, server replacement and the like.

Owner:ZHENGZHOU SEANET TECH CO LTD

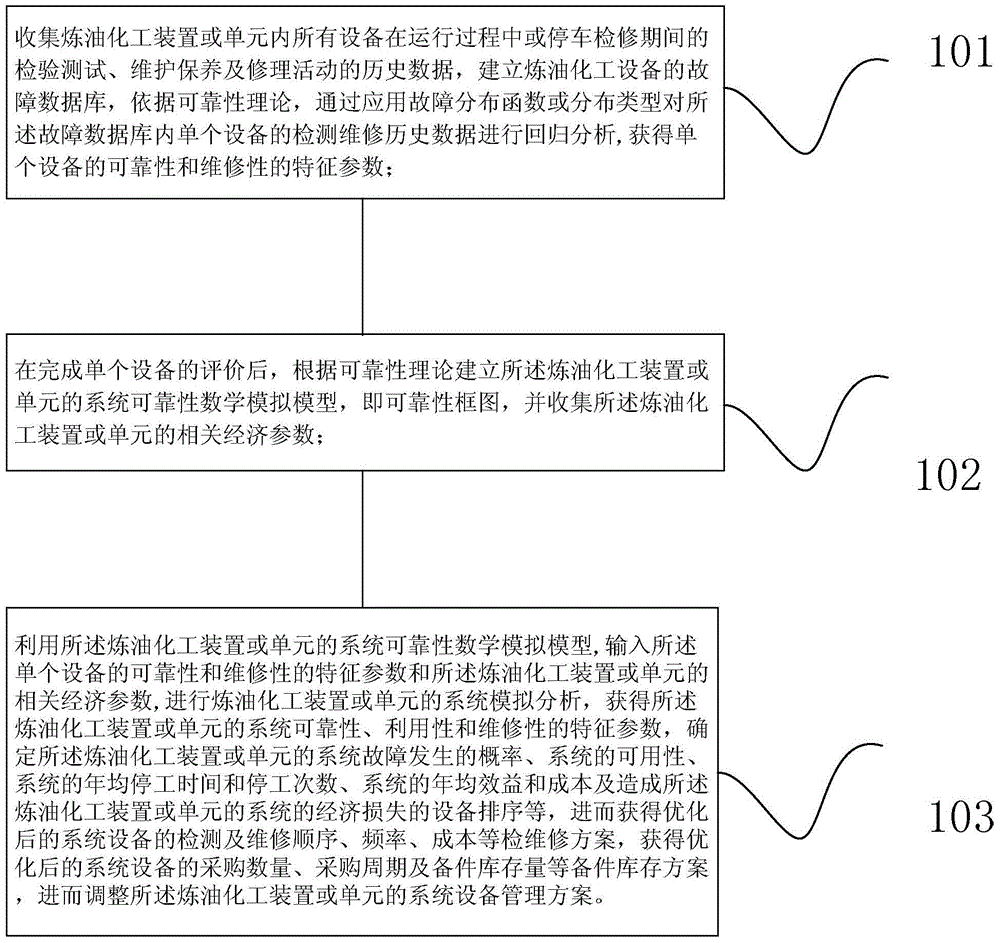

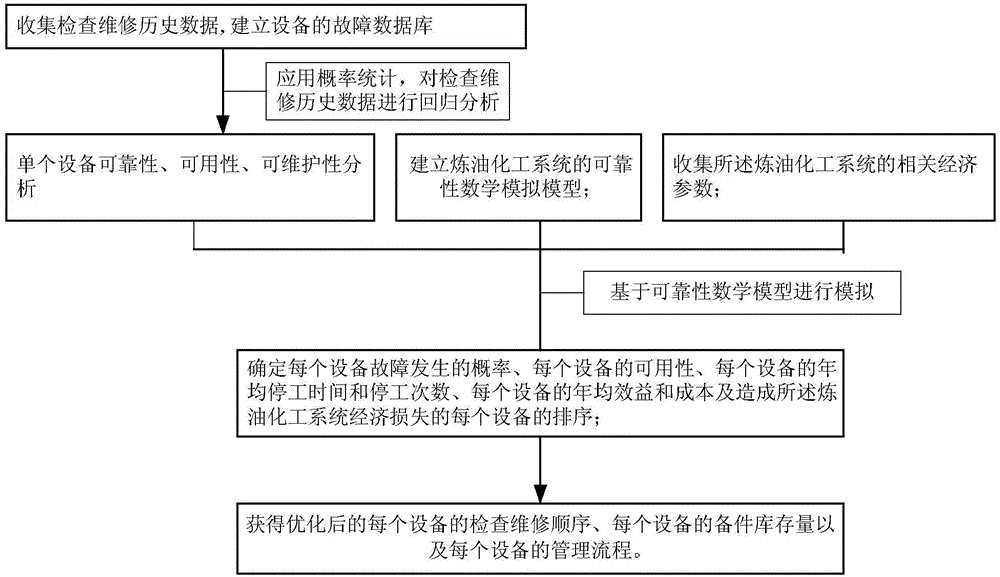

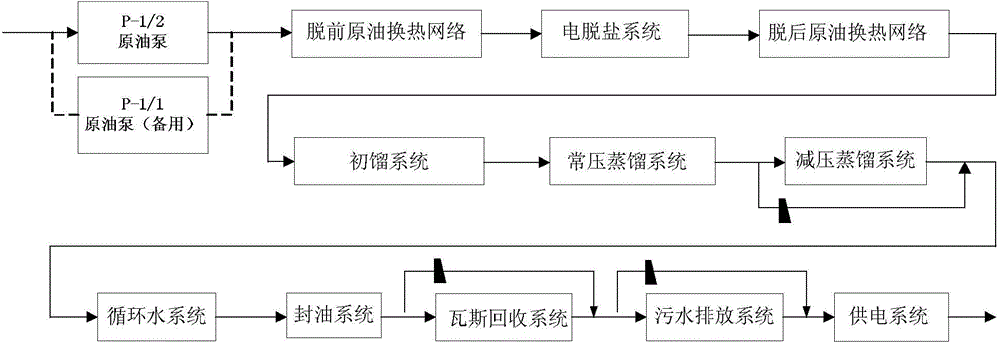

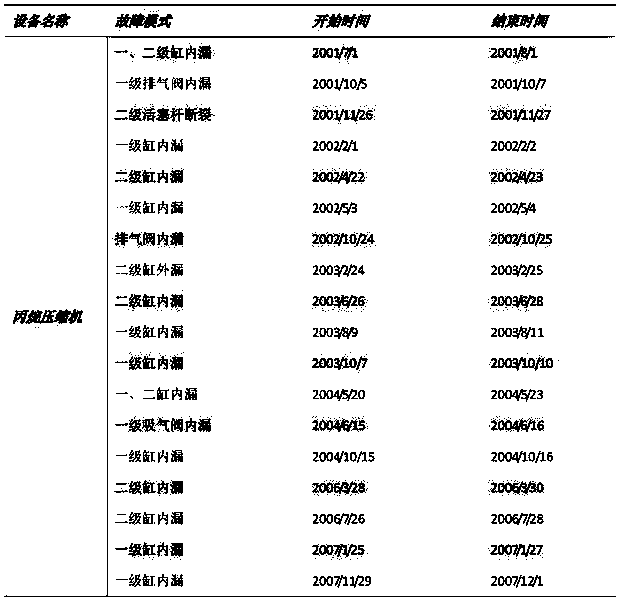

Method for optimizing reliability and maintenance strategy of chemical refining equipment

InactiveCN104636826AImprove reliabilityReduce lossesForecastingRegression analysisMathematical simulation

The invention discloses a method for optimizing reliability and maintenance strategy of a piece of chemical refining equipment. The method comprises the following steps of collecting the historical testing and maintaining data of equipment inside a chemical refining device; carrying out the regression analysis by a failure distribution function for the historical data to obtain the characteristic parameters of the reliability and maintenance of single equipment; establishing a mathematical simulation model of system reliability of the chemical refining device, and collecting the relevant economic parameters of the device; carrying out the system simulation analysis for the chemical refining device by using the mathematical simulation model of system reliability, then obtaining the characteristics parameters of system reliability, usability and maintenance of the device, and then further obtaining the testing and maintaining scheme of the optimized system equipment, such as inspecting and maintaining order, frequency and cost; and obtaining the spare part stock scheme of the optimized system equipment, such as purchasing quantity, purchasing cycle and spare part stock, thus adjusting the equipment managing strategy of the device. The method for optimizing the reliability and maintenance strategy of the chemical refining equipment reduces the unplanned fault rate of the chemical refining equipment, and provides guarantee for long-period safety operation of the chemical refining equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

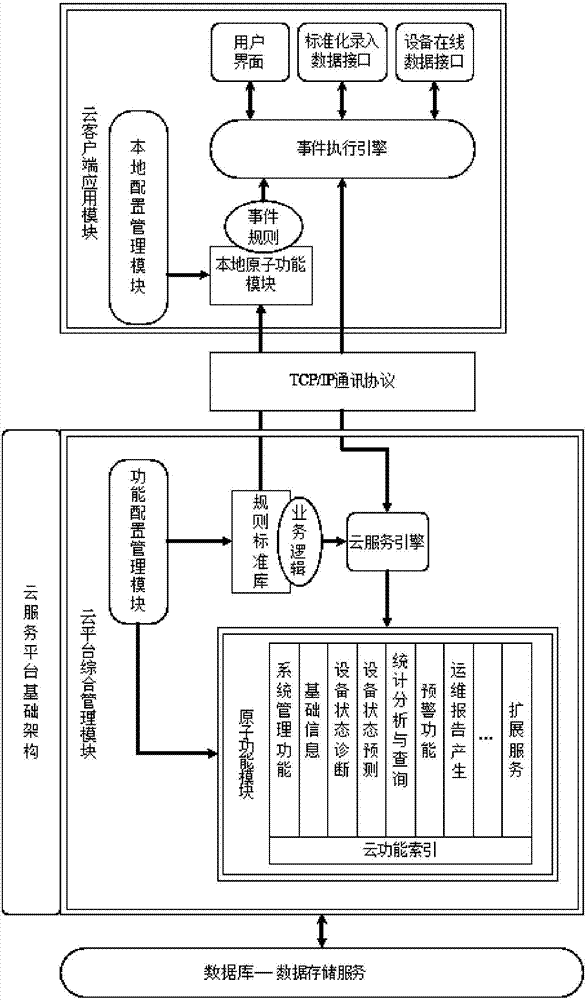

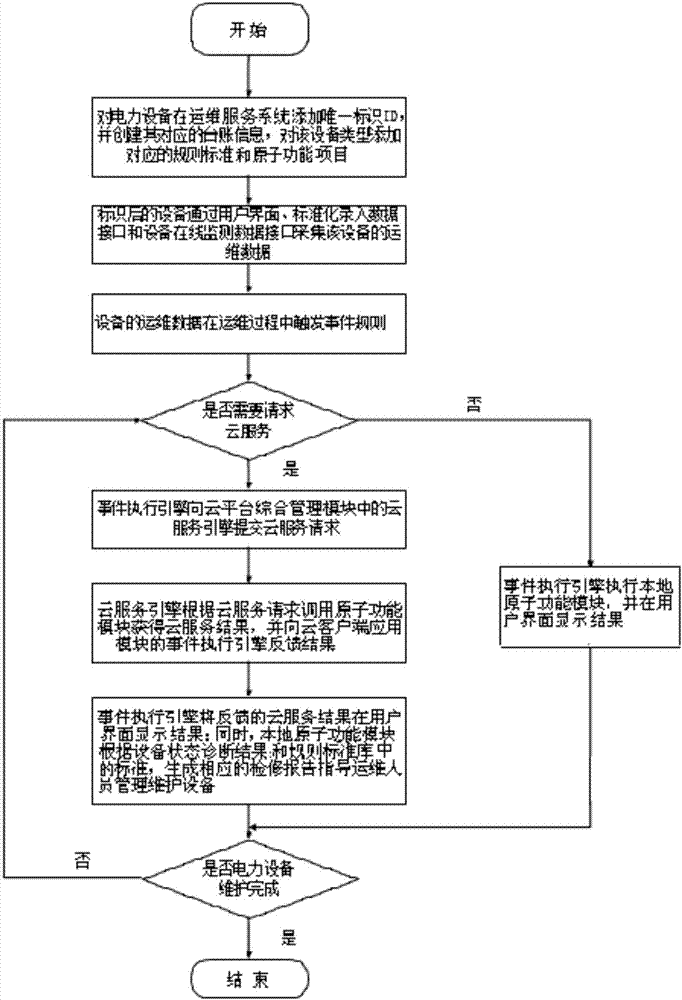

Power equipment operation and maintenance service system and method based on cloud service platform

InactiveCN107463998AQuality improvementImprove efficiencyData processing applicationsVirtualizationMaintenance strategy

The invention provides a power equipment operation and maintenance service system and method based on a cloud service platform. The system comprises a cloud platform comprehensive management module, a cloud client application module and a cloud database, wherein the cloud platform comprehensive management module and the cloud client application module perform information interaction through a TCP / IP communication protocol to provide services for operation and maintenance of power equipment. Through the power equipment operation and maintenance service system and method, all kinds of information collected in the operating and maintaining process of the power equipment can be managed and analyzed, the problems that a current power equipment state diagnosis system has a single function, information is isolated, formats are disordered, input is repeated, operation is inconvenient, and data overall management is lacked are solved through virtualized and distributed computing resources and networked computing power, and an intensive, intelligent and comprehensive equipment operation and maintenance strategy is provided for operation and maintenance of the power equipment and work of maintainers.

Owner:XI AN JIAOTONG UNIV

Method and system for inspecting and maintaining equipment

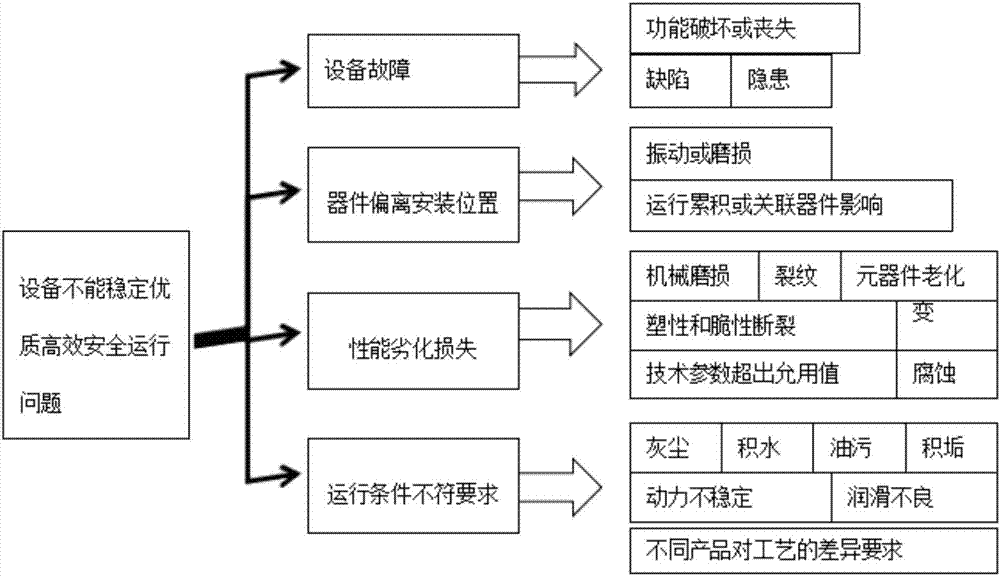

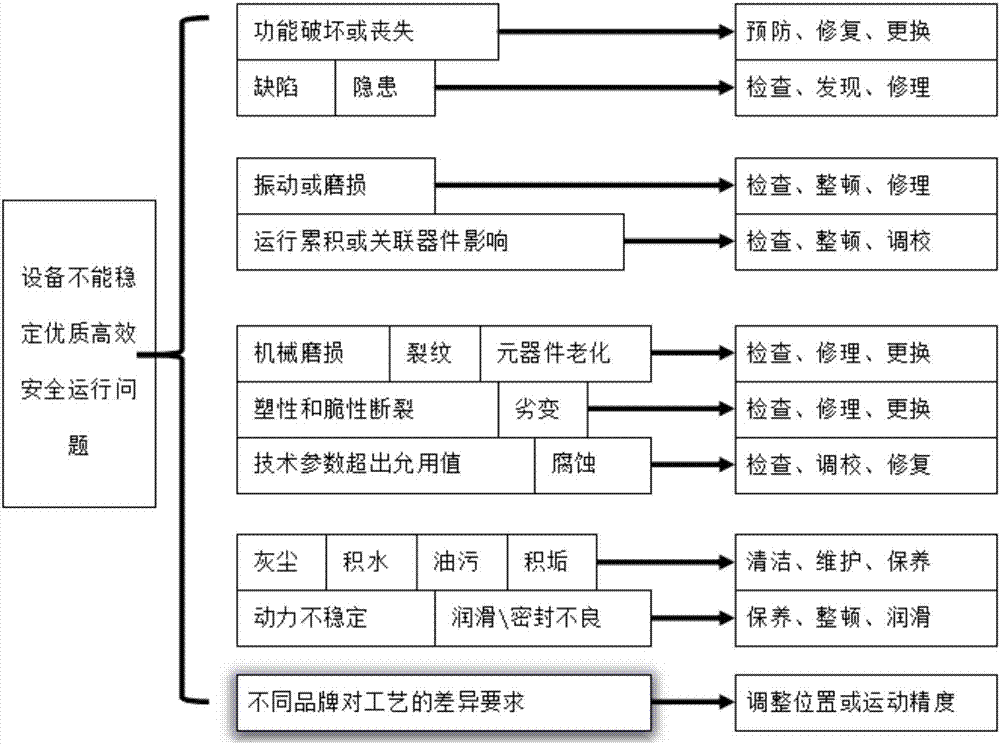

The present invention provides a method and a system for inspecting and maintaining equipment. According to the method, an equipment functional part is adopted as an object. After that, an inspection and maintenance strategy, spare part materials, an inspection and maintenance standard, and an inspection and maintenance service process, which are adaptive to the technical characteristics of the equipment functional part, are established. The method specifically comprises the steps of S1, identifying the critical functional part of the equipment; S2, establishing a standing book for the critical functional part; S3, conducting the factor and precautions analysis on the critical functional part of the equipment; S4, according to the factor analysis result, establishing an inspection and maintenance structure; S5, according to the inspection and maintenance structure, establishing the inspection and maintenance operation standard for the equipment; S6, setting the inspection and maintenance service flow; S7, according to the inspection and maintenance service flow, conducting the routine inspection and maintenance on the equipment. According to the technical scheme of the invention, the service management process and the service operation behavior of the equipment are in the controlled state. Therefore, the efficient and stable operation of equipment is guaranteed. The quality requirements of products are met and the safety production is ensured.

