Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

424 results about "Heat sealer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heat sealer is a machine used to seal products, packaging, and other thermoplastic materials using heat. This can be with uniform thermoplastic monolayers or with materials having several layers, at least one being thermoplastic. Heat sealing can join two similar materials together or can join dissimilar materials, one of which has a thermoplastic layer.

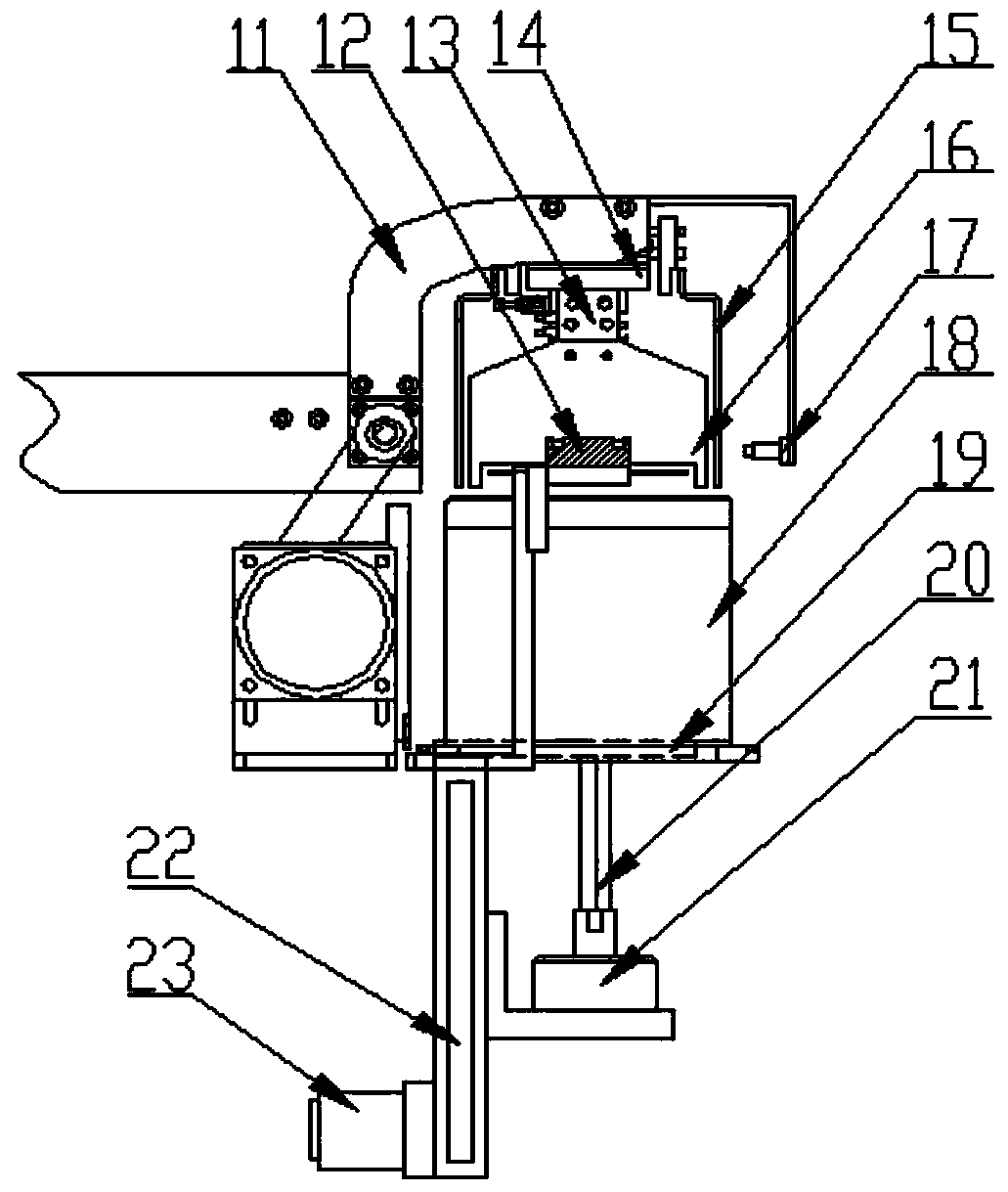

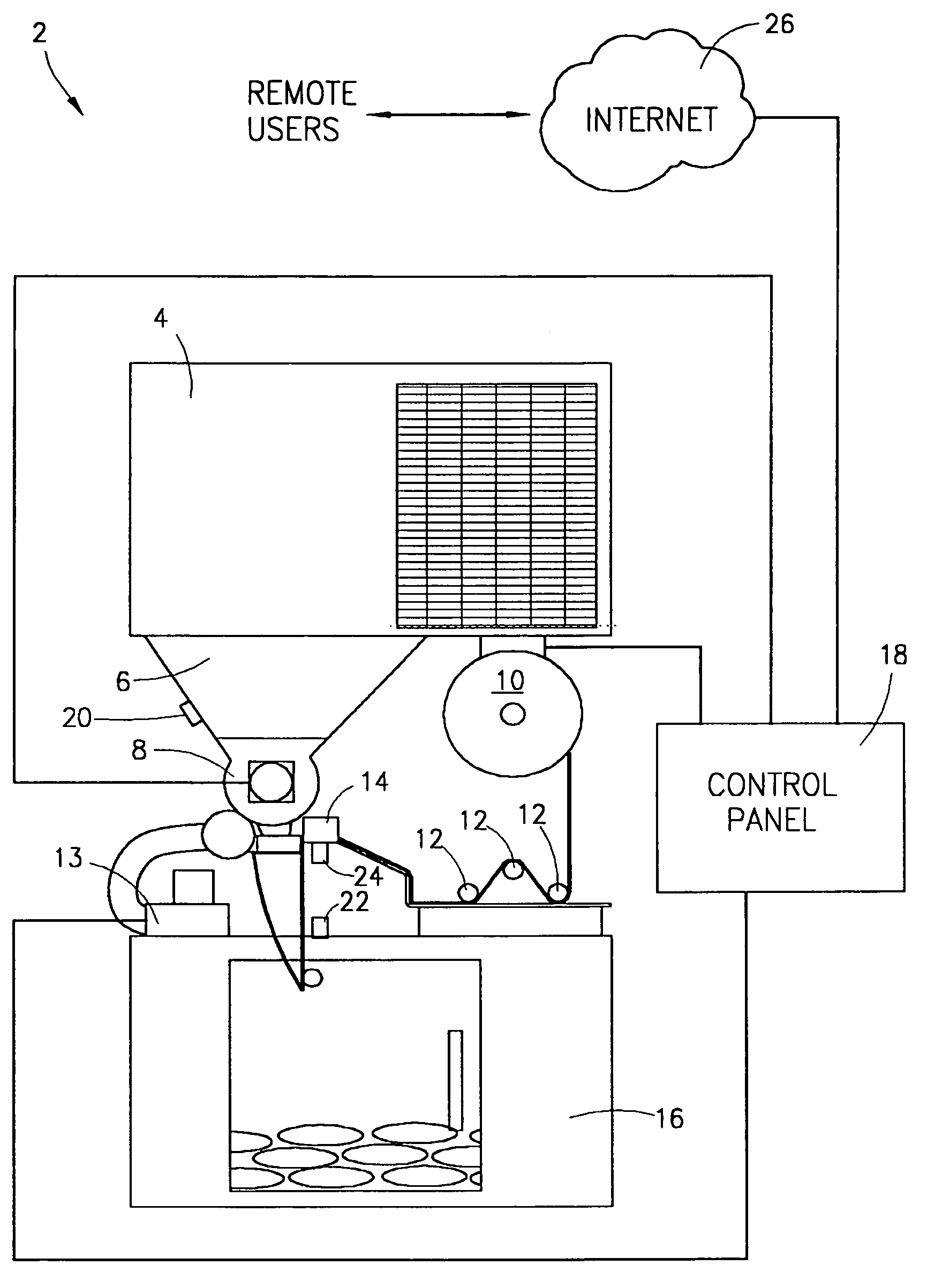

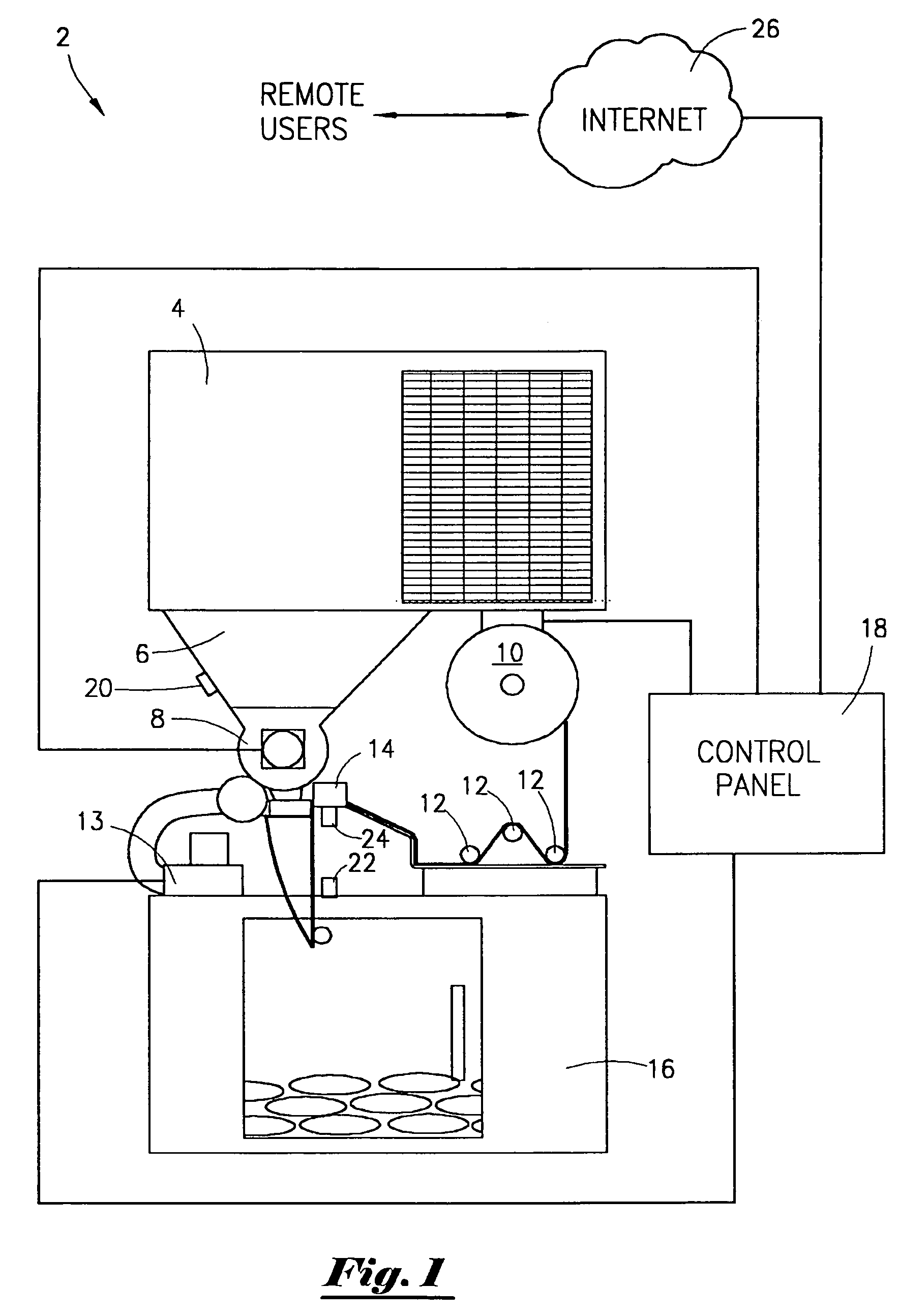

Ice bagging apparatus and method

InactiveUS7062892B2Increase ratingsPotential problemLighting and heating apparatusIce productionHeat sealerData transmission

