Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2303 results about "Wine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The color wine is a dark shade of red. It is a representation of the typical color of red wine. The first recorded use of wine as a color name in English was in 1705. The term "bordeaux" is also sometimes used to describe this color.

Berry ice wine and preparation method thereof

InactiveCN102304452AAlcoholic beverage preparationMicroorganism based processesBiotechnologyNutrition

The invention relates to a berry ice wine and a preparation method thereof. The preparation method comprises the following steps: freezing berries used as the raw material, fermenting the original juice at low temperature, carrying out freeze concentration, aging at low temperature, carrying out aseptic filtration and packaging. The berry ice wine prepared by the method provided by the invention is deep ruby red, deep red or orange in color, appears clear and bright, has the advantages of natural color, abundant nutrients, unique mouthfeel, high quality, outstanding fruit fragrance, pure taste and smooth mouthfeel, is rich in vitamins, organic acids, minerals and various esters, can be conveniently absorbed by human bodies, has favorable color, fragrance and taste, is an ideal potable spirit, has the functions of face beautifying, health care and like, and thus, is a precious high-grade vintage wine.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Okra and maca wine and preparation method of okra and maca wine

ActiveCN102787062AImprove sexual functionImprove microcirculationAlcoholic beverage preparationBiotechnologySexual functioning

The invention relates to a healthcare wine which is okra and maca wine, and a preparation method of the okra and maca wine, wherein the okra and maca wine is prepared by maca powder, okra, penis cervi, antler blood, medlar, arillus longan, deer's sinew, crystal sugar, base liquor and water mixed according to determined proportions. The okra and maca win has functions of improving sexual function, improving fertility, adjusting endocrine, delaying menopause, strengthening immunity and reliving fatigue. The use method and the dosage of the okra and maca wine are as follows: a user drinks 100ml per day by one or two times.

