Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1919results about How to "Increased operating life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

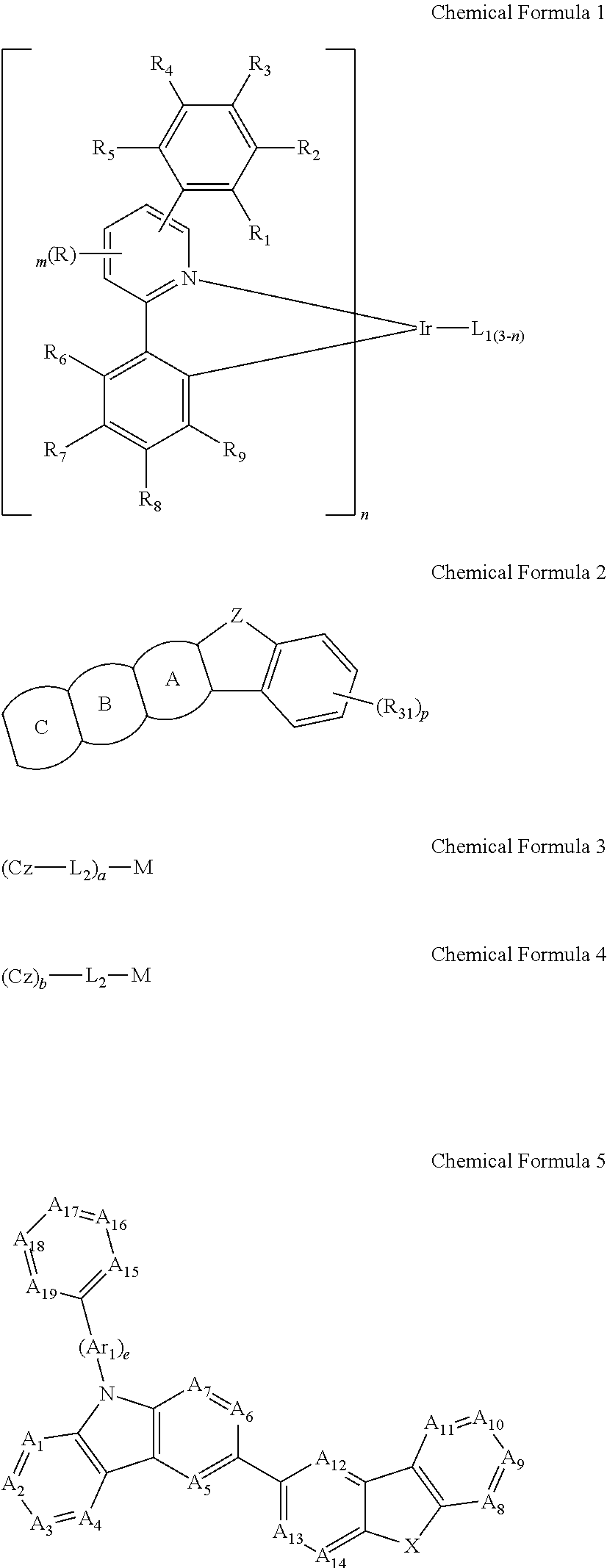

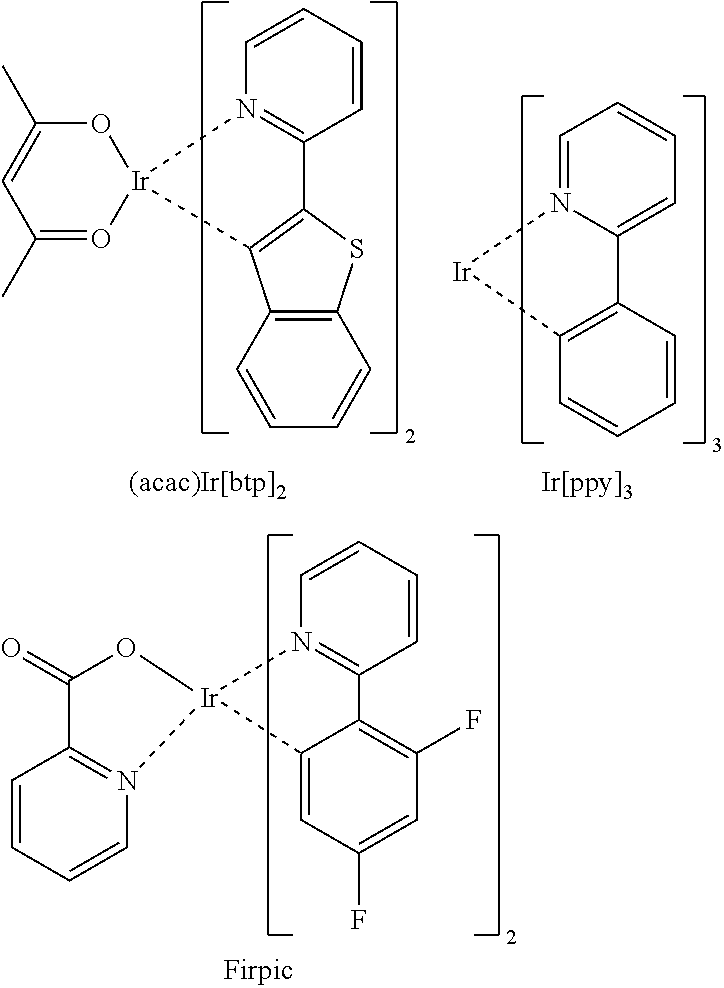

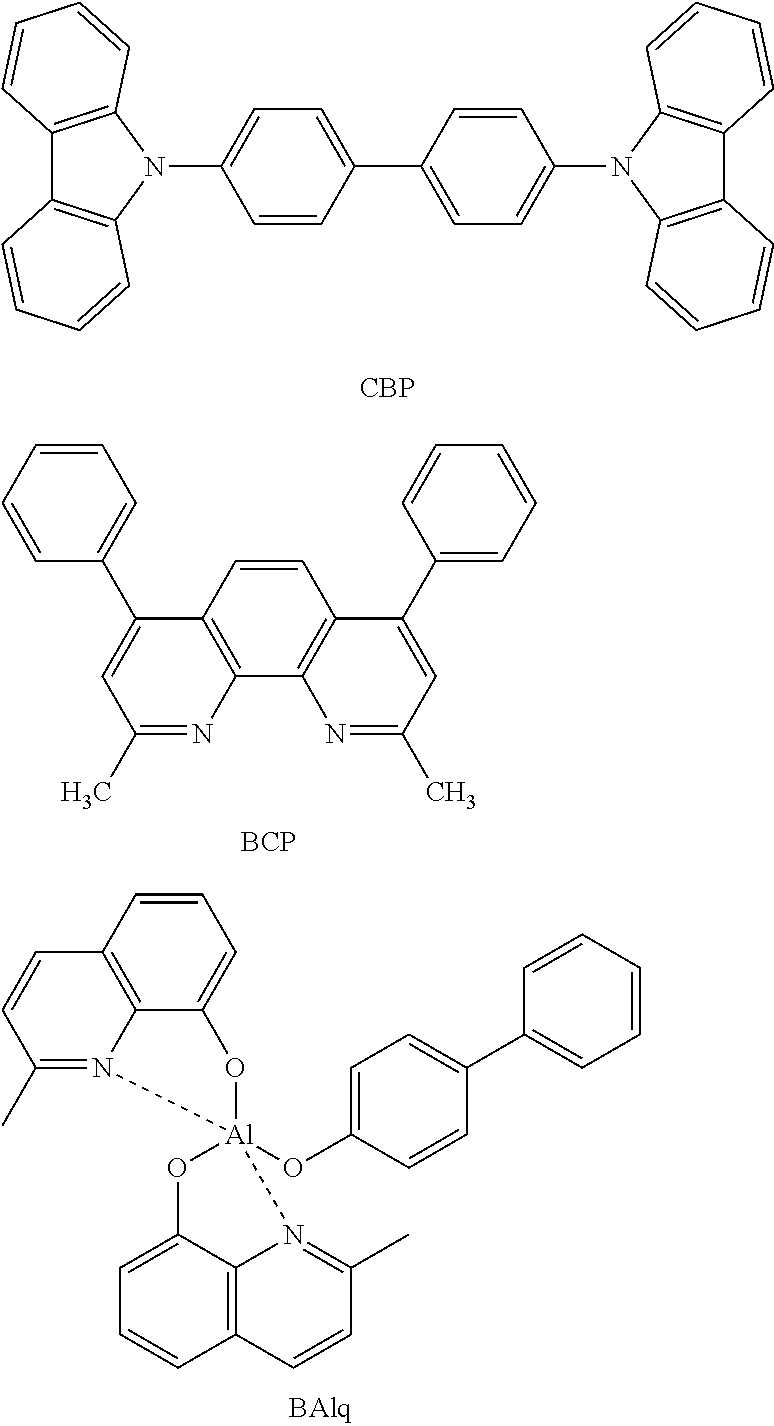

Electroluminescent device using electroluminescent compound as luminescent material

InactiveUS20140054564A1Improve luminous efficiencyIncreased operating lifeIndium organic compoundsElectroluminescent light sourcesEnergy transferOrganic electroluminescence

Provided is an organic electroluminescent device that exhibits an efficient host-dopant energy transfer mechanism, and thus, expresses a certain high-efficiency electroluminescent performance, based on improved electron density distribution. The organic electroluminescent device also overcomes low initial efficiency and short operation life property, and secures high-performance electroluminescent performance with high efficiency and long life property for each color.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

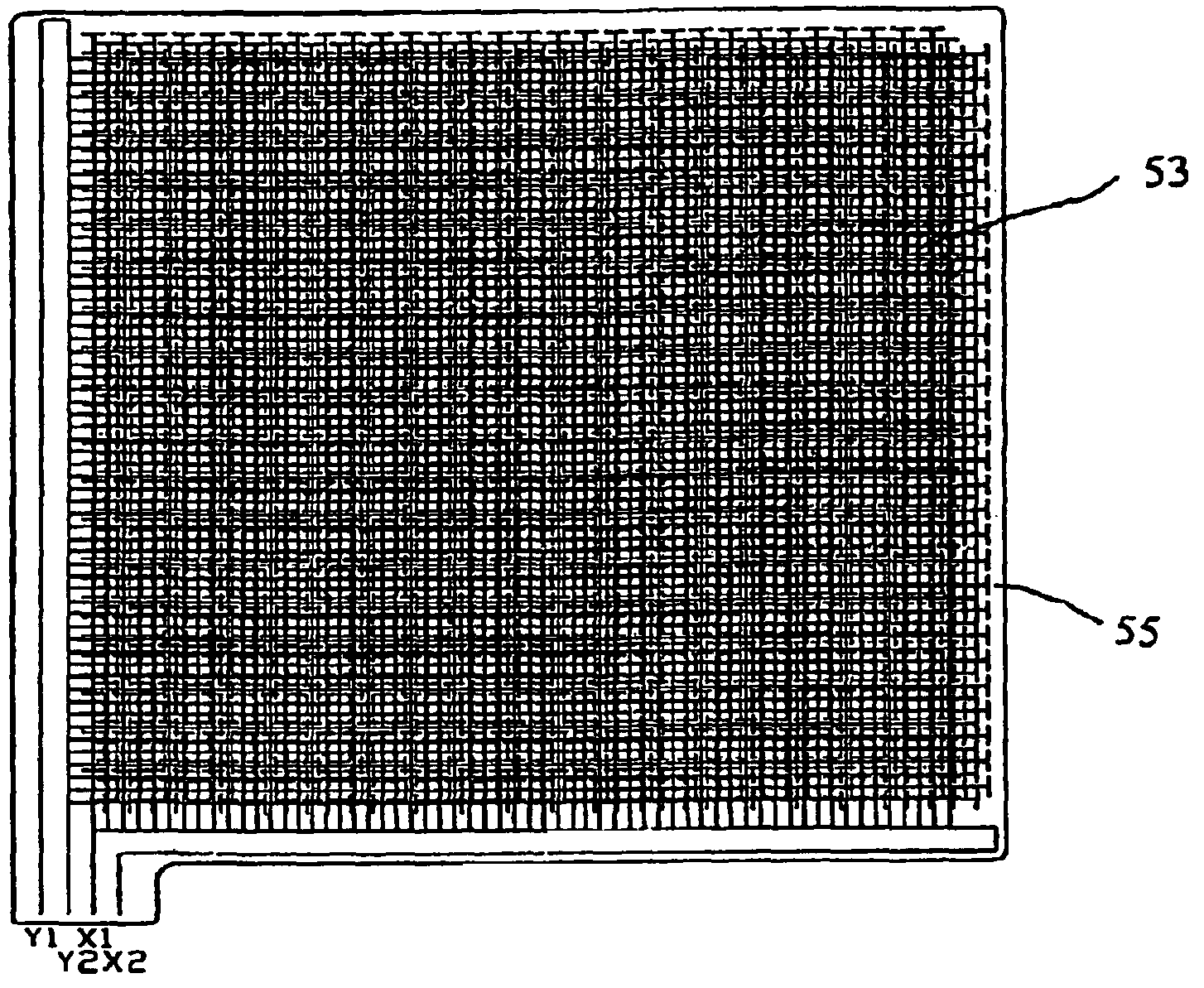

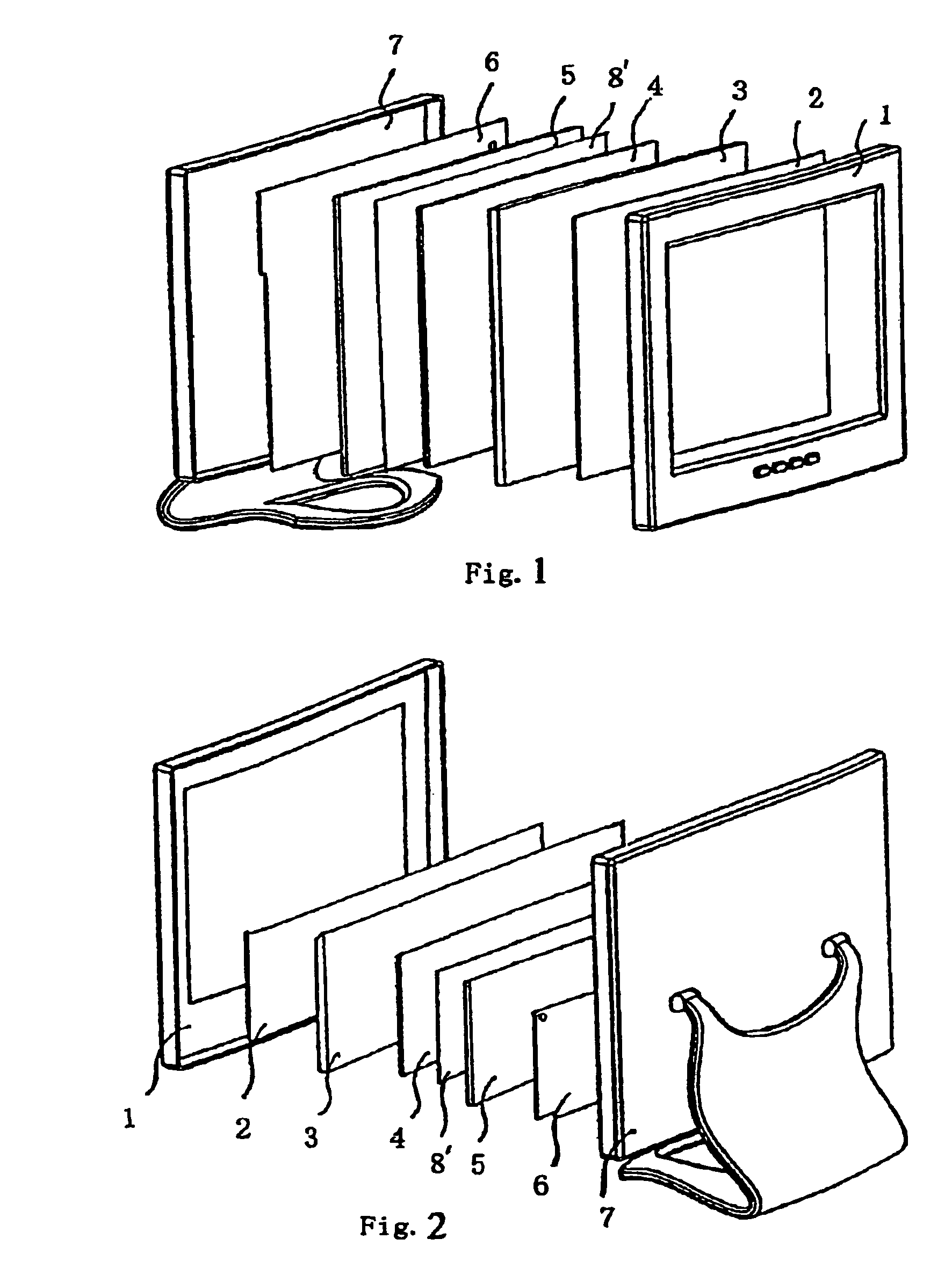

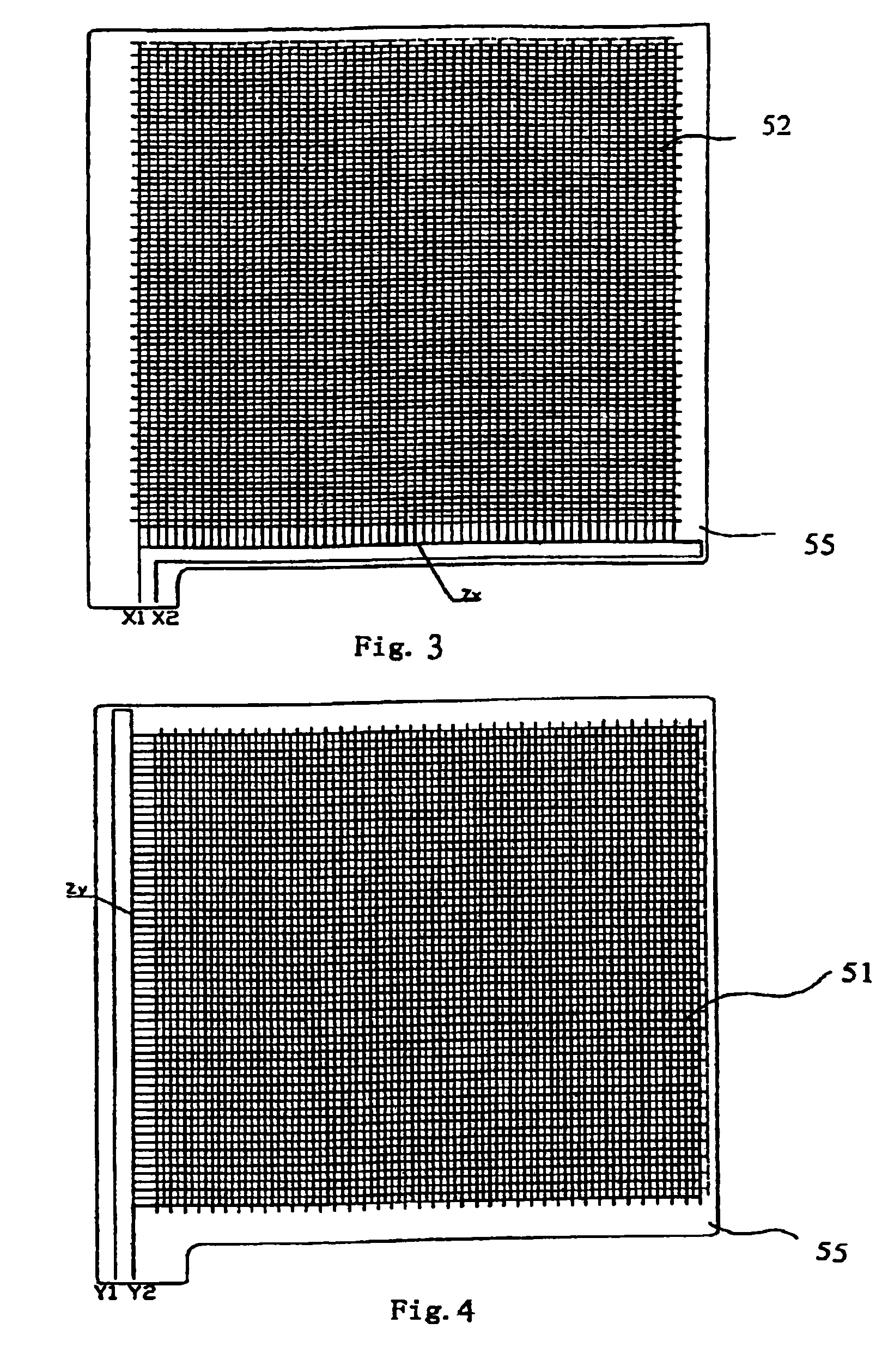

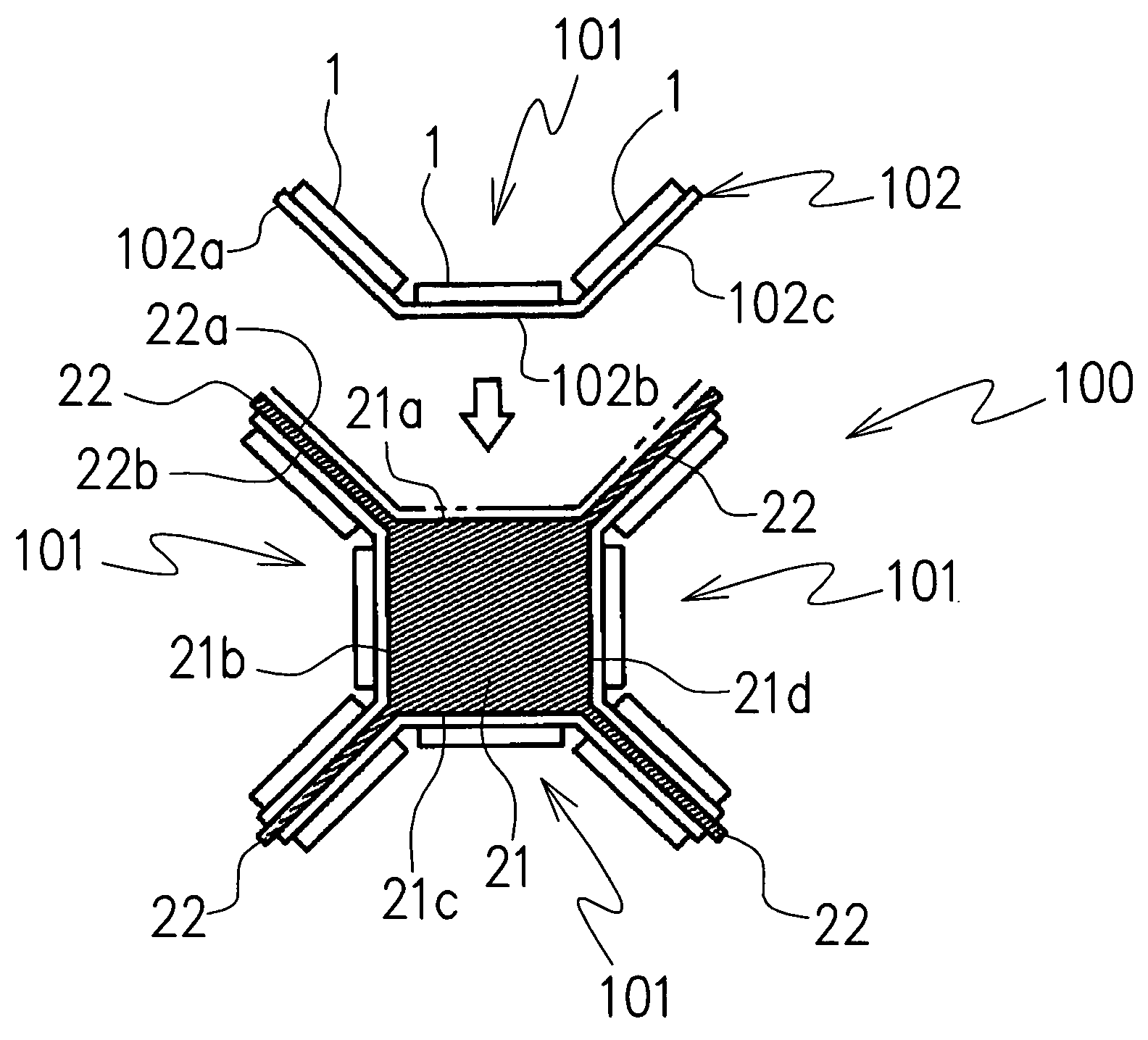

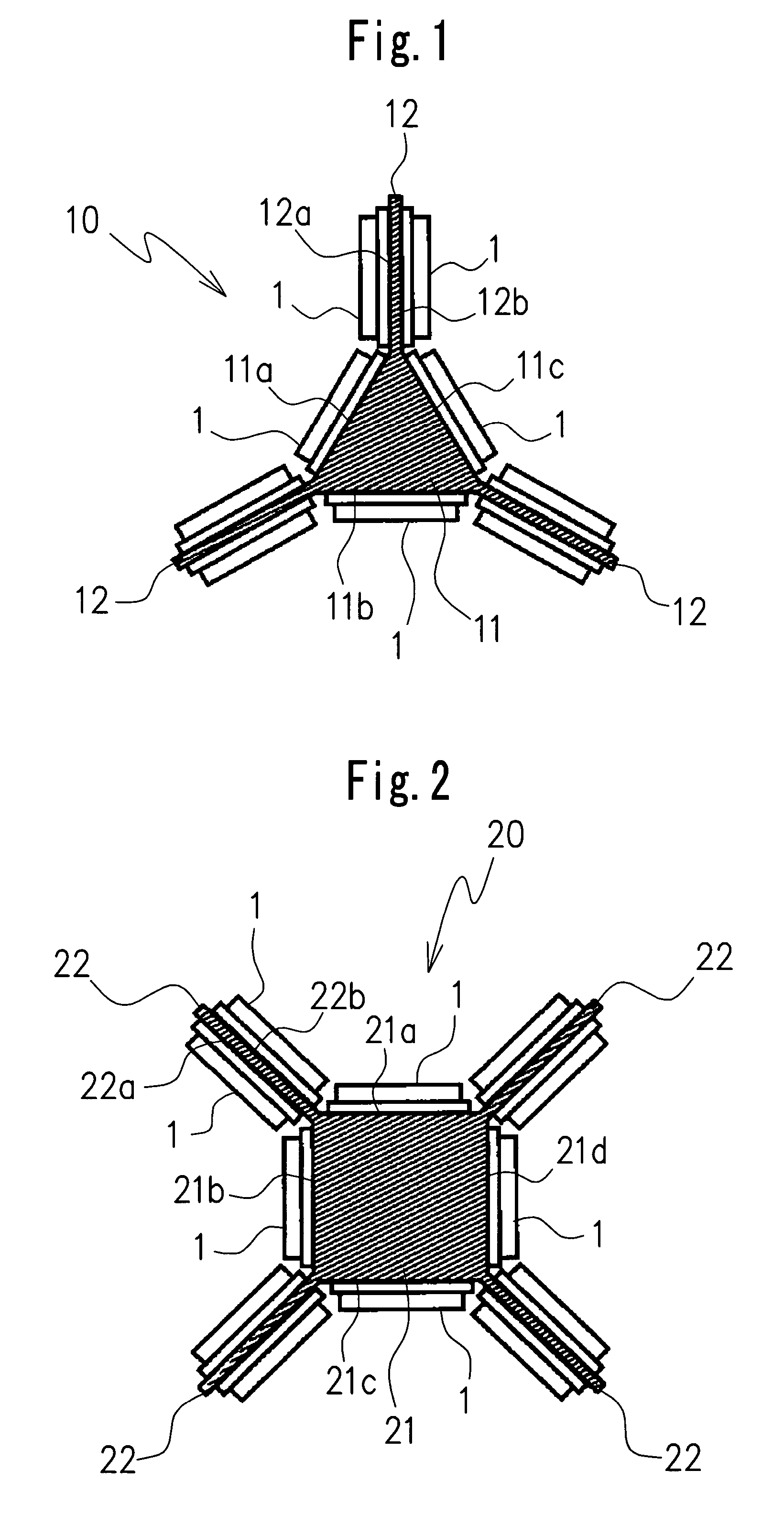

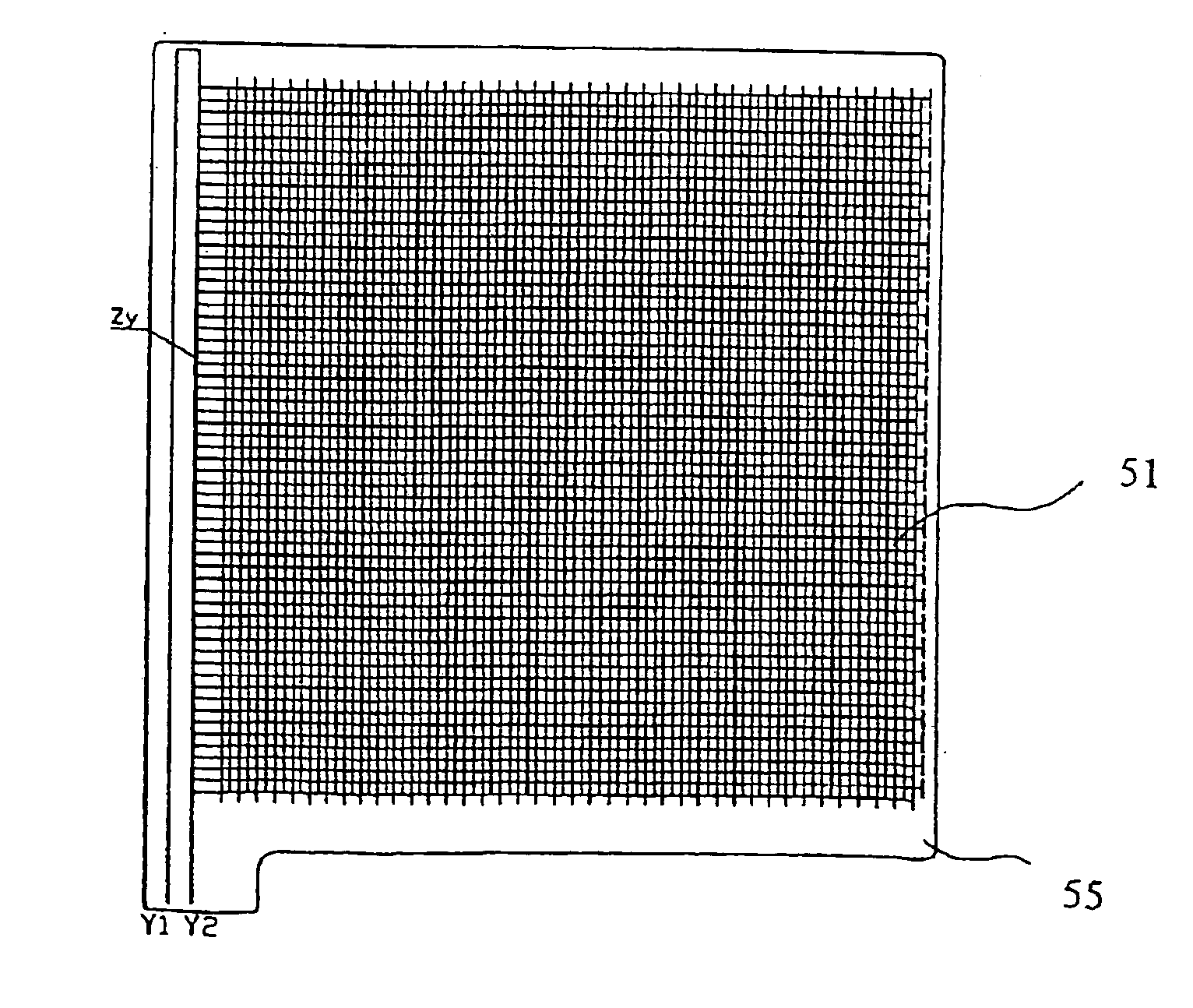

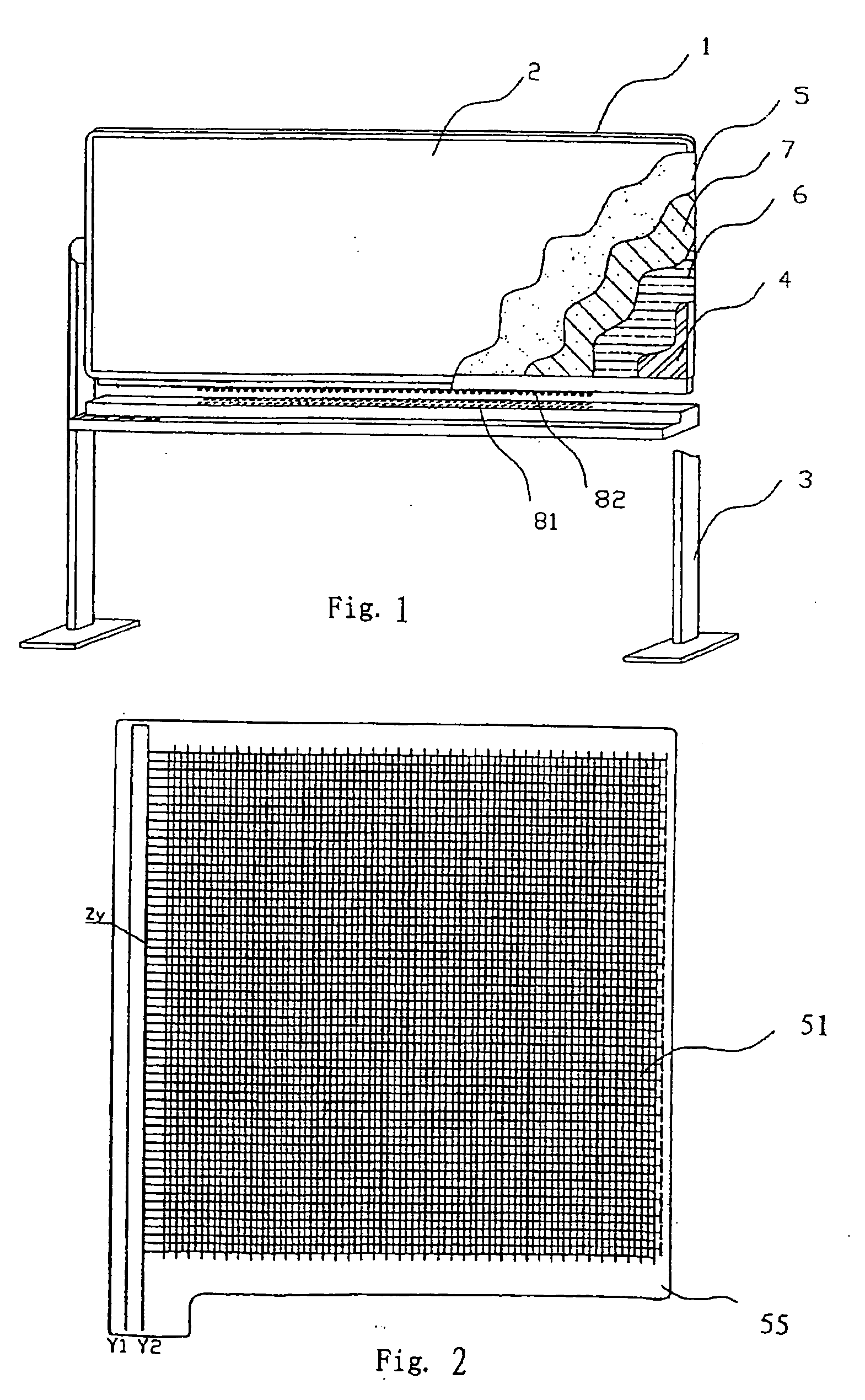

Touch control display screen with a built-in electromagnet induction layer of septum array grids

ActiveUS7796122B2The production process is simpleImprove accuracyTransmission systemsCathode-ray tube indicatorsHandwritingTectorial membrane

A touch control display screen with built-in membrane antenna array lattice electromagnetic induction layer, including at least a display screen and a shell; wherein an induction layer is provided in the rear of the display screen, the output of the induction layer is connected to an induction control circuit, a display screen control circuit is also provided in the shell; the induction layer is the antenna array printed on the insulation membrane and arranged along the X, Y axes, therein the area enclosed by each lattice unit constitutes one induction cell. Because the electromagnetic induction layer is provided in the rear of the display screen and flexible membrane-type, printed electromagnetic induction array antenna is used as the identifying induction component according to the present invention, the manufacture is easy, the cost is low, and the advantage in cost-cut is prominent in comparison with the prior art when the area of the display screen is larger. The accuracy of identification is high, and the mouse information or handwriting information can be input exactly by means of brush strokes of finger strokes; as a touch screen, the display screen is covered by a protecting film to avoid the physical damage, so it has long operating life.

