Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

838results about How to "Highly effective" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

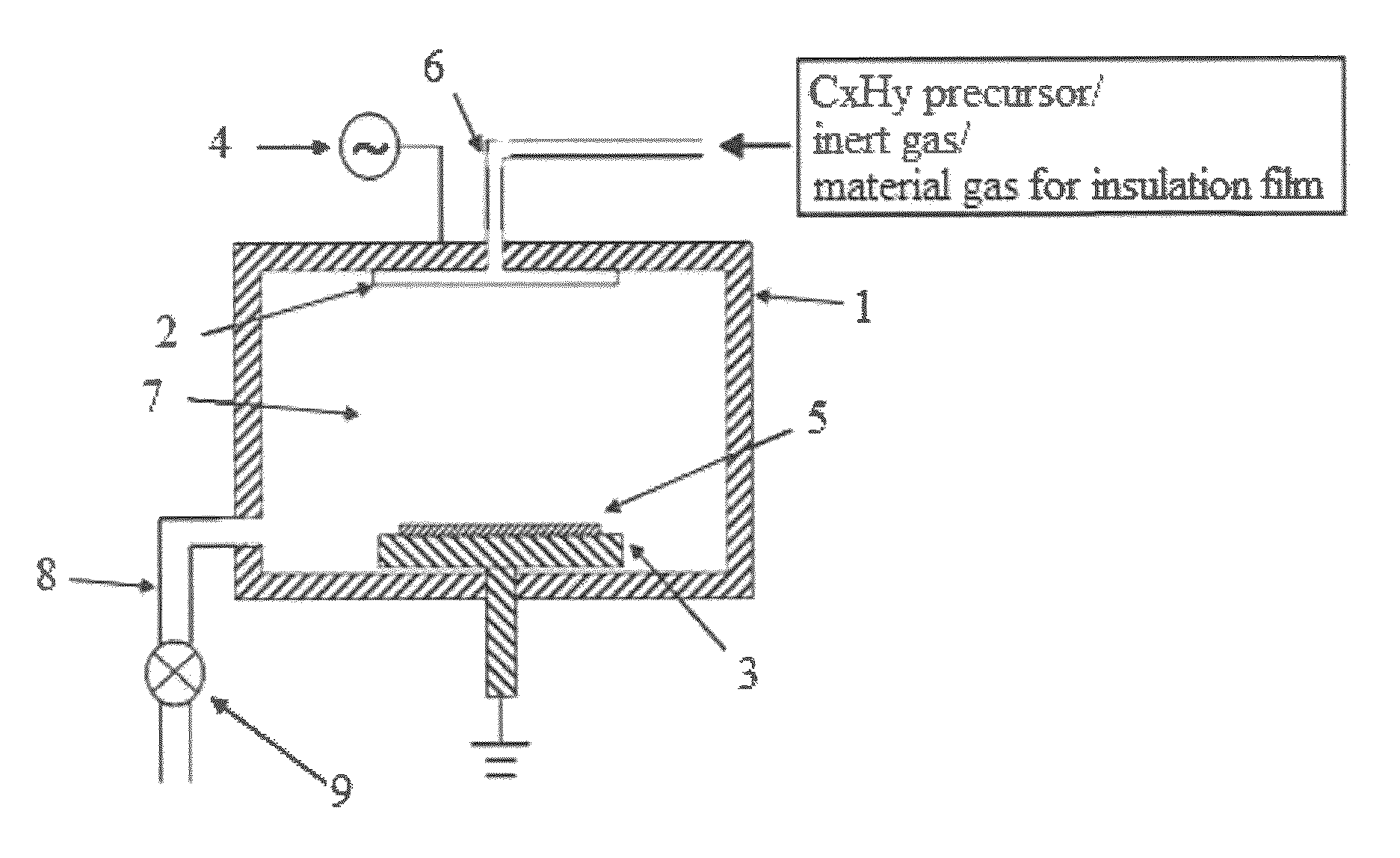

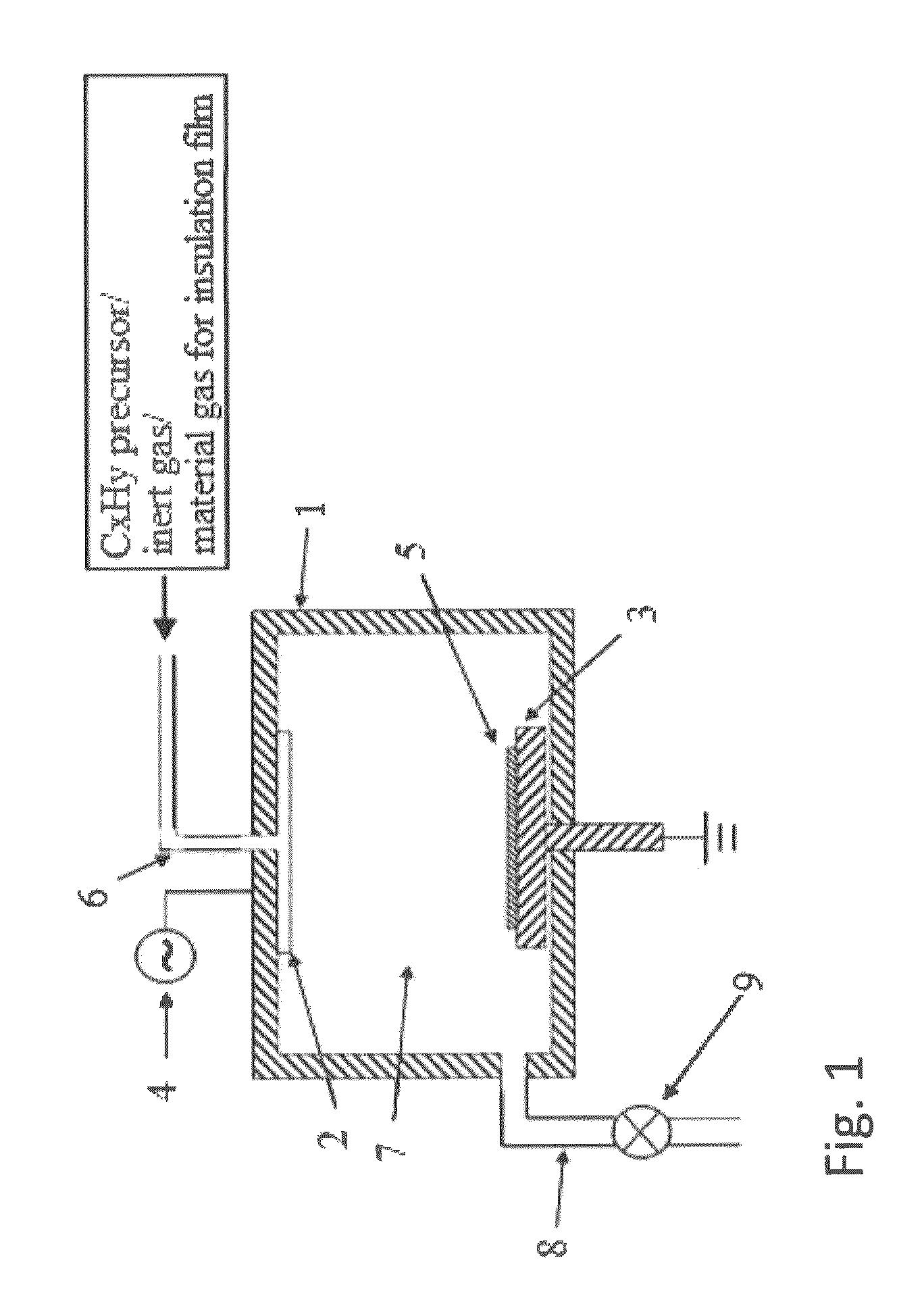

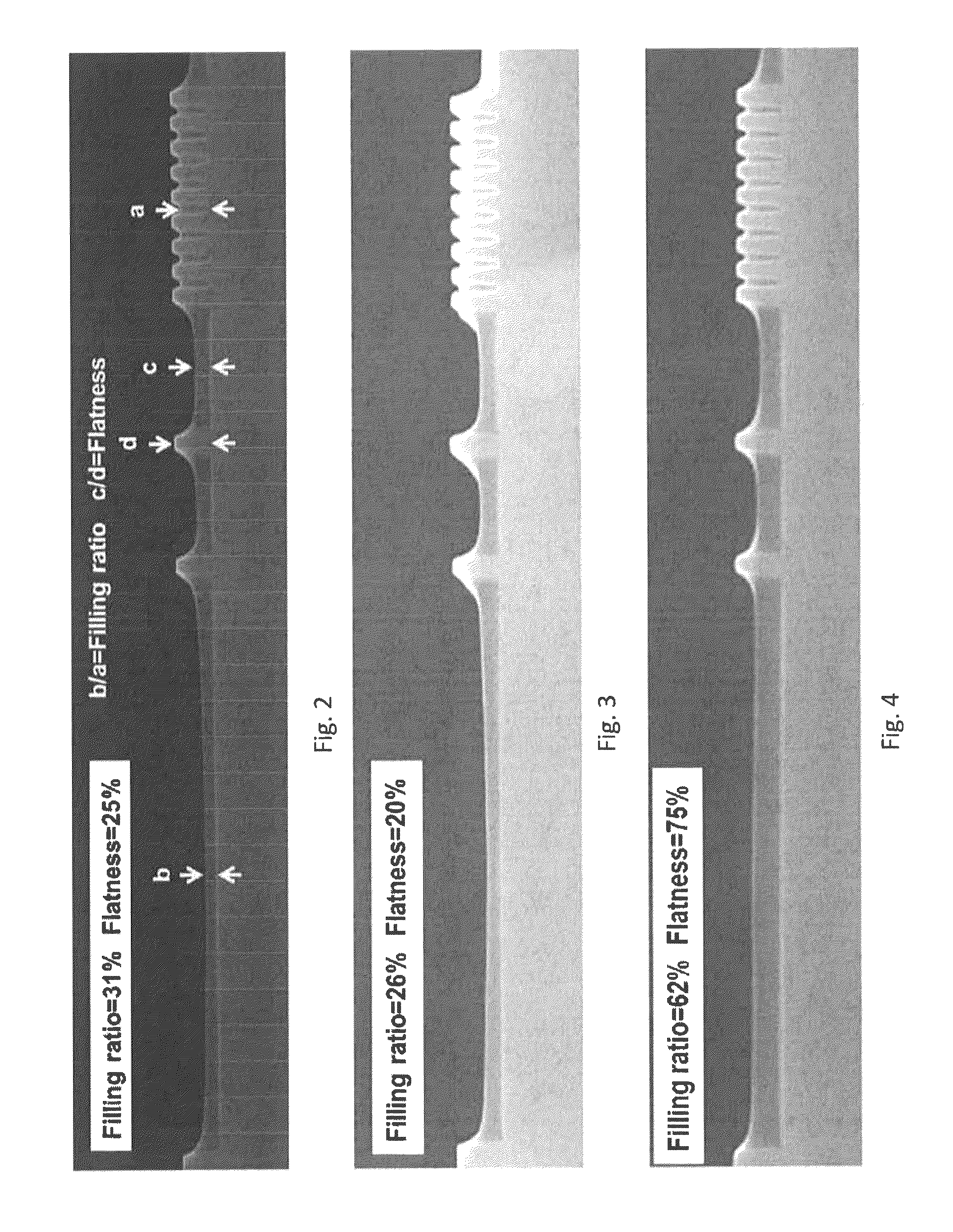

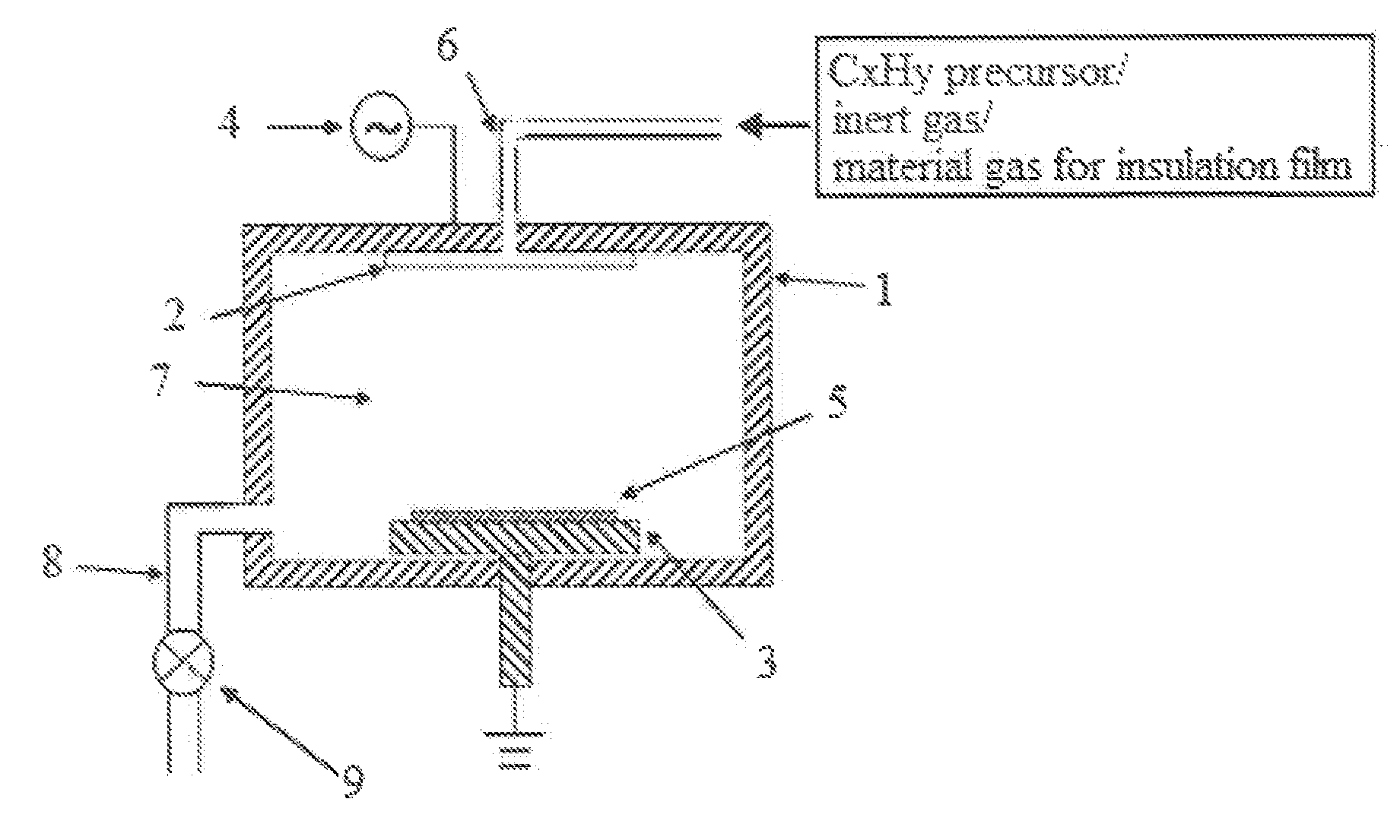

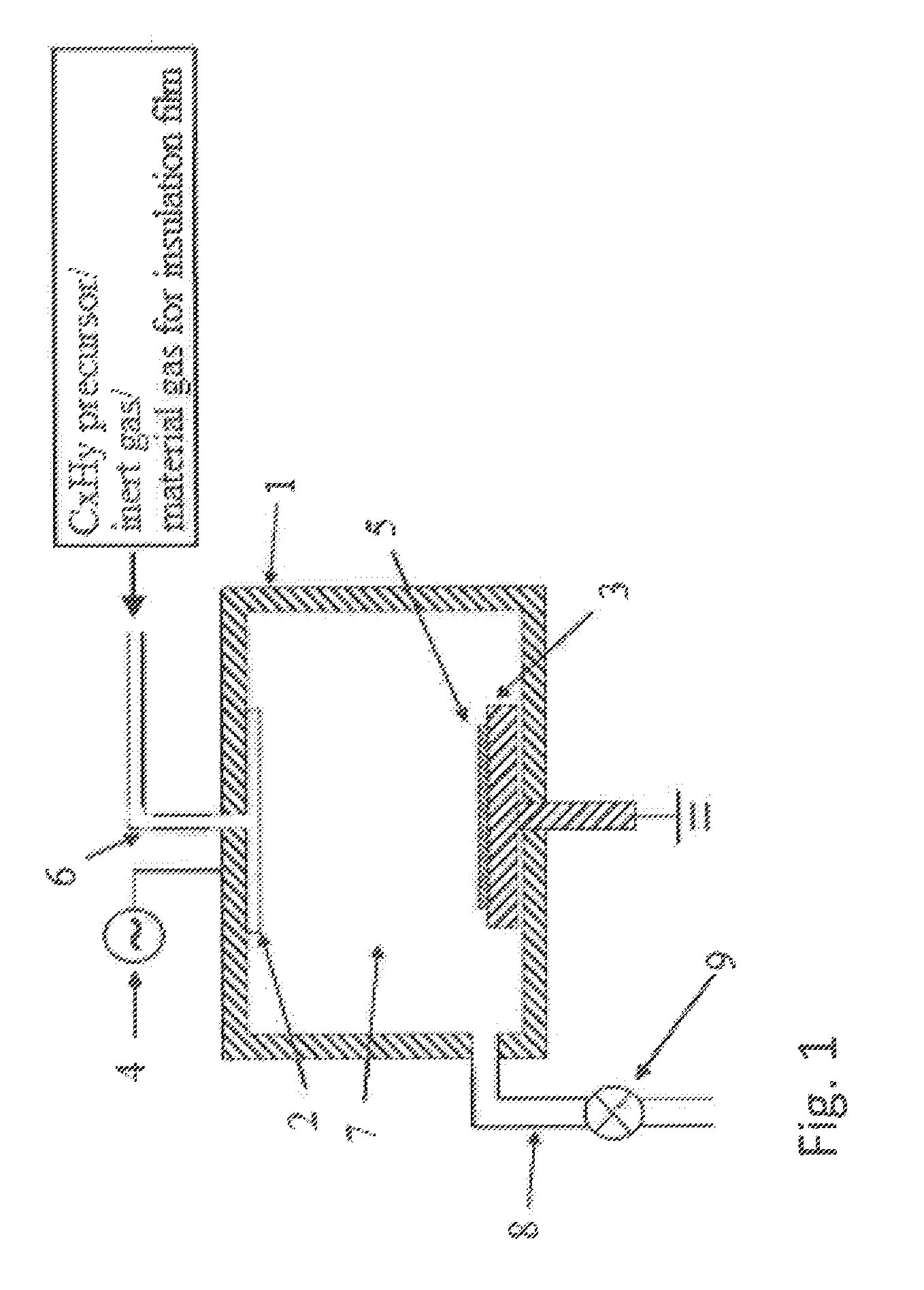

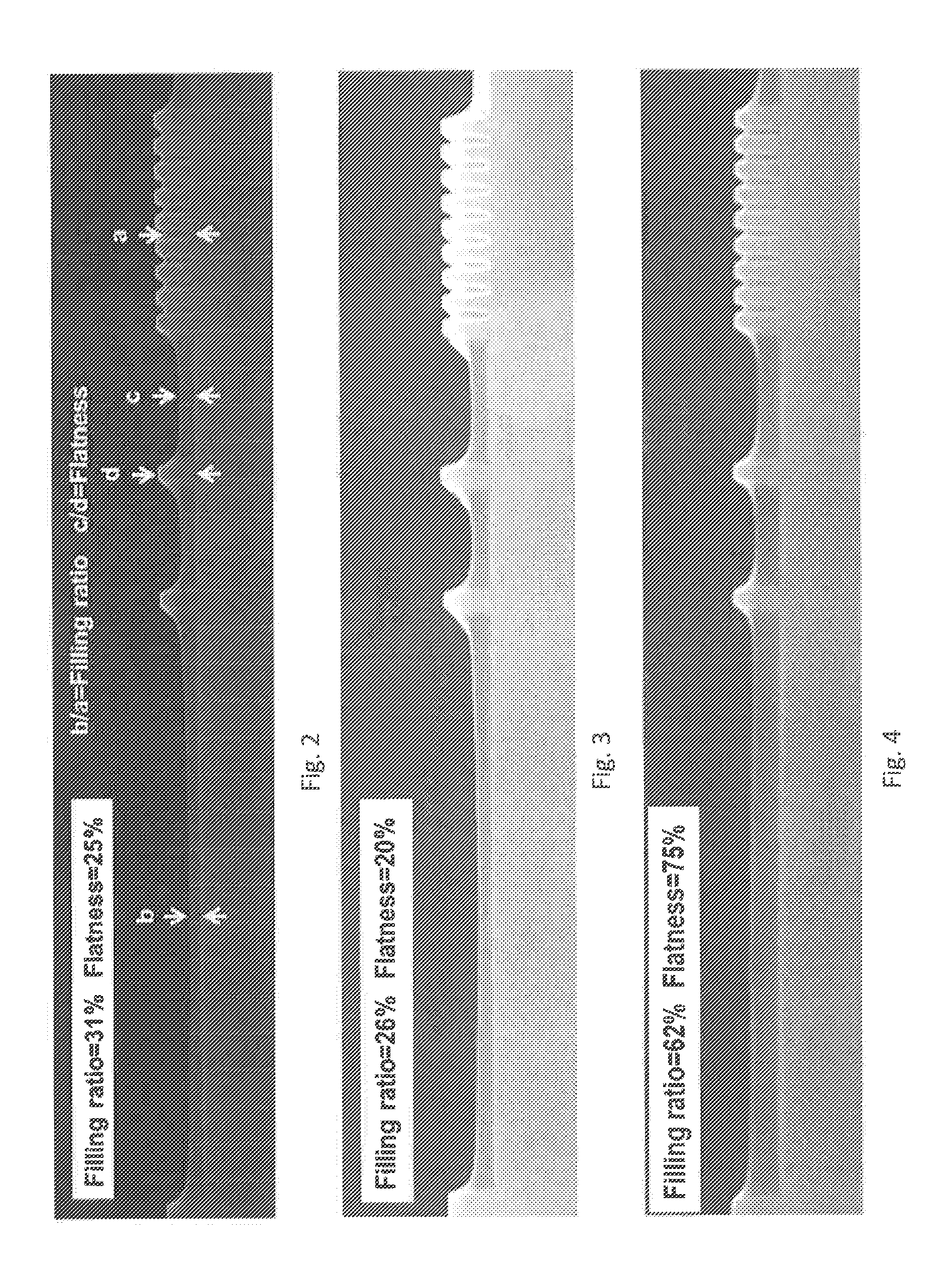

Method for filling recesses using pre-treatment with hydrocarbon-containing gas

ActiveUS9117657B2Improve flatnessHighly effectiveSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPre treatmentPre deposition

A method for filling recesses of a substrate with an insulation film includes: (i) exposing surfaces of the recesses of the substrate to a pre-deposition gas in a reactive state in a reaction space to treat the surfaces with reactive hydrocarbons generated from the pre-deposition gas without filling the recesses; and (ii) depositing a flowable insulation film using a process gas other than the pre-deposition gas on a surface of the substrate to fill the recesses treated in step (i) therewith by plasma reaction. The pre-deposition gas has at least one hydrocarbon unit in its molecule.

Owner:ASM IP HLDG BV

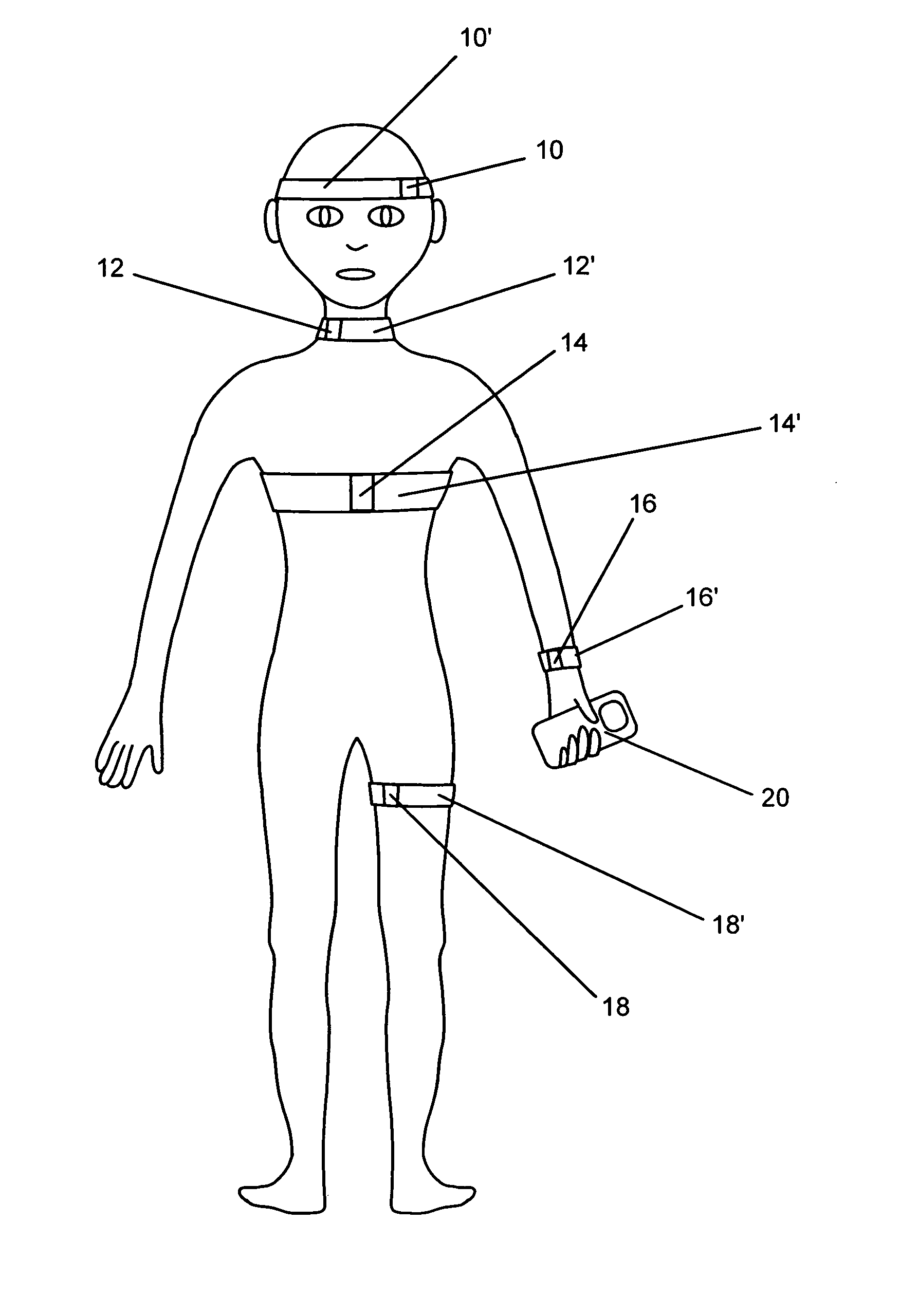

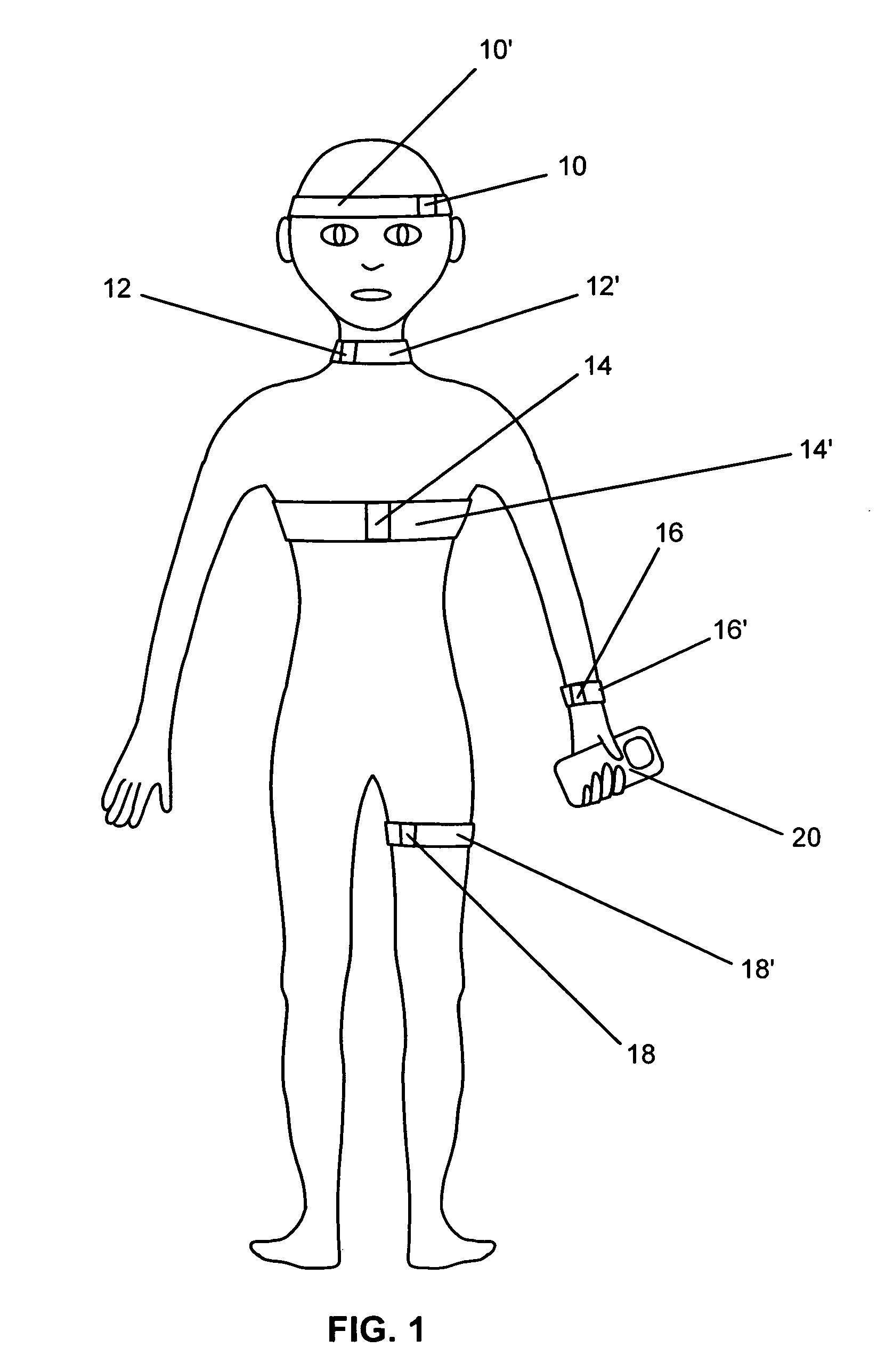

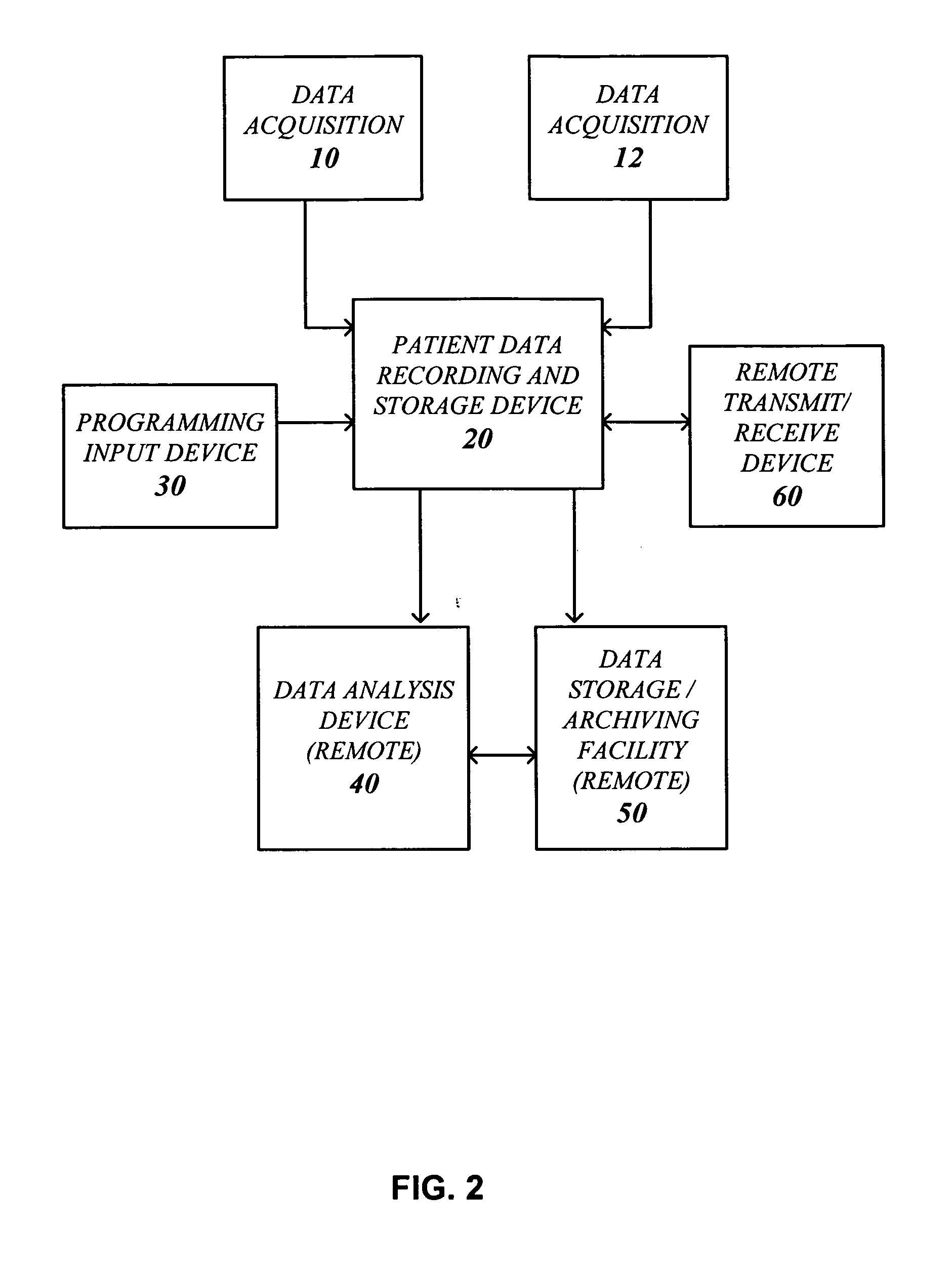

Systems and methods for non-invasive detection and monitoring of cardiac and blood parameters

InactiveUS20060100530A1Easy to detectEffective assessmentBlood flow measurement devicesCatheterData acquisitionNon invasive

Methods and systems for long term monitoring of one or more physiological parameters such as respiration, heart rate, body temperature, electrical heart activity, blood oxygenation, blood flow velocity, blood pressure, intracranial pressure, the presence of emboli in the blood stream and electrical brain activity are provided. Data is acquired non-invasively using ambulatory data acquisition techniques.

Owner:UNIV OF WASHINGTON +1

Method For Filling Recesses Using Pre-Treatment With Hydrocarbon-Containing Gas

ActiveUS20140363983A1Improve flatnessHighly effectiveSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPre treatmentPlasma reaction

A method for filling recesses of a substrate with an insulation film includes: (i) exposing surfaces of the recesses of the substrate to a pre-deposition gas in a reactive state in a reaction space to treat the surfaces with reactive hydrocarbons generated from the pre-deposition gas without filling the recesses; and (ii) depositing a flowable insulation film using a process gas other than the pre-deposition gas on a surface of the substrate to fill the recesses treated in step (i) therewith by plasma reaction. The pre-deposition gas has at least one hydrocarbon unit in its molecule.