Owner:GUANGZHOU KINGTANG DATA

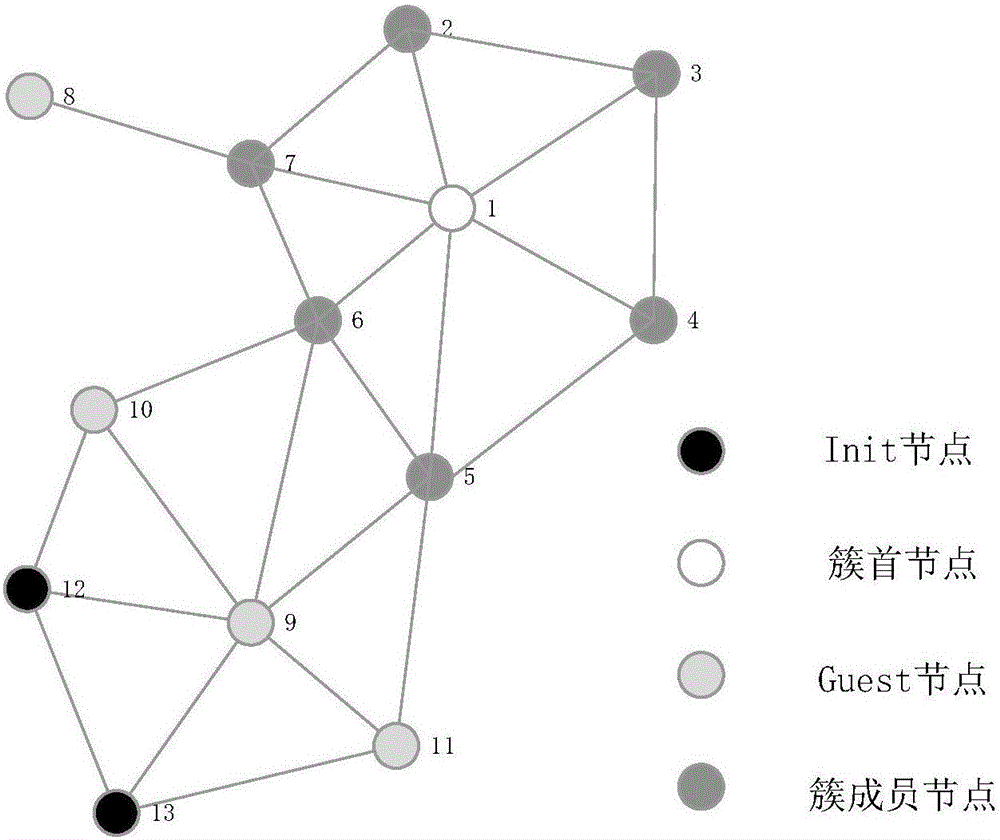

Clustering time synchronization method combining topological maintenance

ActiveCN106804058ASolve the cluster synchronization problemSynchronous adaptationSynchronisation arrangementMaintenance strategyMaintenance stage

The invention relates to a clustering time synchronization method combining topological maintenance. The method comprises the steps that in the election stage, the system selects a node of the maximum connectivity to act as a network root node; in the clustering stage, network clustering is completed with the network root node acting as the start under the scene of network event asynchronization and equipping a directional antenna, and network initial synchronization is also completed; in the synchronization stage, the synchronization effect is stabilized through intra-cluster and inter-cluster synchronization; and in the maintenance stage, maintenance strategy analysis is performed on mobile network accessing and network withdrawing of the node. Compared with the methods in the prior art, the clustering time synchronization method has excellent synchronization performance and can greatly solve the problem of clustering synchronization based on a beam forming antenna, the synchronization efficiency can be effectively enhanced by adopting an inter-cluster synchronization priority policy, and the influence caused by dynamic network topology can be greatly adopted by combining topological maintenance.

Owner:SHANGHAI JIAO TONG UNIV +1

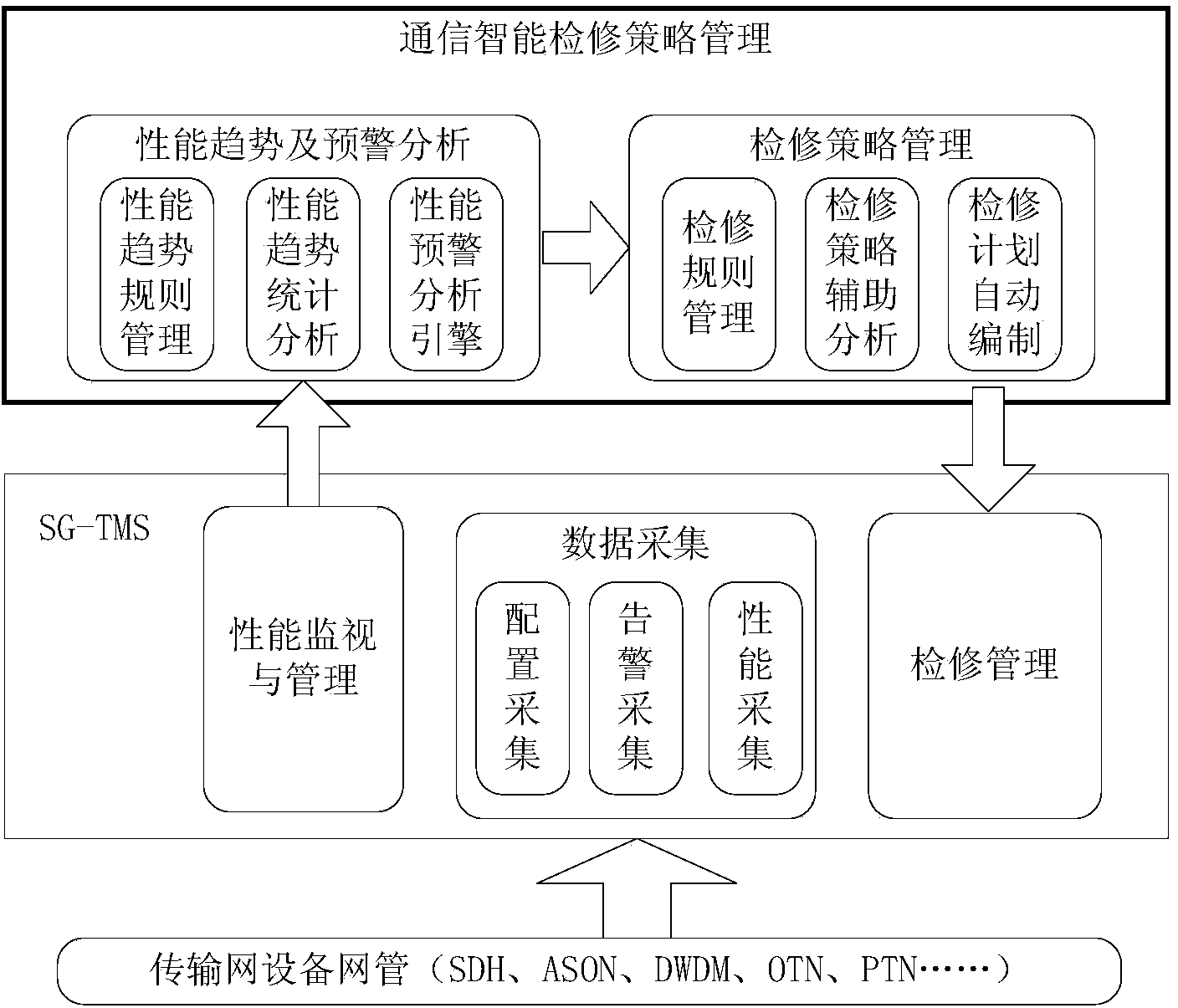

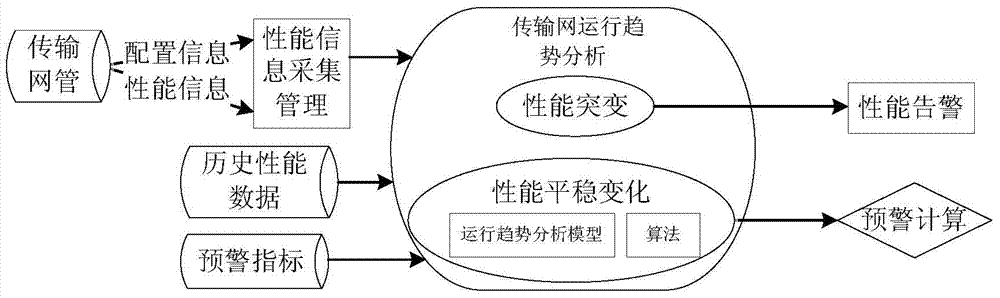

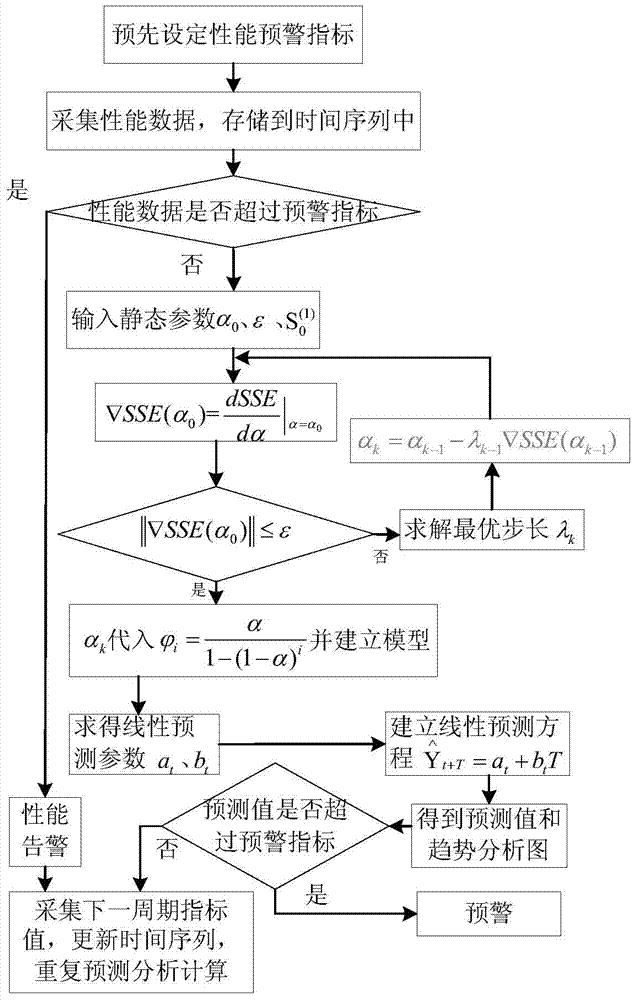

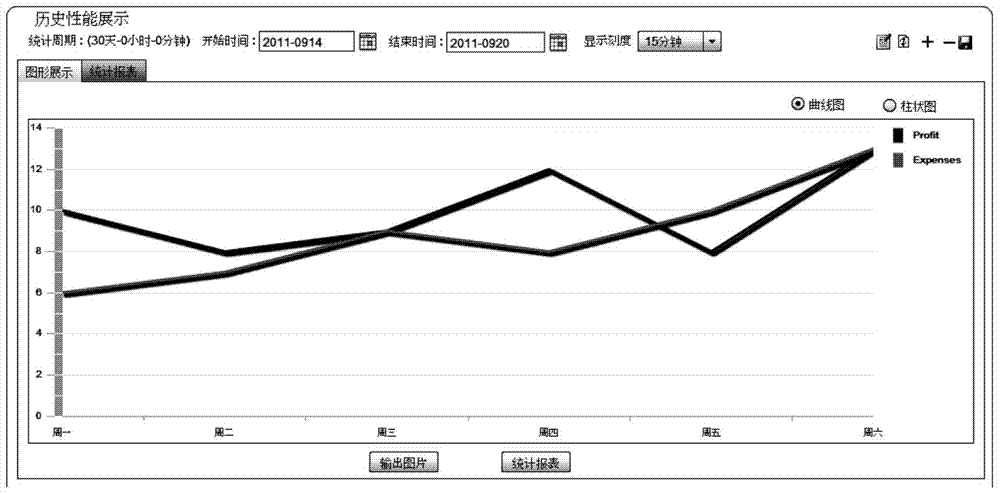

Intelligent maintenance strategy management method for power communication

ActiveCN103716202ARealize integrated intelligent maintenanceData switching networksDaily operationWork task

The invention discloses a power communication transmission network operation trend analysis method. The method is characterized by comprising the following steps: (1) real-time performance monitoring: monitoring the performance of network equipment in real time during transmission network daily operation monitoring; (2) performance trend and early warning analysis: entering a processing link when finding performance fault early warning, calculating the early warning index of monitored performance data according to an early warning algorithm, and grading the early warning according to predetermined levels of faults in aspects of importance, range and urgency; (3) maintenance strategy management: proposing an equipment maintenance strategy including the maintenance object, time, estimated root, influence scope, required resources and the like for different levels of early warning faults according to predetermined rules and further formulating a maintenance task suggestion; and (4) maintenance execution: assisting in forming a maintenance plan according to the maintenance strategy and completing on-site maintenance work according to the maintenance process.

Owner:STATE GRID CORP OF CHINA +3

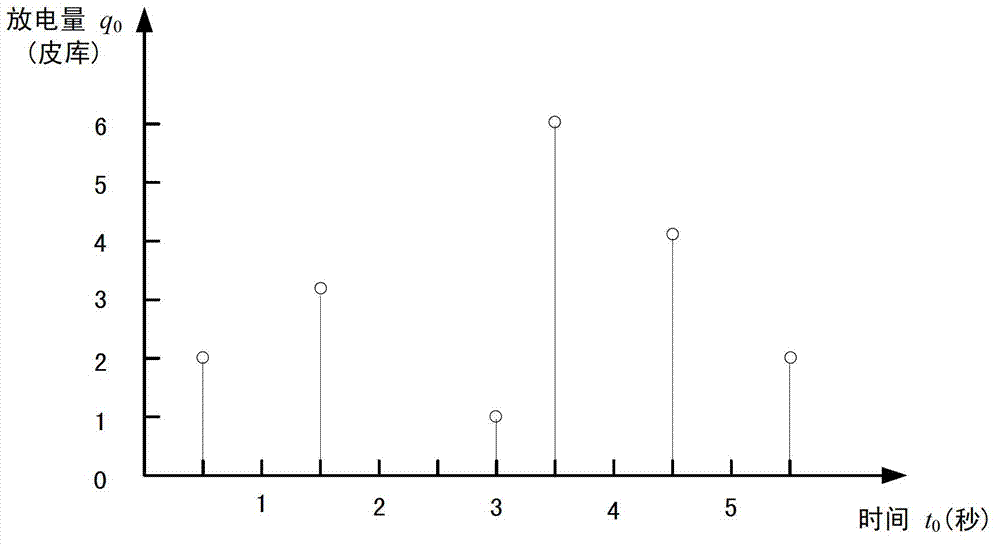

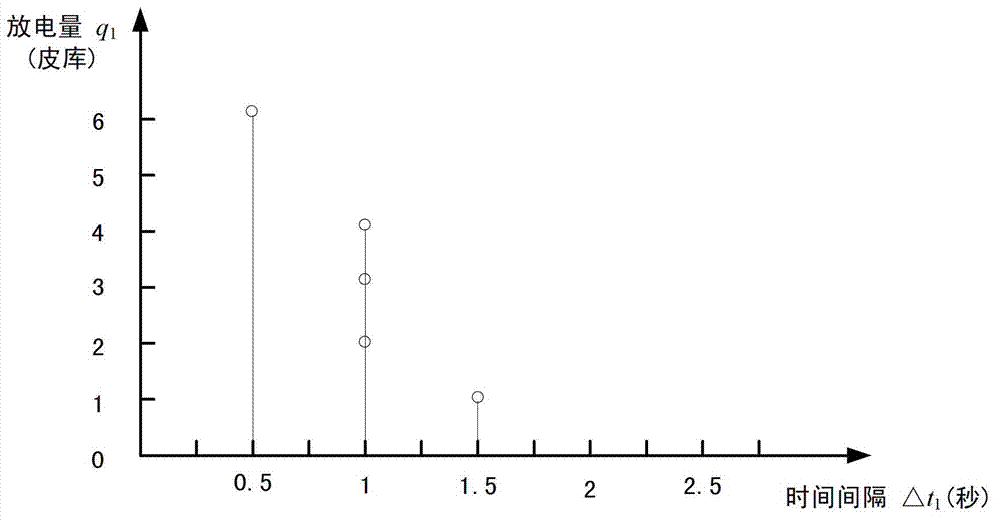

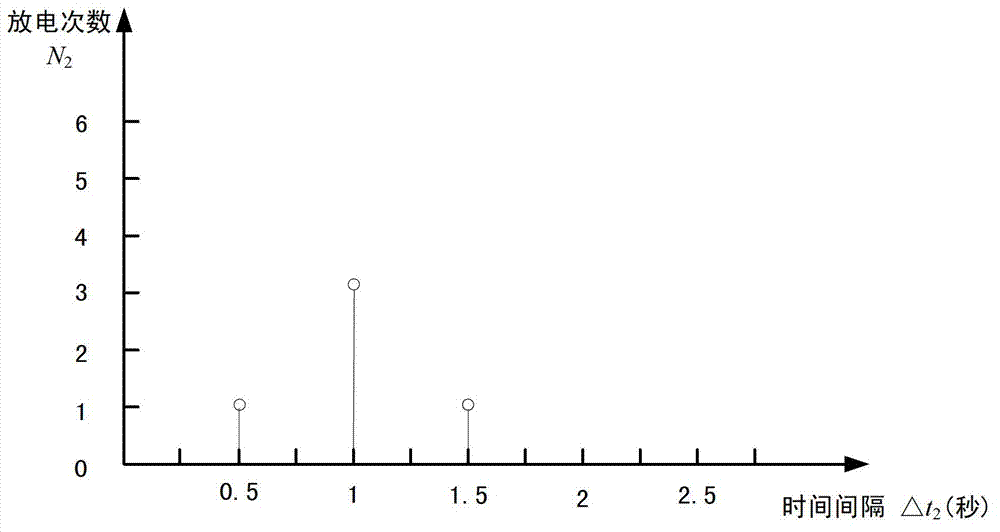

Method for measuring converter transformer paper oil insulation partial discharge characteristic

