Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

178 results about "Nitrogen oxide sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A nitrogen oxide sensor or NO x sensor is typically a high-temperature device built to detect nitrogen oxides in combustion environments such as an automobile, truck tailpipe or smokestack.

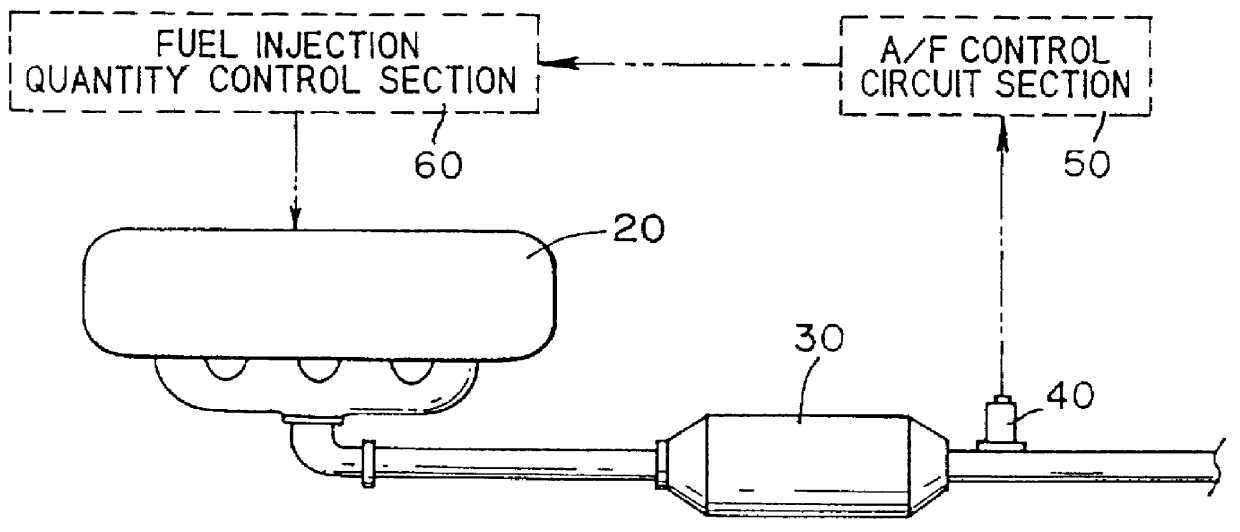

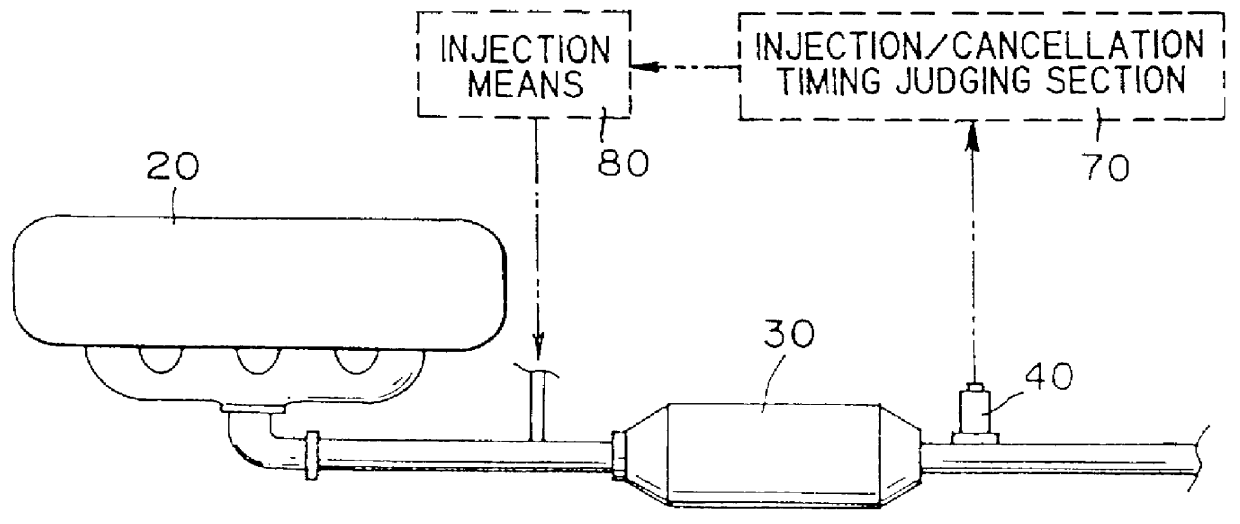

Method of controlling an engine exhaust gas system and method of detecting deterioration of catalyst/adsorbing means

InactiveUS6134883AAccurate detectionElectrical controlInternal combustion piston enginesNitrogen oxide sensorInternal combustion engine

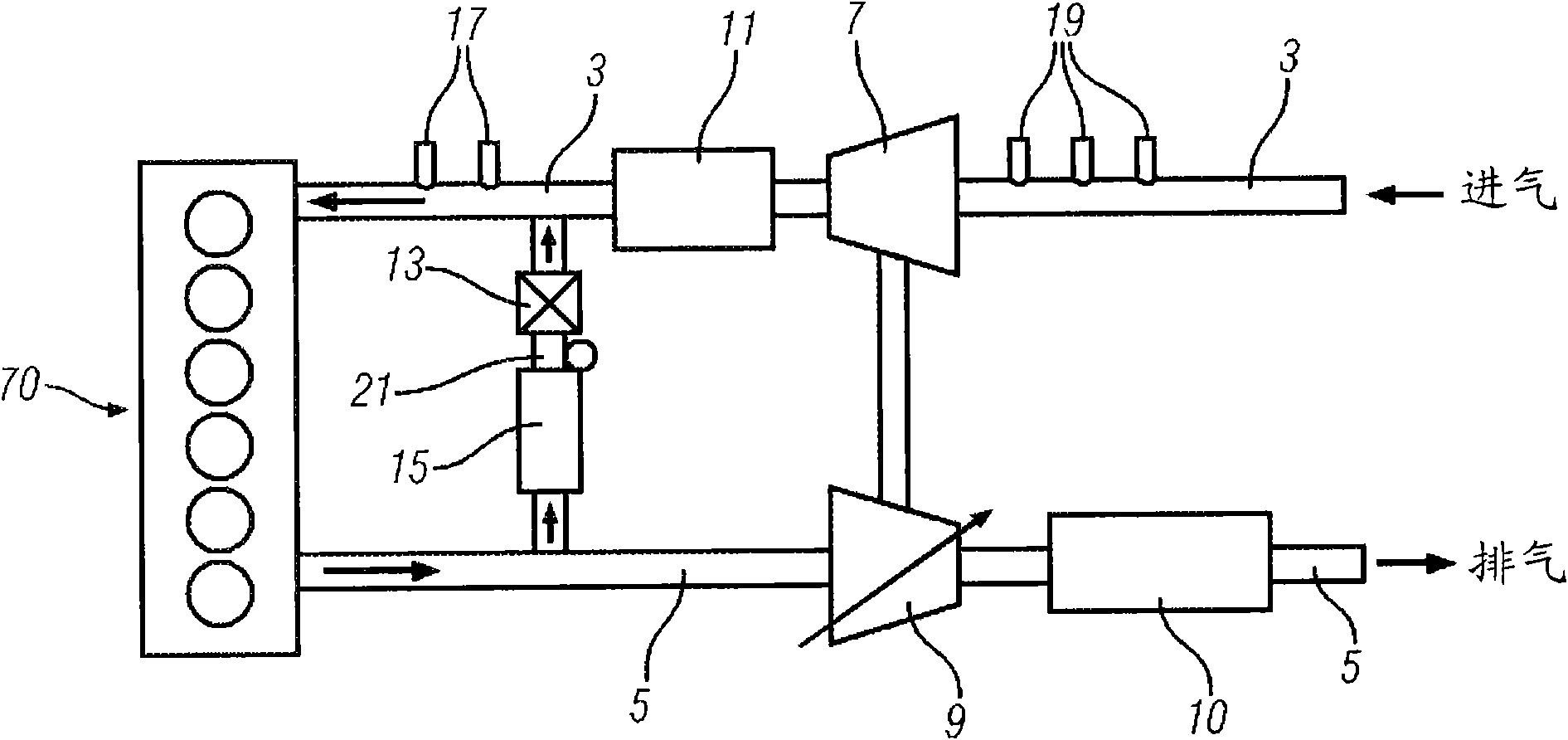

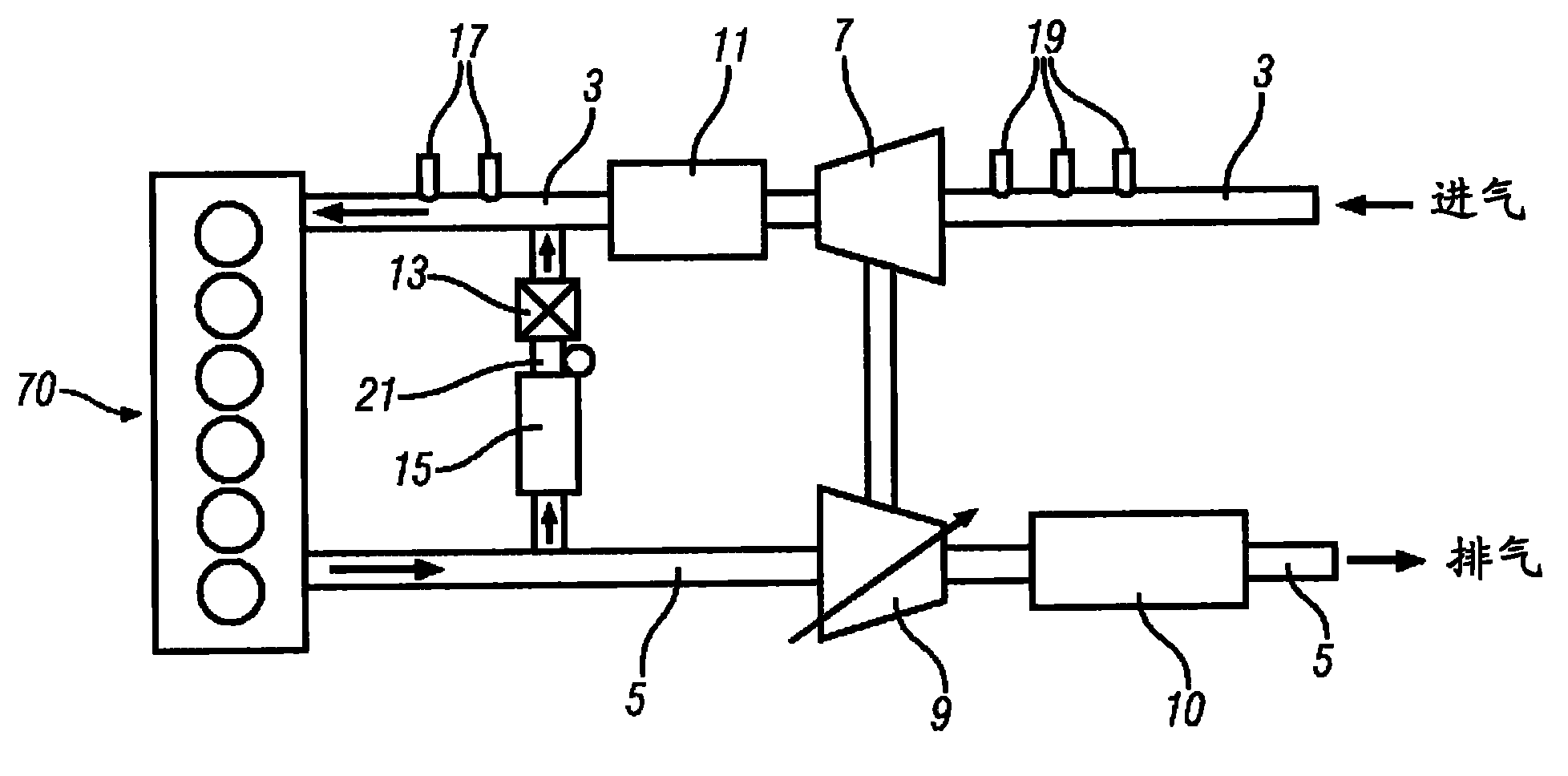

In a method of controlling an exhaust gas system of an internal combustion engine including a nitrogen oxide reducing catalyst capable of adsorbing nitrogen oxide under a lean atmosphere and a nitrogen oxide sensor disposed downstream of the nitrogen oxide reducing catalyst, the nitrogen oxide reducing catalyst and the nitrogen oxide sensor are disposed in the exhaust gas system operated mainly under a lean condition, respectively. An output value of the nitrogen oxide sensor is compared with a predetermined value, and an operation condition of the internal combustion engine is temporarily changed into a stoichiometric condition or a rich condition, or a fuel is injected upstream of the nitrogen oxide reducing catalyst, so that the nitrogen oxide adsorbed to the nitrogen oxide reducing catalyst is detached or decomposed, and again the internal combustion engine is operated under the lean condition. Deterioration of the catalyst is determined based on Nox amount which is calculated from the sensor output, exhaust has flow amount and vehicle running distance.