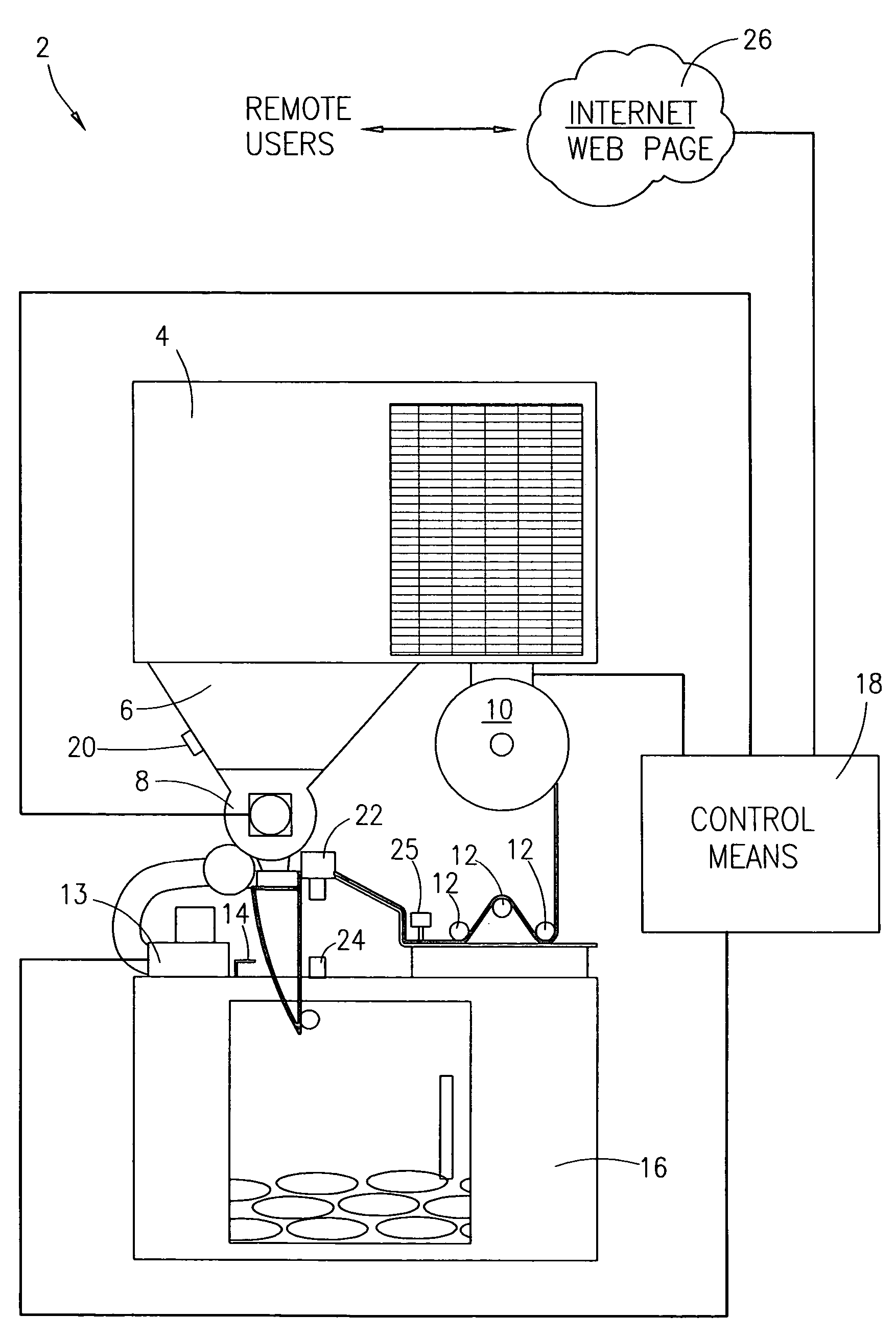

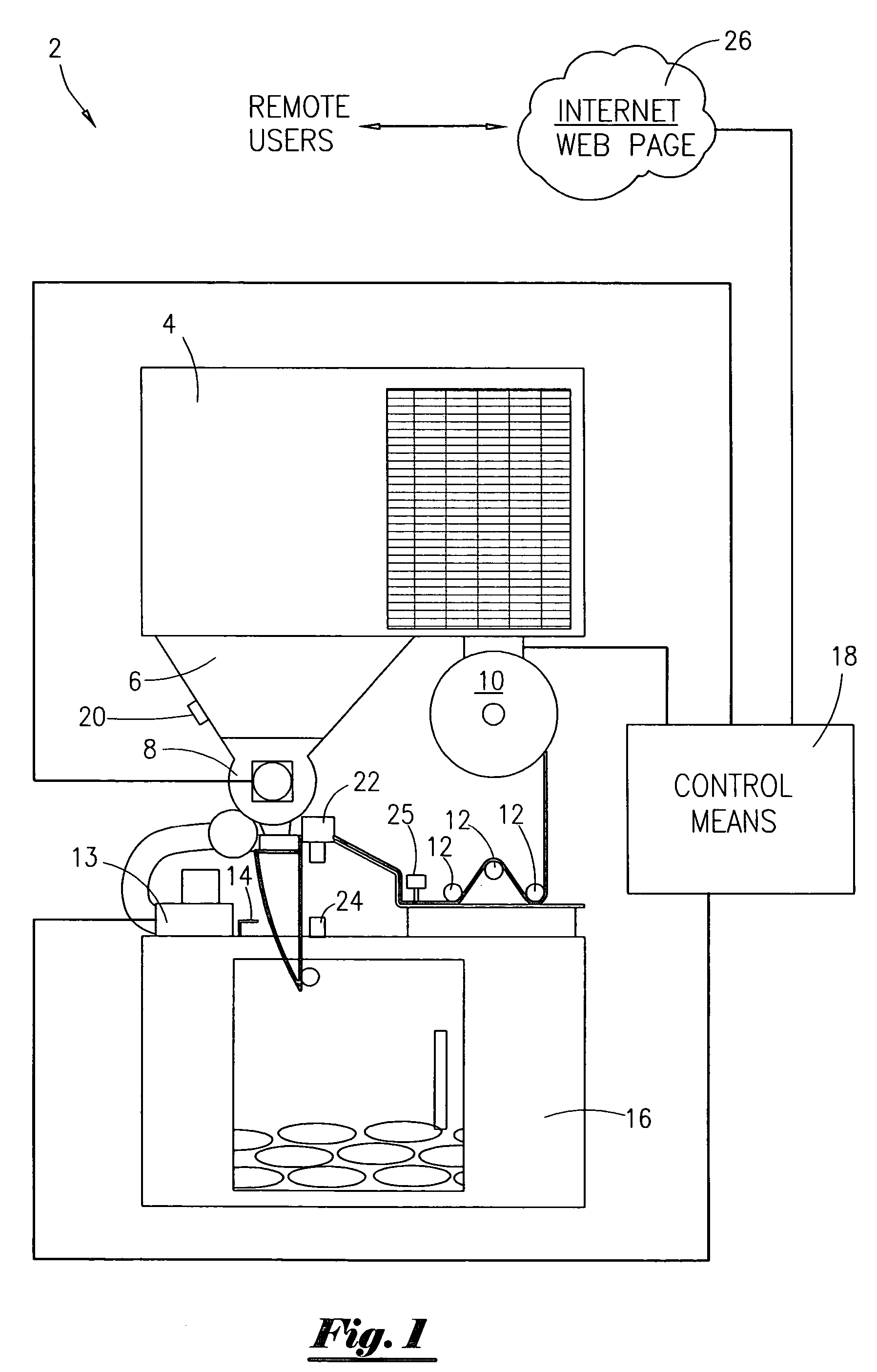

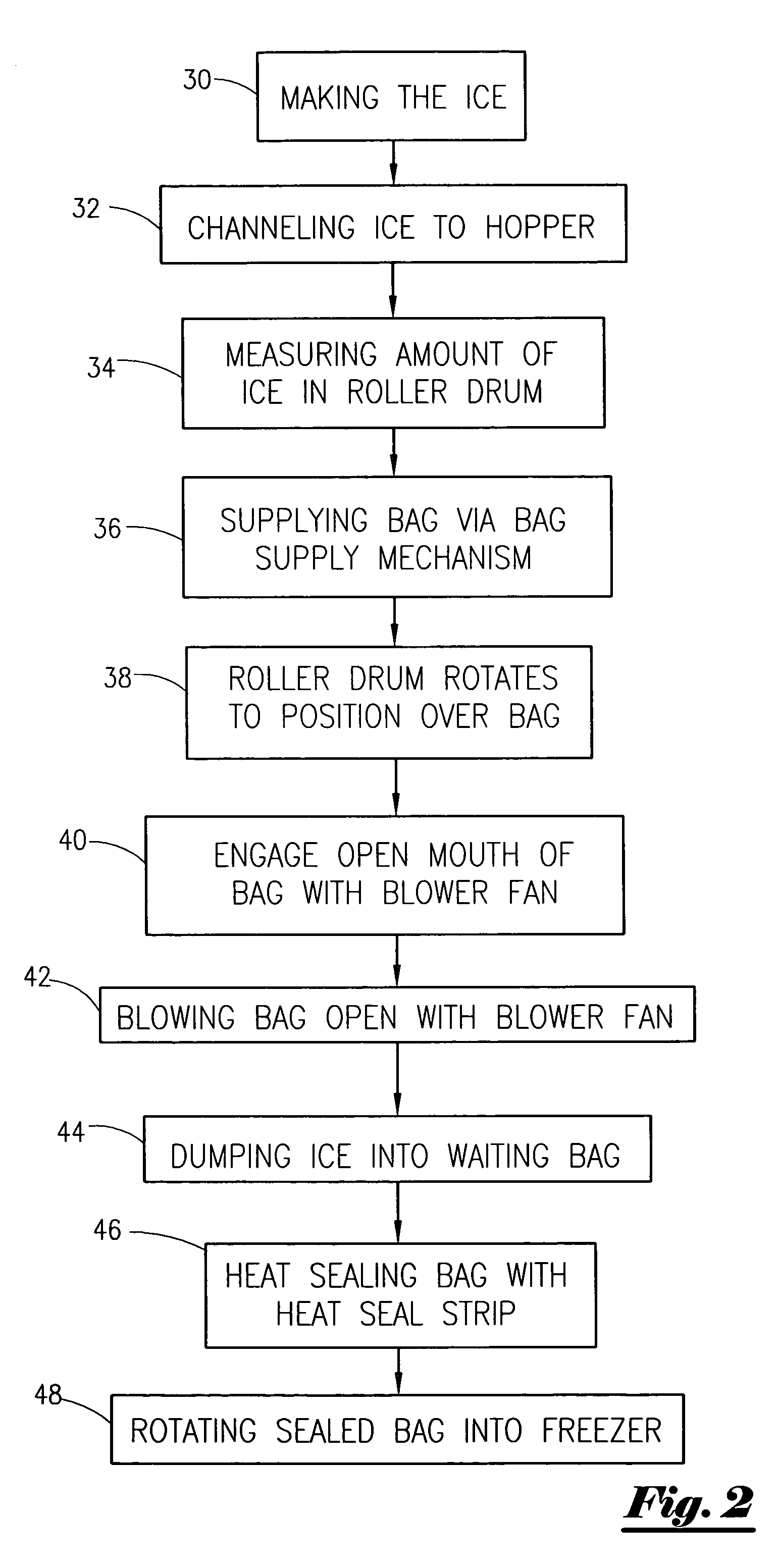

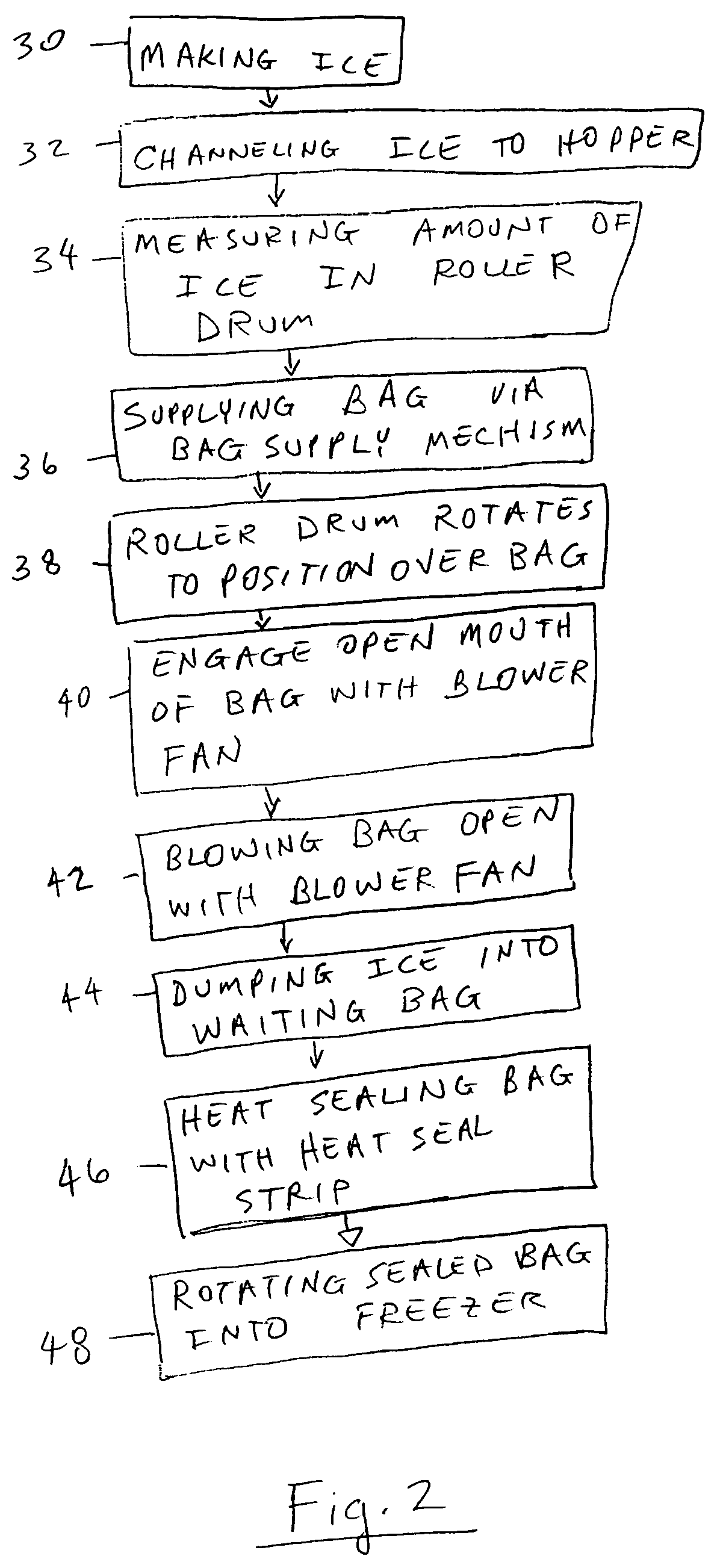

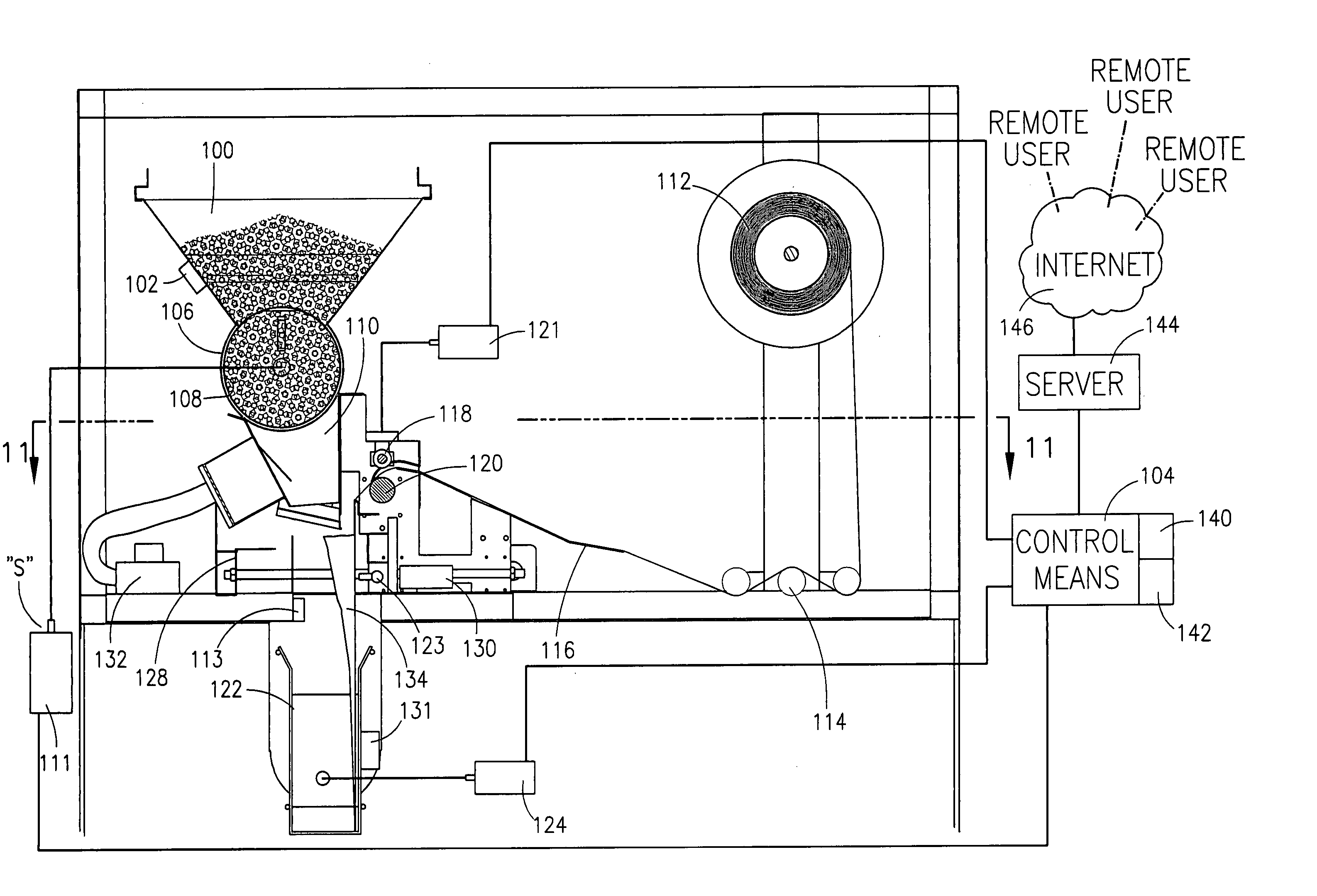

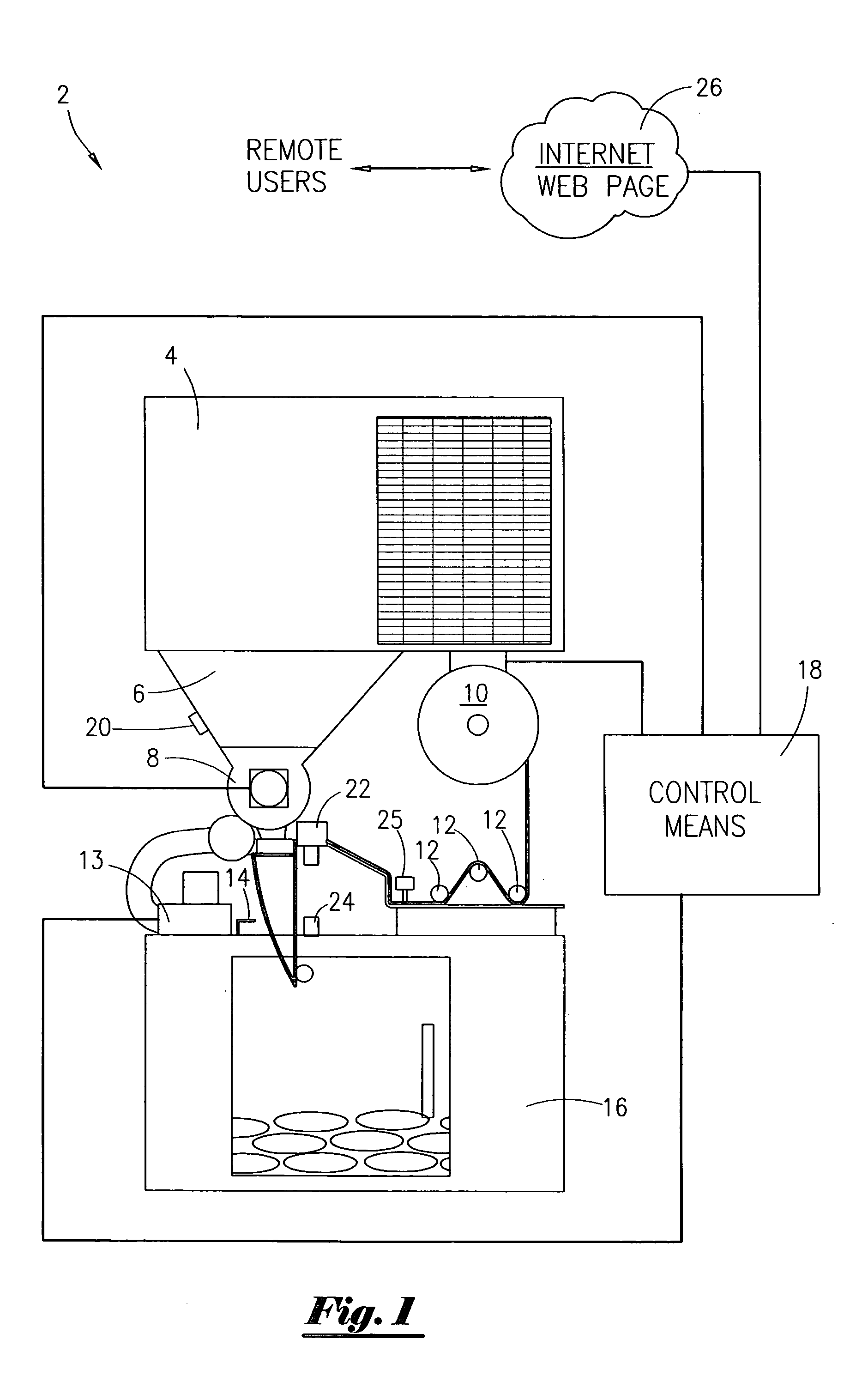

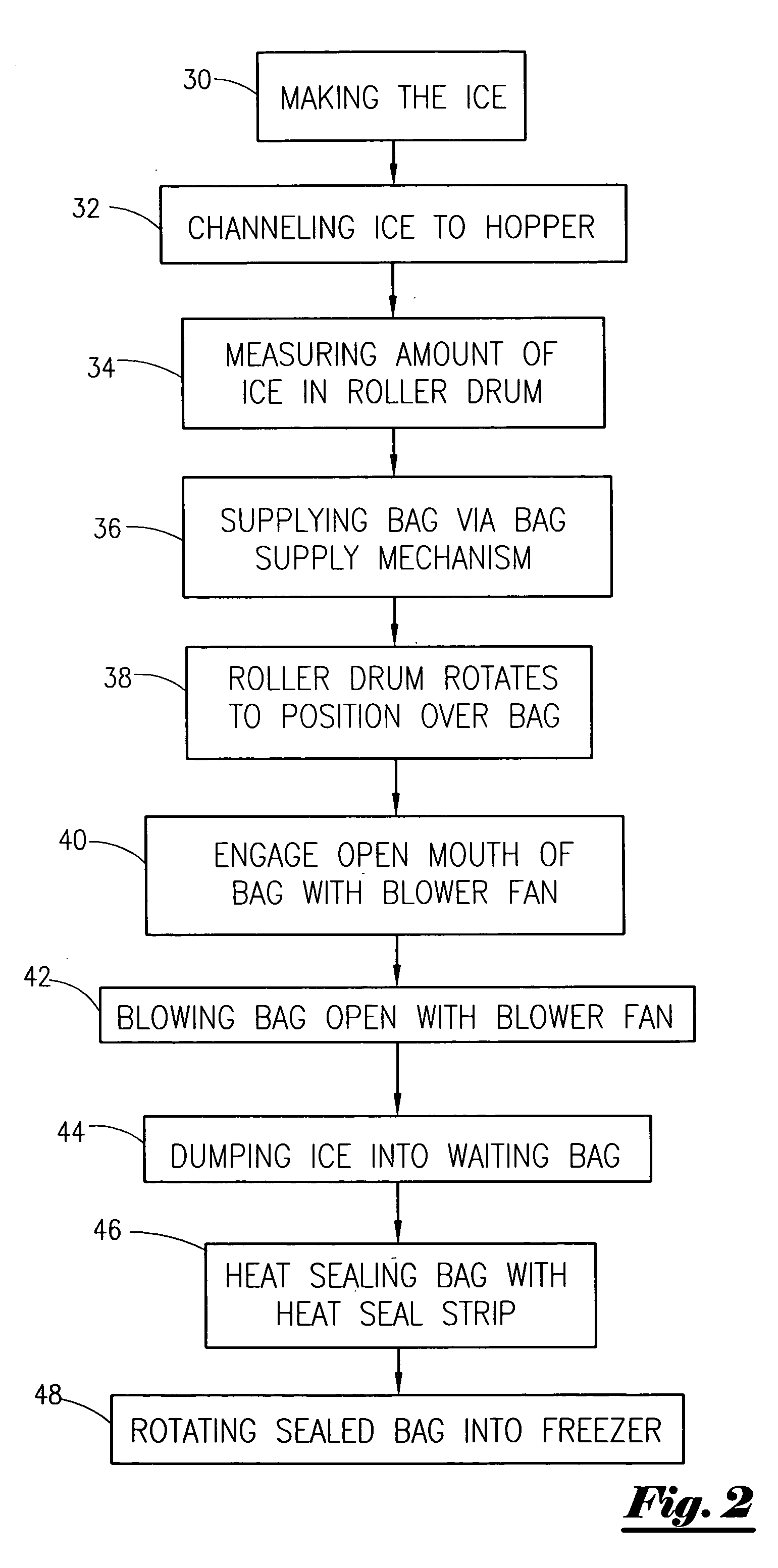

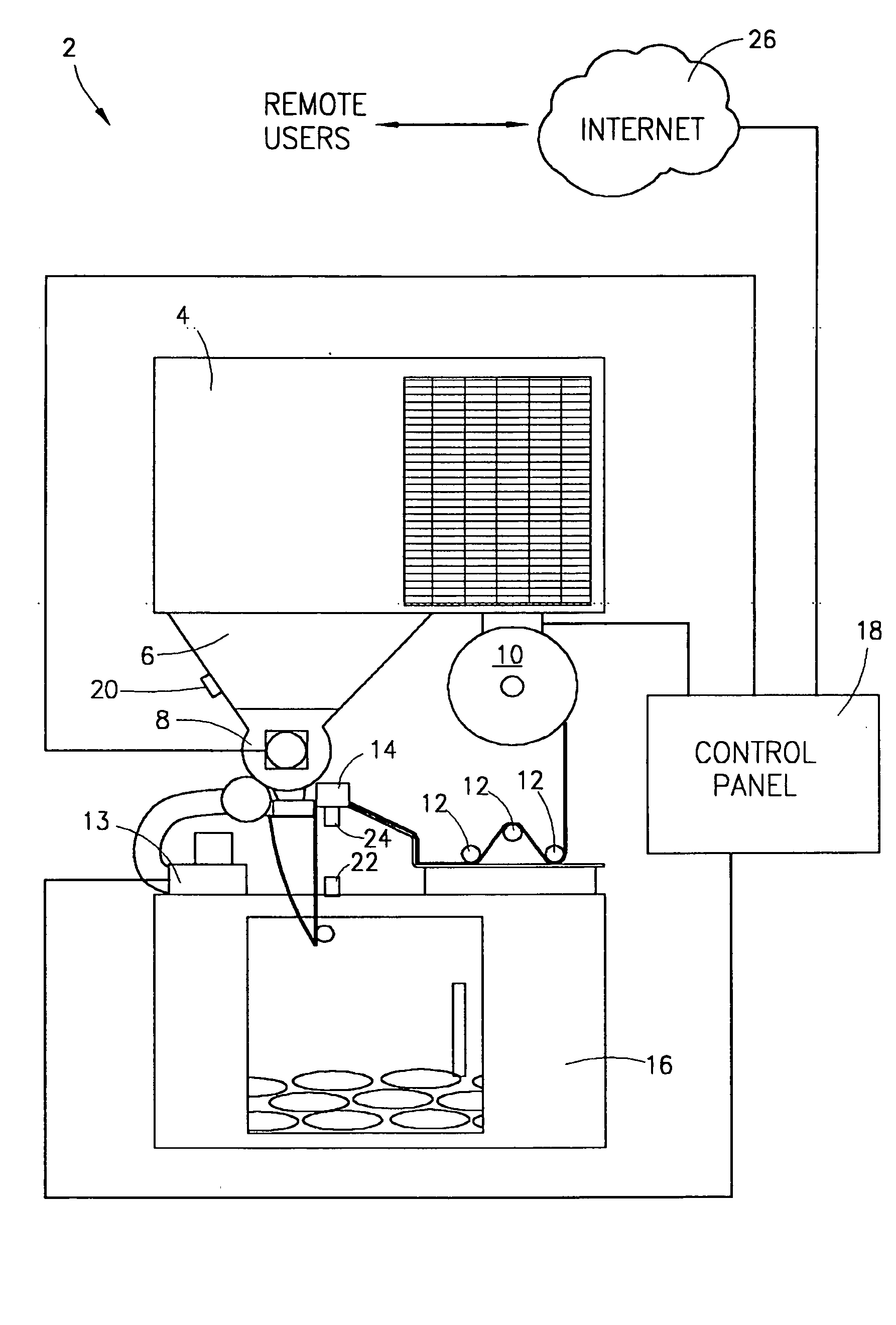

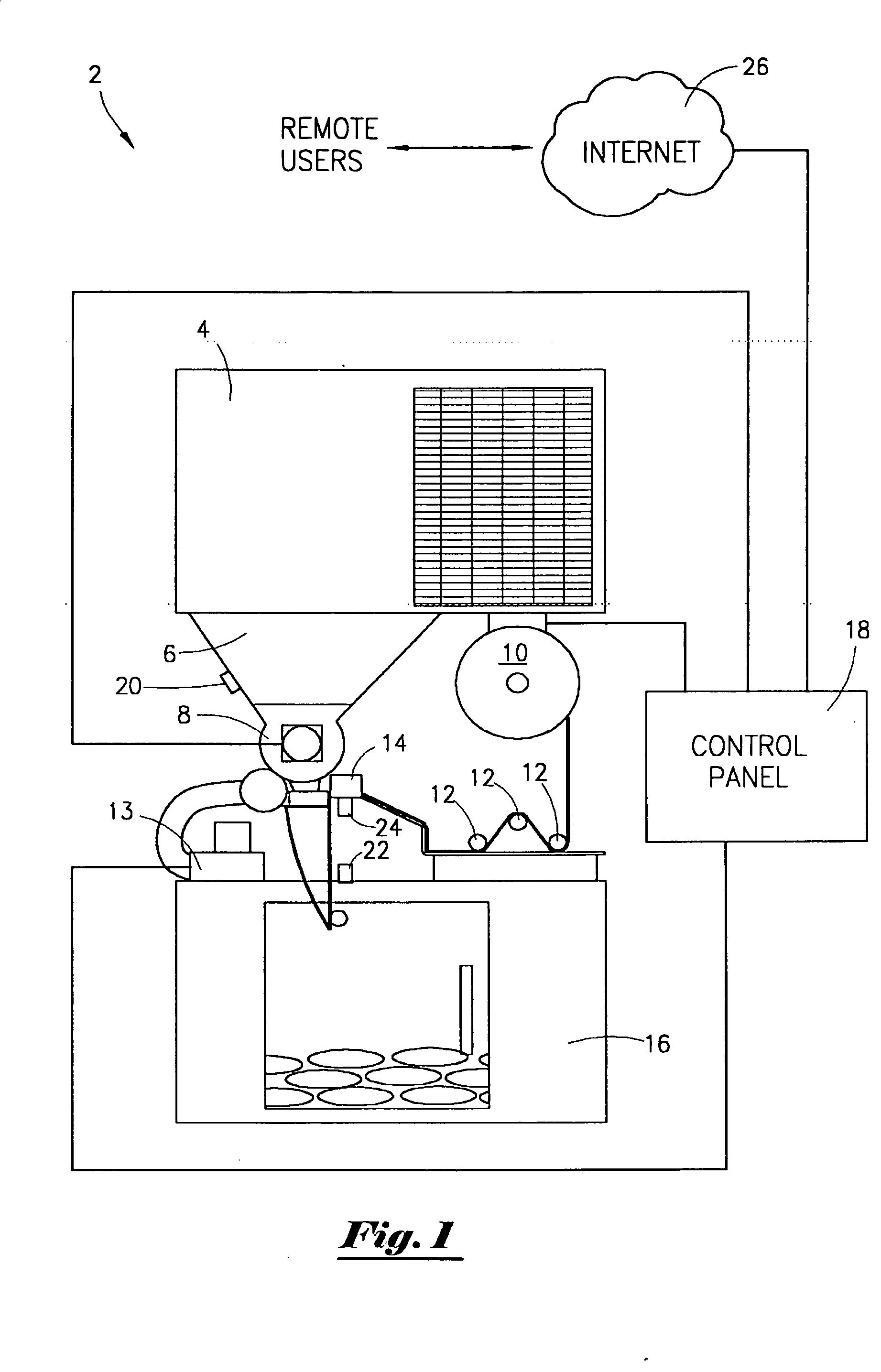

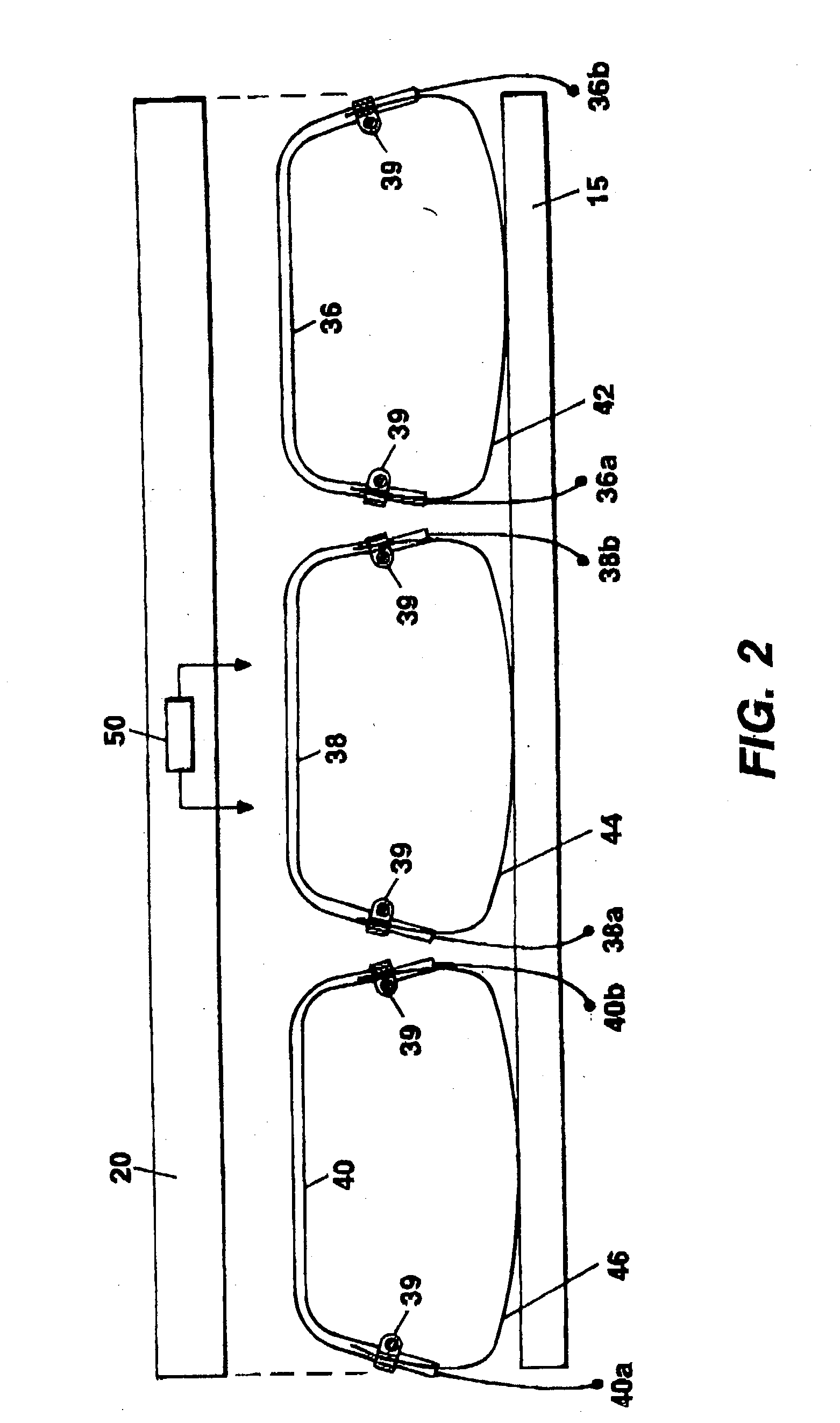

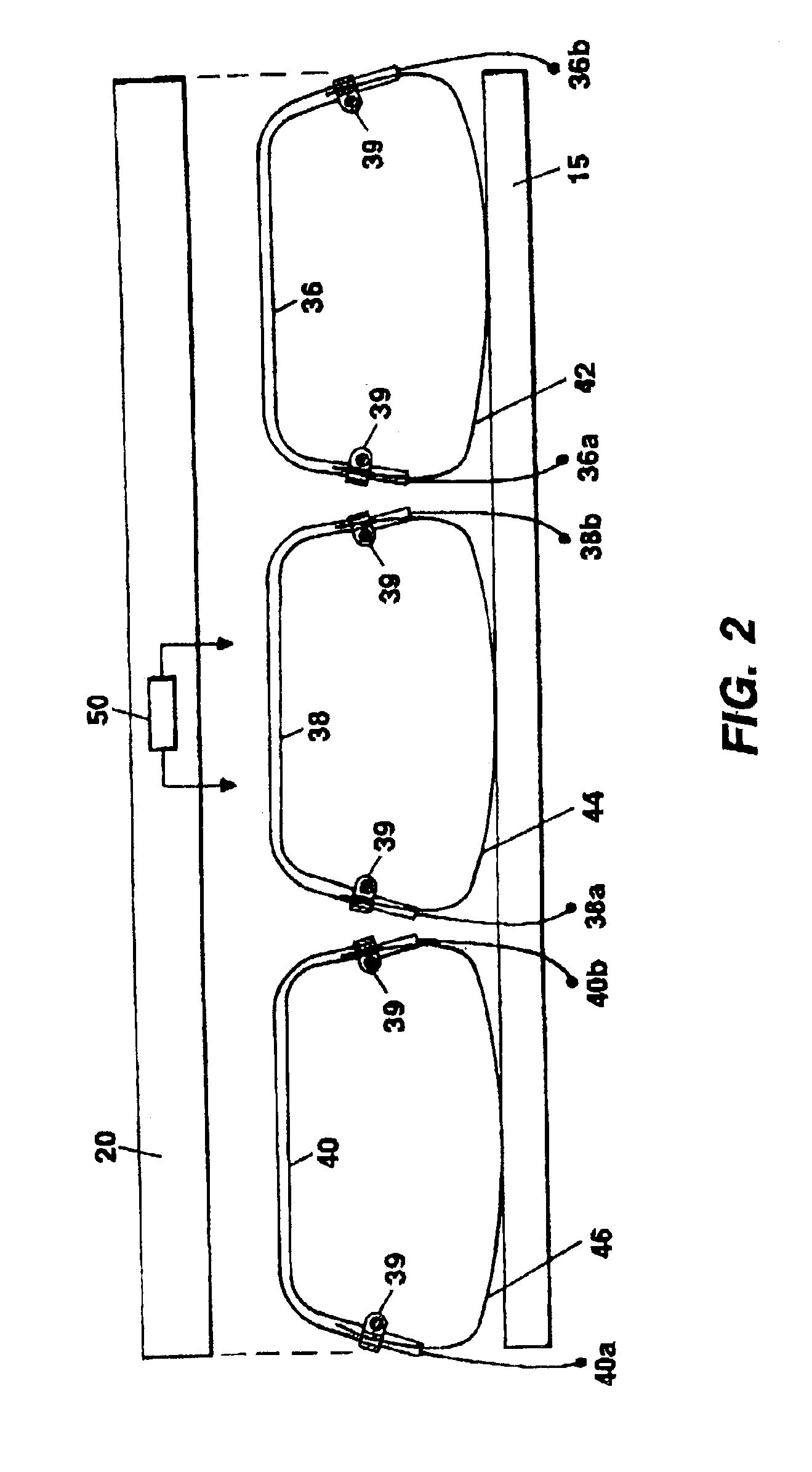

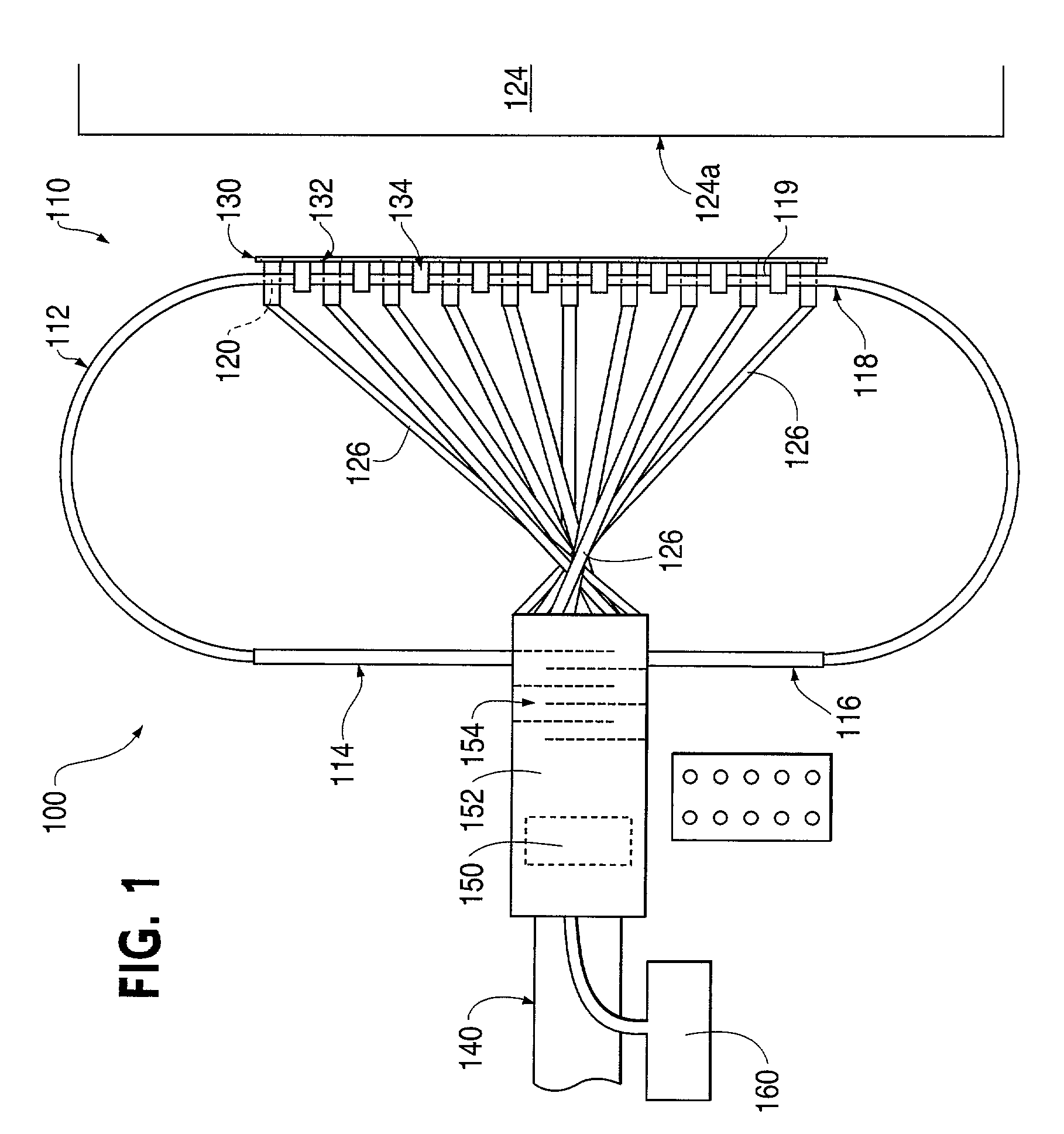

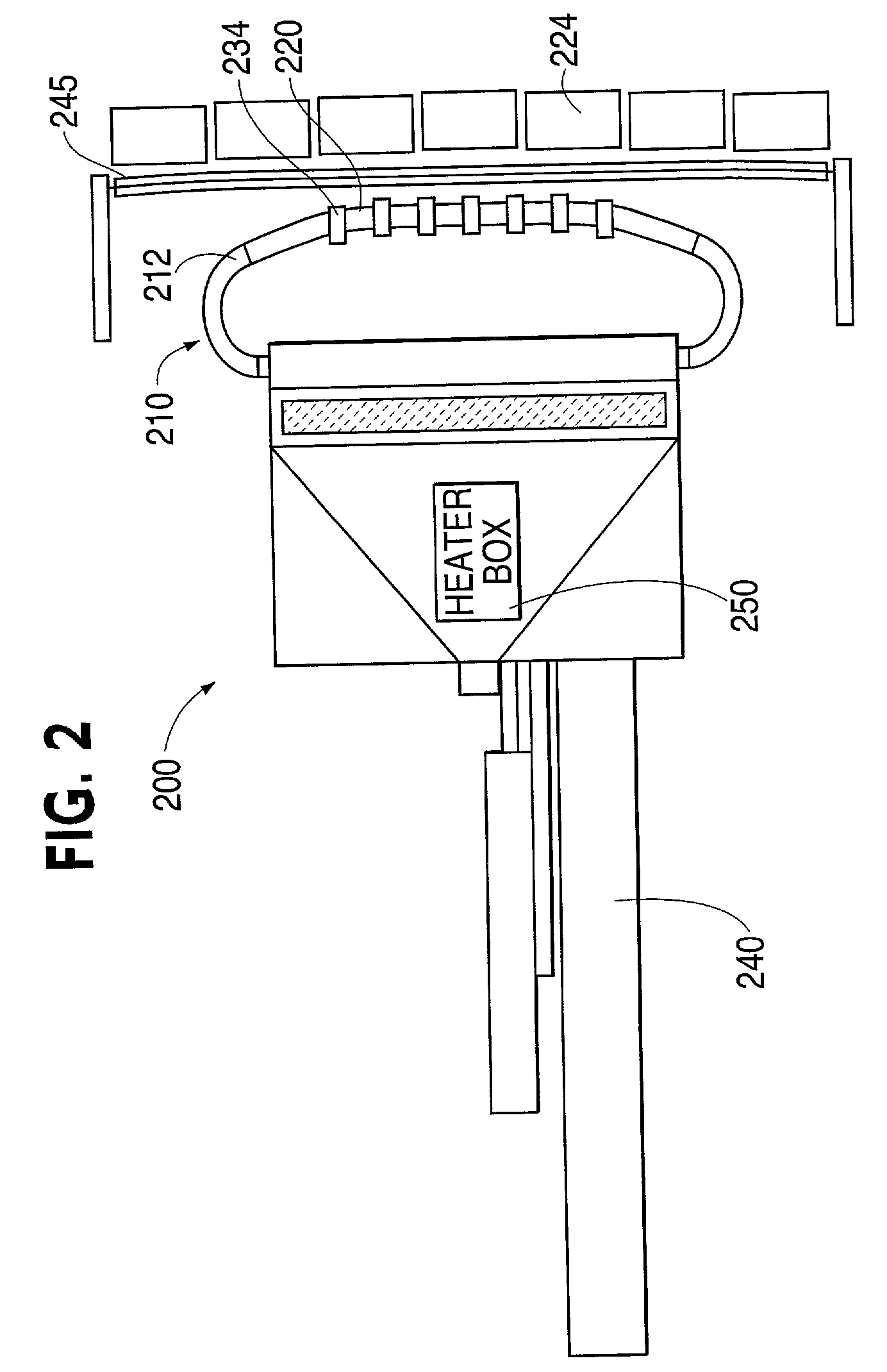

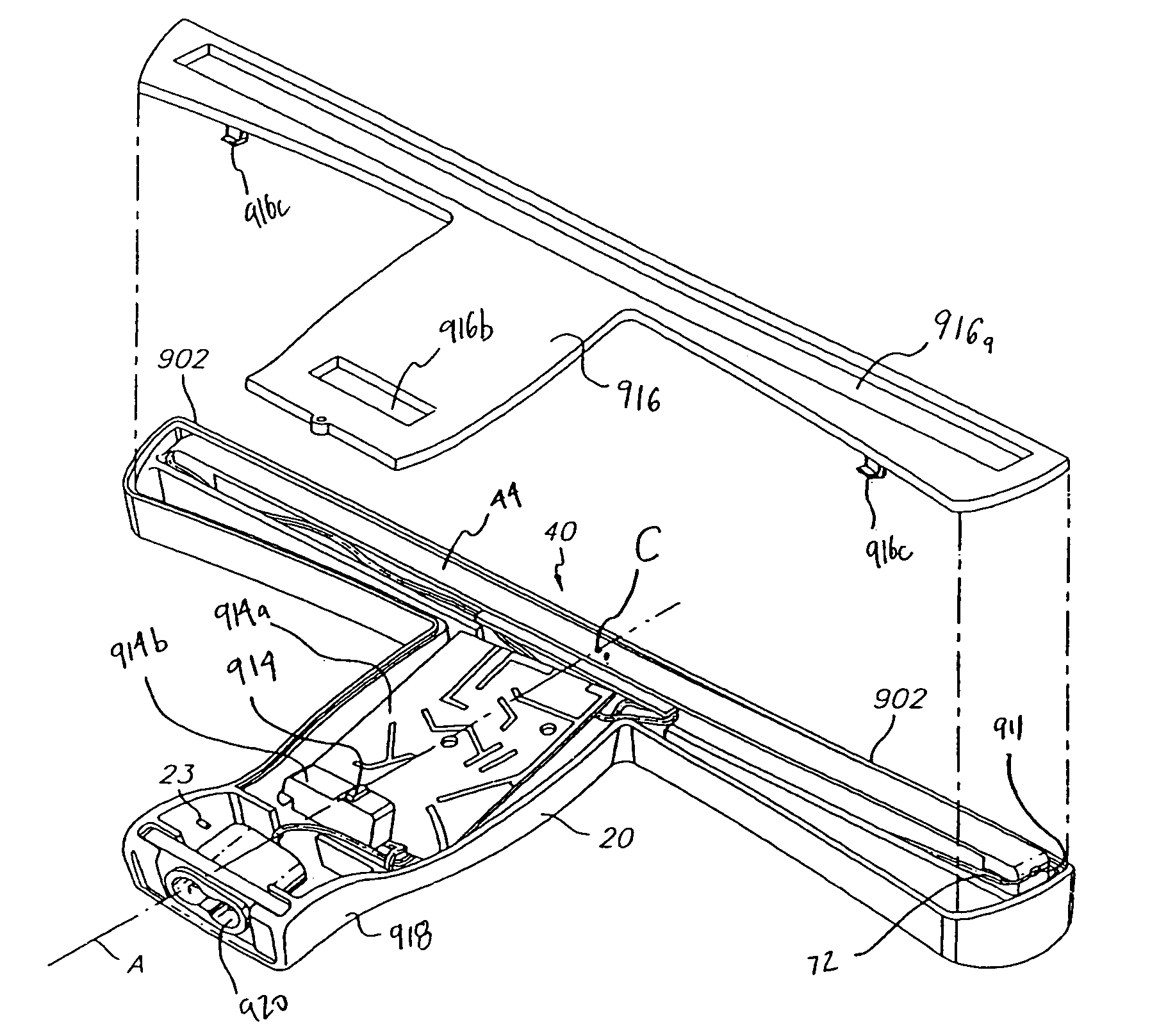

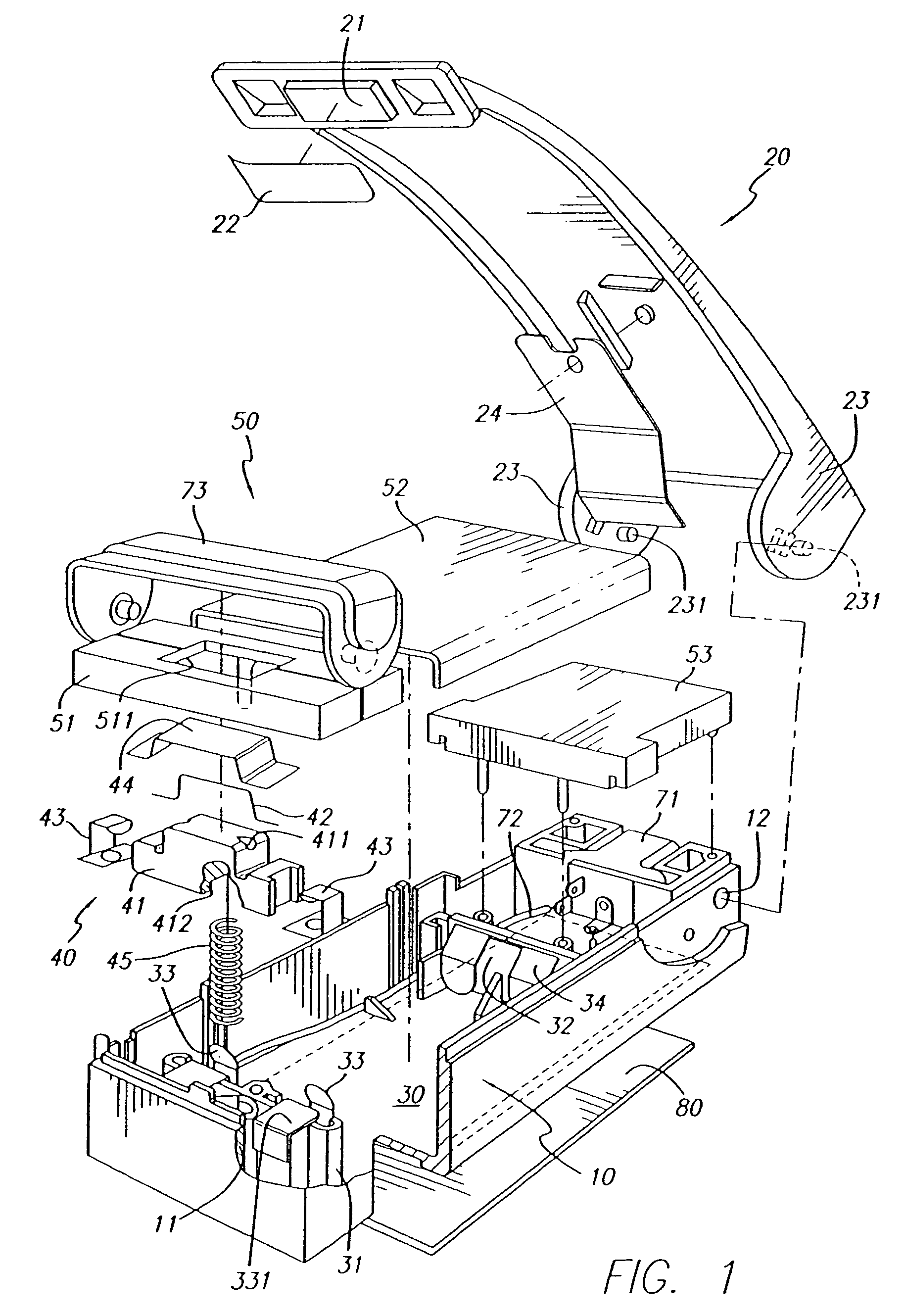

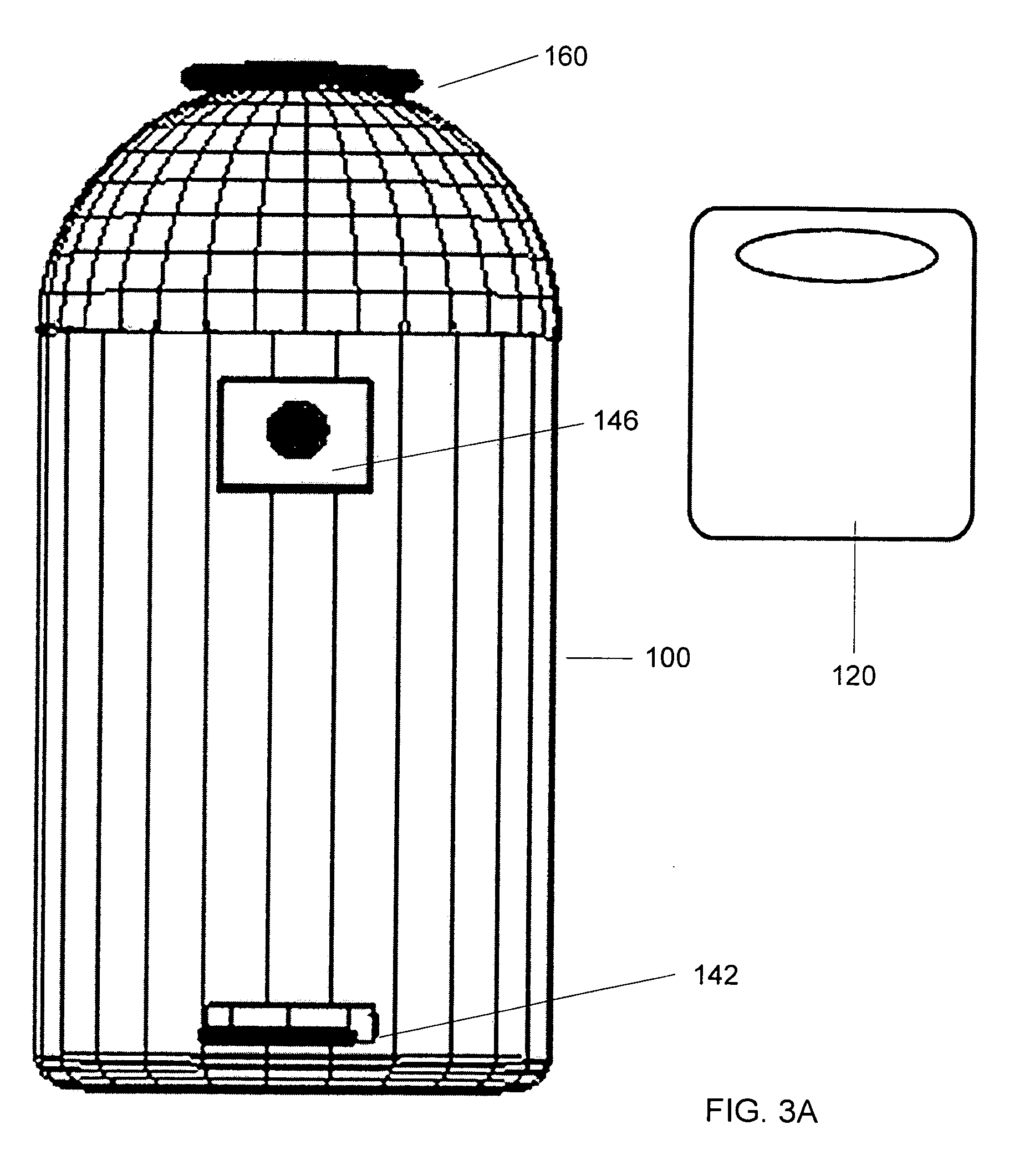

An apparatus and method for bagging ice. The apparatus comprises an ice maker for making ice and a hopper for receiving for receiving the ice from the ice maker. The apparatus further includes a roller drum, operatively associated with the hopper, for measuring the ice and delivering of the ice. The roller drum includes an inner rotating drum. A bag delivery mechanism for placing the ice in a bag is also included, with the bag delivery mechanism including a bag supply mechanism, a fan engaged to open the mouth of the bag to receive the product, and a heat sealer that seals the open mouth of the bag once the bag is filled with the ice. A control device is included that manages and monitors the roller drum and bag delivery mechanism and allows transmission of the collected data to the Internet.