Owner:TONGHUA WANJIA BIOLOGICAL TECH

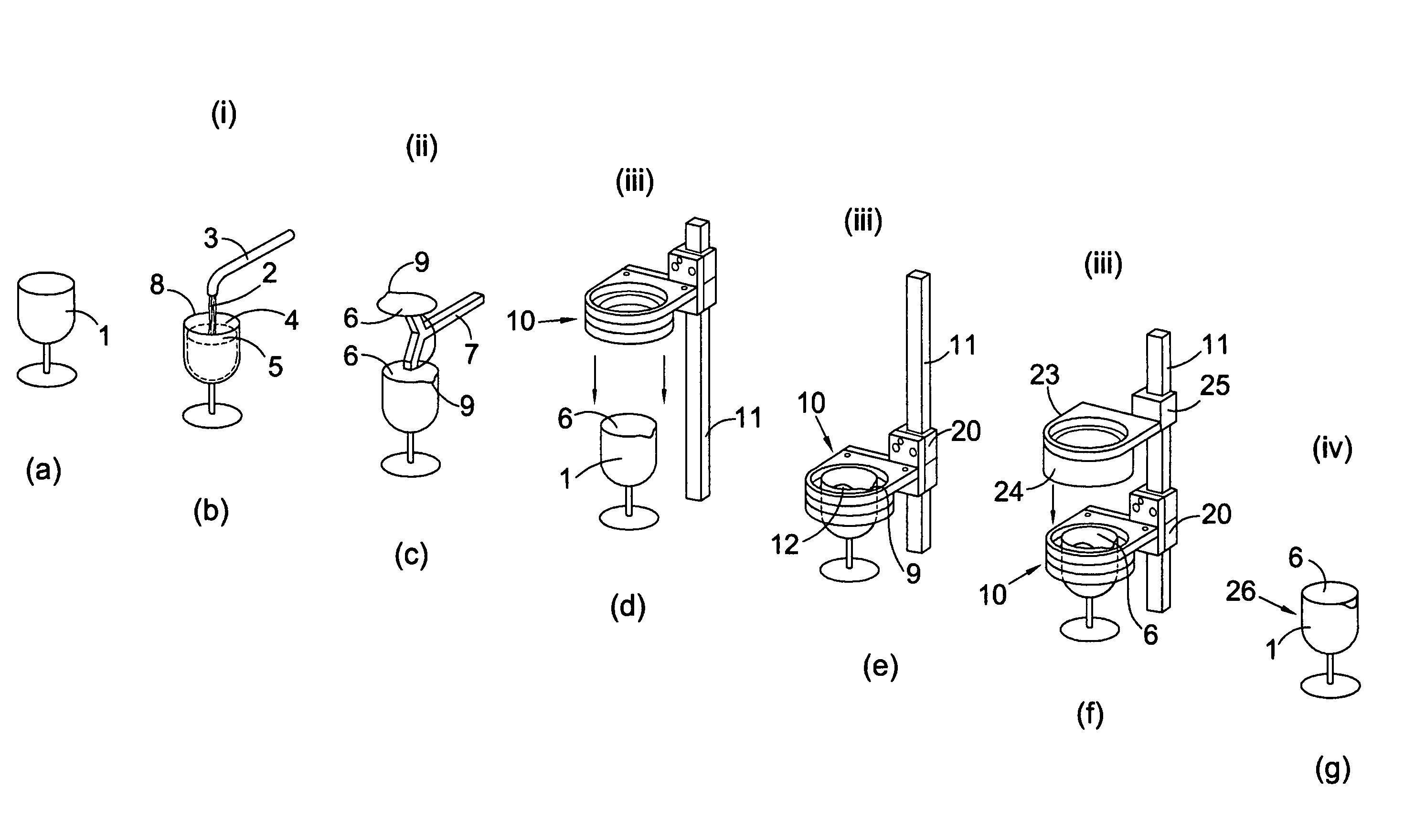

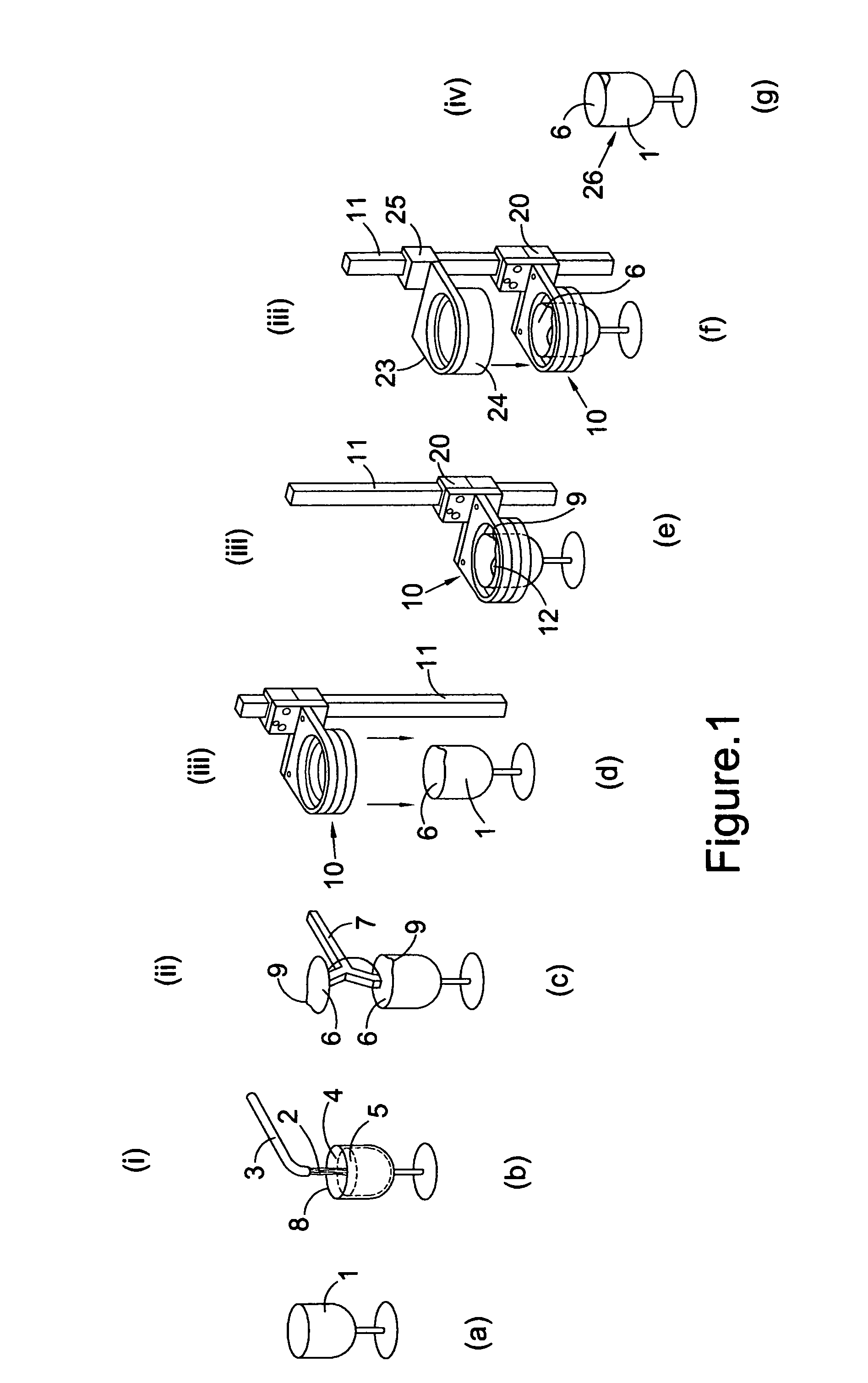

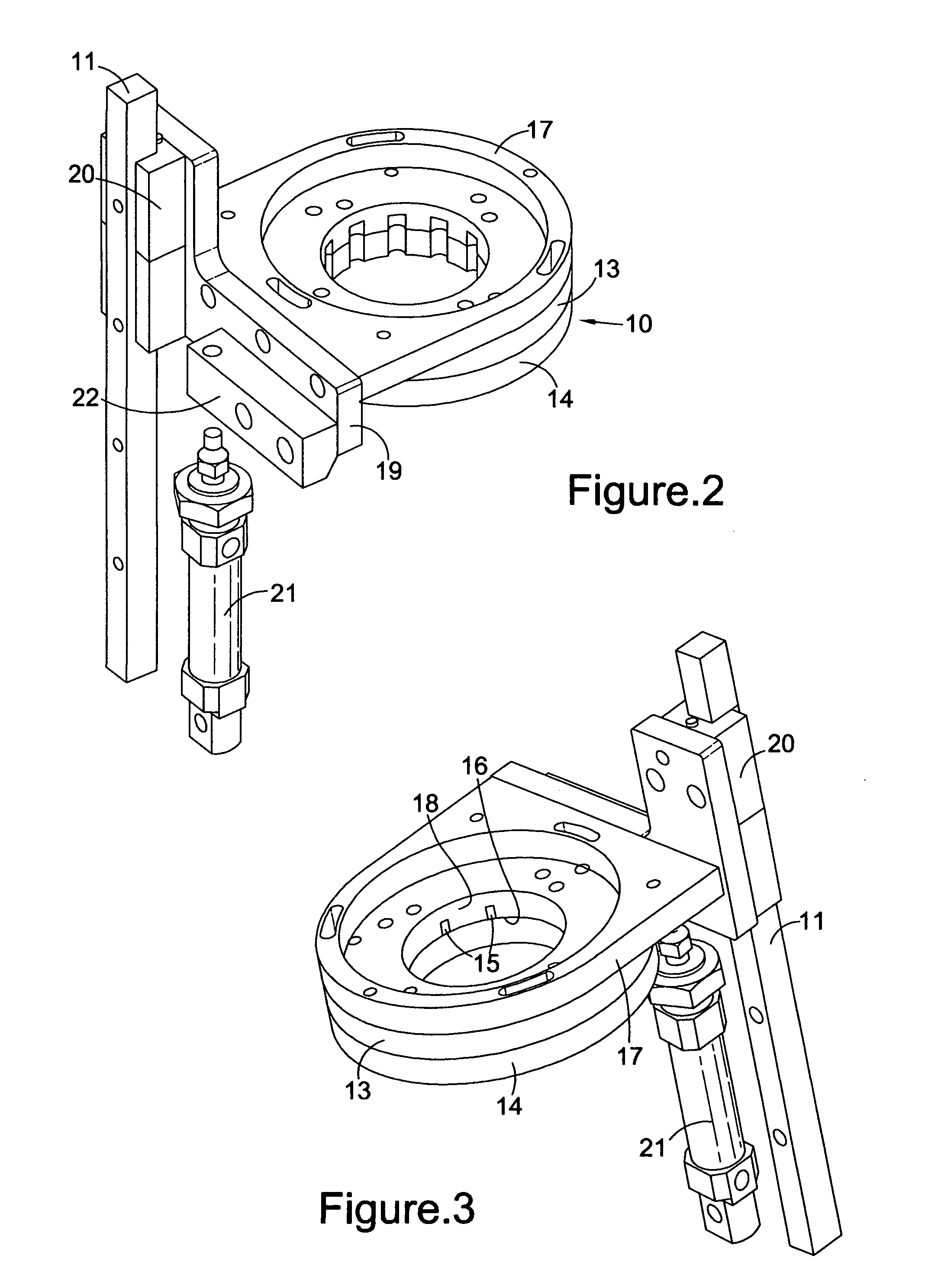

Filling and sealing of beverage containers

The present invention provides, inter alia, a method of filling and sealing a beverage container, the method comprising the steps of:a) dispensing a predetermined amount of beverage, preferably wine, into an open-topped container having a circular rim, preferably a plastics wine glass, to leave a headspace above the beverage in the container;b) temporarily tacking a generally flat flexible film lid sized to fit over the open top to the rim of the container at at least one position around the rim while leaving the remainder of the rim free;c) engaging the tacked lid to cause flexure thereof to create a gap between the lid and the rim on one side;d) dispensing an inert gas, preferably nitrogen, through the gap so created and into the headspace to displace air therefrom; ande) bringing a heat sealer into engagement with the lid to heat seal the lid to the rim about its entire circumference, thereby trapping the inert gas within the headspace.

Owner:WINE INNOVATIONS

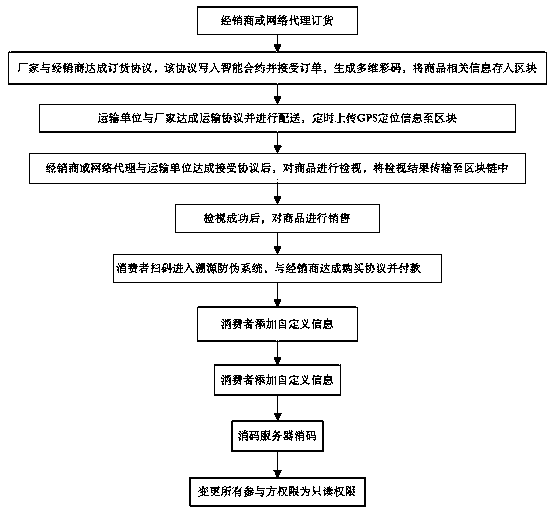

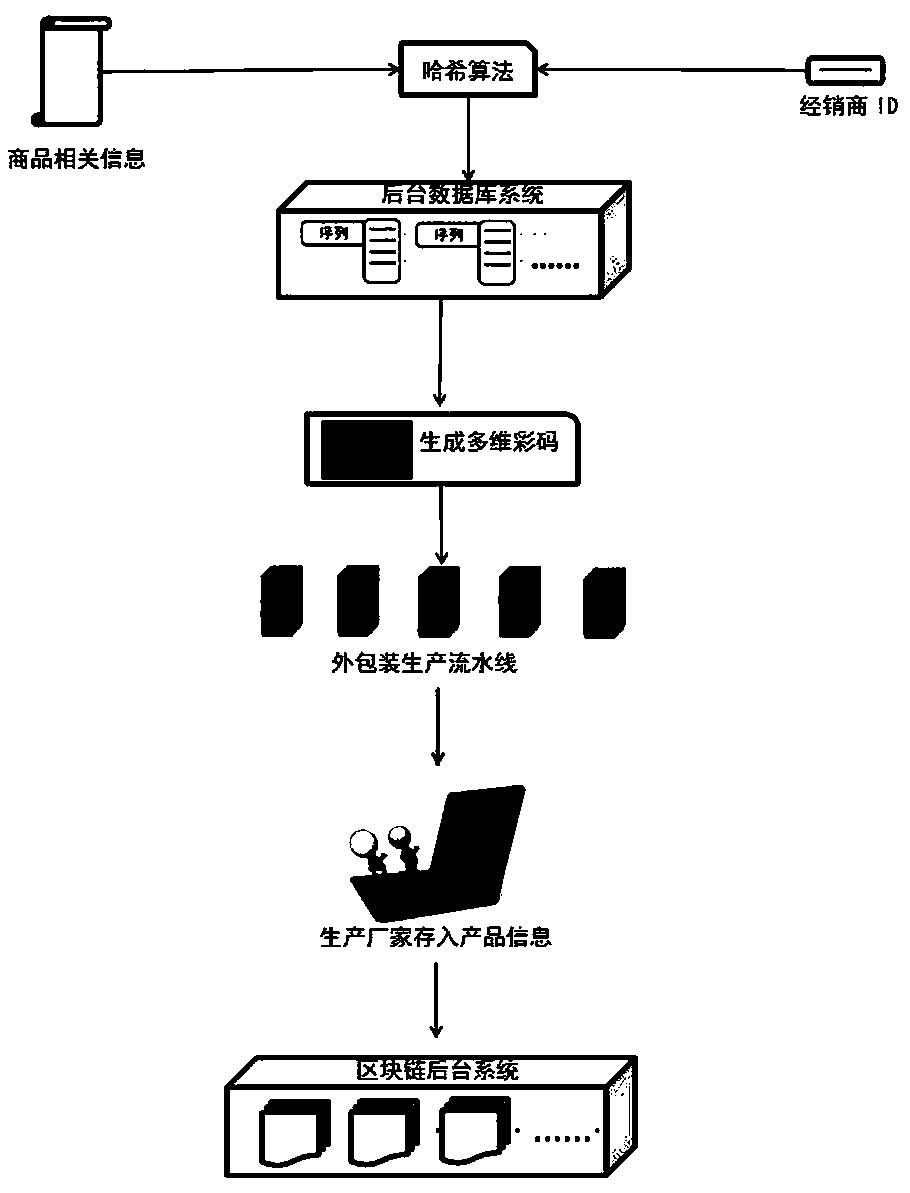

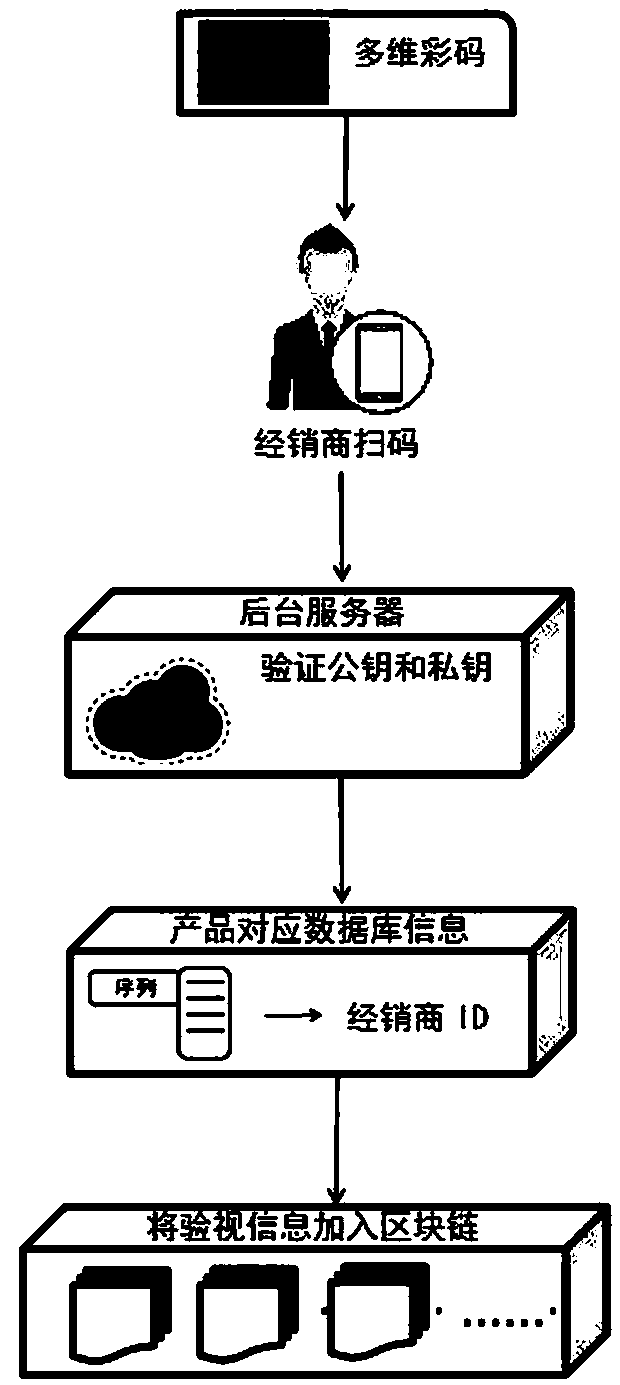

A wine product traceability anti-counterfeiting system and method based on a block chain

ActiveCN109345264AComplete traceability and anti-counterfeiting systemPut an end to the behavior of dropping packagesFinanceCommerceDigital signatureProduct traceability

The invention discloses a wine product traceability anti-counterfeiting system and method based on a block chain, including certificating dealer qualification, ordering, generating multi-dimensional color code, and carrying out transportation and distribution, dealer verification and consumer verification processes, obtaining public and private keys after qualification certification of all participants, enabling the upper level participants and the lower level participants to jointly reach a basic agreement, after both parties digitally sign with the private keys, writing the basic agreement into an intelligent contract, and distributing the intelligent contract to each node; transferring the right to modify the information of the batch of liquor products to the next level of participants;after the user-defined information is successfully added, using the system to start the cancellation server to cancel the code, wherein the permission is read-only and traceable. The system and the method can solve the problems of goods switching and the like in links of packaging, transportation, sales and the like.

Owner:TAIYUAN UNIV OF TECH

Preparation method of cordyceps wine

InactiveCN101717709AReduce manufacturing costRaw materials are abundant and easy to obtainAlcoholic beverage preparationBiotechnologyLees

The invention belongs to the technical field of health wine, and discloses a preparation method of cordyceps wine which has health care effect for human health. The preparation method comprises the following steps of: taking grain and cordyceps substrates according to the proportion of 1:0.8-1.2; crashing; adding water; steaming for sterilization; putting into a cylinder for ferment; separating wine and lees; and slaking to produce the cordyceps wine. In the preparation process, the cordyceps substrates and the grain are adopted as raw materials, the effective components of cordycepin, cordyceps polysaccharide, and the like in the substrates are dissolved into the prepared cordyceps wine. The cordyceps wine prepared by the process has rich raw materials, changes waste into valuable and can greatly reduce the production cost of the cordyceps wine, otherwise, the cordyceps wine can be produced by a solid fermentation process, the effective components of cordycepin, cordyceps polysaccharide, and the like in the cordyceps substrates can be better dissolved into the wine, and the cordyceps wine can generate special flavor and is beneficial to increasing the function and the quality of nutrient wine.