Owner:MORGAN TOUCH TECH (HK) CO LTD +1

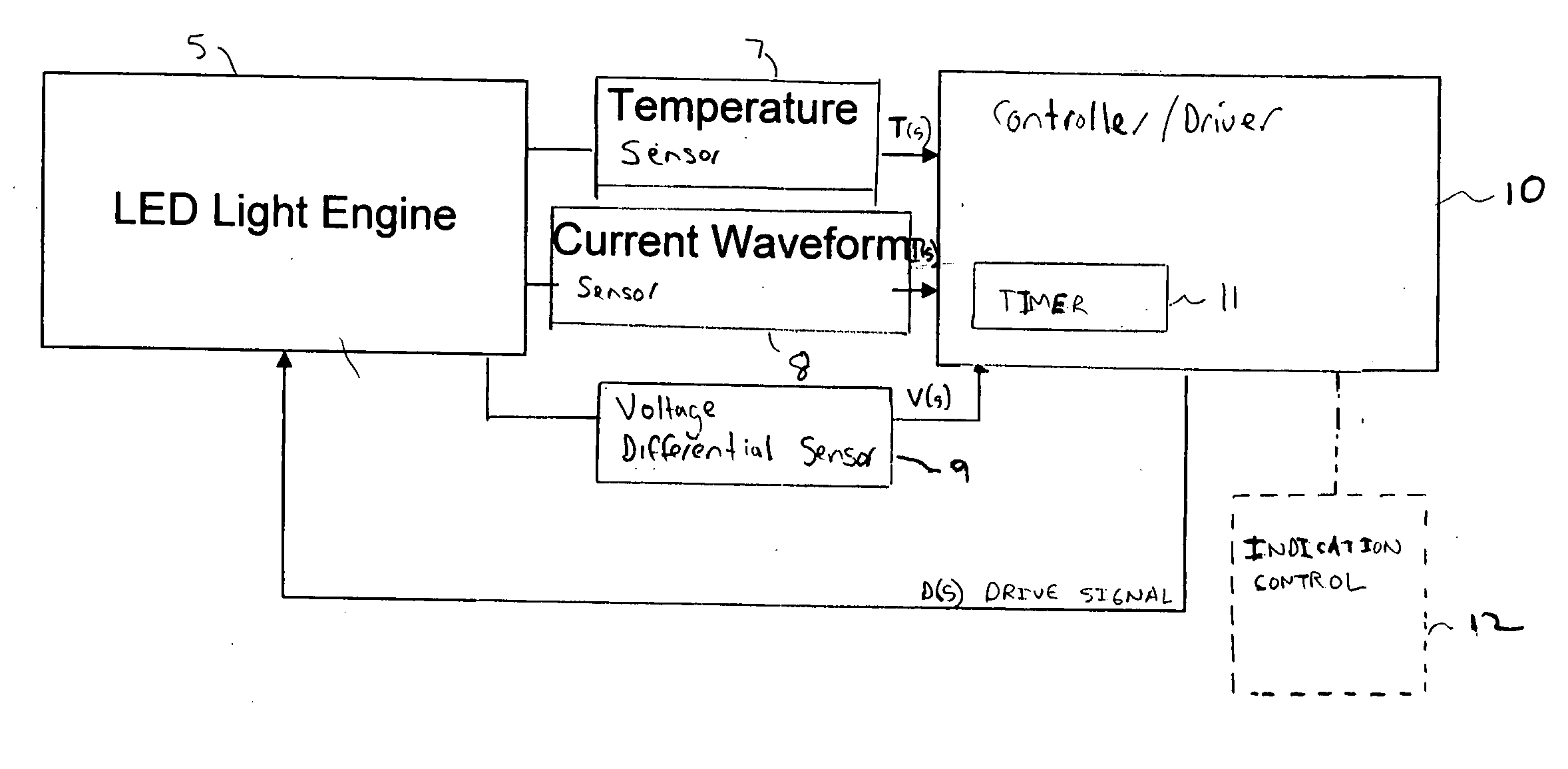

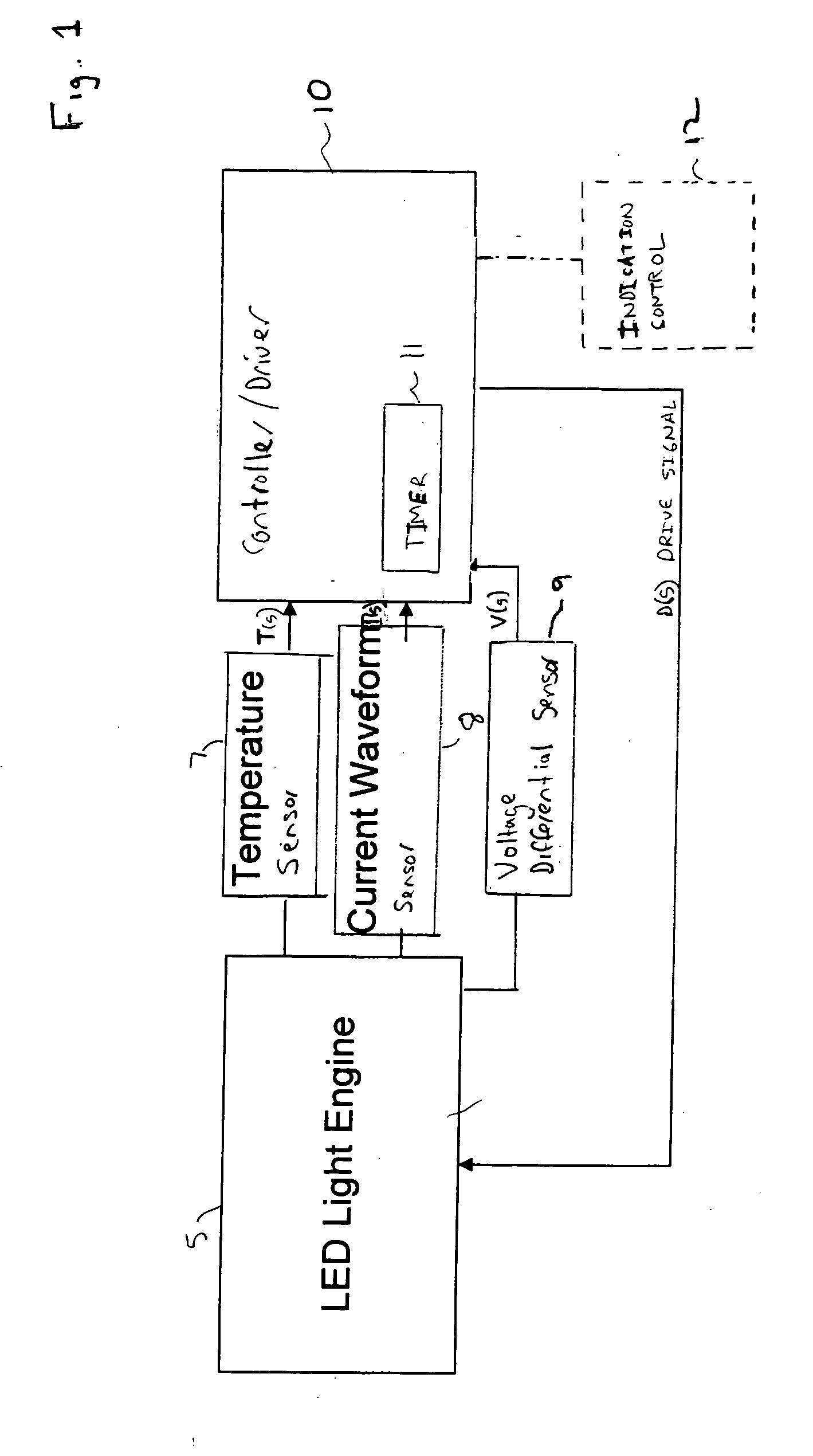

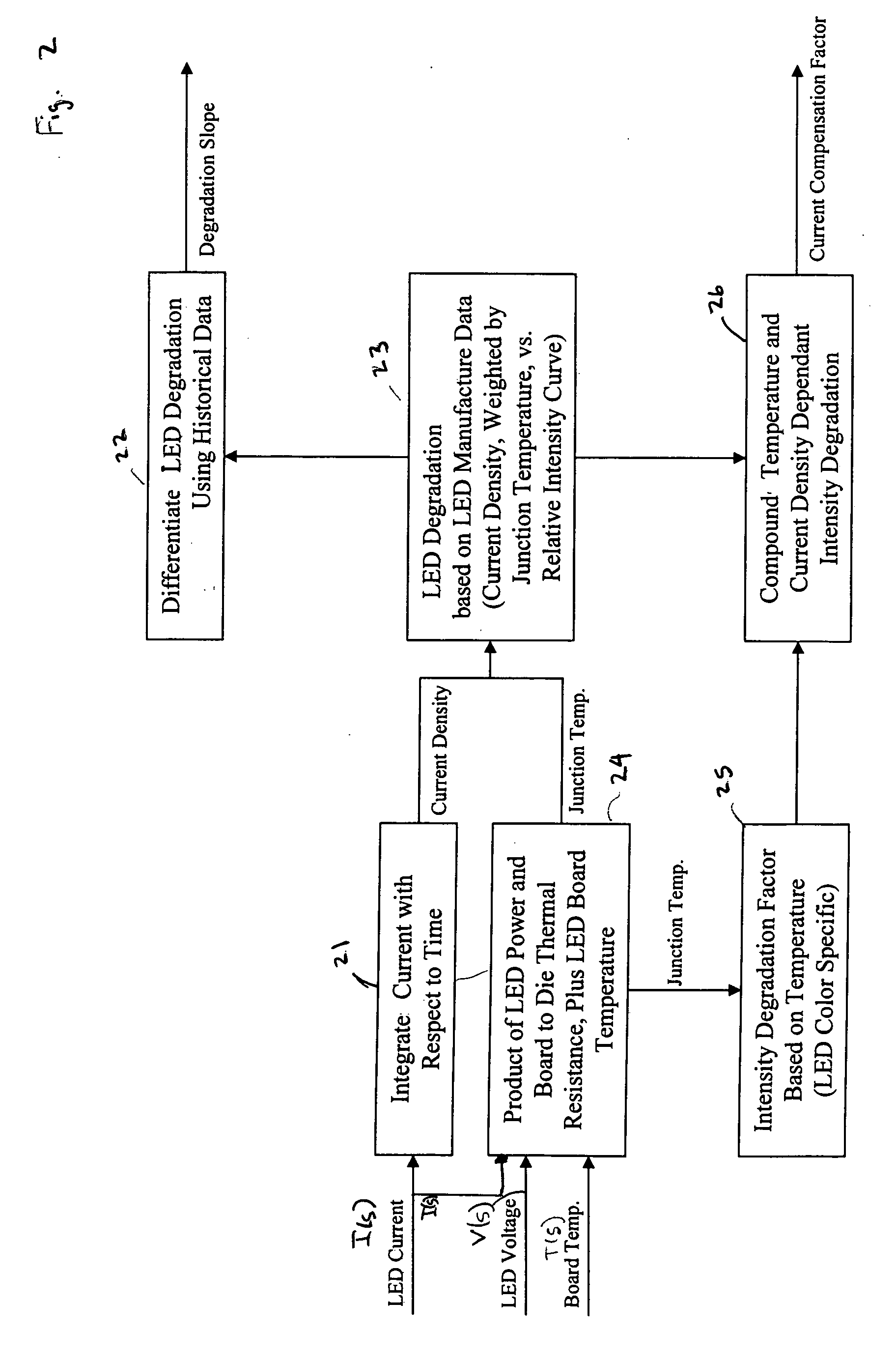

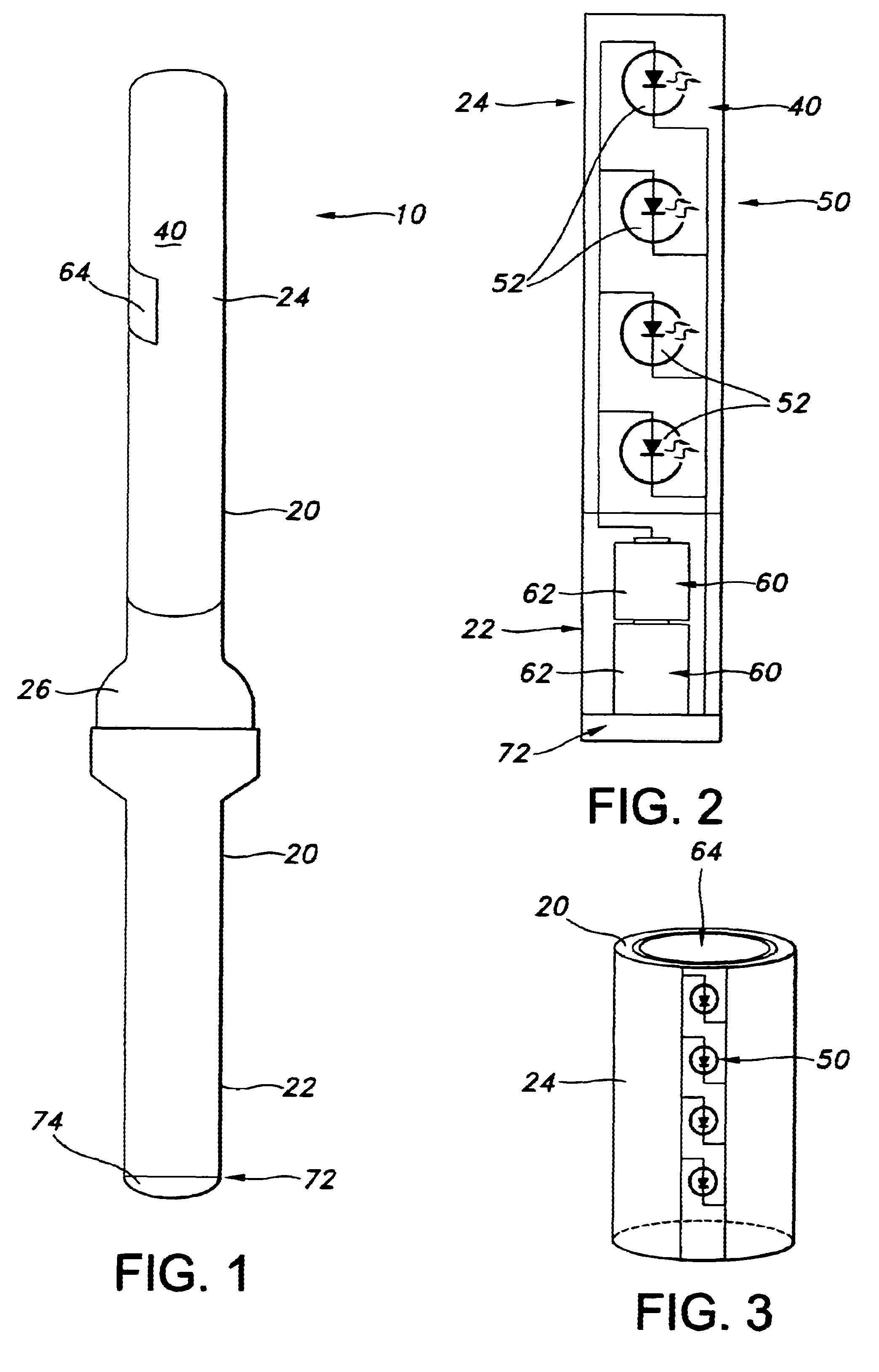

Intelligent drive circuit for a light emitting diode (LED) light engine

ActiveUS20060028155A1Increased operating lifeMore energy efficientElectroluminescent light sourcesElectric light circuit arrangementDriving currentDriver circuit

A controller for controlling a light emitting diode (LED) light engine. The controller includes a temperature sensor configured to sensor temperature at the LED light engine. A current sensor senses a drive current of the LED light engine. A voltage differential sensor senses a voltage differential across LEDs of the LED light engine. A timer monitors a time of operation of the LED light engine. Further, a control device controls the drive current to the LED light engine based on the sensed temperature, the sensed drive current, the sensed voltage differential, and the monitored time of operation. Further, the control device outputs an indication of intensity degradation of an LED, and if the intensity degradation exceeds a predetermined threshold the control can output an indication of such to a user, so that the user can be apprised that the LED needs to be changed.

Owner:DIALIGHT CORP

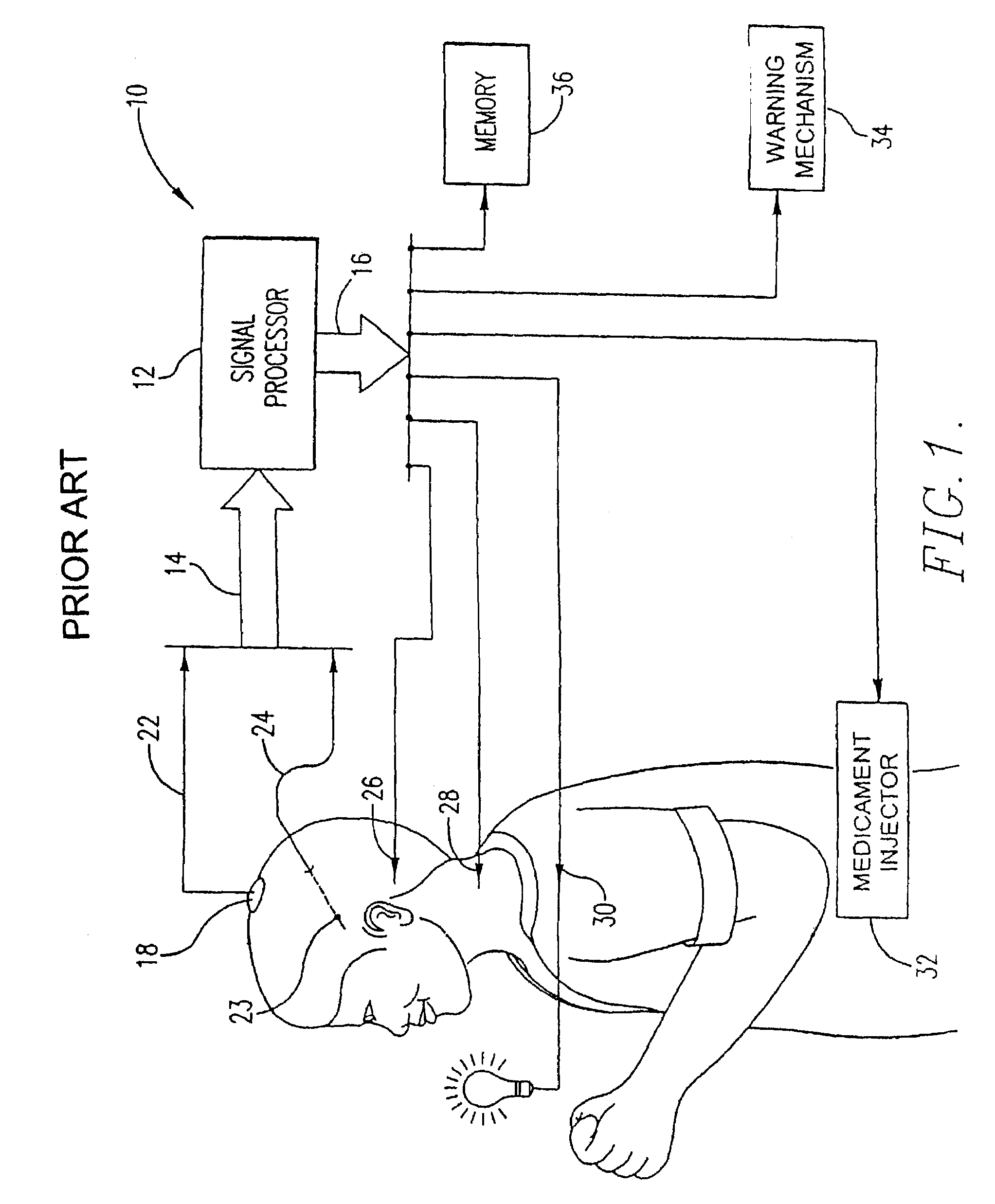

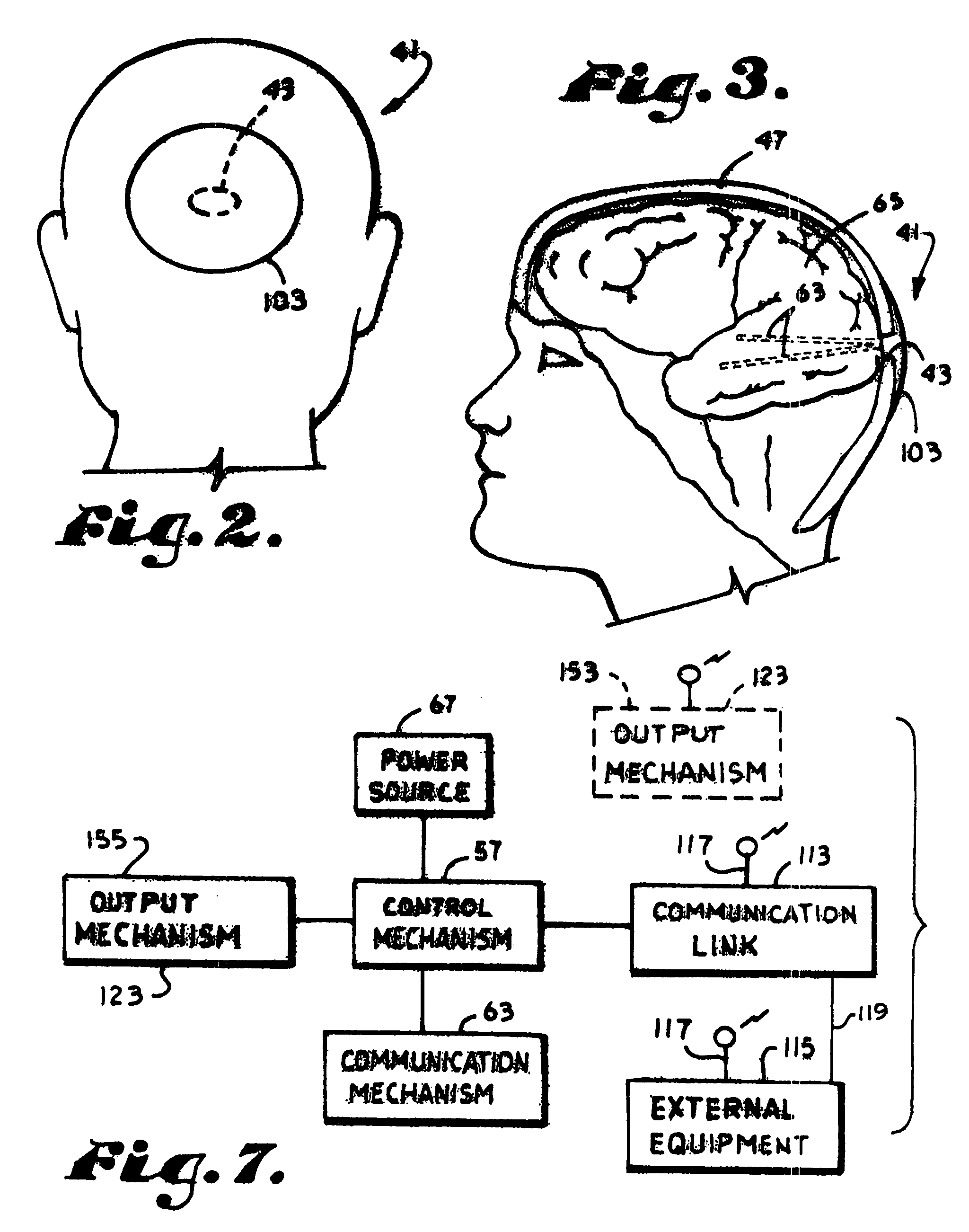

Bi-directional cerebral interface system

InactiveUS7177678B1Good conditionCost-effectiveElectroencephalographyElectrocardiographyTelecommunications linkEngineering

A cerebral interface system including a housing mechanism spaced at least partially in a cavity formed in the subject's skull; an attaching mechanism; a fluid-tight sealing mechanism; a control mechanism; a communication mechanism with one or more sensors embedded in the subject's brain connecting the control mechanism to the subject's brain; a power source; an inner wall substantially aligned with an inner surface of the subject's skull; an outer wall which may include an auxiliary portion extending tangentially outwardly from the cavity formed in the subject's skull; a communication link connecting the control mechanism to external apparatus for transmitting or receiving information related to detecting, predicting, controlling, or aborting abnormal brain activity of the subject; and an output mechanism which is activatable by the control mechanism.