Owner:PRATT ELK GROVE LLC +3

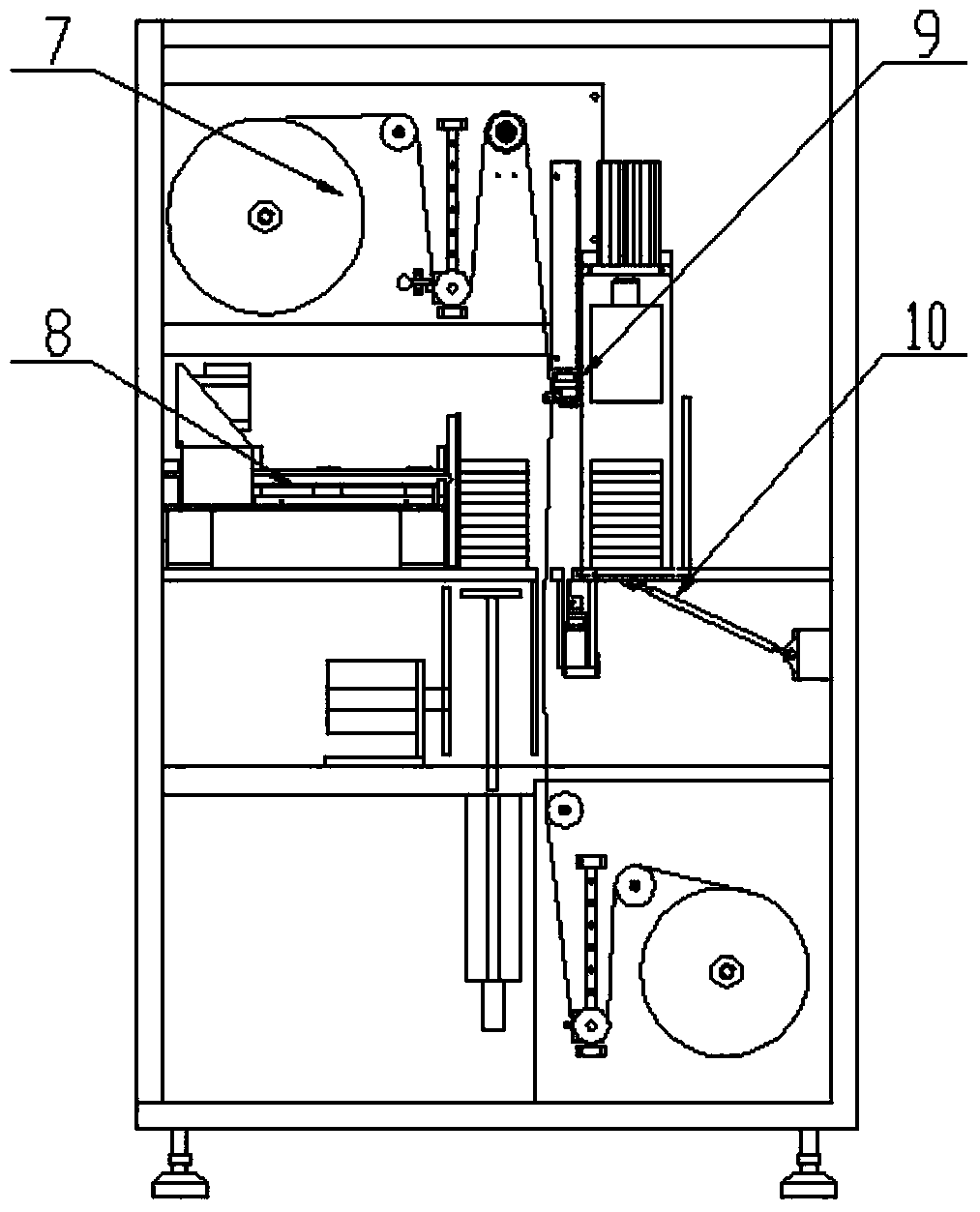

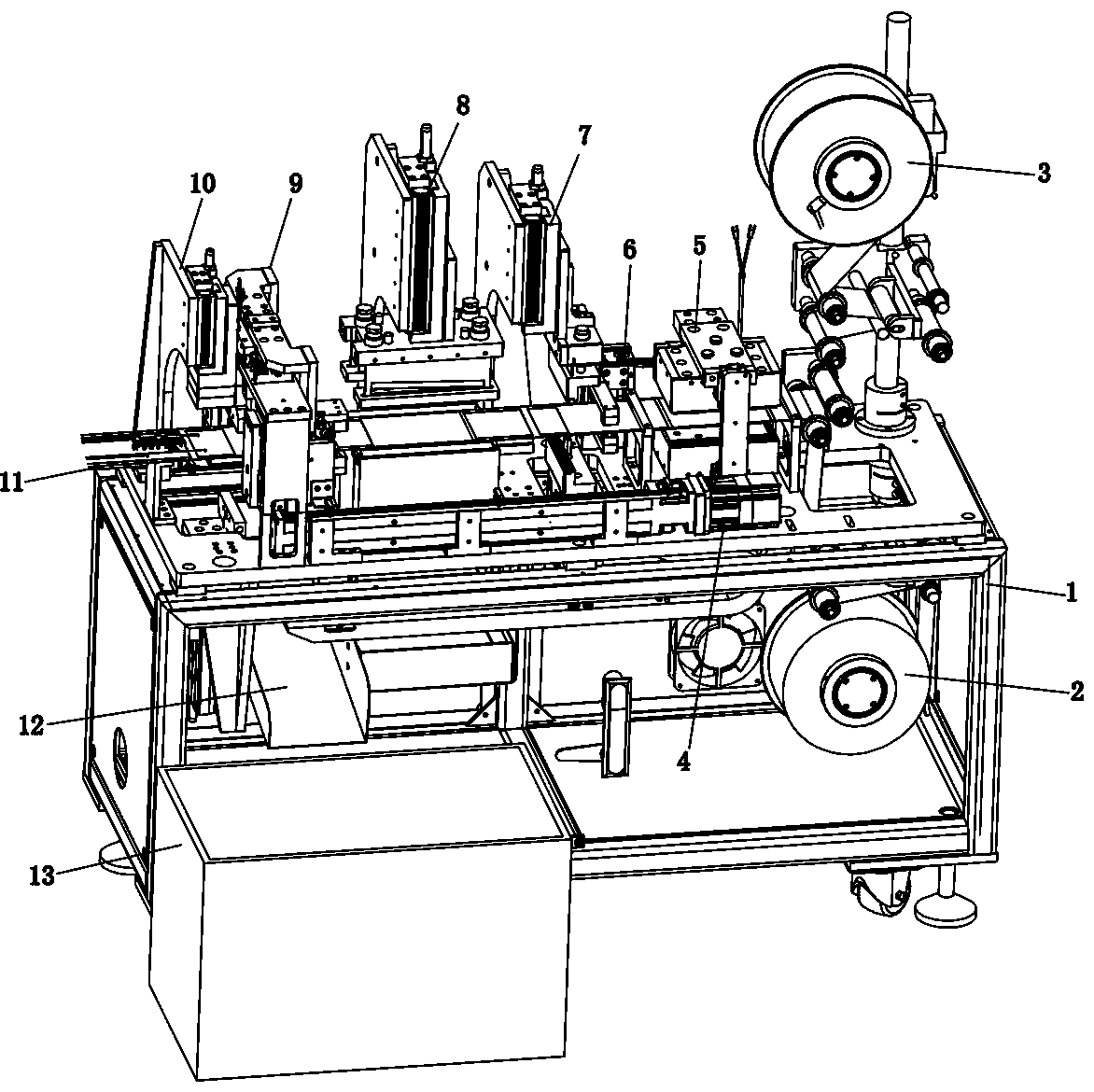

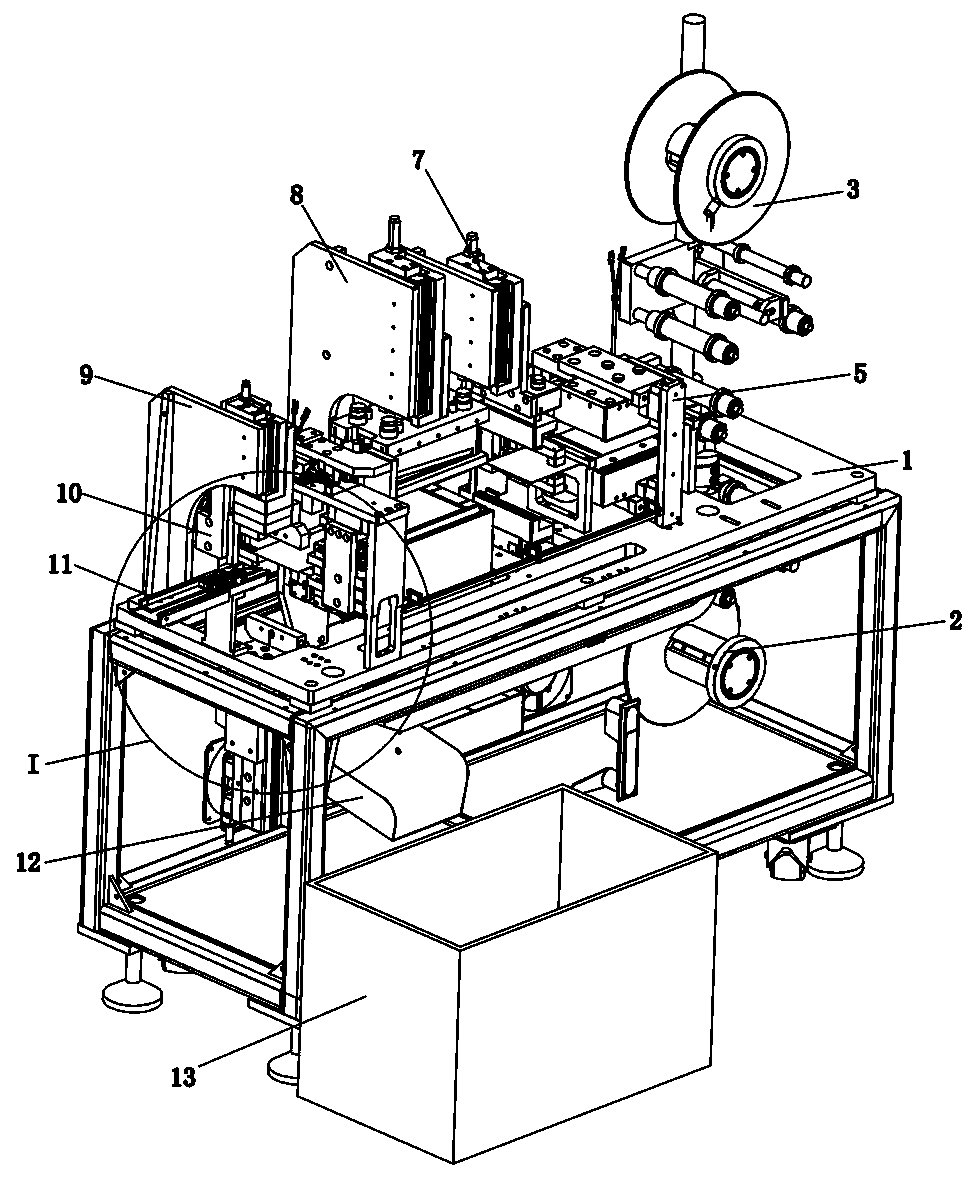

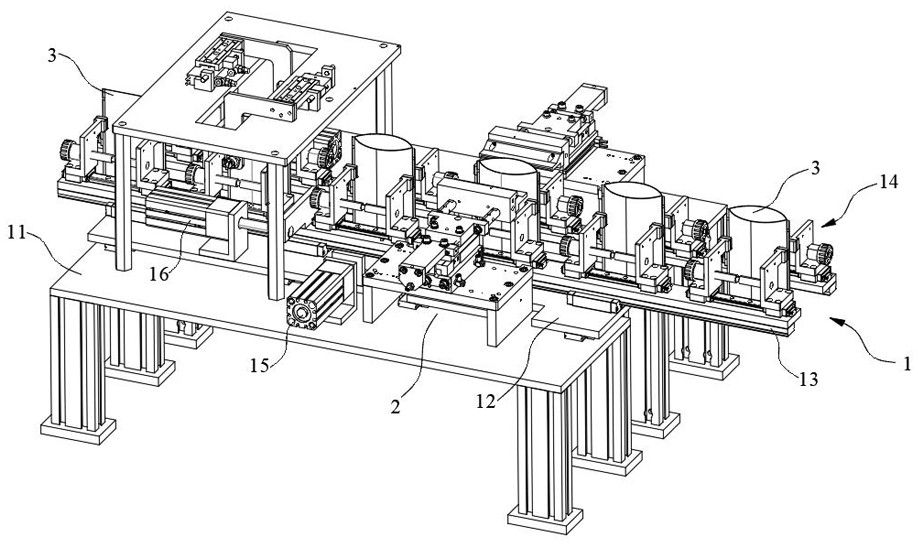

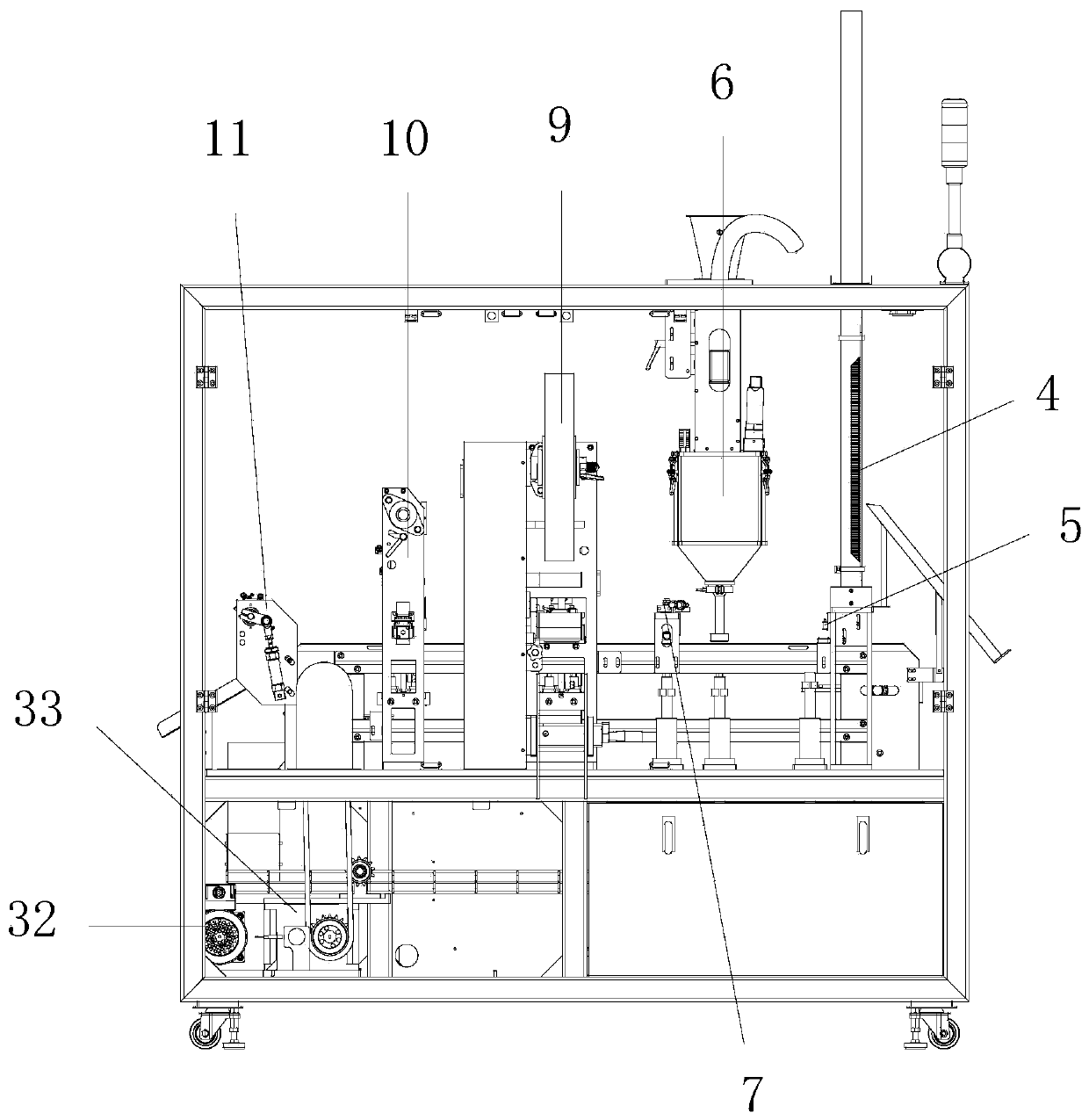

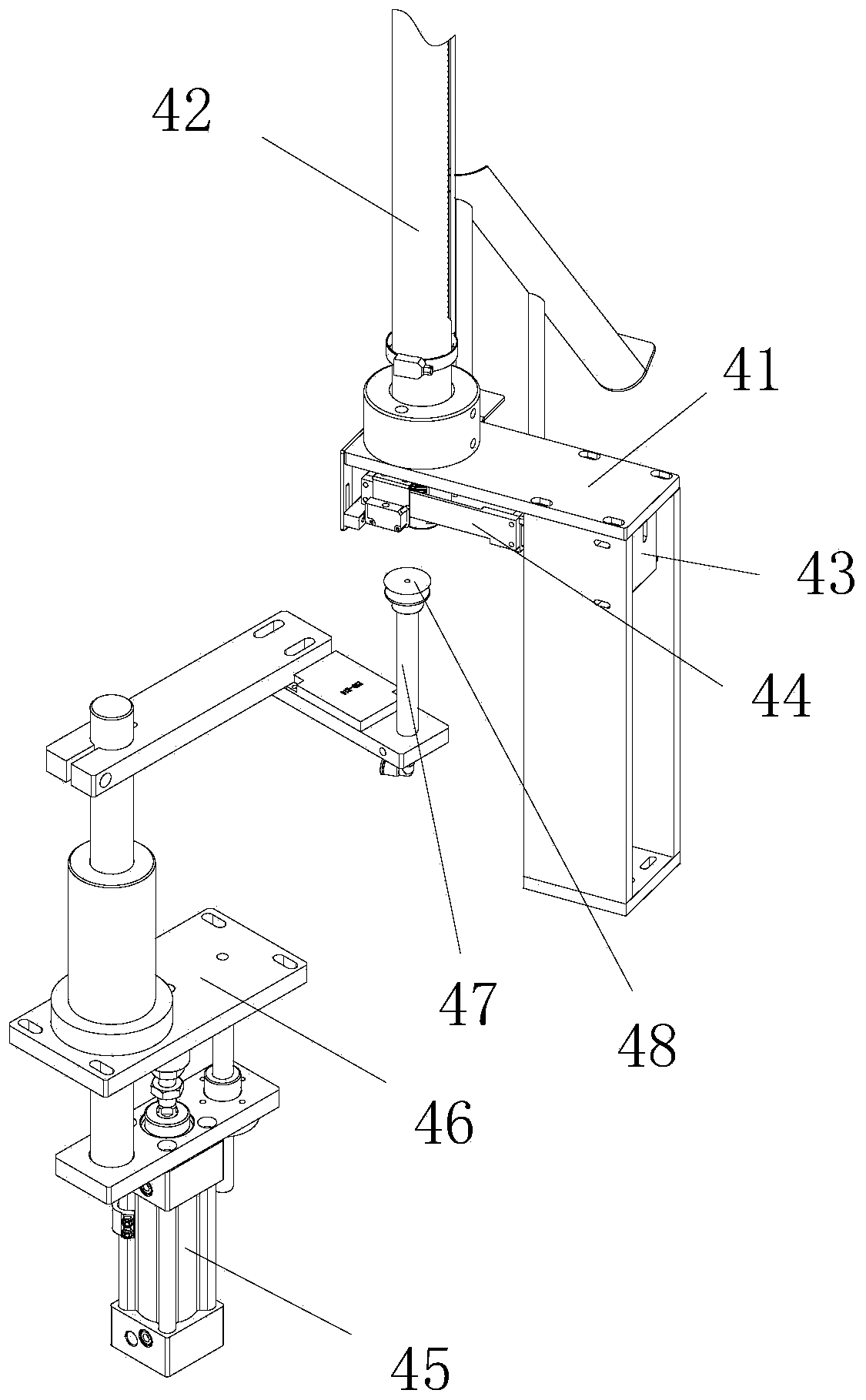

Automatic paper currency stacking and binding integrated machine

ActiveCN103625678AGuaranteed CompatibilityCompact structurePaper article packagingBundling machine detailsHeat sealerControl system

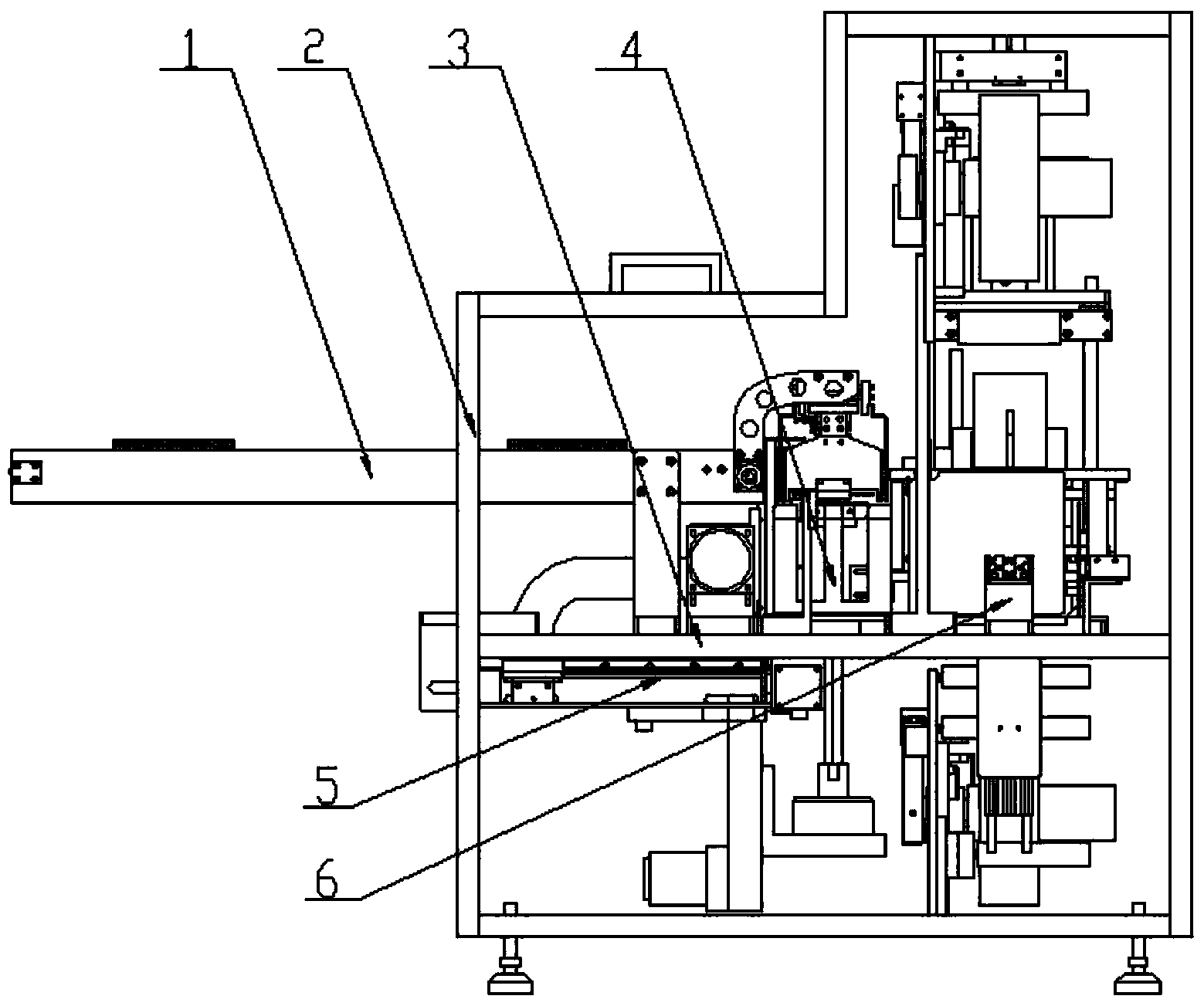

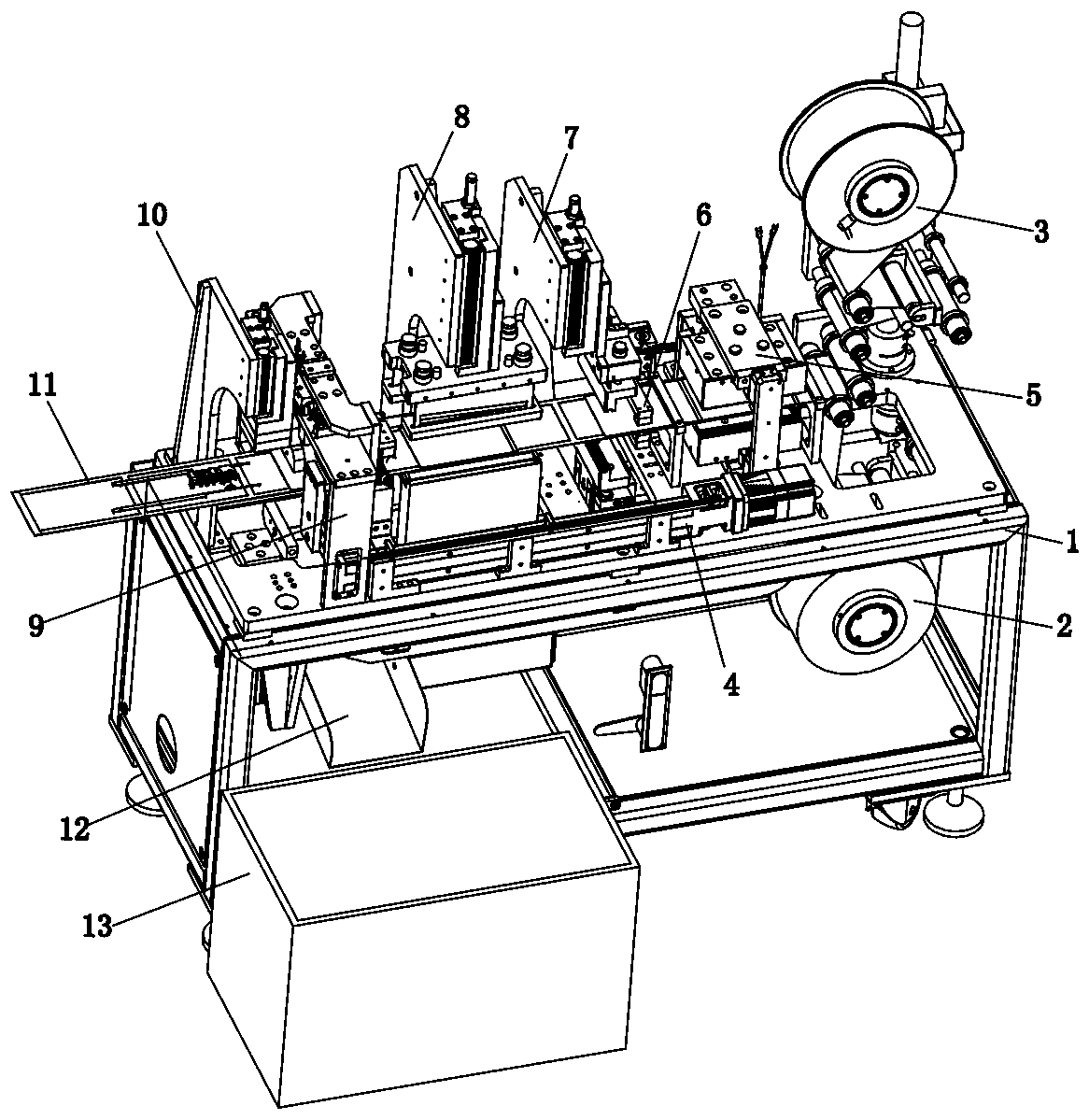

The invention discloses an automatic paper currency stacking and binding integrated machine for packing paper currency with different face values in the financial system. The machine comprises a conveying mechanism, a frame, a supporting base plate, an automatic stacking mechanism, a primary pushing mechanism, an arranging and jacking mechanism, a film packing mechanism, a secondary pushing mechanism, a heat-seal mechanism, a paper currency bundle turnover mechanism and a PLC (programmable logic control) control system, wherein paper currency is sorted and bound, and is fed into the conveying mechanism; the paper currency is fed into the automatic stacking mechanism by the conveying mechanism, and is subjected to pre-arrangement, counting, 5-bundle direction change and stacking; 10 bundles of paper currency is pushed into the arranging and jacking mechanism by the primary pushing mechanism after the paper currency bundles are stacked; the paper currency bundles are jacked to the secondary pushing mechanism after being arranged; the flat arranged paper currency bundles are pushed into the heat-seal mechanism by the secondary pushing mechanism, and are packaged; the paper currency bundles are moved out by the paper currency bundle turnover mechanism after the paper currency bundles are packaged. The automatic paper currency stacking and binding integrated machine has the advantages that paper currency can be automatically treated when the machine is used jointly with a sorting machine and a sealant shrinker, and the machine is compact in structure, stable and reliable, easy to operate and convenient to maintain.

Owner:合肥哈工龙延智能装备有限公司

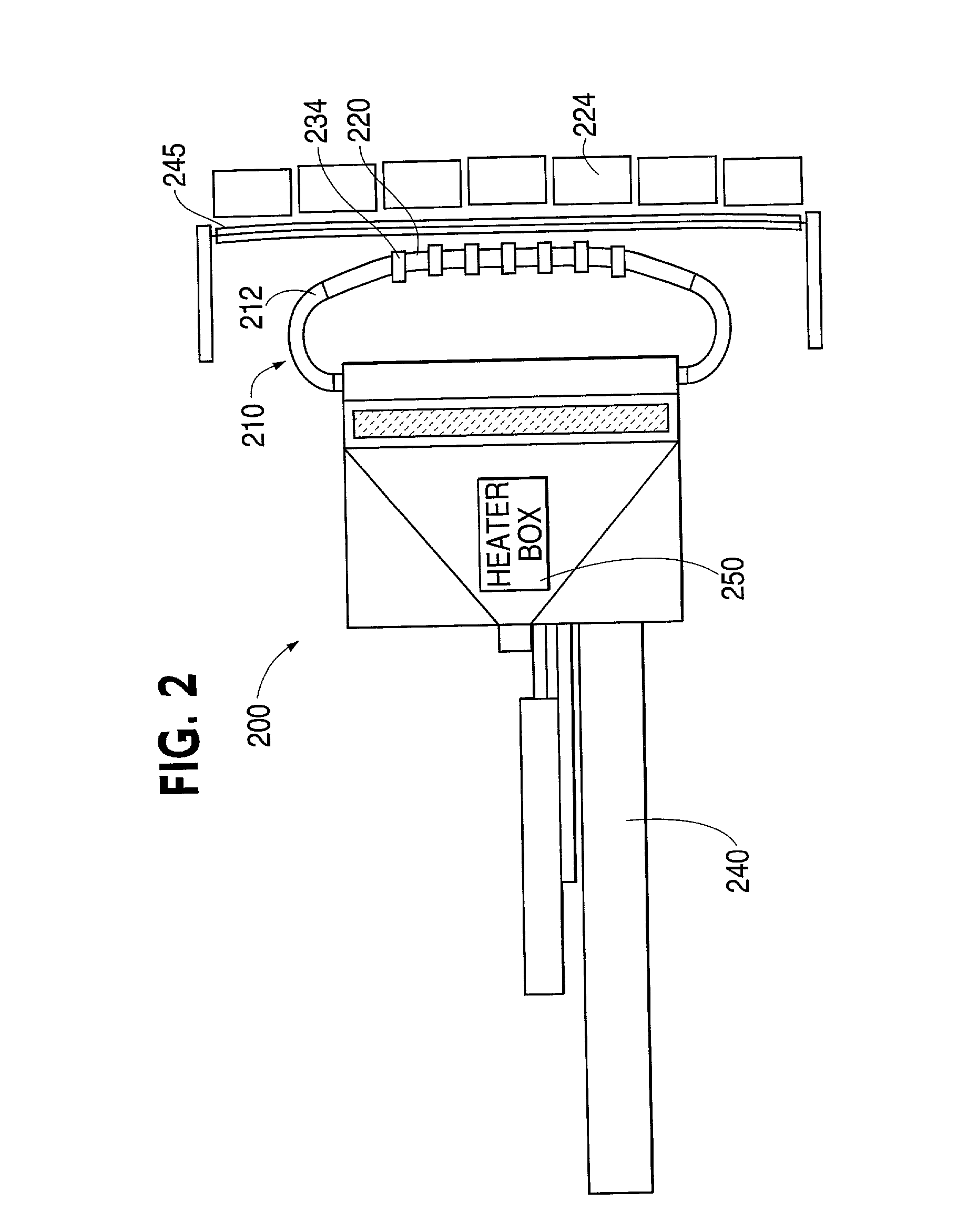

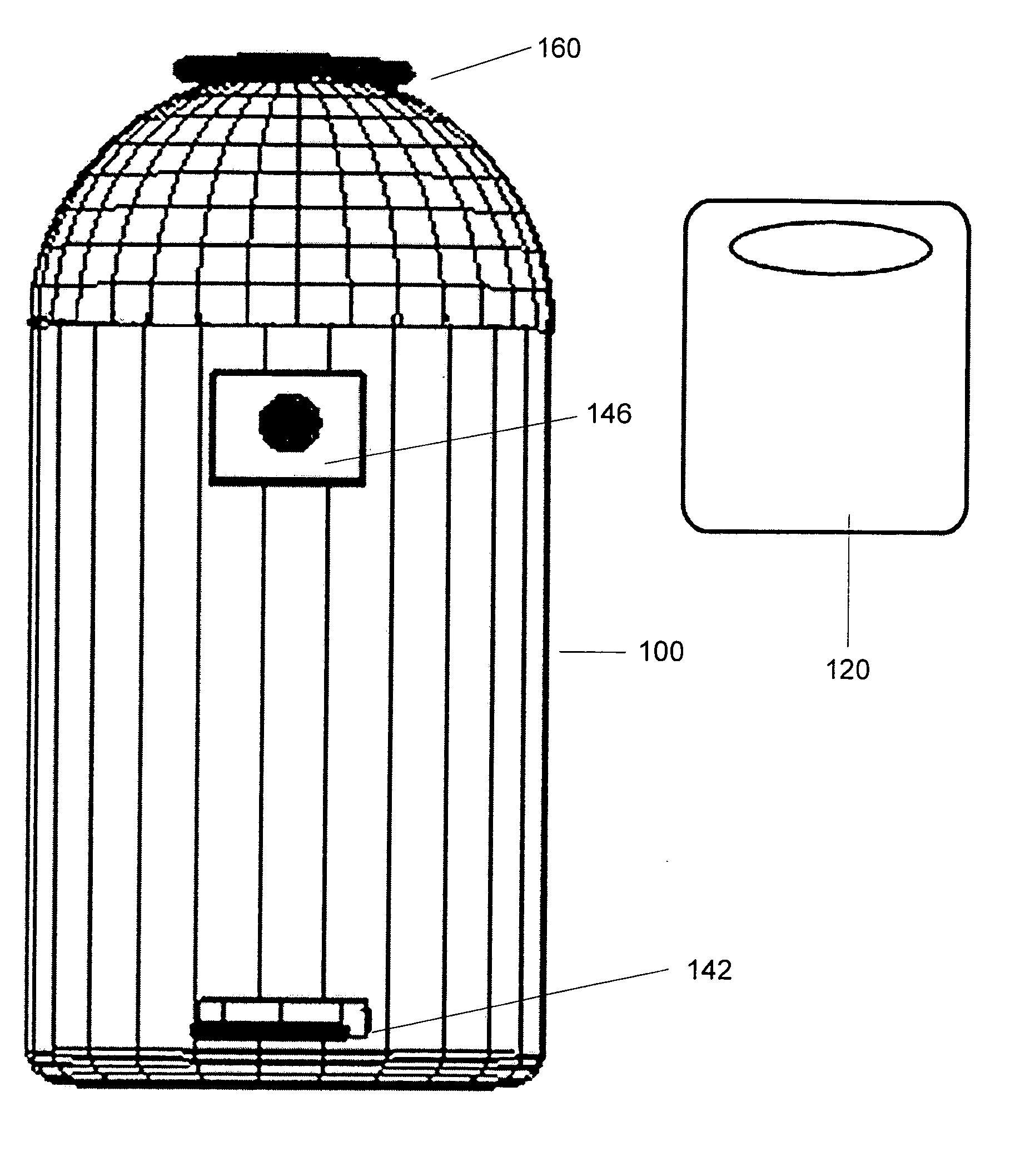

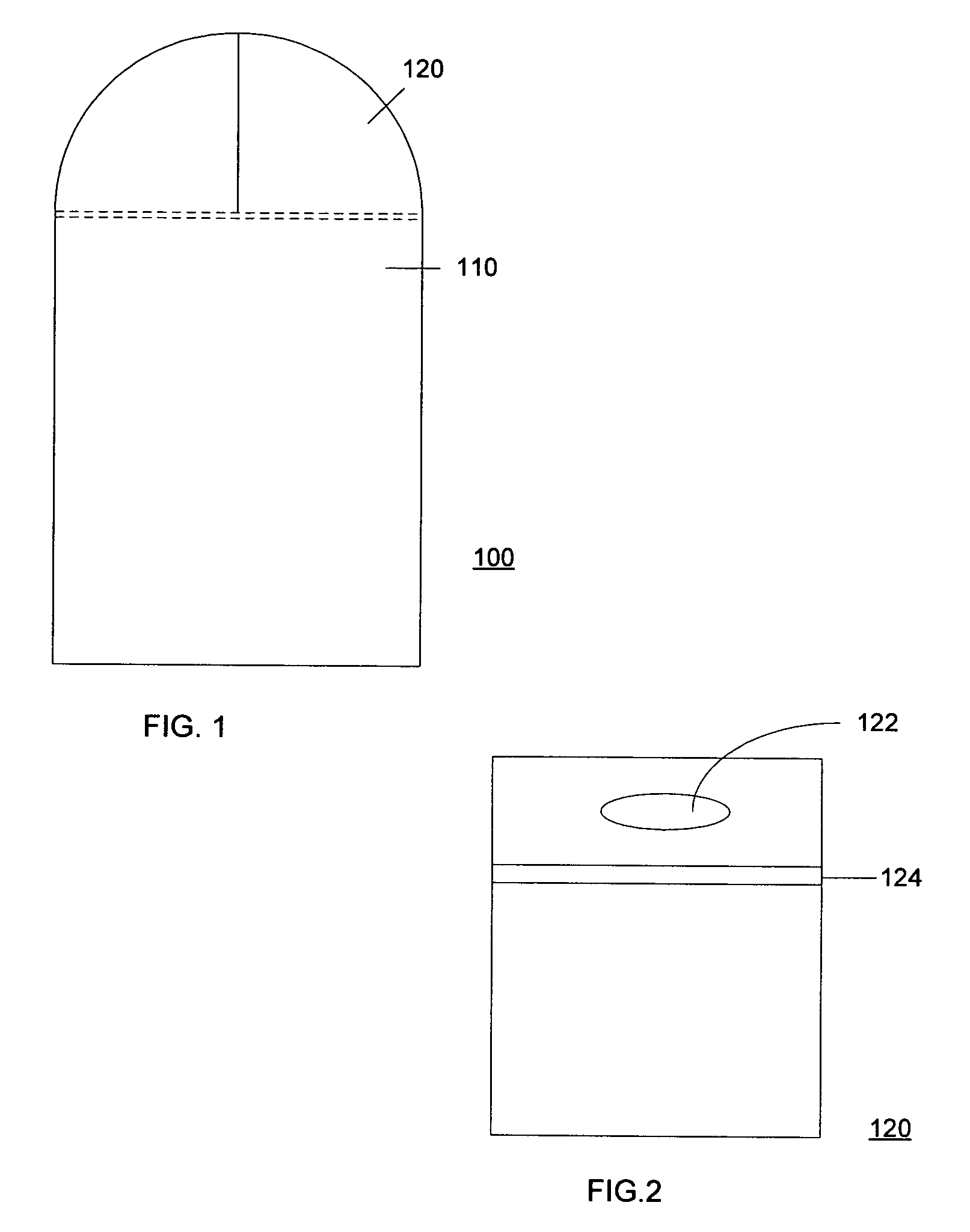

Ice bagging apparatus and method

InactiveUS7207156B2Increase ratingsPotential problemLighting and heating apparatusIce productionHeat sealerEngineering

An apparatus and method for bagging ice. The apparatus comprises an ice maker for making ice and a hopper for receiving for receiving the ice from the ice maker. The apparatus further includes a roller drum, operatively associated with the hopper, for measuring the ice and delivering of the ice. A bag delivery mechanism for placing the ice in a bag is also included, with the bag delivery mechanism including a bag supply mechanism, a blower fan engaged to open the mouth of the bag to receive the product, and a heat sealer that seals the open mouth of the bag once the bag is filled with the ice. A control device is included that manages and monitors the roller drum and bag delivery mechanism and allows transmission of the collected data to the internet.

