Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

517 results about "Flapper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flappers were a generation of young Western women in the 1920s who wore skirts, bobbed their hair, listened to jazz, and flaunted their disdain for what was then considered acceptable behavior. Flappers were seen as brash for wearing excessive makeup, drinking, smoking cigarettes, driving automobiles, treating sex in a casual manner, and otherwise flouting social and sexual norms. Flappers are icons of the Roaring Twenties, the social, political turbulence and increased transatlantic cultural exchange that followed the end of World War I, as well as the export of American jazz culture to Europe.

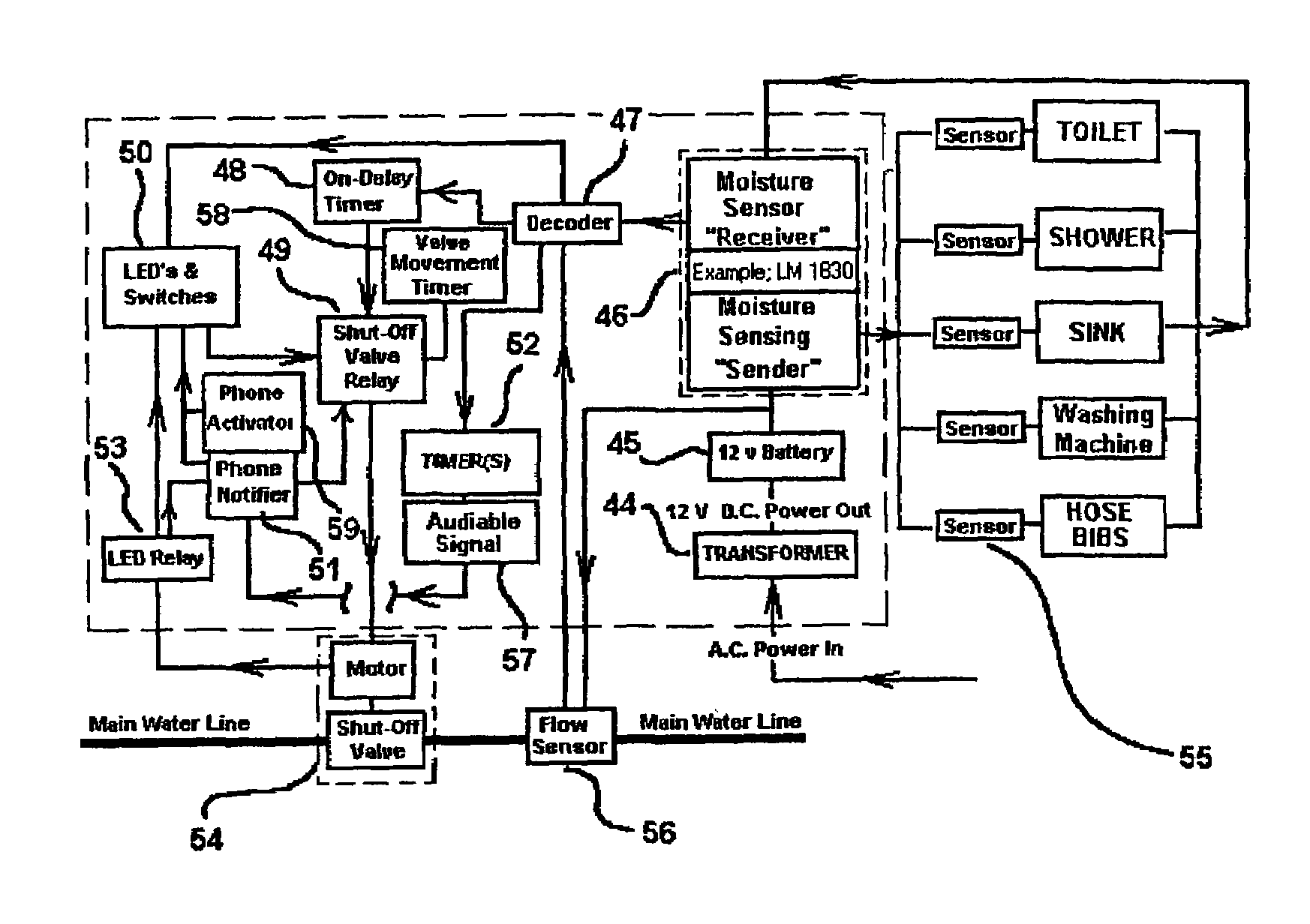

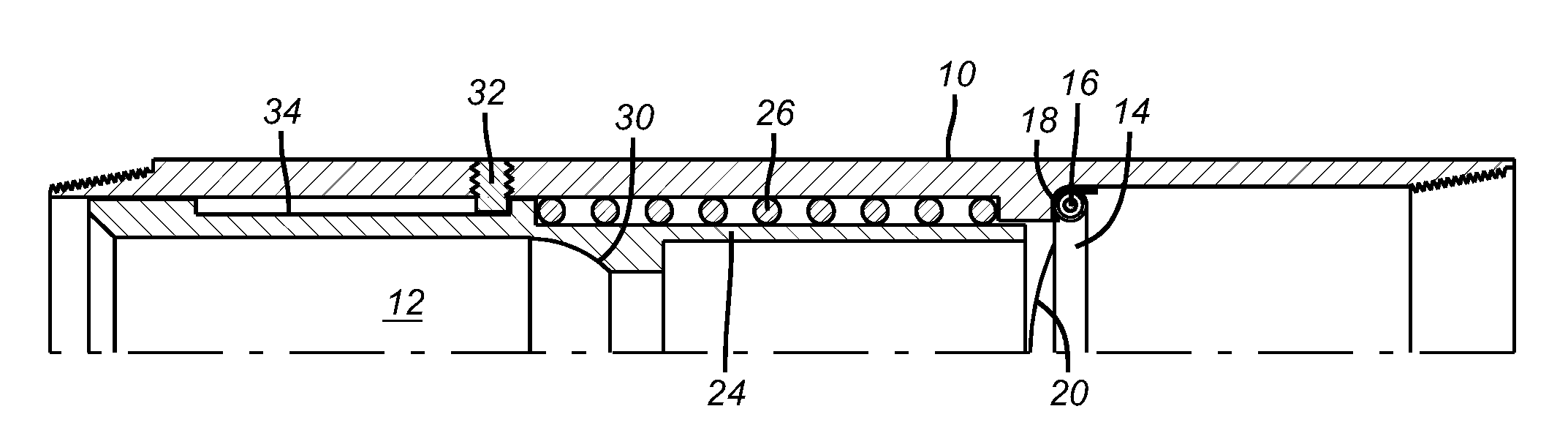

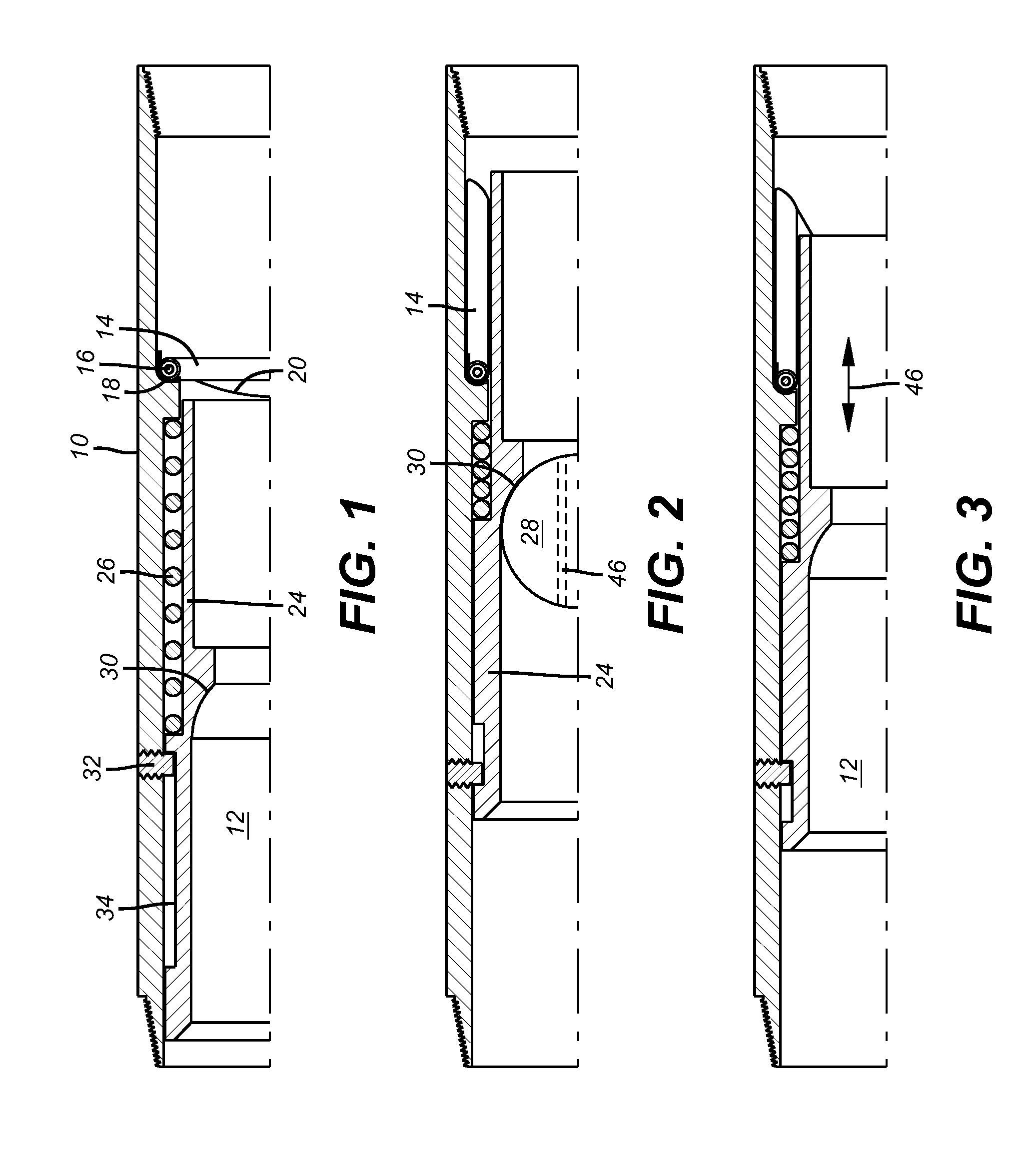

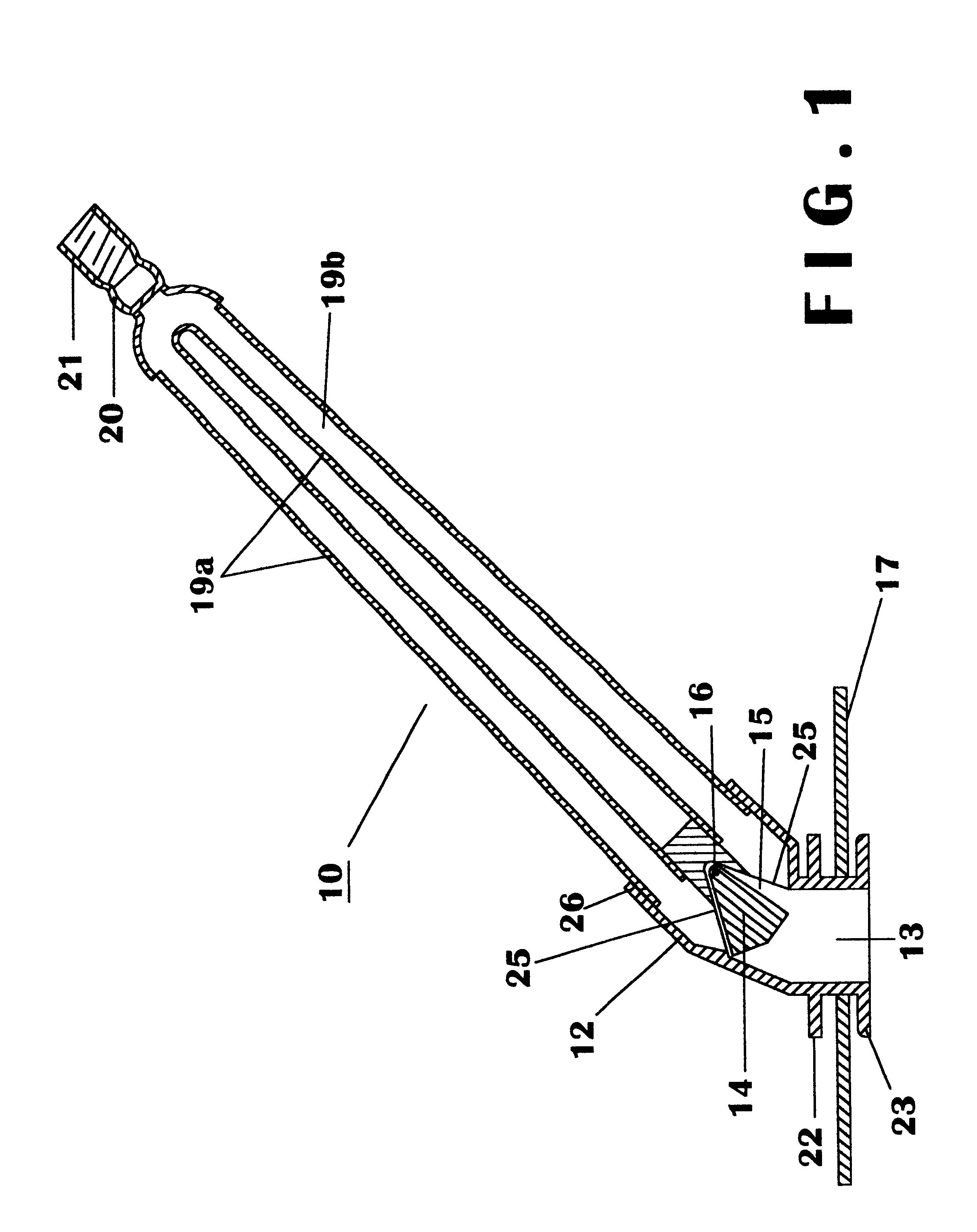

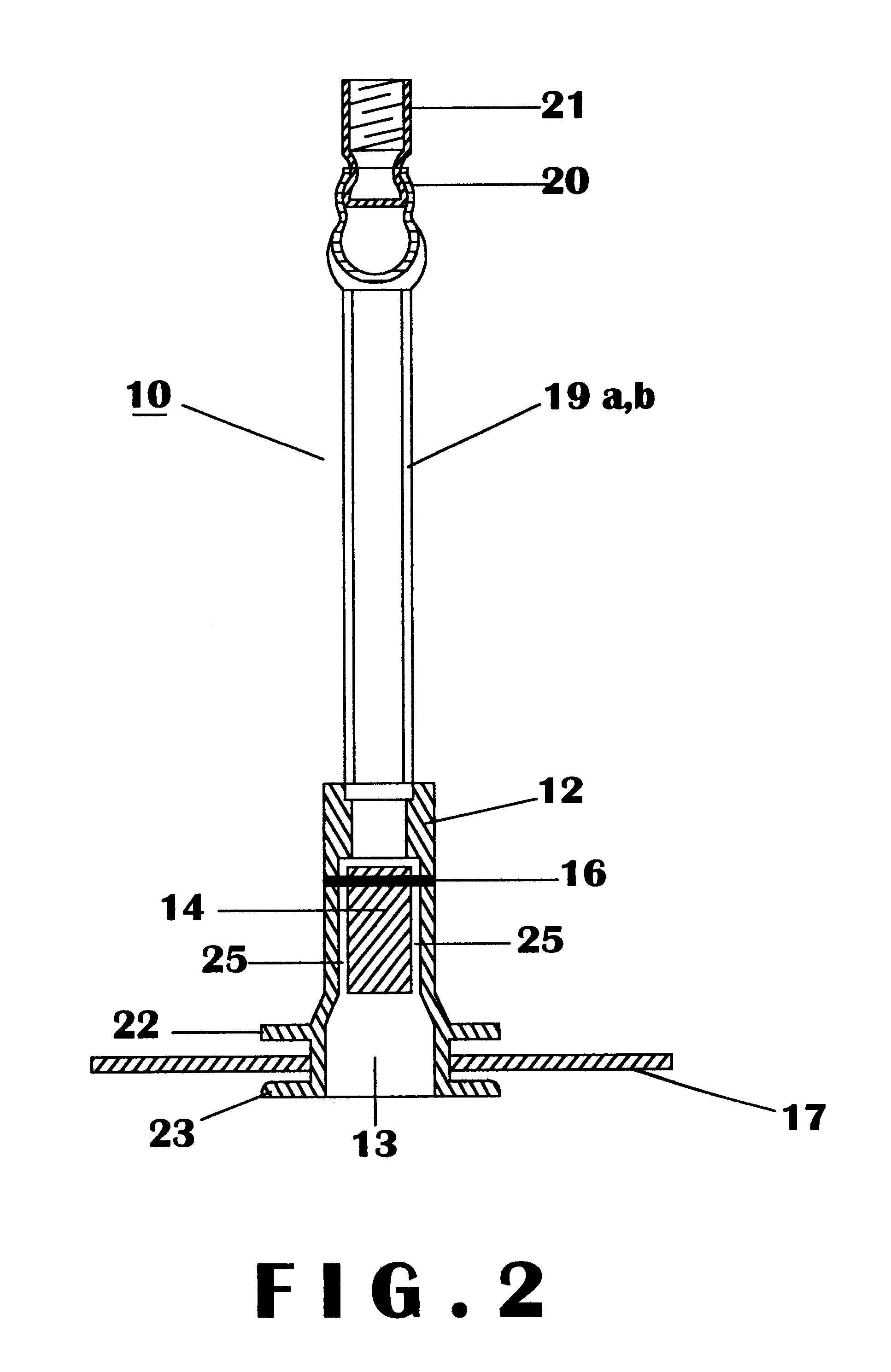

Liquid leak detector and automatic shutoff system

InactiveUS7032435B2Reduce leakageDetection of fluid at leakage pointMeasurement of fluid loss/gain rateCatheterGuide tube

