Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1601results about How to "Avoid jamming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inverting thrombectomy apparatuses and methods

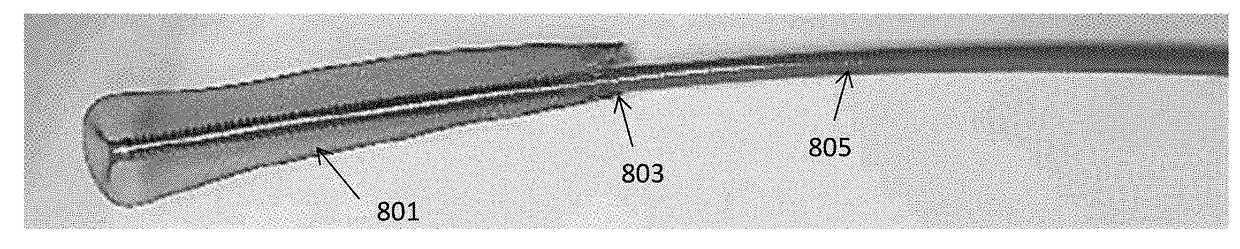

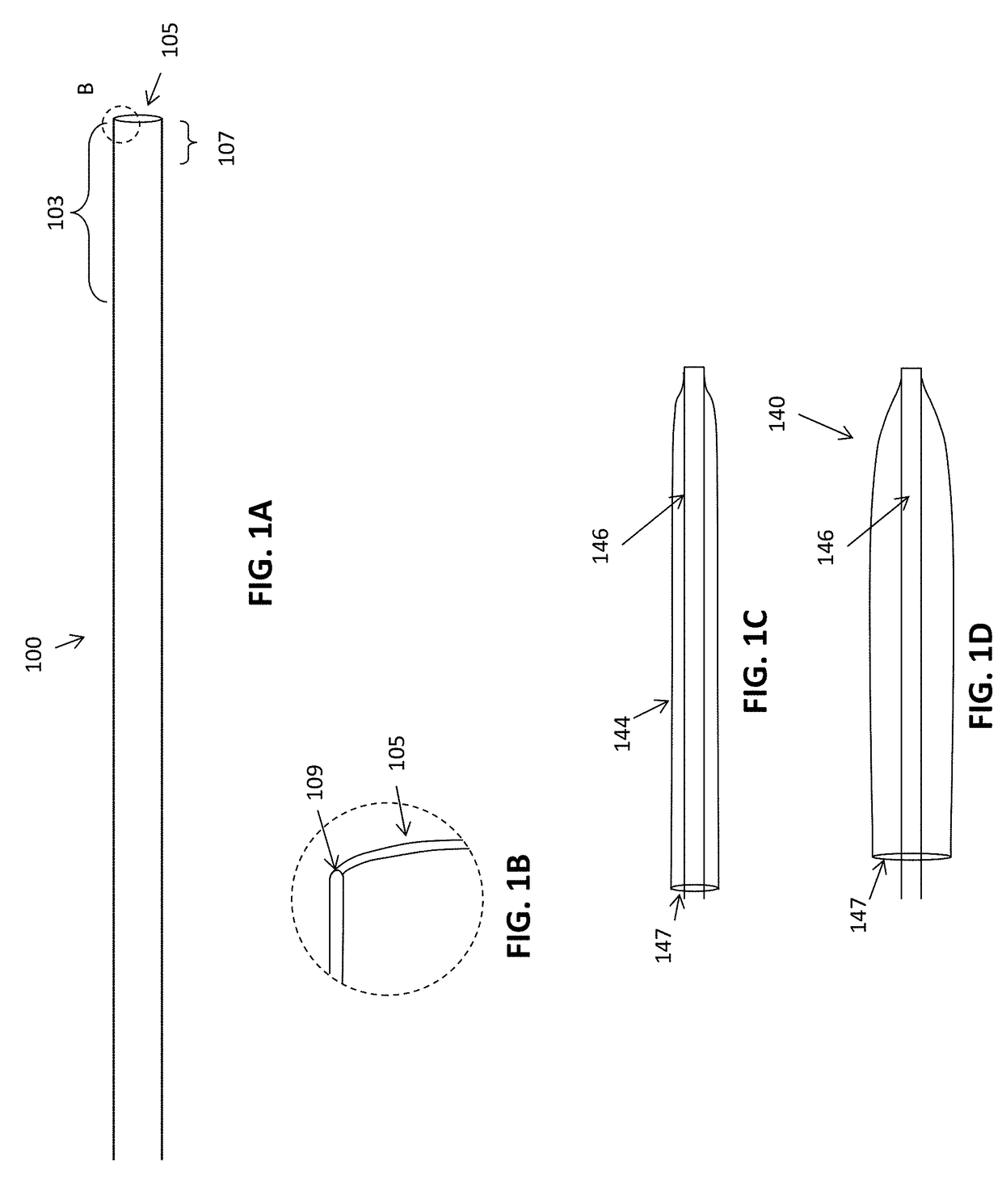

Rolling tractor tube mechanical thrombectomy apparatuses that may be deployed from out of a catheter in situ are described herein. These apparatuses may be delivered out of a catheter from a collapsed delivery configuration within the catheter to a deployed configuration out of the catheter, in which the same catheter is re-inserted between a tubular tractor and an elongate puller. In particular, any of these methods and apparatuses may be adapted to work with a tractor tube having an open end that is biased open, including using an annular bias.

Owner:STRYKER CORP

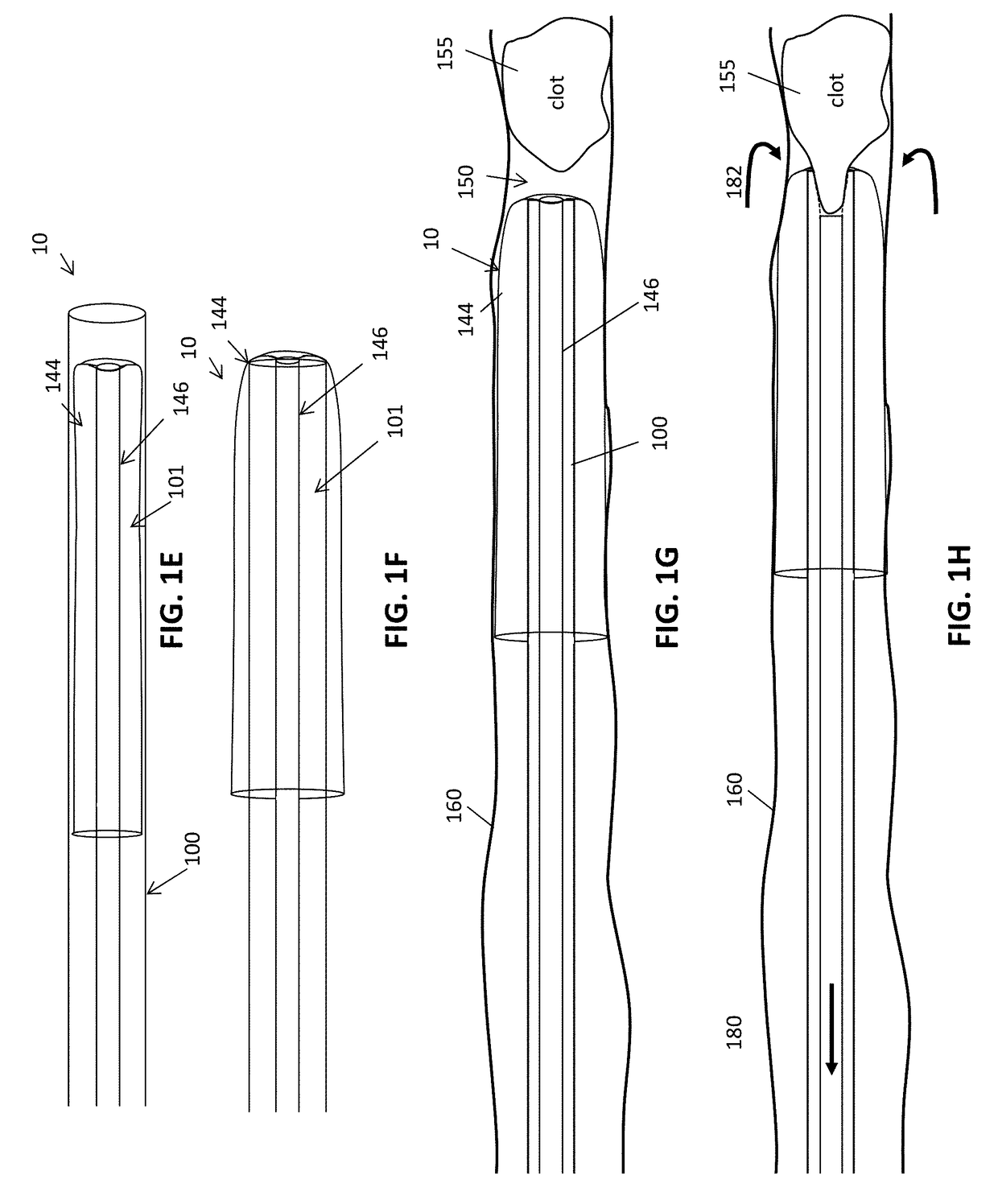

Chemical engineering raw material mixing and stirring device convenient for screening

The invention discloses a chemical engineering raw material mixing and stirring device convenient for screening. The device comprises a stirring box, the top of the stirring box is provided with a material inlet, the bottom of the stirring box is provided with a material outlet, one side of the stirring box is provided with a first motor through a carrier plate, the output end of the first motor is fixedly connected with the axle center of one side of a driving gear, the axle center, opposite to the first motor, of the driving gear is fixedly connected with one end of a driving rotating rod, and the other end of the driving rotating rod traverses through the stirring box, and is movably connected with the internal of the stirring box. A crushing roller is improved, teeth on the crushing roller can crush a chemical engineering raw material, the crushed chemical engineering raw material is screened under the cooperation of a filter screen frame, a stirring screen is improved, and the stirring screen can drive a stirring shaft and a stirring filter screen to simultaneously rotate through the rotating shaft and can stir the chemical engineering raw material in order to realize the screening and breaking effects in the stirring process.