Owner:ASM IP HLDG BV

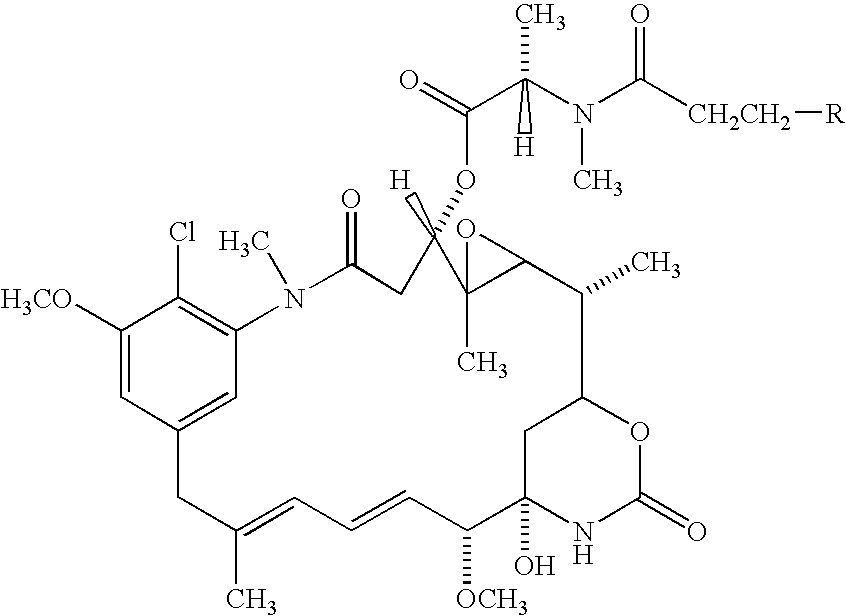

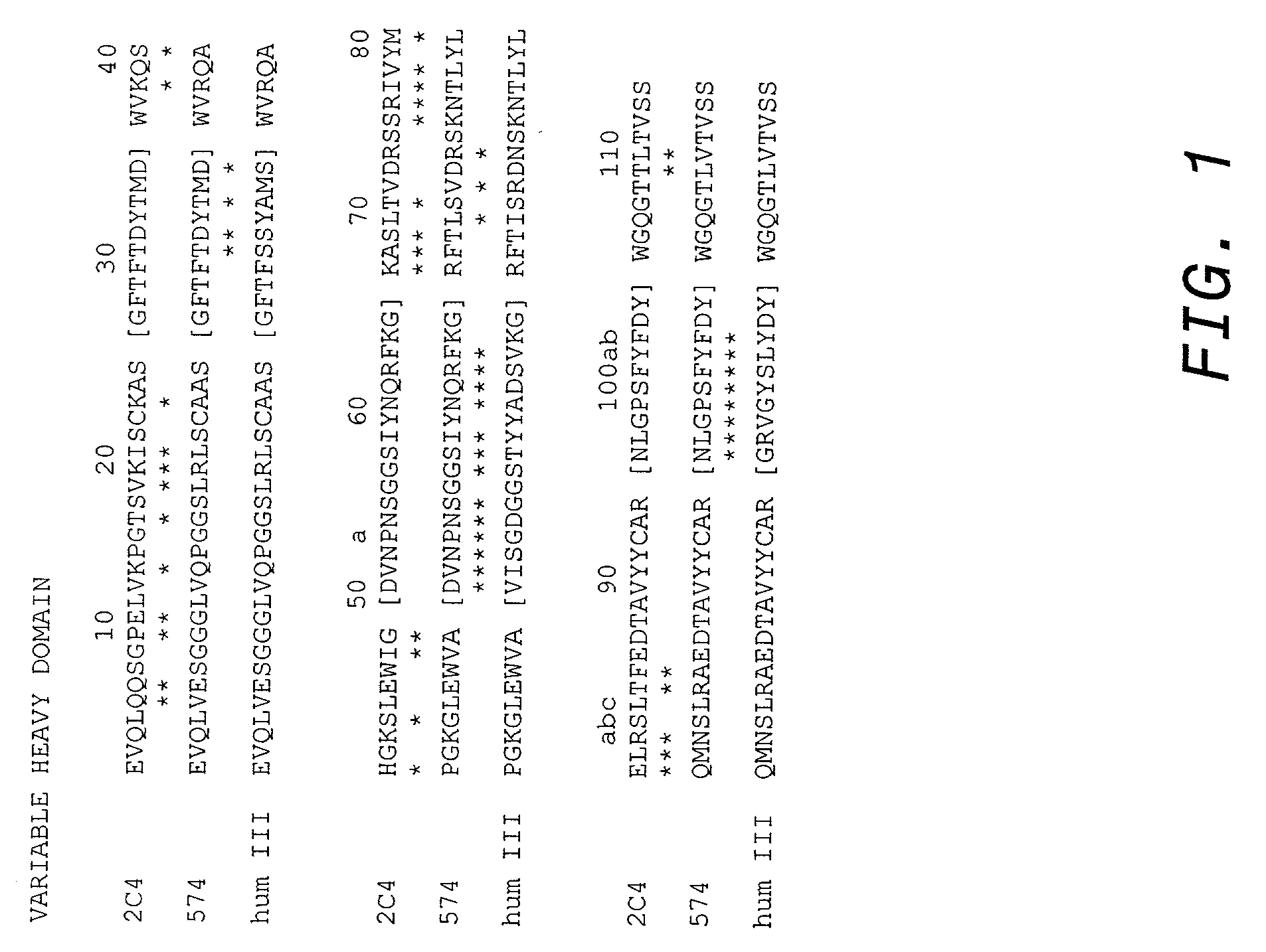

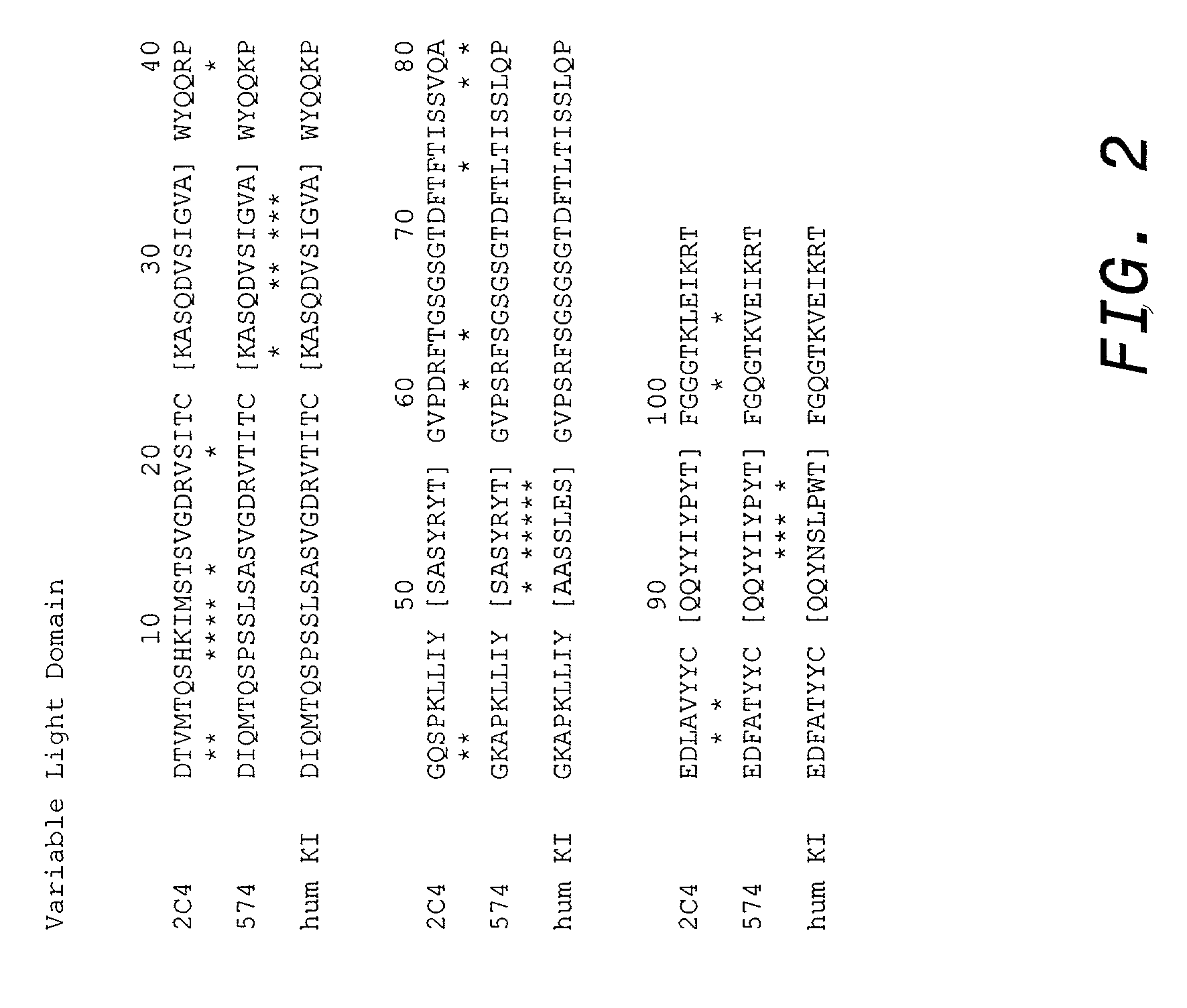

Methods of treatment using anti-ErbB antibody-maytansinoid conjugates

ActiveUS7097840B2Superior clinical activityBetter objective response rateOrganic active ingredientsPharmaceutical delivery mechanismMedicineCancer therapy

The application concerns methods of treatment using anti-ErbB receptor antibody-maytansinoid conjugates, and articles of manufacture suitable for use in such methods. In particular, the invention concerns ErbB receptor-directed cancer therapies, using anri-ErbB receptor antibody-maytansinoid conjugates.

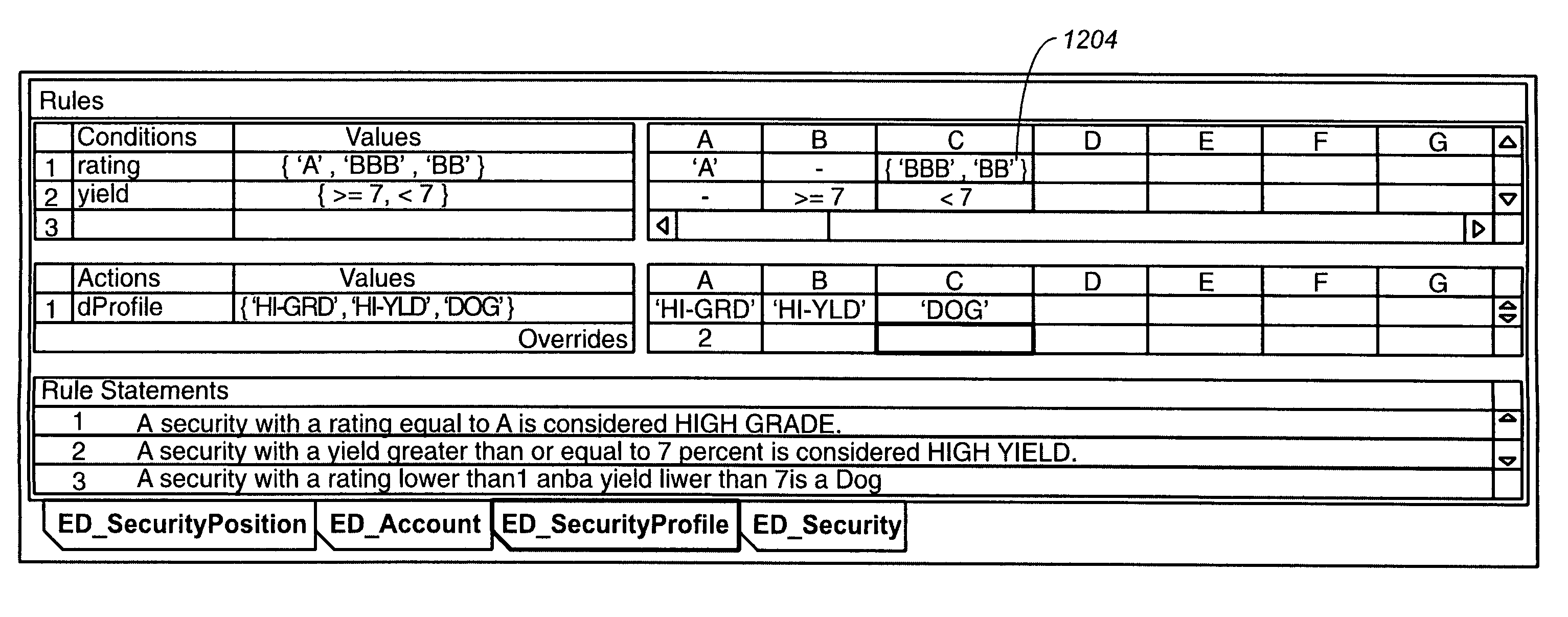

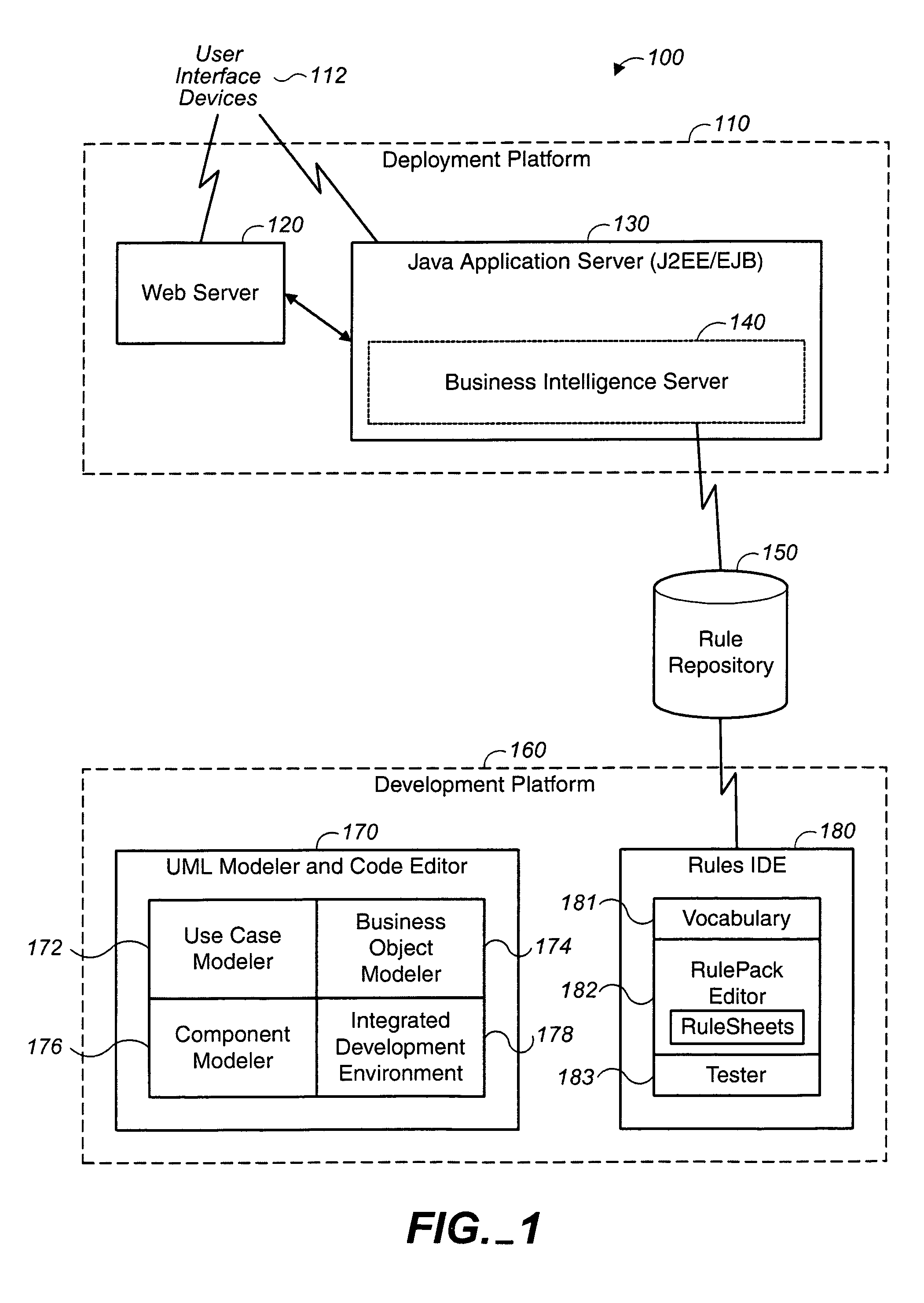

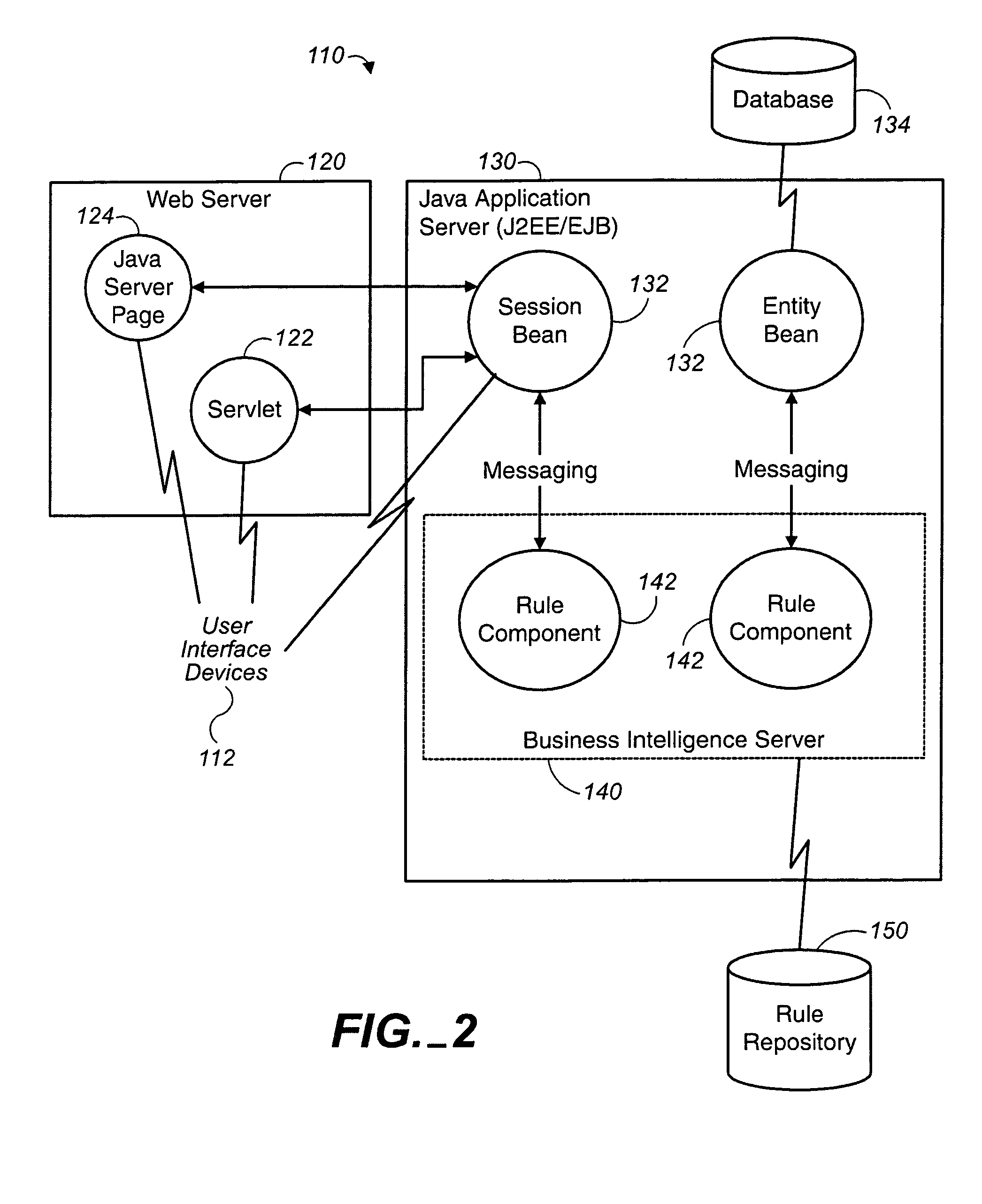

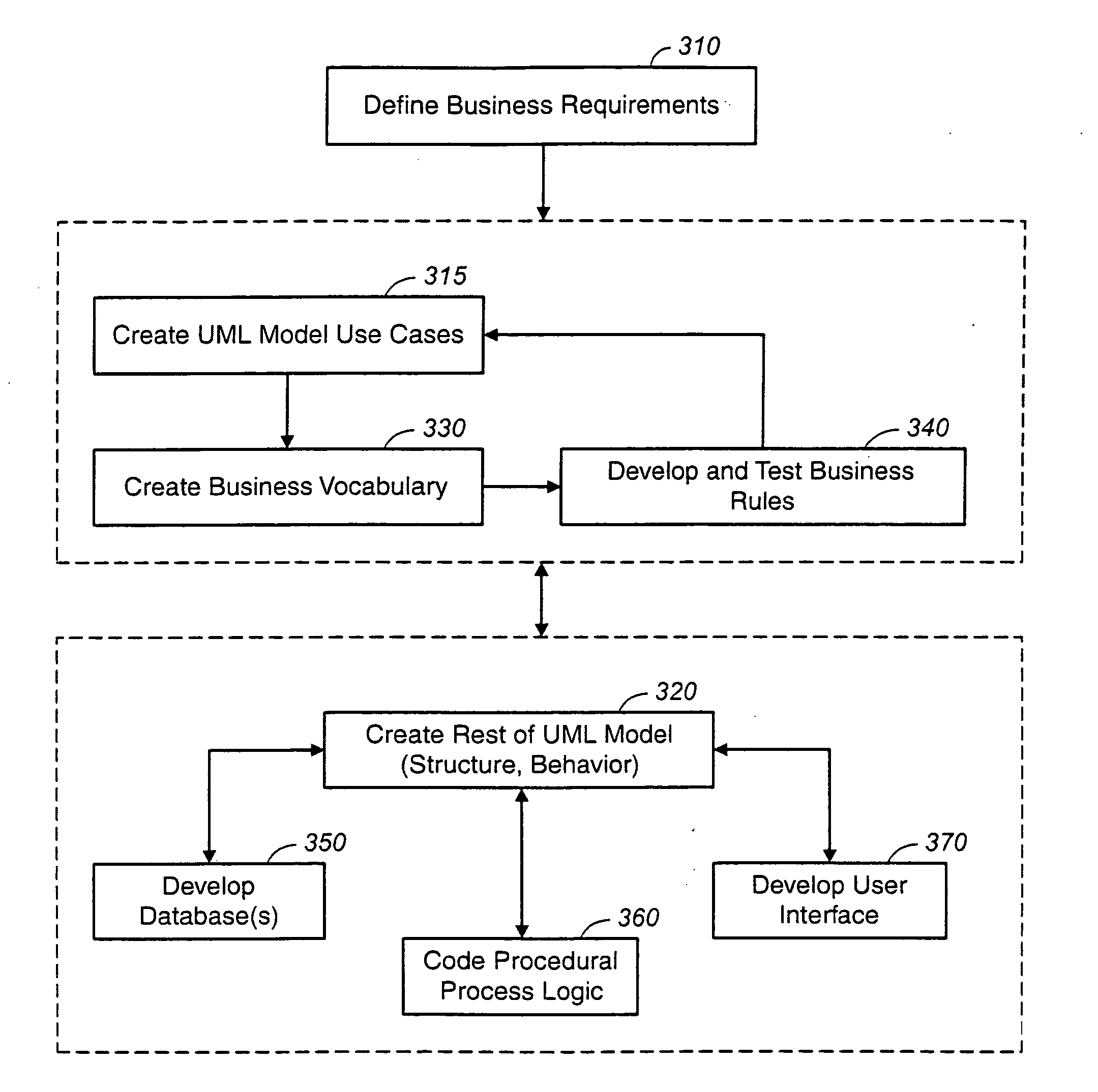

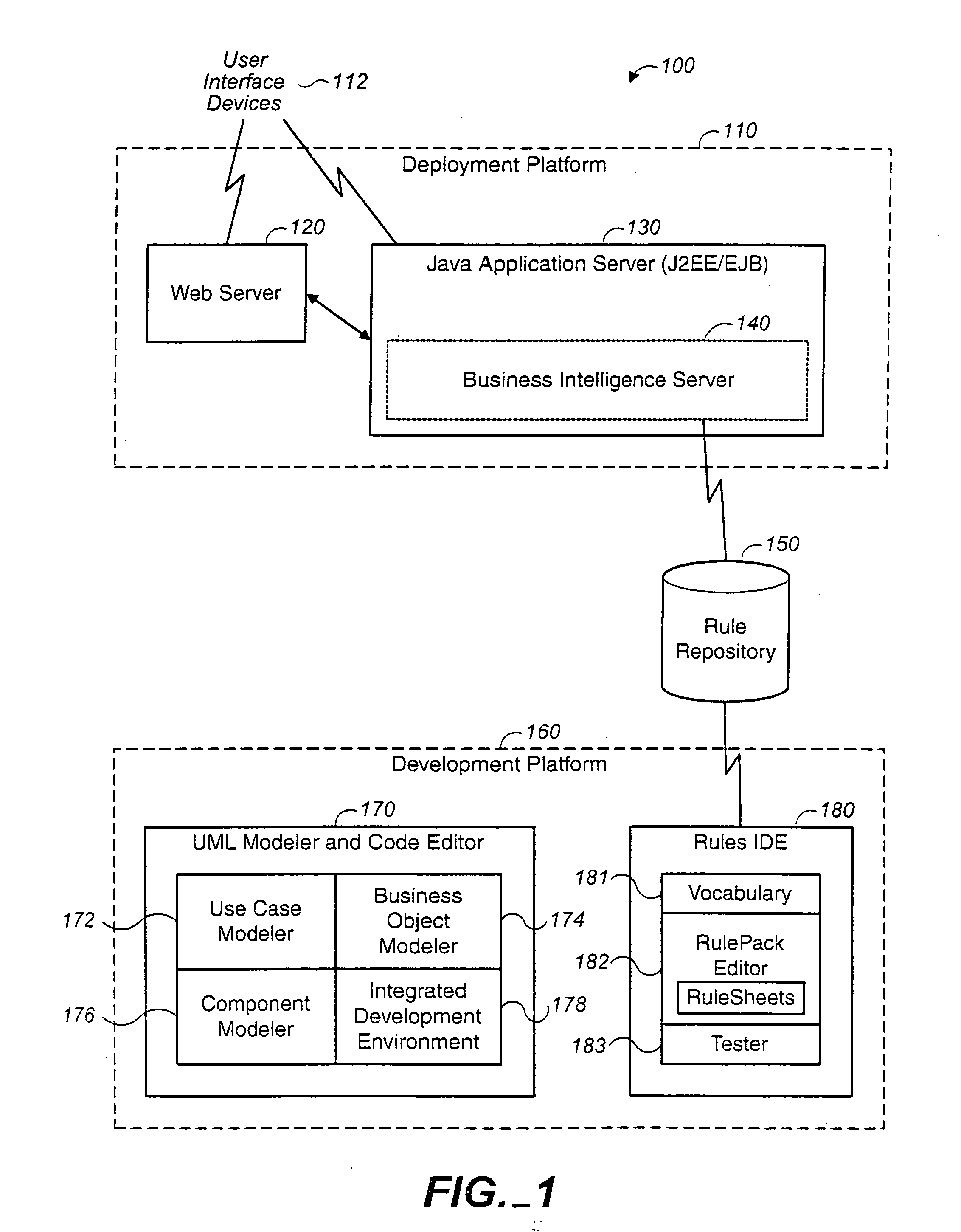

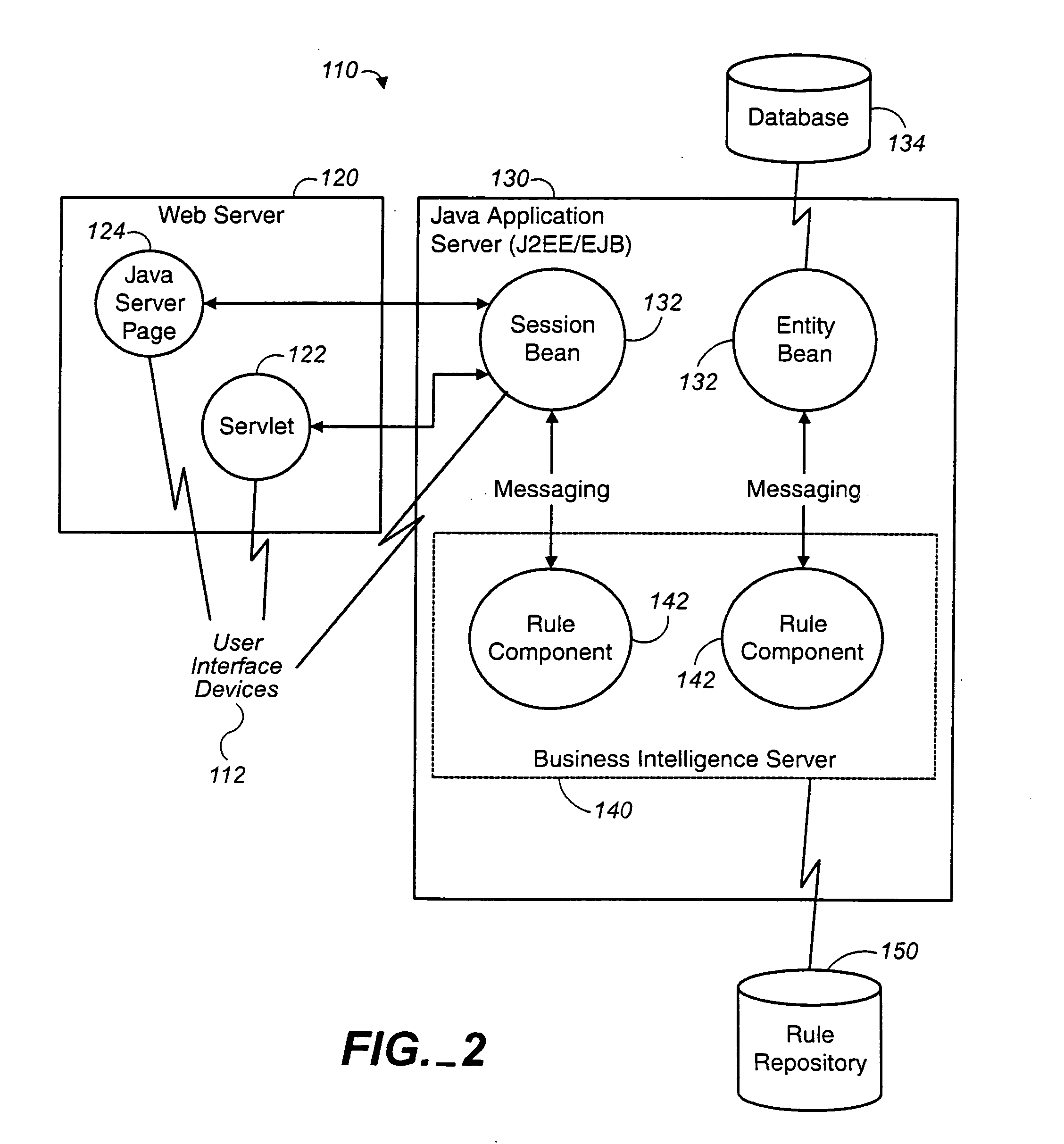

Business rules user interface for development of adaptable enterprise applications

ActiveUS7020869B2Reduce complexityMinimization requirementsTechnology managementVisual/graphical programmingApplication softwareDisplay list

Methods and apparatus, including computer program products, for interacting with a user to define business rules in a declarative manner. The invention operates to display a rule set as an editable list of conditions and an editable list of actions, the conditions and actions being linked to each other by the combination of an editable list of if-values and an editable list of then-values, wherein if-values and then-values are explicitly linked to each other, conditions and if-values are explicitly linked to each other, and then-values and actions are explicitly linked to each other in the displayed lists.

