Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Prevent such non-uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

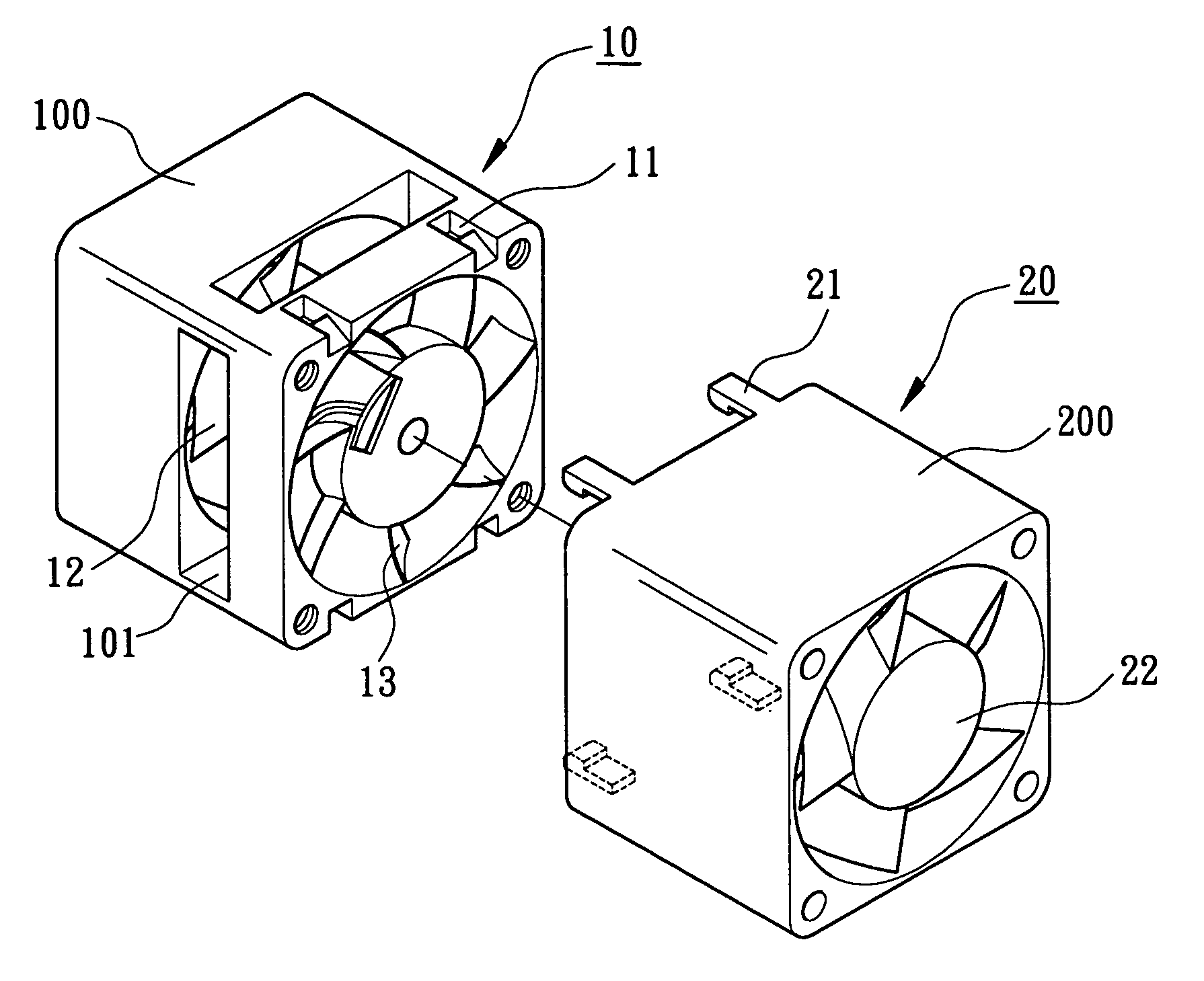

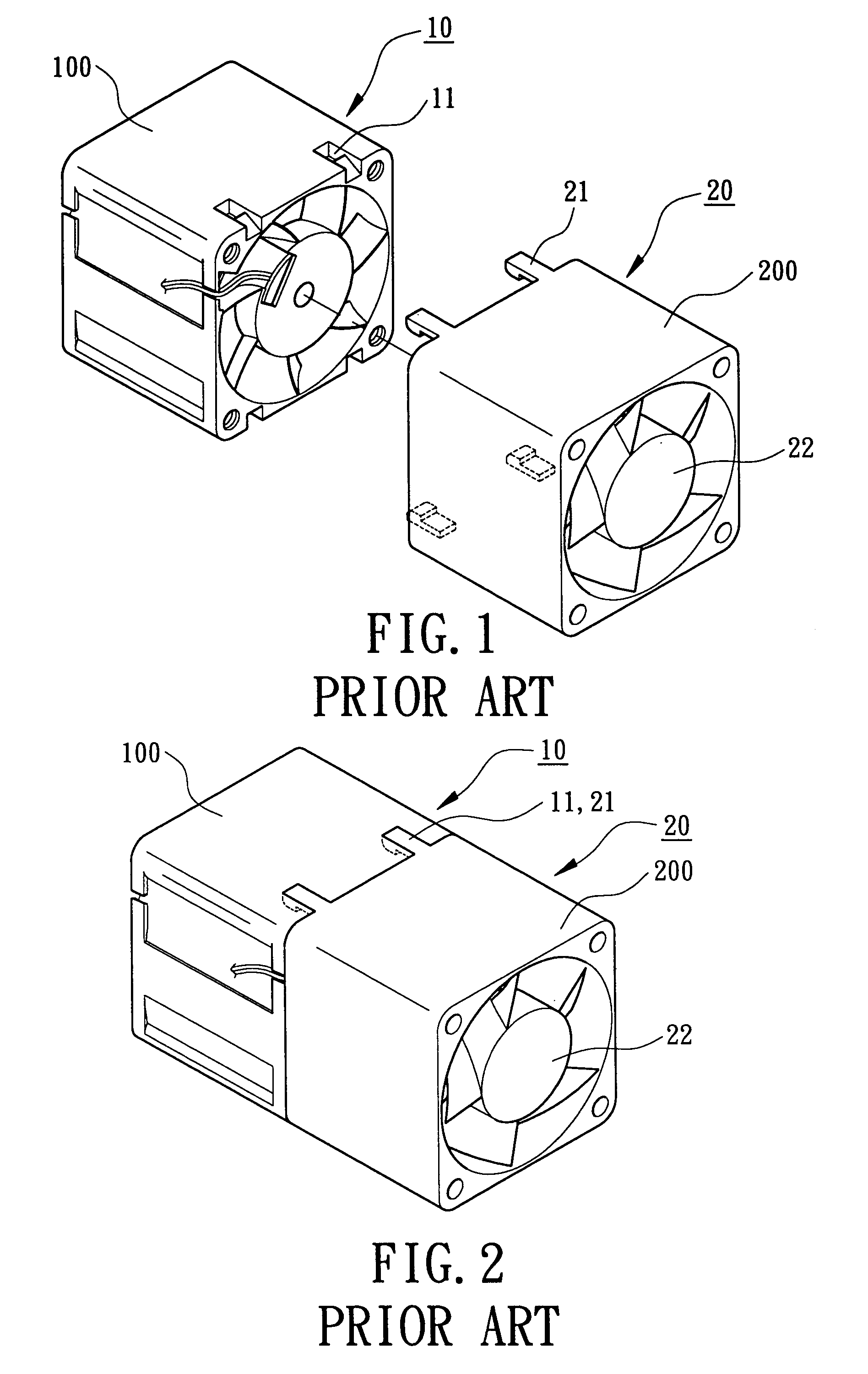

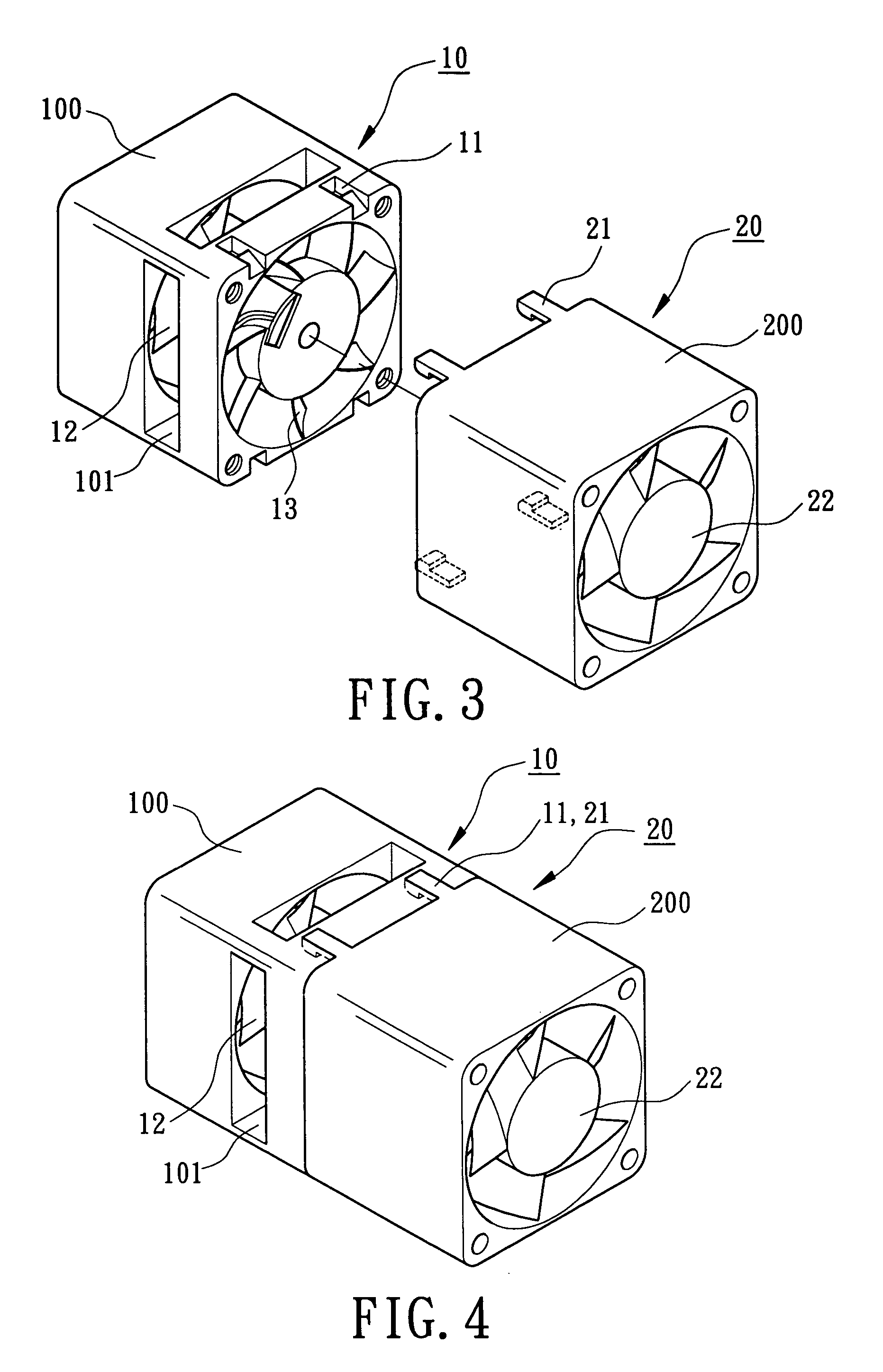

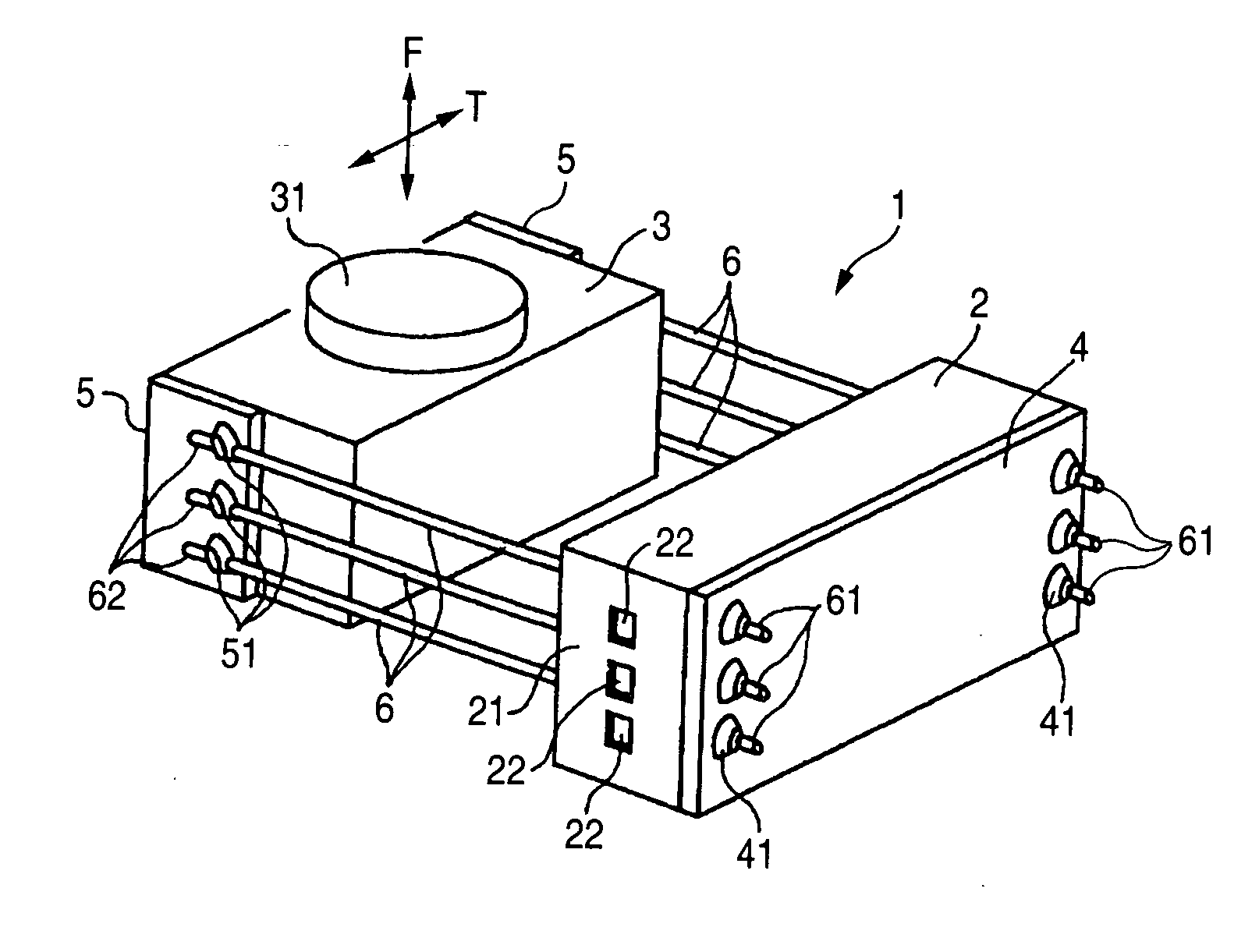

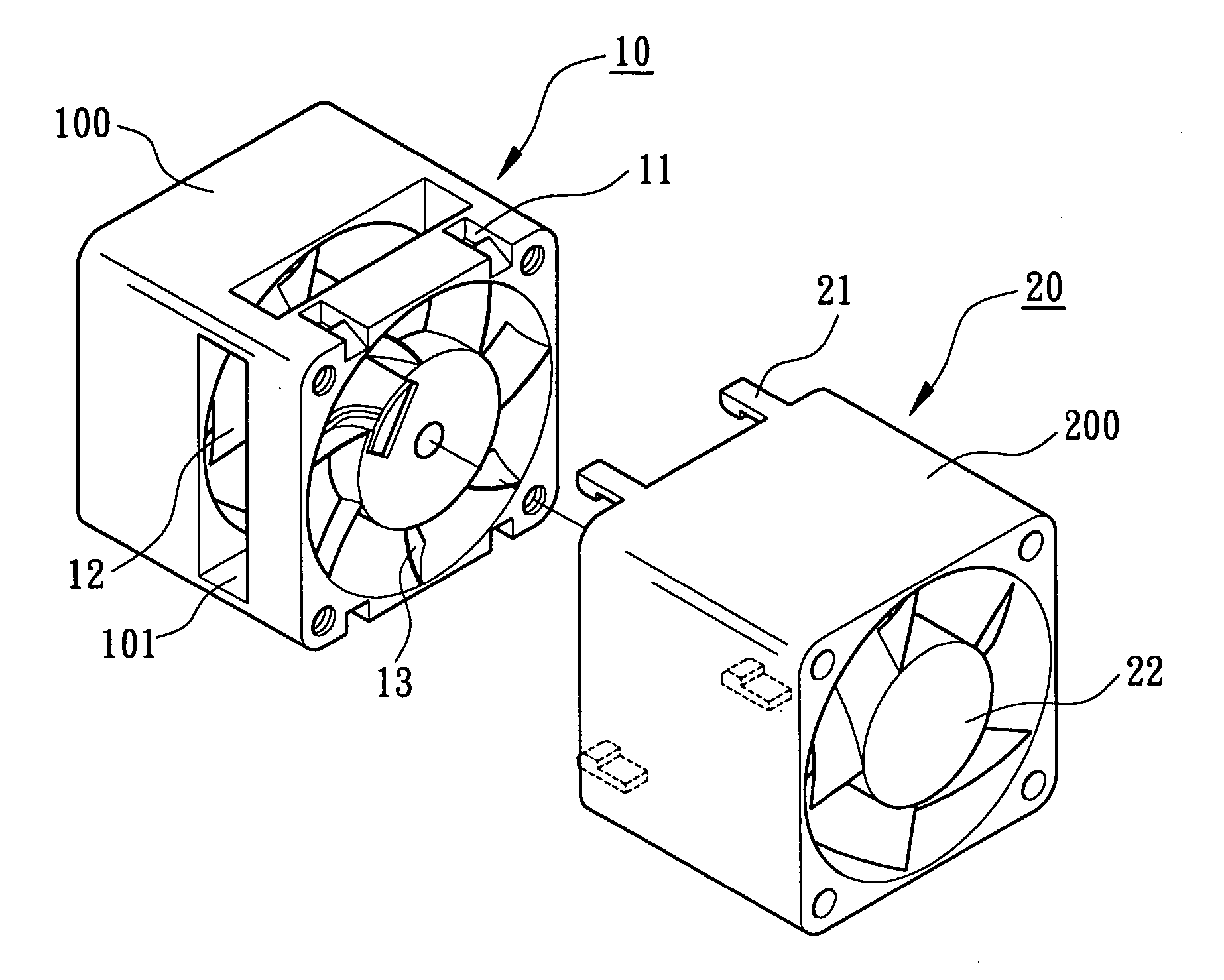

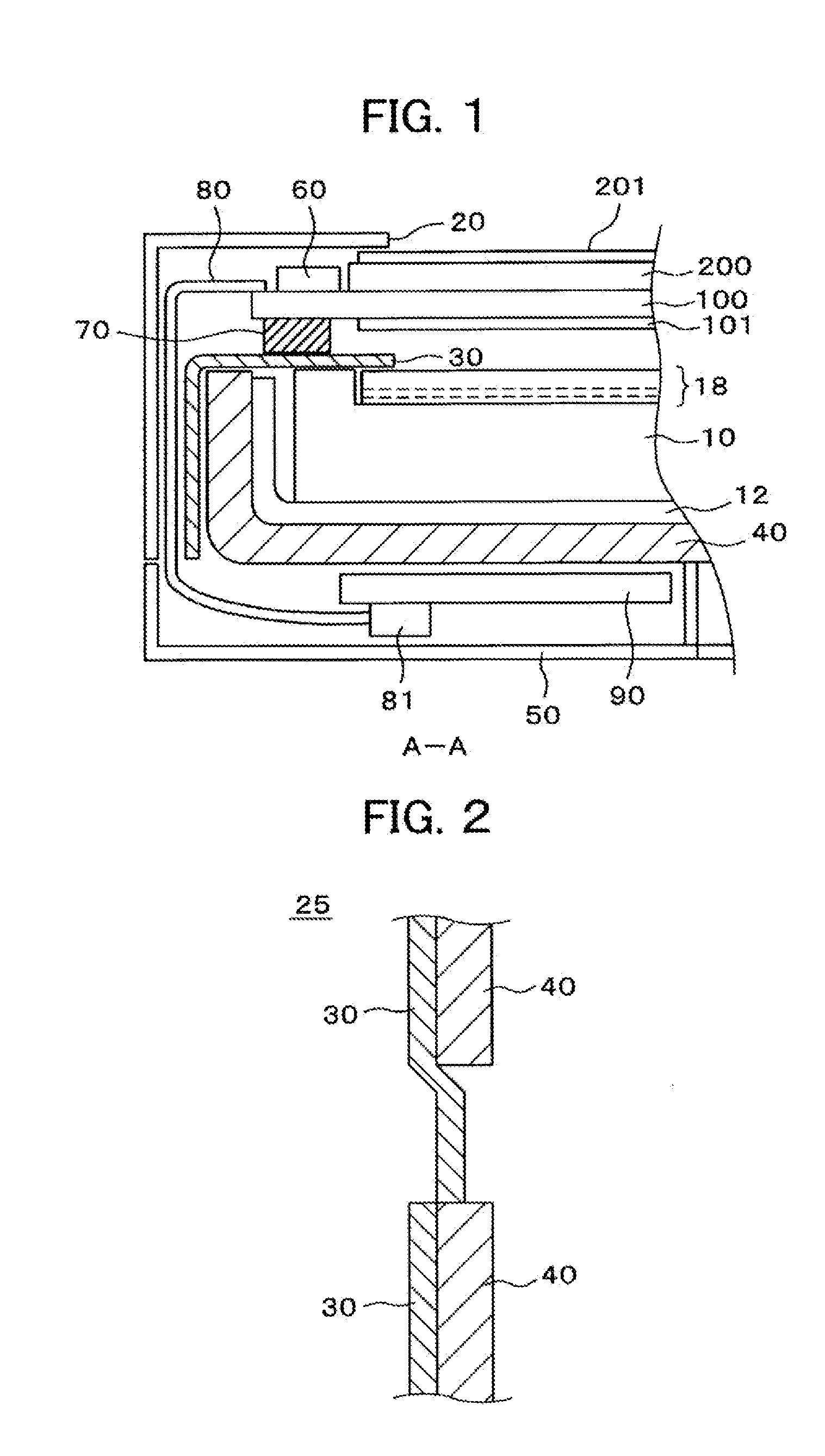

Heat-dissipating module

InactiveUS7031157B2Improve efficiencyIncrease volumePump componentsCombination enginesImpellerDensity distribution

