Model-based diagnostics of NOX sensor malfunction for selective catalyst reduction system

A sensor and detection sensor technology, which is applied to the diagnostic device of the exhaust gas treatment device, the charging system, the machine/engine, etc., and can solve the problems of sensor operation efficiency degradation, failure, and performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

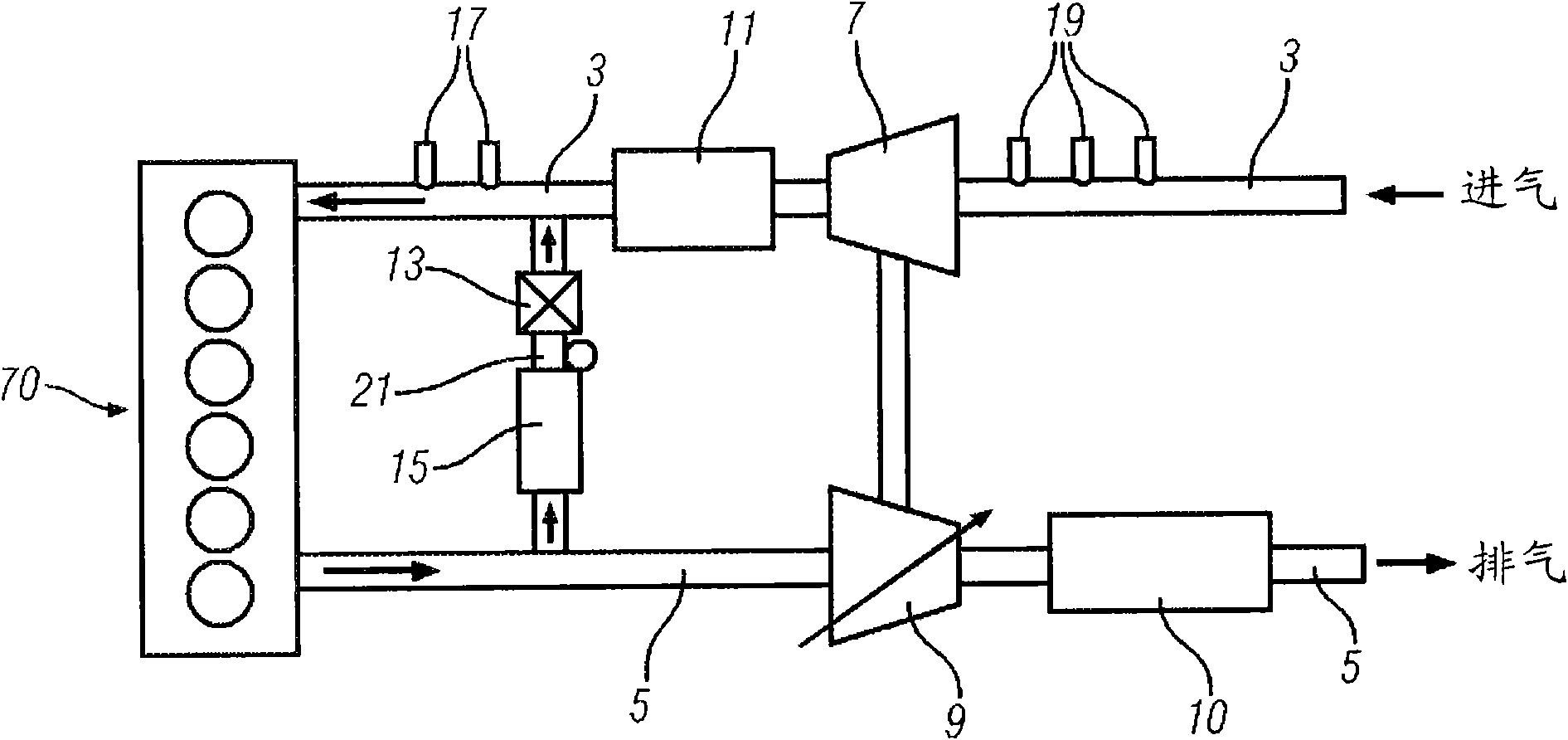

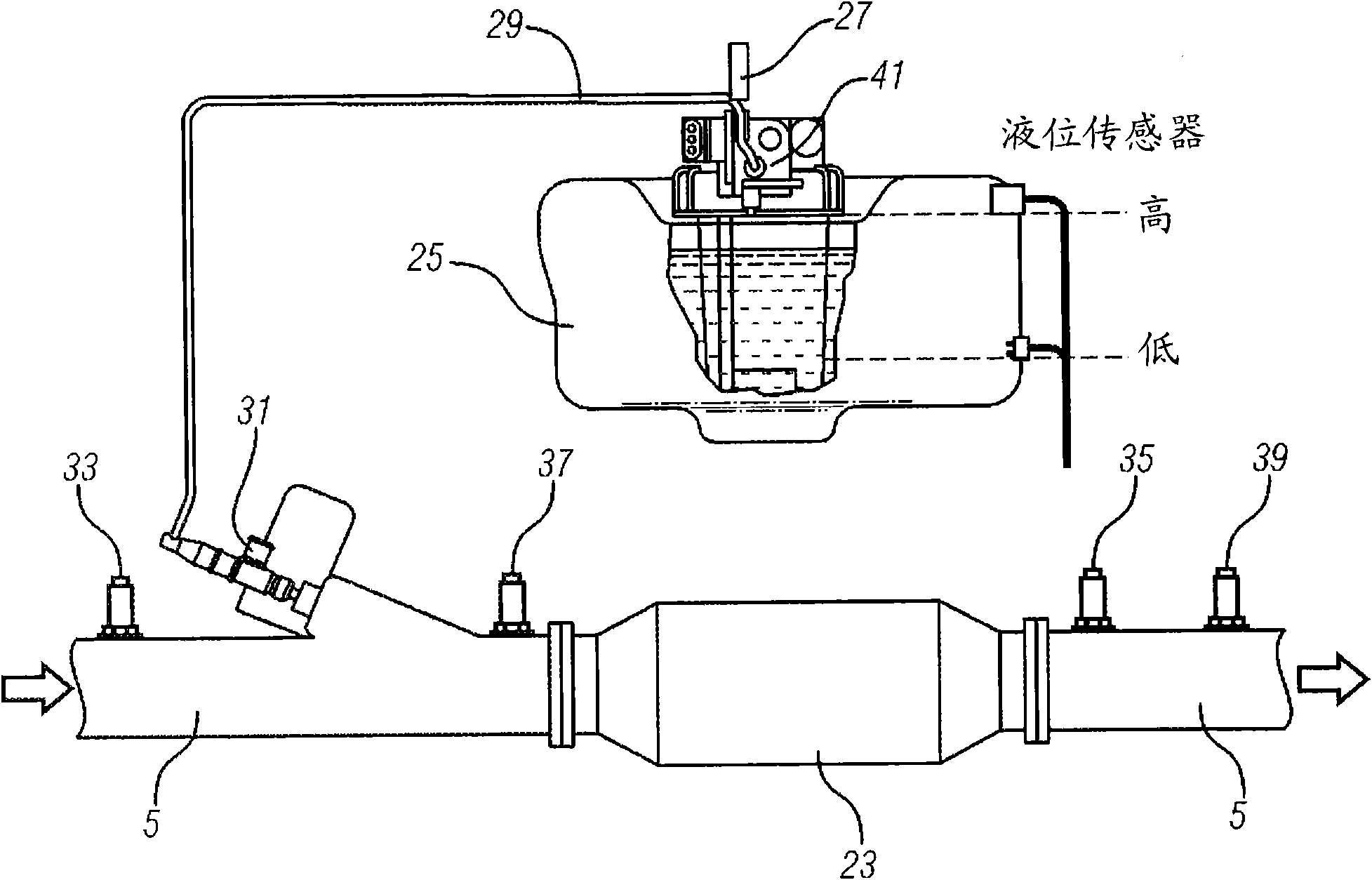

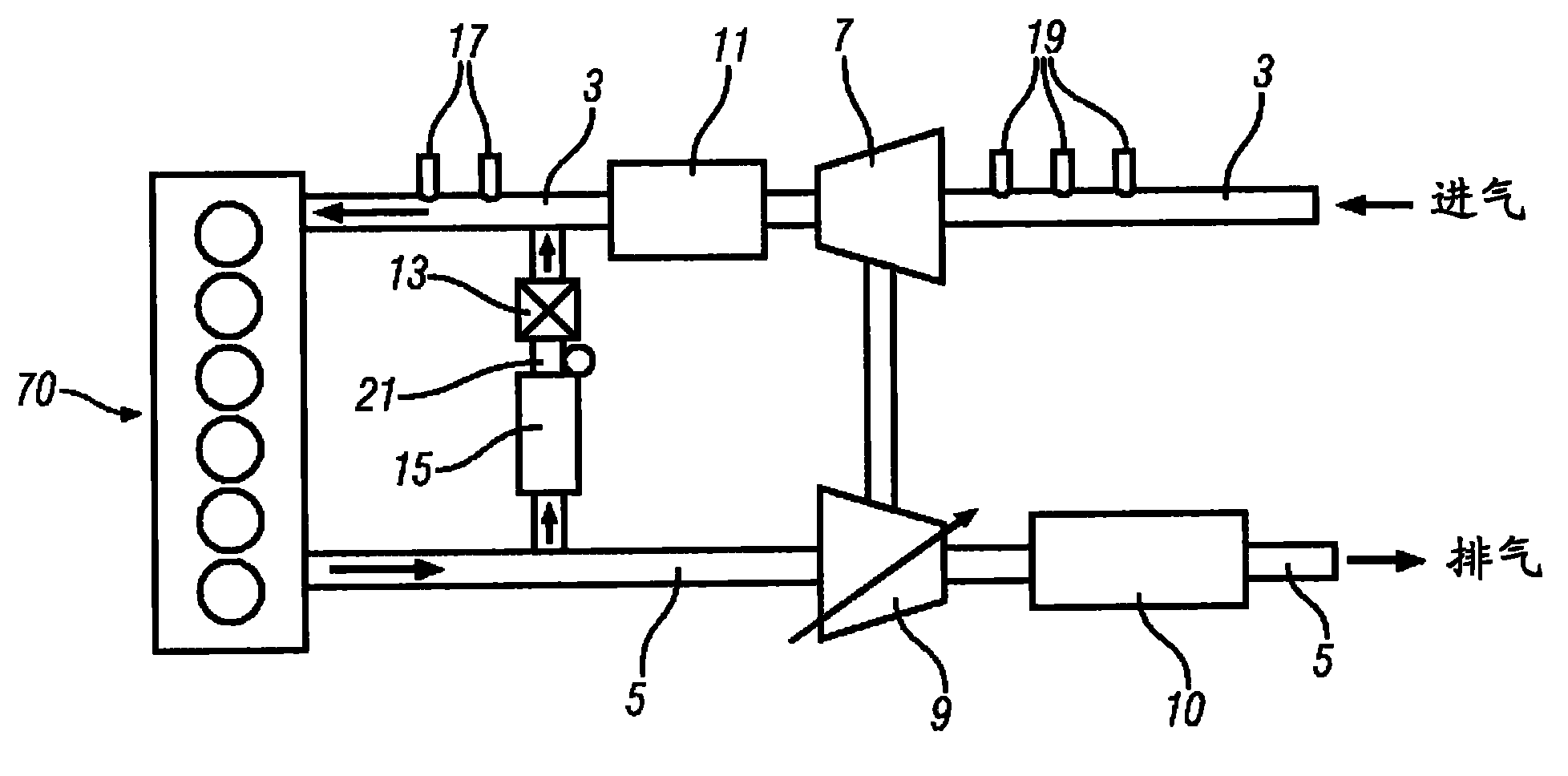

[0062] Referring now to the drawings, the drawings are only provided for illustrating exemplary embodiments and are not used to limit these embodiments. figure 1 A schematic diagram of a combustion engine 70 according to an embodiment of the present invention is shown. The combustion engine includes a piston, a cylinder, and accessories related to its operation. The combustion engine may be a spark-ignition engine or a compression-ignition engine, and in a preferred embodiment is piston-driven. The intake pipe 3 delivers ambient air on the way to one or more engine cylinders. The exhaust pipe 5 conveys exhaust gas discharged by the combustion engine 70 in its normal operation. In some embodiments, a compressor 7 is also provided to compress the intake air, thereby increasing the density of the intake air to provide a higher oxygen concentration in the air supplied to the engine. The compressor 7 may be shaft driven by a turbine 9 provided in the exhaust pipe, as is known in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com