Owner:孙国明

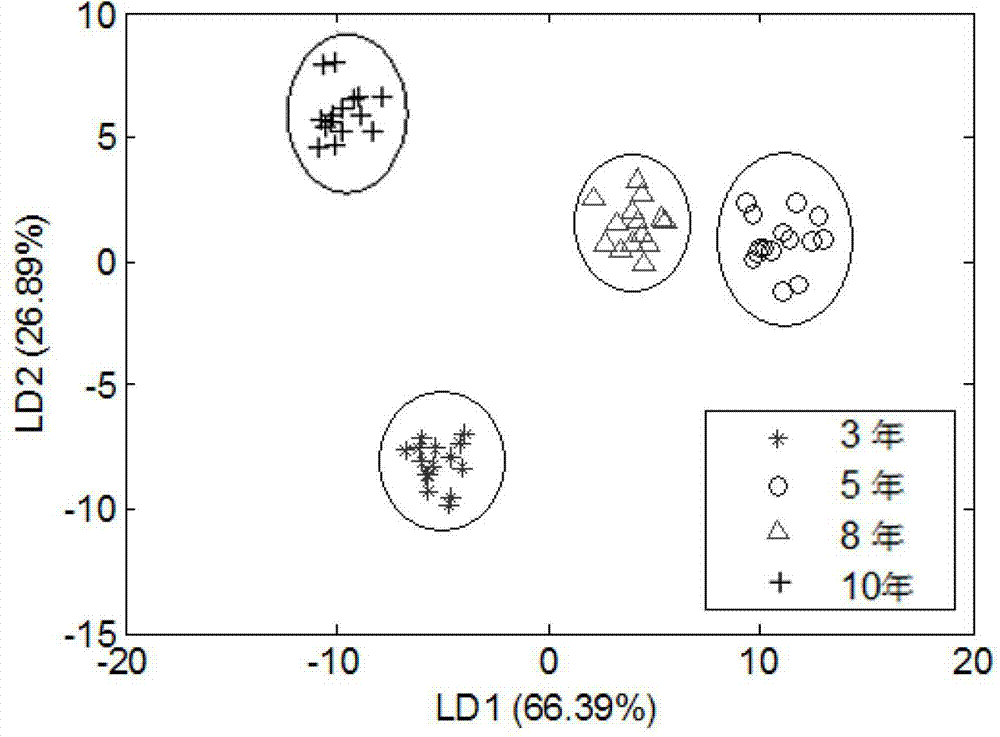

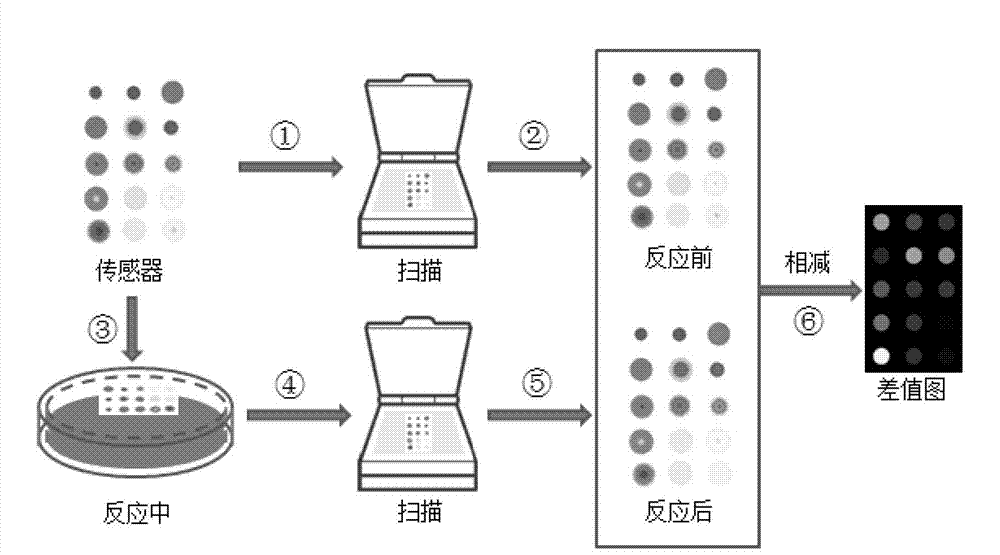

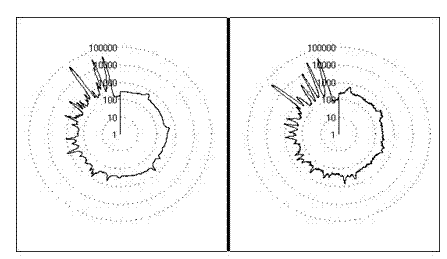

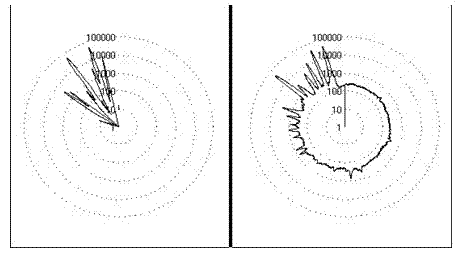

Olfactory imaging sensing technology based yellow wine storage time identification method and identification system

InactiveCN102967597AEffective quality judgmentEasy to judge qualityMaterial analysis by observing effect on chemical indicatorSensor arrayPattern recognition

The invention discloses an olfactory imaging sensing technology based yellow wine storage time identification method and an identification system. The method specifically includes the steps of: making an olfactory imaging sensor; acquiring an image of the olfactory imaging sensor before reaction through a scanner or a CCD camera; reacting the olfactory imaging sensor with yellow wine volatiles; acquiring an olfactory imaging sensor image after reaction; extracting the color features of each color developing agent before and after reaction in an imaging sensor array, and calculating the color feature change before and after reaction; and carrying out classification identification on yellow wine with different wine storage time by combining a chemometric method. The method and the system provided in the invention overcome the defect of humidity sensitivity in traditional smell sensors, and have the advantages of fast detection speed, high sensitivity, and accurate result.

Owner:JIANGSU UNIV

Raspberry compound health preserving wine and production process thereof

ActiveCN103275849APromotes nutrient absorptionFull bodiedMicroorganism based processesAlcoholic beverage preparationAlcoholSugar

The present invention relates to a raspberry compound health preserving wine, which comprises the following fresh fruits, by weight, 50-70 parts of red raspberry, 15-25 parts of black raspberry, 5-15 parts of mulberry, 1-10 parts of medlar, and 1-10 parts of blackcurrant. According to the present invention, the raspberry compound health preserving wine produced by using the formula and the production process meets the national dry wine standard, has characteristics of low sugar and low alcohol, and completely provides health preserving effects of various raw materials in the formula, wherein effectively components in the raw materials are completely extracted through low temperature wall breaking and yeast fermentation so as to easy nutrient absorption of drinking people. In addition, the raspberry compound health preserving wine has characteristics of full wine body, bright color and pleasant aroma, and completely reflects ideas of homology of medicine and food, and treatment before sick in the traditional Chinese medicine culture.

Owner:青岛富润康元健康科技有限公司

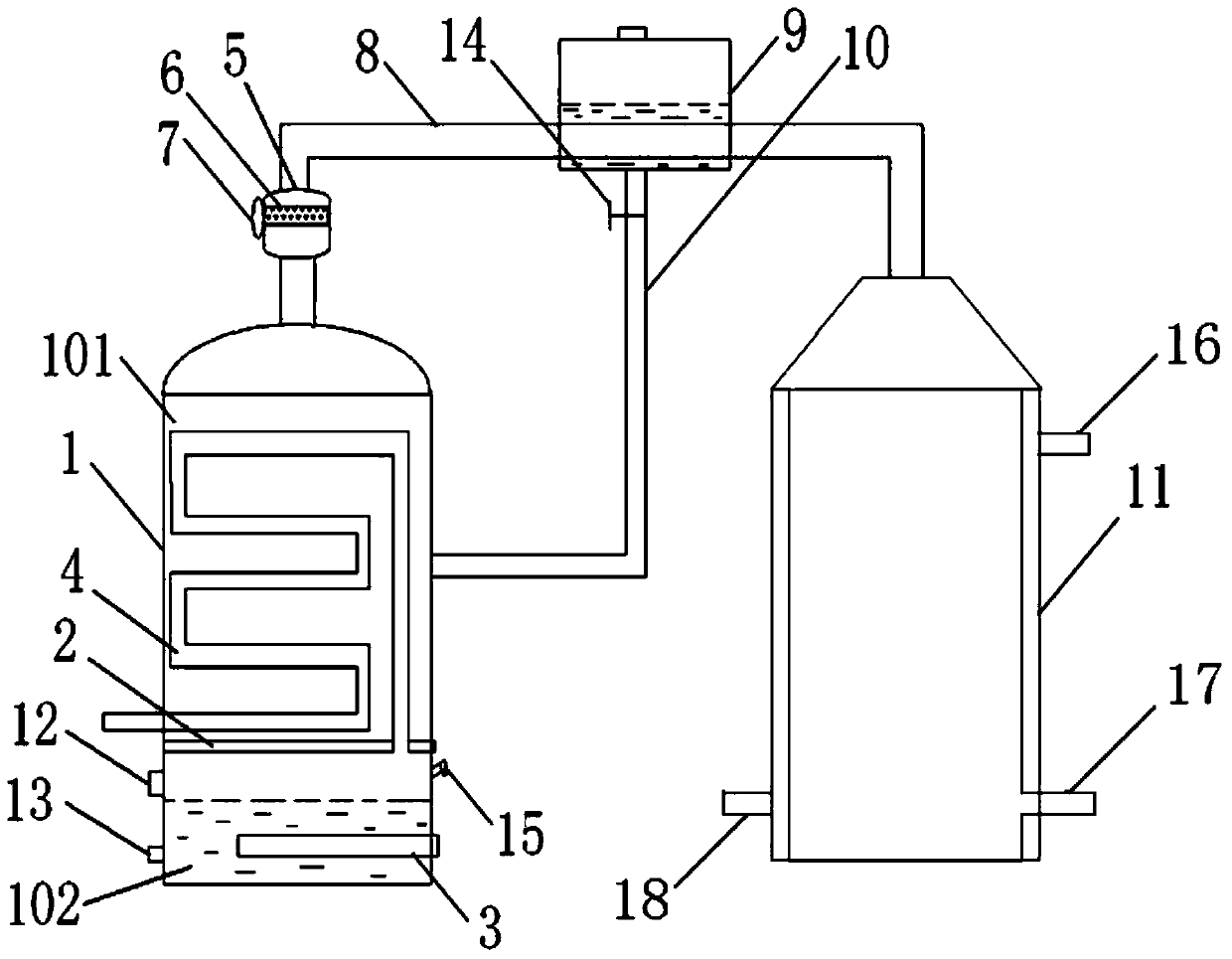

Electric heating wine brewing equipment

ActiveCN103436422AQuality is not affectedElectric heating environmental protectionAlcoholic beverage preparationThermodynamicsProcess engineering

The invention discloses electric heating wine brewing equipment. The electric heating wine brewing equipment comprises a sealed tank body, a ventilation pipeline, a condensation tower, a partition plate pot bottom, an electric heater and a steam pipeline which are connected in sequence, wherein the ventilation pipeline is mounted at the top of the tank body in a communicated way; the ventilation pipeline is connected with the condensation tower; the partition plate pot bottom is mounted on the inner cross section of the tank body to divide the tank body into an upper part and a lower part; the electric heater is arranged in the lower part of the tank body; the steam pipeline is arranged in the upper part of the tank body; the steam pipeline is communicated with a space in the lower part of the tank body. According to the electric heating wine brewing equipment, the partition plate pot bottom is designed, so that water can be heated in a separate electric heating way to generate steam; the steam is used for heating wine material liquor required to be distilled on the partition plate pot bottom through the steam pipeline to generate steam of wine; the electric heating way is more environment-friendly; the structure design of the dual-layer pot bottom guarantees that the steam is not contacted with the wine material liquor required to be distilled; the brewed wine is mellower.

