Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4524 results about "Recipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A recipe is a set of instructions that describes how to prepare or make something, especially a dish of prepared food. The term recipe is also used in medicine or in information technology (e.g., user acceptance). A doctor will usually begin a prescription with recipe, Latin for take, usually abbreviated as Rx or the equivalent symbol (℞).

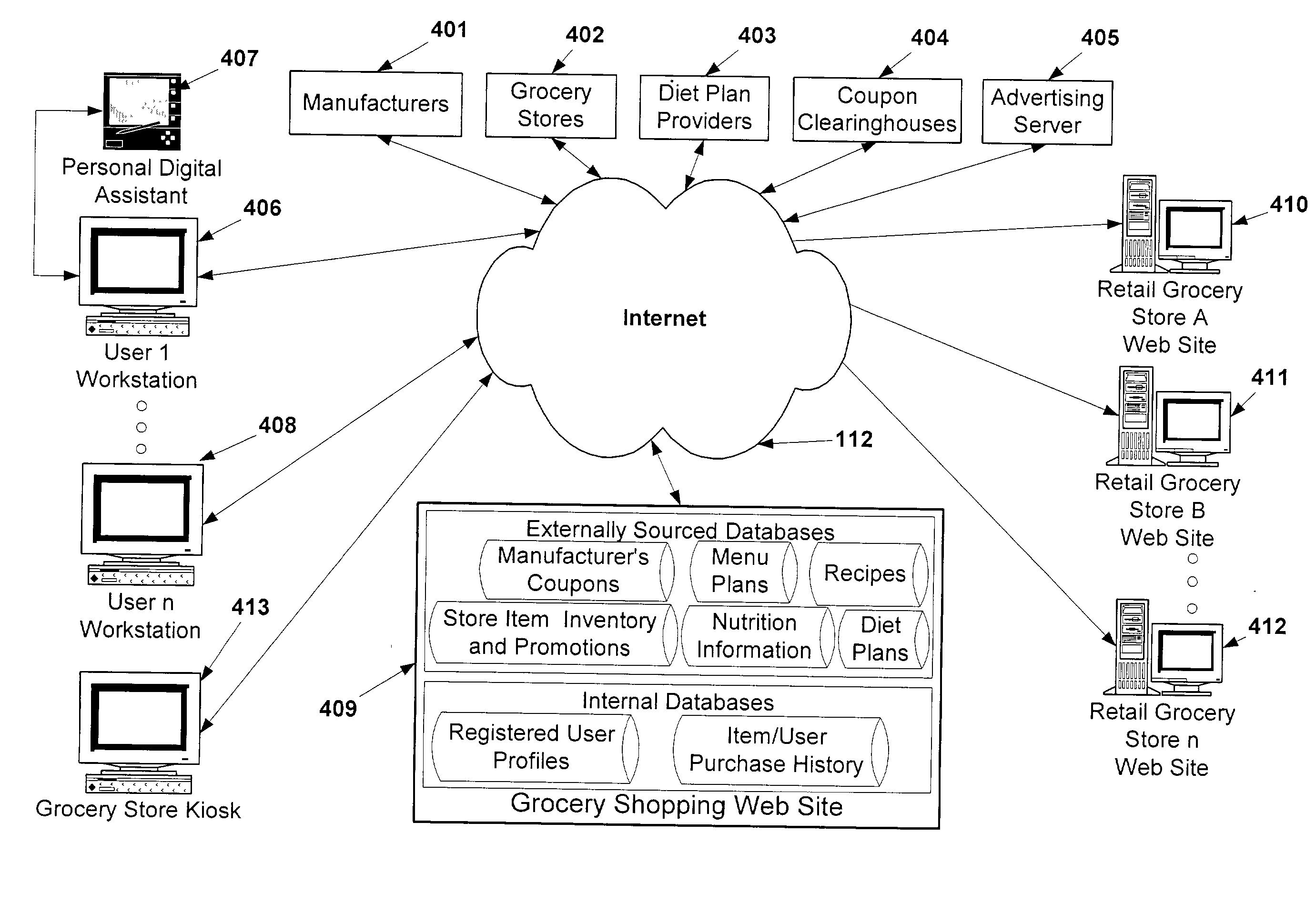

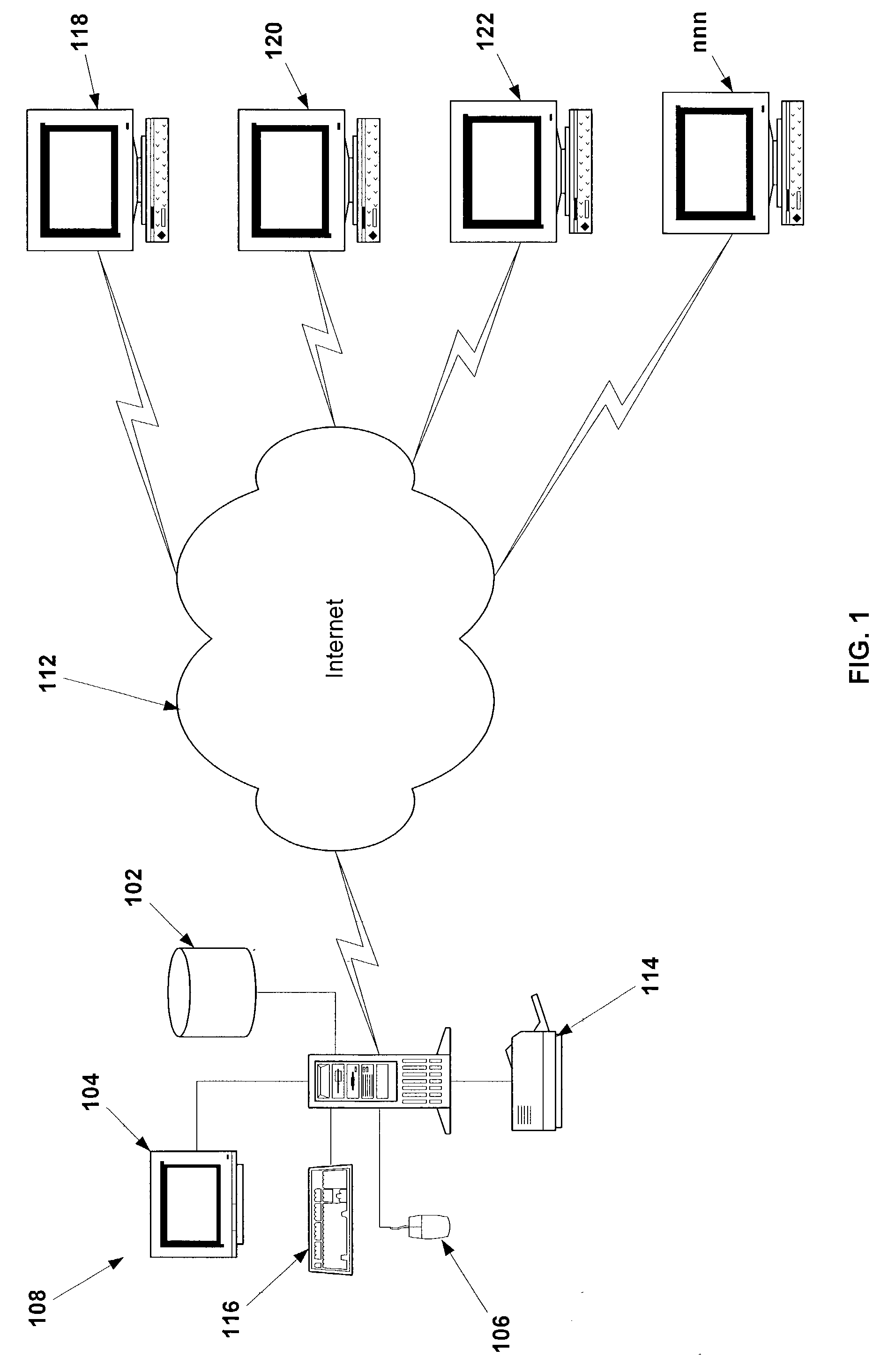

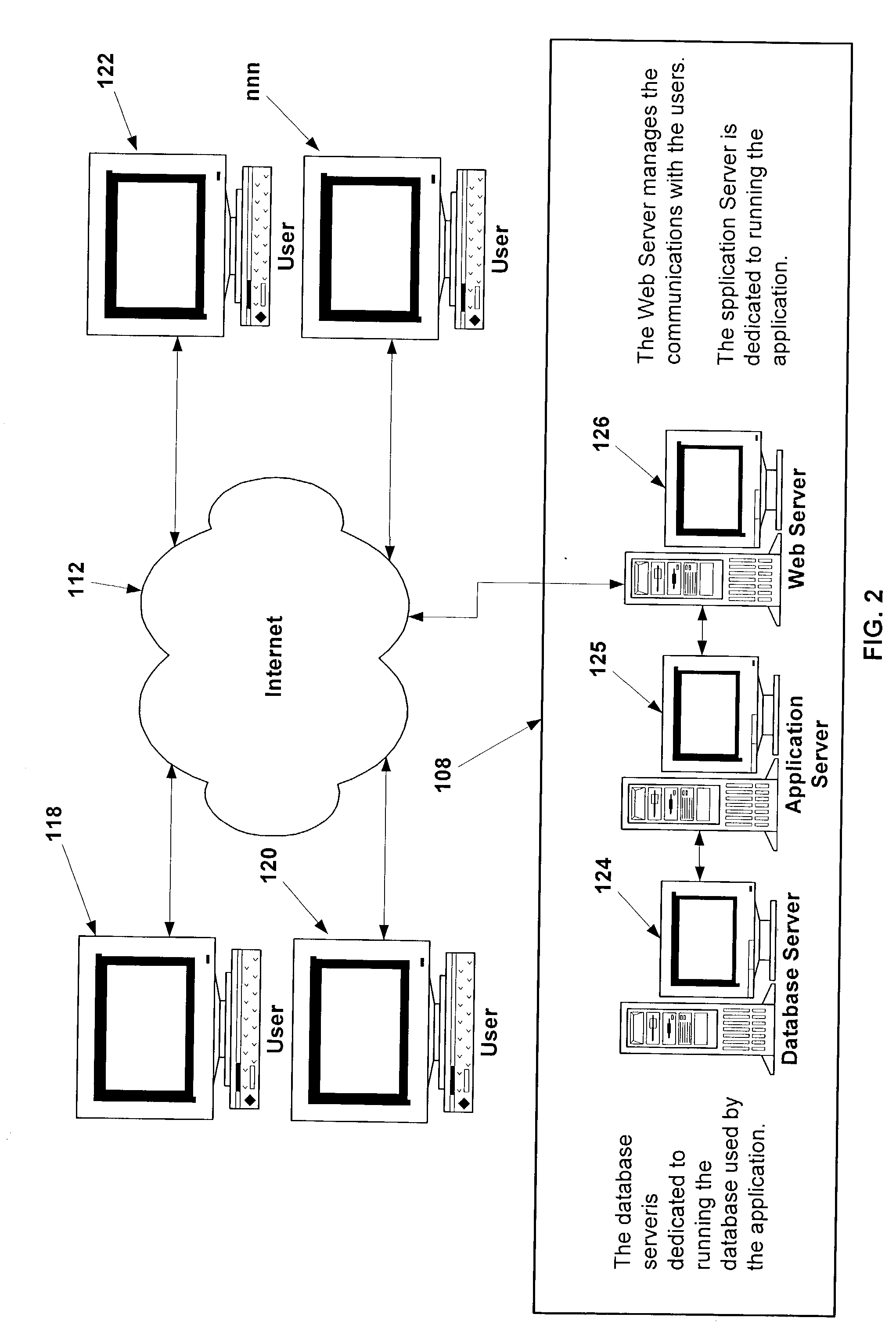

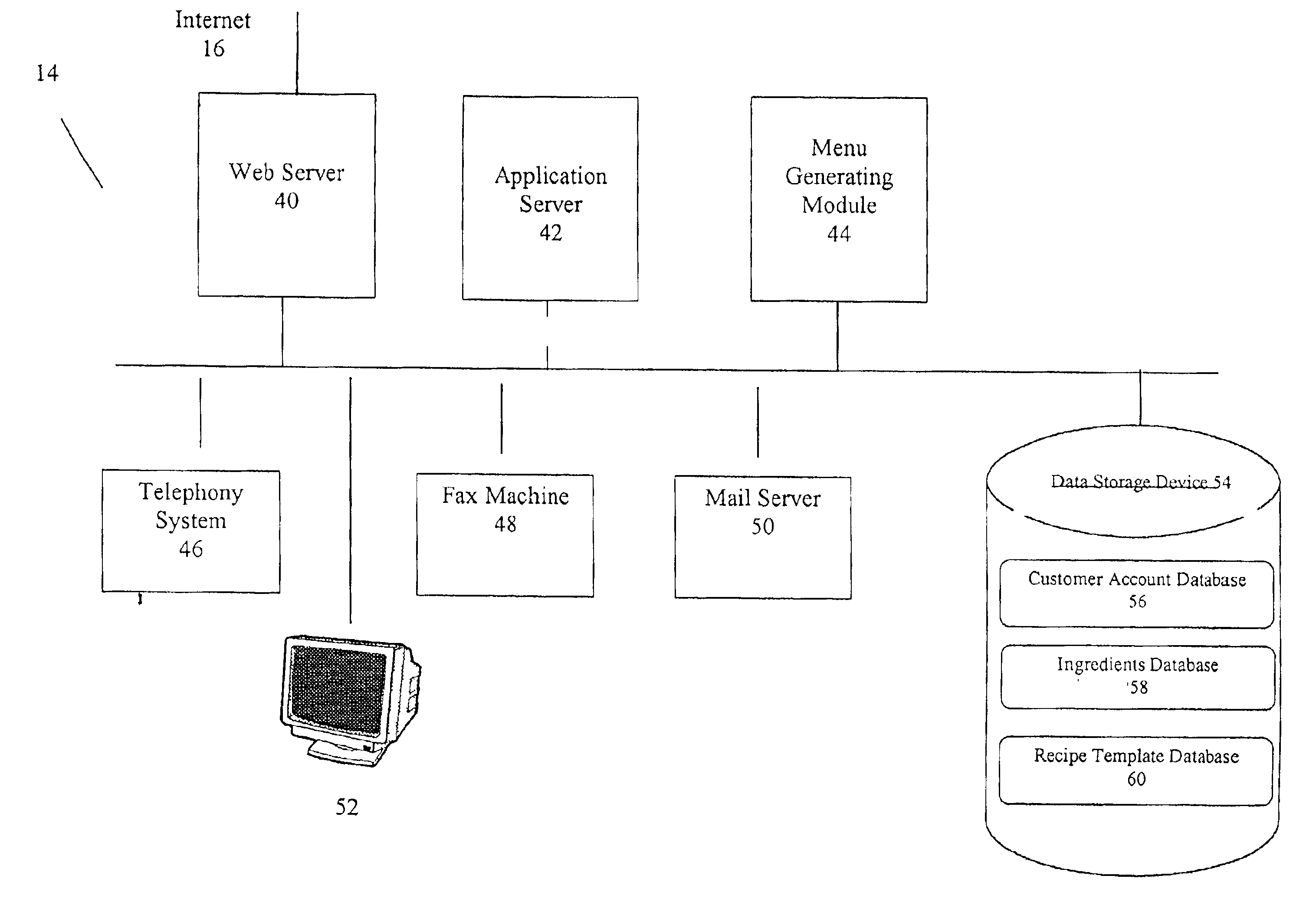

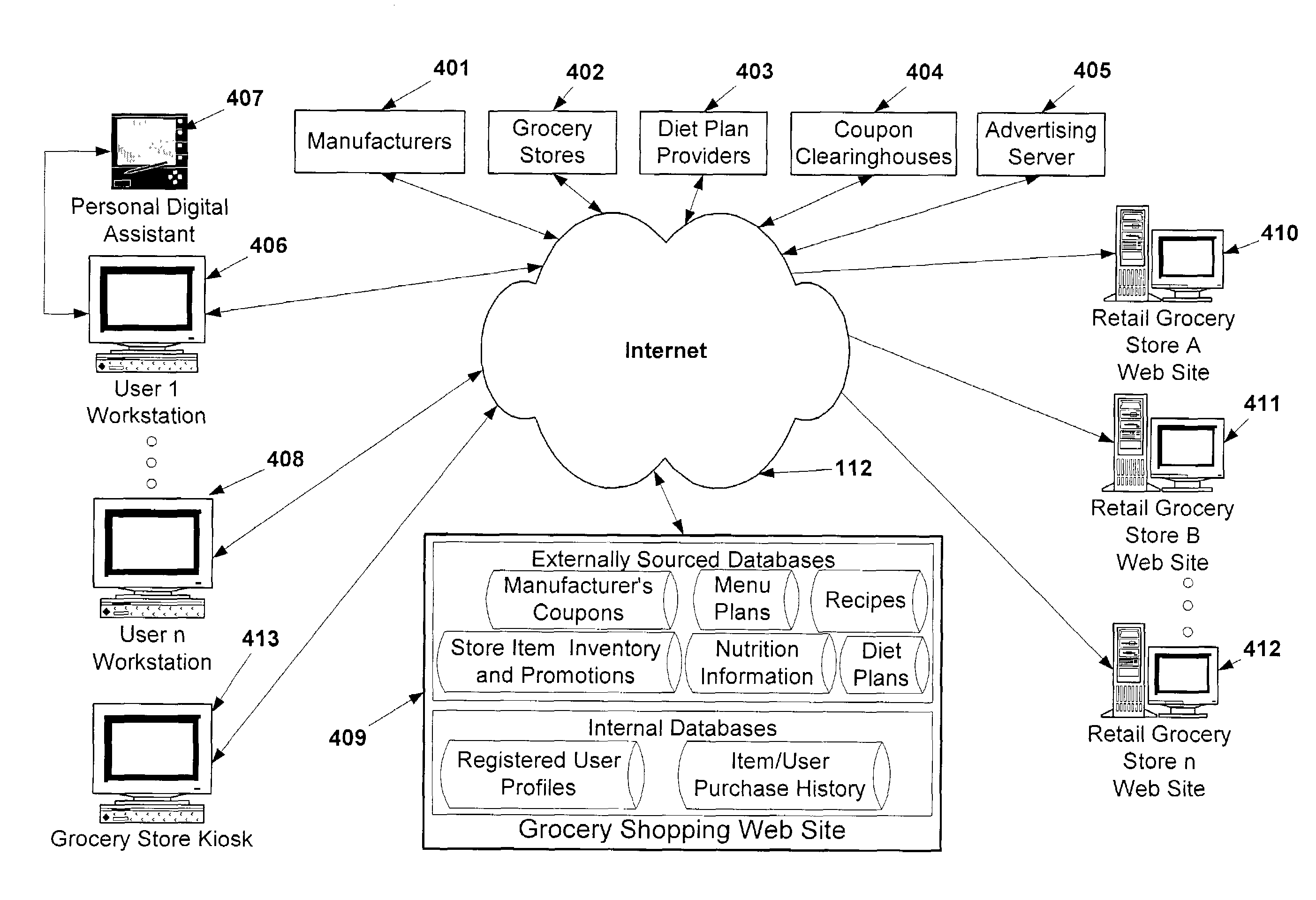

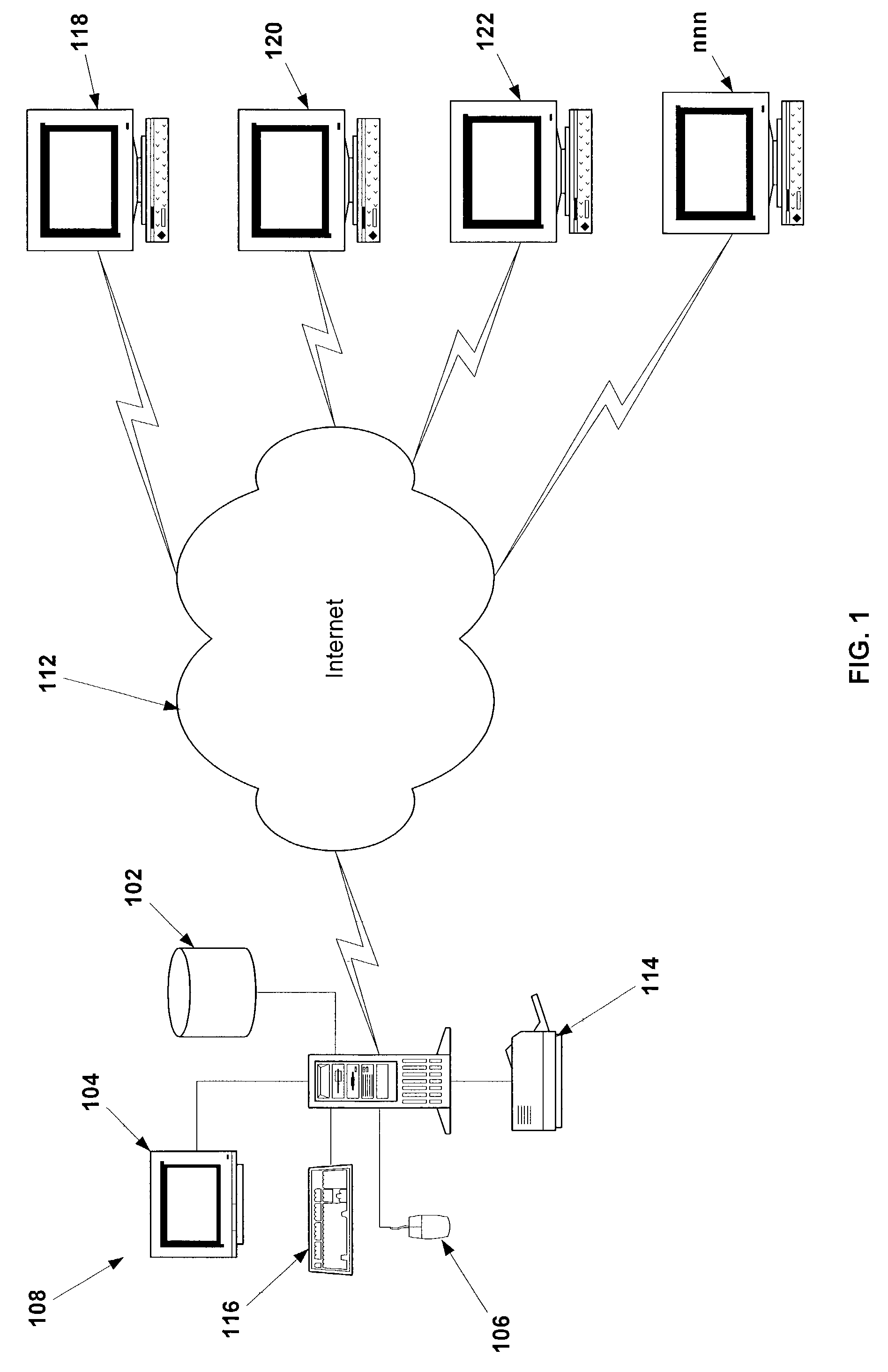

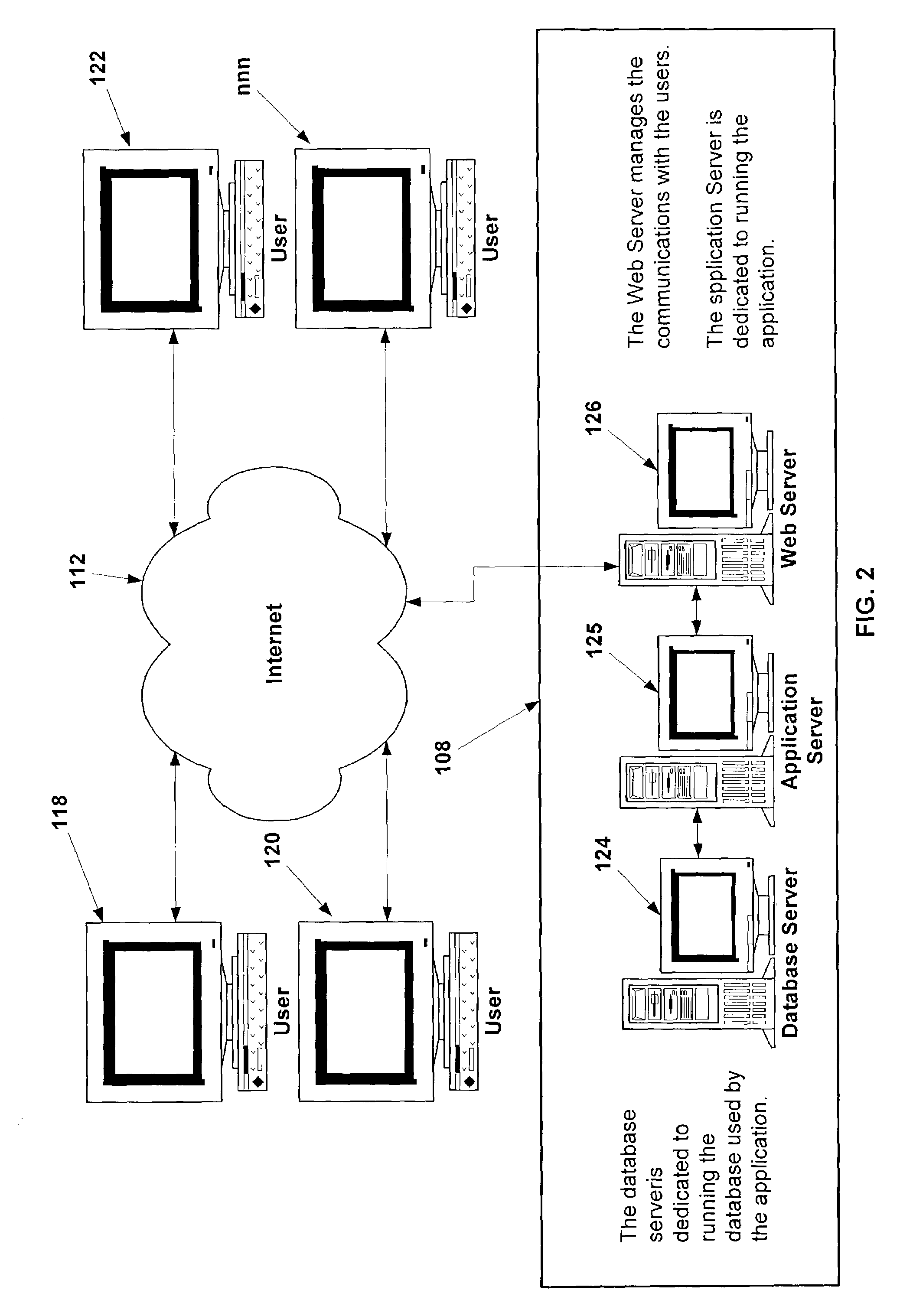

Interactive internet shopping and data integration method and system

ActiveUS20030004831A1Advantage of savingEasy to useAdvertisementsBuying/selling/leasing transactionsWeb sitePayment

A method and system for interactively shopping for groceries, especially on an Internet web site, where the user may create a shopping list, shop for items from the list at a selected Grocery Storey store, arrange for pick up or delivery of the selected items and payment, or to download the list to a PDA or for printing with the store's layout for use in the store. Users are required to register and provide specific demographic information (useful to Manufacturers and stores) to be eligible to receive the benefits of use of the web site, such as menu creation, coupon downloads, menu planning, and recipe input. Shopping lists may be created from a single input screen using standard language text; and products may be automatically suggested to the user based on best regular price or retailer's specials. Recipes may be altered to meet numbers of servings or dietary requirements and changes stored for future use.

Owner:OWENS CSTEPHANI D

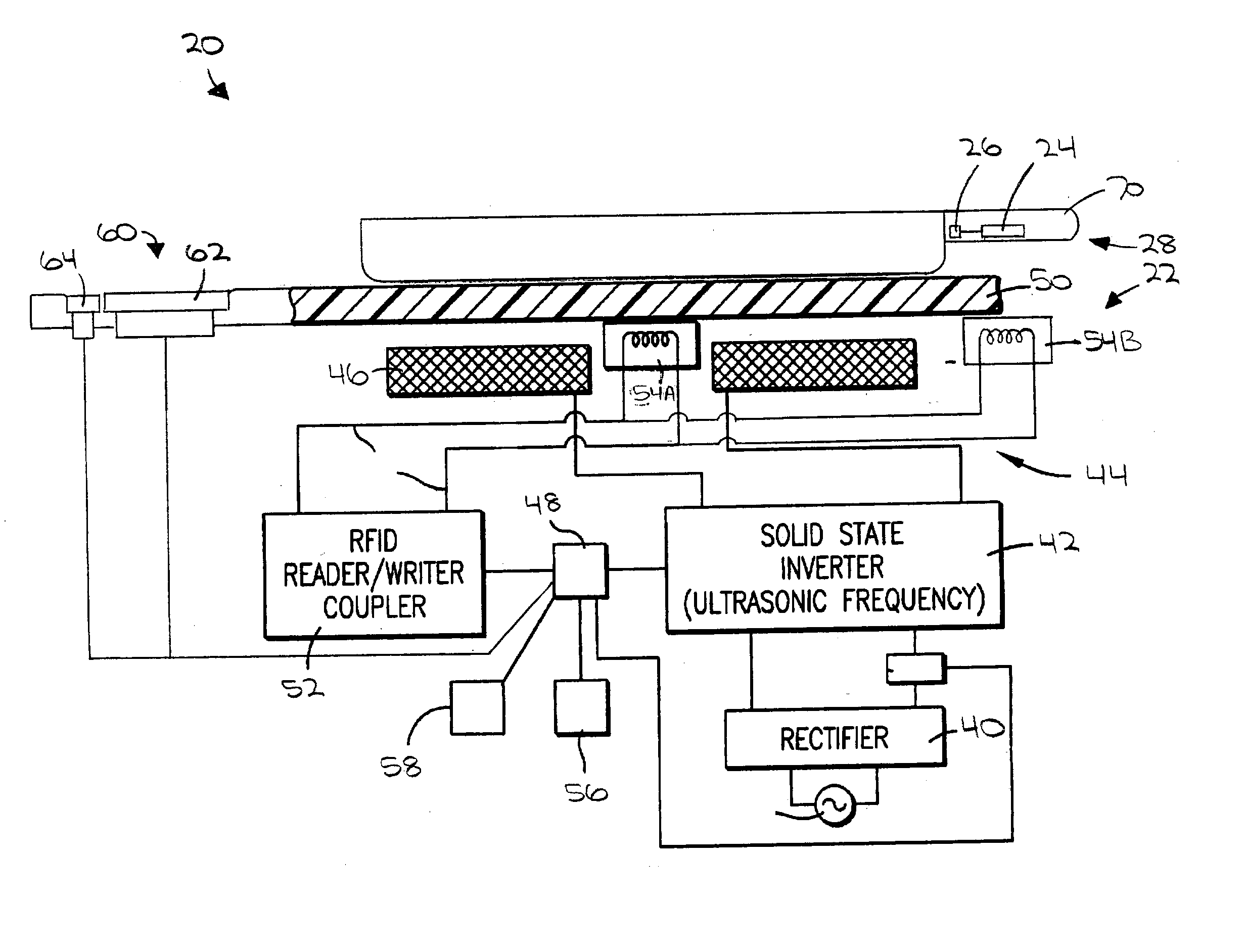

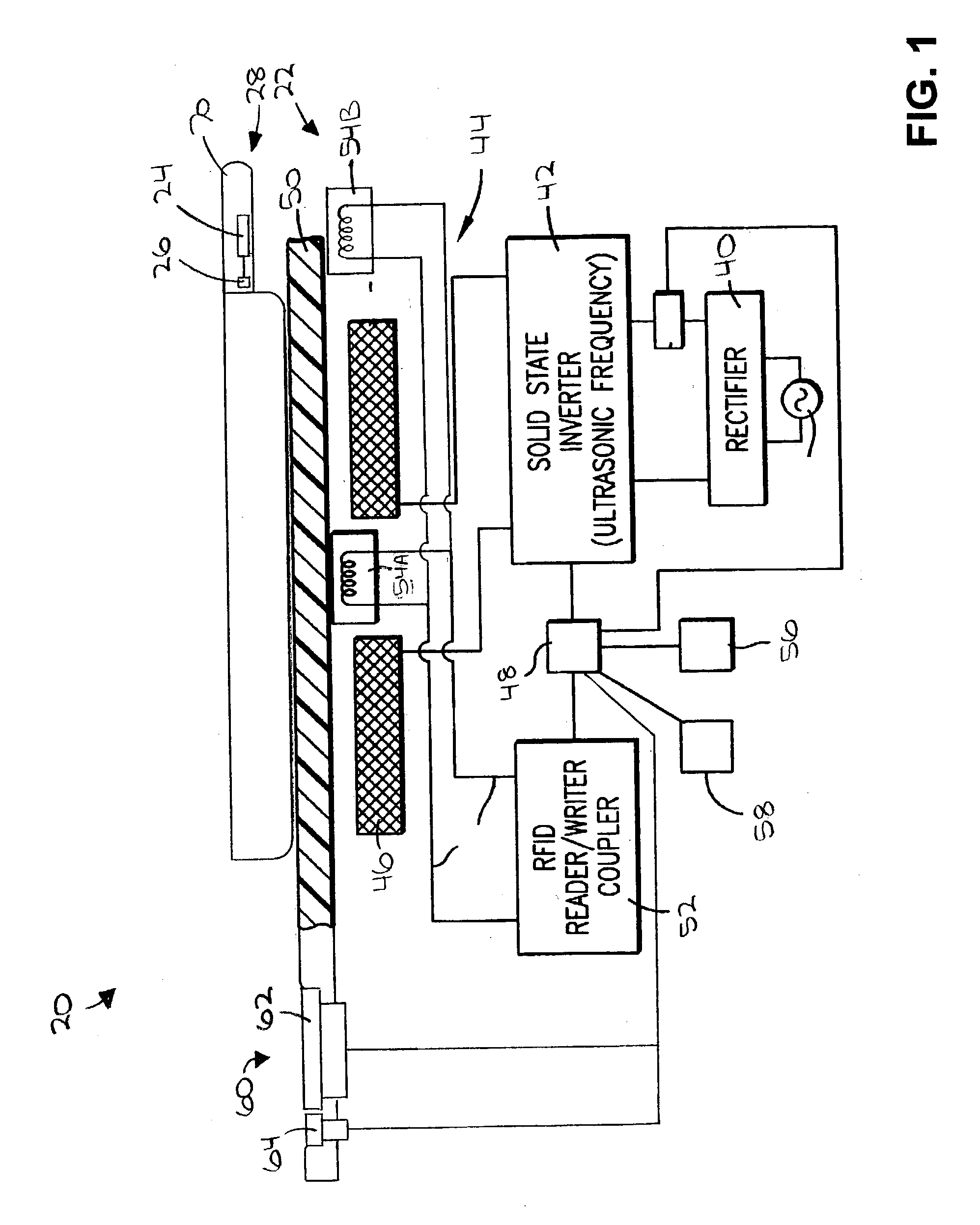

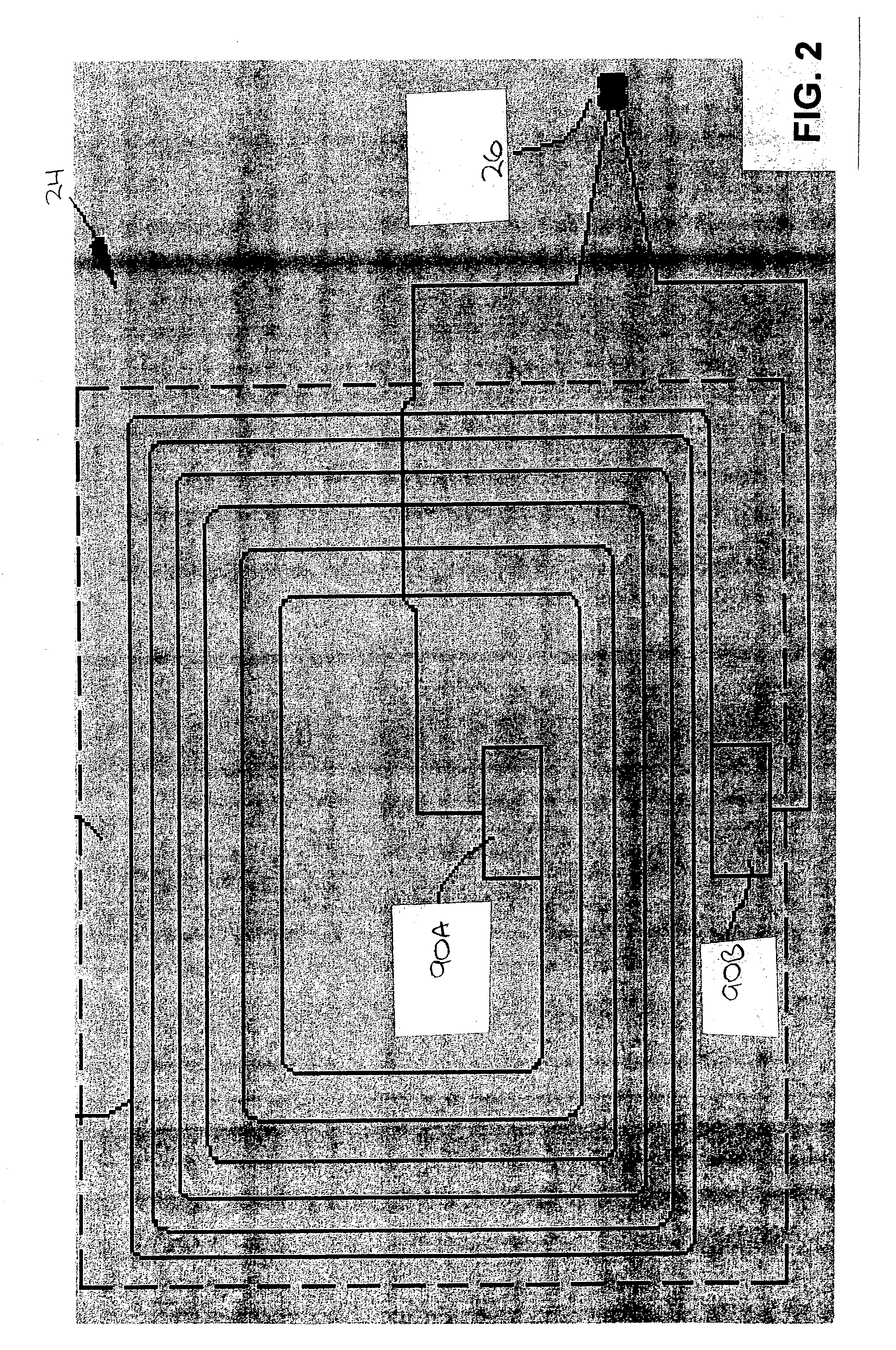

RFID-controlled smart induction range and method of cooking and heating

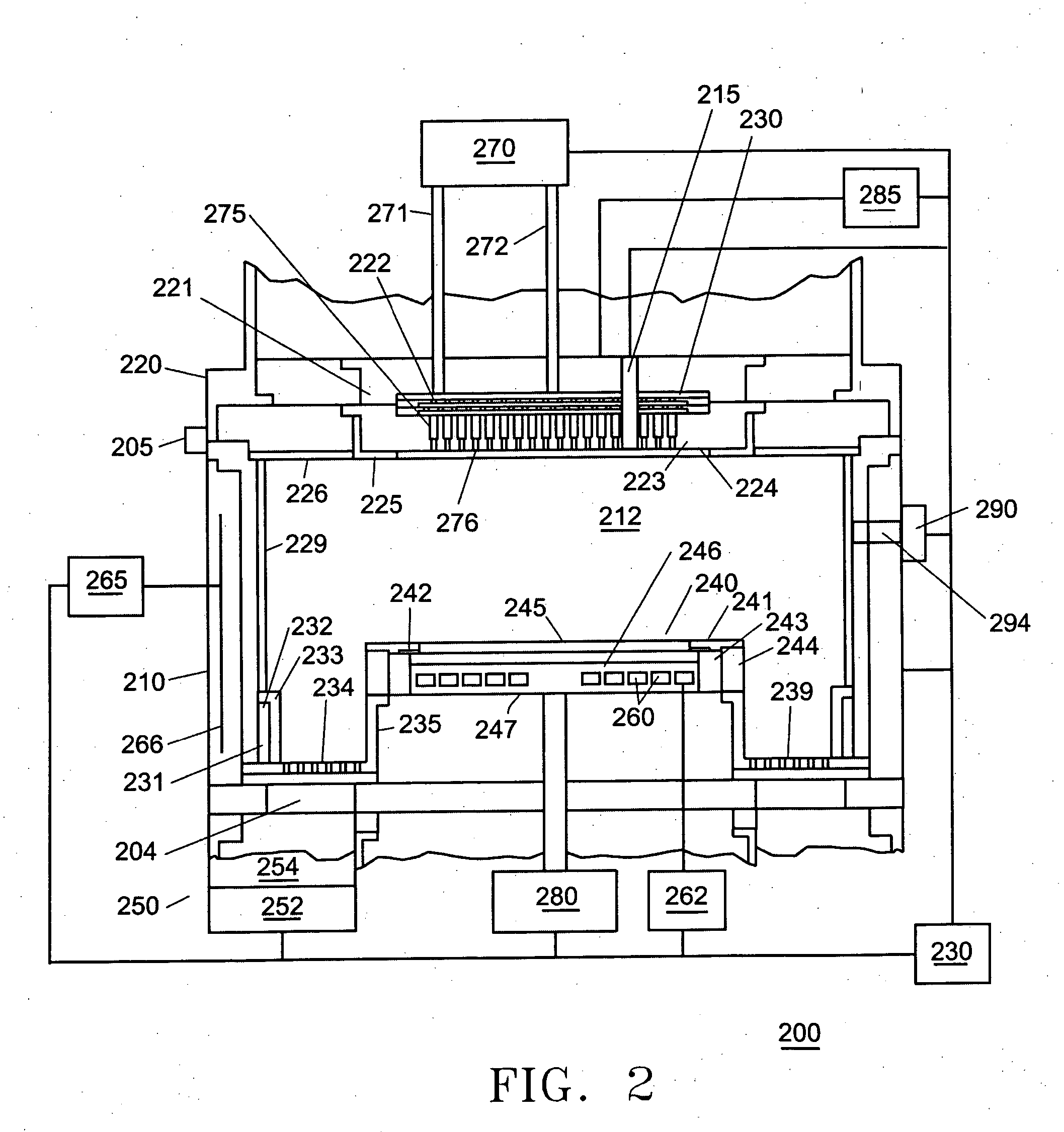

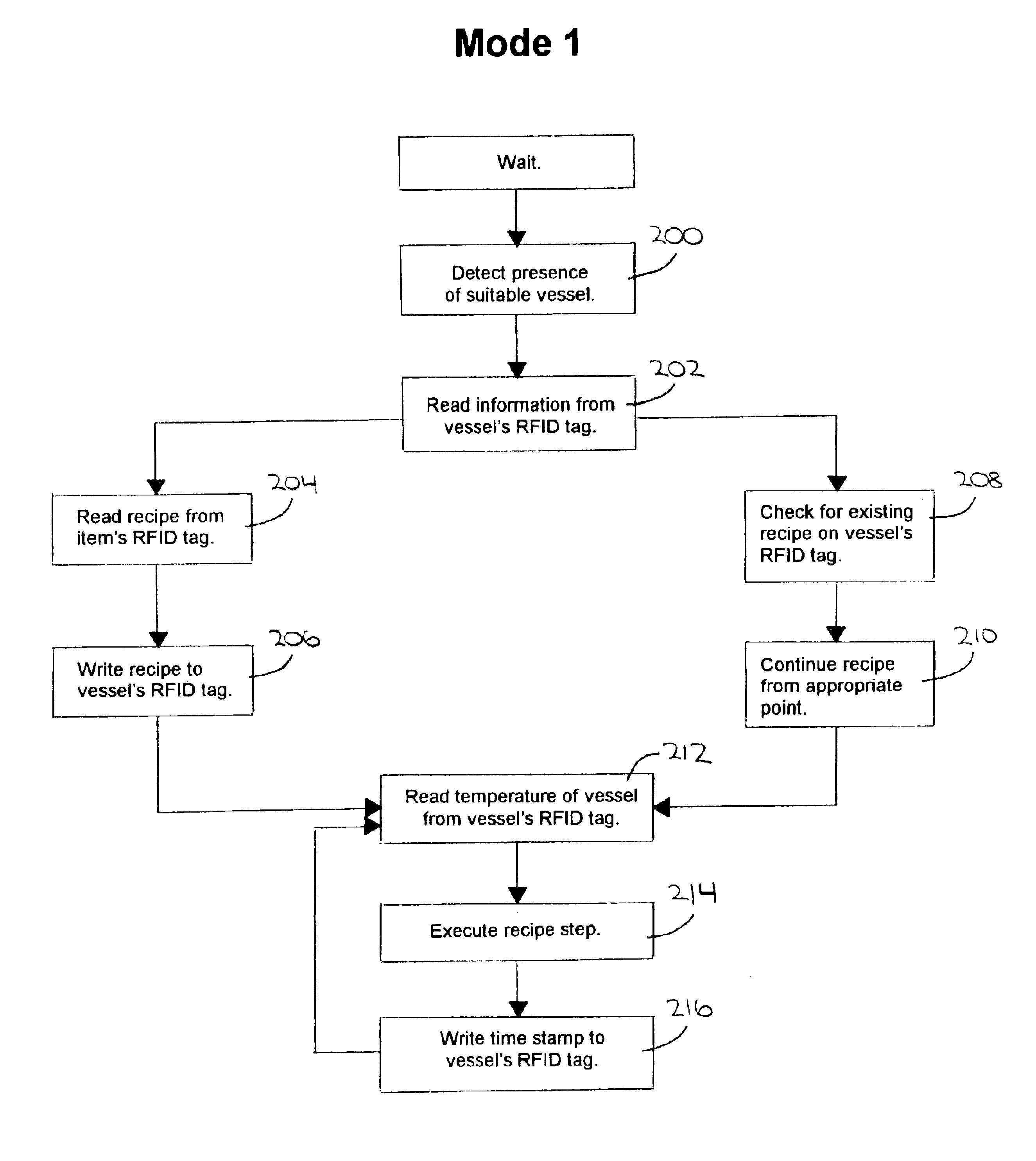

A system and method for providing multiple cooking modes and an ability to automatically heat cooking vessels and other objects using RFID technology, and an ability to read and write heating instructions and to interactively assist in their execution. An induction heating range is provided with two antennas per hob, and includes a user interface display and input mechanism. The vessel includes an RFID tag and a temperature sensor. In a first cooking mode, a recipe is read by the range and the range assists a user in executing the recipe by automatically heating the vessel to specified temperatures and by prompting the user to add ingredients. The recipe is written to the RFID tag so that if the vessel is moved to another hob, into which the recipe has not been read, the new hob can read the recipe from the RFID tag and continue in its execution.