Owner:NOREAST CAPITAL CORP +3

Ice bagging apparatus and method

InactiveUS20060005553A1Improve productivityPotential problemLighting and heating apparatusIce productionHeat sealerEngineering

An apparatus and method for bagging ice. The apparatus comprises an ice maker for making ice and a hopper for receiving for receiving the ice from the ice maker. The apparatus further includes a roller drum, operatively associated with the hopper, for measuring the ice and delivering of the ice. The roller drum includes an inner rotating drum. A bag delivery mechanism for placing the ice in a bag is also included, with the bag delivery mechanism including a bag supply mechanism, a fan engaged to open the mouth of the bag to receive the product, and a heat sealer that seals the open mouth of the bag once the bag is filled with the ice. A control device is included that manages and monitors the roller drum and bag delivery mechanism and allows transmission of the collected data to the Internet.

Owner:PRATT ELK GROVE LLC +3

Heat sealer with algorithm for regulating sealing temperature

A vacuum and sealing appliance comprises a heat sealing element for sealing a container during a sealing cycle. A controller controls the temperature of the heat sealing element during the sealing cycle based on a signal from a temperature sensor that senses the real-time temperature of the heat sealing element. A seal indicator light is provided which is lighted during the sealing cycle and extinguished at its completion. The signal from the controller energizes the heating element for a time to heat the sealing element to a pre-determined temperature for sealing the container and initiates a dwell time corresponding to cooling the heating element after sealing the container. Values of the real-time temperatures of the heat sealing element and values of the sealing times and the dwell times that correspond to the values of the real-time temperatures of the heat sealing element are stored in a look-up table.

Owner:SUNBEAN PROD INC

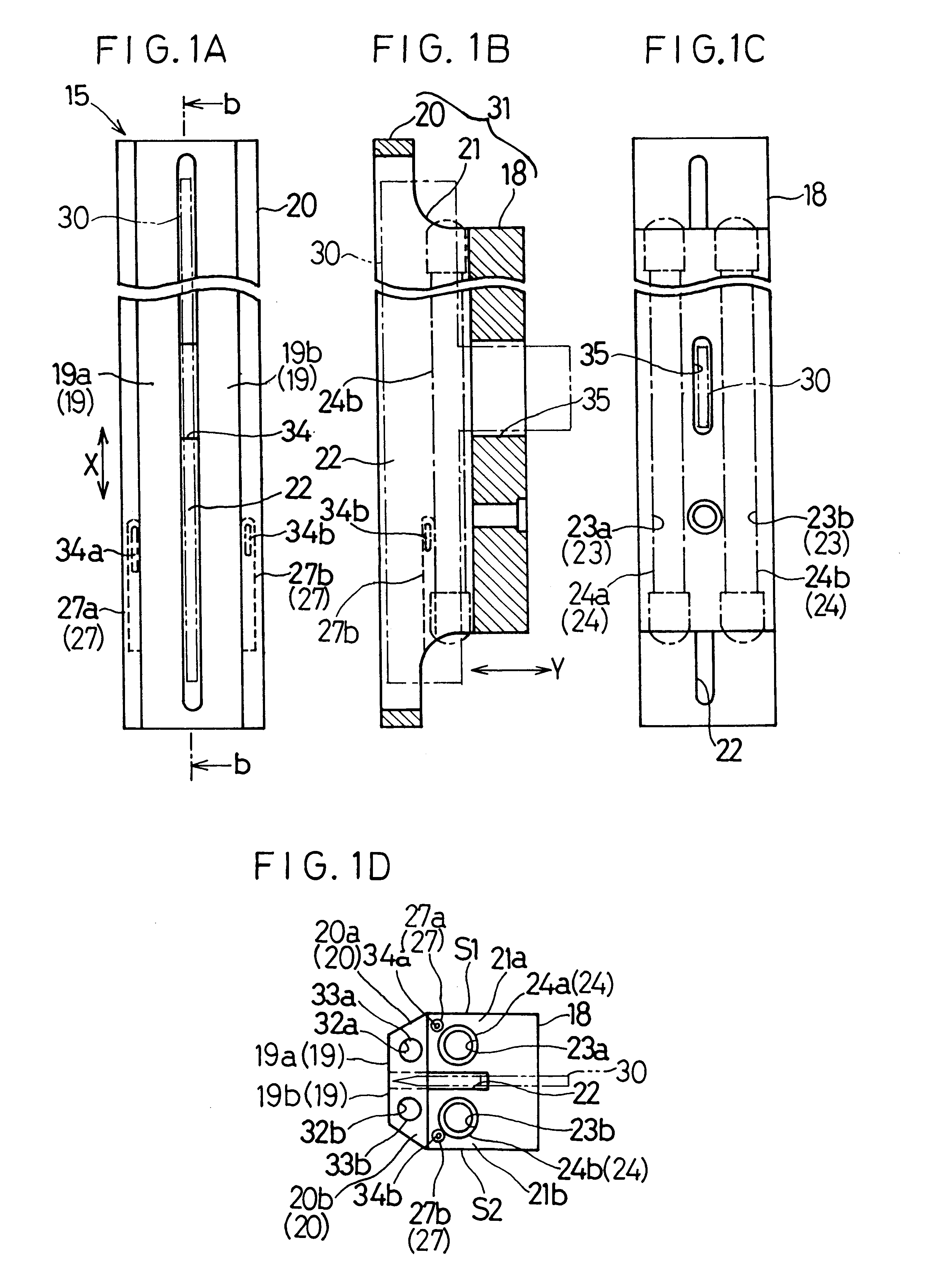

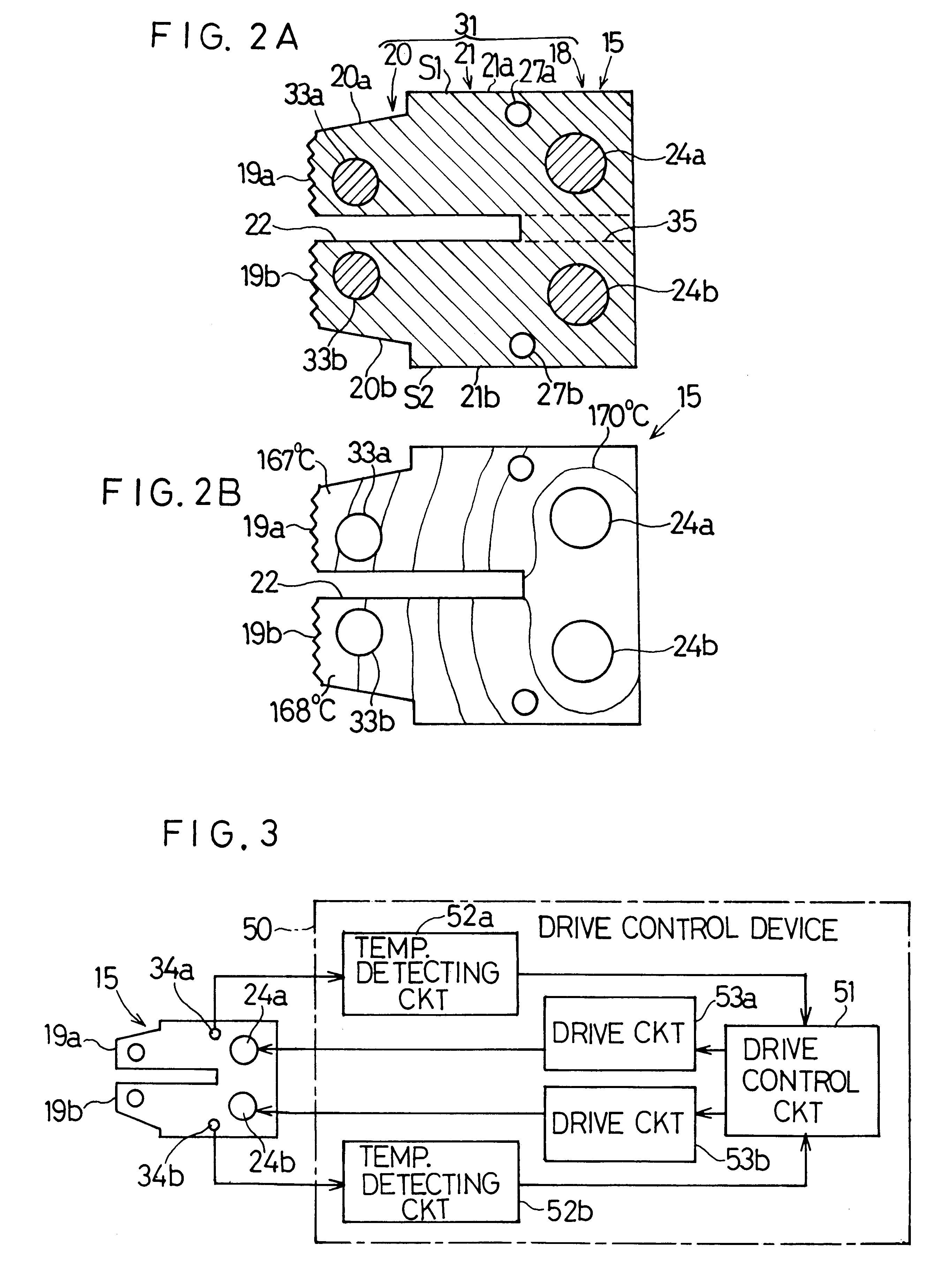

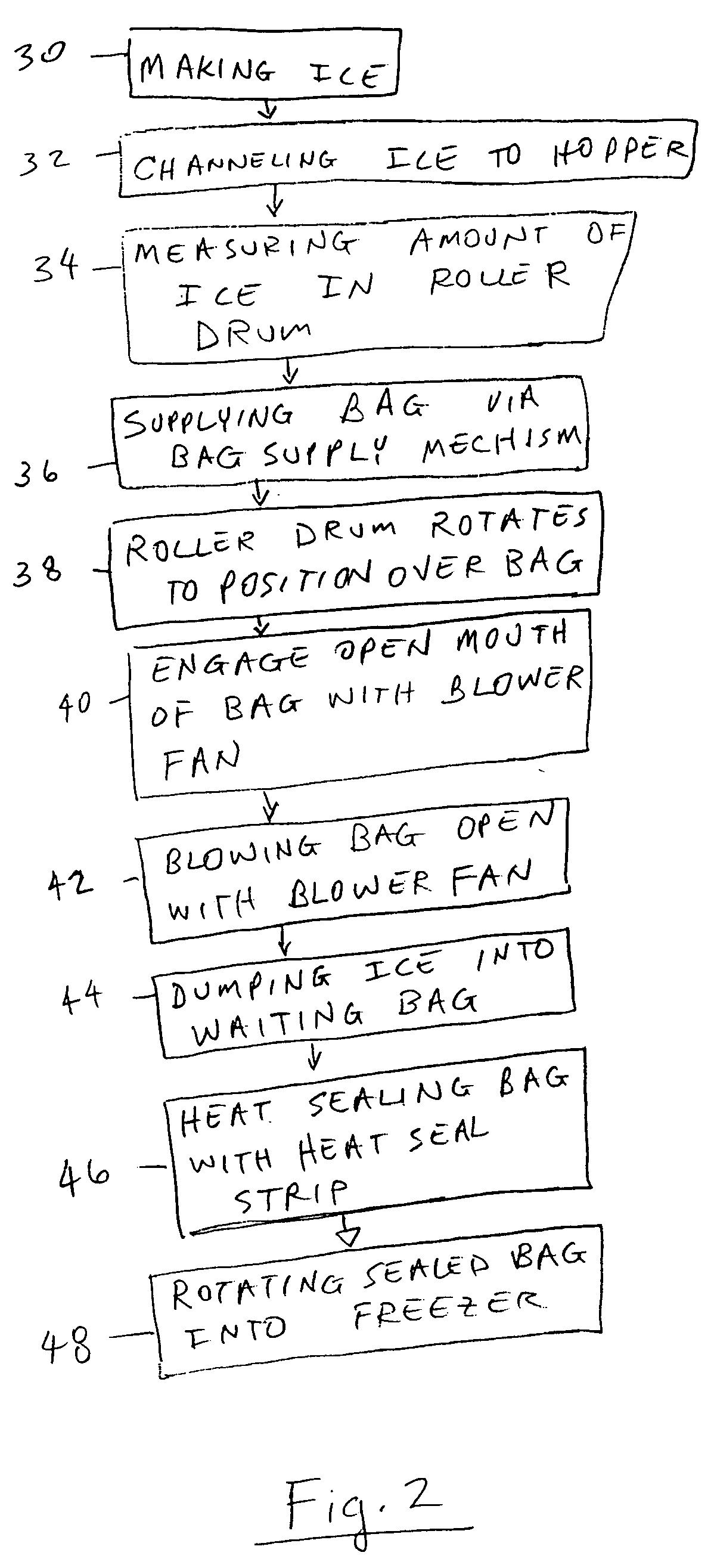

Heat sealer for synthetic resin bag

A heat sealer capable of providing a high sealing strength by appropriating a distribution of temperature at two sheet contact faces (19a, 19b) includes a block (31) made of a metallic material having a high rigidity and operable to heat the resinous sheet (S) while pressing the latter. The block (31) is provided with heaters (24a, 24b) therein and also with heat conducting members (33a, 33b) each having an excellent heat conductive characteristic higher than that of the metallic material. The heat conducting members (33a, 33b) are positioned between the heaters (24a, 24b) and the sheet contact faces (19a, 19b), respectively.

Owner:ISHIDA CO LTD

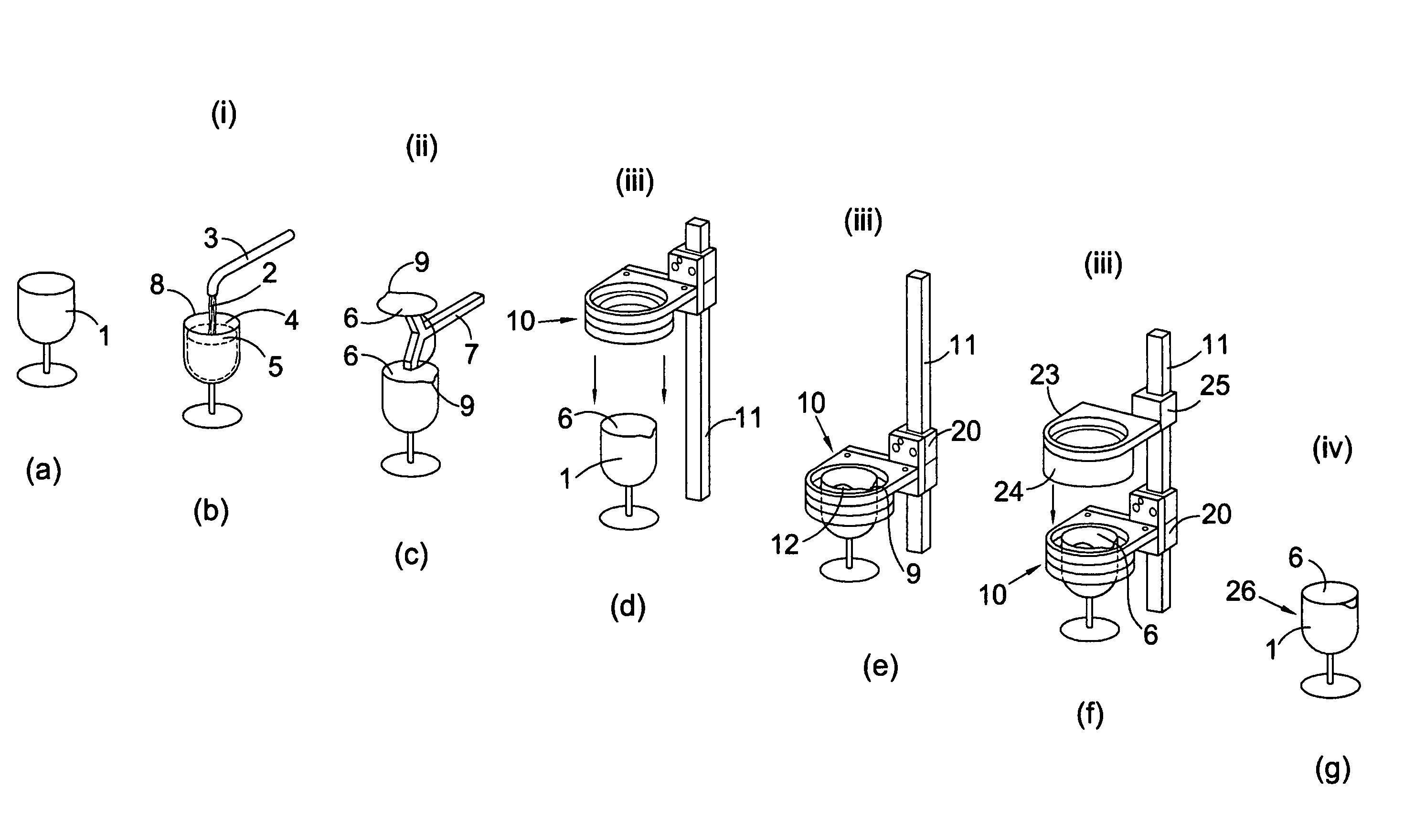

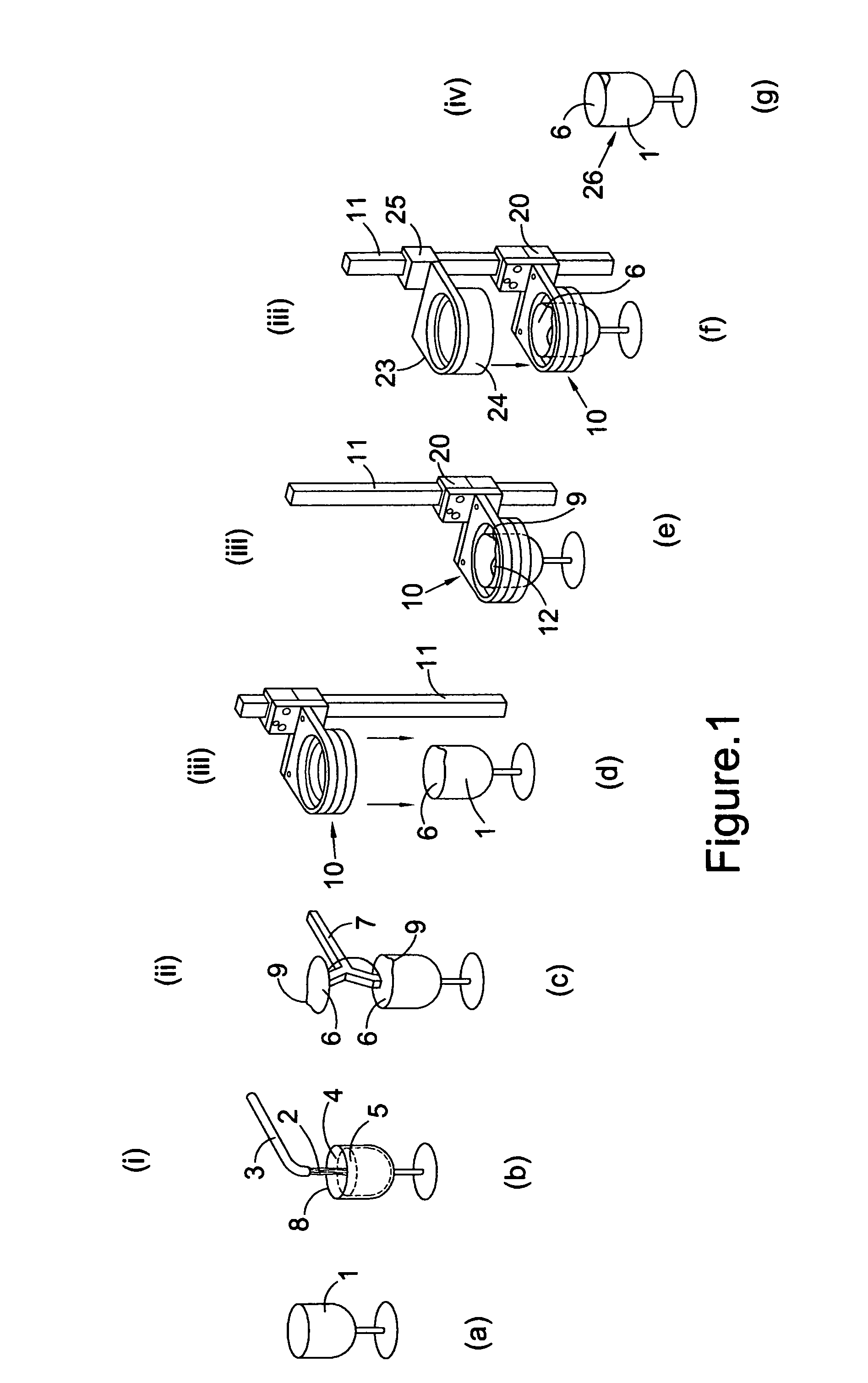

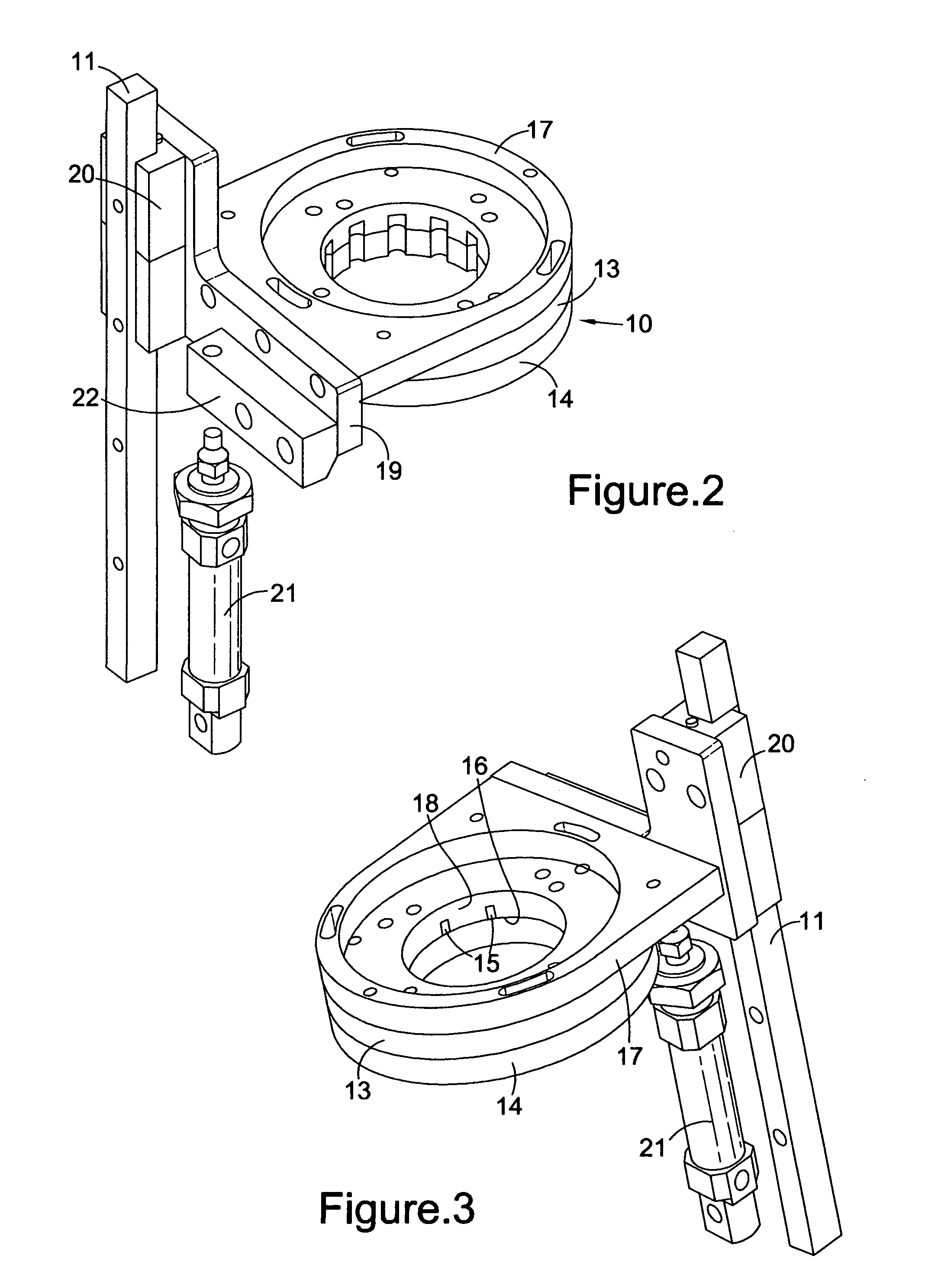

Filling and sealing of beverage containers

The present invention provides, inter alia, a method of filling and sealing a beverage container, the method comprising the steps of:a) dispensing a predetermined amount of beverage, preferably wine, into an open-topped container having a circular rim, preferably a plastics wine glass, to leave a headspace above the beverage in the container;b) temporarily tacking a generally flat flexible film lid sized to fit over the open top to the rim of the container at at least one position around the rim while leaving the remainder of the rim free;c) engaging the tacked lid to cause flexure thereof to create a gap between the lid and the rim on one side;d) dispensing an inert gas, preferably nitrogen, through the gap so created and into the headspace to displace air therefrom; ande) bringing a heat sealer into engagement with the lid to heat seal the lid to the rim about its entire circumference, thereby trapping the inert gas within the headspace.

Owner:WINE INNOVATIONS

Producing method of optical film

InactiveUS20040100708A1Reduce wastePrevent such non-uniformityMirrorsPolarising elementsHeat sealerThin membrane

When it is complete to unwind a first PVA film from a first film roll, it is started to unwind a second PVA film from a second film roll. A trailing end portion of the first and second PVA film and a leading end portion of the second PVA film are overlaid at a film connecting position. A receive stage and a seal head of a heat sealer sandwiches overlaid portions, and a head body of the seal head heats them so as to thermally melt and adhere the first and second PVA films. During the thermal melt-adhesion, a thermal melt-adhesion line is formed in the overlaid portions of the first and second PVA films.