Owner:洛阳毅兴石化电器仪表设备有限公司

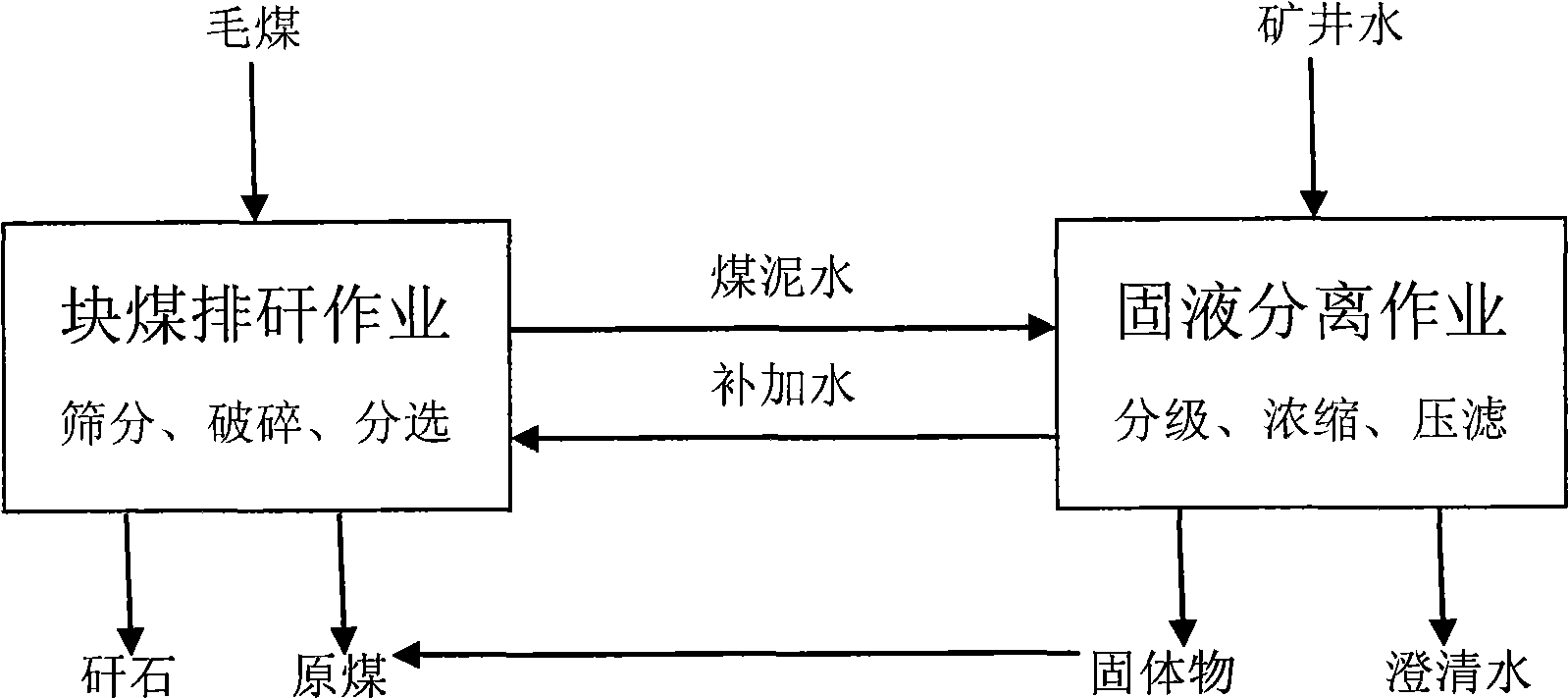

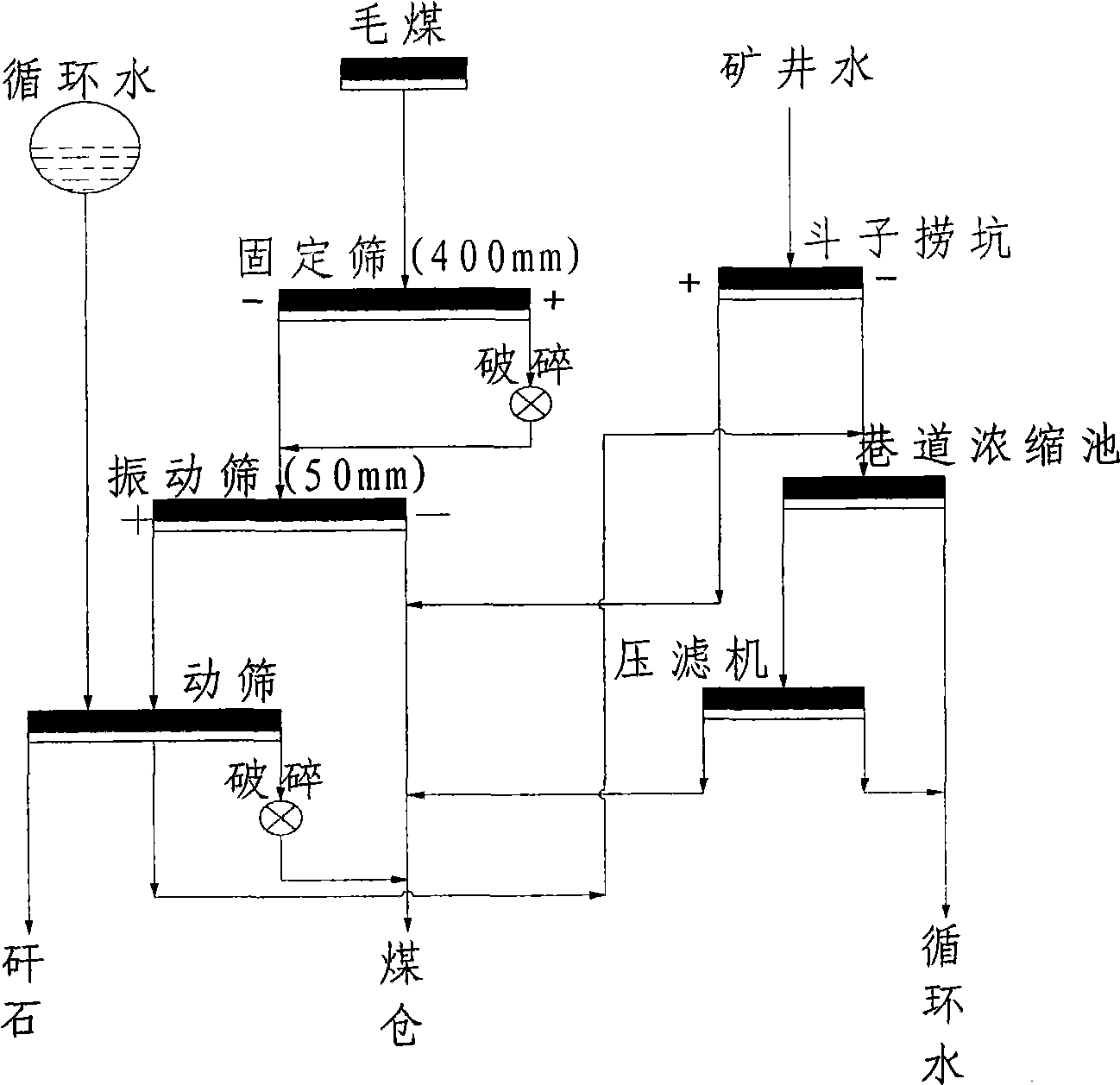

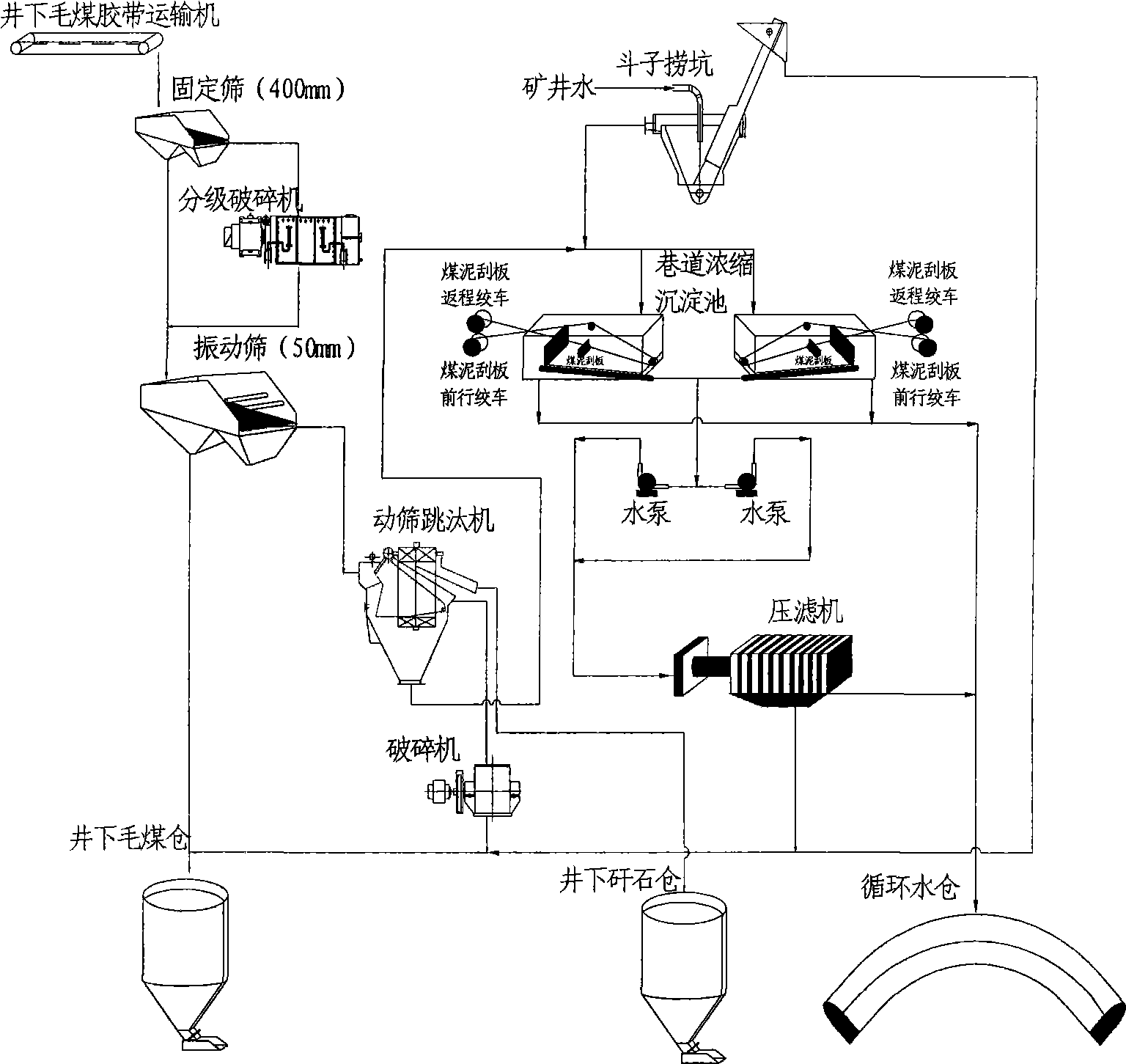

Down-hole gross coal dirt-discharging and mine water treating combined process

An underground gross coal gangue removal and mine water treatment combined process is characterized in that the process comprises two parts: gangue removal operation from lump coal and mine water solid-liquid separation operation, wherein, the gangue removal operation from lump coal comprises screening, crushing and separation steps, and the mine water solid-liquid separation operation comprises hydraulic classification, concentration and pressure filtration steps; by the gangue removal operation from lump coal, chunks of gangues in the gross coal are removed, and simultaneously the large particles thereof are crushed into appropriate size; by the mine water solid-liquid separation operation, the solid substances in the mine water are recycled to a coal streamline, and simultaneously the clear overflow water is delivered to a underground water sump; the coal muddy water generated by the gangue removal operation from lump coal is delivered to a mine water solid-liquid separation system for treatment and the mine water solid-liquid separation system provides water for washing and selection for the gangue removal operation from lump coal, so the coal muddy water and the water for washing and selection are combined into an organic whole.