Owner:PROGRESS SOFTWARE

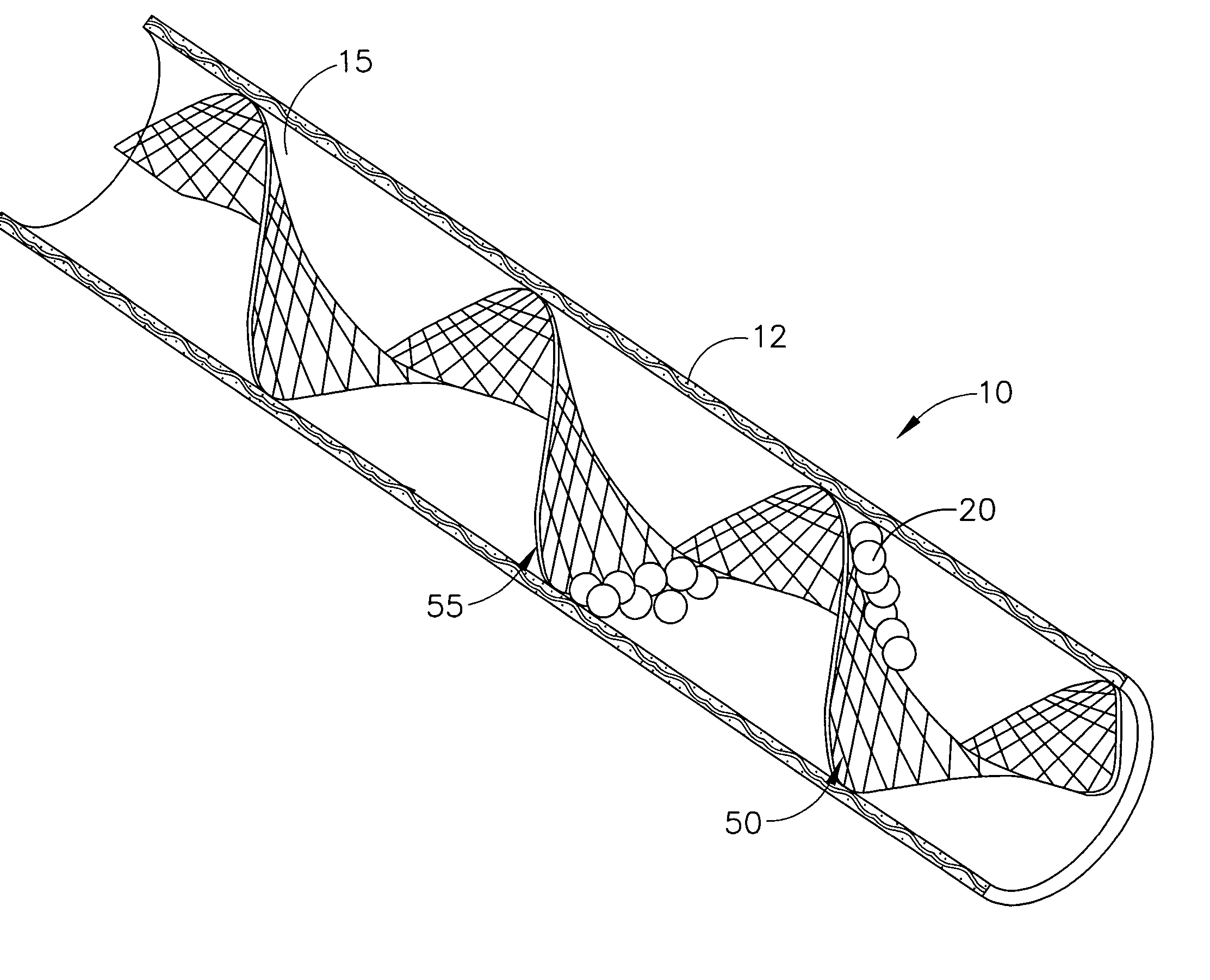

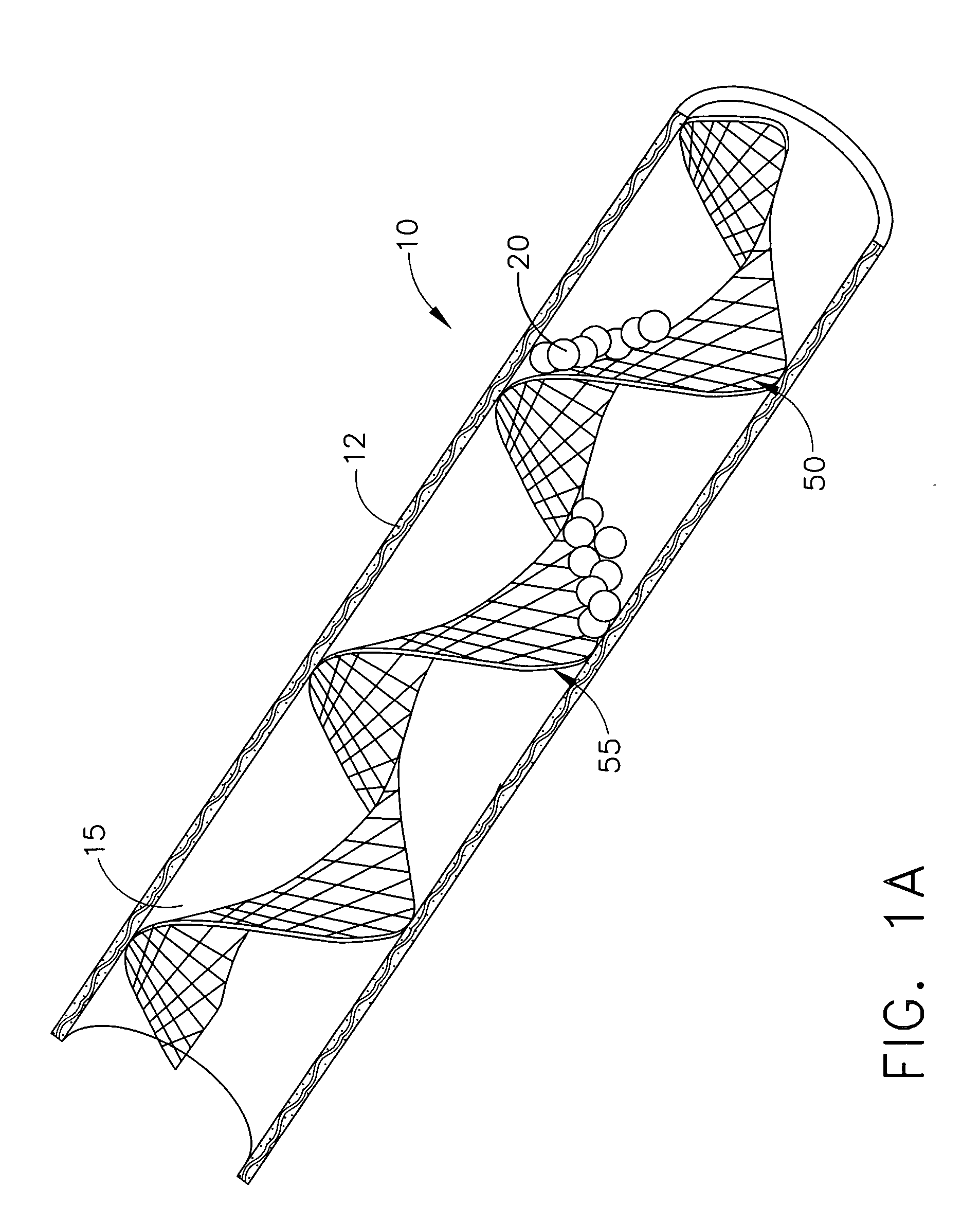

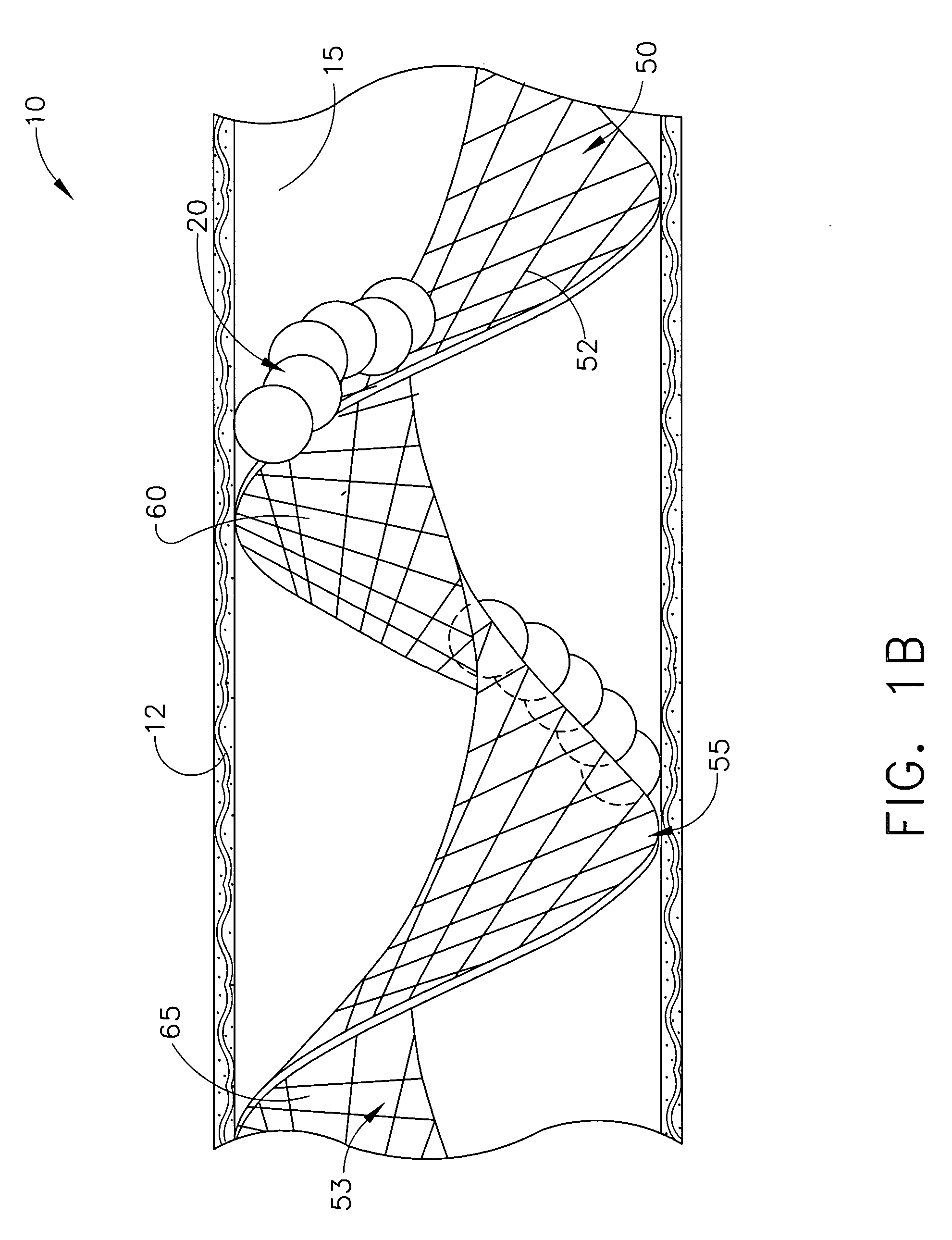

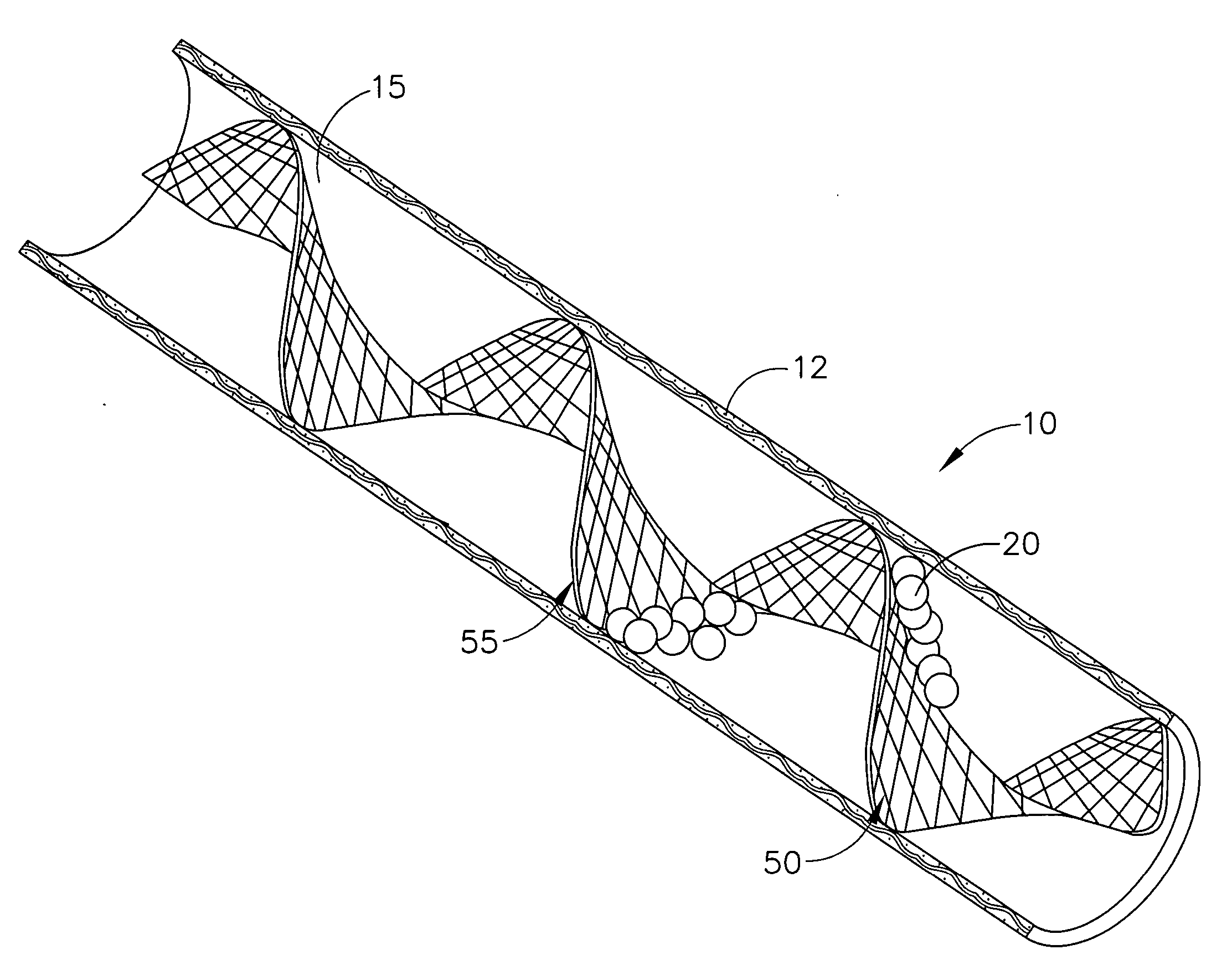

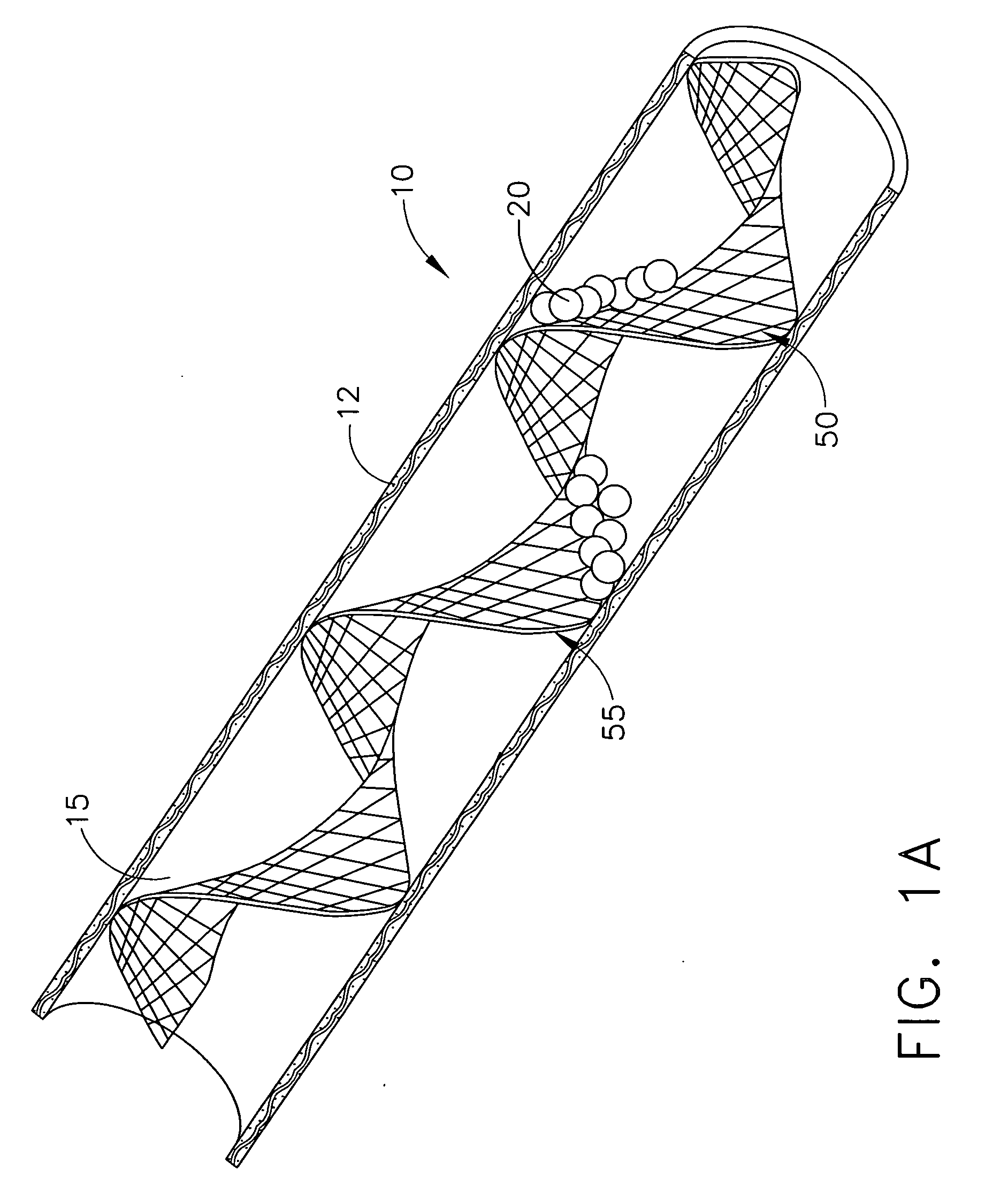

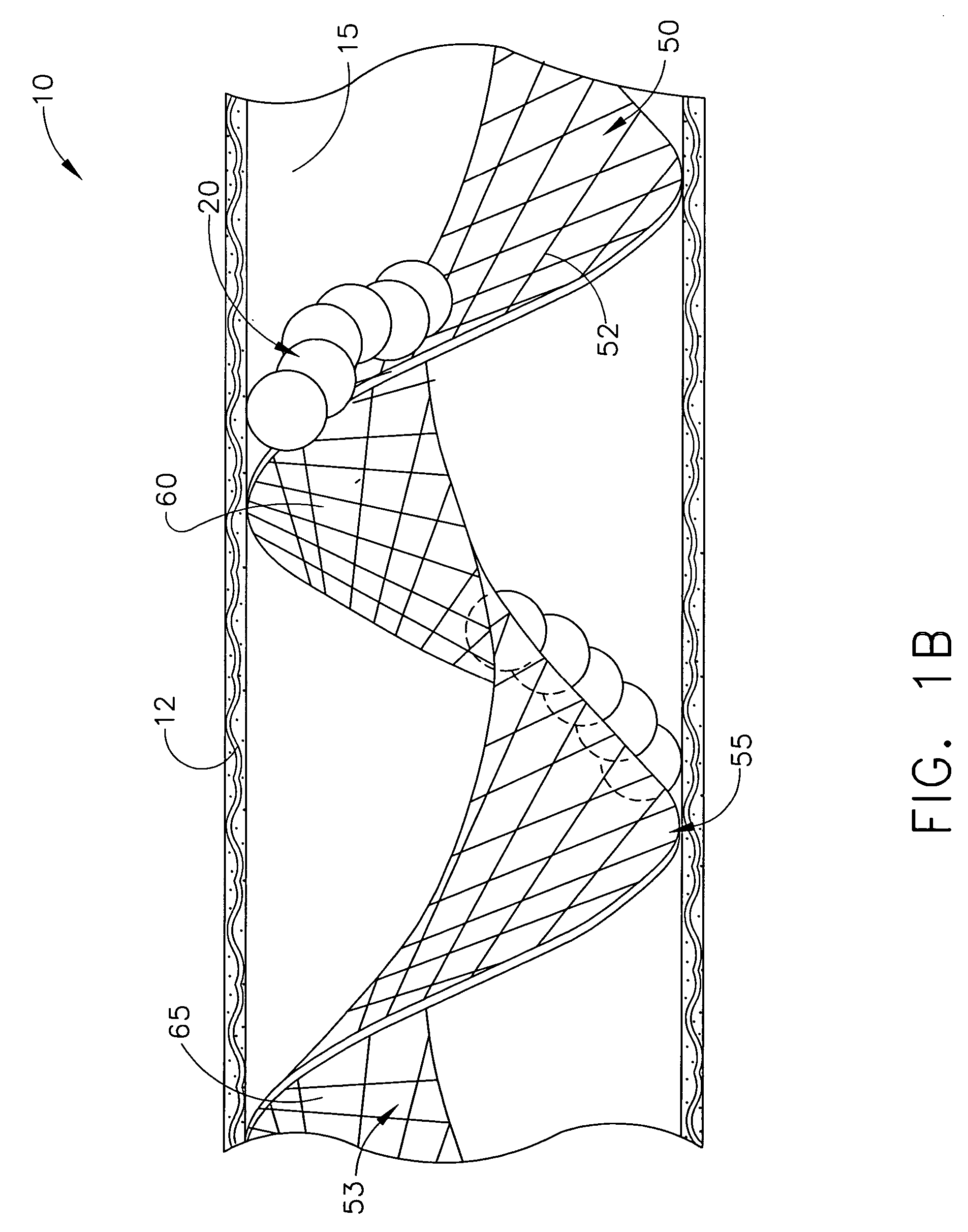

Device for filtering blood in a vessel with helical elements

InactiveUS20060020286A1Efficient capturePreventing pulmonary embolismHaemofiltrationSurgeryMedicineEmbolus

A device for capturing an embolus within a vessel of a patient's body has at least one helix made of a mesh material. The at least one helix has a plurality of turns helically arranged around a longitudinal axis. The mesh material has a plurality of pores therein and the pores have a size ≧120 μm. The at least one helix includes a plurality of panels wherein the panels are movable from a collapsed state to an expanded state when placed within a vessel. The mesh material is made of a self-expanding material such as nickel titanium in one embodiment. In another embodiment, the device has a double helix arrangement.

Owner:CORDIS CORP

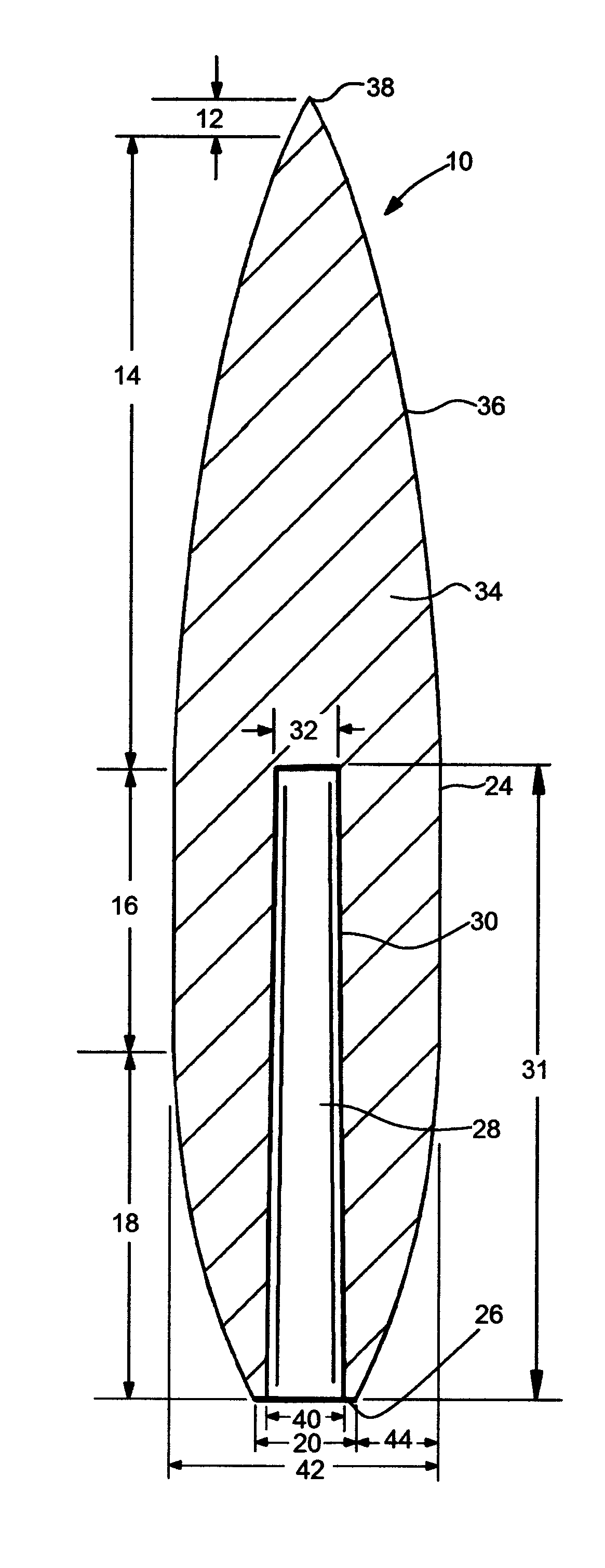

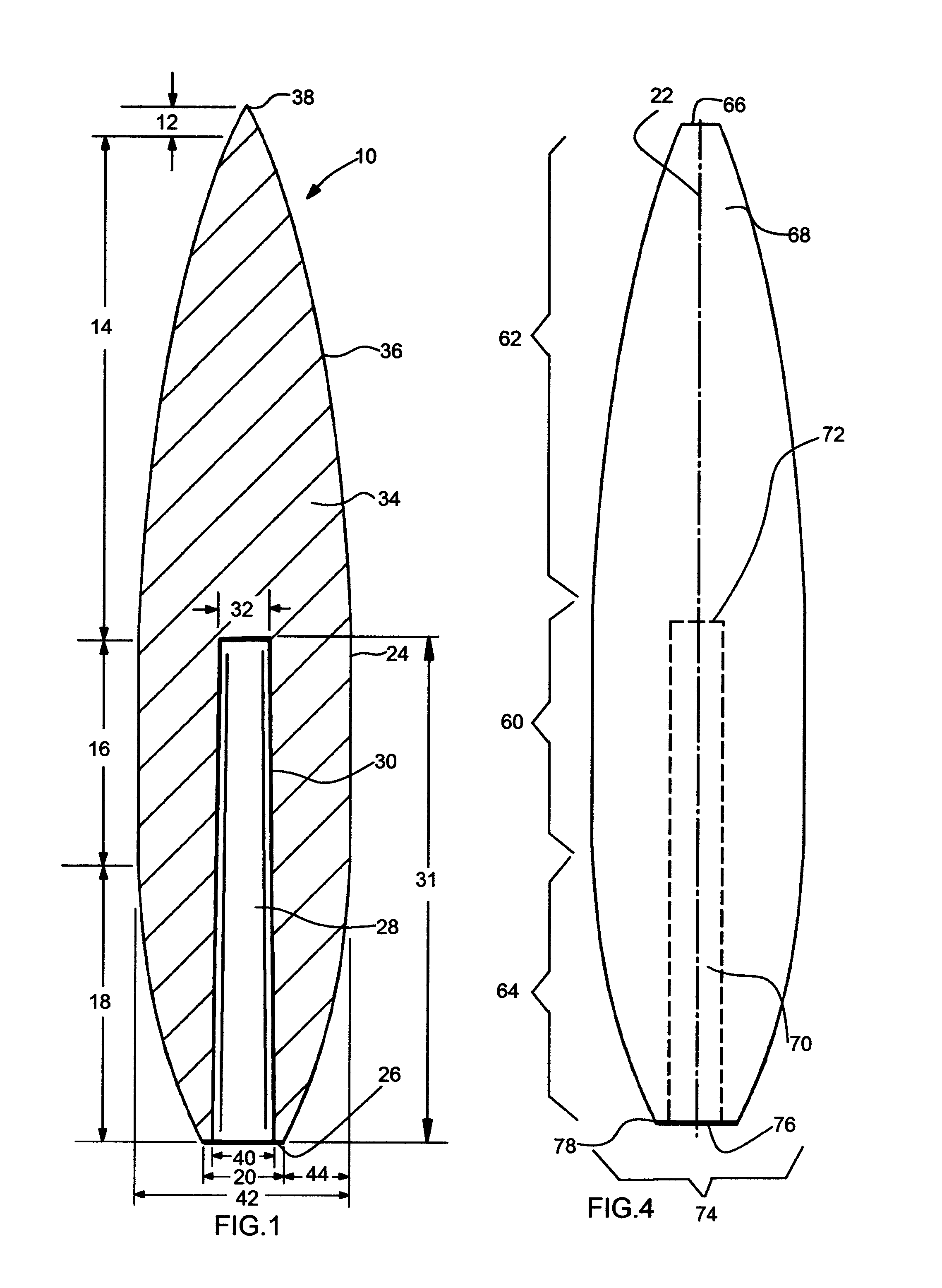

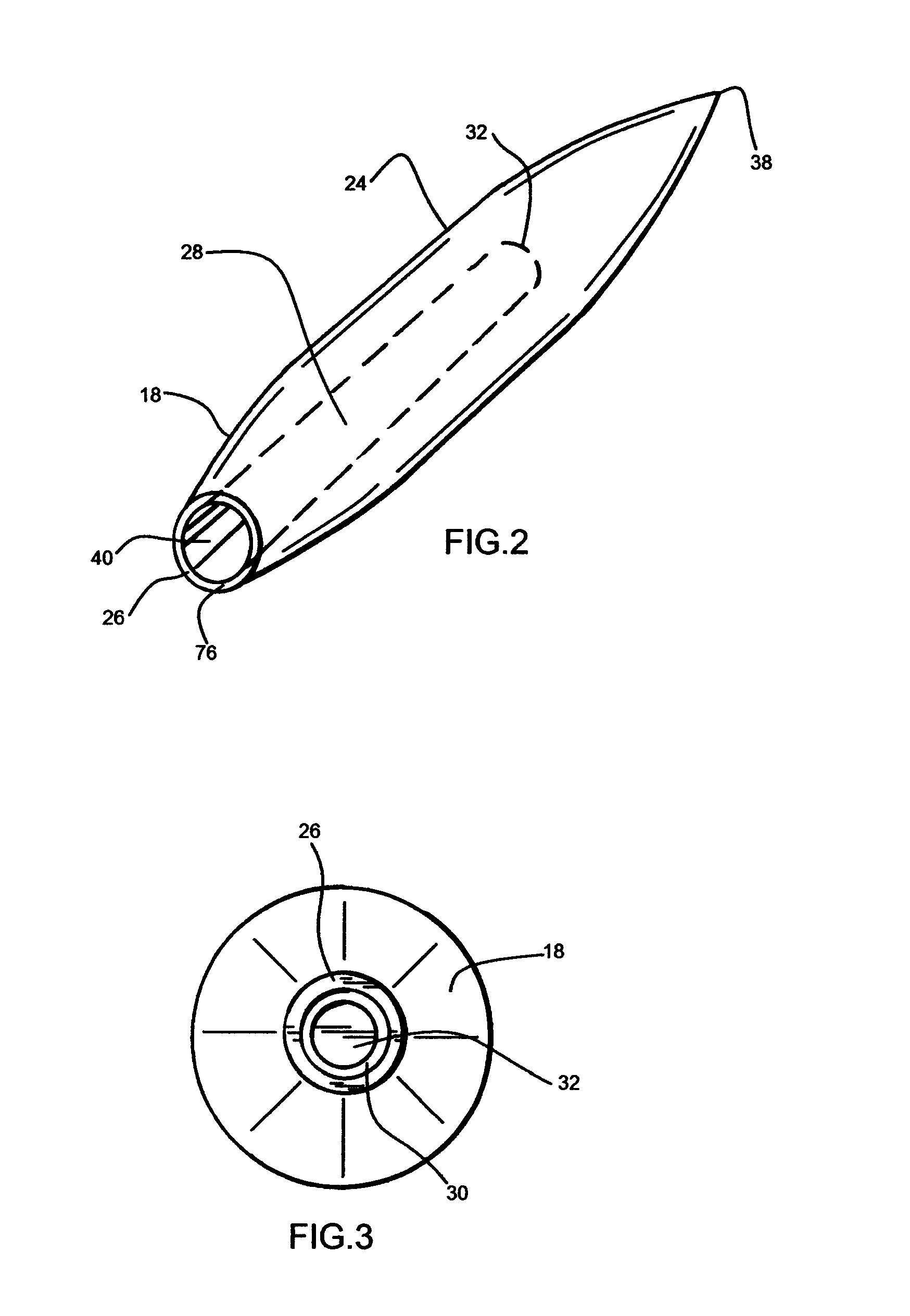

Projectile

ActiveUS8893621B1Superior flight stability characteristicHighly effectiveAmmunition projectilesTraining ammunitionEngineeringBearing surface

A projectile comprised of an ogive section, a bearing surface section and a boattail section. A cavity is formed inside the projectile from an aperture on the aft end of the boattail section and forward to about the transition point (shoulder) between the ogive section and bearing surface section. The cavity is centered about the centerline of the projectile and open on the aft end of the projectile.

