Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1629 results about "Material handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

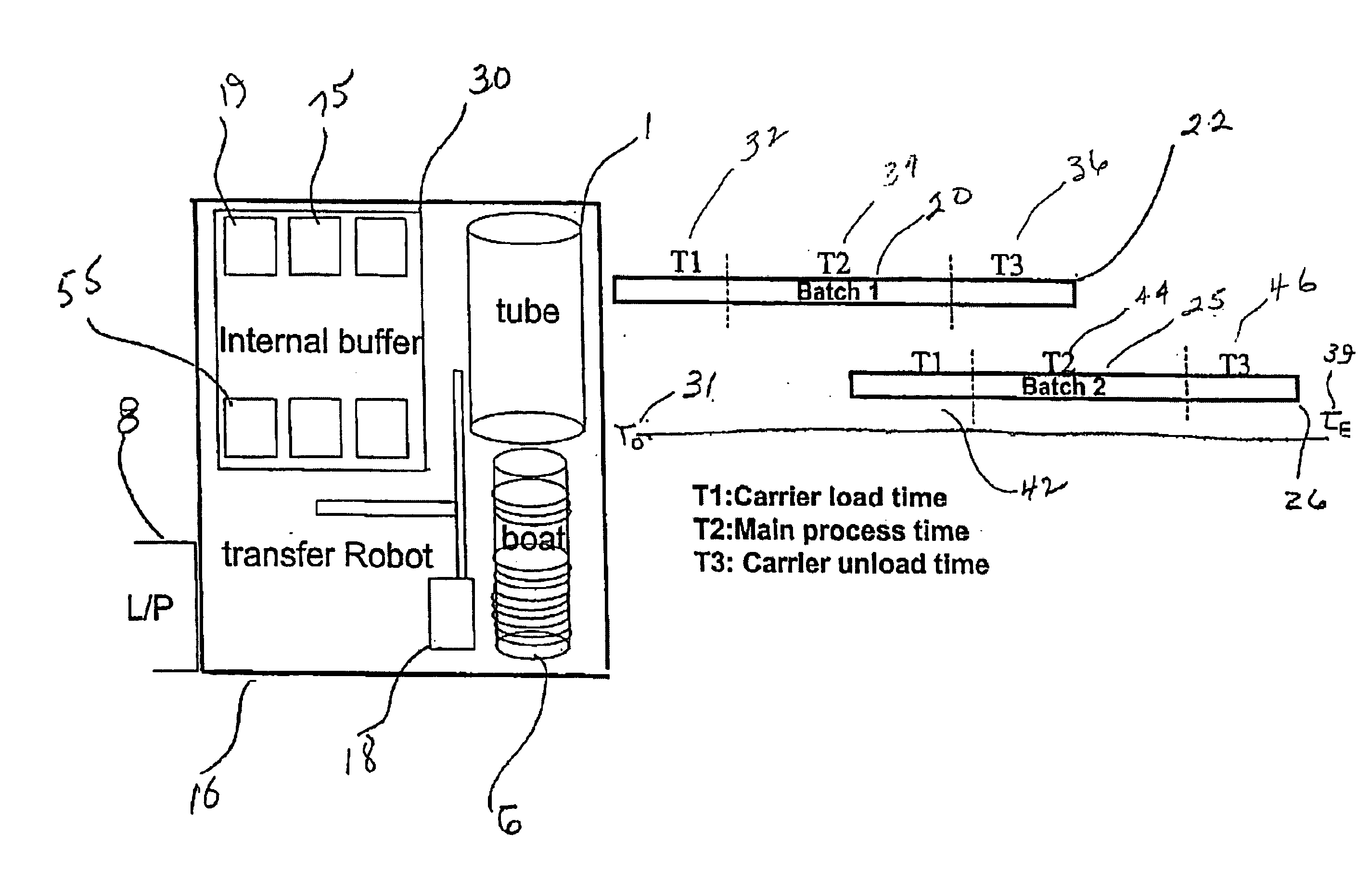

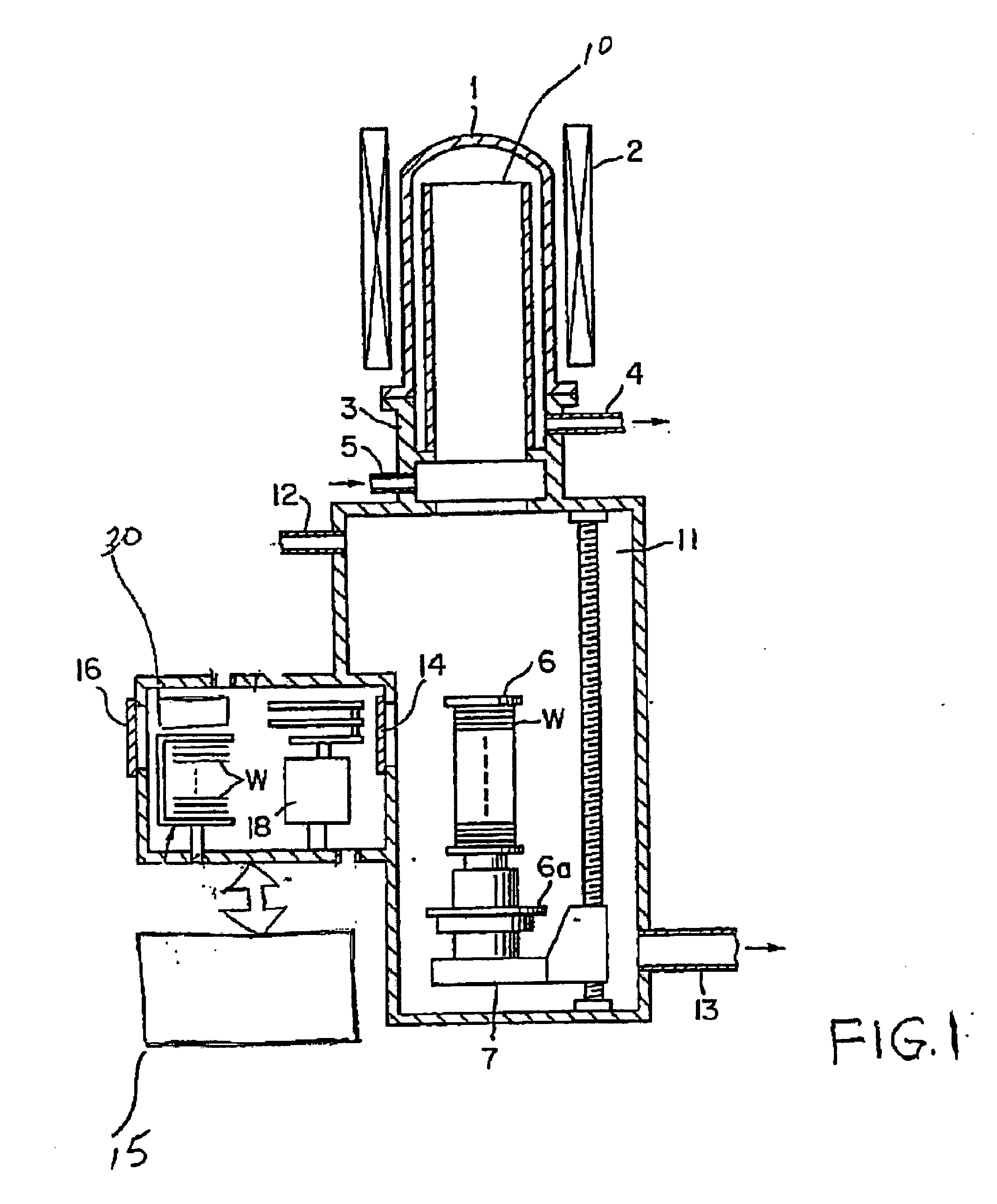

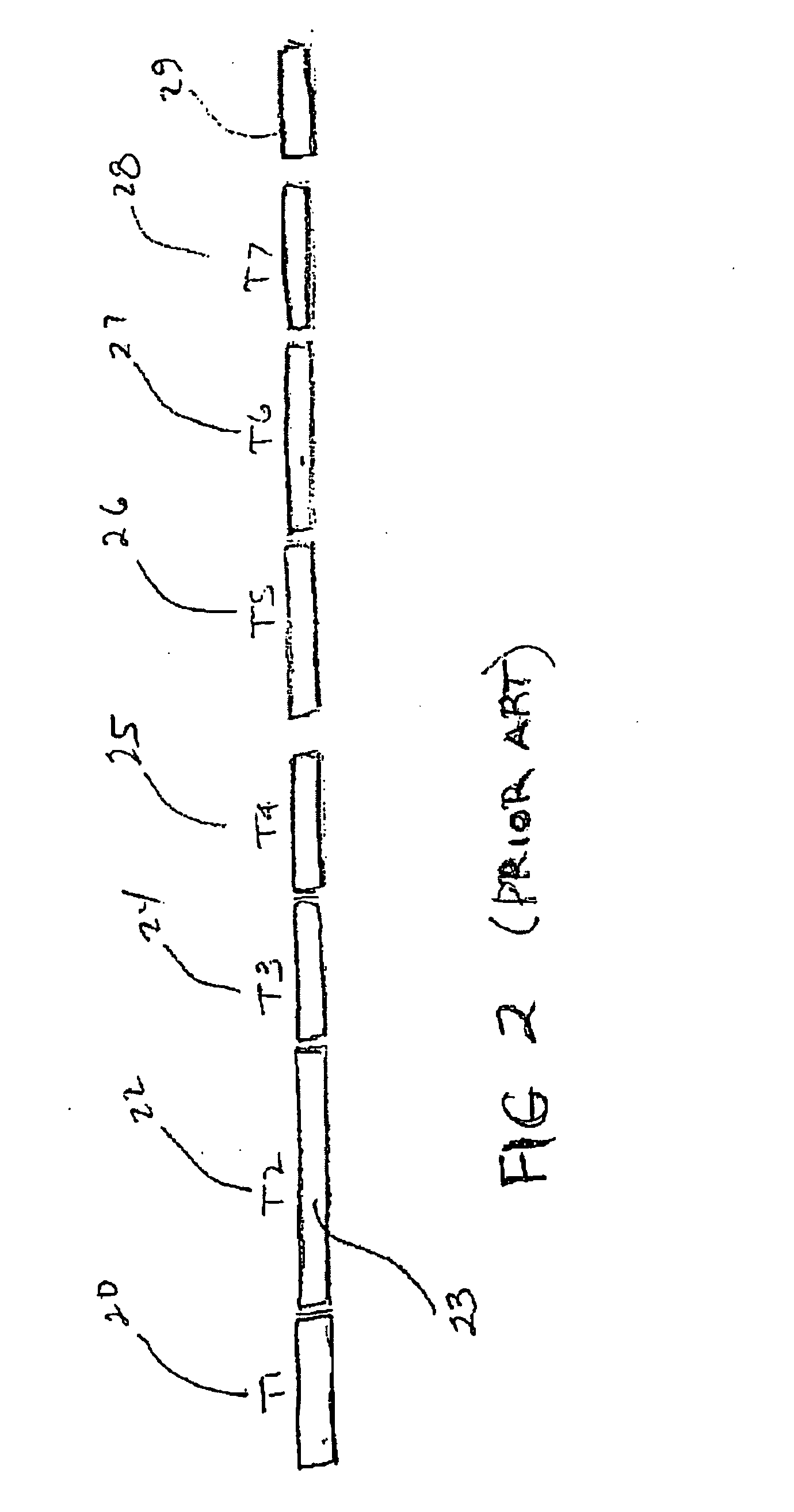

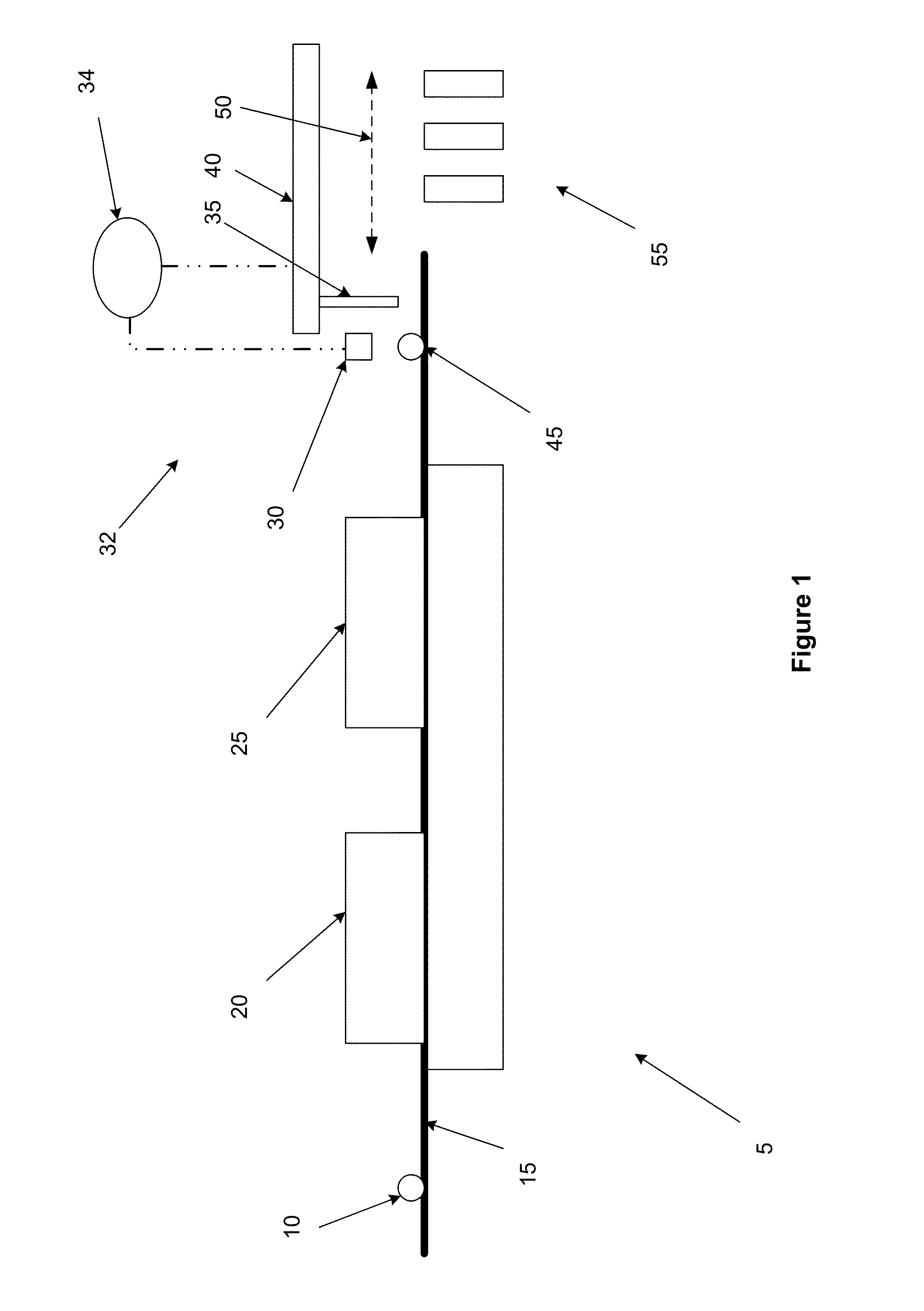

Intelligent full automation controlled flow for a semiconductor furnace tool

InactiveUS20050187647A1Reduce idle timeSemiconductor/solid-state device manufacturingSpecial data processing applicationsControl flowAutomatic control

The present invention relates to an apparatus and method for processing the flow of semiconductor wafers through a furnace tool having a front-opening unified pod (FOUP) material handling system. The invention provides for an automated control flow to realize greater efficiency and assure process quality. In one aspect of the invention the wafer batch completing its operation is discharged simultaneous with the charging of the next batch. Essentially the operation takes place by overlapping processing operations. An embodiment of the invention includes a process comprising the steps of: providing a first batch of semiconductor material, and loading the first batch into a carrier which transports the first batch into a semiconductor manufacturing process, and while the first batch undergoes the process, forming a second batch of semiconductor material, and pausing a second batch process operation until the first batch completes processing, to reduce the idle time of said process.

Owner:TAIWAN SEMICON MFG CO LTD

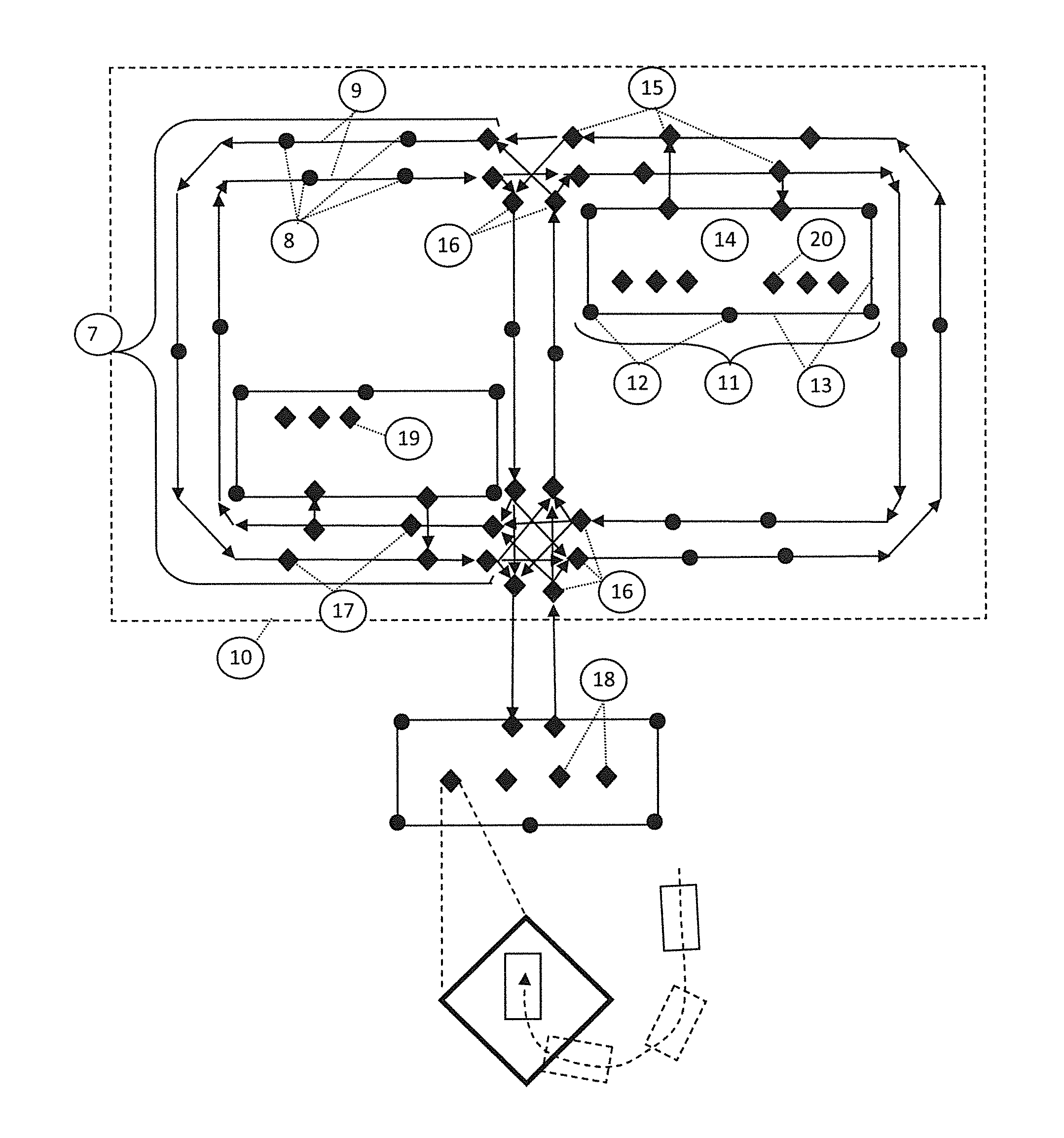

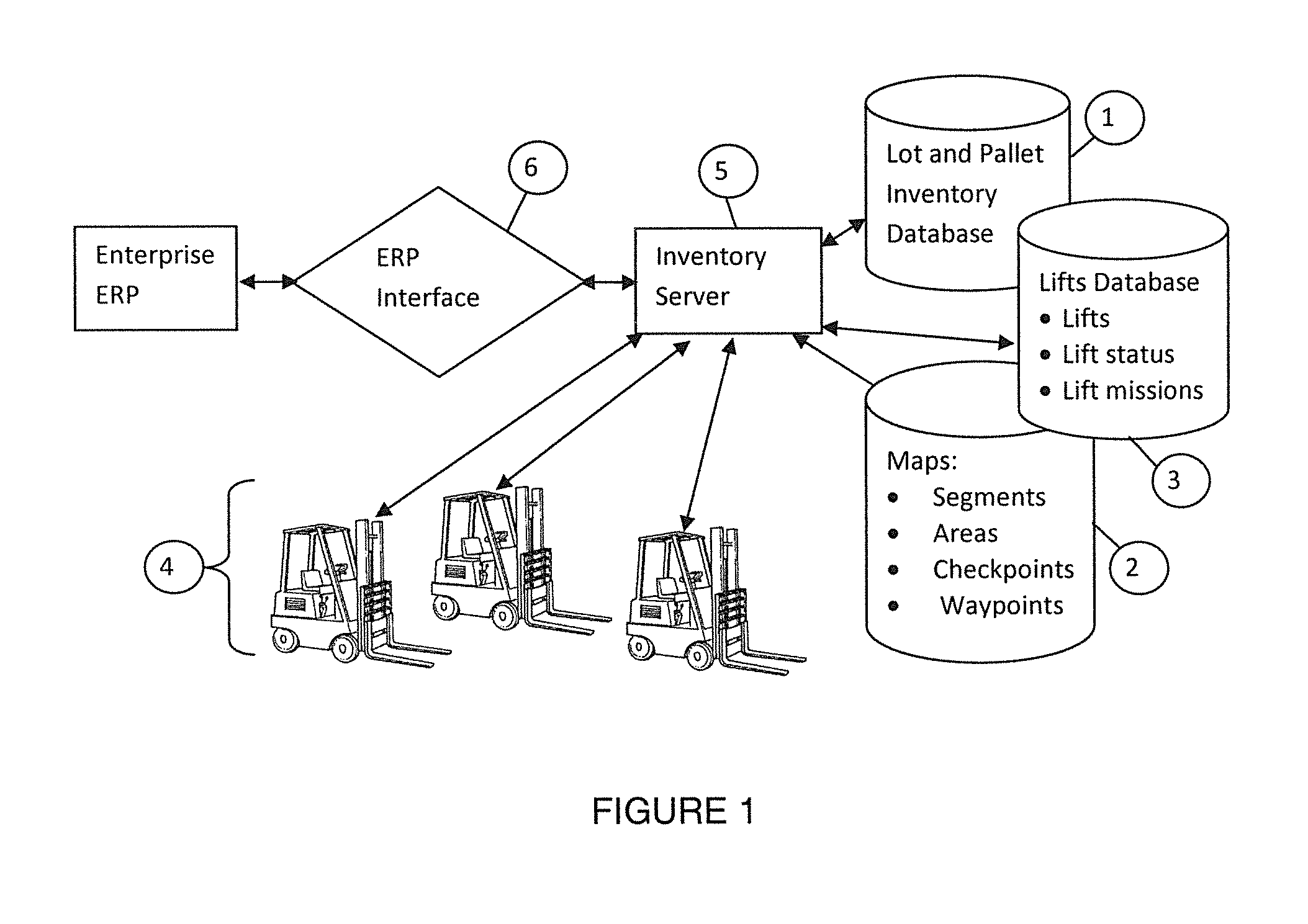

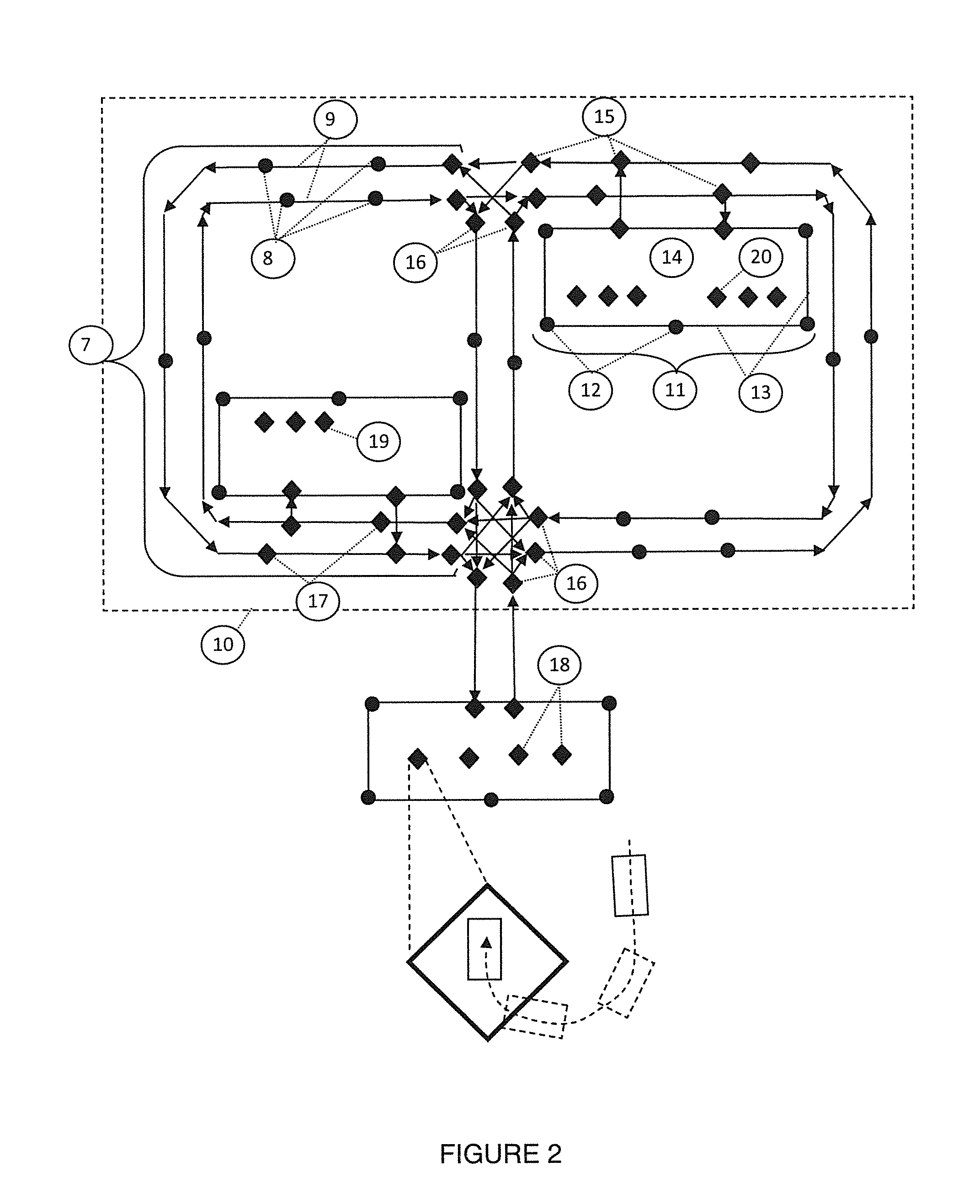

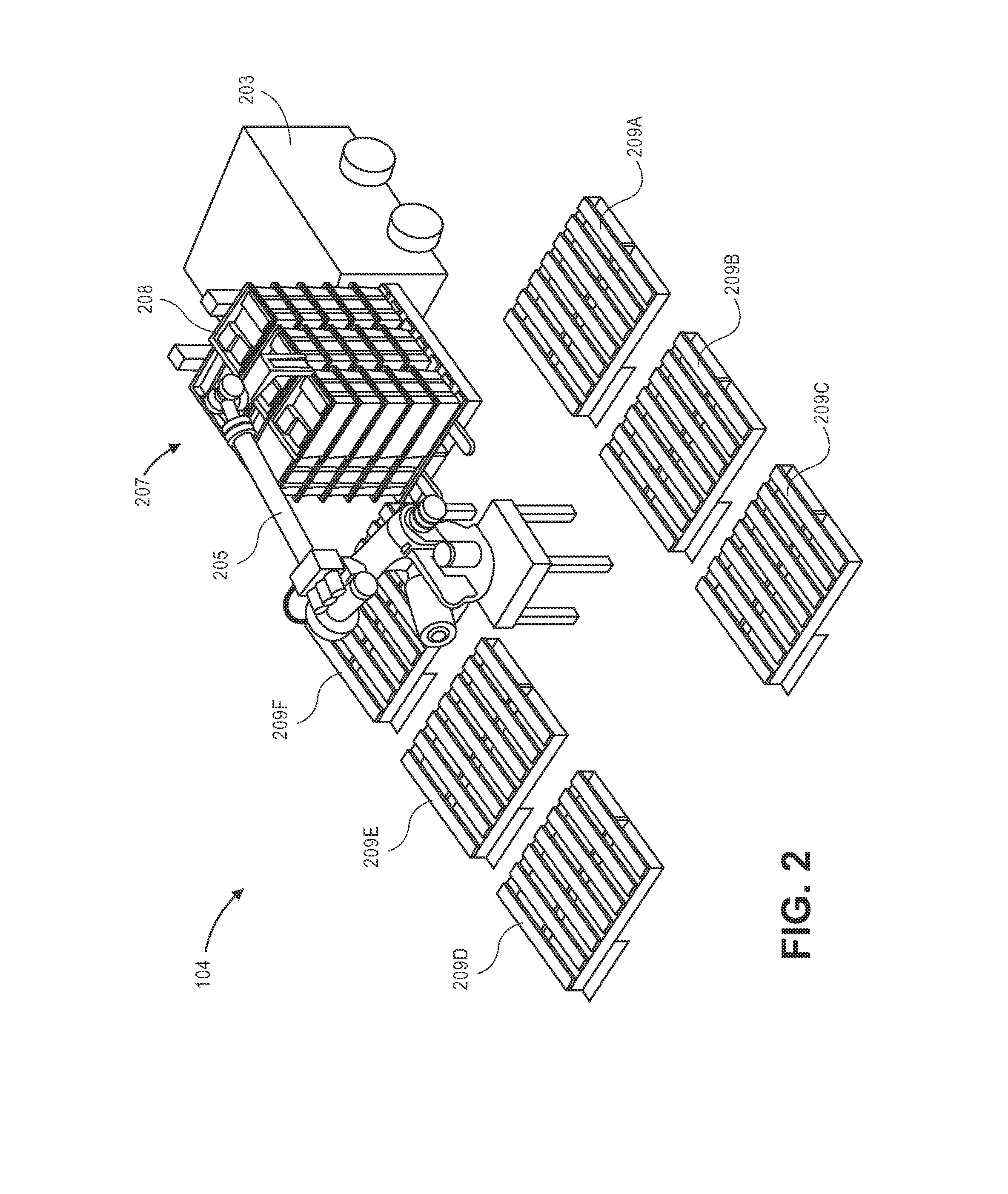

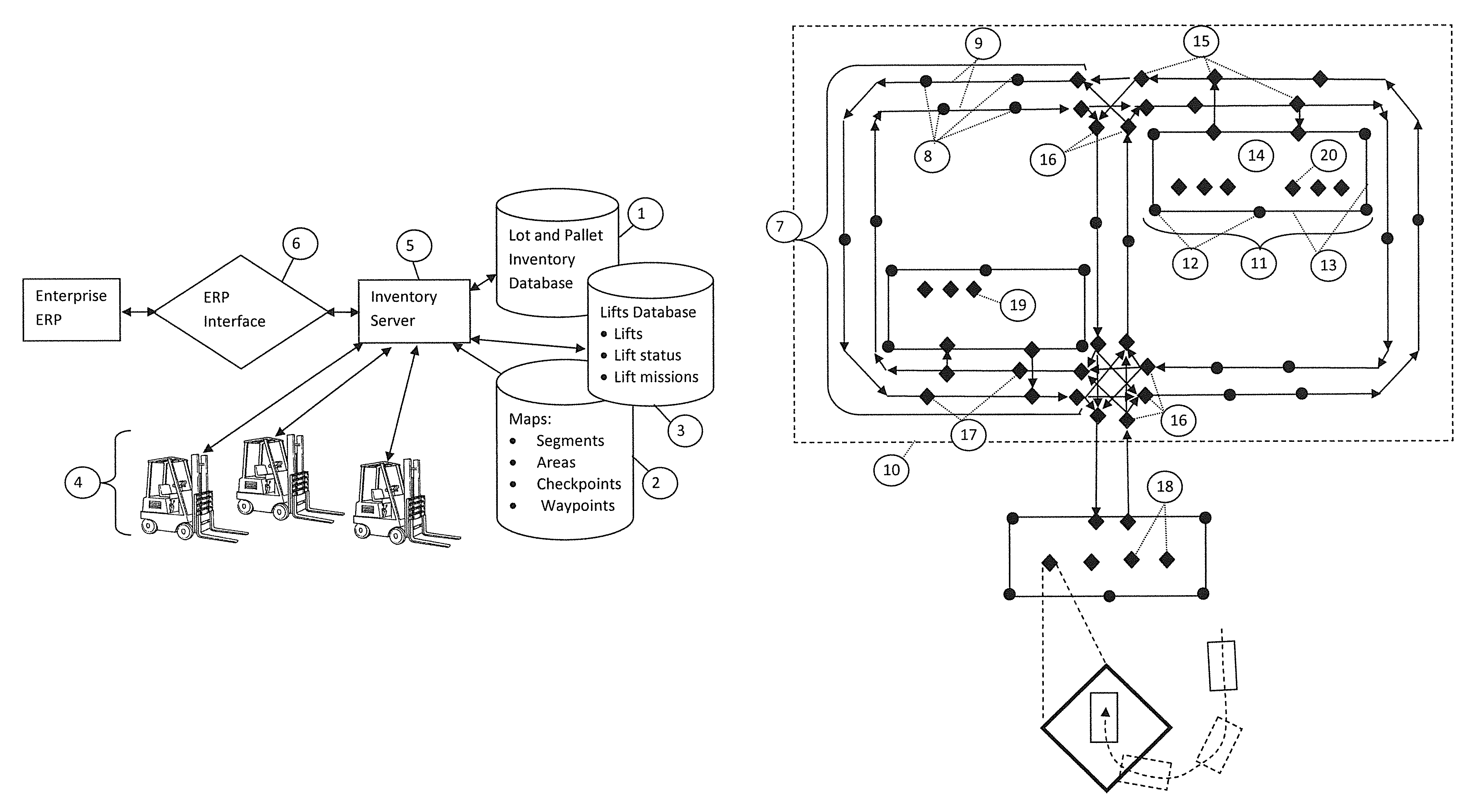

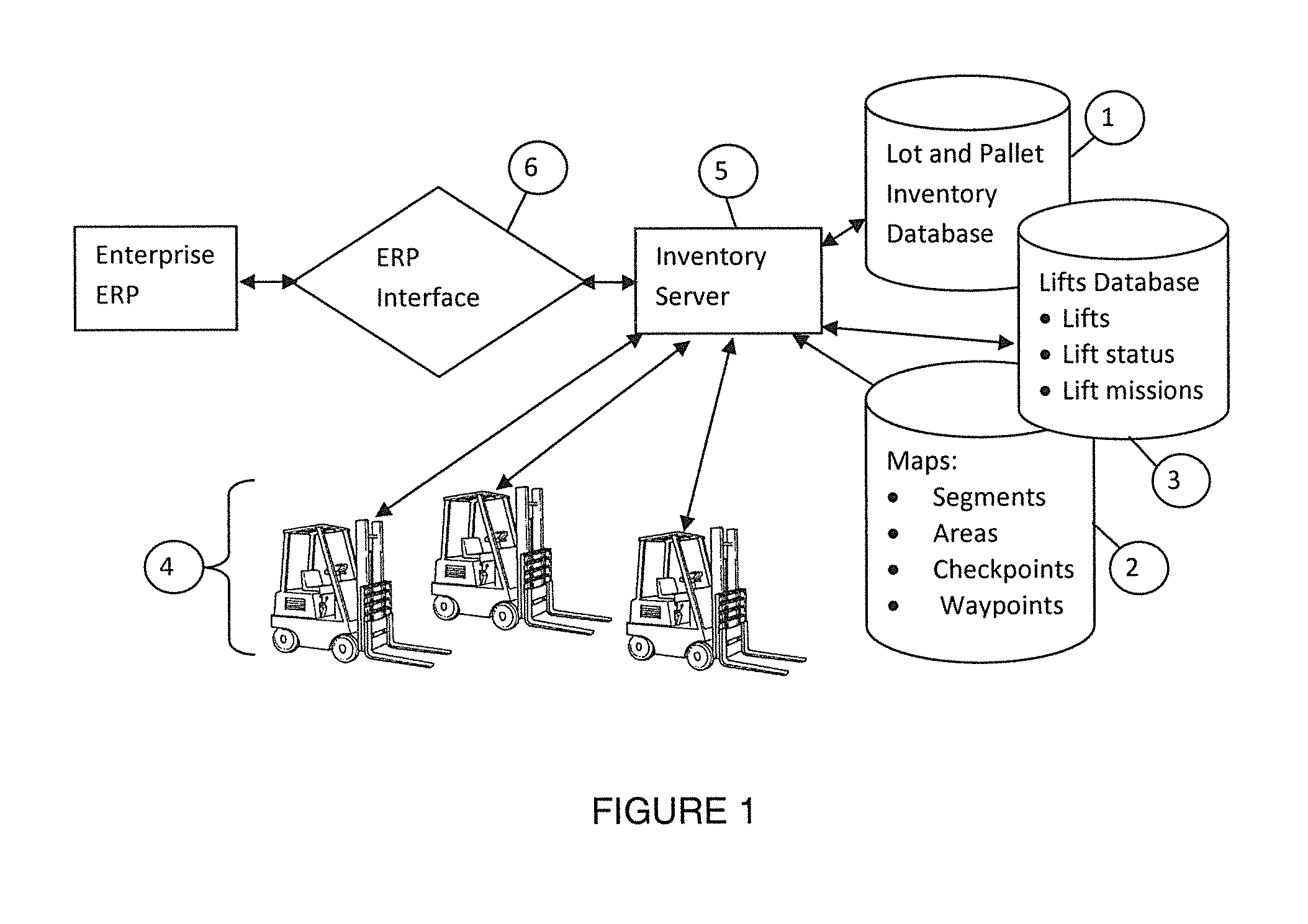

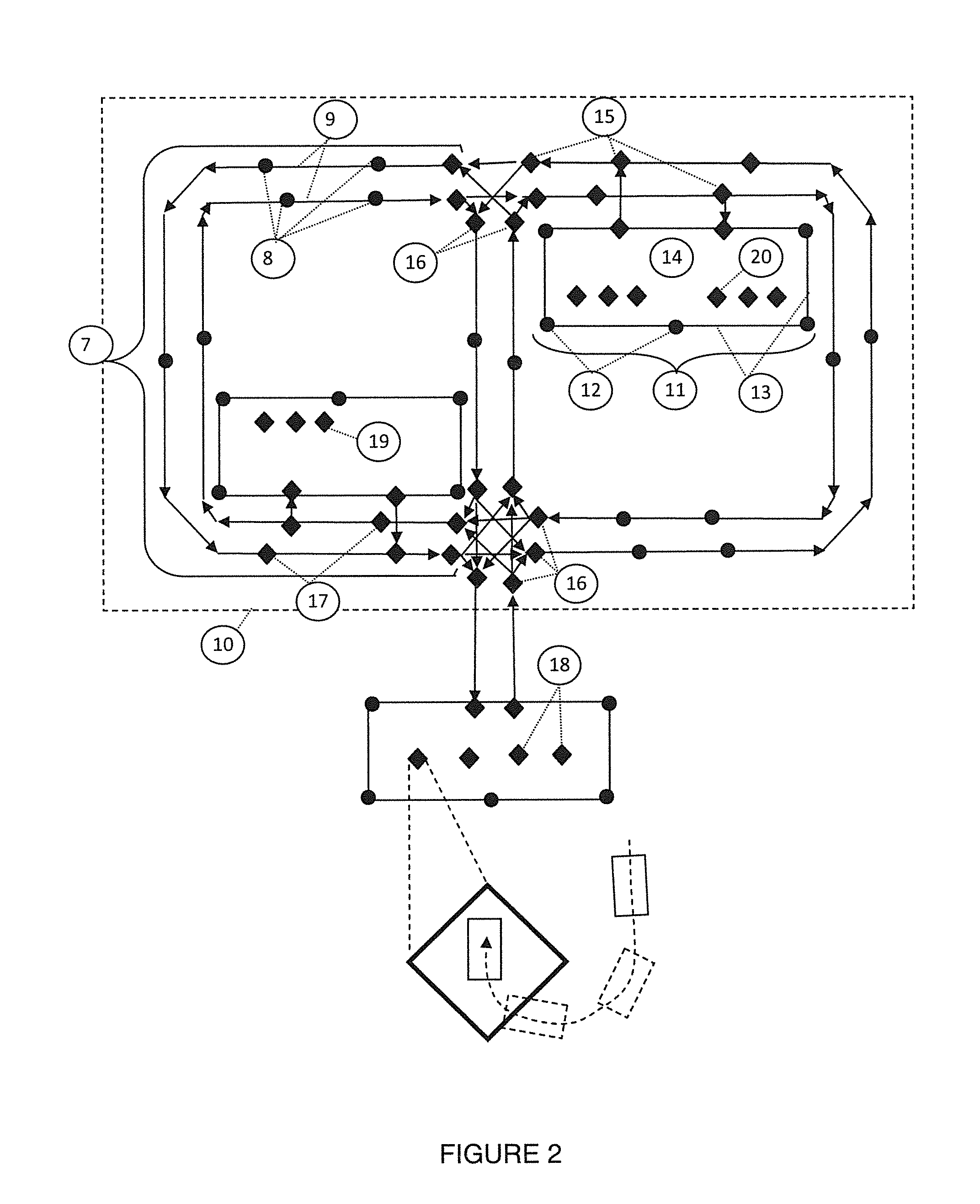

Automated warehousing using robotic forklifts

ActiveUS20140277691A1Low costReduce rateDigital data processing detailsLifting devicesOn boardInventory management

A system for automated inventory management and material handling removes the requirement to operate fully automatically or all-manual using conventional vertical storage and retrieval (S&R) machines. Inventory requests to place palletized material into storage at a specified lot location or retrieve palletized material from a specified lot are resolved into missions for autonomous fork trucks, equivalent mobile platforms, or manual fork truck drivers (and their equipment) that are autonomously or manually executed to effect the request. Automated trucks plan their own movements to execute the mission over the warehouse aisles or roadways sharing this space with manually driven trucks. Automated units drive to planned speed limits, manage their loads (stability control), stop, go, and merge at intersections according human driving rules, use on-board sensors to identify static and dynamic obstacles, and human traffic, and either avoid them or stop until potential collision risk is removed.