Owner:HR TECH

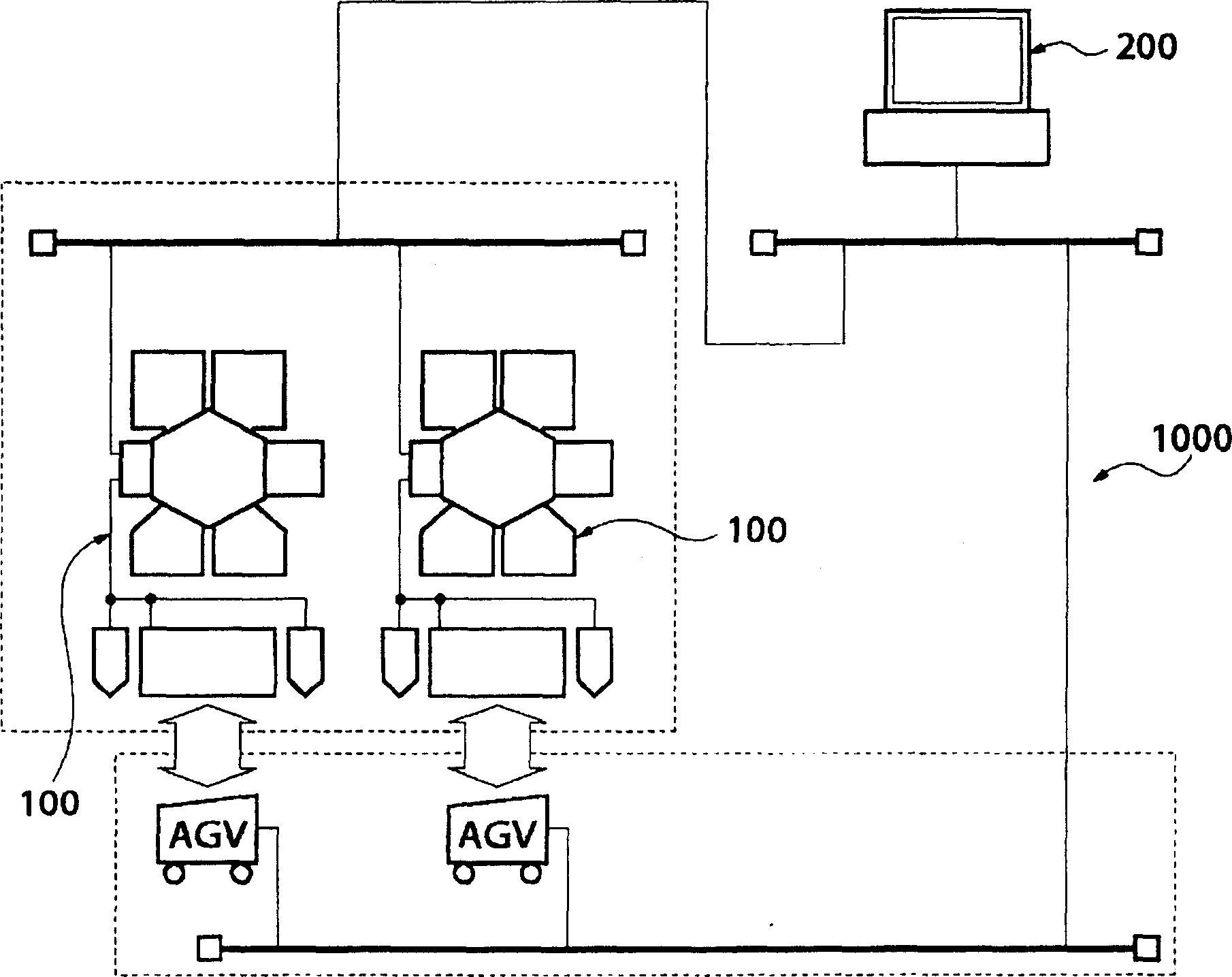

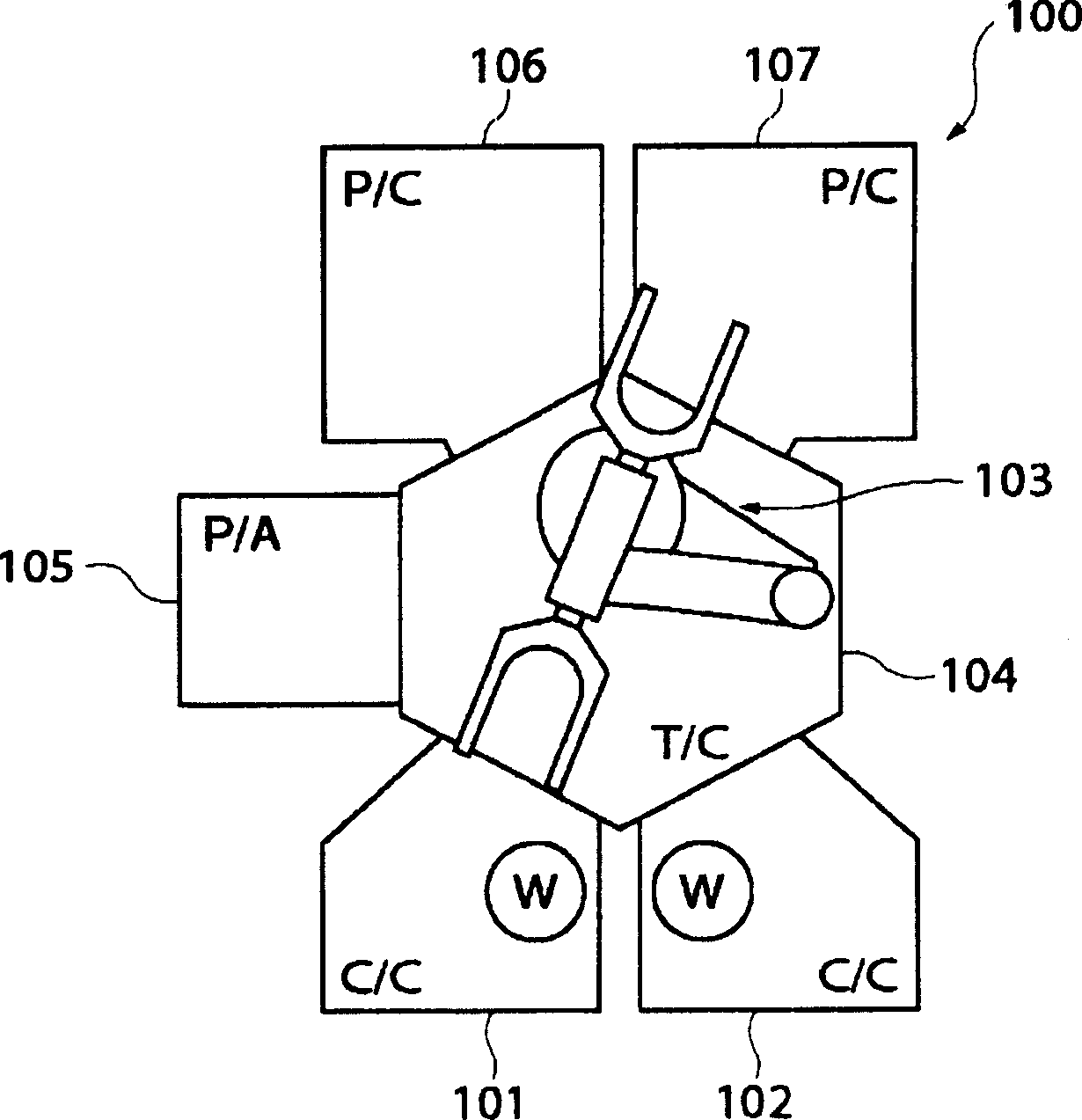

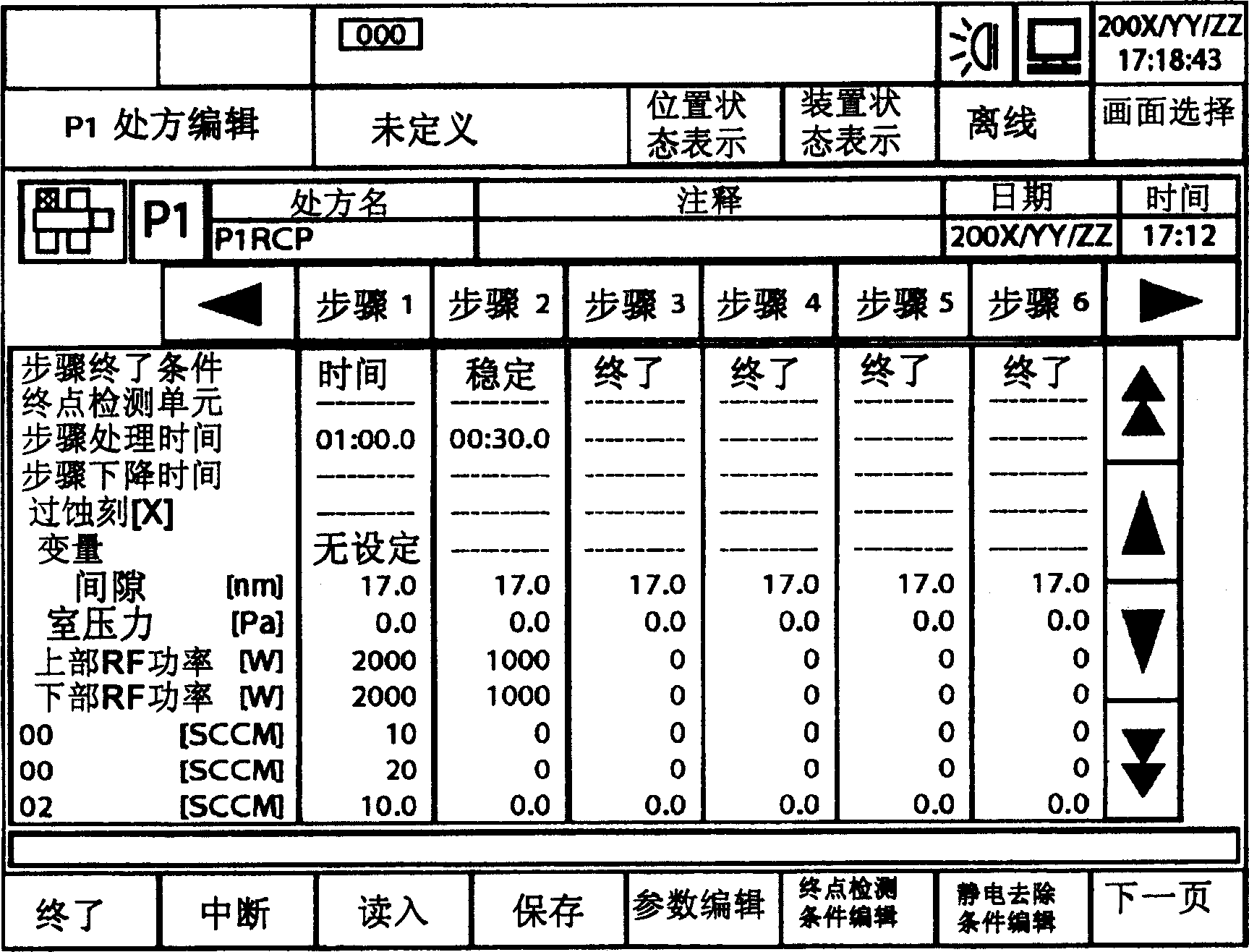

Base plate processing device,base plate processing method and progarm

ActiveCN1664987AIncrease production capacityIndeed implement the requirementsComputer controlSemiconductor/solid-state device manufacturingStable stateProduct processing

An etching apparatus 100 as the substrate processing apparatus is provided with a rotary arm 103 for carrying a substrate included in a lot, and process chambers 106 and 107 for carrying out etching to the substrate as product processing. The etching apparatus 100 is controlled by a host computer 200 in which a transportation recipe, a recipe for product processing and a recipe for dummy processing are registered. When a chamber neglecting time being each neglecting time of the process chambers 106 and 107 does not become time out, the host computer 200 discriminates that processing atmosphere in the process chambers used for etching to the lot is stable, omits the execution of the dummy processing, and executes etching to the substrate of the lot.

Owner:TOKYO ELECTRON LTD

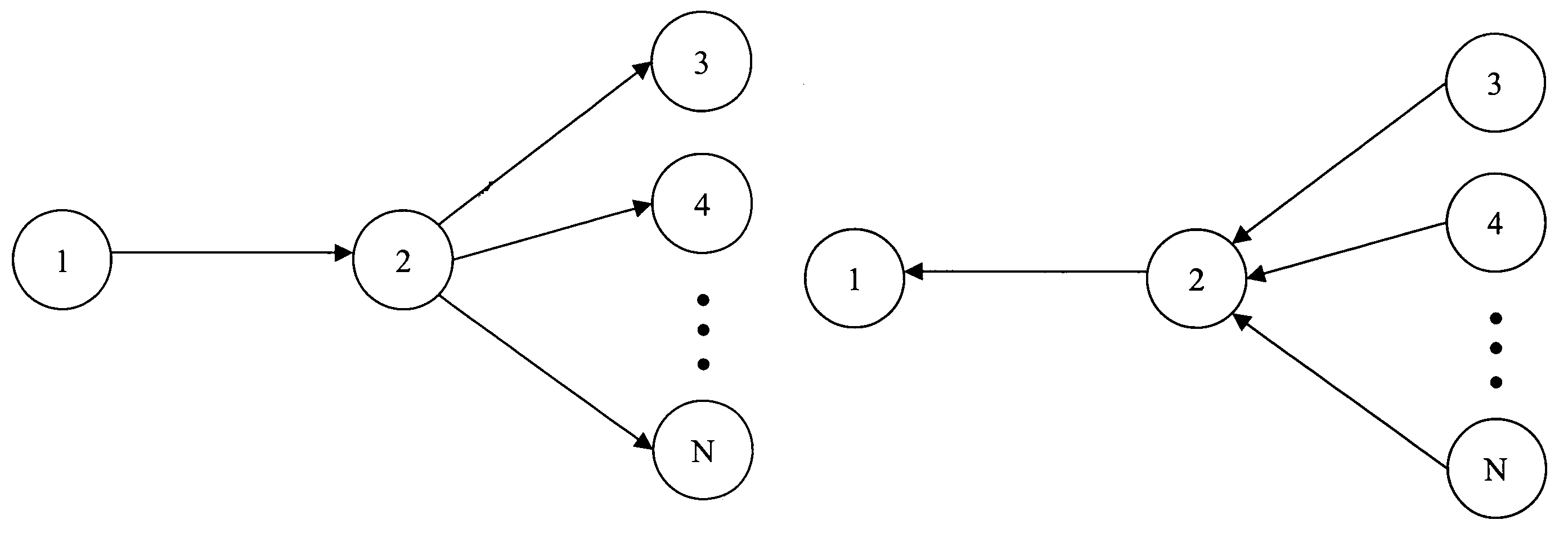

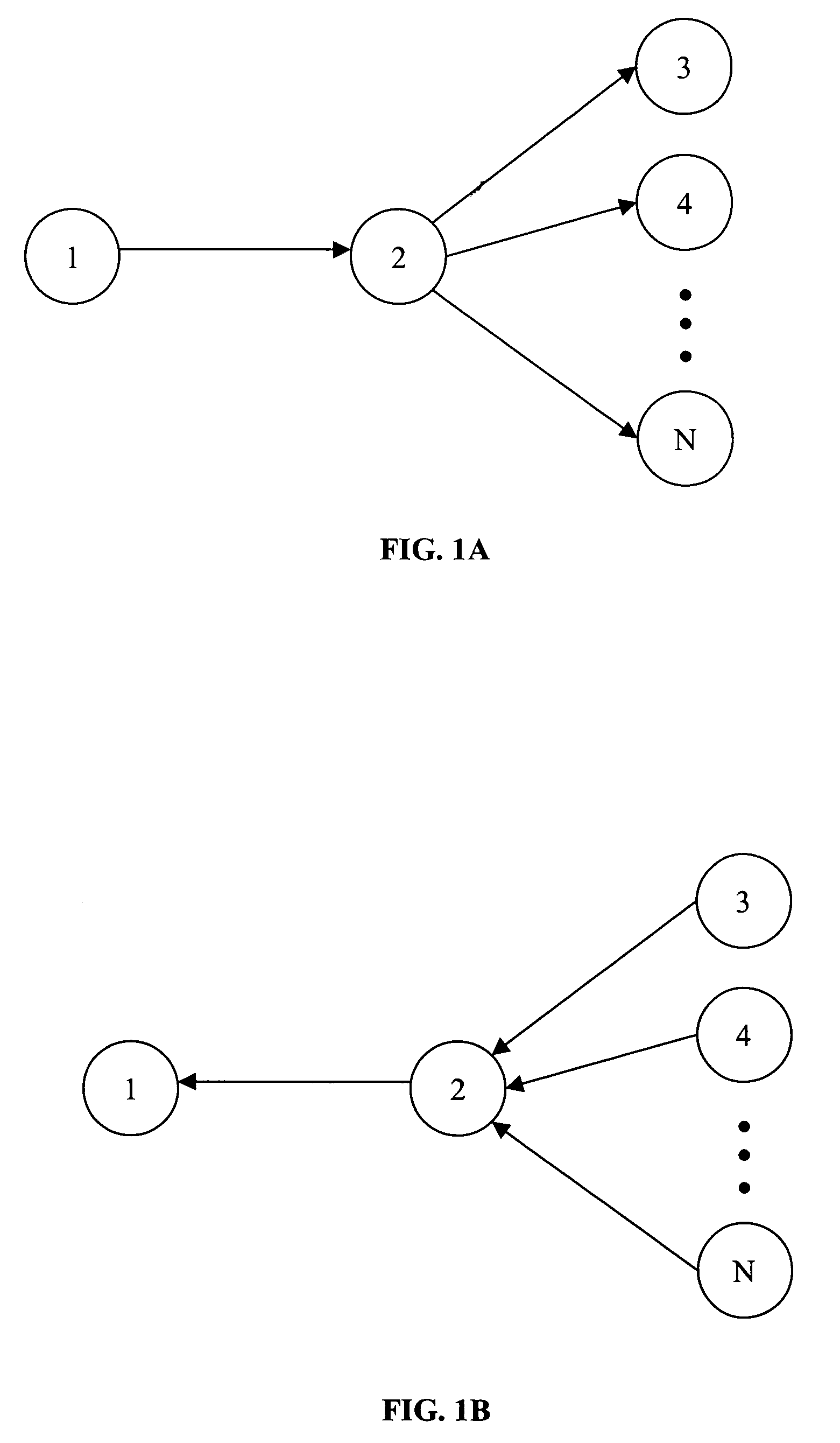

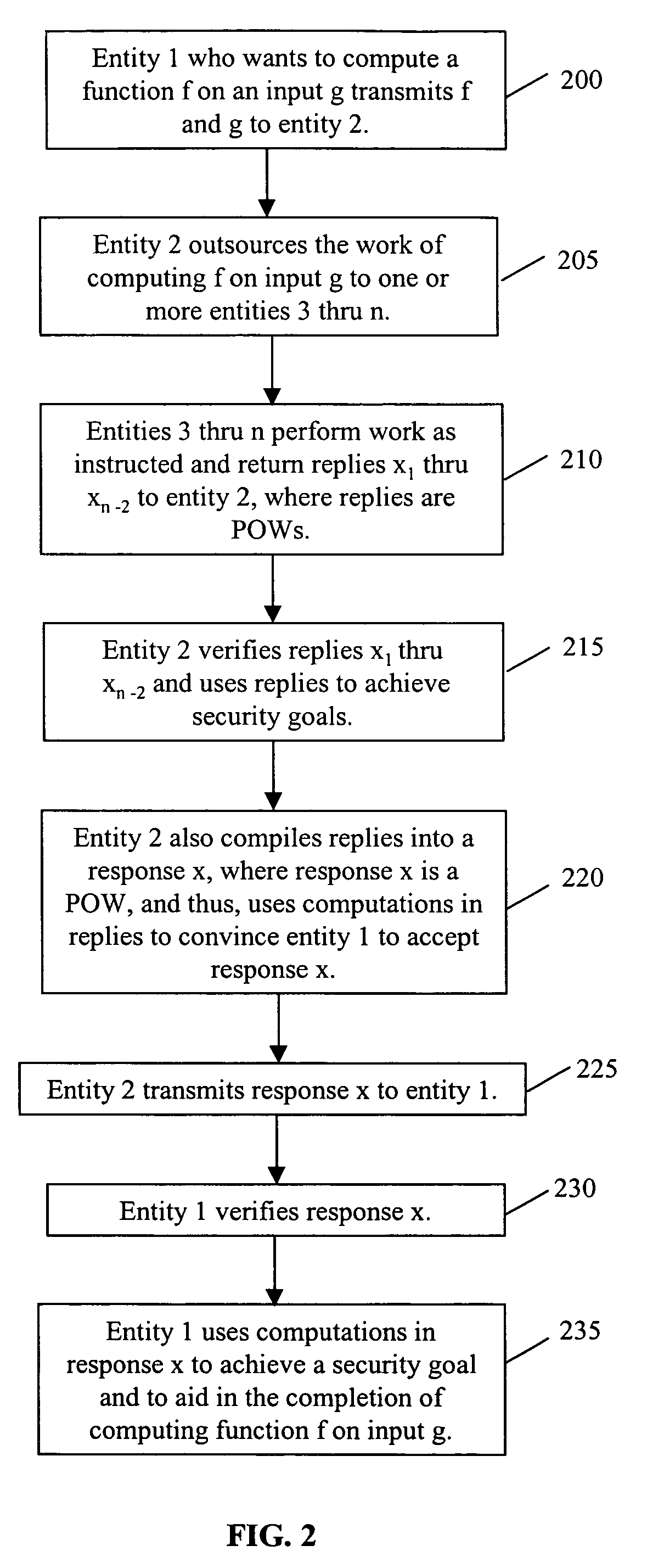

Proofs of work and bread pudding protocols

InactiveUS7356696B1Reduce wasteMaintain privacyDigital data processing detailsUser identity/authority verificationBread puddingComputer science

The bread pudding protocol of the present invention represents a novel use of proofs of work and is based upon the same principle as the dish from which it takes its name, namely, that of reuse to minimize waste. Whereas the traditional bread pudding recipe recycles stale bread, our bread pudding protocol recycles the “stale” computations in a POW to perform a separate and useful task, while also maintaining privacy in the task. In one advantageous embodiment of our bread pudding protocol, we consider the computationally intensive operation of minting coins in the MicroMint scheme of Rivest and Shamir and demonstrate how the minting operation can be partitioned into a collection of POWs, which are then used to shift the burden of the minting operation onto a large group of untrusted computational devices. Thus, the computational effort invested in the POWs is recycled to accomplish the minting operation.

Owner:LUCENT TECH INC +1

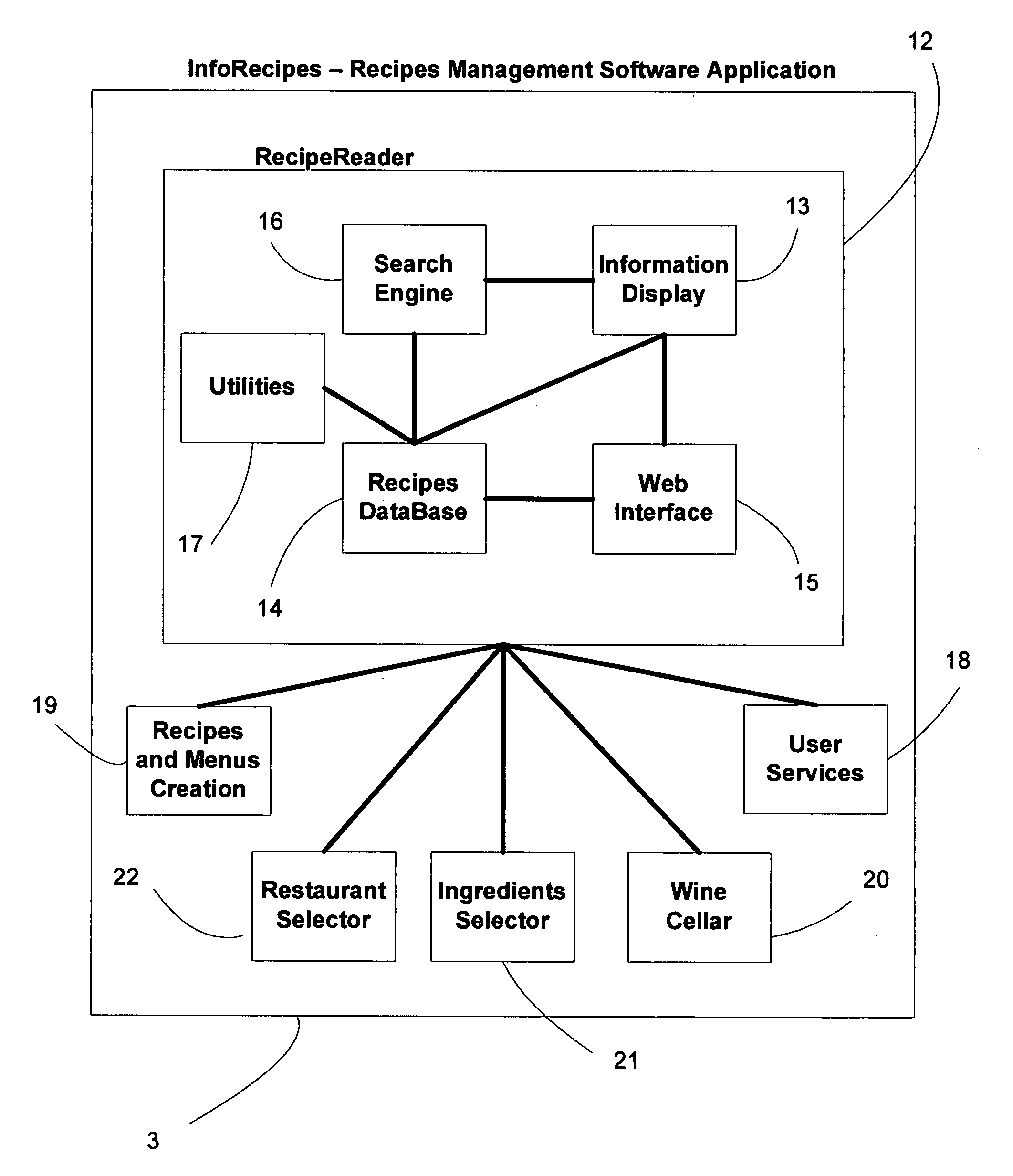

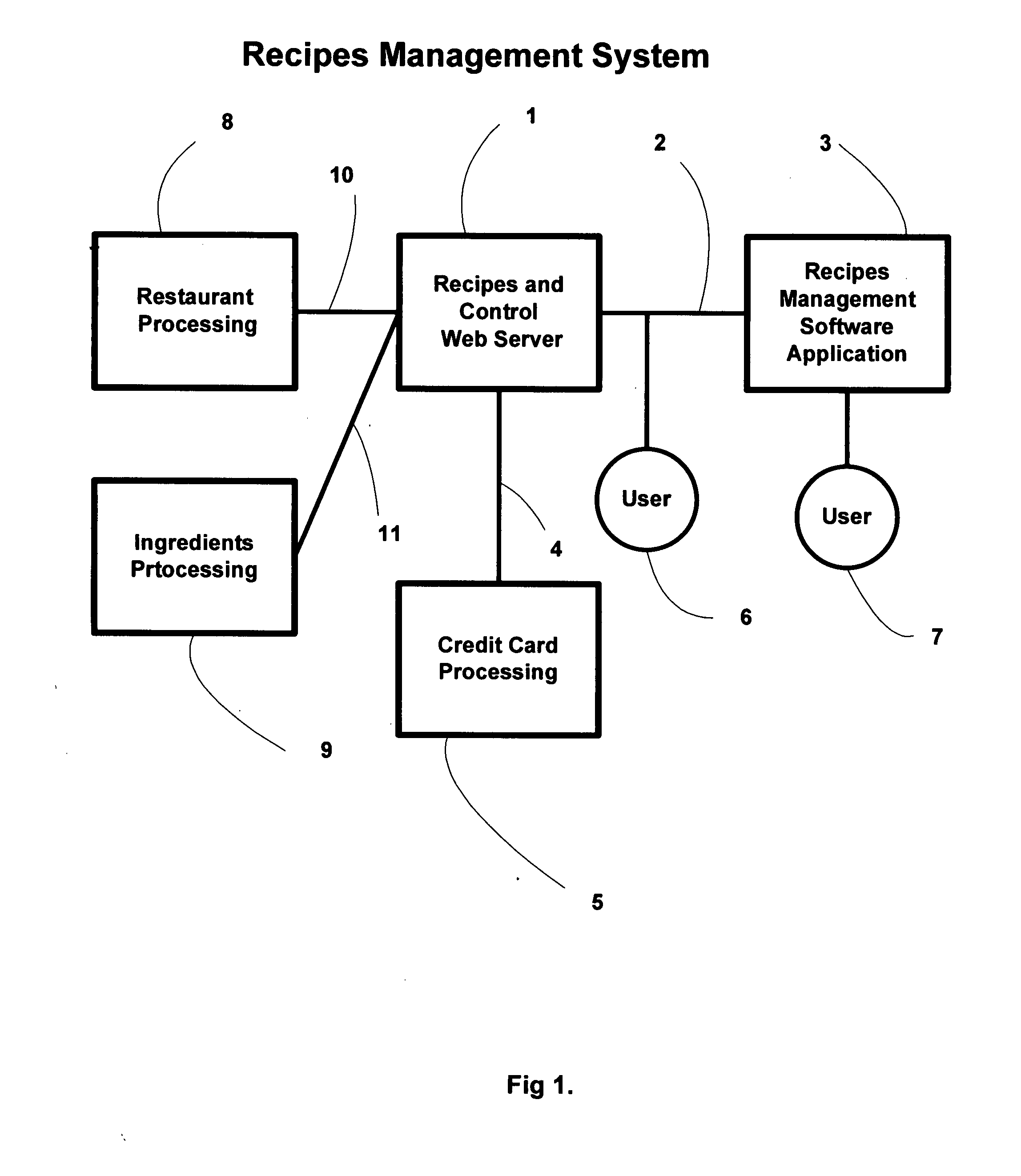

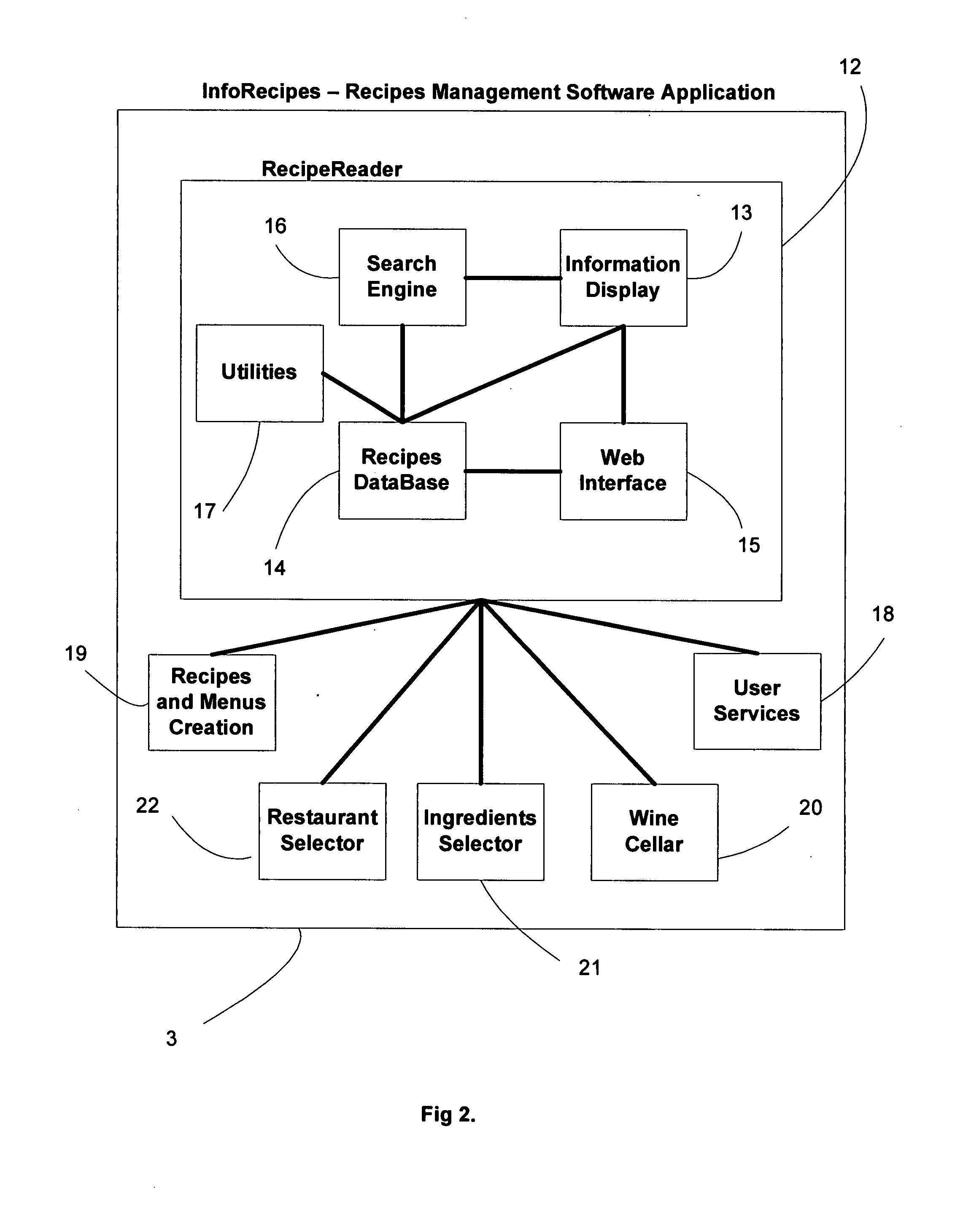

Recipes management system

InactiveUS20090157752A1Buying/selling/leasing transactionsSpecial data processing applicationsProgram managementWeb service

The present invention is generally related to a system for managing recipes using a web server and an off-line software application. A user using the software application will be able to create, display, print, modify, and search recipes and menus. The web server will be a recipe store where a user can buy and download individual recipes and electronic cookbooks into the software application secure database storage. The software application has a web interface to communicate with the recipe store, allowing the user to have an extended set of facilities like posting his / her own recipes for sale, requesting restaurant and food store services for a given recipe or menu, requesting the restoration of their recipe database, and receiving suggested drinking dates for their current wine inventory. The software application comes in two versions: the read-only and the all-inclusive version. With the read-only version a user will not be able to create or modify a recipe or use any of the extended facilities. The read-only version will be free to download from the recipe store.