Owner:FUJIFILM HLDG CORP

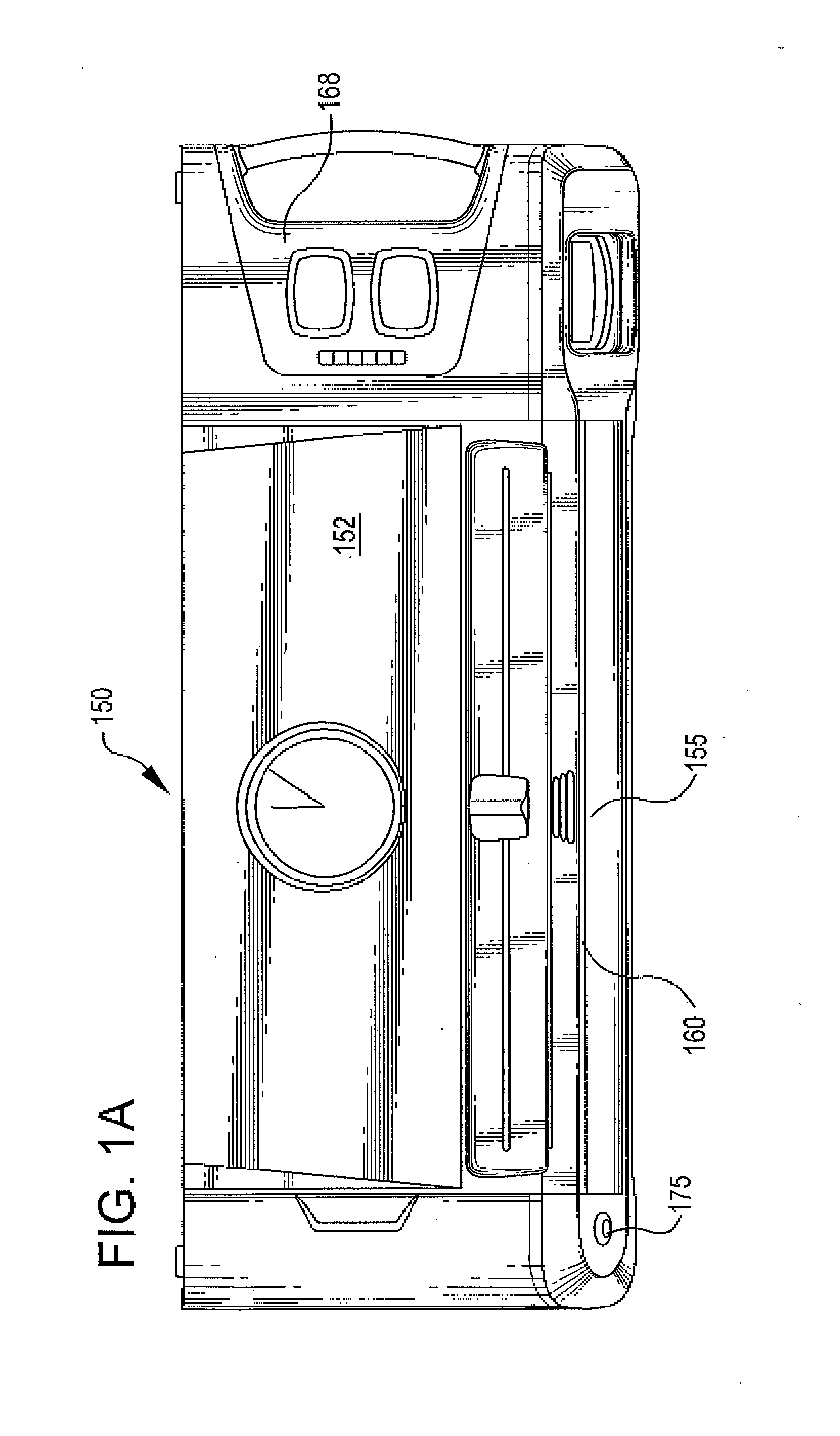

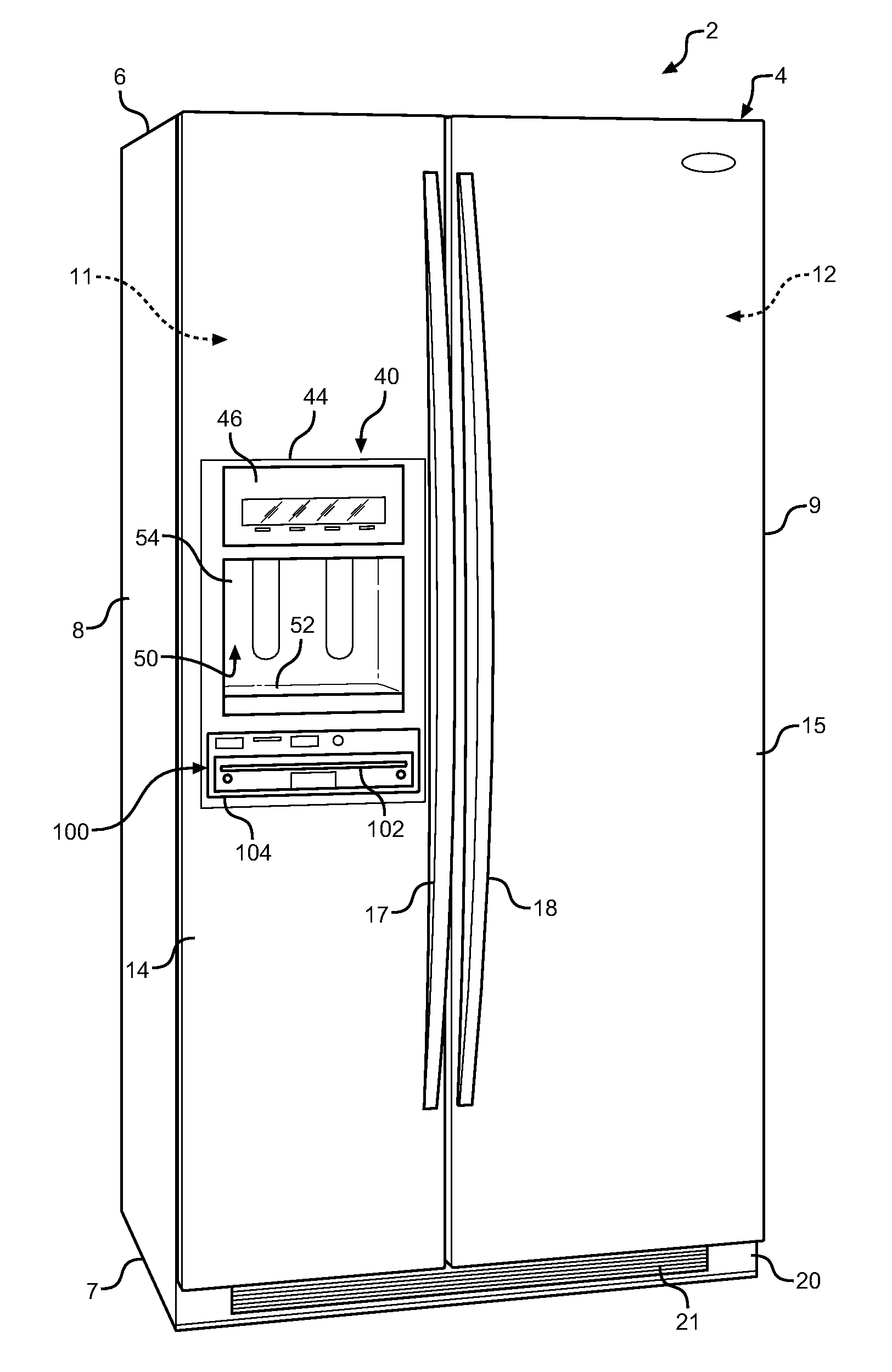

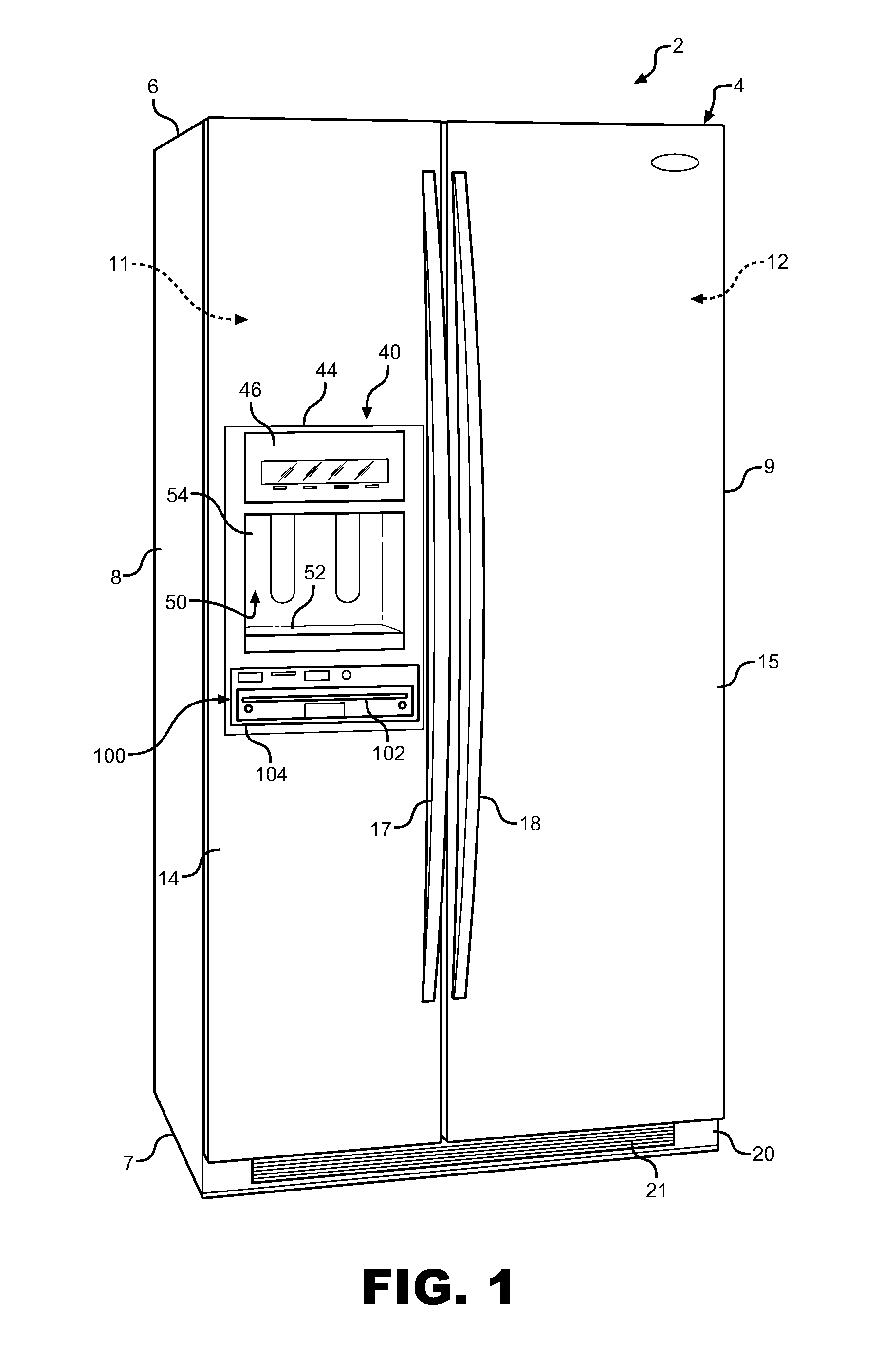

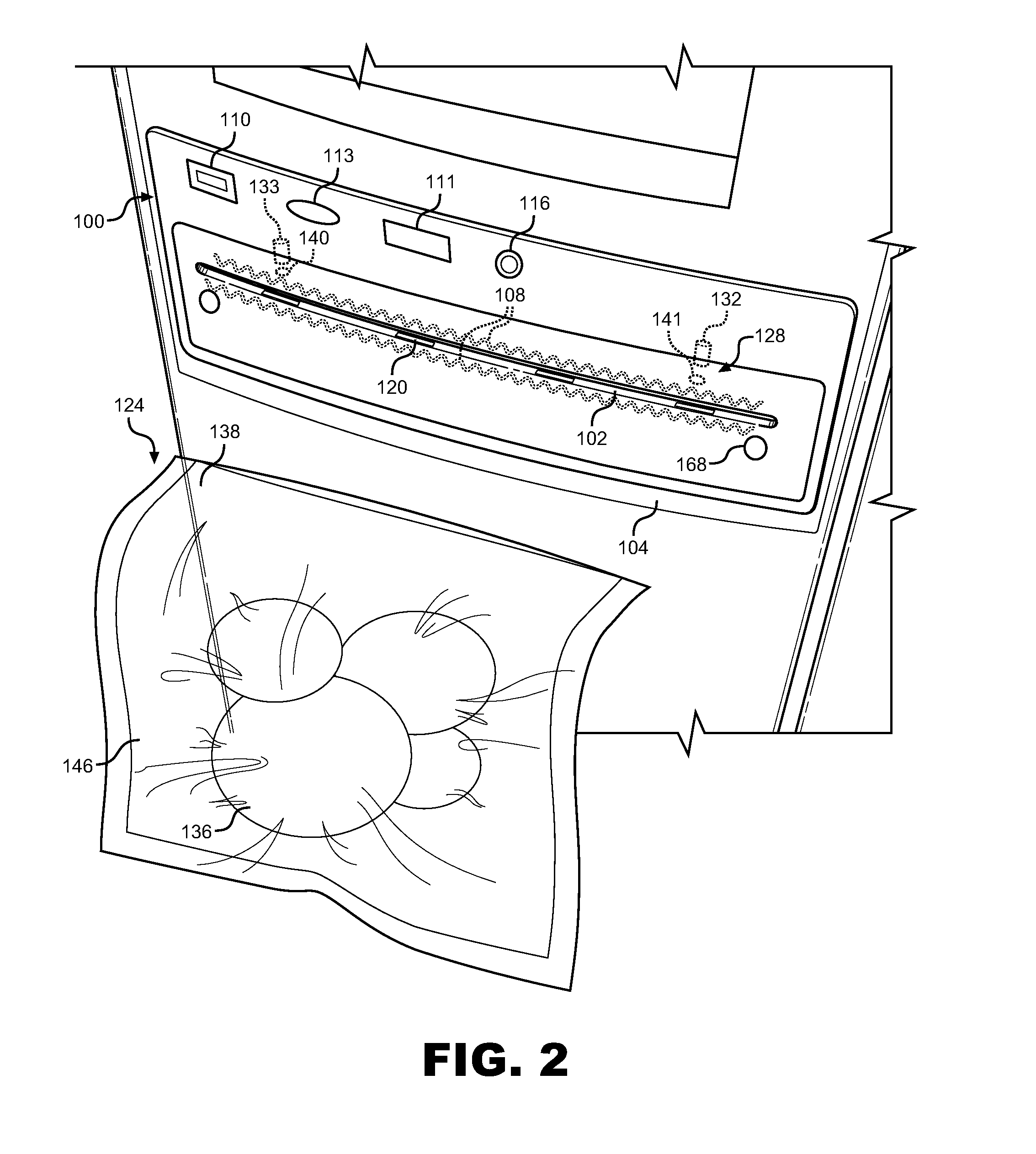

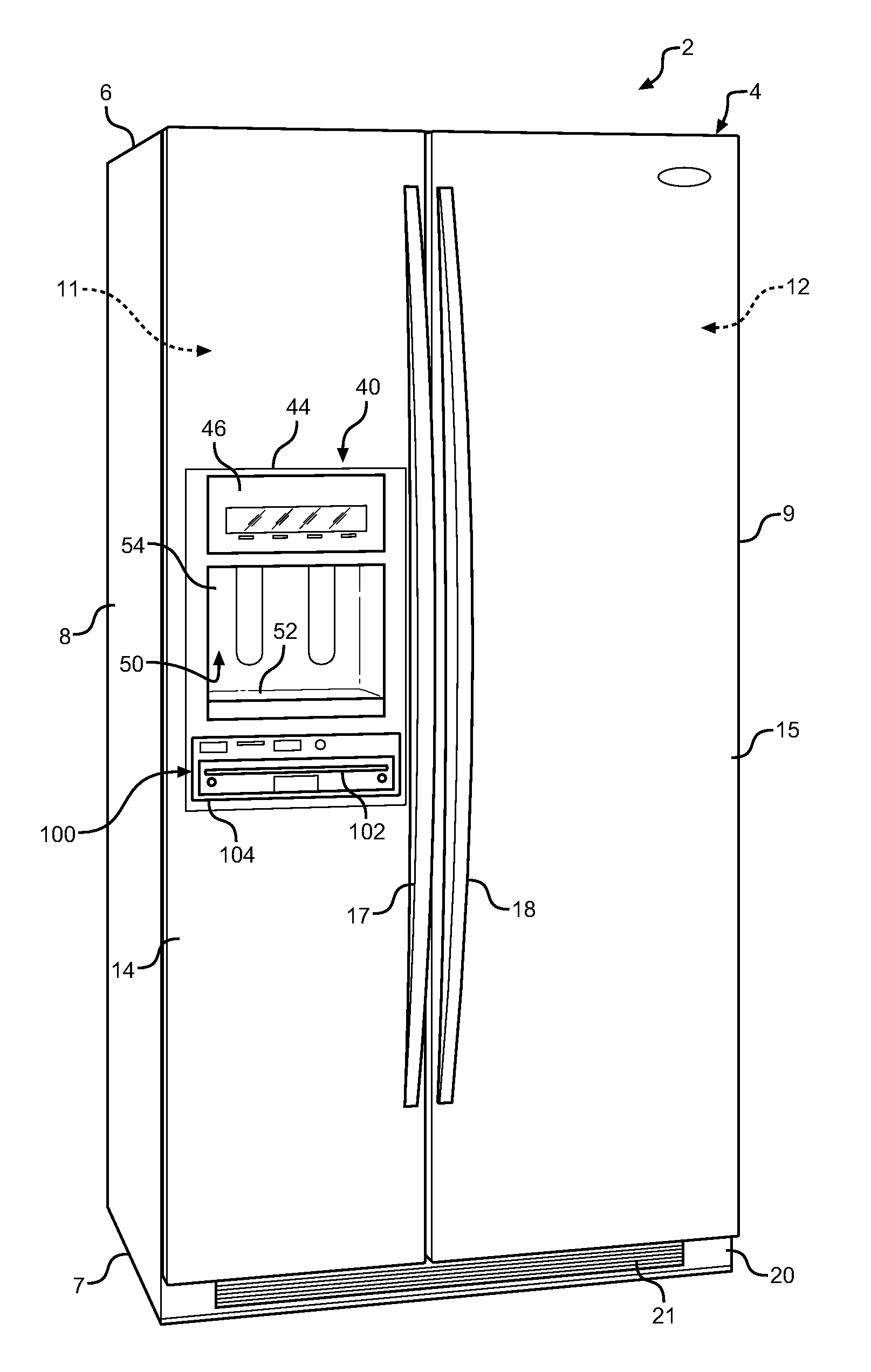

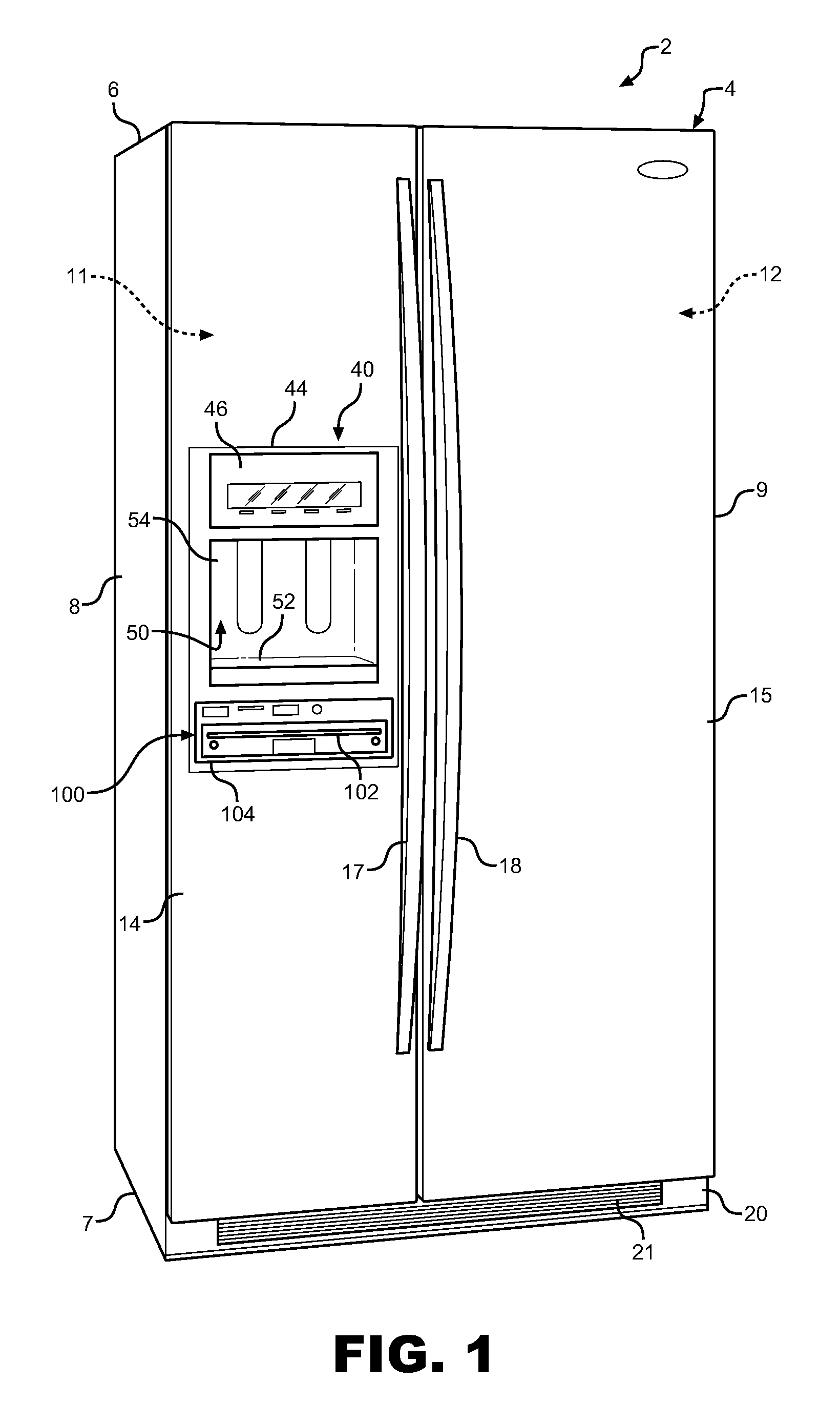

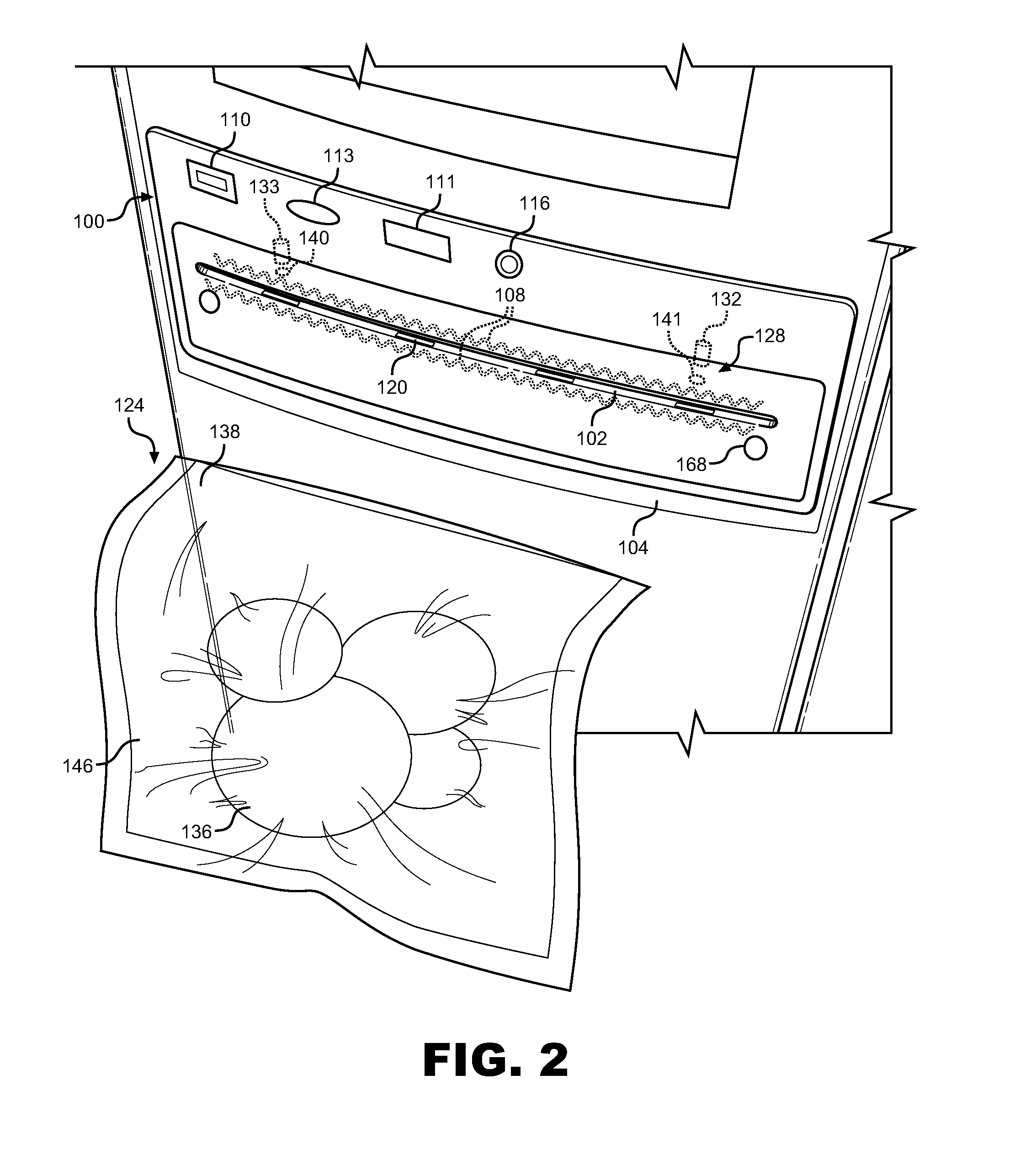

Refrigerator door vacuum preservation system

InactiveUS20090193760A1Lighting and heating apparatusPackaging by pressurising/gasifyingHeat sealerHands free

A refrigerator includes a hands-free vacuum preservation system mounted on a door of the refrigerator comprising a main body portion having a slot therein for receiving an open end of a plastic bag. Sensors within the slot detect the presence of the bag and a retaining device is actuated to punch holes in the bag and retain the bag in position for a vacuum sealing event. An intake port within the system communicates with a vacuum source to remove air from the bag, and a heat sealer seals the bag closed. In a preferred embodiment, once sensors located on the main body portion detect the presence of a consumer's hand, the retaining device releases the bag. The resultant vacuum sealed bag can be stored in a conventional manner, or by hanging the bag from hooks extending through the holes formed therein by the retaining device.

Owner:WHIRLPOOL CORP

Ice bagging apparatus and method

InactiveUS20060005564A1Improve productivityPotential problemLighting and heating apparatusIce productionHeat sealerEngineering

An apparatus and method for bagging ice. The apparatus comprises an ice maker for making ice and a hopper for receiving for receiving the ice from the ice maker. The apparatus further includes a roller drum, operatively associated with the hopper, for measuring the ice and delivering of the ice. A bag delivery mechanism for placing the ice in a bag is also included, with the bag delivery mechanism including a bag supply mechanism, a blower fan engaged to open the mouth of the bag to receive the product, and a heat sealer that seals the open mouth of the bag once the bag is filled with the ice. A control device is included that manages and monitors the roller drum and bag delivery mechanism and allows transmission of the collected data to the internet.

Owner:NOREAST CAPITAL CORP +3

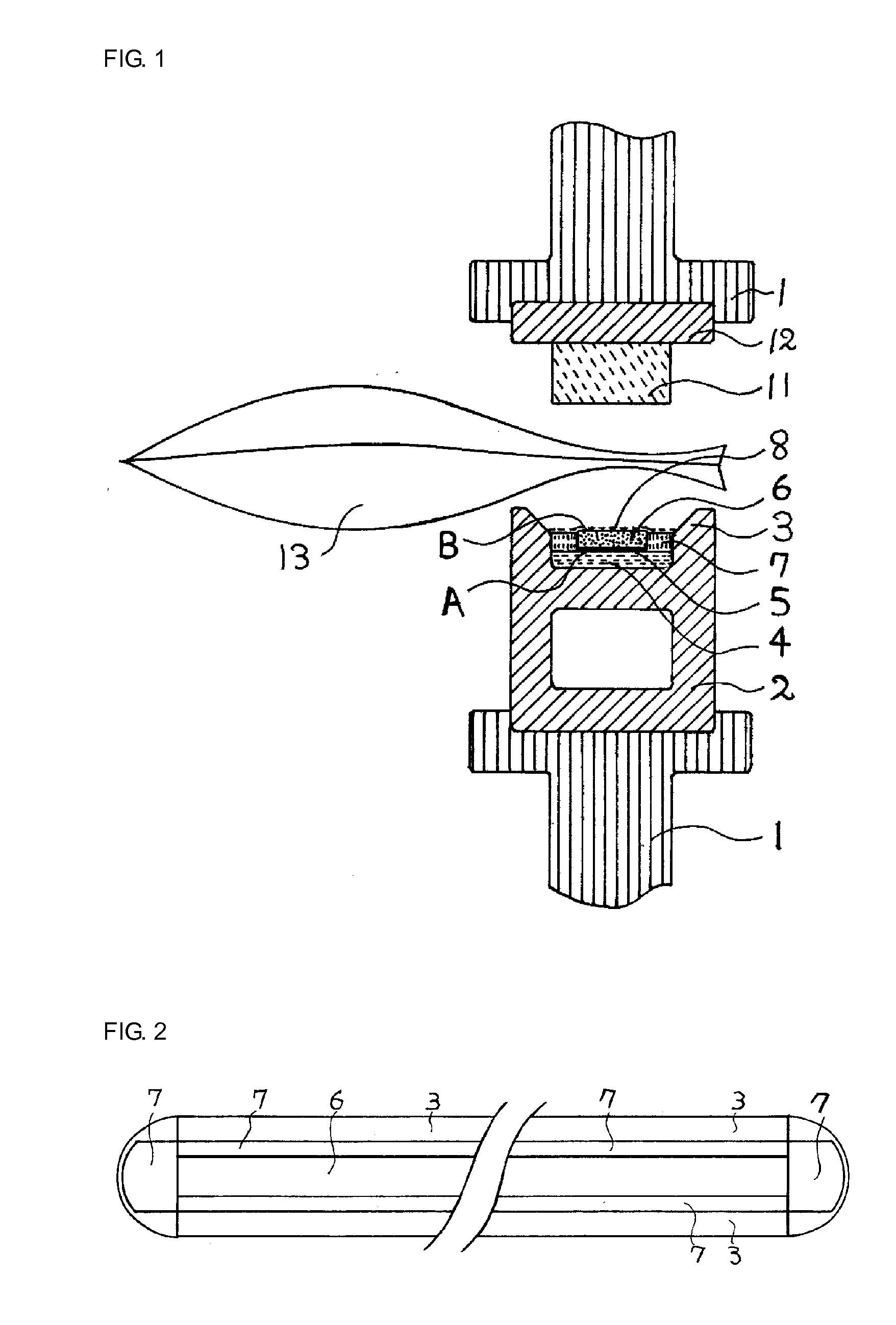

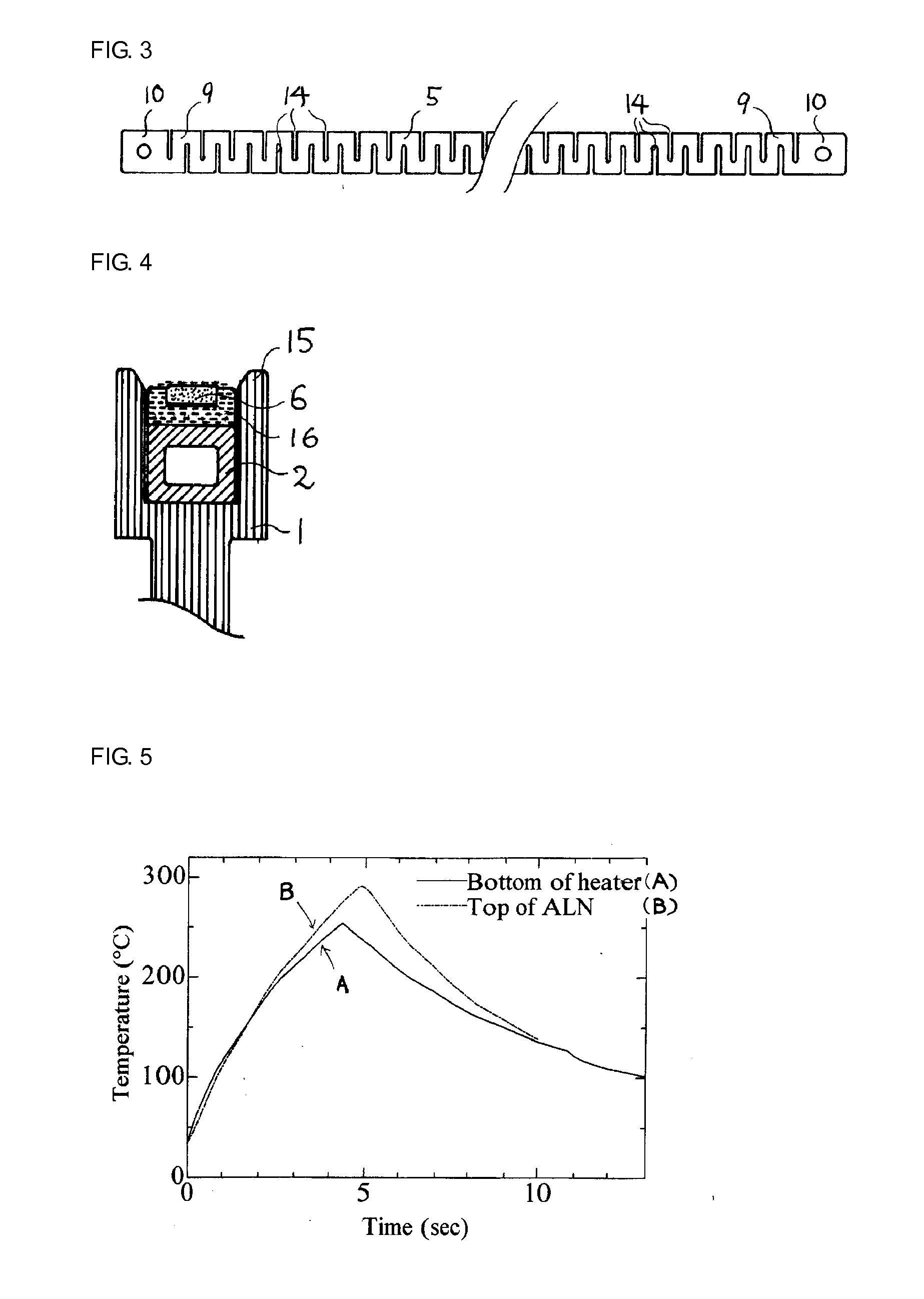

Impulse sealer including ceramic-covered heater

InactiveUS20120080418A1Ohmic-resistance heating detailsWrapper twisting/gatheringThin metalElectric force

A heat sealer includes a press mechanism, a heater, and an electric power circuit. The heater includes: a thin thermal-electrical insulator plate superposed on a heat dissipating base or on a jaw of the press mechanism; one or more heater wires each of which is a thin metal resistor plate superposed on the thin thermal-electrical insulator plate, each heater wire including an electrode and a heat generating portion; a thermally conductive electrical insulator superposed on the heat generating portion, the thermally conductive electrical insulator being an electrical insulator and having a thermal conductivity that is equal to or higher than that of alumina; a thermal-electrical insulator that covers exposed portions of the heater wires and the electrode; and a thin release film superposed on the thermally conductive electrical insulator. The elements of the heater are made to closely contact each other and fixed by using an adhesive or the like.

Owner:SAKAMOTO ATSUNOBU +2

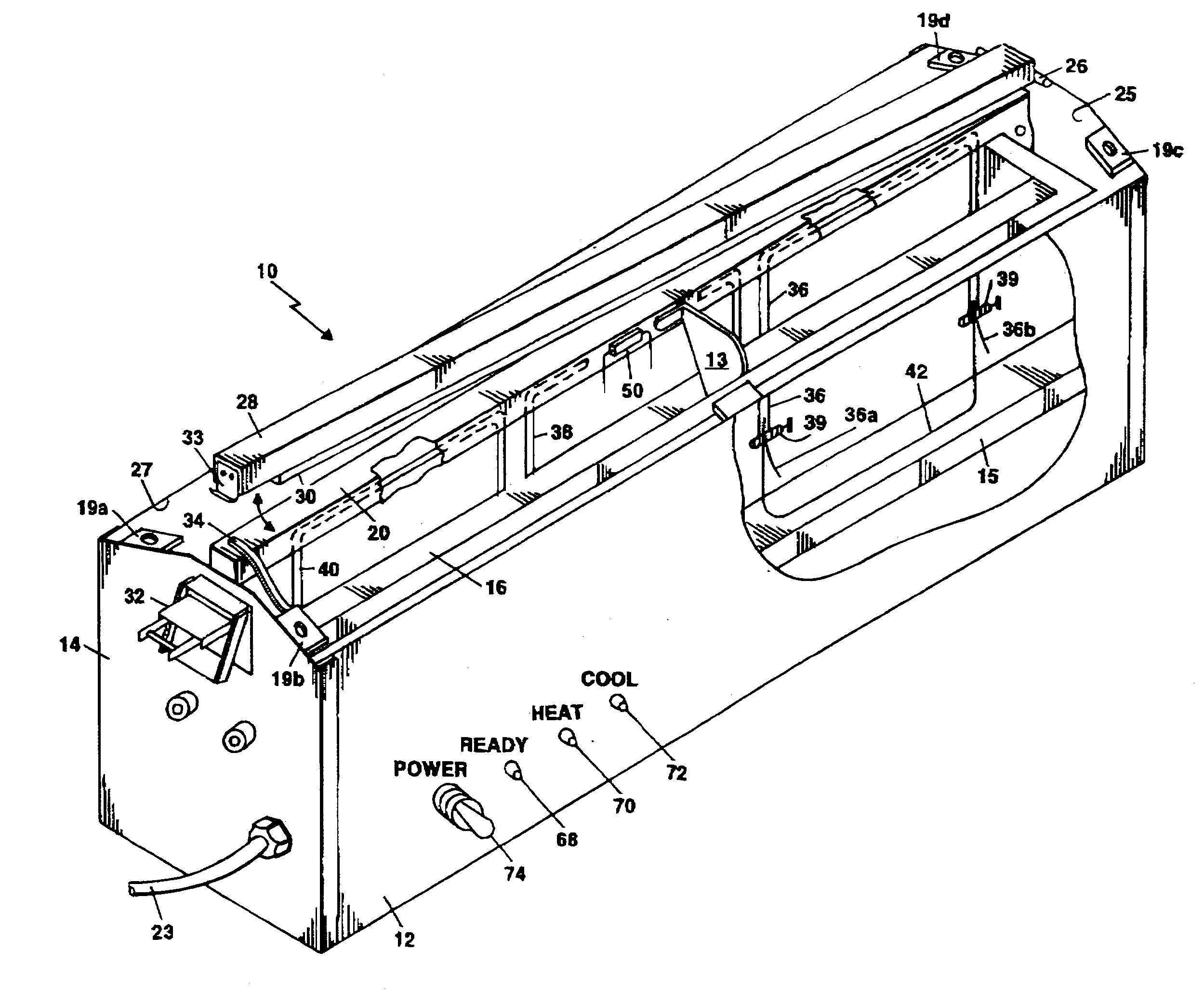

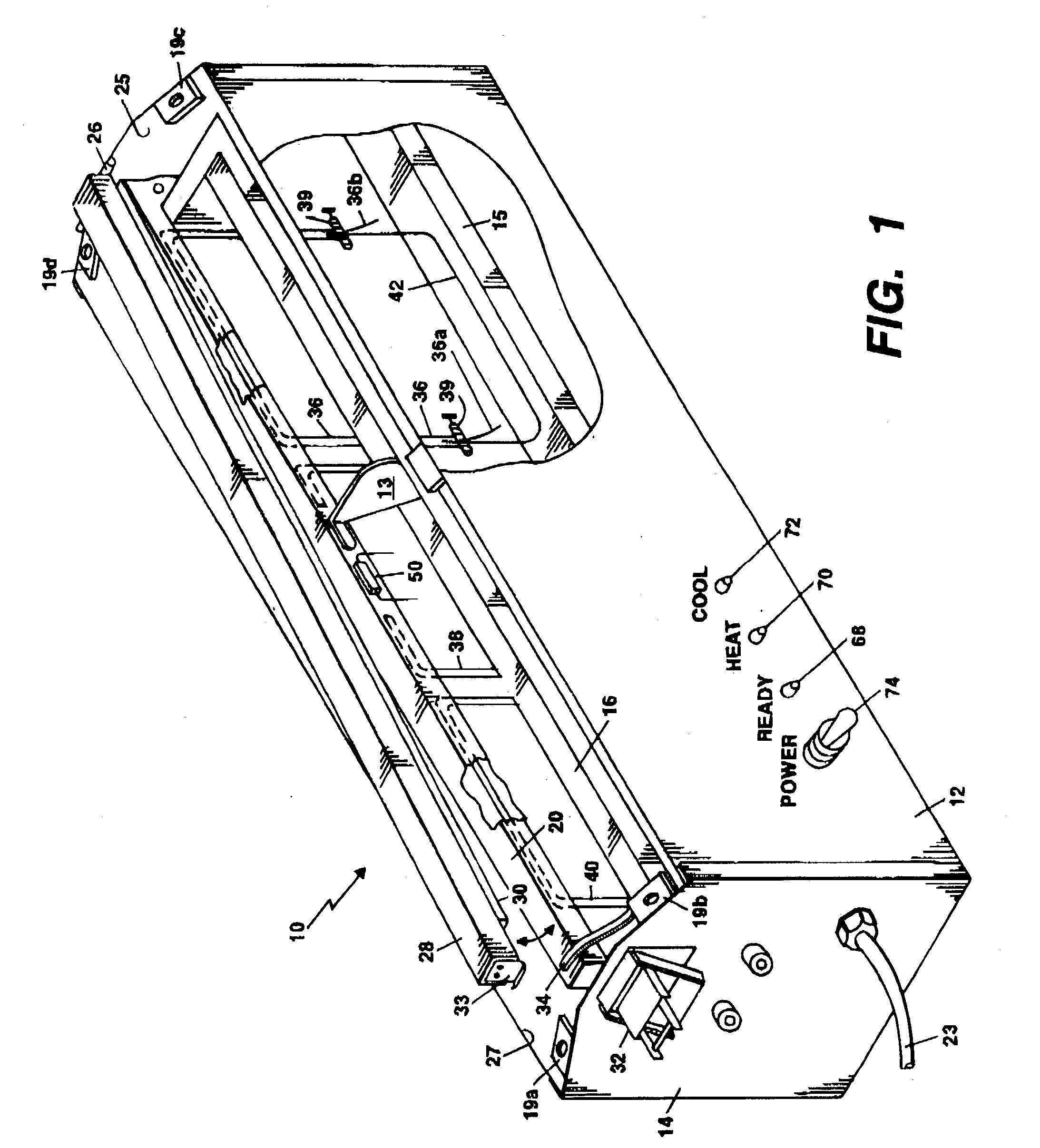

Portable heat sealer

InactiveUS20040020913A1Even heat distributionImprove thermal conductivityAdhesive processesOhmic-resistance heating detailsHeat sealerEngineering