Owner:CYBERNET SYST

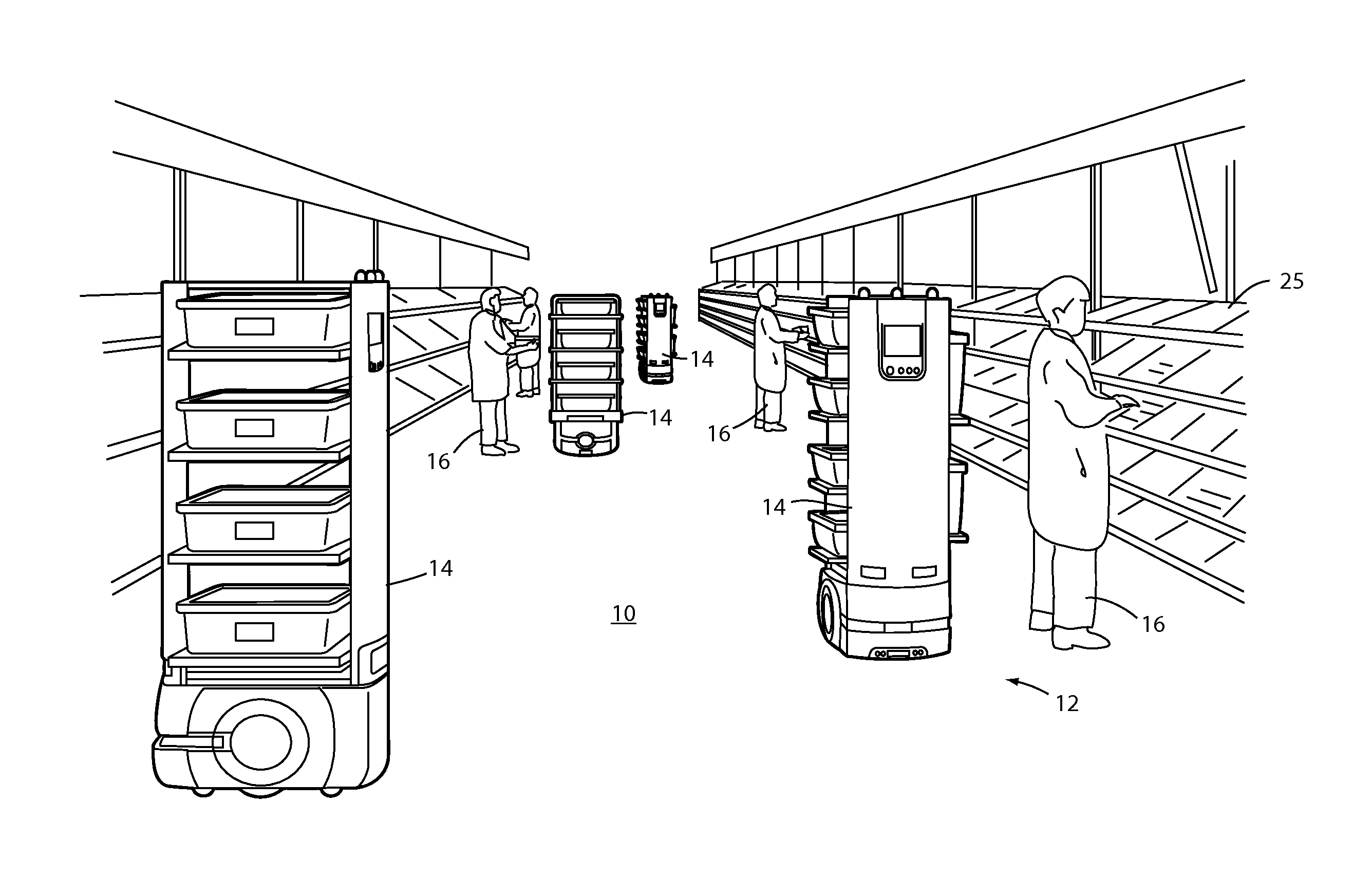

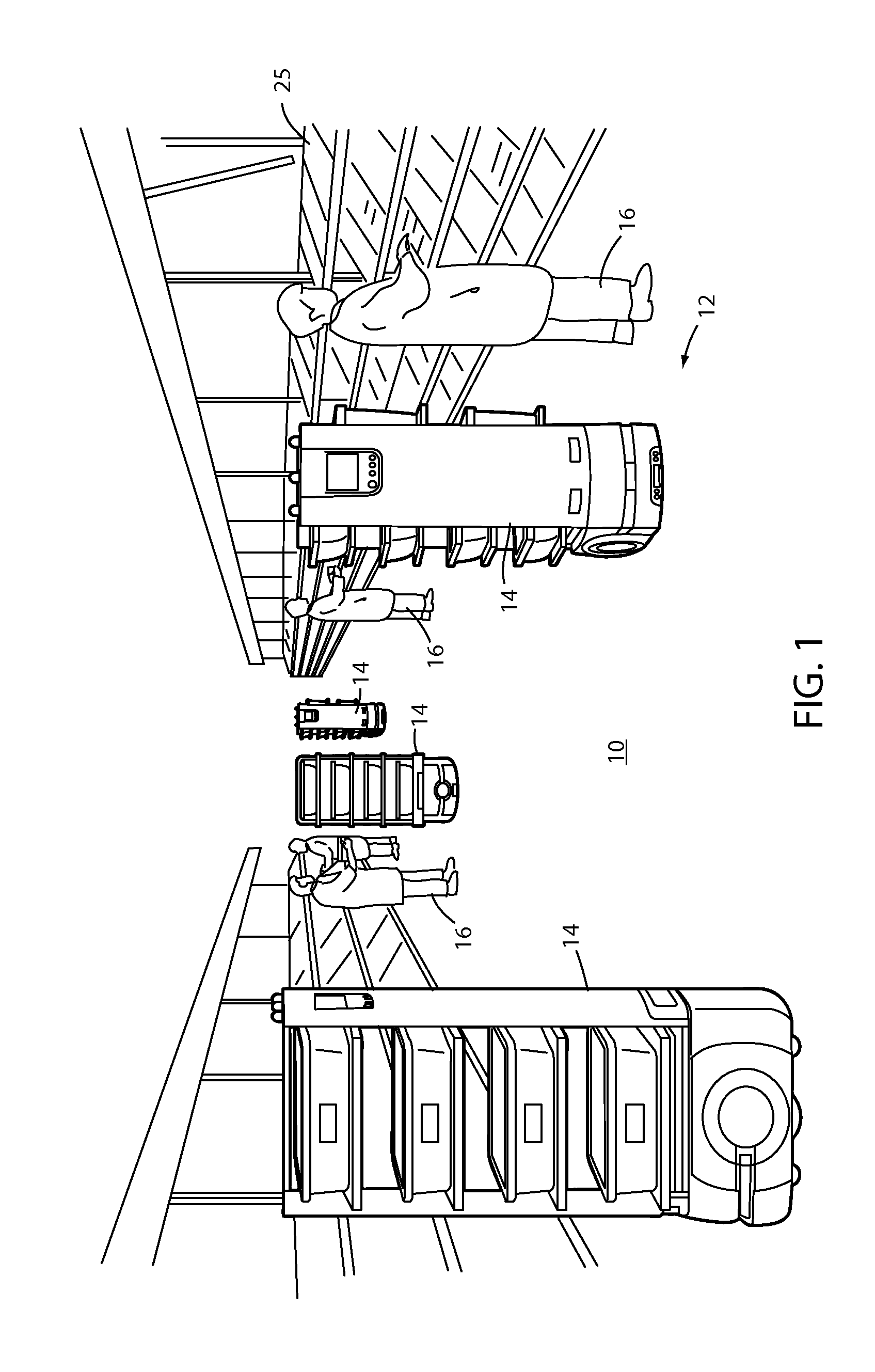

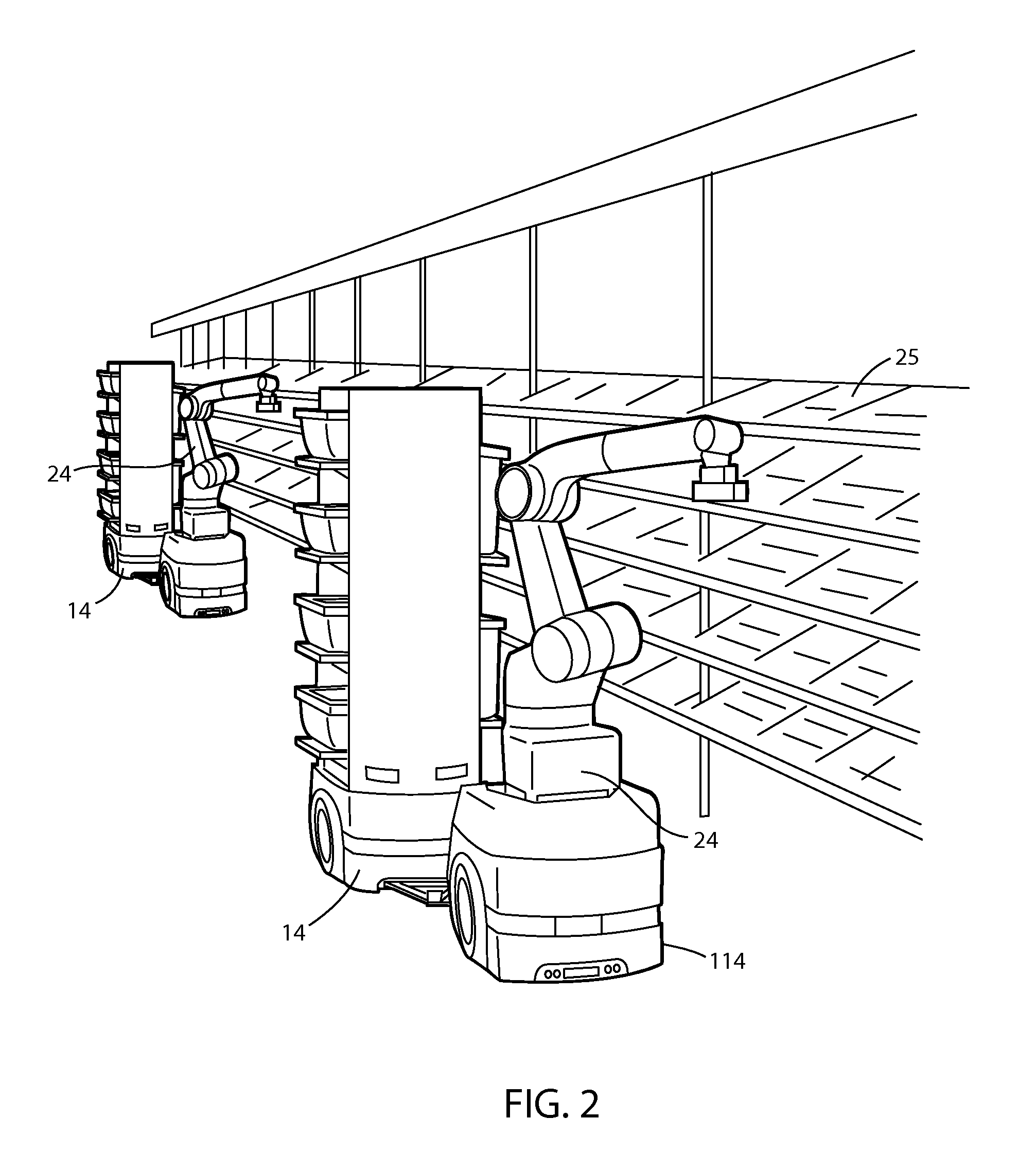

Autonomous mobile picking

ActiveUS20150073589A1Reduce labor costsFacilitates picking articleProgramme-controlled manipulatorData processing applicationsMobile vehicleOrder fulfillment

An order-picking method includes autonomously routing a plurality of mobile robotic units in an order fulfillment facility and picking articles to or putting articles from the robotic units in the order fulfillment facility. A material-handling robotic unit that is adapted for use in an order fulfillment facility includes an autonomous mobile vehicle base and a plurality of article receptacles positioned on the base. A visual indicator associated with the receptacle facilitates picking articles to or putting articles from the robotic unit.

Owner:DEMATIC

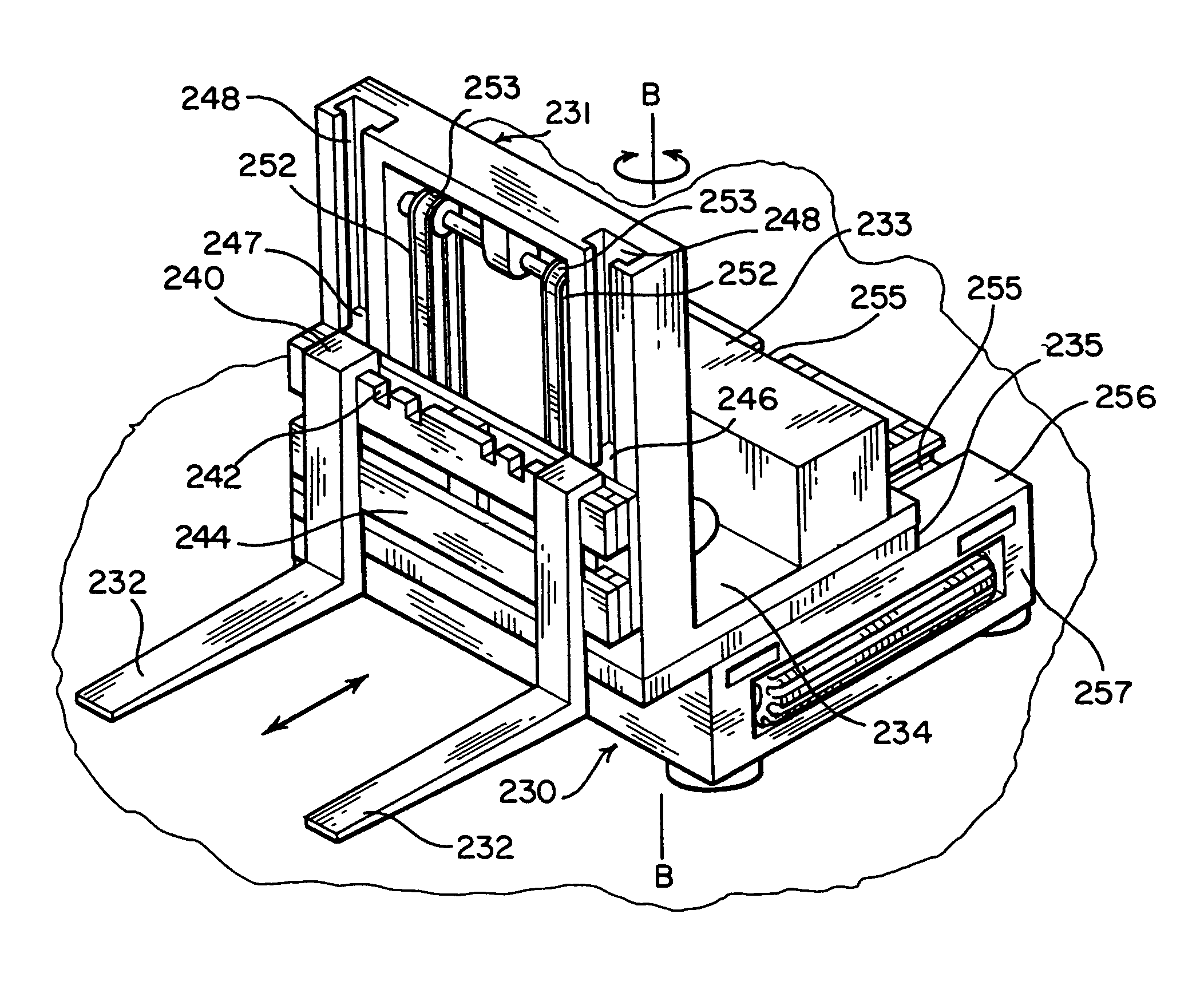

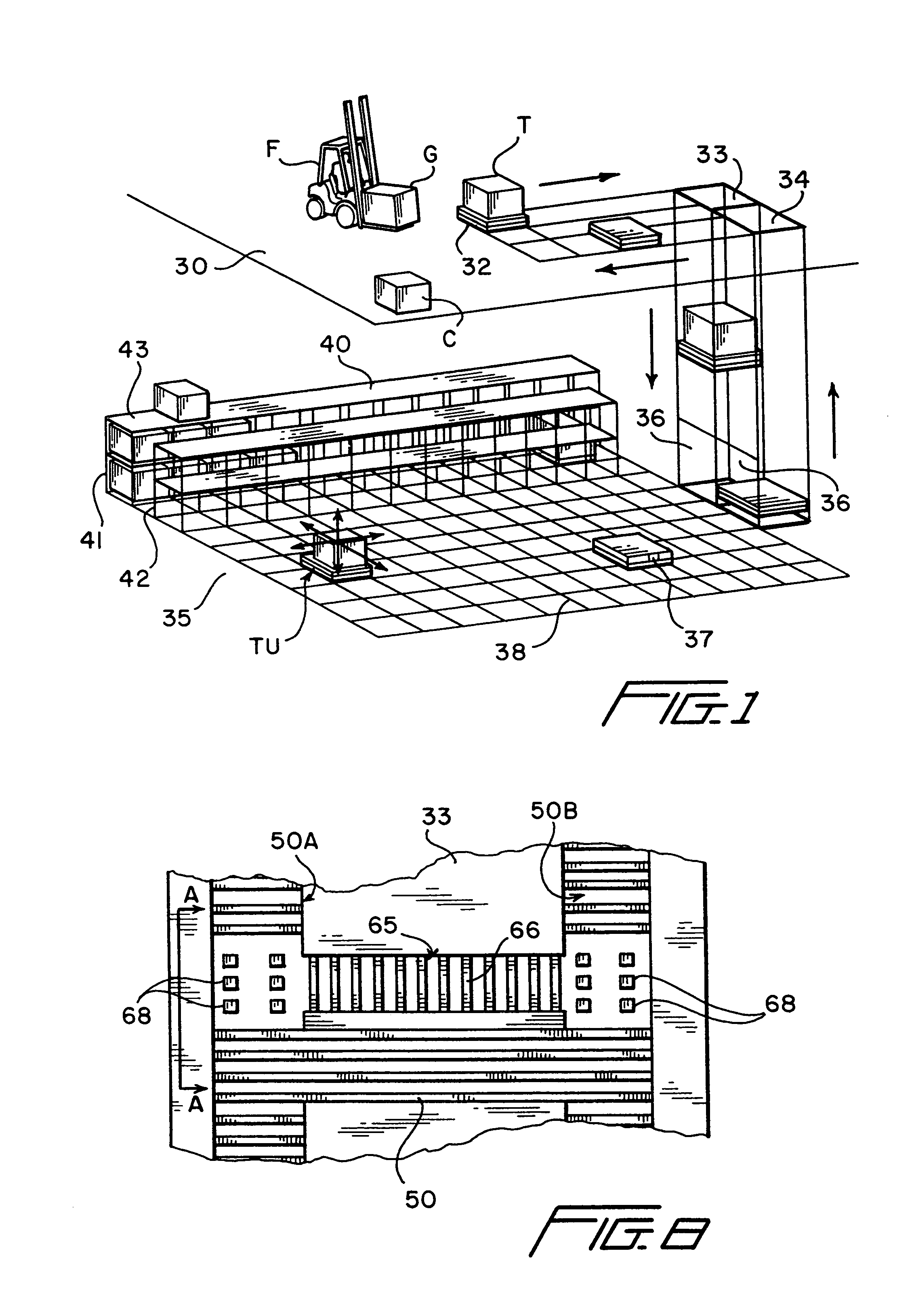

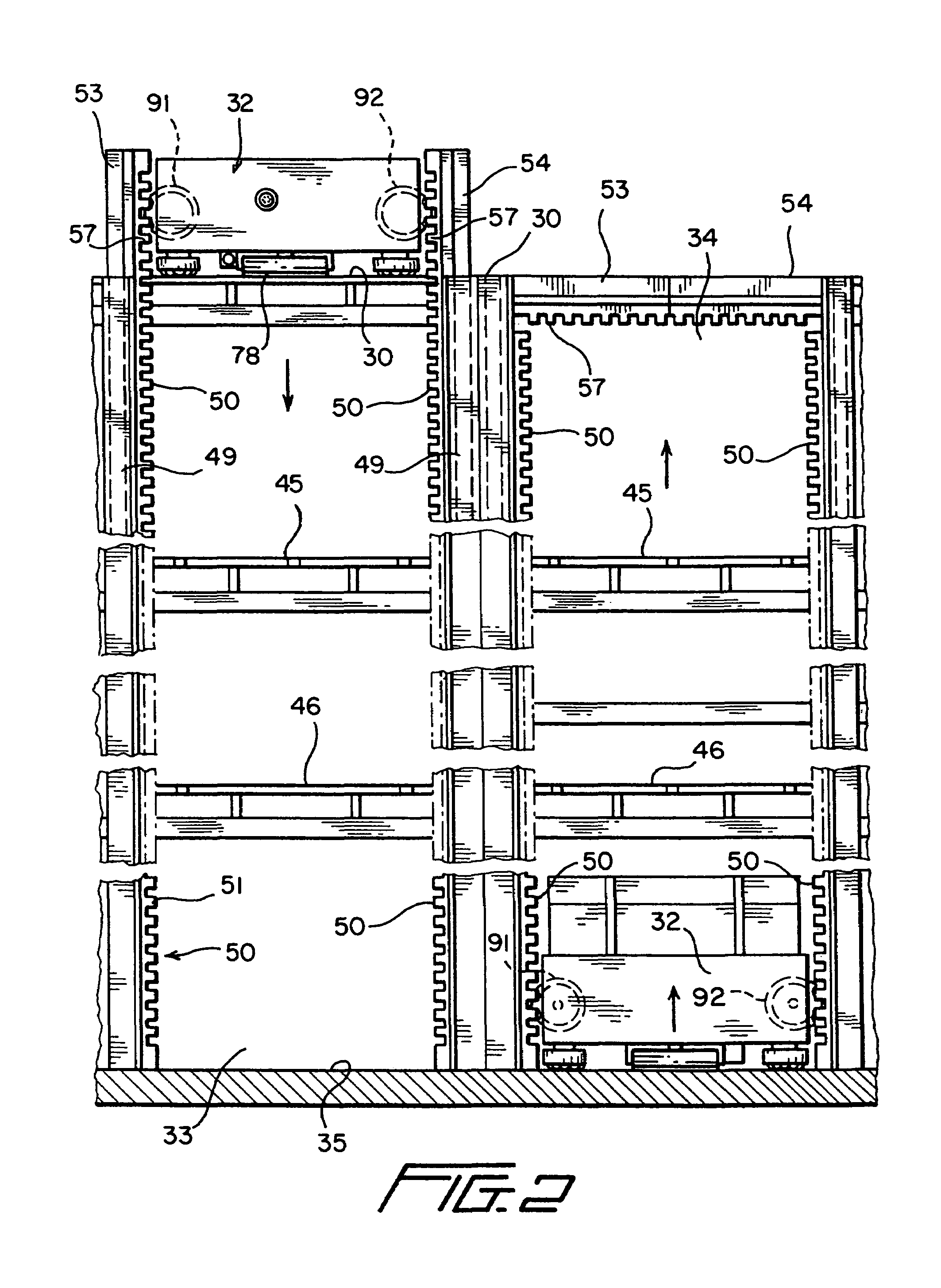

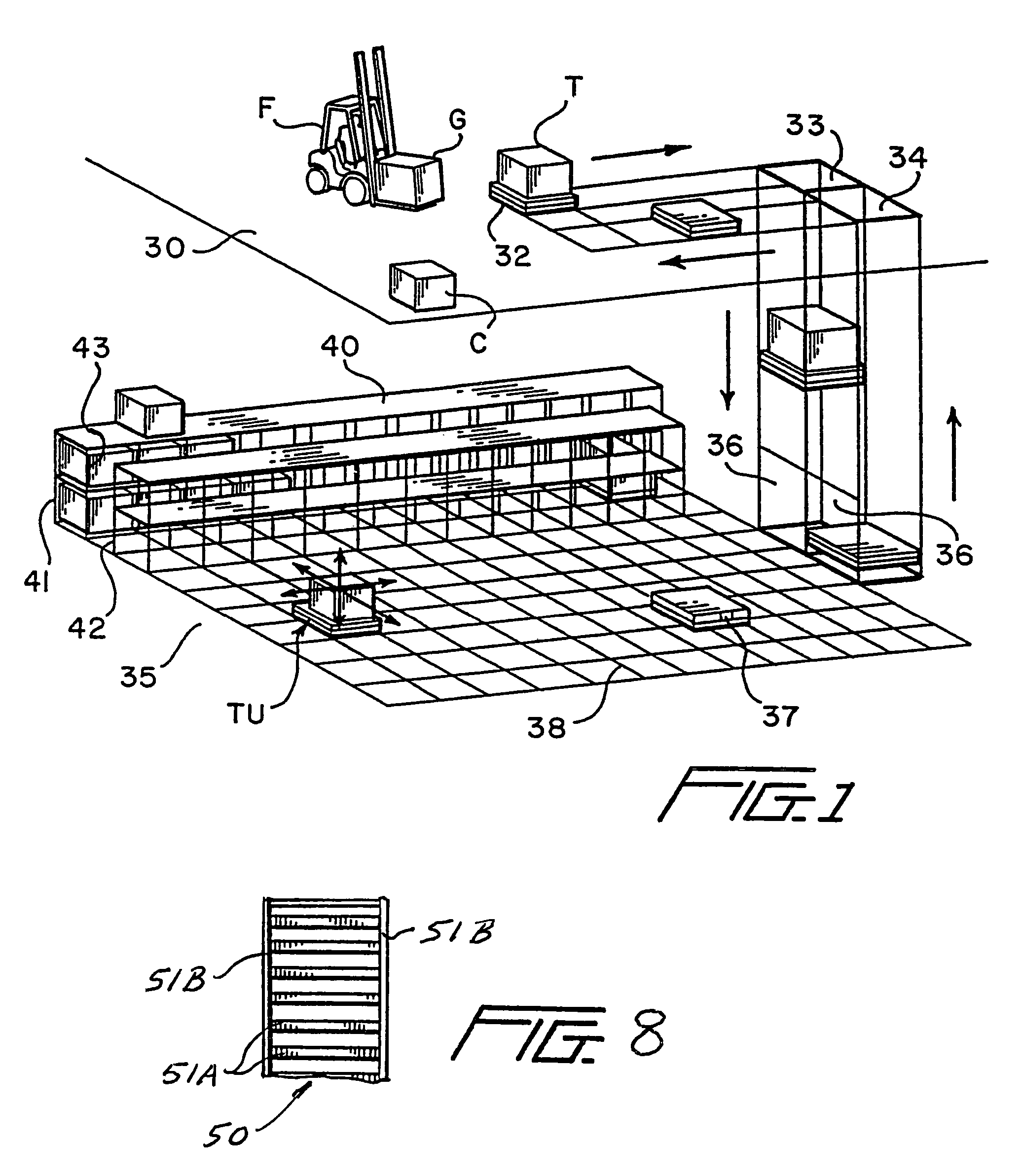

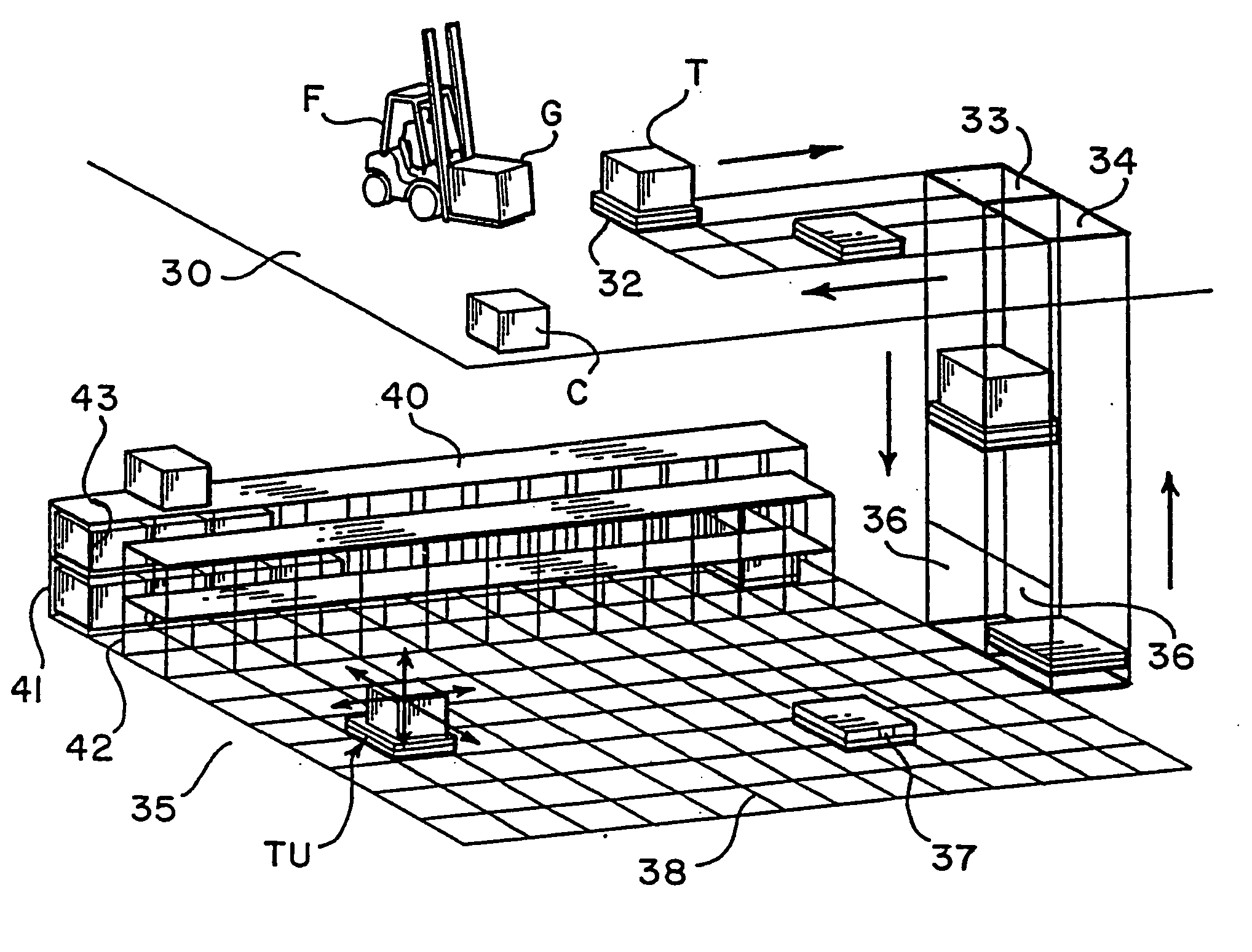

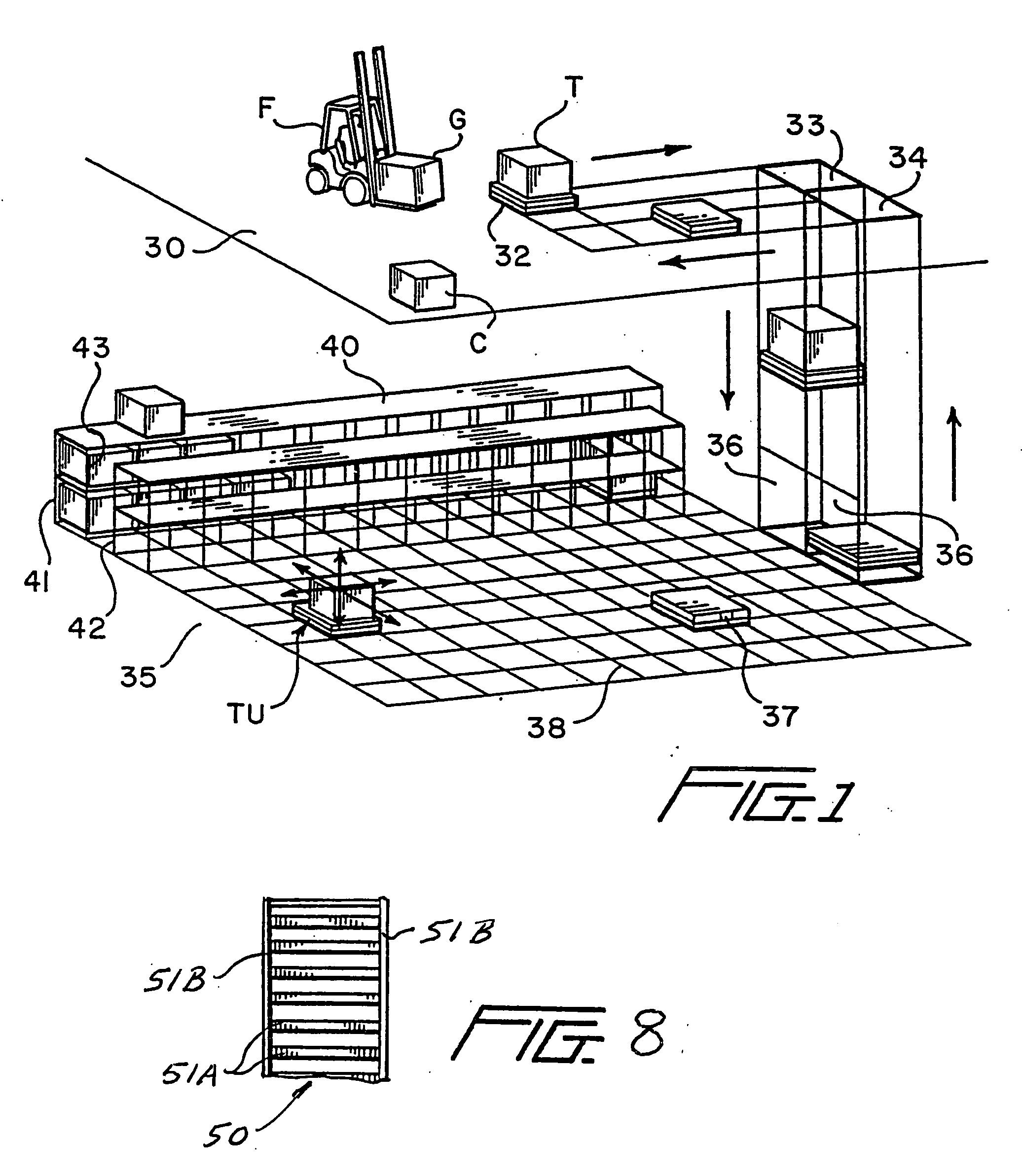

Automated material handling system with motorized transfer vehicles

InactiveUS7101139B1Improve securityProvide energyAutomatic initiationsLoad accommodationMaterial handlingTreatment system

A material handling system for use in storing and moving goods within multi-level storage warehouses, ocean going vessels and the like wherein storage areas are provided on at least one of the levels and wherein goods are automatically transferred to and from the storage areas and between the various levels by self-propelled load transfer vehicles. The load transfer vehicles move across the surface of the various levels and deliver are also movable within open vertical trunks between the levels to thereby move goods to any desired area.