Owner:HASSENFLUG BRIAN EDWARD

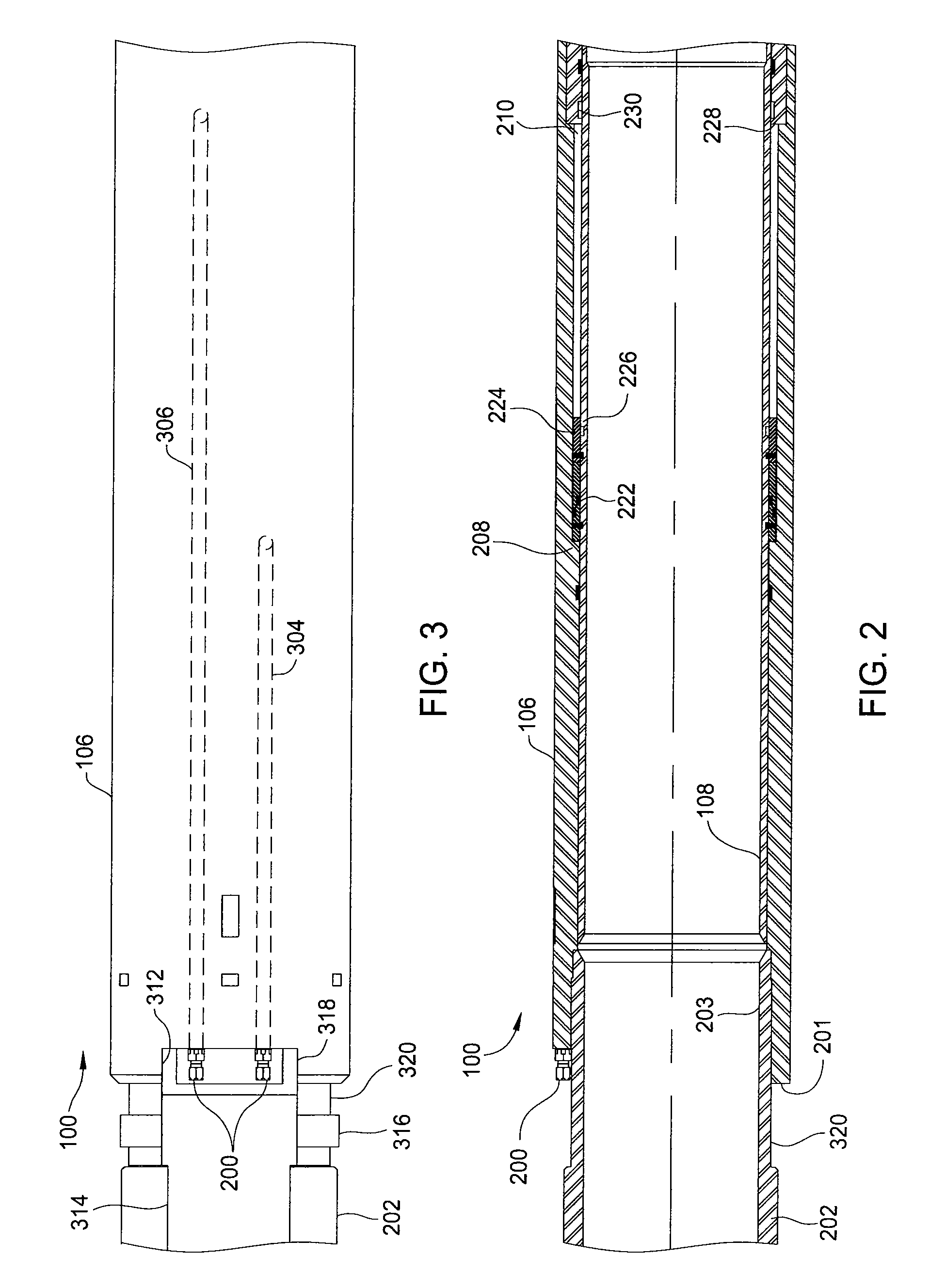

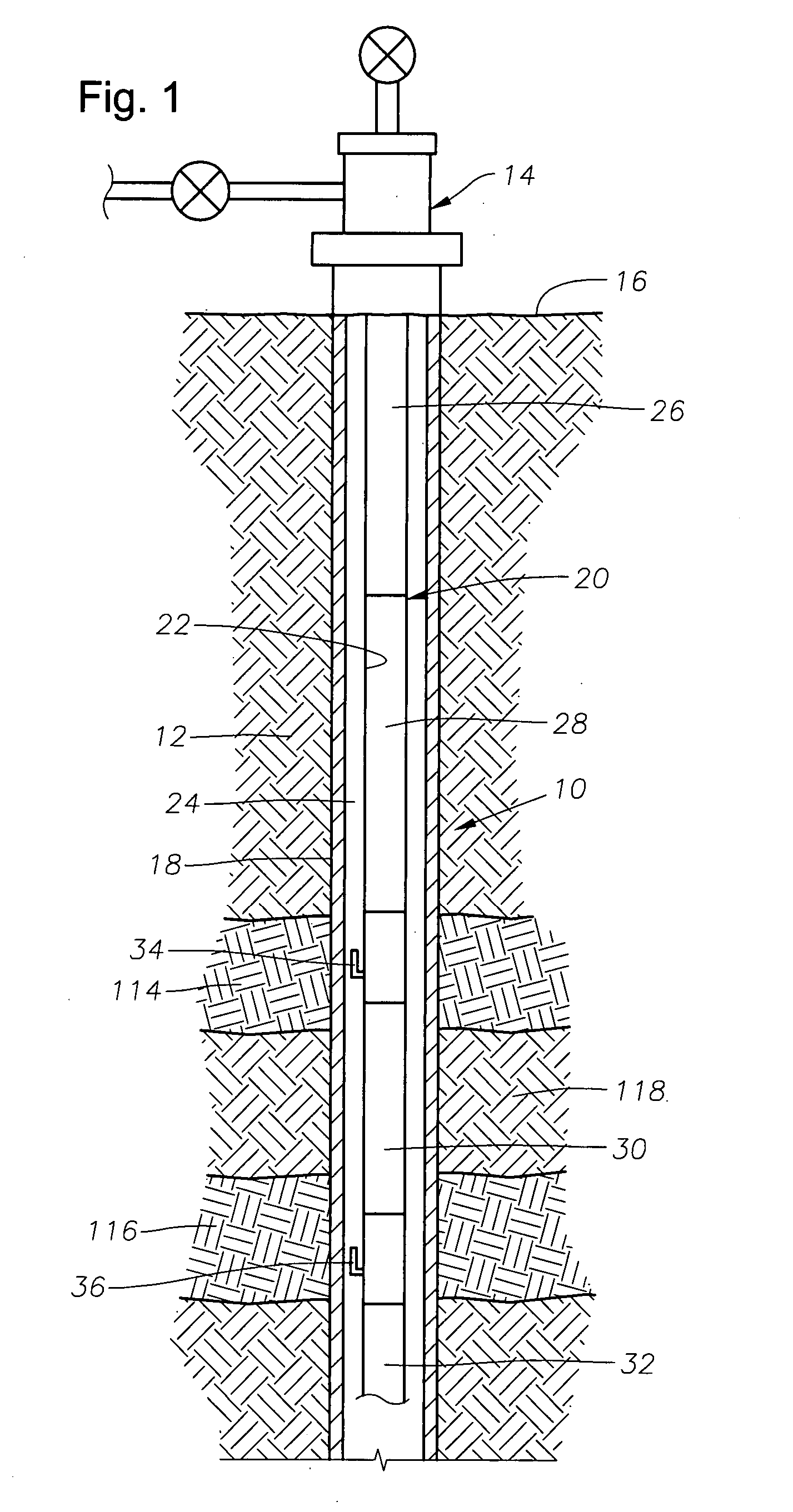

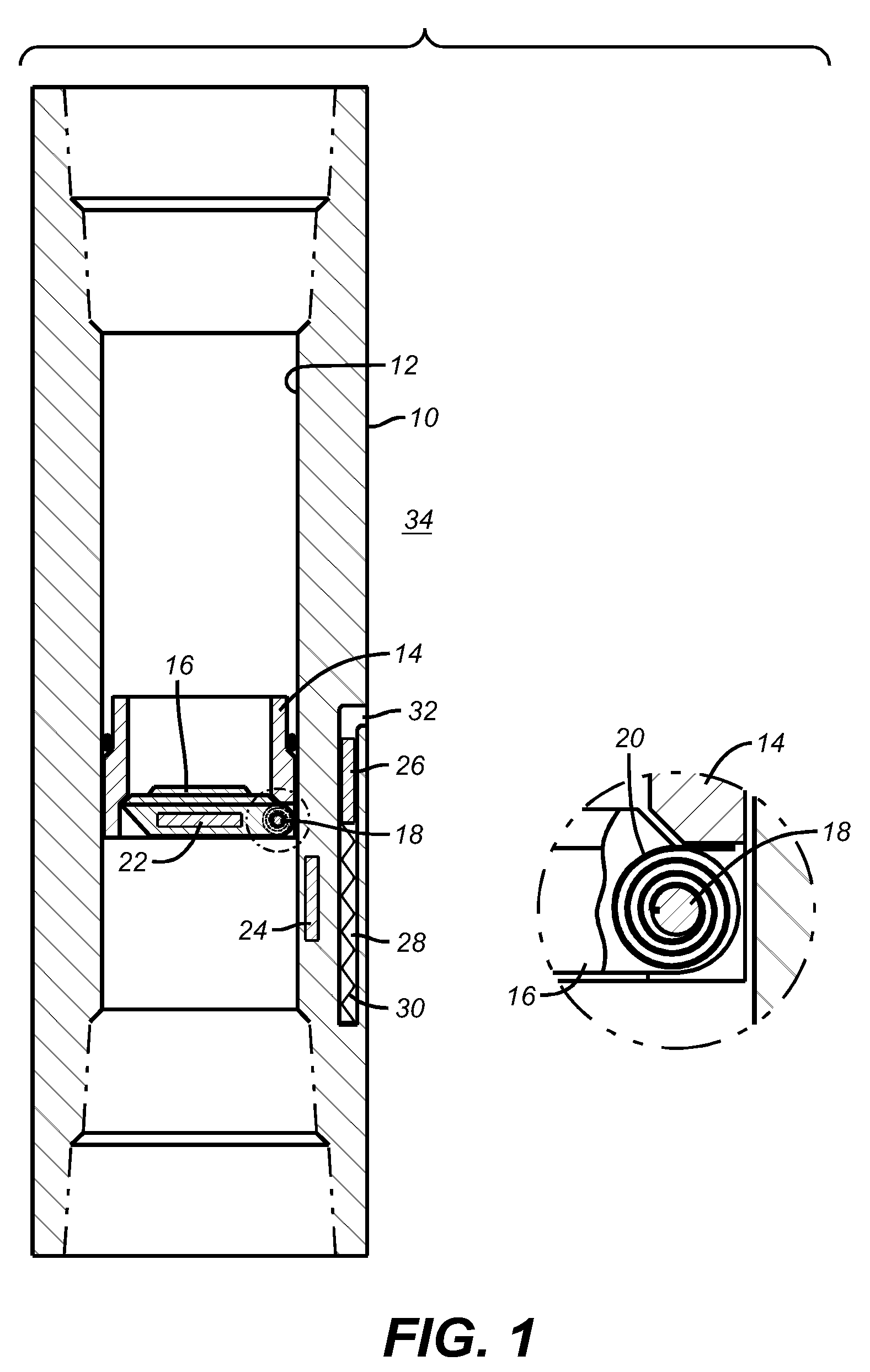

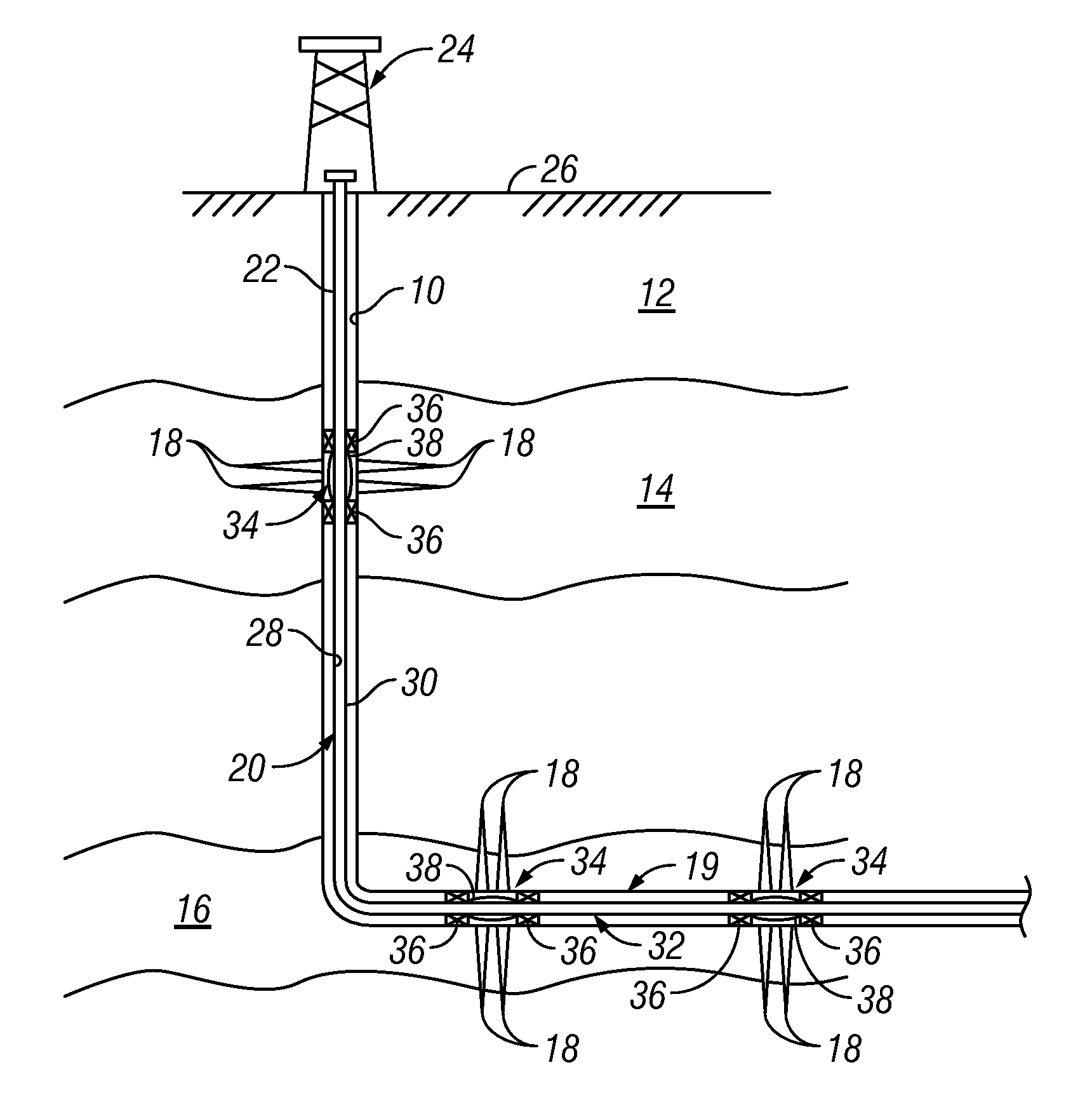

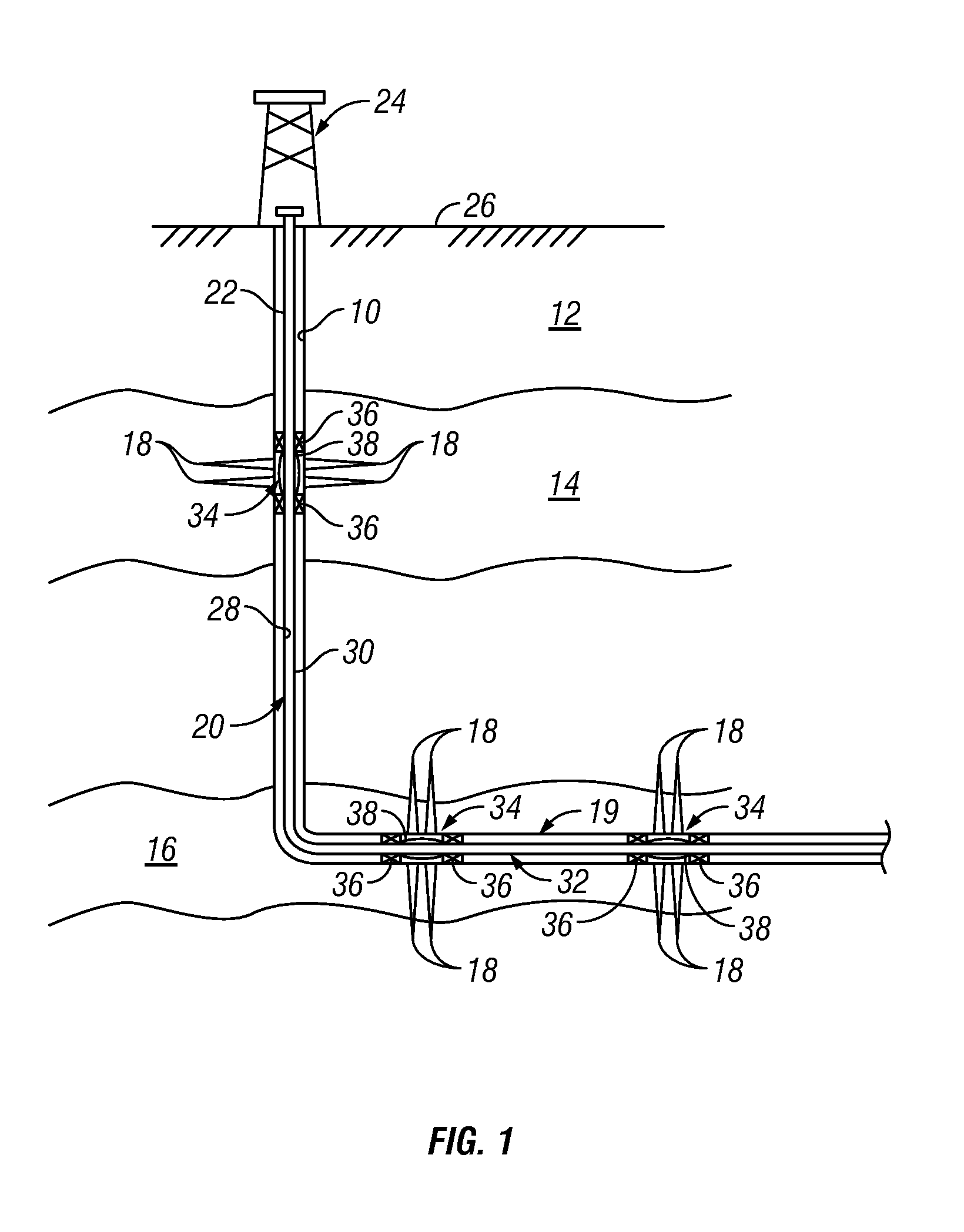

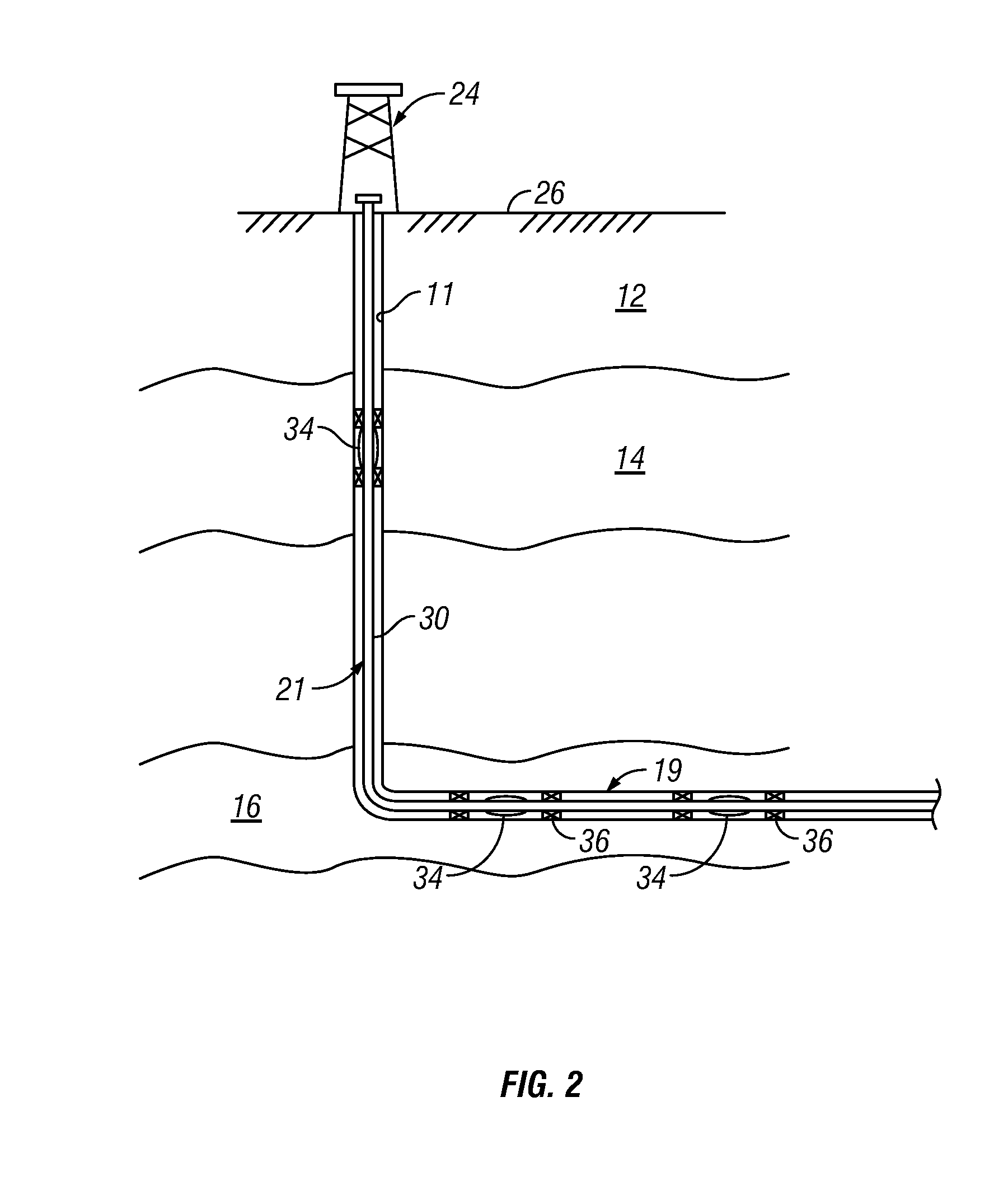

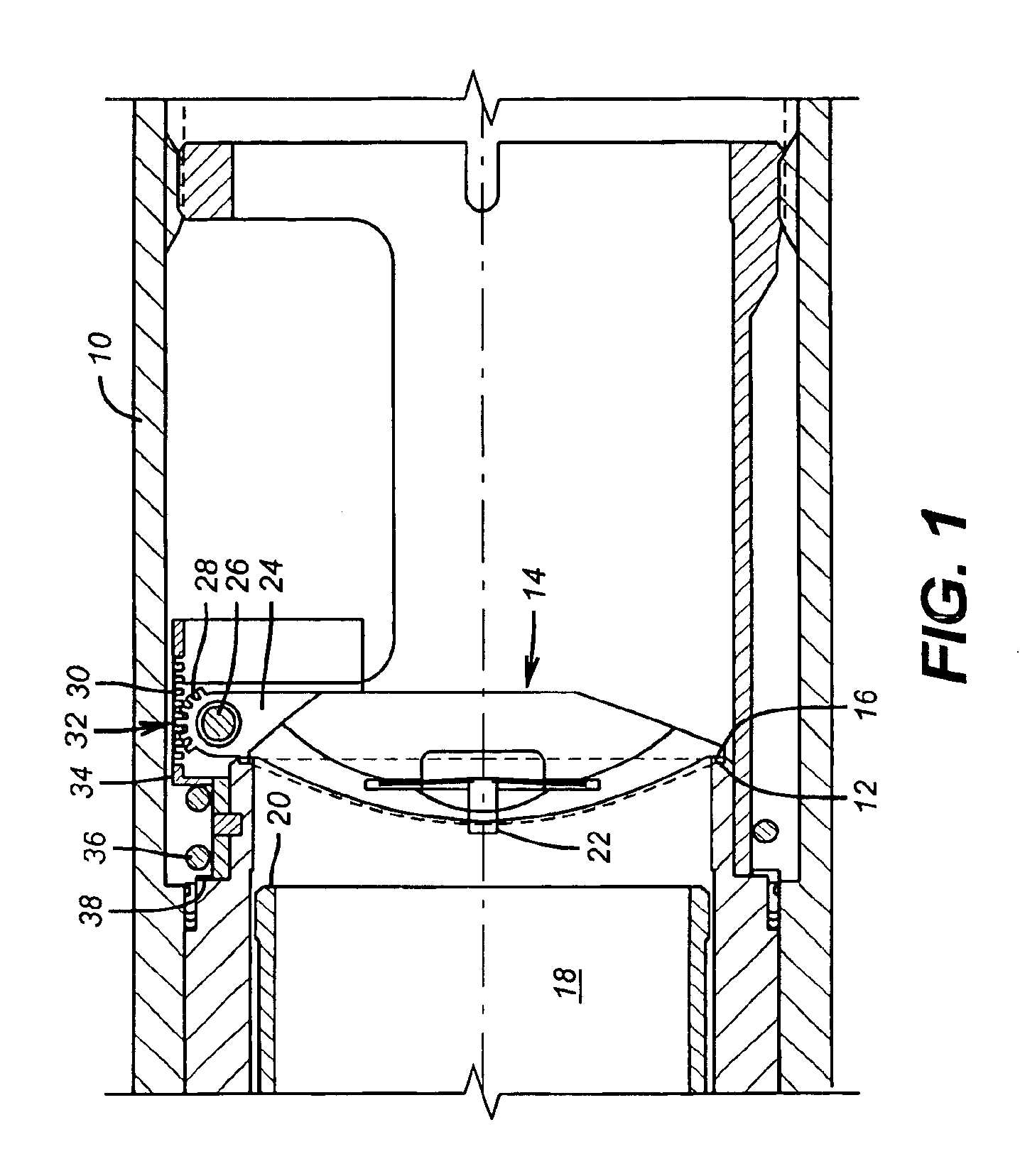

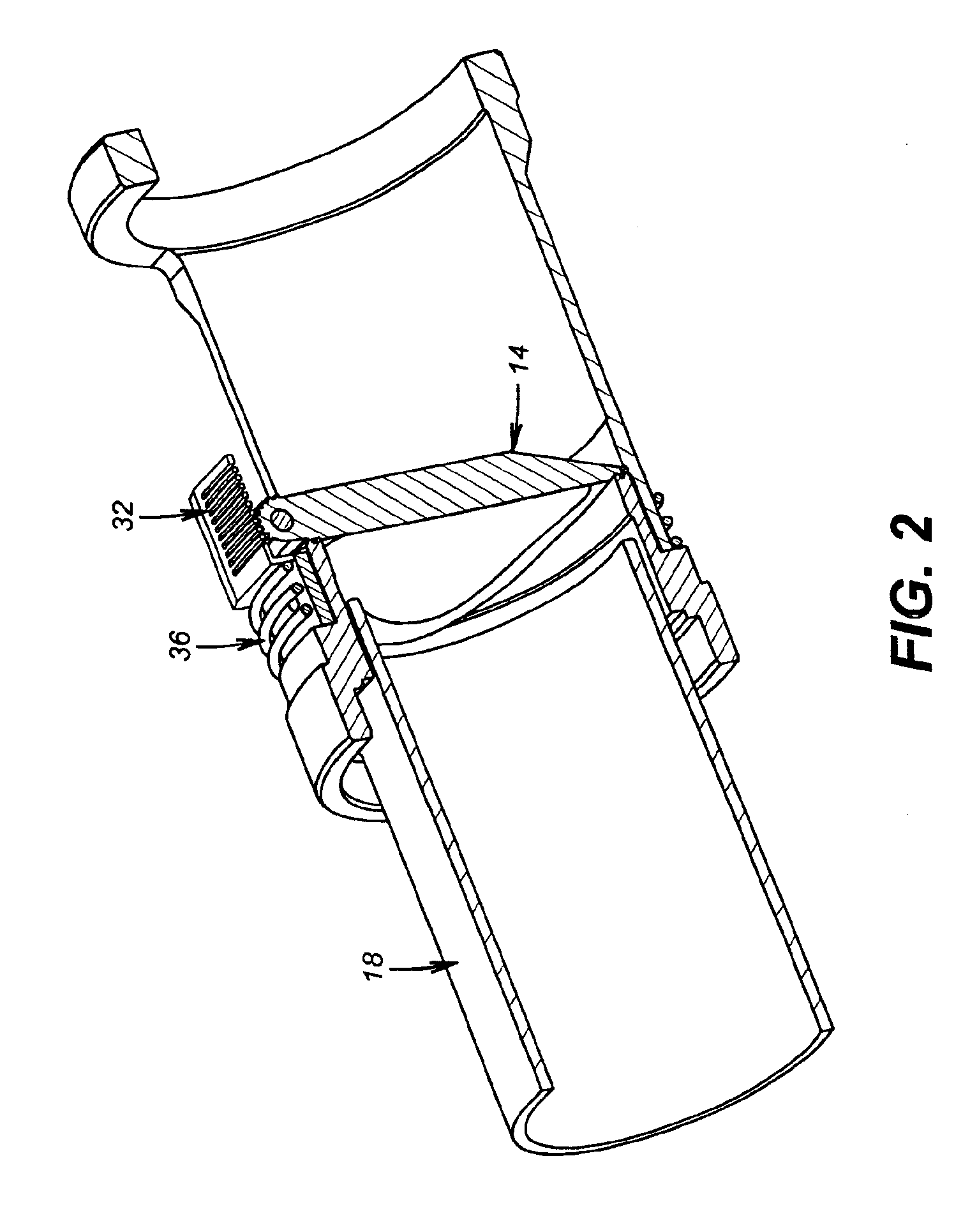

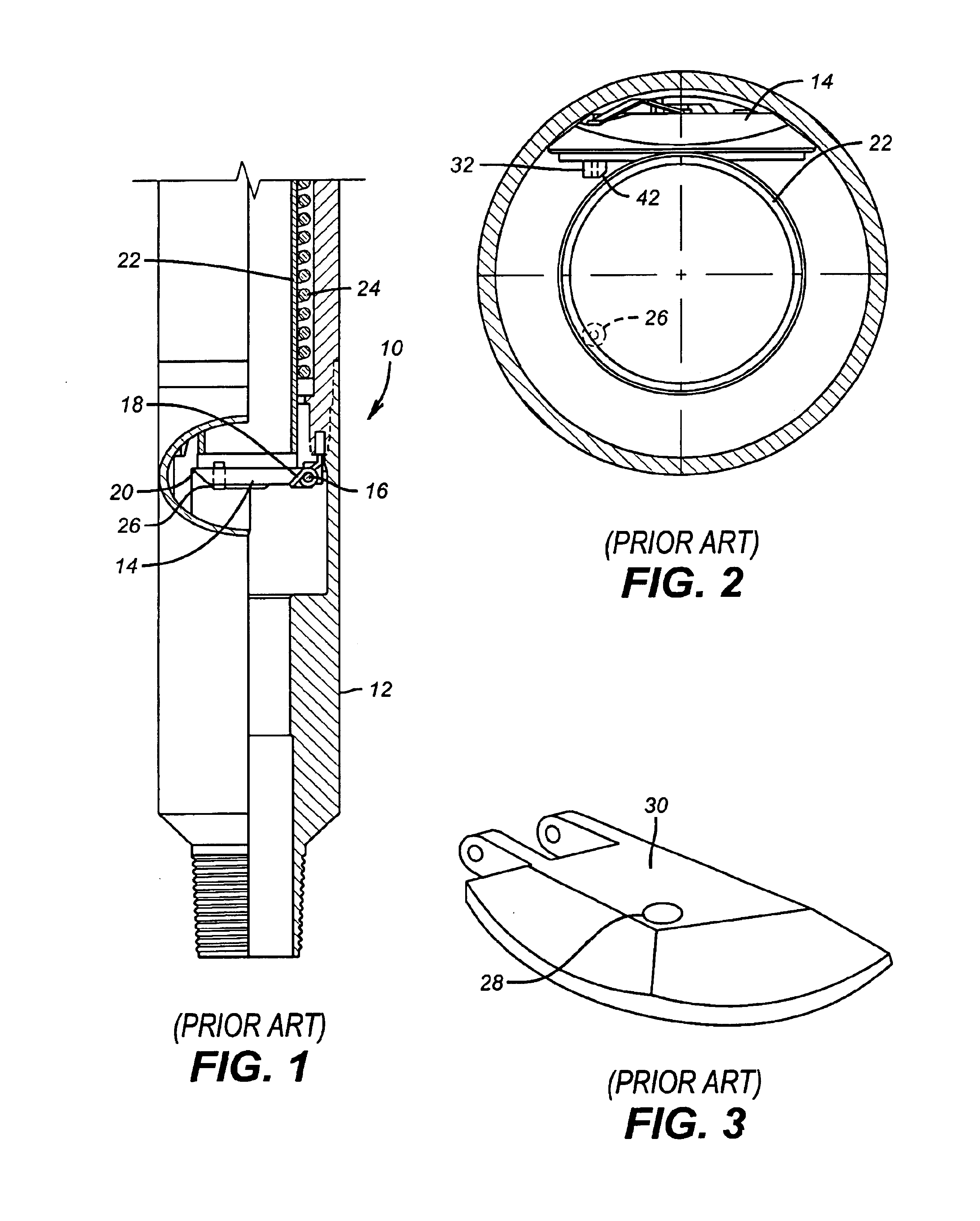

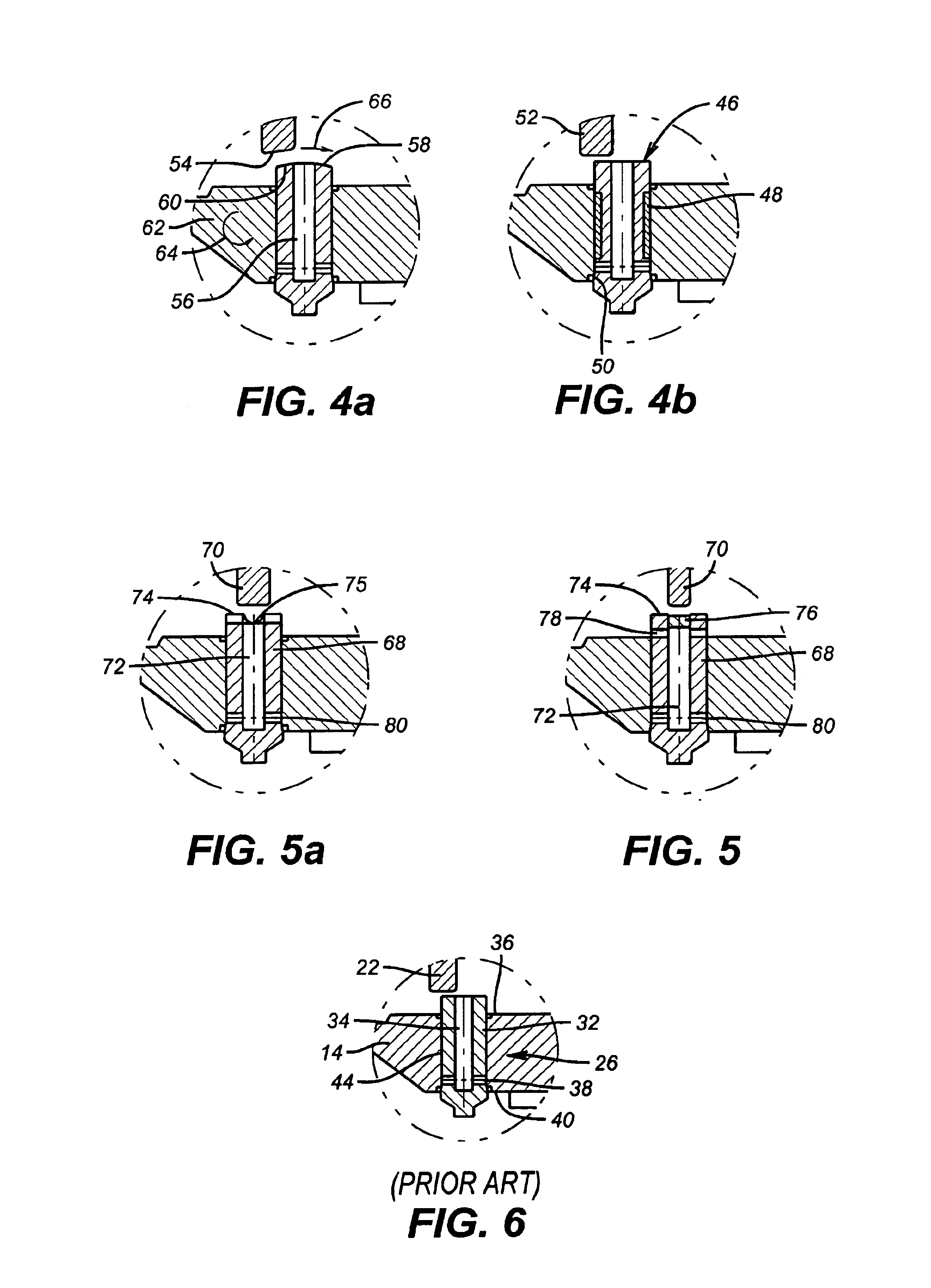

Downhole deployment valves

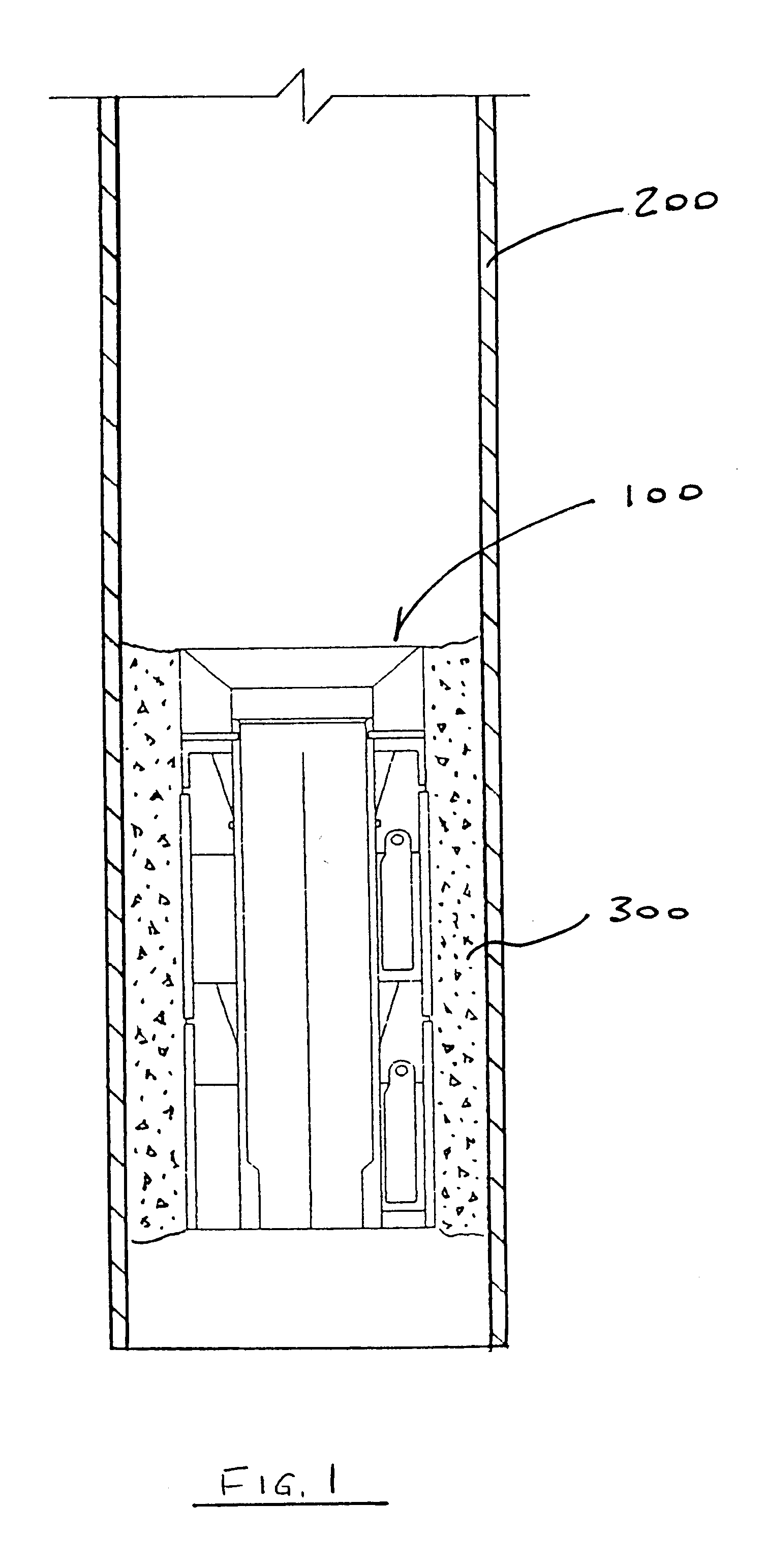

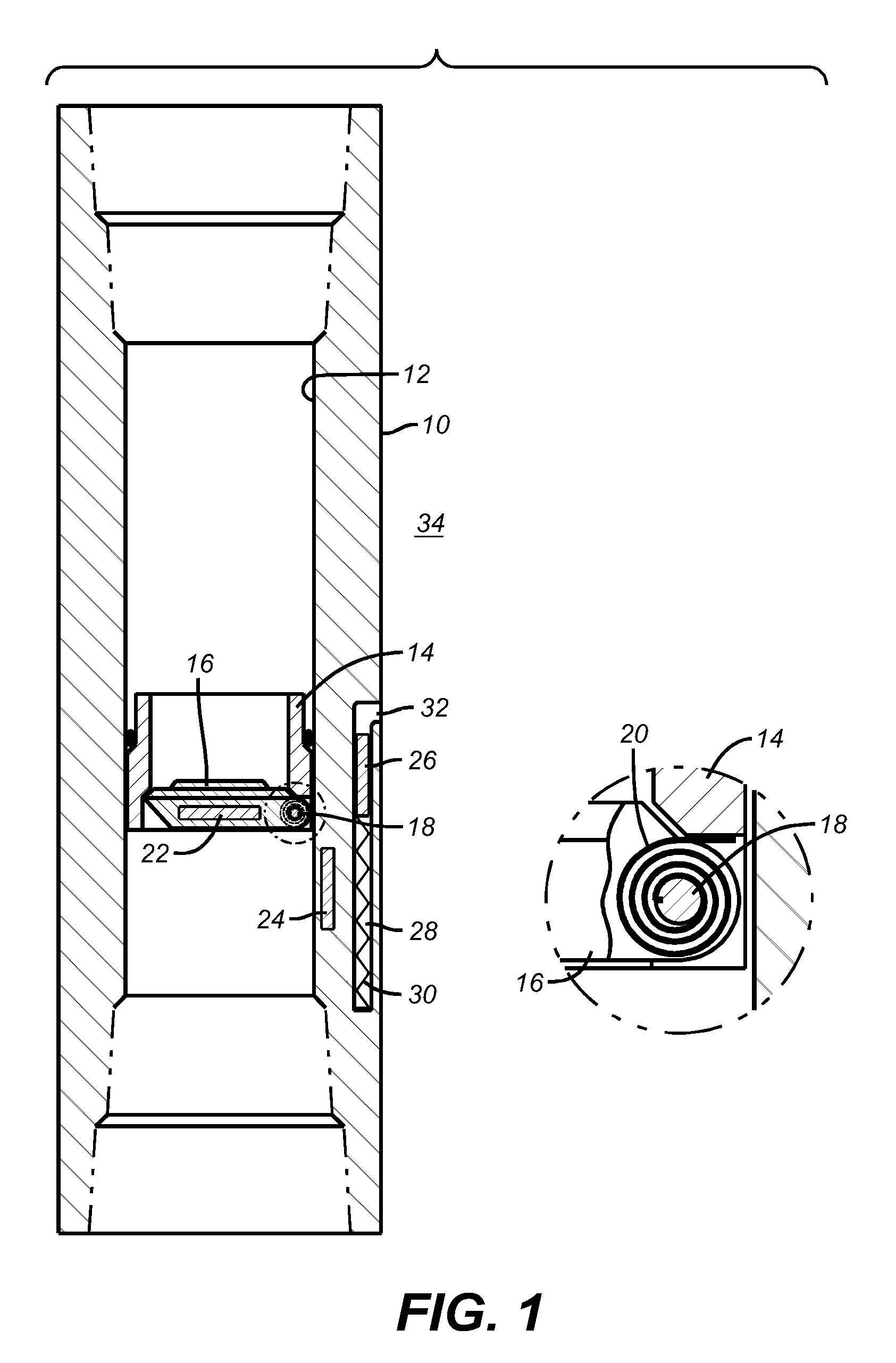

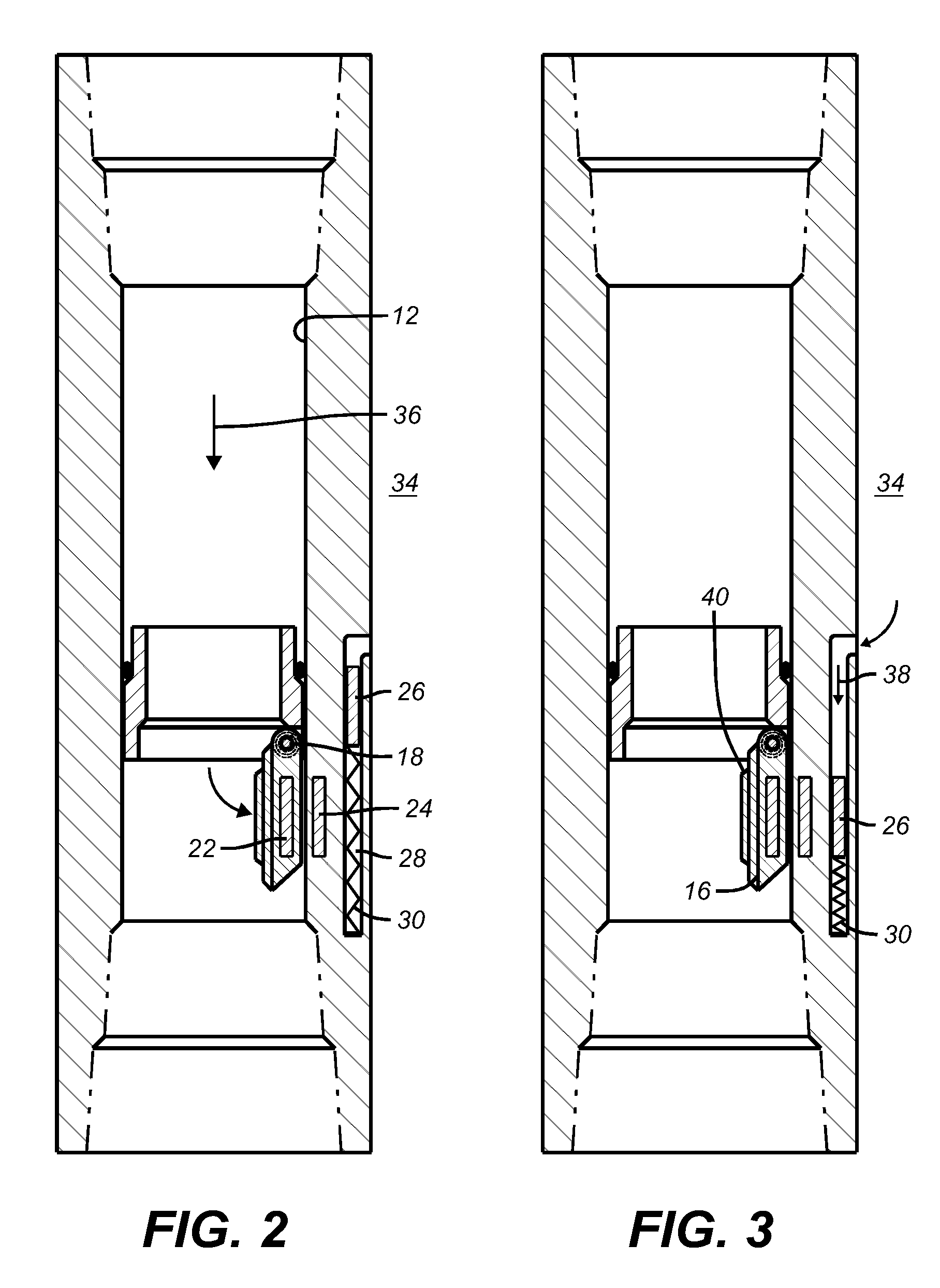

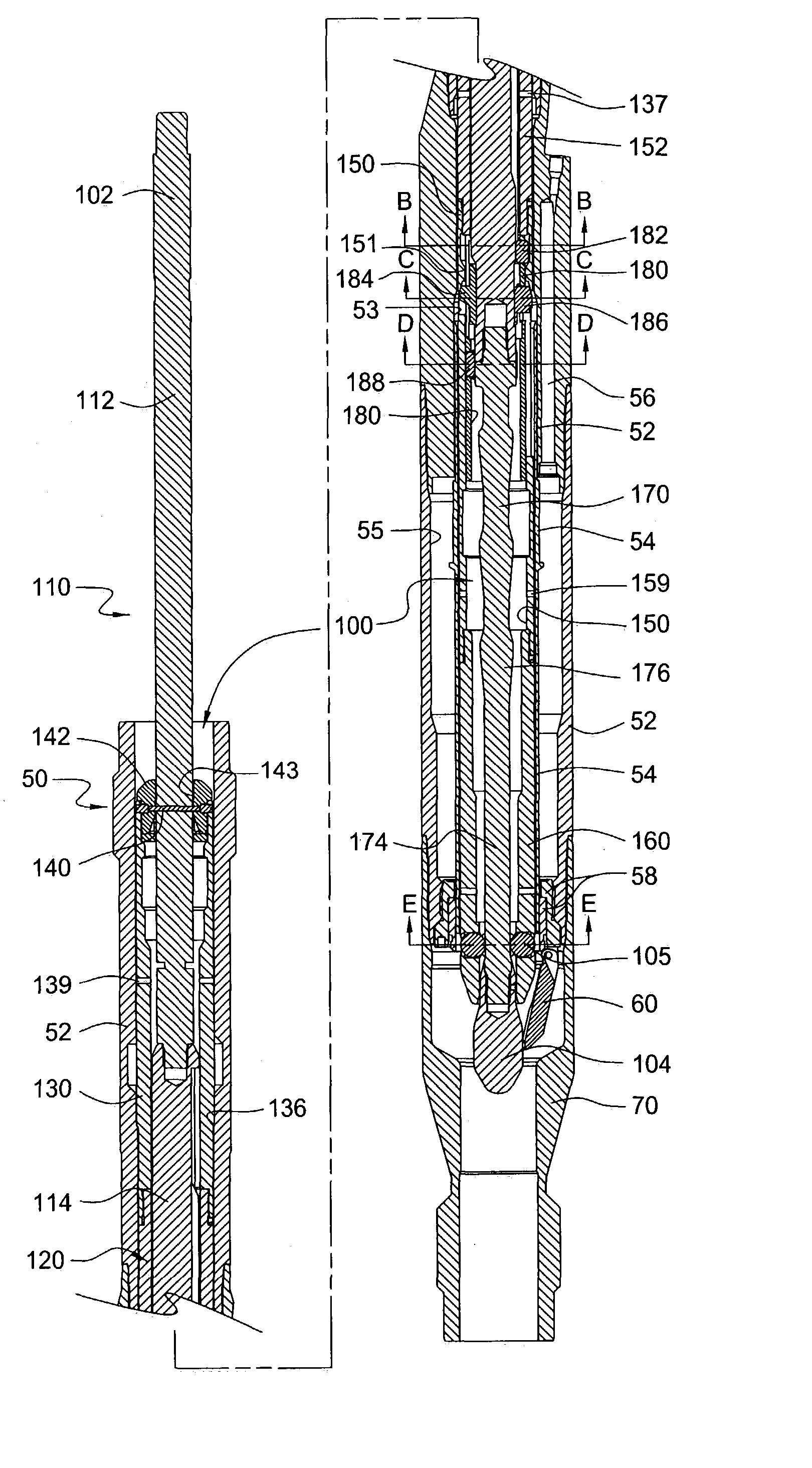

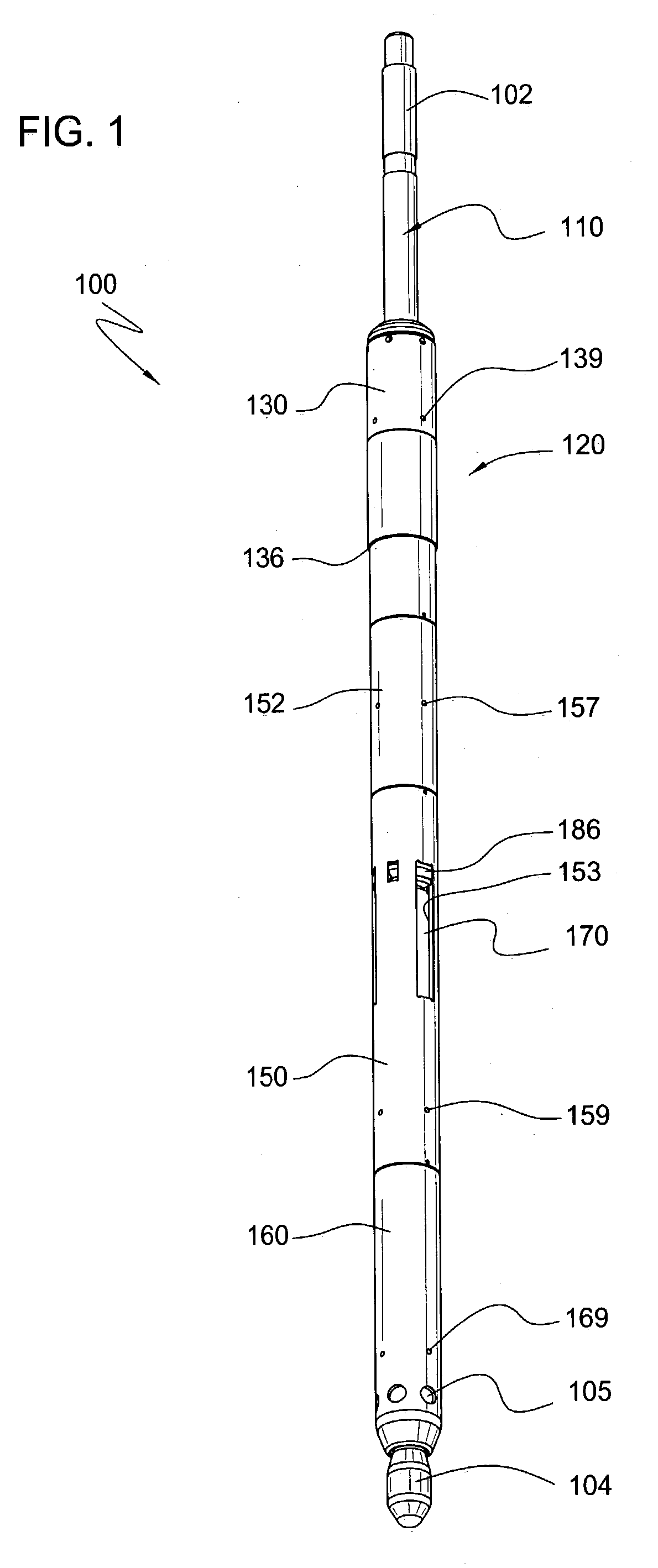

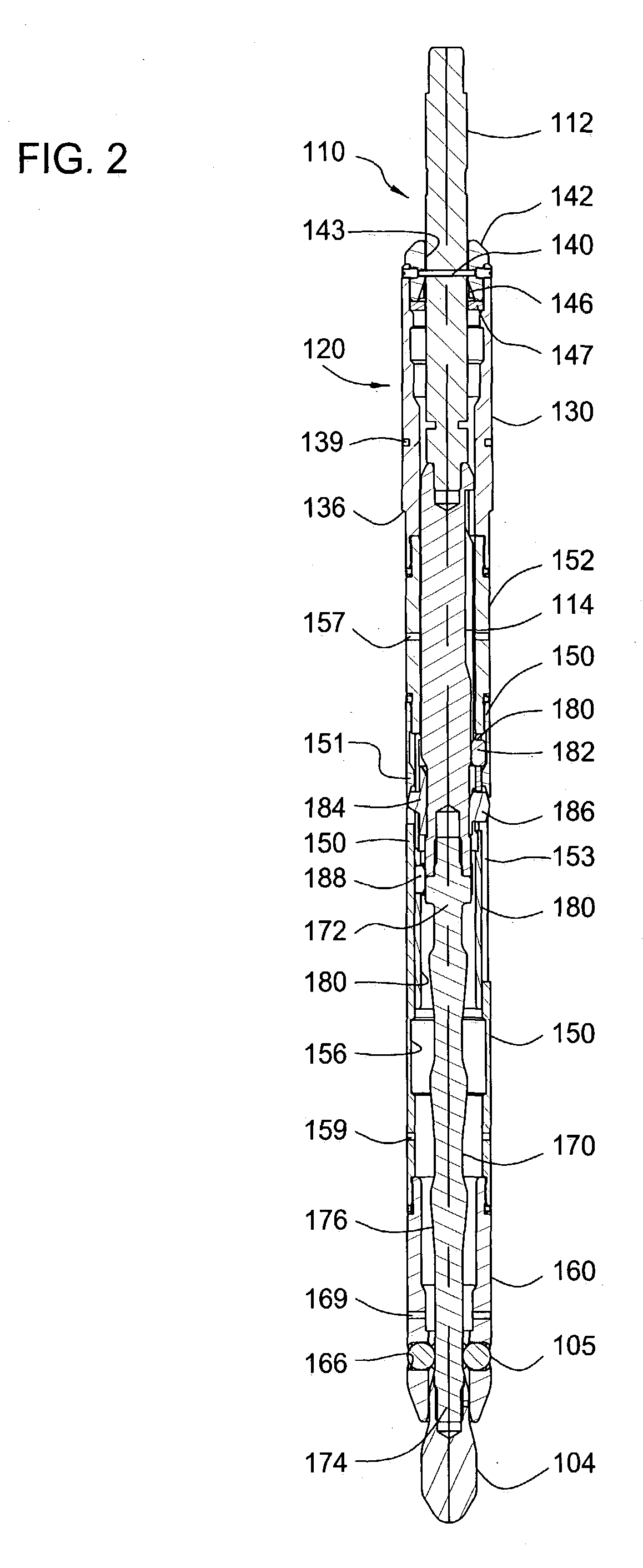

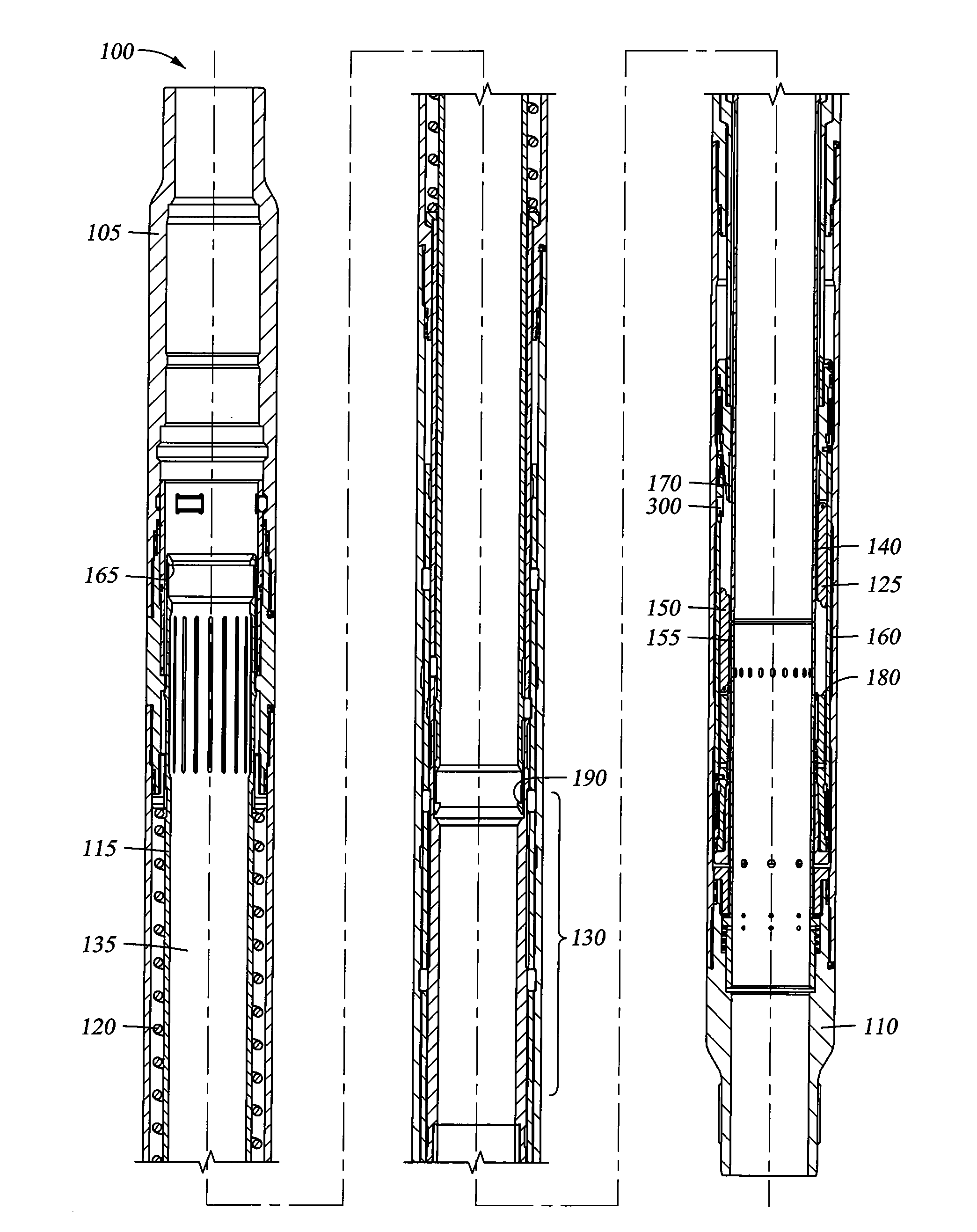

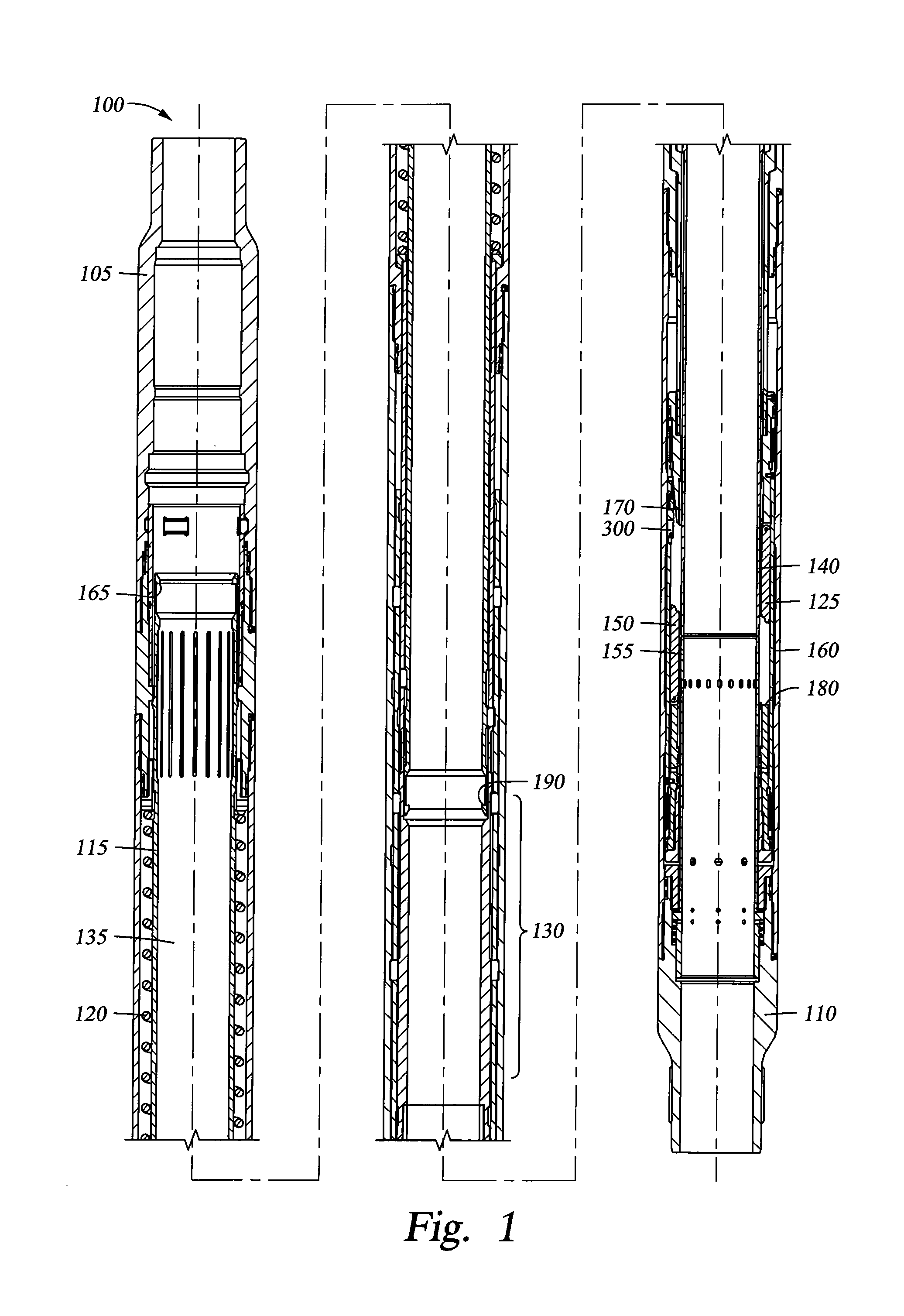

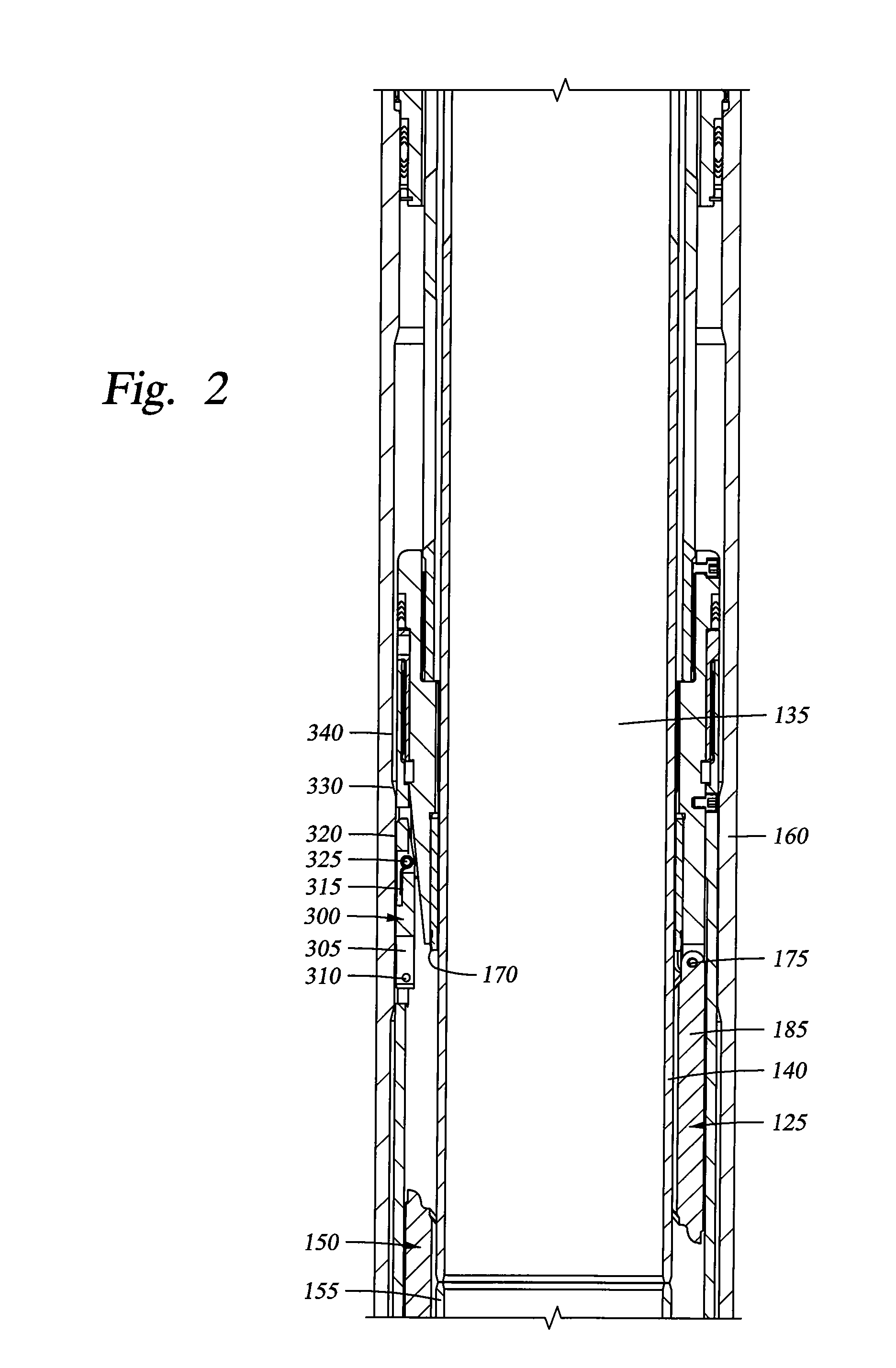

Methods and apparatus enable reliable and improved isolation between two portions of a bore extending through a casing string disposed in a borehole. A downhole deployment valve (DDV) may provide the isolation utilizing a valve member such as a flapper that is disposed in a housing of the DDV and is designed to close against a seat within the housing. The DDV includes an operating mechanism for opening / closing the DDV. In use, pressure in one portion of a well that is in fluid communication with a well surface may be bled off and open at well surface while maintaining pressure in another portion of the casing string beyond the DDV.