A heat-dissipating module includes a first fan unit and a second fan unit, which are serially connected together to provide an air inlet and an air outlet. Each of the first fan unit and the second fan unit includes a casing and an impeller. At least one side air inlet is defined in at least one of a plurality of sides of the casing of the first fan unit and a plurality of sides of the casing of the second fan unit. The air inlet amount and the air outlet amount of the second fan unit are increased by the side air inlet. The air density distribution is uniform, and the wind noise during operation is lowered.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

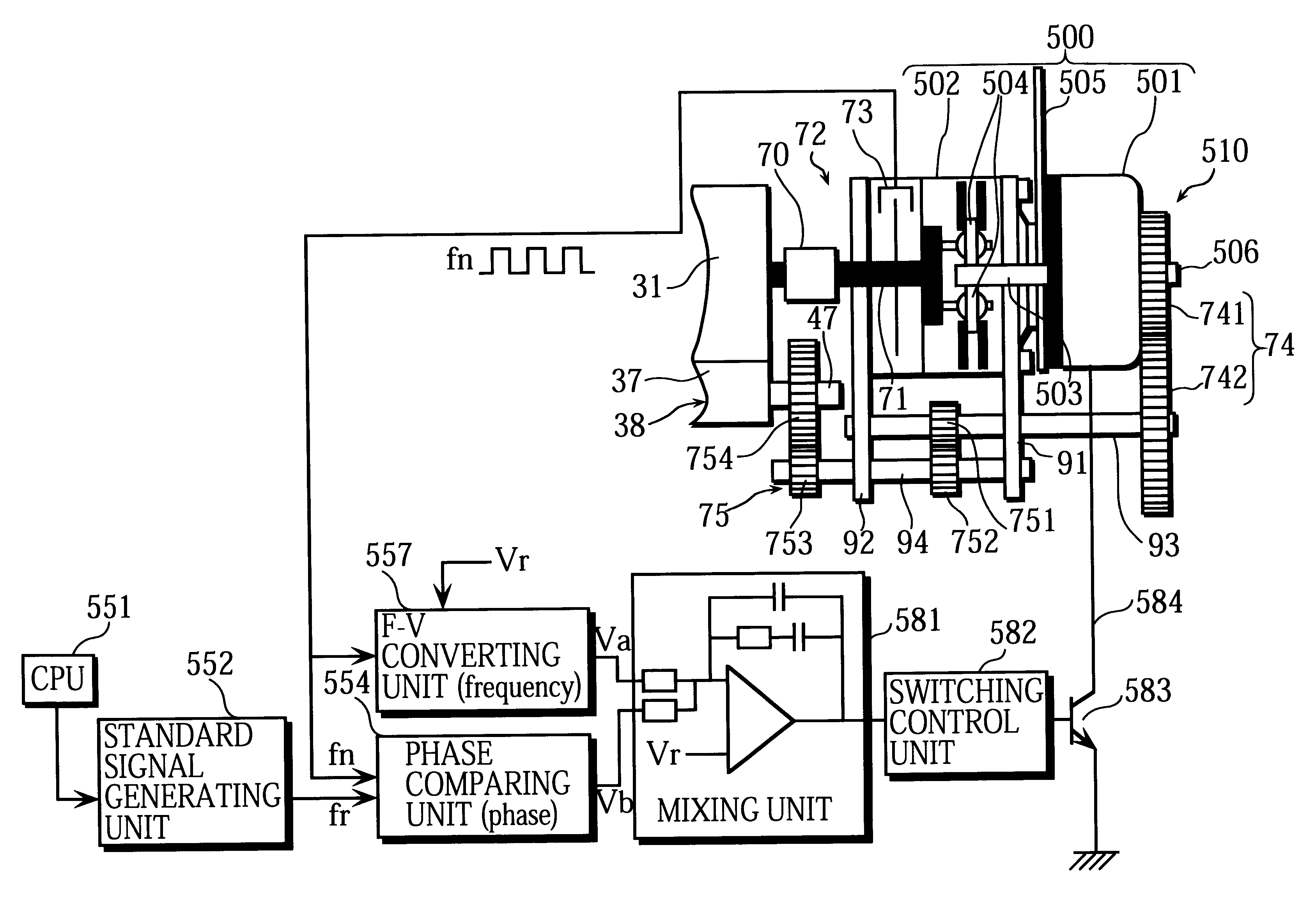

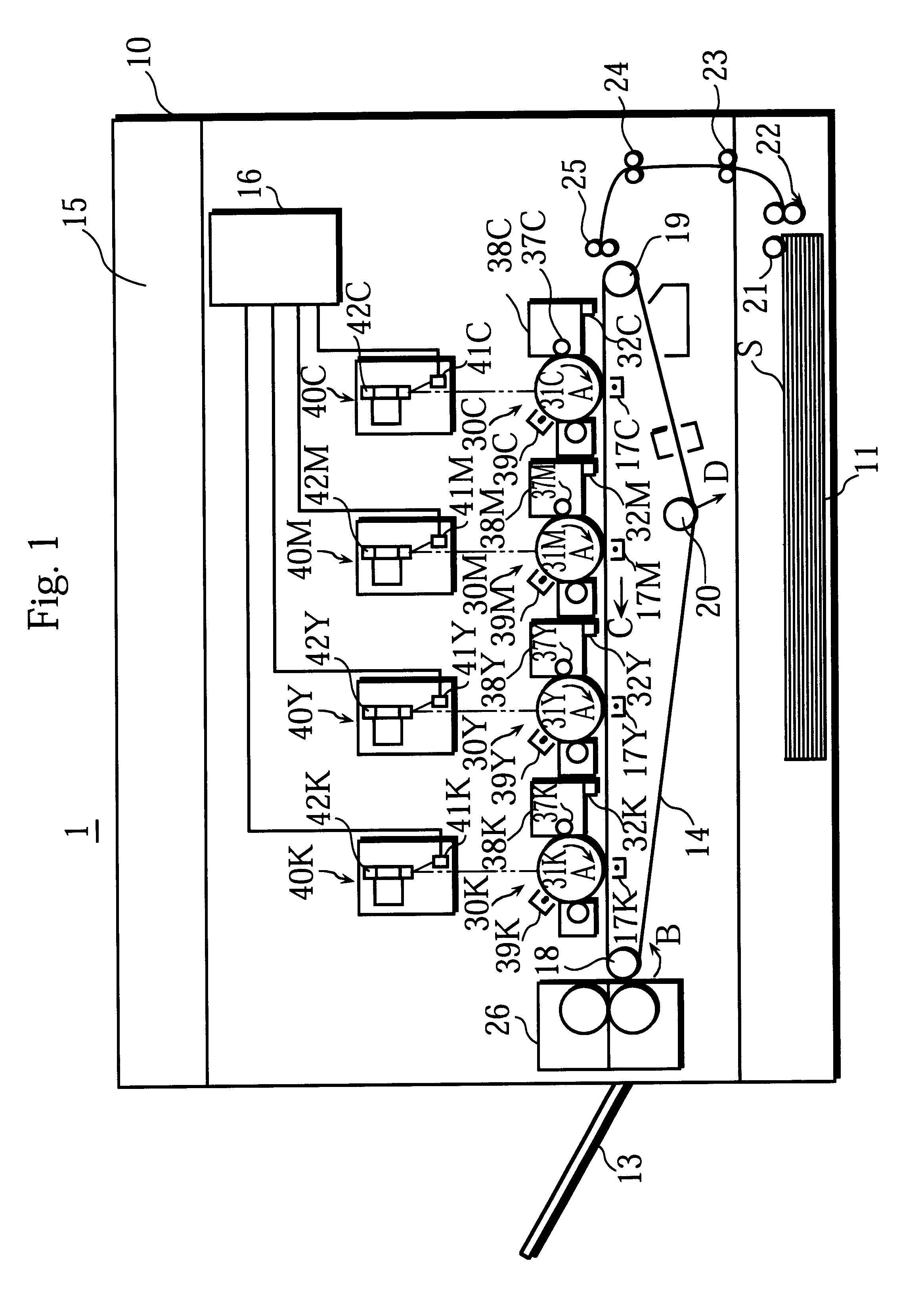

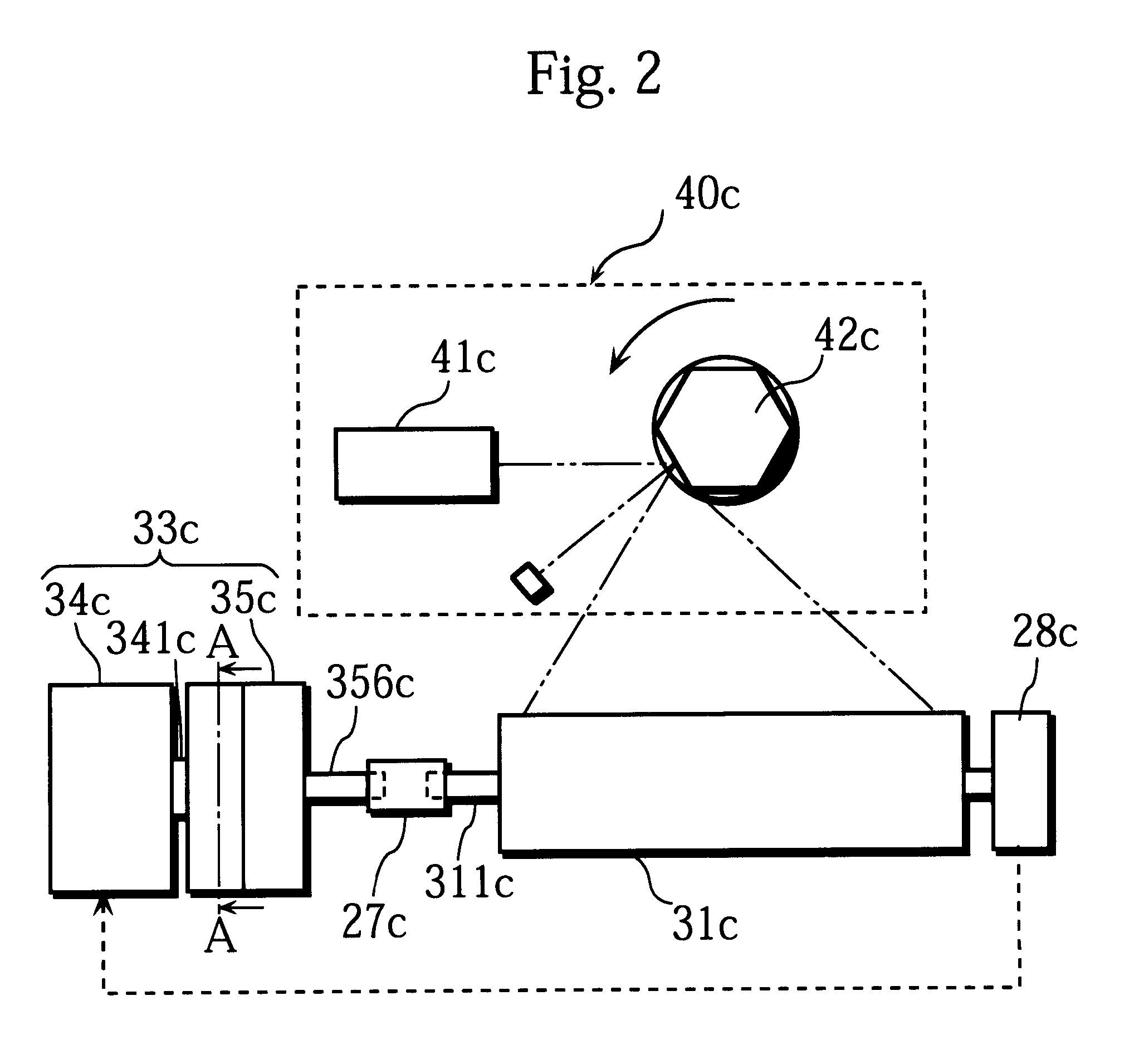

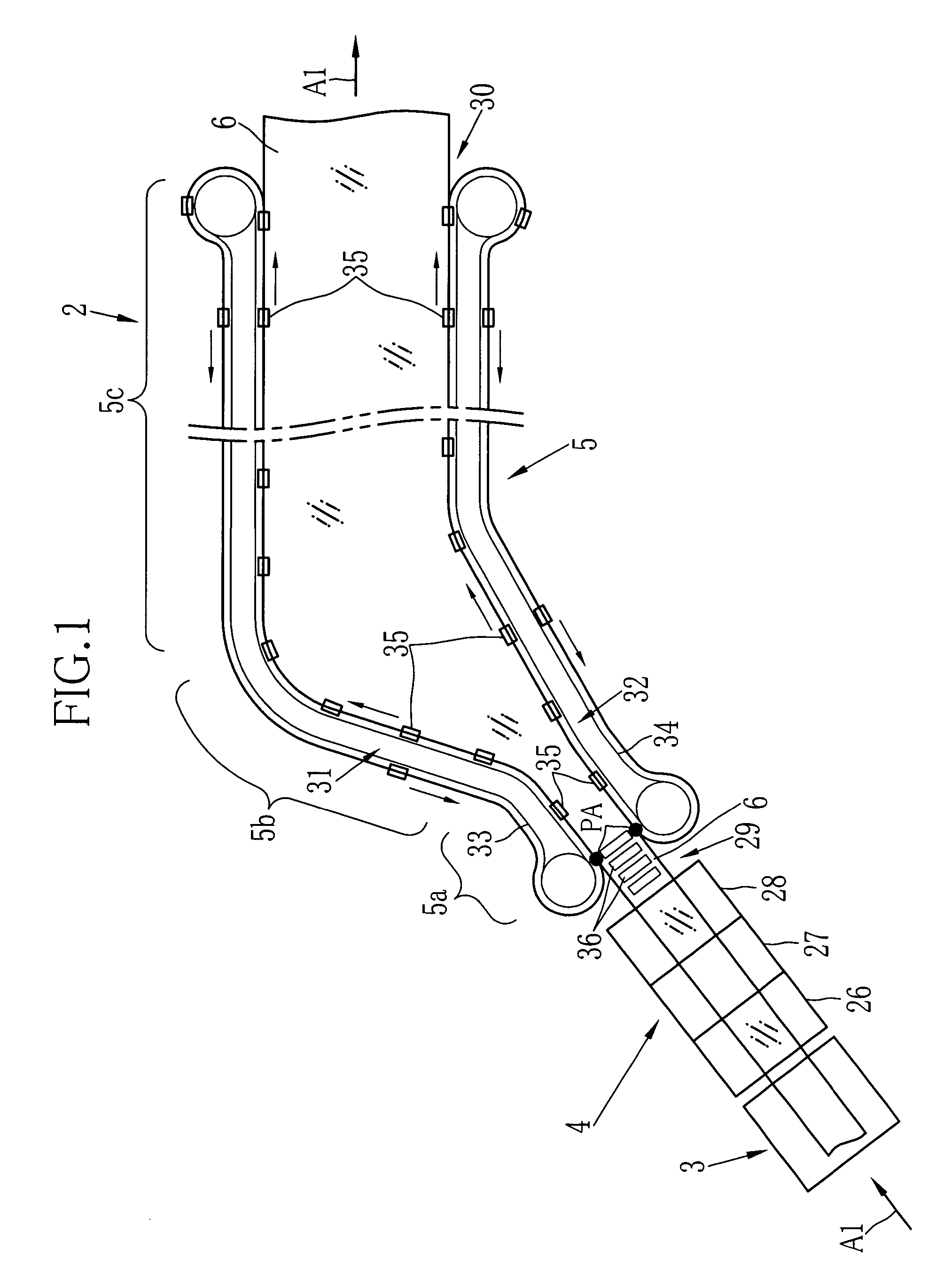

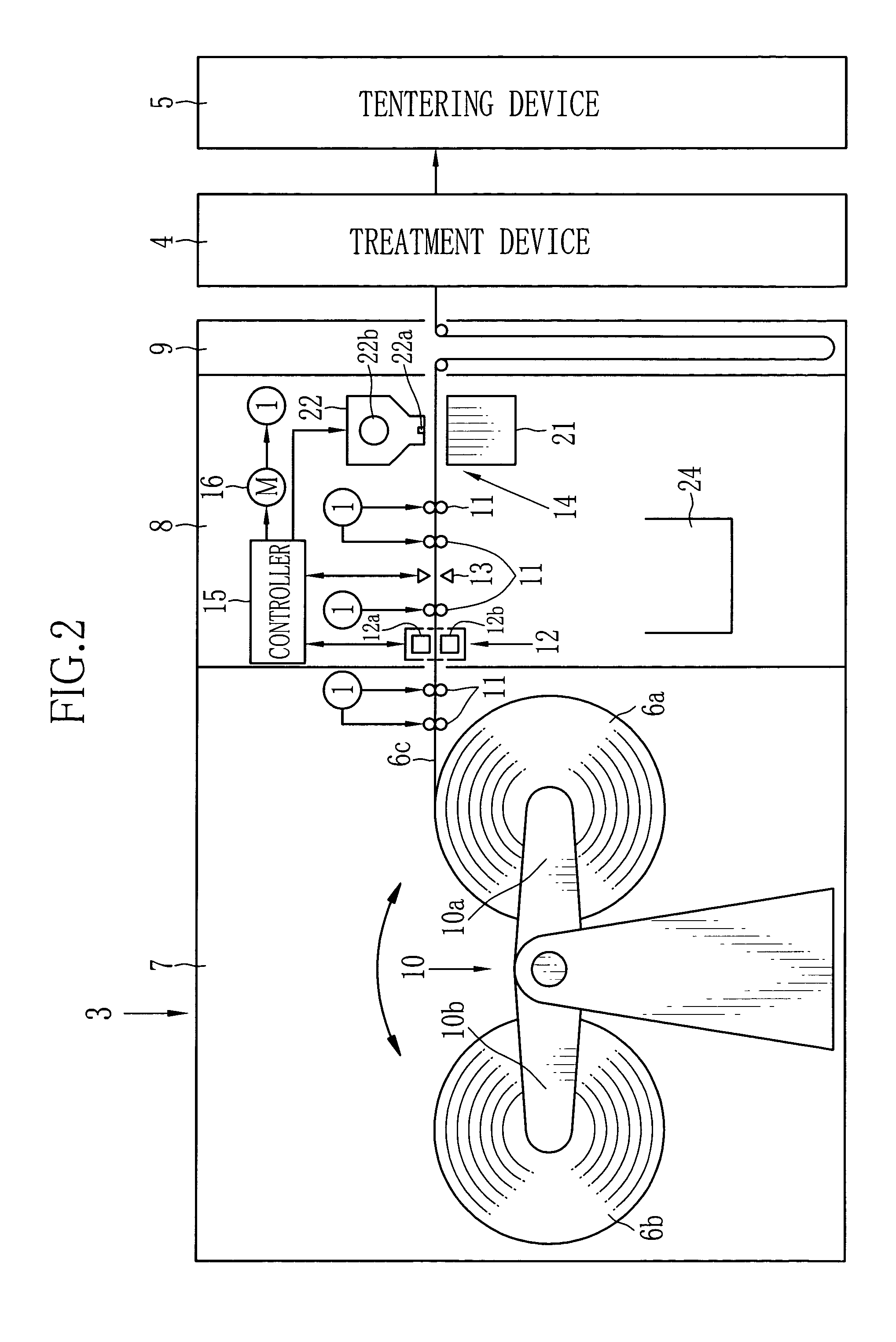

Rotator driving device, image forming apparatus using the rotator driving device, and method of driving rotator

InactiveUS6420807B1Prevent rotationAvoid vibrationDynamo-electric brakes/clutchesDynamo-electric gearsDrive motorControl theory

Rotational force of a driving motor is transferred to a photosensitive drum via a planetary-roller reduction device, so that the photosensitive drum is rotated. A speed detector set on the shaft of the photosensitive drum detects the rotational speed of the photosensitive drum. In accordance with the detected rotational speed of the photosensitive drum, the rotational speed of the driving motor is adjusted so that the photosensitive drum is rotated at a constant speed.