Owner:苏正宇

Method for detecting age of yellow rice wine by using high-speed gas chromatography type electronic nose fingerprint analysis system

InactiveCN102645502AImprove anti-interference abilityShort detection timeComponent separationBiotechnologyOrganoleptic evaluation

The invention discloses a method for detecting age of yellow rice wine by using a high-speed gas chromatography type electronic nose fingerprint analysis system. The method comprises the following steps: firstly building up a yellow rice wine age detection model; then, shaking up a yellow rice wine sample to be detected; putting 5mL of the yellow rice wine sample to be detected into a 20mL closed sample bottle in the high-speed gas chromatography type electronic nose fingerprint analysis system, acquiring the smell fingerprint information of the yellow rice wine sample to be detected by using the high-speed gas chromatography type electronic nose fingerprint analysis system so as to obtain a chromatography type smell fingerprint map of the yellow rice wine sample to be detected; carrying out principal component analysis on the chromatography type smell fingerprint map of the yellow rice wine sample to be detected to form a characteristic smell fingerprint vector; and finally calling the characteristic smell fingerprint vector in the yellow rice wine age detection model so as to obtain the age of the yellow rice wine sample to be detected. The method for detecting the age of yellow rice wine by using the high-speed gas chromatography type electronic nose fingerprint analysis system has high detection accuracy, is simple to operate and has the advantage of shorter detection time as compared with the traditional sensory evaluation method. The method is a new method for detecting the age of yellow rice wine.

Owner:SHANGHAI INST OF TECH

Sea cucumber blueberry health care wine and method for processing same

ActiveCN101584474AProtects Active NutrientsIncrease profitAlcoholic beverage preparationFood preparationBiotechnologyNutritive values

The invention provides a sea cucumber blueberry health care wine and a method for processing the same. Sea cucumber, ginseng, medlar and blueberry are taken as main raw materials, honey, a sweetening agent and Vc are taken as auxiliary raw materials, the main raw materials and the auxiliary raw materials undergo pre-treatment and liquor alcoholization to separate and extract active substances of the raw materials, and the active materials are processed by the methods of health care wine blending, filtering, sterilization and the like to prepare the sea cucumber blueberry health care wine. The sea cucumber blueberry health wine has the advantages of transparency, even liquid, rich nutrition, no fishy smell, pleasant sweetness and sourness, good nourishing effect and quick and convenient drinking. The processing method has the advantages that the activity of nutrient substances in the mixture are kept and stabilized in a liquid state, the original flavor, the taste and the color of the materials are kept, and the medicinal value, nutrient value and drinking value of the mixture of a few raw materials are improved.

Owner:辽宁阿里郎生物工程股份有限公司

Red date health-care yellow wine with fatigue eliminating effect and preparation method thereof

ActiveCN103114017ALong climbing timeExtend climbing timeAlcoholic beverage preparationAntinoxious agentsTremellaFood flavor

The invention relates to a preparation method of a red date health-care yellow wine with the fatigue eliminating effect and belongs to the technical field of the yellow wine, and specially relates to a preparation method of a yellow wine added with auxiliary materials such as red date. The invention aims to provide the preparation method of the red date yellow wine which is good in flavor and taste and rich in nutrition and has the health care function; and the technical proposal is that the following raw materials are blended in parts by weight: 10 parts of broomcorn millet, 0.4-1 part of red date, 1-3 parts of barbary wolfberry fruit, 1-4 parts of dried currant, 1-3 parts of tremella and 1-4 parts of dried hawthorn. The preparation method provided by the invention is widely applied to the technical field of the red date health-care yellow wine.

Owner:交城天娇红农业科技有限公司

Dry or semidry type litchi wine and its production method

A dry or semi-dry litchi wine as a green beverage with health-care function is prepared from fresh litchi fruit through squeezing to obtain juice, clarifying, regulating copmonents, fermenting, mingling, filtering, storing, freezing and sterilizing.

Owner:李志坚 +1

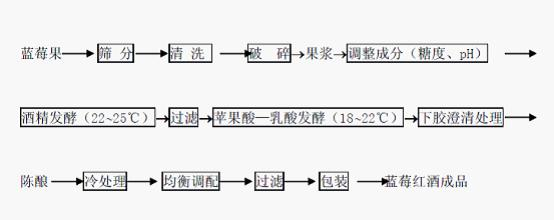

Production method for blueberry red wine

ActiveCN102399664AReduce lossPure aromaAlcoholic beverage preparationMicroorganism based processesBiotechnologyAlcohol drink

The invention discloses a production method for blueberry red wine and belongs to a preparation method for an alcoholic beverage. The method comprises the following steps of: (1) screening, crushing and pulping blueberries; (2) adjusting ingredients of raw materials; (3) fermenting pulp; (4) filtering and separating; (5) performing malic acid-lactic acid fermentation; (6) adding colloid and clarifying; (7) ageing; (8) filtering for multiple times; and (9) encapsulating and storing. The method is characterized in that: fermenting raw materials and treatment thereof, design of the fermenting process and control over process parameters of the fermenting process are innovated; the method is a new technology for deeply processing the blueberries; loss of the raw material blueberries is effectively reduced; the alcoholic strength of the fermented red wine is 8 to 12 volume percent; the produced blueberry red wine has pure and pleasant fragrance, refreshing and elegant taste and unique tasteof the blueberries; and the method is applicable to production processing enterprises of the blueberries.

Owner:贵州蓝美食品科技有限公司

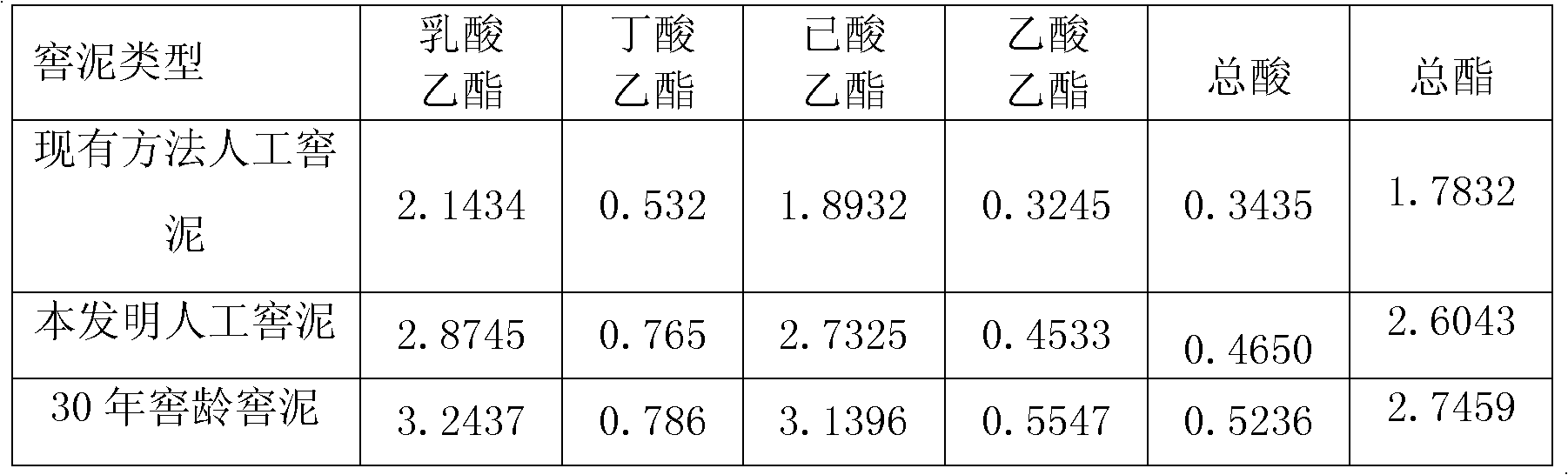

Artificial pit mud and preparation method thereof

The invention relates to artificial pit mud and a preparation method thereof, which belong to the technical field of wine brewing. The invention solves the technical problem of providing the artificial pit mud and the preparation method thereof. By using the artificial pit mud, a white spirit with higher quality can be brewed. The method for preparing the artificial pit mud, provided by the invention, comprises the following steps of: (a) taking yellow mud, adding yellow water and tail water and uniformly mixing so that the water content of the yellow mud is 48-55 wt%; (b) taking pit sealing mud, adding the yellow water and the tail water and uniformly mixing so that the water content of the pit sealing mud is 48-55 wt%; (c) uniformly mixing the mud and the pit sealing mud obtained in the steps (a) and (b) according to a weight ratio of (2-5):1 to obtain basic mud; (d) taking excellent pit mud, adding the tail water, the yellow water and a distilled grain squeezed liquor and uniformly mixing so that the water content of the excellent pit mud is 48-55%; and (e) uniformly mixing the basic mud obtained from the steps (c) and (d) according to a weight ratio of (4-8):1, and adding a yeast and fermenting in a sealed state for 50-120 days so as to obtain the artificial pit mud.

Owner:LUZHOU PINCHUANG TECH CO LTD

Method for reducing acid and removing fusel oil of plum wine

The invention discloses a method for reducing acid and removing fusel oil of a plum wine, belonging to the field of improvement of fruit wine quality. According to the method, an immersion type plum wine is used as a raw material, anion-exchange resin is adopted to reduce acid and ultrasonic waves are adopted to remove fusel oil, so that the problems of high acidity and easy drunkenness of the immersion type plum wine are solved. The flow of reducing acid of the plum wine comprises the steps of pretreating with resin, mixing the plum wine with resin for adsorption acid reduction, filtering and regenerating the resin; the flow of removing the fusel oil comprises the steps of filling the plum wine into a glass ware, putting the glass ware into an ultrasonic treatment field, treating for 10-50 minutes under different powers, taking the glass ware out, and placing for 15 days. The maximum reduction amplitude of the acid reaches 28%, and the maximum reduction amplitude of the fusel oil reaches 20%. The method disclosed by the invention adopts the anion-exchange resin to reduce the acid, so that the effect is good, no impurity is introduced, and the flavor of the wine is well preserved; through continuous alternate treatment with low and medium frequency ultrasonic waves, the fusel oil content can be reduced, and the maturation of the wine can be accelerated. The method for reducing the acid and removing the fusel oil of the plum wine is favorable for quick maturation of a newly-prepared immersion type plum wine.

Owner:GUANGDONG JIAHAO FOOD +1

Blueberry SOD (Superoxide Dismutase) red wine and preparation method thereof

ActiveCN102250741AImprove stabilityRich in nutrientsAlcoholic beverage preparationTrehaloseSuperoxide dismutase

The invention discloses a blueberry SOD (Superoxide Dismutase) red wine and a preparation method thereof. The blueberry SOD red wine comprises 75ml of blueberry primary extraction solution, 100,000-200,000 units of blueberry SOD crude enzyme and 675ml of red wine. The preparation method of the blueberry SOD red wine comprises the following steps of: (1) cleaning blueberry; (2) draining water on the surface of the blueberry; (3) crushing and pulping by using a crushing and pulping machine, adding one time of volume of 4DEG C de-ionized water and carrying out ultrasound crushing at the constant temperature for 2 hours; (4) centrifuging to obtain supernate as the primary extraction solution; (5) intercepting the primary extraction solution to obtain a concentrated solution with the molecular weight of 20,000-60,000; (6) adding fucose as an SOD protecting agent and carrying out vacuum freezing and drying to obtain the blueberry SOD crude enzyme; and (7) mixing the blueberry SOD crude enzyme with the primary extraction solution, then adding the mixture into the red wine, sterilizing and bottling. The blueberry SOD wine obtained by the preparation method disclosed by the invention has the advantages of abundant nutrient components, favorable mouth feeling and high SOD survival rate.

Owner:成都非凡生物高新科技有限公司

Lychee liqueur and brewing method thereof

The invention discloses a lychee liqueur and a brewing method thereof. The brewing method comprises the steps of: squeezing lychee to obtain juice, adjusting the sourness of the juice, and carrying out low-temperature fermentation on the juice to obtain lychee fermented wine; carrying out component adjustment, low-temperature fermentation, distillation by stages, storage in a wine tank and aging storage in an oak tank on the lychee residues to obtain 68-72vol% lychee brandy; mixing the lychee fermented wine and the lychee brandy in a certain proportion, blending, freezing, testing and packaging to obtain a lychee liqueur finished product. The lychee liqueur obtained in the invention is golden in color, clear and transparent, and has pure and dense lychee flavor, wine flavor and oak flavorand soft, natural and mellow tastes.

