Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3612 results about "Maintenance system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System maintenance is an ongoing activity, which covers a wide variety of activities, including removing program and design errors, updating documentation and test data and updating user support.

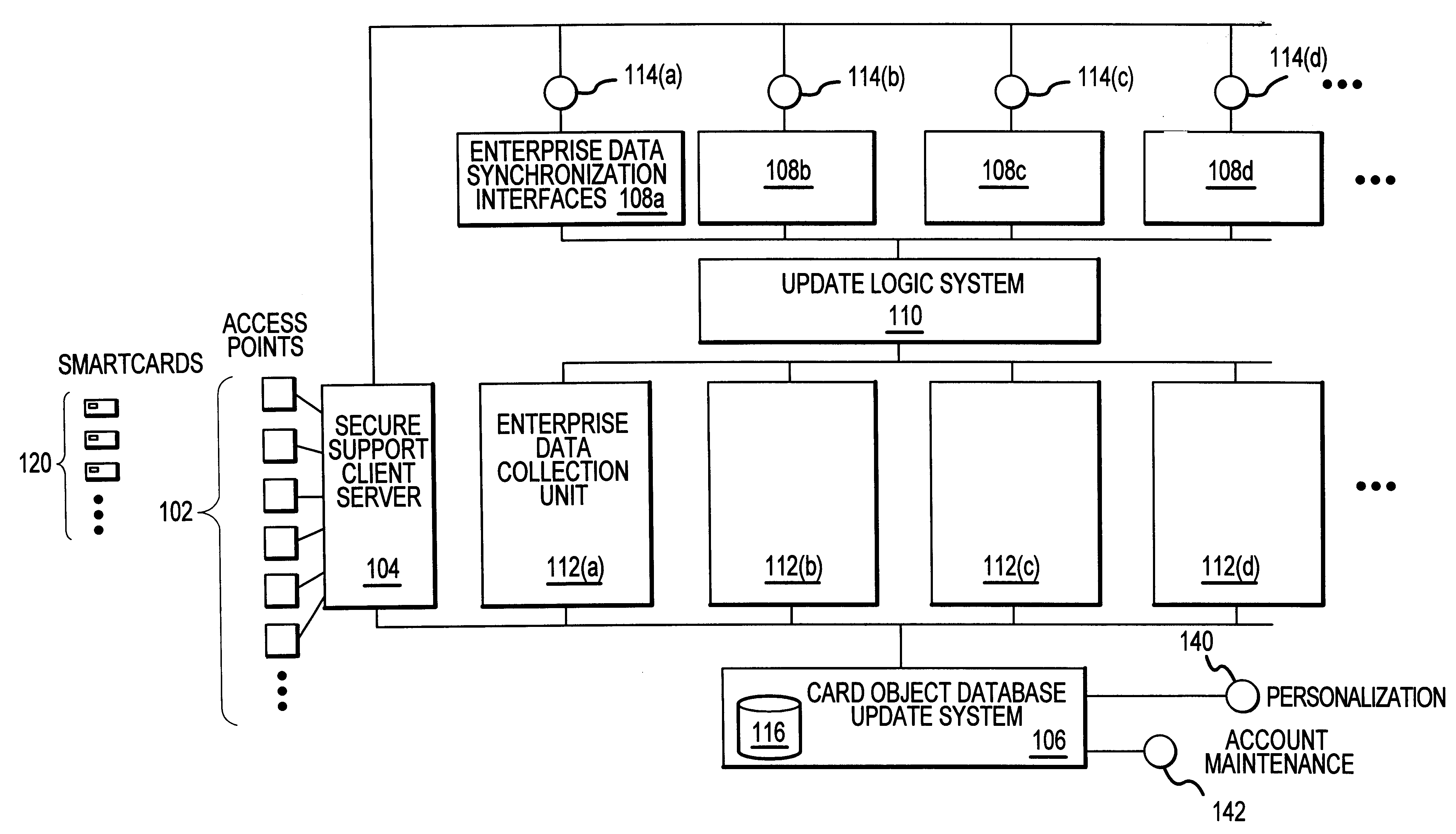

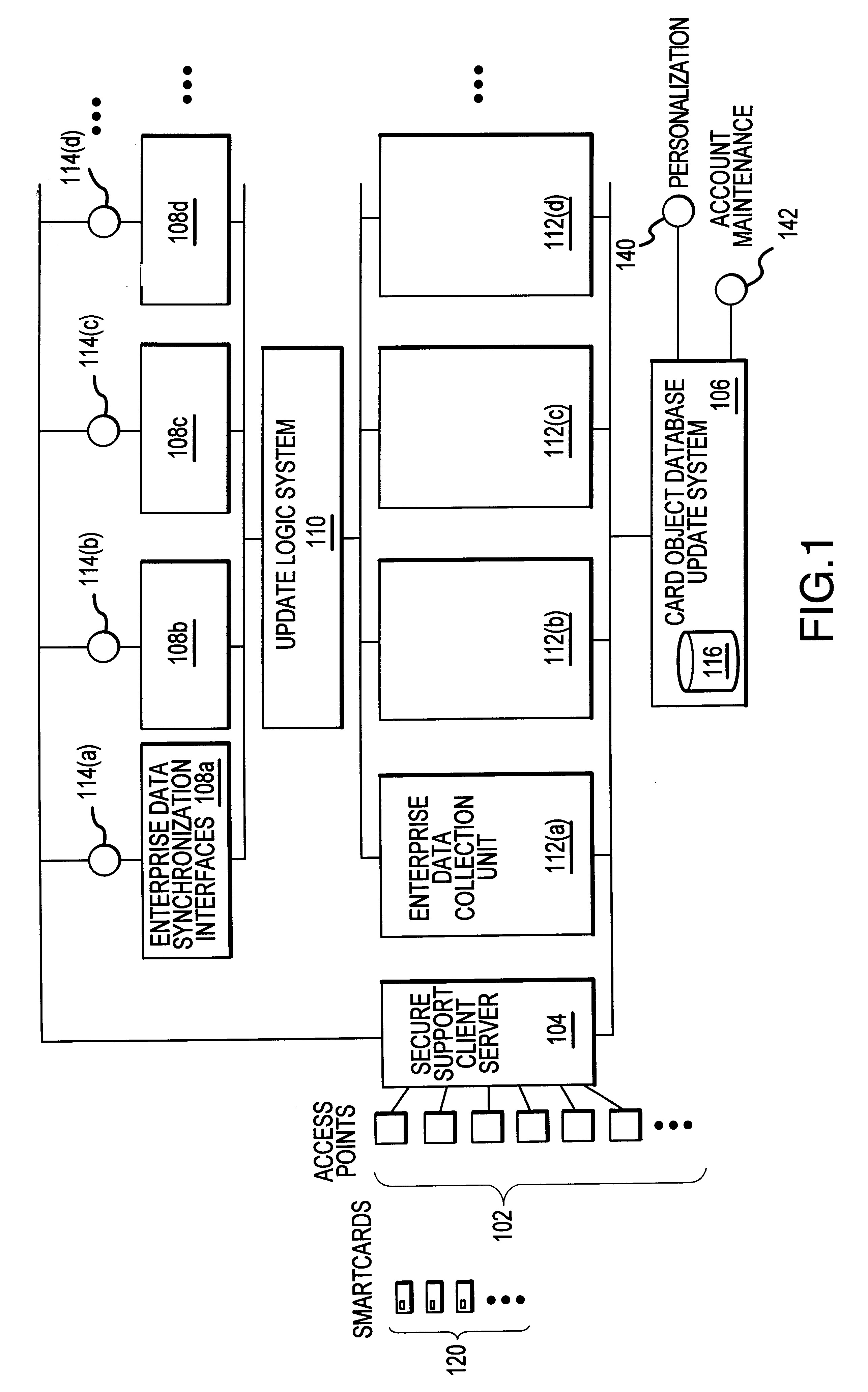

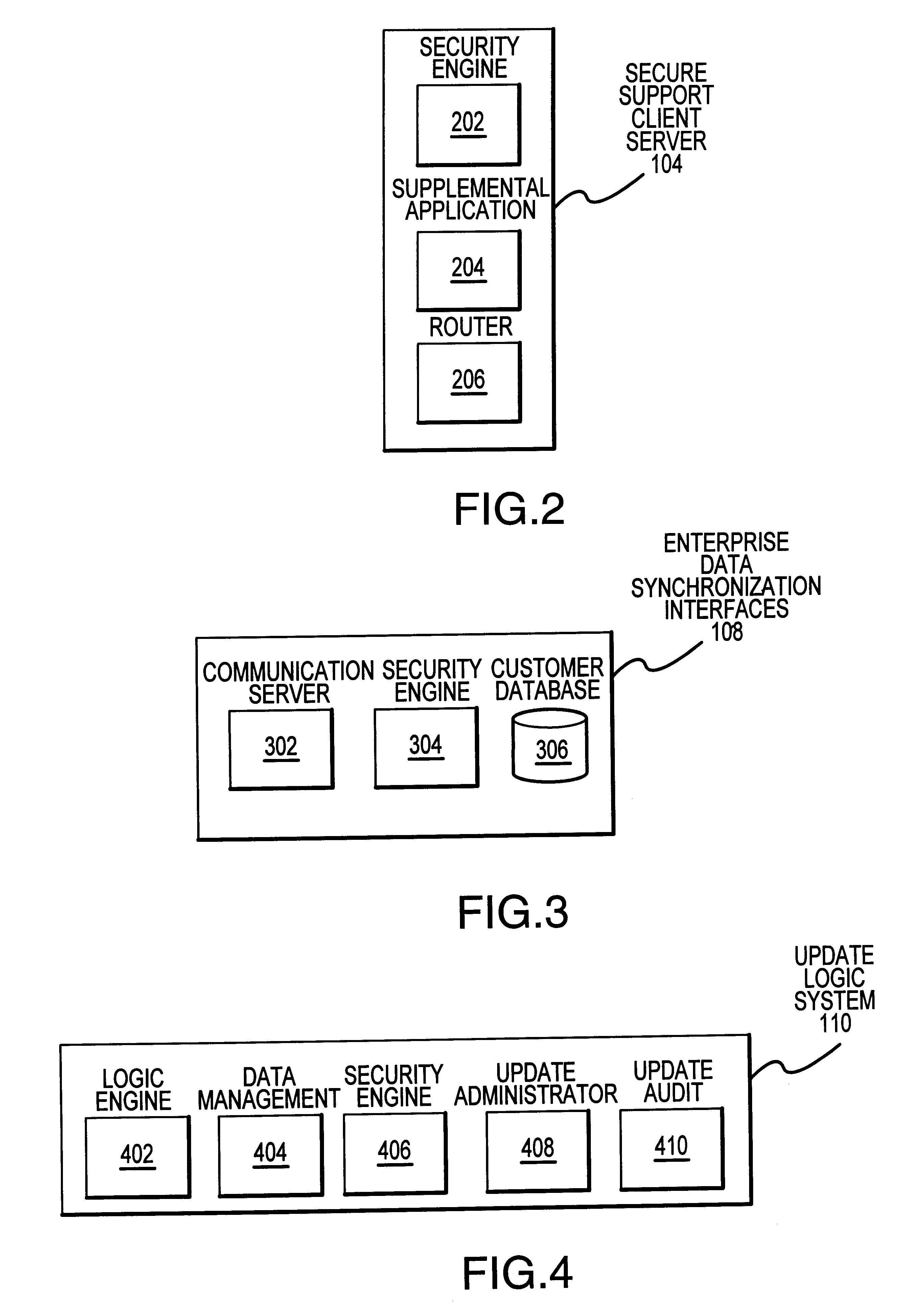

Methods and apparatus for dynamic smartcard synchronization and personalization

InactiveUS6199762B1Sensing by mechanical meansCo-operative working arrangementsPersonalizationData synchronization

A system generally for personalizing and synchronizing smartcard data in the context of a distributed transaction system is disclosed. A dynamic smartcard synchronization system comprises access points configured to initiate a transaction in conjunction with a smartcard, an enterprise data collection unit, and a card object database update system. An exemplary dynamic synchronization system (DSS) preferably comprises various smartcard access points, a secure support client server, a card object database update system (CODUS), one or more enterprise data synchronization interfaces (EDSI), an update logic system, one or more enterprise data collection units (EDCUs), and one or more smartcard access points configured to interoperably accept and interface with smartcards. In an exemplary embodiment, DSS comprises a personalization system and an account maintenance system configured to communicate with CODUS. Personalization of multi-function smartcards is accomplished using a security server configured to generate and / or retrieve cryptographic key information from multiple enterprise key systems during the final phase of the smartcard issuance process.

Owner:LIBERTY PEAK VENTURES LLC

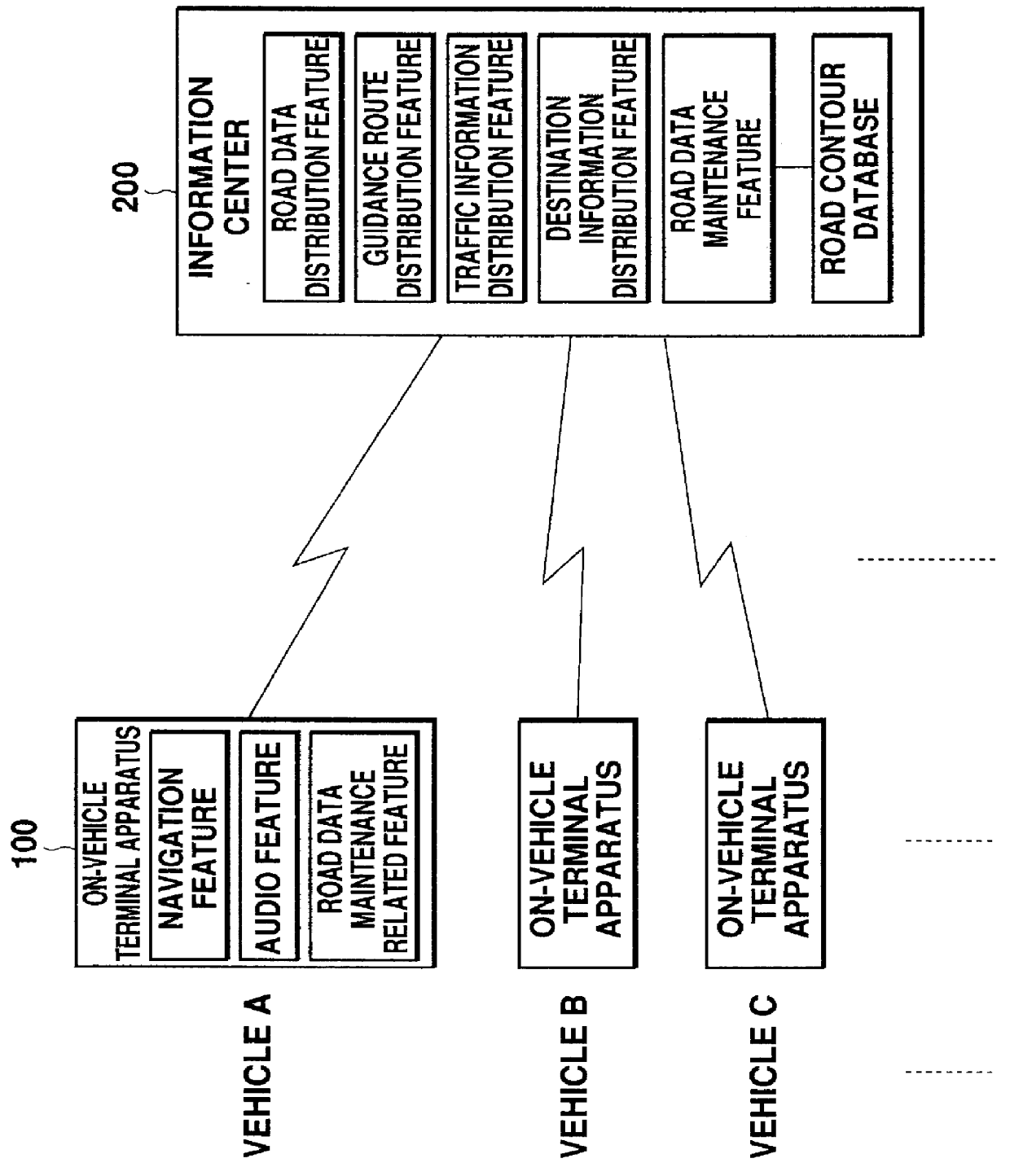

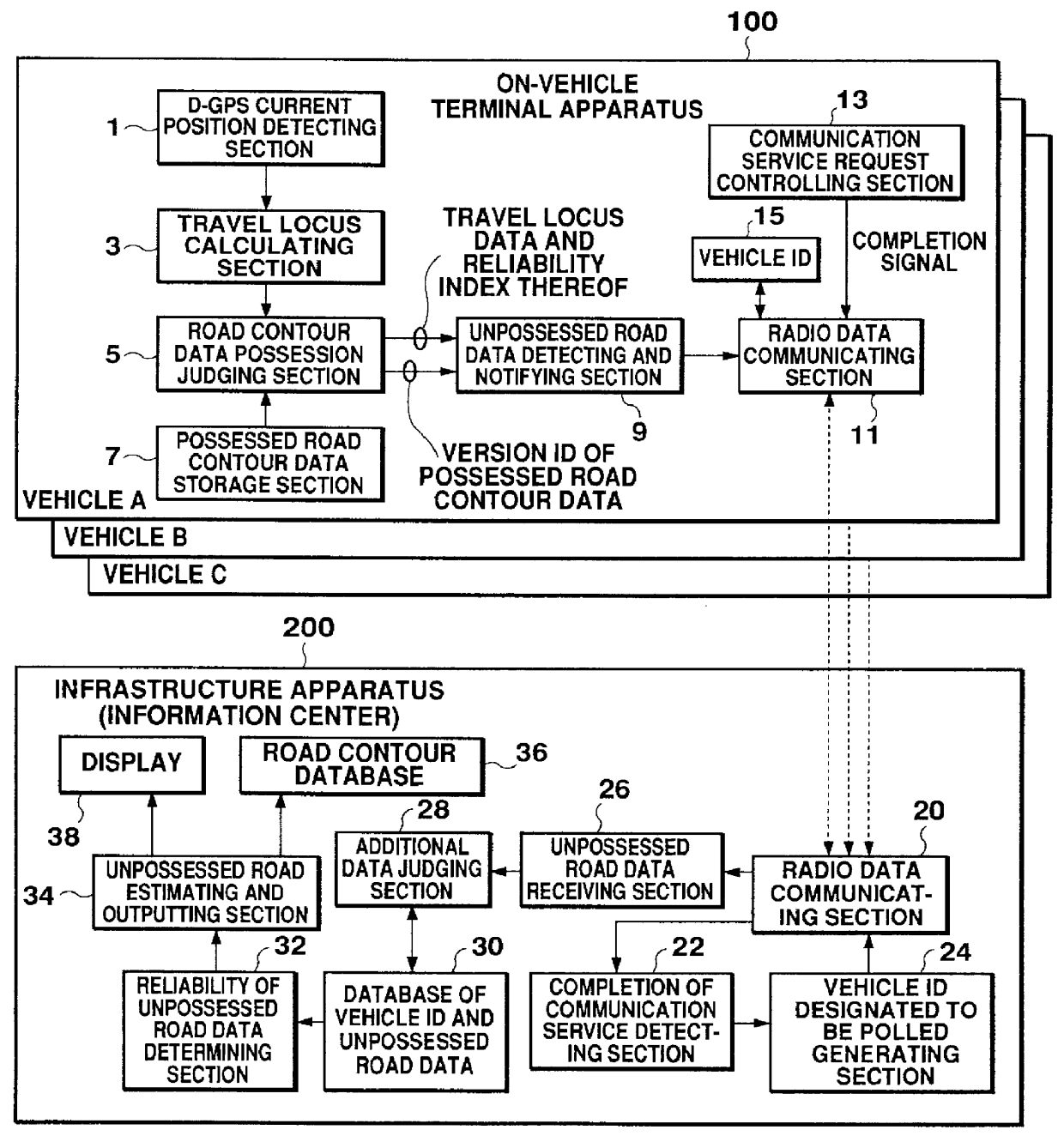

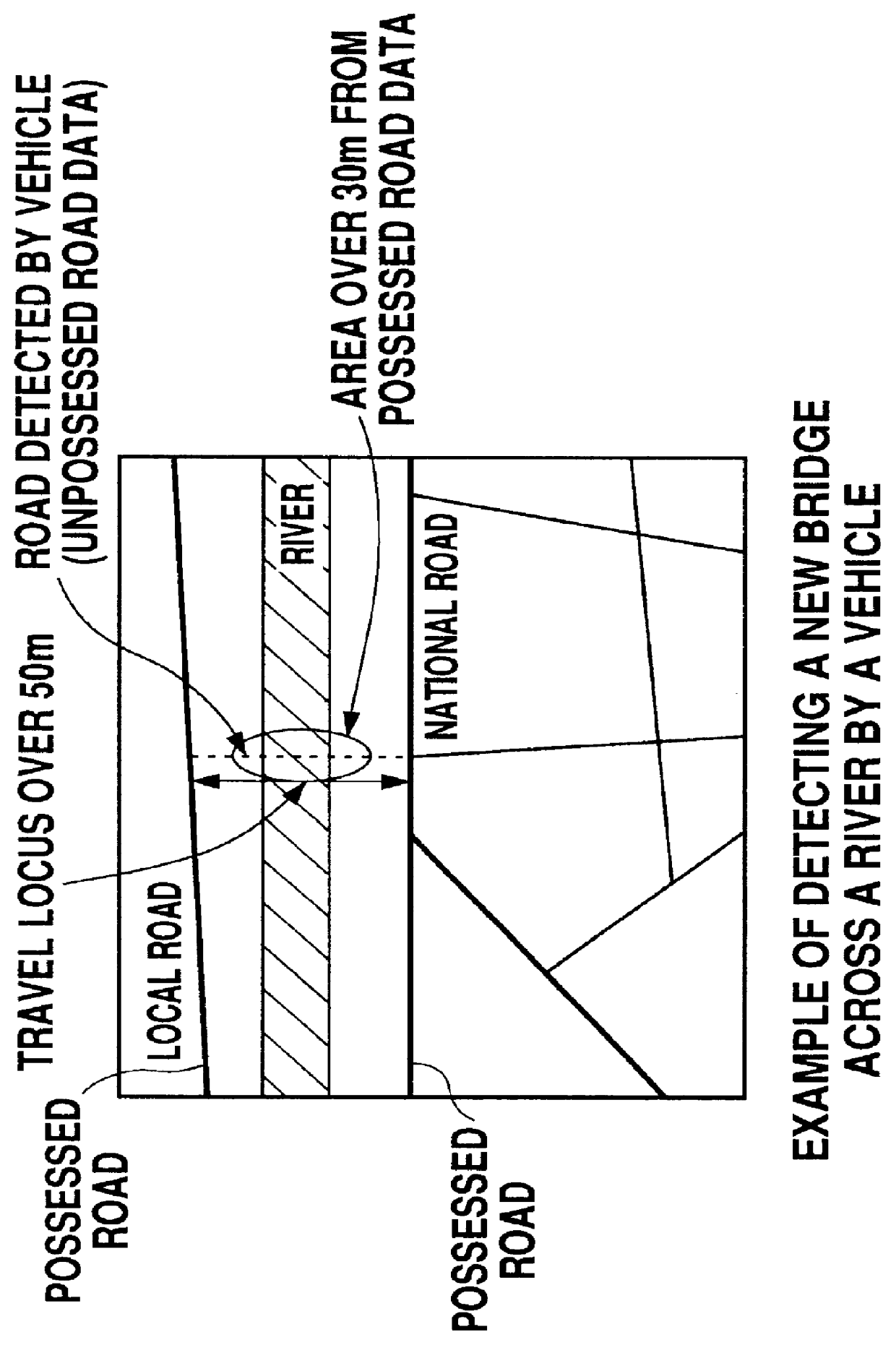

Road data maintenance system and on-vehicle terminal apparatus compatible therewith

InactiveUS6154152AEasy accessInstruments for road network navigationArrangements for variable traffic instructionsComputer terminalEngineering

Unpossessed road data is added to possessed road data stored in a road contour database of an information center. An on-vehicle terminal apparatus first compares a current position of a vehicle detected by a D-GPS unit against the road data stored in a storage section for storing road contour data of possessed roads. If the current position deviates from a known existing road, it is determined that the vehicle travels on an unpossessed road. Road data of the unpossessed road is then obtained based on a travel locus of the vehicle and sent to the information center together with a reliability index of the road data. The information center collects unpossessed road data from a plurality of sources, evaluates the reliability index for each data, and adds sufficiently reliable road data to the possessed road data. Thus, the information center can quickly obtain and utilize new and reliable road data.

Owner:TOYOTA JIDOSHA KK

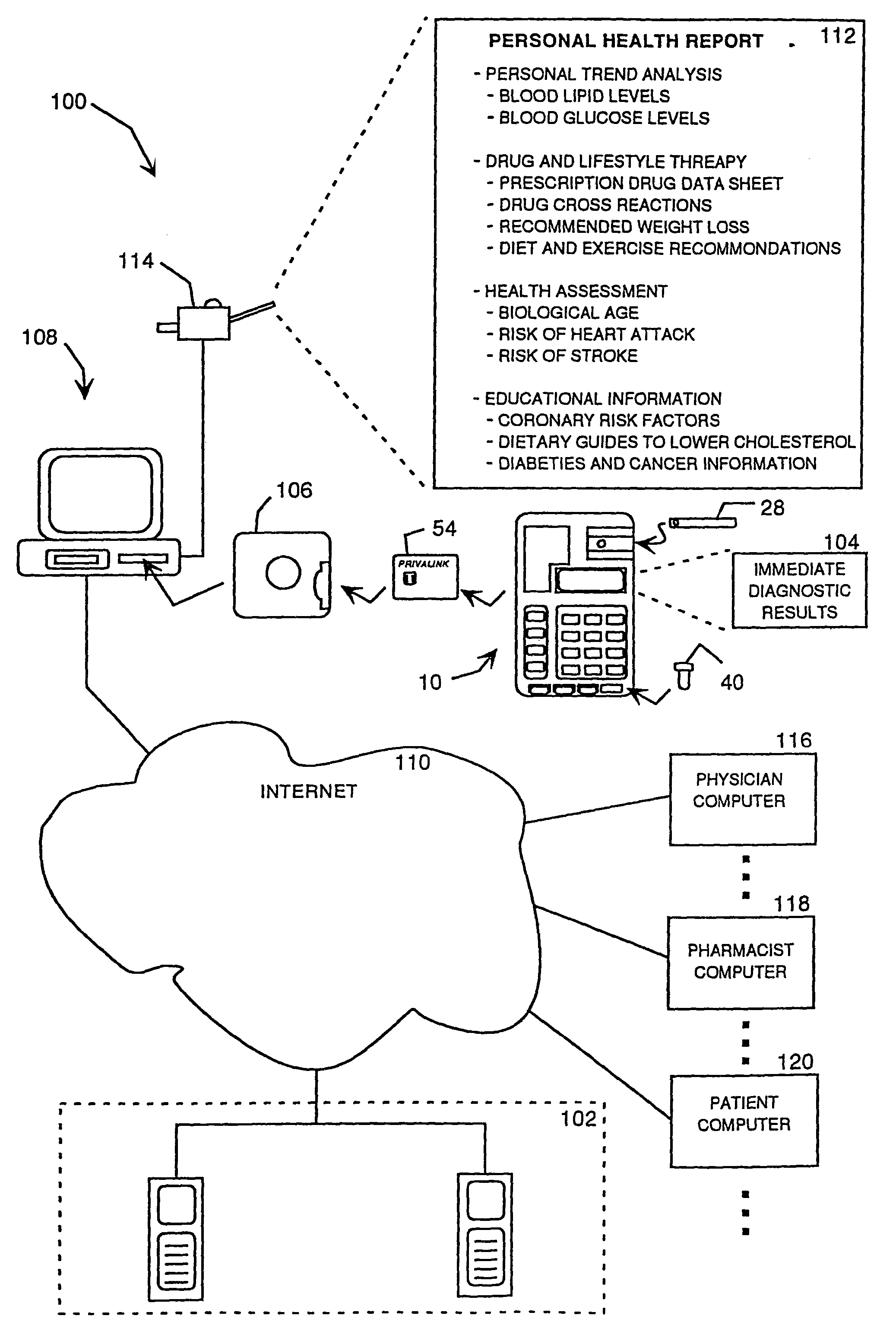

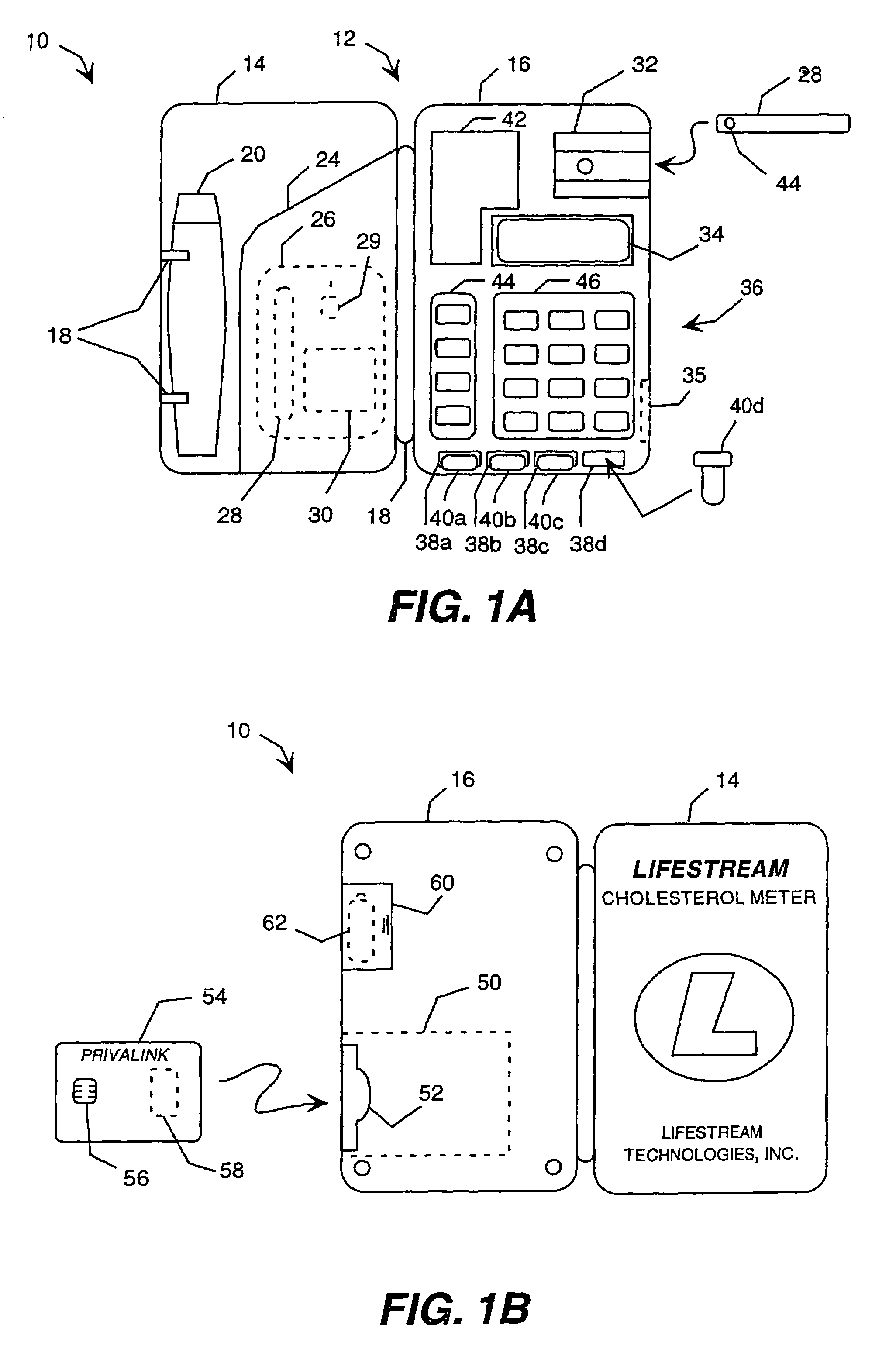

Secure medical records maintenance system

InactiveUS7092891B2Low costReduce inconvenienceBiomass after-treatmentAngiographyMedical recordRemovable media

A secure medical records maintenance system including a first server that stores patient identification information indexed by patient identification numbers (PINs) and a second server that stores patient medical data indexed by medical record identification numbers. For security purposes, the medical data maintained in the second remote server cannot be correlated to the associated patient identification information maintained in the first server based on the information contained in the servers. A correlation table uniquely associating each medical record identification number with a particular one of the patient identification numbers is used to allow correlation of the databases. The correlation table for a particular patient typically resides on a patient's removable memory storage device (smartcard). The correlation table for a practaioner's patients may also reside on the practitioner's computer, which is associated with the licensed medical practitioner having an assigned professional registration number