Owner:GEBRR BECKER

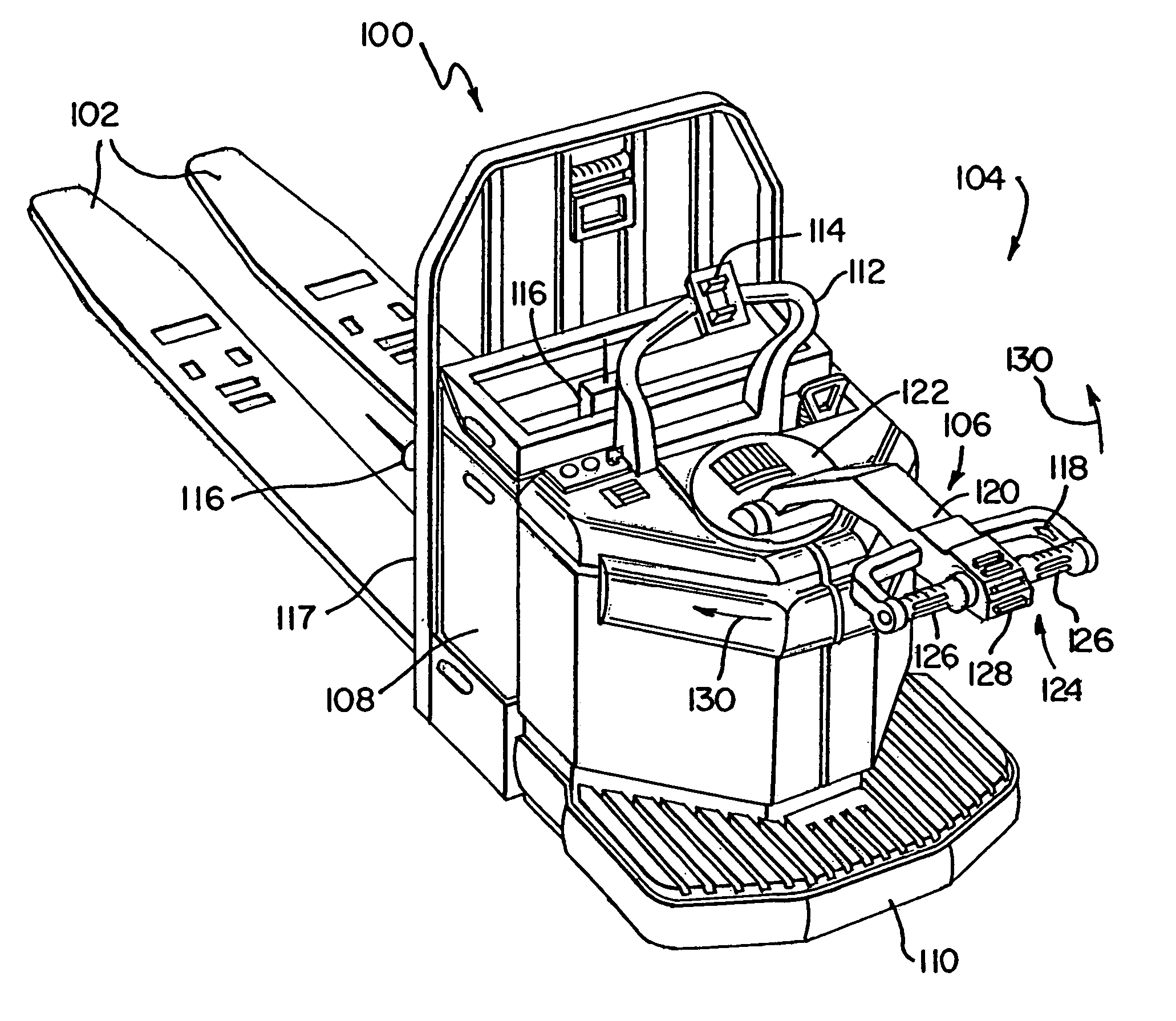

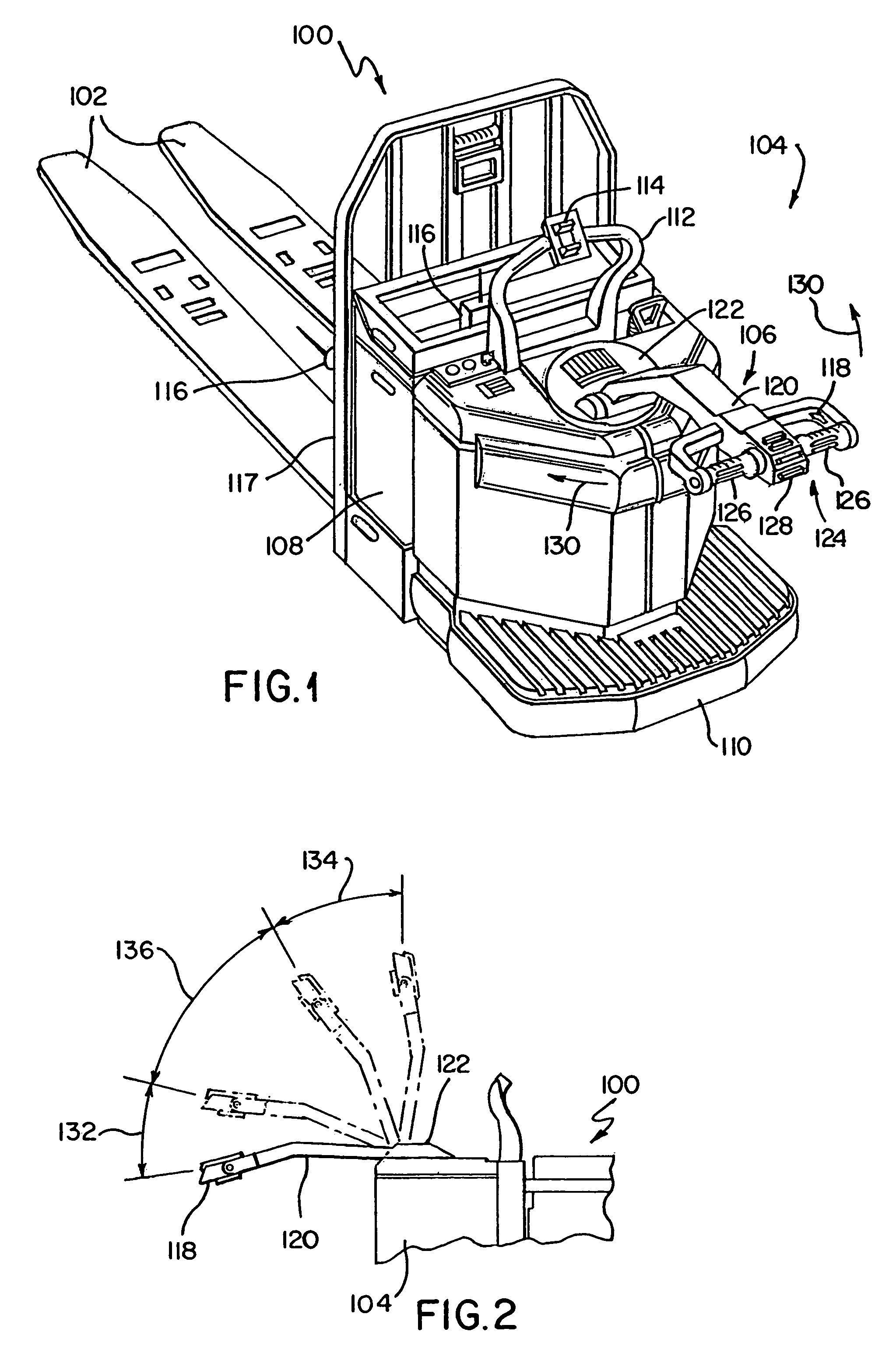

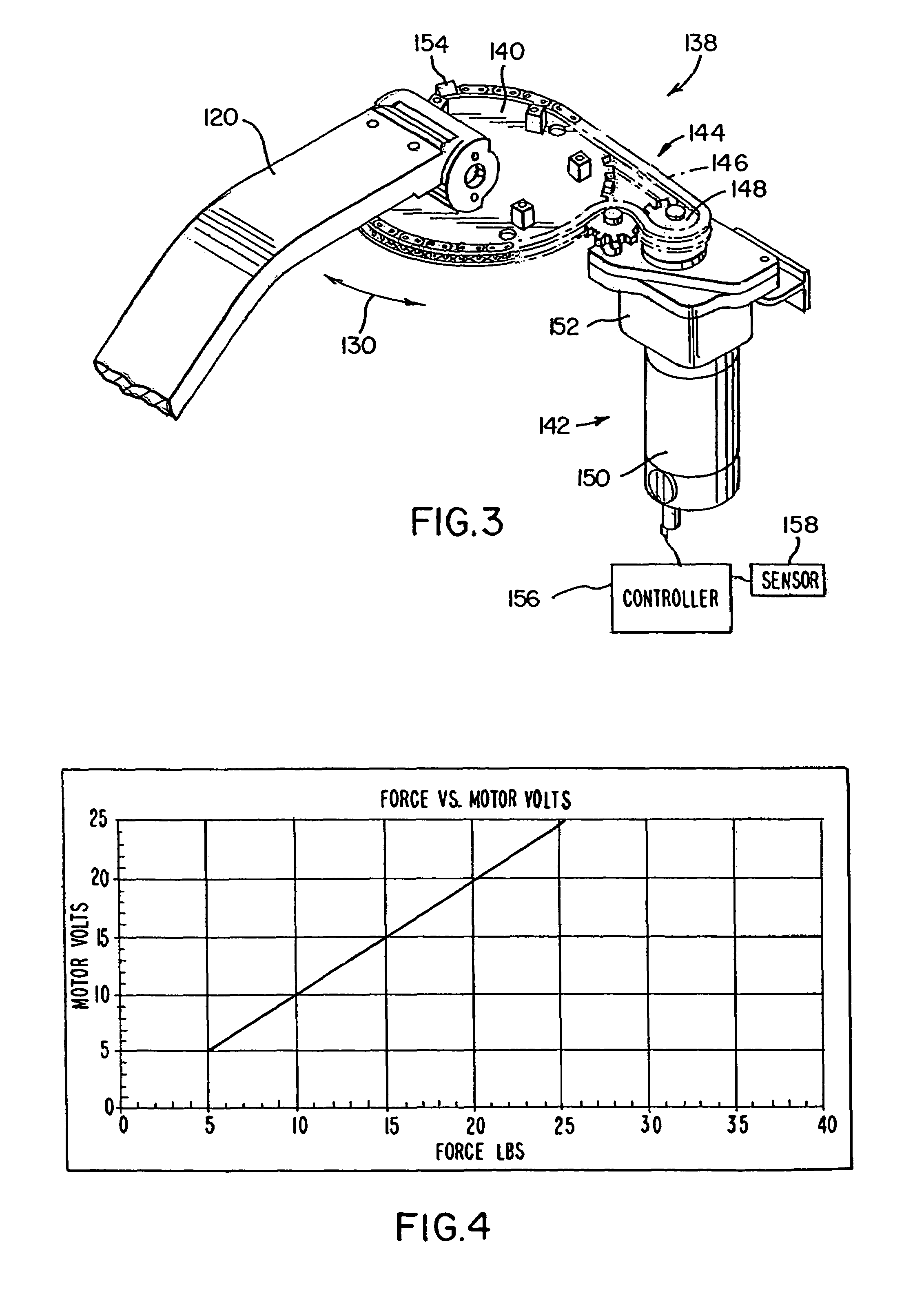

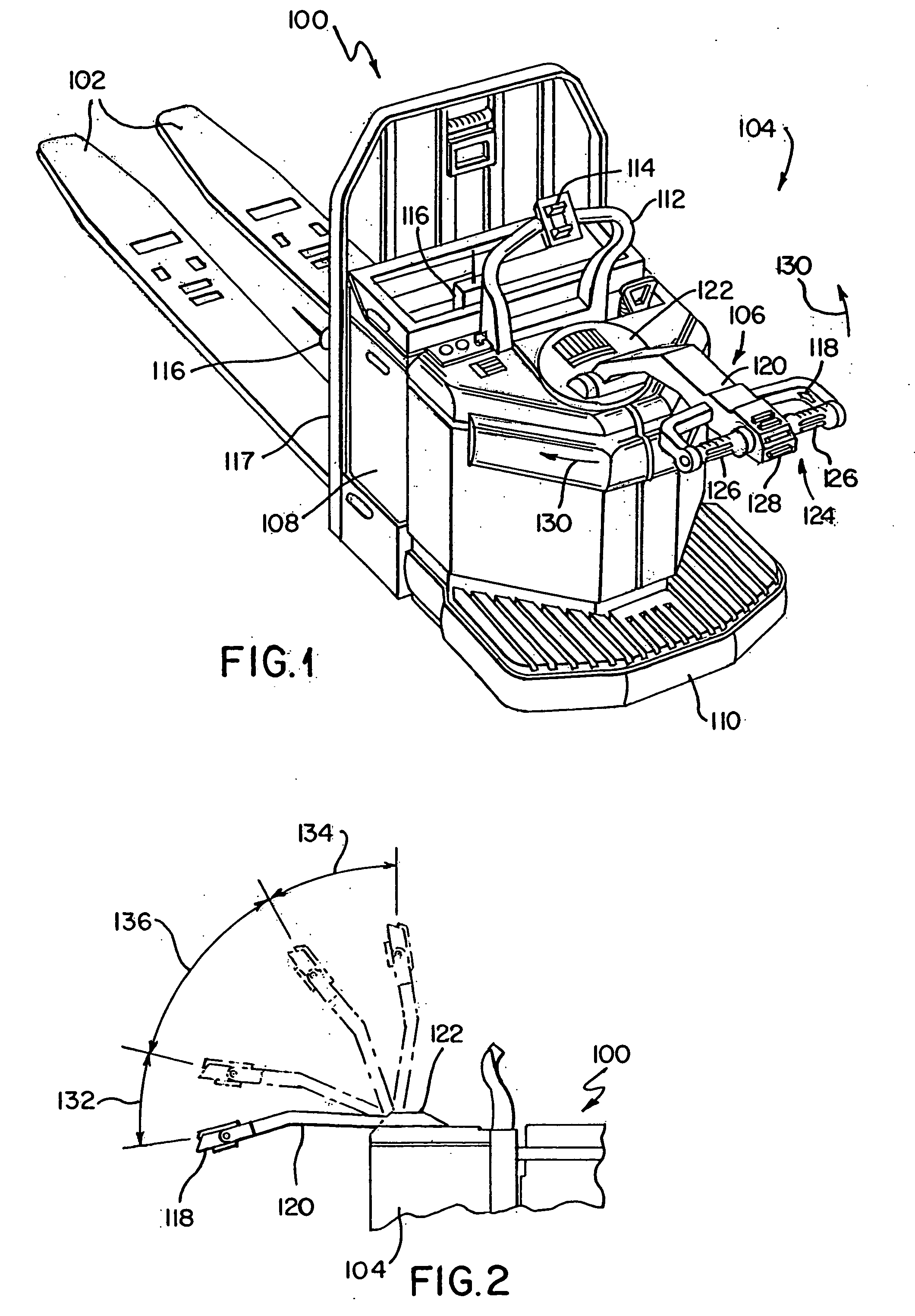

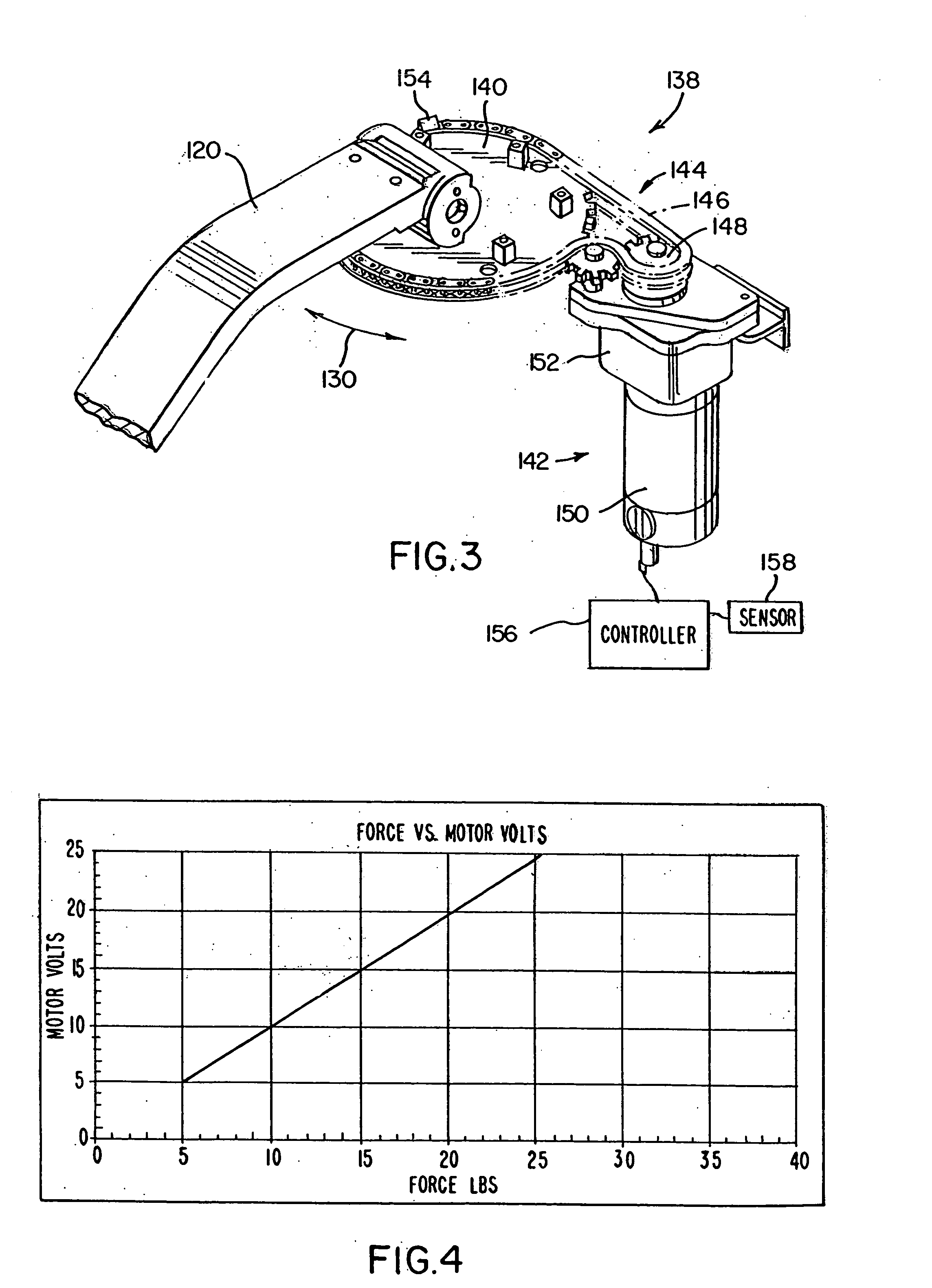

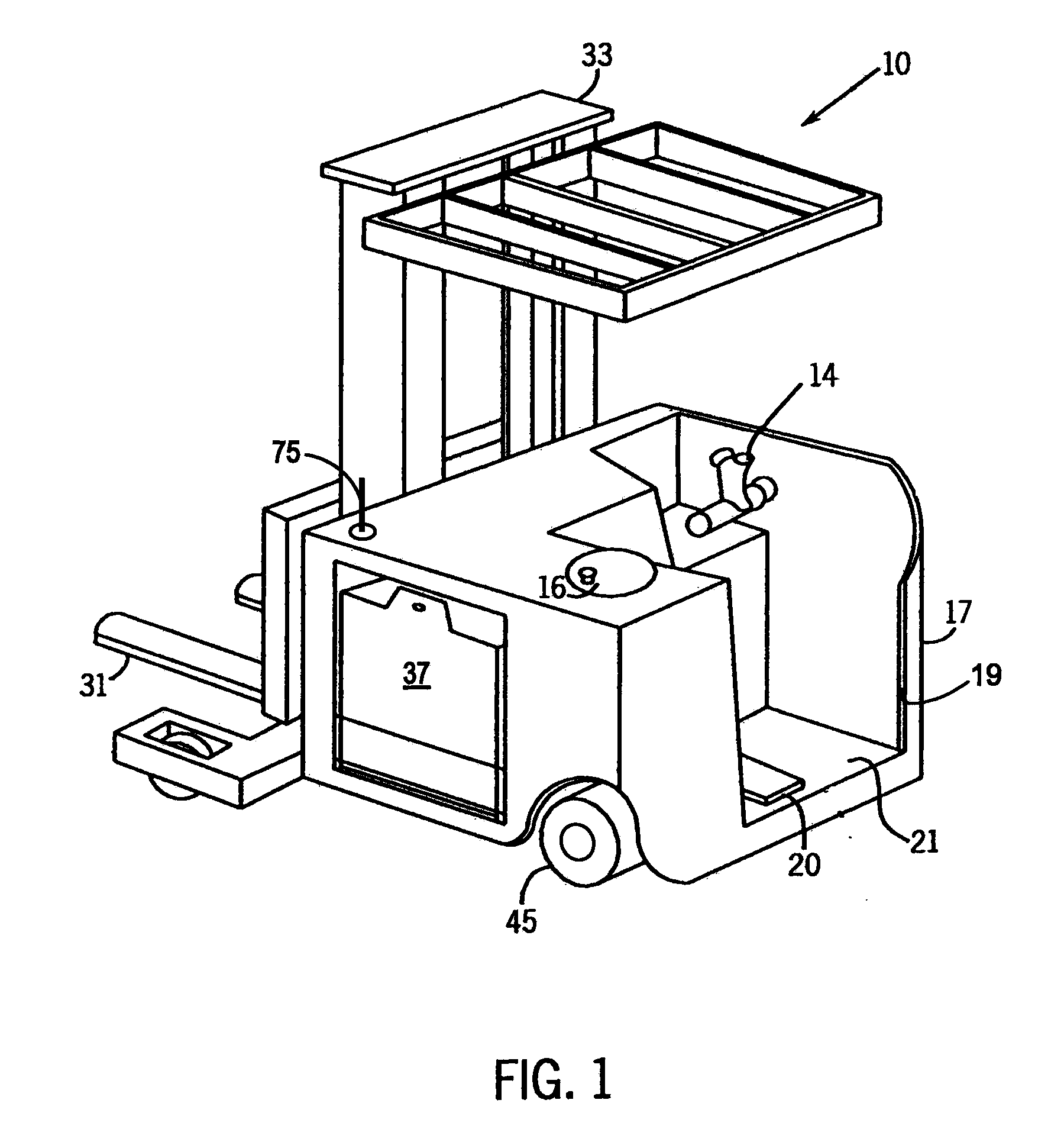

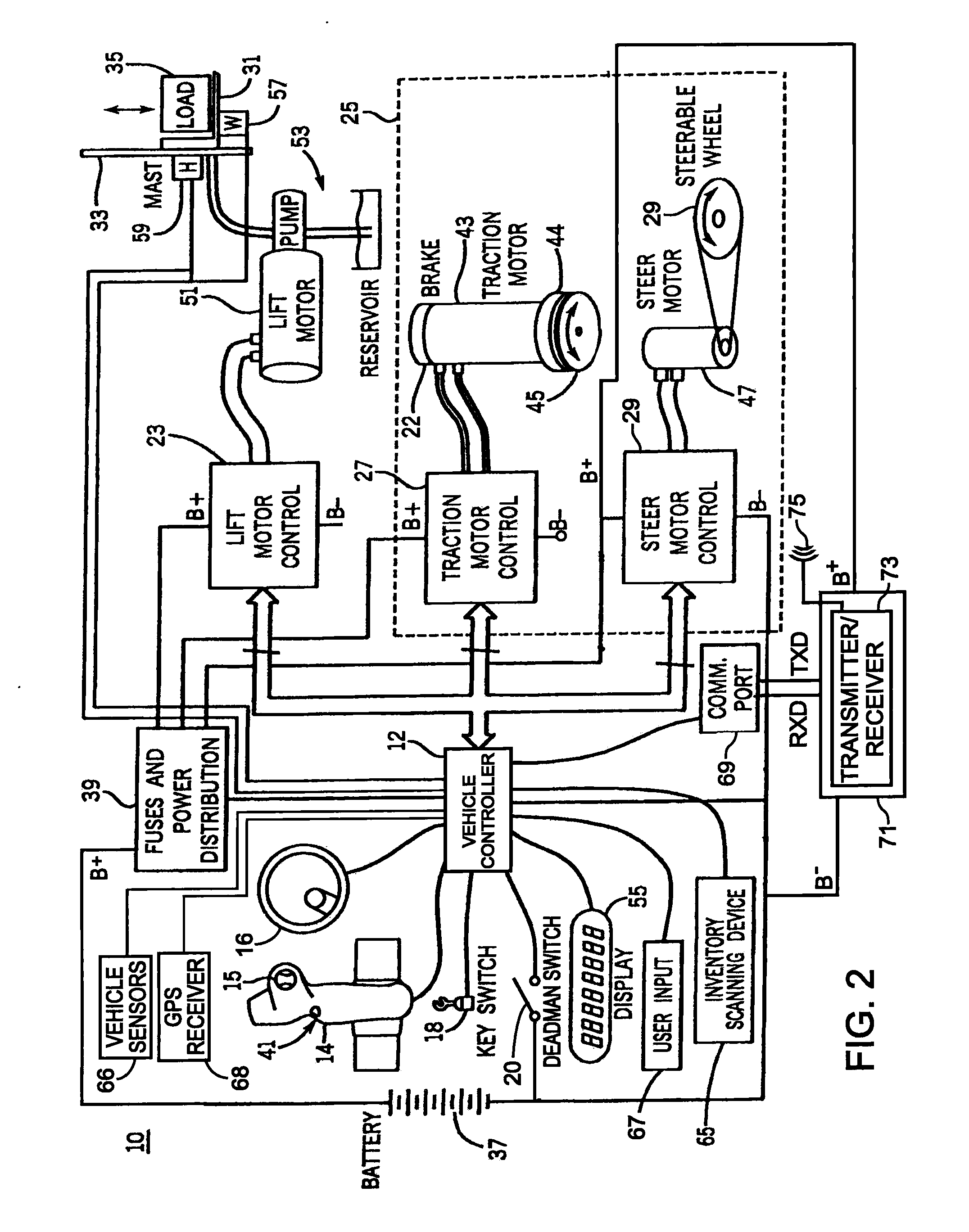

Electrical steering assist for material handling vehicles

Electrical steering assist systems reduce the operator applied steering effort necessary to operate material handling vehicles. A steer drive unit including a motor is coupled to a steerable wheel for providing steering assist. The amount of steering assist provided by the steer drive unit is determined by a controller that receives input from one or more input sensing devices. The input sensing device(s) may include force sensors that detect an operator applied turning force. The input sensing device(s) may also detect the movement of one steering component relative to another. Further, the input sensing device(s) may include operator activated controls such as a joystick, potentiometer, switches and voice initiated commands. Input sensing device(s) may additionally be provided to detect operational parameters such as the load on the material handling vehicle, vehicle speed, or environmental conditions such as travel path obstruction detection, homing and proximity sensing.