Owner:HENAN POLYTECHNIC UNIV

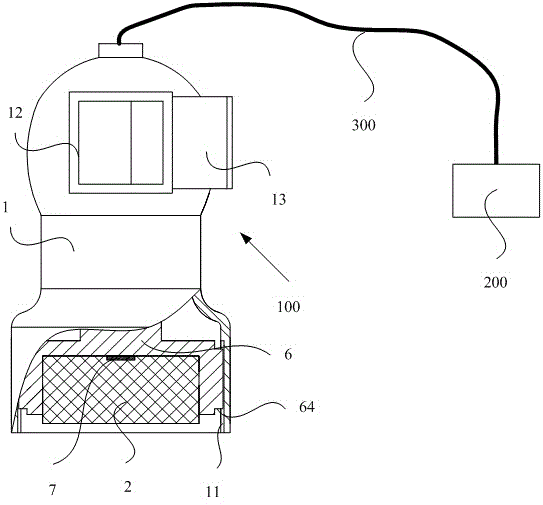

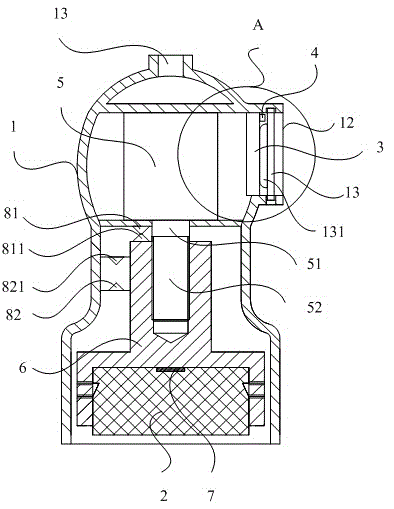

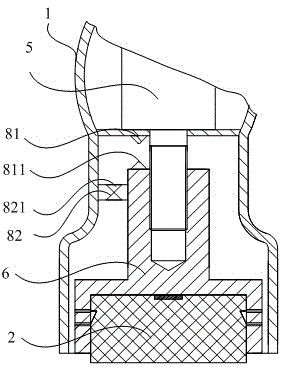

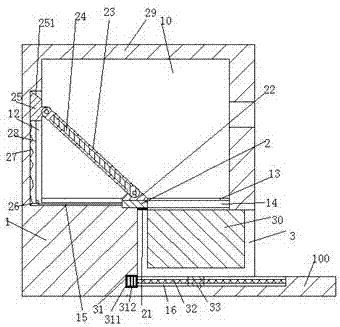

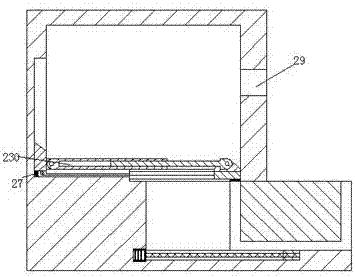

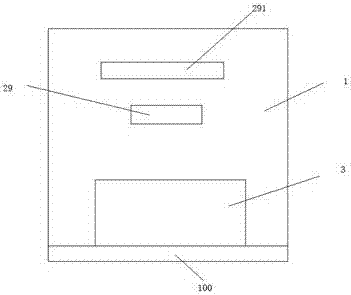

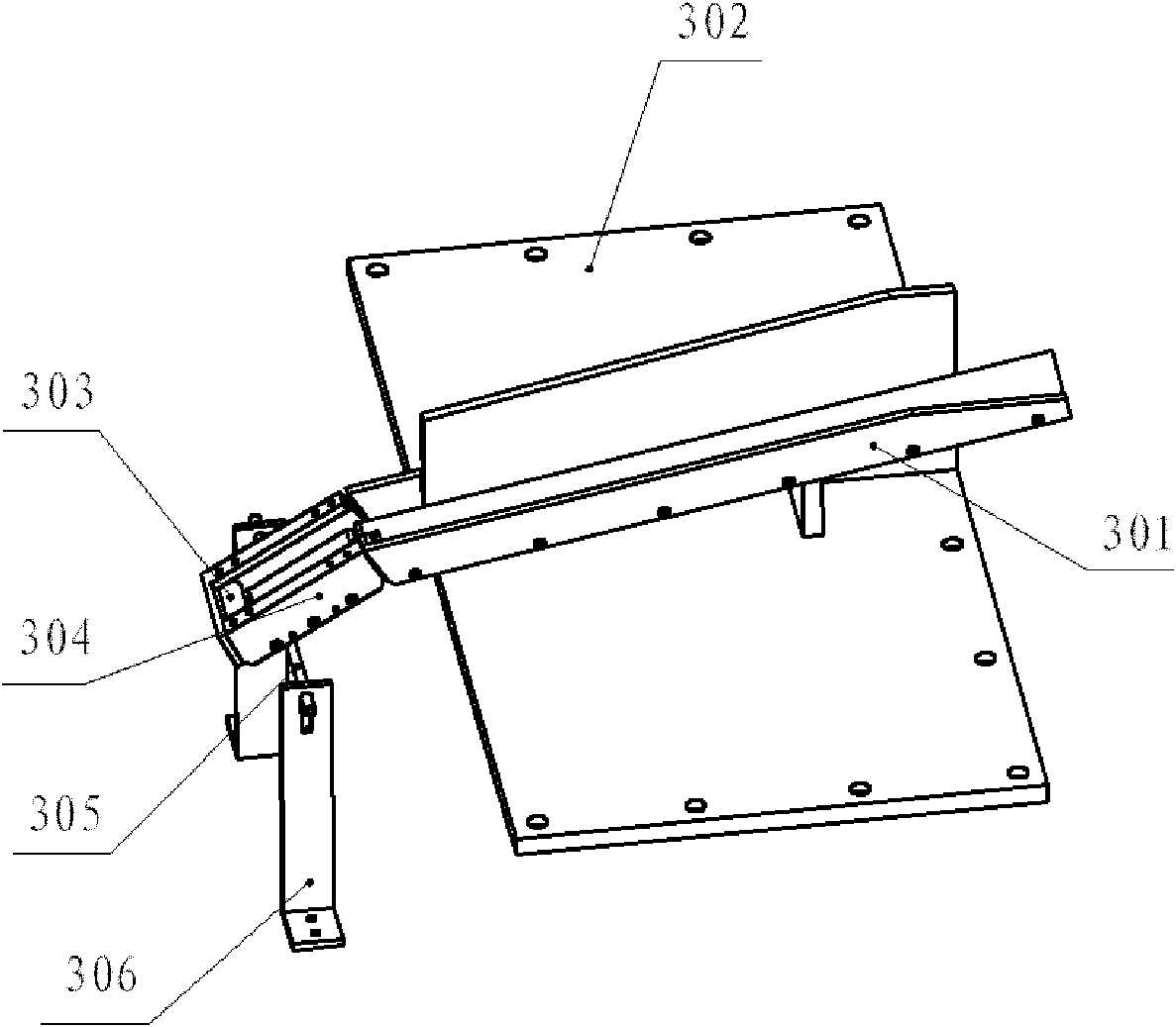

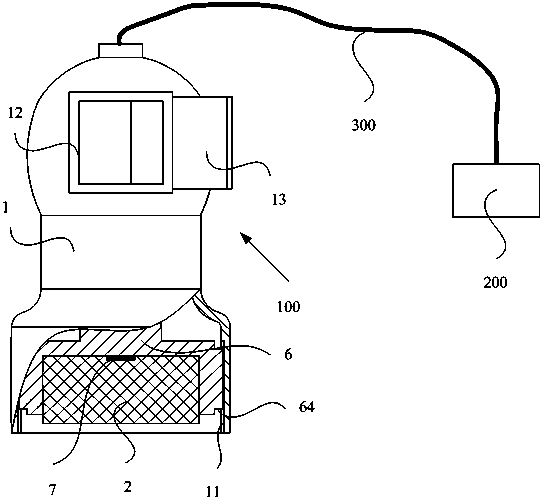

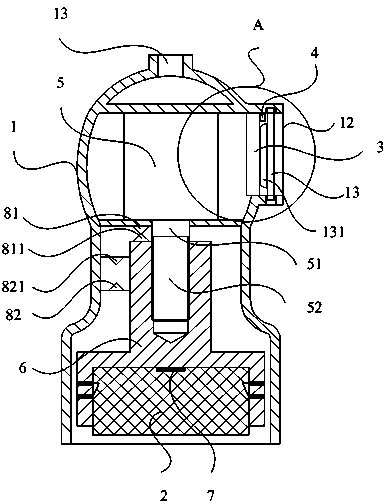

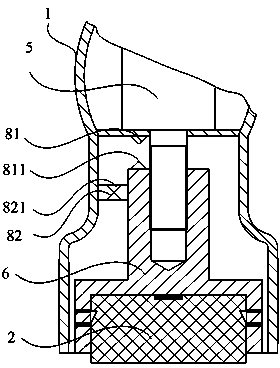

Concavely-embedded hidden stamp system

ActiveCN102873998AImprove securityPrevent theftCharacter and pattern recognitionStampingExecution unitEngineering

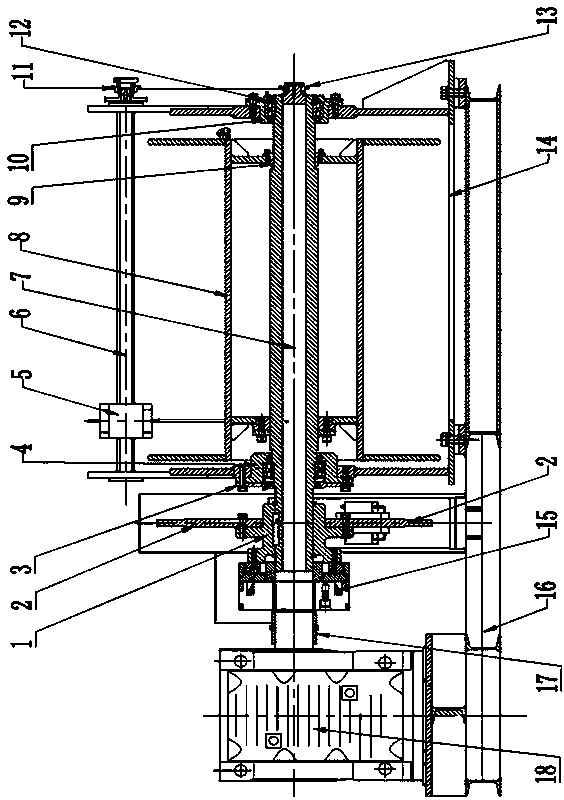

The invention provides a concavely-embedded hidden stamp system, which comprises a control unit and an executing unit, wherein the executing unit comprises a shell, a stamp arranged inside the shell, a motor and a transmission frame; the shell is provided with an acquisition window; a finger induction sensor and a fingerprint sensor are arranged in the acquisition window; a revolving shaft of the motor is connected with a screw rod; the transmission frame is provided with a threaded hole; the screw rod is in threaded connection in the threaded hole; the transmission frame is in sliding connection with the shell; the stamp is fixed on the transmission frame; when a finger extends into the acquisition window, a trigger signal is transmitted to the control unit through the finger induction sensor, the control unit is used for starting the fingerprint sensor for acquiring the fingerprint information of a user, and the motor rotates to drive the stamp to extend out of the shell if the fingerprint information of the user is matched; and when a finger is separated from the acquisition window, the finger induction sensor stops transmitting the trigger signal, the motor rotates reversely, the stamp is automatically moved into the shell, and the stamp is hidden in the shell in a concave embedding way for protecting, so that the safety of the concavely-embedded hidden stamp system is improved.

