Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

425 results about "Manufacturing execution system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing execution systems (MES) are computerized systems used in manufacturing, to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision makers understand how current conditions on the plant floor can be optimized to improve production output. MES works in real time to enable the control of multiple elements of the production process (e.g. inputs, personnel, machines and support services).

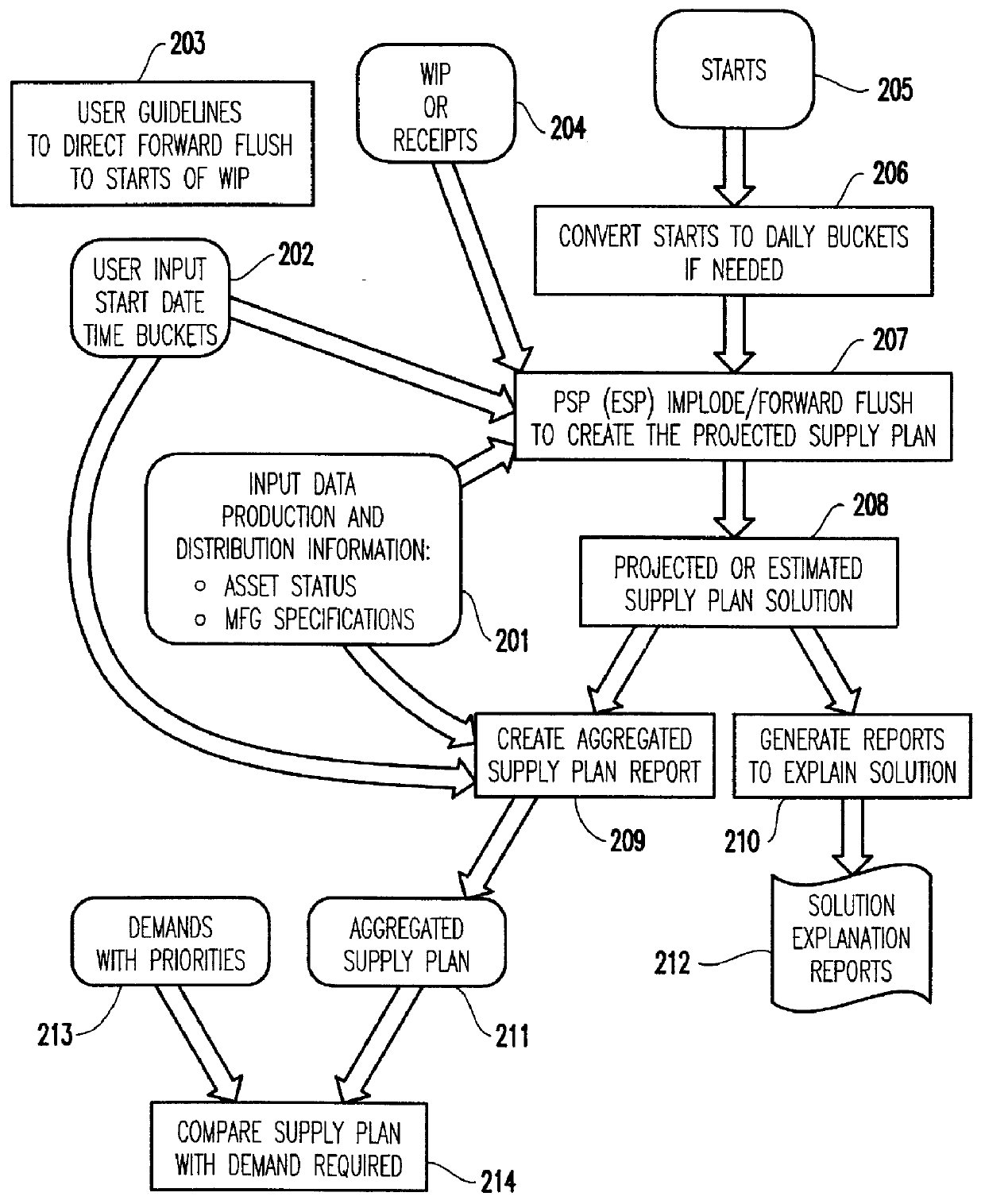

Projected supply planning matching assets with demand in microelectronics manufacturing

A computer-implemented decision-support tool serves as a solver to generate a projected supply planning (PSP) or estimated supply planning (ESP) match between existing assets and demands across multiple manufacturing facilities within the boundaries established by the manufacturing specifications and process flows and business policies to determine what supply can be provided over what time-frame by manufacturing and establishes a set of actions or guidelines for manufacturing to incorporate into their manufacturing execution system to ensure that the delivery commitments are met in a timely fashion. The PSP or ESP tool resides within a data provider tool that pulls the required production and distribution information. PSP matching is driven directly by user-supplied guidelines on how to flow or flush assets "forward" to some inventory or holding point. After the supply plan is created, the analyst compares this plan against an expected demand profile.

Owner:INDUCTIVE AUTOMATION LLC

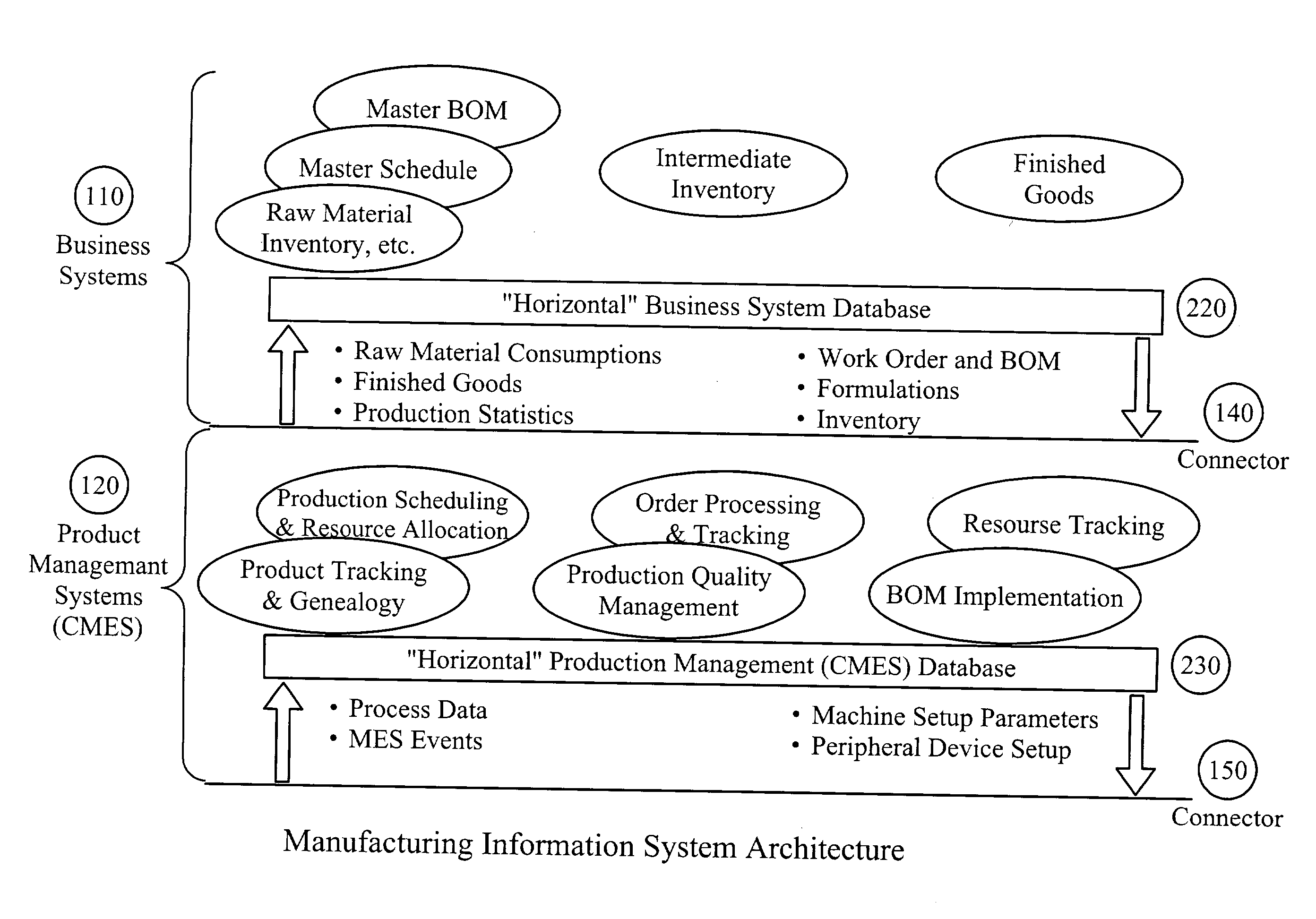

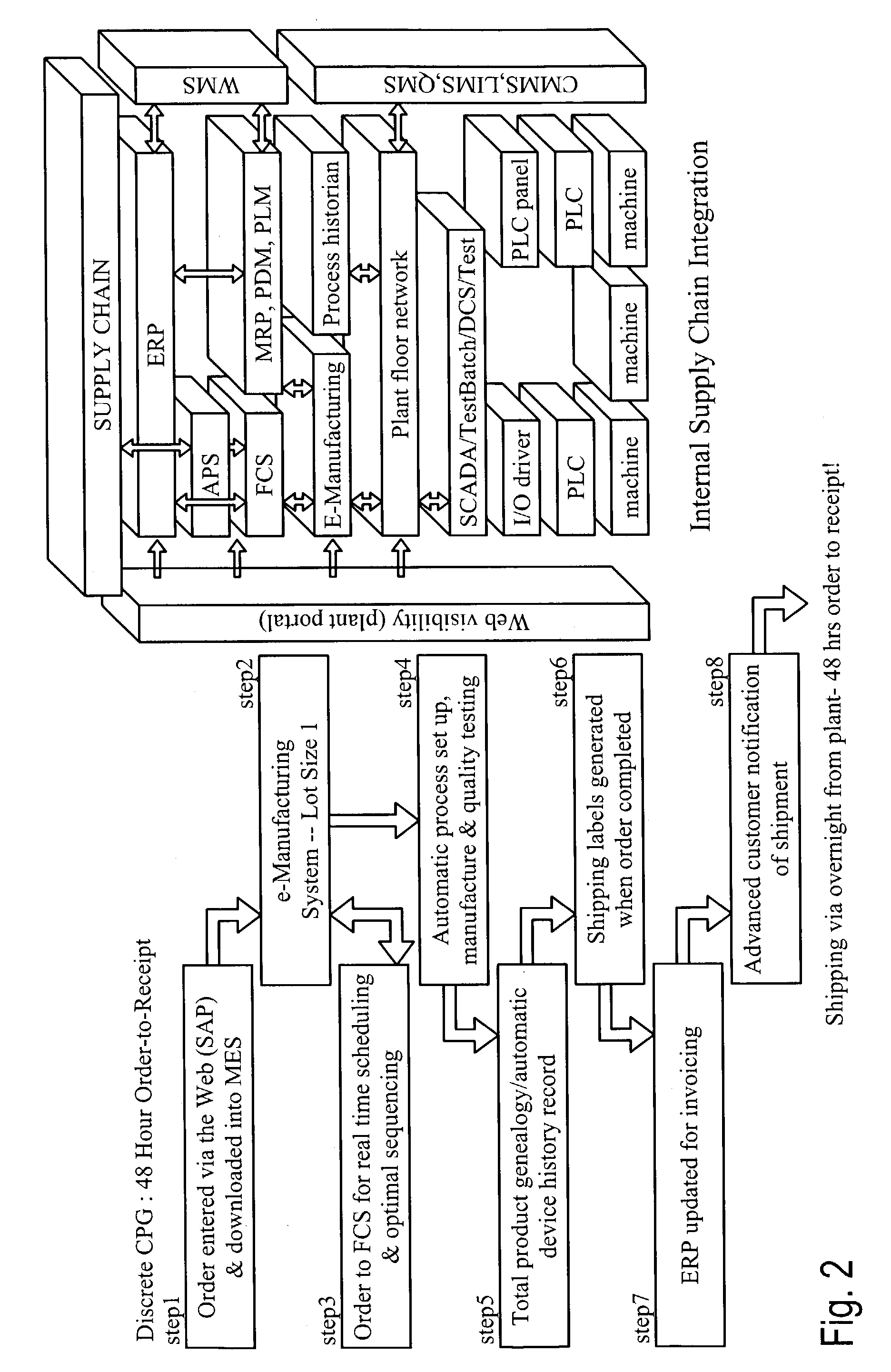

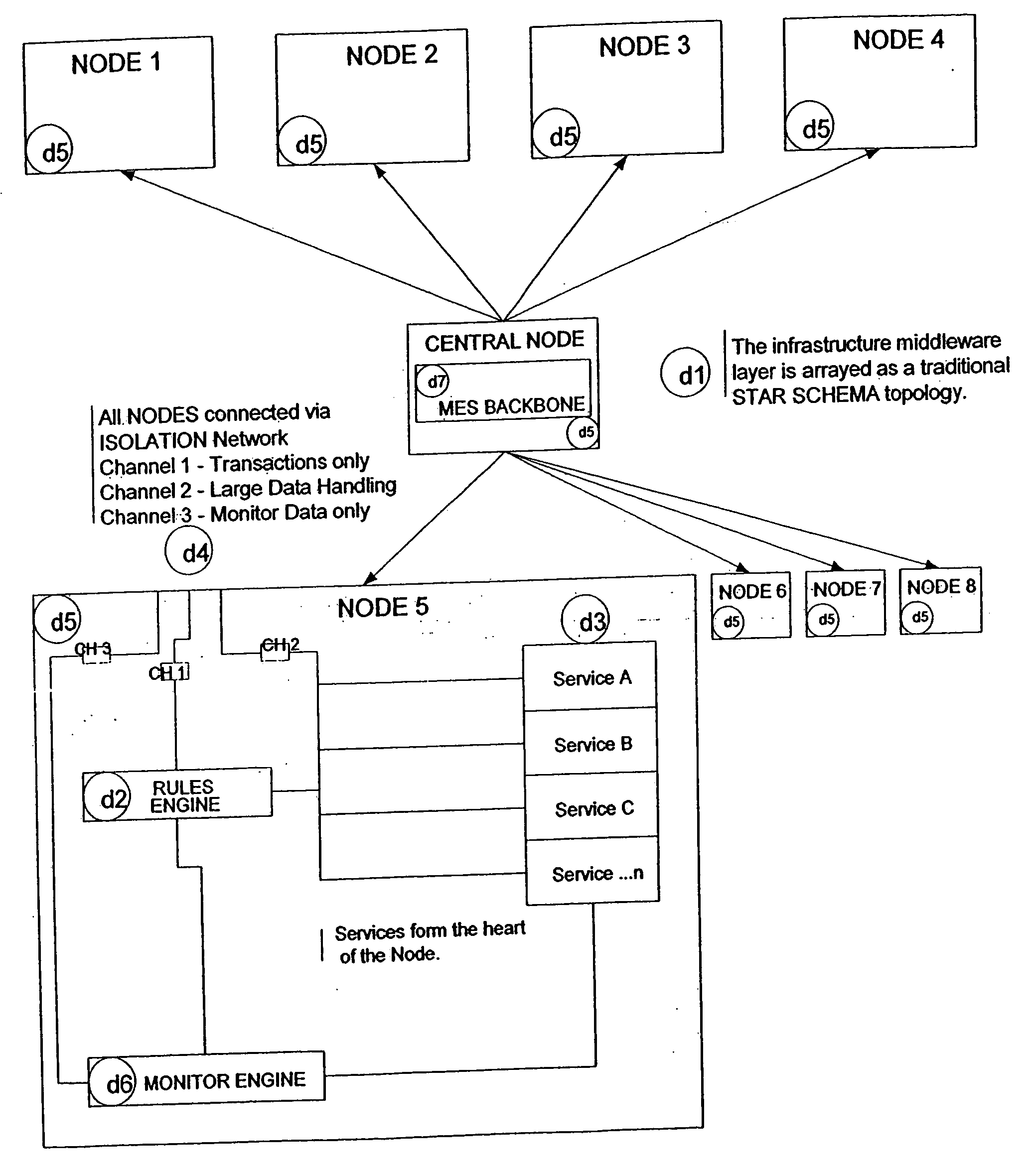

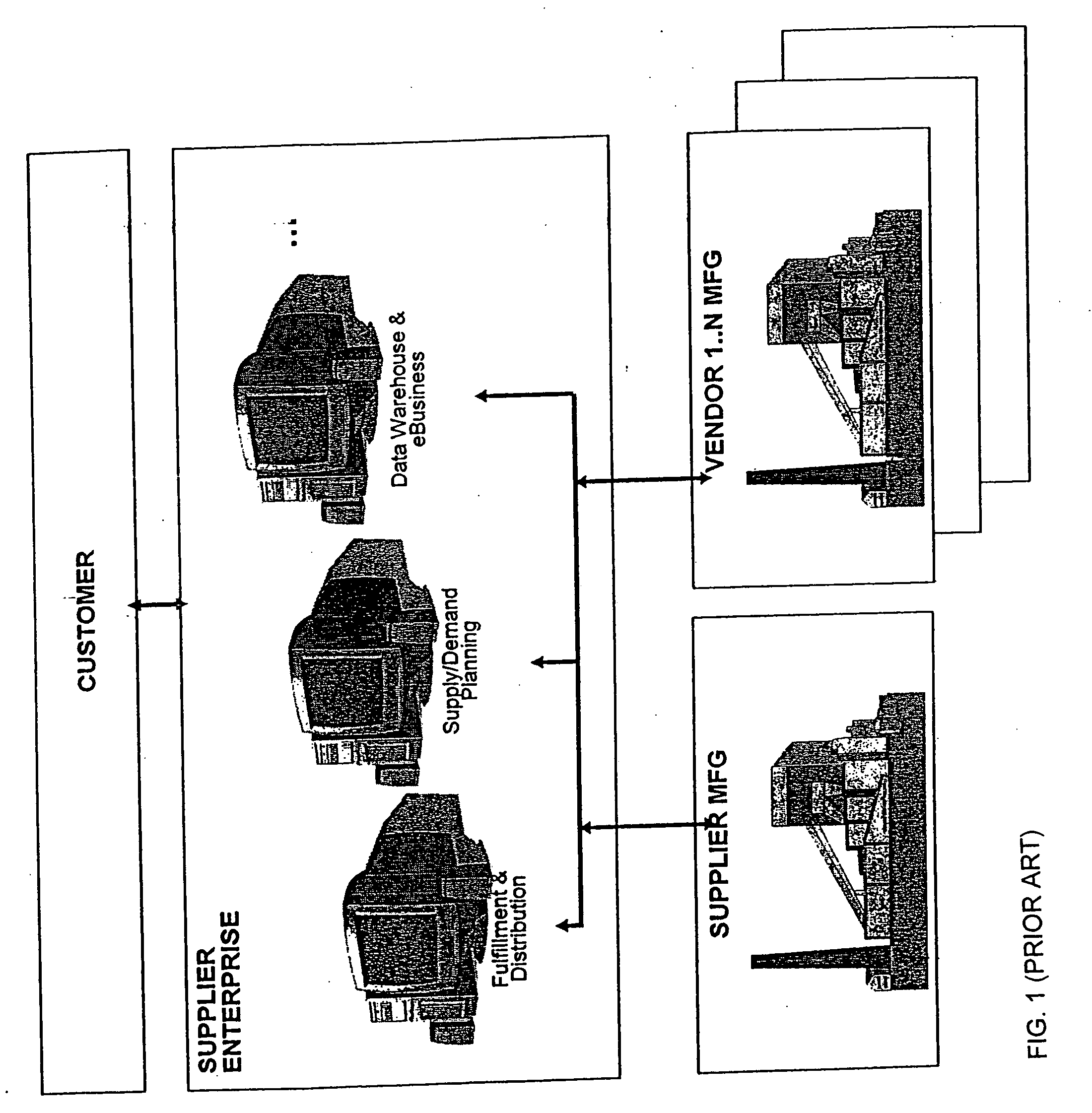

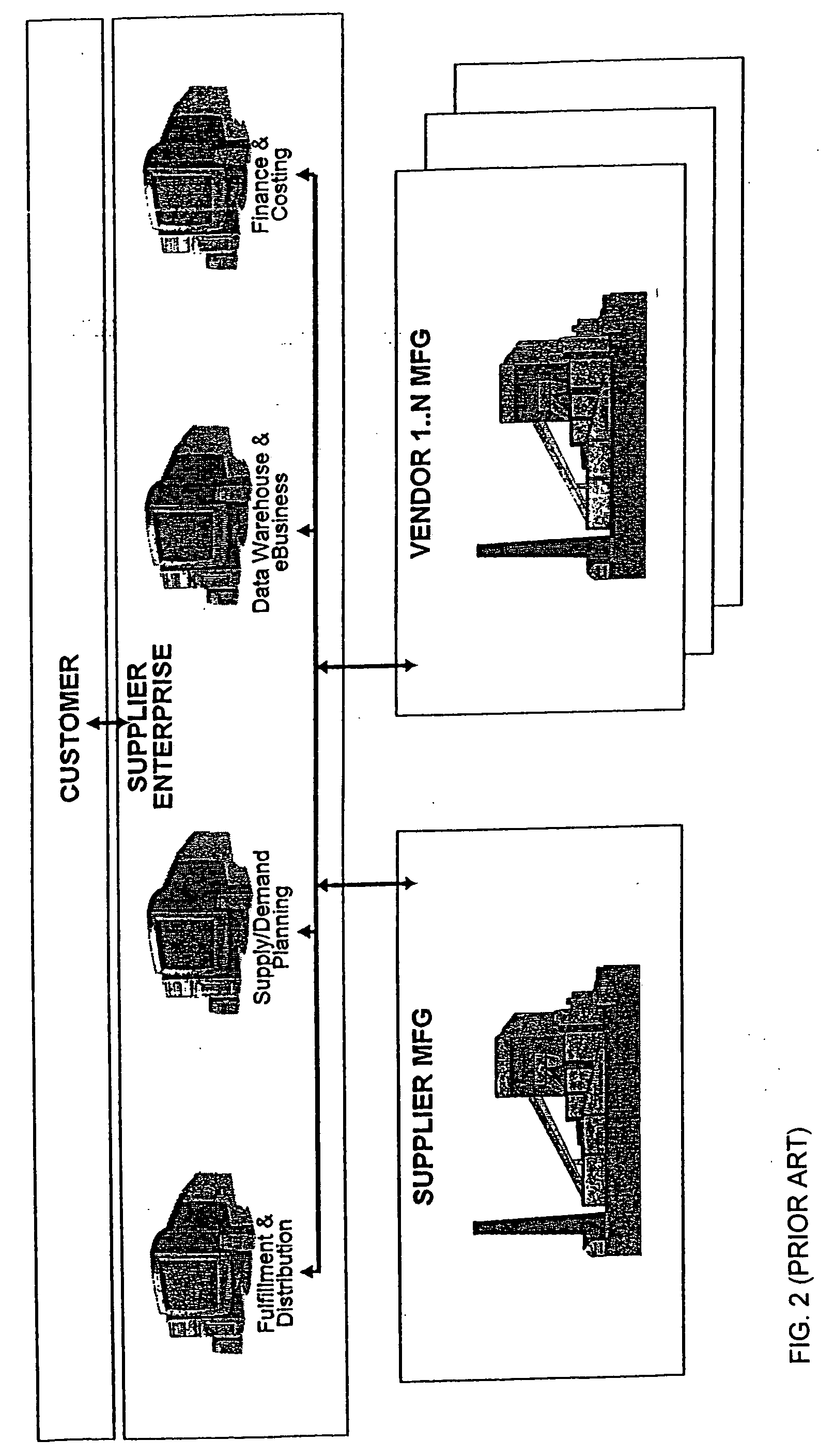

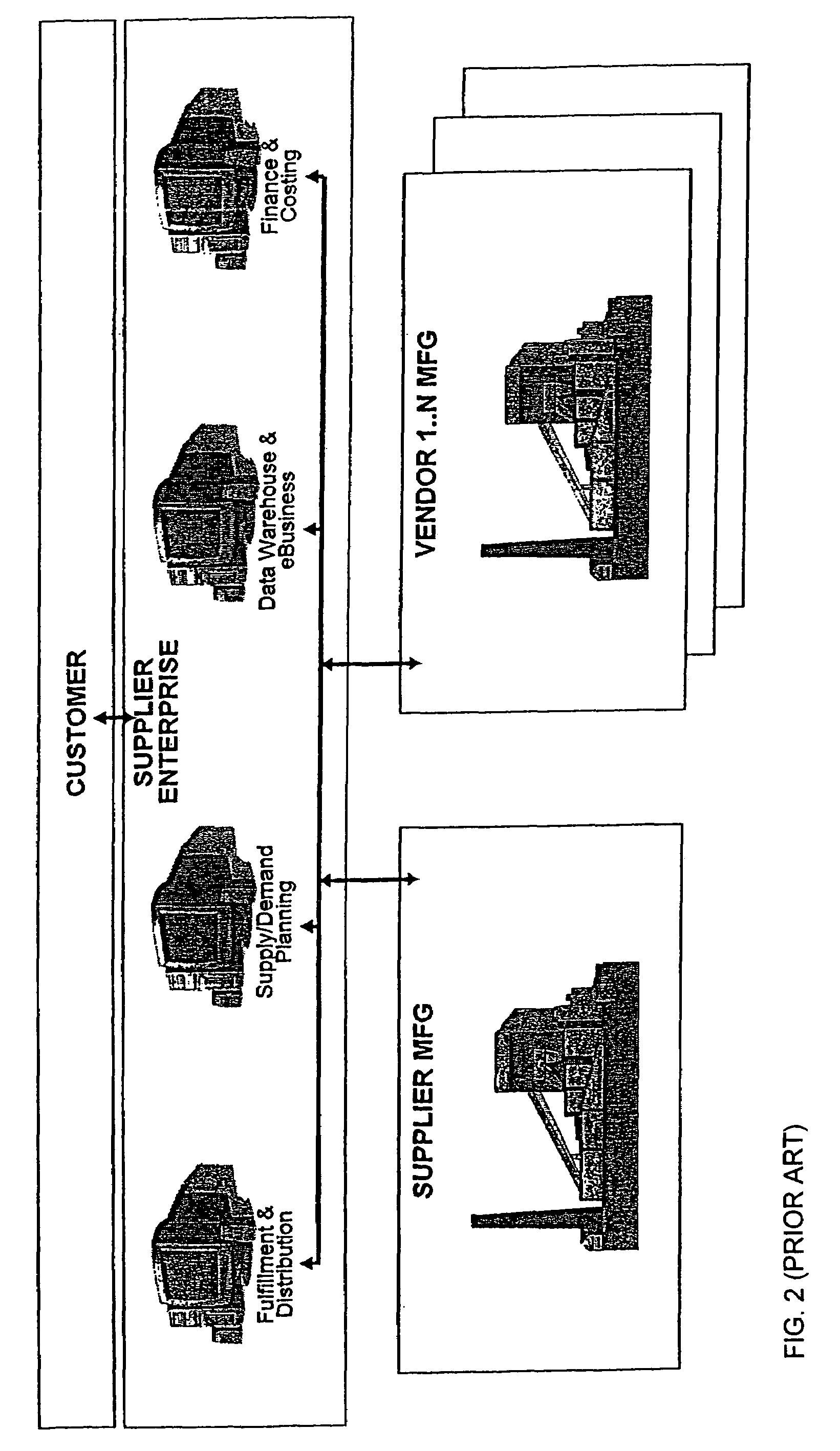

Suite of configurable supply chain infrastructure modules for deploying collaborative e-manufacturing solutions

ActiveUS20030200130A1ResourcesSpecial data processing applicationsManufacturing execution systemE-commerce