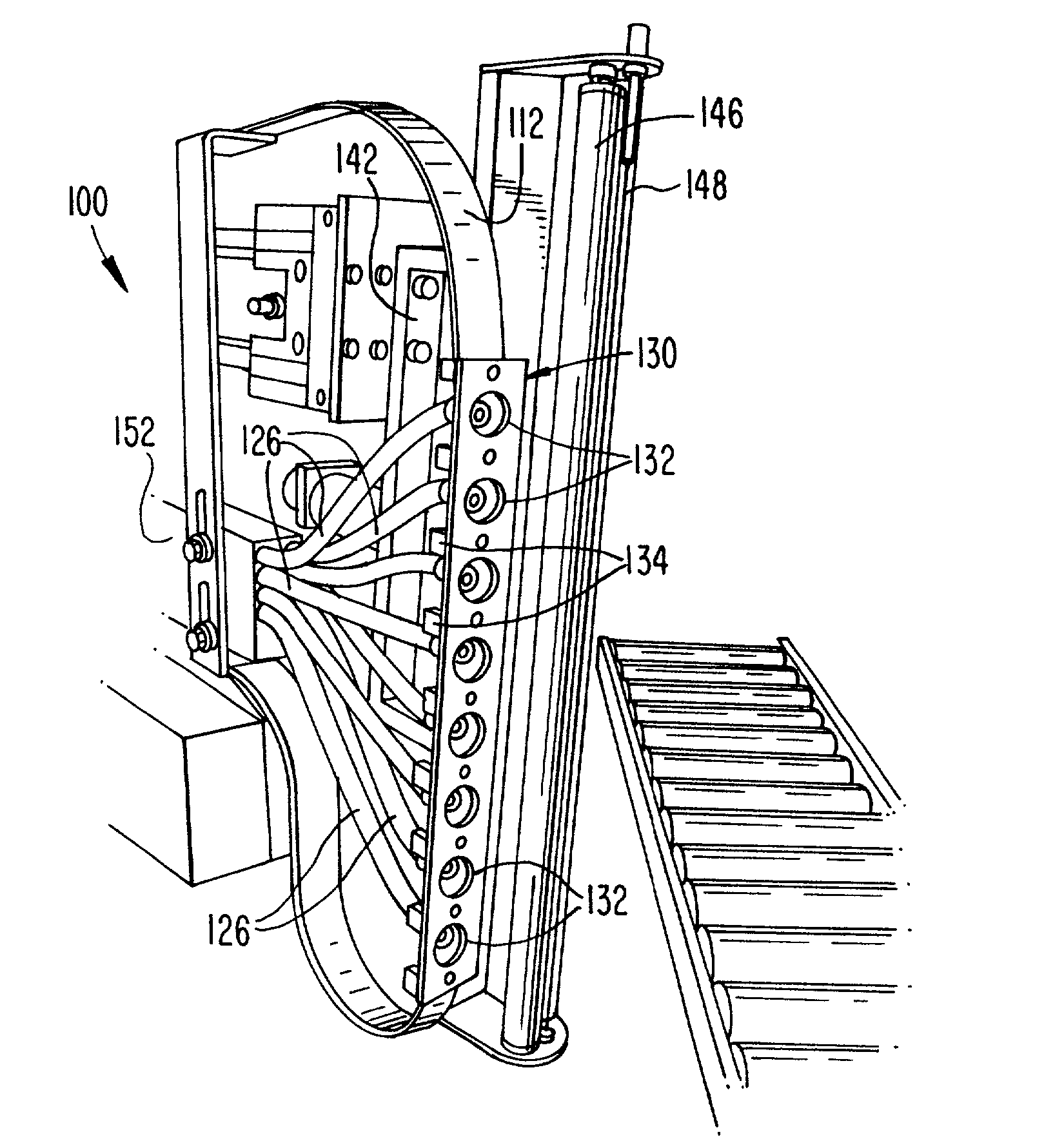

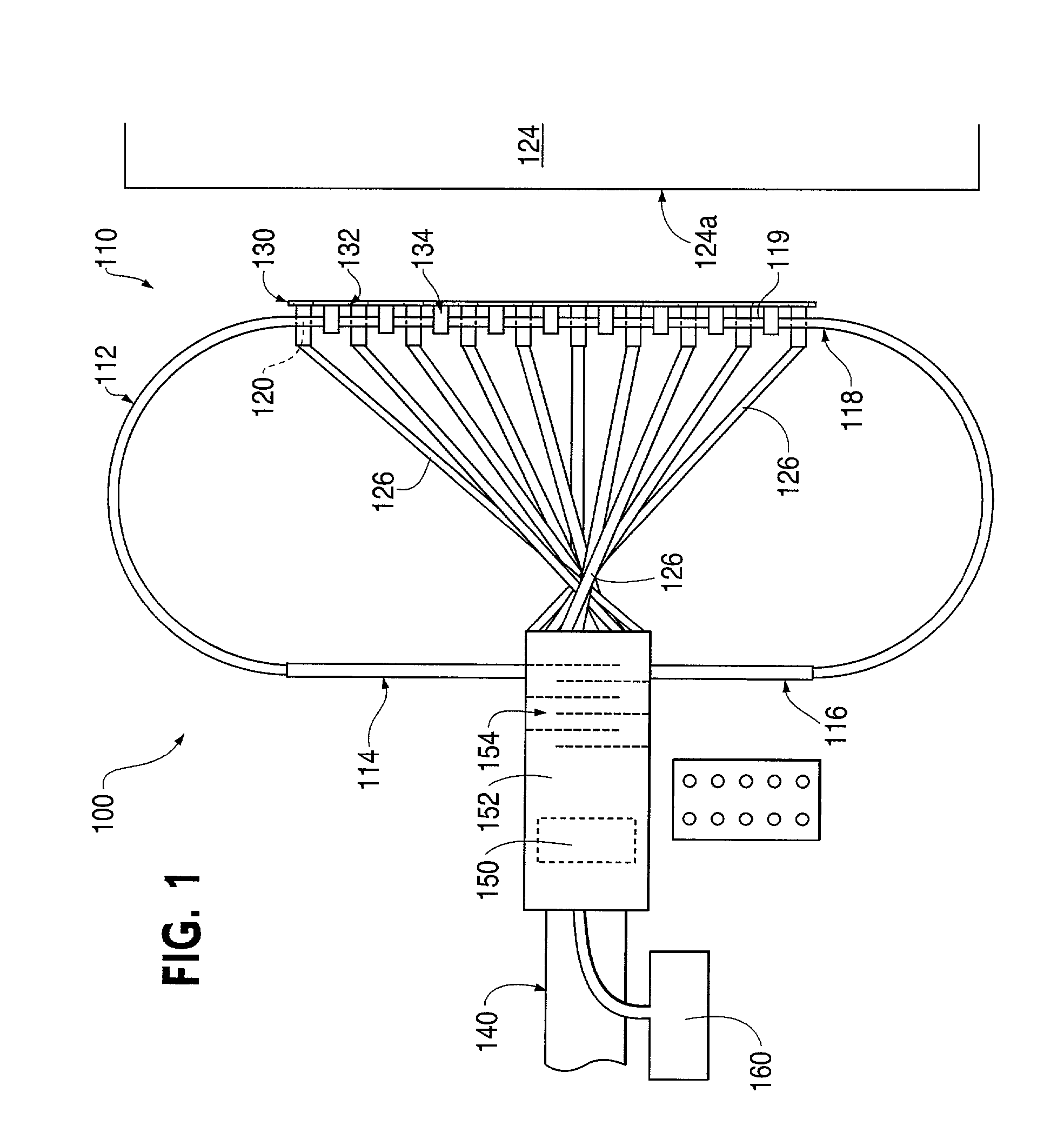

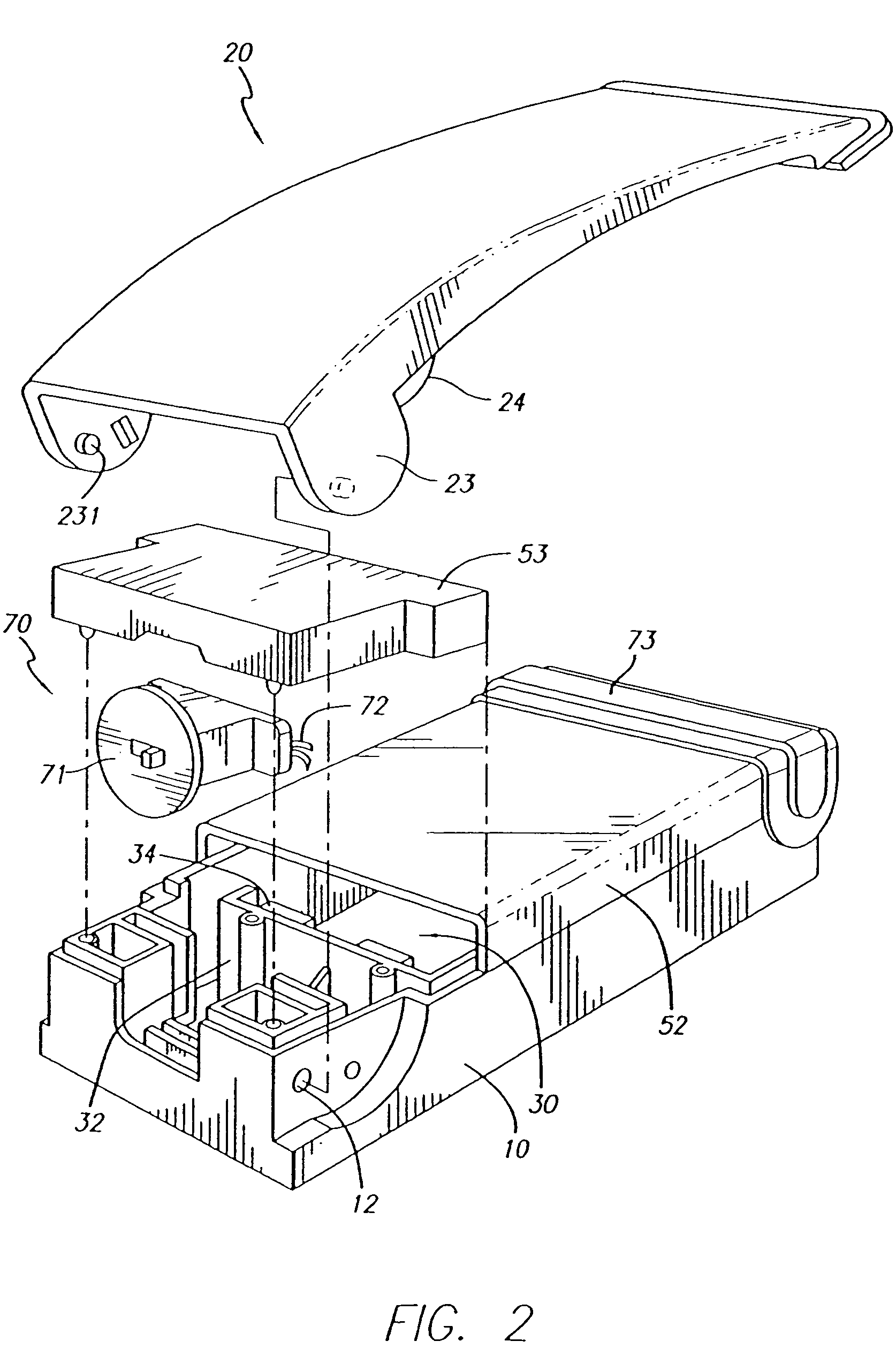

A portable heat sealer for sealing heavy grade thermoplastic films comprises a plurality of adjacent, segmented heating elements positioned along the underside of a heated sealing bar. The segmented heating elements are under the control of a microprocessor for controlling the energy applied to the heated sealing bar to avoid the formation of hot spots and to obtain a strong seal. Each heating element is maintained in firm contact with the heated sealing bar by means of a tension spring. A thermoplastic film bag is placed on the heated sealing bar and a movable sealer jaw is lowered on top of the bag. A jaw switch is activated by the sealer jaw which turns-on power to the heat sealer. A latch 32 attaches to a clip on the end of the sealer jaws and secures the sealer jaw in place. Pilot lights are provided to indicate to an operator the cycles of "ready", "heat" and "cool".

Owner:IDOLON TECH

Portable heat sealer

InactiveUS6881929B2Inhibition formationQuality improvementAdhesive processesHeater elementsHeat sealerEngineering

A portable heat sealer for sealing heavy grade thermoplastic films comprises a plurality of adjacent, segmented heating elements positioned along the underside of a heated sealing bar. The segmented heating elements are under the control of a microprocessor for controlling the energy applied to the heated sealing bar to avoid the formation of hot spots and to obtain a strong seal. Each heating element is maintained in firm contact with the heated sealing bar by means of a tension spring. A thermoplastic film bag is placed on the heated sealing bar and a movable sealer jaw is lowered on top of the bag. A jaw switch is activated by the sealer jaw which turns-on power to the heat sealer. A latch 32 attaches to a clip on the end of the sealer jaws and secures the sealer jaw in place. Pilot lights are provided to indicate to an operator the cycles of “ready”, “heat” and “cool”.

Owner:IDOLON TECH

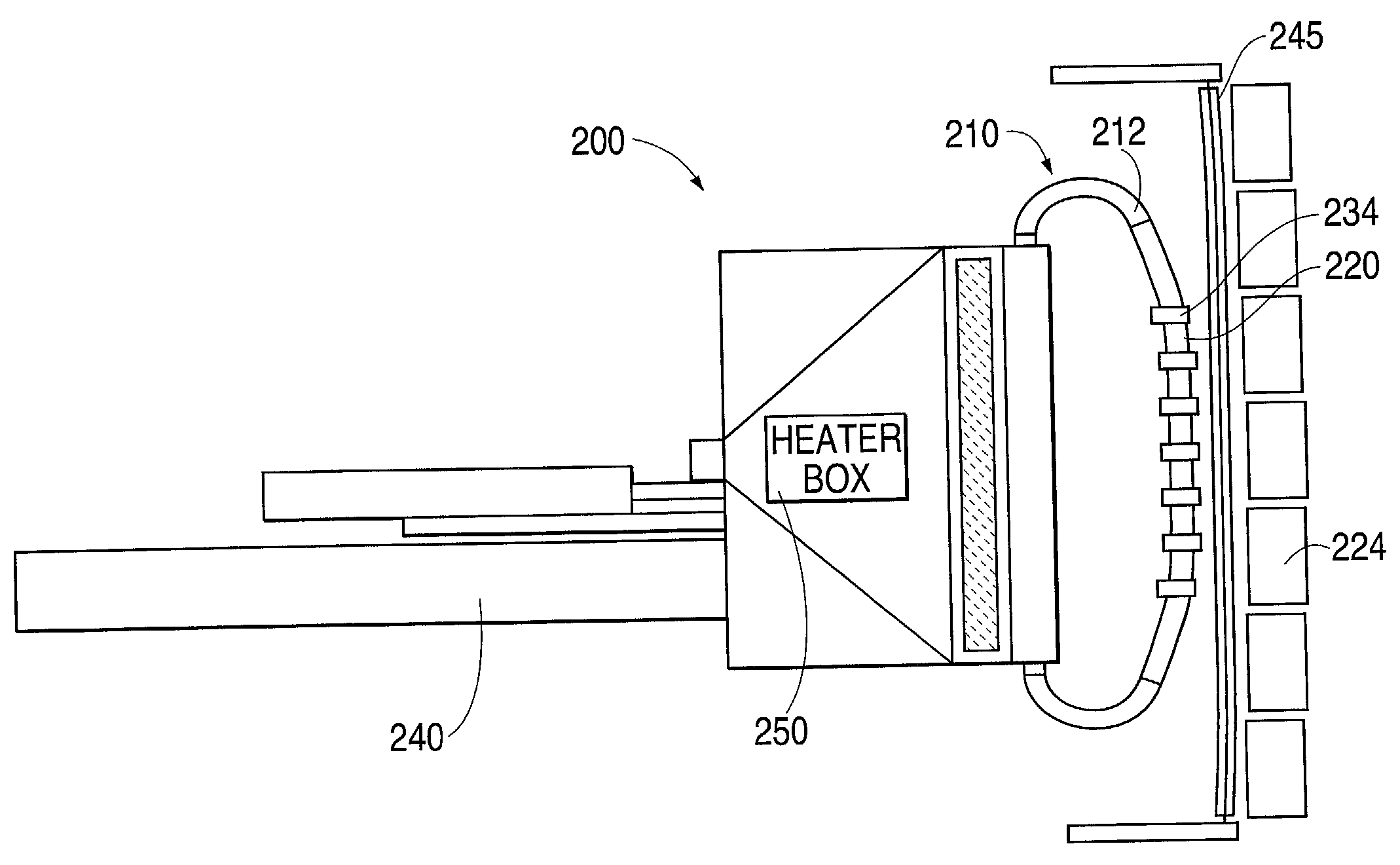

Heat sealer for stretch wrapping apparatus

A heat sealing device for sealing layers of plastic film together is provided. In a preferred embodiment, the heat sealing device is incorporated into a stretch wrapping apparatus for wrapping a load. The heat sealing device includes a heater element, an air compressor or blower, and a sealing head in fluid communication with the heater element to distribute the heated air. The sealing head is preferably flexible and includes a plurality of convection ports configured to apply heated air to a portion of the packaging material without being completely covered by the packaging material. At least one insulated film contact portion is provided to distance the convection ports from the plastic film.

Owner:LANTECH COM

Refrigerator door vacuum preservation system

InactiveUS7669434B2Lighting and heating apparatusPackaging by pressurising/gasifyingHeat sealerHands free

A refrigerator includes a hands-free vacuum preservation system mounted on a door of the refrigerator comprising a main body portion having a slot therein for receiving an open end of a plastic bag. Sensors within the slot detect the presence of the bag and a retaining device is actuated to punch holes in the bag and retain the bag in position for a vacuum sealing event. An intake port within the system communicates with a vacuum source to remove air from the bag, and a heat sealer seals the bag closed. In a preferred embodiment, once sensors located on the main body portion detect the presence of a consumer's hand, the retaining device releases the bag. The resultant vacuum sealed bag can be stored in a conventional manner, or by hanging the bag from hooks extending through the holes formed therein by the retaining device.

Owner:WHIRLPOOL CORP

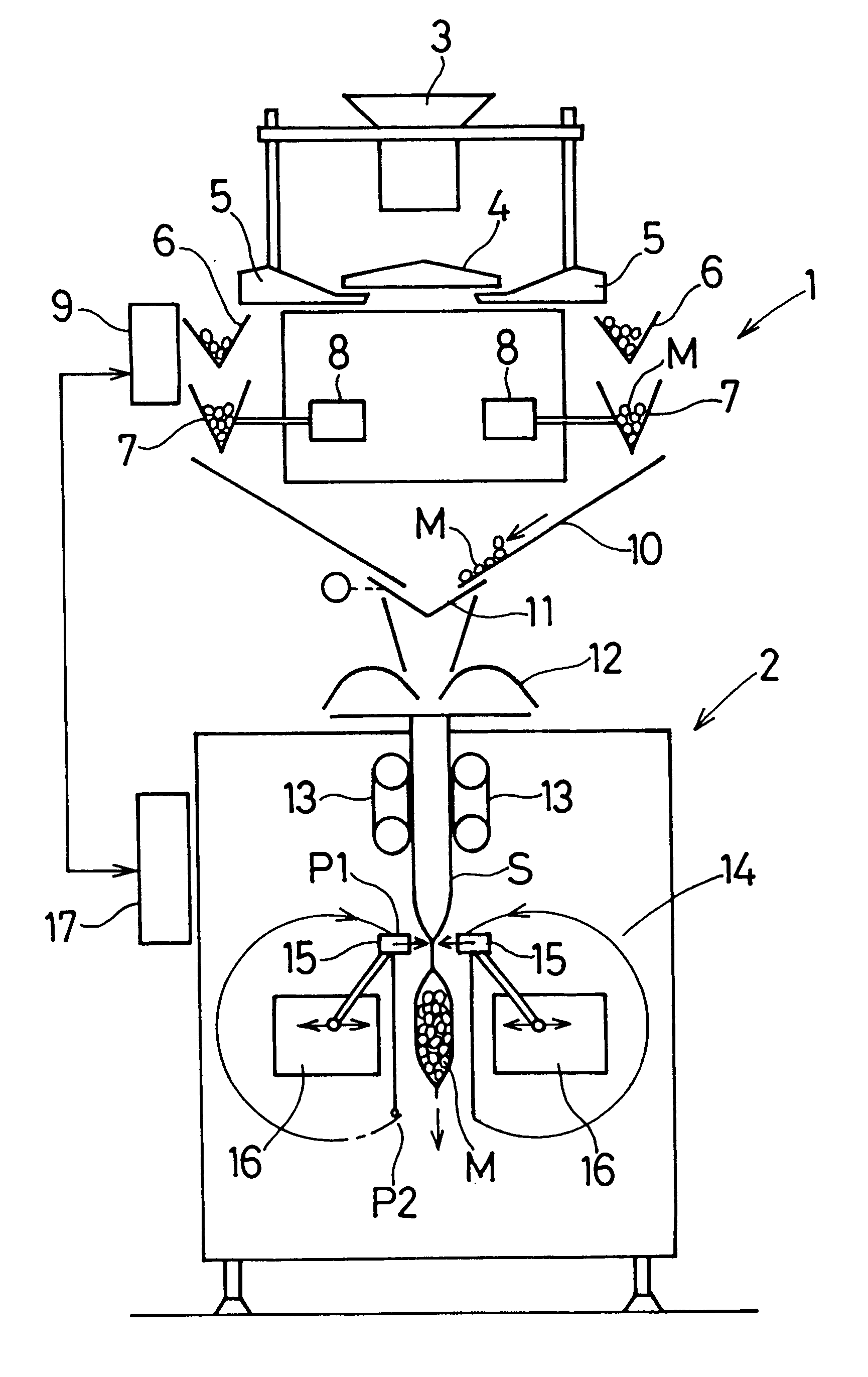

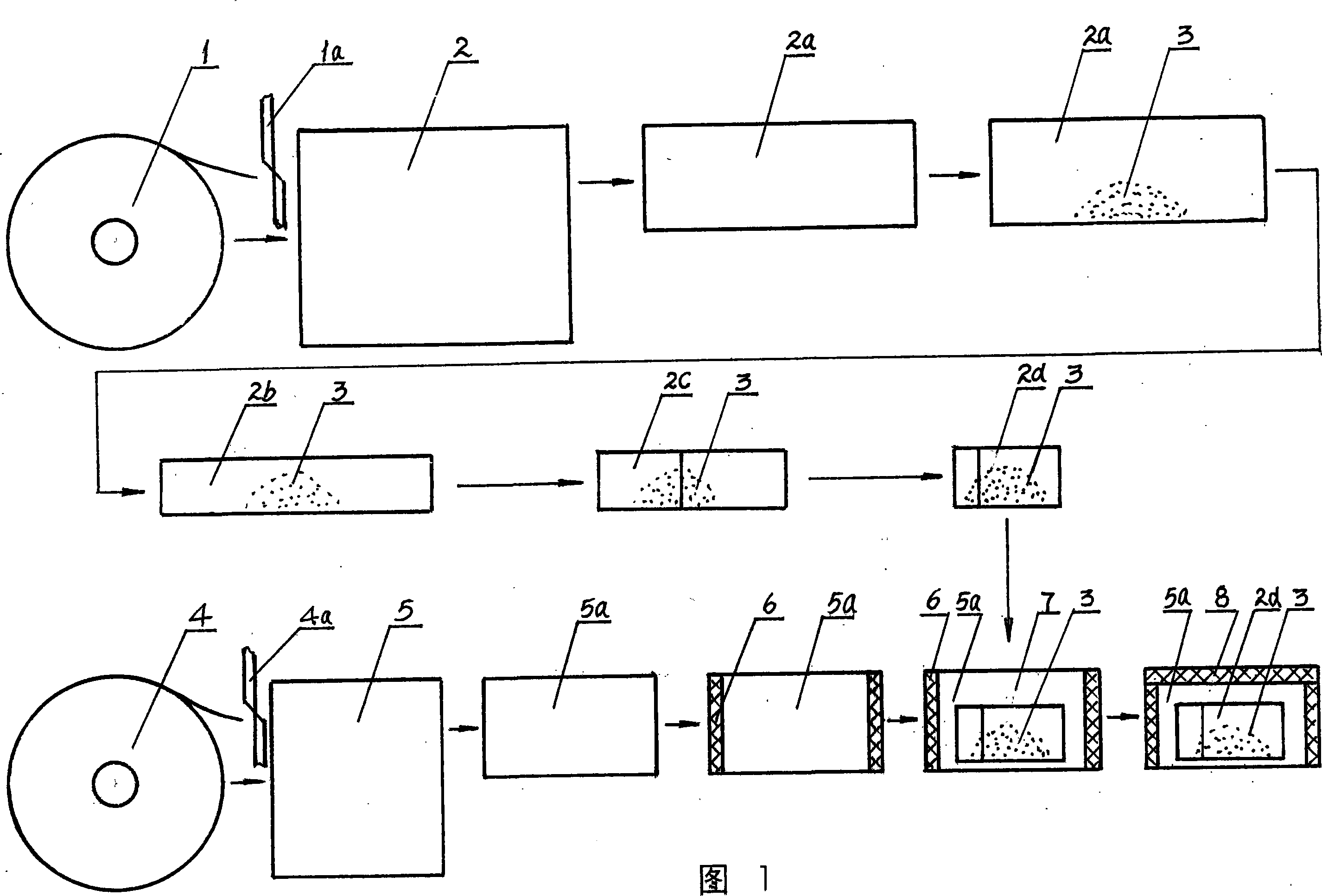

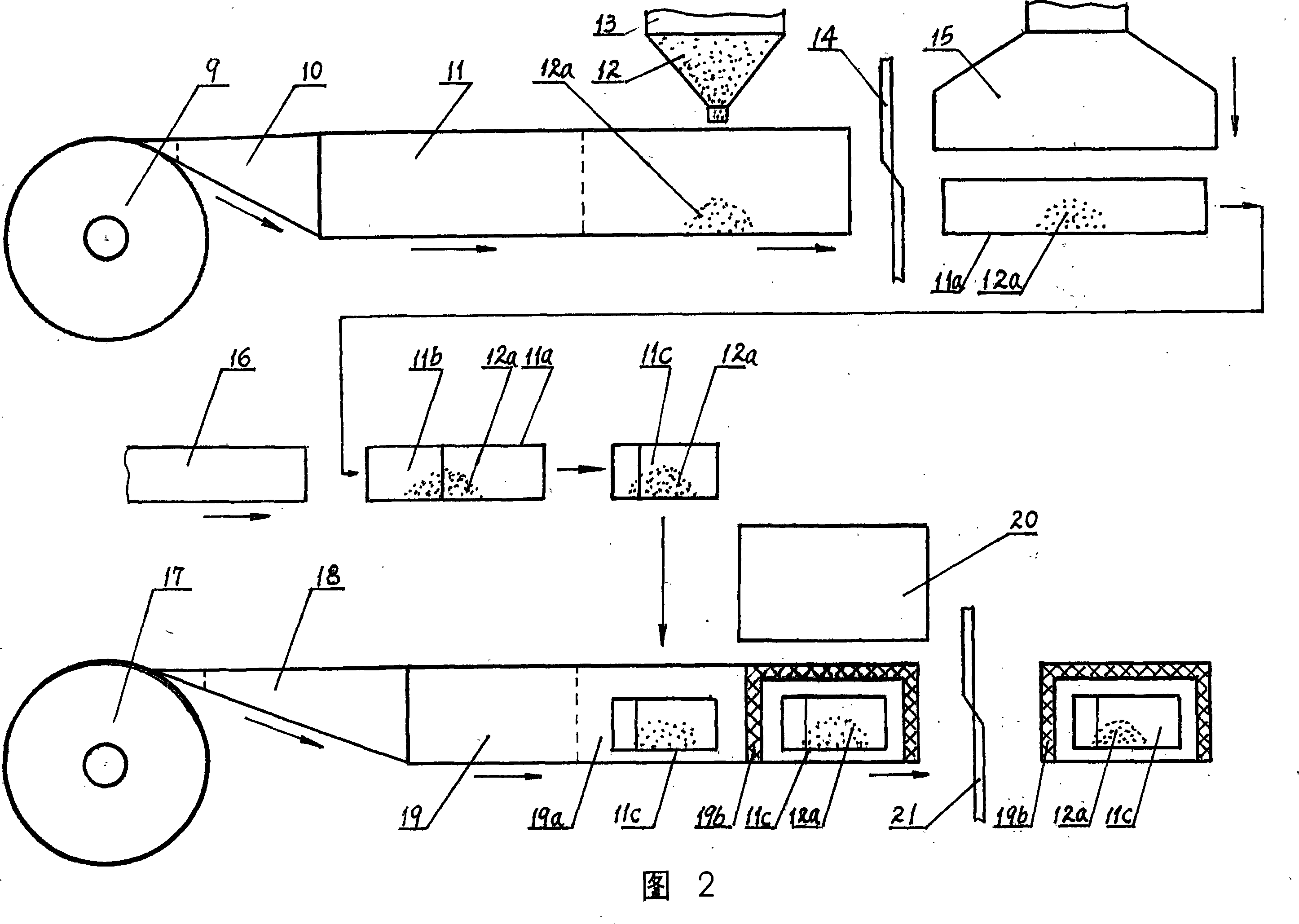

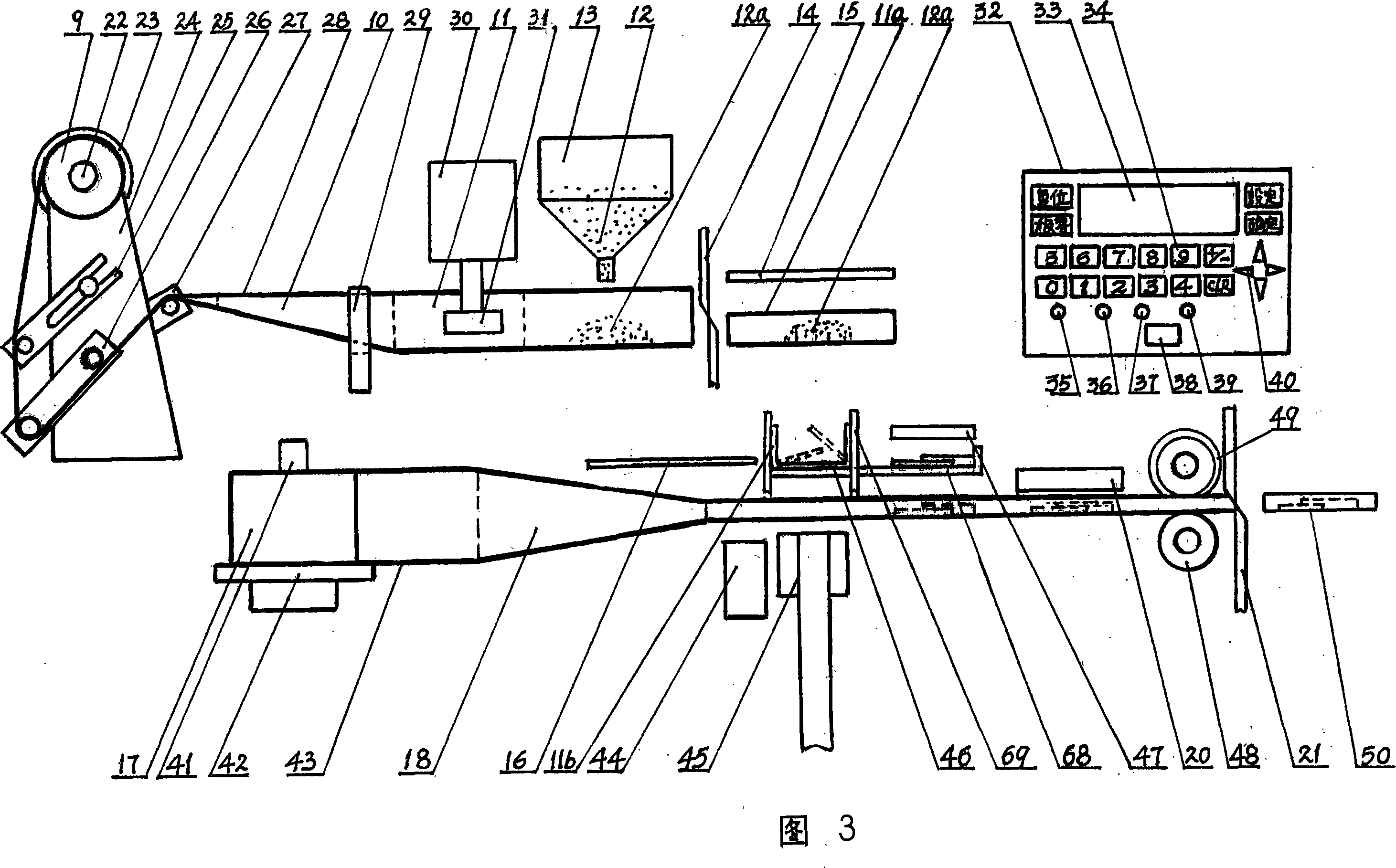

Full-automatic shaping packing machine of bag-in-bag

InactiveCN101177171AWrapper folding/bending apparatusWrapper twisting/gatheringHeat sealerControl system

The invention relates to a bag-in-bag full automatic forming packaging machine, applicable for the bag-in-bag full automatic forming package to repack an internal bag containing powder material in an external bag, which comprises a mechanical operation system, a mechanical transmission system and a control system. The mechanical operation system comprises an internal bag forming part, an external bag forming part and a double packaging part for bag-in-bag combination. The internal bag forming part comprises a cross break former, an internal bag forming head, an internal bag forming base, a further cross break pushing plate and a side-to-side break pushing plate, which enables the internal bag containing powder to be formed. After the external bag is formed with the cross break forming device, the internal bag is pushed into the external bag by a pushing plate of internal bag packing, and then the three side openings of the external bag are heat-sealed with a heat-sealer to form the bag-in-bag structure, thus the external bag forming part is formed. The invention has the advantages of high production efficiency, low cost, and hygiene and safety.

Owner:张建军

Method and apparatus for manipulating pre-sterilized components in an active sterile field

The connection, assembly, or fill of two or more pre-sterilized components having at least one terminal end each for attachment to another component, and an apparatus for performing such a connection, while maintaining the sterility of the components is disclosed. The resulting connection is made permanent by bonding the contacting components together using either a solvent bonding technique, a radio frequency sealer, a heat sealer, or any other suitable process. The connection is preferably made within an active sterile field. Using a low-voltage electron beam instrument, such as the MIN-EB™, a suitable sterile field sphere can be created. The terminal ends of the multiple components remain within the sterile field sphere until the possibility of contamination within the sealed components is significantly reduced to industry acceptable standards.

Owner:BAXTER INT INC

Heat sealer for stretch wrapping apparatus

A heat sealing device for sealing layers of plastic film together is provided. In a preferred embodiment, the heat sealing device is incorporated into a stretch wrapping apparatus for wrapping a load. The heat sealing device includes a heater element, an air compressor or blower, and a sealing head in fluid communication with the heater element to distribute the heated air. The sealing head is preferably flexible and includes a plurality of convection ports configured to apply heated air to a portion of the packaging material without being completely covered by the packaging material. At least one insulated film contact portion is provided to distance the convection ports from the plastic film.