Owner:MINOLTA CO LTD

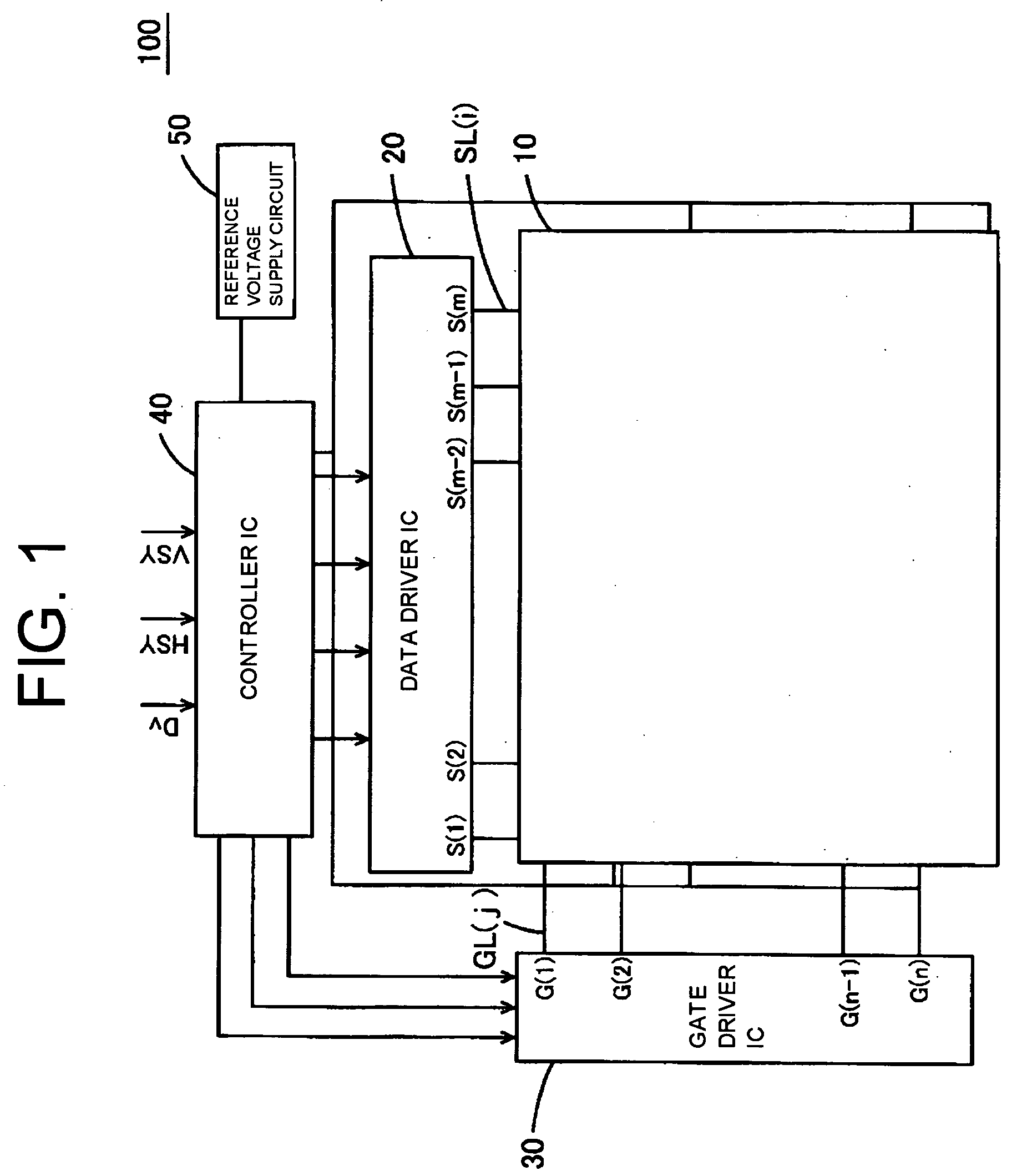

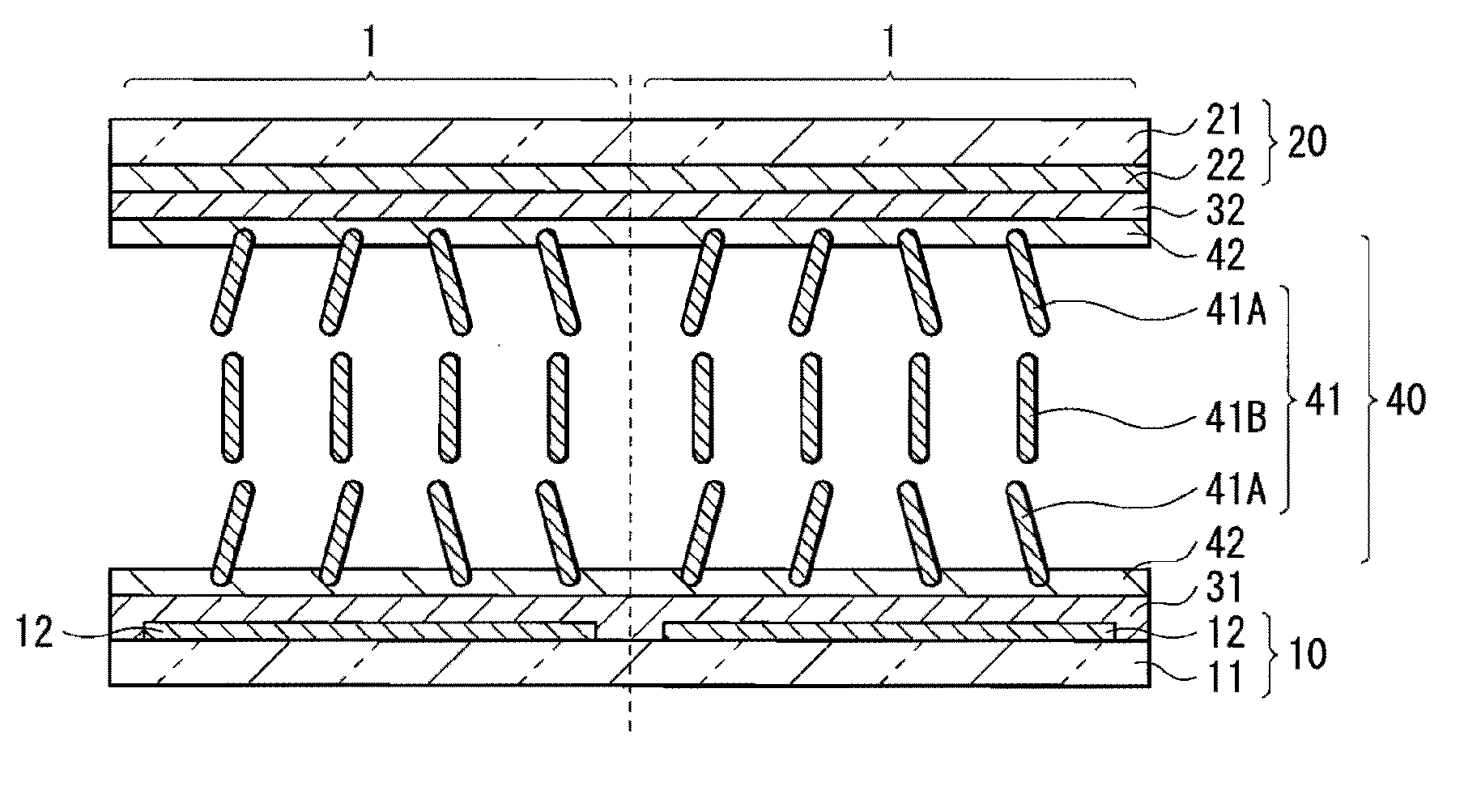

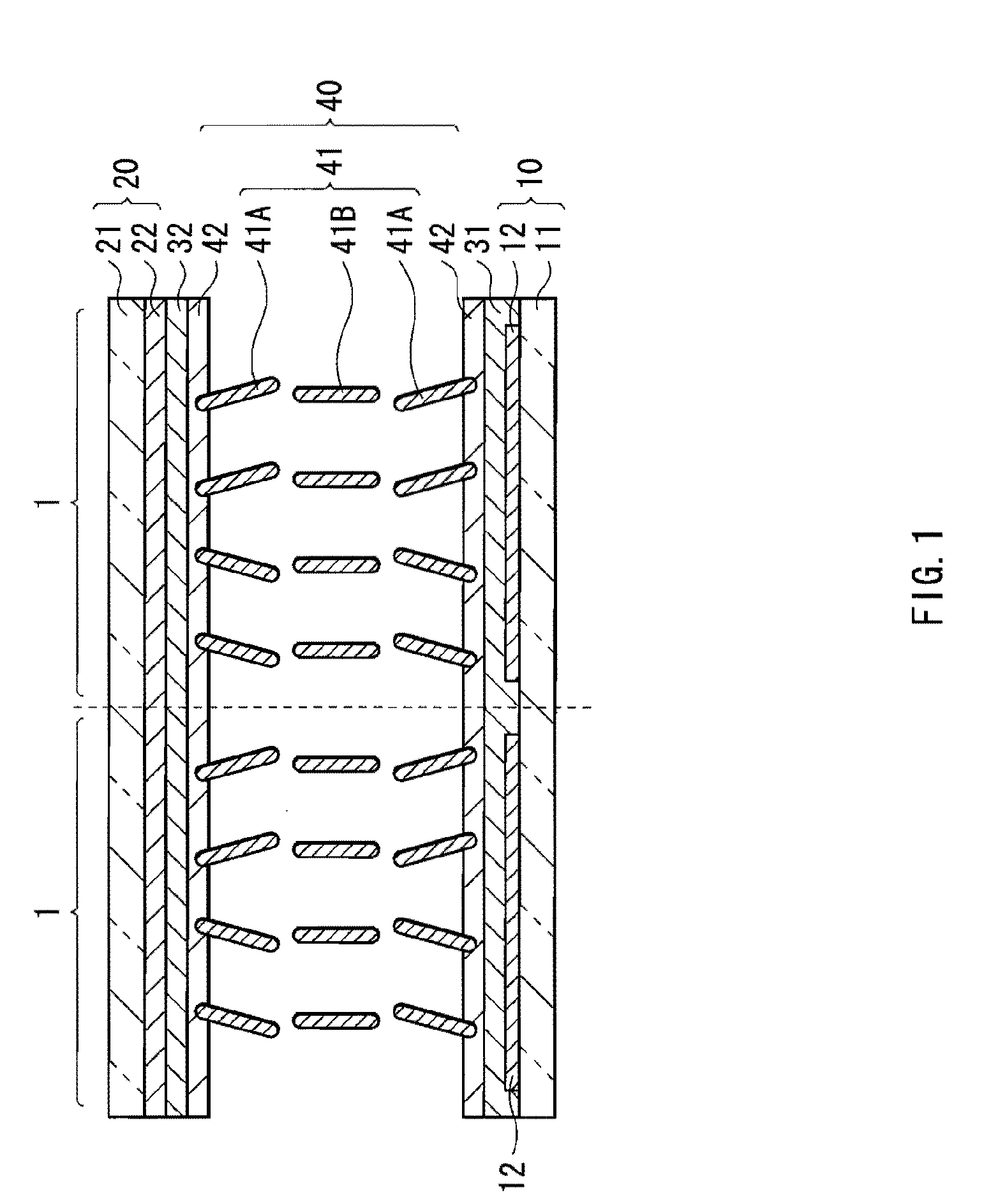

Liquid crystal display device

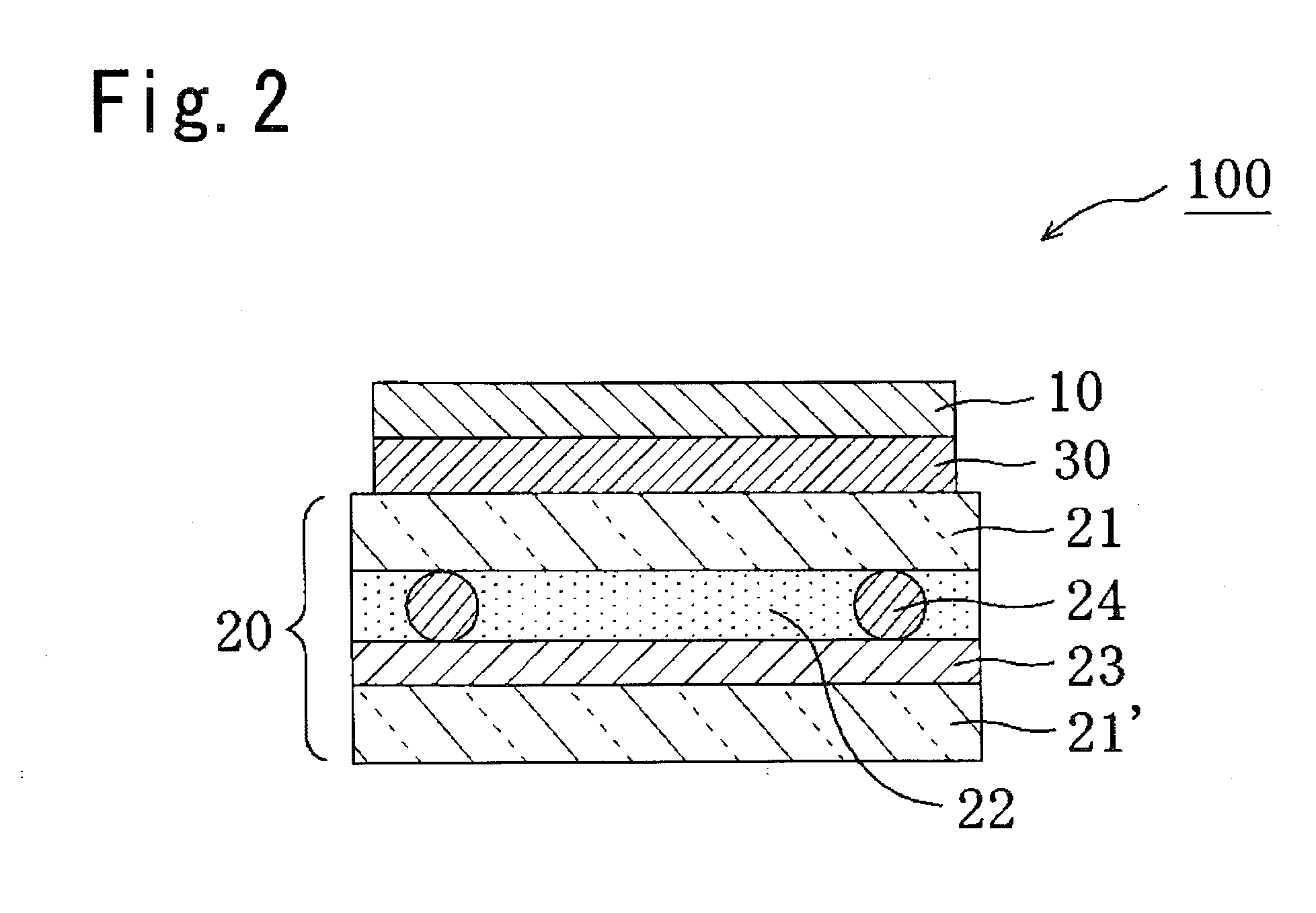

ActiveUS20090135124A1Prevent such non-uniformityImprove display qualityCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayPotential difference

The liquid crystal display device 100 has a matrix arrangement of pixels which are formed by a liquid crystal layer, display electrodes disposed across the liquid crystal layer, and a counter electrode made of a transparent material and represents a tone (gray scale level) per pixel by applying a drive voltage to the liquid crystal layer, the drive voltage corresponding to a potential difference between each of the display electrodes and the counter electrode. The device also includes a common voltage supplying part 42 that detects a charge in a certain area T1 of the counter electrode 15 and compares a feedback voltage corresponding to the detected charge in the area, thereby providing common voltage Vcom feedback control. Consequently, flickers on the screen can be prevented by common voltage Vcom feedback control.

Owner:FUNAI ELECTRIC CO LTD

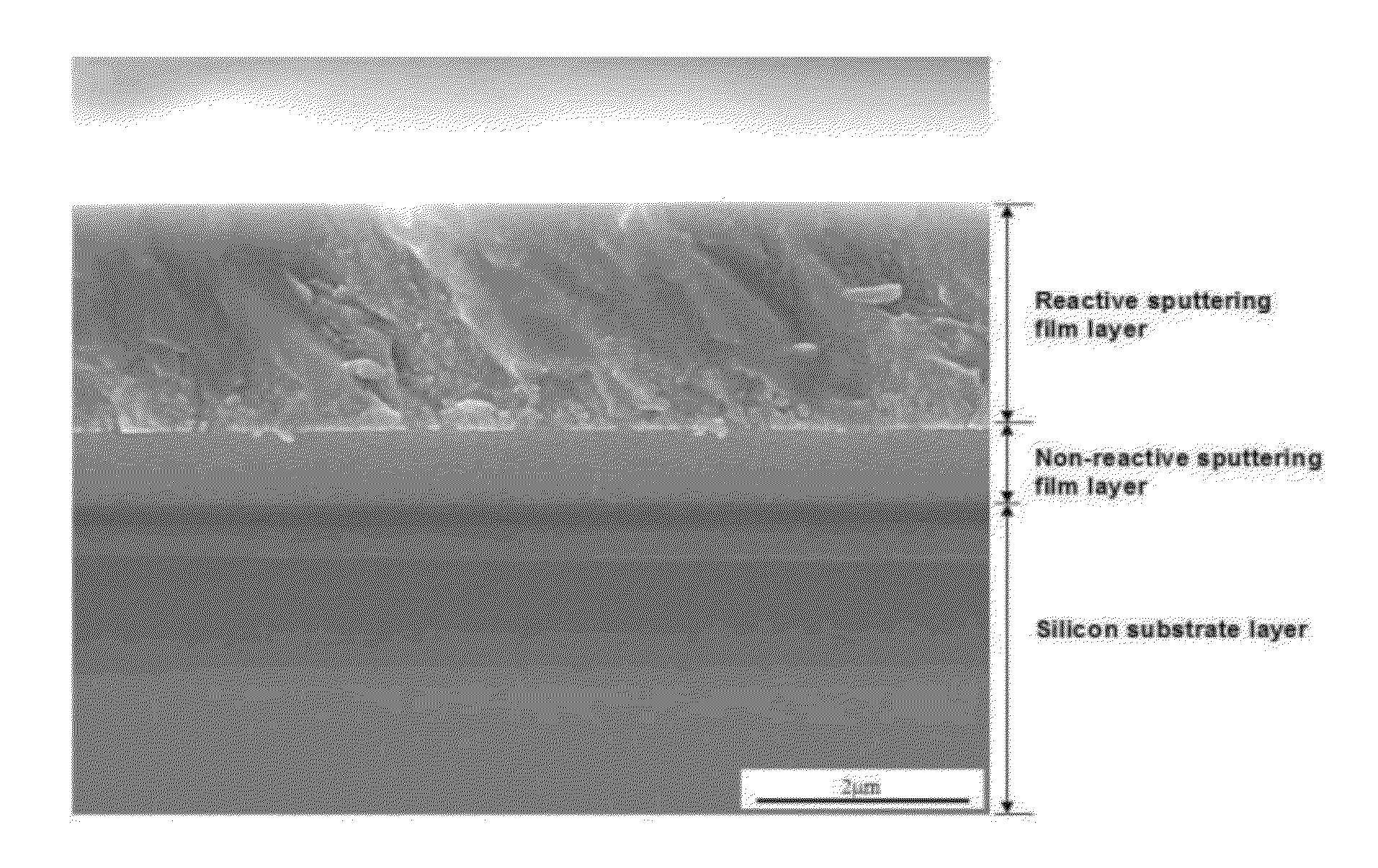

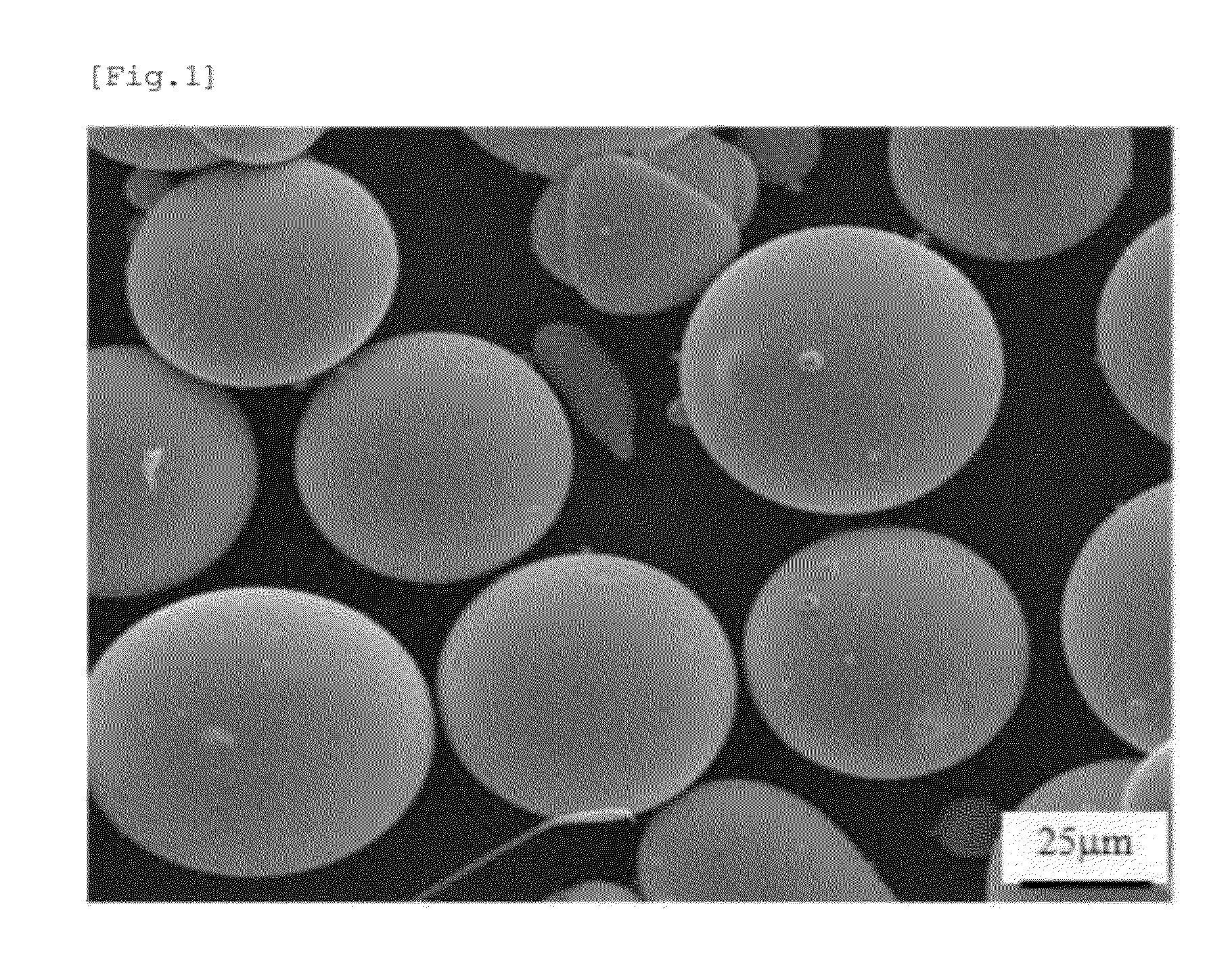

Sputtering target of multi-component single body and method for preparation thereof, and method for producing multi-component alloy-based nanostructured thin films using same

InactiveUS20120247948A1Prevent such non-uniformityEvenly distributedCellsVacuum evaporation coatingNitrogenAlloy

The present invention relates to a sputtering target of a multi-component single body, a preparation method thereof, and a method for fabricating a multi-component alloy-based nanostructured thin film using the same. The sputtering target according to the present invention comprises an amorphous or partially crystallized glass-forming alloy system composed of a nitride forming metal element, which is capable of reacting with nitrogen to form a nitride, and a non-nitride forming element which has no or low solid solubility in the nitride forming metal element and does not react with nitrogen or has low reactivity with nitrogen, wherein the nitrogen forming metal element comprises at least one element selected from Ti, Zr, Hf, V, Nb, Ta, Cr, Y, Mo, W, Al, and Si, and the non-nitride forming element comprises at least one element selected from Mg, Ca, Sc, Ni, Cu, Ag, In, Sn, La, Au, and Pb.

Owner:KOREA INST OF IND TECH

Light emitting device and illumination apparatus including same

ActiveUS20120275150A1Reduce directivityGood light distributionPoint-like light sourceLighting support devicesLight emitting deviceSolid-state

A light emitting device includes a plurality of solid-state light emitting elements; a board on which the solid-state light emitting elements are arranged in the form of an array; and a light distribution adjusting member for adjusting a distribution of lights outputted from the solid-state light emitting elements. The light distribution adjusting member is provided to commonly cover at least two of the solid-state light emitting elements, and includes an accommodating portion which accommodates the solid-state light emitting elements; a concave curved surface portion provided above light output surfaces of the solid-state light emitting elements and immediately above the solid-state light emitting elements; and a pair of convex curved surface portions which are provided in opposite sides of the concave curved surface portion, each of the convex curved surface portions being smoothly connected to the concave curved surface portion.