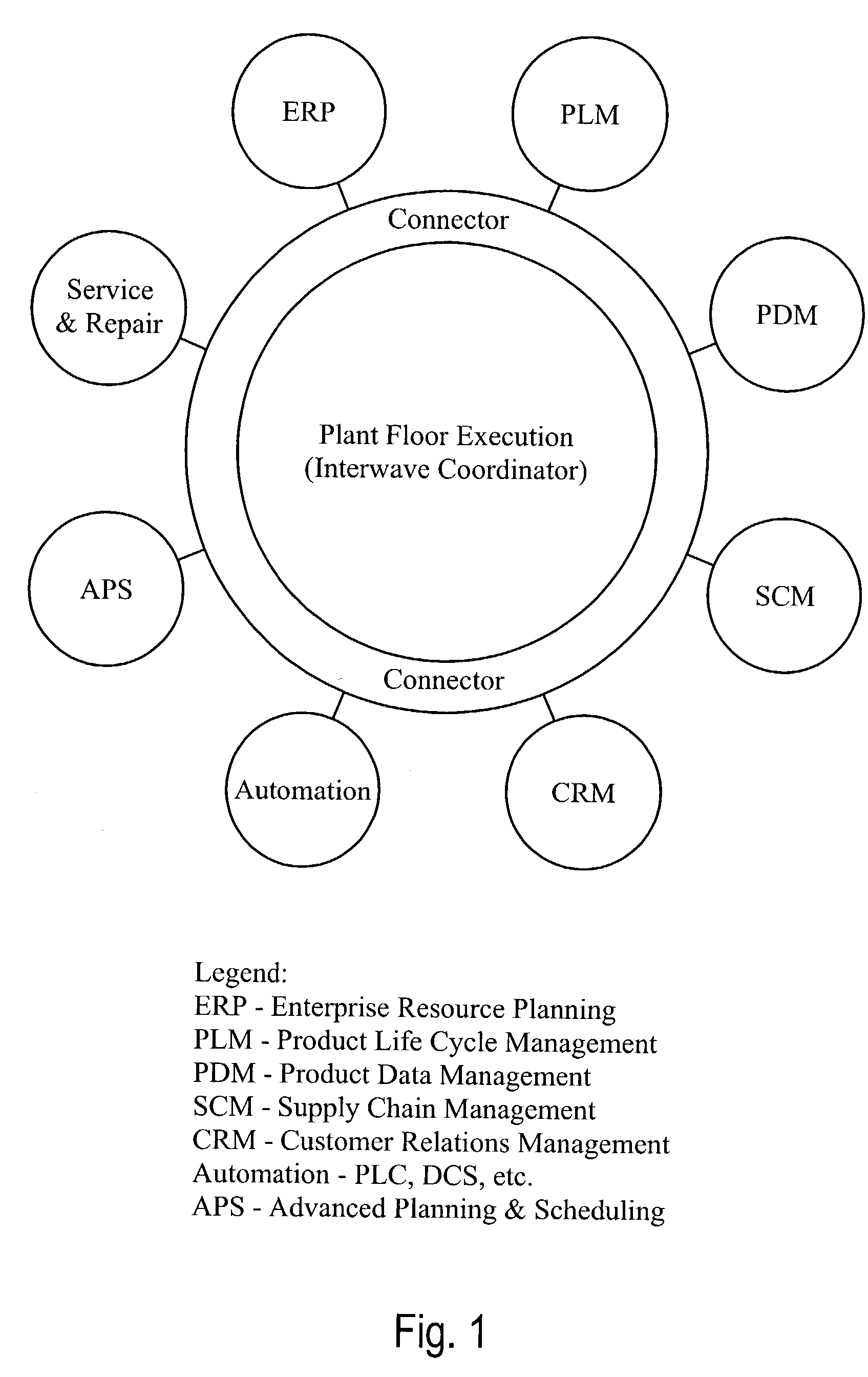

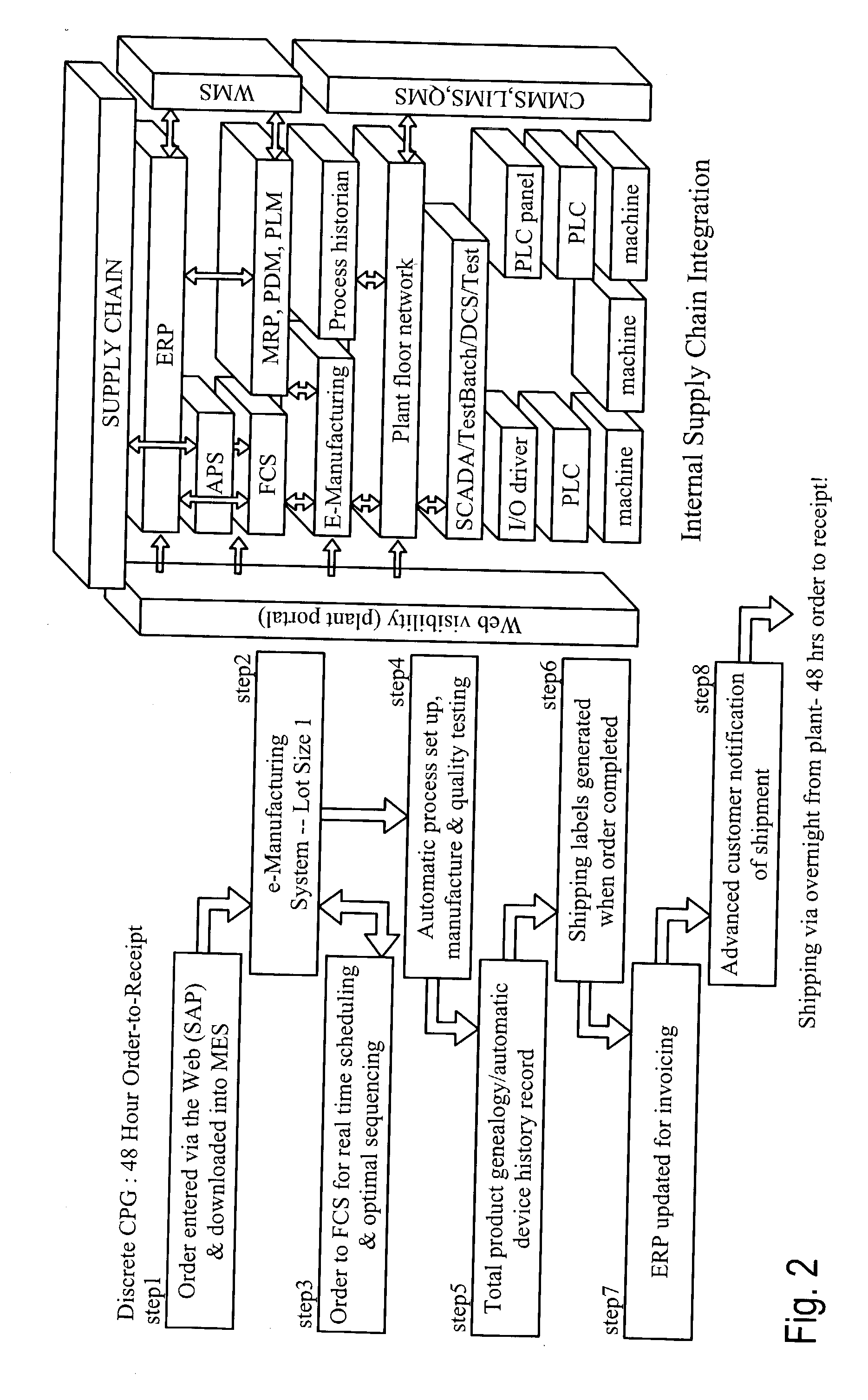

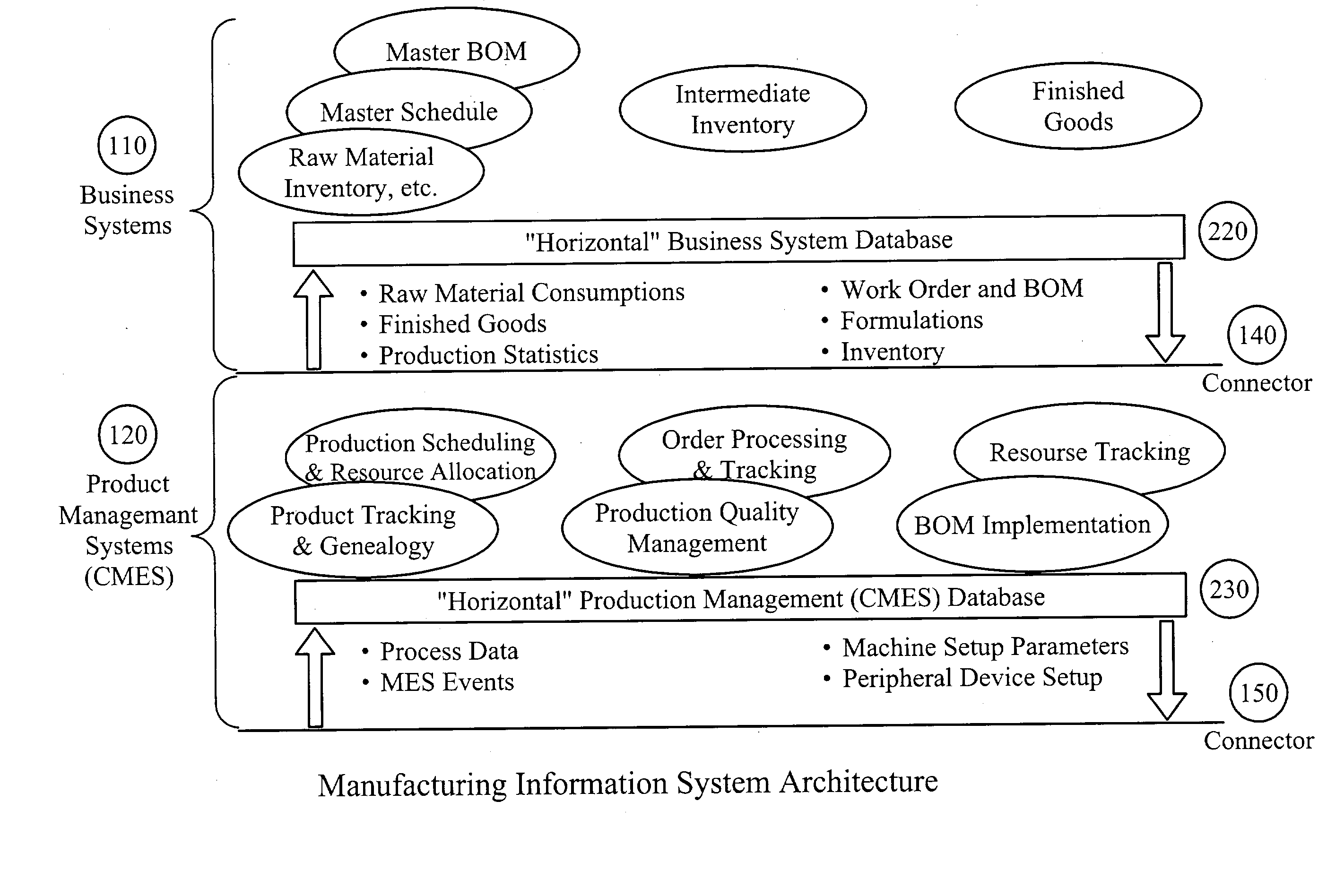

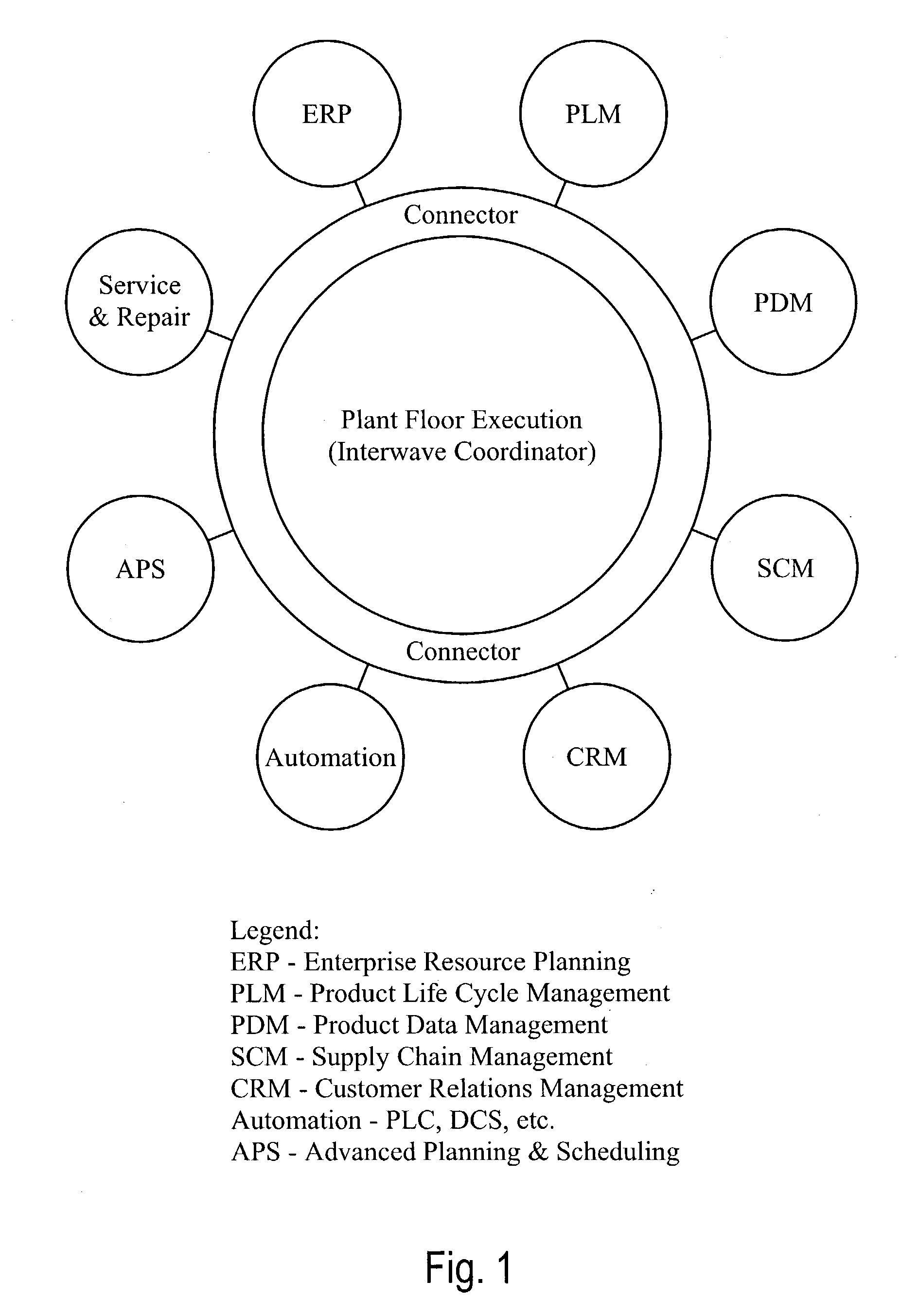

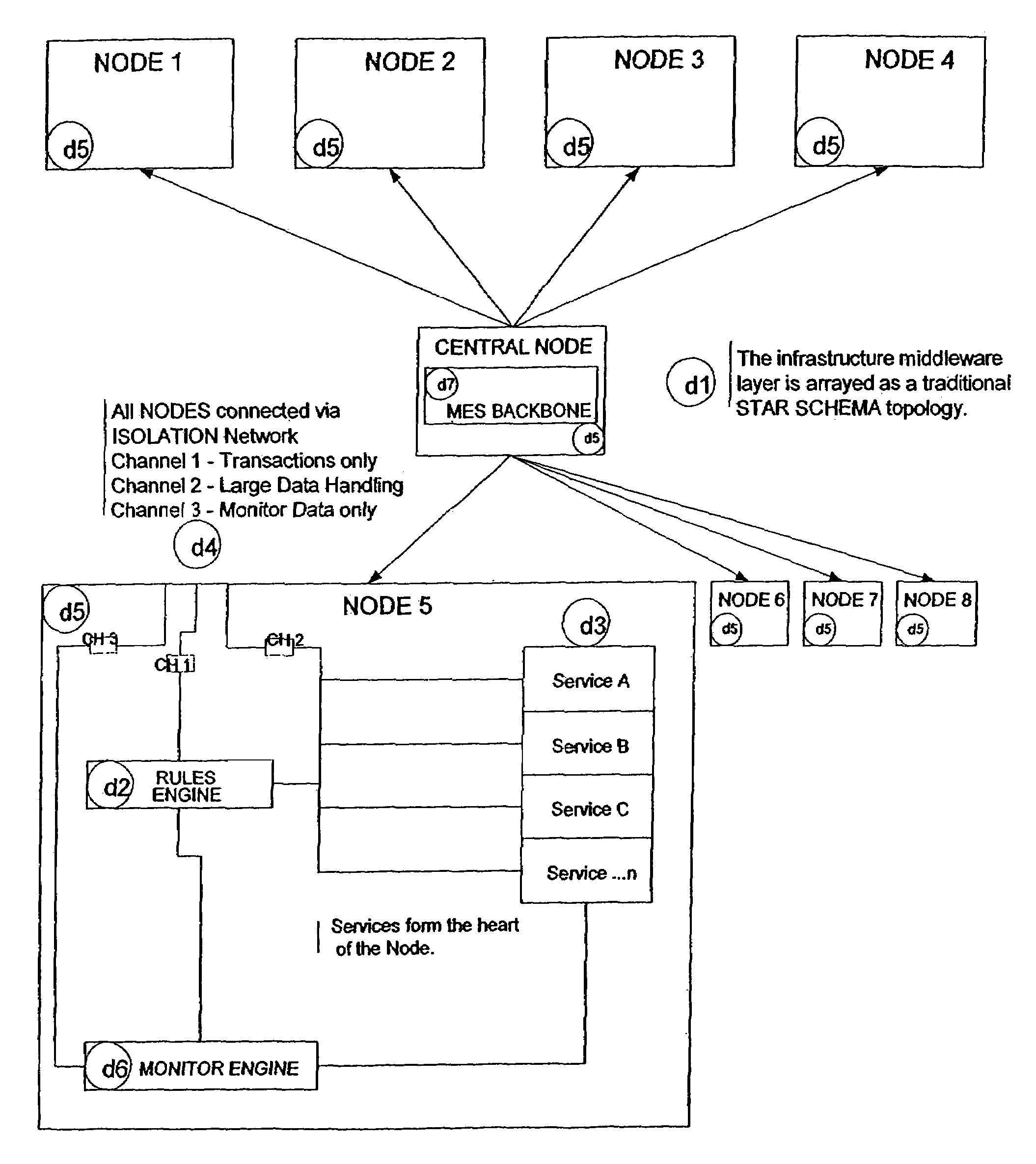

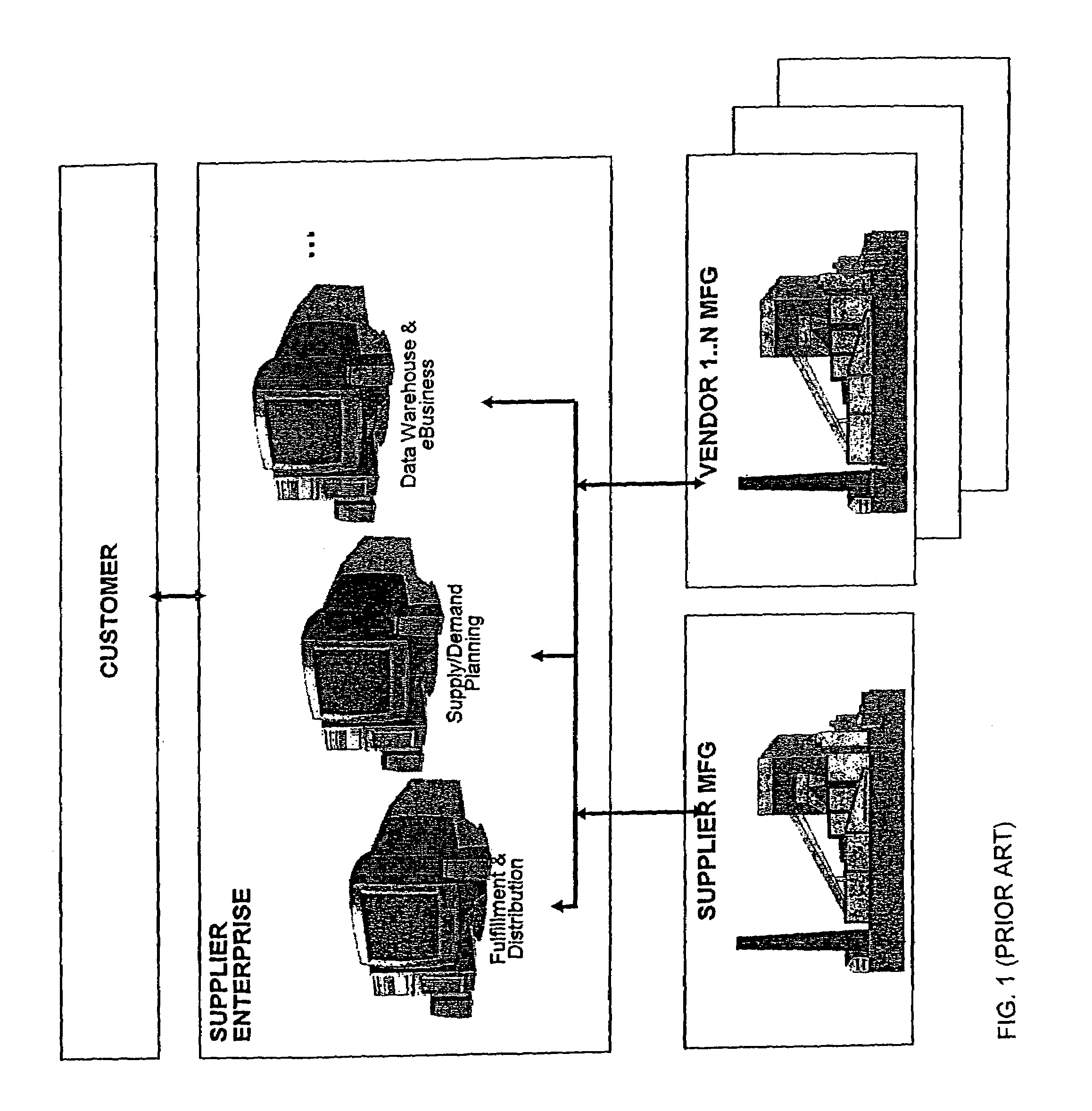

A suite of configurable supply chain infrastructure modules provides the "collective manufacturing management infrastructure" necessary to support a high velocity e-business initiative. At the core of the collaboration scheme is the Business Process Modeling Module. The Business Modeling Module consists of two components: Business Process Event Coordinator, and Business Process Modeler. To further support the collaborative scheme, a suite of highly configurable application templates and pre-configured industry applications provide an interface or wrapper around the business rules. The application templates are designed to be used as stand-alone components, or can be assembled / configured into a cohesive solution to provide a basic foundation layer for a Collaborative Manufacturing Execution System (CMES). To address the connectivity of the CMES layer to the business layer and the shop floor automation layer, an Extensible Markup Language (XML) Business Connector and Optical Photo Conductor (OPC) Shop Floor Connector fulfill the interface needs required to support a collaborative infrastructure.

Owner:ROCKWELL AUTOMATION TECH

Suite of configurable supply chain infrastructure modules for deploying collaborative e-manufacturing solutions

InactiveUS20030149608A1ResourcesSpecial data processing applicationsManufacturing execution systemApplication software

A suite of configurable supply chain infrastructure modules provides the "collective manufacturing management infrastructure" necessary to support a high velocity e-business initiative. At the core of the collaboration scheme is the Business Process Modeling Module. The Business Modeling Module consists of two components: Business Process Event Coordinator, and Business Process Modeler. To further support the collaborative scheme, a suite of highly configurable application templates and pre-configured industry applications provide an interface or wrapper around the business rules. The application templates are designed to be used as stand-alone components, or can be assembled / configured into a cohesive solution to provide a basic foundation layer for a Collaborative Manufacturing Execution System (CMES). To address the connectivity of the CMES layer to the business layer and the shop floor automation layer, an Extensible Markup Language (XML) Business Connector and Optical Photo Conductor (OPC) Shop Floor Connector fulfill the interface needs required to support a collaborative infrastructure.

Owner:ROCKWELL AUTOMATION

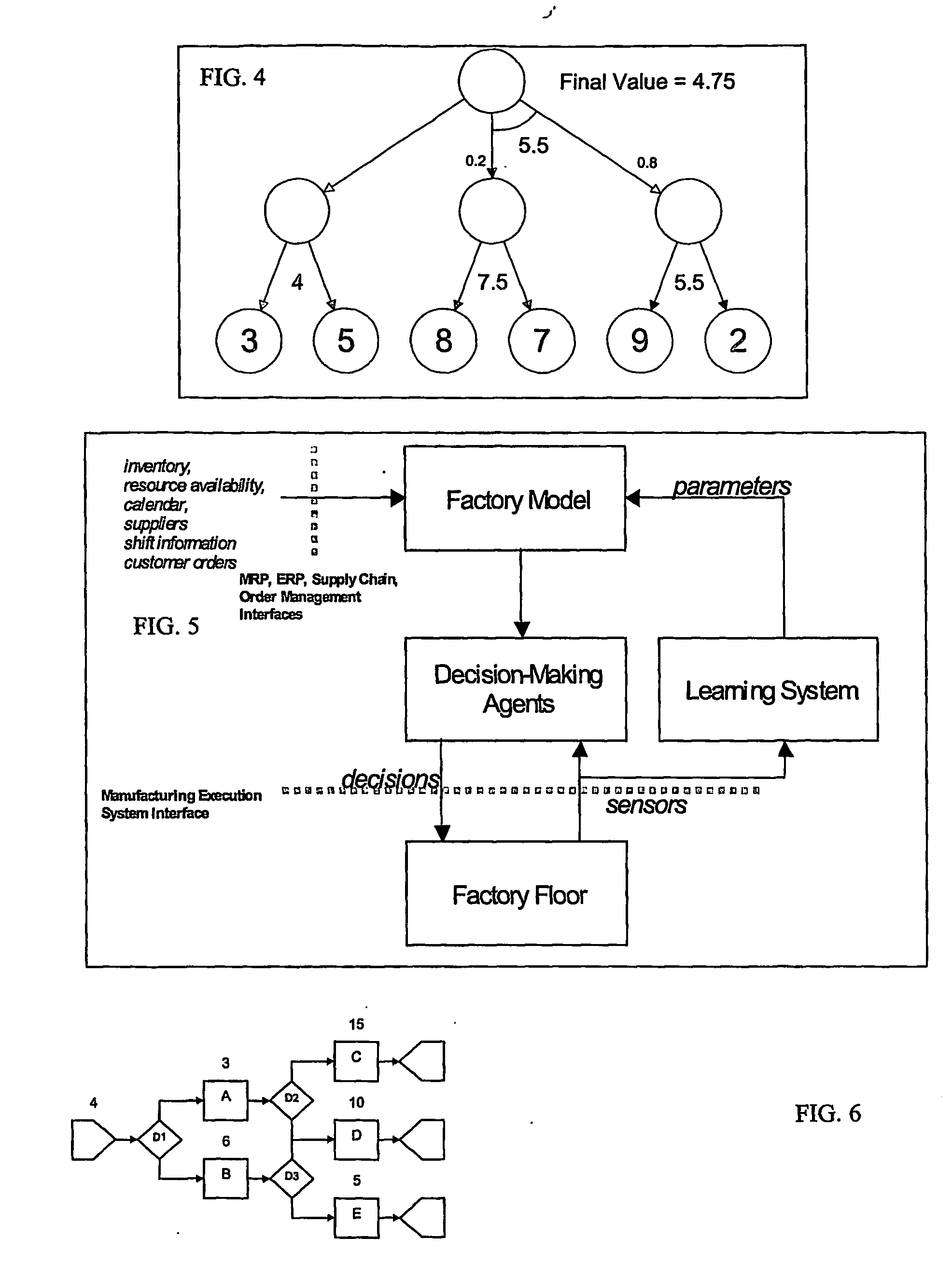

Optimizing active decision making using simulated decision making

InactiveUS20060200333A1Increase speedComputationally efficientError preventionFrequency-division multiplex detailsManufacturing execution systemComputer science

A method and a computer implemented system for improving an active decision making process by using a simulation model of the decision making process. The simulation model is used to evaluate the impact of alternative decisions at a choice point, in order to select one alternative. The method or system may be integrated with an external system, like a manufacturing execution system. The simulation model may be stochastic, may be updated from monitoring the external system or the simulations, or may contain a Bayesian network

Owner:DALAL MUKESH +1

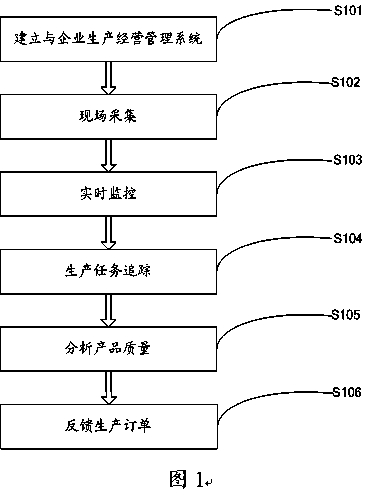

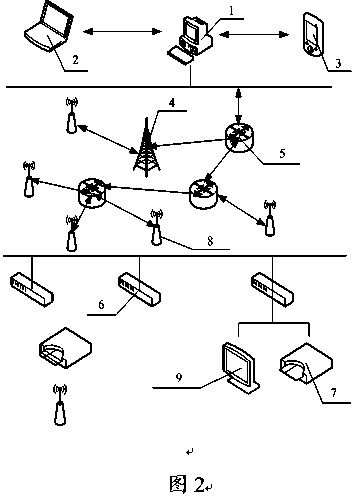

Workshop production management method and system based on Internet of Things

InactiveCN103810576AAchieve integrationAchieve sharingCo-operative working arrangementsResourcesData informationManufacturing execution system

The invention discloses a workshop production management method and system based on Internet of Things. The management method includes the steps of establishment of an enterprise production and operation management system, on-site acquisition, real time monitoring, productive task tracking, product quality analyzing and production order feeding back. The workshop production management system based on Internet of Things comprises a terminal management server, a receiving computer, a mobile phone with bluetooth or wireless fidelity (WiFi), a ZigBee coordinator, a ZigBee router, a station controller, a radio frequency identification (RFID) reader-writer, an electronic tag and a process displayer. According to the workshop production management method and system based on Internet of Things, workshop site is connected with an upper decision system by the aid of the RFID reader-writer and electronic tag manufacturing execution system (MES), integration and sharing of various data information of workshops can be achieved, thereby, the 'fault' phenomenon caused by incomplete sharing and exchange of enterprise data information in enterprises can be avoided, the management process is simplified, and the management efficiency is increased.

Owner:XIAN TECHNOLOGICAL UNIV

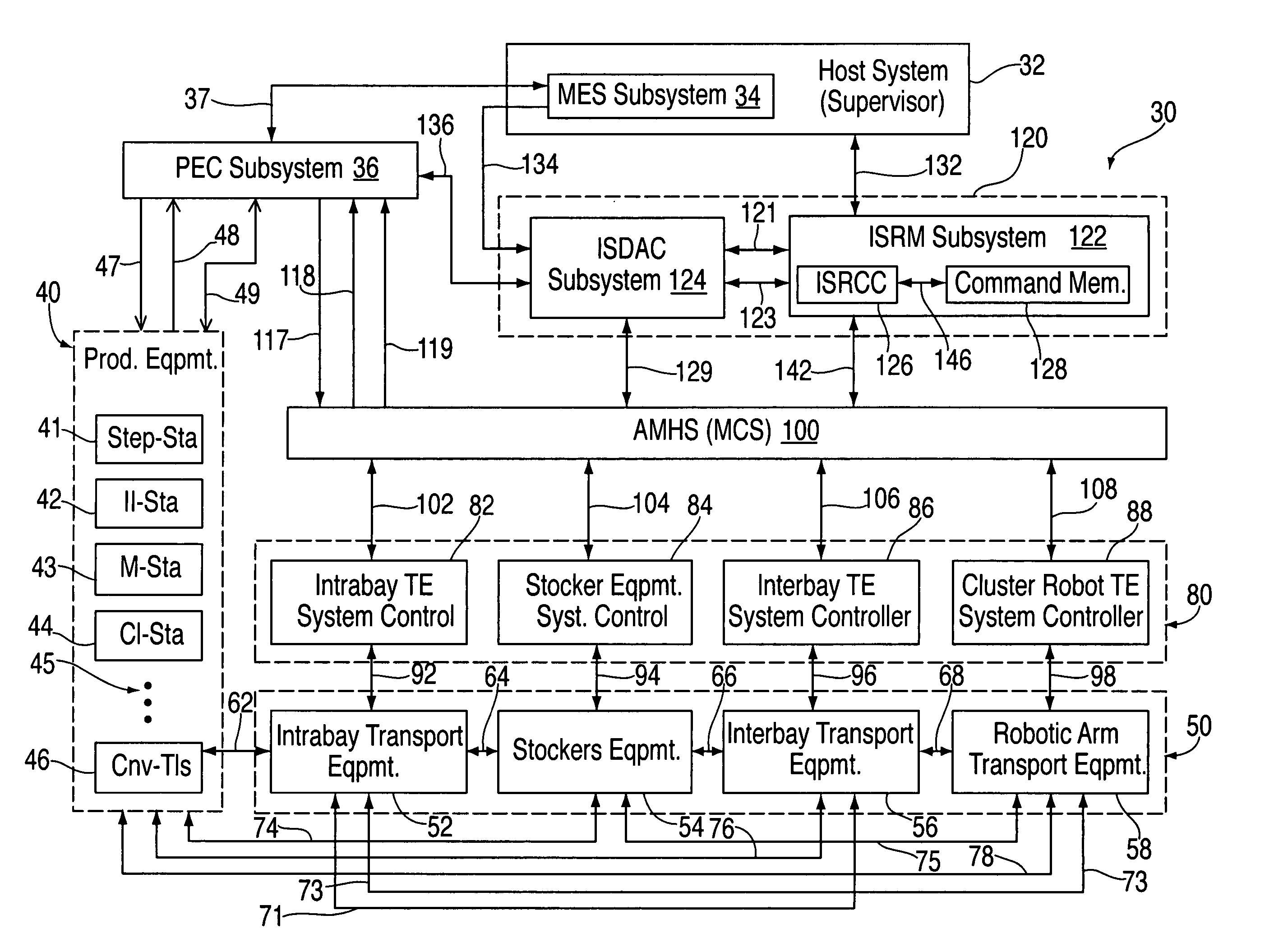

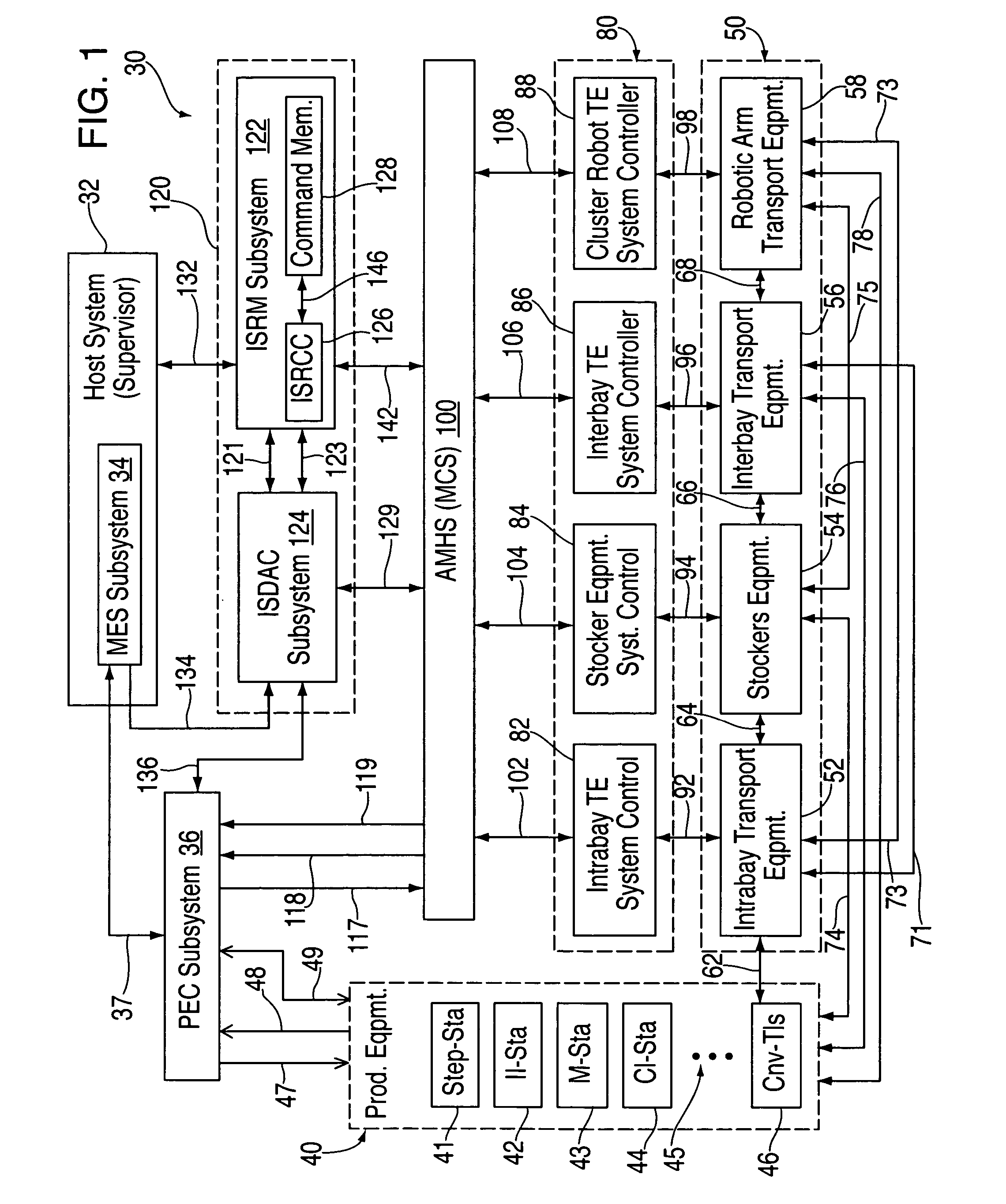

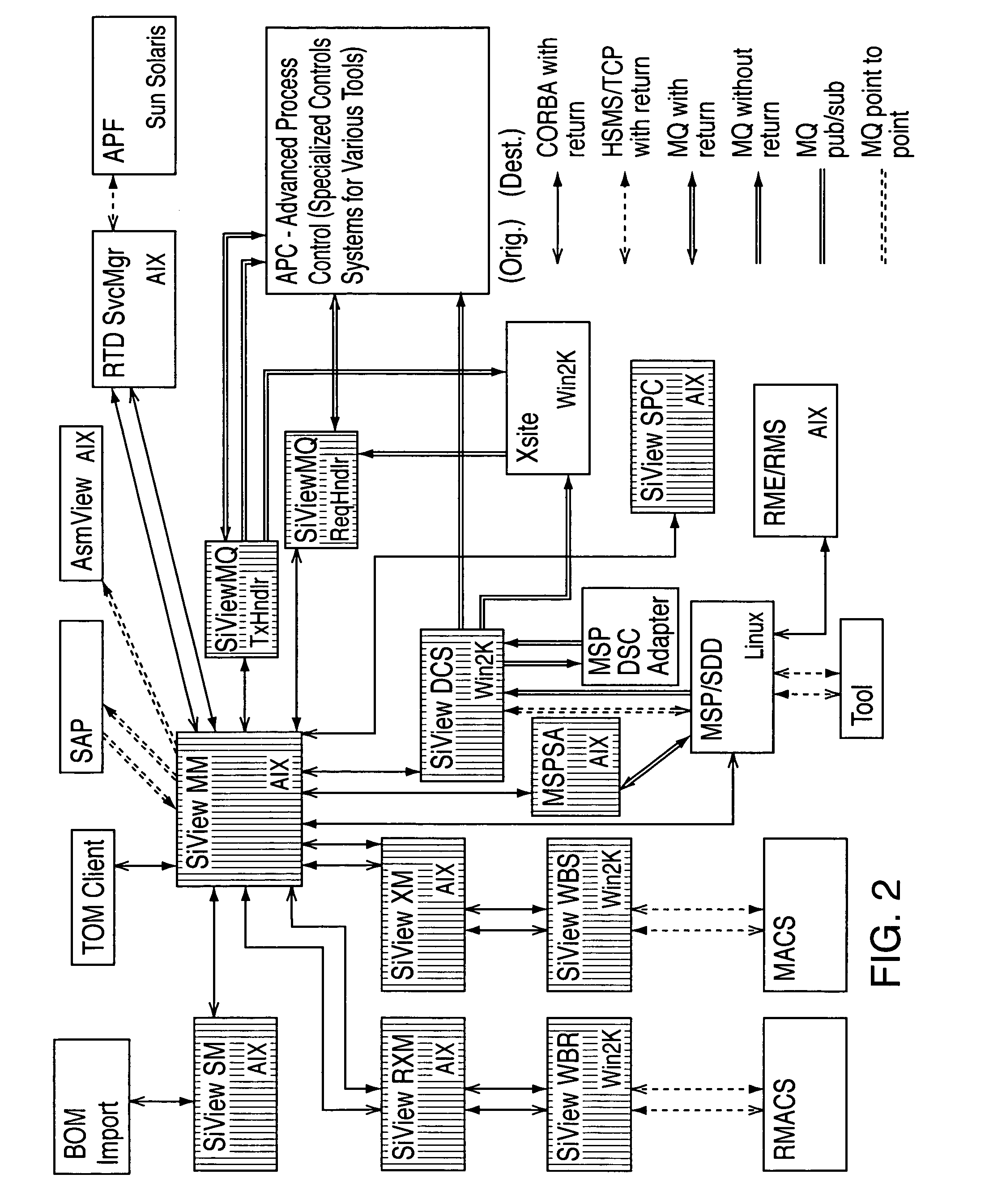

Method and system for automating issue resolution in manufacturing execution and material control systems