Owner:广州市顺昌源酒业有限公司

Litch dry-wine and brewing method

This inventionm discloses a method for brewing dry-type lichee wine including taking lichees as the raw material, squeezing them, fermenting with barm at low temperature, hydrolyzing them with bio-enzymes, metabolic controlling fermentation and clarifying and filtering them to get the raw wine, which is processed for stability including: adding metal ionic complexant to coordinate metallic ions in the spirit to suppress browning of non-biologies, adding silica gel at low temperature to adsorb cold turbid proteins in the spirit and adding bio-antioxidation enzyme resisting against oxidation browning of the lichee wine.

Owner:广东荔枝庄园酒业有限公司

Nondestructive testing method for bonding defects of shell of wind turbine blade and web plate

ActiveCN104458910AEffectively judge the defects of bondingAnalysing solids using sonic/ultrasonic/infrasonic wavesTurbine bladeBonding process

The invention discloses a method for testing bonding defects of a shell of a wine turbine blade and a web plate by using ultrasonic nondestructive testing means. According to the method, the defect of a hungry joint existing in the bonding process of the shell of the wine turbine blade and the web plate can be effectively detected. The method comprises the following parts: detection of preparation work, detection of an implementation process, and a defect judgment criterion. The wine turbine blade is detected by using an ultrasonic flaw detection technology; the internal acoustic reflection situation of the blade can be objectively reflected; and the internal defects of the blade can be effectively judged.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

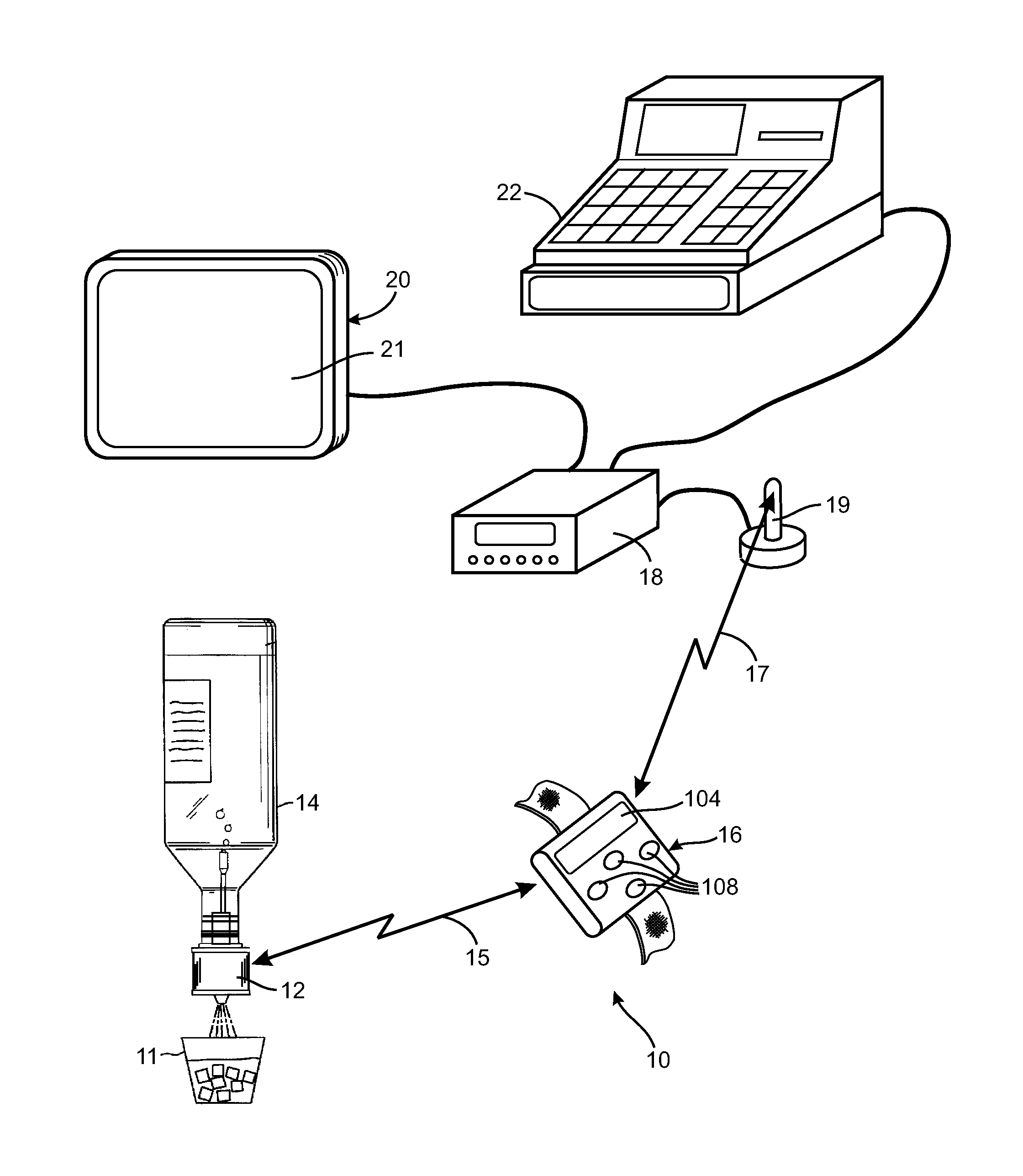

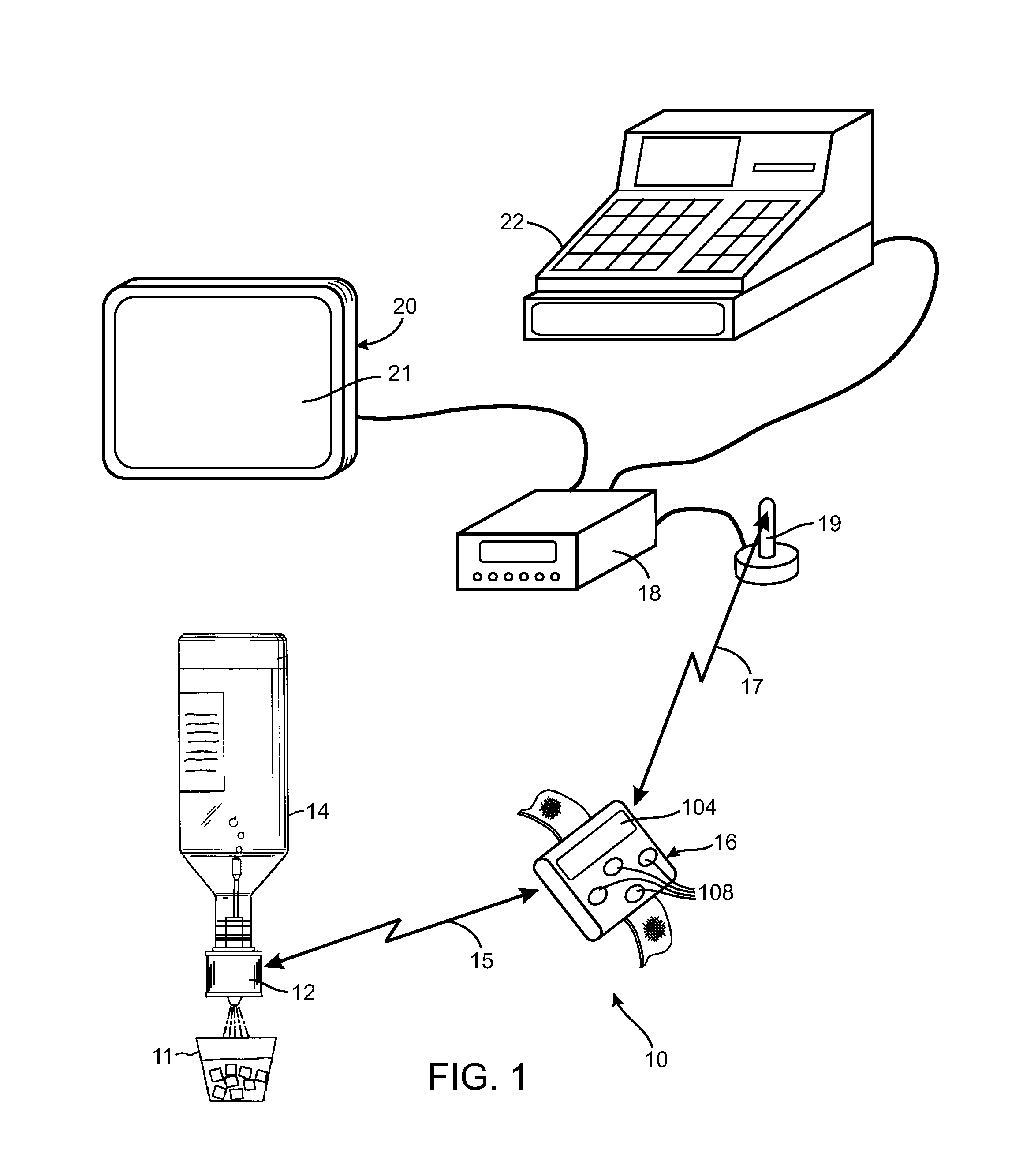

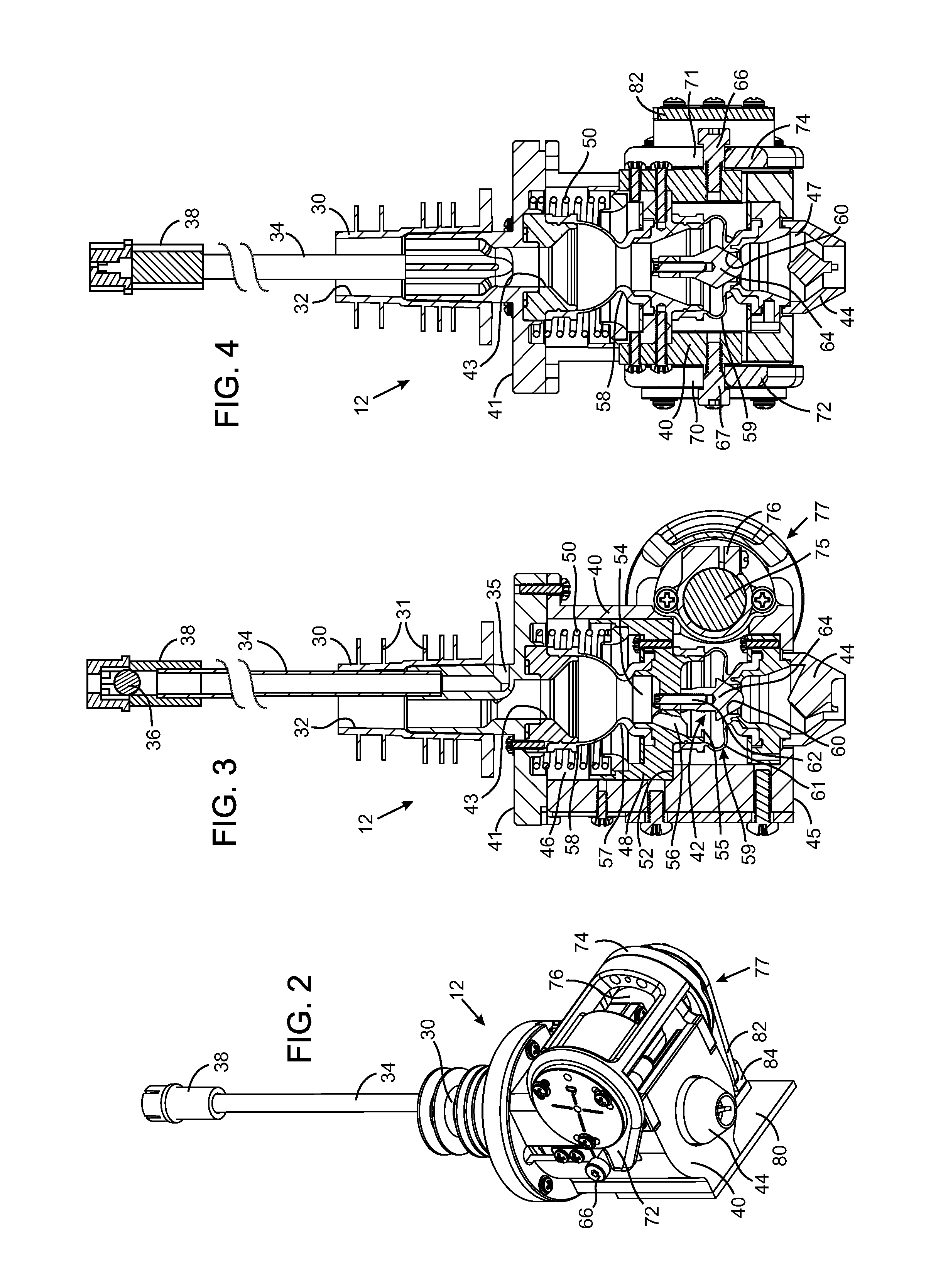

Wireless control system for dispensing beverages from a bottle

A pour spout, for attaching to a bottle, has a first wireless transceiver and a valve for selectively controlling flow of a beverage from the bottle. A server interface, adapted to be carried by a person who serves beverages, has a second wireless transceiver. A control unit is provided to wirelessly communicate with the second transceiver. In one mode, the pour spout transmits a spout identifier to the server interface, which responds by transmitting the spout identifier and a server identifier to the control unit. The control unit responds with a reply transmission causing the server interface to command the pour spout to open the valve. In another mode, a person selects a cocktail, that results in the control unit sending designations of a plurality of liquor ingredients to the server interface. The server interface controls dispensing each of the plurality of liquor ingredients.