Owner:GONZALEZ CARLOS

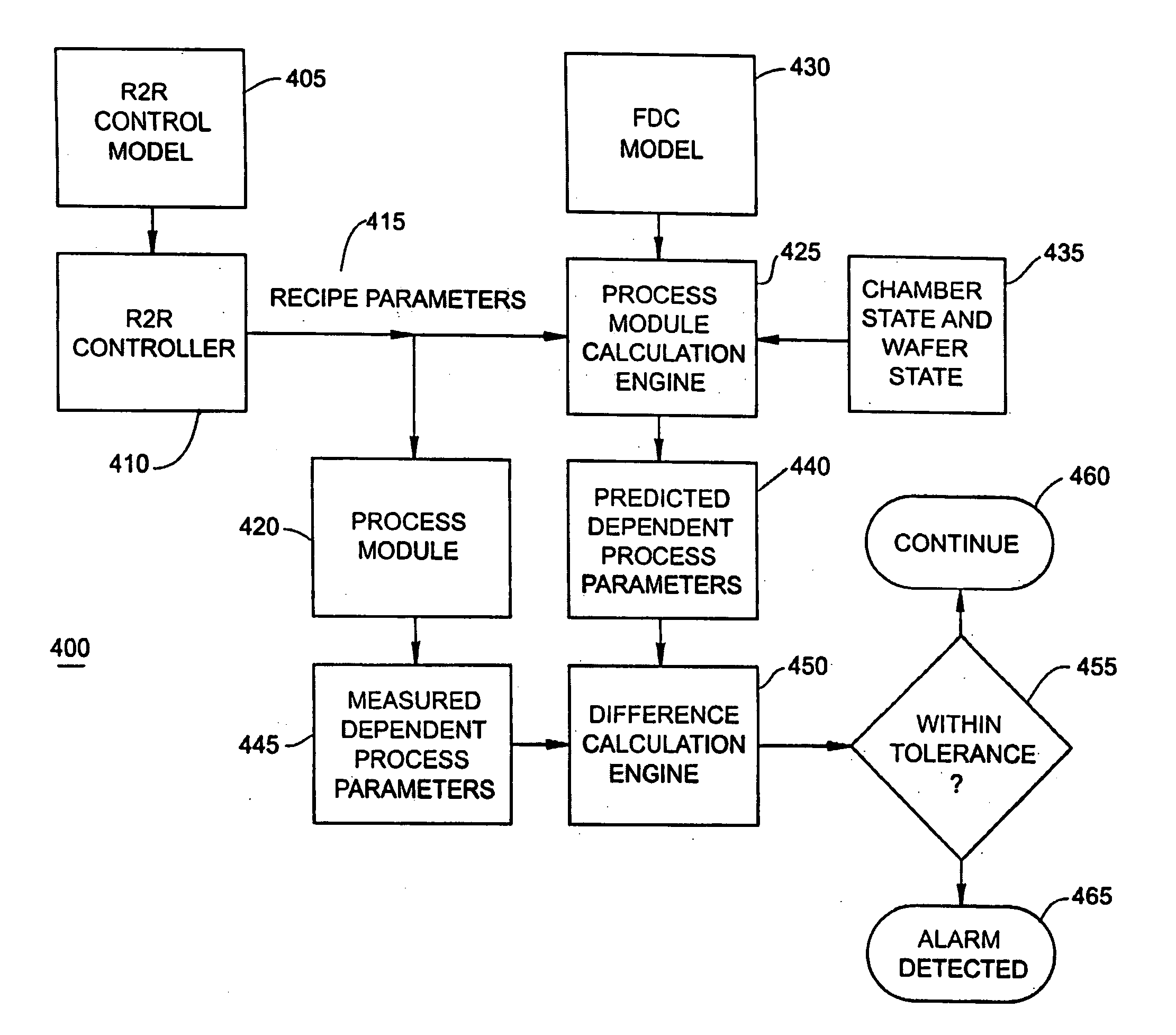

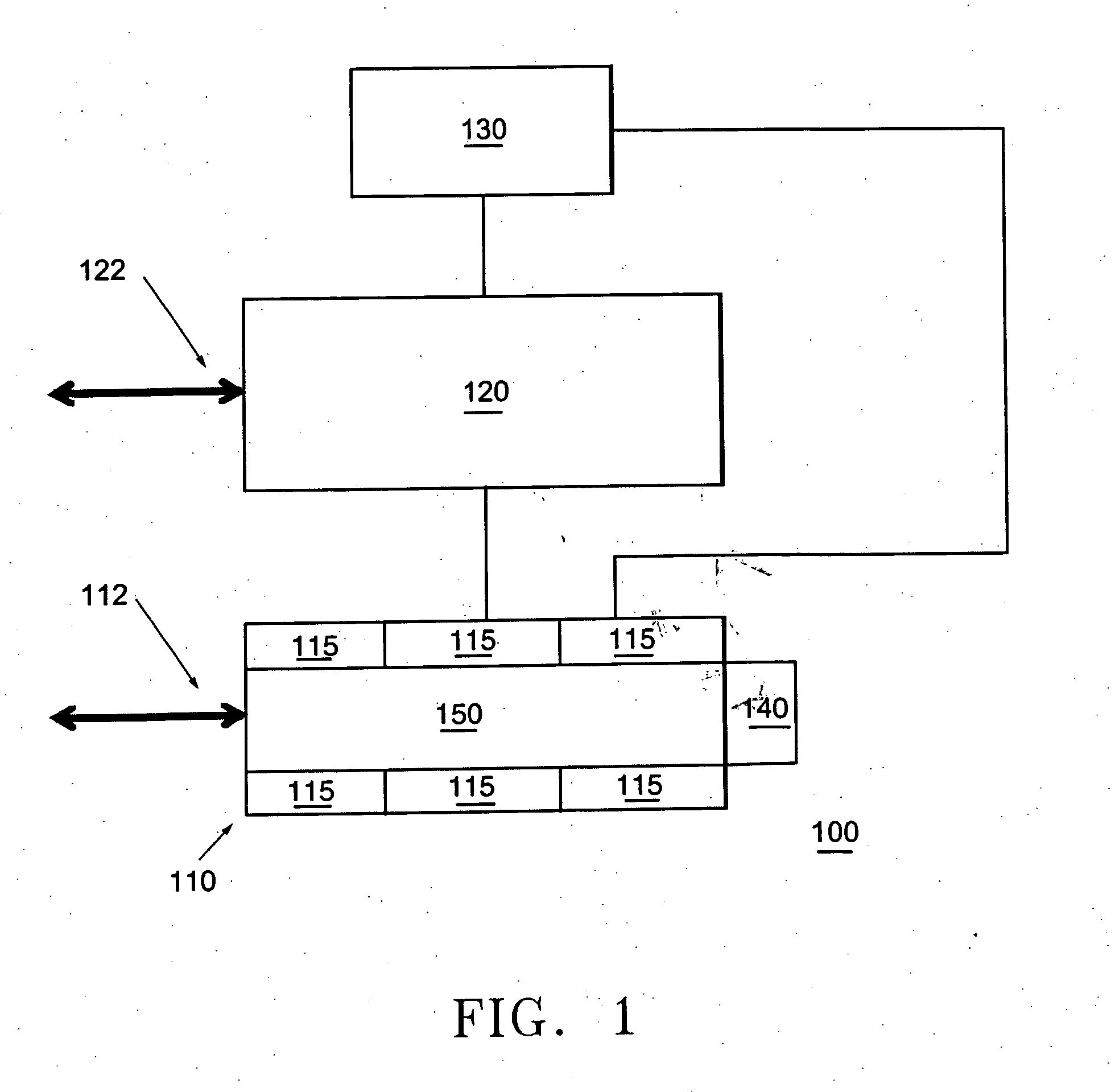

Fault detection and classification (FDC) using a run-to-run controller

ActiveUS20060184264A1Programme controlSemiconductor/solid-state device testing/measurementProcess moduleComputer science

A method for implementing FDC in an APC system including receiving an FDC model from memory; providing the FDC model to a process model calculation engine; computing a vector of predicted dependent process parameters using the process model calculation engine; receiving a process recipe comprising a set of recipe parameters, providing the process recipe to a process module; executing the process recipe to produce a vector of measured dependent process parameters; calculating a difference between the vector of predicted dependent process parameters and the vector of measured dependent process parameters; comparing the difference to a threshold value; and declaring a fault condition when the difference is greater than the threshold value.

Owner:TOKYO ELECTRON LTD

Method for conditioning a process chamber

A method of conditioning a processing chamber for a production process includes performing a conditioning step at a conditioning process recipe substantially different than a process recipe of the production process, and performing a warm-up process at a warm-up process recipe substantially the same as the process recipe of the production process. The method can be performed after a wet-cleaning process has been performed. The conditioning procedure can allow the maintenance time to be decreased and can cause the etched features to be more accurate.

Owner:TOKYO ELECTRON LTD

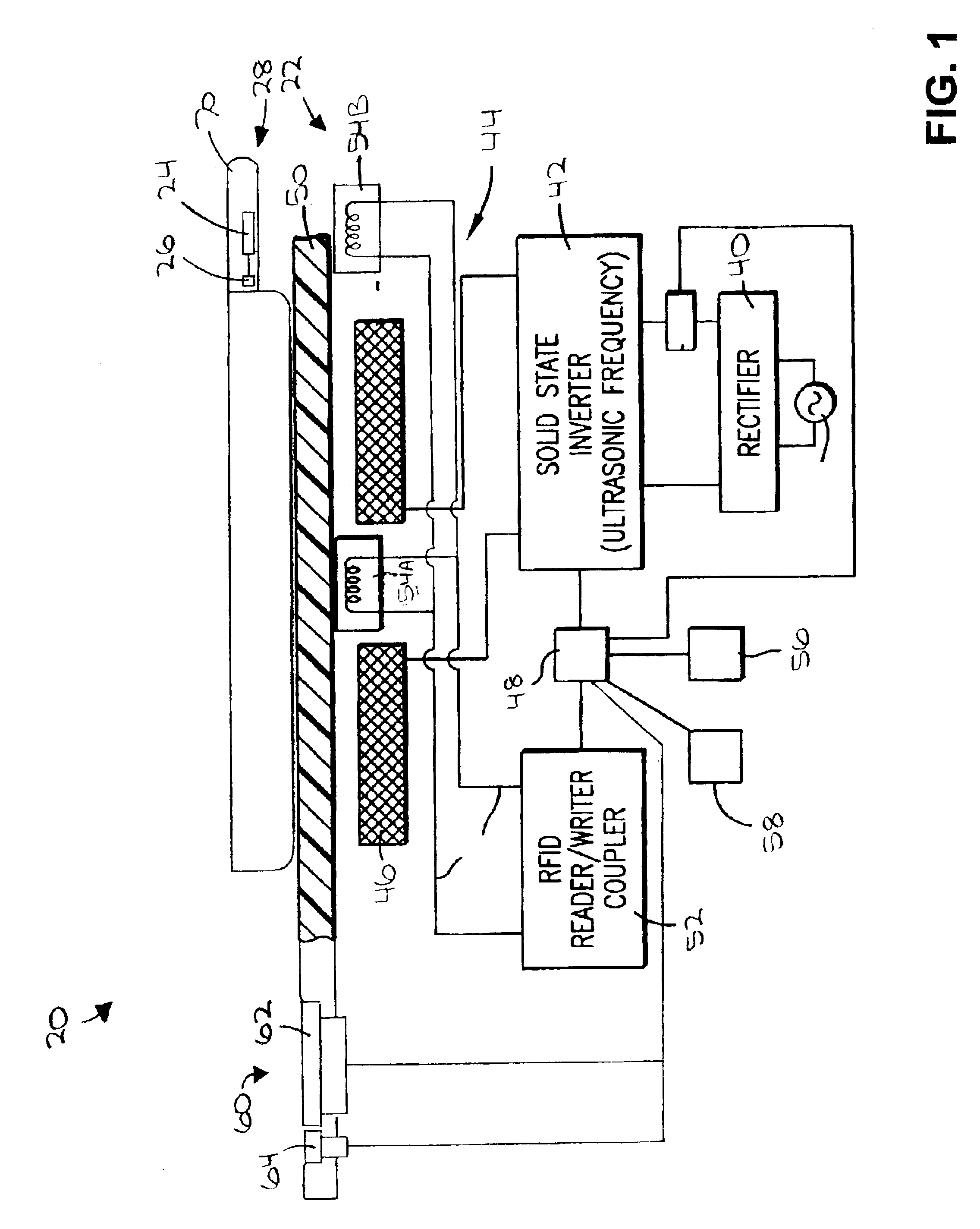

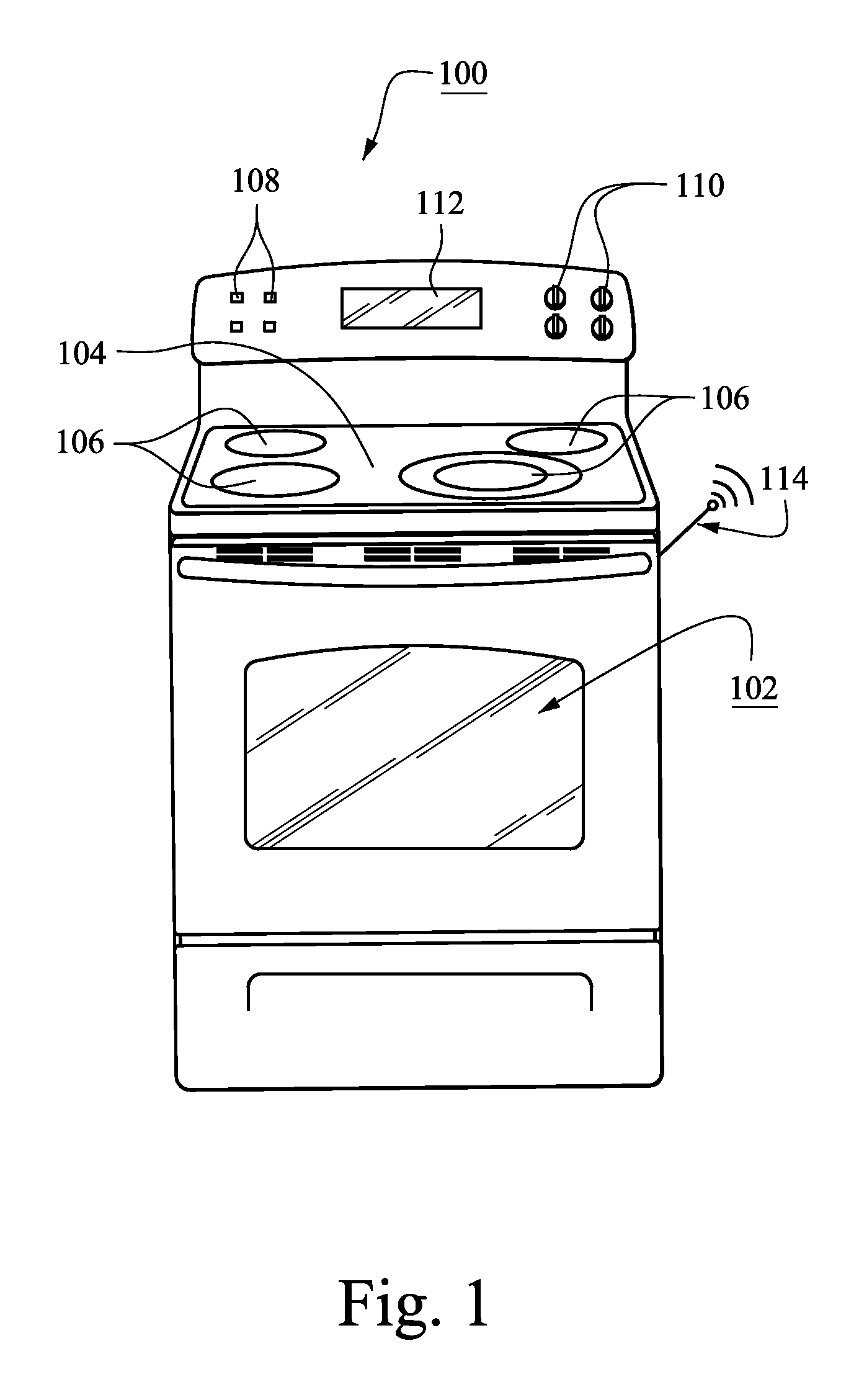

RFID-controlled smart range and method of cooking and heating

InactiveUS6953919B2Facilitate communicationFacilitates informationCooking vesselsDeep fat fryersAdditive ingredientEngineering

A system and method for providing multiple cooking modes and an ability to automatically heat cooking vessels and other objects using RFID technology, and an ability to read and write heating instructions and to interactively assist in their execution. An induction heating range is provided with two antennas per hob, and includes a user interface display and input mechanism. The vessel includes an RFID tag and a temperature sensor. In a first cooking mode, a recipe is read by the range and the range assists a user in executing the recipe by automatically heating the vessel to specified temperatures and by prompting the user to add ingredients. The recipe is written to the RFID tag so that if the vessel is moved to another hob, into which the recipe has not been read, the new hob can read the recipe from the RFID tag and continue in its execution.

Owner:HR TECH

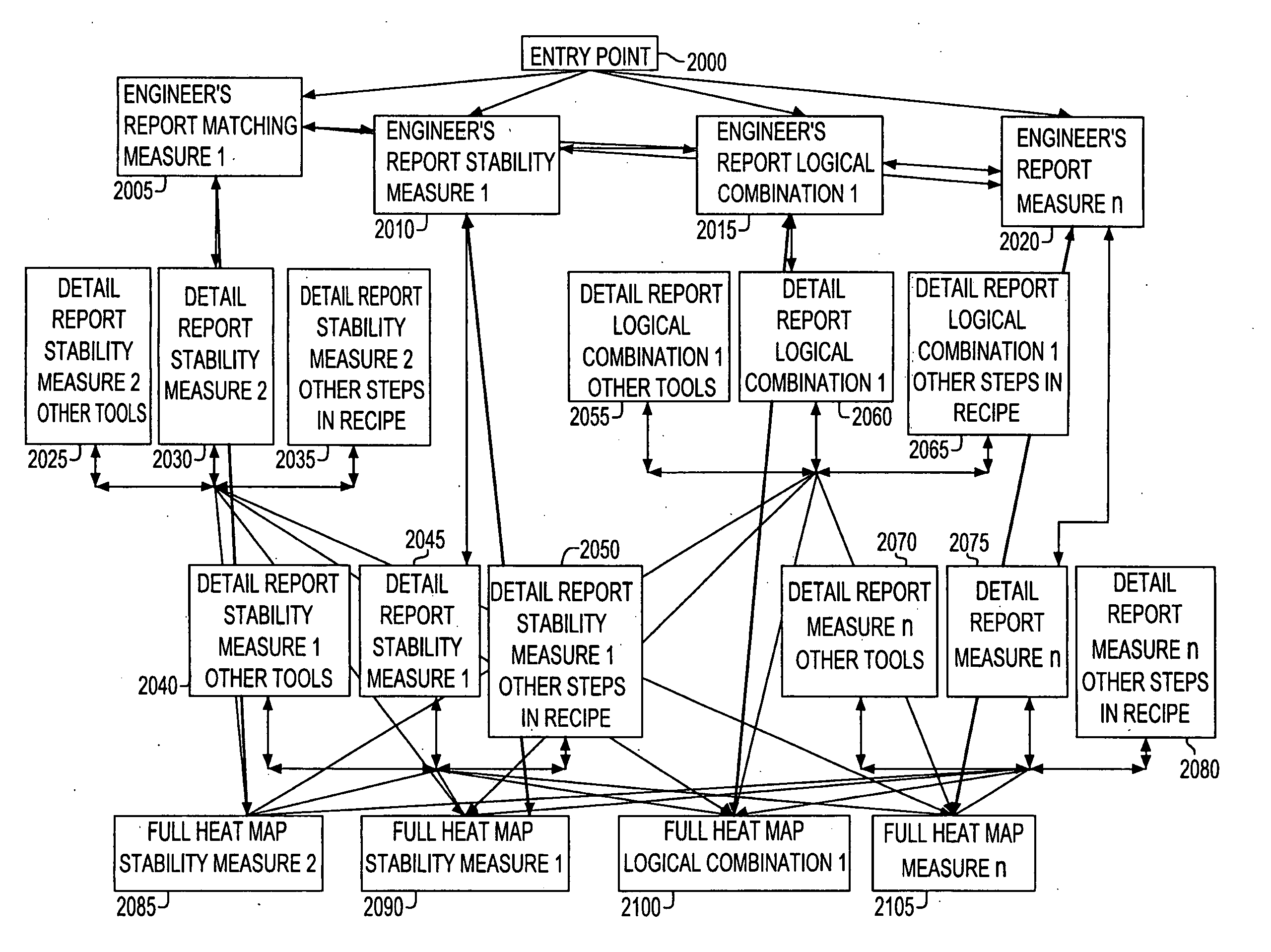

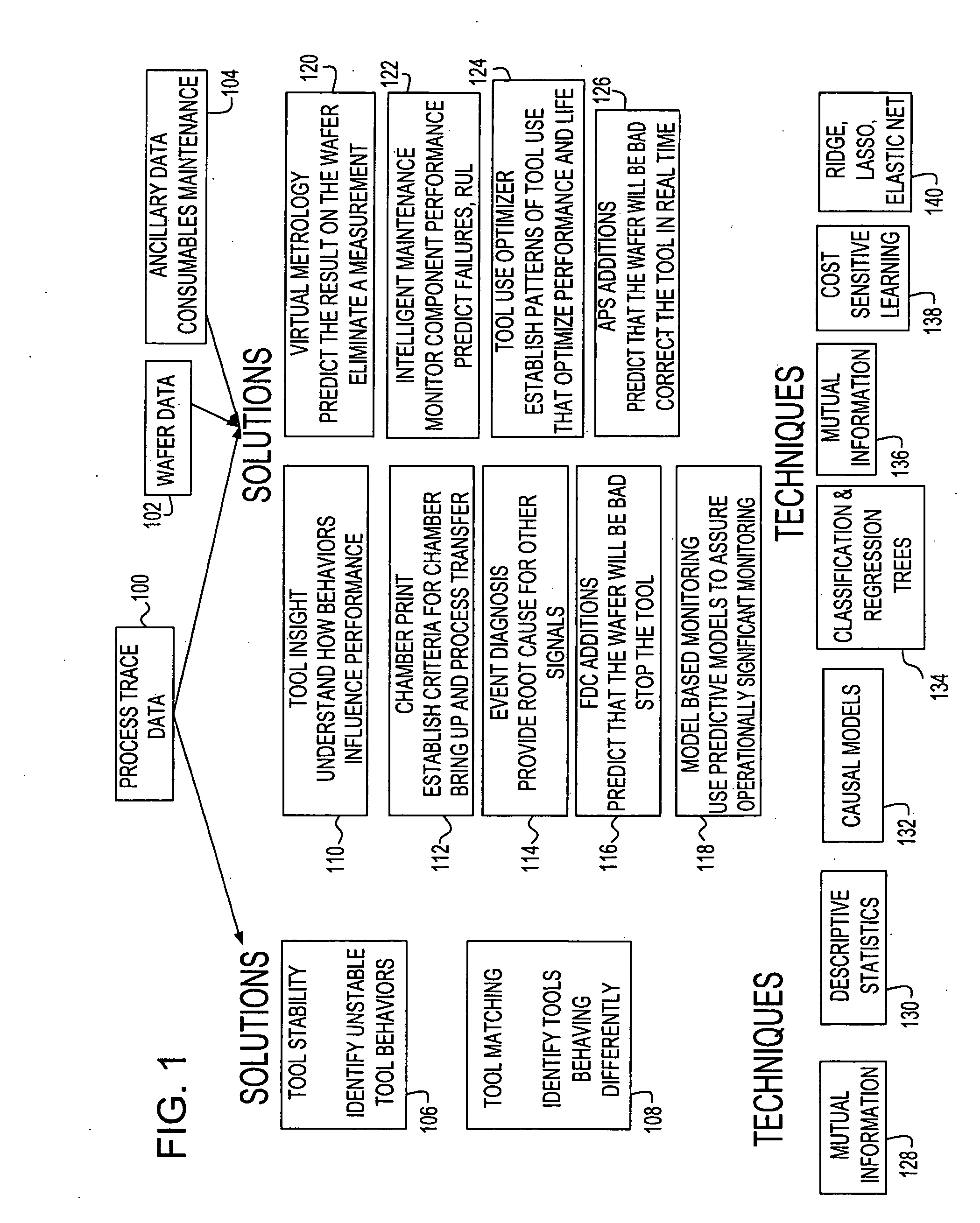

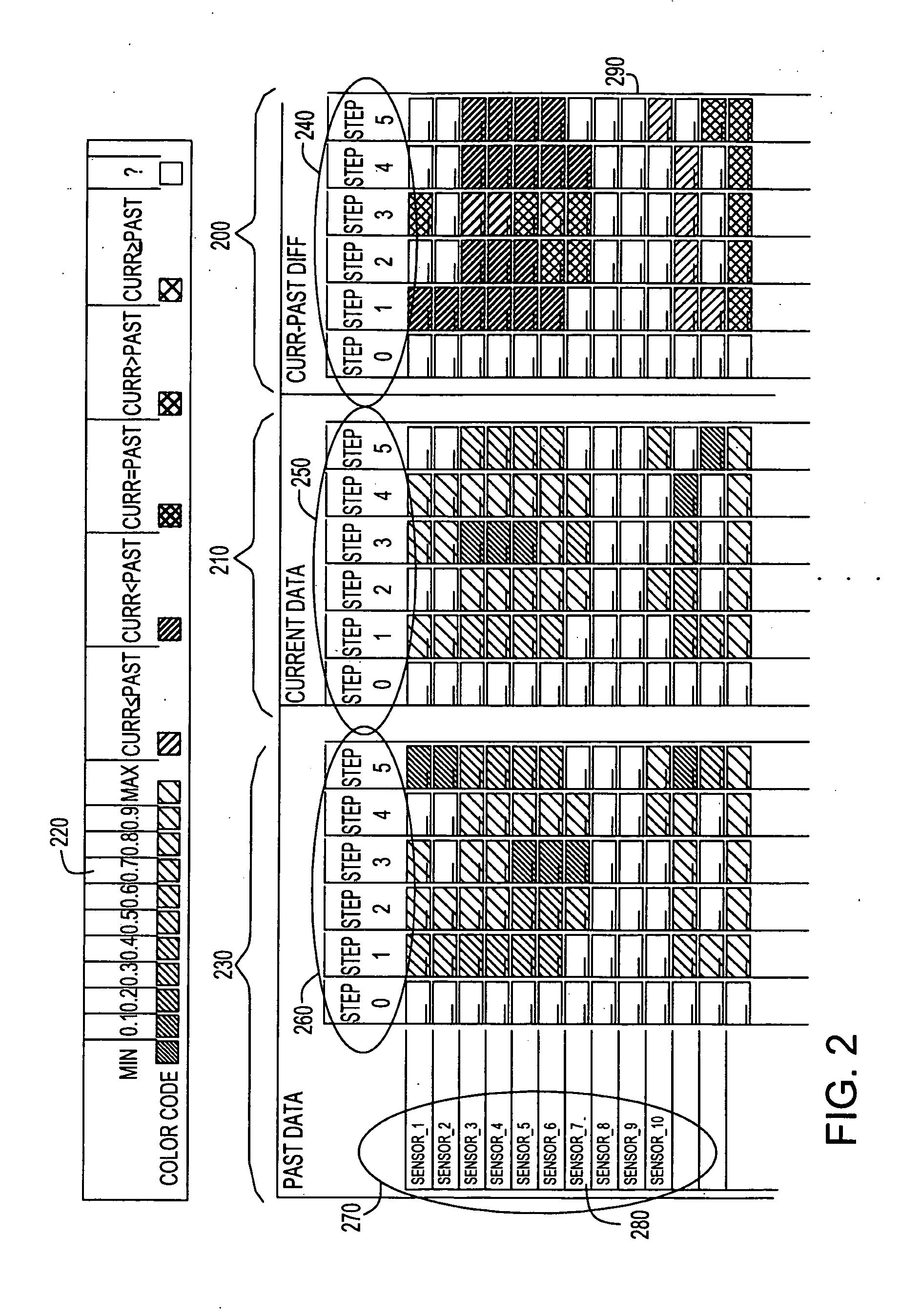

Method and system for evaluating a machine tool operating characteristics

A method and system for evaluating a performance of a semiconductor manufacturing tool while manufacturing microelectronic devices are disclosed. At least one report is generated based on executions of at least one statistical test. The report includes at least one heat map having rows that correspond to sensors, columns that correspond to trace data obtained during recipe steps, and cells at the intersection of the rows and the columns. At least one sensor in the tool obtains trace data of a recipe step while manufacturing at least one microelectronic device. A computing device analyzes the obtained trace data to determine a level of operational significance found in the data and assigns a score to the trace data that indicates a level of operational significance. Then, the computing device places the score in a corresponding cell of the heat map. A user uses the cell for evaluating the tool performance.

Owner:GLOBALFOUNDRIES INC

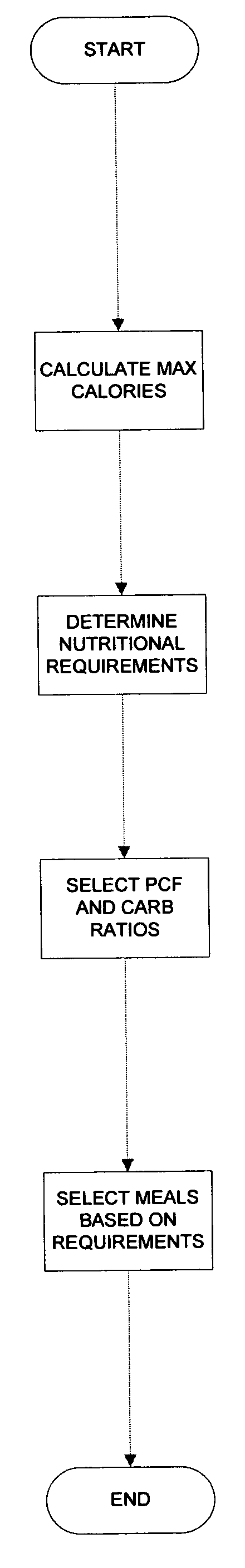

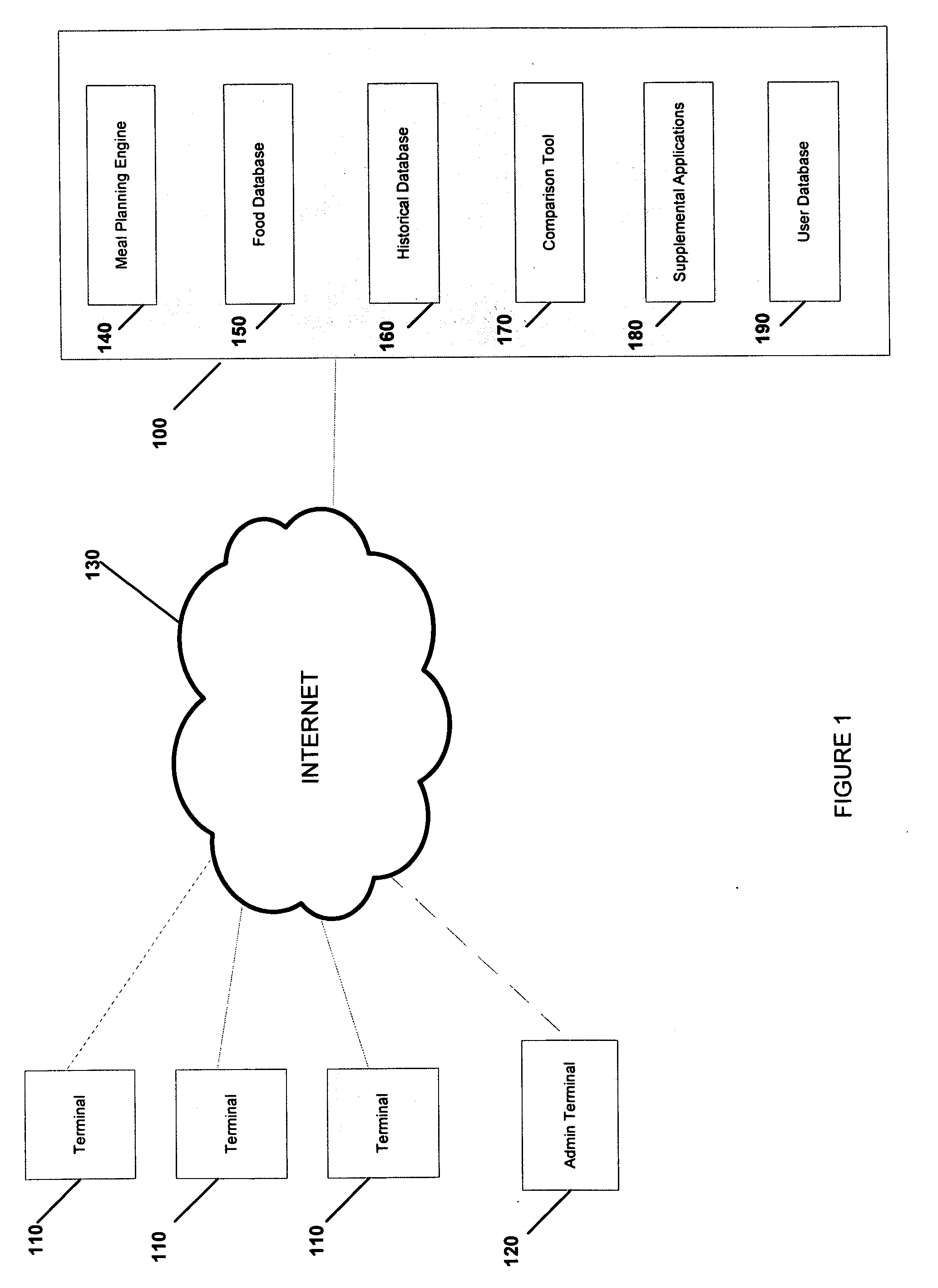

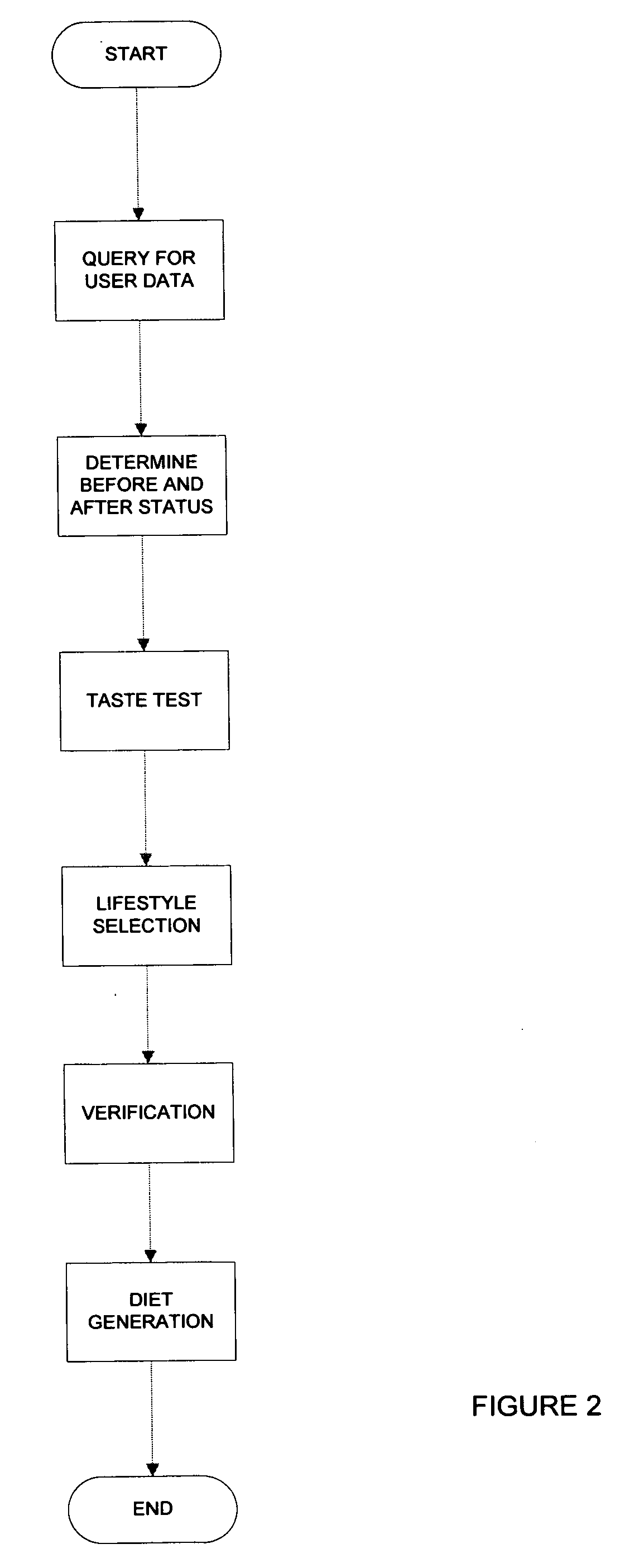

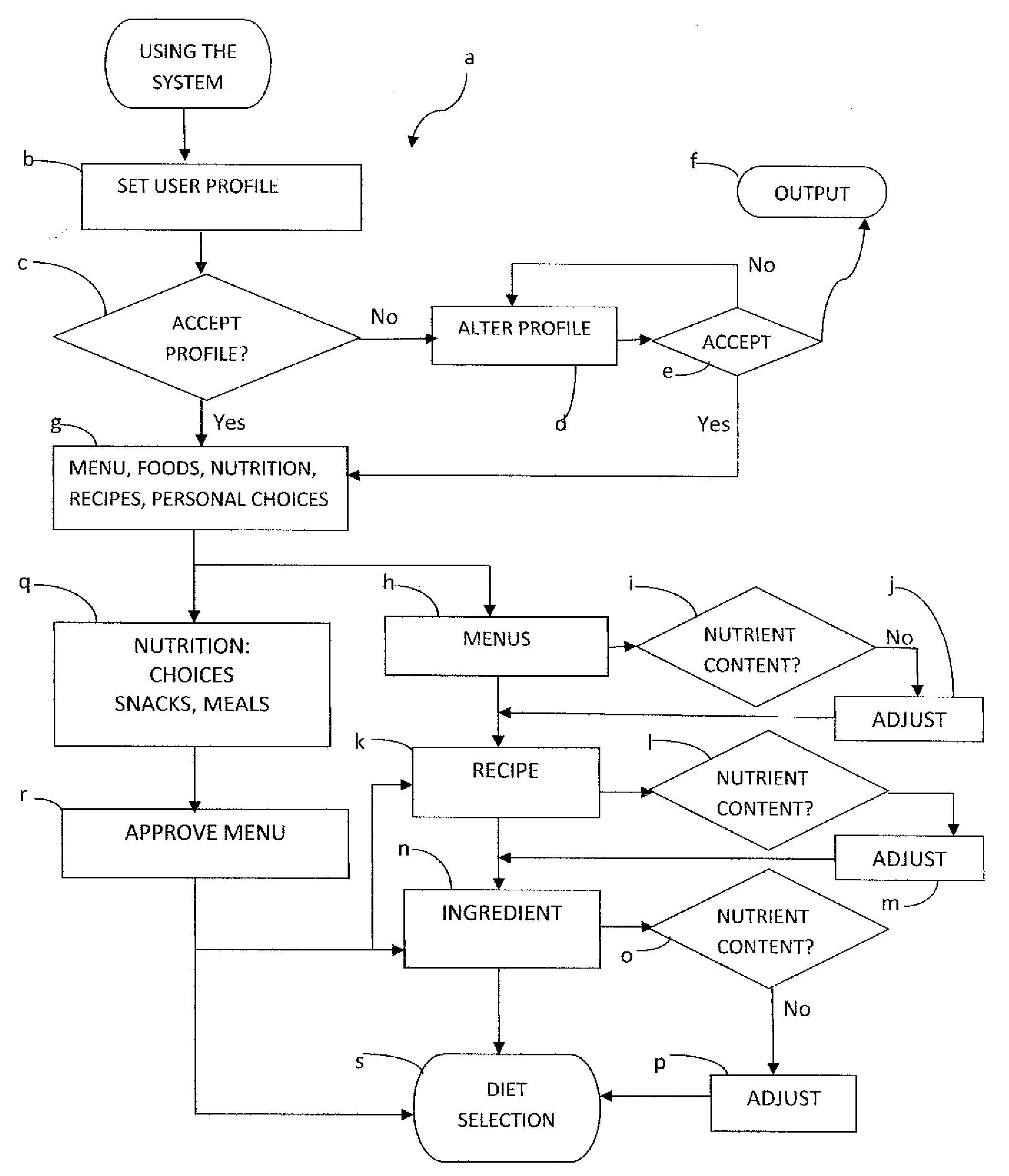

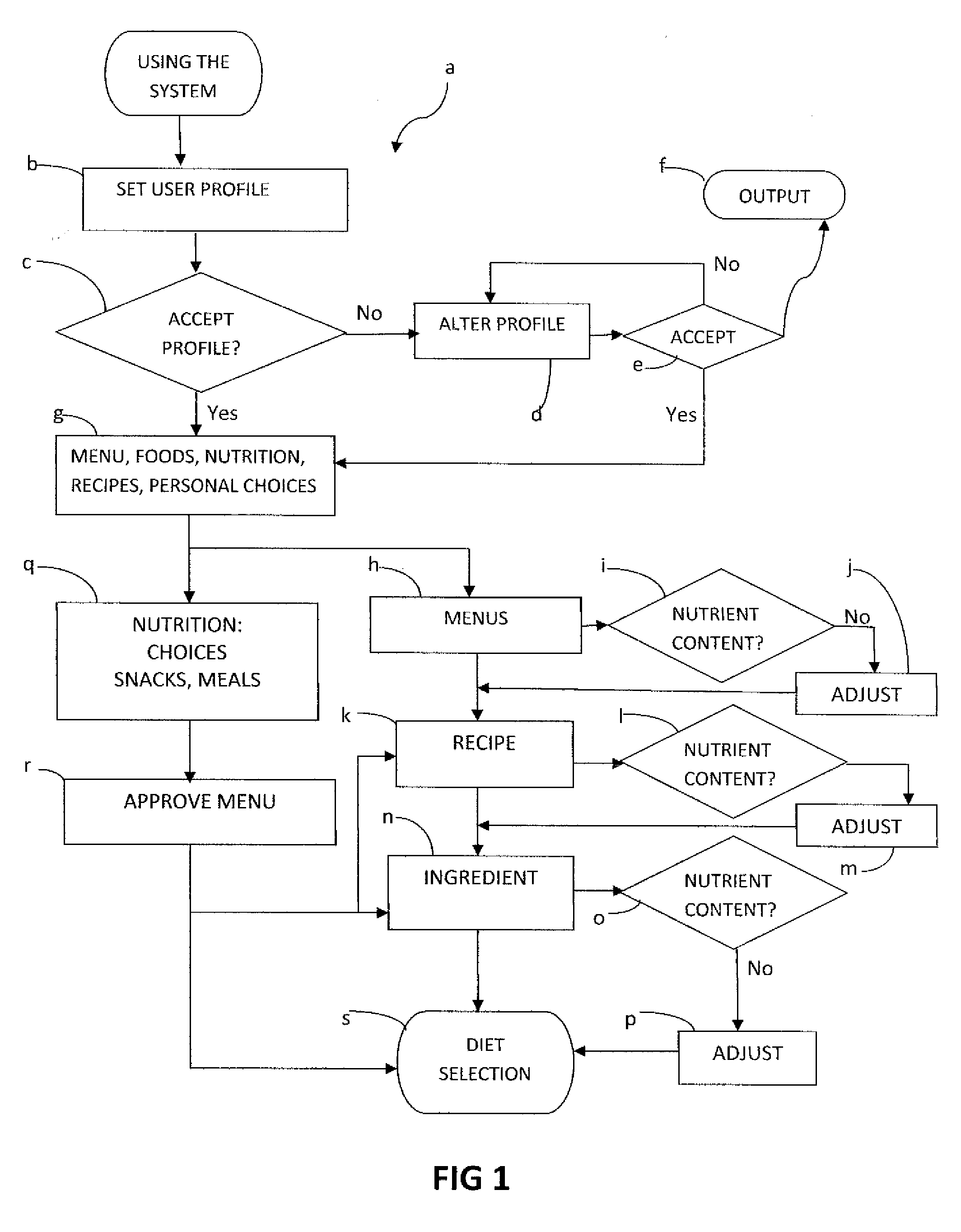

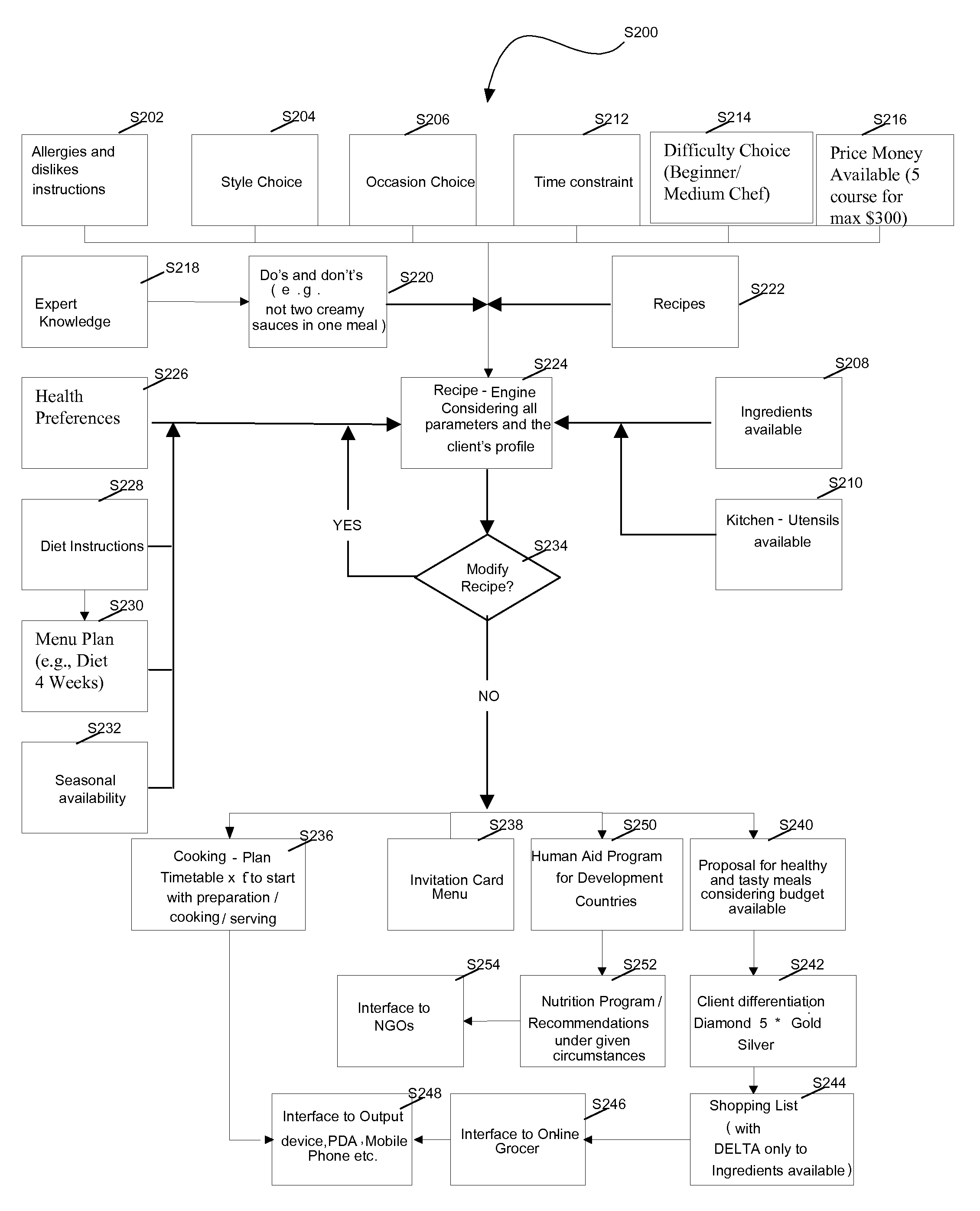

System and method for automated dietary planning

InactiveUS20060199155A1Nutrition controlComputer-assisted treatment prescription/deliveryPersonalizationFood preference