Owner:NGK INSULATORS LTD

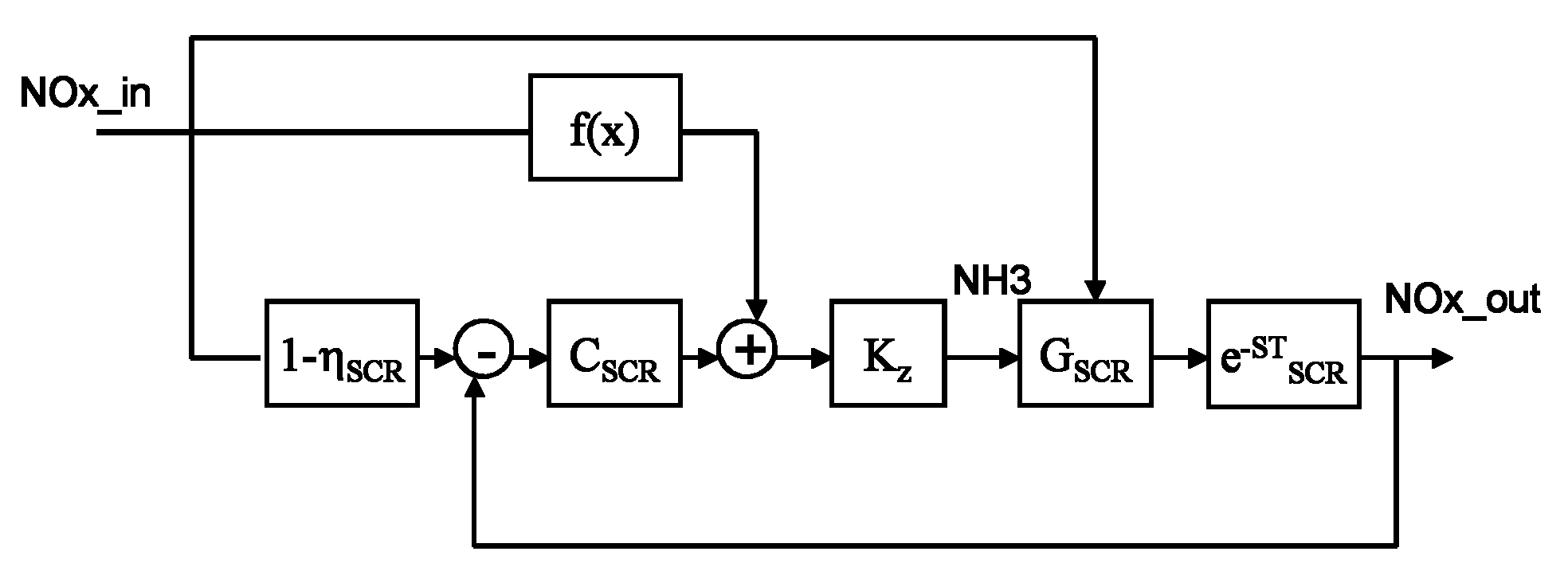

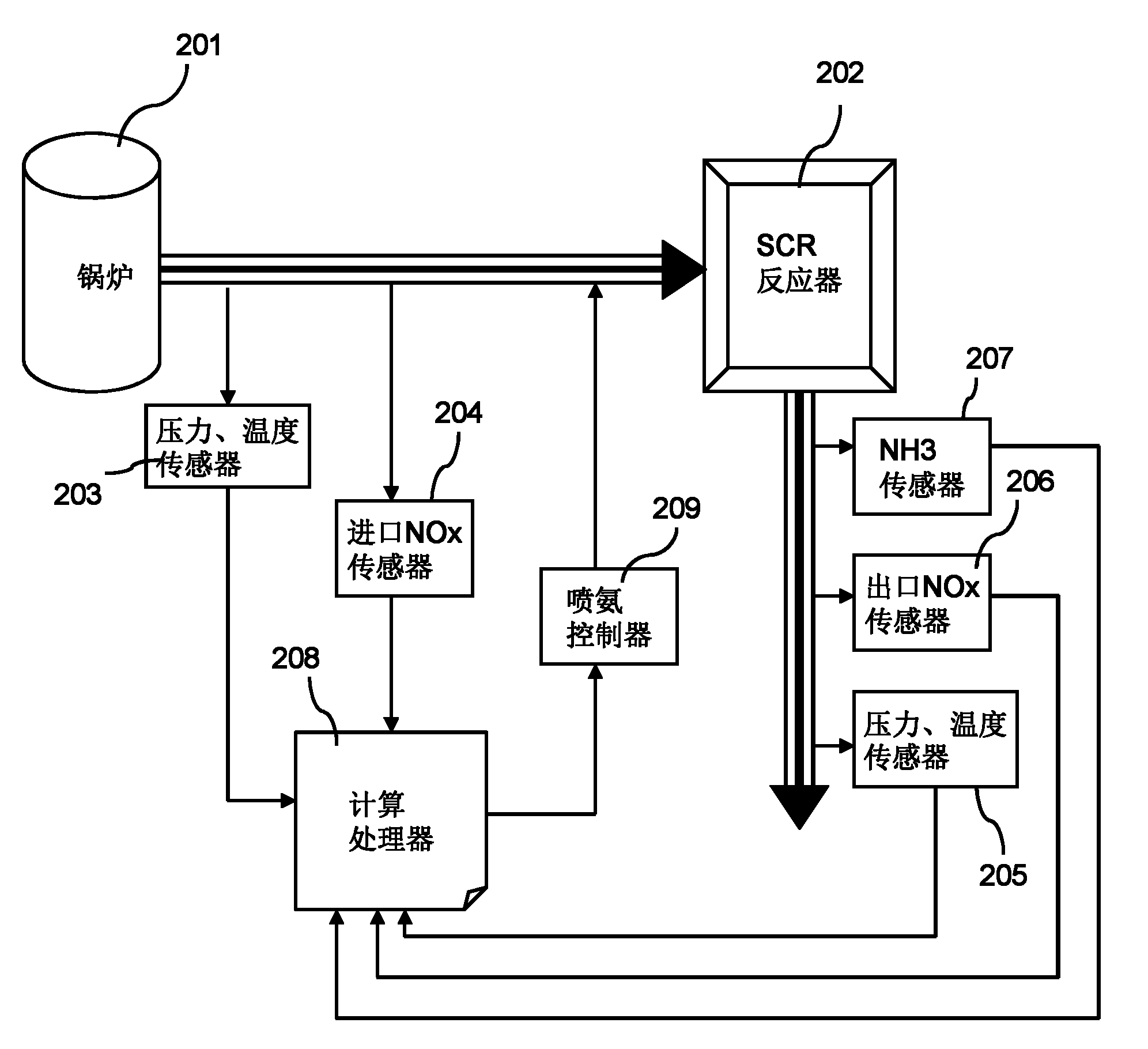

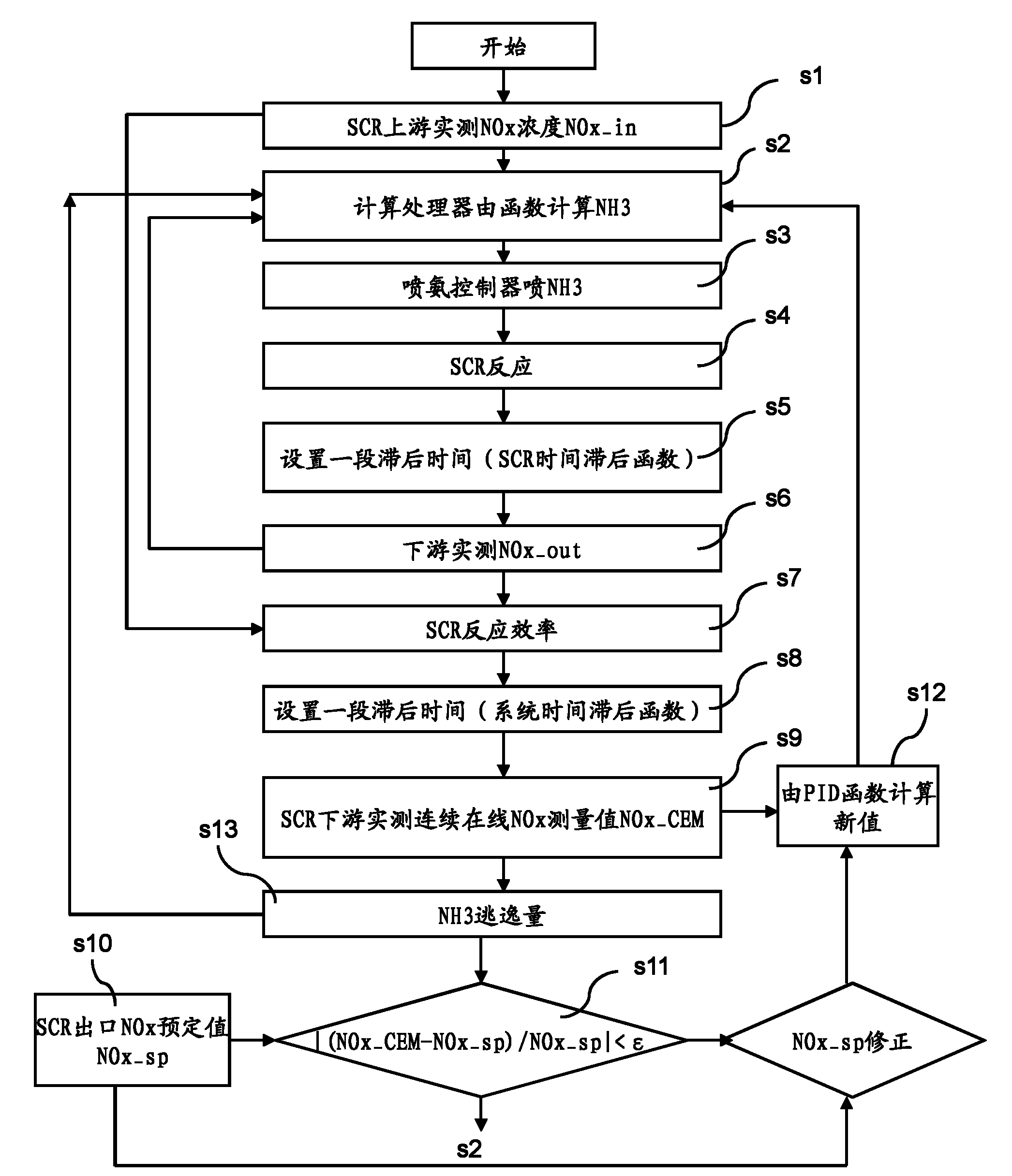

System and method for controlling oxynitride removal

InactiveCN102000482AEligible emission indicatorsPrevent escapeDispersed particle separationNegative feedbackTime lag

The invention provides a system and a method for optimally controlling ammonia denitration, which are characterized in that according to the content of oxynitride which is detected by an oxynitride sensor at the inlet of a reactor and fed into the reactor, the content of oxynitride which is detected by the oxynitride sensor at the outlet of the reactor and discharged from the reactor, and the continuous online measuring value of the oxynitride at the outlet of the reactor and the escaped ammonia amount detected by an ammonia sensor at the outlet of the reactor, the ammonia-injected amount is calculated according a transfer function; the control system has positive and negative feedback correction effects on feedforward loops, and monitors the continuous online measuring value of the oxynitride, thereby ensuring the implementation of meeting the qualified oxynitride discharge index; the control system is provided with two lag time functions so as to overcome the effect of time lag, eliminate the fluctuations of the oxynitride content and ammonia-injected amount at the outlet of the reactor; and meanwhile, the control system is also provided with an ammonia escape detection sensor for preventing the escape of ammonia.

Owner:无锡科立泰科技有限公司

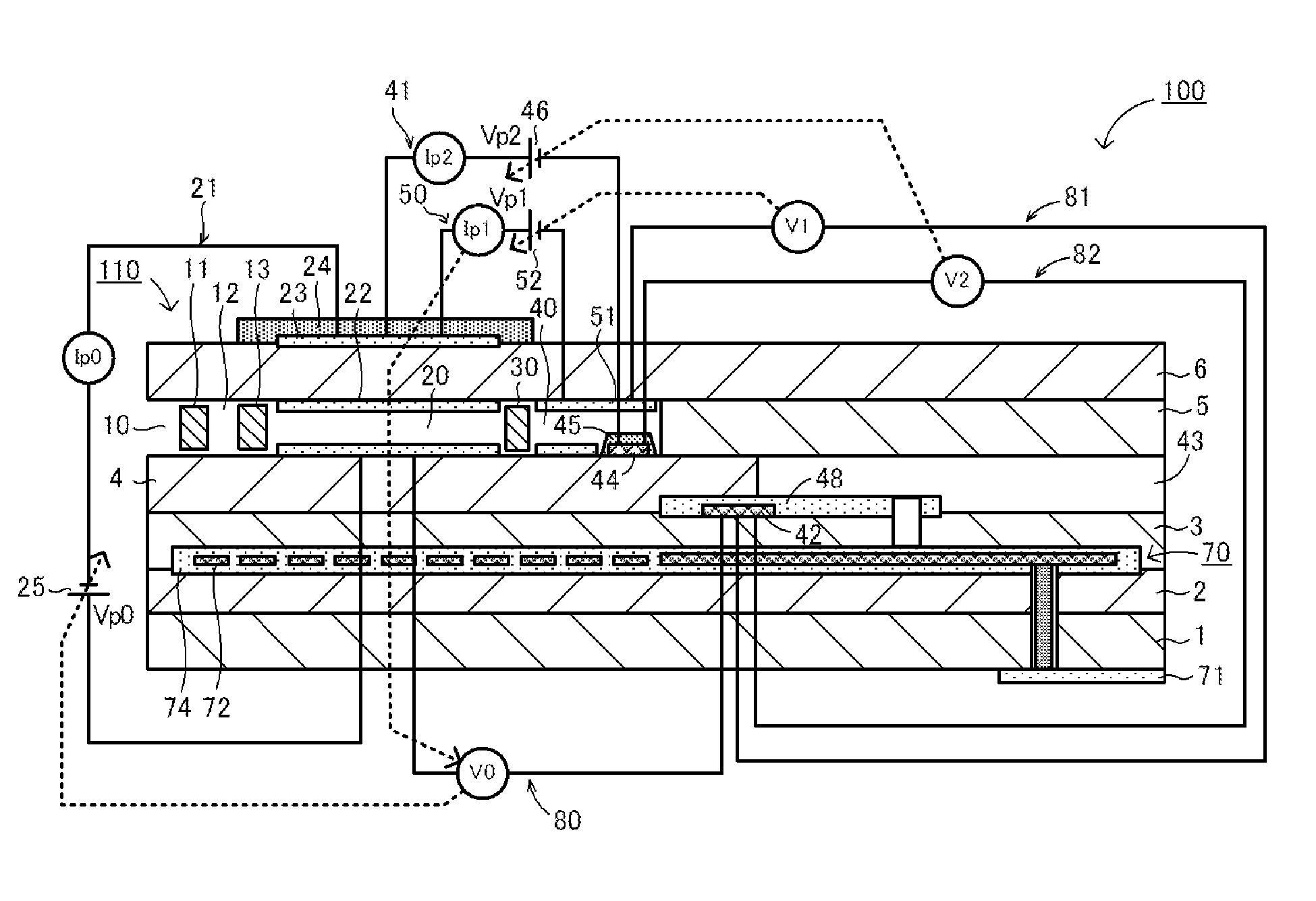

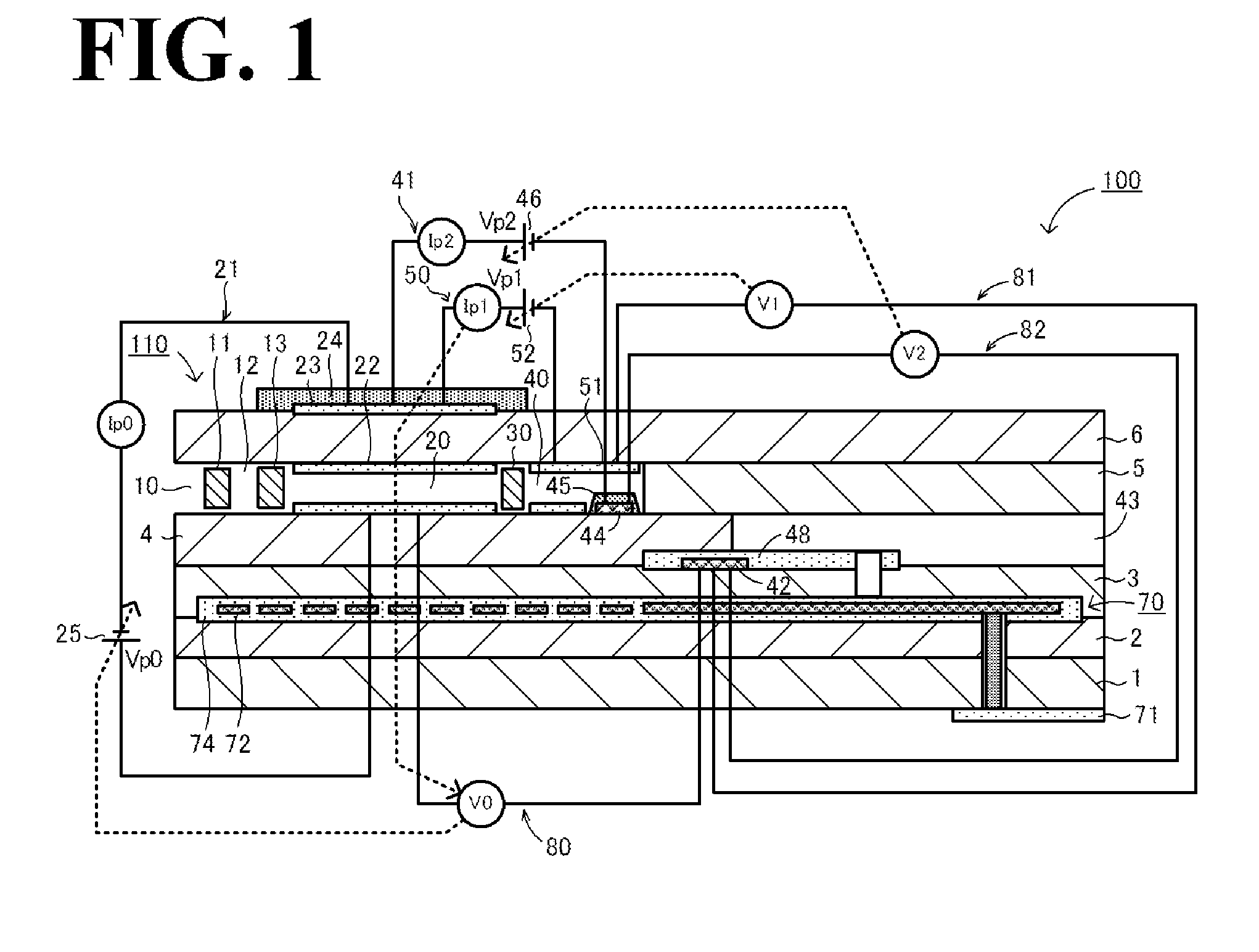

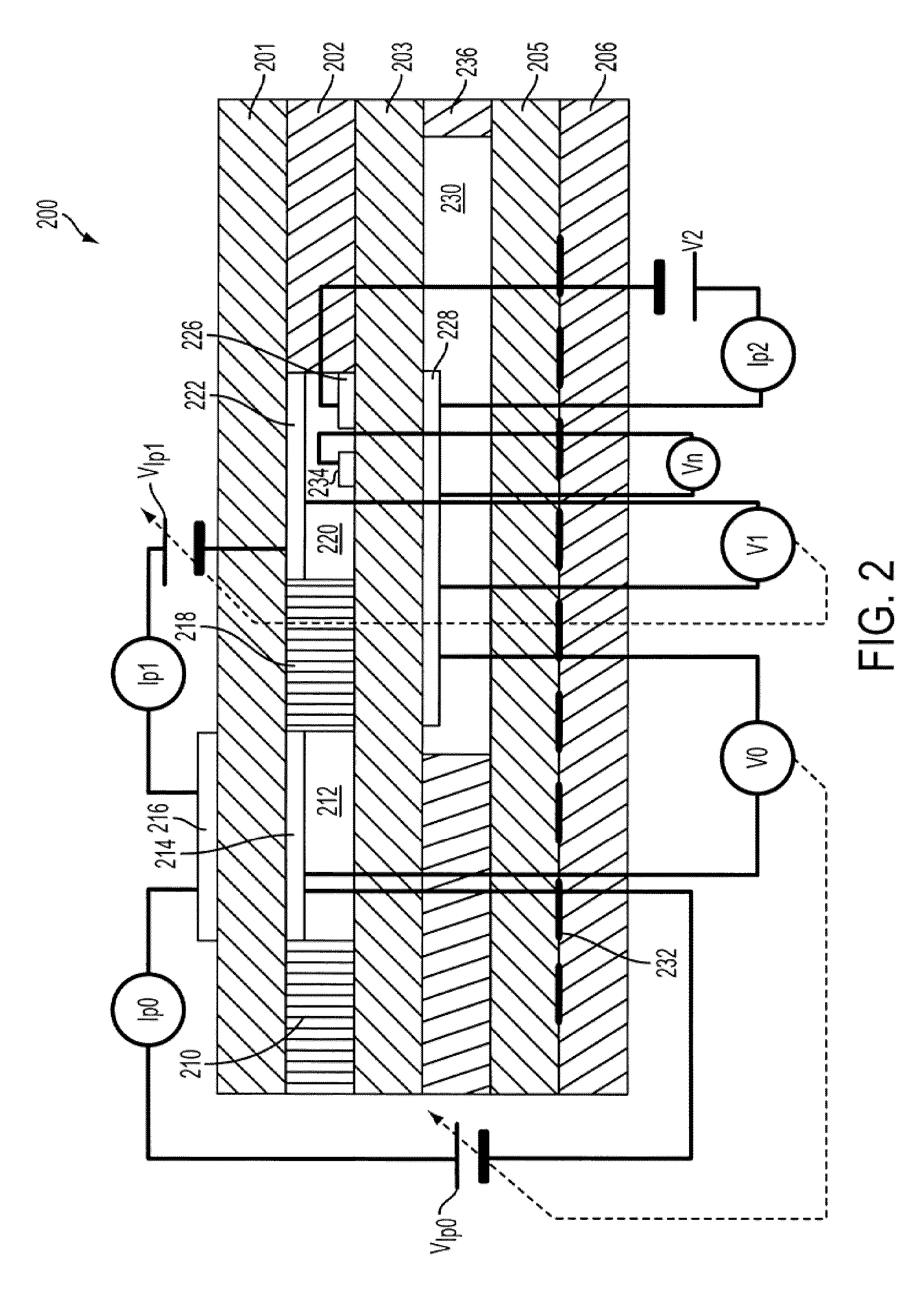

Gas sensor and method for manufacturing same

ActiveUS20110186431A1High levelAvoid timeMaterial electrochemical variablesAir quality improvementEngineeringOxygen

