Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about "Chain fastenings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

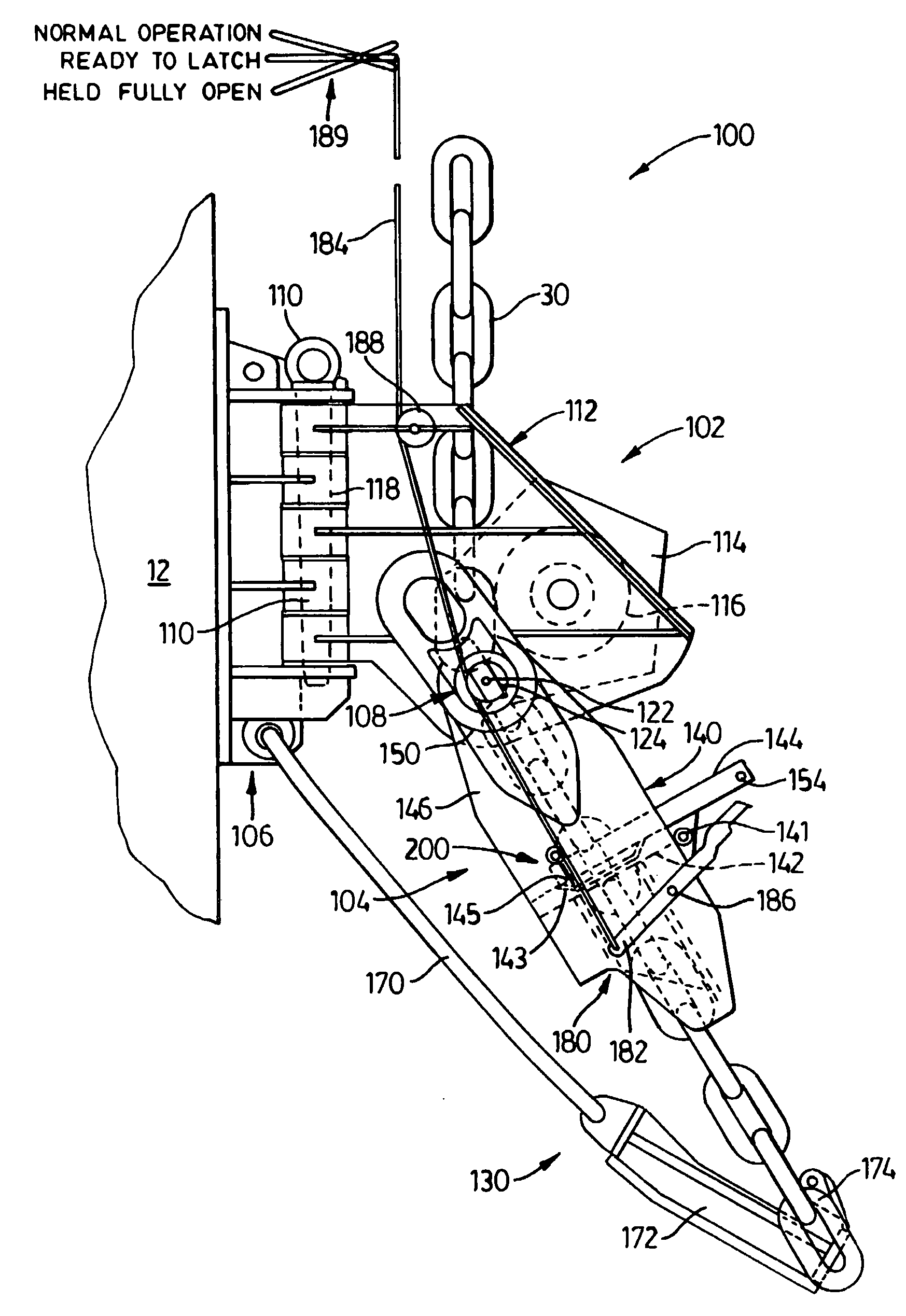

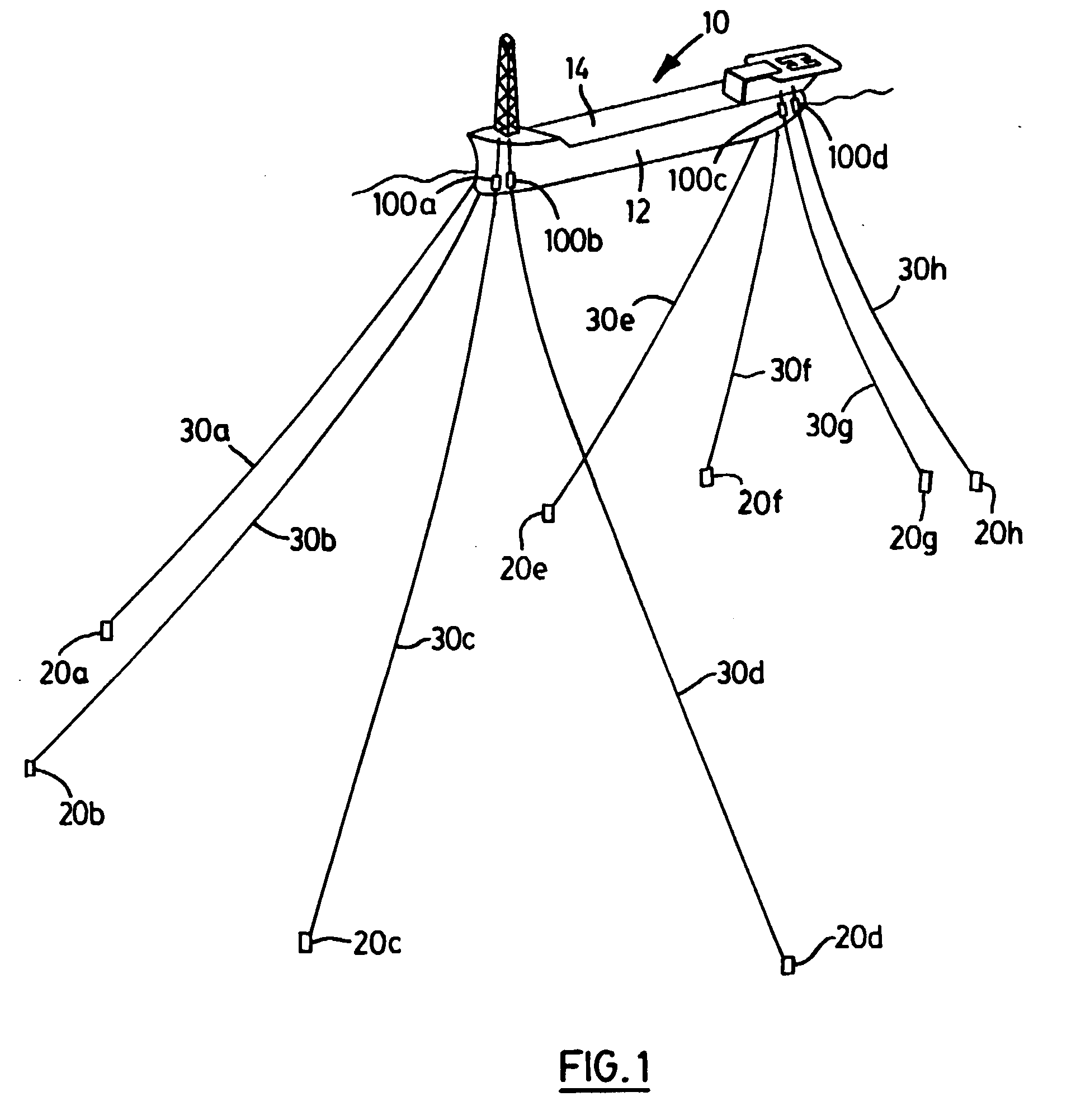

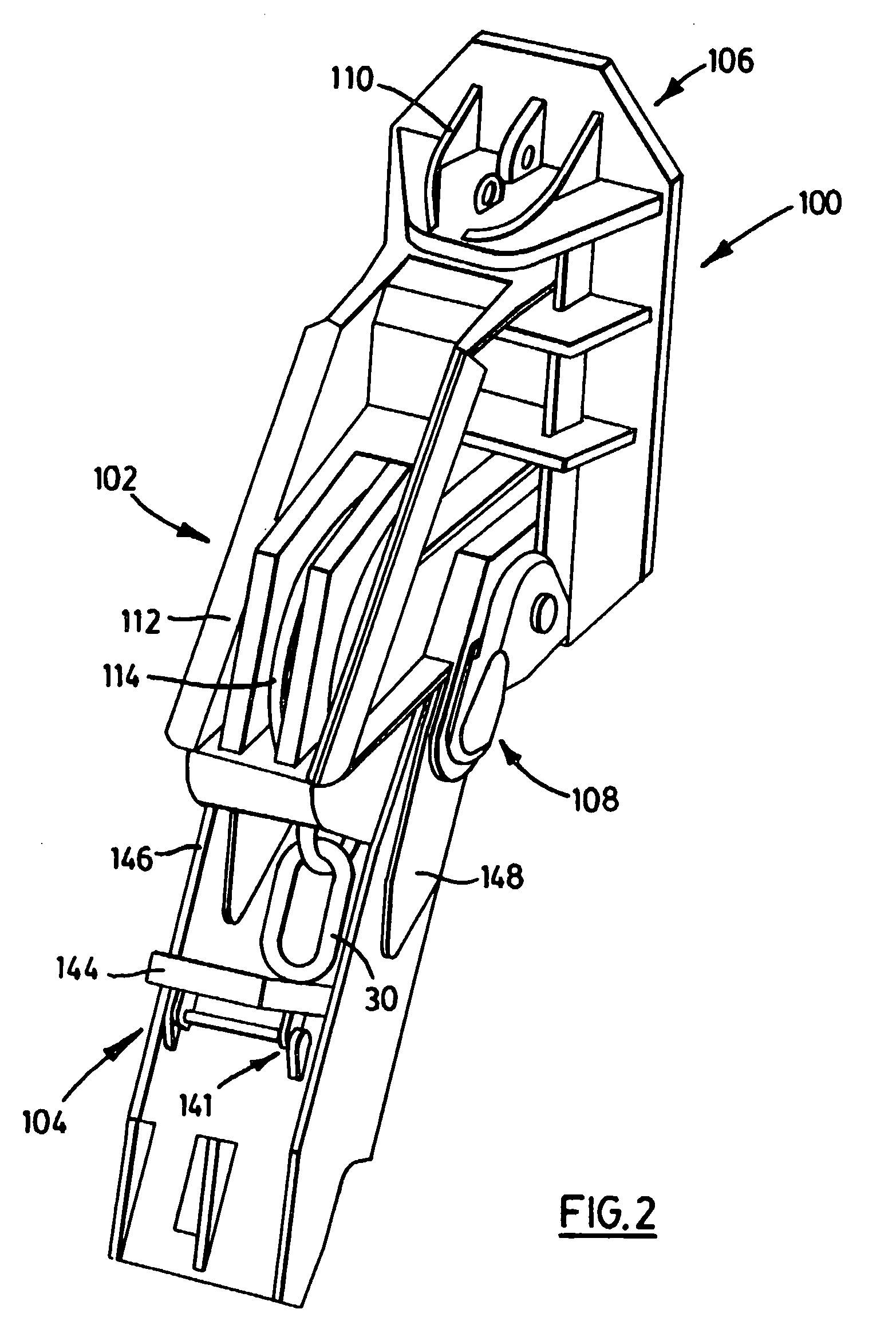

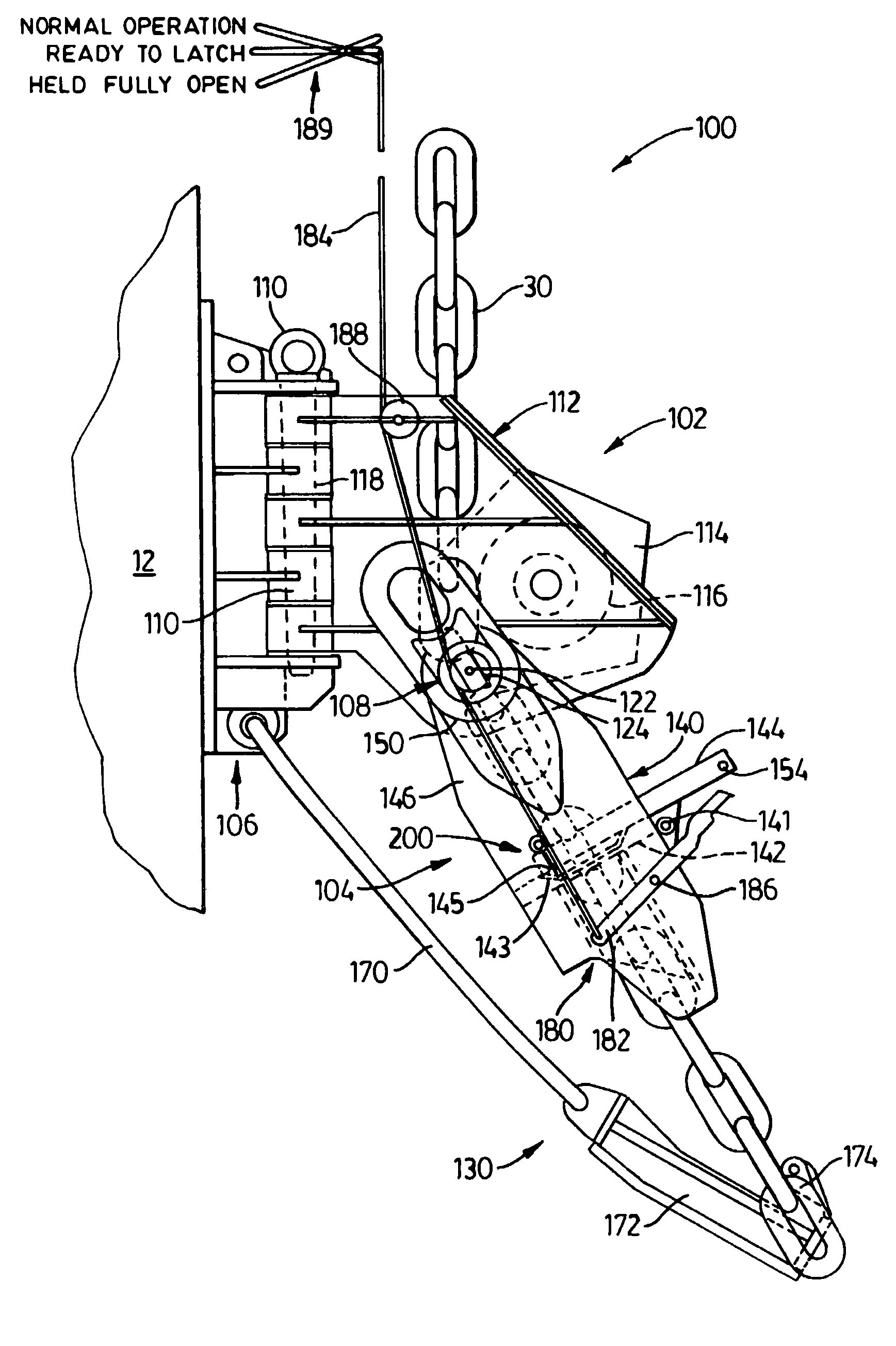

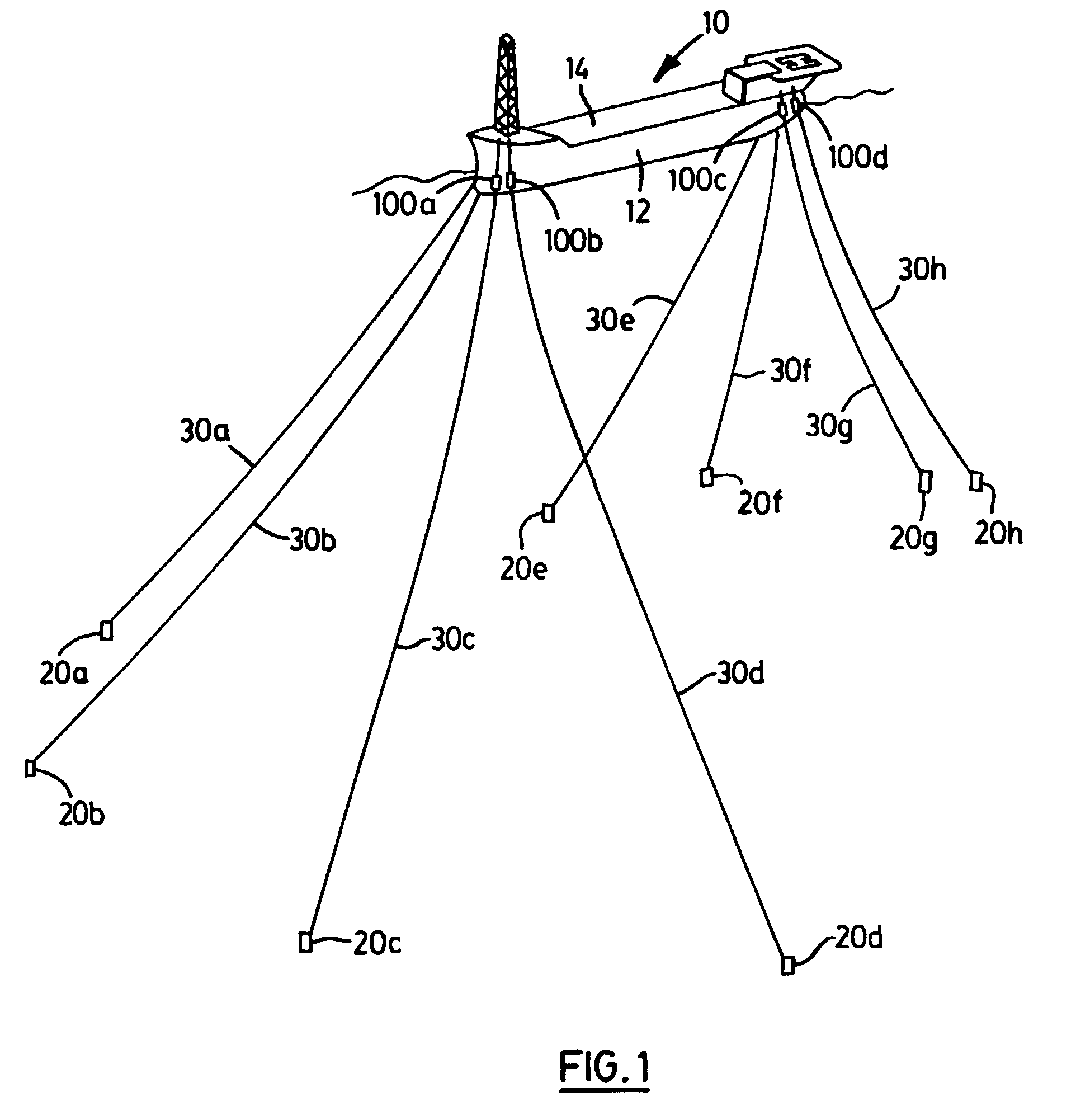

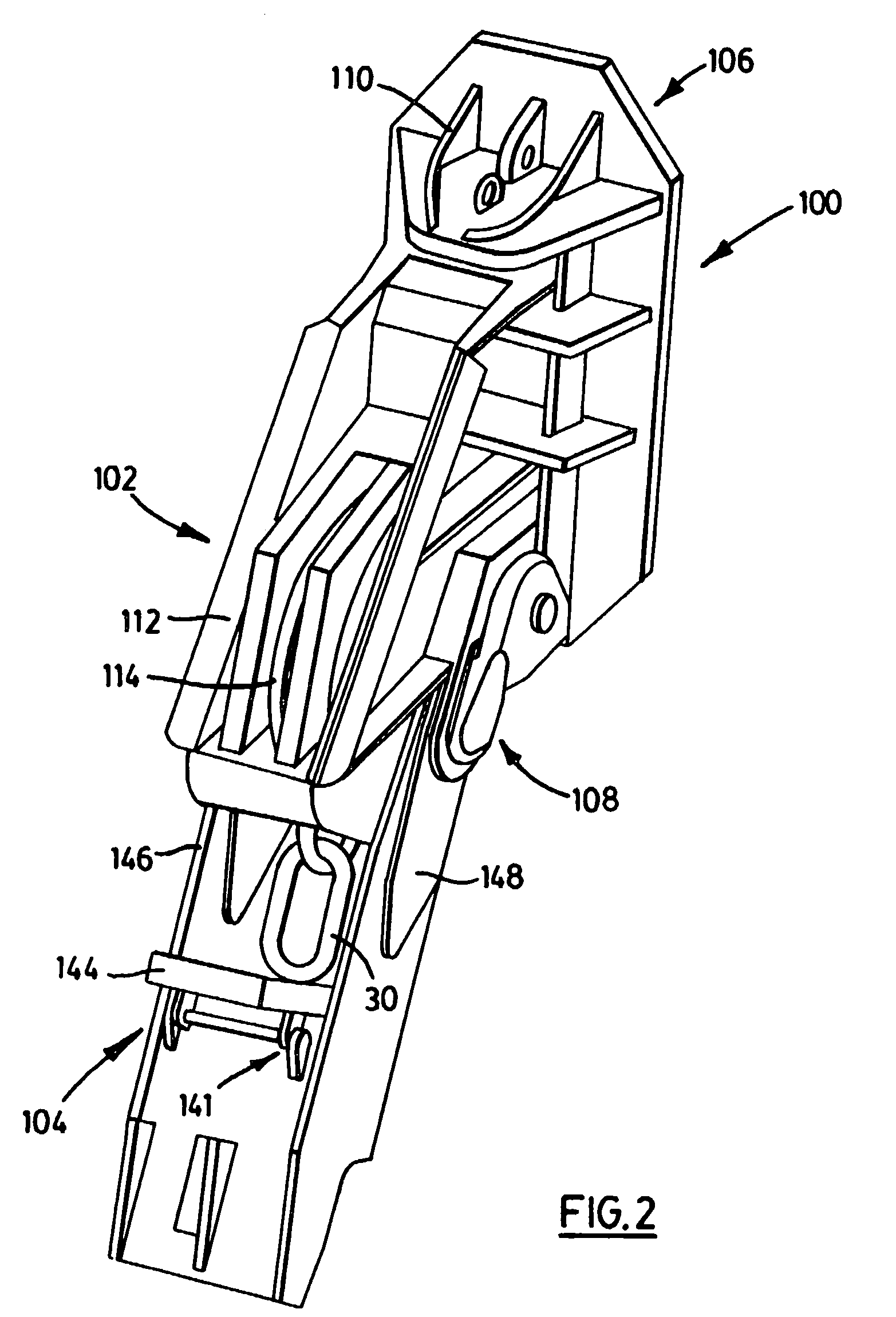

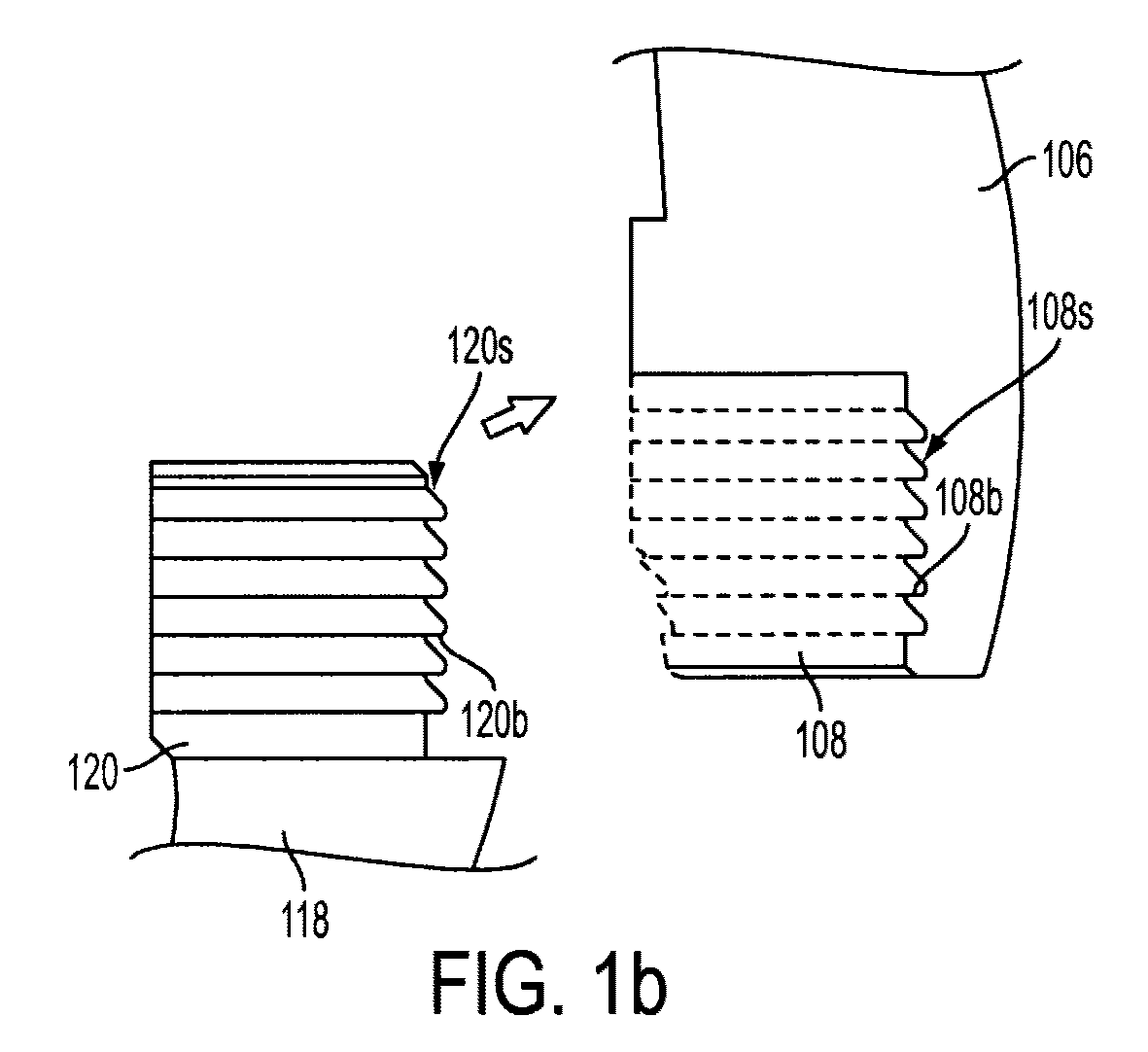

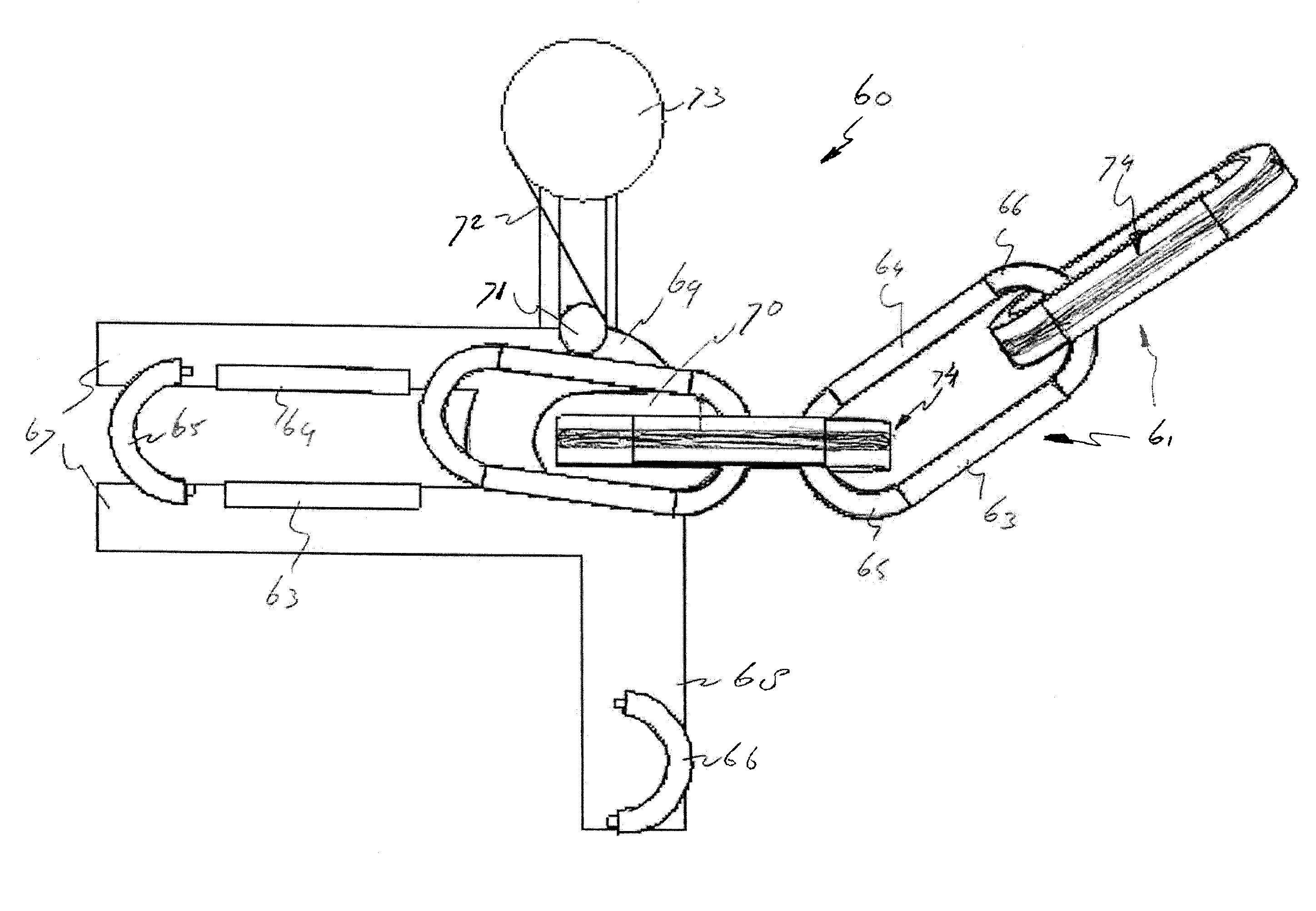

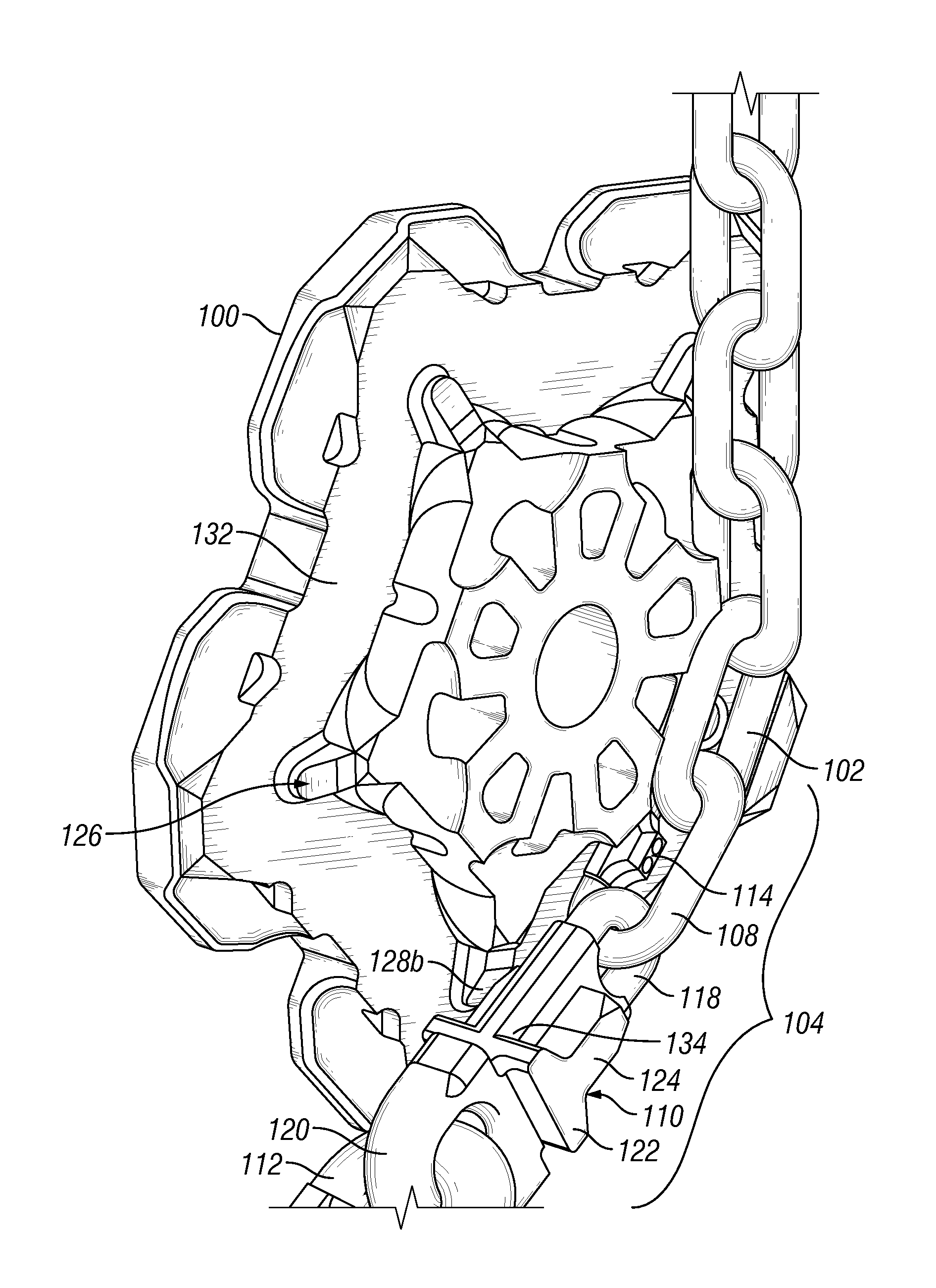

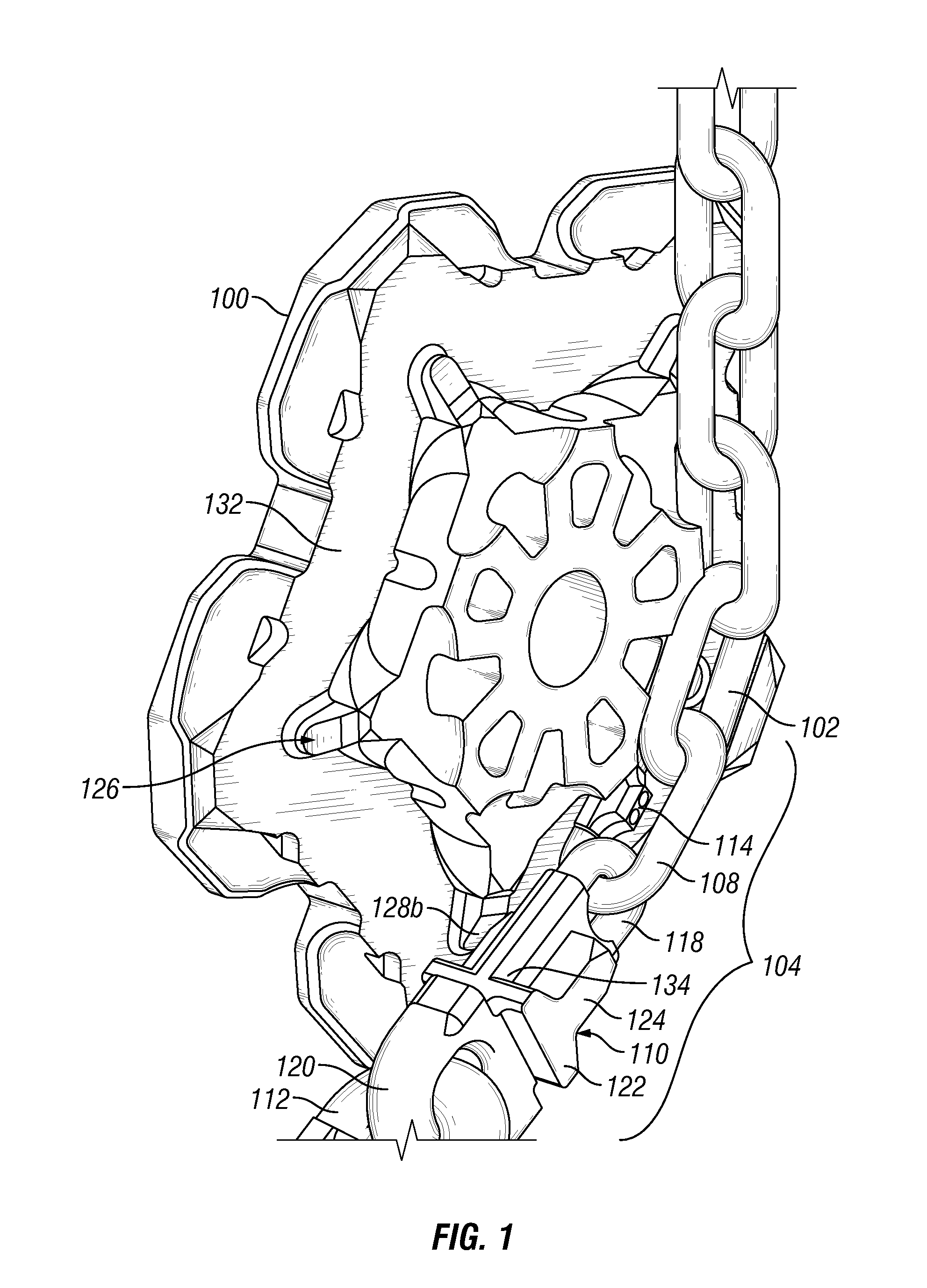

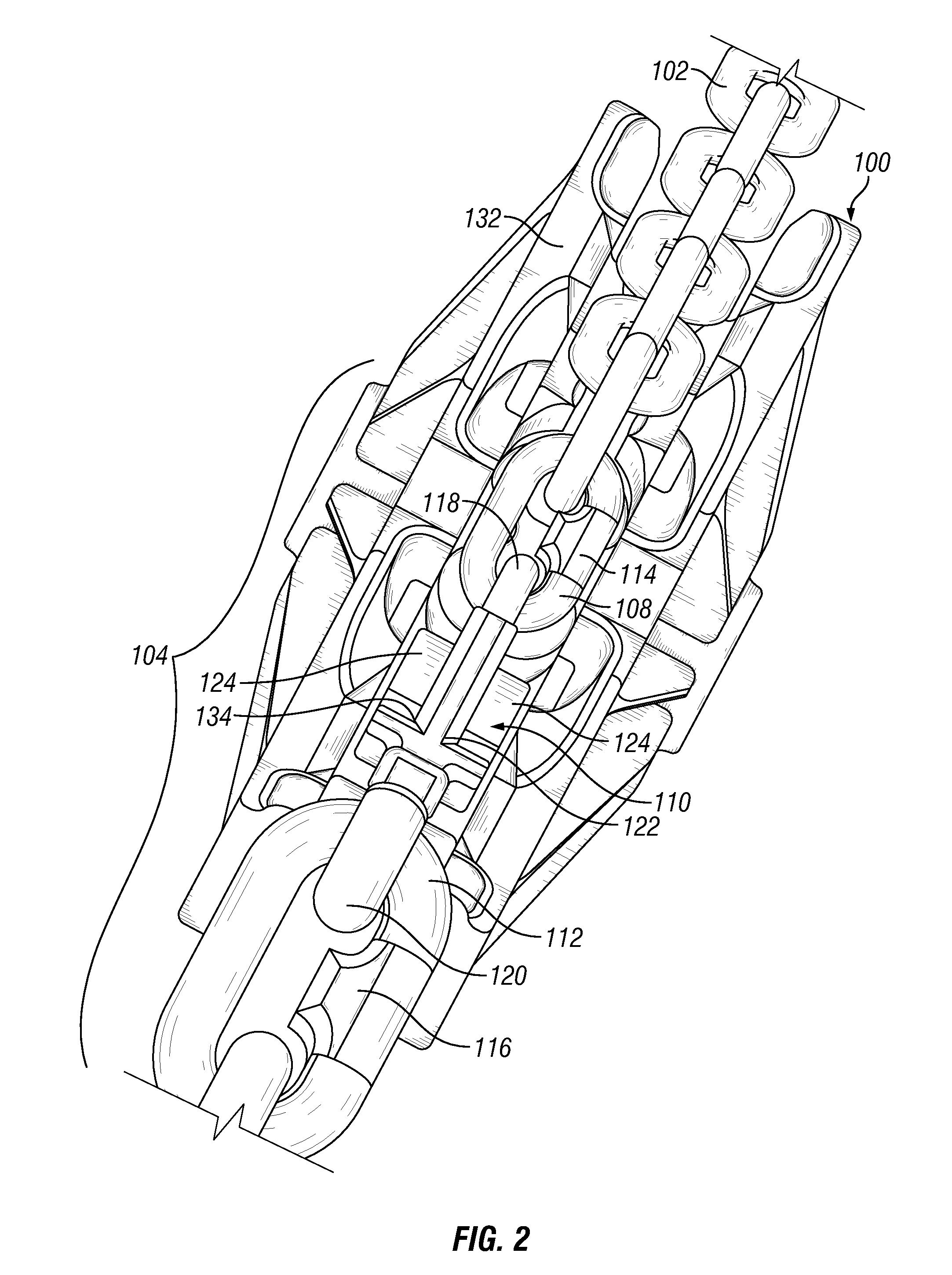

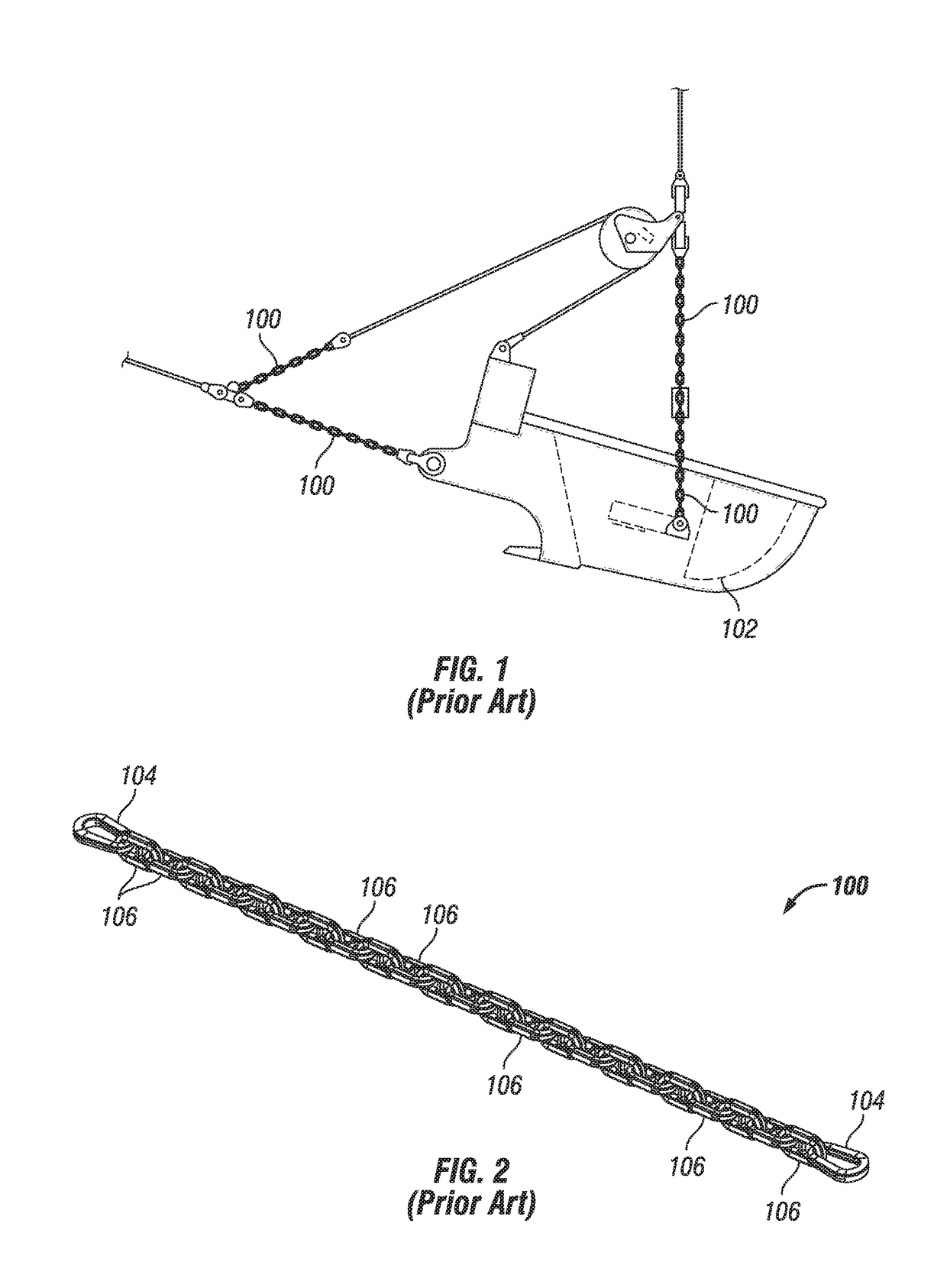

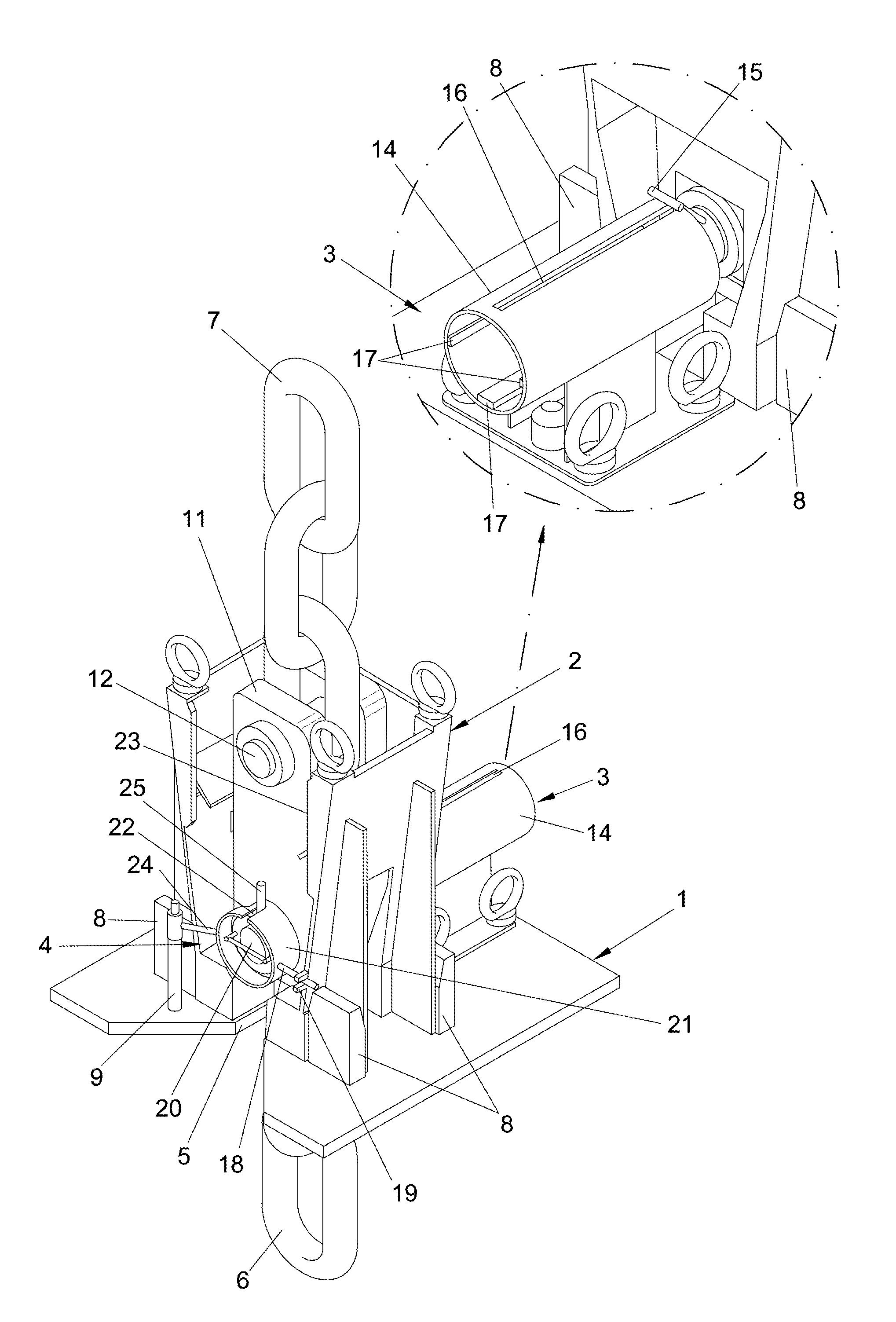

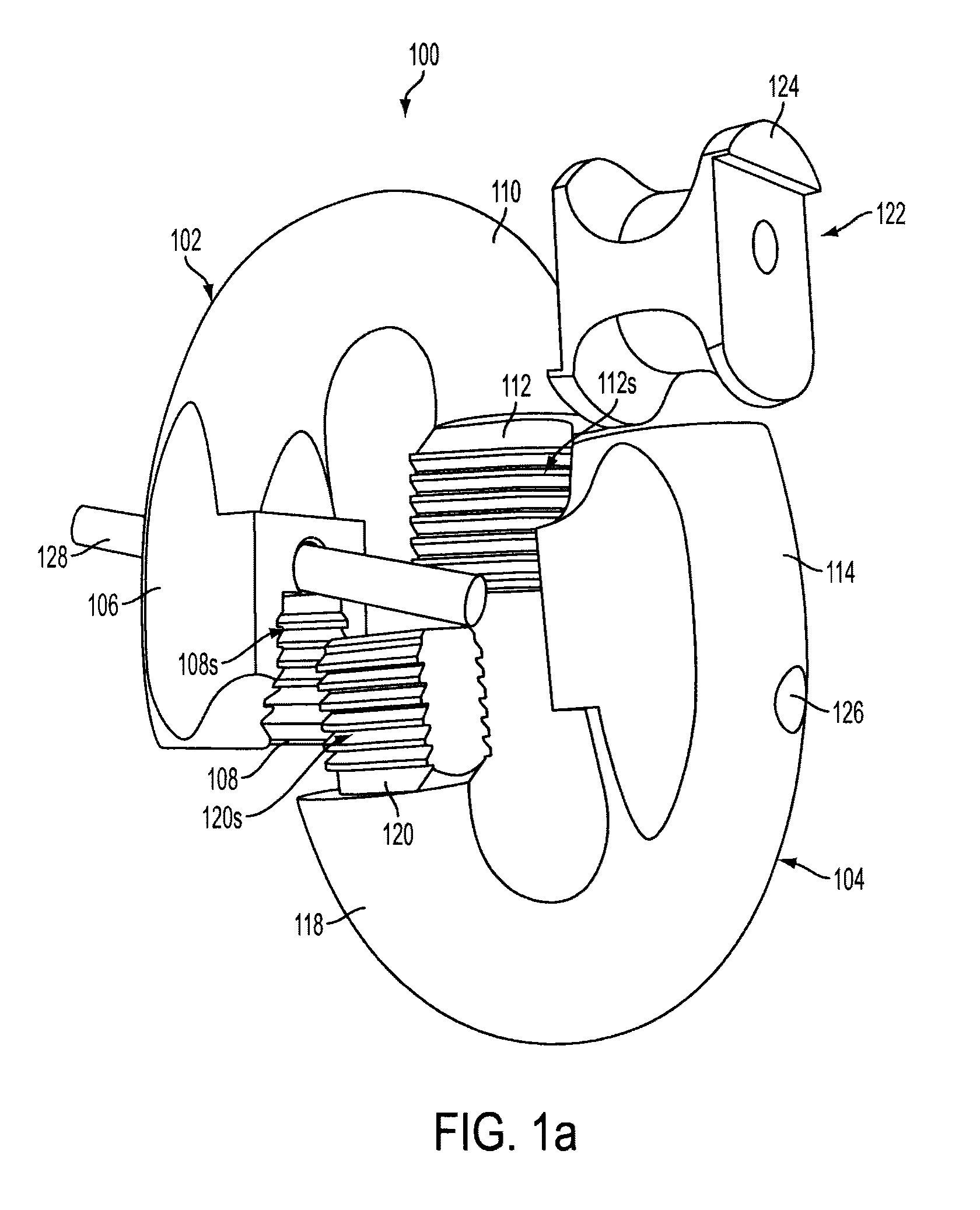

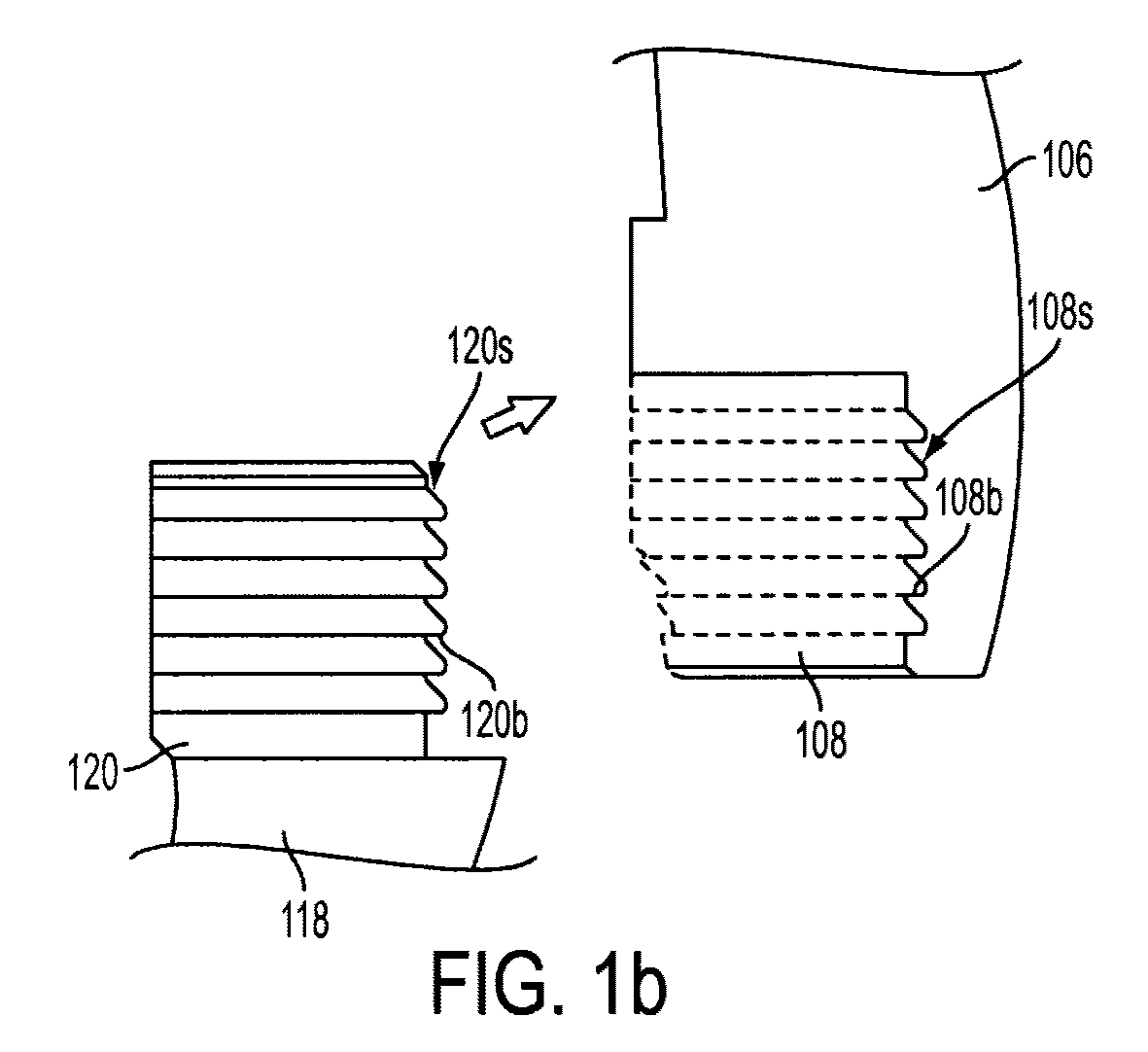

Underwater chain stopper and fairlead apparatus for anchoring offshore structures

ActiveUS20050241558A1Avoid large movementsChain fasteningsAnchoring arrangementsVertical planeSelf locking

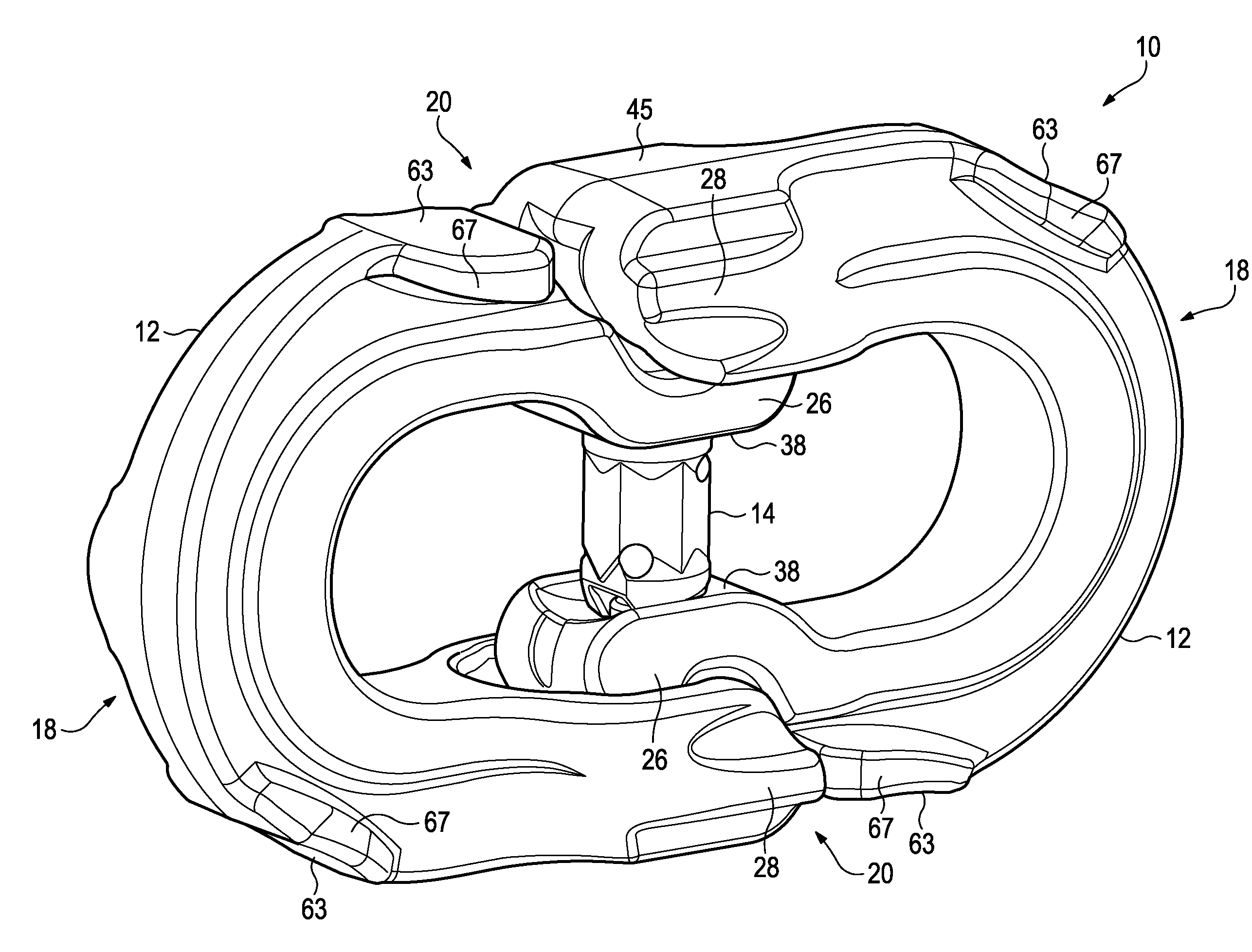

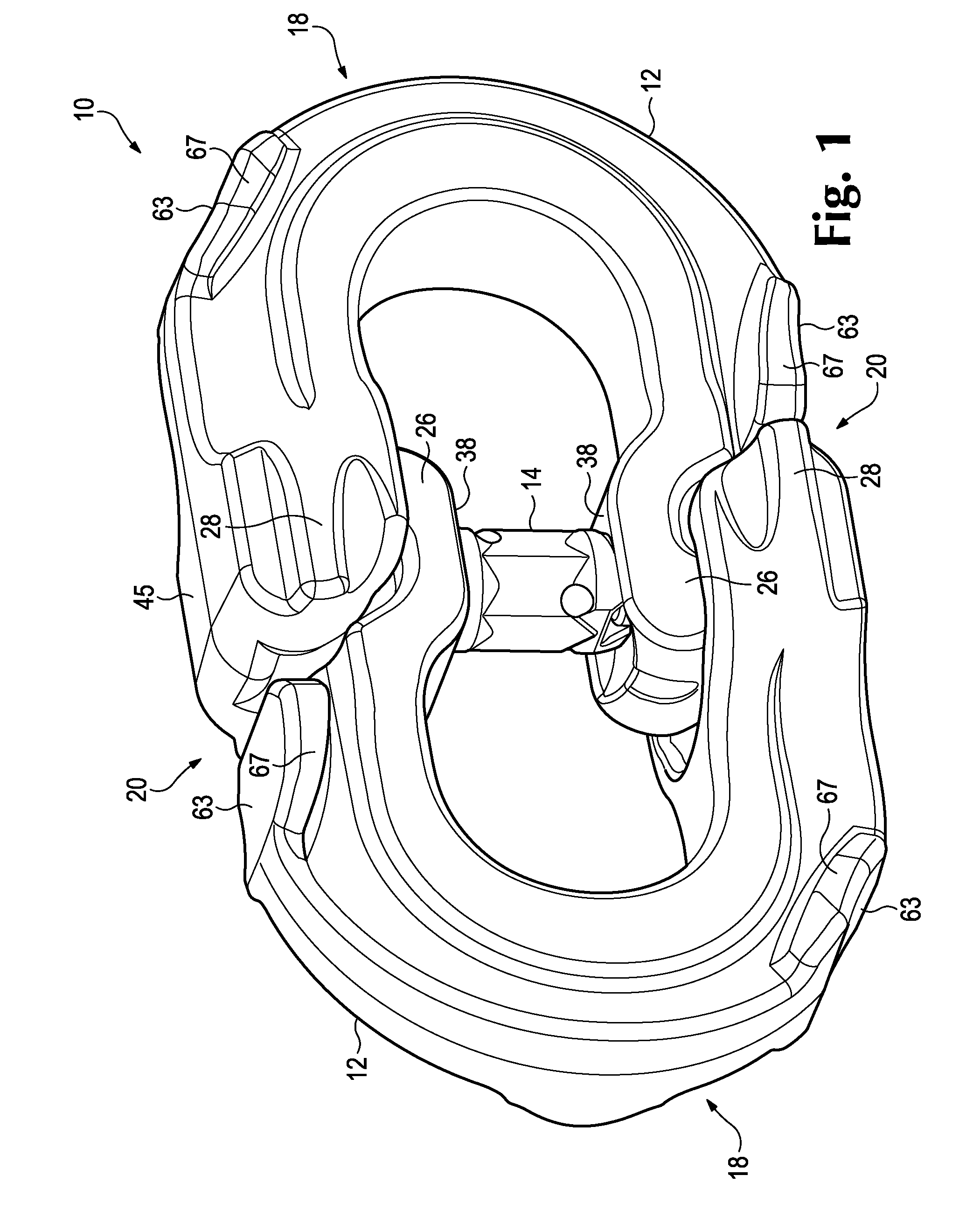

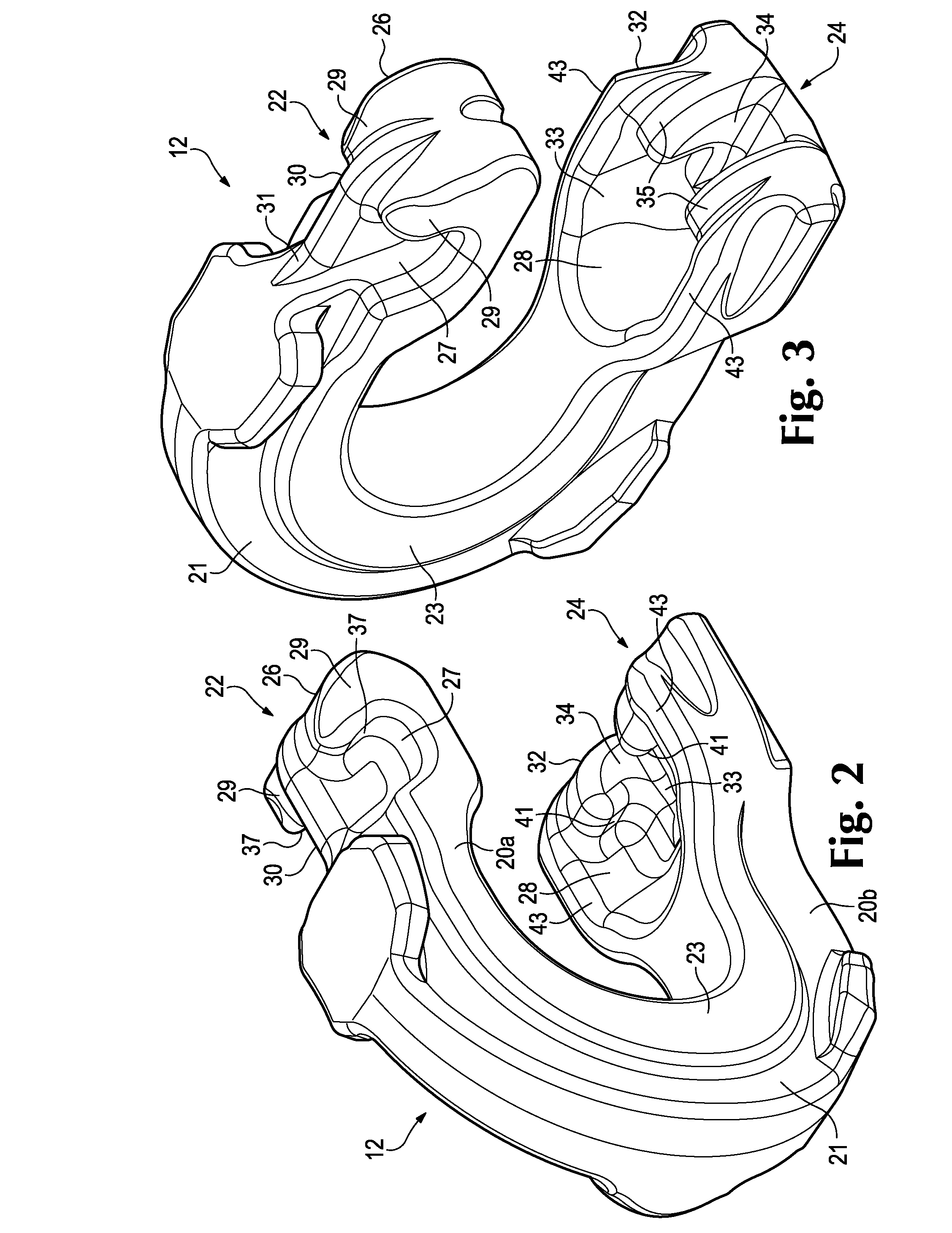

An underwater chain stopper and fairlead apparatus for offshore structures, drilling platforms, ships or other vessels. The apparatus comprises a mounting member, a fairlead member and a chain stopper member. The mounting member is attached to an underwater surface of the offshore structure or vessel and includes a bracket for coupling the fairlead member. The bracket may comprise a hinge allowing the fairlead member to pivot in an approximately horizontal plane. The chain stopper member is coupled to the fairlead member through a hinge which allows the chain stopper member to pivot with respect to the fairlead member in an approximately vertical plane. The chain stopper member includes a chain stopper flapper having a horseshoe shaped opening at one end. The other end of the flapper is connected to the chain stopper member through a hinge which allows the flapper to swing between an open position and a closed position. In the open position, the chain links for the anchor chain are allowed to pass by the