Owner:孟友新

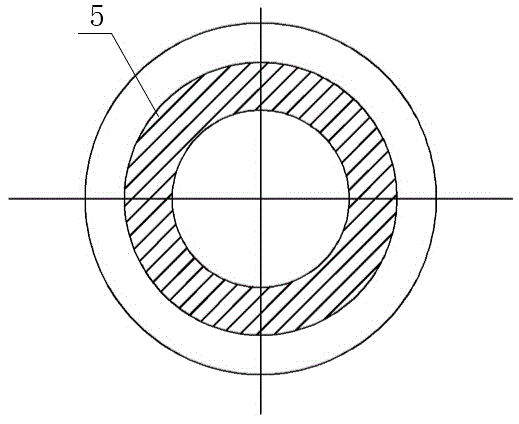

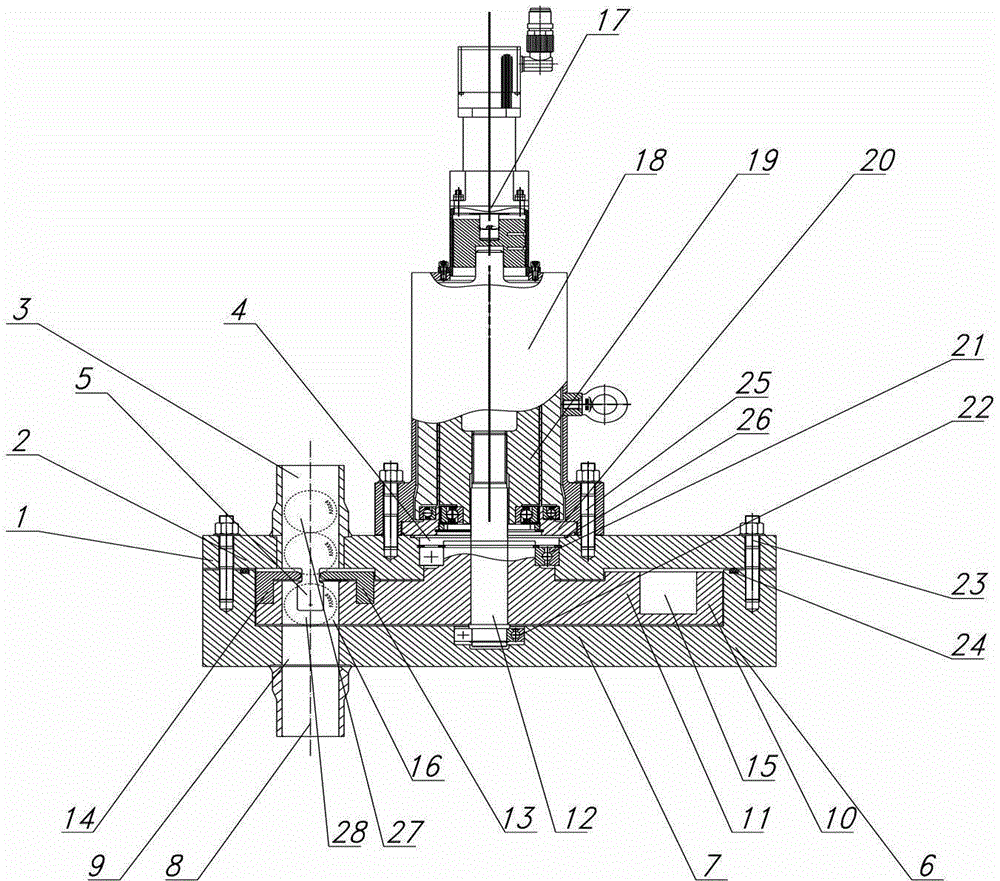

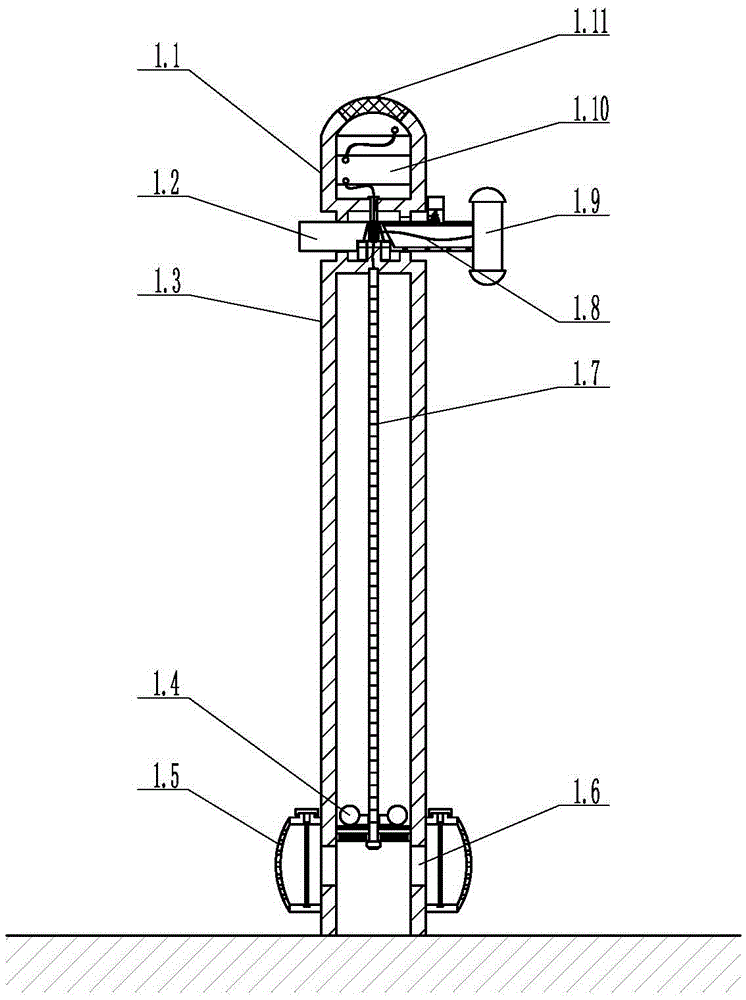

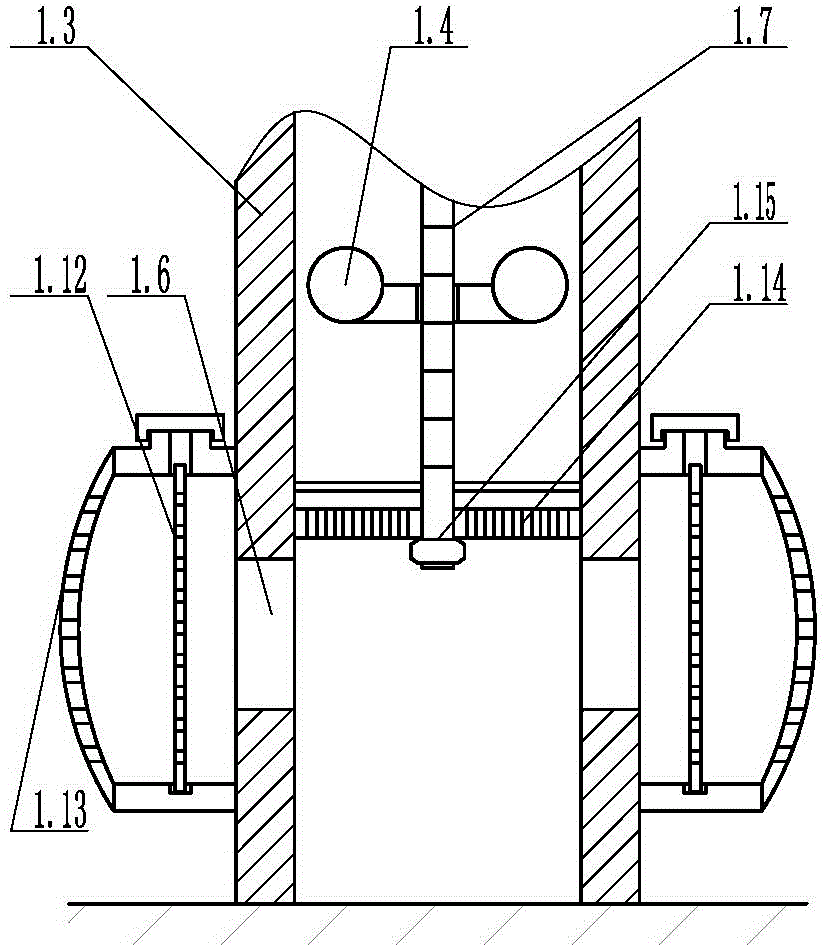

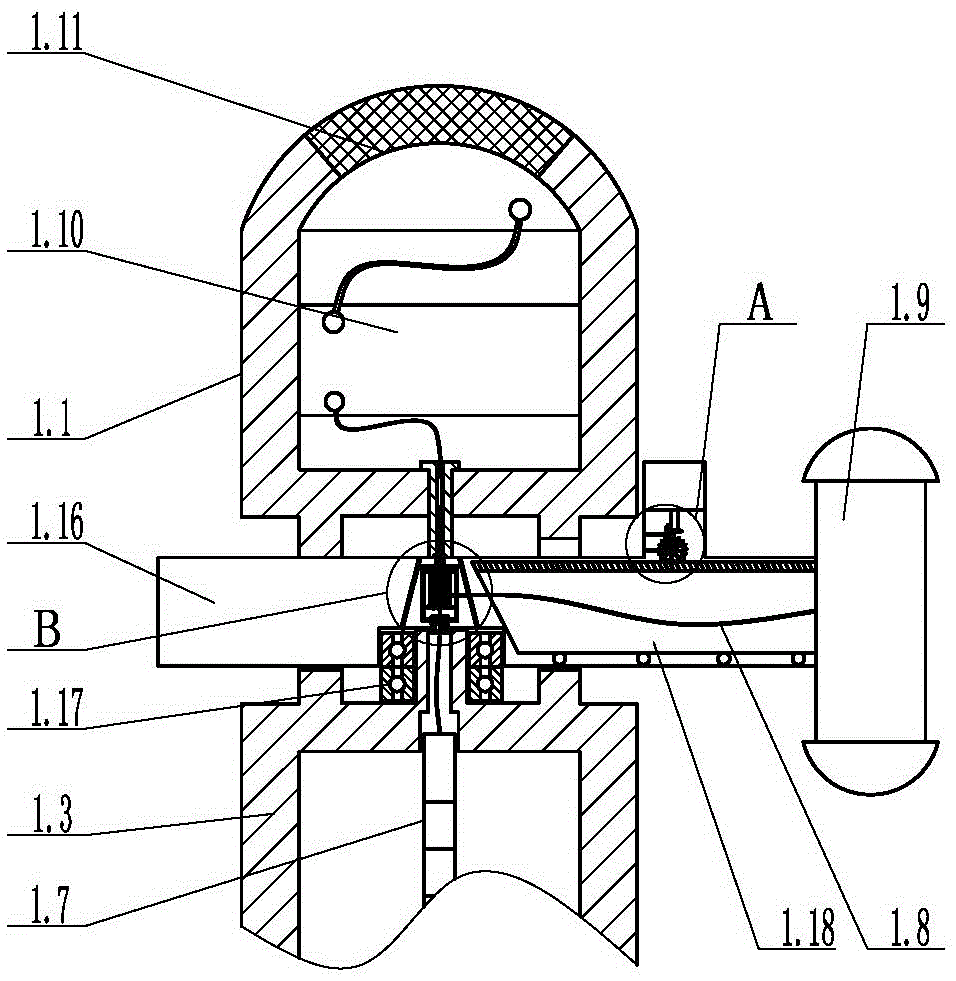

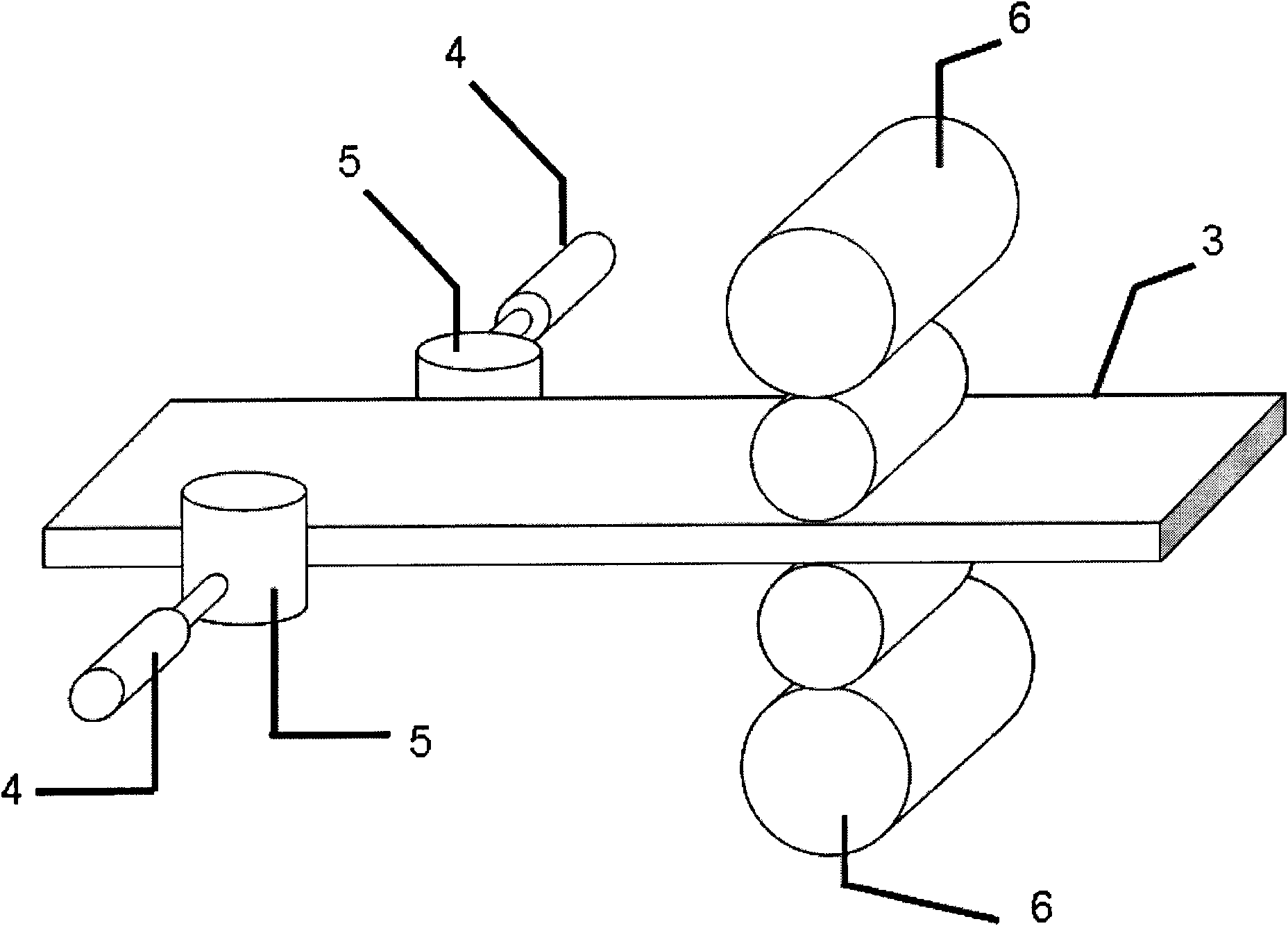

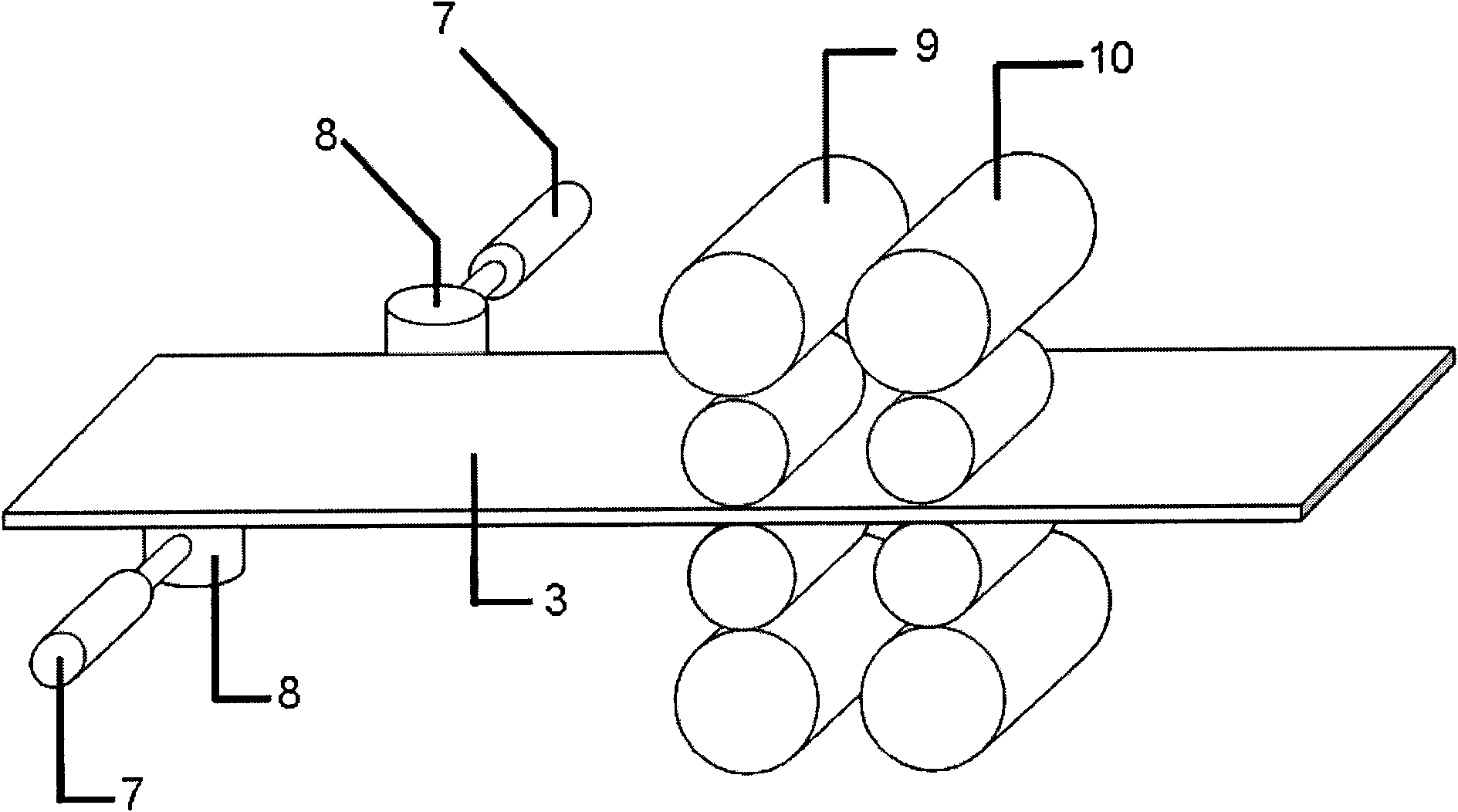

Automatic descaling device and method for shafts

ActiveCN104100231AReduce card rotationEnhanced descaling abilityCleaning apparatusImpellerEngineering

The invention discloses an automatic descaling device for shafts. The automatic descaling device comprises a pump shell (1), a pump body, a mandrel (3), an inflow head (4), a rubber sleeve (5), a connector (6), impellers (7) and scraper devices. The mandrel (3) is fixedly connected with the pump body. The impellers (7) and blade wheels (11) are mounted on the mandrel (3) at intervals. The scraper devices are mounted on the outer peripheries of the blade wheels (11). The inflow head (4) and the rubber sleeve (5) are communicated with the water inlet end of the mandrel (3). The water outlet end of the pump shell (1) is sequentially connected with a pressure control valve (17) and the connector (6). The invention further discloses a descaling method. The automatic descaling device and method has the advantages that downhole gas-liquid kinetic energy is converted into operation mechanical energy of the descaling device so as to achieve automatic descaling, descaling time is shortened, and combination of high-speed gas-liquid descaling and mechanical descaling is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