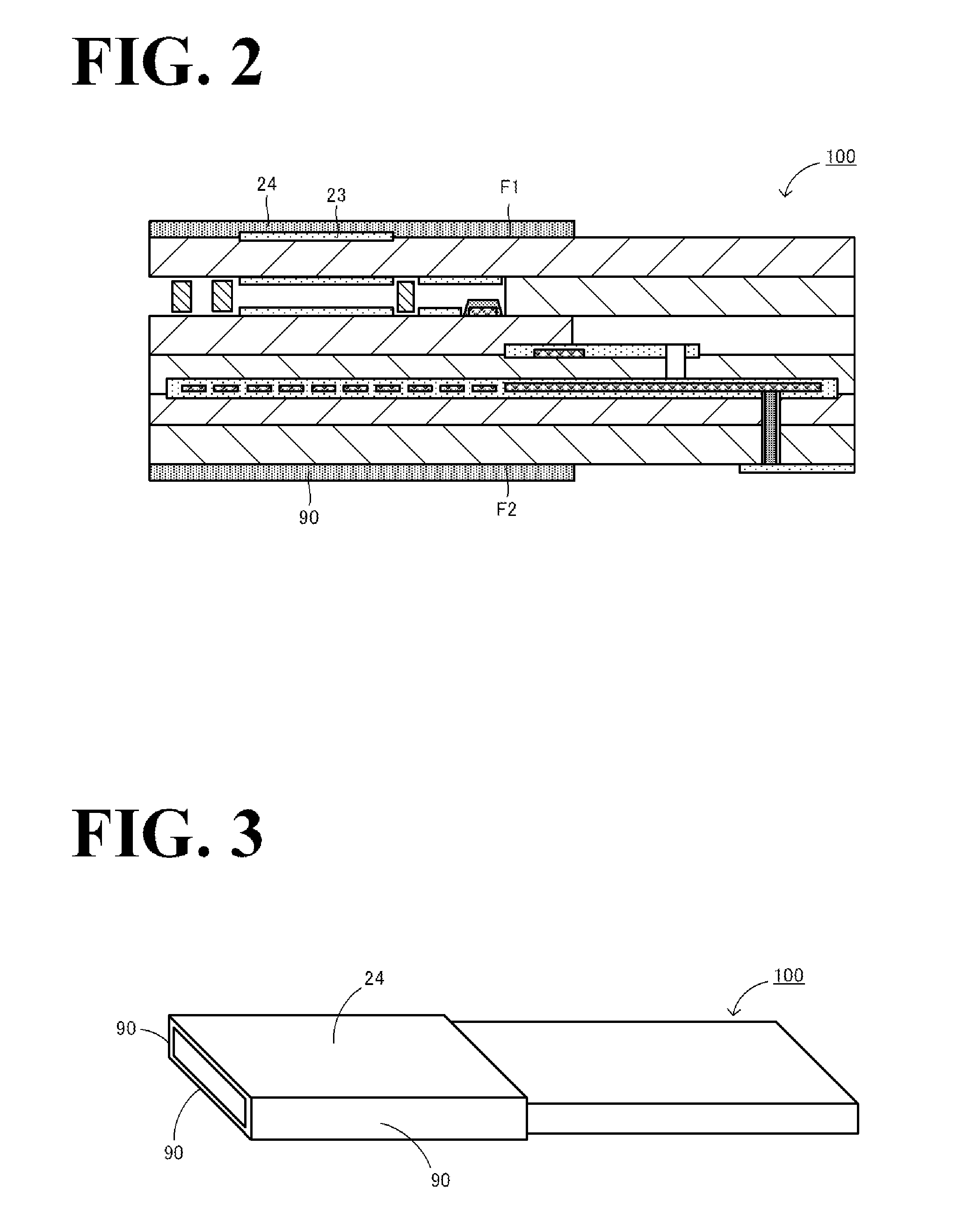

A NOx sensor 100 includes a sensor device 110 and a heater 70 capable of heating the sensor device 110. The sensor device 110 includes an inner pump electrode 22 and an outer pump electrode 23 disposed respectively on the inner side and the outer side of a solid electrolyte layer 6. The sensor device 110 detects the concentration of NOx by introducing a gas to be measured into a first inner vacancy 20, pumping out oxygen in the gas to be measured from the inner pump electrode 22 to the outer pump electrode 23, introducing the gas to be measured, from which the oxygen has been pumped out, into a second inner vacancy 40, reducing the NOx in the gas to be measured, to thereby generate oxygen, and detecting the generated oxygen. A characteristic stabilizing layer 24 covers the outer pump electrode 23 and is made of a porous body with a thickness of 10 to 200 μm and a thickness variation of 20% or less.

Owner:NGK INSULATORS LTD

Method of controlling an engine exhaust gas system and method of detecting deterioration of catalyst/adsorbing means

InactiveUS6026640AAccurate detectionEasy to controlElectrical controlInternal combustion piston enginesNitrogen oxide sensorInternal combustion engine

In a method of controlling an exhaust gas system of an internal combustion engine including a nitrogen oxide reducing catalyst capable of adsorbing nitrogen oxide under a lean atmosphere and a nitrogen oxide sensor disposed downstream of the nitrogen oxide reducing catalyst, the nitrogen oxide reducing catalyst and the nitrogen oxide sensor are disposed in the exhaust gas system operated mainly under a lean condition, respectively. An output value of the nitrogen oxide sensor is compared with a predetermined value, and an operation condition of the internal combustion engine is temporarily changed into a stoichiometric condition or a rich condition, or a fuel is injected upstream of the nitrogen oxide reducing catalyst, so that the nitrogen oxide adsorbed to the nitrogen oxide reducing catalyst is detached or decomposed, and again the internal combustion engine is operated under the lean condition.

Owner:NGK INSULATORS LTD

Nitrogen oxide sensor

InactiveUS6319377B1Improve abilitiesHigh and stable sensor outputMaterial analysis by electric/magnetic meansAir quality improvementNitrogen oxide sensorGas chamber

A nitrogen oxide sensor enabled to enhance the measurement concentration of a total of nitrogen oxides by oxidizing or reducing the nitrogen oxides on the surfaces of electrodes in addition to the control of an oxygen concentration by an oxygen pump. An electrode (3a) in a gas chamber (18) constructing an oxygen pumping portion (3) is made of a material (e.g., Pt-3 wt % Rh) having a function to oxidize a nitrogen oxide gas.

Owner:RIKEN CO LTD

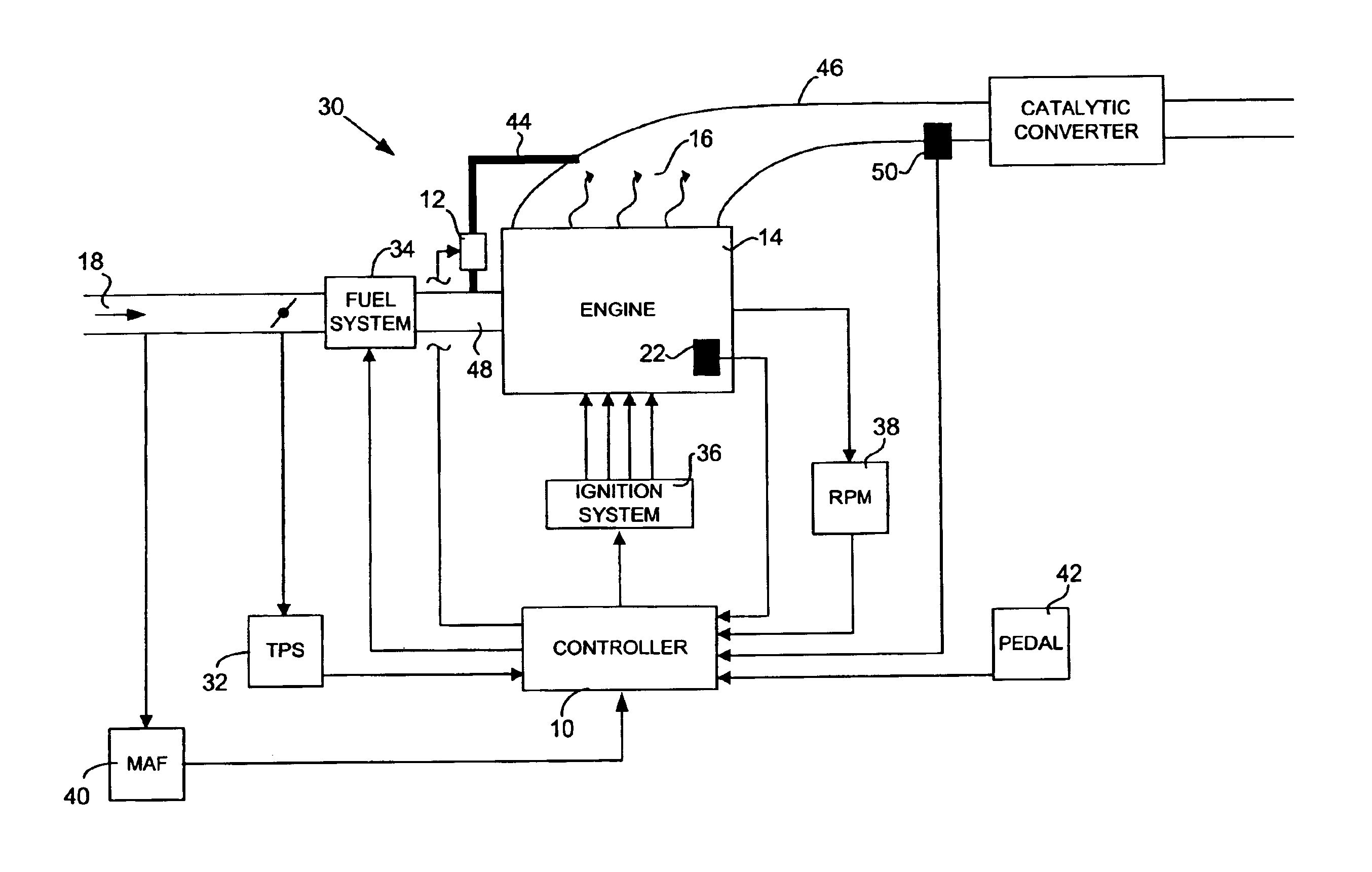

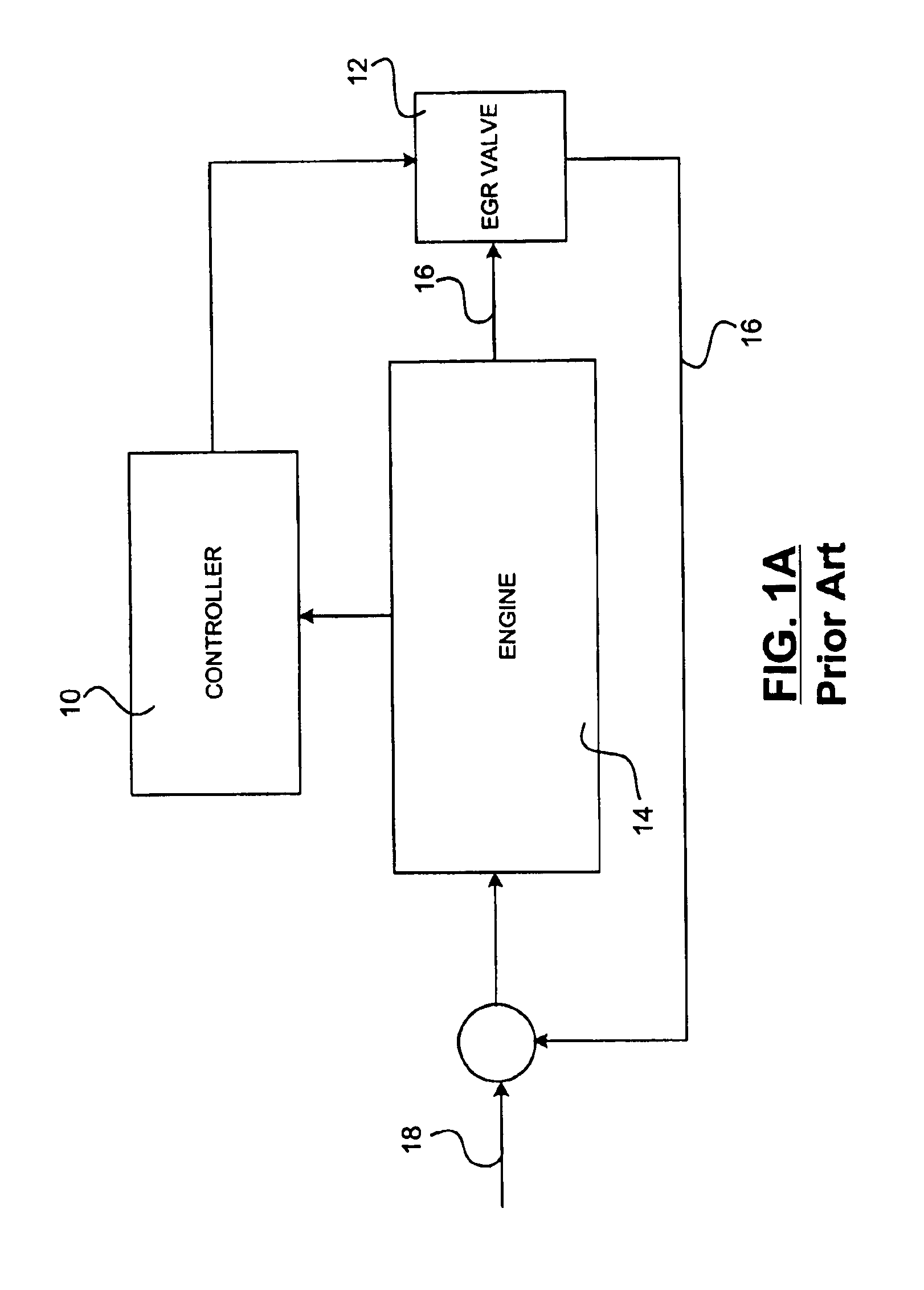

Control system for NOx control for cam phaser and/or EGR systems

A vehicle control system regulates oxides of nitrogen levels in vehicle emissions. Recirculation of exhaust gas in an engine is controlled with an exhaust gas regulator valve and / or a cam phaser. An oxides of nitrogen sensor determines the level of oxides of nitrogen levels in the exhaust gas and communicates the information to a vehicle controller. The controller determines if the oxides of nitrogen levels are within a predetermined threshold according to a lookup table. The controller adjusts the valve and / or cam phaser if the oxides of nitrogen levels are not within the threshold.

Owner:GM GLOBAL TECH OPERATIONS LLC

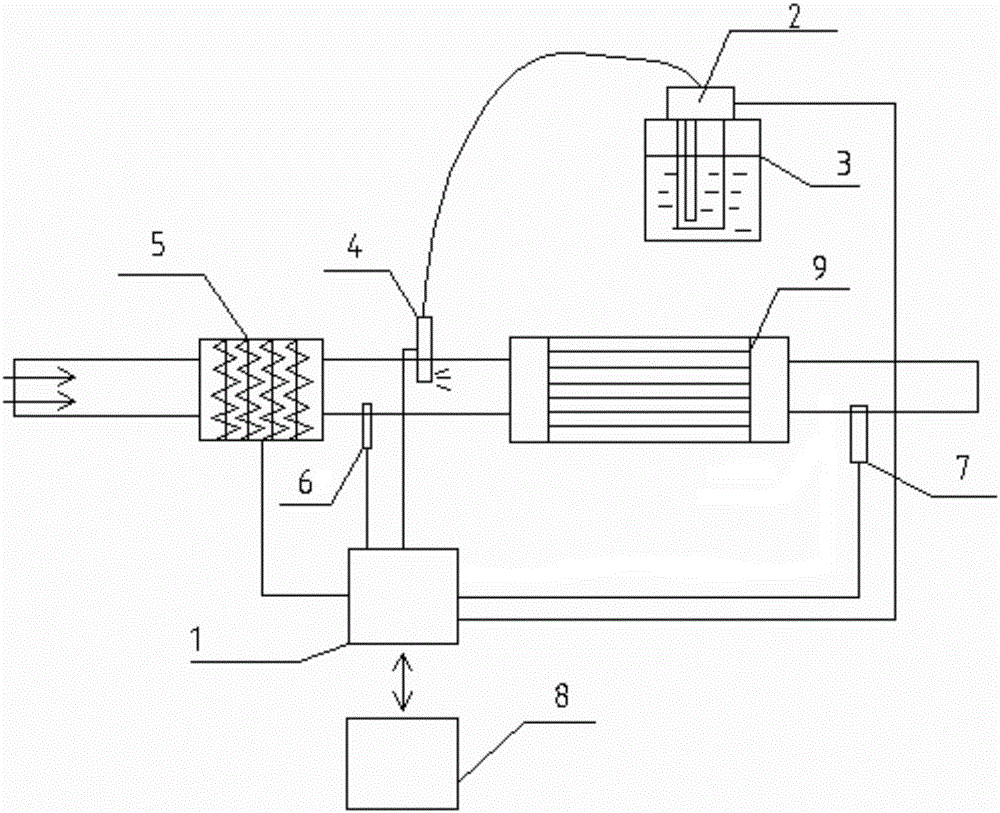

Detection system and method for oxynitride sensor

ActiveCN102608277ASimulation is accurateImprove the heating effectMaterial analysisSilicon-controlled rectifierElectricity