Owner:OSORIO IVAN +1

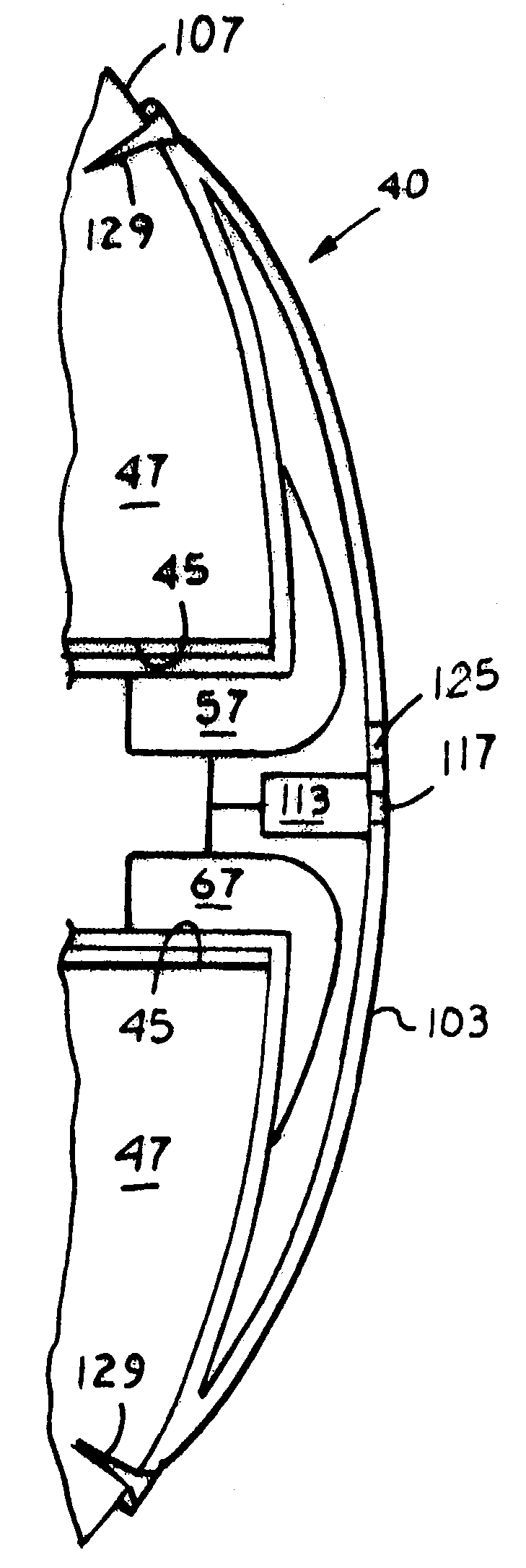

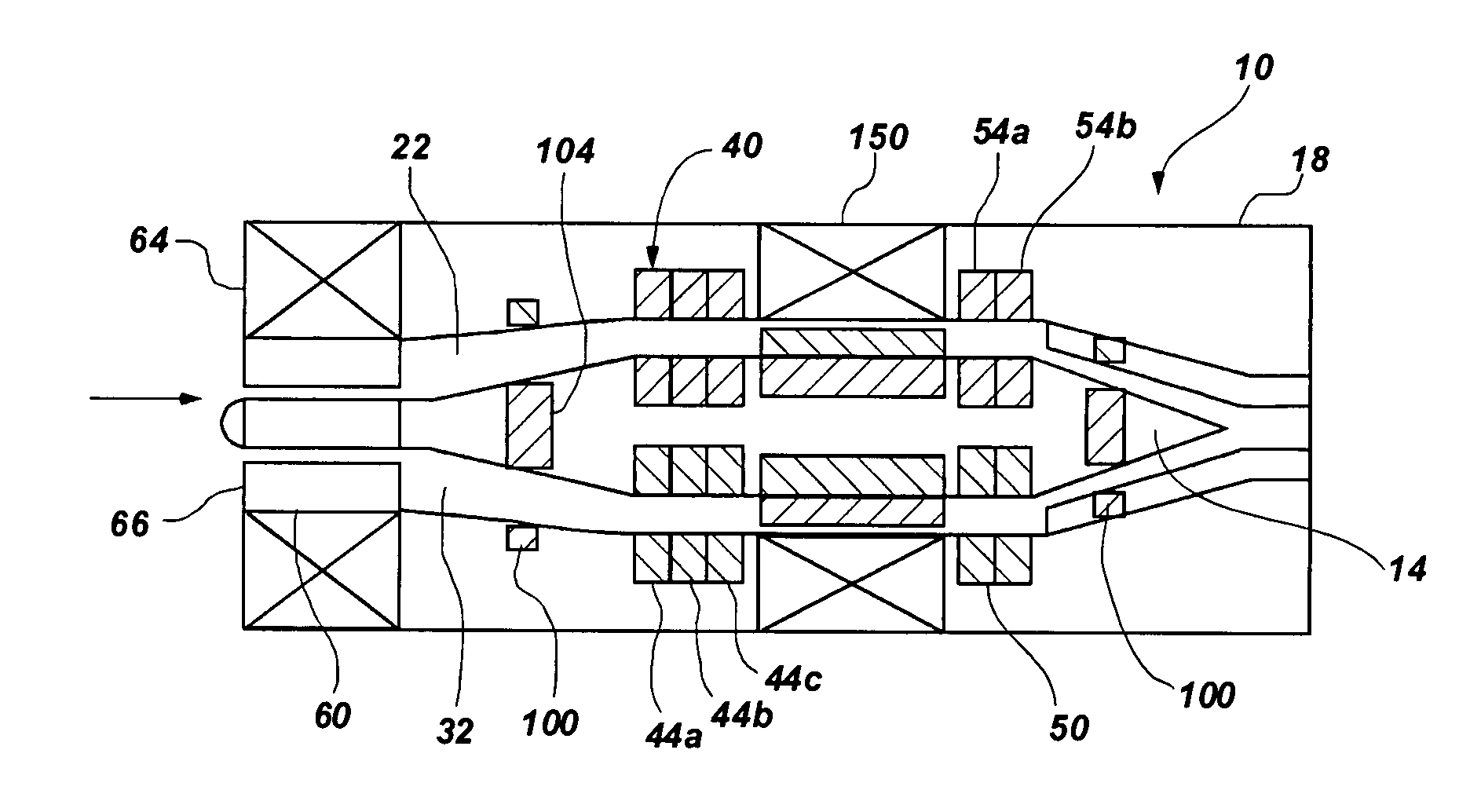

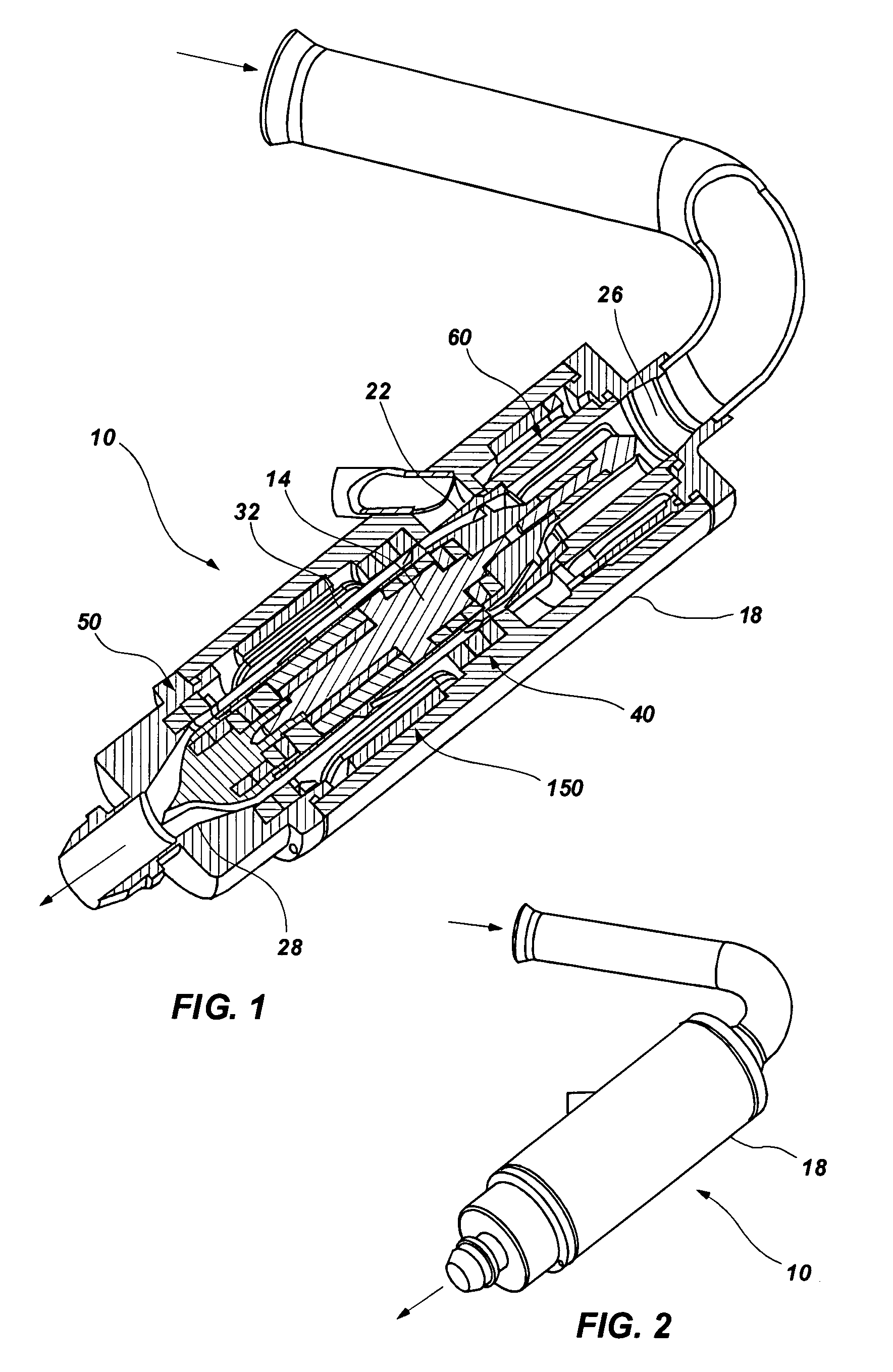

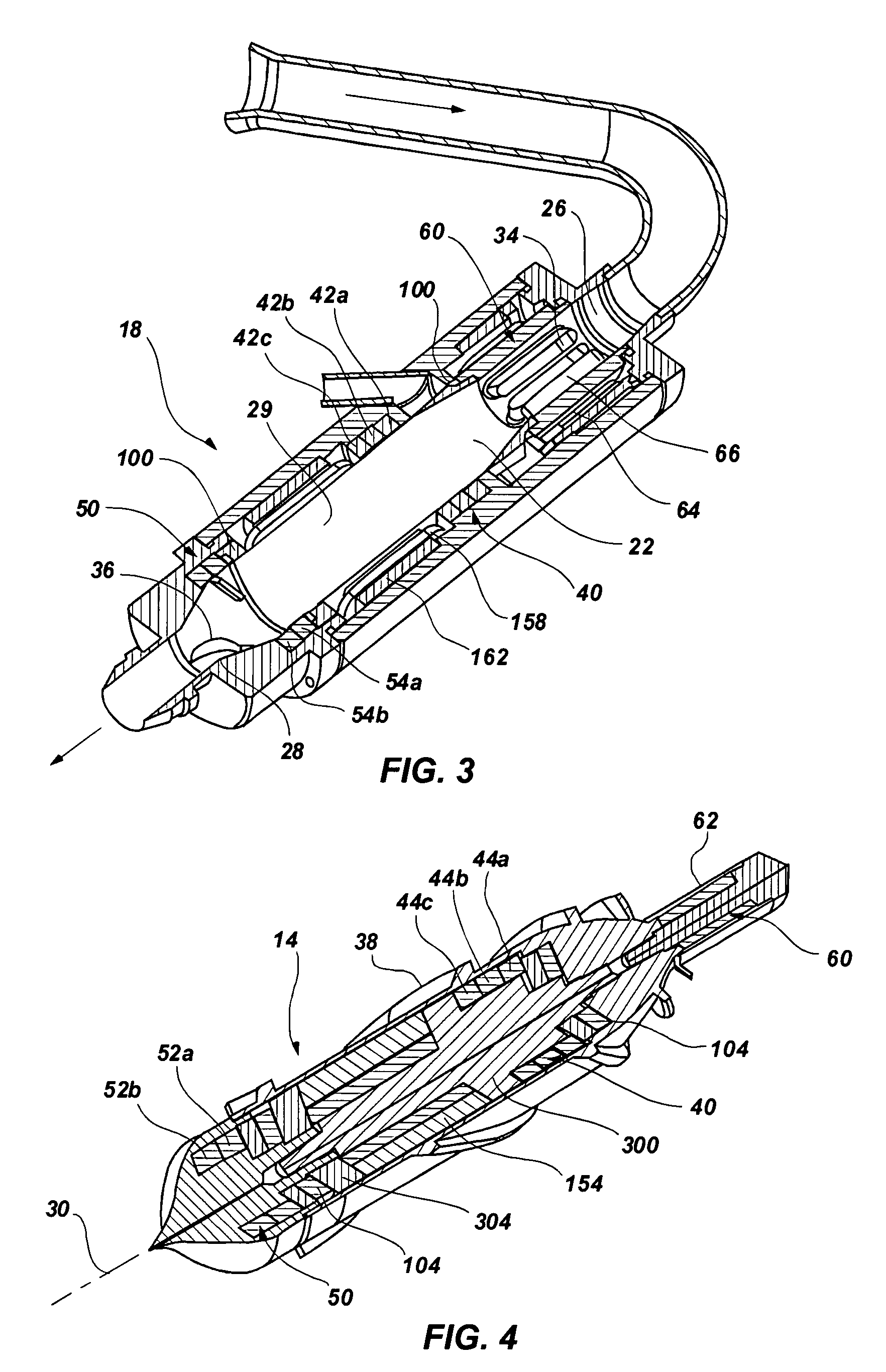

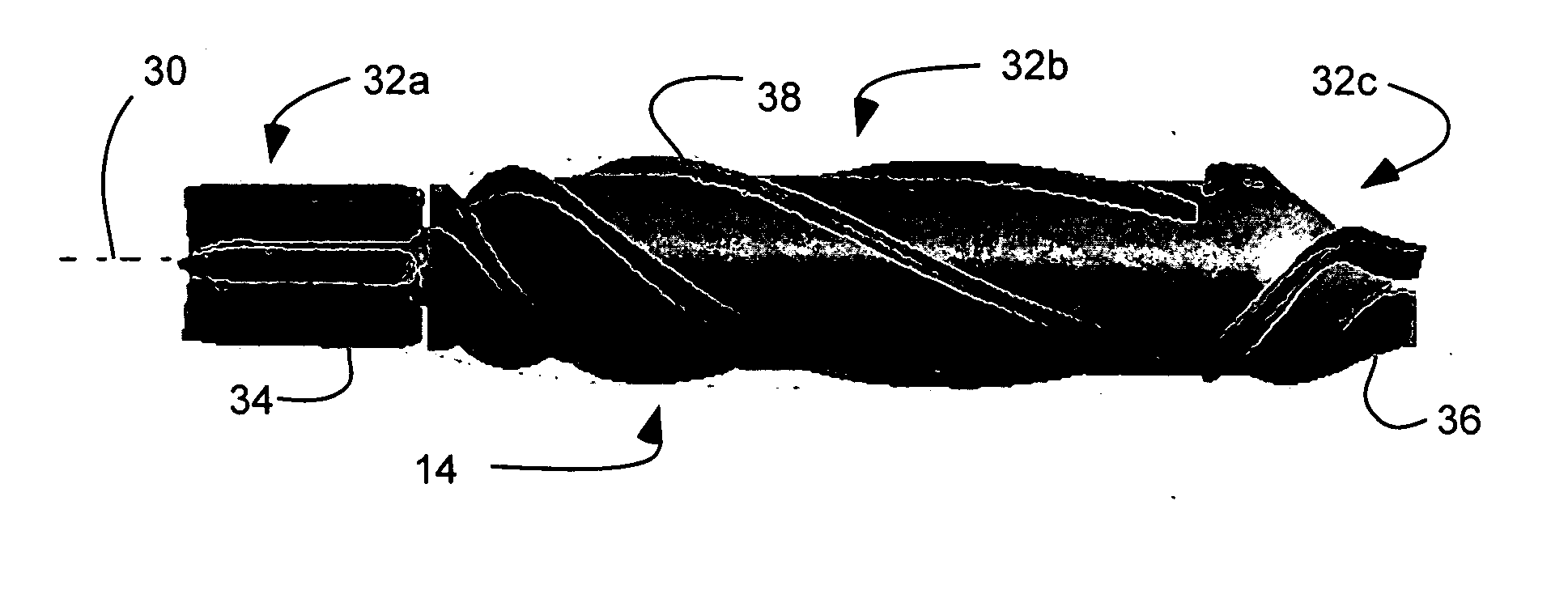

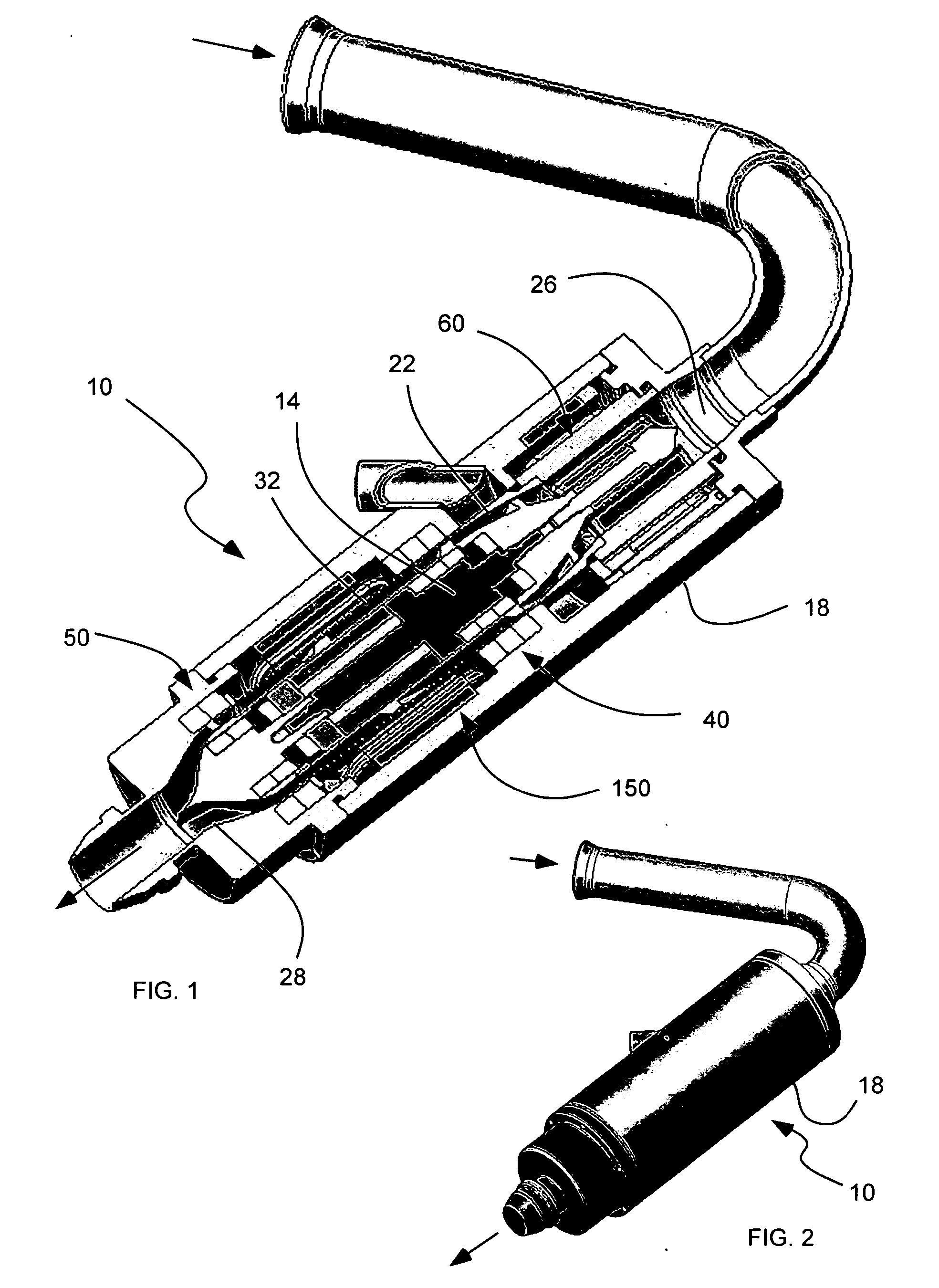

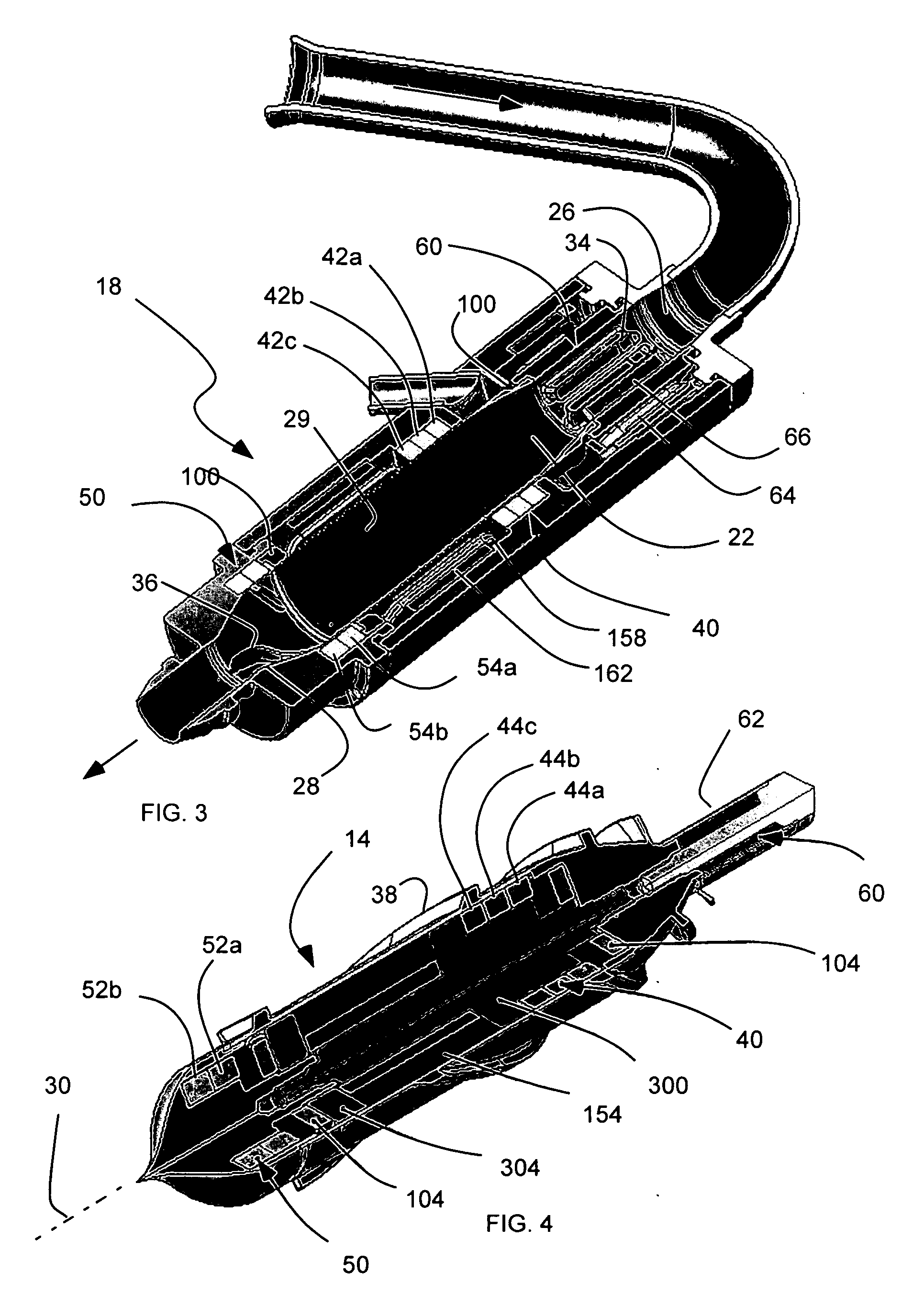

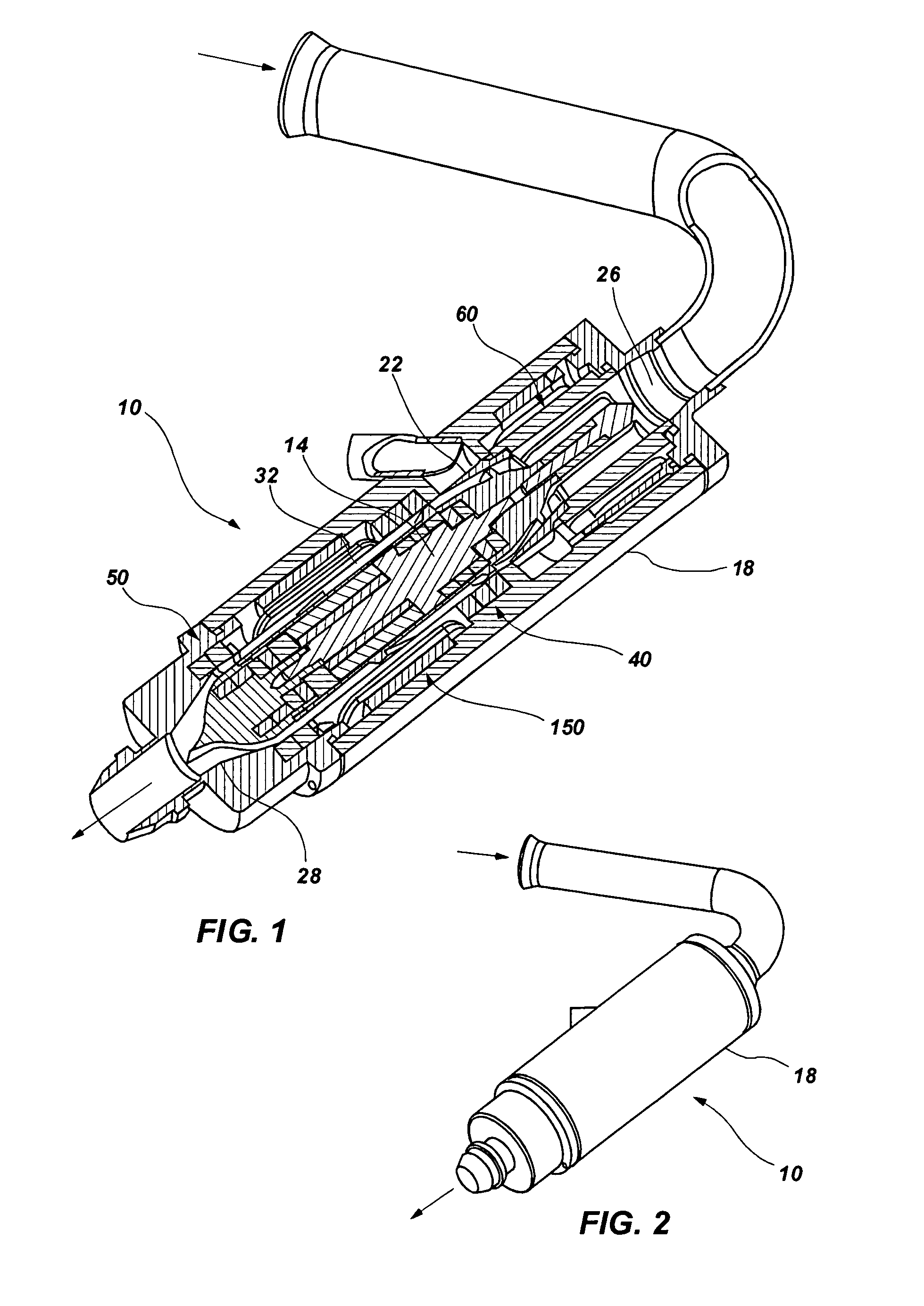

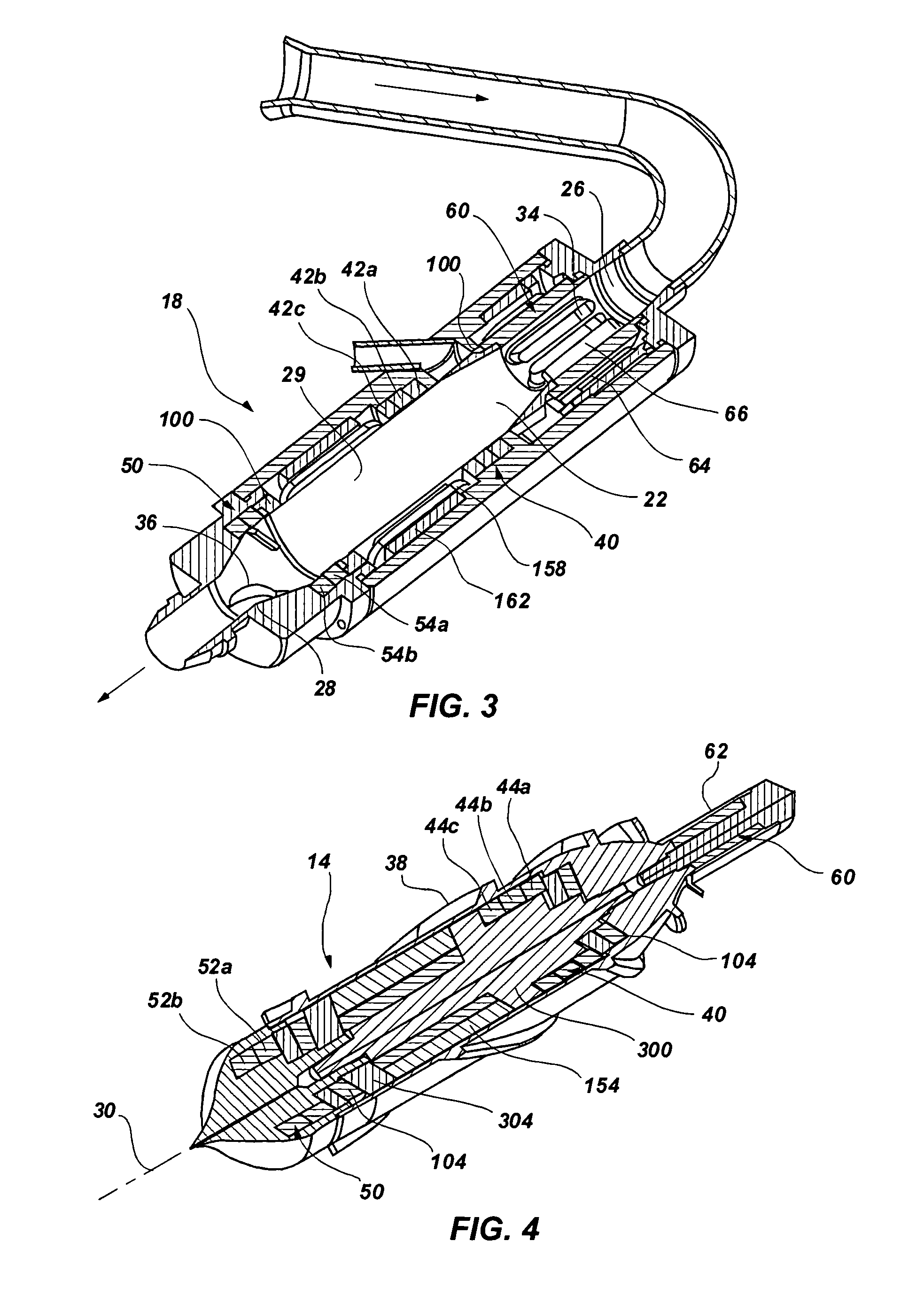

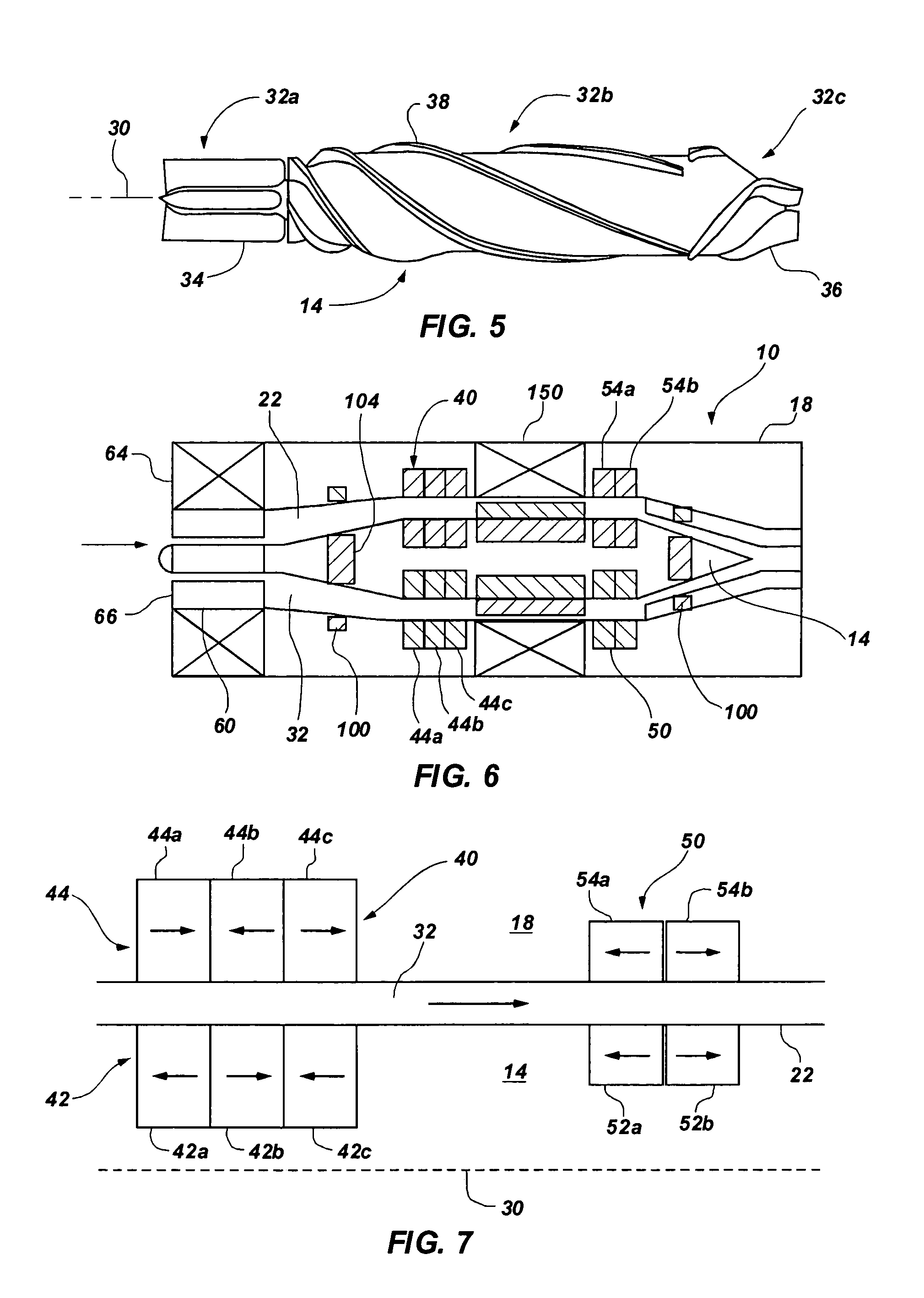

Streamlined unobstructed one-pass axial-flow pump

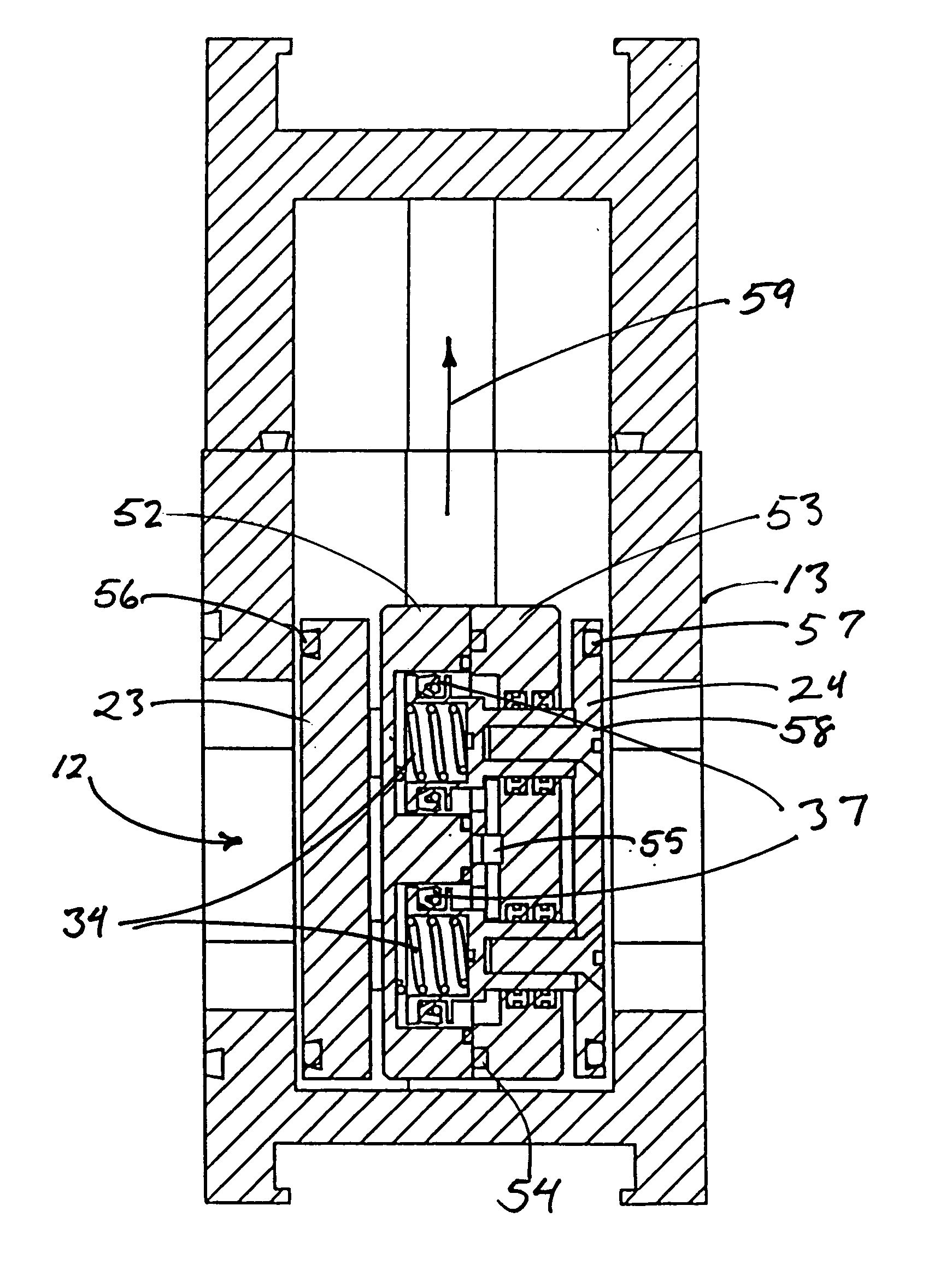

InactiveUS7229258B2Small sizeIncreased operating lifeBlood pumpsIntravenous devicesAxial-flow pumpOne pass

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings (passive permanent and active electromagnetic) having impeller magnets on the impeller and stator magnets or coils / poles on the stator. A motor includes impeller magnets on the impeller and coils / poles associated with the stator. A single, annular blood flow path extends axially through the cavity between the impeller and the stator, and between the impeller magnets on the impeller and the stator magnets or the coils / poles on the stator.

Owner:MEDFORTE RES FOUND +1

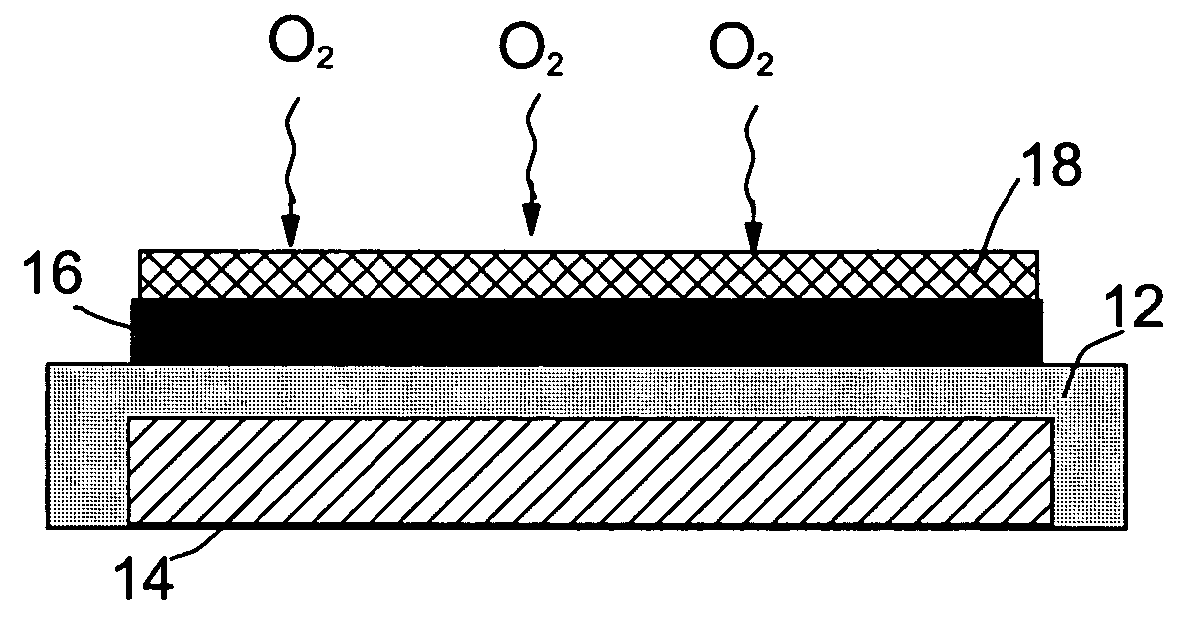

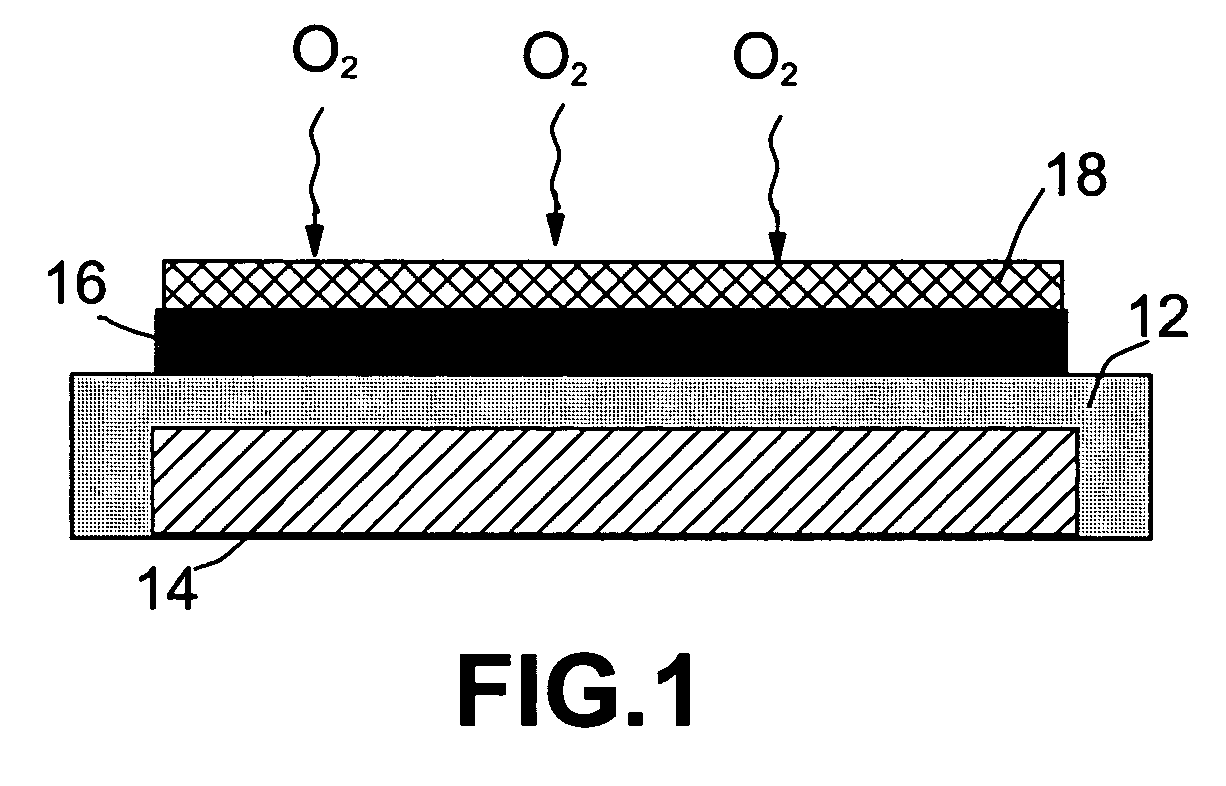

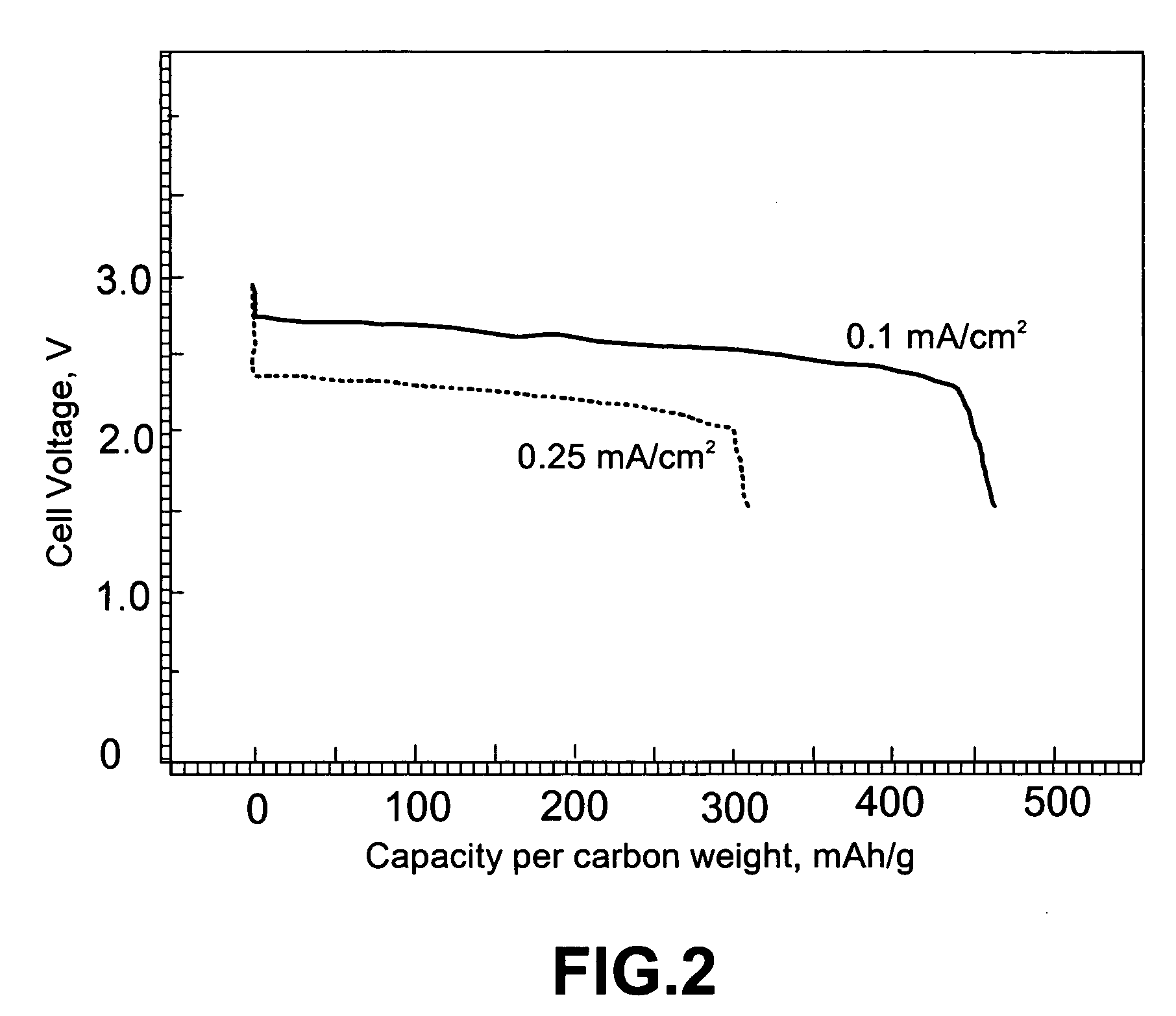

Metal-air battery with ion-conducting inorganic glass electrolyte

InactiveUS20060063051A1Safe and reliable solid-stateIncrease energy densityFuel and primary cellsSolid electrolytesMetal–air electrochemical cellIonic conductivity

A solid-state metal-air electrochemical cell comprising: (A) a metal-containing electro-active anode; (B) an oxygen electro-active cathode; and (C) an ion-conducting glass electrolyte disposed between the metal-containing anode and the oxygen electro-active cathode. The cathode active material, which is oxygen gas, is not stored in the battery but rather fed from the environment. The oxygen cathode is preferably a composite carbon electrode which serves as the cathode current collector on which oxygen molecules are reduced during discharge of the battery to generate electric current. The glass electrolyte typically has an ion conductivity in the range of 5×10−5 to 2×10−3 S / cm. The electrolyte layer is preferably smaller than 10 μm in thickness and further preferably smaller than 1 μm. The anode metal is preferably lithium or lithium alloy, but may be selected from other elements such as sodium, magnesium, calcium, aluminum and zinc.