Owner:PANASONIC CORP

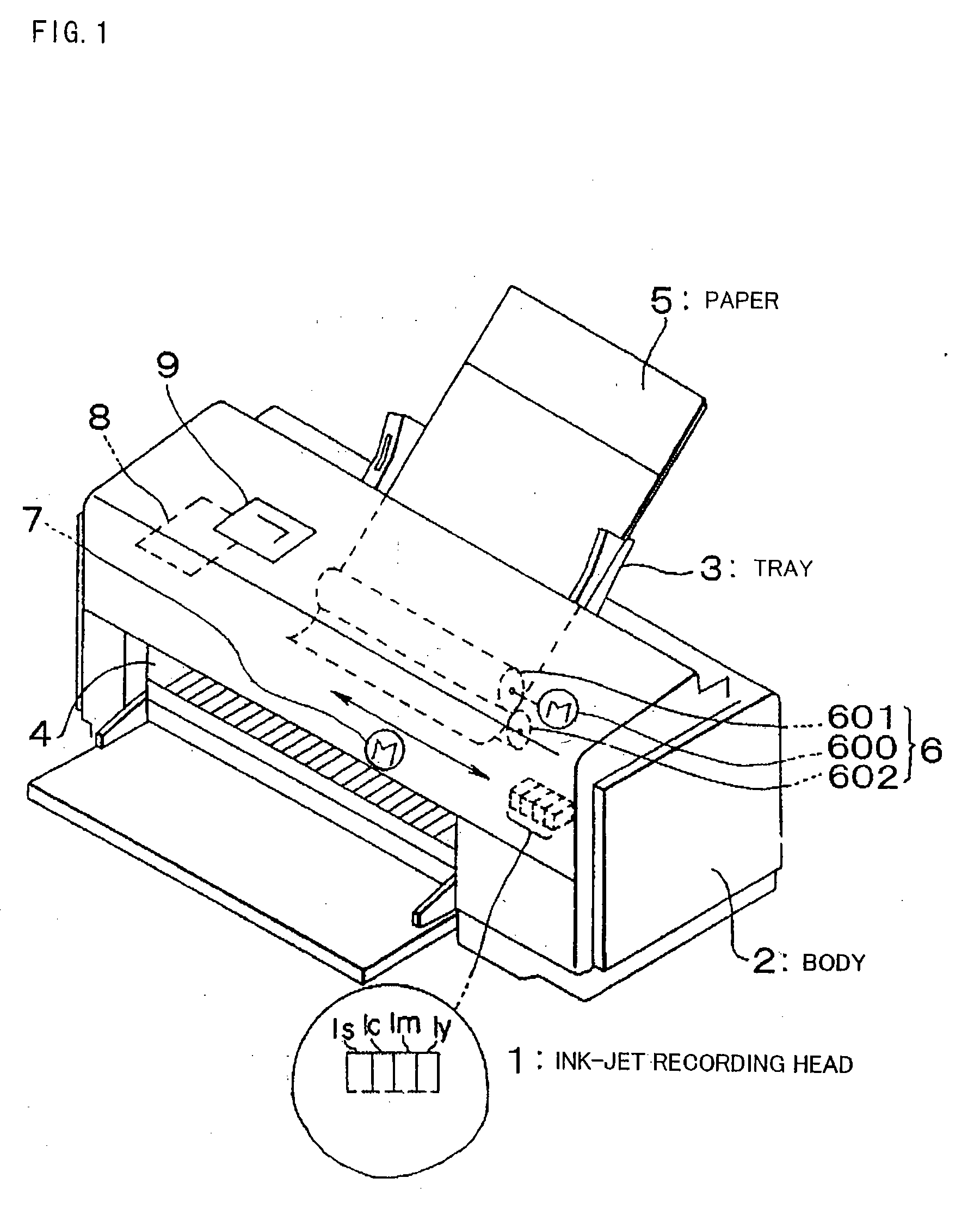

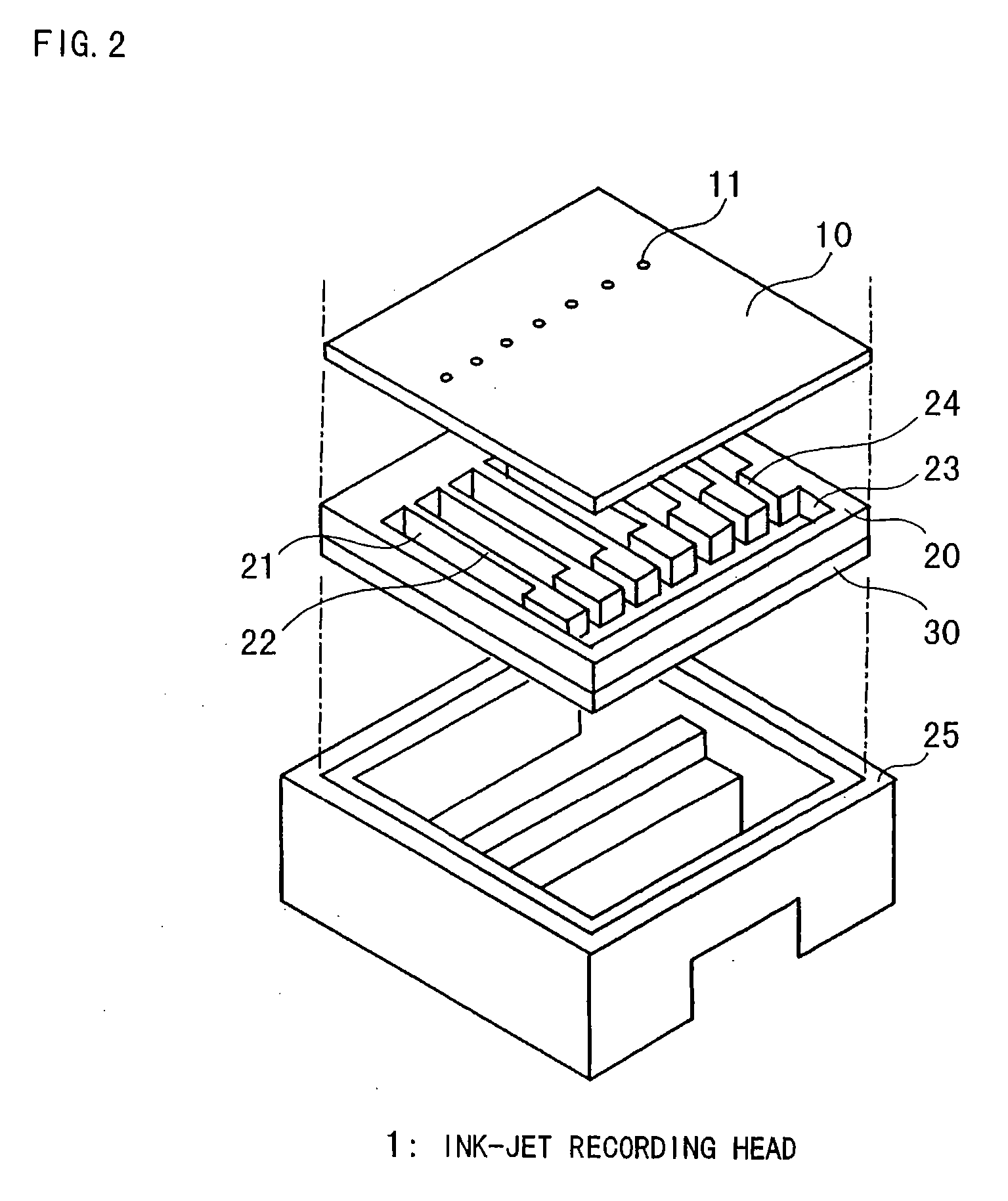

Ink jet head and ink supplying method thereof

An Inkjet head according to an exemplary embodiment of the present invention includes an ink storage unit including an inner storage space, a head unit connected to the ink storage unit, and a plurality of nozzles discharging the ink, wherein the floors of the inner storage space of the ink storage unit form a step. Accordingly, in the Inkjet head of an exemplary embodiment of the present invention, the floors of the inner storage space of the ink storage unit form a step, and the ceiling of the inner flow space of the head unit is inclined, thereby preventing the ink vapor from being confined inside the head unit. Therefore, the ink to be discharged through the nozzle flows in a predetermined direction and does not include ink vapor, thereby preventing discharge deterioration.

Owner:SAMSUNG DISPLAY CO LTD

Producing method of optical film

InactiveUS20040100708A1Reduce wastePrevent such non-uniformityMirrorsPolarising elementsHeat sealerThin membrane

When it is complete to unwind a first PVA film from a first film roll, it is started to unwind a second PVA film from a second film roll. A trailing end portion of the first and second PVA film and a leading end portion of the second PVA film are overlaid at a film connecting position. A receive stage and a seal head of a heat sealer sandwiches overlaid portions, and a head body of the seal head heats them so as to thermally melt and adhere the first and second PVA films. During the thermal melt-adhesion, a thermal melt-adhesion line is formed in the overlaid portions of the first and second PVA films.

Owner:FUJIFILM HLDG CORP

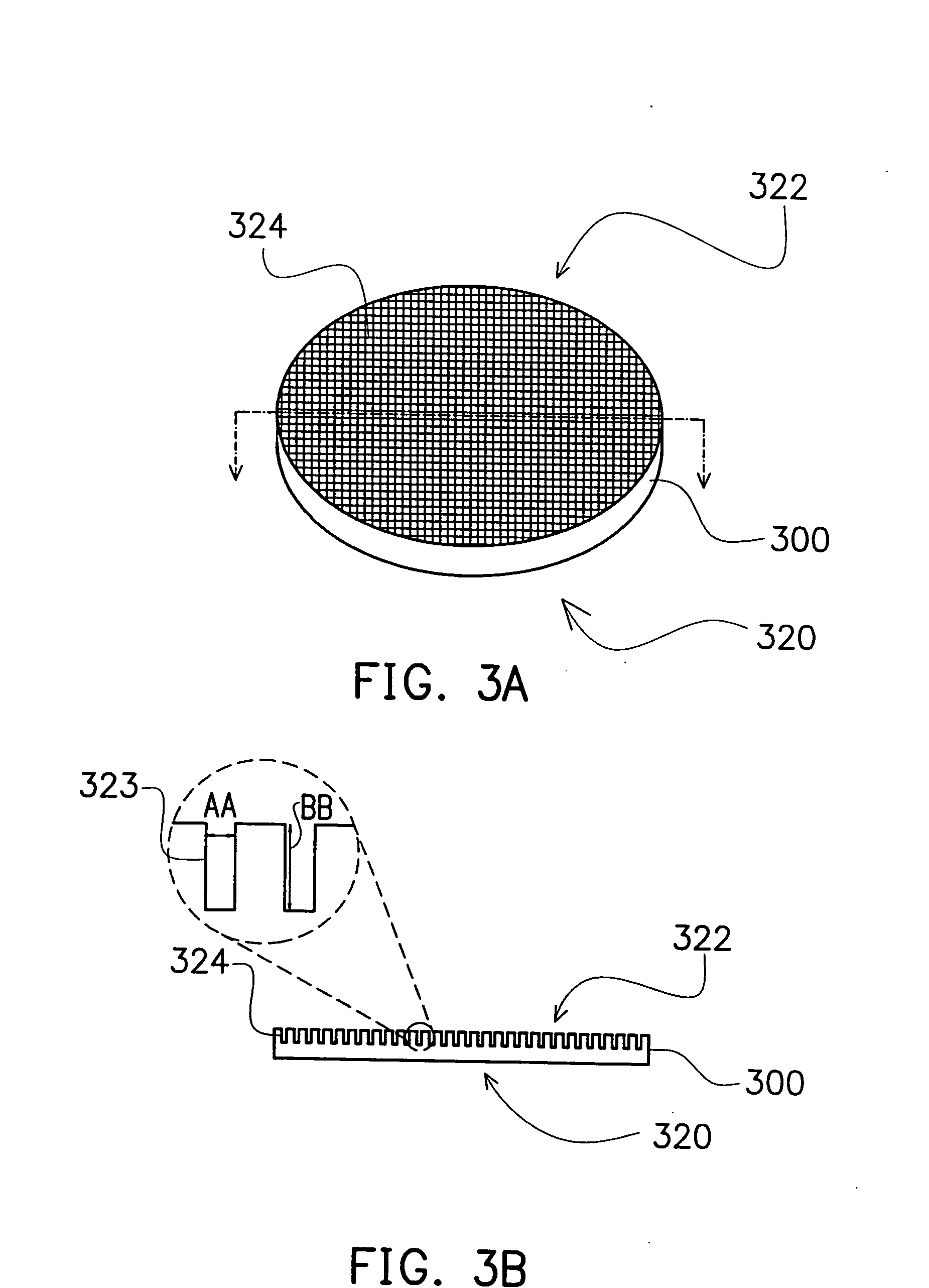

Manufacturing method for microdisplay

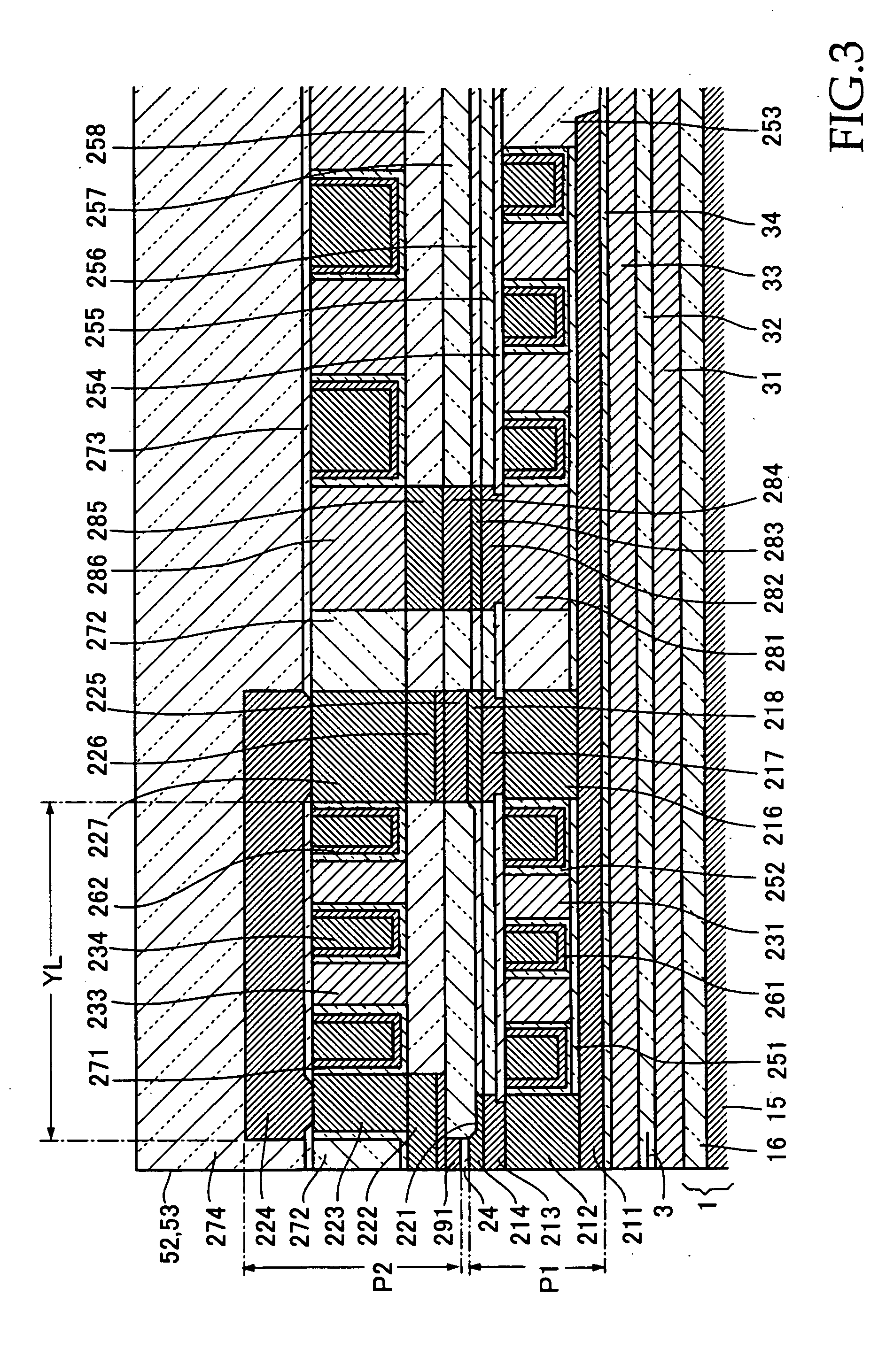

InactiveUS20050057718A1Prevent such non-uniformityImprove inconsistencyNon-linear opticsLiquid crystalEngineering

The present invention provides a manufacturing method for a microdisplay. After providing a wafer with a plurality of pixel structures on the front side, trenches with a pattern are formed on the backside of the wafer. A transparent plate is disposed above the front side of the wafer and a sealant is applied to join the wafer and the transparent plate. After cutting the wafer and the transparent plate into display cells of suitable sizes, liquid crystal is then introduced in-between the sealant of the display cells.