ActiveCN102955108AReasonable Condition Maintenance StrategyIntuitive fault warningTesting dielectric strengthTransformerMaintenance strategy

The invention relates to a method for measuring a converter transformer paper oil insulation partial discharge characteristic, and belongs to the technical field of insulation detection of high-voltage electrical equipment. The converter transformer paper oil insulation partial discharge phenomenon belongs to a random process, in the method, based on the relation between the discharge capacity and the time interval in the discharge phenomenon, a series of relational graphs are built, and statistic characteristic parameters of partial discharge are extracted from the rational graphs, wherein the parameters include a degree of skewness Sk (representing the deviation degree of a spectrogram distribution curve relative to normal distribution), a kurtosis Ku (representing the sharpness of the spectrogram distribution curve relative to normal distribution), a Weibull distribution parameter scale parameter alpha and a shape parameter beta. Twenty characteristic parameters obtained by the method are used as the criterion for judging the types and order of severity of the converter transformer paper oil insulation partial discharge, according to the criterion, operators make a rational state maintenance strategy for the converter transformer, and a reliable technical support is provided for manufacturing and operating of the converter transformers.

Owner:TSINGHUA UNIV +2

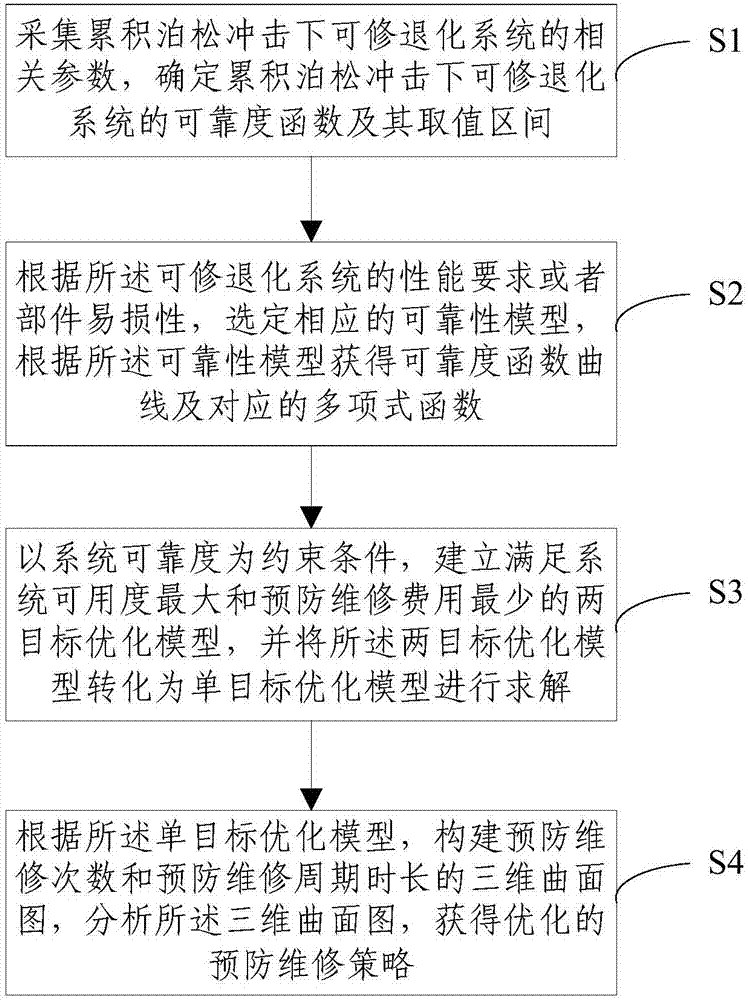

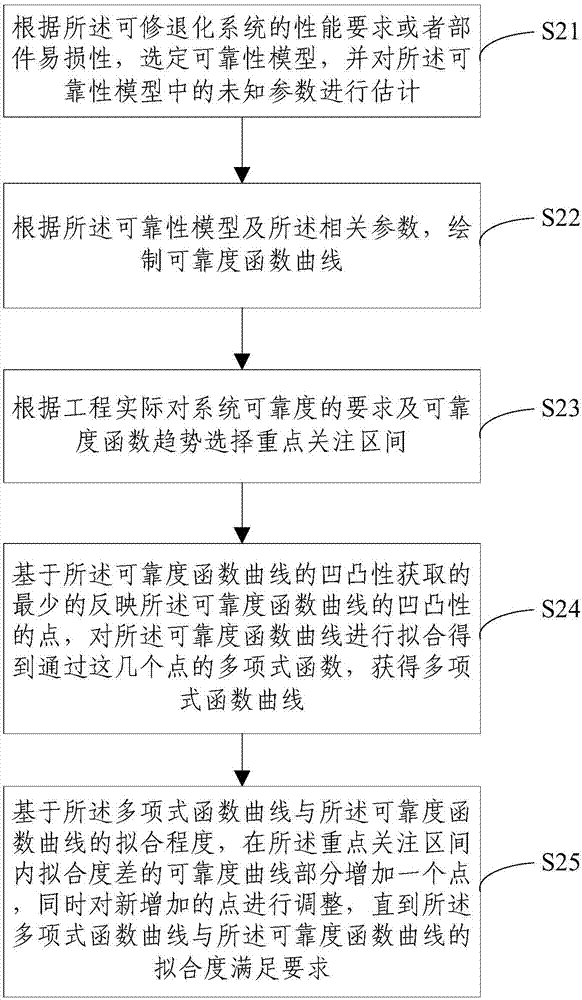

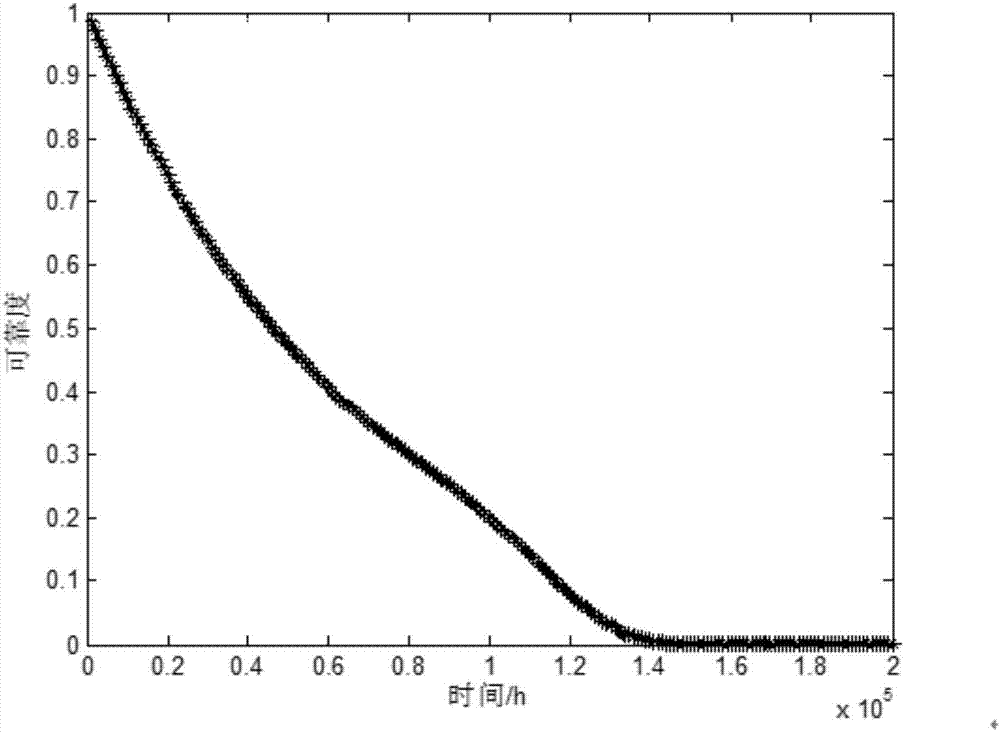

Optimization method for periodical preventive maintenance strategy of repairable deteriorating system

InactiveCN107229979AAvoid inconvenienceAvoid economic lossForecastingMaintenance strategySystem maintenance

The invention provides an optimization method for the periodic preventive maintenance strategy of a repairable degraded system. The reliability model of the repairable degraded system under the cumulative Poisson shock is classified, a suitable reliability model is selected according to the situation and simplified, and the It is applied to the preventive maintenance strategy optimization model as a constraint condition, and a more practical preventive maintenance strategy optimization model is obtained. The invention comprehensively considers the system maintenance cost and the probability that the system is in a normal state at any time, and determines the optimal preventive maintenance period and the system update period under the premise of satisfying the reliability index. It avoids the loss of human and material resources caused by excessive maintenance, and also avoids inconvenience and economic losses caused by untimely maintenance, and obtains maximum benefits for the company in system maintenance. It can also guide enterprises to formulate reasonable equipment maintenance strategies and reduce production costs.

Owner:BEIHANG UNIV

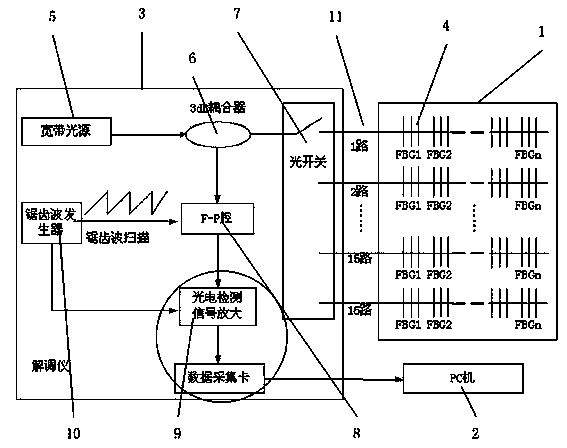

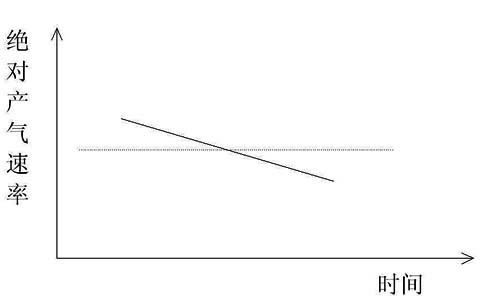

Method for predicting service life of transformer based on fiber grating temperature measurement system

InactiveCN103364658AImprove operation and maintenance strategyDescribe lifeThermometers using value differencesTransformers testingFiberGrating

The invention relates to a method for predicting the service life of a transformer based on a fiber grating temperature measurement system. The method comprises the following steps: performing quasi-distributed description on the internal temperature of the transformer by utilizing the fiber grating temperature measurement system; determining the position of a hottest point in the transformer; performing service life assessment on a local area in the transformer; and performing scientific and reasonable transformer service life prediction by combining the insulating properties of the transformer and the influence of the service life of the part on the overall service life of the transformer according to the service life loss of each position of the transformer. By the method disclosed by the invention, the loss of the insulation life in the transformer and the change rate of the insulation life can be calculated and assessed by utilizing the fiber grating temperature measurement system so as to guide an operation and maintenance department to improve the operation and maintenance strategy scientifically, safely and reliably.

Owner:TAIYUAN POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER +2

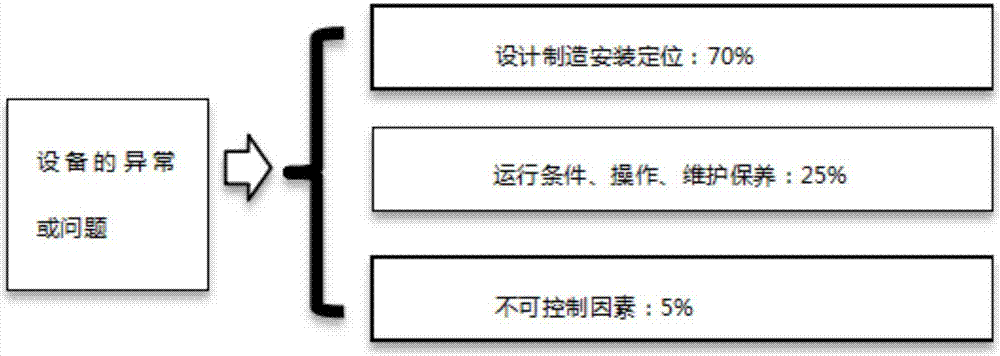

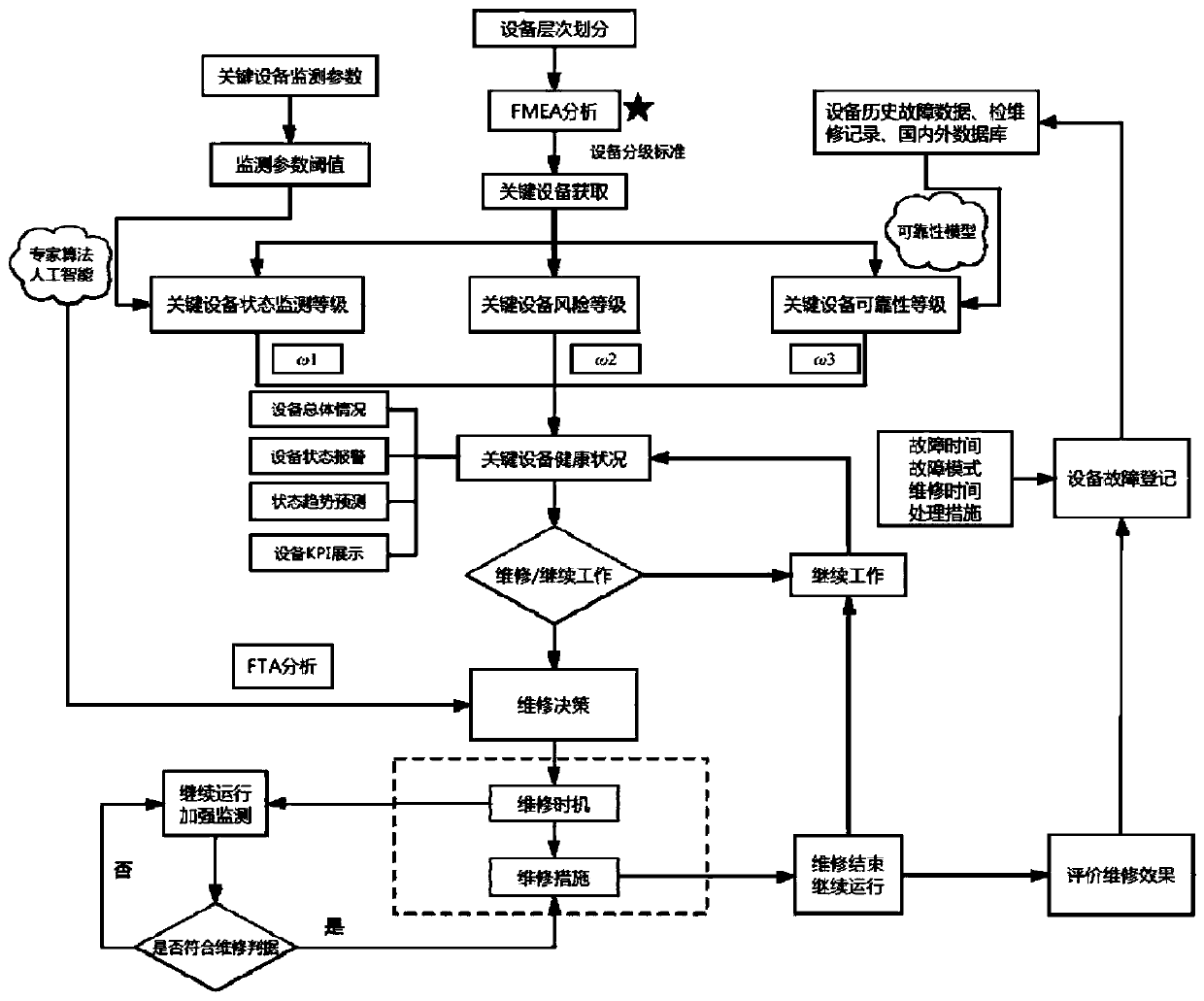

Maintenance decision-making method based on equipment comprehensive health condition analysis and management

InactiveCN111160685ARealize closed-loop processingRealize automatic registrationResourcesRisk levelMaintenance strategy

The invention relates to a maintenance decision-making method based on equipment comprehensive health condition analysis and management. The maintenance decision-making method comprises the followingsteps: collecting data; carrying out equipment hierarchical division; acquiring key equipment; evaluating the risk level of key equipment; evaluating the state monitoring grade of the key equipment; evaluating the reliability level of key equipment; key equipment health conditions; maintenance decision making; device fault management. According to the method, the health condition of the equipmentis comprehensively evaluated from three aspects, namely the reliability level, the risk level and the state monitoring level of the equipment, and the situation that the health condition of one part of equipment is obtained from one side to be overhauled or lost is avoided. A corresponding maintenance strategy is given in combination with the health condition of the equipment, the service life ofthe equipment is prolonged to the maximum extent, and maintenance cost is saved. The fault tree is combined with the state monitoring relation variable of the equipment, and the fault type of the equipment is automatically judged by utilizing the change condition of the relation variable so as to give a reasonable maintenance strategy. The equipment fault, the maintenance record and the operationof the equipment form a closed-loop influence, and the newly added equipment fault record is used as basic data of reliability calculation to re-optimize the reliability model so as to reflect the reliability state of the equipment more accurately and discover the fault of the equipment in time.