Owner:WEATHERFORD TECH HLDG LLC

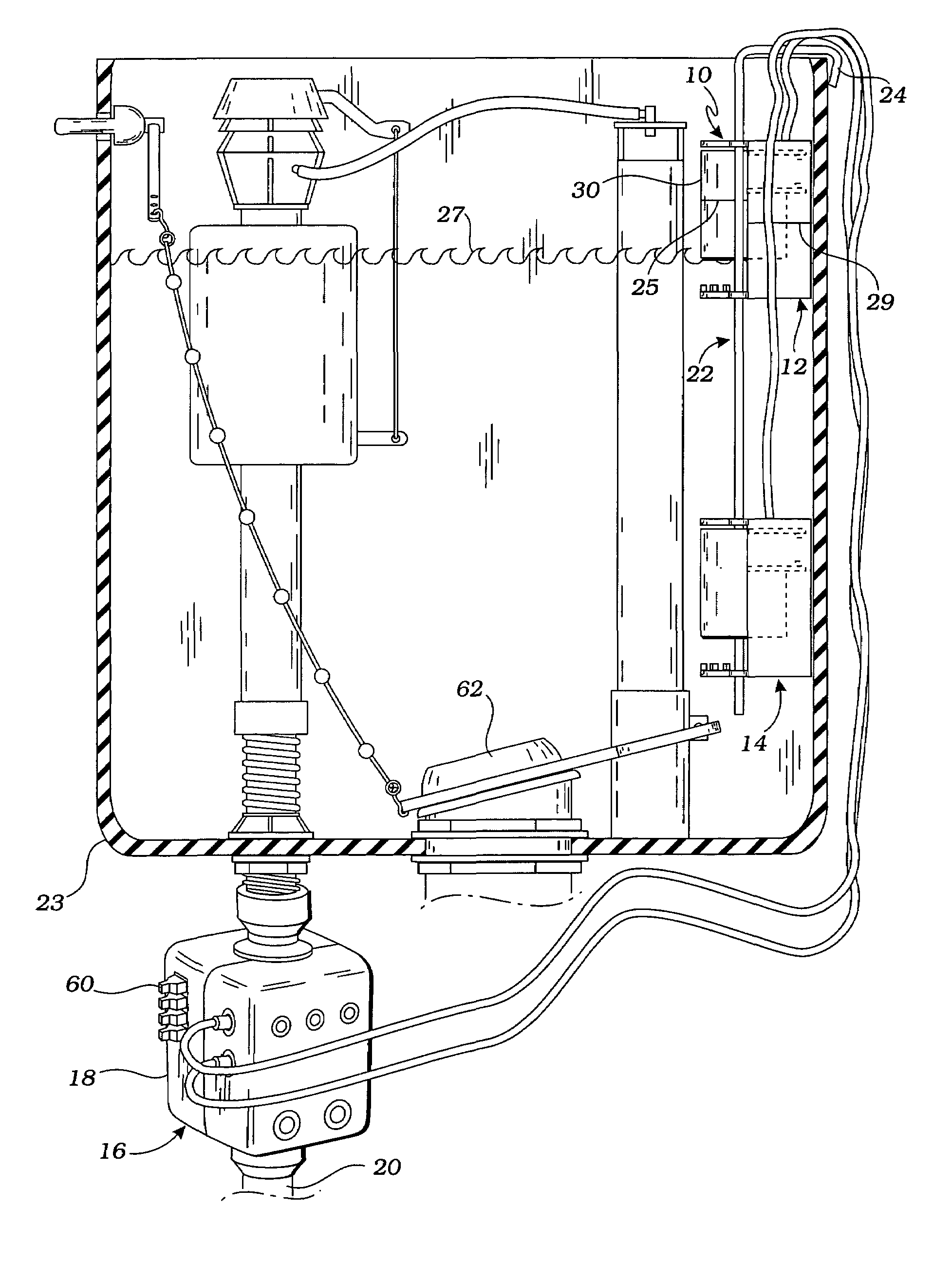

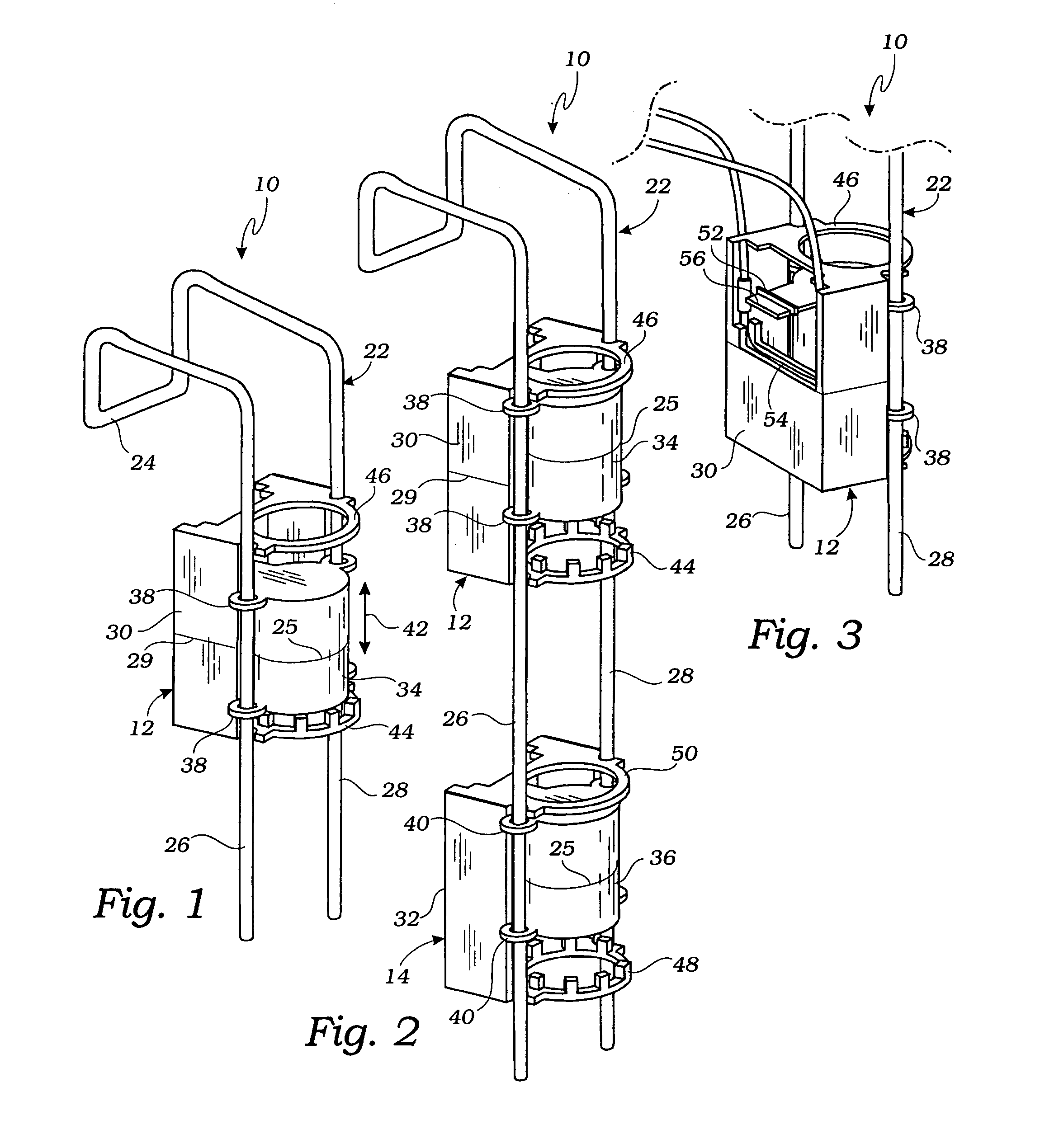

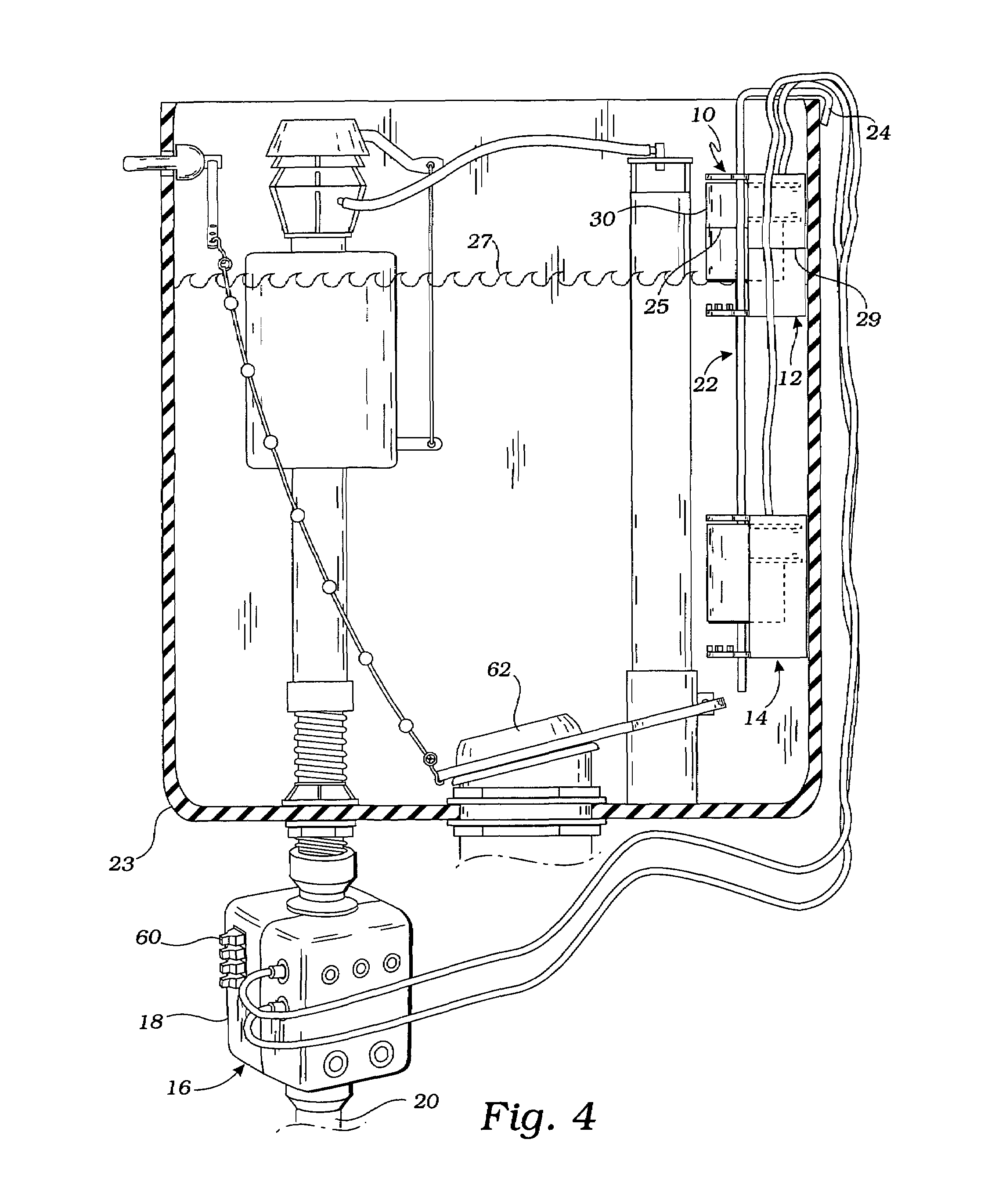

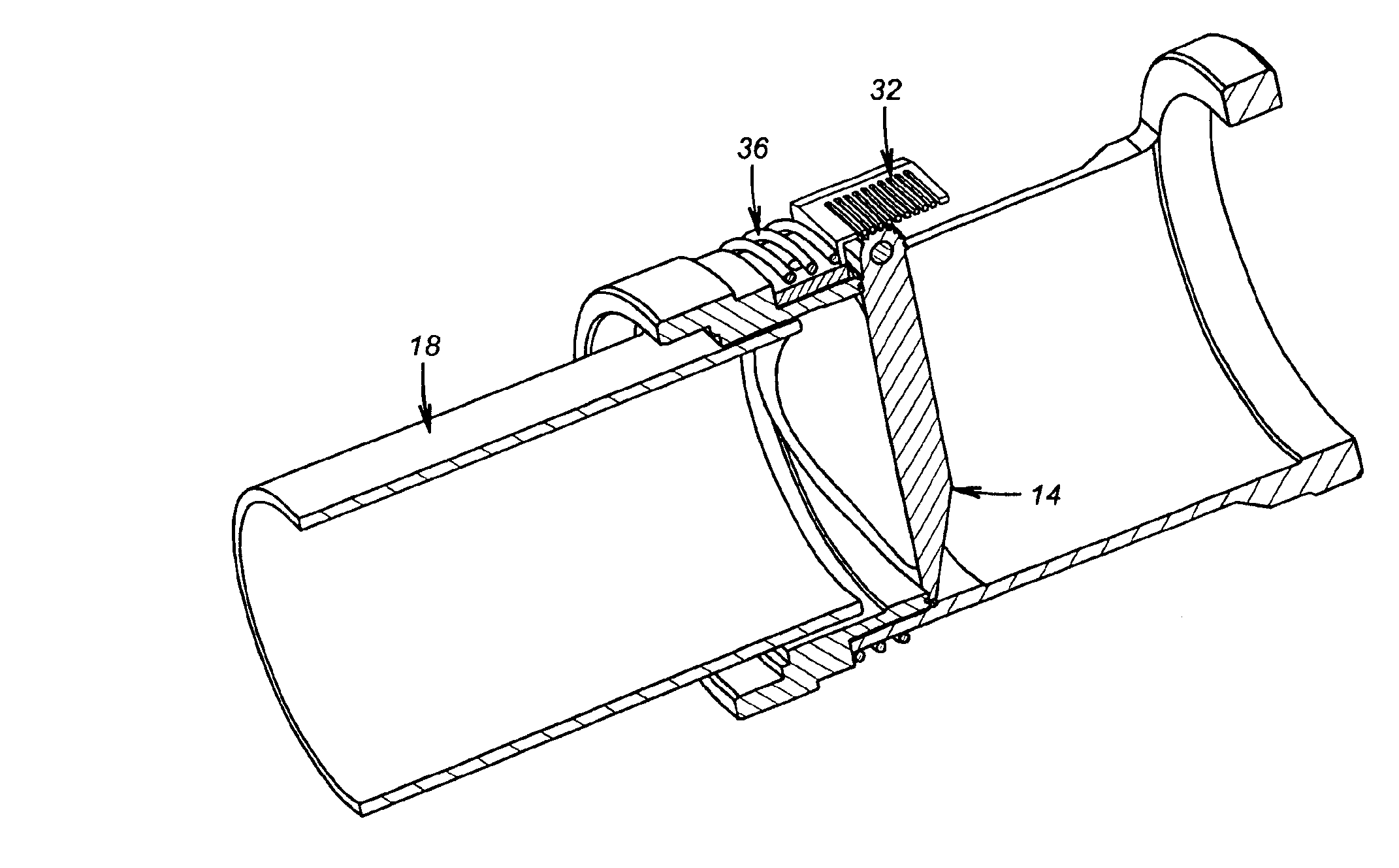

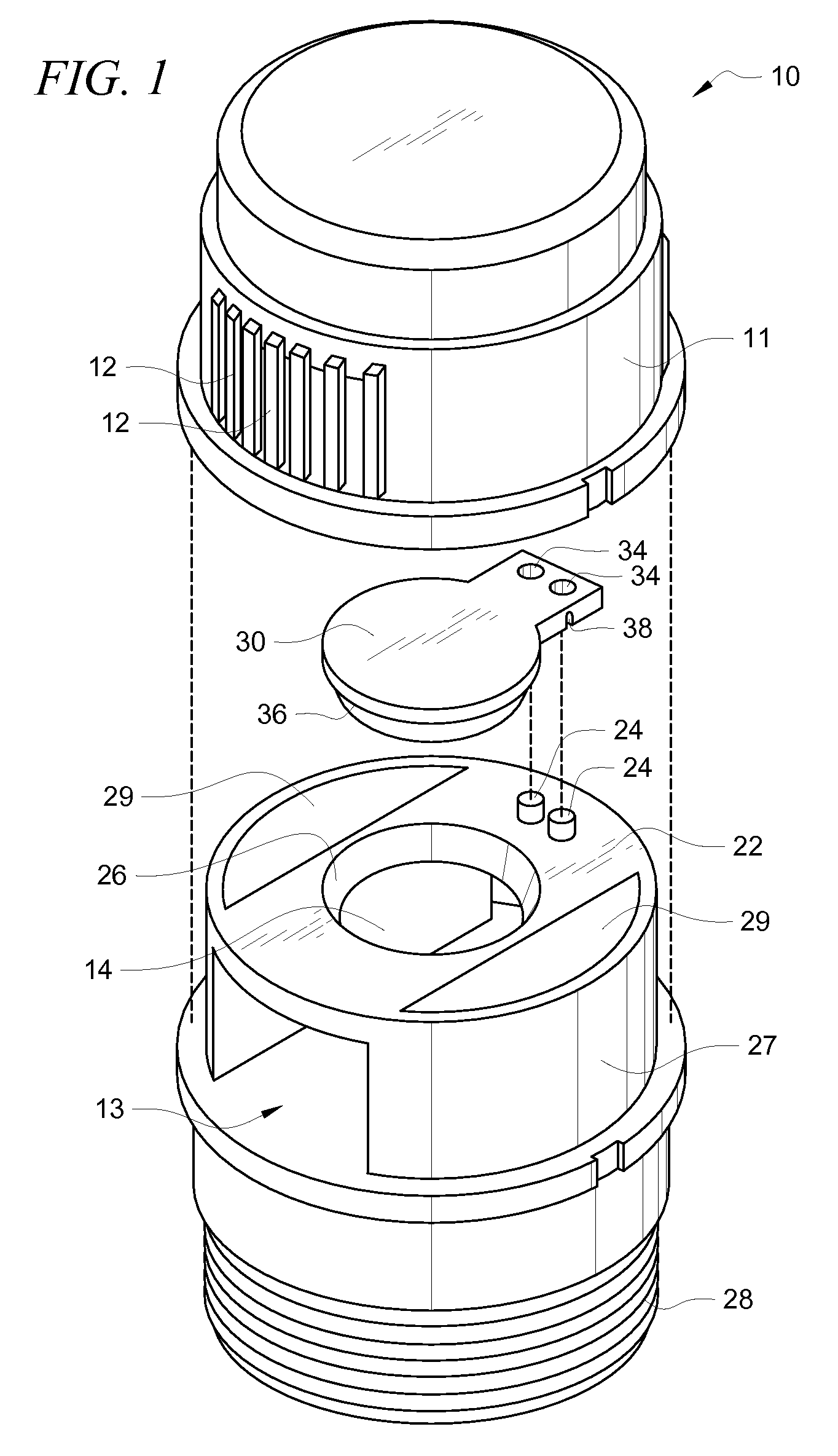

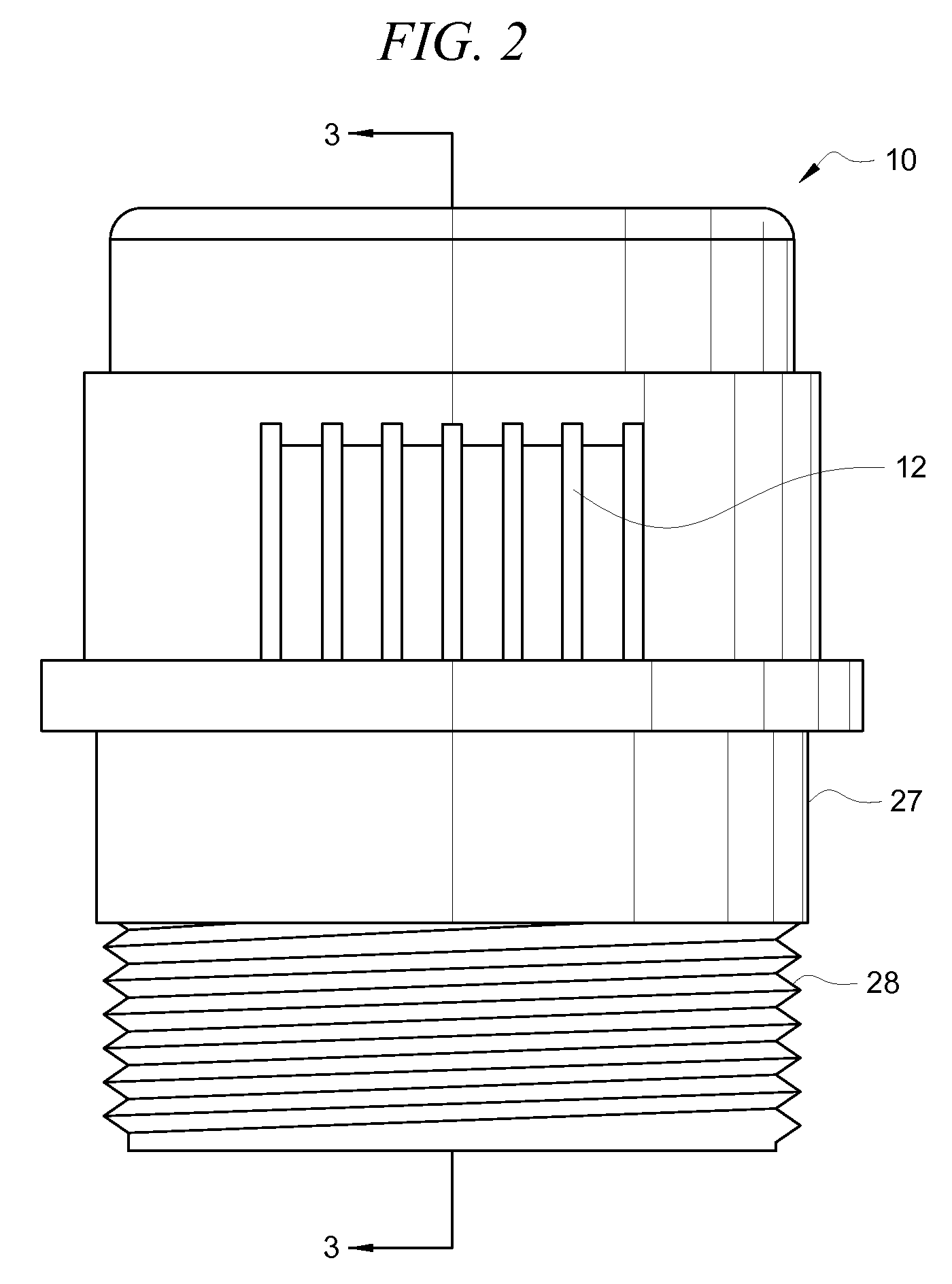

Toilet leak detection and overflow prevention system

InactiveUS6934977B1Improved and simplifiedWater closetsClimate change adaptationWater level riseTime segment

Water leak detecting or overflow devices for a toilet may be inserted into or formed integrally with the toilet. The devices include at least one water leak sensor assembly mounted in a position in a toilet tank so as to detect the rise and fall of the water level in the toilet tank and an overflow detector in a toilet bowl. If the water level rises and falls a predetermined number of times, or if water continues to flow to the toilet longer than a measured increment of time, a microprocessor operates a normally-open valve and shuts off flow of water to the toilet tank. The devices also include a second sensor, whereby if a flapper remains open or water reaches a level where it might overflow the bowl or tank and stays there for a predetermined period of time, the microprocessor will also shut off flow to the toilet.

Owner:QUINTANA RICHARD +1

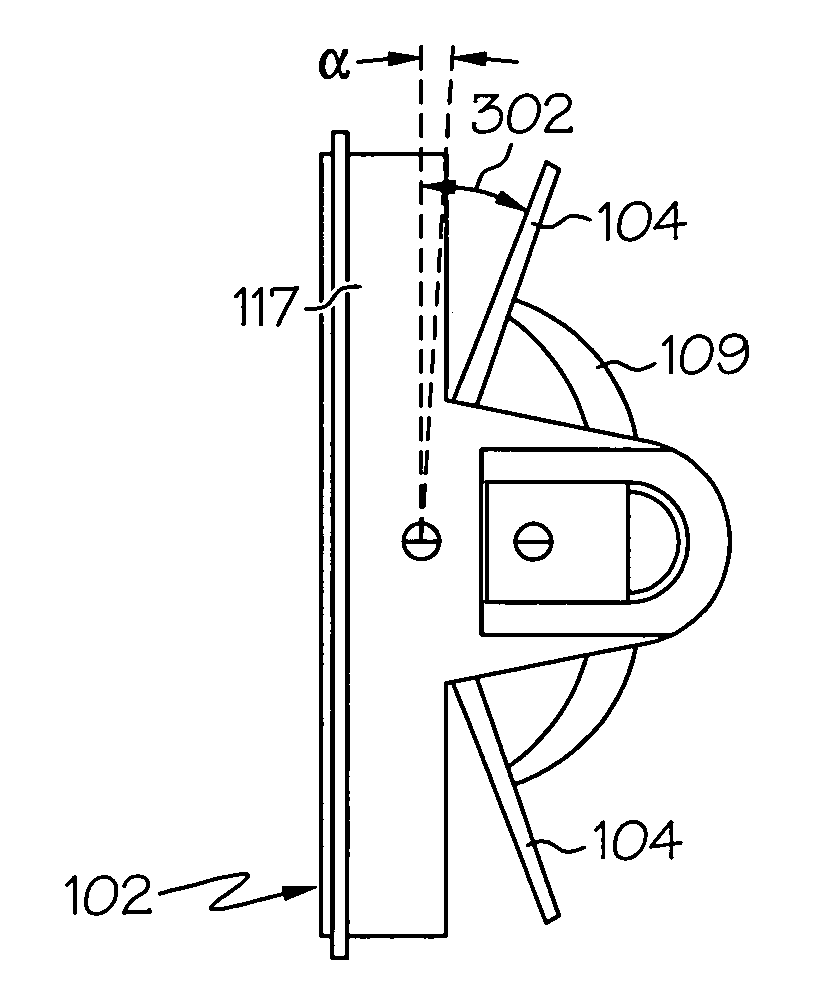

Barrier orifice valve for gas lift

ActiveUS20070181312A1Increase flow ratePrevent backflowPressure pumpsFluid removalEngineeringGas lift

Gas lift valve designs and gas lift systems are described that feature a positive closure mechanism that is highly resistant to significant wear or damage that would result in fluid leakage. A pivotable flapper member is incorporated into a gas lift valve and used as a flow control mechanism. The flapper member provides a positive barrier to fluid flow from the production tubing to the annulus, even after substantial wear or damage.