Owner:ORANGEHOOK INC

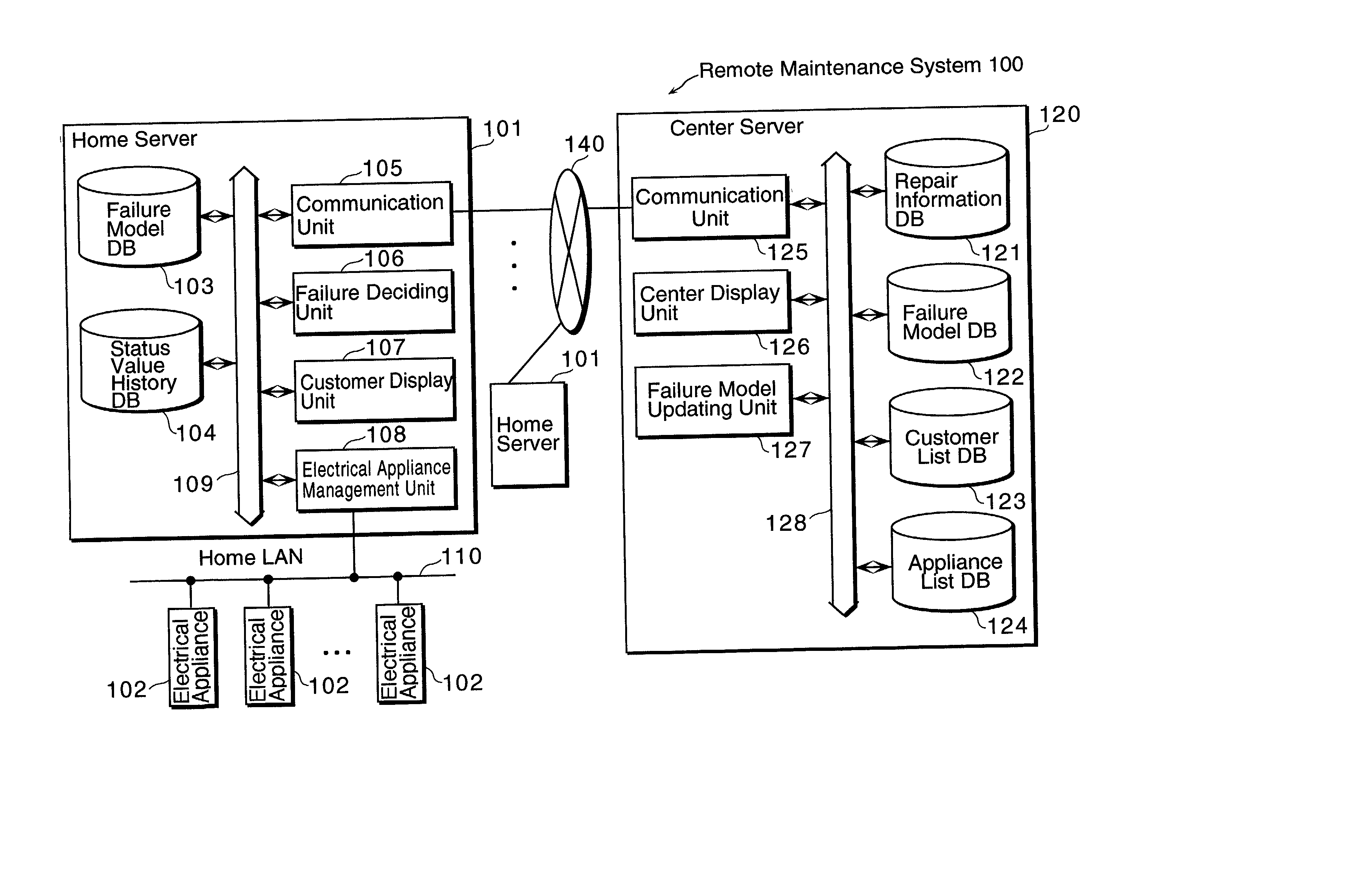

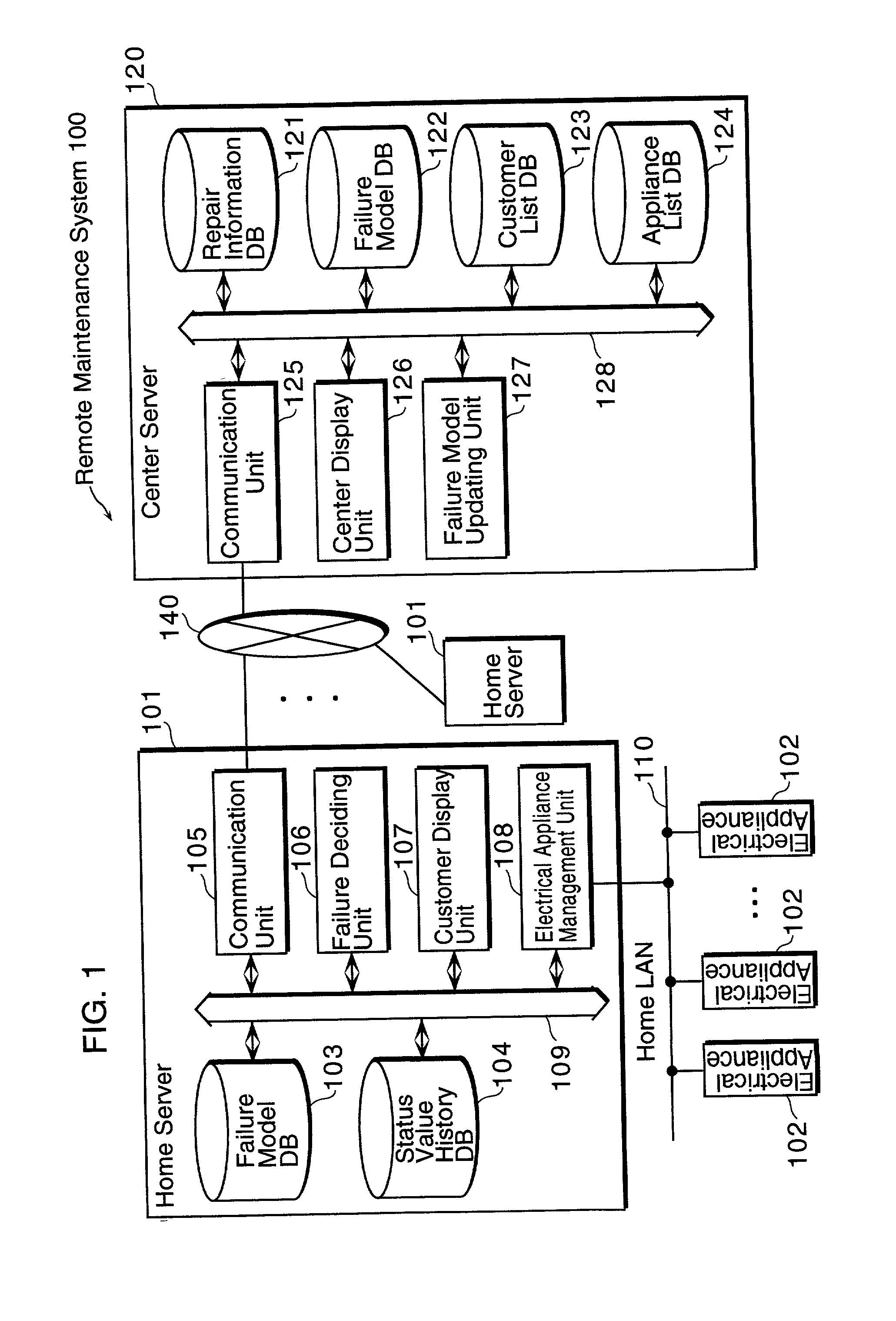

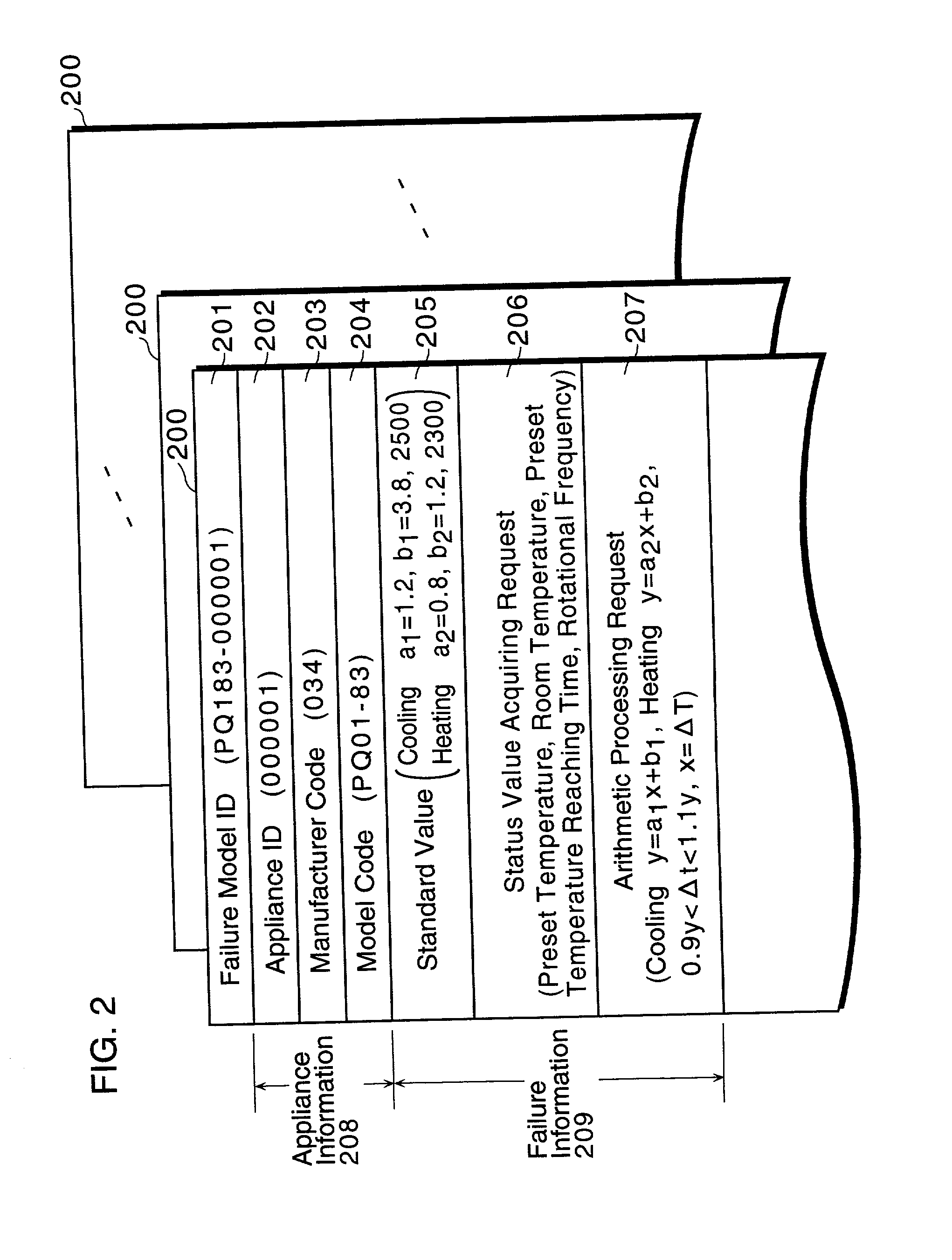

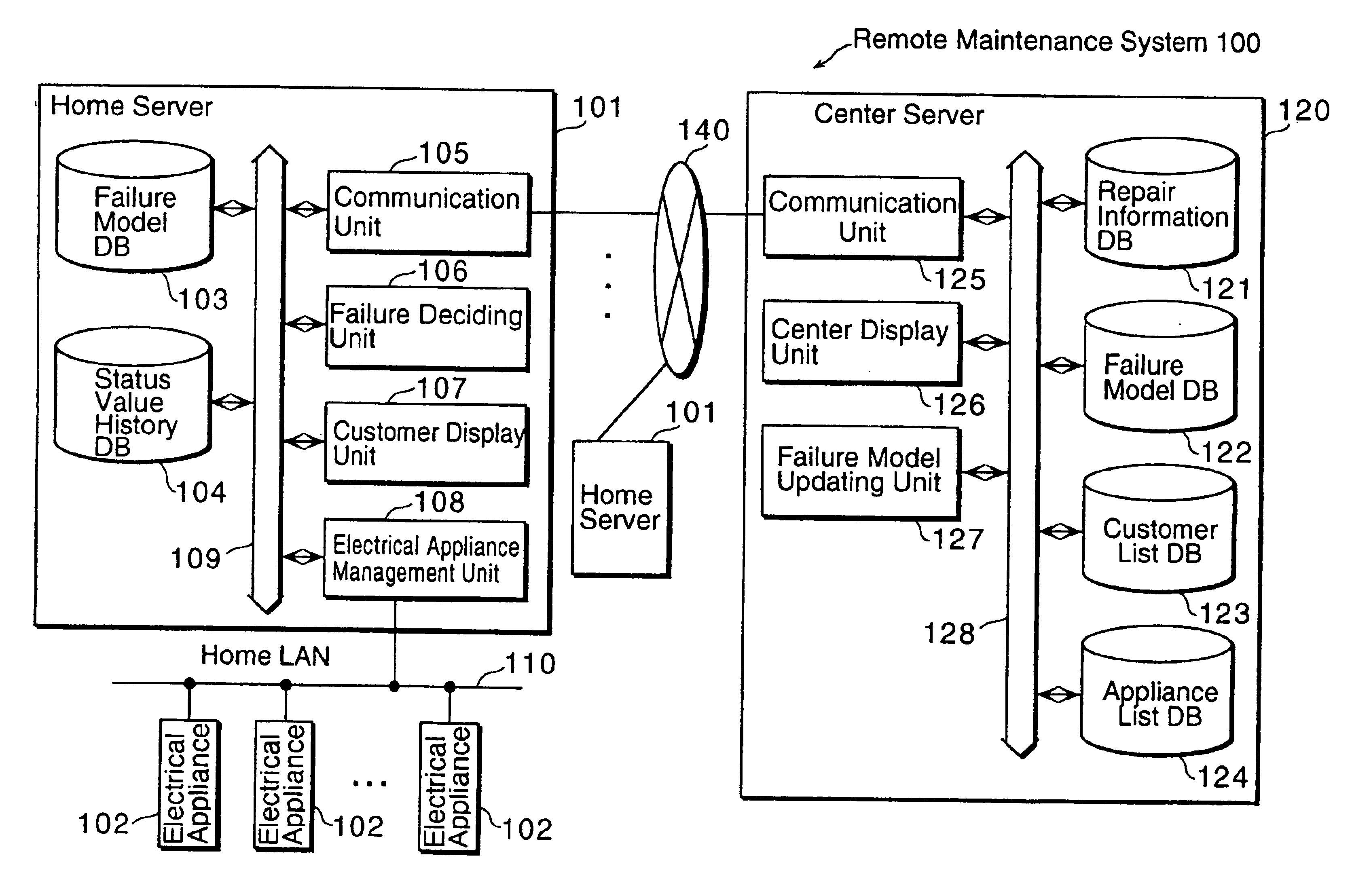

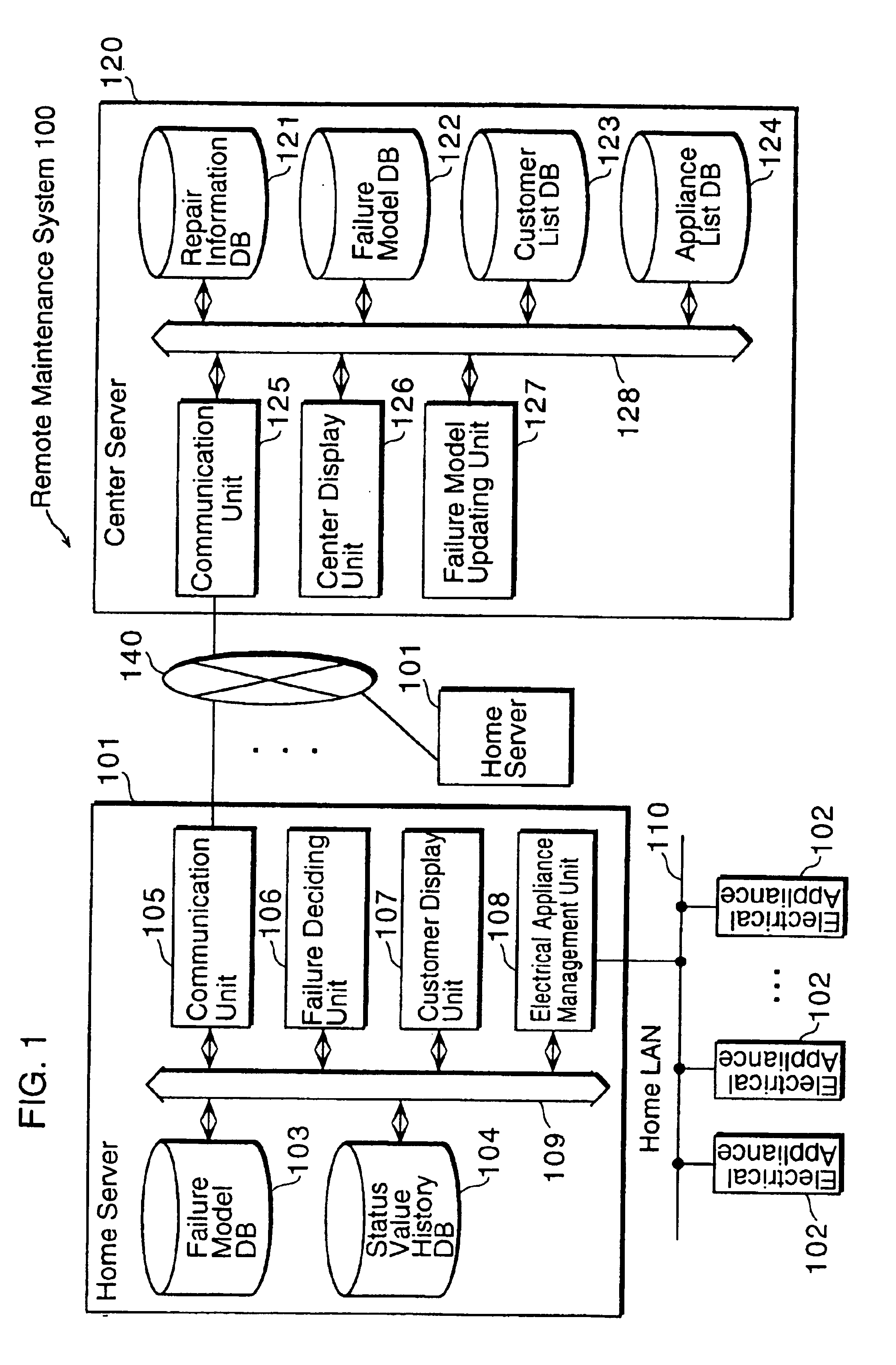

Remote maintenance system

InactiveUS20020128728A1Incorrect actionTelemetry/telecontrol selection arrangementsData processing applicationsCommunication unitManagement unit

A remote maintenance system 100 in which a center server 120 that is located in a service center for performing maintenance of an electrical appliance 102 and a home server 101 that is located in each house and monitors a status of the electrical appliance 102 in the house are connected via a communication network 140, wherein (A) the home server 101 includes an electrical appliance management unit 108 that acquires a status value of the electrical appliance 102, a communication unit 105 that receives from the center server 120 a failure model which is information defining a method of deriving a decision whether the electrical appliance 102 is failed or not from the status value, and a failure deciding unit 106 that decides whether the electrical appliance is failed or not based on the acquired status value and the received failure model using qualitative reasoning, and (B) the center server 120 includes a failure model updating unit 127 that updates a failure model and send the updated failure model to the home server 101 via a communication unit 125.

Owner:PANASONIC CORP

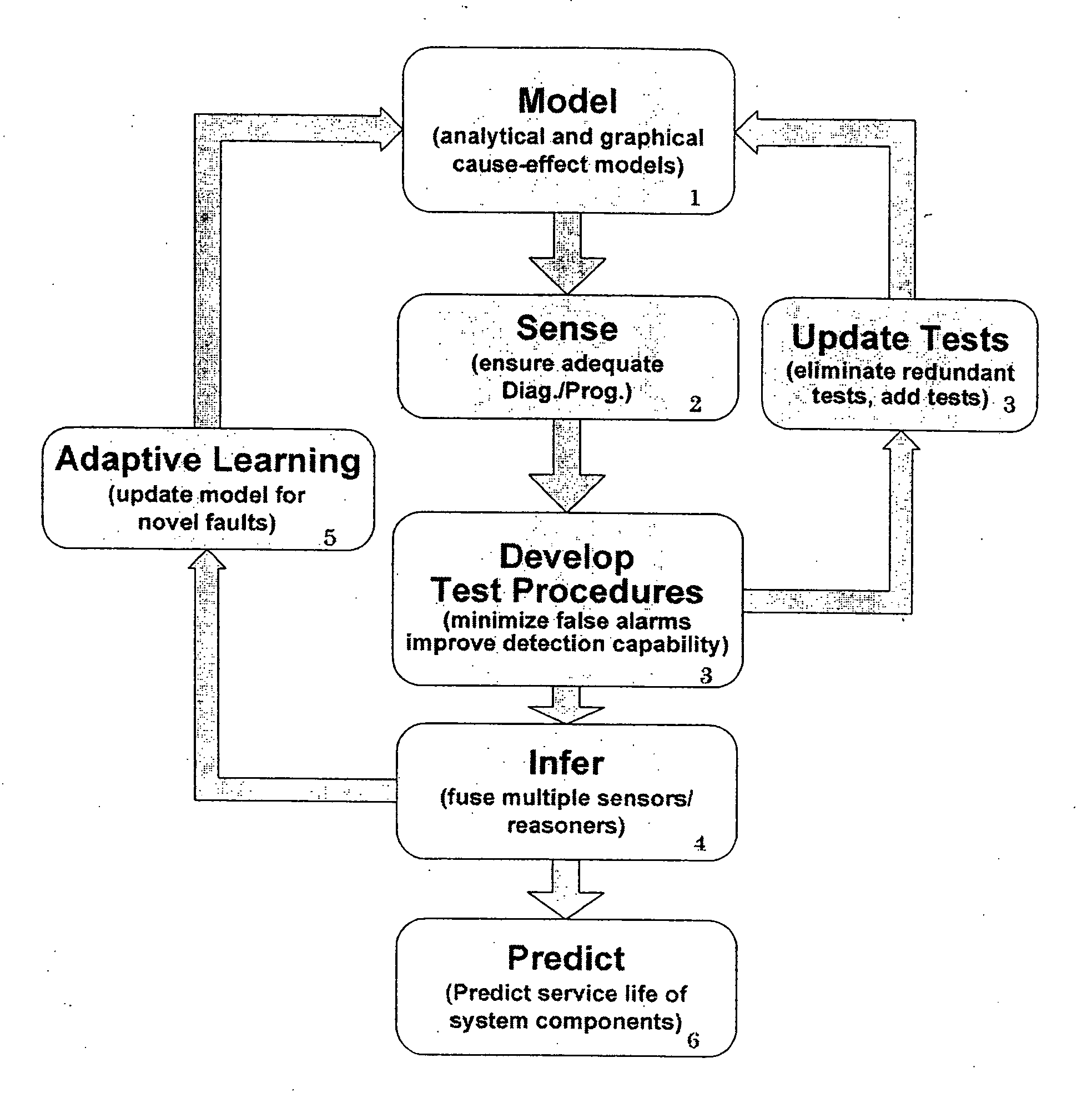

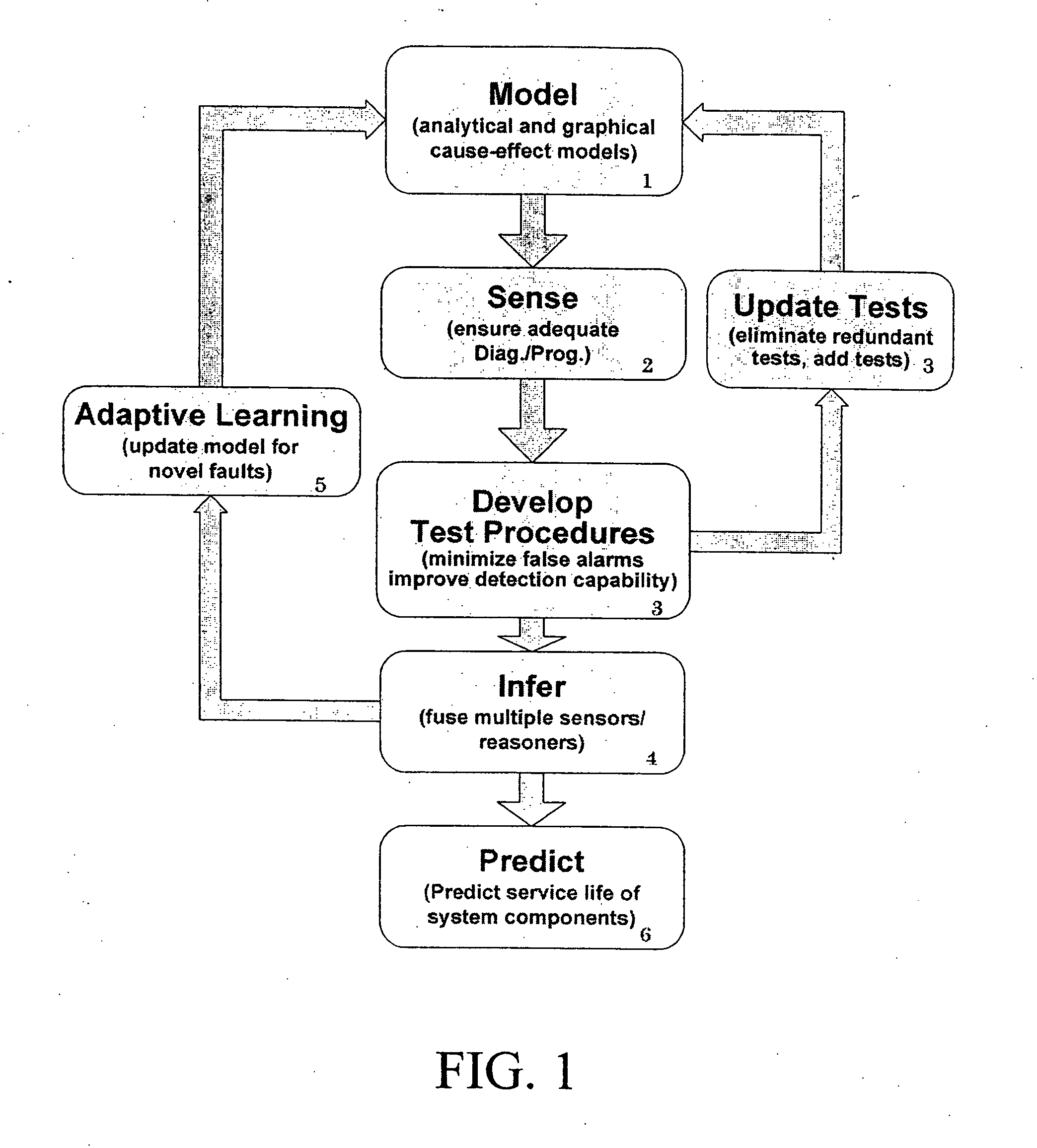

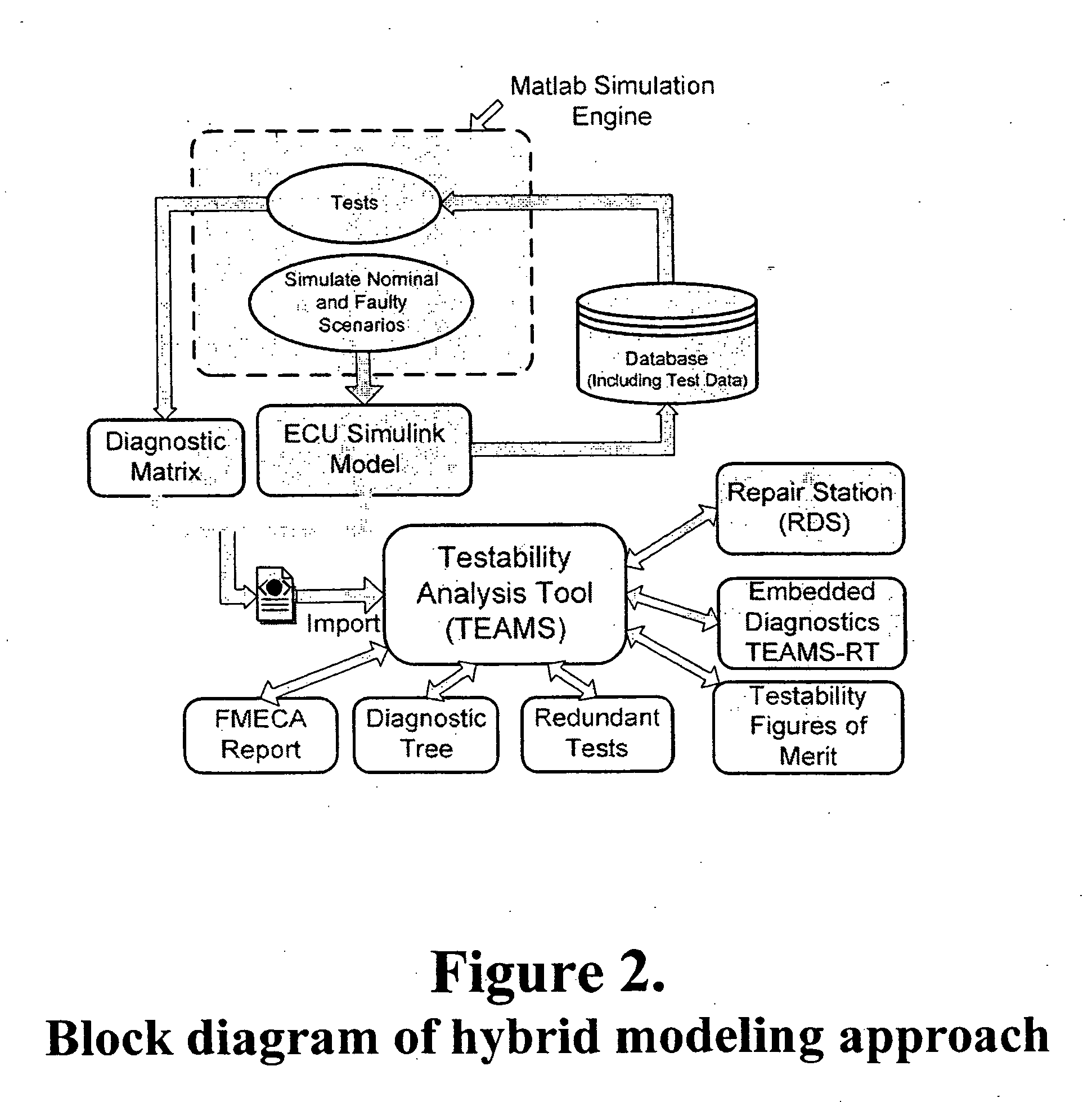

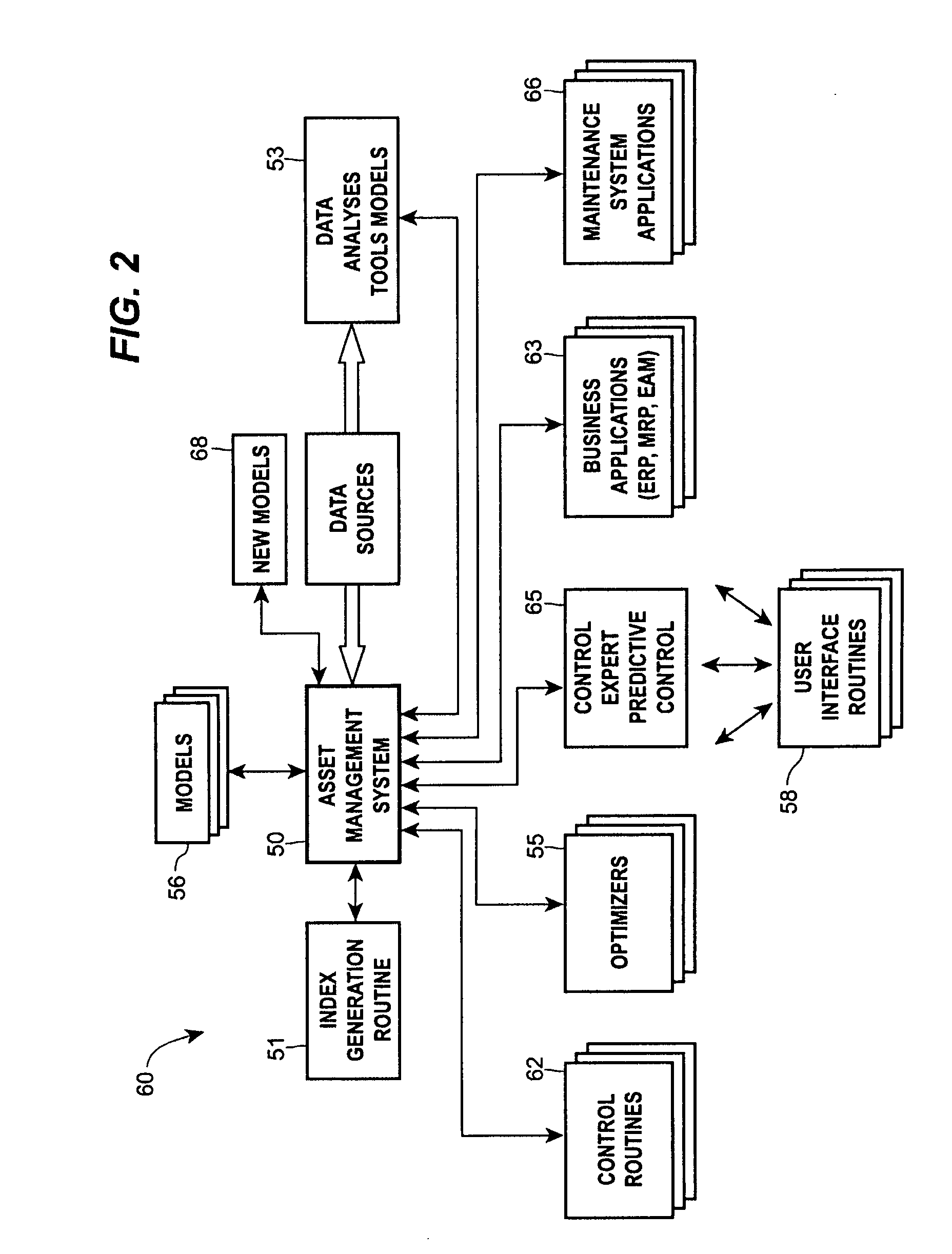

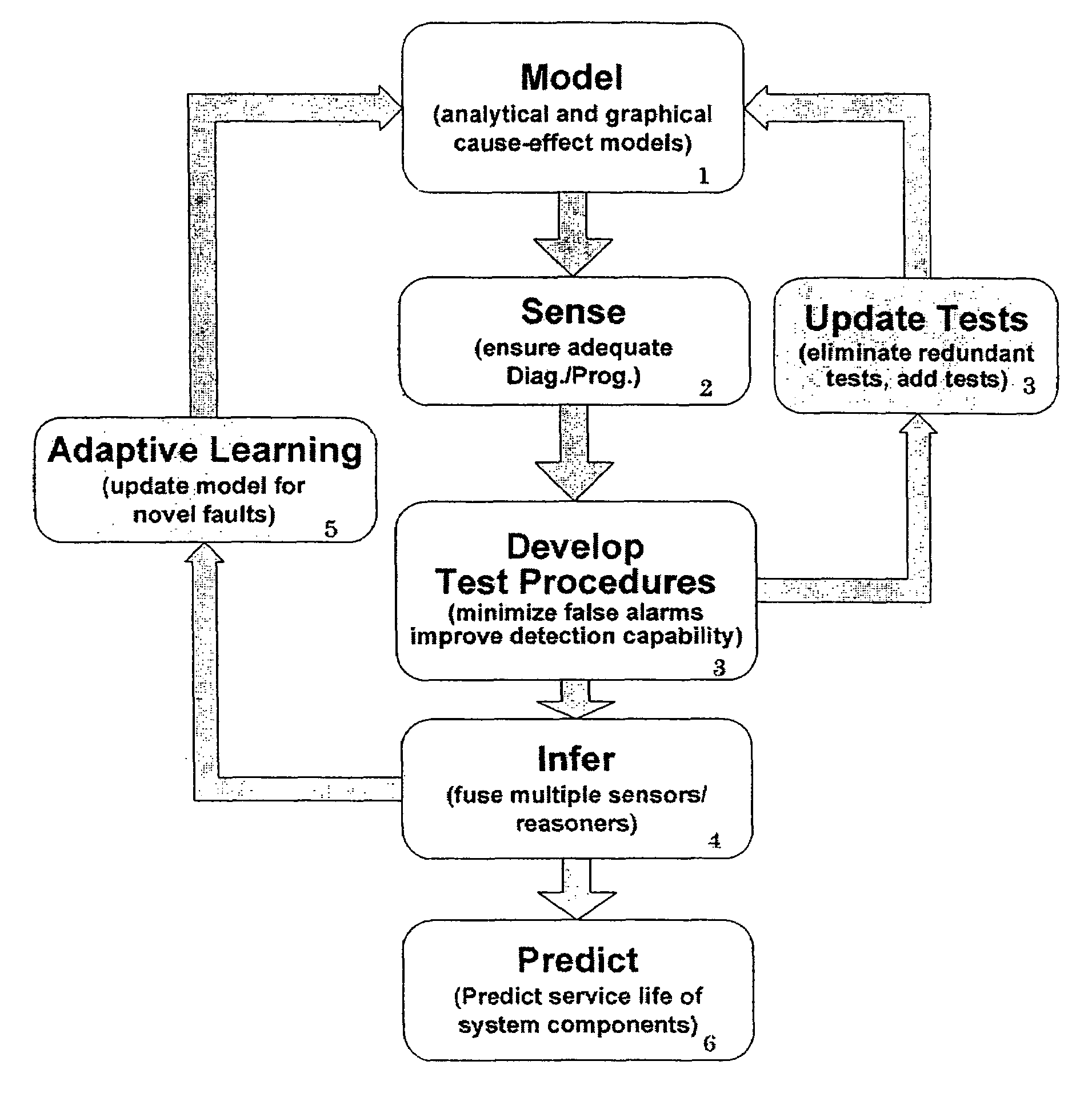

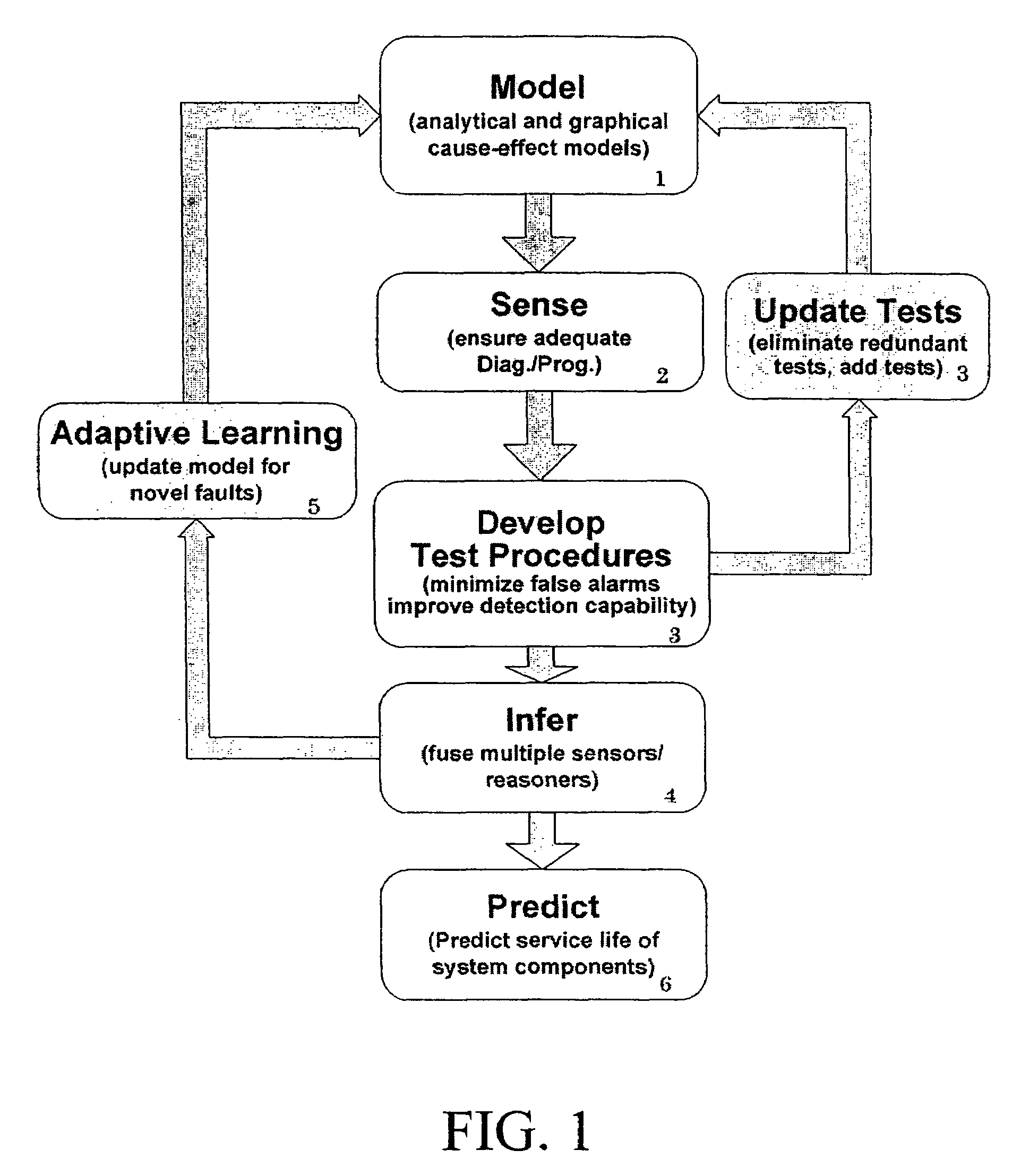

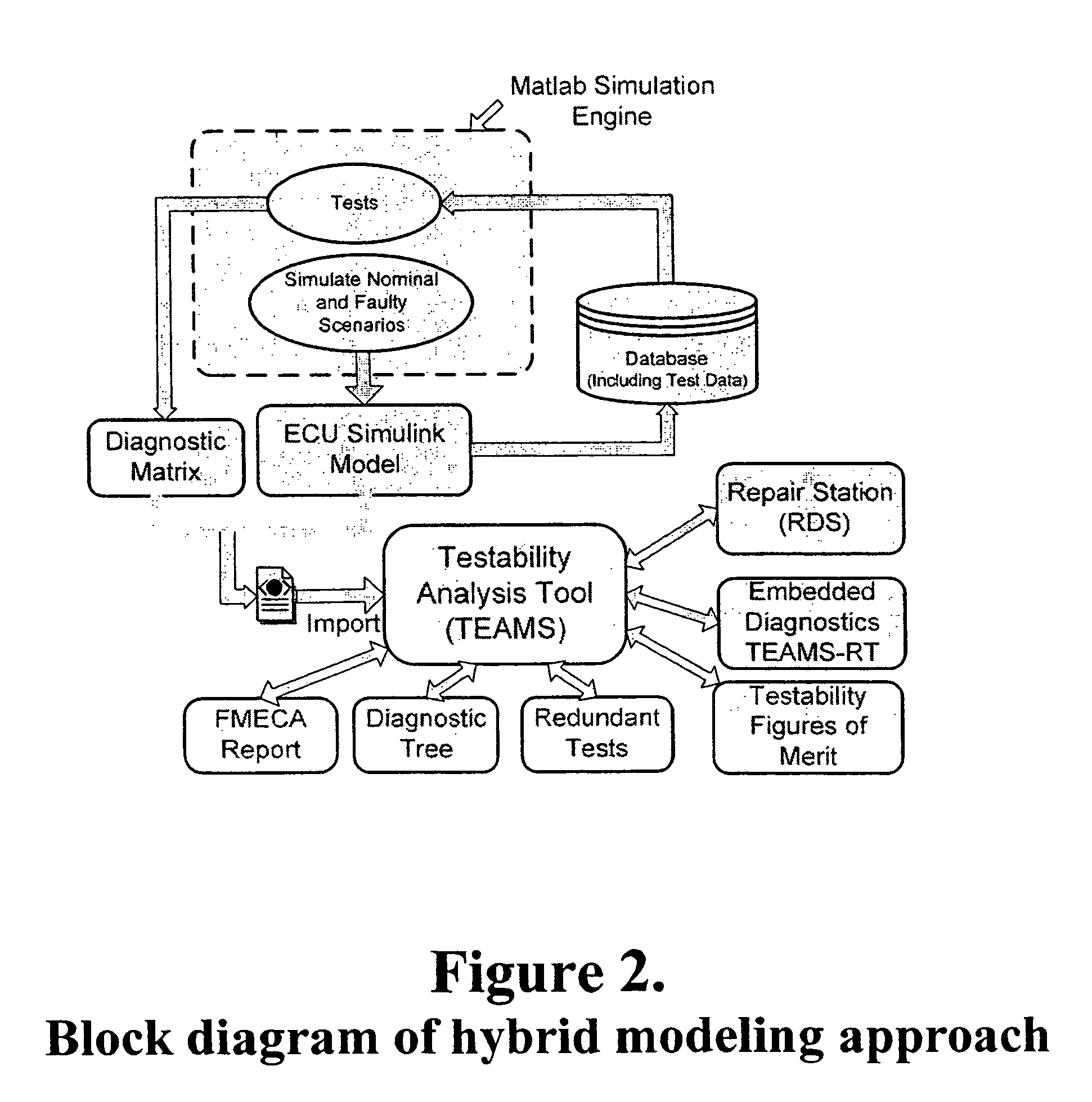

Intelligent model-based diagnostics for system monitoring, diagnosis and maintenance

InactiveUS20060064291A1Improve accuracyImprove consistencyAmplifier modifications to reduce noise influenceTesting/monitoring control systemsElectric power systemCompound (substance)

Systems and methods are provided for monitoring, diagnosis and condition-based maintenance of mechanical systems. The disclosed systems and methods employ intelligent model-based diagnostic methodologies to effectuate such monitoring, diagnosis and maintenance. According to exemplary embodiments of the present disclosure, the intelligent model-based diagnostic methodologies combine or integrate quantitative (analytical) models and graph-based dependency models to enhance diagnostic performance. The disclosed systems and methods may be employed a wide variety of applications, including automotive, aircraft, power systems, manufacturing systems, chemical processes and systems, transportation systems, and industrial machines / equipment.