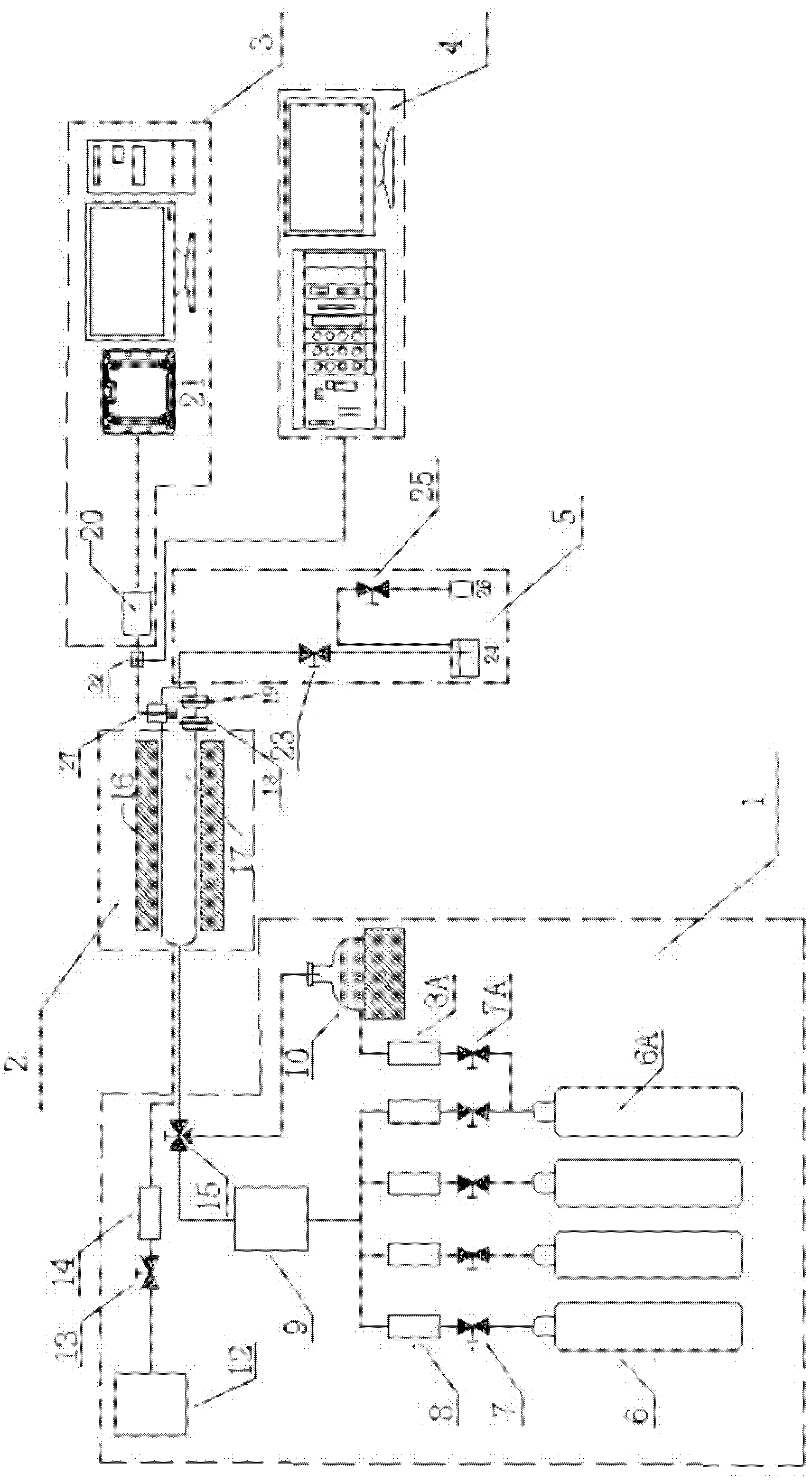

The invention discloses a detection system and method for an oxynitride sensor. The detection system comprises a tail gas distribution simulation device, a heating device, a silicon controlled rectifier (SCR) detection device, an electric signal test device and a tail gas discharging processing device, wherein the tail gas distribution simulation device is connected with one end of the heating device; and the other end of the heating device is connected in parallel with the SCR detection device, the electric signal test device and the tail gas discharging processing device. The detection system has a simple structure, can perform an experiment with different test requirements on the oxynitride sensor, can detect the real-time working state of the oxynitride sensor and can record relevant data, and can be used for researching and developing the oxynitride sensor; and the problem about exploration of researchers for an oxynitride sensor test carrier is solved.

Owner:WUXI LONGSHENG TECH

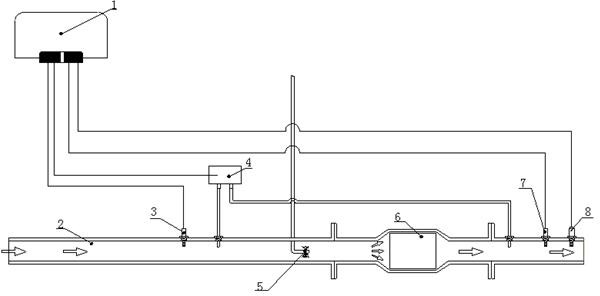

Jet control system utilizing air power to atomize urea reductant

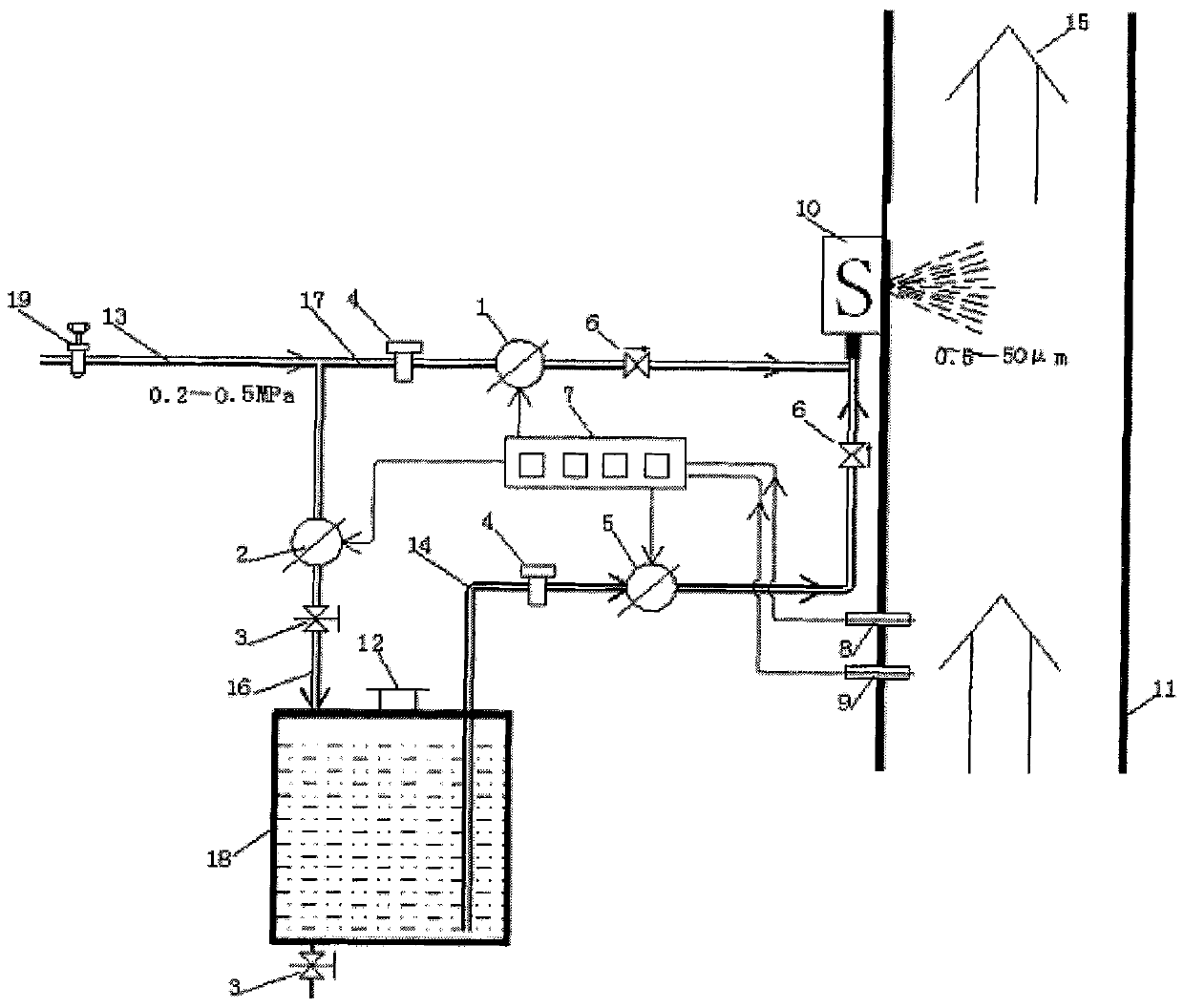

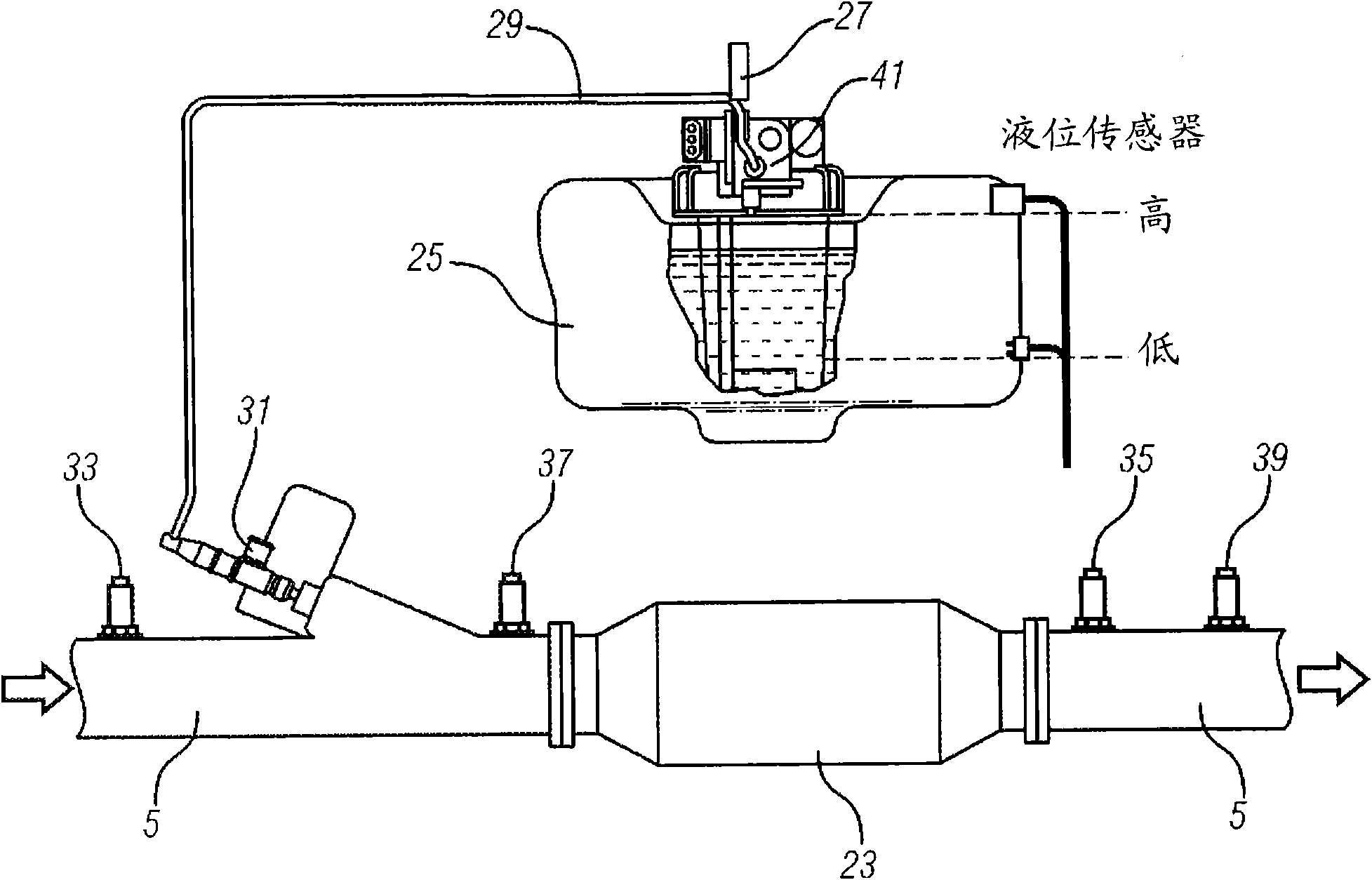

InactiveCN101793183AEliminate NOXImprove reliabilityInternal combustion piston enginesExhaust apparatusNitrogen oxidesSolenoid valve

The invention relates to a jet control system utilizing air power to atomize urea reductant, which is characterized in that the air inlet end of a compressed air main pipe is provided with a pressure regulating valve, the air outlet end thereof is respectively communicated with a compressed air branch pipe for a blowing nozzle and a urea reductant storage tank compressed air branch pipe; the urea reductant storage tank compressed air branch pipe is connected on a urea reductant container; the compressed air branch pipe for the blowing nozzle is communicated with a single-cavity urea reductant nozzle, one end of a urea reductant delivery pipe is arranged in the urea reductant container, the other end thereof is communicated with the urea reductant nozzle, and a temperature sensor arranged on the exhaust pipe of an engine and a nitric oxide sensor are electrically connected with a control unit. The filtered urea reductant is mixed and atomized in the urea nozzle through being driven by the power of compressed air, and is atomized in the single-cavity nozzle by depending on the regulation and control of a flow solenoid valve, thereby achieving purification treatment on NOX in car tail gas. The invention has reliable system, low cost and strong practicability.

Owner:FAW GROUP

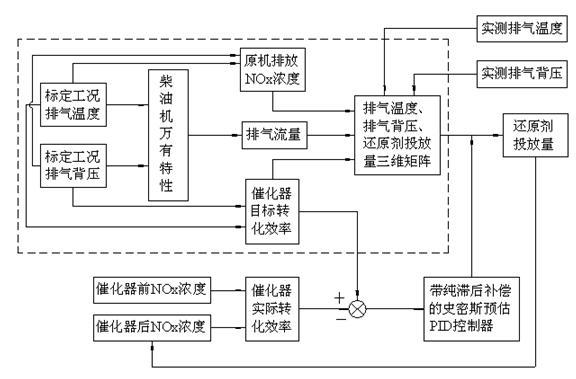

Closed loop control method for SCR (Selective Catalyst Reduction) system of all-working-condition diesel engine

InactiveCN102493860AEasy to controlInternal combustion piston enginesExhaust apparatusProportion integration differentiationClosed loop

The invention discloses a closed loop control method for an SCR (Selective Catalyst Reduction) system of an all-working-condition diesel engine. The method is carried out according to the following steps of: (1) establishing a novel three-dimensional matrix of the adding amount of reducing agent for the SCR system based on exhaust temperature and exhaust backpressure of the all-working-condition diesel engine; and (2) forming a precise control mode of a closed loop of the SCR system of the all-working-condition diesel engine by utilizing a nitrogen oxide sensor and a PID (Proportion Integration Differentiation) controller. By using the closed loop control method for the SCR system of the all-working-condition diesel engine in the invention, the acquisition of working-condition parameters of the diesel engine can not depend on an electronic control unit (ECU) of the diesel engine, the technical obstacle that the current home and abroad SCR systems are only suitable for electrically controlling the diesel engine is broken through, and an approach for reducing the discharging amount of NOx is provided for vehicles assembled with light, middle and heavy non-electric control diesel engines.

Owner:MILITARY TRANSPORTATION UNIV PLA

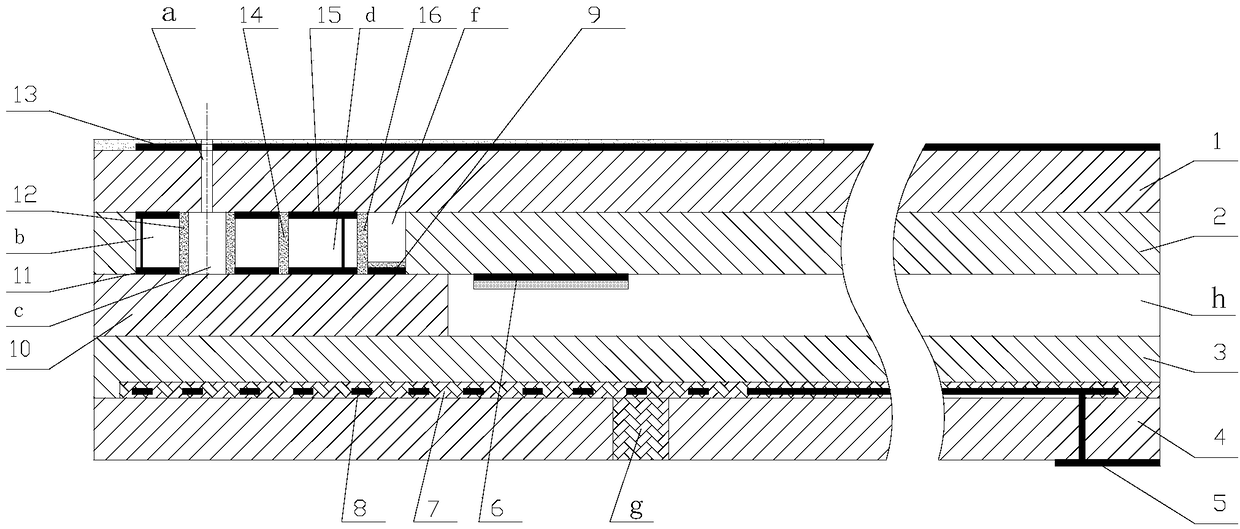

Nitrogen oxide sensor chip

InactiveCN102043007AAvoid pollutionCatalytic activity is not affectedMaterial analysis by electric/magnetic meansNitrogen oxide sensorDiffusion barrier

The invention discloses a nitrogen oxide sensor chip. The nitrogen oxide sensor chip is formed by laminating six layers of substrates which are made of zirconium oxide, wherein the second layer of substrate comprises four cavities, namely a first cavity, a second cavity, a third cavity and a fourth cavity; three rows of diffusion barrier layers are respectively arranged among the four cavities in turn; a first electrode is arranged in the third cavity; a second electrode and a third electrode are arranged in the fourth cavity; the third layer of substrate is provided with a reference gas channel connected with atmosphere; a reference electrode is arranged between the third layer of substrate and the fourth layer of substrate; a porous aluminum oxide layer is covered on the reference electrode; the reference gas channel is communicated with the porous aluminum oxide layer through small holes; a heating electrode is arranged between the fourth layer of substrate and the fifth layer of substrate; an insulating layer is arranged on the upper part and the lower part of the heating electrode respectively; the first layer of substrate is provided with a fourth electrode; and a protective layer is covered on the fourth electrode. The nitrogen oxide sensor chip with the structure can prevent gold in a non-activated electrode from polluting an activated electrode due to volatilization during sintering, is not required to be sintered stepwise, and is formed by laminating the six layers of substrates and sintering at one time.

Owner:WUXI LONGSHENG TECH

Gas sensor and nitrogen oxide sensor

ActiveUS20090120791A1Increased durabilityLittle influenceMaterial analysis by electric/magnetic meansDiffusion resistanceTrapping

A gas sensor and nitrogen oxide sensor, which, when fitted to the exhaust system of an internal combustion engine, can suppress the influence of harmful substances contained in a measurement gas and can prevent the reduction in sensitivity over time. A harmful substance-trapping layer is formed at a gas inlet for introducing a to-be-measured gas from an external space into an internal space, and in a buffering space formed between diffusion resistance portions. In a trap-formed portion of a gas passage in which the harmful substance-trapping layer is formed, the measurement gas can pass in an amount of 80% or more of when the harmful substance-trapping layer is not formed in the trap-formed portion. A diffusion resistance is attained in the diffusion resistance portions; a harmful substance is trapped in the harmful substance-trapping layer; and the measurement gas is allowed to flow into a detection electrode side.