Owner:ESCOBAR ROLANDO

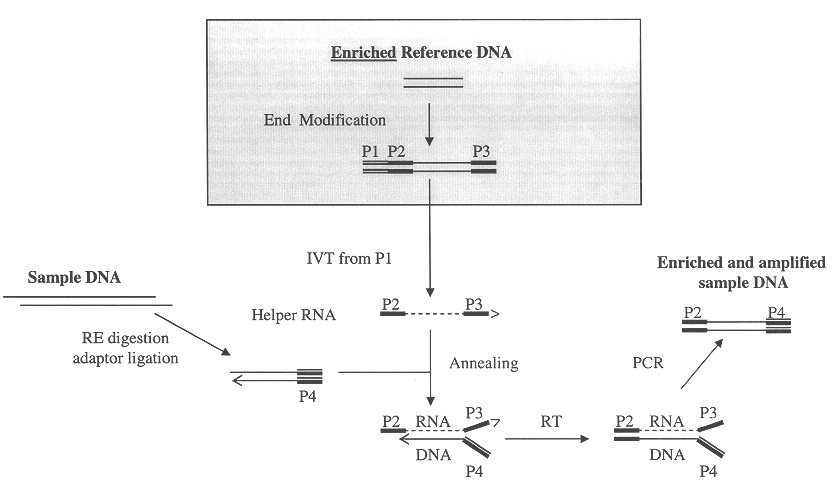

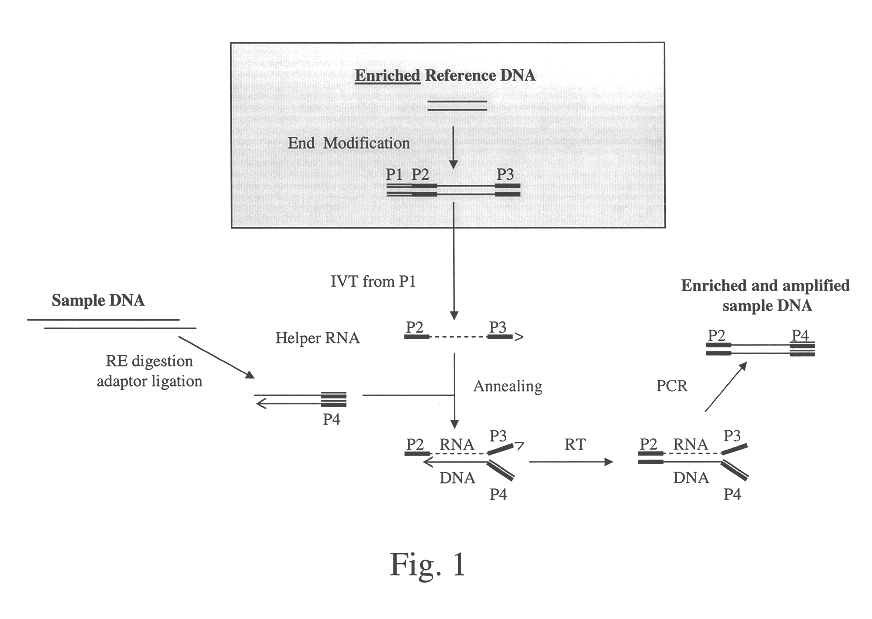

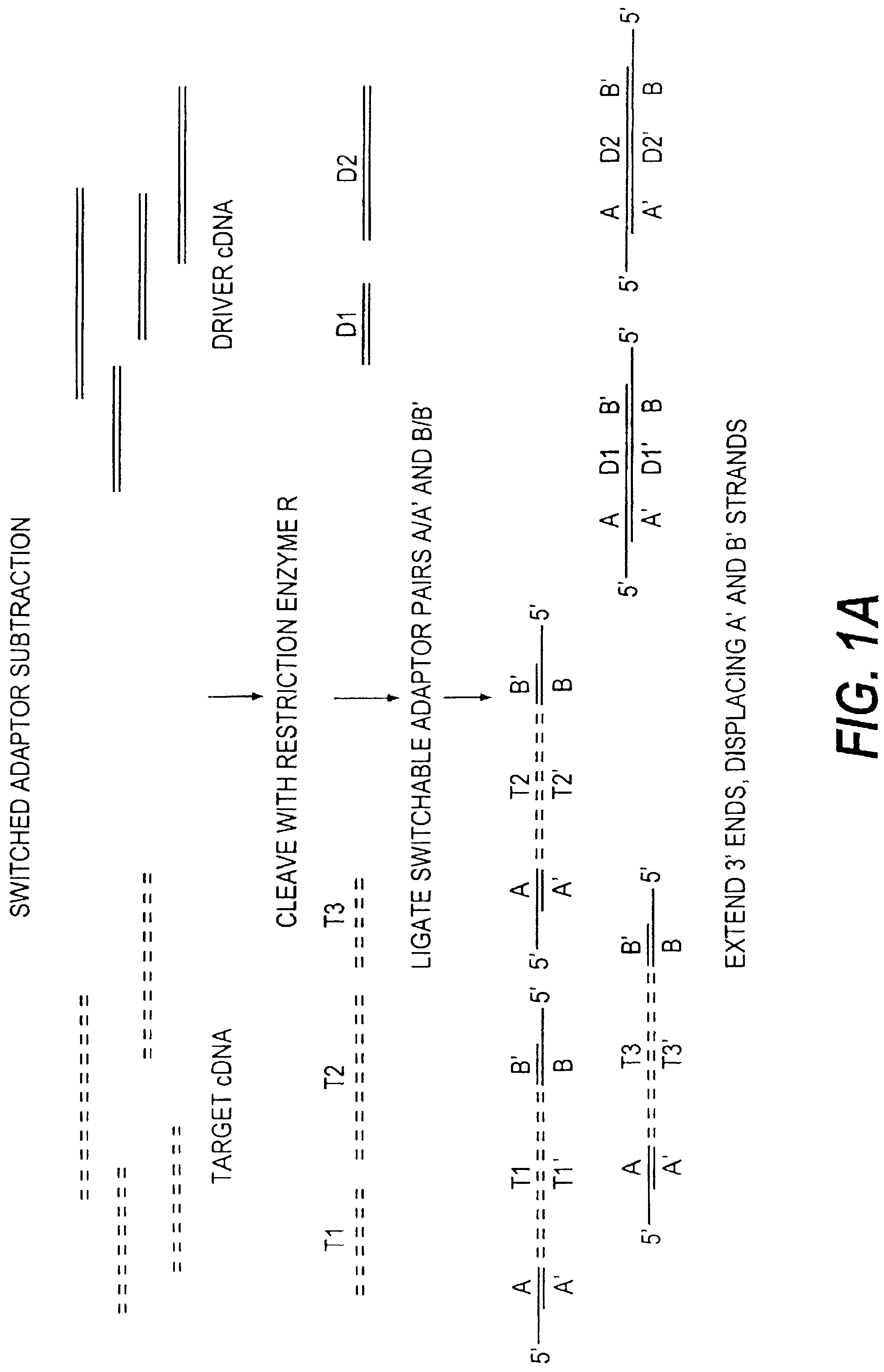

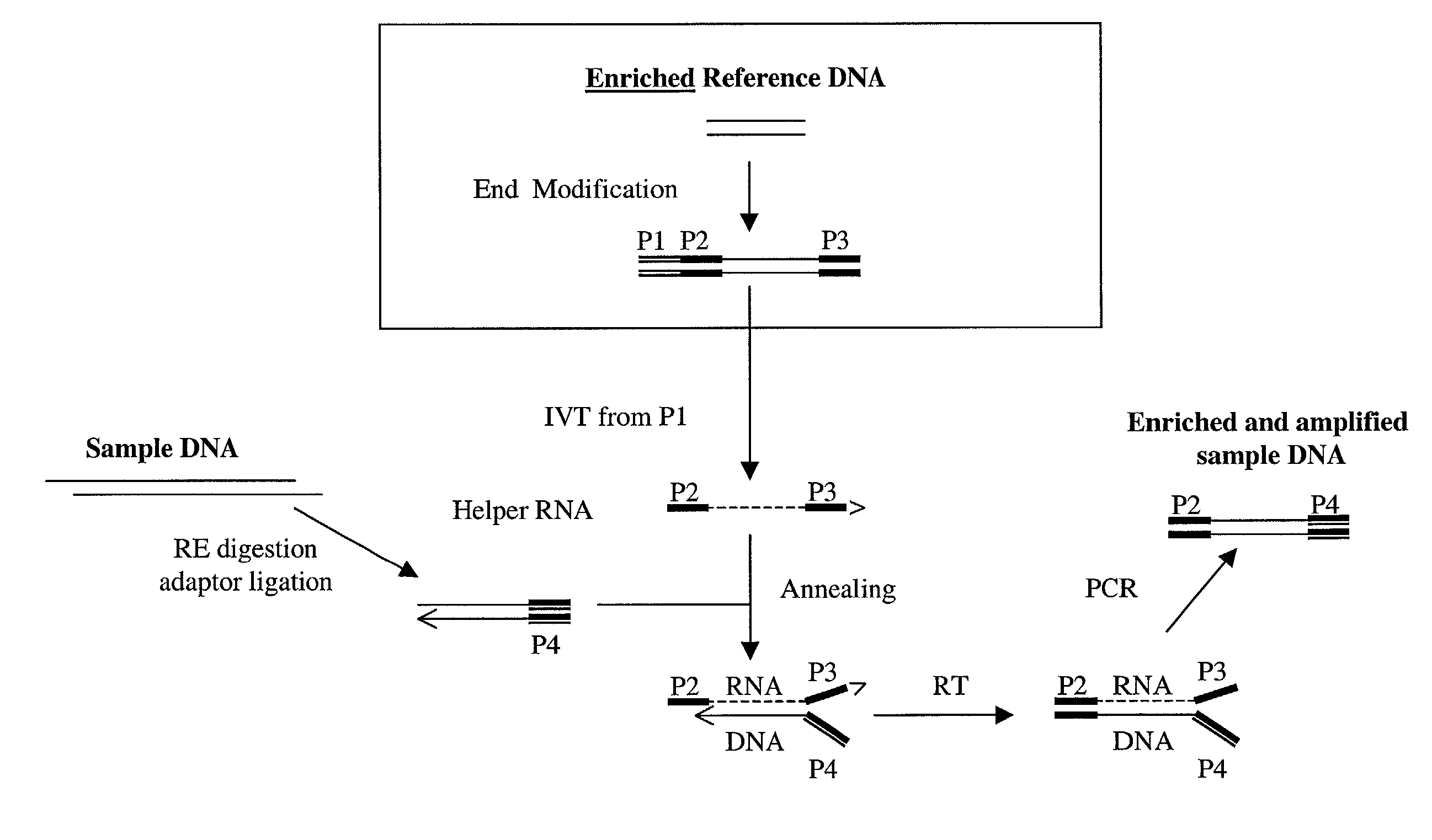

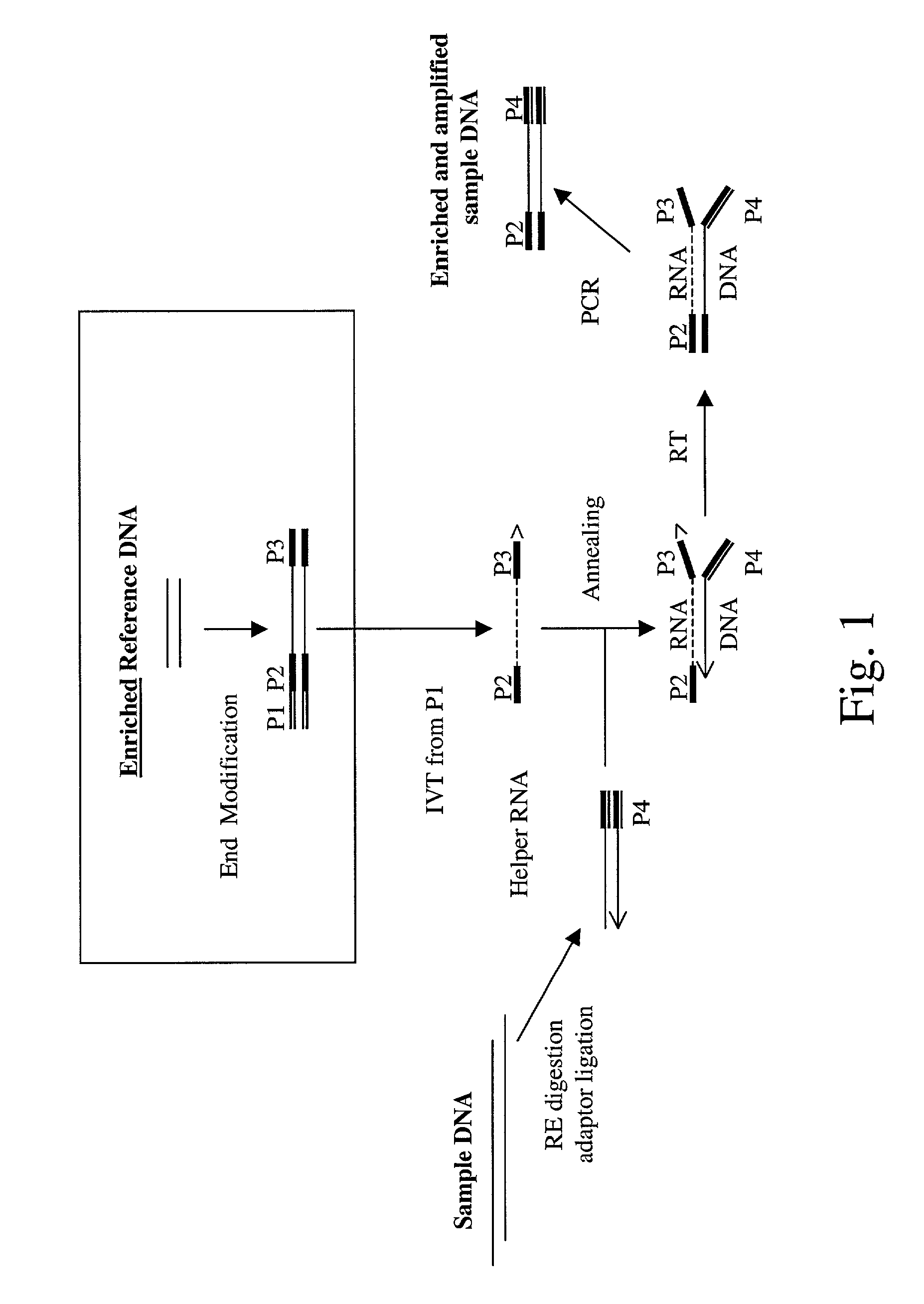

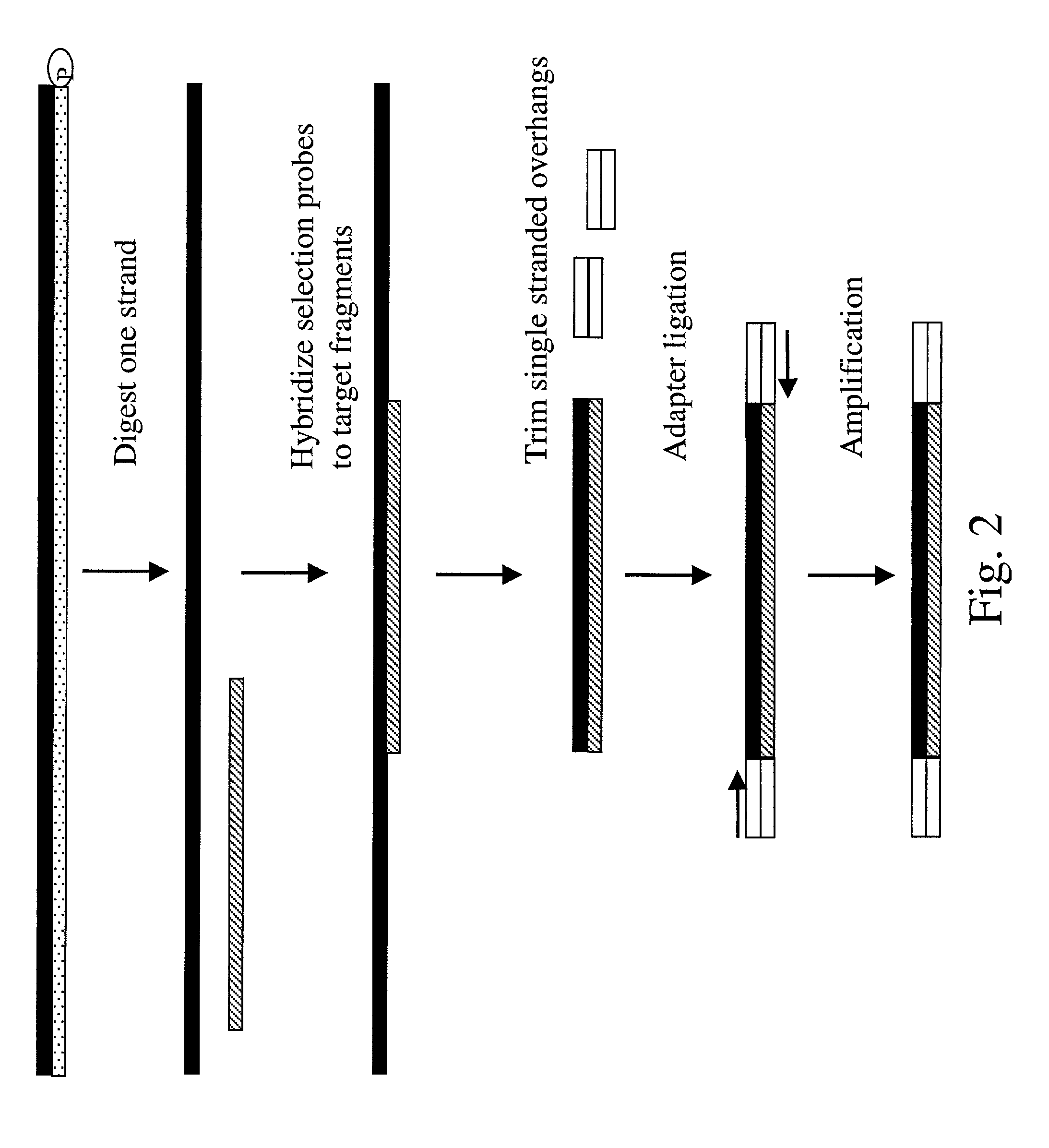

Method of target enrichment and amplification

InactiveUS6632611B2Highly effectiveGreat incentiveSugar derivativesMicrobiological testing/measurementTarget enrichmentBioinformatics

The presently claimed invention provides methods and kits for amplifying a target sequence from within a nucleic acid population. The presently claimed invention provides selection probes which are complementary to at least a portion of said target sequence and mechanisms for adding a probe sequence to the 3' end of a target sequence that is hybridized to a selection probe. The added 3' probe sequence and a probe sequence added at the 5' end of the target by adaptor ligation allow for selective amplification of the target sequence.< / PTEXT>

Owner:AFFYMETRIX INC

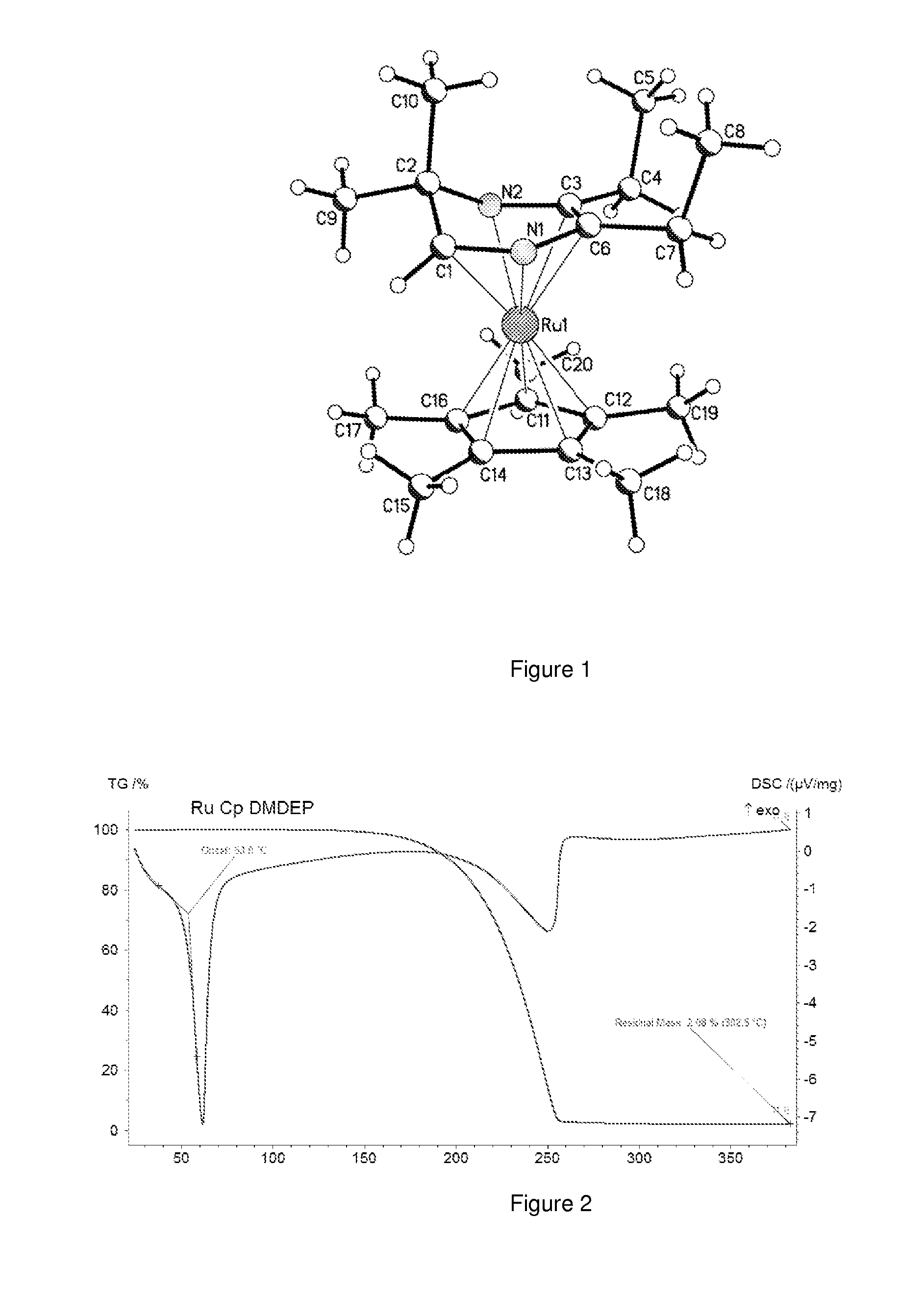

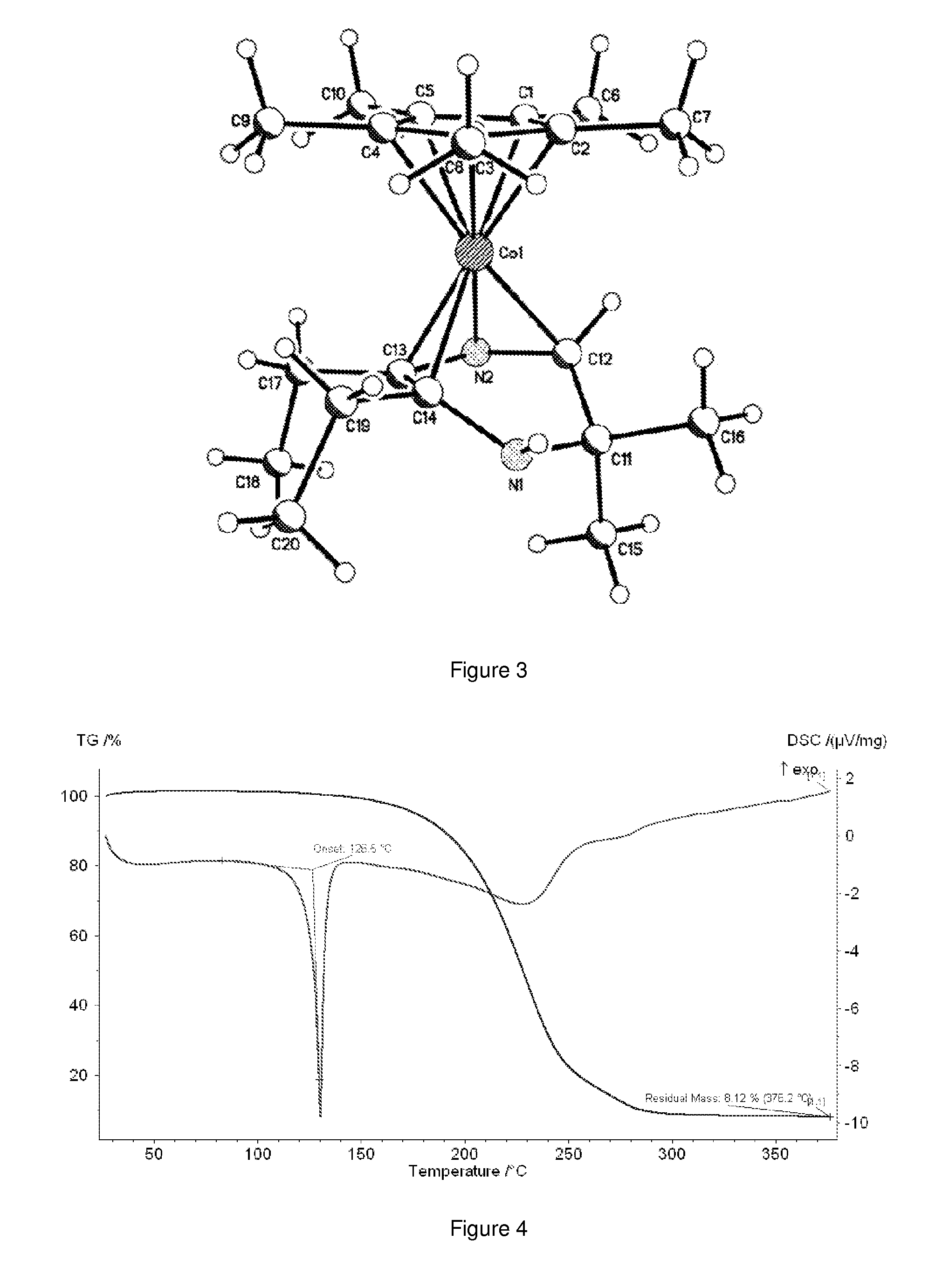

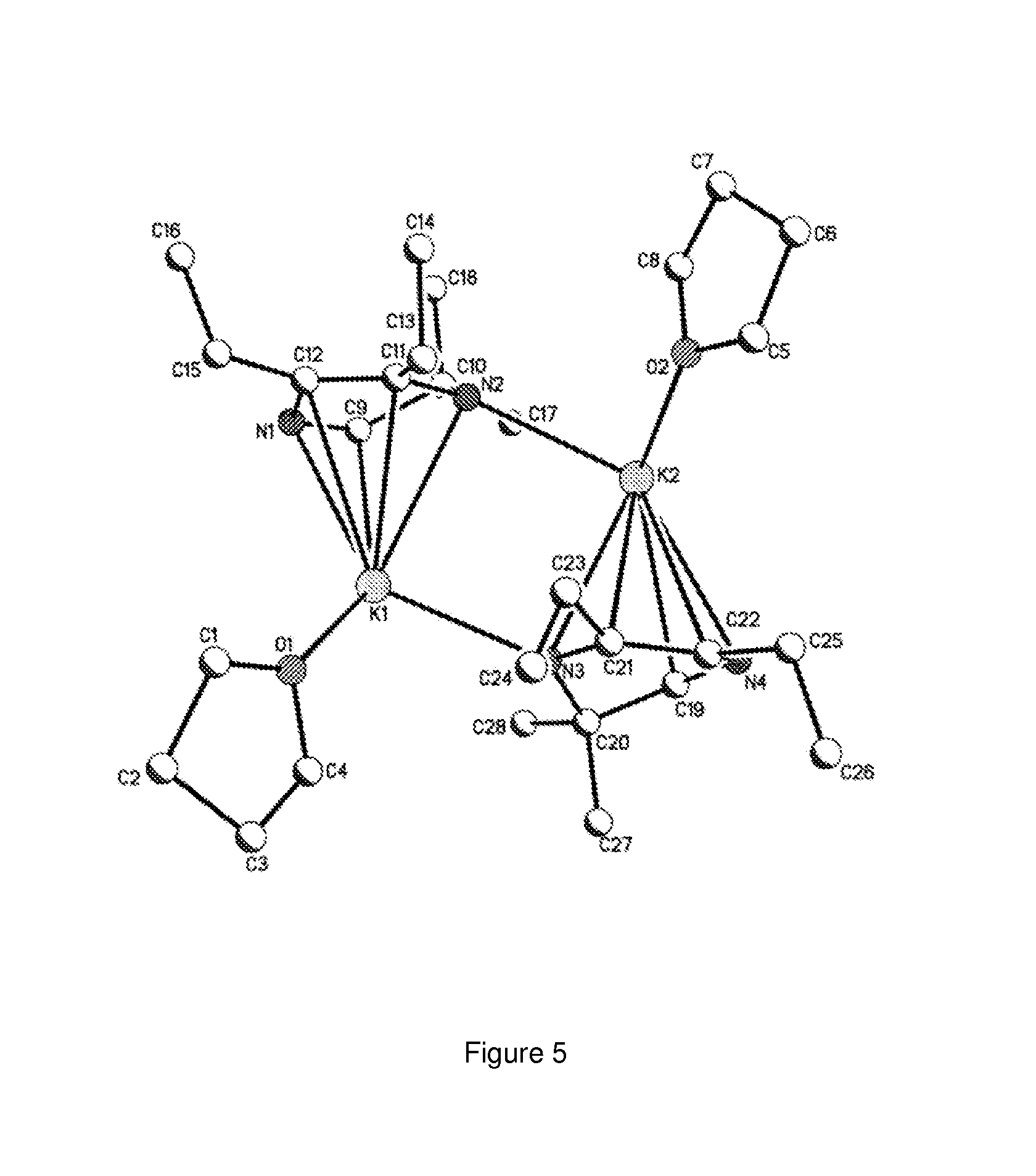

Volatile dihydropyrazinly and dihydropyrazine metal complexes

ActiveUS20150030782A1Improve responseHighly effectiveGroup 5/15 element organic compoundsVacuum evaporation coatingProtonationRuthenium

A composition comprising dihydropyrazinyl anions that can be coordinated as 6 electron ligands to a broad range of different metals to yield volatile metal complexes for ALD and CVD depositions are described herein. Also described herein are undeprotonated dihydropyrazines that can coordinate to metals as stabilizing neutral ligands. In one embodiment, the composition is used for the direct liquid injection delivery of the metal dihydropyrazinyl complex precursor to the chamber of an ALD or CVD chamber for the deposition of metal-containing thin films such as, for example, ruthenium or cobalt metal films.

Owner:VERSUM MATERIALS US LLC

Method for filtering blood in a vessel with helical elements

InactiveUS20060020285A1Efficient capturePreventing pulmonary embolismHaemofiltrationSurgeryEmbolusBiomedical engineering

A method for capturing an embolus within a vessel of a patient's body includes the steps of providing a device having at least one helix made of a mesh material. The at least one helix has a plurality of turns helically arranged around a longitudinal axis. The mesh material has a plurality of pores therein wherein the pores have a size ≧120 μm. The device is placed within the vessel of the patient's body by moving the device from a collapsed state to an expanded state.

Owner:WYETH

Business rules user interface for development of adaptable enterprise applications

InactiveUS20060129978A1Highly effectiveRobust and scalable deploymentTechnology managementVisual/graphical programmingDatabaseUser interface

Methods and apparatus, including computer program products, for interacting with a user to define business rules in a declarative manner. The invention operates to display a set of business rules as editable conditions and editable actions, the conditions and the actions being linked to each other by a combination of editable if-values and editable then-values.

Owner:PROGRESS SOFTWARE

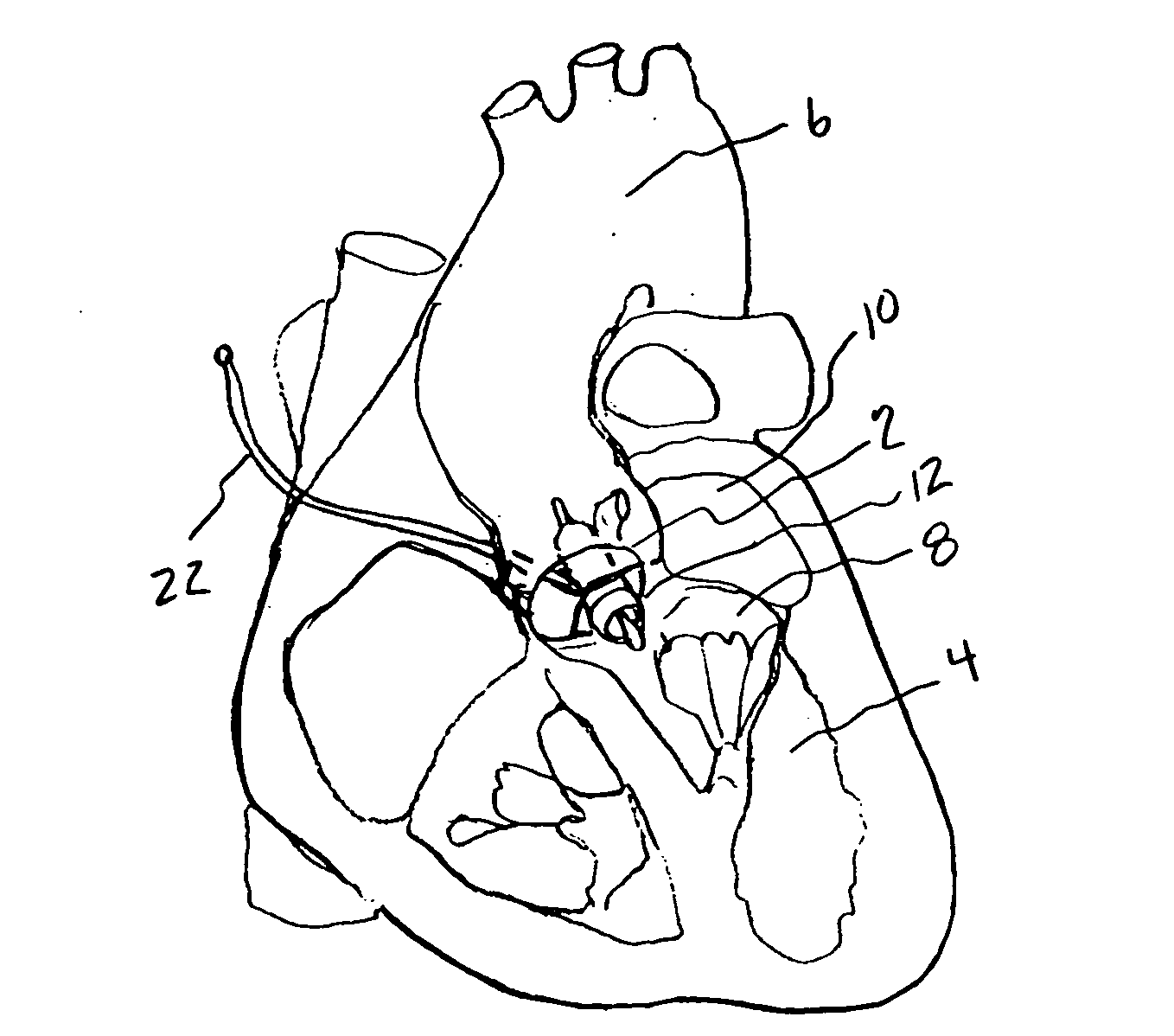

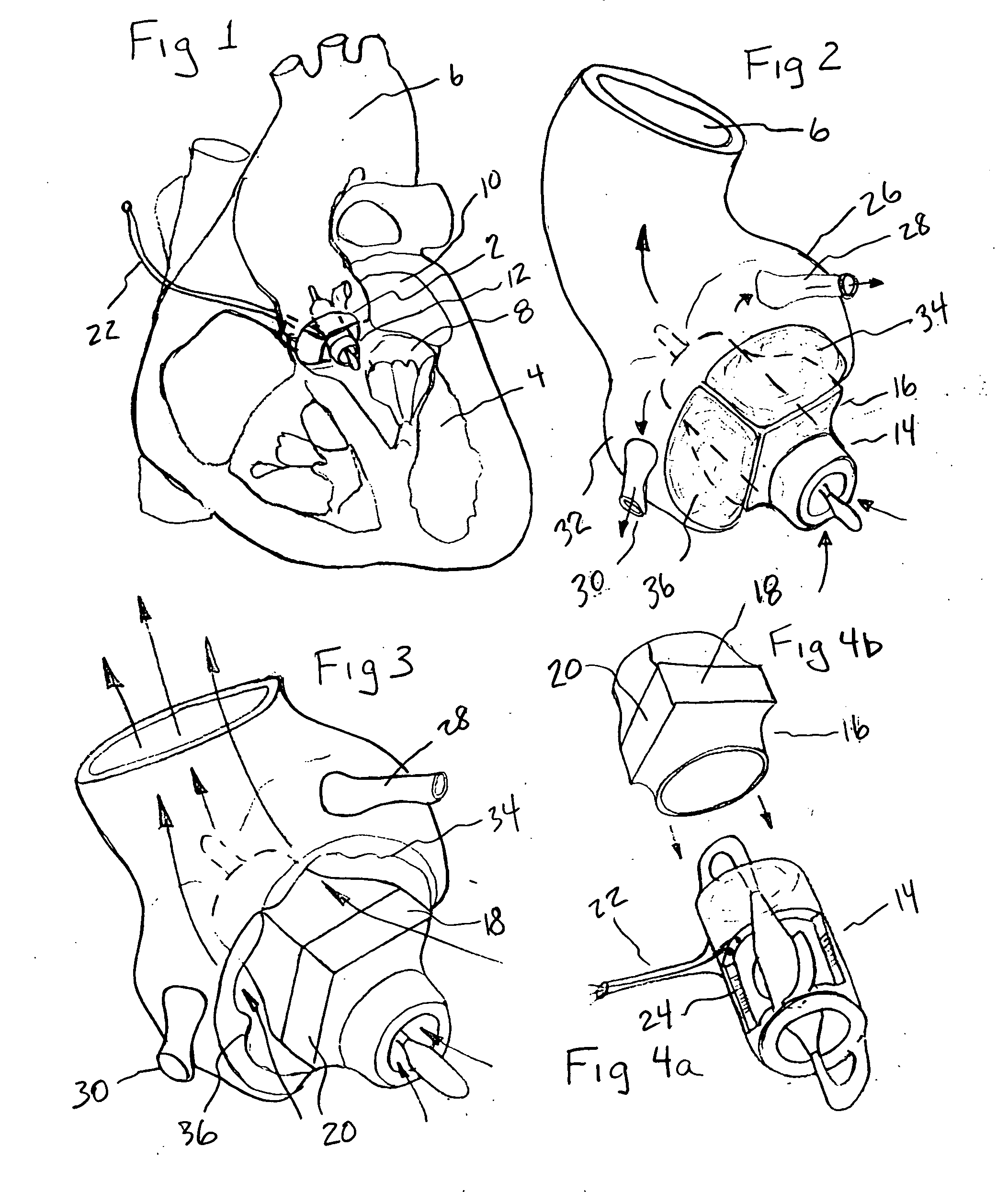

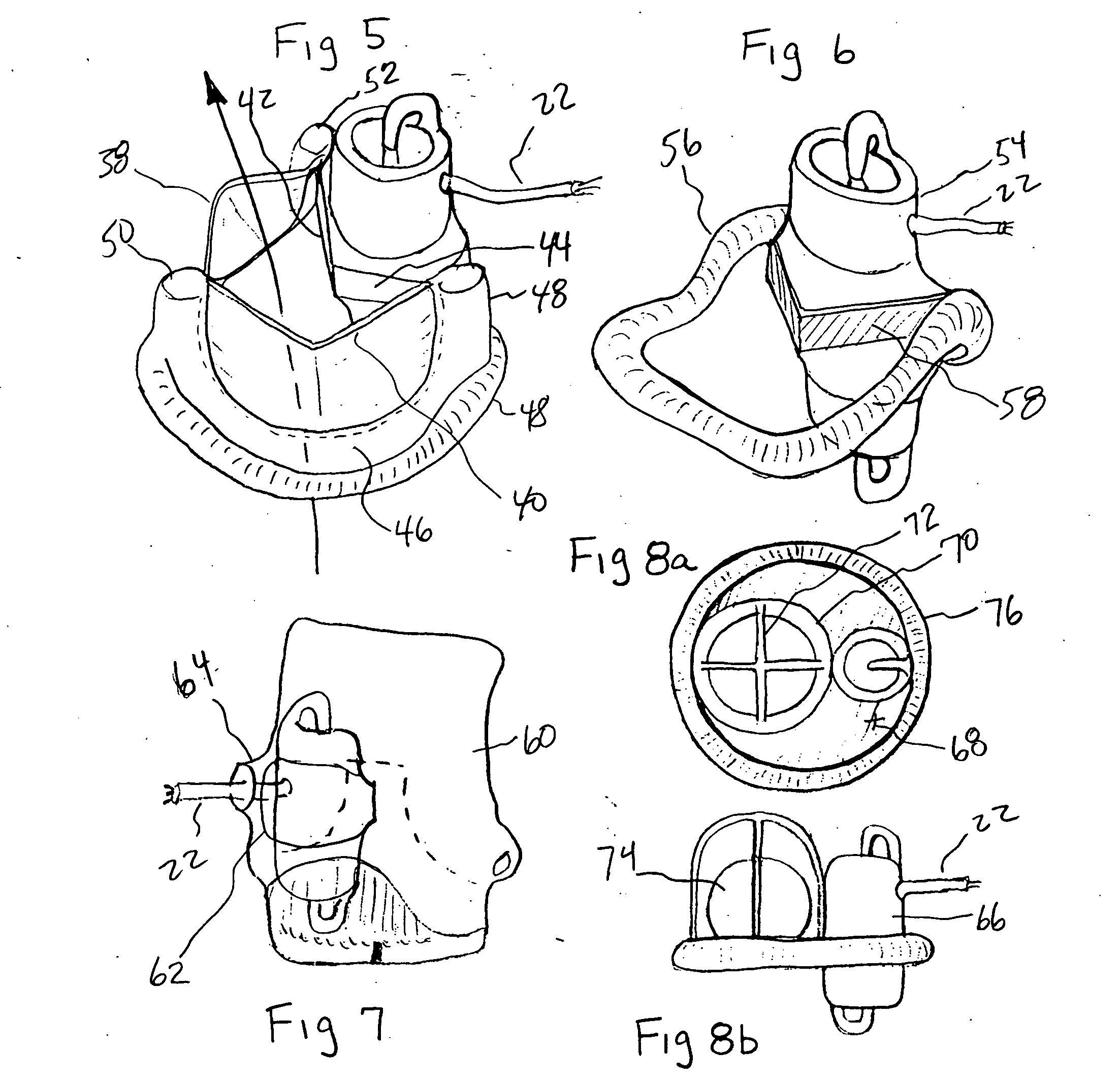

Minimally invasive transvalvular ventricular assist device

ActiveUS20060195004A1Highly effectiveHighly miniaturizedAdditive manufacturing apparatusBlood pumpsThree dimensional ctVentricular cavity

A tiny electrically powered hydrodynamic blood pump is disclosed which occupies one third of the aortic or pulmonary valve position, and pumps directly from the left ventricle to the aorta or from the right ventricle to the pulmonary artery. The device is configured to exactly match or approximate the space of one leaflet and sinus of valsalva, with part of the device supported in the outflow tract of the ventricular cavity adjacent to the valve. In the configuration used, two leaflets of the natural tri-leaflet valve remain functional and the pump resides where the third leaflet had been. When implanted, the outer surface of the device includes two faces against which the two valve leaflets seal when closed. To obtain the best valve function, the shape of these faces may be custom fabricated to match the individual patient's valve geometry based on high resolution three dimensional CT or MRI images. Another embodiment of the invention discloses a combined two leaflet tissue valve with the miniature blood pump supported in the position usually occupied by the third leaflet. Either stented or un-stented tissue valves may be used. This structure preserves two thirds of the valve annulus area for ejection of blood by the natural ventricle, with excellent washing of the aortic root and interface of the blood pump to the heart. In the aortic position, the blood pump is positioned in the non-coronary cusp. A major advantage of the transvalvular VAD is the elimination of both the inflow and outflow cannulae usually required with heart assist devices.