InactiveUS20050075748A1Decrease productivityImprove productivitySafety arrangmentsTesting/monitoring control systemsProduction rateImage resolution

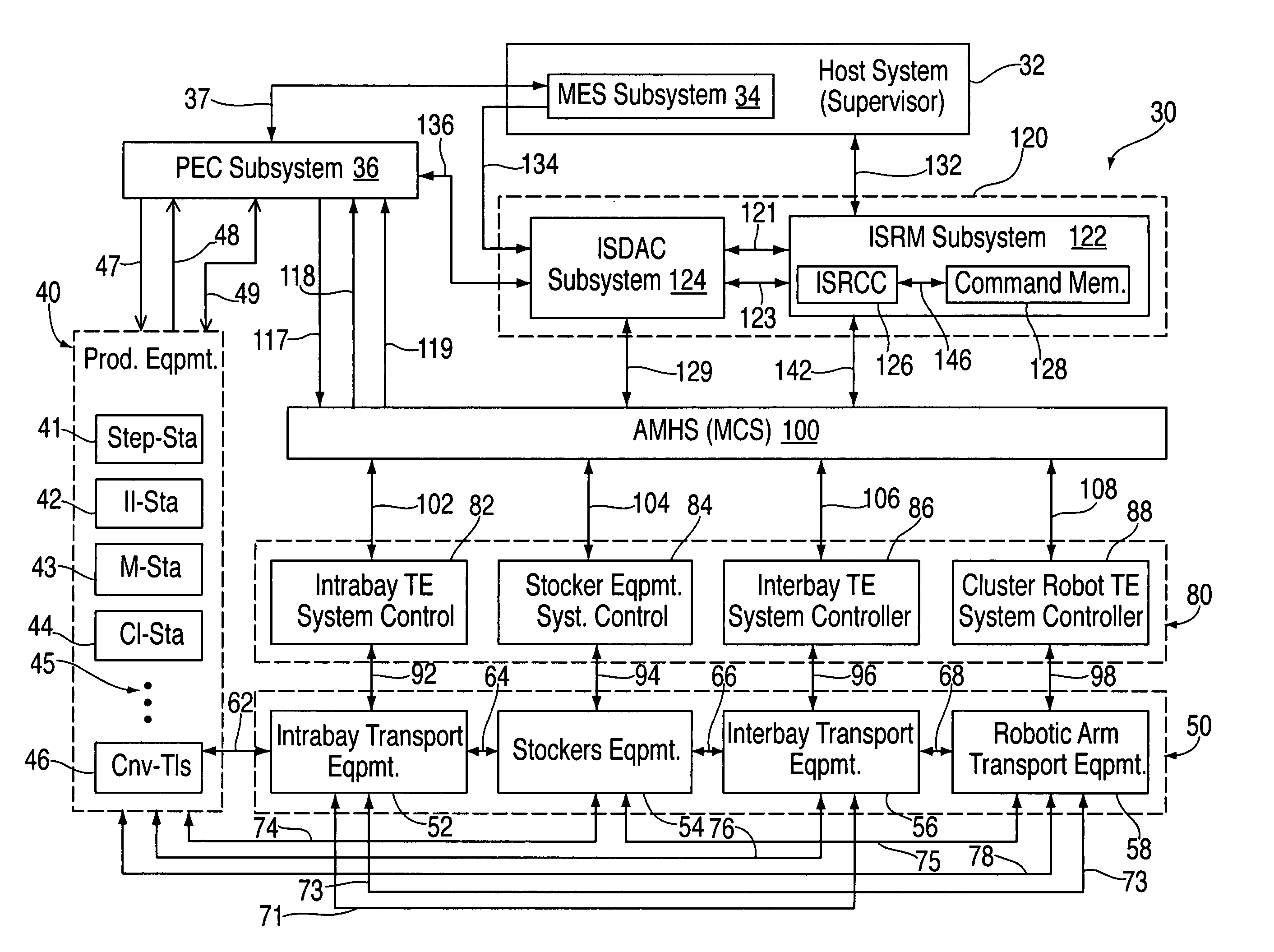

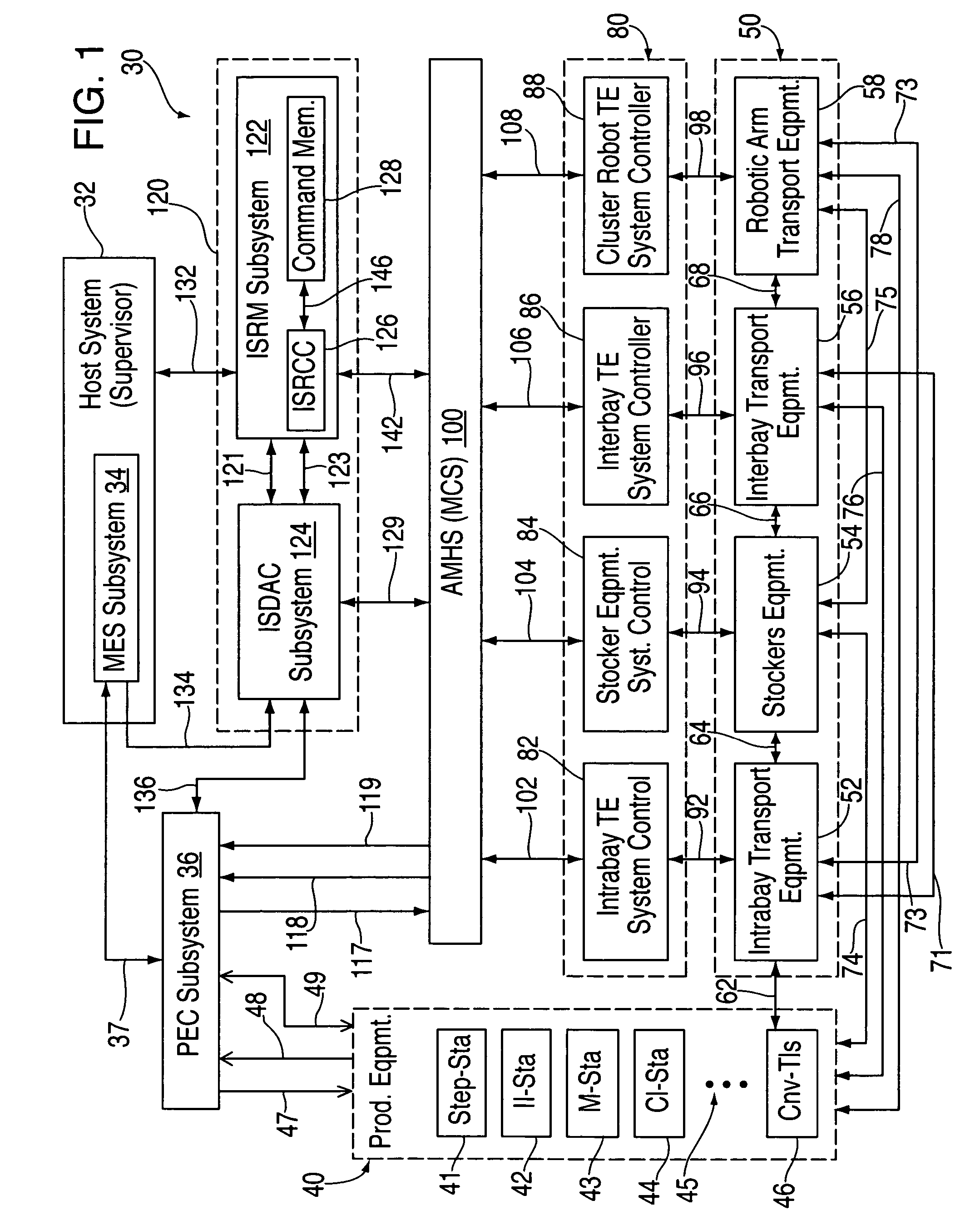

Automatic error recovery systems and methods for automated manufacturing plants and factories are disclosed. Such facilities normally have multiple automated control systems, including an automated material handling system (AMHS), all of which run automatically, typically under the control of a computerized manufacturing execution system (MES). The disclosed issue resolution (ISR) systems and methods involve providing components, which may be supervised and operated by an issue resolution management (ISRM) system, if desired, that interfaces with the MES, AMHS, and / or production control system(s) which operate the tools and other stations within the automated factory. The components, which may be considered customized logic cells, may each be written for handling a specific kind of incoming error condition, problem or other issue that might occur and which is amenable to automatic resolution or recovery. These errors often occur between or across the boundaries of the various interactive systems and automated equipment. Each cell may cycle through a sequence of possible error resolution or recovery steps until the specific issue is resolved or until the sequence of steps is exhausted. Other components of the ISR system may provide results-oriented messages and / or facilitate the collection of data as to whether and which corrective commands from the ISR system resolved the reported error conditions automatically. The disclosed ISR systems and methods for resolving errors and other issues automatically helps improve the overall productivity of automated factories by reducing downtime and the need for human intervention to correct problems, thereby increasing factory throughput.

Owner:IBM CORP

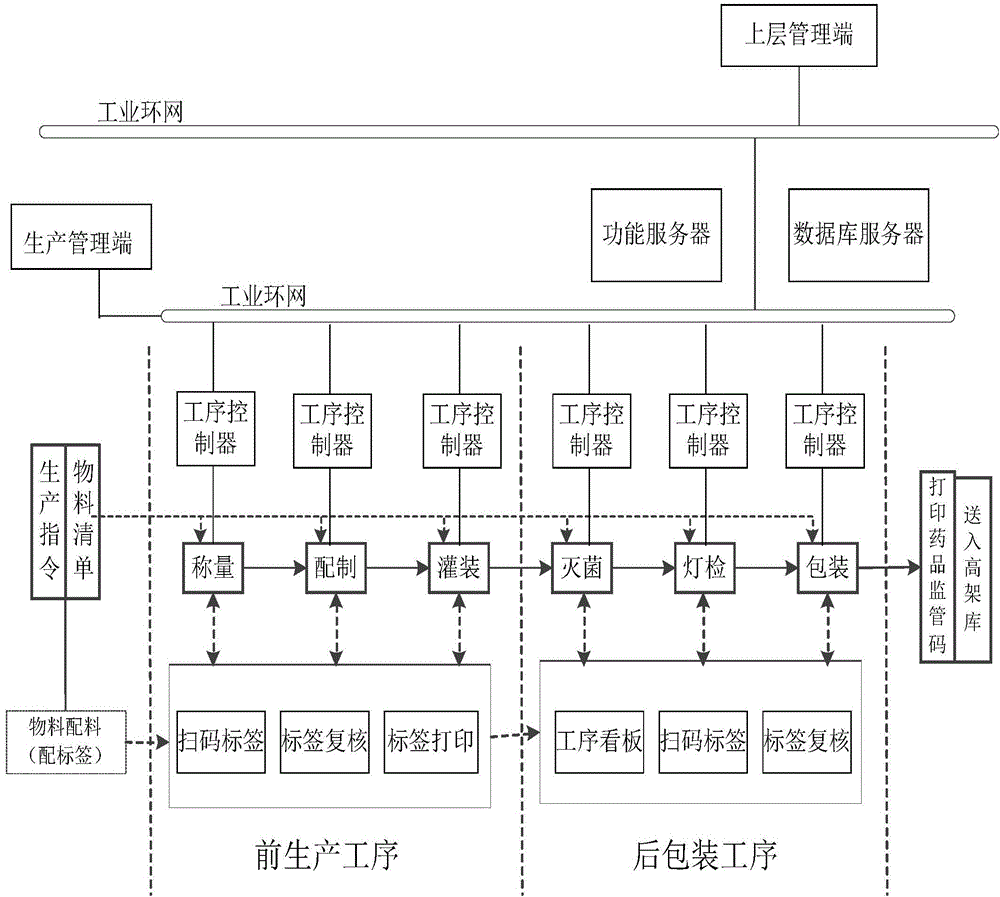

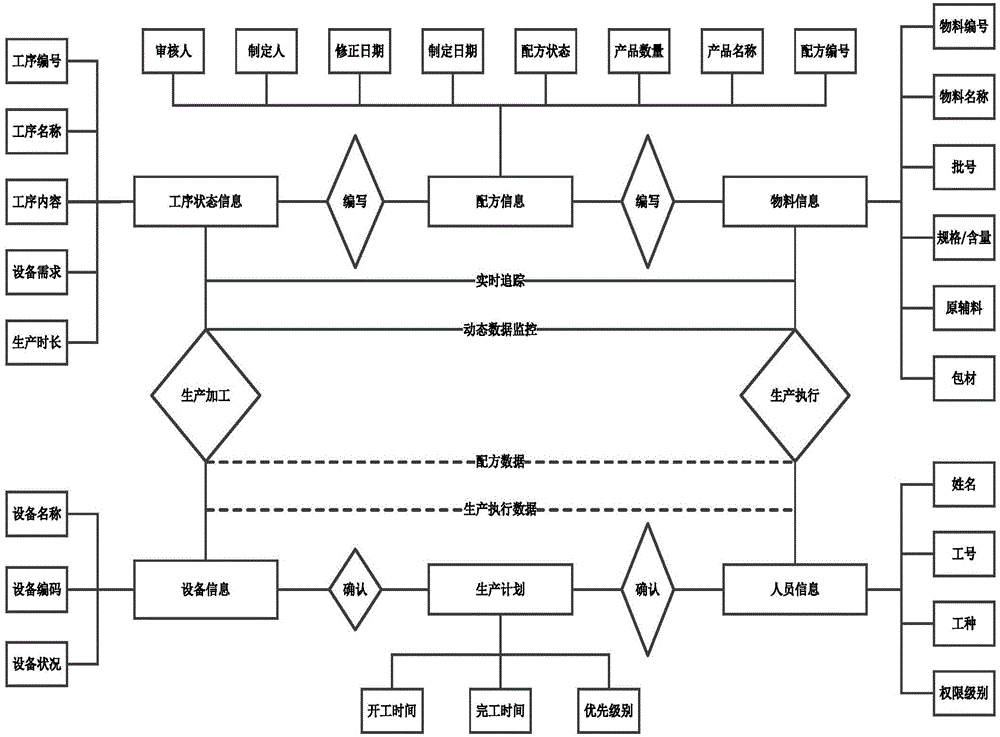

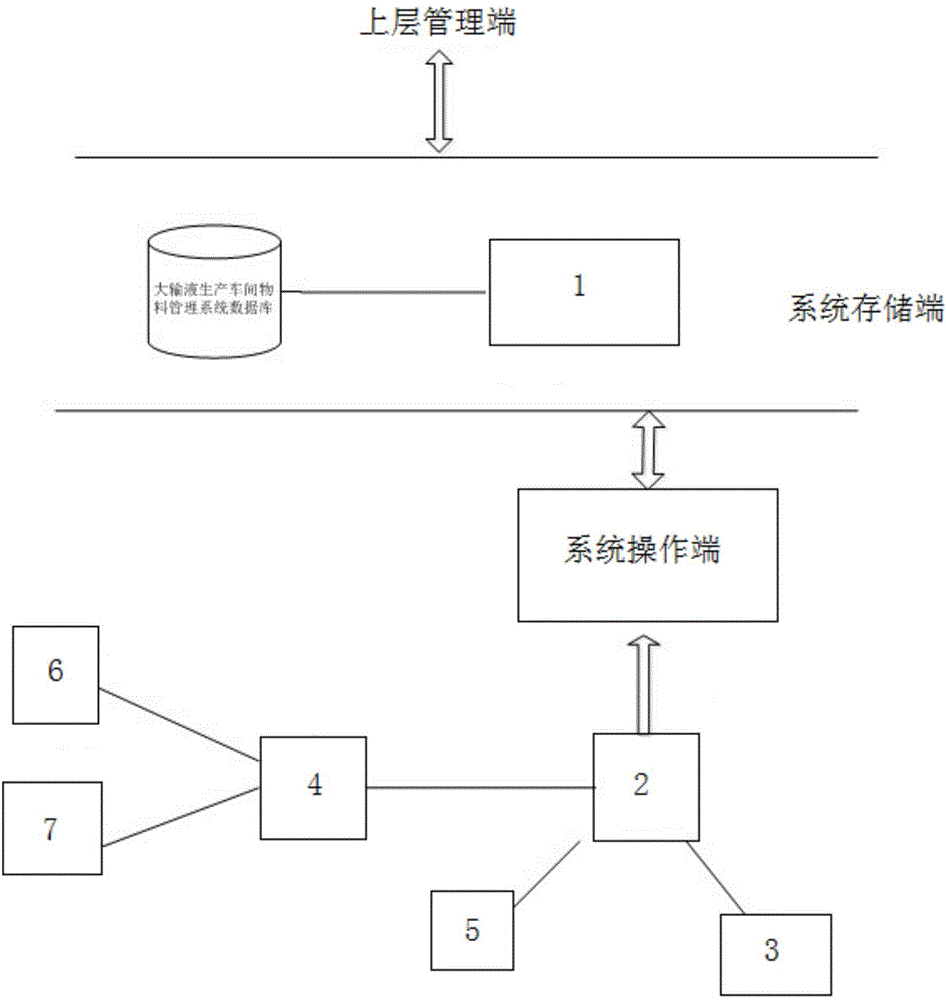

Pharmaceutical product manufacturing execution system and method

InactiveCN104808639AImprove development efficiencyImprove maintainabilityTotal factory controlProgramme total factory controlDatabase serverManufacturing execution system

The invention discloses a pharmaceutical product manufacturing execution system and method. The method includes connecting a manufacturing execution system function server and a manufacturing execution system database server to an upper-level management terminal through an industrial loop network; allowing the manufacturing execution system function server to perform data exchange with a production management terminal through the industrial loop network; allowing the production management terminal to connect to a bottom procedure controller through the industrial loop network; allowing the production management terminal to receive a production planning instruction from the upper-level management terminal, divide the production planning instruction into a production instruction and a material list and transmit the production instruction to the bottom procedure controller, and allowing the bottom procedure controller to control corresponded production procedures and acquire staff producing operation information and corresponded equipment information. The method has the advantages that the corresponded material is encoded correspondingly and respectively, the workshop producing material data management and tracking are implemented, the statistical graph and report support is provided, and the material management is simplified.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Enterprise factory control method and system

InactiveUS20060106473A1Easy to controlDigital computer detailsResourcesMonitoring and controlManufacturing execution system

A system, method, service and media for managing both supplier-owned and non-owned manufacturing asset types utilizing a supplier model of a product which goes across the manufacturing asset types. The invention maps the model to instances of the asset types and uses a network to control and monitor the assets. The monitoring and control occur according to the model, rules and services and does not require the vendors of non-owned manufacturing asset types to change their manufacturing execution systems.

Owner:SERVICENOW INC

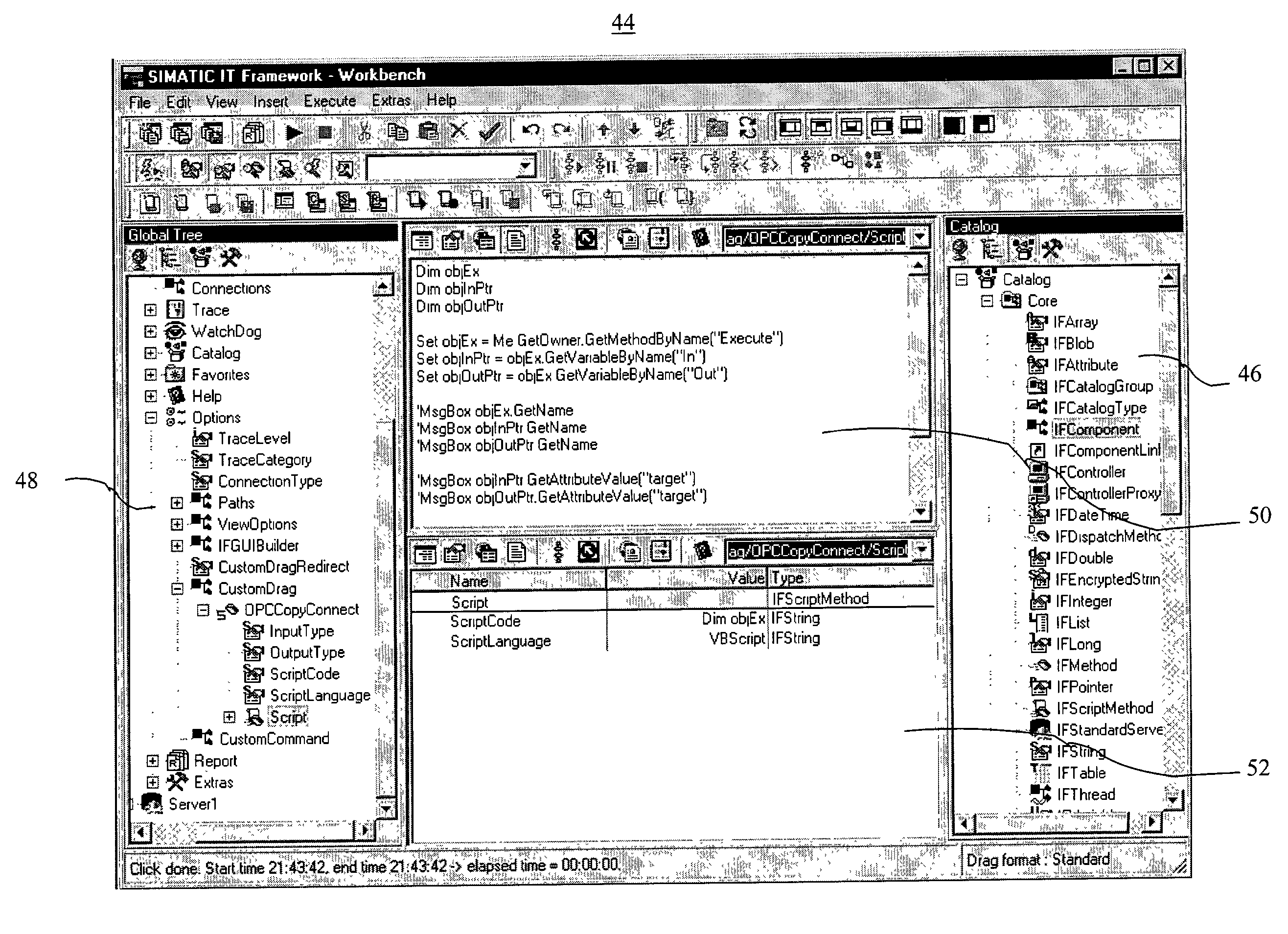

Customizable drag and drop for industrial software applications

ActiveUS7337409B2Extend semanticsCathode-ray tube indicatorsSpecial data processing applicationsDrag and dropSpecific function

Customizable Drag & Drop enables easy activation of user defined or project specific functions concerning two related objects: A user interface graphically displays objects of a particular module. An extending function extends the drag and drop operation to allow the user to define a new set of semantics that is applied when a drag and drop operation is executed. In this way communication can be established using Customizable Drag & Drop extended by a user defined function. Also definition and modification of the deployment of an industrial automation system and hyperlinking of objects in manufacturing execution systems is achieved by Customizable Drag & Drop.