Owner:上海安恪企业管理股份有限公司

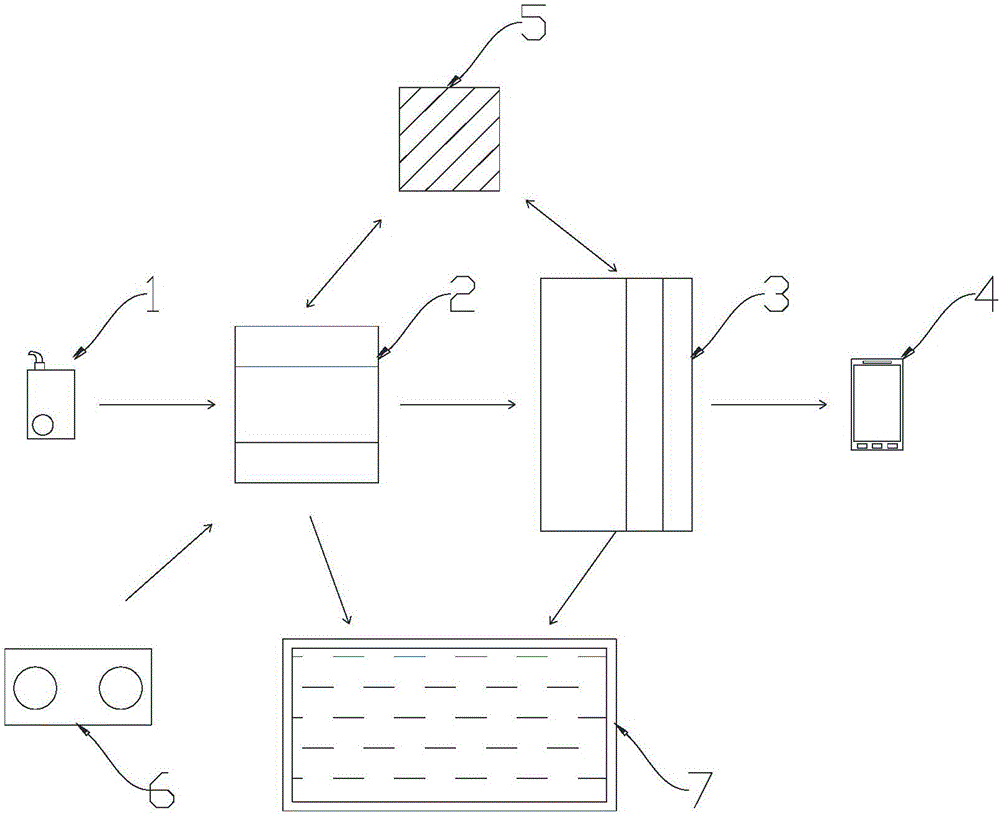

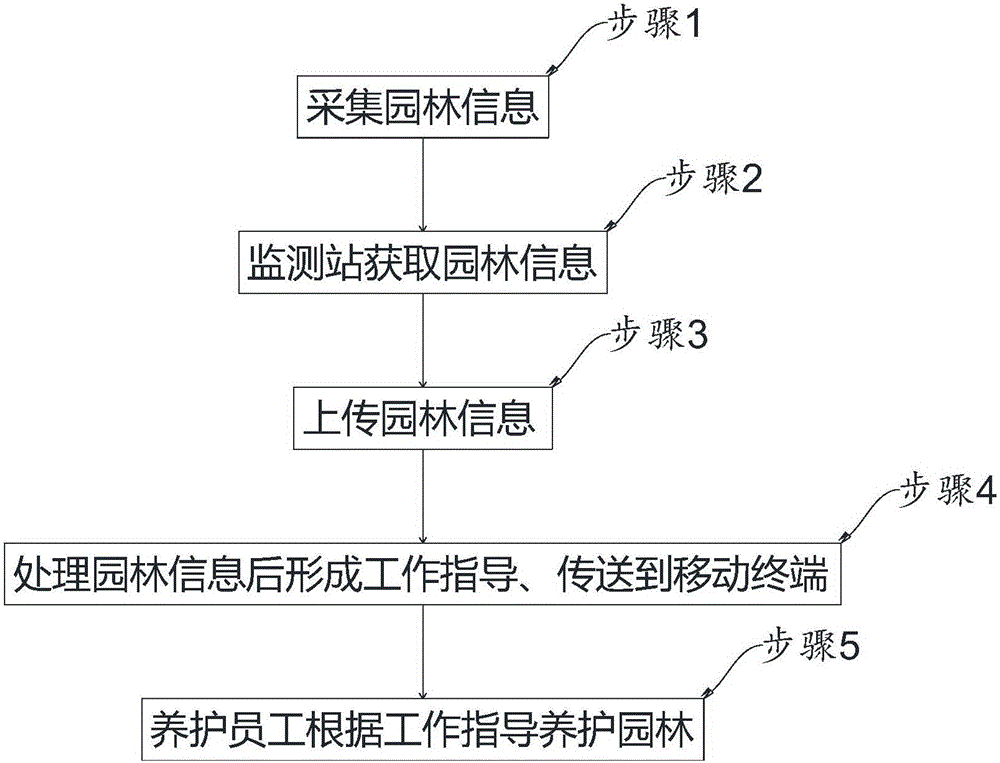

Garden maintenance management service system and method

InactiveCN106295971ARealize remote managementFull accessClimate change adaptationResourcesMaintenance strategyMaintenance management

The invention discloses a garden maintenance management service system and method. The system comprises a sensor, a monitoring station, a network server and a mobile terminal, wherein the sensor is connected with the monitoring station; the monitoring station is connected with the network server; the network server is wirelessly connected with the mobile terminal; and a maintenance worker has the mobile terminal. The method comprises the following steps: the sensor is used for collecting garden information, the monitoring station is used for obtaining the garden information collected by the sensor, the monitoring station uploads the garden information to the network server, and the maintenance worker obtains the processed maintenance information through the mobile terminal and guides maintenance work. Garden maintenance and remote management control are combined, the garden information is detected, a maintenance strategy is made according to plant attributes, the garden information and the maintenance strategy are processed as big data so as to improve a green plant landscape effect and guide a garden maintenance process, and the scientific management and the integrated management of the garden green plate are realized. The system and the method also have the advantages that resource configuration is optimized, management cost is lowered and the like.

Owner:北京京林园林集团有限公司

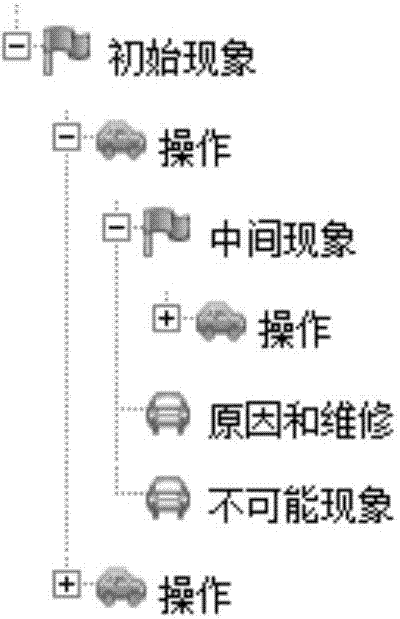

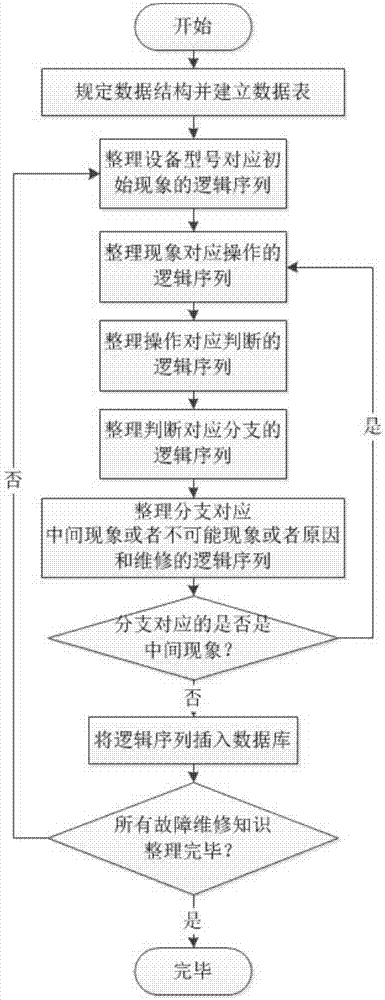

General fault detecting and maintenance method for equipment

InactiveCN103617576ARealize accumulationAchieve sharingDetecting faulty computer hardwareForecastingMaintenance strategySimulation training

The invention discloses a general fault detecting and maintenance method for equipment. The general fault detecting and maintenance method for the equipment comprises the following steps of carrying out modeling on maintenance knowledge of the equipment faults, automatically detecting and diagnosing the faults and carrying out auxiliary maintenance based on a model, simulating maintenance training based on the model, optimizing an experience knowledge model in real time in the maintenance training process, and synchronizing maintenance information and experience knowledge model information in the maintenance training process. Compared with an existing equipment maintenance method, the general fault detecting and maintenance method for the equipment enables the accumulation and the sharing of equipment maintenance experience knowledge and the automatic diagnosis of equipment faults to be achieved, and assistance can be provided for related maintenance strategies through the analysis and the exploitation of the maintenance record information. In addition, effective transmission of the experience of experts to primary maintainers is achieved through the step of simulation training. The general fault detecting and maintenance method for the equipment is especially suitable for chemical defense troops and other occasions where a large amount of complex equipment needs to be maintained frequently and where the turnover rate of maintenance personnel is high. Practice proves that the general fault detecting and maintenance method for the equipment can obvious improve equipment maintenance efficiency, promote maintenance levels and improve maintenance quality.