Owner:TOYOTA TECHN CENT USA +1

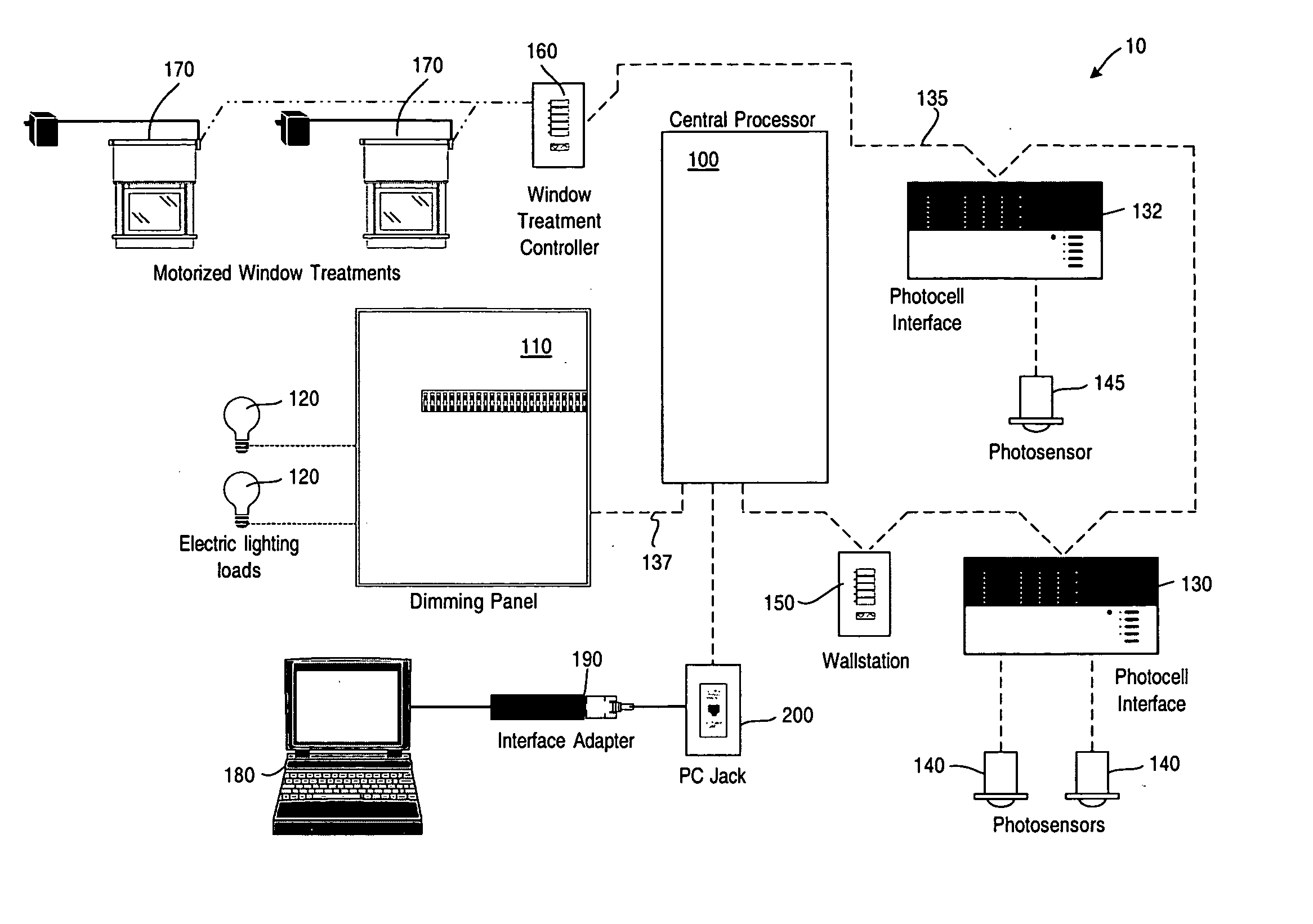

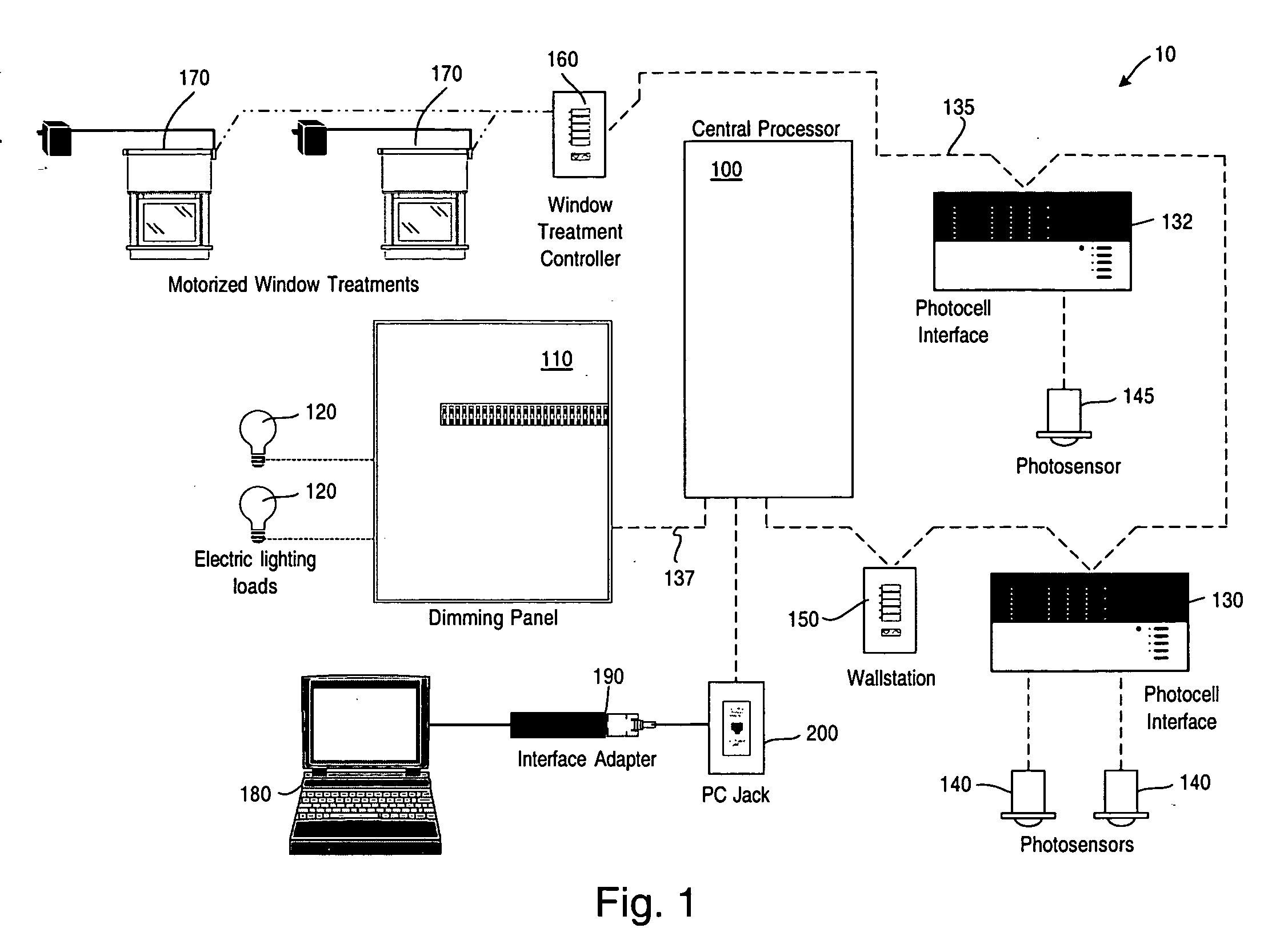

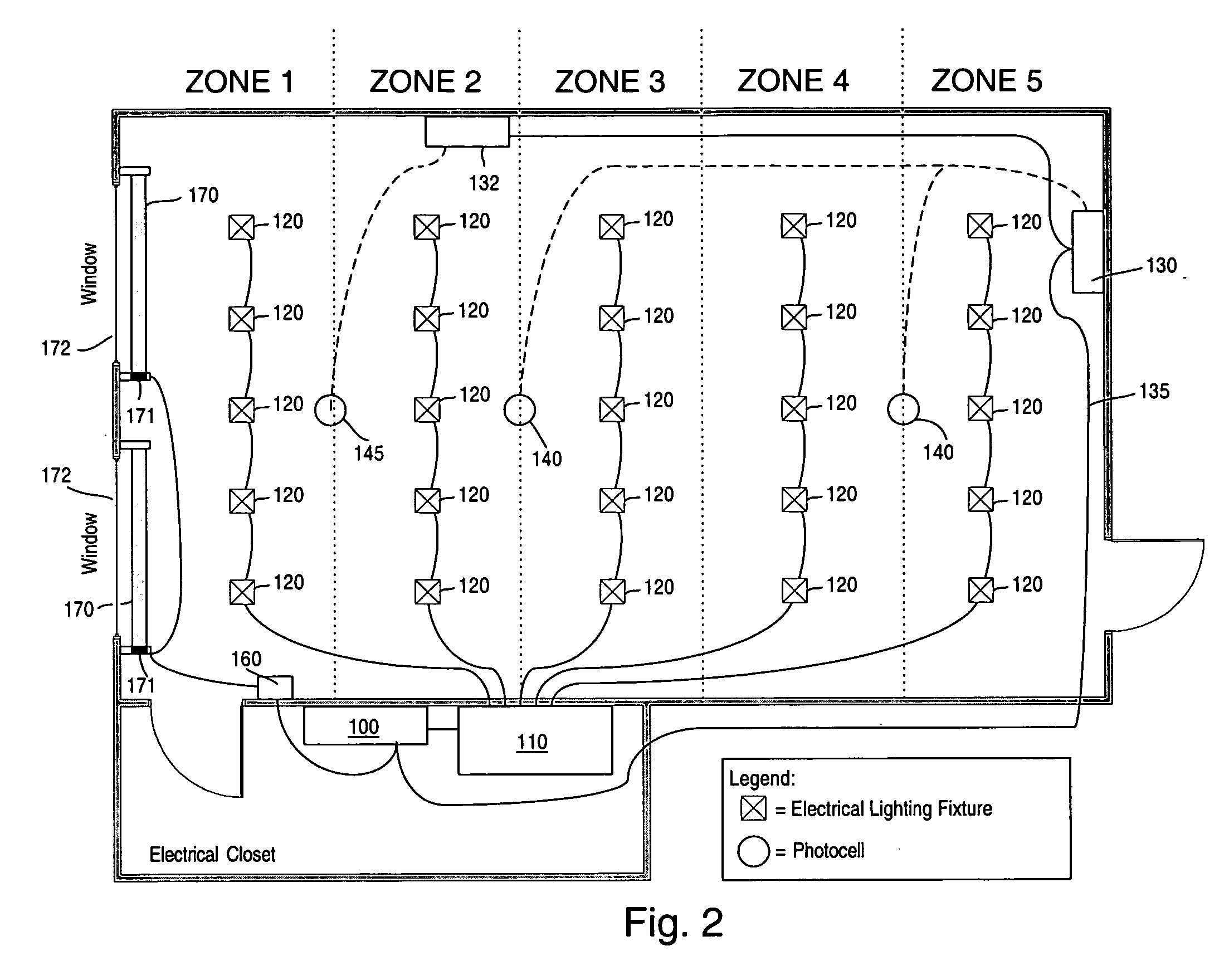

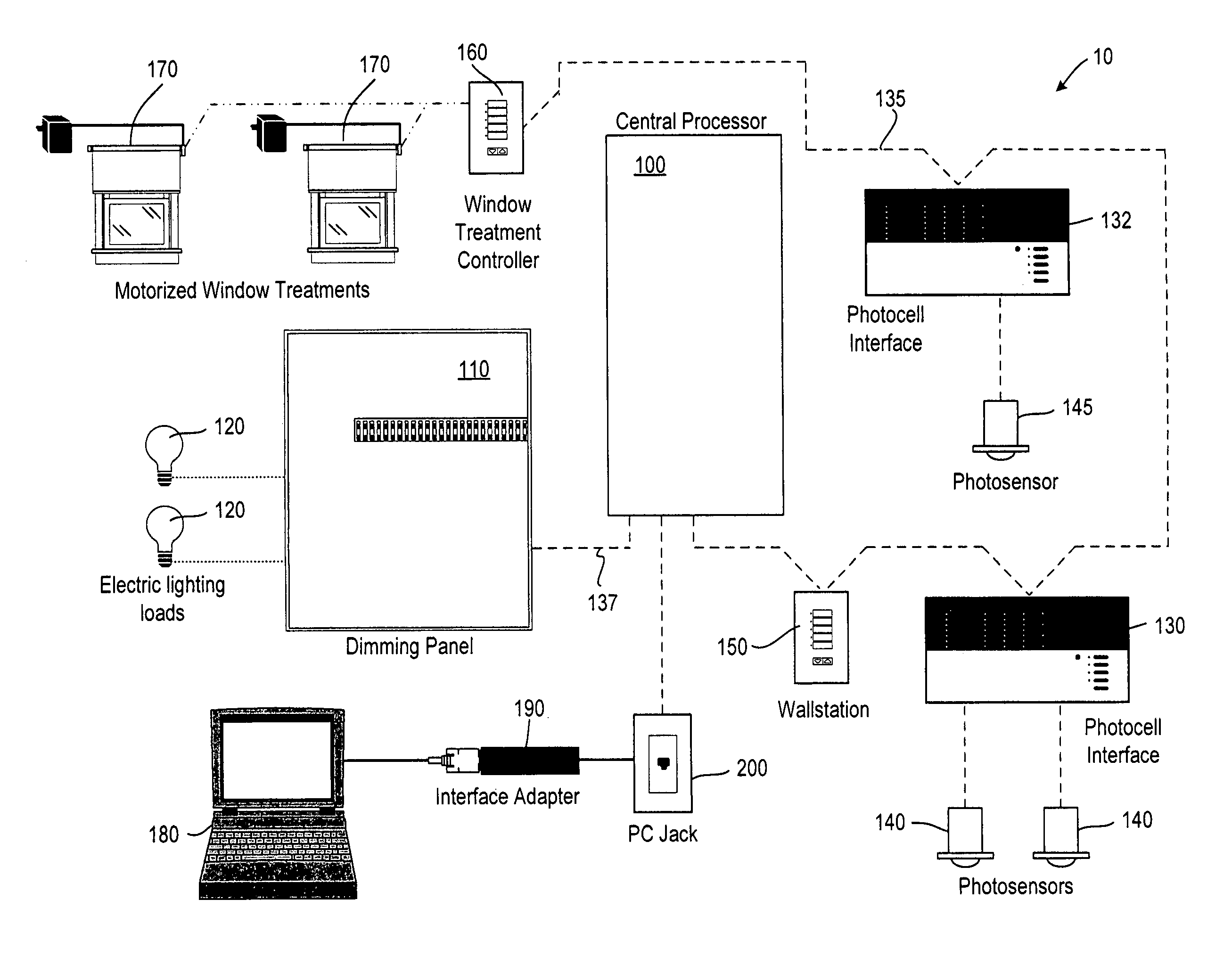

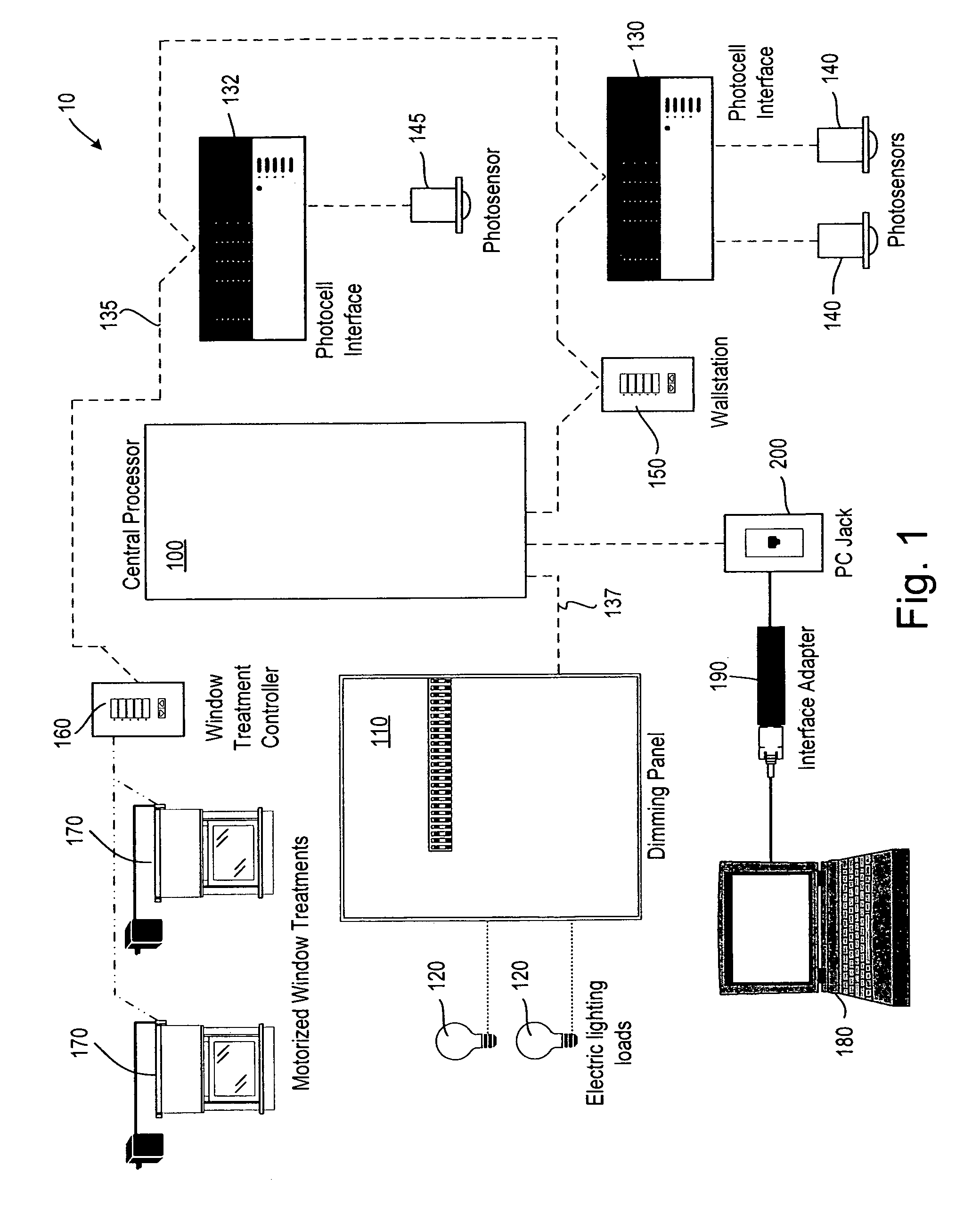

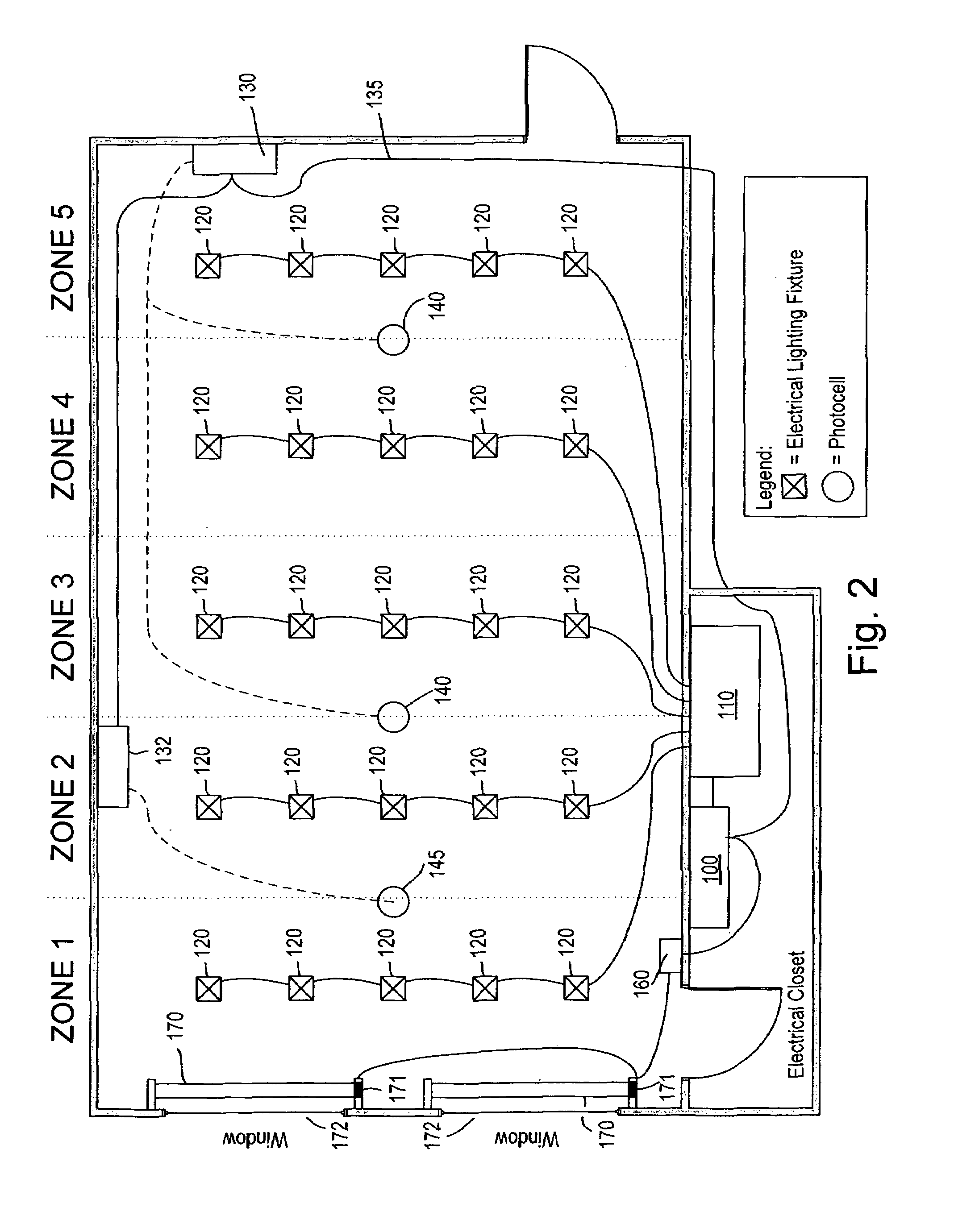

System to control daylight and artificial illumination and sun glare in a space

ActiveUS20050110416A1Reduce system costEliminate needLight dependant control systemsElectrical apparatusControl systemElectric light

An illumination maintenance system for maintaining a desired illumination profile in a space throughout at least a portion of a day where the illumination sources include daylight and artificial light, the system comprising a first sensor for sensing an illumination level in at least a portion of the space, at least one window treatment for at least one opening for allowing daylight into the space, the window treatment selectively altering the amount of daylight entering the space, a plurality of electric lamps providing artificial light to supplement the daylight illumination of the space; the electric lamps being dimmable, a control system controlling the at least one window treatment and the plurality of electric lamps to maintain the desired illumination profile in the space, the control system controlling the plurality of electric lamps so that the dimming level of each lamp is adjusted to achieve the desired lighting profile and compensate for the daylight illumination in the space throughout at least the portion of the day; and the control system further operating to adjust the window treatment in the event of sun glare through the opening to reduce the sun glare and such that when the desired illumination profile within a defined tolerance is achieved, the control system stops varying the dimming levels of the lamps and the adjustment of the at least one window treatment.

Owner:LUTRON TECH CO LLC

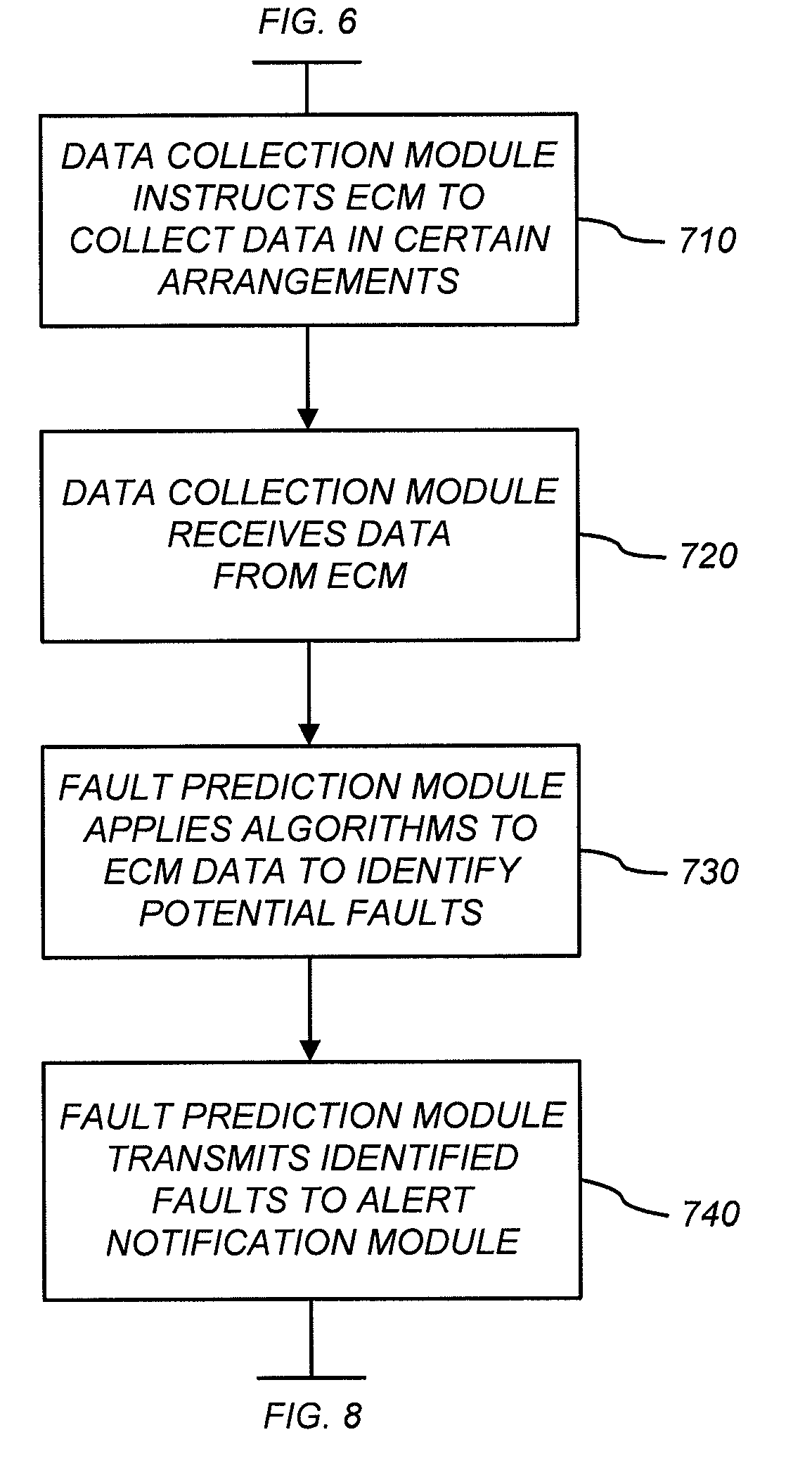

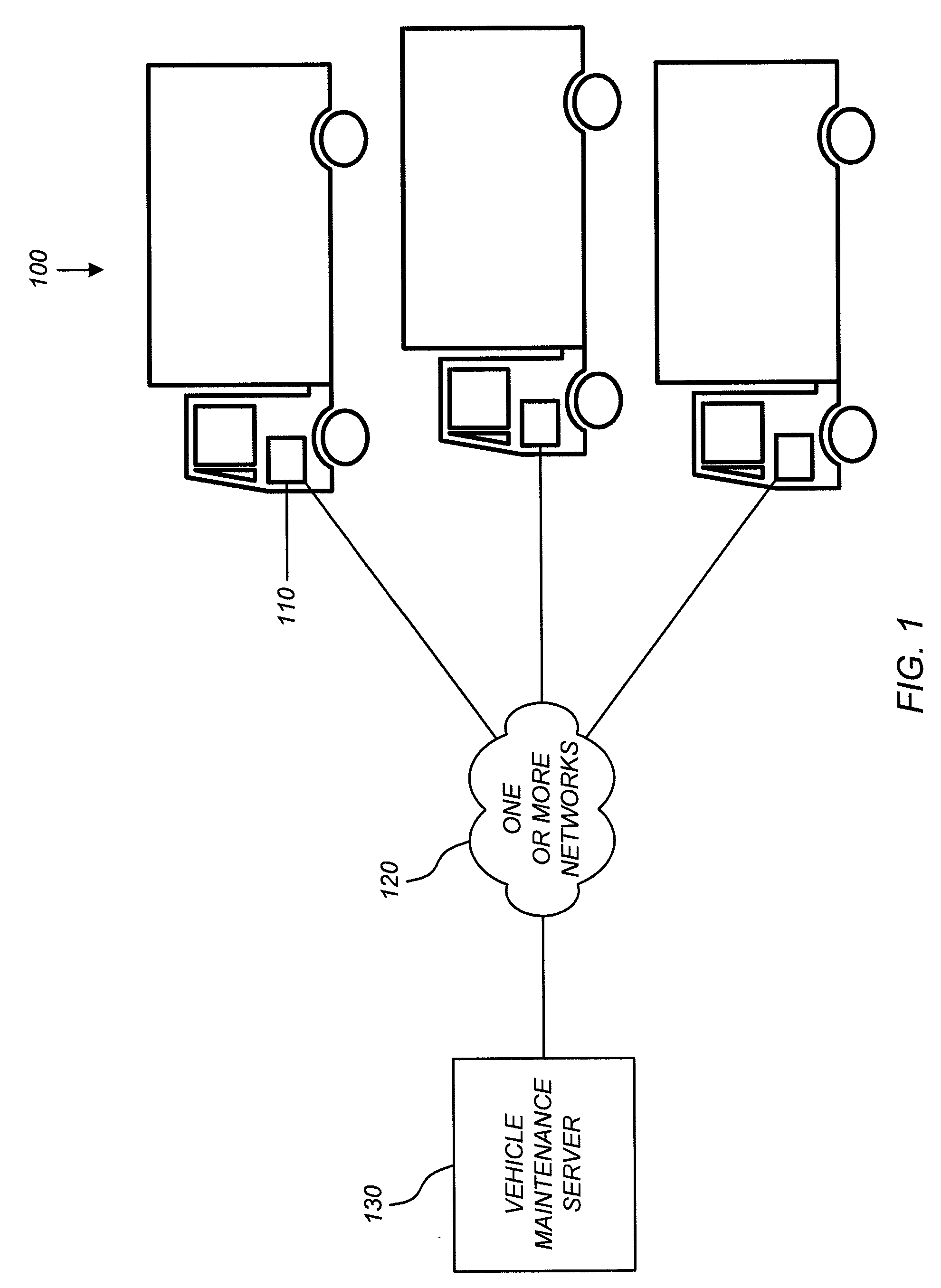

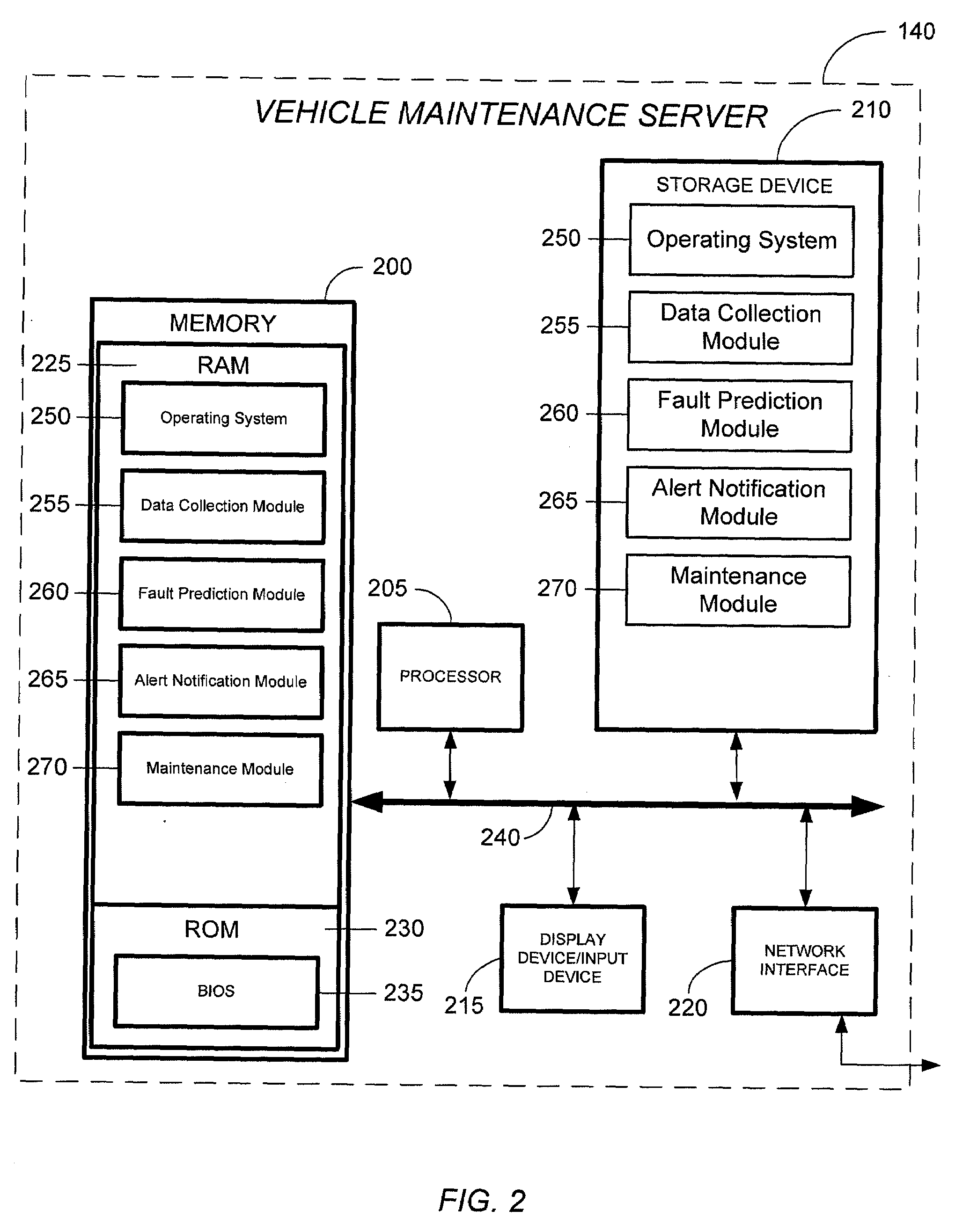

Vehicle maintenance systems and methods

ActiveUS20090254240A1Reduce in quantityImprove performanceVehicle testingRegistering/indicating working of vehiclesDriver/operatorIn vehicle

A system that enables a fleet of vehicles to be maintained is provided. The disclosed system allows a fleet operator to review the history of the vehicles in the fleet along with vehicle sensor data to identify earmarks in the vehicle sensor data that are predictive of faults that the vehicles have experienced. The operator develops statistical algorithms that can detect an earmark in vehicle sensor data. The system then collects vehicle sensor data and applies the statistical algorithms the vehicle data to determine if a potential fault is going to occur in a vehicle. In response to determining that a potential fault is going to occur, the disclosed system automatically alerts the vehicle driver, automatically schedule a maintenance visit, automatically check the fleet inventory for components required for a maintenance visit and order unavailable components, and automatically dispatch the components to the mechanic.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