horseshoe shaped opening on the flapper. The horseshoe shaped opening also includes a chain link seat which stops movement of the anchor chain through the chain stopper member when the flapper is in the closed position. The chain stopper flapper moves to the closed position under the force of gravity to provide a self-locking chain stopper. A latch mechanism is provided for latching the chain stopper flapper in an open position.

Owner:TIMBERLAND EQUIP

Underwater chain stopper and fairlead apparatus for anchoring offshore structures

ActiveUS7240633B2Avoid large movementsChain fasteningsAnchoring arrangementsVertical planeEngineering

An underwater chain stopper and fairlead apparatus for offshore structures, drilling platforms, ships or other vessels. The apparatus comprises a mounting member, a fairlead member and a chain stopper member. The mounting member is attached to an underwater surface of the offshore structure or vessel and includes a bracket for coupling the fairlead member. The bracket may comprise a hinge allowing the fairlead member to pivot in an approximately horizontal plane. The chain stopper member is coupled to the fairlead member through a hinge which allows the chain stopper member to pivot with respect to the fairlead member in an approximately vertical plane. The chain stopper member includes a chain stopper flapper having a horseshoe shaped opening at one end. The other end of the flapper is connected to the chain stopper member through a hinge which allows the flapper to swing between an open position and a closed position. In the open position, the chain links for the anchor chain are allowed to pass by the horseshoe shaped opening on the flapper. The horseshoe shaped opening also includes a chain link seat which stops movement of the anchor chain through the chain stopper member when the flapper is in the closed position. The chain stopper flapper moves to the closed position under the force of gravity to provide a self-locking chain stopper. A latch mechanism is provided for latching the chain stopper flapper in an open position.