Owner:JARVIK ROBERT

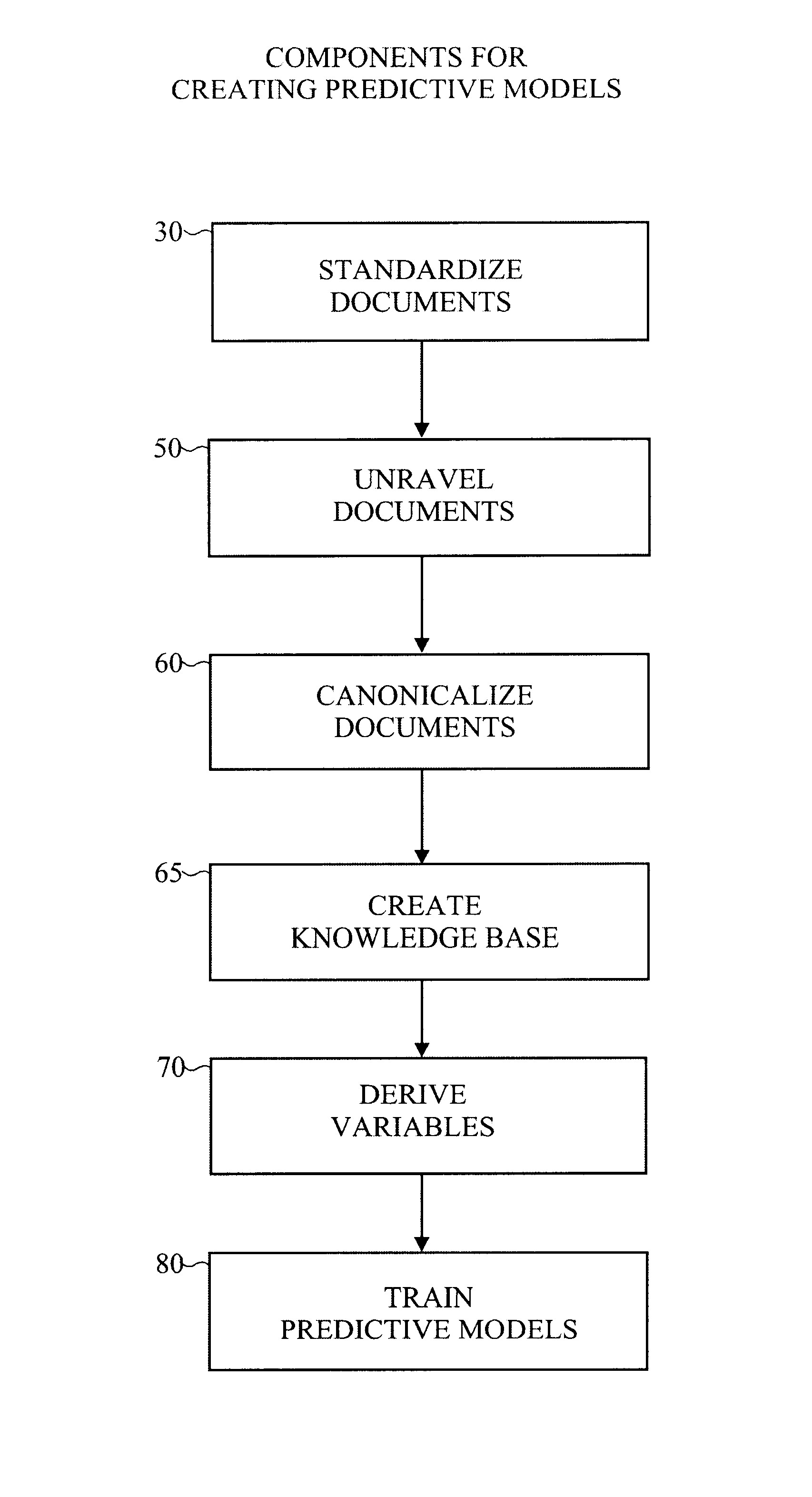

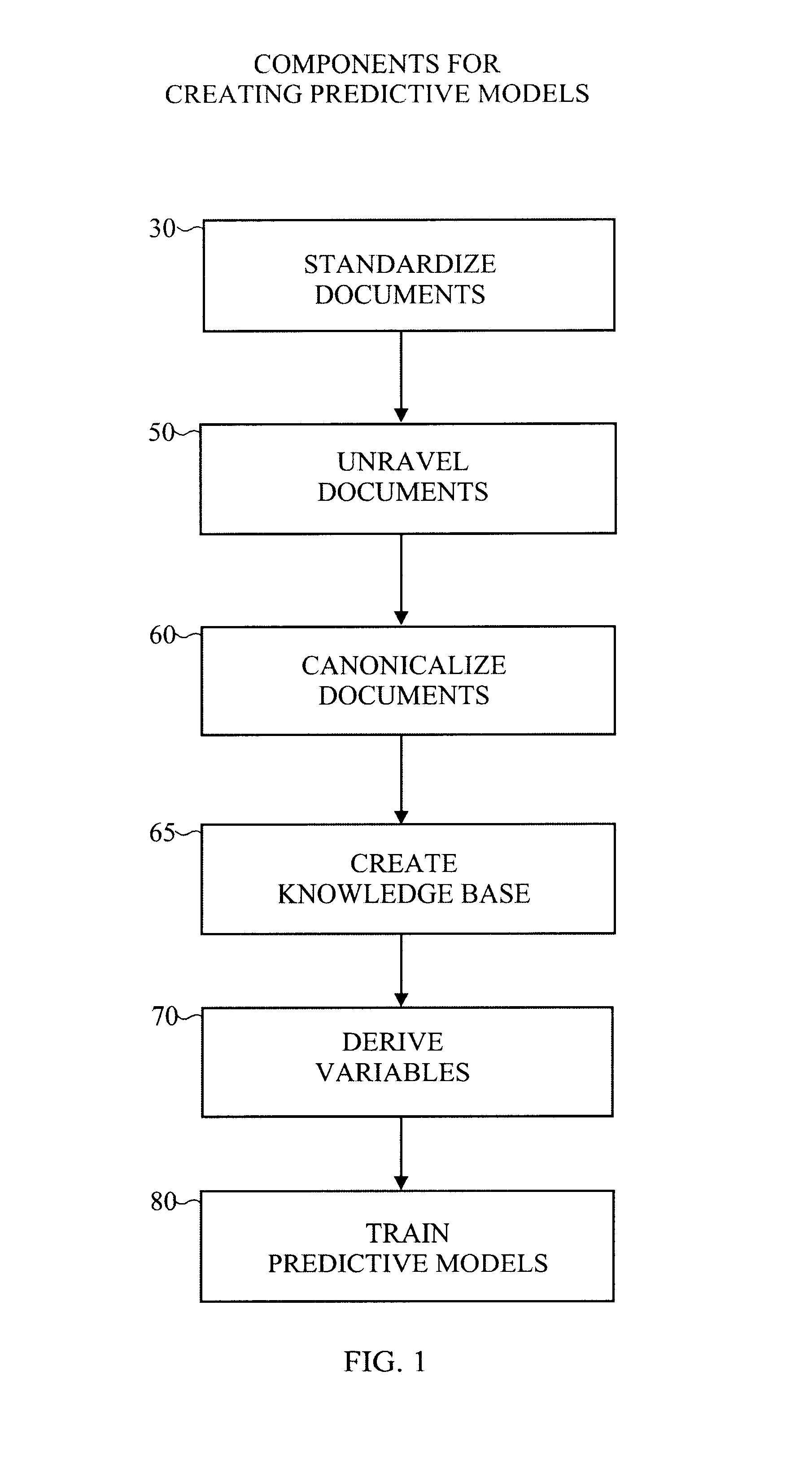

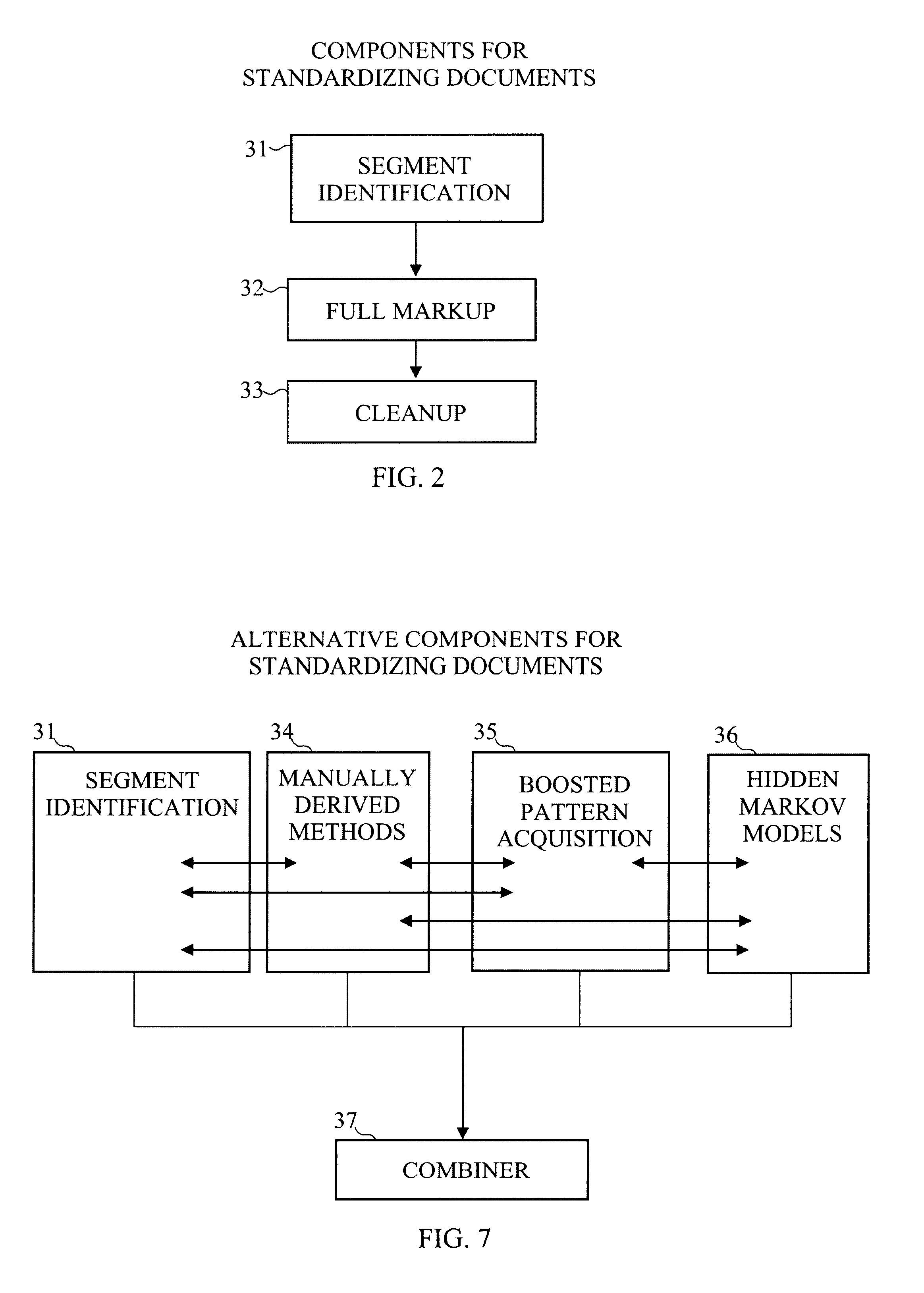

Method and apparatus for making predictions about entities represented in documents

InactiveUS6728695B1Highly effectiveImprove efficiencyData processing applicationsDigital data information retrievalInformation analysisSpecification document

A method and apparatus is disclosed for making predictions about entities represented in documents and for information analysis of text documents or the like, from a large number of such documents. Predictive models are executed responsive to variables derived from canonical documents to determine documents containing desired attributes or characteristics. The canonical documents are derived from standardized documents, which, in turn, are derived from original documents.

Owner:BURNING GLASS TECH

Method of target enrichment and amplification

InactiveUS20030082543A1Speed up breedingHighly effectiveSugar derivativesMicrobiological testing/measurementTarget enrichmentBioinformatics

The presently claimed invention provides methods and kits for amplifying a target sequence from within a nucleic acid population. The presently claimed invention provides selection probes which are complementary to at least a portion of said target sequence and mechanisms for adding a probe sequence to the 3' end of a target sequence that is hybridized to a selection probe. The added 3' probe sequence and a probe sequence added at the 5' end of the target by adaptor ligation allow for selective amplification of the target sequence.

Owner:AFFYMETRIX INC

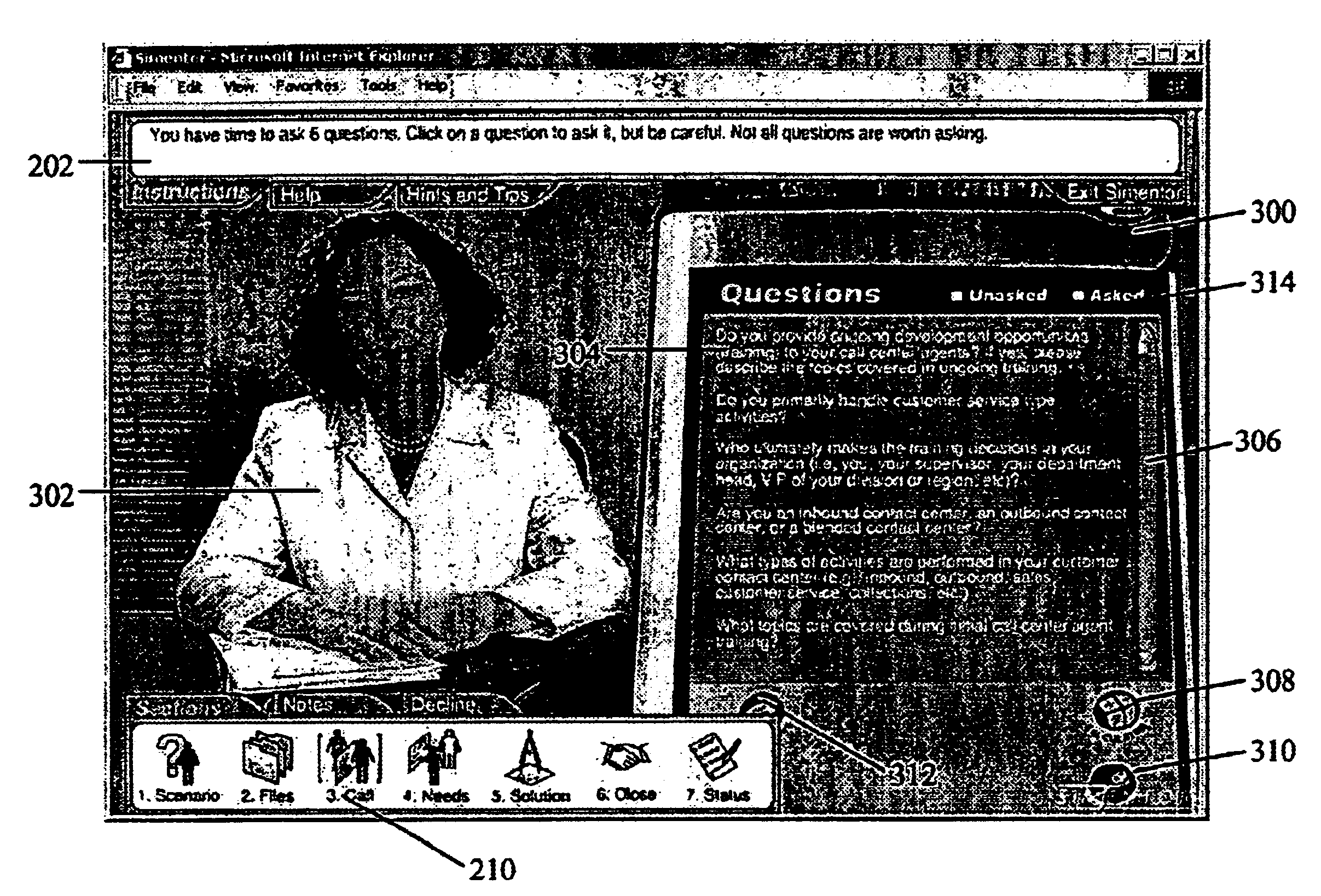

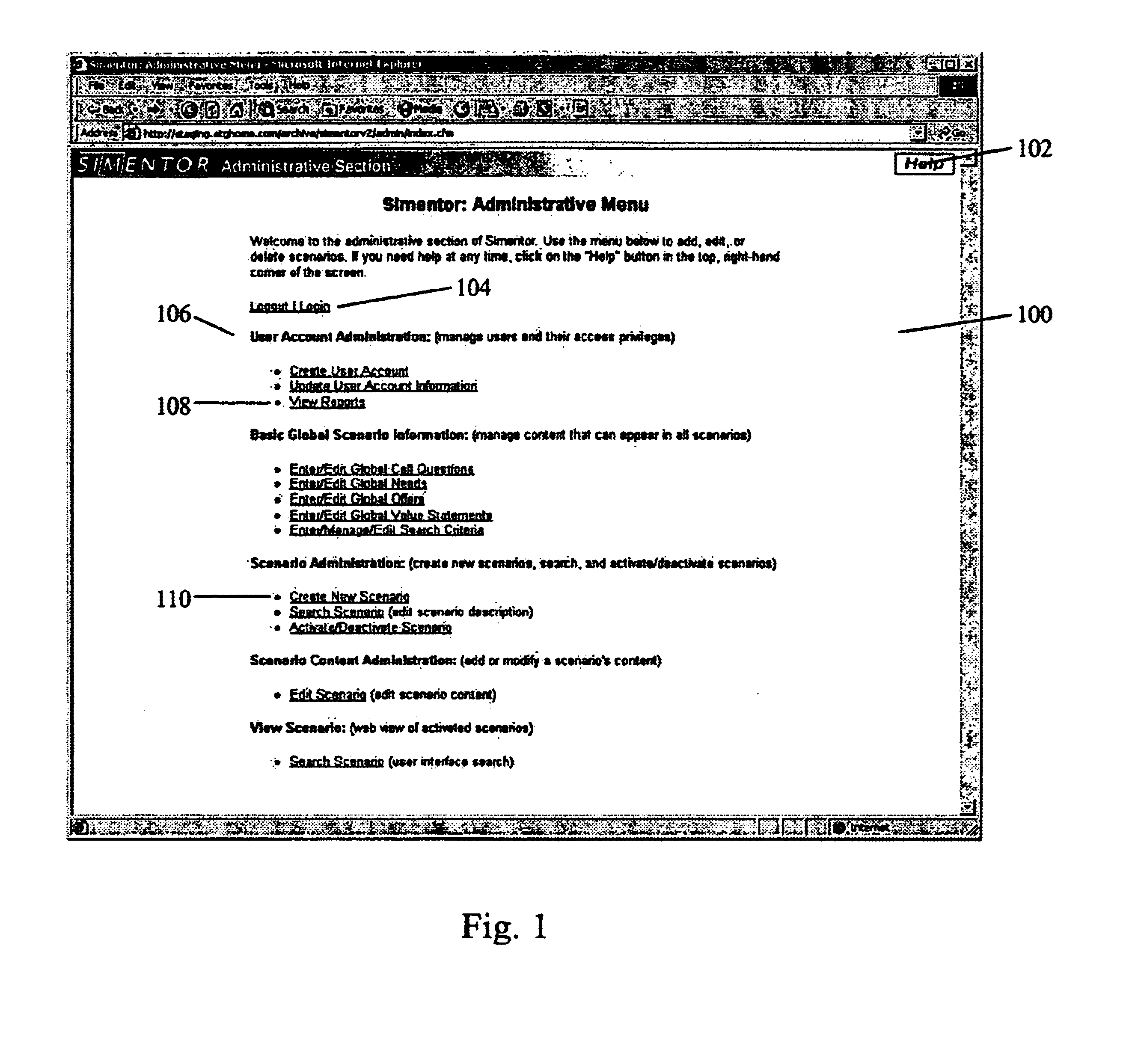

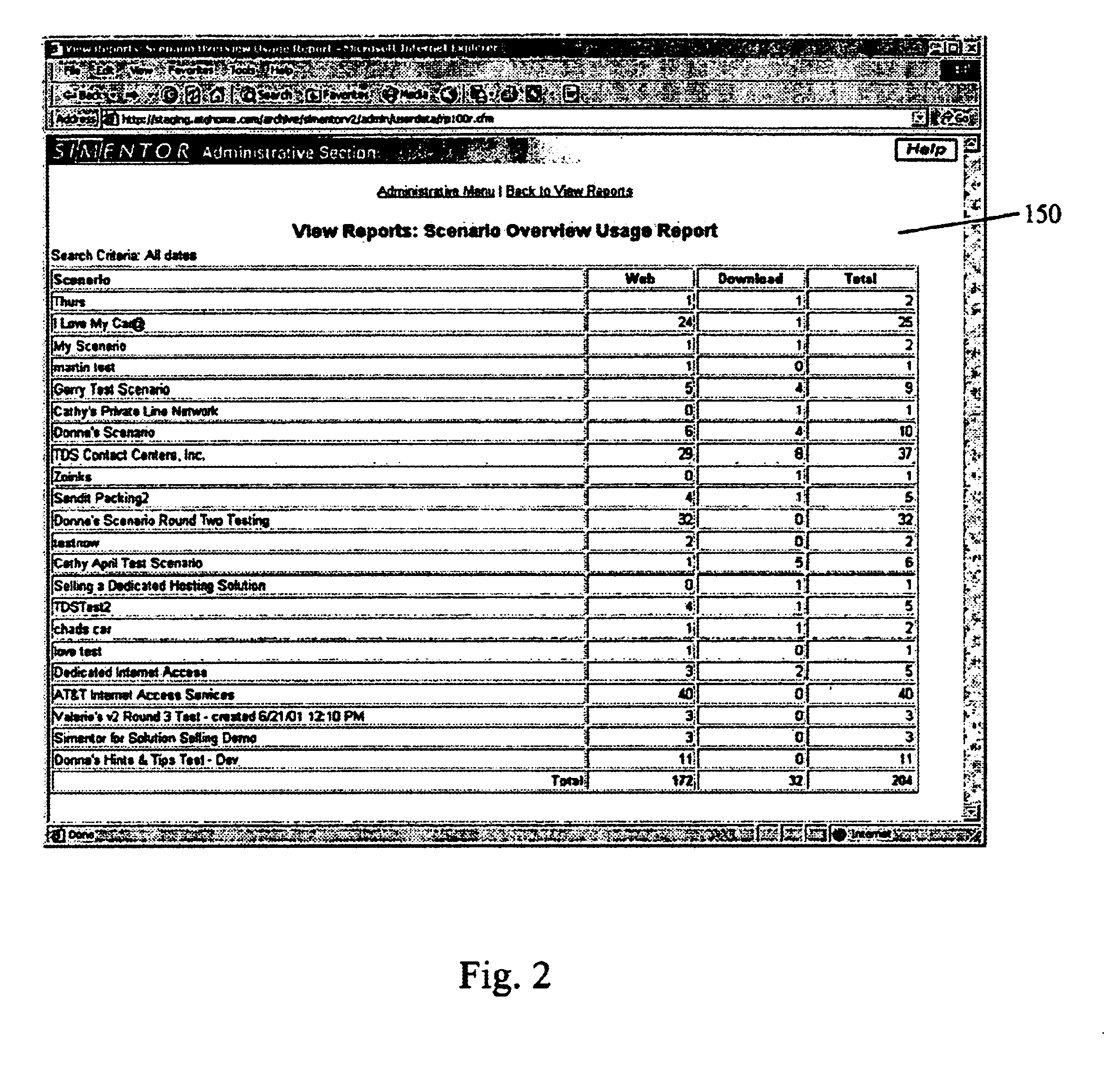

Interactive training system and method

InactiveUS6755659B2Efficient creation and implementation and utilizationFacilitate creation and implementation and utilizationElectrical appliancesSpecial data processing applicationsAugmentation systemComputer based simulation

The present disclosure relates to a system and method for facilitating personnel education and training, and more particularly to a system and method that allows efficient creation, implementation and utilization of interactive training modules and / or scenarios. The disclosed system and method facilitate creation, implementation and utilization of computer-based simulations by personnel involved in a wide range of educational, professional and / or business pursuits, and include administrative functionalities that greatly enhance system / method efficiency, flexibility and the ease and speed with which educational / training modules and scenarios may be customized and / or implemented.

Owner:ACCESS TECH

Essential oil compositions for killing or repelling ectoparasites and pests and methods for use thereof

InactiveUS20080193387A1Pleasant scentWithout burdensome safety precautionBiocideCosmetic preparationsTickFlea

Essential-oil compositions comprising Lippia javanica essential oil in combination with one, two, three, four, five, six or more essential oils are provided. The Lippia javanica essential-oil compositions are effective for killing and / or repelling ectoparasites and / or pests, including lice, ticks, mosquitoes, mites, ants and fleas. Methods of using the compositions comprising Lippia javanica essential oil in combination with one, two, three, four, five, six or more essential oils for killing or repelling ectoparasites and / or pests also are provided. Also provided are articles of manufacture and kits that include the Lippia javanica essential-oil compositions.

Owner:RICKI DE WOLFFE

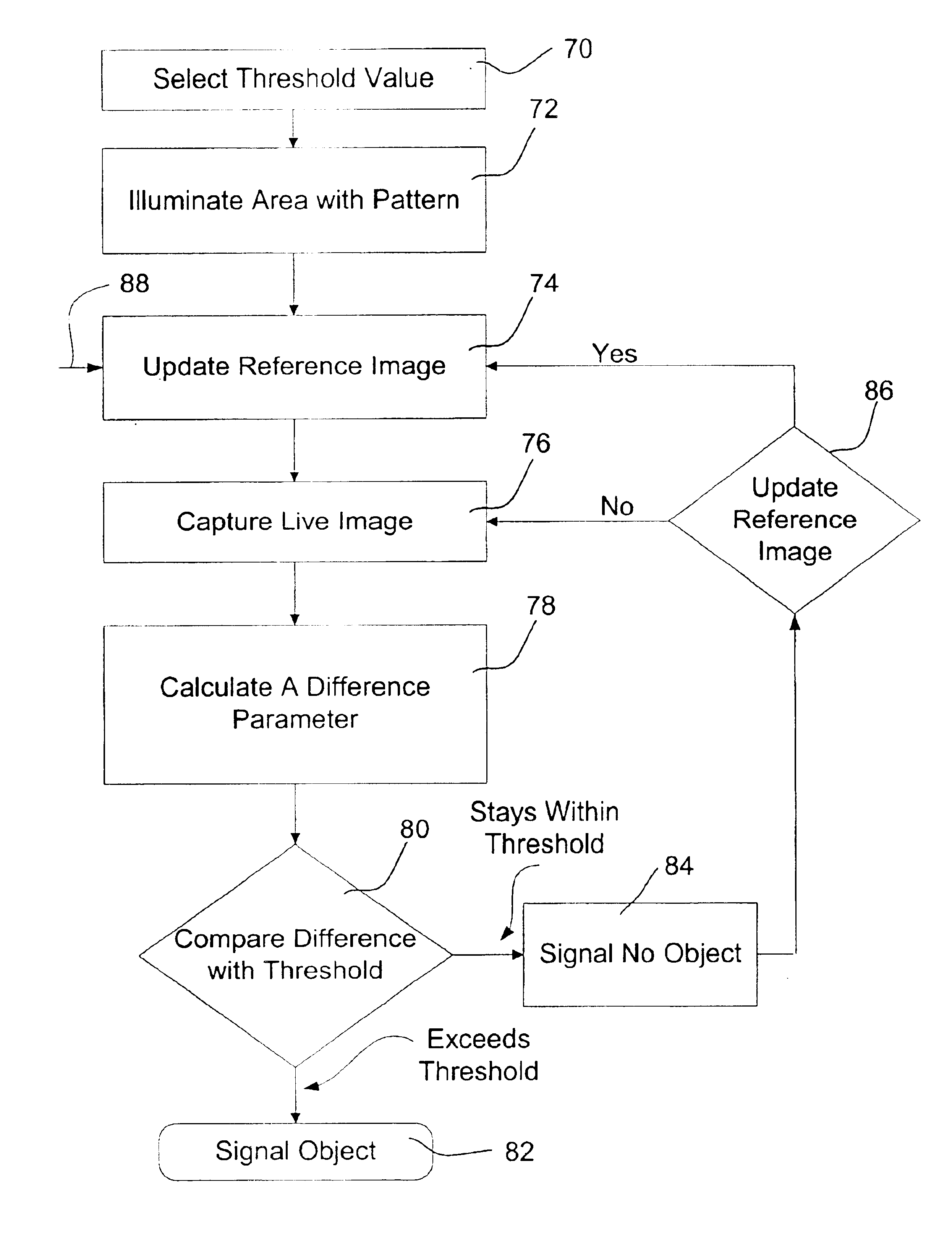

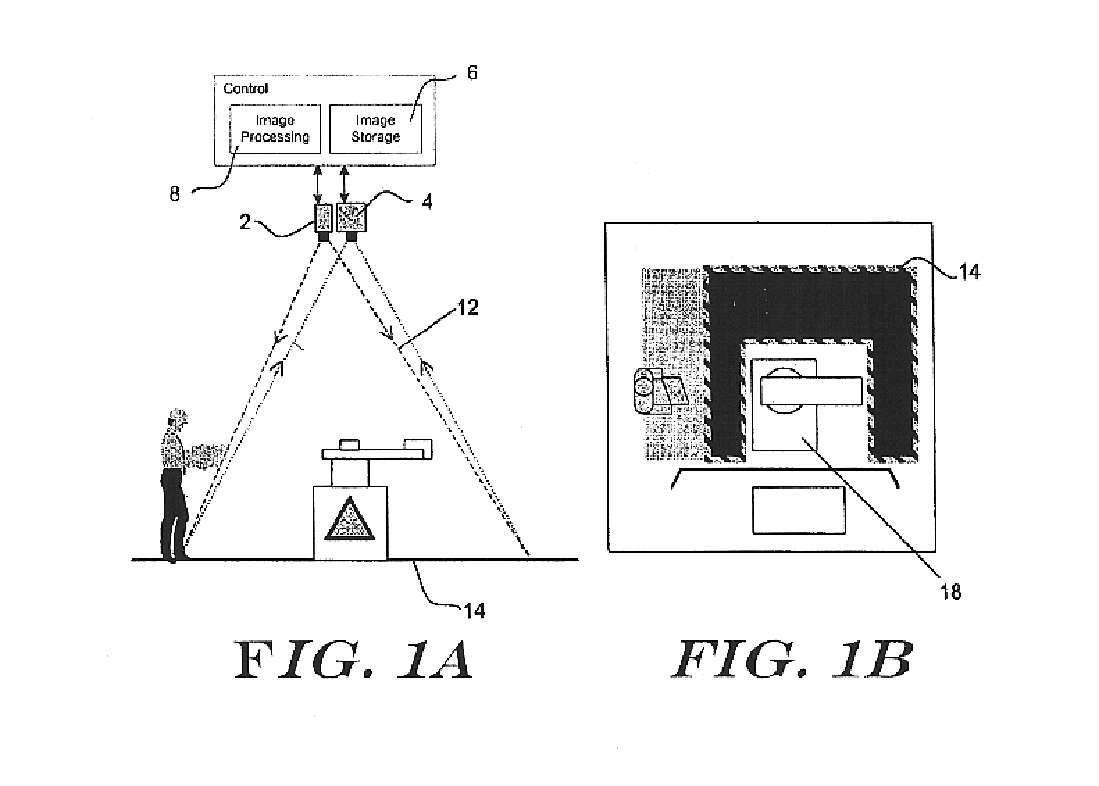

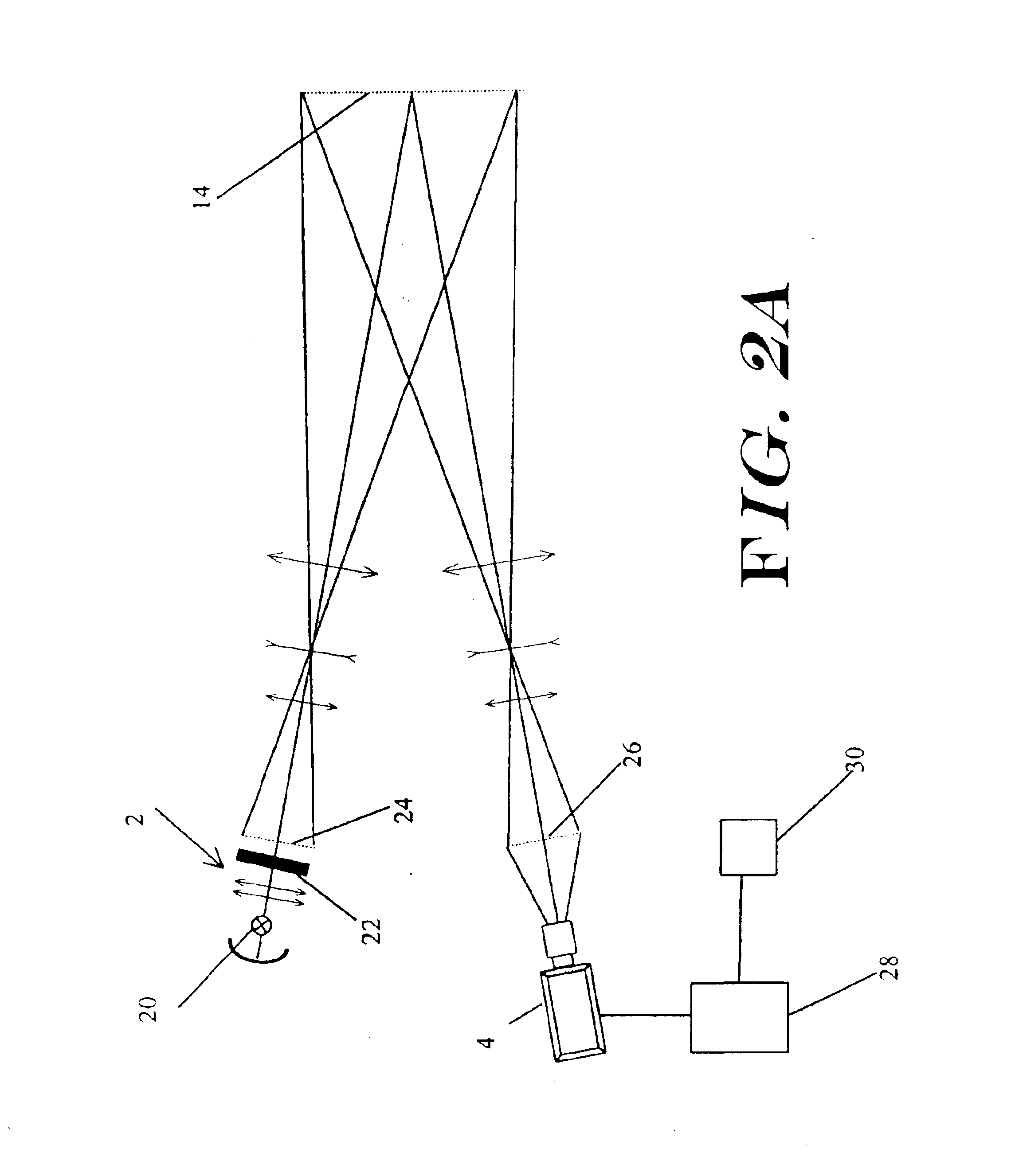

Method and apparatus for detecting objects

InactiveUS6841780B2Less effect efficacyHighly effectiveRadiation pyrometryImage analysisObject motionComputer science

An object detection system is provided that projects one or more patterns onto a monitored area, captures one or more live images of the monitored area, and detects objects that enter the monitored area by detecting changes in the one or more patterns in the live images. Such an object detection system may be less susceptible to dynamic lighting conditions, and more sensitive to object motion and / or presence.