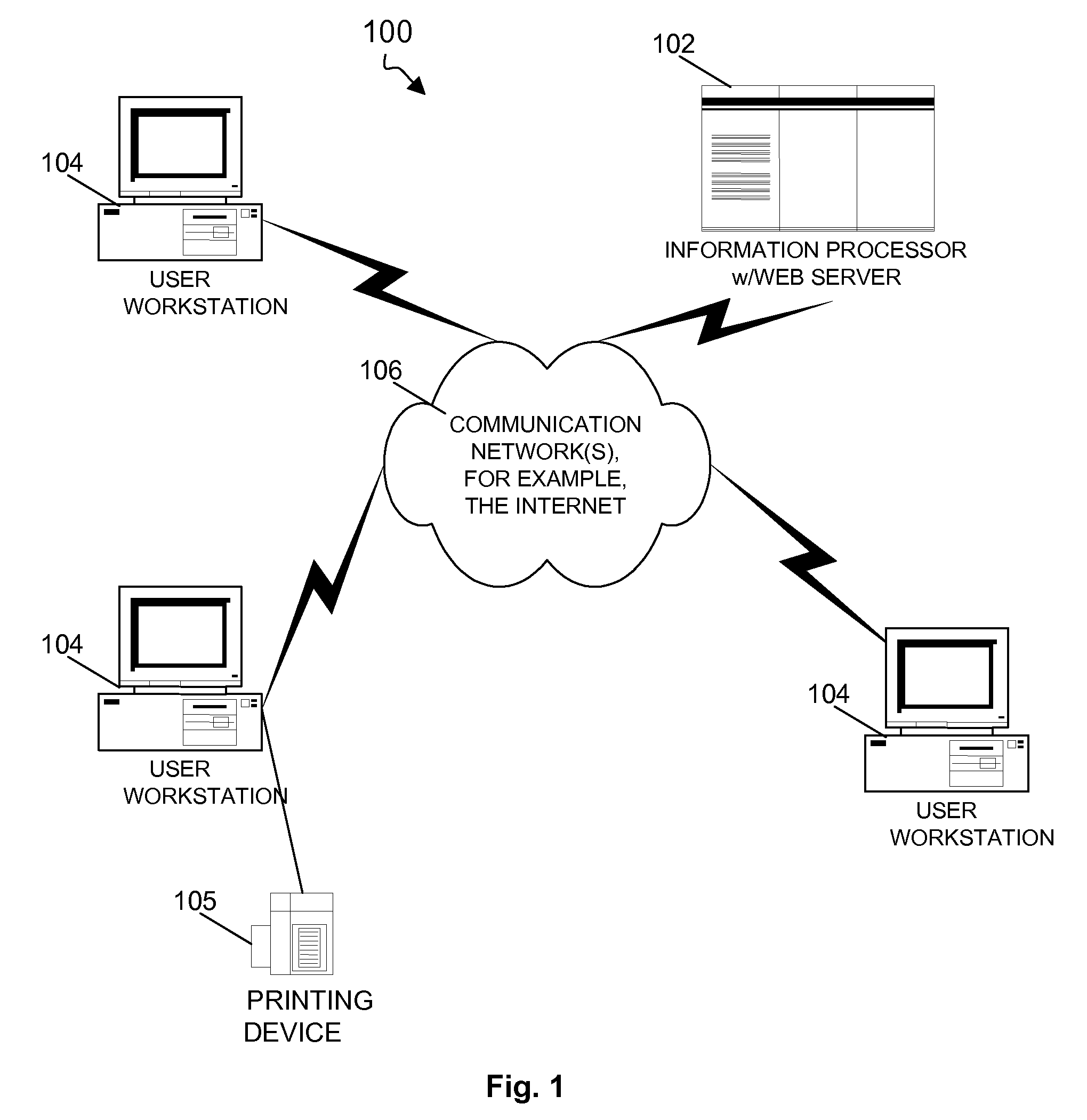

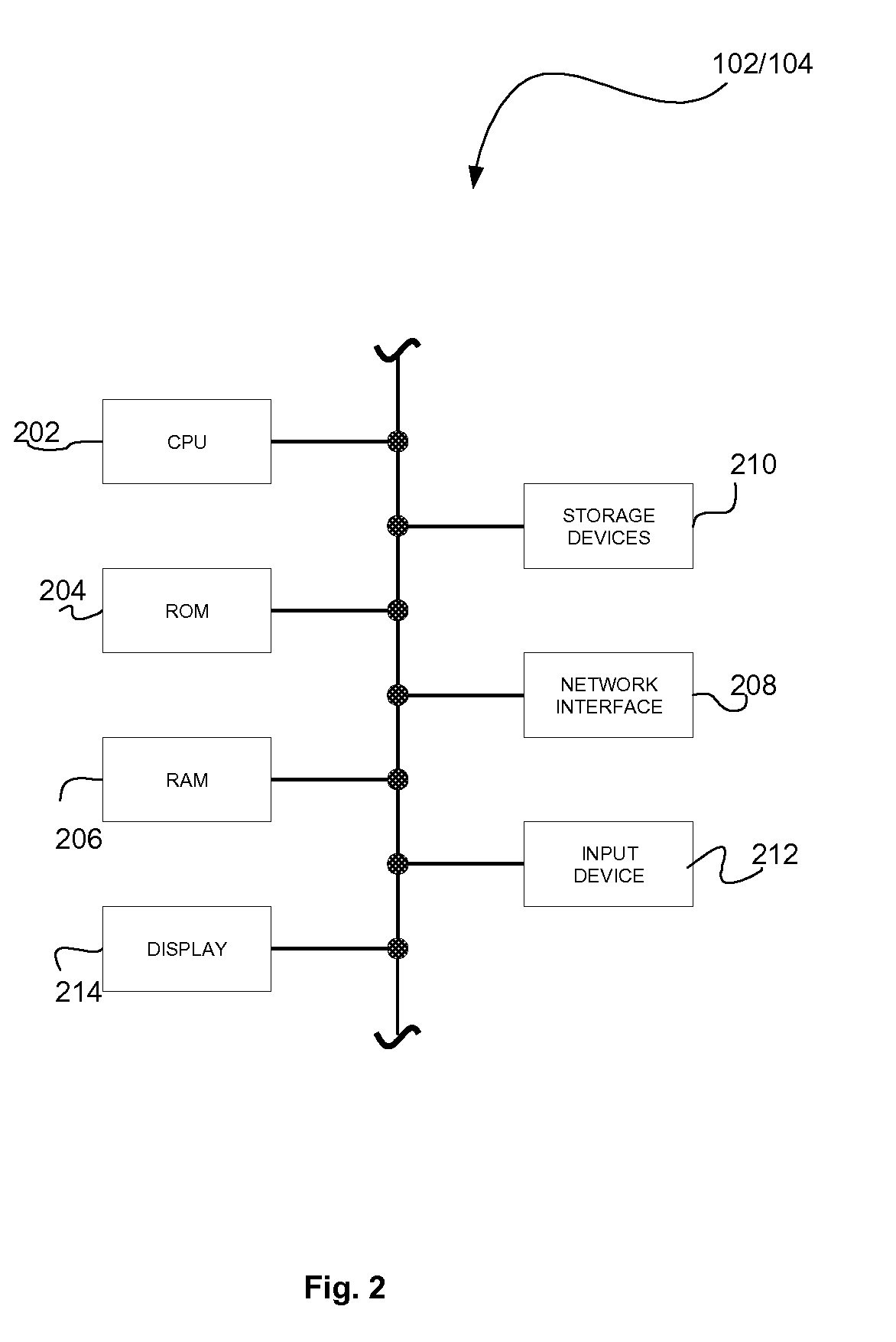

A novel system and methodology for dietary and medical treatment planning wherein meals and treatment plans are specifically individualized for a user according to a number of unique characteristics associated with that user. These characteristics are provided to the system of the present invention and one or more resulting meal plans and / or therapies are generated. According to the present invention, particular dieter specific characteristics that may be considered in developing the meal plan include daily caloric limitations and or recommendations, daily nutritional requirements including minimum and maximum vitamin, mineral, water, and electrolyte intake as well as specific genetic characteristics concerning the individual. Dieter food preferences and other factors may also be considered. The system of the present invention uses this dieter specific information to generate one or more meal plans for that dieter in connection with an ingredient, food, supplement, drug and recipe database containing a universe of foods, supplements, and drugs available for generating meals and treatment plans in accordance with the diet. The system of the present invention may function as a standalone application or it may be web-based wherein users may access the application on a server accessible through the internet or some other public or private network.

Owner:MOSHER MICHELE L

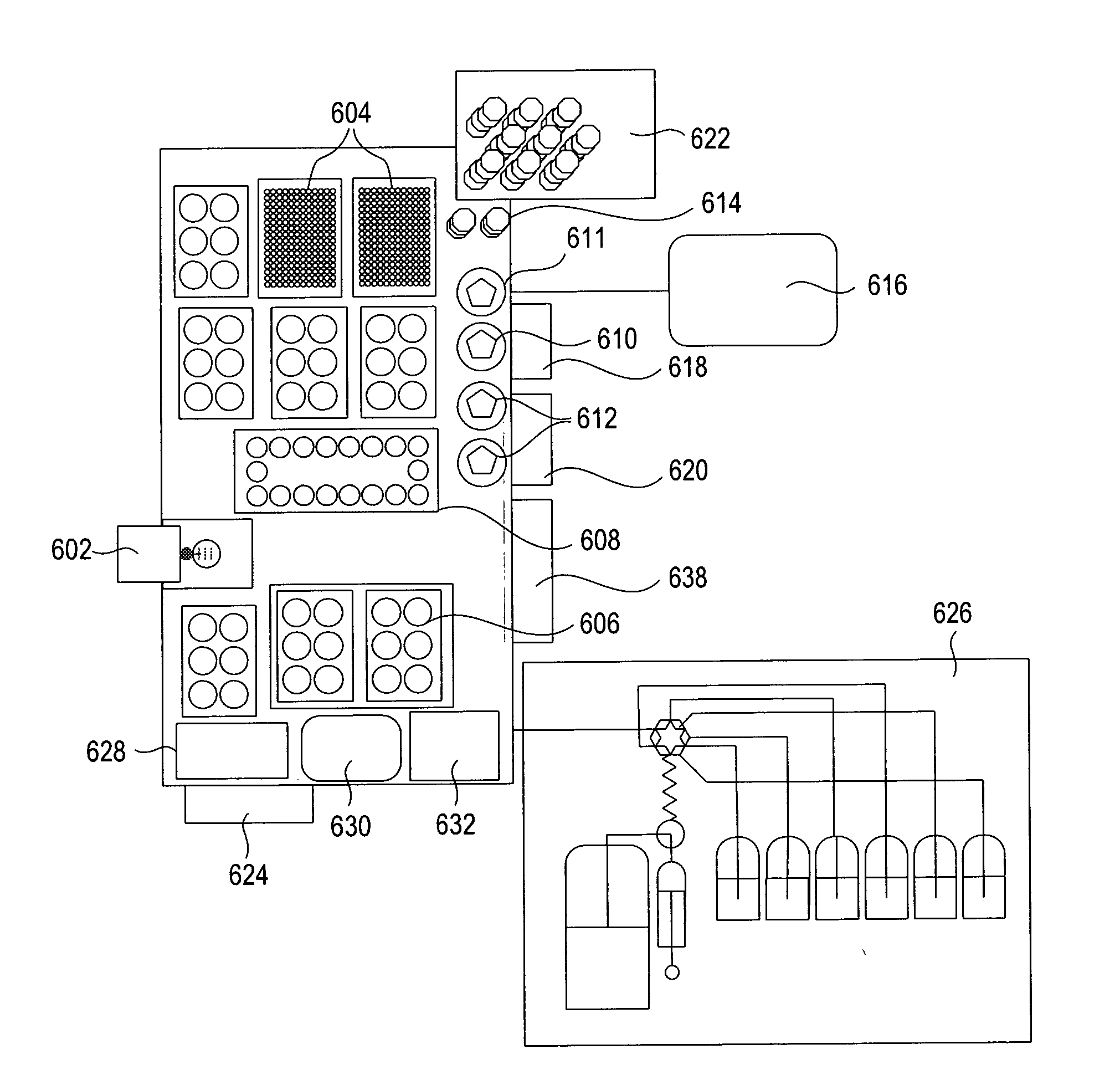

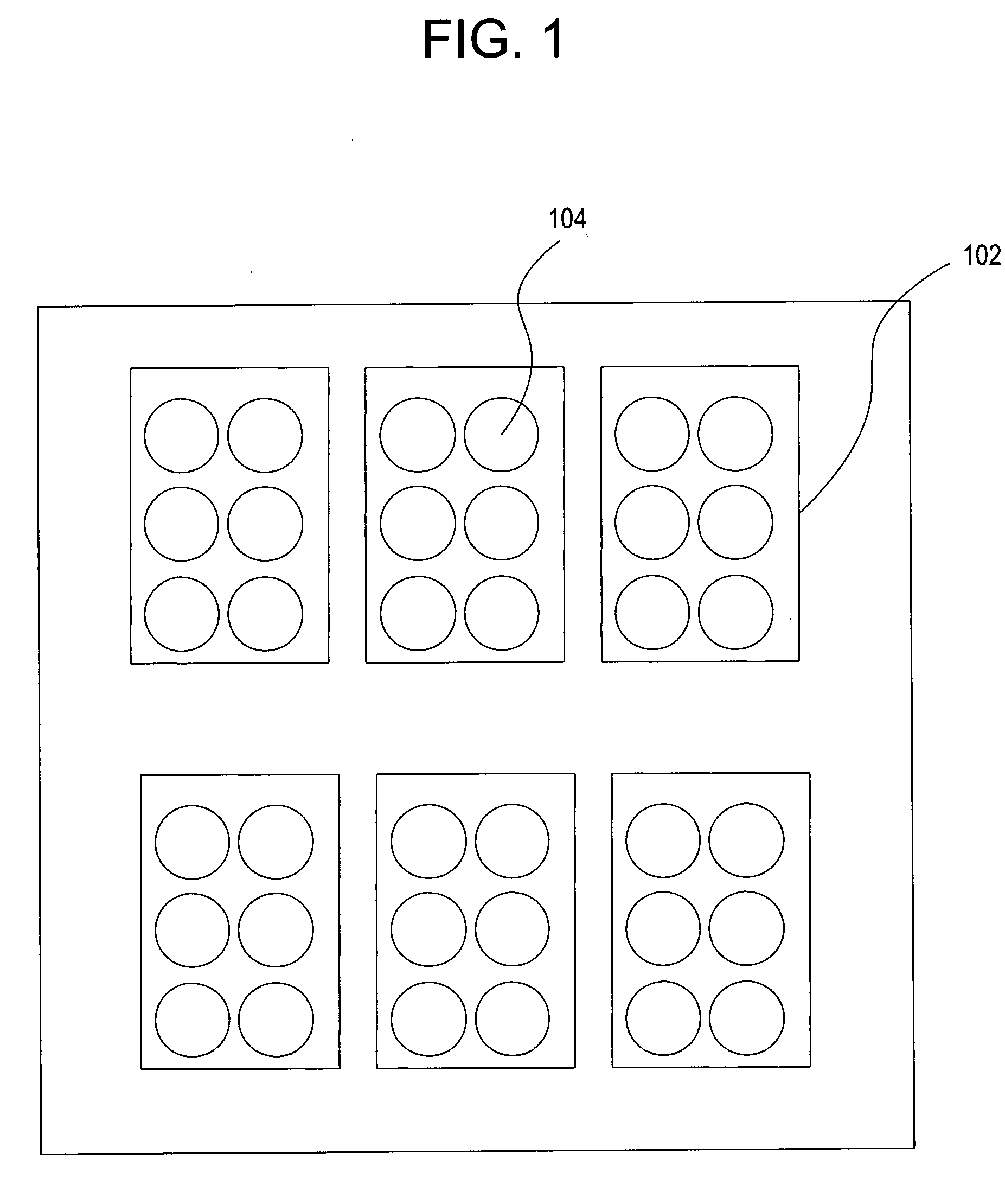

Preparation and characterization of formulations in a high throughput mode

ActiveUS20050058574A1Improve throughputFormula flexibleLibrary tagsFlow propertiesAnalysis dataAdditive ingredient

The invention is an automated robotic system for the production and testing of formulations at a very high throughput. It is an integrated system of hardware and software capable of preparing and evaluating hundreds of emulsions per day. The system can formulate aqueous solutions (SL), oil in water emulsions (EW), suspo-emulsions (SE), micro capsule suspensions (CS), micro-emulsions (ME), and suspension concentrates (SC) at the 1 ml to 25 ml scale. The system can process emulsions rapidly in an automated way and enable very flexible formulation recipes to be introduced. The system allows chemists to generate experimental samples of varying recipe and method to be conducted in parallel with projected throughput of up to 1200 formulations processed and characterized per day. Materials and consumables can be distributed from storage storage systems to the work stations where dispensing of ingredients in various states can be performed, including solids, liquids, gels, pastes, suspensions and waxes. The emulsions formed can be characterized using methods including phase diagnosis, turbidity analysis, viscosity and particle sizing using automated test equipment. An integrated module can also perform Tank Mix Compatibility testing in high throughput mode. The modular system allows future processes and tests to be added, either to a station, or as a new station. The software capability includes tracking of processes from start to finish and the integration of analytical data with the as-designed and as-formulated experimental results.

Owner:SYNGENTA LTD

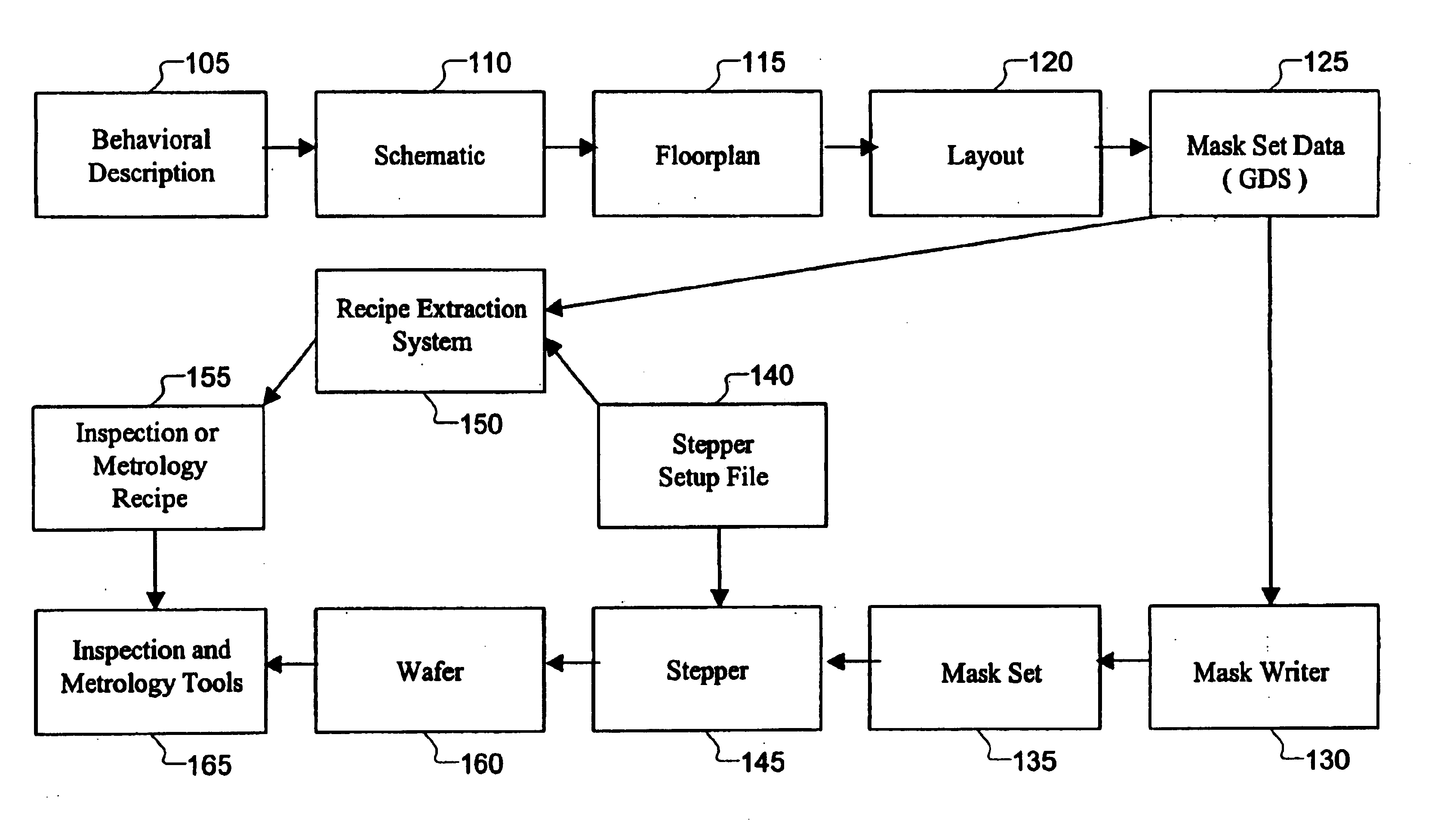

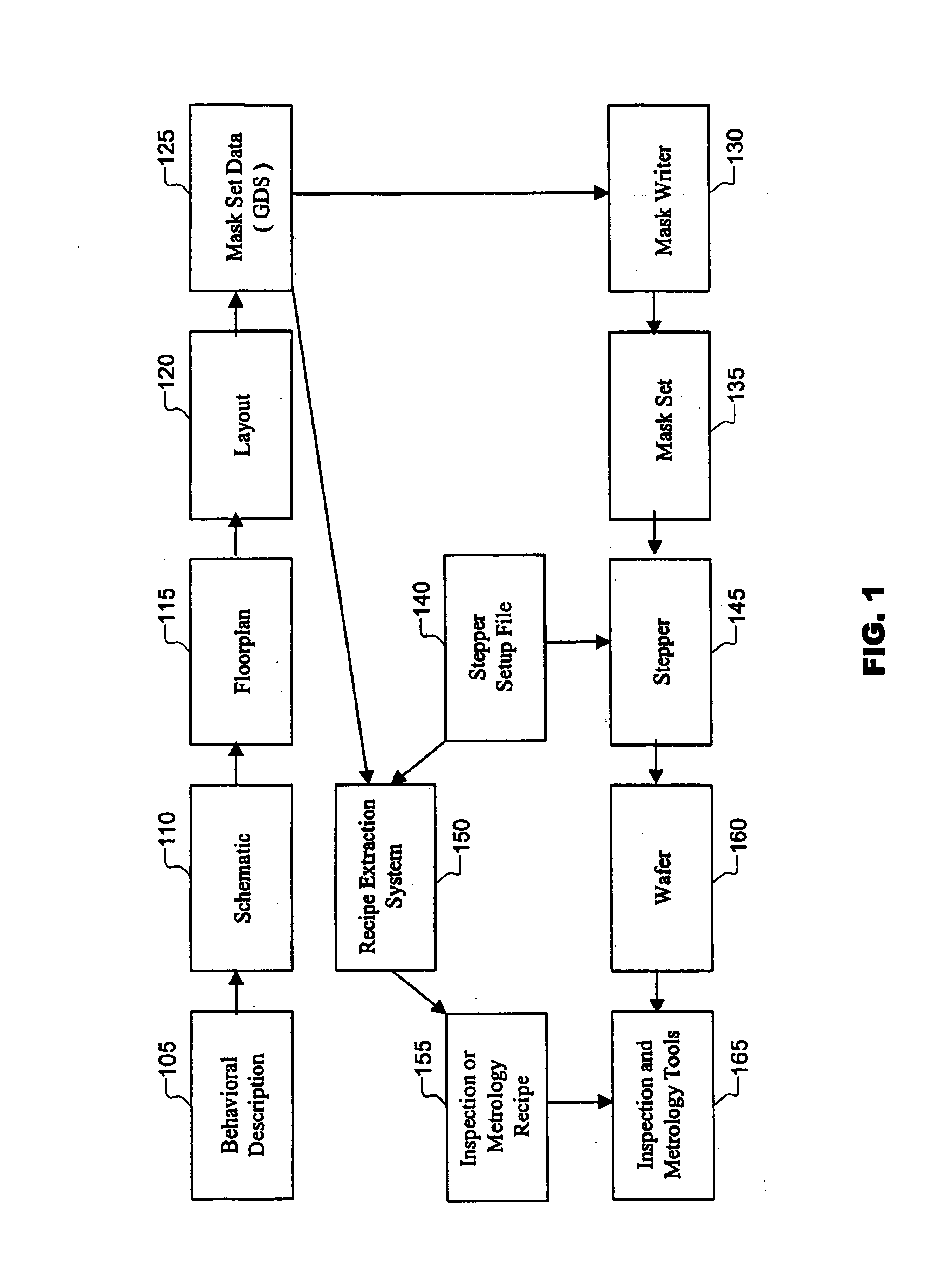

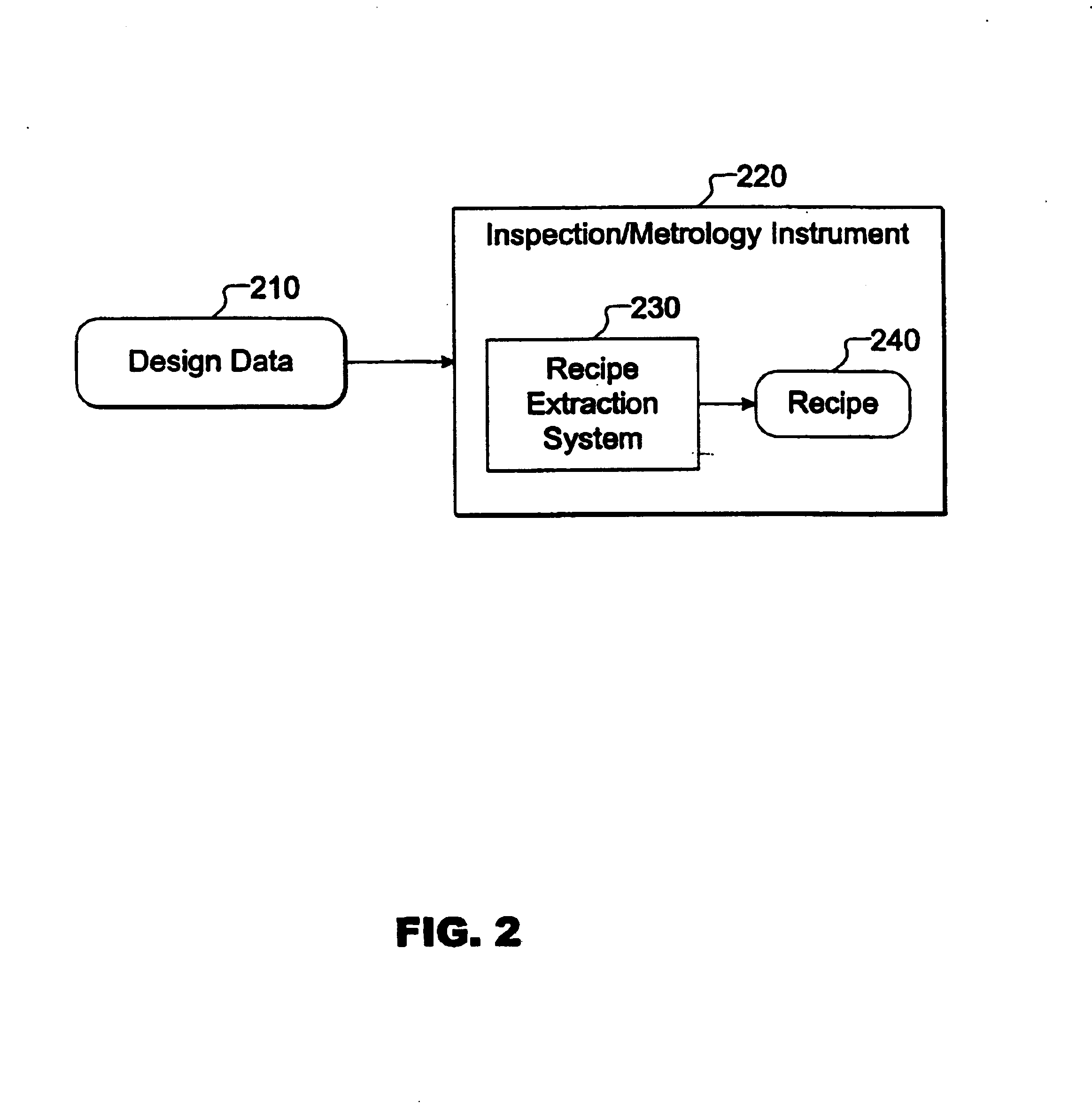

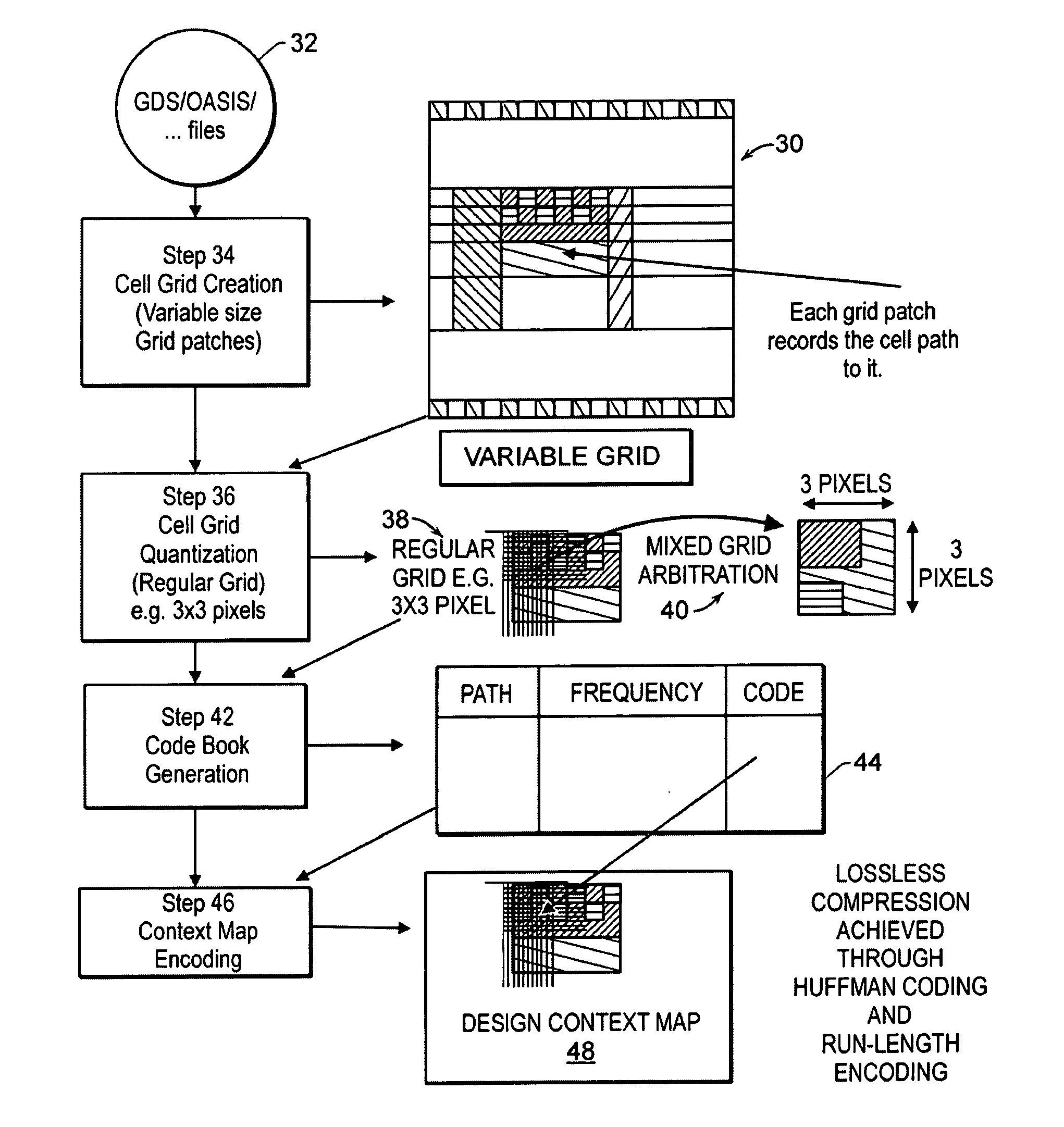

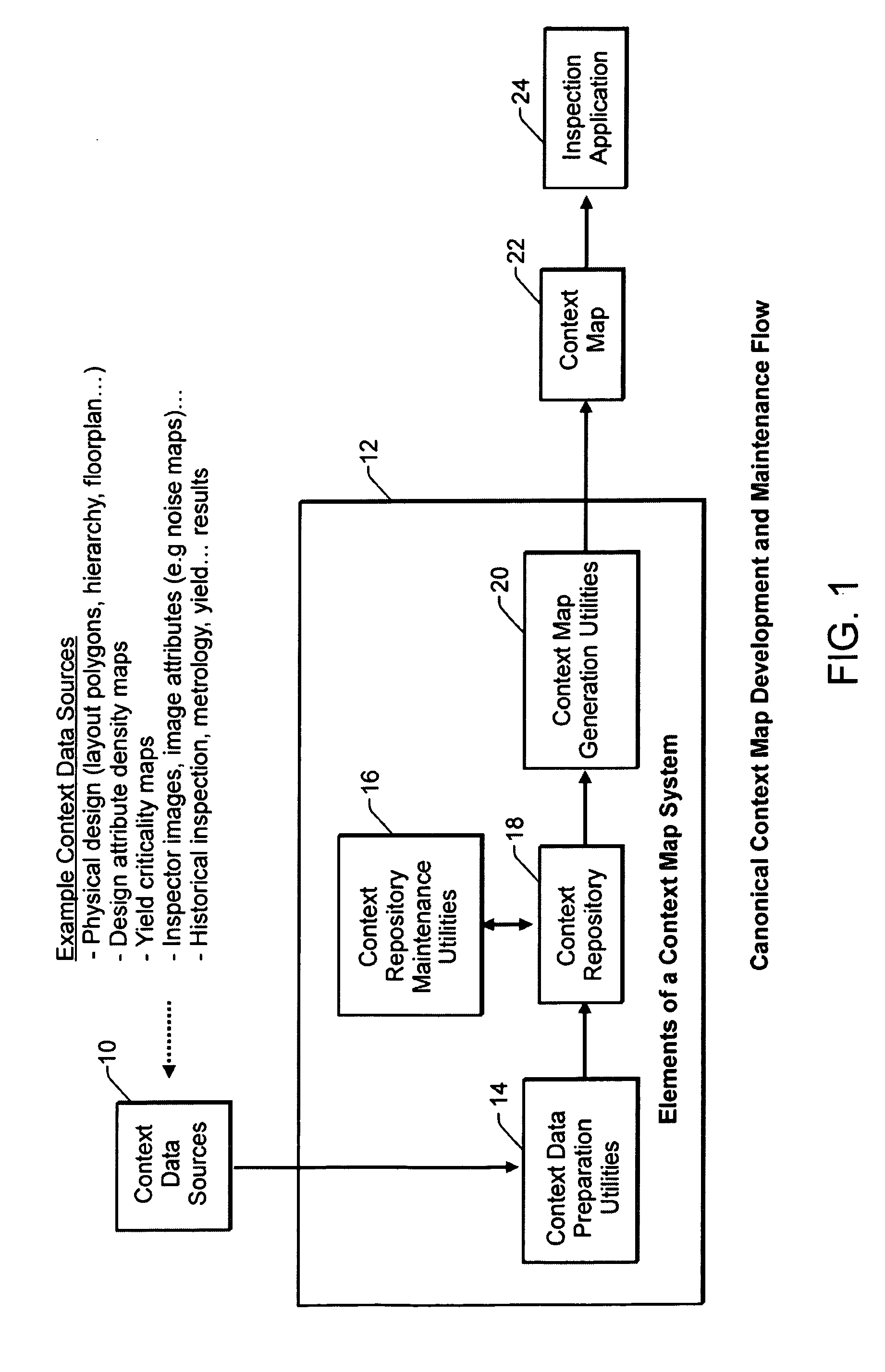

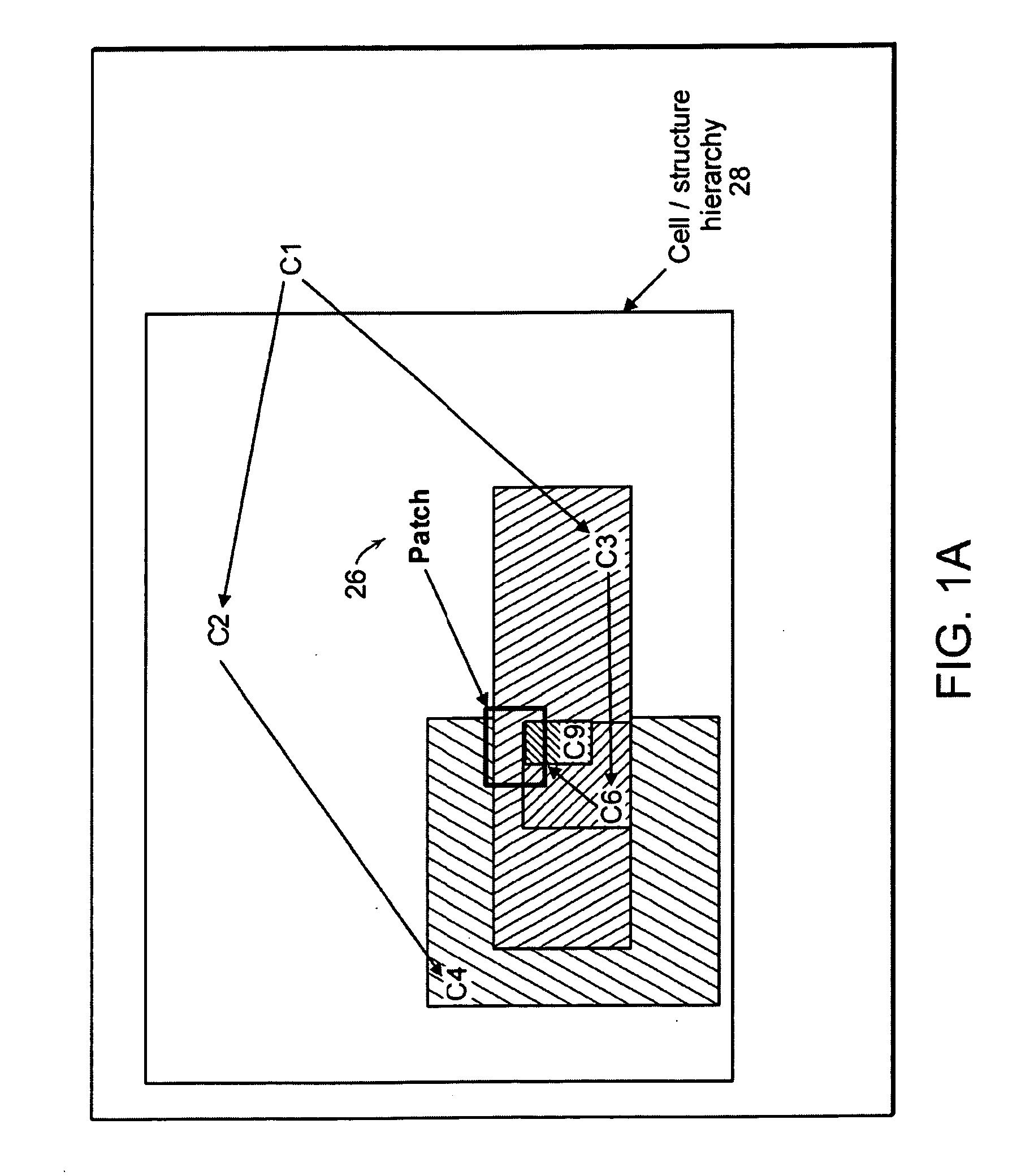

Design driven inspection or measurement for semiconductor using recipe

InactiveUS6886153B1Reduces instrument setup timeReduce setup timeSemiconductor/solid-state device testing/measurementPhotomechanical exposure apparatusMetrologySemiconductor

Design driven inspection / metrology methods and apparatus are provided. A recipe is a set of instructions including wafer processing parameters, inspection parameters, or control parameters for telling an inspection / metrology system how to inspect / measure a wafer. Design data is imported into a recipe extraction system that recognizes instances of target structures and configures recipe parameters accordingly, thereby reducing manual instrument setup time, improving inspection / measurement accuracy, and improving fabrication efficiency.