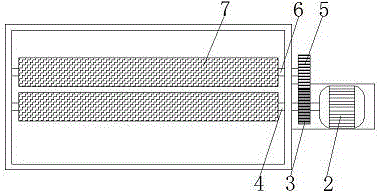

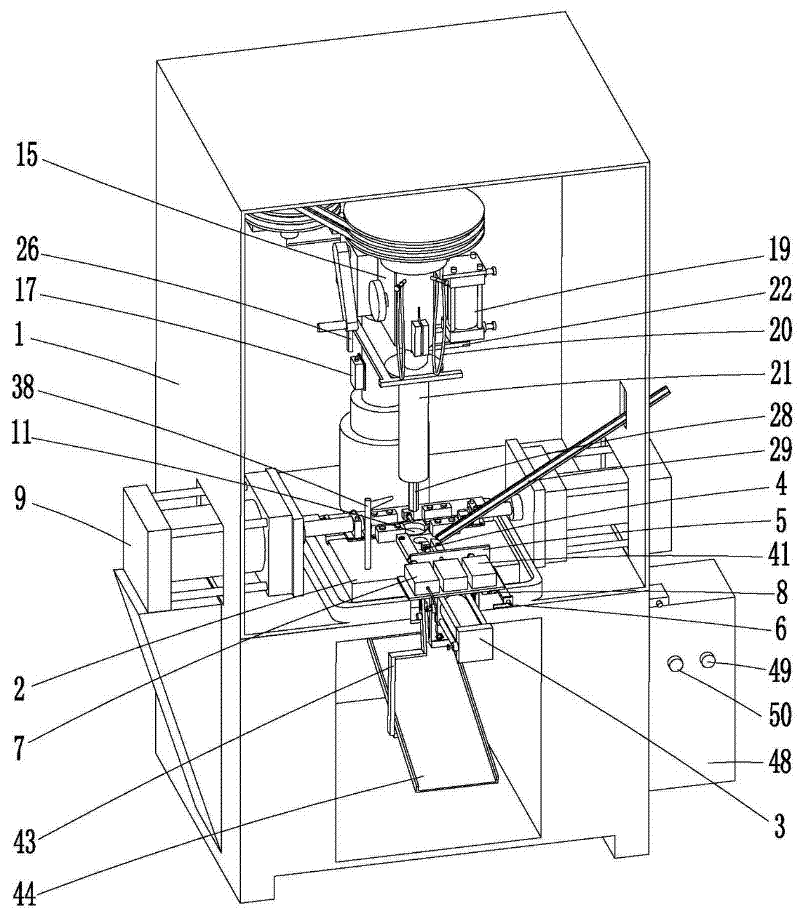

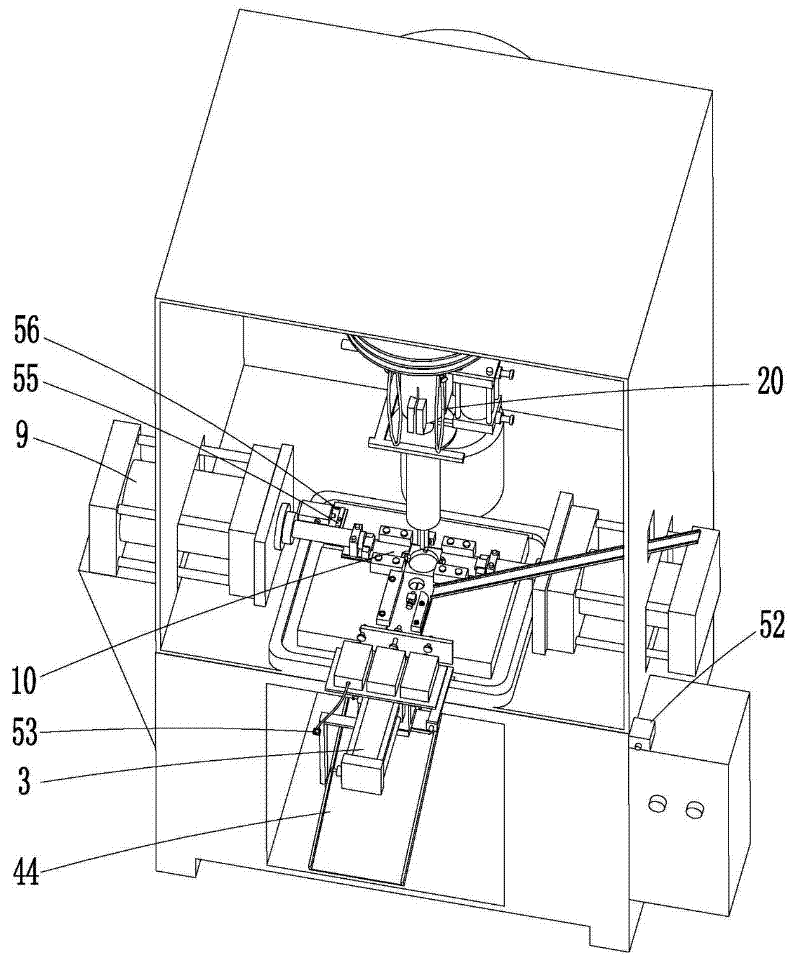

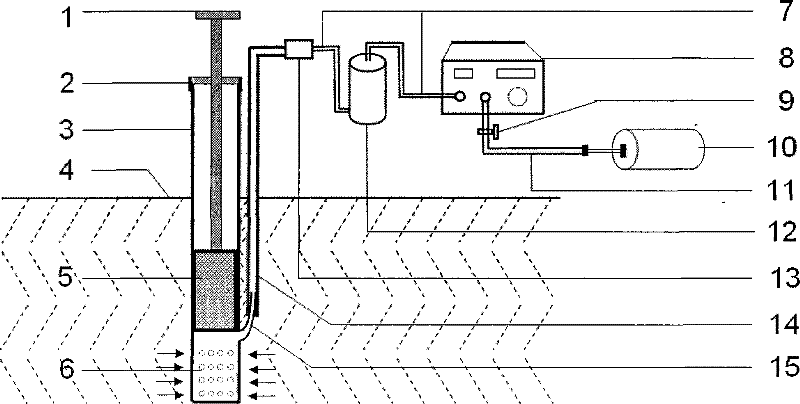

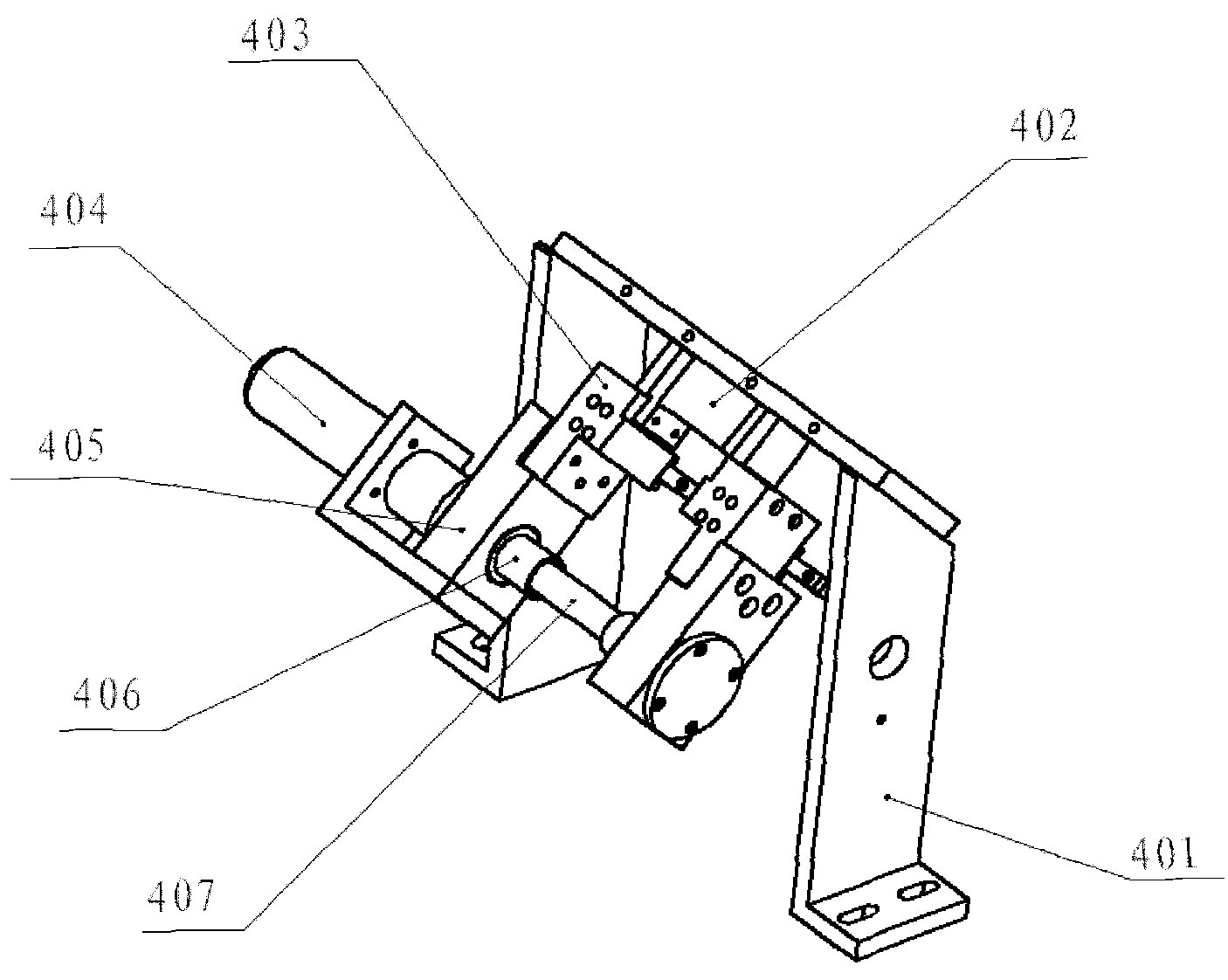

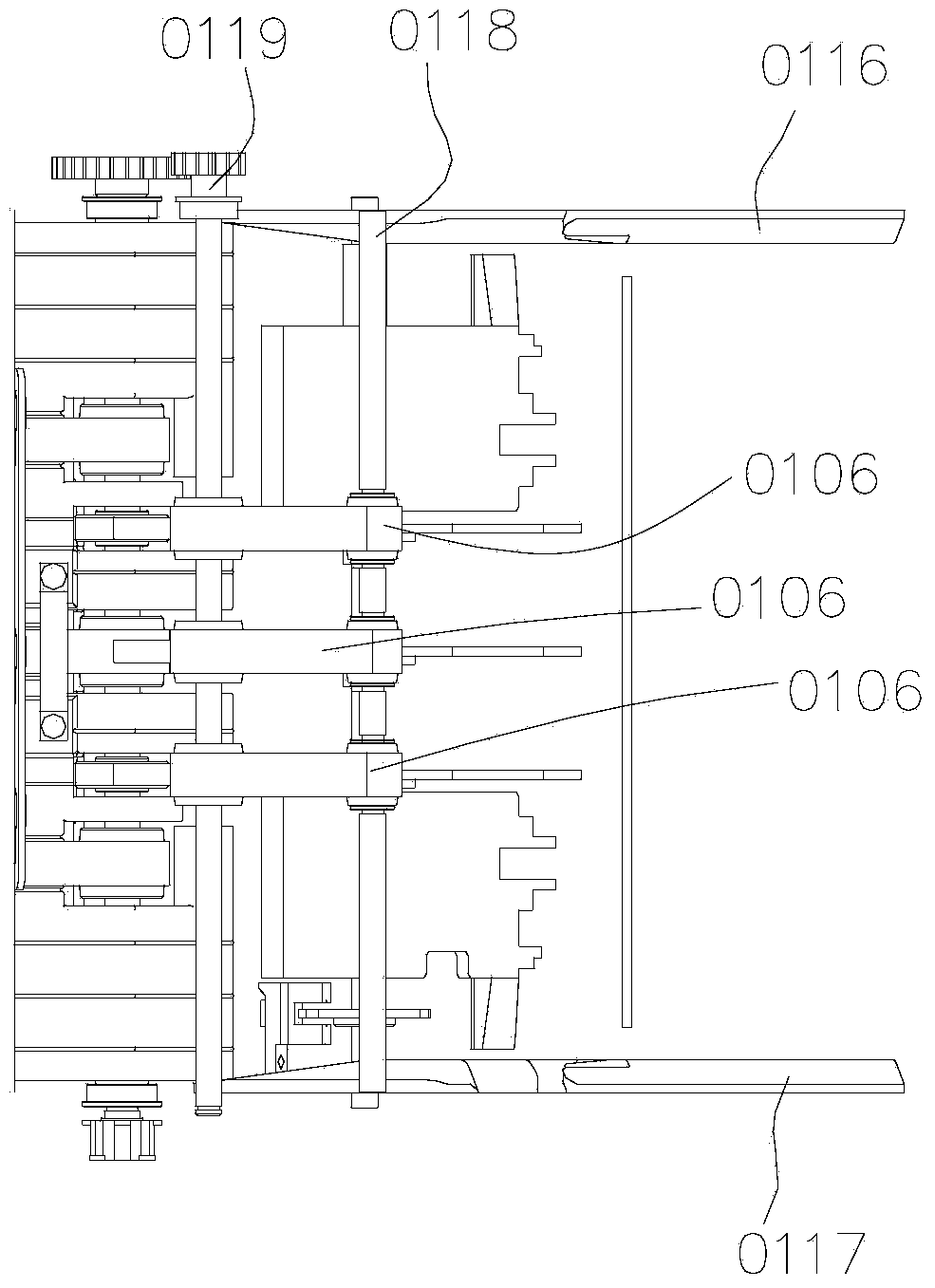

Fully-automatic tapping machine

ActiveCN102642055APrecise feedingEfficient separationThread cutting feeding devicesThread cutting machinesEngineeringFully automatic

The invention relates to a fully-automatic tapping machine which comprises a machine frame, wherein the machine frame is provided with an operating platform, and the operating platform is provided with an automatic feeding mechanism, an automatic clamping mechanism and an automatic tapping mechanism. According to the fully-automatic tapping machine, the operating platform, the automatic feeding mechanism, the automatic clamping mechanism, the automatic tapping mechanism, a material receiving plate and the like are reasonably arranged on the machine frame, so that the whole machine integrates the functions of automatic feeding, feed-linkage clamping, automatic tapping, automatic cutter retracting, automatic blanking, automatic material and residue separation, automatic cycle and the like, many problems of the traditional equipment and currently-emerging equipment are solved, the tapping accuracy is effectively improved, the production cost is reduced, and the production and machining efficiency is increased. The fully-automatic tapping machine has a compact and reasonable structure and is convenient to operate and control, a plurality of fully-automatic tapping machines can be simultaneously managed by one person during use, and the machining efficiency is several times higher than that of the traditional tapping machine; and the machining accuracy is high, and the service effect is good, thus the fully-automatic tapping machine is worthy of popularization and application.