Owner:TIMBERLAND EQUIP

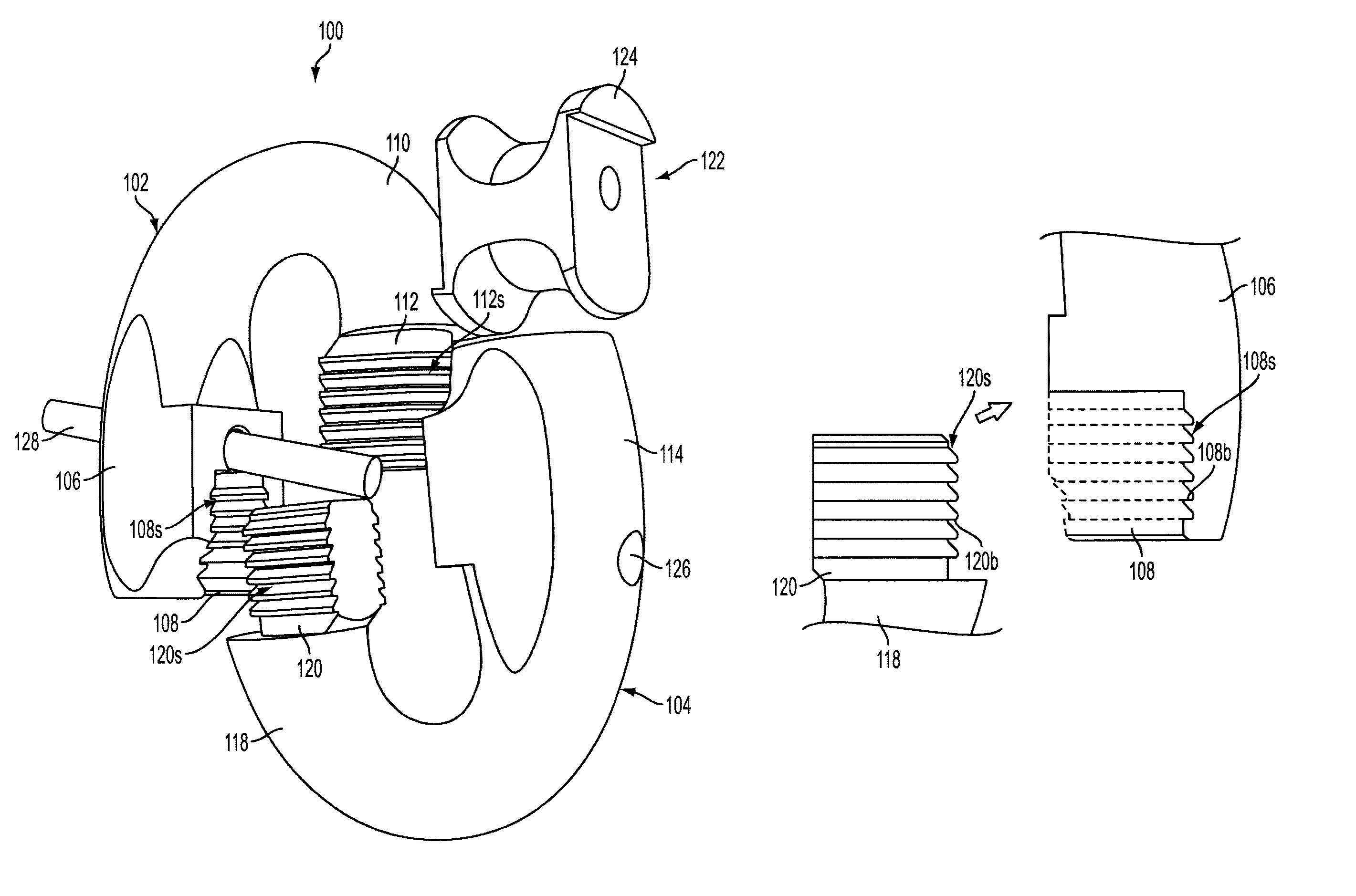

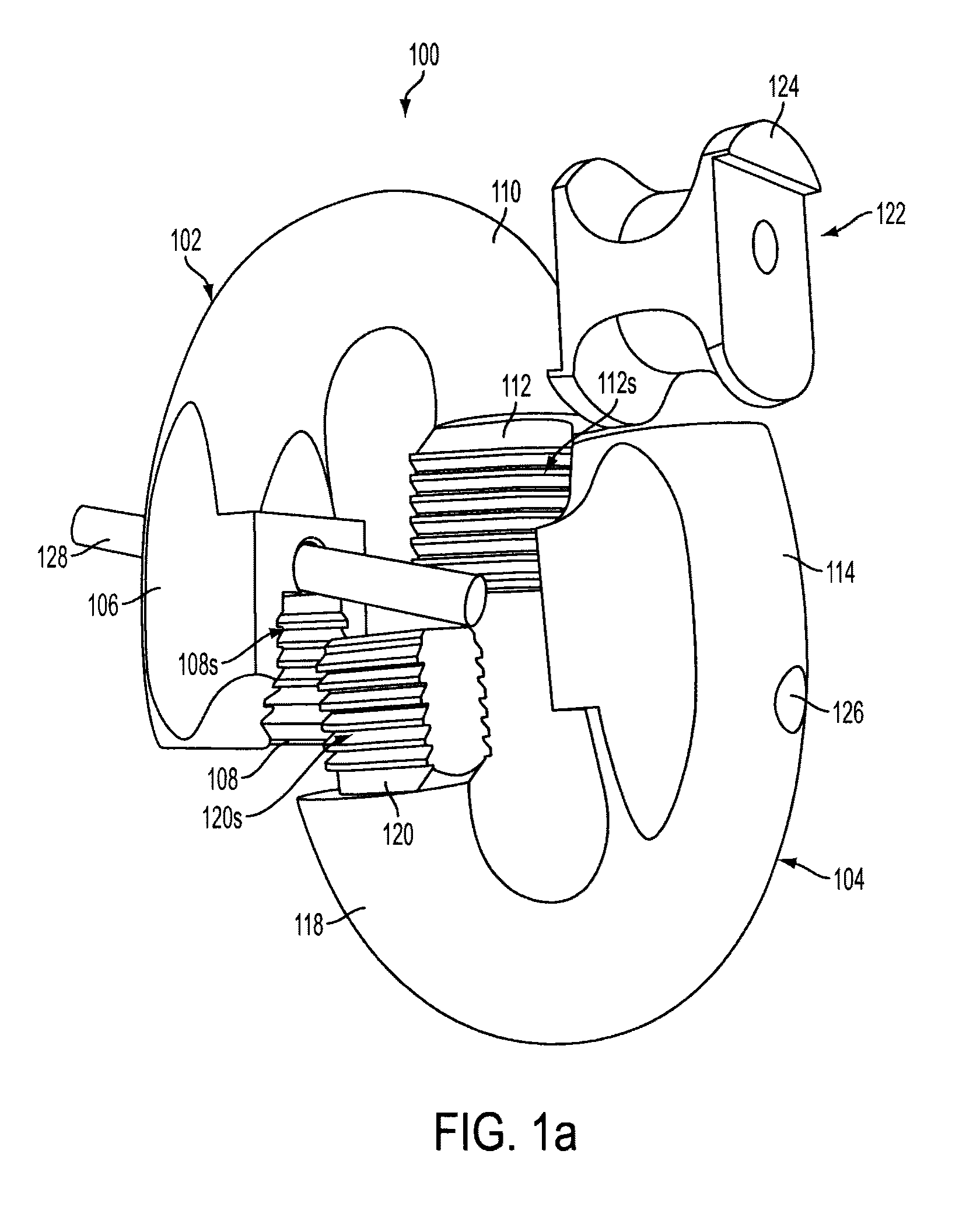

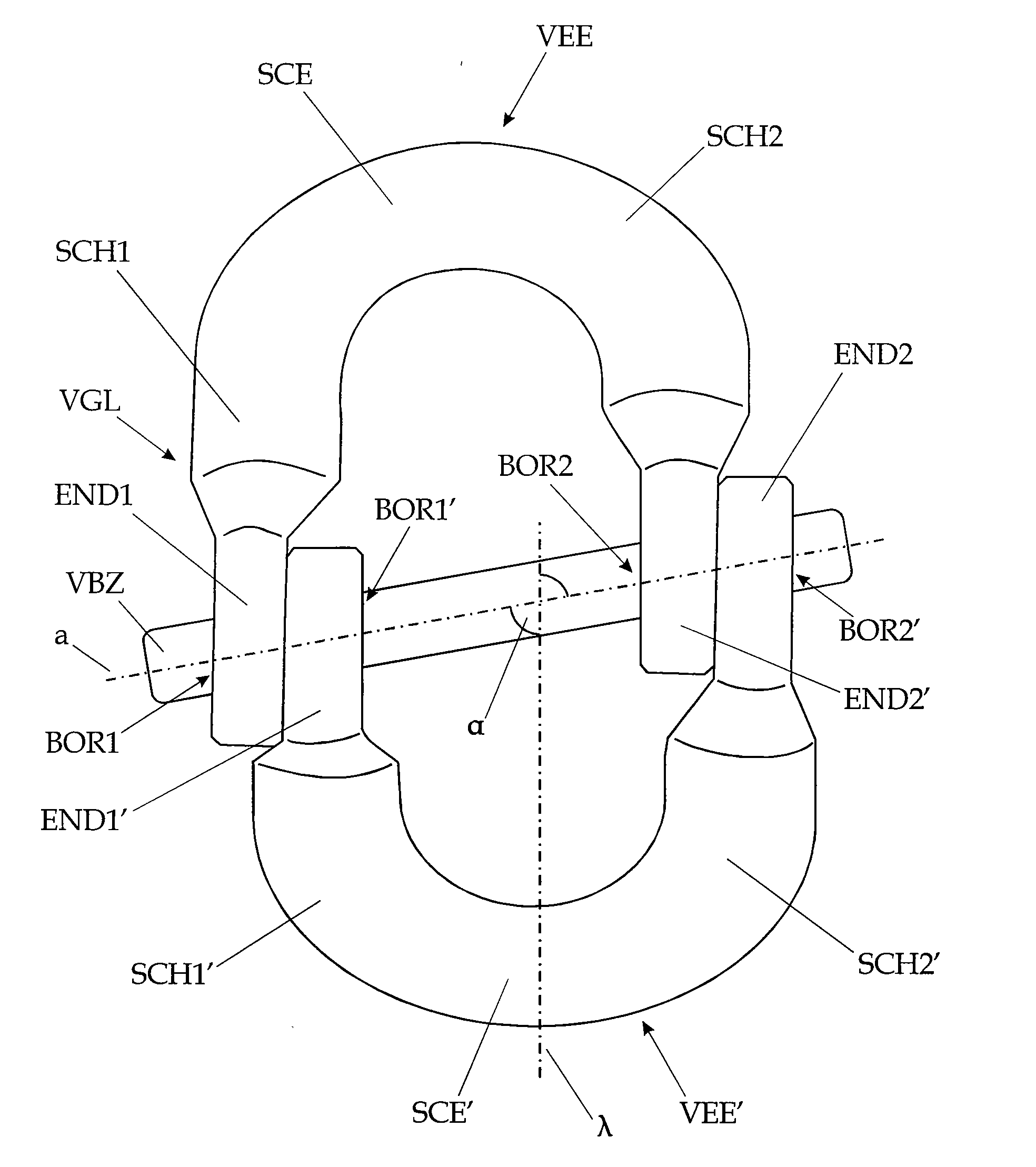

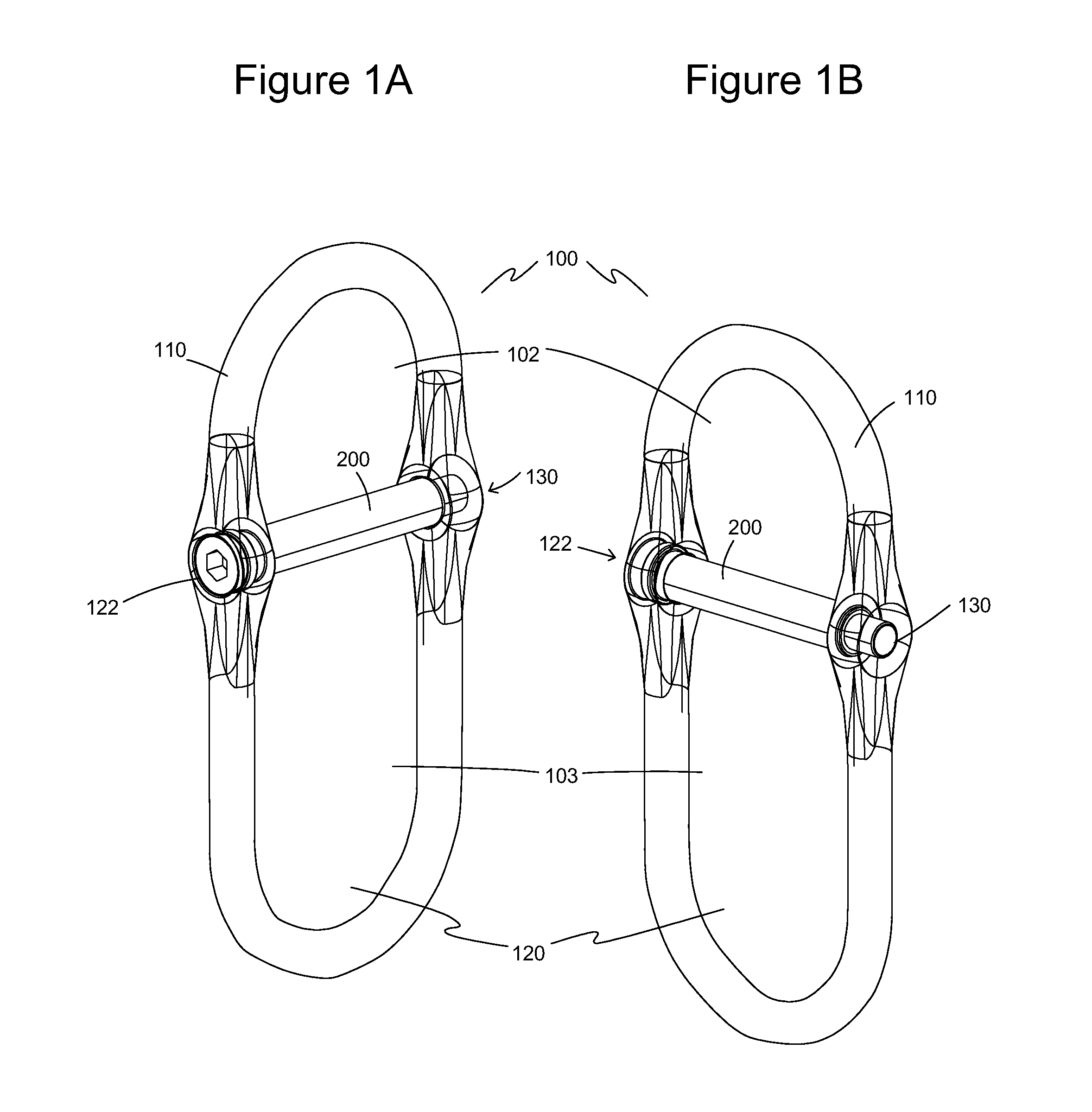

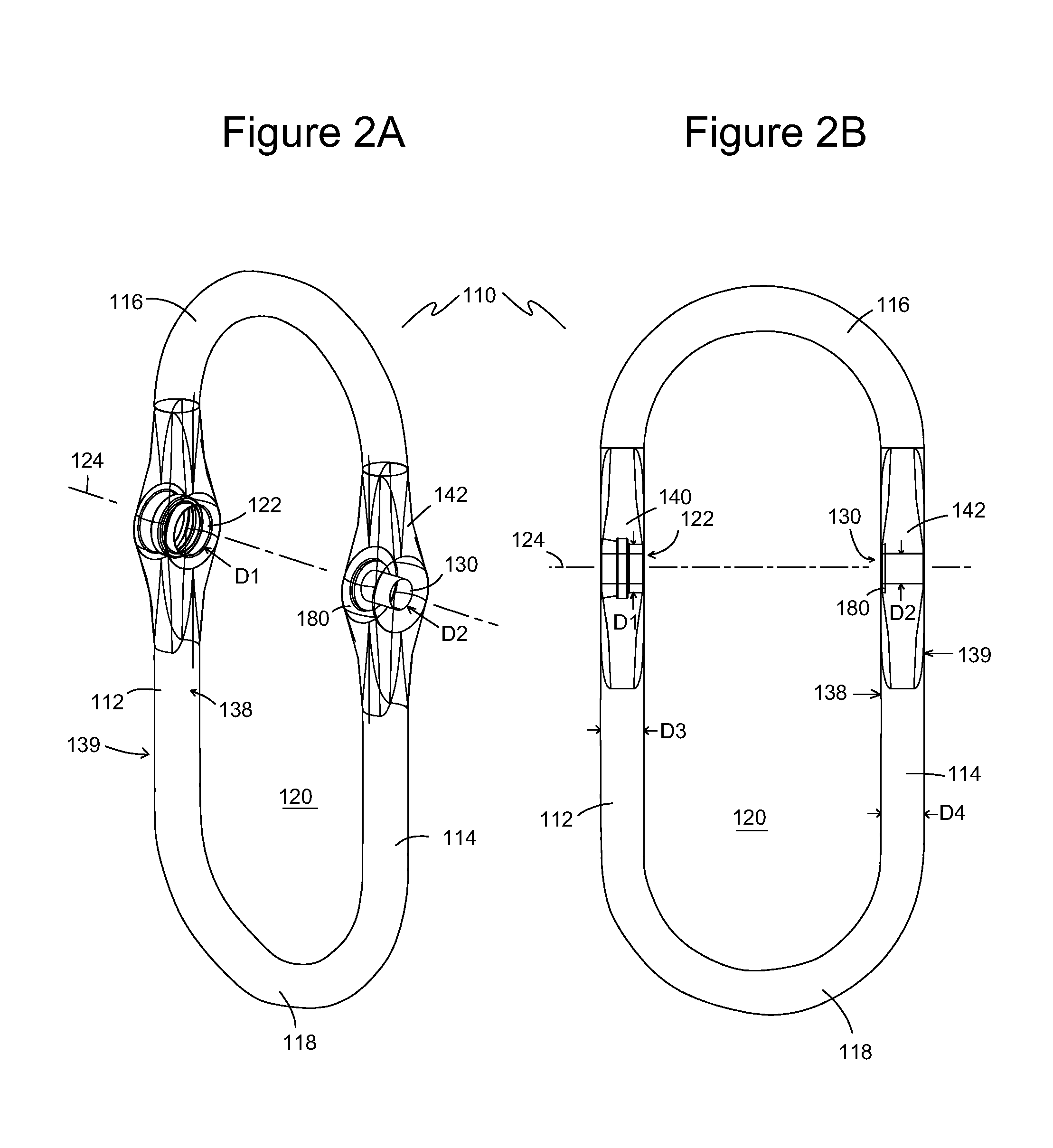

Connector

ActiveUS8087227B2Reduces tendency towards movementMore forceChain fasteningsShacklesBearing surfaceShackle

This invention relates to a connector, particularly to a shackle suitable for use in connecting two links of a chain or a chain to an anchor, more particularly to a connector comprising a first portion and a second portion, at least one first connector arm on the first portion and at least one second connector arm on the second portion, wherein both the first and second connector arms have multiple bearing surfaces, preferably six, and are able to engage one another when the connector is coupled by means of the bearing surfaces. The connector of the present invention has the advantage of having a break load of 1.3[0.0274 d2(44−0.08 d) kN, wherein d is the nominal diameter, and preferably a thickness of 1.3 d.

Owner:SCHMIEDESTUCK VERTRIEB FEUERSTEIN

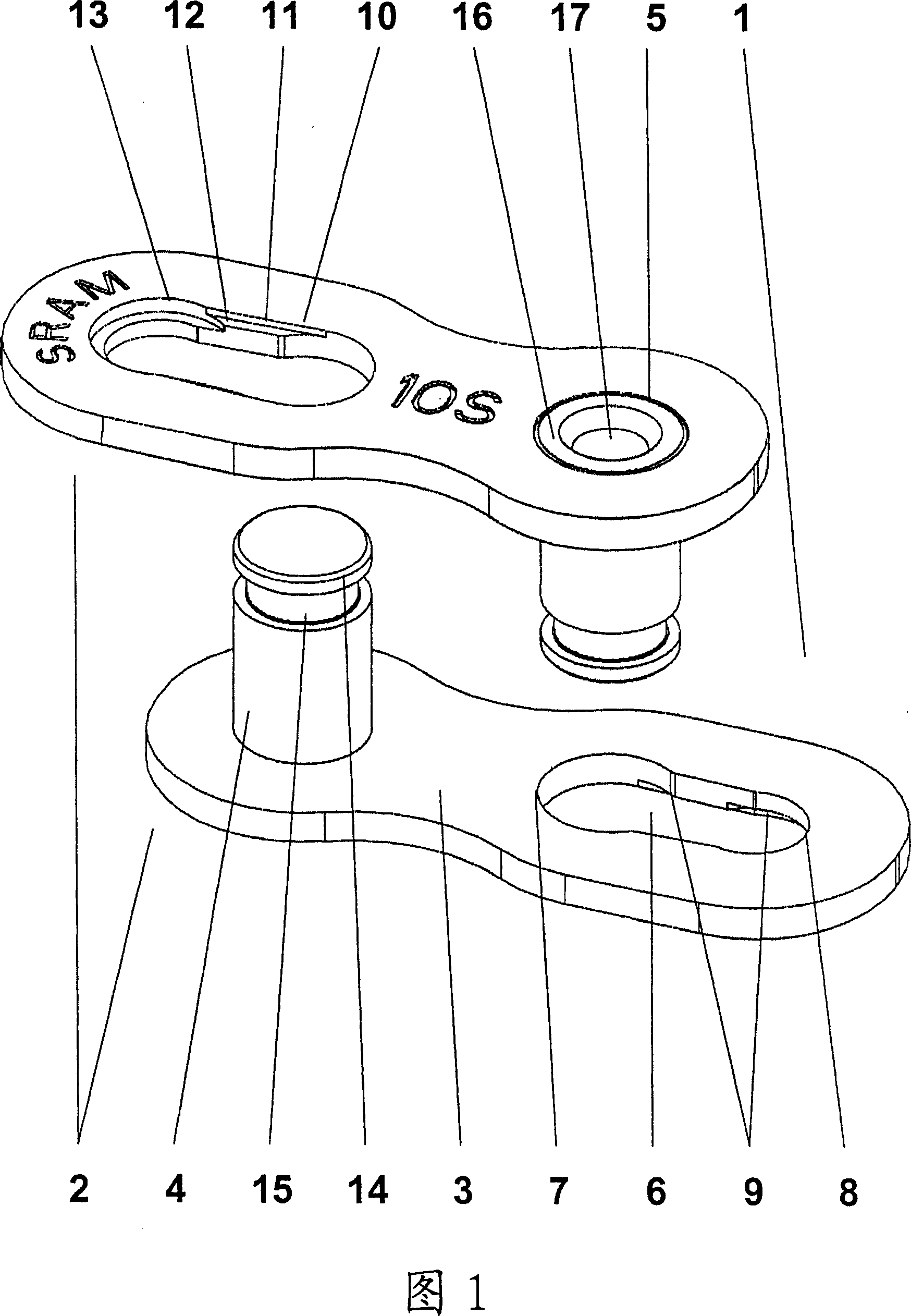

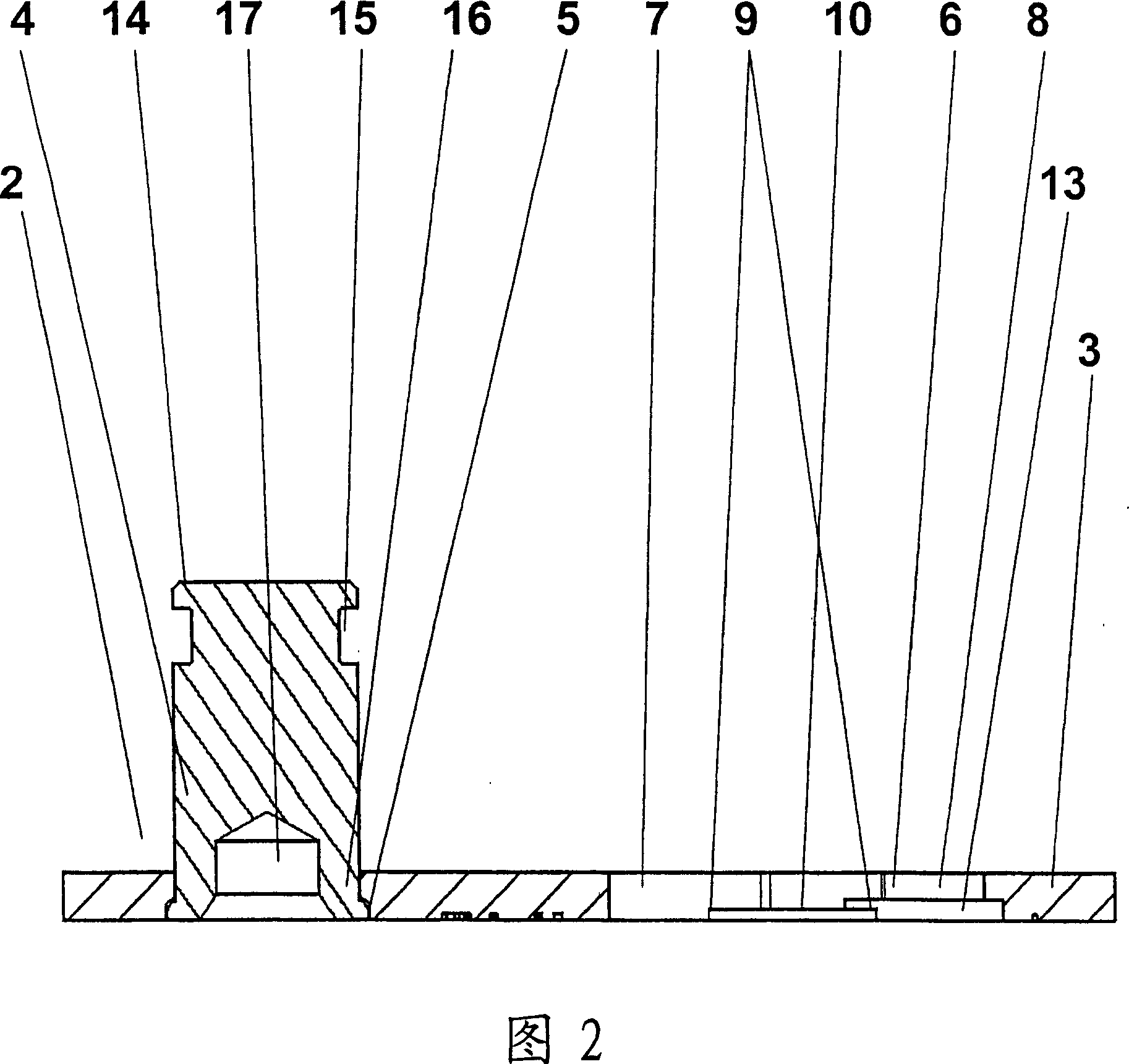

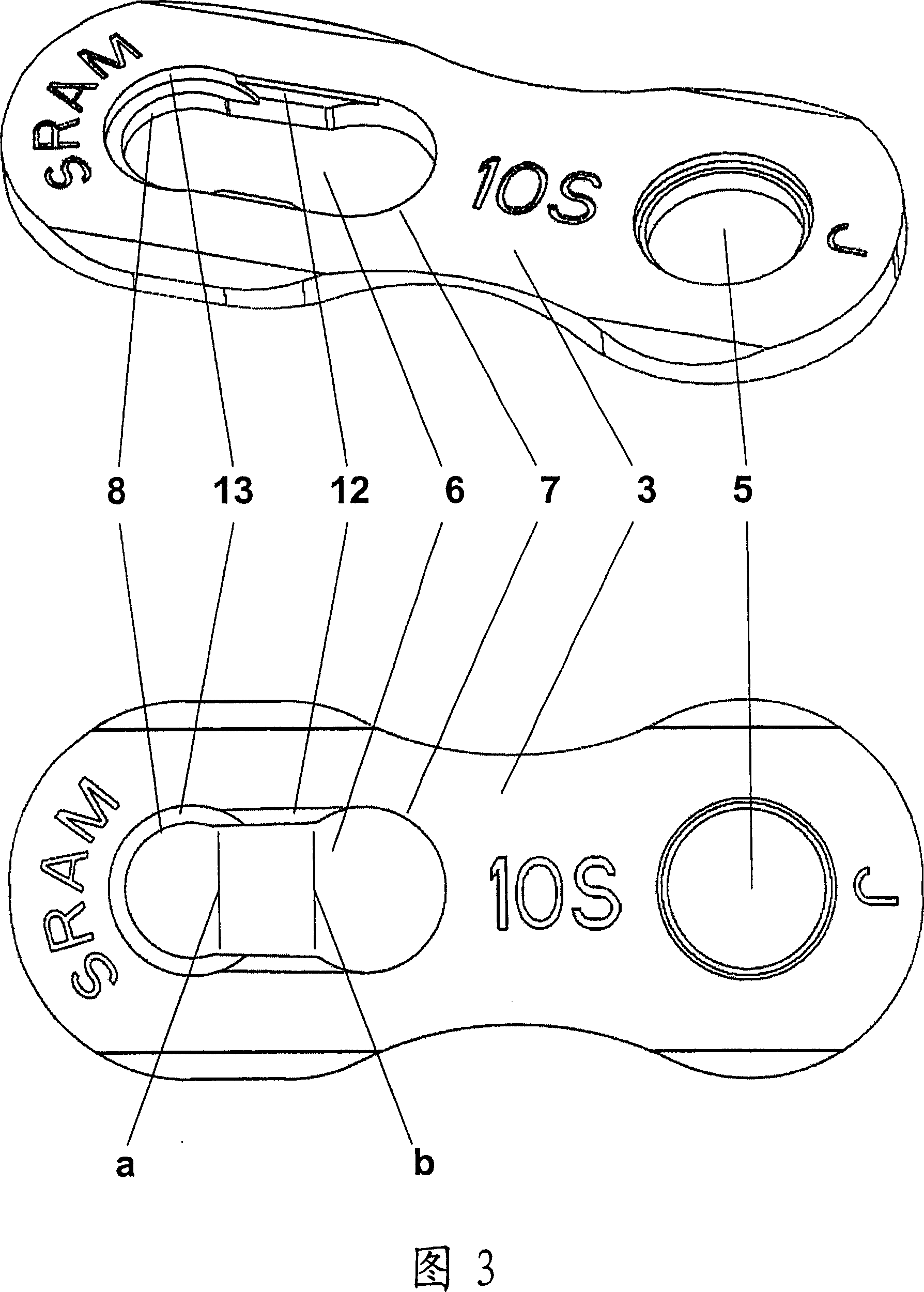

Closing link chain

The present invention relates to a closing lock link for a bicycle chain with narrow and long structure, the lock link is composed of two closing lock members that respectively has an external plate and a chain pin fixed on the external plate. The external plate is disposed with a long hole and a pin hole which has a larger diameter in external profile area. The chain pin has a pin head, a pin groove and a pin tail having a cavity extends along axial direction. The cavity is enlarged when mounting the closing lock member thereby the pin tail can tightly contact the pin hole profile to further form a shape coupling connection. In order to obtain minimum chain width, the pin head is short that the thickness of the plate. The pin head is in a concave part at the small diameter end of the long hole. In order to prevent disassembling the locked closing lock chain, the concave part is disposed with one or more narrow parts. The narrow part can effectively engage to the circumferential surface of the pin head or the circumferential surface of the pin groove, or act on the annular surface of the pin groove, or engage to their combination, therefore, the closing lock chain can be prevented from being opened suddenly.