Owner:NANJING UNIV +1

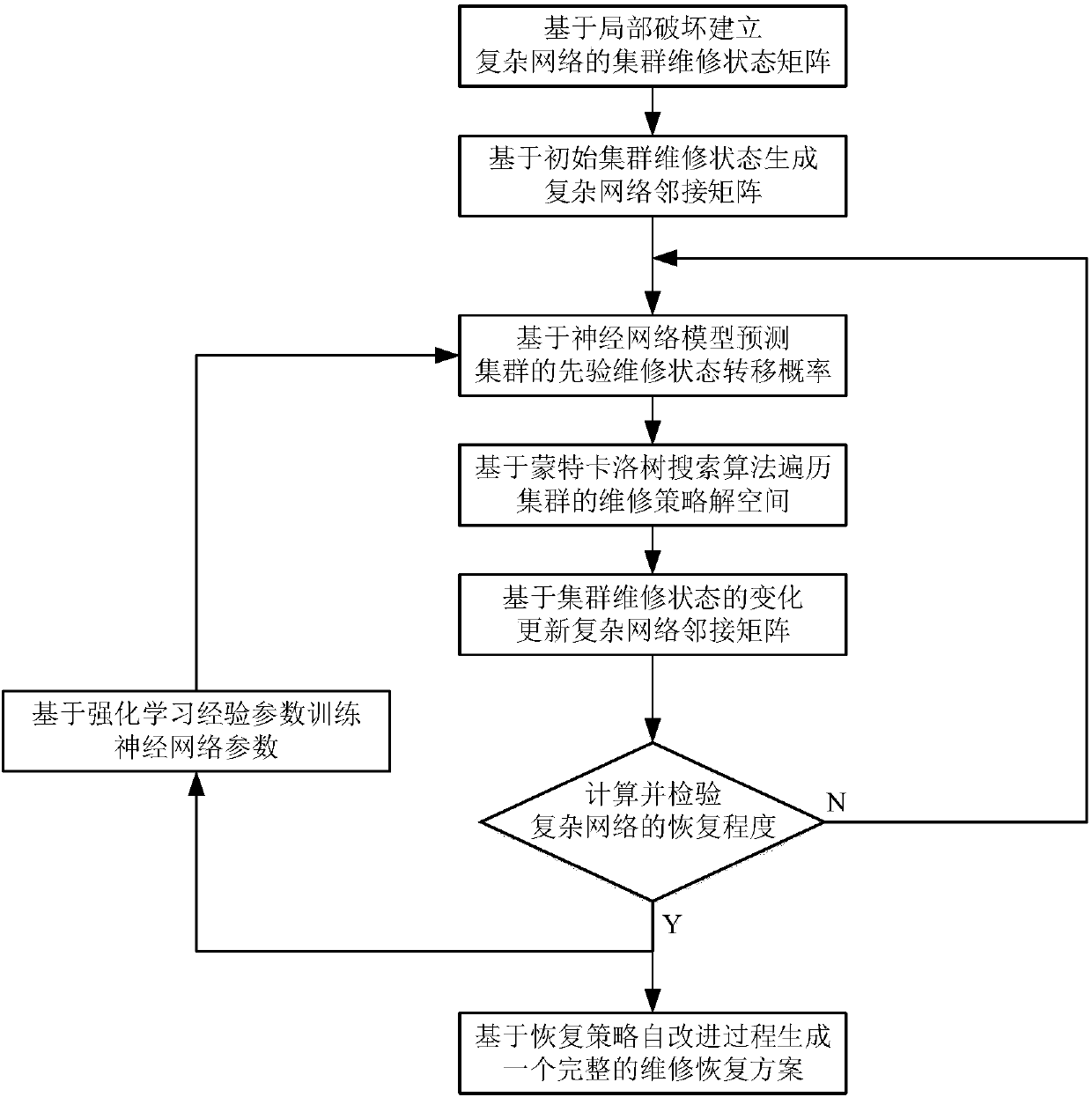

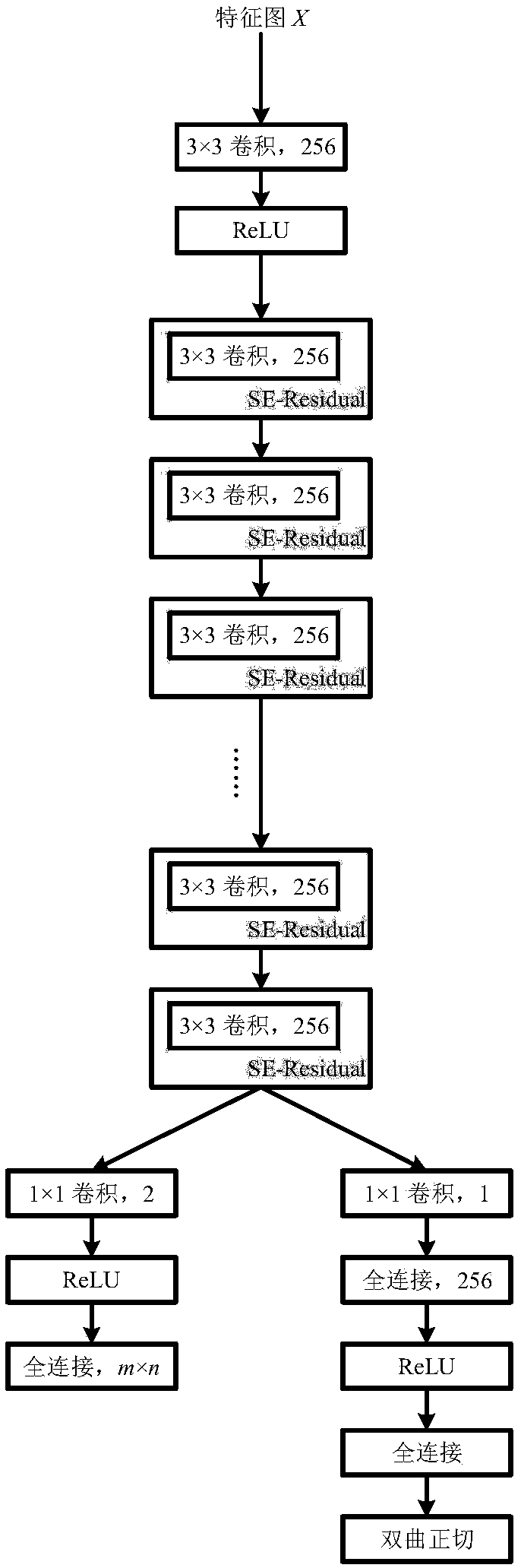

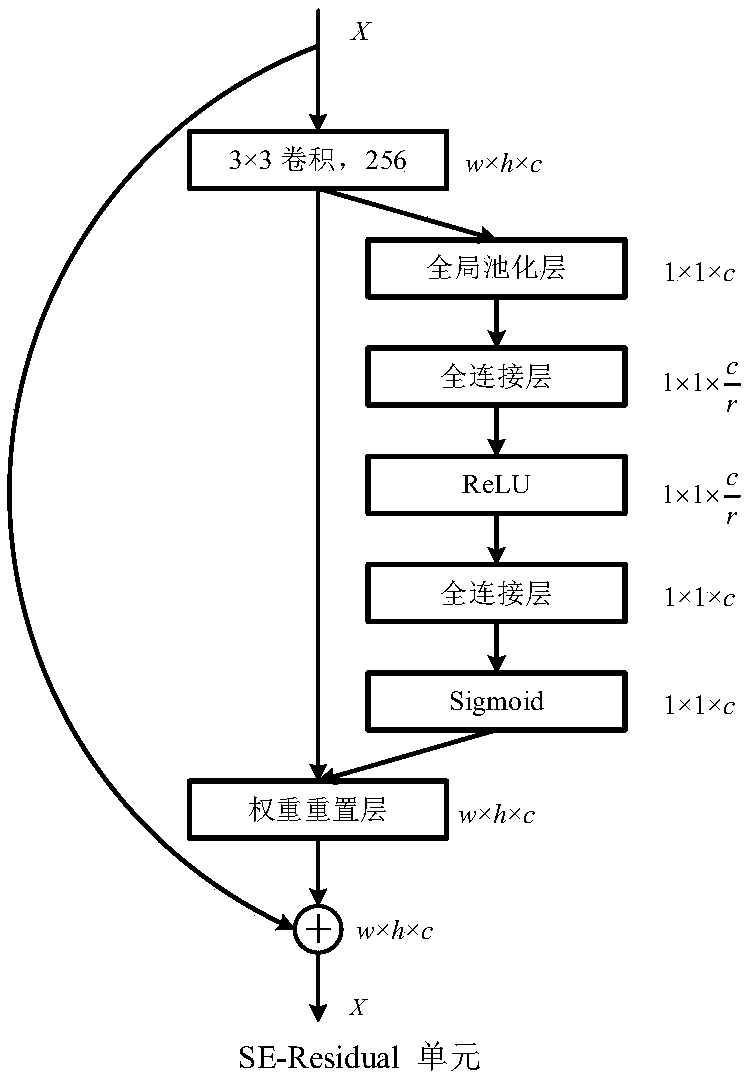

Self-improved recovery strategy for complex network local destruction based on improved reinforcement learning

InactiveCN108573303AAvoiding Combinatorial Explosion ProblemsNeural architecturesNeural learning methodsComputer scienceReinforcement learning

The invention discloses a self-improved recovery strategy method for complex network local destruction based on improved reinforcement learning, so as to solve the problem of recovery strategy generation when a complex network is subjected to cluster maintenance. The method comprises the following steps: 1, according to local destruction information, a complex network cluster maintenance state matrix is built; 2, based on an initial cluster maintenance state, a complex network adjacency matrix is generated; 3, based on a neural network model, a cluster prior maintenance state transition probability and a maintenance strategy value are predicted; 4, based on a Monte Carlo tree search algorithm, cluster maintenance strategy solution space is traversed, and the global best maintenance actionat present time is selected; 5, based on changes of the cluster maintenance state, the complex network adjacency matrix is updated; 6, based on the cluster maintenance state and the adjacency matrix,the recovery degree of the complex network is calculated and checked; 7, based on reinforcement learning experiment parameters, neural network parameters are trained; and 8, based on a series of bestmaintenance actions during a recovery strategy self improvement process, a complete maintenance recovery scheme is generated.

Owner:BEIHANG UNIV

Method for analyzing running trend of electric power communication transmission network

The invention discloses a method for analyzing a running trend of an electric power communication transmission network. The method is characterized by comprising the following steps: (1) acquiring basic data, and providing dynamic parameters and static parameters for a trend analysis model; (2) performing mutation analysis on performance; judging whether the acquired dynamic parameters are out of limit or not based on a performance parameter early warning threshold value; directly generating a performance alarm if the acquired dynamic parameters are out of limit; (3) performing trend analysis when the performance is steadily changed; constructing an error rate and optical power analysis model according to dynamically acquired performance parameters by adopting secondary dynamic exponential smoothing; obtaining a trend analysis weight through a steepest descent iteration method by combining the dynamic parameters and historical data, and further, constructing a linear prediction equation; (4) performing early warning computation, and outputting a performance prediction result. The method disclosed by the invention is applied to a communication management system, and therefore, a powerful data support is provided for the whole-process intelligent computational analysis from data acquisition, trend prediction, early warning analysis and a maintenance strategy.

Owner:STATE GRID CORP OF CHINA +3

Field operation and maintenance method for operation composite insulator based on performance evaluation

ActiveCN102361250ASimple methodEasy to operateCable installation apparatusComposite insulatorsMaintenance strategy

The invention relates to a field operation and maintenance method for an operation composite insulator based on performance evaluation. The field operation and maintenance method is simple and strong in maneuverability. Electromechanical properties and physical and chemical properties of different batches of composite insulators in different operation environments are determined by combining operation detection with sampling inspection, and further a pointed operation and maintenance strategy is formulated. According to the field operation and maintenance method, unnecessary maintenance can be reduced and faults caused by improper operation maintenance of the composite insulator can be avoided. The field operation and maintenance method comprises the following steps of: firstly, determining electrical properties of the operation composite insulator; secondly, determining mechanical properties of the operation composite insulator; thirdly, determining the physical and chemical properties of the operation composite insulator; and fourthly, determining the operation and maintenance strategy of the operation composite insulator: analyzing and evaluating the electrical, mechanical and physical and chemical properties of the operation composite insulator, determining the operation state and the ageing condition of the composite insulator and pointedly formulating the operation and maintenance strategy for different operation composite insulators according to different conditions.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

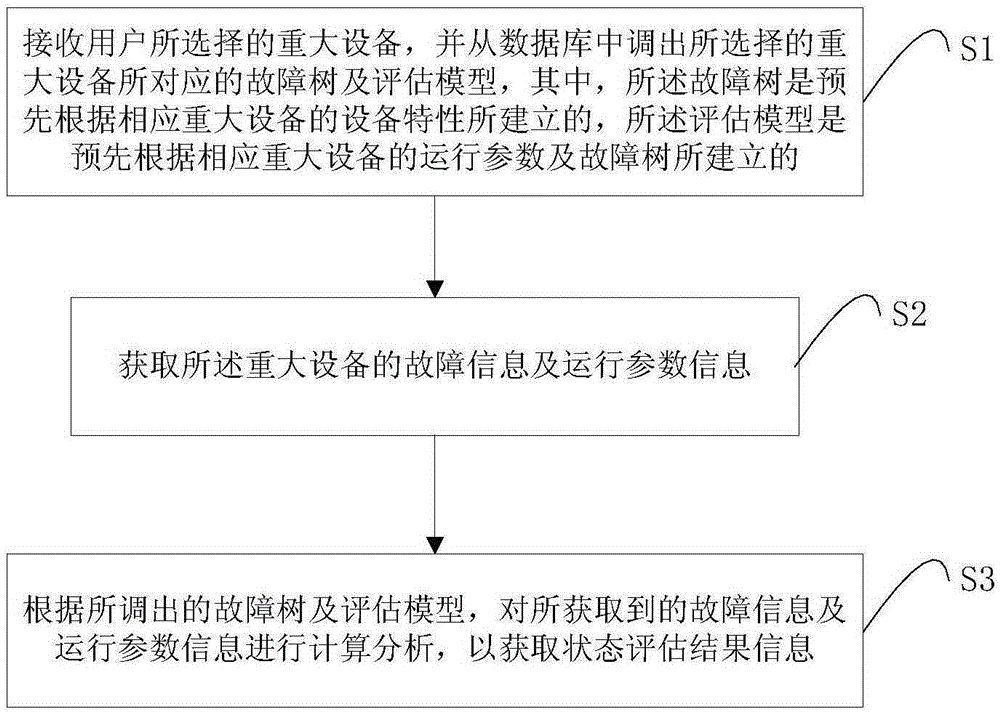

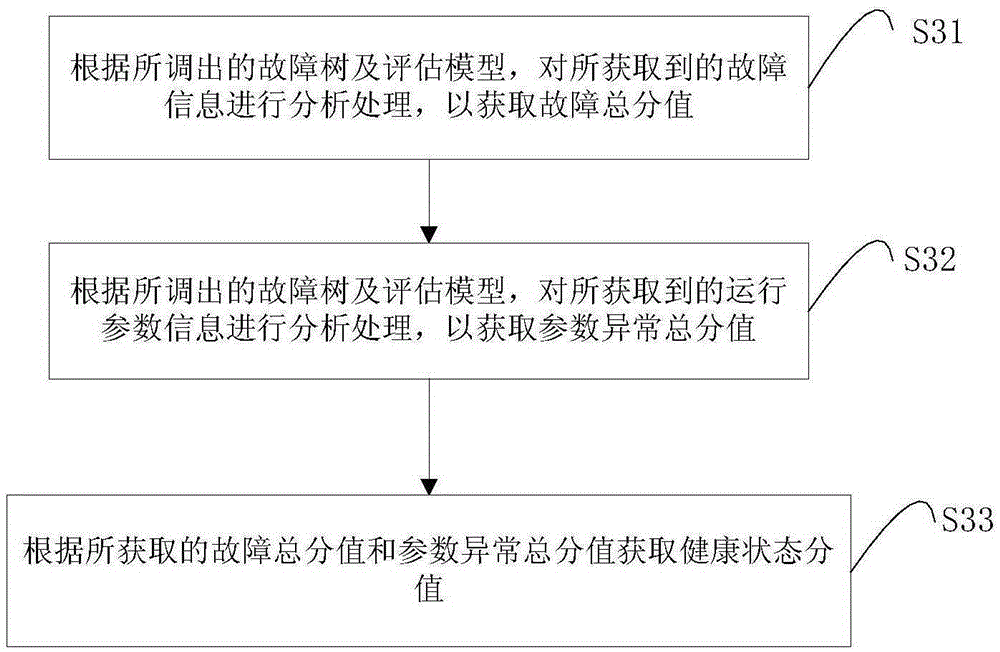

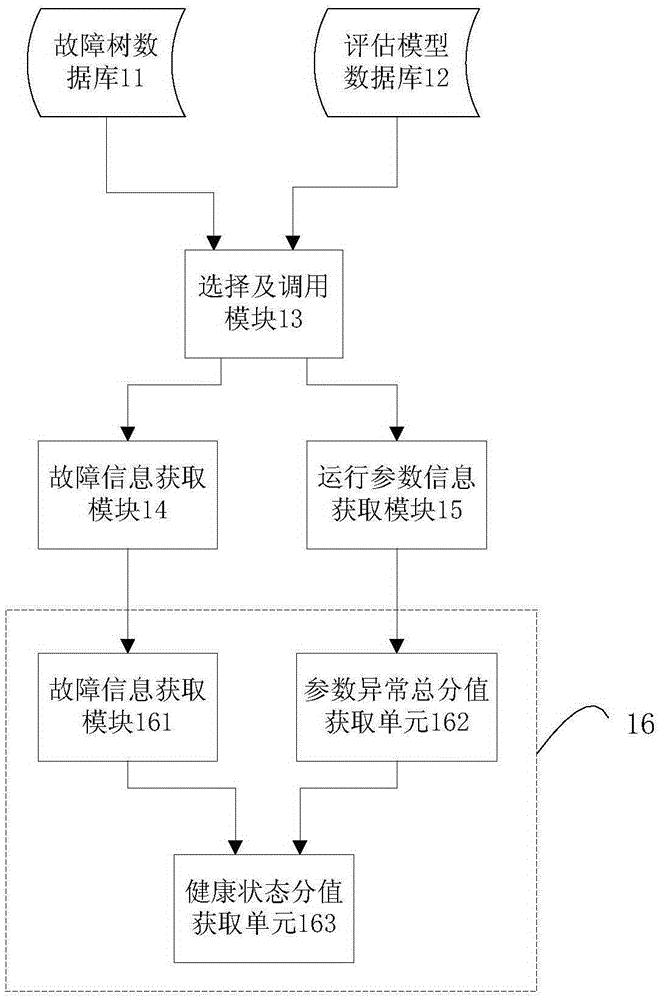

Method and system for evaluating health status of major equipment

The invention discloses a method and a system for evaluating the health status of major equipment. the evaluating method comprises the steps of S1, receiving major equipment selected by a user, and evoking a fault tree and an evaluation model both corresponding to the selected major equipment out of a database, wherein the fault tree is pre-established based on the corresponding equipment characteristics of the major equipment and the evaluation model is pre-established based on the corresponding operating parameters of the major equipment and the above fault tree; S2, acquiring the fault information of the major equipment and the information of the operating parameters of the major equipment; S3, according to the evoked fault tree and the evaluation model, conducting the calculation and analysis on the acquired fault information and the information of the operating parameters of the major equipment so as to acquire the information of a status assessment result. According to the technical scheme of the invention, the health status of the major equipment can be timely and correctly evaluated, so that a reasonable maintenance strategy can be conveniently formulated. Therefore, the reliability of the major equipment is improved, and the service life of the major equipment is prolonged.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +4