Owner:JANG BOR Z

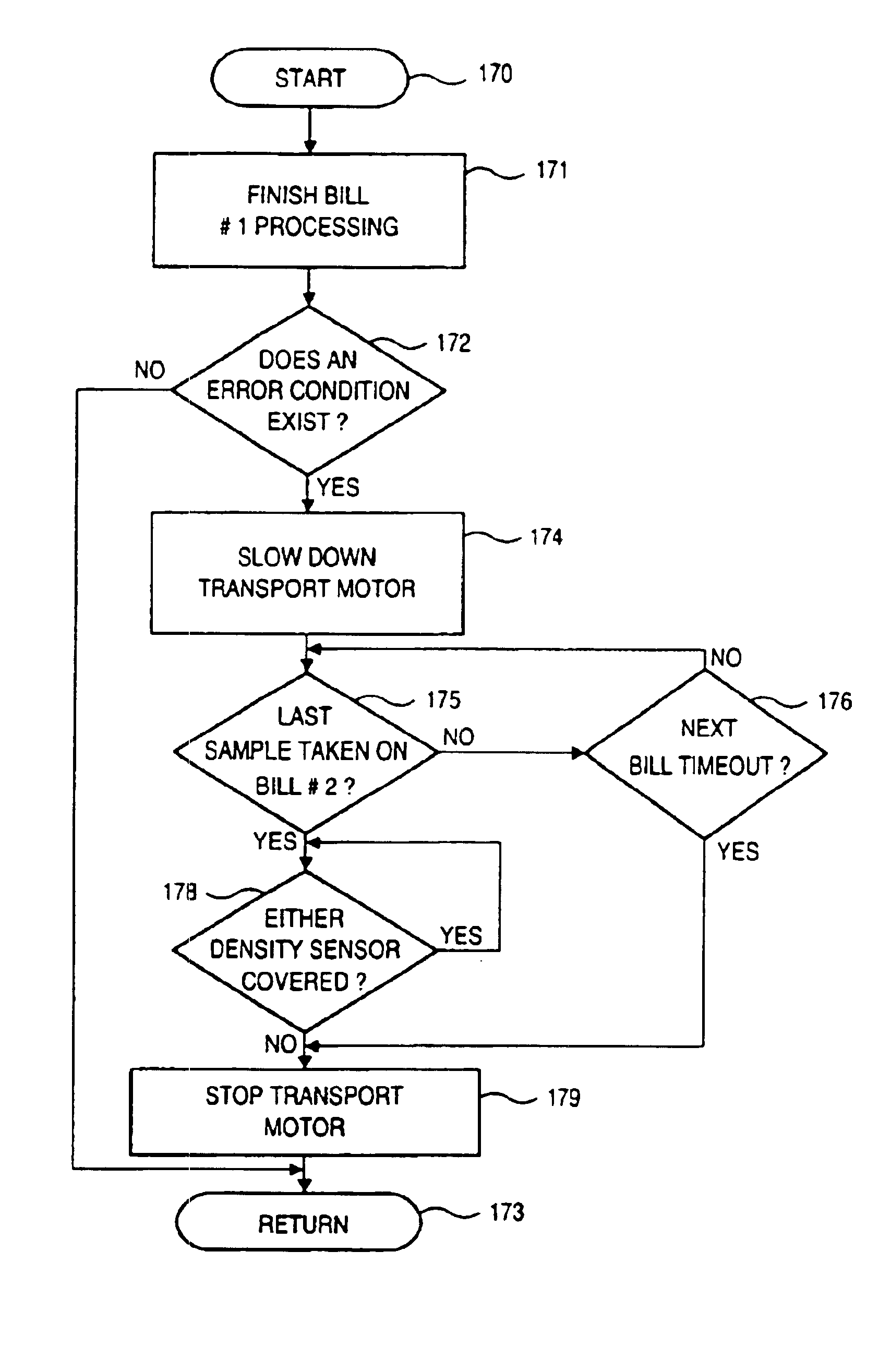

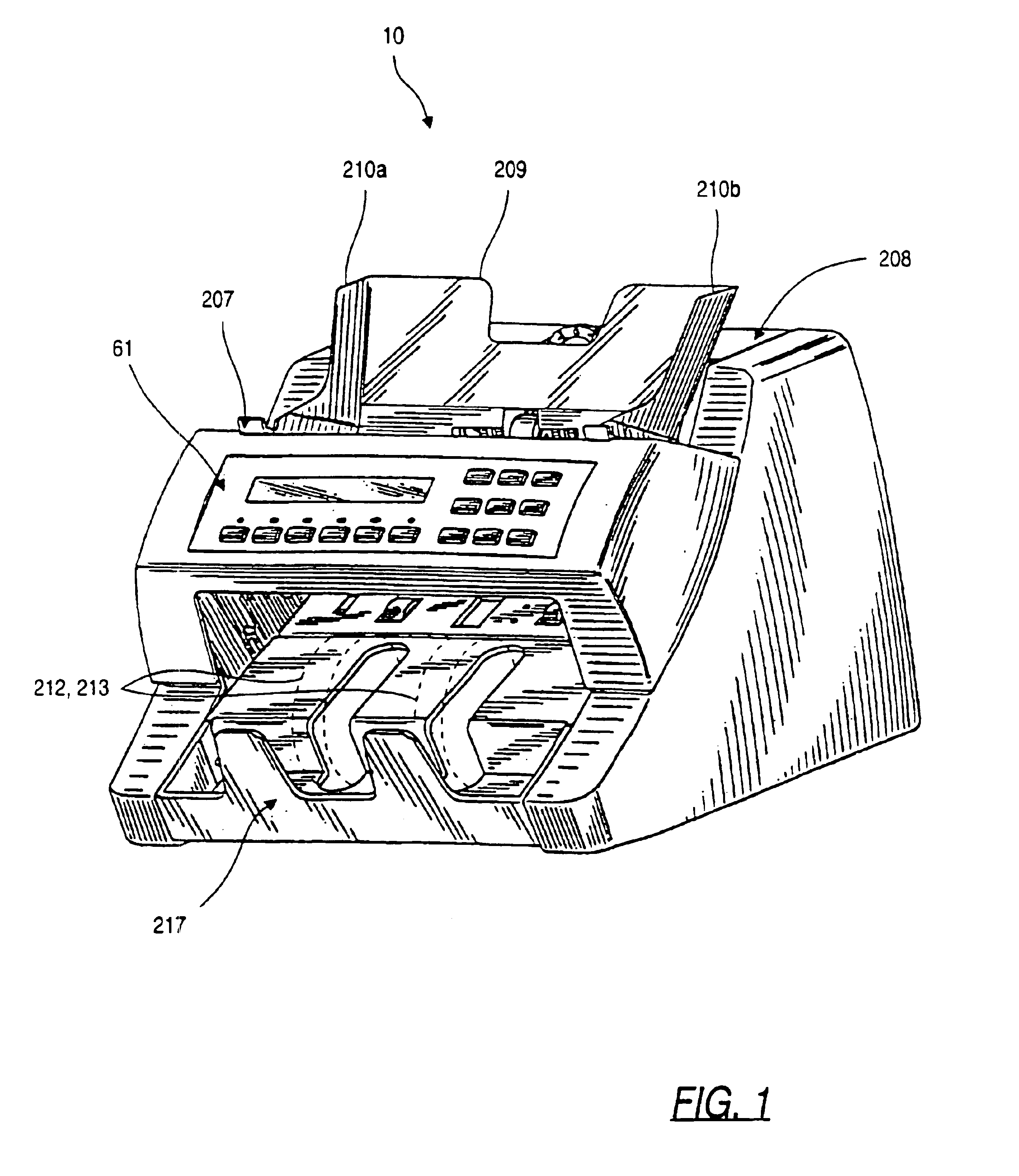

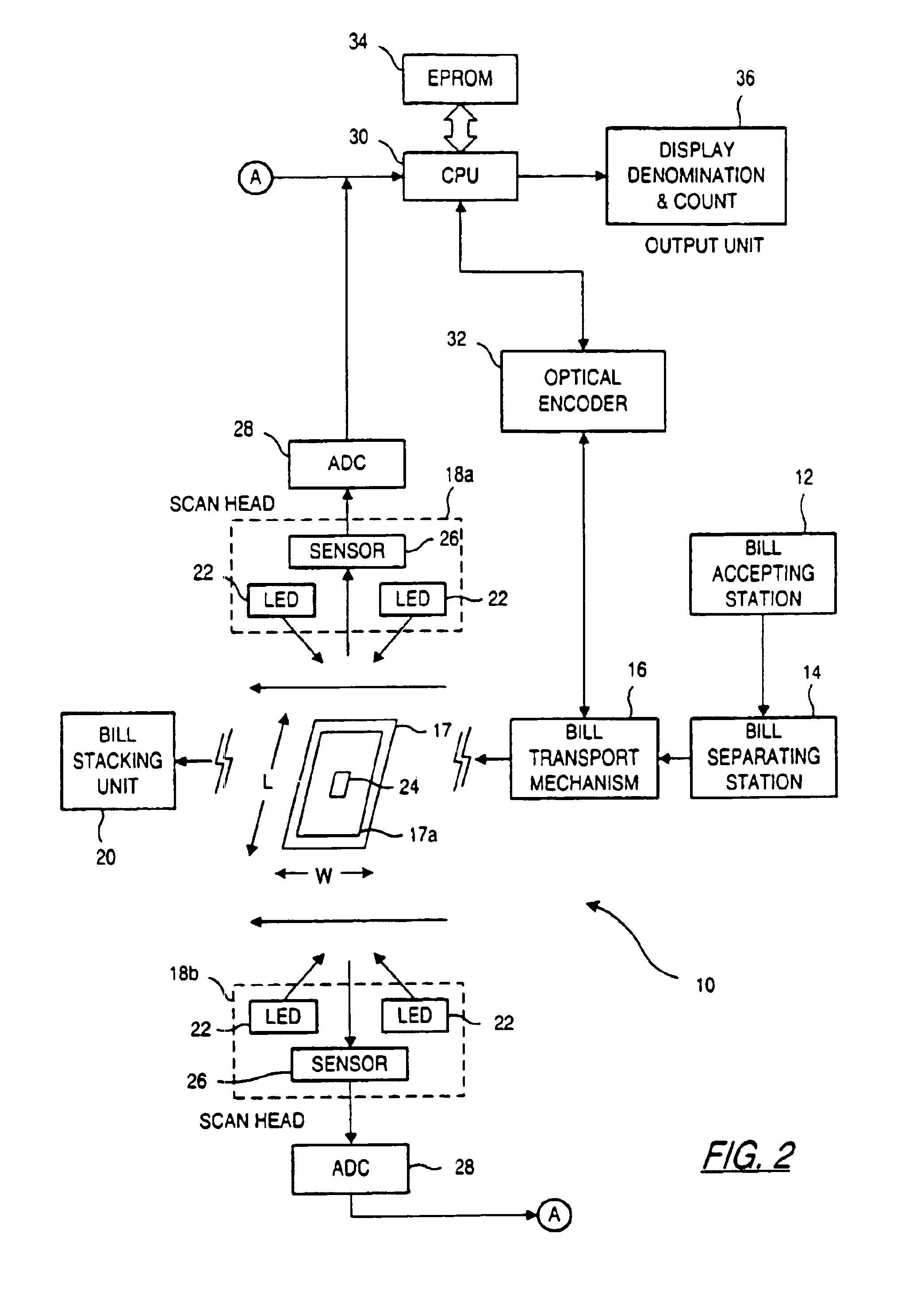

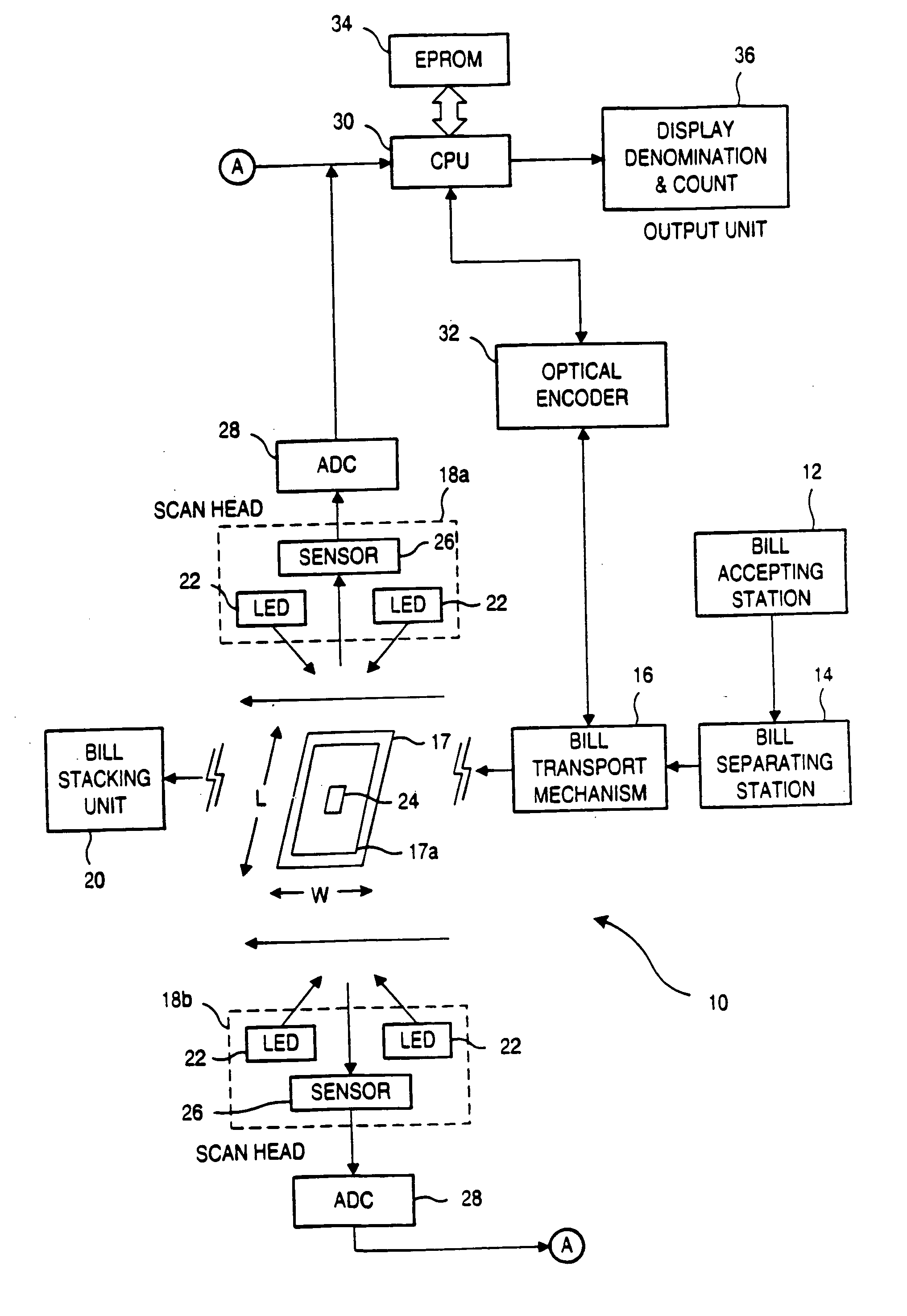

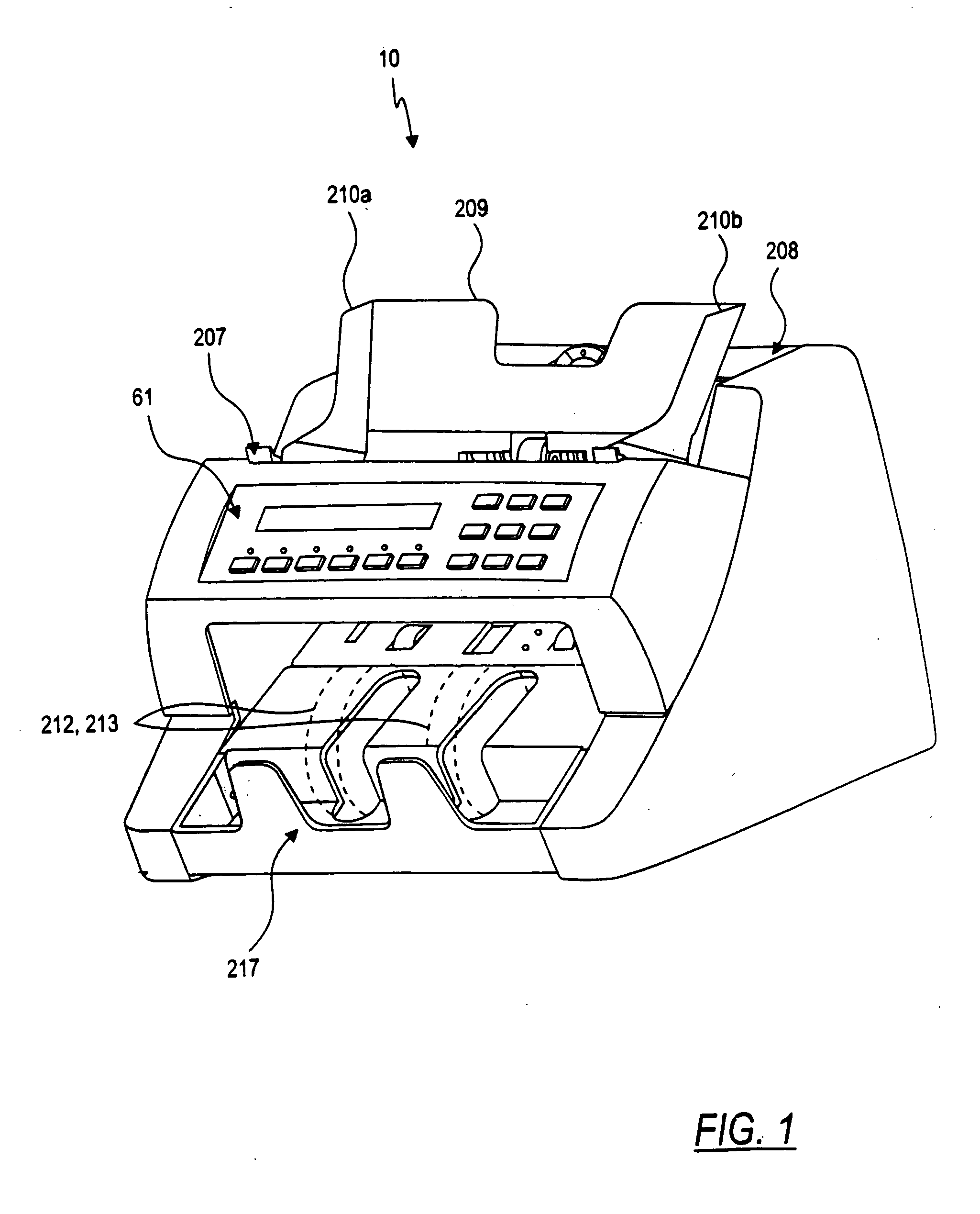

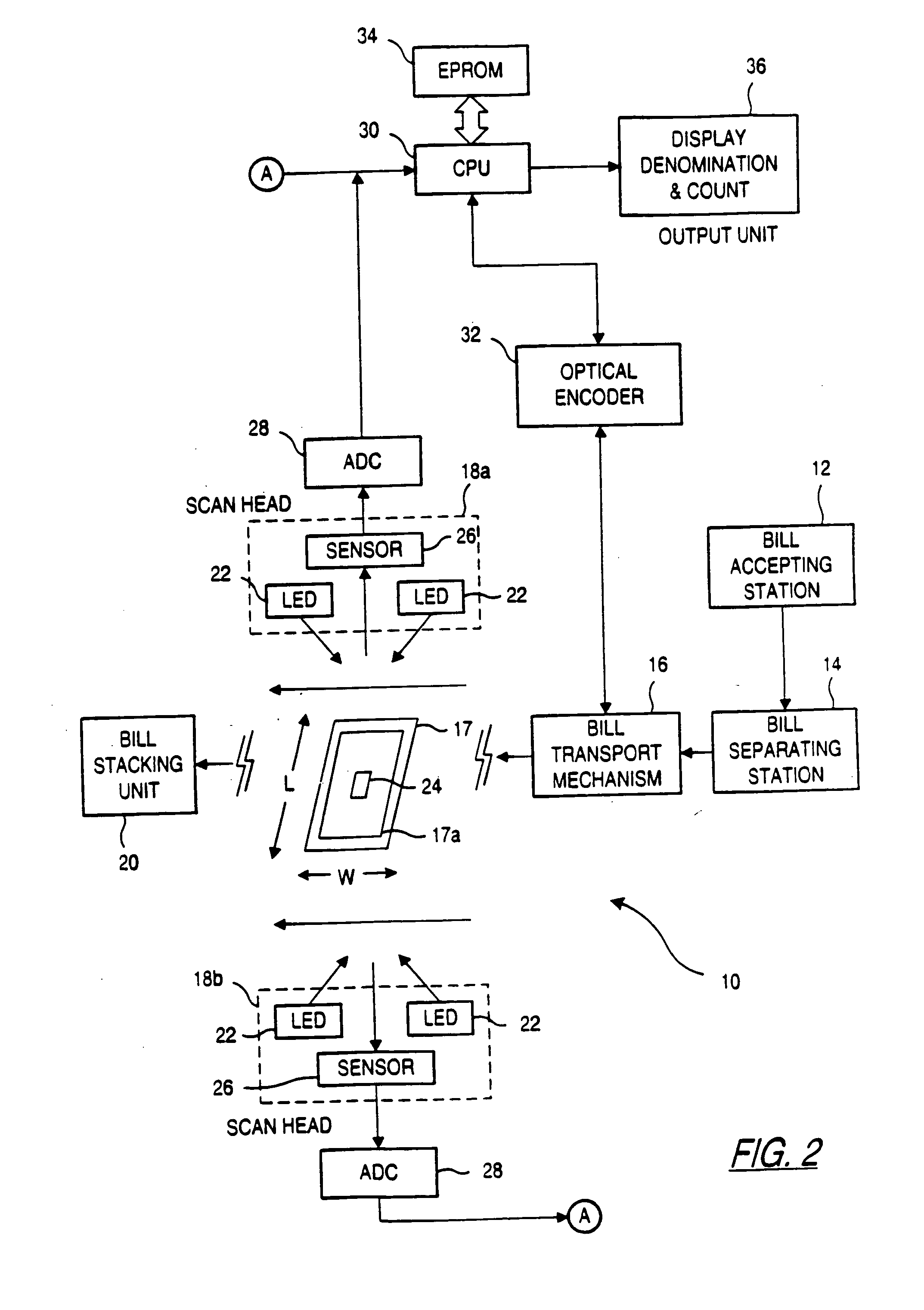

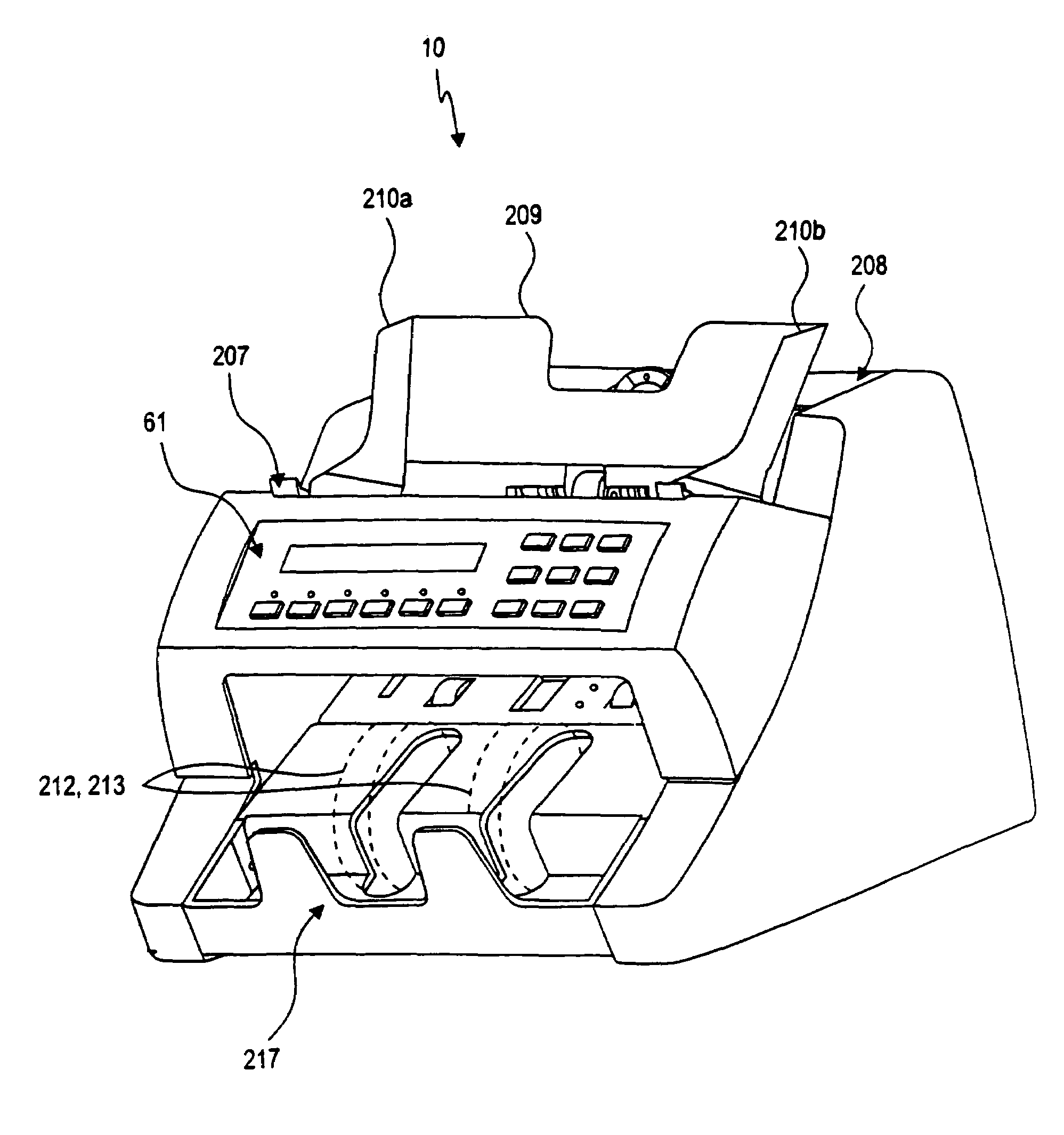

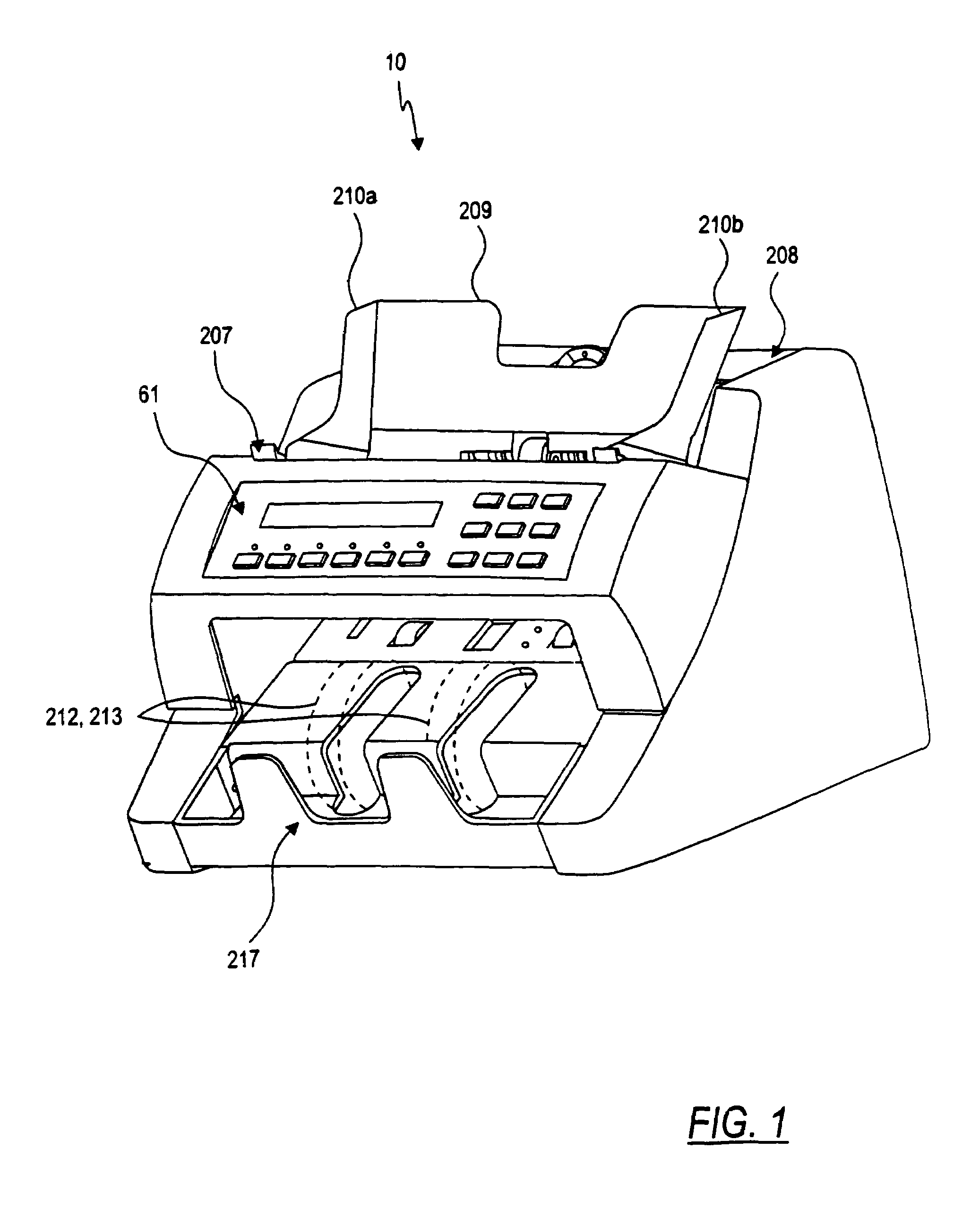

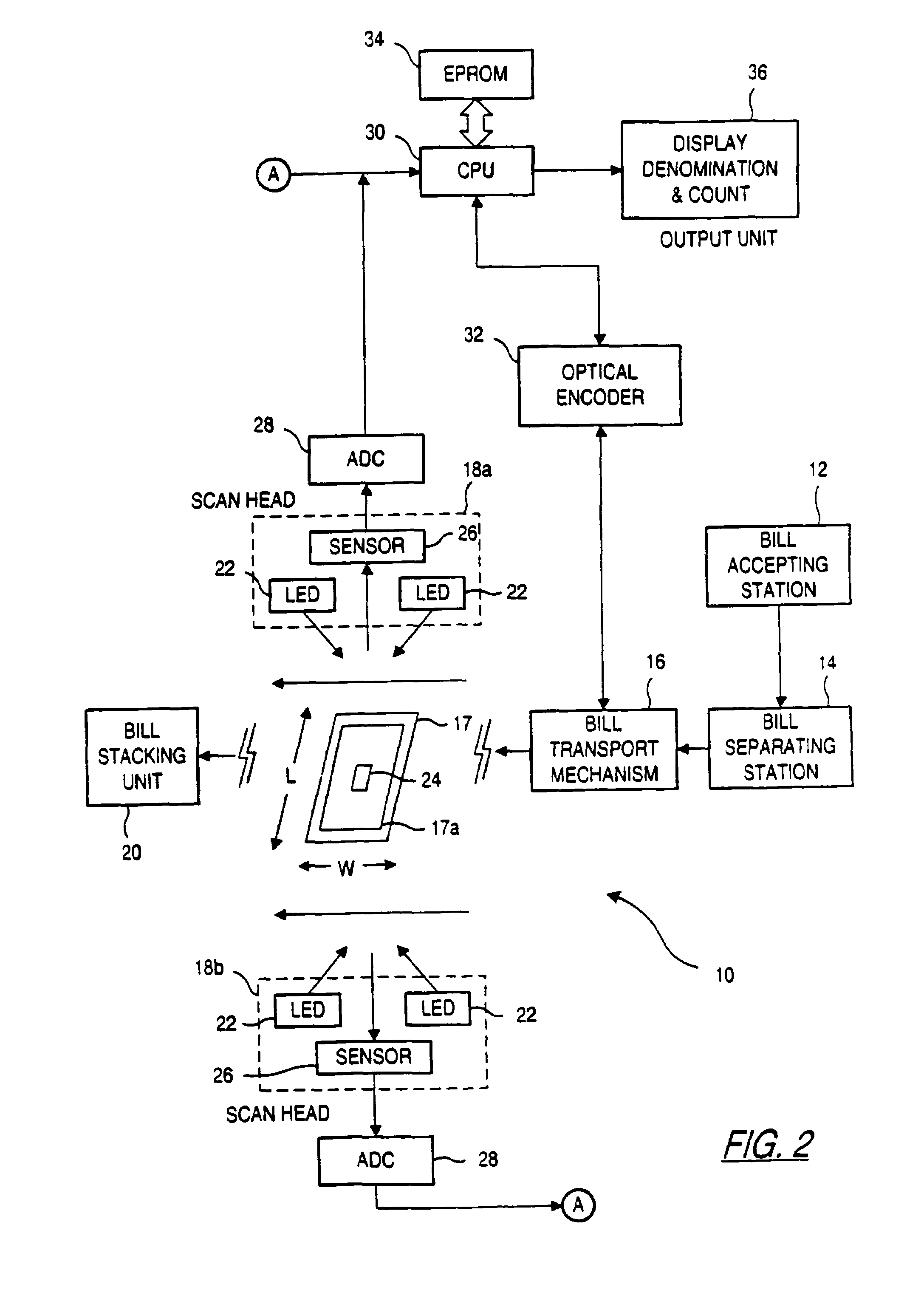

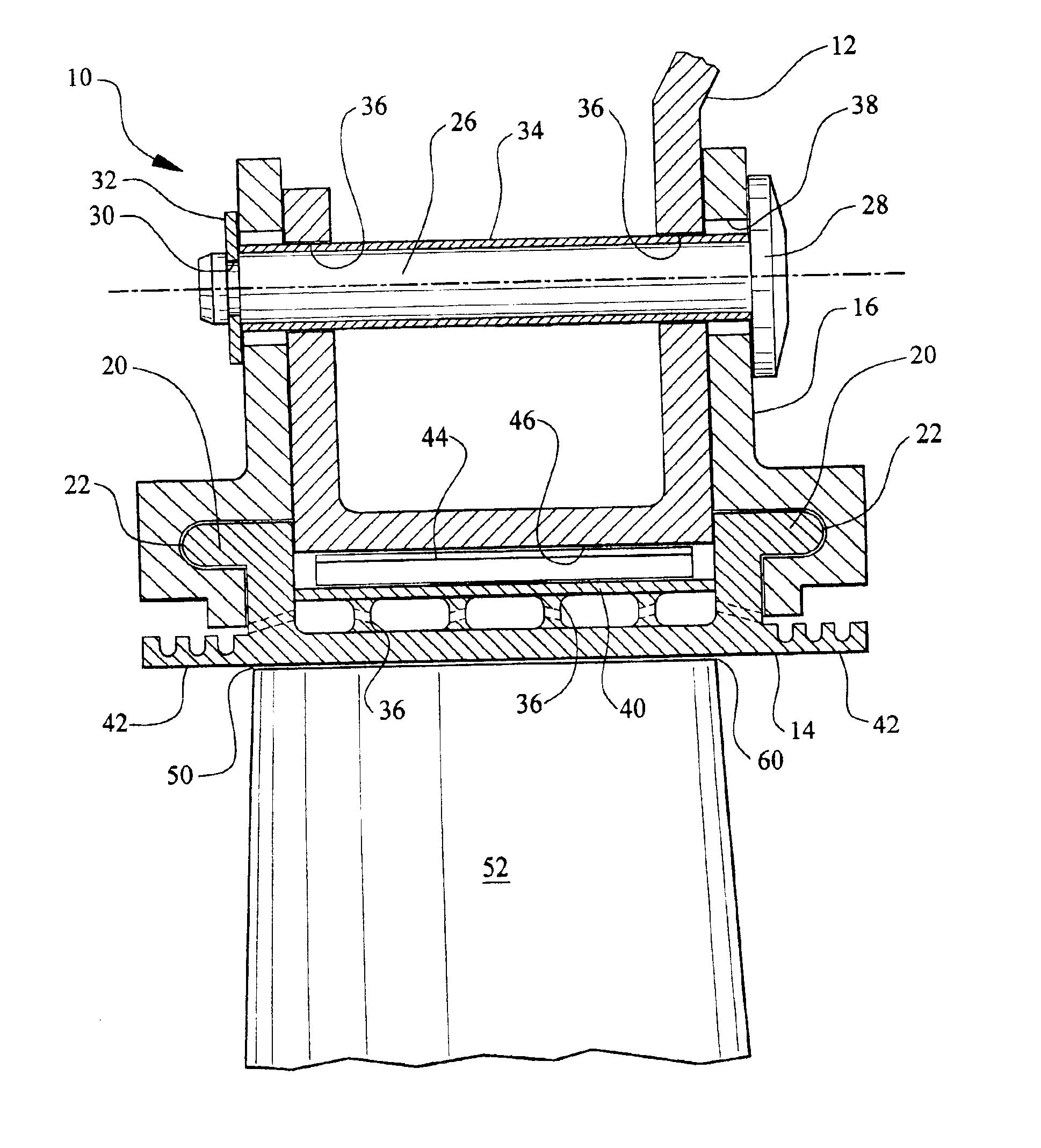

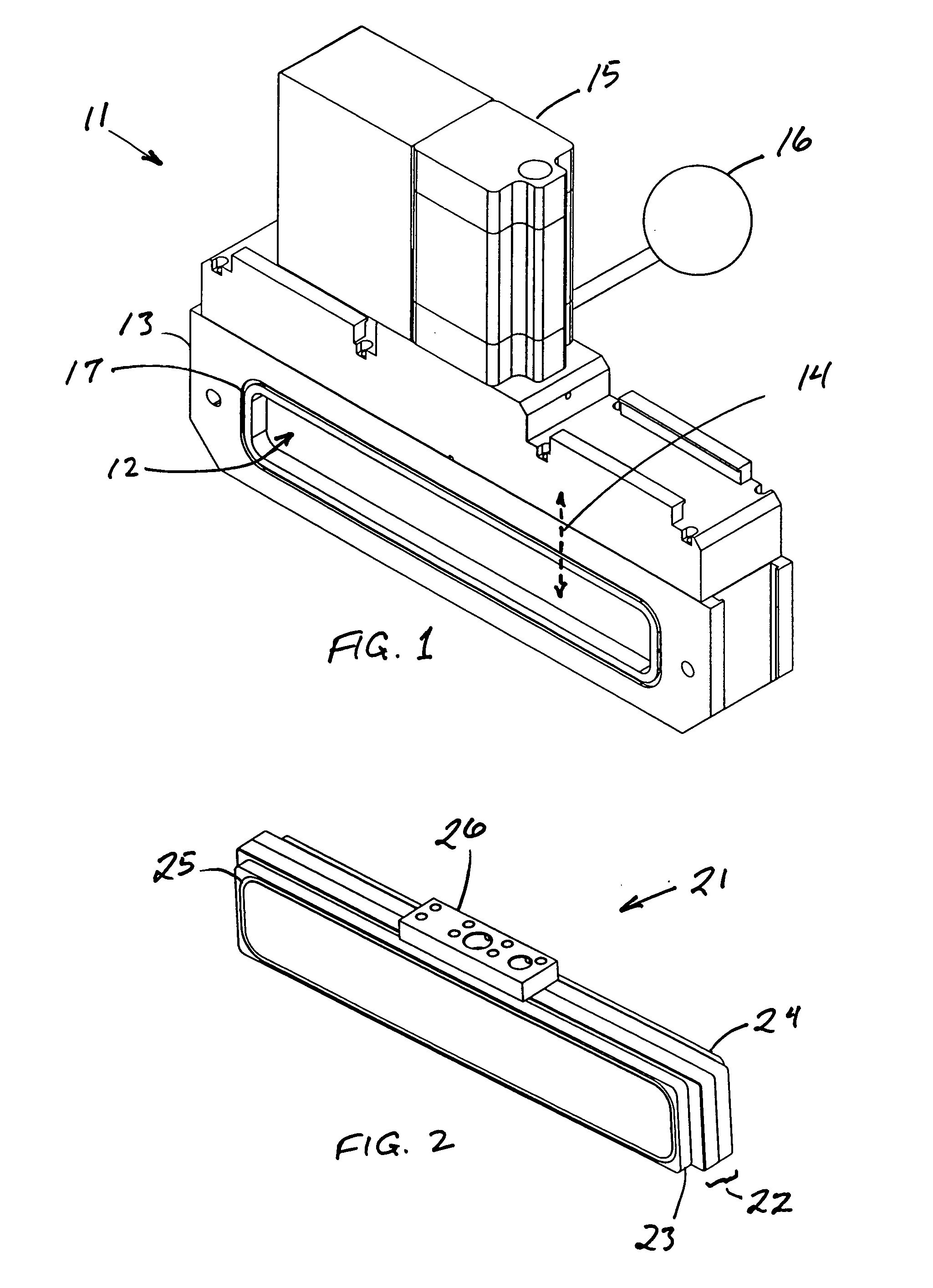

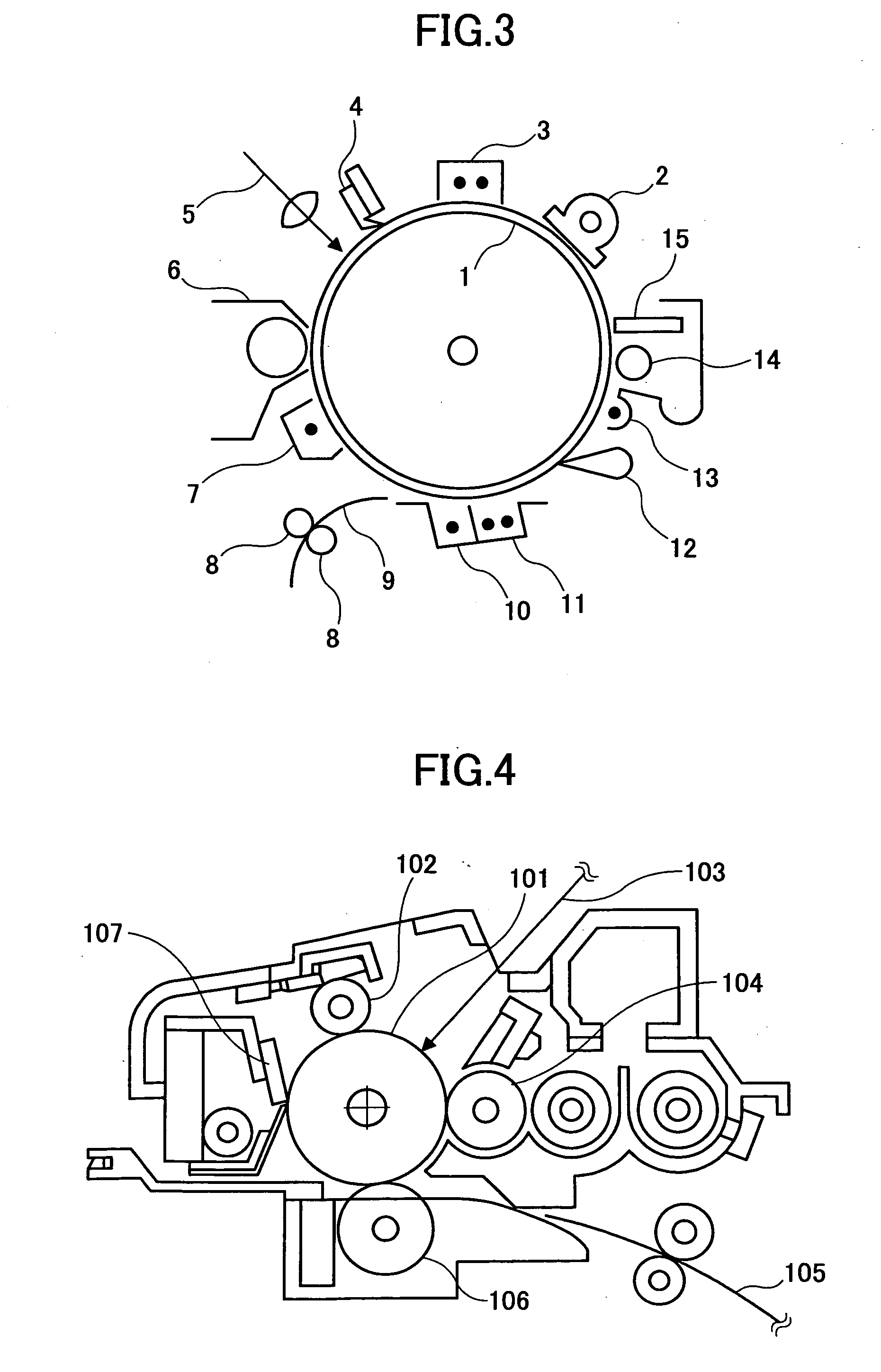

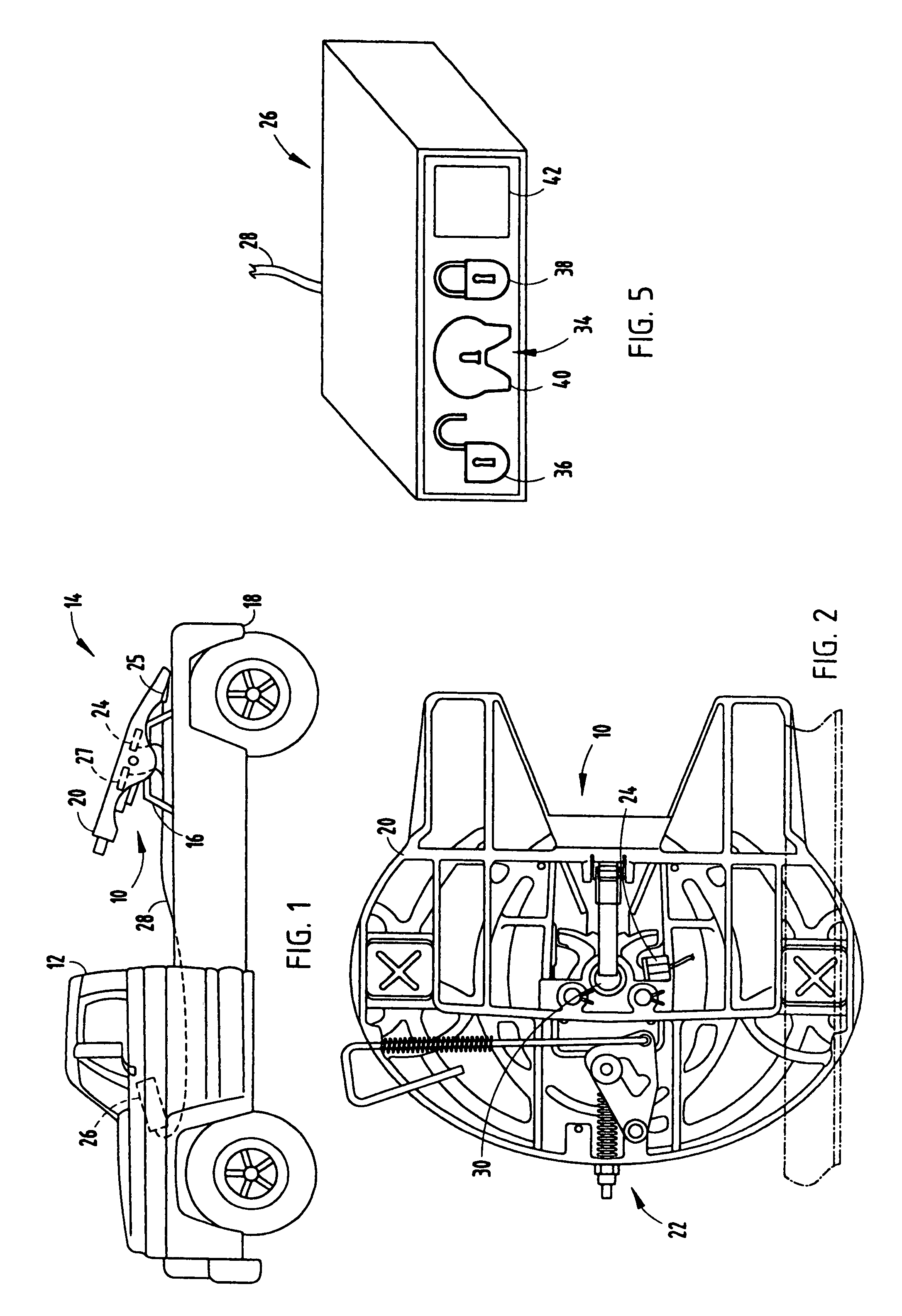

Method and apparatus for discriminating and counting documents

InactiveUS6915893B2Simple and compactEasy to usePaper-money testing devicesCoin/currency accepting devicesEngineeringMechanical engineering

A currency evaluation device for receiving a stack of currency bills and rapidly evaluating all the bills in the stack. The device includes an input receptacle for receiving a stack of bills to be evaluated and a single output receptacle for receiving the bills after they have been evaluated. A transport mechanism transports the bills, one at a time, from the input receptacle to the output receptacle along a transport path. The device further includes a discriminating unit that evaluates the bills. The discriminating unit comprises two detectors positioned along the transport path between the input receptacle and the output receptacle. The detectors are disposed on opposite sides of the transport path so that they are disposed adjacent to opposite sides of the bills. The discriminating unit counts and determines the denomination of the bills. The evaluation device also includes means for flagging a bill when the denomination of the bill is not determined by the discriminating unit.

Owner:CUMMINS-ALLISON CORP

Method and apparatus for discriminating and counting documents

InactiveUS20050213803A1Simple and compactEasy to usePaper-money testing devicesCoin/currency accepting devicesEngineeringPaper document

A currency evaluation device for receiving a stack of currency bills and rapidly evaluating all the bills in the stack. The device includes an input receptacle for receiving a stack of bills to be evaluated and a single output receptacle for receiving the bills after they have been evaluated. A transport mechanism transports the bills, one at a time, from the input receptacle to the output receptacle along a transport path. The device further includes a discriminating unit that evaluates the bills. The discriminating unit comprises two detectors positioned along the transport path between the input receptacle and the output receptacle. The detectors are disposed on opposite sides of the transport path so that they are disposed adjacent to opposite sides of the bills. The discriminating unit counts and determines the denomination of the bills. The evaluation device also includes means for flagging a bill when the denomination of the bill is not determined by the discriminating unit.

Owner:CUMMINS-ALLISON CORP

Streamlined unobstructed one-pass axial-flow pump

InactiveUS20050135942A1Reduce coagulationSmall sizeBlood pumpsIntravenous devicesAxial-flow pumpImpeller

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings (passive permanent and active electromagnetic) having impeller magnets on the impeller and stator magnets or coils / poles on the stator. A motor includes impeller magnets on the impeller and coils / poles associated with the stator. A single, annular blood flow path extends axially through the cavity between the impeller and the stator, and between the impeller magnets on the impeller and the stator magnets or the coils / poles on the stator.