Owner:KLA TENCOR TECH CORP

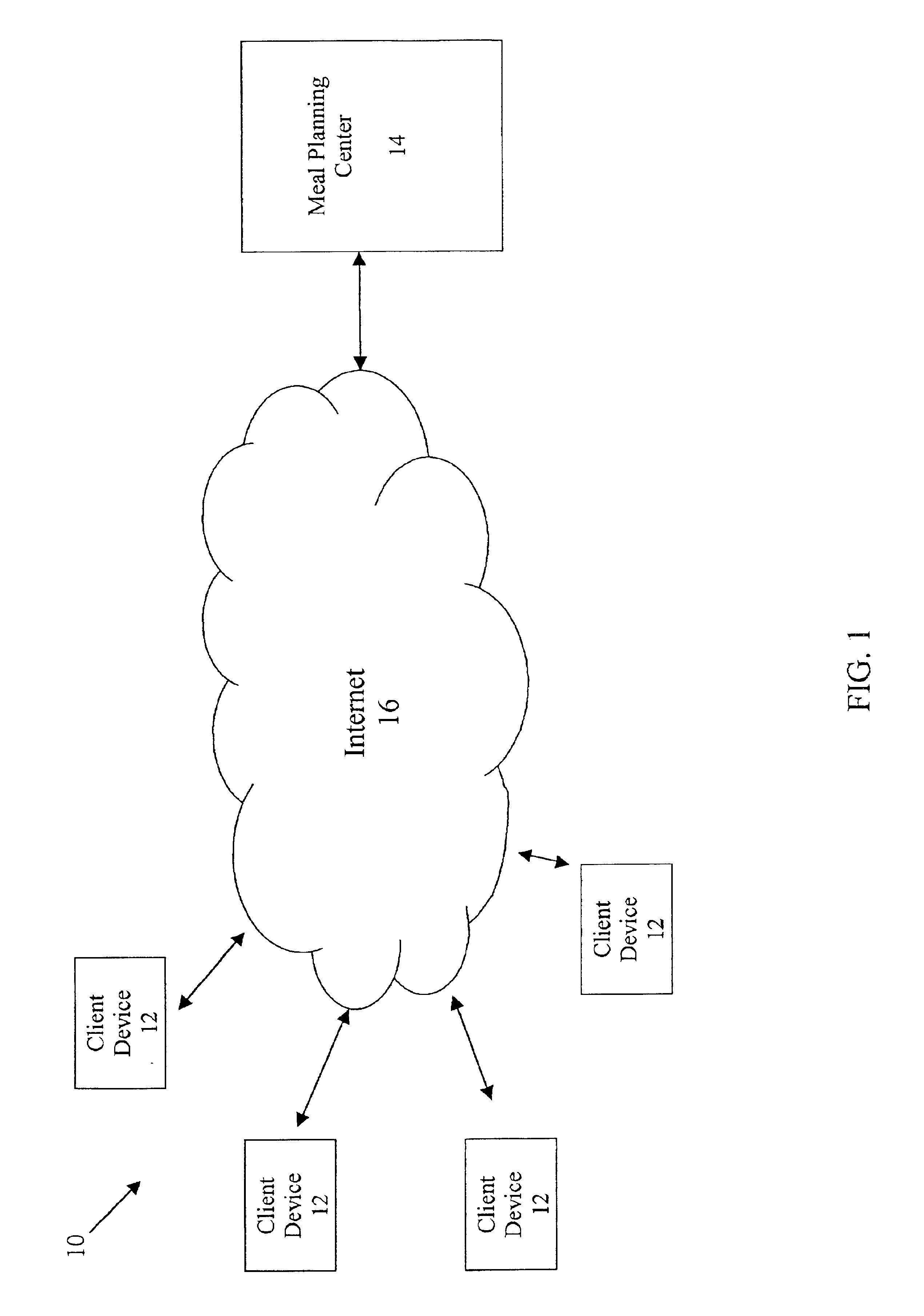

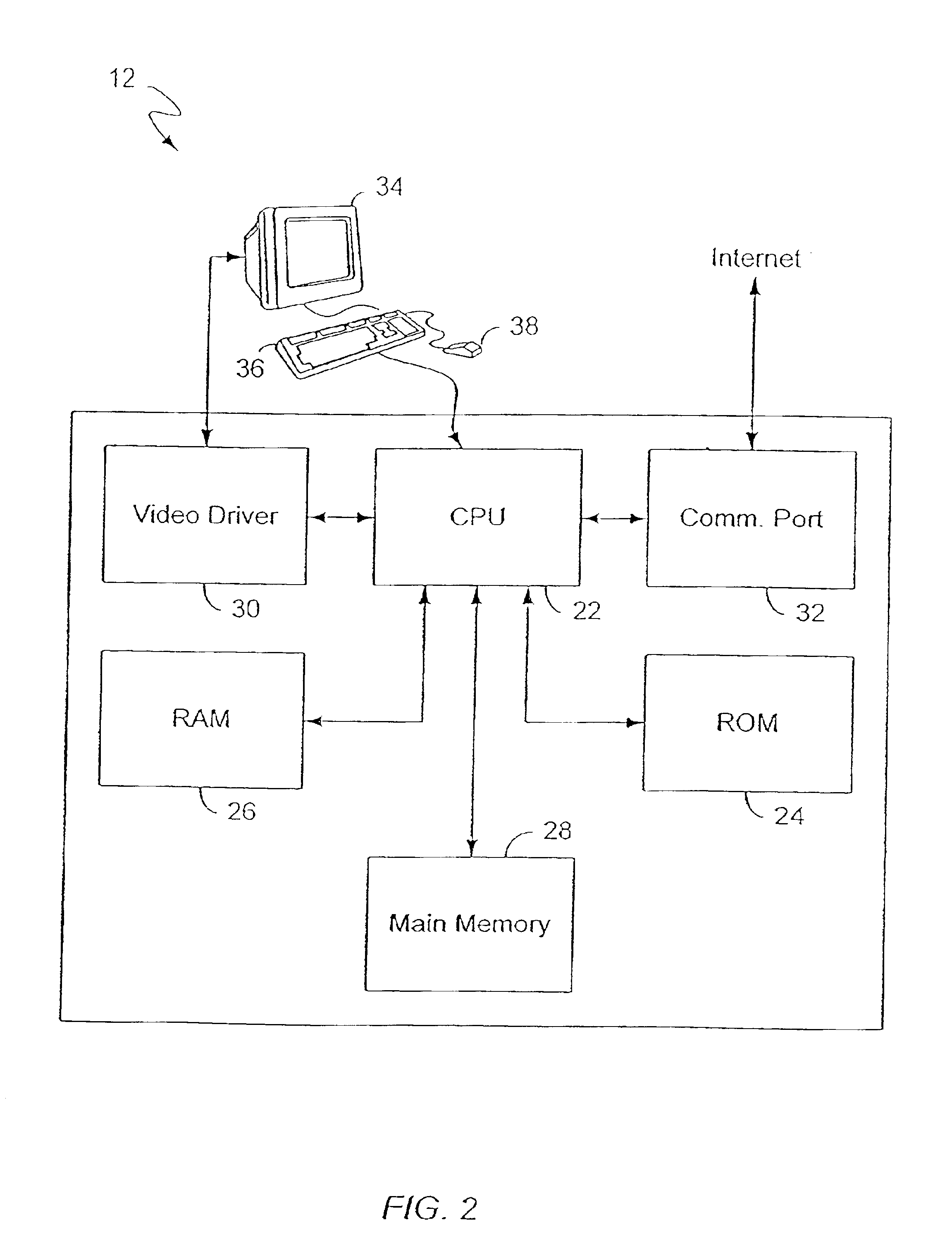

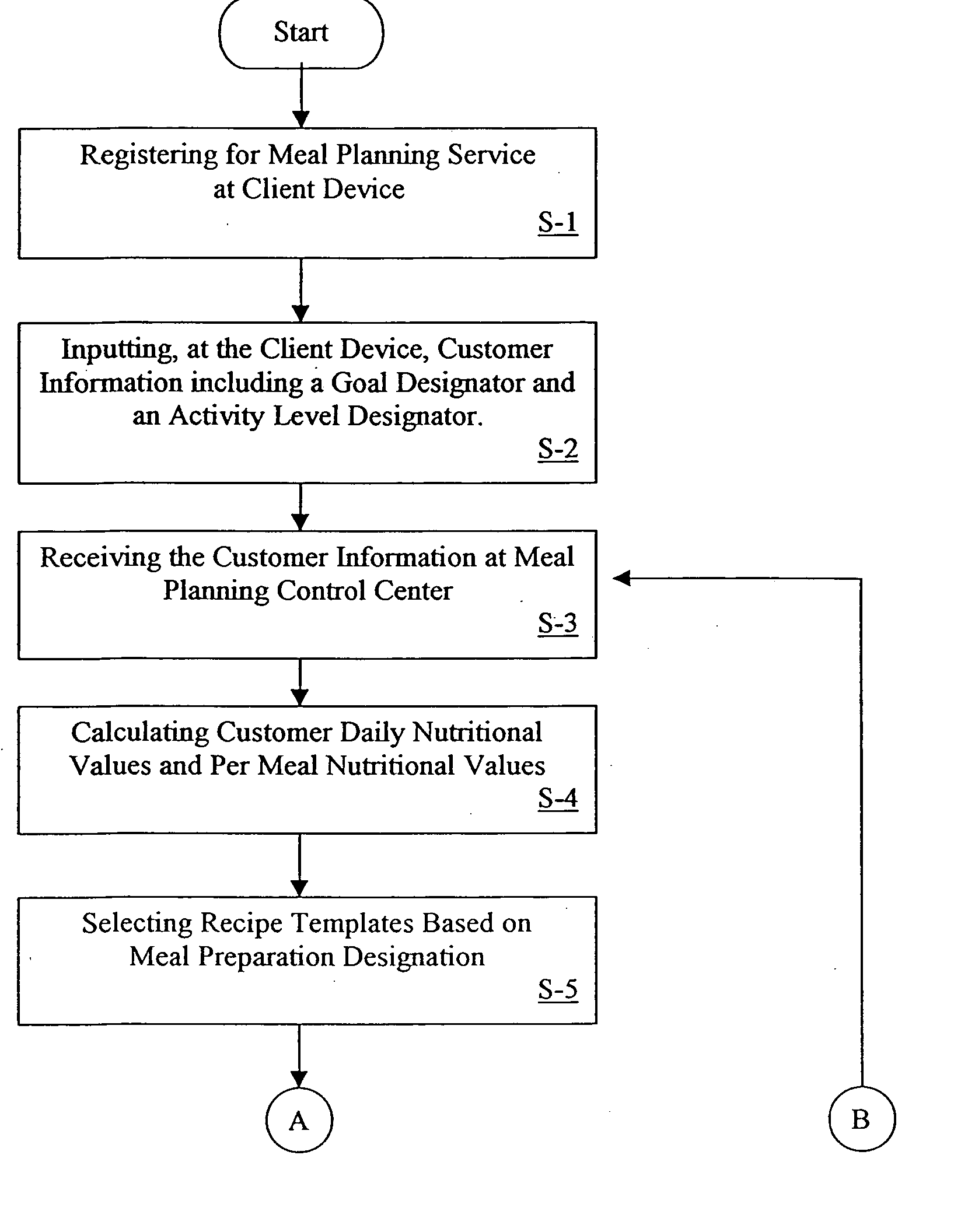

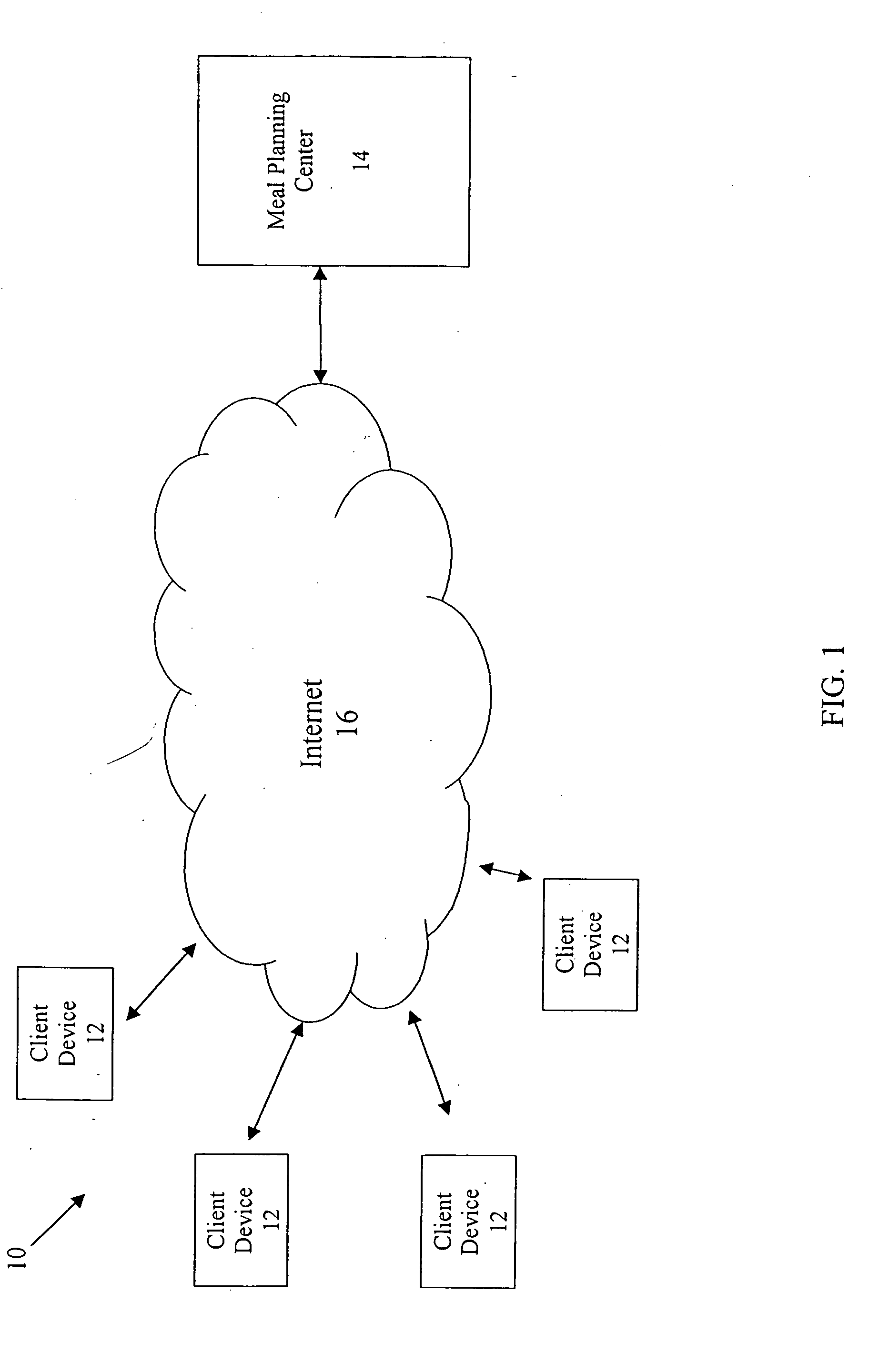

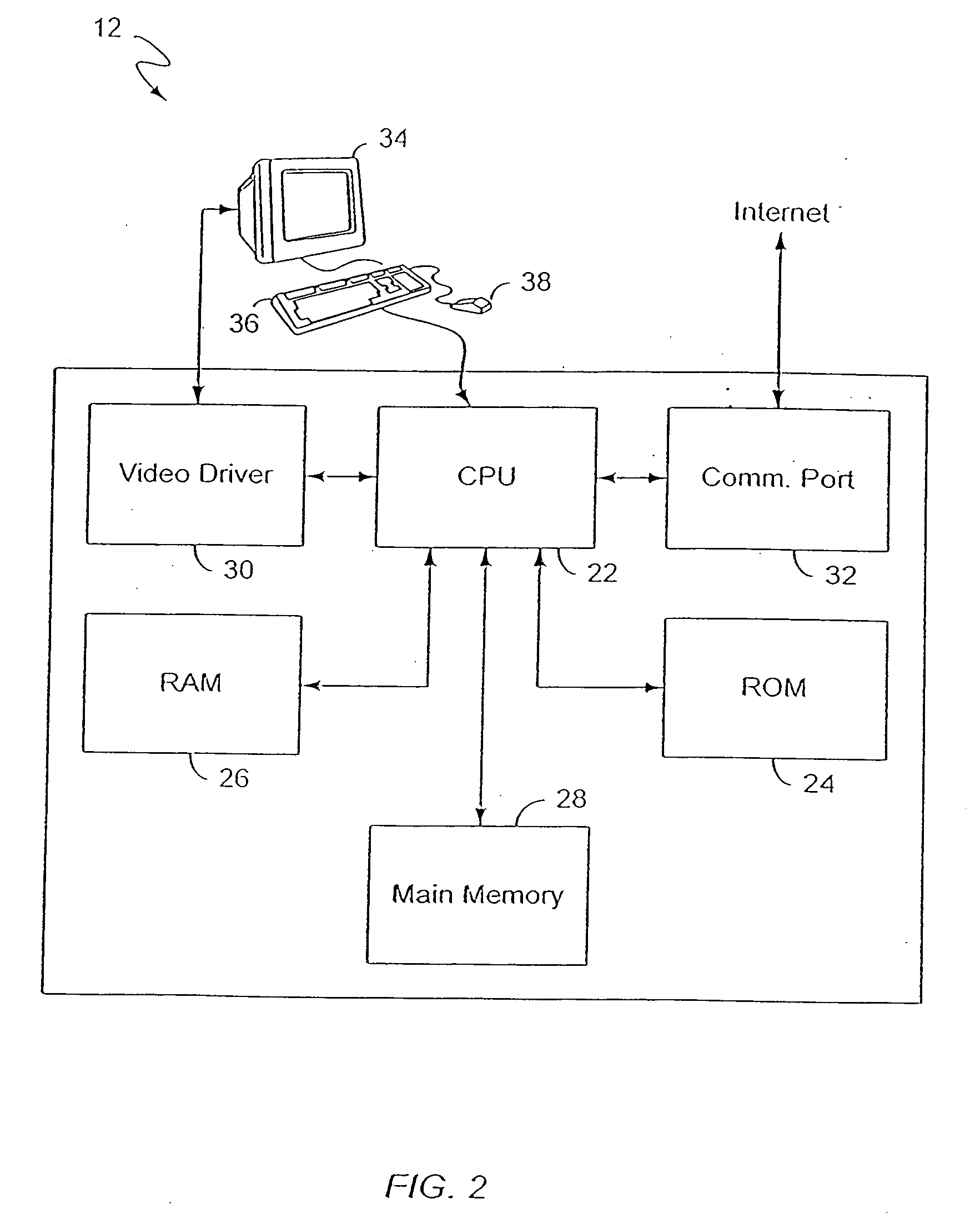

System and method for generating personalized meal plans

InactiveUS6872077B2Reduces knowledgeReduce effortNutrition controlComputer-assisted diets prescription/deliveryPersonalizationAdditive ingredient

A system for personalized meal planning is provided which includes a client device and a meal planning center configured to communicate with the client device and to receive a customer's information, including a weight designator, a gender designator, a goal designator, and an activity level designator. The meal planning center includes a storage device and a processing unit. The storage device is configured to store recipe template files having an ingredient designator and a plurality of recipe rule factors, which include a nutrient contribution value, a minimum ingredient value, and a maximum ingredient value. A plurality of recipe rule factors are each assigned to each ingredient designator. The processing unit is configured to determine a nutritional allowance based upon the customer information and to create a recipe that satisfies the nutritional allowance by using the recipe rule factors assigned to the ingredient. The meal planning center is further configured to transmit the recipe to the client device.

Owner:SOLOS HEALTH

Interactive internet shopping and data integration method and system

ActiveUS7376591B2Intuitive experienceAdvertisementsBuying/selling/leasing transactionsPaymentWeb site

A method and system for interactively shopping for groceries, especially on an Internet web site, where the user may create a shopping list, shop for items from the list at a selected Grocery Storey store, arrange for pick up or delivery of the selected items and payment, or to download the list to a PDA or for printing with the store's layout for use in the store. Users are required to register and provide specific demographic information (useful to Manufacturers and stores) to be eligible to receive the benefits of use of the web site, such as menu creation, coupon downloads, menu planning, and recipe input. Shopping lists may be created from a single input screen using standard language text; and products may be automatically suggested to the user based on best regular price or retailer's specials. Recipes may be altered to meet numbers of servings or dietary requirements and changes stored for future use.

Owner:OWENS CSTEPHANI D

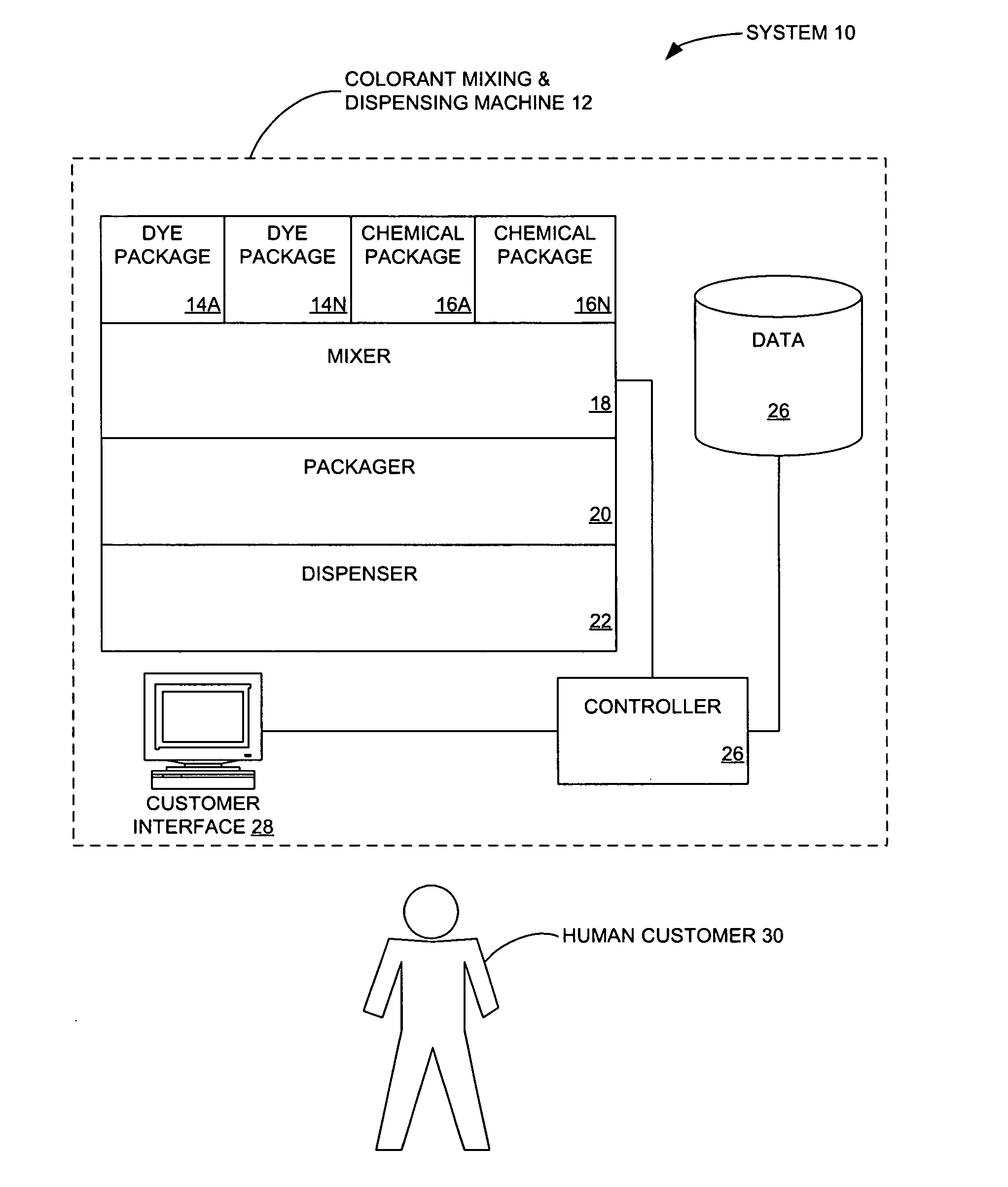

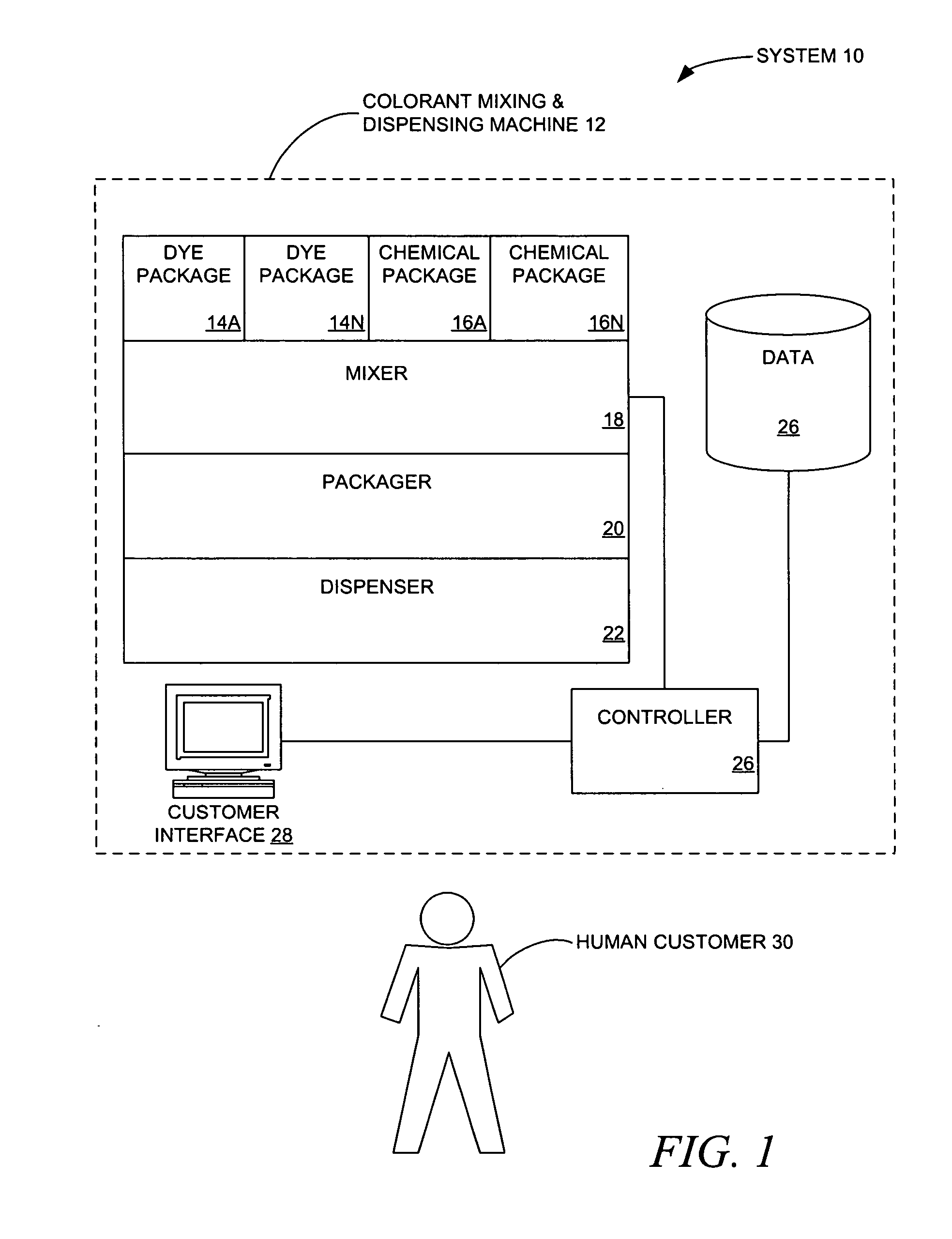

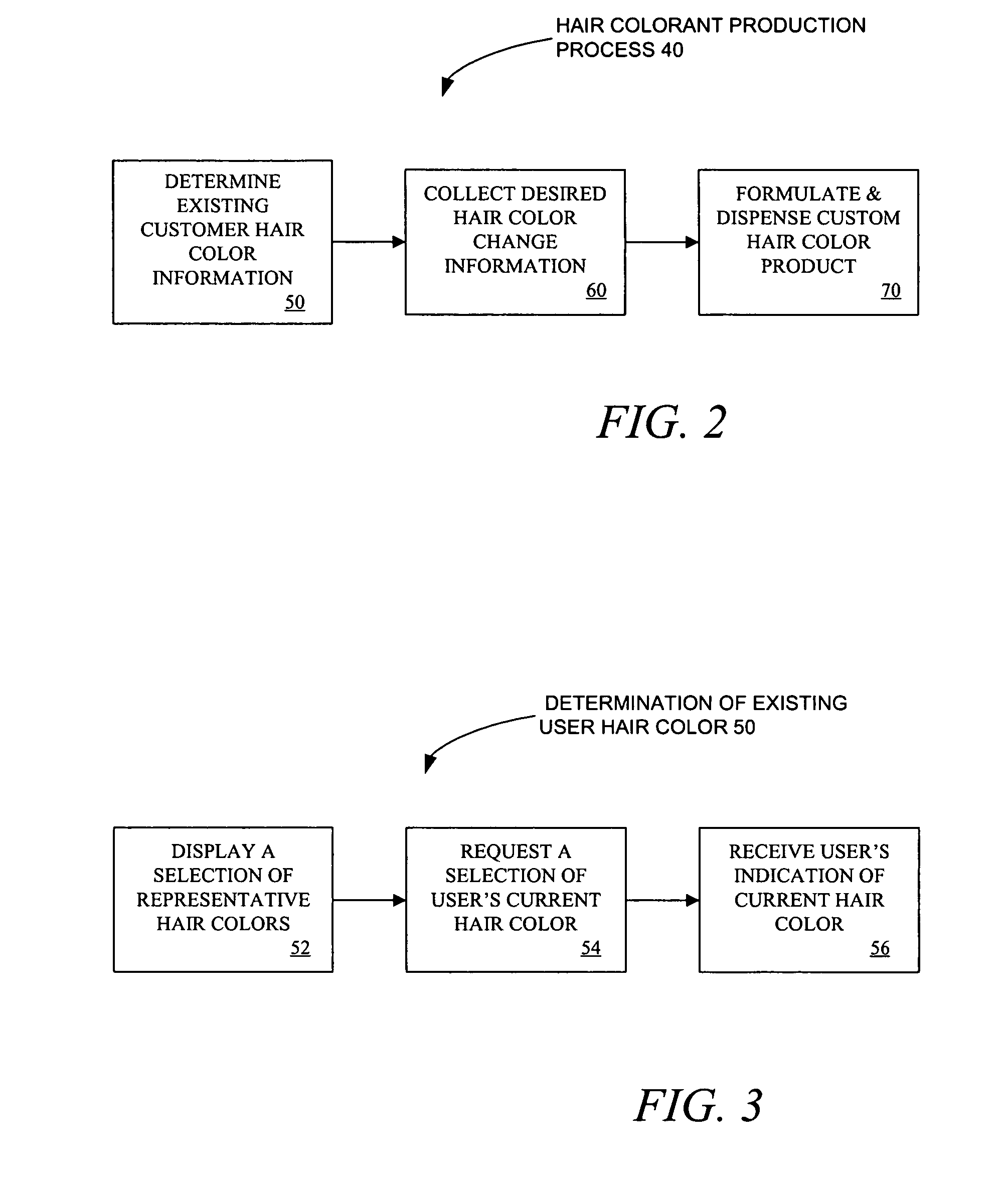

Apparatus and methods for selecting, formulating, mixing & dispensing custom hair coloring products for a user

InactiveUS20050165705A1Space minimizationReduce areaHair cosmeticsMixer accessoriesHair dyesCompound (substance)

Graphical interfaces are provided to a customer enabling her to identify her existing hair color and to select a desired change to that hair color, based upon which there is produced hair dyes and / or intensive toners in which the intermediates (developer and coupler) and the direct dyes are dissolved in liquid or creamy carrier masses that are mixed together by a computer-controlled device based on recipes stored in a computer. Using packaged dyes and chemicals, there is formulated, mixed, packaged and dispensed to the customer a custom hair colorant.

Owner:HCD

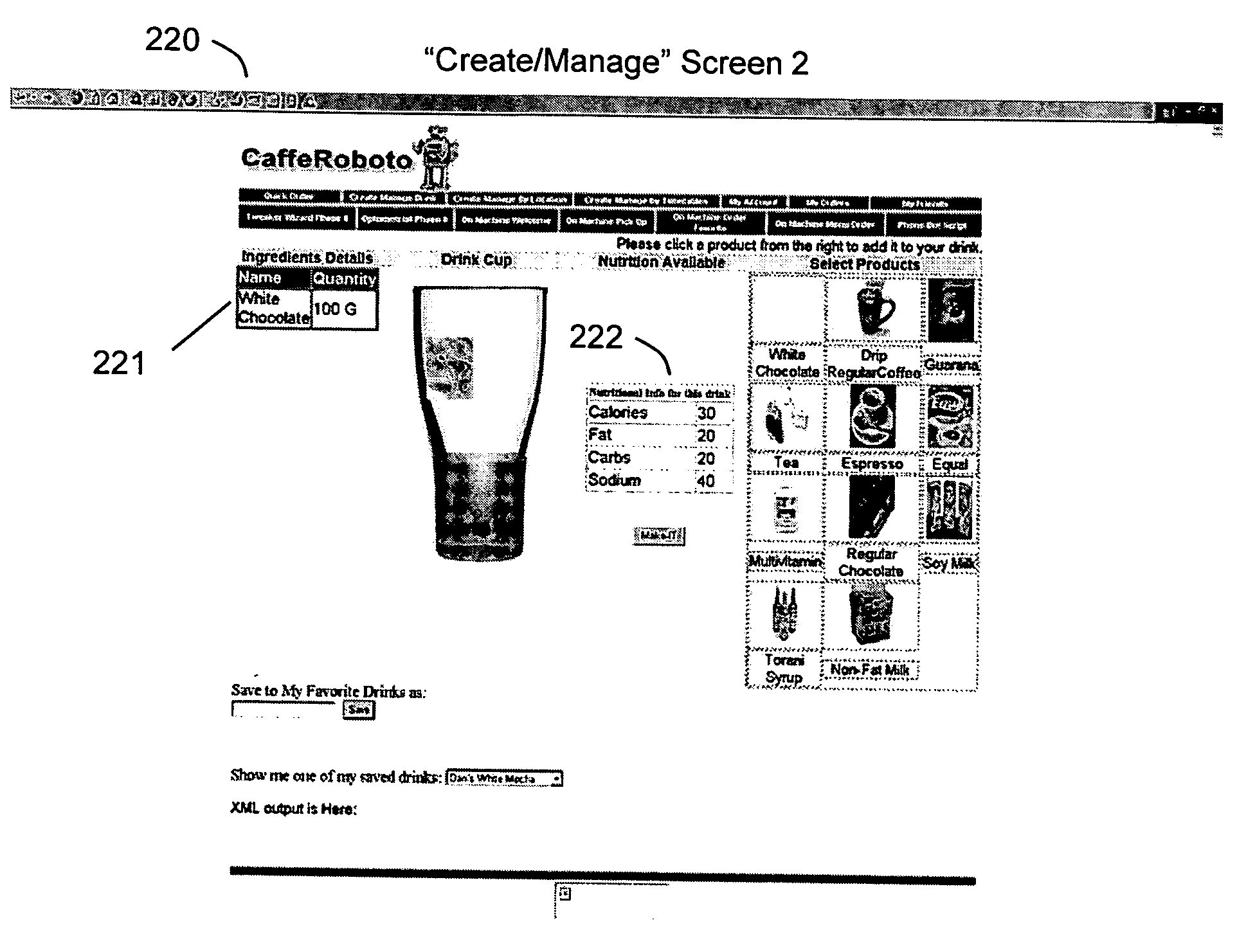

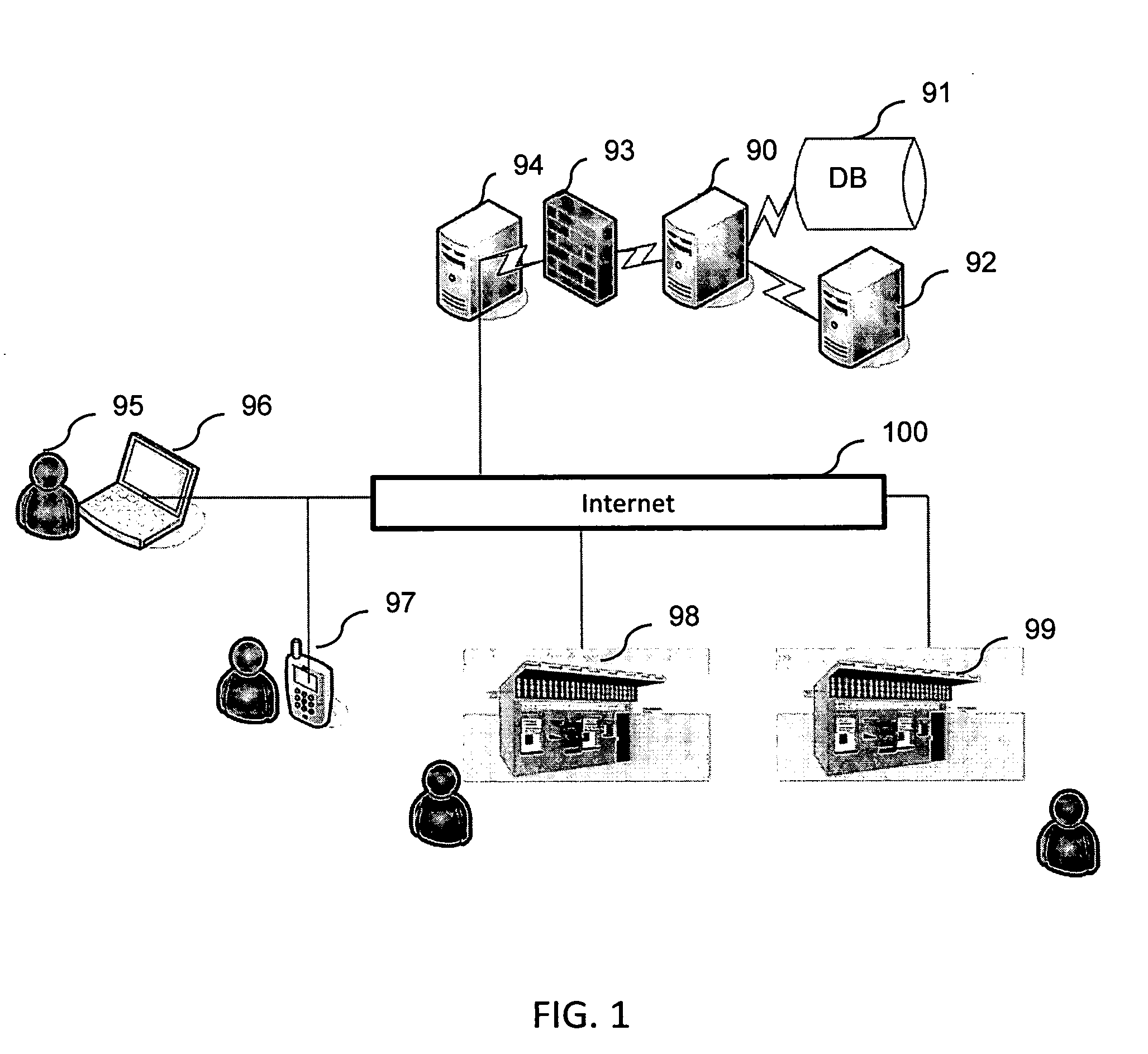

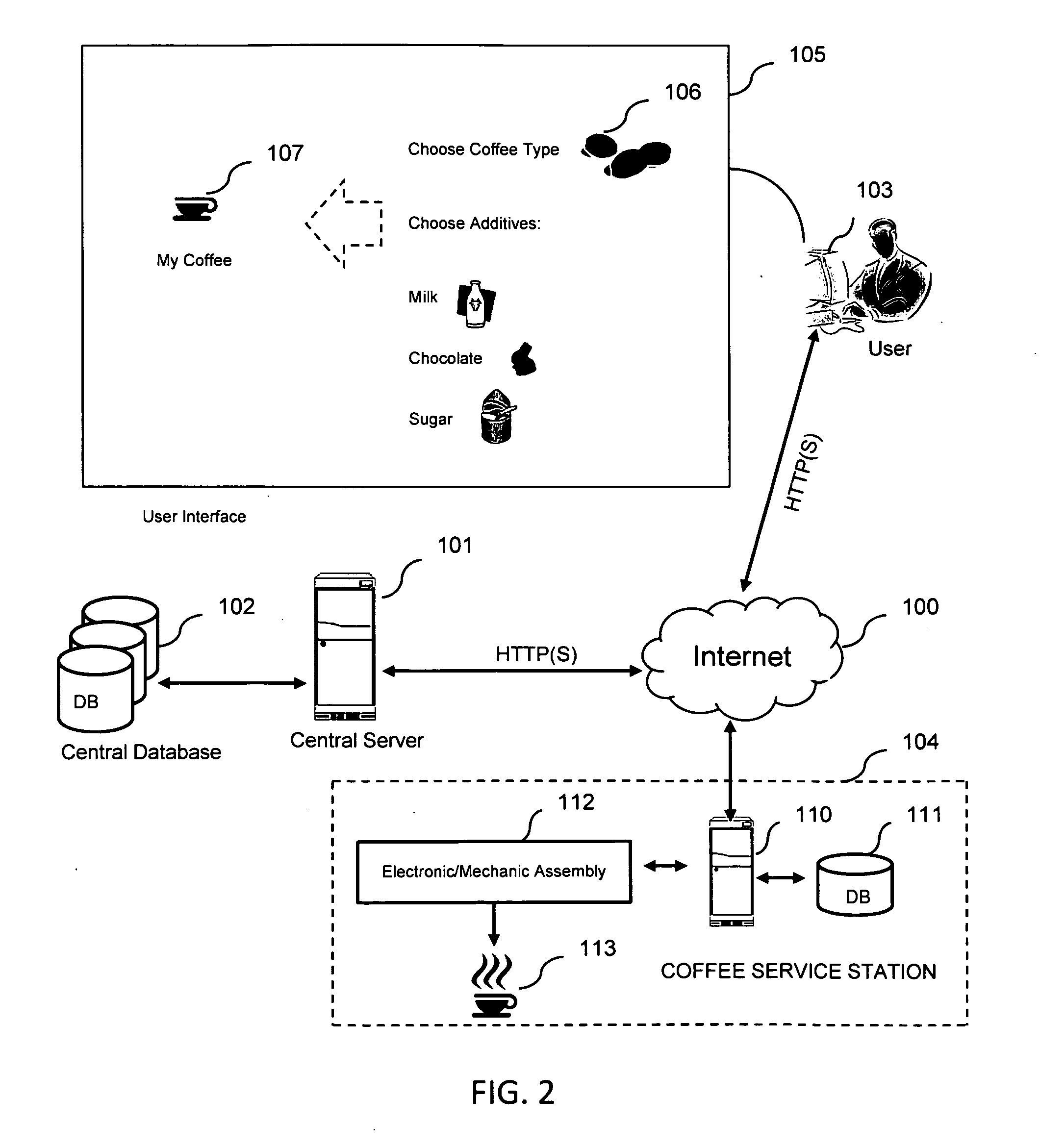

Automated coffee system

InactiveUS20080201241A1Quality improvementGood mixtureBeverage vesselsBuying/selling/leasing transactionsTime schedulePersonalization

The invention provides a system in which a user may make a personalized recipe for food or beverage such as coffee and place an order online. A central server processes the order and redirects the recipe, timetable and a reference number associated with the order to a local service station designated by the user. The local service station prepares the ordered product pursuant to the recipe and timetable, and delivers the drink to the customer who enters a correct reference number.