Owner:SRAM

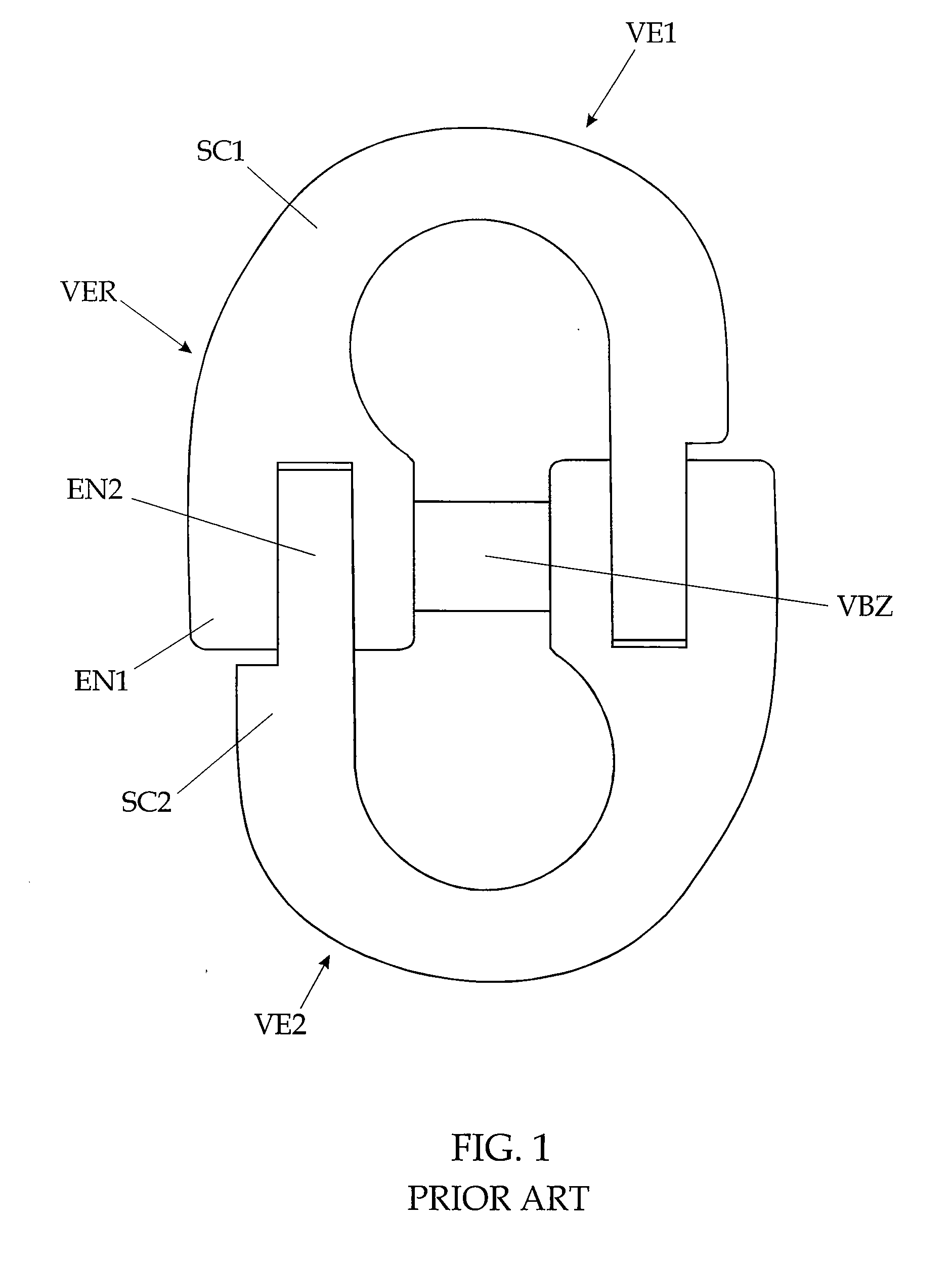

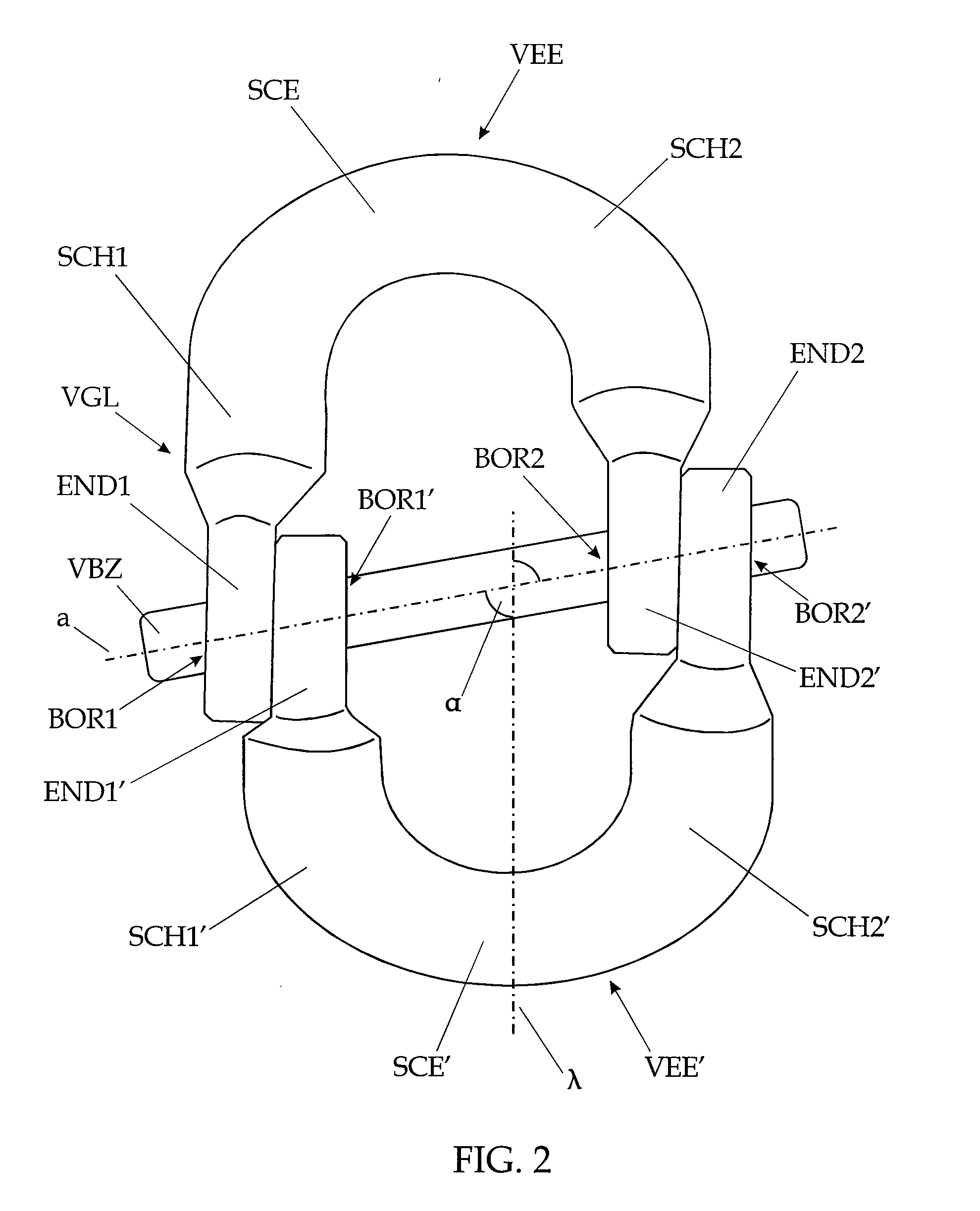

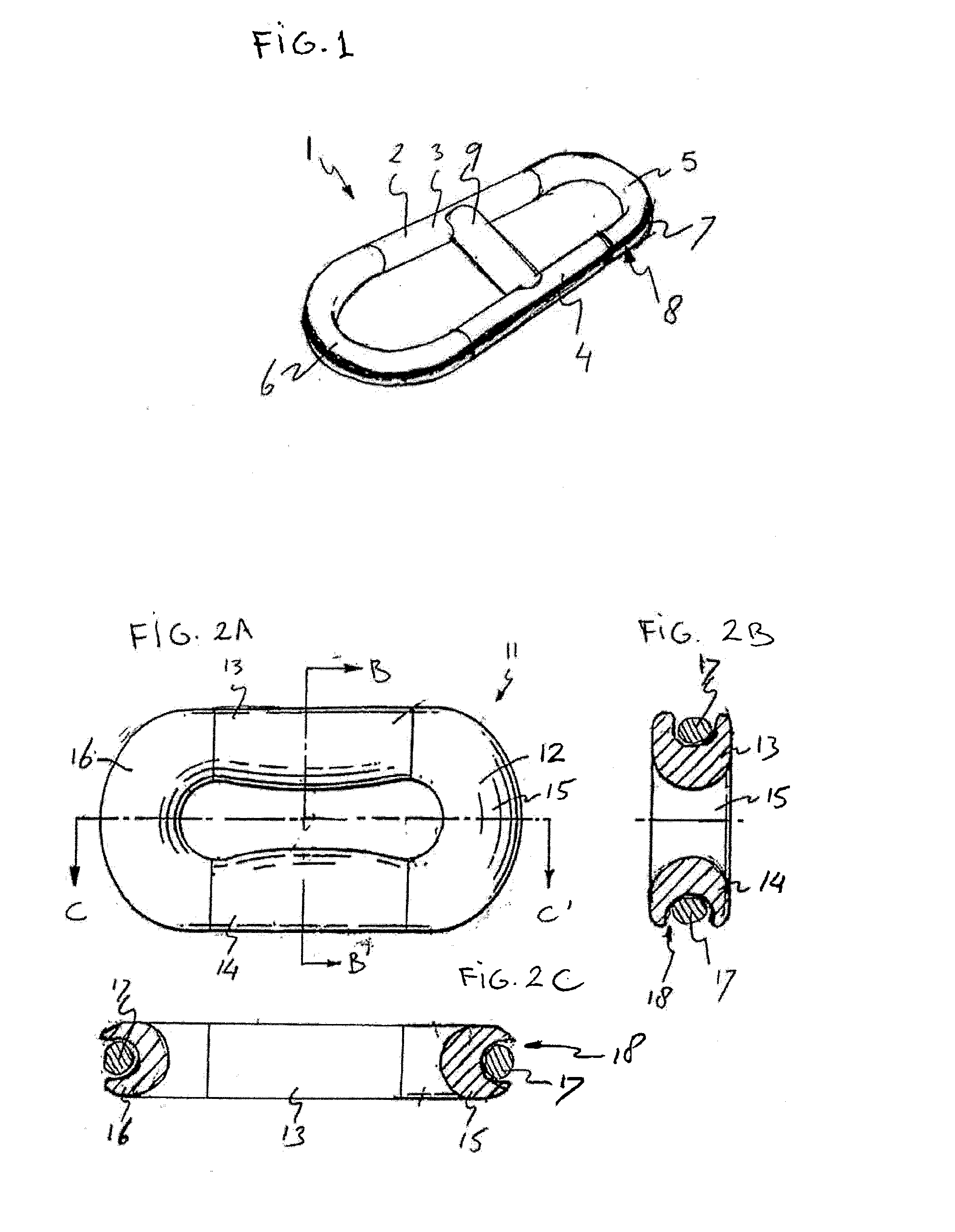

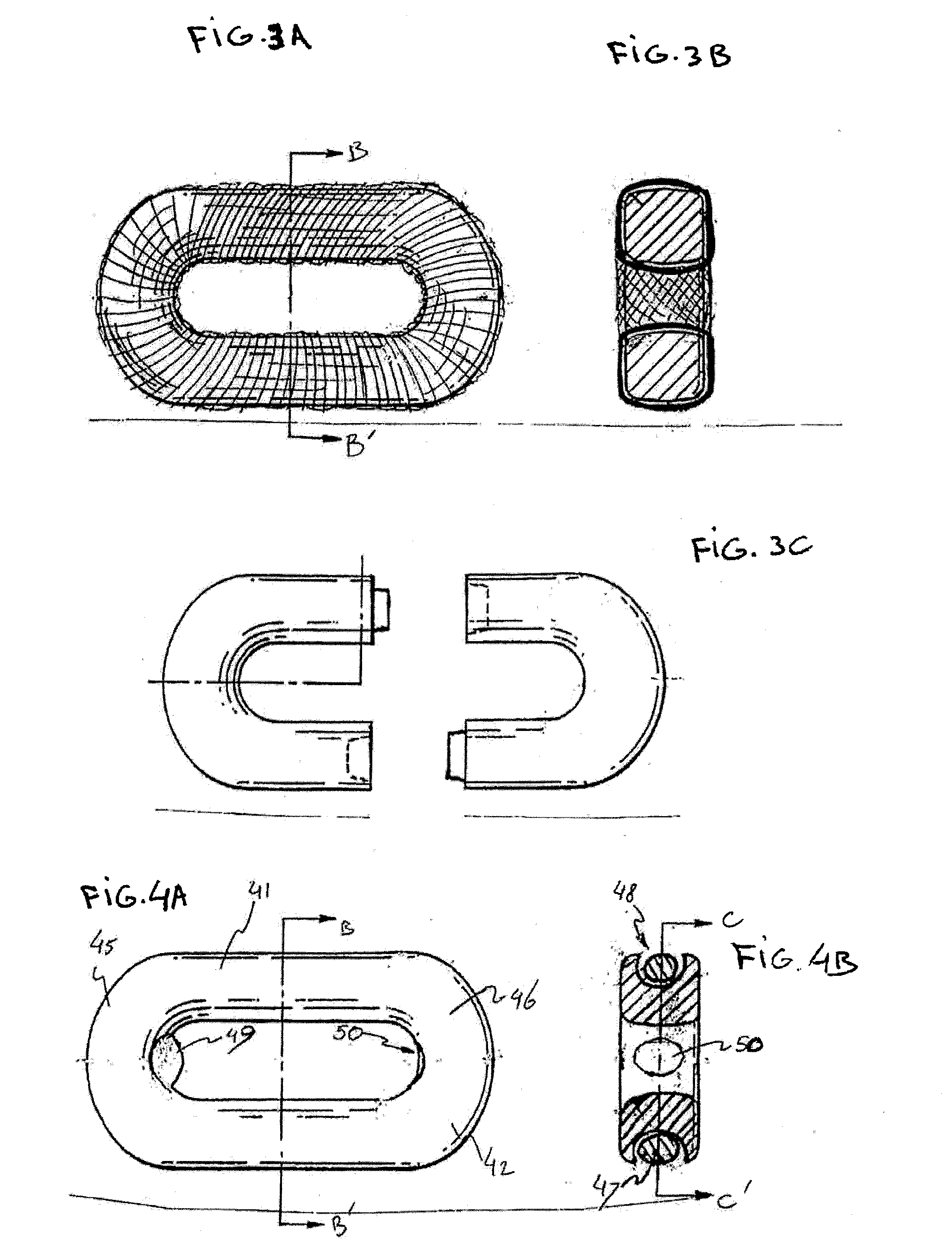

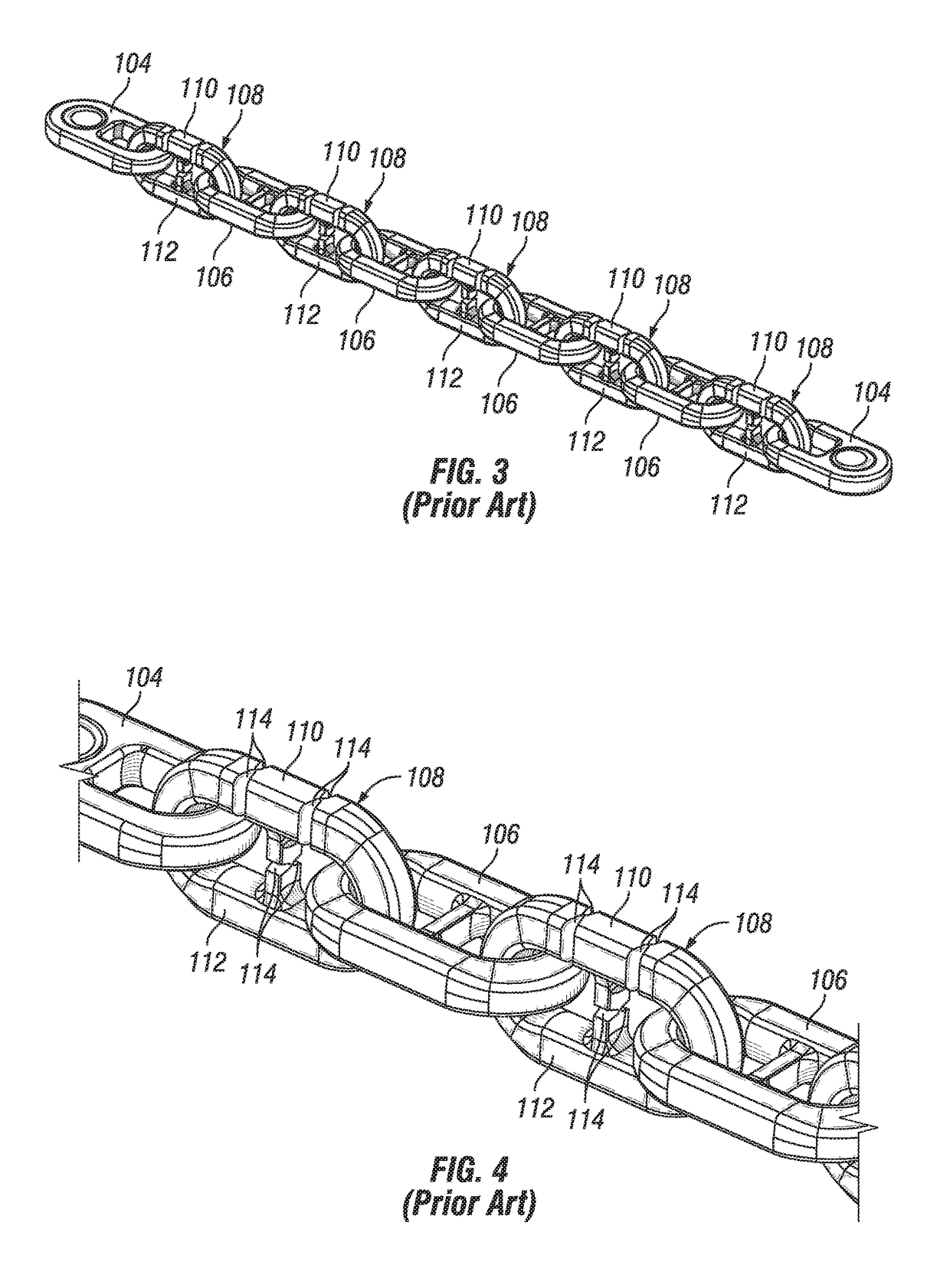

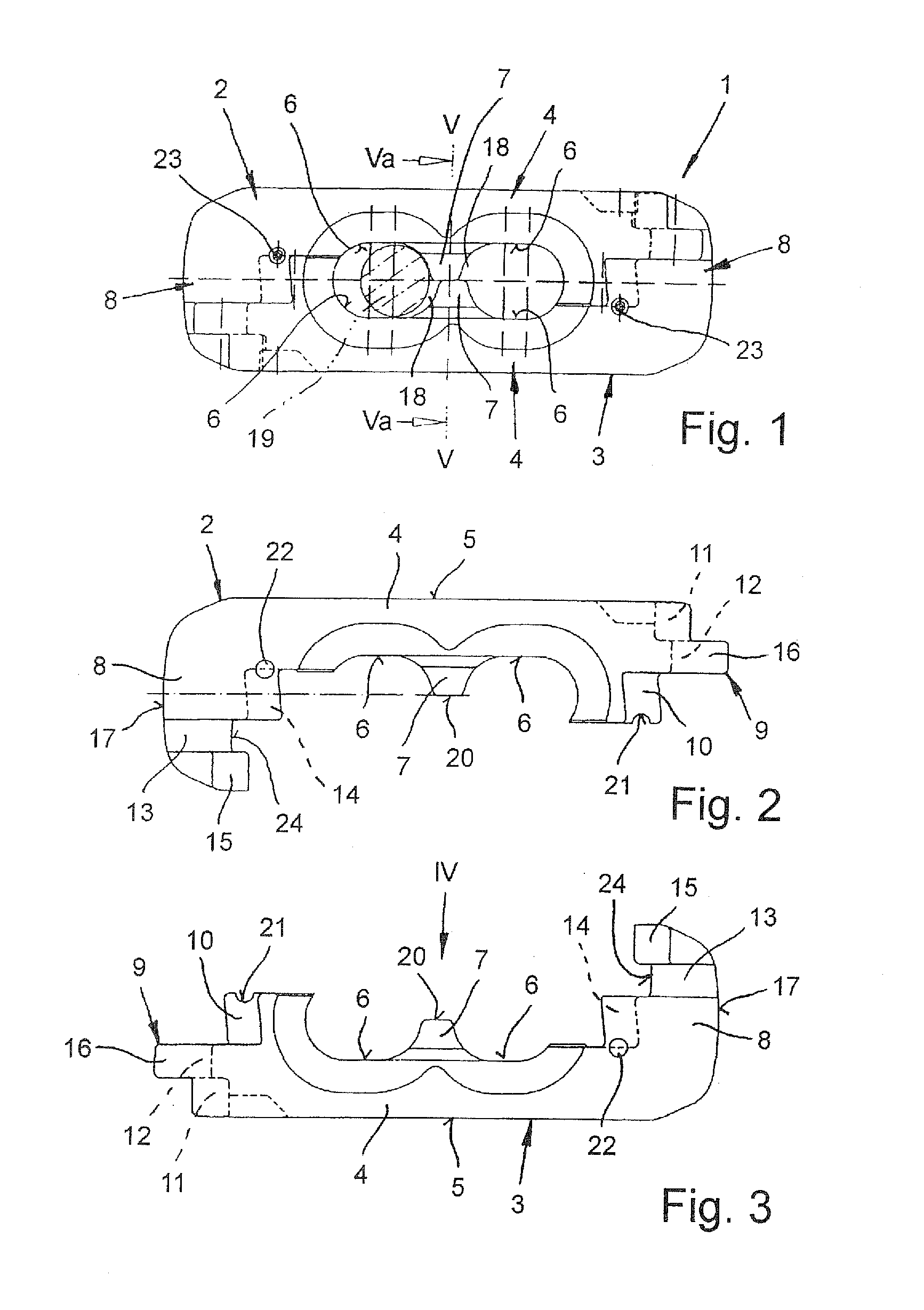

Chain connecting link

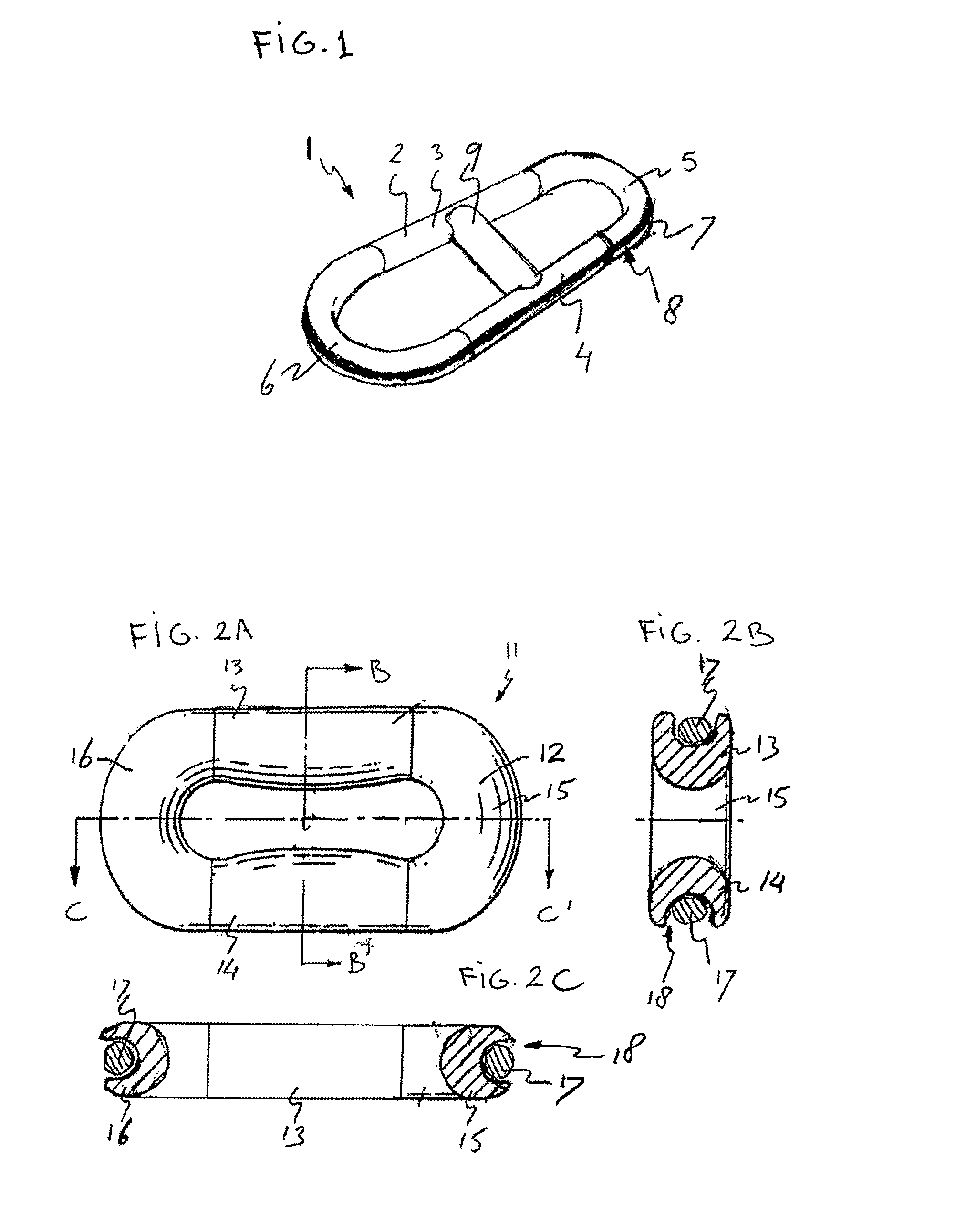

InactiveCN101421538AImprove carrying capacitySimple structureChain fasteningsLongitudinal planeEngineering