Owner:MEDFORTE RES FOUND +1

Axial-flow blood pump with magnetically suspended, radially and axially stabilized impeller

InactiveUS7070398B2Small sizeIncreased operating lifeBlood pumpsIntravenous devicesImpellerMagnetic bearing

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings including an axial bearing to support the impeller axially in the cavity. The axial bearing includes adjacent impeller magnets and adjacent stator magnets with axially aligned polarities and reverse polarities with respect to adjacent magnets. A motor includes impeller magnets on the impeller and coils and poles associated with the stator. Radial permanent magnet and electromagnetic bearings are also included. The magnetic bearings and the motor have stator magnets or coils and poles disposed radially across the fluid passage from corresponding impeller magnets to define an annular gap positioned radially between the impeller and the stator, and positioned radially between all of the plurality of magnetic bearings, creating a straight through blood path without secondary flow paths.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND +1

LED illumination lamp device

InactiveUS7690813B2Reduce heat release valueIncreased operating lifePoint-like light sourceLighting support devicesPrismEngineering

Owner:CITIZEN ELECTRONICS CO LTD

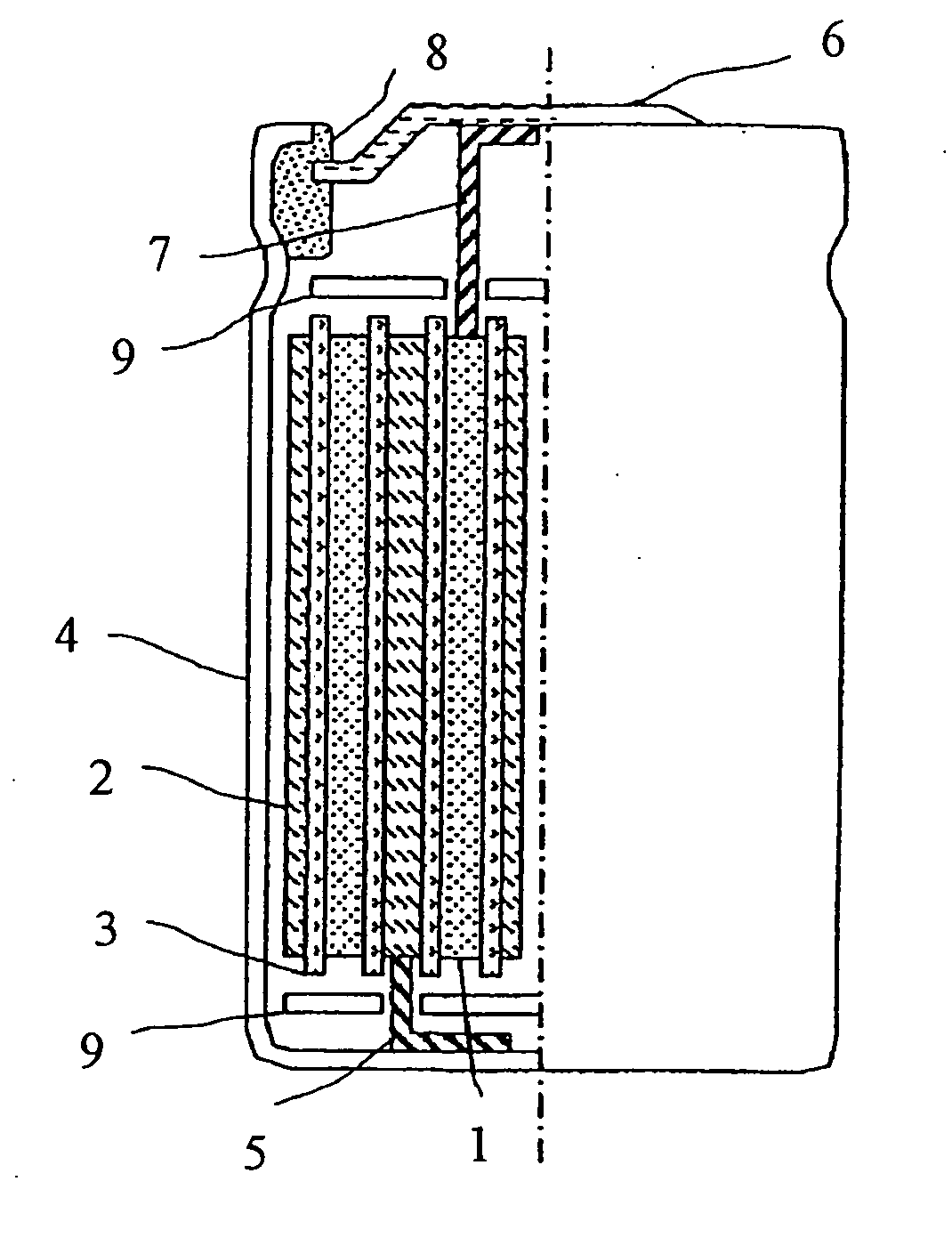

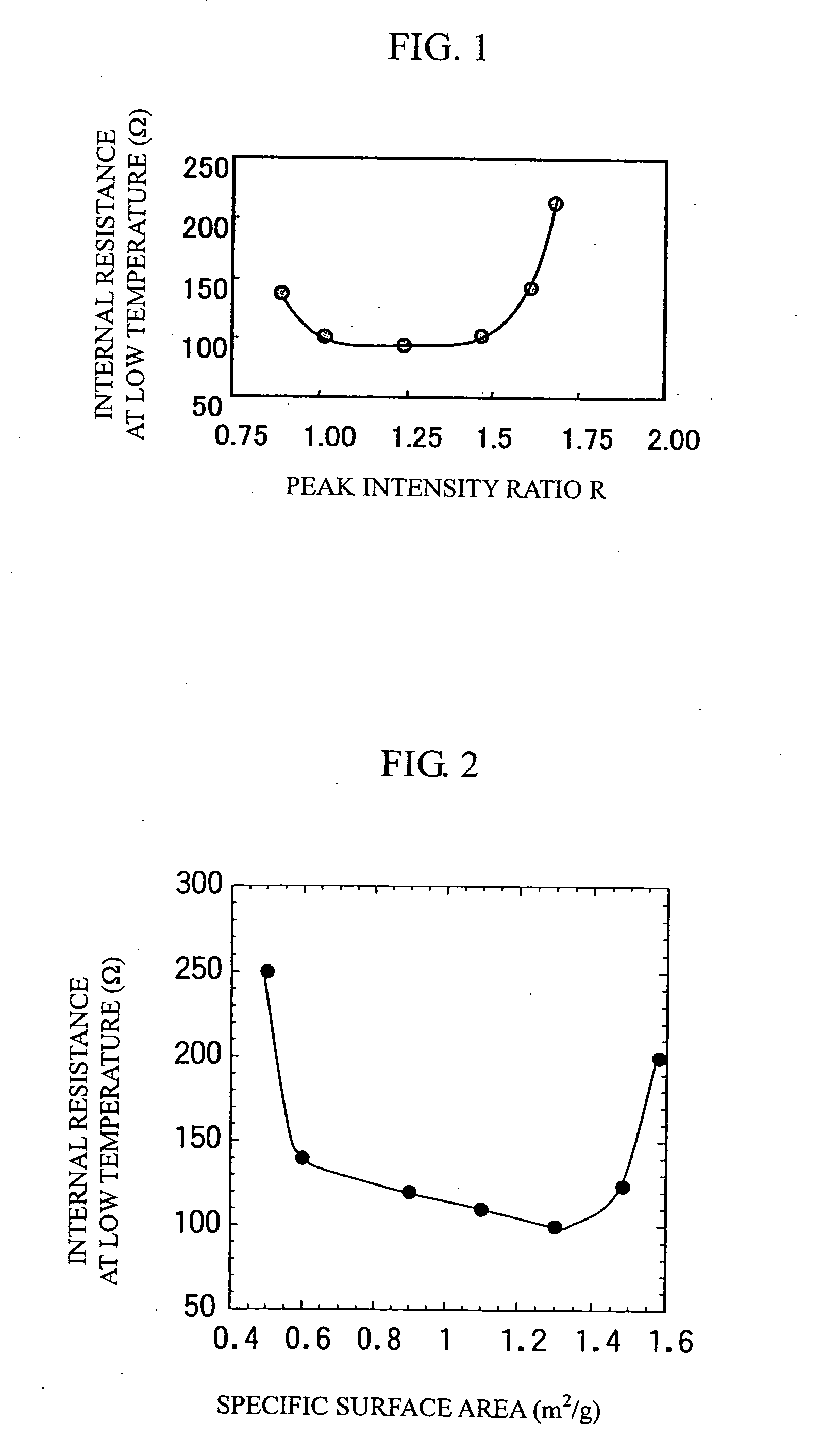

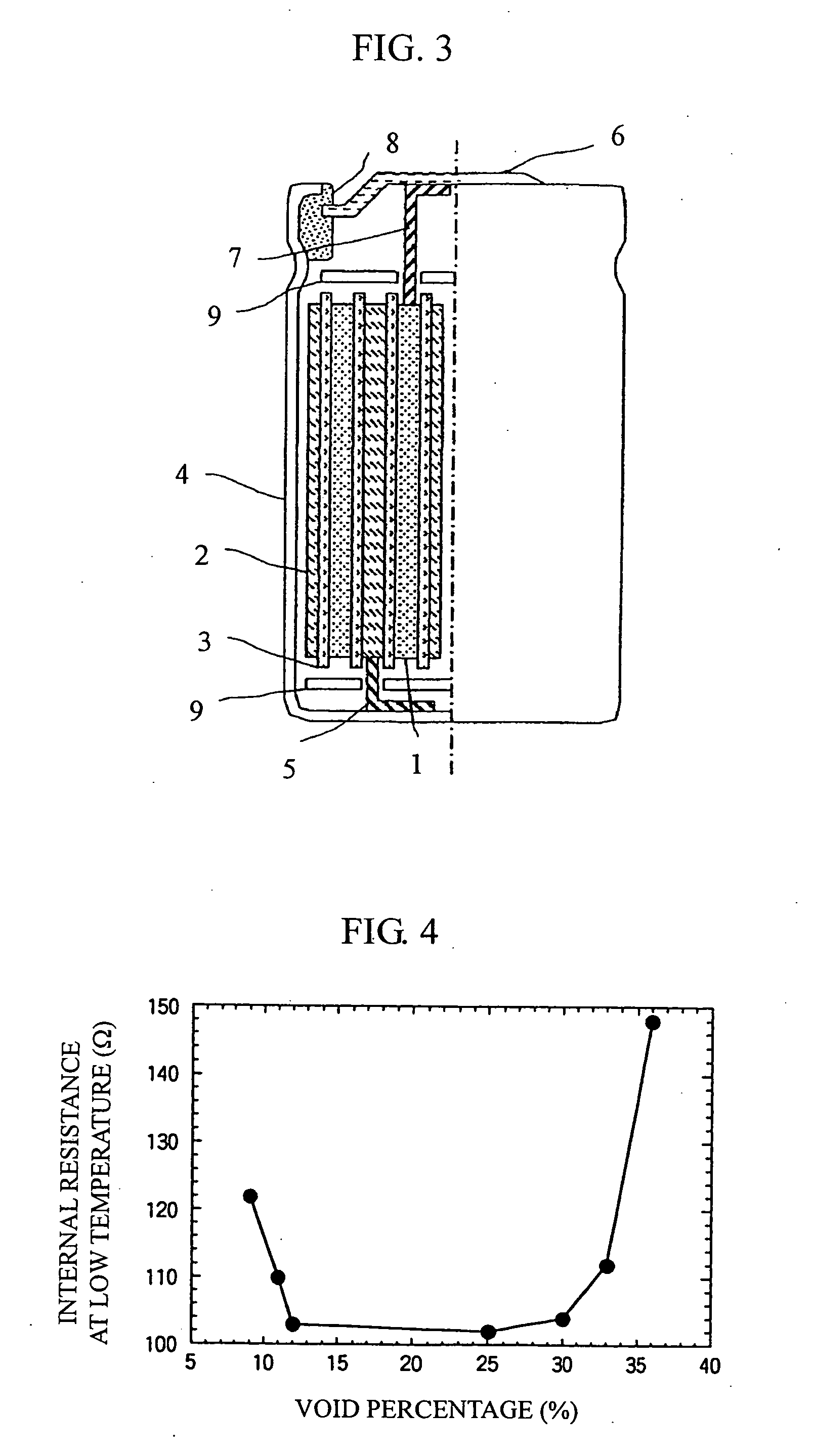

Positive electrode material for lithium secondary battery and lithium secondary battery using the same

ActiveUS20050142442A1Good cycle life and safetyIncrease internal resistanceNon-aqueous electrolyte accumulatorsAlkali metal oxidesLayered structureEngineering

A positive electrode material for a nonaqueous lithium secondary battery and a lithium secondary battery that has superior cycle life and safety and reduced internal resistance of the battery at low temperature is provided. The positive electrode material for a nonaqueous lithium secondary battery comprise a layered structured complex oxide expressed by a composition formula LiaMnxNiyCozMαO2, where 0<a≦1.2, 0.1≦x≦0.9, 0≦y≦0.44, 0.1≦z≦0.6, 0.01≦α≦0.1, and x+y+z+α=1. A diffraction peak intensity ratio between the (003) plane and the (104) plane (I(003) / I(104)) in an X-ray powder diffractometry using a Cu—Kα line in the X-ray source is not less than 1.0 and not more than 1.5.

Owner:HITACHI VEHICLE ENERGY

Lighting system and device

InactiveUS6612712B2Increase light intensityImprove energy efficiencyNon-electric lightingPoint-like light sourceWater immersionEffect light

The present invention is a light-producing technology exemplified by lighting that is safe, reliable, energy efficient, long lasting, and capable of operating under a wide range of weather and other conditions. The device incorporates a durable housing, a light element, a liquid solution, and a power supply. Subject only to its power source, it is capable of indefinitely producing intensely visible light at 100 yards or more during both daytime and nighttime. It can be configured for higher or lower intensities in a wide variety of foreseen applications. The device is not flammable, explosive, or toxic, and without loss of function withstands shock, extended water immersion, and heating and cooling to temperatures below freezing and approaching boiling.

Owner:NEPIL JAMES

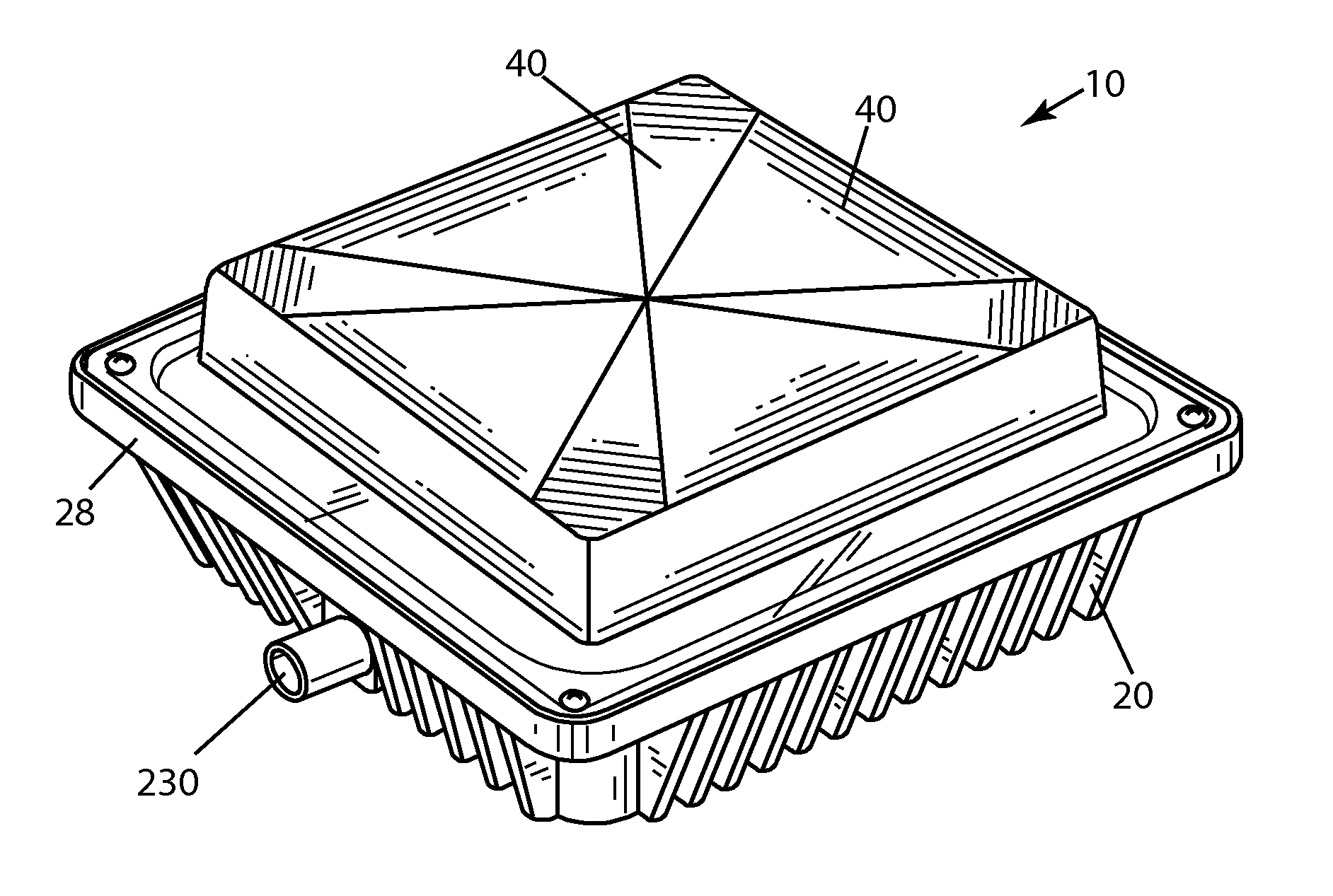

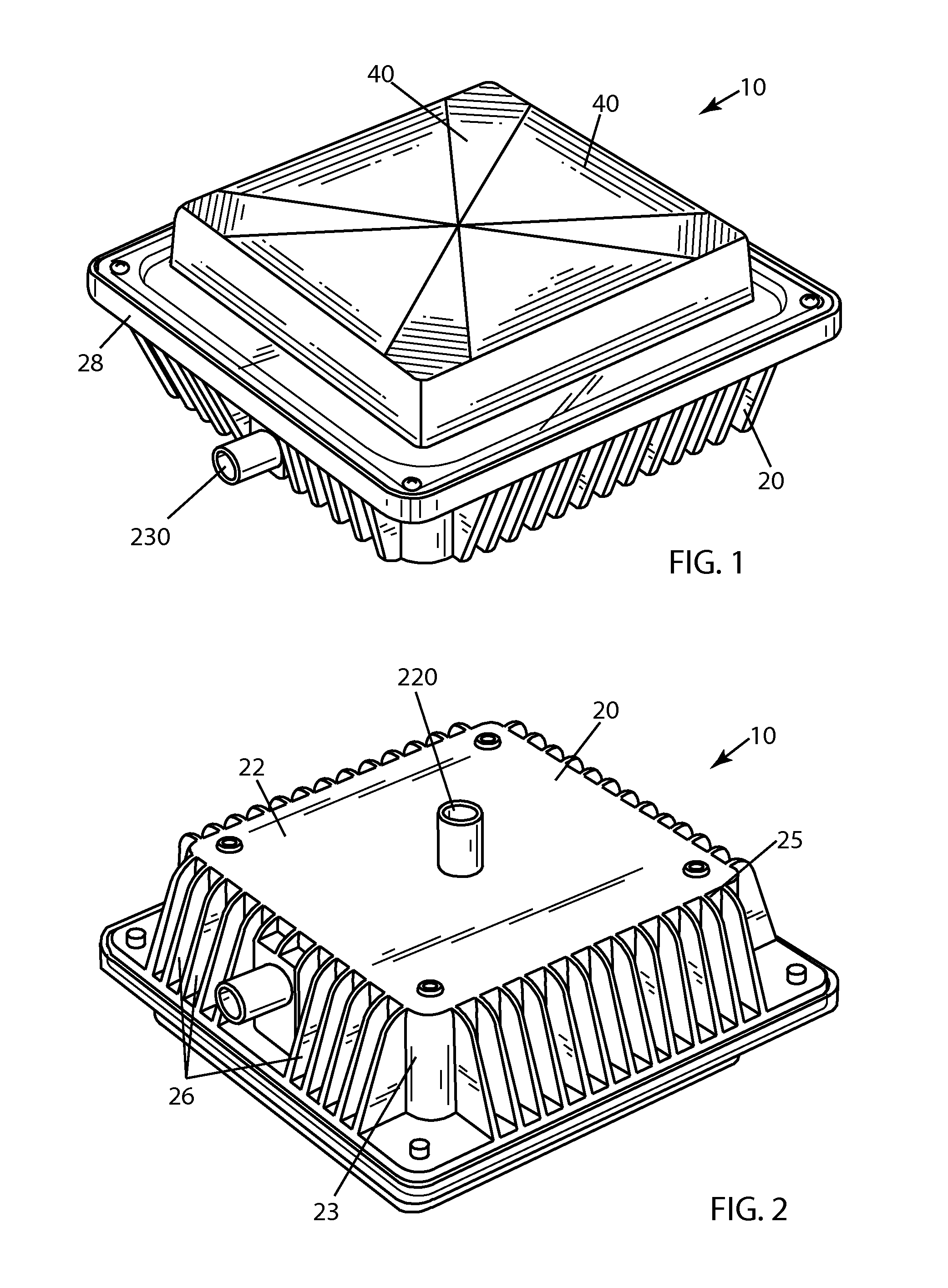

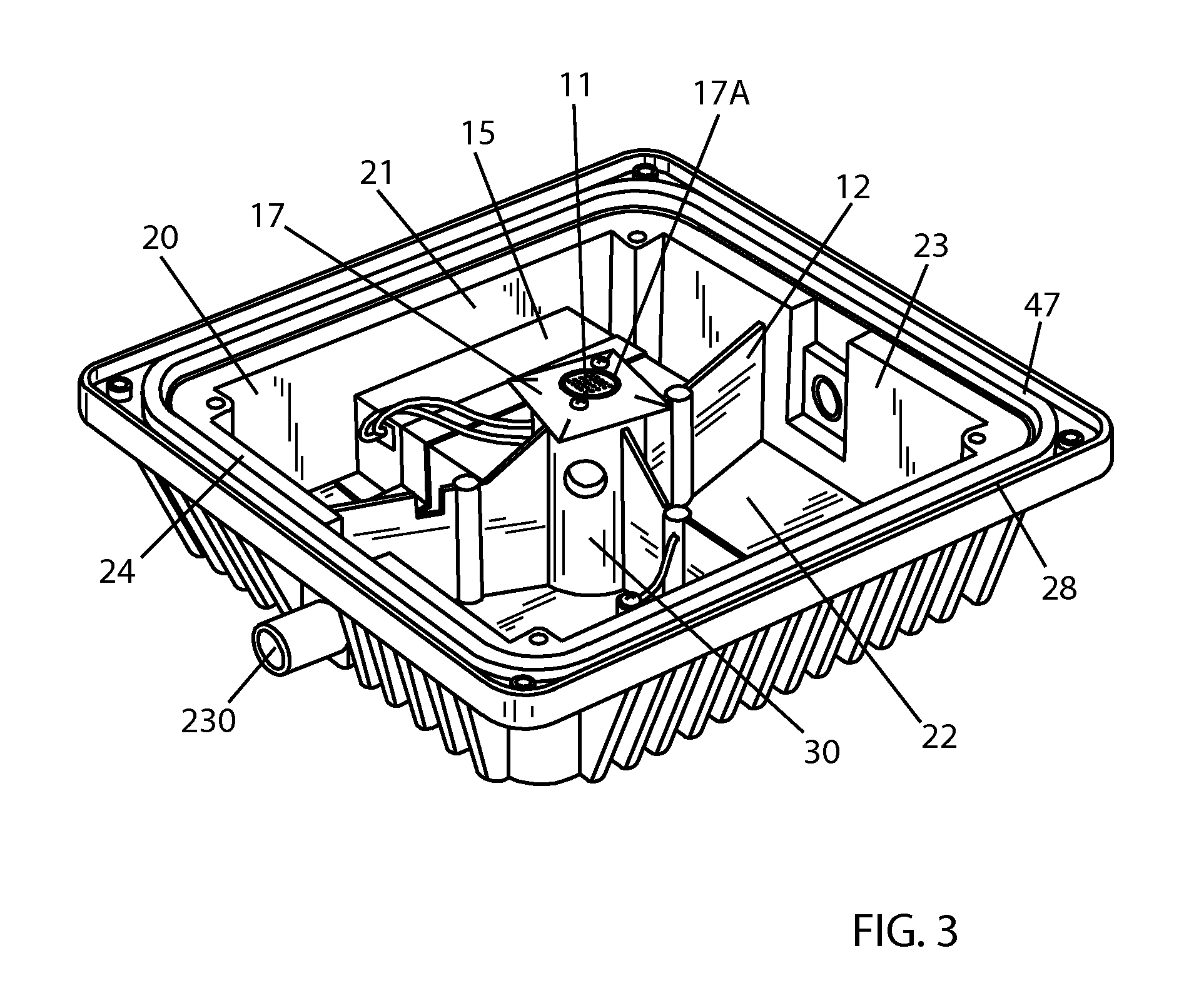

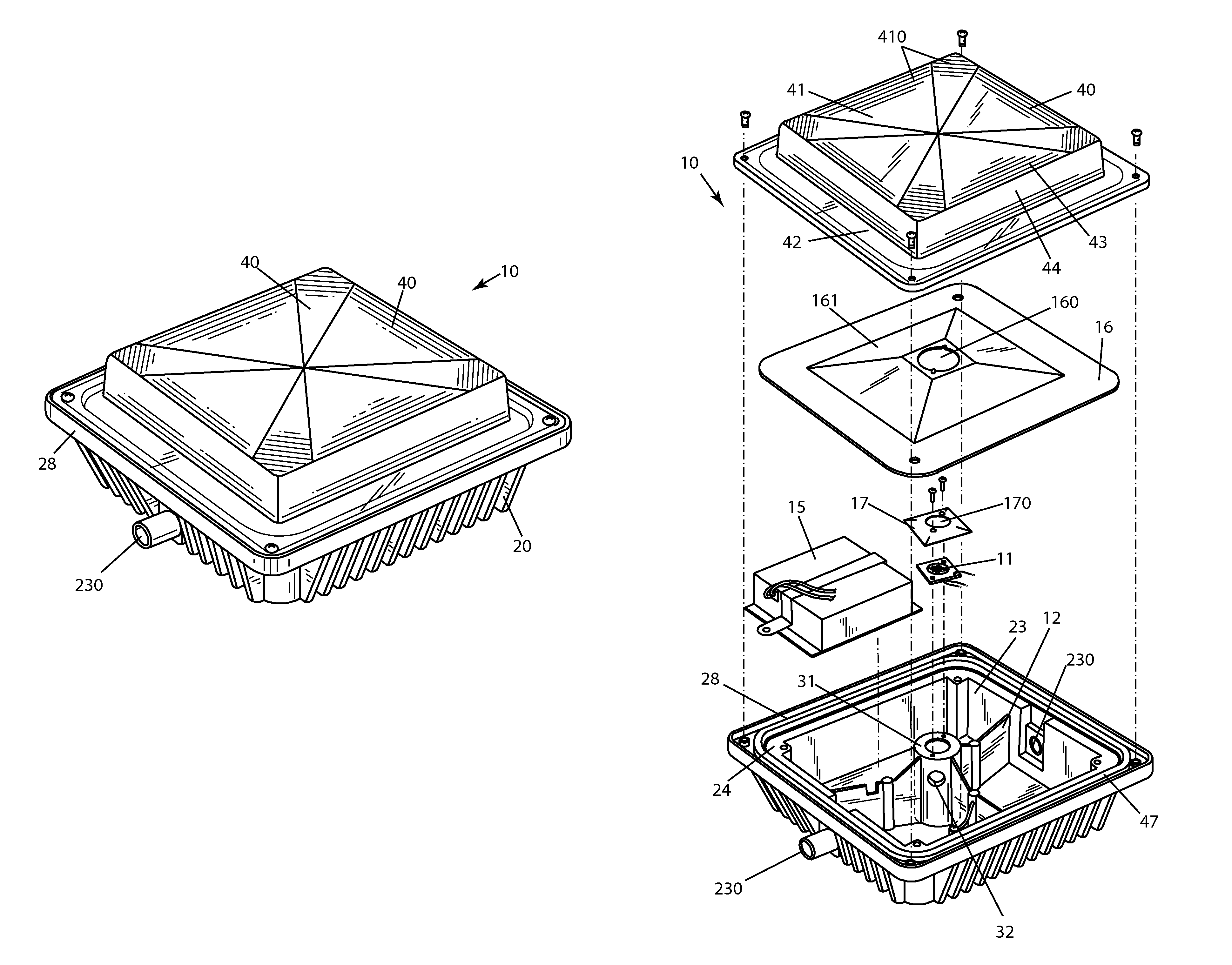

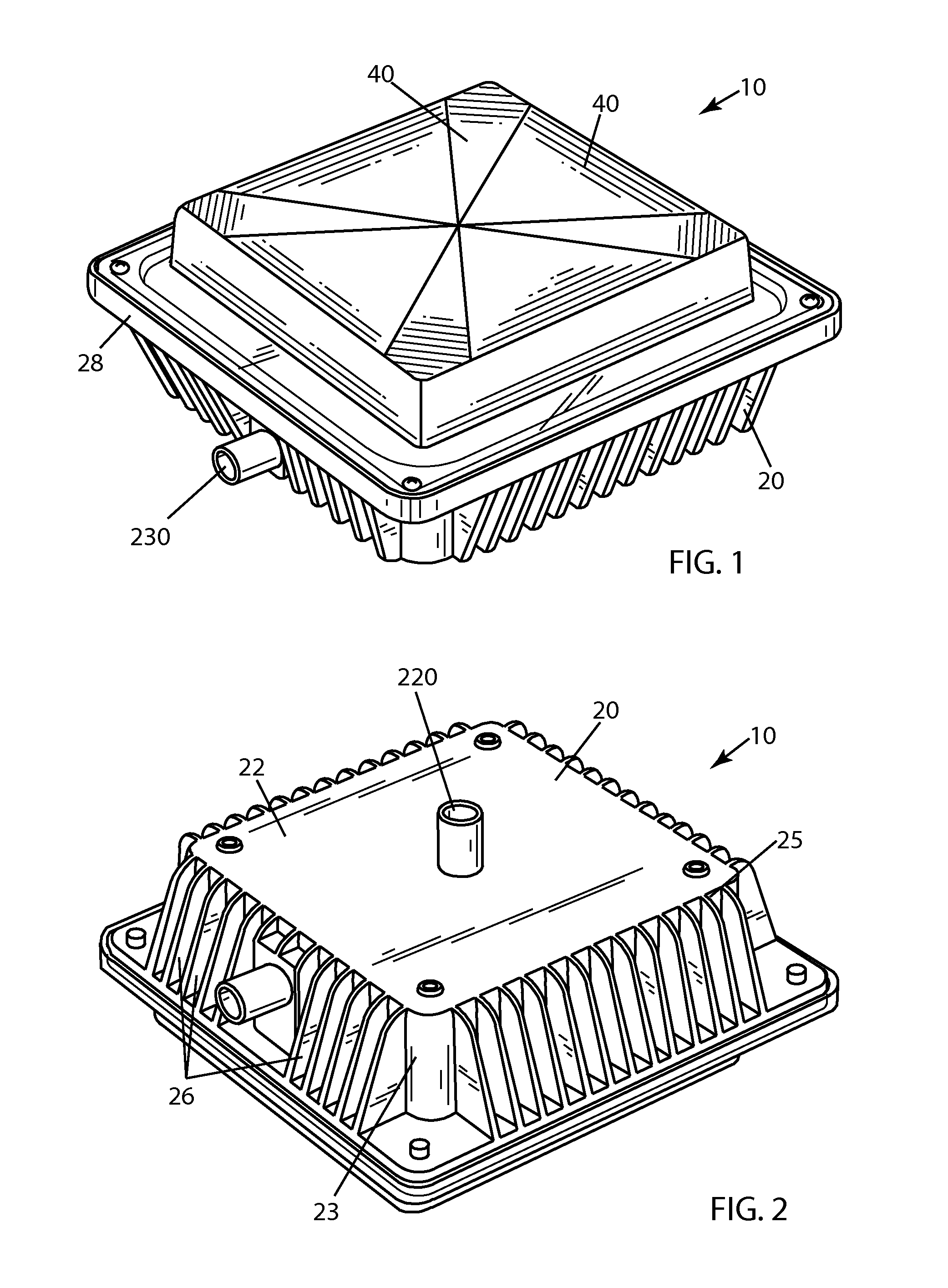

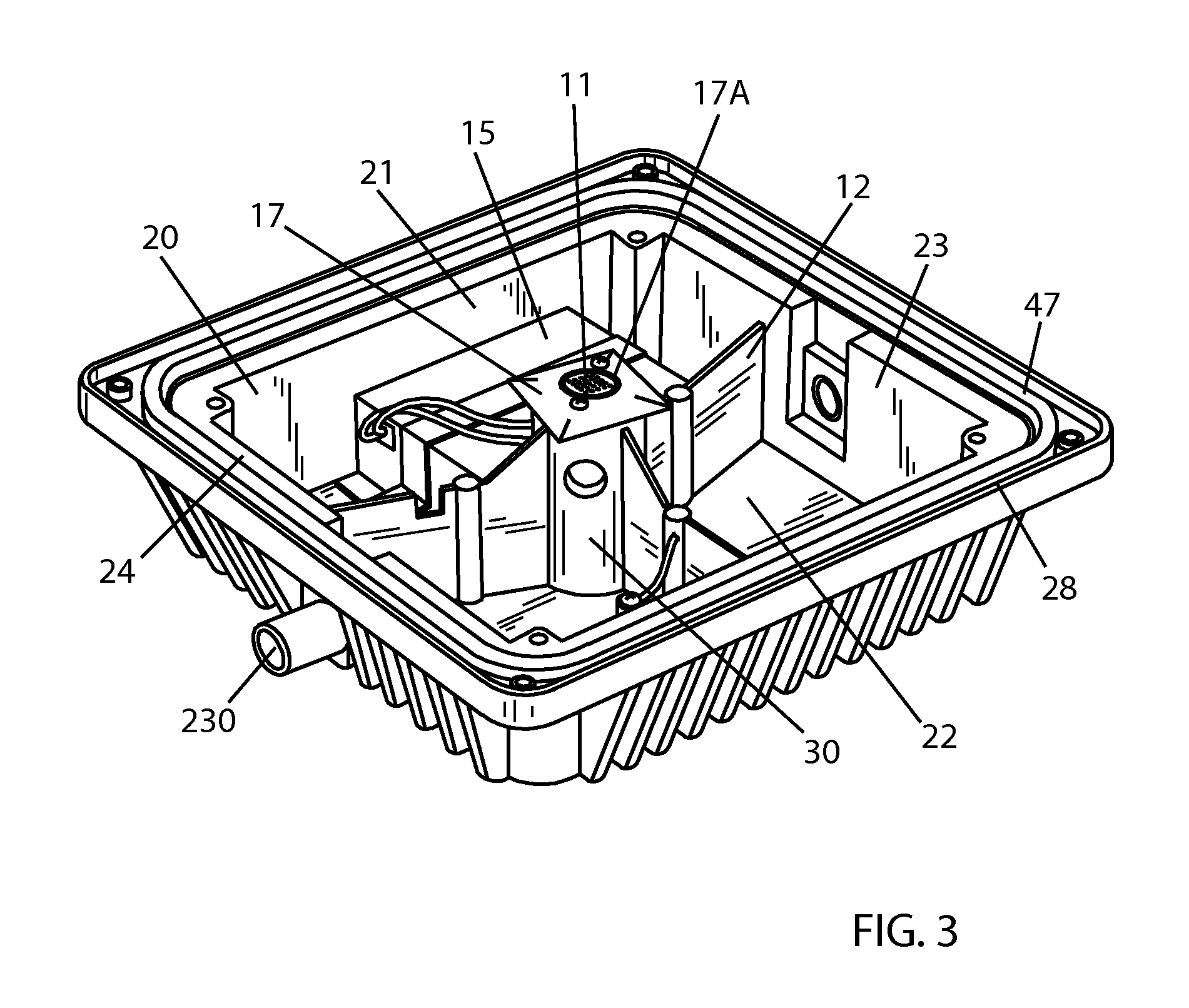

LED Lighting Fixture

ActiveUS20120057351A1Easy to adaptImprove protectionPlanar light sourcesLighting support devicesEffect lightEngineering

An LED lighting fixture including a housing having a hollow interior cavity defined by a backwall and a surrounding wall extending therefrom to a forward edge. An LED illuminator is mounted in the housing. An LED-support structure extends in the interior cavity from the housing to an LED-supporting surface positioning the LED illuminator in a desired orientation and spaced from the backwall. The LED-support structure is a heat sink transferring heat from the LED illuminator to the housing.

Owner:IDEAL IND LIGHTING LLC

Method and apparatus for discriminating and counting documents

InactiveUS7817842B2Simple and compactEasy to usePaper-money testing devicesCoin/currency accepting devicesEngineeringDocumentation

A currency evaluation device for receiving a stack of currency bills and rapidly evaluating all the bills in the stack. The device includes an input receptacle for receiving a stack of bills to be evaluated and a single output receptacle for receiving the bills after they have been evaluated. A transport mechanism transports the bills, one at a time, from the input receptacle to the output receptacle along a transport path. The device further includes a discriminating unit that evaluates the bills. The discriminating unit comprises two detectors positioned along the transport path between the input receptacle and the output receptacle. The detectors are disposed on opposite sides of the transport path so that they are disposed adjacent to opposite sides of the bills. The discriminating unit counts and determines the denomination of the bills. The evaluation device also includes means for flagging a bill when the denomination of the bill is not determined by the discriminating unit.

Owner:CUMMINS-ALLISON CORP

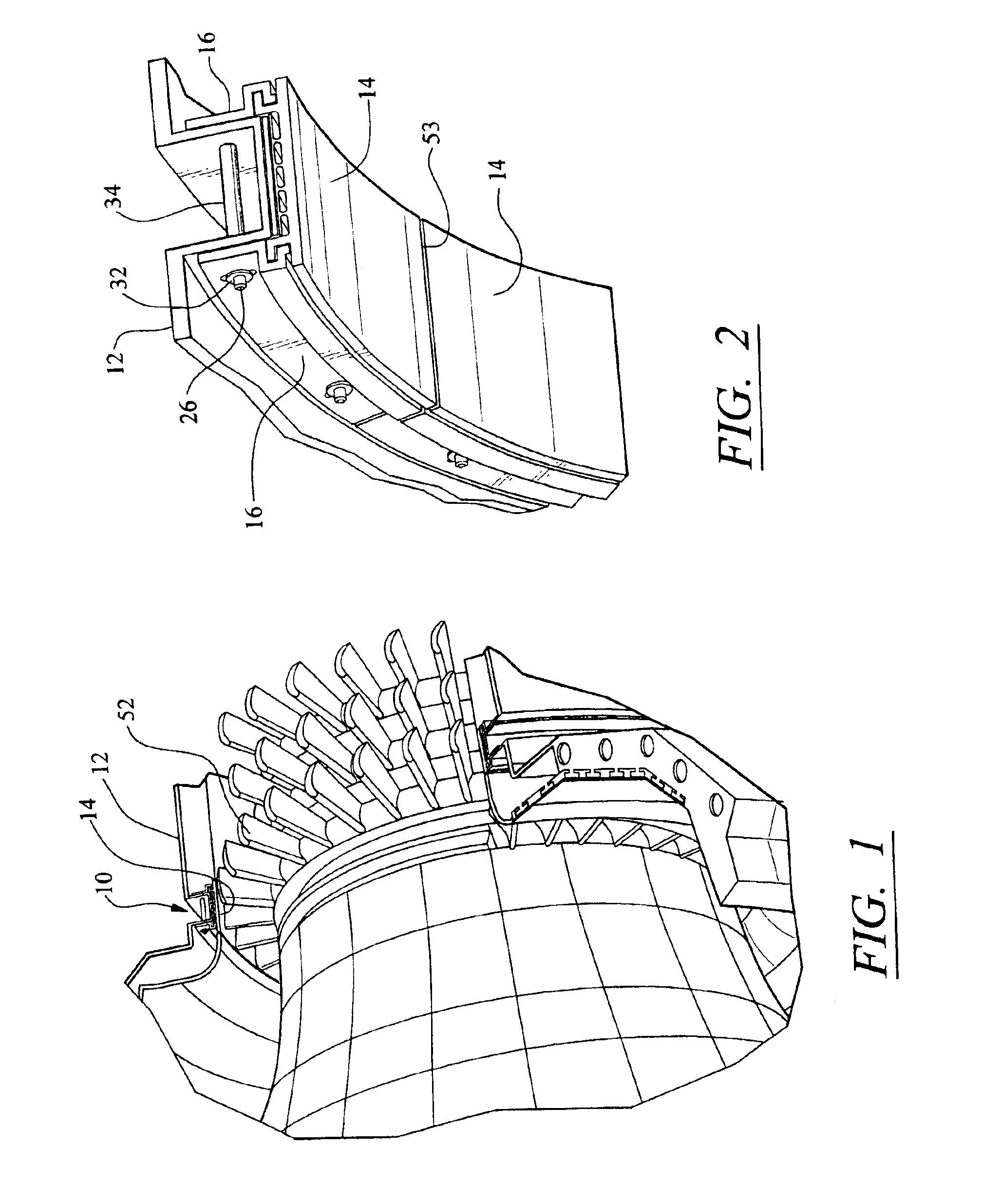

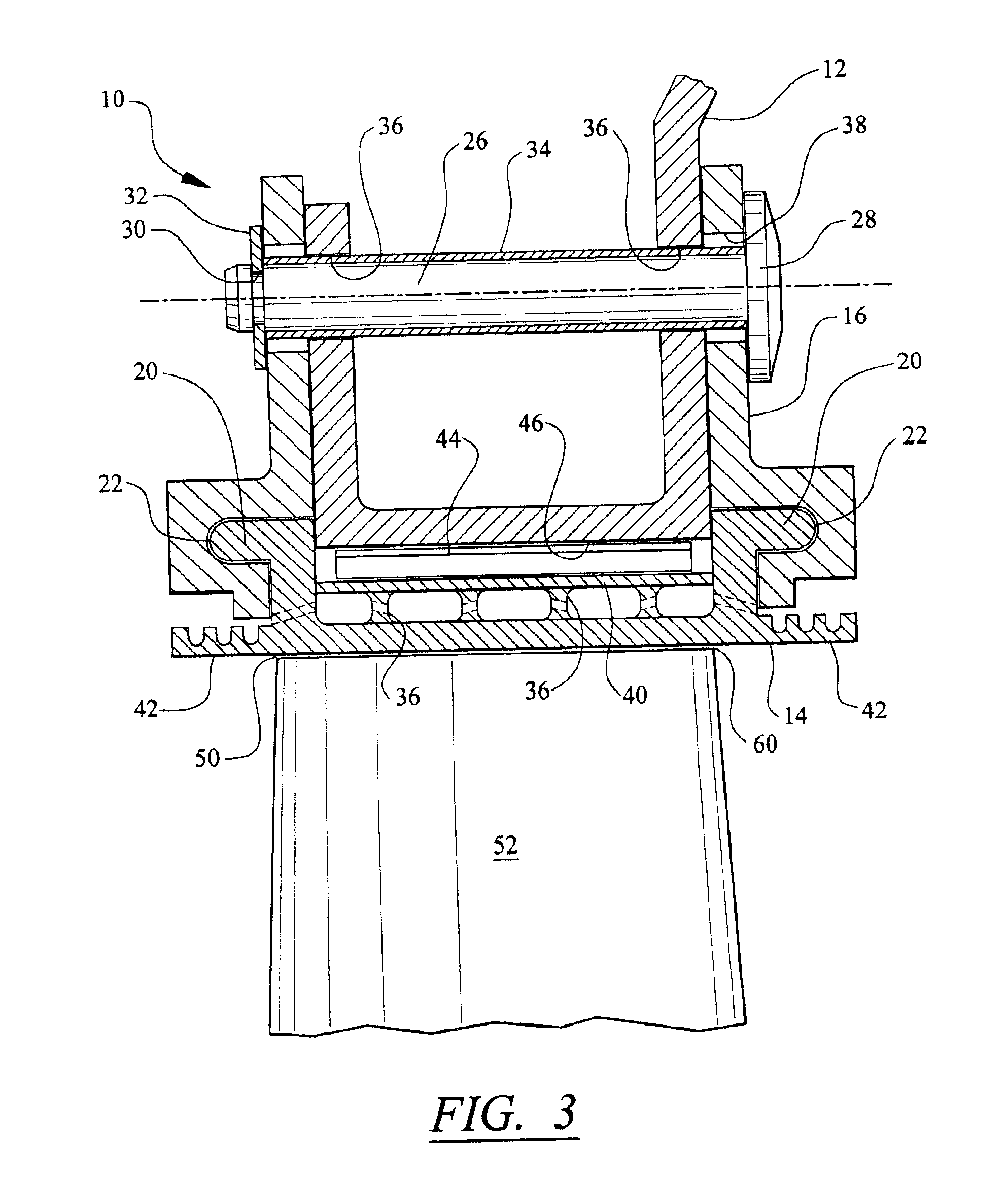

Passive clearance control

ActiveUS6877952B2Easy to processEasy to assemblePump componentsBlade accessoriesRadial positionEngineering

The clearance between the tips of the rotor blades and the segmented shroud of a gas turbine engine is controlled by a passive clearance control that includes a support ring made from a low thermal expansion material supporting a retainer for the blade outer air seal that is slidable relative thereto so that the segments expand circumferentially and move radially to match the rate of change slope of the rotor during expansion and contraction for all engine operations. A leaf spring between the support ring and outer air seal biases the outer air seal in the radial direction and maintains the desired radial position during steady state operation of the gas turbine engine.