Owner:NGK INSULATORS LTD

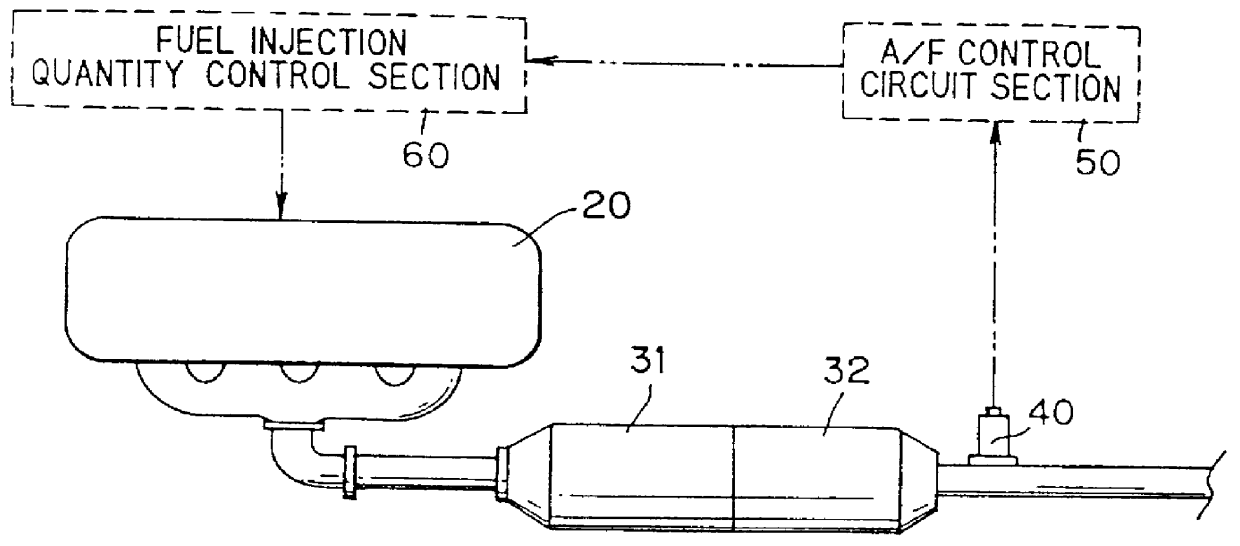

Purification device for decreasing particulate matter and nitrogen oxides in diesel engine

InactiveUS20080115485A1Achieve purificationExhaust apparatusSilencing apparatusDecompositionDifferential pressure

A diesel exhaust purification device for decreasing the amount of particulate matter and nitrogen oxides includes a Catalyzed Diesel Particulate Filter (CDPF) disposed in an exhaust conduit to capture particulate matter (PM). A differential pressure sensor detects the amount of PM contained in the CDPF. A post-injection injector is in the exhaust conduit. A Diesel Fuel Decomposition Catalyst (DFC) forms a reducing agent by decomposing the fuel injected from the post-injection injector. A nitrogen oxide adsorbing catalyst reduces nitrogen oxides accumulated therein and removes them using the reducing agent. A nitrogen oxide sensor in the exhaust conduit detects the amount of nitrogen oxides in exhaust gases. A control unit determines the regeneration time of the CDPF from signals detected by the differential pressure sensor, controls the amount of the fuel post-injected, determines the regeneration time of the nitrogen oxide adsorbing catalyst from signals detected by the nitrogen oxide sensor, controls the fuel post-injected through the post-injection injector.

Owner:HYUNDAI MOTOR CO LTD

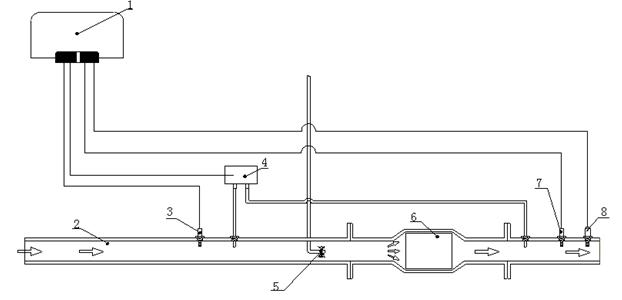

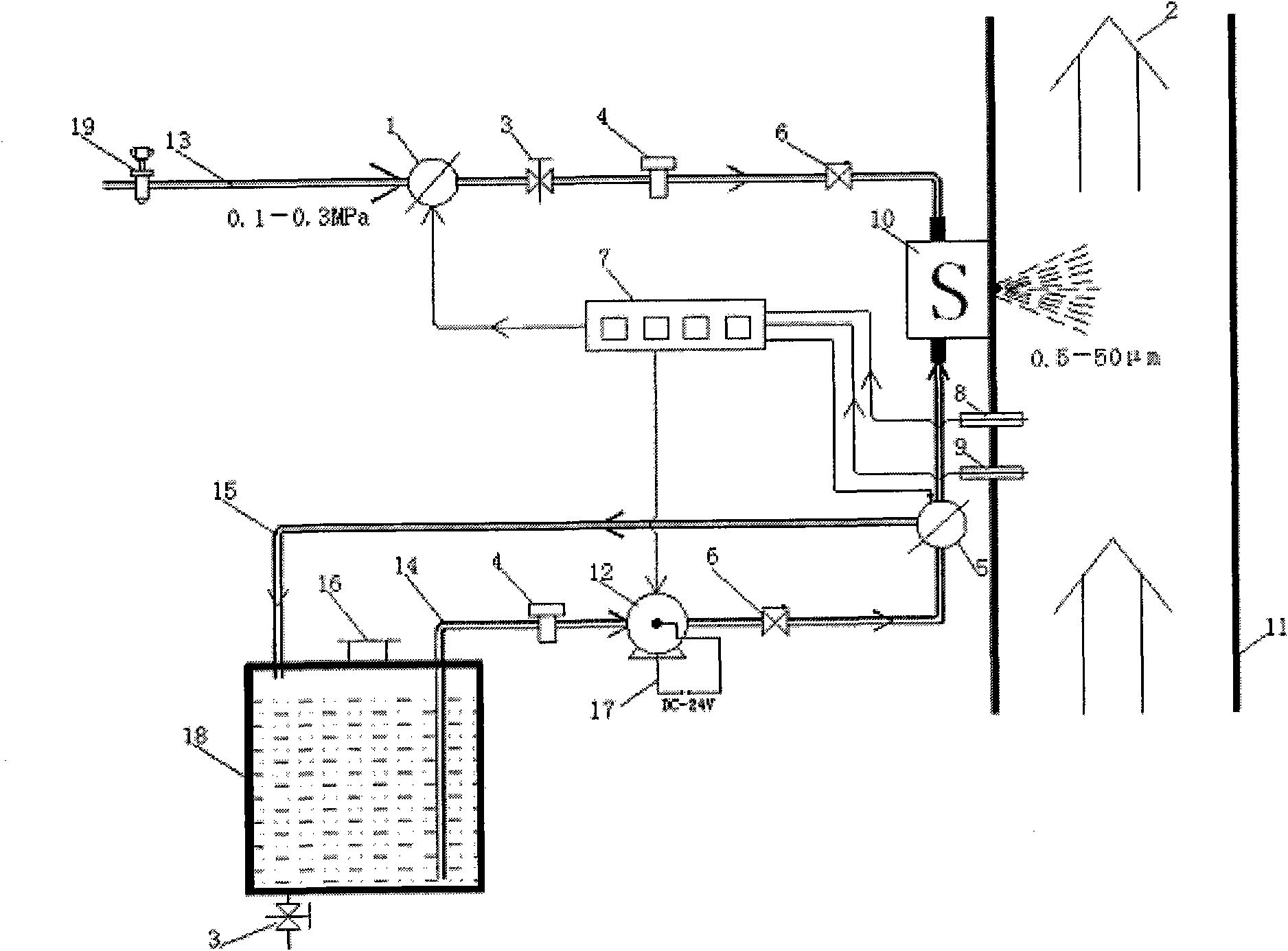

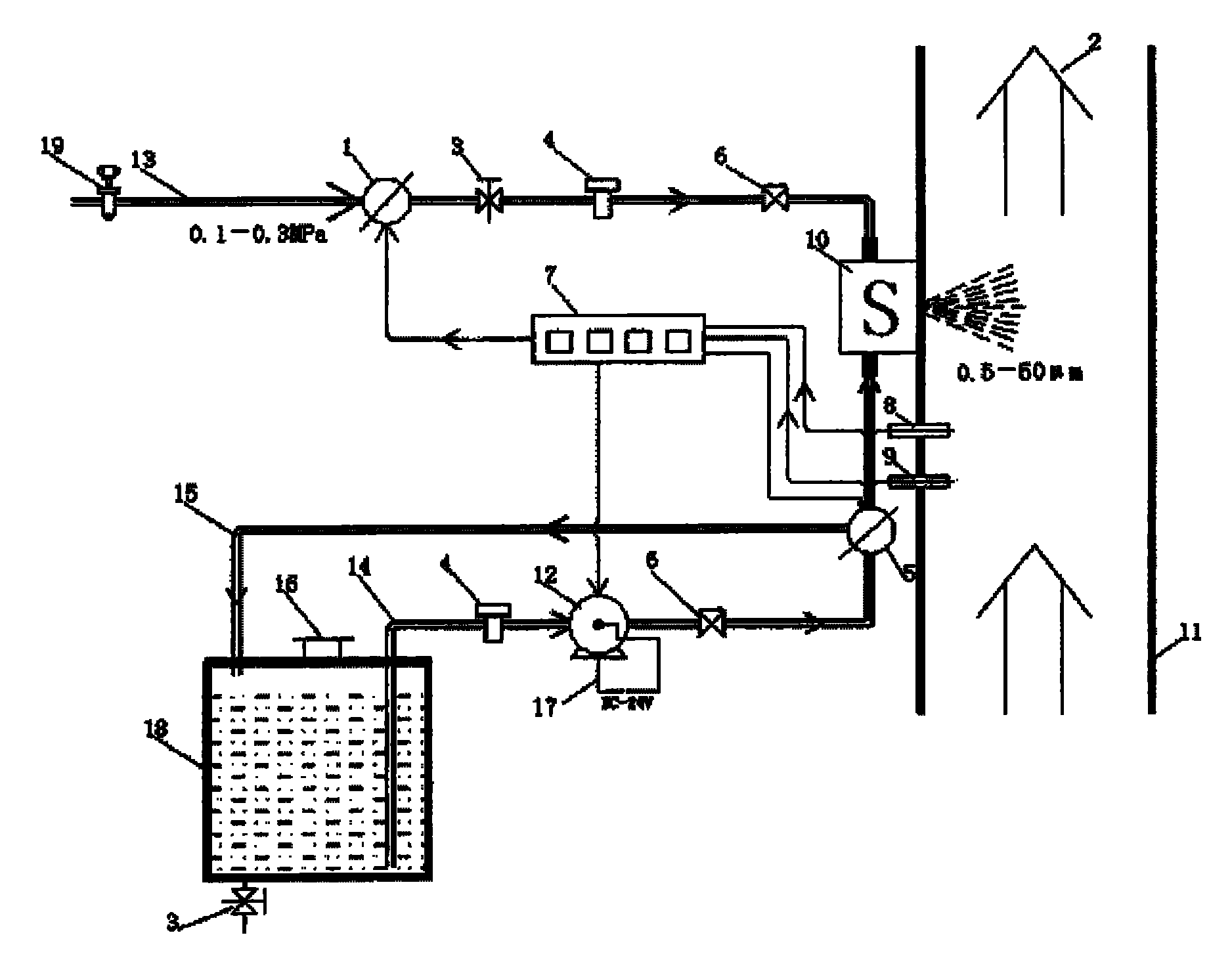

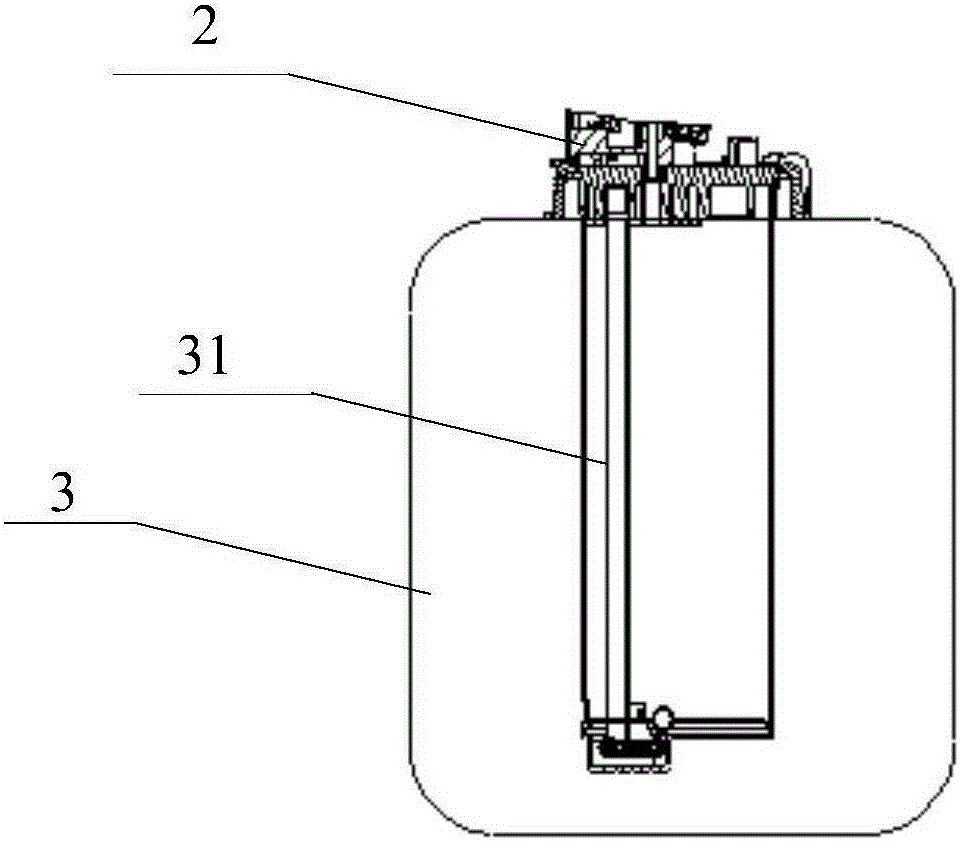

Air-assisted atomized urea reducing agent spraying controlling system of pump power

InactiveCN101806238AFully atomizedImprove reliabilityInternal combustion piston enginesExhaust apparatusSolenoid valveNitrogen oxide sensor

The invention relates to an air-assisted atomized urea reducing agent spraying controlling system of pump power. The system is characterized in that the air inlet end of an air compressing main pipe is provided with a pressure adjusting valve; the air outlet end of the air compressing main pipe is communicated with an urea reducing agent nozzle; an urea reducing agent reflowing pipeline is connected with an urea reducing agent container; a cover of the urea reducing agent container is fixed on the urea reducing agent container; the bottom of the urea reducing agent container is connected with a manual liquid switch; an urea reducing agent pipeline and the urea reducing agent reflowing pipeline are communicated with the urea reducing agent nozzle through a liquid flow solenoid valve; and a temperature sensor and a nitric oxide sensor, which are arranged on an exhaust pipe of an engine, are electrically connected with a control unit. The system has low cost which is about equal to 1 / 2-1 / 3 of the cost of an imported system, high reliability, and high practical applicability, and is easily industrially applied with domestic resources.

Owner:FAW GROUP

Diesel engine tail gas after-treatment system and heating control method

InactiveCN106014563AGuaranteed temperatureImprove catalytic reaction efficiencyInternal combustion piston enginesExhaust apparatusNitric oxideNitrogen oxide sensor

The invention provides a diesel engine tail gas after-treatment system. The diesel engine tail gas after-treatment system comprises a SCR catalyst, a urea pump, a urea tank, a urea nozzle, a control unit, a temperature sensor and a nitric oxide sensor, and further comprises a waste gas temperature adjusting device for heating control of the temperature of exhausted tail gas; the urea pump is integrated on the urea tank, and is connected with the urea nozzle through a urea solution pipeline; and the urea nozzle is mounted on an exhaust pipe. The diesel engine tail gas after-treatment system is provided with the waste gas temperature adjusting device, and is provided with an internal heating body for heating the tail gas to keep the temperature of the tail gas in a set range so as to always keep the catalytic reaction efficiency on a higher level. The diesel engine tail gas after-treatment system can output different heating powers for different working conditions to realize instant and different active control of the exhaust temperature so as to adapt to the demands on different working condition points through controlling such parameters as the electrifying time and frequency of the heating body.