Owner:CROWN EQUIP CORP

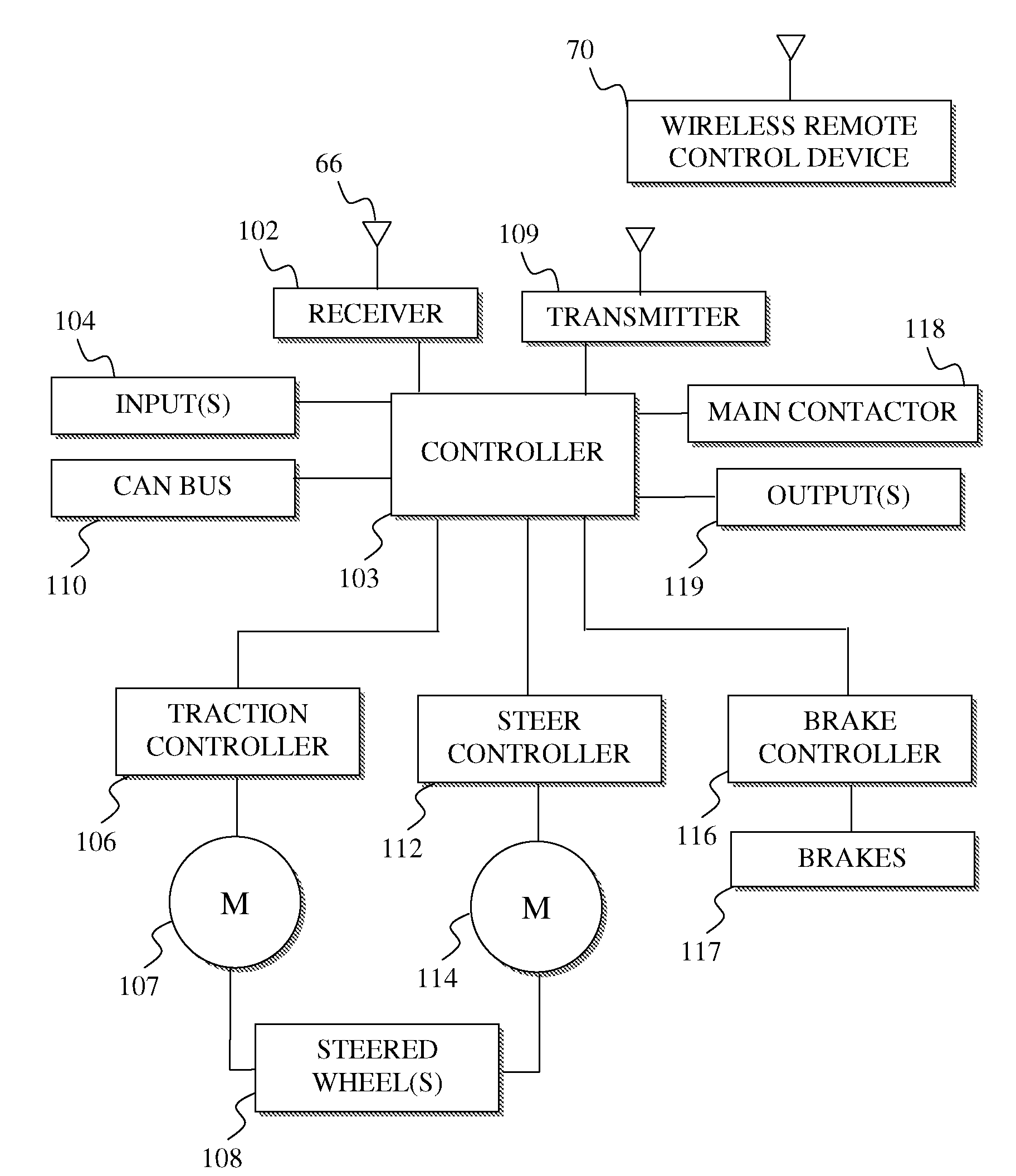

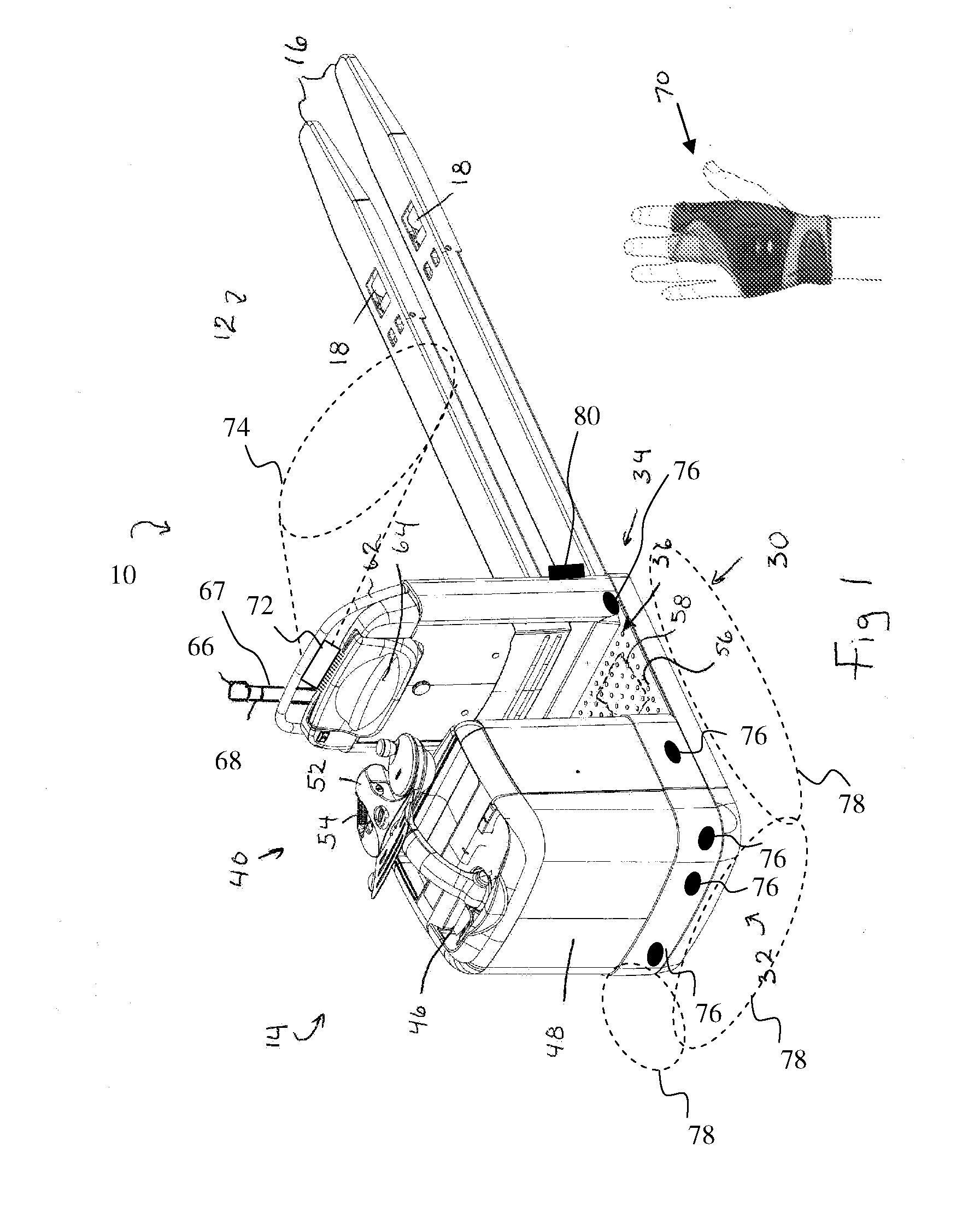

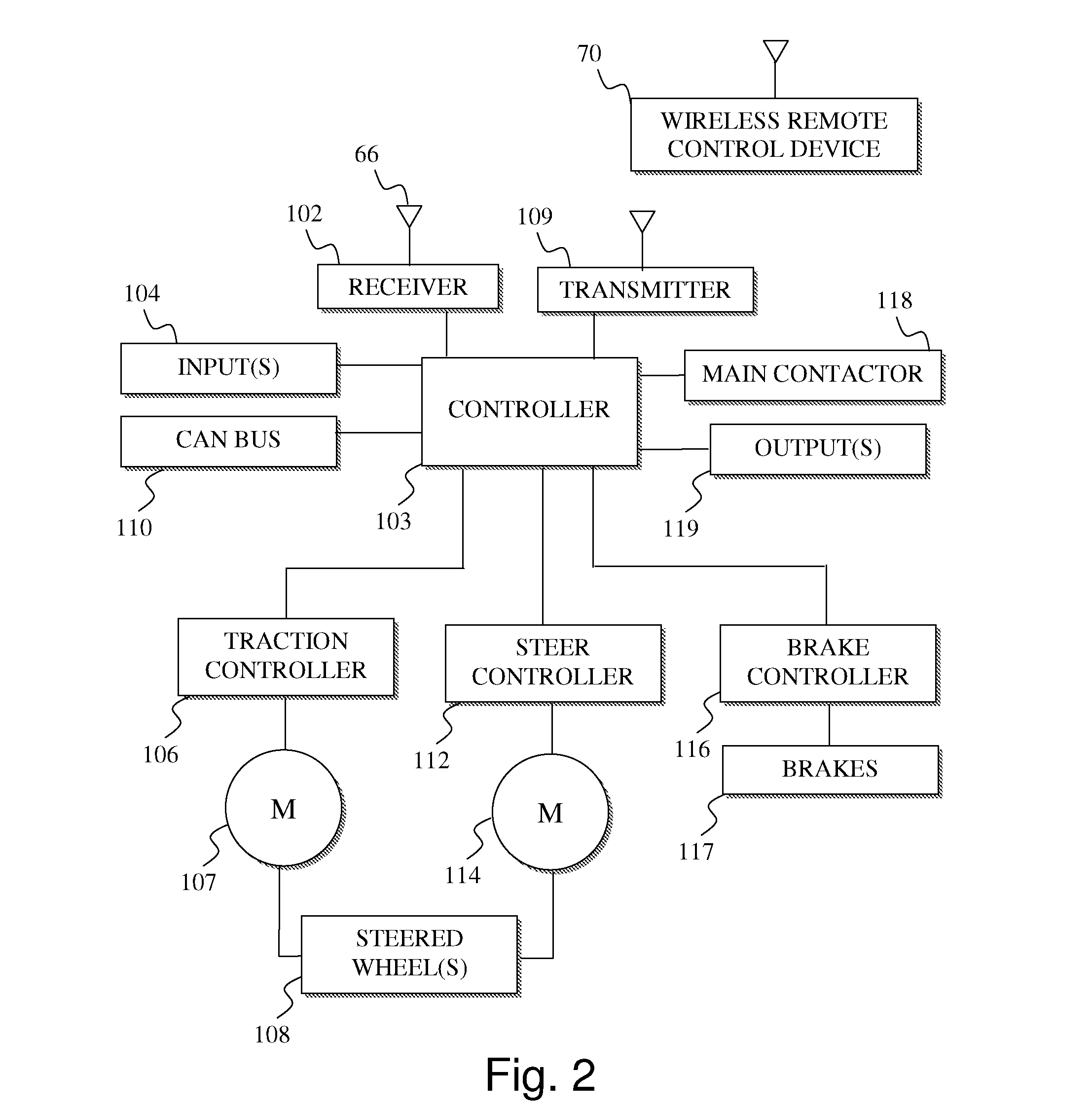

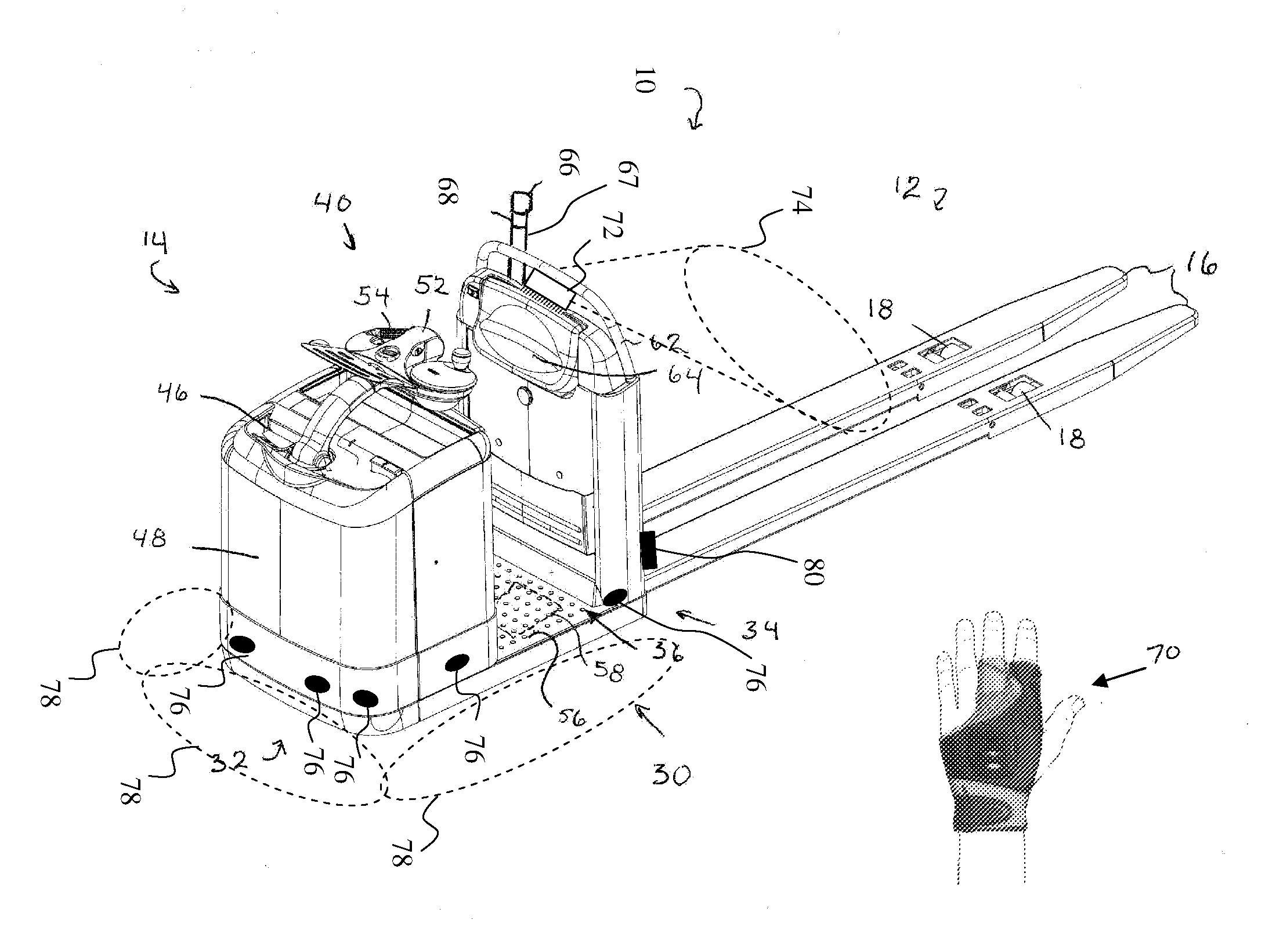

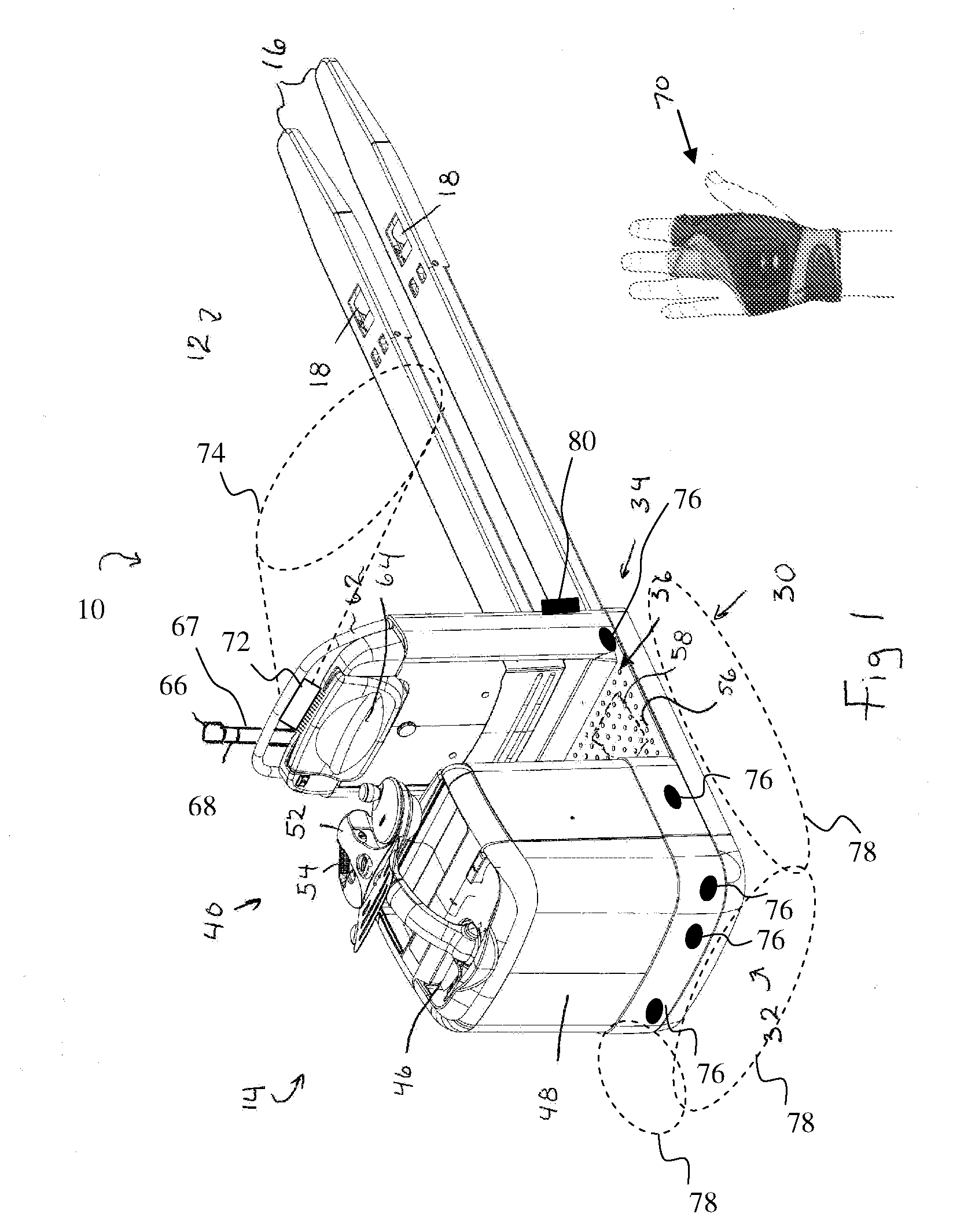

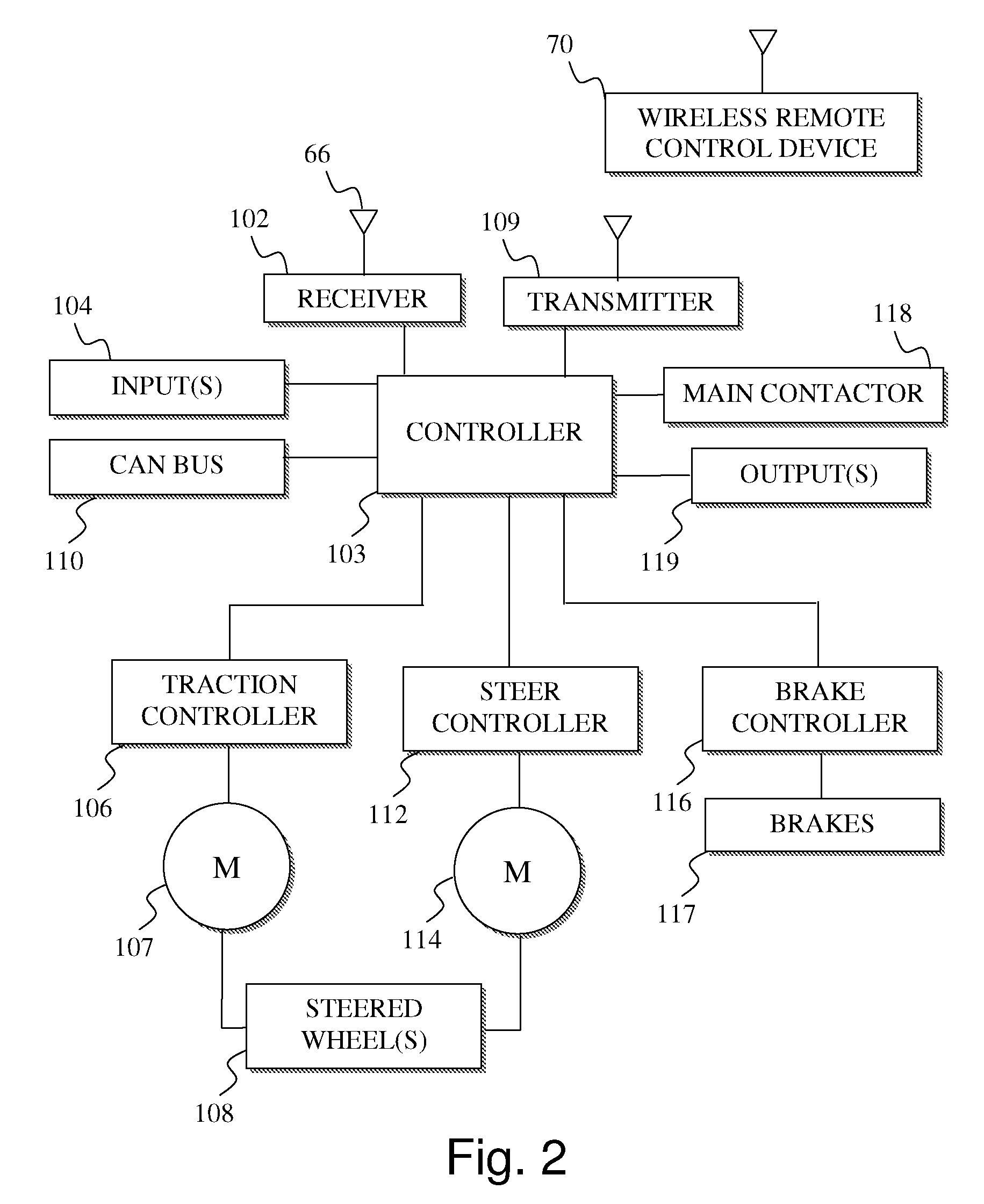

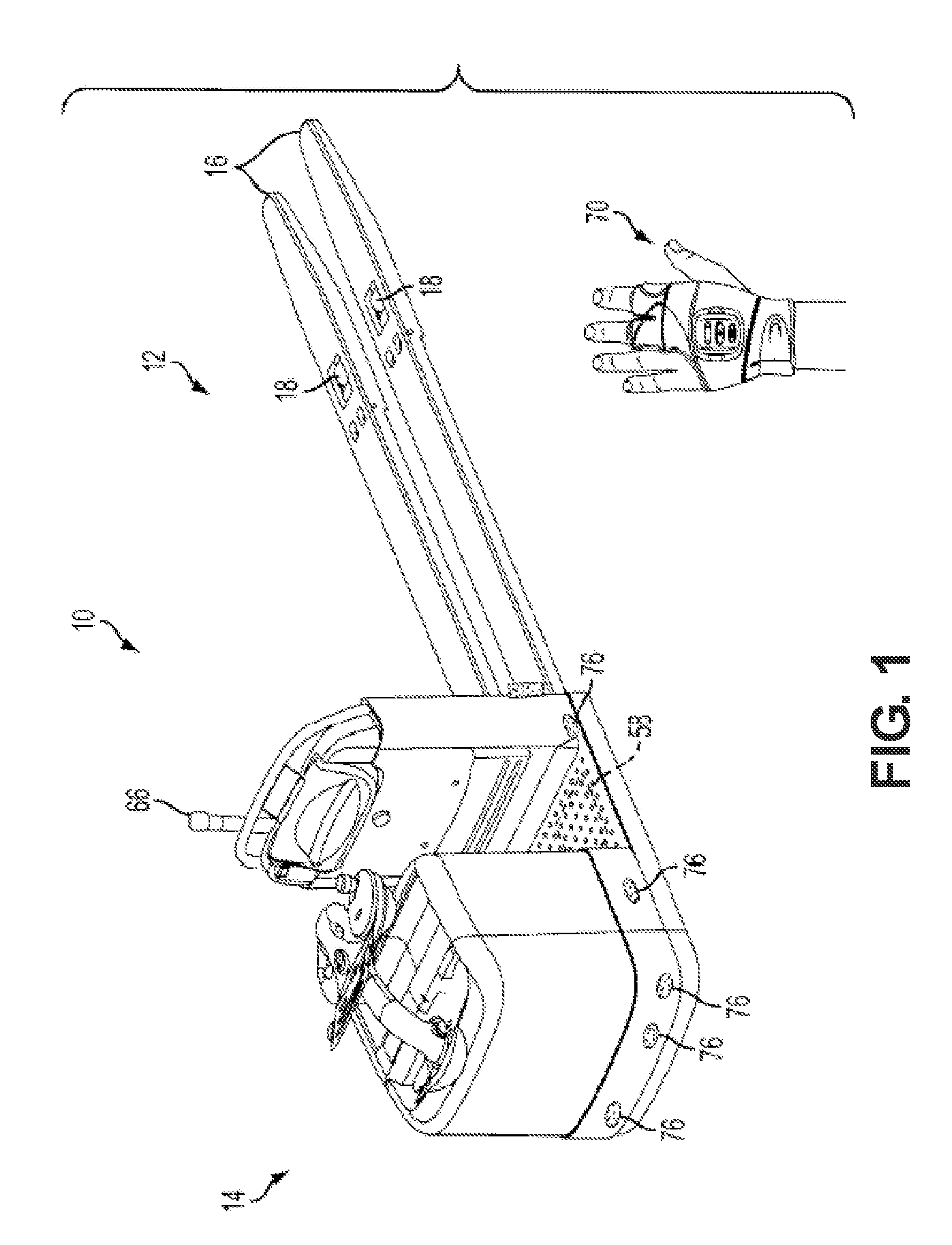

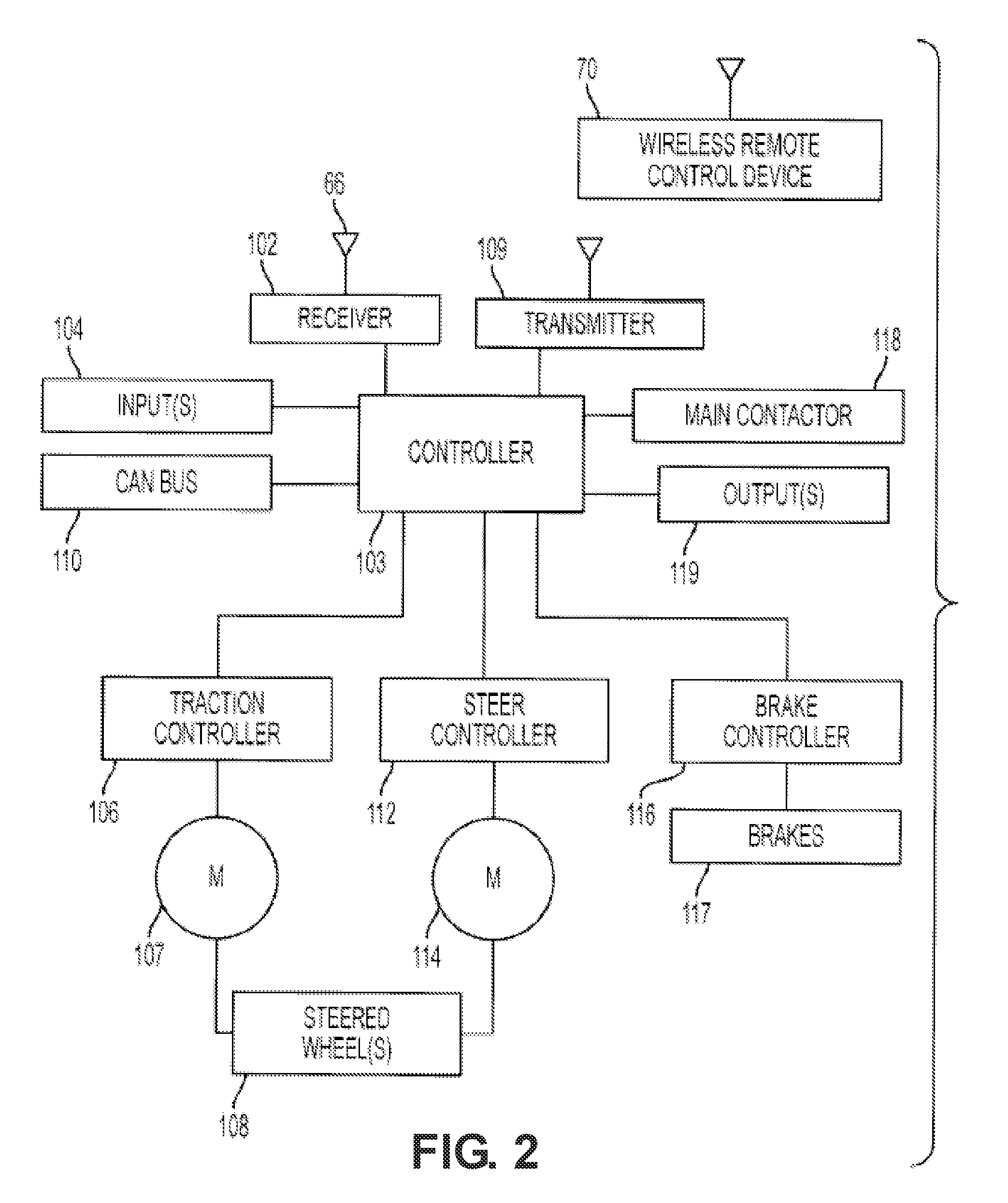

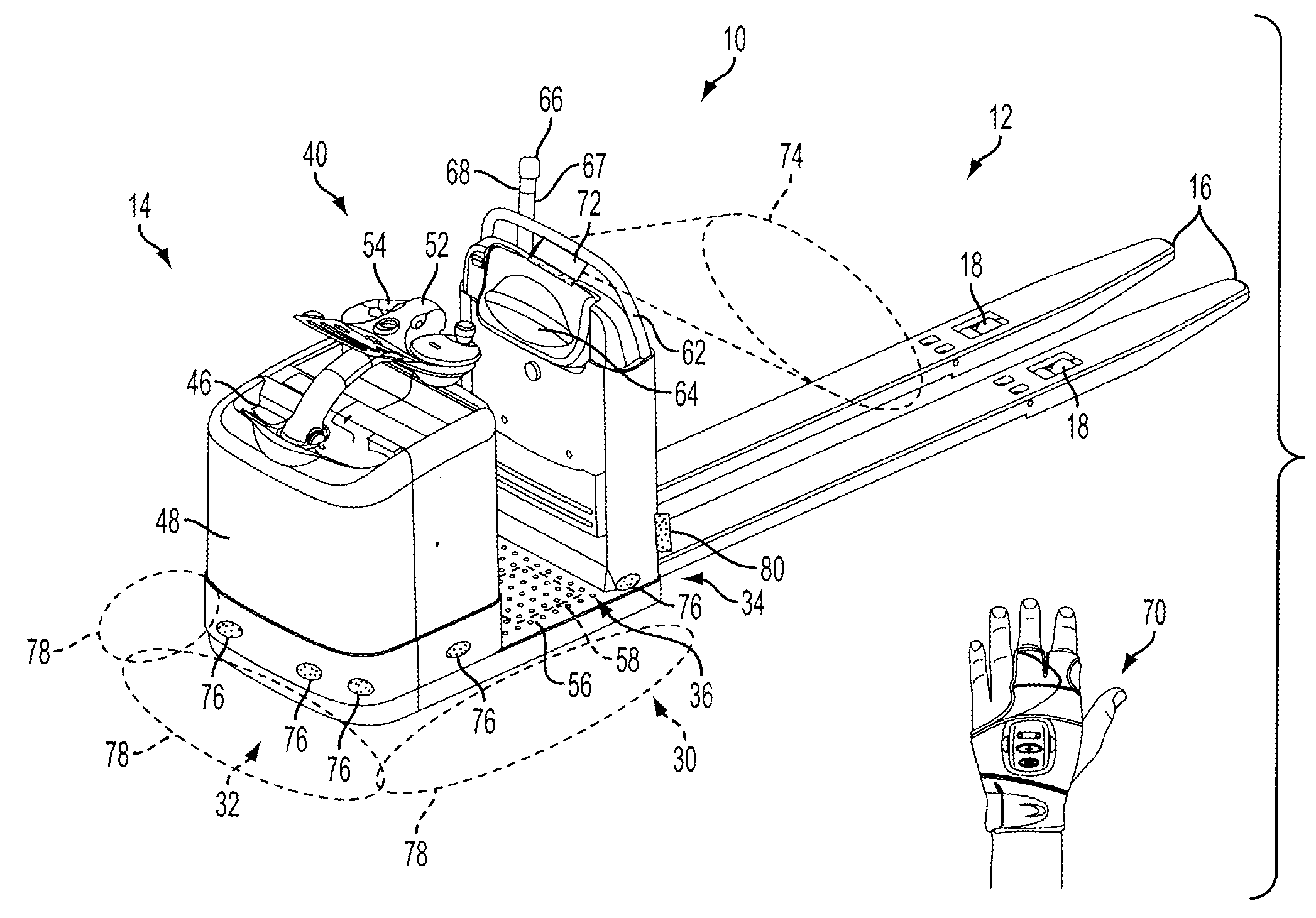

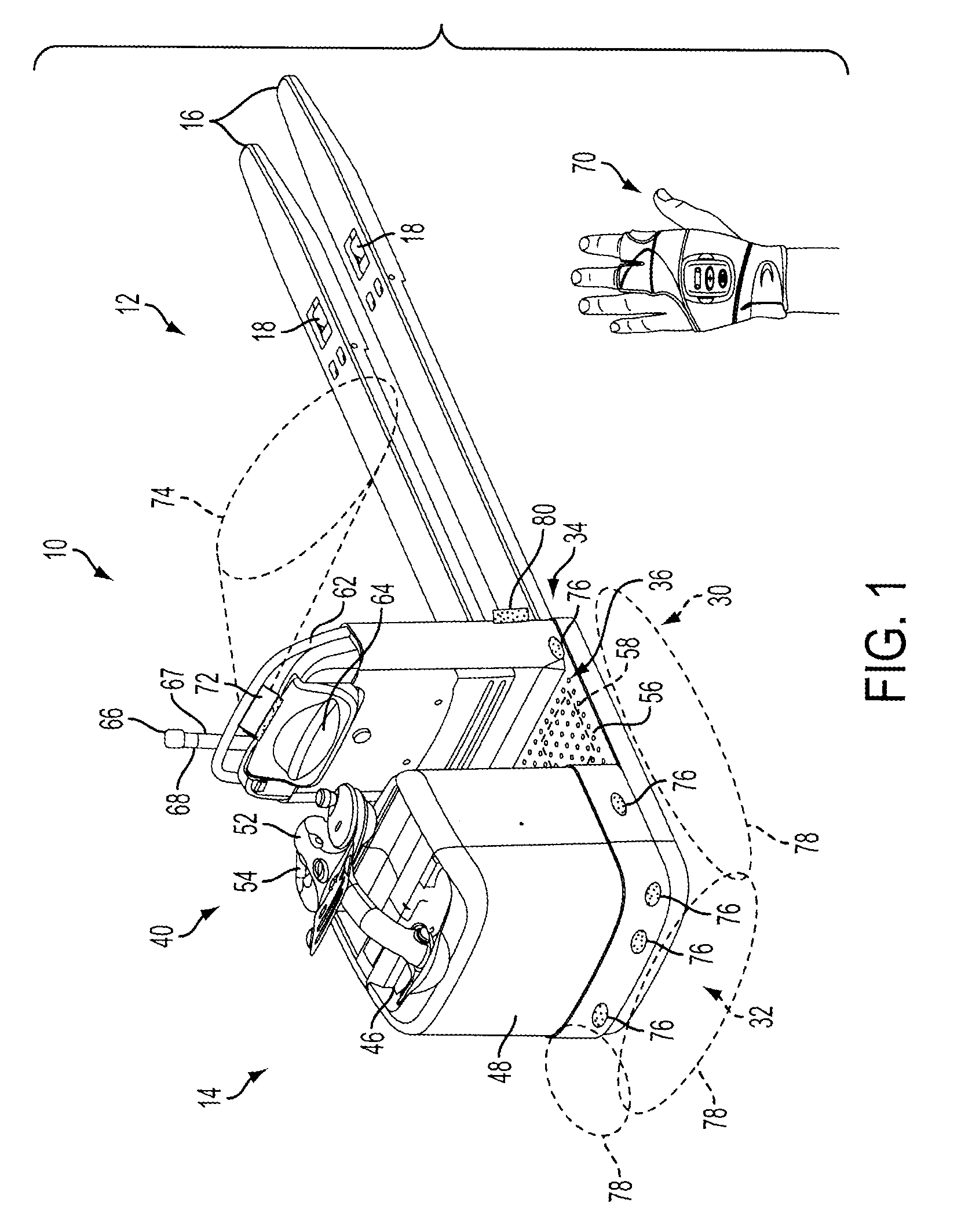

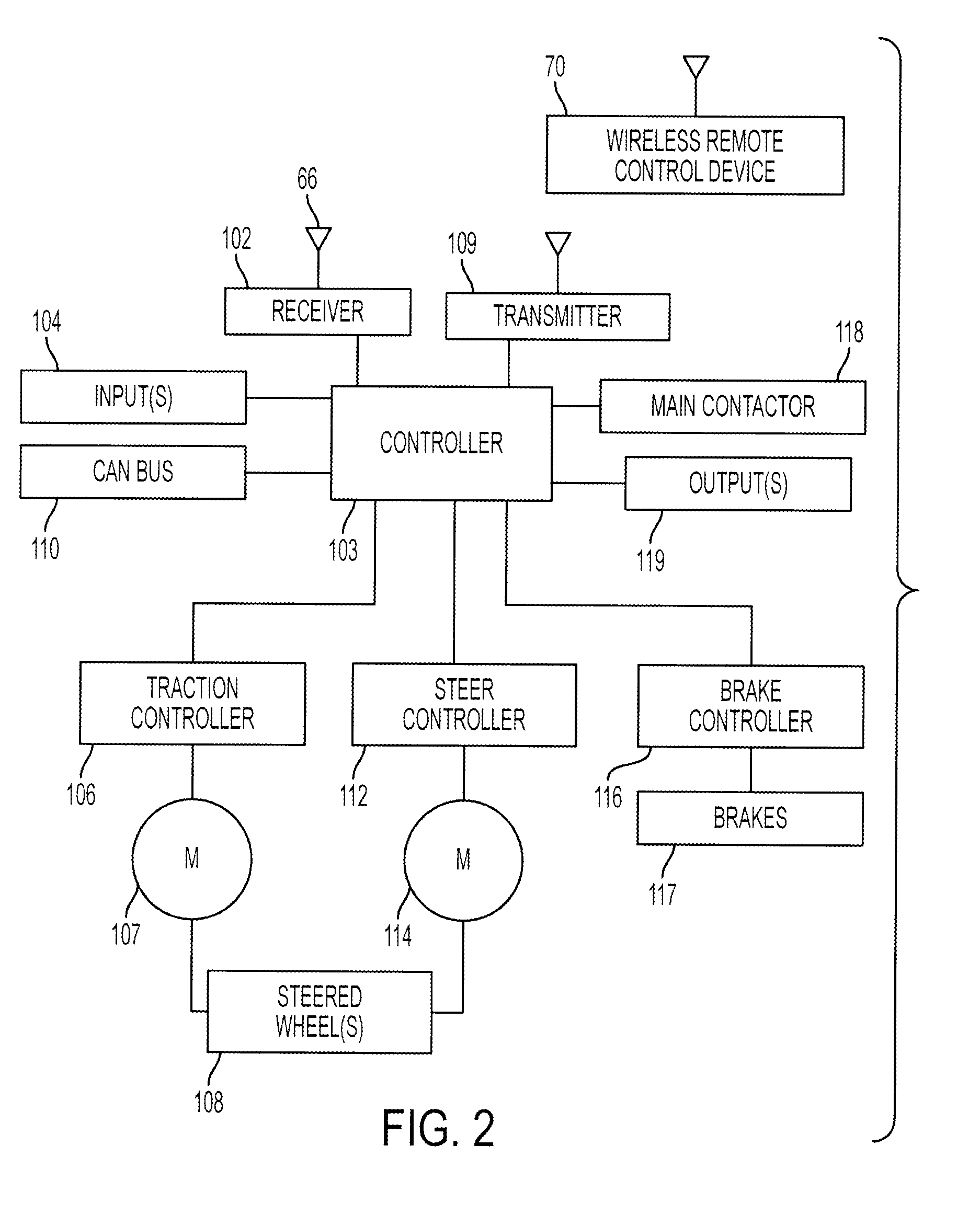

Systems and methods of remotely controlling a materials handling vehicle

ActiveUS20080129445A1Electric signal transmission systemsMultiple keys/algorithms usageControl systemEngineering

A supplemental control system for a materials handling vehicle comprises a wearable control device, and a corresponding receiver on the materials handling vehicle. The wearable control device is donned by an operator interacting with the materials handling vehicle, and comprises a wireless transmitter and a travel control communicably coupled to the wireless transmitter. Actuation of the travel control causes the wireless transmitter to transmit a first type signal designating a request to advance the vehicle in a first direction. The receiver is supported by the vehicle for receiving transmissions from the wireless transmitter. A traction control of the vehicle is responsive to a receipt of the first type signal by the receiver to cause the vehicle to advance.

Owner:CROWN EQUIP CORP

Systems and methods of remotely controlling a materials handling vehicle

A supplemental control system for a materials handling vehicle comprises a wearable control device, and a corresponding receiver on the materials handling vehicle. The wearable control device is donned by an operator interacting with the materials handling vehicle, and comprises a wireless transmitter and a travel control communicably coupled to the wireless transmitter. Actuation of the travel control causes the wireless transmitter to transmit a first type signal designating a request to advance the vehicle in a first direction. The receiver is supported by the vehicle for receiving transmissions from the wireless transmitter. A traction control of the vehicle is responsive to a receipt of the first type signal by the receiver to cause the vehicle to advance.

Owner:CROWN EQUIP CORP

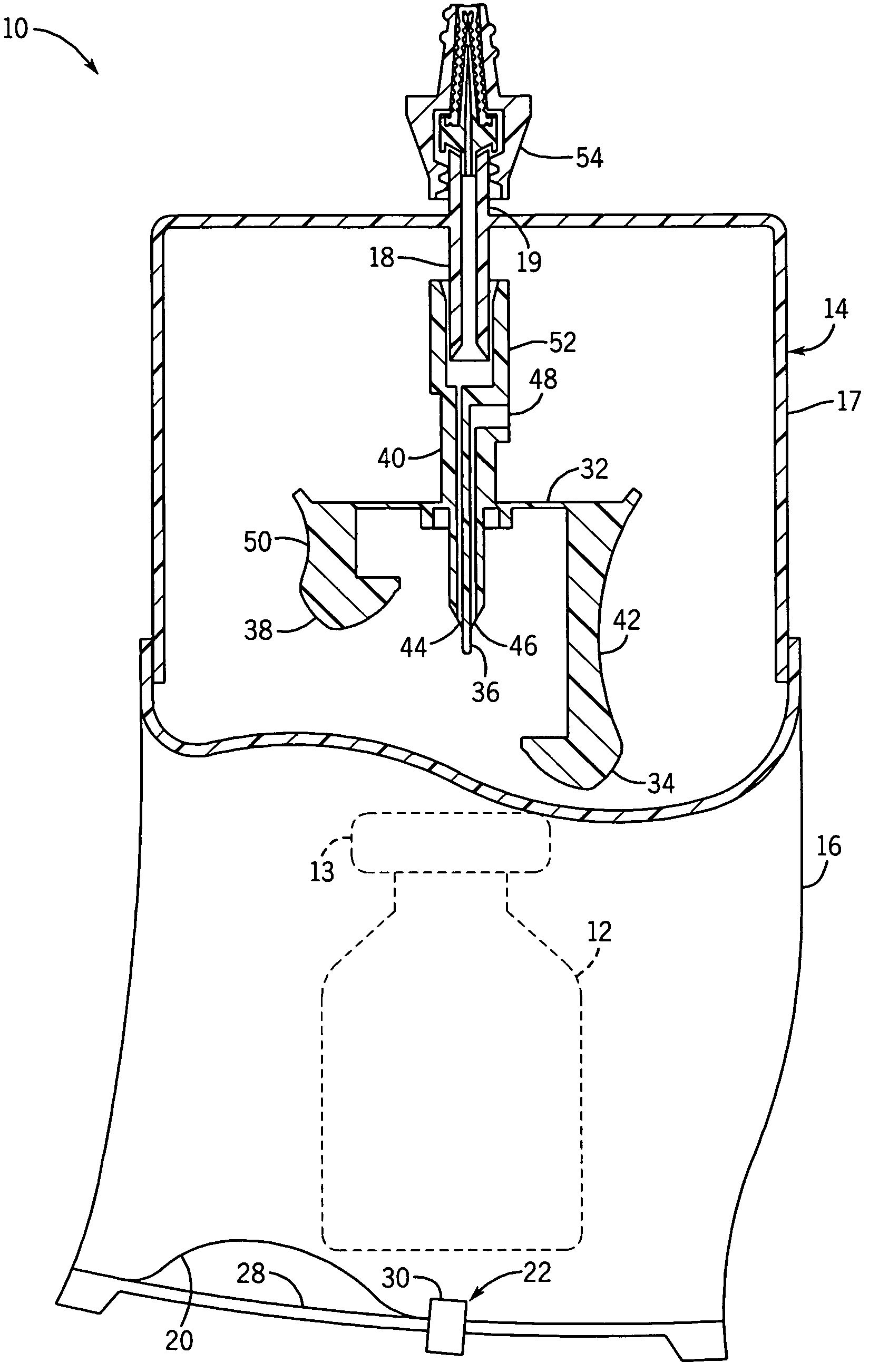

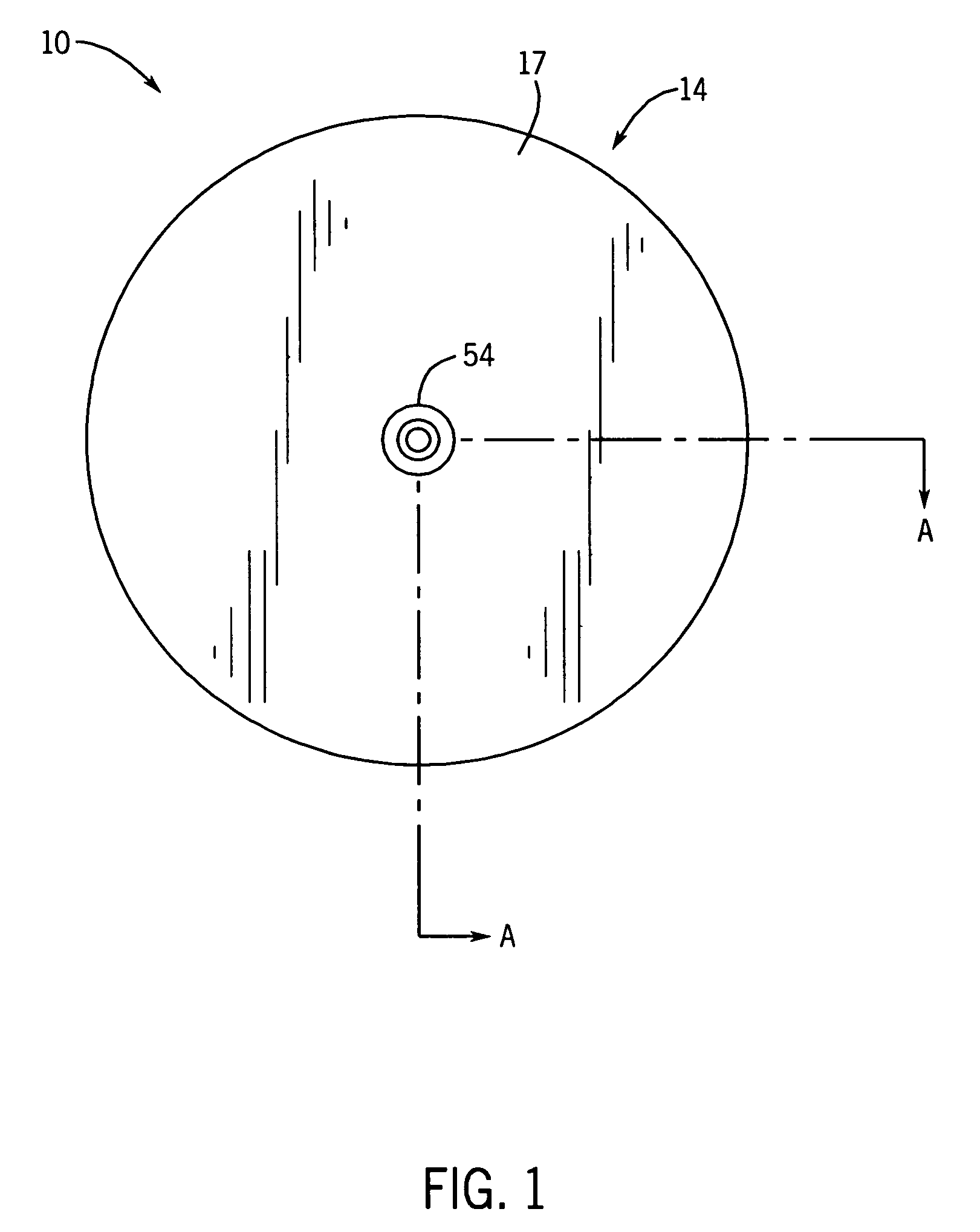

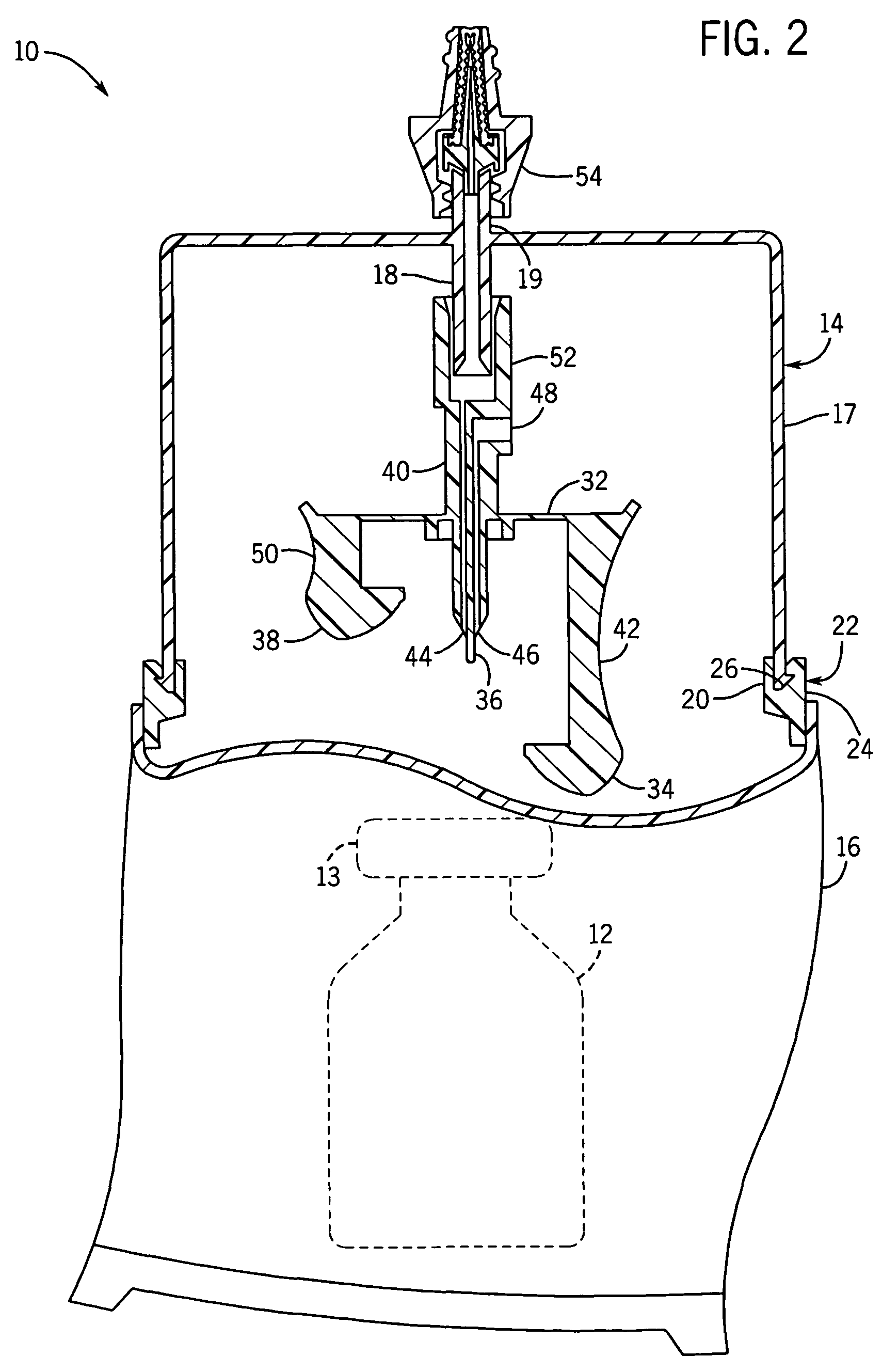

Hazardous material handling system and method

A method and system for handling hazardous materials contained in a vial includes an isolation enclosure having an opening selectively sealable about the vial, a bag body portion, and a cap portion. A latching extraction element is attached to the cap portion and has a preceding engaging member to secure the vial to the isolation enclosure, an extraction member to be inserted into the vial and remove material therefrom, and a primary engaging member to secure the vial to the extraction member. A valve is mounted outside the isolation enclosure and controls the flow of fluid from the vial. An adaptor having a reseal member permits flow when coupled to the valve and restricts flow when uncoupled from the valve. Once uncoupled, the adaptor is removably associated with a second valve located remotely from the isolation enclosure, allowing fluid to pass into the second valve.

Owner:HOSPIRA

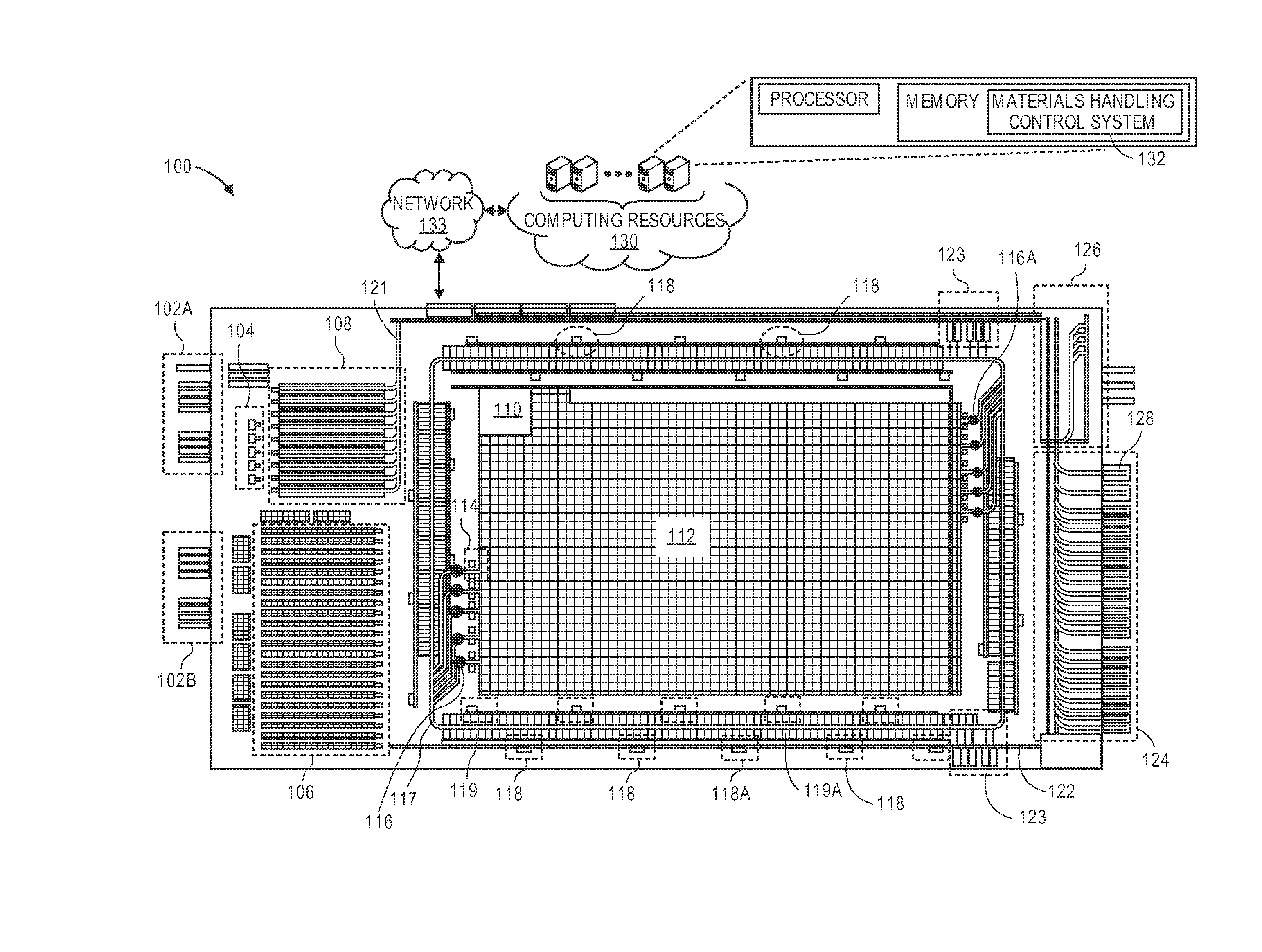

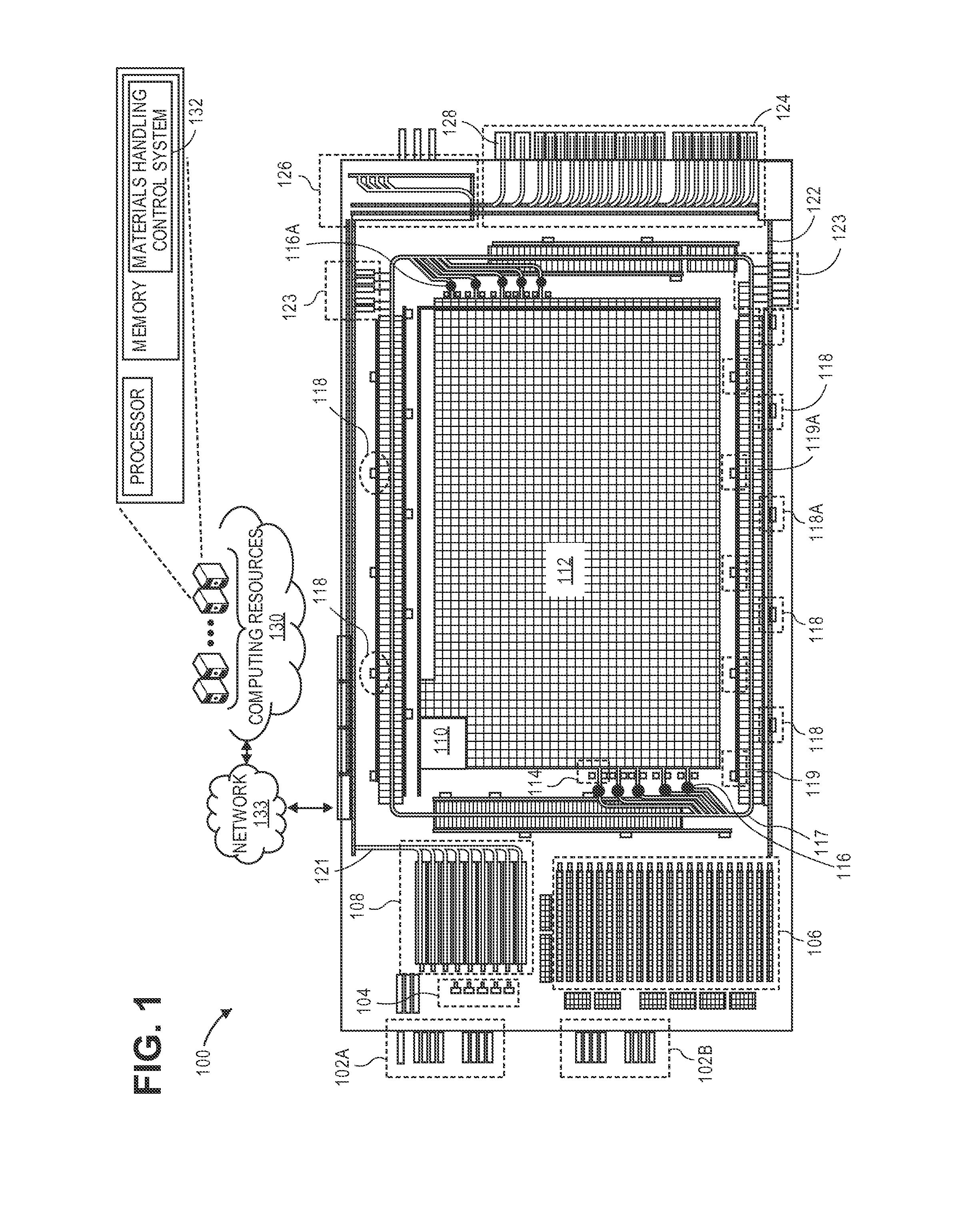

Automated materials handling facility

ActiveUS20170043953A1Programme-controlled manipulatorData processing applicationsRobotic armControl system

Disclosed are systems and methods for an automated materials handling facility. The automated materials handling facility uses a series of automated devices, such as automated guidance vehicles, mobile drive units, robotic arms, automated sorters, etc., to facilitate item receive, stow, pick, shipping and other aspects of materials handling. The automated devices are controlled by a materials handling control system that sends instructions to the various devices to coordinate operation of those devices and to coordinate flow of items through the materials handling system.

Owner:AMAZON TECH INC

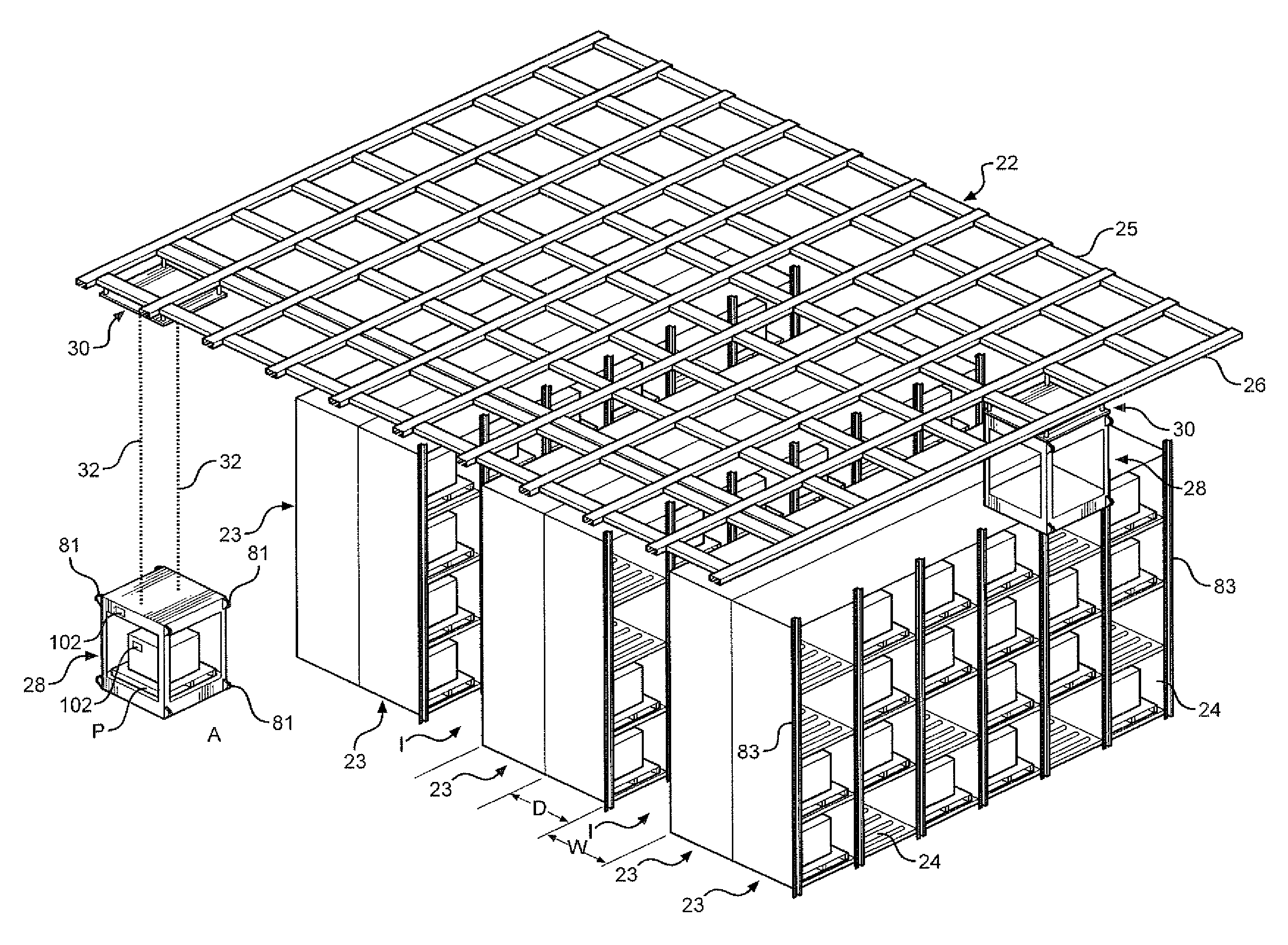

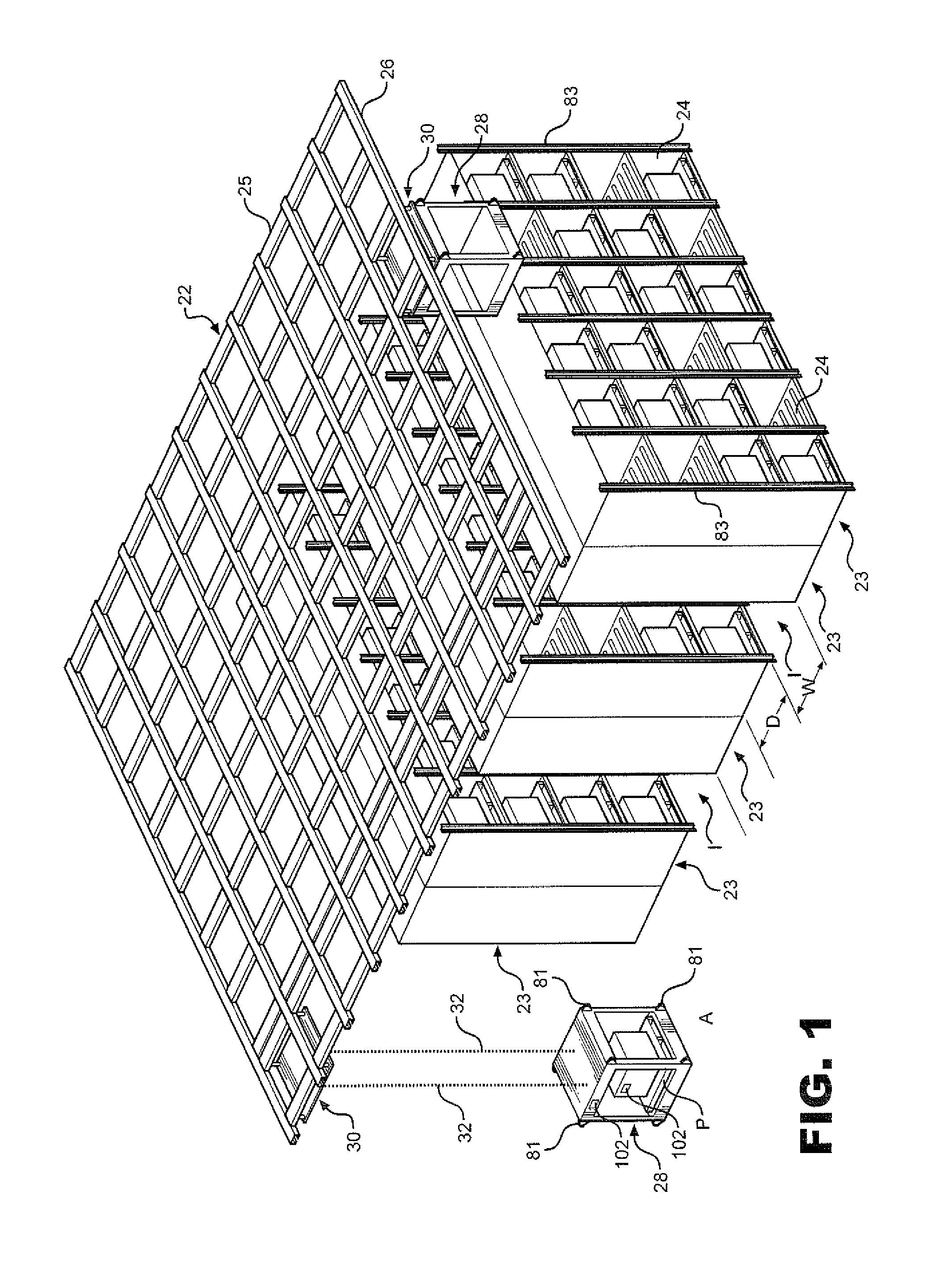

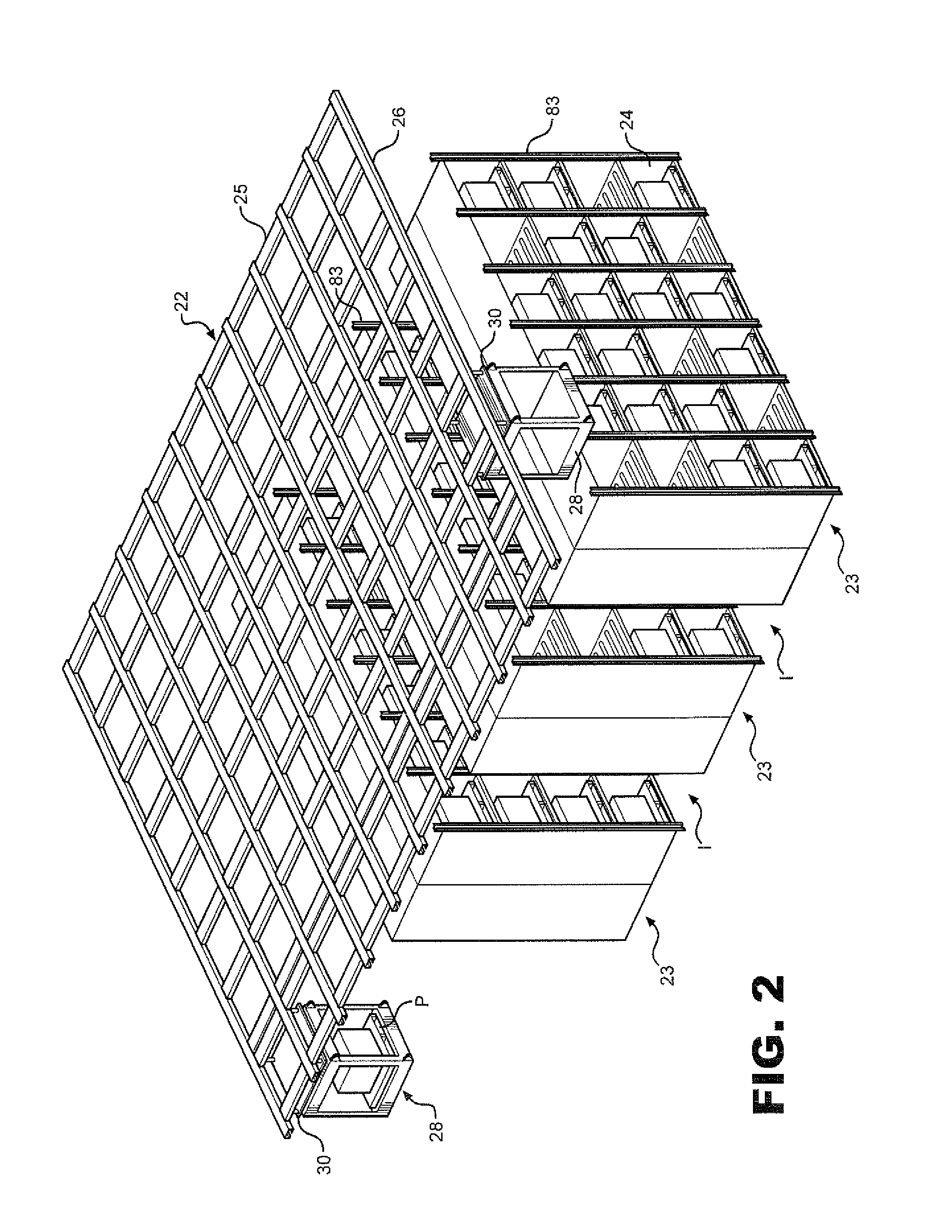

Automated material handling system with load transfer vehicles

InactiveUS7931431B2Improve securityCargo handling apparatusPedestrian/occupant safety arrangementHandling systemMaterial handling