Owner:HONEYWELL INT INC

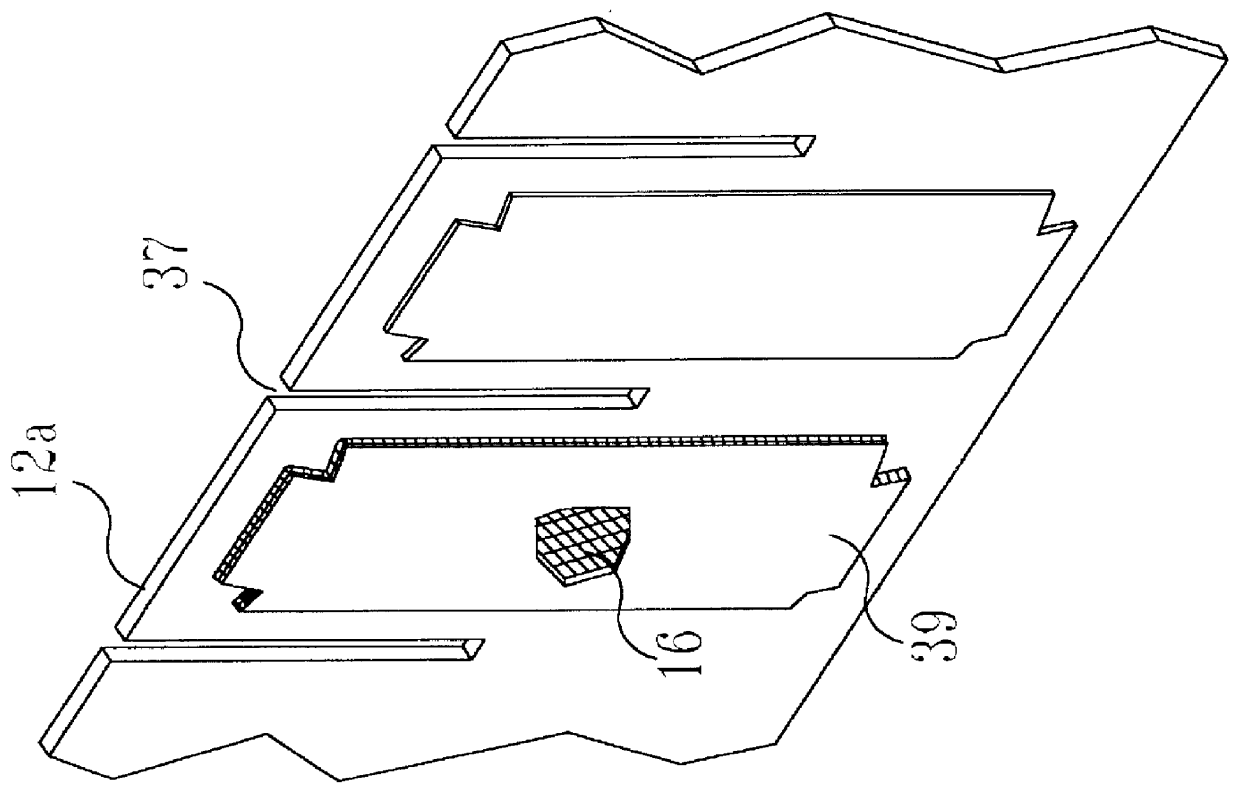

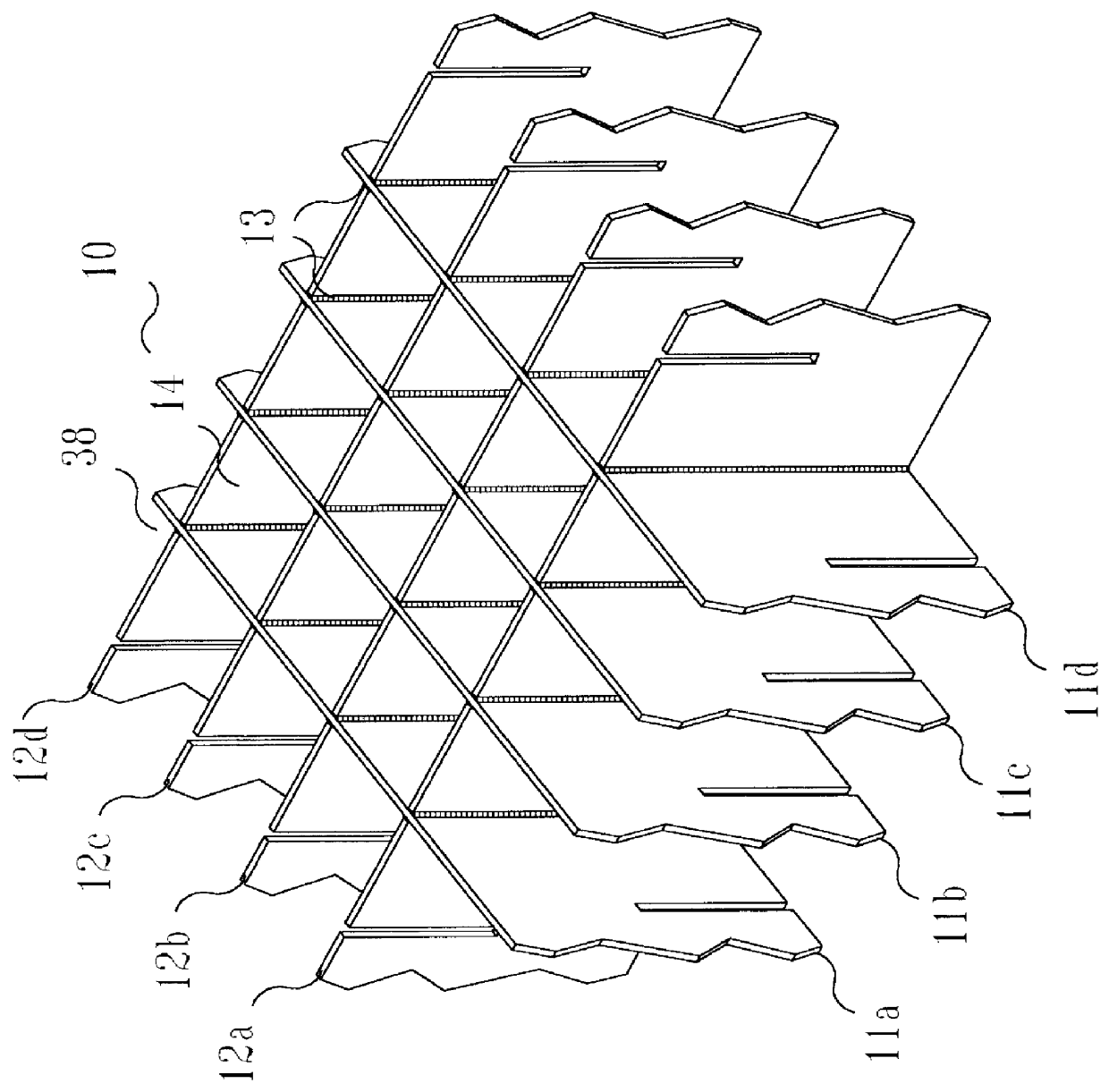

Apparatus suitable for transporting and storing nuclear fuel rods and methods for using the apparatus

InactiveUS6064710ARugged and convenient to handleHighly effectiveReactor fuel elementsPortable shielded containersHoneycombHoneycomb like

Apparatus suitable for transporting and storing nuclear fuel rods comprising a basket having storage cells formed from a honeycomb gridwork of metal plates in a rectilinear configuration, the plates welded to each other at their intersections so that all contiguous corners of the storage cells formed by the gridwork are completely connected so as to allow conduction heat transfer, the metal plates having neutron absorber material positioned in areas which form walls of the storage cells. Method of making an apparatus suitable for transporting and storing nuclear fuel rods comprising a) providing metal plates having slots and having neutron absorber material positioned on sides of the metal plates, b) arranging the plates so that the slots intersect to form a honeycomb gridwork of storage cells having contiguous corners and having the neutron absorbing material on sides of the storage cells, and c) welding the plates to each other at their intersections so that all contiguous corners of the storage cells formed by the gridwork are completely connected so as to allow conduction heat transfer and to provide a rigid structure.

Owner:SINGH KRIS

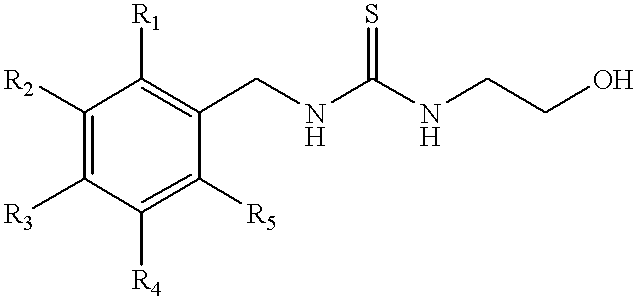

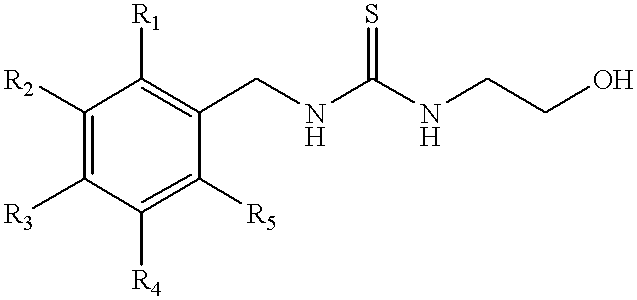

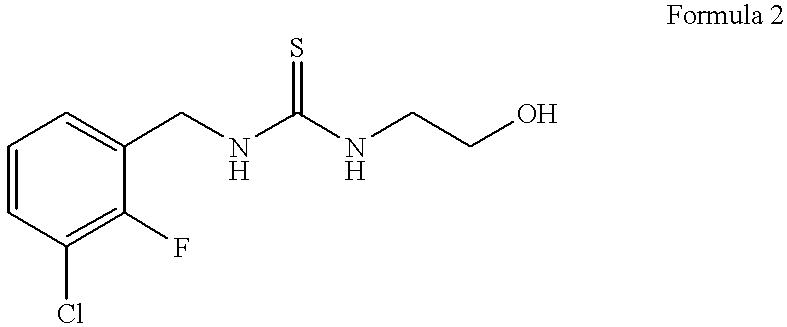

Methods and compositions for modulating alpha adrenergic receptor activity

InactiveUS6545182B2High activityHighly effectiveBiocideSenses disorderAdrenergicAlpha-2 adrenergic receptor

Methods and compositions for the treatment of pain using thiourea derivatives. Particularly disclosed are new compositions for the treatment of chronic pain, and methods for their use.

Owner:ALLERGAN INC

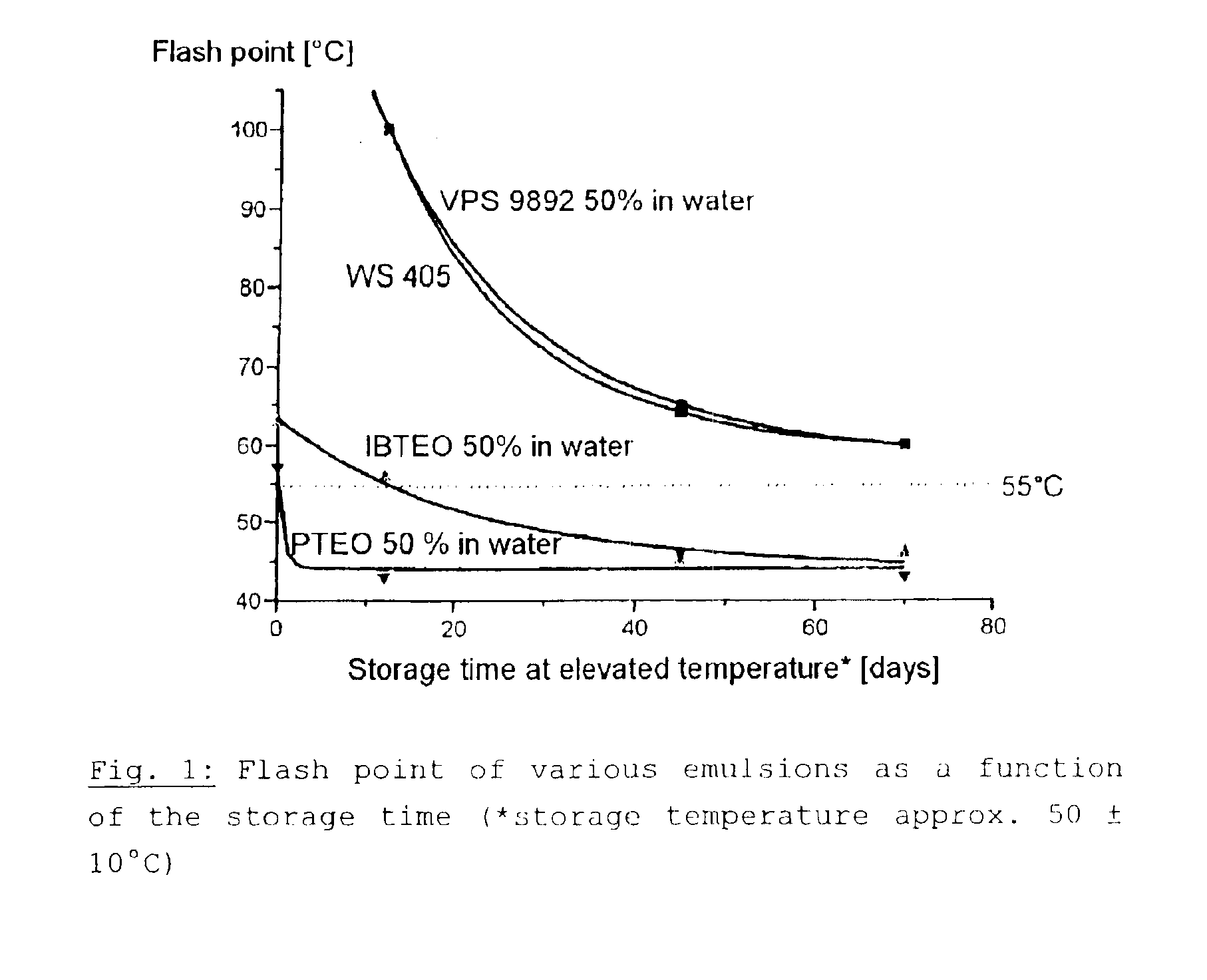

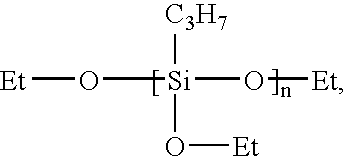

n-Propylethoxysiloxanes, their preparation and use

InactiveUS6841197B2High flash pointGood application effectMixing methodsPretreated surfacesOligomerChemistry

Owner:EVONIK DEGUSSA GMBH

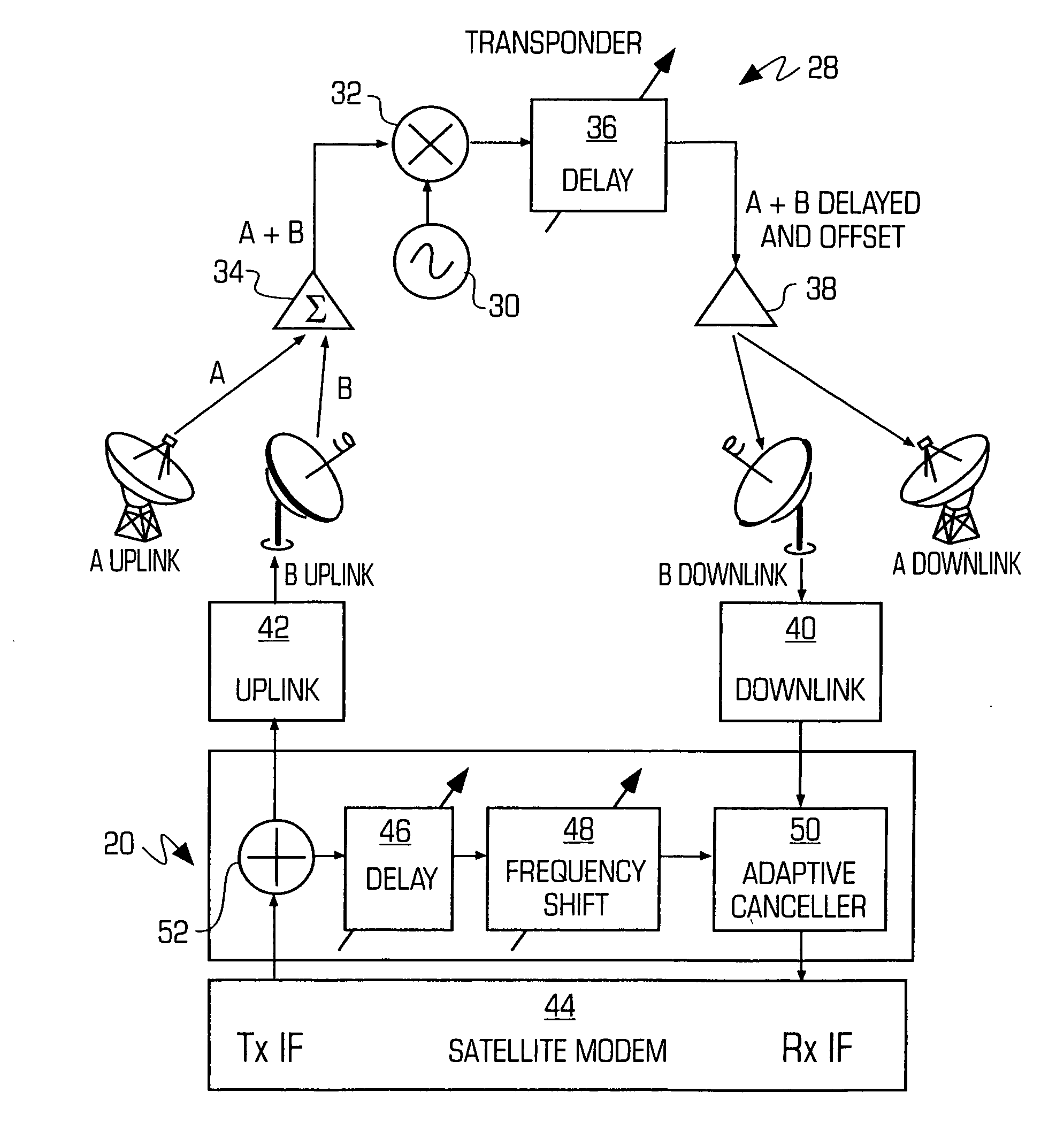

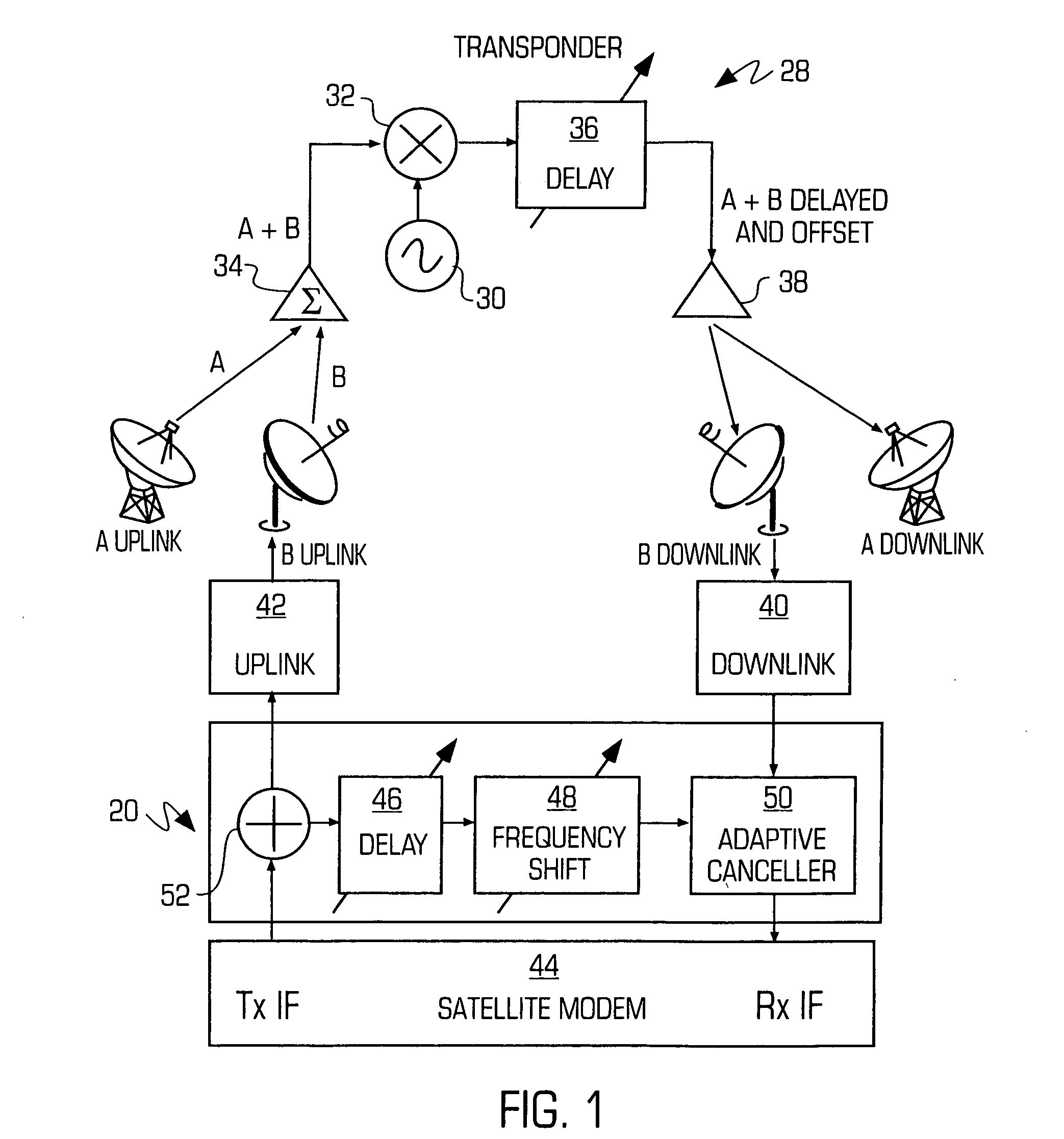

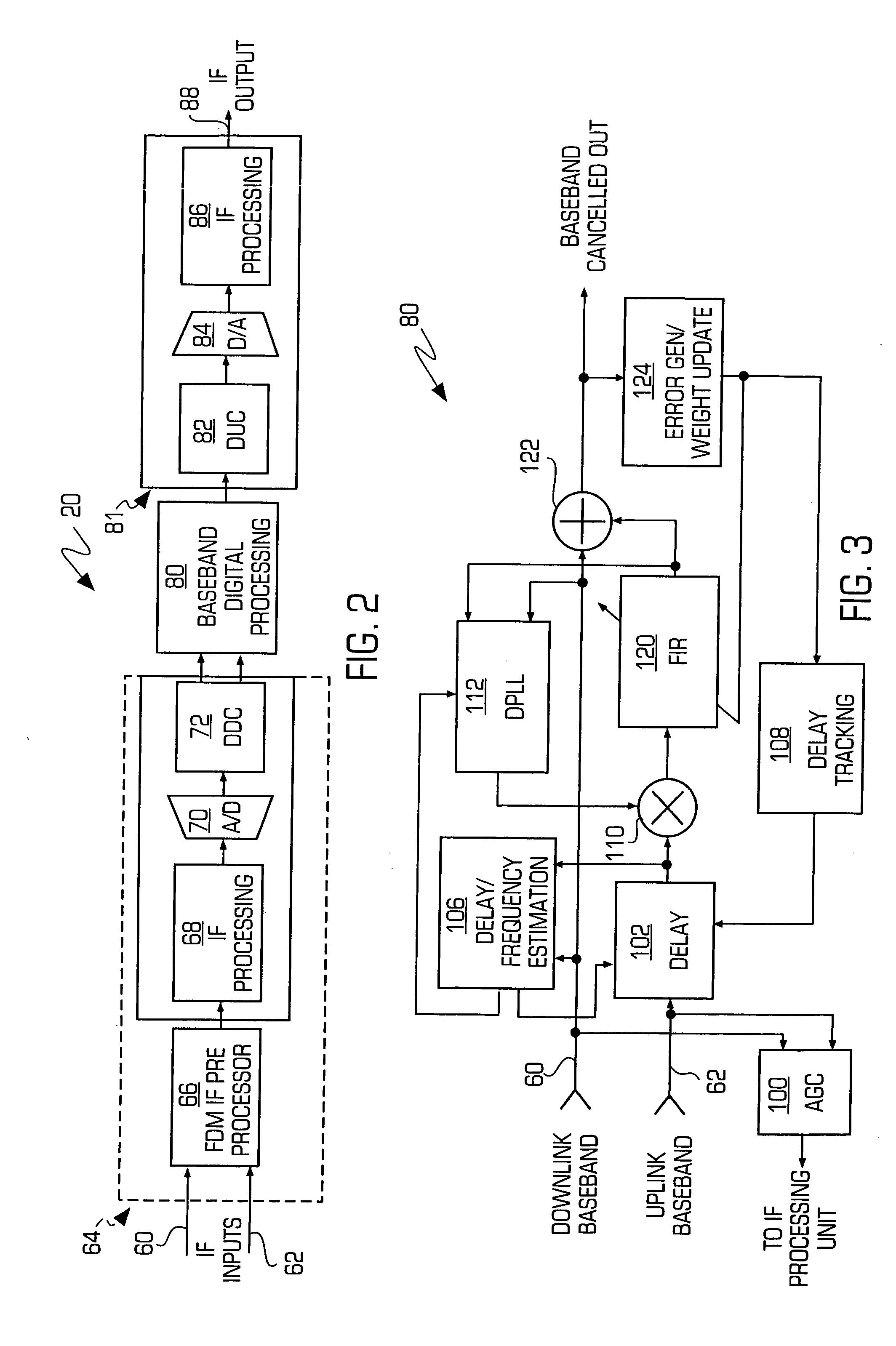

Adaptive canceller for frequency reuse systems

InactiveUS20050159128A1Easy to useHighly effectiveRadio transmissionTransmission noise suppressionFinite impulse responseAdaptive filter

An adaptive interference canceller for canceling an interfering signal corresponding to a delayed, frequency translated, amplitude and phase offset version of a transmitted signal contained in a composite received signal relayed through a relay system such as a satellite transponder. The canceller digitally downconverts the received signal and a local replica of the transmitted signal from IF to baseband, applies a variable delay and frequency compensation to the replica as a coarse delay and frequency correction, and tracks fine delay, amplitude and phase differences using an adaptive finite impulse response filter to generate a cancellation signal corresponding to the delayed and frequency shifted version. A minimum output power process produces an error signal that drives the variable delay and adaptive filter to minimize the power in the signal of interest to maximize cancellation of the interfering signal.

Owner:RAYTHEON APPLIED SIGNAL TECH

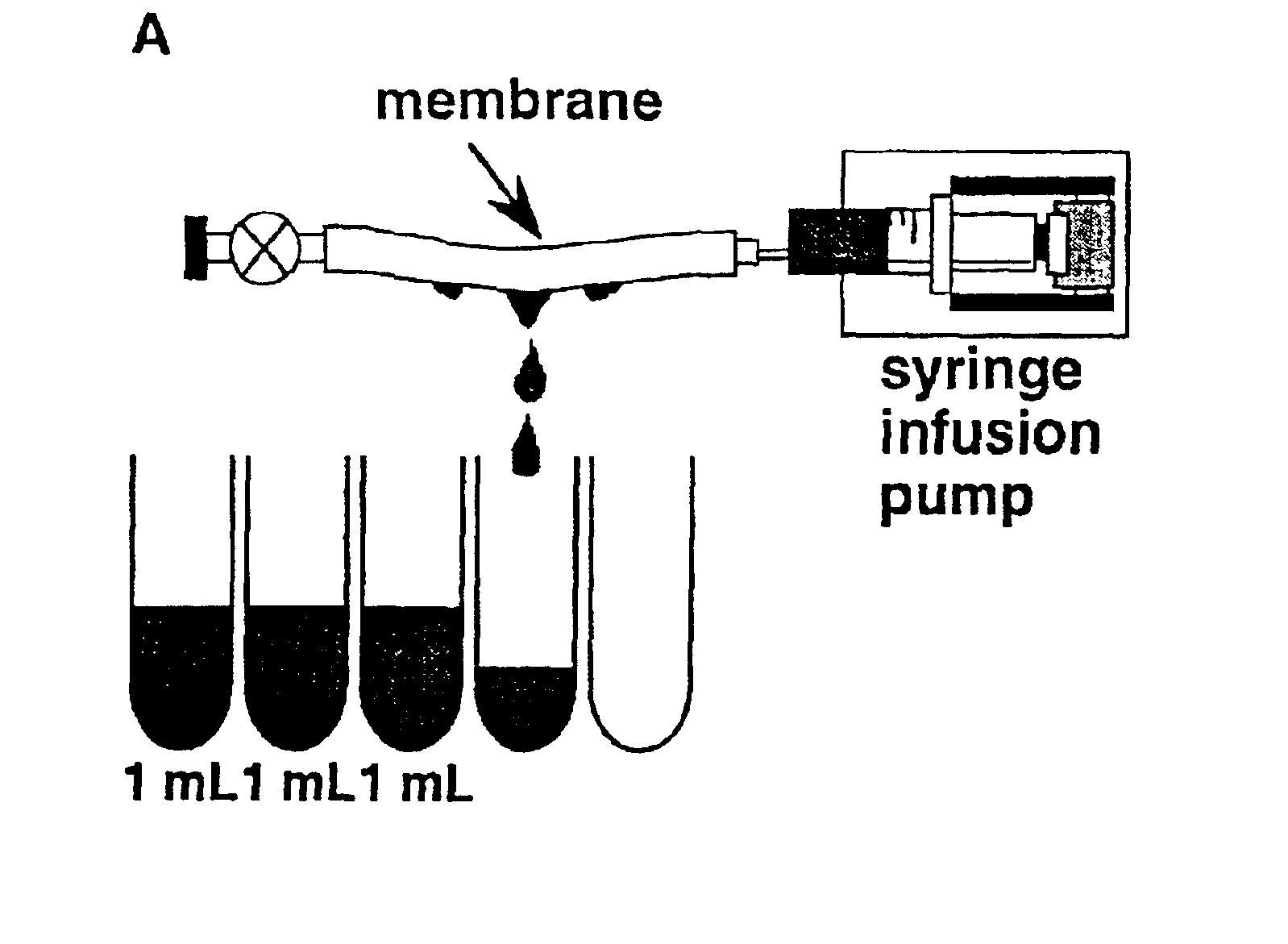

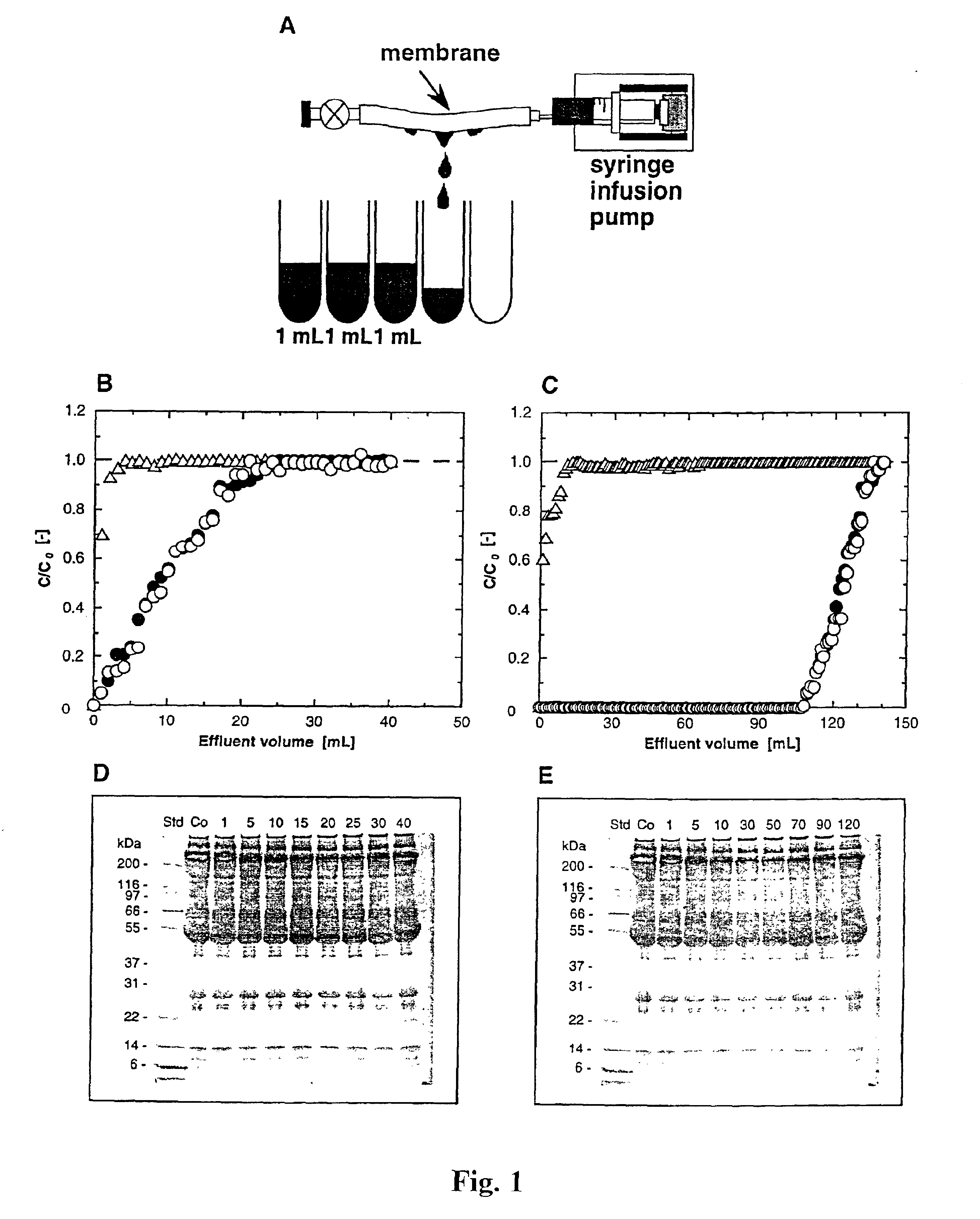

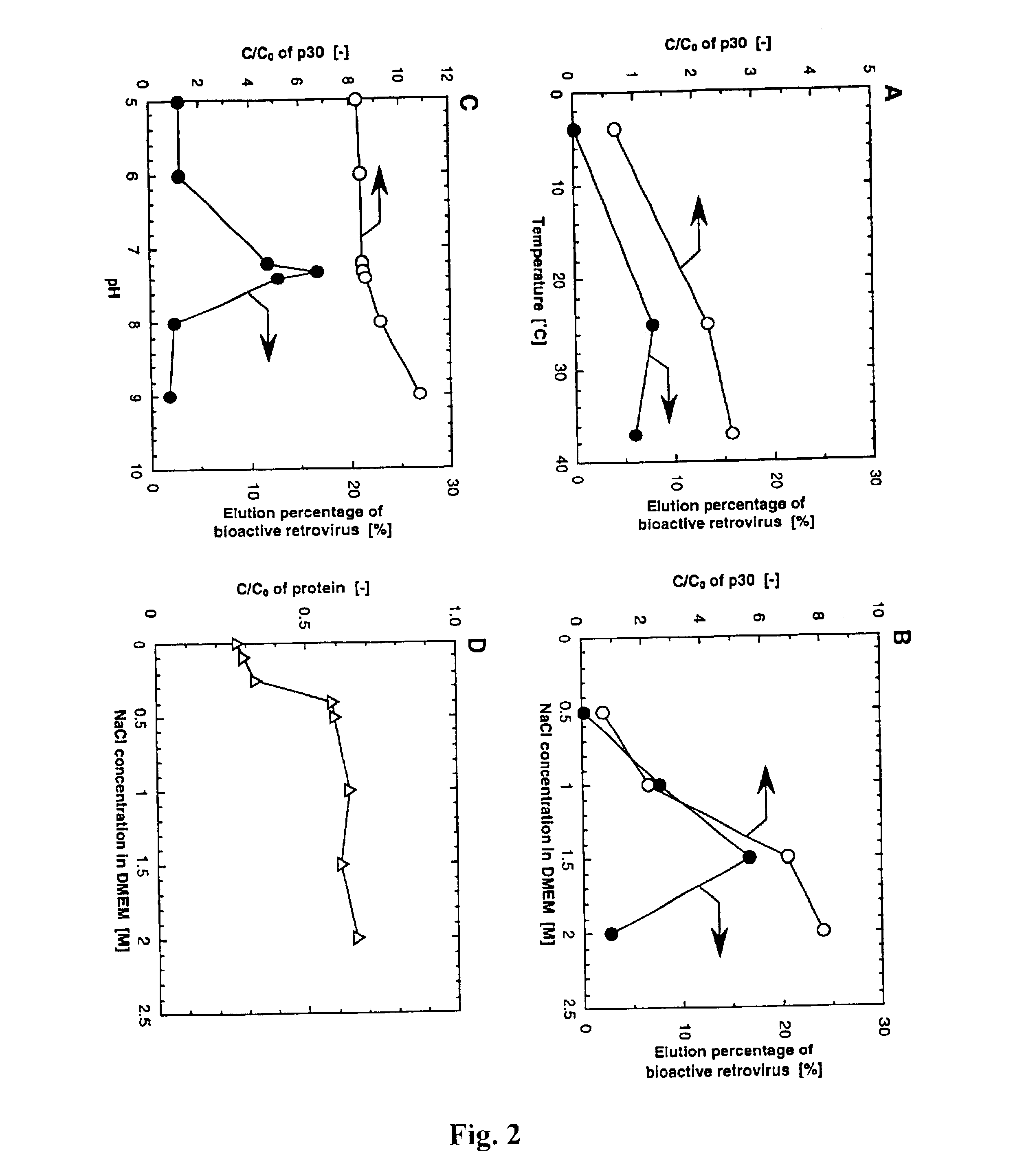

Methods for removal, purification, and concentration of viruses, and methods of therapy based thereupon

InactiveUS6861001B2Effect clotting timeEasy to zoom inBioreactor/fermenter combinationsBiological substance pretreatmentsSide chainBlood plasma

The invention is based on the discovery that certain membranes, which include side chains or molecular “brushes” having, for example, tertiary amino functional groups, can be used as highly effective filters to capture viruses / virus particles from liquids without removal of proteins. New methods based on this discovery include removing viruses from liquids such as blood or plasma, removing viruses from pharmaceuticals, concentrating and / or purifying viruses, e.g., for use in gene therapy, and producing recombinant viruses in new bioreactors. The invention also includes new methods of therapy or adjunct therapy for viral infections, in which a patient's blood or plasma is filtered through the membranes to remove viruses to reduce the viral load. The invention also includes new bioreactors and viral filters containing the membranes.