Owner:LANTECH COM

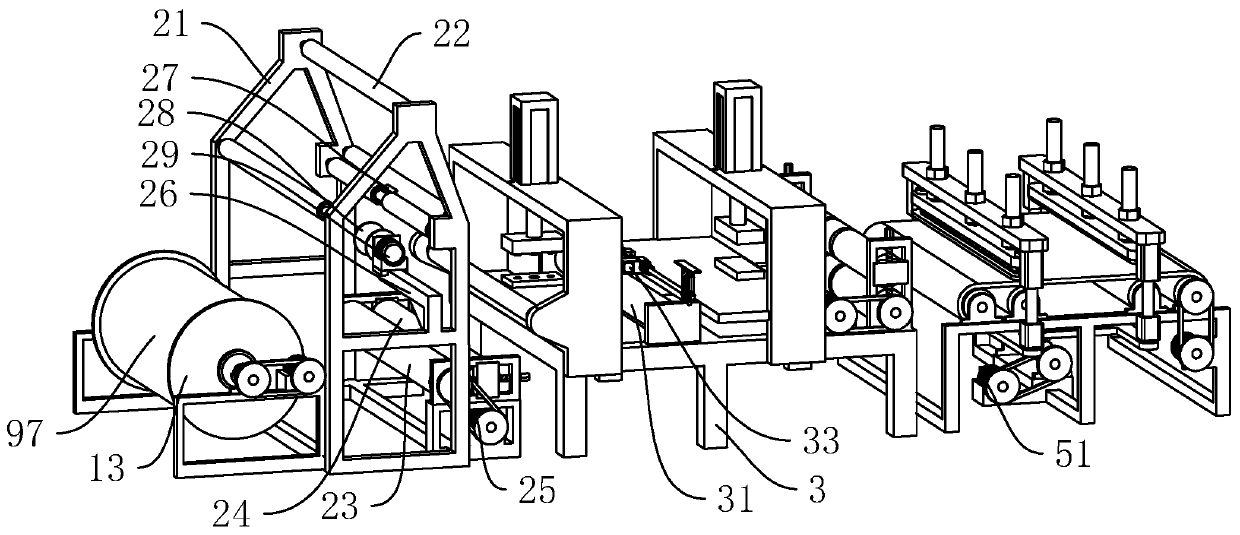

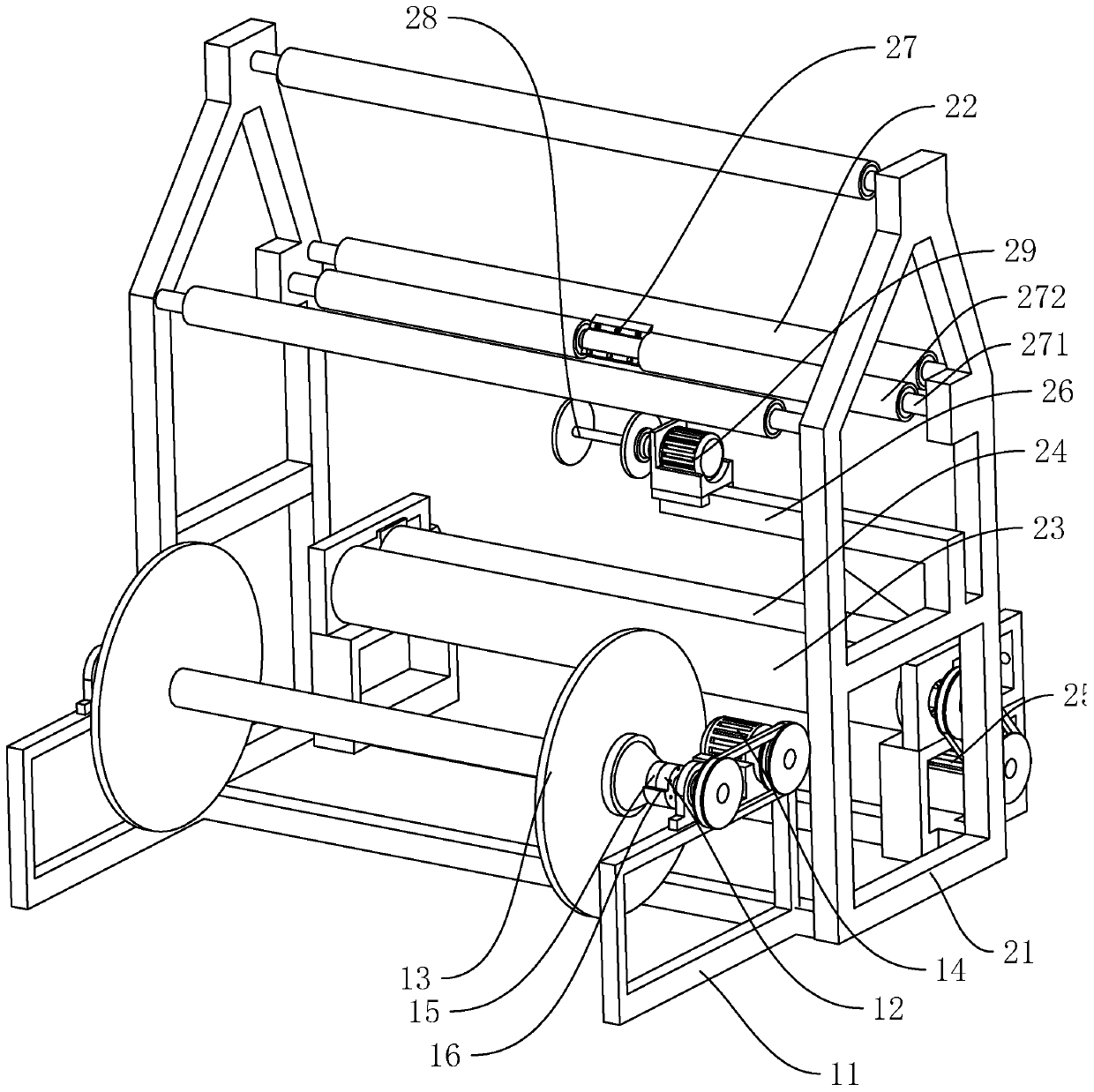

Hot pressing bag making equipment for packaging bags

PendingCN111331927AIncrease productivityGuaranteed installation stabilityBag making operationsPaper-makingHeat sealerPunching

The invention discloses hot pressing bag making equipment for packaging bags, relates to packaging bag production, and aims to solve the problem that the prior art lacks equipment for directly processing plastic bag films. According to the technical scheme, the hot pressing bag making equipment for packaging bags comprises a feeding device, a strip detaching device, a punching mechanism, an incision mechanism, a traction mechanism, a hot pressing cutting device and a blanking mechanism; the strip detaching device comprises an upward guide frame, guide rollers, a material pulling mechanism anda coil cutting mechanism; the incision mechanism comprises incision supporting rollers, tooth blade cutter discs and incision motors; the hot pressing cutting device comprises a heat sealing mechanism, a cutting mechanism, a crankshaft transmission mechanism and an alternating current motor. The hot pressing bag making equipment for packaging bags provided by the invention has the functions of detachment of waste strips, punching, incision and heat sealing cutting, so that the technical effect that packaging bags disclosed in the background technology can be produced by single equipment is realized, and the production efficiency is effectively improved.

Owner:嘉兴华悦包装用品有限公司

Table-top electric heat sealer

Owner:XEROX CORP

Double film bag type automatic packaging machine and automatic packaging process thereof

PendingCN109229565AIncrease packing capacitySimple and powerful mechanical structure designWrapper twisting/gatheringPackaging machineHeat sealer

The invention discloses a double film bag type automatic packaging machine and an automatic packaging process thereof. The machine comprises a lower film winding mechanism, an upper film winding mechanism, a bag body pulling mechanism, a three-side heat sealing mechanism, a bag clamping mechanism, a bag cutting mechanism, a side cutting mechanism, a bag opening mechanism, a sealing mechanism and apushing mechanism, and strip-shaped films exported by the lower film winding mechanism and the upper film winding mechanism are superposed on each other; the bag body pulling mechanism clamps the ends of the sides of the strip-shaped films superposed on each other; the three-side heat sealing mechanism continuously heat-closes the three side edges of the strip-shaped films; the bag clamping mechanism clamps the inner side portion of an outer end bag body, and the bag cutting mechanism cuts the outer end bag body from the strip-shaped films; the side of the bag body is trimmed neatly by the side cutting mechanism; the bag opening mechanism opens a bag mouth of the bag body, and a product on the pushing mechanism is pushed into the bag body through the bag mouth; the sealing mechanism heat-closes the bag mouth of the bag body. The machine can simultaneously achieve the production of a packaging bag and the packaging of a kit.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

Apparatus and method for temporary storage of animal waste

InactiveUS20070089688A1Safe and cleanSafe removalRefuse receptaclesTaming and training devicesRefuse collectionHeat sealer

Sealable feces disposal bags are provided in a temporary storage system. The bags are used to collect animal feces. After feces collection, the bags are temporarily sealed and then taken to a waste storage receptacle. The receptacle houses a bag heat sealer, mechanical sealer, or adhesive sealer which is used to provide an odor-free seal to the bag. Sealed bags are stored on the receptacle until they are removed for garbage pick-up.

Owner:NITZSCHE CHRISTINE +1

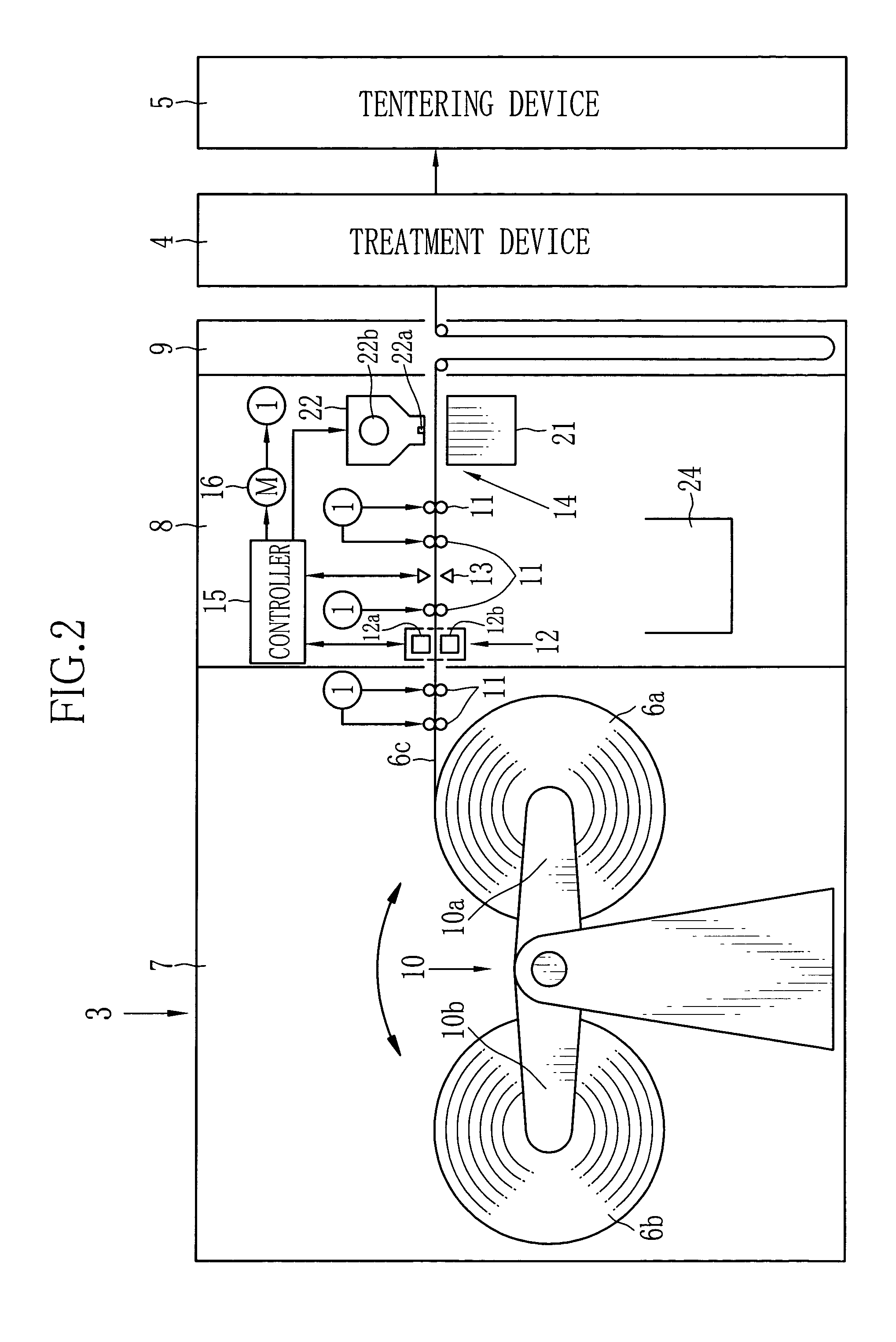

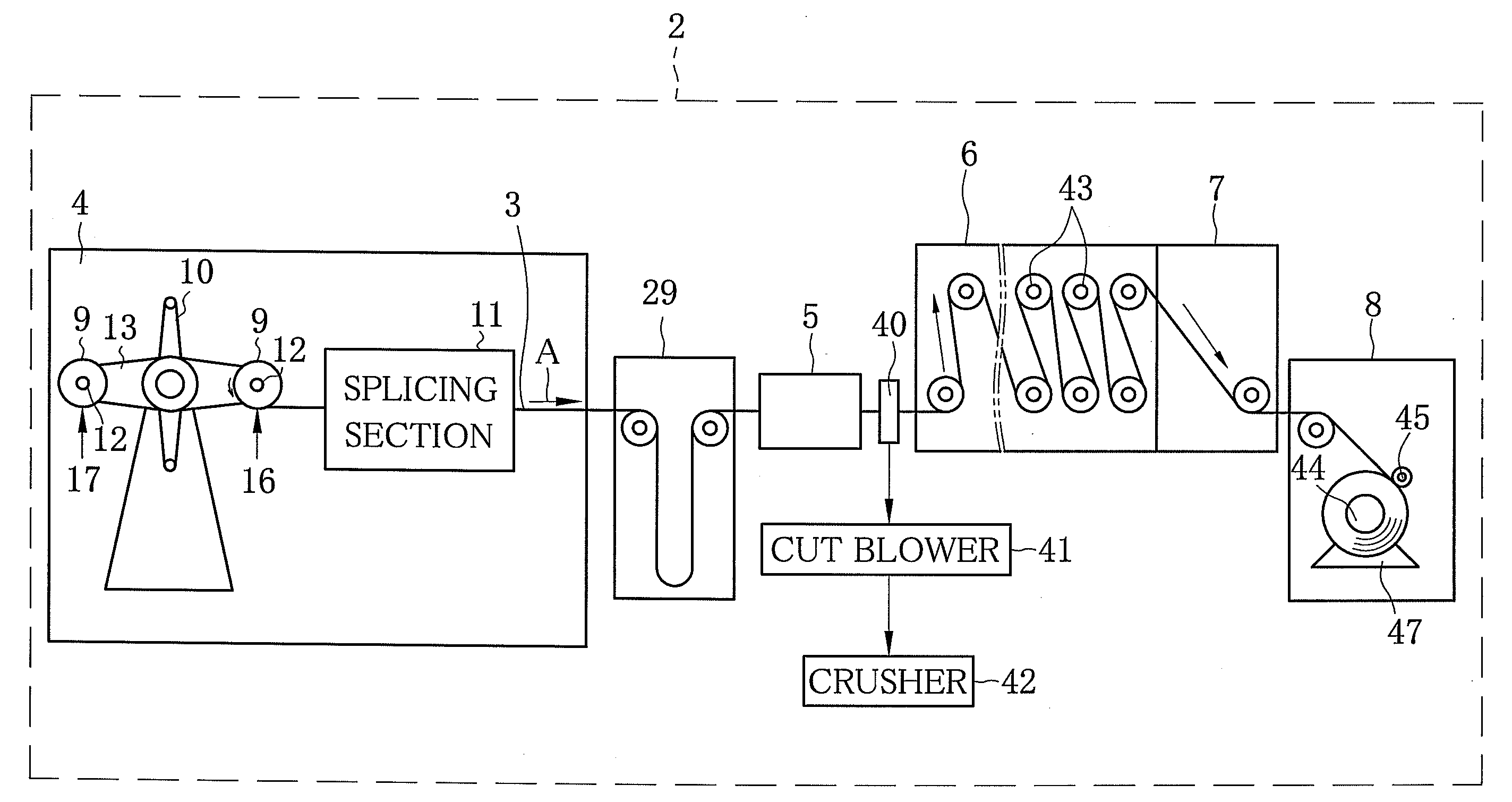

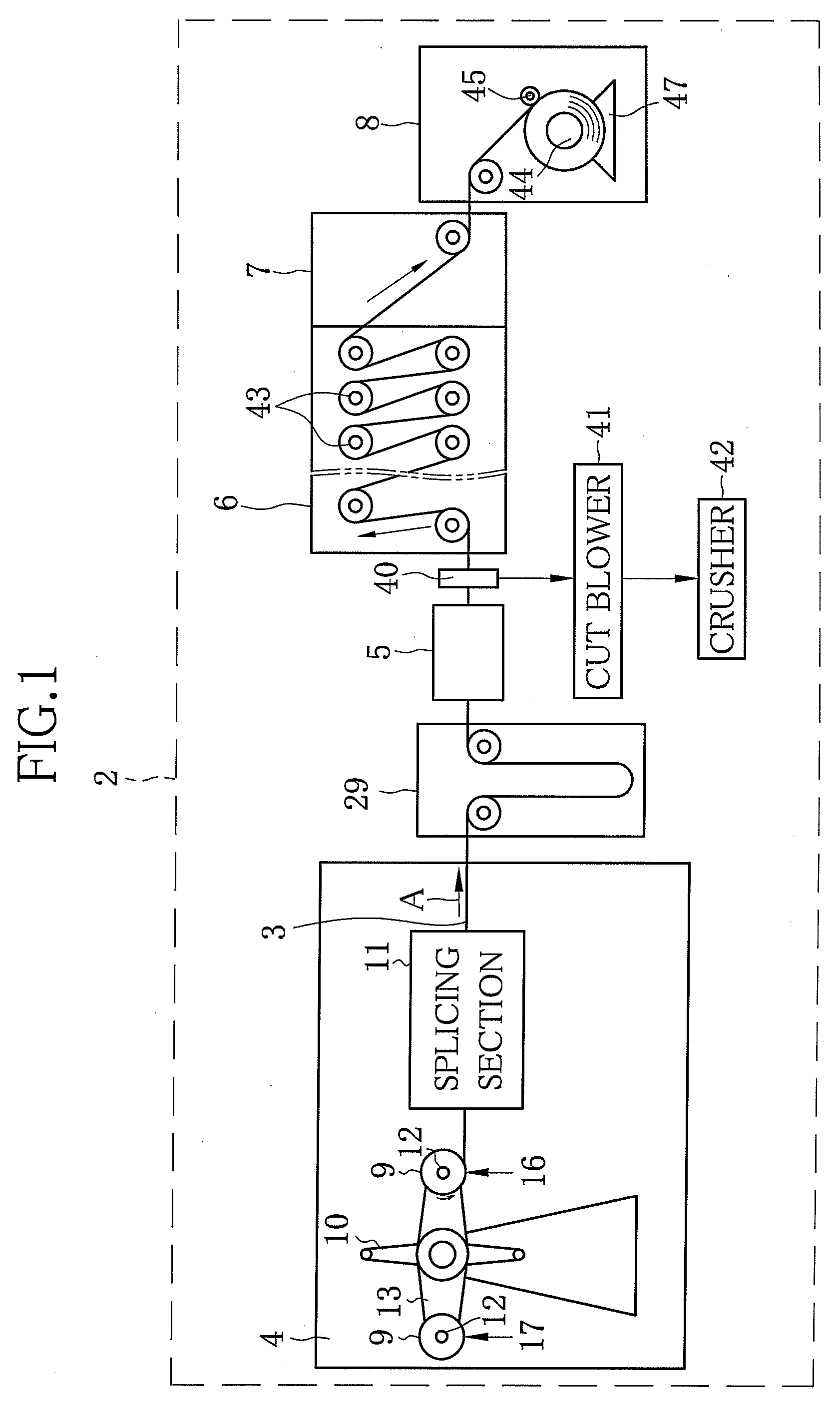

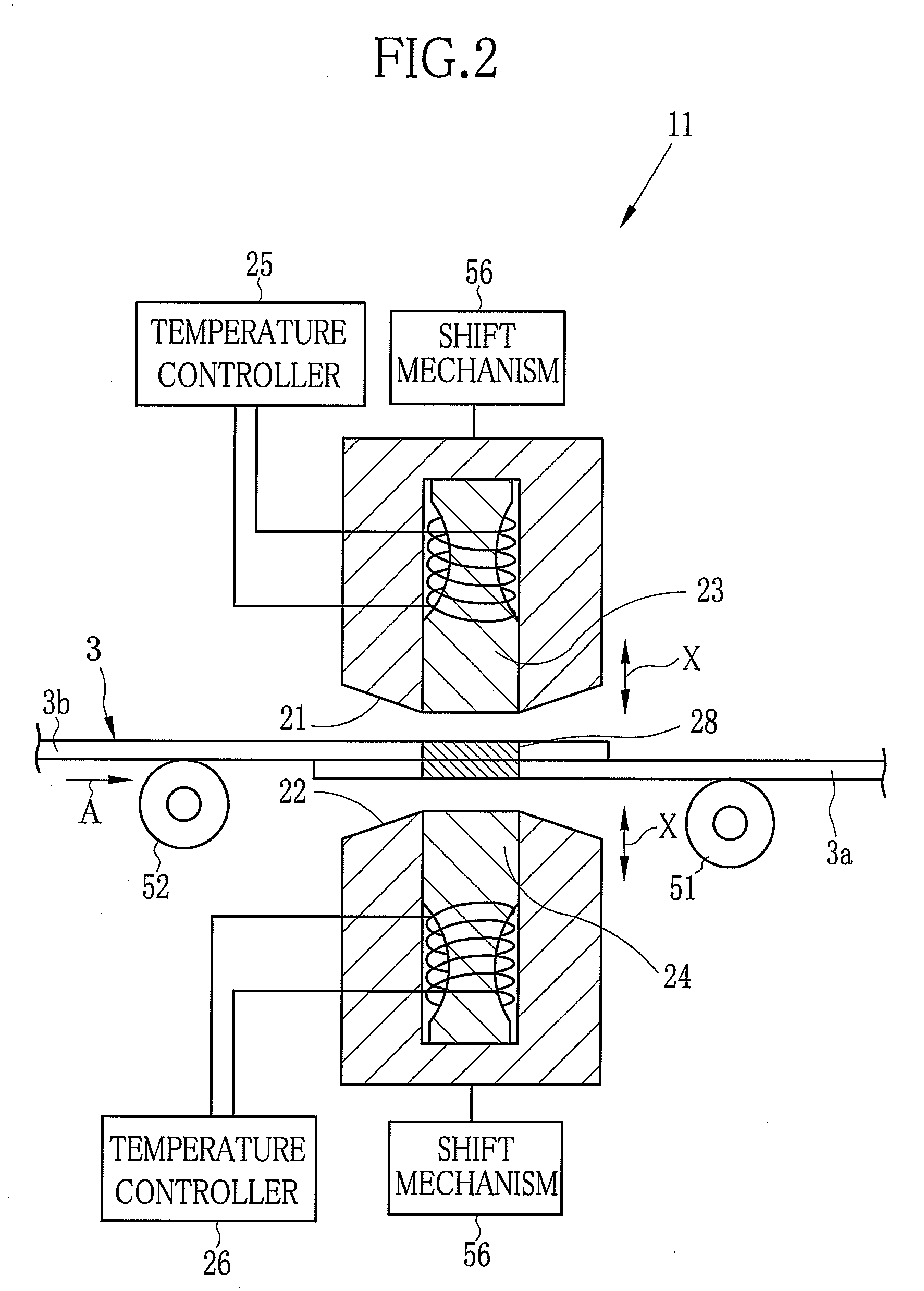

Polymer film splicing method and device, and stretching method

InactiveUS20090032166A1Easily thermally decomposedAvoid it happening againWelding/cutting auxillary devicesLaminationWrinkle skinHeat sealer

An off-line stretching device includes a film supply chamber, a tenter section, a relaxation chamber, a cooling chamber, and a winding chamber. The film supply chamber includes a splicing section, where a rear end of a preceding film and a front end of a trailing film are overlapped to be spliced to each other by thermal welding. The thermal welding is performed from above and below the film while a temperature of welding heads of a heat sealer, contacting with the film, is kept at a level equal to or less than a decomposition temperature of the preceding and trailing films. The spliced film is stretched in the tenter section and subjected to heat treatment for stress relaxation in the relaxation chamber, to shrink in a film width direction. Since the shrinkage amount of a spliced area and that of a peripheral area become equal to each other, the occurrence of wrinkles in the spliced area and tears of the film in the peripheral area can be prevented. Additionally, since a heat transfer distance between a film surface and a film splicing surface can be shortened, the heating from above and below the film enables high-speed welding.

Owner:FUJIFILM CORP

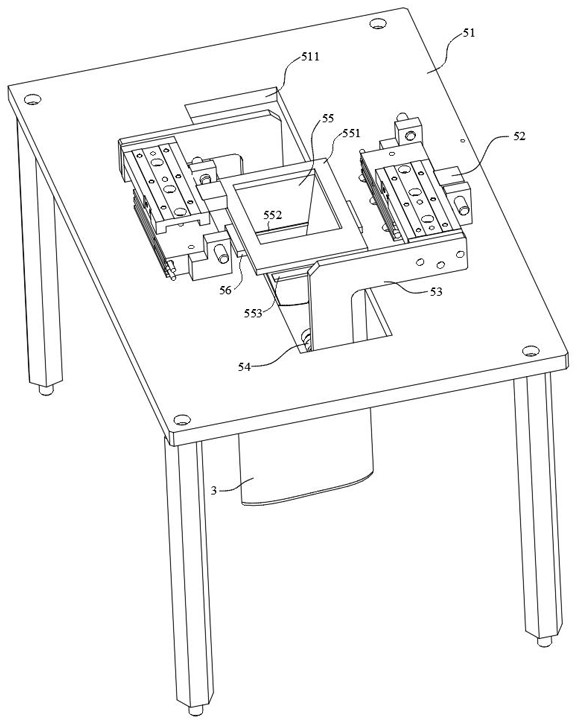

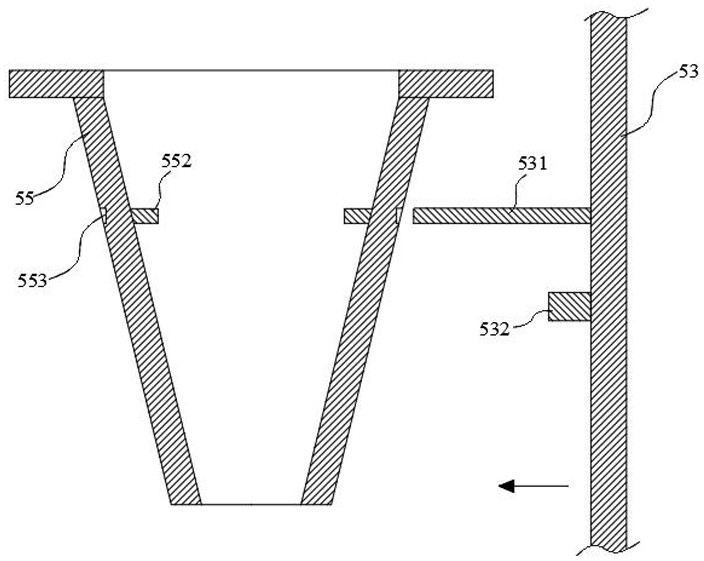

Freshness protection package heat sealing device and heat sealing method facilitating material filling

ActiveCN112722445APrevent splashPrevent overflowWrapper twisting/gatheringSolid materialAir compressionHeat sealer

The invention relates to the technical field of bag making, in particular to a freshness protection package heat sealing device and heat sealing method facilitating material filling. The freshness protection package heat sealing device facilitating material filling comprises bag clamping mechanisms and heat sealing mechanisms, wherein the bag clamping mechanisms are suitable for clamping a bag body; the two heat sealing mechanisms are oppositely arranged and can slide oppositely and conduct heat sealing on the bag body; an opening support is erected between the two bag clamping mechanisms; a material filling hole is formed in the opening support; a liftable material guide pipeline is arranged on the upper end surface of the opening support; the material guide pipeline is funnel-shaped; the cross section area of the material guide pipeline is gradually reduced from top to bottom; and the material guide pipeline extends into the material filling hole. After the bag body is opened, the material guide pipeline descends to extend into the bag body, the material guide pipeline is deformed by extruding the material guide pipeline to compress air, the compressed air blows air to the bag body, and the bottom of the bag body is also opened, so that the bag body is ensured to be completely opened, and the situation that materials overflow is avoided.

Owner:常州江苏大学工程技术研究院 +1

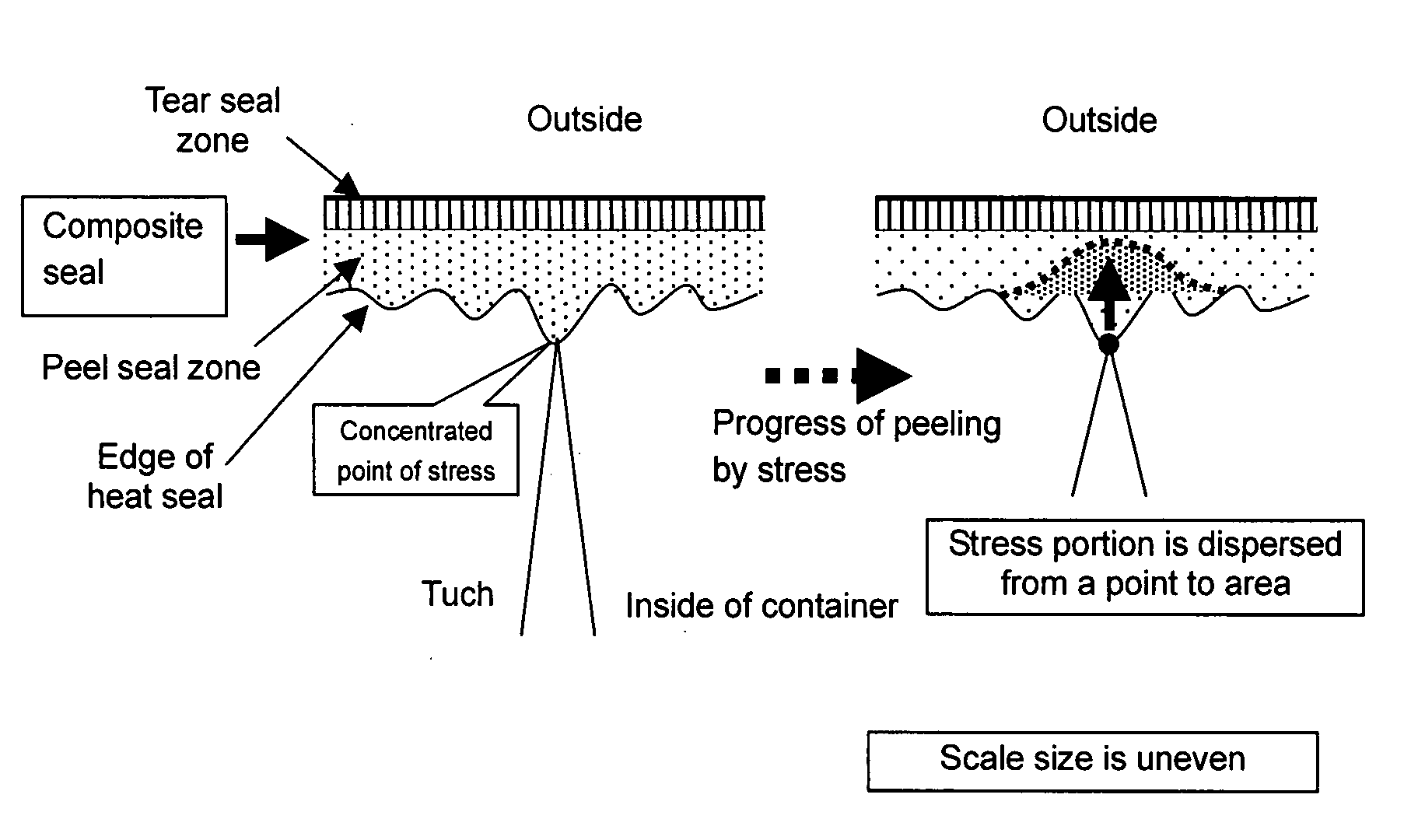

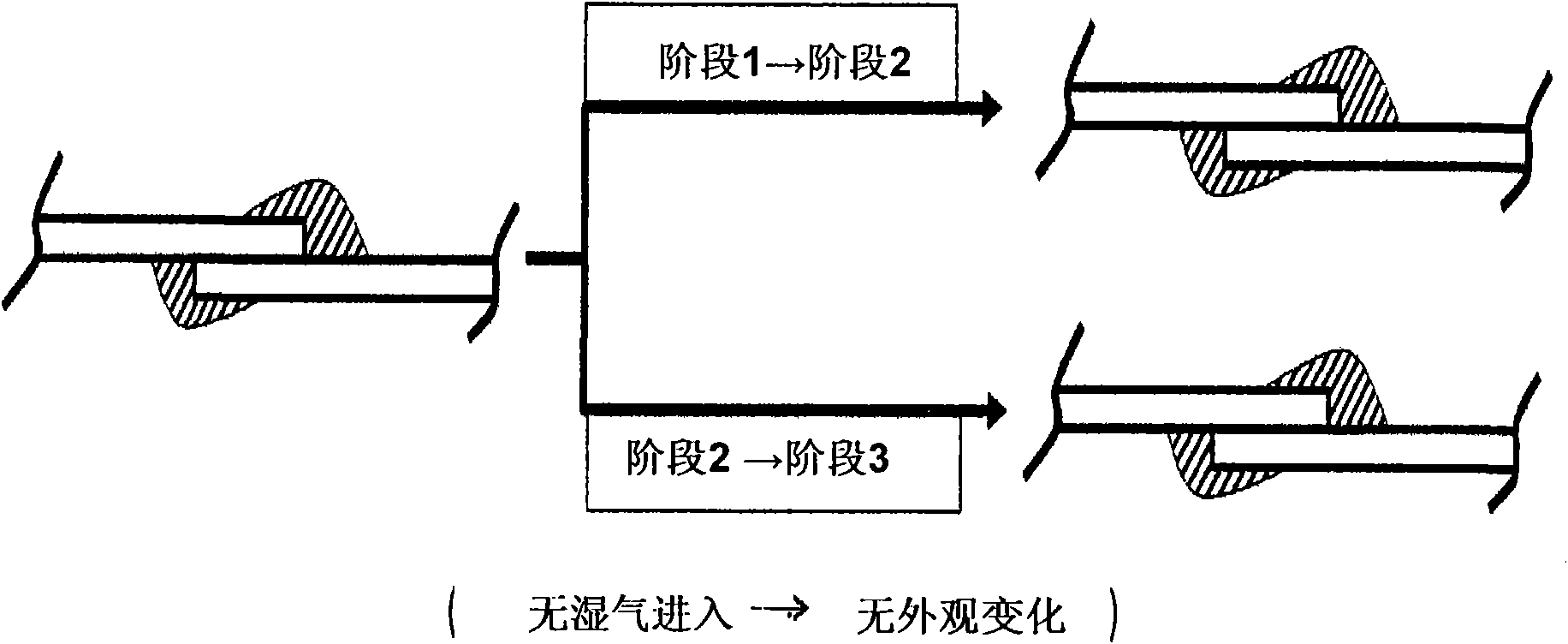

Method of forming composite seal structure of peel seal and tear seal

InactiveUS20080187256A1Increasing the thicknessImprove reliabilityClosuresClosure using stoppersHeat sealerEngineering