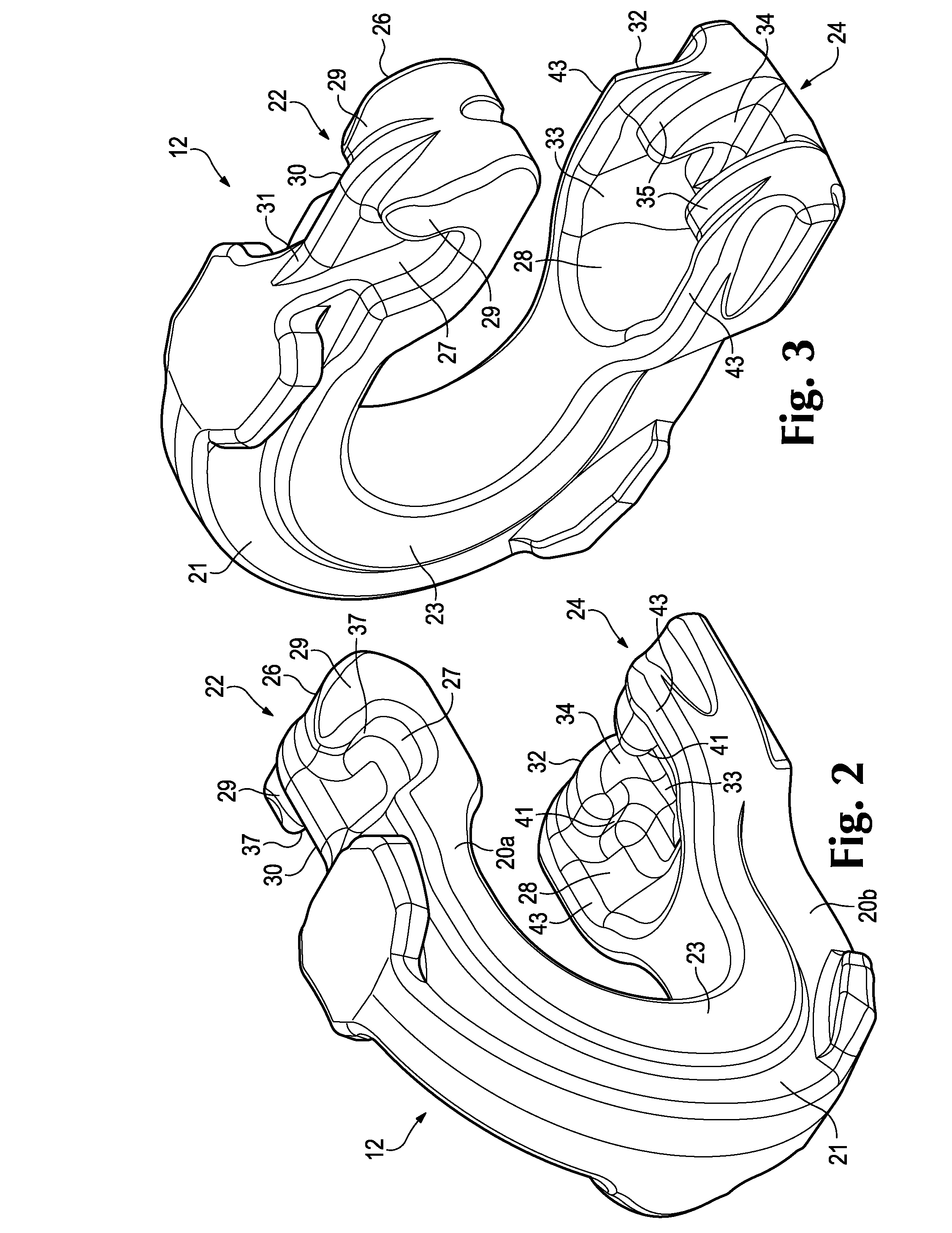

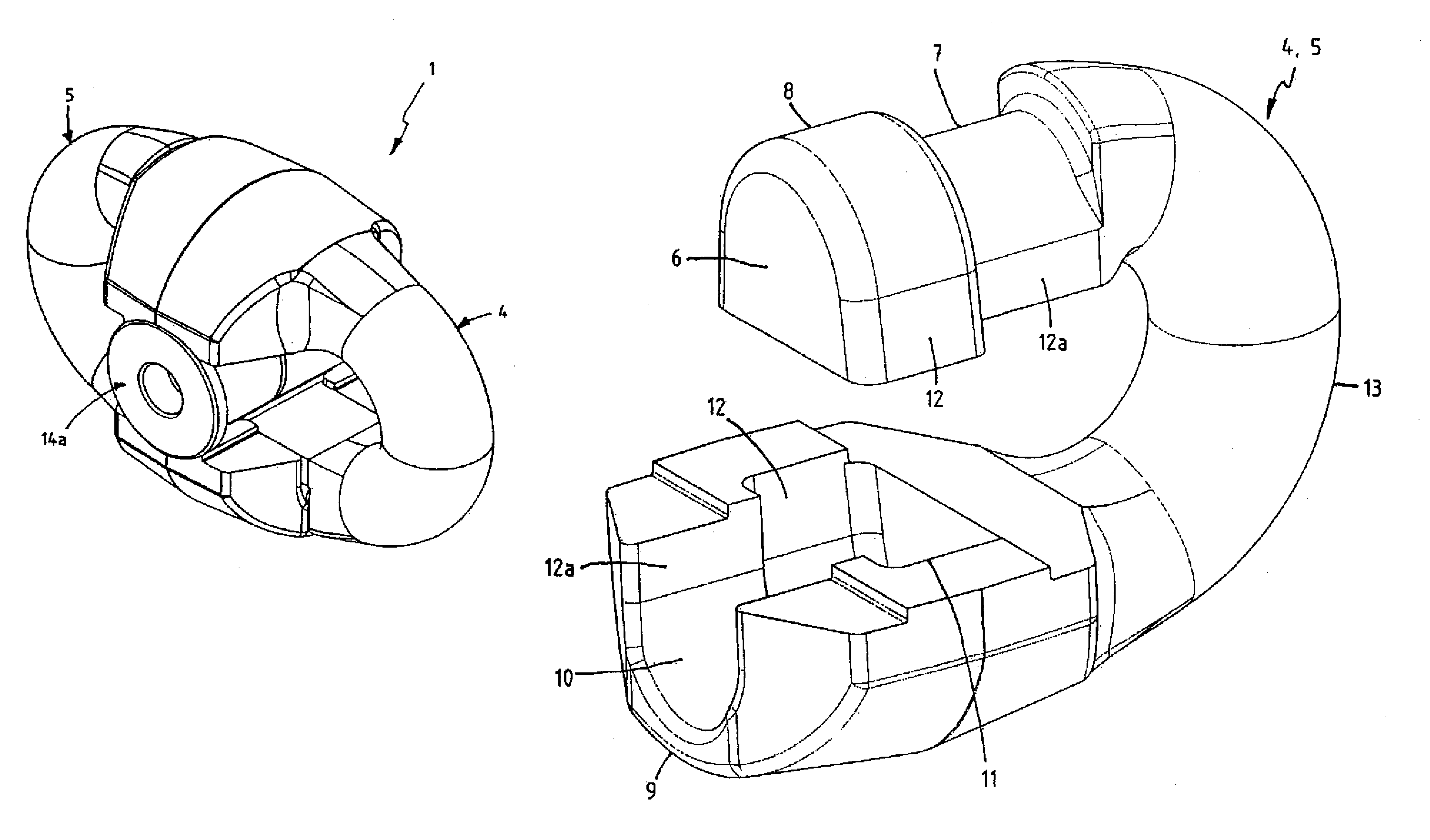

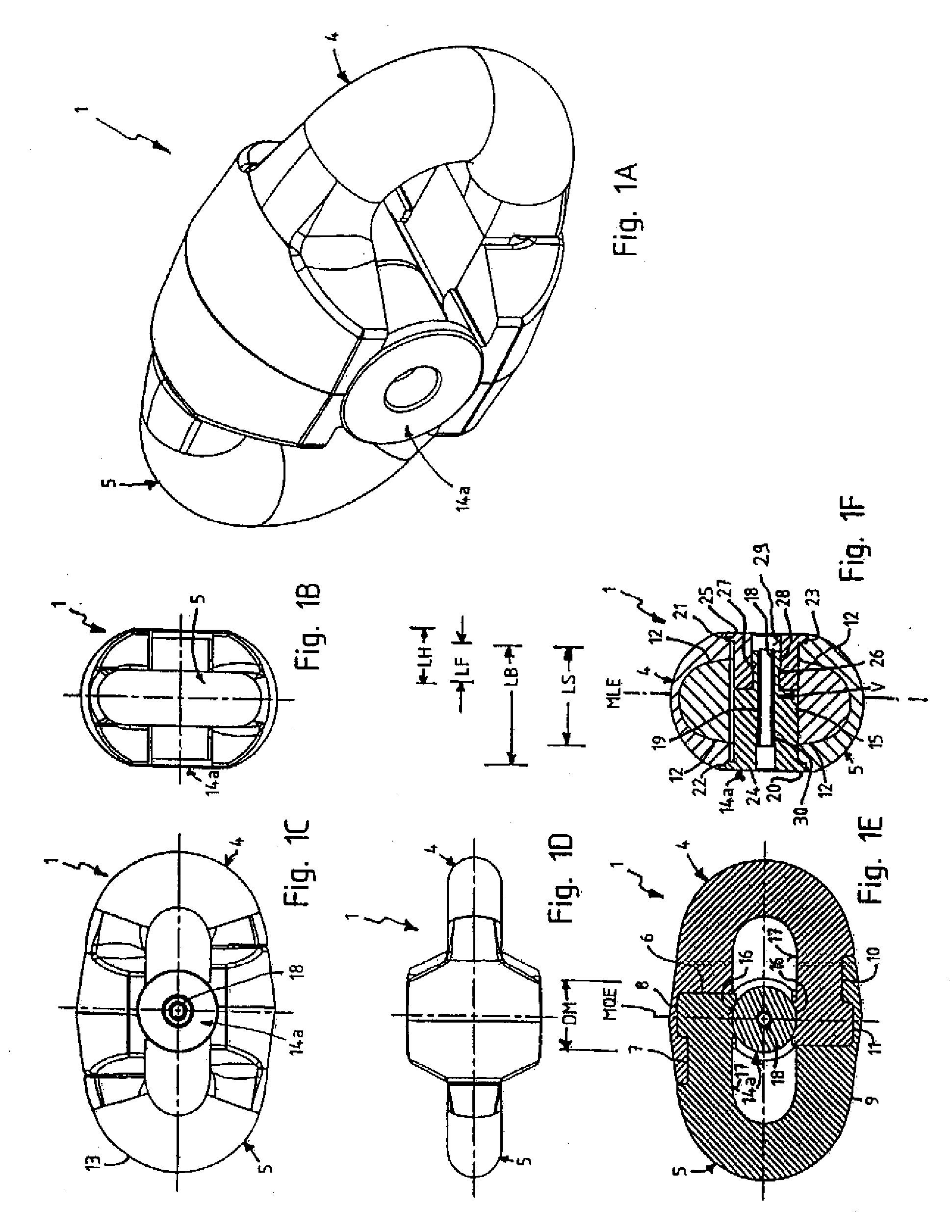

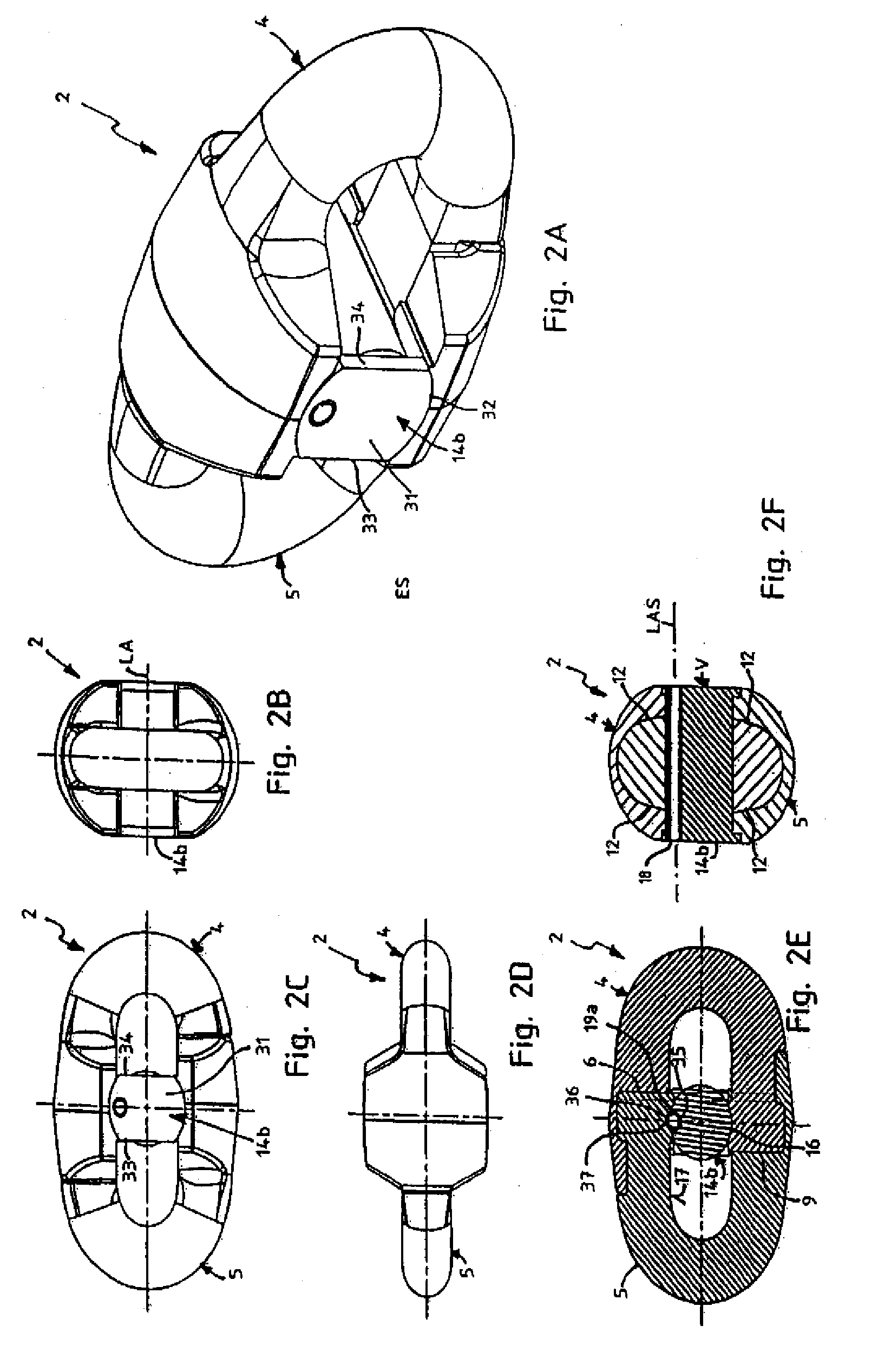

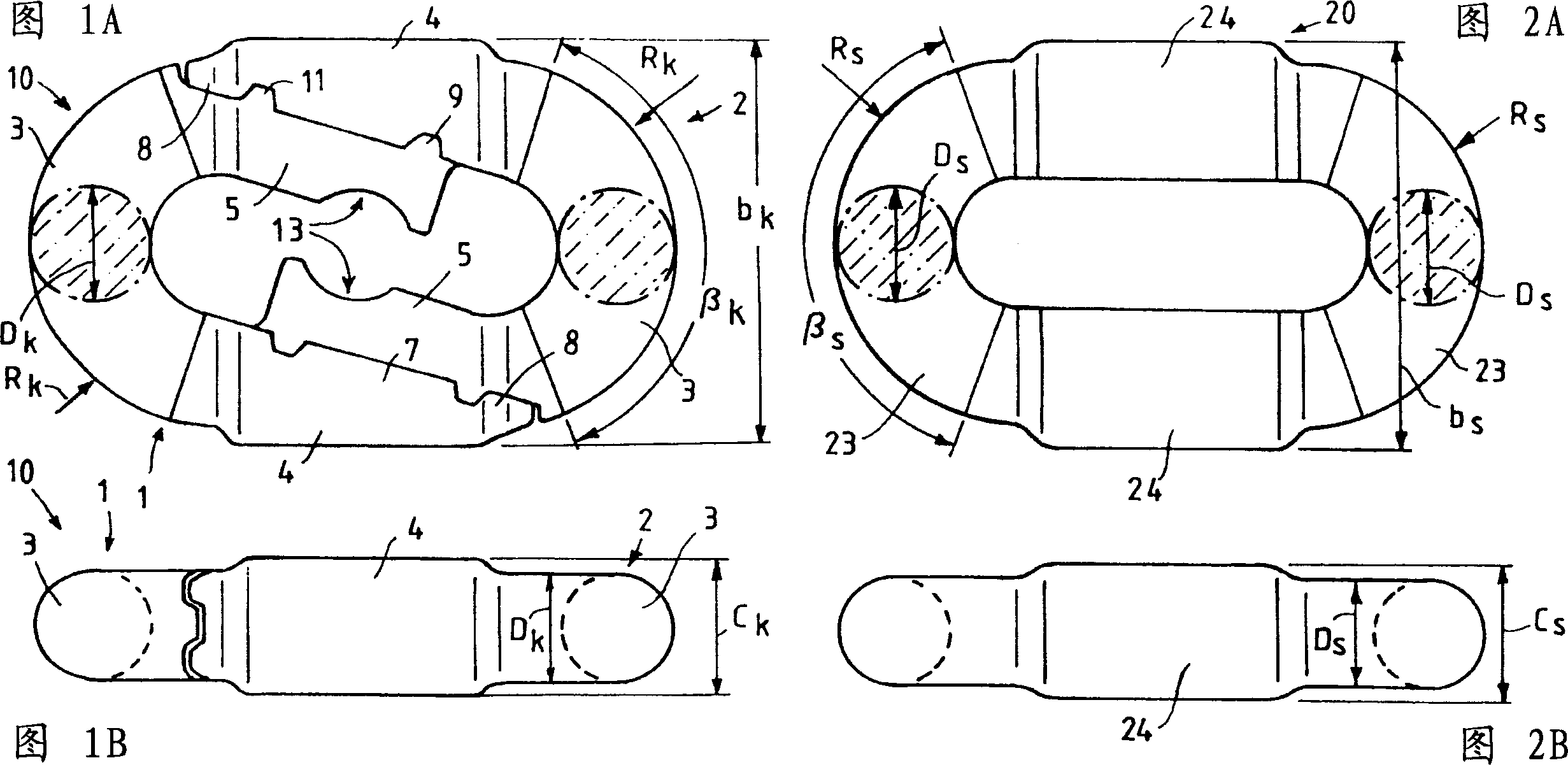

The invention relates to a chain connecting link, which has two link brackets (4, 5) coupled via their limbs (6, 9), and a bar (14a-14c) that is inserted transversely between the limbs (6, 9) of the link brackets (4, 5). One limb (6) of each link bracket (4, 5) comprises a neck section (7) and a journal (8) thicker than the neck section, and a neck recess (10) and a journal recess (11) are provided in a matching fashion at the other limb (9) of the link bracket (4, 5). According to the invention, conically configured flank surfaces (12) with respect to the vertical central longitudinal plane (MLE) are provided at each journal (8) and at each journal recess (11).

Owner:THIELE GMBH & CO KG

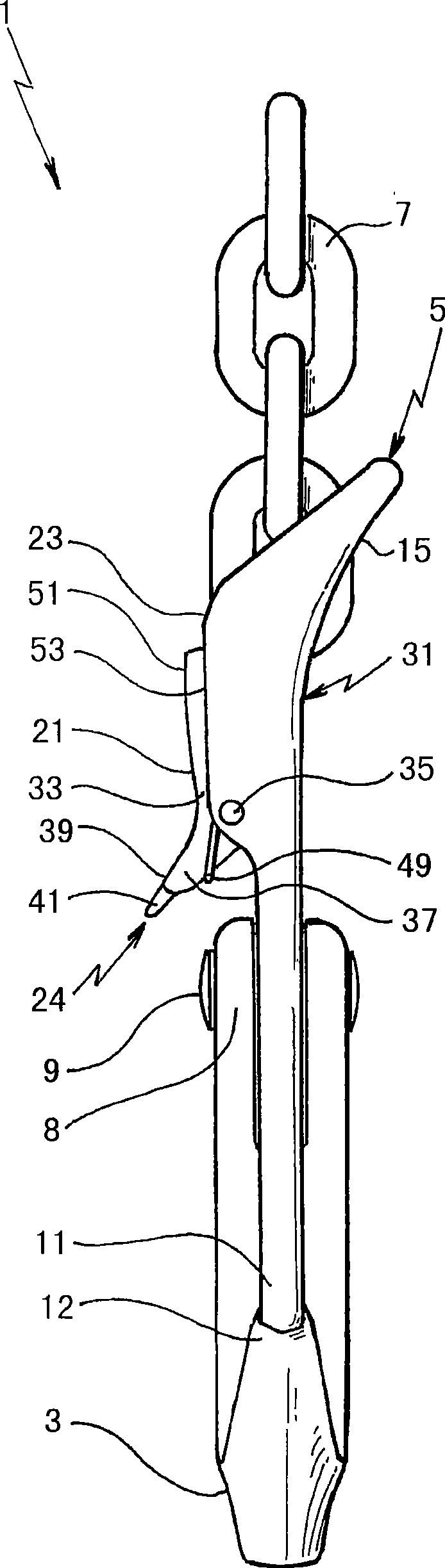

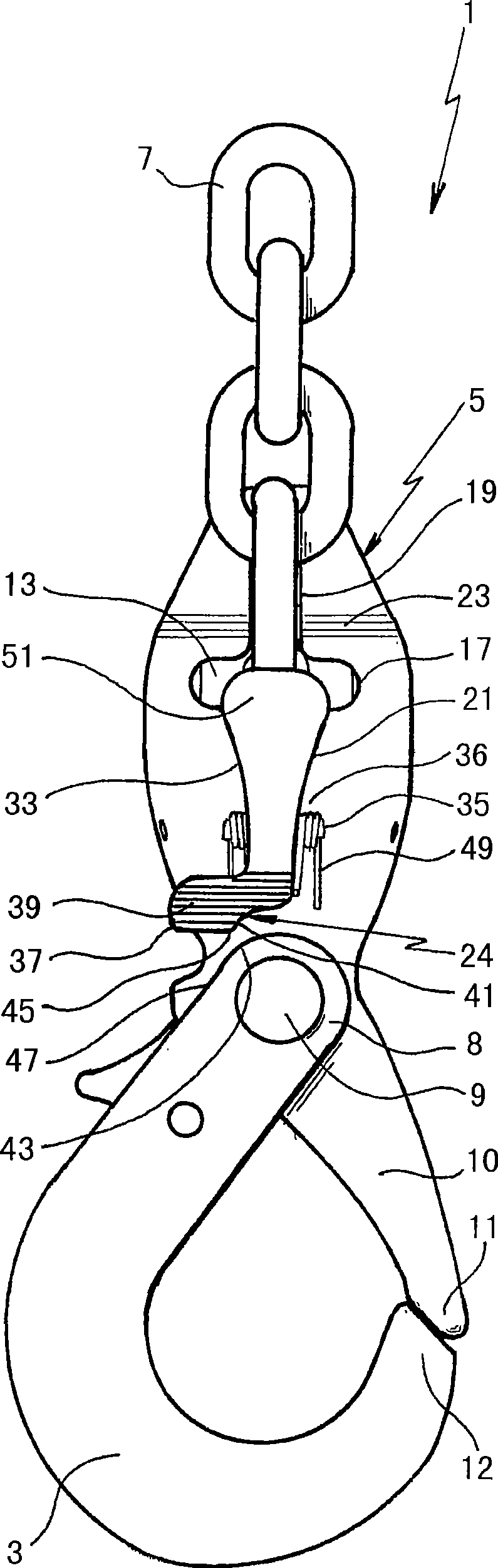

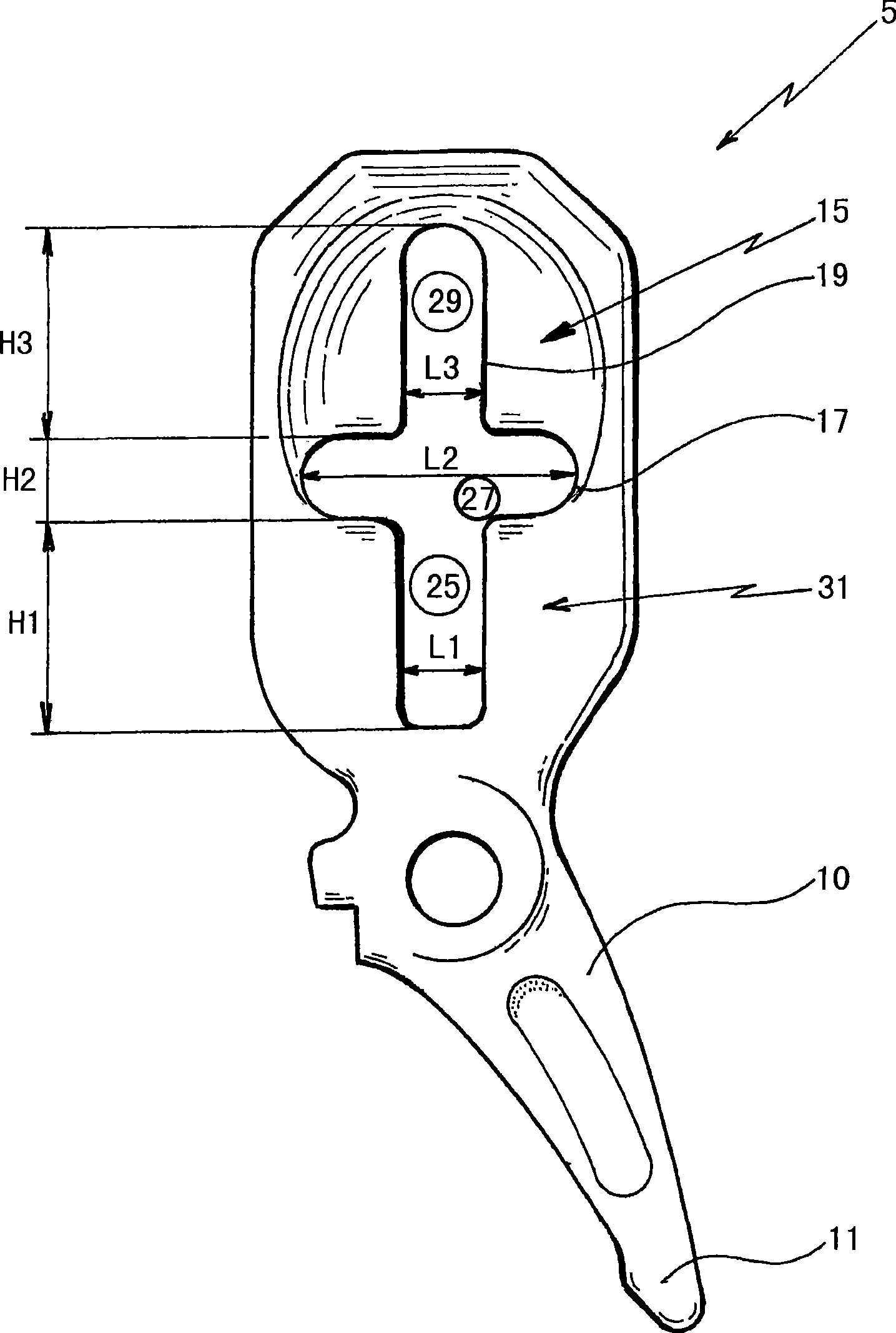

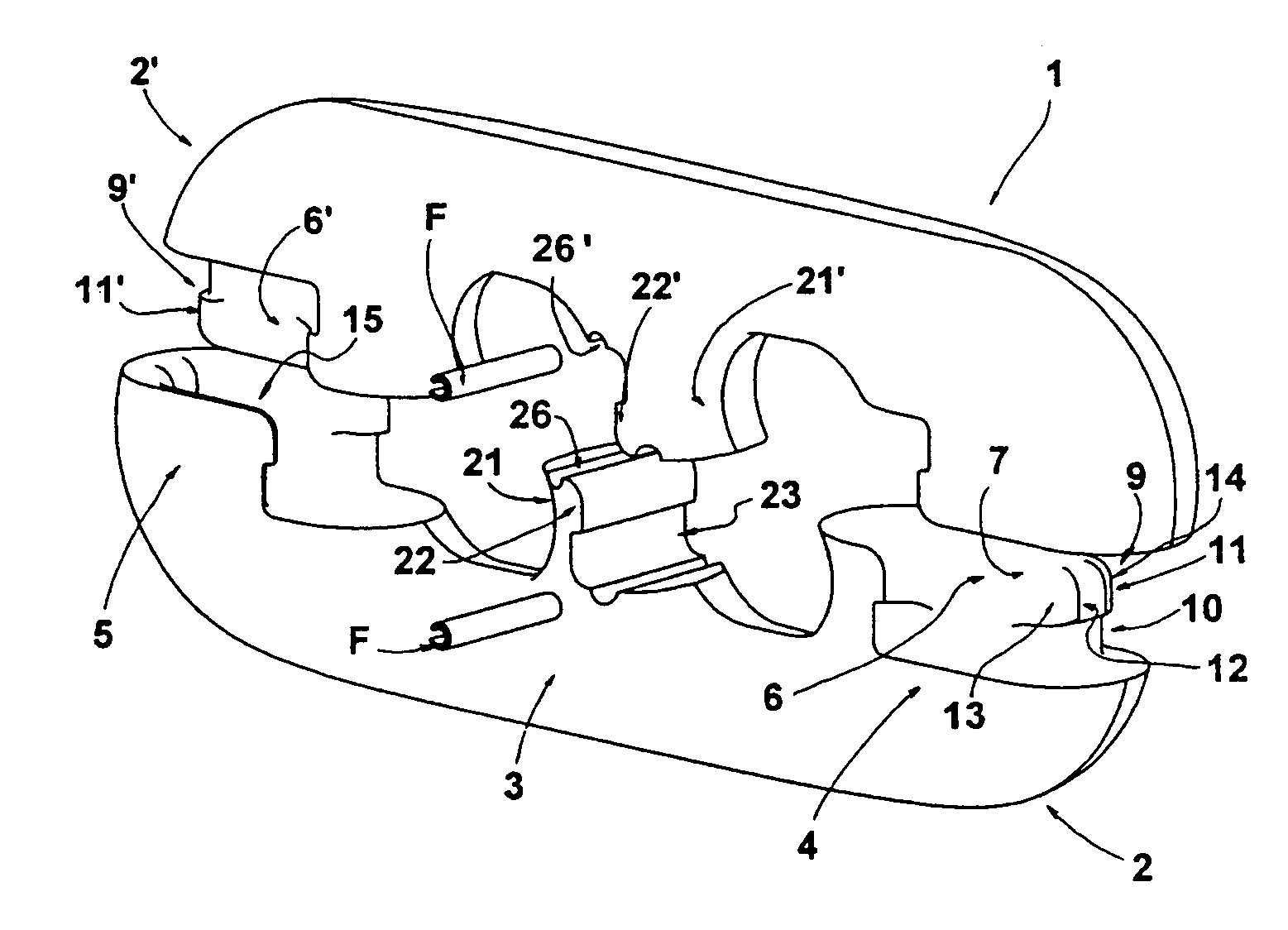

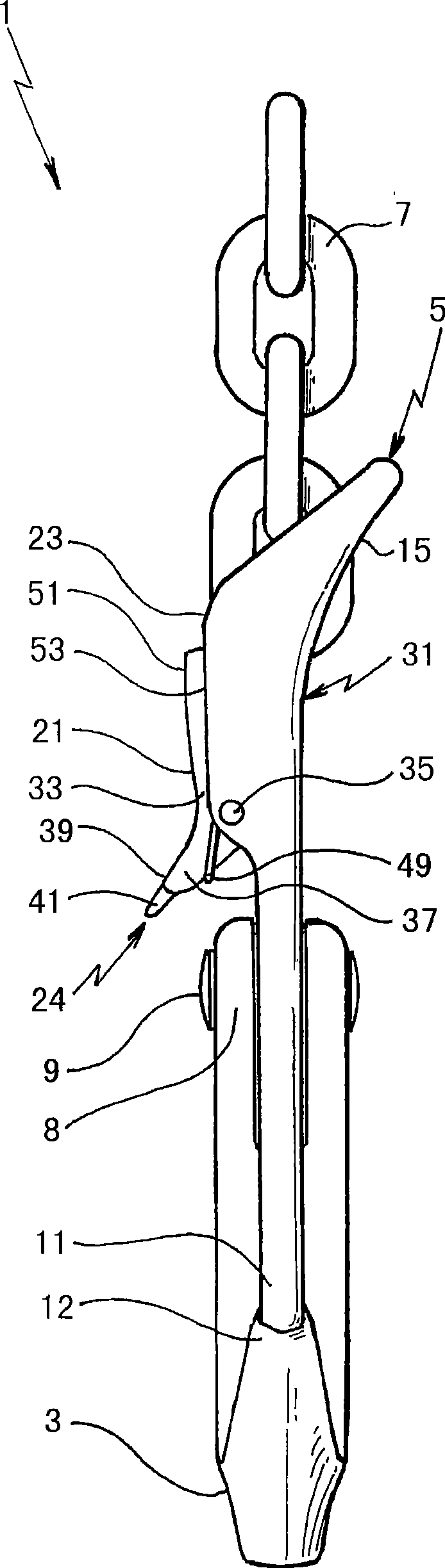

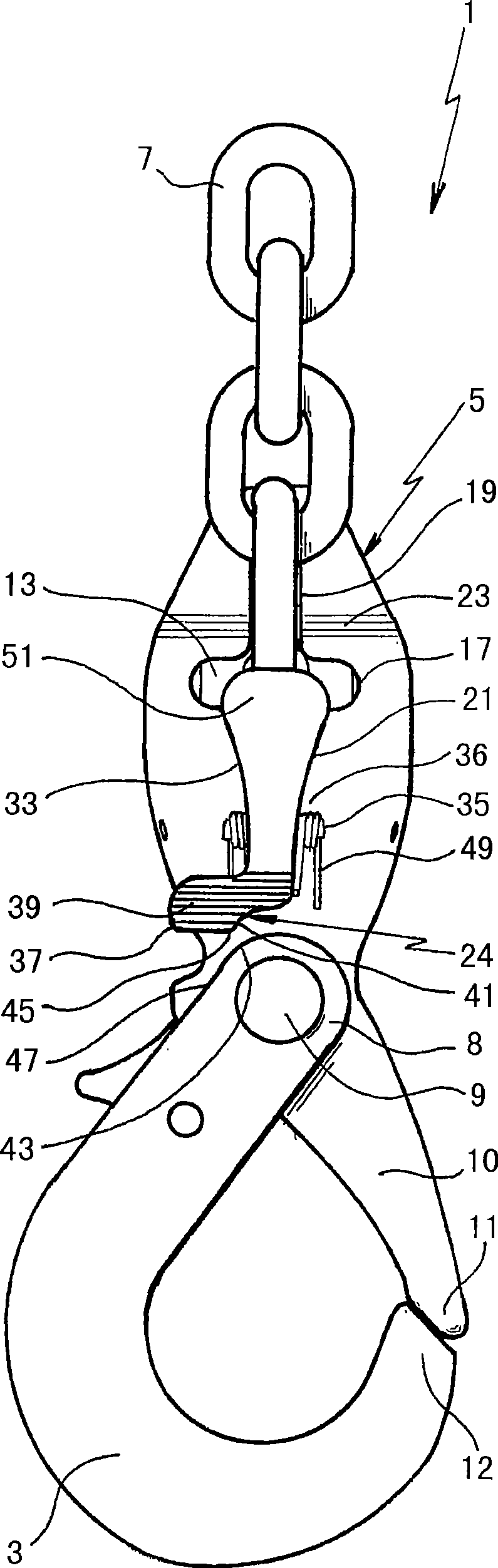

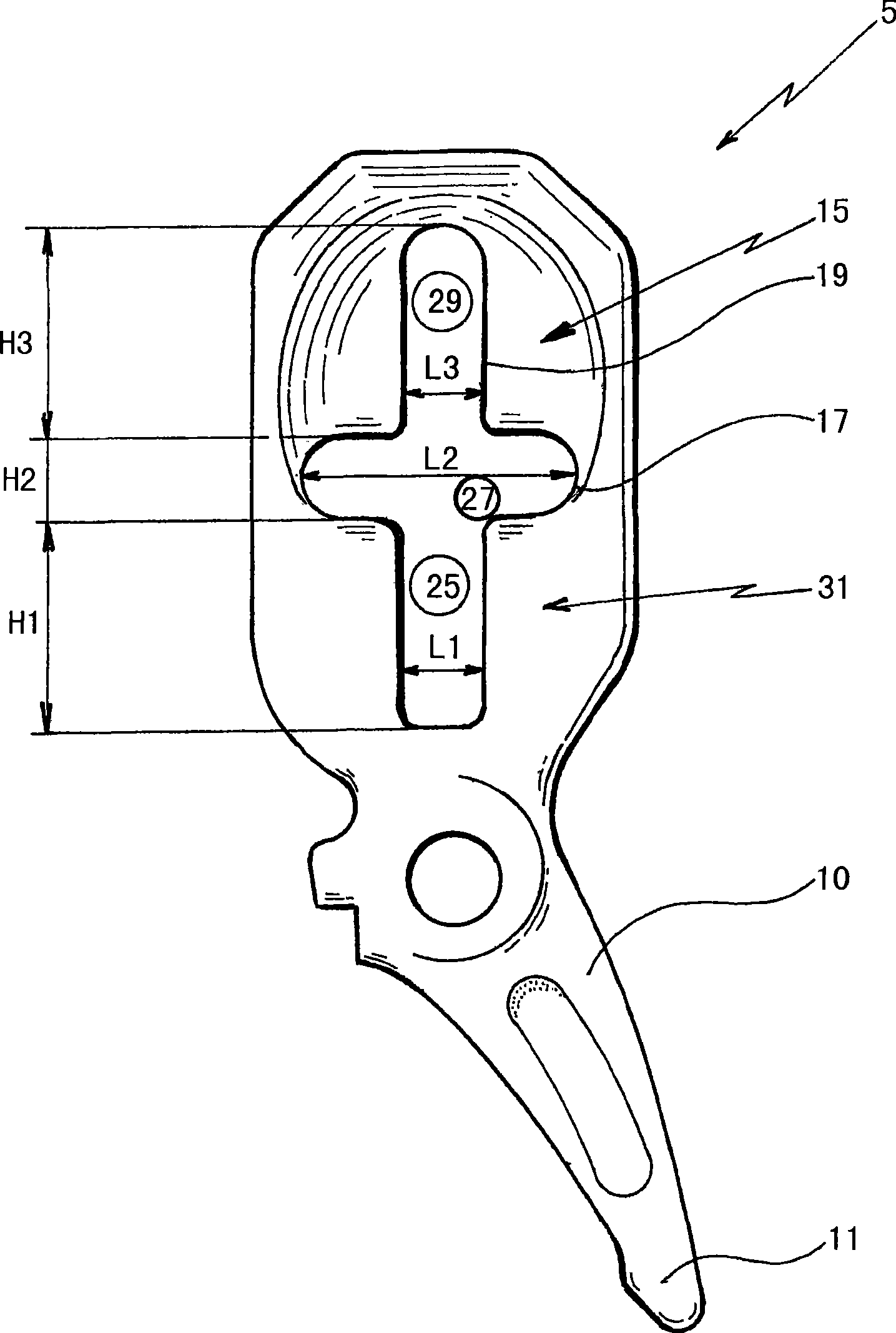

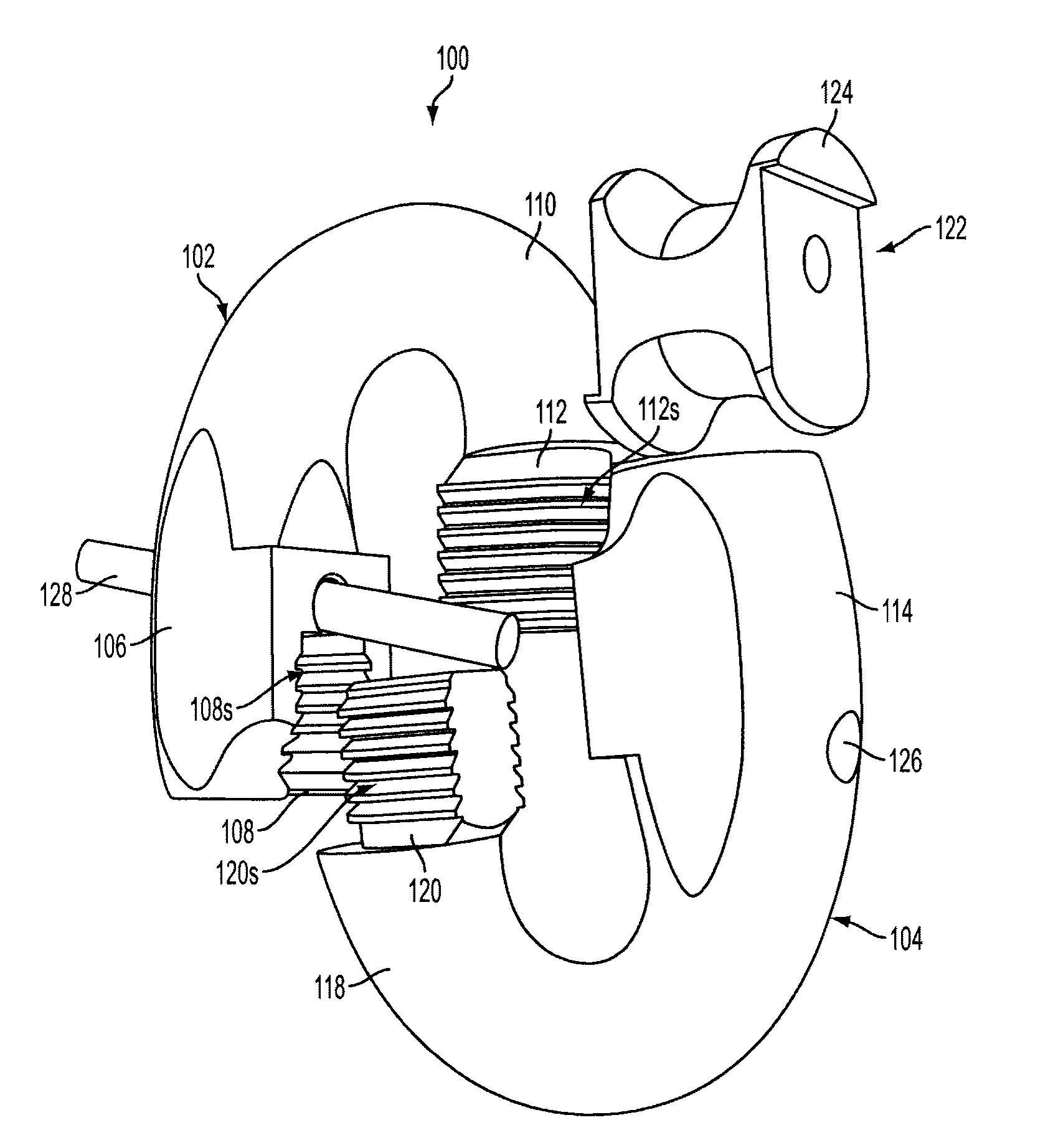

Lifting hook with chain length reducer

InactiveCN101400921AAdjustable lengthPrevent load decouplingChain fasteningsChain hooksChain lengthReducer

The present invention relates to a lifting hook (1) that can be used to lift loads using lifting gear, comprising a hook-shaped part (3) which hooks onto the load that is to be lifted and a chain length reducer (5) secured to the hook, the said reducer (5) comprising, on the one hand, an orifice (17) the dimensions of which allow the links of the chain (7) to pass through and then allow one (13) of the said links to be locked in position when the said chain (3) is taut and, on the other hand, means (21) for partially closing off the orifice (17) which are hinged so that they can be released manually simply by pressing them so as to allow the length of the chain (7) to be adjusted, notable in that the reducer (5) comprises a closure finger (10) that closes off the hook-shaped part (3) to prevent the load from becoming unhooked, and in that the closing-off means (21) comprise self-locking means (24) which hold the closure finger (10) in the locked position on the part (3) of the hook as long as the closing-off means (21) are disengaged from the orifice (17) and have not yet been returned to a position in which they bear against the external face (23).