Owner:SIEMENS AG

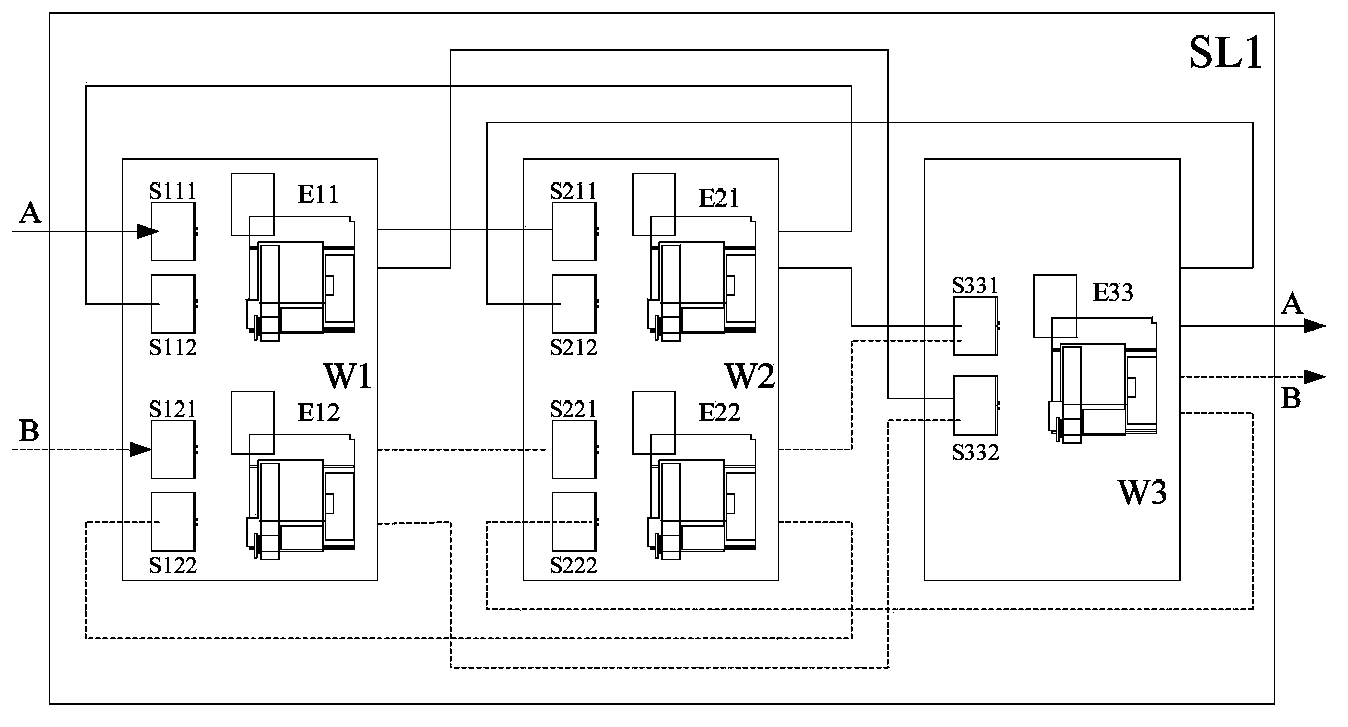

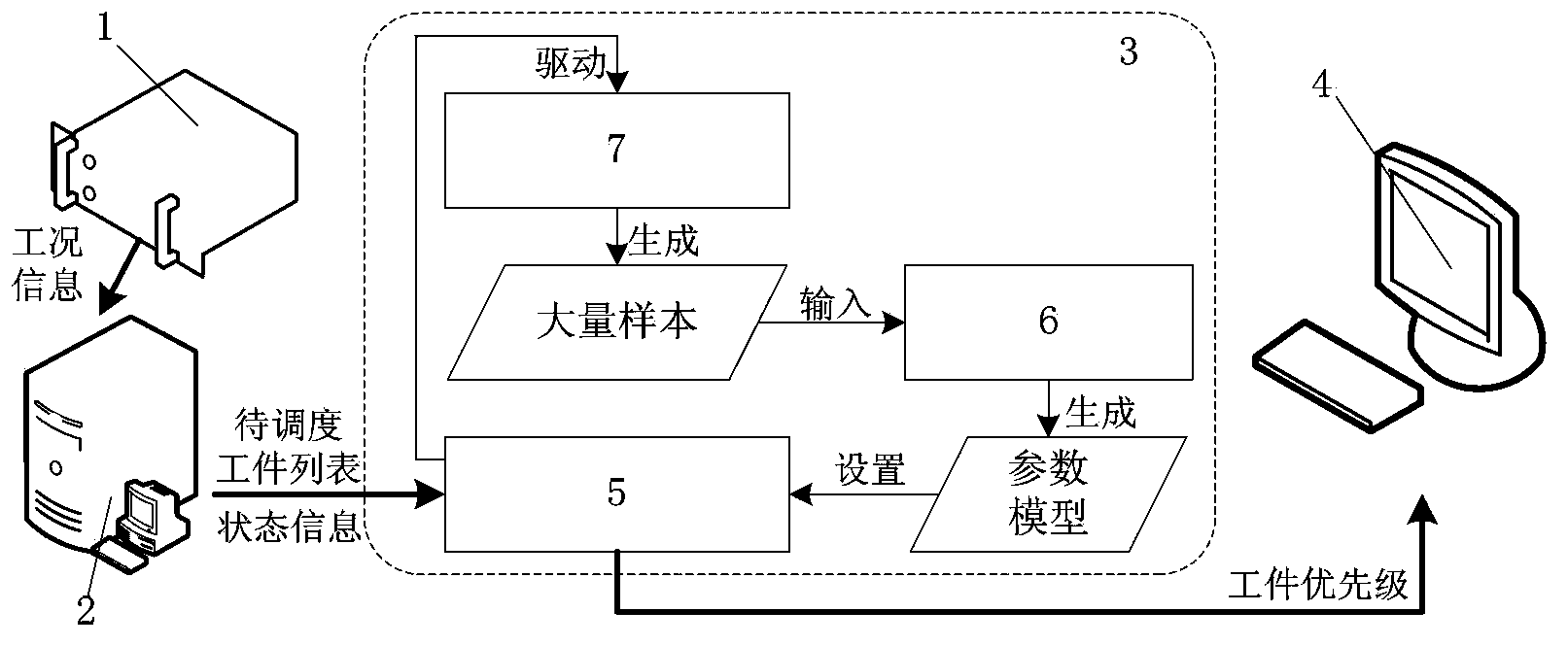

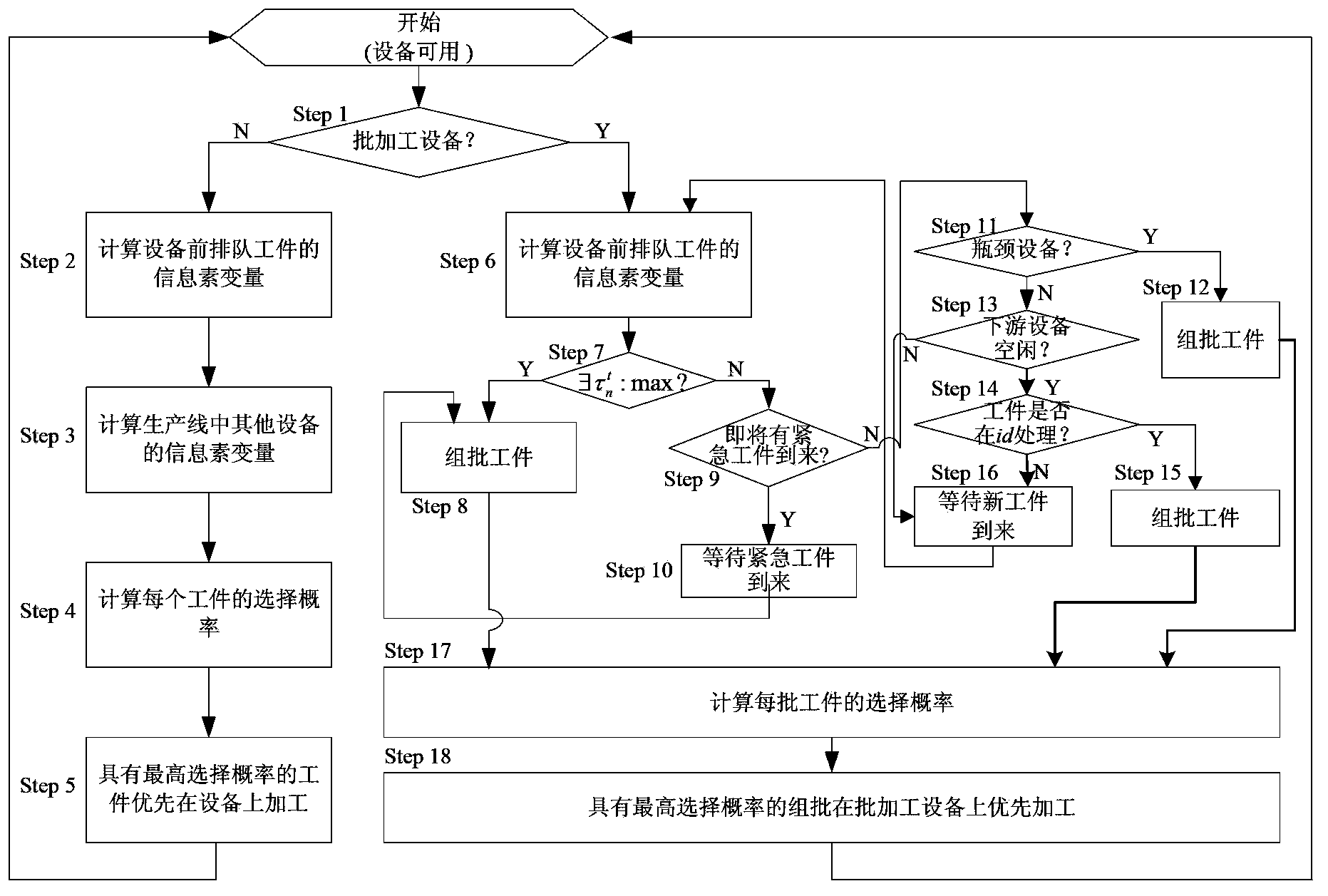

Semiconductor production line self-adaptation dynamic dispatching device

InactiveCN103439886AIncrease profitOn-Time Delivery ImprovementAdaptive controlDisplay deviceManufacturing execution system

The invention relates to a semiconductor production line self-adaptation dynamic dispatching device which is connected with a manufacturing execution system. The dispatching device comprises a dispatching management device, a learning device and a display device. The dispatching management device is connected with the manufacturing execution system, and the dispatching management device, the learning device and the display device are connected in sequence. The dispatching management device acquires a list of current workpieces to be dispatched through the manufacturing execution system and transmits the list of the current workpieces to be dispatched to the learning device, the learning device calculates machining priorities of the current workpieces to be dispatched according to a dispatching rule stored in the learning device and transmits the priorities of the current workpieces to be dispatched to the display device, and the display device displays the priorities of the current workpieces to be dispatched. Compared with the prior art, the semiconductor production line self-adaptation dynamic dispatching device has the advantages of being capable of improving workpiece machining efficiency and bottleneck equipment use ratios, good in dynamic regulation performance, and the like.

Owner:TONGJI UNIV

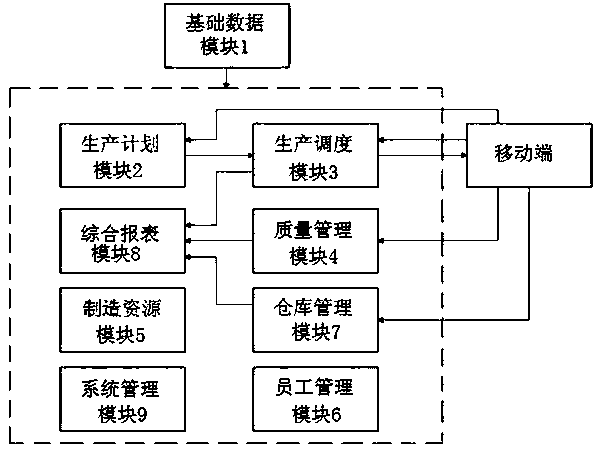

IMES intelligent manufacturing execution system

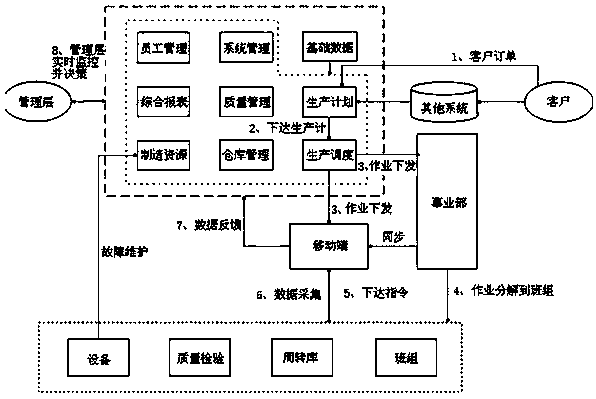

PendingCN107831750ASolve the problem of missing ringsResolving conflicts in using different information systemsTotal factory controlProgramme total factory controlUser needsIslanding

An IMES intelligent manufacturing execution system is featured by comprising a basic data module, a production planning module, a production scheduling module, a qualify management module, a manufacturing resource management module, an employee management module, a warehouse management module, an integral report module, a system management module and an equipped mobile terminal system; the advantages are that the system can solve the information isolated island problems existing in MES and the defect ring problems formed between a MRP layer and a DCS layer; novel modules are developed according to user demands and used by a plurality of departments in the same time, thus solving the contradictions of different departments using different information systems, and improving the working efficiency; the IMES intelligent manufacturing execution system can monitor the factory flow data, thus enabling the management layer to make rapid decisions aiming at problems.

Owner:QINGDAO PENGHAI SOFT CO LTD

Enterprise factory control method and system

InactiveUS7305278B2Digital computer detailsResourcesMonitoring and controlManufacturing execution system

A system, method, service and media for managing both supplier-owned and non-owned manufacturing asset types utilizing a supplier model of a product which goes across the manufacturing asset types. The invention maps the model to instances of the asset types and uses a network to control and monitor the assets. The monitoring and control occur according to the model, rules and services and does not require the vendors of non-owned manufacturing asset types to change their manufacturing execution systems.

Owner:SERVICENOW INC

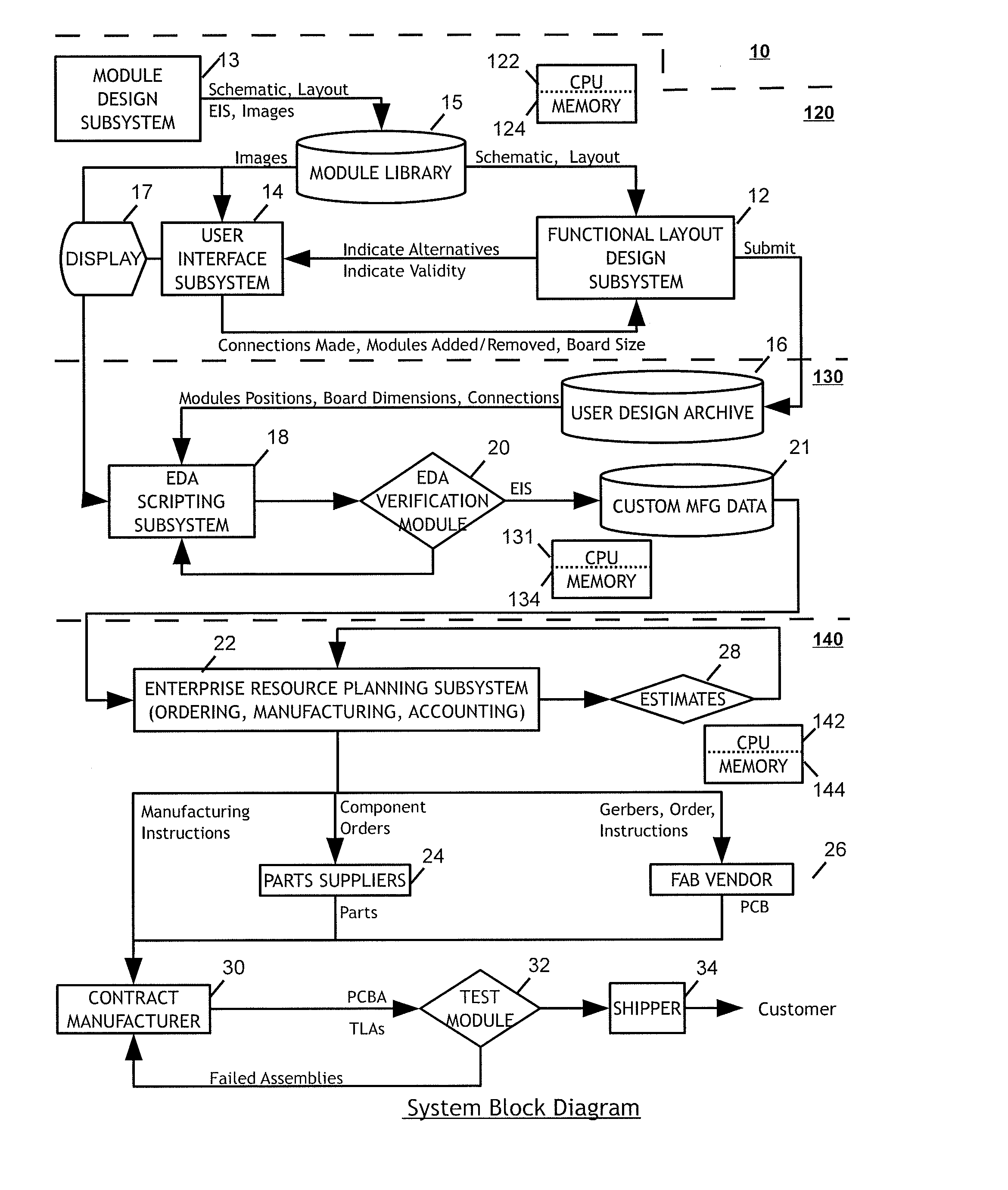

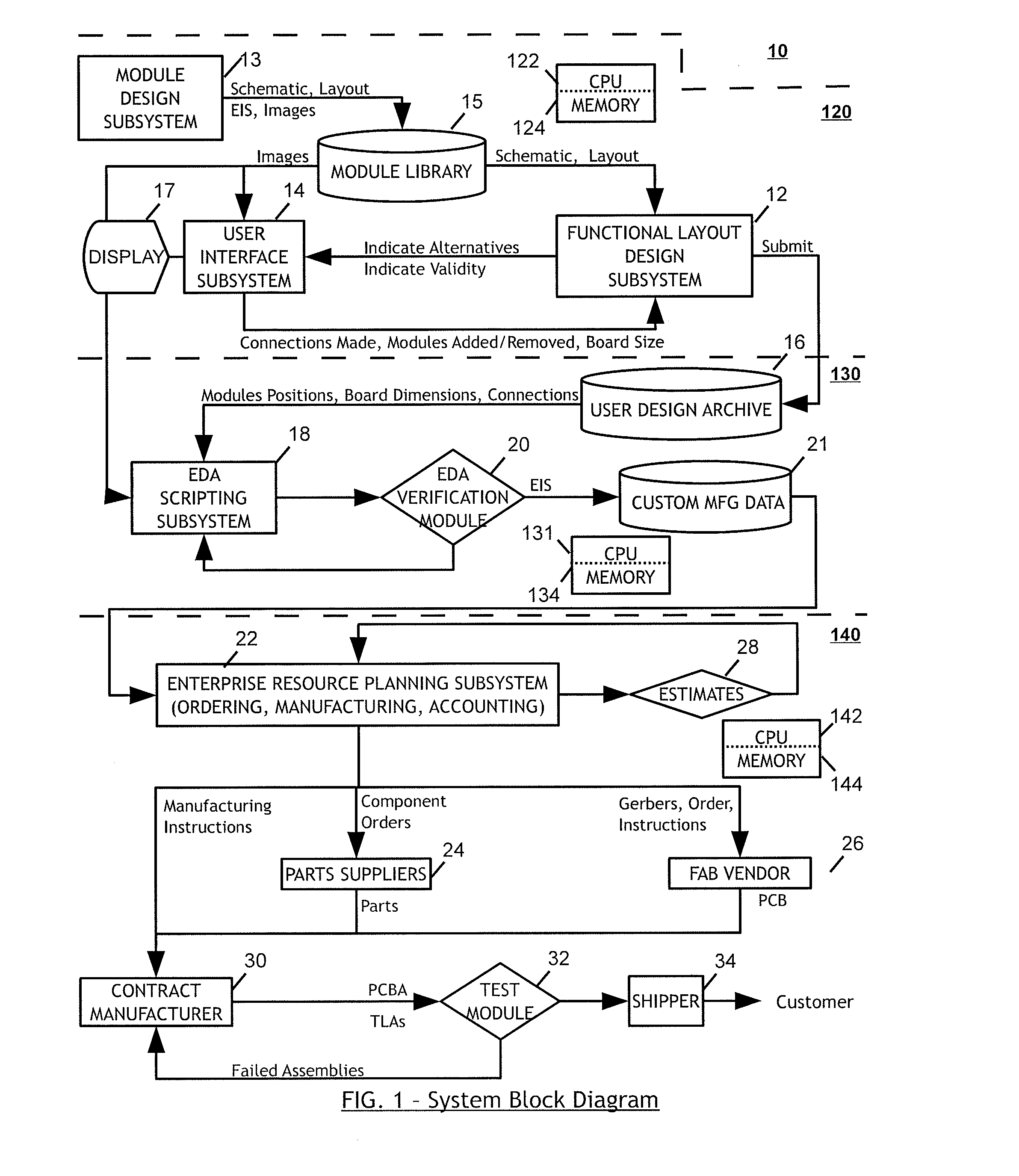

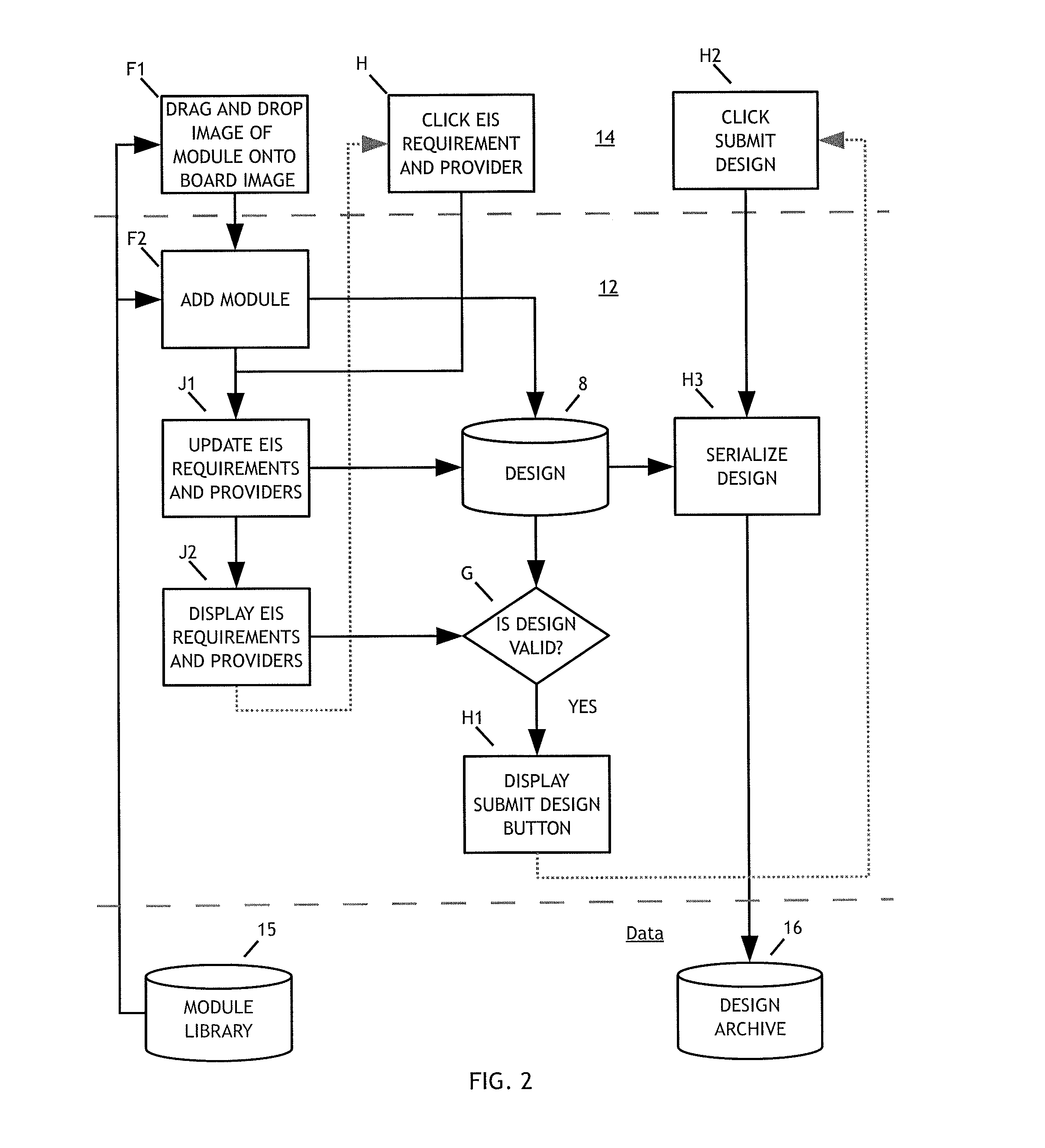

Integrated electronic design automation system

ActiveUS20130326457A1Minimal human interventionEliminate needConfiguration CADTotal factory controlManufacturing execution systemElectronic design automation

An electronic design automation system combines features of discrete EDA / CAD systems and manufacturing systems into a monolithic system to enable a layperson to efficiently design, construct and have manufactured a specific class of custom electronic device, namely a computer processing unit with embedded software. A Graphical User Interface (GUI) is provided as the front-end to a Computer Aided Design (CAD) server that generates sophisticated control and manufacturing instructions that are delivered to a fabrication supply chain, which produces a specified device that is then transported via managed logistics into inventory and ordering systems at vendors for delivery to a designated customer.

Owner:ALTIUM LLC

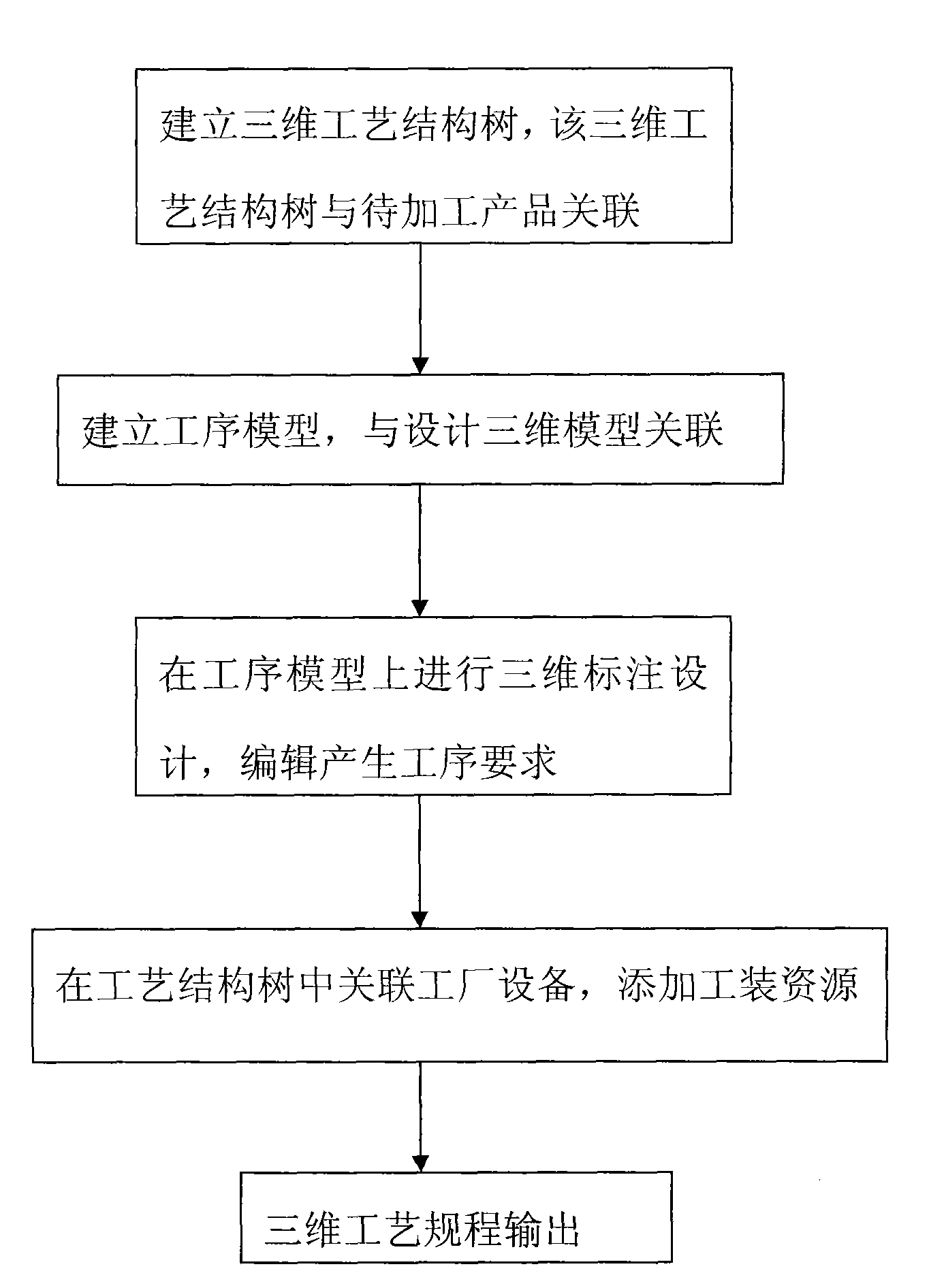

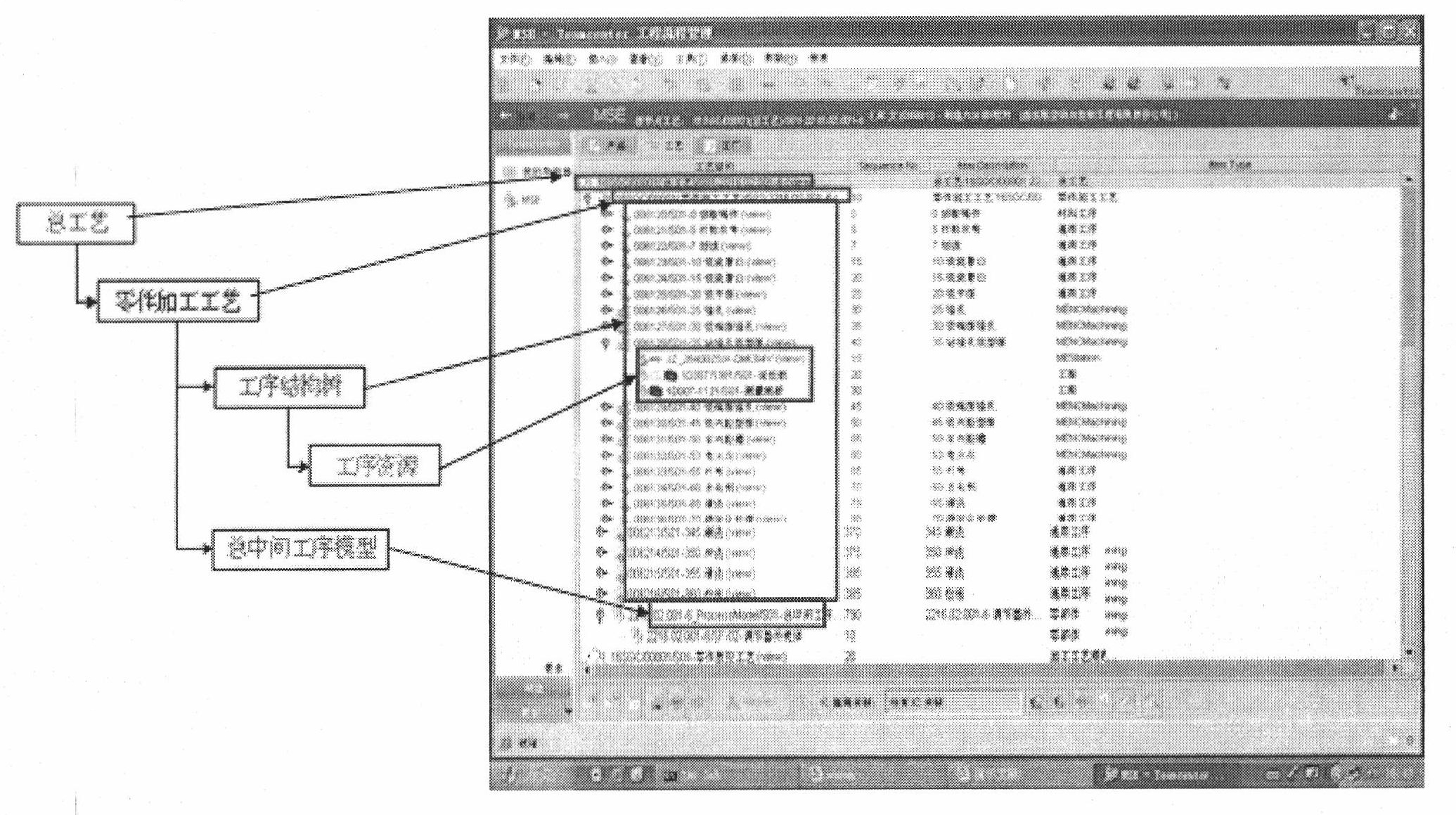

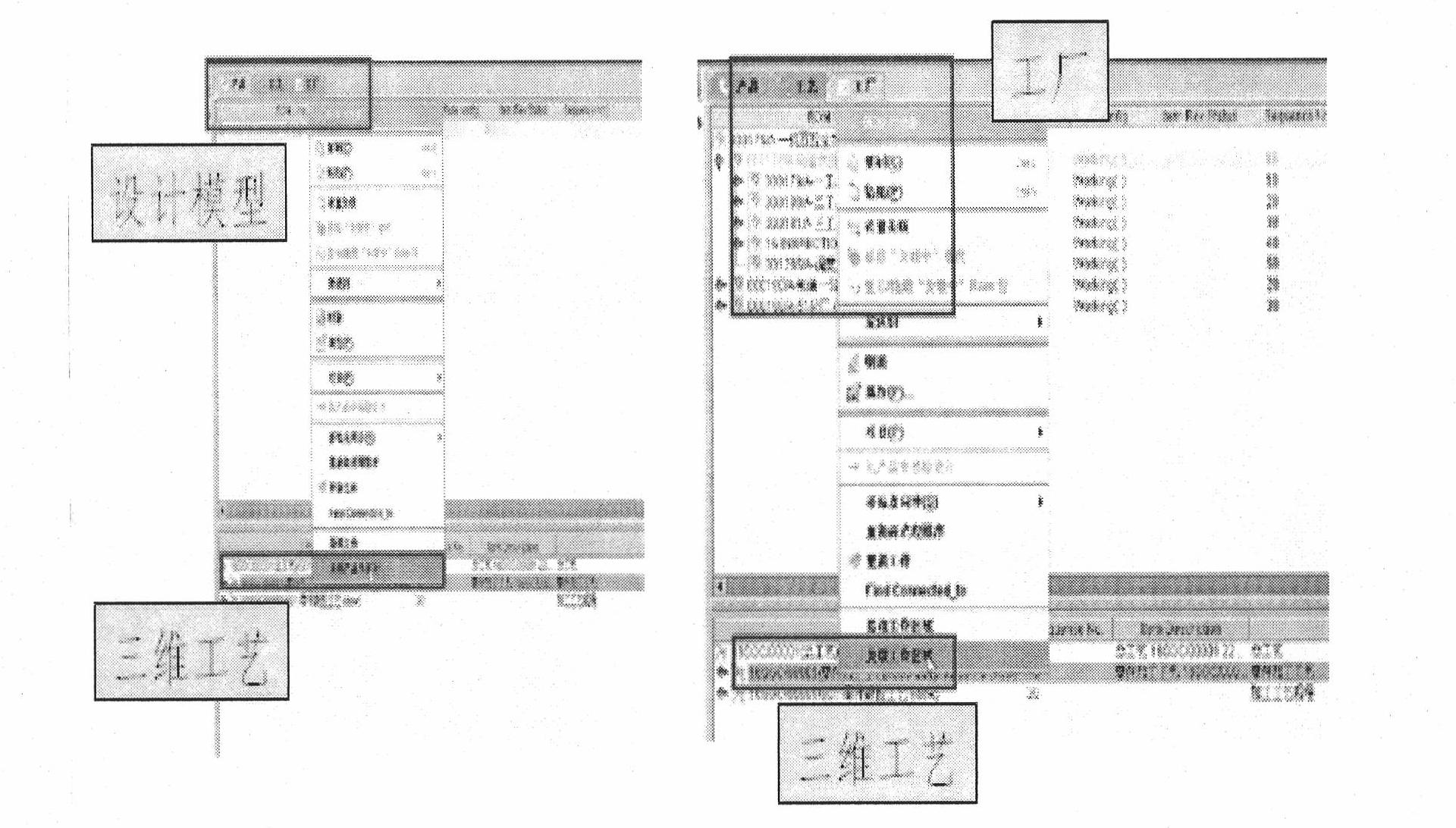

Three-dimensional labeling method for part processing

ActiveCN101877015AInformativeGet rid of inconsistenciesProgramme controlComputer controlAlgorithmInformation quantity

The invention relates to a three-dimensional labeling method for part processing, comprising the following steps of: (1) labeling sizes, tolerances and other manufacturing information generating procedure requirements on the basis of a procedure model established in each procedure of a part processing process; (2) naming procedure content views: carrying out three-dimensional labeling on the procedure models to generate procedure contents, wherein the procedure models and the three-dimensional labeling are organized by adopting a mode of a view structure tree; and (3) setting the three-dimensional labeling of the procedure contents. The method belongs to a structurized process so that three-dimensional models have more comprehensive and specific information and downstream users have a unique data source, thereby getting rid of the phenomenon that digital control programs are compiled according to the three-dimensional models and two-dimensional pictures have nonuniform data sources; and the three-dimensional labeling method has the advantages of more visual two-dimensional function, good visualization effect and comprehensive information content; and the structurized three-dimensional labeling data can rapidly generate checking and counting data directly transmitted to systems comprising a downstream MES (Manufacturing Execution System) and the like, thereby reducing a great amount of repeated workload of process personnel.