Owner:GEBRR BECKER

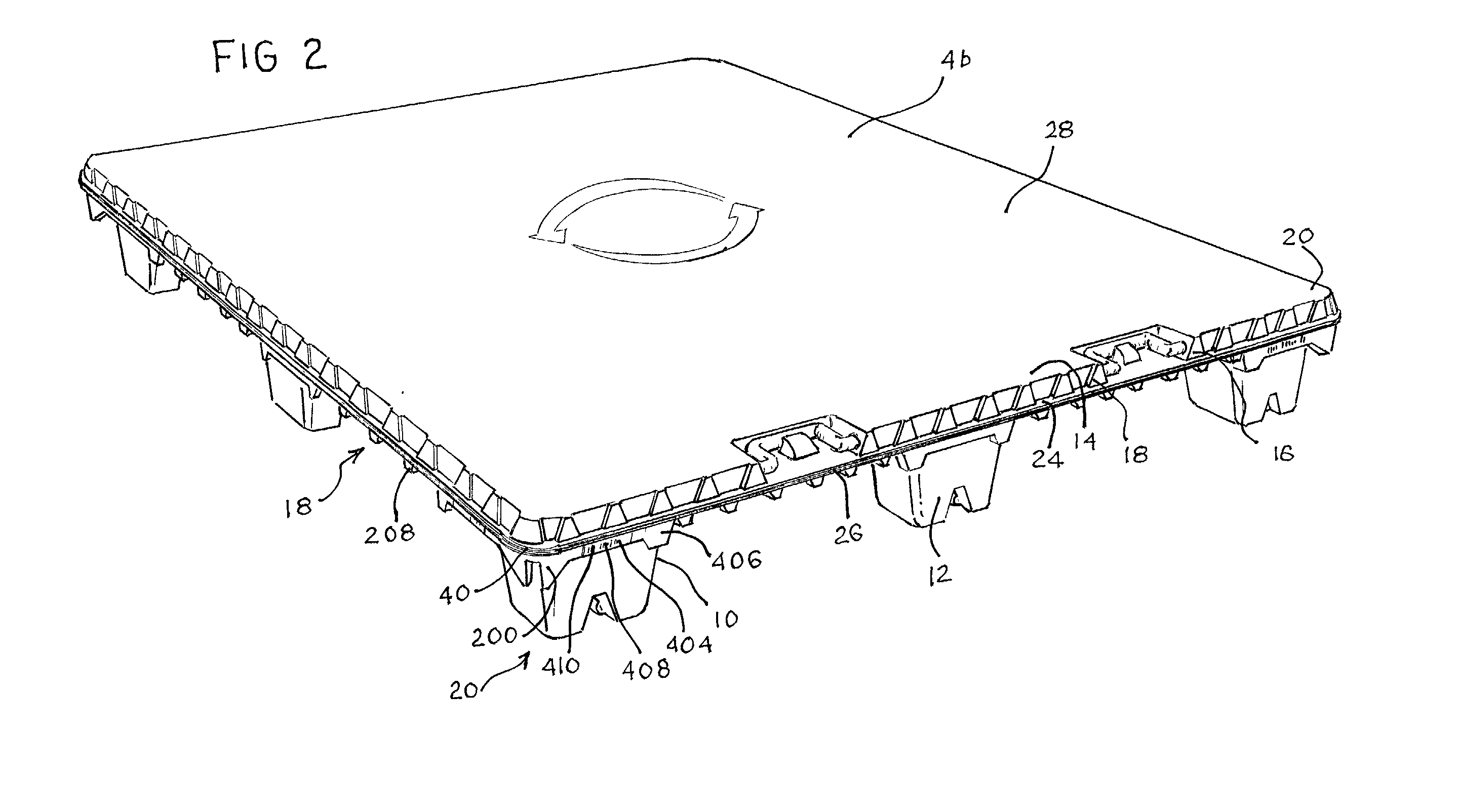

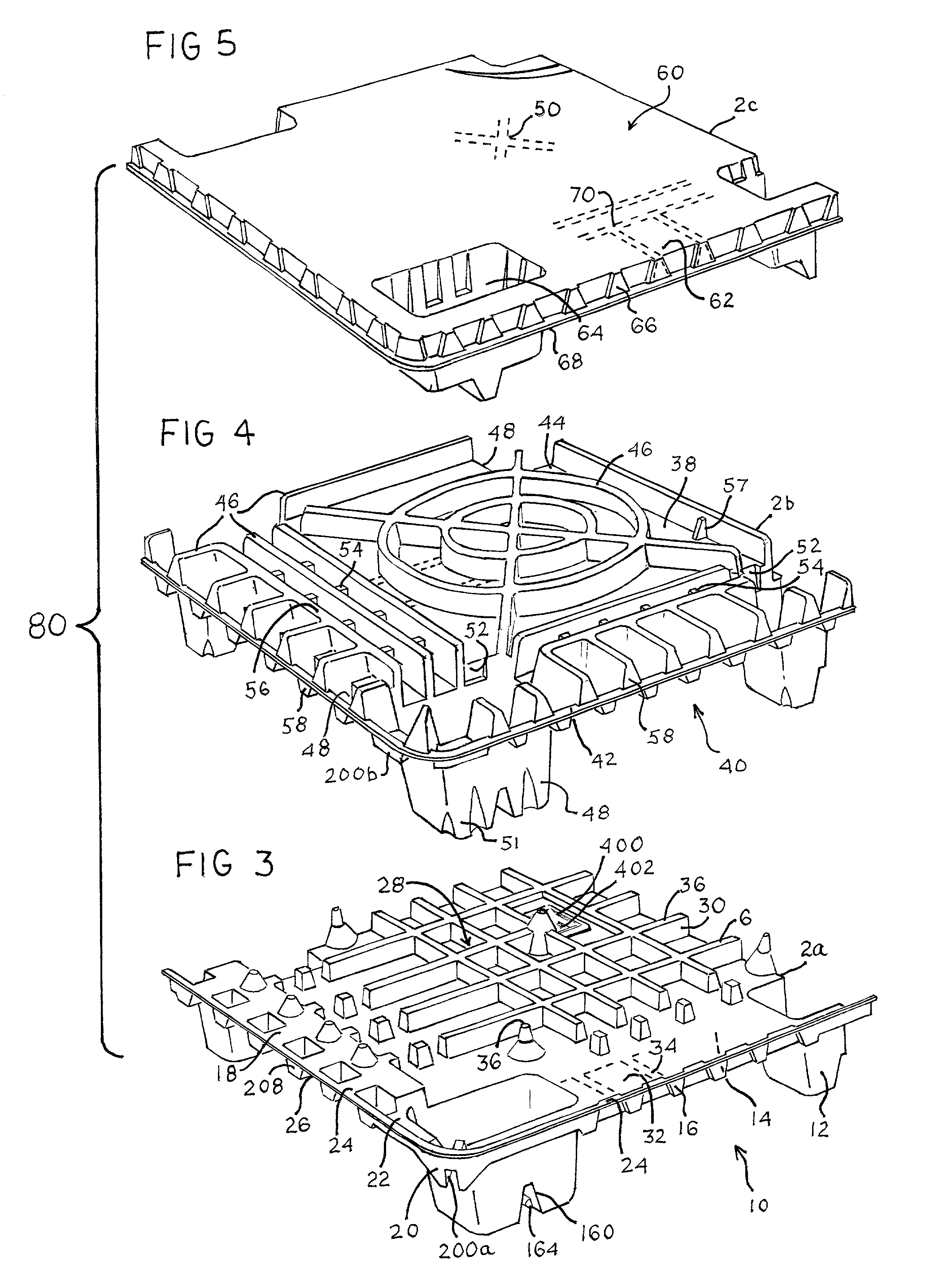

RF-enabled pallet

InactiveUS20050237184A1Small sizeContainer decorationsLevel indicationsElectrostatic couplingEngineering

The inventions involve material handling apparatus developed to operate in radio frequency rich environments. Articles are provided having at least one large compartment capable of enclosing at least one electronic device or a package populated with a plurality of devices. RFID tags are also provided having three antenna arrays situated on three planes to improve electromagnetic and electrostatic coupling with an external distributed network of devices. Pallets are provided with cellular communications devices to provide track and trace functionality. Sensors and actuators are used in connection with the material handling apparatus.

Owner:NEXTREME

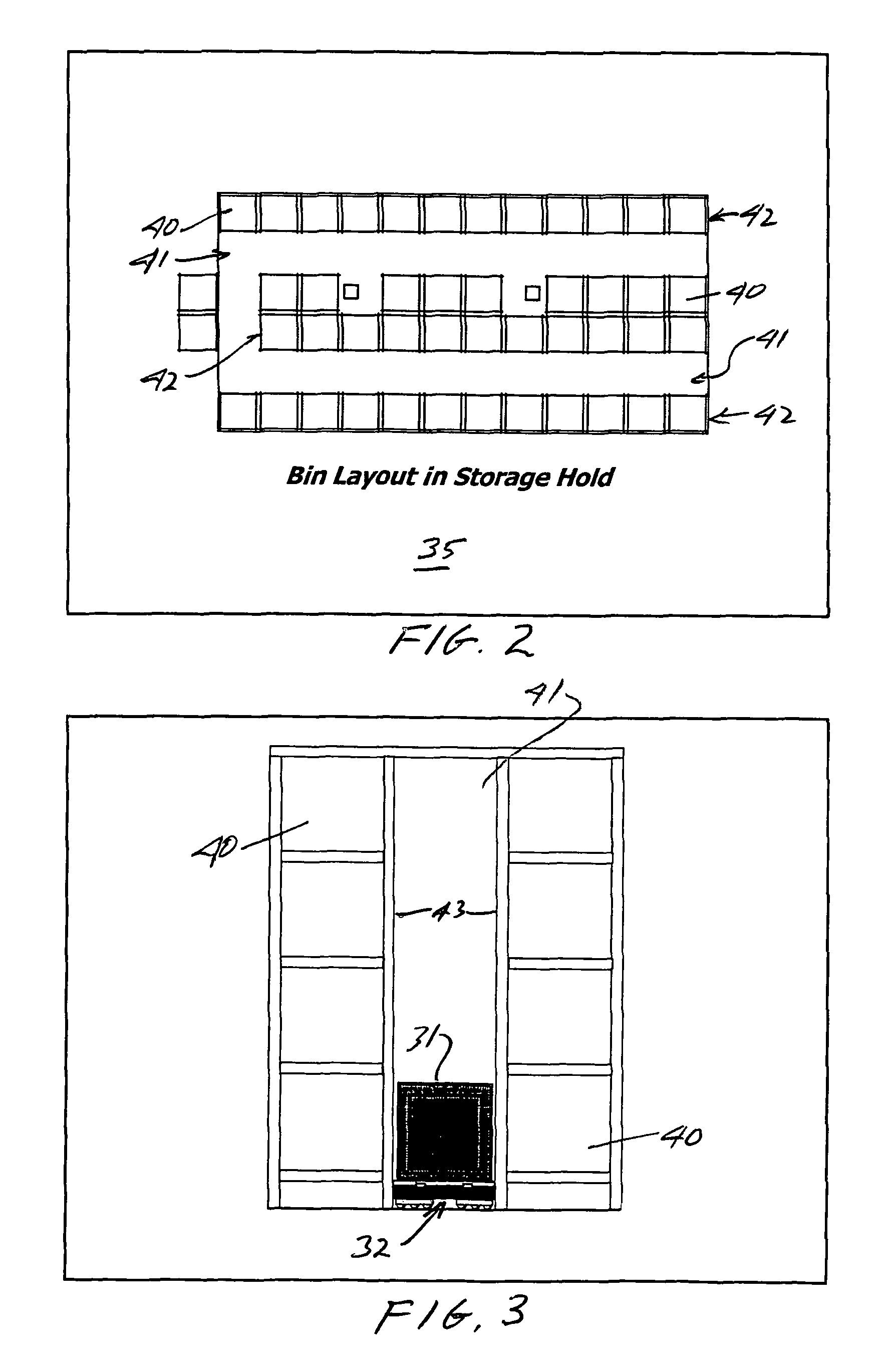

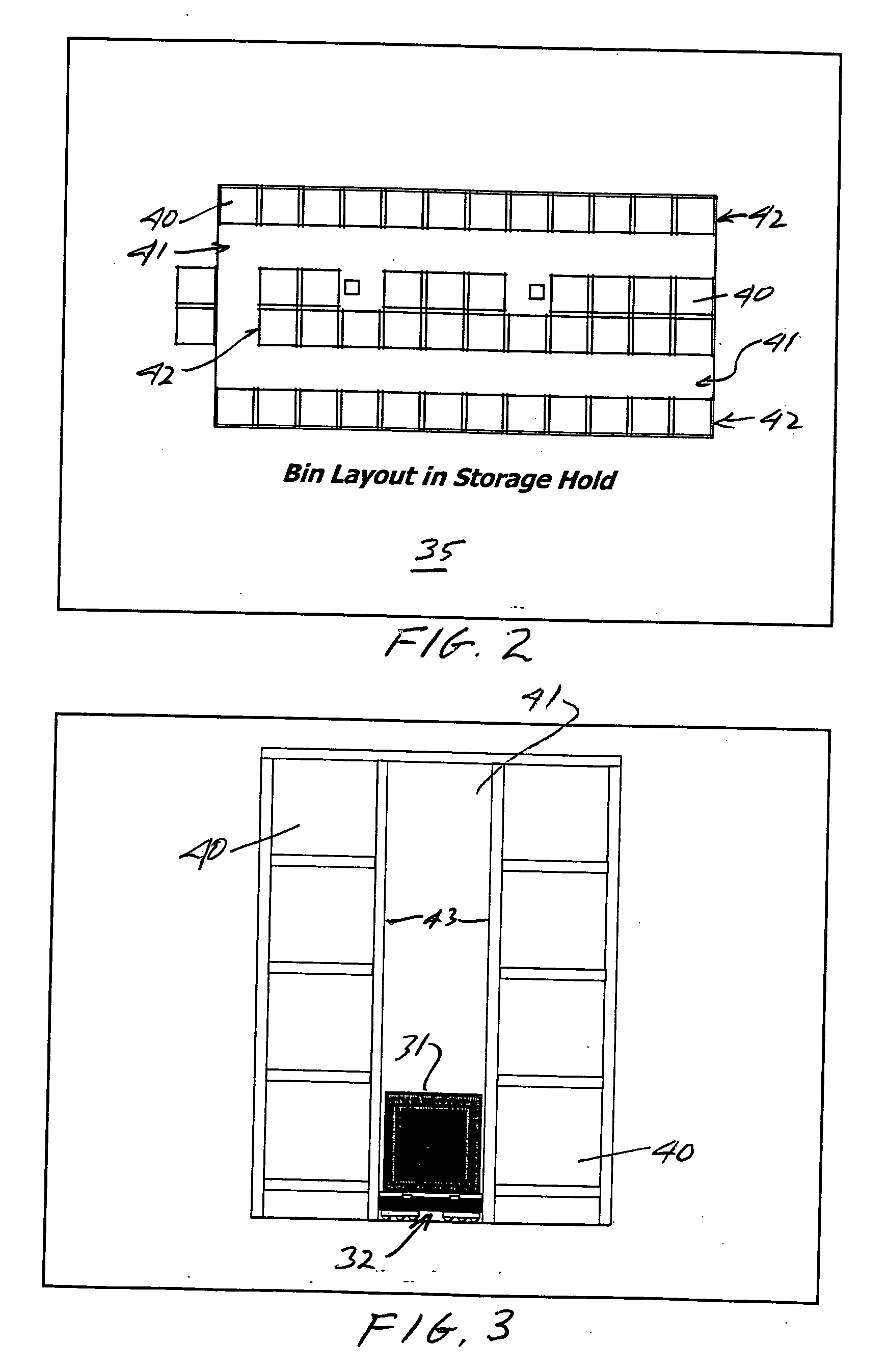

Material handling and storage/warehouse system

ActiveUS8628289B1Maximize storage spaceSpace maximizationSemiconductor/solid-state device manufacturingArticle unpackingEngineeringMaterial handling

A system and method for optimizing the storage capacity of an automated material handling and storage system wherein rows of vertical columns of storage bins are spaced in opposing relationship with one another such that at least one elevator is vertically movable in engagement with the opposing columns of storage bins so that pallets, support platforms or containers may be transferred to or from the elevator to bins of the opposing rows and wherein the elevator may be selectively elevated by overhead carriers that are movable along an intersecting grid track system that is disposed above the storage bins. In one embodiment, the at least one elevator may be independently vertically movable between the opposing column of storage bins.

Owner:GEBRR BECKER

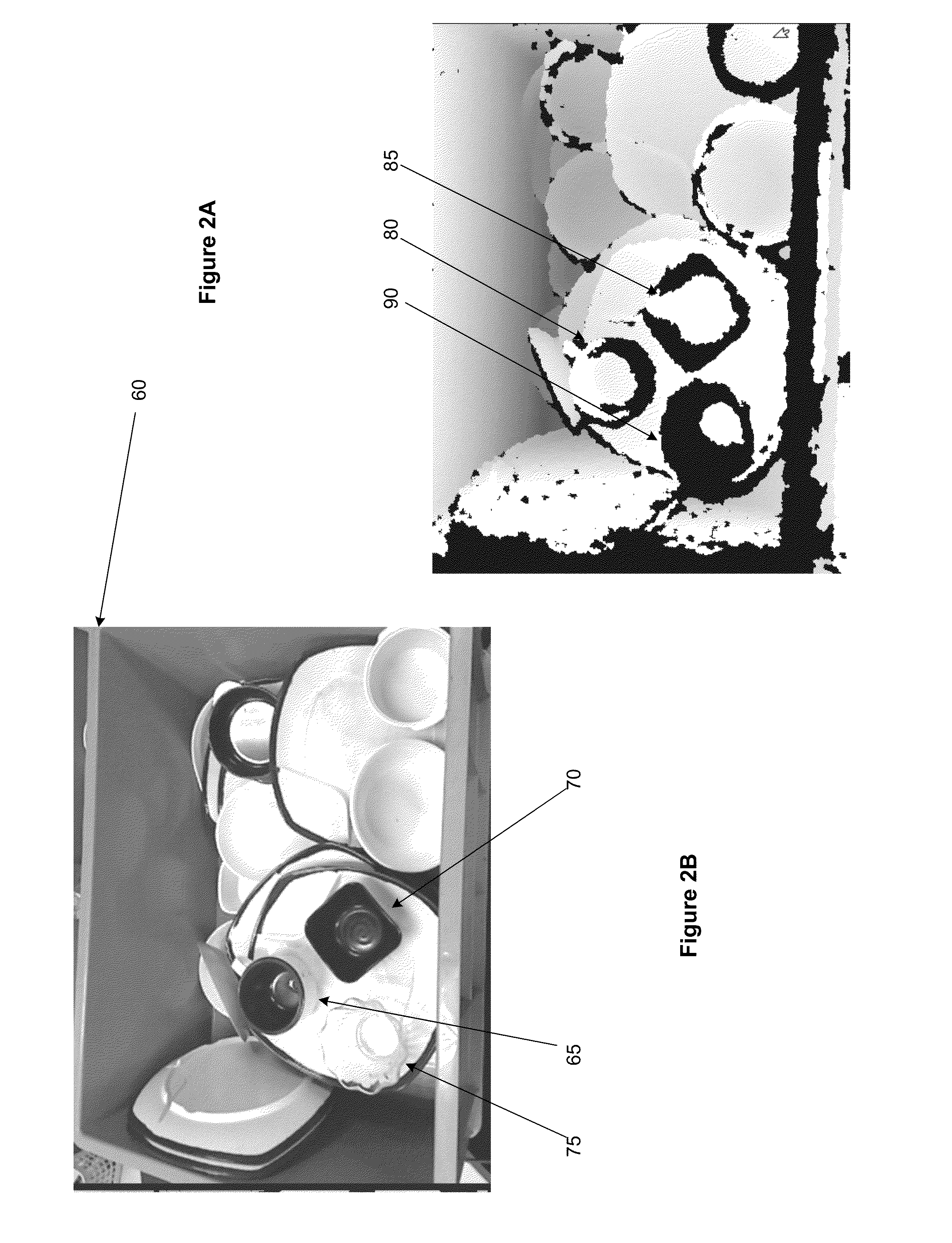

Material handling system and method

ActiveUS20150081090A1Reduce margin of errorIncrease speedProgramme controlImage enhancementHandling systemMaterial handling

A material handling system comprising: a platform for receiving a plurality of articles; a plurality of sorting bins, each bin in corresponding to an article type; an object recognition system for identifying an article on the platform and categorizing said article by specific article type; said 3D object recognition system including a 3D detector for detecting said article and a database containing data on characteristics of article types; an article engagement assembly for engaging and delivering said article to said corresponding sorting bin; wherein the object recognition system is arranged to identify the article based upon the data within said database and instructs the article engagement assembly to engage and place the article in said sorting bin.

Owner:JCS ECHIGO PTE

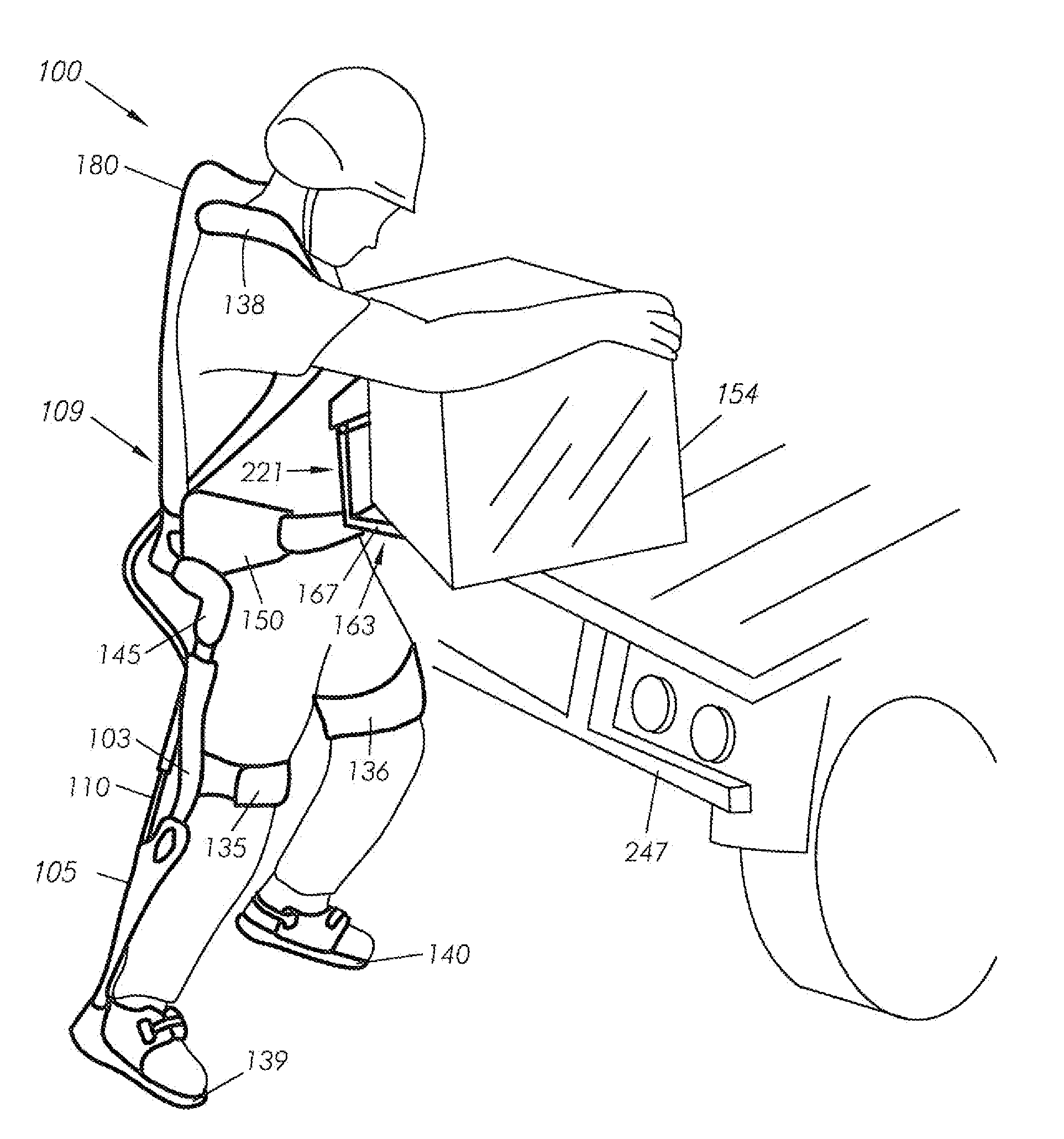

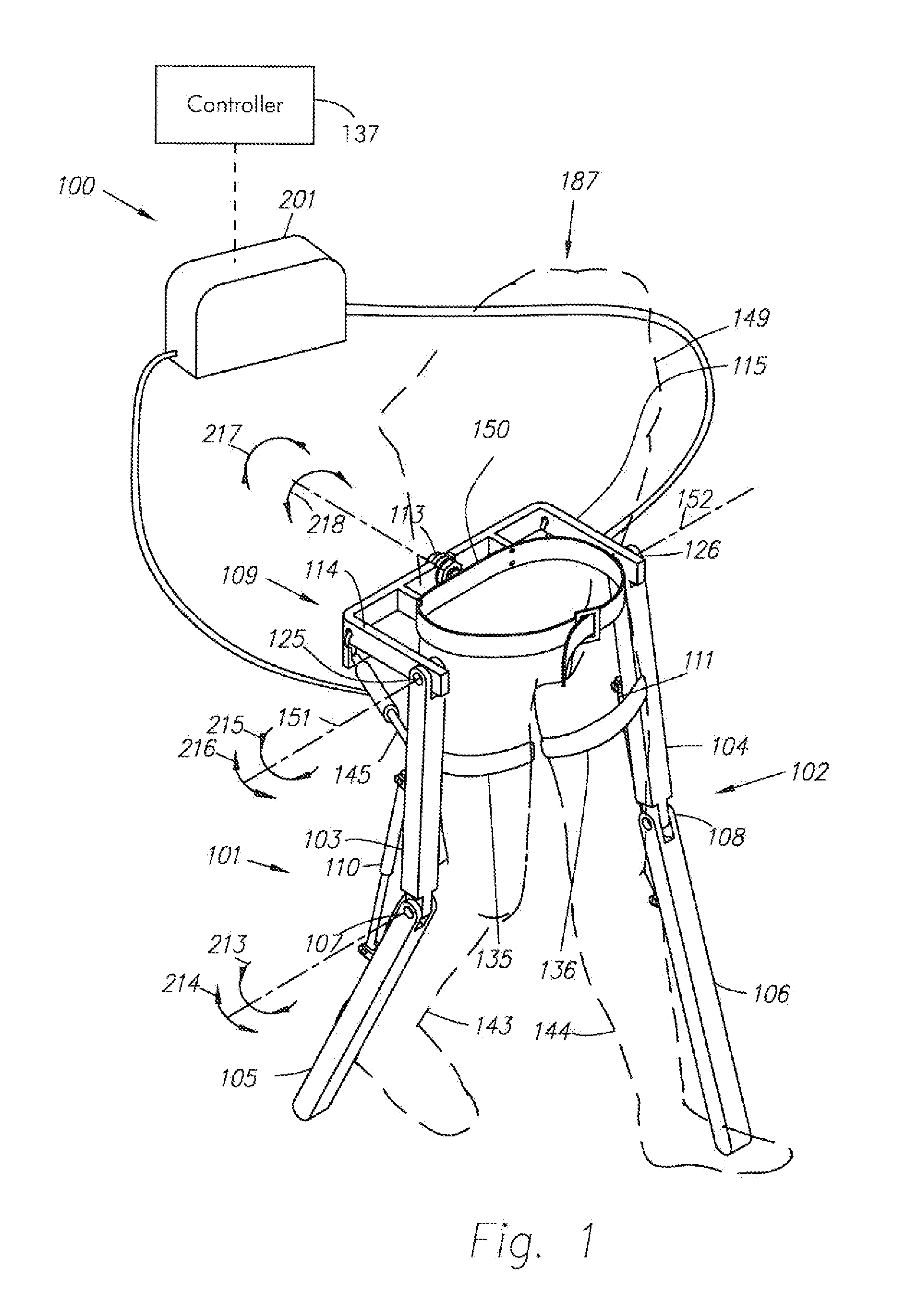

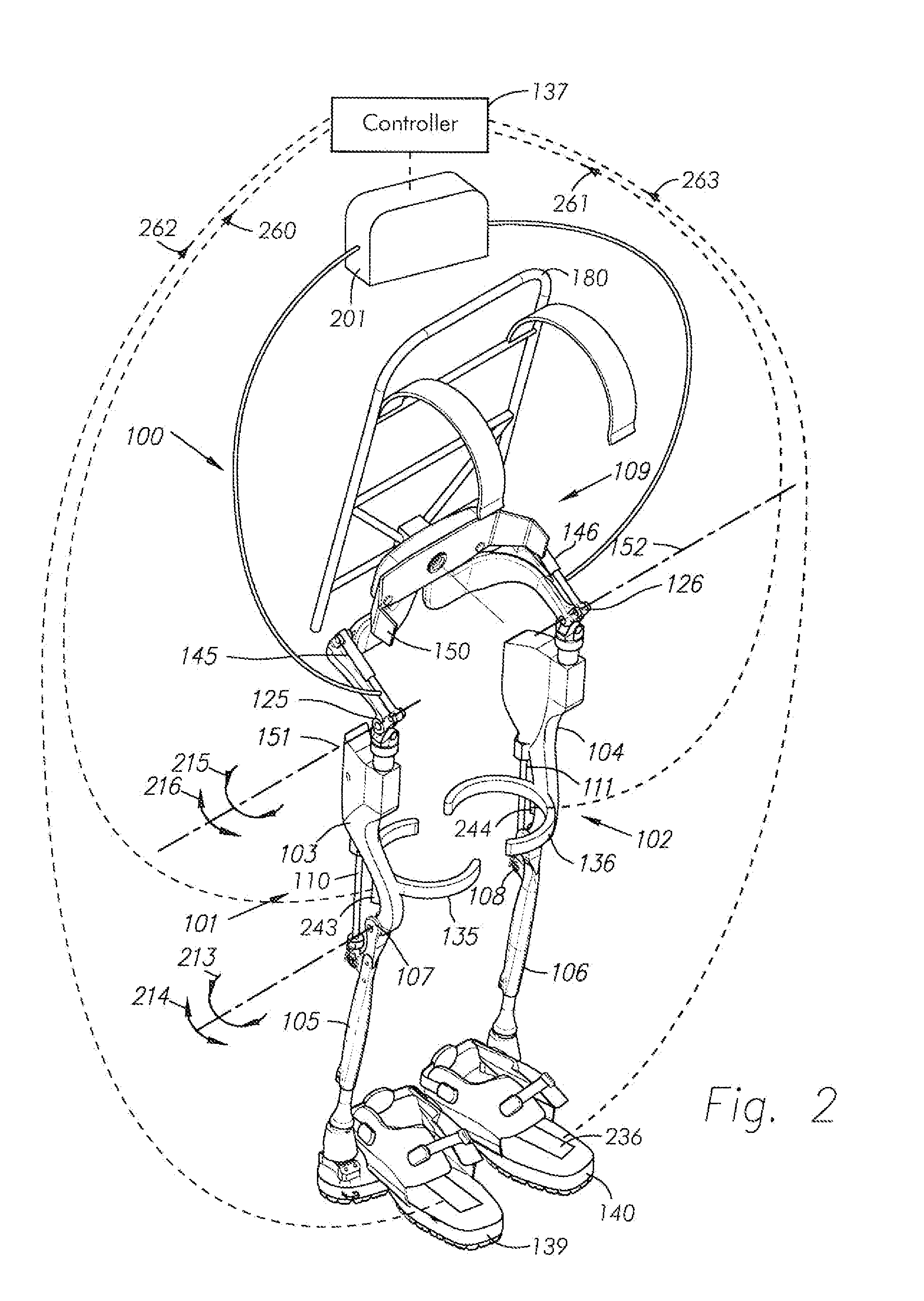

Wearable Material Handling System

An exoskeleton configured to be coupled to a person includes an exoskeleton trunk and leg supports adapted to contact the ground. Hip torque generators extend between the exoskeleton trunk and respective leg supports. A load holding mechanism is rotatably coupled to the exoskeleton trunk, preferably via over-shoulder members configured to support a load in front of the person. In use, hip torque generators create torque between the exoskeleton trunk and respective leg supports in the stance phase, wherein at least one torque generator is configured to create a first torque between the exoskeleton trunk and one of the first and second leg supports in the stance phase opposing a second torque generated on the exoskeleton by a weight of the load. Load bearing sensors may be utilized to determine the torque generated by the load and communicate with a controller to control power to the torque generators.

Owner:RGT UNIV OF CALIFORNIA +1

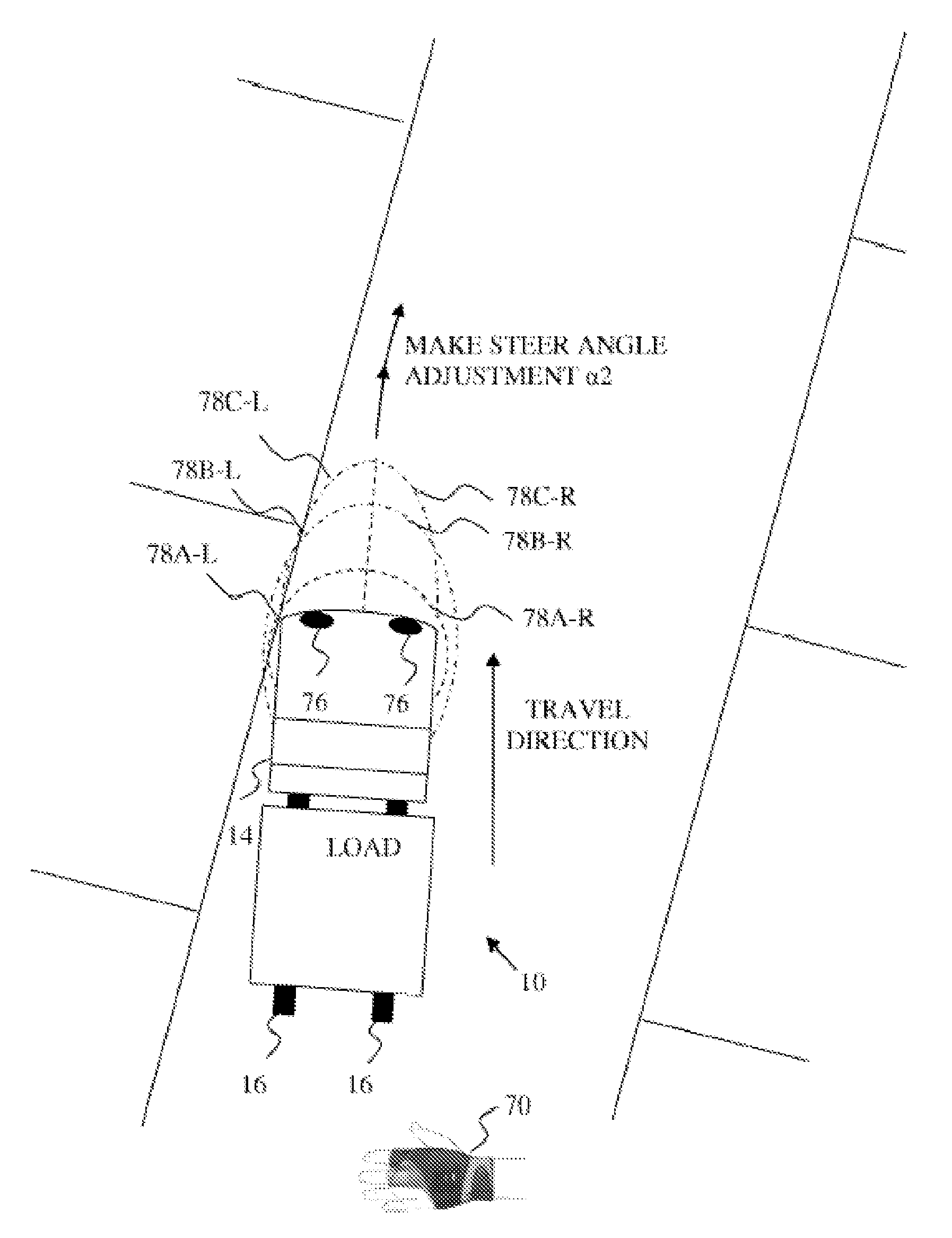

Multiple zone sensing for materials handling vehicles

ActiveUS20100114405A1Transmission systemsDigital data processing detailsSteering angleControl system

A supplemental control system for a materials handling vehicle comprises one or more sensors capable of defining multiple contactless detection zones at least towards the front of the forward travel direction of a remotely controlled vehicle. The vehicle responds to the detection of objects within the designated zones based upon predetermined actions, such as to slow down or stop the vehicle, and / or to take other action, such as to perform a steer angle correction.