Owner:BAKER HUGHES INC

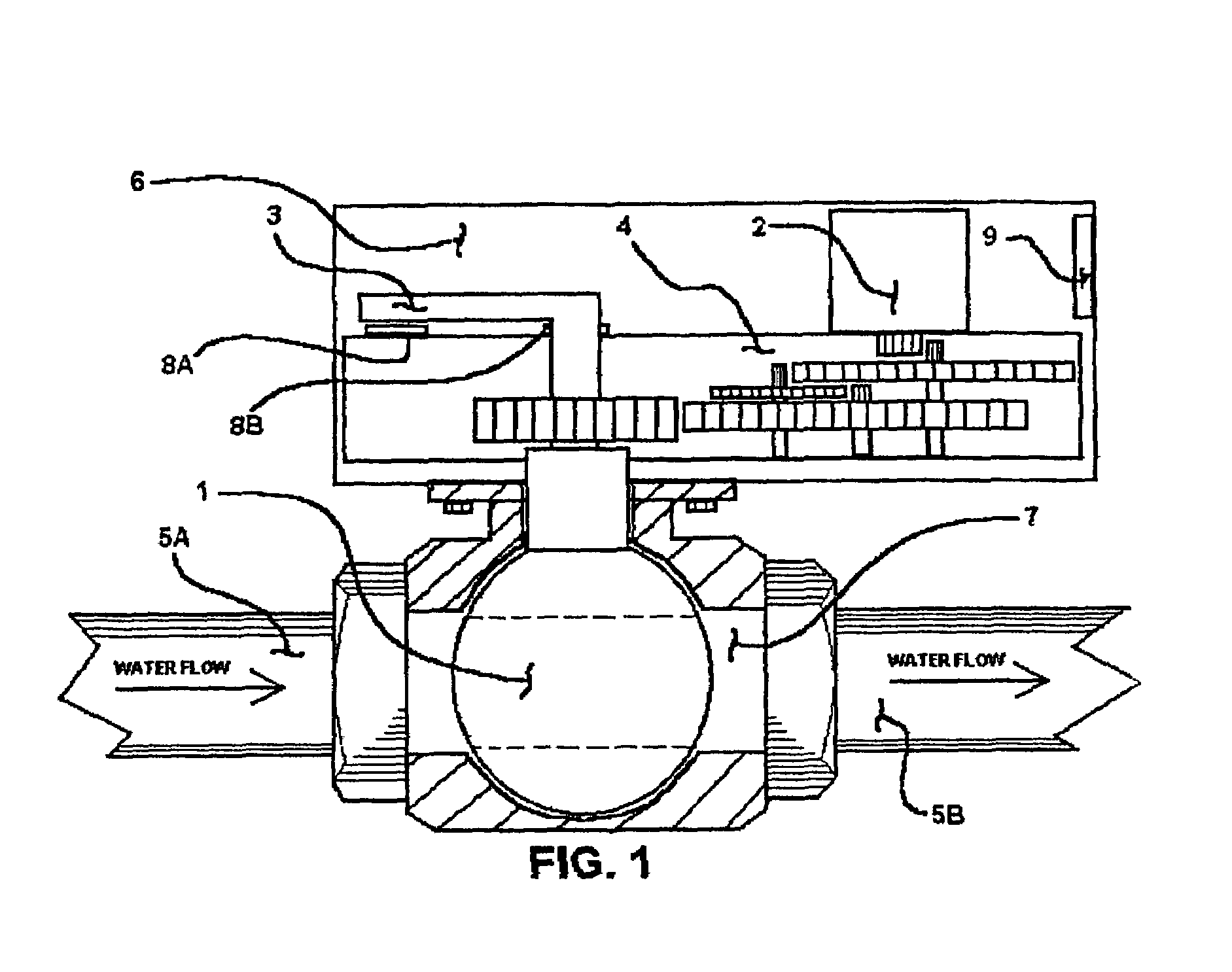

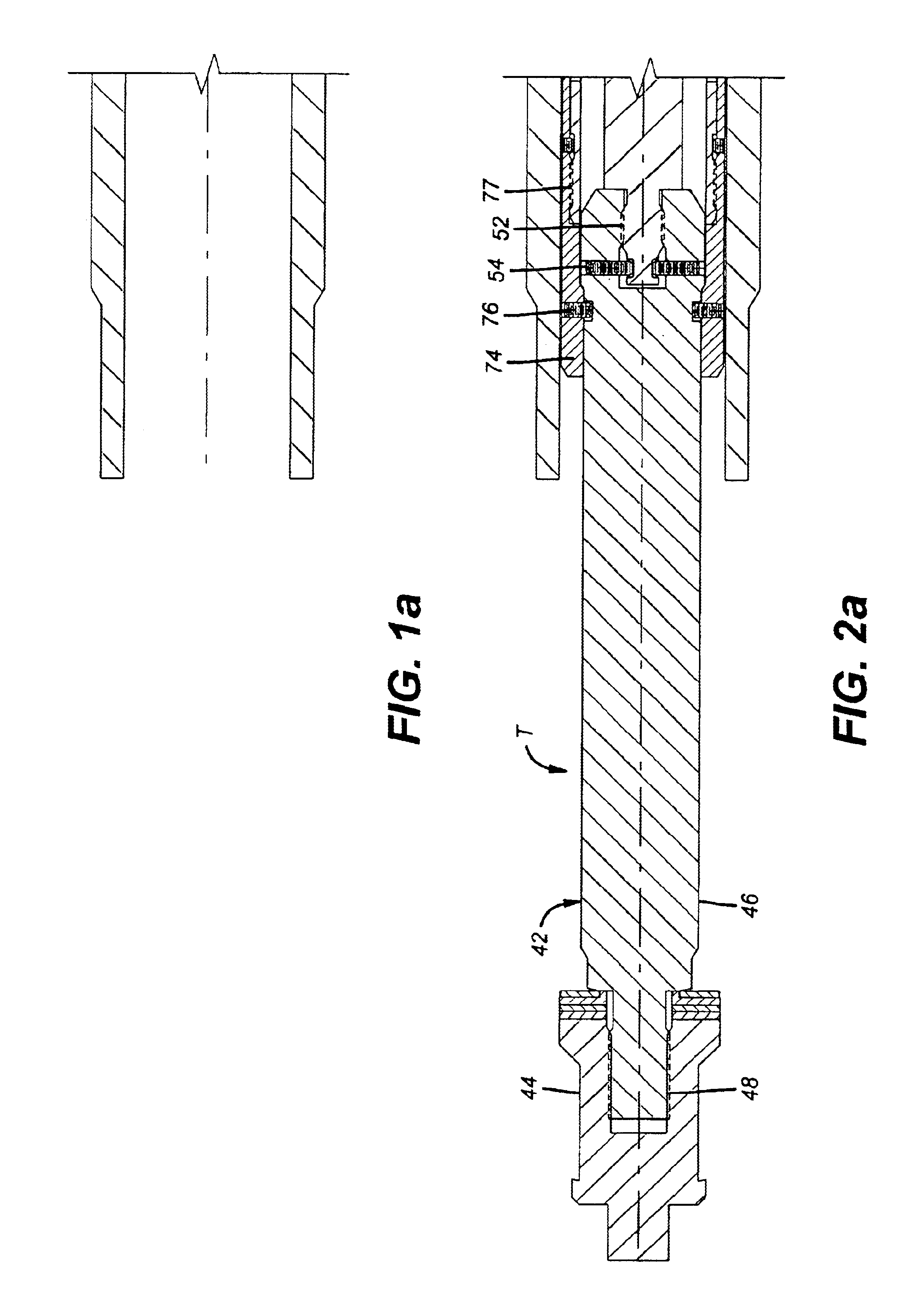

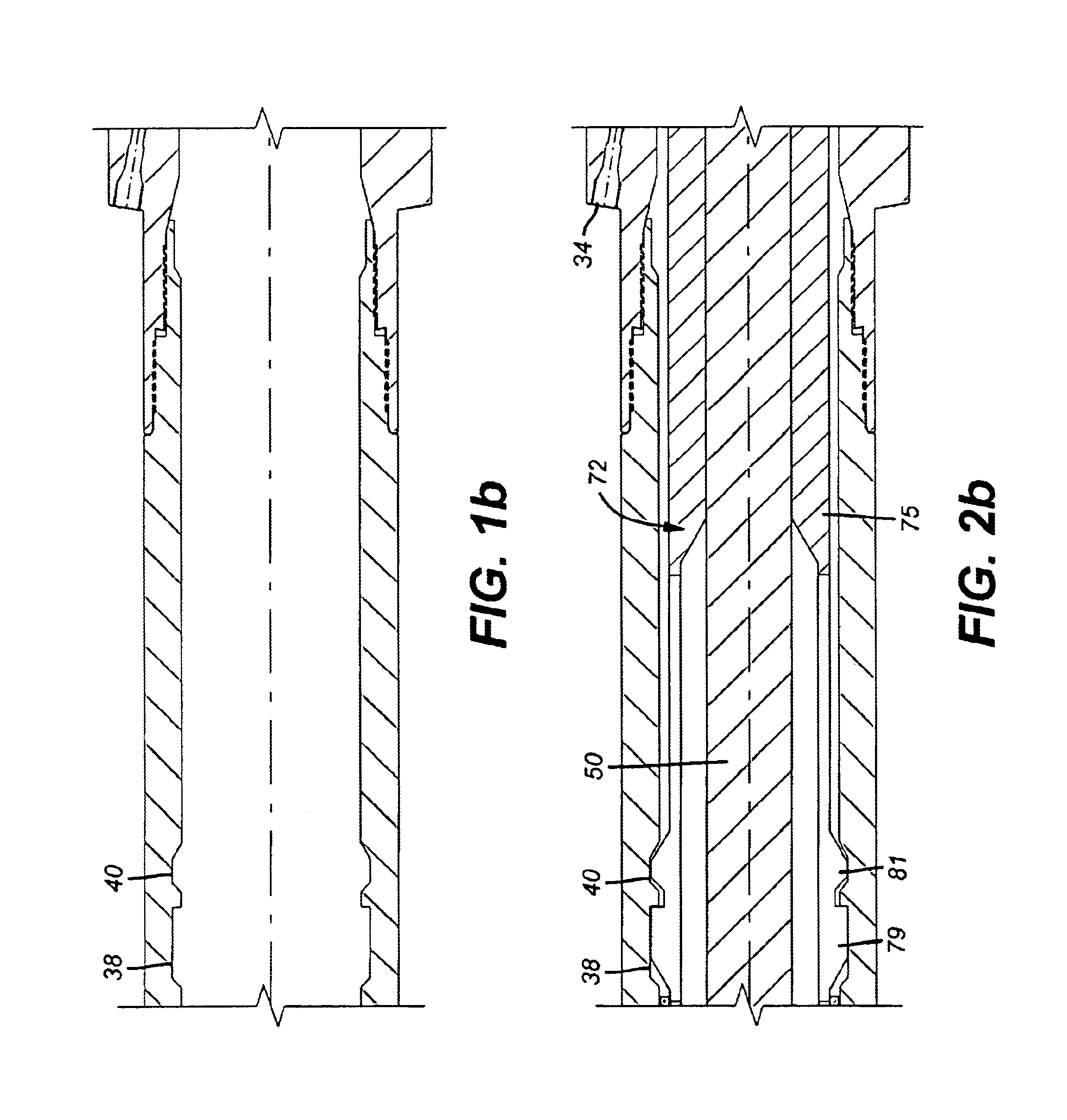

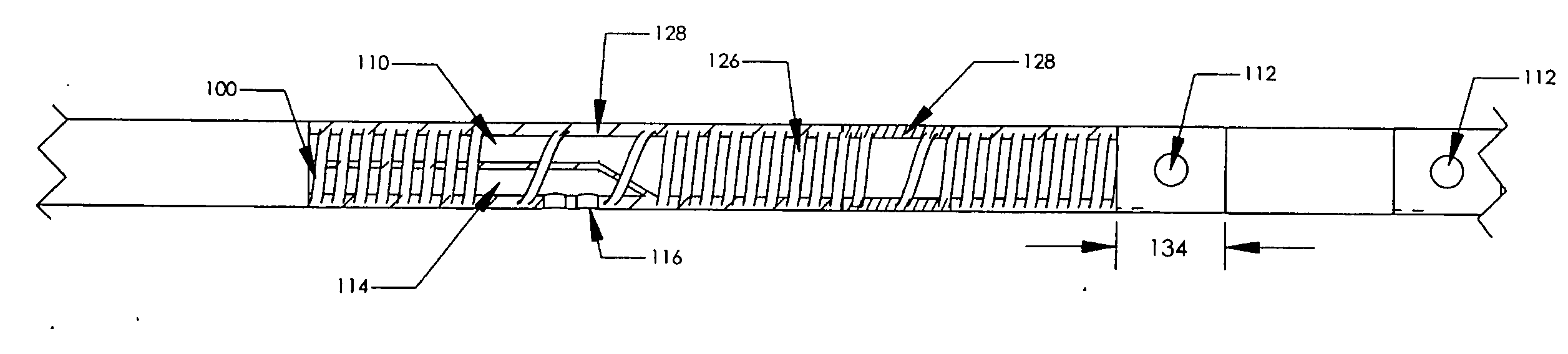

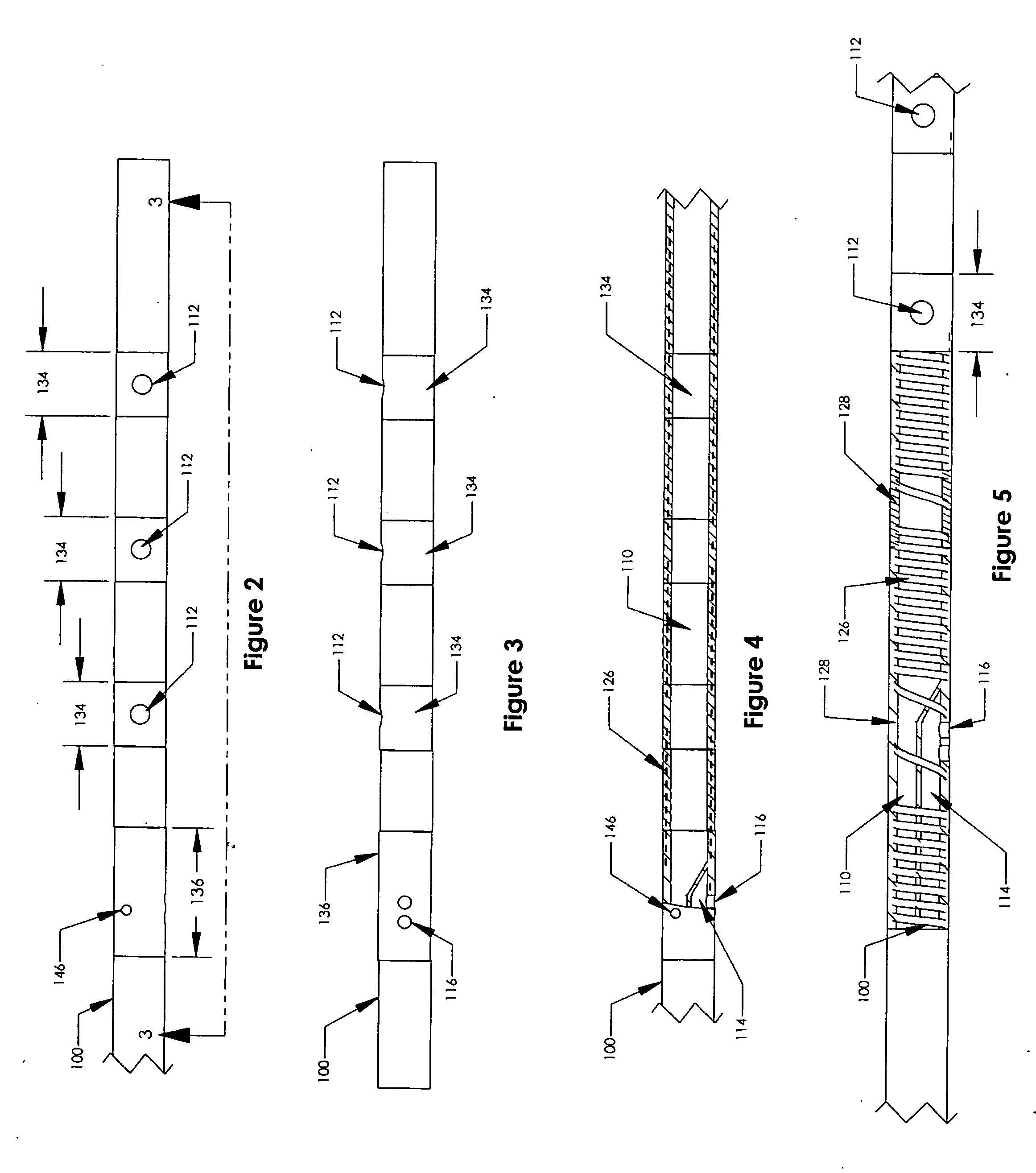

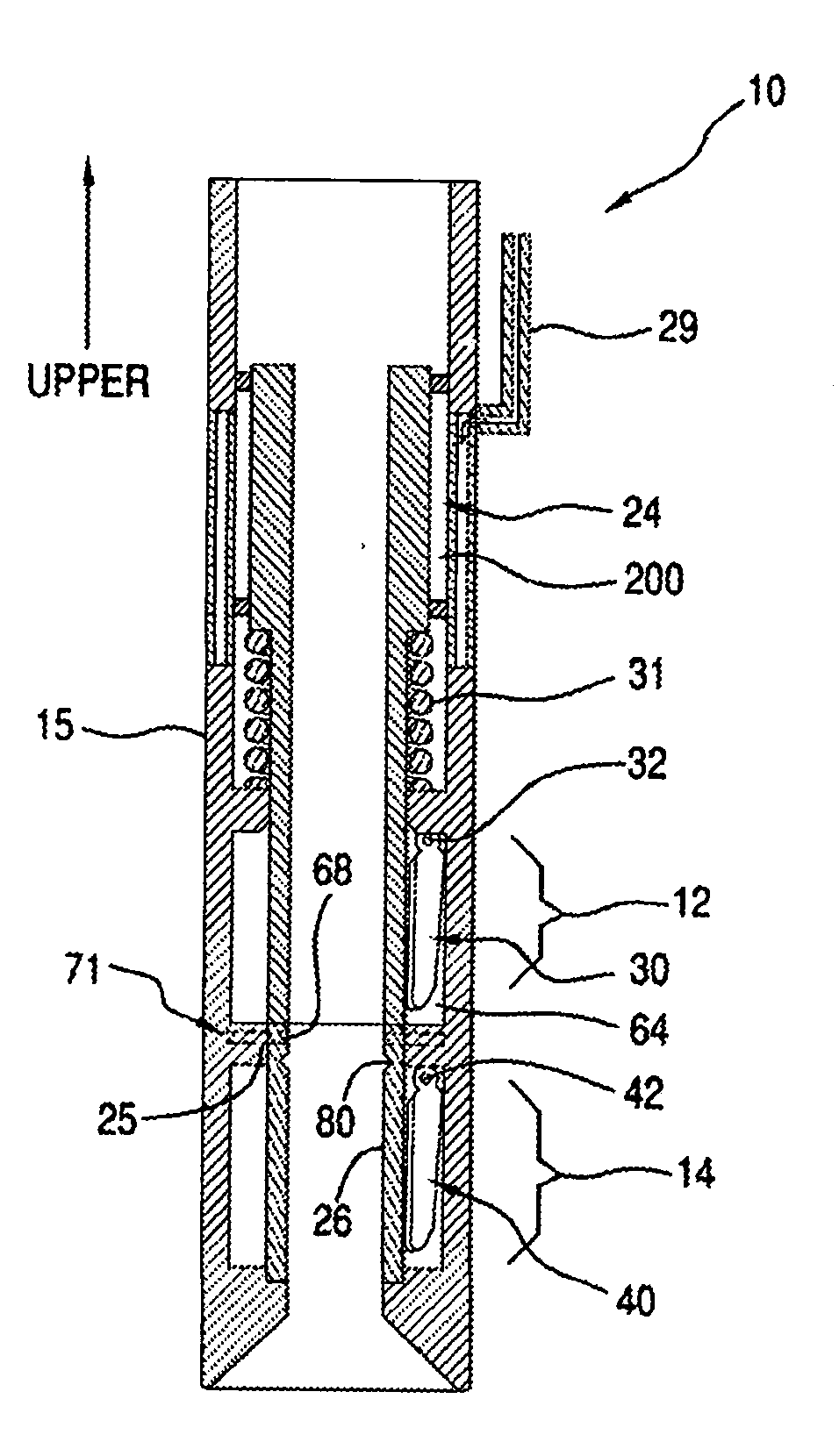

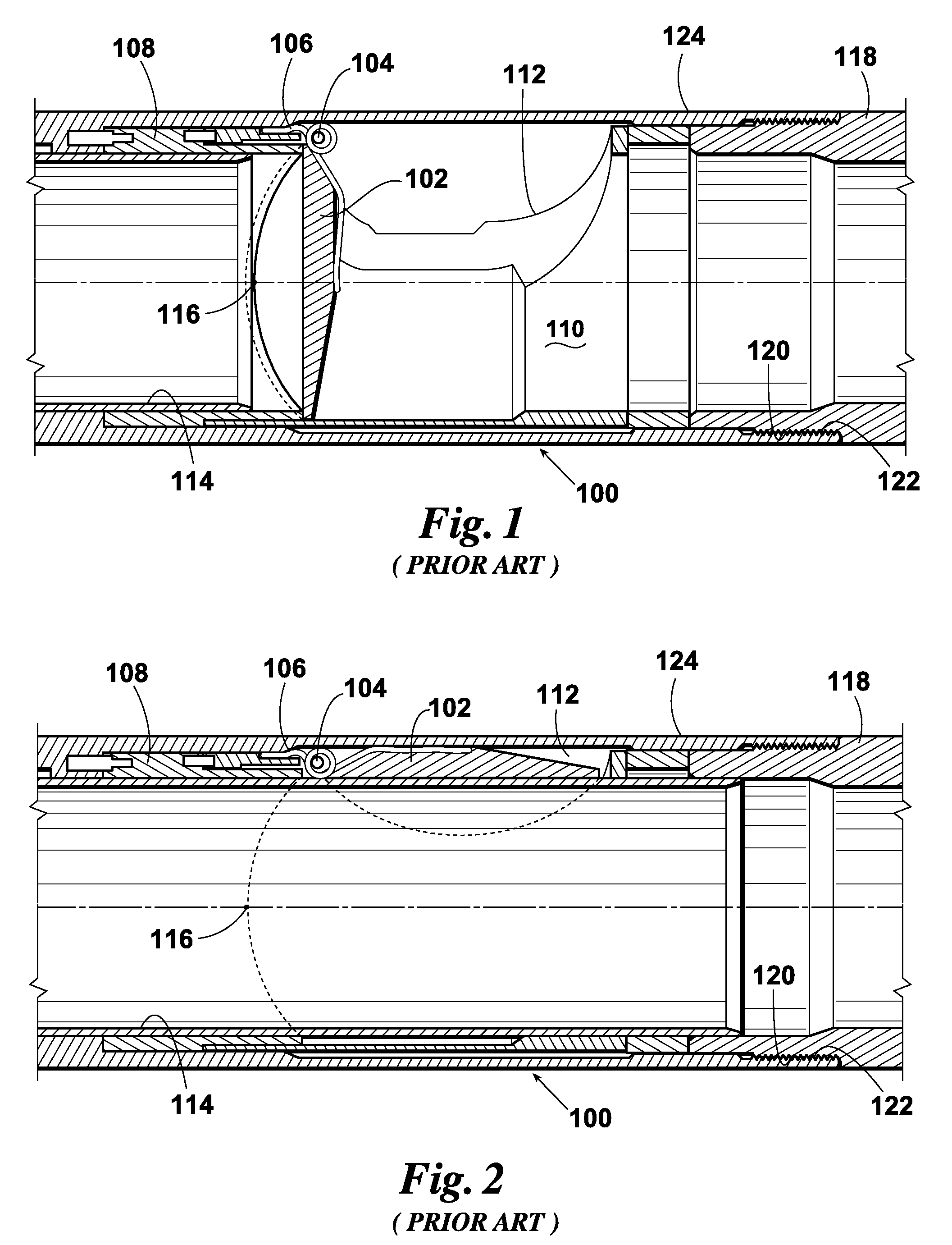

Float collar

The present invention relates to a float collar apparatus for regulating the passage of fluid through a drilling / production liner or sub-sea casing. Apparatus of the present invention is fabricated using plastic flapper valves and valve-actuating sleeve components in contrast to prior art float collar components which are fabricated almost entirely of hard metals. Particularly, the plastic may be nylon, phenolic, or a phenolic-nylon laminate. The use of plastic components in the float collar apparatus of the present invention provides a substantial reduction in time and resources expended during drilling out of the float collar once cementing operations are completed. Additionally, the float collar apparatus of the present invention is fabricated from a pre-determined combination of plastic components and metal components thereby ensuring that the improved float collar can still endure substantial hydrostatic stresses encountered during casing liner running in and cementing operations.