Owner:XIAN AERONAUSTIC POWER CONTROL ENG

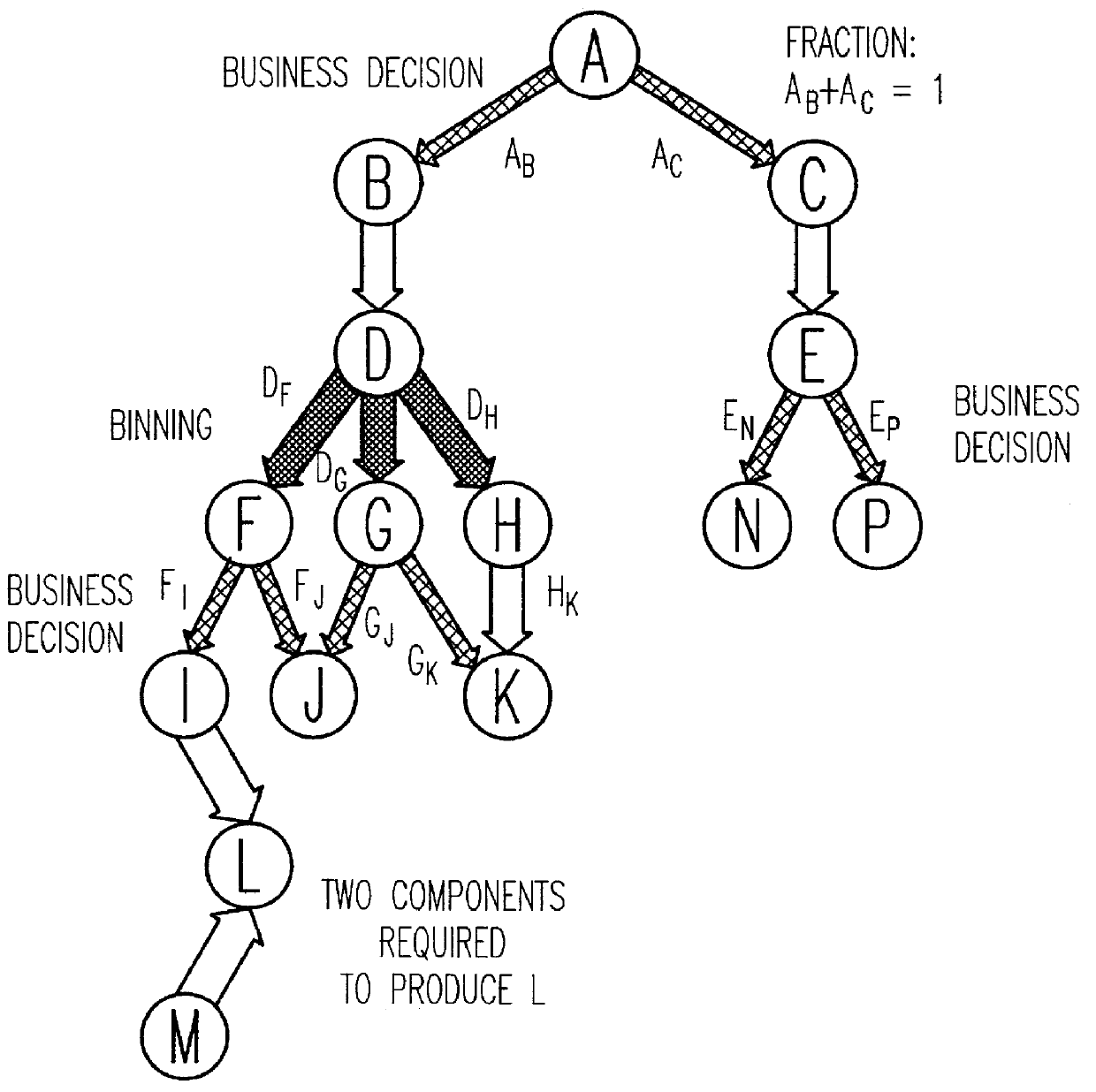

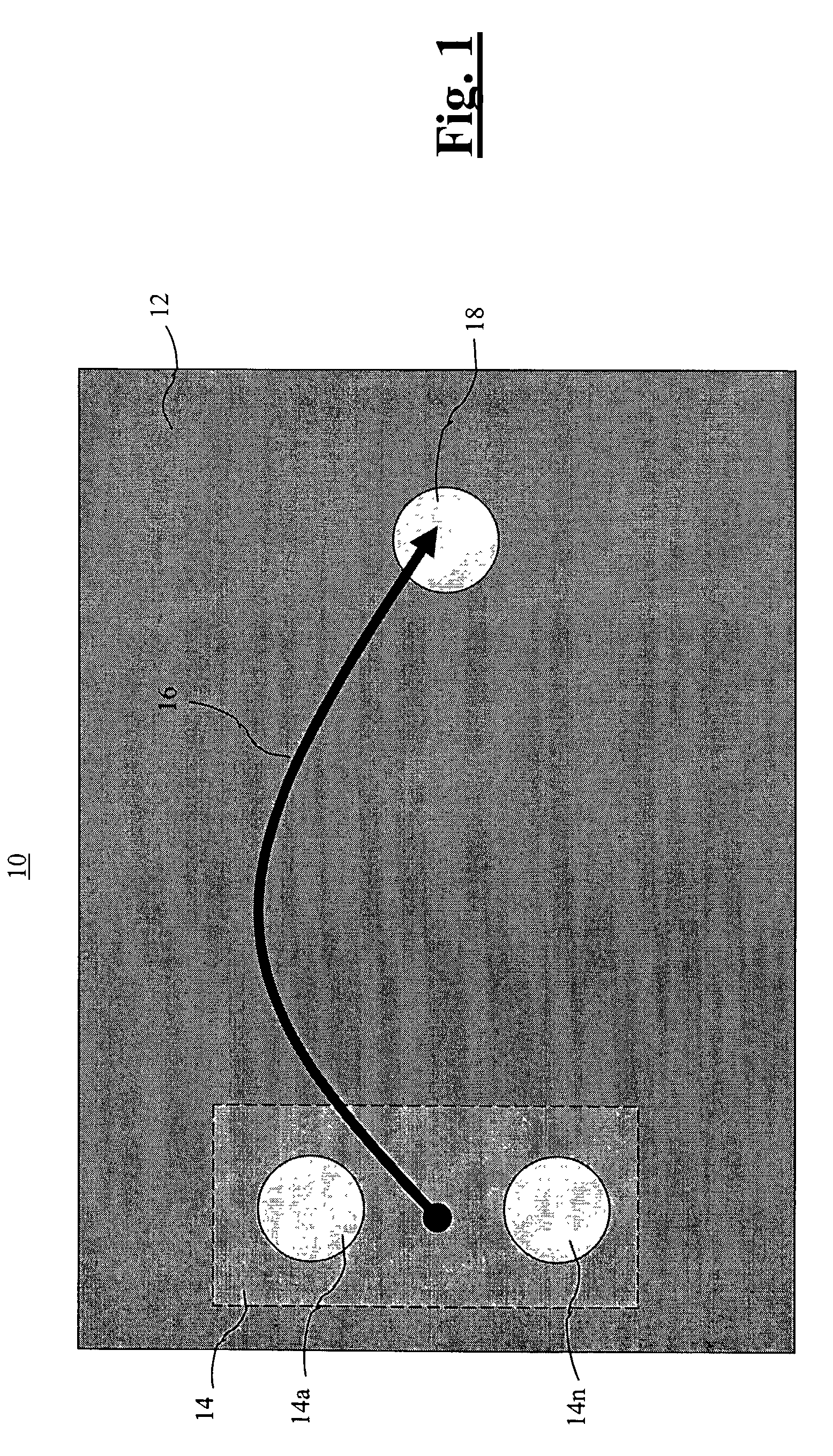

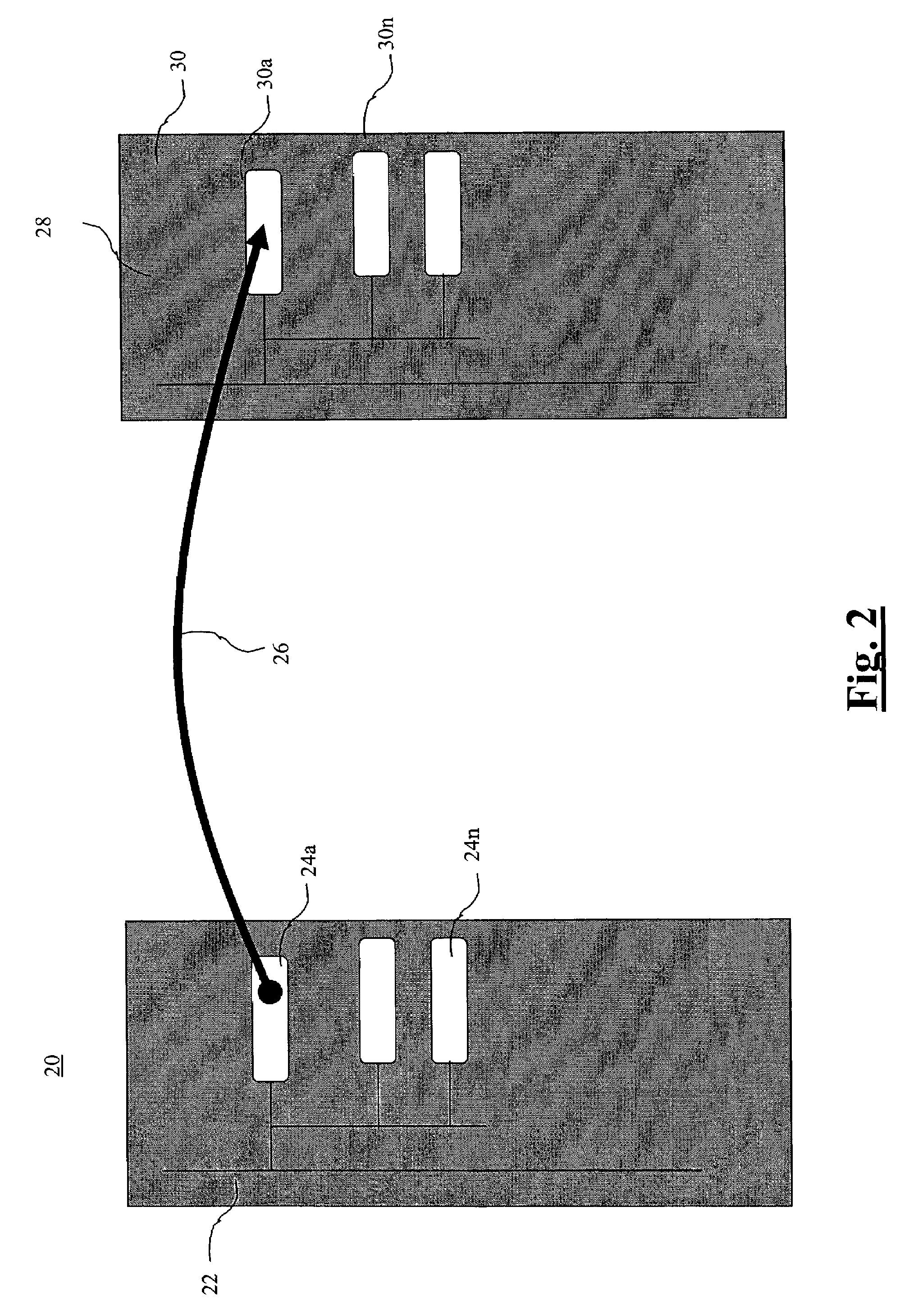

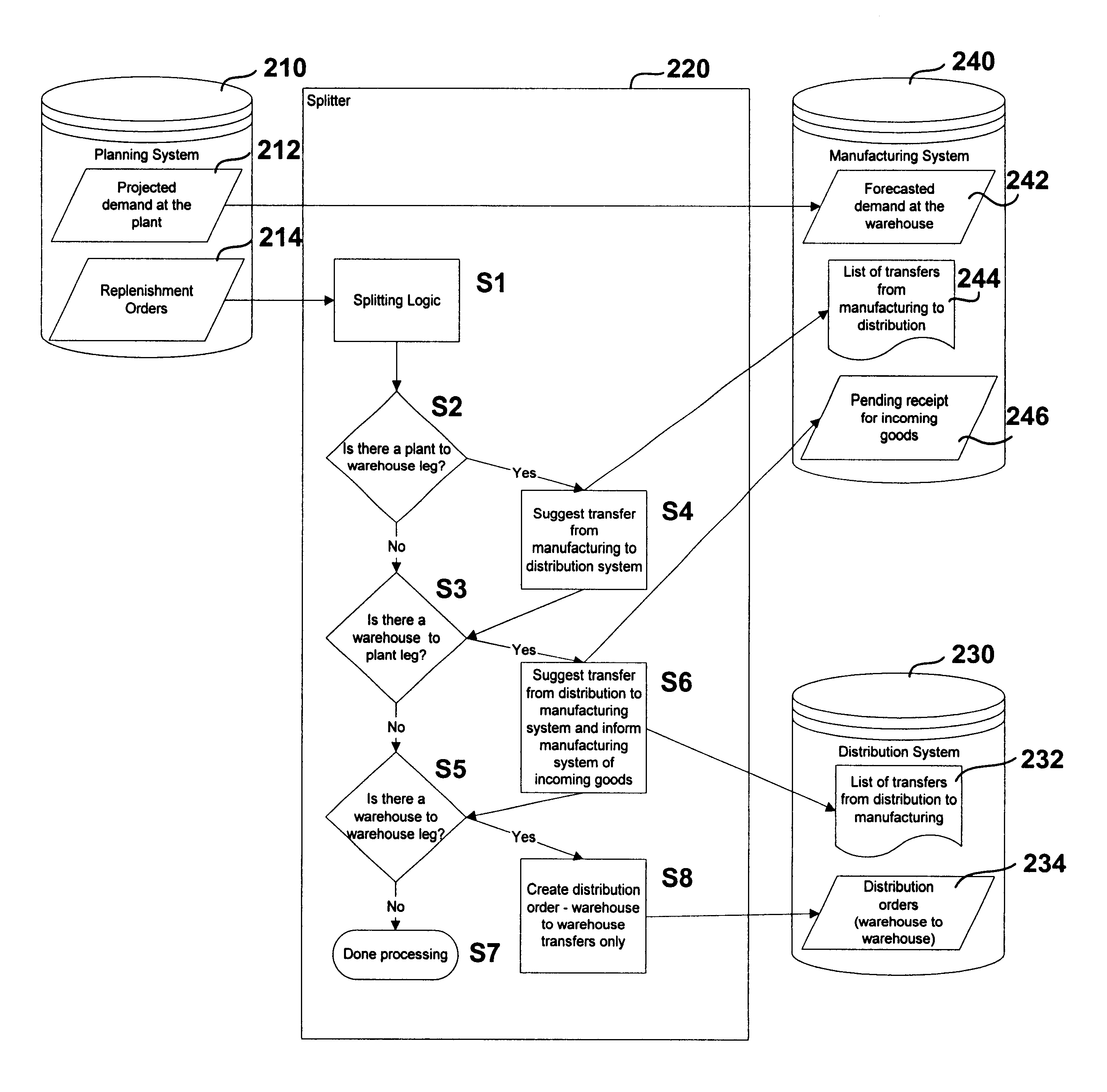

Methods, devices and systems for splitting an integrated manufacturing and distribution plan for use by separate manufacturing and distribution execution systems

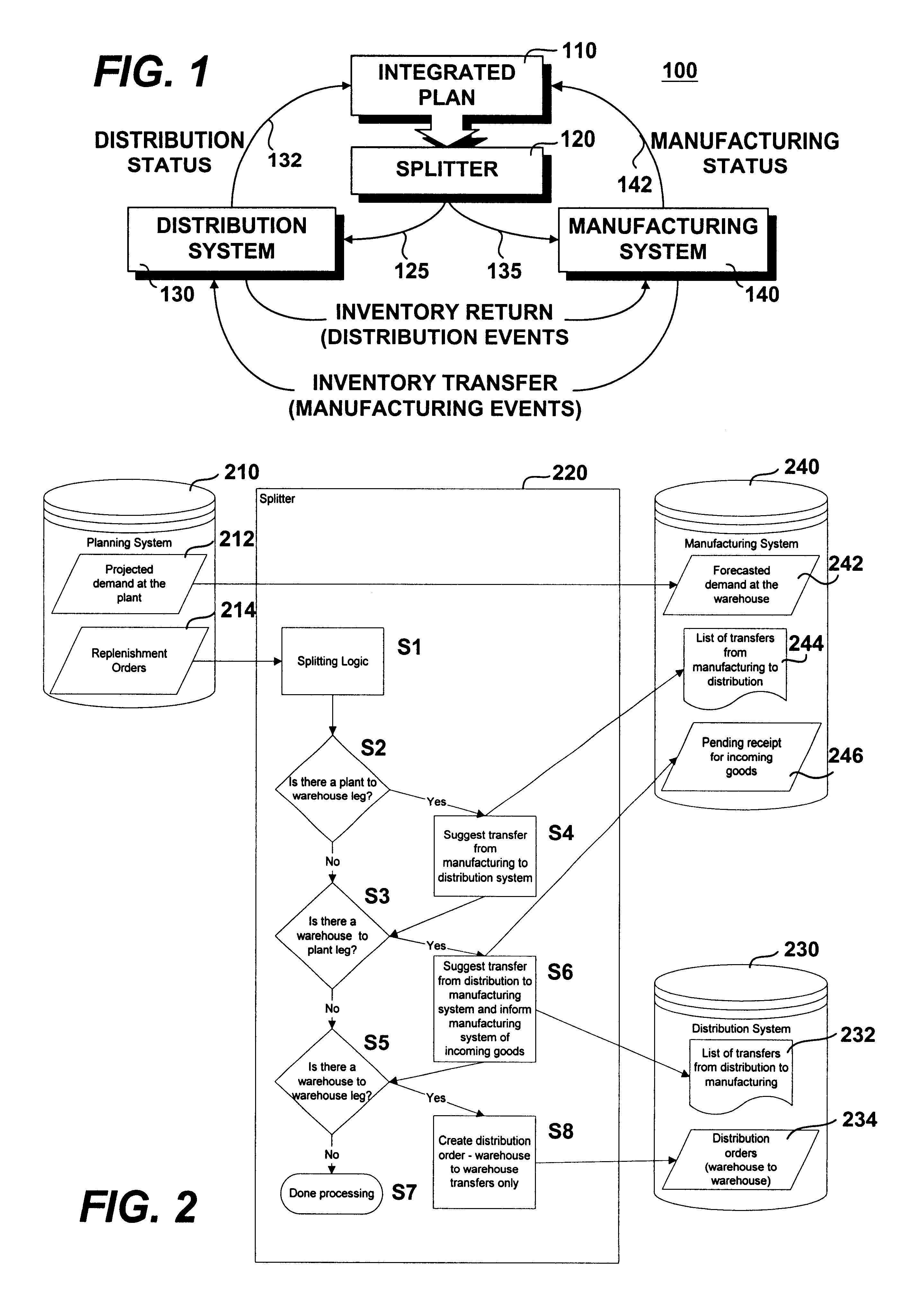

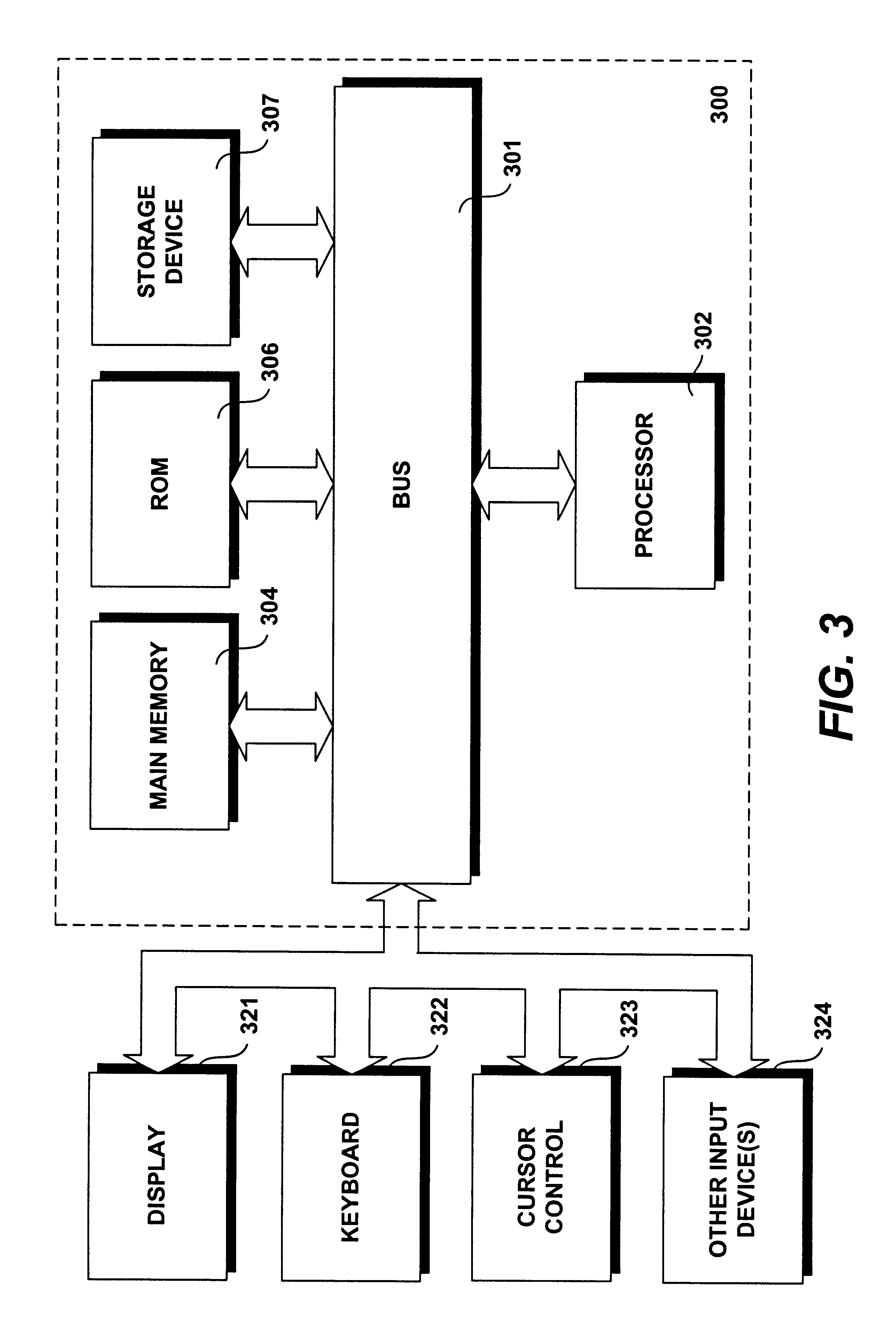

A consolidated plan splitting methodology sends distribution orders to a distribution execution system and planned production to a manufacturing execution system. Instructions from the planning system involving only movements of inventory within the distribution s system (e.g., warehouse to warehouse transfers) are passed directly to the distribution execution system. Instructions from the planning system involving movements of inventory where either the source or destination is in the manufacturing system causes a splitter located between the planning system and the distribution and manufacturing execution systems to carry out a decisional process wherein the movement of inventory is broken down into a selected number of distinct intermediate legs. Control of inventory balances is passed between the distribution and manufacturing execution systems as appropriate as the inventory moves from one execution system to another.

Owner:ORACLE INT CORP

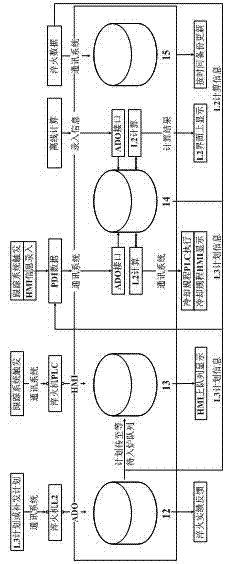

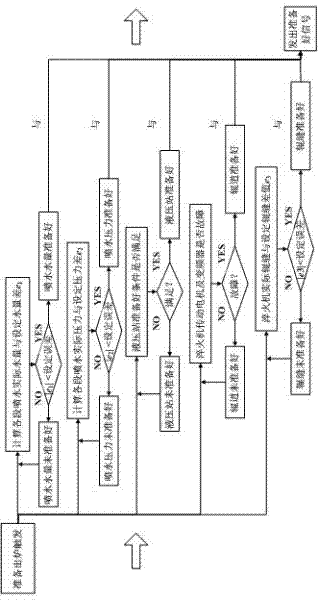

Automatic control system for moderate-thickness plate roller quenching machine

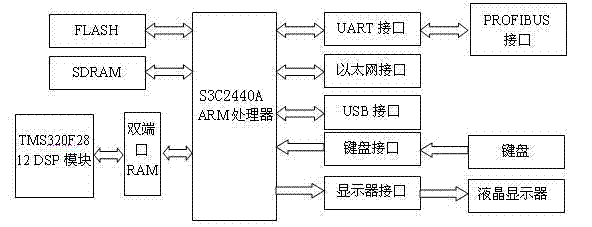

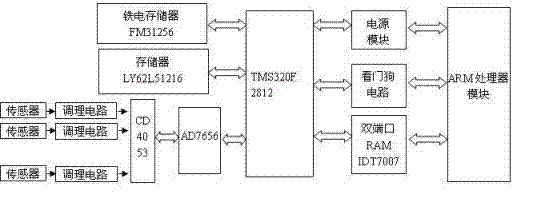

ActiveCN102409158AIncrease productivityImprove production accuracyHeat treatment process controlQuenching devicesData connectionAutomatic control

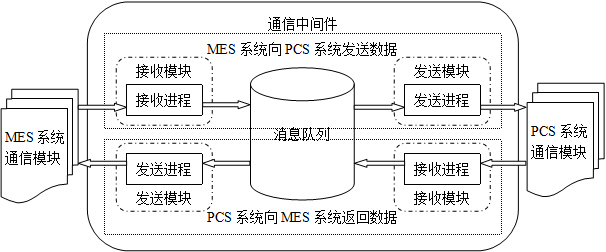

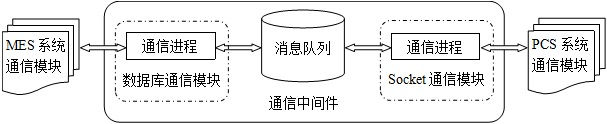

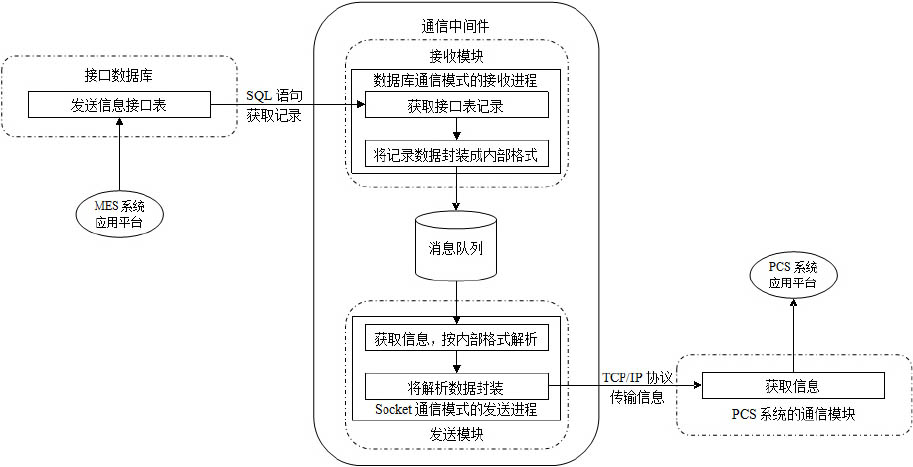

The invention discloses an automatic control system for a moderate-thickness plate roller quenching machine, and belongs to the technical field of heat treatment automatic control. The system consists of a PLC (Programmable Logic Controller) and interface system, a process control system and a track communication system, and is characterized in that: 1, water spray parameters are accurately controlled by using an intelligent algorithm to realize flow and pressure double-closed-loop control; 2, calculation is performed through procedure distribution, function trigger and quenching parameters to realize high-accuracy temperature control, plate shape control and model self-study; 3, a communication intermediate packet developed on the basis of TCP / IP (Transmission Control Protocol / InternetProtocol), OPC (Optical Proximity Correction) and PROFIBUS-DP can realize smooth data connection of the quenching machine and the MES (Manufacturing Execution System) as well as upstream and downstream equipment and meanwhile realize accurate transfer of data between subsystems; and 4, a trigger mechanism is adopted to realize queue macro tracking and position micro tracking of a steel plate of aquenching region. By adopting the system, the problems of complex control and low control accuracy of the roller quenching machine are solved well, and automatic and one-key operation of the roller quenching machine is realized.