Owner:景宁畲族自治县通用机械配件厂(普通合伙)

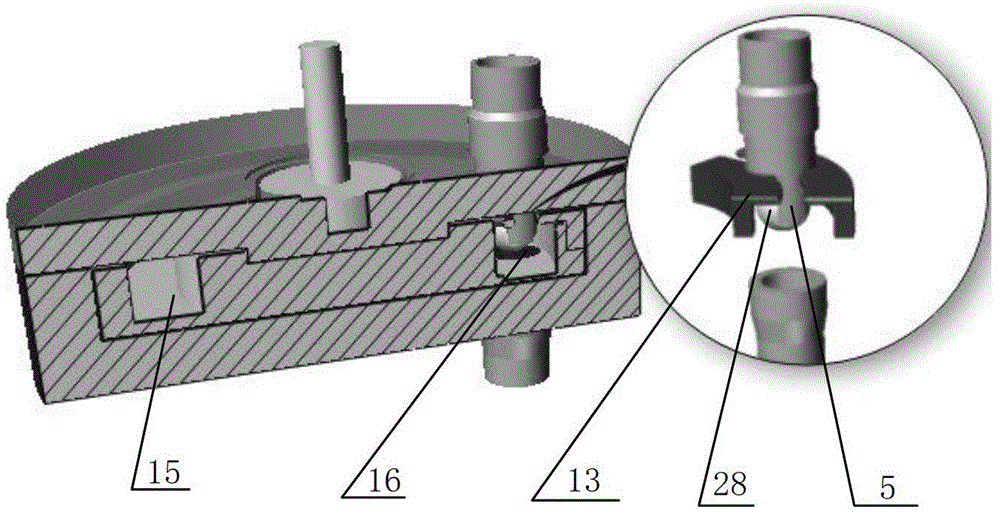

Device for isolating and conveying fuel spheres of sphere bed high temperature reactor

ActiveCN102982855AAvoid ball jamming failureGuaranteed reliabilityNuclear energy generationReactor fuel elementsEngineeringRotating disc

The invention provides a device for isolating and conveying fuel spheres of a sphere bed high temperature reactor, belonging to the technical field of reactor engineering. The device mainly comprises an end cover component, a box component, a rotating disc component and a driving component, wherein the main body of the rotating disc component is a rotating disc with two structural characteristics of a sphere guide groove and a sphere through hole; two arced supports are arranged above the sphere through hole and at two sides of the sphere guide groove; the end cover component is welded with a sphere through connecting pipe which passes through the end cover; two ear plates are machined at the lower part of the sphere through connecting pipe; and after being assembled, the ear plates of the sphere through connecting pipe in the end cover component are arranged at the upper part inside the sphere guide groove; and the sphere through connecting pipe on the box component is arranged in equal diameter and coaxial with the sphere through connecting pipe in the end cover component. By utilizing the device for isolating and conveying the fuel spheres of the sphere bed high temperature reactor in such a technical scheme, the fault that spheres are crushed and blocked is avoided, the reliability of single fuel sphere conveying and the utilizability of the reactor are ensured, the installation space of a pipeline system is effectively saved, and the working quantity in installation is reduced.

Owner:CHINERGY CO LTD

Full road condition ponding water level monitoring alarm and drainage device

ActiveCN105651359AMonitor waterloggingReal-time monitoring of water accumulationMachines/enginesLubrication indication devicesDisplay deviceEngineering

The invention provides a full road condition ponding water level monitoring alarm and drainage device and belongs to the field of ponding monitoring alarm and drainage devices for traffics. The device is characterized by comprising a road ponding monitoring device, an overpass tunnel ponding monitoring device, a water level monitoring display device, a water level monitoring alarm device and an automatic drainage device. The road ponding monitoring device and the overpass tunnel ponding monitoring device are connected with the water level monitoring display device. The device can monitor the ponding water level of various road conditions in real time, and transmit data to a monitoring center in real time, and the data can also be directly displayed to serve as action reference for municipal administration and passers-by. In addition, the device can drain water intelligently and actively according to the monitored water level data, and urban water logging is avoided.

Owner:SHANDONG XINGZHI INTELLIGENT TRANSPORTATION TECH CO LTD

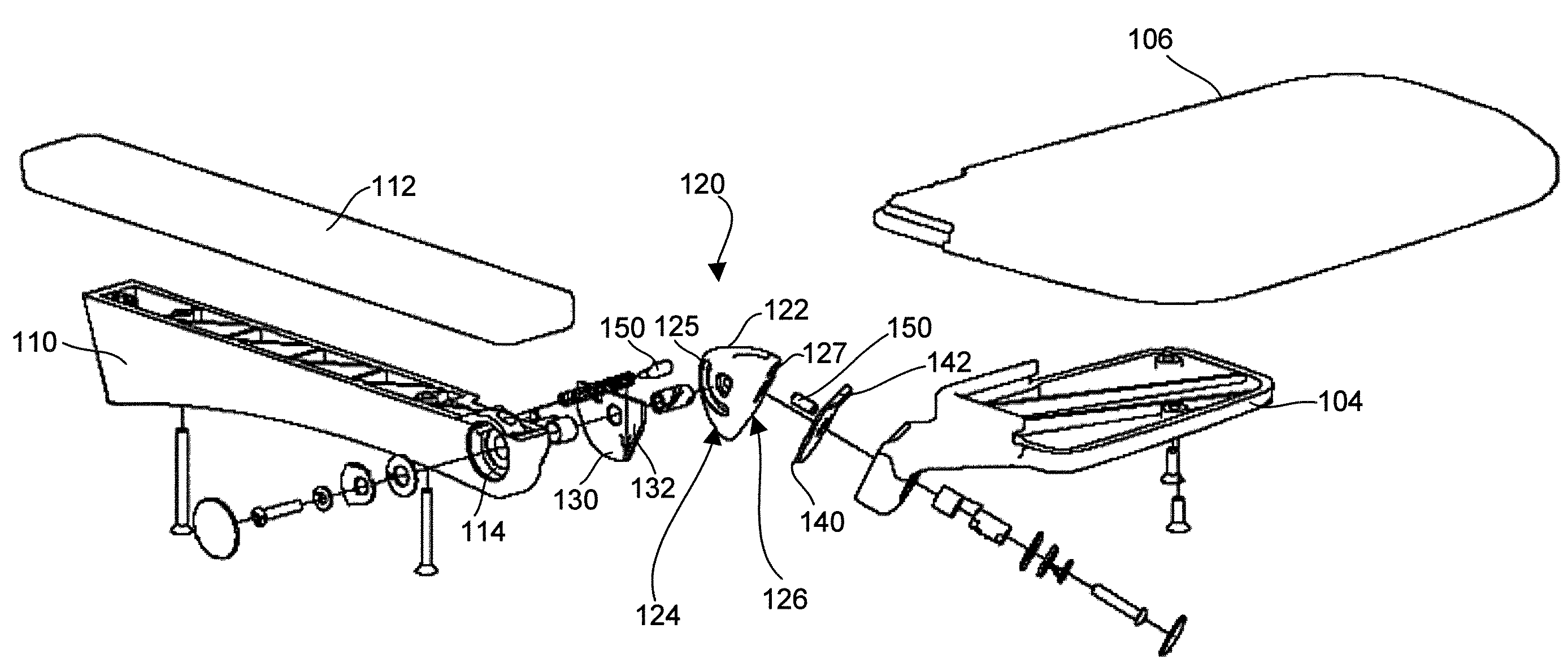

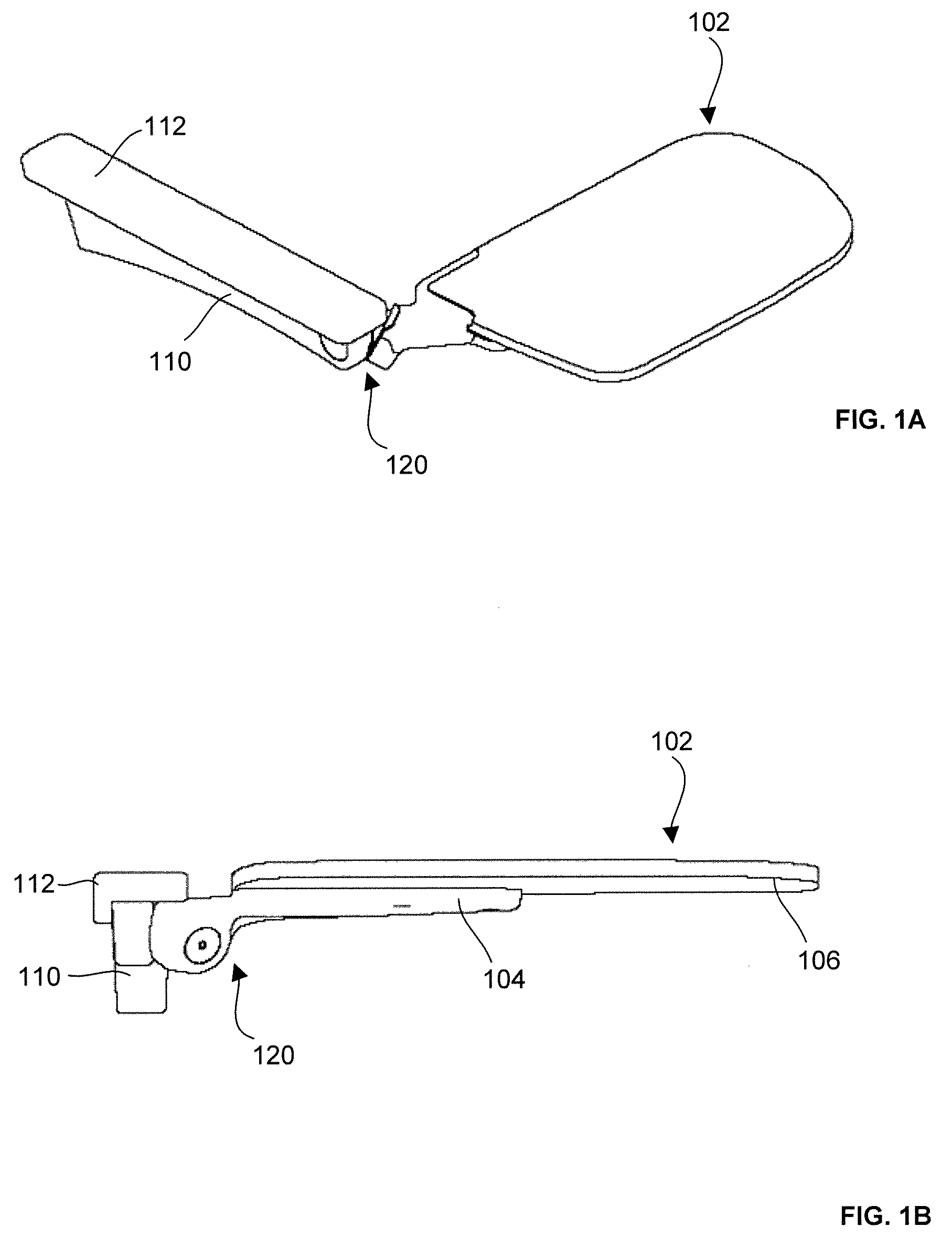

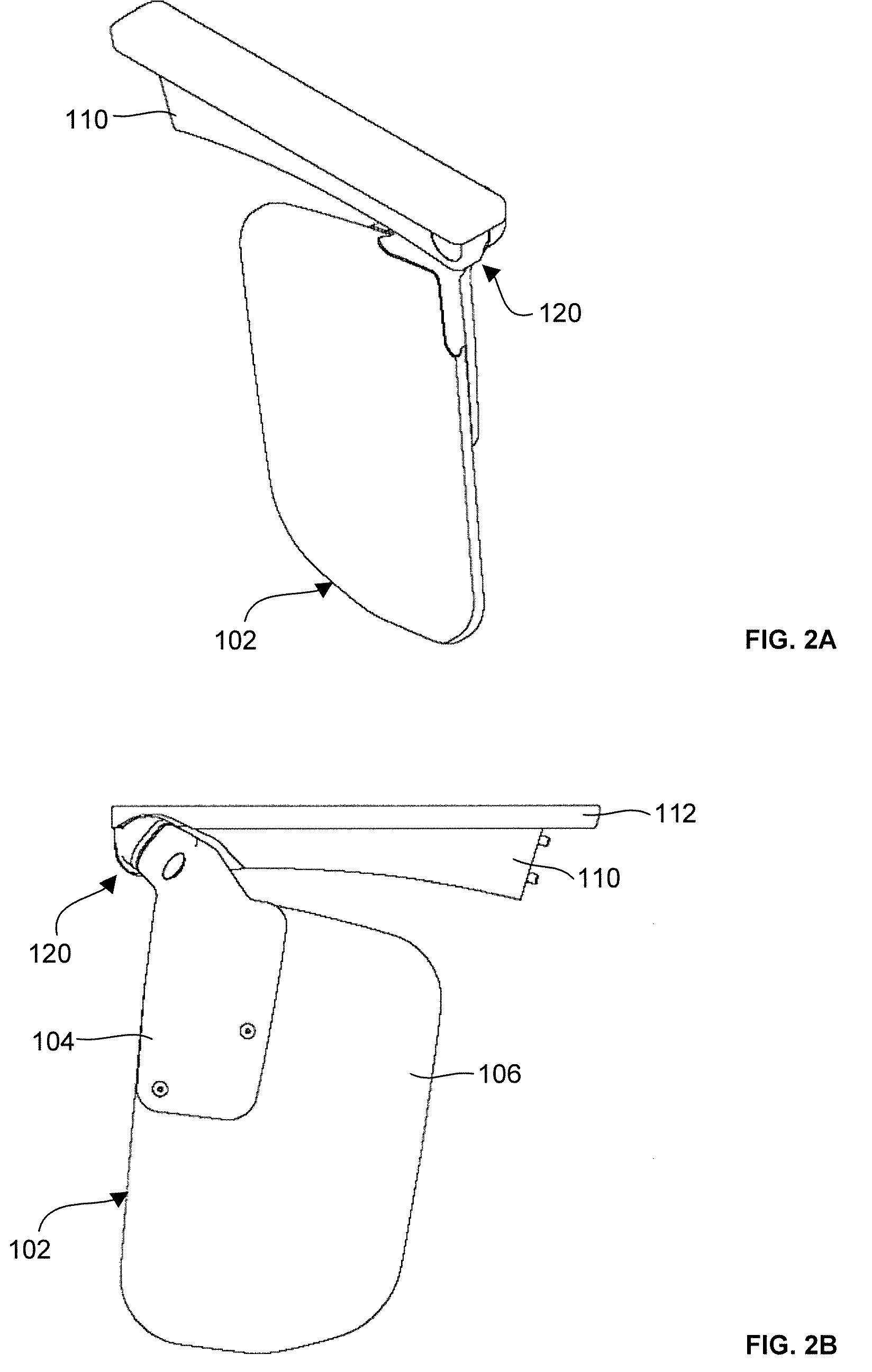

Tablet arm assembly

A tablet assembly including a tablet movable between a generally vertical stored position and a generally horizontal in-use position, and a swivel joint operable between the tablet and a mount, the swivel joint comprising an elbow, a first plate, and a second plate, wherein the first plate is rotateably attached to a first surface of the elbow and the second plate is rotateably attached to a second surface of the elbow, and wherein the first plate is fixedly attached to the mount and the second plate is fixedly attached to the tablet.