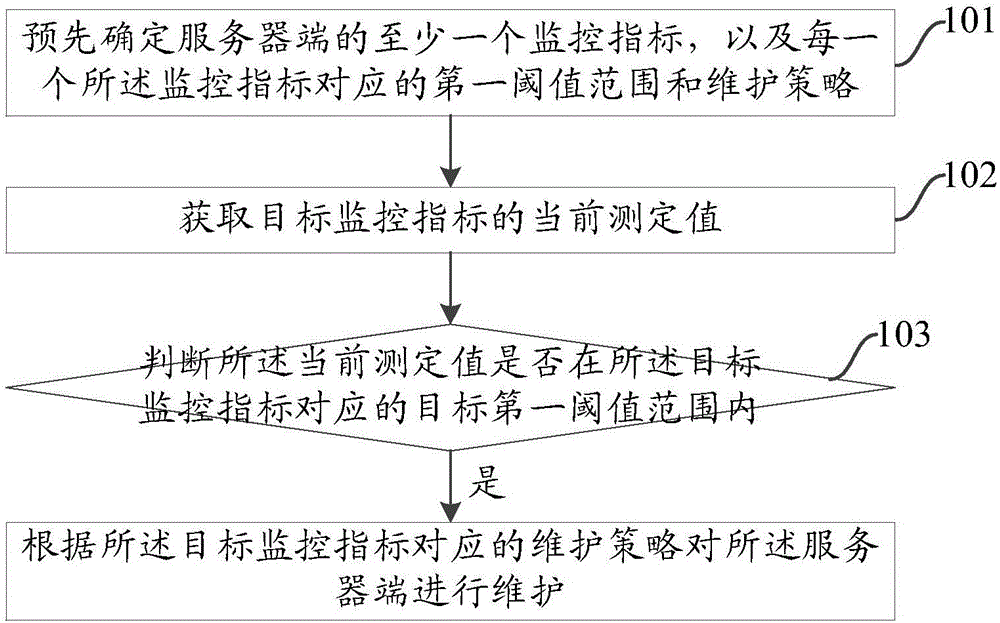

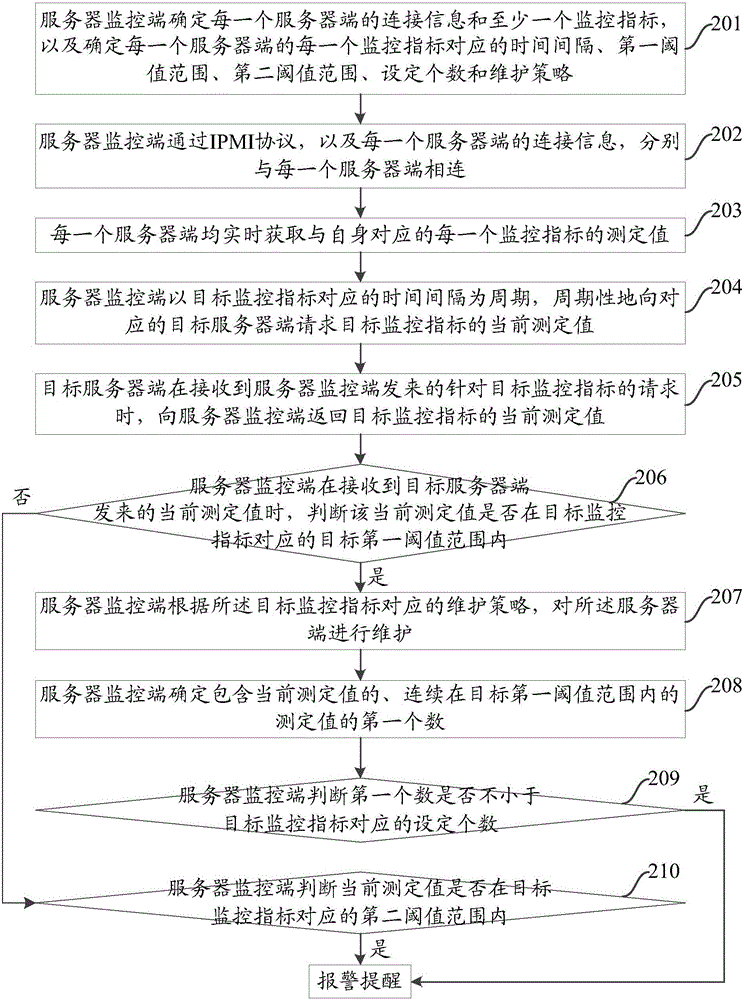

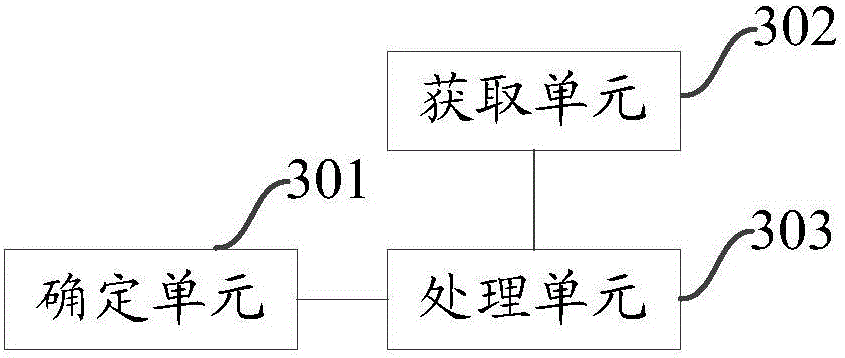

Method, device and system for regulating operating state of server

The invention provides a method, device and system for regulating an operating state of a server, and the method comprises the steps: determining at least one monitoring index of the server and the threshold range and maintenance strategy corresponding to each monitoring index; and transmitting the maintenance strategy corresponding to the monitoring index to the server when the current measurement value of any monitoring index is obtained if the current measurement value is within the threshold range corresponding to the monitoring index. The method can monitor whether the server works normally or not according to the measurement values of all monitoring indexes of the server, and can carry out regulation and timely removing of abnormality in a targeted manner through a corresponding maintenance strategy, thereby avoiding the hidden troubles. Therefore, the method can carry out the timely maintenance of the sever with an abnormality.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

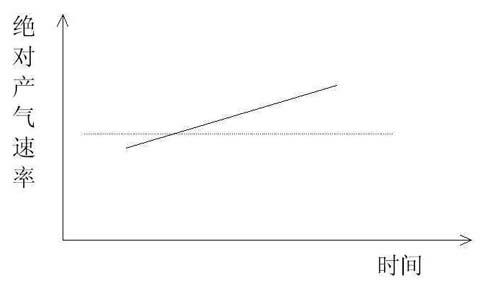

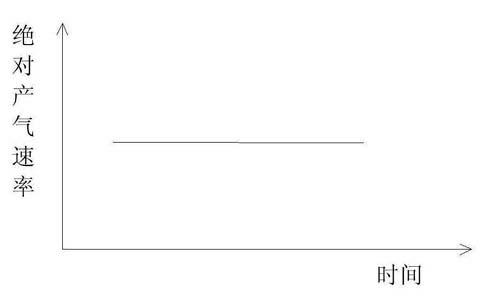

Method for diagnosing severity degree of transformer fault

ActiveCN102680814AGuaranteed safe operationPrevent damage eventsElectrical testingMaintenance strategyPower grid

The invention relates to a method for diagnosing the severity degree of a transformer fault. The method comprises analyzing the gas content in transformer oil by using chromatography; accumulating the dissolved gas content in the transformer oil tested over a certain period; calculating the nitrogen or total hydrocarbon absolute aerogenesis rate and the change rate of the aerogenesis rate; and drawing a diagram, in which the absolute aerogenesis rate is the vertical coordinate and the time is the horizontal coordinate; and judging whether a fault occurs to the interior of a transformer according to the absolute aerogenesis rate and the change rate of the aerogenesis rate. According to the method, the development and the severity degree of the fault in the interior of the transformer are judged by calculating the absolute aerogenesis rate and the change rate of the aerogenesis rate in a mode of diagram; a corresponding transformer monitoring and maintenance strategy is made; the accurate master of the operation and the interior fault situation of the transformer is achieved; the security operation of the transformer in a power grid is guaranteed; and the accident that the transformer is damaged is prevented.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

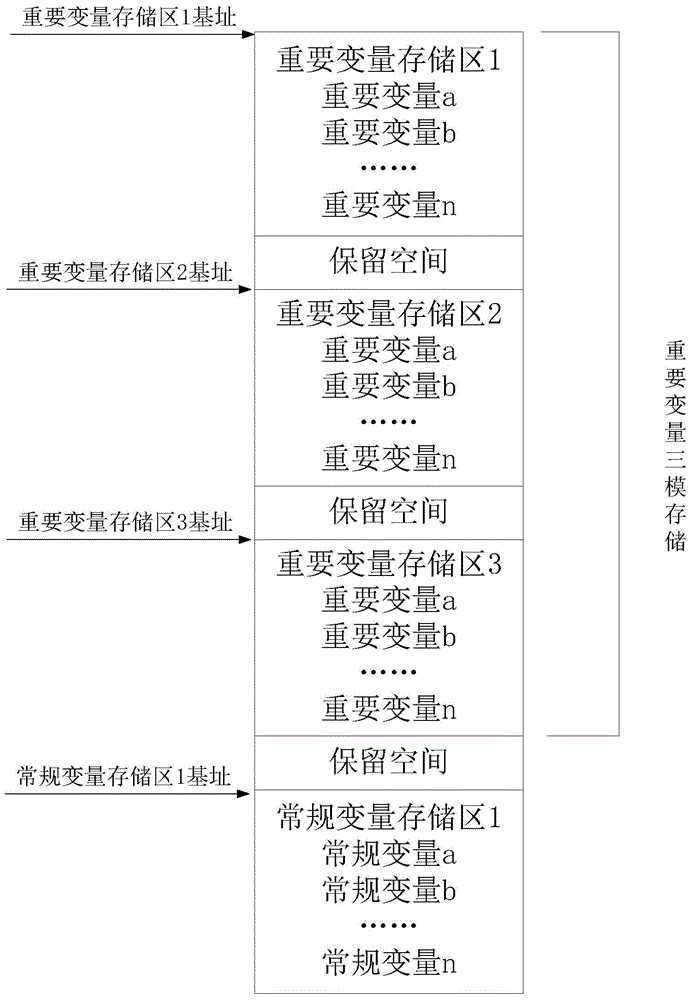

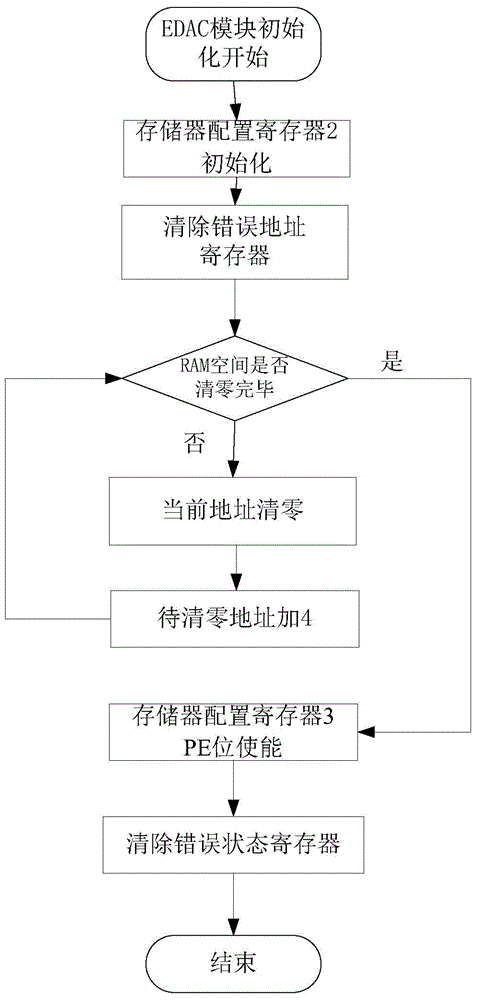

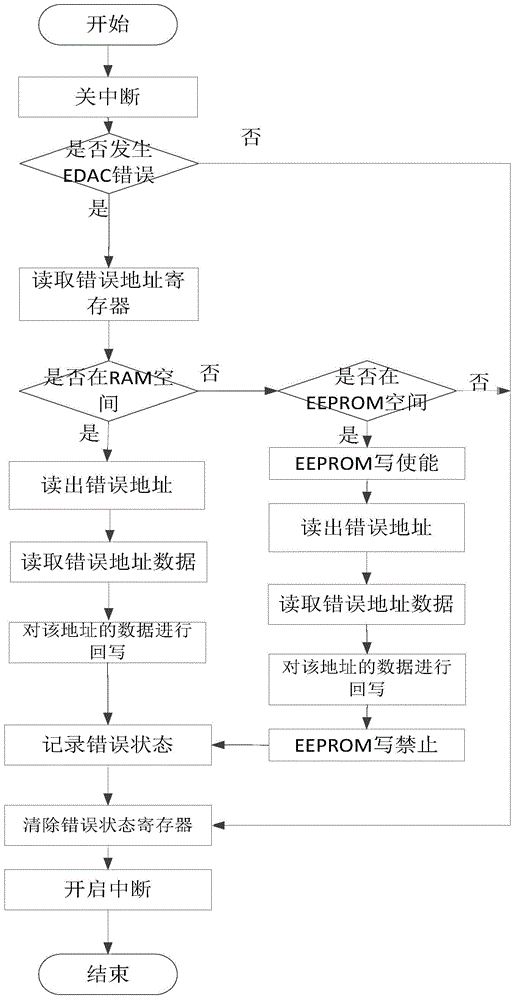

Single event upset fault processing method based on AT697 processor

InactiveCN103984630AImprove reliabilityImprove securitySoftware testing/debuggingProgrammable read-only memoryMaintenance strategy

The invention provides a single event upset fault processing method based on an AT697 processor. The method comprises a step 101) of defining the format of variables of the AT697 processor, a step 102) initializing the data of an Error Detection And Correction (EDAC) functional module and a Random Access Memory (RAM)space of the AT697 processor, a step 103) detecting and modifying errors, caused by single vent upset, of an RAM or Electrically Erasable Programmable Read-Only Memory (EEPROM) connected with the EDAC module, and a step 104) of establishing a maintenance strategy and carrying out initiatively periodic traversal access to the storage spaces of all RAMs and EEPROMs, thereby reducing and eliminating single bit errors. The single event upset fault processing method is used for providing a set of complete software processing design scheme for spatial single event faults according to the characteristic that the AT697 processor provides an EDAC detection interface. The single event upset fault processing method does not need to add an extra chip, so that the weight, volume and power consumption of equipment are not increased; the processing method is simple and efficient; the single event upset fault processing method is flexible in interfaces and high in portability, and has great significance for improving the reliability and safety of satellite development of China.