Owner:NORTHEASTERN UNIV

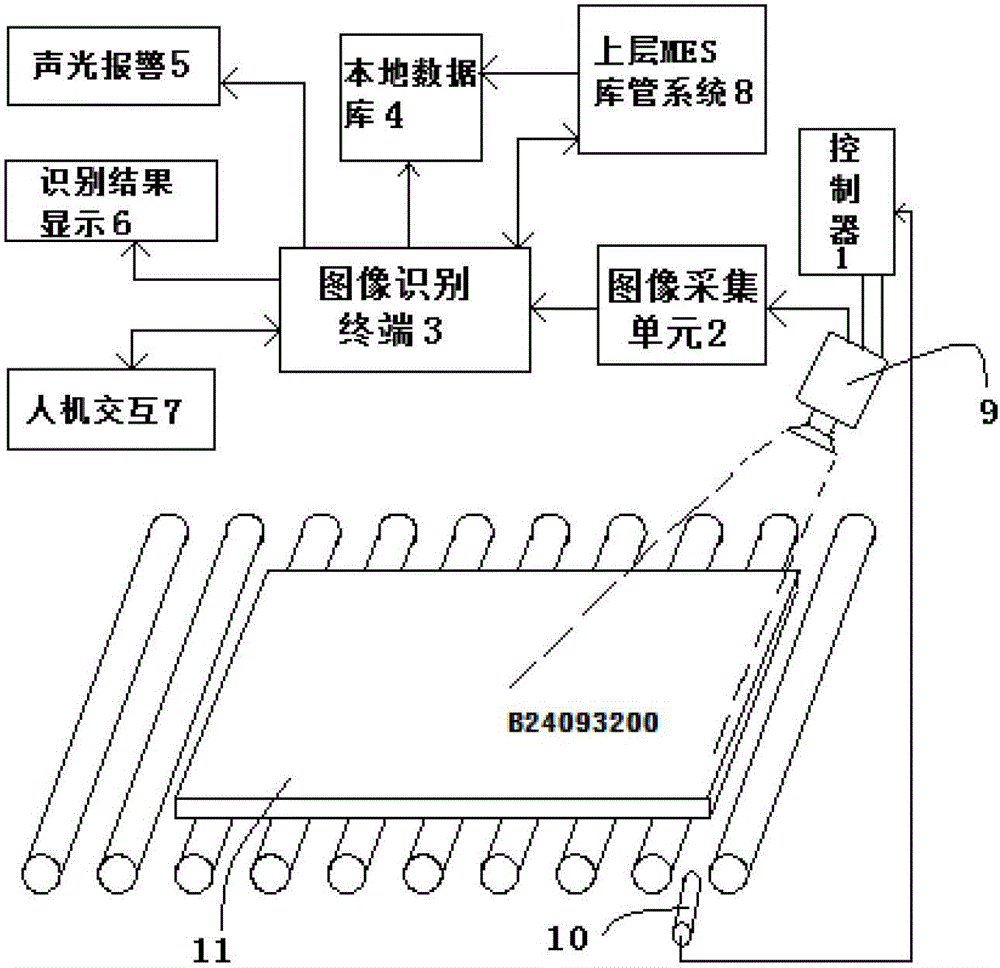

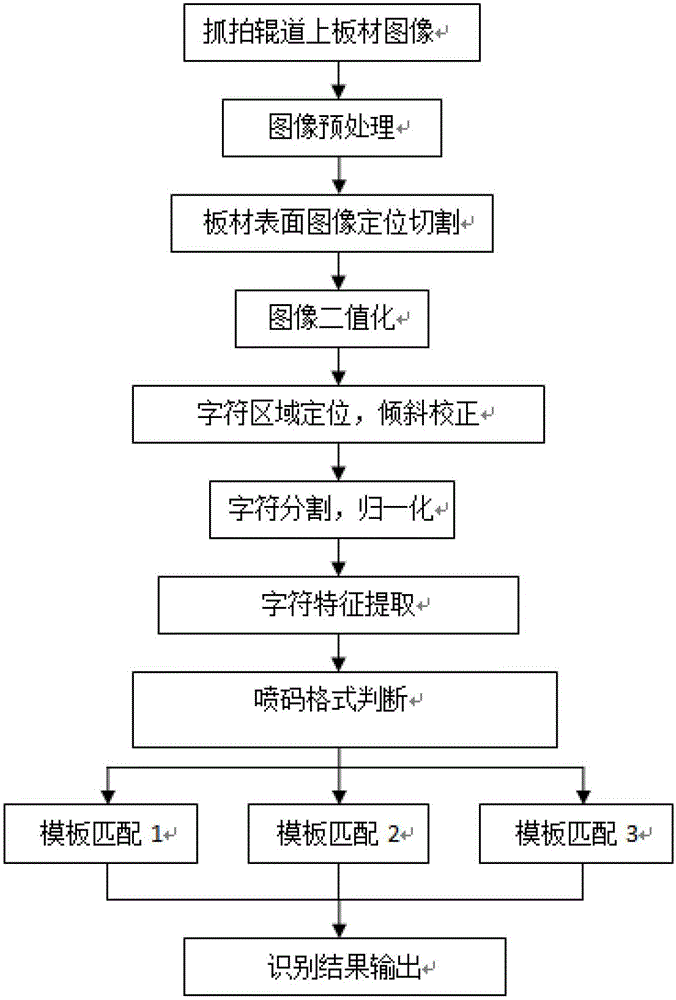

Plate surface code spraying character recognition device and method thereof

InactiveCN103150564AChangeable formatDifficult to deal withCharacter and pattern recognitionInteraction systemsManufacturing execution system

The invention relates to a plate surface code spraying character recognition device and a method thereof, belonging to the technical field of character recognition. The plate surface code spraying character recognition device comprises a detector, a controller, a CCD (Charge Coupled Device) camera, an image acquisition unit, an image recognition processing terminal, a local data base, a sound-light alarm, a recognition result display, a human-computer interaction system and an upper-layer MES (Manufacturing Execution System) warehouse system, wherein the detector is connected with the controller to form a bottom-layer detection system; the controller is connected with the CCD camera, and the CCD camera is connected with the image acquisition unit to form an image snapshot system; the image acquisition unit is connected with the image recognition processing terminal, and the image recognition processing terminal is connected with the local data base, the sound-light alarm, the recognition result display and the human-computer interaction system respectively so as to form a character recognition processing system; and the image recognition processing terminal is connected with the upper-layer MES warehouse system via the Ethernet, and the upper-layer MES warehouse system is connected with the local data base via a network to form a character information interaction platform. The plate surface code spraying character recognition device has the advantage of realizing the fast and accurate recognition of plates during the roller bed transportation process.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

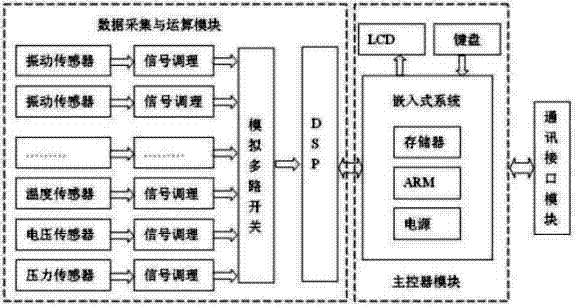

Device for on-line monitoring and evaluating state of air blower

InactiveCN103195727AHelps find early failuresTimely and reasonable predictive maintenancePump controlNon-positive displacement fluid enginesData acquisitionEngineering

The invention discloses a device for on-line monitoring and evaluating state of an air blower. The device comprises a data collection and operation module, a master controller module and a communication interface module, wherein the data collection and operation module is used for collecting parameter information of vibration of the air blower, temperature, voltage, electrical current, pressure, and the like; vibration signals of the air flow are decomposed by adopting a method of multiwavelet; early failure characteristic signals are extracted; performance evaluation is performed by adopting state performance evaluation algorithm based on a cloud model; the collected signals of the temperature, the pressure, and the like are distinguished and displayed by the master controller; and the device is equipped with a plurality of communication interfaces, so that data exchange between information and factory control net and manufacturing execution system can be realized. Through adoption of the device, performance state of the air flow can be evaluated accurately, so that reasonable maintenance for the air flow is realized.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method and system for automating issue resolution in manufacturing execution and material control systems

InactiveUS7440932B2Decrease productivityImprove productivitySafety arrangmentsTesting/monitoring control systemsProduction rateAutomatic control

Automatic error recovery systems and methods for automated manufacturing plants and factories are disclosed. Such facilities normally have multiple automated control systems, including an automated material handling system (AMHS), all of which run automatically, typically under the control of a computerized manufacturing execution system (MES). The disclosed issue resolution (ISR) systems and methods involve providing components, which may be supervised and operated by an issue resolution management (ISRM) system, if desired, that interfaces with the MES, AMHS, and / or production control system(s) which operate the tools and other stations within the automated factory. The components, which may be considered customized logic cells, may each be written for handling a specific kind of incoming error condition, problem or other issue that might occur and which is amenable to automatic resolution or recovery. These errors often occur between or across the boundaries of the various interactive systems and automated equipment. Each cell may cycle through a sequence of possible error resolution or recovery steps until the specific issue is resolved or until the sequence of steps is exhausted. Other components of the ISR system may provide results-oriented messages and / or facilitate the collection of data as to whether and which corrective commands from the ISR system resolved the reported error conditions automatically. The disclosed ISR systems and methods for resolving errors and other issues automatically helps improve the overall productivity of automated factories by reducing downtime and the need for human intervention to correct problems, thereby increasing factory throughput.

Owner:INT BUSINESS MASCH CORP

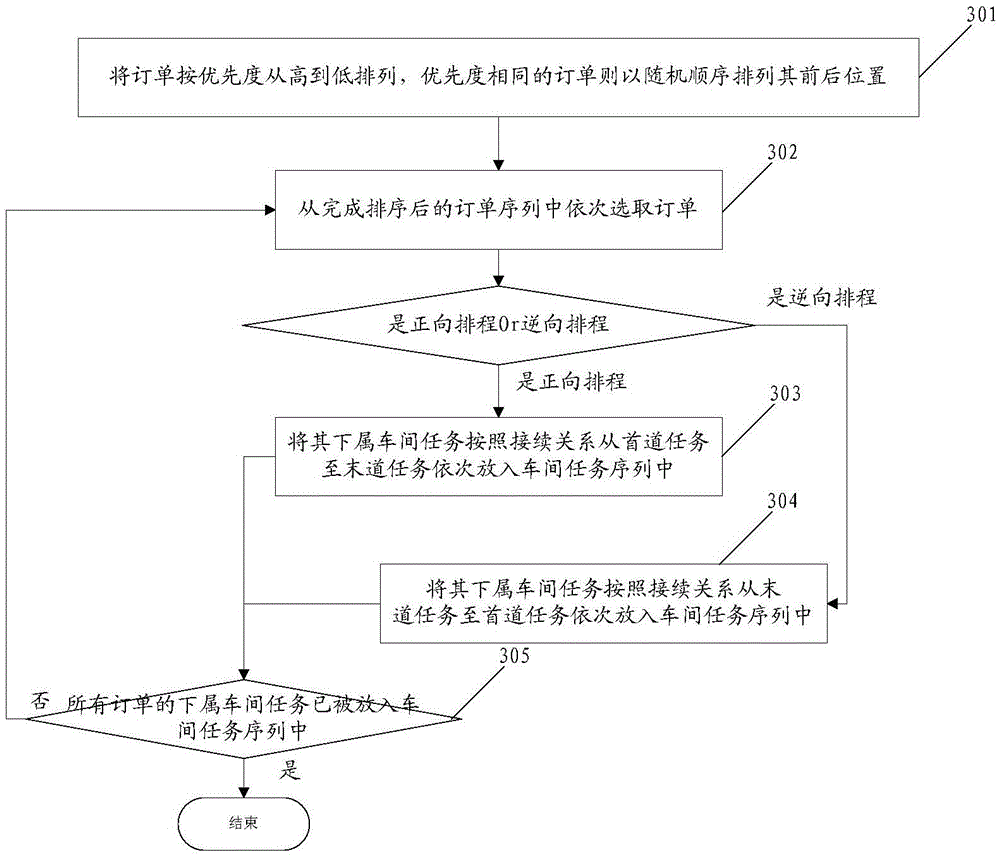

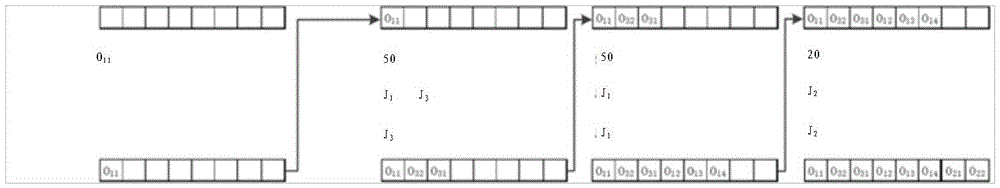

Hybrid genetic algorithm-based MES (Manufacturing Execution System) production planning and scheduling method

InactiveCN105629927AMaintain population diversityAvoid premature convergenceTotal factory controlProgramme total factory controlRandom assignmentPopulation

The invention is applicable to the technical field of workshop production planning management, and provides a hybrid genetic algorithm-based MES (Manufacturing Execution System) production planning and scheduling method. According to an order priority generation mode and / or random generation mode, a workshop task sequence which meets constraint relations between tasks and a genetic algorithm coding rule is generated for a preset number of initial scheduling schemes; according to the best task starting and ending time and according to one or more distribution combination modes in resource load balancing principle distribution and random distribution, execution resources are set for each workshop task in the preset number of initial scheduling schemes; the preset number of initial scheduling schemes are converted into a series of chromosomes through a coding process to serve as an initial population for the hybrid genetic algorithm; and the initial population is introduced to the hybrid genetic algorithm, and a scheduling result after optimization is calculated according to a preset optimization target. High efficiency of the MES production planning and scheduling results in the prior art is improved.

Owner:WUHAN KAIMU INFORMATION TECH

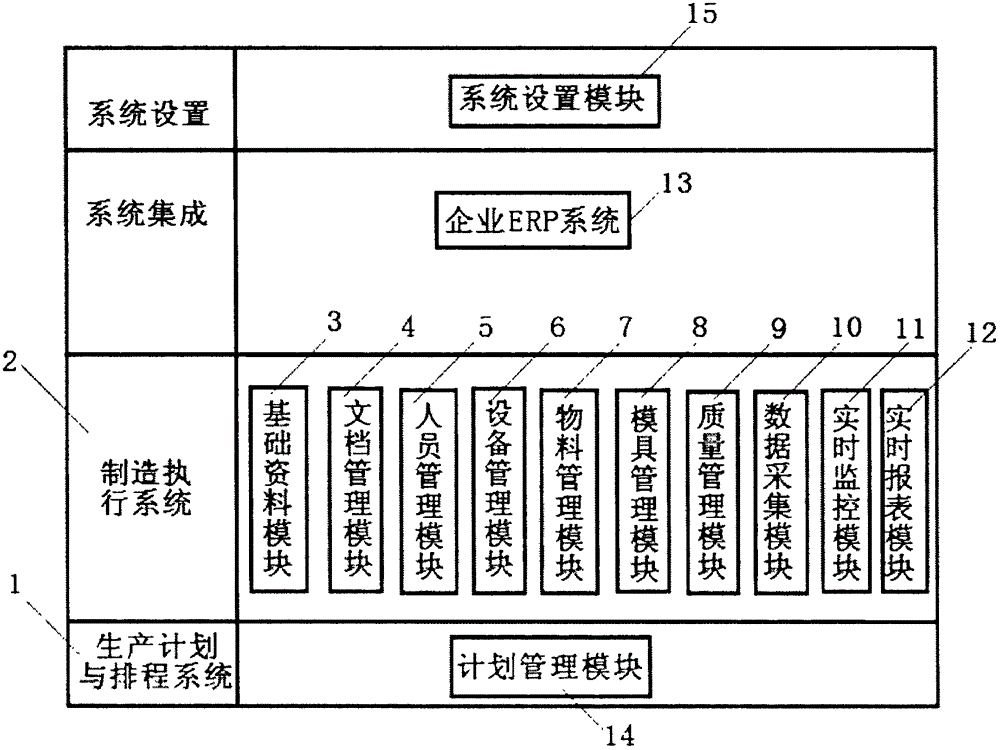

Manufacturing execution system

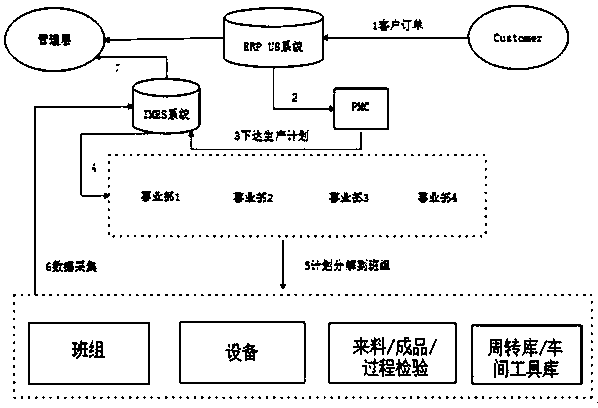

InactiveCN102945512ASolve the problem of real-time managementSolve the problem of real-time demand informationResourcesManufacturing computing systemsData acquisitionManufacturing execution system

The invention discloses a manufacturing execution system which comprises a production planning and scheduling system, wherein a manufacturing execution system is integrated on the basis of the production planning and scheduling system. The manufacturing execution system comprises a basic material module, a document management module, a personnel management module, an equipment management module, a material management module, a die management module, a quality management module, a data acquisition module, a real-time monitoring module and a real-time reporting module. An upper layer of the manufacturing execution system is integrated with an ERP (Enterprise Resource Planning) system of an enterprise, and a bottom layer of the manufacturing execution system is connected with a data acquisition device and a man-machine interaction terminal interface in a product field. According to the manufacturing execution system provided by the invention, the problem of real-time material demand information in the production field of the discrete manufacturing industry is solved, the material demand information can be timely sent to a warehouse by automatic system triggering or manual triggering, and the problems of monitoring and feeding back the efficiency of production equipment in real time are solved by the scientifically planned OEE (Overall Equipment Efficiency) management.

Owner:SUZHOU JIANGSHAN SOFTWARE SCI & TECH

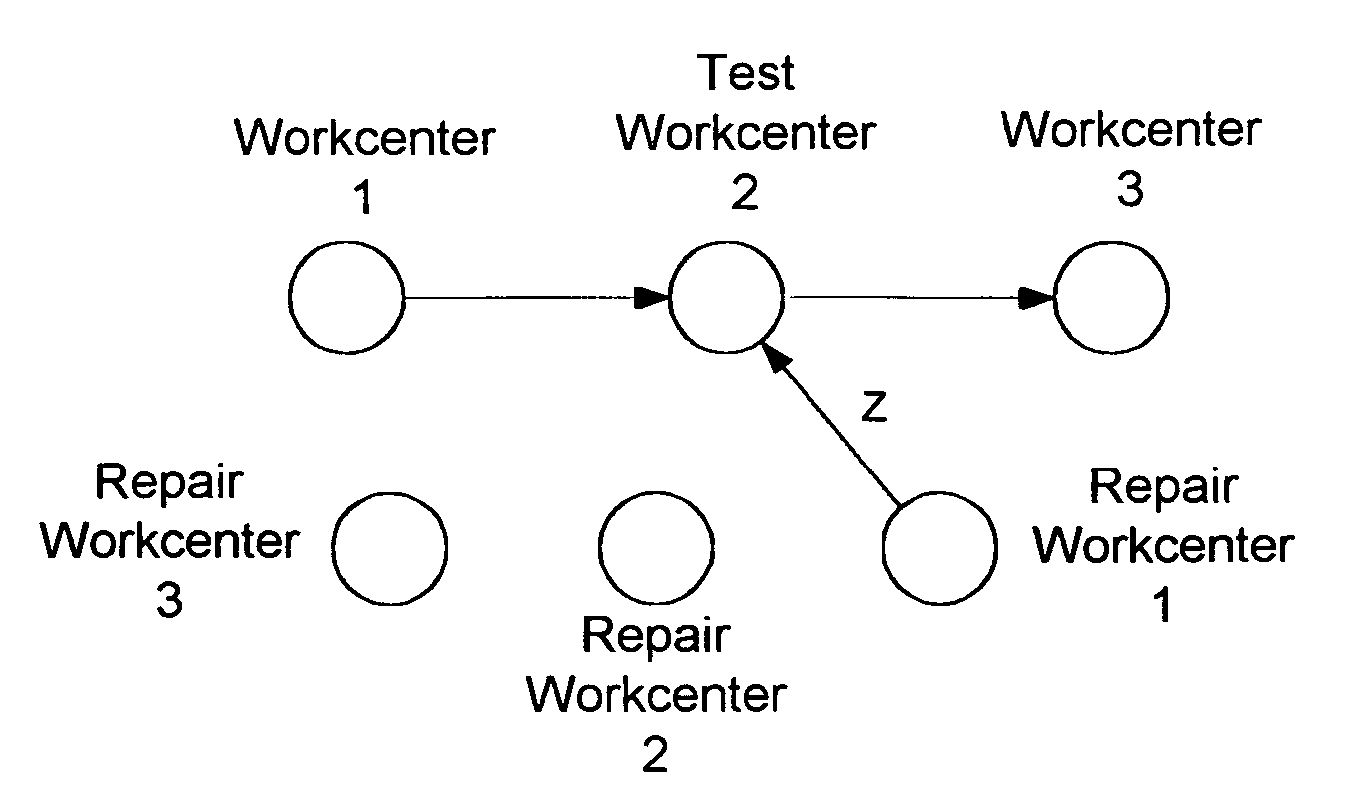

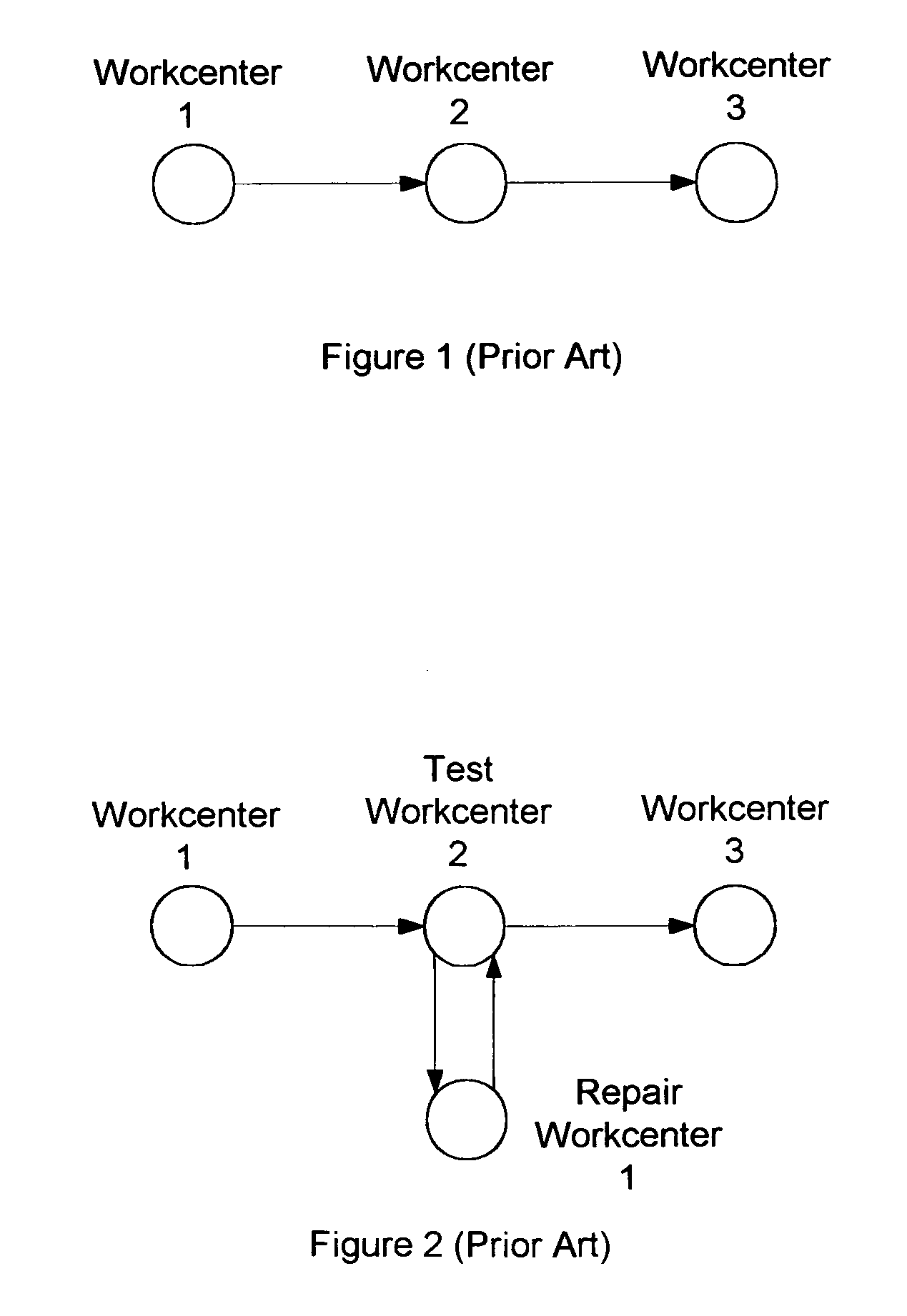

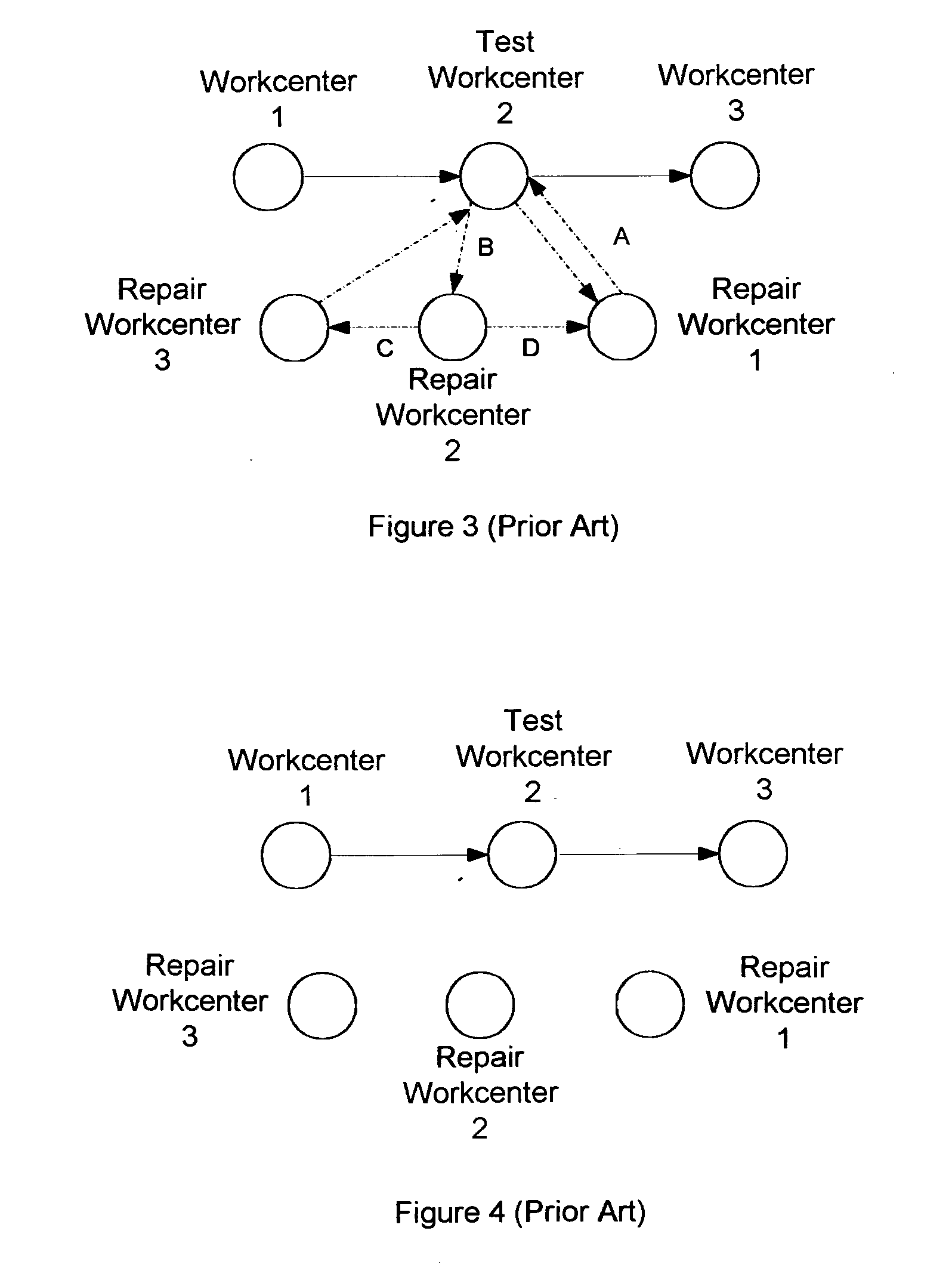

Directed defective item repair system and methods

InactiveUS20060129265A1ResourcesSpecial data processing applicationsManufacturing execution systemComputer science

The field of the present invention is the repair of a defective item where the item is directed through the repair process by a system. In the present invention, a manufacturing execution system controls and tracks an item through a sequence of workcenters that implement a process. A route defines the sequence of work centers for the process without repairing a defective item. An item is tested at a test workcenter and fails. A defect symptom describes the defect. A quality information screen collects quality information for the defect and presents a list of repair workcenters. Based on the defect symptom description, a repair workcenter is selected. The manufacturing execution system suspends the route and directs the item to the repair workcenter. The item is repaired at the repair workcenter and the quality information screen presents a list of workcenters including the test workcenter. If the repair of the item is complete, the test workcenter is selected. The manufacturing execution system directs the item to the test workcenter. The test workcenter tests the item. When the item passes the test, the route is resumed and the item is directed to the workcenter in the route after the test workcenter. If the repair is not complete, the repair workcenter selects the workcenter to continue the repair and the manufacturing execution system directs the item to the selected workcenter.

Owner:OUCHI NORMAN KEN

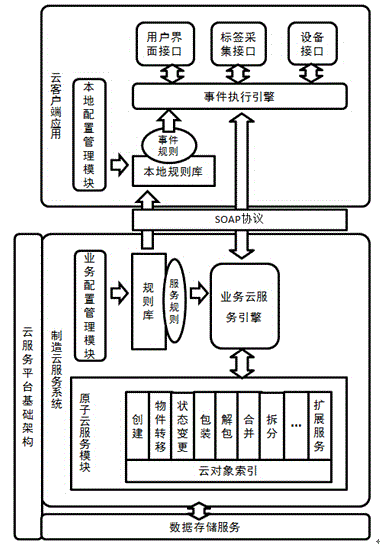

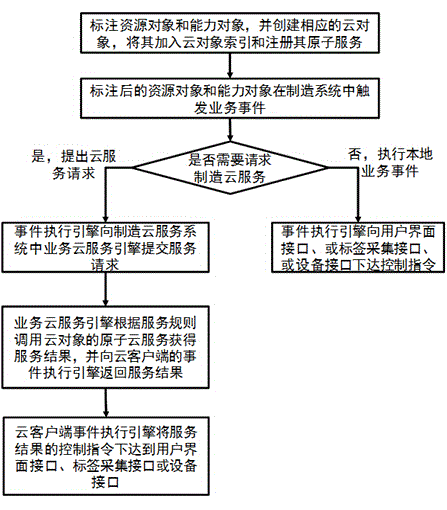

Cloud manufacturing execution system and method based on cloud services

The invention discloses a cloud manufacturing execution system and method based on cloud services. The cloud manufacturing execution system comprises a cloud service manufacturing system and a cloud client application, wherein the cloud service manufacturing system is deployed on a cloud service platform infrastructure and used for providing cloud services for a service manufacturing request of the cloud client application, and the cloud client application is deployed on a mobile terminal or a computer and used for collecting field data of the manufacturing execution process in real time, triggering a local control instruction or requesting cloud service manufacturing according to event rules, and feeds the result back to a user interface or a label collection interface or an equipment interface. According to the cloud manufacturing execution system adopting the infrastructure of the cloud service manufacturing system and the cloud client application, virtualization and distributed computing resources and the computing power are used as services through the internet to be provided for a user, system services are deployed in the cloud service platform infrastructure, management is carried out by a small number of professionals, and the problems that enterprise human resource shortage, informatization foundation shortage, fund shortage and the like are solved.

Owner:GUANGDONG UNIV OF TECH

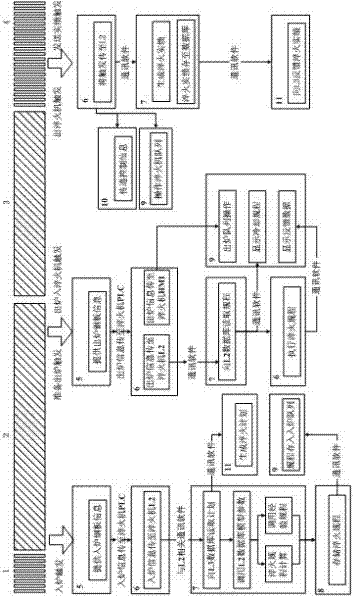

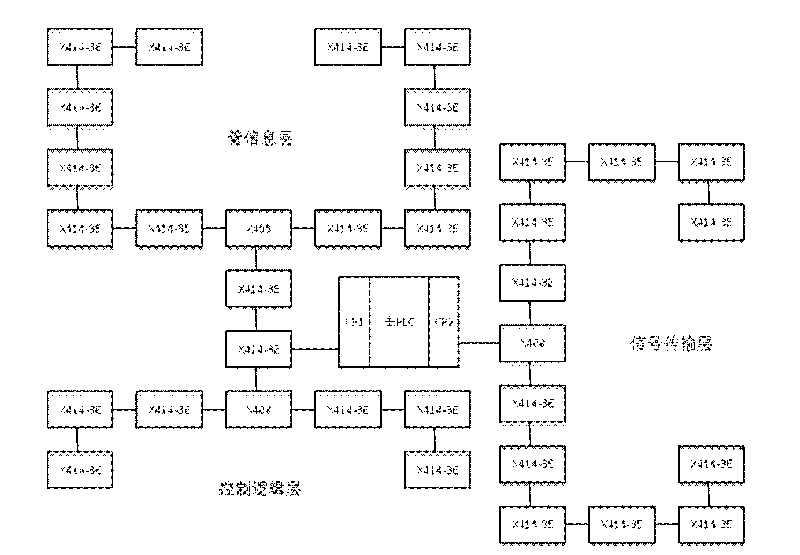

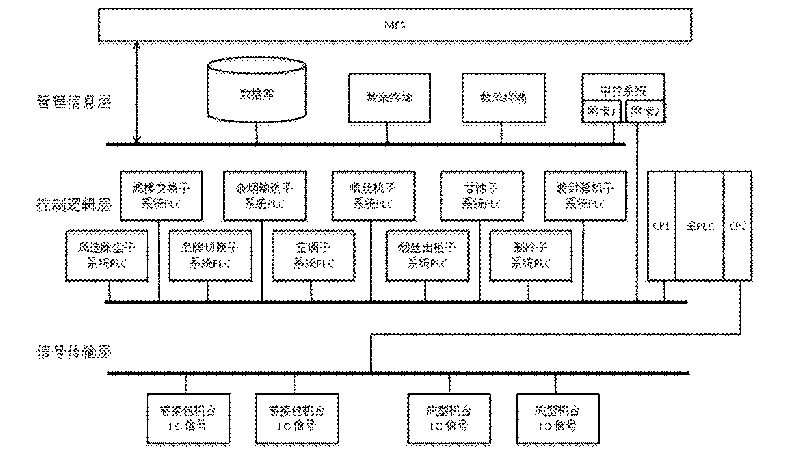

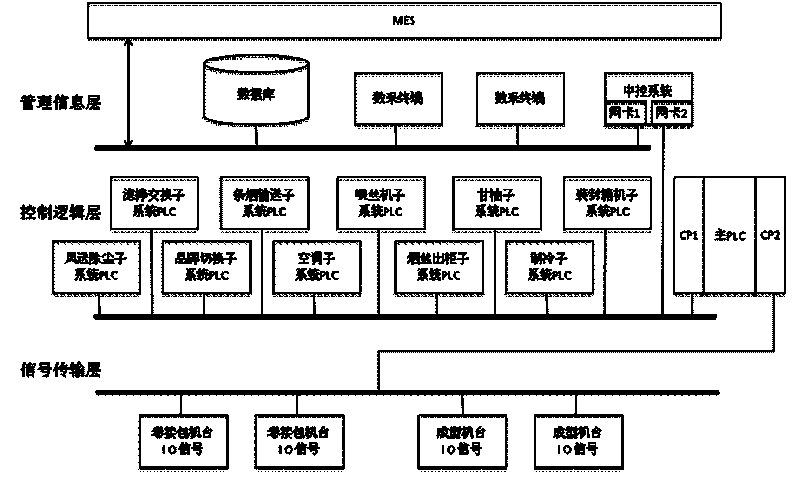

Integrated system for controlling production processes of coiling, connecting and wrapping cigarettes

ActiveCN101763109AEasy to passEasy to masterTotal factory controlProgramme total factory controlIndustrial EthernetInformation layer

The invention discloses an integrated system for controlling the production processes of coiling, connecting and wrapping cigarettes, which comprises a management information layer, a logical control layer and a signal transmission layer; the management information layer comprises a manufacture execution system, a database, a data collection terminal and a central control system, wherein the manufacture execution system, the database, the data collection terminal and the central control system are interconnected by a first-layer industrial Ethernet; the logical control layer comprises a main PLC and a plurality of subsystem PLCs, wherein the main PLC and the subsystem PLCs are interconnected by a second-layer industrial Ethernet; the signal transmission layer comprises distributed type remote I / O substations which are respectively disposed at a coiling, connecting and wrapping board, a forming board and various auxiliary united equipment subsystems; and the remote I / O substations of the signal transmission layer are interconnected by a third-layer industrial Ethernet. The integrated system for controlling the production processes of coiling, connecting and wrapping the cigarettes improves the productive synergic capability of the production processes of coiling, connecting and wrapping effectively and enhances the production efficiency.