Owner:PECORARO DANIEL BEN

Systems and methods for creating inspection recipes

ActiveUS20080250384A1Photomechanical apparatusSpecial data processing applicationsRecipeManufacturing engineering

Systems and methods for creating inspection recipes are provided. One computer-implemented method for creating an inspection recipe includes acquiring a first design and one or more characteristics of output of an inspection system for a wafer on which the first design is printed using a manufacturing process. The method also includes creating an inspection recipe for a second design using the first design and the one or more characteristics of the output acquired for the wafer on which the first design is printed. The first and second designs are different. The inspection recipe will be used for inspecting wafers after the second design is printed on the wafers using the manufacturing process.

Owner:KLA CORP

Nutrition informatics method

The present invention provides a method for providing a user the information and tools for determining individual nutritional information and requirements particularly pertaining to menus and recipes that are suited to that user and that may be individually and easily tailored in a method that is heretofore unknown in the prior art.

Owner:HEALTH PROJECT PARTNERS

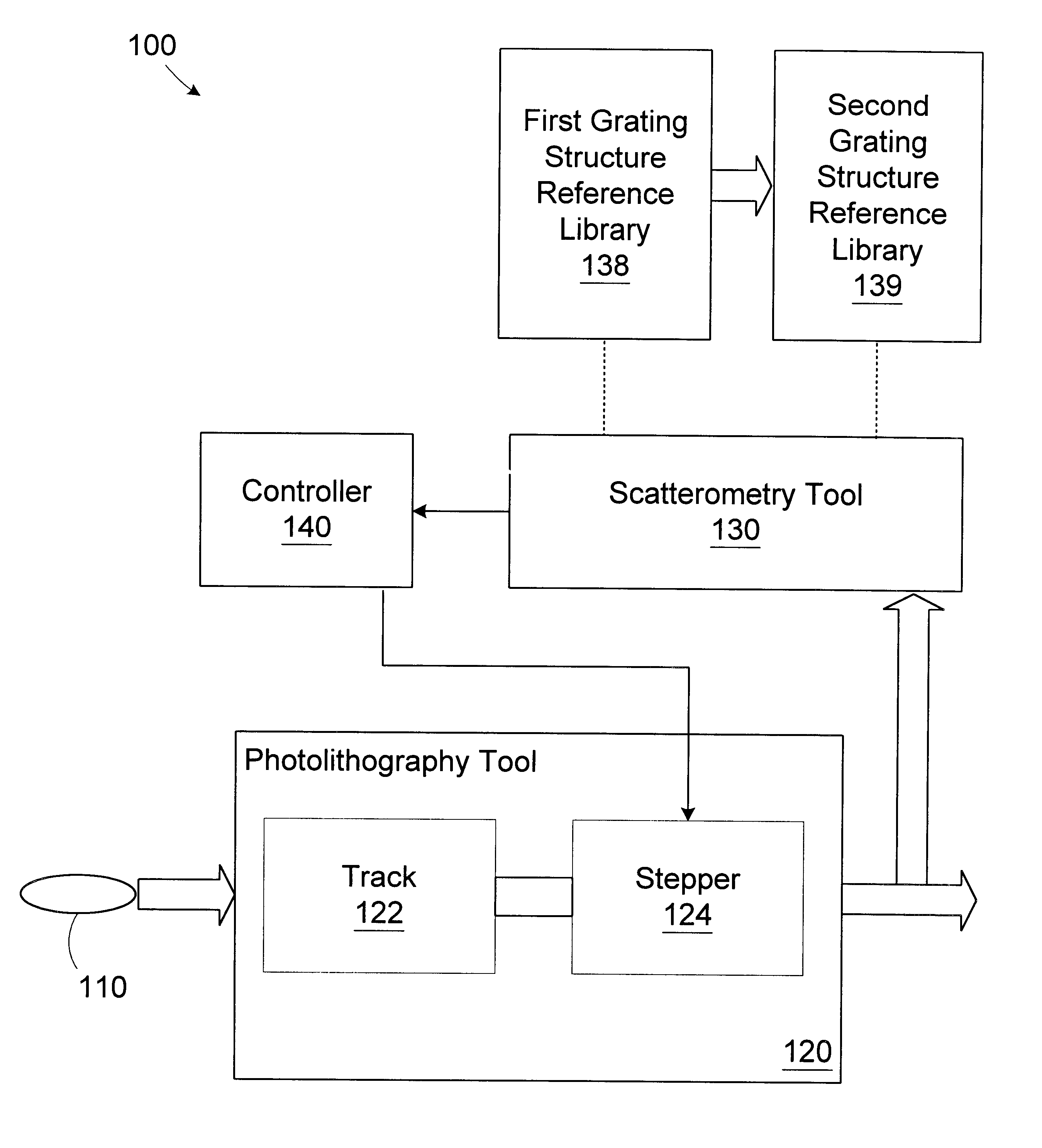

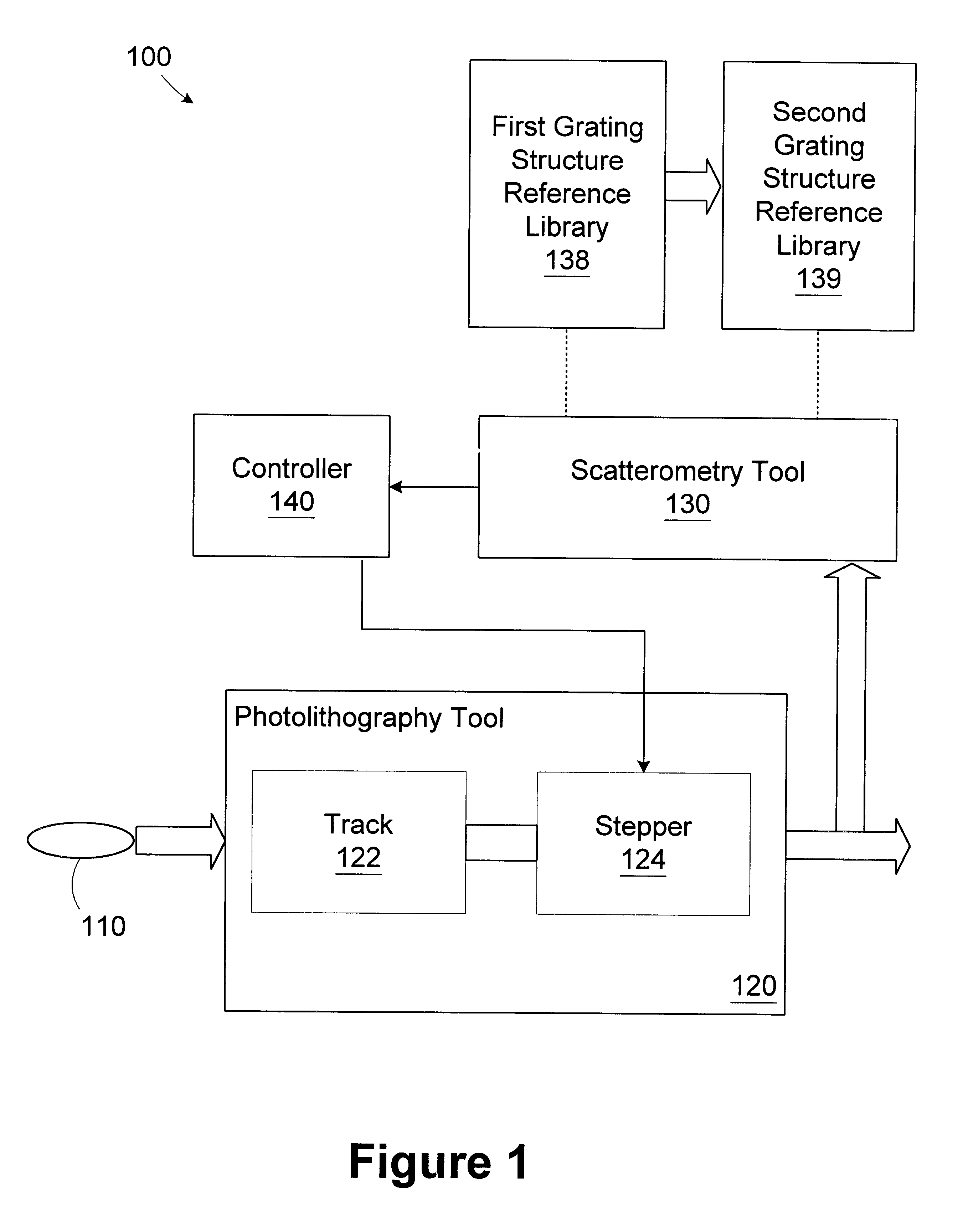

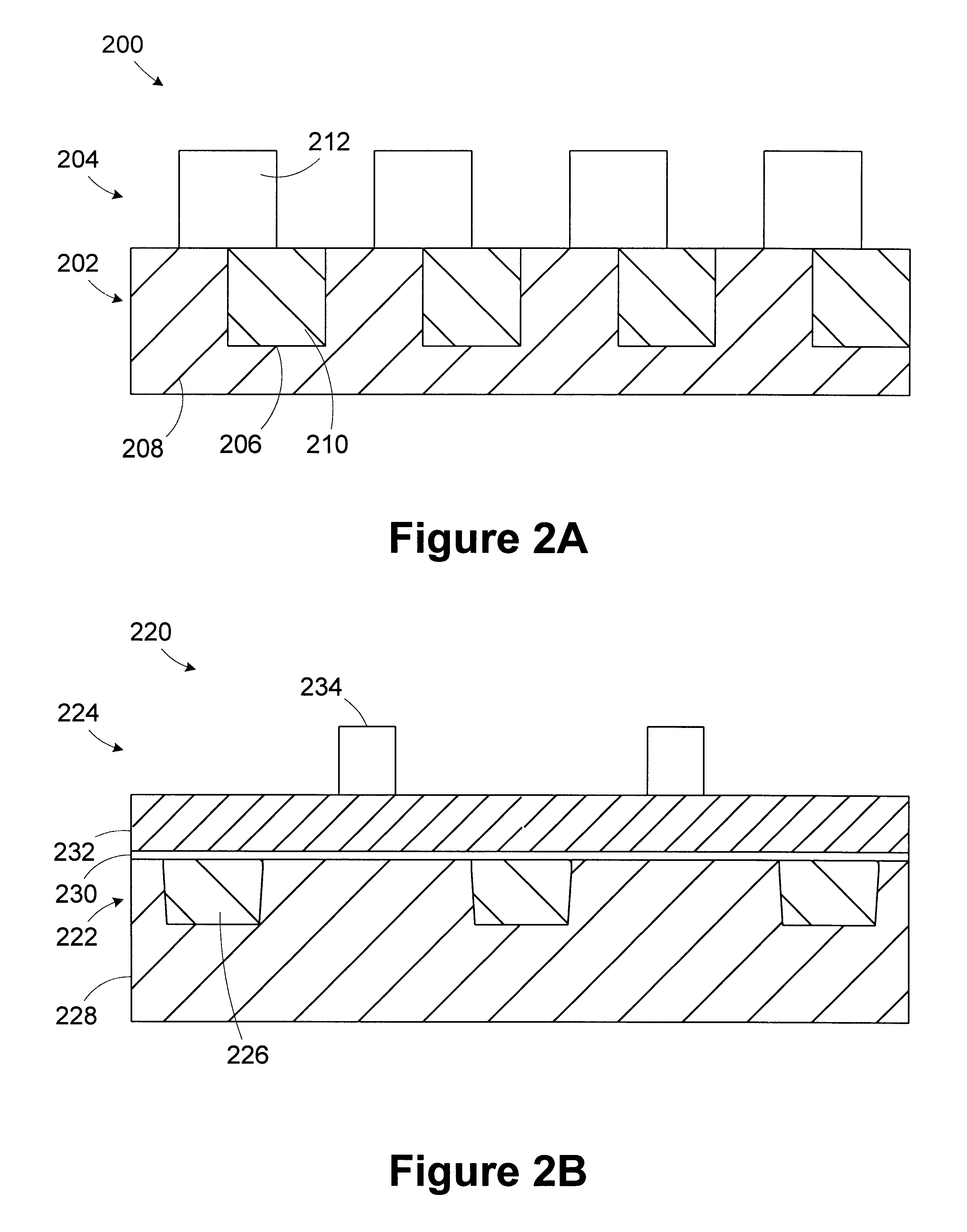

Method and apparatus for controlling photolithography overlay registration

InactiveUS6458605B1Electrolytic capacitorsSemiconductor/solid-state device manufacturingGratingMetrology

A method for controlling a photolithography process includes providing a wafer having a first grating structure and a second grating structure overlying the first grating structure; illuminating at least a portion of the first and second grating structures with a light source; measuring light reflected from the illuminated portion of the first and second grating structures to generate a reflection profile; determining an overlay error between the first and second grating structures based on the reflection profile; and determining at least one parameter of an operating recipe for a photolithography stepper based on the determined overlay error. A processing line includes a photolithography stepper, a first metrology tool, and a controller. The photolithography stepper is adapted to process wafers in accordance with an operating recipe. The first metrology tool is adapted to receive a wafer having a first grating structure and a second grating structure overlying the first grating structure. The metrology tool includes a light source, a detector, and a data processing unit. The light source is adapted to illuminate at least a portion of the first and second grating structures. The detector is adapted to measure light reflected from the illuminated portion of the first and second grating structures to generate a reflection profile. The data processing unit is adapted to determine an overlay error between the first and second grating structures based on the reflection profile. The controller is adapted to determine at least one parameter of the operating recipe of the photolithography stepper based on the determined overlay error.

Owner:FULLBRITE CAPITAL PARTNERS

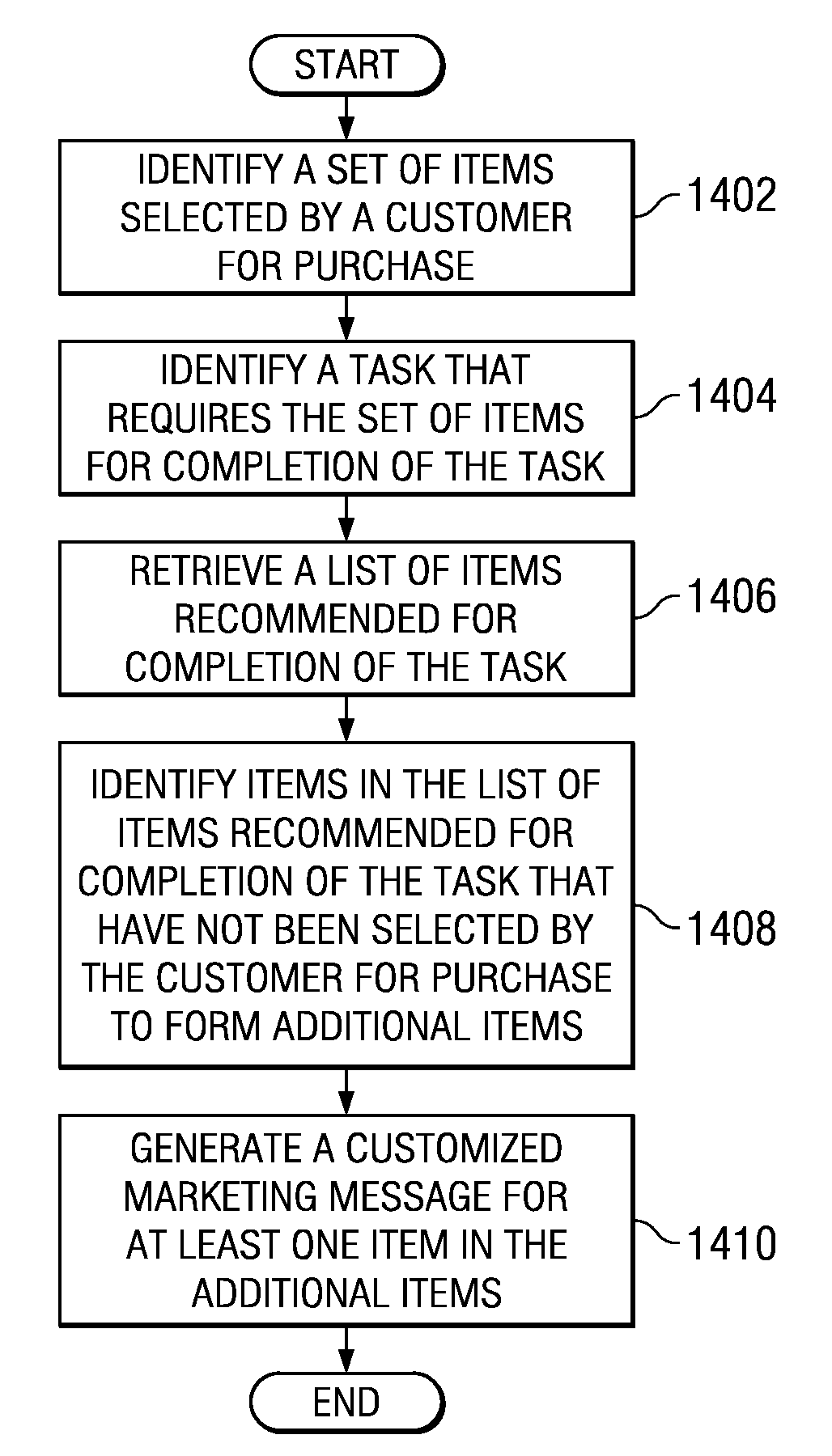

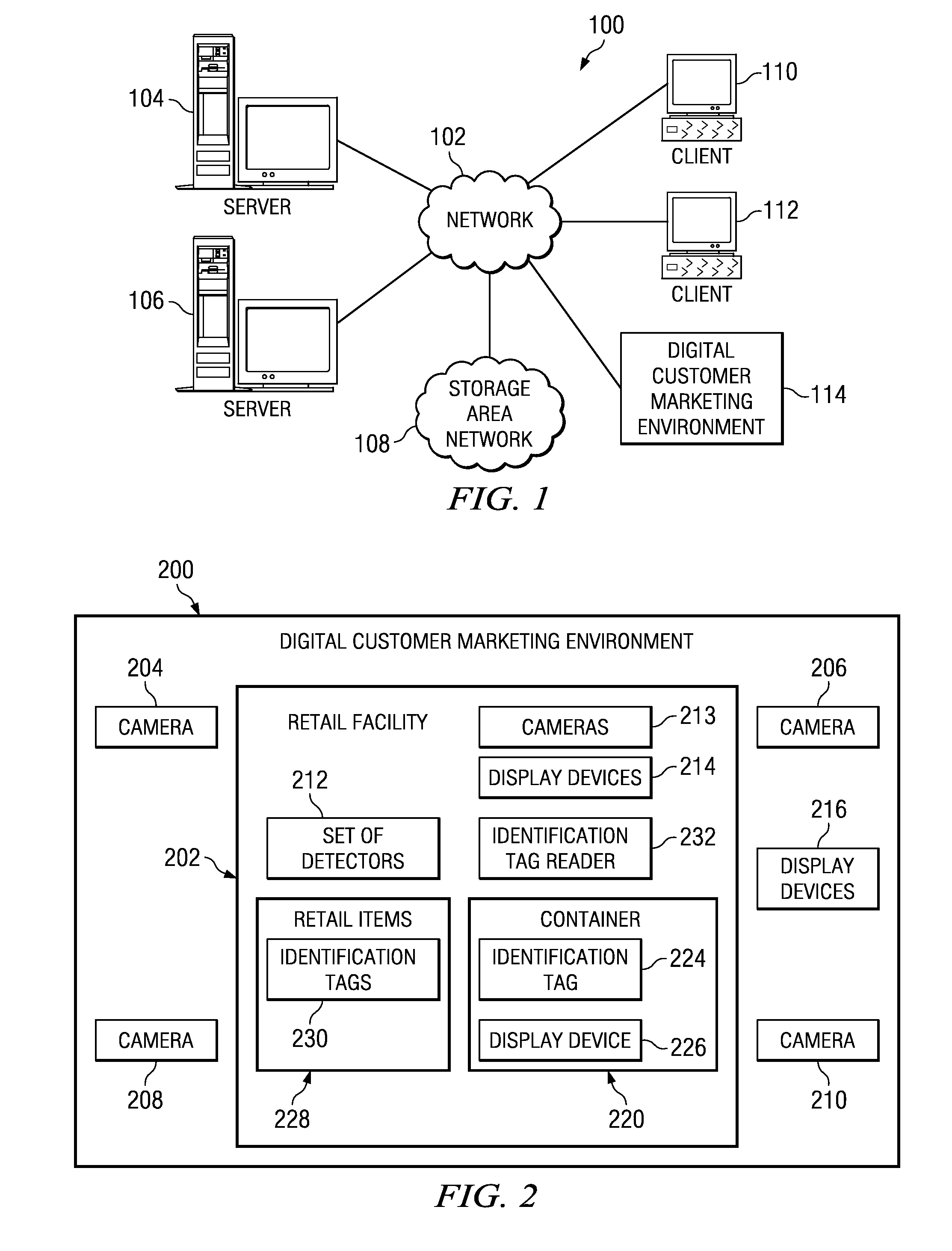

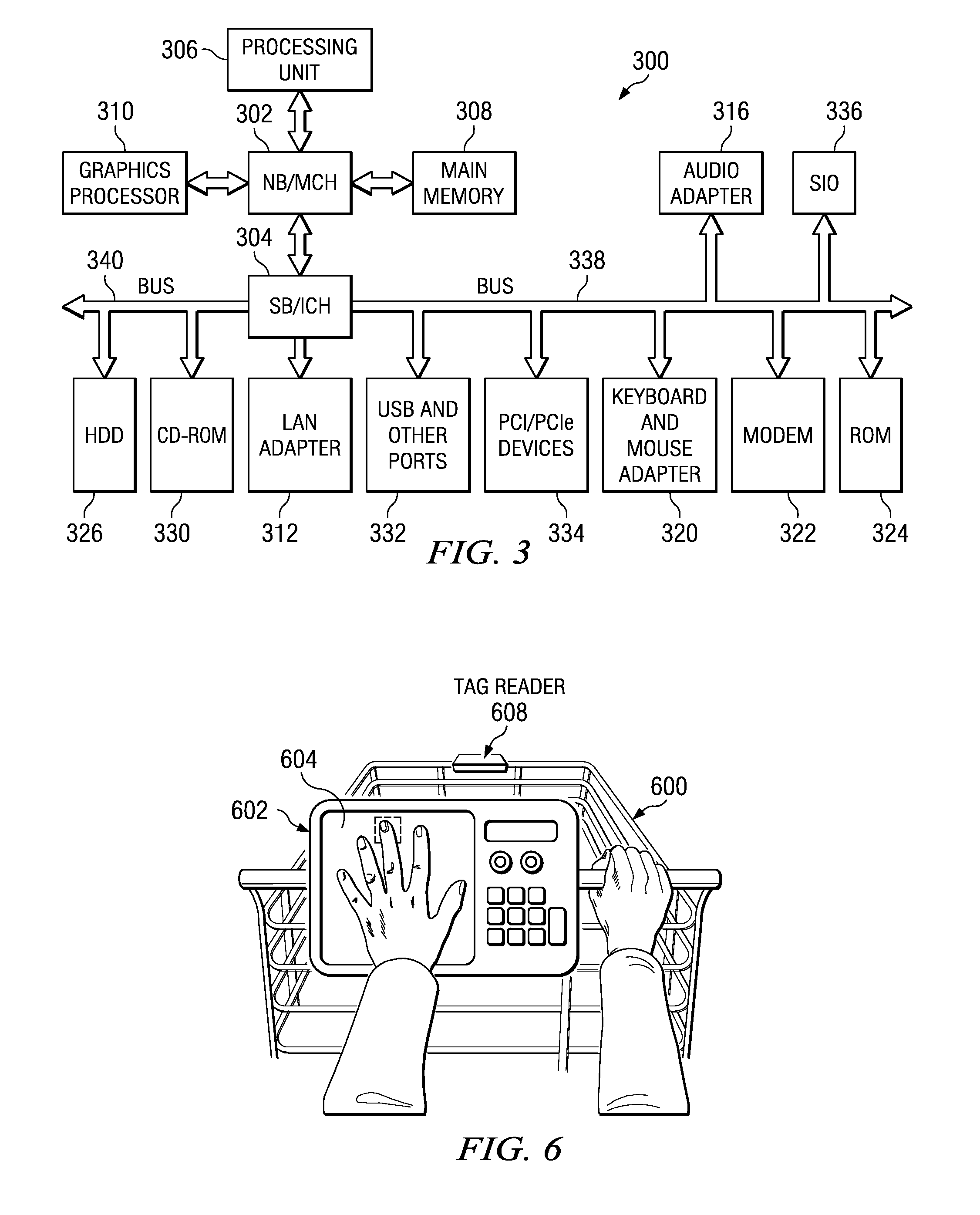

Recipe and project based marketing and guided selling in a retail store environment

A computer implemented method, apparatus, and computer program product for generating project based marketing messages to a customer in a retail facility. In one embodiment, at least one item selected by the customer for purchase is identified. A task that requires the at least one item for completion of the task is identified. A set of additional items recommended for completion of the task is retrieved. The customer has not selected the items in the set of additional items for purchase. A customized marketing message for at least one item in the set of additional items recommended for completion of the task is generated. The customized marketing message is generated in real-time as the customer is shopping.

Owner:DAEDALUS BLUE LLC

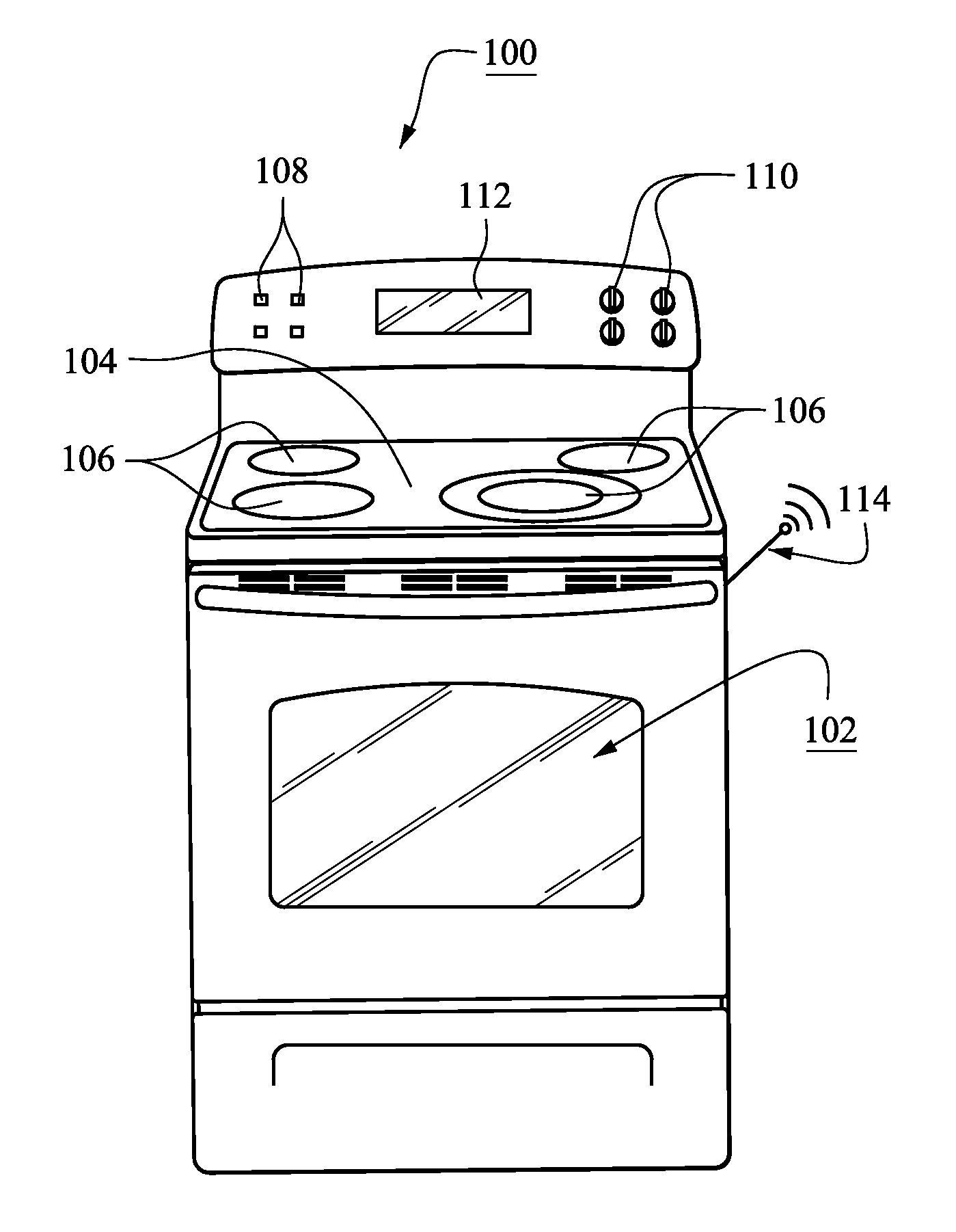

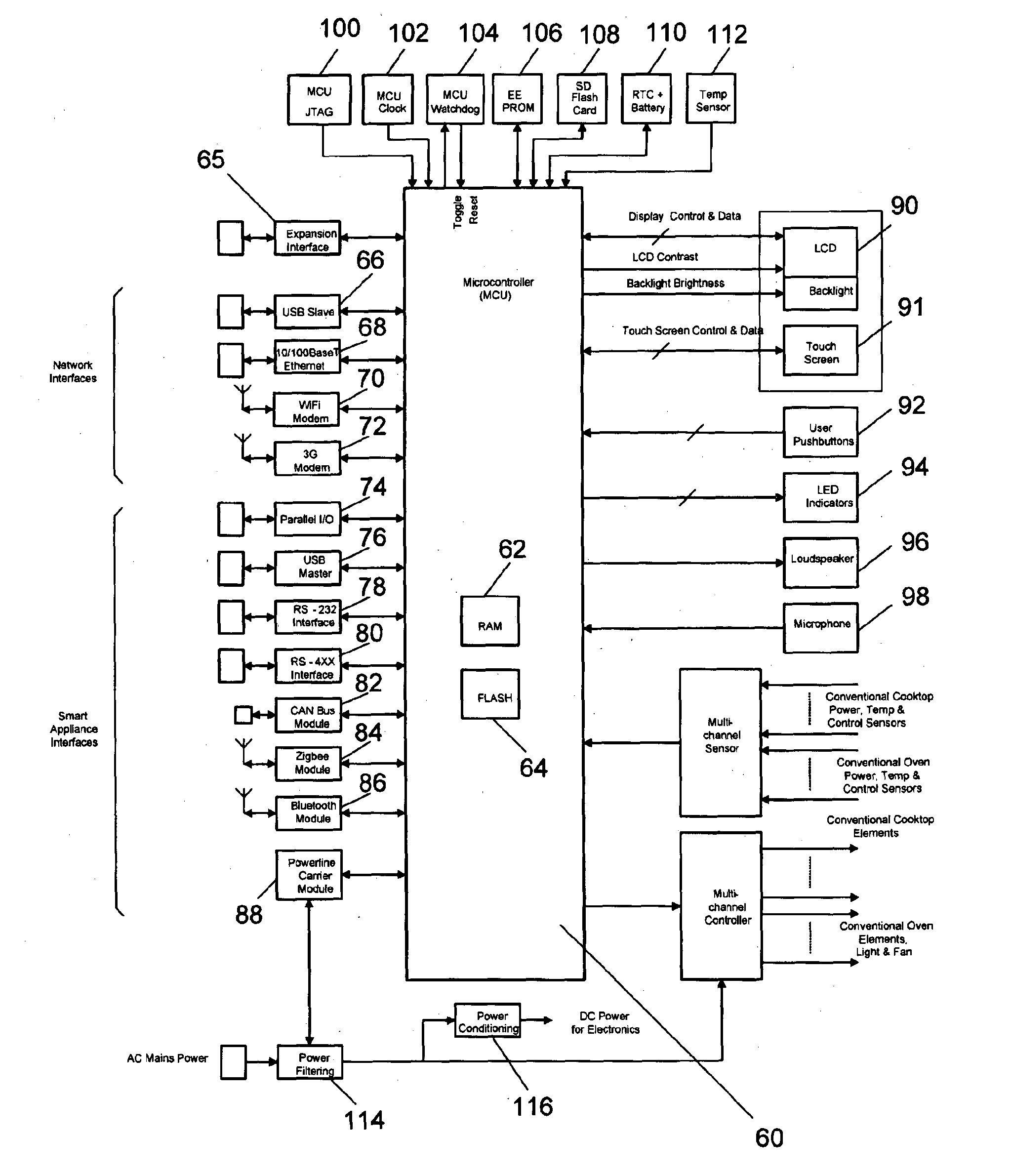

Intelligent home cooking appliance, associated systems, and/or methods

InactiveUS20130092032A1Reduce the possibilityReduce chanceDomestic stoves or rangesLighting and heating apparatusHuman–computer interactionRecipe

The technology disclosed herein relates to intelligent home / residential cooking appliances and interactive content that is interpretable to send instructions to such intelligent cooking appliances, as well as associated systems and / or methods for generating and / or processing the same. In certain instances, an intelligent home / residential appliance may receive and / or display the content for a user and, at appropriate times, possibly prompt a user to take actions or automatically take appropriate actions for the user. Such activities advantageously may prompt a user in some examples to more actively participate in, and / or interact with, a cooking show or program. A user therefore may be more immersed in a cooking experience and feel more comfortable trying out new recipes, given the expectation that the cooking appliance itself may help to resolve problems as they arise and / or suggest solutions to detected abnormalities.