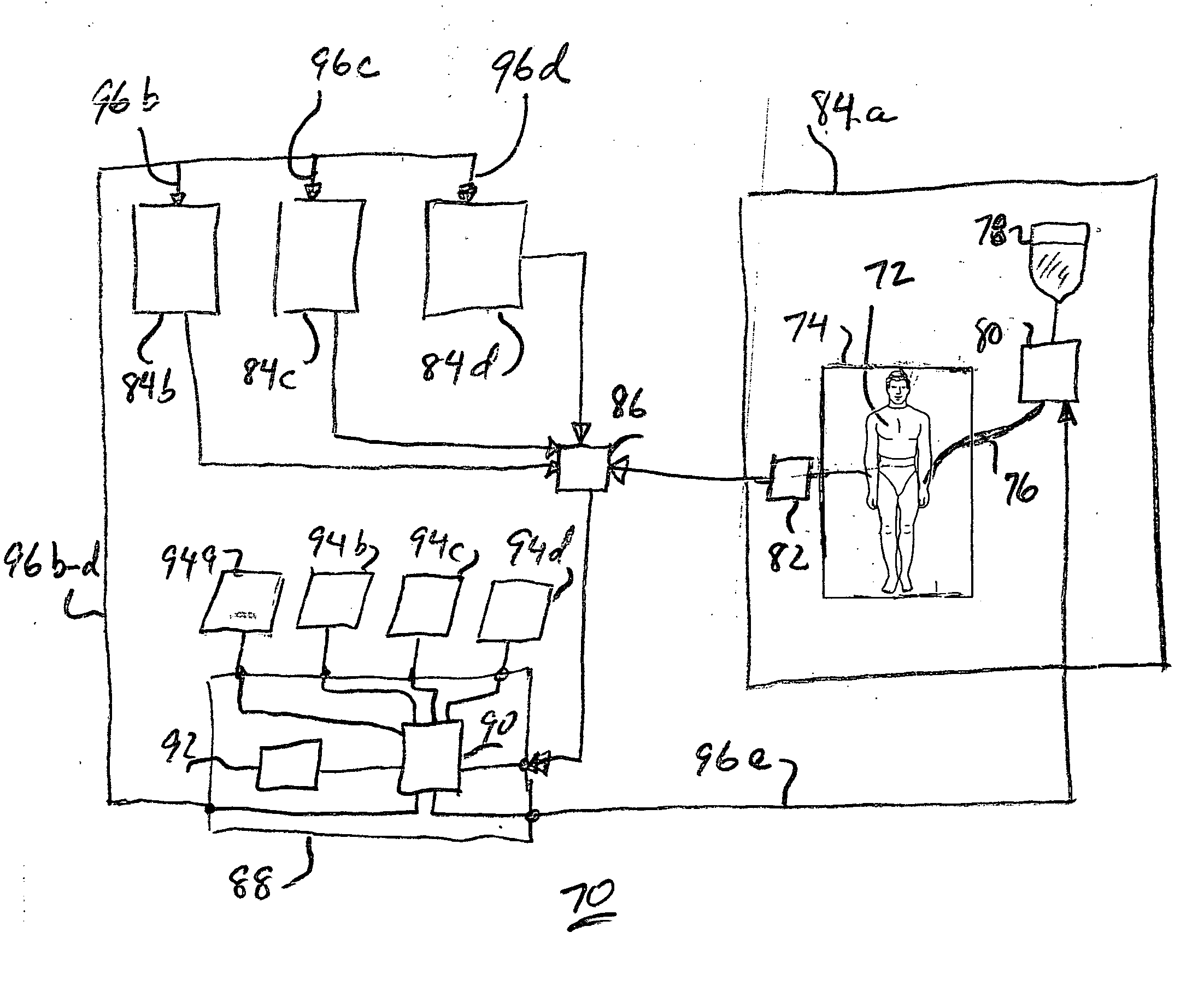

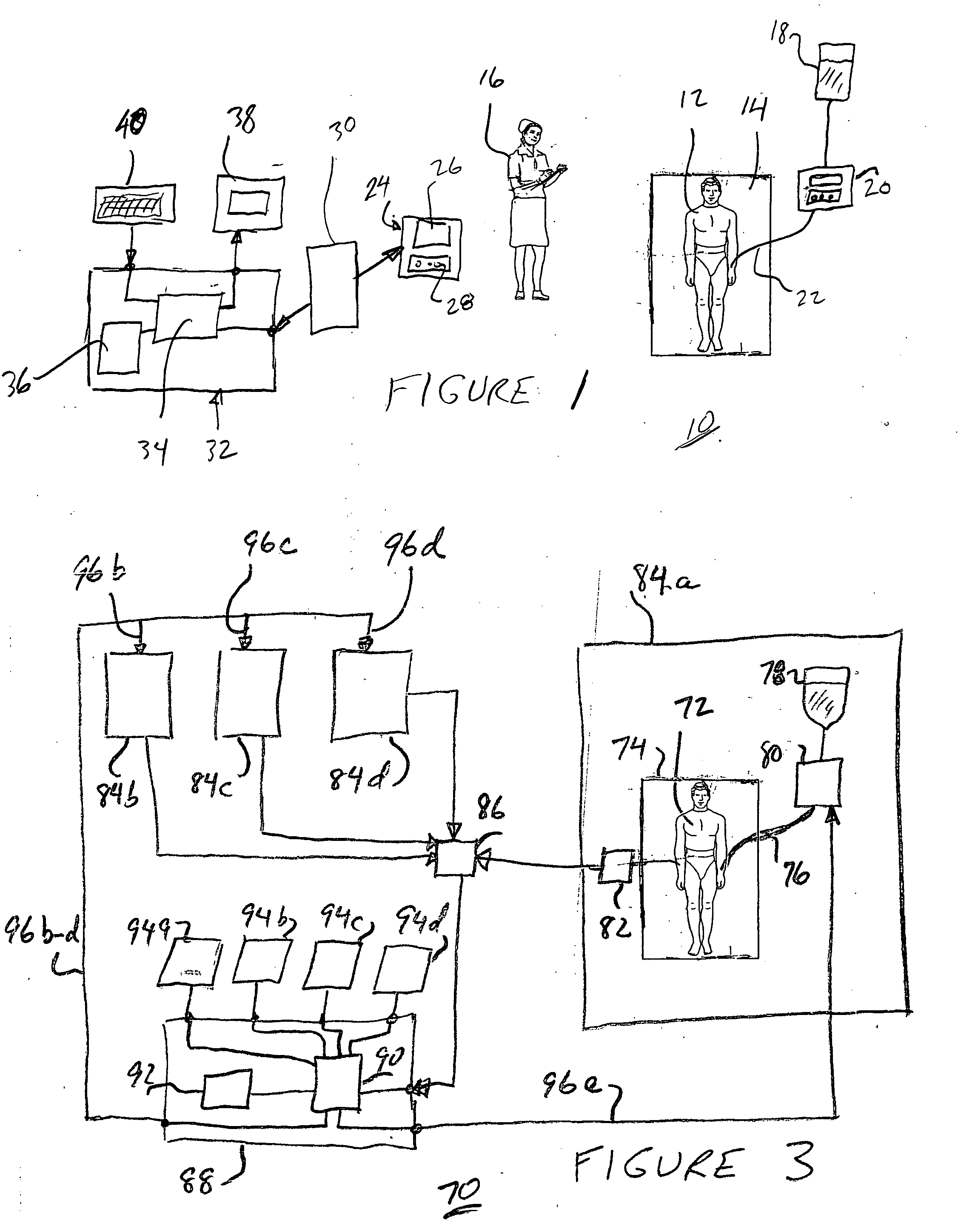

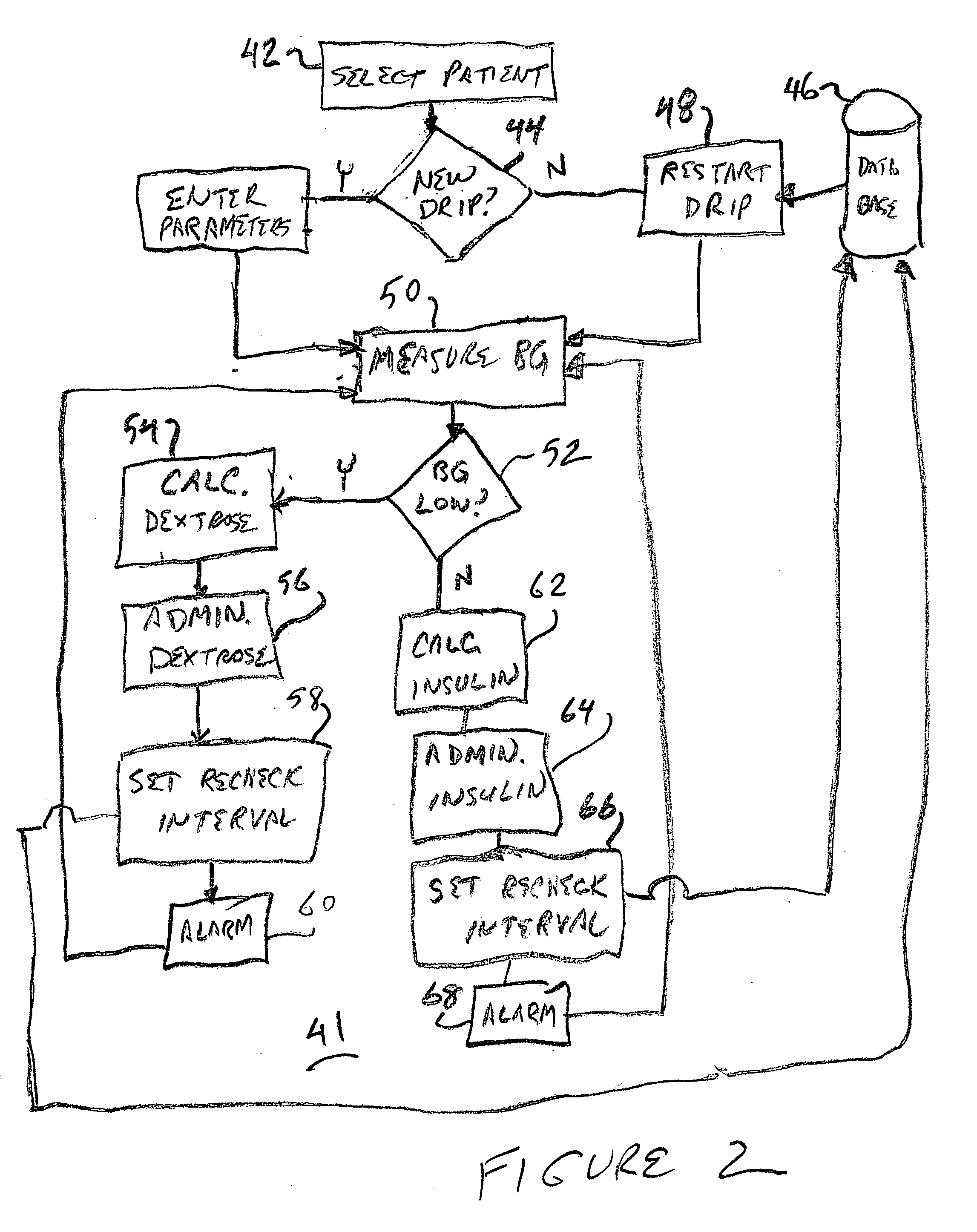

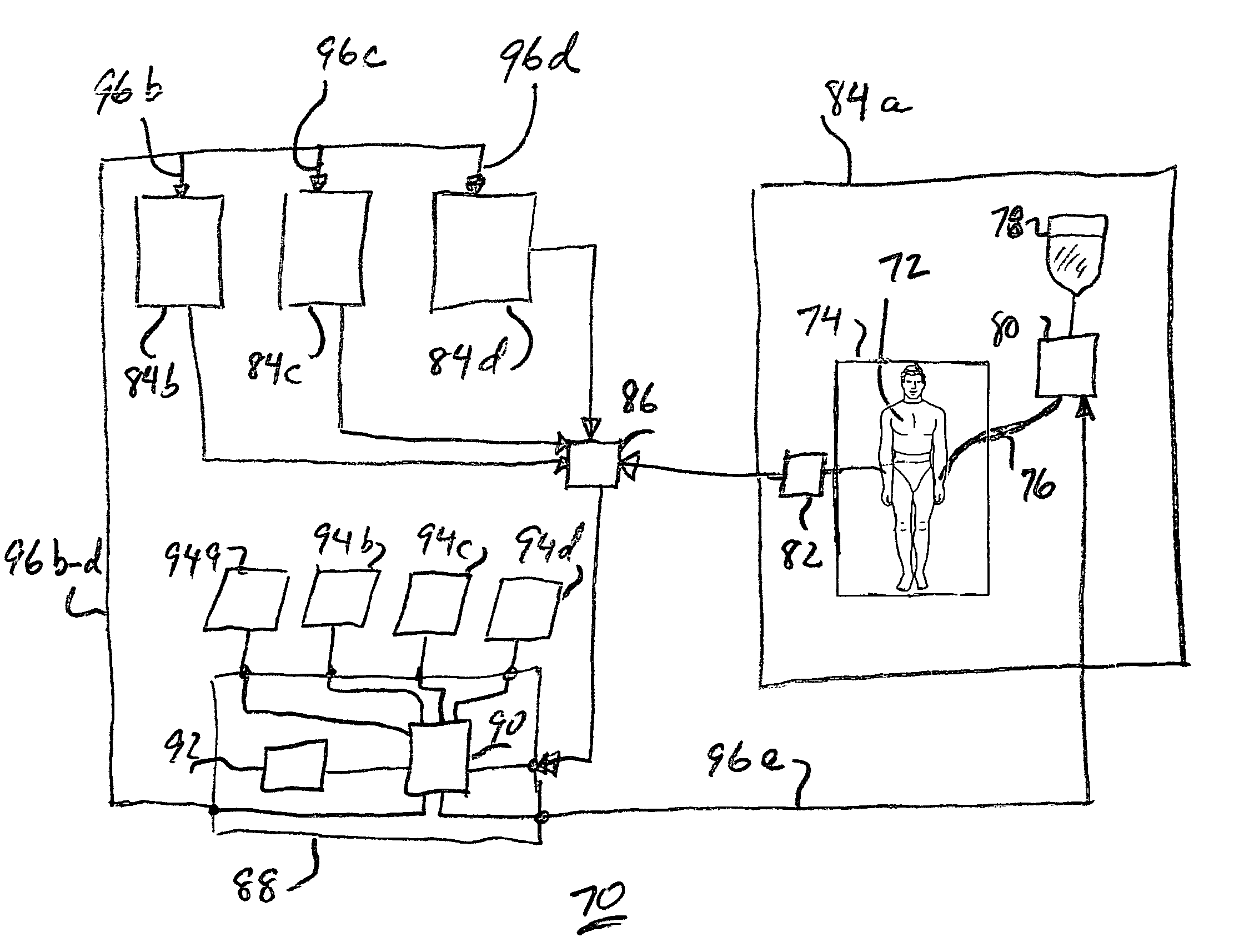

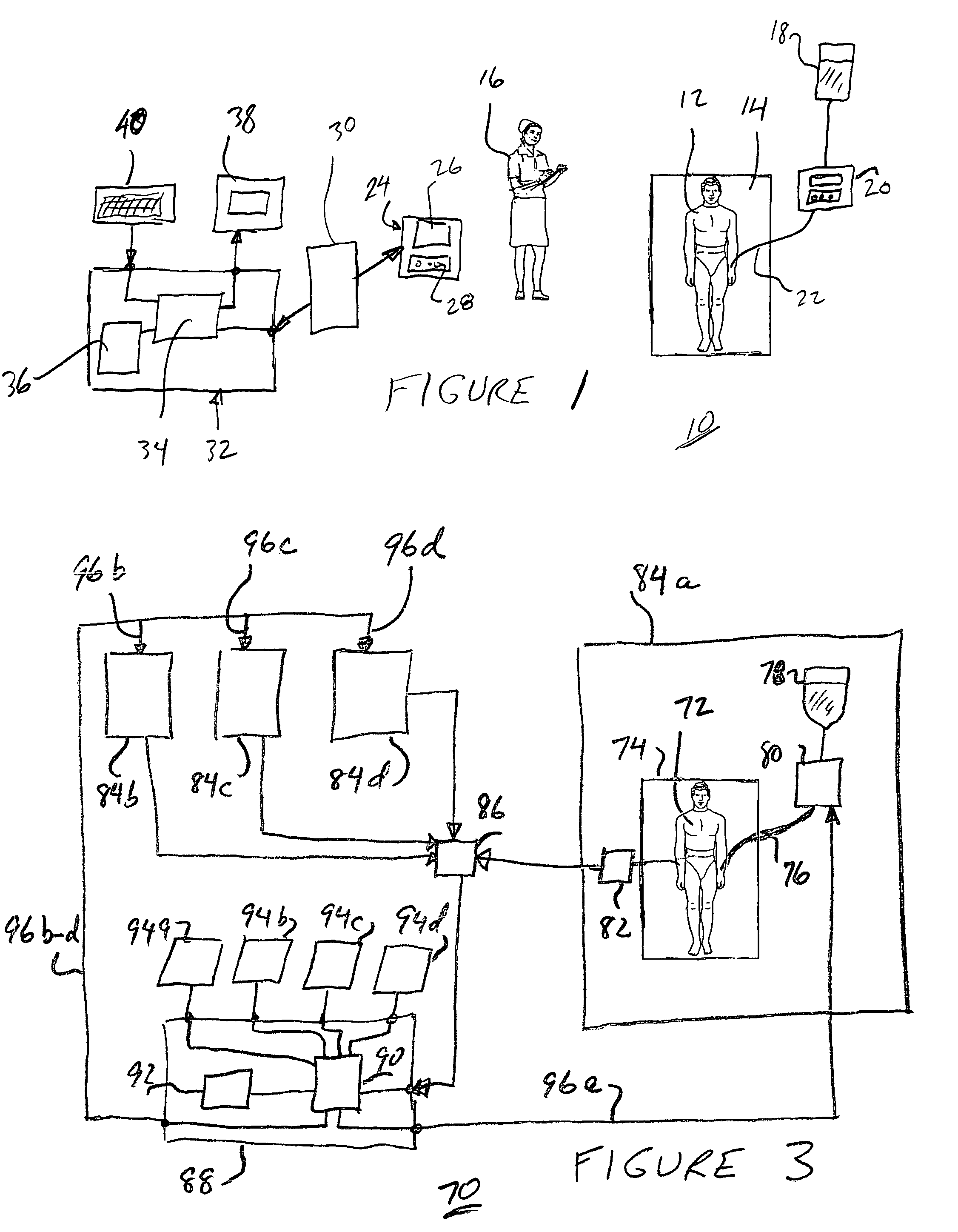

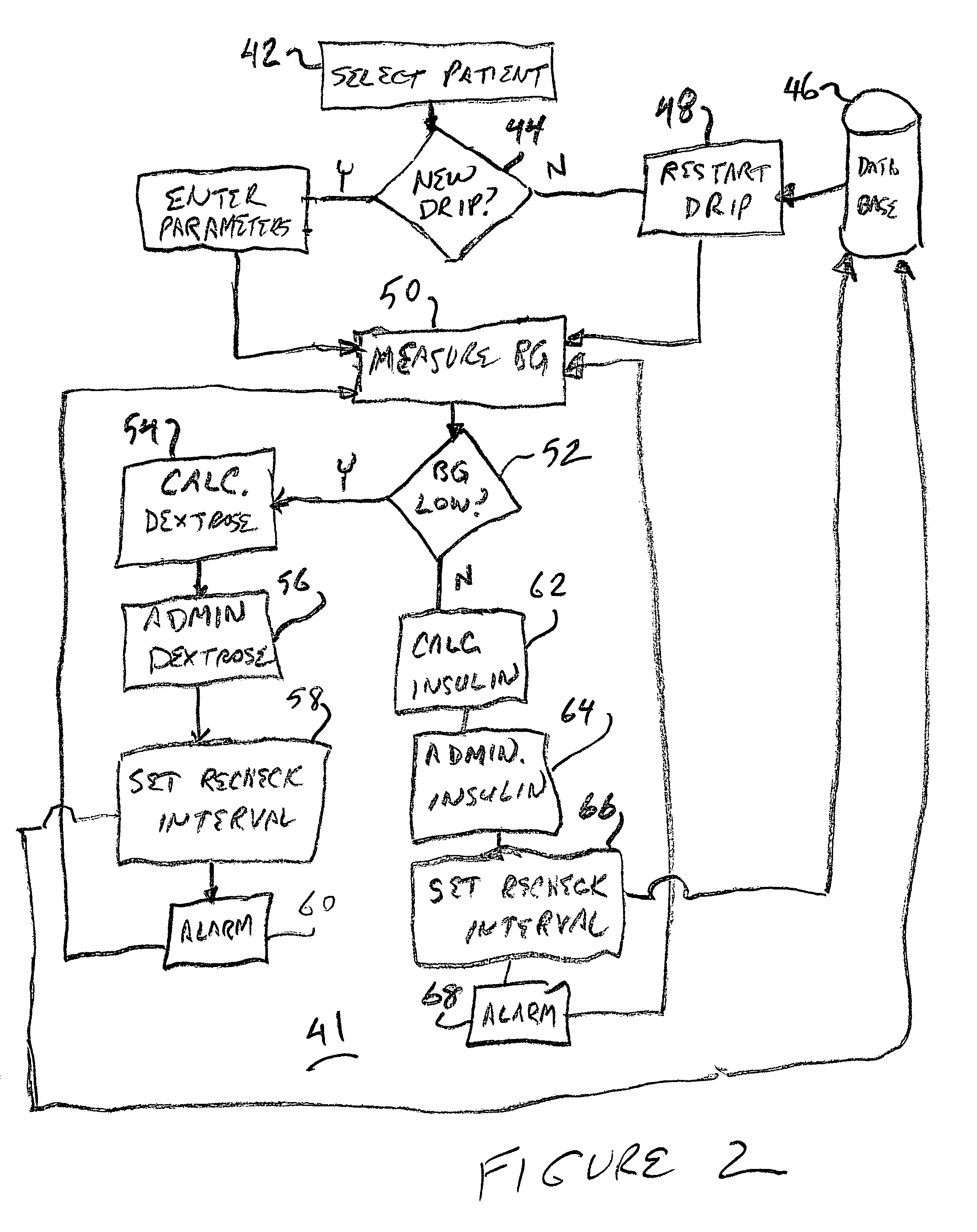

System for managing glucose levels in patients with diabetes or hyperglycemia

A blood glucose maintenance system for use by hyperglycemic individuals measures their blood glucose level and calculates an appropriate glucose or insulin dosage based on the measurement. Recheck intervals responsive to dosage history are determined. Warning or alert messages or signals are produced if certain measurements or calculations fall outside established normal ranges. It is particularly useful for patients in a hospital or in-patient environment.

Owner:INDIANA UNIVERSITY HEALTH

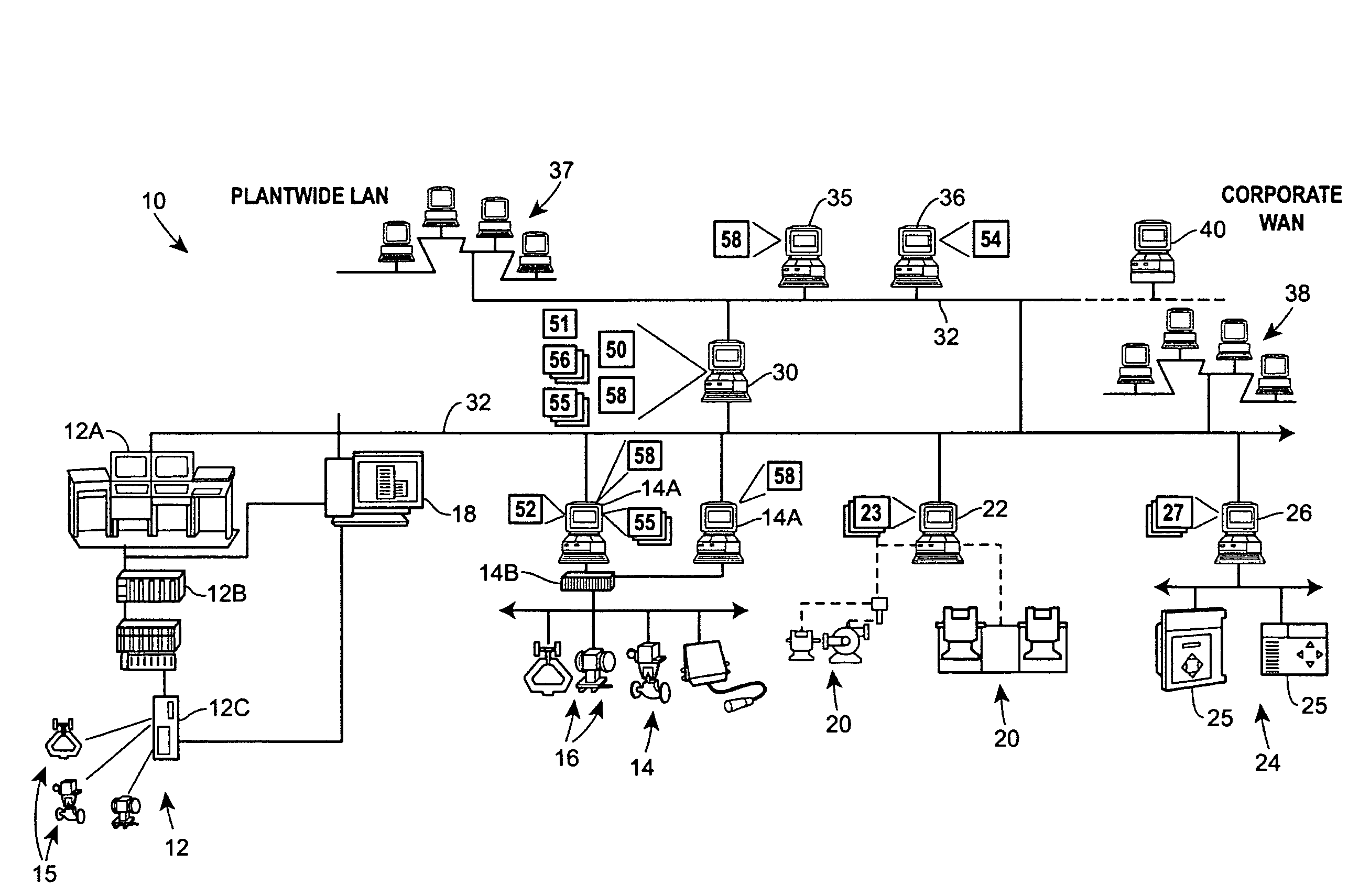

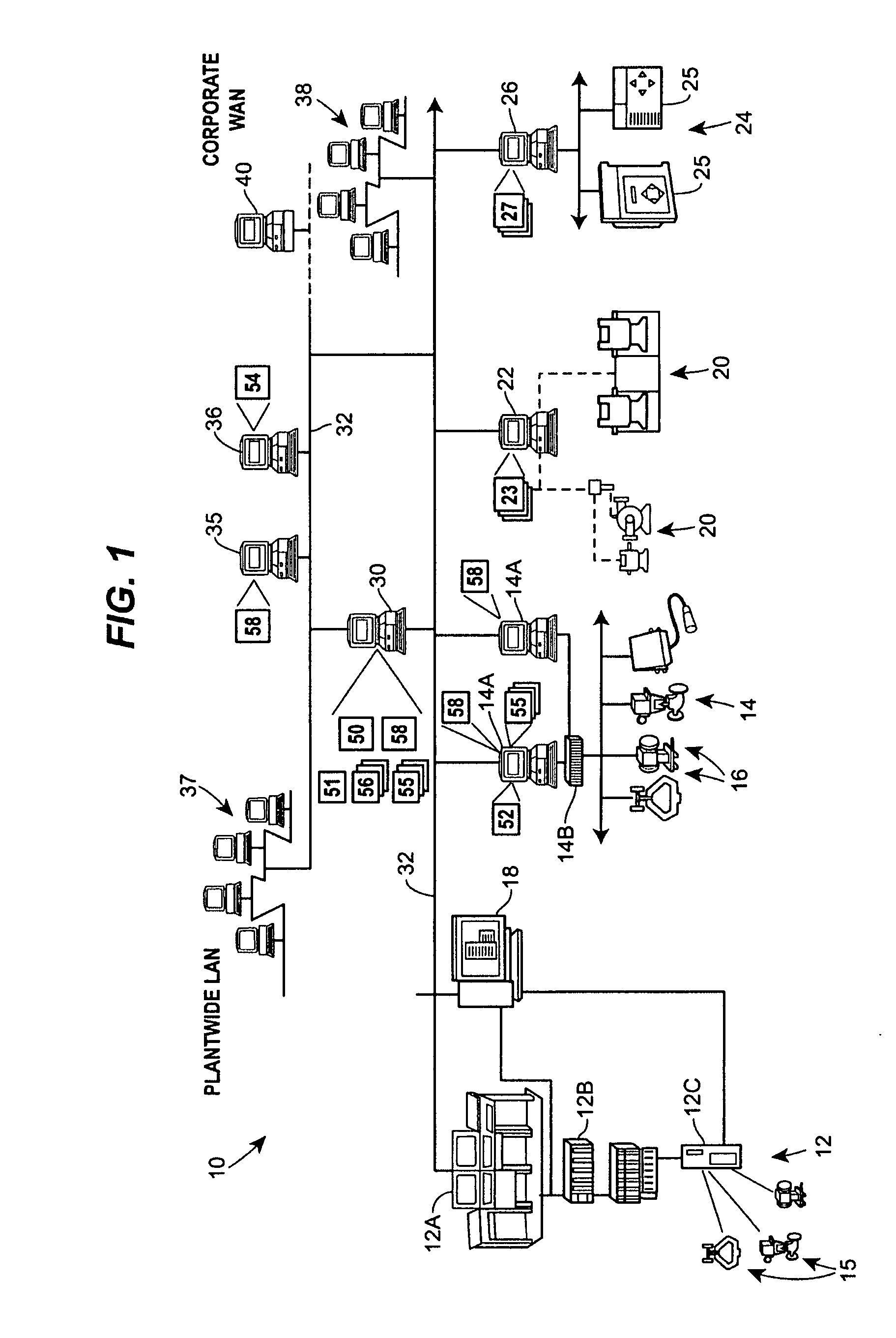

Automatic maintenance estimation in a plant environment

A maintenance system for a process plant collects and uses historical data about maintenance orders. The data identifies the maintenance items for completing an order, such as the labor, materials, and maintenance tasks required. The data is historical data developed from actual completed maintenance orders. The system uses archived historical data and estimates various maintenance information, such as estimated cost for completing the maintenance order, and estimated start and completion times. The estimated data may be based on averaged data as a result. This estimated data along with the other maintenance order information may be sent to a scheduler for identifying a priority to the maintenance order and scheduling it accordingly.

Owner:FISHER-ROSEMOUNT SYST INC

System to control daylight and artificial illumination and sun glare in a space

ActiveUS7111952B2Eliminate needEasy to controlLight dependant control systemsElectrical apparatusControl systemEffect light

An illumination maintenance system for maintaining a desired illumination profile in a space throughout at least a portion of a day where the illumination sources include daylight and artificial light, the system comprising a first sensor for sensing an illumination level in at least a portion of the space, at least one window treatment for at least one opening for allowing daylight into the space, the window treatment selectively altering the amount of daylight entering the space, a plurality of electric lamps providing artificial light to supplement the daylight illumination of the space; the electric lamps being dimmable, a control system controlling the at least one window treatment and the plurality of electric lamps to maintain the desired illumination profile in the space, the control system controlling the plurality of electric lamps so that the dimming level of each lamp is adjusted to achieve the desired lighting profile and compensate for the daylight illumination in the space throughout at least the portion of the day; and the control system further operating to adjust the window treatment in the event of sun glare through the opening to reduce the sun glare and such that when the desired illumination profile within a defined tolerance is achieved, the control system stops varying the dimming levels of the lamps and the adjustment of the at least one window treatment.

Owner:LUTRON TECH CO LLC

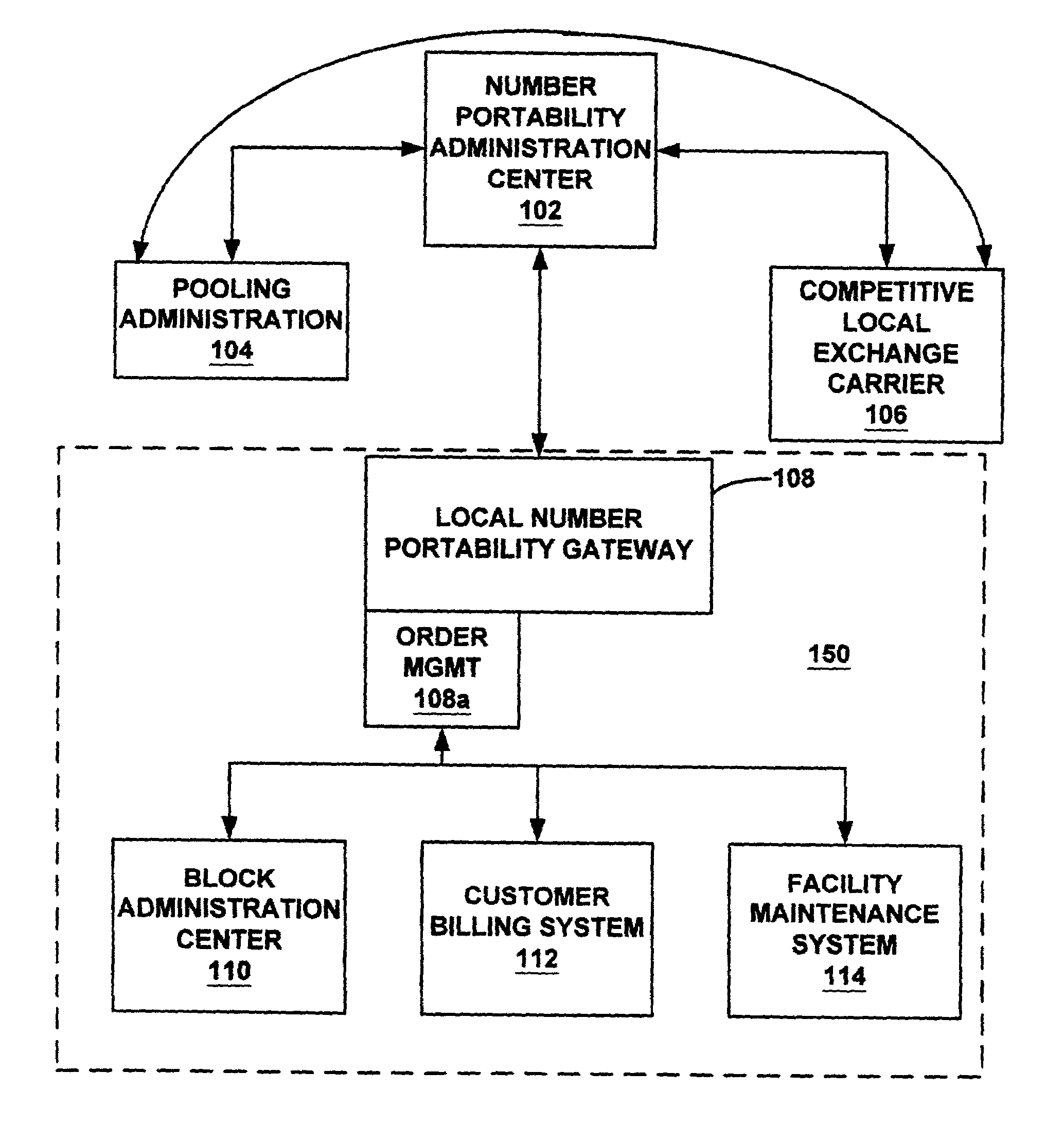

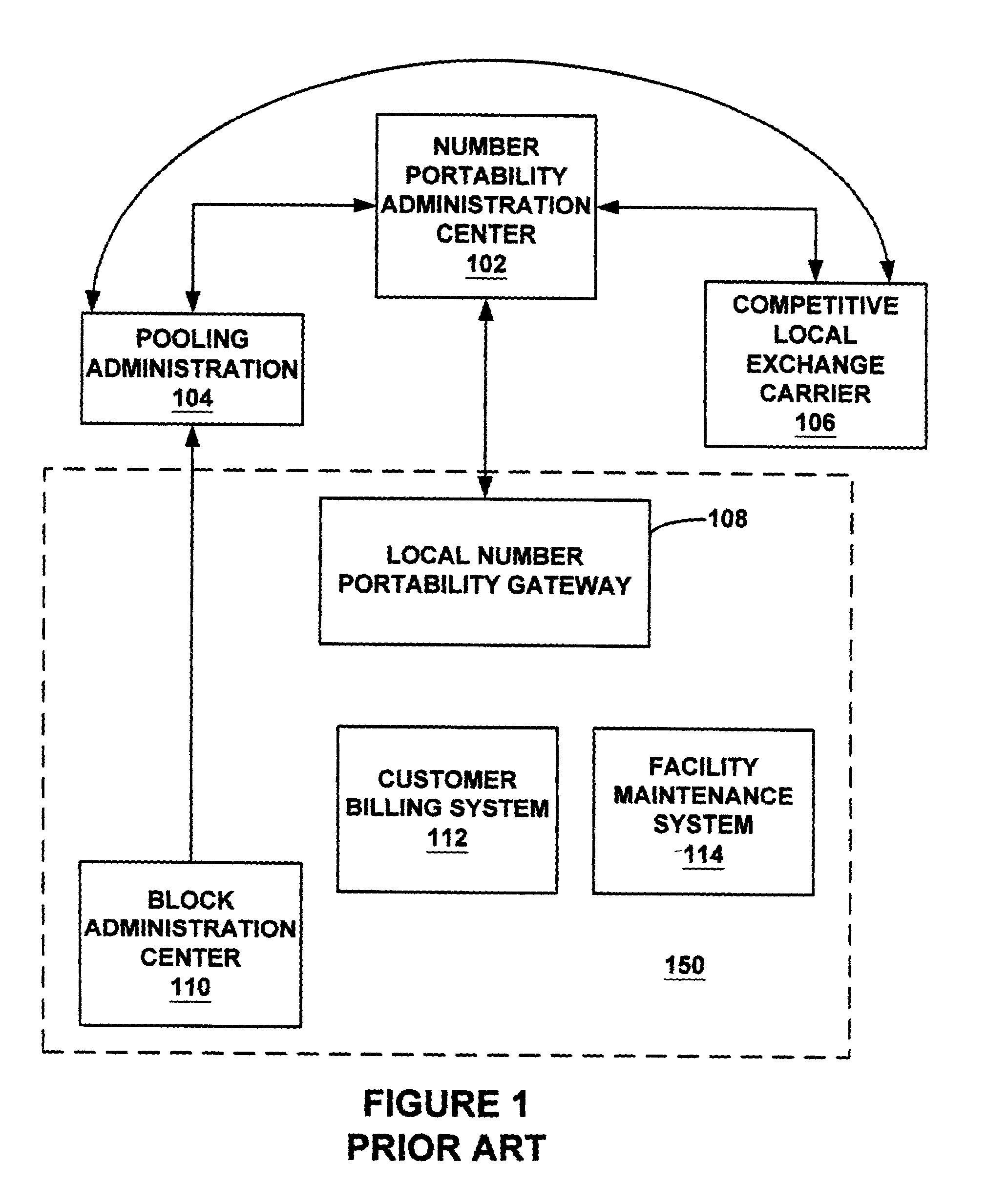

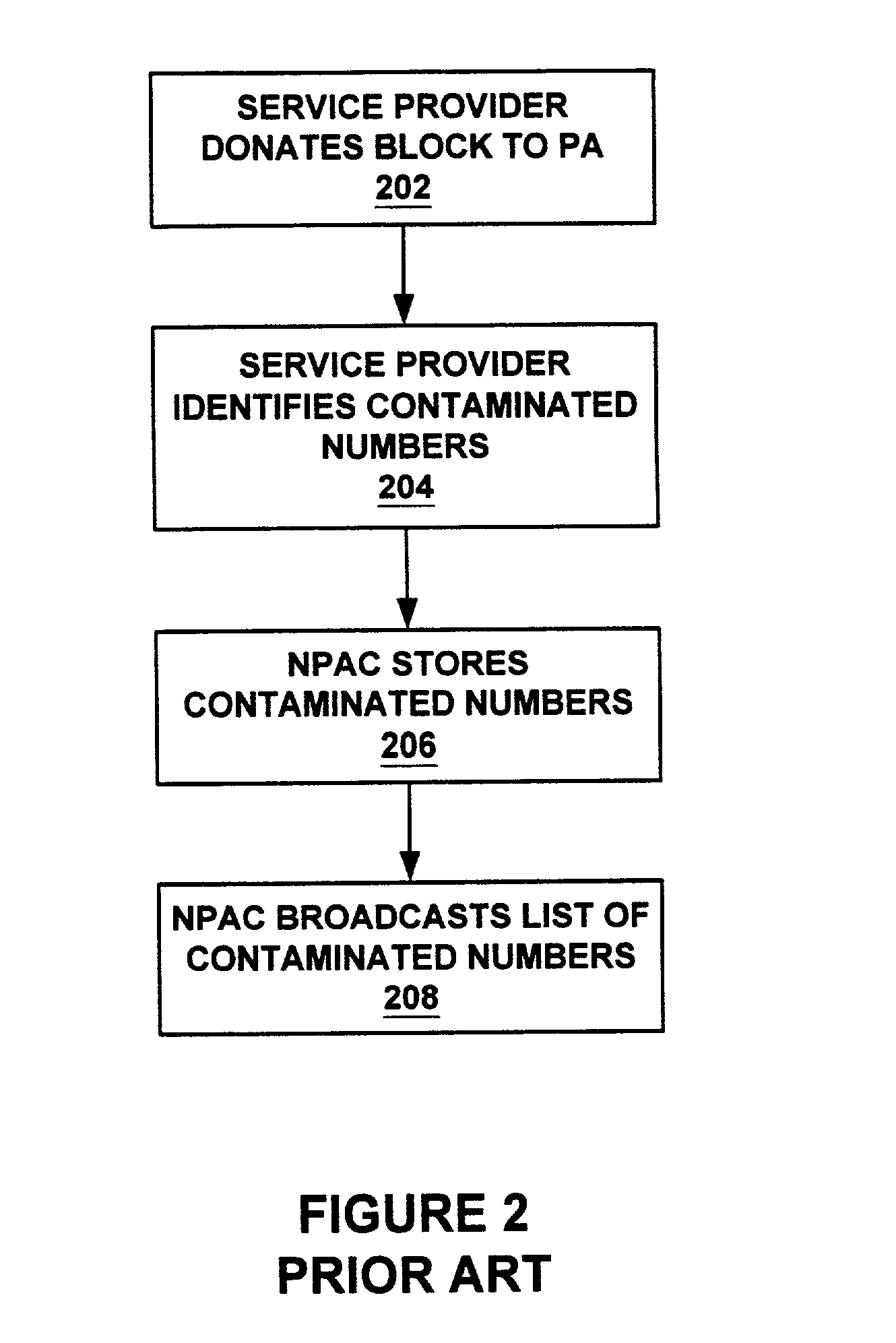

System and method for identifying contaminated telephone numbers and correct LRN under number pooling

InactiveUS7106844B1Interconnection arrangementsSpecial service for subscribersDistributed computingBilling system

A service provider's system components such as but not limited to a billing system and facilities maintenance system are sent a message that identifies contaminated telephone numbers contained within a block of numbers released to a service provider from a number pooling authority. The message also identifies the (location routing number) LRN associated with the switch of the uncontaminated numbers.

Owner:AT&T INTPROP I L P

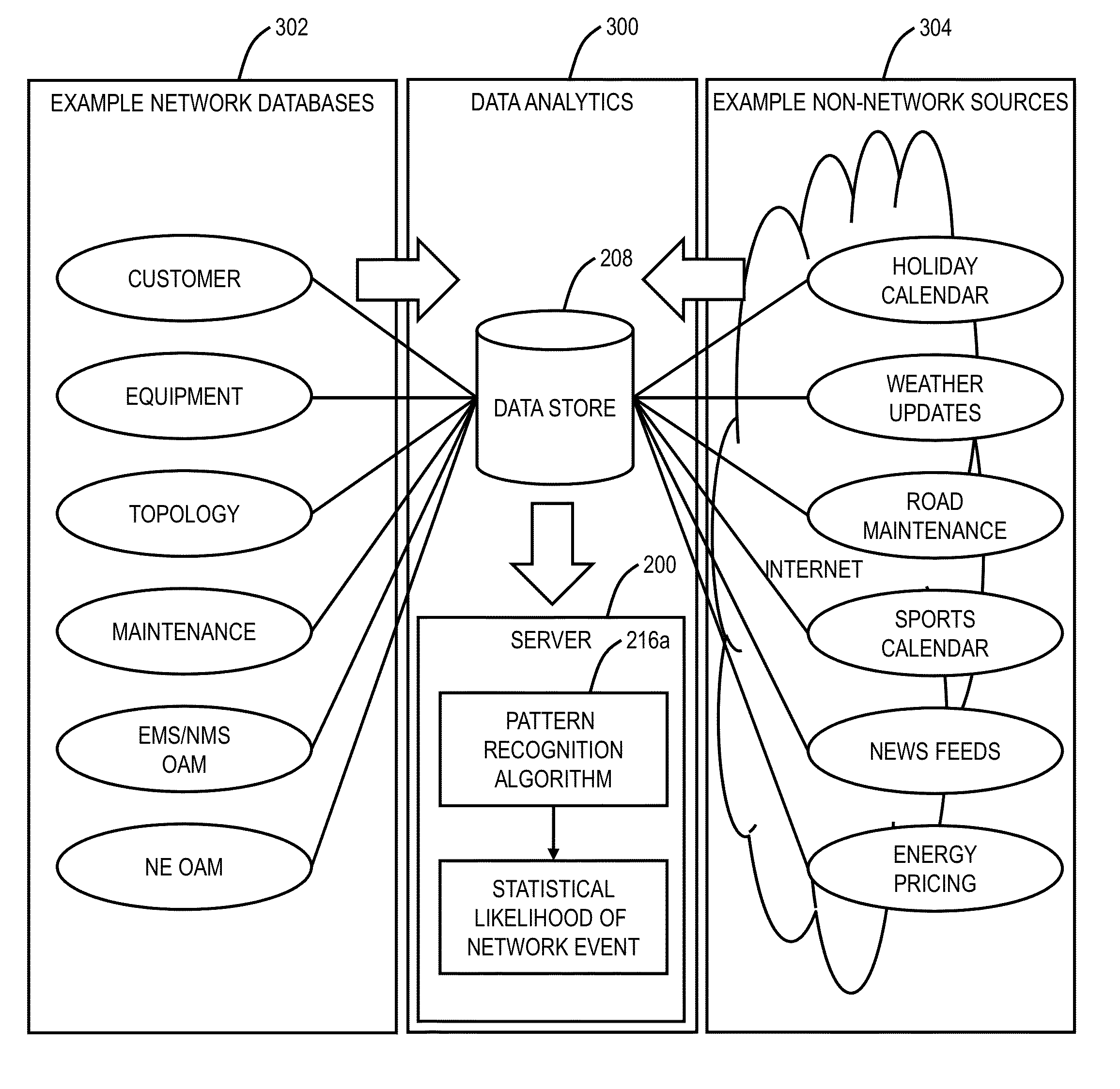

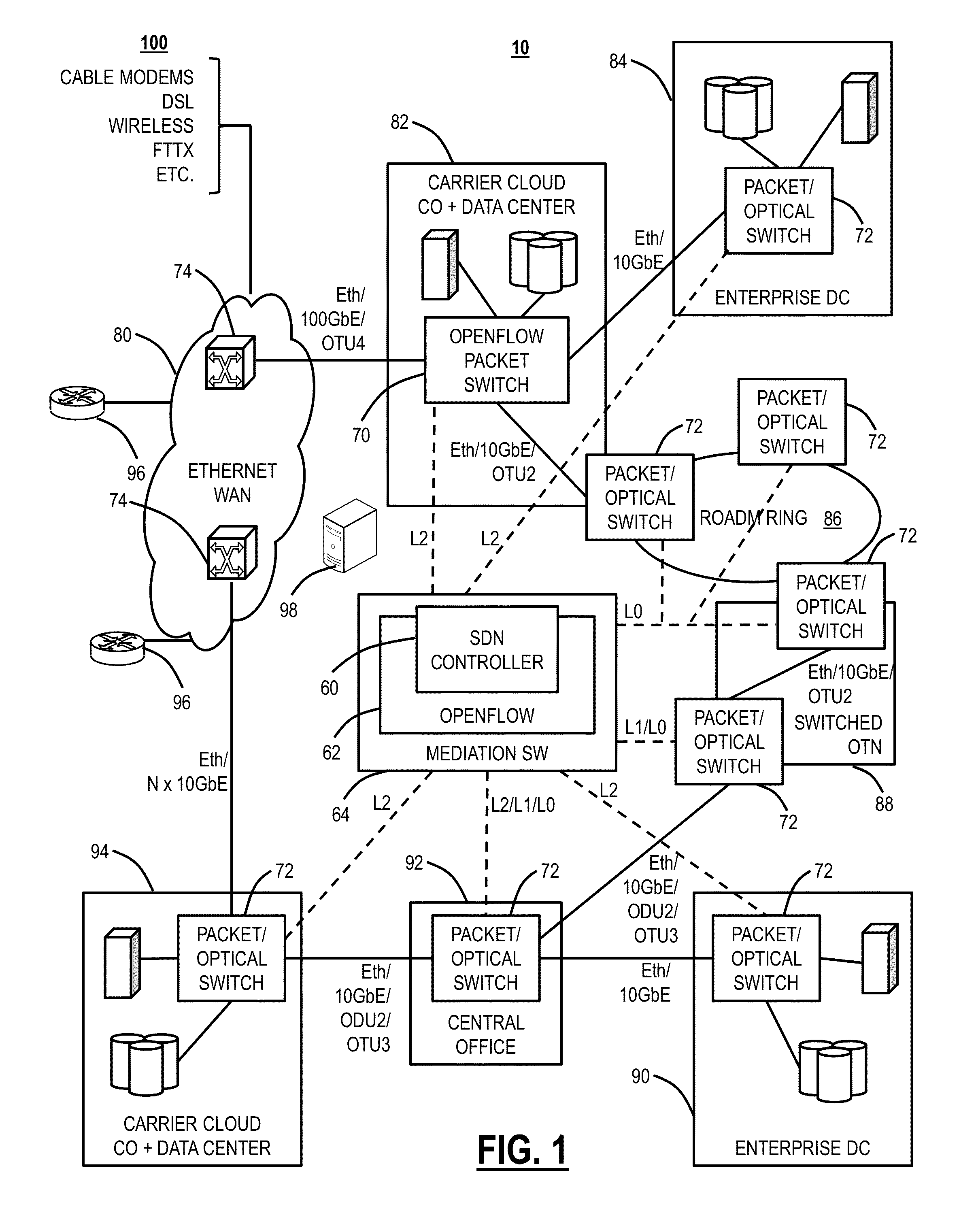

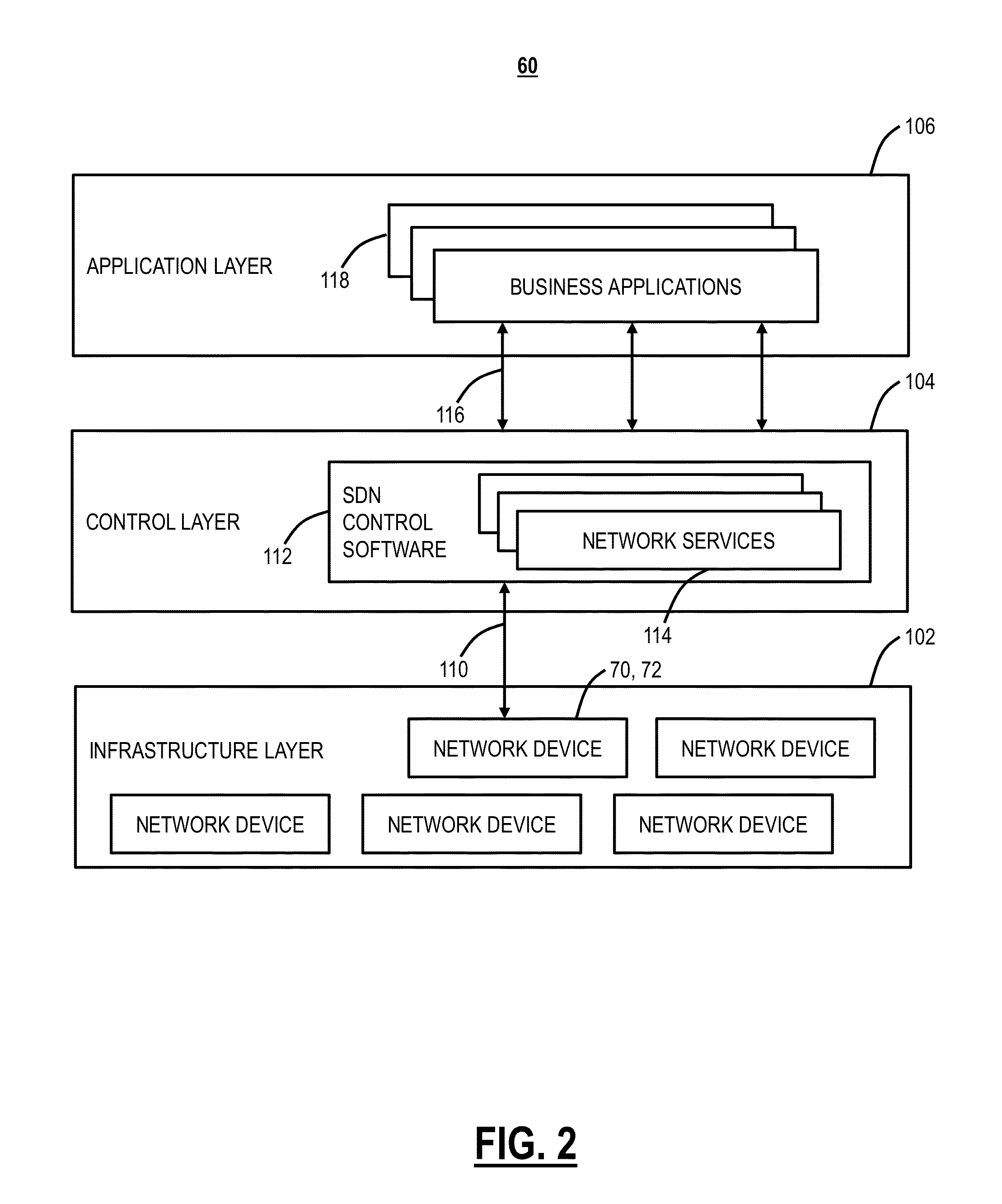

Proactive operations, administration, and maintenance systems and methods in networks using data analytics

A computer-implemented method, a system, and a network include receiving network data from a network and non-network sourced data from one or more external sources relative to the network; performing data mining on the network data and the non-network sourced data; developing a predictive analytics model based on the data mining; and performing predictive analytics on the network data and the non-network sourced data using the predictive analytics model to detect likely future failures in the network. The network can include a Software Defined Network (SDN) operating at any of Layers 0, 1, 2 and / or 3.