Owner:CHINA TOBACCO HUNAN INDAL CORP

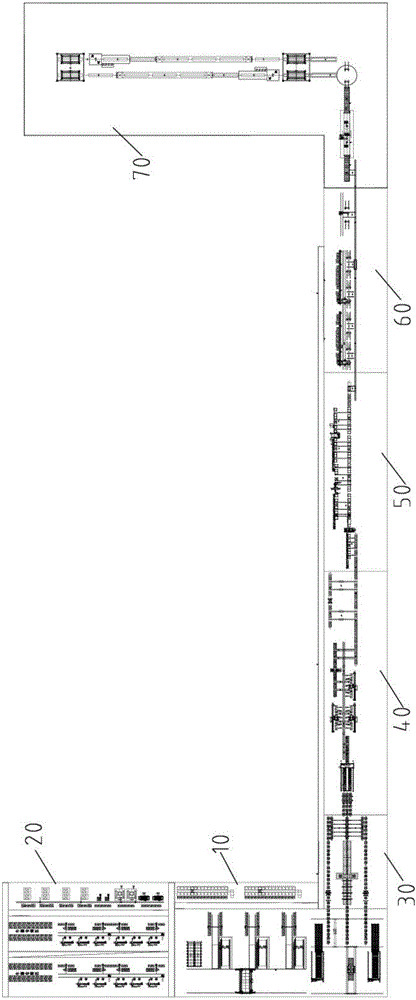

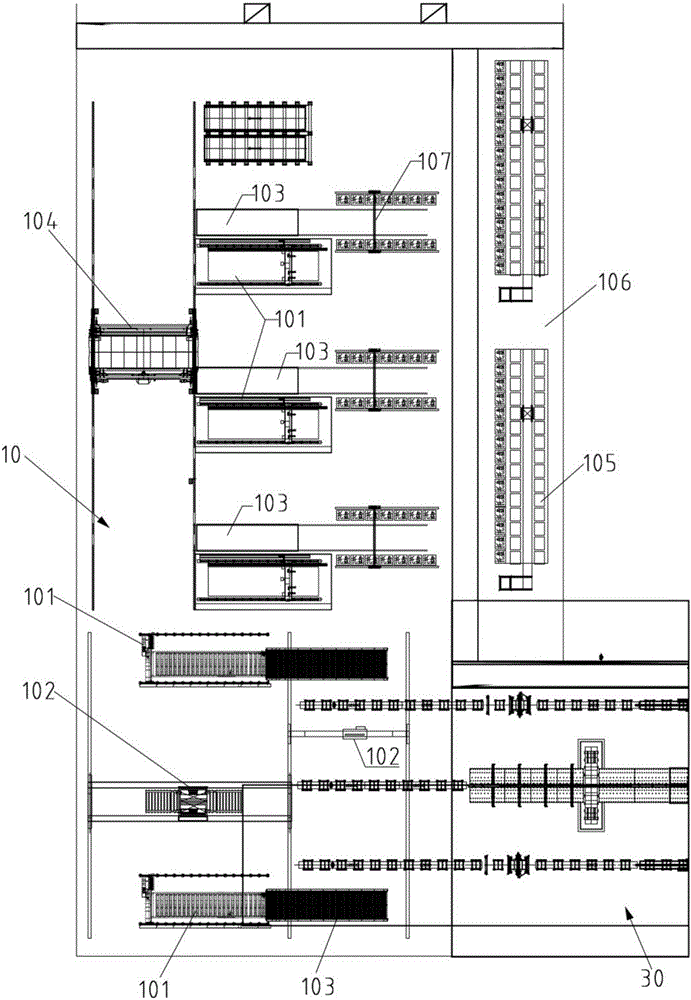

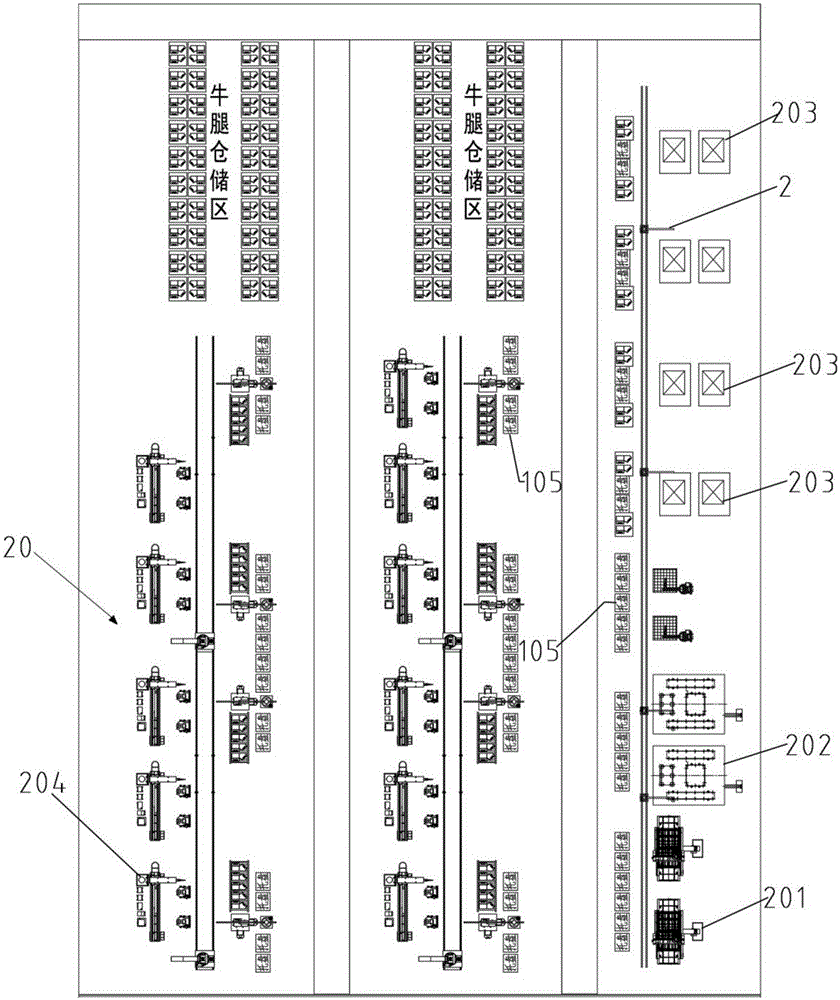

Intelligent production line for H-shaped steel workpieces

ActiveCN106334944AHigh speedAutomate storageOther manufacturing equipments/toolsTotal factory controlProduction lineManufacturing execution system

The invention belongs to the technical field of production equipment for steel workpieces, and provides an intelligent production line for H-shaped steel workpieces. The intelligent production line comprises a manufacturing execution system, an automatic conveying system, a transfer robot, an intelligent discharging center, a part machining center, an automatic milling and grinding center, a horizontal assembly welding center, a drill saw locking center and a robot assembly welding center. The manufacturing execution system is used for production scheduling, storing a machining technological requirement database and sending machining information to the machining centers. Information of the machining centers interacts in real time, and thus the machining quality condition of the prior procedure is transmitted to the next procedure in real time. According to the intelligent production line for H-shaped steel workpieces, a flow line production mode is adopted, so that the production efficiency is improved. An unmanned logistics and storage way is adopted for parts, automatic storage of non-standard parts is achieved, and the part logistics speed is increased. An H-shaped steel horizontal machining technique is adopted, two flanges are completed at the same time in the assembling process, two weld joints are welded at the same time in the welding process, and thus the machining efficiency is improved.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD

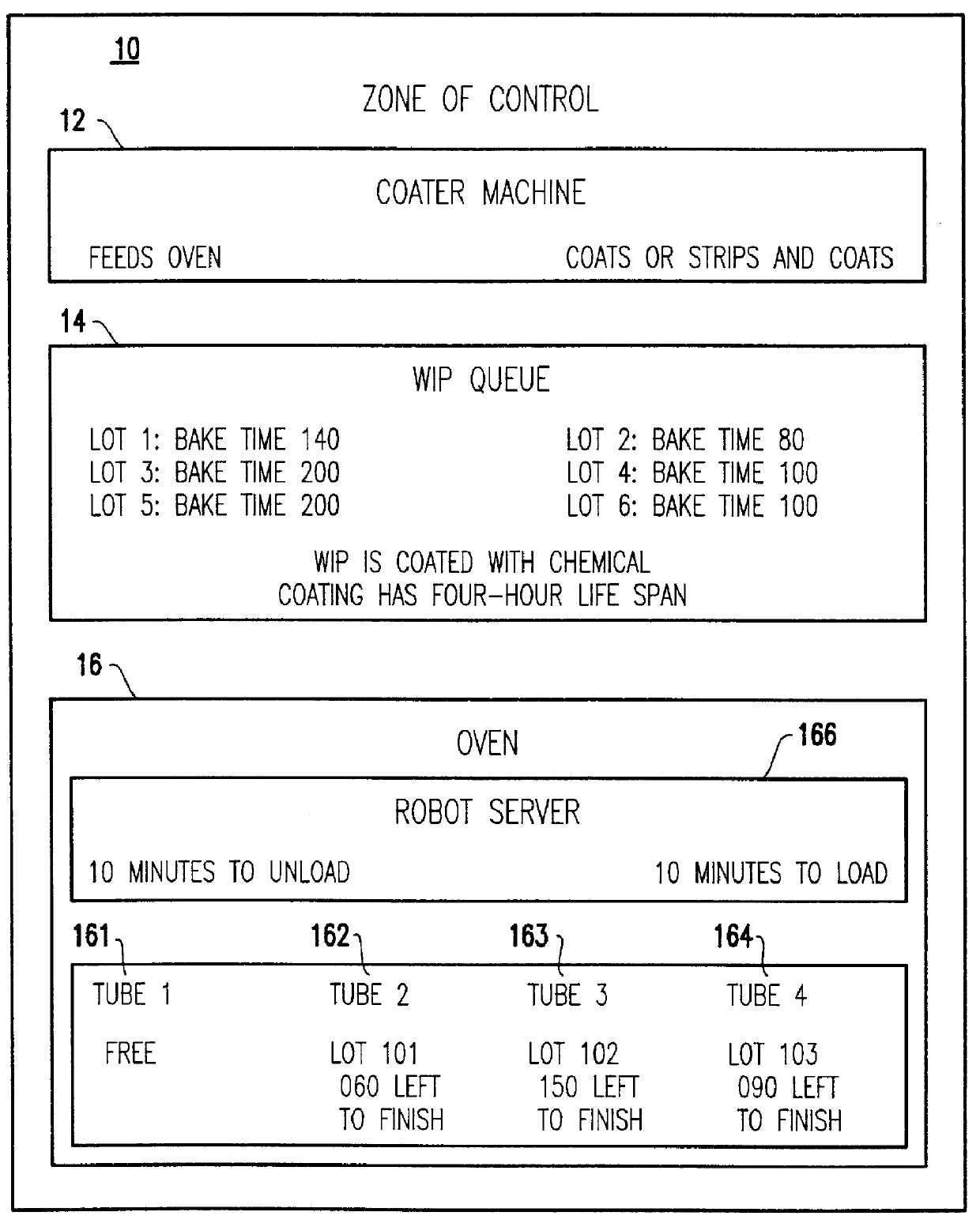

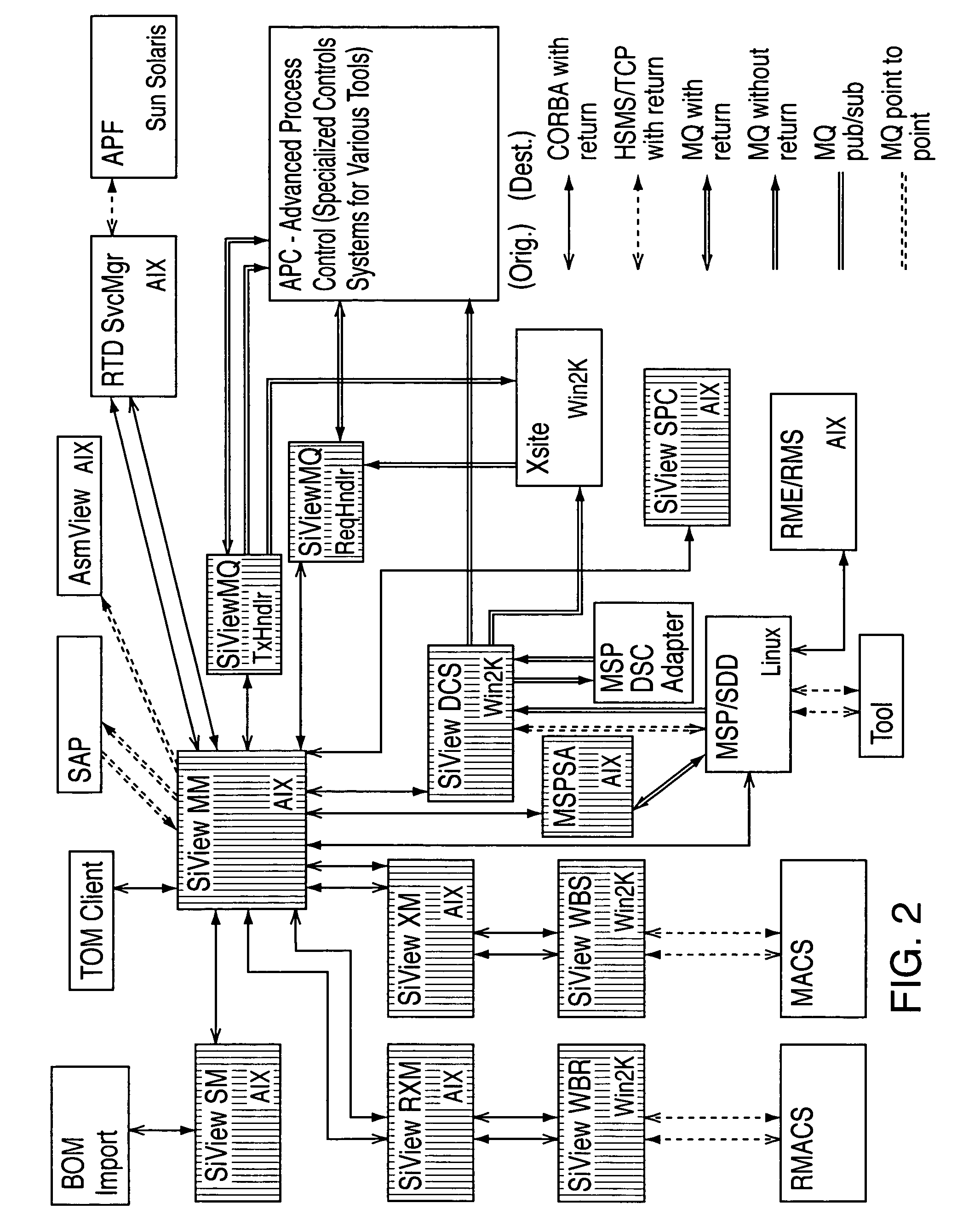

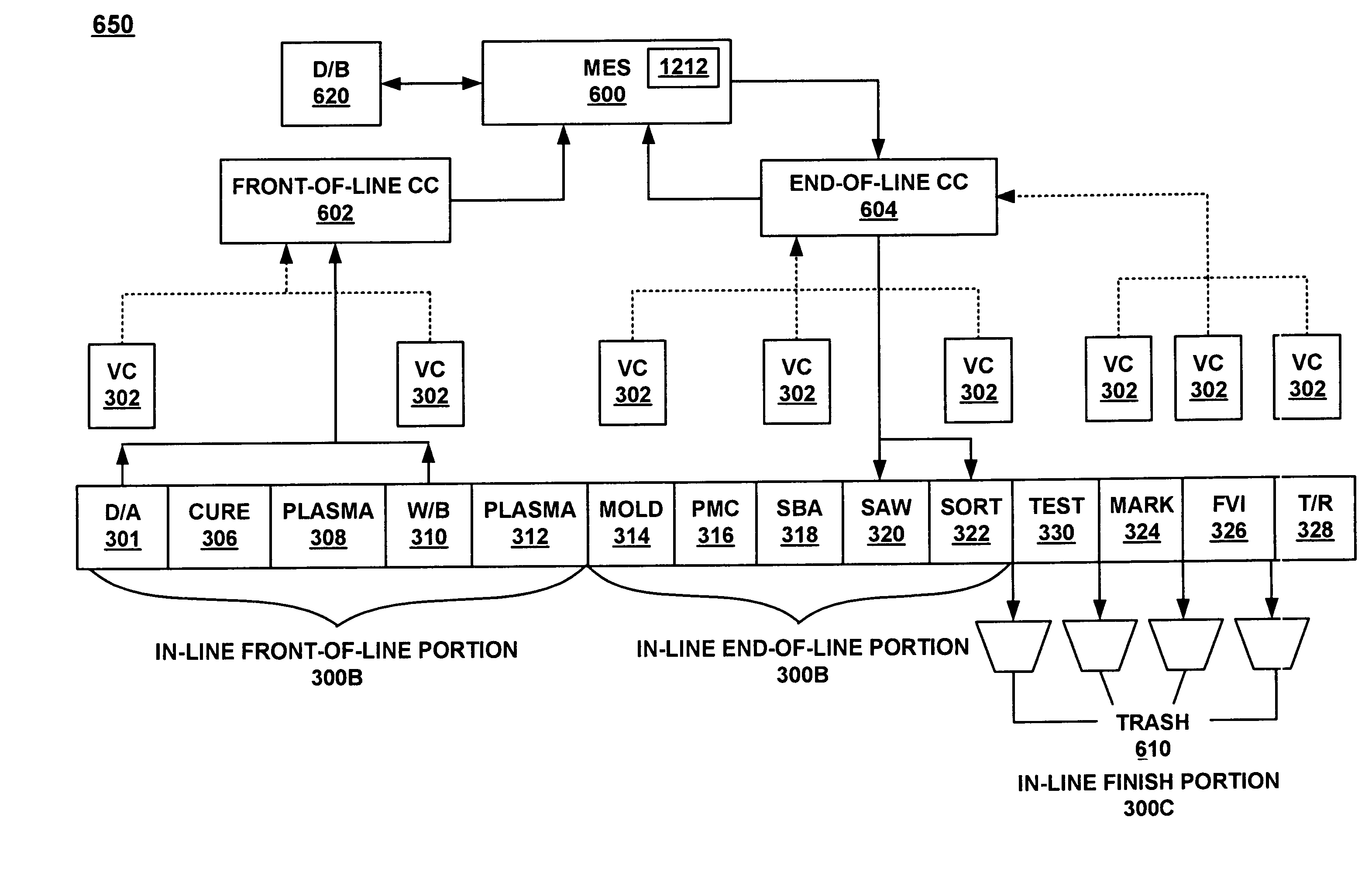

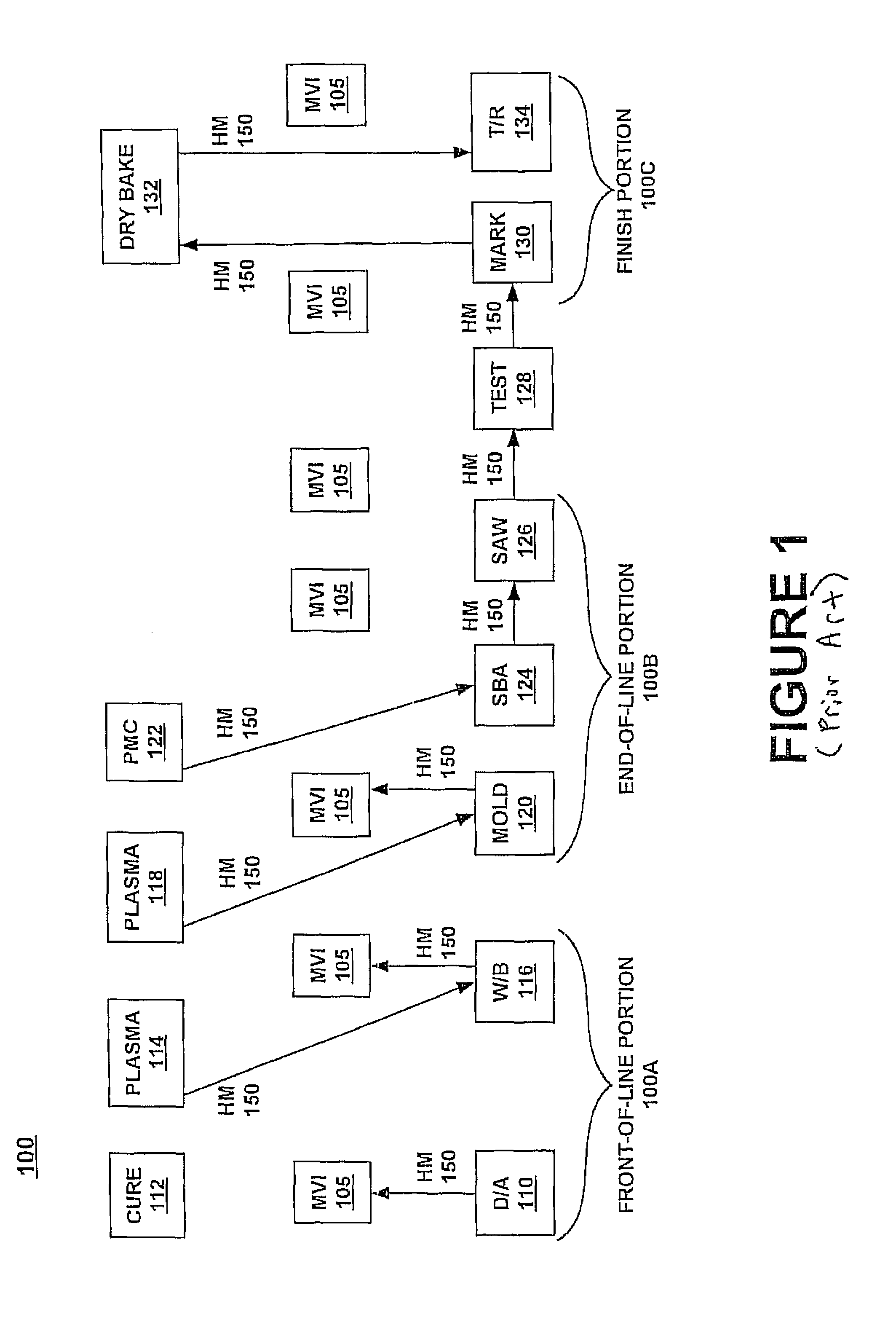

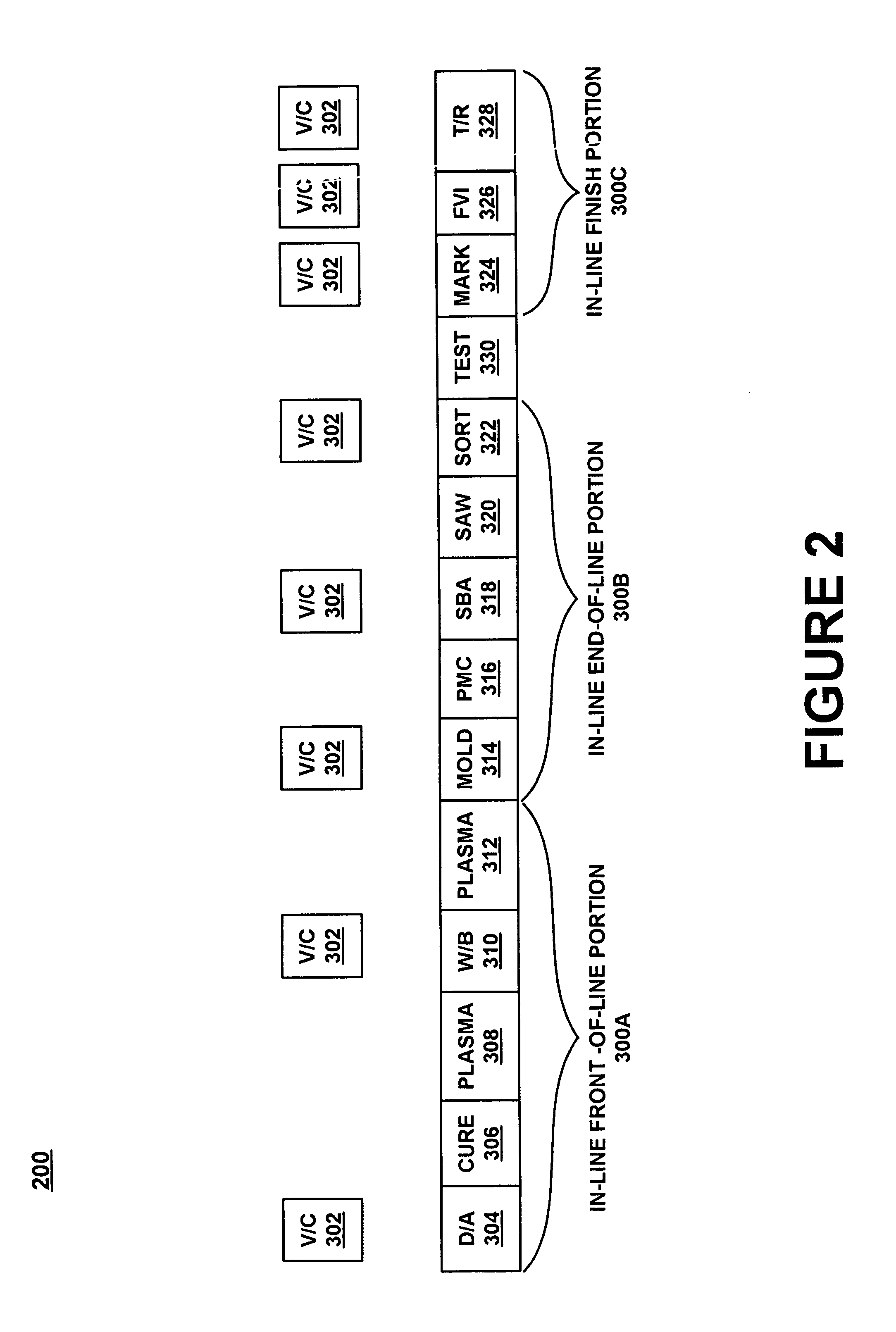

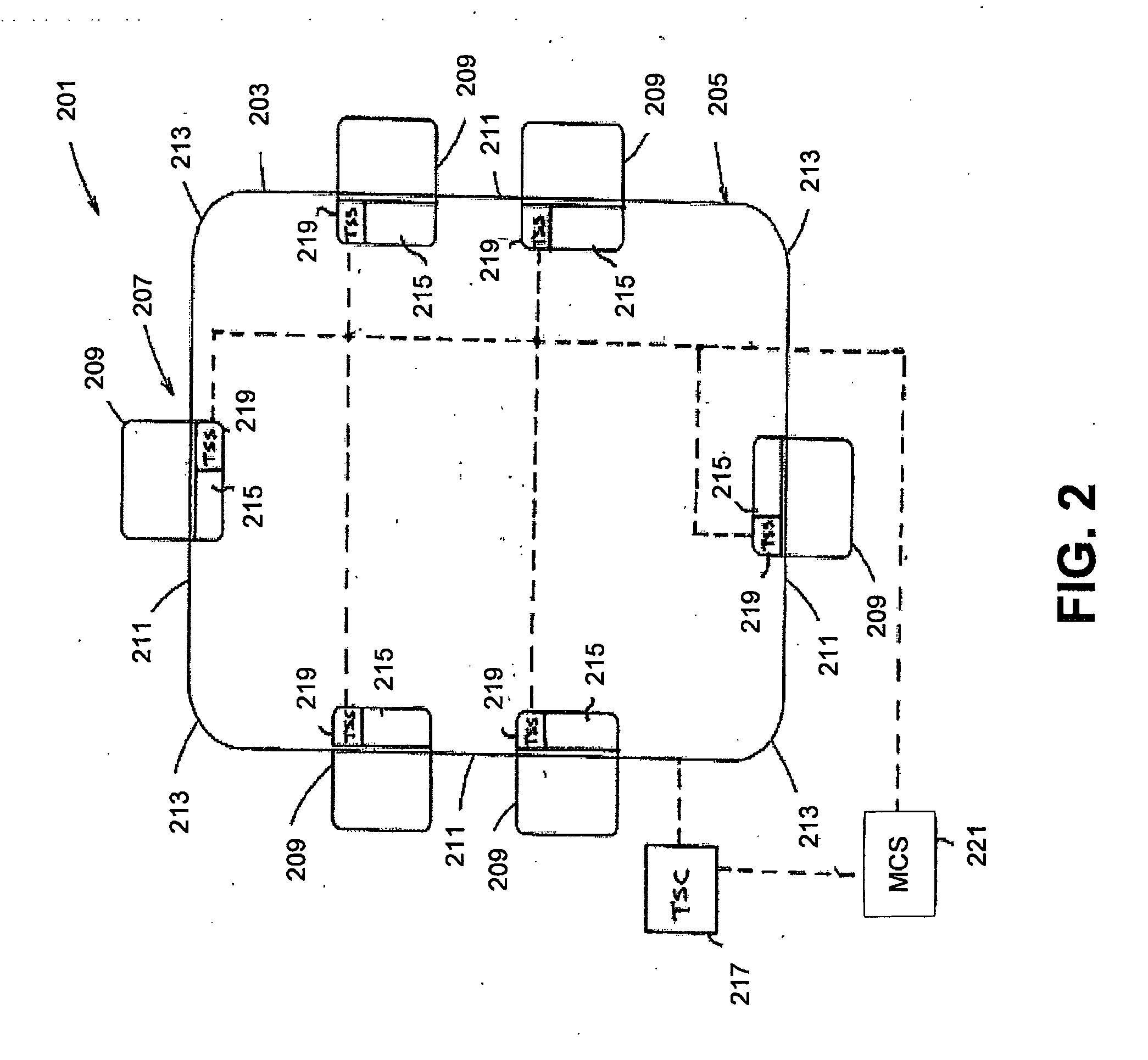

System for controlling the processing of an integrated circuit chip assembly line