Owner:FLORIDA TURBINE TECH

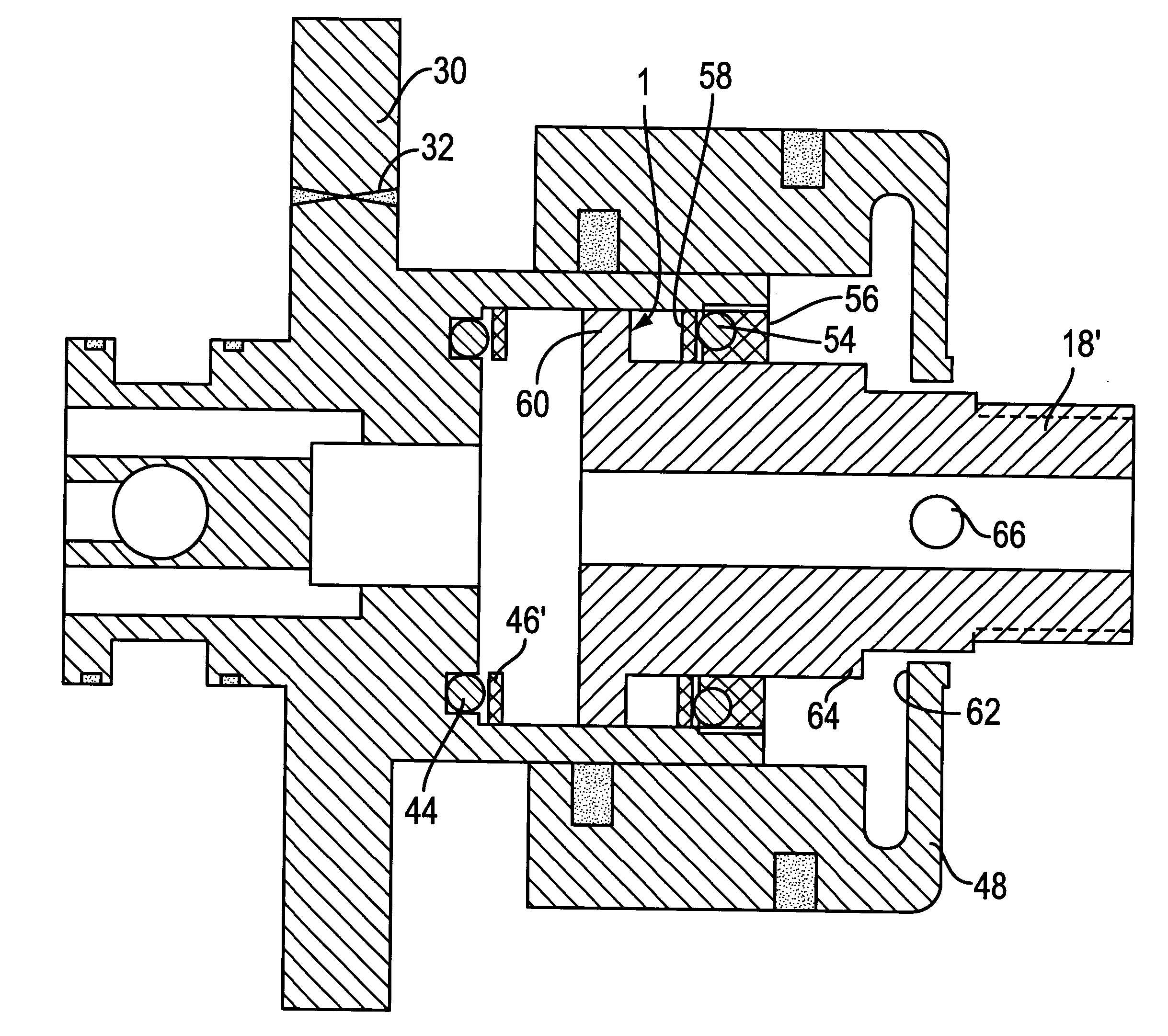

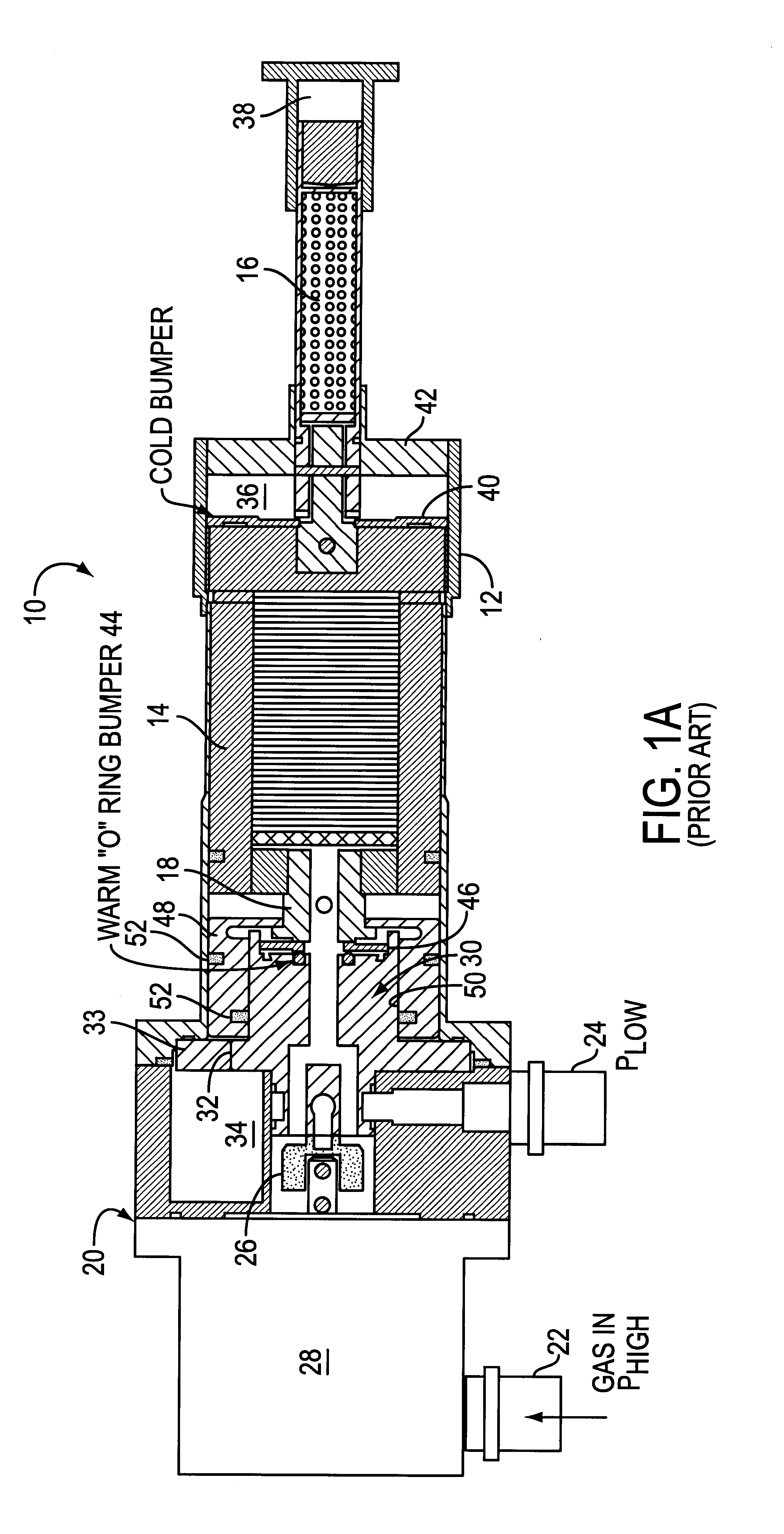

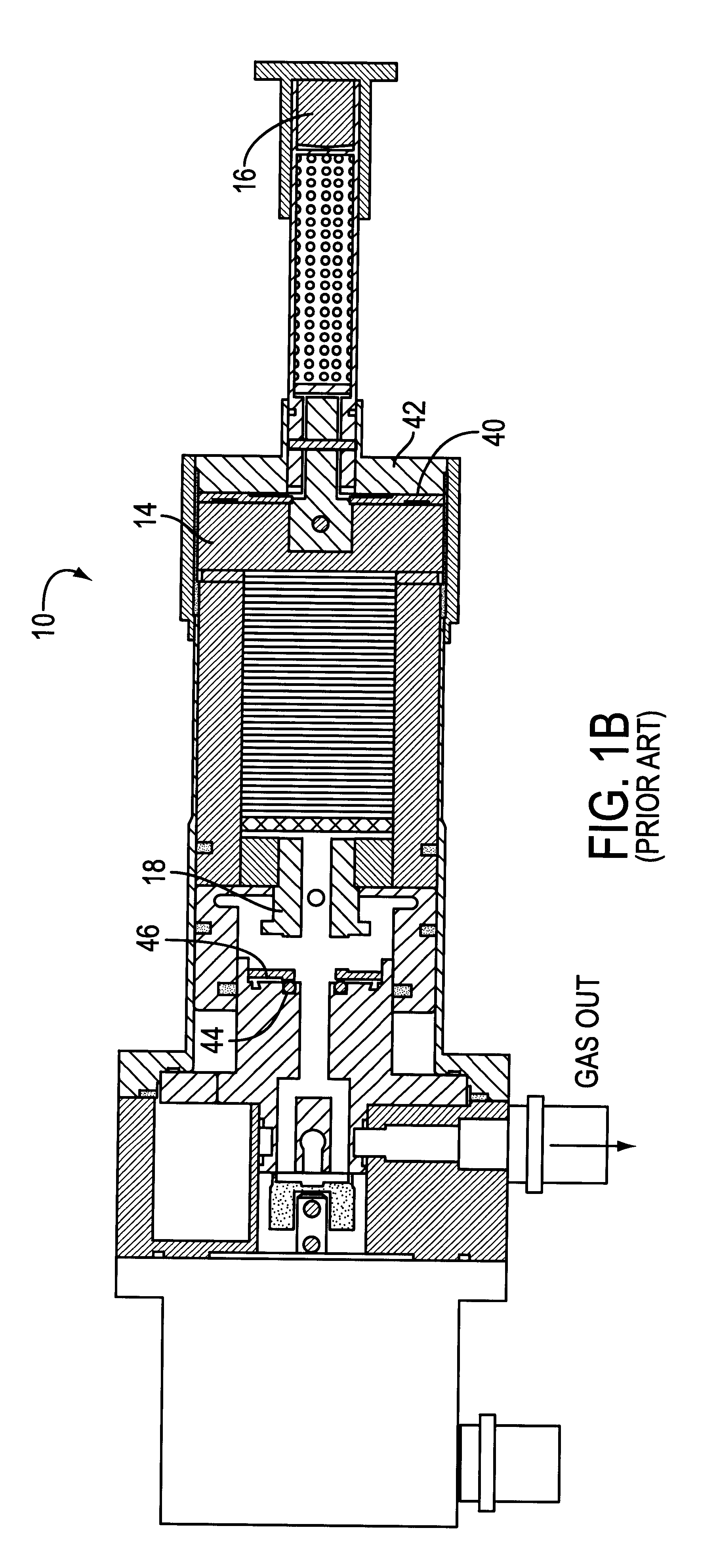

Reduced vibration cooling device having pneumatically-driven GM type displacer

InactiveUS6256997B1Reduce electrical noiseReduce vibrationCompression machinesRefrigeration componentsElastomerEngineering

A GM type displacer has an elastomer "O" ring at the warm end to absorb impact energy when the displacer reaches the bottom of the stroke before it would hit the cylinder end cap. When the displacer reaches the top of its stroke, before the displacer would hit the internal mechanism of the expander, another elastomer "O" ring absorbs the kinetic energy of the displacer. Both absorbers are at or near ambient temperature.

Owner:GENERAL ELECTRIC CO

LED lighting fixture

ActiveUS8465178B2Easy to adaptImprove protectionPlanar light sourcesPoint-like light sourceEffect lightEngineering

An LED lighting fixture including a housing having a hollow interior cavity defined by a backwall and a surrounding wall extending therefrom to a forward edge. An LED illuminator is mounted in the housing. An LED-support structure extends in the interior cavity from the housing to an LED-supporting surface positioning the LED illuminator in a desired orientation and spaced from the backwall. The LED-support structure is a heat sink transferring heat from the LED illuminator to the housing.

Owner:IDEAL IND LIGHTING LLC

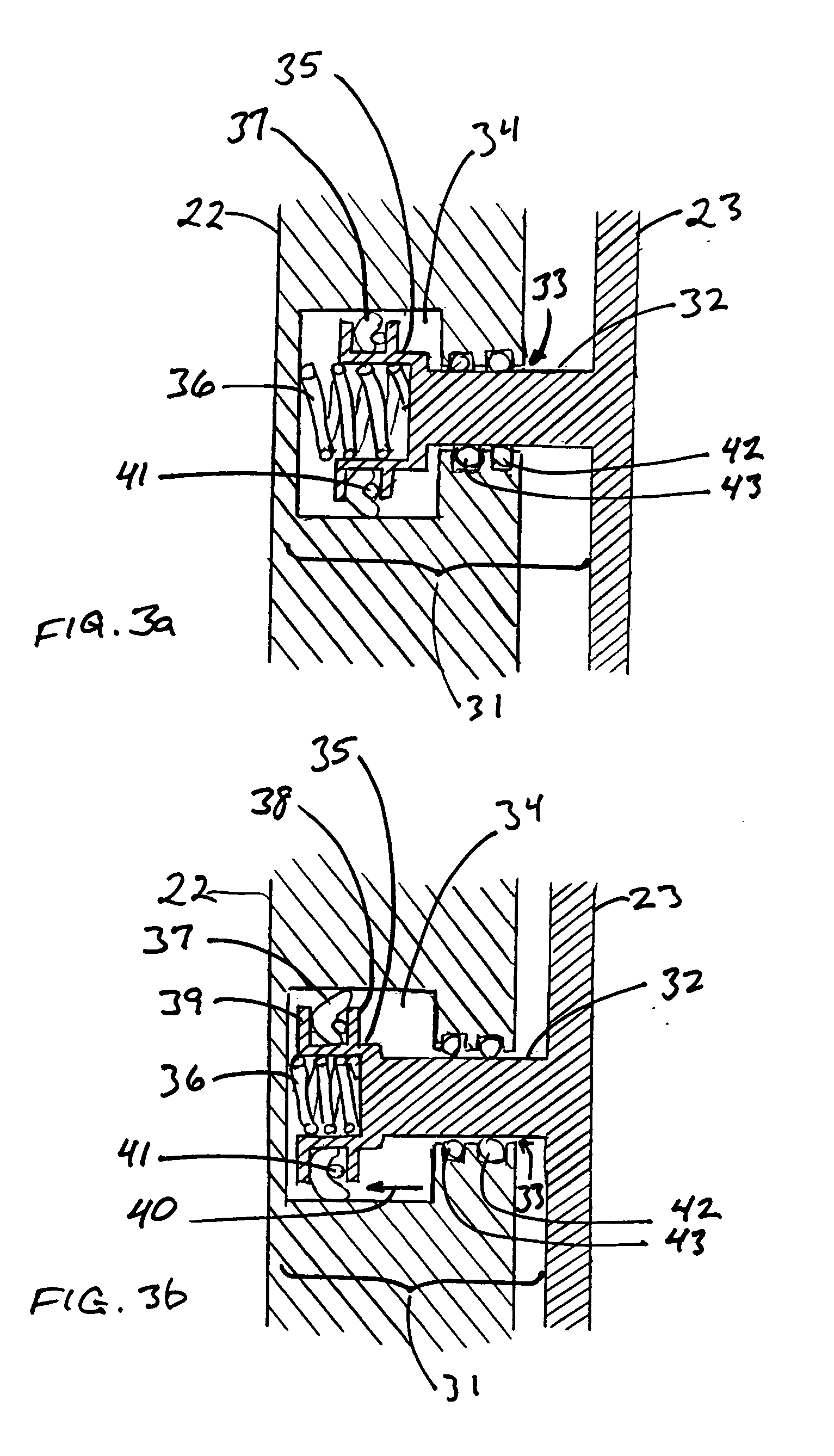

High-vacuum valve with retractable valve plate to eliminate abrasion

InactiveUS20040079915A1High yieldIncreased operating lifeSlide valveValve member-seat contactsEngineeringVALVE PORT

A valve achieves a high-vacuum seal and opens and closes with no sliding or otherwise abrading contact between the sealing plate and the valve seat, while maintaining pressure of the plate against the valve seat in the event of a failure in the valve actuation mechanism. These results are attained by use of a composite valve plate that includes a sealing plate joined to a support block through a retractable resilient connector. During retraction, the sealing plate is drawing close to the block by a pneumatic actuator internal to the composite valve plate, the actuator arranged to oppose and overcome a mechanical resilient element also contained within the valve plate that urges the sealing plate outward from the support block to effect the seal when the actuator is not engaged.

Owner:MDC VACUUM PRODS

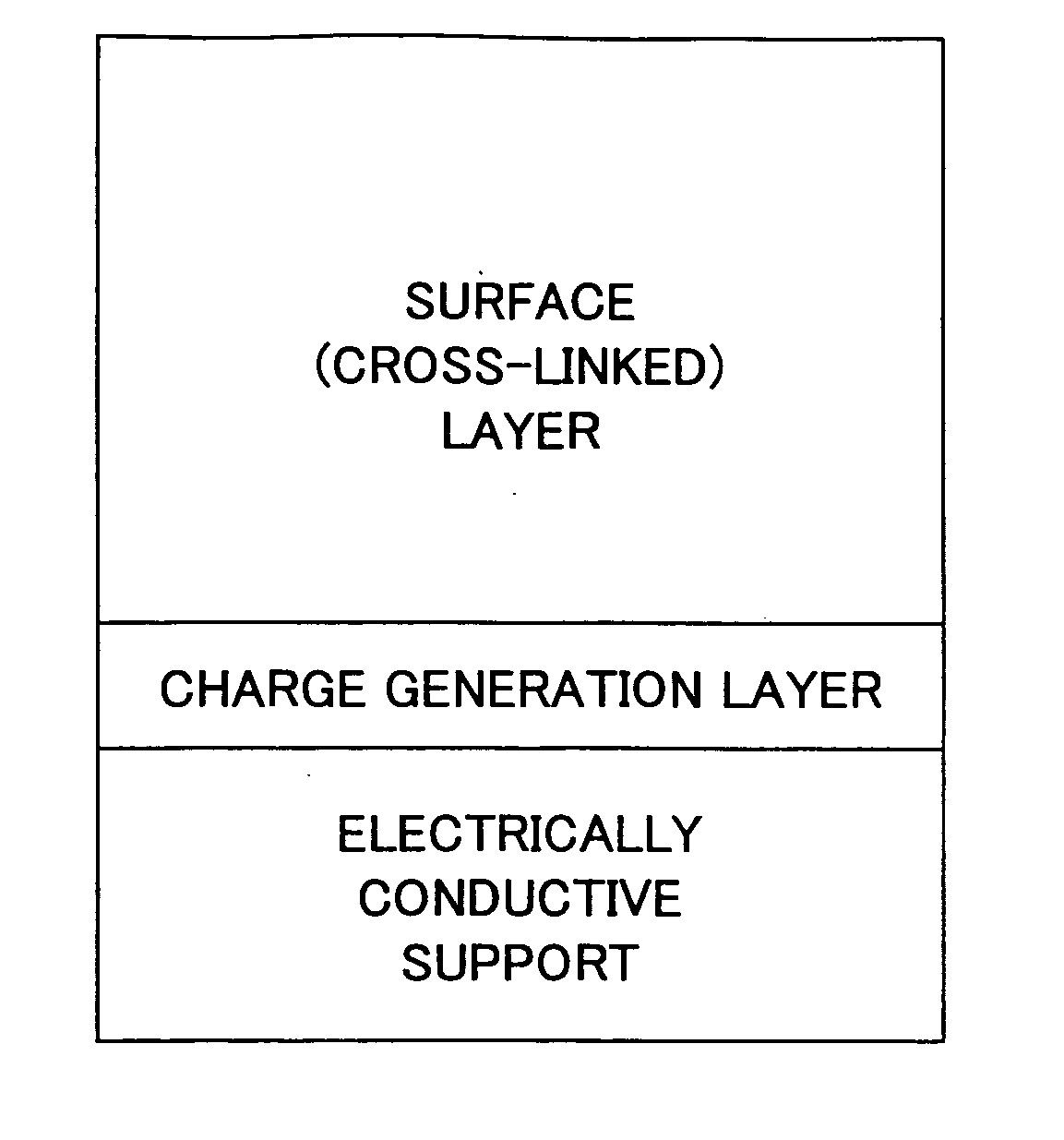

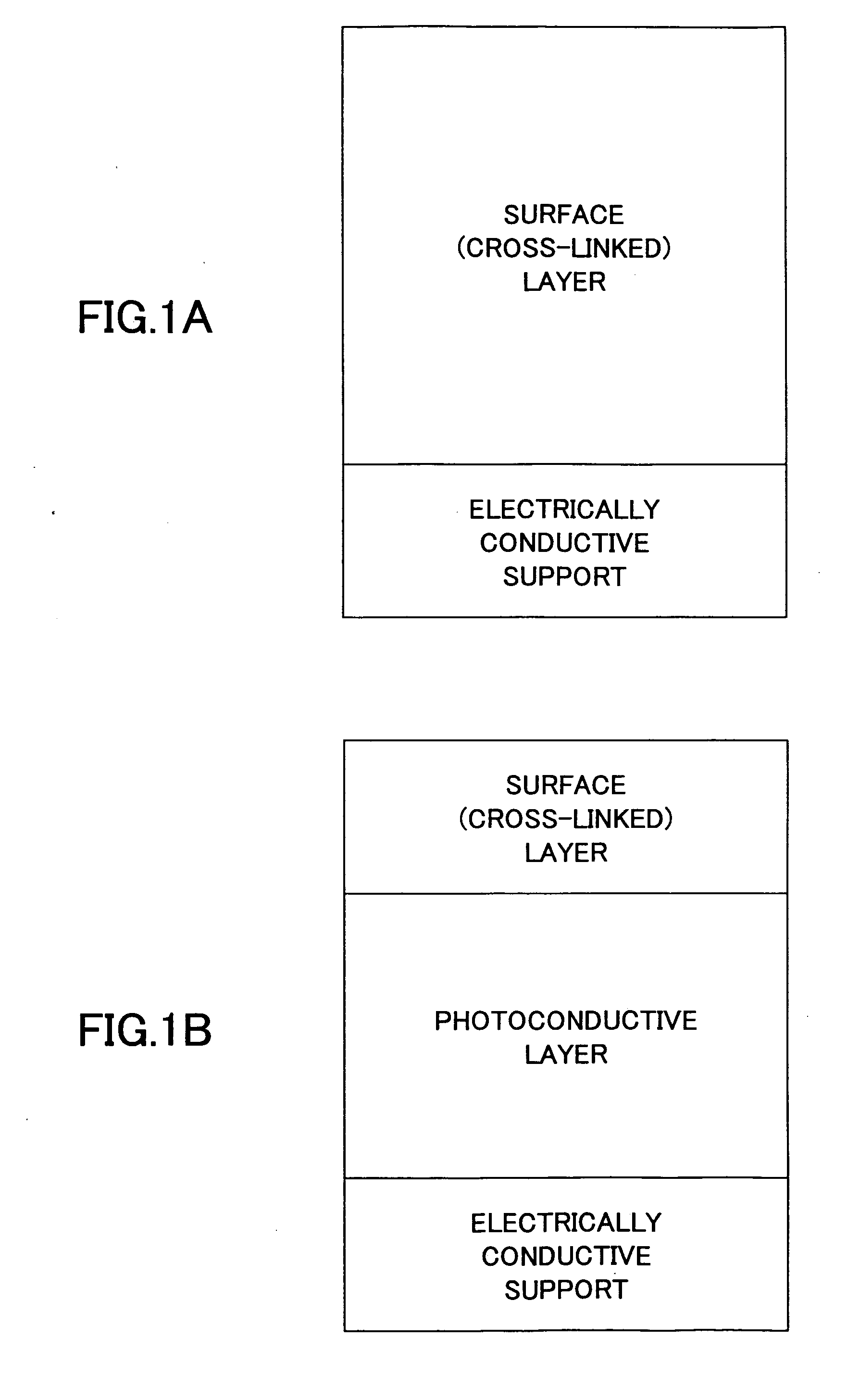

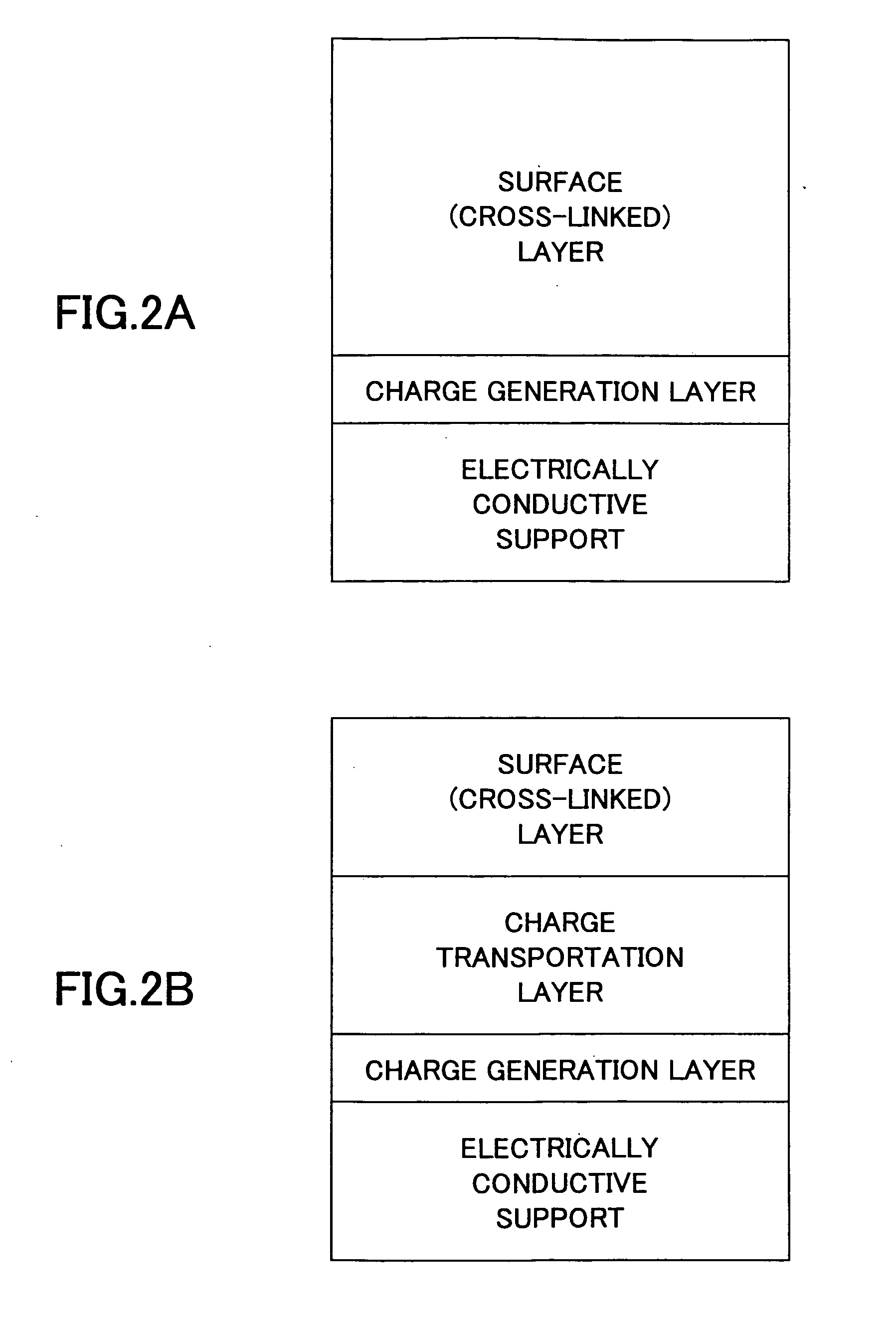

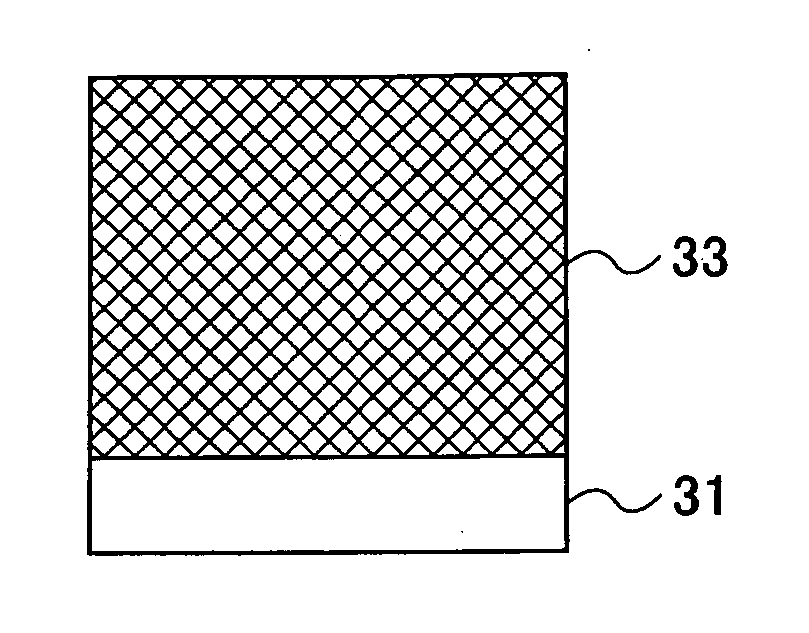

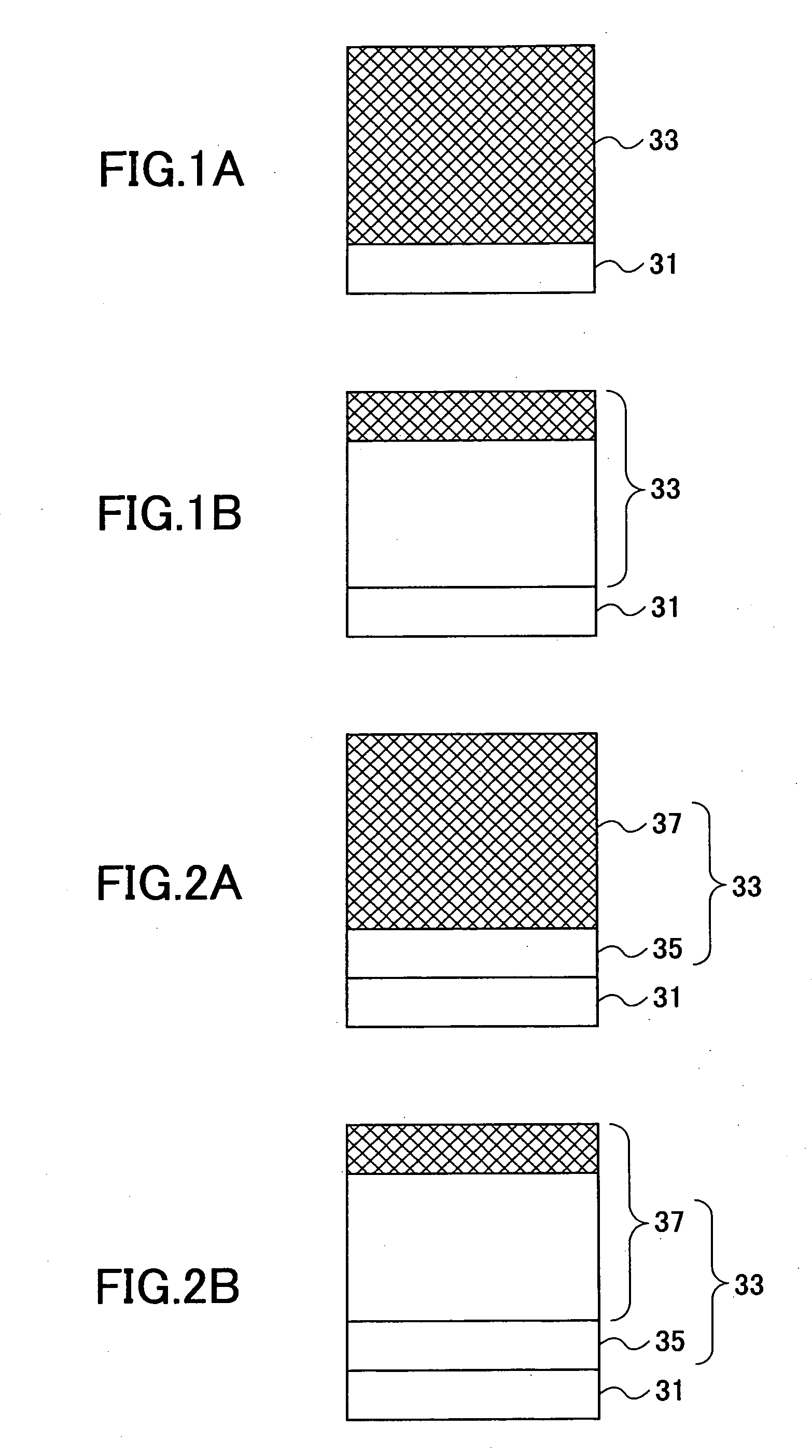

Electrophotographic photoconductor, and image formation method, image formation apparatus, and process cartridge for image formation apparatus using the same

ActiveUS20050158641A1Excellent service durabilityStable electrical characteristicsElectrographic process apparatusElectrographic processes using charge patternSurface layerElectrical conductor

An electrophotographic photoconductor having at least a photoconductive layer on an electrically conductive support, in which a surface layer of the photoconductive layer can be obtained by curing at least a free-radical-polymerizable monomer having no electron transporting structure, represented by general formula (A) and a one-functional free-radical-polymerizable compound having an electron transporting structure, wherein R71, R72, R73, R74, R75, and R76 are described in the specification.