Owner:THE GENERAL HOSPITAL CORP

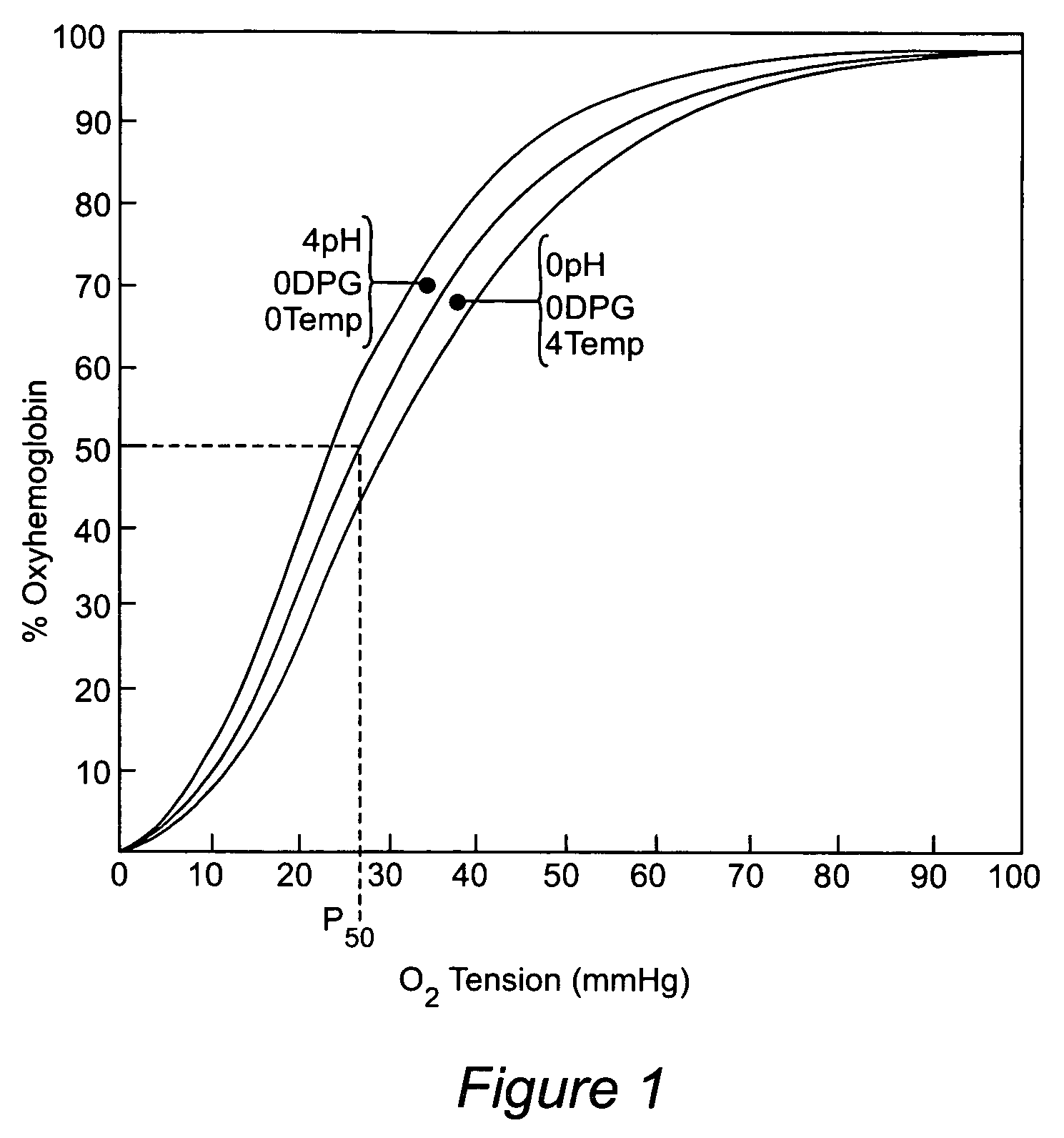

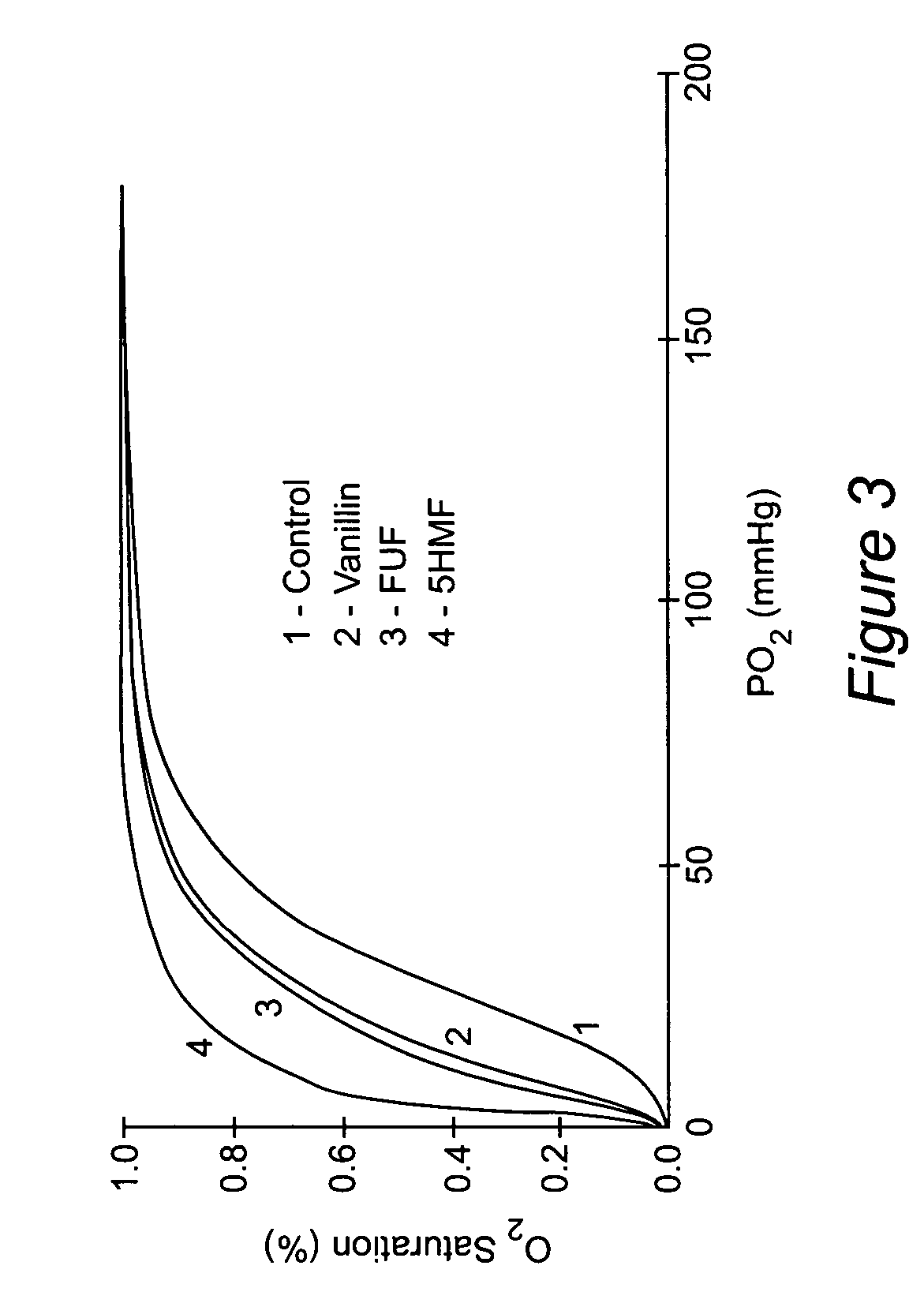

Anti-sickling agents

The provides compounds for the treatment of sickle-cell disease. In particular, the invention provides 5-membered heterocyclic anti-sickling agents that are highly effective and non-toxic, and methods for their use. The compounds include analogues and derivatives of naturally occurring occurring 5-hydroxymethyl-2-furfuraldehyde, 5-Ethyl-2-furfuraldehyde, 5-Methyl-2-furfuraldehyde, and 2-furfuraldehyde, and prodrug forms of the compound.

Owner:VIRGINIA COMMONWEALTH UNIV

Composition with docosapentaenoic acid

InactiveUS20090054329A1Stimulate barrier integrityImproving barrier integrityBiocidePeptide/protein ingredientsEPA - Eicosapentaenoic acidBarrier integrity

This invention concerns a method for stimulating barrier integrity in a subject by administering to a subject a composition comprising docosapentaenoic acid (22:5 n3; DPA). Also the invention concerns a composition comprising DPA and eicosapentaenoic acid (EPA).

Owner:NUTRICIA

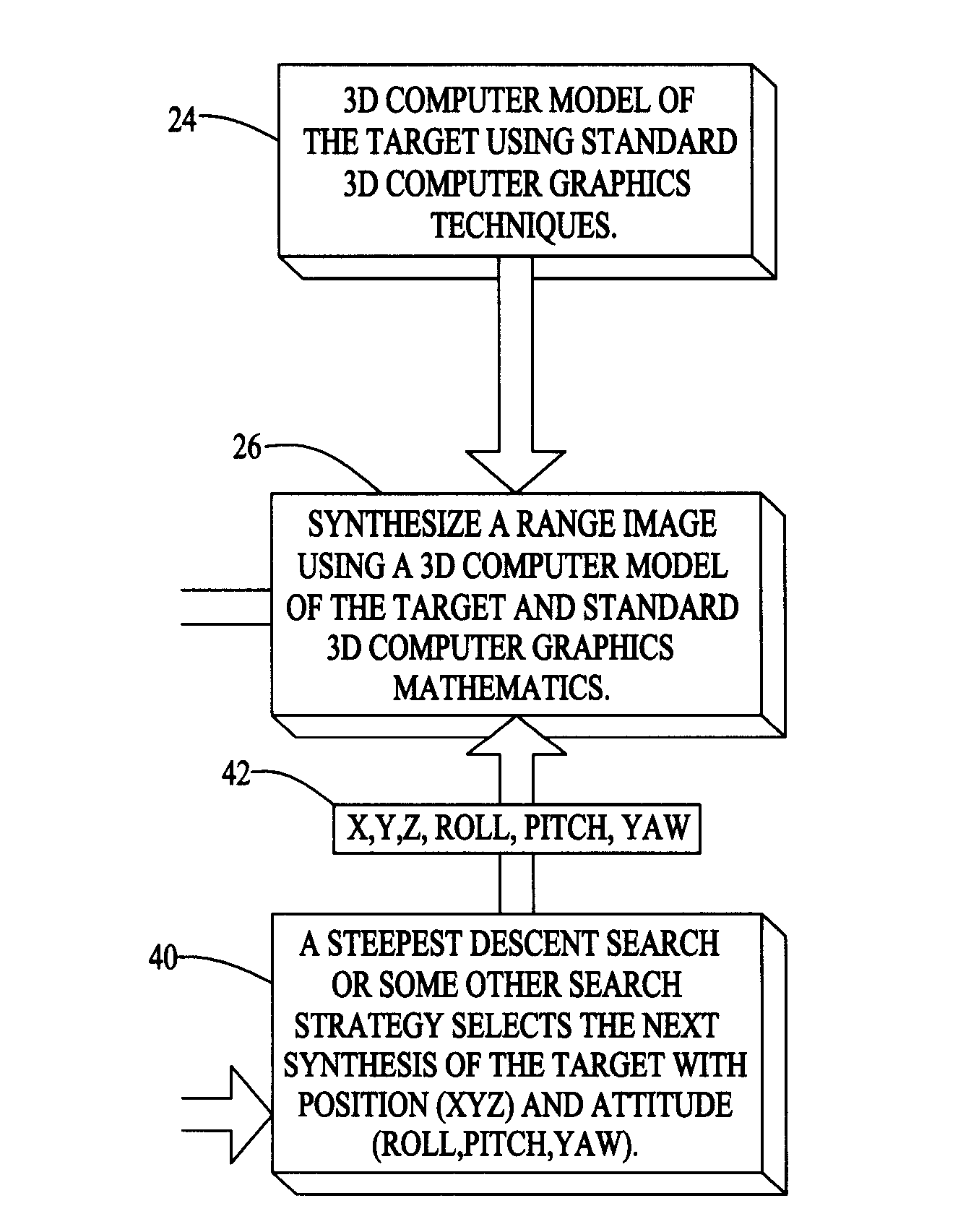

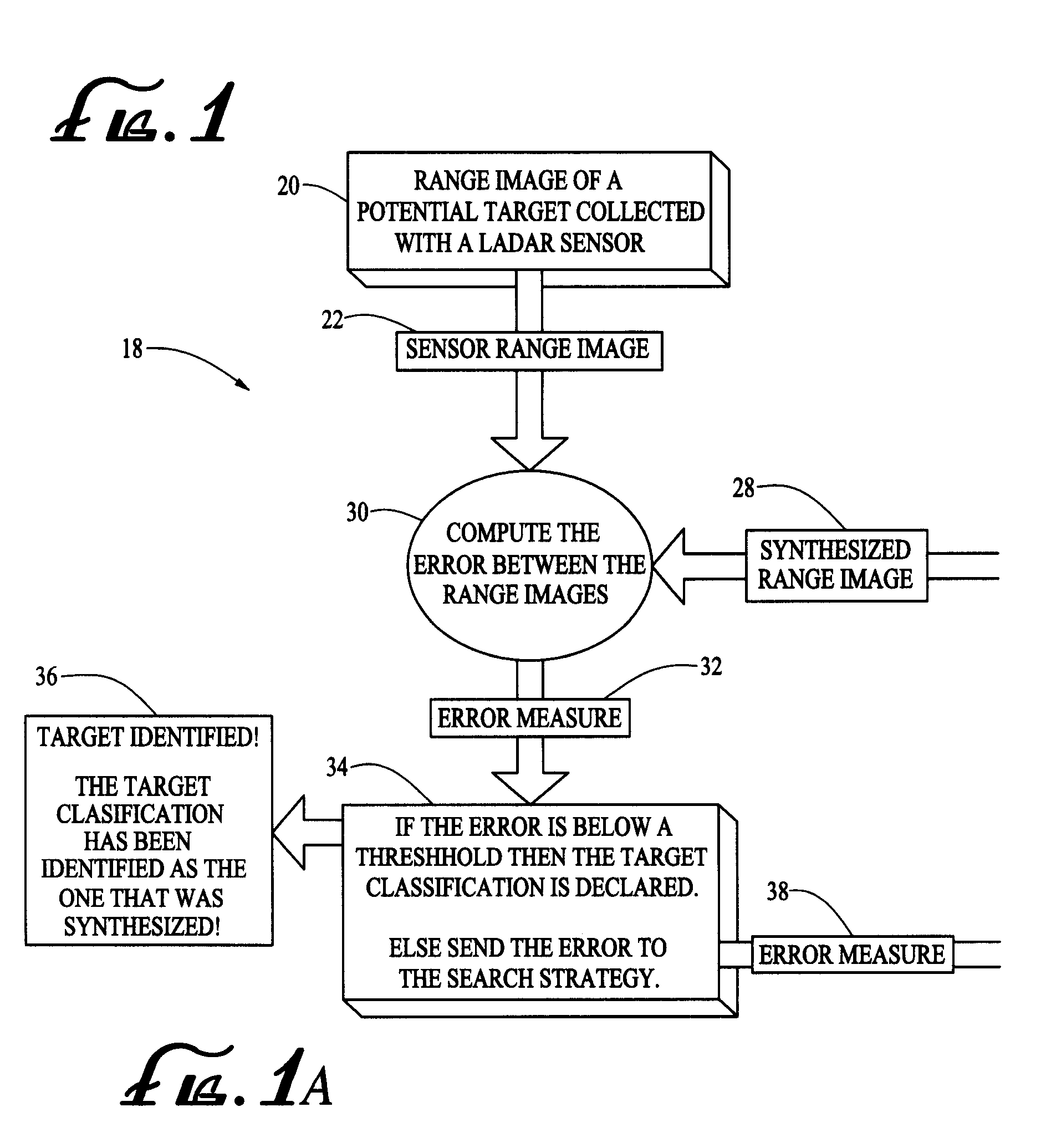

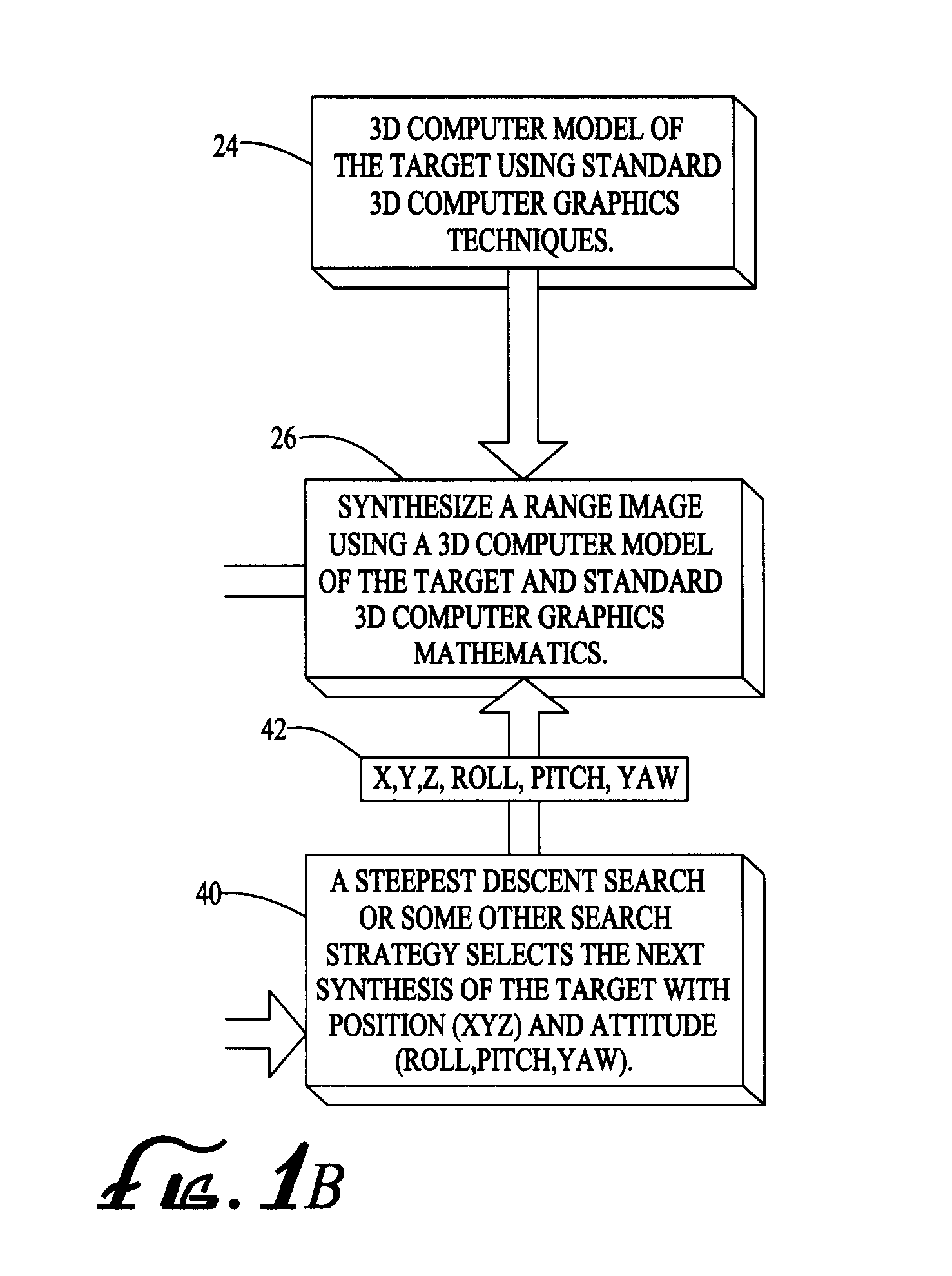

Three dimensional shape correlator

InactiveUS20080273210A1Fast and accurate and efficient target recognitionHighly effectiveUsing optical meansElectromagnetic wave reradiationRadarGoal recognition

A three dimensional shape correlation computer software program which uses laser radar data for target identification. The correlation program obtains a scan of laser radar data of a target from a Ladar sensor. The data includes a plurality of X,Y,Z coordinate detection points for the target. The software simulates the sensor scan using a 3D wire-frame model of the target. An X,Y,Z coordinate location is computed for every point in the computer model of the target. The software compares the X,Y,Z coordinate detection points for the target with the X,Y,Z coordinate points for the computer model to determine if the points match. When there is a match a target identification is declared.