Owner:SERIES INT

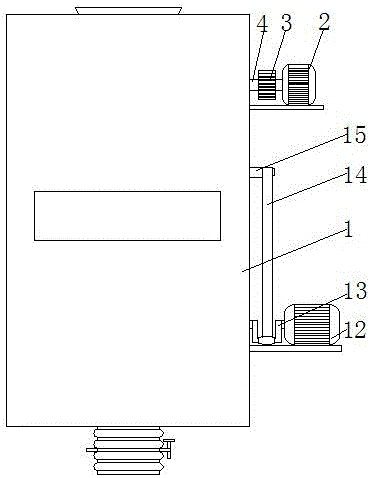

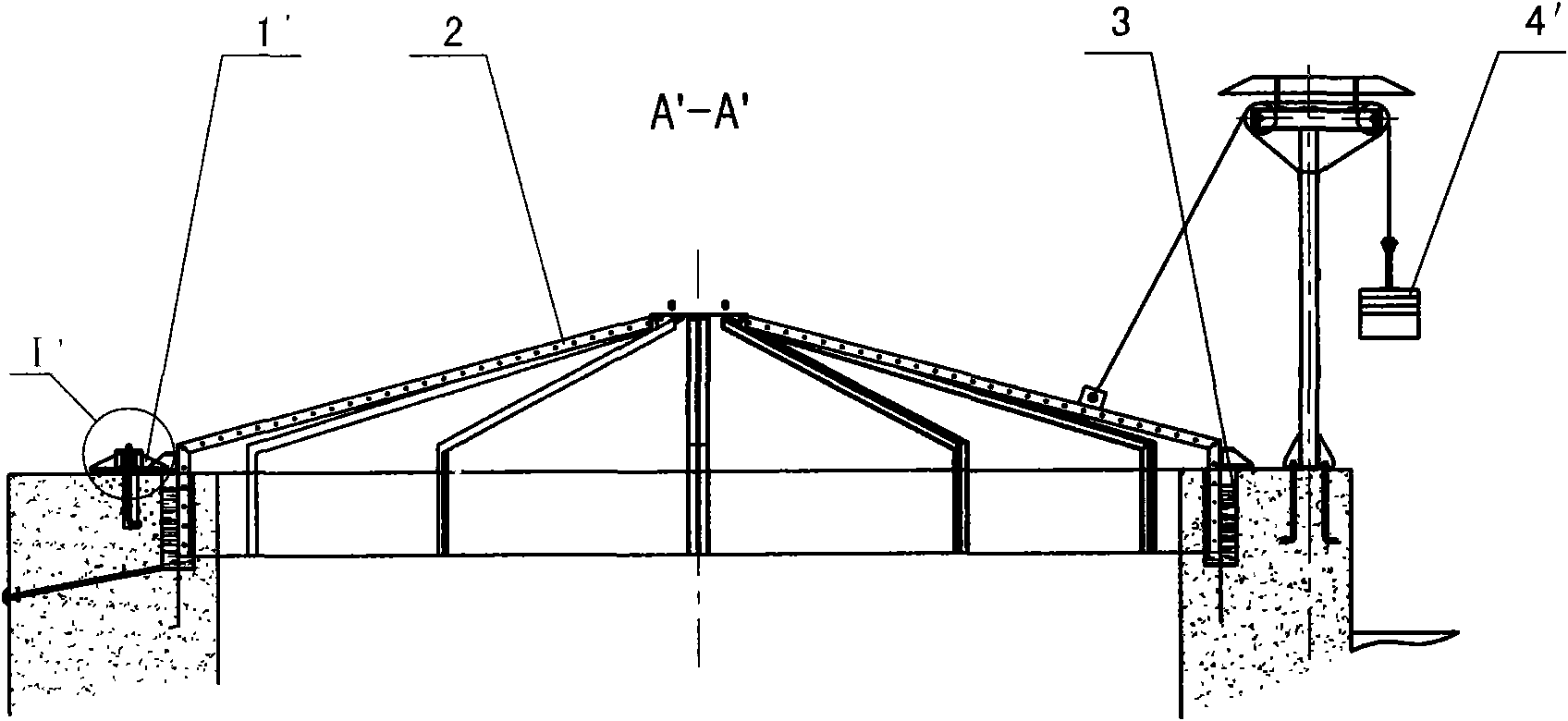

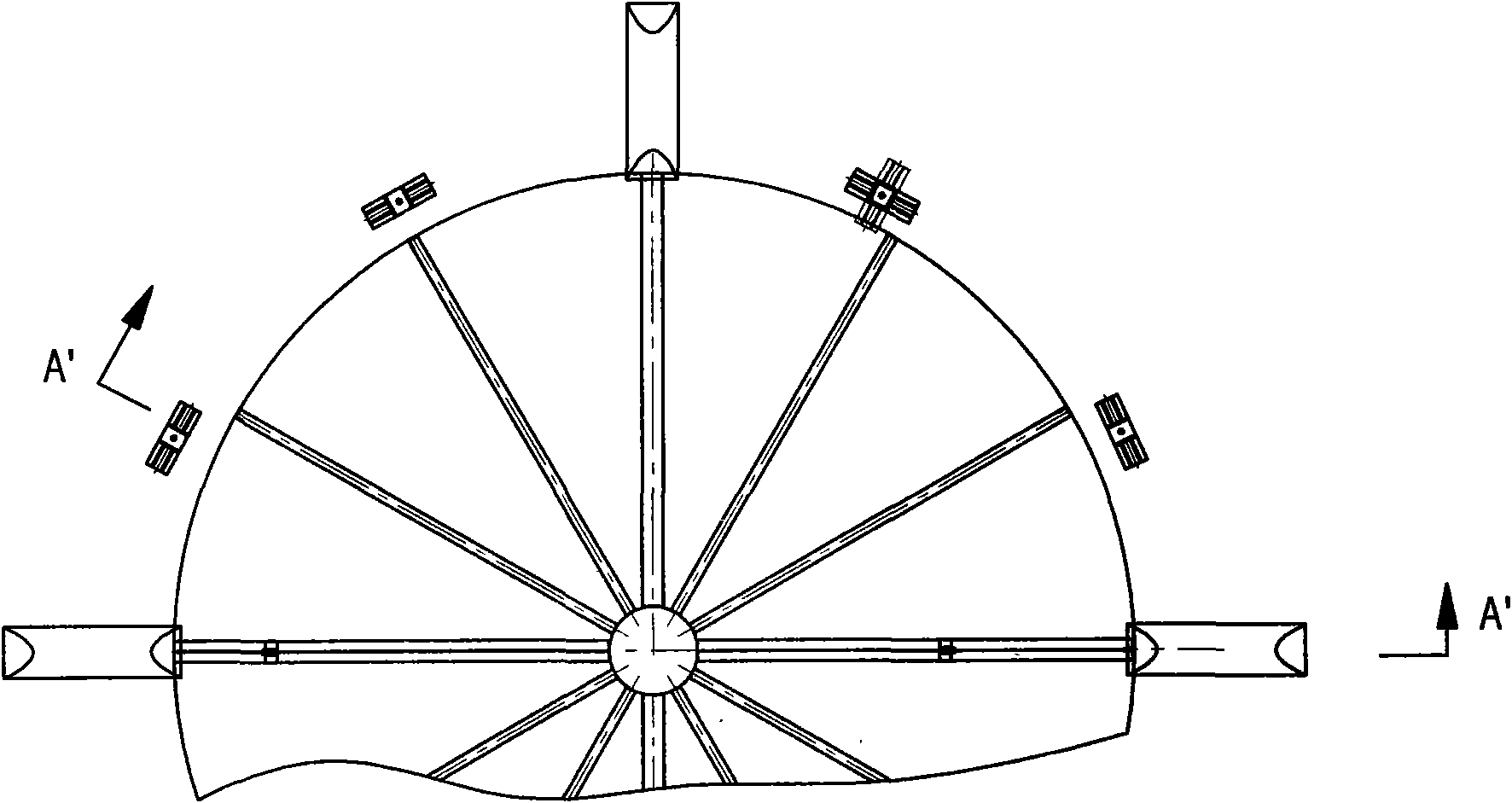

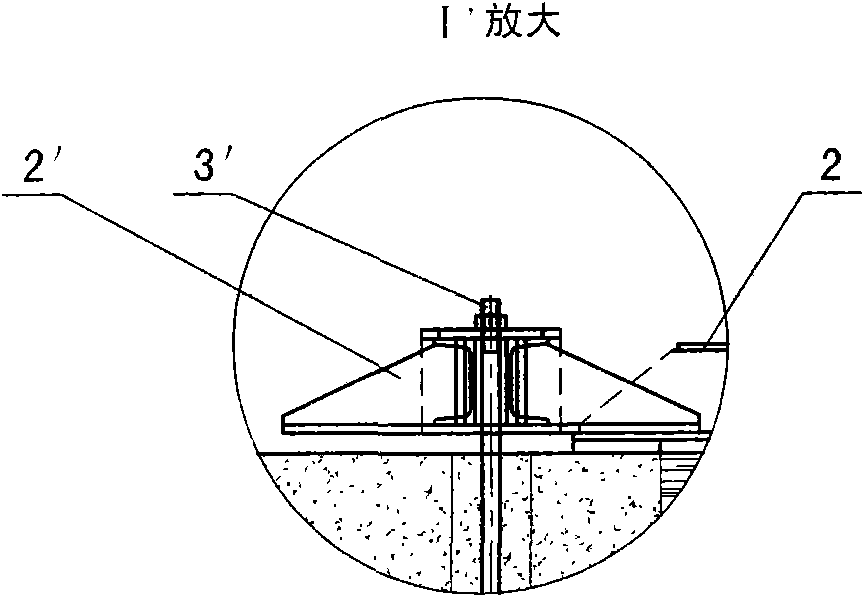

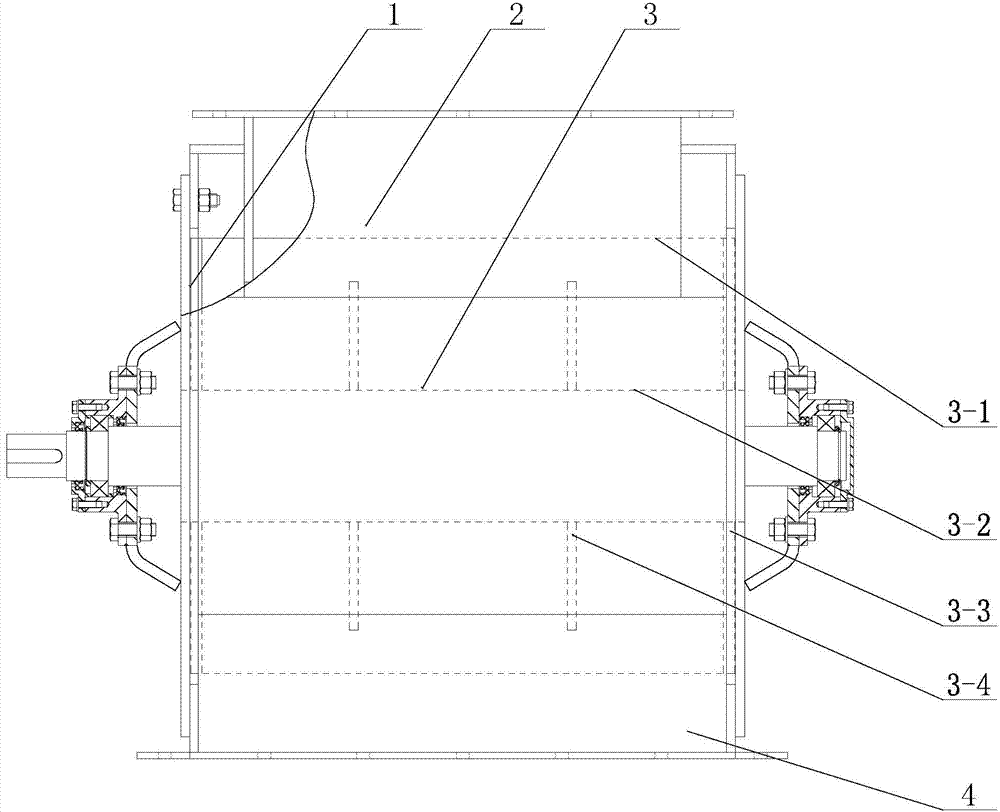

Vertical air shaft explosion protection door capable of quickly resetting

InactiveCN101943025AReduce labor intensityEliminate potential safety hazardsMining devicesTunnel/mines ventillationArray data structureExplosion protection

The invention discloses a vertical air shaft explosion protection door / cover capable of quickly resetting, belonging to a coal mine ventilation safety facility. The vertical air shaft explosion protection door is mainly composed of a door body 2, a heavy punch part, an inverted ventilation lock catch device and an oiling small shaft, wherein multiple groups of heavy punch assemblies of the heavy punch part are variable quality tank heavy punch assemblies 4 or variable quality tanks 19, and the variable quality tank heavy punch assemblies 4 or the variable quality tanks 19 are connected with the explosion protection door body 2 by a steel wire rope 7 and a pulley block 8; the variable quality tanks 19 are liquid storage tanks and are connected with a water supply by a water inlet and outlet pipe 13; and water reserve in the variable quality tanks is increased or reduced to replace the action of increasing or reducing the number of the weight, thus controlling the weight of the heavy punch assembly. The explosion protection door is also provided with the quick inverted ventilation lock catch device 1 and a stable synchronous elevator mechanism. The explosion protection door adopts mechanical operation to realize remote monitoring of the latch and the reset of the explosion protection door, changes outdoor operation into indoor operation, has the advantages of high resetting and latching speed, time and labour saving and safe operation, lightens physical work and improves the coal mine ventilation safety.