Owner:BSH HOME APPLIANCES CORP

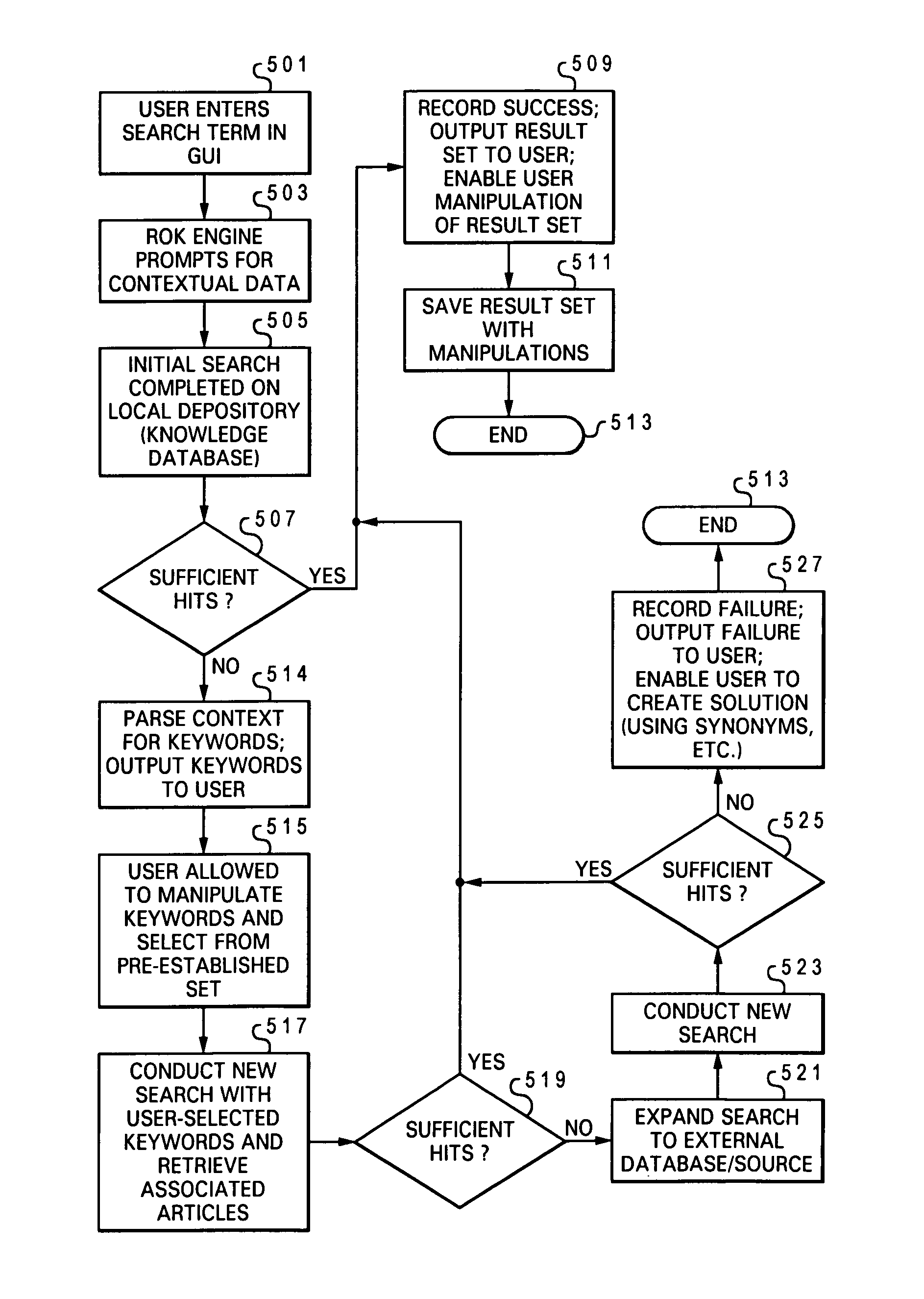

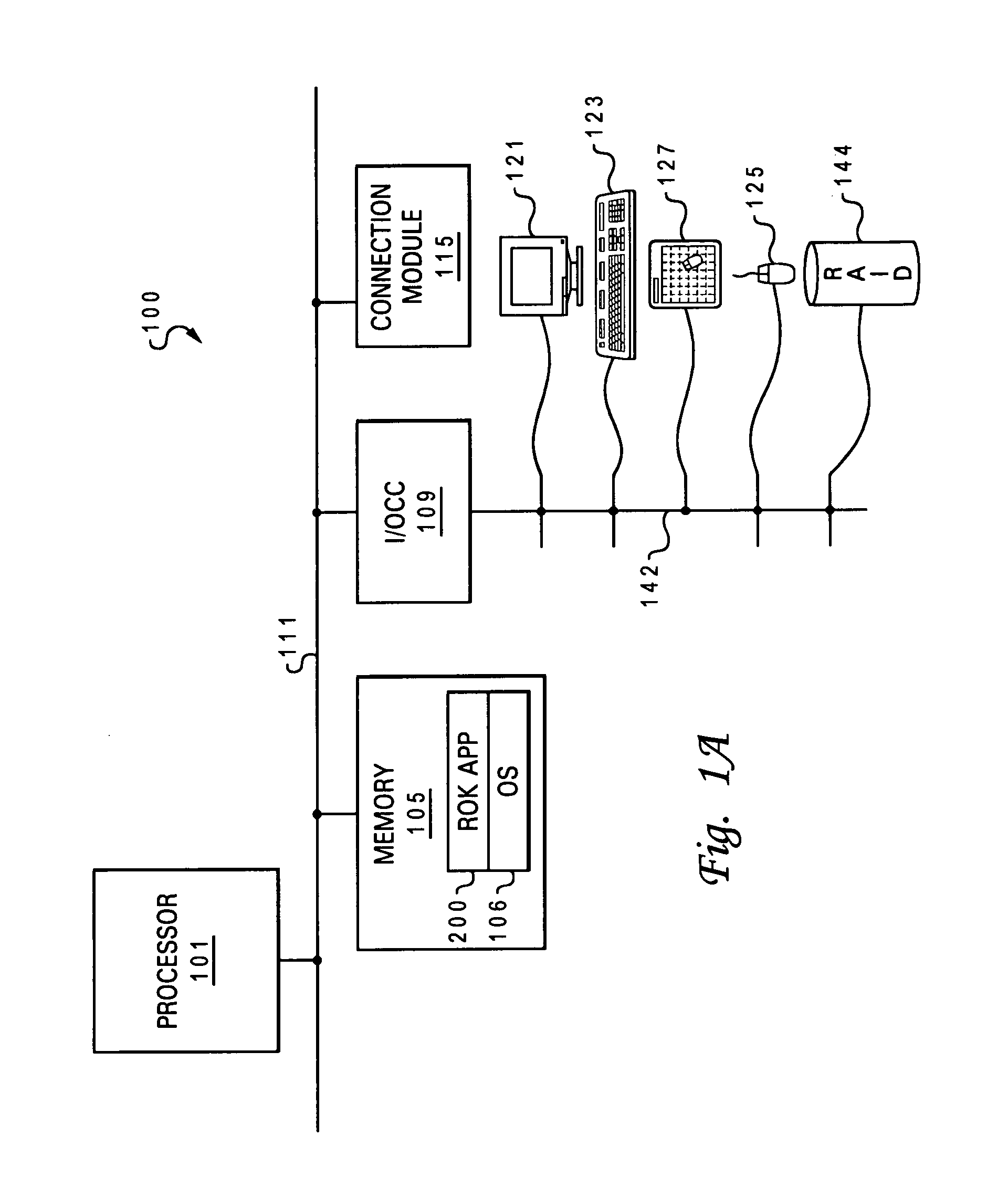

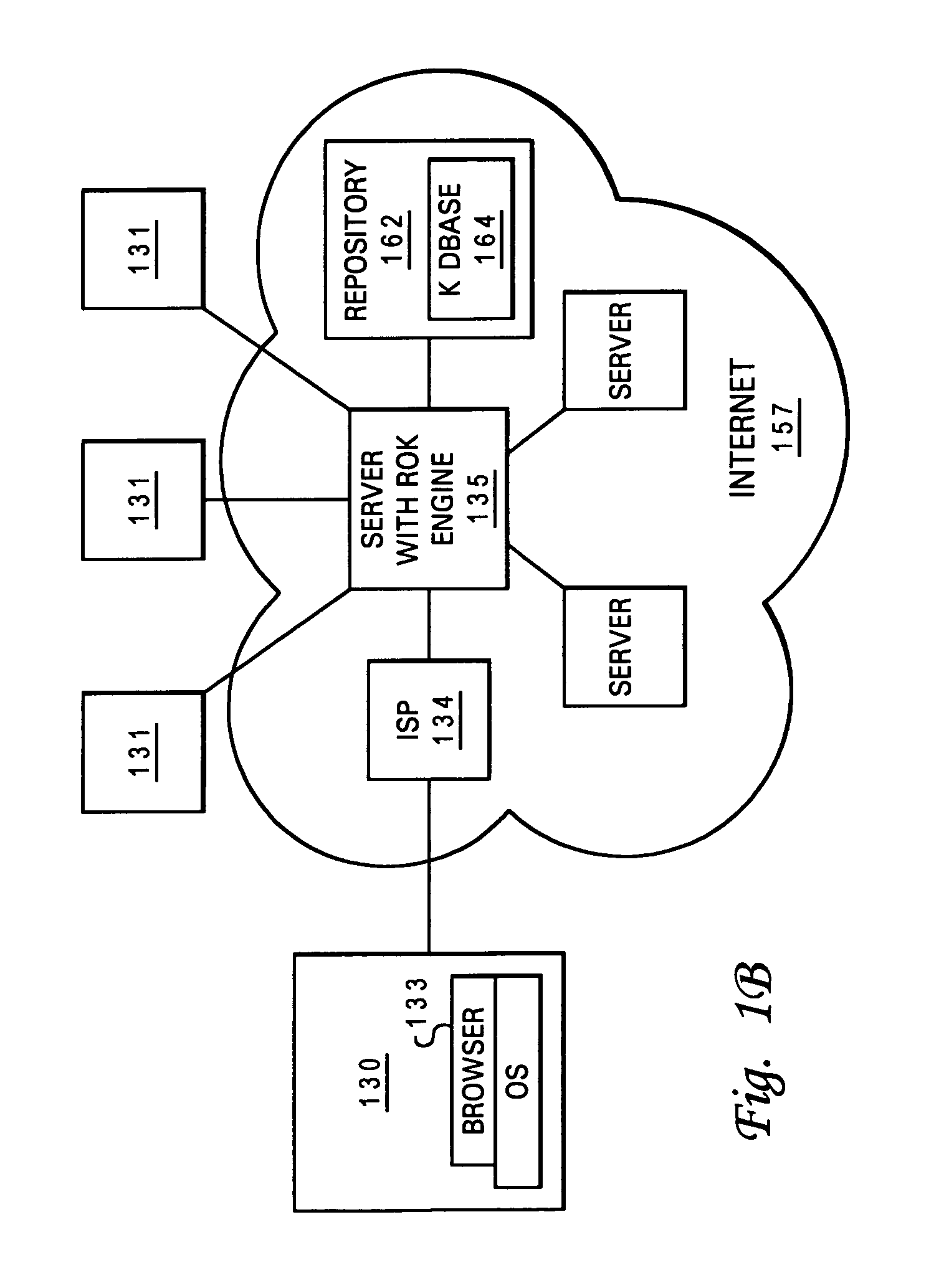

Search engine facility with automated knowledge retrieval, generation and maintenance

A system for generating and retrieving relevant electronic information required by a user initiating an electronic search on the system. The system comprise a user-interactive search engine and a knowledge database, which stores knowledge information that is formatted. Additionally, the system includes a plurality of functional software modules that enables a user to complete an interactive search and find a solution to a task based on entered context information and keywords. A list of keywords are displayed to the user and the user selects those keywords that are relevant to the solution desired. The search engine looks for the articles containing the identified keywords. If no article is found with the search terms, the search is expanded to the Internet. The user may then modify the information returned from the Internet, format the information and save the information as a new recipe.

Owner:IBM CORP

System and method for generating personalized meal plans

InactiveUS20050287499A1Reduces knowledge and effortIncrease opportunitiesNutrition controlDiagnostic recording/measuringPersonalizationAdditive ingredient

Owner:SOLOS HEALTH

Recipe engine system and method

ActiveUS20110055044A1Input/output for user-computer interactionPayment architectureTime informationAdditive ingredient

Disclosed is a system and method for providing electronic meal information to a user. At least one database stores recipe information, recipe attribute information process information and time information for recipes. A web site linked to the Internet includes a prompt for a user to submit at least one characteristic of a meal and another prompt for available ingredient information. Recipe information is generated by a selection of at least some of the stored electronic recipe information that corresponds to the characteristic of the meal and the available ingredients. An electronic list of ingredients is generated that includes the difference between ingredients for the meal, and the at least one ingredient that the user has available for the meal.

Owner:WIEDL PETER

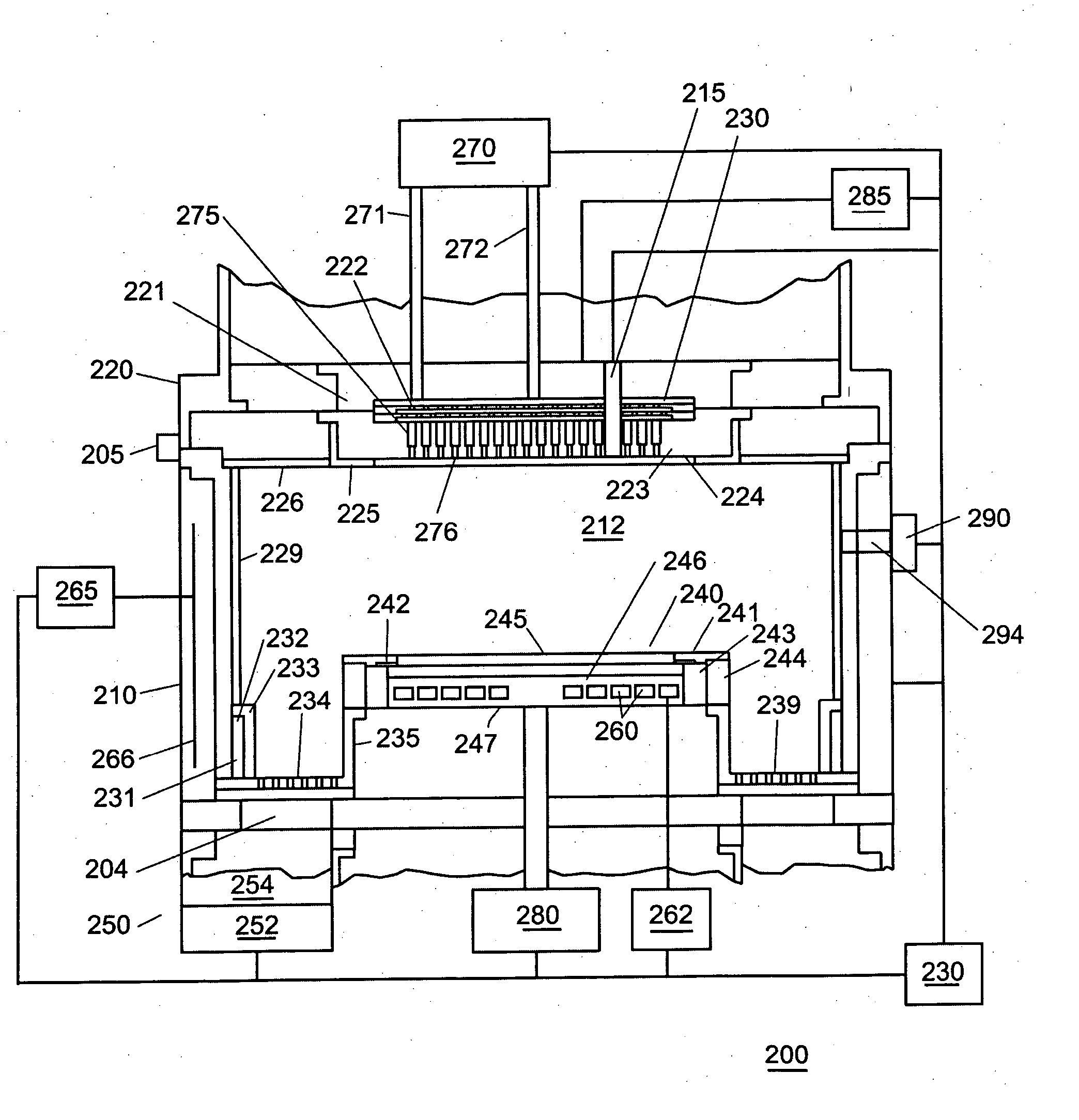

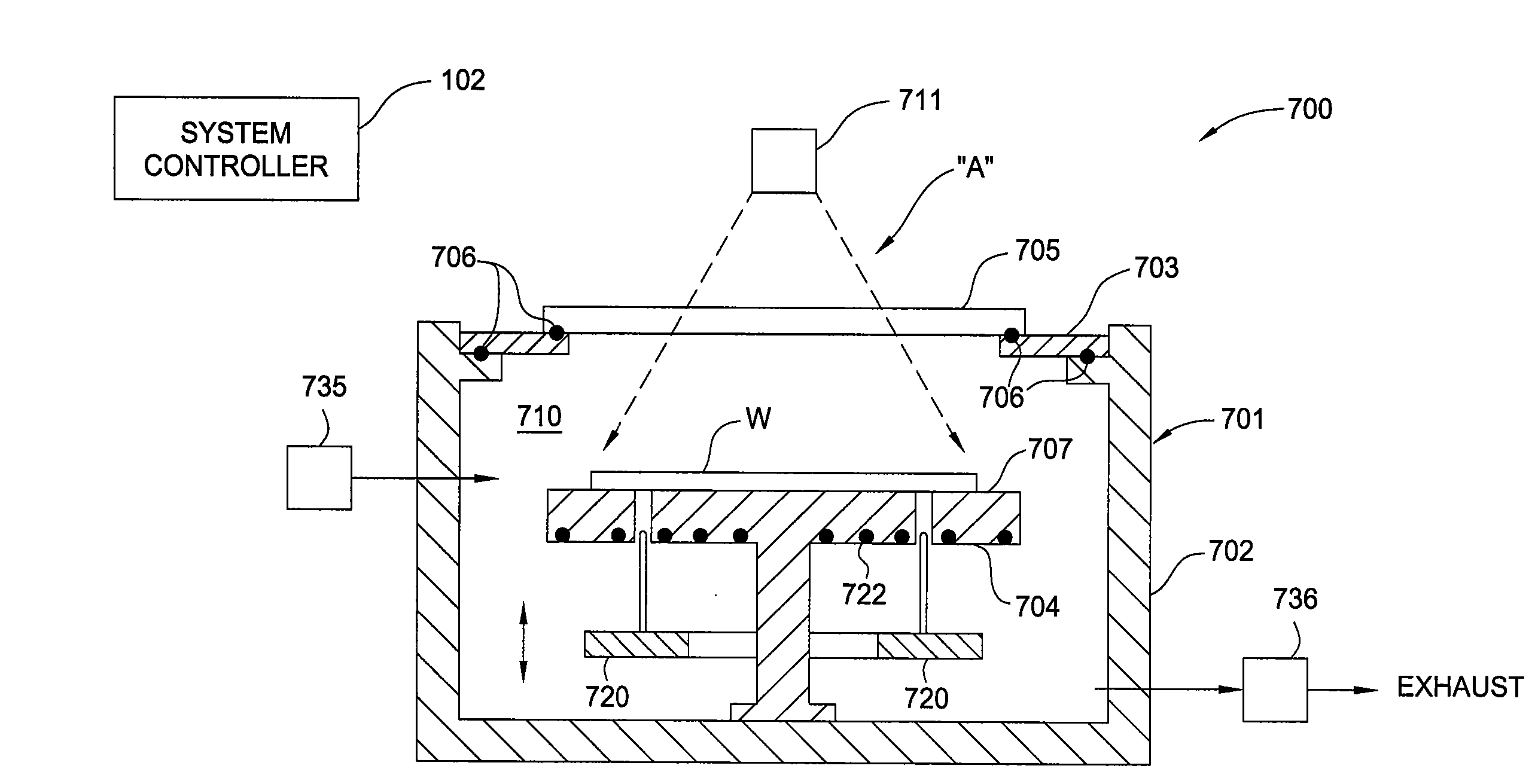

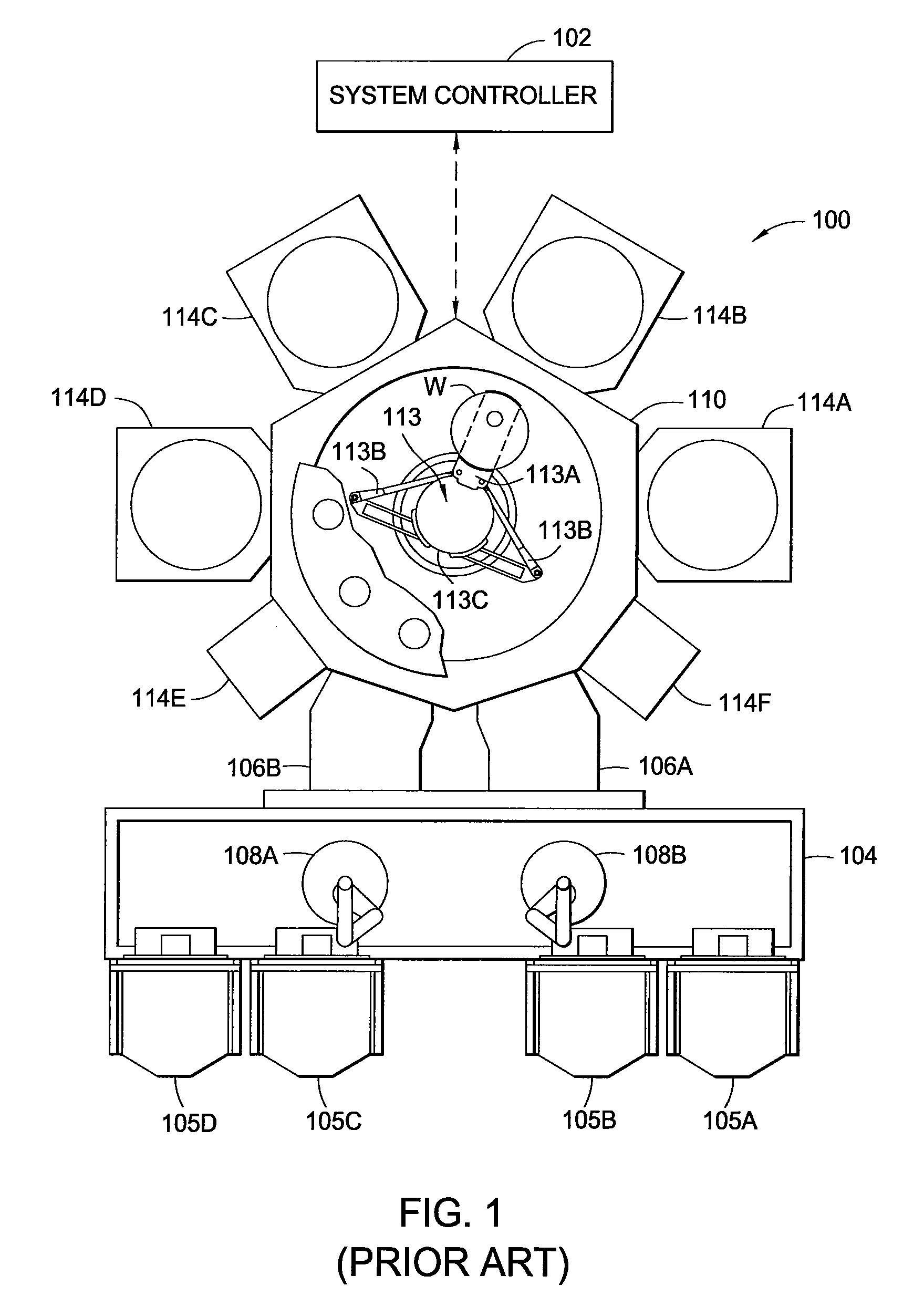

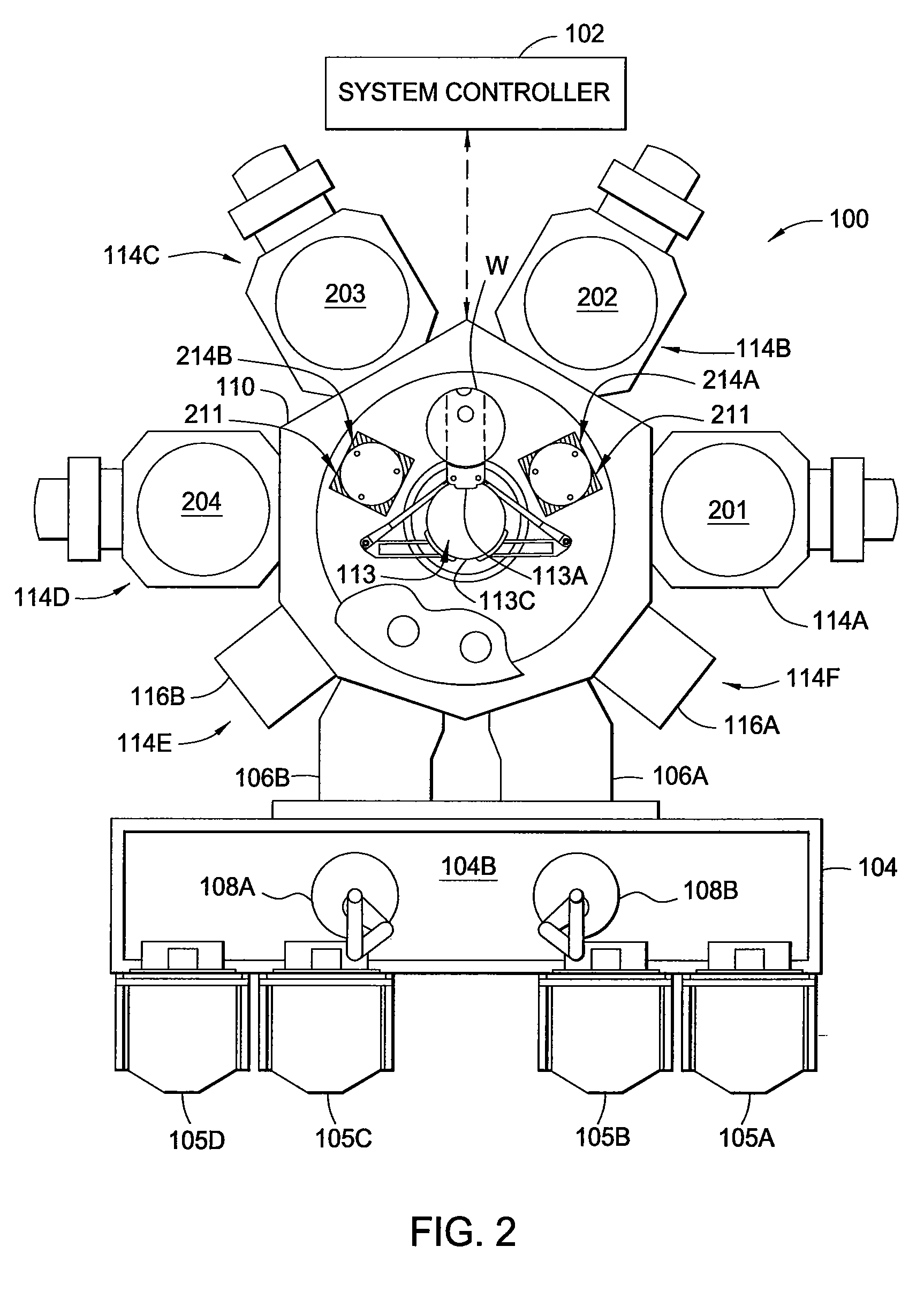

Integrated vacuum metrology for cluster tool

InactiveUS20070196011A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetrologyDevice material

Aspects of the invention generally provide an apparatus and method for processing substrates using a multi-chamber processing system that is adapted to process substrates and analyze the results of the processes performed on the substrate. In one aspect of the invention, one or more analysis steps and / or pre-processing steps are performed on the substrate to provide data for processes performed on subsequent substrates. In one aspect of the invention, a system controller and one or more analysis devices are utilized to monitor and control a process chamber recipe and / or a process sequence to reduce substrate scrap due to defects in the formed device and device performance variability issues. Embodiments of the present invention also generally provide methods and a system for repeatably and reliably forming semiconductor devices used in a variety of applications.

Owner:APPLIED MATERIALS INC

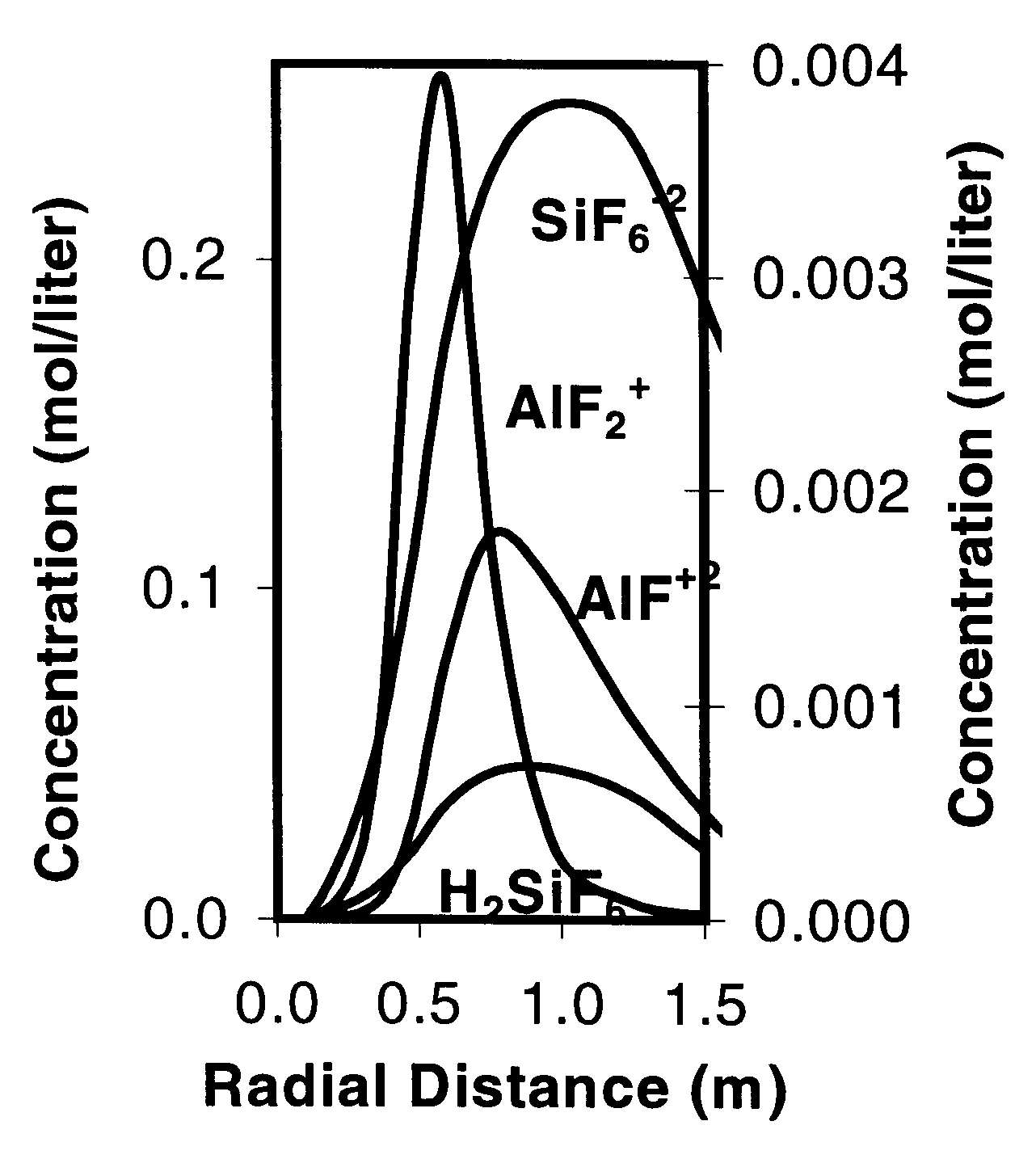

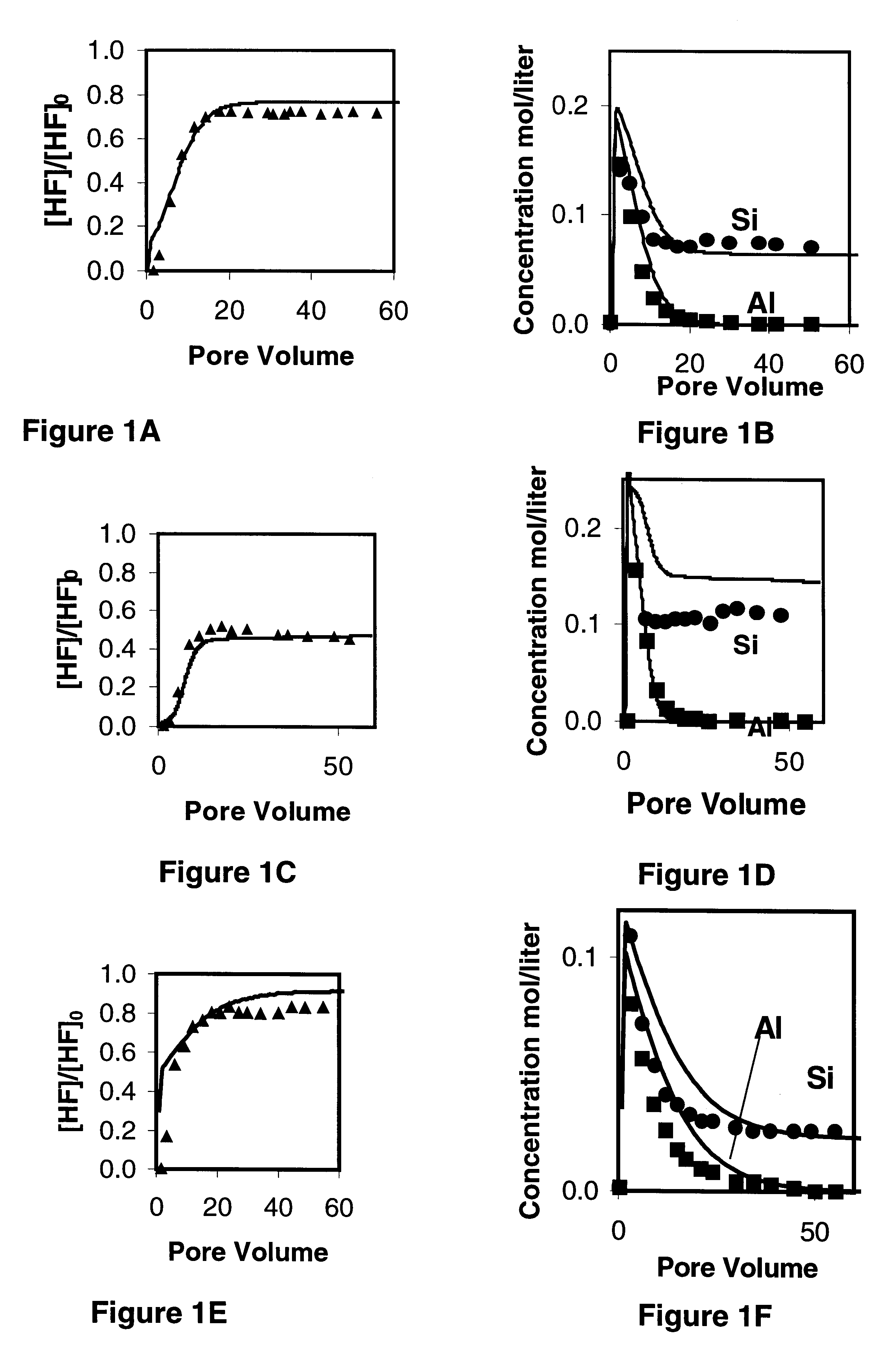

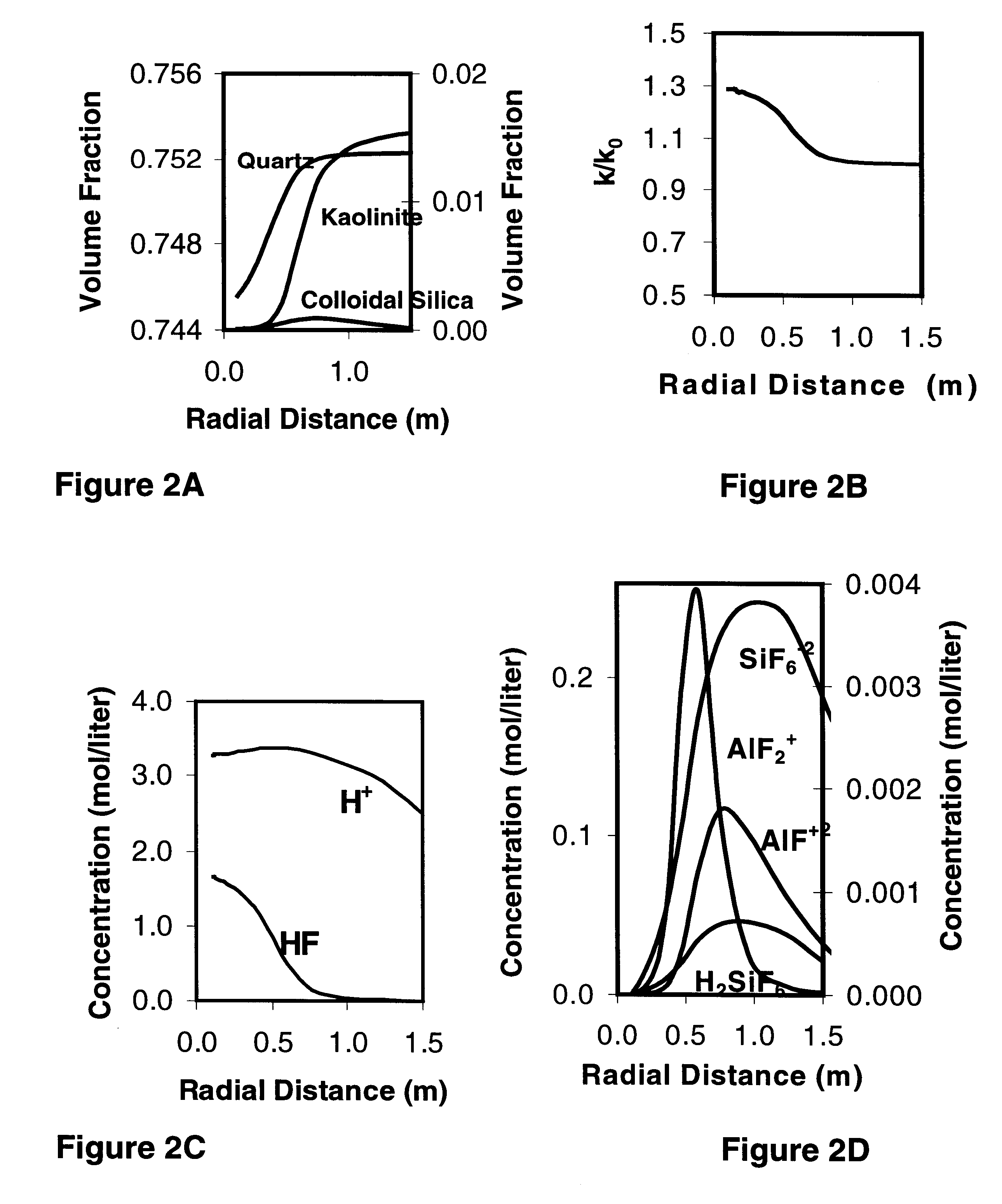

Method of optimizing the design, stimulation and evaluation of matrix treatment in a reservoir

InactiveUS6668922B2Easy to optimizeSimple calculationSurveyPackage sterilisationMathematical modelTreatment strategy

A method for designing acid treatments provides for the selection of optimal treatment for well stimulation wherein reservoir characteristics are obtained to further select the reaction kinetic data on the minerals of interests, the treatment to the reservoir is scaled up using a mathematical model and real time damage are computed based on bottomhole pressure and injection rate and compared to that predicted by the mathematical model to adjust the treatment. The model generated facilitates optimization of matrix treatments by providing a rapid quantitative evaluation of various treatment strategies for a formation. Stimulation with non-traditional fluid recipes containing mixtures of inorganic and organic acids, and chelating agents can be readily computed. The computed values can then be used in an economic model to justify the additional costs associated with the use of the non-traditional fluids. Apart from optimizing matrix treatments, the method can be used as a development tool for new fluid systems, as a tool for prediction and removal of inorganic scale and for fluid compatibility testing such as that required in water flooding projects.

Owner:SCHLUMBERGER TECH CORP

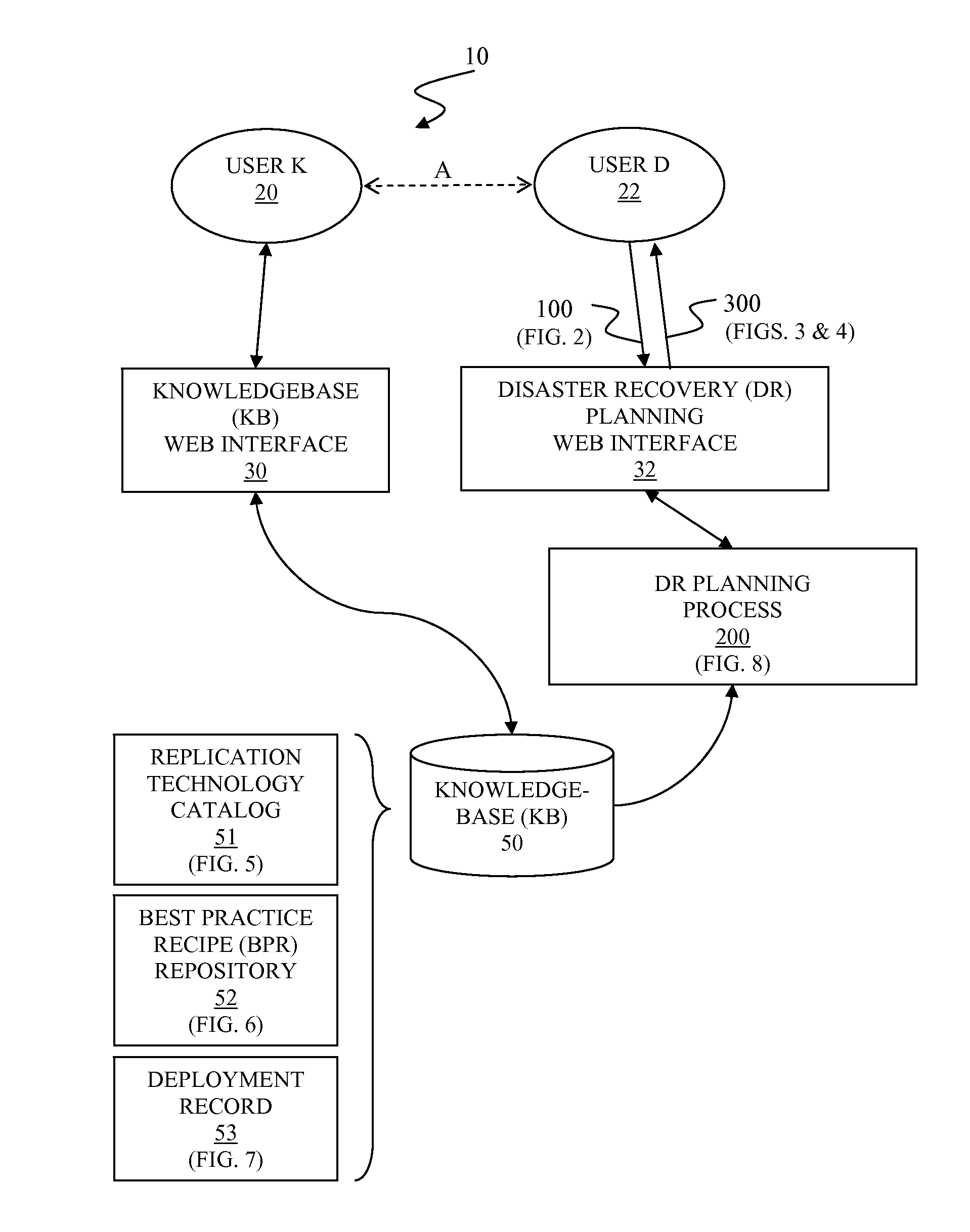

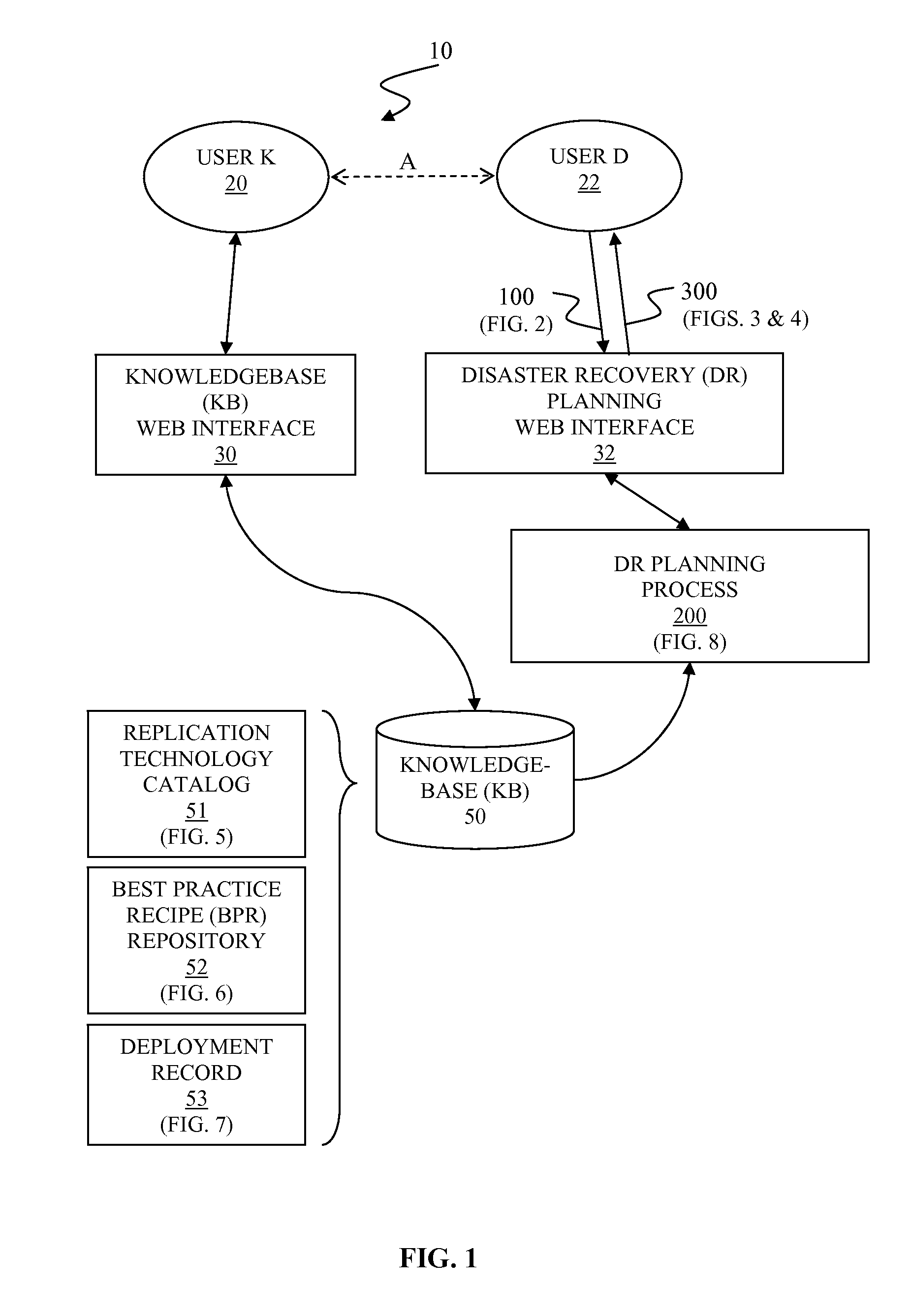

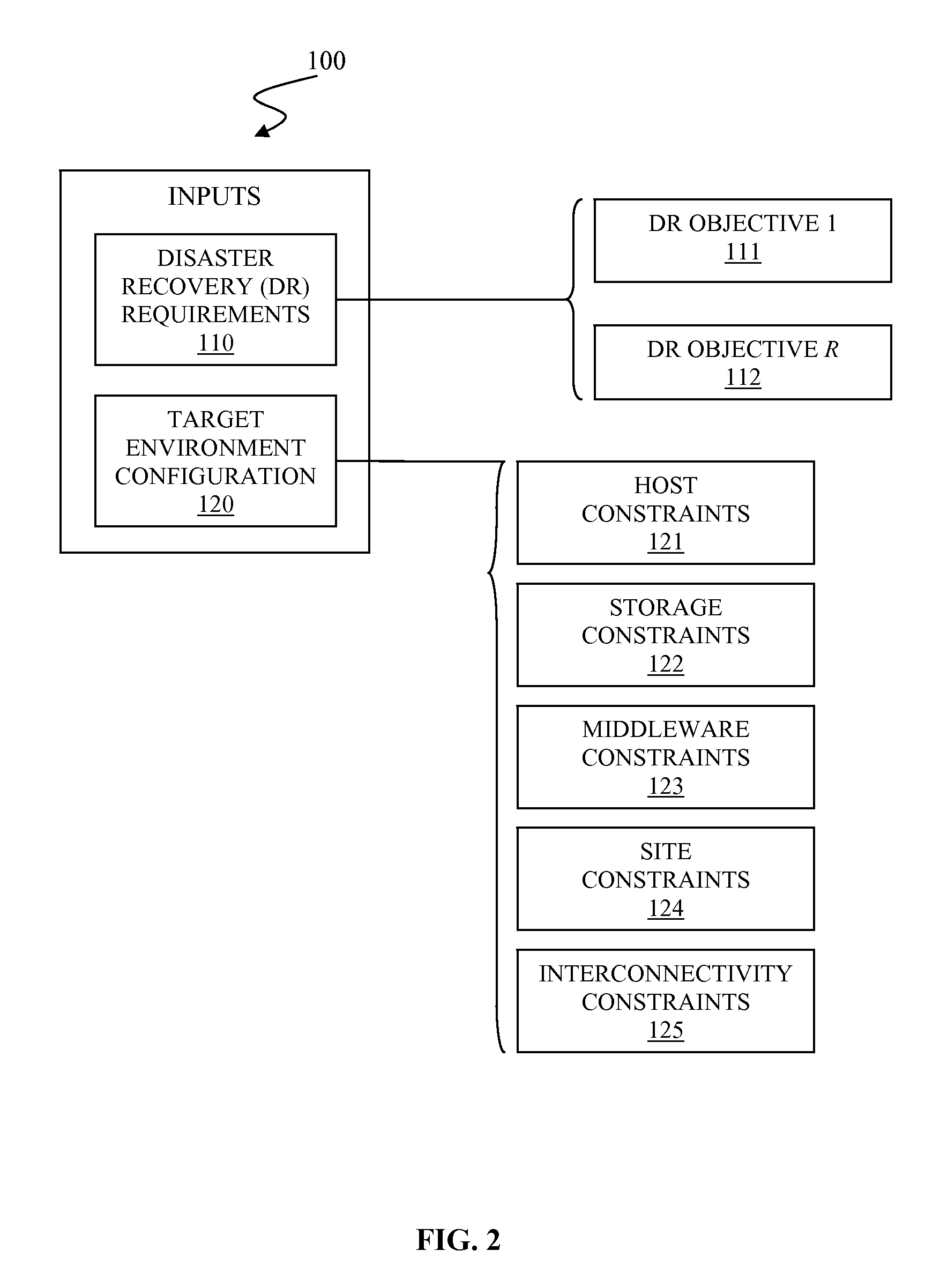

Automated disaster recovery planning

InactiveUS20110022879A1Non-redundant fault processingKnowledge representationProgram planningGood practice

A system and associated method for automated disaster recovery (DR) planning. A DR planning process receives disaster recovery requirements and a target environment configuration from a user to design DR plans for the target environment configuration that meets disaster recovery requirements. The DR planning process accesses a knowledgebase containing information on replication technologies, best practice recipes, and past deployment instances. The DR planning process creates the DR plans by analyzing the disaster recovery requirements into element risks, associating replication technologies to protect each element risks, combining associated replication technologies based on the best practice recipes, and selecting highly evaluated combination based on the past deployment instances. The DR planning process presents the DR plans as classified by replication strategy-architecture combination for each DR plans and marks how strongly each DR plans are recommended.