Owner:BERG

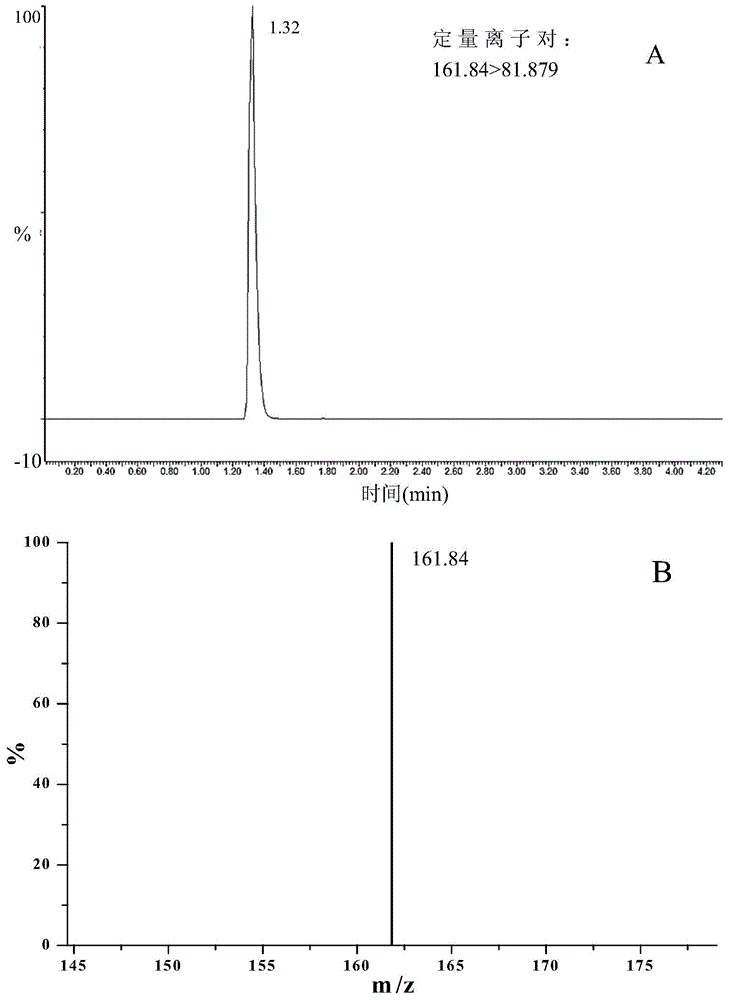

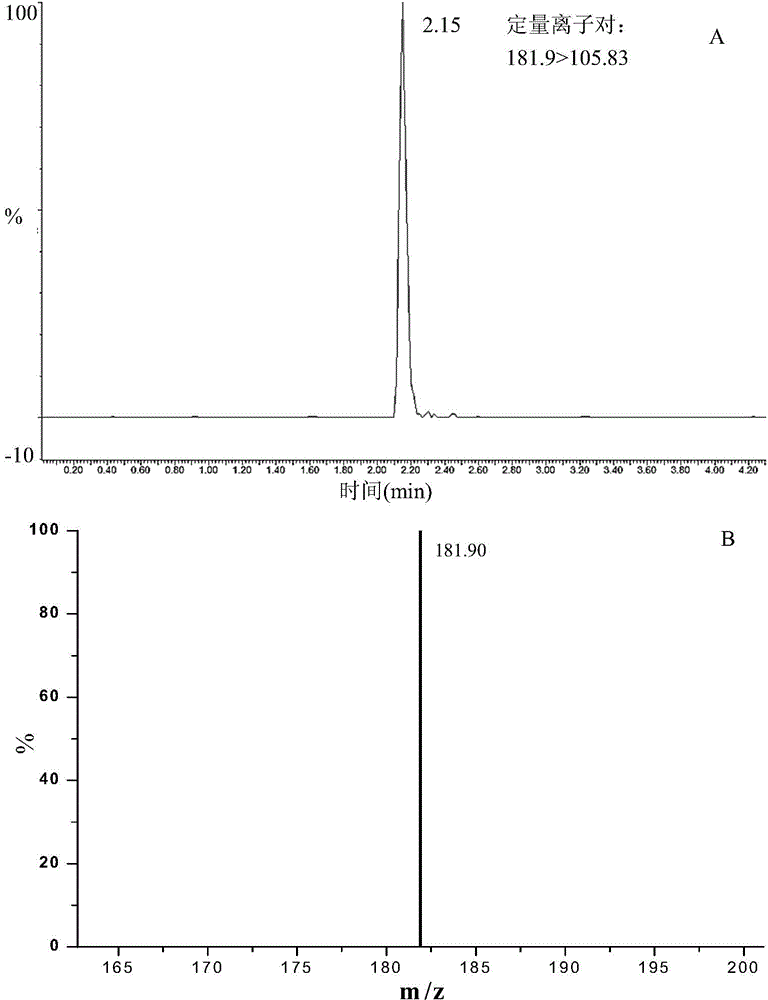

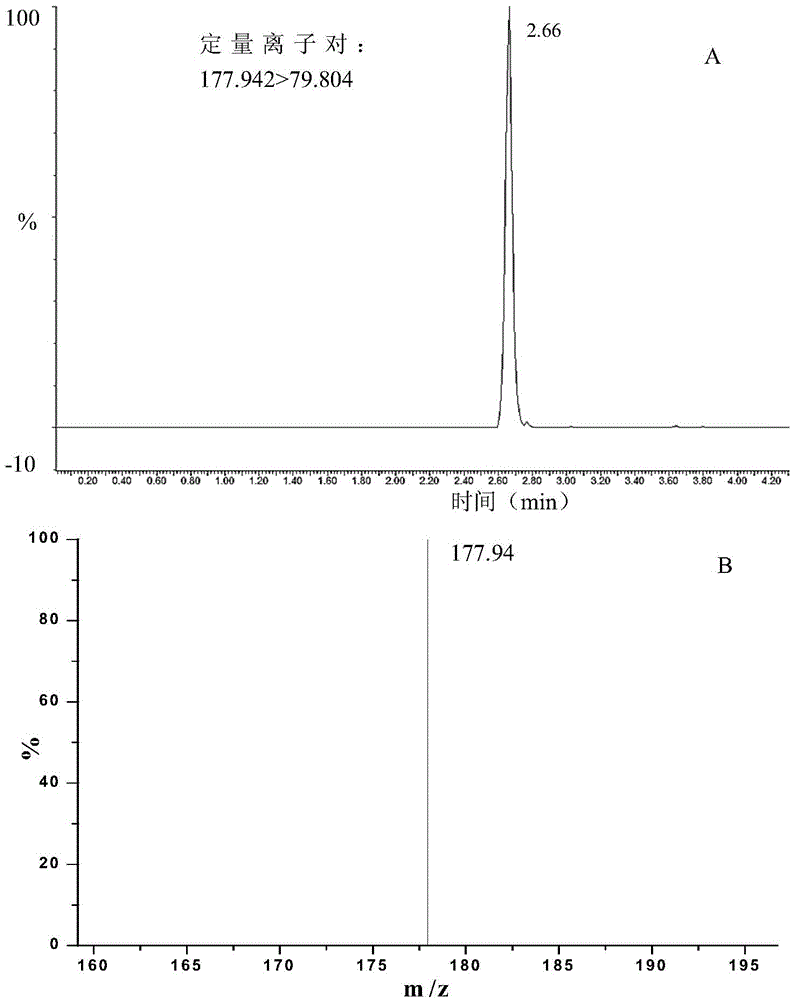

Method for synchronously detecting six sweetening agents in distilled spirit by using ultra-high performance liquid chromatography-triple quadrupole tandem mass spectrometer

ActiveCN104634895AQualitatively accurateQuantitatively accurateComponent separationLinear relationshipQuadrupole

The invention discloses a method for synchronously detecting six sweetening agents (namely acesulfame, saccharin sodium, sodium cyclamate, aspartame, trichlorosucrose and neotame) in a distilled spirit by using an ultra-high performance liquid chromatography-triple quadrupole tandem mass spectrometer. The method comprises the following steps: performing nitrogen blowing on a wine sample to remove alcohol, separating the wine sample by using an ultra-high performance liquid chromatograph, and then performing multi-reaction ion monitoring mode detection by using a triple quadrupole tandem mass spectrometer. The six sweetening agents have good linear relationships in a range of 50-1000ng / mL, correlation coefficients r2 of the six sweetening agents are more than 0.993, the average recovery rate of the sample is 90-120%, and the limit of detection is 2.69-5.16ng / mL. The method disclosed by the invention is accurate, reliable, simple and fast, and can be used for synchronously detecting the six sweetening agents in the distilled spirit.

Owner:ANHUI GUJING DISTILLERY +1

Preparing method for pomelo wine

ActiveCN104450411AAvoid inhibitionRetain flavor substancesAlcoholic beverage preparationBiotechnologyPectinase

The invention discloses a preparing method for pomelo wine. According to the method, water, sugar, honey, acid, pectinase, yeast cell wall, nutrimental agents and yeast are added into a crushed pomelo and mixed uniformly to be fermented at the temperature of about 18 DEG C, an odor absorber is added when the alcoholic strength is about 6% vol, after fermentation is finished, wine liquid is taken and stored in the environment with the temperature of about 2 DEG C, wine sediment is removed after 60 days, then the wine liquid is stored for about 90 days, then the wine liquid is placed in the environment with the temperature of about minus 4 DEG C for 3 days, clarification is carried out, and the wine liquid is filtered and sterilized after being placed in the environment with the temperature of about minus 4 DEG C for 4 days. According to the method, the skin can also be fermented for generating the pomelo wine, the inhibiting effect on the fermenting effect from special ingredients in the pomelo skin is overcome, and the pomelo wine with the special taste can be brewed, and has the dense lemon scent; the way of adding the odor absorber to the special fermenting process is fished out, bitterness of the pomelo can be covered up, flavor compounds in the pomelo wine are effectively preserved, the scent of the pomelo wine is more complex, and the mouthfeel is enhanced.

