Configurable monitor and parts management system

a monitor and configurable technology, applied in the field of heavy equipment, can solve the problems of high equipment cost, high equipment cost, and high equipment downtime, and achieve the effects of reducing the cost of heavy equipment, and improving the service li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

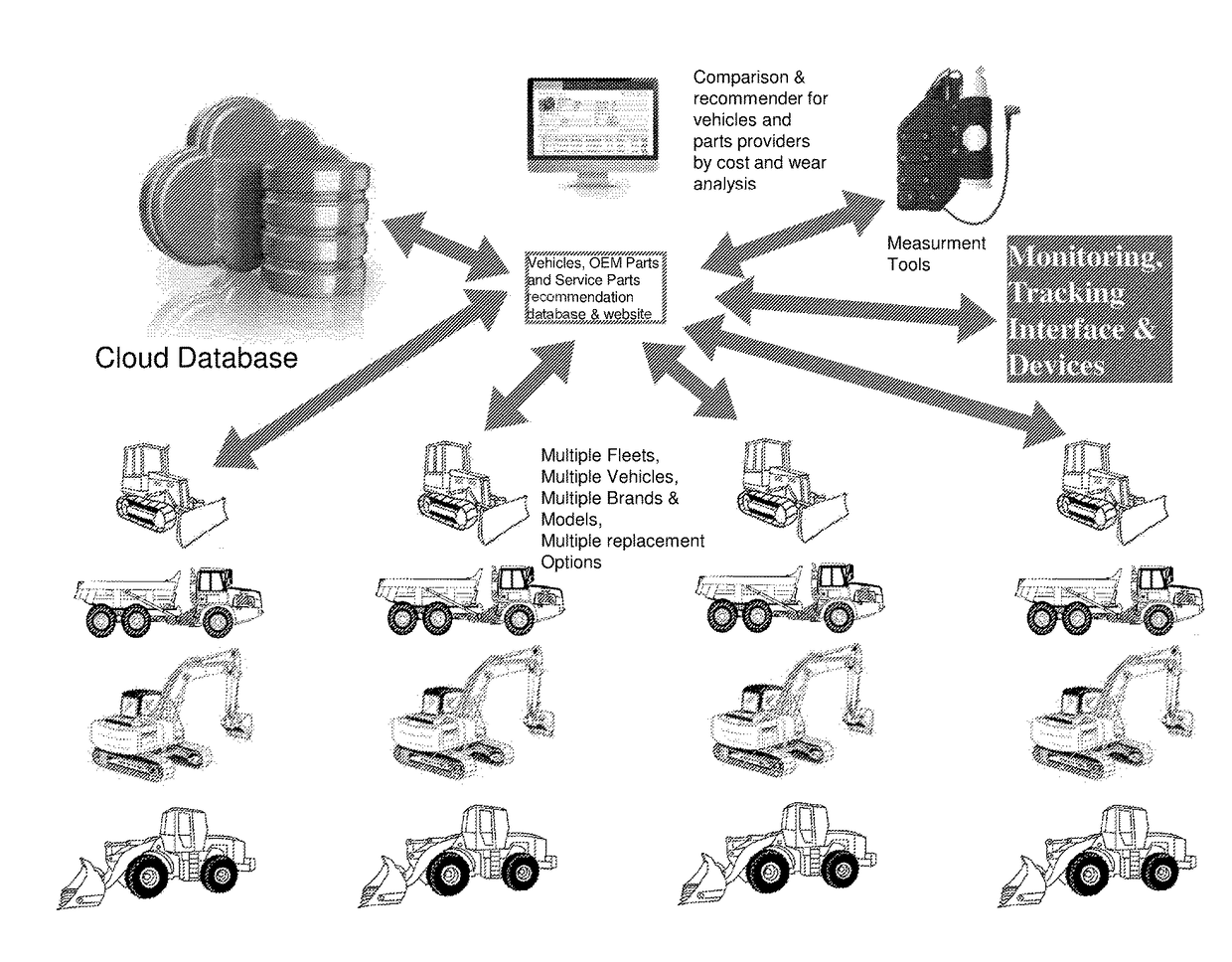

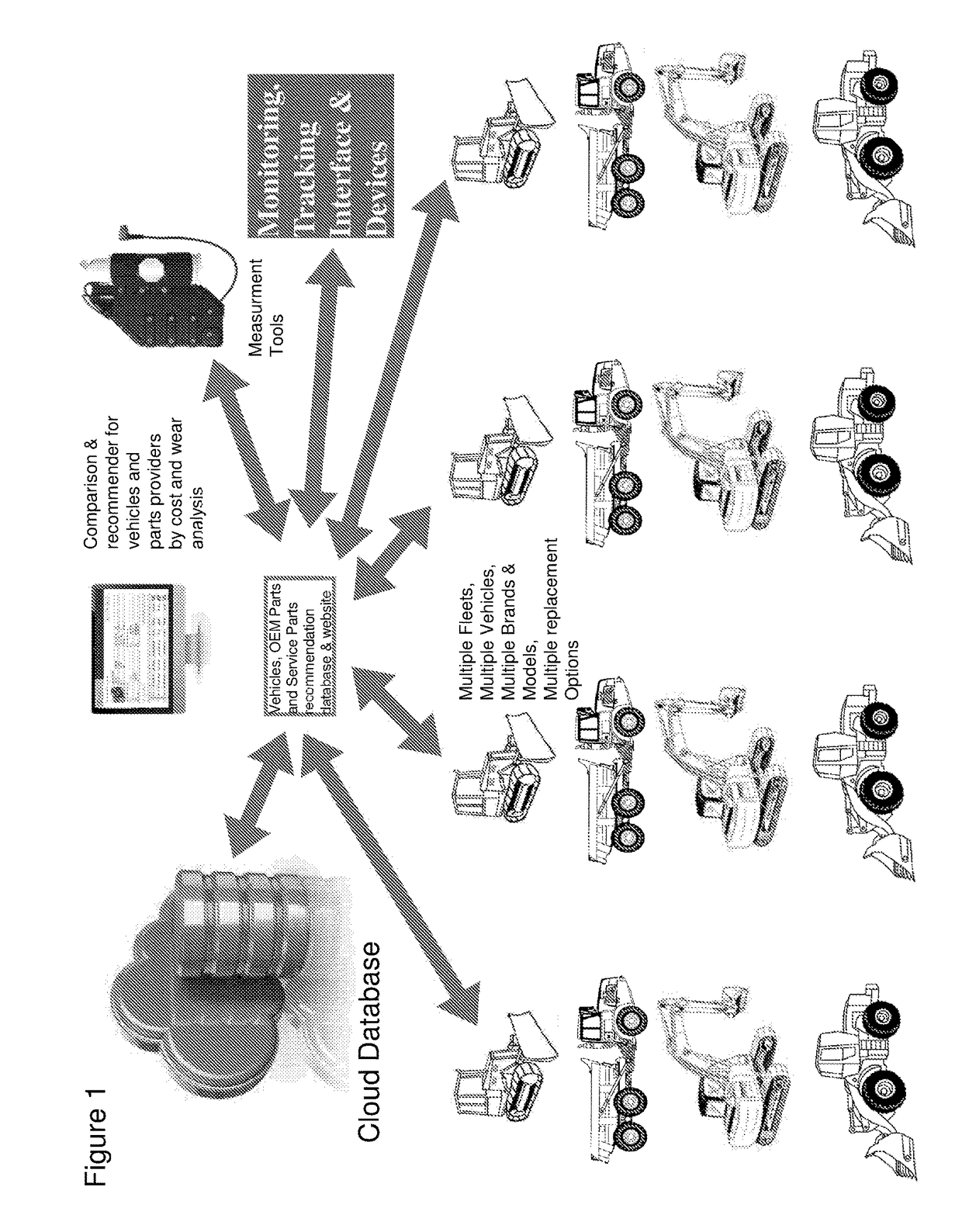

[0347]In the first embodiment we show an information management system that allows fleets to monitor the performance of vehicles, brands, parts, replacement parts and operator performance.