Owner:INNOVATION ASSET COLLECTIVE

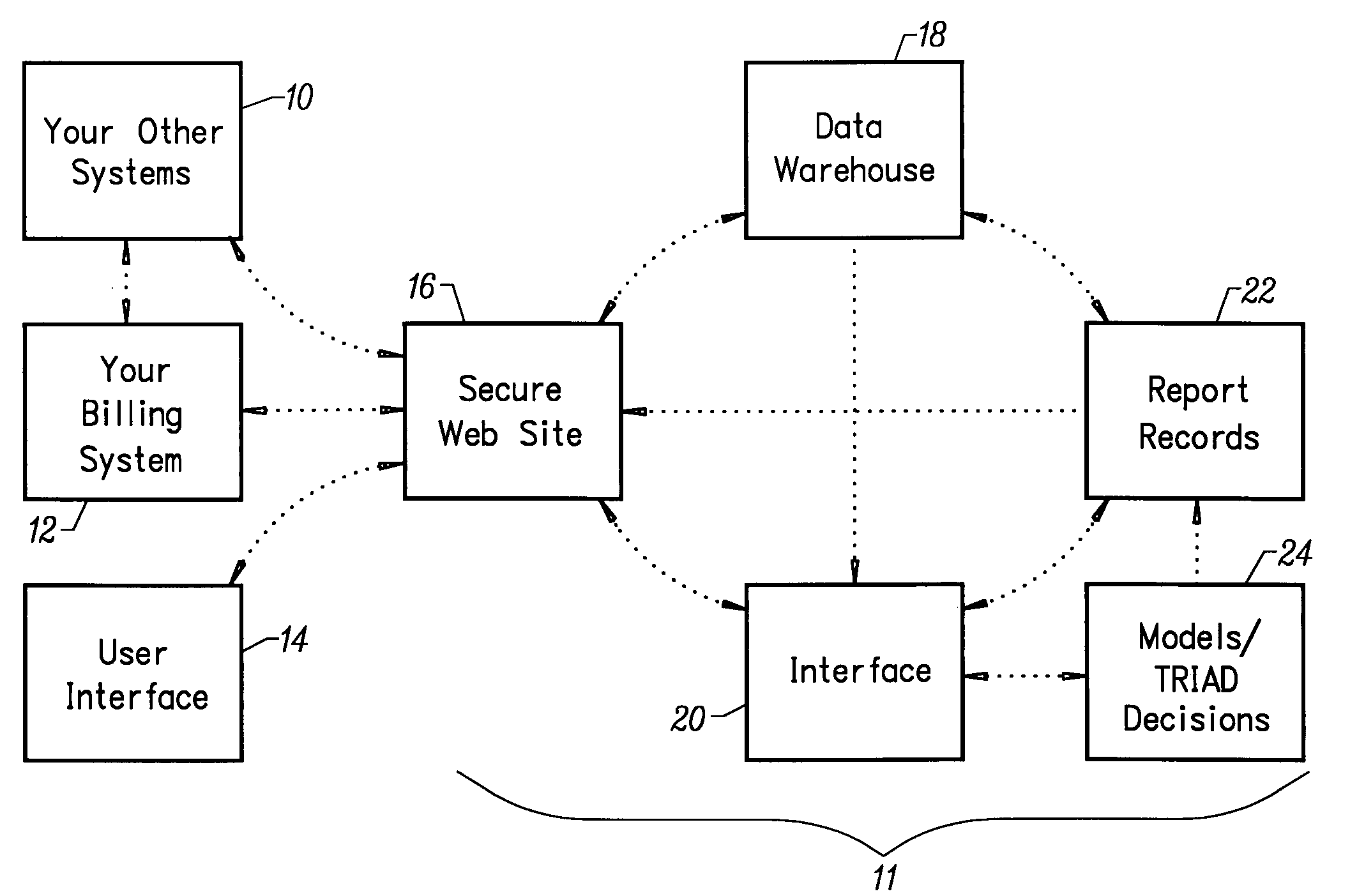

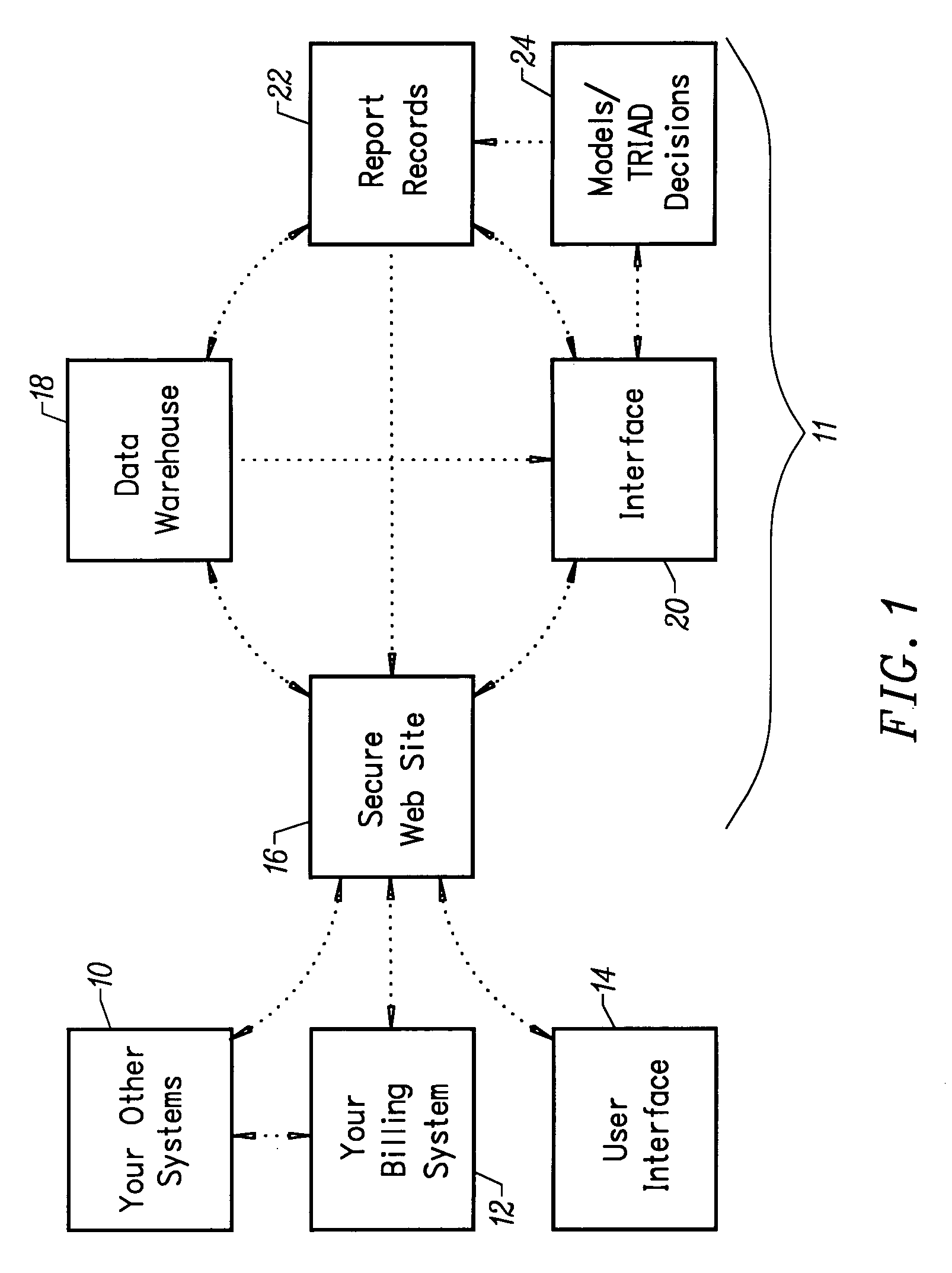

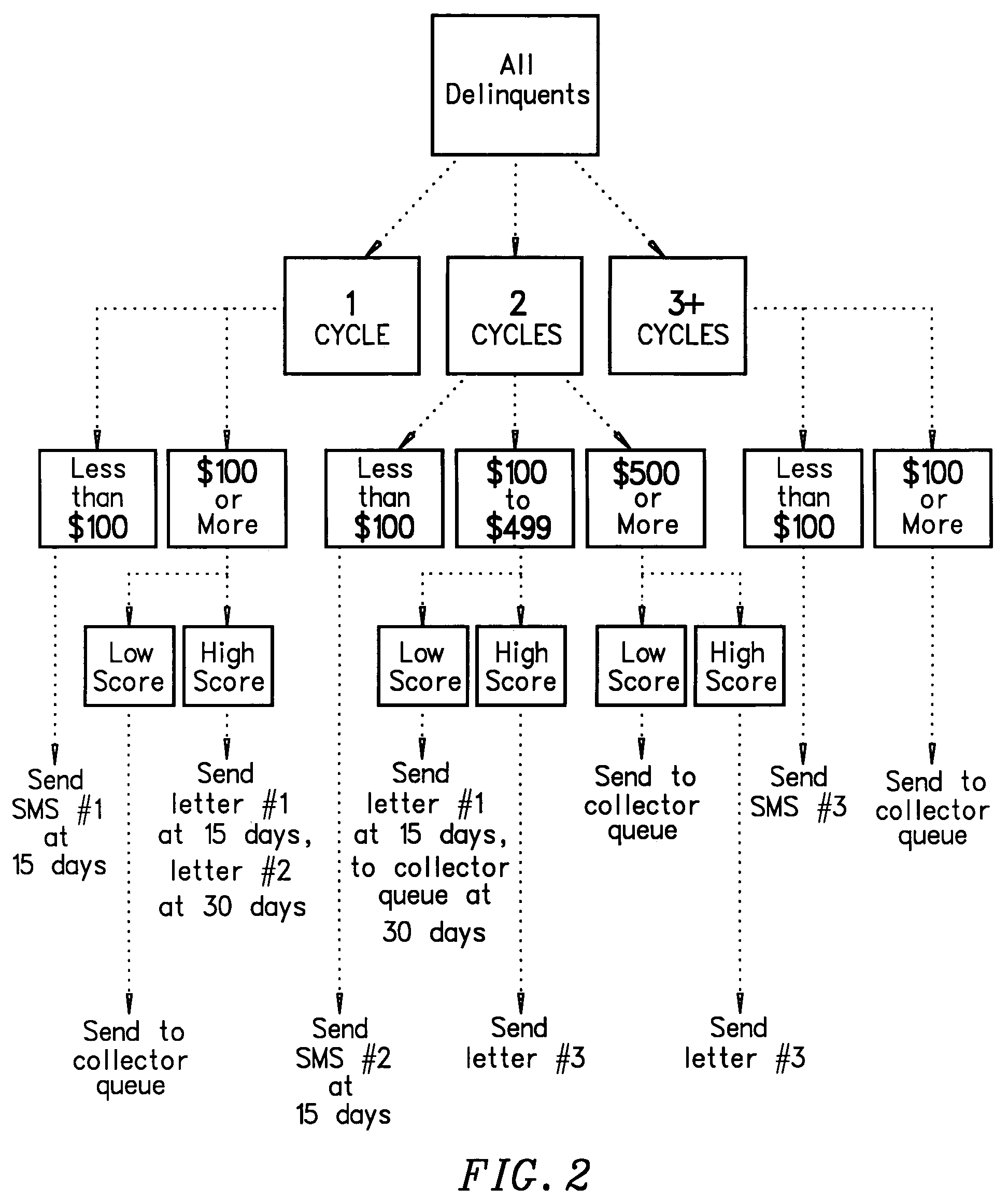

Data center for account management

InactiveUS7383215B1Reduces implementation scheduleEnd users more quicklyComplete banking machinesFinanceData centerCommunication link

The invention provides an account manager and database system that allows end users to bypass the need to integrate such systems in to their legacy information management systems. The account management and database systems are developed and maintained at a host service-bureau data center. The client accesses the account management and database systems through a communication link, usually a secure website. Decisions recommended by the account management system are then sent back to the client systems to take action. The client controls the account management system by utilizing the PCTable Maintenance System installed in the PC at the client site. Client also accesses the database at the data center for reporting and analysis.The invention reduces the implementation schedule for such account management and database systems and thus provides such systems to end users more quickly.

Owner:FAIR ISAAC & CO INC

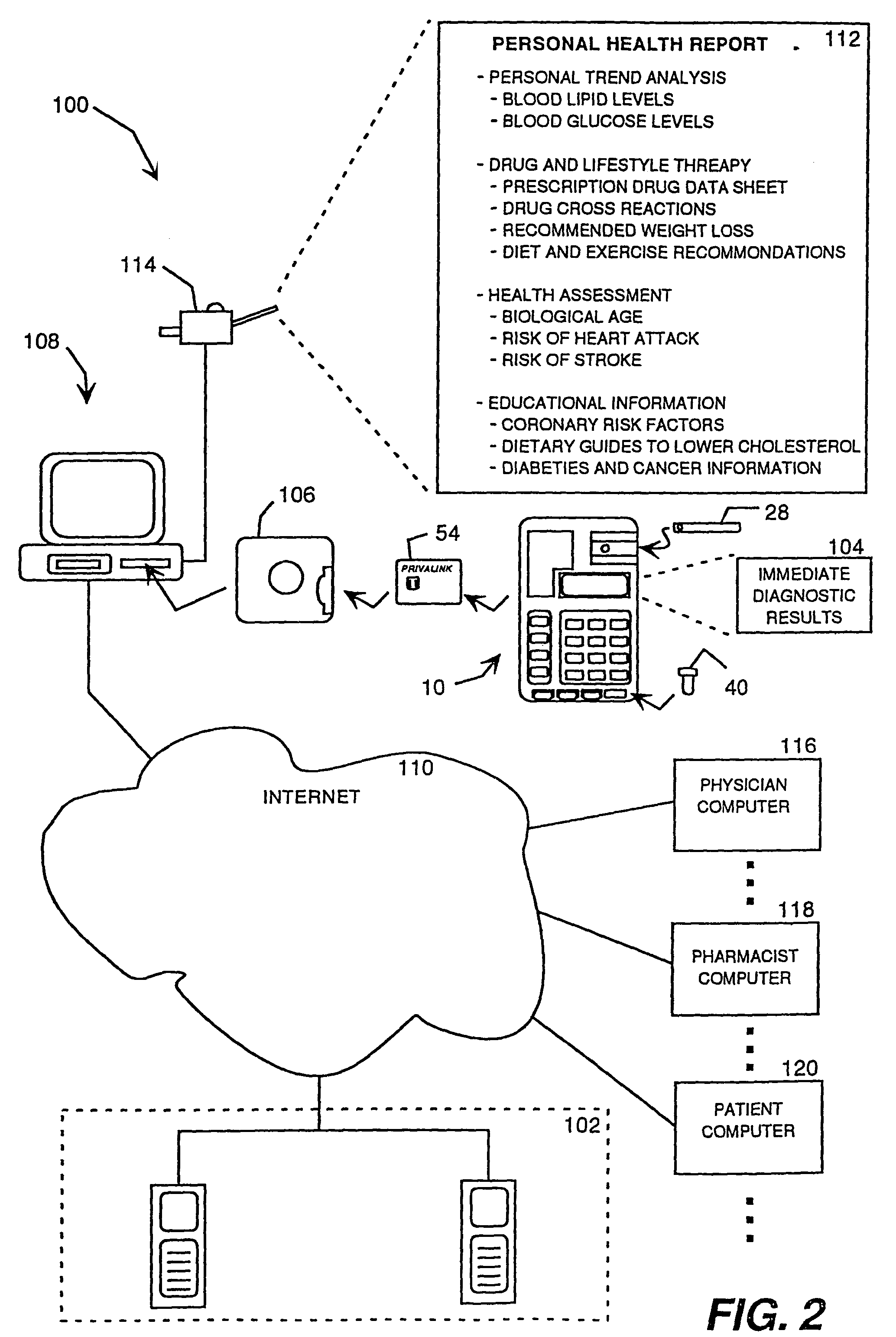

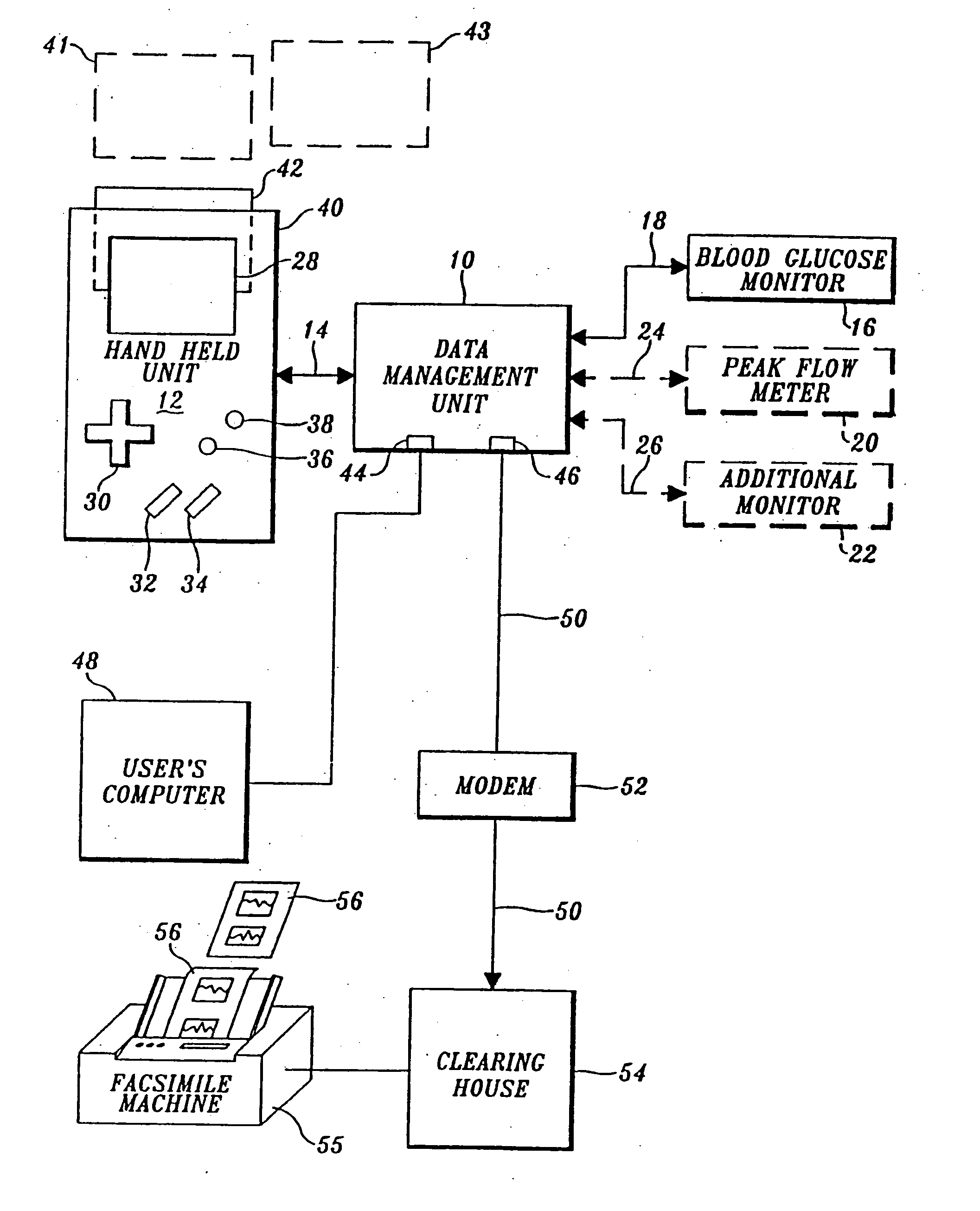

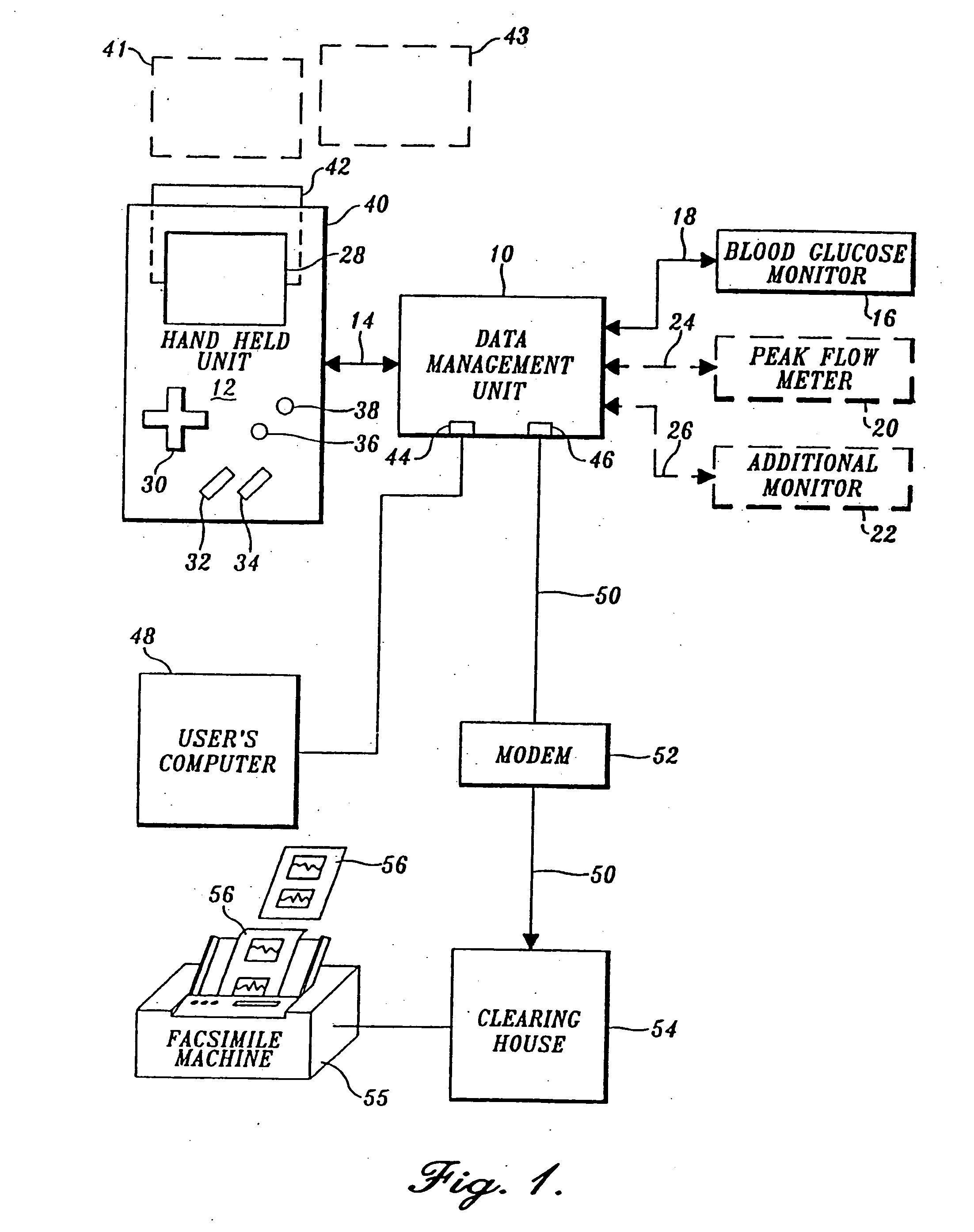

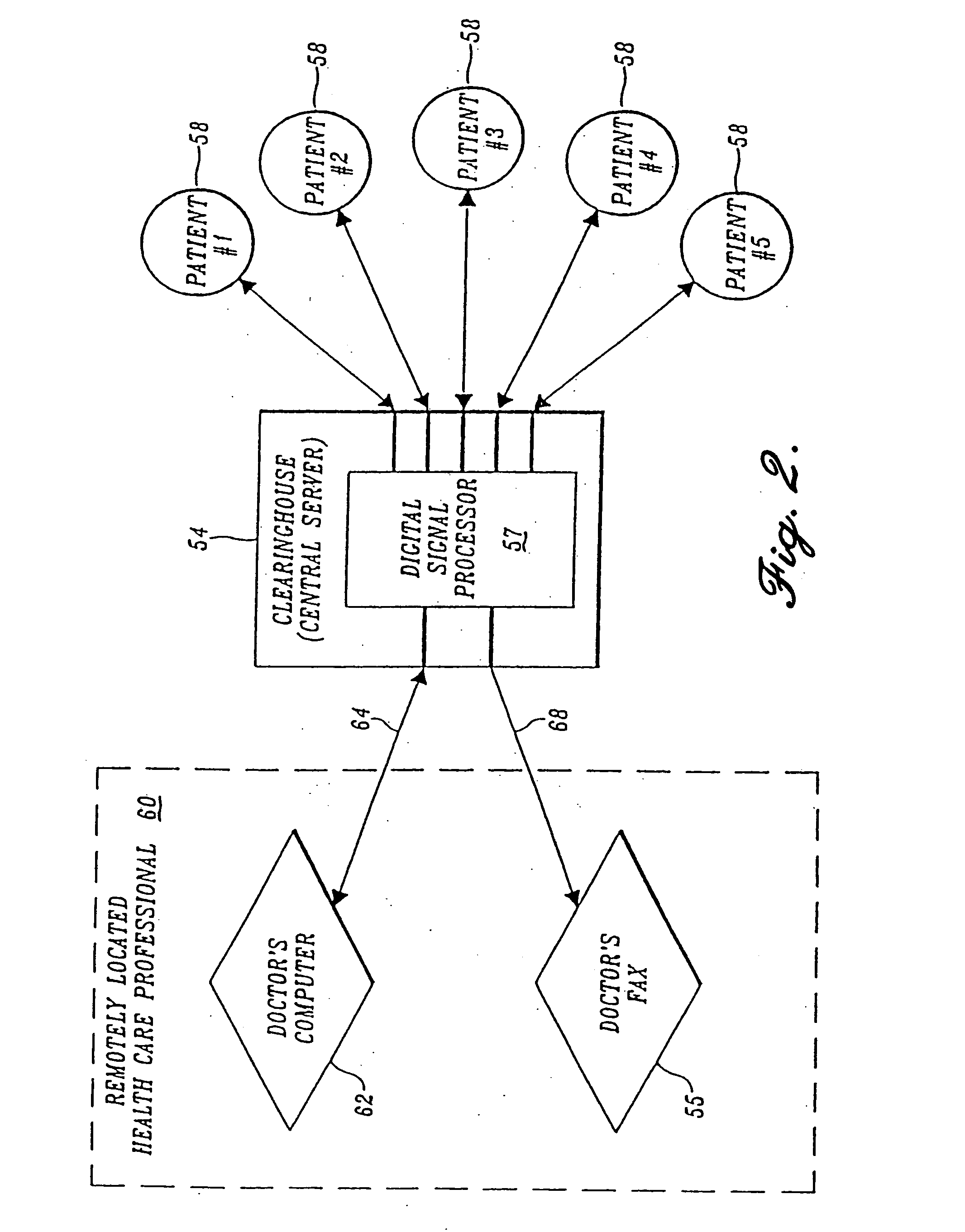

Remote health monitoring and maintenance system

A system and method is described that enables a health care provider to monitor and manage a health condition of a patient. The system includes a health care provider apparatus operated by a health care provider and a remotely programmable patient apparatus that is operated by a patient. The health care provider develops a script program using the health care provider apparatus and then sends the script program to a remotely programmable patient apparatus through a communication network such as the World Wide Web. The script program is a computer-executable patient protocol that provides information to the patient about the patient's health condition and that interactively monitors the patient health condition by asking the patient questions and by receiving answers to those questions. The answers to these health related questions are then forwarded as patient data from the remotely programmable patient apparatus to the health care provider apparatus through the communication network. The patient data may also include information supplied by a physiological monitoring device such as a blood glucose monitor that is connected to the remotely programmable patient apparatus. When the patient data arrives at the health care provider apparatus, the patient data is processed for further management of the patient's health condition by the health care provider, such as forwarding another script program to the remotely programmable patient apparatus.