Owner:广州市顺昌源酒业有限公司

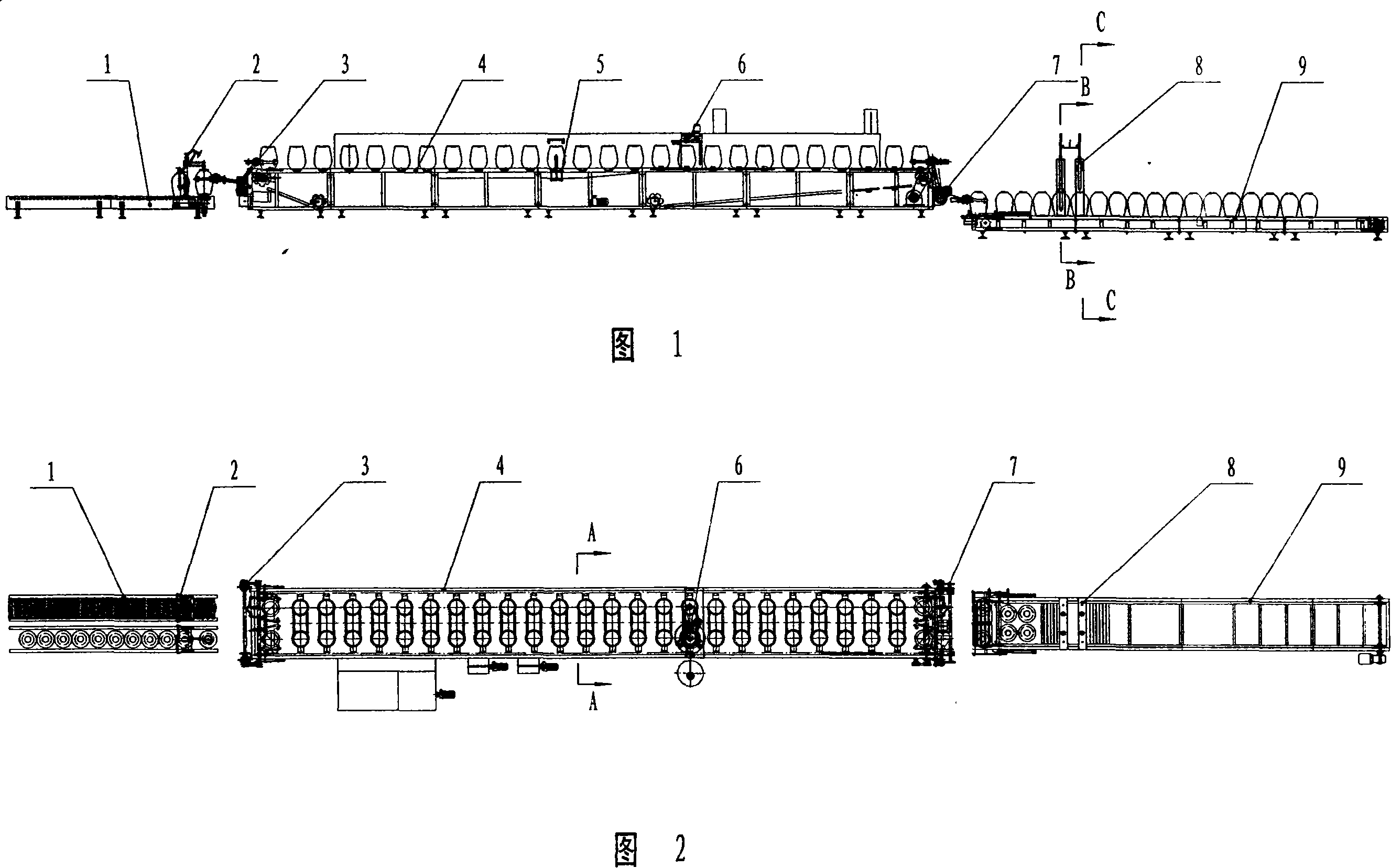

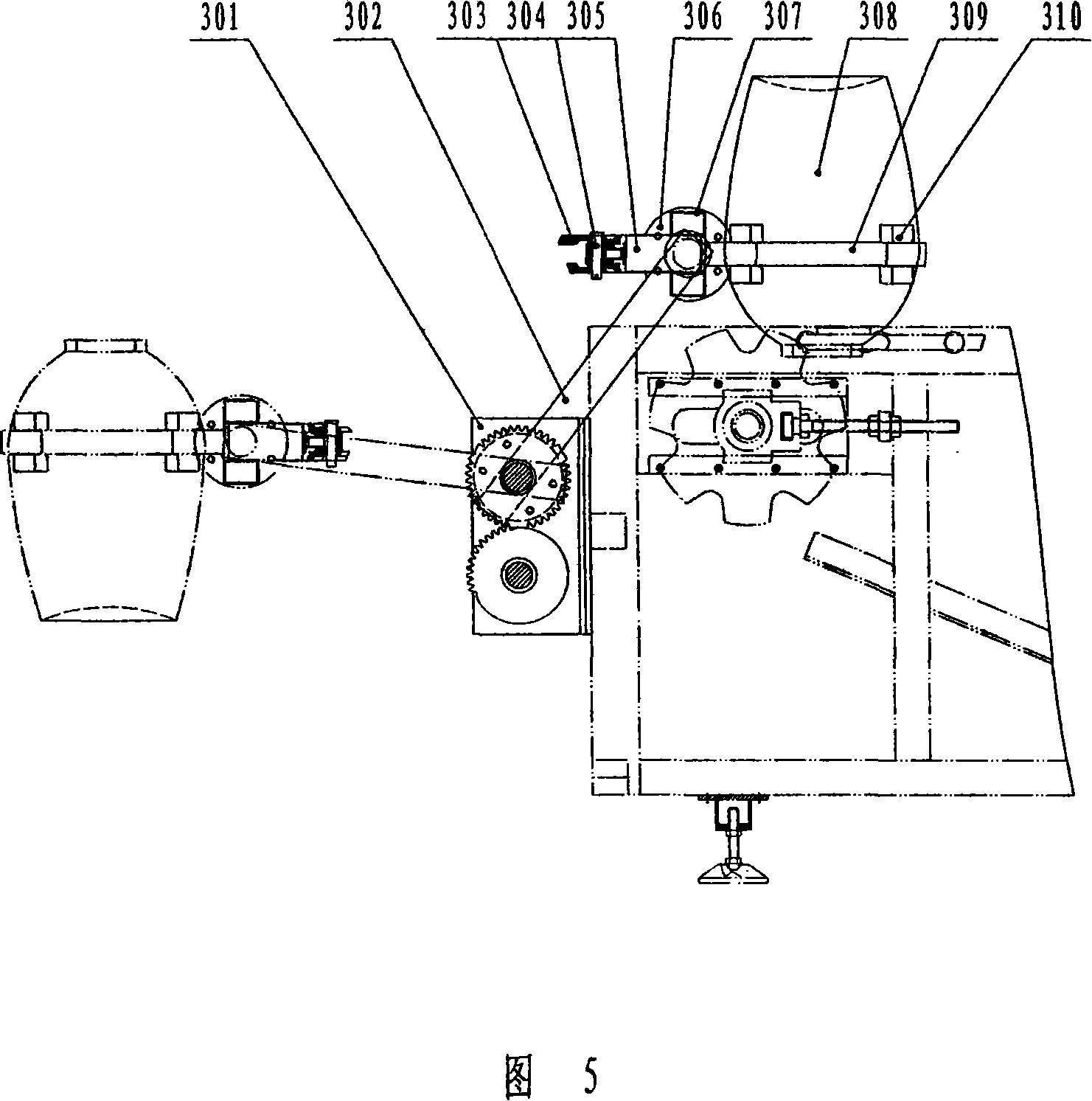

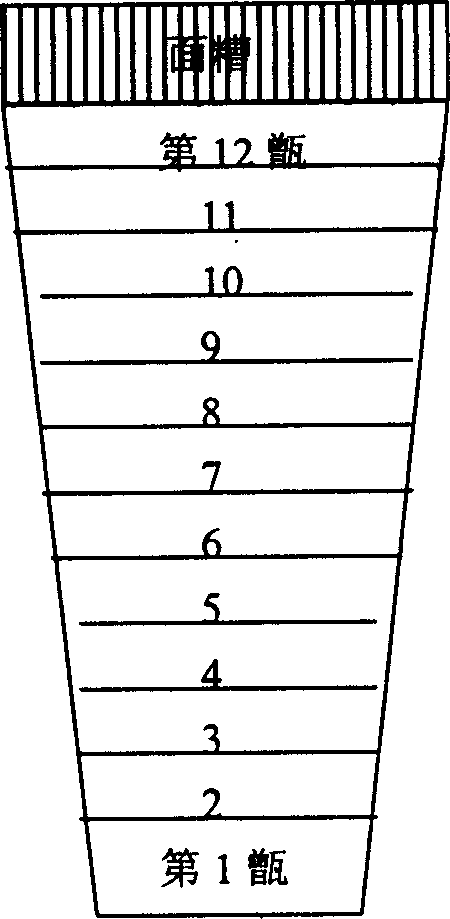

Wine crock cleaning and filling machine set

ActiveCN101125635AAchieving Pipeline OperationsContinuous productionBottle-handling machinesAutomatic controlLimewater

The invention provides an oinochoe washing filling machine unit, which is used for the mechanization package of the jarred wine, comprising a jar transmission mechanism, a positioning mechanism, a washing mechanism, a limewater brushing mechanism and a filling mechanism; wherein, the transmission mechanism is provided with a first transmission machine, a second transmission machine and a third transmission machine; wherein, the first transmission machine is provided with the positioning mechanism; a first manipulator is arranged between the first transmission machine and the second transmission machine, while a second manipulator is positioned between the second transmission machine and the third transmission machine; moreover, the second transmission machine is provided with the washing mechanism and the limewater brushing mechanism, and the third transmission machine is provided with the filling mechanism; whereas, a motor, an air cylinder, an electromagnetic valve, a vacuum valve and a steam heater and a photoelectric detector which are related in the mechanisms are all connected with an electronic automatic control system. The invention automatically complete a mechanism manner of the processes of washing jars in different shapes, brushing limewater and filling wine, further realizes an operation line and a continuous production, thereby improving the production efficiency and saving a large amount of labor as well as releasing the labor intensity.