Owner:CROWN EQUIP CORP

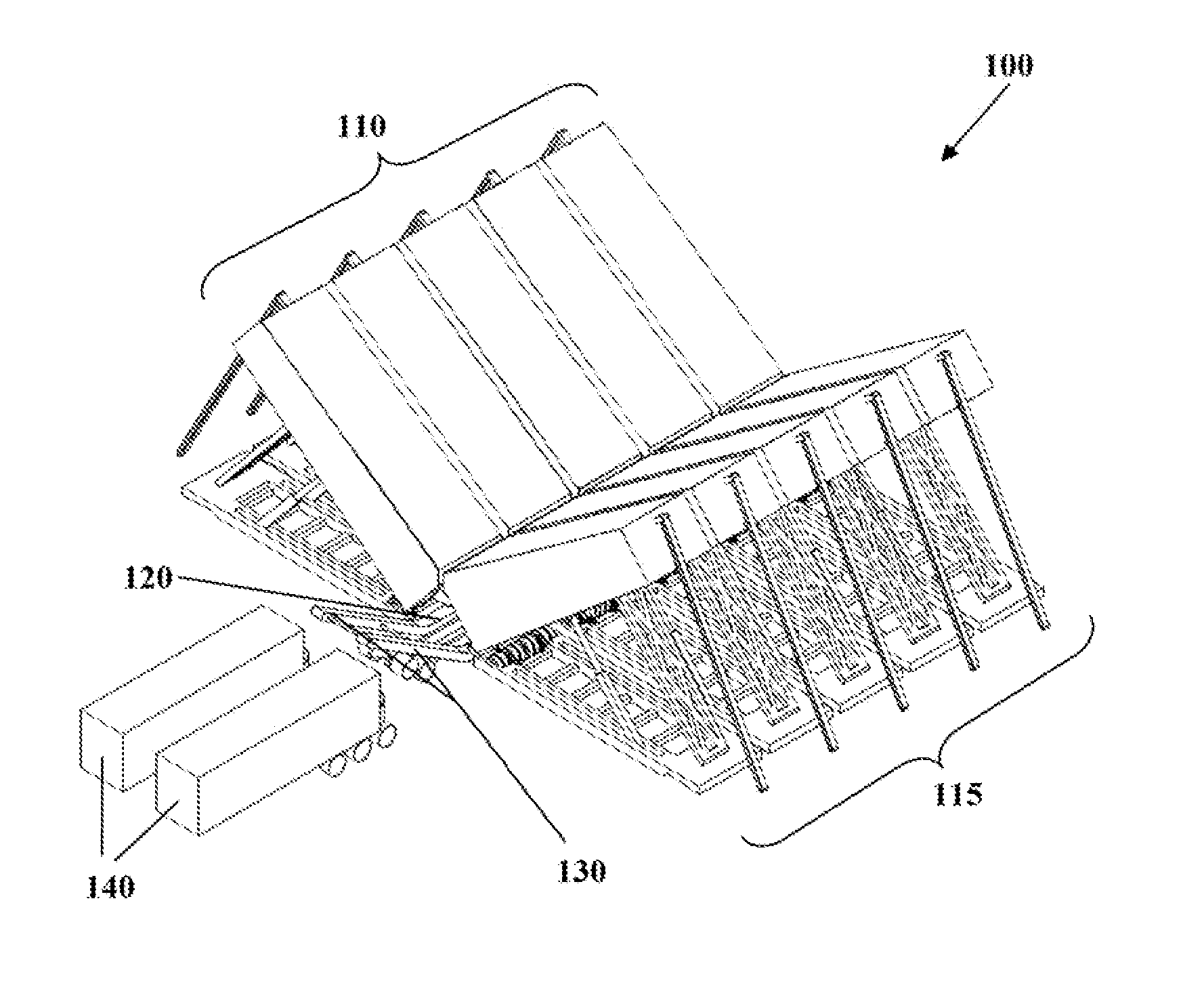

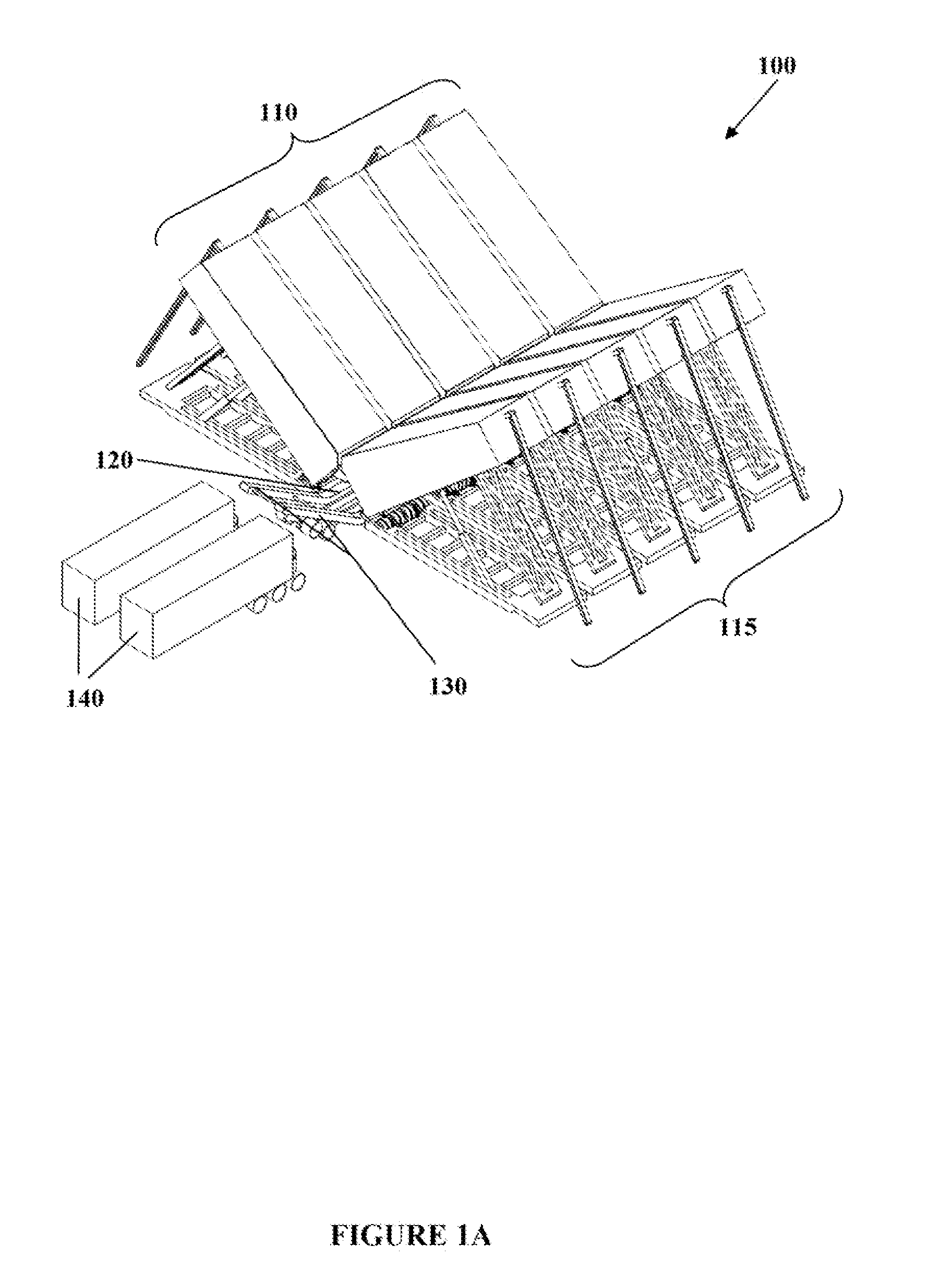

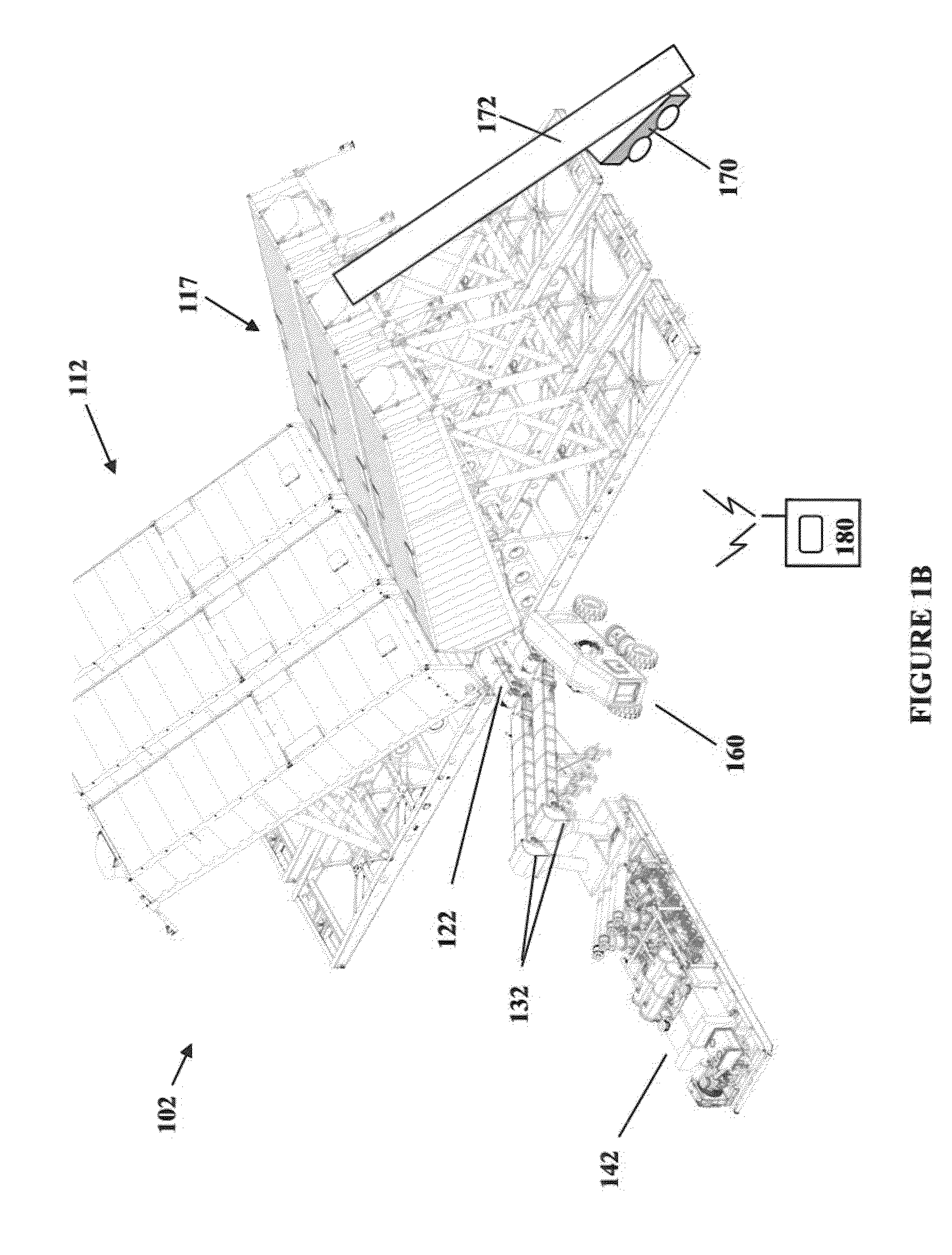

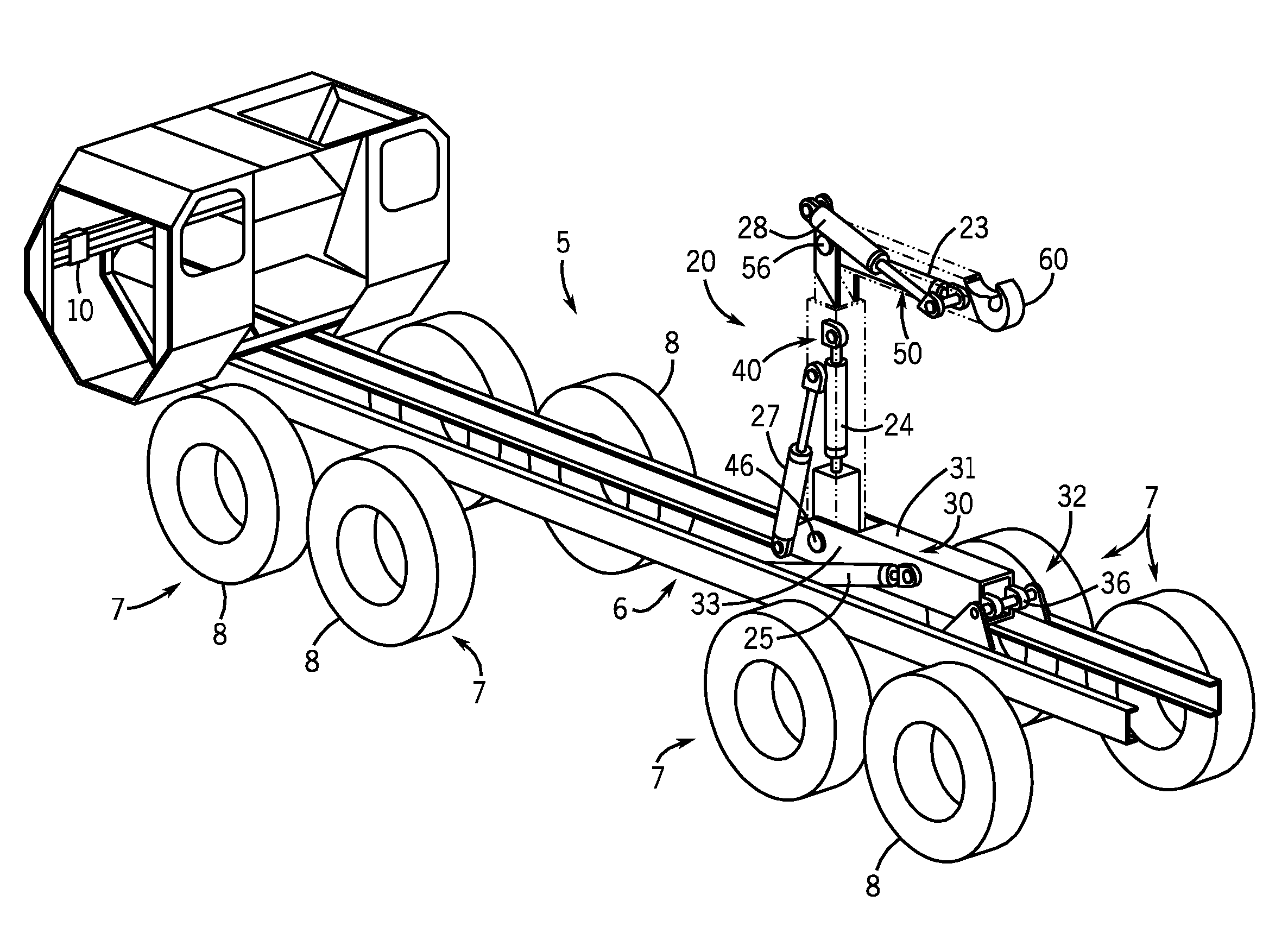

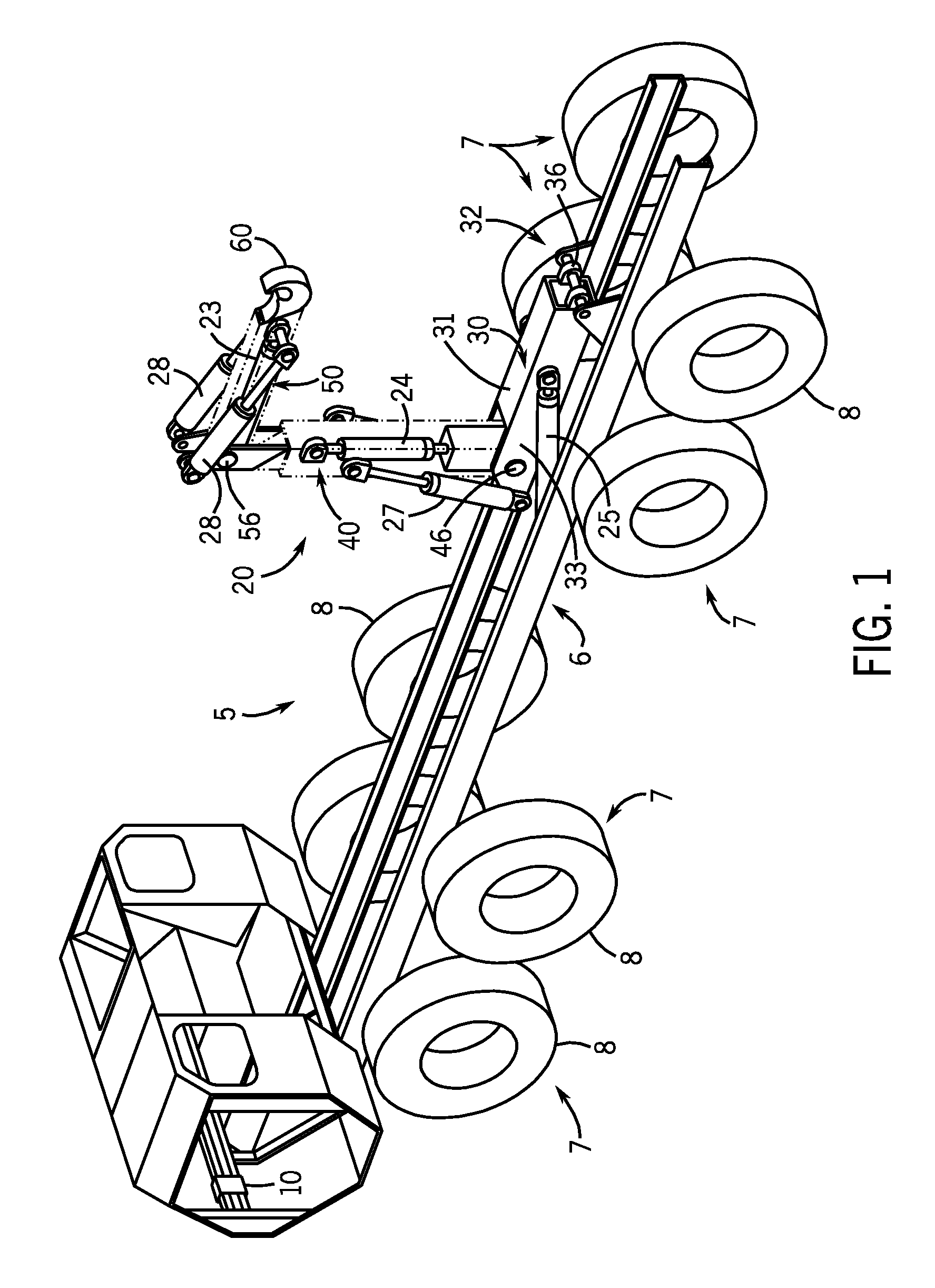

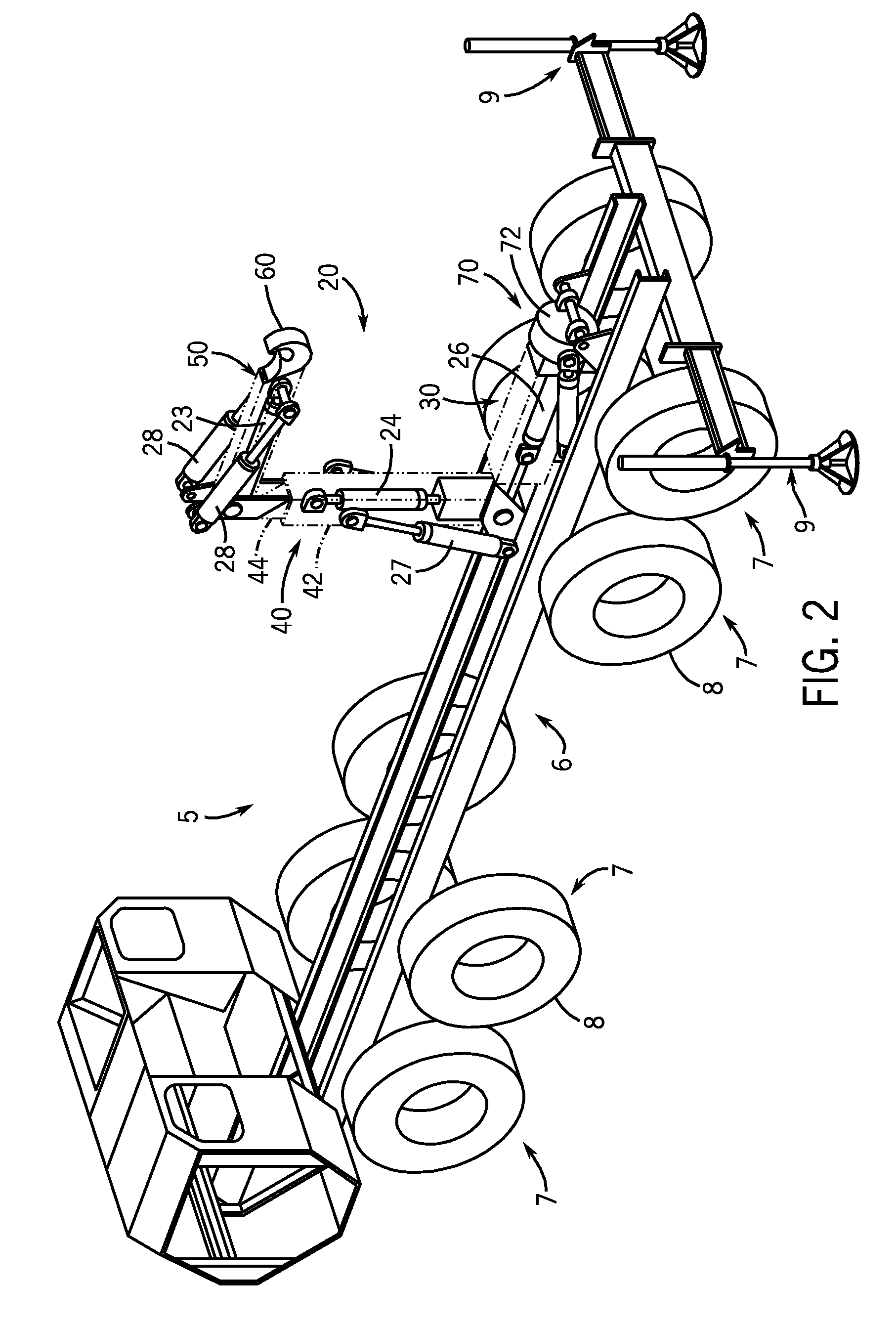

Mobile Material Handling and Metering System

ActiveUS20120219391A1Convenient for centralized processingEasy remote controlLarge containersRefuse transferringWell drillingRemote control

A method and system for handling granular material, such as proppant used in hydraulic fracturing in well drilling, is provided. In an operational configuration, a delivery module having conveyors receives and conveys granular material to a delivery location, and one or more mobile storage modules receive, hold and dispense granular material downward to the delivery module. The mobile storage modules comprise a raised, angular container portion for holding granular material. Each mobile storage module may comprise a rock-over chassis for support against ground. A remote control module provides centralized, remote control of the system. Mobile support unit modules may also be provided as a remotely controlled vehicle capable of providing power, control, heating, and the like to other modules. Mobile in-feed elevator modules may also be provided as a remotely controlled vehicle for feeding granular material to mobile storage modules. In a transportation configuration, each module is separately transportable.

Owner:CONTINENTAL INTERMODAL GRP TRUCKING LLC

Rotatable and articulated material handling apparatus

A material handling apparatus for mounting on a support structure. The material handling apparatus comprises a telescopic riser portion coupled to the support structure. A telescopic boom portion is coupled to the riser portion. A telescopic jib portion is coupled to the riser portion. A hook is coupled to the jib portion. A control apparatus is coupled to each of the riser, boom, and jib portions. Wherein, each of the telescopic portions can be independently, selectively moved in a push-pull mode to manipulate material.

Owner:OSHKOSH CORPORATION

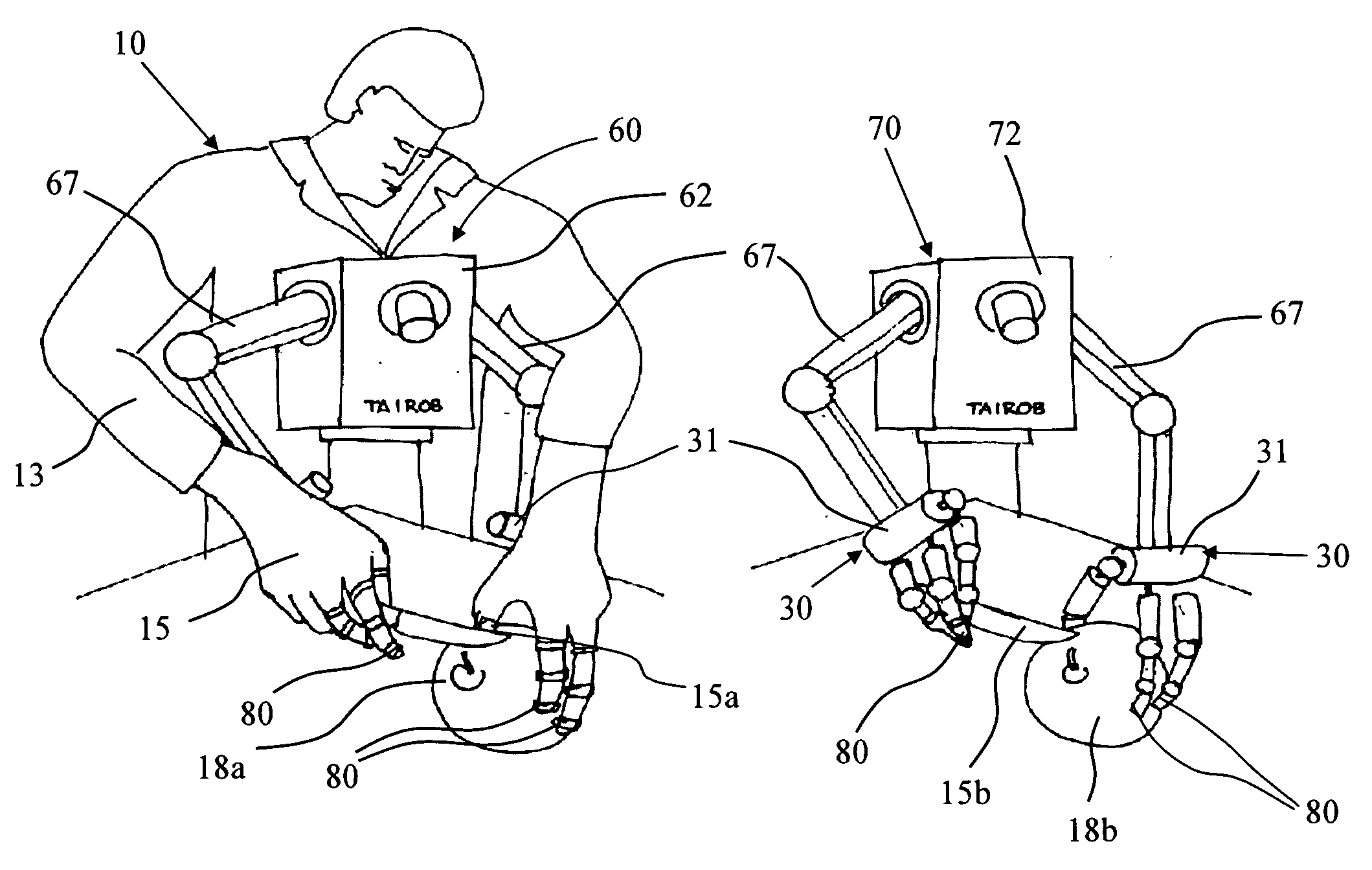

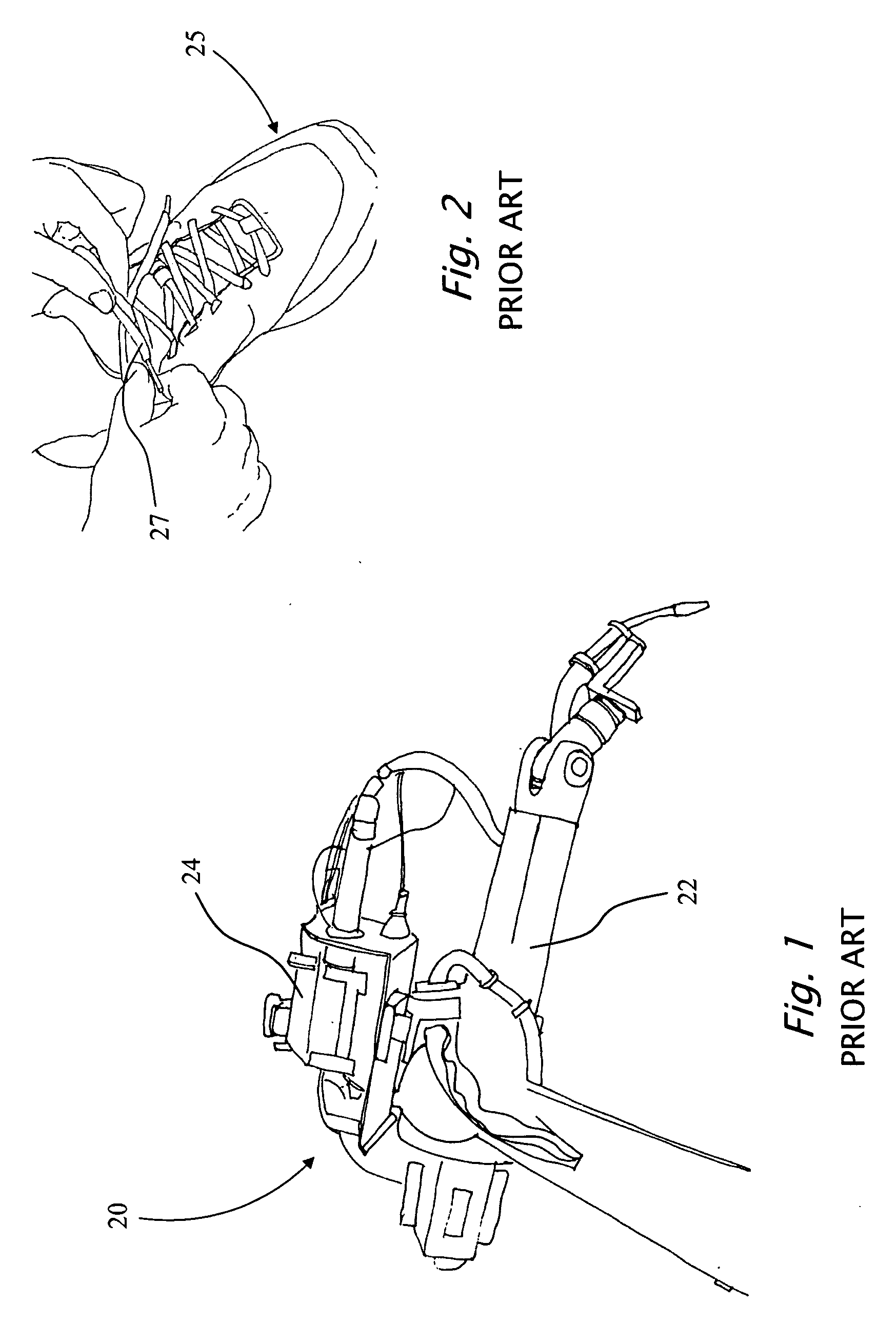

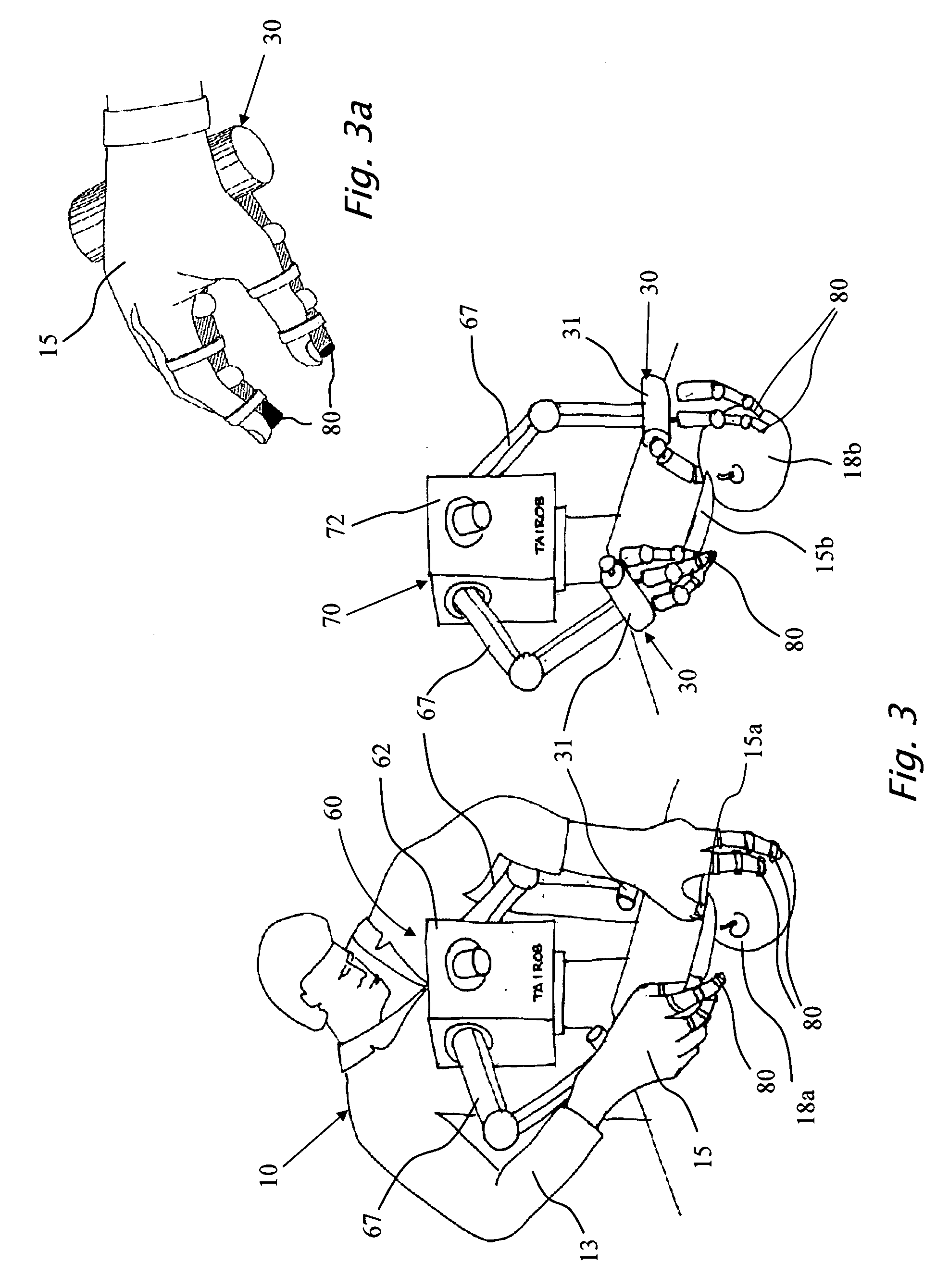

Transfer of knowledge from a human skilled worker to an expert machine - the learning process

InactiveUS20090132088A1Improve operational sensitivityComputer controlSimulator controlSoftware engineeringLearning methods

A learning environment and method which is a first milestone to an expert machine that implements the master-slave robotic concept. The present invention is of a learning environment and method for teaching the master expert machine by a skilled worker that transfers his professional knowledge to the master expert machine in the form of elementary motions and subdivided tasks. The present invention further provides a stand alone learning environment, where a human wearing one or two innovative gloves equipped with 3D feeling sensors transfers a task performing knowledge to a robot in a different learning process than the Master-Slave learning concept. The 3D force\torque, displacement, velocity\acceleration and joint forces are recorded during the knowledge transfer in the learning environment by a computerized processing unit that prepares the acquired data for mathematical transformations for transmitting commands to the motors of a robot. The objective of the new robotic learning method is a learning process that will pave the way to a robot with a “human-like” tactile sensitivity, to be applied to material handling, or man / machine interaction.

Owner:TAIROB

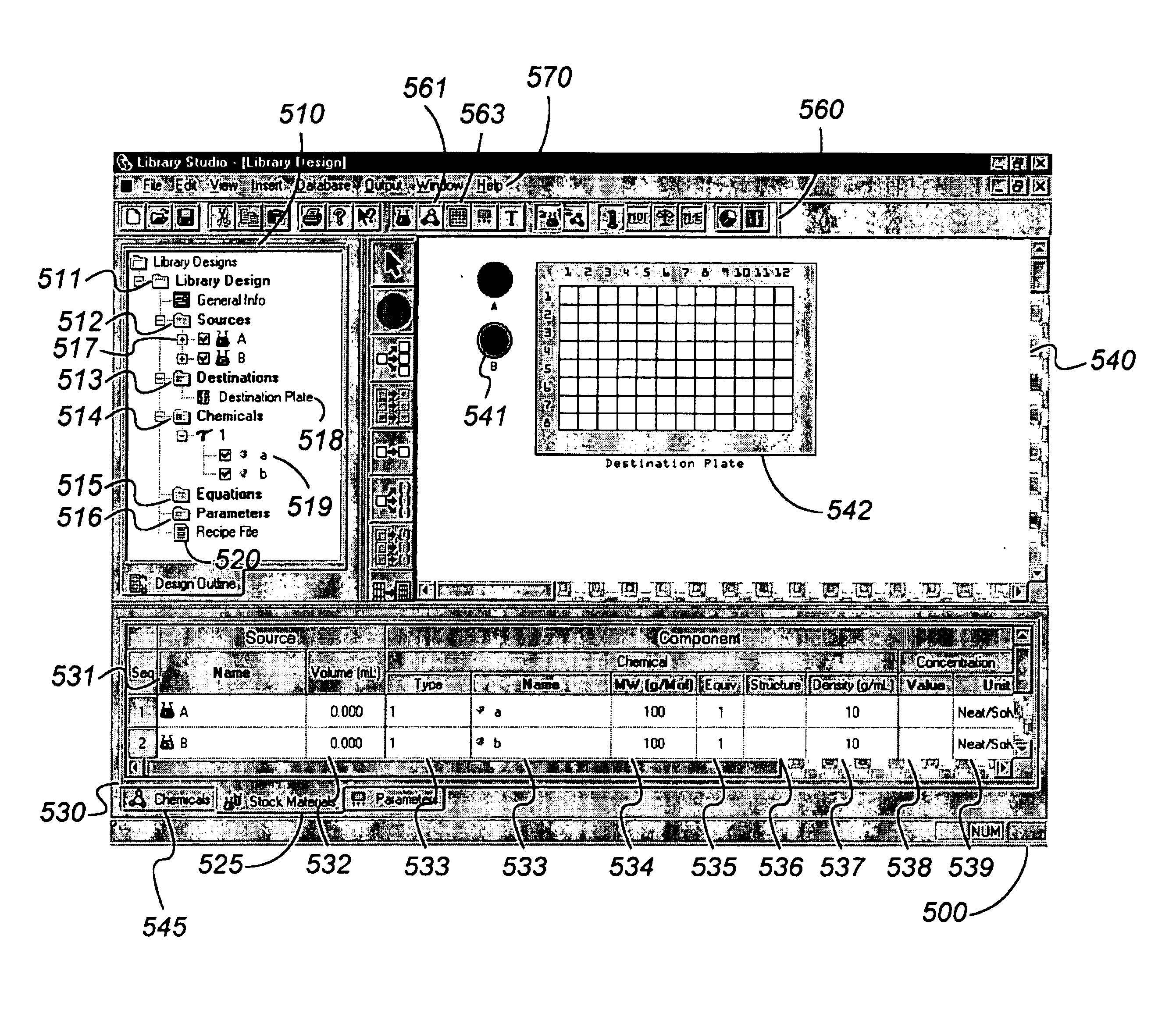

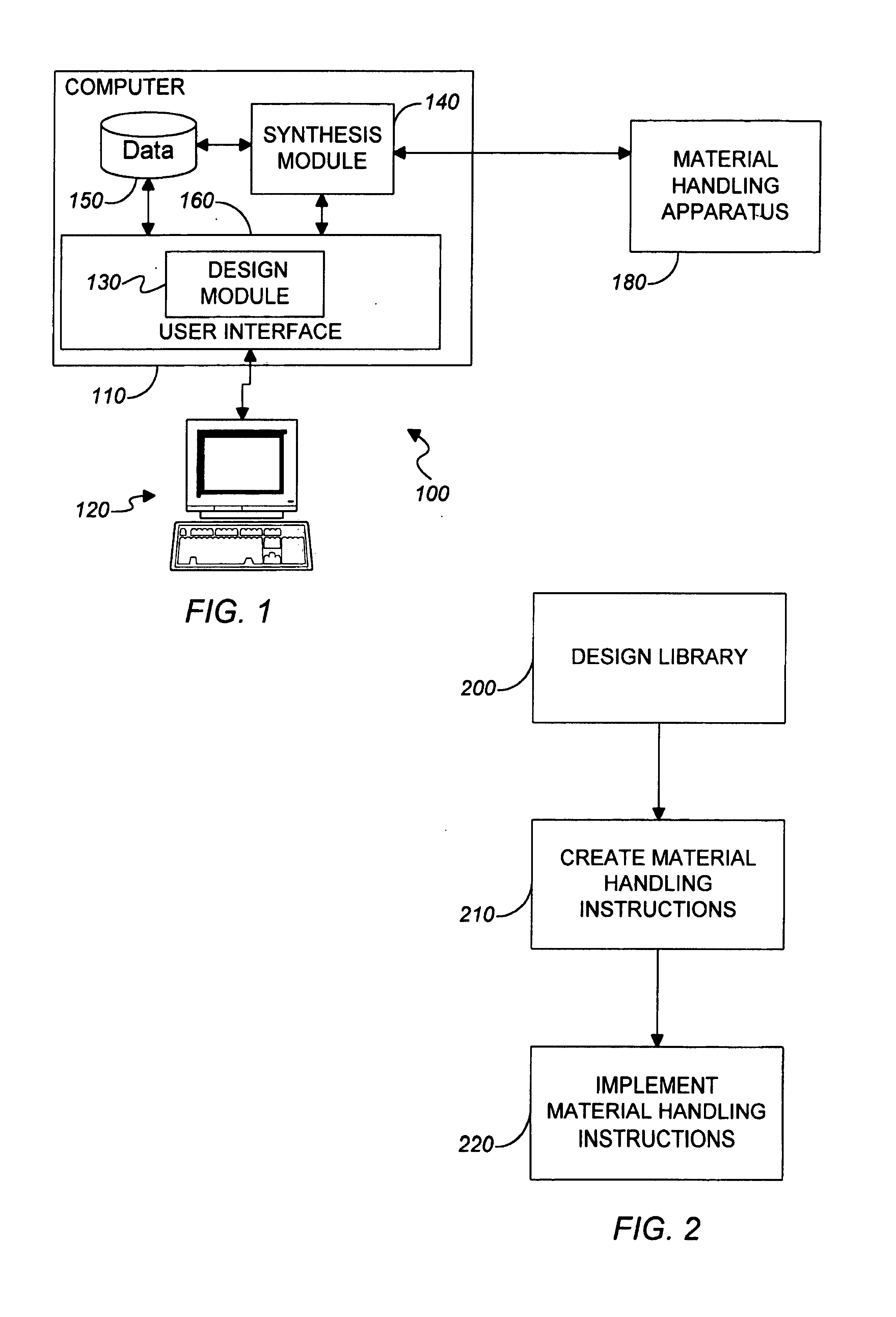

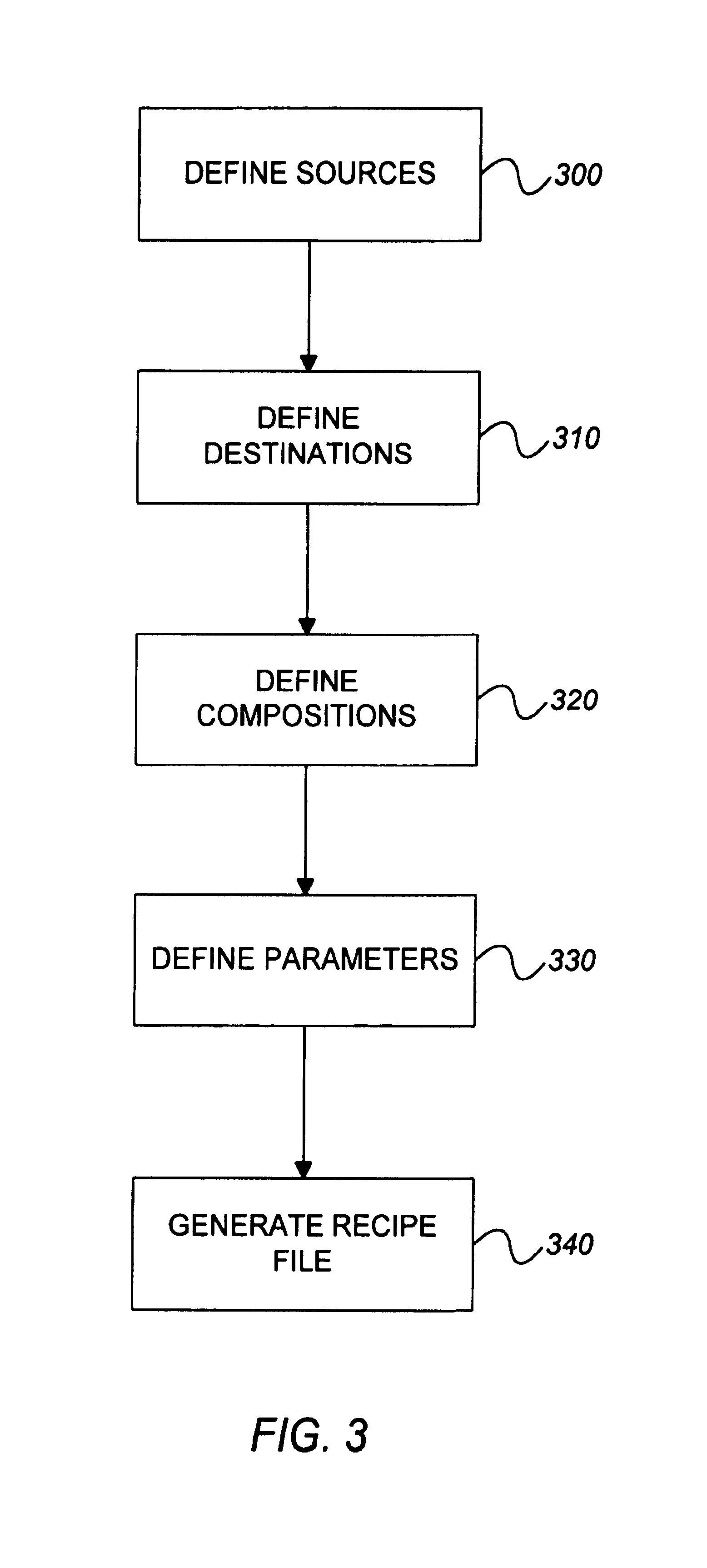

Graphic design of combinatorial material libraries

InactiveUS7199809B1Flexible definitionSpeed up library designOrganic chemistry methodsLibrary screeningGraphicsData file

Computer-implemented methods, programs and apparatus for generating a library design for a combinatorial library of materials. A library design includes a set of sources representing components to be used in preparing the combinatorial library, destinations replying arrangements of cells and mappings, defining one or more distribution patterns for assigning components to cells in the destination arrangement or arrangements. Mappings include gradients and sets of user-defined equations, and are used to calculate the amount of on components to be assigned to a cell or cells in an arrangement. A library design can also include one or more process parameters defined to vary over time or across a plurality of destination cells. The invention outputs a data file defining the library design, including electronic data representing the sources, the destinations and the mapping, in a format suitable for implementing manually or using automated material handling apparatus.

Owner:UNCHAINED LABS

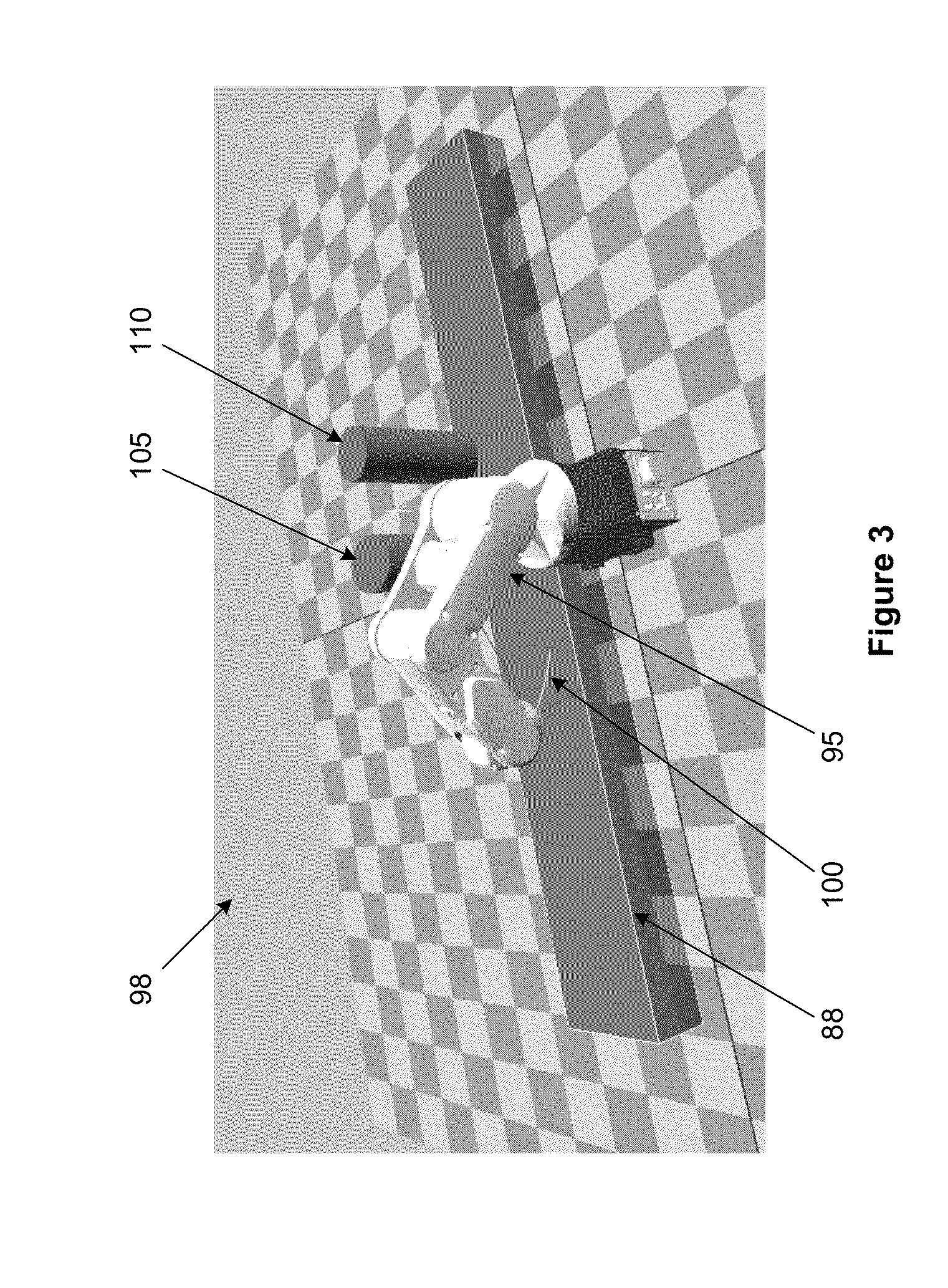

Automated warehousing using robotic forklifts

ActiveUS8965561B2Low costReduce rateDigital data processing detailsLifting devicesOn boardEngineering

A system for automated inventory management and material handling removes the requirement to operate fully automatically or all-manual using conventional vertical storage and retrieval (S&R) machines. Inventory requests to place palletized material into storage at a specified lot location or retrieve palletized material from a specified lot are resolved into missions for autonomous fork trucks, equivalent mobile platforms, or manual fork truck drivers (and their equipment) that are autonomously or manually executed to effect the request. Automated trucks plan their own movements to execute the mission over the warehouse aisles or roadways sharing this space with manually driven trucks. Automated units drive to planned speed limits, manage their loads (stability control), stop, go, and merge at intersections according human driving rules, use on-board sensors to identify static and dynamic obstacles, and human traffic, and either avoid them or stop until potential collision risk is removed.