Owner:CHEN SHENG LUNG +1

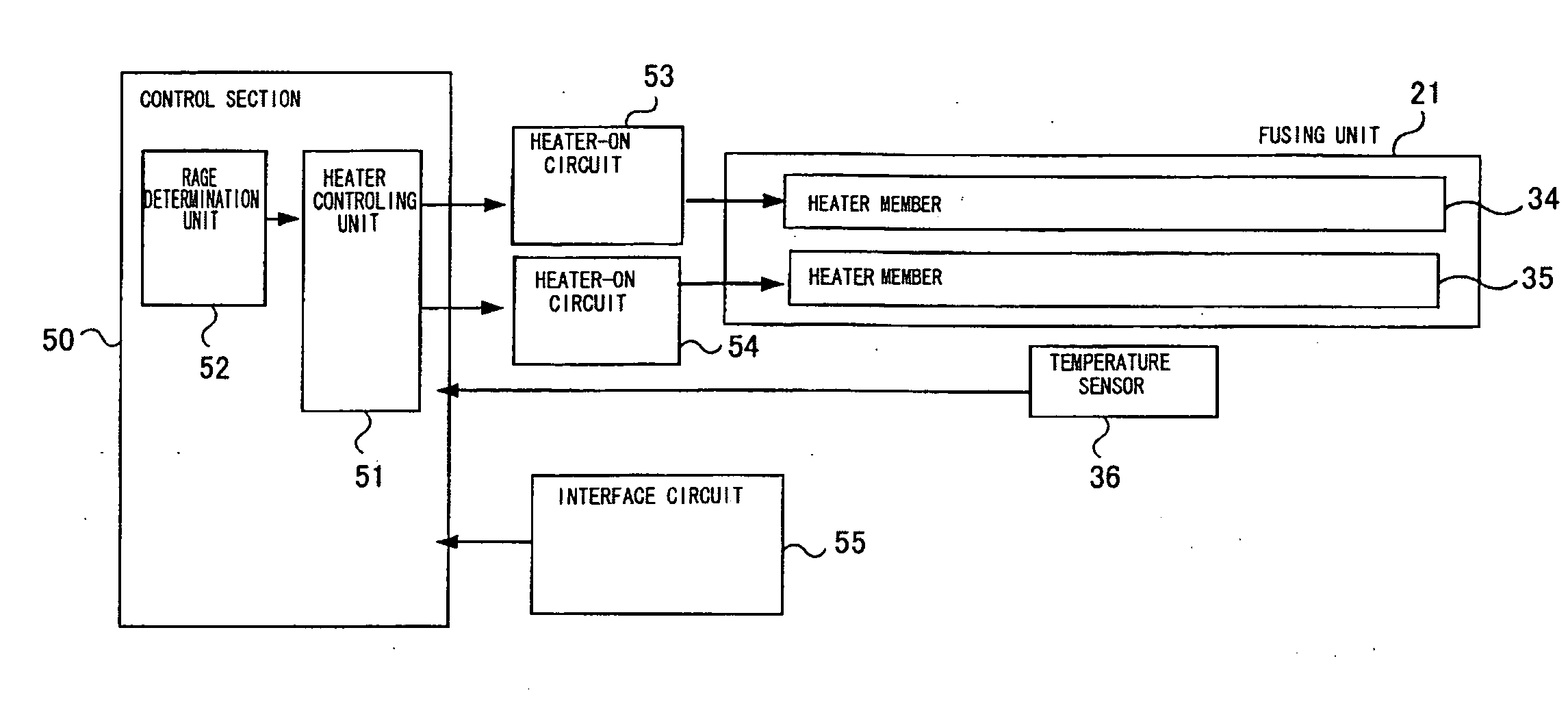

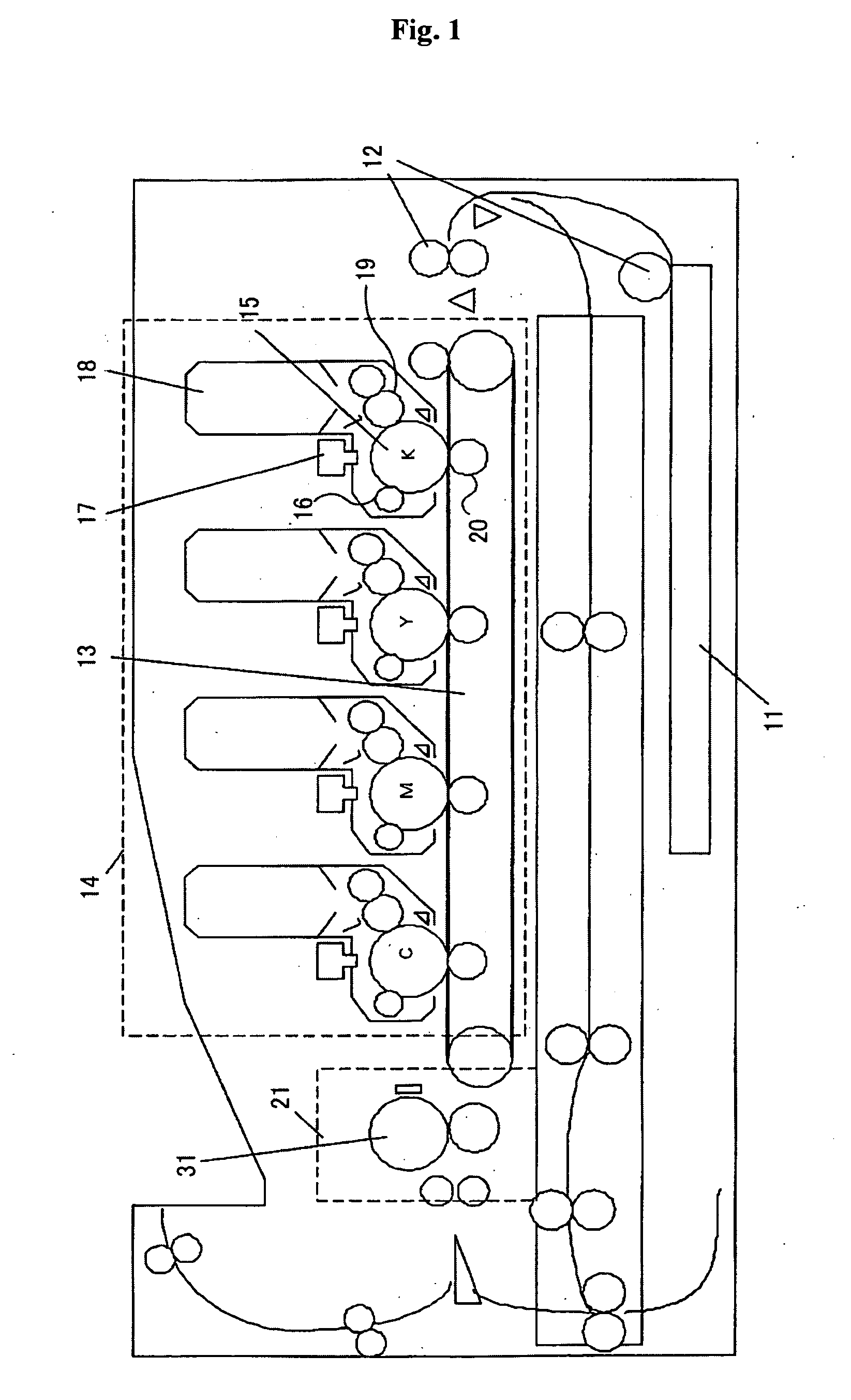

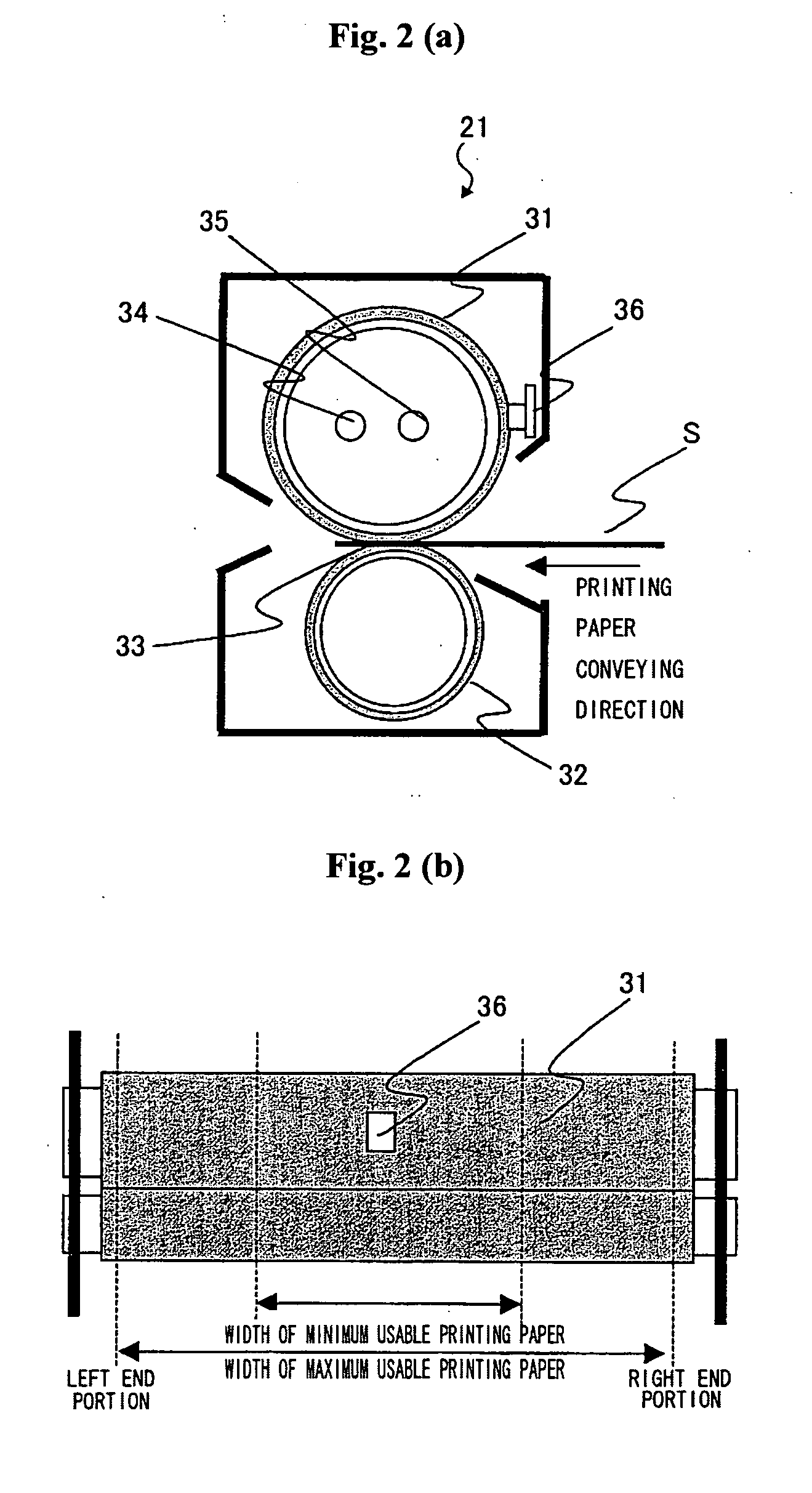

Image recording apparatus

InactiveUS20060204266A1Prevent any nonuniformityMinimize temperature differenceElectrographic process apparatusHeat distributionImage recording

A purpose of the present invention is to minimize a temperature difference between end portions and a central portion of a print medium caused by a difference of fusing conditions. The image recording apparatus according to the present invention includes a plurality of heater members 34, 35 having different heat distributions, a temperature detecting unit 36 for detecting a temperature of an area where a print medium passes through, a heat controlling unit 51 for controlling a fusing unit at a prescribed temperature by an individual heat controlling of the plurality of heater members on the basis of the temperature detected by the temperature detecting unit, a rate determination unit 52 for determining a divisional rate of heat amount to be charged per unit time to said fusing unit by means of said plurality of heater members. The rate determination unit determines the divisional rate of the heat amount to be charged per unit time to the fusing unit by means of the plurality of heater members on the basis of the fusing conditions input through a condition input unit and the heat controlling unit heat controls the plurality of heater members individually on the basis of the divisional rate determined by the rate determination unit.

Owner:OKI DATA CORP

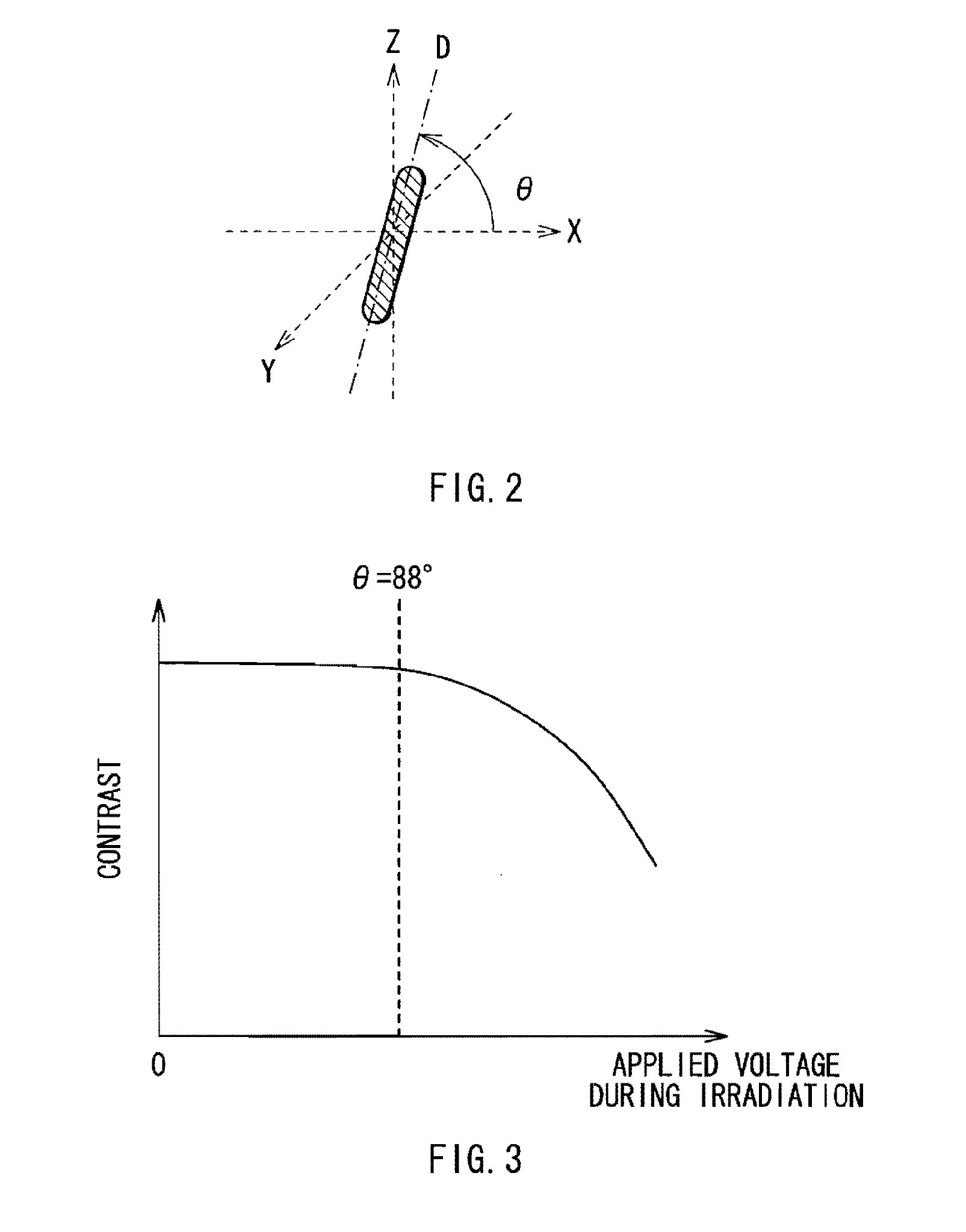

Liquid crystal display device

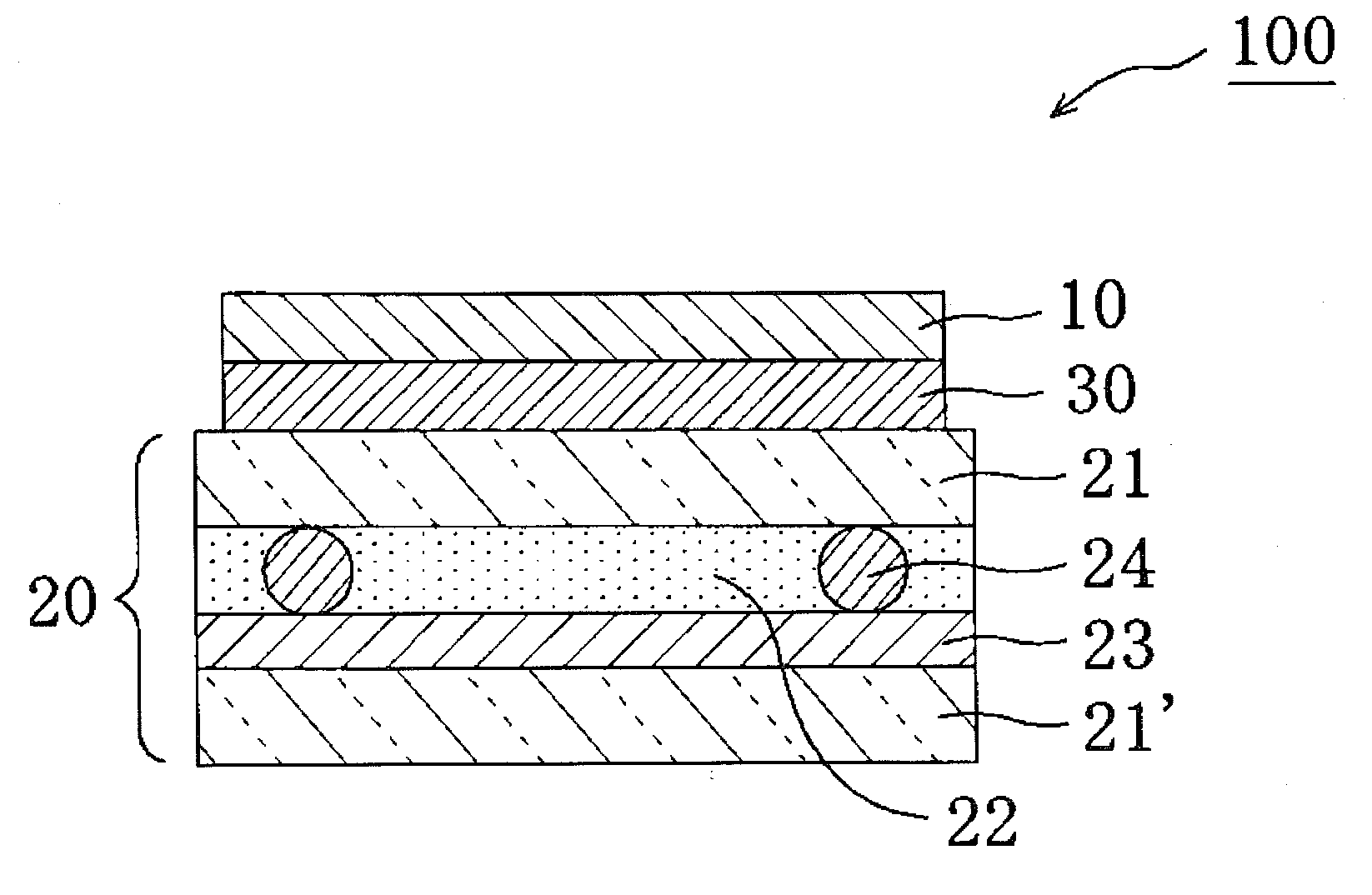

InactiveUS20090269515A1Resistant to displaySecuring configurational stabilityLiquid crystal compositionsThin material handlingResponsivityStructural stability

A liquid crystal display device being resistant to display unevenness without loss of responsivity and being capable of securing configurational stability is provided. A liquid crystal display device includes: a liquid crystal layer including liquid crystal molecules and a polymer compound including a structure represented by Chemical Formula 1; and a pair of substrates facing each other with the liquid crystal layer in between,where m and n each are an integer of 1 to 4 both inclusive.

Owner:JAPAN DISPLAY WEST

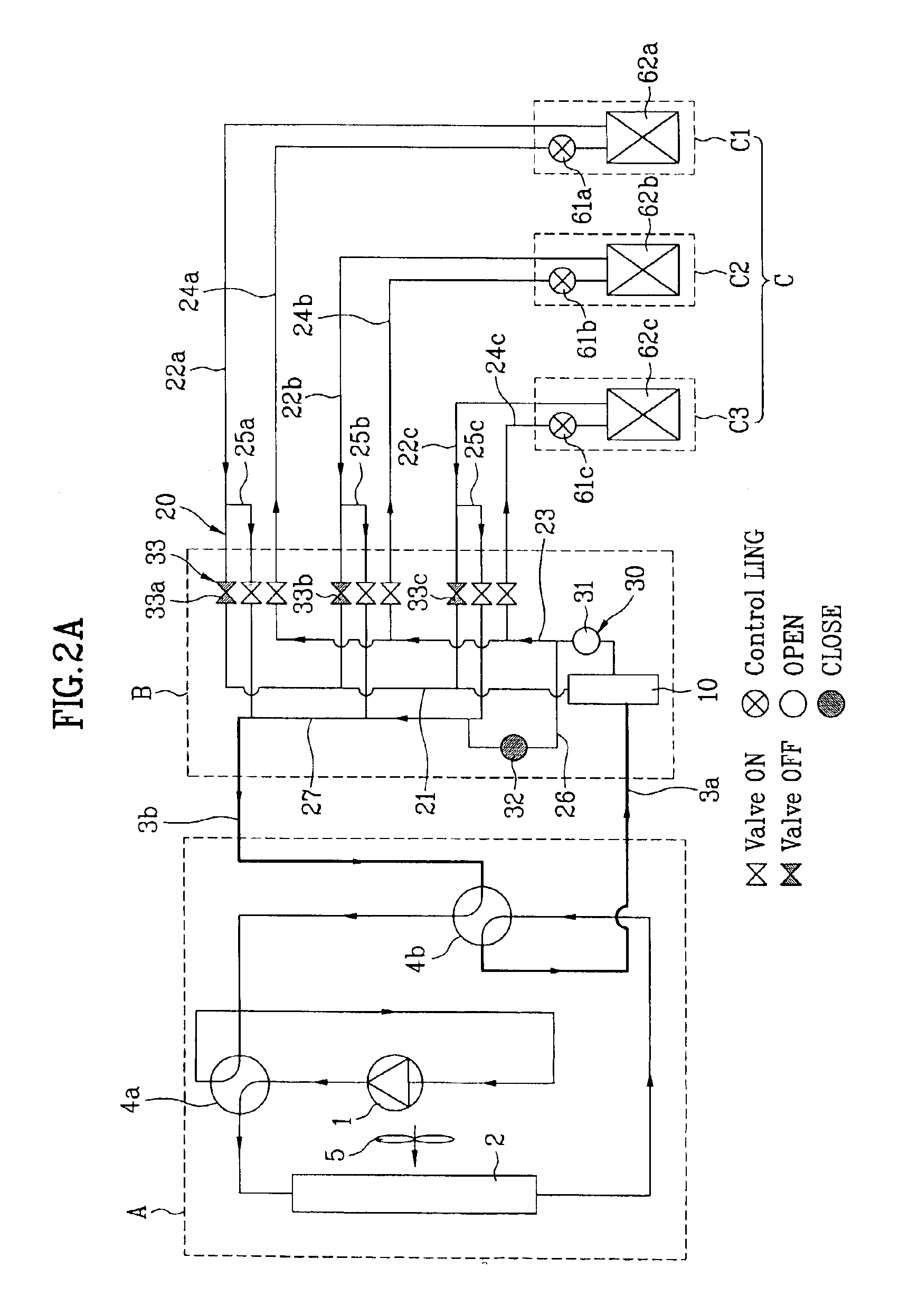

Multi-type air conditioner and method for operating the same

InactiveUS6883345B2Improve efficiencySimplify the manufacturing processSpace heating and ventilation safety systemsSpace heating and ventilation control systemsVapor–liquid separatorFour-way valve

Multi-type air conditioner including an outdoor unit installed outside of a room having a compressor and an outdoor unit mounted therein, a plurality of indoor units each installed in a room having an electronic expansion valve and an indoor heat exchanger, a distributor for separating refrigerant from the outdoor unit at a gas-liquid separator and guiding separated refrigerant to the plurality of indoor units selectively depending on operation conditions, a first connection pipe for guiding the refrigerant from the outdoor unit to the gas-liquid separator in the distributor, a second connection pipe for guiding the refrigerant from the distributor to the outdoor unit, and a switching part in the outdoor unit having a first four way valve provided to a discharge side of the compressor for selective switching of a flow direction of the refrigerant flowing in the outdoor heat exchanger, and a second four way valve provided to be switched in conformity with switching of the first four way valve for maintaining the first connection pipe as a high pressure section high pressure refrigerant flows therein, and the second connection pipe as a low pressure section low pressure refrigerant flows therein, thereby permitting optimal dealing with individual room conditions.

Owner:LG ELECTRONICS INC

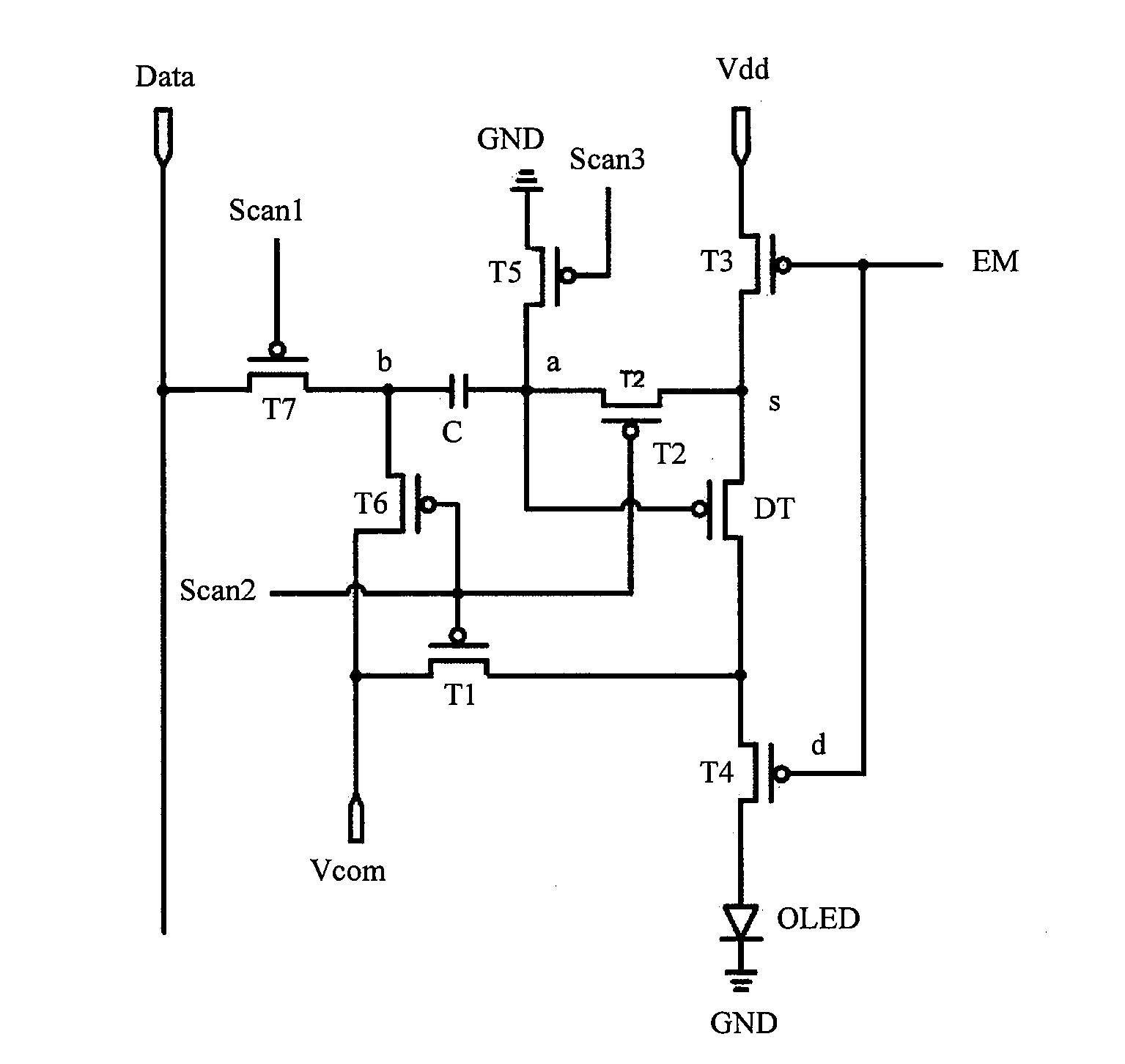

Pixel circuit and driving method thereof, display device

ActiveUS20160232836A1Prevent such non-uniformityStatic indicating devicesControl signalComputer module

A pixel circuit is disclosed, comprising: a driving module, an energy storage module, an electroluminescence module, a data voltage write module and a threshold compensation module, the threshold compensation module being connected with a compensation voltage input end, a first end of the energy storage module and at least one control signal input end, adapted to compensate the voltage of the first end of the energy storage module as a sum of the startup threshold of the driving module and the compensation voltage accessed by the compensation voltage input end in response to the control signal accessed by the connected control signal input end.