Owner:RICOH KK

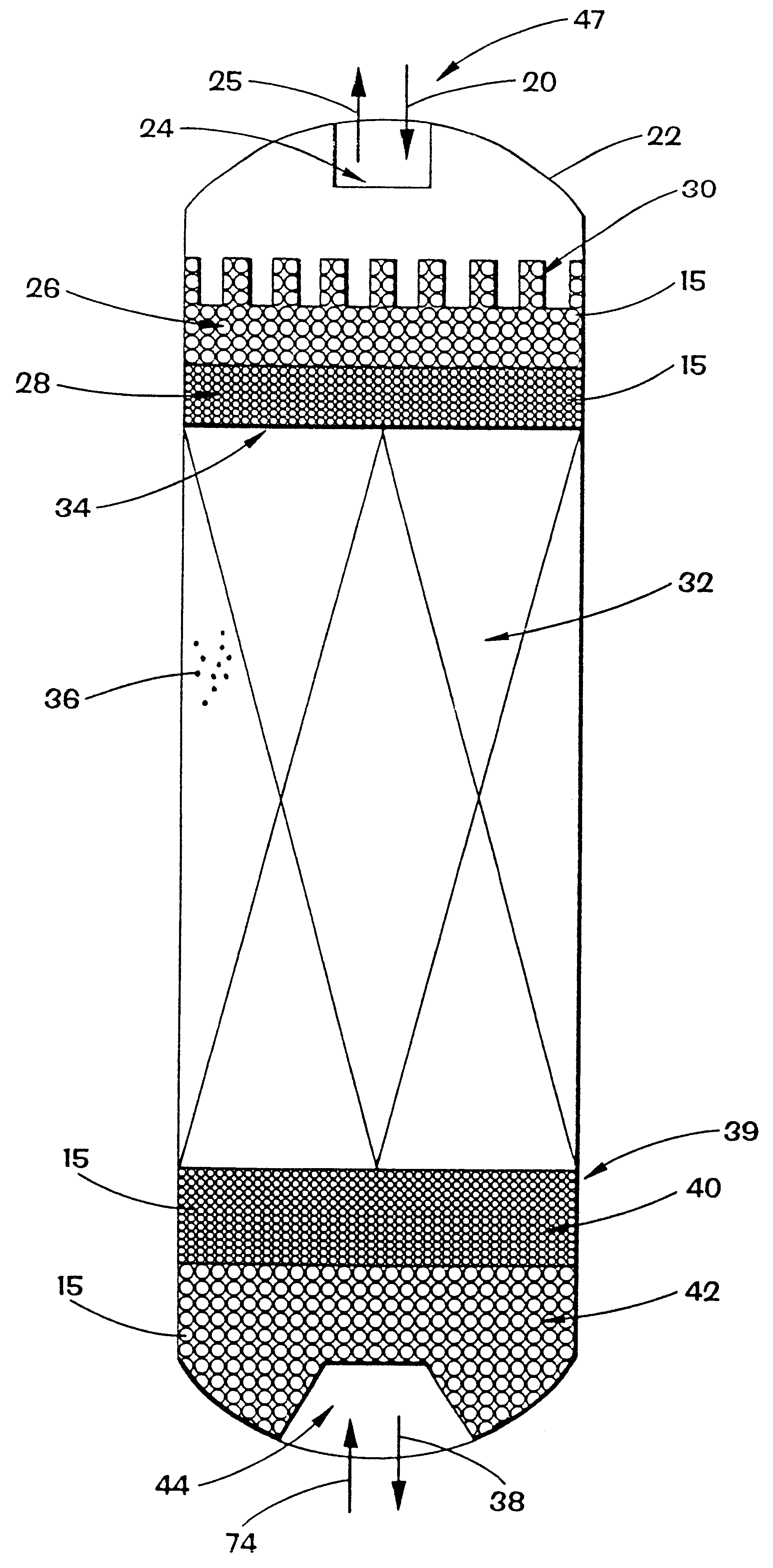

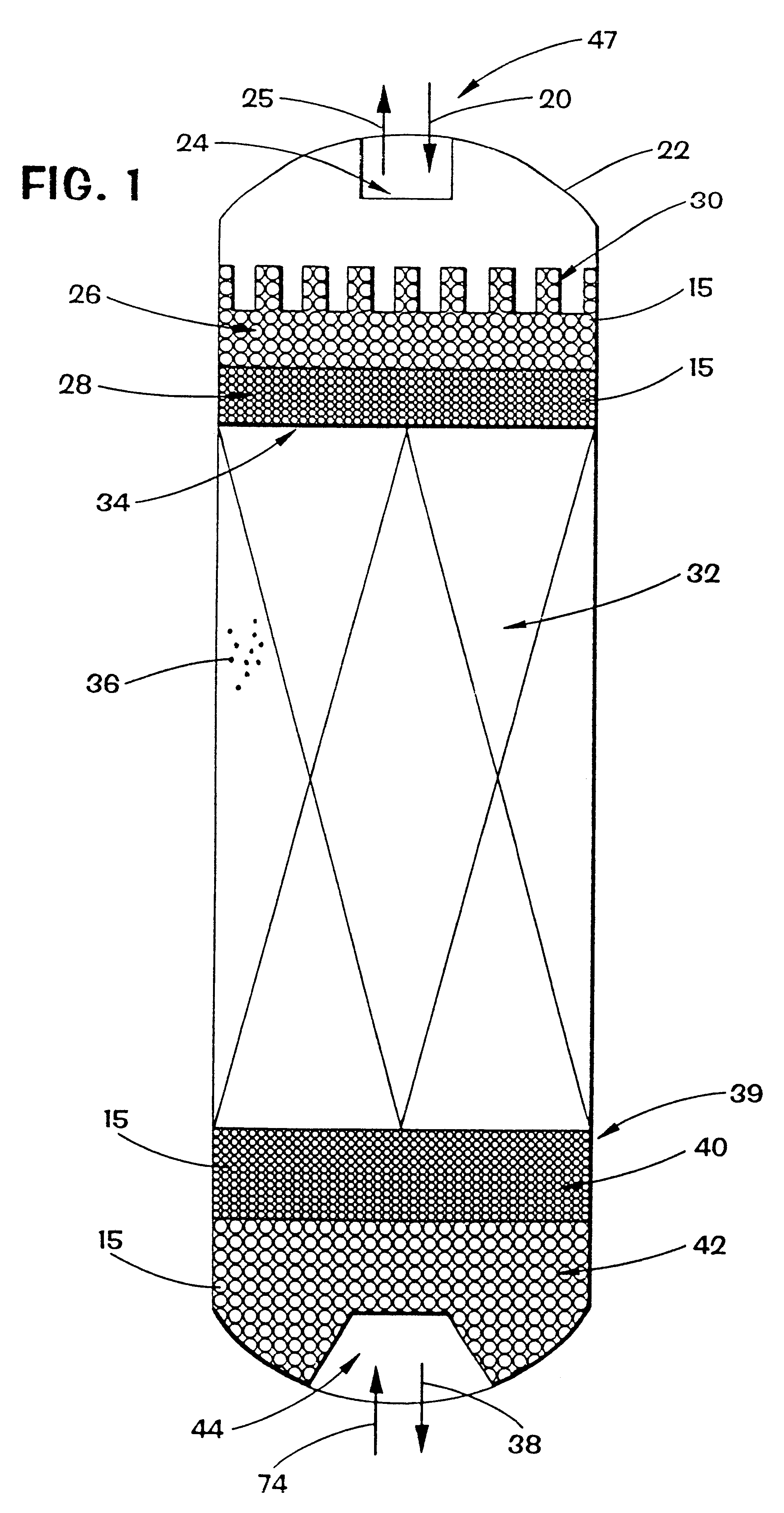

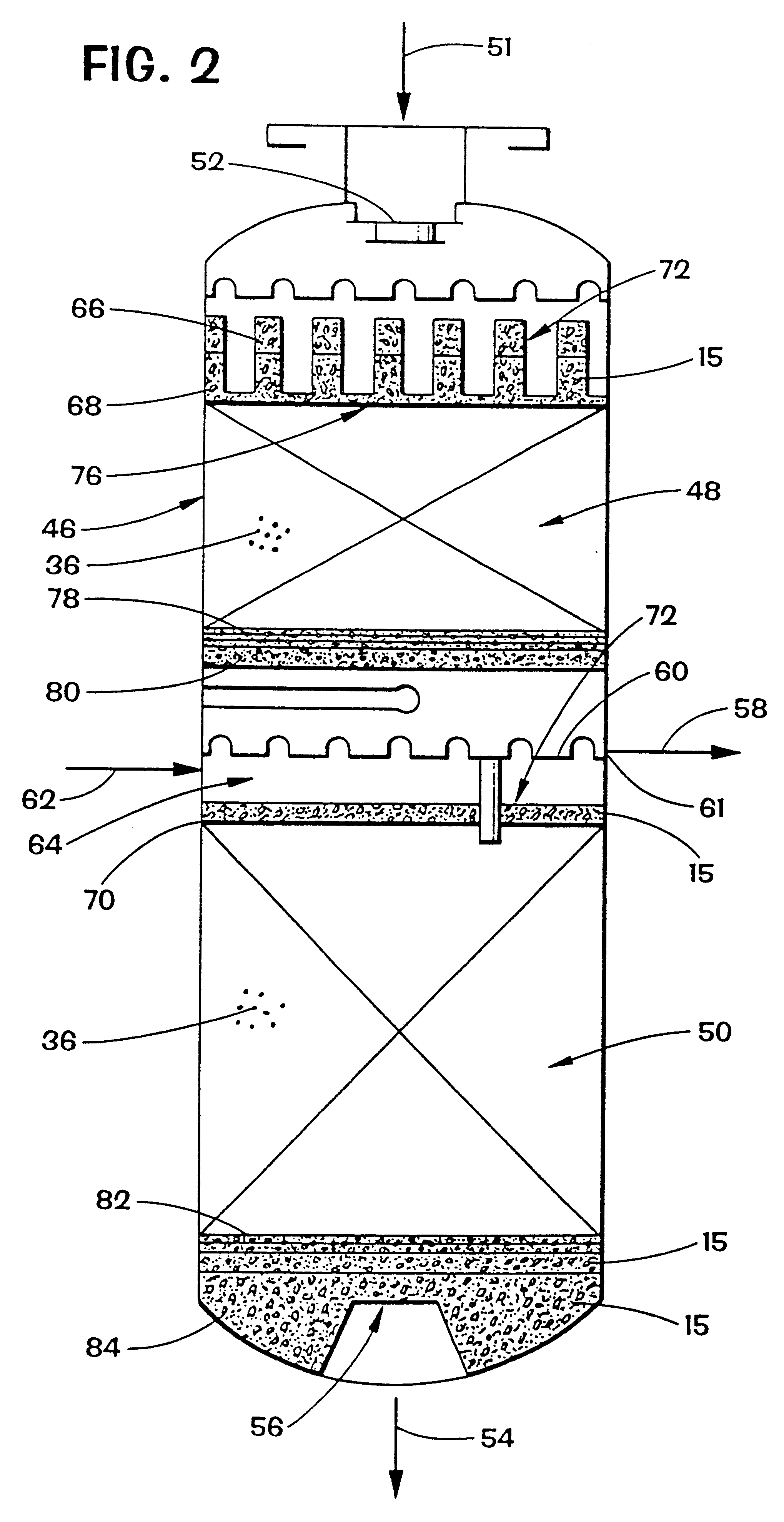

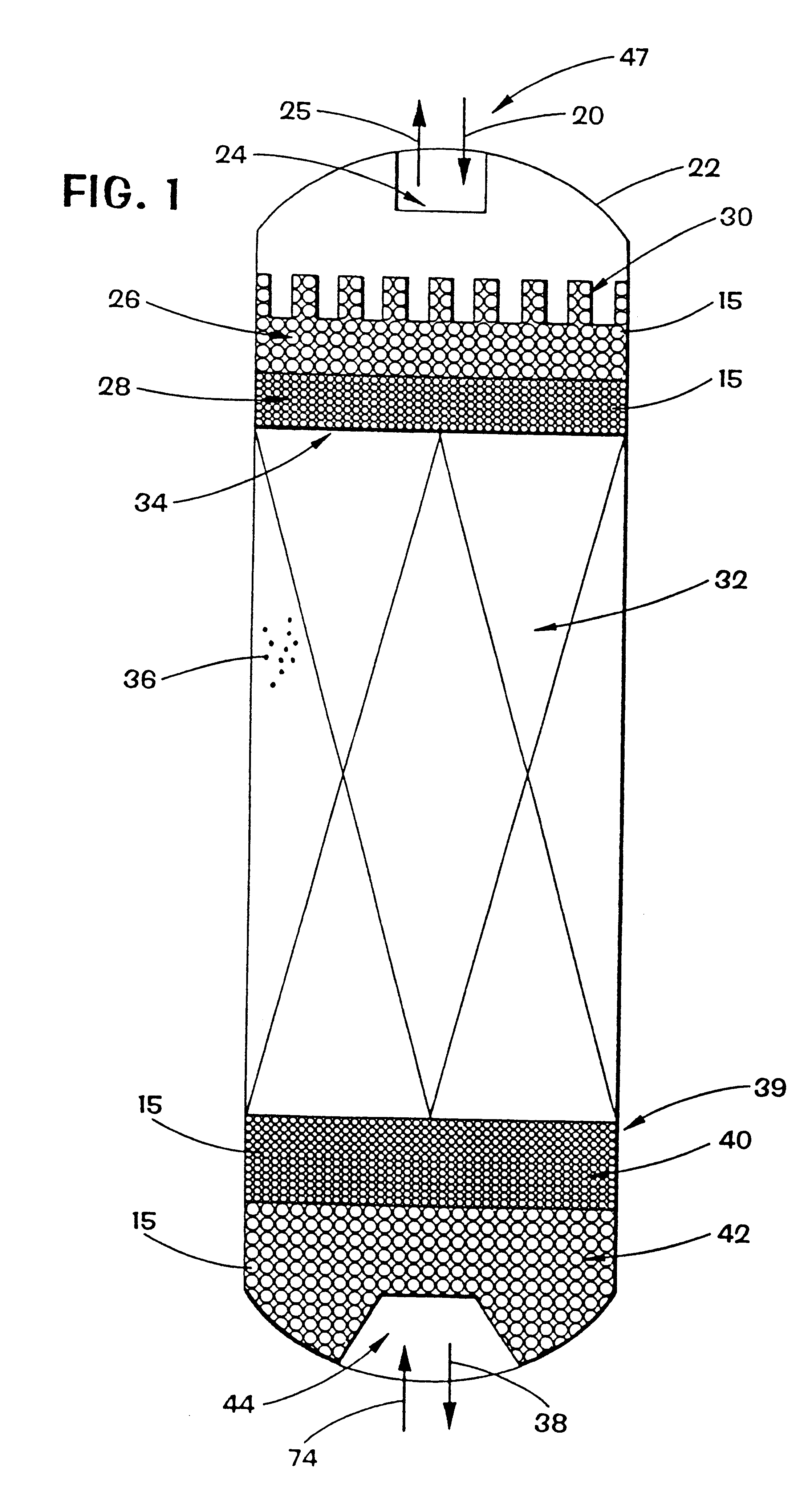

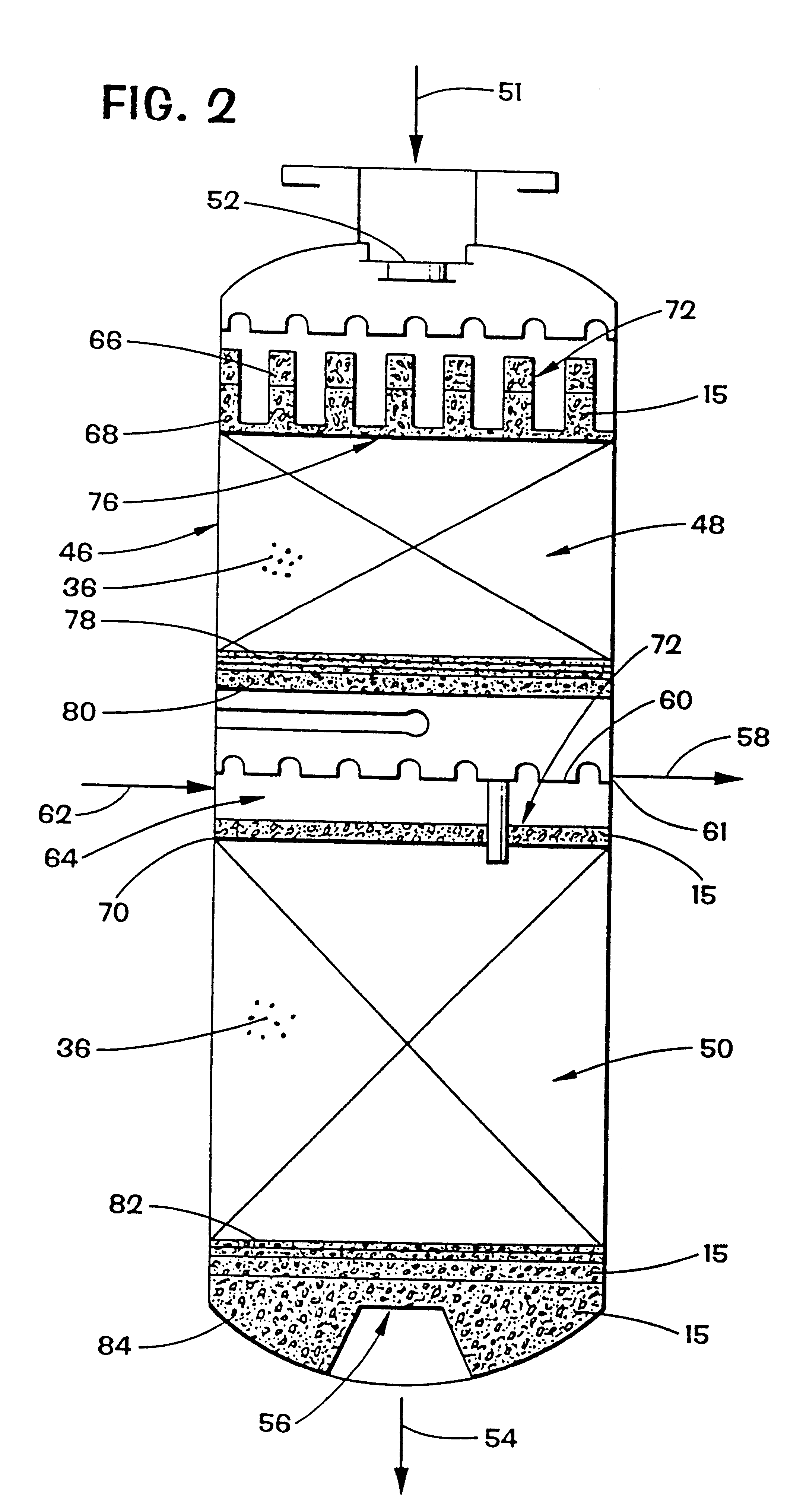

Filtration and flow distribution method for chemical reactors

InactiveUS6258900B1Reduce turbulenceHigh trafficCatalytic naphtha reformingMembrane filtersChemical reactorFiltration

Owner:CRYSTAPHASE PRODS

Electrophotographic photoconductor and image formation method, image formation apparatus, and process cartridge for image formation apparatus using the electrophotographic photoconductor

InactiveUS20050221210A1Improve wear resistanceImprove smoothnessElectrographic process apparatusCorona dischargeElectrical conductorSurface layer

An electrophotographic photoconductor having at least a photoconductive layer on an electrically conductive support, wherein a surface layer of the photoconductive layer is a crosslinked layer obtainable by curing at least a three or more-functional radical-polymerizable monomer having no charge transporting structure and a charge transportation compound having a radical-polymerizable functional group by using an acylphosphine oxide compound as a photo-polymerization initiator under light energy irradiation.

Owner:RICOH KK

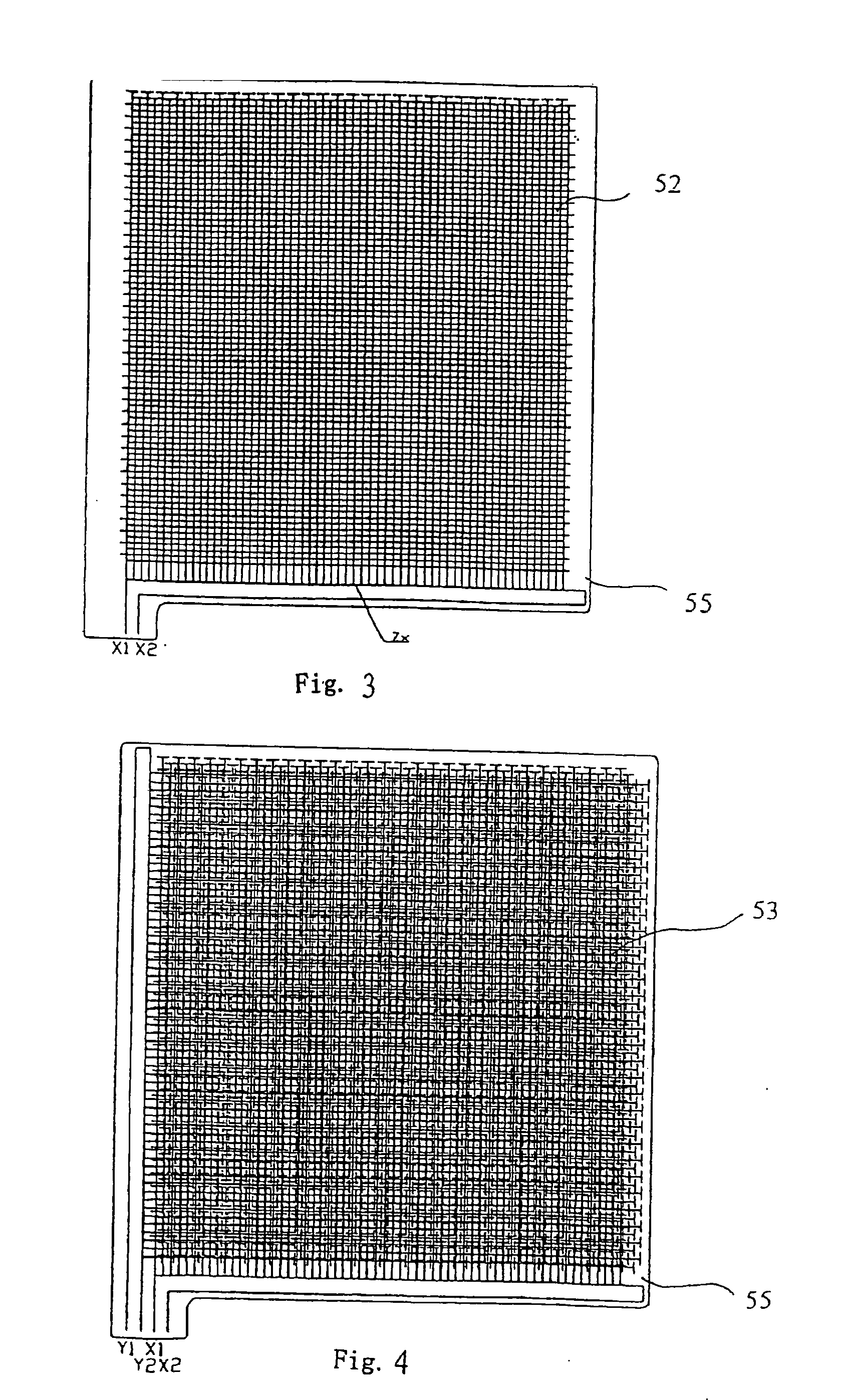

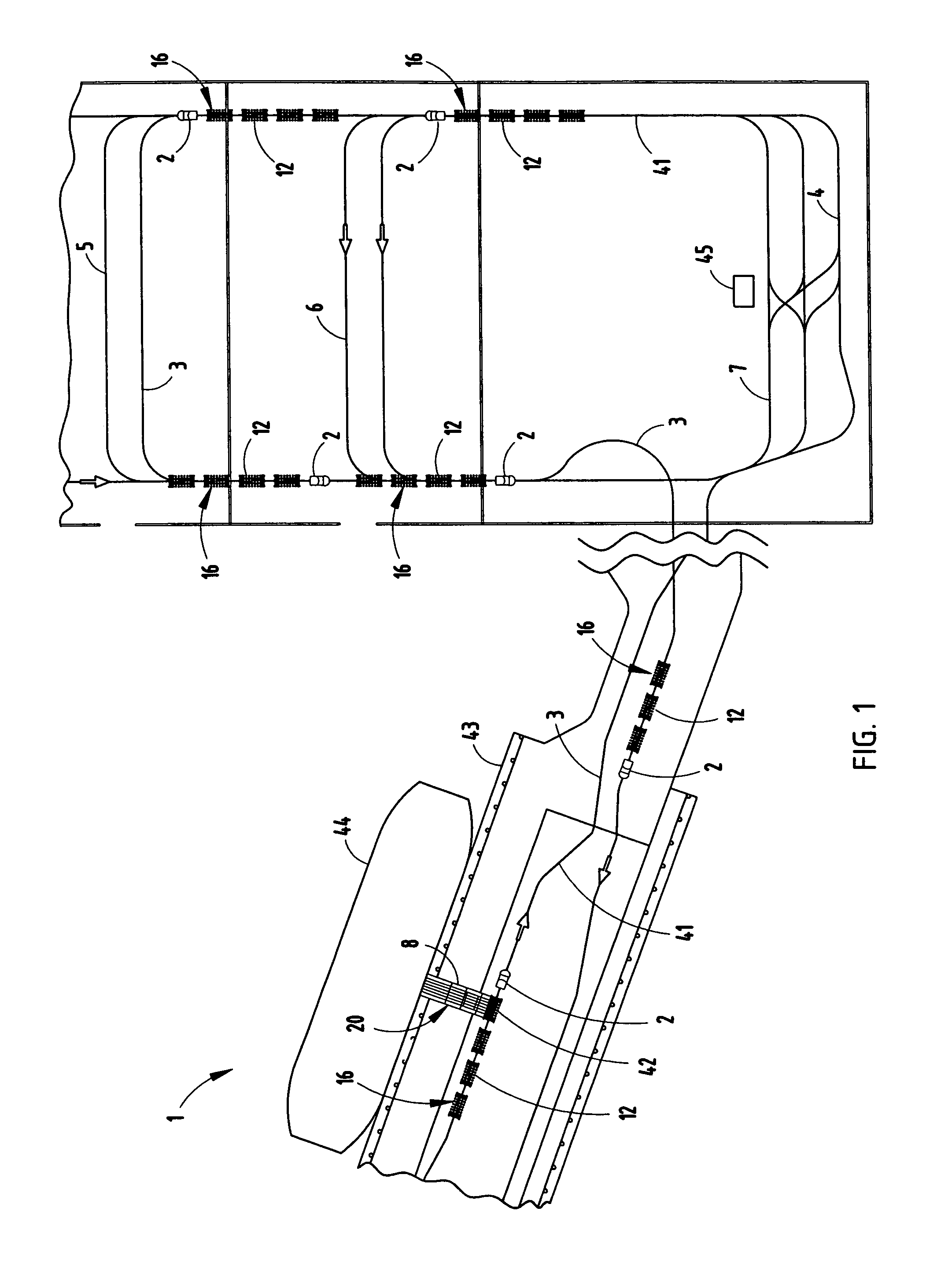

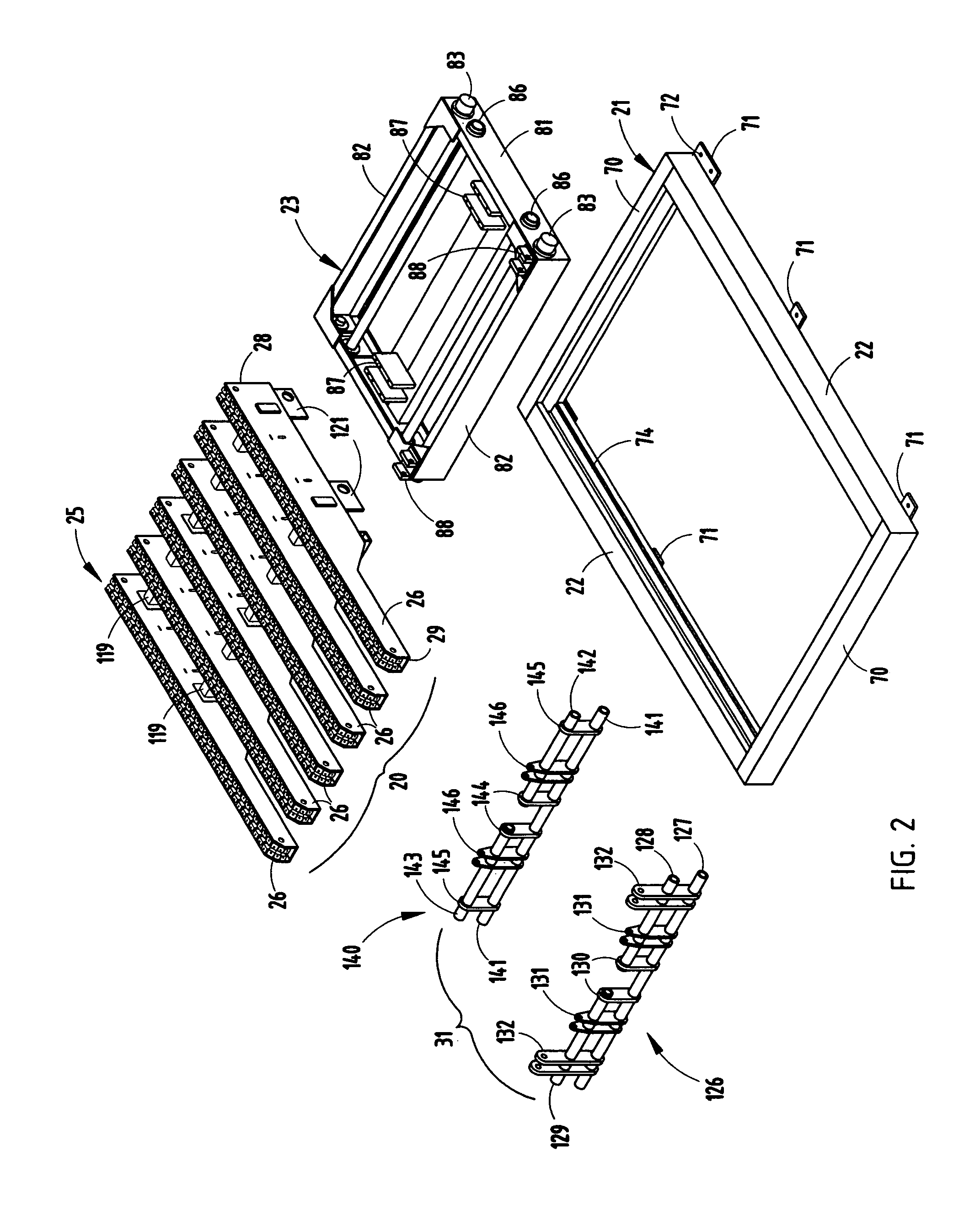

Electromagnetic induction electronic board with antenna arrayed in gridding inside

ActiveUS20050052424A1Low costSimple manufacturing procedureWriting boardsCathode-ray tube indicatorsElectromagnetic inductionMembrane configuration

An electronic whiteboard with built-in membrane antenna array lattice electromagnetic induction layer includes: a writing input portion; a covering frame provided around the periphery of the electronic whiteboard; and a control circuit; wherein, the writing input portion has multilayer structure and is enclosed in the frame, the said writing input portion includes a surface writing layer, an underlayer, and an input induction layer which is connected to the control circuit by its output; the said induction layer may be the antenna array printed on the insulation membrane and arranged along the X, Y axes, therein the area enclosed by each lattice unit constitutes one induction cell.

Owner:MORGAN TOUCH TECH (HK) CO LTD +1

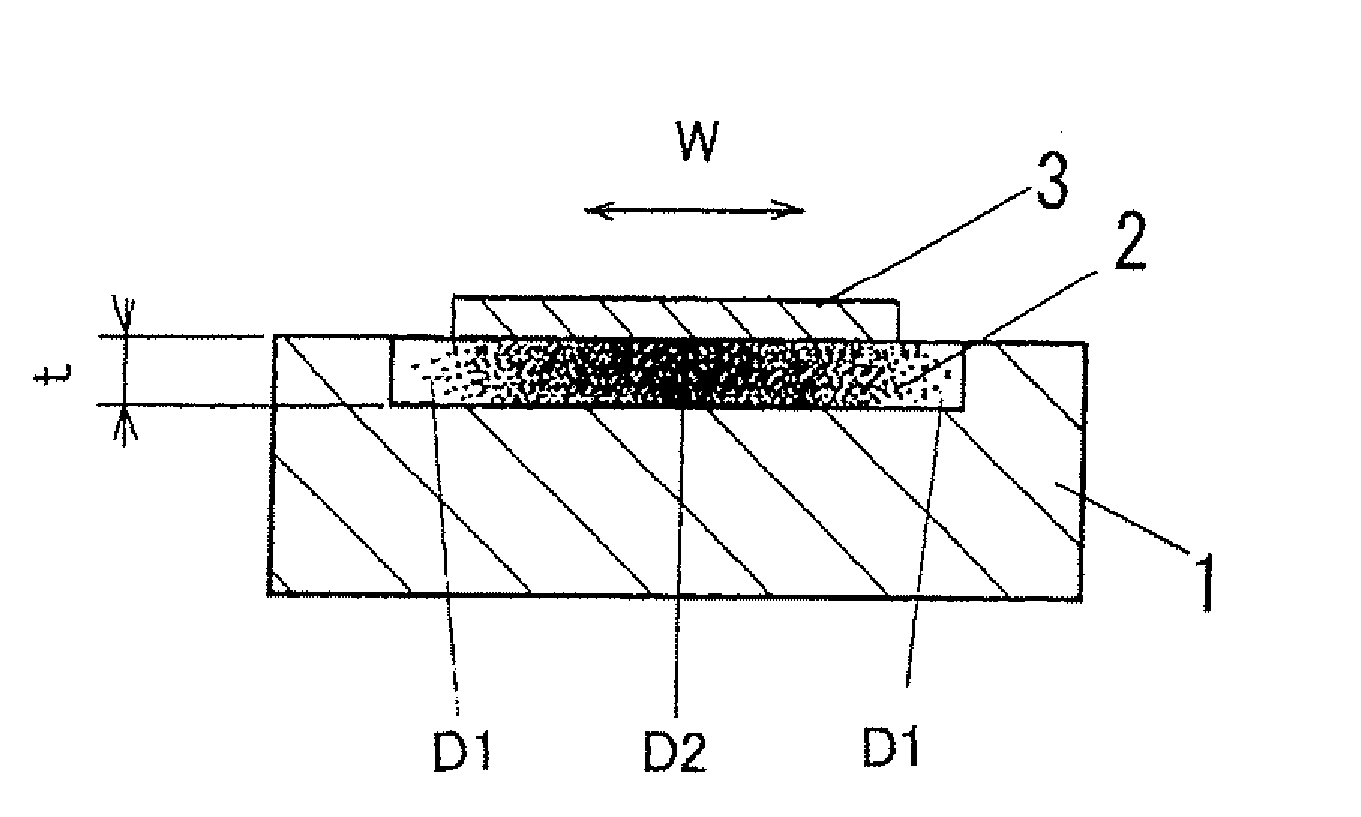

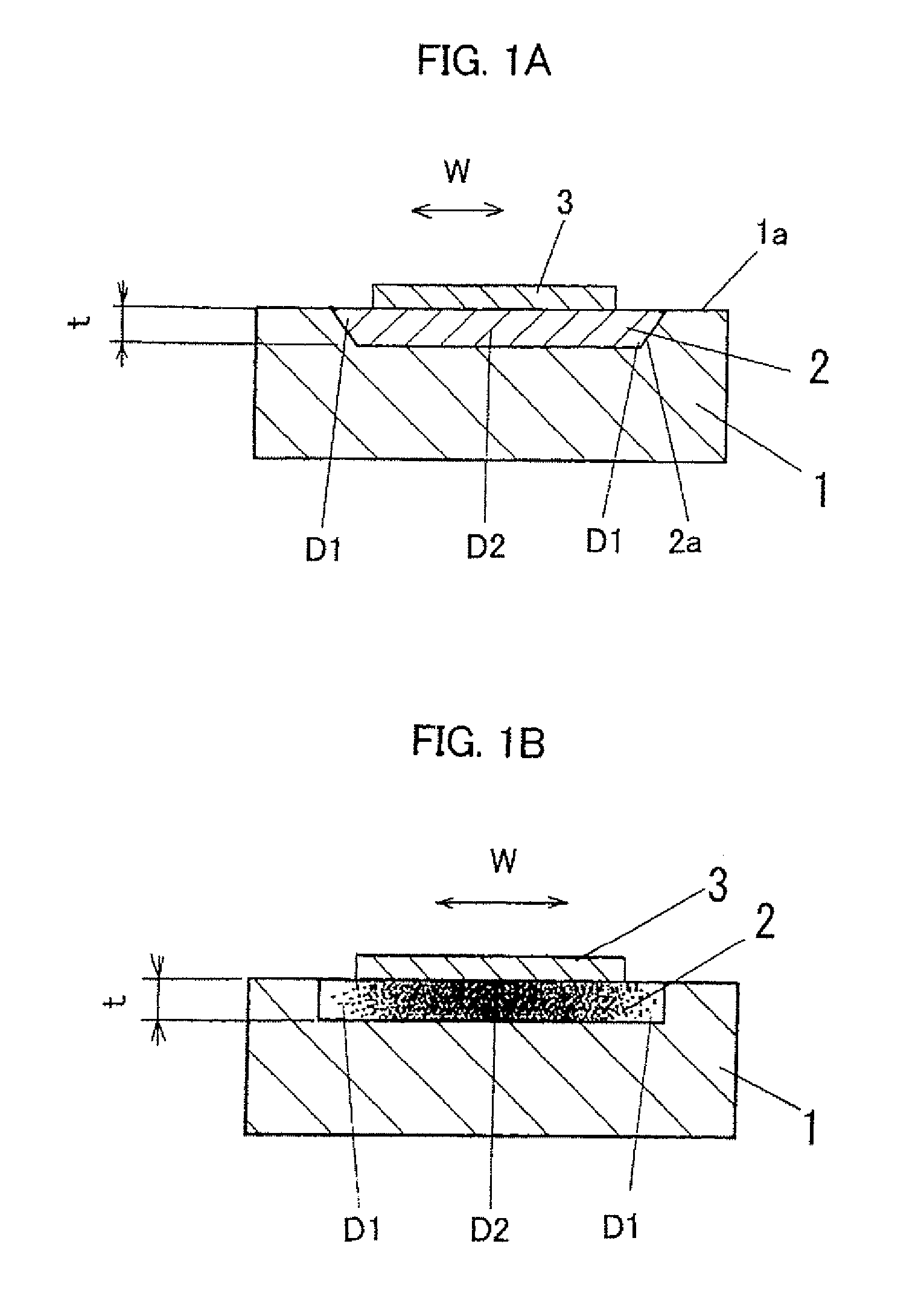

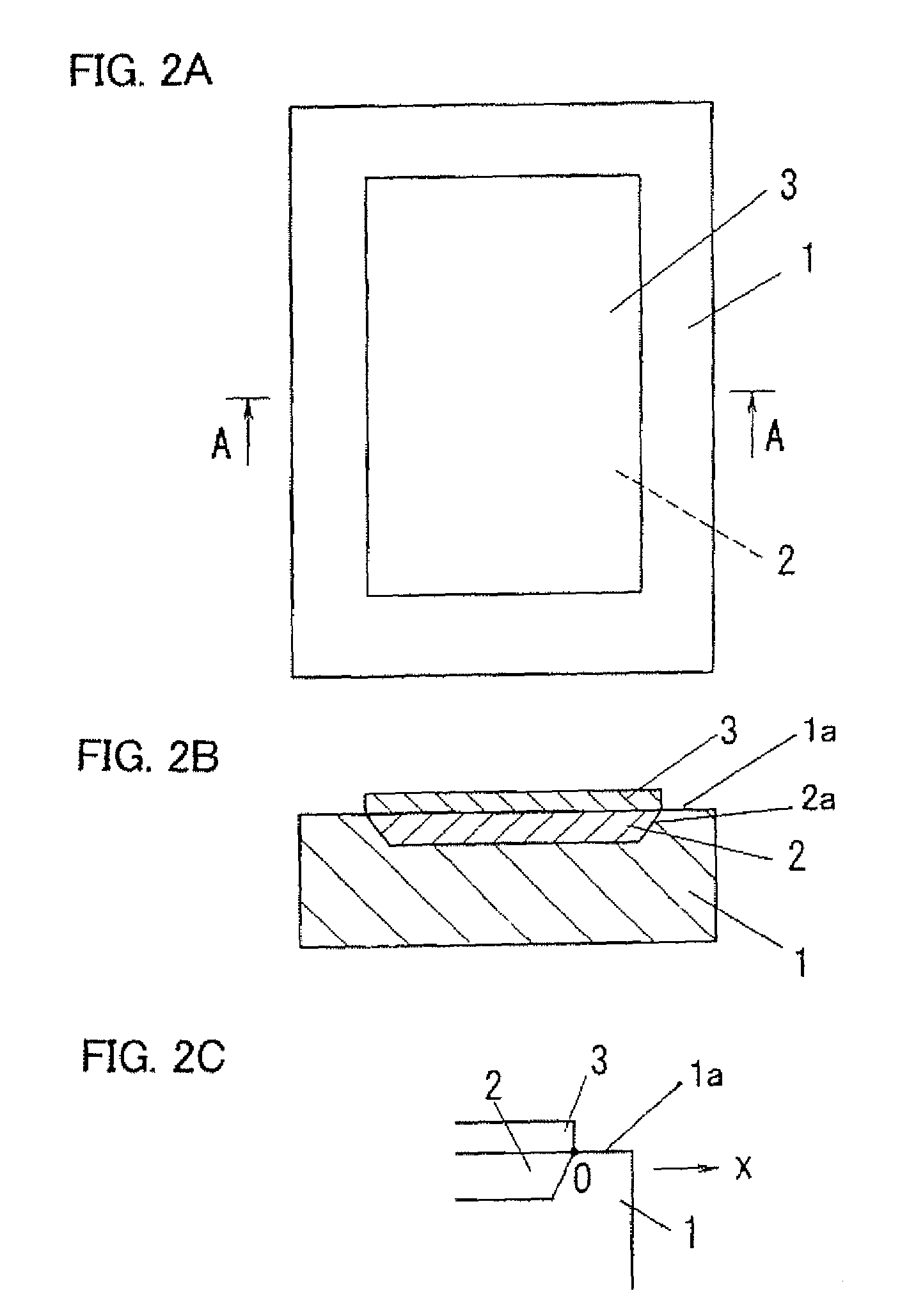

Pressure wave generator and process for manufacturing the same

InactiveUS7474590B2Reduce the likelihood of occurrenceMade smallMicrophonesElectrothermic-effect transistorPorosityElectrical conductor

Even when compression stress is generated because a volume of a thermal insulation layer 2 is expanded due to oxidized by oxygen in the air, occurrence of cracks and fractures of the thermal insulation layer and a heating conductor 3 caused by the cracks are prevented by dispersing the compression stress. A pressure wave generator comprises a substrate 1, the thermal insulation layer 2 of porous material which is formed on a surface of the substrate 1 in thickness direction, and the heating conductor 3 of thin film formed on the thermal insulation layer 2, and generates pressure waves by heat exchange between the heating conductor 3 and a medium. When a thickness at the center of the thermal insulation layer 2 in width direction W is used as a reference thickness, and it is assumed that distribution of thickness of thermal insulation layer in the width direction is averaged with the reference thickness, porosity in an outer peripheral portion of the thermal insulation layer is made smaller than porosity in the center portion. By making the porosity in the outer peripheral portion of the thermal insulation layer 2 smaller, a number of immovable points on the outer periphery of the thermal insulation layer 2 restricted by the substrate 1 is increased and the positions of them are dispersed, so that the compression stress compressed in the outer peripheral portion of the thermal insulation layer 2 can be dispersed.