Owner:ALLAMON JERRY P +2

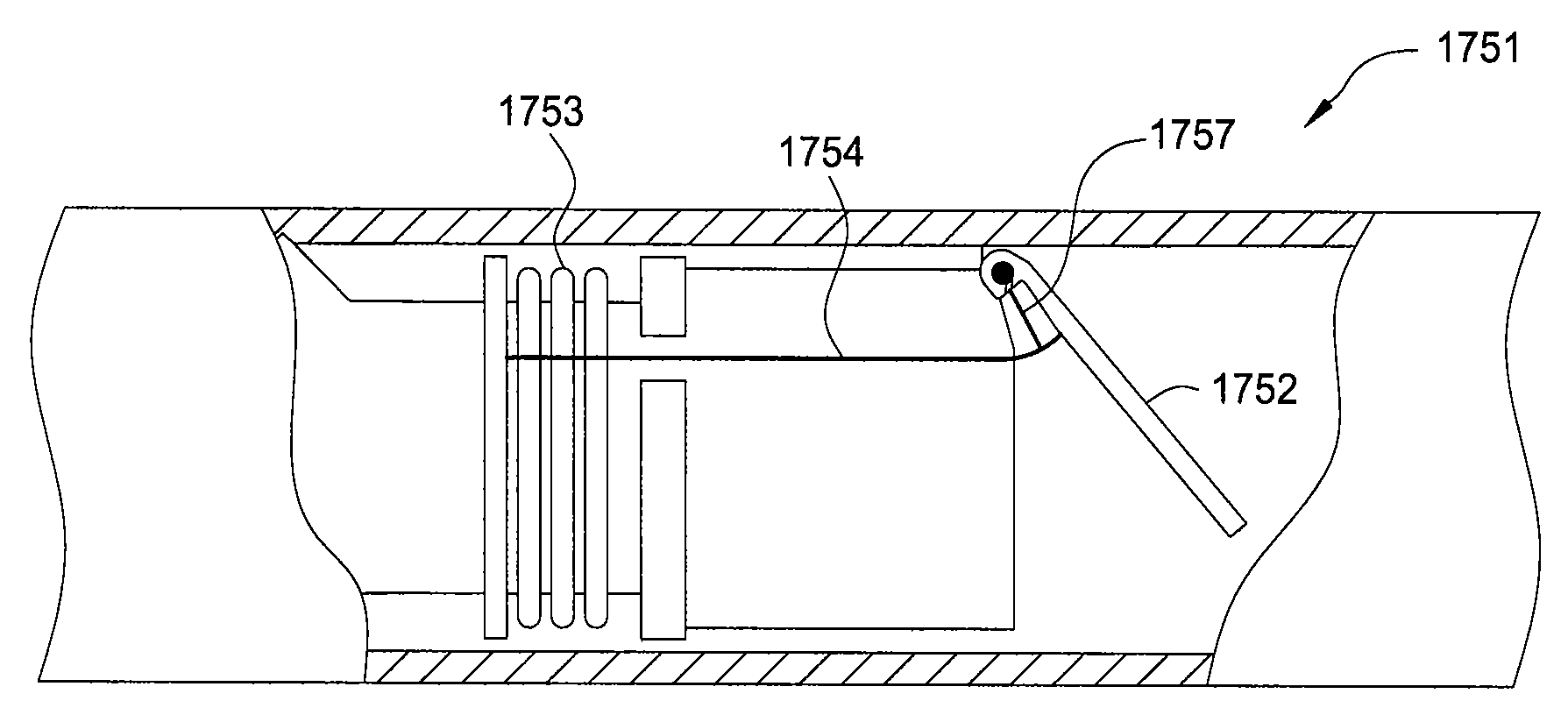

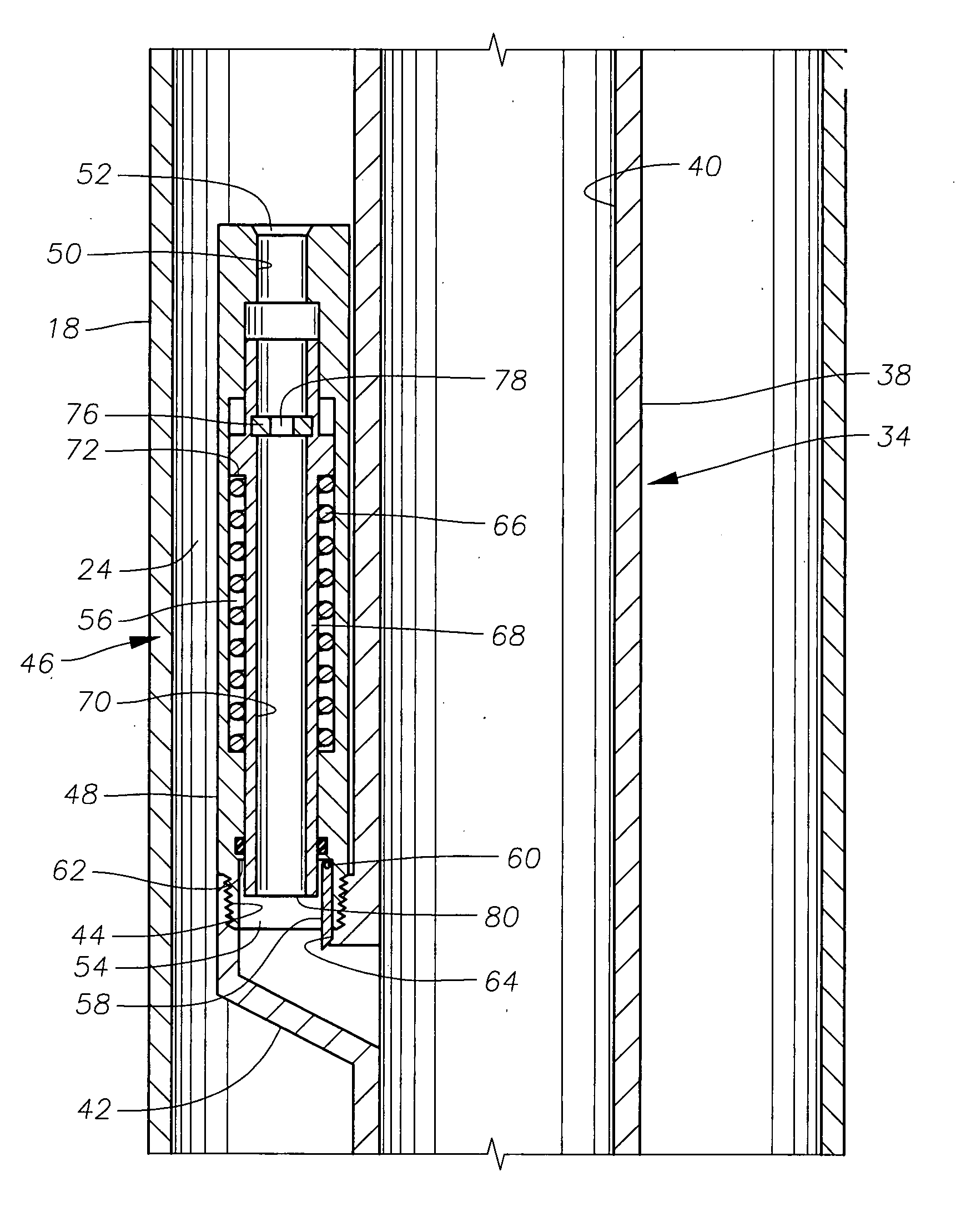

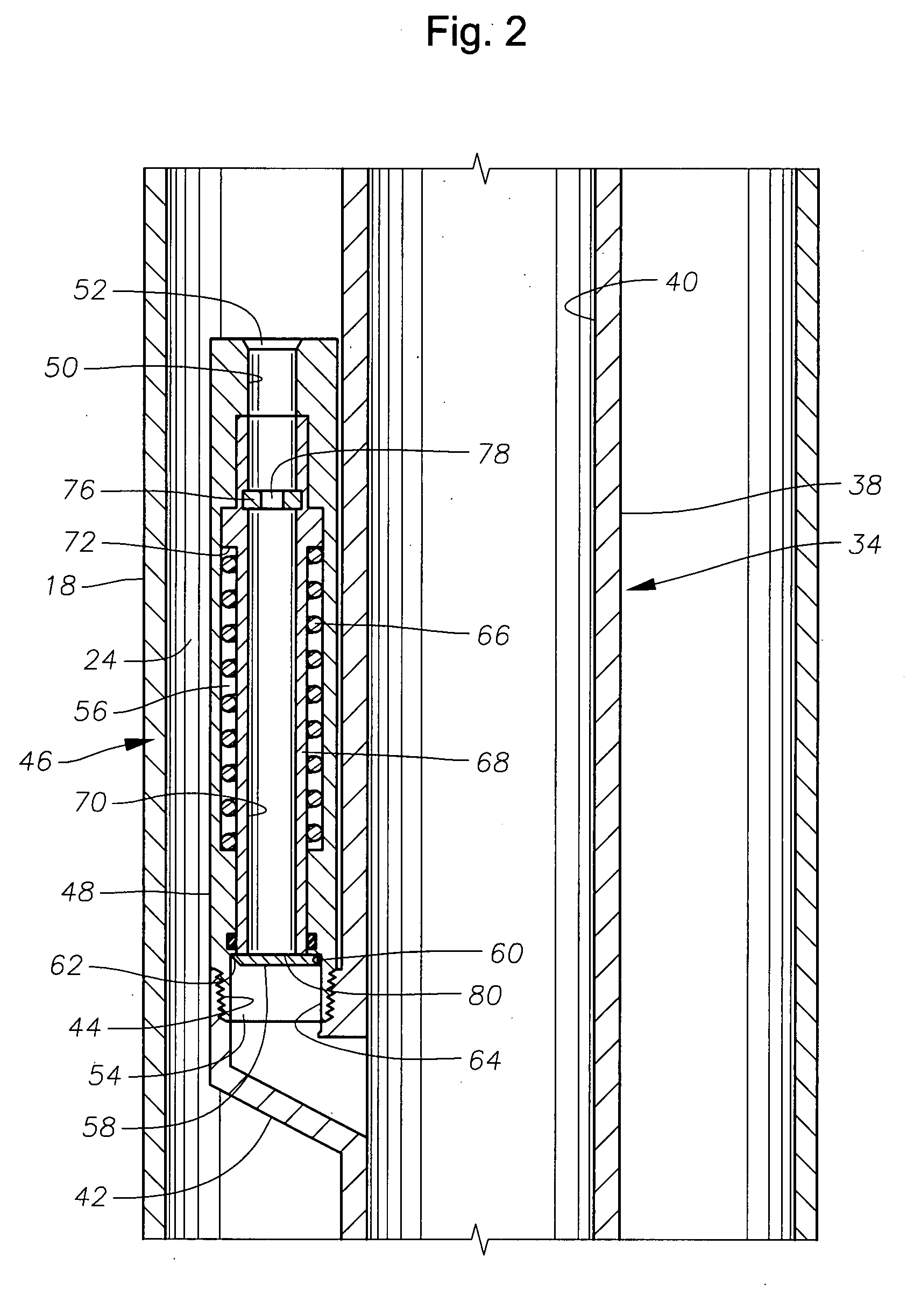

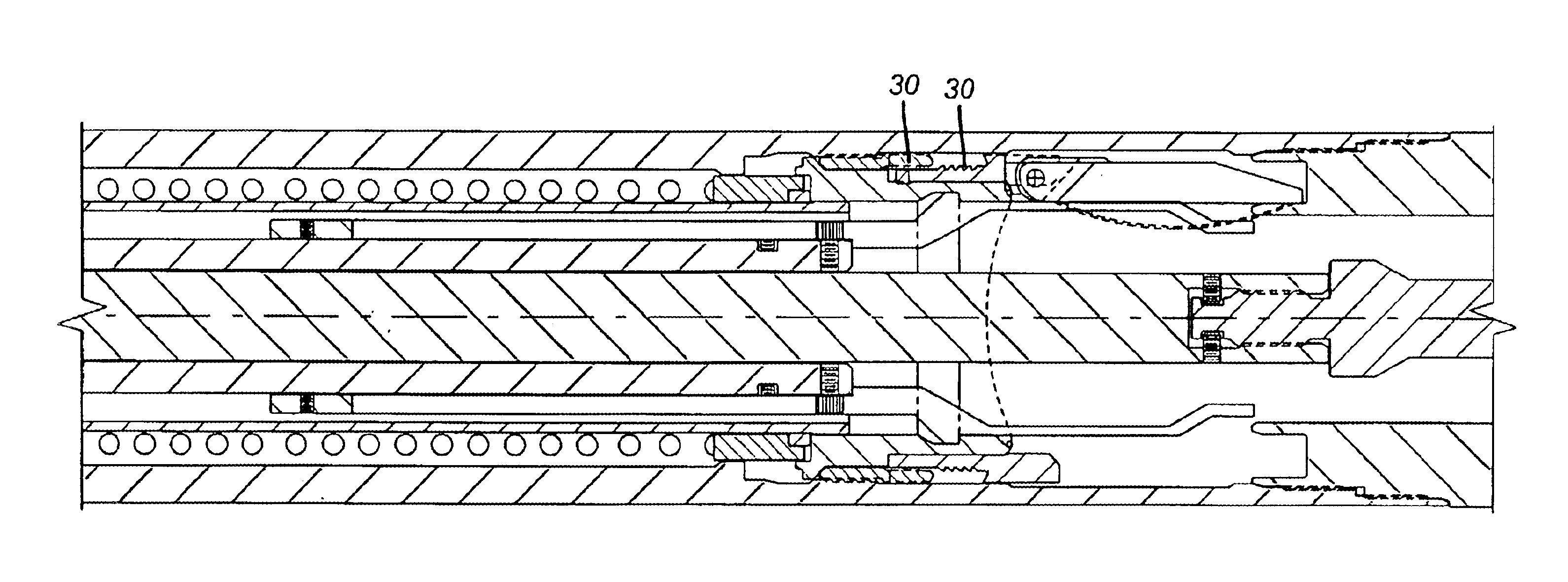

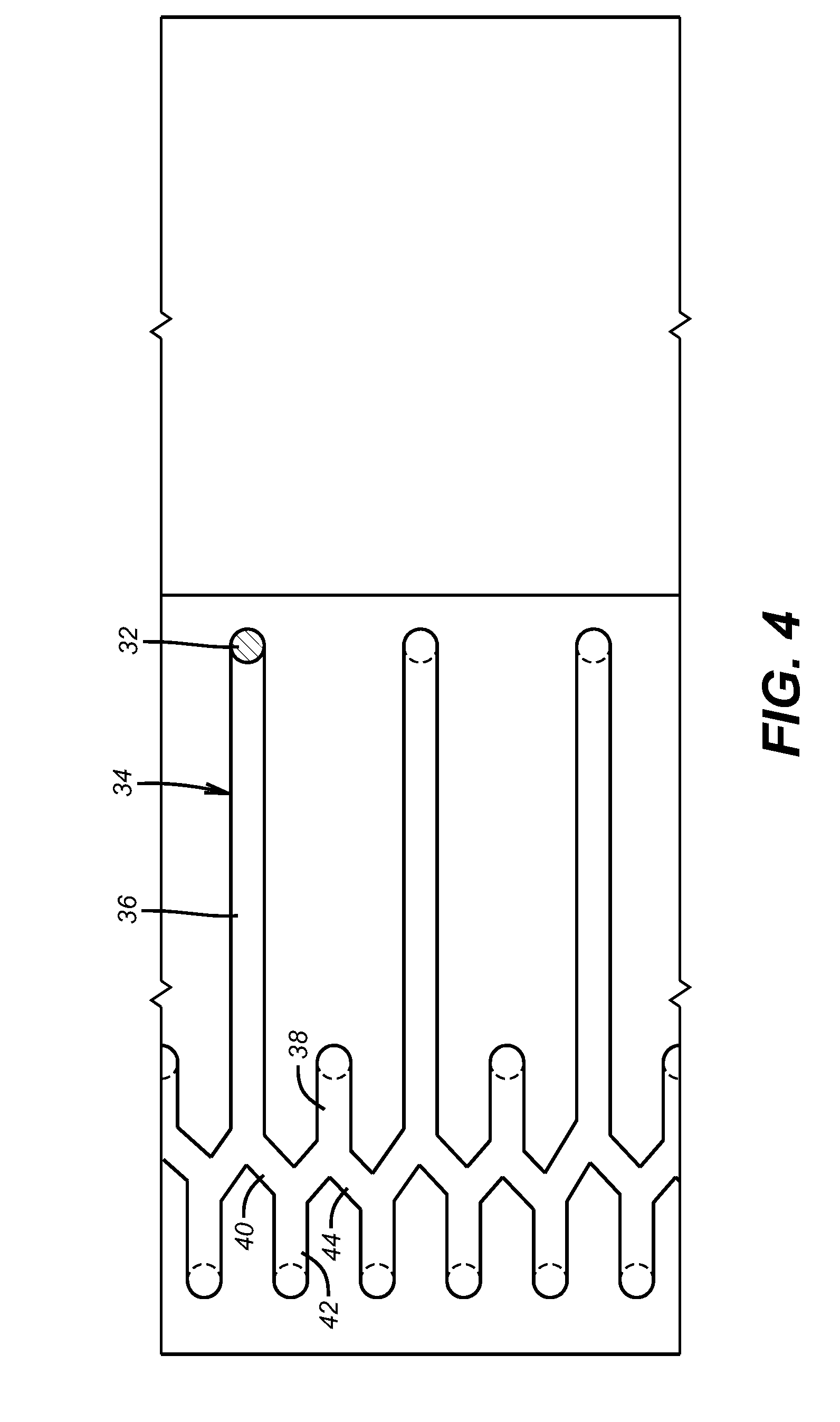

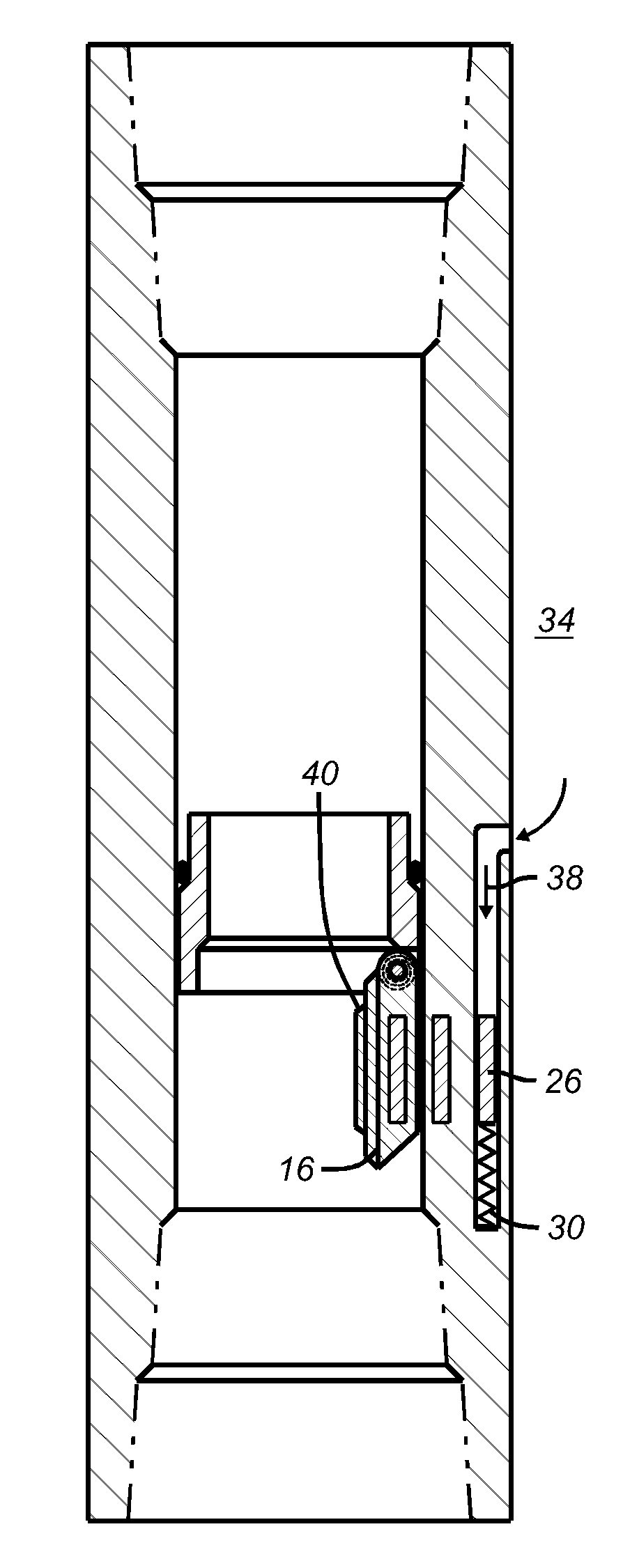

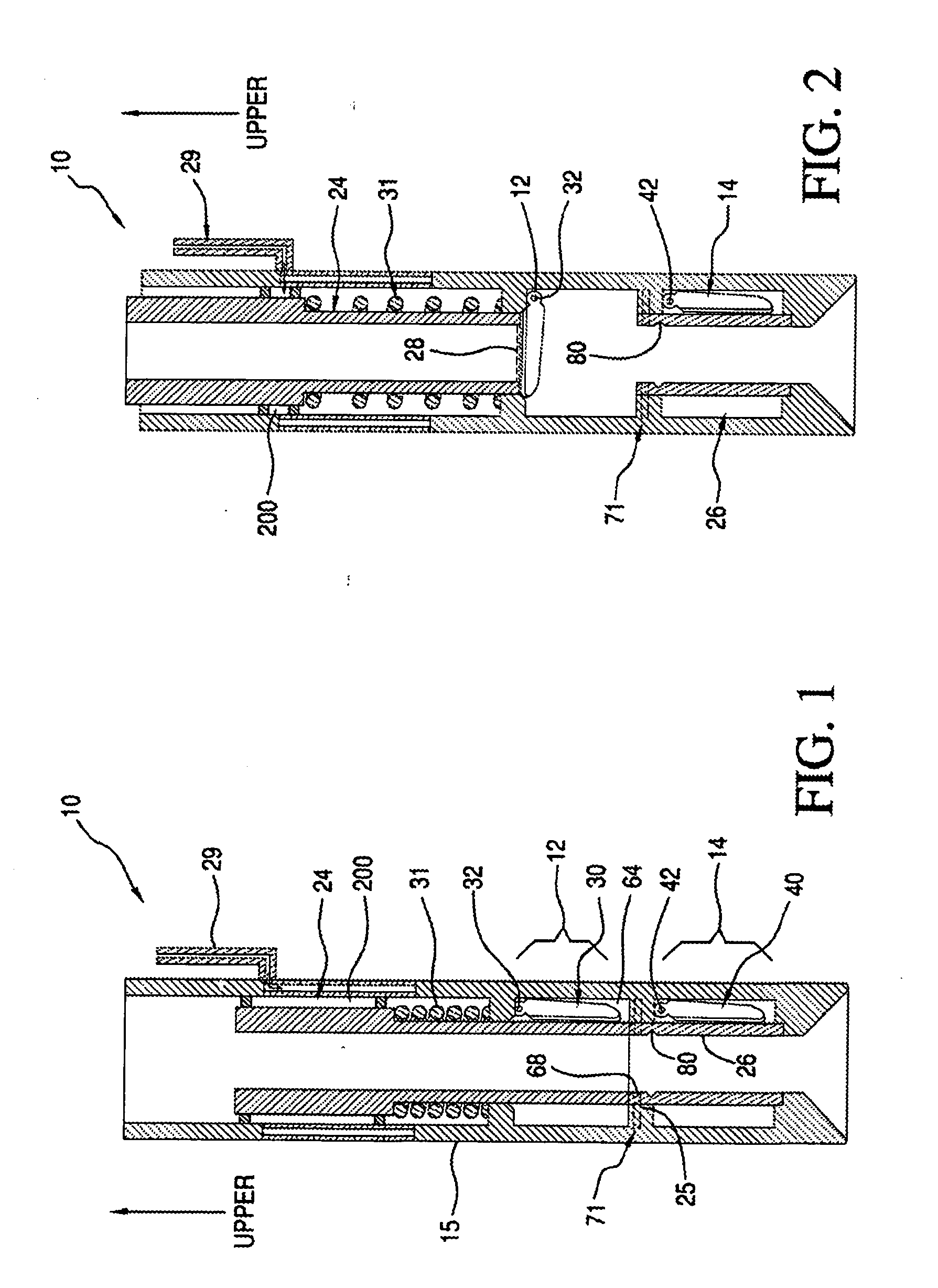

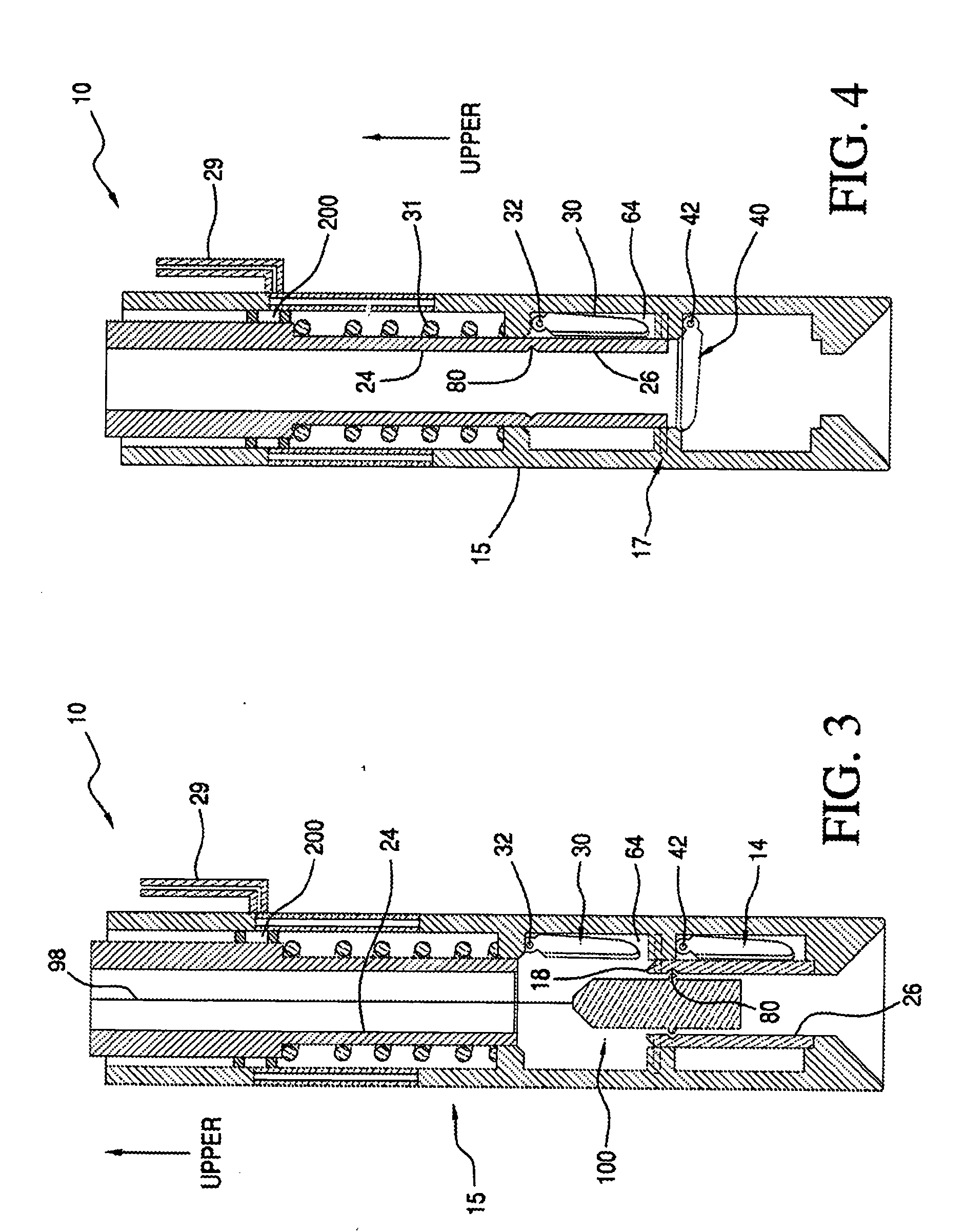

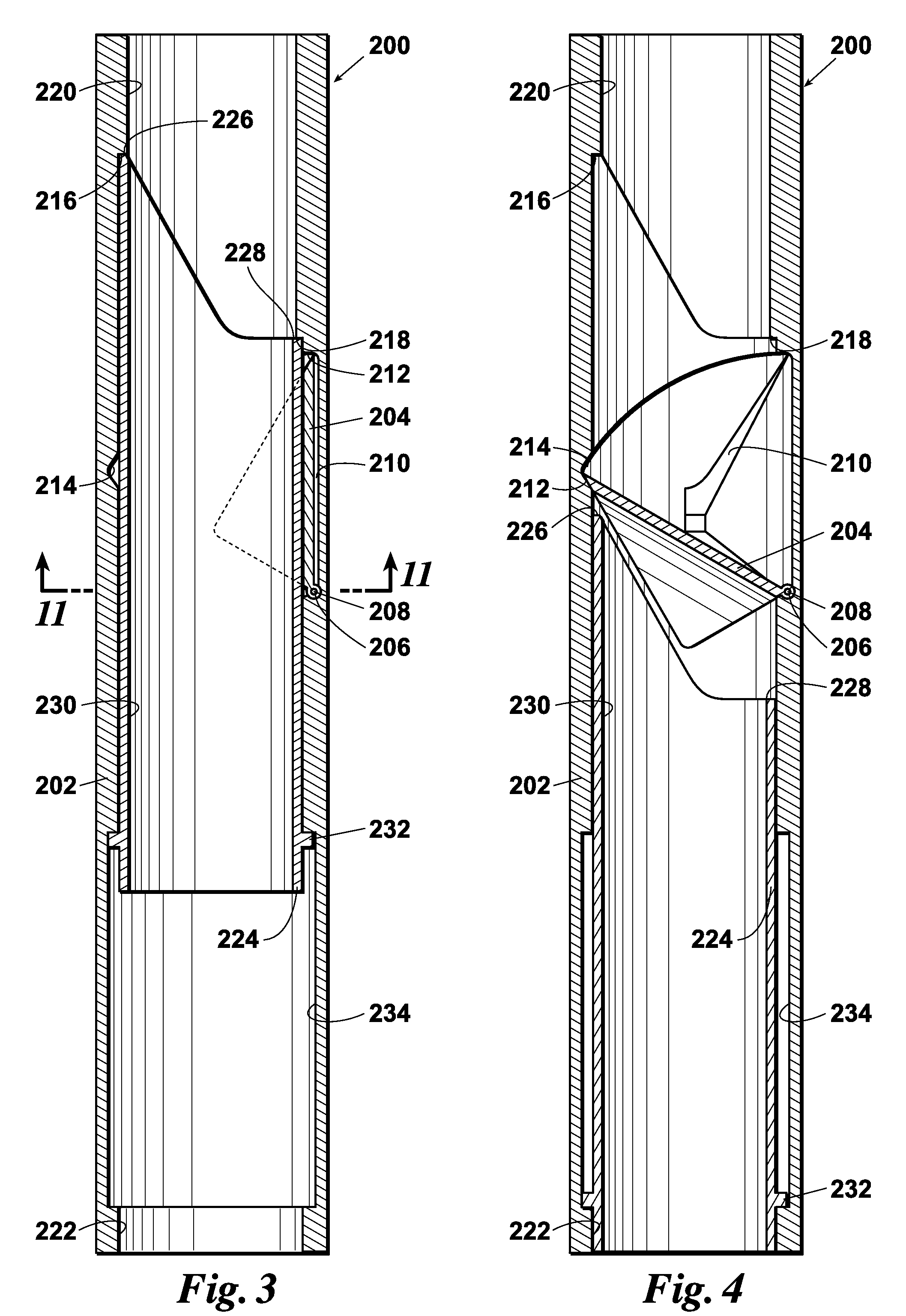

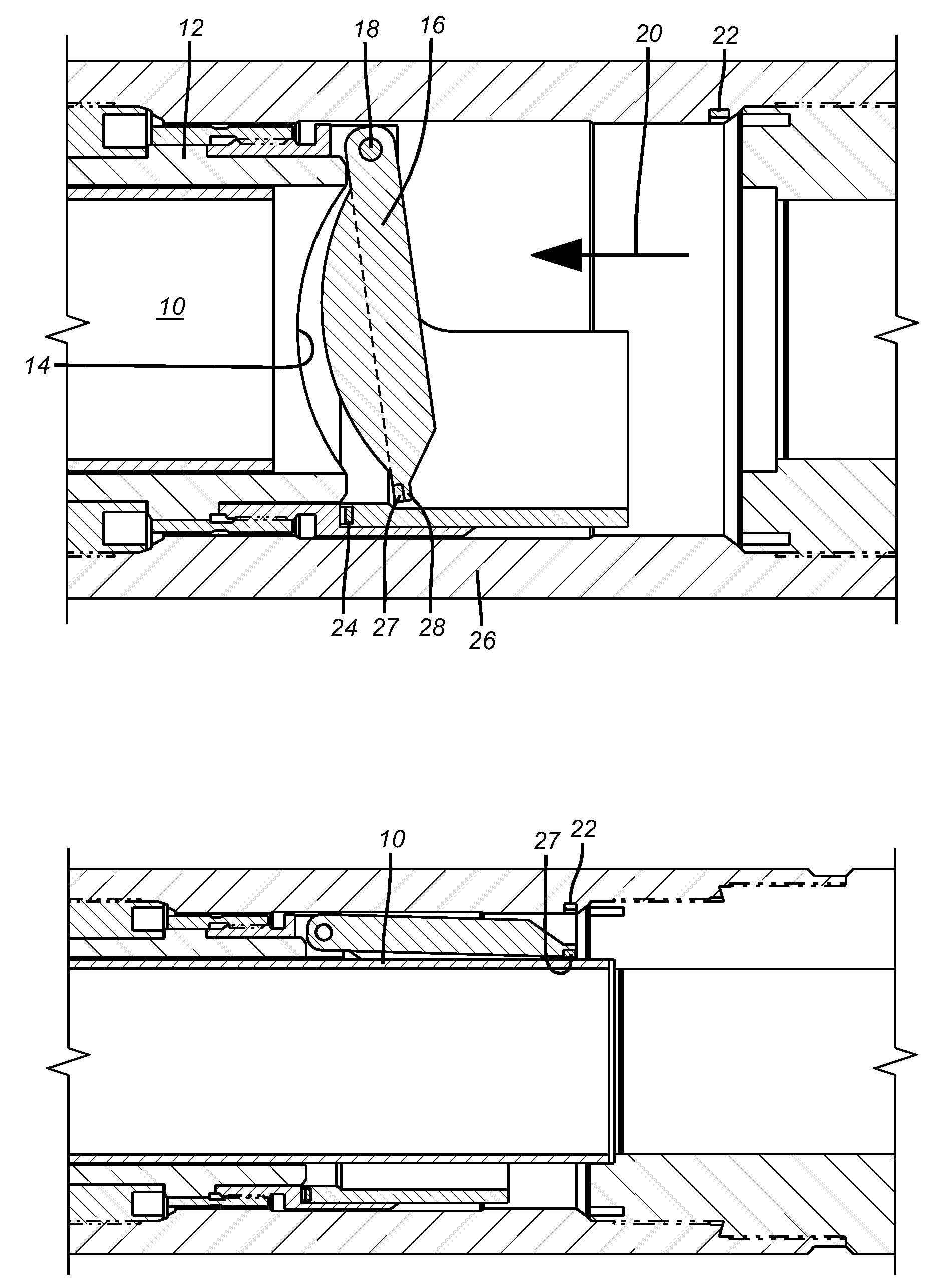

Apparatus and methods for utilizing a downhole deployment valve

Methods and apparatus for utilizing a downhole deployment valve (DDV) to isolate a pressure in a portion of a bore are disclosed. Any combination of fail safe features may be used with or incorporated into the DDV such as redundant valve members, an upward opening flapper valve or a metering flapper below a sealing valve. In one aspect, a barrier or diverter located in the bore above a valve member of the DDV permits passage through the bore when the valve member is open and actuates when the valve member is closed. Once actuated, the barrier or diverter either stops or diverts any dropped objects prior to the dropped object reaching and potentially damaging the valve member. In another aspect, the tool string tripped in above the DDV includes an acceleration actuated brake that anchors the tool string to a surrounding tubular if the tool string is dropped.

Owner:WEATHERFORD TECH HLDG LLC

Lock open and control system access apparatus and method for a downhole safety valve

A lock open device for a flapper is disclosed. The tool engages in the sub-surface safety valve (SSSV) body and rotates the flapper to the open position, without shifting the flow tube. The flapper base is preferably held by a shearable thread and has a groove for engagement by the tool. The tool jars down on the flapper base to shear the thread and force the held open flapper into a retaining groove. Optionally, a penetrating tool can be connected so that, in a single trip, the flapper can be locked open and the pressurized control system can be accessed. Shearing the thread allows the flow tube spring to bias the held open flapper into its retaining groove.

Owner:BAKER HUGHES INC

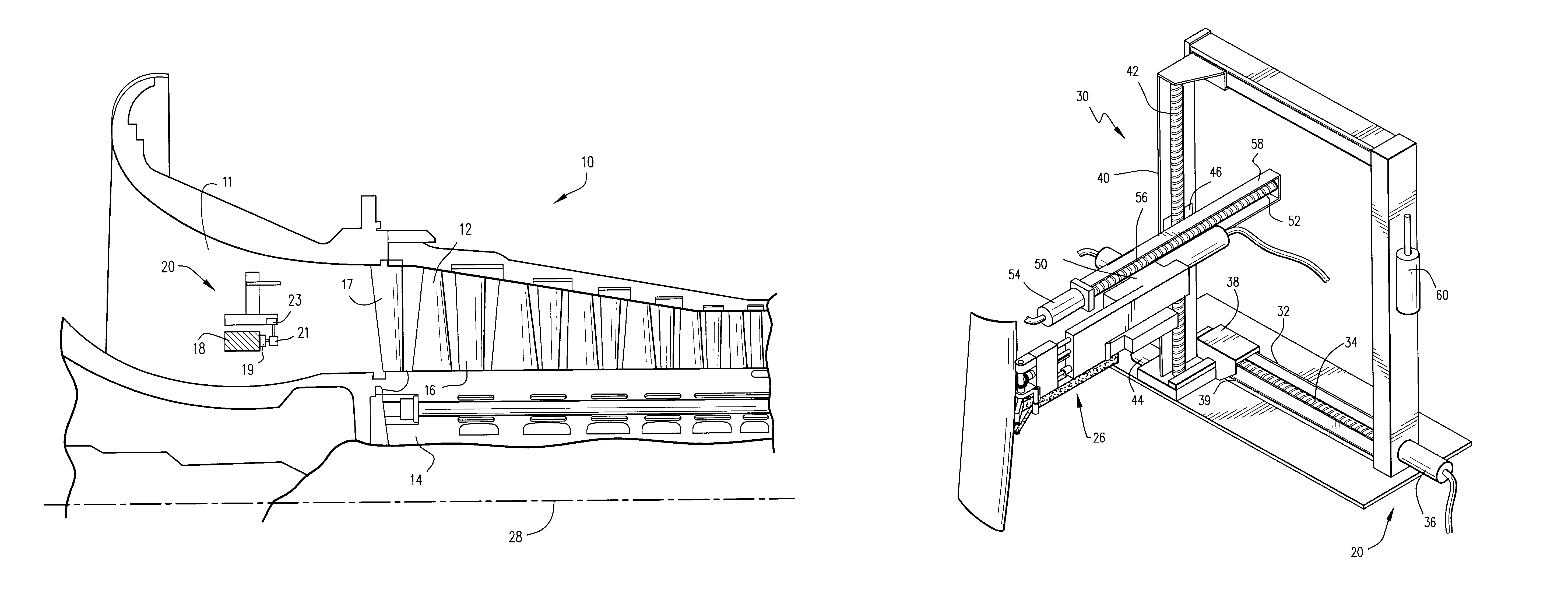

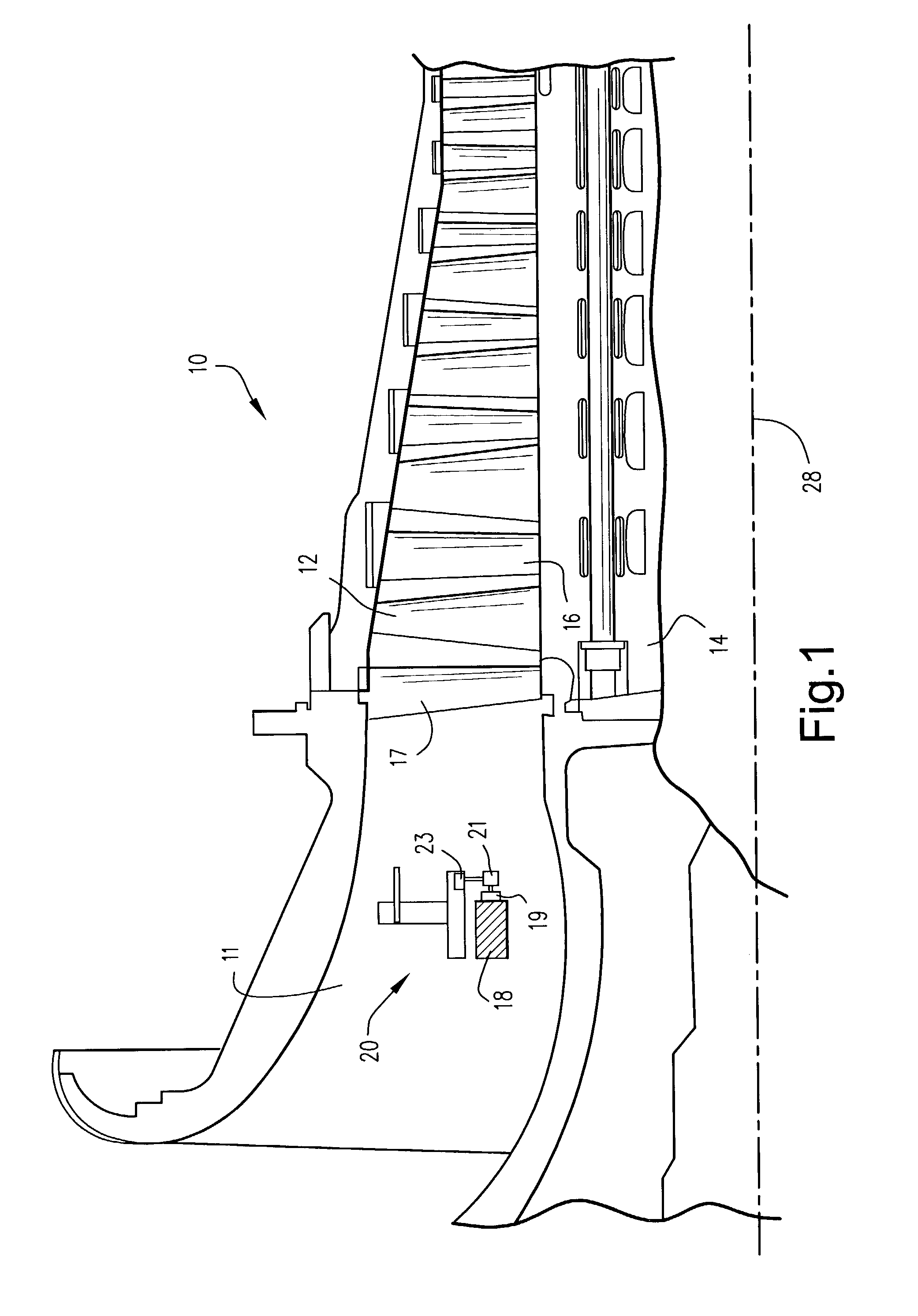

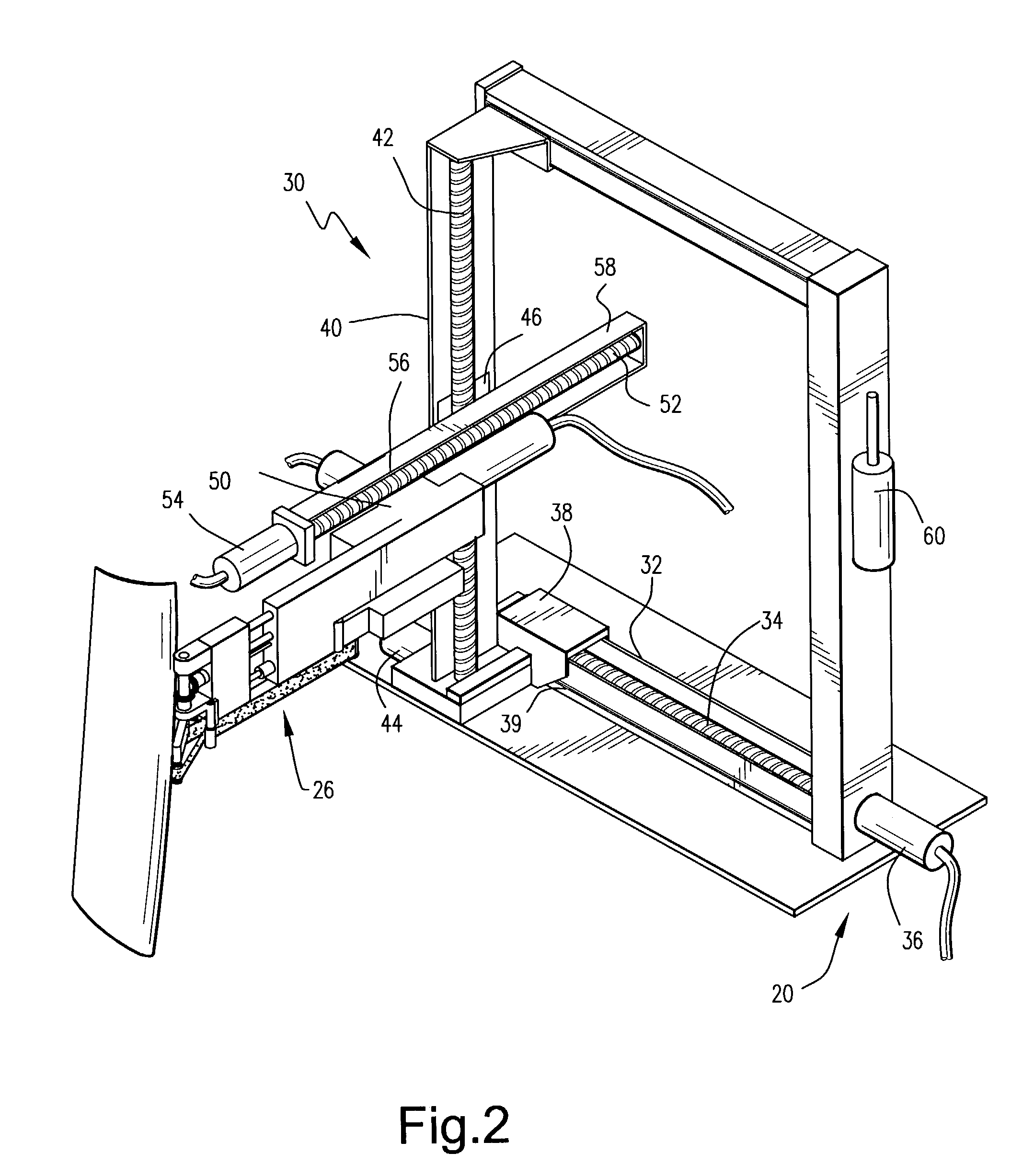

Apparatus and methods for repairing compressor airfoils in situ

InactiveUS7032279B2Maximize impactFine surfacePump componentsAssembly machinesEngineeringManipulator

The apparatus includes a track mounted in the inlet of a compressor. A manipulator is mounted for movement about the track and carries three modules, the last of which mounts a tool head for movement in a Cartesian coordinate system and about the track. A measuring head measures the location of the airfoil surface. An abrading tool mounted on the third module removes surface material from the airfoil. Subsequently, a shot-peening device, either a flapper with embedded shot or free shot is impacted against the abraded surface to strengthen the surface. Final inspection is performed by a light and camera head mounted on the third module.

Owner:GENERAL ELECTRIC CO

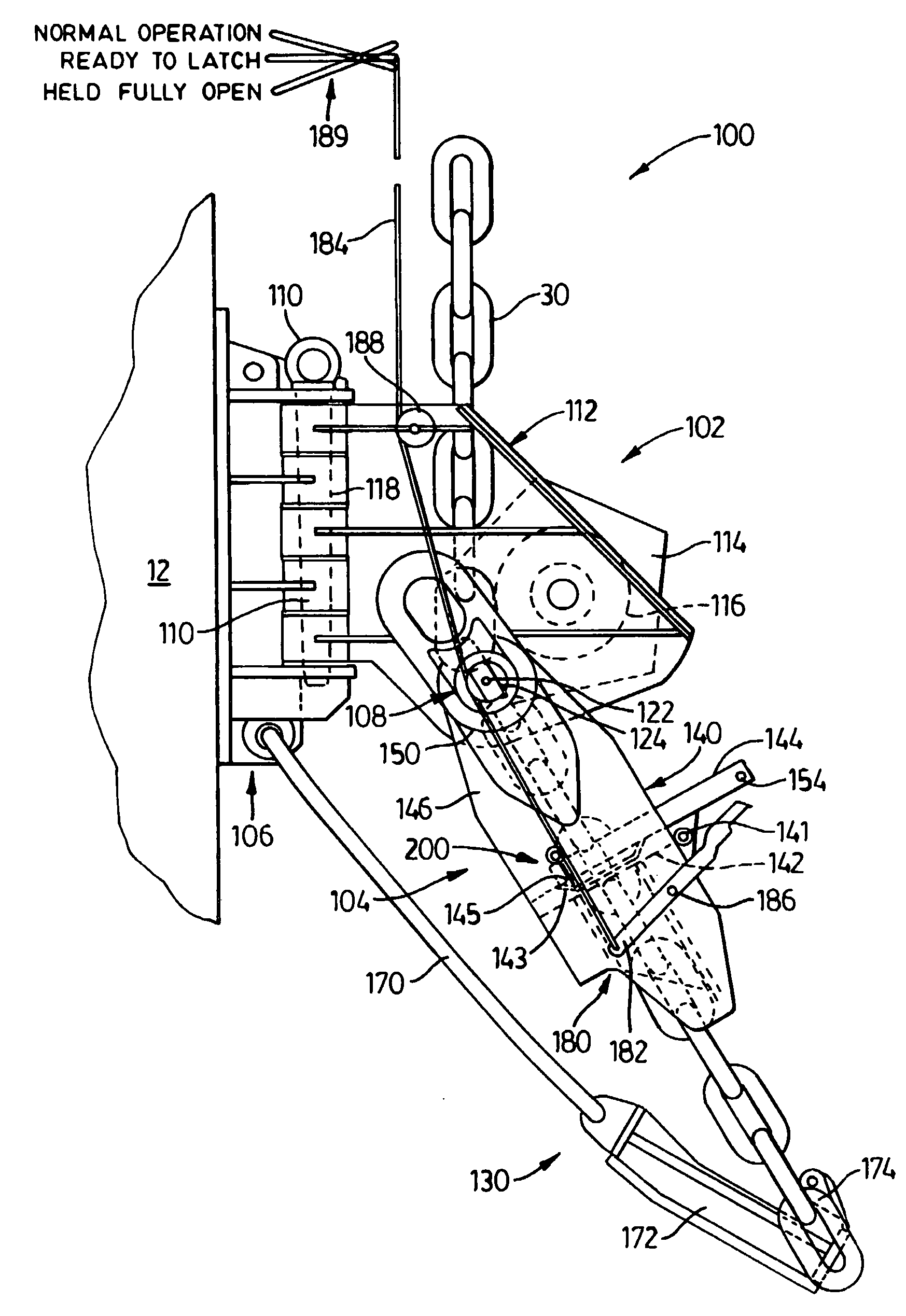

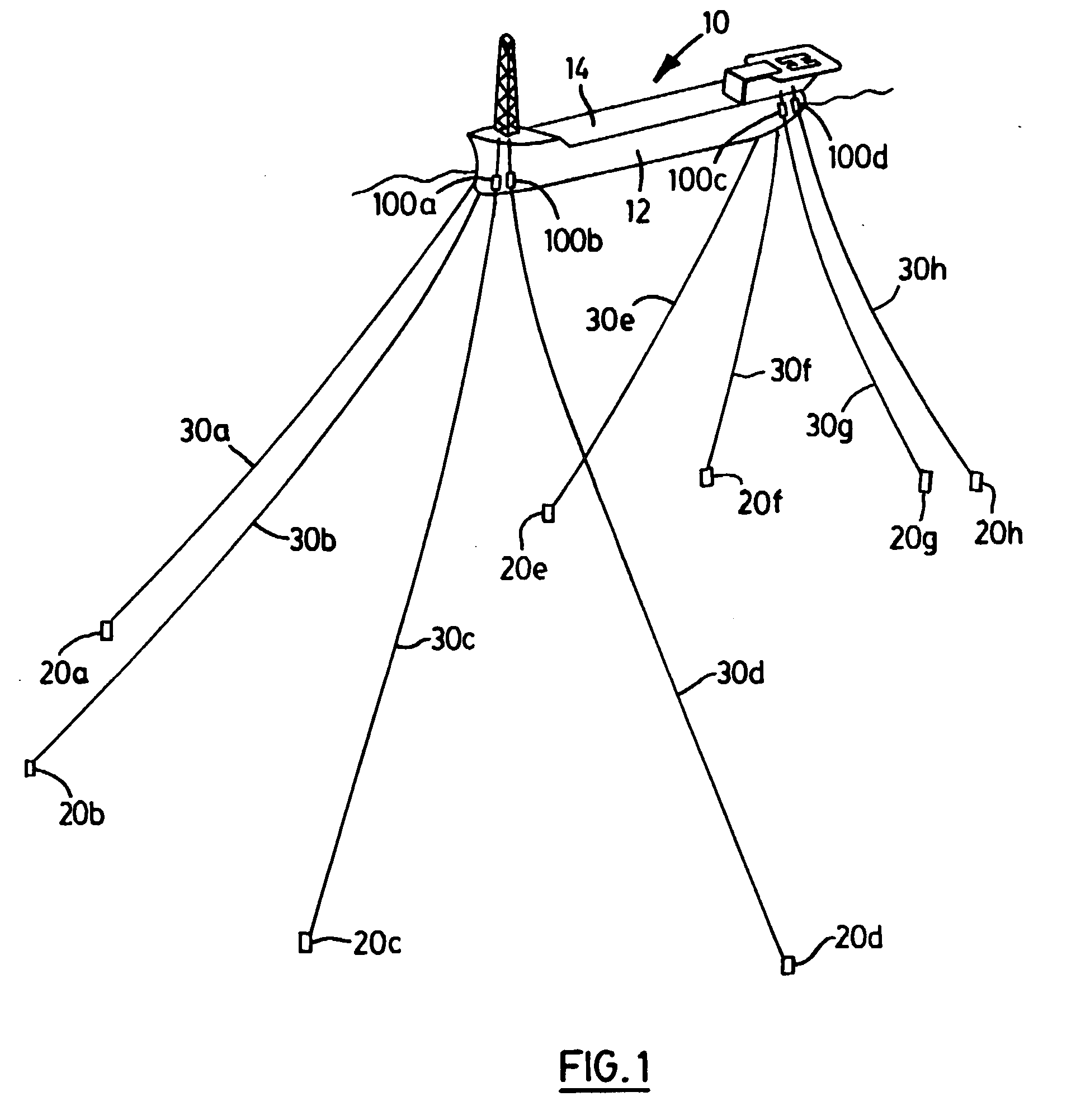

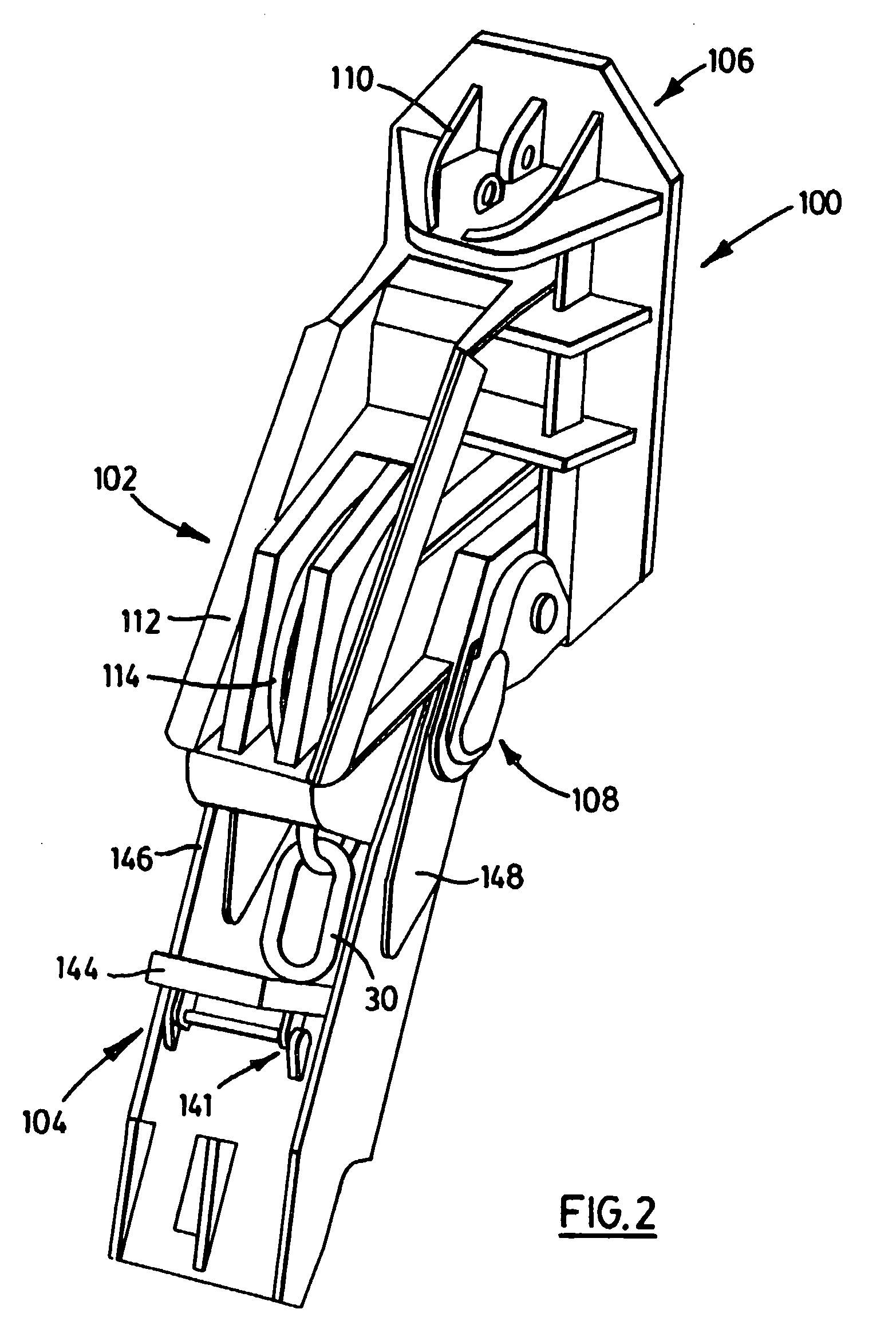

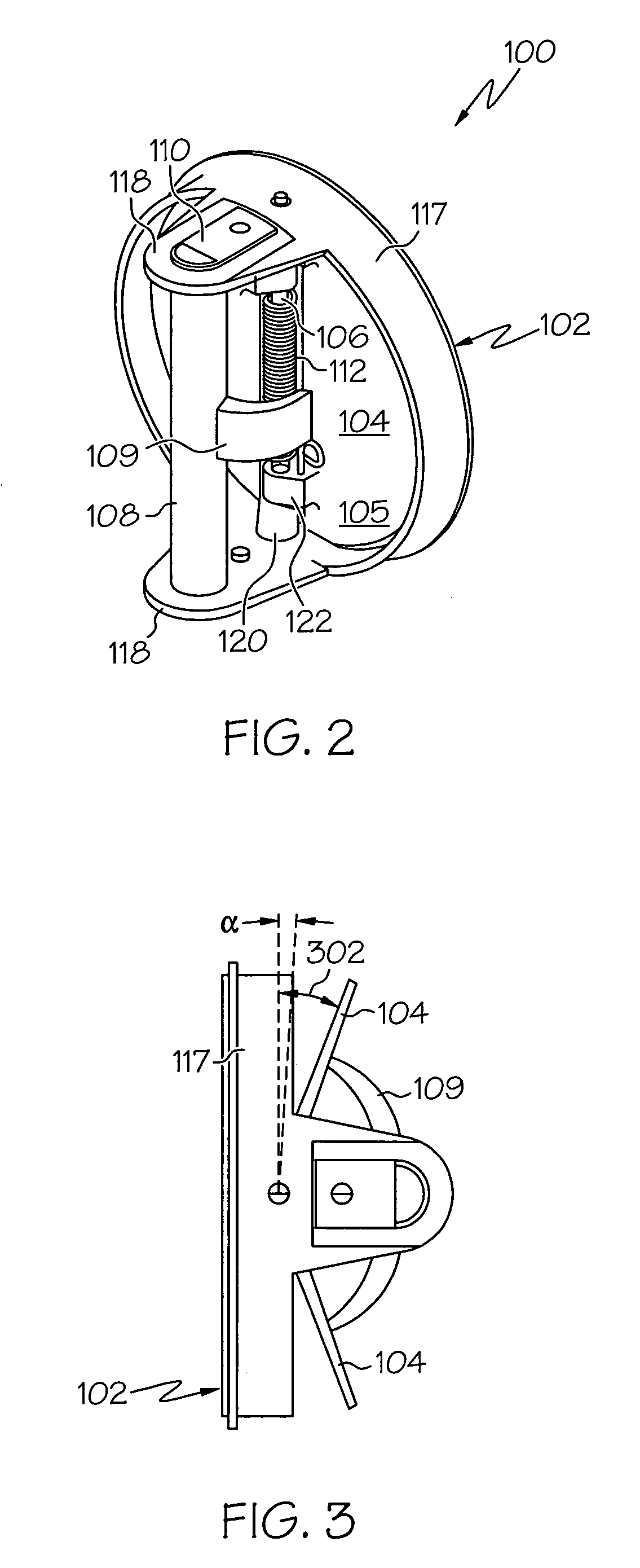

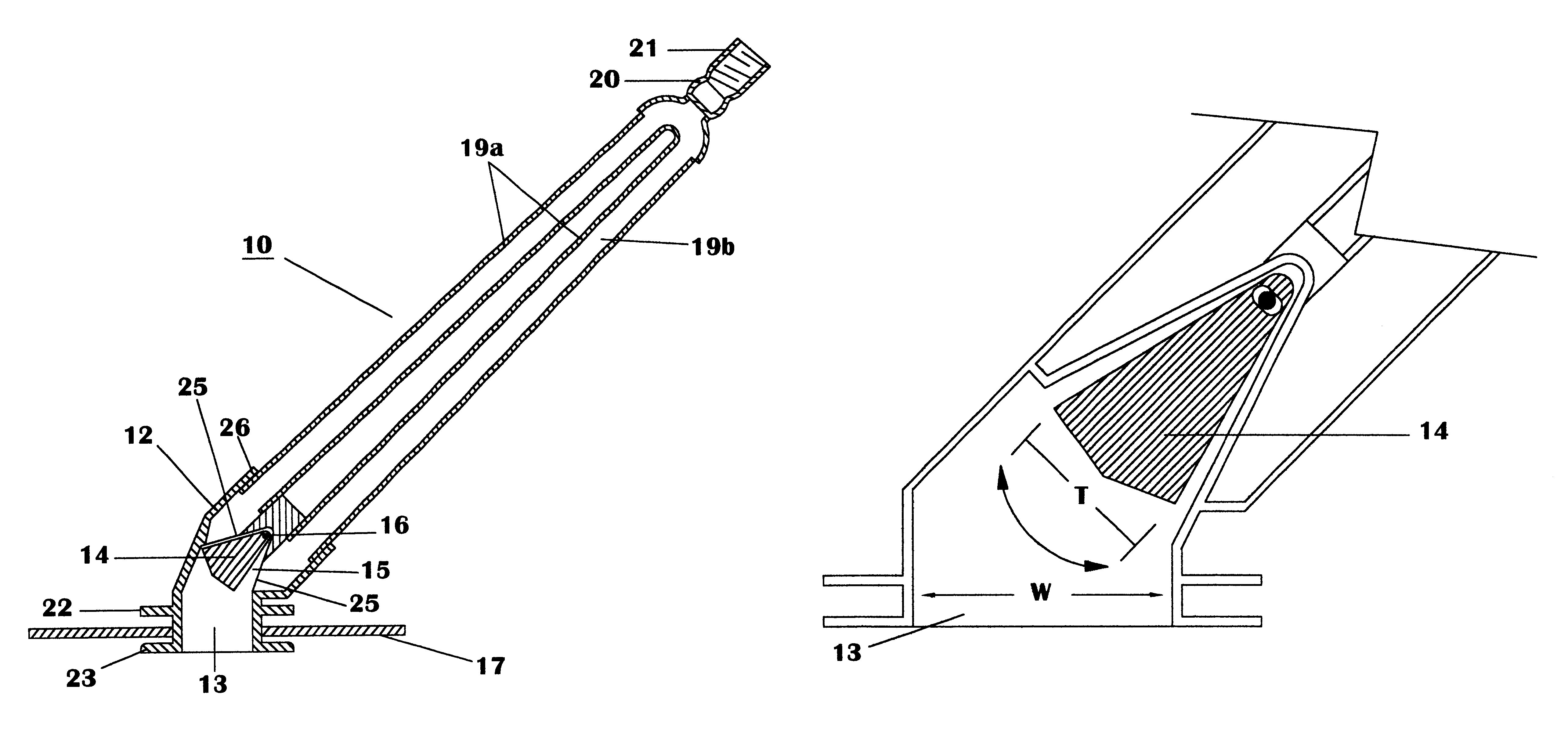

Underwater chain stopper and fairlead apparatus for anchoring offshore structures

ActiveUS20050241558A1Avoid large movementsChain fasteningsAnchoring arrangementsVertical planeSelf locking

An underwater chain stopper and fairlead apparatus for offshore structures, drilling platforms, ships or other vessels. The apparatus comprises a mounting member, a fairlead member and a chain stopper member. The mounting member is attached to an underwater surface of the offshore structure or vessel and includes a bracket for coupling the fairlead member. The bracket may comprise a hinge allowing the fairlead member to pivot in an approximately horizontal plane. The chain stopper member is coupled to the fairlead member through a hinge which allows the chain stopper member to pivot with respect to the fairlead member in an approximately vertical plane. The chain stopper member includes a chain stopper flapper having a horseshoe shaped opening at one end. The other end of the flapper is connected to the chain stopper member through a hinge which allows the flapper to swing between an open position and a closed position. In the open position, the chain links for the anchor chain are allowed to pass by the horseshoe shaped opening on the flapper. The horseshoe shaped opening also includes a chain link seat which stops movement of the anchor chain through the chain stopper member when the flapper is in the closed position. The chain stopper flapper moves to the closed position under the force of gravity to provide a self-locking chain stopper. A latch mechanism is provided for latching the chain stopper flapper in an open position.

Owner:TIMBERLAND EQUIP

Injection Valve with Indexing Mechanism

A flapper valve preferably used in injection application in deep subterranean locations has an actuating sleeve with a seat to accept an object. A j-slot connects the actuation sleeve movement to the housing so that with an object on the seat and an applied pressure cycle the sleeve moves the flapper to the open position. The plug is dissolved and the injection begins. The plug can have an opening so as to allow continuous injection flow as the flapper is operated. Closing the flapper involves a second object on the same seat and a pressure cycle so that a spring can push the sleeve away from the flapper to allow a torsion spring on the flapper to close it.