InactiveUS7818085B1Proficiently performSmall scaleSemiconductor/solid-state device testing/measurementSolid-state devicesComputerized systemNetwork Communication Protocols

Owner:MONTEREY RES LLC

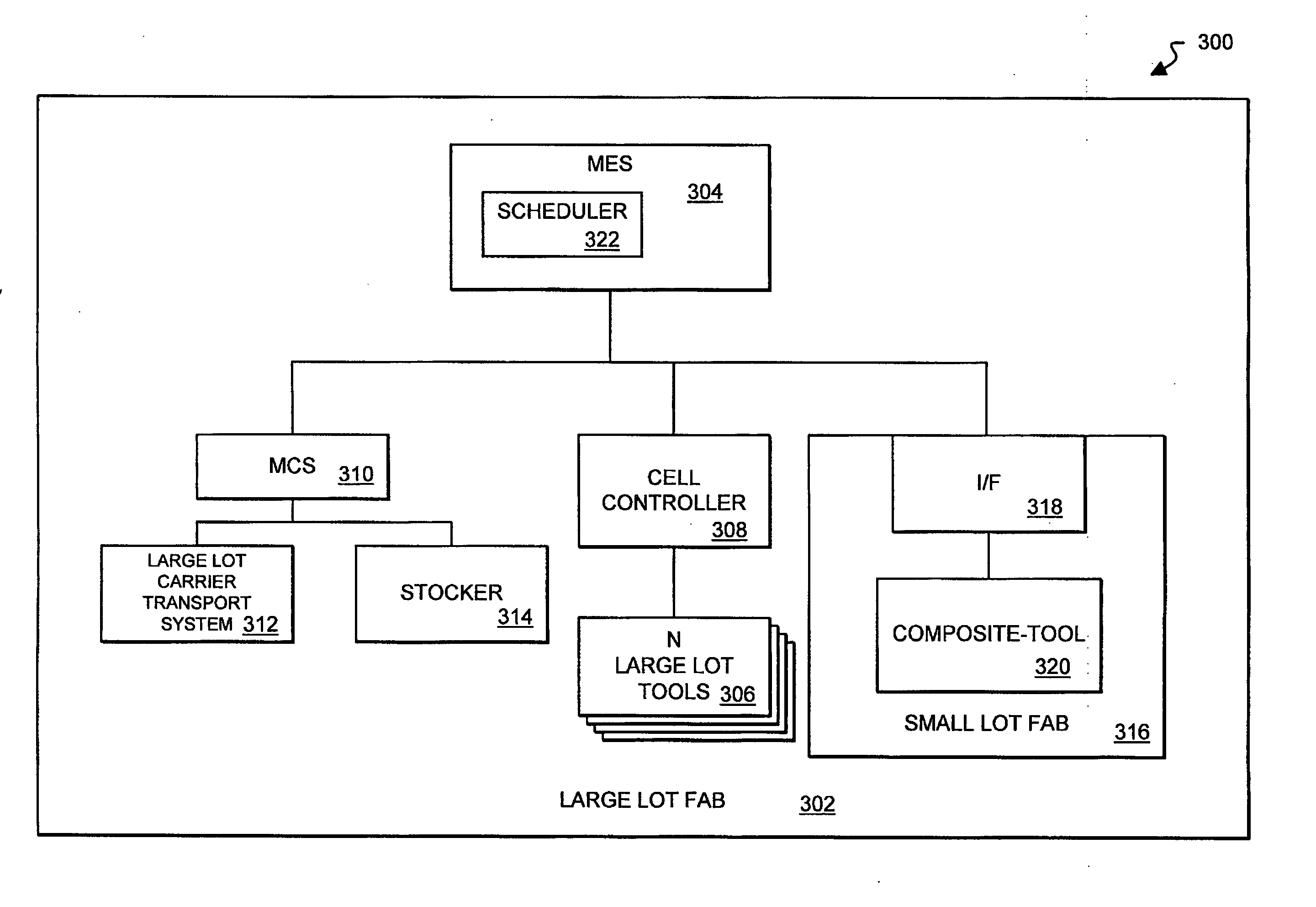

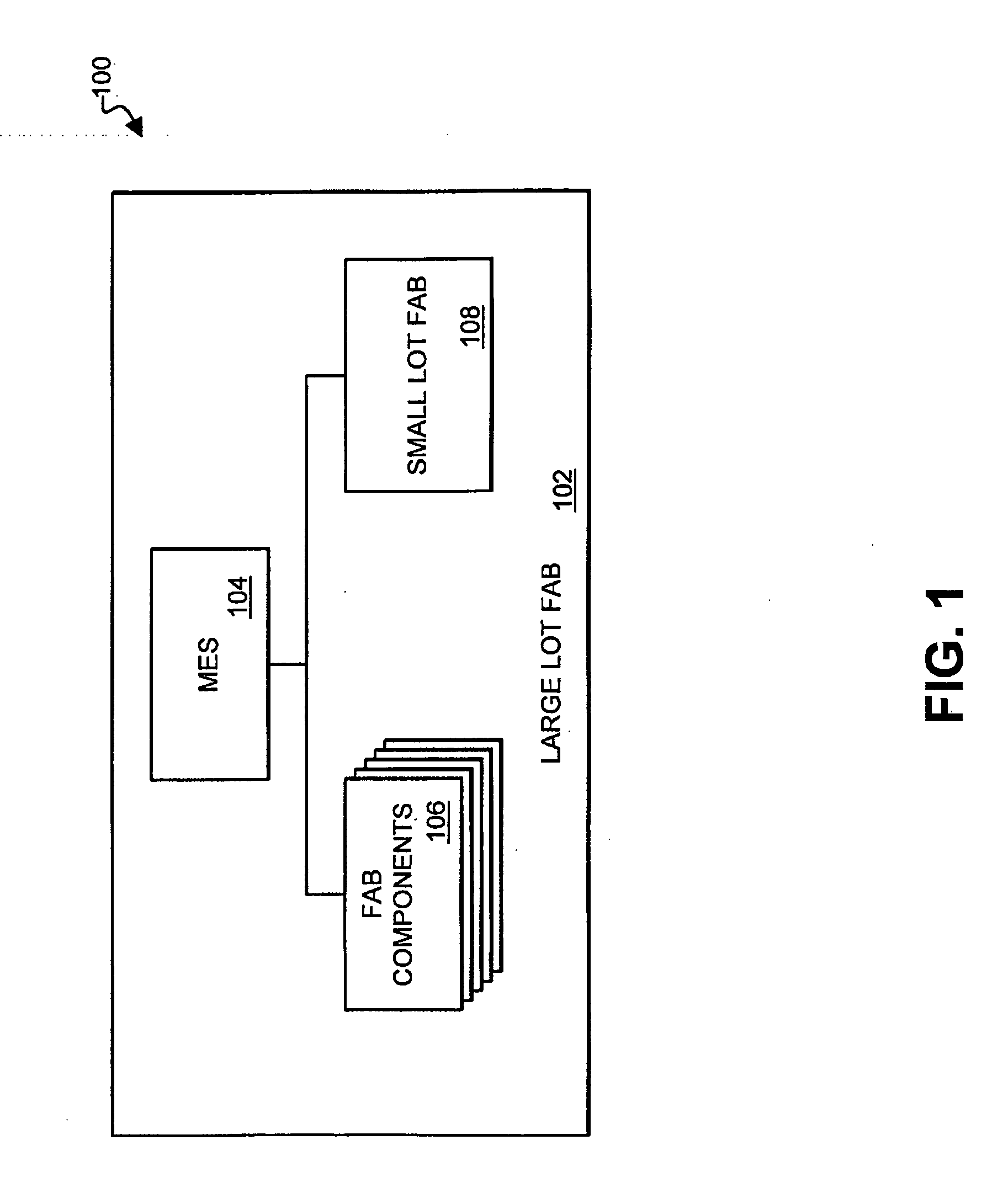

Method and apparatus for integrating large and small lot electronic device fabrication facilities

InactiveUS20050125089A1Digital data processing detailsSemiconductor/solid-state device manufacturingManufacturing execution systemIndustrial engineering

In at least one aspect, the invention provides an electronic device fabrication facility (Fab) that uses small lot carriers that may be transparently integrated into an existing Fab that uses large lot carriers. A manufacturing execution system (MES) may interact with the inventive small lot Fab as if the small lot Fab is any other Fab component in an existing large lot Fab without requiring knowledge of how to control small lot Fab components (e.g., beyond specifying a processing recipe). A small lot Fab according to the present invention may encapsulate the small lot Fab's internal use of small lot components and present itself to a large lot Fab's MES as if the small lot Fab is a component that uses large lot carriers.

Owner:APPLIED MATERIALS INC

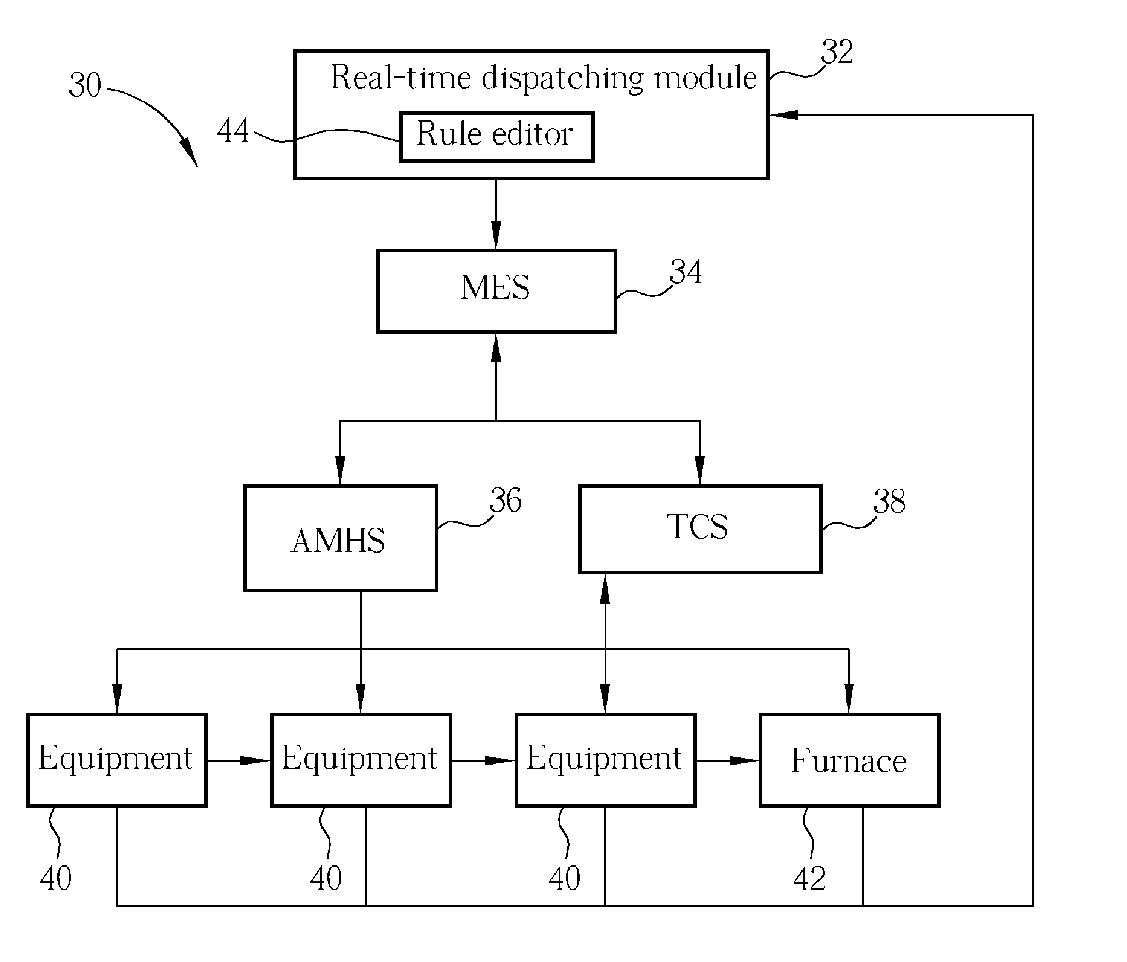

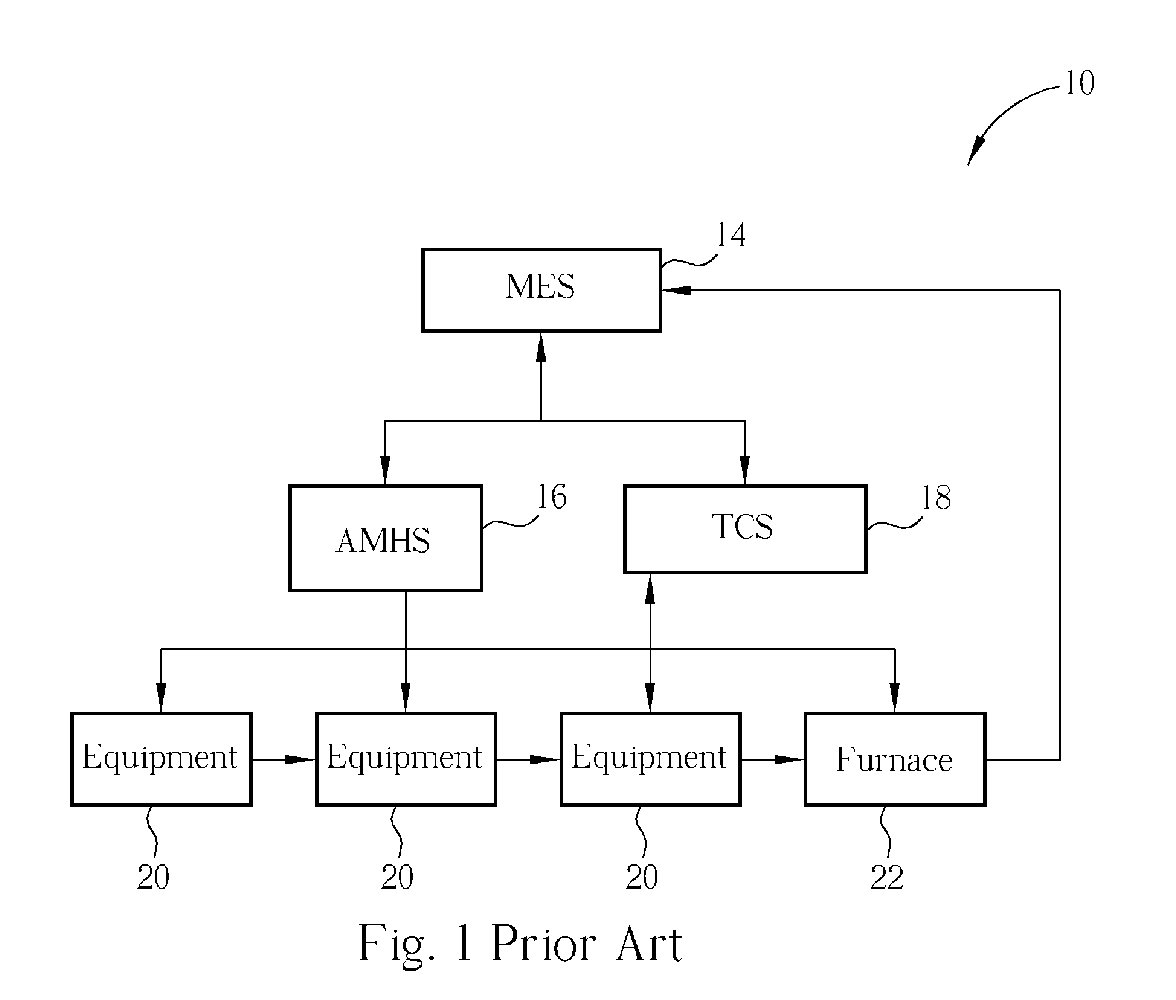

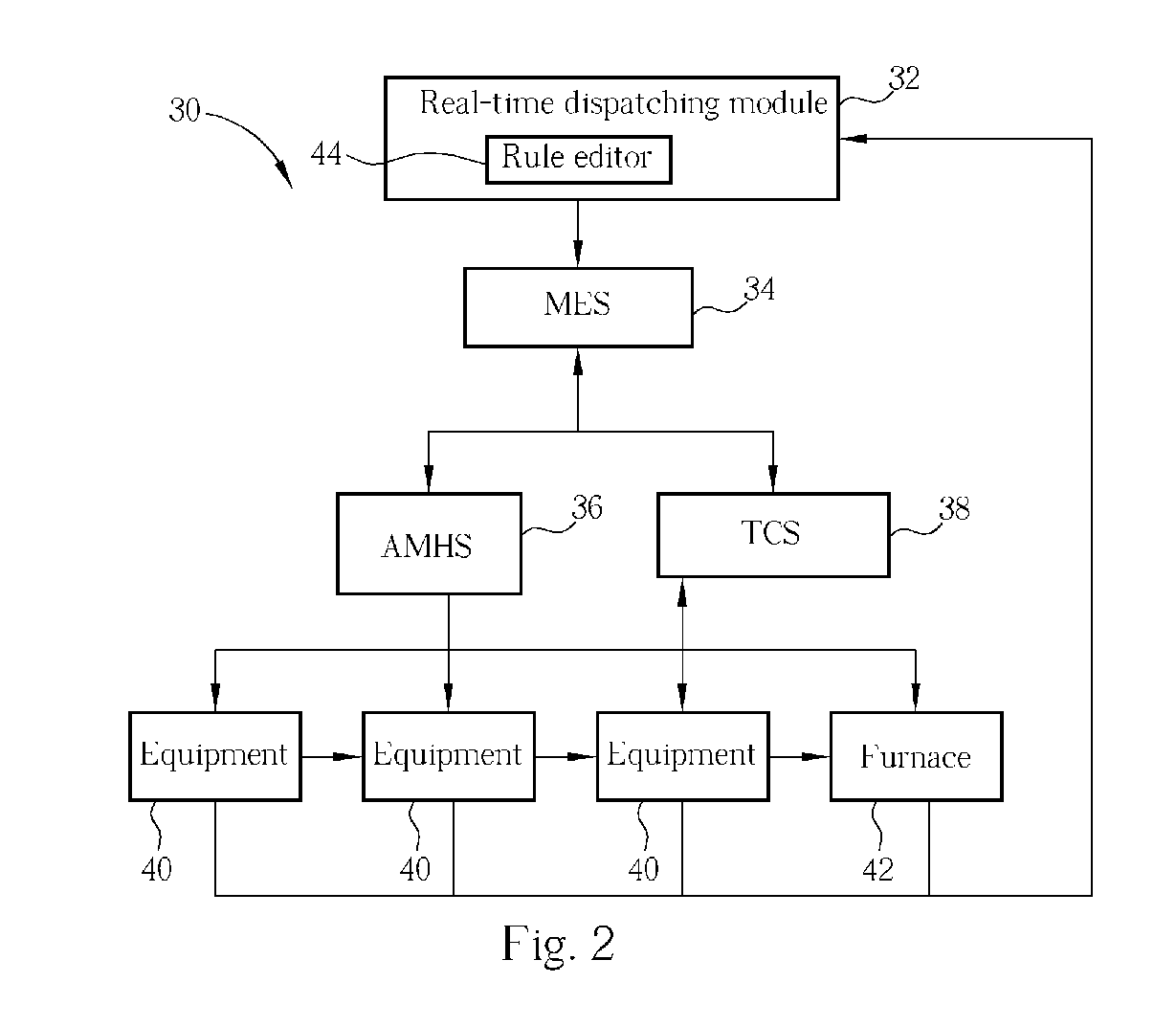

System and method thereof for real-time batch dispatching manufacturing process

InactiveUS20050256599A1Reduce standby timeIncrease profitSemiconductor/solid-state device manufacturingResourcesComputer moduleManufacturing execution system

The present invention provides a system and method for real-time batch dispatching in a manufacturing process. The system includes a bottleneck equipment, a real-time dispatching module for calculating a time point of forming a batch and deciding the lot numbers of a plurality of products which are included in the batch at the time point, and a manufacturing execution system electronically connected to the bottleneck equipment and the real-time dispatching module for receiving the batch transmitted from the real-time dispatching module so as to choose the plurality of products according to the lot numbers and controlling the plurality of products to be simultaneously processed by the bottleneck equipment at the same time point.

Owner:POWERCHIP SEMICON CORP

Method for performing real-time communication between manufacturing execution system (MES) and process control system (PCS) and middleware

InactiveCN102006309ARealize intelligent conversionFulfilling Data Communication RequirementsData switching networksSoftware engineeringManufacturing execution system

Owner:XINYU IRON & STEEL CO LTD

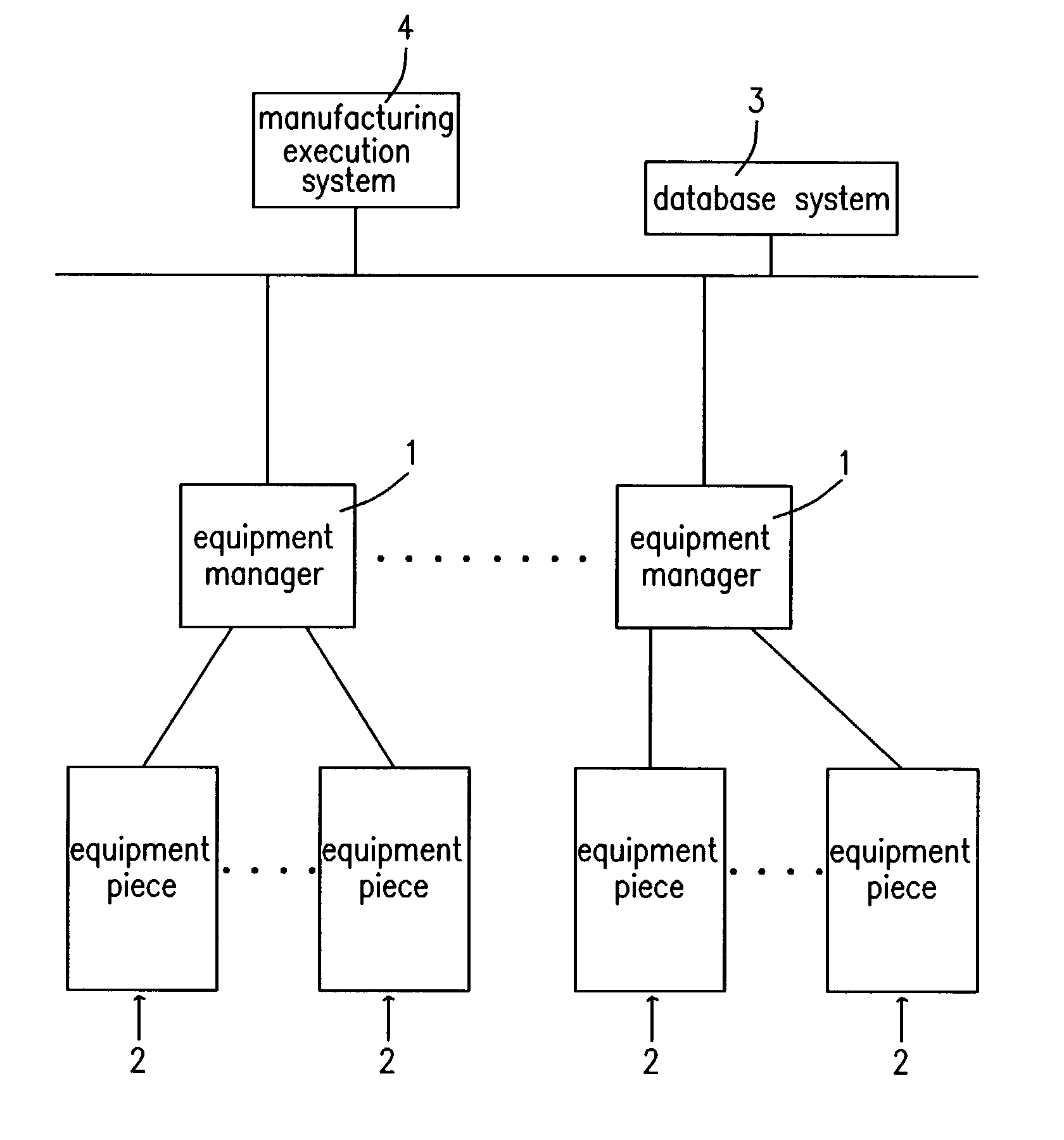

Equipment management method

InactiveUS7003367B2Easy to changeComputer controlSimulator controlManufacturing execution systemComputer science

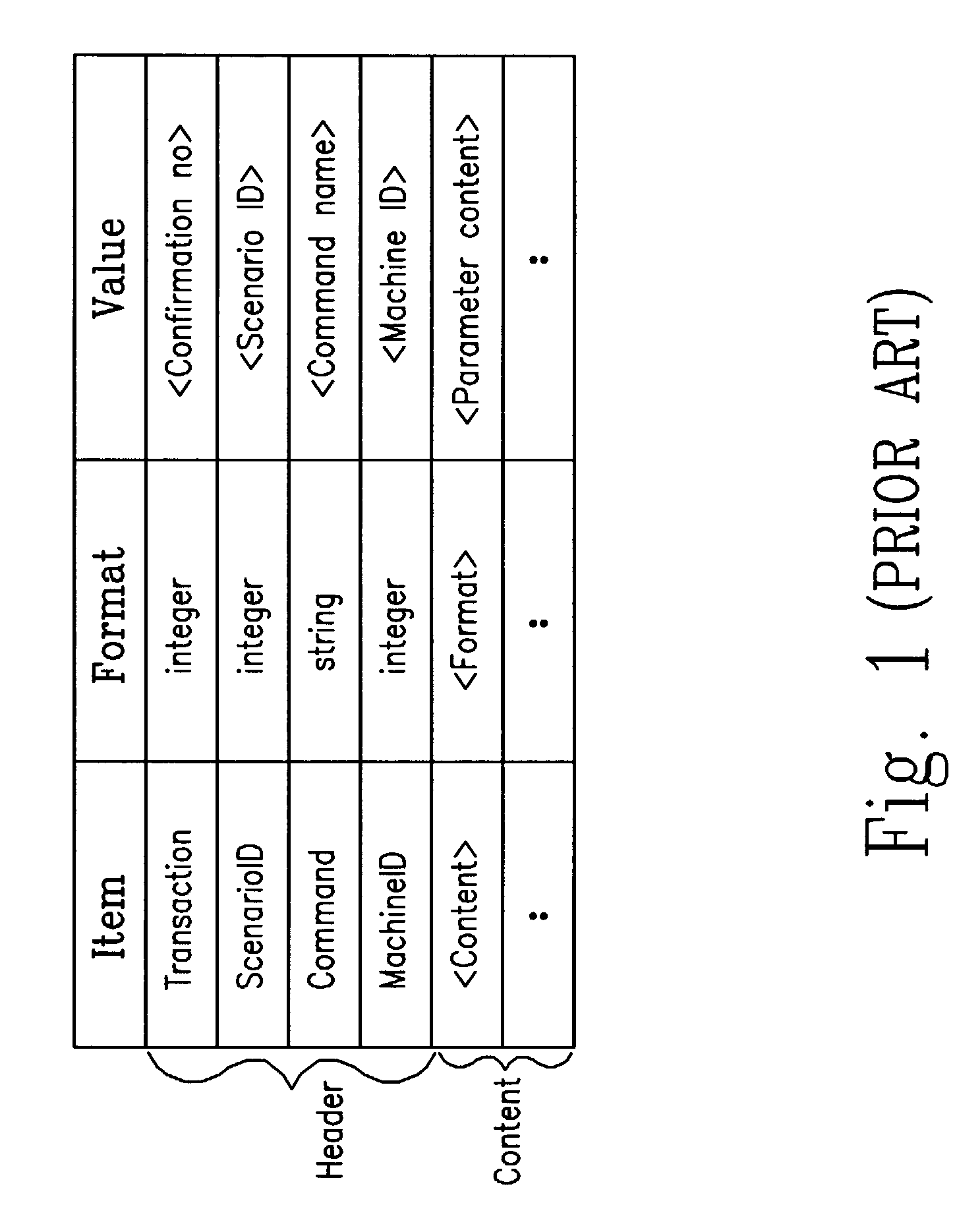

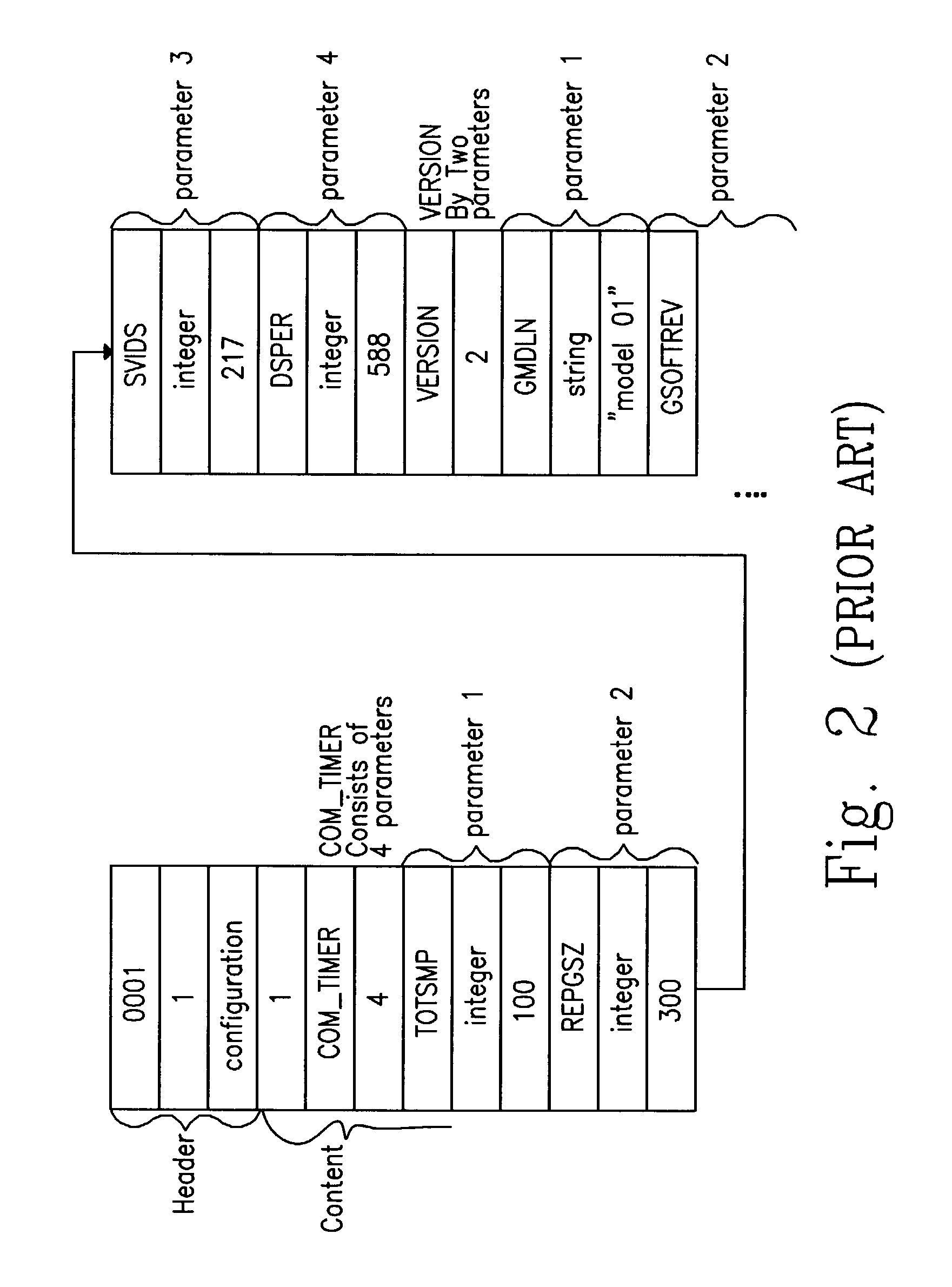

An equipment management method for managing semiconductor equipment via an equipment manager. In the equipment management method, production scenario rules and equipment behavior rules are first defined respectively in a production scenario database of a configuration controller and an equipment behavior database of an equipment driver. Them, a command is received from a manufacturing execution system (MES), and is converted into a production process scenario by looking up the corresponding production scenario rule in the production scenario database. Thereafter, the production process scenario is converted into a GEI (generic equipment interface) message with a GEI message specification, and the GEI message is transmitted to the equipment driver. Then, the GEI message is converted into equipment communication messages regulated by an equipment communication protocol by looking up the corresponding equipment behavior rule in the equipment behavior database. Then, the equipment communication messages are transmitted to equipment.

Owner:NAT SCI COUNCIL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com