Owner:天津星洁汽车排放控制系统有限公司

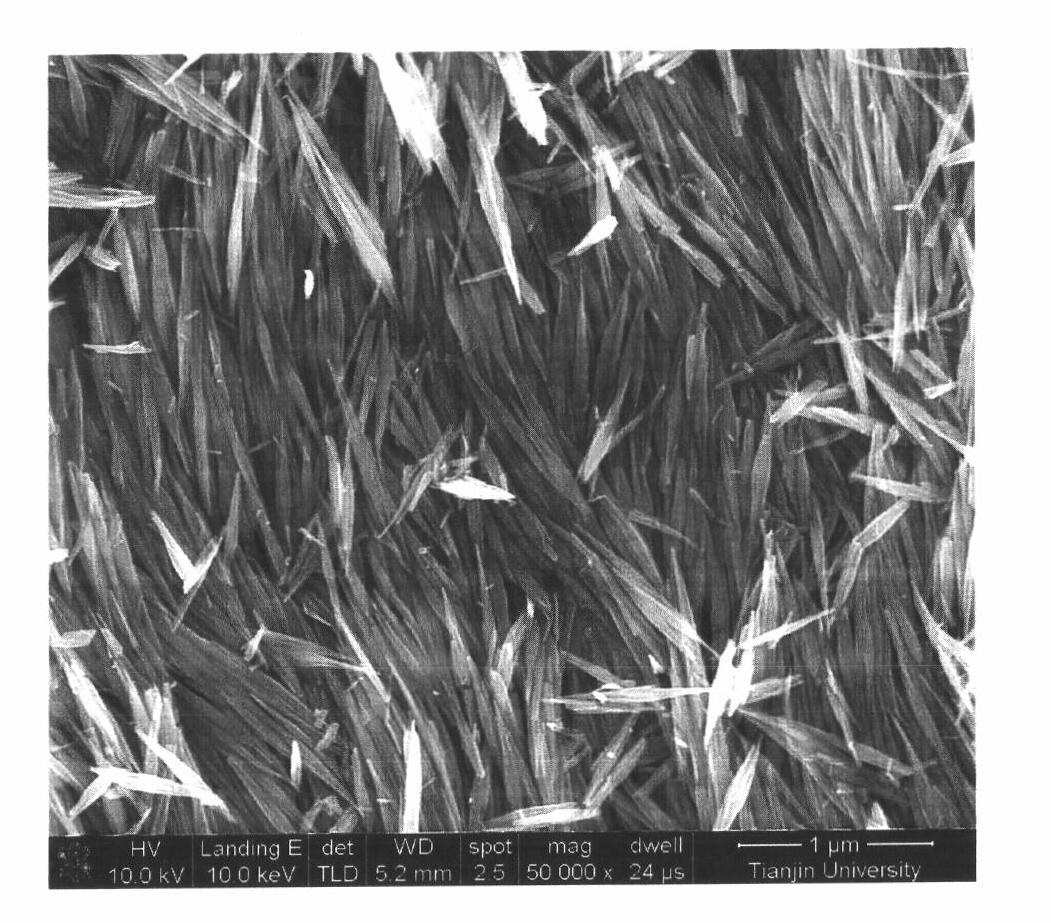

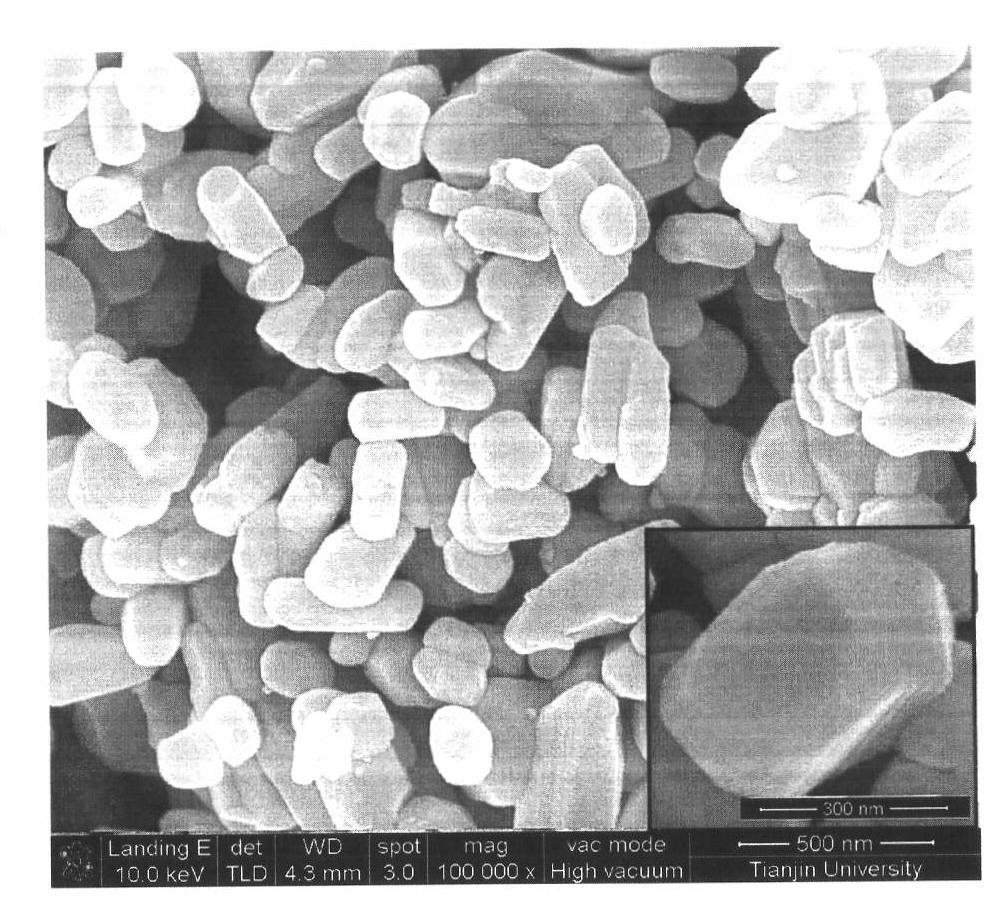

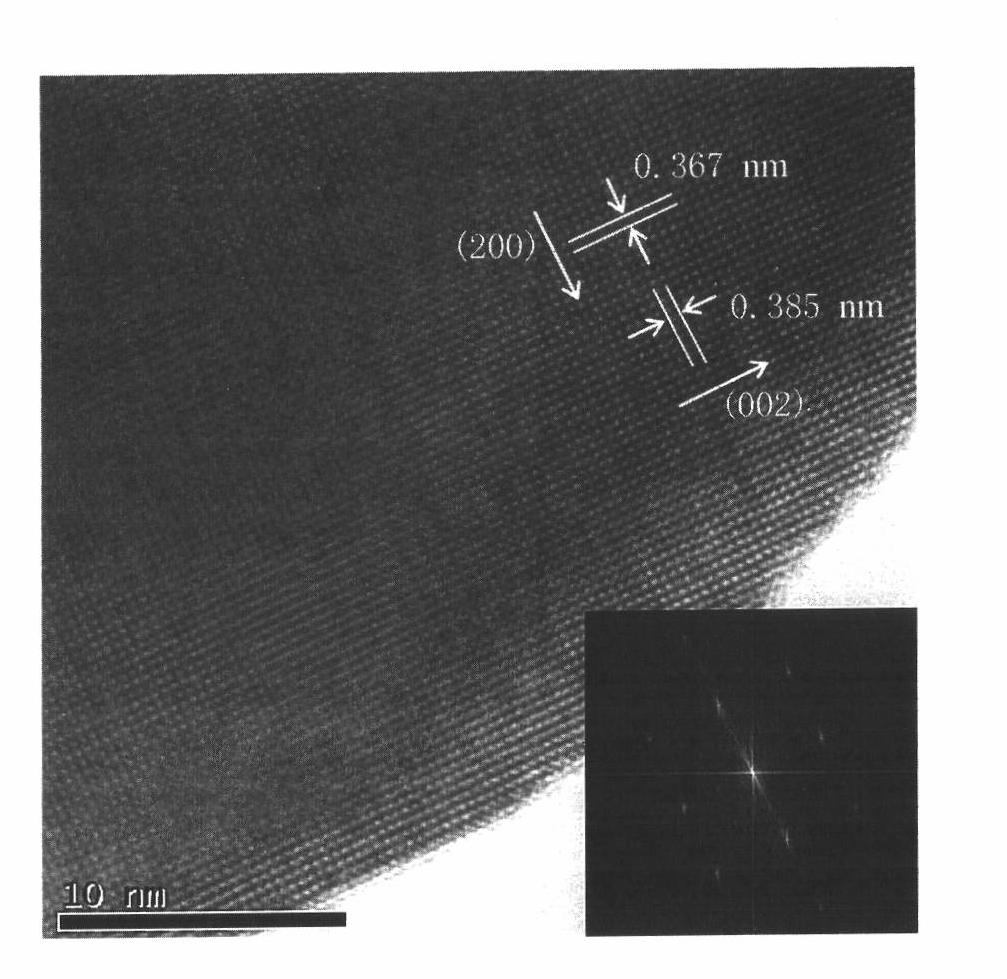

Preparation method of nitrogen oxide sensor component based on WO3 single-crystal particle

InactiveCN102495109AComplete structureHigh degree of crystallizationMaterial resistanceNanowireSingle crystal

The invention discloses a preparation method of a nitrogen oxide sensor component based on WO3 single-crystal particles, which comprises: (1) preparing tungsten hexachloride solution; (2) adjusting the molar concentration of tungsten hexachloride to be 0.003-0.014M; (3) synthesizing quasi-oriented tungsten oxide nanowires; (4) preparing nanowire-based sensitive slurry; and (5) preparing the nitrogen oxide sensor component based on the WO3 single-crystal particles. The prepared WO3 single crystal has a pure single inclined-phase structure, and the single-crystal particles have a complete structure, a high degree of crystallization, a clear crystal face and regular morphology. By adopting the gas sensor based on the single-crystal tungsten trioxide material, high-sensitivity and high-selectivity rapid response can be realized for NO2 at the level of ppm to ppb.

Owner:TIANJIN UNIV

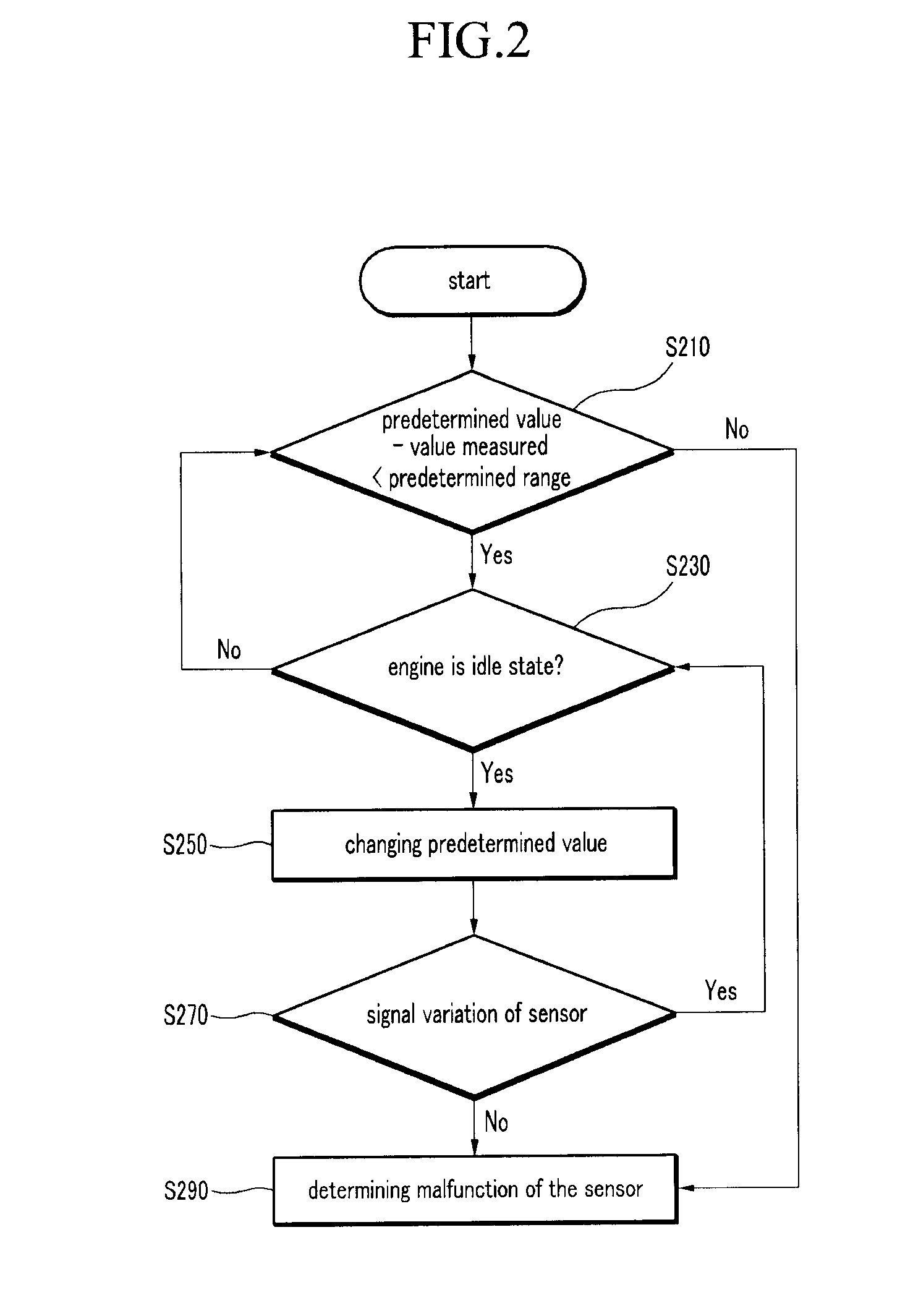

Method for determining malfunction of nitrogen oxide sensor and selective catalytic reduction system operating the same

ActiveUS20090013666A1Electrical controlInternal combustion piston enginesStable stateNitrogen oxides

A method for determining malfunction of a nitrogen oxide sensor compares a nitrogen oxide amount detected by the sensor with a predetermined value of nitrogen oxide. If the difference between the predetermined value and the amount detected by the sensor is within a predetermined range, the method determines whether an engine is in a steady state. If the engine is in a steady state, the method changes one or more engine control parameters, thereby varying an actual nitrogen oxide amount. After changing the parameters, the method determines whether the amount detected by the sensor changes. The method determines that the sensor is malfunctioning if the amount detected by the sensor does not change. A selective catalytic reduction system includes a first nitrogen oxide sensor, a selective catalytic reduction apparatus, and a second nitrogen oxide sensor, all disposed in an exhaust pipe. A control portion performs the above-described method.

Owner:HYUNDAI MOTOR CO LTD +1

NOx SENSOR COMPENSATION

ActiveUS20110023459A1Continuous monitoringSimple introductionElectrical controlExhaust apparatusNitrogen oxide sensorExhaust gas

Various systems and methods are described for controlling an engine in a vehicle during engine operation, the engine having an exhaust and a NOx sensor coupled in the engine exhaust. One example includes correcting the NOx sensor to account for transients in exhaust gas flow, such as transients in exhaust gas flow rate. Such transients may cause NOx sensor temperature to deviate from a desired value as the sensor heater is unable to maintain temperature during such transients. In this way, even during such transients, accurate NOx readings are still available.

Owner:FORD GLOBAL TECH LLC

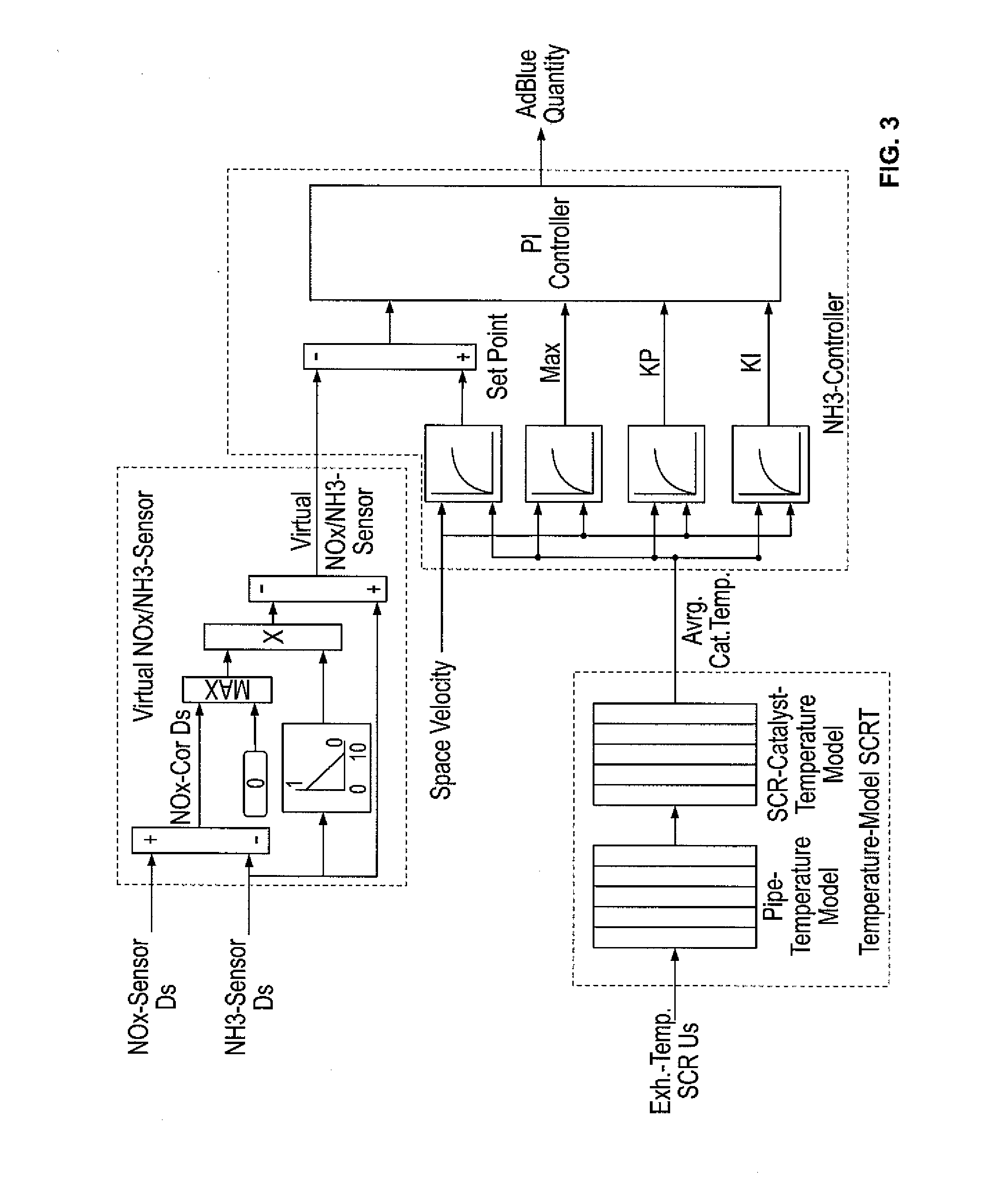

Method for reducing nitrogen oxide levels in diesel engine exhaust gases

InactiveUS20140020364A1Lower Level RequirementsLittle or no provisionGas treatmentInternal combustion piston enginesNitrogen oxide sensorAmmonia

A method is described for reducing the nitrogen oxide levels in diesel engine exhaust gases with the aid of an exhaust gas treatment system, which includes a device for feeding ammonia and / or a compound decomposing to form ammonia, and two SCR units. An ammonia sensor is situated between the first and second SCR unit. A nitrogen oxide sensor is located in the exhaust pipe downstream from the second SCR unit. The signals of the ammonia sensor and the NOx sensor are combined in a defined manner to form the actual value of a virtual NOx / NH3 sensor, which is used as the input variable for a PI or PID controller, which regulates the quantity of reducing agent to be fed into the exhaust gas as needed.