Owner:BAKER HUGHES INC

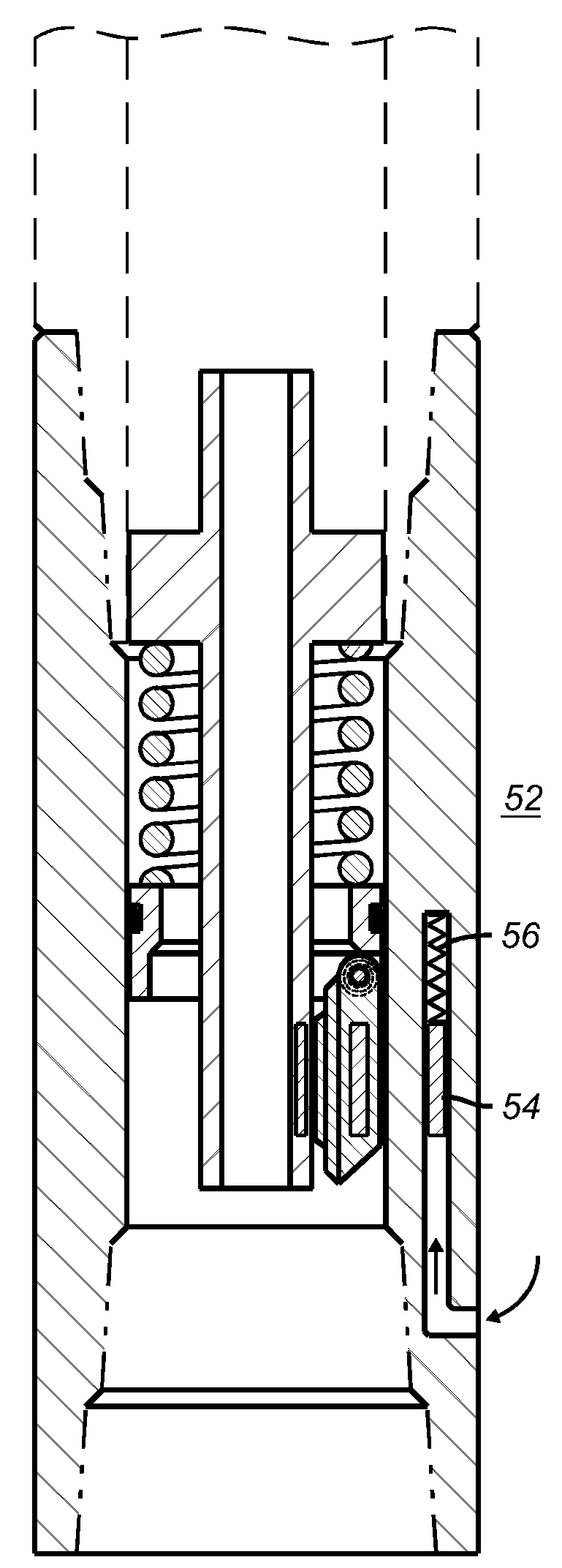

Tubing Retrievable Injection Valve

A flapper type downhole valve is opened by flow against the flapper. The flapper and the housing contain magnets that hold the flapper open after it has been opened by flow to keep the flapper from chattering from the flow going past it. The strength of the force is not sufficient to hold the flapper open against a torsion spring on a pivot pin, when there is no flow through the valve. The valve can still be held in the locked open position with no flow through the housing by pressurizing the surrounding annulus to position another magnet to increase the holding force to a level greater than the force of the torsion spring. The additional magnet is spring biased so that upon removal of annulus pressure it shifts to allow the flapper to close. Alternative designs with and without a flow tube are possible. Fixed or movable restrictions can be associated with the flow tube to create a force to shift it to open a flapper with flow into the well.

Owner:BAKER HUGHES INC

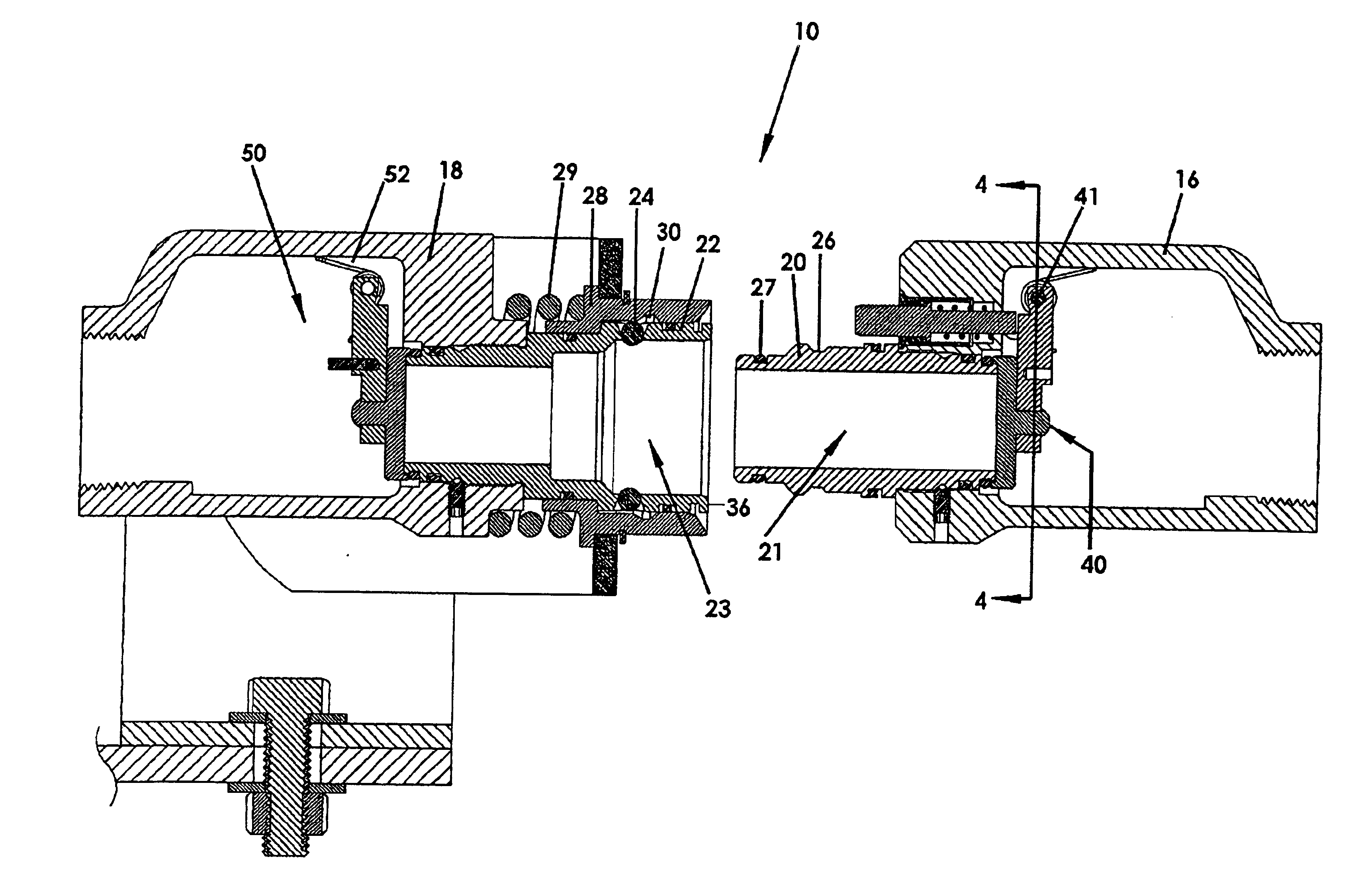

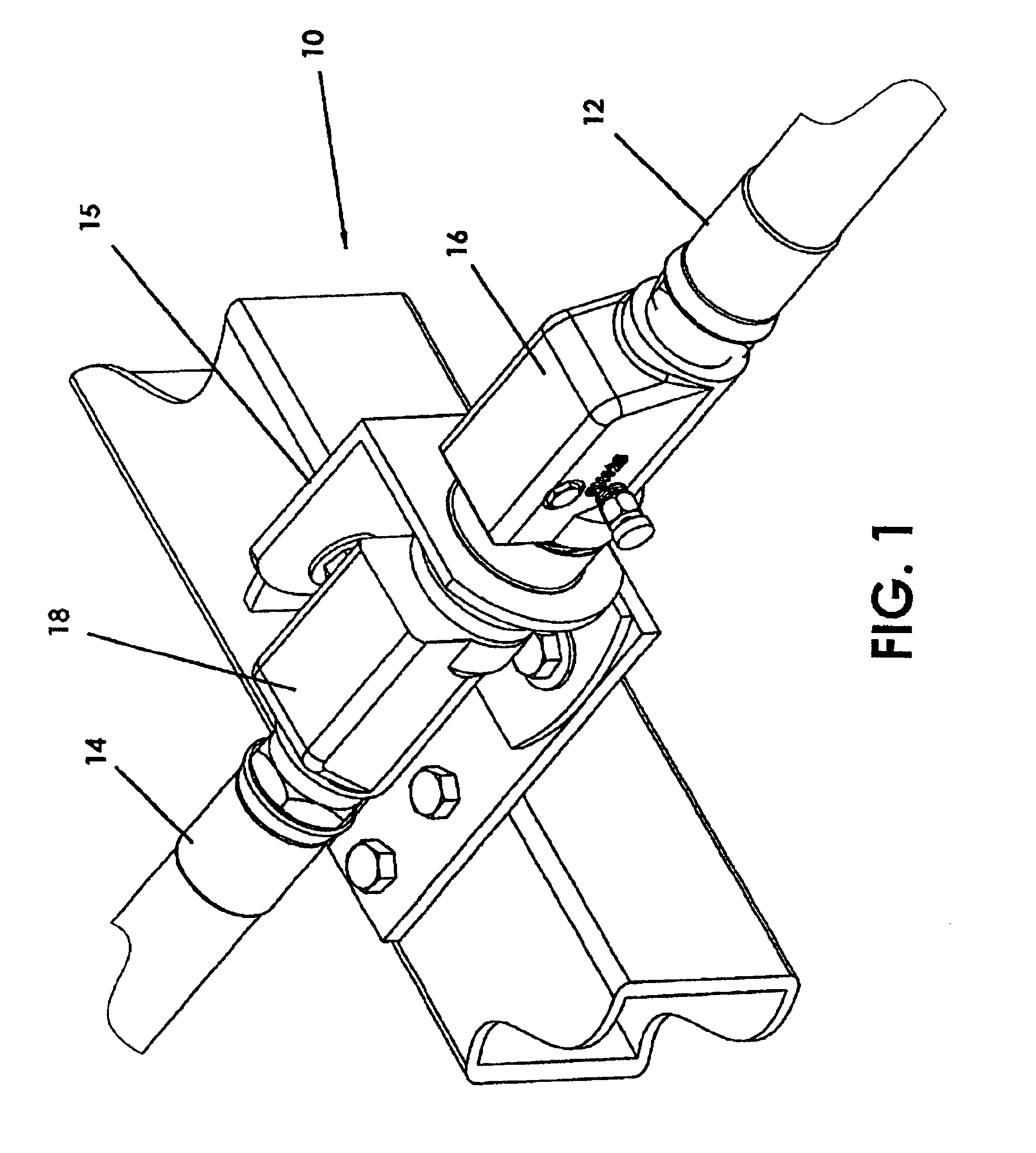

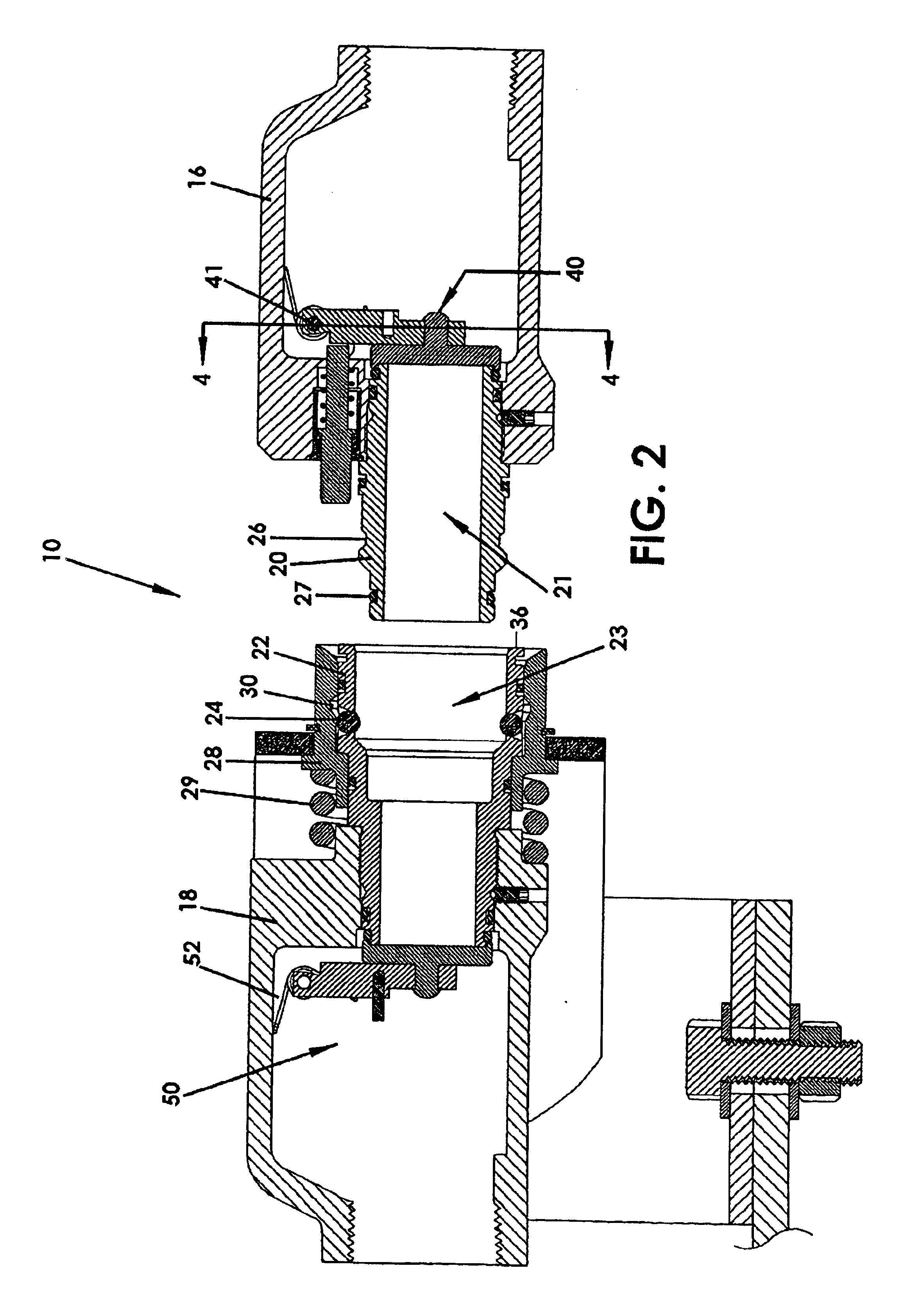

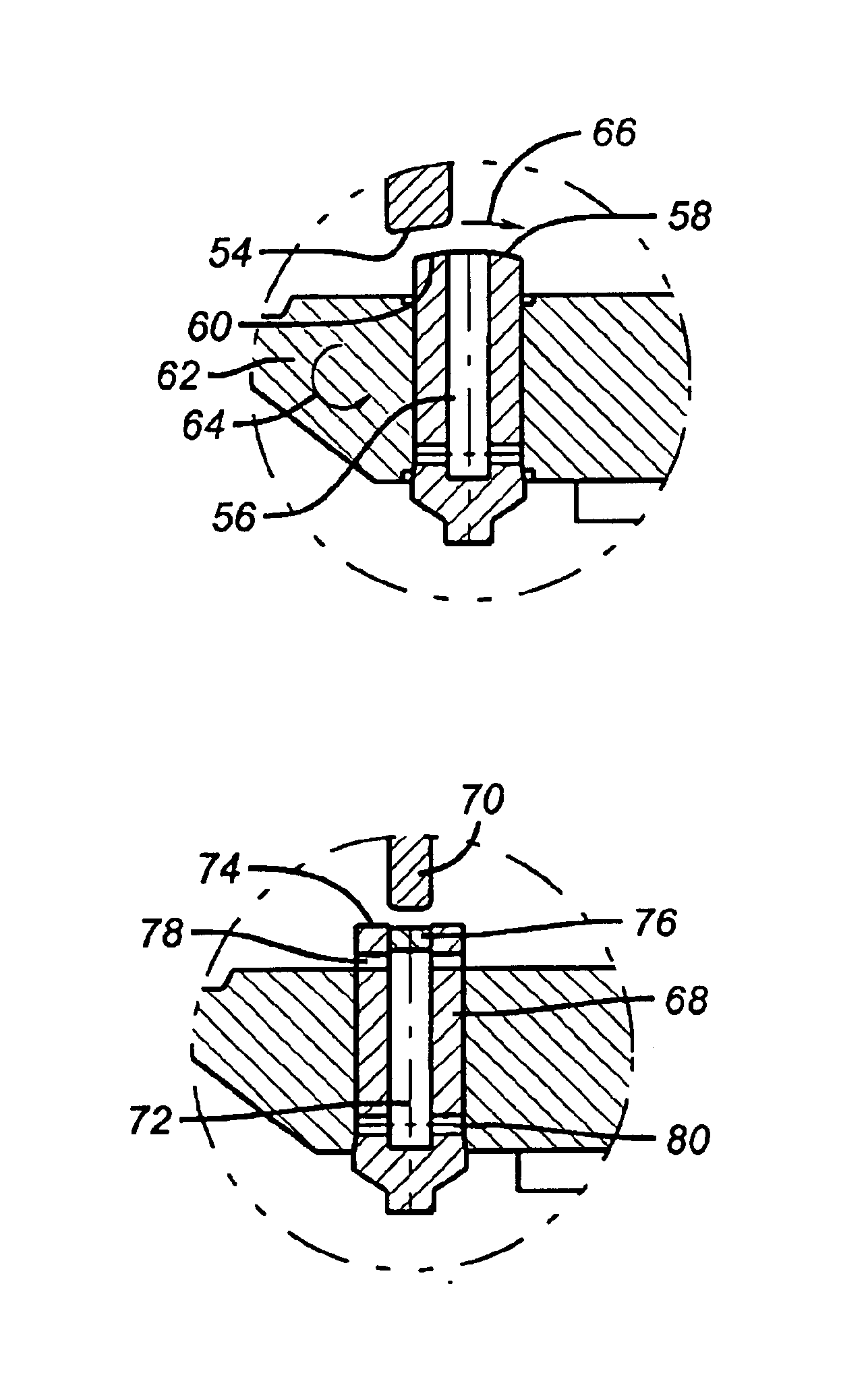

Breakaway coupling with flapper valve

A breakaway coupler for coupling upstream and downstream hose includes one or more locking balls carried by a downstream coupling member. An upstream flapper is pivotally secured with respect to an upstream housing. A pushrod is axially movable in response to engagement by the downstream coupling member. A pry recess on the downstream coupling member is spaced between the downstream housing g and the upstream housing, such that a tool inserted into the pry recess is leverageable to move the downstream coupling member to unlock the breakaway coupler.

Owner:PARKER INTANGIBLES LLC

Method and apparatus for locking out a subsurface safety valve

The present invention is directed to a method and apparatus of locking out a subsurface safety valve (SSV) in a hydrocarbon wellbore. A lockout tool is provided that is dimensioned to be received within the housing of the safety valve. The lockout tool generally comprises an elongated housing, and an expander mandrel slidably received within the housing. Together, the housing and expander mandrel are run into the wellbore and landed into the housing of the SSV such that the end of the expander mandrel opens the flapper valve. A portion of the lockout tool housing shoulders against the flow tube in the SSV to drive the flow tube downward, thereby maintaining the flapper of the SSV in its open position. As the expander mandrel moves downward through the hard seat of the SSV, the mandrel engages the flow tube and expands it against the hard seat. In this manner, the flow tube is expanded into permanent, frictional engagement with the hard seat. This, in turn, locks the flapper member of the SSV in its open position.

Owner:WEATHERFORD TECH HLDG LLC

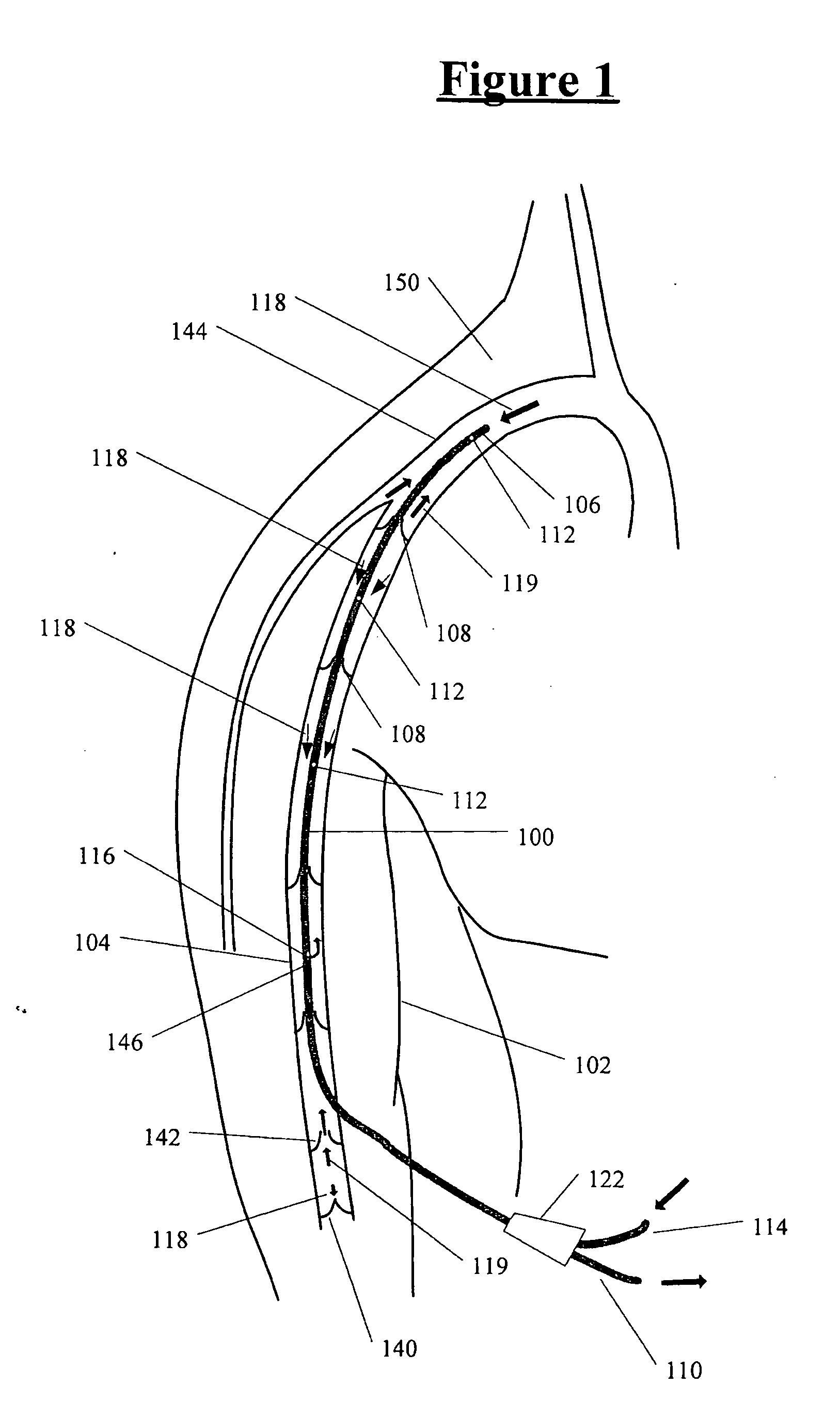

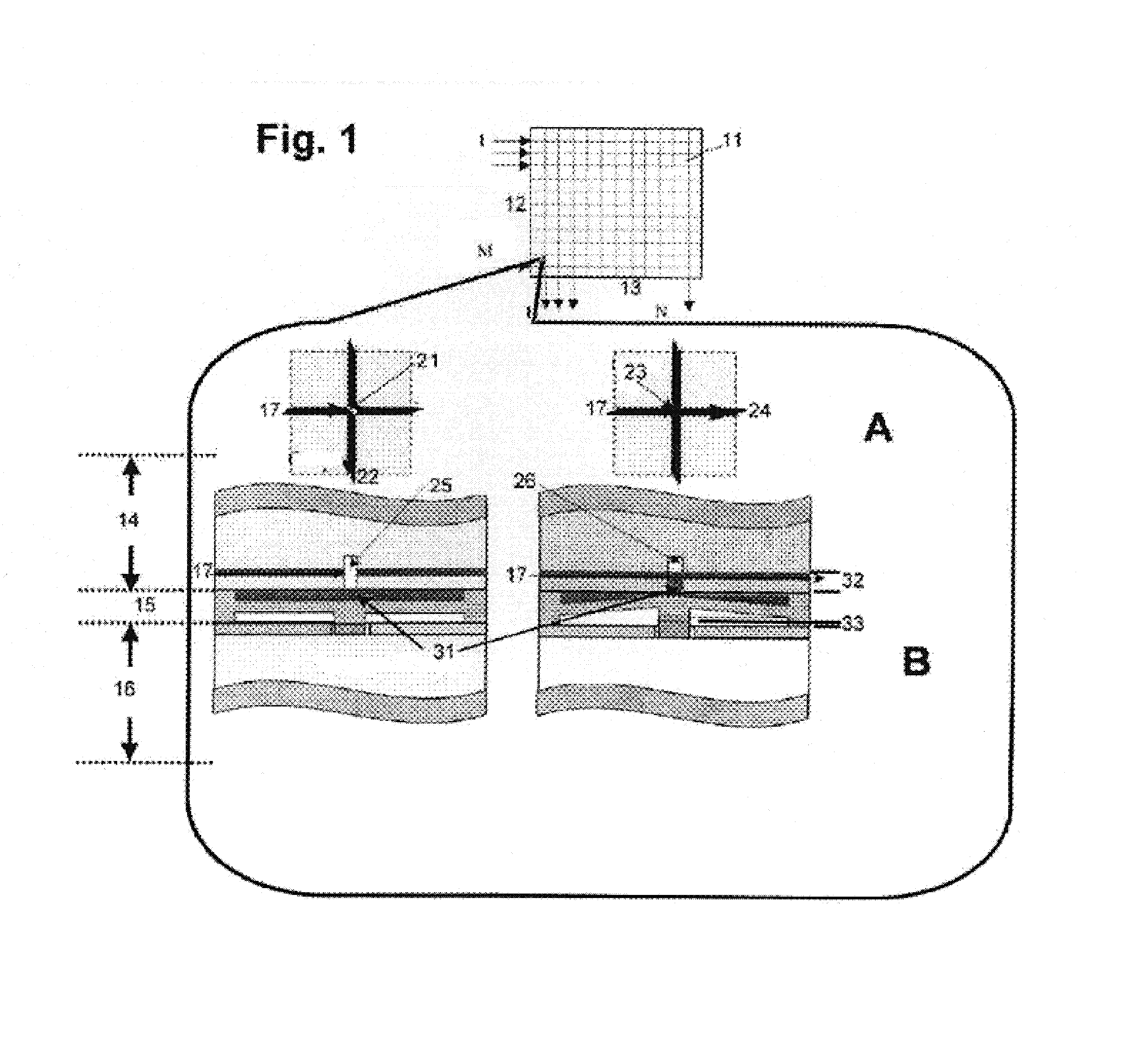

Peripheral access venous cannula with infusion side holes and embedded reinforcement

A peripherally inserted catheter assembly having multiple side holes to be inserted in a peripheral vein and maneuvered upward through the vascular system to access the reservoir of blood beyond and between the venous flappers for continuous blood withdrawal and treatment.

Owner:CHF SOLUTION

Reciprocating microfluidic pump system for chemical or biological agents

InactiveUS7195465B2Raise the potentialLong processPositive displacement pump componentsFlexible member pumpsFuel tankElectron microscope

A miniature pump has at least one controllable expansion-and-contraction chamber, and associated pair of tiny ducts interconnecting a fluid source and destination. The ducts communicate with the chamber(s); an linking tunnel links the ducts. Valves interact with fluid pressures due to expansion and contraction, imposing directionality on flow in the ducts and tunnel. Preferences: making the valve a passive flapper, implanting the pump in a creature, making the source a medication reservoir for supplying the creature; making the source a fuel tank and destination a tiny engine; making the source provide a specimen for assay and destination an observation slide; human or automatic examination of the slide under a microscope (e. g. electron microscope); making the source a reagent and destination a process stream; making the source a colorant and destination a colorant application system. Preferably included is an optical channel with intersecting fluid duct for optically monitoring pumped fluid.

Owner:KANE DAVID +1

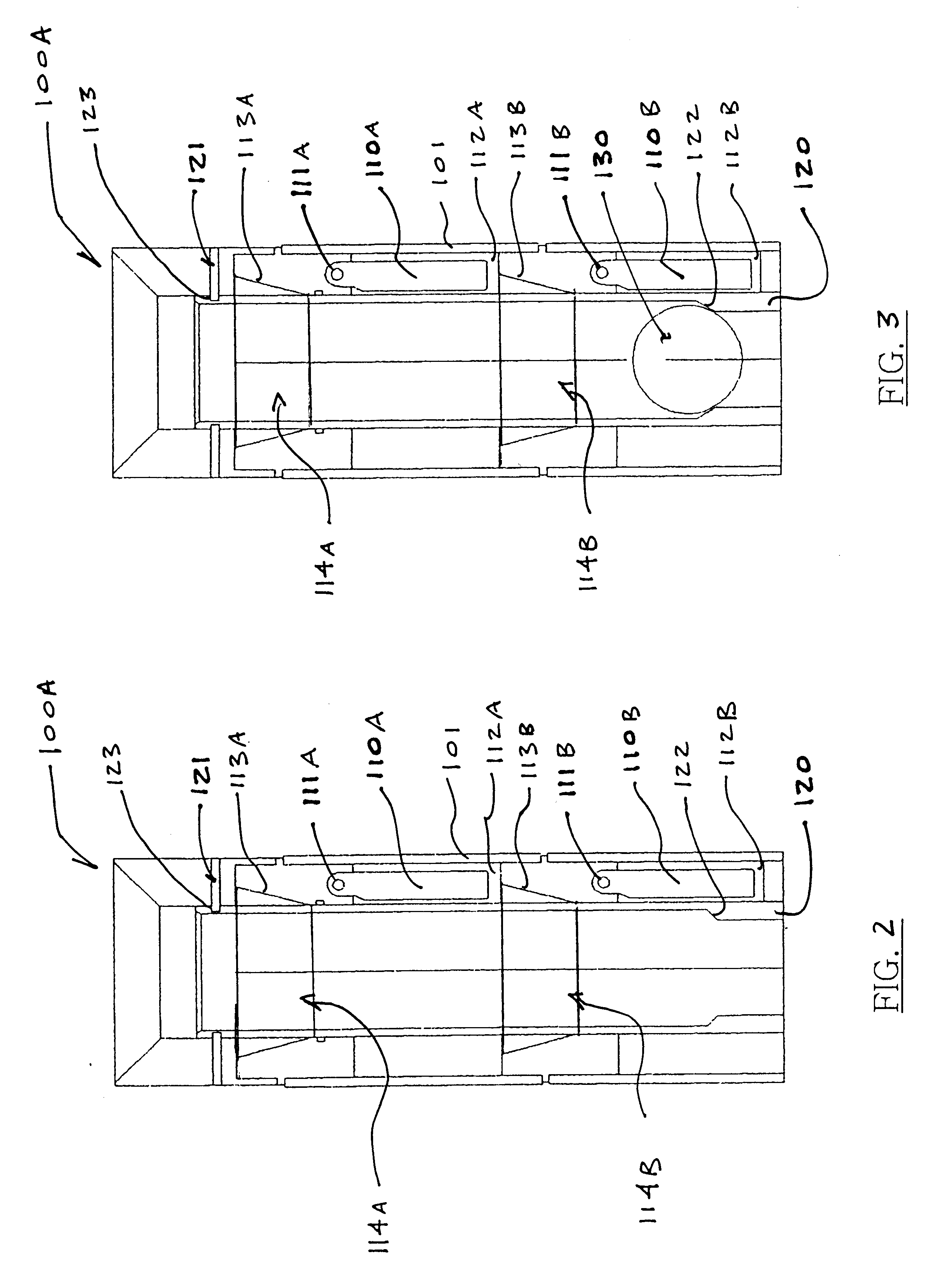

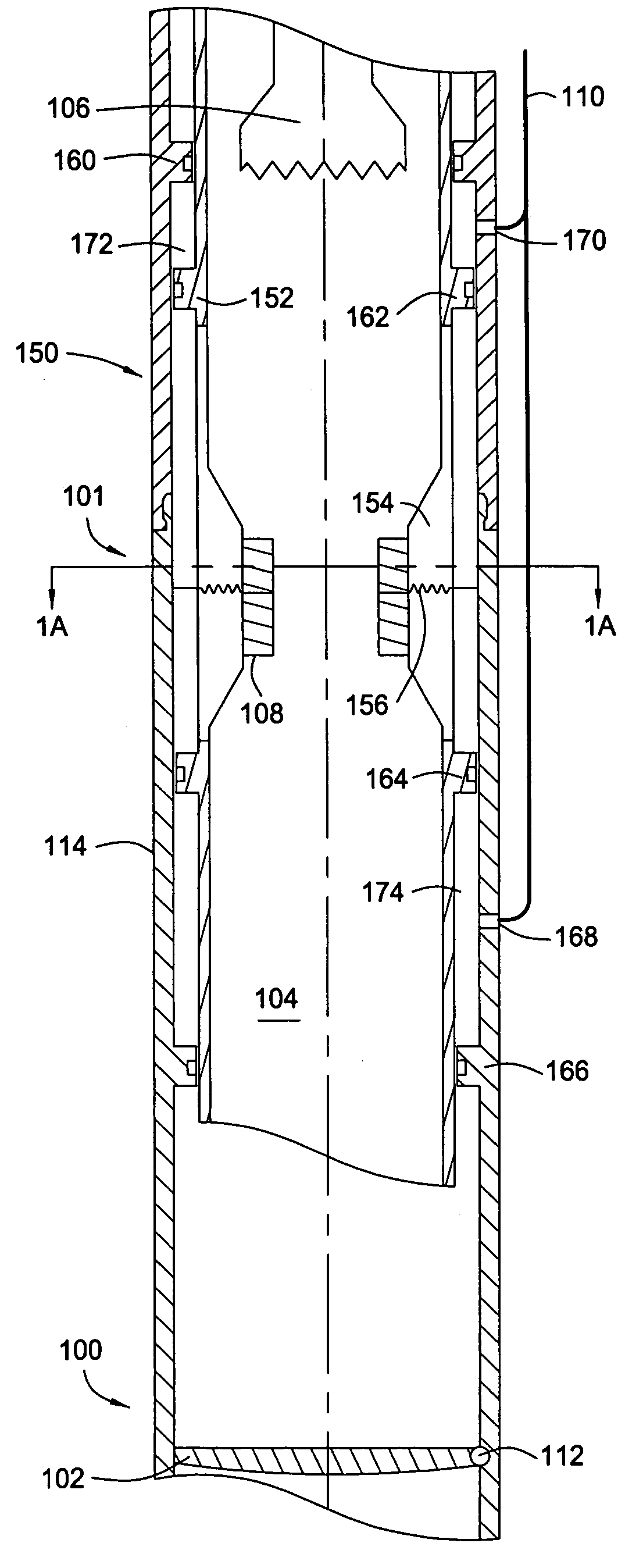

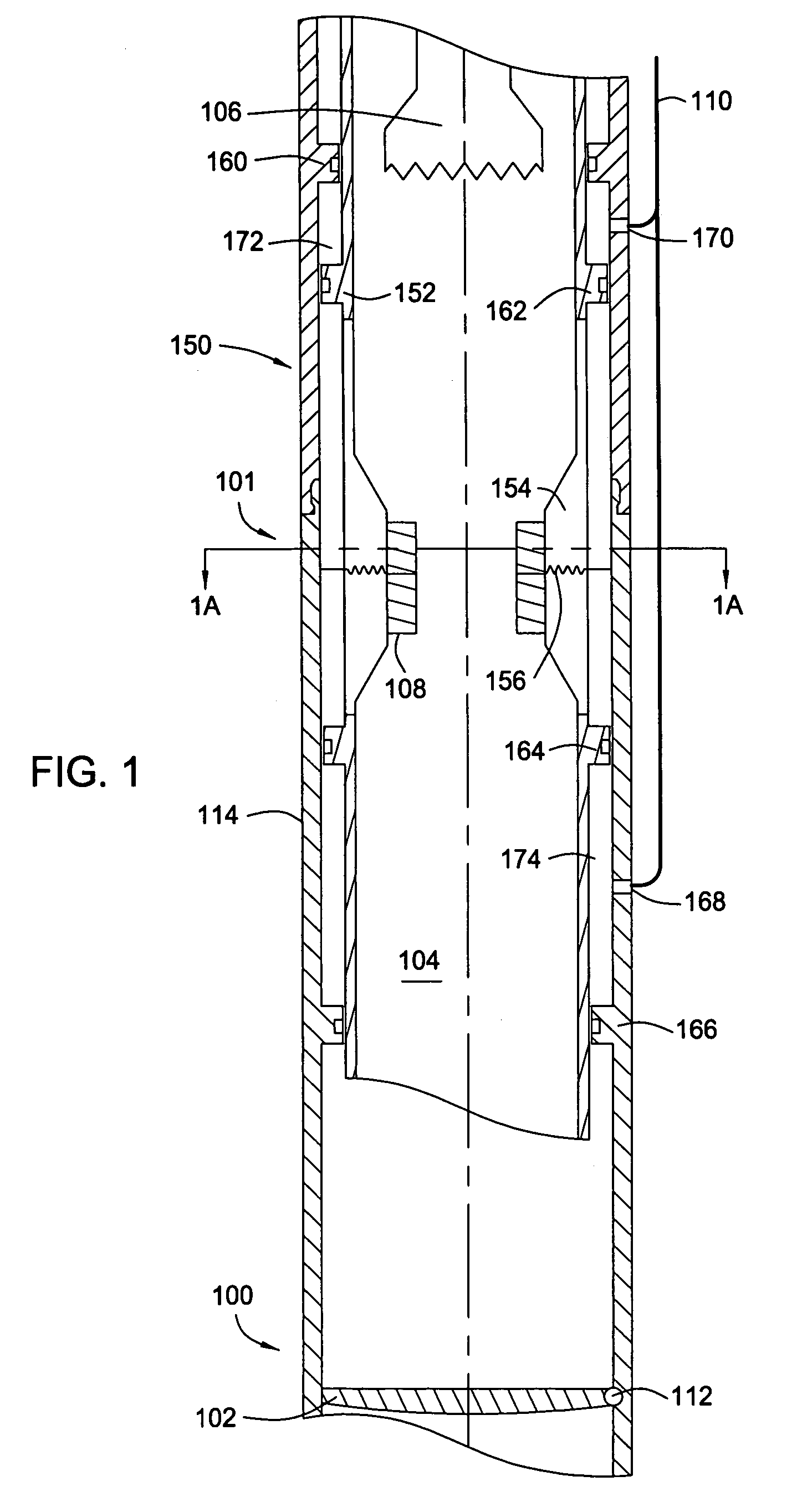

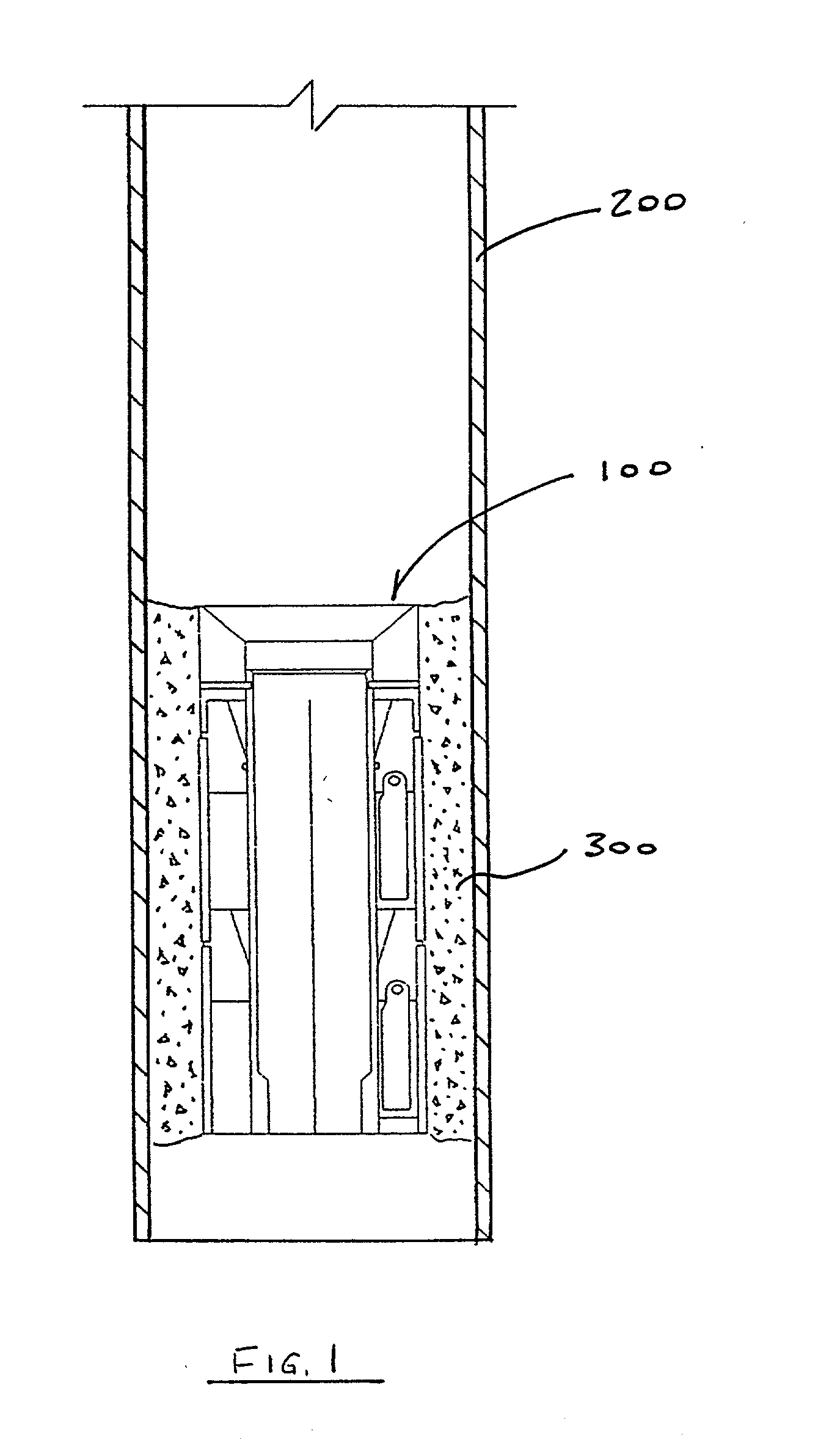

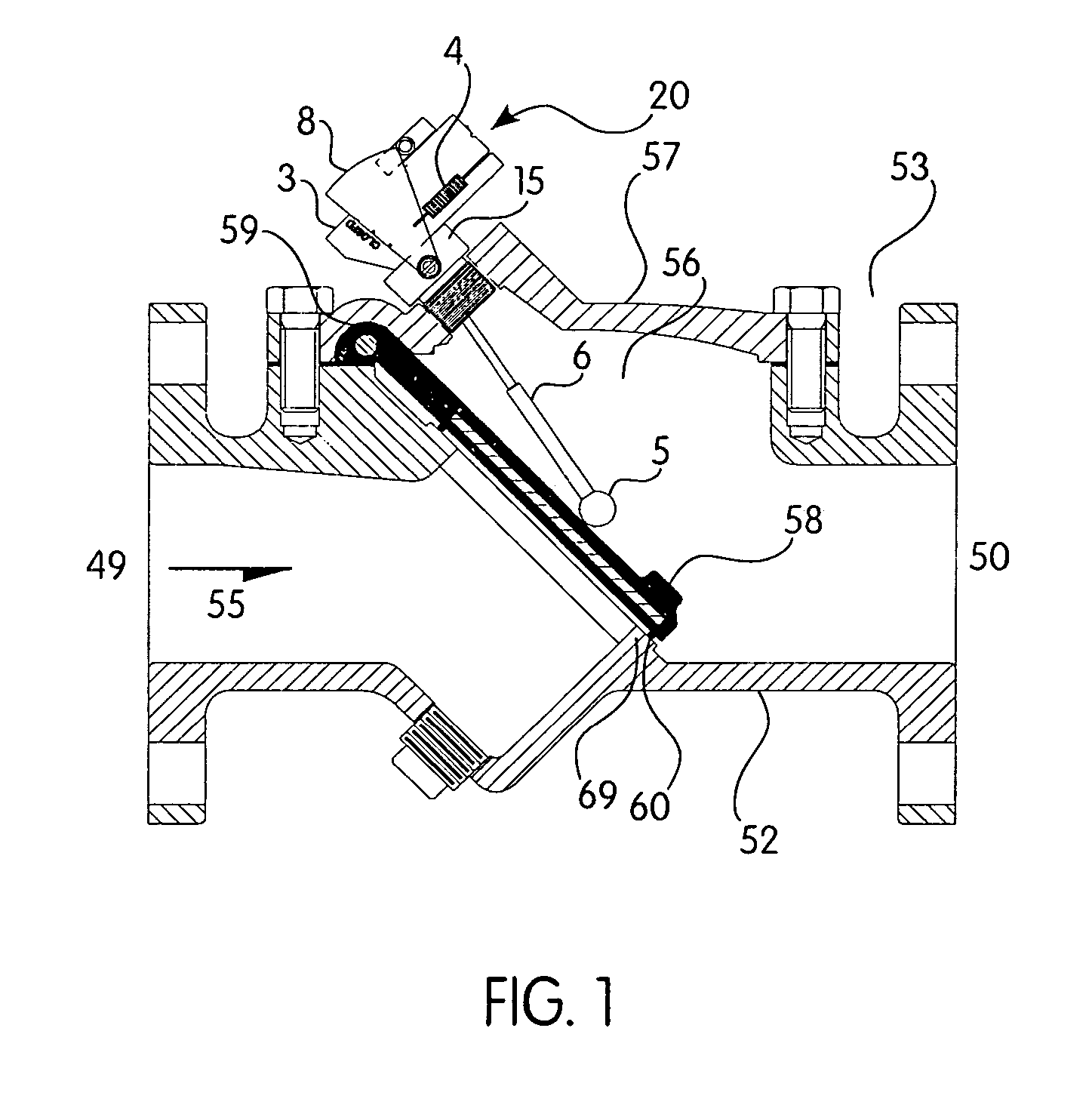

Flapper latch

The present invention generally relates to a method and an apparatus for selectively isolating a portion of a wellbore. In one aspect, an apparatus for isolating a zone in a wellbore is provided. The apparatus includes a body having a bore. The apparatus further includes a first flapper member and a second flapper member, each flapper member selectively rotatable between an open position and a closed position. Additionally, the apparatus includes a flapper latch assembly disposed in the bore, the flapper latch assembly movable between an unlocked position and a locked position, wherein the flapper latch assembly is configured to hold the first flapper member in the closed position when the flapper latch assembly is in the locked position. In another aspect, a method for selectively isolating a zone in a wellbore is provided. In yet a further aspect, a flapper latch assembly for use with a flapper valve is provided.