Owner:MATSUSHITA ELECTRIC WORKS LTD

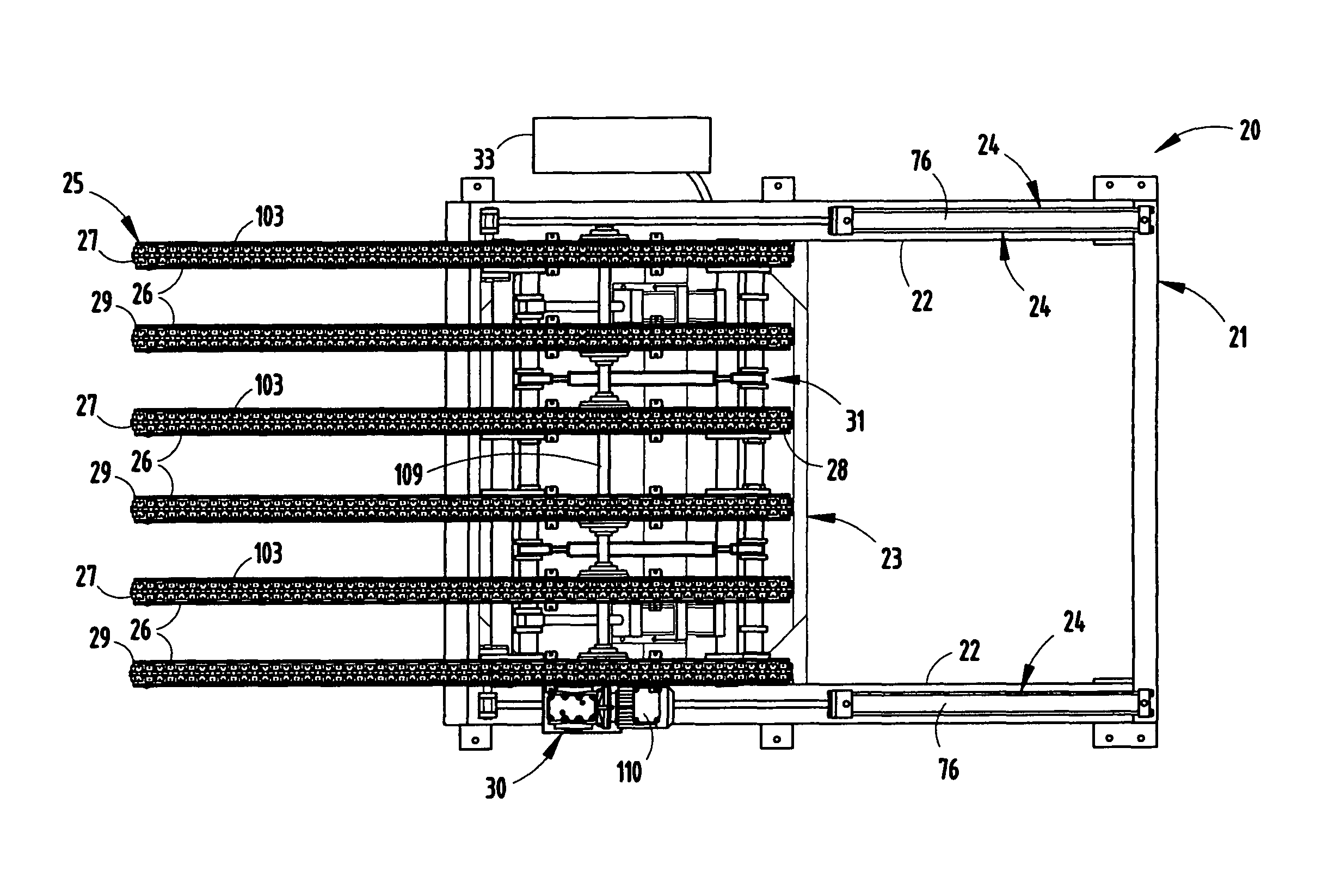

Automatic load transfer device and method for automated material handling systems

InactiveUS8047756B2Efficiently and reliably transport loadHigh uptime reliability and durabilitySpeed controllerOperating modesMaterial handlingWaste management

Owner:SAVANT AUTOMATION

Filtration and flow distribution method for chemical reactors using reticulated ceramics with uniform pore distributions

InactiveUS6291603B1Reduce turbulenceEntrance losses may be reducedCatalytic naphtha reformingMembrane filtersPore distributionFiltration

Owner:CRYSTAPHASE PRODS

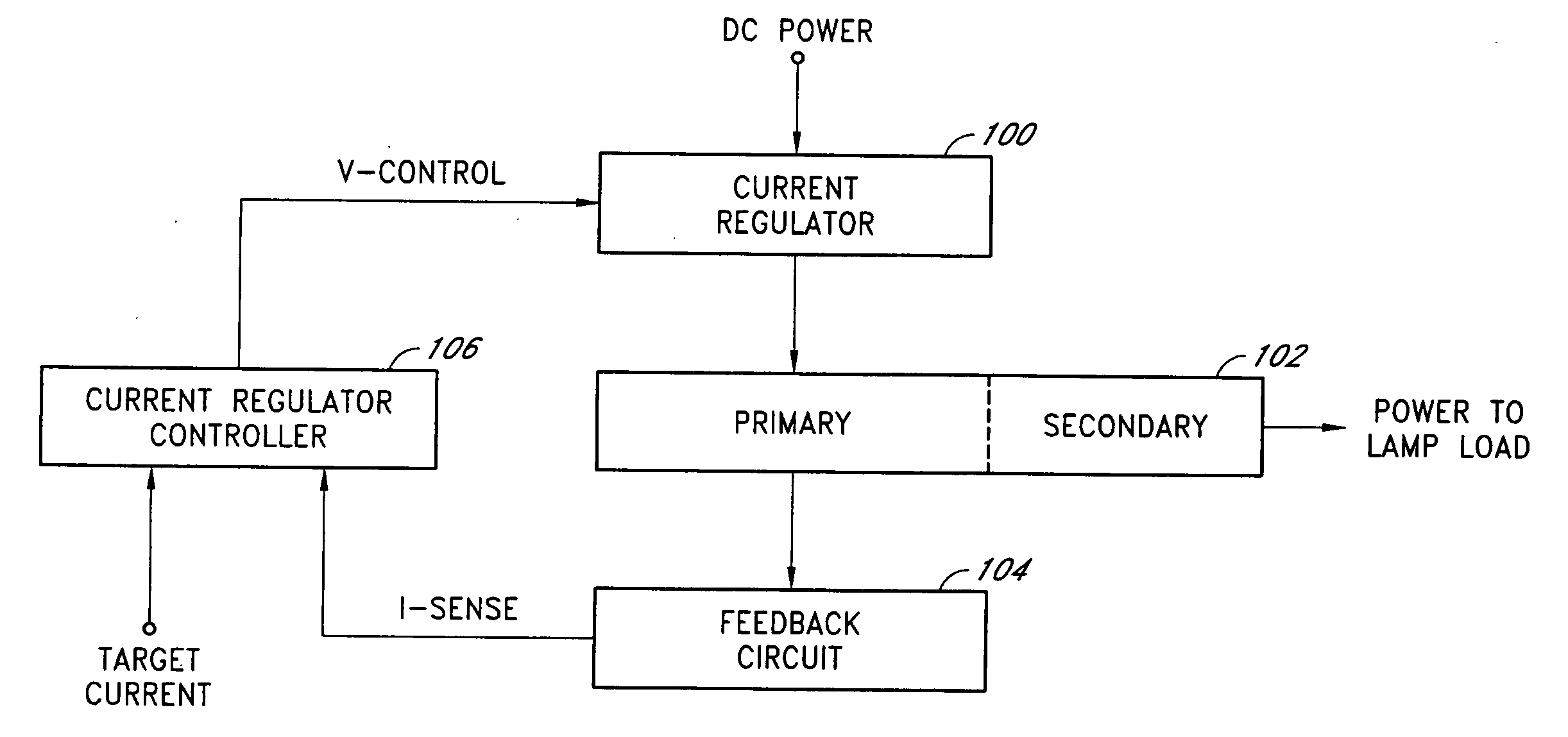

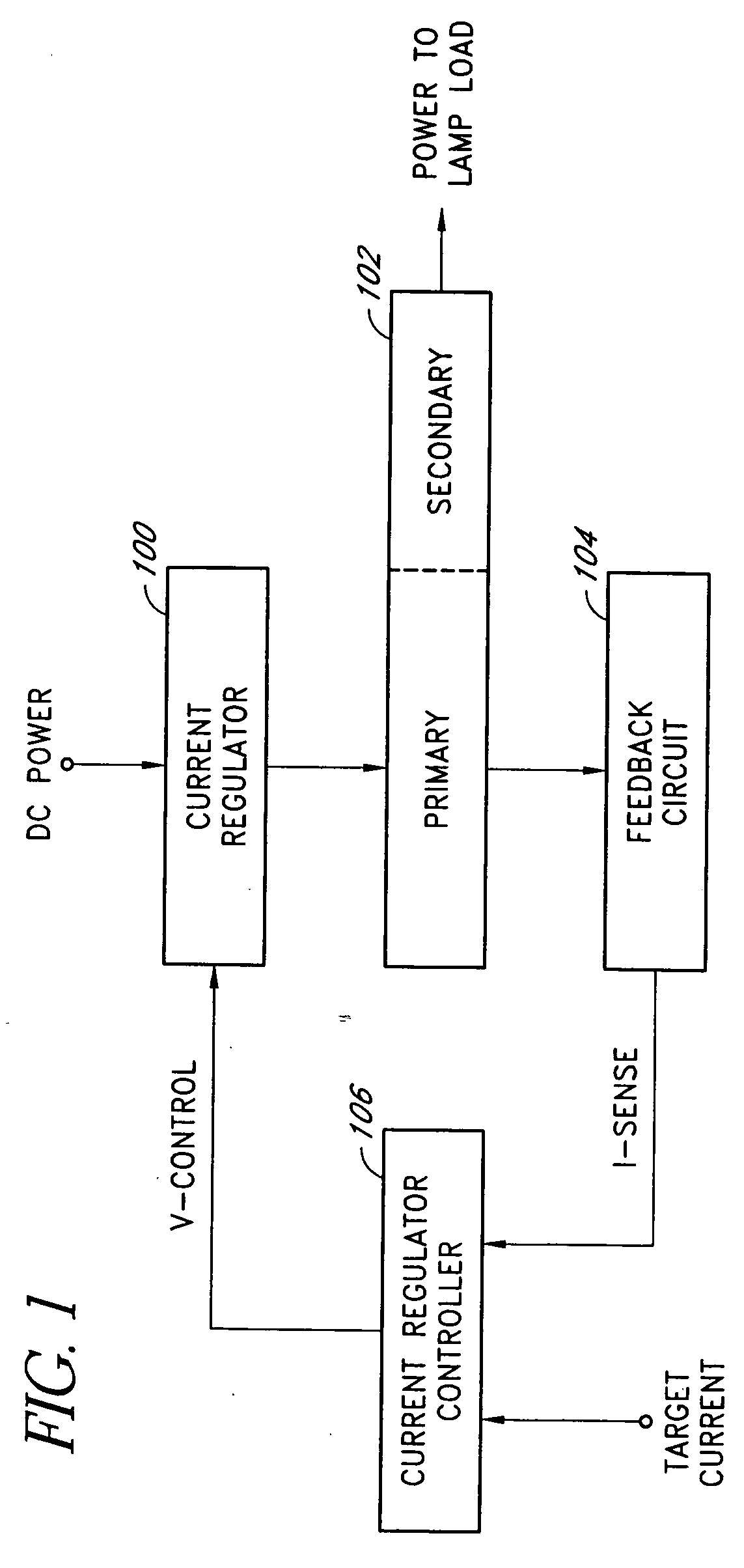

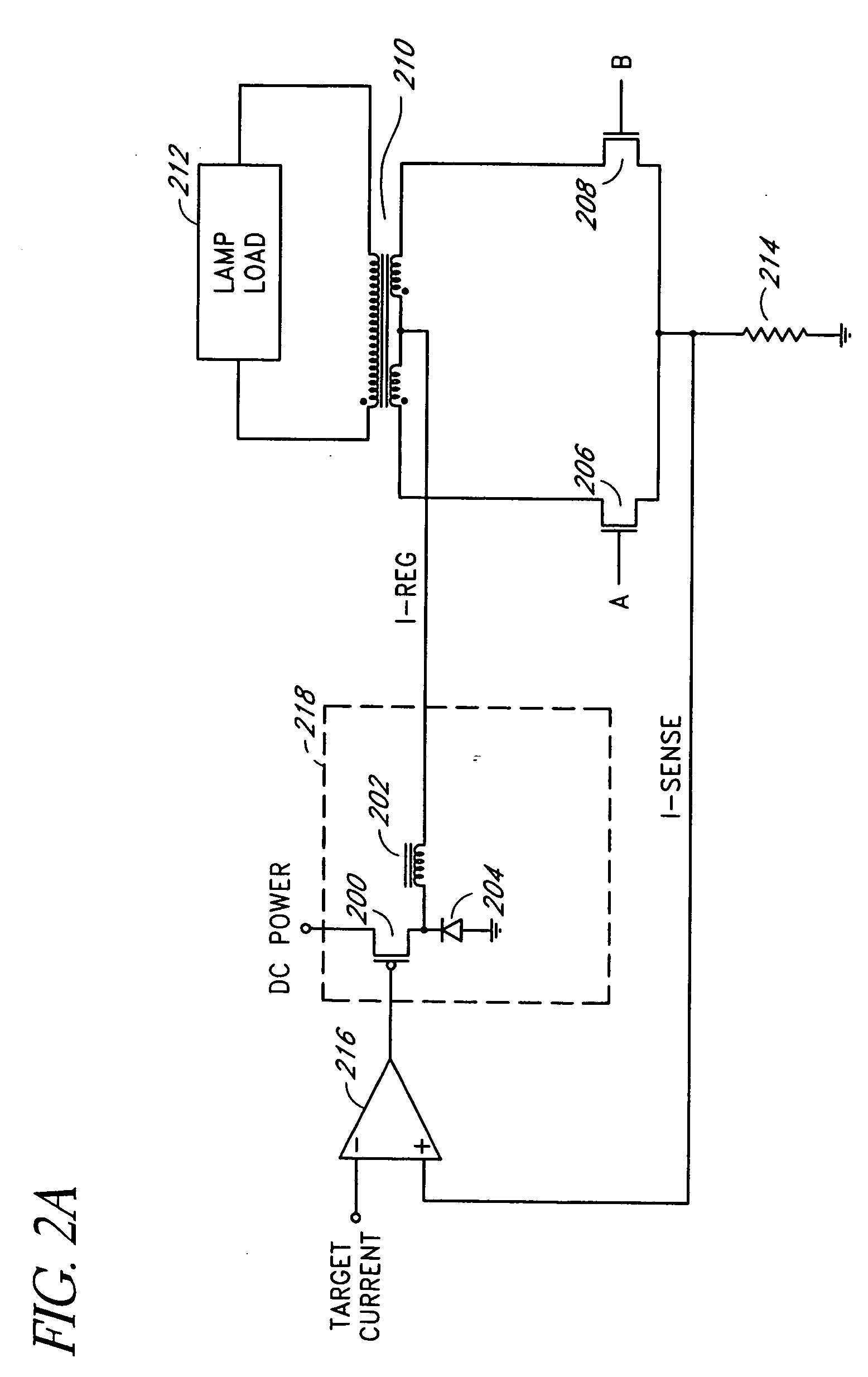

Current-mode direct-drive inverter

InactiveUS20050162098A1Increased operating lifeStable light outputElectroluminescent light sourcesSemiconductor lamp usageOutput transformerTime-sharing

An efficient and flexible current-mode driver delivers power to one or more light sources in a backlight system. In one application, the current-mode driver is configured as an inverter with an input current regulator, a non-resonant polarity-switching network, and a closely-coupled output transformer. The input current regulator can output a regulated current source in a variety of programmable wave shapes. The current-mode driver may further include a rectifier circuit and a second polarity-switching network between the closely-coupled output transformer and a lamp load. In another application, the current-mode driver delivers power to a plurality of light sources in substantially one polarity by providing a regulated current to a network of time-sharing semiconductor switches coupled in series with different light sources coupled across each semiconductor switch.

Owner:POLARIS POWERLED TECH LLC

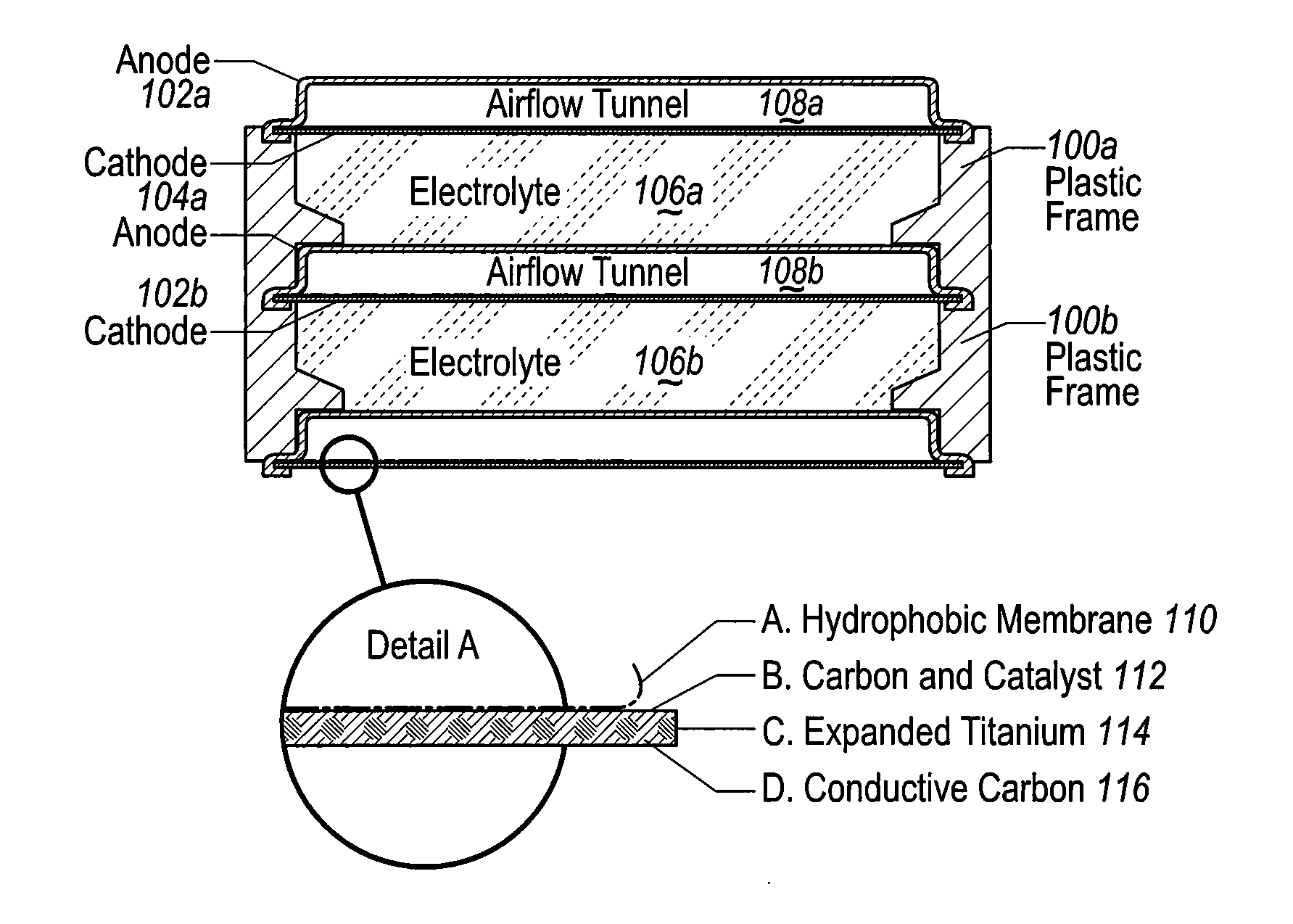

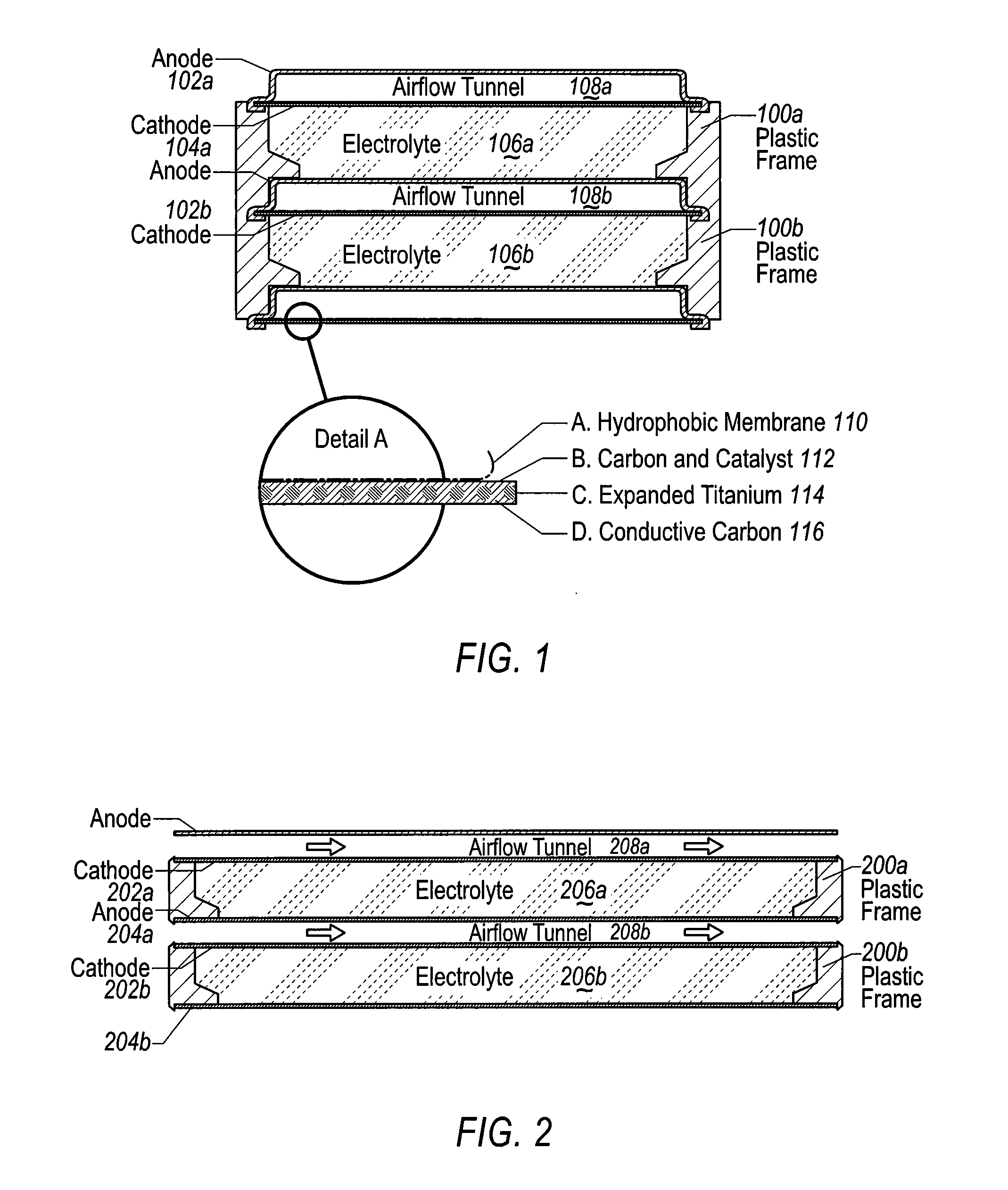

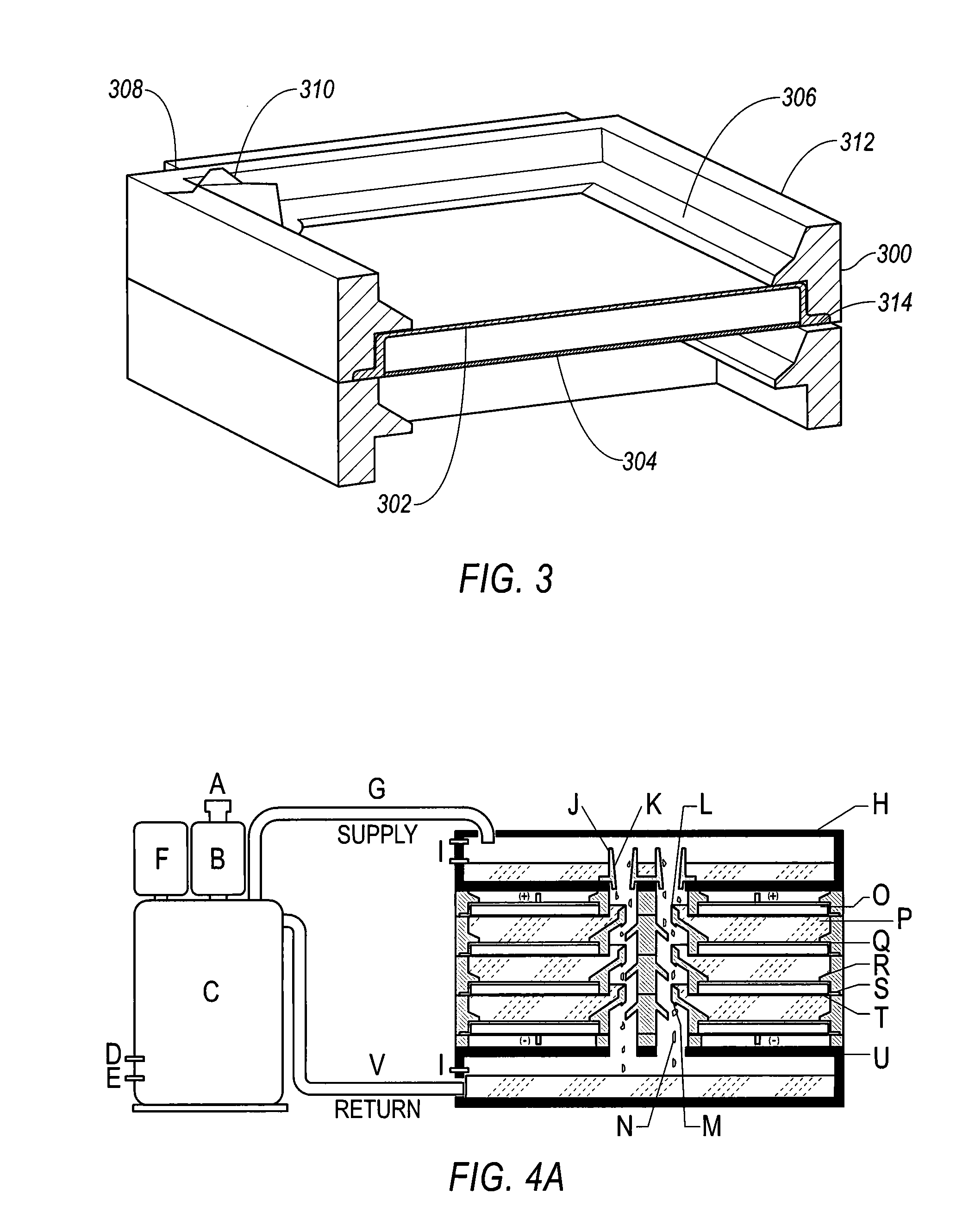

Electrically rechargeable, metal anode cell and battery systems and methods

ActiveUS20150010833A1Increased operating lifeAffordable and practicalAlkaline accumulatorsFuel and secondary cellsElectricityElectrical battery

The invention provides for a fully electrically rechargeable metal anode battery systems and methods of achieving such systems. An electrically rechargeable metal anode cell may comprise a metal electrode, an air contacting electrode, and an aqueous electrolyte separating the metal electrode and the air contacting electrode. In some embodiments, the metal electrode may directly contact the liquid electrolyte and no separator or porous membrane is needed between the air contacting electrode and the electrolyte. Rechargeable metal anode cells may be electrically connected to one another through a centrode connection where a metal electrode of one cell and an air contacting electrode of a second cell are electrically connected. Air tunnels or pathways may be provided between individual metal anode cells arranged in a stack. In some embodiments, an electrolyte flow management system may also be provided to maintain liquid electrolyte at constant levels during charge and discharge cycles.

Owner:EOS ENERGY TECH HLDG LLC

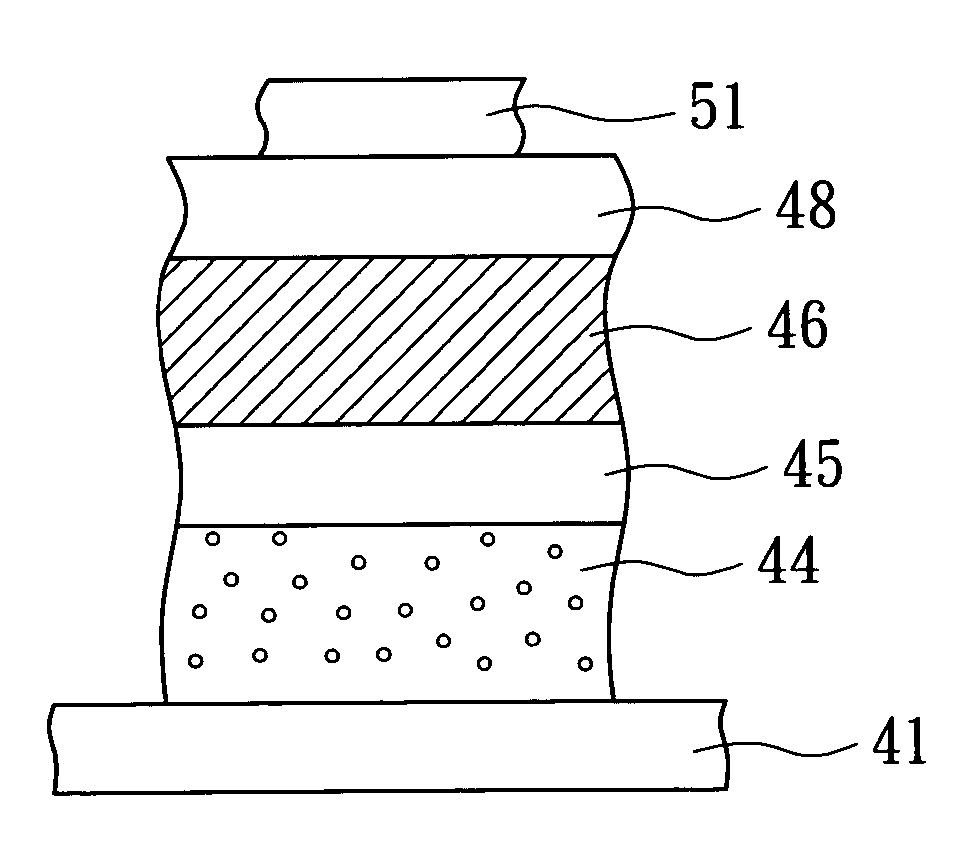

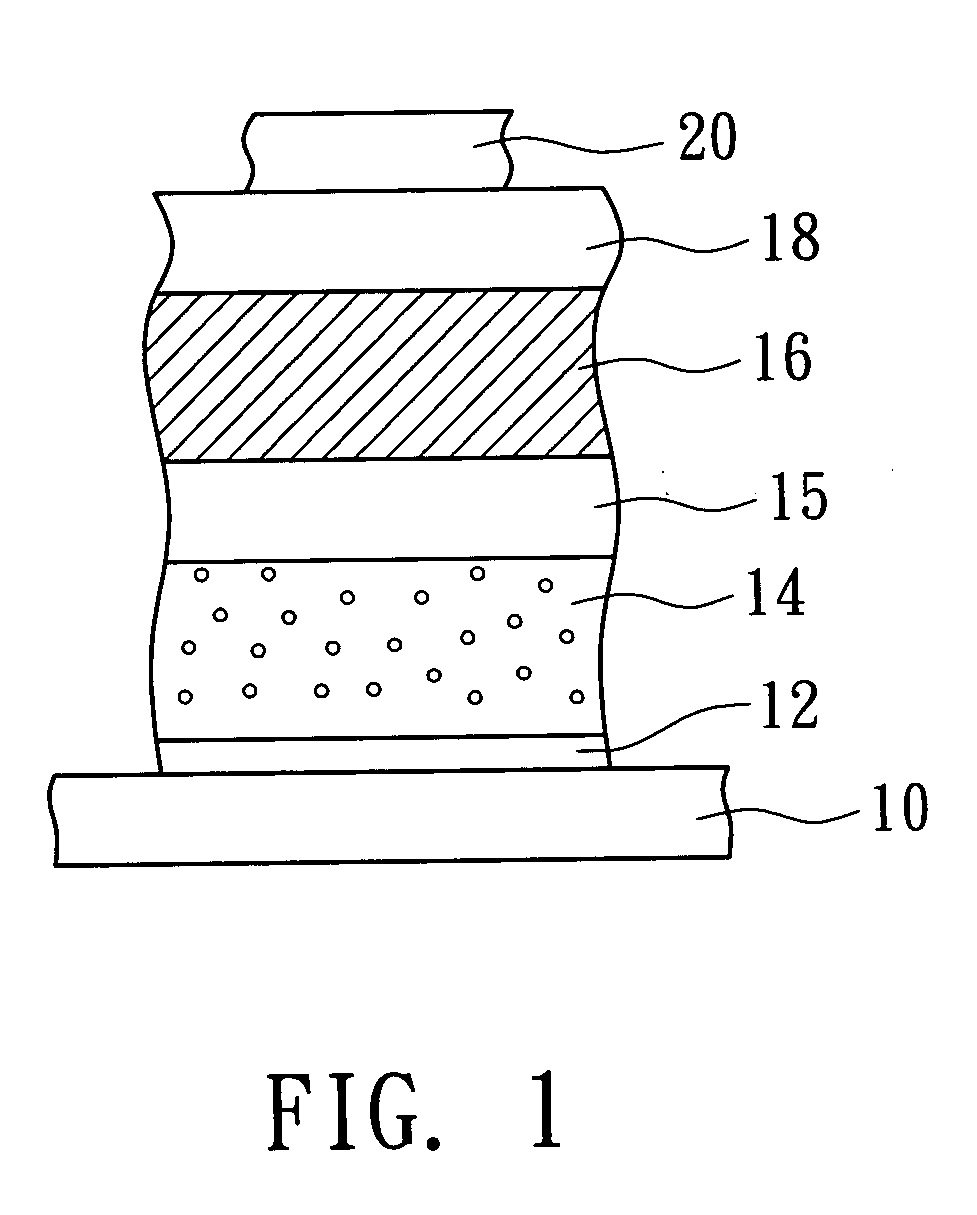

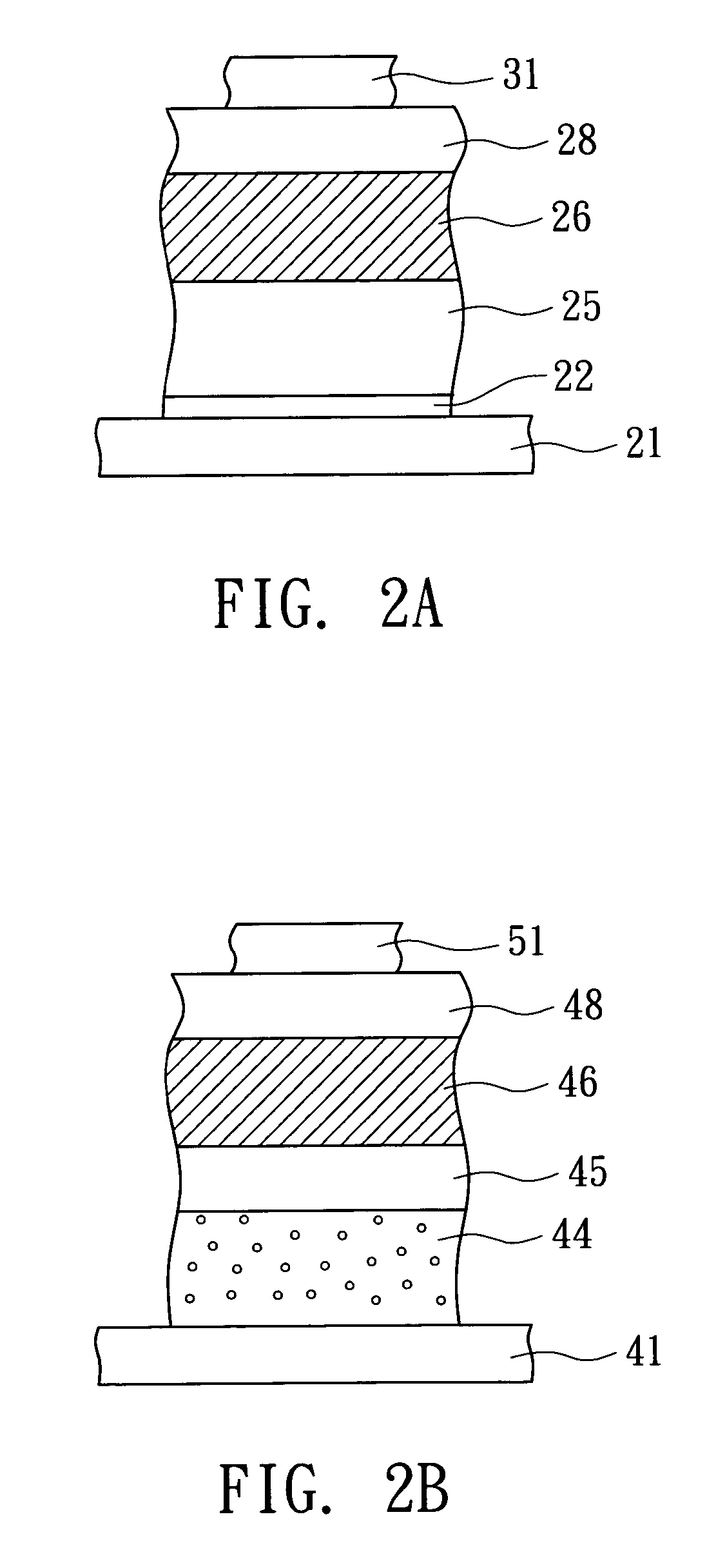

Organic electroluminescent device and manufacuring method thereof

InactiveUS20050274961A1Improve stabilityStable maintenanceSolid-state devicesSemiconductor/solid-state device manufacturingDopantHole injection layer

An organic electroluminescent device comprises an anode, a hole injection layer as CFx formed on the anode, a first hole transport layer formed on the hole injection layer and the first hole transport layer doped with a P-type dopant, a second hole transport layer formed on the first hole transport layer, a light emitting layer formed on the second hole transport layer, an electron transport layer formed on the light emitting layer, and a cathode formed on the electron transport layer. According to the structure of the organic electroluminescent device disclosed in the present invention, the hole injection layer and the first hole transport layer provide the function of increasing the efficiency of the hole injection so as to improve the operating life and stability of the device.

Owner:AU OPTRONICS CORP

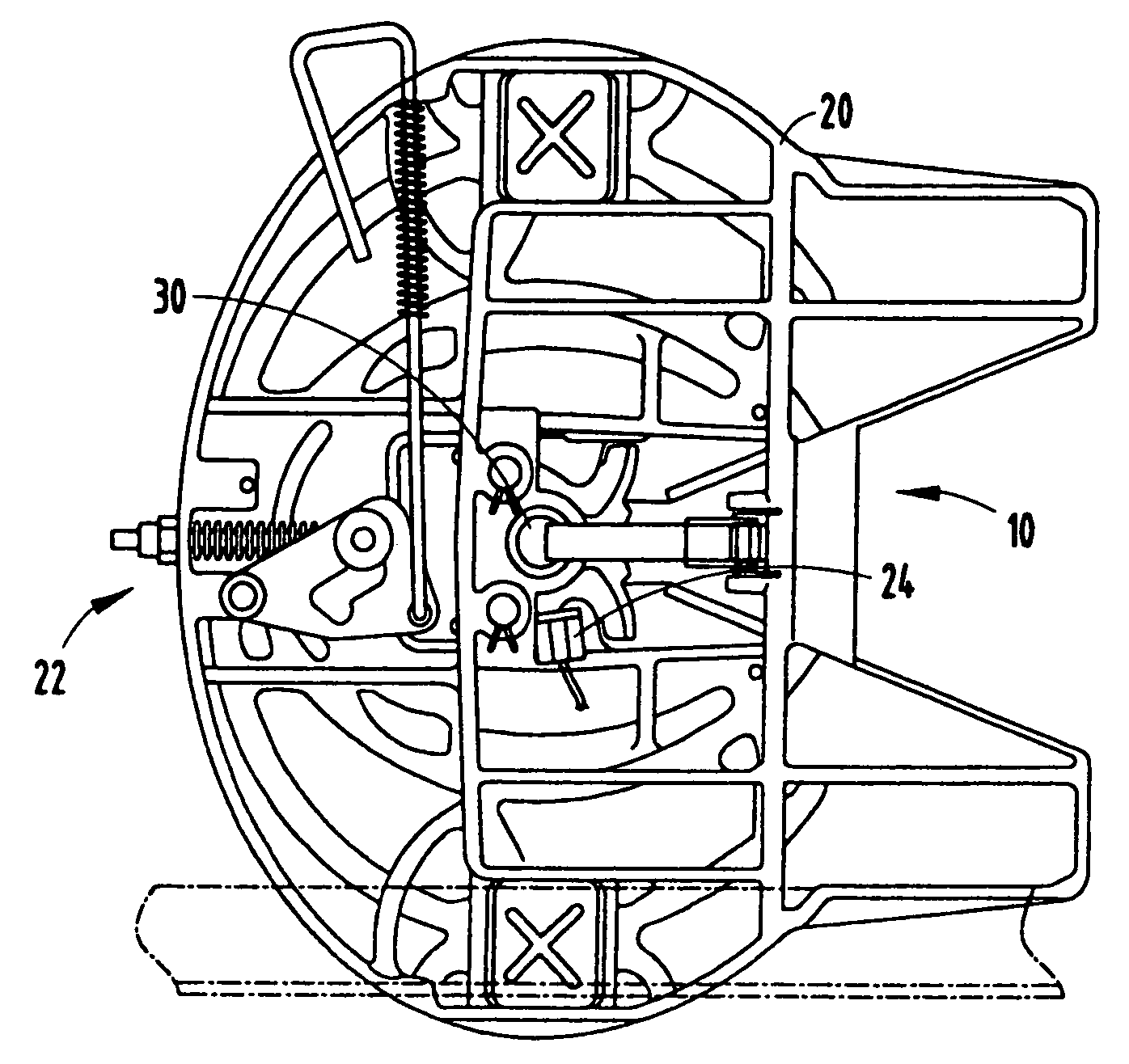

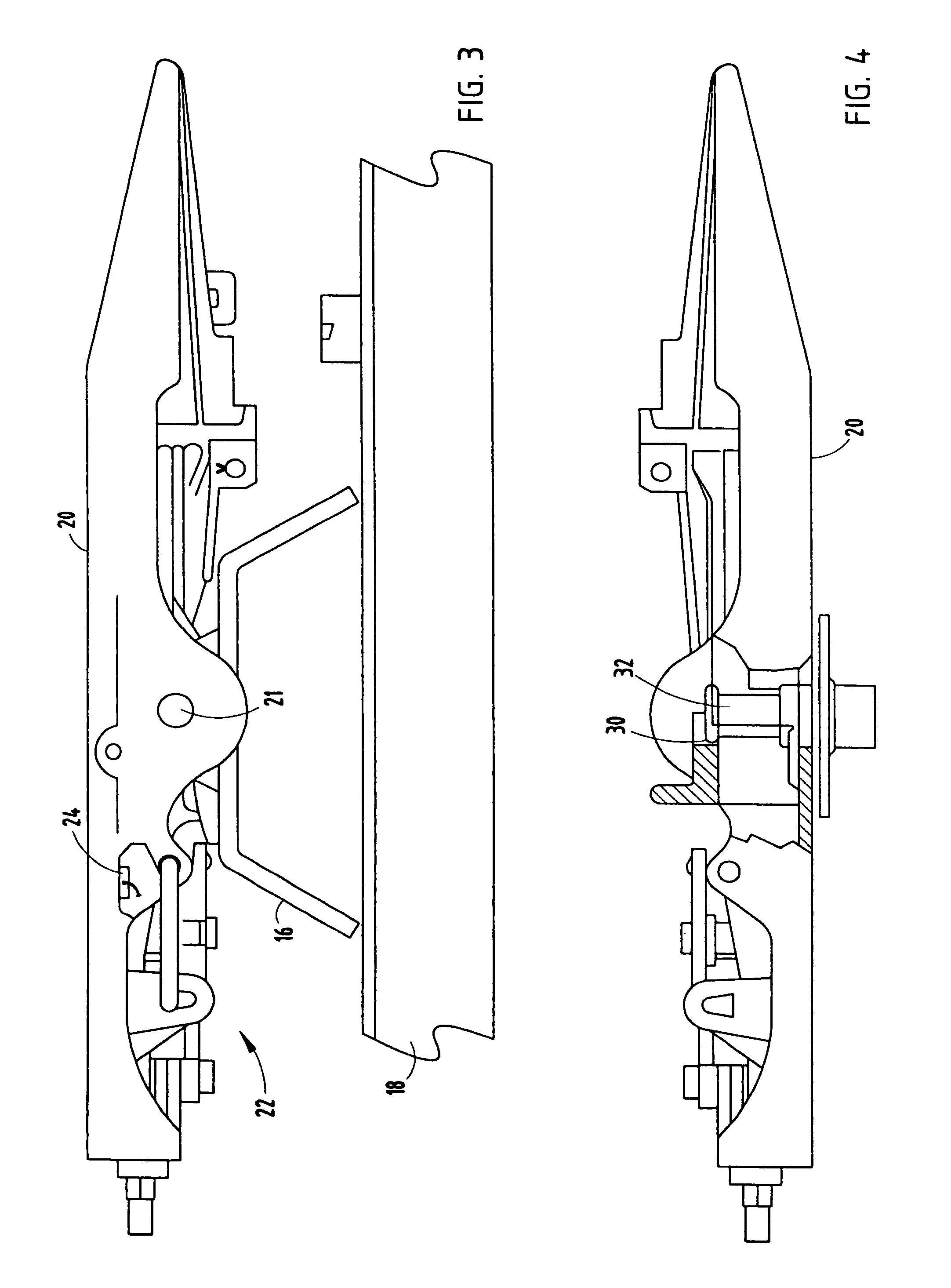

Fifth wheel sensor assembly

ActiveUS7548155B2Increased operating lifeReliable distinctionVehicle seatsSolid-state devicesElectronic systemsLocking mechanism

An electronic system that monitors a trailer hitch assembly having a plate hitch with a throat for receiving a kingpin of a trailer and a locking mechanism for locking the kingpin within the throat. The electronic system determines whether the trailer hitch assemblies is properly coupled to the trailer, and comprises a first magnet creating a first magnetic flux, and a first Hall-effect sensor for sensing the position of the kingpin of the trailer relative to the throat of the hitch plate by measuring the first magnetic flux. The system further comprises a control circuit operably coupled with the first Hall-effect sensor in determining whether the first magnetic flux indicates a proper location of the kingpin of the trailer relative to the throat of the hitch plate. The electronic system discriminates between the kingpin and foreign materials, thereby assuring proper locking of the locking mechanism.

Owner:THE HOLLAND GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com