Owner:DEUTZ AG

Control system for NOx control for cam phaser and/or EGR systems

A vehicle control system regulates oxides of nitrogen levels in vehicle emissions. Recirculation of exhaust gas in an engine is controlled with an exhaust gas regulator valve and / or a cam phaser. An oxides of nitrogen sensor determines the level of oxides of nitrogen levels in the exhaust gas and communicates the information to a vehicle controller. The controller determines if the oxides of nitrogen levels are within a predetermined threshold according to a lookup table. The controller adjusts the valve and / or cam phaser if the oxides of nitrogen levels are not within the threshold.

Owner:GM GLOBAL TECH OPERATIONS LLC

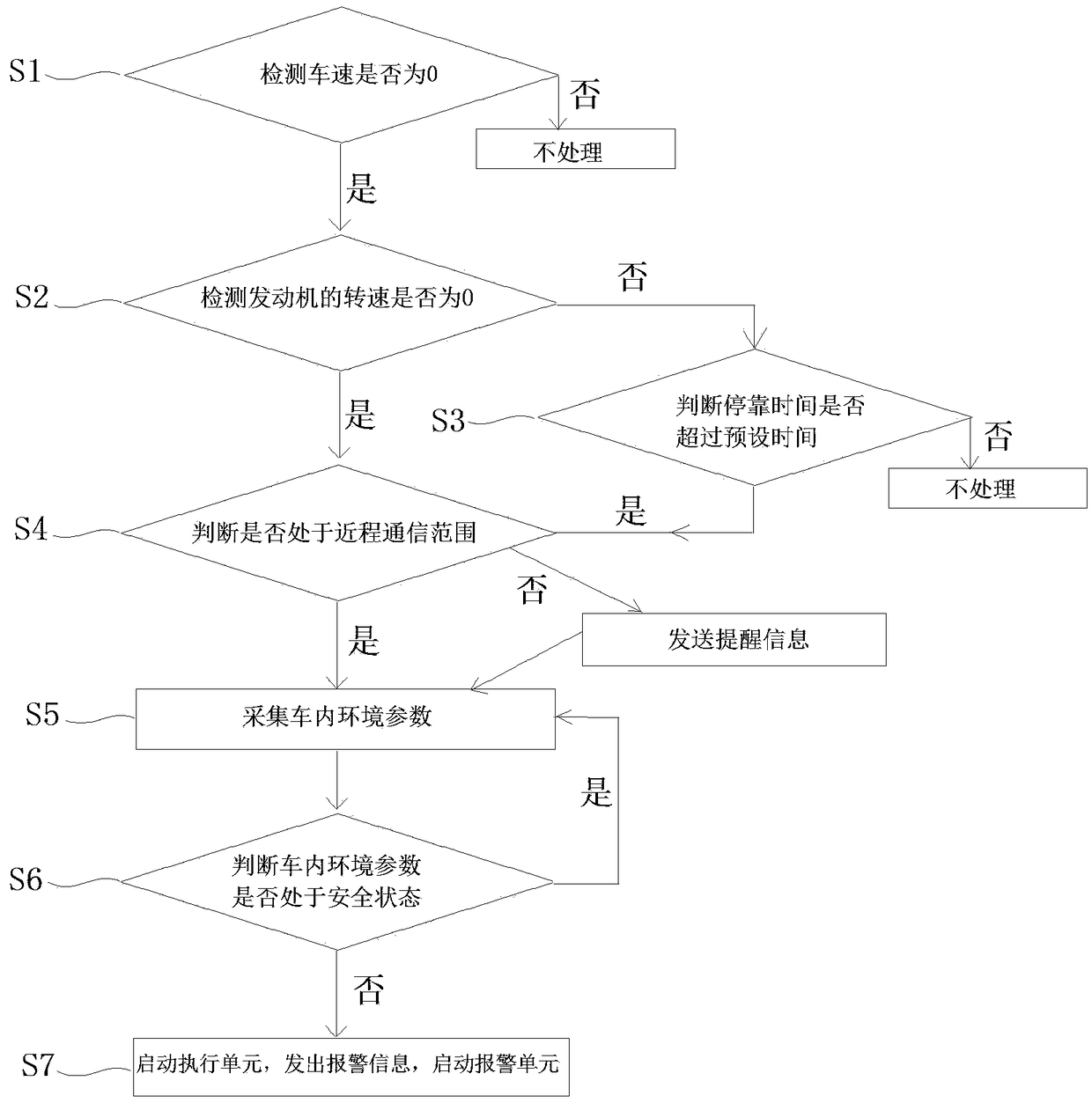

Device for preventing personnel in car from choking and method thereof

ActiveCN108819658AAvoid suffocationEnsure safetyAir-treating devicesPedestrian/occupant safety arrangementElectricityOxygen sensor

The invention discloses a device for preventing personnel in a car from choking and a method. The device comprises a controller electrically connected with a vehicle power supply, wherein the controller is electrically connected with a gathering module, an execution module, a communication module and a warning module. The gathering module comprises a rotating speed sensor, a speed sensor, an oxygen sensor, a carbon monoxide sensor and a nitric oxide sensor, wherein the rotating speed sensor is used for inspecting the rotating speed of an engine, the speed sensor is used for inspecting the vehicle speed, oxygen sensor is used for inspecting oxygen concentration in a driving cab, the carbon monoxide sensor is used for inspecting the carbon monoxide concentration in the driving cab, and the nitric oxide sensor is used for inspecting the nitric oxide concentration in the driving cab. The execution module comprises a window opening unit used for opening car windows and an unlocking unit used for unlocking a car lock. The communication module comprises a GSM unit used for remote communication and a Bluetooth unit used for short range communication. The warning module is electrically connected with car warning lights, car horns and in-car stereos correspondingly. Based on the device, the occurrence of choking situation of personnel in the car can be effectively avoided, and car usingsafety can be guaranteed.

Owner:葛丁阳

Purification device for decreasing particulate matter and nitrogen oxides in diesel engine

A purification device is disclosed for a reduction in the amount of particulate matter and nitrogen oxides. The device comprises a catalytic diesel particulate filter (CDPF), a differential pressure transducer, a rearward injector, diesel fuel decomposition catalysts (DFC), nitrogen oxides absorption catalysts (de-NOx catalysts), a nitrogen oxide sensor and a controlling device.

Owner:HYUNDAI MOTOR CO LTD

Ceramic chip of NOx sensor

ActiveCN109001284AImprove stress concentrationHigh strengthMaterial electrochemical variablesNitrogen oxide sensorSlurry

The invention discloses a ceramic chip of a NOx sensor. An oxygen pump anode covered with a protective layer on the surface is arranged on a first-layer membrane, an acquisition cavity is formed on the oxygen pump anode and the first-layer membrane, second to fourth through holes are formed in a second-layer membrane, a first diffusion barrier is formed in the second through hole and divides the second through hole into a first measurement chamber and a buffer cavity, a main oxygen pump cathode is arranged in the first measurement chamber, a second diffusion barrier is arranged between the second through hole and a third through hole, the third through hole is a second measurement chamber, an auxiliary pump cathode is arranged in the second measurement chamber, a third diffusion barrier isarranged between the third through hole and the fourth through hole, the fourth through hole is a third measurement chamber, a measurement electrode covered with a protective layer on the surface isarranged in the third measurement chamber, a reference channel is formed in a third-layer membrane, a reference electrode covered with a protective layer on the surface is arranged in the reference channel, a heating electrode wrapped in a heating electrode insulating layer is arranged between the fourth-layer membrane and a fifth-layer membrane, an outer lead of the heating electrode penetrates through the fifth-layer membrane to be located on the lower surface of the fifth-layer membrane, and a stress release hole filled with heating electrode insulating layer slurry is formed in the fifth-layer membrane.

Owner:西安创研电子科技有限公司

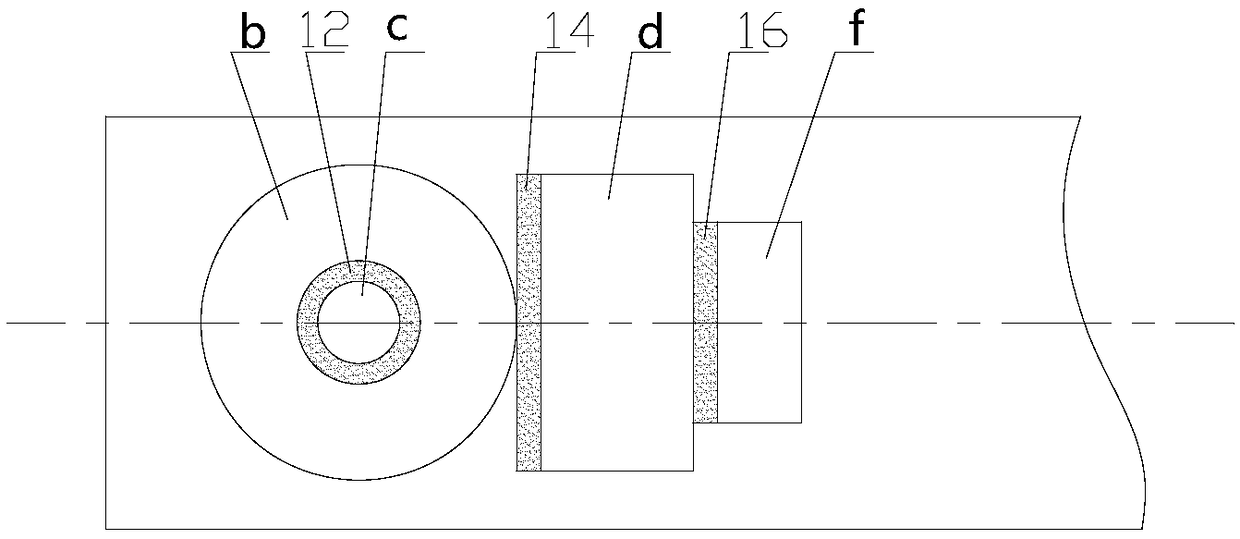

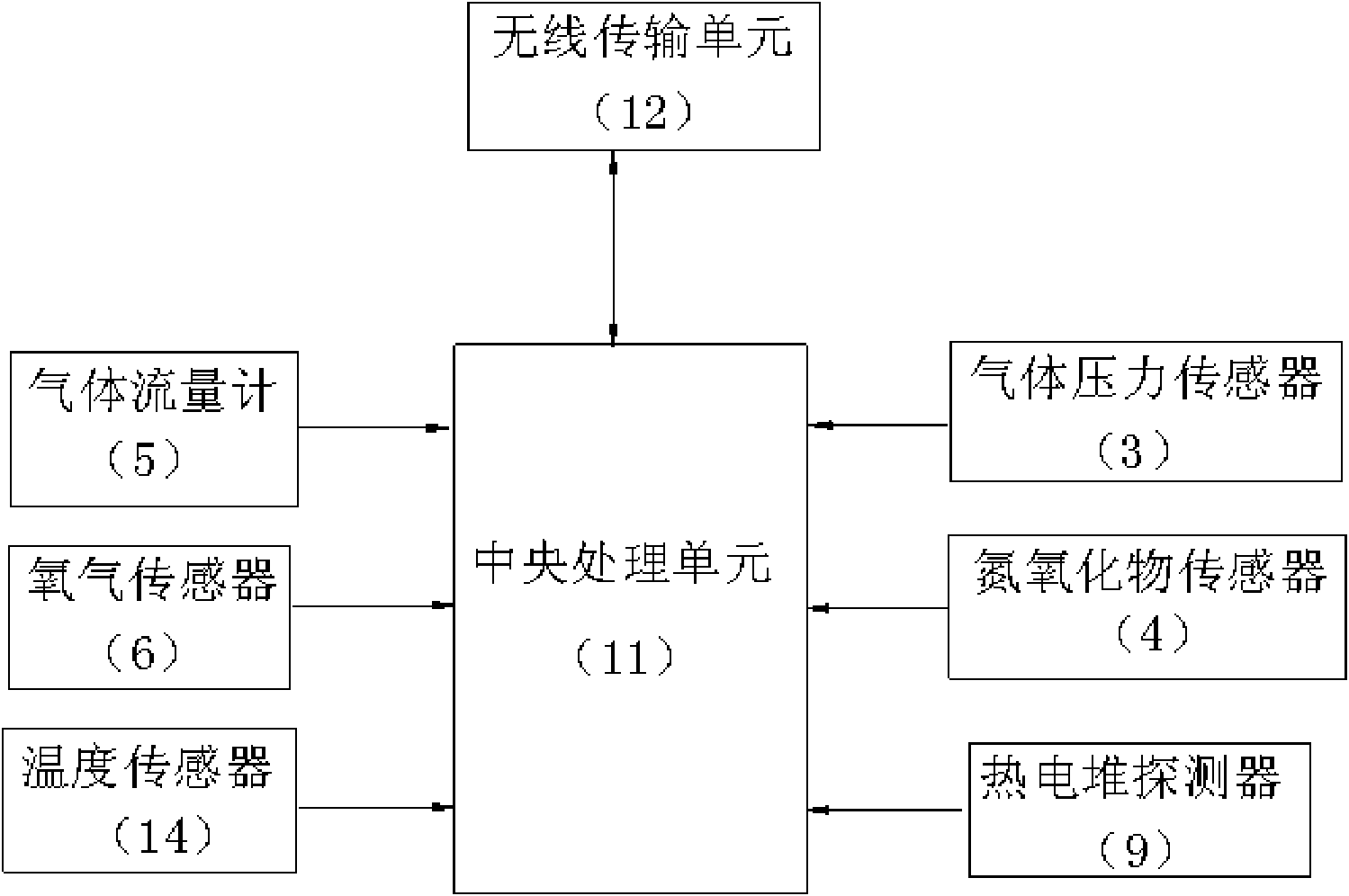

Intelligent wireless vehicular embedded analytical equipment for automobile exhaust

InactiveCN101551326AImprove detection efficiencyEasy to useVolume/mass flow by electric/magnetic effectsFluid pressure measurementEngineeringNitrogen oxide sensor

The invention relates to an intelligent wireless vehicular embedded analytical equipment for automobile exhaust, which includes housing with gaseous current alley way, central processing element and wireless transfers unit electrically connects with central processing element set in, the wireless transfers unit wireless connects with wireless vehicle speed sensor set at the automobile. In the gaseous current alley way, there sets gas pressure sensor which electrically connects with central processing element, nitrous oxides feeler unit, gas flow meter, oxygen gas feeler unit, heat meter, oxycarbide and oxyhydride feeler unit. This invention can get the concentration values of oxygen gas, nitrous oxides, oxycarbide and oxyhydride contained in automobile exhaust and the flow, pressure, temperature and other parameters of automobile exhaust at one time, which makes comprehensive and perfect judgment on the exhaust discharged by the automobile, obtains the mass discharged values of automobile exhaust, and wirelessly sends to detecting person or unit in long distance, and the detecting efficiency of the invention is high.