Owner:WEATHERFORD TECH HLDG LLC

Tubing retrievable injection valve

A flapper type downhole valve is opened by flow against the flapper. The flapper and the housing contain magnets that hold the flapper open after it has been opened by flow to keep the flapper from chattering from the flow going past it. The strength of the force is not sufficient to hold the flapper open against a torsion spring on a pivot pin, when there is no flow through the valve. The valve can still be held in the locked open position with no flow through the housing by pressurizing the surrounding annulus to position another magnet to increase the holding force to a level greater than the force of the torsion spring. The additional magnet is spring biased so that upon removal of annulus pressure it shifts to allow the flapper to close. Alternative designs with and without a flow tube are possible. Fixed or movable restrictions can be associated with the flow tube to create a force to shift it to open a flapper with flow into the well.

Owner:BAKER HUGHES HLDG LLC

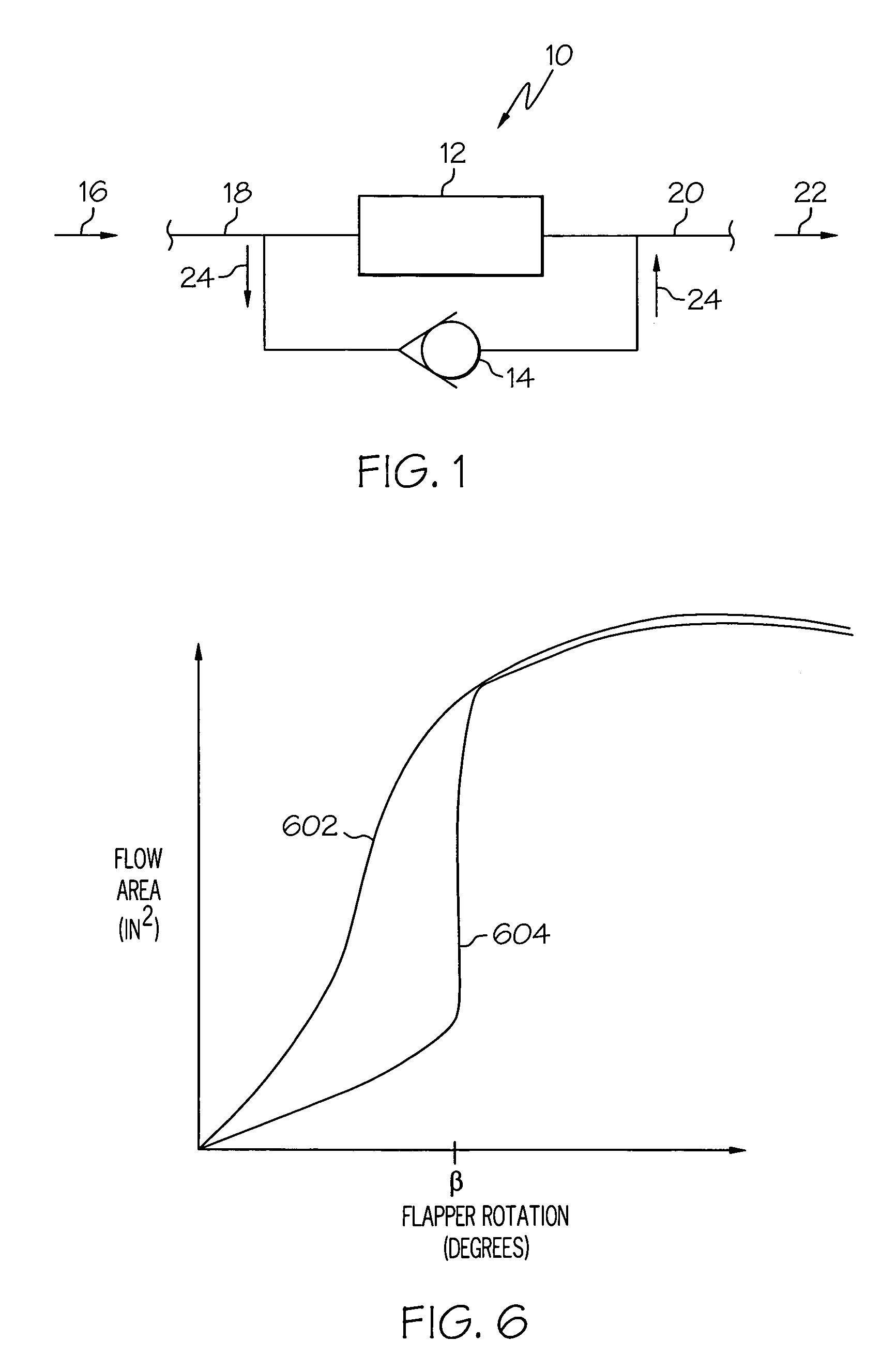

Snap acting split flapper valve

Owner:HONEYWELL INT INC

Water sensitive variable counterweight device driven by osmosis

InactiveUS20090236102A1Fluid removalWell/borehole valve arrangementsControl flowHydrocotyle bowlesioides

A method for producing fluid from a subterranean formation includes configuring a body to at least partially fill with a selected fluid; and actuating a flow restriction element using the body. The selected fluid may be water. An apparatus for controlling flow of a fluid into a wellbore tubular may include a selectively buoyant body, and a flow restriction element responsive to a movement of the selectively buoyant body. The selectively buoyant body includes a membrane configured to block a flow of hydrocarbons into the selectively buoyant body. The flow restriction element may include a flapper, a sliding sleeve, and a poppet valve. The body may be at least partially filled with a permeable material, which includes, but is not limited to, open-cell foam, reticulated metal foam, shaped sintered powder and capillary tubes.

Owner:BAKER HUGHES INC

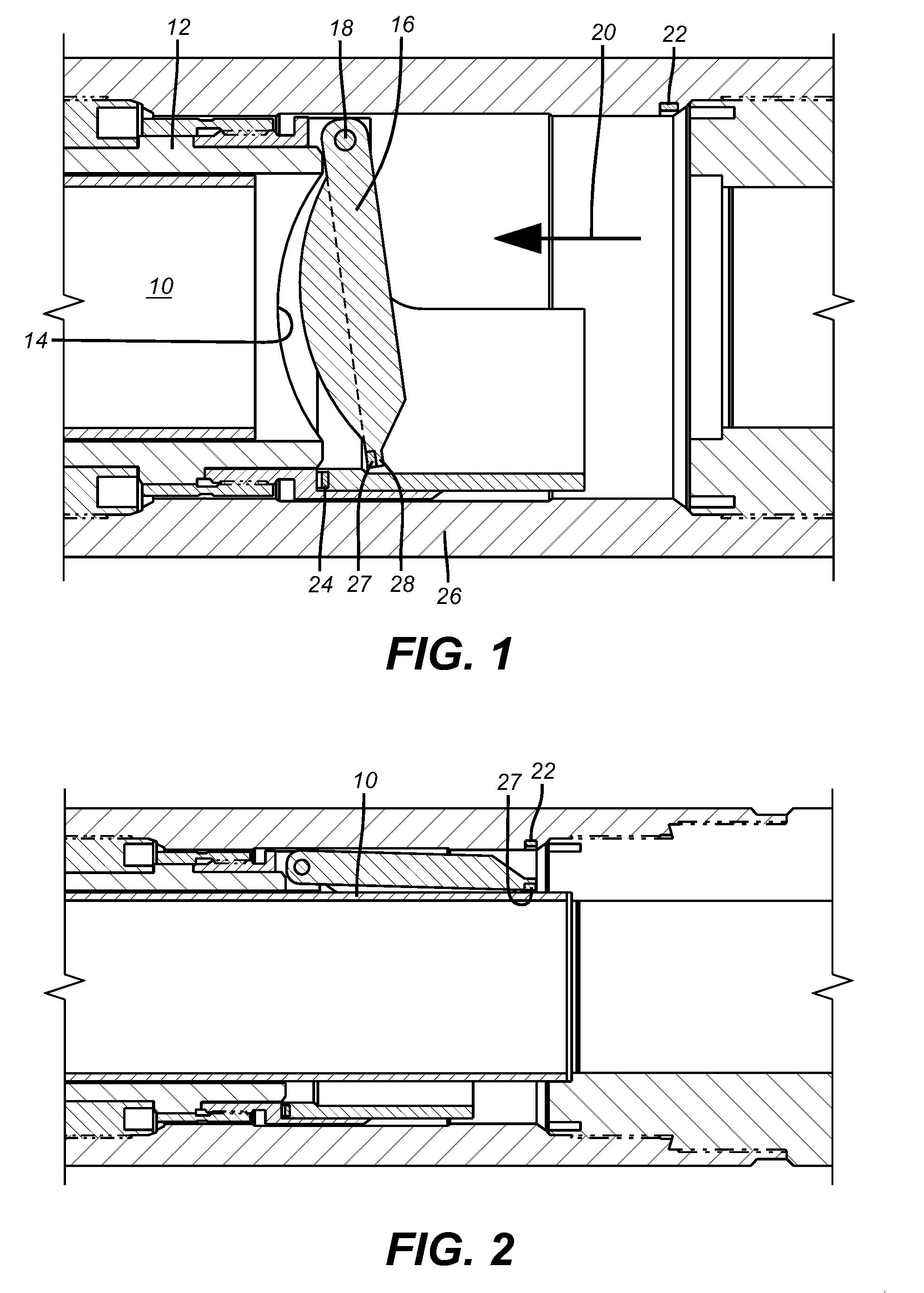

Flapper closure mechanism

A closure mechanism for a flapper features a pinion on the ear extending from the flapper that is used to mount it for pivotal movement. A spring-loaded rack meshes with the pinion or pinions on the flapper so that when the flow tube swings the flapper open, rotation of the pinion teeth advances the teeth on the rack against the force of a spring. When the flow tube is retracted, the spring pushes the teeth on the rack in the opposite direction causing a rotational movement of the flapper toward closure in contact with a conforming seat.

Owner:BAKER HUGHES INC

Surface controlled subsurface safety valve assembly with primary and secondary valves

A surface controlled subsurface safety valve assembly includes primary and secondary valves, such as an upper and lower flapper valve. Only one of the valves is in service at a time. In the event that the primary valve is compromised, and therefore leaks, the SCSSV is shifted to position the primary valve out of service and the secondary valve in service. The SCSSV may have more than two flappers, thereby providing multiple secondary valves, with only one valve in operation at any one time.