Owner:NAT SPACE SCI CENT CAS

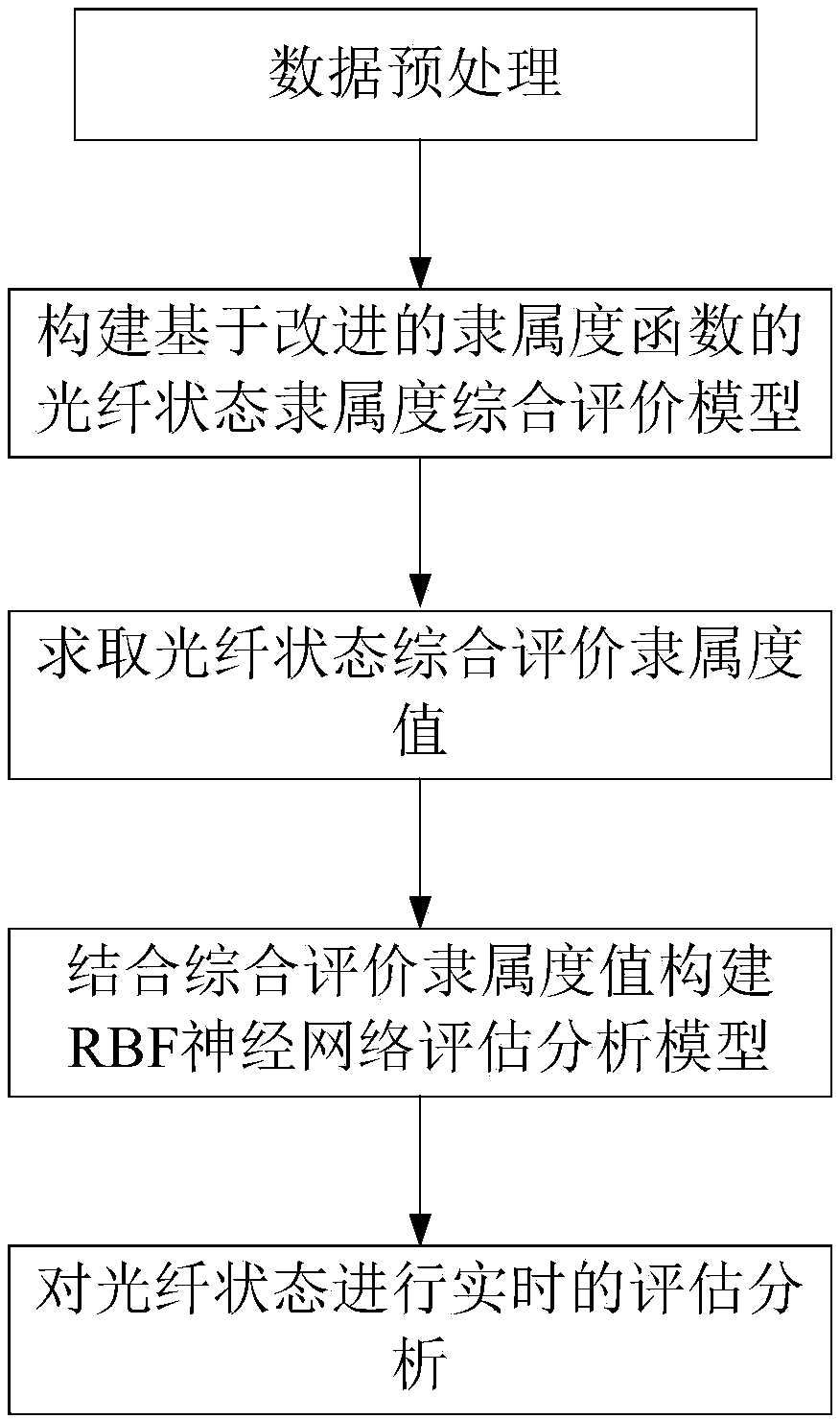

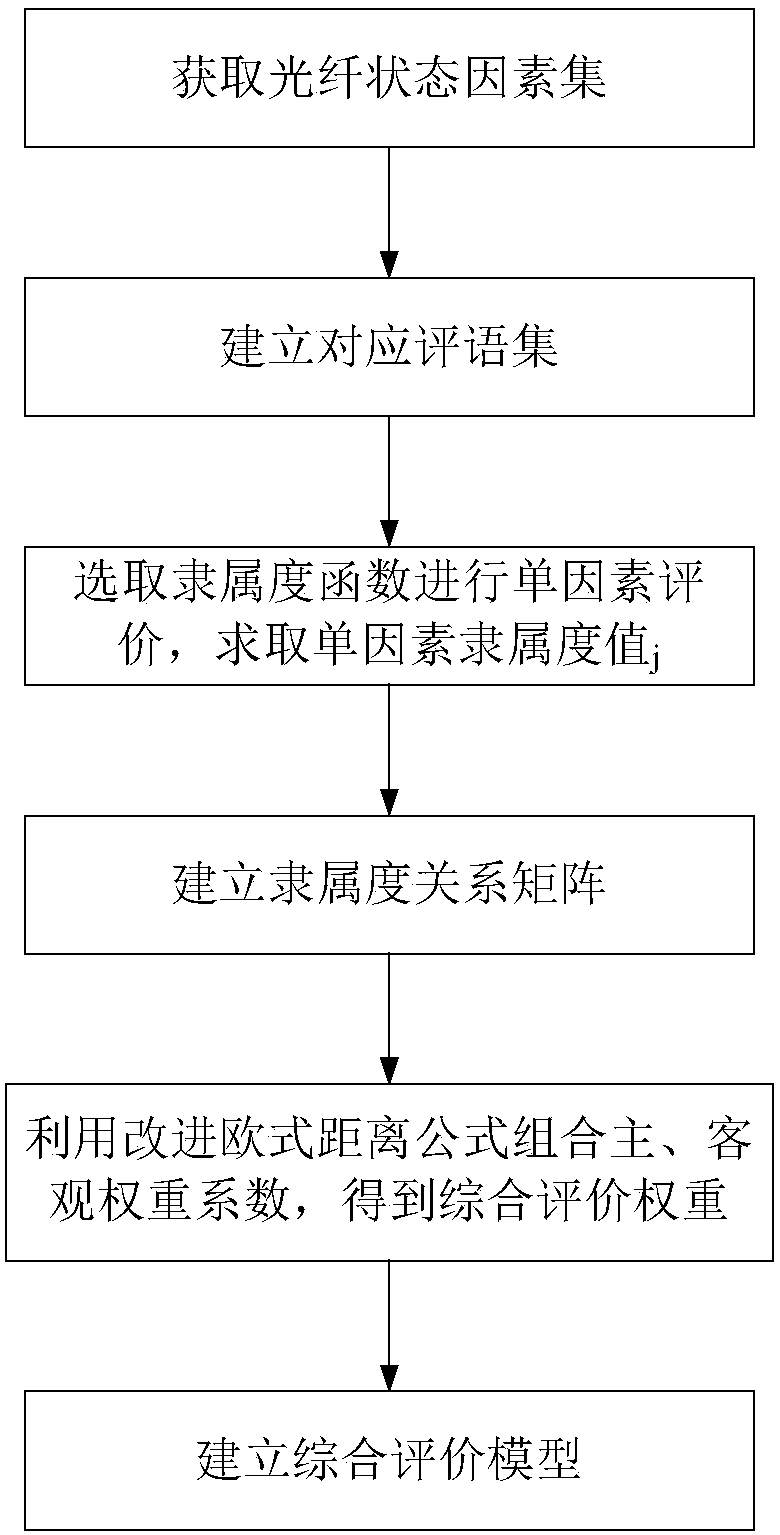

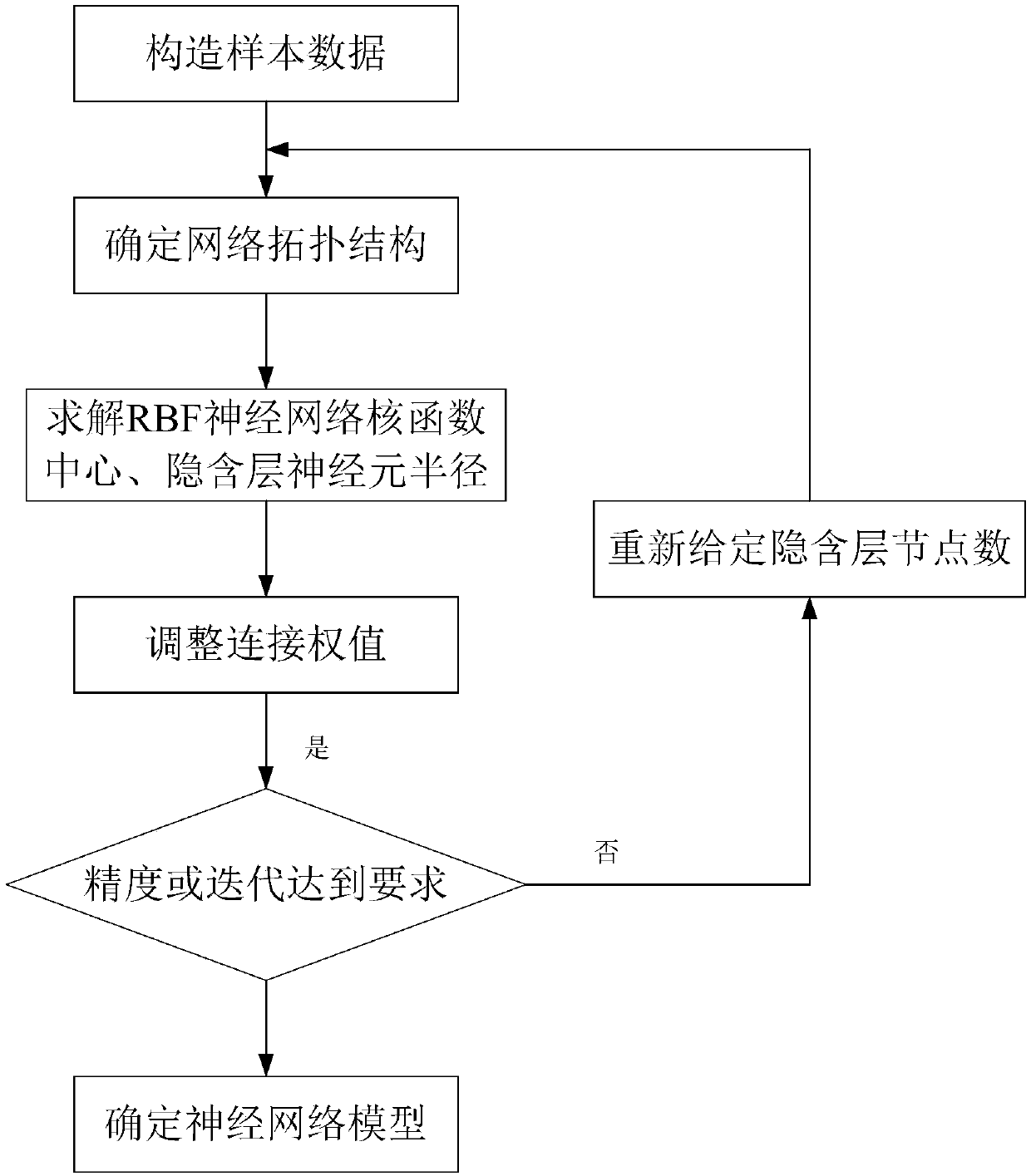

Optical fiber state evaluating method based on combination of improved membership function and neural network

ActiveCN108038300AImprove fitting accuracyFast convergenceDesign optimisation/simulationNeural learning methodsNerve networkMaintenance strategy

The invention discloses an optical fiber state evaluating method based on the combination of an improved membership function and a neural network, and relates to the technical field of optical fiber circuit state evaluating and analyzing. The problems that potential failures in a circuit state can not be analyzed and evaluated in the prior art and failures going to happen can not be avoided are solved. By means of the evaluating and analyzing method, the membership weight of an attached optical fiber state membership comprehensive evaluating method is optimized and combined through an improvedEuclidean distance formula, the circuit state healthy degree is accurately evaluated and analyzed, whether potential failures exist in a circuit or not is analyzed, a maintenance strategy is formulated in advance, and the requirement for optical fiber communication ceaseless transmission is met. By means of an RBF neural network evaluating and analyzing model, evaluating performance has good fitting precision and convergence speed, and the evaluating of the optical fiber state is better achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

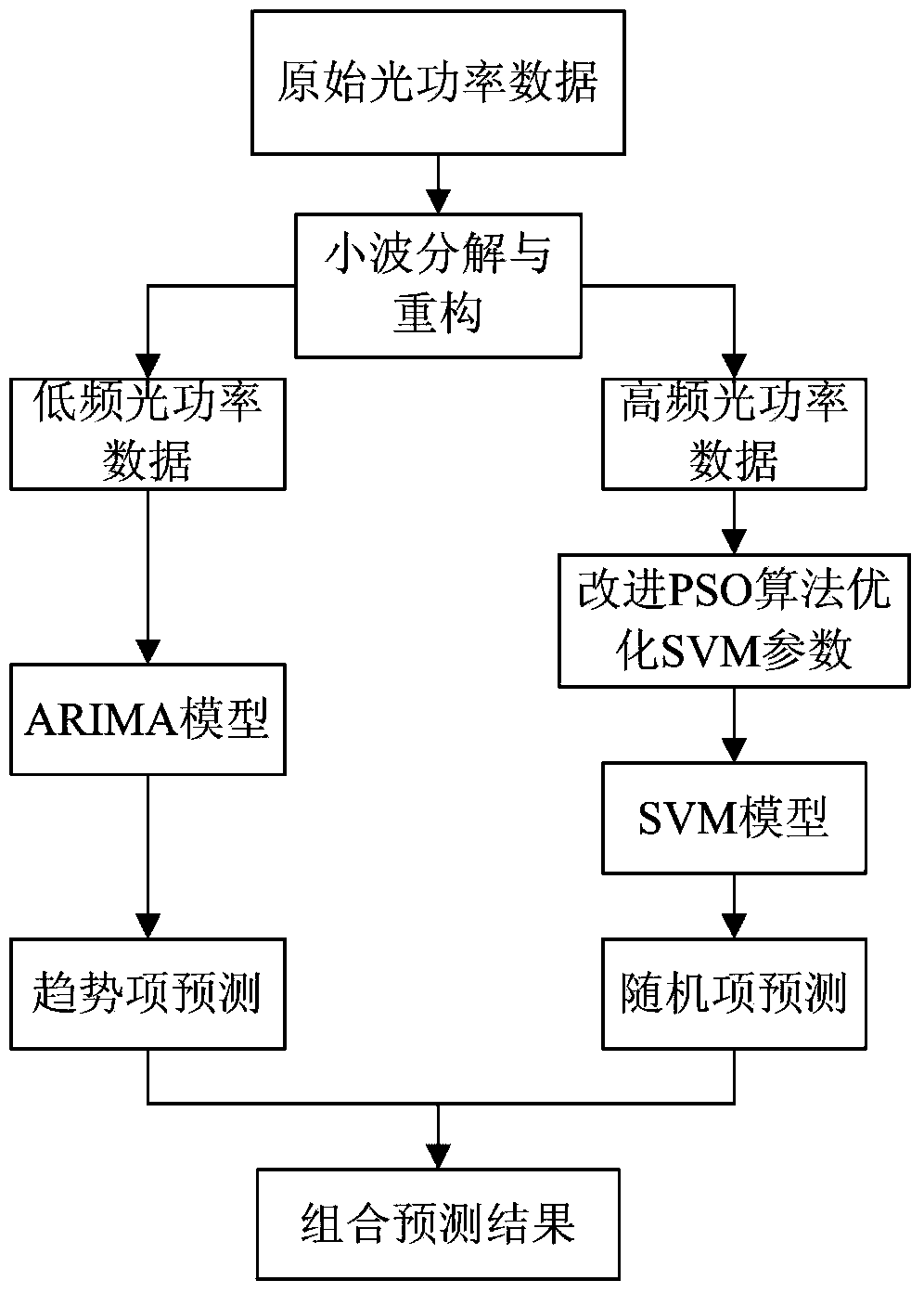

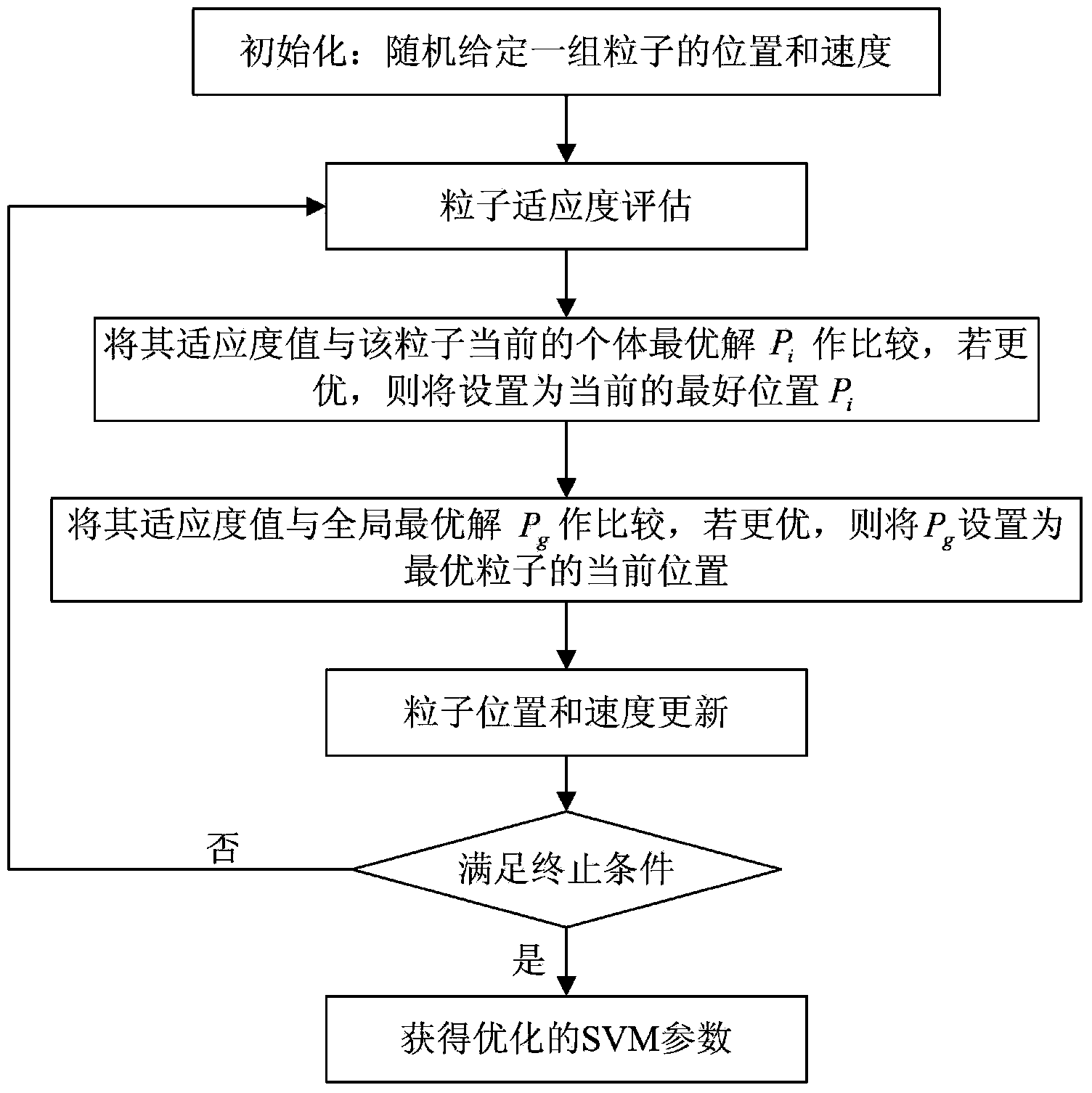

Predication method for electric power optical fiber communication optical power

ActiveCN104331635AImprove performanceFast calculation convergence speedSpecial data processing applicationsOptical powerMaintenance strategy

The invention discloses a predication method for electric power optical fiber communication optical power, relates to the technical field of optical fiber communication predication, and solves the problems that analysis and predication of a circuit state tendency cannot be achieved in the prior art and accordingly impending faults and the like cannot be avoided. According to the method, an improved particle swarm optimization algorithm is provided to optimize parameters in a predication model, so as to achieve a mixed predication based electric power optical fiber communication optical power predication method, accurately predicate a future state tendency of a circuit, predicate future possible faults of the circuit, make a maintenance strategy in advance, avoid fault generation and satisfy an optical fiber communication requirement for intermittent transmission. According to the predication method for the electric power optical fiber communication optical power, the parameters of the SVM model are optimized through the improved particle swarm optimization algorithm, the model not only has a quick operation convergence rate, but also has good predication accuracy and stability, a mixed predication model is adopted, respective advantages of every single predication model are effectively composited, mutual disadvantages are remedied, and improvement of the performance of the integral predication model is facilitated.