Owner:U S OF A AS REPRESENTED BY THE SEC OF THE NAVY

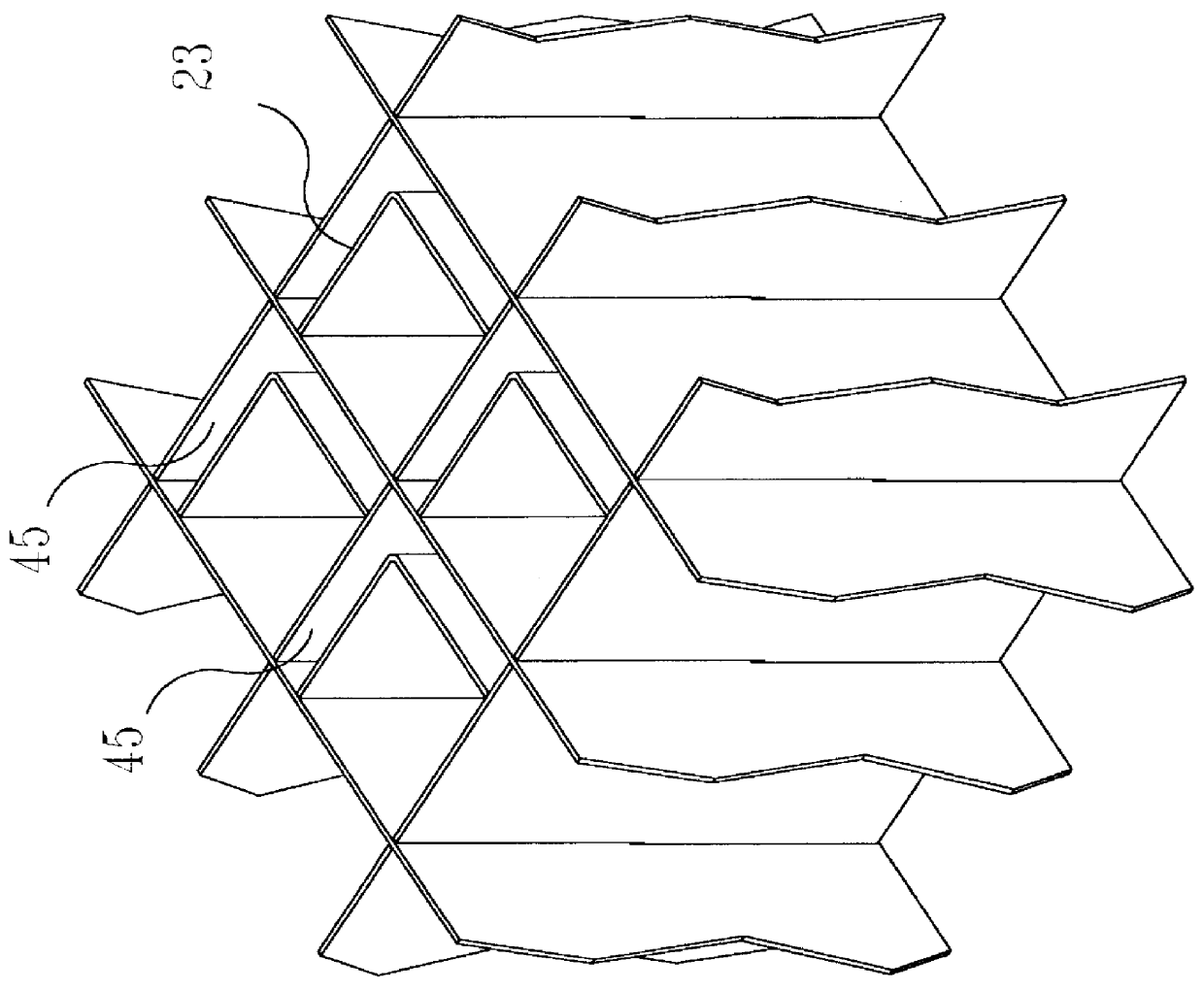

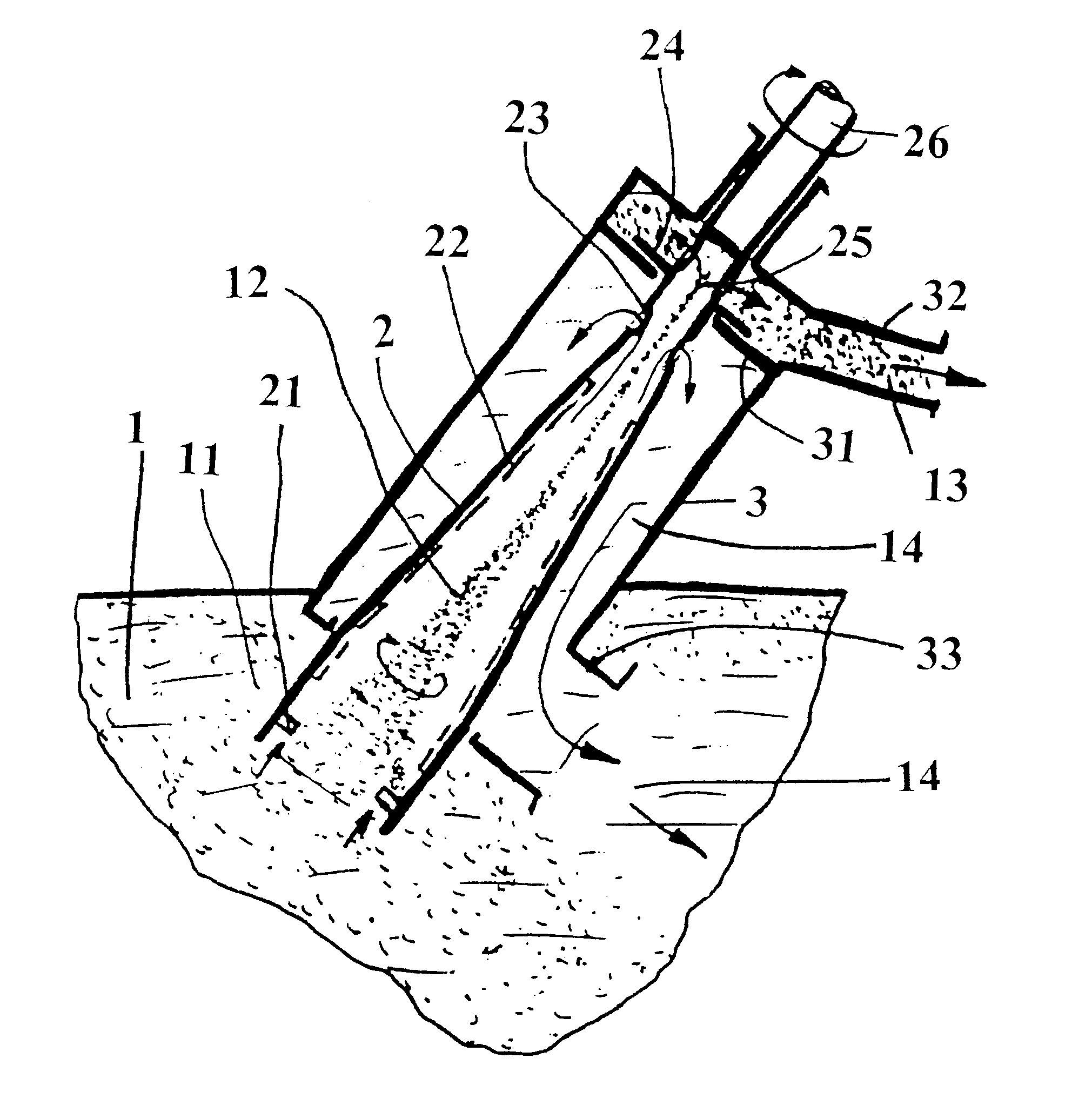

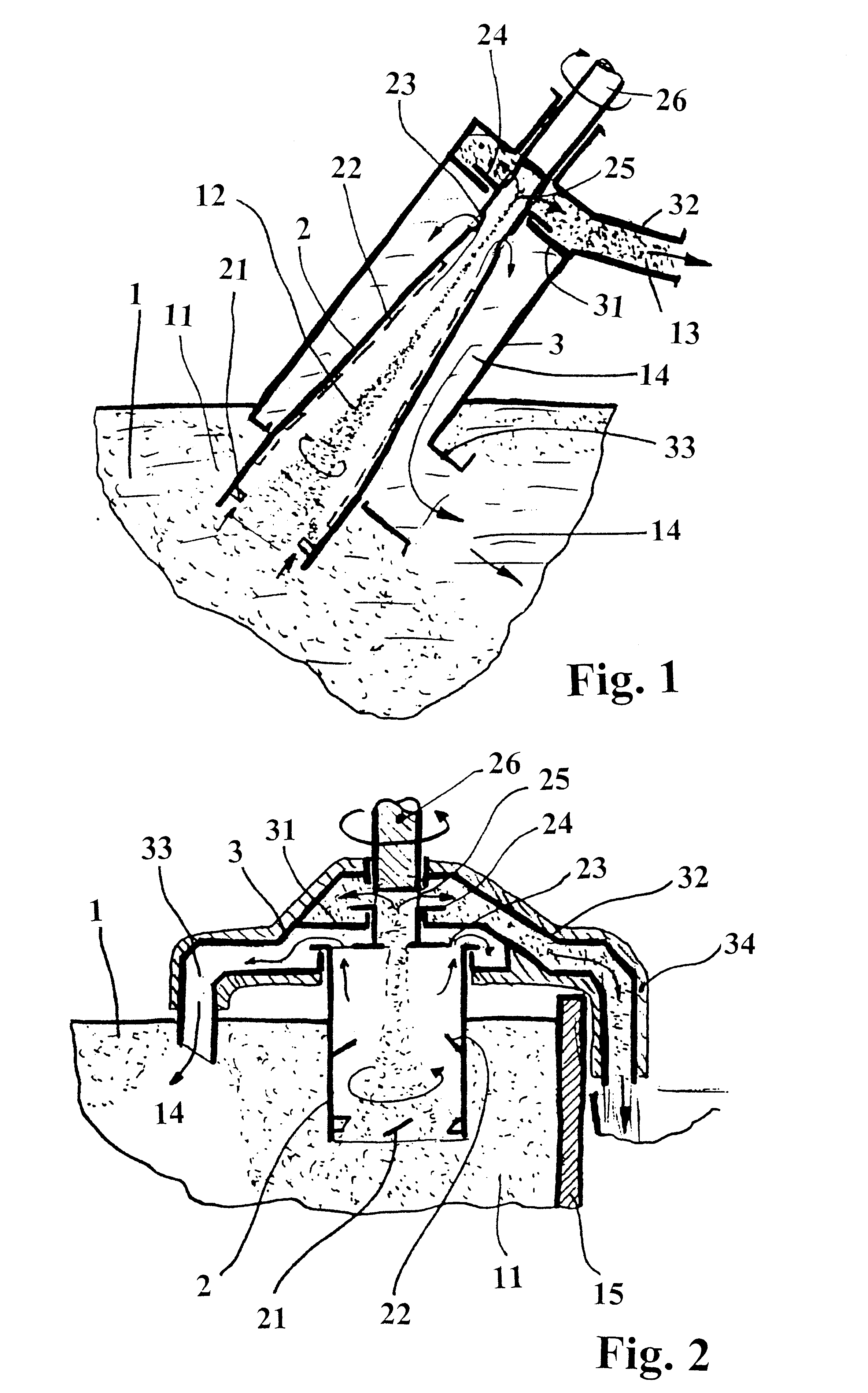

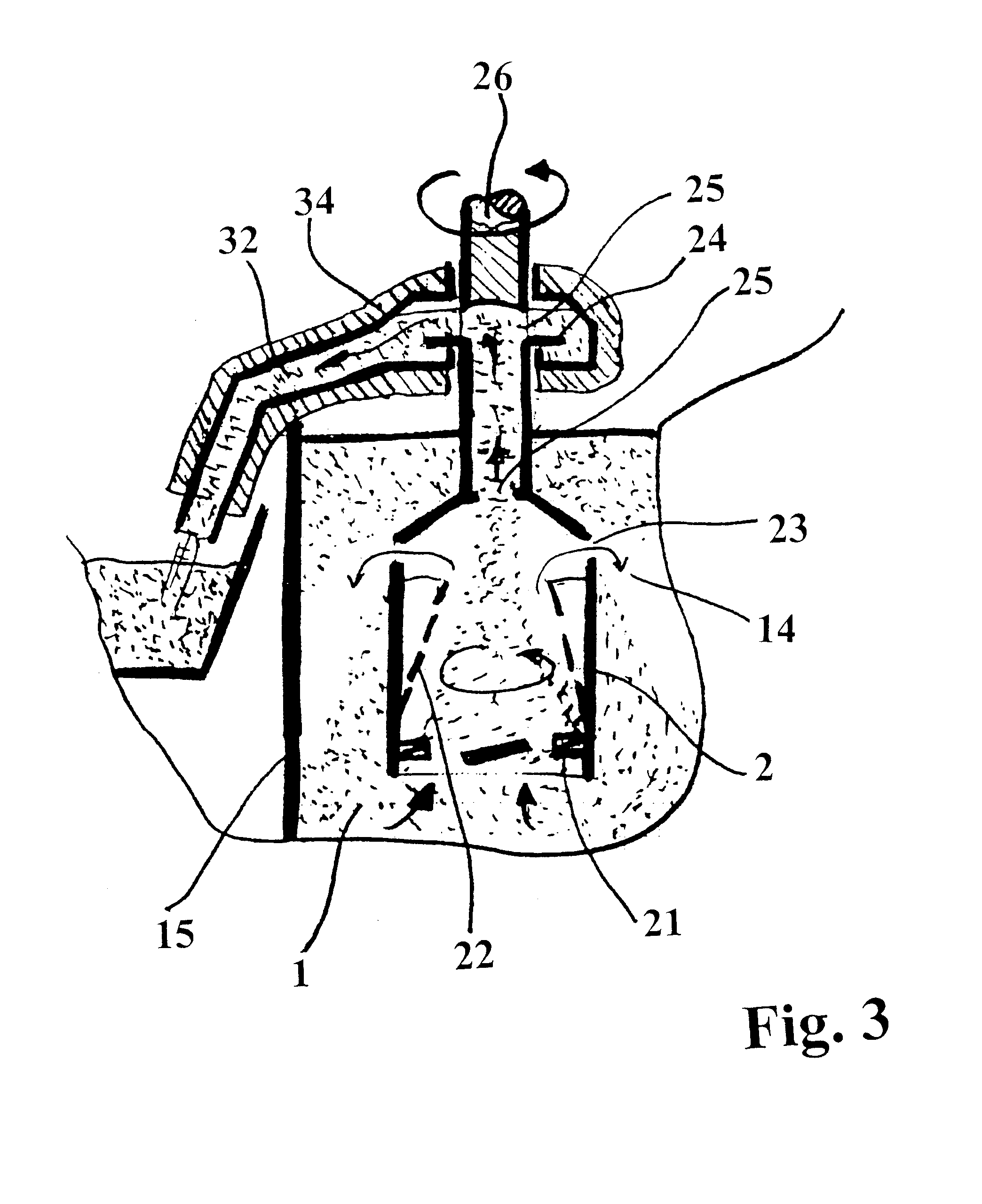

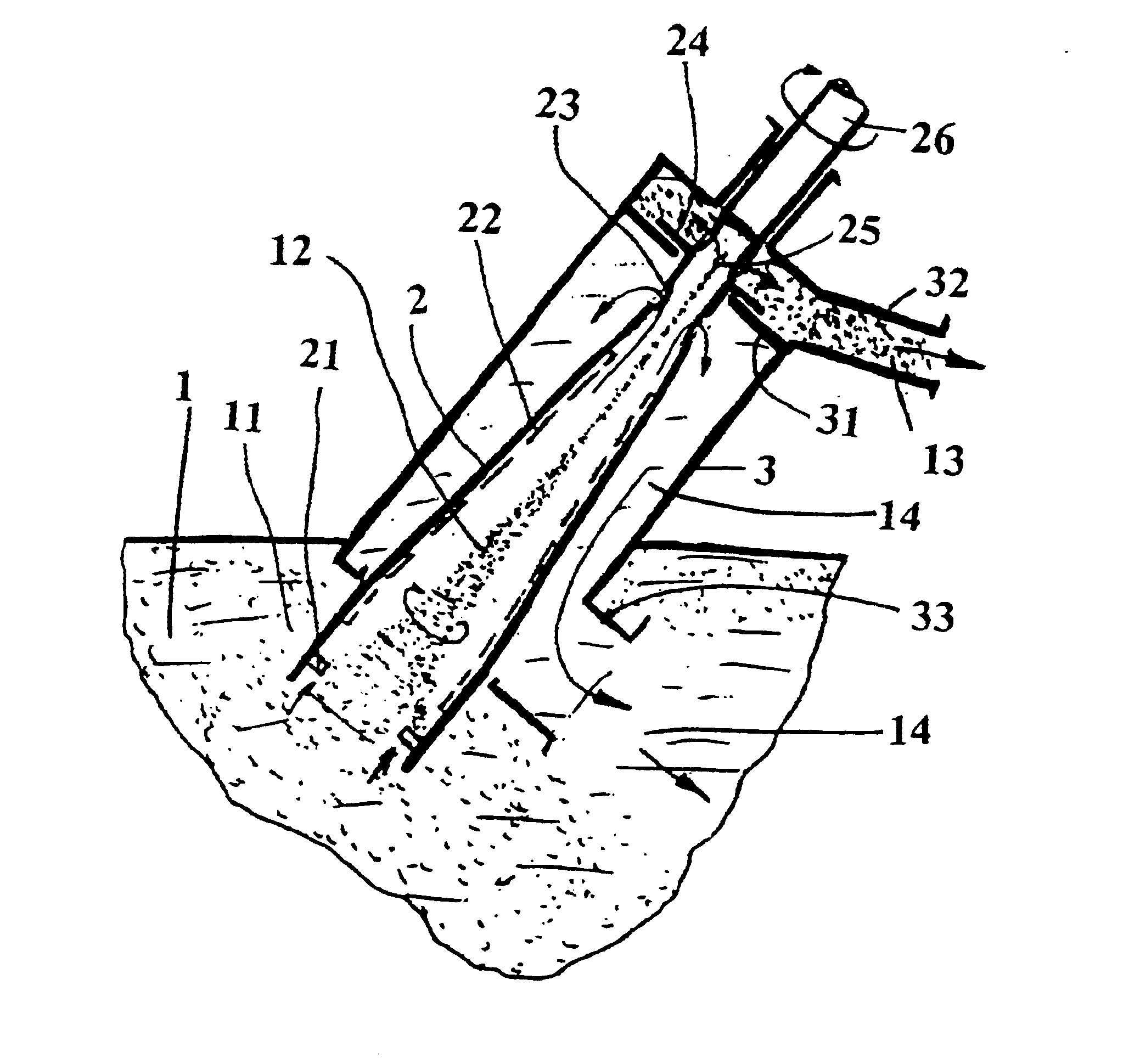

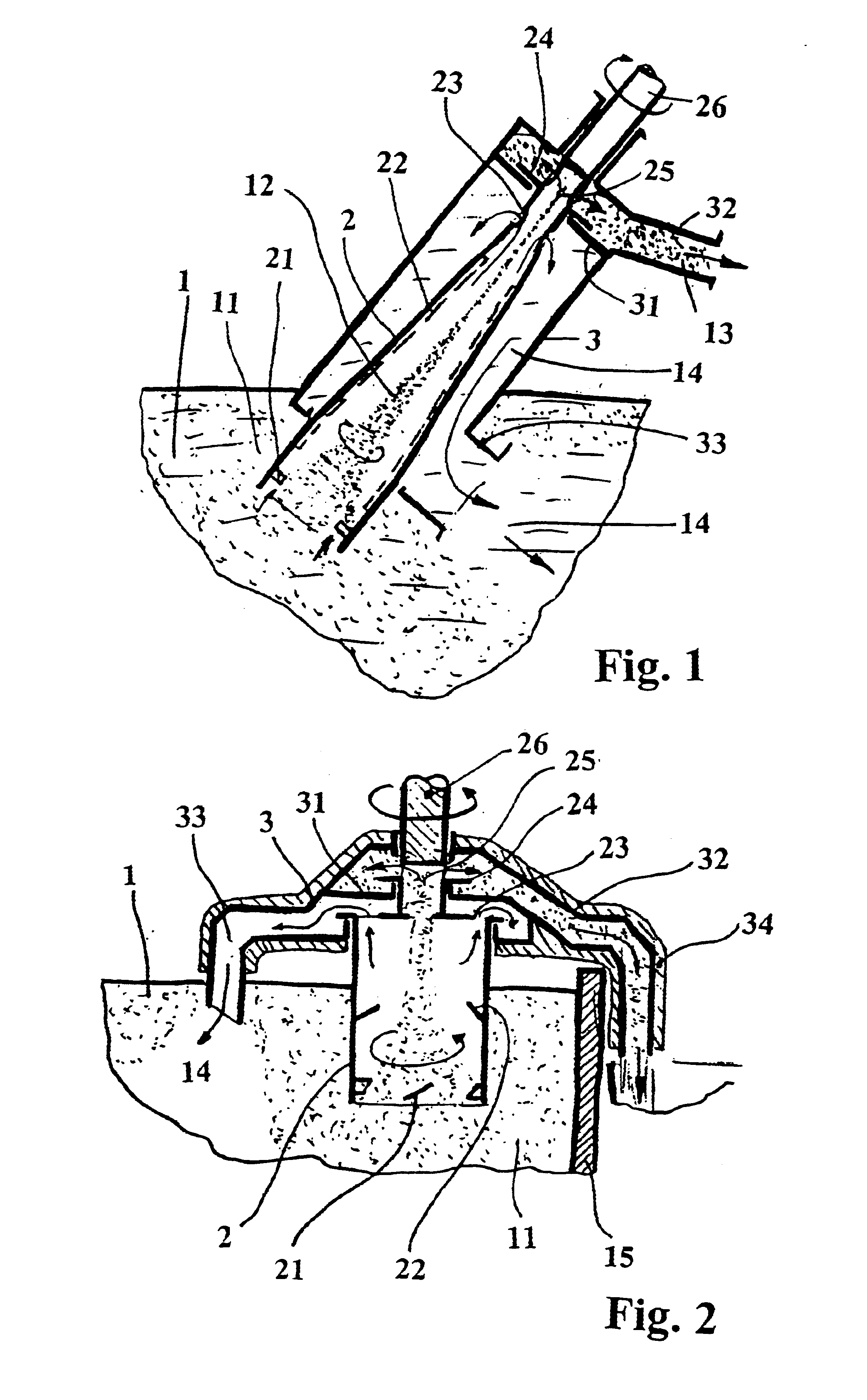

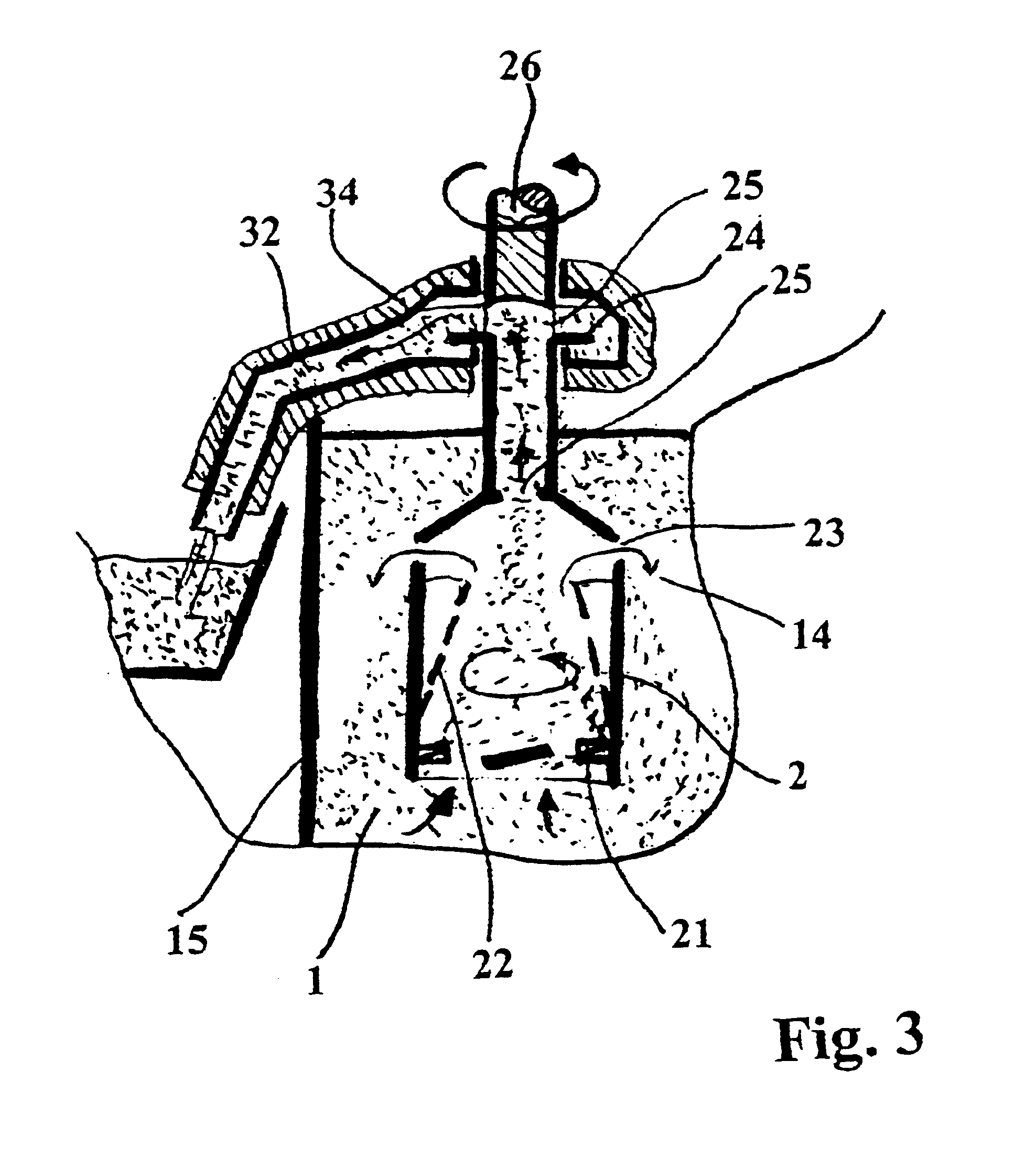

Process for precipitating compounds from zinc metal baths by means of a hollow rotary body that can be driven about an axis and is dipped into the molten zinc

InactiveUS6364930B1High acceleration of the metalRapid and highly effective separationHot-dipping/immersion processesSpecific fluid pumpsZinc metalLiquid metal

A process and device are disclosed for precipitating solid compounds from the liquid zinc or liquid zinc-based alloys of a metal bath. According to the disclosed process, partial amounts of the metal phase containing the compound(s) are exposed to an acceleration higher than the acceleration due to gravity and at least partially dissociated thereby into fractions containing heavier and / or lighter components. The molten mass depleted of solid compounds is returned to the metal bath and the part of the molten mass enriched with the desired compounds is discharged. The disclosed device is substantially characterized in that a hollow rotary body (2) is introduced into the molten mass (1). The hollow rotary body (2) can be driven about an axis and is fitted in the submerged or lower area with conveyor means (21) which project into the cavity. In its discharge or upper area, the hollow rotary body (2) is provided with at least one discharge opening (23) for the depleted molten mass (14) eccentrically arranged in its wall and with at least one further discharge opening (25) for the liquid metal enriched with the desired compounds centrally arranged and / or eccentrically arranged on the discharge side. At least one of the upper molten mass discharge openings (23, 24) in the rotary body (2) opens into a discharge area of a housing (3) which at least partially surrounds the rotary body (2).

Owner:ANDRITZ PATENTVERW GES

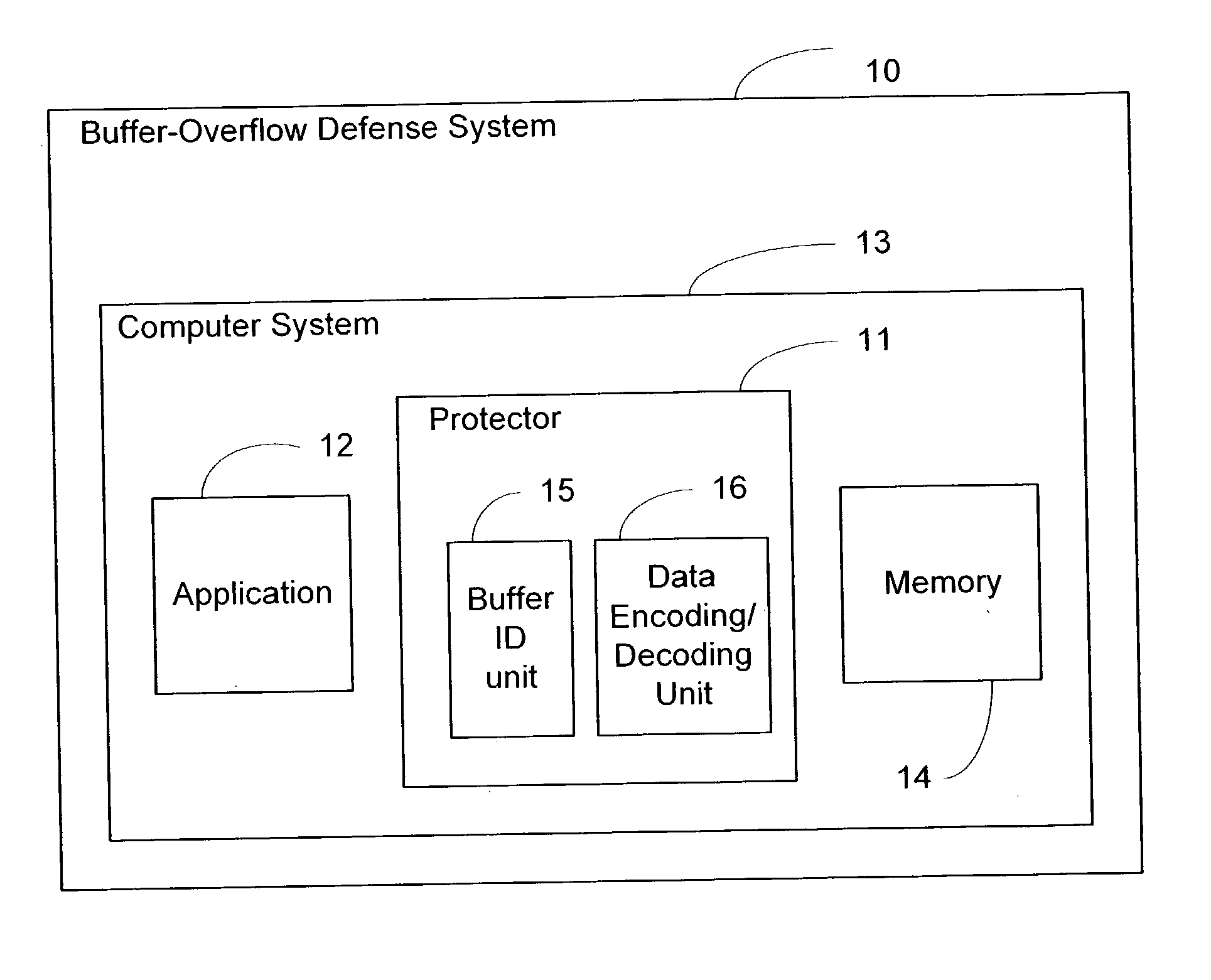

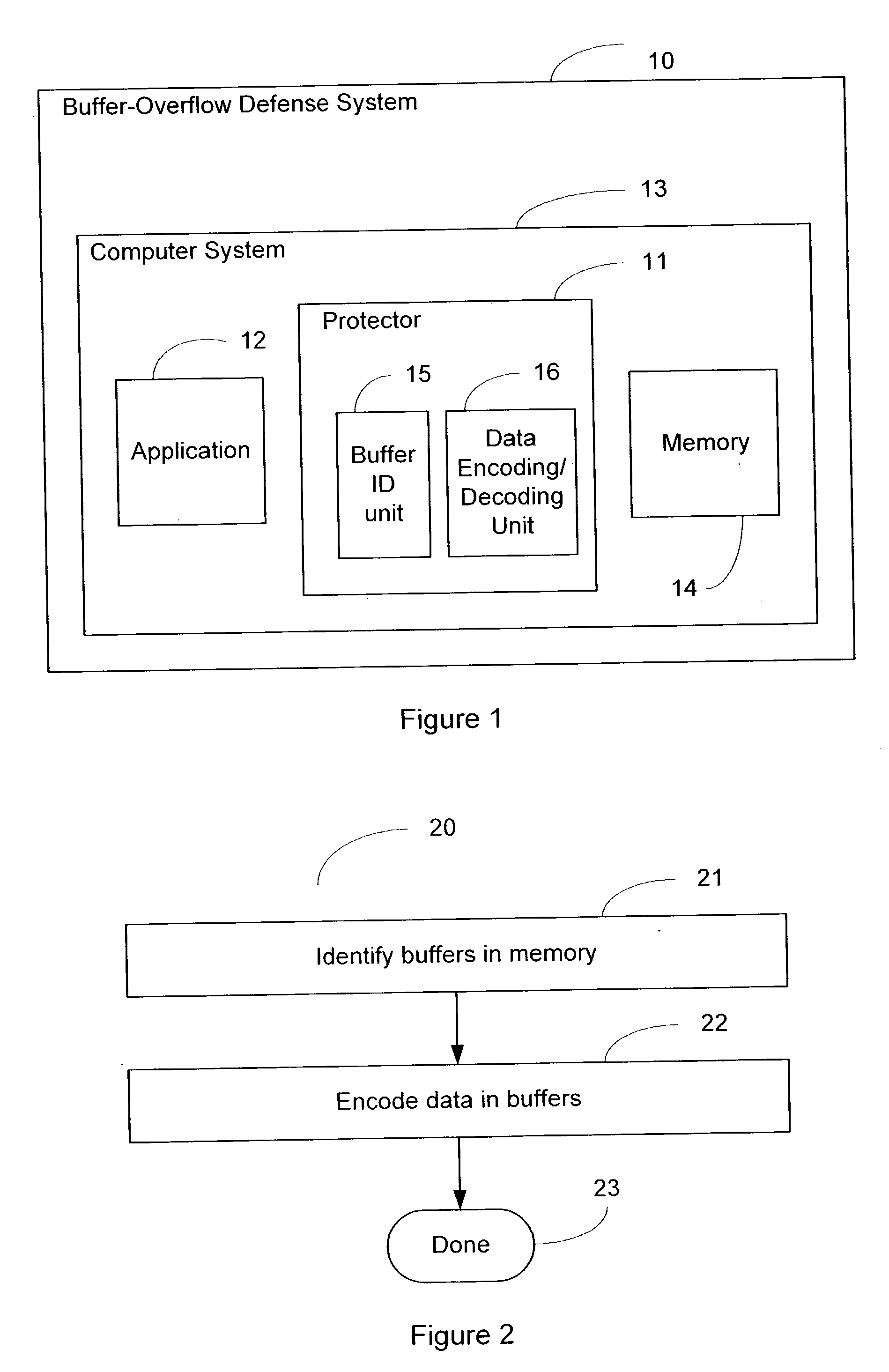

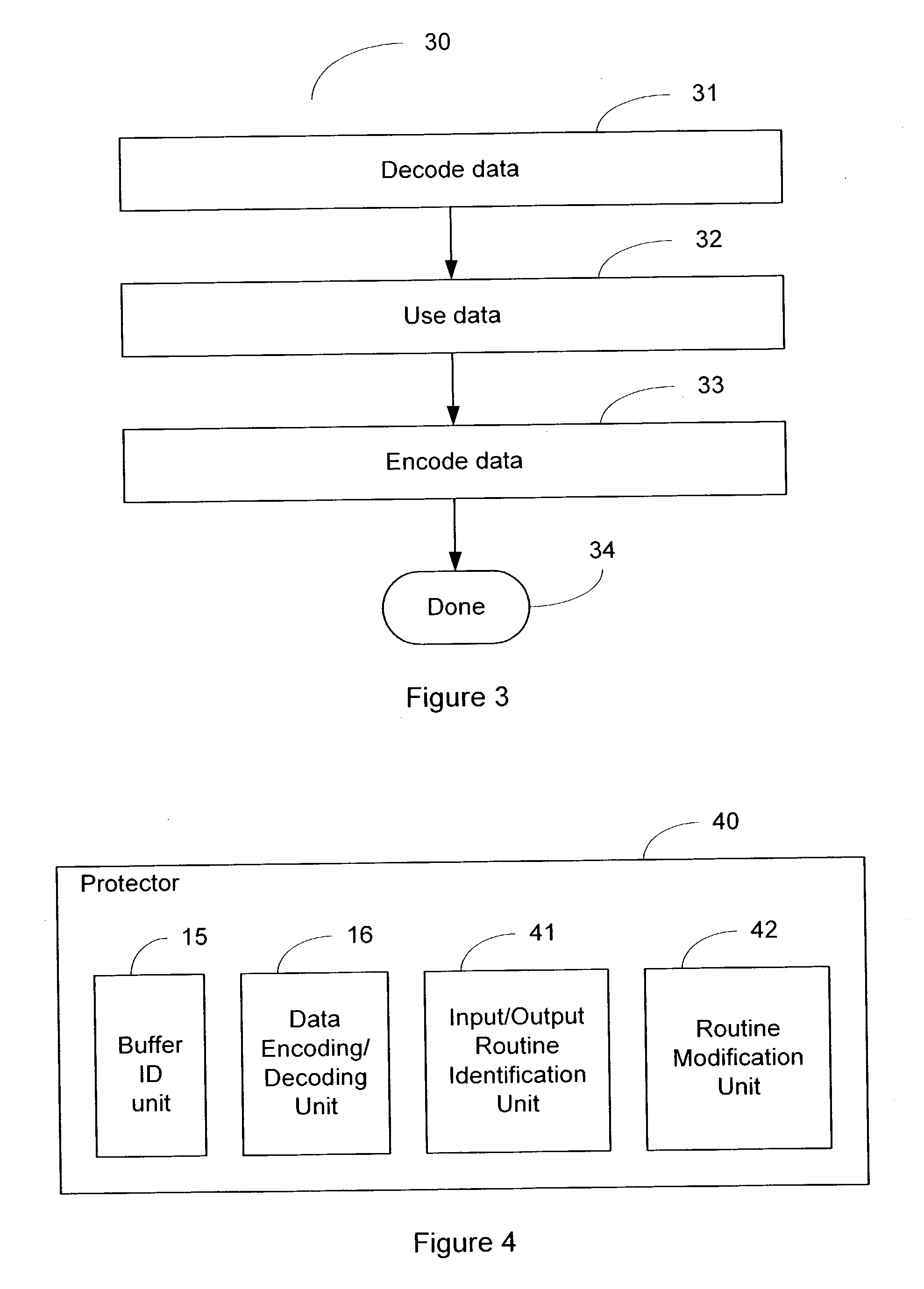

System and method of foiling buffer-overflow and alien-code attacks

InactiveUS20030172293A1Protected growthShuts down buffer overflow attacksMemory loss protectionUnauthorized memory use protectionBuffer overflowApplication software

The present invention relates generally to computer software, and more specifically, to a system and method of foiling buffer-overflow and alien-code attacks. The invention protects computers from such attacks by encoding data placed in storage, and varying the encodings used in different storage areas. When the data is needed by a software application, the data is simply decoded in a complementary manner. This prevents storage areas written according to one usage from being used effectively for some other purpose. The method of the invention can be done in a number of ways. For example, a "protector" engine can be placed between a software application and memory, or the function calls in the software application itself, could be amended to include encoding and decoding. Other embodiments and alternatives are also described.

Owner:IRDETO CANADA CORP

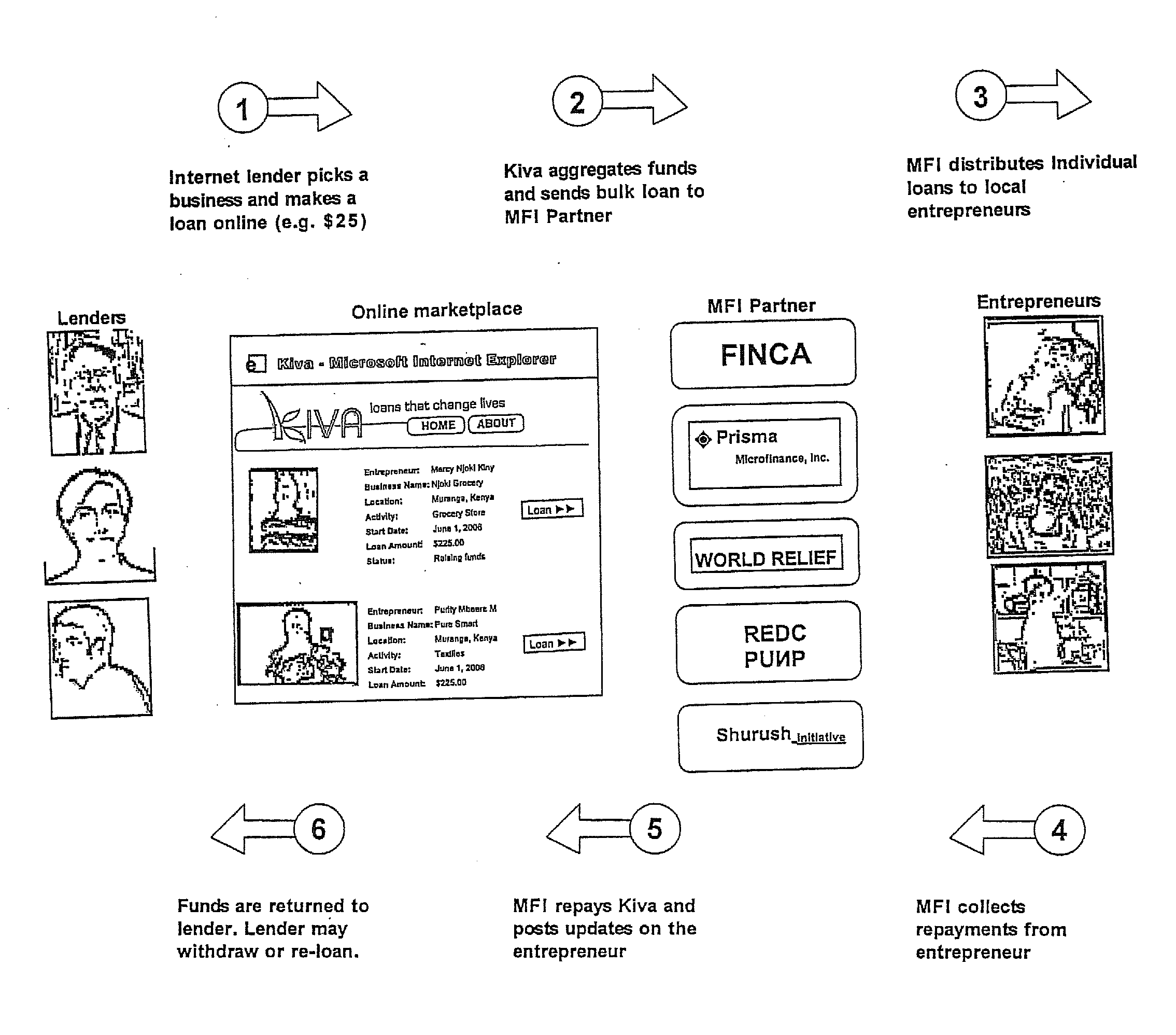

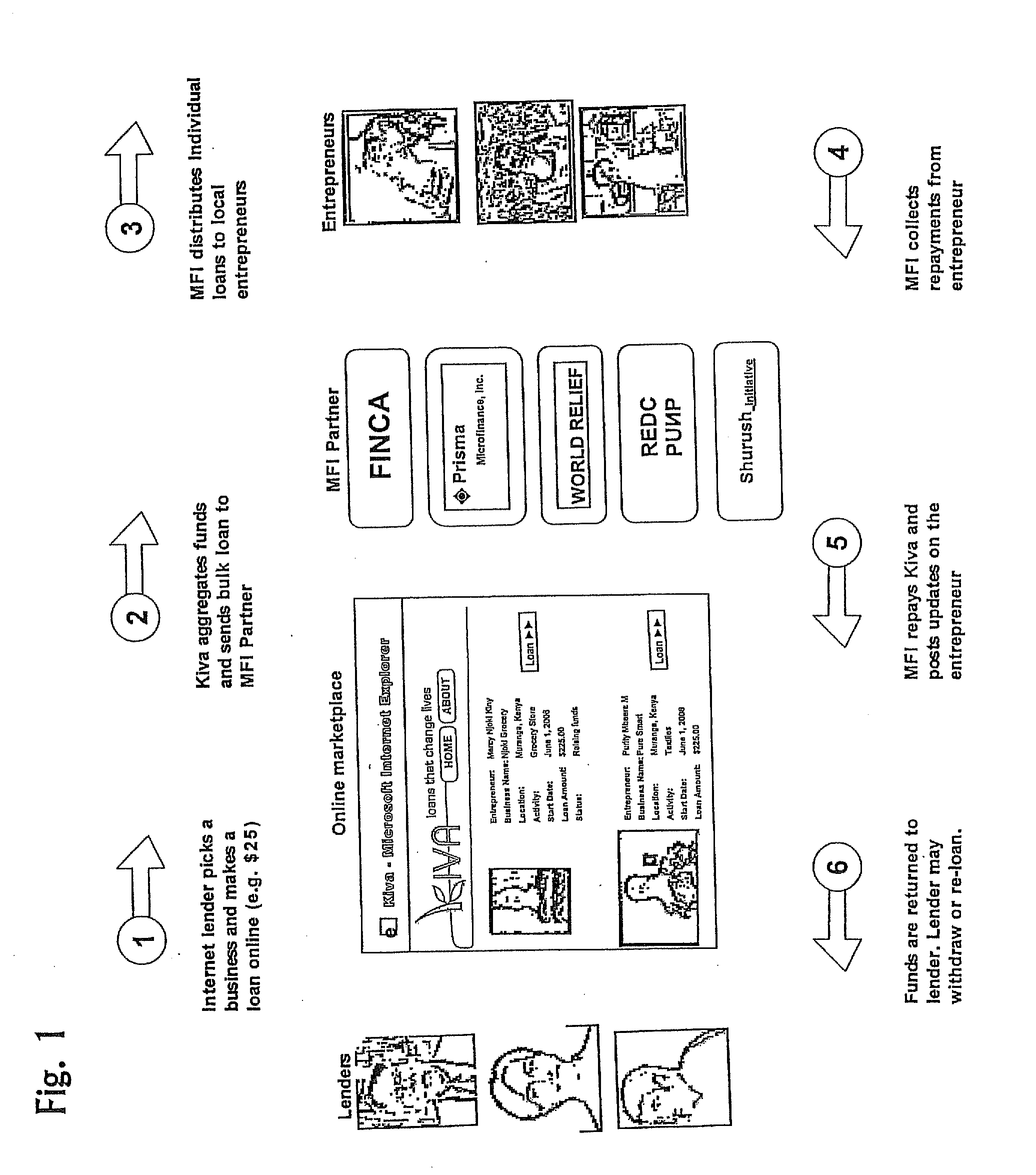

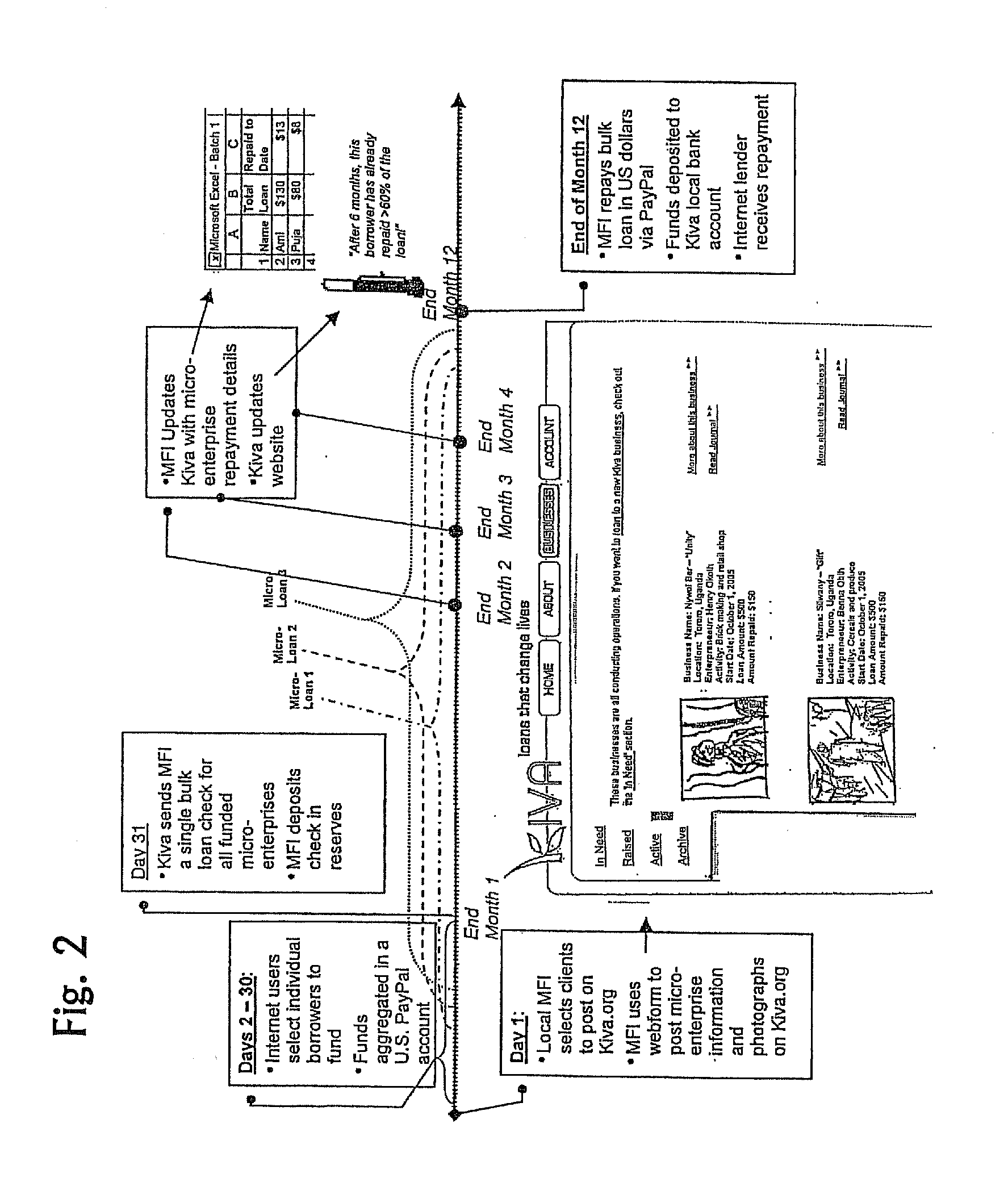

System and method for peer-to-peer financing

A system and method for an online, peer-to-peer lending platform for microfinance is disclosed. Through the system and method of the present invention, individual and personal lenders across the world can uniquely loan to specific micro-enterprises in many countries and geographic areas in a highly personal and effective manner. This system and method functions as a unique bridge between individual lender and borrower by providing elements and steps for facilitating and processing microfinance institution (MFI) transactions.

Owner:FLANNERY MATTHEW

Process and device for precipitating compounds from zinc metal baths by means of a hollow rotary body that can be driven about an axis and is dipped into the molten zinc

InactiveUS6656415B2High acceleration of the metalRapid and highly effective separationHot-dipping/immersion processesSpecific fluid pumpsLiquid stateZinc metal

Process and device for precipitating solid compounds from zinc metal baths. Partial amounts of the metal phase containing these compounds are exposed to an acceleration higher than gravity and dissociated into fractions containing heavier or lighter components. The molten mass depleted of solid compounds is returned to the metal bath. The device has a hollow rotary body for introduction into the molten mass and provided with a discharge opening for the depleted molten mass and a discharge opening for the liquid metal enriched with the solid compounds.

Owner:ANDRITZ PATENTVERW GES

Automatic toilet flushing system

An automatic toilet flushing system for use with toilets in either commercial or private dwellings and which comprises a replaceable water tank top or tank lid carrying the major components of the automatic toilet flushing system. In this case, the toilet flushing system is an adaptive system, since it converts a conventional toilet into an automatic flushing toilet. The adaptive system also comprises a pair of infrared light sources and sensors located on forwardly protruding portions of the tank lid. The sensors are located forwardly of the water tank or water chest of the toilet and the timing is adjusted so that raising and lowering of the lid of the toilet seat will not interfere with operation of the sensors. A control circuit is also provided and mounted on the underside of the replaceable water tank cover plate. The circuit is connected to the sensors and operated by batteries so that when a light beam is interrupted for at least a predetermined time period, the control circuit will automatically initiate a flushing operation. The circuit initiates a flushing signal to a solenoid which shifts a connecting rod and which, in turn, is connected to a flapper valve at the lower end of the water chest. Thus, when the light beam is interrupted for the predetermined time period, the control circuit causes the solenoid to operate the rod which opens the flapper valve and thereby causes a flushing operation of the toilet.

Owner:GUROWITZ JOHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com