Owner:HEALTH HERO NETWORK

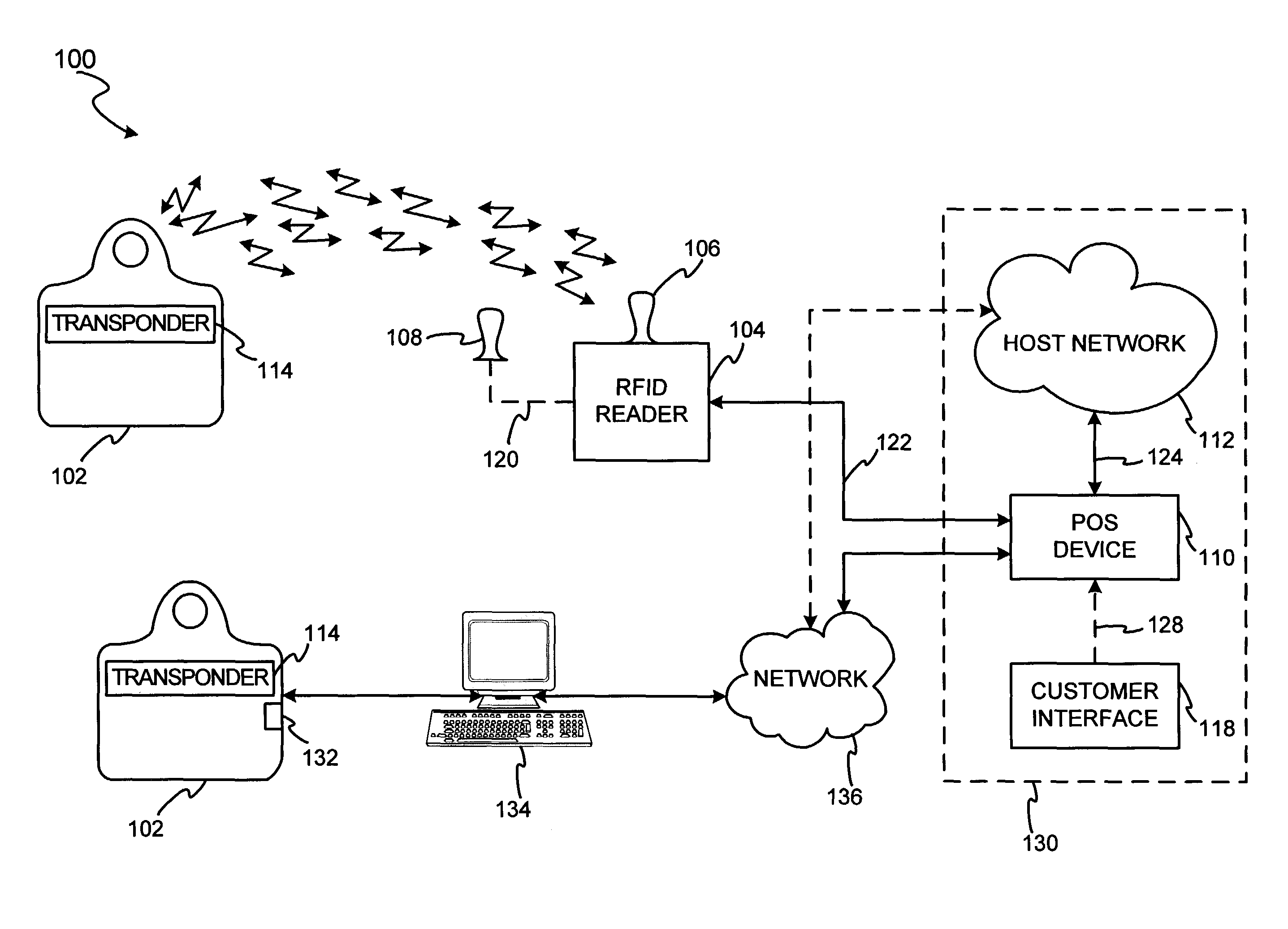

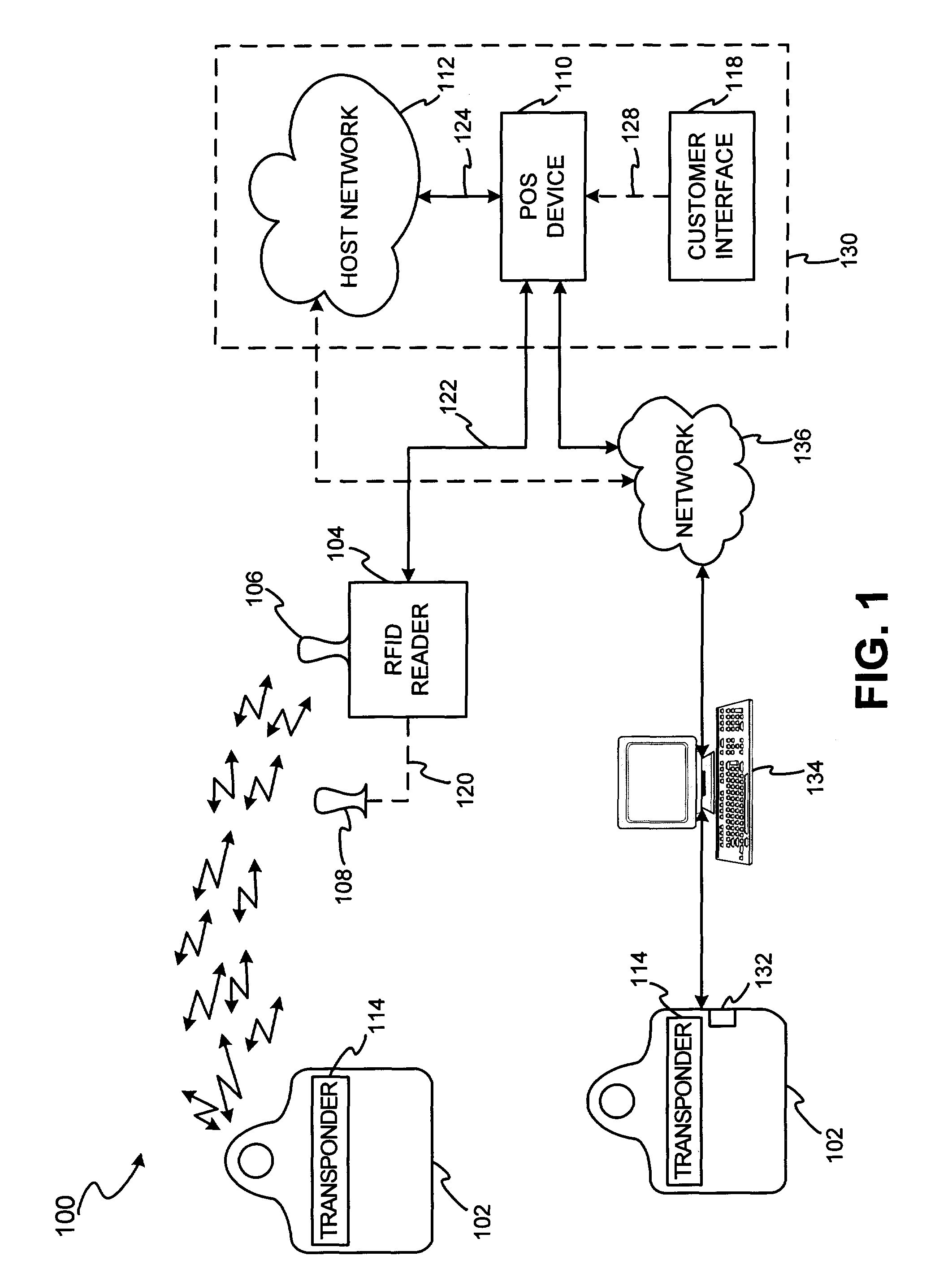

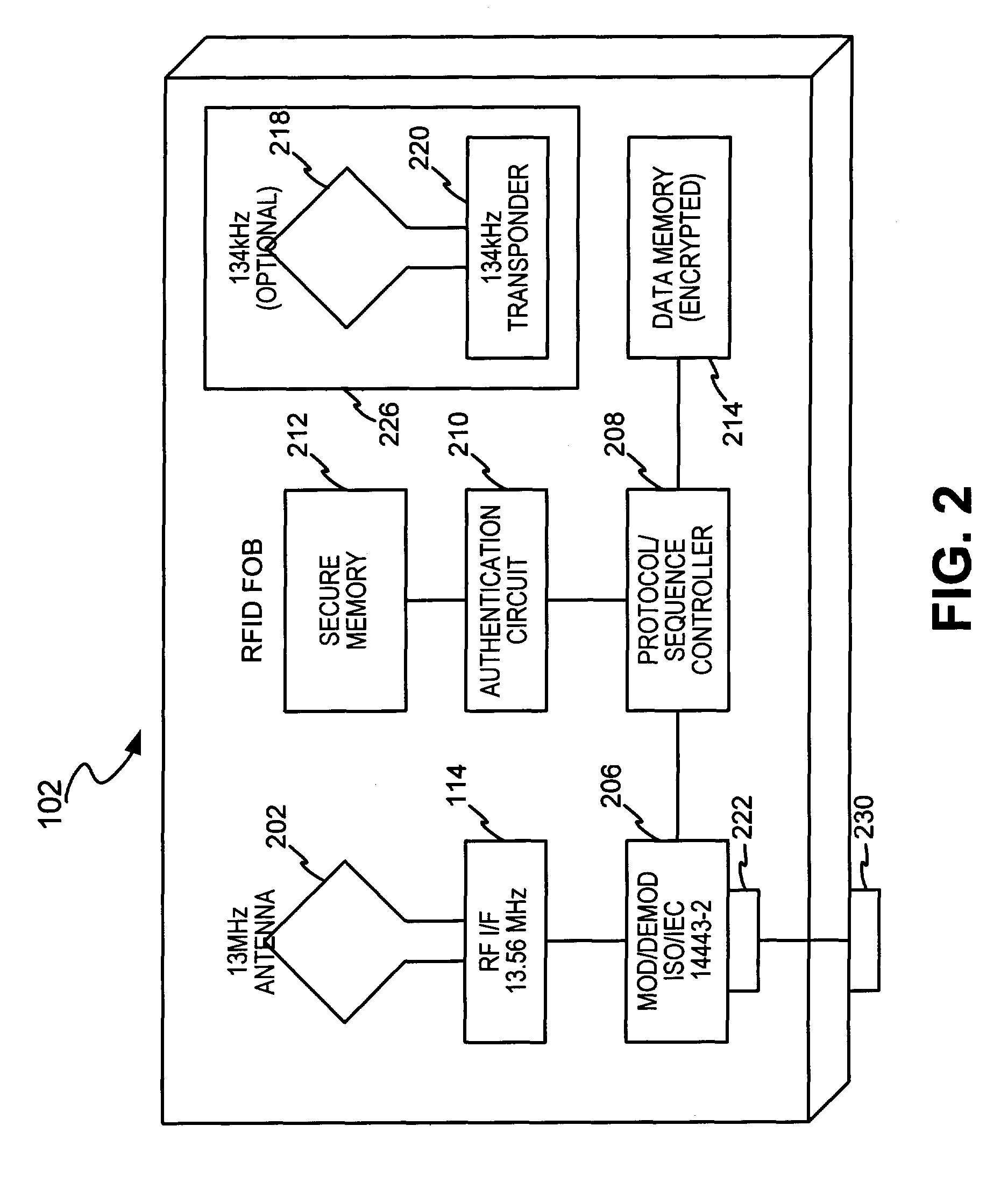

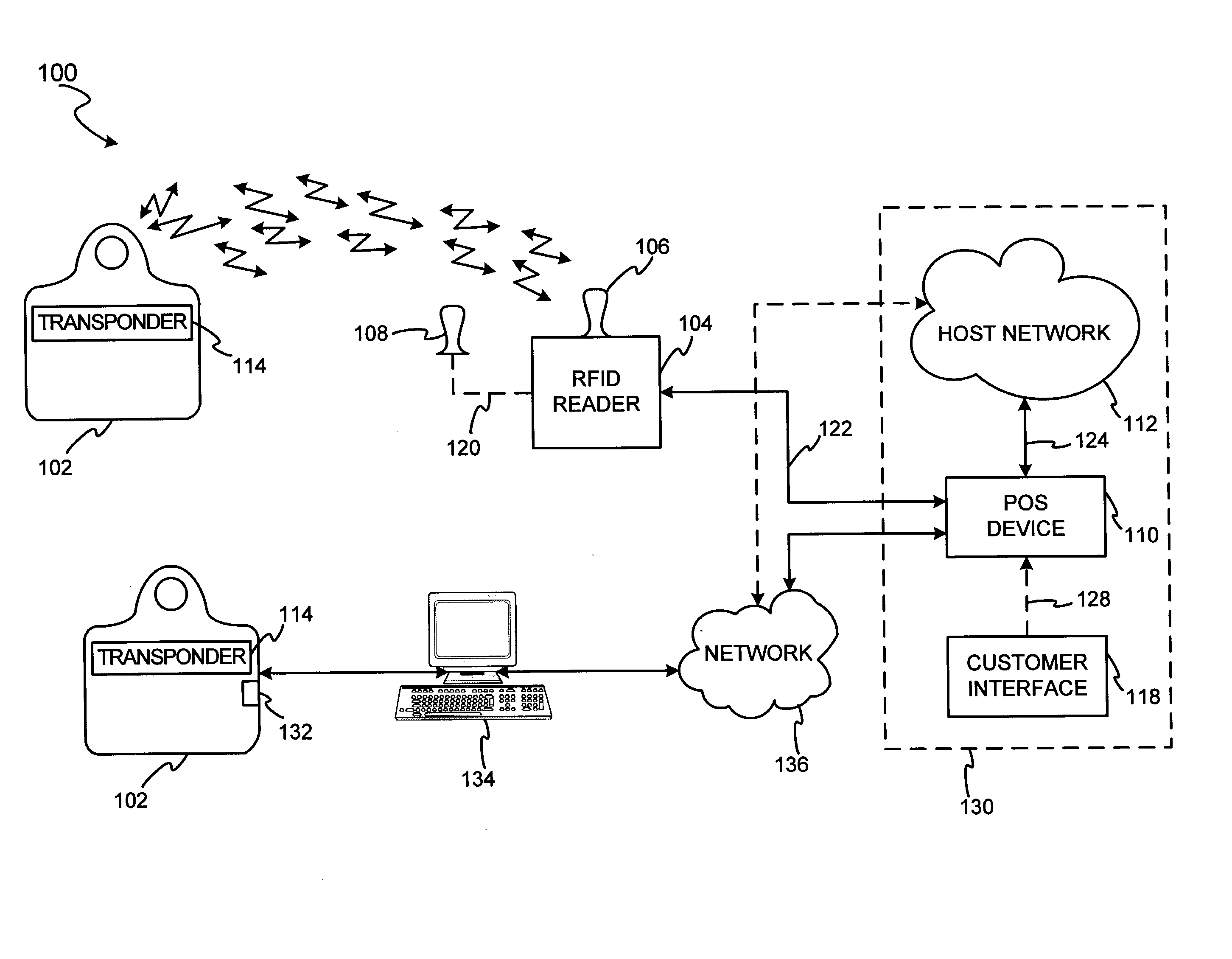

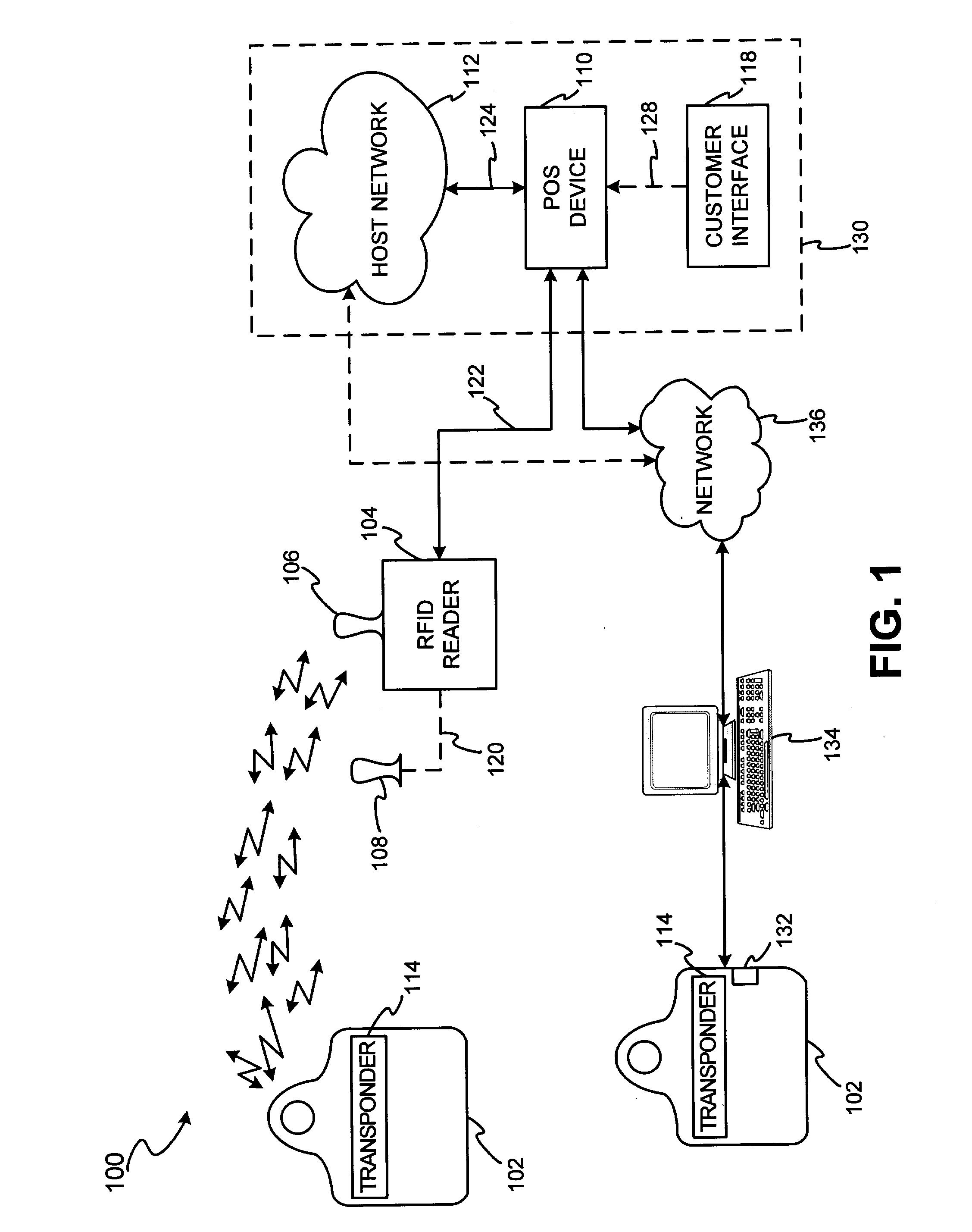

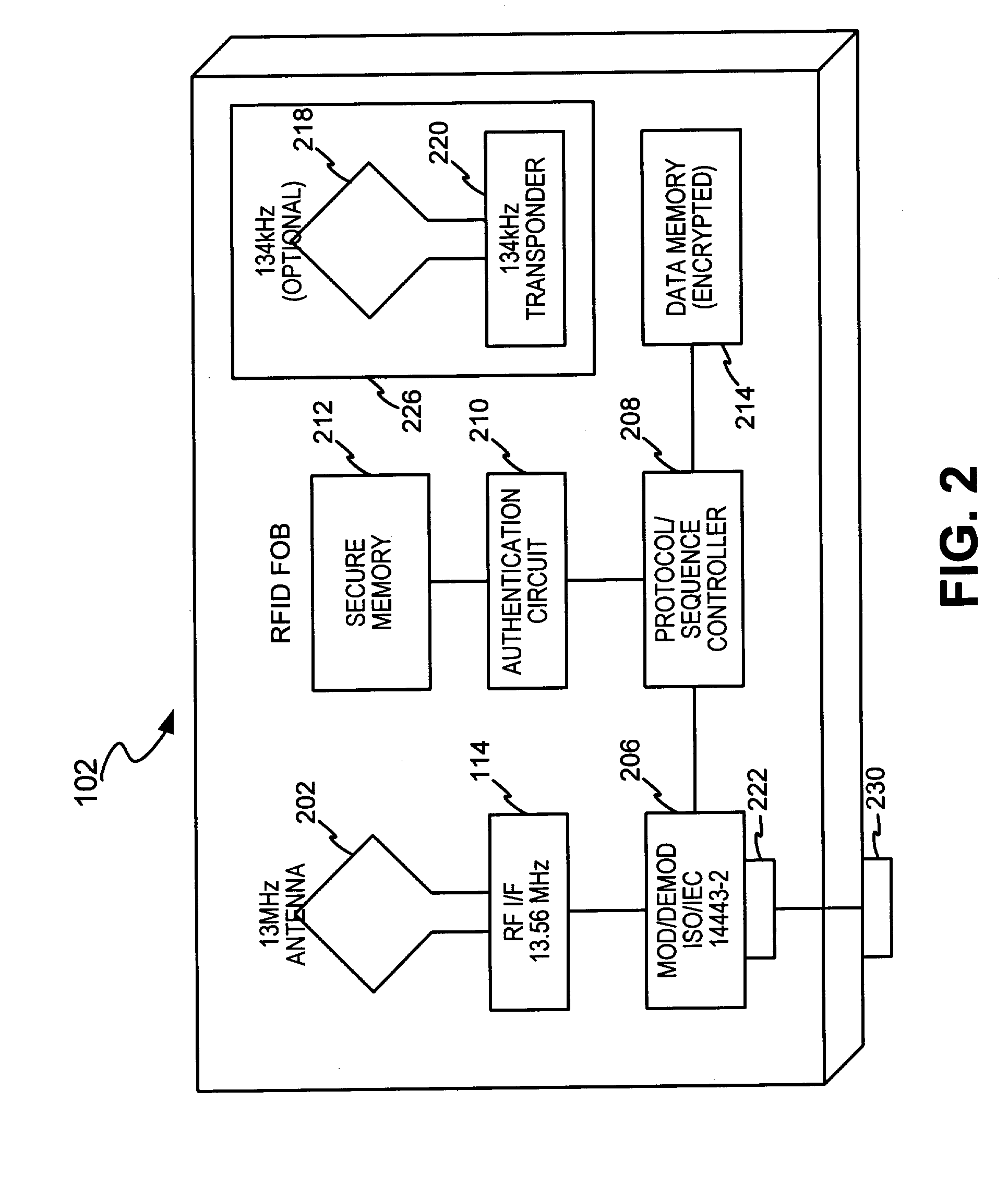

System and method for dynamic fob synchronization and personalization

A system generally for personalizing and synchronizing fob data in the context of a distributed transaction system is disclosed. A dynamic fob synchronization system may comprise point of service (POS) devices configured with transponder-readers to initiate a transaction in conjunction with a fob, an enterprise data collection unit, and a fob object database update system. An exemplary dynamic synchronization system (DSS) may comprise various fob POS devices, a secure support client server, a fob object database update system (FODUS), one or more enterprise data synchronization interfaces (EDSI), an update logic system, one or more enterprise data collection units (EDCUs), and one or more fob POS devices configured to interoperably accept and interface with fobs. In an exemplary embodiment, DSS may comprise a personalization system and an account maintenance system configured to communicate with FODUS. Personalization of multi-function fobs may be accomplished using a security server configured to generate and / or retrieve cryptographic key information from multiple enterprise key systems during the final phase of the fob issuance process.

Owner:LIBERTY PEAK VENTURES LLC

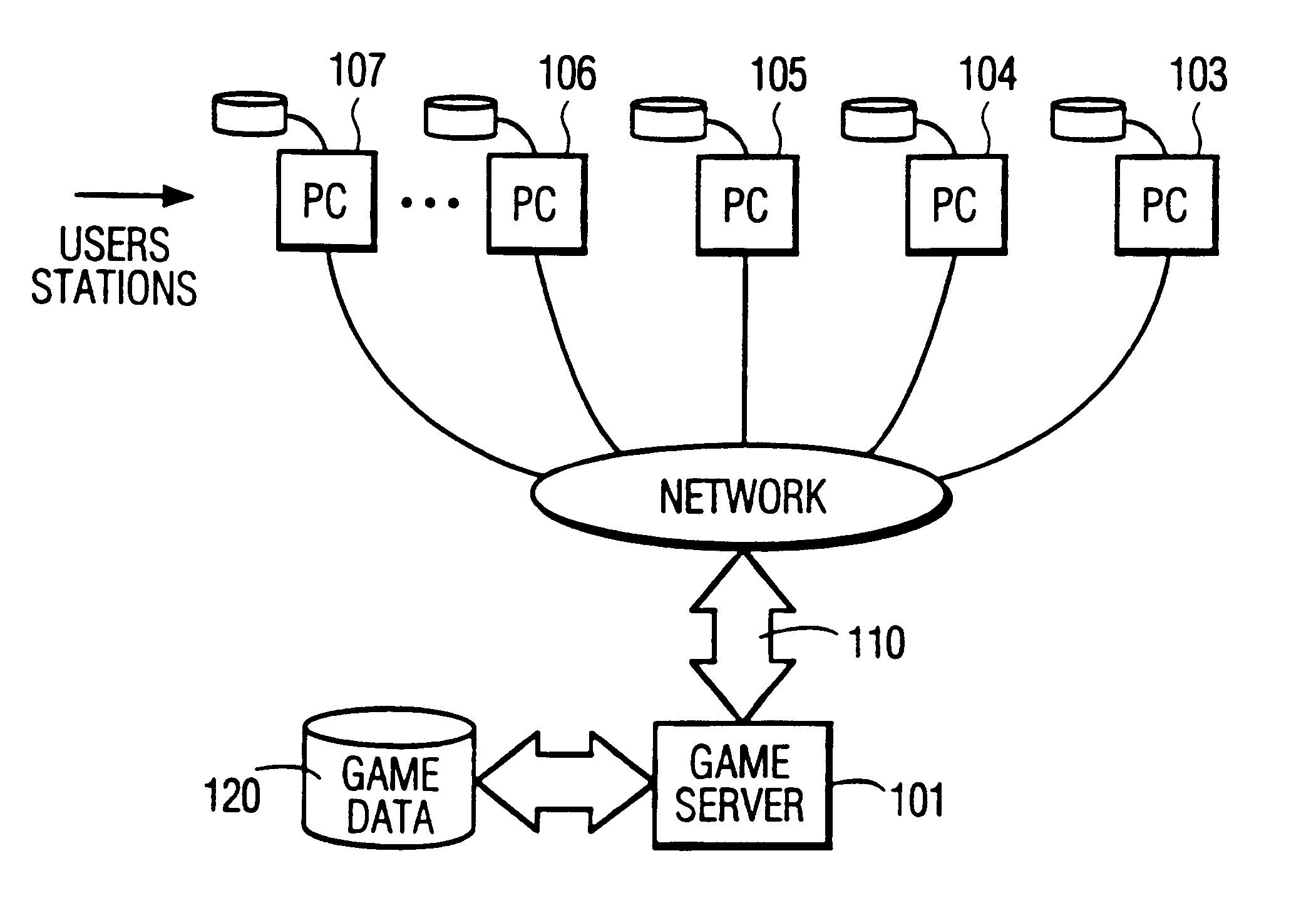

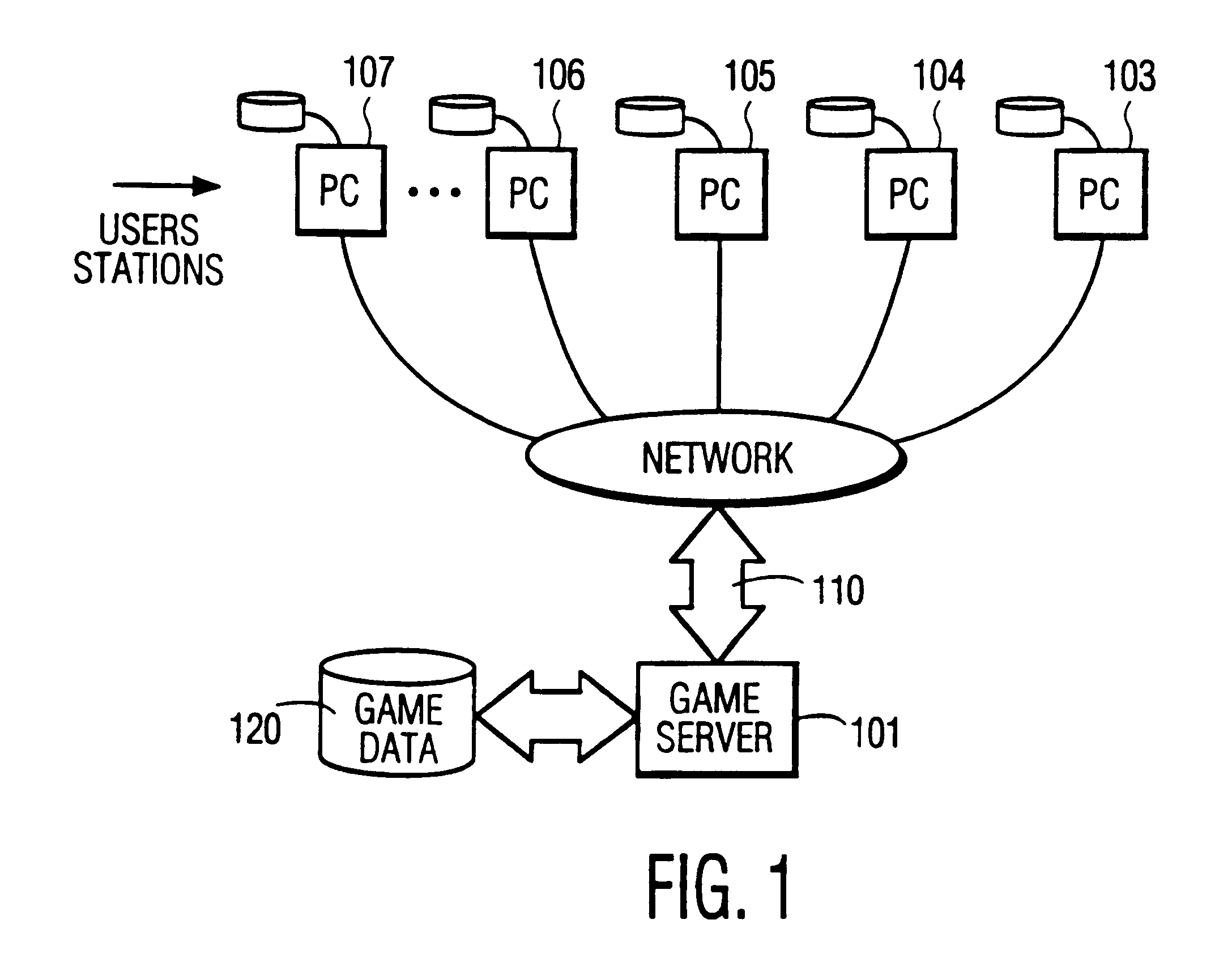

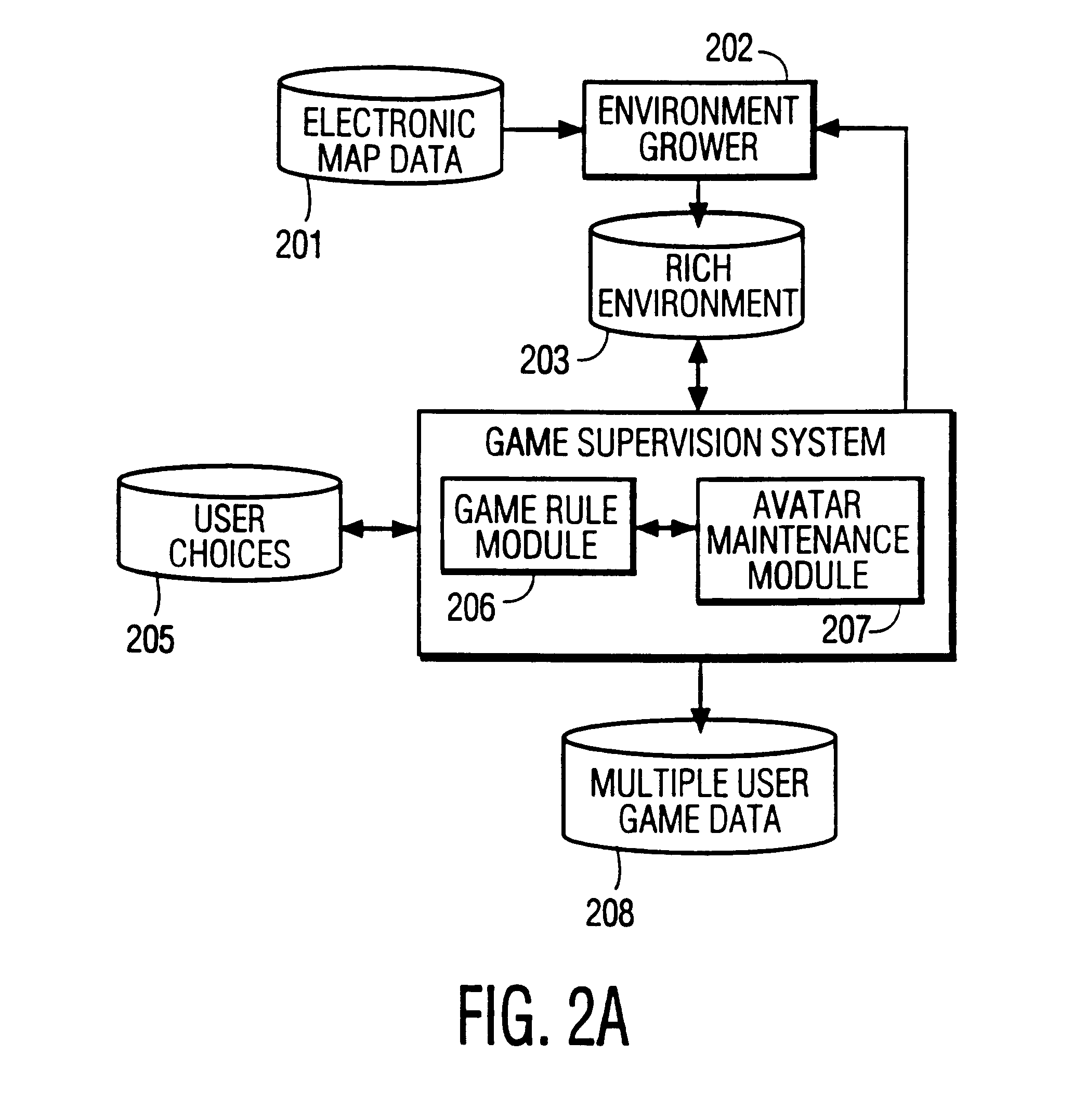

Simulated environment using procedural animation in a simulated city

InactiveUS6183364B1Video gamesSpecial data processing applicationsAnimationHuman–computer interaction

An electronic game uses electronic map data and an environment grower to create a rich environment. An avatar maintenance system further enhances the game environment. The game is then sufficiently complex to be used by thousands of users.

Owner:U S PHILIPS CORP

Operation and maintenance automation system and method

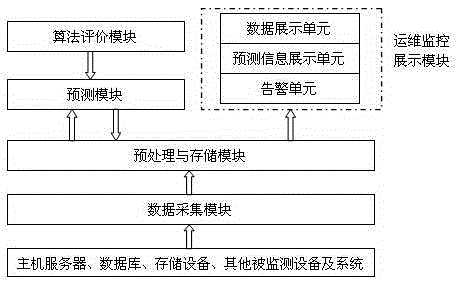

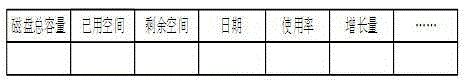

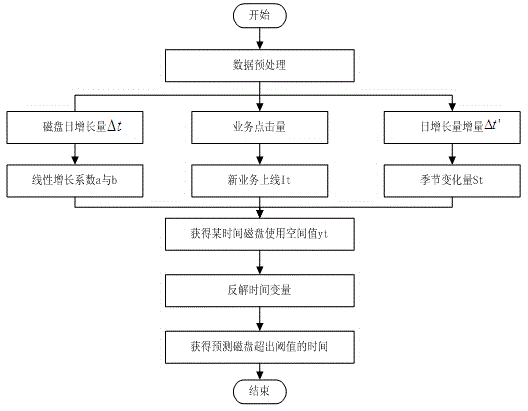

ActiveCN105323111AEasy to viewImprove the difficulty of operation and maintenanceData switching networksPrediction algorithmsData acquisition

The invention discloses an operation and maintenance automation system and method. The system comprises a data acquisition module, a pre-processing and storing module, a prediction module, an algorithm evaluation module and an operation and maintenance monitoring management module, wherein the data acquisition module is used for acquiring key performance indexes and running states of monitored units in an operation and maintenance system through a network management protocol or a log file; the pre-processing and storing module is used for performing pre-processing work and sorted storing on data acquired by the data acquisition module; the prediction module is used for performing predictions, including a CPU (Central Processing Unit) load prediction and a disk load prediction according to the data processed by the pre-processing and storing module; the algorithm evaluation module is used for establishing an evaluation criterion of a prediction algorithm and the prediction module, comparing an actual value with a predicted value of the prediction algorithm, and establishing a self-learning process; and the operation and maintenance monitoring management module is used for interacting with operation and maintenance management personnel. A load prediction mechanism and an algorithm prediction model are established in order to finish predictions specific to resource use situations of CPUs, memories, disks and the like. Alarm information is analyzed by further referring to a load prediction result in order to give a relevant auxiliary decision. Resource expansion and fault handling are realized in a way of using scripts, an API (Application Programming Interface) interface and the like.

Owner:NANJING NARI GROUP CORP

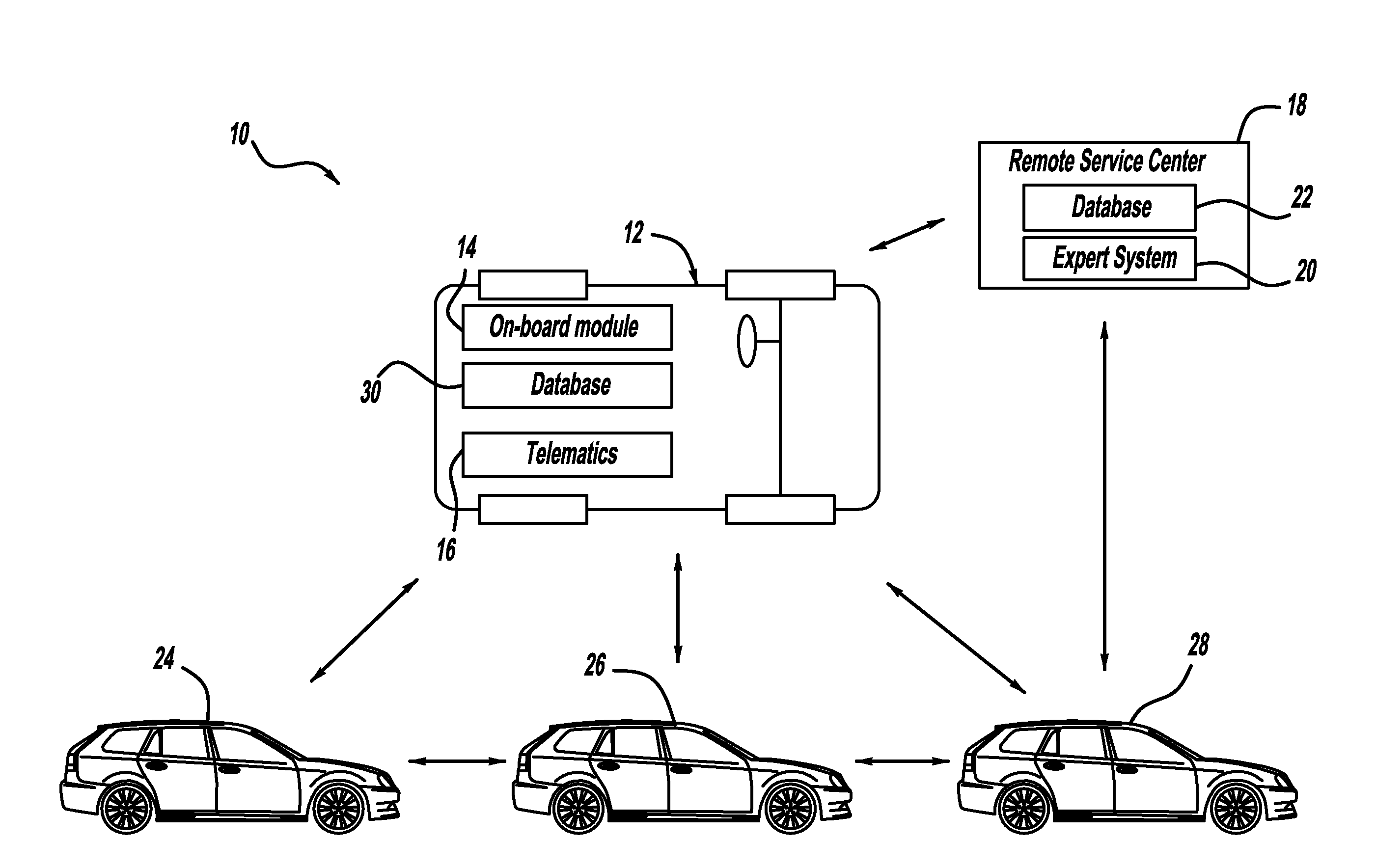

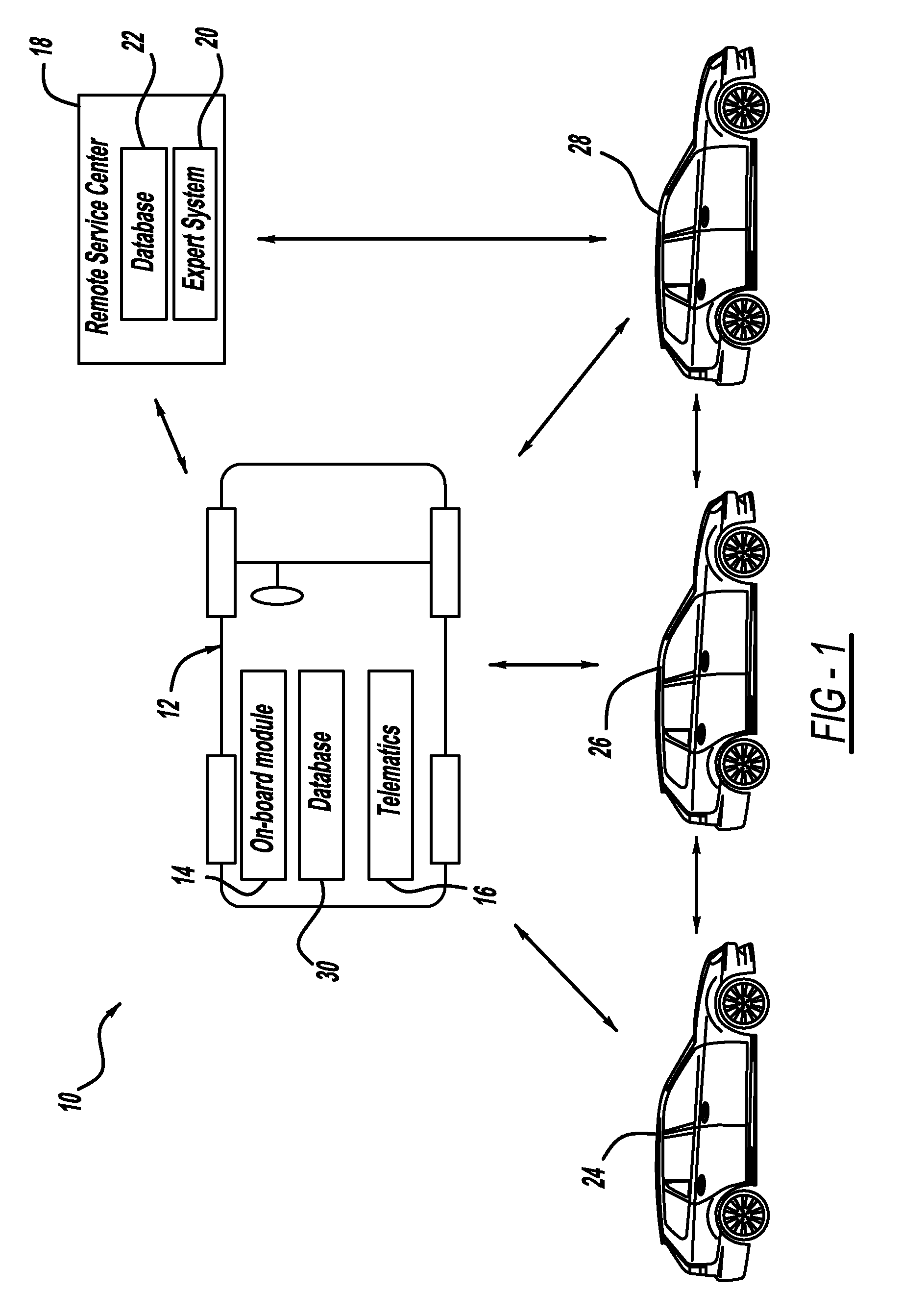

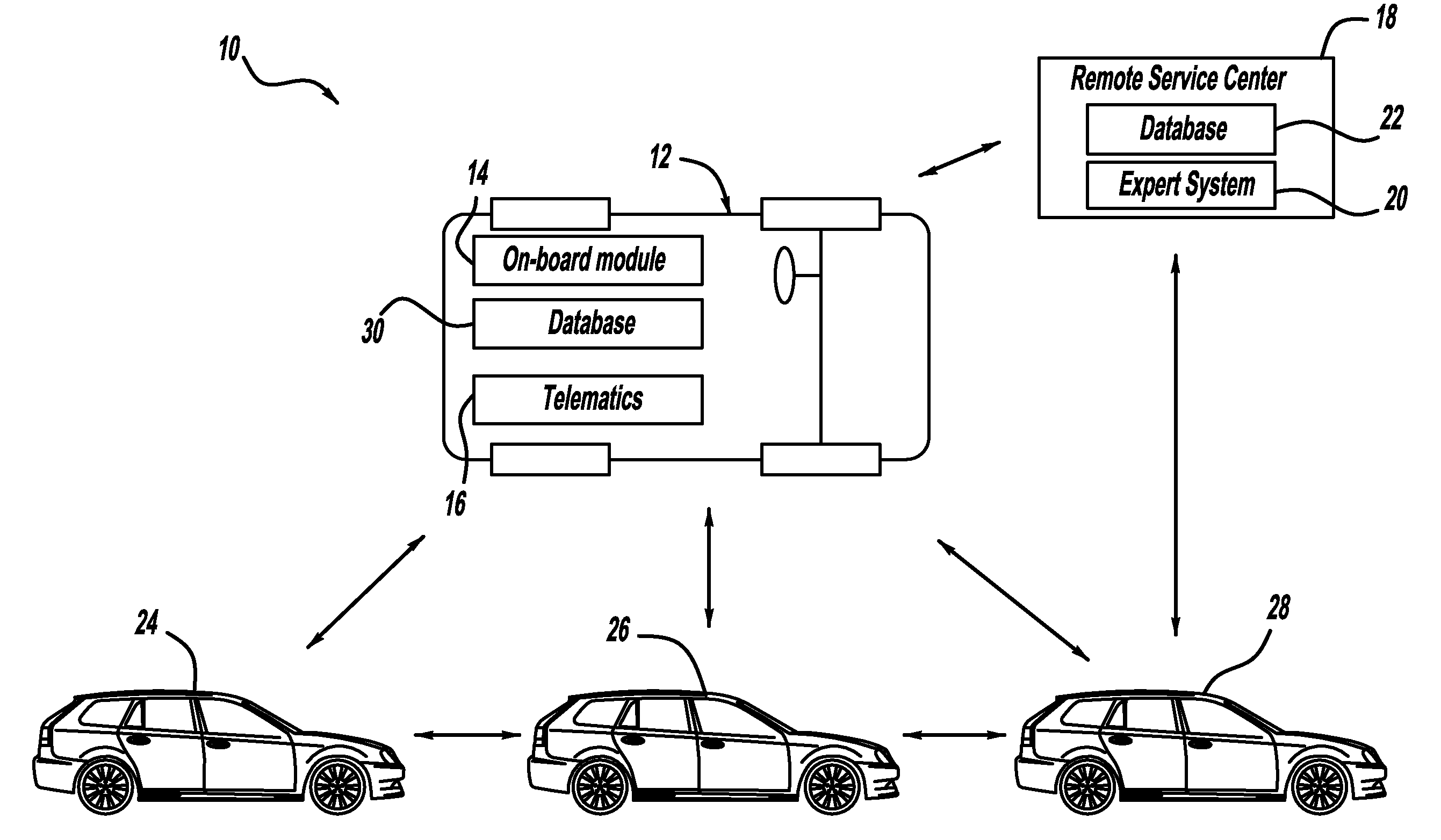

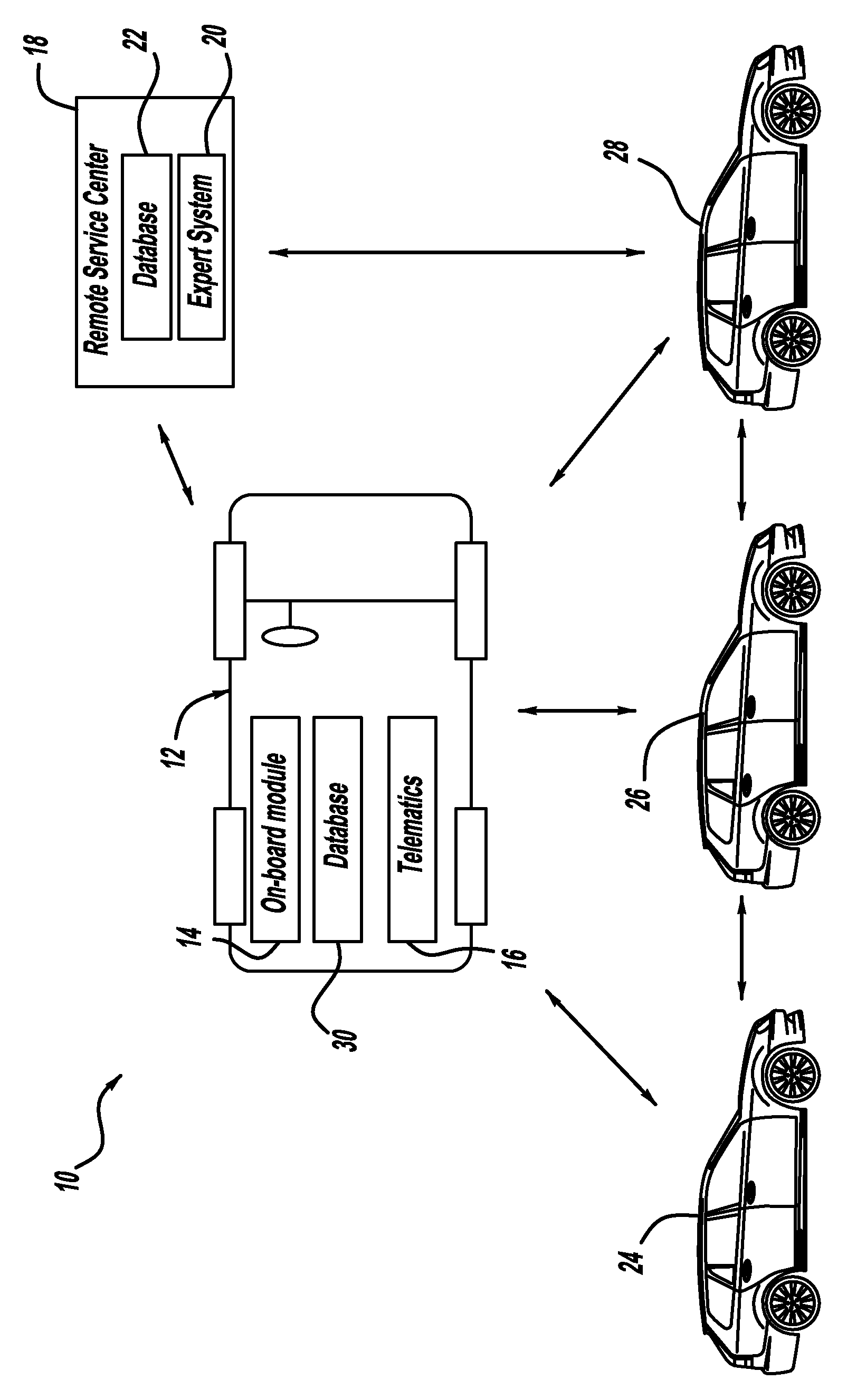

Autonomous vehicle maintenance and repair system

A system and method for providing autonomous and remote vehicle maintenance and repair. The system employs an on-board diagnosis and prognosis module that monitors one or more vehicle buses to identify trouble codes and other information indicating a vehicle problem. The on-board module causes a telematic device on the vehicle to broadcast a message including a problem code that identifies the problem the vehicle is having. A remote repair center may receive the message and may identify a software upgrade patch associated with the problem that can be transmitted to the vehicle to upgrade its software to correct the problem. Also, the message may be received by another vehicle that is part of a broadcast network that has previously received the software upgrade patch to fix a problem on that vehicle, where the receiving vehicle may transmit the software upgrade patch to the vehicle having the problem.