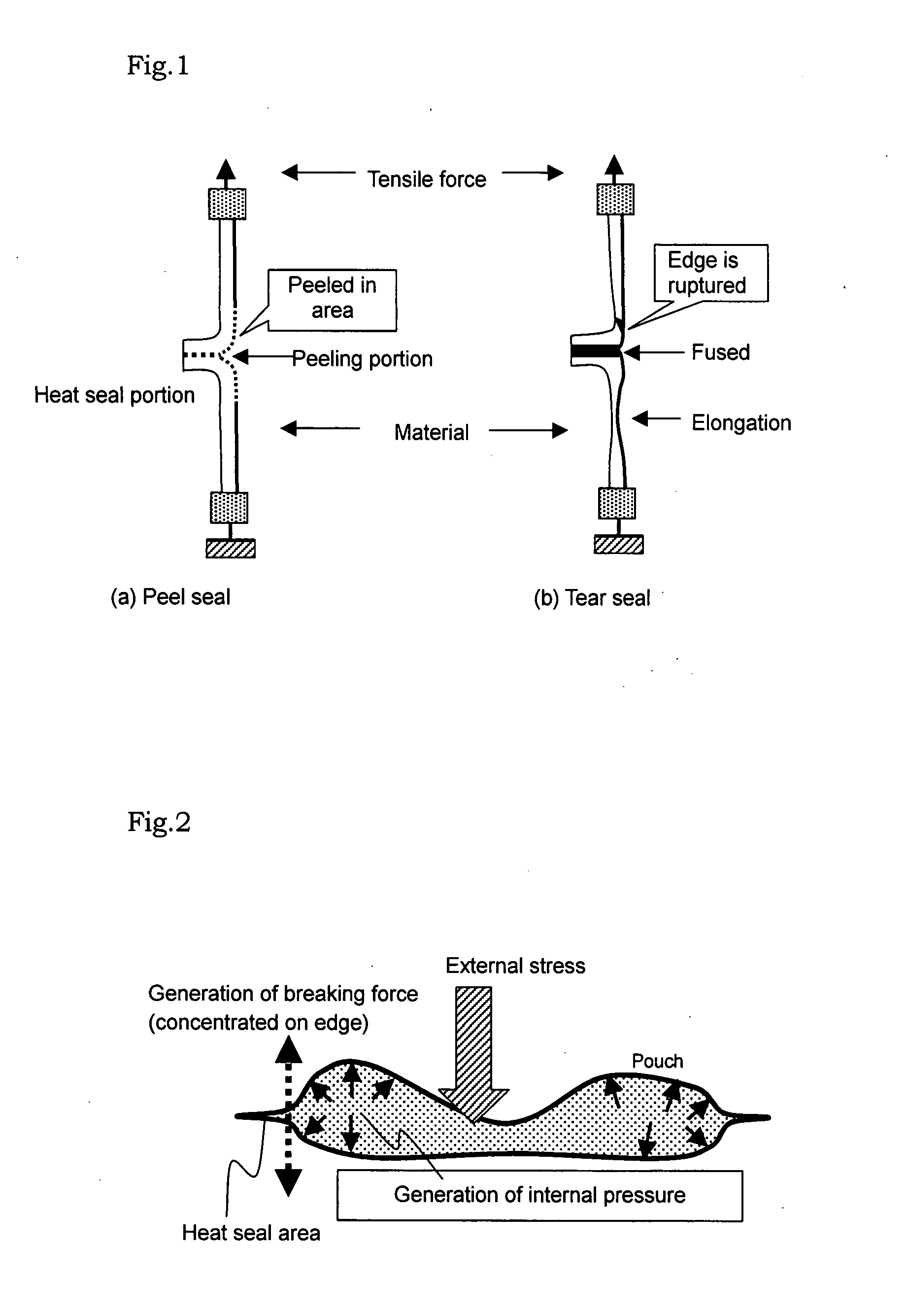

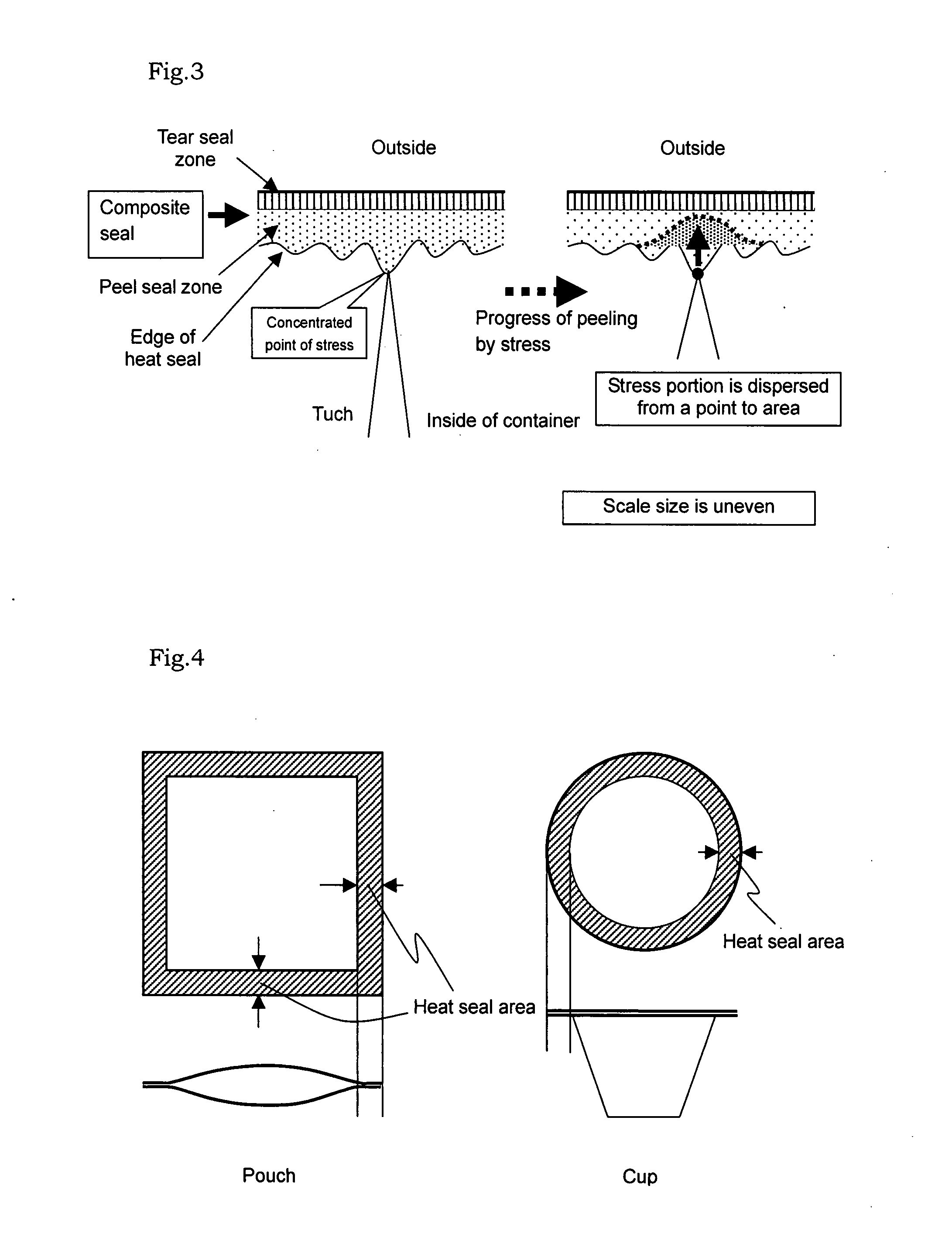

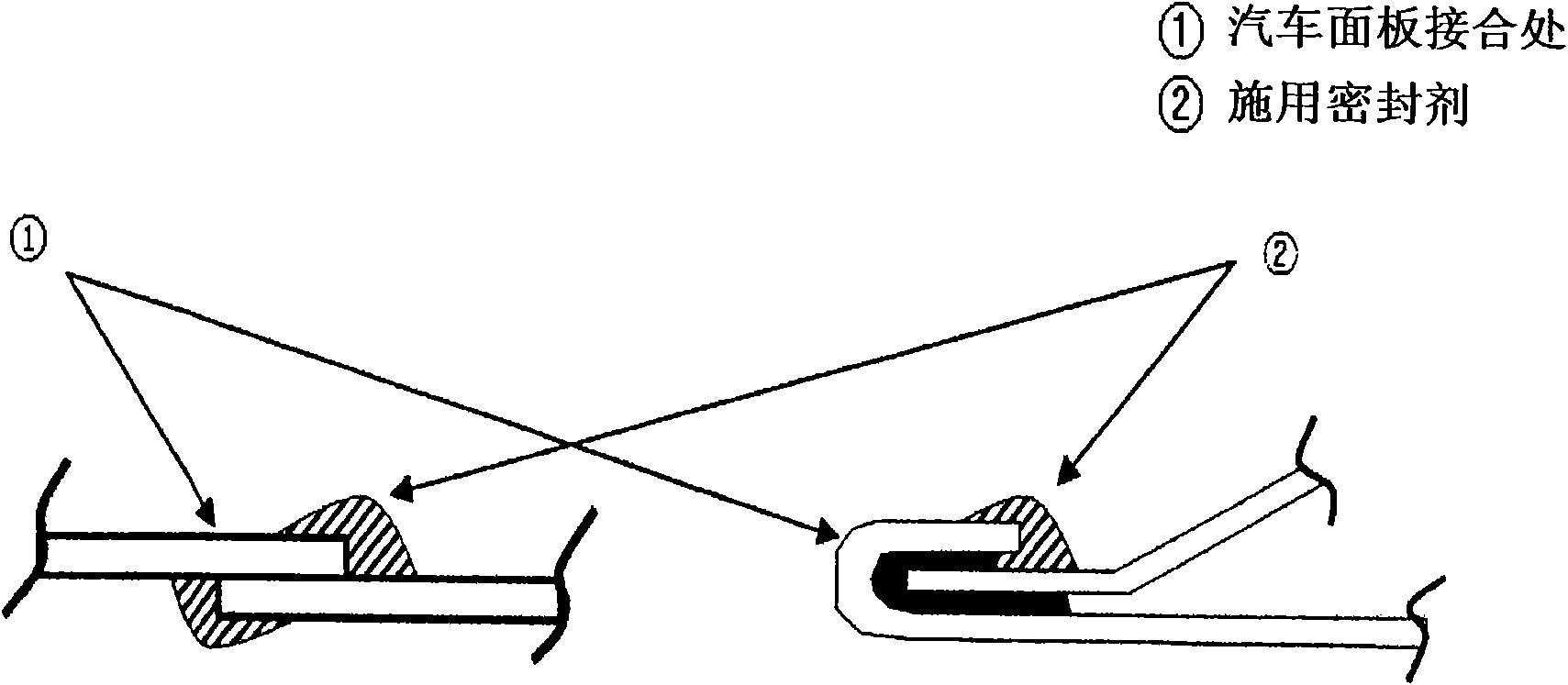

A method of forming a composite seal structure having great resistance to rupture, rare generation of pinholes is provided which comprises using a heat sealer having two blocks which presses sheets to be heat-sealed and at least one of which is a heating block provided with a seat which renders its surface at a temperature forming peel seal, on a part of its surface pressing the sheets, heating the heating block at a temperature forming tear seat, and pressing the sheets to form a heat seal having the composite seal structure of peel seal and tear seal.

Owner:HISHINUMA KAZUO

Compositions for humidity proof heat sealer having low specific gravity

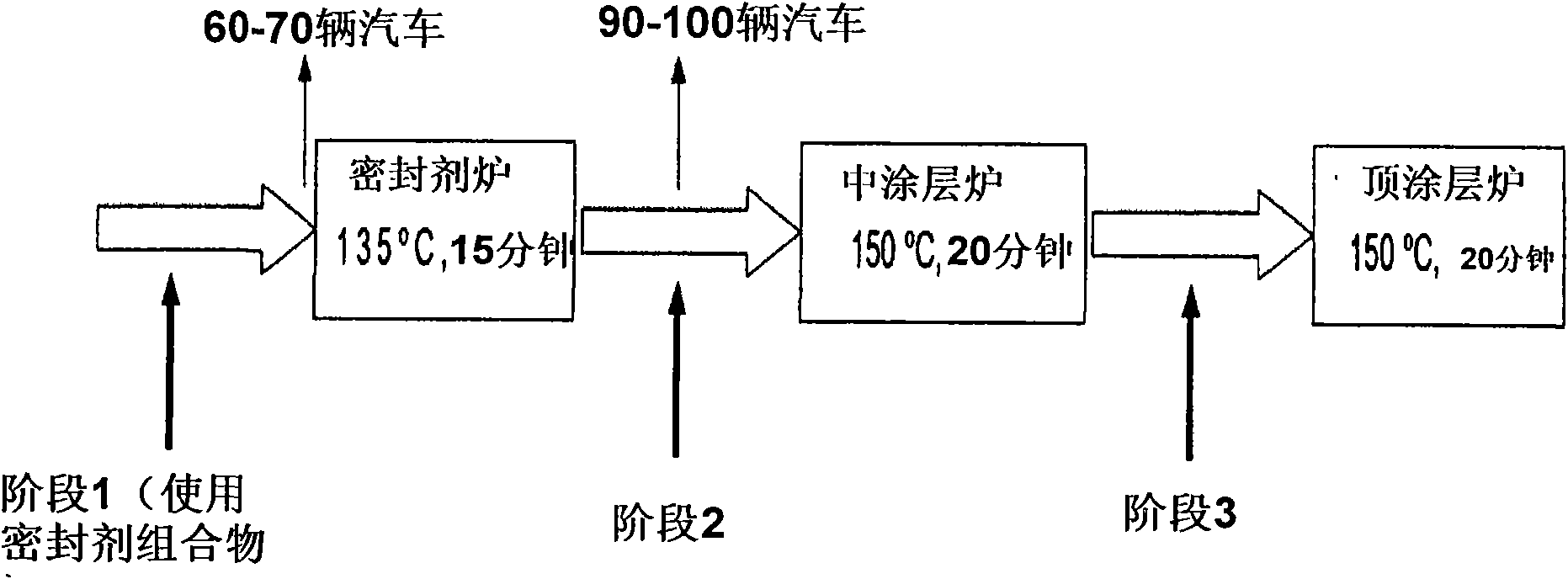

InactiveCN101555398AReduce weightImprove efficiencyOther chemical processesVehicle sealing arrangementsHeat sealerPlasticizer

The present invention relates to humidity-proof heat sealer compositions having low specific gravity, which comprise a polyvinyl chloride resin, a filler, a moisture absorbent, a plasticizer, an adhesion promoter, an additive, and so forth, for use in automotive steel sheet joints or outside panel joints. When compared with conventional sealer compositions, the present compositions provide improved humidity resistance, as well as improved fuel efficiency.

Owner:HYUNDAI MOTOR CO LTD

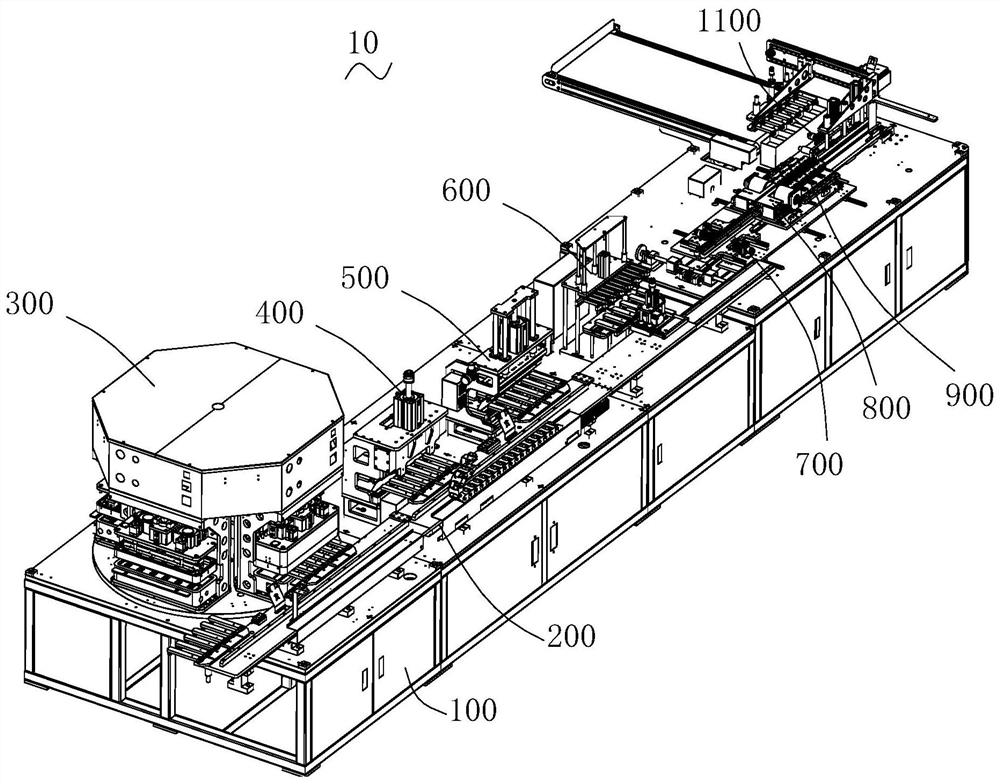

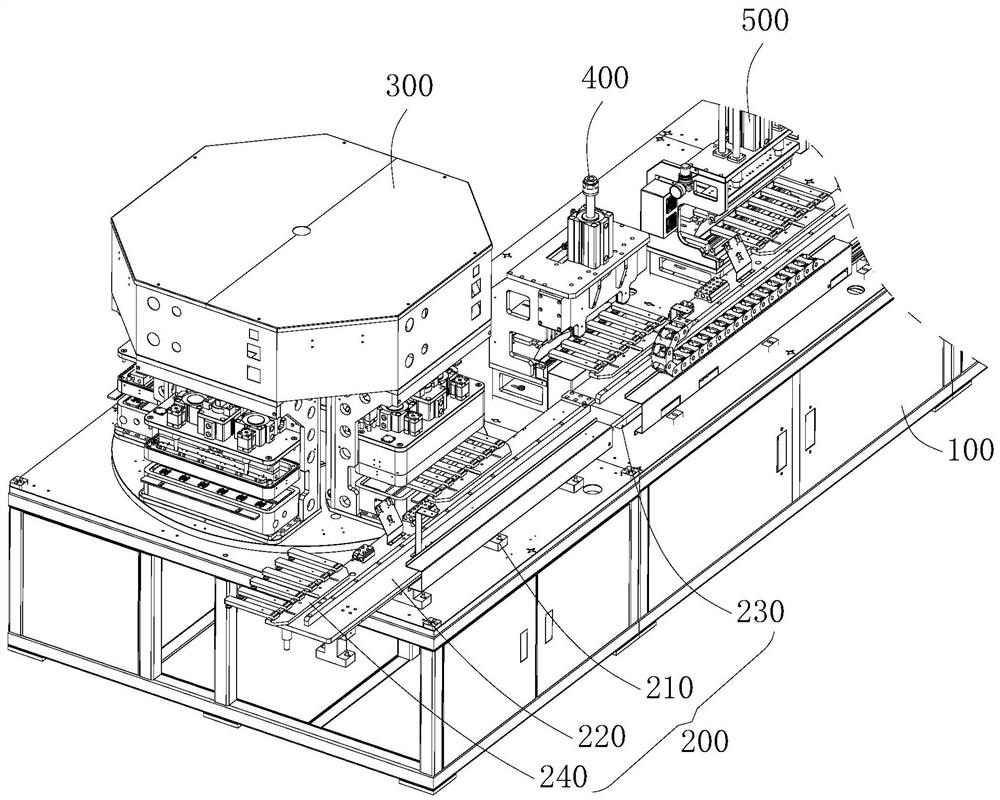

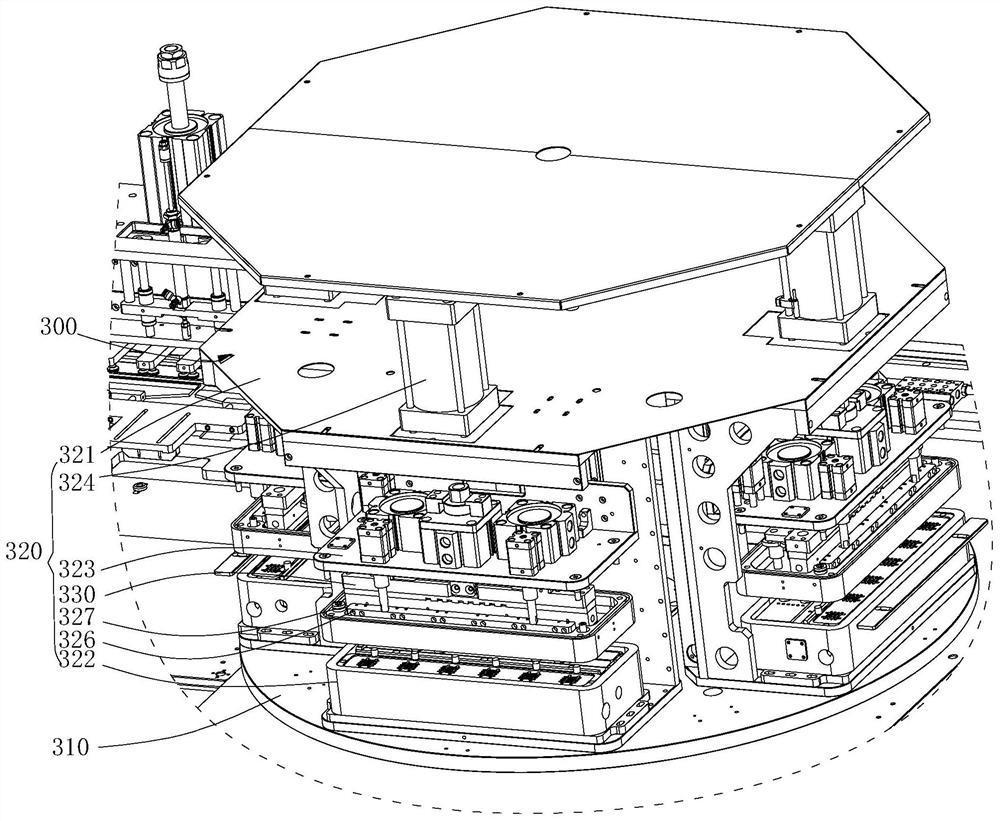

Vacuumizing packaging mold and equipment, and battery cell manufacturing system

PendingCN111864247AGuaranteed compactnessEnsure normal dischargeAssembling battery machinesFinal product manufactureHeat sealerEngineering

The invention provides vacuumizing packaging equipment, and a battery cell manufacturing system. The vacuumizing packaging equipment comprises a mounting frame, a first die holder, a second die holder, an opening and closing driving assembly, a piercing mechanism, a heat sealing mechanism and a pressing mechanism, wherein the first die holder is arranged on the mounting frame, a first connecting hole is formed in the first die holder, the second die base covers the first die base, a containing cavity is defined between the second die base and the first die holder, the first connecting hole iscommunicated with the containing cavity, a containing table is arranged on an inner wall of the containing cavity in a protruding mode, the opening and closing driving assembly is arranged on the mounting frame, a power output end of the opening and closing driving assembly is connected with the second die holder, and the opening and closing driving assembly drives the second die holder to move relative to the first die holder, and the piercing mechanism is partially positioned in the accommodating cavity and is used for piercing the battery cell. Due to the fact that when the battery cell ispunctured, the pressing assembly presses the battery cell on the supporting plate assembly, exhaust efficiency in the battery cell is improved, and meanwhile, that gas in the battery cell is completely exhausted is guaranteed.

Owner:惠州市华维机电设备有限公司

Apparatus for manipulating pre-sterilized components in an active sterile field

InactiveUS20050161614A1Material analysis using wave/particle radiationElectric discharge tubesHeat sealerLow voltage

The connection, assembly, or fill of two or more pre-sterilized components 10, 12 having at least one terminal end 14 each for attachment to another component, and an apparatus for performing such a connection, while maintaining the sterility of the components is disclosed. The resulting connection is made permanent by bonding the contacting components 10, 12 together using either a solvent bonding technique, a radio frequency sealer, a heat sealer, or any other suitable process. The connection is preferably made within an active sterile field 60. Using a low-voltage electron beam instrument 54, such as the MIN-EB™, a suitable sterile field sphere can be created. The terminal ends 14 of the multiple components 10, 12 remain within the sterile field sphere 60 until the possibility of contamination within the sealed components is significantly reduced to industry acceptable standards.

Owner:C R F SOC CONSORTILE ER AZIONI +1

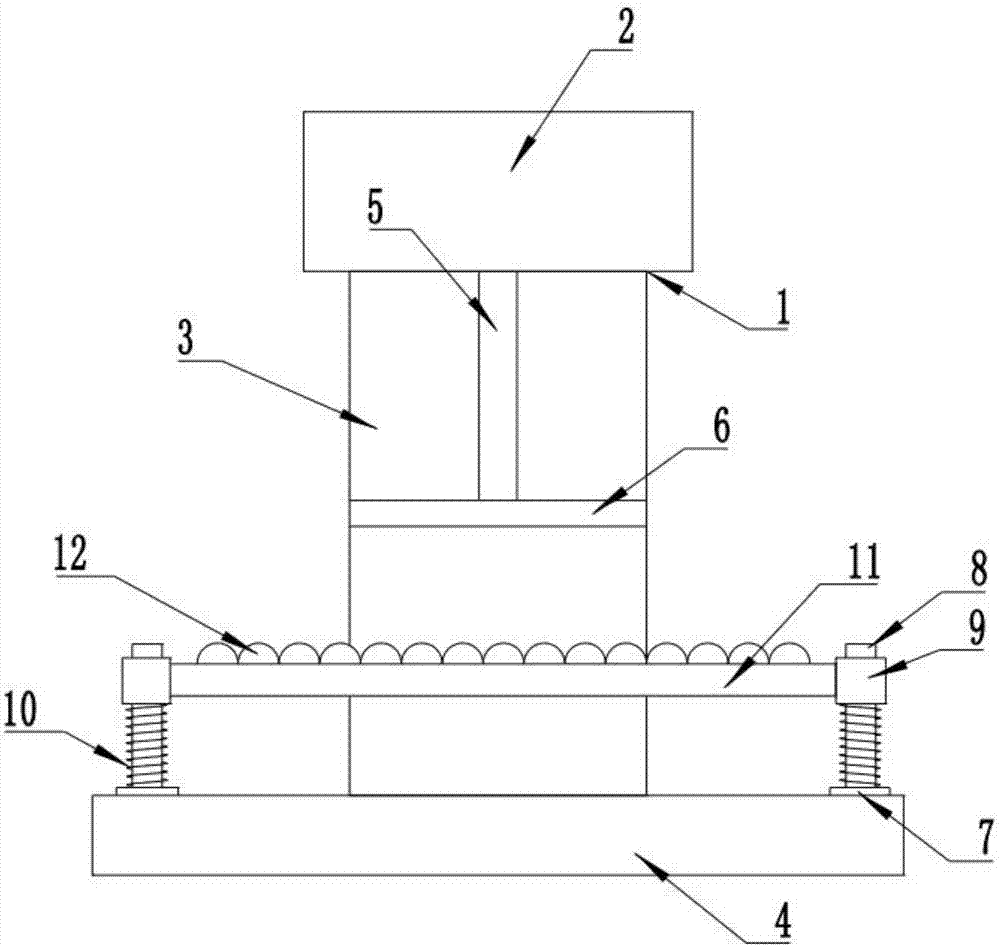

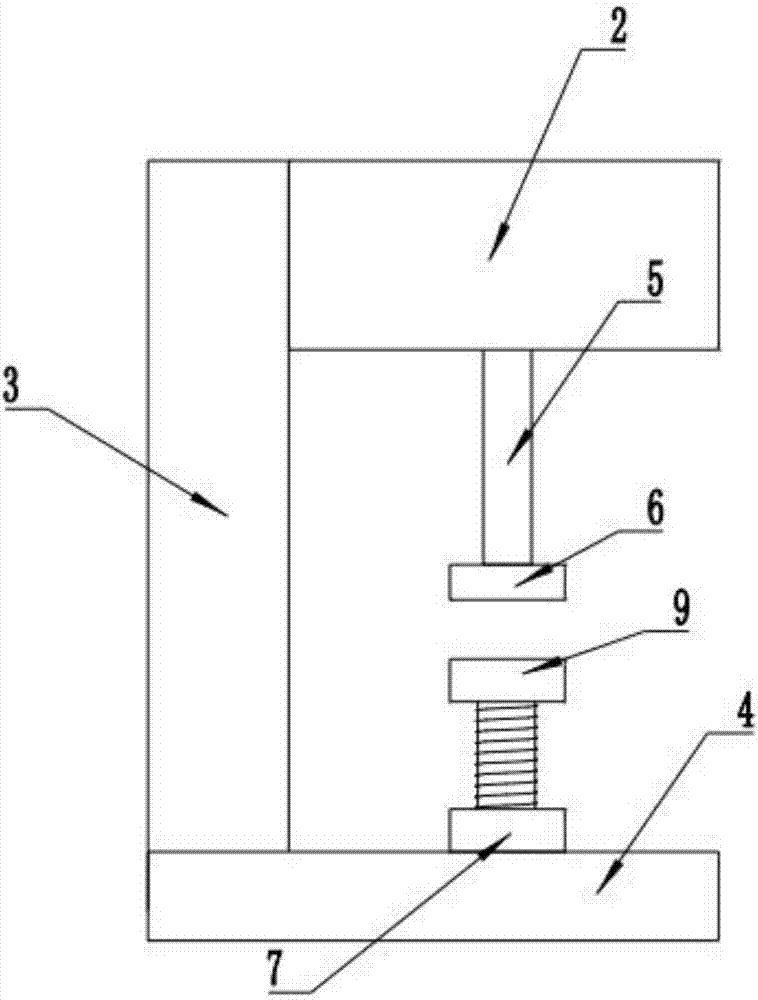

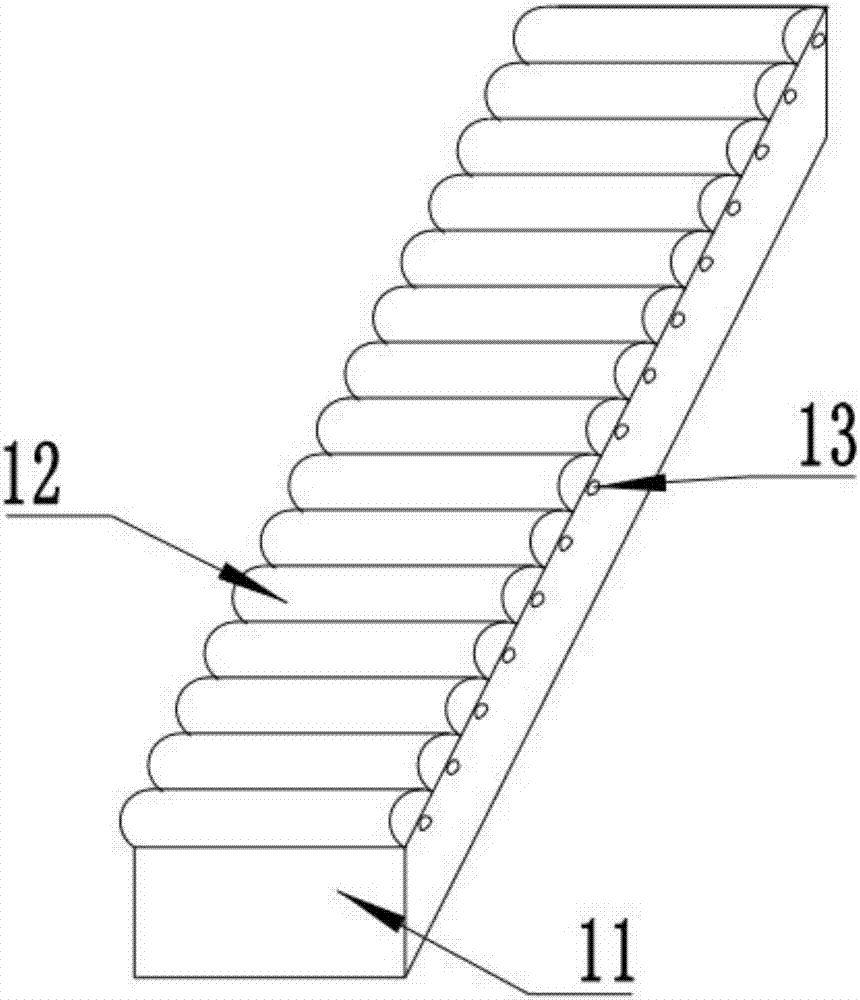

Packaging heat sealing machine convenient to use

InactiveCN106864868AImprove shock absorptionNo vibrationWrapper twisting/gatheringHydraulic cylinderHeat sealer

The invention discloses an easy-to-use packaging heat-sealing machine, which comprises a heat-sealing machine body; the heat-sealing machine body is mainly composed of a hydraulic cylinder, a support frame, a base, and a melting pressure plate; a telescopic rod is connected to the bottom of the hydraulic cylinder; The welding pressure plate is fixedly welded, the base is connected with a shock-absorbing pad, the shock-absorbing pad is fixedly connected with a support column, the support column is provided with a sliding part, and a spring is fixedly connected between the sliding part and the base, and the side wall of the sliding part is fixed by welding A heat-sealing groove is connected, and a plurality of connecting rods are arranged on the top of the heat-sealing groove, and a connecting pipe is fixedly connected to the side wall of the heat-sealing groove, and a valve is arranged on the connecting pipe. The heat-sealing machine can effectively smooth the heat-sealed part of the packaging bag when heat-sealing the packaging bag, avoiding the wrinkling of the packaging bag mouth when heat-sealing, and effectively cooling the packaging bag mouth after heat-sealing, avoiding the The opening of the bag is rolled up, and the heat-sealing machine has good shock absorption, and there is no vibration during heat-sealing.

Owner:HAINING XIANFENG PRINTING

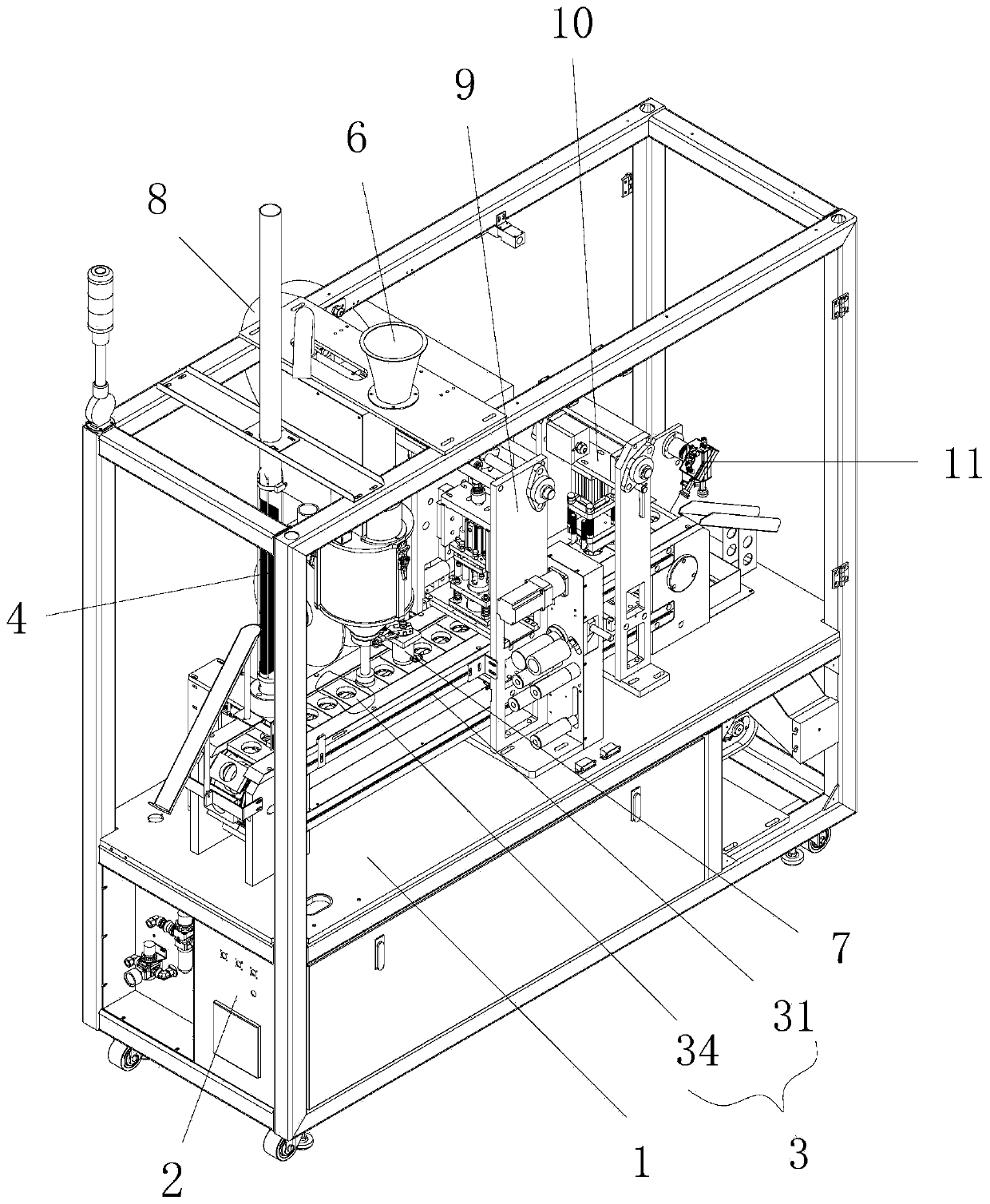

Linear filling and sealing machine

PendingCN111547317ACompact structureGuaranteed uptimeWrapper twisting/gatheringSolid materialHeat sealerElectric machine

The invention discloses a linear filling and sealing machine. The linear filling and sealing machine comprises a machine frame, an electric box, a transmission mechanism, a cup dropping device, a cupdetection sensor, a feeding device, a powder pressing and sucking device, a film pay-off device, a cutting sealing machine, a heat sealing machine and a cup discharging device, wherein the electric box is arranged in the machine frame, the transmission mechanism is arranged on the machine frame, and the cup dropping device, the cup detection sensor, the feeding device, the powder pressing and sucking device, the film pay-off device, the cutting sealing machine, the heat sealing machine and the cup discharging device are arranged on the machine frame in sequence in the transmission direction ofthe transmission mechanism. The transmission mechanism comprises a chain conveyor belt, a motor, a divider and mold plates, the chain conveyor belt is arranged on the machine frame, the motor drivesthe divider to rotate, the divider drives the chain conveyor belt to perform transmission through a chain, and the mold plates on which coffee capsule cups are placed are arranged on the chain of thechain conveyor belt at equal intervals. In this way, the linear filling and sealing machine is compact in structure, stable in operation, complete in function, small in occupied area, free of repeatedpositioning, low in manufacturing cost, short in cycle, high in efficiency, high in adaptability and capable of meeting flexible production requirements.

Owner:江苏神翌机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com