Owner:BOE TECH GRP CO LTD +1

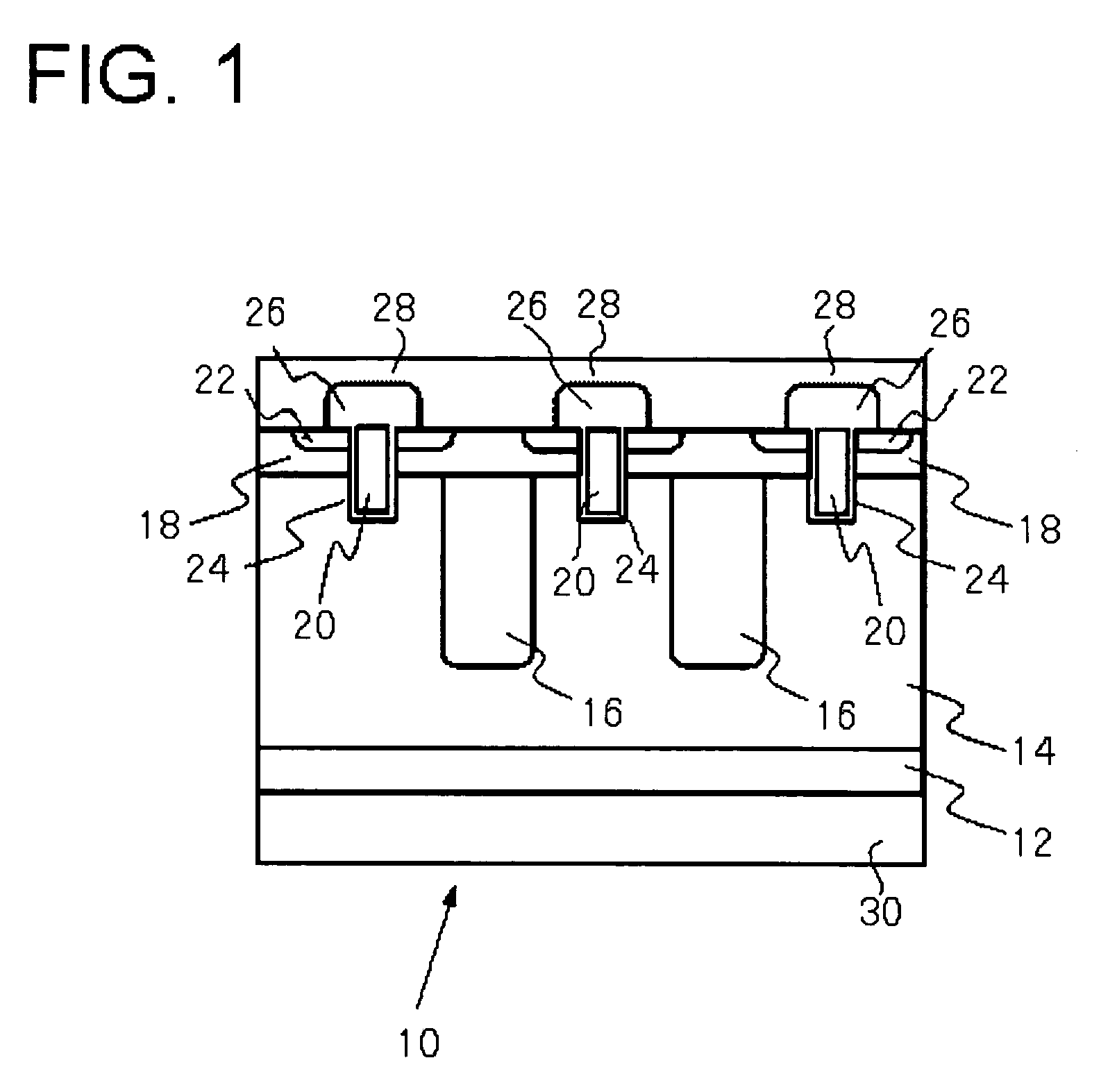

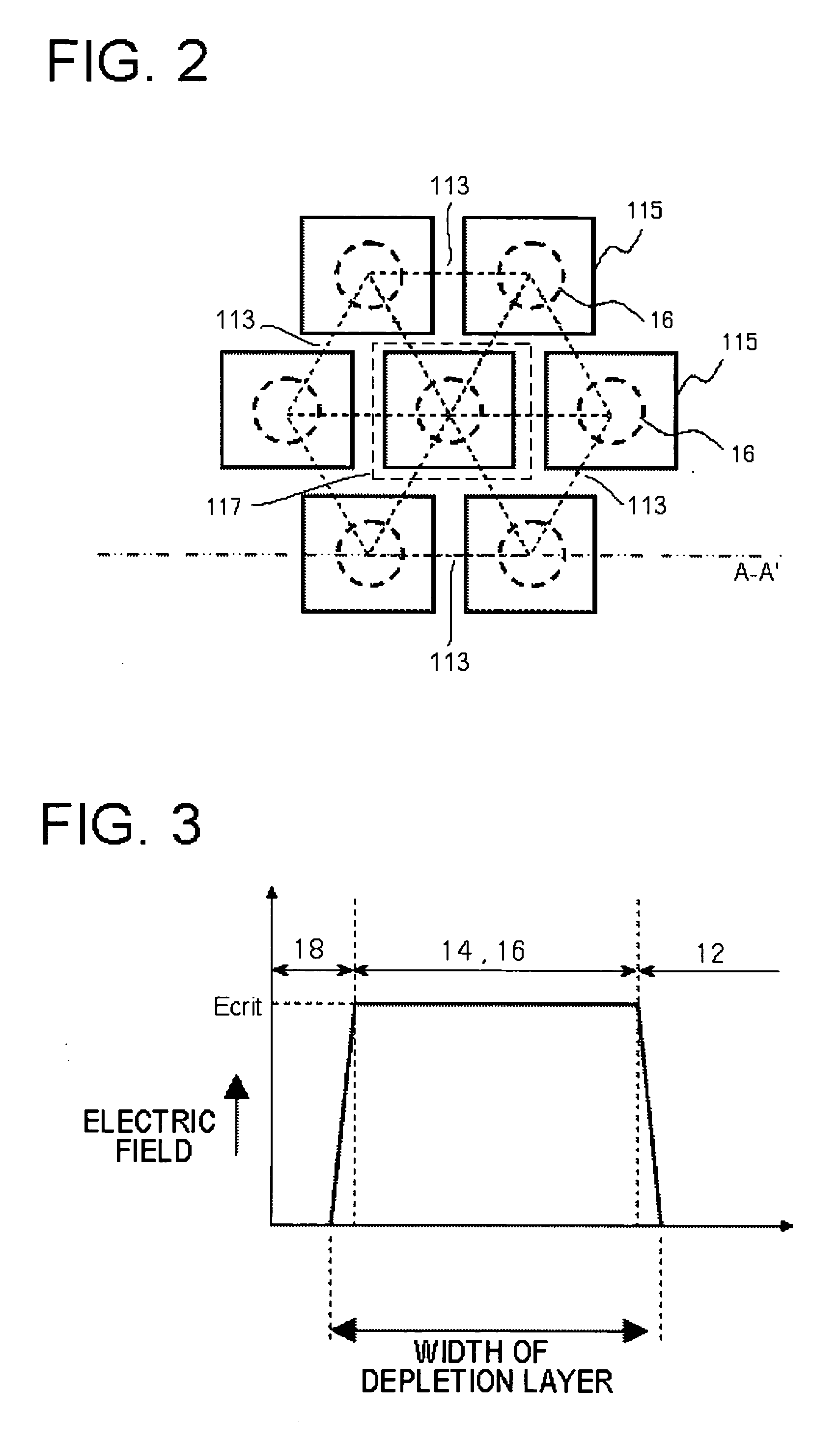

Semiconductor device

InactiveUS20060076614A1Avoid flowPrevent such non-uniformitySemiconductor devicesElectrical resistance and conductanceSemiconductor

A semiconductor device well balanced between high voltage applicability and low ON resistance, includes an n+-type semiconductor substrate; an n-type drift region formed thereon; a p-type base region formed on the n-type drift region; a plurality of p-type column regions in the n-type drift region so as to contact with the p-type base region and having a predetermined depth in a direction perpendicular to the p-type base region; a plurality of gate electrodes spaced by a regular distance from the centers, as viewed in the depth-wise direction, of each p-type column region, and penetrating the p-type base region, and partly buried in the n-type drift region; n-type source regions provided in the surficial region of the p-type base region around each of the gate electrodes; a drain electrode connected to the back surface of the n+-type semiconductor substrate; and a source electrode connected to the n-type source regions.

Owner:NEC ELECTRONICS CORP

Thin film magnetic head having spiral coils and manufacturing method thereof

ActiveUS7085099B2Reduce in quantityIncrease the number ofConstruction of head windingsHeads using thin filmsEngineeringLower pole

The invention is directed to improvement of a write element of a thin film magnetic head. In the write element, a lower coil surrounds in a spiral form a back gap portion, arranged within a height of a lower pole. An upper coil is disposed above the lower coil, surrounding in a spiral form the back gap portion and arranged within a height of an upper pole. A gap film is at an intermediate level in the pole length that is defined by the height of the lower pole and the height of the upper pole.

Owner:HEADWAY TECH INC +1

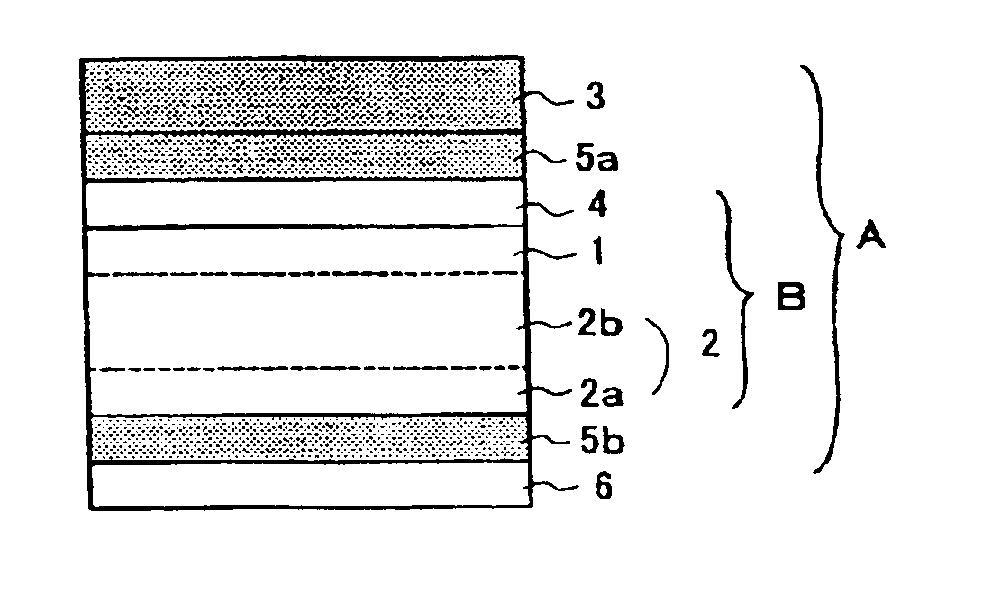

A Method for the Manufacture of a Piezoelectric Element

InactiveUS20060209128A1Stable and good piezoelectric characteristicImprove uniformityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineering

A piezoelectric element with stable and excellent piezoelectric properties is made by: a step of forming a diaphragm 30 (31, 32) on a substrate 20 (S1); a step of forming a bottom electrode 33 on the diaphragm 30 (S2); a step of forming a first piezoelectric layer 43a on the bottom electrode 33 (S3); a step of patterning both the piezoelectric layer 43a and the bottom electrode 33 (S4); a step of forming a second piezoelectric layer on the piezoelectric layer 43a and on the diaphragm 30 to mature a piezoelectric film 43 (S5); and a step of forming a top electrode 44 on the piezoelectric film 43 (S6).

Owner:SEIKO EPSON CORP

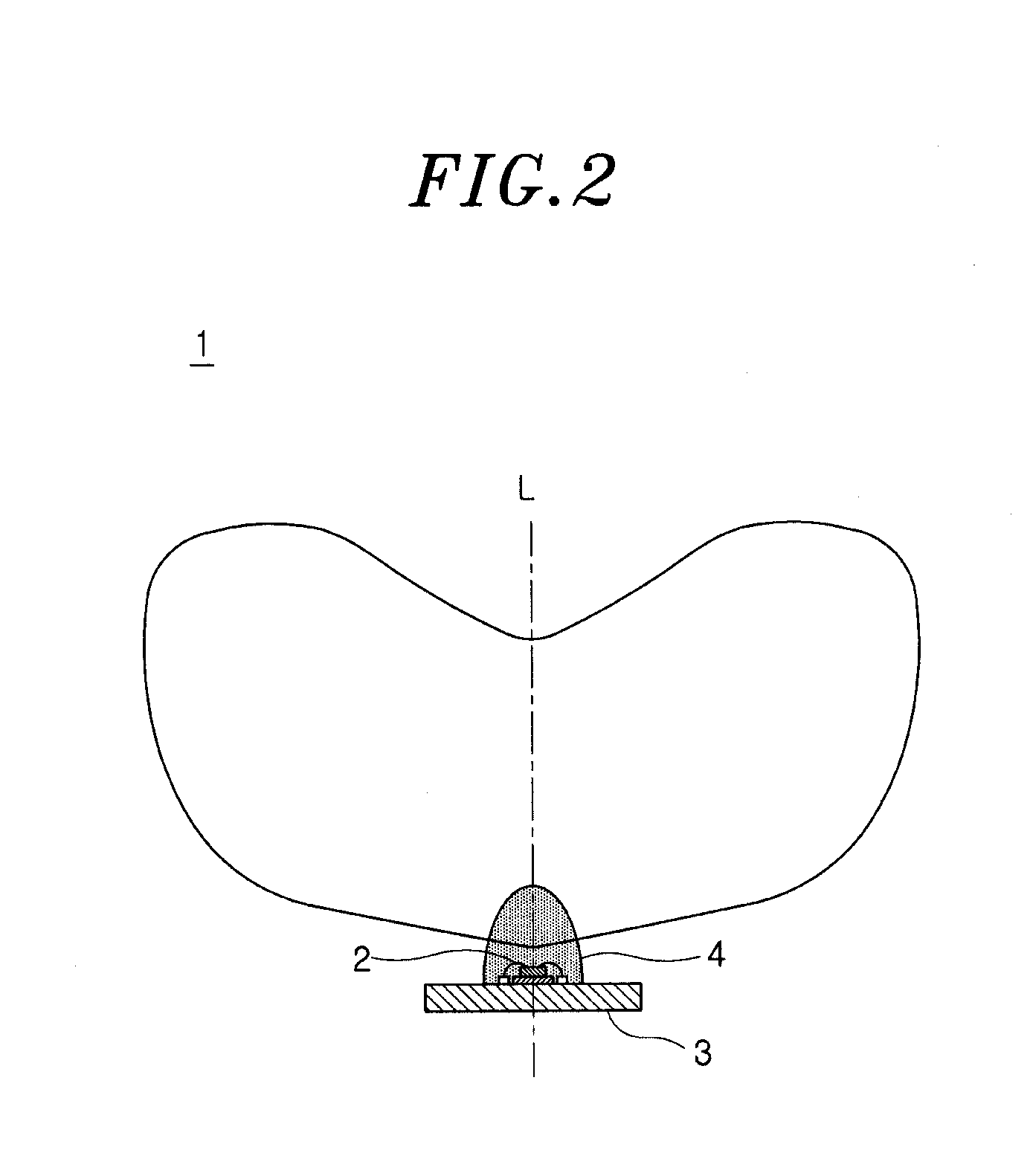

Light emitting device and illumination apparatus including same

InactiveUS20120274203A1Good light distributionEasy to controlNon-electric lightingDischarge tube luminescnet screensLength waveLight emitting device

A light emitting device includes a solid-state light emitting element; and a wavelength converting member made of a transparent resin containing a fluorescent material, the transparent resin being coated on an output surface of the solid-state light emitting element. The wavelength converting member is formed to have a thickness larger in a vertical direction of the solid-state light emitting element than that in a lateral direction of the solid-state light emitting element in a cross section that is parallel to a light output direction of the solid-state light emitting element and have a zenith in the light output direction.

Owner:PANASONIC CORP

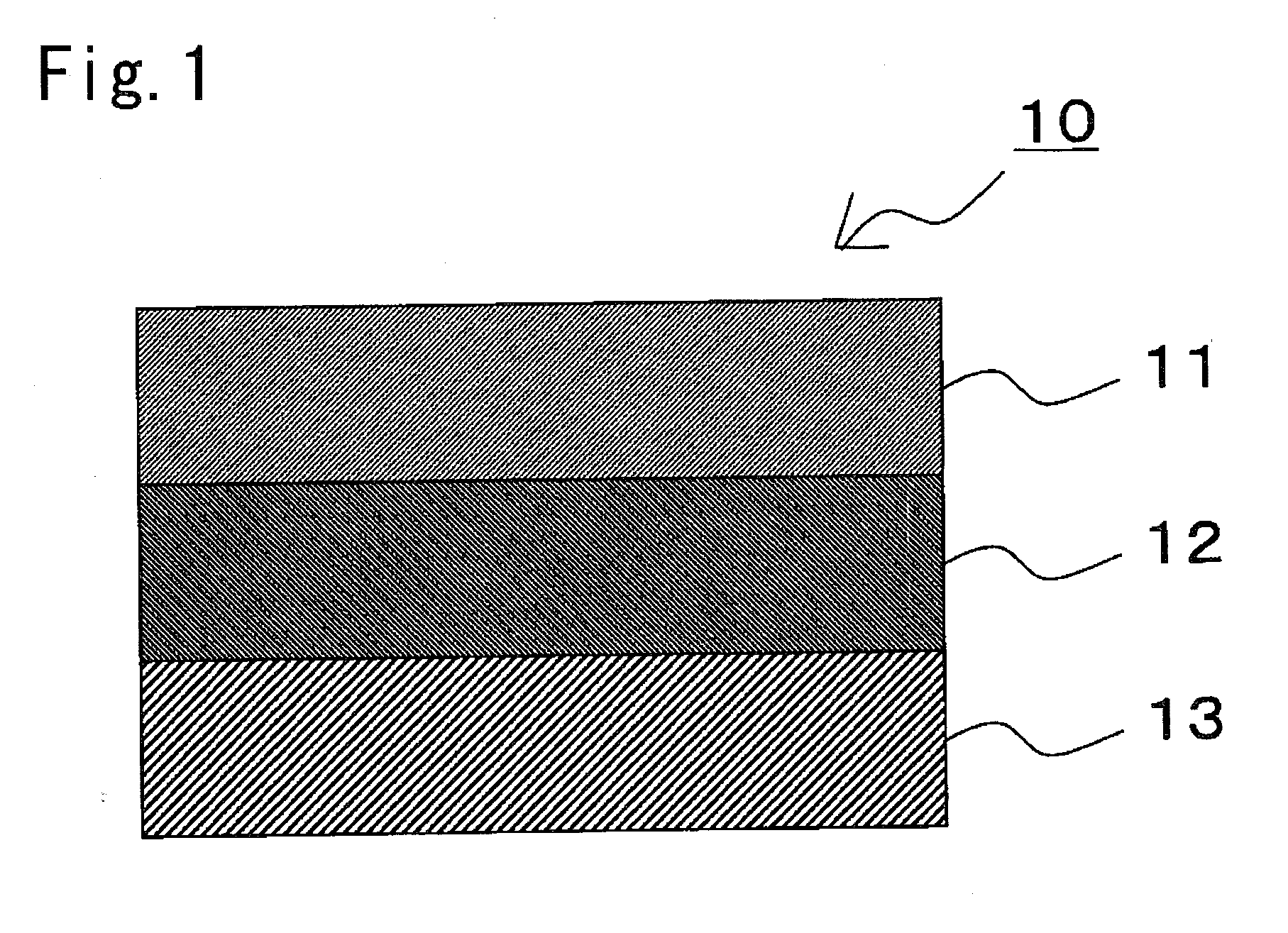

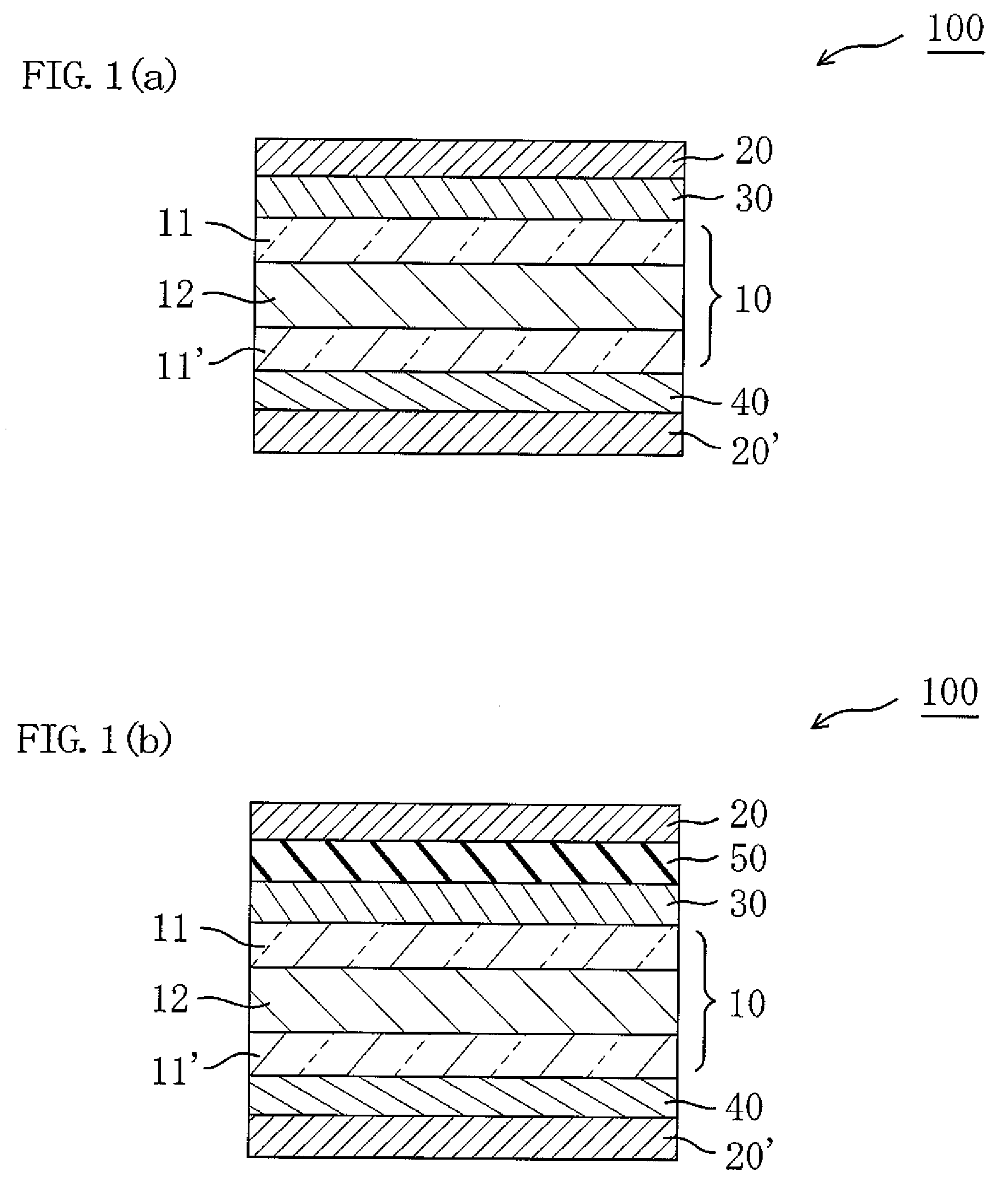

Liquid crystal display wide viewing angle polarizing film and liquid crystal display wide viewing angle polarizing adhesive film

InactiveUS6888592B2Improve heat resistanceWide viewing anglePolarising elementsNon-linear opticsLiquid-crystal displayLightness

A liquid crystal display comprising a liquid crystal display wide viewing angle polarizing adhesion film, which comprising a polarizing layer laminated on an optical compensation film and a retardation film and / or a brightness enhancement film laminated on said polarizing layer, wherein said polarizing layer is directly laminated on said optical compensation film, adhered onto at least one side of a liquid crystal panel, is less brightness nonuniformities.