Owner:国网吉林省电力有限公司信息通信公司 +1

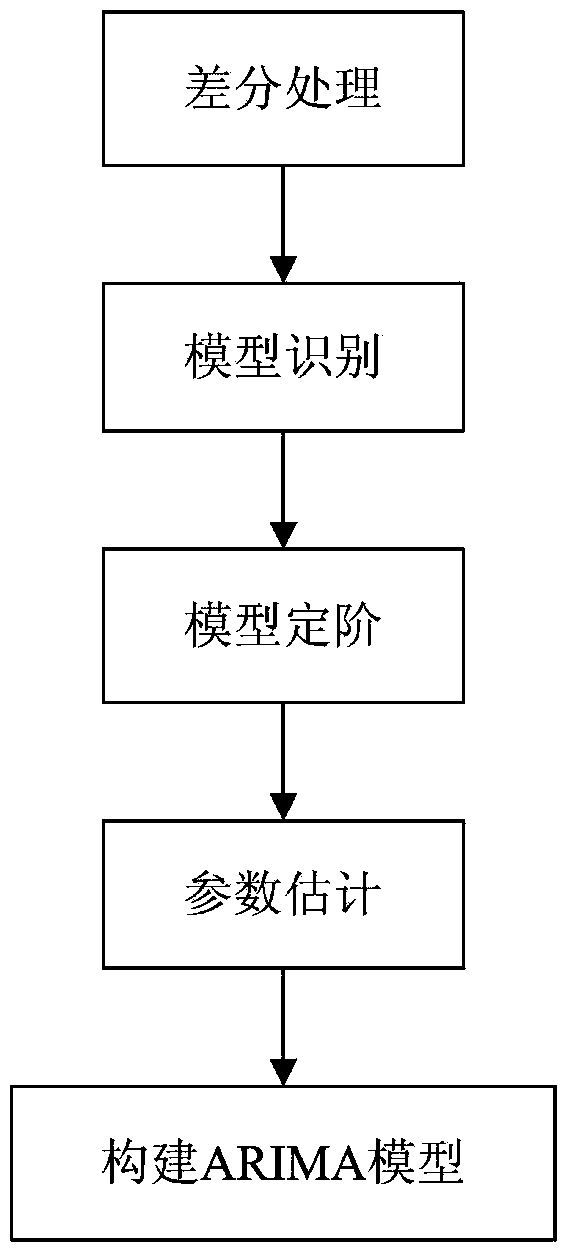

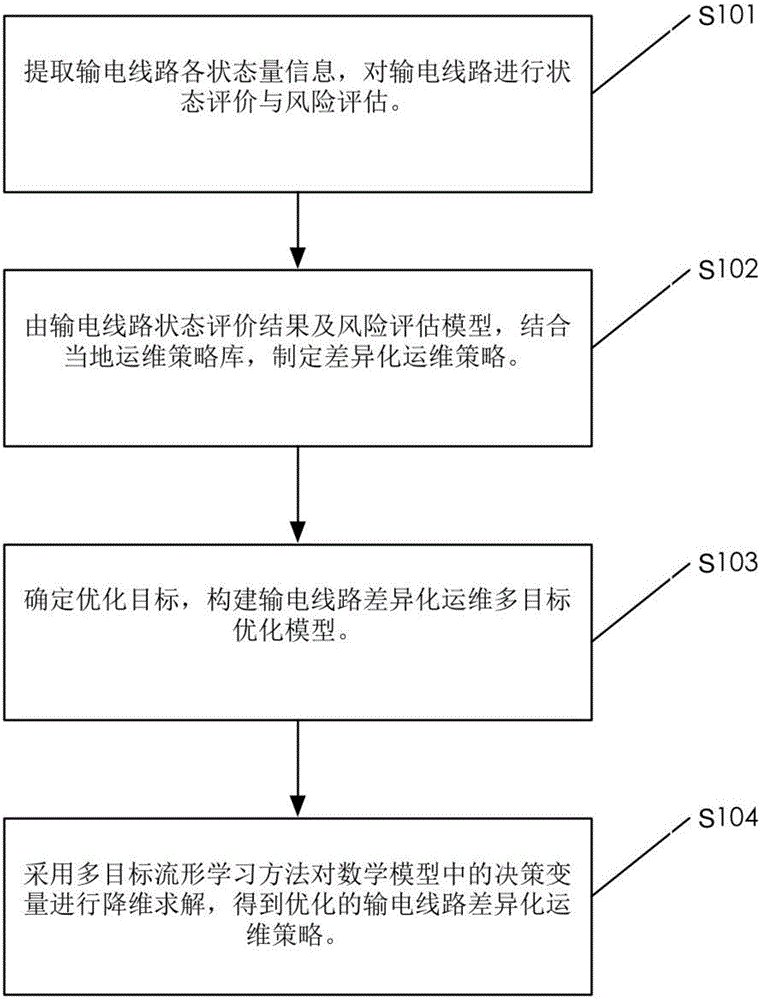

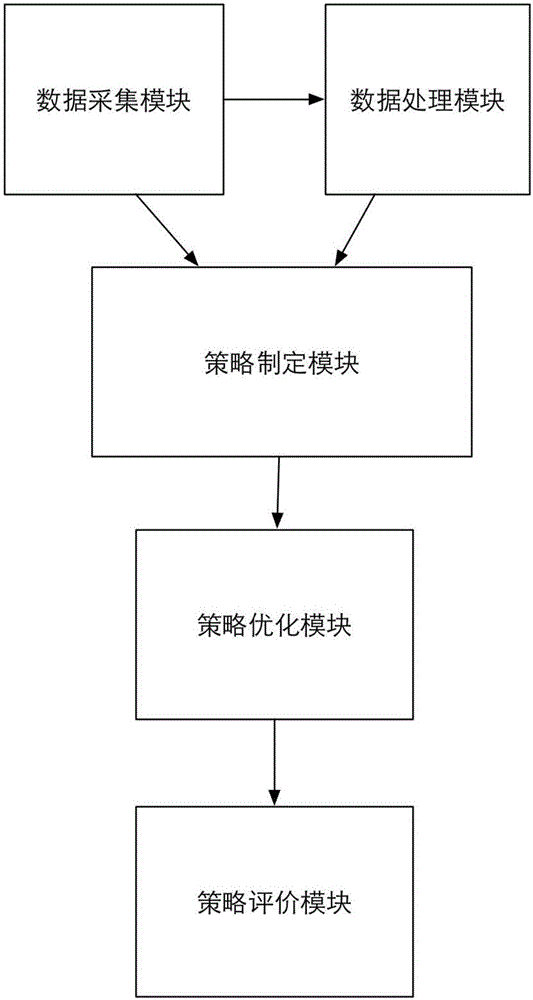

Electric transmission line maintenance plan optimization method and system based on manifold learning

InactiveCN106780141AEasy to masterImprove economyForecastingResourcesMathematical modelStudy methods

The invention relates to an electric transmission line maintenance plan optimization method and system based on manifold learning. The method comprises the following steps: extracting state variable information of an electric transmission line, and performing a state evaluation and a risk assessment on the electric transmission line; combining a transmission line state evaluation result and a risk assessment model with a local operation and maintenance strategy library to make an operation and maintenance strategy; determining an optimization object, and building an operation and maintenance multi-objective optimization model of the electric transmission line; performing a dimensionality reduction solution on a decision variable in a mathematics model by adopting a multi-object manifold learning method, thus acquiring an optimized operation and maintenance strategy of the electric transmission line; and performing research and development on an operation and maintenance system of the electric transmission line to realize intelligence and high-efficiency generated by the operation and maintenance strategy. By adopting the electric transmission line maintenance plan optimization method and system based on manifold learning, the operation and maintenance strategy of the electric transmission line can be made optimally, and the economy, reliability and safety are improved.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

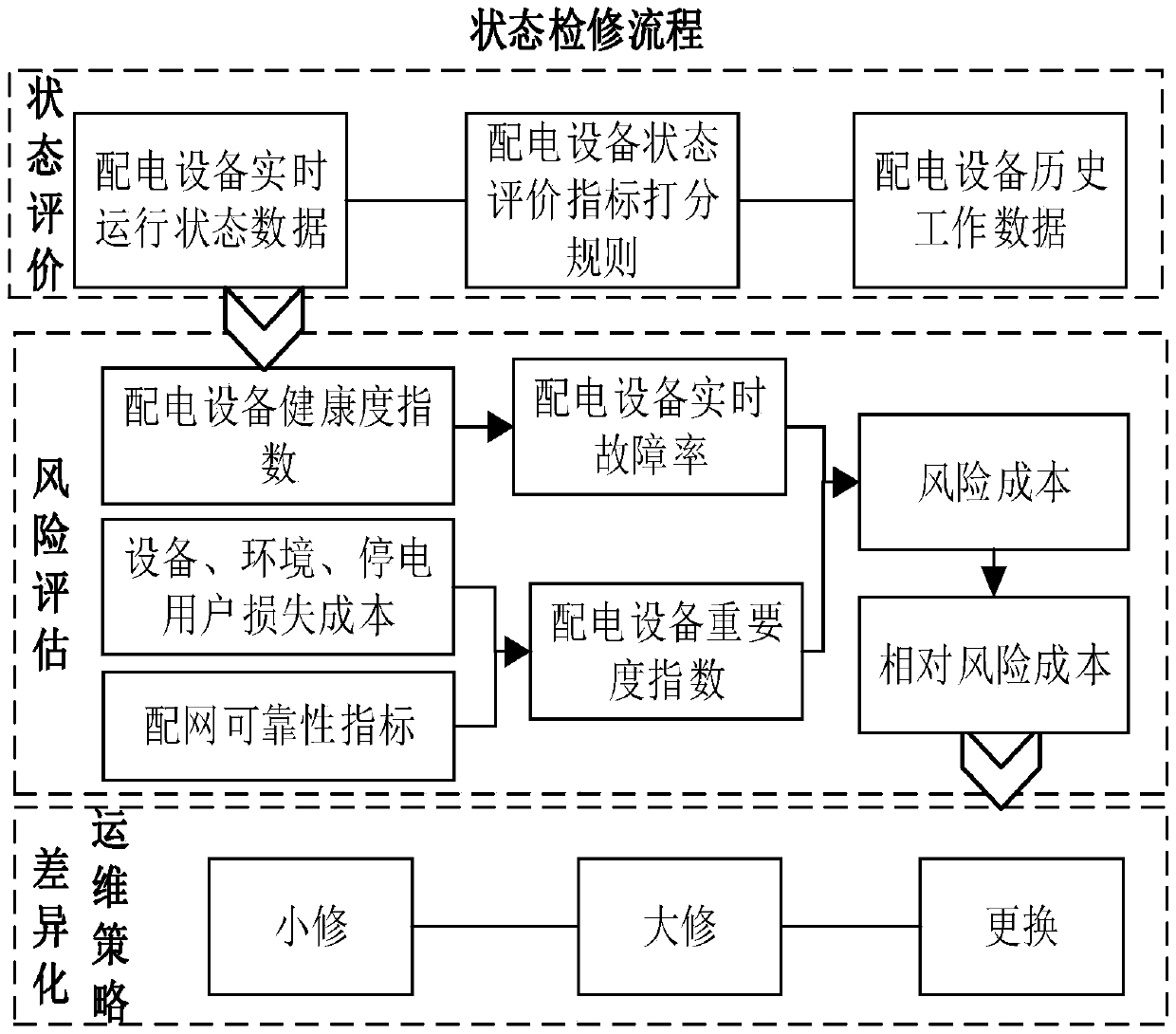

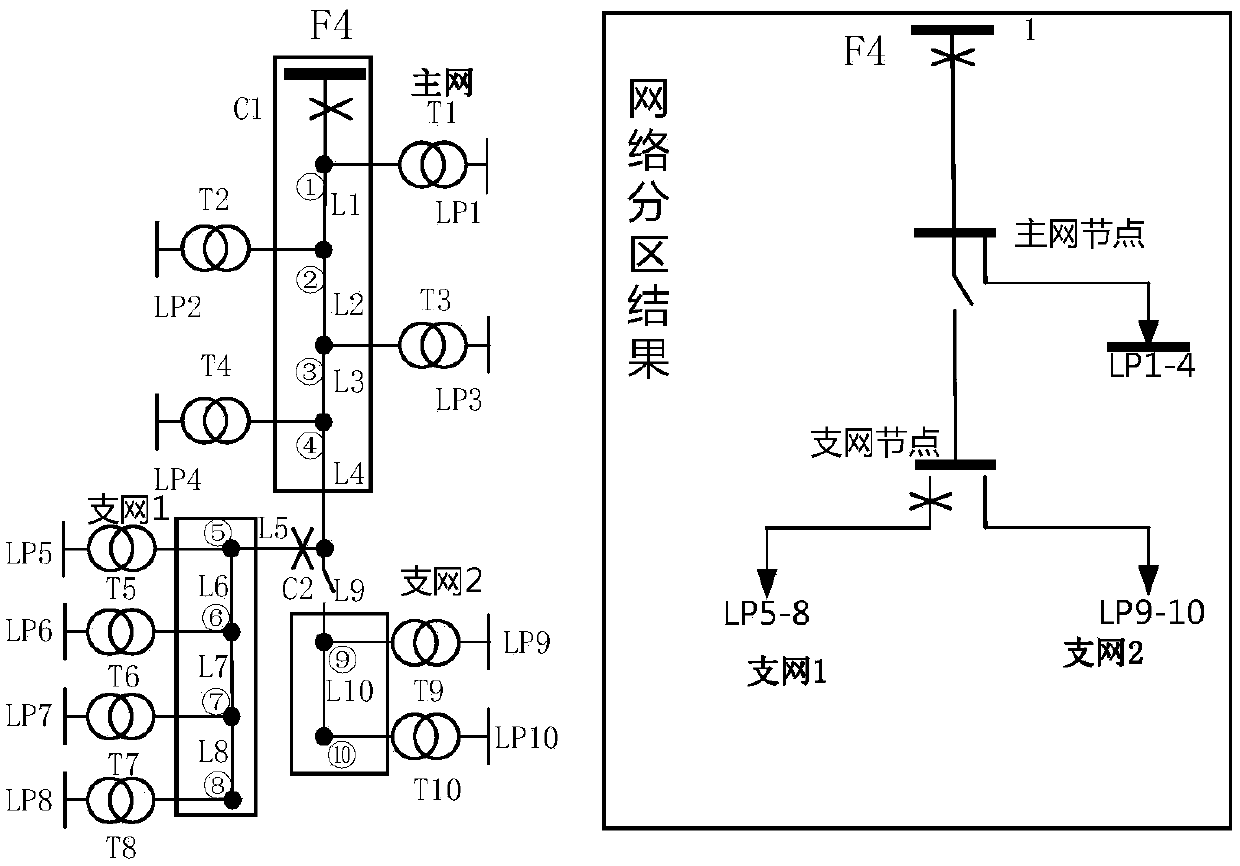

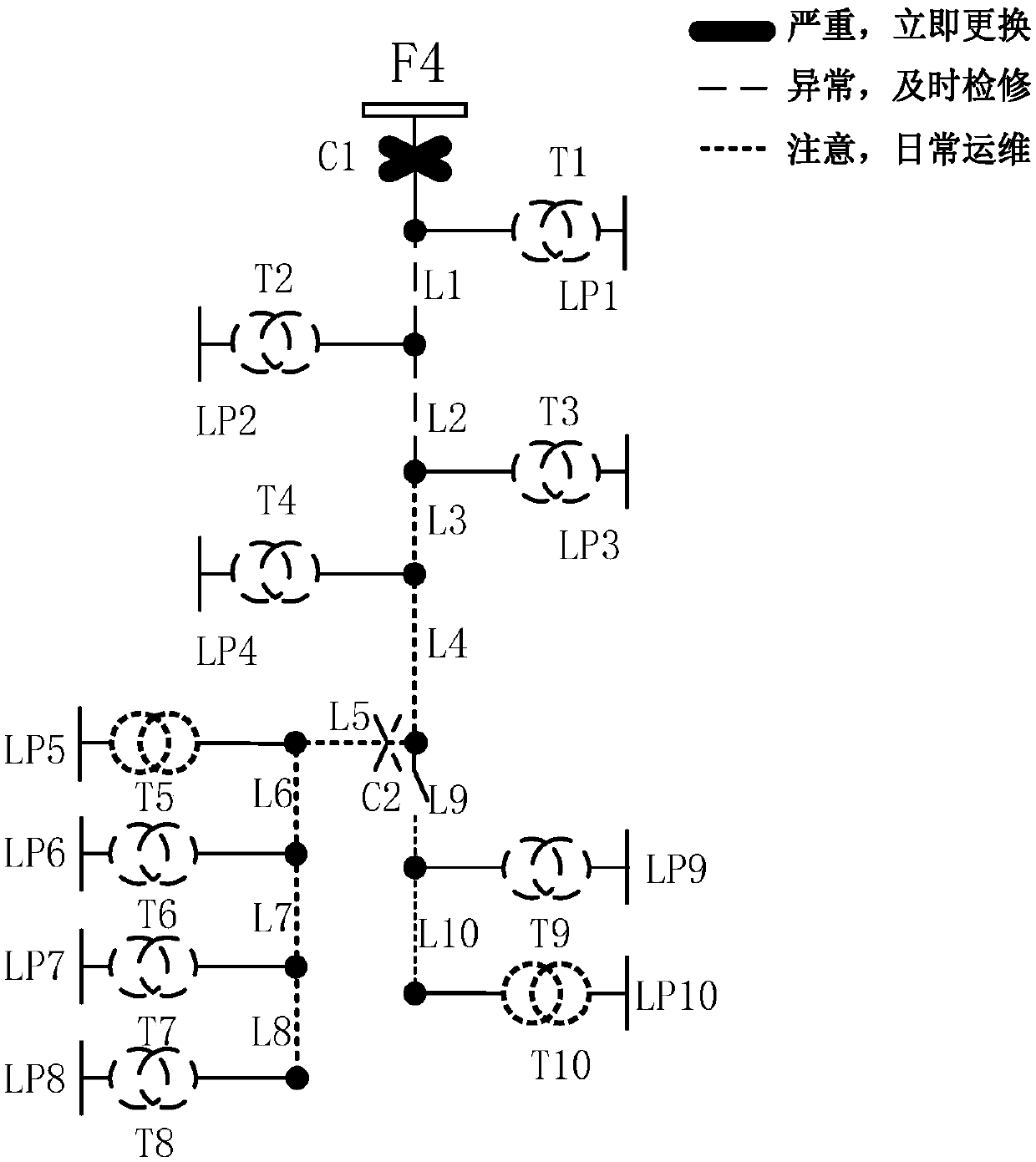

A power distribution system equipment state maintenance decision-making method based on risk assessment

InactiveCN109559043AFormulate simple, economical and intuitiveOvercome the shortcoming of poor real-time performanceResourcesInformation technology support systemReal-time dataMaintenance strategy

The invention discloses a power distribution system equipment state maintenance decision-making method based on risk assessment. The method comprises the steps of collecting operation data of power distribution system equipment for state evaluation and risk evaluation, and finally formulating differential operation and maintenance strategies. The method has the advantages that the equipment risk cost is determined from the two aspects of the equipment health degree and the importance degree. When the health degree index is calculated, real-time data and historical data are comprehensively considered, and the defect of poor real-time performance in traditional risk assessment is overcome; when the importance degree is calculated, the importance degree of the equipment is measured from the perspective that the influence of a single equipment fault on the whole power distribution system is not limited to the consideration of the self loss of the single equipment fault. Furthermore, the operation and maintenance sequence and the operation and maintenance mode are determined on the basis of the relative risk cost, so that the establishment of the operation and maintenance strategy is simple, economical and visual, the advantage of differential operation and maintenance is embodied, and scientific reference can be provided for the establishment of the operation and maintenance strategy of the power distribution equipment.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com