Owner:FORDE LEMINEE

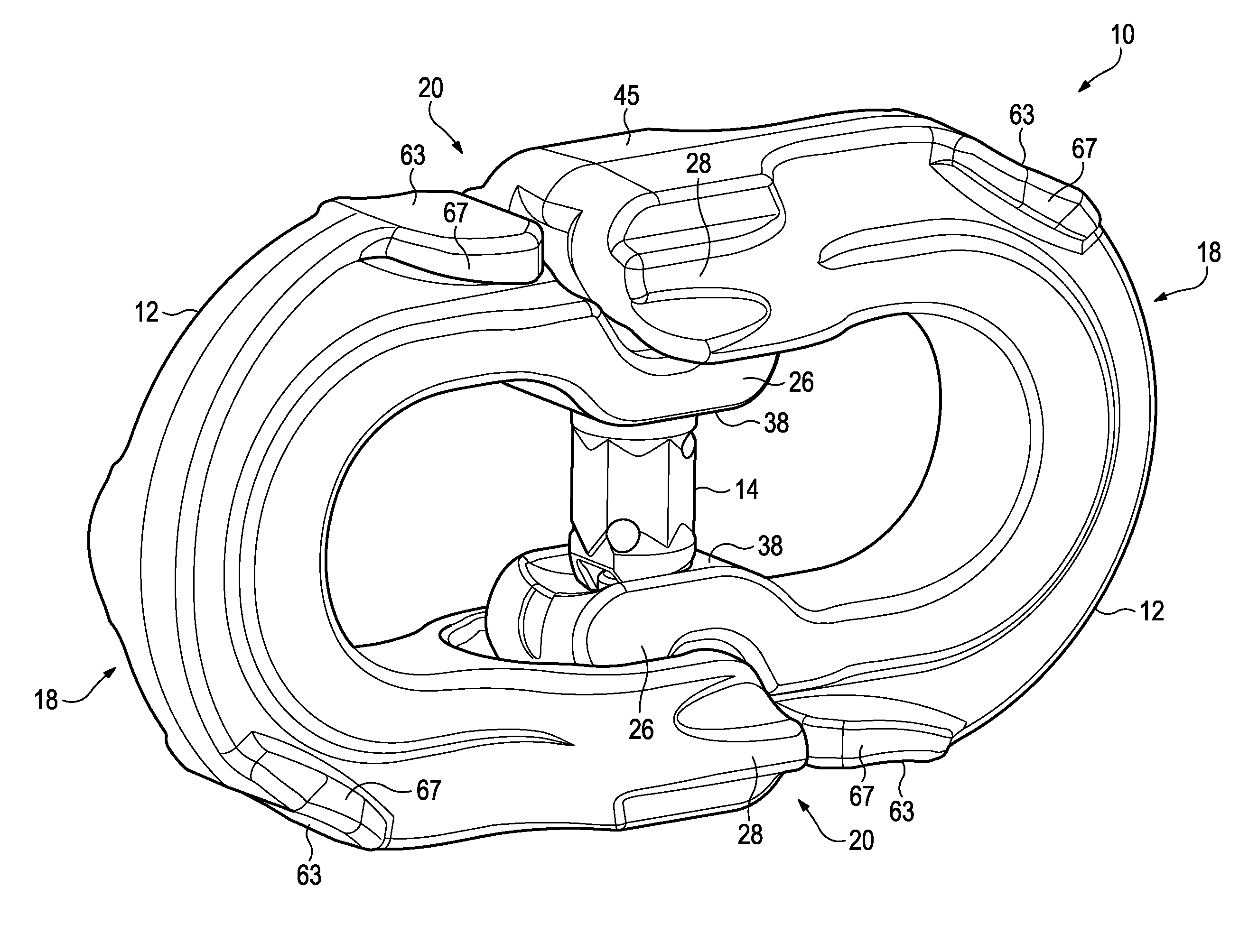

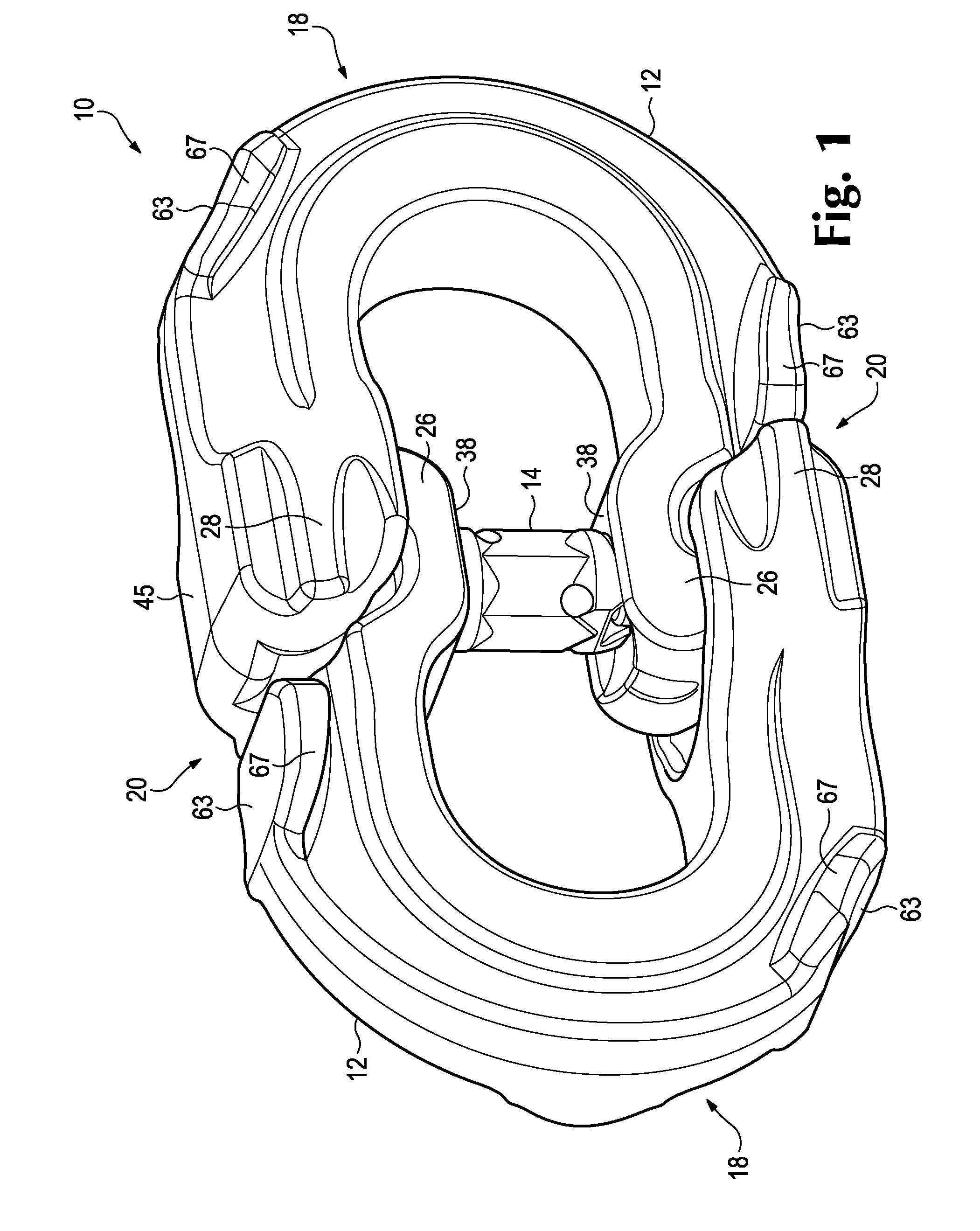

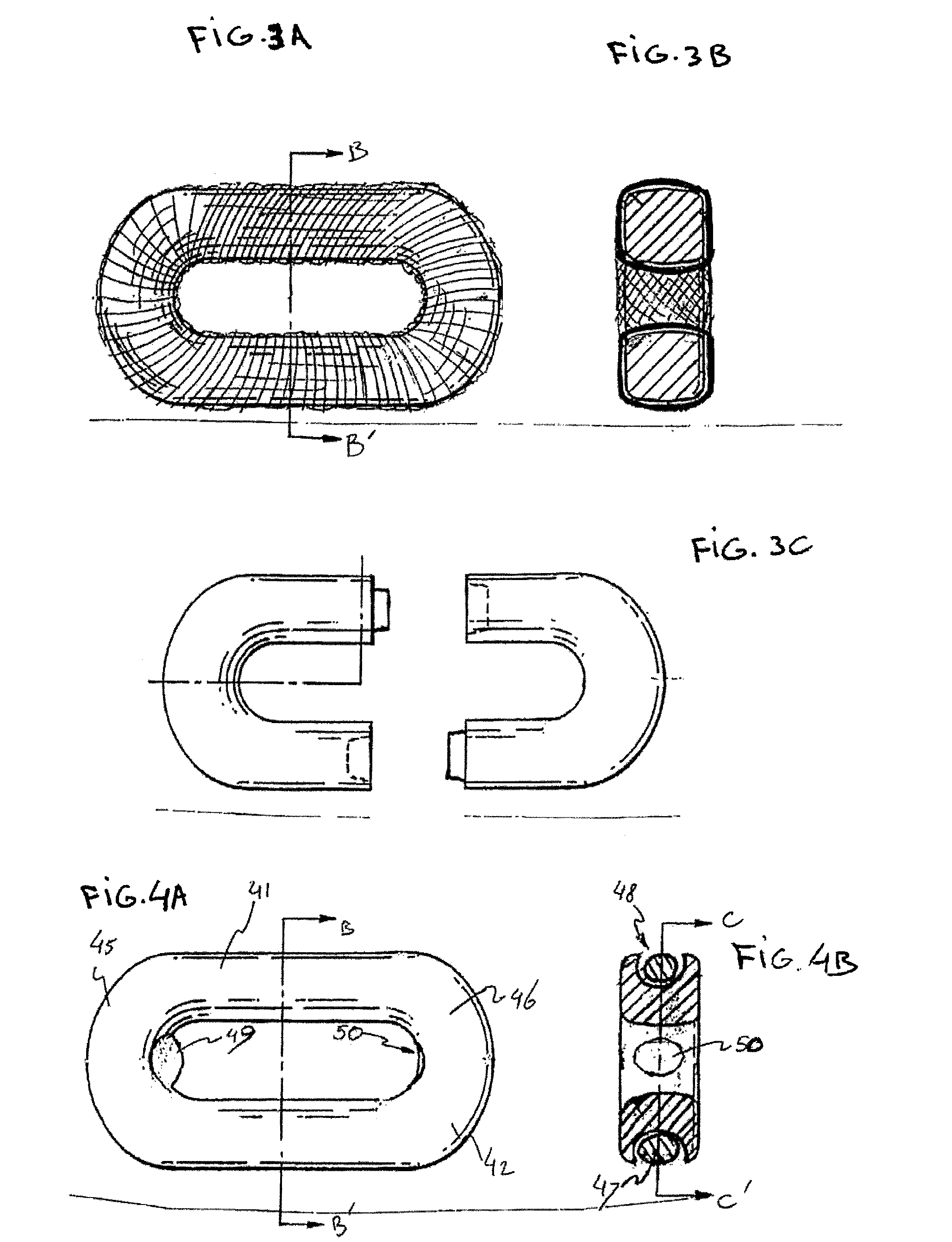

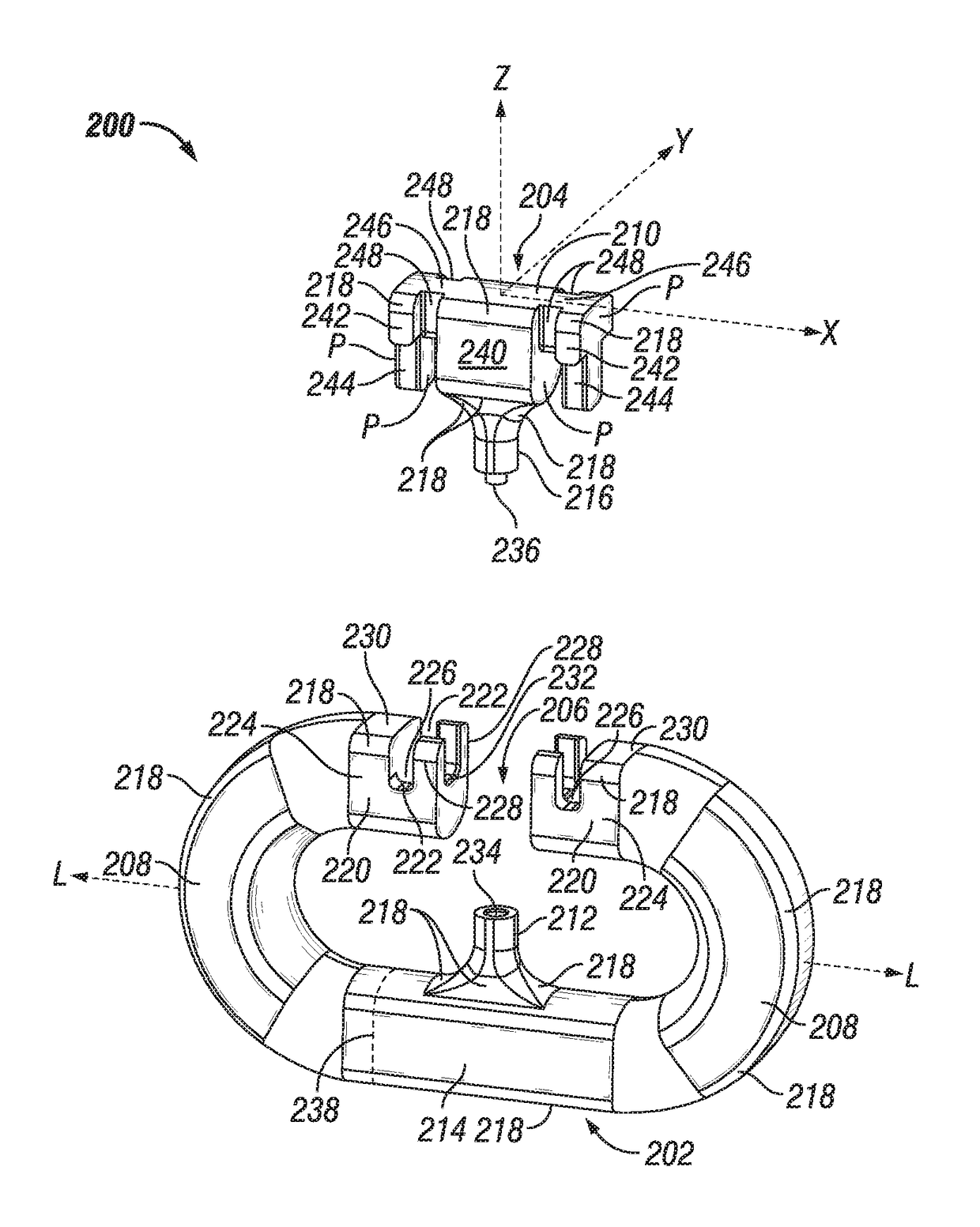

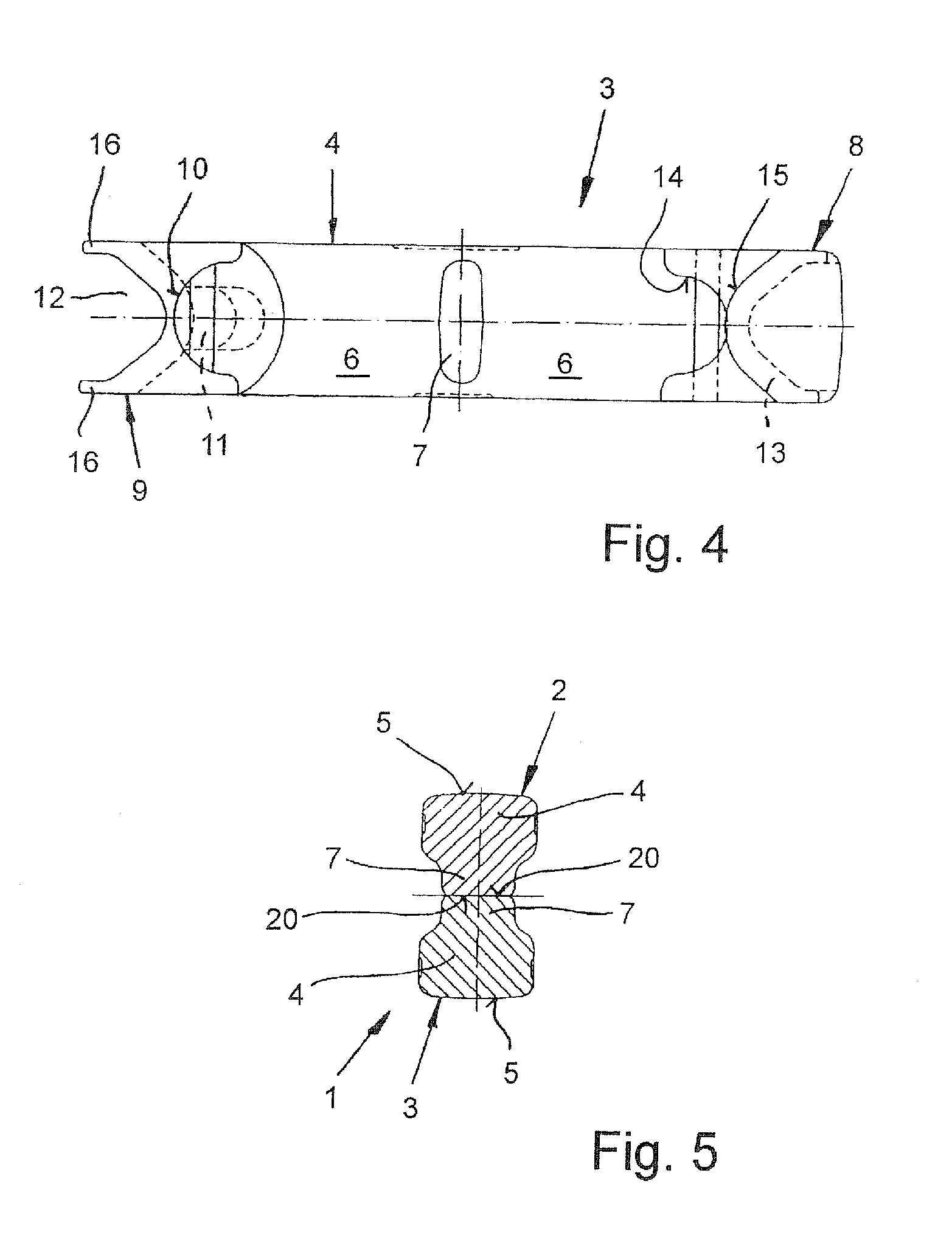

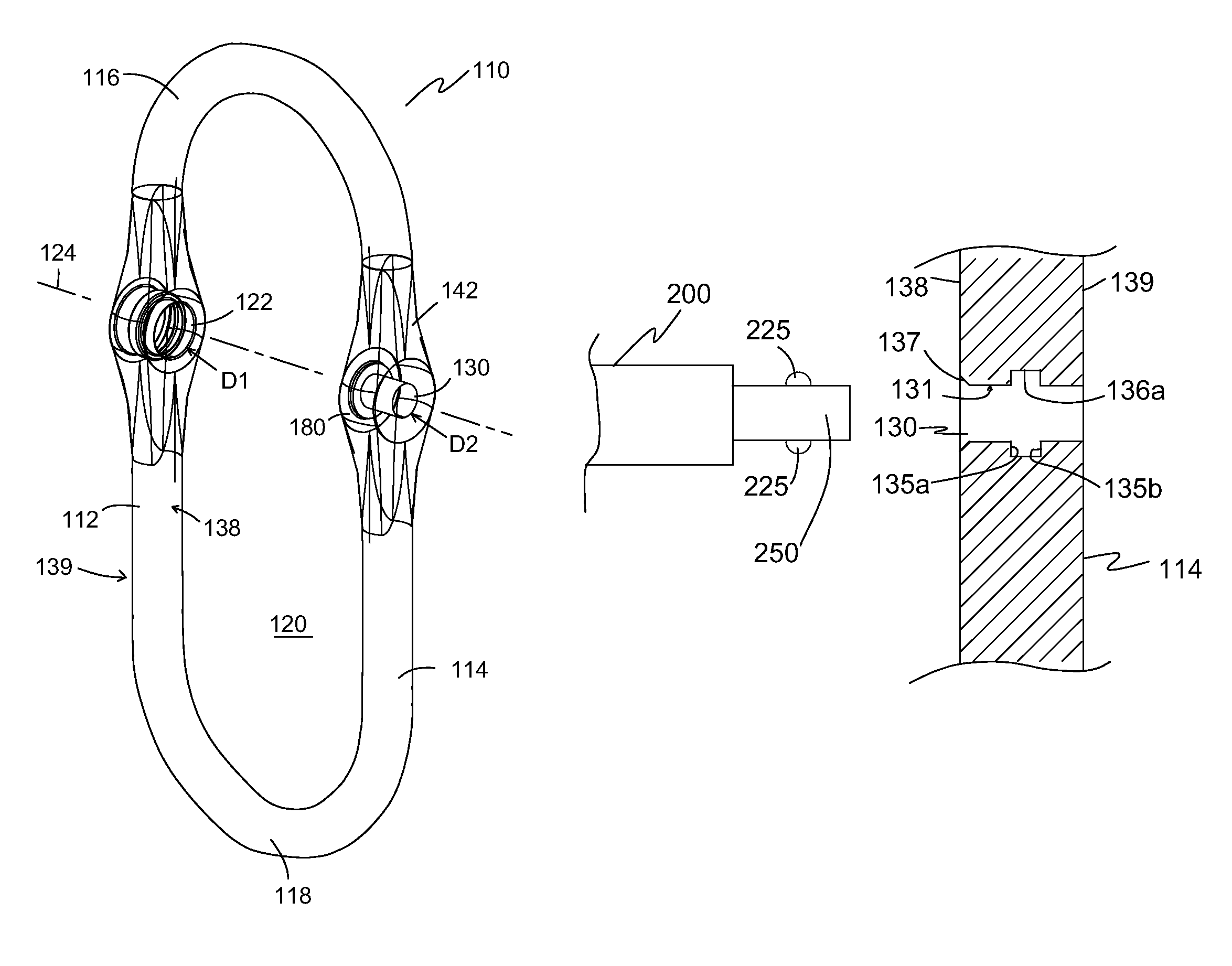

Chain and Coupling Links

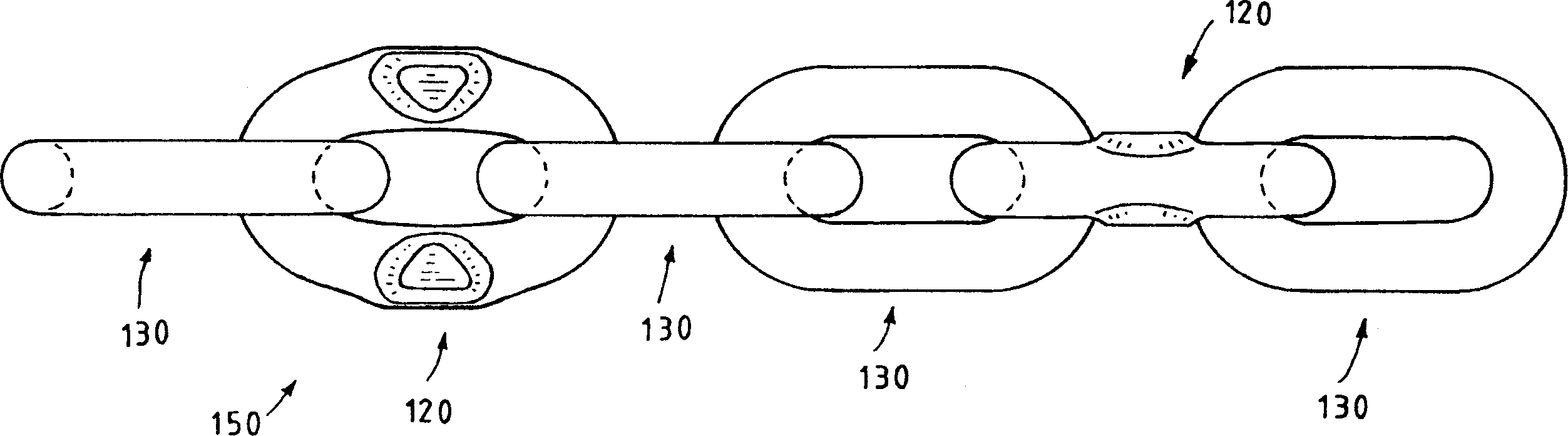

ActiveUS20130227927A1Extended usable chain lifeProlong lifeChain fasteningsShacklesCouplingEngineering

A coupling link for connecting two parts together includes link components (which each form a partial link) that are joined together with a removable support. The support and link components are coupled together to withstand high loads and / or adverse wear conditions. The inventive construction is strong, durable, efficient, cost effective and easy to use. Wear caps are provided to facilitate extended usable chain life.

Owner:ESCO GRP LLC

Chain connecting link

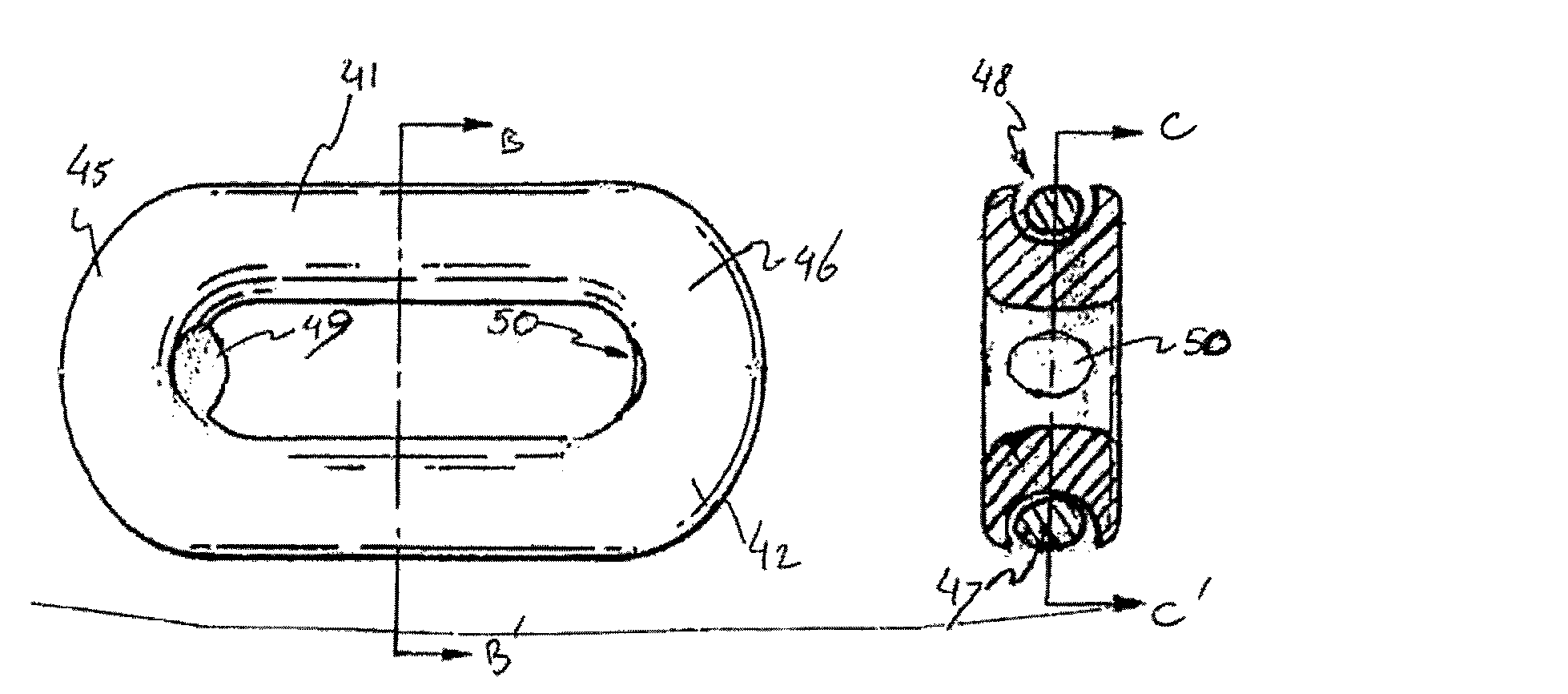

ActiveUS8056315B2Easy to assembleImprove rigidityChain fasteningsShacklesMechanical engineeringEngineering

The invention relates to a chain connecting link, which has two link brackets (4, 5) coupled via their limbs (6, 9), and a bar (14a-14c) that is inserted transversely between the limbs (6, 9) of the link brackets (4, 5). One limb (6) of each link bracket (4, 5) comprises a neck section (7) and a pin (8) thicker than the neck section, and a neck recess (10) and a pin recess (11) are provided in a matching fashion at the other limb (9) of the link bracket (4, 5). According to the invention, conically configured flank surfaces (12) with respect to the vertical central longitudinal plane (MLE) are provided at each pin (8) and at each pin recess (11).

Owner:THIELE GMBH & CO KG

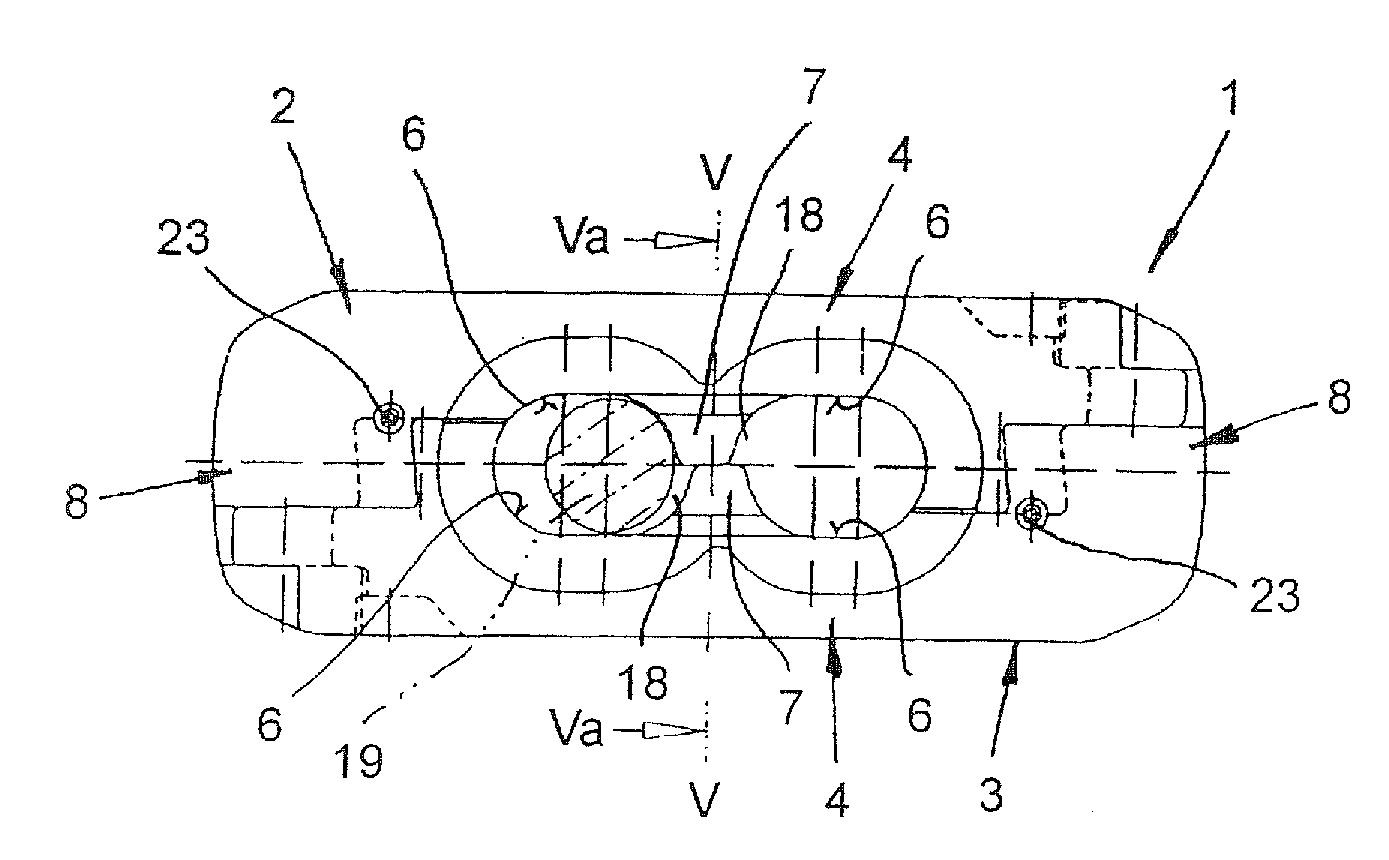

Chain lock

A chain lock for high-strength steel chains has two lock parts that are the same and can be joined together in a rotation-symmetry arrangement with one another, in the longitudinal direction. Each lock part has a longitudinal stay having arc segments that follow it at both ends. There are two coupling elements that are configured complementary to one another and are assigned to the two arc segments of each lock part. One of the elements is configured as a locking stay that follows the longitudinal extension of the lock part, and the other element is configured as a stay accommodation. The locking stay of the one lock part engages in the stay accommodation of the other lock part and rests against the complementary coupling surface of the stay accommodation with its coupling surface formed by the face end in the joining direction. The coupling surfaces comprise a coupling surface segment having a defined width, which has no curvature or only an insignificant curvature pointing in the joining direction.

Owner:J D THEILE

Coupling element for a shackle

InactiveUS20080245049A1Simple and cheap to produceGood strength performanceChain fasteningsShacklesCouplingEngineering

A coupling element of a shackle for load-carrying elements, such as chains, hooks, or the like, is disclosed. The coupling element has two substantially parallel legs, whose free ends each have a bore for the accommodation of a connecting bolt, by means of which the coupling element can be linked to another coupling element of the same design to form the shackle, the coupling elements being held together only by the connecting bolt, which bores extend in the same direction relatively to each other, wherein the bores are out-of-line and extend at an angle to a longitudinal center line of the coupling element.

Owner:PENGG AGYD

Chain and coupling links

A coupling link for connecting two parts together includes link components (which each form a partial link) that are joined together with a removable support. The support and link components are coupled together to withstand high loads and / or adverse wear conditions. The inventive construction is strong, durable, efficient, cost effective and easy to use. Wear caps are provided to facilitate extended usable chain life.

Owner:ESCO GRP LLC

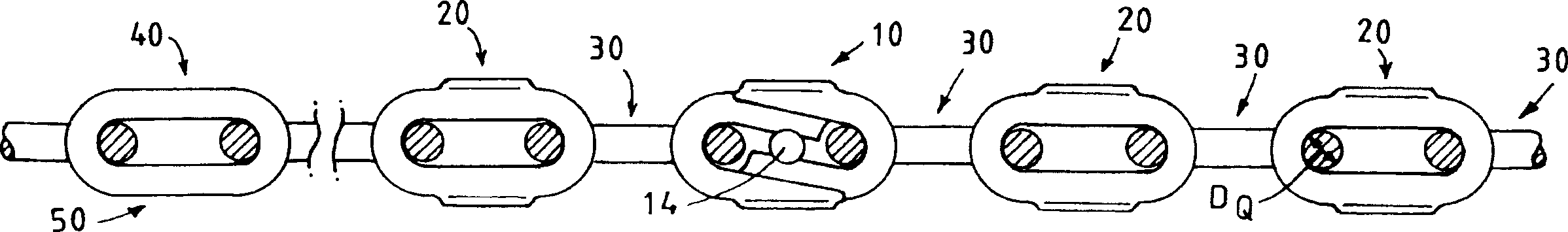

Plane chain strand comprising a chain lock link

The invention relates to a plane chain strand (50) provided with horizontal and vertical normal chain links (30, 40) which are mounted in an alternating manner and which engage into each other in a nondetachable manner with the limbs and arcs thereof. In the chain strand (50), directly in front and directly behind a chain lock link (10), at least one special chain link (20) is mounted in the same position as said chain locking link (10). The limbs of the lock links have the same outer contour, especially the same width and thickness, as the outer limbs of the two lock parts of the chain lock link (10). The wear and tear of the chain lock link (10) of said inventive plane chain strand (50) can be reduced or eliminated in comparison with conventional plane chains, by means of equal or slightly larger previous and subsequent special chain links (20).

Owner:CATERPILLER GLOBAL MINING EURO GMBH

Chain link

ActiveUS8161723B2Improve impact resistanceHigh tensile strengthChain fasteningsHauling chainsFiberChain link

Owner:DE VRIES OSCAR

Chain link

ActiveUS20100257835A1High tensile strengthOvercome problemsChain fasteningsHauling chainsFiberChain link

Chain link (1) comprising two side limbs (3,4) at both ends joint by curved end portions (5,6). The chain Link comprises at least one endless band (7) of fiber material wound along the perimeter of the chain link. The fiber material follows the longitudinal direction of the limbs and the curvature of the end-portions. In a chain made of interlocking chain links of this type, all tensile loads are absorbed by the fiber material, whereas the bearing load due to interlink contact, plus the link shear and bonding stresses near the contact points are absorbed by the end portions.

Owner:DE VRIES OSCAR

Mooring chain connecting link

A connecting link assembly for connecting two chain sizes together. The connecting link assembly includes a smaller connecting link assembly sized according to the smaller chain size, a larger connecting link assembly sized according to the larger chain size, and a connecting component. The connecting component is sized and shaped to be accepted by a dual chain wheel.

Owner:BARDEX CORP

Chain connecting element with security connector piece

InactiveCN104641145APrevent axial playNo damageChain fasteningsShacklesMechanical engineeringEngineering

The invention relates to a chain connecting element (1) which has two link bow sections (4, 5), which can be coupled via their limbs (6), and a connector piece (50), which can be inserted transversally between the limbs (9), one limb (9) of each link bracket (4, 5) having a neck section (7) and a journal (8) that is thicker relative thereto, a neck recess (10) and a journal recess (11) being provided on the other, opposite lying limb (9) in a corresponding manner, wherein the two link bow sections (5), which are inserted into one another, can be locked by the connector piece (50) and the connector piece (50) is formed by a bolt, a sleeve and a spring journal. The connector piece (50) is of mirror-symmetrical design, an outer-lying bearing sleeve (51) being provided on each side of said piece for form-locked locking engagement in the link bow sections (4, 5) and an inner-lying locking bolt (53) has a spring journal (26) on each of its ends, wherein a clamping pin (63) can be inserted or retracted on both sides of the locking bolts (53) and secures each of the spring journals (26) in a respective bearing sleeve (51) in form-locked manner.