Owner:NITTO DENKO CORP

Fastener Chain and Slide Fastener

ActiveUS20130185903A1High tensile strengthHigh flame retardancyChemical protectionSnap fastenersPolyesterFastener

In a fastener chain, at least some warps constituting a woven fastener tape are provided with a flame retardant phosphorus-copolymerized polyester fiber fiber and wefts constituting the same fastener tape are provided with a synthetic fiber that is not phosphorus-copolymerized and that has a higher degree of tensile strength than the flame retardant polyester fiber. With this configuration, superior flame retardancy can be stably obtained and there is no variance in the flame retardancy of the fastener chains. In the fastener chain, the heat contraction of the warp is used to improve the chain horizontal pull force, and by increasing the frictional resistance between the warp and the weft, shifting of the weave pattern of the fastener tape can be prevented. Further, the fastener chain can be provided at a low cost because of the small amount of flame retardant polyester fiber used.

Owner:YKK CORP

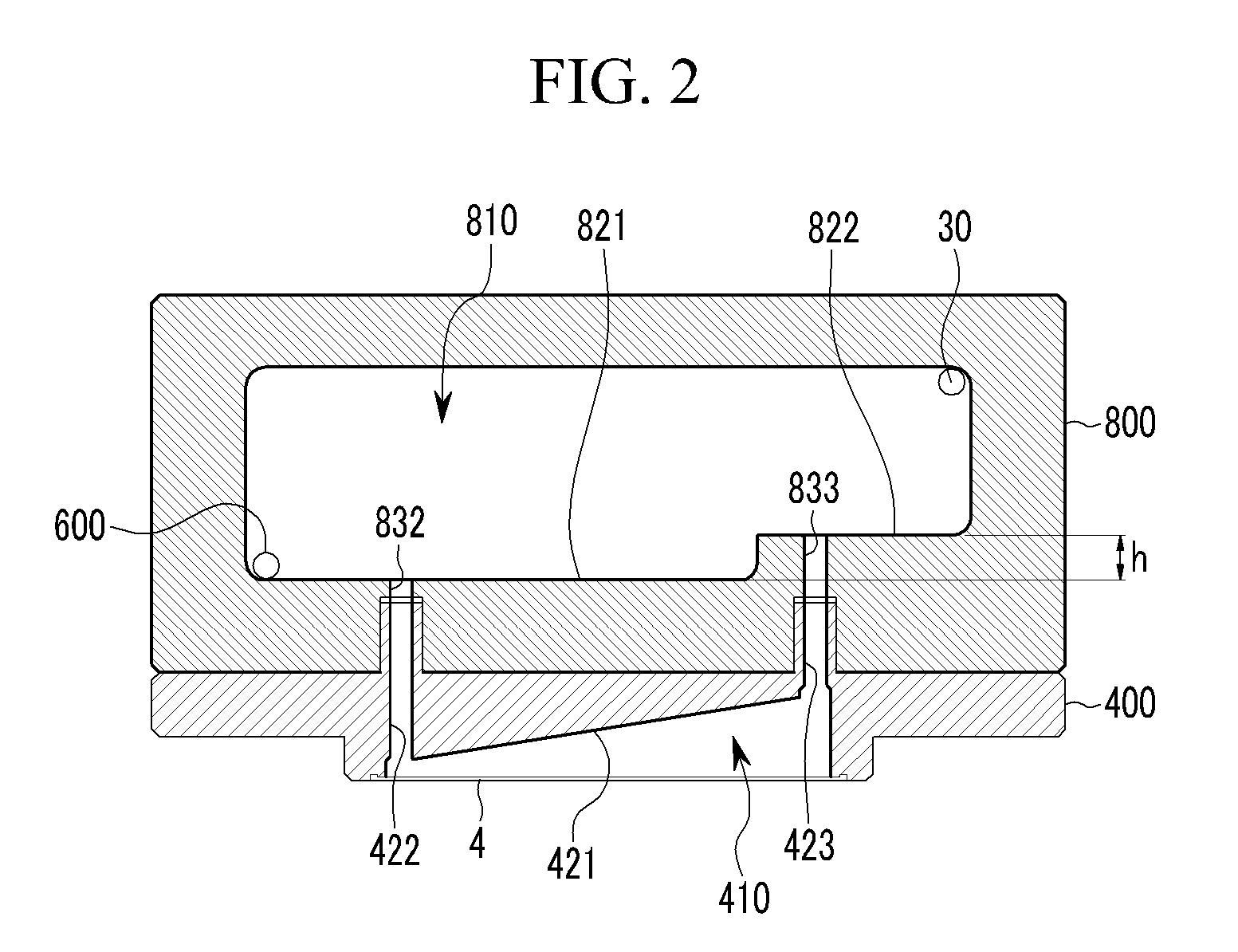

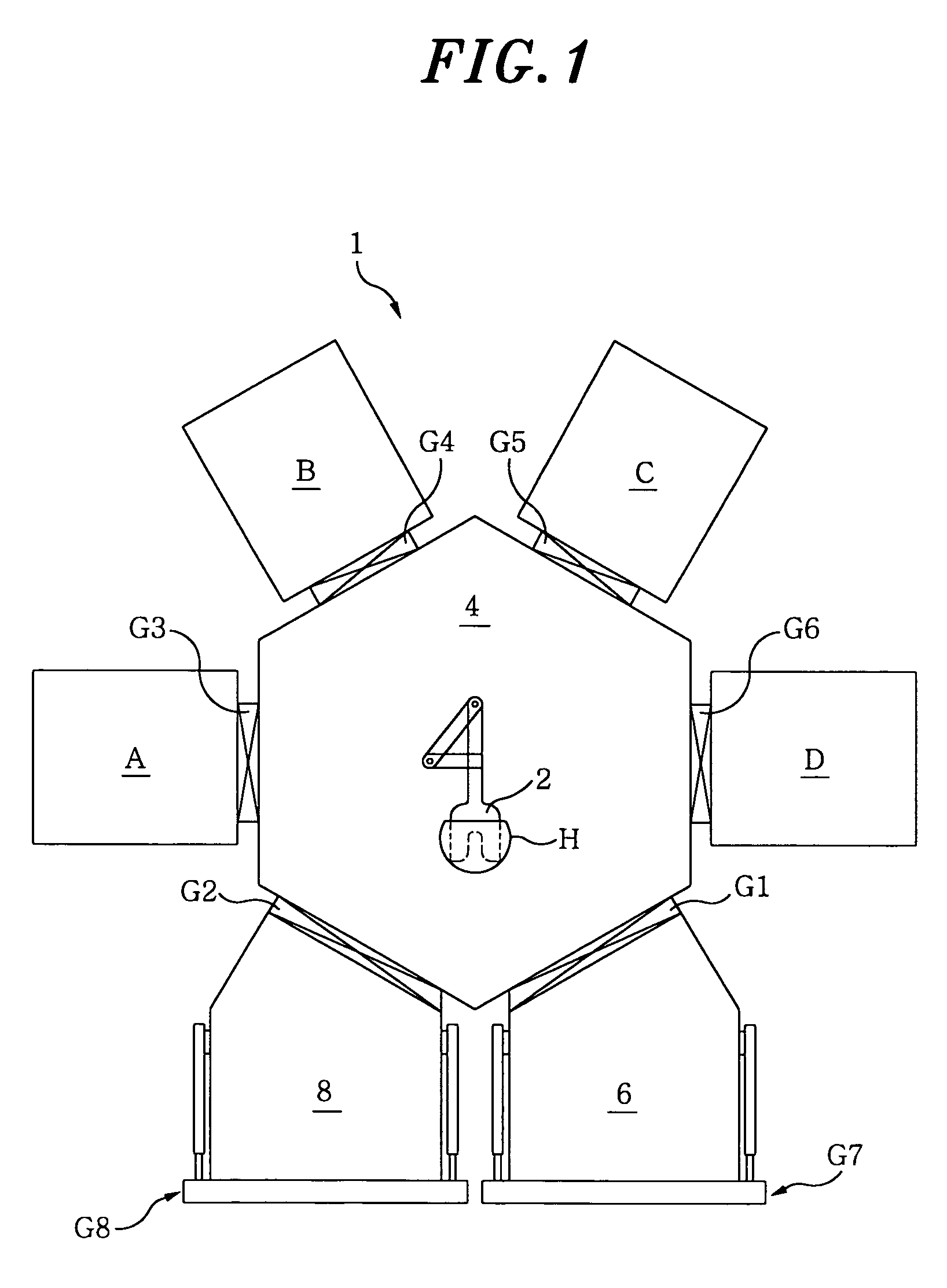

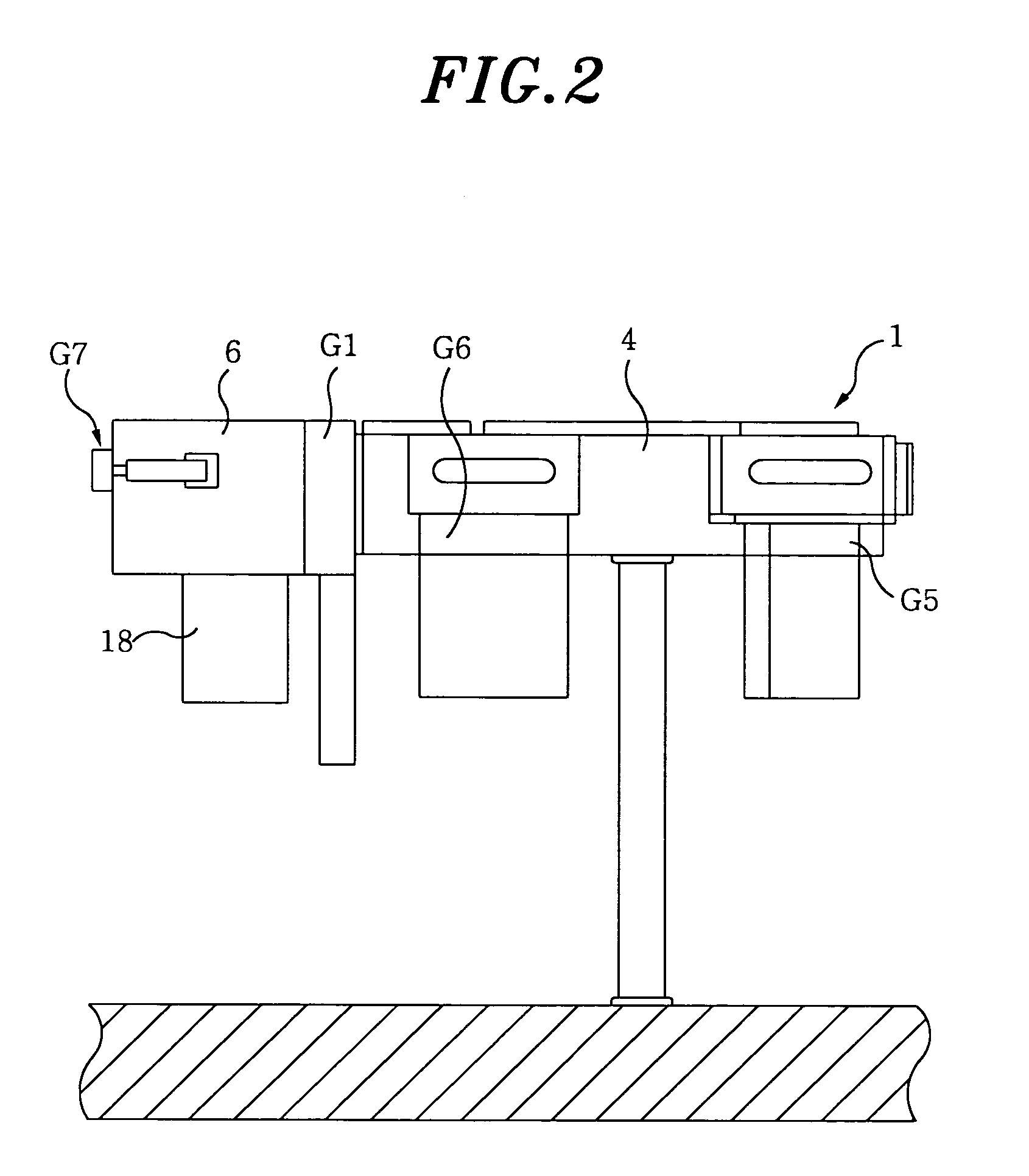

Optical pickup device

InactiveUS20050210488A1Easy to fillDifficult to fillRecord information storageDisposition/mounting of headsOptical pickupEngineering

Other end portion of a wire member 6 having elasticity one end portion of which is fixed to a fixed support member 2 is fixed to a movable lens holder 3 having an object lens 31. The wire member 6 is arranged to penetrate through a layer of a damper member 8 filled to a filling portion 7 of the fixed support member 2. The filling portion 7 is formed by a groove-like face 71 and an inner face 21a of a lid portion 21. The lid portion 21 is provided with a damper member filling port 22. A front and rear width c and an up and down width d of the damper member filling port 22 are narrower than a front and rear width a and an up and down width b of a groove shaped hollow portion.

Owner:FUNAI ELECTRIC CO LTD

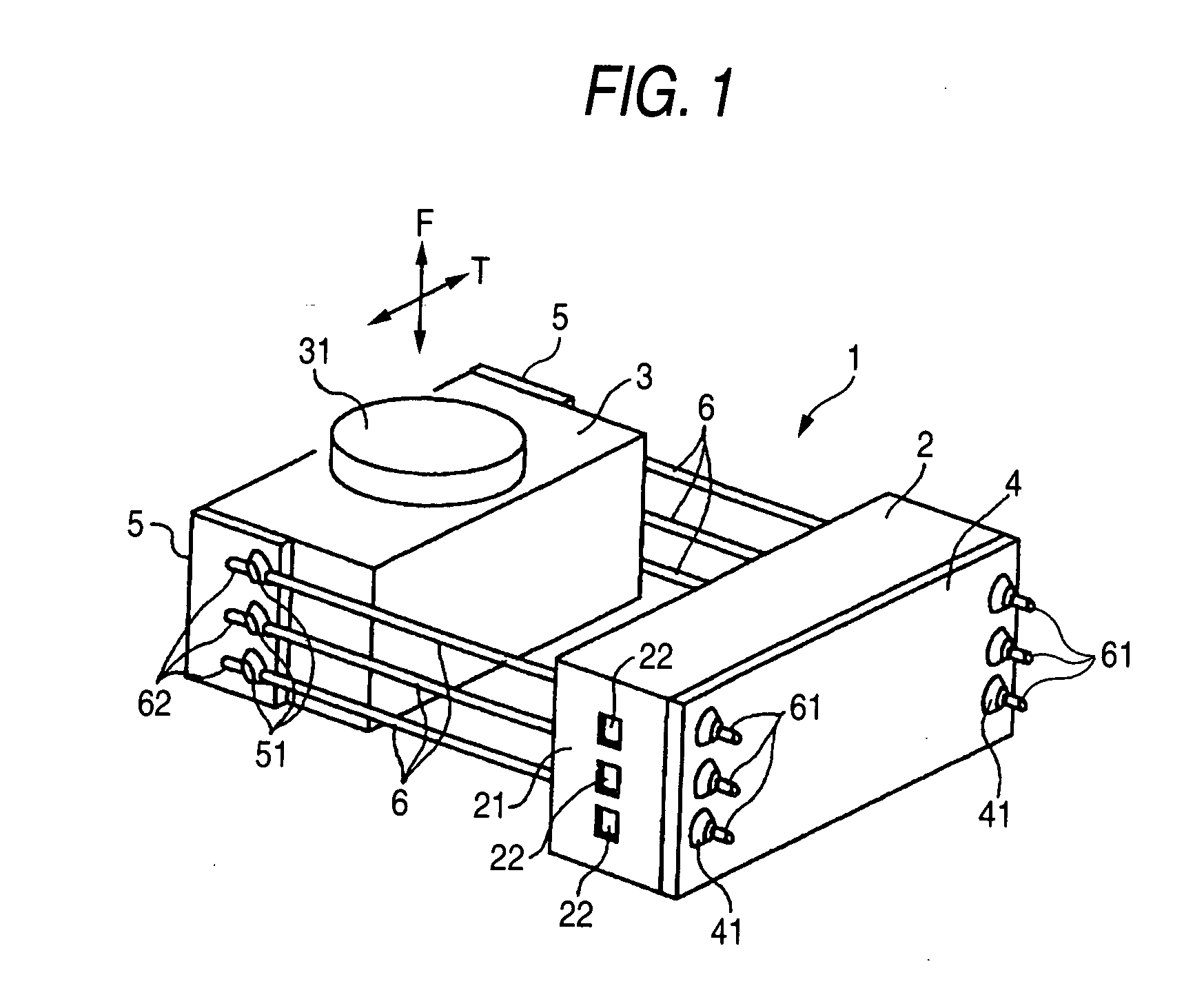

Method and device for processing semicounductor wafer

InactiveUS20050015174A1Reliable and reliablePrevent such non-uniformitySemiconductor/solid-state device manufacturingTotal factory controlStart timeTransfer mechanism

A method of processing a semiconductor wafer, characterized by comprising the steps of executing a permutation processing for processing (Pi) the semiconductor wafers by using a plurality of processing containers (A, B, C, D) for performing the processings different from each other while sequentially transferring (Ci) the wafers into the processing containers or performing a parallel processing for processing the wafers in the processing containers by using the plurality of processing containers for performing the processings identical to each other and a transfer mechanism used commonly for the processing containers while sequentially transferring the wafers into the processing containers by the transfer mechanism, wherein the processings of the wafers in the processing vessels are performed after the completion of the conditioning (Si) of the processing vessels and, in a first processing, a conditioning start time for a next processing container is adjusted so that the conditioning of the next processing container can be completed when the processing of the previous processing container is completed and, in a second processing, the conditioning start time for the latter processing container is adjusted so that the conditioning of the processing container allowing the wafers to be next transferred therein can be completed when the transfer of the wafers into the processing container is completed.