Owner:REAUX JAMES

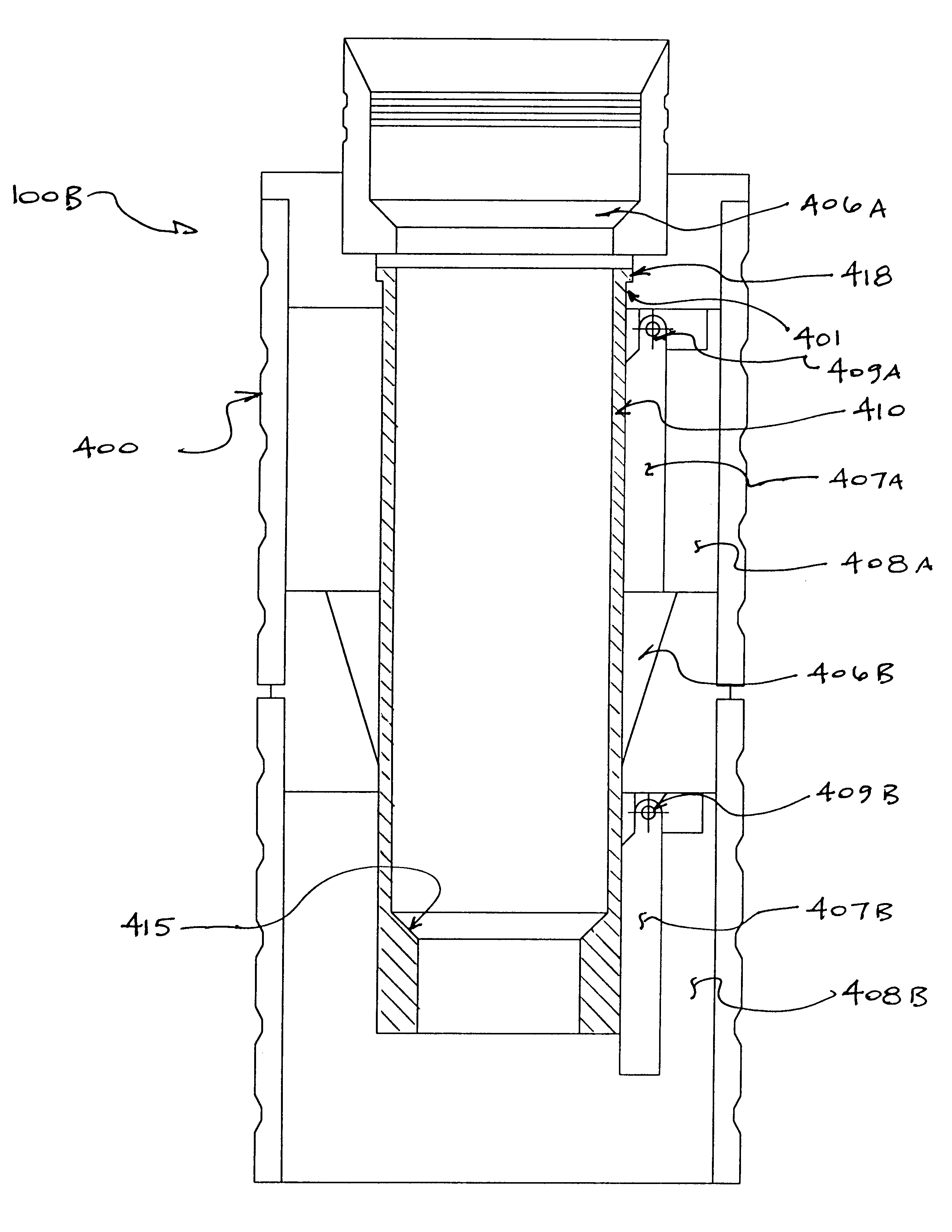

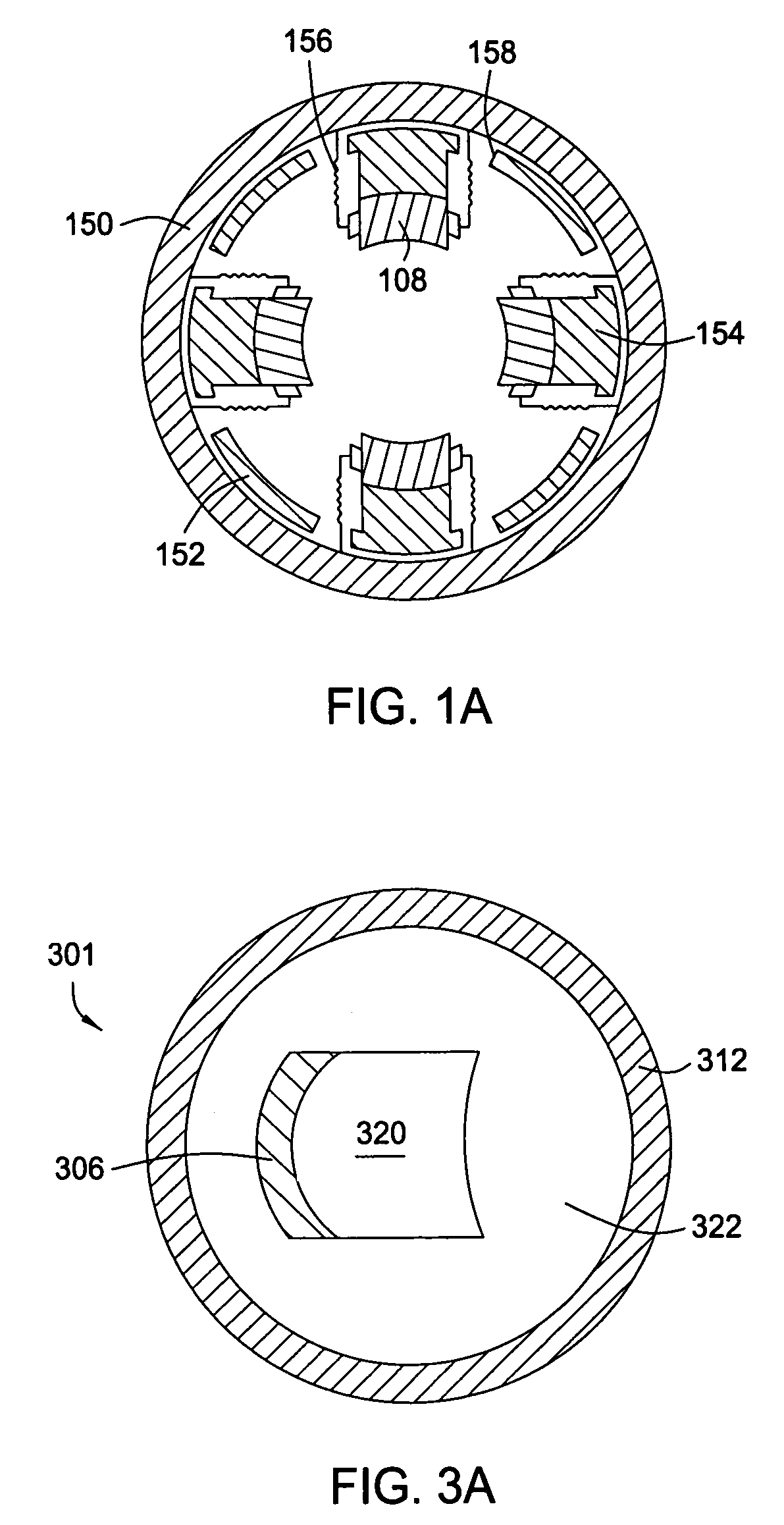

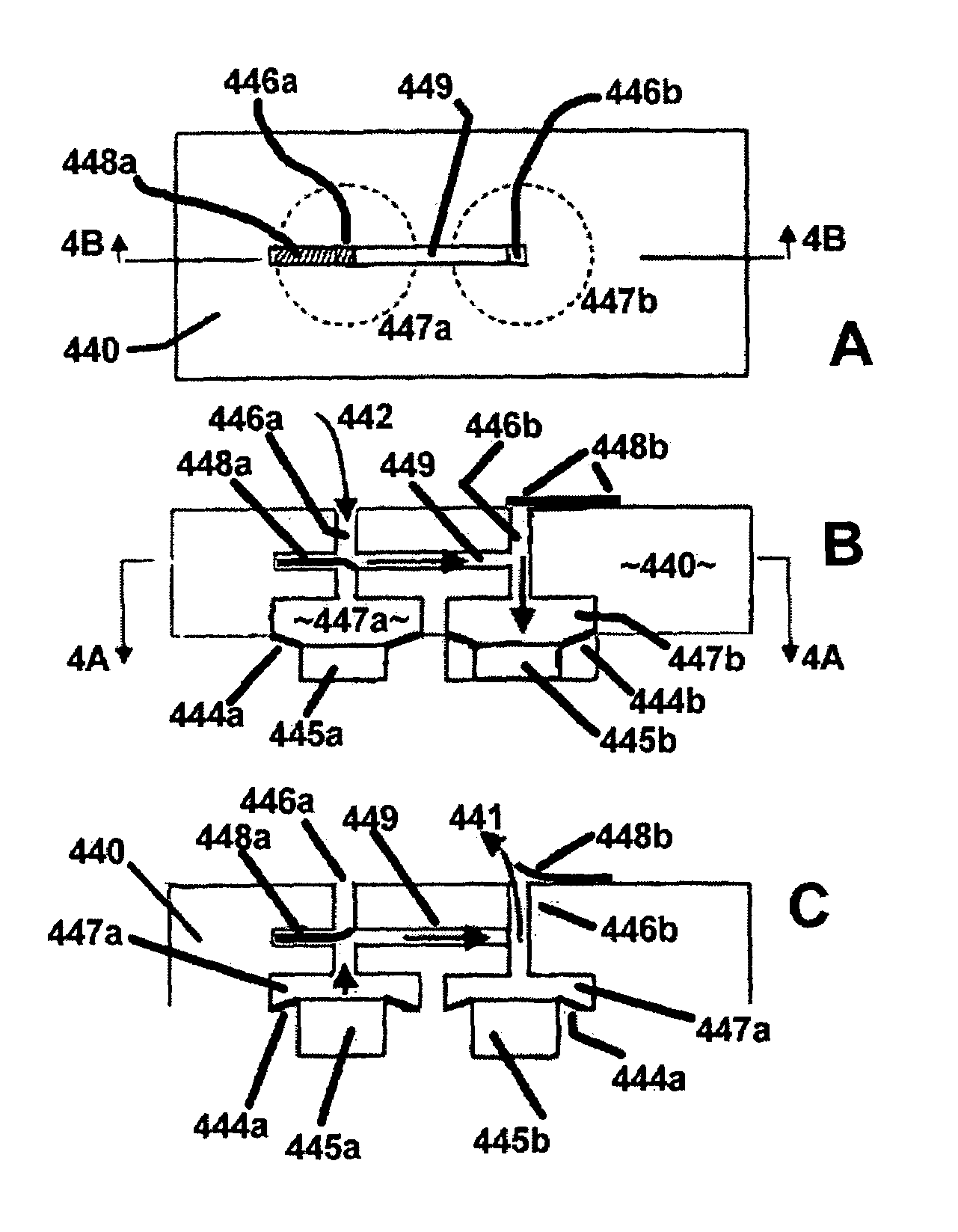

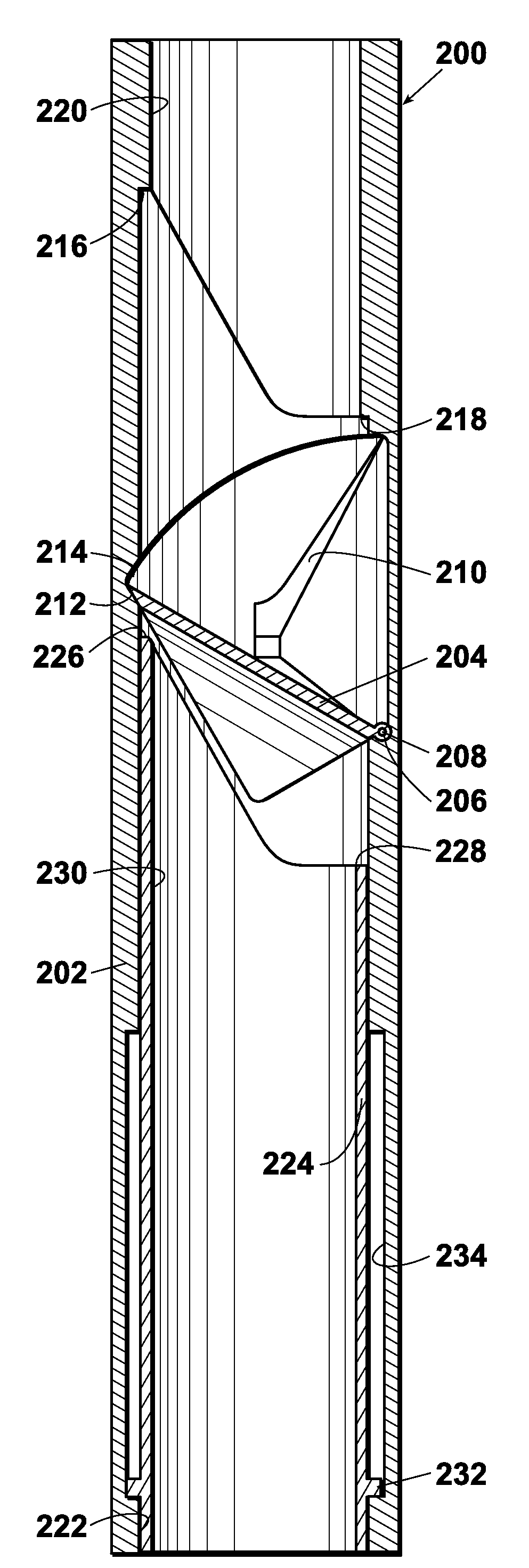

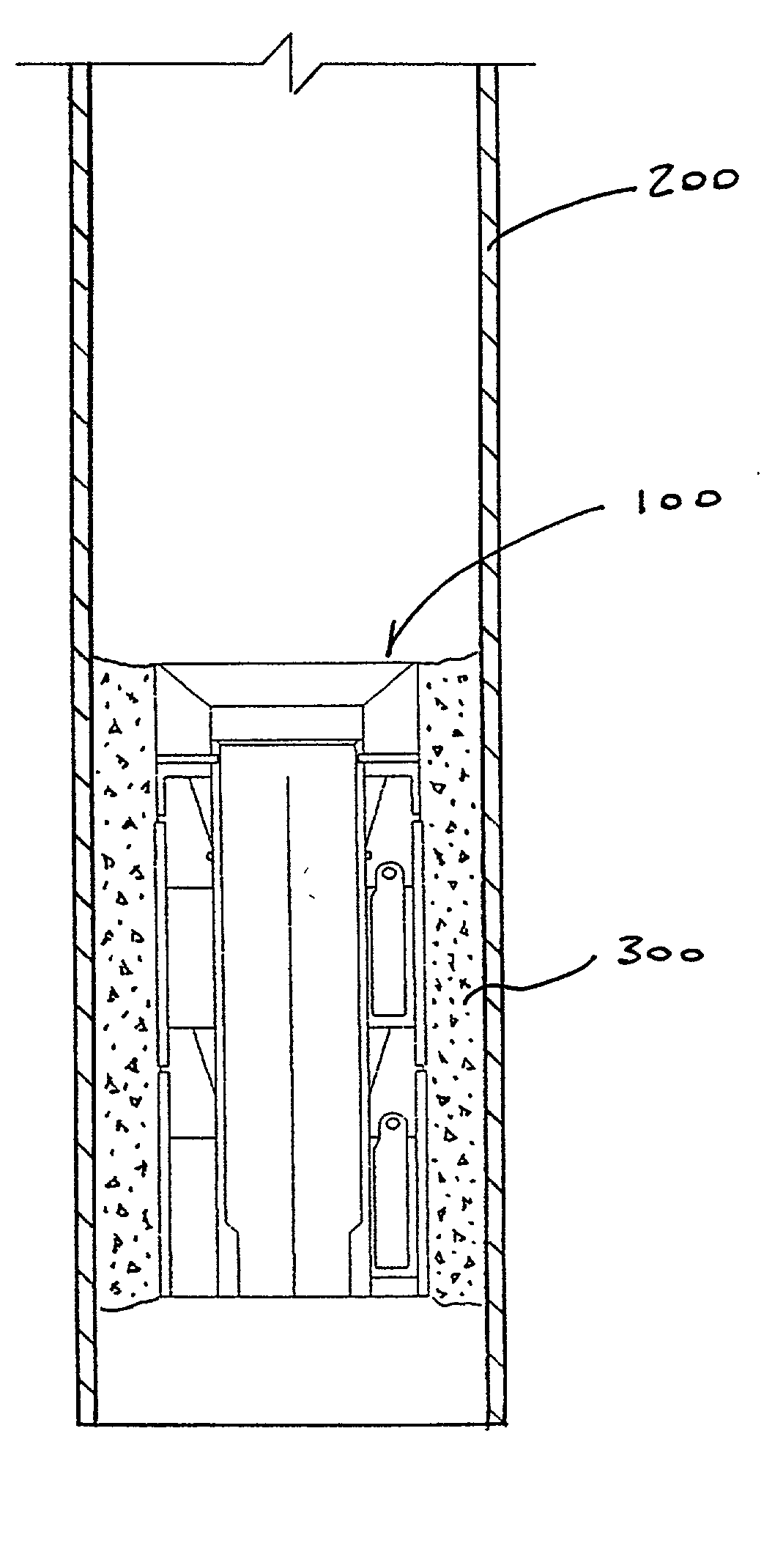

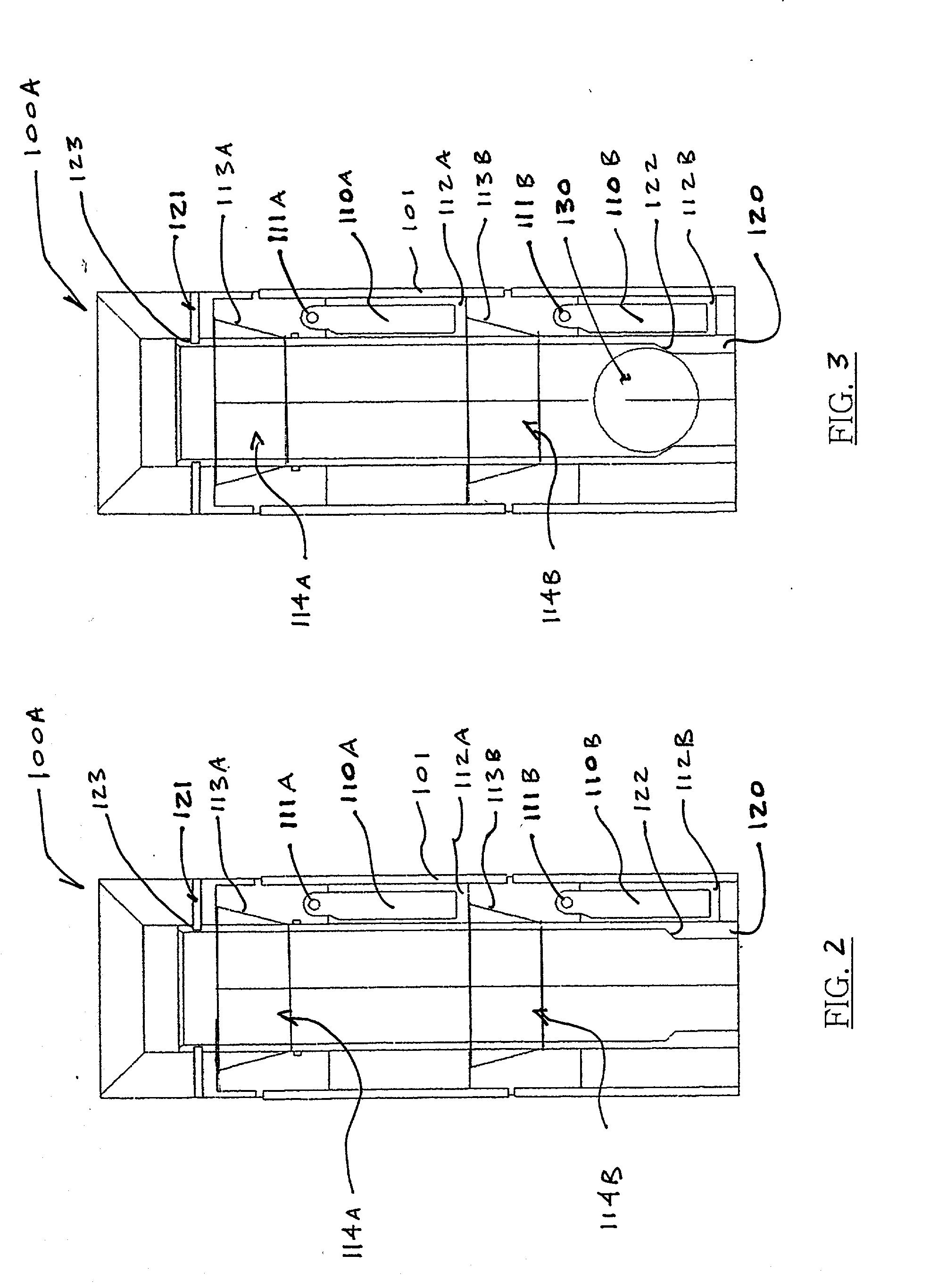

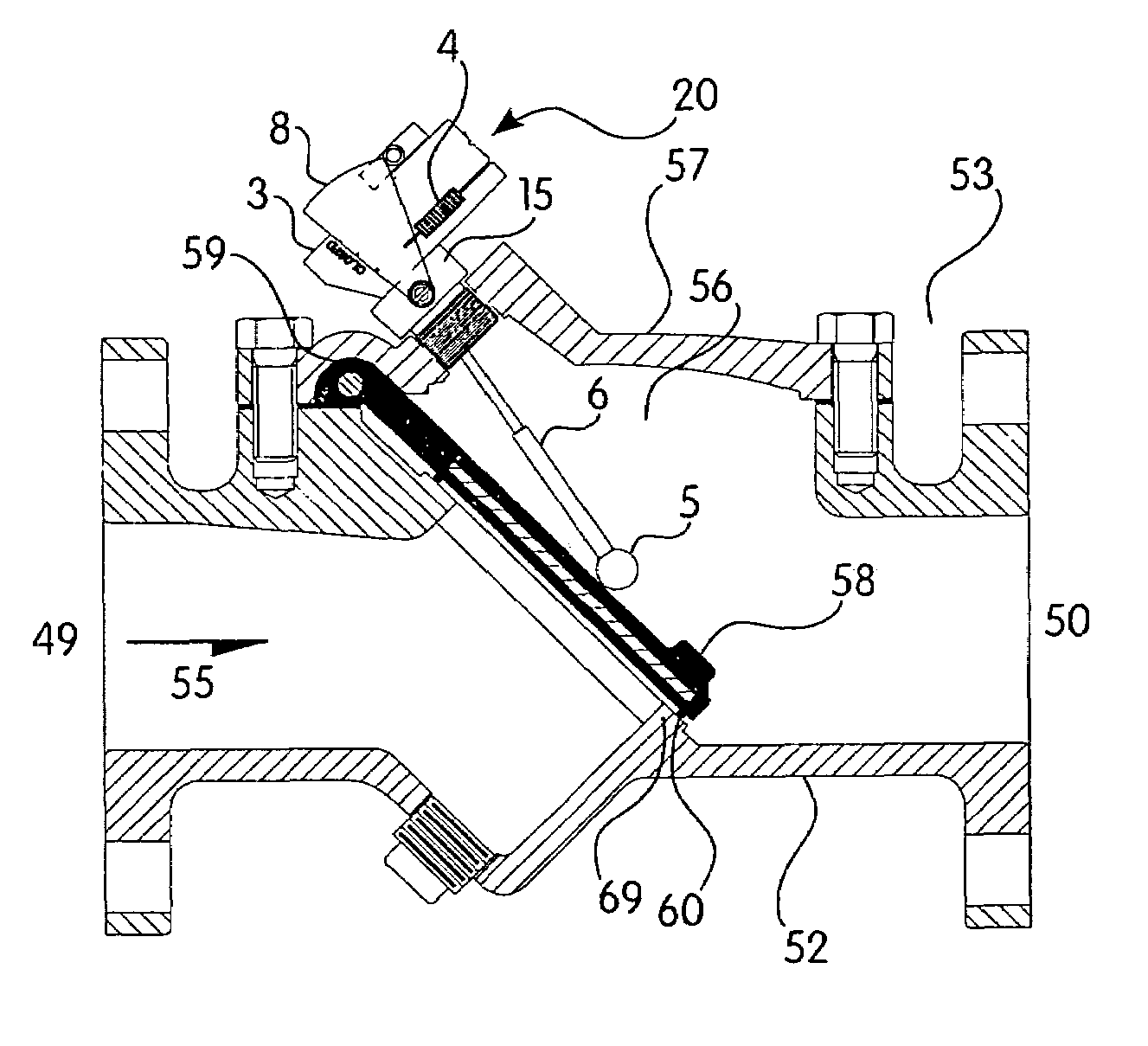

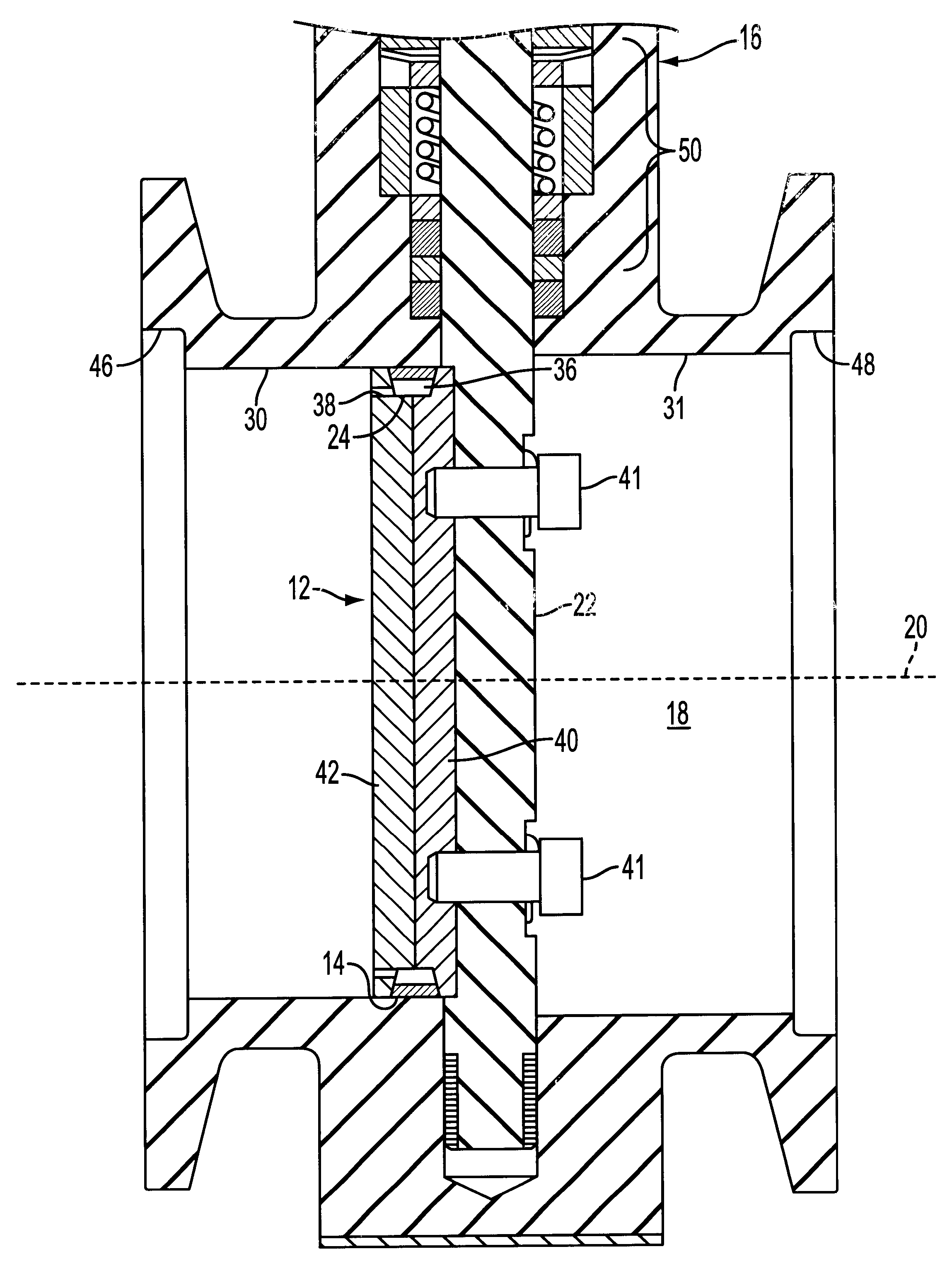

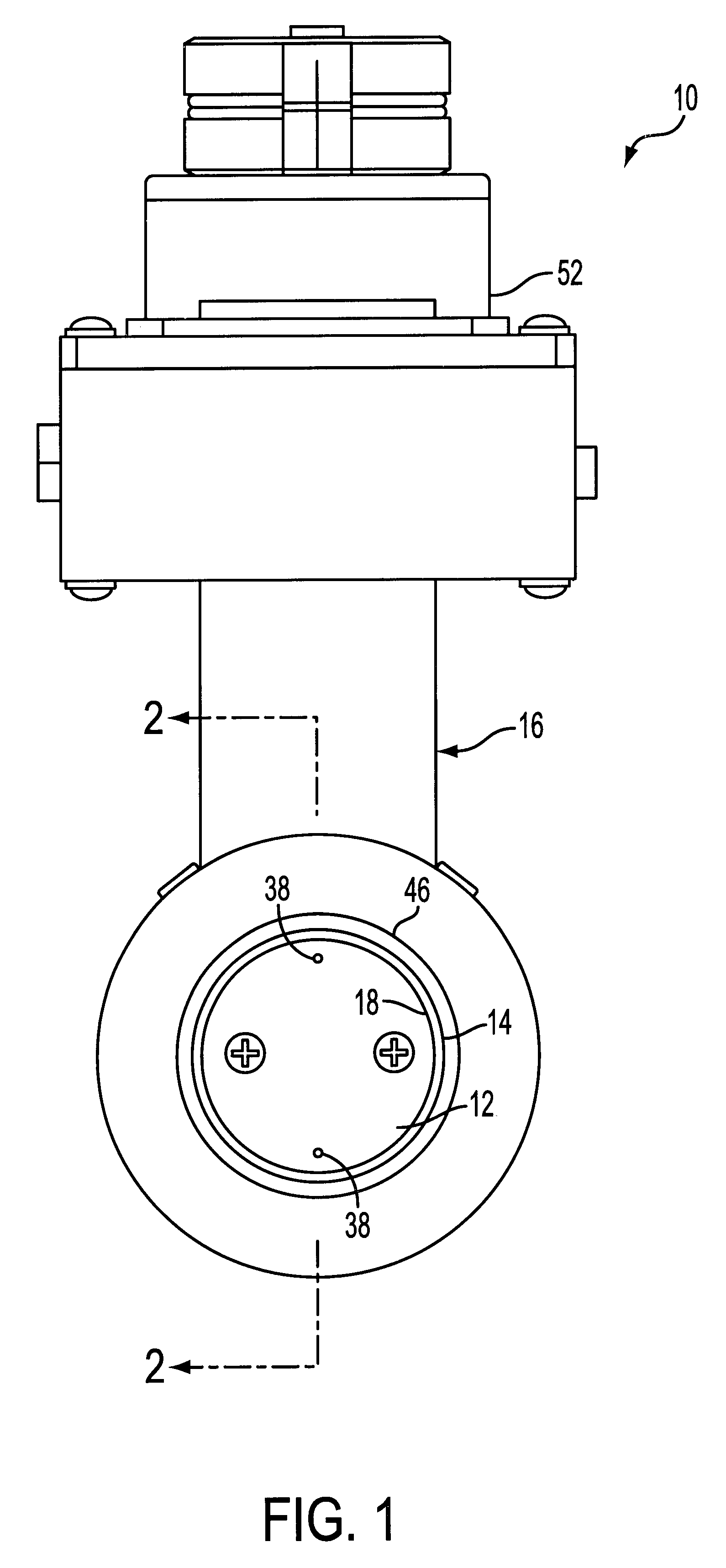

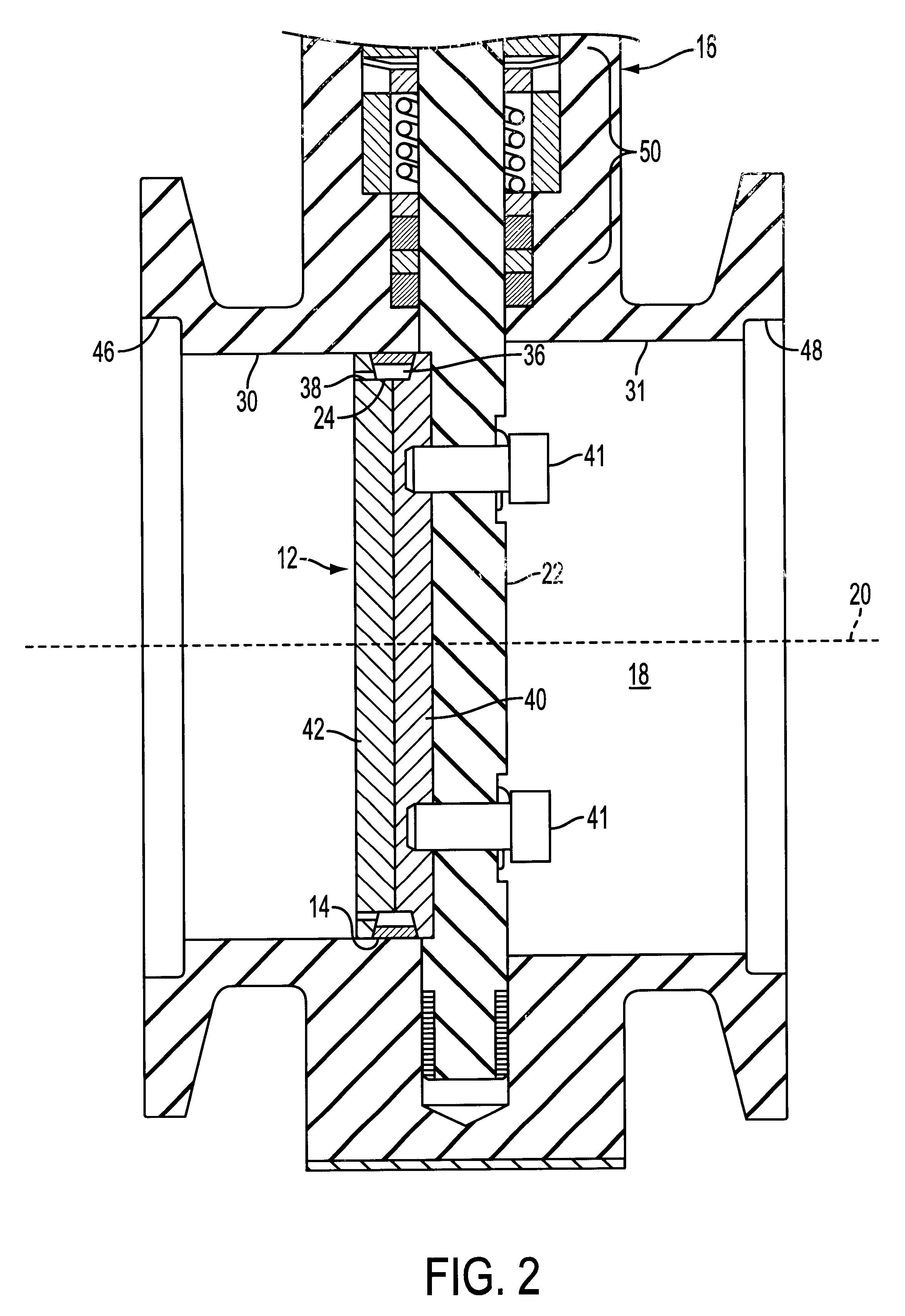

Dual flapper barrier valve

The present invention generally relates to a wellbore tool for selectively isolating a portion of a wellbore from another portion of the wellbore. In one aspect, a method of selectively isolating a zone in a wellbore is provided. The method includes the step of positioning a downhole tool in the wellbore. The downhole tool includes a bore with a first flapper member and a second flapper member disposed therein, whereby each flapper member is initially in an open position. The method also includes the step of moving the first flapper member to a closed position by rotating the first flapper member in one direction. Further, the method includes the step of moving the second flapper member to a closed position by rotating the second flapper member in an opposite direction, whereby each flapper member is movable between the open position and the closed position multiple times. In another aspect, an apparatus for isolating a zone in a wellbore is provided.

Owner:WEATHERFORD TECH HLDG LLC

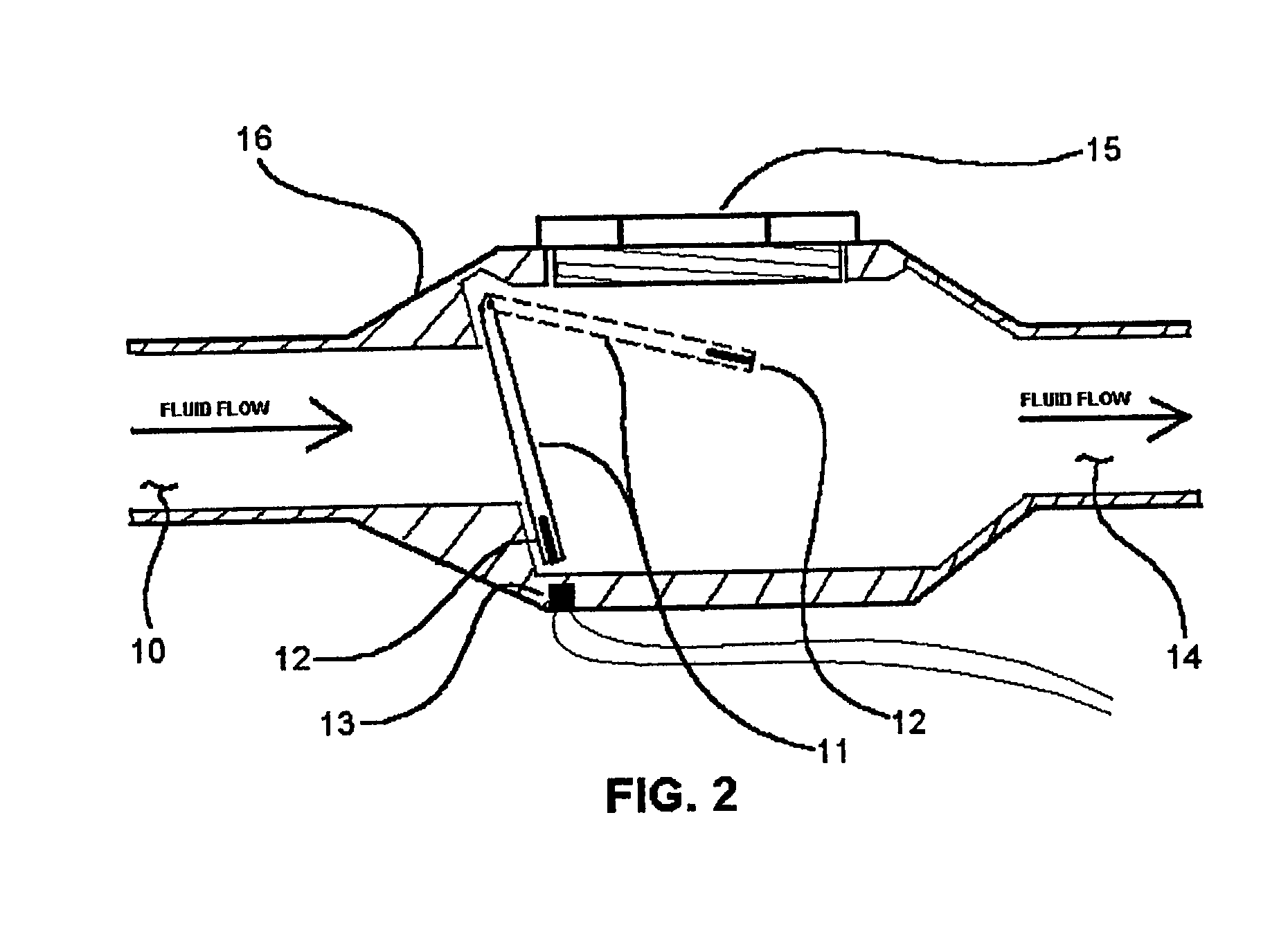

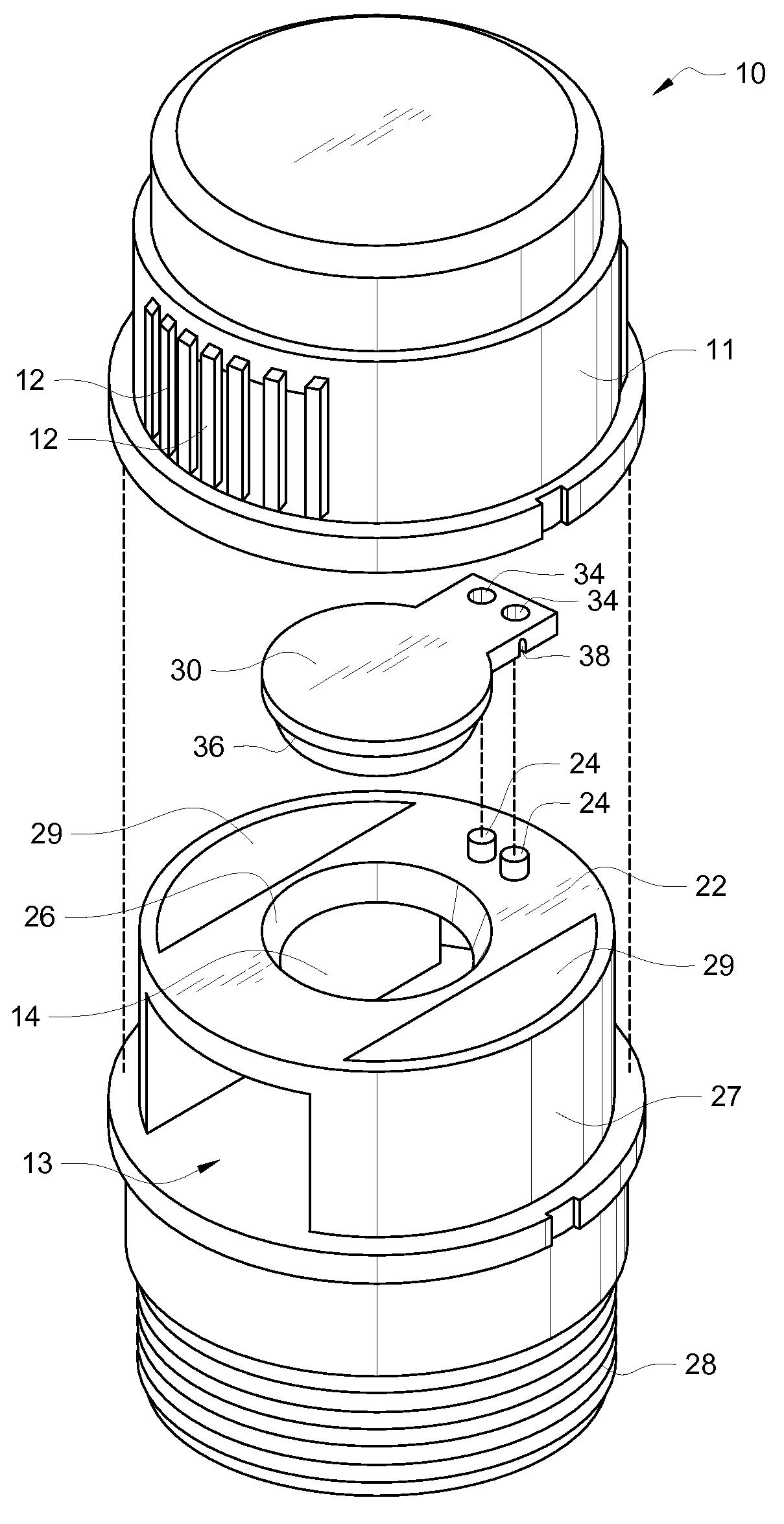

Pool cleaner with open-ended pin supported flapper valve

InactiveUS6298513B1Reduce frictional resistanceClean outGymnasiumSwimming poolsMarine engineeringFlapper

A domestic automatic swimming pool cleaner which randomly travels about and cleans the walls and bottom surfaces of a swimming pool includes two parallel or non-parallel impact tubes, the top ends of which are connected to a flexible suction hose which in turn is connected to the suction side of the pool's filter pump. The bottom ends of the tubes are served intermittent shots of water by a hinged self-starting flapper valve with an unrestricted upstream opening in the cleaner's pool surface contacting head. By the action of the valve alternately delivering pool water to the two tubes, kinetic forces are generated which move the automatic pool cleaner about the pool.

Owner:HAYWARD IND INC

Living-hinge air vent valve

InactiveUS20090071551A1Inhibit gas flowAvoid flowCheck valvesDomestic plumbingGuide tubeLiving hinge

An application for a living-hinge air vent valve connectable to a sewer conduit includes a base and a cover sealed to the base forming a cavity between the cover and the base. A fluid inlet shaft depends from a roof of the base and is connected to external air passages passing through a side of the base and through vents in a side of the cover. A living-hinge flapper is situated above the fluid inlet shaft and within the cavity. The living-hinge flapper allows air to flow from the fluid inlet shaft into the cavity and prevents sewerage gasses from flowing from the cavity out through the fluid inlet shaft. One or more connecting shafts in the base fluidly connect the cavity with a sewer system.

Owner:CHALICH WAYNE D

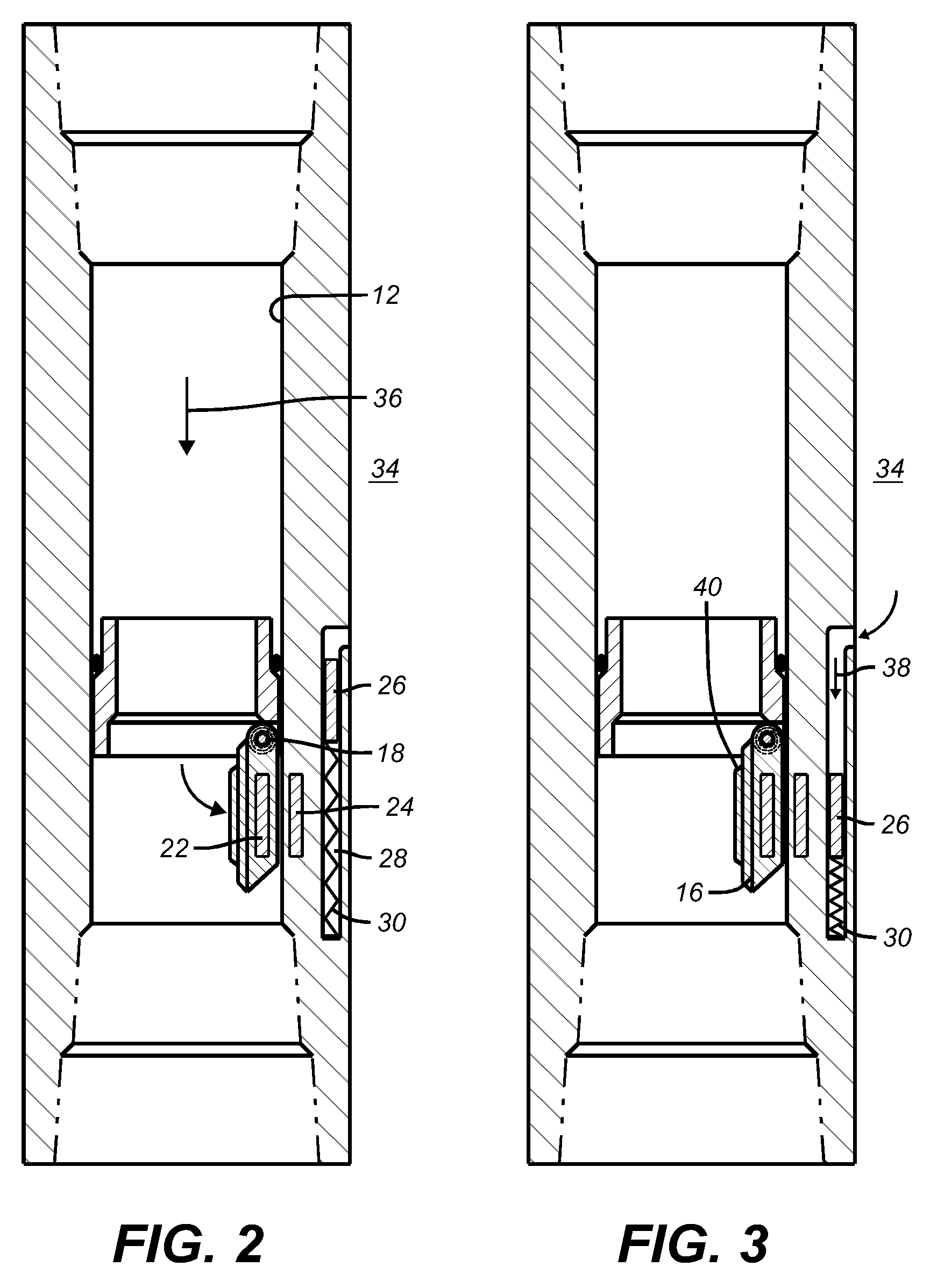

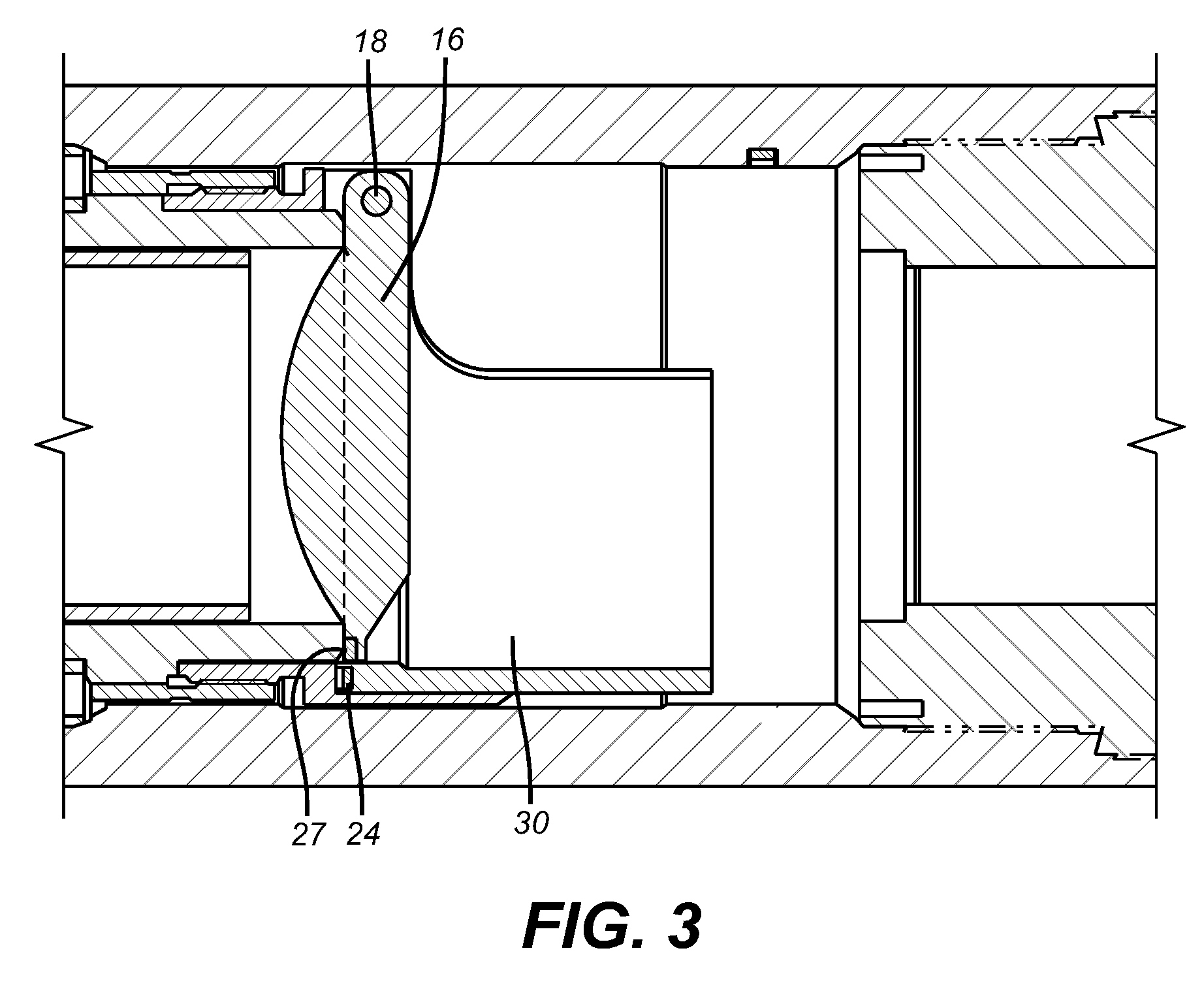

Flapper valve and actuator

An improved flapper valve is disclosed comprising a housing, a flapper pivotally engaged to the housing, and an actuator slidingly engaged in the housing and adapted to make initial contact with the flapper at a seat end. The seat end is an area surrounding a point on a flapper bottom surface that is furthest from the location of pivotal engagement of the flapper and the housing but not in contact with the housing. The flapper closes at an acute angle to the longitudinal axis of the housing. The actuator is hollow and the interior of the actuator forms a through bore. In the closed position the flapper prevents fluid from the passing through the bore.

Owner:SUNSTONE TECH

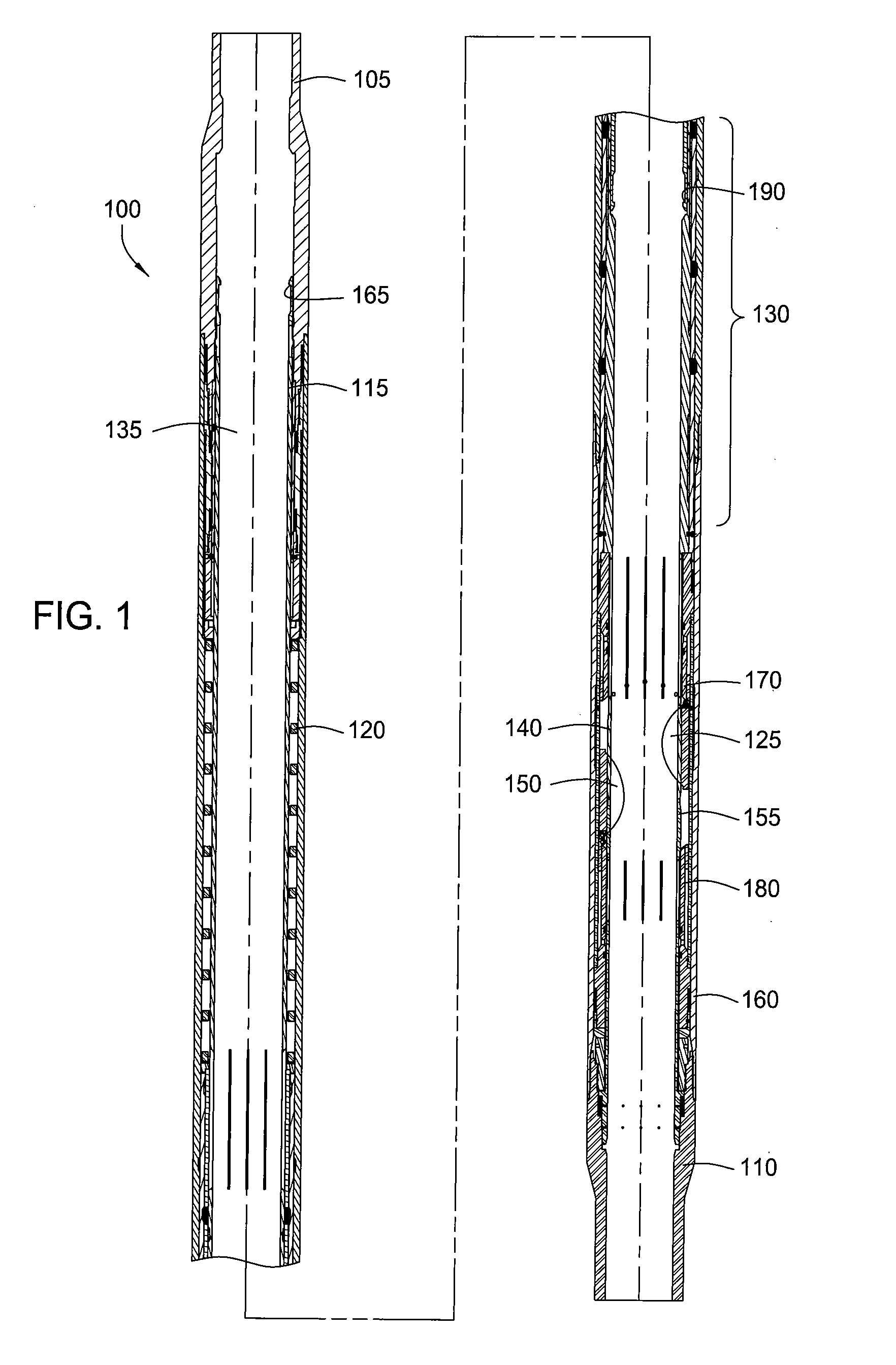

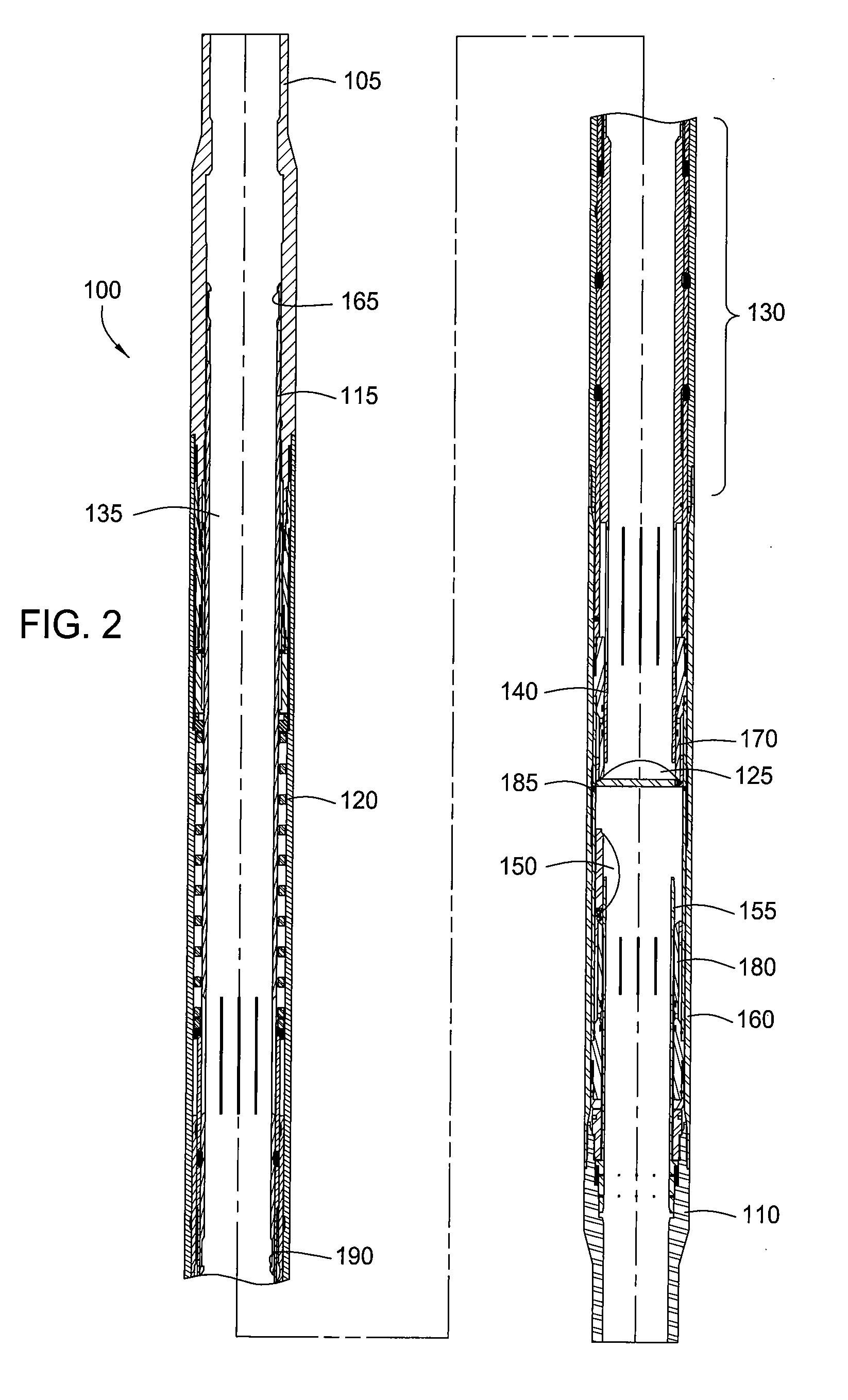

Float collar

The present invention relates to a float collar apparatus for regulating the passage of fluid through a drilling / production liner or sub-sea casing. Apparatus of the present invention is fabricated using plastic flapper valves and valve-actuating sleeve components in contrast to prior art float collar components which are fabricated almost entirely of hard metals. Particularly, the plastic may be nylon, phenolic, or a phenolic-nylon laminate. The use of plastic components in the float collar apparatus of the present invention provides a substantial reduction in time and resources expended during drilling out of the float collar once cementing operations are completed. Additionally, the float collar apparatus of the present invention is fabricated from a pre-determined combination of plastic components and metal components thereby ensuring that the improved float collar can still endure substantial hydrostatic stresses encountered during casing liner running in and cementing operations.

Owner:ALLAMON JERRY P +2

Pressure equalizing plunger valve for downhole use

An equalizer valve for a flapper in an SSV has one embodiment where the plunger body is covered with a lubricious material in the bore in the flapper to counteract wear caused by off-center contact with the plunger by the flow tube. In another embodiment the flow tube and the plunger have matching angled surfaces to reduce the resultant moment of the plunger from offset contact of the flow tube. In another embodiment the flow tube contacts the plunger on center to eliminate a resultant moment, which can cause wear in the flapper bore or to the plunger.

Owner:BAKER HUGHES INC

Magnetic Flapper Shock Absorber

ActiveUS20100294502A1Damp and eliminates shock loadingEliminate shock loadsConstructionsFluid removalEngineeringSafety valve

A flapper in a subsurface safety valve has at least one magnet that comes in close proximity with another magnet mounted in a fixed position on the valve body. There is a fixed magnet on the body adjacent to the fully open and the fully closed positions of the flapper. In each case like poles on the flapper magnet and the housing magnet come in close proximity as the flapper reaches its fully open and fully closed positions. The orientation of like poles adjacent each other creates a repelling force that damps or eliminates shock loading.

Owner:BAKER HUGHES INC

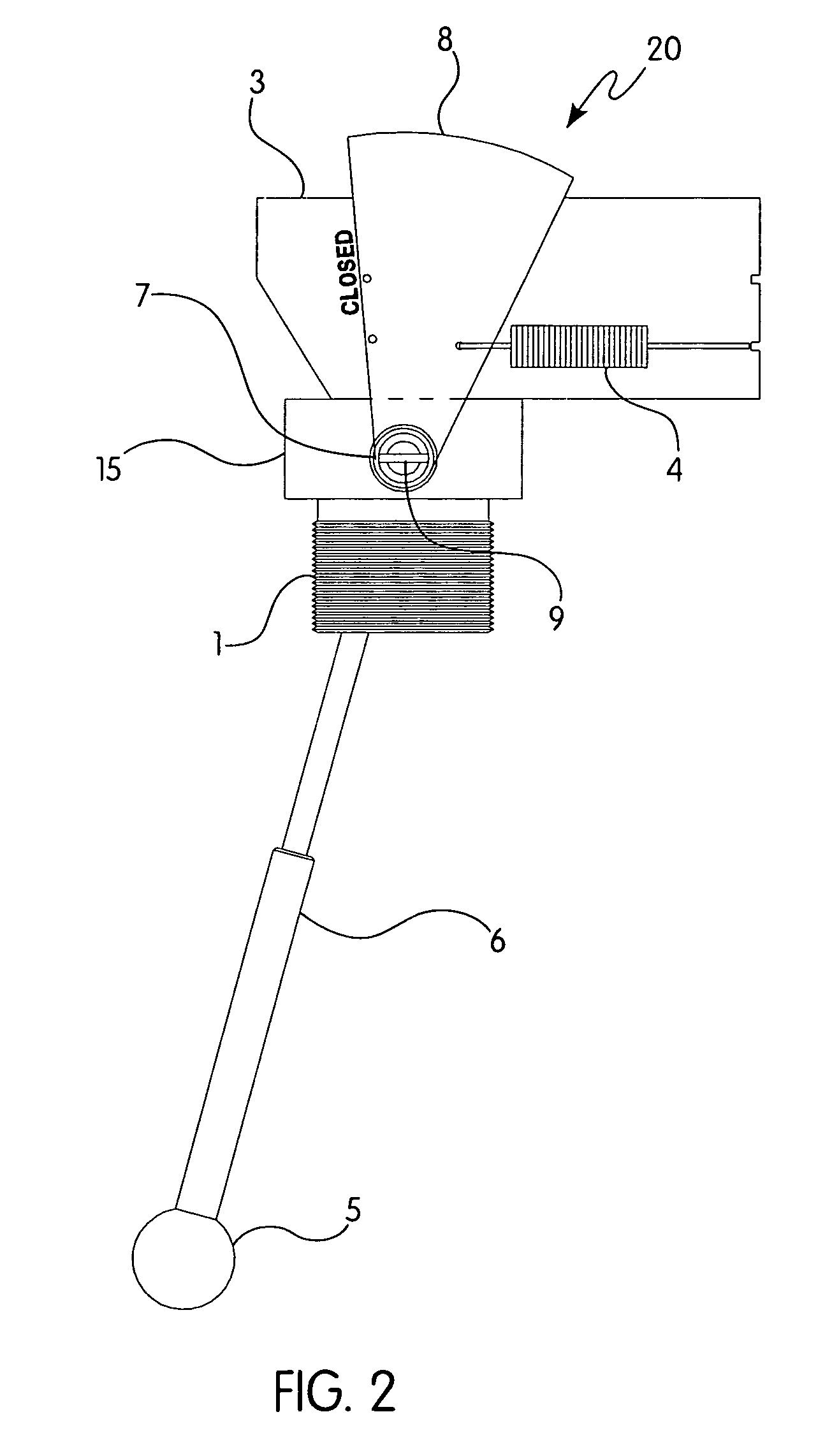

Side-mounted position indicator for flapper check valve

InactiveUS7533693B2Prevent leakagePrevent pressureCheck valvesEqualizing valvesEngineeringCheck valve

The present invention is a side-mounted position indicator for use with a flapper check valve. The indicator is located outside the valve body and attaches to an internal, cylindrically-shaped roller that allows limited rotation about one axis. This roller has a tripper rod that extends from one side of the roller and has a round, non-marring plastic ball on its opposite end. The ball is held in contact with the valve flapper using a mechanical spring. A separate flush port is provided to allow for periodic internal cleaning without substantial disassembly.

Owner:GA INDS

Valve flapper with dynamic circumference seal

A valve assembly including a body defining a passageway having a longitudinal axis, a rotatable shaft extending into the passageway, generally perpendicular to the axis of the passageway, and a flapper secured to the shaft within the passageway and movable upon rotation of the shaft between an opened position and a closed position. The flapper includes a groove in an outer circumference, and a seal is received in the groove. The seal has an outer circumference greater than the outer circumference of the flapper so the entire outer circumference of the seal contacts a wall of the passageway when the flapper is moved to the closed position. The seal also has an inner circumference greater than an inner circumference of the groove of the flapper such that an enclosed space is defined between the seal and the groove. An aperture provides fluid communication between the enclosed space and the passageway.

Owner:MKS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com