Owner:GM GLOBAL TECH OPERATIONS LLC

Autonomous vehicle maintenance and repair system

A system and method for providing autonomous and remote vehicle maintenance and repair. The system employs an on-board diagnosis and prognosis module that monitors one or more vehicle buses to identify trouble codes and other information indicating a vehicle problem. The on-board module causes a telematic device on the vehicle to broadcast a message including a problem code that identifies the problem the vehicle is having. A remote repair center may receive the message and may identify a software upgrade patch associated with the problem that can be transmitted to the vehicle to upgrade its software to correct the problem. Also, the message may be received by another vehicle that is part of a broadcast network that has previously received the software upgrade patch to fix a problem on that vehicle, where the receiving vehicle may transmit the software upgrade patch to the vehicle having the problem.

Owner:GM GLOBAL TECH OPERATIONS LLC

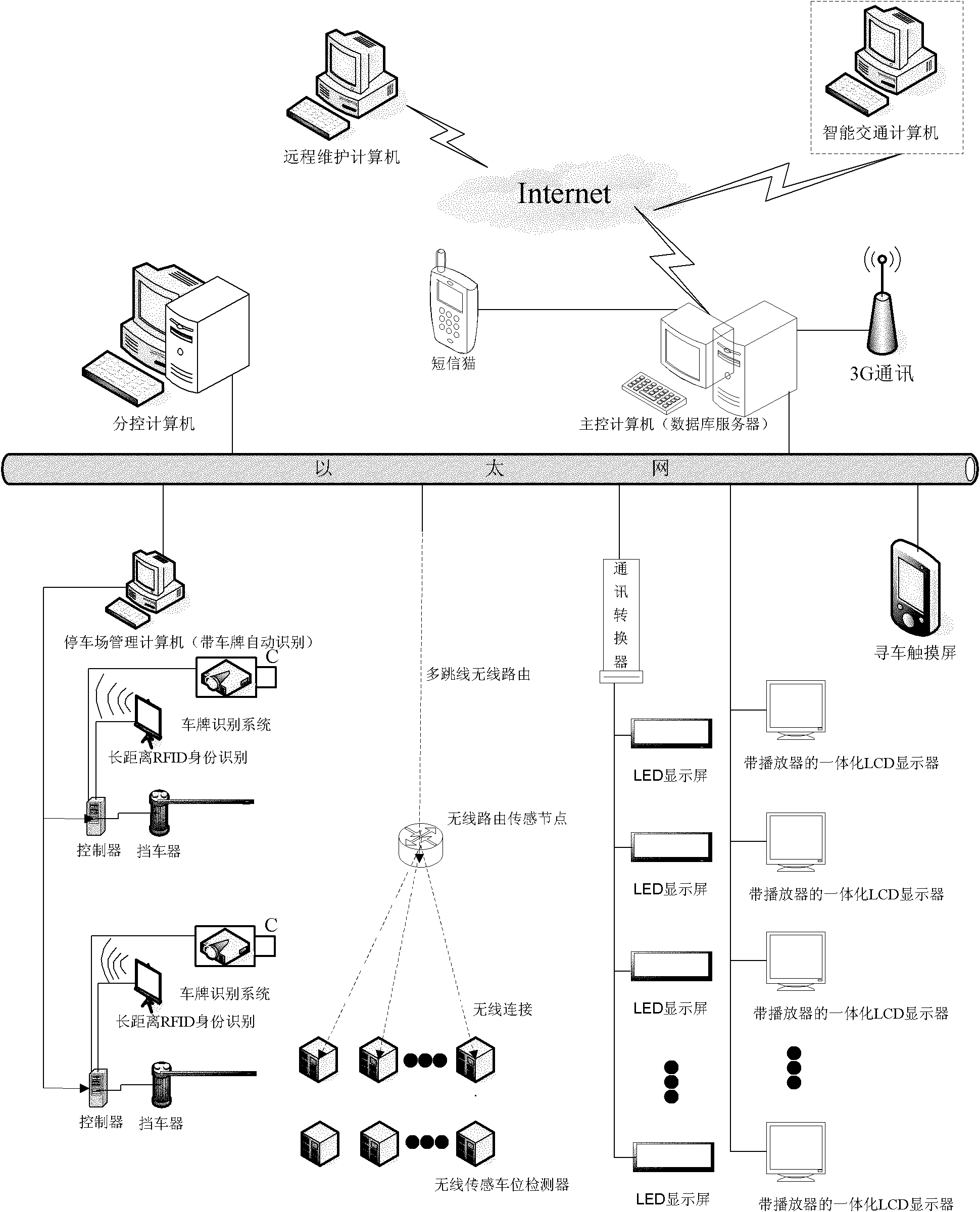

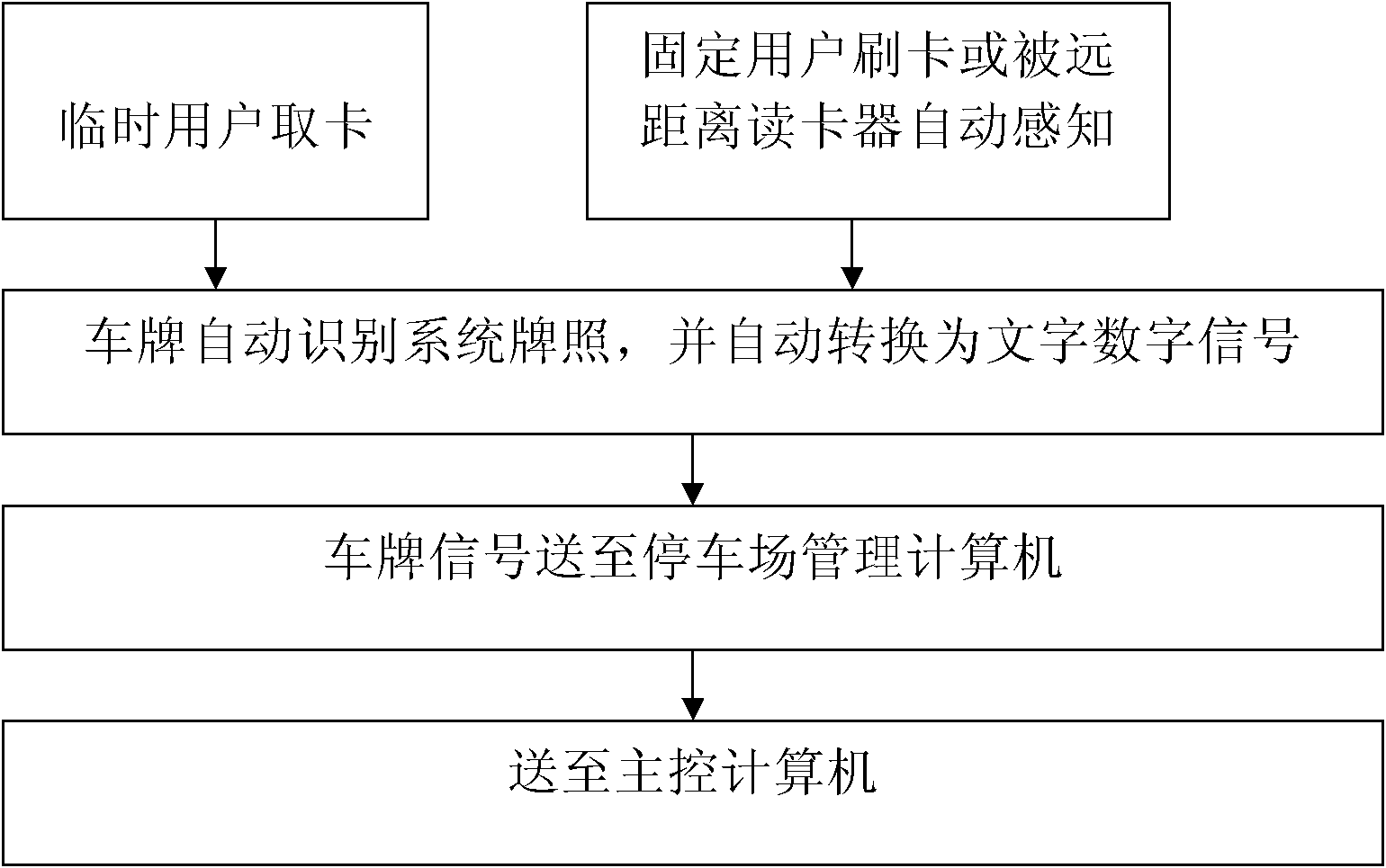

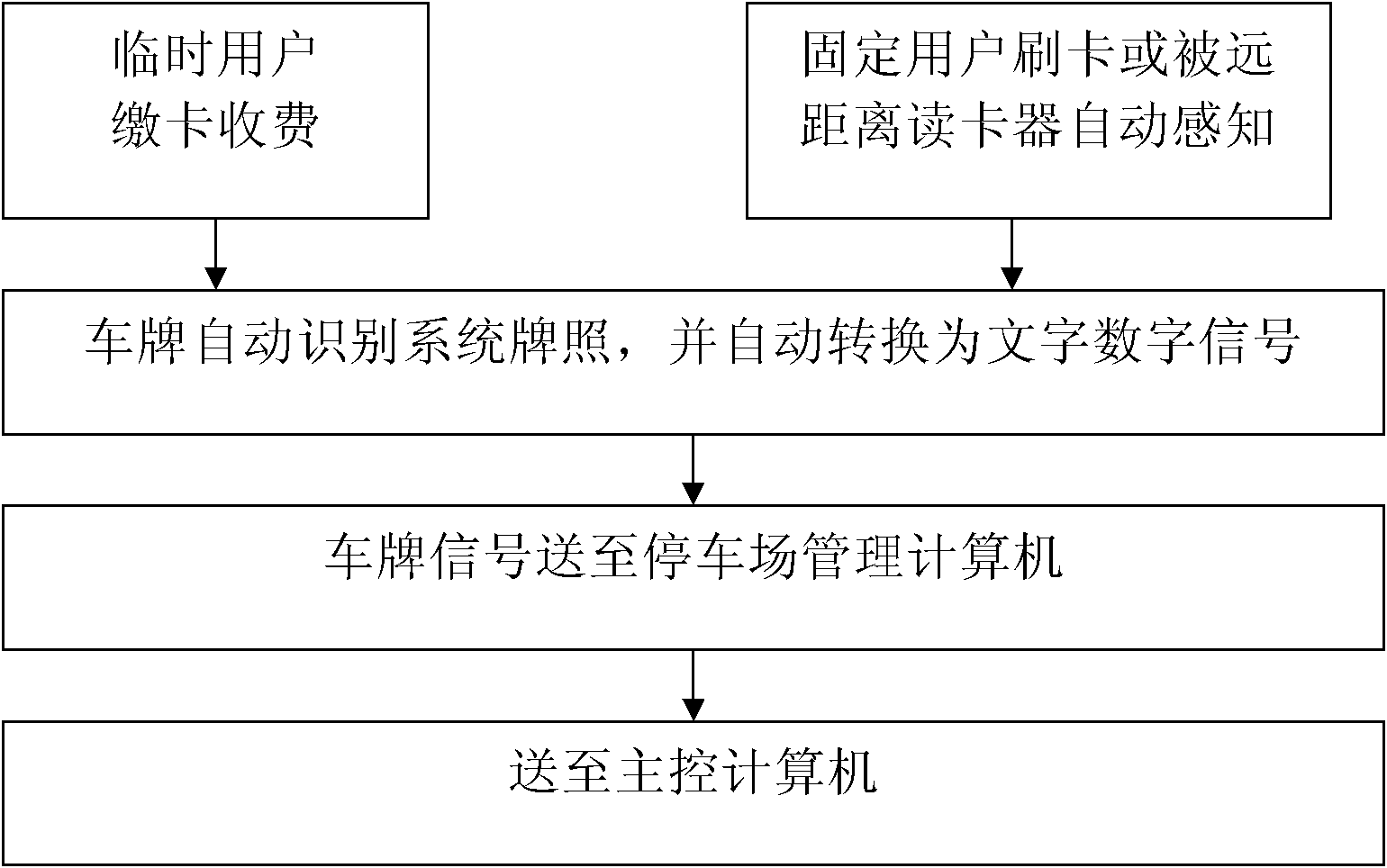

Parking navigation and finding system based on object networking wireless sensing and video perception

ActiveCN101937619AAccurate parking navigationCar owners find parking spaces efficientlyIndication of parksing free spacesCo-operative working arrangementsDisplay deviceThird generation

The invention provides a parking navigation and finding system based on object networking wireless sensing and video perception, comprising a main control computer. The main control computer is connected with a plurality of park control systems with number plate automatic identification and a plurality of integrated LCD displays with players and wireless stall sensors through a network; the wireless stall sensor is installed at each stall; the park control system comprises a number plate identification system, an RFID (Radio Frequency Identification Device) reader-writer and a matched radio frequency identification electronic tag; and the LCD display comprises a navigation screen at the garage entrance and the LCD display arranged on a client forwarding path. The parking navigation and finding system has the advantages of actively informing a related internal part or a common platform of characteristic vehicle information and having a remote maintenance system transmitted through 3G and is a typical object networking perception system. The parking navigation is precise through an object networking wireless perception technique and a number plate identification technique, a vehicle owner finds a stall efficiently and the identity identification is in advance.

Owner:江苏瑞孚特物联网科技有限公司

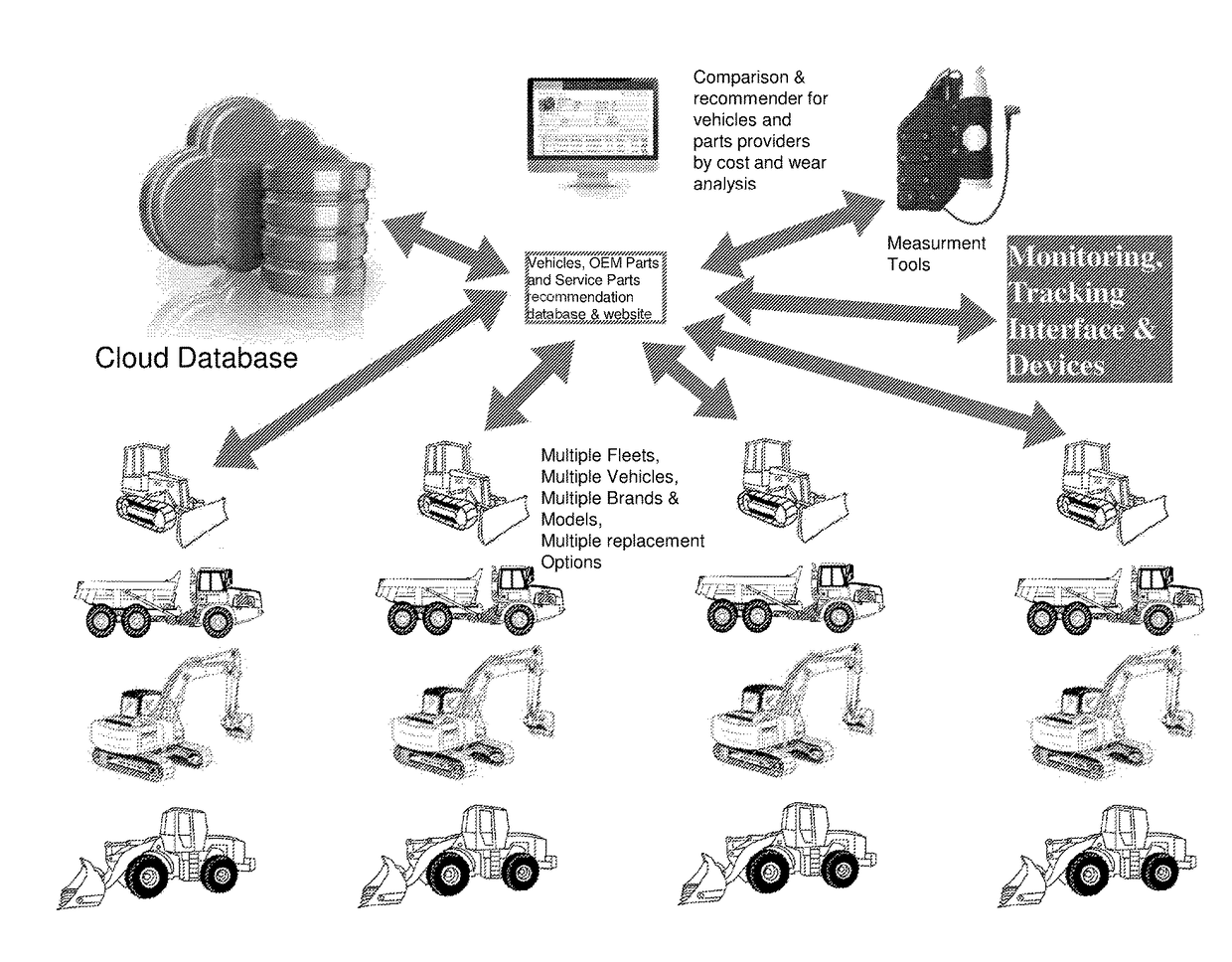

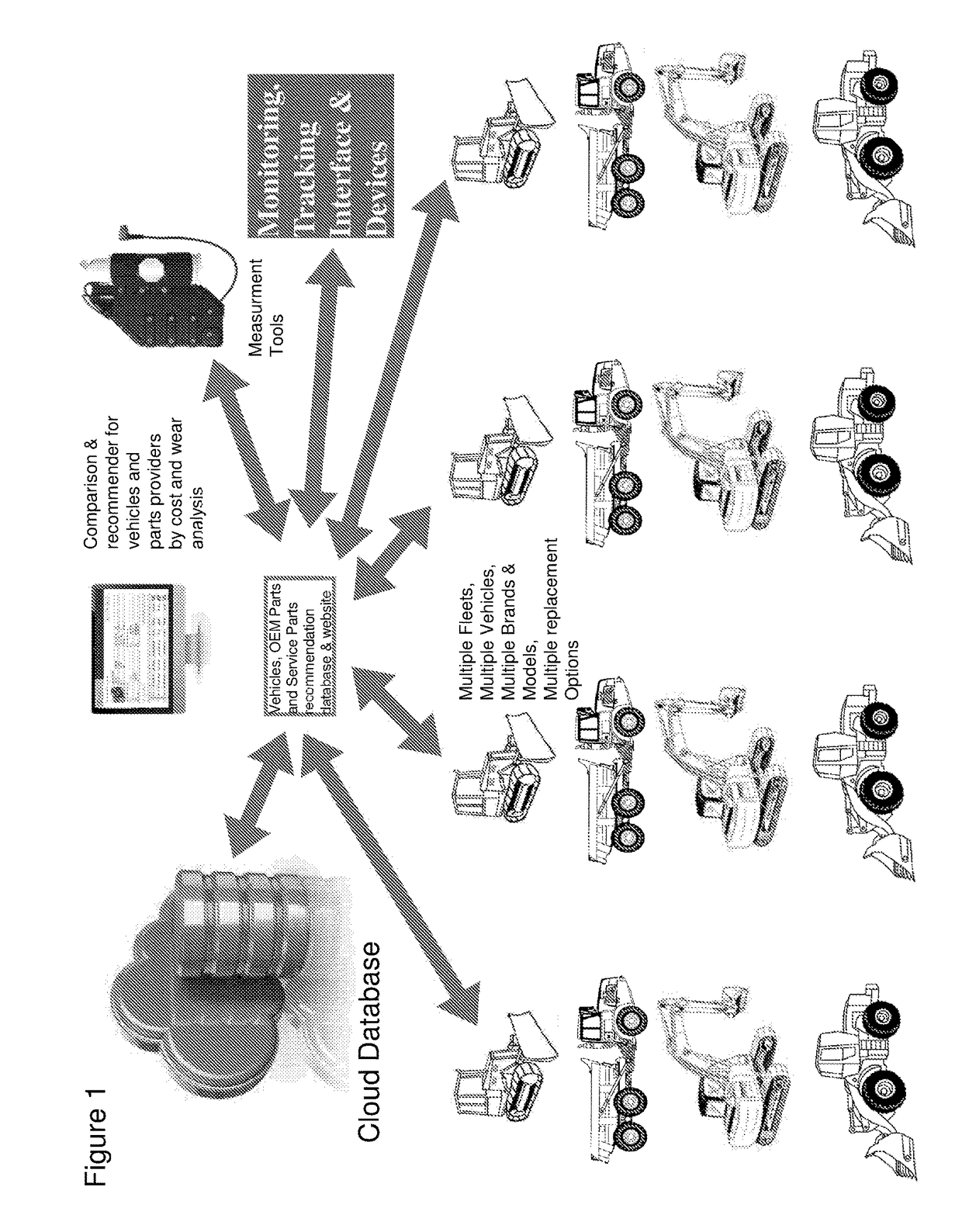

Configurable monitor and parts management system

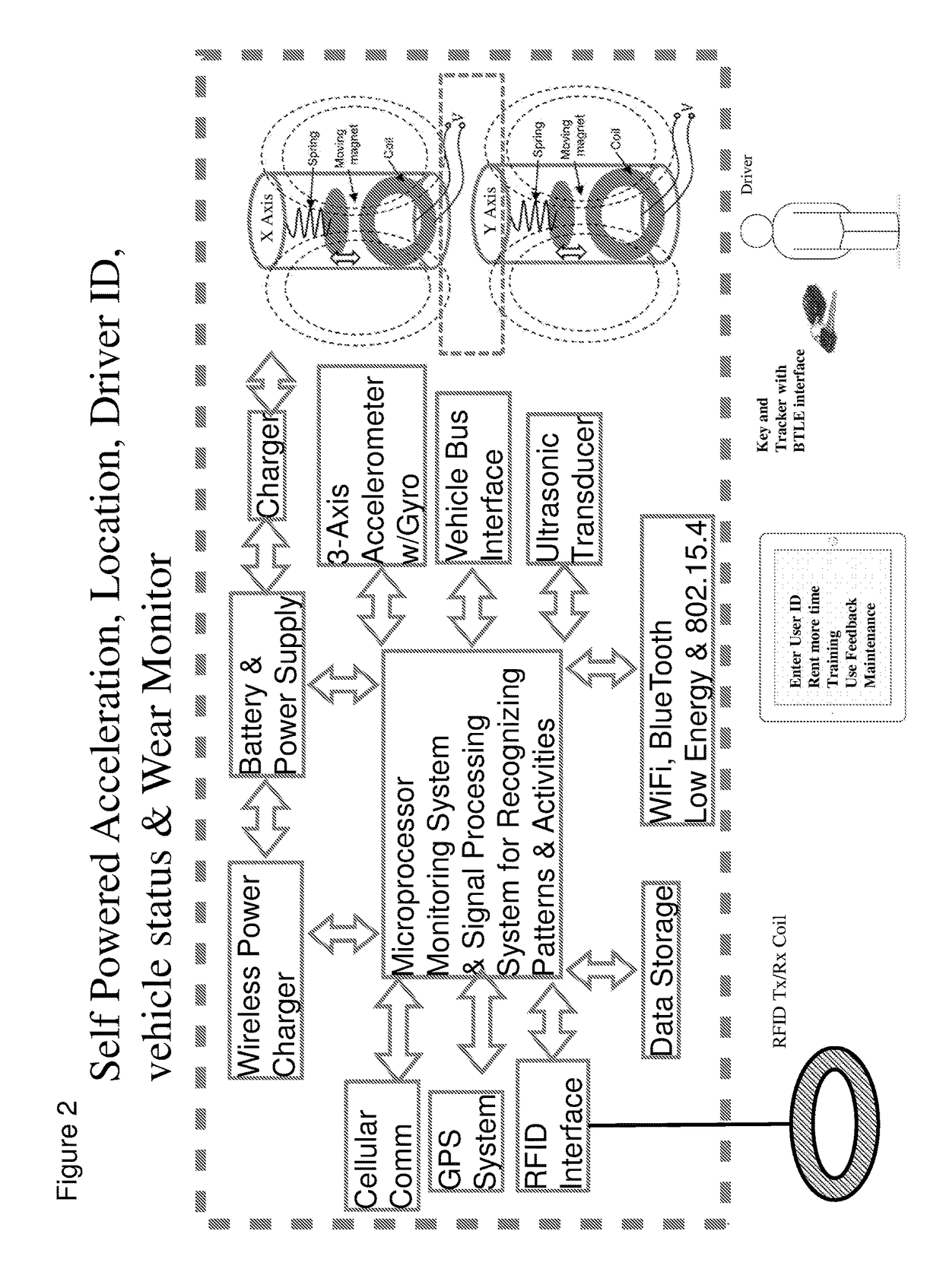

InactiveUS20170372534A1Facilitate communicationRegistering/indicating working of vehiclesMechanical machines/dredgersFleet managementHeavy duty

A monitoring and maintenance system that utilizes imperial and theoretical data to compare parts, vehicles, users, regions, wear intensity indexes over time and tracking information to provide a sophisticated data collection system for heavy-duty equipment or rental equipment. This tracking is designed to better the specifications, designs, training, preventative maintenance, and replacement wear understanding of fleet management.

Owner:CATERPILLAR INC

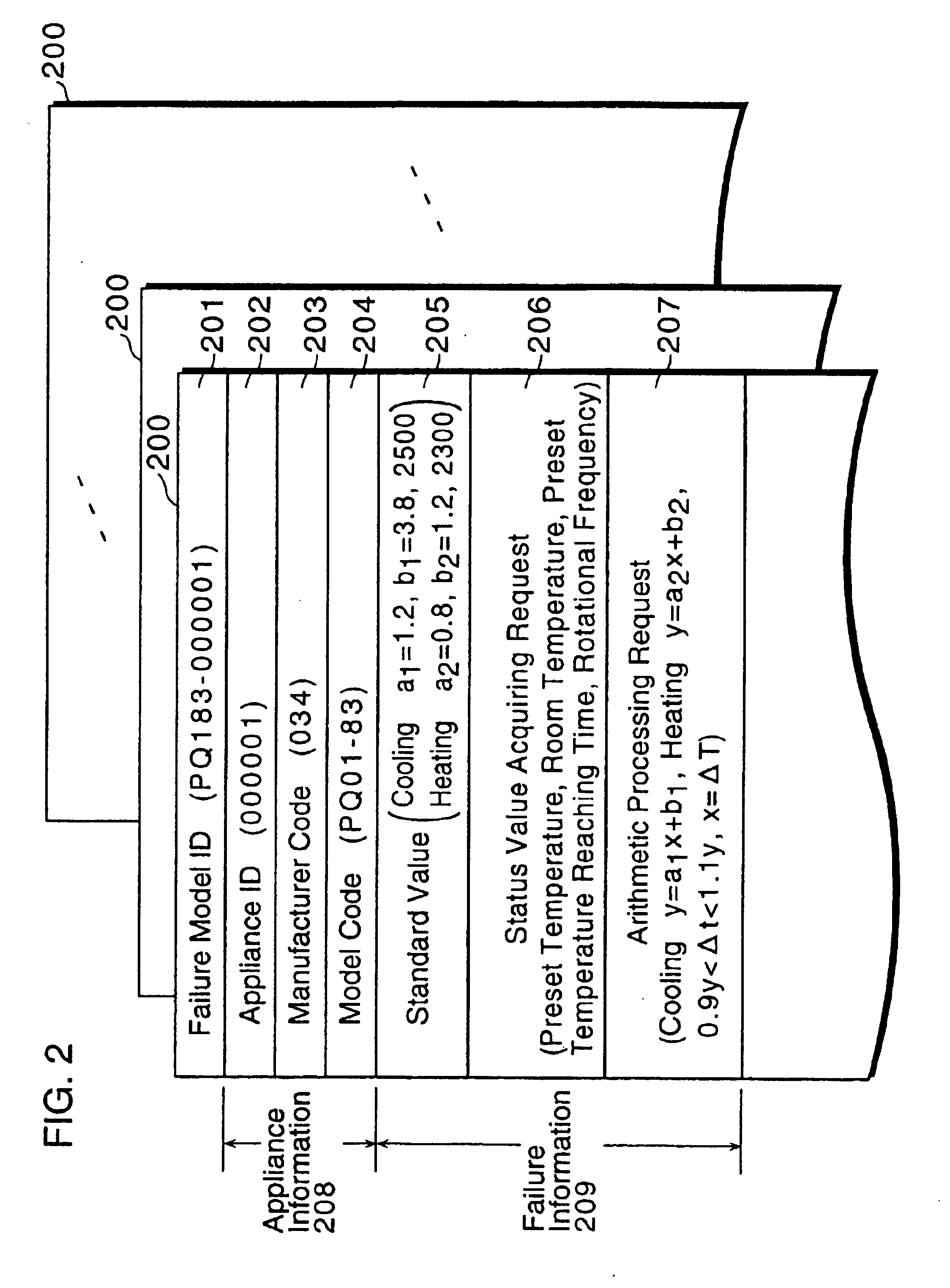

Remote maintenance system

InactiveUS6772096B2Accurate operationIncorrect actionData processing applicationsTelemetry/telecontrol selection arrangementsManagement unitCommunication unit

A remote maintenance system has a center server that is located in a service center for performing maintenance of an electrical appliance and a home server that is located in a house and monitors a status of the electrical appliance 102 in the house which are connected via a communication network. The home server includes an electrical appliance management unit that acquires a status value of the electrical appliance, a communication unit that receives from the center server a failure model which is information defining a method of deriving a decision whether the electrical appliance has failed or not from the status value, and a failure deciding unit that decides whether the electrical appliance has failed or not based on the acquired status value and the received failure model using qualitative reasoning. The center server includes a failure model updating unit that updates a failure model and sends the updated failure model to the home server via a communication unit.

Owner:PANASONIC CORP

Intelligent model-based diagnostics for system monitoring, diagnosis and maintenance

InactiveUS7260501B2Improve accuracyImprove consistencyAmplifier modifications to reduce noise influenceTesting/monitoring control systemsTransit systemElectric power system

Owner:TOYOTA TECHN CENT USA +1

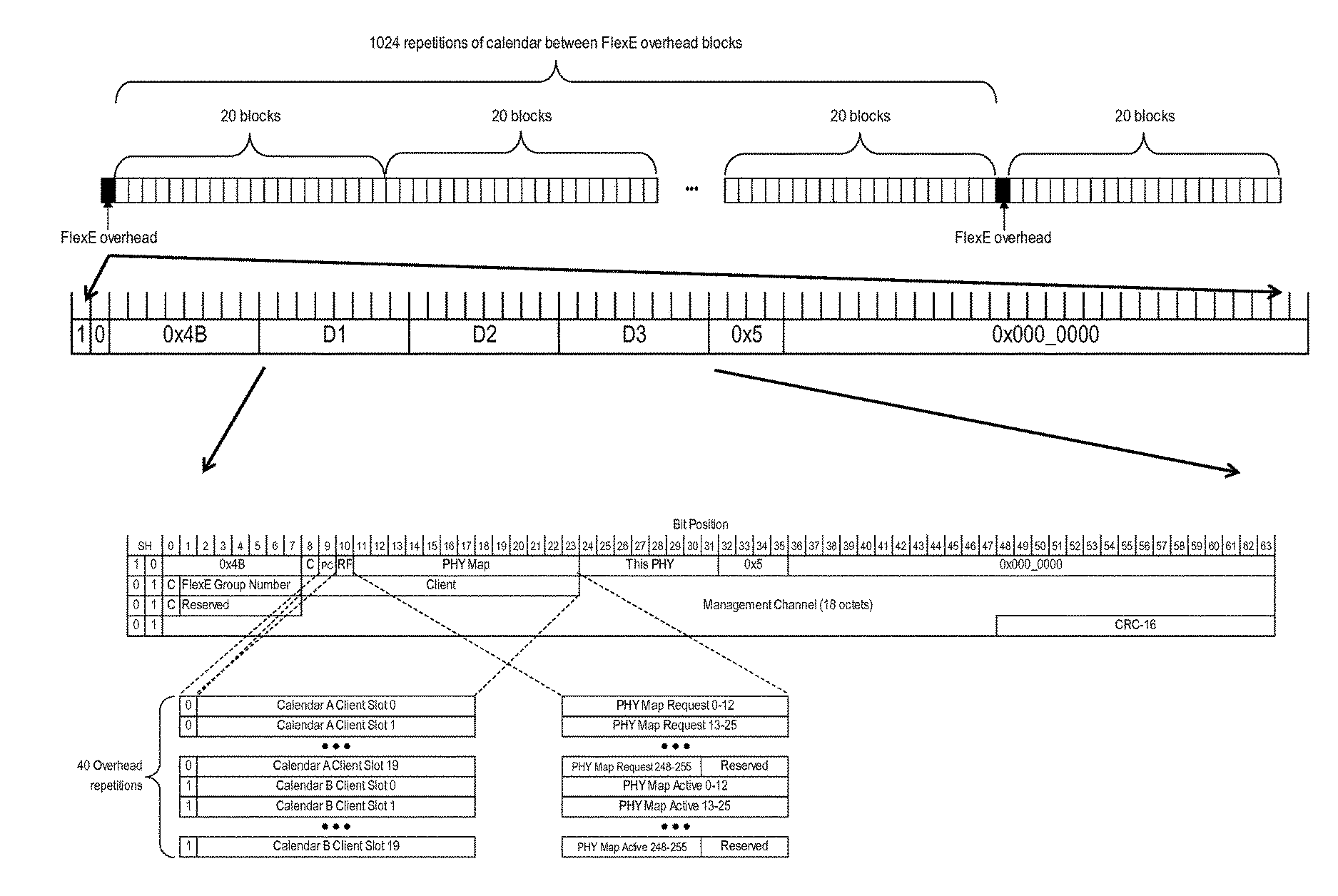

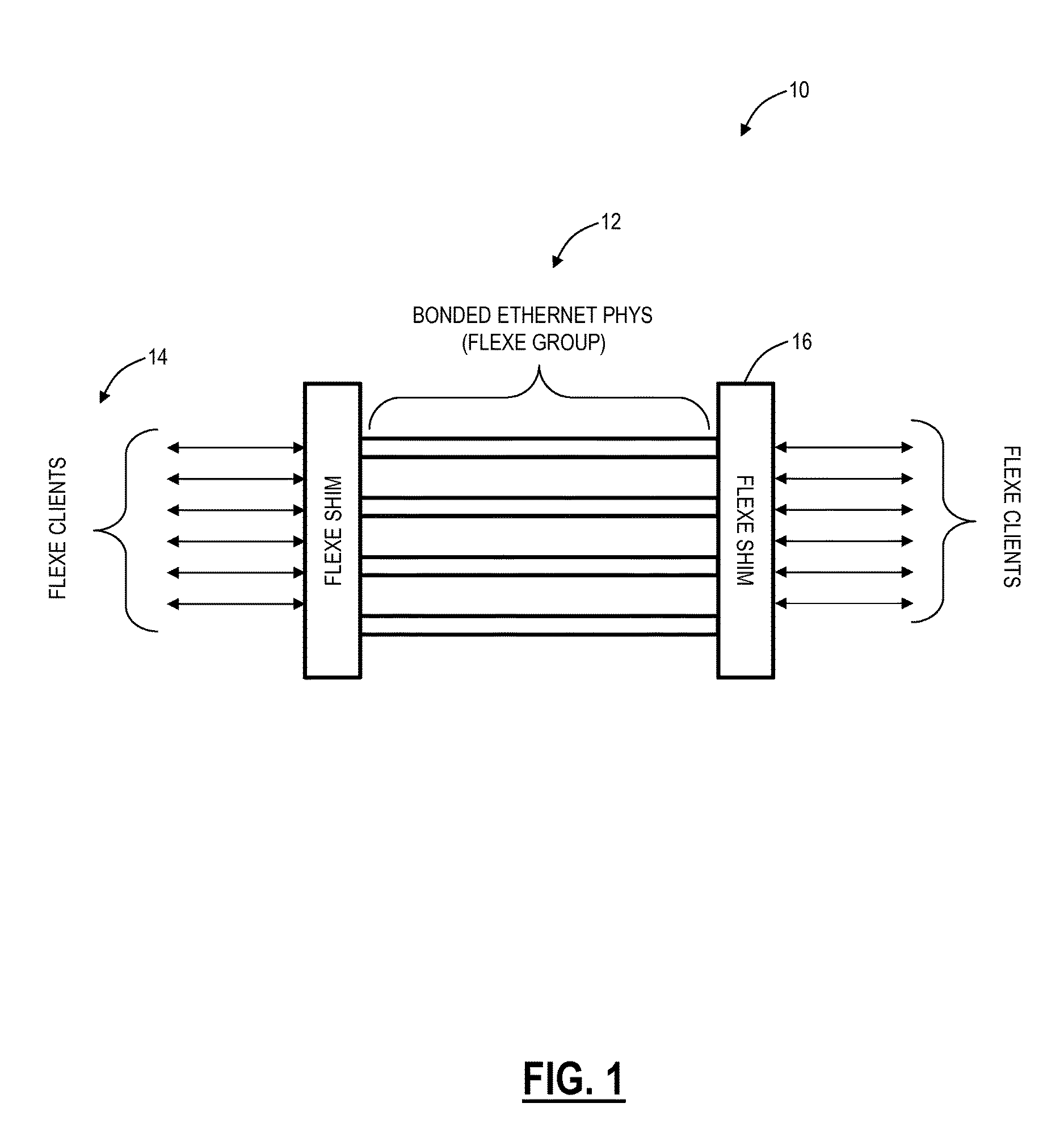

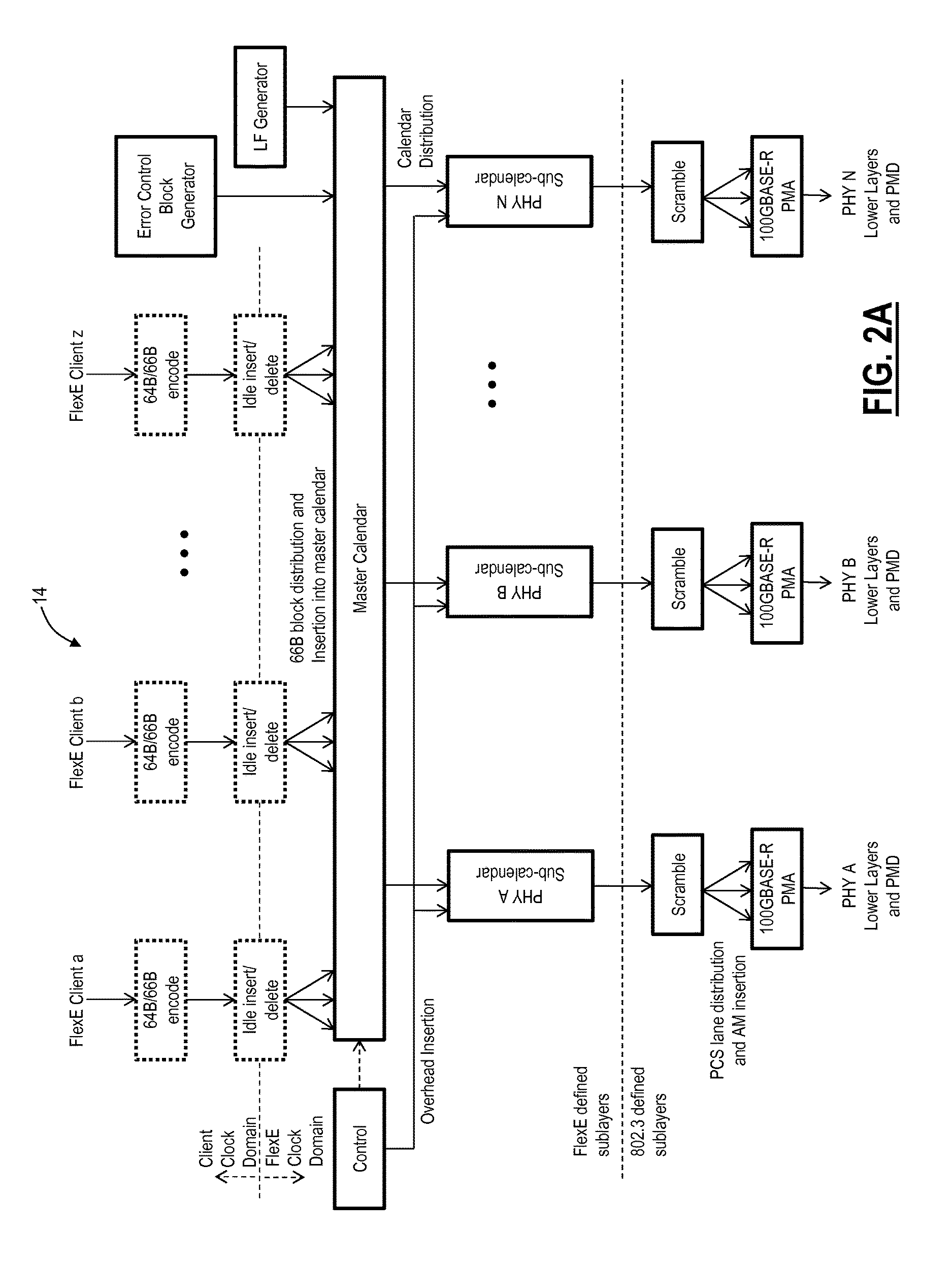

Flexible ethernet operations, administration, and maintenance systems and methods

A node configured to support a Flexible Ethernet (FlexE) client service in a network includes circuitry configured to receive a FlexE client; and circuitry configured to at least one of monitor and update one or more Operations, Administration, and Maintenance (OAM) fields in FlexE overhead, wherein the OAM fields cover a single client path along many network segments (sections) for the FlexE client. A method, implemented in a node, for supporting a Flexible Ethernet (FlexE) client service in a network includes receiving a FlexE client; and at least one of monitoring and updating one or more Operations, Administration, and Maintenance (OAM) fields in FlexE overhead, wherein the OAM fields cover a single client path along many network segments (sections) for the FlexE client.