Owner:CYBERNET SYST

Automated material handling system with load transfer vehicles

Owner:GEBRR BECKER

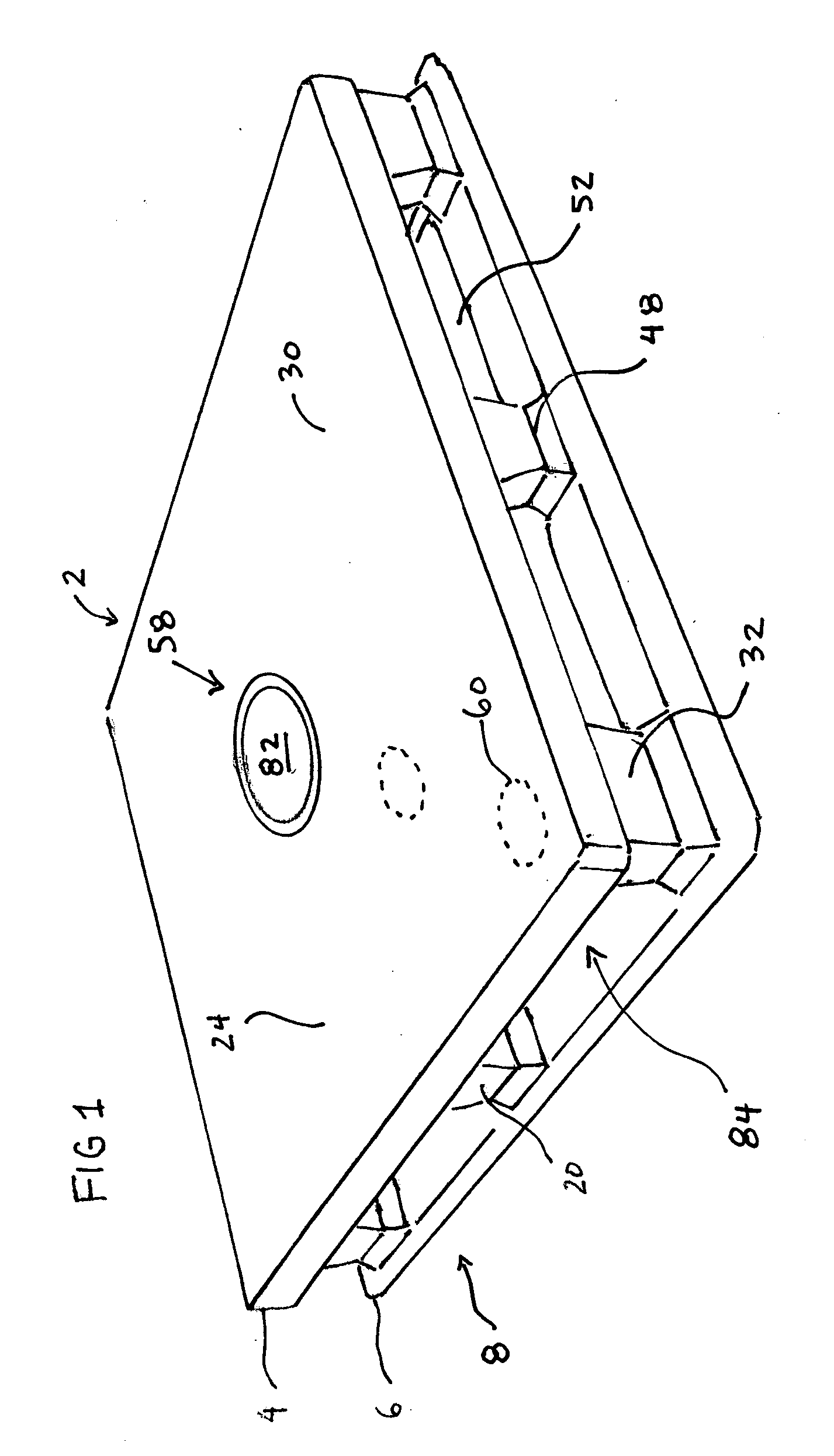

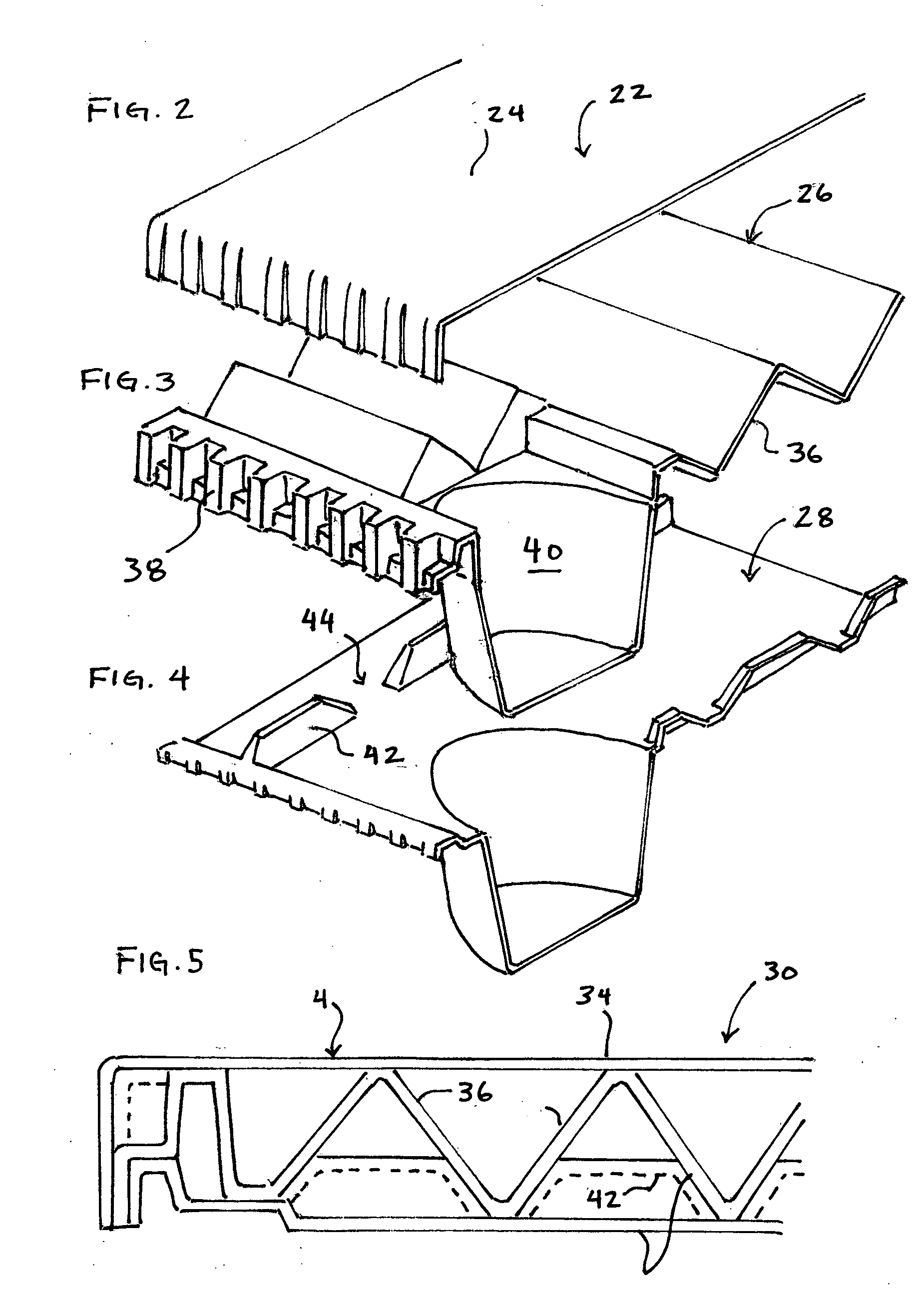

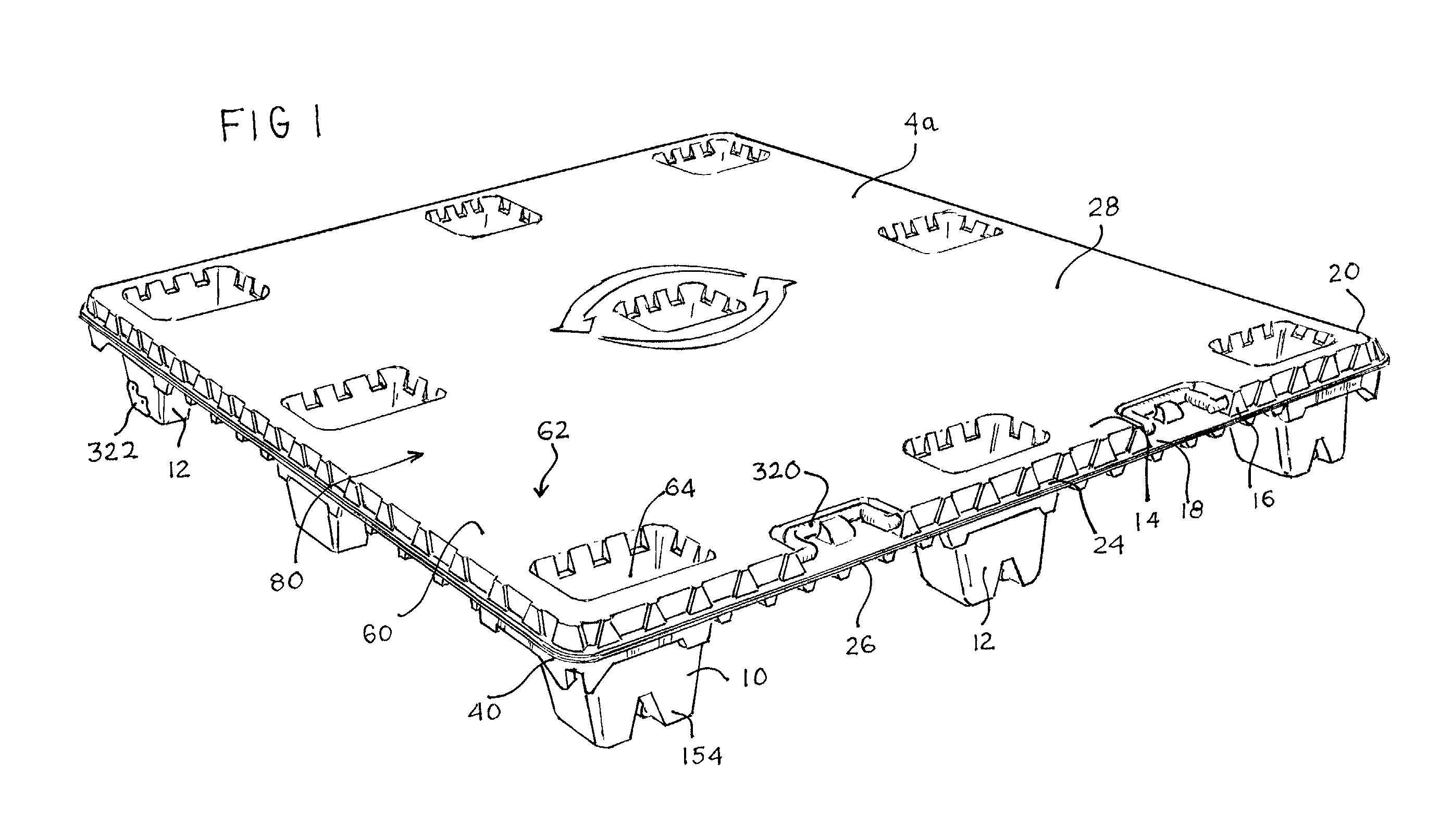

Thermoformed platform

Articles constructed of a plurality of scuffed sheets have improved sheet-to-sheet bond strength and surfaces with high coefficients of friction. Articles constructed out of three scuffed sheets include exterior intumescent polymeric surfaces resisting the spread of combustion flames and insulating the interior surfaces from the high temperature of fire. Articles include electronic apparatus sending an emergency 911 call to a remote monitoring station. Articles are advantageously reinforced with optional rigidifying structures without article modification. Members are joined with snap together features providing an assembled article. Articles include handles for ergonomic manipulation by workers. Articles include elements amenably receiving unitization accessories. The article improvements are demonstrated in the form of industrial platforms, particularly material handling pallets.

Owner:NEXTREME

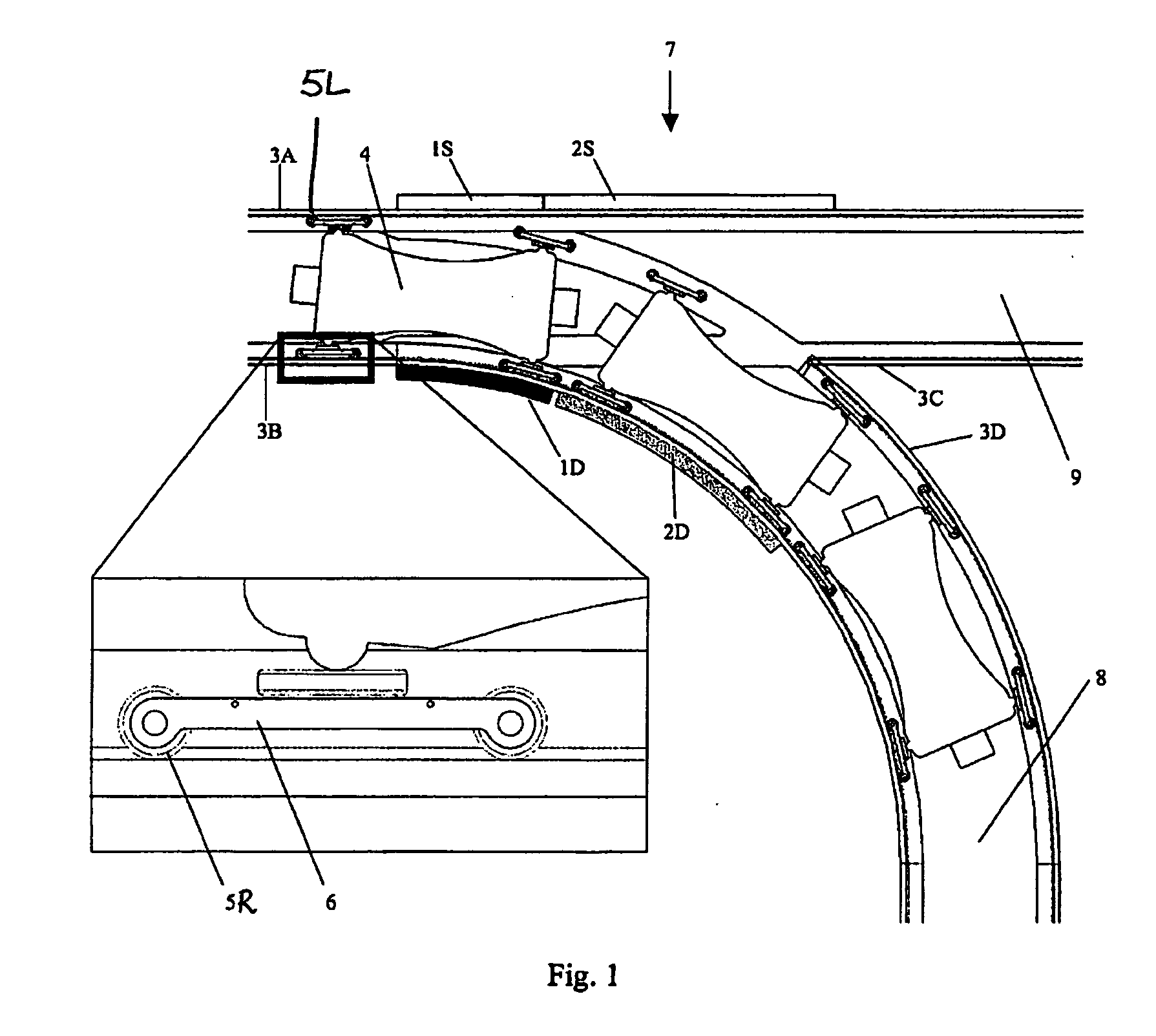

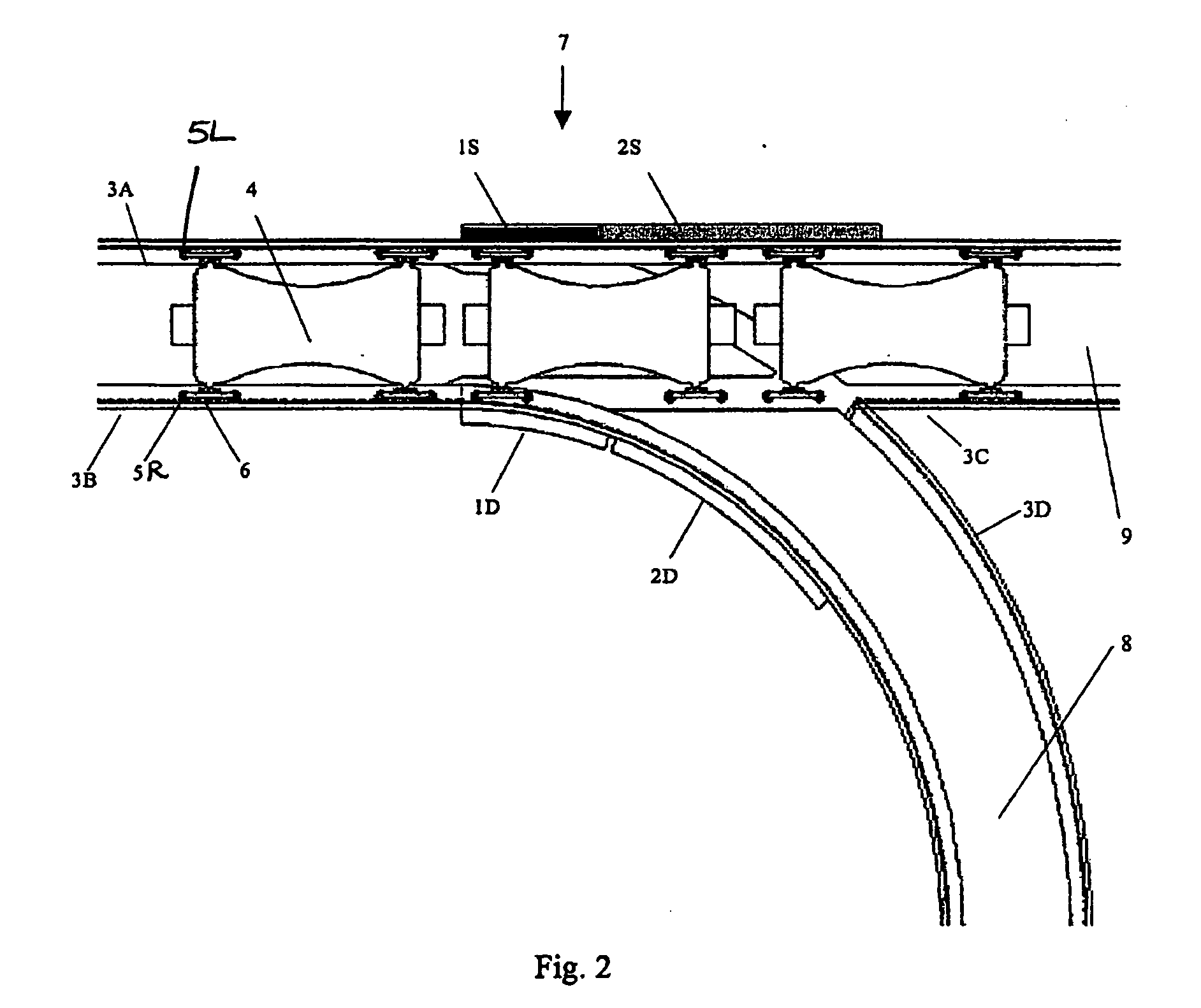

Guideway activated magnetic switching of vehicles

A system for switching a transport vehicle comprising: a guideway, a vehicle that moves along the guideway, and a magnetic field source that creates a force on the vehicle to affect motion in a desired direction at a switch. Once the vehicle has started motion through the switch the guidance can be continued by use of permanent magnets until the normal guidance system is effective. The switching scheme can work with any suspension scheme, including wheels and maglev, and can work with any lateral guidance scheme, including horizontal guide wheels and magnetic guidance. The system can be used with very closely spaced vehicles, such as with Personal Rapid Transit, material handling, and elevators with multiple cabs in the same shaft.

Owner:MAGNEMOTION INC

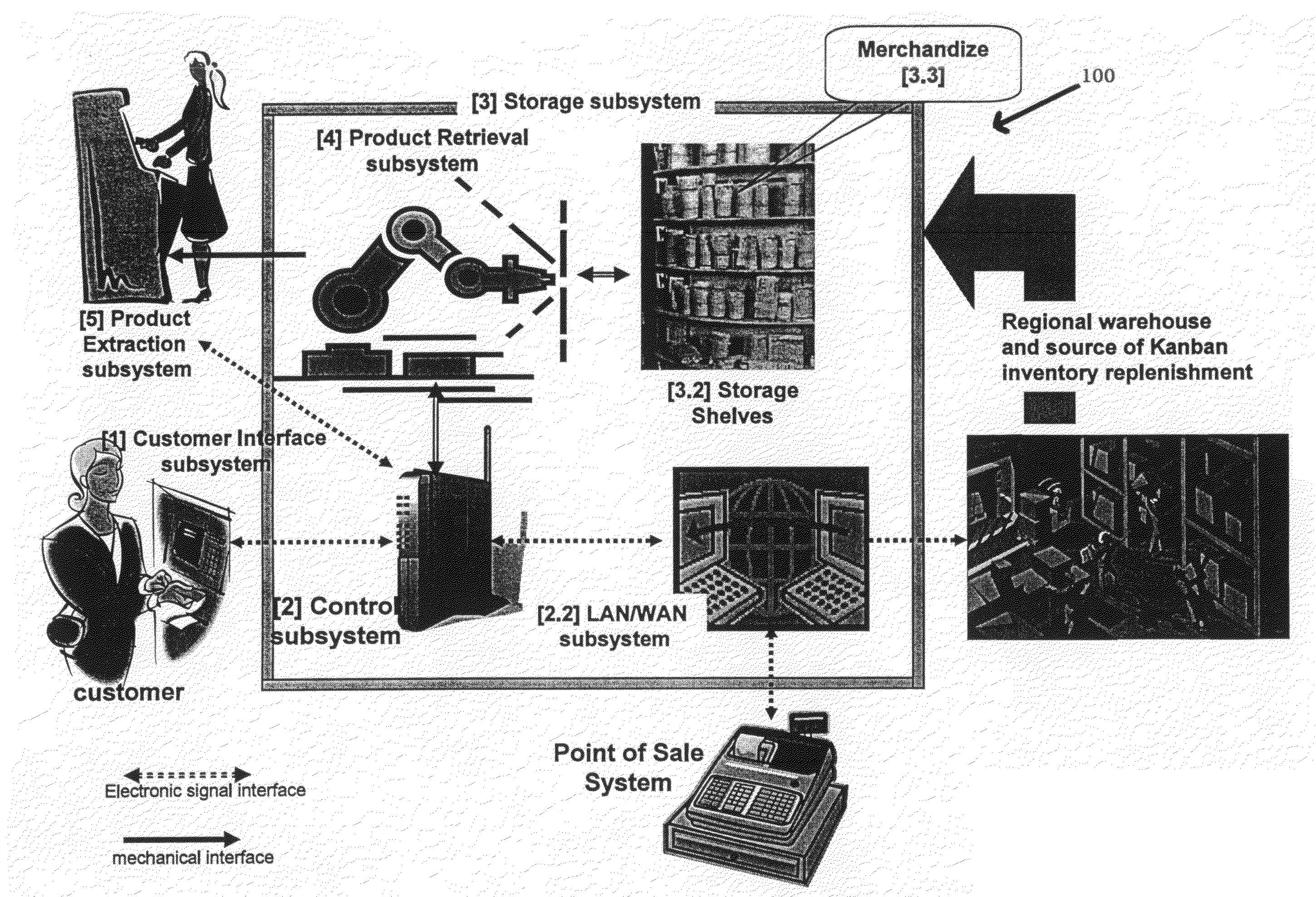

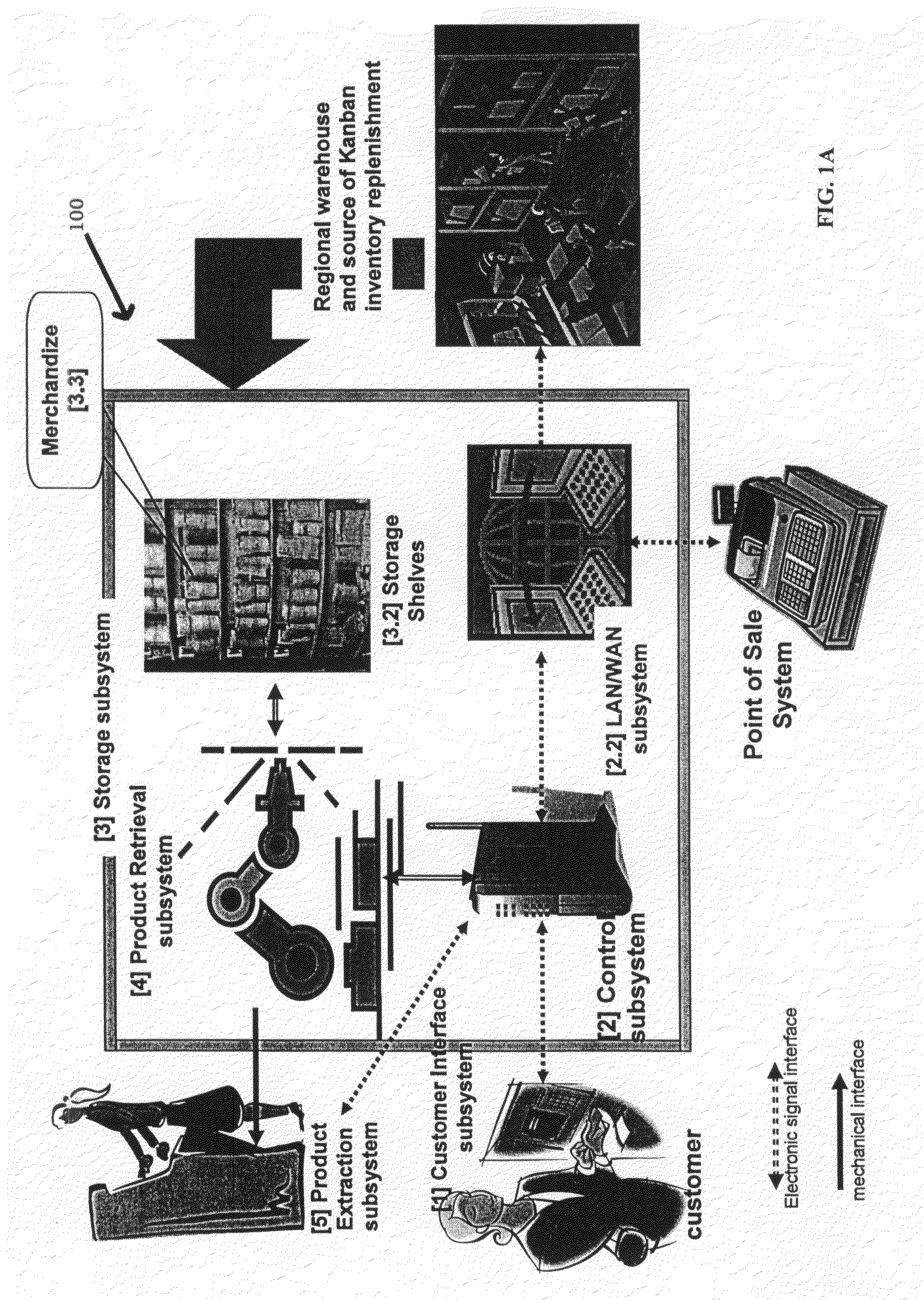

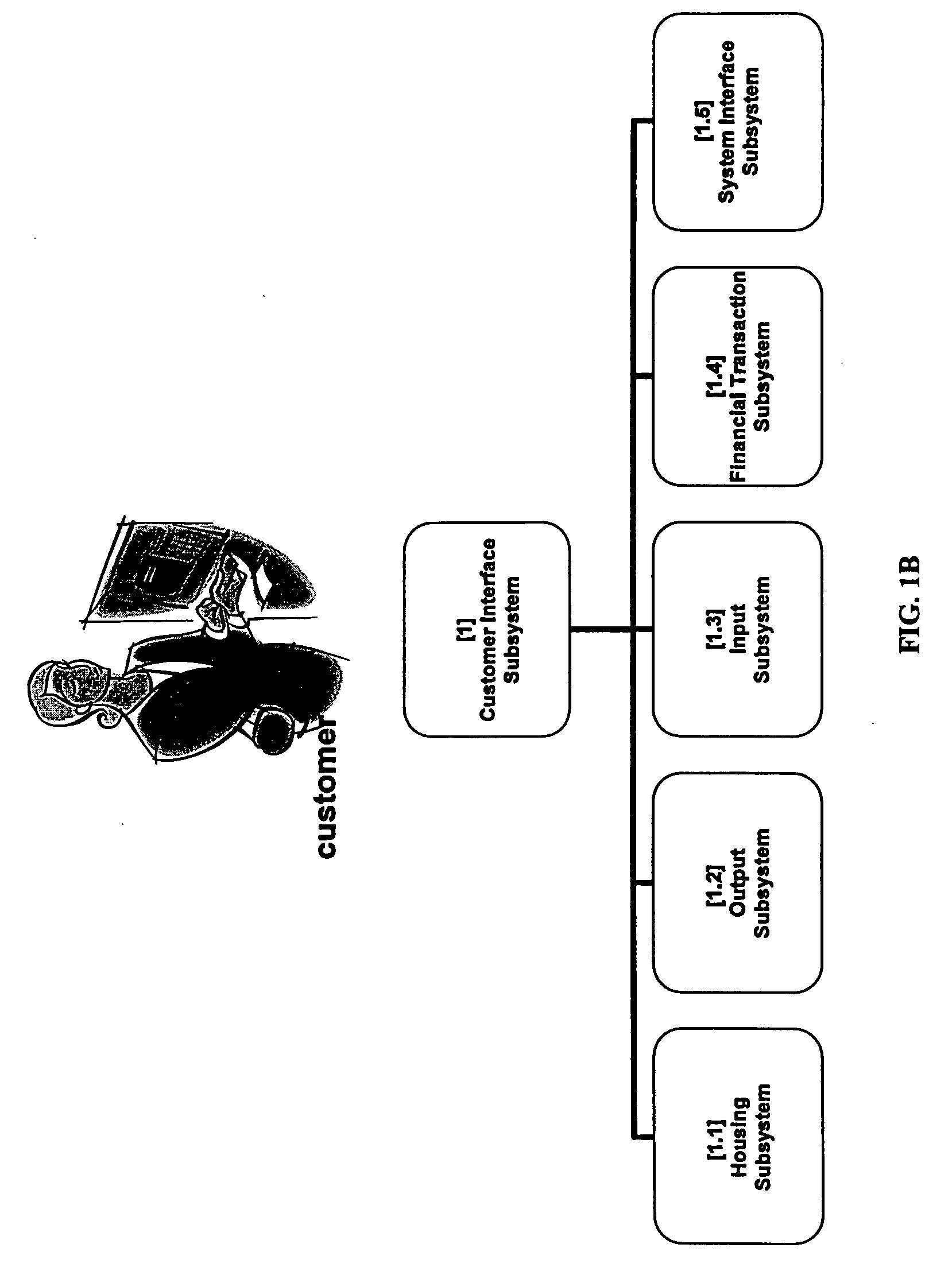

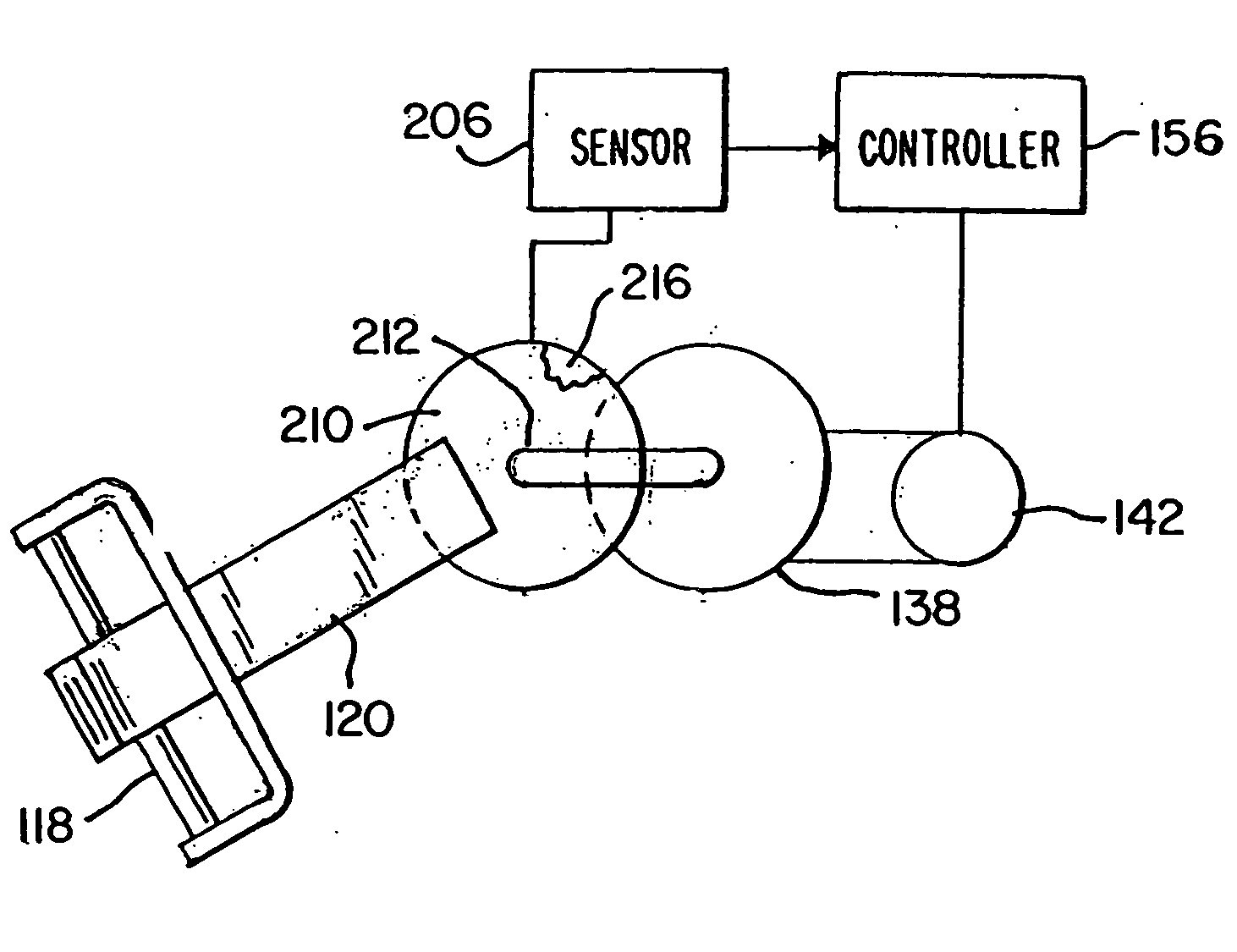

Self-service autonomous merchandising machine

InactiveUS20070284442A1Efficient mechanismCoin-freed apparatus detailsPayment architectureEngineeringHandling system

A solution for consumer self-service merchandise order placement, payment, and pick up, integrated with a merchant's Internet e-commerce site and with an effective merchant point-of-sale management system. The solution includes a system and apparatus and of a set of specific business methods. A self-service merchandising machine for un-attended, autonomous, and automatic dispensing of retail products includes an input / output subsystem; a control subsystem having and being based upon a computer; a specially configured storage subsystem; a unique pick-and-place robotic-based product retrieval subsystem with an adaptive material handling system; and a product extraction subsystem. A related method of using the machine includes the steps of enabling self-service retail sale; permitting Internet sale with local merchandise pick-up; managing the business operations of the system; replenishing inventory using Kanban methods; restocking inventory; operating and monitoring a security camera; handling Category I error; and handling Category II error.

Owner:HERSKOVITZ MICHAEL

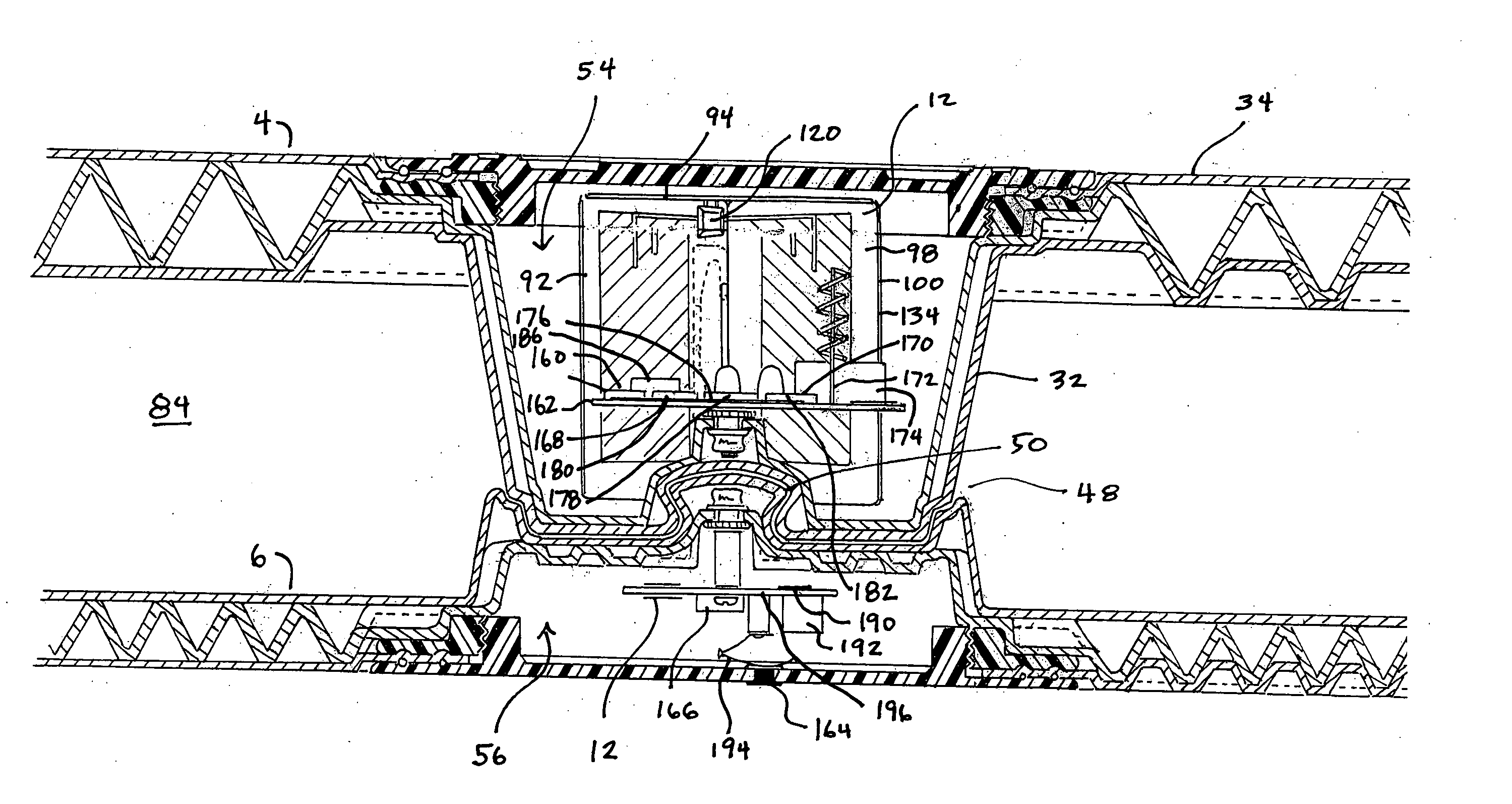

Electrical steering assist for material handling vehicles

ActiveUS20050247508A1Reduce effortOvercome disadvantagesLifting devicesHand leversJoystickElectric machinery

Electrical steering assist systems reduce the operator applied steering effort necessary to operate material handling vehicles. A steer drive unit including a motor is coupled to a steerable wheel for providing steering assist. The amount of steering assist provided by the steer drive unit is determined by a controller that receives input from one or more input sensing devices. The input sensing device(s) may include force sensors that detect an operator applied turning force. The input sensing device(s) may also detect the movement of one steering component relative to another. Further, the input sensing device(s) may include operator activated controls such as a joystick, potentiometer, switches and voice initiated commands. Input sensing device(s) may additionally be provided to detect operational parameters such as the load on the material handling vehicle, vehicle speed, or environmental conditions such as travel path obstruction detection, homing and proximity sensing.