Owner:THIELE GMBH & CO KG

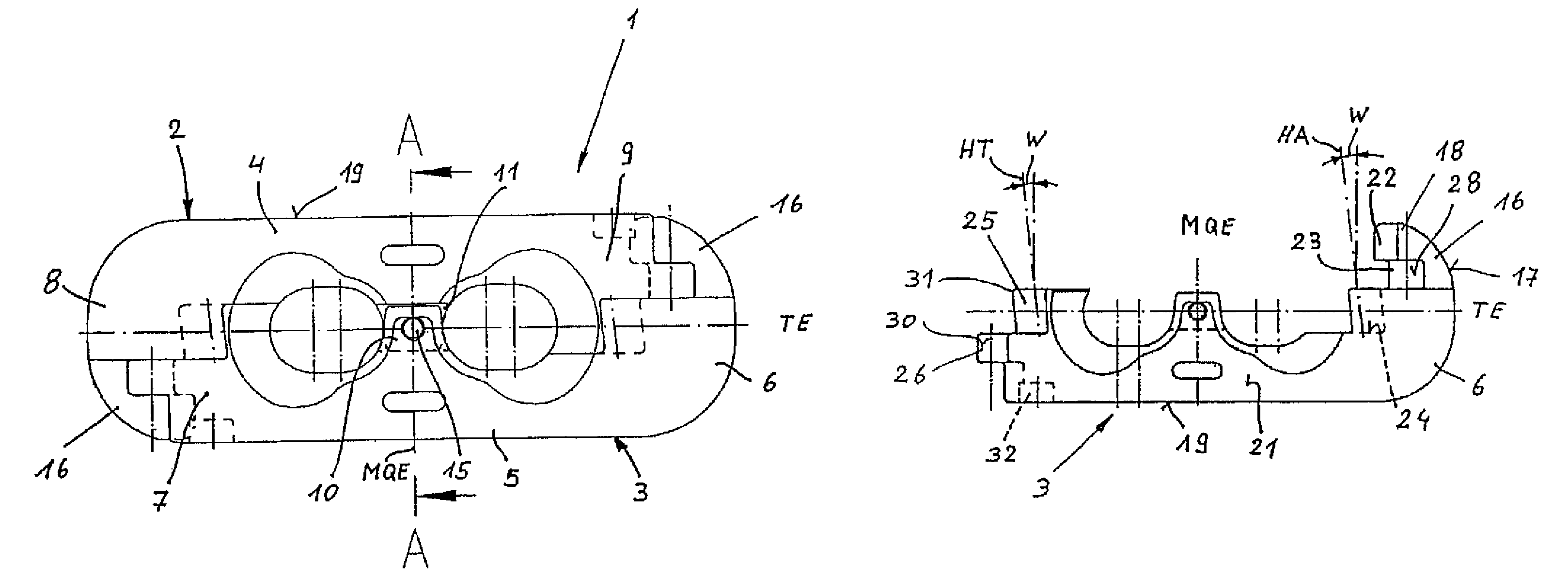

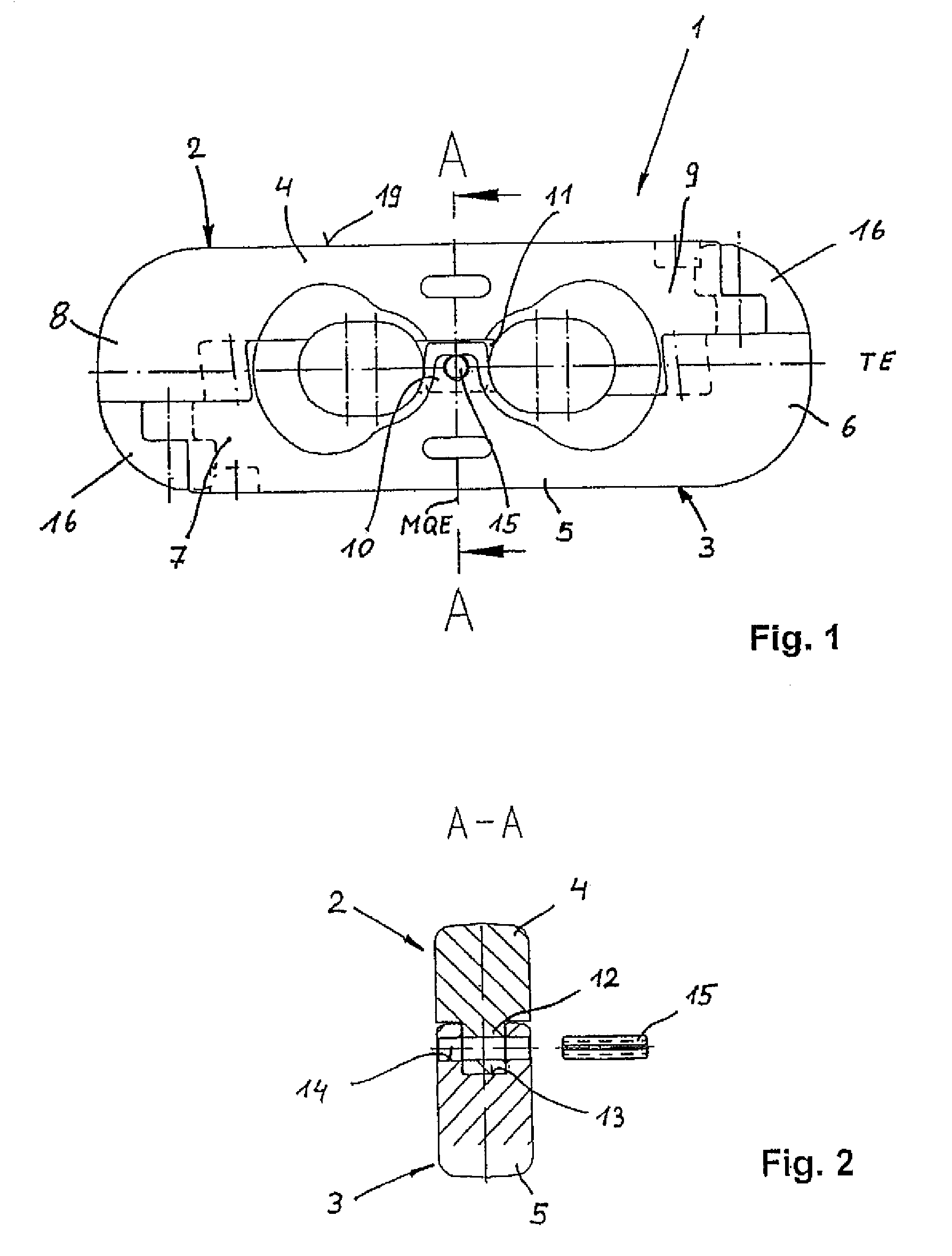

Chain lock for round steel chains

Disclosed is a chain lock for round steel chains, comprising two lock halves, each of which is provided with a rear section (4, 5) that extends in the longitudinal direction of the chain lock (1) as well as coupling sections (6 to 9) that adjoin the ends of the rear section (4, 5). One respective coupling section (6, 8) is fitted with a locking pin (16) which extends perpendicular to a parting plane (TE) of the chain lock (1) and encompasses a web-like projection (22) at the free end (18) thereof, on the side facing the other coupling section (7, 9). The projection (22) borders a pocket that extends from one side surface (20) to another side surface (21) of the lock half (2, 3) and accommodates a forked leg (26) of the other lock half (2, 3), which conforms to the contour of the pocket (23). The pocket (23) has external, essentially rectilinear flanks (27, 28) which face the side surfaces (20, 21), the angle (W1) enclosed by the flanks (27, 28) ranging from 120° to 150°.

Owner:THIELE GMBH & CO KG

Chain link using a pressed-in member

Owner:CATERPILLAR INC

Block lock for a round link chain

Owner:THIELE GMBH & CO KG

Shackle assembly with pin and retaining ring

A shackle assembly has a body that includes a first side member with a first side aperture, a second side member with a second side aperture, and at least one end portion extending between and connecting the first side member and the second side member. At least one of the apertures defines an annular recess. A pin has a first end portion received in the first side aperture, a second end portion received in the second side aperture, and a pin body extending between the first end portion and the second end portion. At least one end portion of the pin defines an annular groove corresponding to the annular recess(es). A retaining ring with a pair of open ends is seated in the annular groove and extends radially into the corresponding annular recess, thereby preventing the pin from being removed from the body.

Owner:PURE SAFETY GRP INC

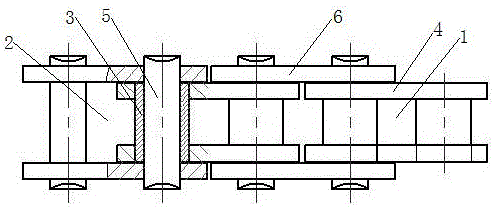

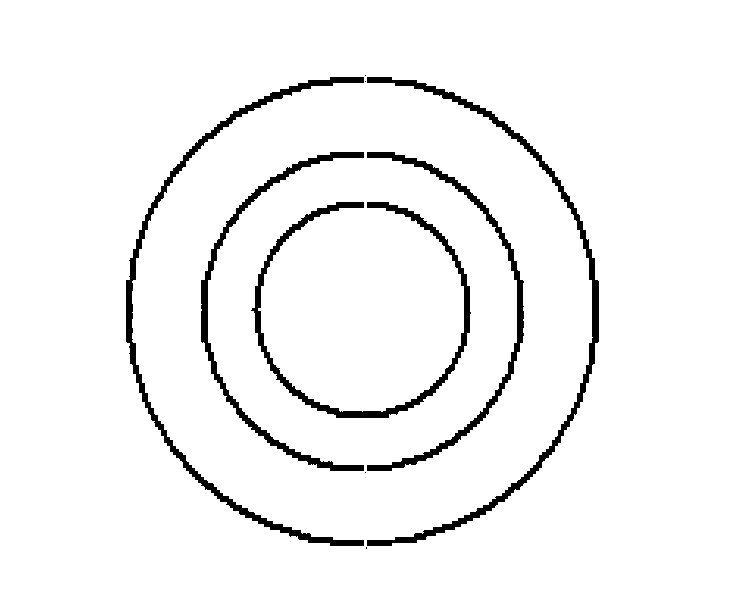

Anti-fatigue eccentric sleeve chain

InactiveCN106195124ACompact structureIncrease torqueChain fasteningsDriving chainsStatic strengthAgricultural engineering

The invention discloses an anti-fatigue eccentric sleeve chain. The anti-fatigue eccentric sleeve chain comprises an inner link and an outer link which are embedded to form a chain in an internal-and-external staggered manner, the inner link comprises a sleeve and an inner chain plate, and the sleeve is in interference fit with the inner chain plate; the outer link comprises a pin shaft and an outer chain plate, the pin shaft is in interference fit with the outer chain plate, and the pin shaft is inserted into the sleeve; the inner chain plate comprises an inner chain plate hole and an inner chain plate outer edge arc, the circle center of the inner chain plate hole and the circle center of the inner chain plate outer edge arc offset by 0.10 mm to 0.40 mm; and the outer chain plate comprises an outer chain plate hole and an outer chain plate outer edge arc, and the circle center of the outer chain plate hole and the circle center of the outer chain plate outer edge arc offset by 0.10 mm to 0.40 mm. The anti-fatigue eccentric sleeve chain is provided. By means of the chain, eccentric design is adopted, and the anti-fatigue eccentric sleeve chain has the beneficial effects of being compact in structure, high in torque, high in static strength, high in fatigue strength and long in service life.

Owner:HANGZHOU CHIZHENG TECH

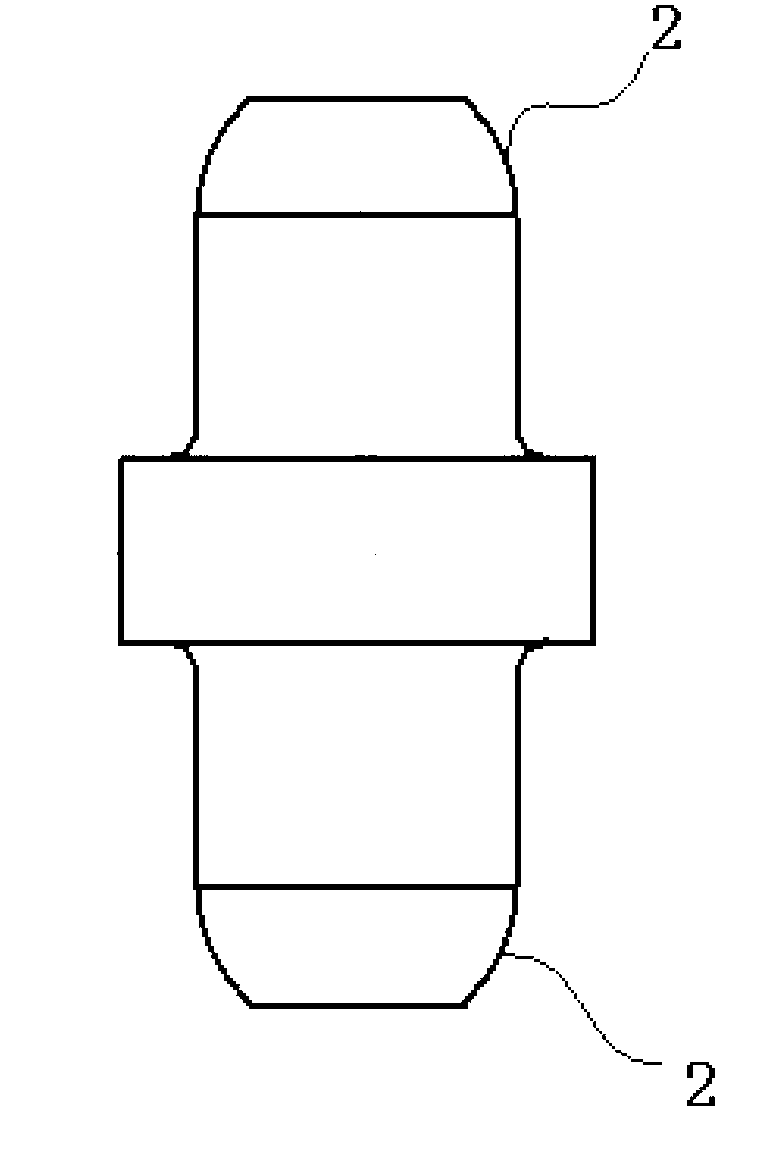

Chain shaft of chain saw

The invention discloses a chain shaft of a chain saw. The chain shaft of the chain saw comprises two ends and a peripheral surface around a central axis of the chain shaft, and is characterized in that the each end comprises the peripheral surface with a certain curvature. The chain shaft provided by the invention can ensure that the stress is uniformly distributed on the head of the chain shaft subjected to a cold heading process and the stress is uniformly distributed on the surface of a riveting wheel of a riveting machine in the process of spin riveting, so that the probability of damaging the chain shaft is reduced and the production cost is effectively lowered.

Owner:SHANGHAI JIAO TONG UNIV

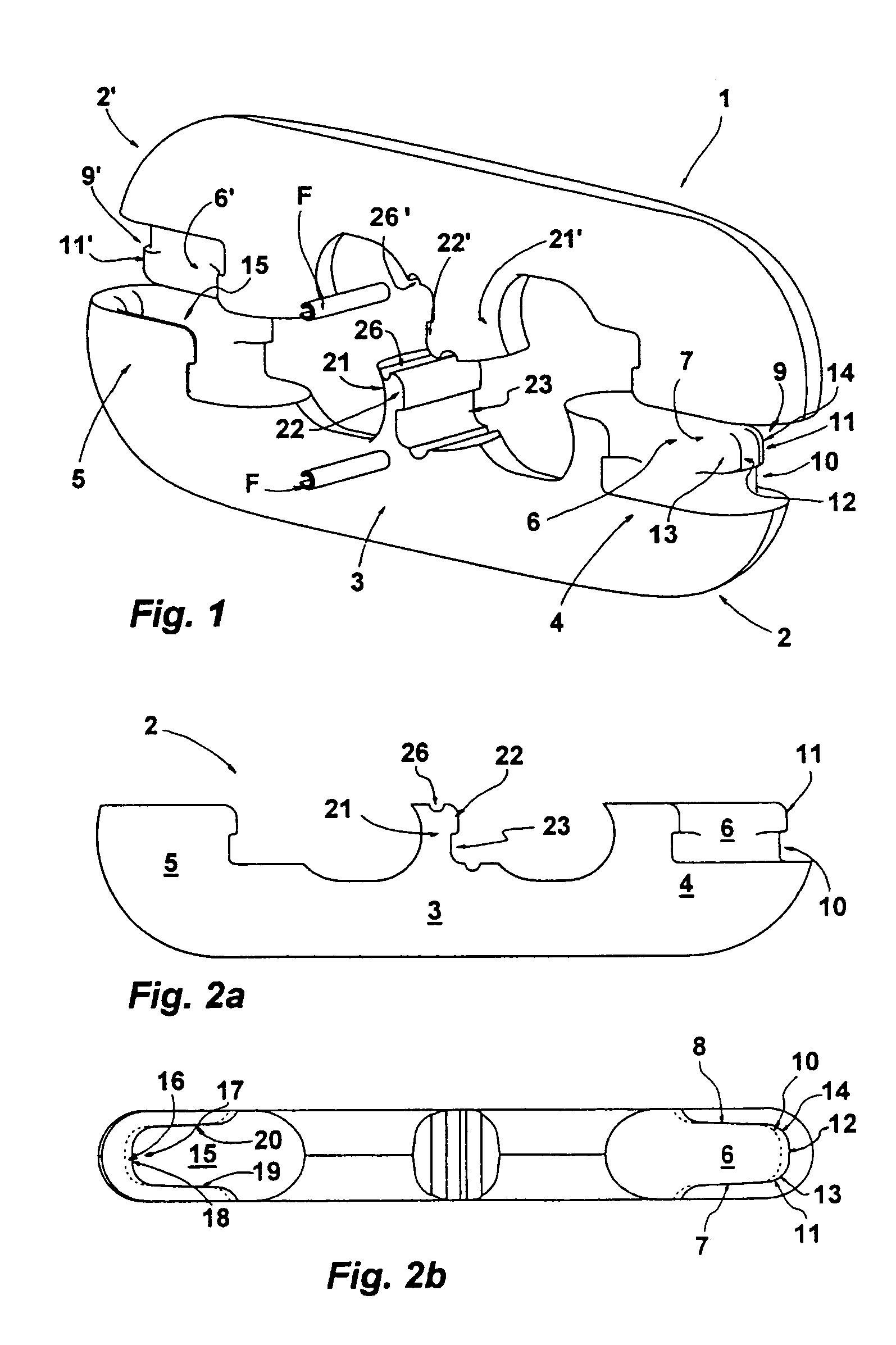

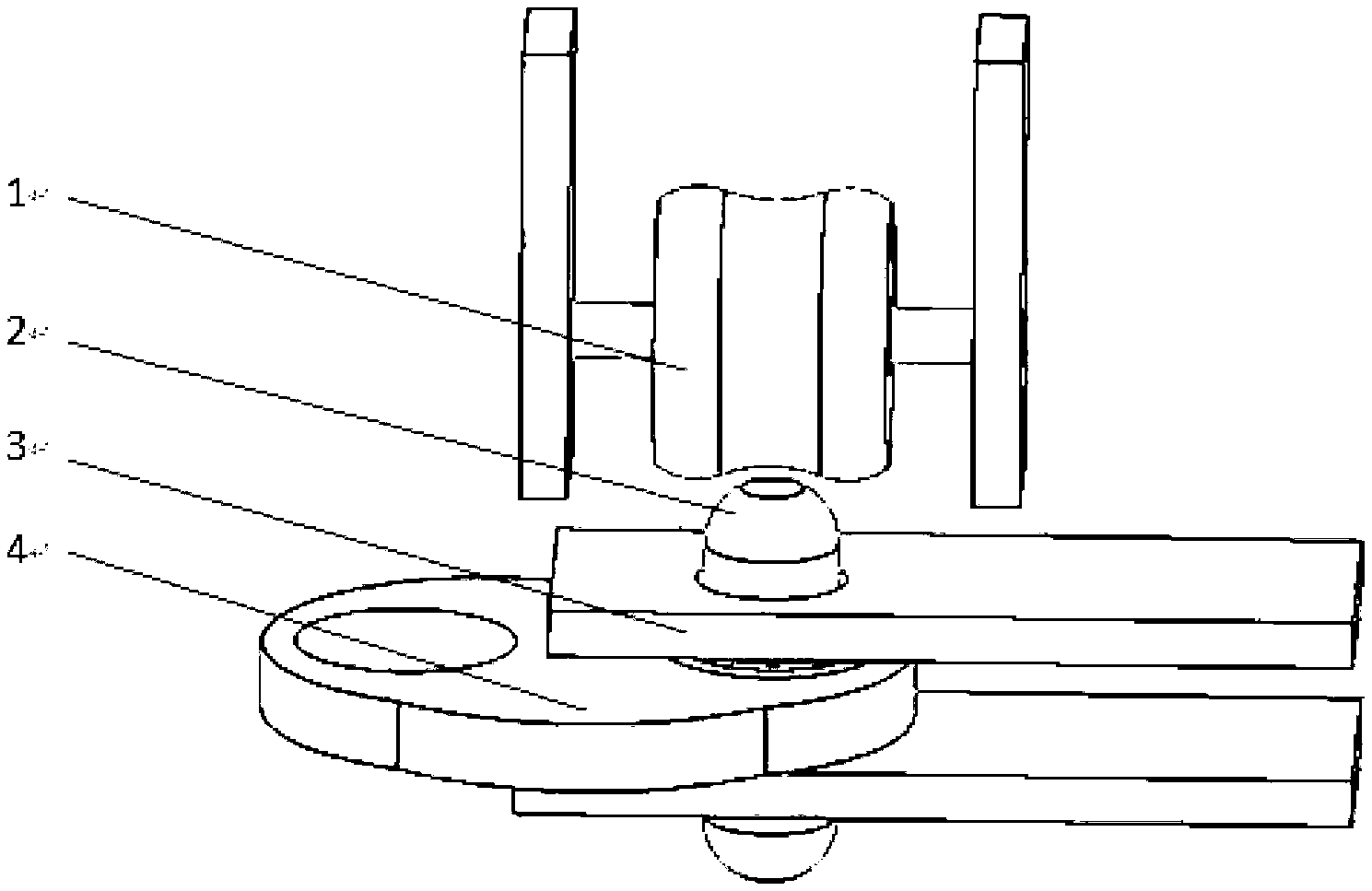

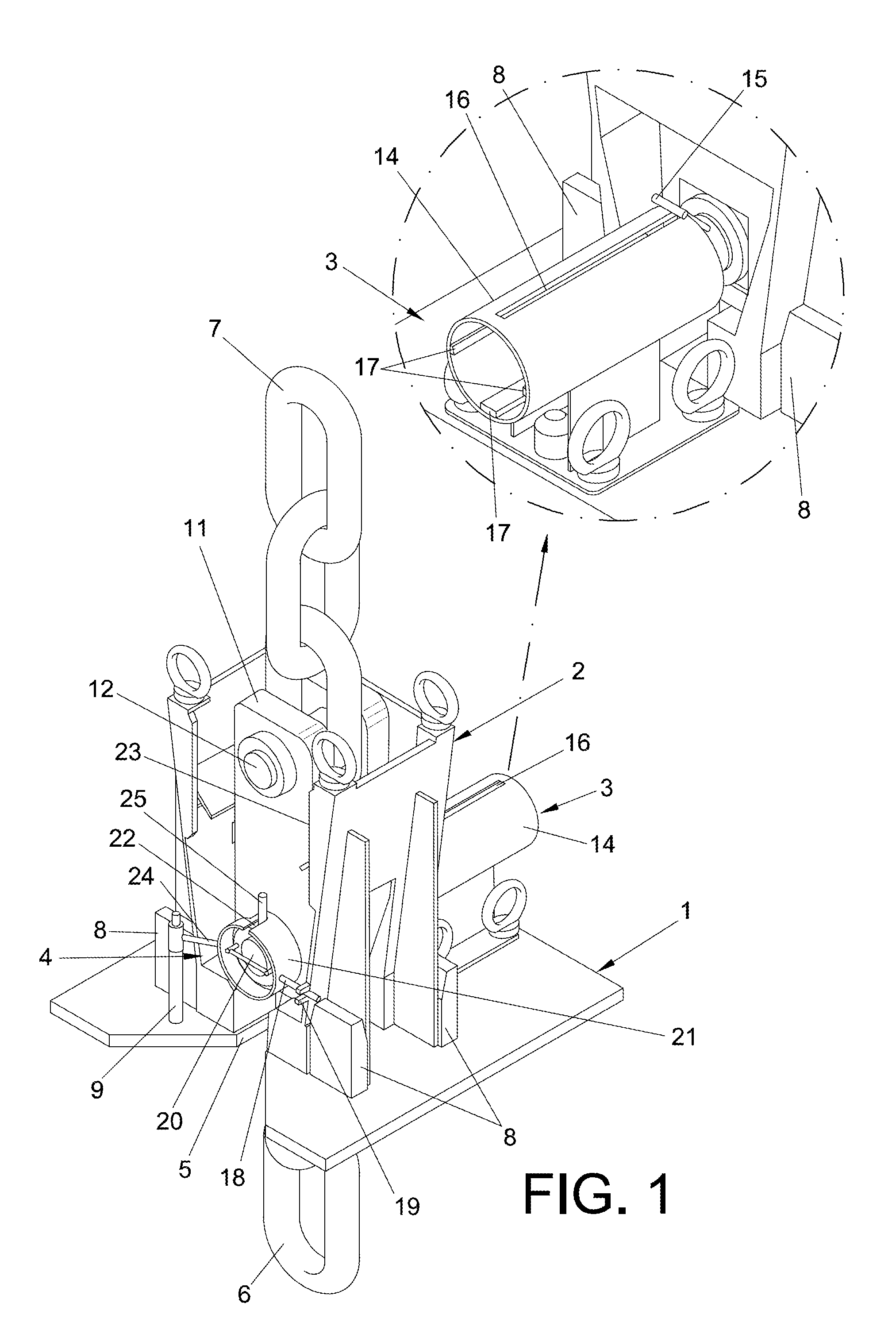

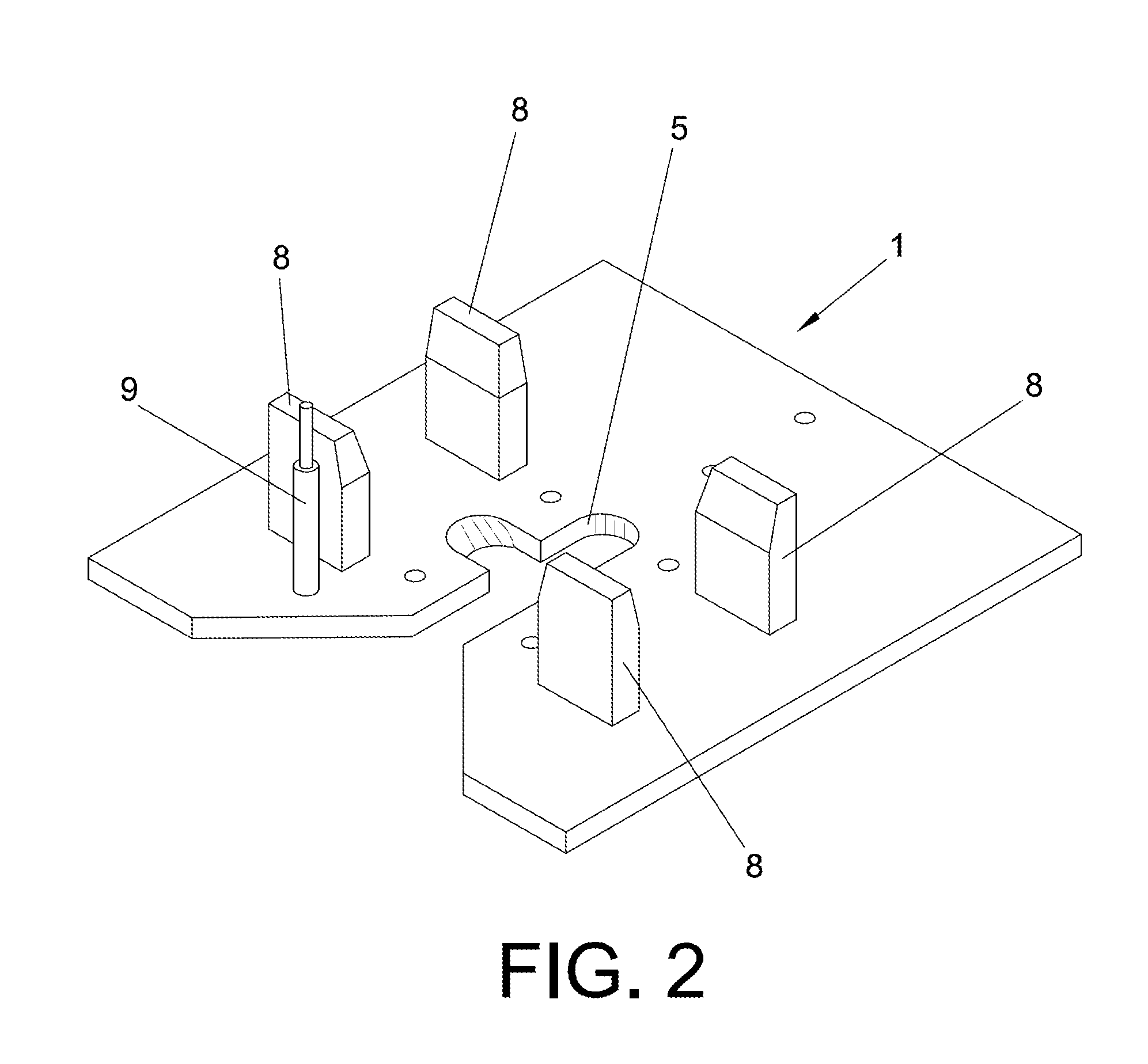

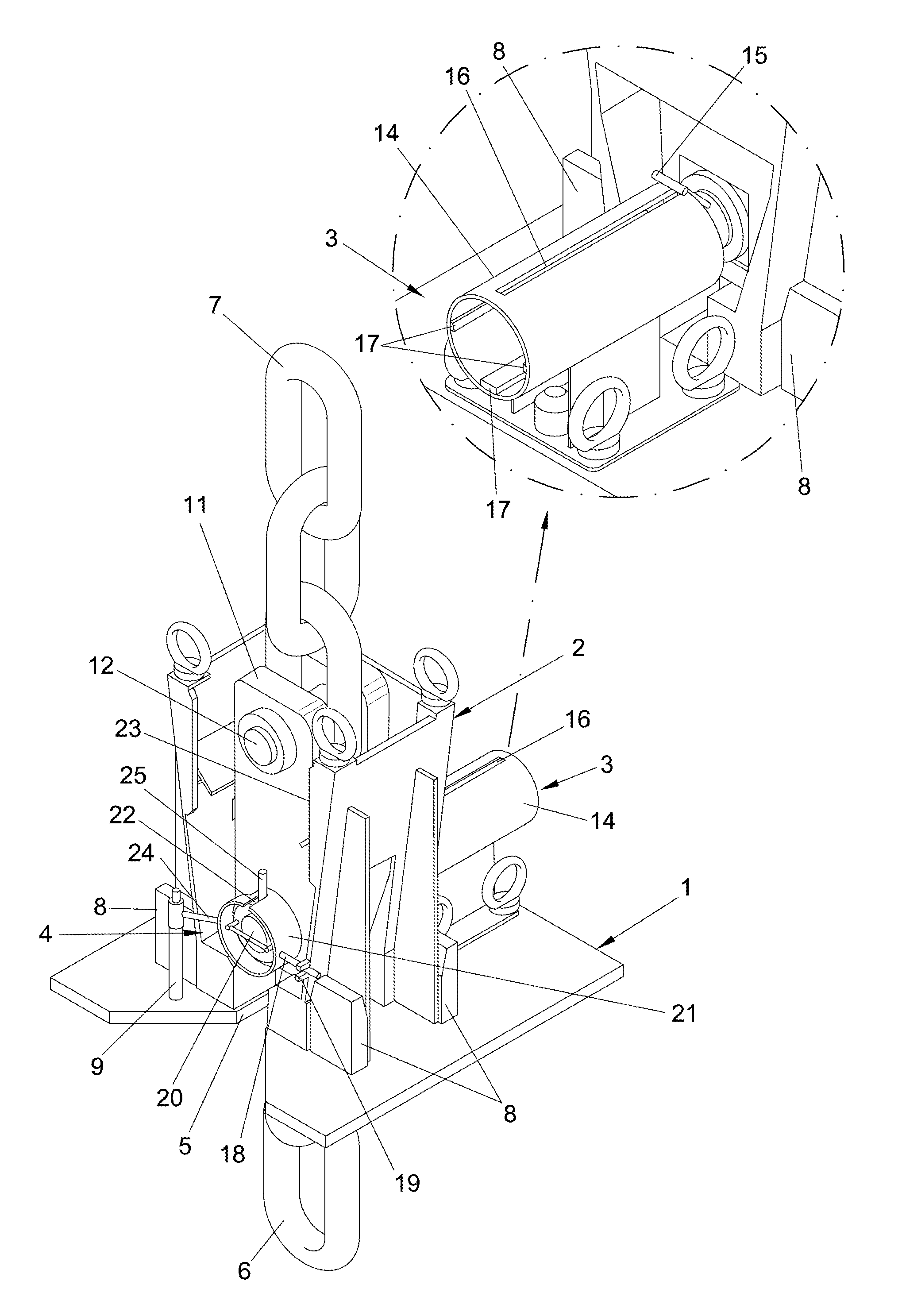

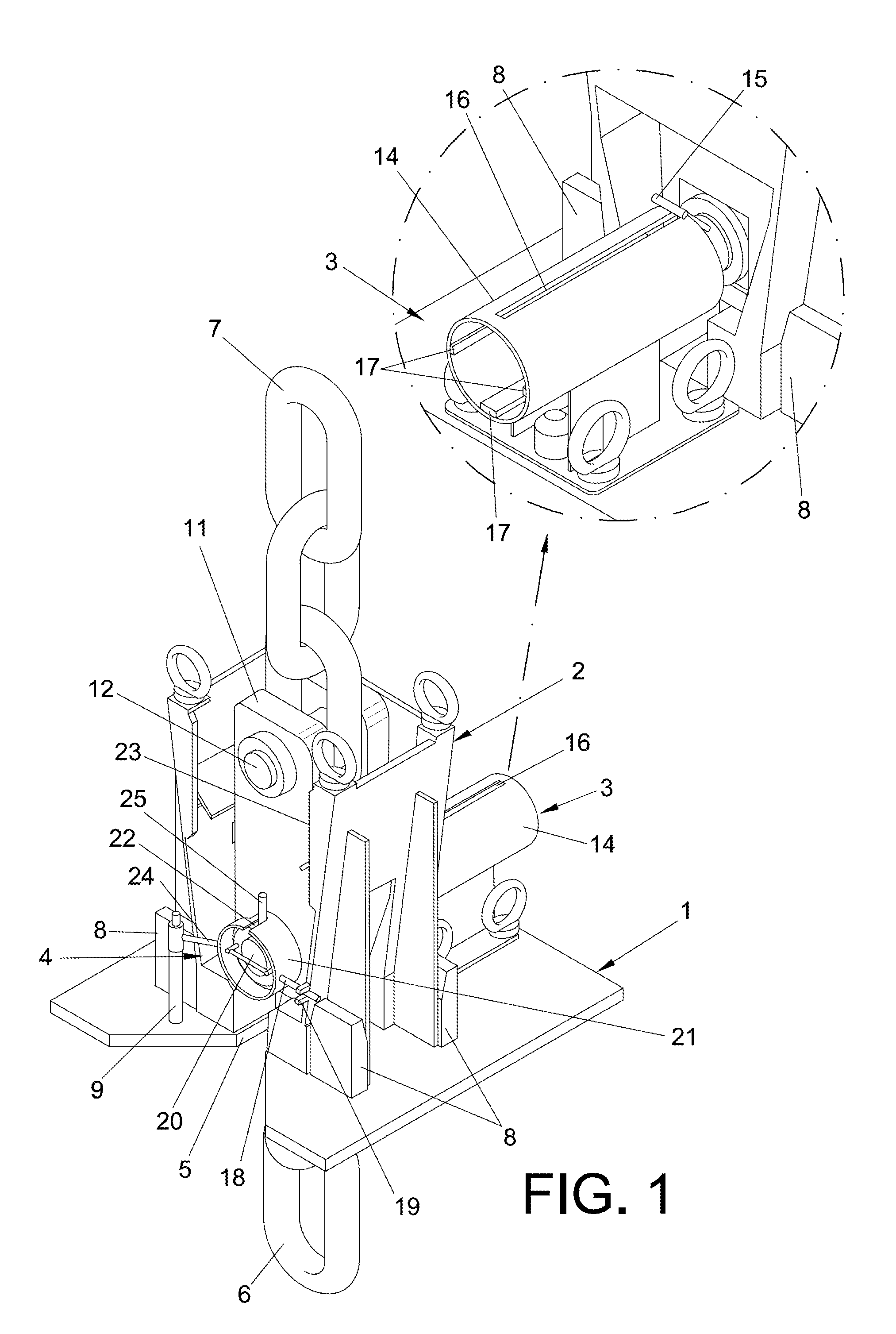

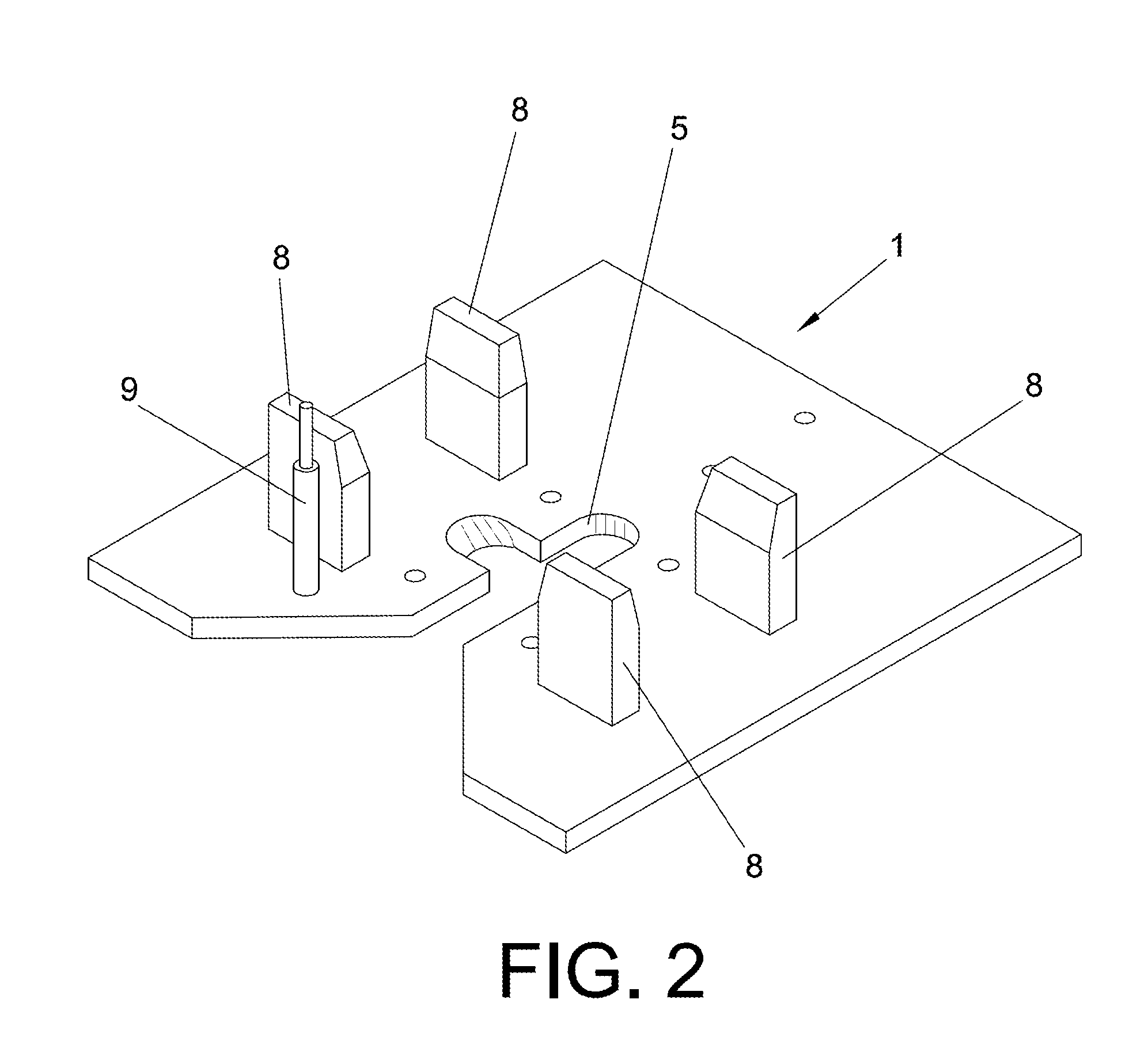

Apparatus for vertically linking two sections of chain

The apparatus is intended for vertically linking a first chain and a second chain under water. The apparatus is characterised in that it comprises a lower base (1) with an open cross-shaped slot (5) into which the last link of the first chain (6) is inserted, extending above said lower base (1), while a guide / holder (2) for the second chain (7) is attached to the lower base (I) over said slot, said guide / holder containing an H-shaped shackle (II) that is coupled to the last link of said second chain (7) by means of a first bolt (12), the last link of the first chain (6) being inserted in the free space in the shackle (11) so that both chains (6-7) are coupled by means of a second bolt (13).