Owner:CIENA

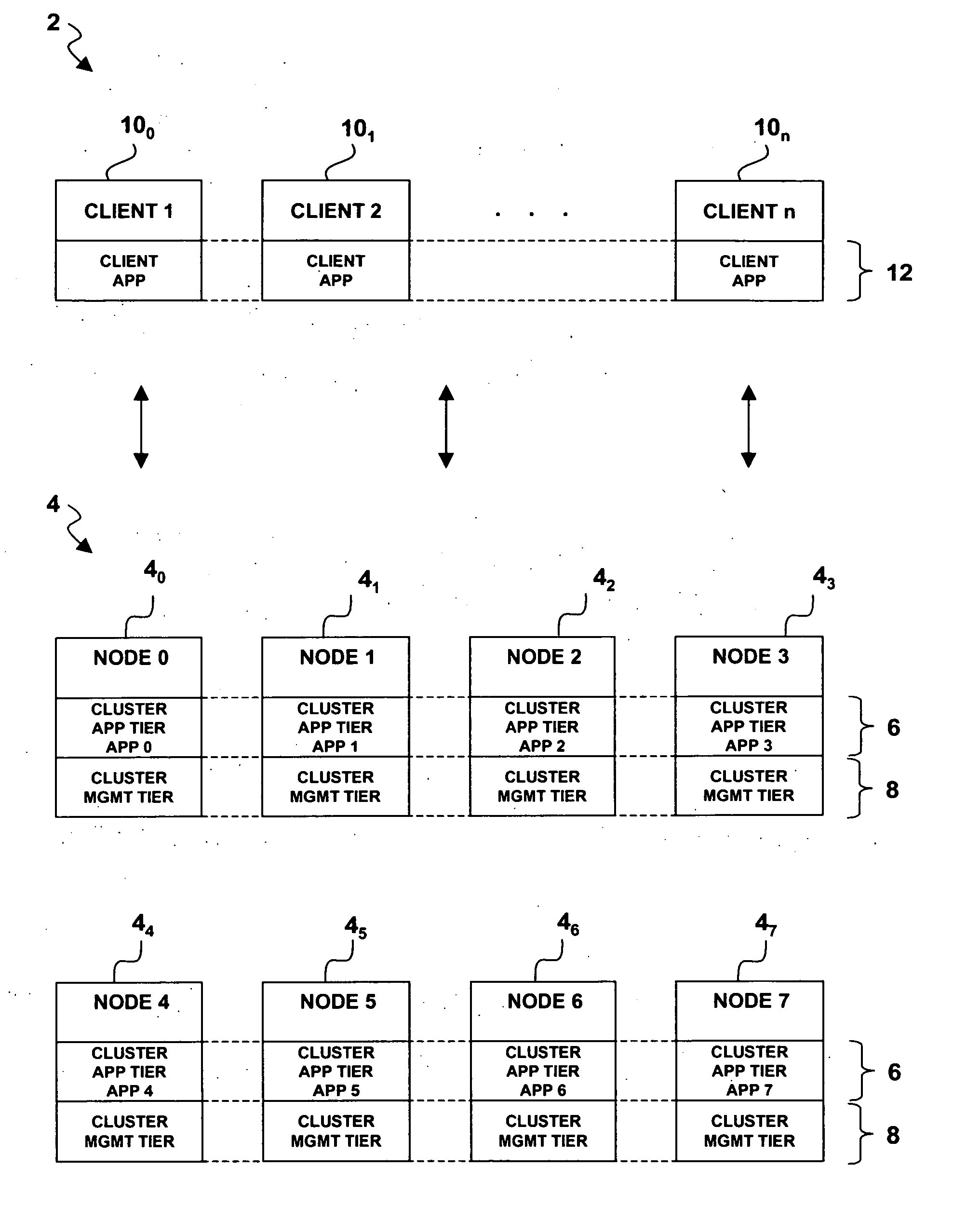

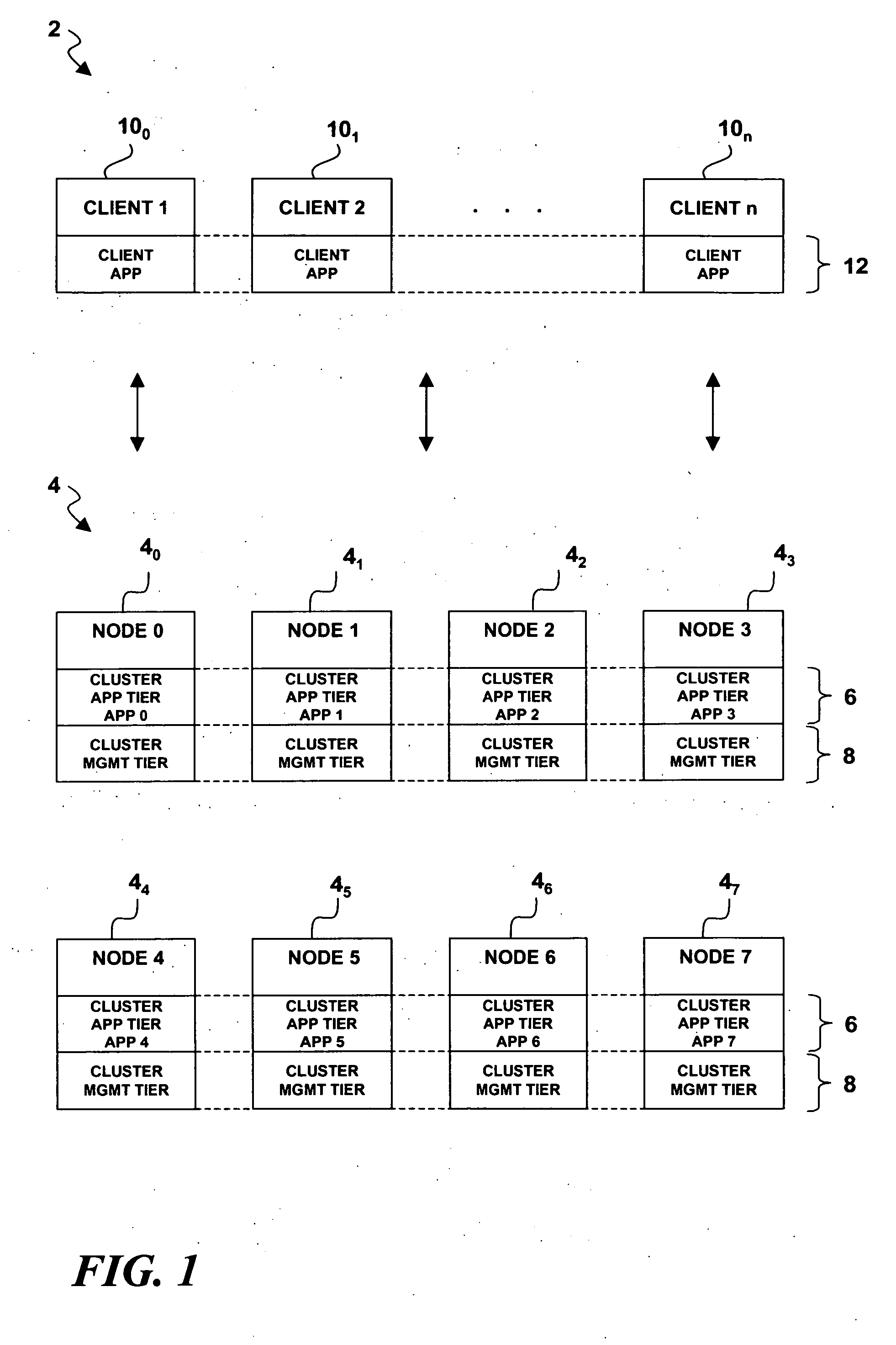

Fault-tolerance and fault-containment models for zoning clustered application silos into continuous availability and high availability zones in clustered systems during recovery and maintenance

InactiveUS20070006015A1No impact on transaction processingSmall sizeError detection/correctionTransmissionFault toleranceIslanding

A cluster recovery and maintenance system, method and computer program product for use in a server cluster having plural nodes implementing a server tier in a client-server computing architecture. A first group of N active nodes each run a software stack comprising a cluster management tier and a cluster application tier that actively provides services on behalf of one or more client applications running in a client application tier on the clients. A second group of M spare nodes each run a software stack comprising a cluster management tier and a cluster application tier that does not actively provide services on behalf of client applications. First and second zones in the cluster are determined in response to an active node membership change involving one or more active nodes departing from or being added to the first group as a result of an active node failing or becoming unreachable or as a result of a maintenance operation involving an active node. The first zone is a fault tolerant zone comprising all active nodes that remain operational. The second zone is a fault containment zone comprising all active nodes participating in the membership change and at least a corresponding number of spare nodes to the extent that the membership change involves a node departure. During recovery and maintenance, fast recovery / maintenance and high application availability are implemented in the fault containment zone, while continuous application availability is maintained in the fault tolerant zone.

Owner:IBM CORP

A system and method for dynamic fob synchronization and personalization

InactiveUS20050033689A1Digital data processing detailsPayment architecturePersonalizationData synchronization

A system generally for personalizing and synchronizing fob data in the context of a distributed transaction system is disclosed. A dynamic fob synchronization system may comprise point of service (POS) devices configured with transponder-readers to initiate a transaction in conjunction with a fob, an enterprise data collection unit, and a fob object database update system. An exemplary dynamic synchronization system (DSS) may comprise various fob POS devices, a secure support client server, a fob object database update system (FODUS), one or more enterprise data synchronization interfaces (EDSI), an update logic system, one or more enterprise data collection units (EDCUs), and one or more fob POS devices configured to interoperably accept and interface with fobs. In an exemplary embodiment, DSS may comprise a personalization system and an account maintenance system configured to communicate with FODUS. Personalization of multi-function fobs may be accomplished using a security server configured to generate and / or retrieve cryptographic key information from multiple enterprise key systems during the final phase of the fob issuance process.

Owner:LIBERTY PEAK VENTURES LLC

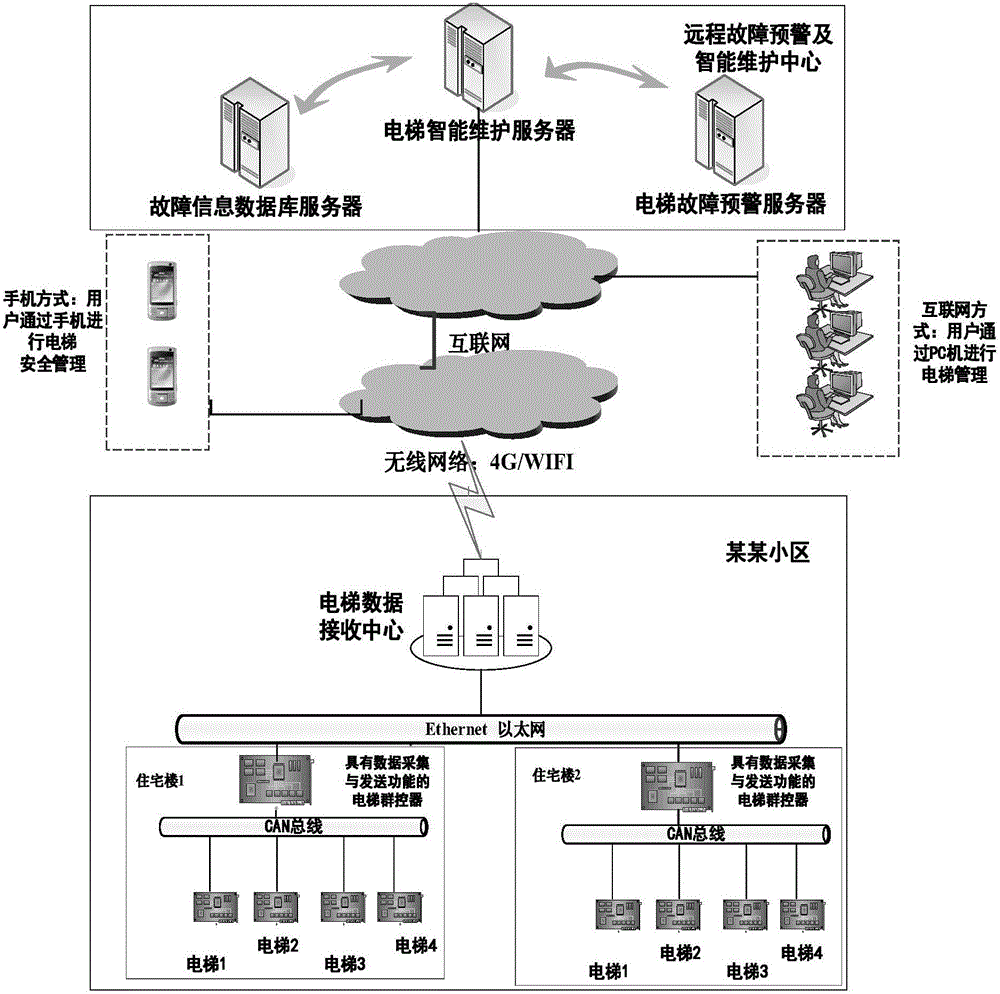

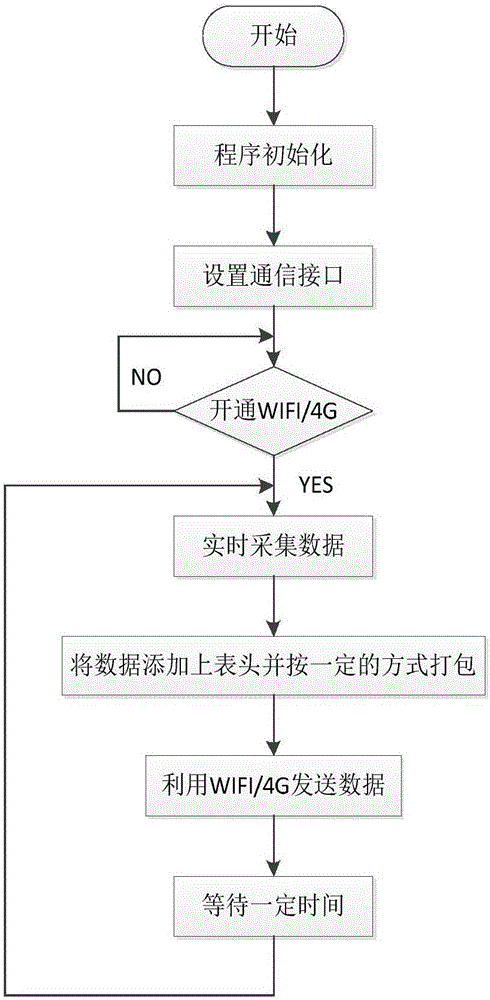

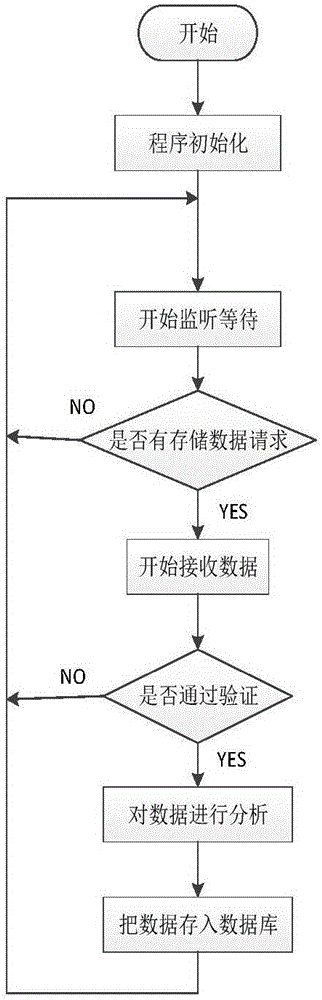

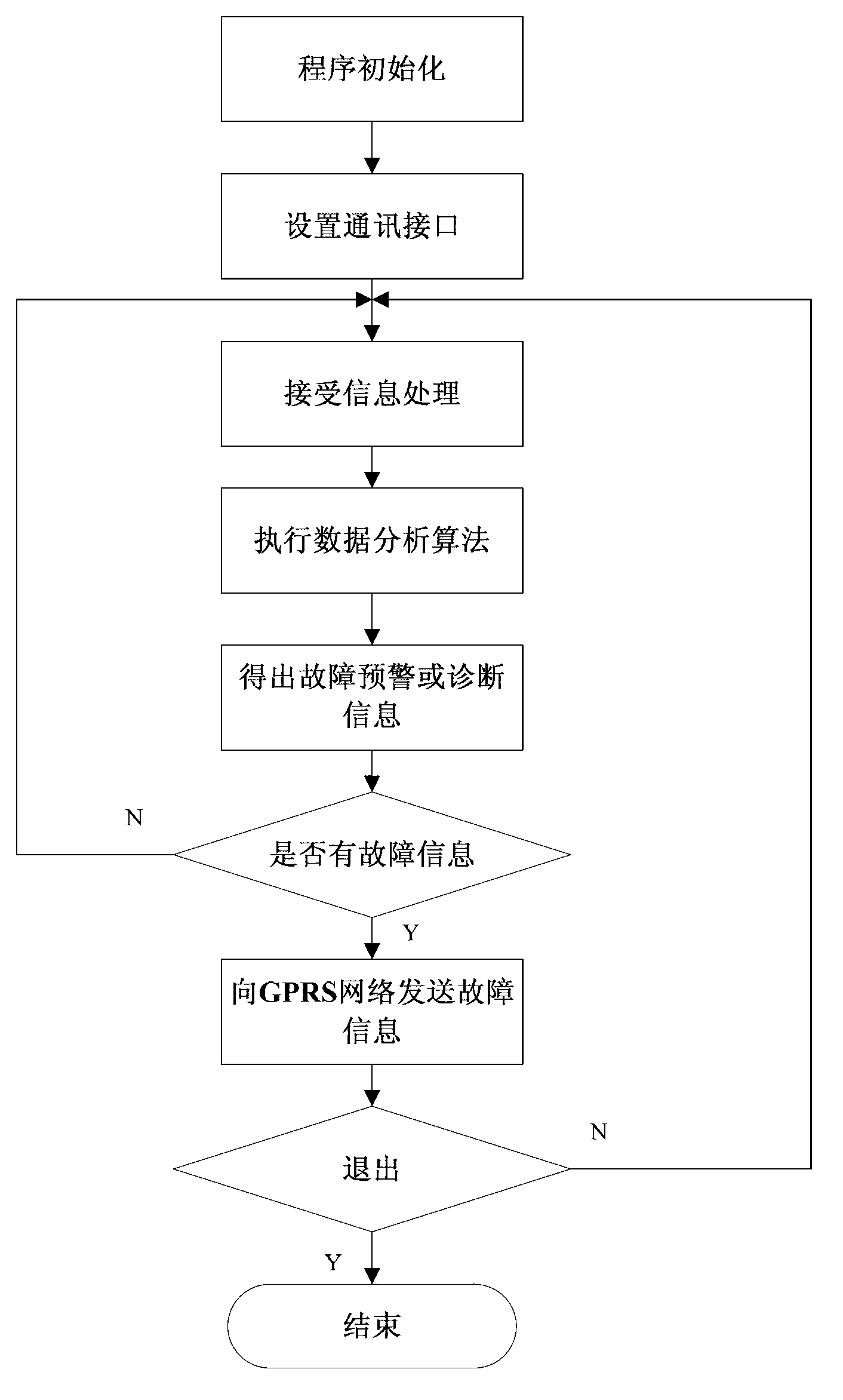

Intelligent prediction, diagnosis and maintenance method for elevator faults on basis of Internet of Things

The invention relates to the elevator control field and the field of the Internet of Things, and provides an intelligent prediction, diagnosis and maintenance system for elevator faults on the basis of the Internet of Things. The intelligent prediction, diagnosis and maintenance system can effectively shorten the time of elevator halt caused by the elevator faults, improve the reliability of elevator running and the elevator maintenance efficiency and guarantee the personal safety and the property safety. According to the technical scheme of an intelligent prediction, diagnosis and maintenance method for the elevator faults on the basis of the Internet of Things, a data acquisition module collects elevator data in real time and transmits the collected data to a server through WIFI or the 4G wireless communication technology, the data are analyzed on the server side through the big data technology, and therefore the elevator faults which are possibly to occur can be predicted; if the elevator faults occur, a fault diagnosis system on the server side can be used for analyzing the faults, then the positions and the reasons of the faults can be provided, and then an intelligent maintenance system on the server side provides solutions to the faults. The intelligent prediction, diagnosis and maintenance method is mainly applied to the elevator control occasion.

Owner:TIANJIN UNIV

System for managing glucose levels in patients with diabetes or hyperglycemia

A blood glucose maintenance system for use by hyperglycemic individuals measures their blood glucose level and calculates an appropriate glucose or insulin dosage based on the measurement. Recheck intervals responsive to dosage history are determined. Warning or alert messages or signals are produced if certain measurements or calculations fall outside established normal ranges. It is particularly useful for patients in a hospital or in-patient environment.

Owner:INDIANA UNIVERSITY HEALTH

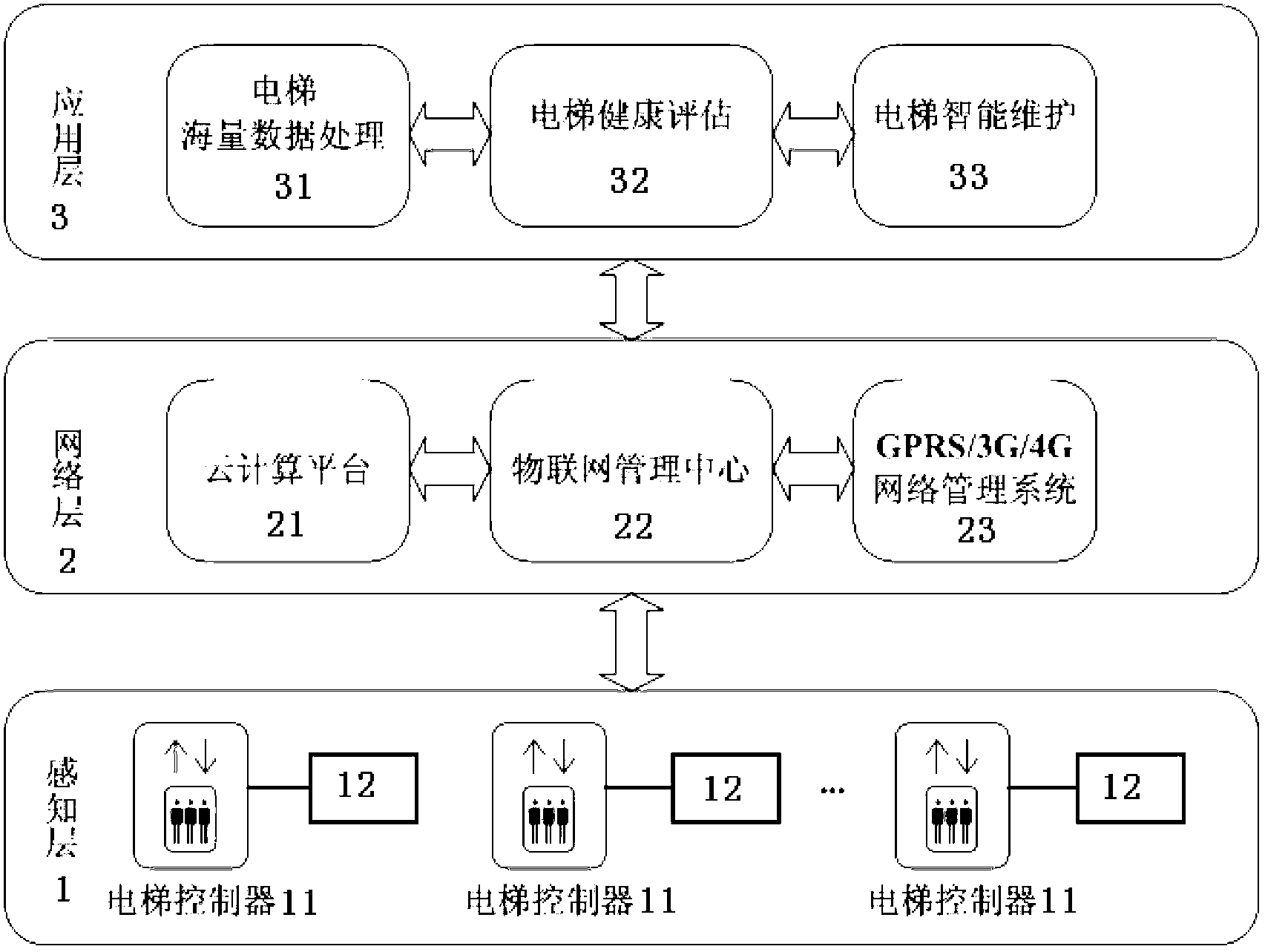

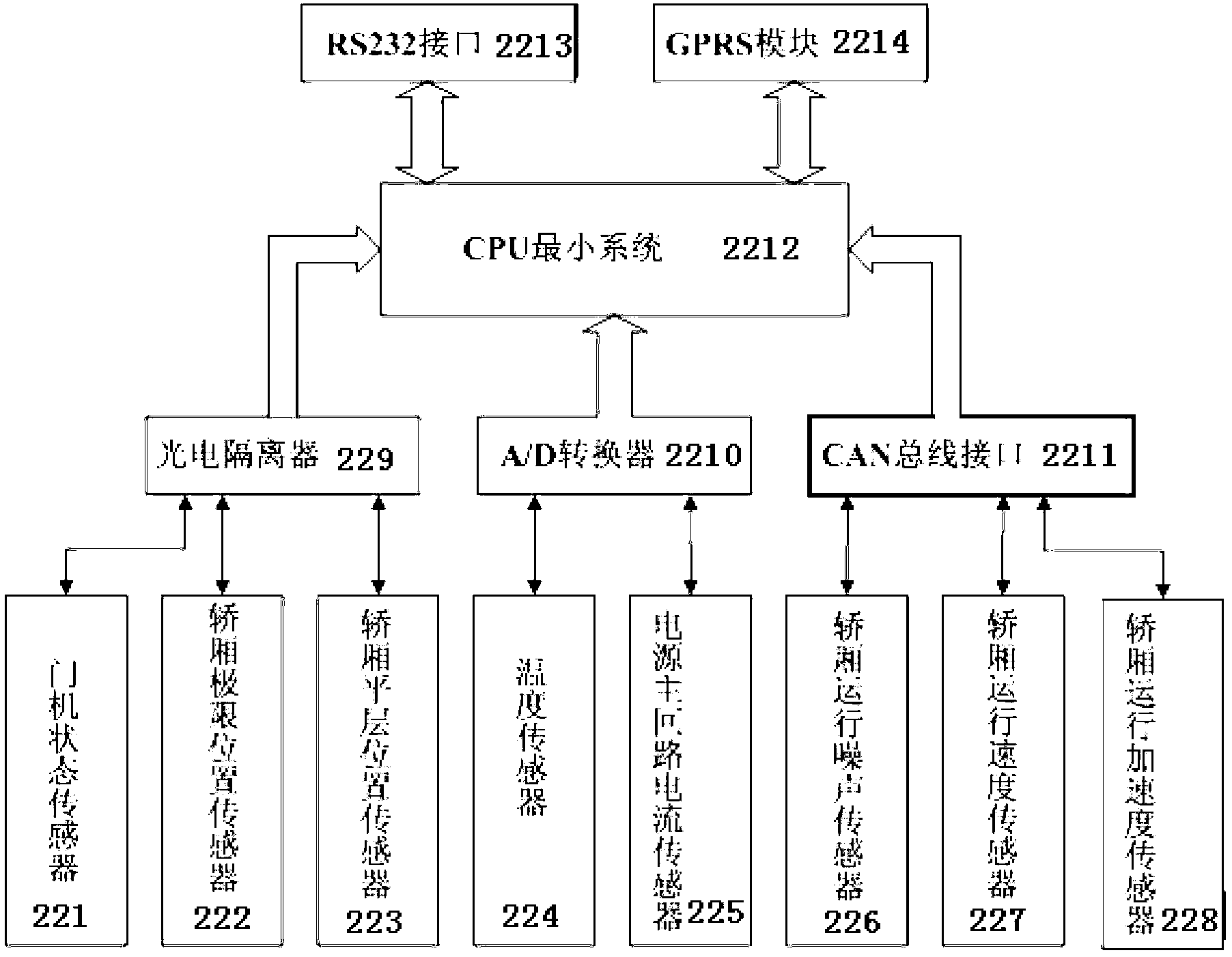

Elevator health management and maintenance system based on Internet of things and collection and assessment method

InactiveCN102923538AFix security issuesSolve the problem of unification of maintenance standardsElevatorsGeneral Packet Radio ServicePrivate network

The invention relates to an elevator health management and maintenance system based on the Internet of things and a collection and assessment method, wherein the elevator health management and maintenance system based on the Internet of things comprises a perception layer, a network layer and an application layer which are sequentially communicated through a network, the perception layer performs communication with the network layer by a VPN (virtual private network) or M2M (machine-to-machine), and the perception layer comprises a plurality of elevator data collection terminals which are respectively correspondingly arranged on a plurality of elevator controllers and have the same structure; the network layer comprises a cloud computing platform, a management center of the Internet of things and a GPRS (general packet radio service), 3G (third generation) and 4G (fourth generation) network management system; and the application layer comprises an elevator mass data processing module, an elevator health assessment module and an elevator intelligent maintenance module which are sequentially connected. The elevator health management and maintenance system disclosed by the invention can support large-scale elevator health monitoring and maintenance, is favorable for reducing the elevator maintenance cost and improving the elevator maintenance efficiency, and can keep minimal maintenance resource demands in reliability, availability and safety.

Owner:TIANJIN UNIV

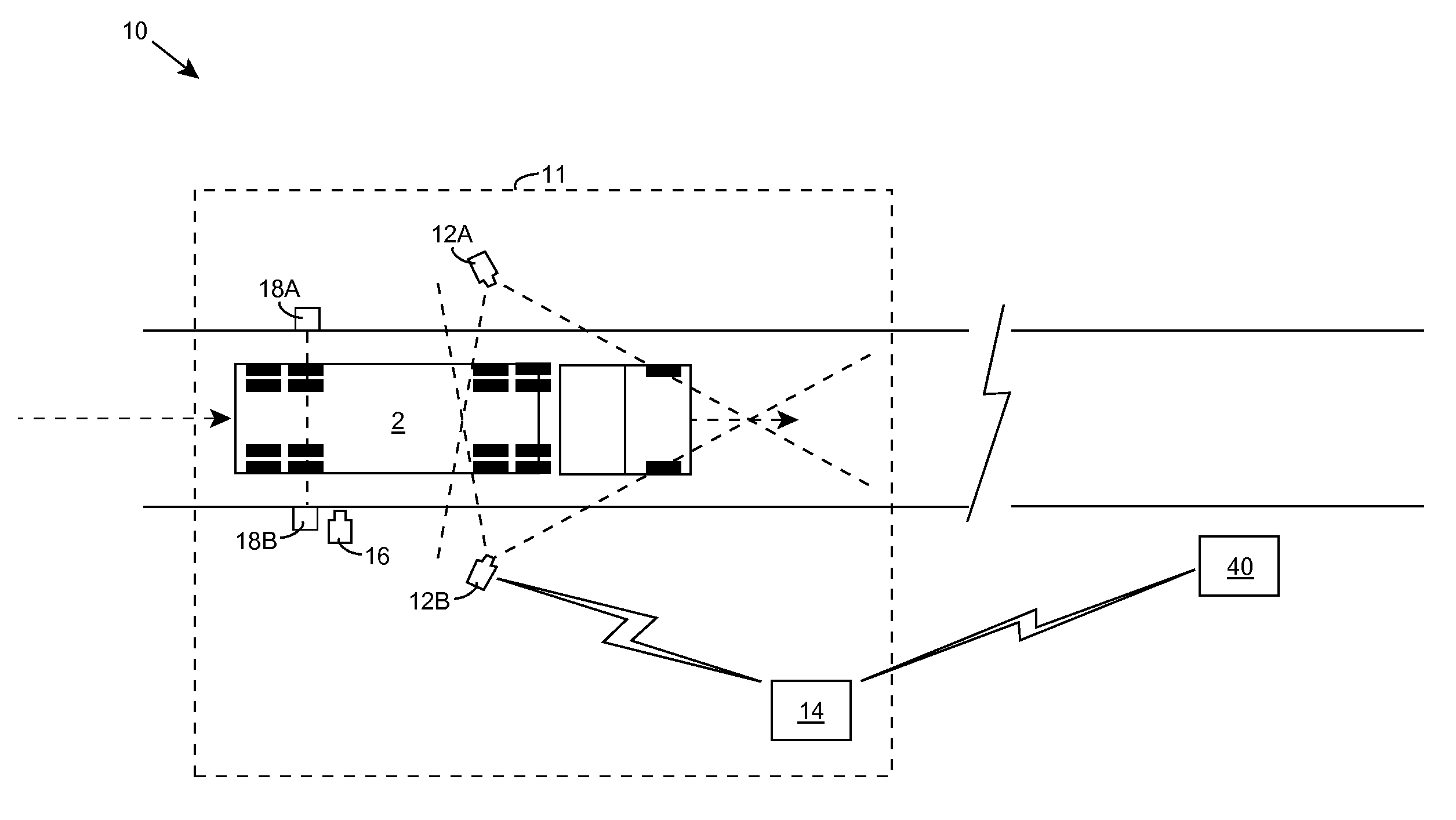

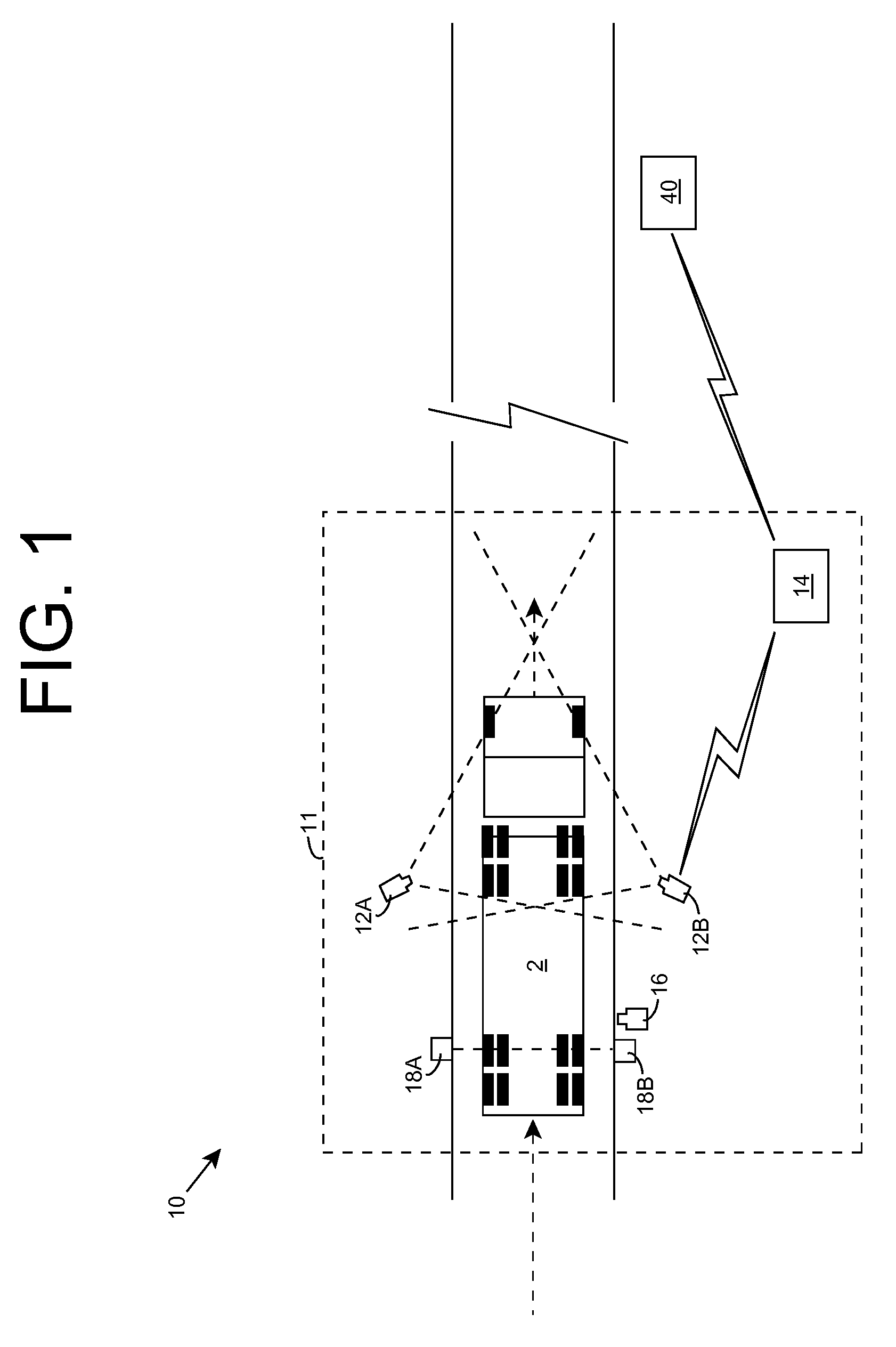

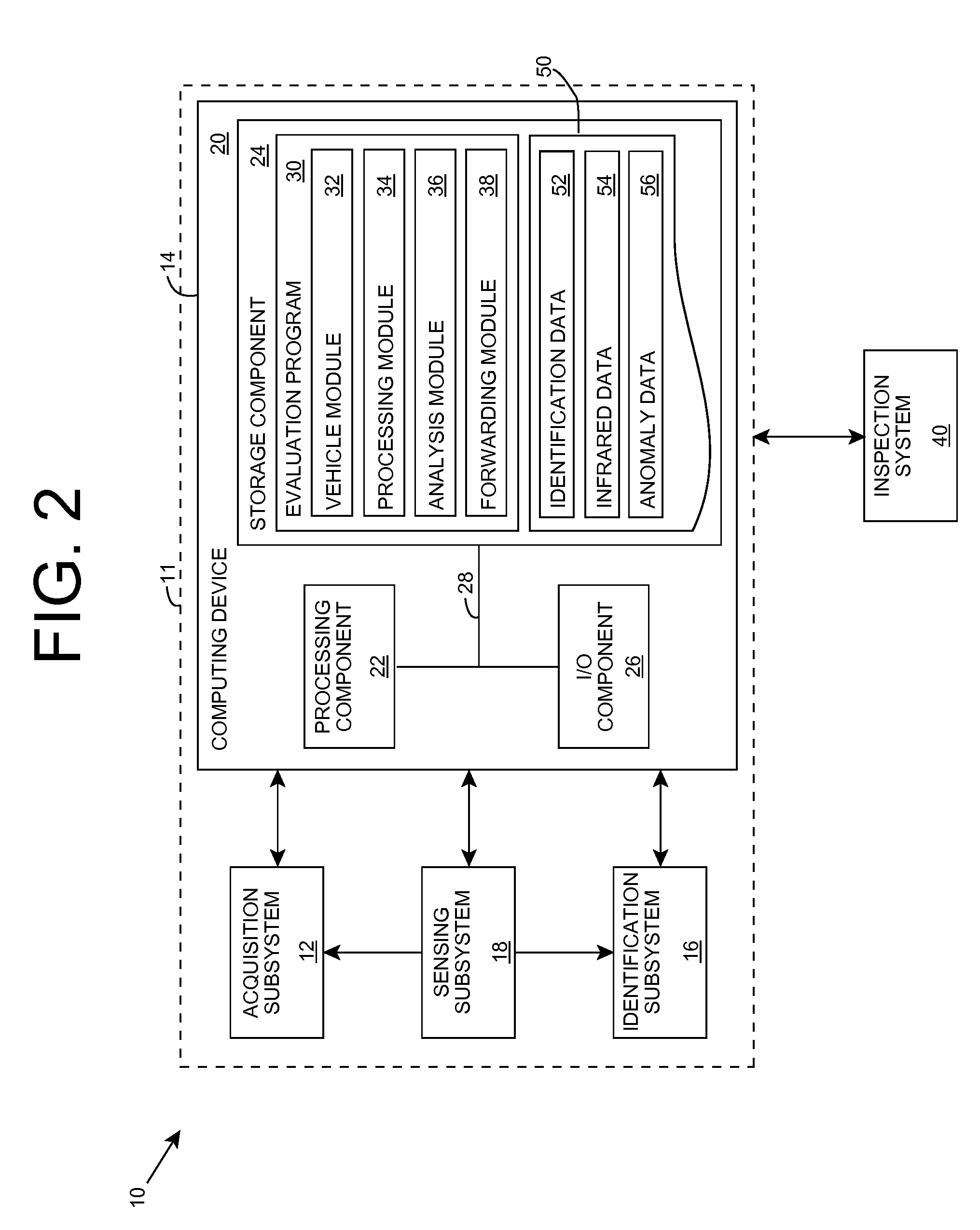

Vehicle evaluation using infrared data

A solution for evaluating a vehicle using infrared data is provided. In particular, evaluation data for the vehicle is obtained, which includes infrared data for a plurality of sides of the vehicle as well as vehicle identification data for distinguishing the vehicle from another vehicle. The infrared data is processed to enhance a set of signal features. Additional non-infrared based data also can be obtained for evaluating the vehicle. The evaluation data is analyzed to determine whether one or more anomalies are present. The anomaly(ies) can be correlated with a possible problem with a component of the vehicle. Data on the anomaly, problem, and / or vehicle identification can be provided for use on another system, such as a remote inspection station, maintenance system, and / or the like.

Owner:INT ELECTRONICS MACHINES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com