Owner:GLOBALFOUNDRIES INC

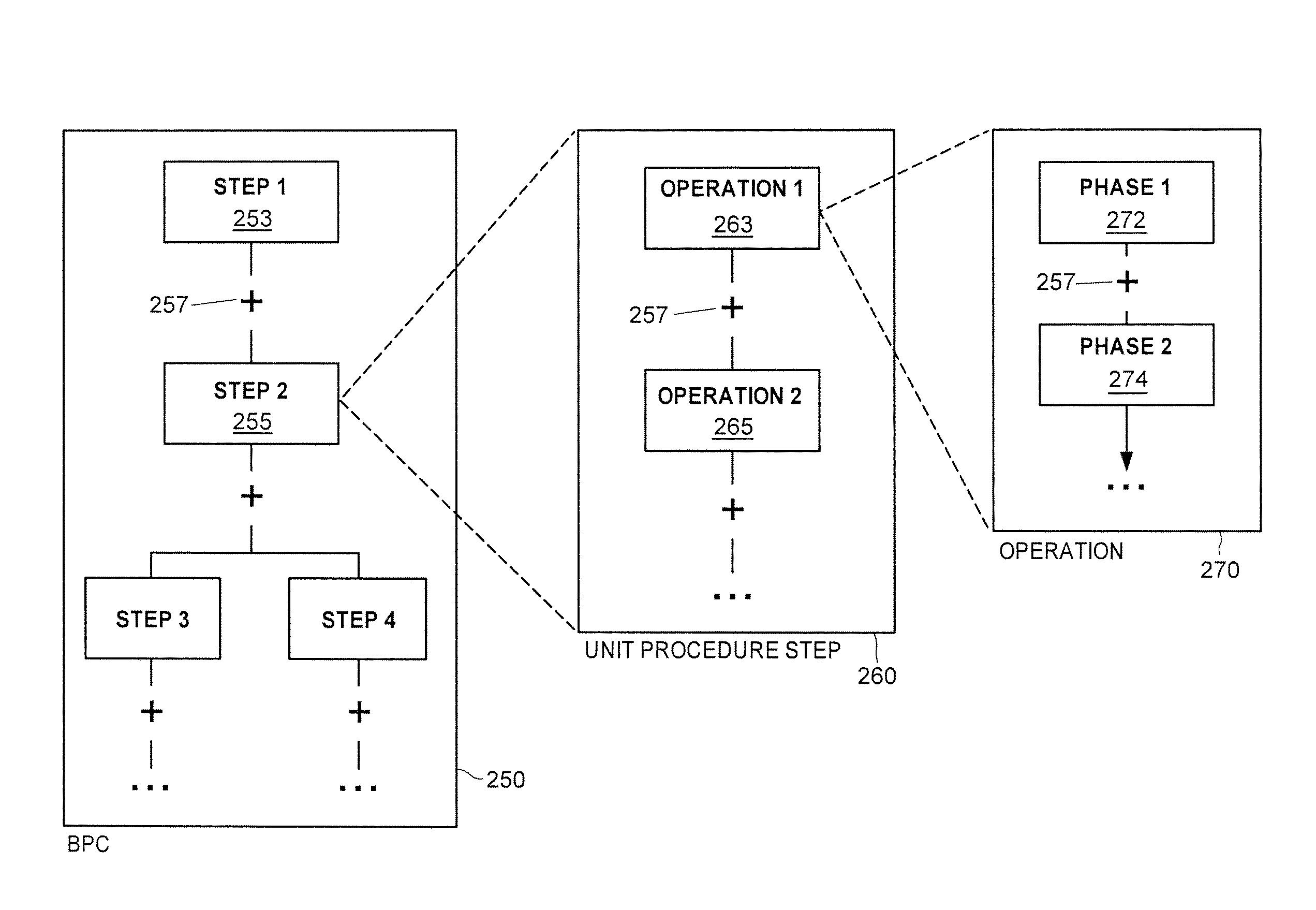

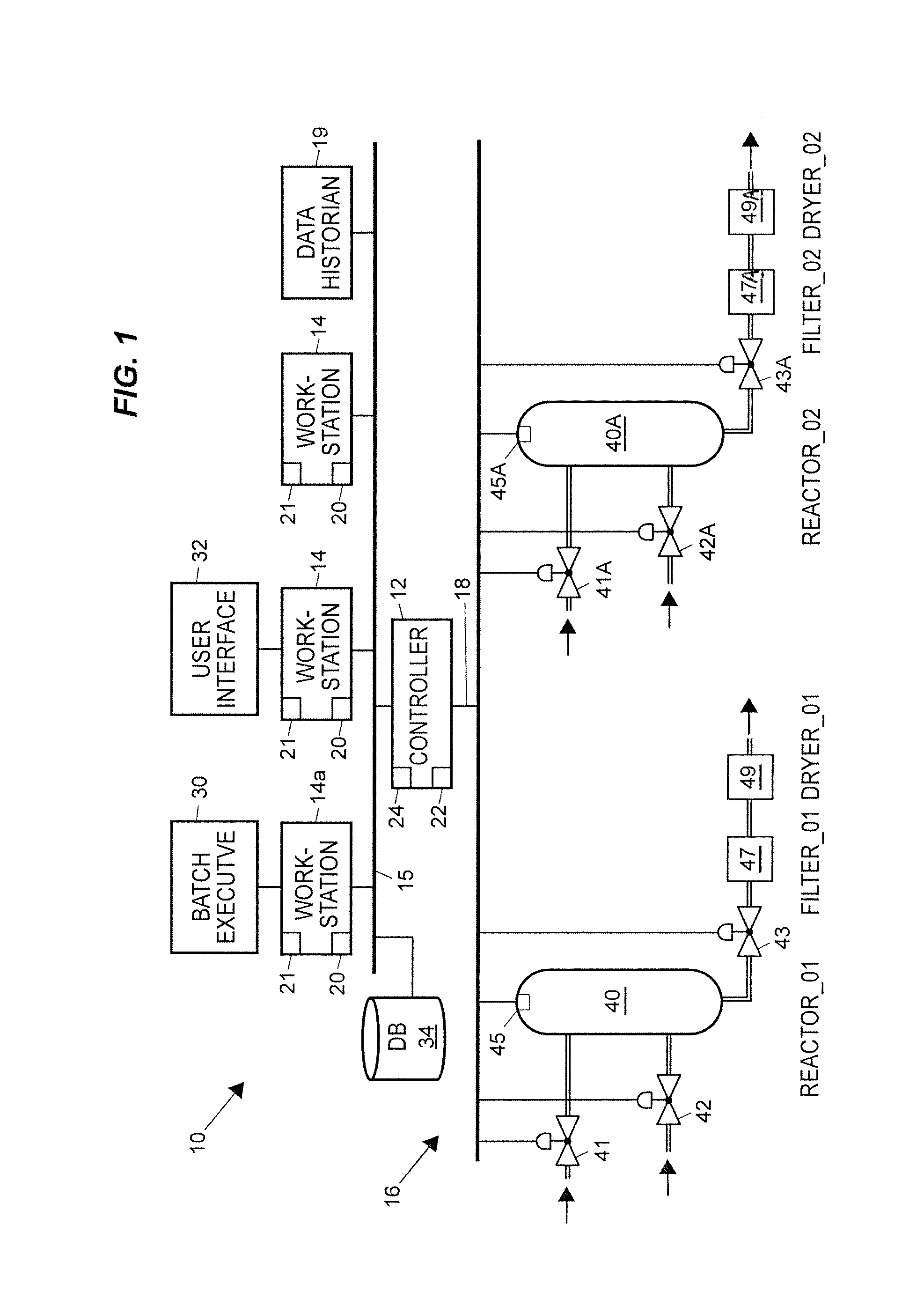

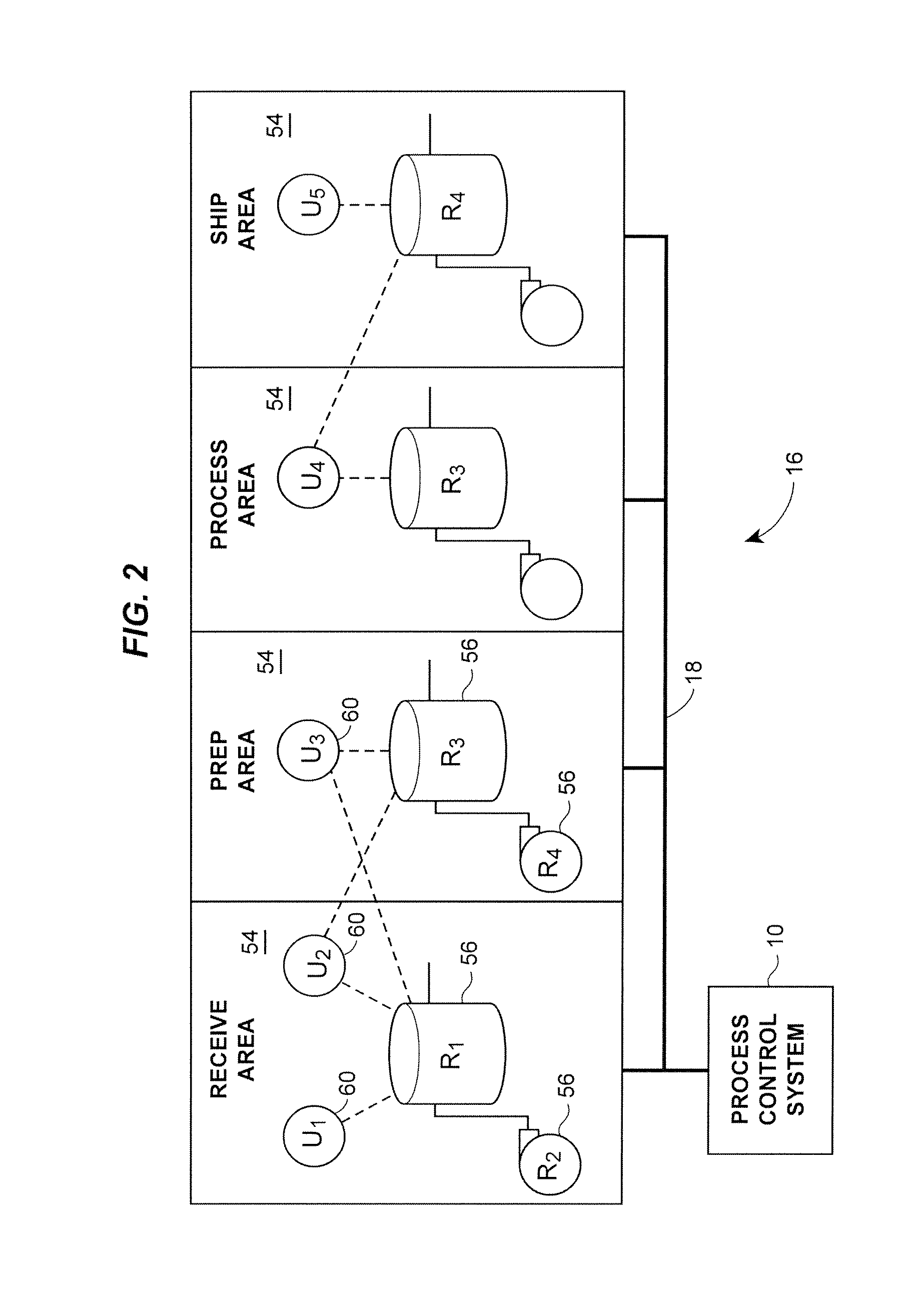

Recipe Command Steps and Recipe Inputs from External Logic

ActiveUS20100082132A1Increase flexibilityEffective regulationComputer controlSimulator controlComputer scienceRecipe

A method of generating a product recipe for execution by a batch process in an automated manufacturing environment, such the product recipe is associated with a plurality of actions, a set of transitions, and a set of parameters, and such that the plurality of actions define a plurality of logical levels including a phase level at which the batch process interacts with equipment, includes receiving a procedure definition specifying the plurality of actions, receiving a transaction definition specifying the set of transitions so that each one in the set of transitions is associated with two or more of the plurality of actions, and receiving the set of parameters. Receiving the set of parameters includes receiving at least one dynamic input parameter that resolves to a value without obtaining the value from the recipe or an operator prompt associated at the phase level of the recipe.

Owner:FISHER-ROSEMOUNT SYST INC

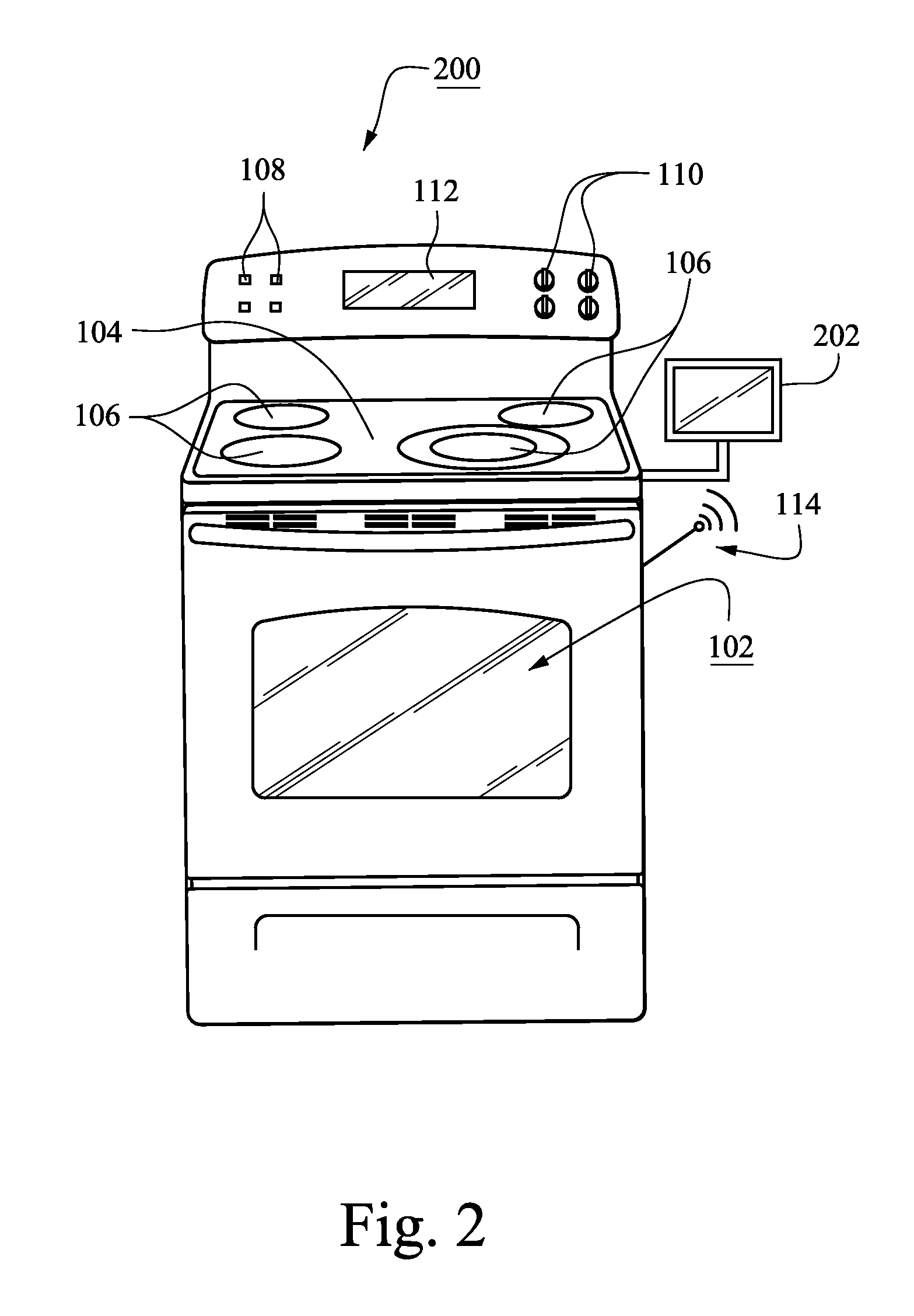

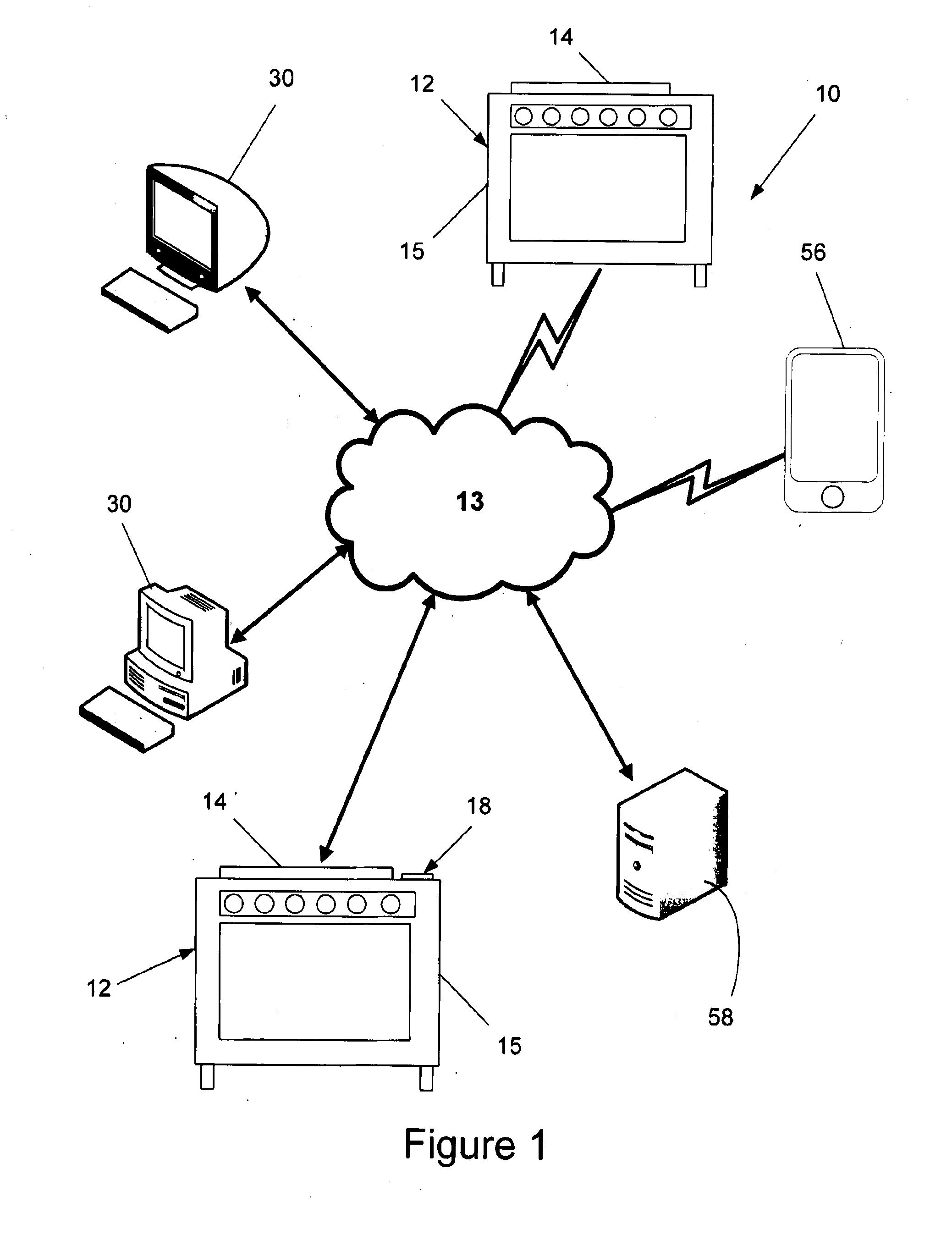

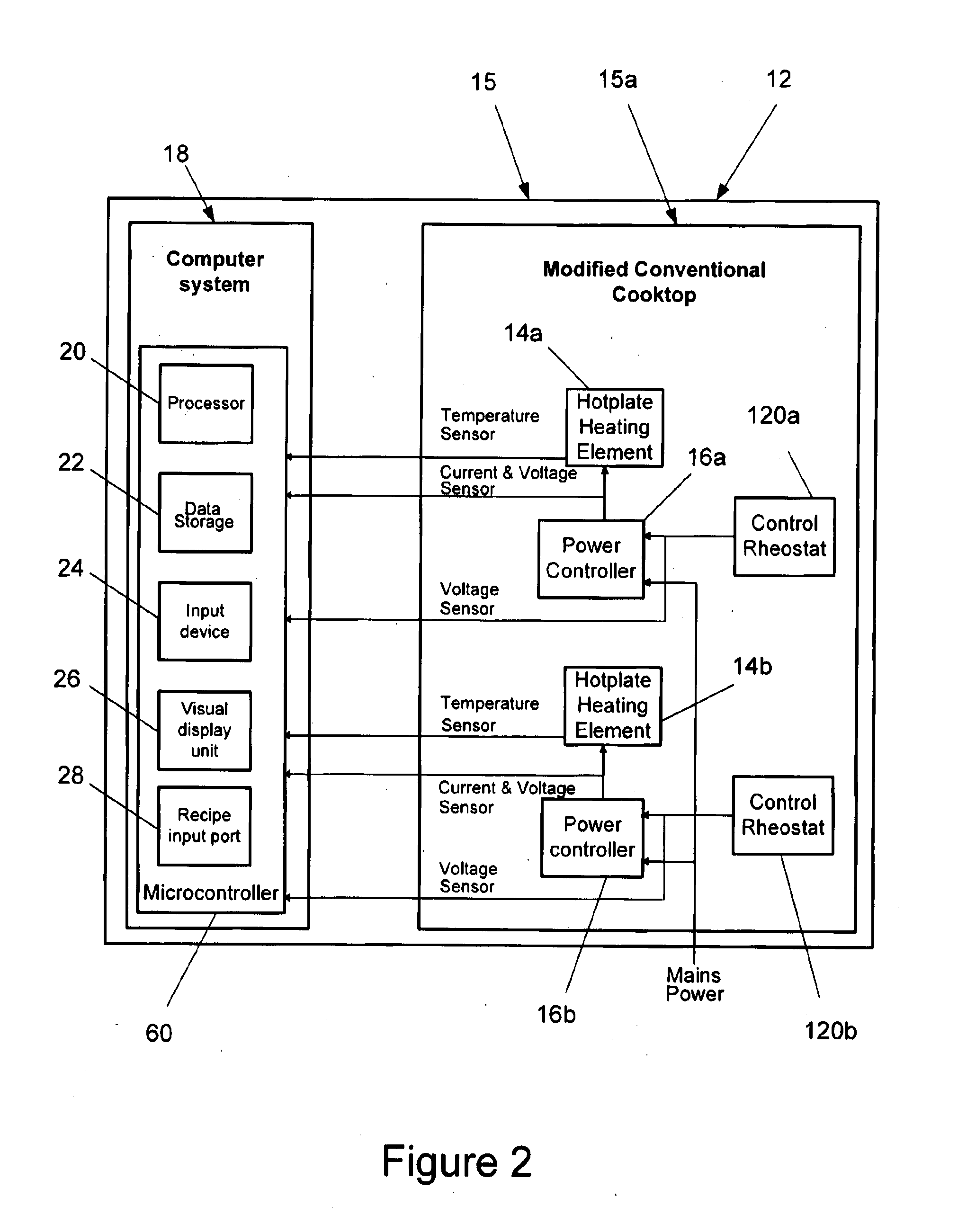

System For Automating Cooking Steps

A cooking system for automating cooking steps of a recipe on a stove comprising a stove including a plurality of cooking elements; power controller for controlling the operation of each one of the cooking elements; and computer system in communication with the power controller, said computer system including a processor, computer readable data storage, and a visual display unit. The processor causes the computer system to perform the steps of: for each automated step of said recipe, generates a control signal for actuating at least one of the cooking elements and sends said control signal to the power controller; and for each manual or user step of said recipe, generates data representing user readable instructions for performing the user step and displays said data on the visual display unit. The power controller is adapted to actuate the cooking elements in accordance with each control signal received from the computer system.

Owner:ICOOKIT

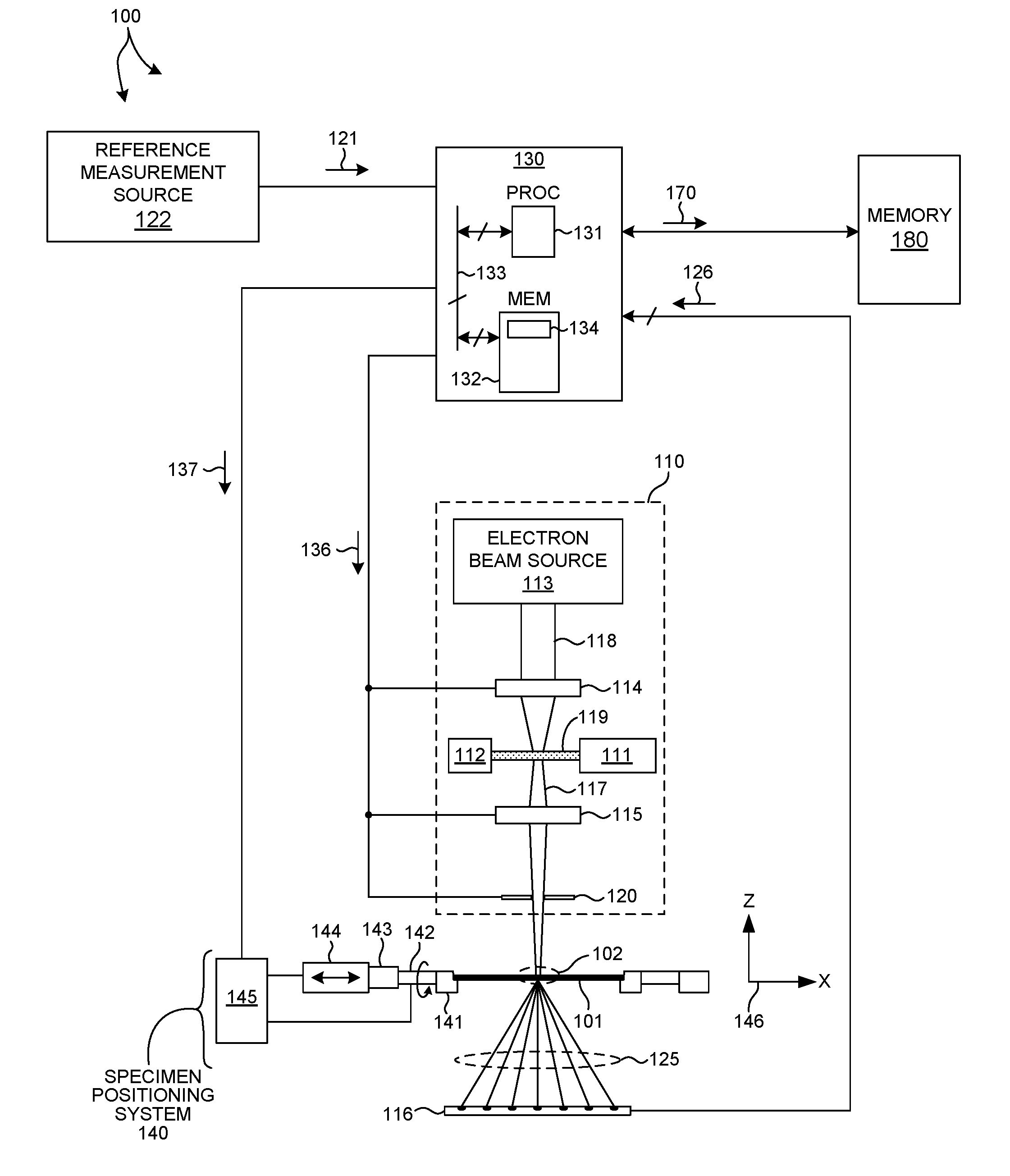

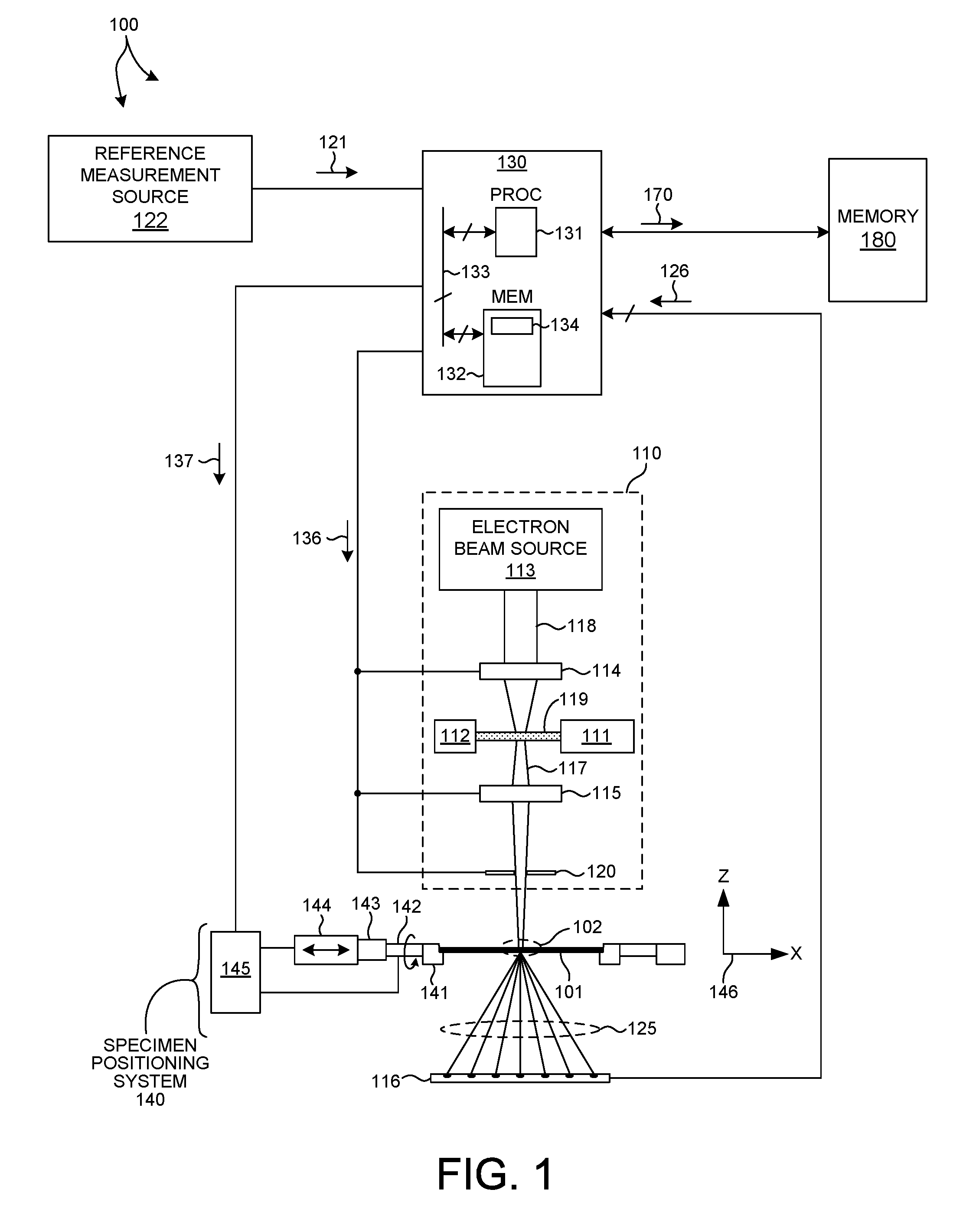

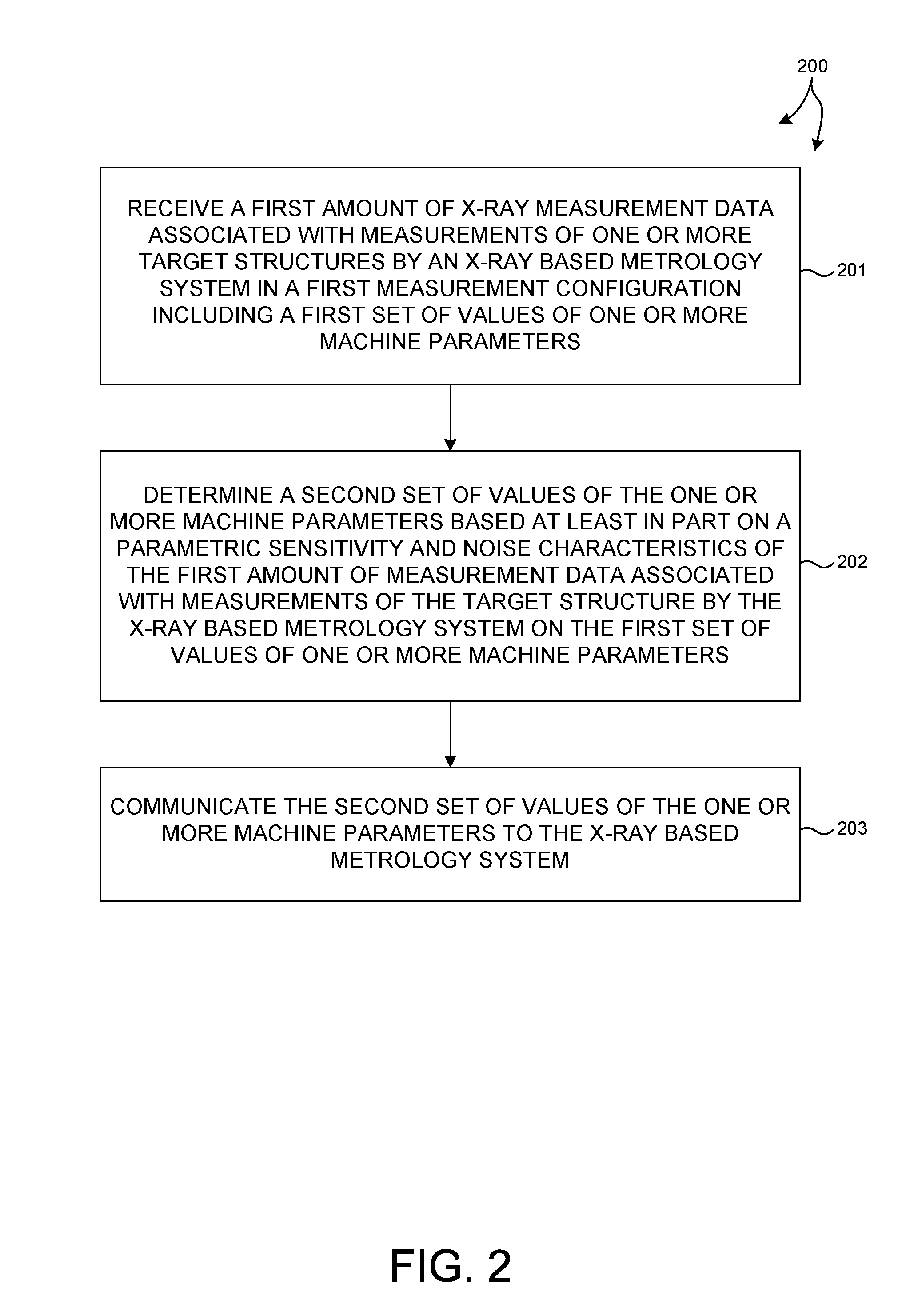

Measurement System Optimization For X-Ray Based Metrology

ActiveUS20160202193A1Maximize precisionMinimize correlationMaterial analysis by optical meansSemiconductor/solid-state device manufacturingSoft x rayMetrology

Methods and systems for optimizing measurement system parameter settings of an x-ray based metrology system are presented. X-ray based metrology systems employing an optimized set of measurement system parameters are used to measure structural, material, and process characteristics associated with different semiconductor fabrication processes with greater precision and accuracy. In one aspect, a set of values of one or more machine parameters that specify a measurement scenario is refined based at least in part on a sensitivity of measurement data to a previous set of values of the one or more machine parameters. The refinement of the values of the machine parameters is performed to maximize precision, maximize accuracy, minimize correlation between parameters of interest, or any combination thereof. Refinement of the machine parameter values that specify a measurement scenario can be used to optimize the measurement recipe to reduce measurement time and increase measurement precision and accuracy.

Owner:KLA TENCOR TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com