Owner:象山恒大机械制造有限公司 +1

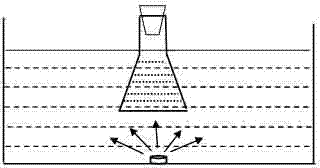

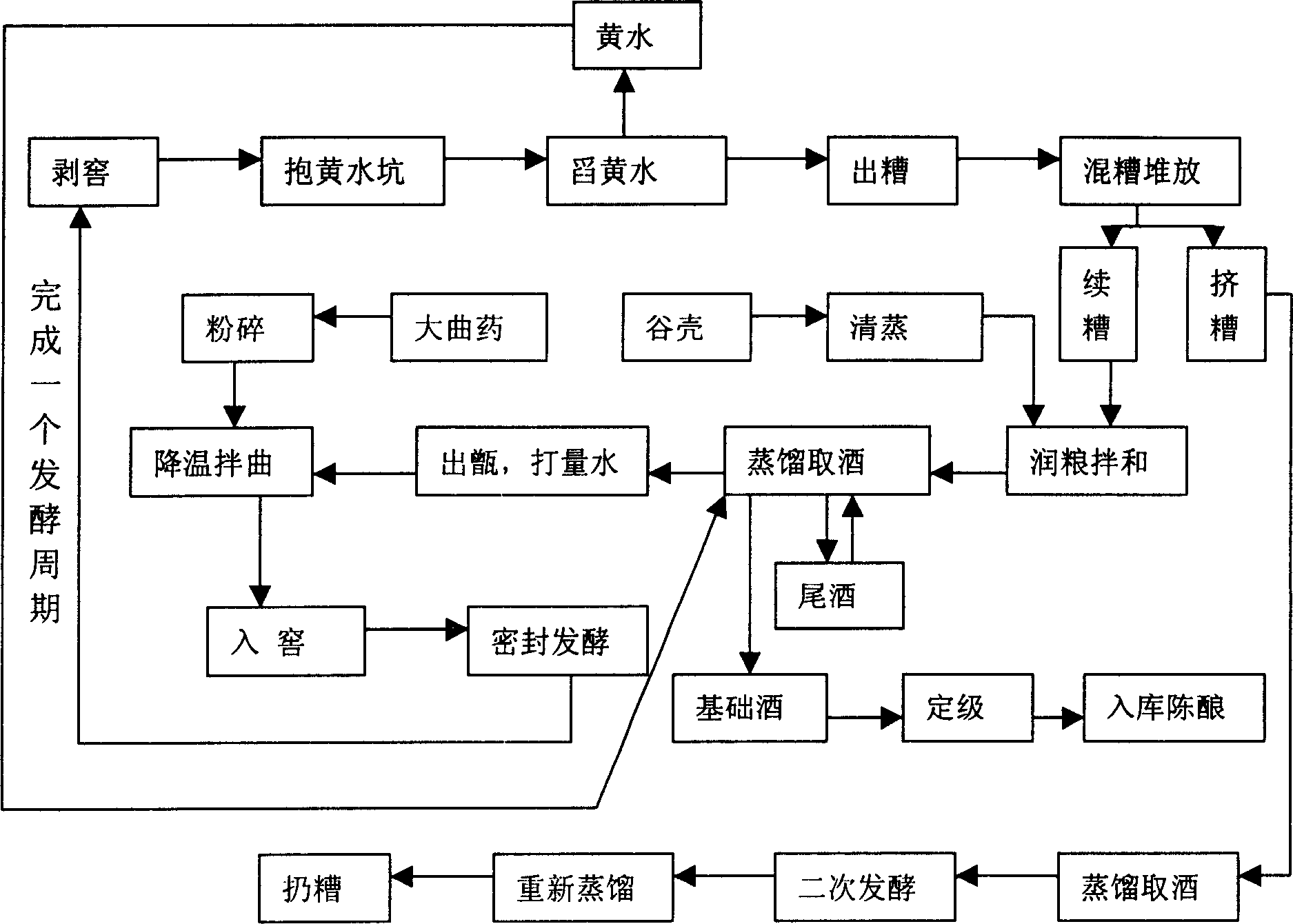

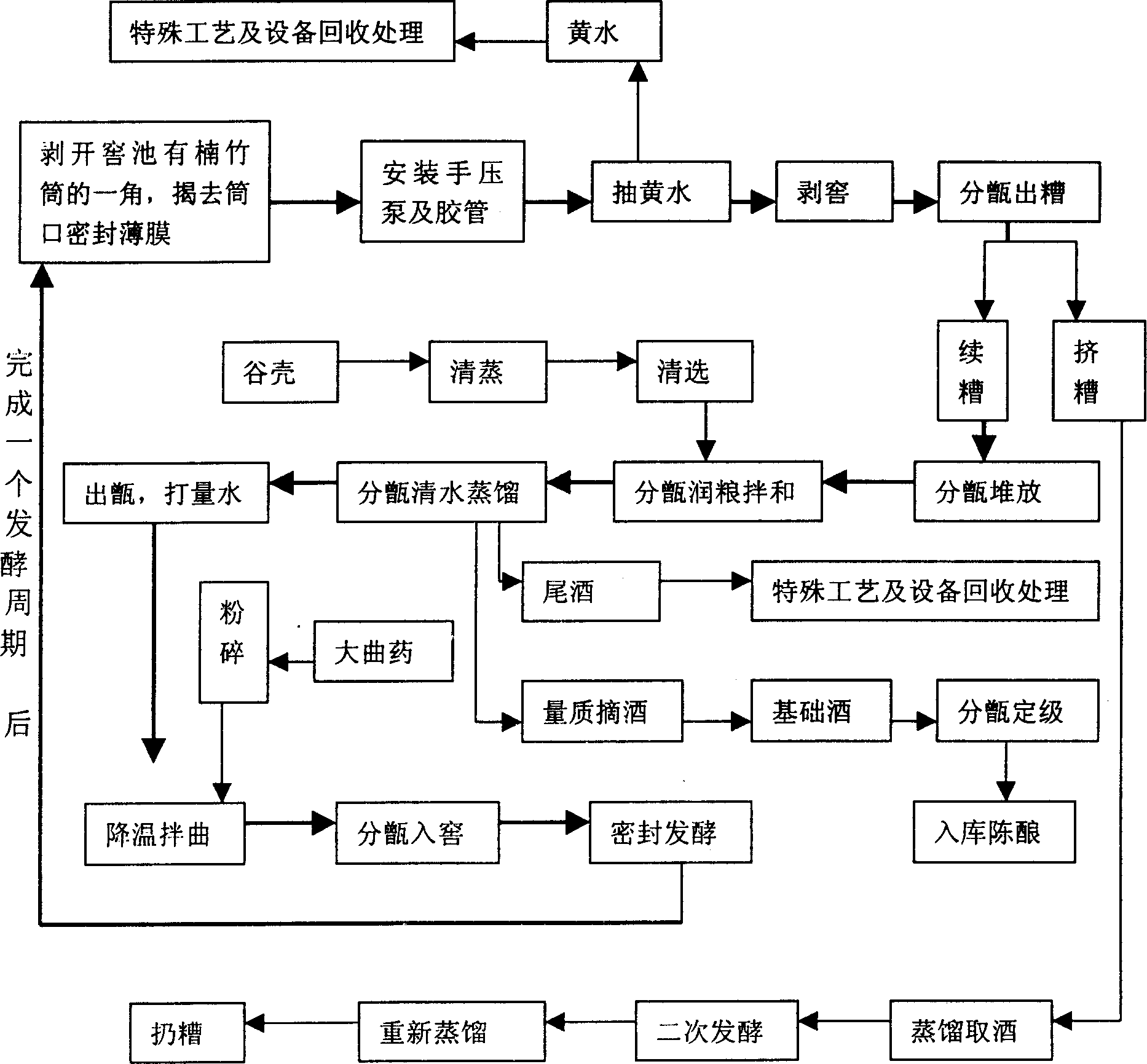

'Whole clear' process of brewing aroma type white spirit

ActiveCN1733888AReduce dosageReduce furfural contentAlcoholic beverage preparationTissue/virus culture apparatusEngineeringDrinking straw

The invention discloses a technique to brew aromatic wine, based on traditional technique, which relates to reform and innovate to draw water, steam supplementary material, distill to obtain wine, and put dreg into cellar clear layered. Wherein, the said four steps are technical core; the cellar is constructed on bottom of pond near wall with inner wall fixed and cover on its head with center hole inserted hollow pipe; after putting dreg into cellar, sealing the pipe and cellar for fermentation; before putting out, stripping off the yellow mud to show pipe mouth, and taking out seal; inserting sucker to draw the yellow water in cellar by connected pump as possible as far; mixing, obtaining wine, storing in cellar; all processes with Zeng(traditional measuring tool) as unit. The method can decrease labor strength, save material, and increases wine quality.

Owner:SICHUAN TUOPAI SHEDE WINE

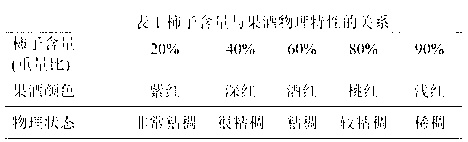

Red composite persimmon fruit wine and preparation method thereof

ActiveCN103232924AUnique styleTo make up for the shortcomings of light yellow tasteAlcoholic beverage preparationMicroorganism based processesFruit wineVitis vinifera

The invention discloses a red composite persimmon fruit wine and a preparation method thereof. According to the invention, persimmon and at least one selected from the group consisting of grape, Hylocereus polyrhizus, mulberry and myrtle are subjected to pulping and fermentation so as to prepare an old wine composite persimmon fruit wine or a blended composite persimmon fruit wine; the other fruits endow the persimmon fruit wine with new colors and flavors and compensate for the disadvantages of thin taste and a yellow color of a single persimmon fruit wine. The composite persimmon fruit wine is bright red or claret, has a unique style, is greatly popular among consumers and has wide market prospects and a great commercial value.

Owner:李阳 +1

Health care wine and preparation method

InactiveCN1660386ARegulate immunityTo achieve the purpose of prolonging lifeSenses disorderNervous disorderAllergic dermatitisDisease

A health-care wine for improving immunity, nourishing liver and spleen, invigorating the function of organs, and preventing and treating tens diseases including cancer, sexual disfunction, constipation, hypertension, senile dementia, etc is prepared through immersing 31 Chinese-medicinal materials in spirit.

Owner:刘克禄

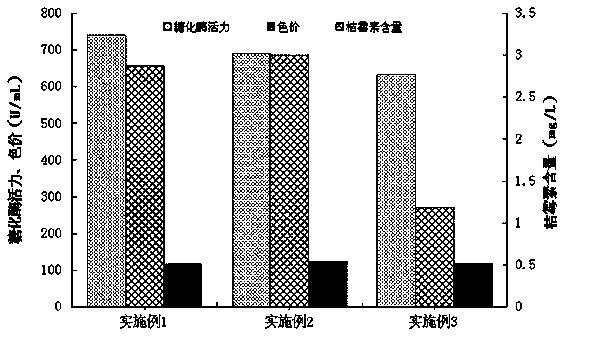

Production method of monascus liquid state fermentation yeast

InactiveCN103468463AMicroorganism based processesAlcoholic beverage preparationBiotechnologyFood additive

The invention discloses a production method of a monascus liquid state fermentation yeast. A Monascus strain L producing pigment and citrinin in high yield is used in the method, is preserved in China Center for Type Culture Collection and has a preservation number of CCTCC M2013039. The color value level, the fermenting period and the glucoamylase vitality of the liquid state fermentation yeast produced under technical conditions in the invention are 110-120U / mL, 5-7d and 630-740U / mL, and the citrinin content of the liquid state fermentation yeast is 2-3mg / L and is lower than a content limit index of citrinin in monascorubin of 0.2mg / kg (a color value reference is 5mu / g, 1%) in Food Additive in Japan promulgated in 1999 and revised in 2003 by Ministry of Health and Welfare, Japan. The liquid state fermentation yeast has no hidden safety troubles, and can be used in a monascus rice wine brewing system.

Owner:FUZHOU UNIV

Wine of longan, and brewing method

ActiveCN1872982ASolve the problem of deterioration and wasteIncrease the variety of wineAlcoholic beverage preparationFruit wineAlcohol

This invention relates to a method for breeding longan wine with alcohol degree of 10-12% (V / V). The total sugar content is 2-4 g / L (measured by glucose), the total acid content is 5-6.5 g / L (measured by tartaric acid), and the dry precipitate content is 17-22 g / L. The method comprises: utilizing longan as the raw material, pressing to obtain juice, fermenting at a low temperature, clatifying, filtering, and post-treating to obtain longan wine. The post-treatment comprises: adding silica gel into the wine at a low temperature to adsorb the precipitated proteins, and adding antioxidant bioenzyme. The longan wine has good fragrance, good taste and beautiful color.

Owner:广东荔枝庄园酒业有限公司

Dry type kiwi wine and preparation method thereof

InactiveCN103773651AEfficient separationEasy to separateAlcoholic beverage preparationYeastPectinase

The invention discloses a dry type kiwi wine and preparation method thereof, belonging to the technical field of preparing fermented fruit wine. The preparation method comprises the steps of: 1) freezing and peeling kiwi fruit, stripping and slicing, soaking in color protection solution and standing, and then extruding and pulping to obtain fruit pulp; 2) adding pectinase for enzymolysis, then carrying out heating treatment and filtering, adding concentrated fruit juice into filtrate and regulating the needed concentration to obtain kiwi juice; 3) adding Angel active yeast into the kiwi juice for twice, carrying out primary fermentation and after fermentation until the amount of the residual sugar in the fermentation liquor is less than or equal to 4g / L, thus obtaining after-fermentation wine; 4) carrying out deacidification, astringency removal and clarifying, bottling and sterilizing, to obtain dry type kiwi wine. The preparation method is simple to operate, and the dry type kiwi wine prepared by adopting the method is low in the amount of residual sugar, high in alcohol degree, rich in nutrition values, and excellent in wine taste.

Owner:陕西秦驰鲜辉实业有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com