Owner:VICINAY MOORING CONNECTORS SA

Lifting hook with chain length reducer

InactiveCN101400921BAdjustable lengthPrevent load decouplingChain fasteningsChain hooksChain lengthReducer

The present invention relates to a lifting hook (1) that can be used to lift loads using lifting gear, comprising a hook-shaped part (3) which hooks onto the load that is to be lifted and a chain length reducer (5) secured to the hook, the said reducer (5) comprising, on the one hand, an orifice (17) the dimensions of which allow the links of the chain (7) to pass through and then allow one (13) of the said links to be locked in position when the said chain (3) is taut and, on the other hand, means (21) for partially closing off the orifice (17) which are hinged so that they can be released manually simply by pressing them so as to allow the length of the chain (7) to be adjusted, notable in that the reducer (5) comprises a closure finger (10) that closes off the hook-shaped part (3) to prevent the load from becoming unhooked, and in that the closing-off means (21) comprise self-locking means (24) which hold the closure finger (10) in the locked position on the part (3) of the hook aslong as the closing-off means (21) are disengaged from the orifice (17) and have not yet been returned to a position in which they bear against the external face (23).

Owner:FORDE LEMINEE

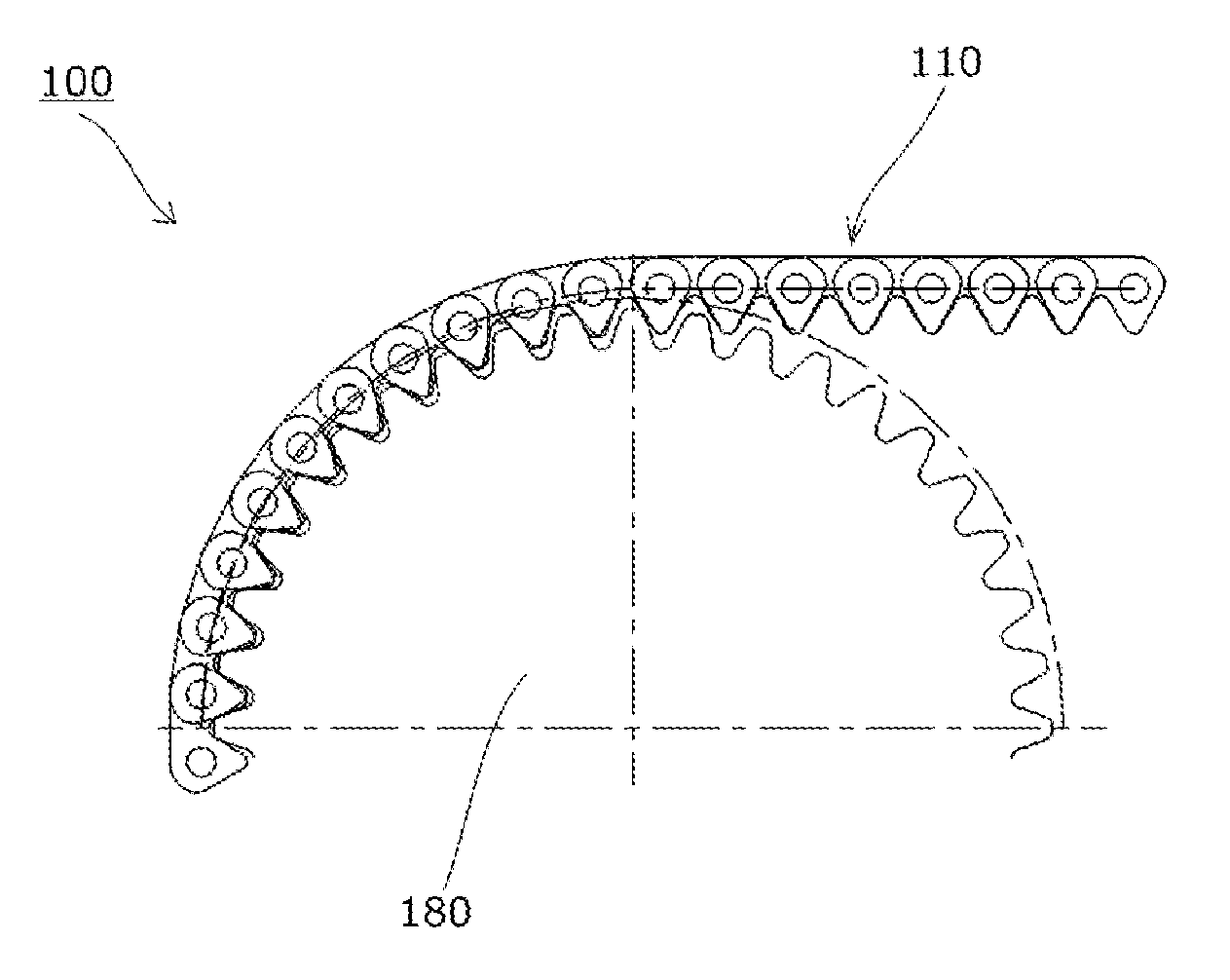

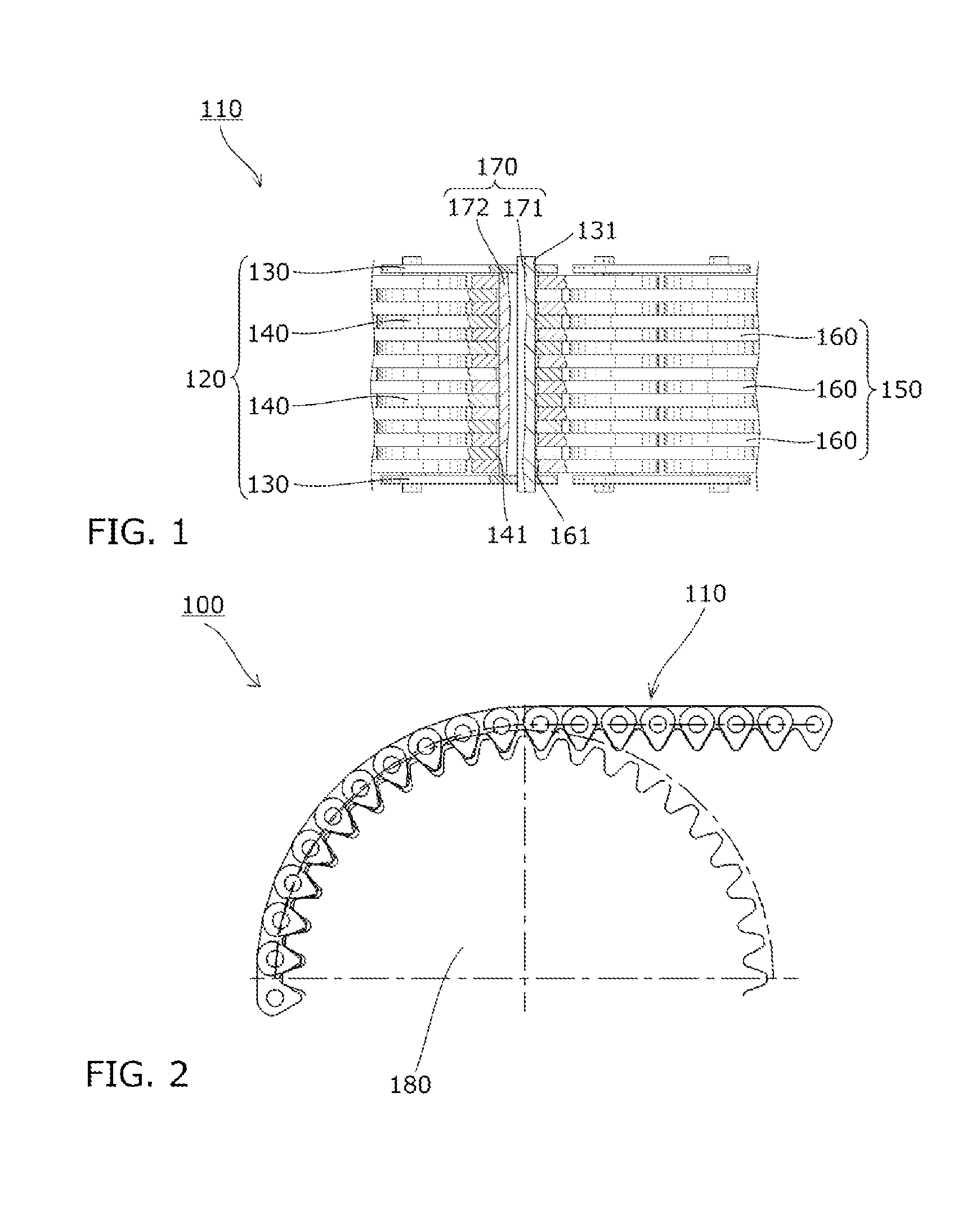

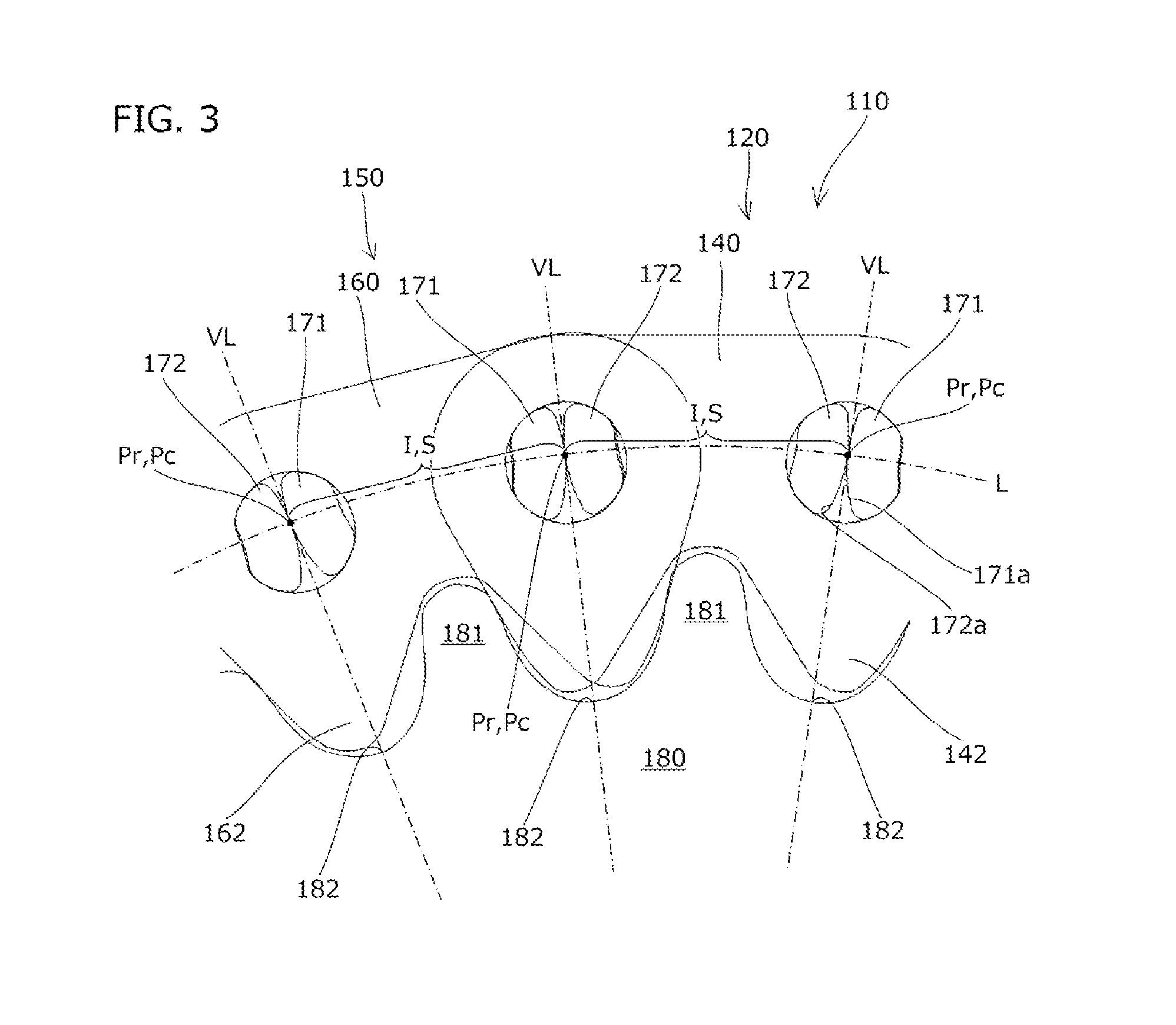

Silent chain and silent chain transmission device

ActiveUS20160040750A1Guaranteed uptimeSuppress noiseChain fasteningsDriving chainsEngineeringChain link

An object of the present invention is to provide a silent chain and a silent chain transmission device which stabilize chain behavior during chain travel to suppress an occurrence of tooth skipping and to reduce a string vibration sound and a meshing noise with simple configurations. In a silent chain 110, a pin hole 161 of an inner plate 160 and a pair of locker pins 170 are configured in such a size that a gap is formed between a seat surface 163 and a back surface of a short pin 172 in a state where the pair of locker pins 170 are in contact with each other on rolling surfaces 171a and 172a.

Owner:TSUBAKIMOTO CHAIN CO

Apparatus for vertically linking two sections of chain

The apparatus is intended for vertically linking a first chain and a second chain under water. The apparatus is characterized in that it comprises a lower base (1) with an open cross-shaped slot (5) into which the last link of the first chain (6) is inserted, extending above said lower base (1), while a guide / holder (2) for the second chain (7) is attached to the lower base (1) over said slot, said guide / holder containing an H-shaped shackle (11) that is coupled to the last link of said second chain (7) by means of a first bolt (12), the last link of the first chain (6) being inserted in the free space in the shackle (11) so that both chains (6-7) are coupled by means of a second bolt (13).

Owner:VICINAY MOORING CONNECTORS SA

Connector

ActiveUS20110265441A1Reduces tendency towards movementTransmission force is excessiveChain fasteningsShacklesEngineeringBearing surface

This invention relates to a connector, particularly to a shackle suitable for use in connecting two links of a chain or a chain to an anchor, more particularly to a connector comprising a first portion and a second portion, at least one first connector arm on the first portion and at least one second connector arm on the second portion, wherein both the first and second connector arms have multiple bearing surfaces, preferably six, and are able to engage one another when the connector is coupled by means of the bearing surfaces. The connector of the present invention has the advantage of having a break load of 1.3[0.0274 d2(44−0.08 d) kN, wherein d is the nominal diameter, and preferably a thickness of 1.3 d.

Owner:SCHMIEDESTUCK VERTRIEB FEUERSTEIN

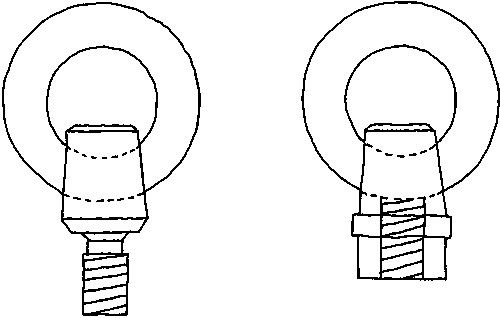

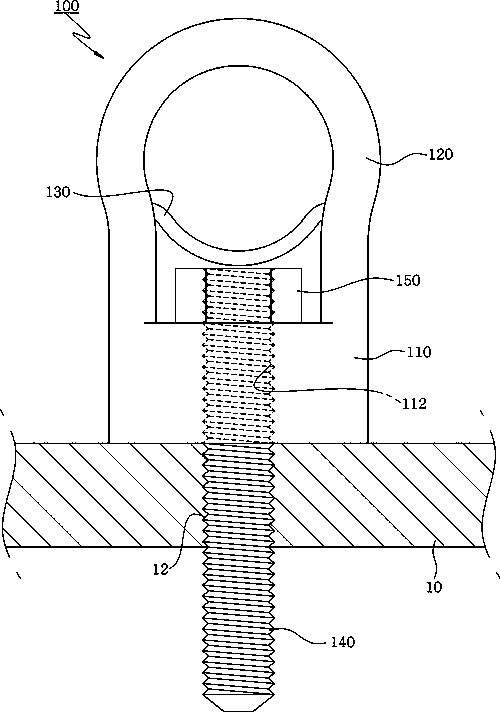

Lifting fastener

The present invention relates to a lifting fastener comprising: a body through which a mounting hole is formed; a lifting ring which is connected to the body such that a hook of a crane or a rope is latched; and a coupling nut which is provided inside the lifting ring and, if an object to be lifted has a bolt, is coupled to the bolt. According to the present invention, in addition to the basic function of a transformation preventing portion which supports the structure of the lifting ring so as to increase the tensile strength of the lifting ring, considering that the tensile force increases due to the force of lifting the lifting ring and the weight of the object to be lifted during the lifting, the lifting ring can be prevented from transforming due to the pull toward the coupling nut and a space for the rotation of the coupling nut can be acquired. Moreover, if a coupling hole is provided on the object to be lifted, the object to be lifted is coupled by means of a coupling nut mounted on the lifting fastener. And if a bolt is provided on the object to be lifted, the object to be lifted is coupled by means of the coupling nut while the coupling bolt is separated from the liftingfastener. And if the coupling bolt mounted on the lifting fastener or the bolt provided on the object to be lifted is long, the interfering transformation preventing portion is omitted for effective use.

Owner:金仲镐

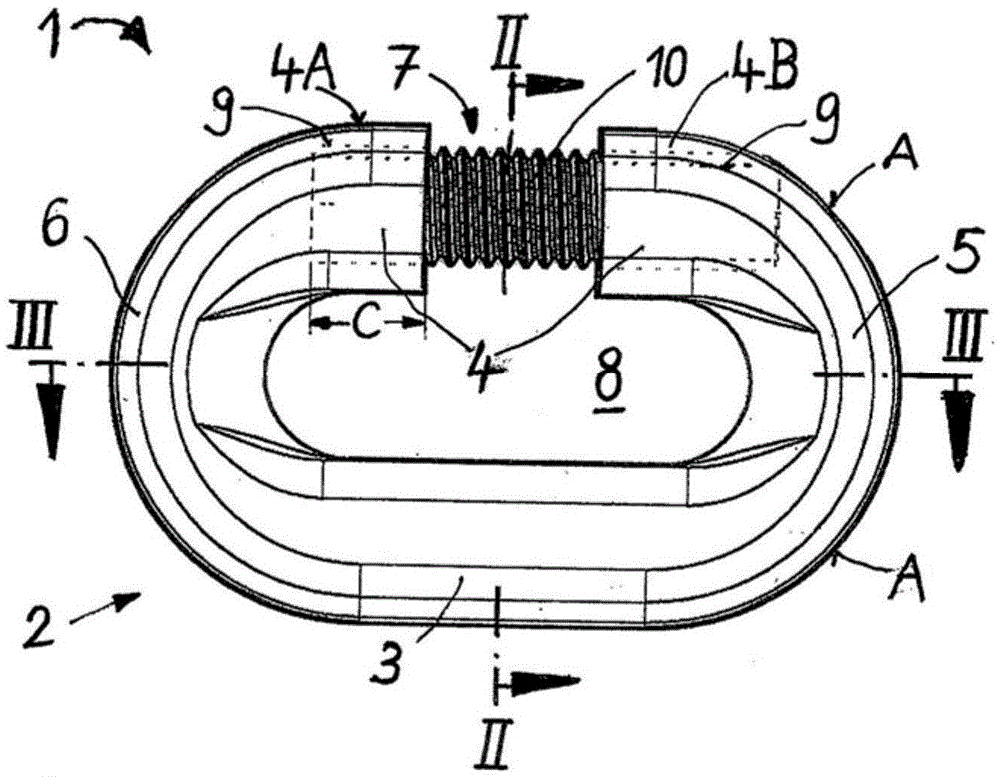

Chain Joints for Links

ActiveCN104487756BHigh tensile strengthIncrease the cross-sectional areaChain fasteningsShacklesEngineeringScrew thread

Owner:PEWAG AUSTRIA

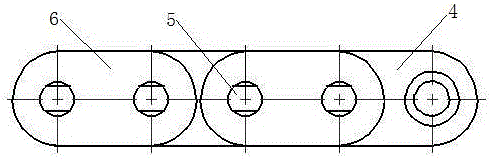

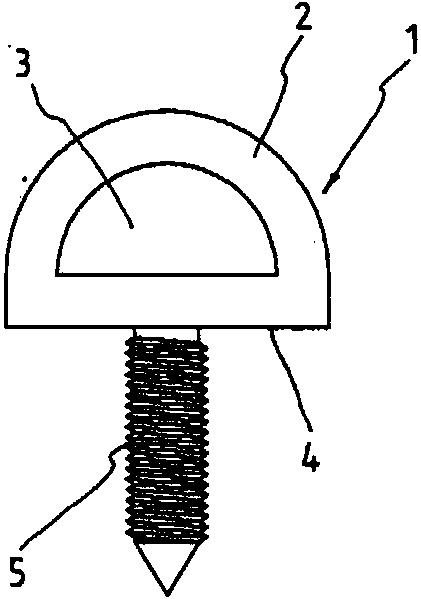

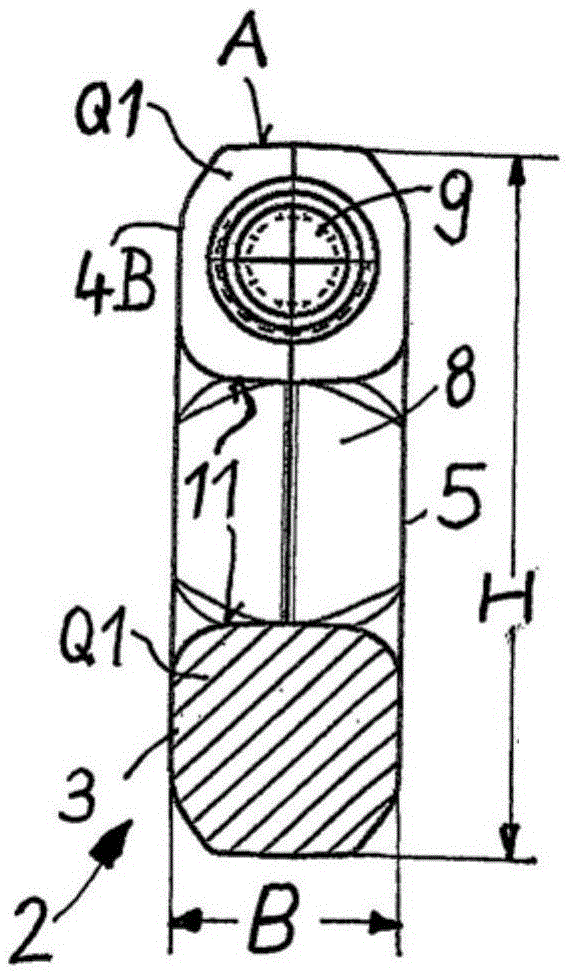

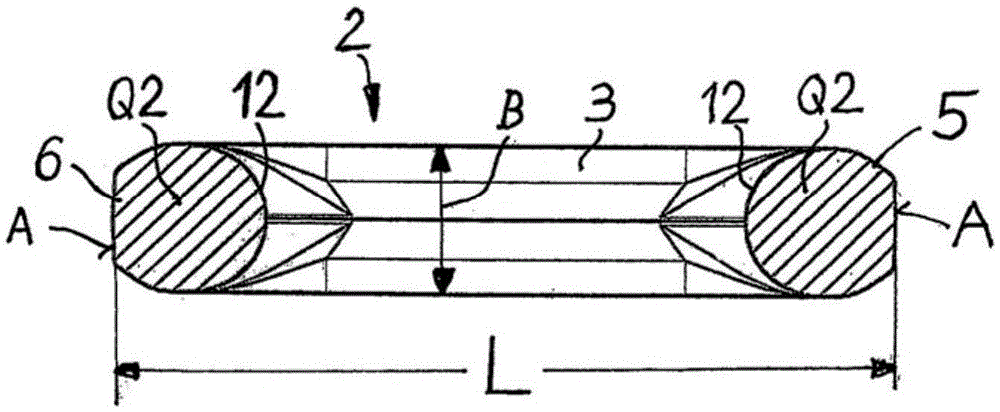

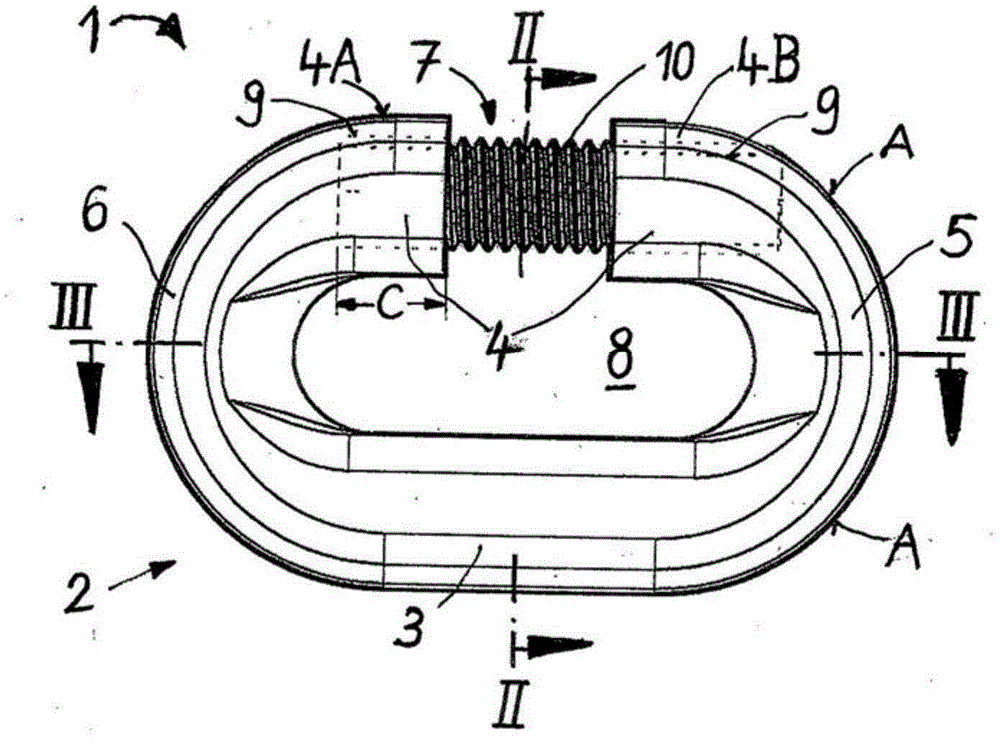

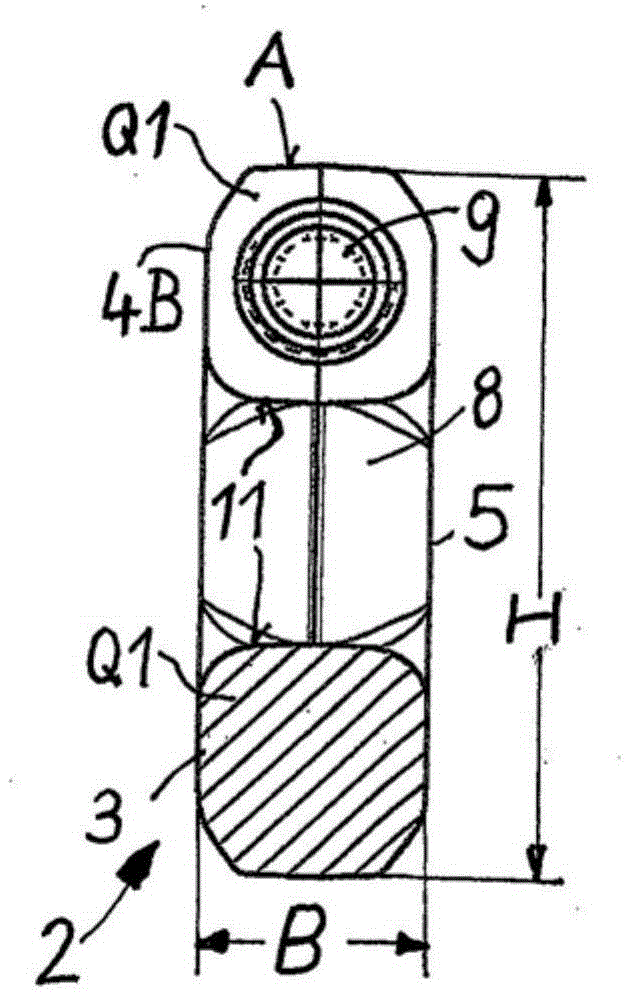

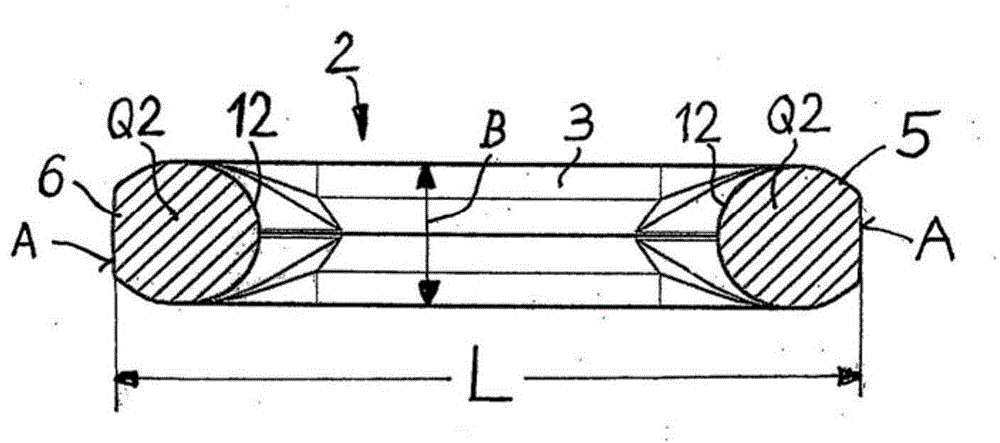

Chain joint for link chains

ActiveCN104487756AHigh tensile strengthIncrease the cross-sectional areaChain fasteningsShacklesEngineeringHooking

In a chain joint (1) for link chains, having a main body (2) in the form of an oval chain link with two mutually parallel longitudinal legs (3, 4) which are connected to one another at their ends in each case via a rounded link portion (5, 6) and one of which has an interruption for forming a receiving opening (7) for the hooking-in of oval chain links into an internal opening (8) of the main body (2), said receiving opening being bounded at its ends by in each case one longitudinal leg section (4A, 4B), wherein, in said longitudinal leg (4), there is provided a threaded bore (9) which runs in the longitudinal direction of said longitudinal leg and which extends in both longitudinal leg sections (4A, 4B) and into which there can be screwed a closure screw (10) which, in the screwed-in state, engages with the threaded bore (9) in both longitudinal leg sections (4A, 4B), it is provided that, while maintaining the predefined sizes for outer circumference (A) and link width (B) of the main body (2), said main body is provided, in the region of its longitudinal legs (3, 4), with a profile cross section (Q1) that is larger than the profile cross section (Q2) in the region of its rounded link portions (5, 6).

Owner:PEWAG AUSTRIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com