Owner:CHINA JILIANG UNIV

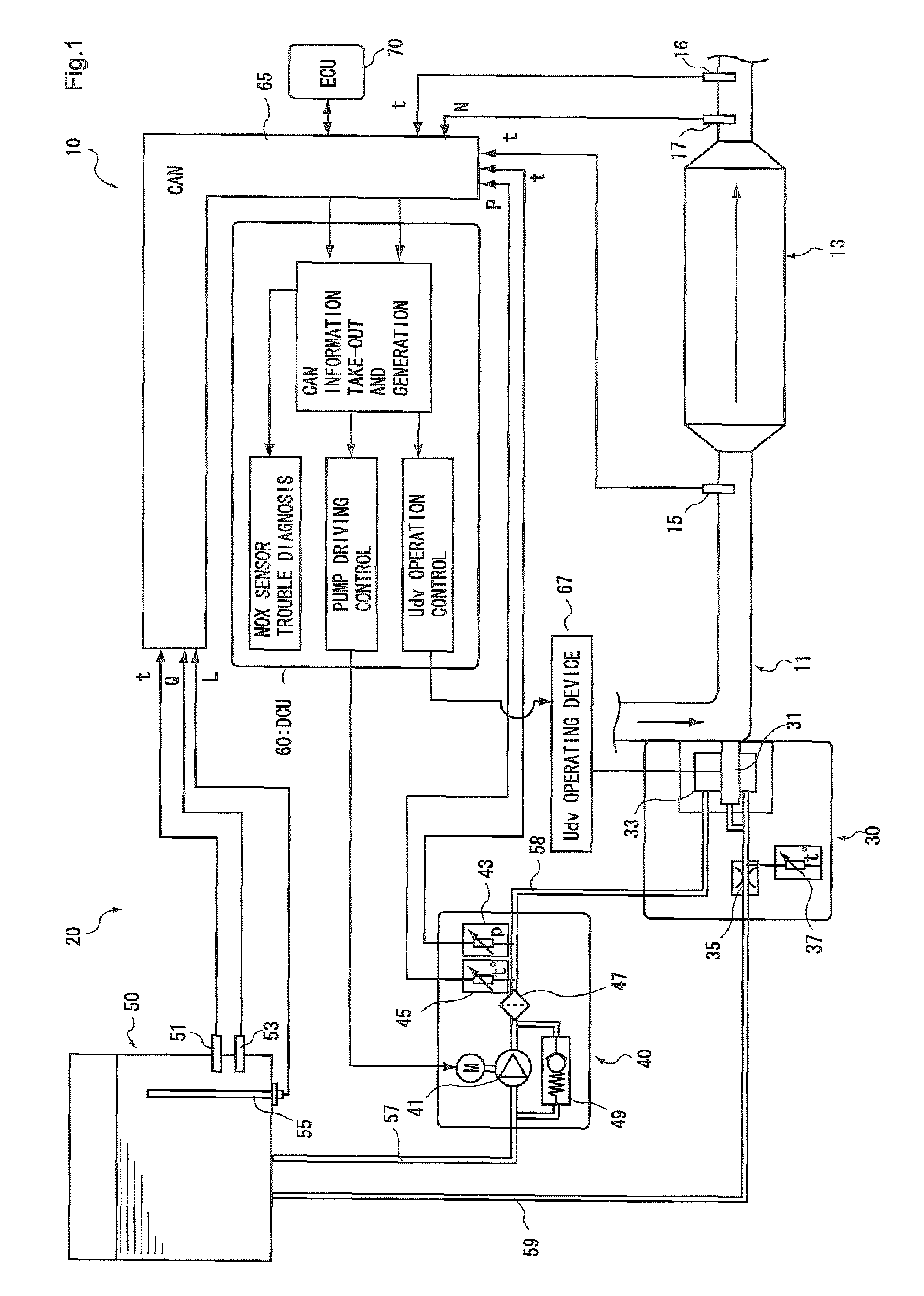

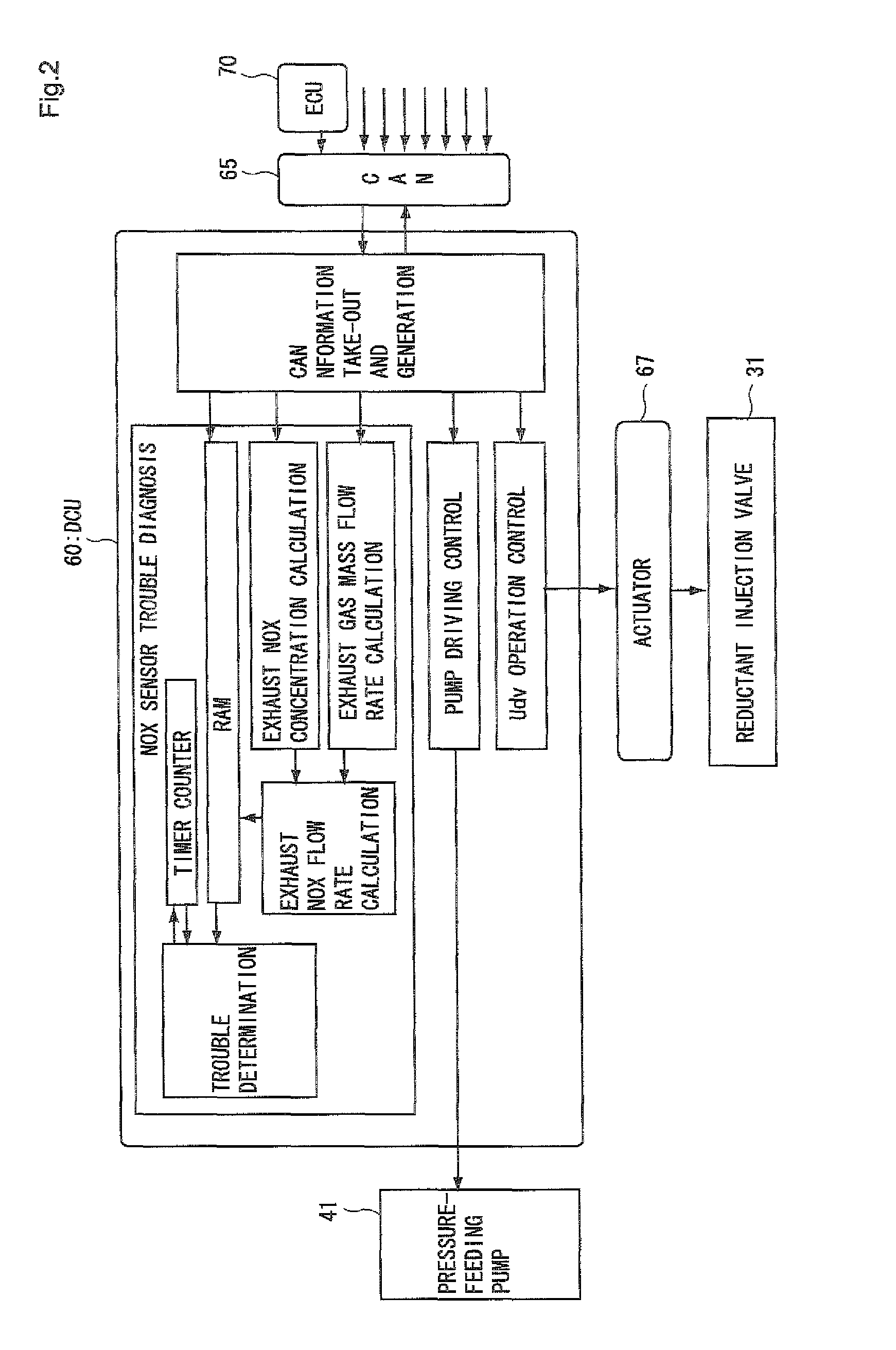

Trouble diagnosis device and trouble diagnosis method for NOx sensor

ActiveUS8359826B2Lower Reliability RequirementsEfficient purificationNitrous oxide captureInternal-combustion engine testingDiagnosis methodsOperation mode

A trouble diagnosis device and method for an NOx sensor for determining abnormality of an NOx sensor used in an exhaust gas purification system. The device can perform a trouble diagnosis without forcedly creating a diagnosis mode during operation of an internal combustion engine and without deterioration of drivability or fuel consumption. The device detects the time-lapse variation of the exhaust NOx flow rate suitable for diagnosis in a normal operation mode and determines whether the NOx sensor responds with following this variation.

Owner:BOSCH CORP

Nitrogen oxygen sensor ceramic chip

InactiveCN109298057AIncrease contact areaFix stability issuesMaterial analysis by electric/magnetic meansOxygen sensorNitrogen

The invention discloses a nitrogen oxide sensor ceramic chip. The nitrogen oxide sensor ceramic chip comprises a six-layer substrate laminated from top to bottom. The NOX catalytic decomposition witha nitrogen oxygen sensor and measurement regions are designed as a three-dimensional porous structure, which greatly increases the contact area between the gas and the electrode. The close combinationof the interface of each functional layer material solves the problem of heat uniformity and stability of the test area, and the measurement of the concentration of NOX gas is more accurate. The structure of the nitrogen oxide sensor ceramic chip improves the heat uniformity and stability of the test area of the chip, and also improves the structural strength of the chip to a certain extent. Moreover, the contamination of the test electrode by the volatilization of the catalytically inactive metal Au during high-temperature sintering can be effectively prevented. The measurement accuracy is higher. The production process is simple. The production is easy. The service life is long.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

Nitric oxide gas sensitive material manufacturing method, sensor, monitoring device and control method

InactiveCN103760199ALow costReduce energy consumptionElectrical controlMachines/enginesNitrogen oxide sensorNitric oxide gas

The invention discloses a nitric oxide gas sensitive material manufacturing method, a sensor, a monitoring device and a control method. The prepared gas sensitive material is composed of a SnO2 nanometer powder body and a WO3 nanometer powder body, the sensor of the prepared nitric oxide based on the gas sensitive material comprises the gas sensitive material which is obtained according to the claim 1, an MEMS (Micro-Electromachanical) control unit, a silicon dioxide insulating layer, an electrode as well as a reference electrode, a heating wire and a thermocouple. Compared with the prior art, the nitric oxide sensor provided by the invention has the beneficial effects that the cost is low, the volume is reduced, and the energy consumption is low.

Owner:NANJING ZHIKUO ELECTRONICS TECH

Model-based diagnostics of NOX sensor malfunction for selective catalyst reduction system

ActiveCN101845982AElectrical controlNon-fuel substance addition to fuelCombustionNitrogen oxide sensor

The invention relates to a model-based diagnostics of NOX sensor malfunction for selective catalyst reduction system. Methods and systems for detecting faults with nitrogen oxides sensors used to detect the presence of nitrogen oxides in an exhaust effluent gas stream emitted from a combustion engine during its operation include providing a virtual nitrogen oxides sensor measurement compared with actual nitrogen oxides content measured by nitrogen oxides sensors.

Owner:GM GLOBAL TECH OPERATIONS LLC

Jet control system utilizing air-assisted power to atomize urea reductant

InactiveCN101793184AEliminate NO

<sub>X</sub>Improve reliabilityExhaust apparatusSilencing apparatusNitrogen oxide sensorEngineering

The invention relates to a jet control system utilizing air-assisted power to atomize urea reductant, which is characterized in that the air inlet end of a compressed air main pipe is provided with a pressure regulating valve, the air outlet end thereof is respectively communicated with a compressed air branch pipe for a blowing nozzle and a urea reductant storage tank compressed air branch pipe; the urea reductant storage tank compressed air branch pipe is connected on a urea reductant container; the compressed air branch pipe for the blowing nozzle is communicated with a single-cavity urea reductant nozzle, one end of a urea reductant delivery pipe is arranged in the urea reductant container, the other end thereof is communicated with the urea reductant nozzle, and a temperature sensor arranged on the exhaust pipe of an engine and a nitric oxide sensor are electrically connected with a control unit. The temperature measured by a cheap industrial thermocouple with very high reliability is taken as a main control parameter to control urea flow, thus urea reductant can be fully atomized in a two-cavity hybrid unit, while the cost is equivalent to 1 / 2-1 / 3 of an imported system. The system has high reliability, and is easy to realize industrialized application by depending on resources in China.

Owner:FAW GROUP

Nitrogen oxide sensor-used platinum-rhodium electrode paste and preparation method thereof

ActiveCN102798652APrinting changeChange appearanceMetal/metal-oxides/metal-hydroxide catalystsMaterial electrochemical variablesPlatinumNitrogen oxide sensor

The present invention discloses nitrogen oxide sensor-used platinum-rhodium electrode paste and a preparation method thereof. The platinum-rhodium electrode paste is prepared from the following raw materials by mass percentage: 1-10 wt% of an inorganic binder,10-20 wt% of an organic binder, 10-50 wt% of ultrafine rhodium powder, 30-60 wt% of ultrafine platinum powder, and 5-10 wt% of zirconium dioxide. The preparation method comprises: (1) preparing the inorganic binder, (2) preparing the organic binder, (3) weighing the organic binder, the inorganic binder, the ultrafine rhodium powder, the ultrafine platinum powder and zirconium dioxide by taking the preparation of 100 g of platinum-rhodium electrode paste as a reference, adding to the container in accordance with the principle of from less to more, stirring sufficiently for uniform dispersion on adding each material, then grinding by a three-roll mill, removing agglomerated particles, and then stirring for dispersion to obtain the uniformly dispersed paste. The paste is good in printing, drying, and sintering performances and good in adhesion after sintering at high temperature.

Owner:WUXI LONGSHENG TECH

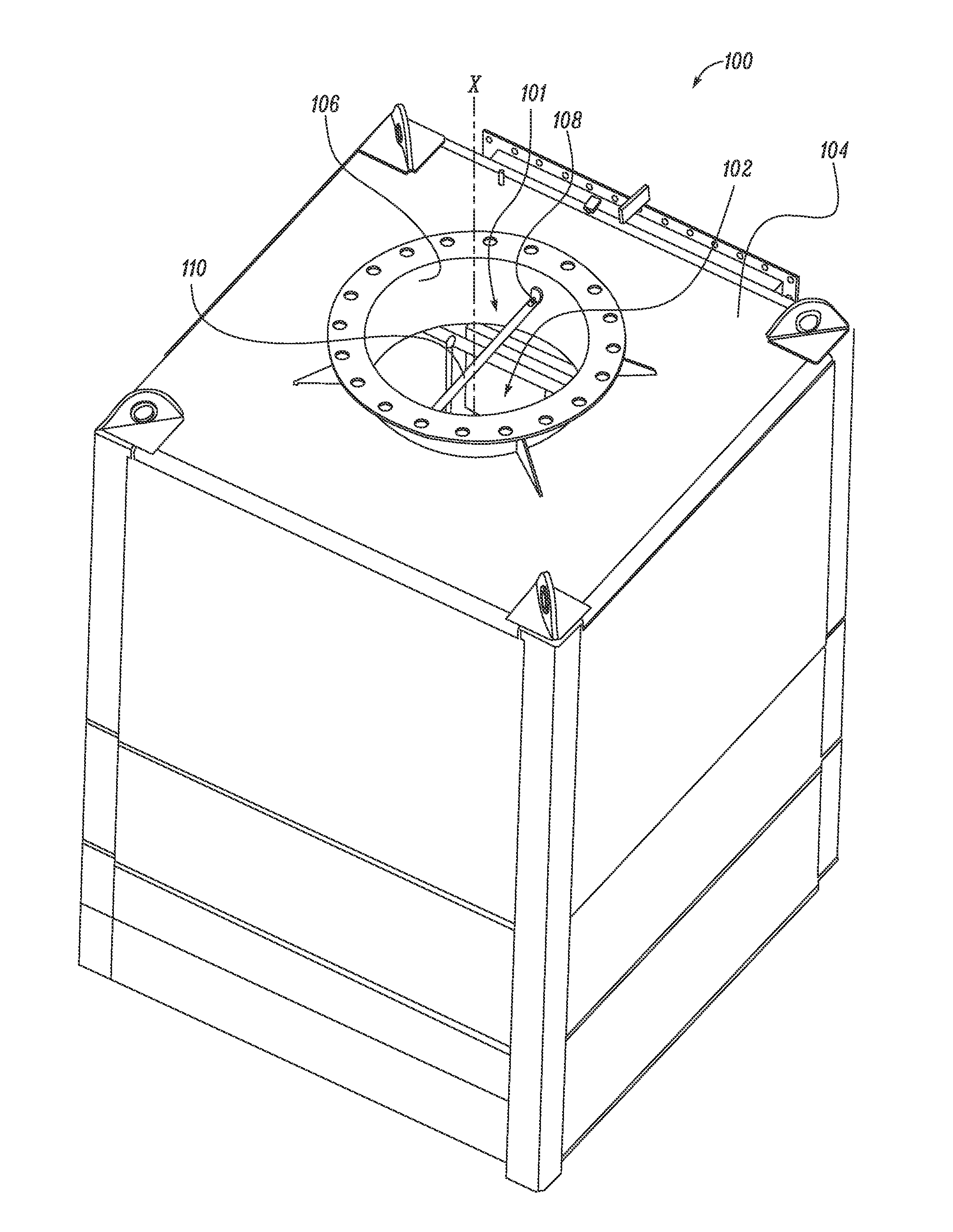

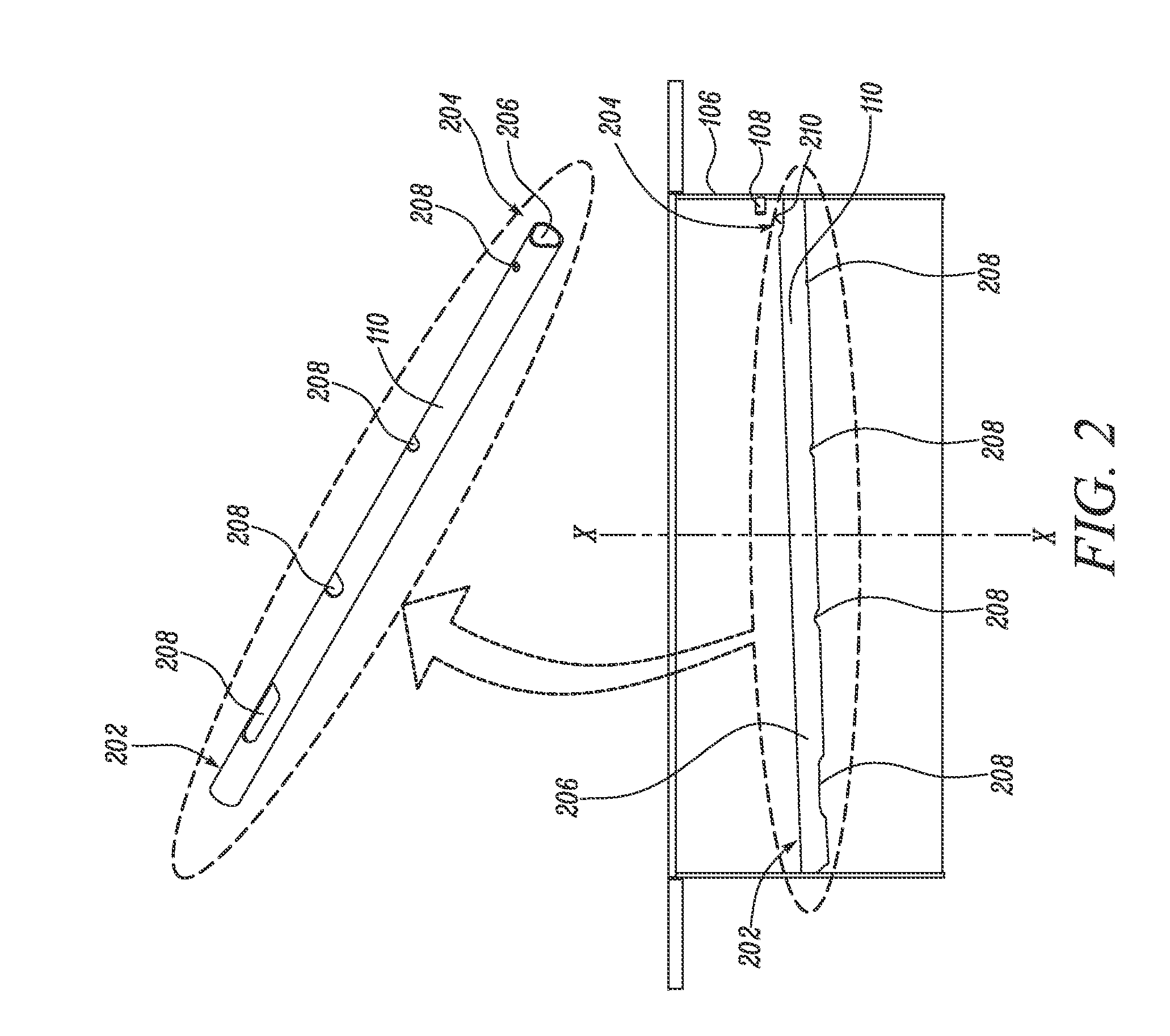

System and method for sampling of fluid

InactiveUS20150160102A1Internal combustion piston enginesExhaust apparatusCatheterNitrogen oxide sensor

A system including a sampling flute is provided. The sampling flute defines a conduit therein. The sampling flute includes a plurality of holes configured for allowing passage of an exhaust gas flow therethrough. The system also includes a hood provided on the sampling flute. The hood is configured to enclose a nitrogen oxide sensor therein. The hood includes an inlet in fluid communication with the sampling flute. The hood also includes an outlet positioned opposed to the inlet. The hood is configured to cause the exhaust gas flow to impact a side of the nitrogen oxide sensor.

Owner:CATERPILLAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com