Owner:CROWN EQUIP CORP

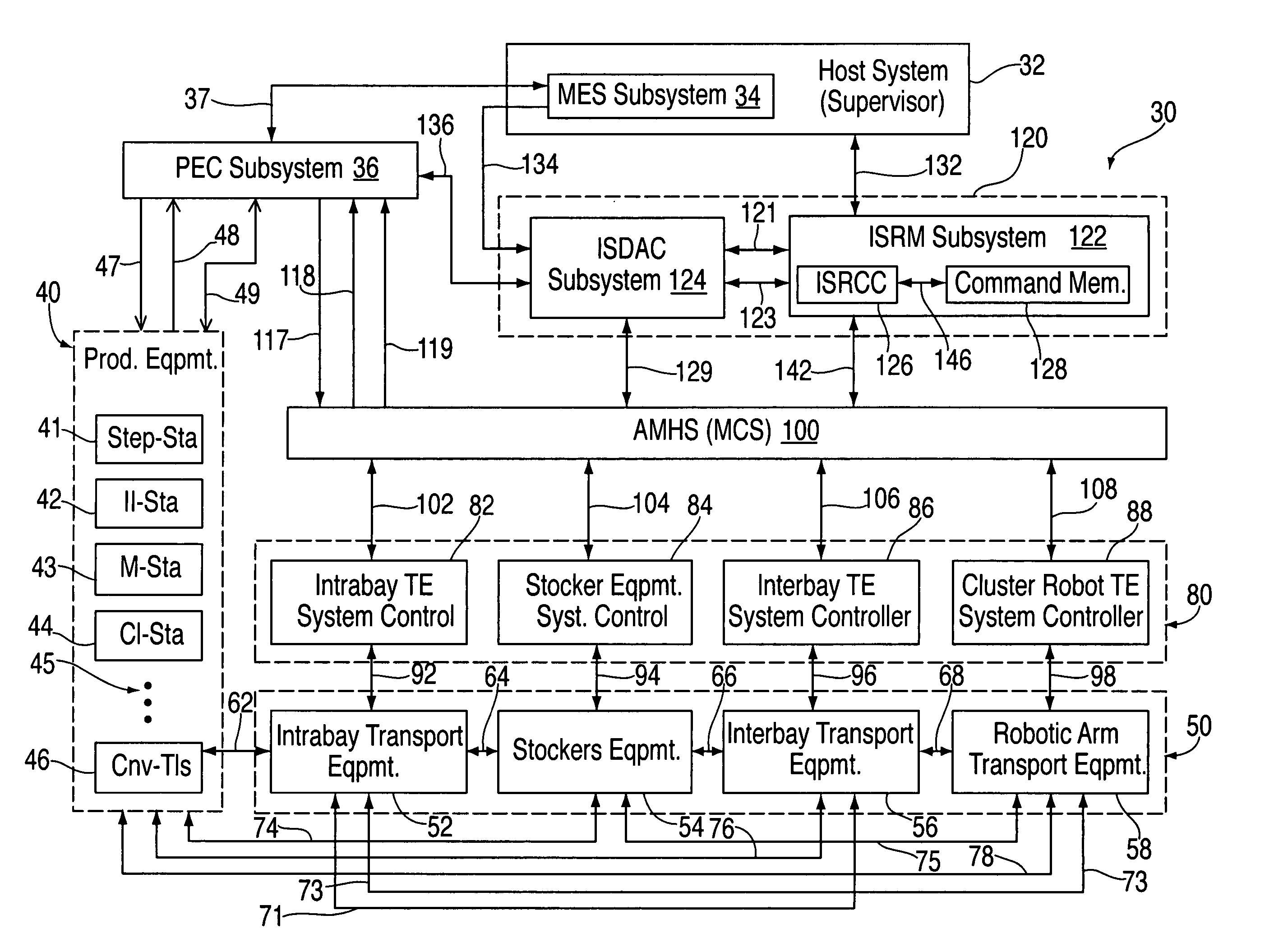

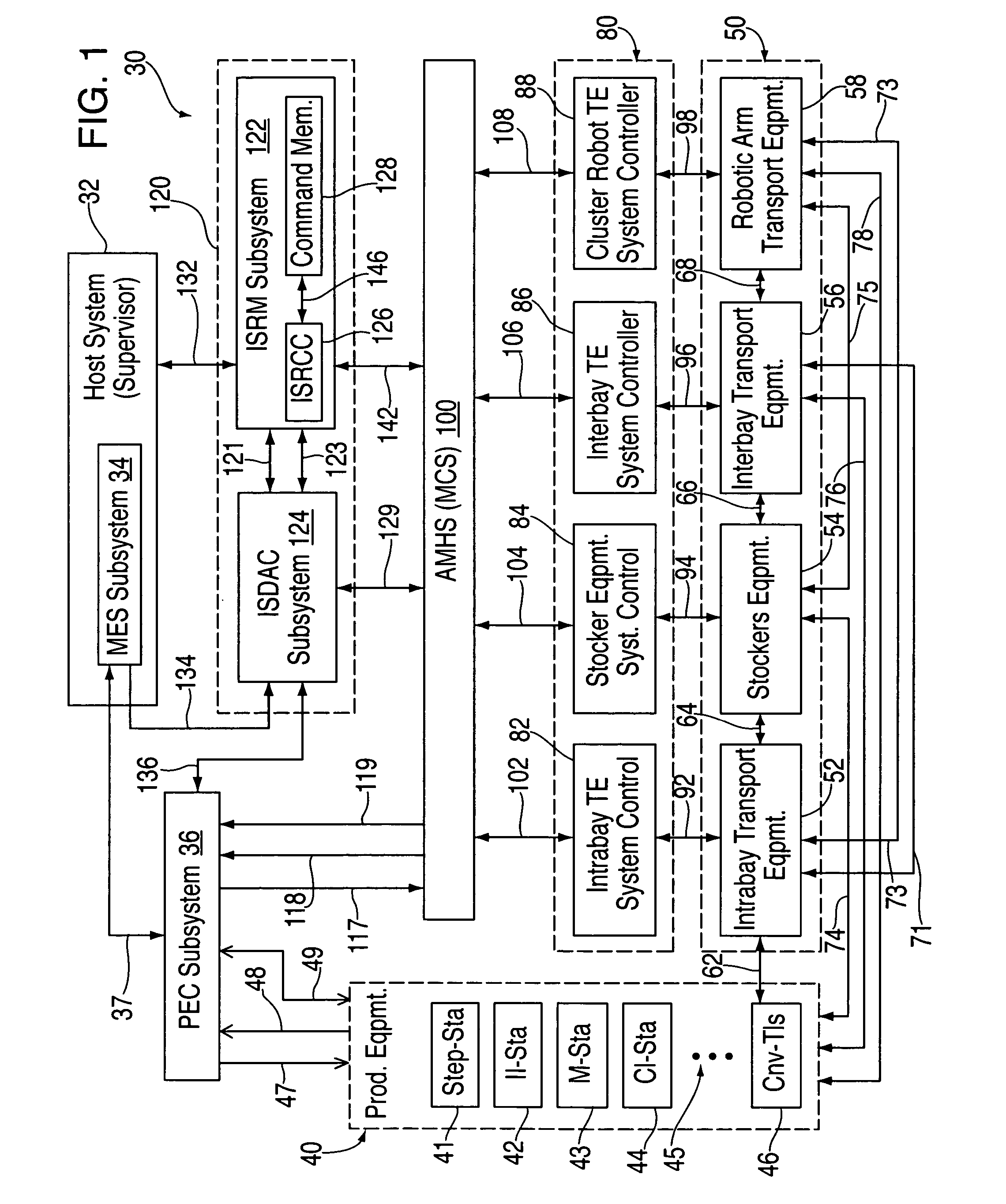

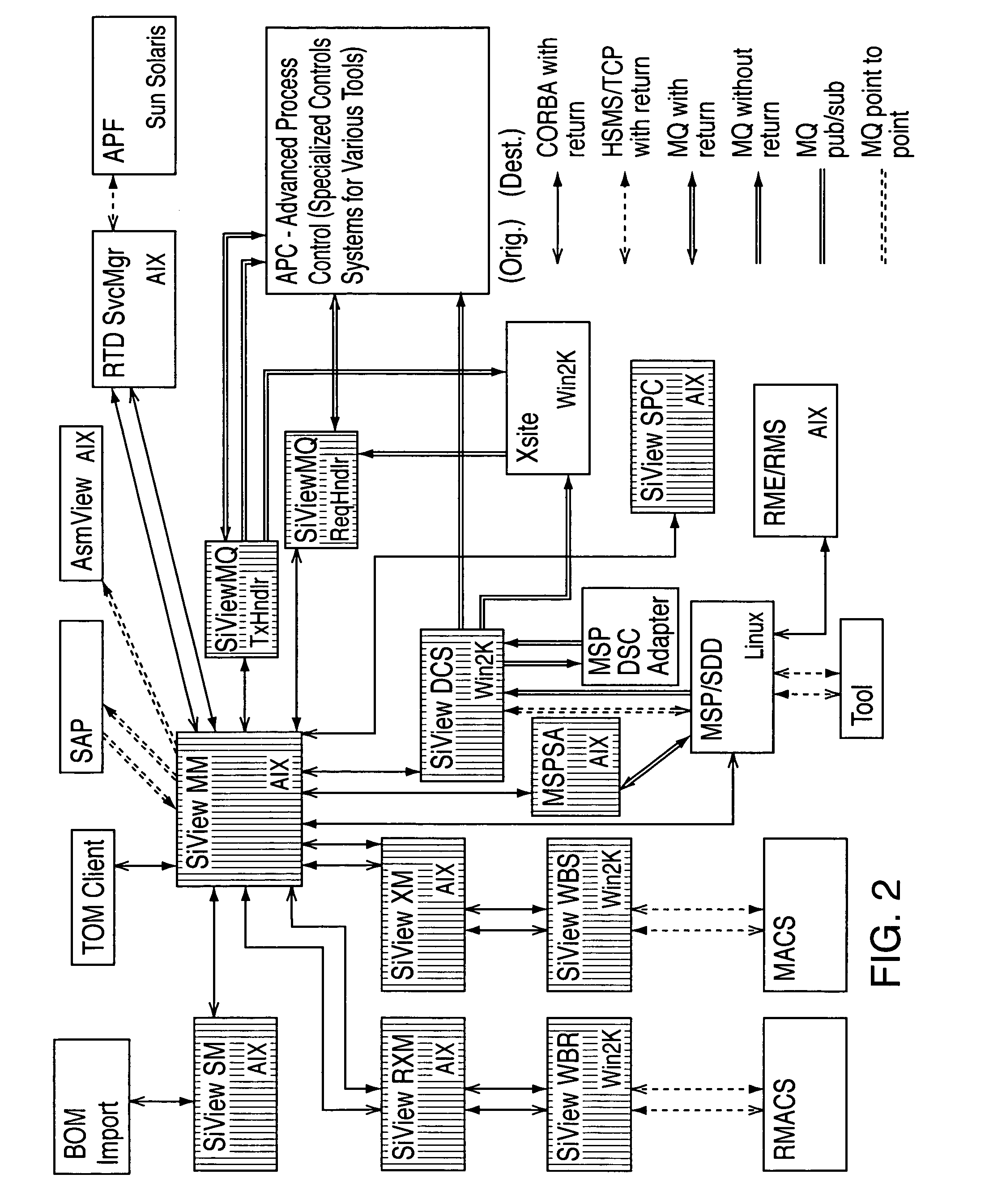

Method and system for automating issue resolution in manufacturing execution and material control systems

InactiveUS20050075748A1Decrease productivityImprove productivitySafety arrangmentsTesting/monitoring control systemsProduction rateImage resolution

Automatic error recovery systems and methods for automated manufacturing plants and factories are disclosed. Such facilities normally have multiple automated control systems, including an automated material handling system (AMHS), all of which run automatically, typically under the control of a computerized manufacturing execution system (MES). The disclosed issue resolution (ISR) systems and methods involve providing components, which may be supervised and operated by an issue resolution management (ISRM) system, if desired, that interfaces with the MES, AMHS, and / or production control system(s) which operate the tools and other stations within the automated factory. The components, which may be considered customized logic cells, may each be written for handling a specific kind of incoming error condition, problem or other issue that might occur and which is amenable to automatic resolution or recovery. These errors often occur between or across the boundaries of the various interactive systems and automated equipment. Each cell may cycle through a sequence of possible error resolution or recovery steps until the specific issue is resolved or until the sequence of steps is exhausted. Other components of the ISR system may provide results-oriented messages and / or facilitate the collection of data as to whether and which corrective commands from the ISR system resolved the reported error conditions automatically. The disclosed ISR systems and methods for resolving errors and other issues automatically helps improve the overall productivity of automated factories by reducing downtime and the need for human intervention to correct problems, thereby increasing factory throughput.

Owner:IBM CORP

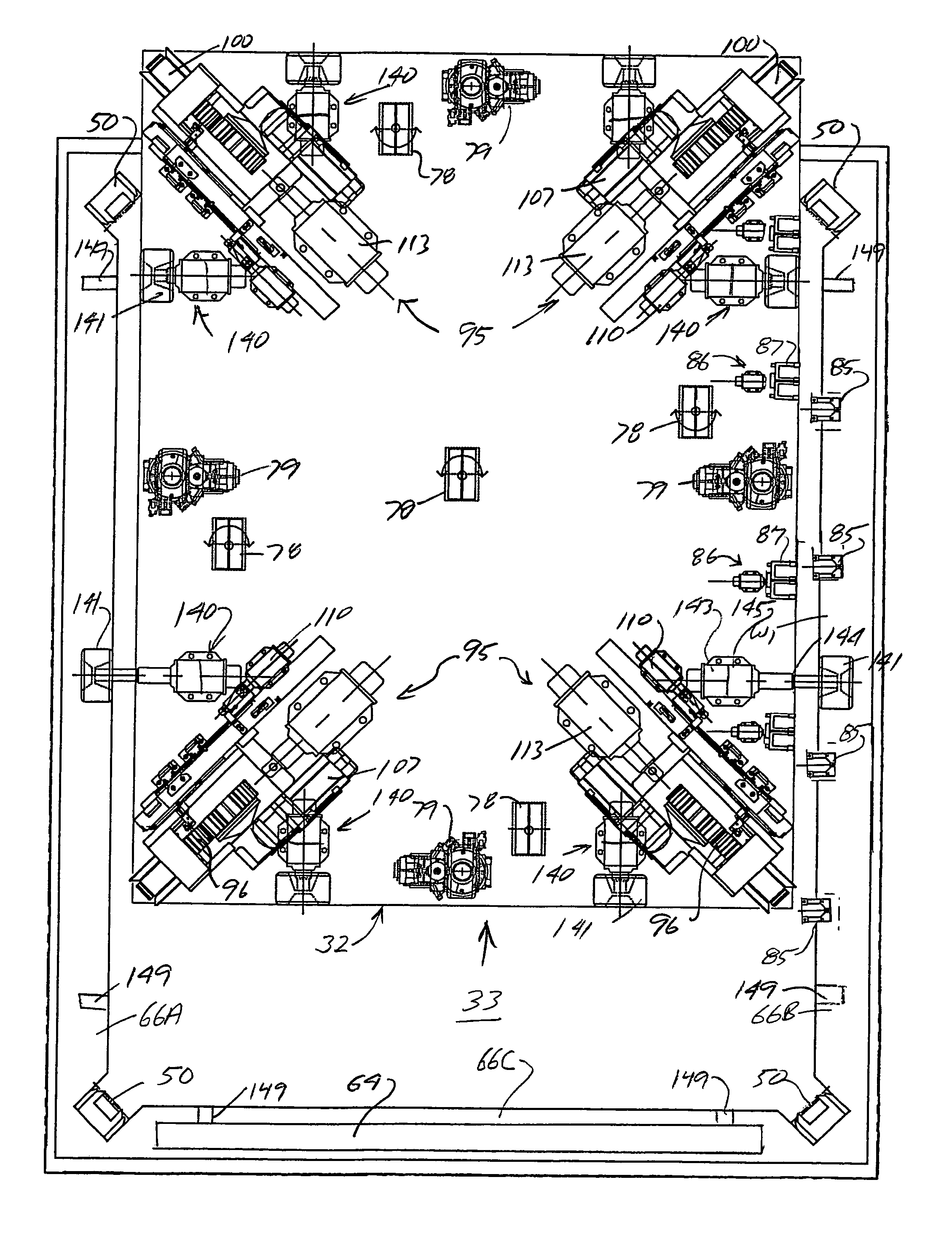

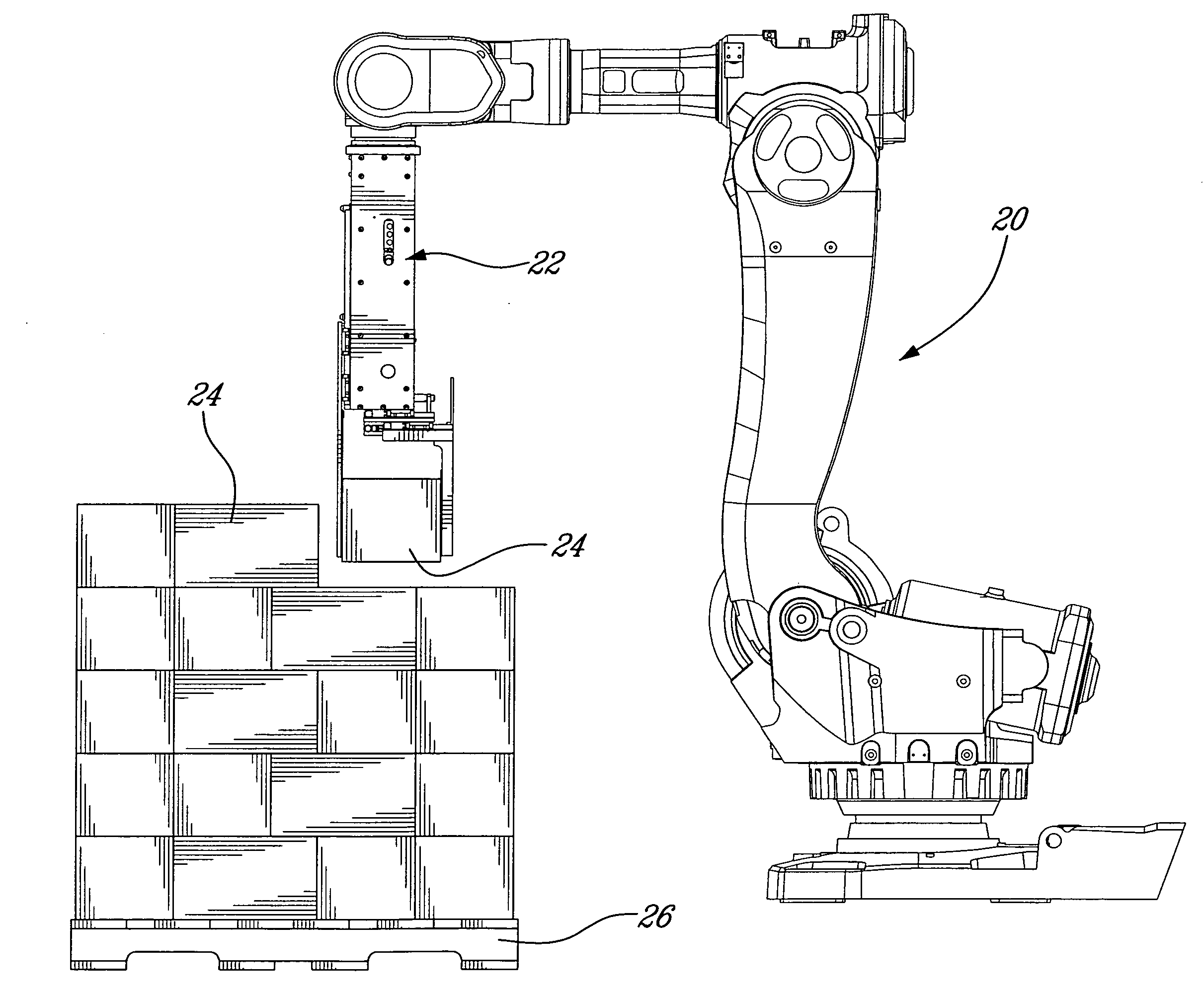

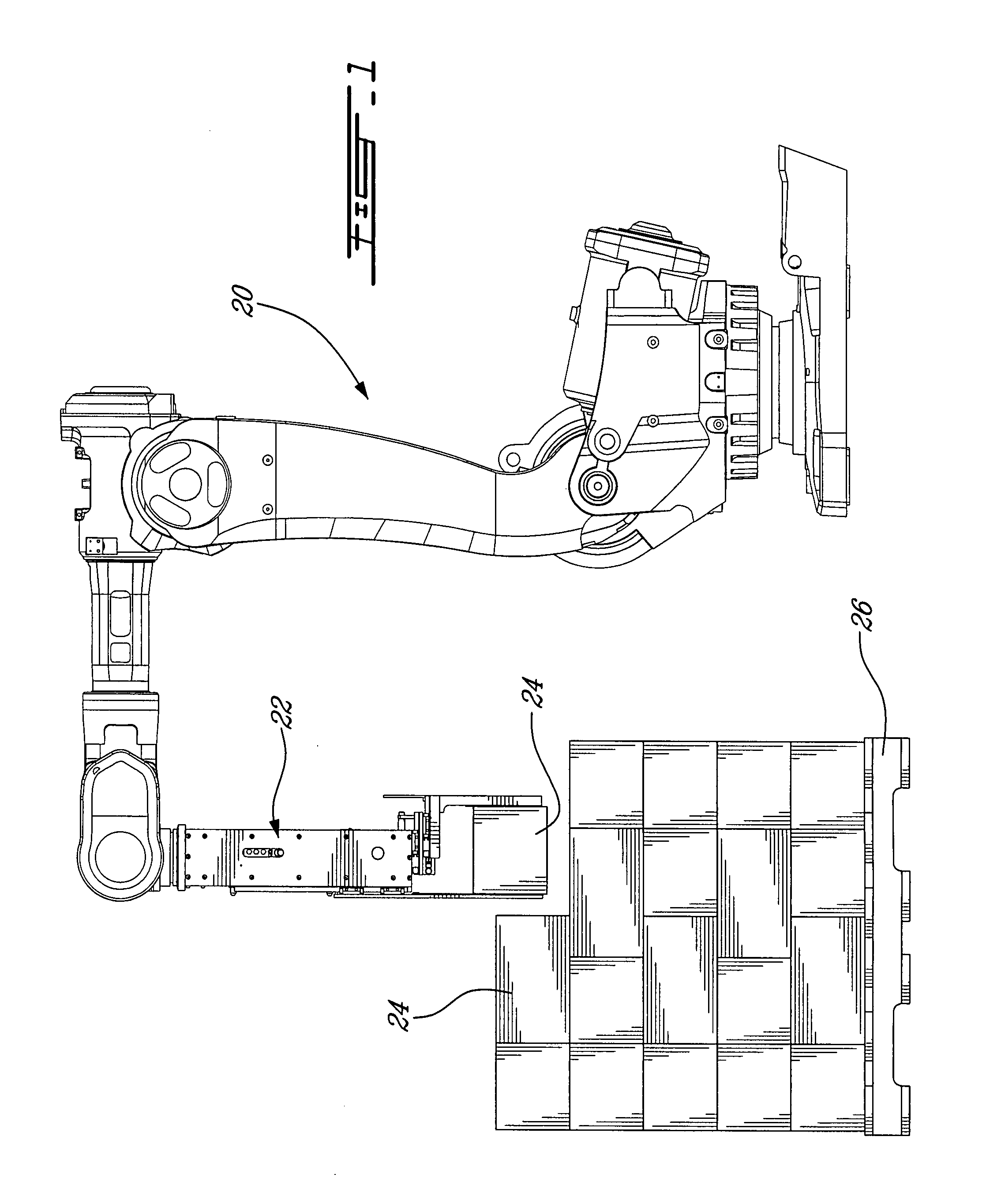

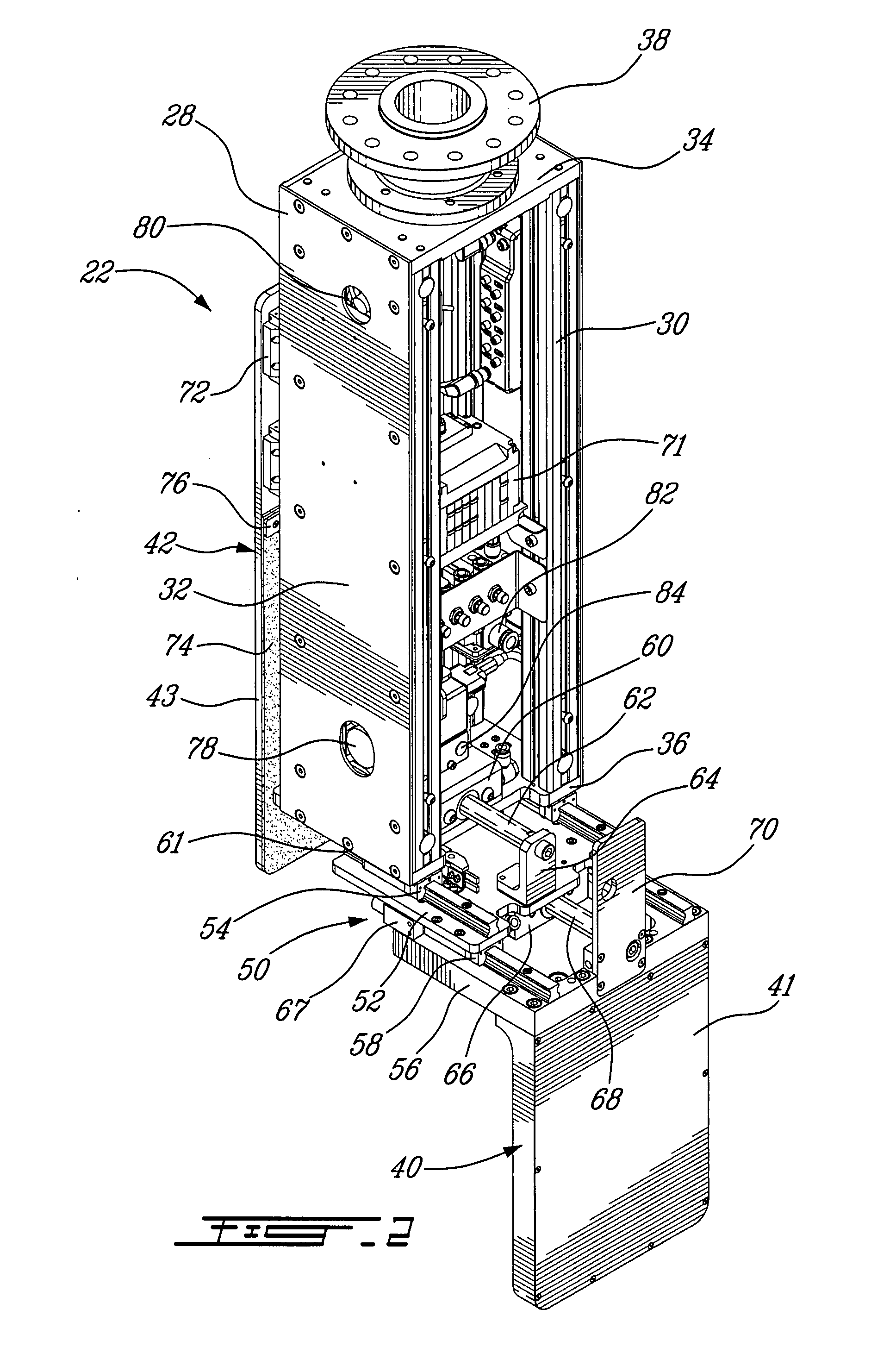

Tool and method for mixed palletizing/depalletizing

A material handling tool comprising a longitudinal body provided with a proximate end and a distal end is described herein. The handling tool includes a vacuum jaw assembly so mounted to the distal end of the body as to be transversally movable; and a longitudinally movable jaw assembly so mounted to the longitudinal body as to be longitudinally movable between a retracted position where the movable jaw assembly is adjacent to the longitudinal body and an extended position where the movable jaw assembly faces the vacuum jaw assembly.

Owner:AXIUM

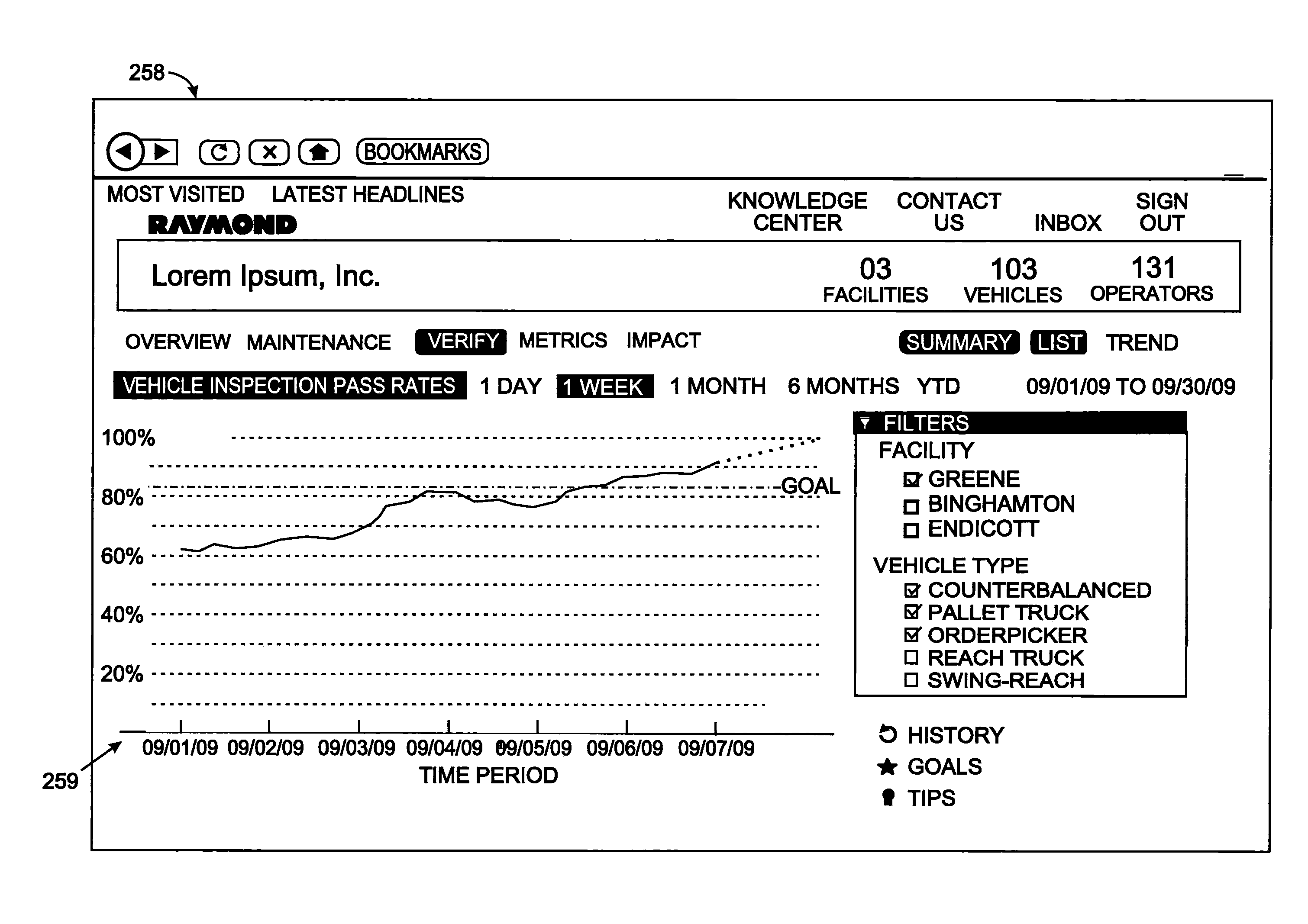

Information reporting system for managing a fleet of an industrial vehicles

ActiveUS20100179844A1Vehicle testingDrawing from basic elementsCommunications systemMaterial handling

Operational data are transmitted, by each of a plurality of material handling vehicles at a facility, into a communications system. A computer connected to the communications system processes the operational data and presents reports on a monitor screen. The computer operates in an impact report mode which provides reports about material handling vehicle impacts with objects, a maintenance report mode for reports pertaining to vehicle maintenance, a verify report mode presenting reports about vehicle inspections, and a metrics report mode for reports describing amounts of work performed by the vehicles, and an overview mode summarizes information from each of other report modes. Each report mode has different display modes which summarize data for a group of the vehicles or provide detailed information about one particular vehicle or one specific vehicle operator.

Owner:RAYMOND LTD

Systems and methods of remotely controlling a materials handling vehicle

ActiveUS20110118903A1Registering/indicating working of vehiclesDigital data processing detailsControl systemMaterial handling

A supplemental control system for a materials handling vehicle comprises a wearable control device, and a corresponding receiver on the materials handling vehicle. The wearable control device is donned by an operator interacting with the materials handling vehicle, and comprises a wireless transmitter to be worn on the wrist of the operator and a travel control communicably coupled to the wireless transmitter. Actuation of the travel control causes the wireless transmitter to transmit a first type signal designating a request to the vehicle. The receiver is supported by the vehicle for receiving transmissions from the wireless transmitter.

Owner:CROWN EQUIP CORP

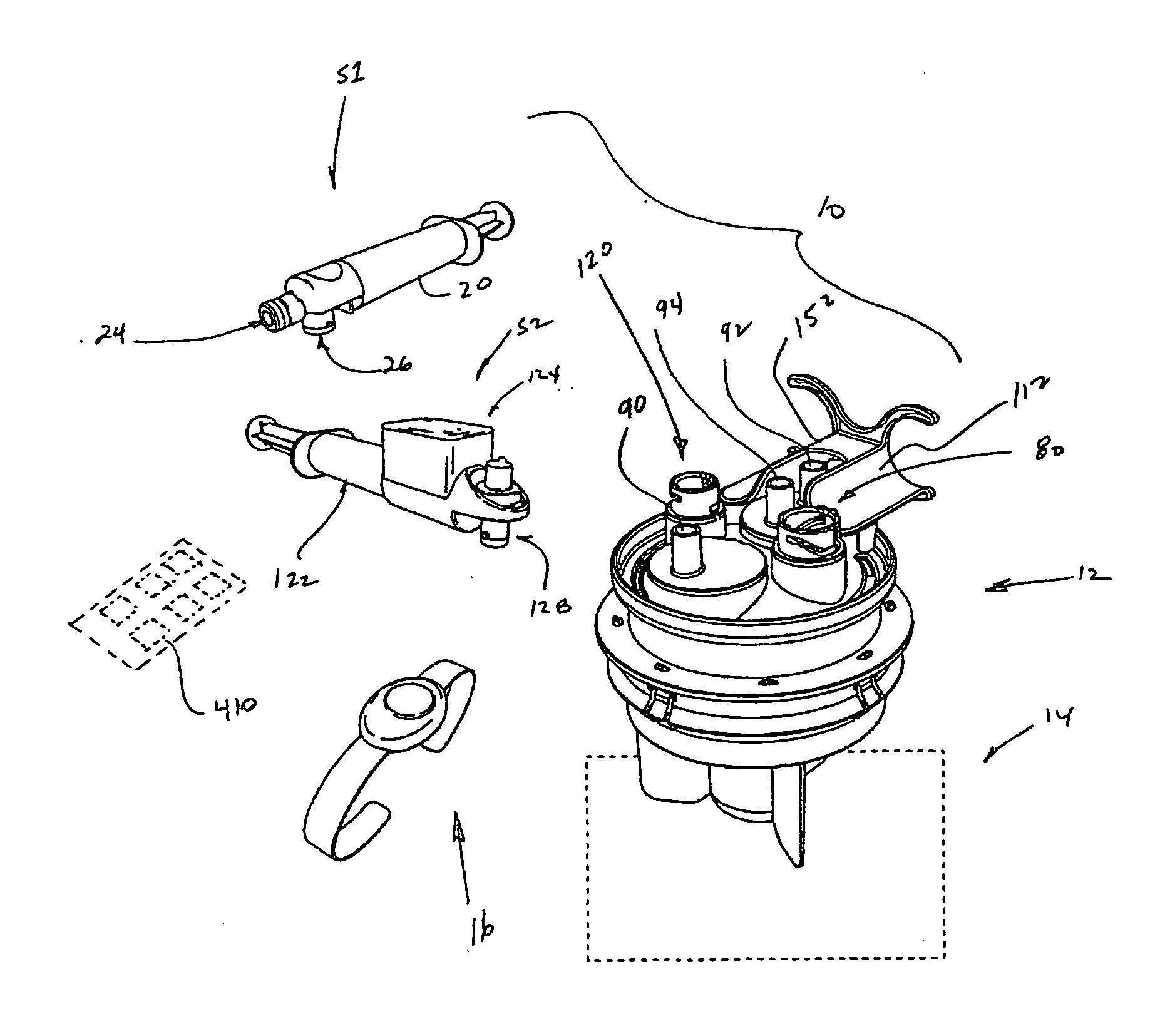

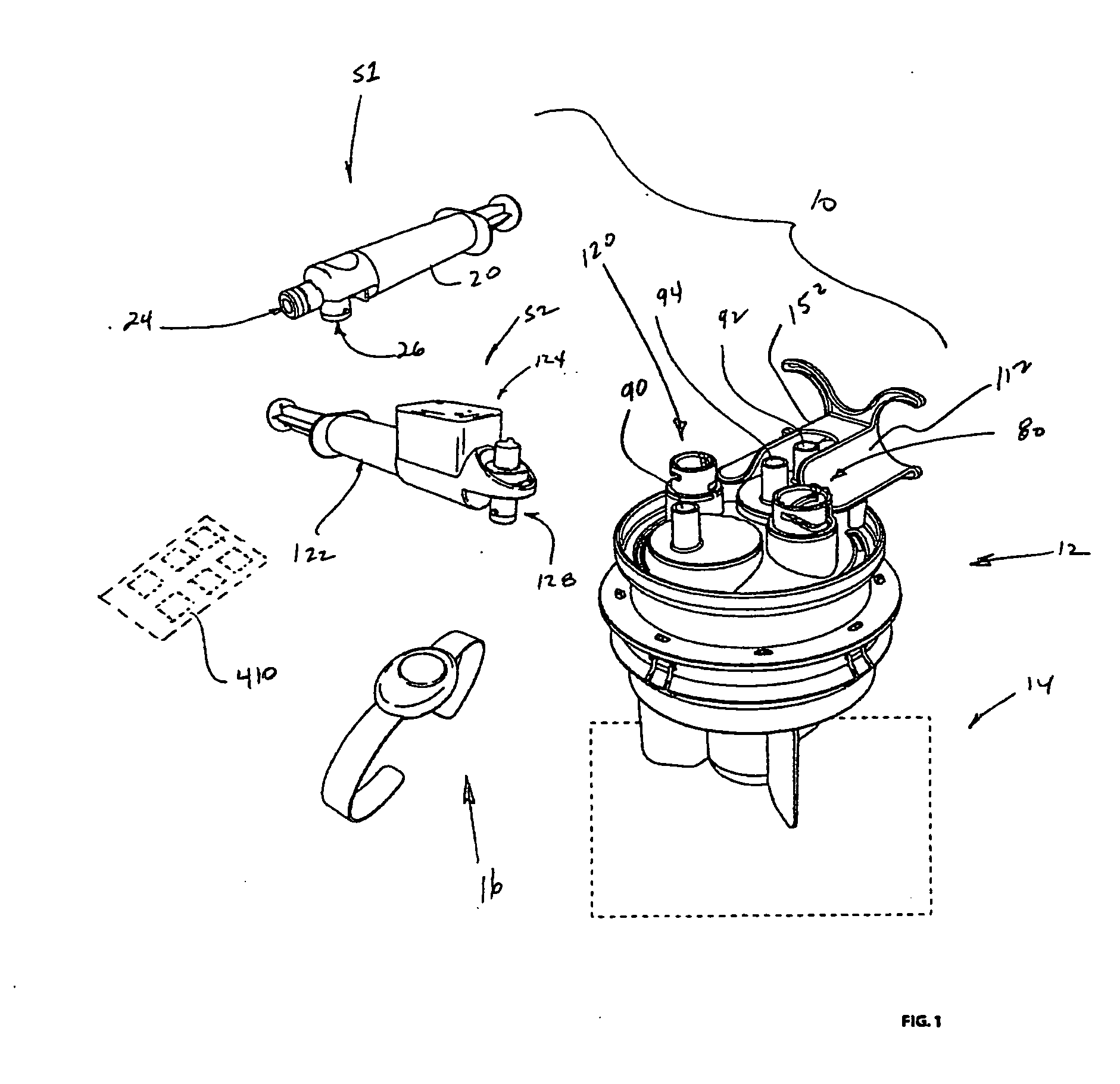

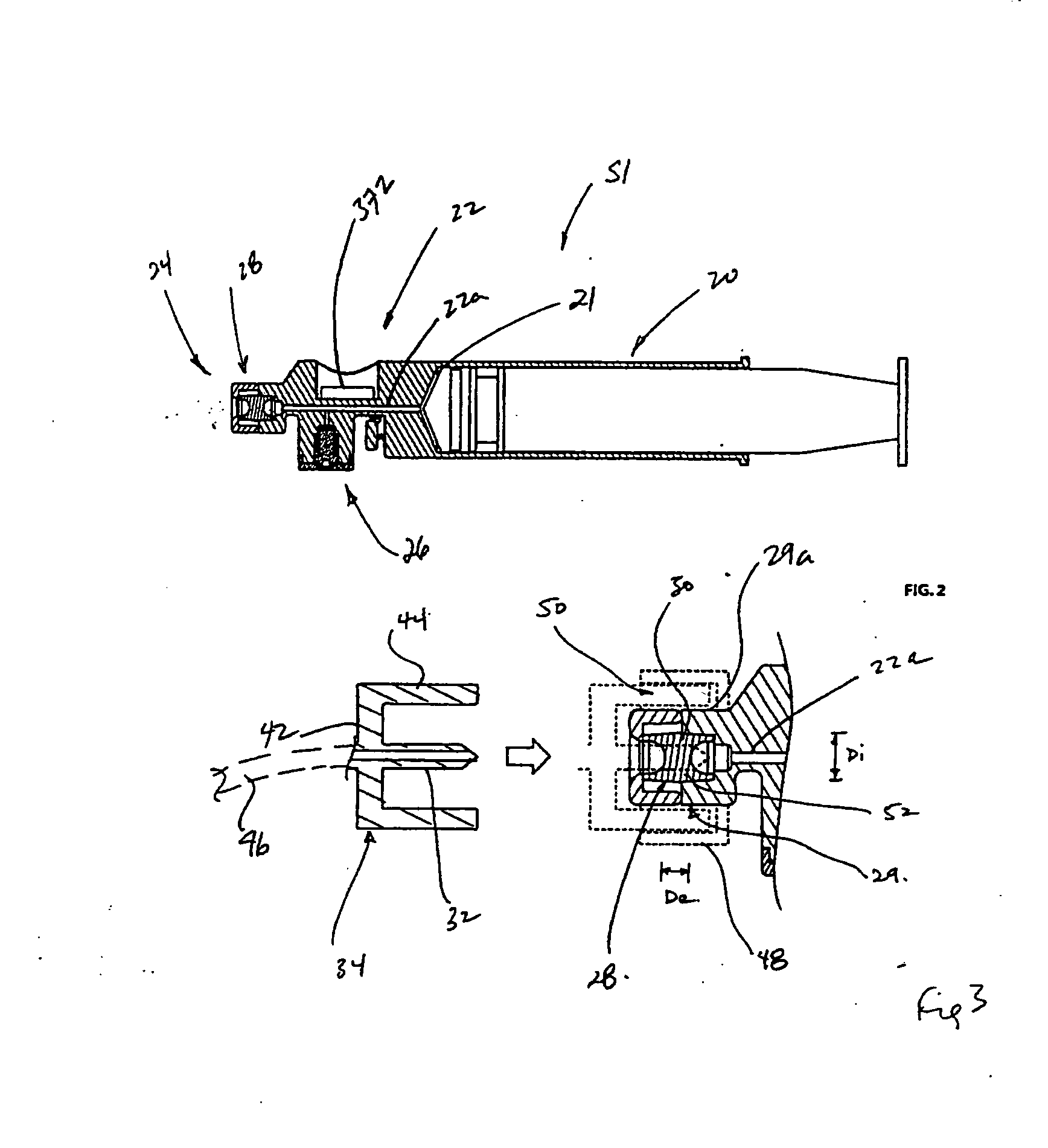

Medical material handling systems

InactiveUS20050154368A1Inhibition releaseAvoid treatmentInfusion syringesSurgeryFluid couplingAutologous blood

Disclosed herein is a system for the collection, treatment and delivery of an autologous blood sample, comprising a first syringe having a first body portion. A first sample transfer portion has a first syringe inlet for drawing an untreated blood sample from a patient and a first syringe outlet for dispensing the untreated blood sample. A blood sample treatment chamber having a chamber inlet, the first syringe outlet being operable to establish a dedicated first fluid coupling with the chamber inlet to dispense the untreated blood sample to the blood sample treatment chamber. The blood sample treatment chamber having a chamber outlet for dispensing a treated blood sample following treatment. The second syringe has a second body portion and a second sample transfer portion, the second sample transfer portion having a passage with a first access location which is operable to form a dedicated second fluid coupling with the chamber outlet. The second body portion has a second syringe outlet, the passage having a second access location for fluid communication with the second syringe outlet, releasable lock means for forming a locked third fluid coupling between the second access location and the second syringe outlet. The lock means is operable in response to a release signal to release the third fluid coupling, the second syringe outlet being operable when released from the third fluid coupling to form a fourth fluid coupling with a blood sample delivery unit.

Owner:VASOGEN IRELAND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com