Owner:TOKYO ELECTRON LTD

Heat-dissipating module

InactiveUS20050024829A1Increase volumeImprove cooling efficiencyPump componentsCombination enginesImpellerDensity distribution

A heat-dissipating module includes a first fan unit and a second fan unit, which are serially connected together to provide an air inlet and an air outlet. Each of the first fan unit and the second fan unit includes a casing and an impeller. At least one side air inlet is defined in at least one of a plurality of sides of the casing of the first fan unit and a plurality of sides of the casing of the second fan unit. The air inlet amount and the air outlet amount of the second fan unit are increased by the side air inlet. The air density distribution is uniform, and the wind noise during operation is lowered.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

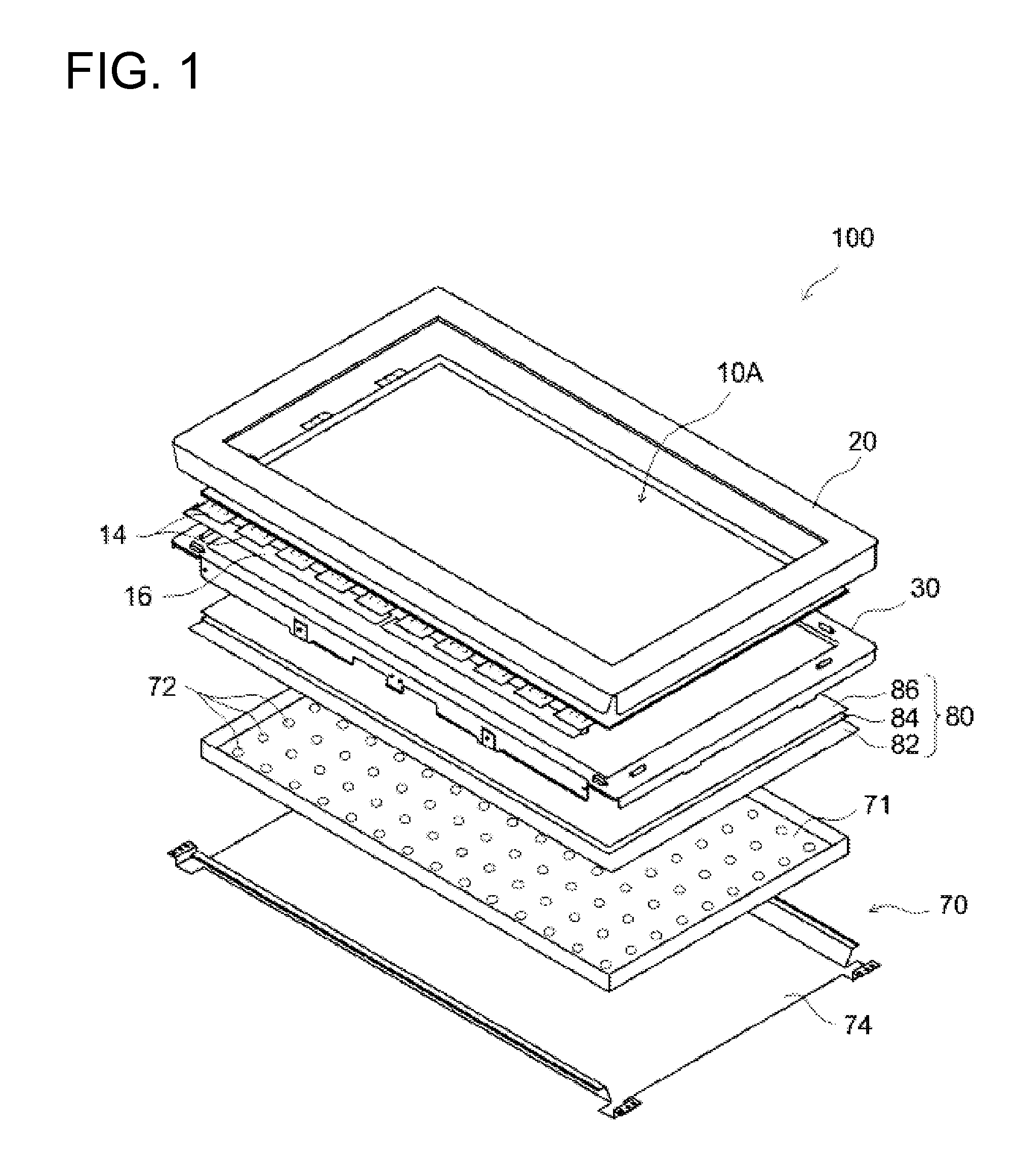

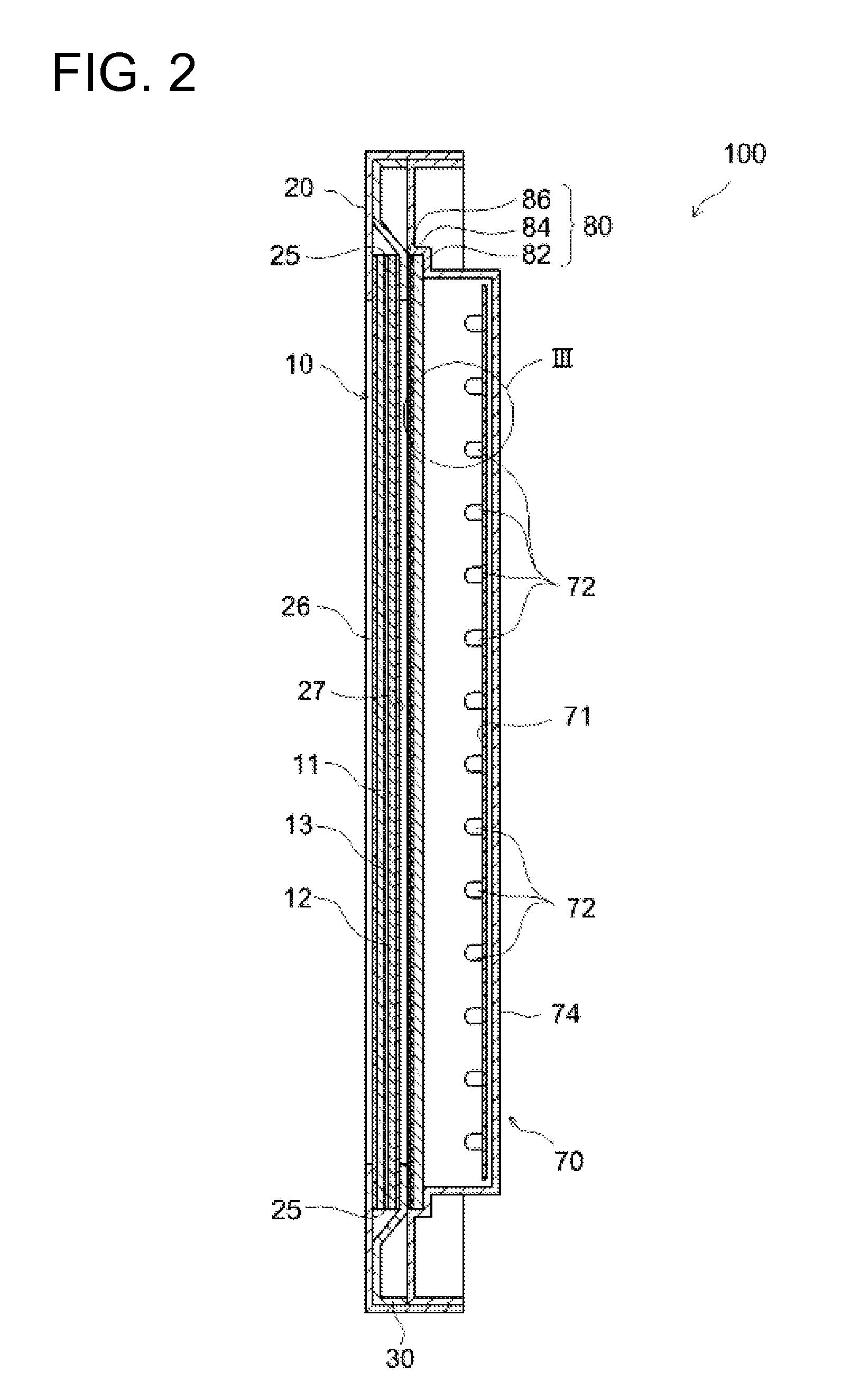

Liquid crystal display device

ActiveUS20140176872A1Avoid uneven brightnessIncrease brightnessMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

Occurrence of an event can be prevented, whereby, when a backlight expands with heat, a light guide plate might move a group of optical sheets into contact with a middle frame and deform the sheets, thereby causing nonuniformity of luminance on a screen. In particular, a protrusion is formed at an edge of the plate, and the sheets are mounted on the plate to avoid the protrusion. The frame covers the protrusion and the edge of the sheets. Even if a spatial gap with respect to the frame is lost by expansion of the plate, the sheets suffer no deformation due to interference between an edge of the sheets and the frame. Therefore, the nonuniformity of luminance on the screen does not occur, either. Also, unusual sounds due to movement of the plate under vibration do not arise since a gap between the protrusion and the frame can be small.

Owner:JAPAN DISPLAY INC

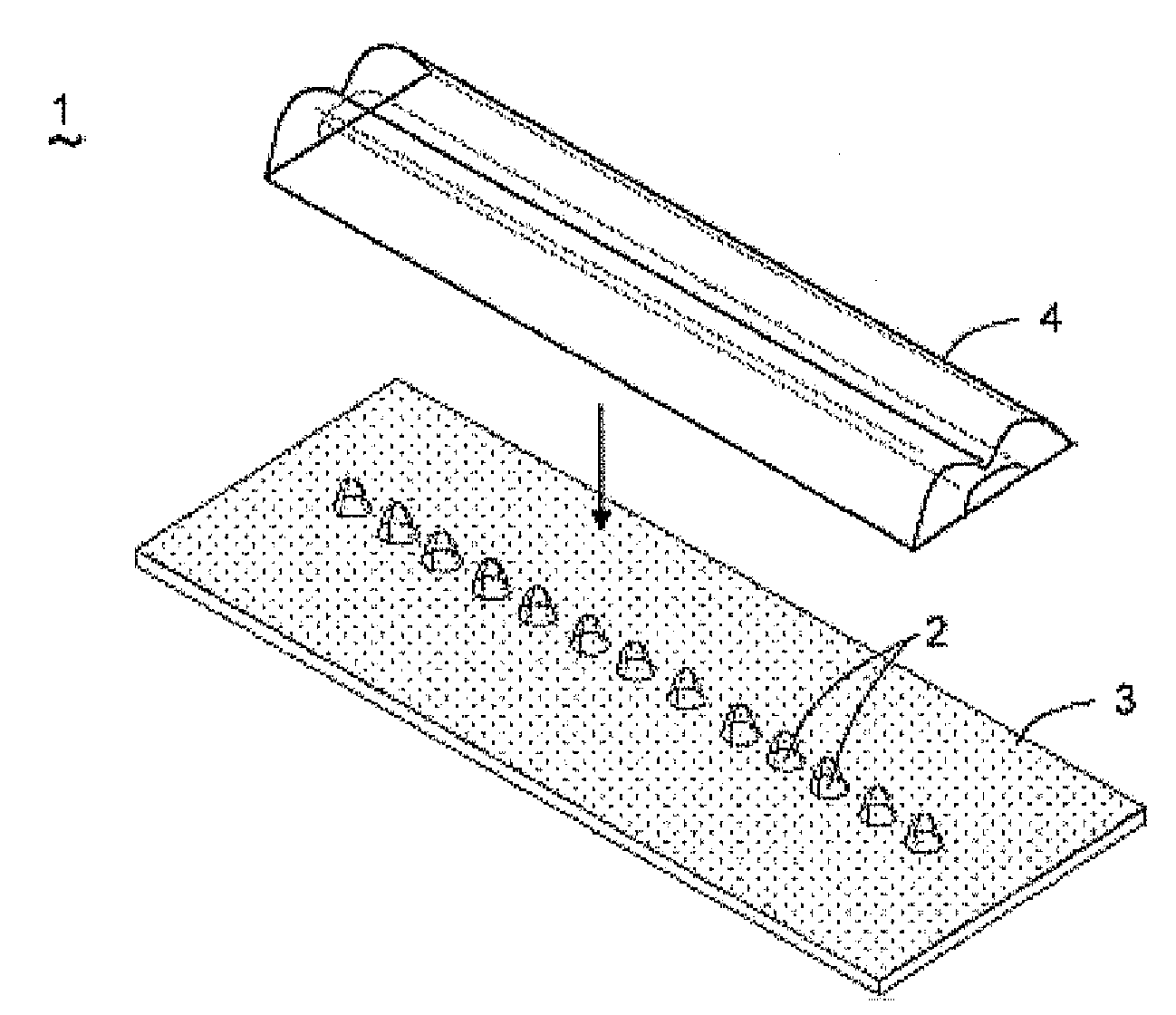

Liquid crystal display device

InactiveUS20120008063A1Increase the number ofAvoid lightNon-linear opticsPoint lightLight irradiation

An object of the present invention is to provide a liquid crystal display device capable of uniformly irradiating the entire liquid crystal panel with light (that is, capable of preventing light irradiation non-uniformity that can be recognized by viewers), without excessively increasing the number of point light sources (LEDs). In the liquid crystal display device of the present invention, in a backlight substrate region where a plurality of point light sources (L1 to L8) are disposed in a grid arrangement pattern, a position which is within a virtual rectangular region surrounded by four adjacent point light sources, and which is furthest from each of the adjacent point light sources is defined as an anisotropy reference position (G1 to G3). Light emitted from the point light source closest to the anisotropy reference position is selectively diffused in a direction toward the reference position (G1 to G3) by the anisotropic optical member (82), thereby realizing the optical anisotropy is that direction.

Owner:SHARP KK

Thin film magnetic head and manufacturing method thereof

ActiveUS20050157423A1Lower coil resistanceQuantity of generated heat is reducedConstruction of head windingsHeads using thin filmsLower poleIntermediate level

The invention is directed to improvement of a write element of a thin film magnetic head. In the write element, a lower coil surrounds in a spiral form a back gap portion, arranged within a height of a lower pole. An upper coil is disposed above the lower coil, surrounding in a spiral form the back gap portion and arranged within a height of an upper pole. A gap film is at an intermediate level in the pole length that is defined by the height of the lower pole and the height of the upper pole.

Owner:HEADWAY TECH INC +1

Polarizing plate with an optical compensation layer, liquid crystal panel, liquid crystal display apparatus, and image display apparatus using the polarizing plate with an optical compensation layer

InactiveUS20090103016A1Reduce thicknessViewing angle property is improvedPolarising elementsNon-linear opticsLiquid-crystal displayColor shift

The present invention provides a polarizing plate with an optical compensation layer capable of contributing to the reduction in thickness, enhancing viewing angle properties, realizing a high contrast, preventing interference nonuniformity and heat nonuniformity, suppressing a color shift, realizing satisfactory color reproducibility, and preventing light leakage in a black display satisfactorily, and a liquid crystal panel, a liquid crystal display apparatus, and an image display apparatus using the polarizing pate with an optical compensation layer. A polarizing plate with an optical compensation layer of the present invention comprises a polarizer, a first optical compensation layer, and a second optical compensation layer in the stated order, wherein the first optical compensation layer has a refractive index profile of nx>ny=nz, exhibits wavelength dispersion properties in which an in-plane retardation Re1 decreases toward a shorter wavelength side, and has the in-plane retardation Re1 of 90 to 160 nm; and the second optical compensation layer comprises a film layer, and has a refractive index profile of nx=ny>nz, an in-plane retardation Re2 of 0 to 20 nm, and a thickness direction retardation Rth2 of 30 to 300 nm.

Owner:NITTO DENKO CORP

Image recording apparatus including a fusing unit having a plurality of heater members

InactiveUS7664416B2Prevent such non-uniformityAvoid inhomogeneityElectrographic process apparatusImage recordingHeat control

Owner:OKI DATA CORP

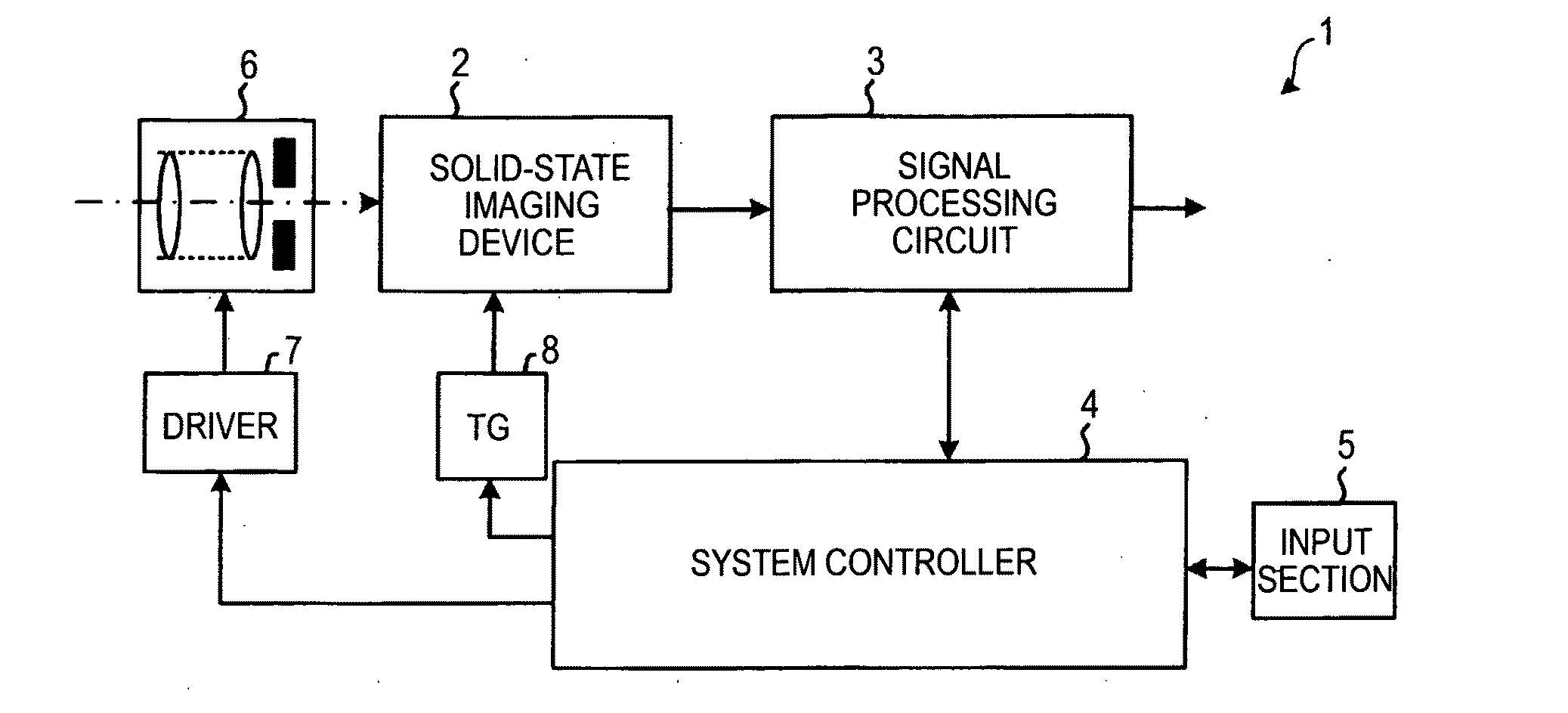

Solid-state imaging device and imaging apparatus

ActiveUS20110187910A1Non uniformAvoid image noiseTelevision system detailsTelevision system scanning detailsPhotoelectric conversionEngineering

A solid-state imaging device includes: a pixel array section having an effective pixel region formed by a plurality of pixels which are disposed in the form of a matrix, each of which includes a photoelectric conversion device and a transistor reading out an electric charge obtained by photoelectric conversion at the photoelectric conversion device, and which are illuminated by light and a light-shielded pixel region formed by a plurality of pixels which are shielded from light; a row scan section selecting and controlling each row of pixels of the pixel array section to output a signal from each of the pixels of the selected row of pixels to a column signal line provided in association with the row of pixels; and an A-D conversion section converting the signal output from the signal line into a digital signal.

Owner:SONY SEMICON SOLUTIONS CORP

Liquid crystal panel and liquid crystal display apparatus

ActiveUS7630038B2Increase contrastReduce colorPolarising elementsNon-linear opticsColor shiftPolarizer

Owner:NITTO DENKO CORP

Biaxially oriented polyester film, process for producing the same, and use thereof as substrate for photographic sensitive material

InactiveUS6440532B1Reduce the amount requiredPrevent such non-uniformityMagnetic materials for record carriersSynthetic resin layered productsDual axisPolyester

A biaxially oriented polyester film whose thermal shrinkage factors satisfy relationships represented by the following expressions (1) to (5) at the same time when it is heated at 120° C. for 20 seconds:wherein SMD is a thermal shrinkage factor (%) in machine direction of the film under the above conditions, STD is a thermal shrinkage factor (%) in a direction perpendicular to that direction under the above conditions, and S45 and S135 are thermal shrinkage factors (%) in a 45° direction and a direction perpendicular to the 45° direction under the above conditions when the machine direction of the film is 0° and a direction perpendicular to that direction is 90°, respectively, and a production method thereof.

Owner:TEIJIN LTD

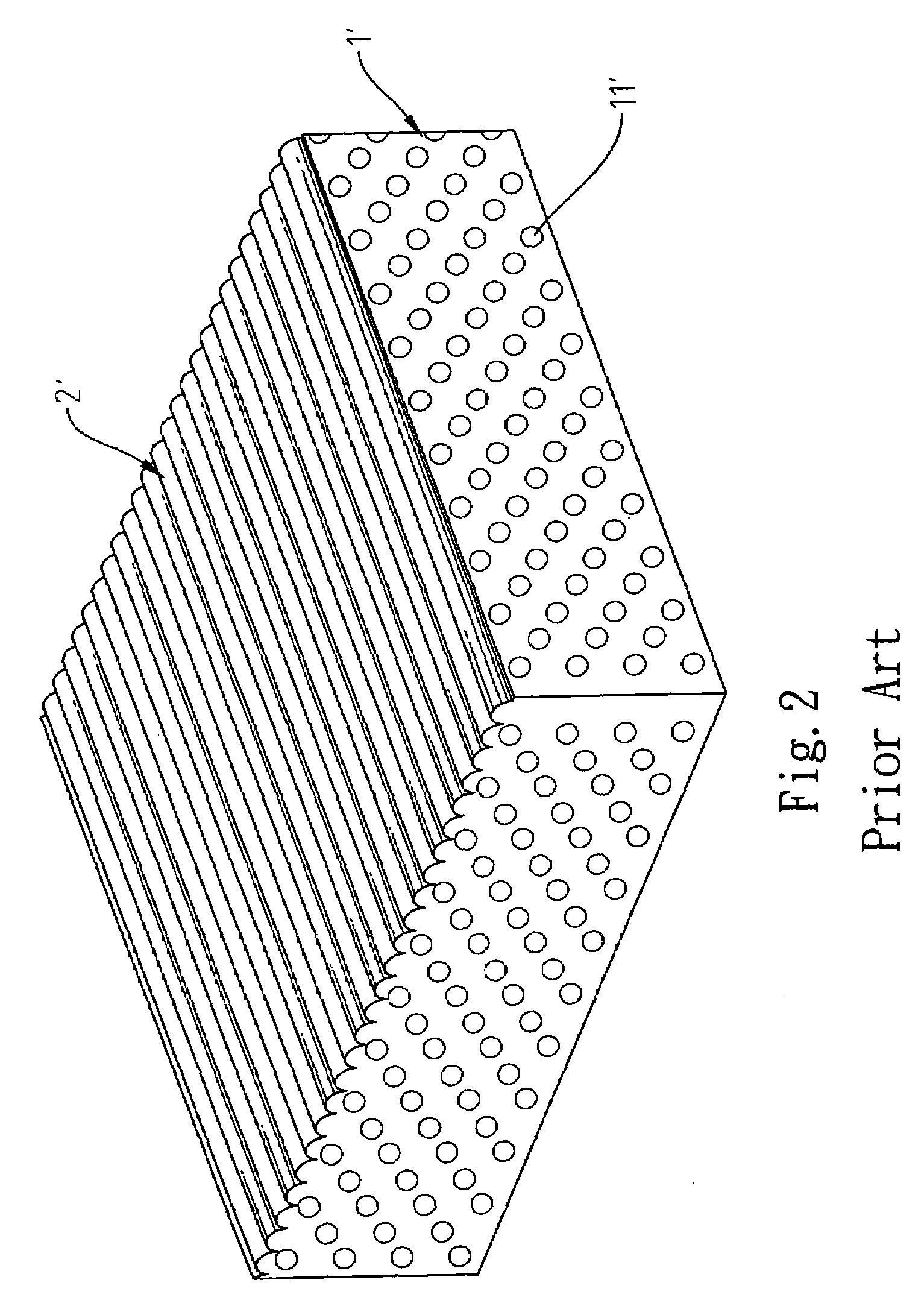

Diffuser plate having multi-aspheric structure

InactiveUS20080084609A1Improve brightnessAvoid non uniformityDiffusing elementsLensMicrostructureEngineering

A diffuser plate having a multi-aspheric structure comprises a plate and at least one aspheric microstructure. The plate is made of a transparent polymer. The plate is doped with a UV absorbent and several diffusion particles. The aspheric microstructure is formed on at least one surface of the plate. By the use of the aforesaid structure, the present invention can improve the conventional problems and provide the advantages including high light transmission rate, raised diffusion capability, improved brightness, and uniform light beams.

Owner:ENTIRE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com