second embodiment

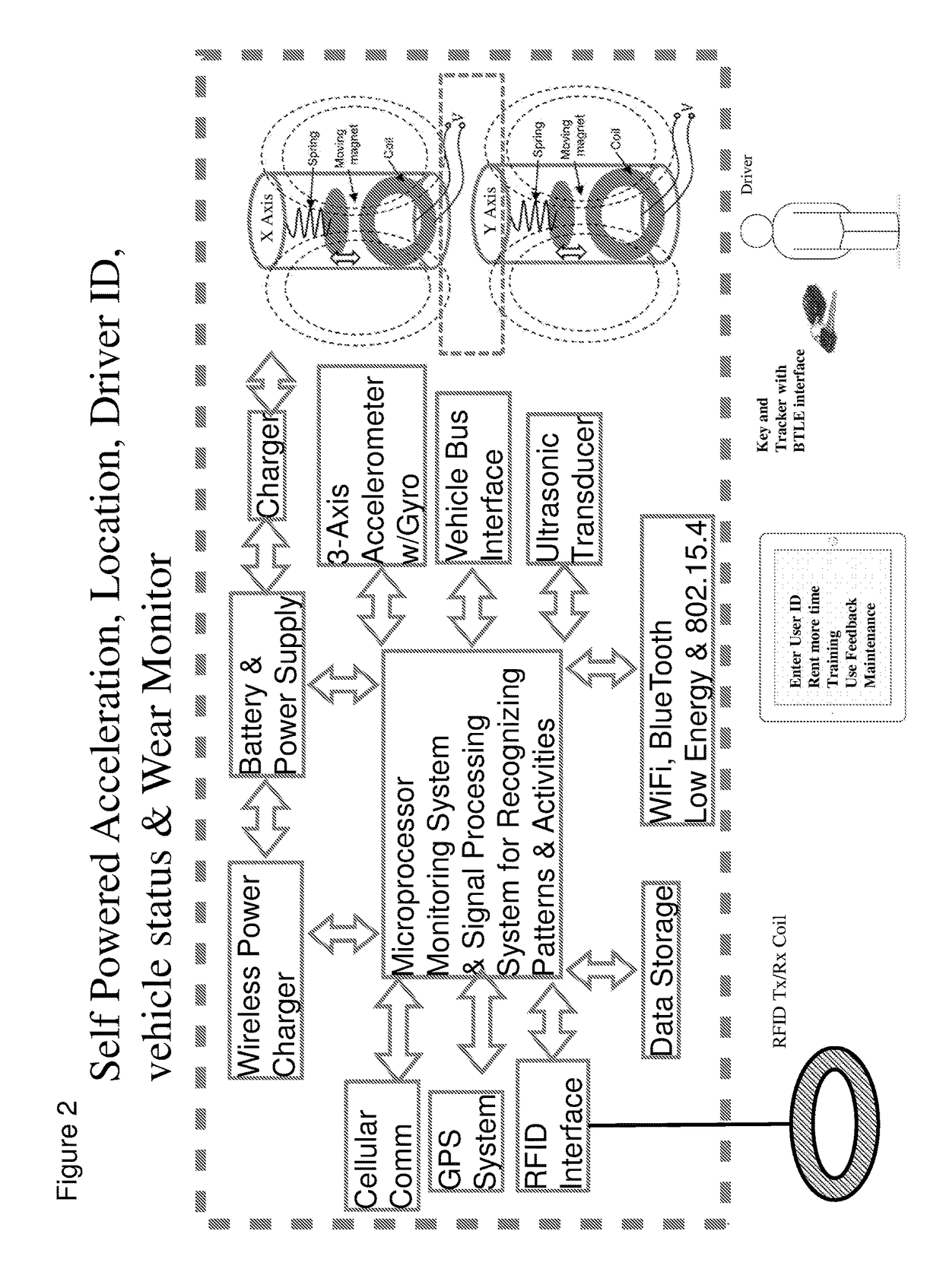

[0348]In a second embodiment the system requires a tracking and monitoring system. This system is designed to track the specific directions and the acoustic noise created by the effects of wear throughout the body of the equipment.

[0349]Operator monitor system for a heavy equipment operator that tracks and monitors operational use of the machine and provides a rating index of 1-10 on capability of operator and overall wear being applied to the machine by the operator.[0350]Tracks number of fault codes triggered on average.[0351]Tracks number of reverse time machine run, times machine was operated on angles, and other operations that might accelerate the wear of the machine.

third embodiment

[0352]A third embodiment uses an identification system in an identification and control system for tracking, renting and operator rating by user habits.

[0353]Operator “key” system that allows a user to utilize a smart phone or tablet to register, start the machine, and provide visual cues on the operation of the machine enabling:[0354]User can download an application that will connect via Bluetooth or hard cable to the machine, register their personal and payment information, and purchase an amount of time to use the machine.[0355]Application will track users location and use of machine via GPS.[0356]Application will integrate with the machine's telematics feed to provide guidance on operation through the monitor system.[0357]Application will allow user to rate the machine, and owner of the machine to rate the user.[0358]Rating system will alter the cost per hour in a beneficial or negative manner based on the users rating.[0359]Application will enable user to connect with technical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com