Owner:兖矿能源集团股份有限公司

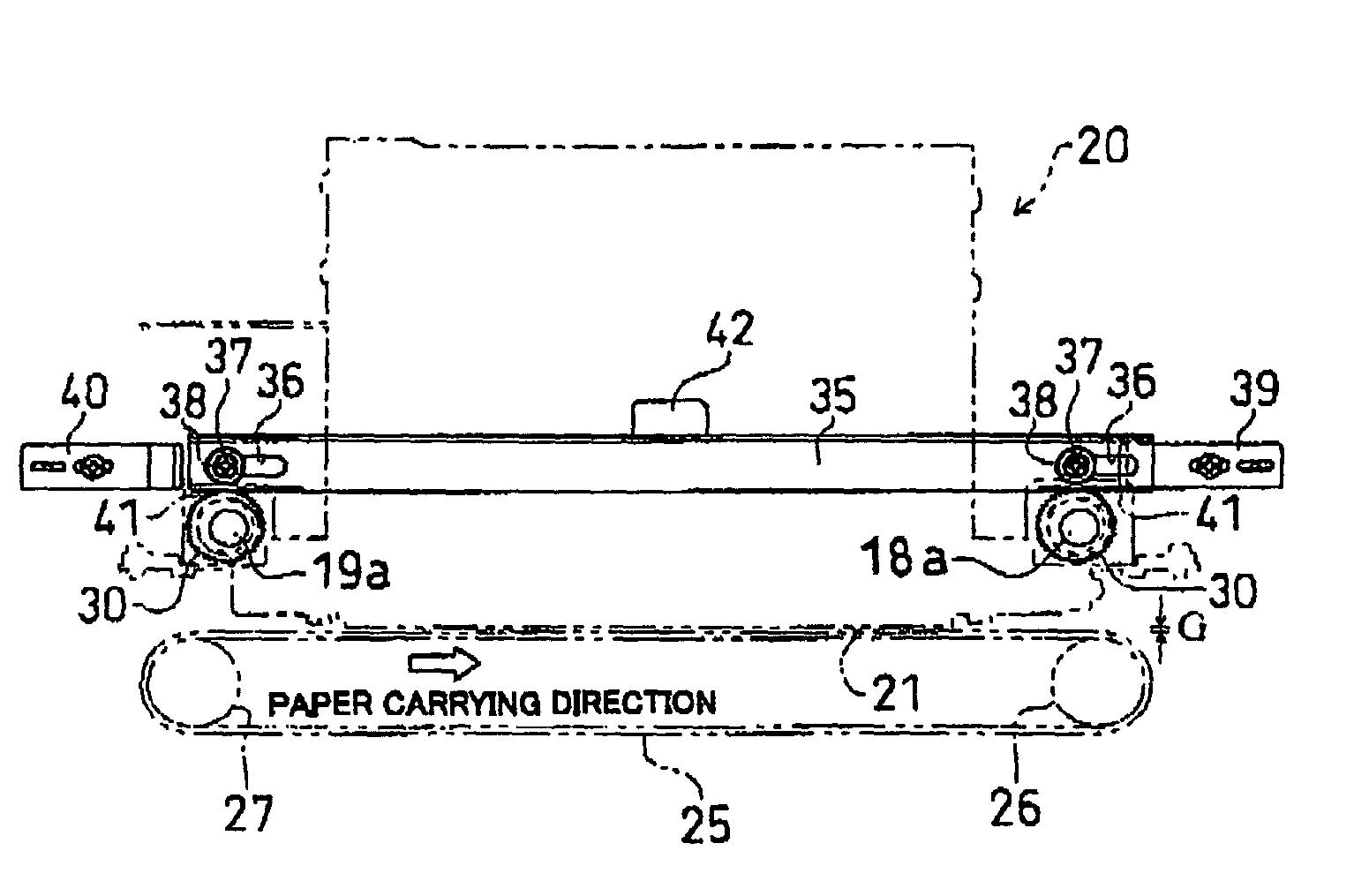

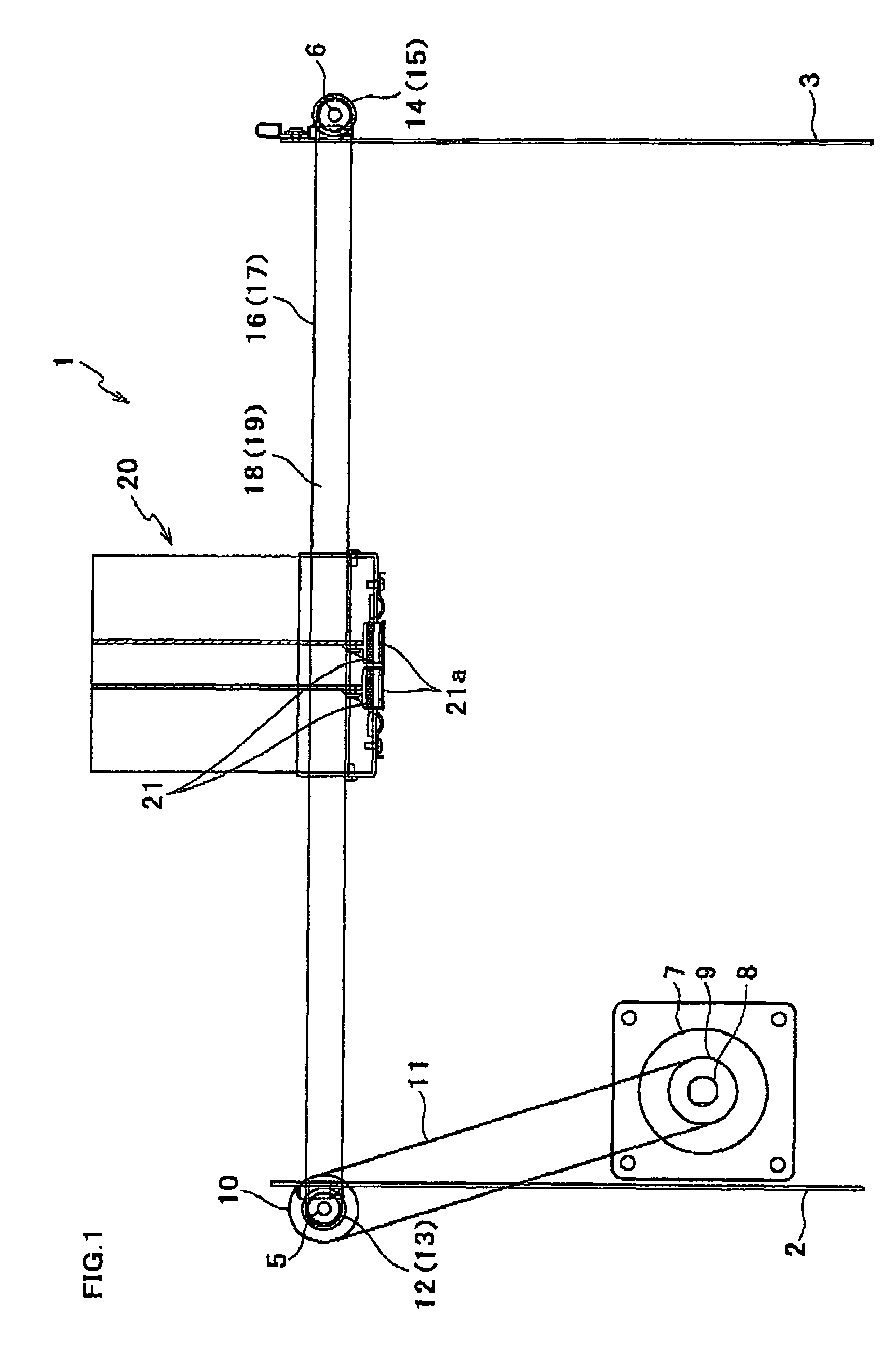

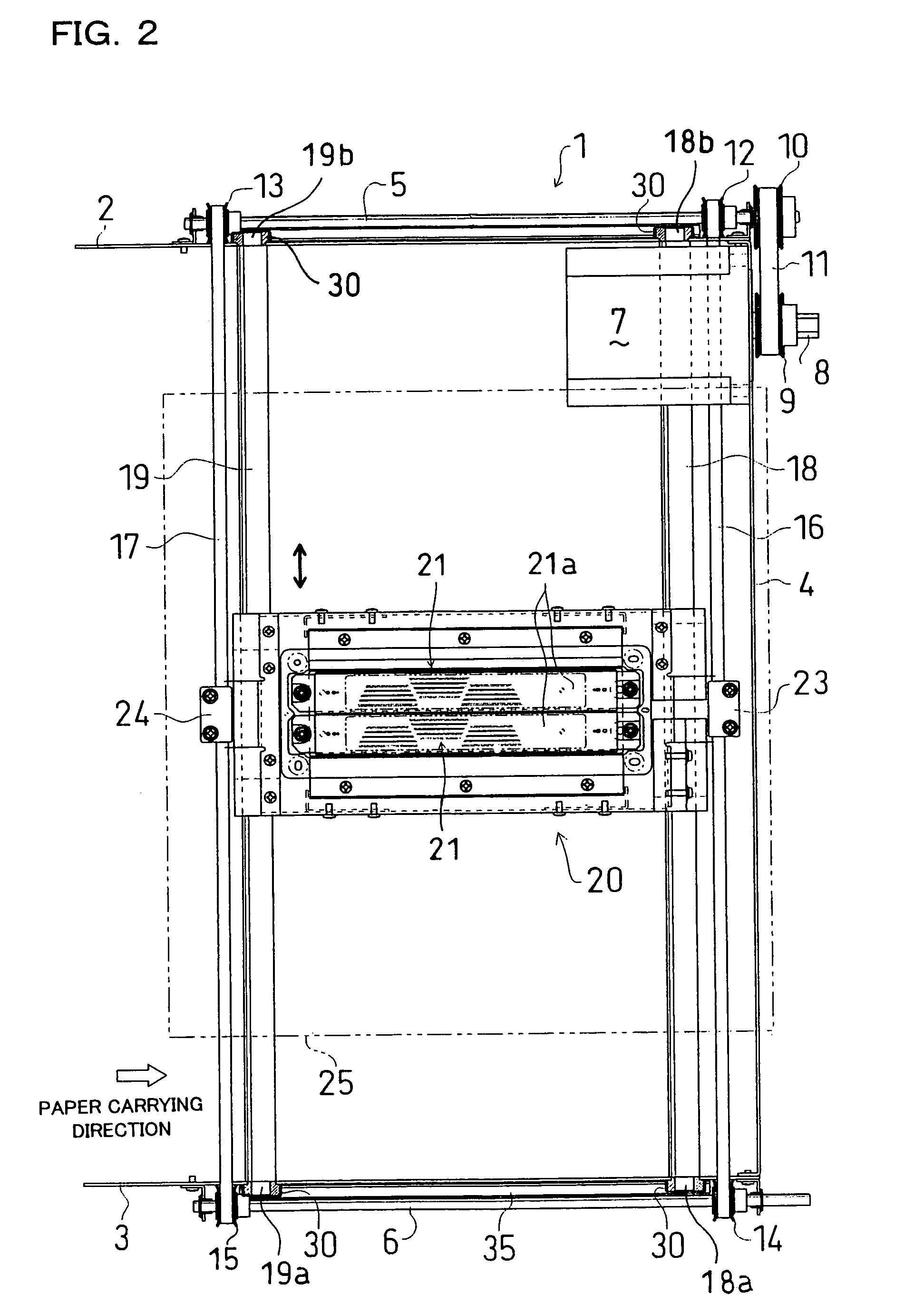

Ink-jet recording apparatus

ActiveUS6964476B2High qualityQuality improvementPower drive mechanismsOther printing apparatusEngineeringReciprocating motion

An ink-jet recording apparatus comprises an ink-jet head having an ink ejection surface on which a plurality of nozzles are arrayed; a medium carrier forming a carrying surface on which a record medium is carried; a carriage mounted with the ink-jet head such that the ink ejection surface confronts the carrying surface; a carriage drive mechanism including a plurality of parallel guide rods supporting the carriage and extending across the direction where the record medium is carried by the medium carrier, the carriage drive mechanism reciprocating the carriage along the guide rods; and a guide shift mechanism for shifting the plurality of guide rods in a direction where the gap between the ink ejection surface and the carrying surface varies.

Owner:BROTHER KOGYO KK

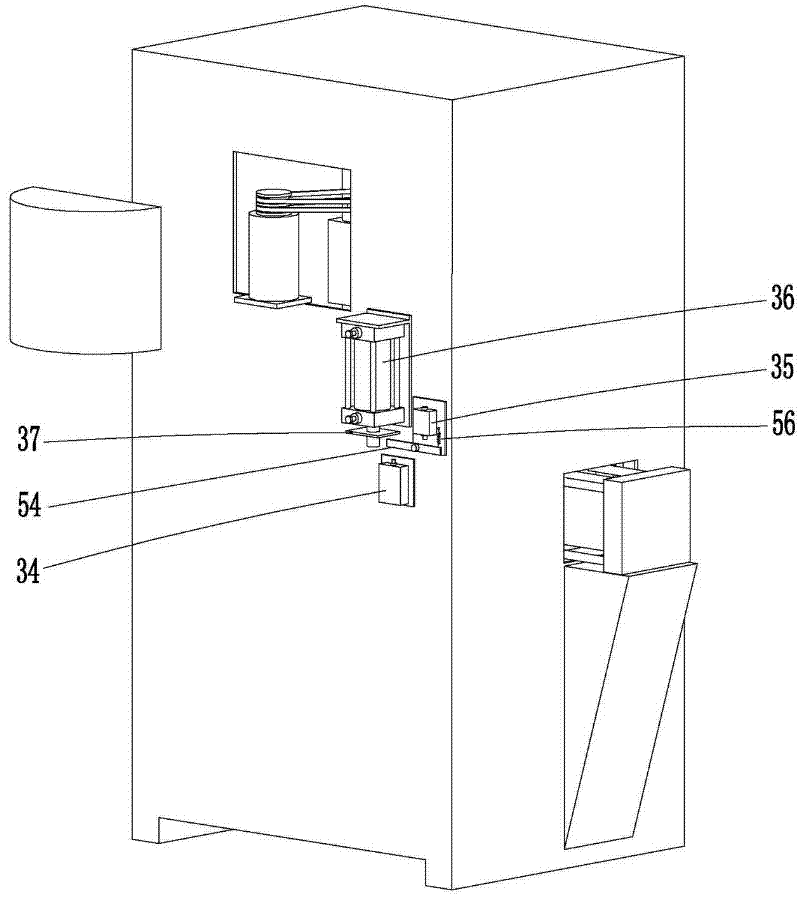

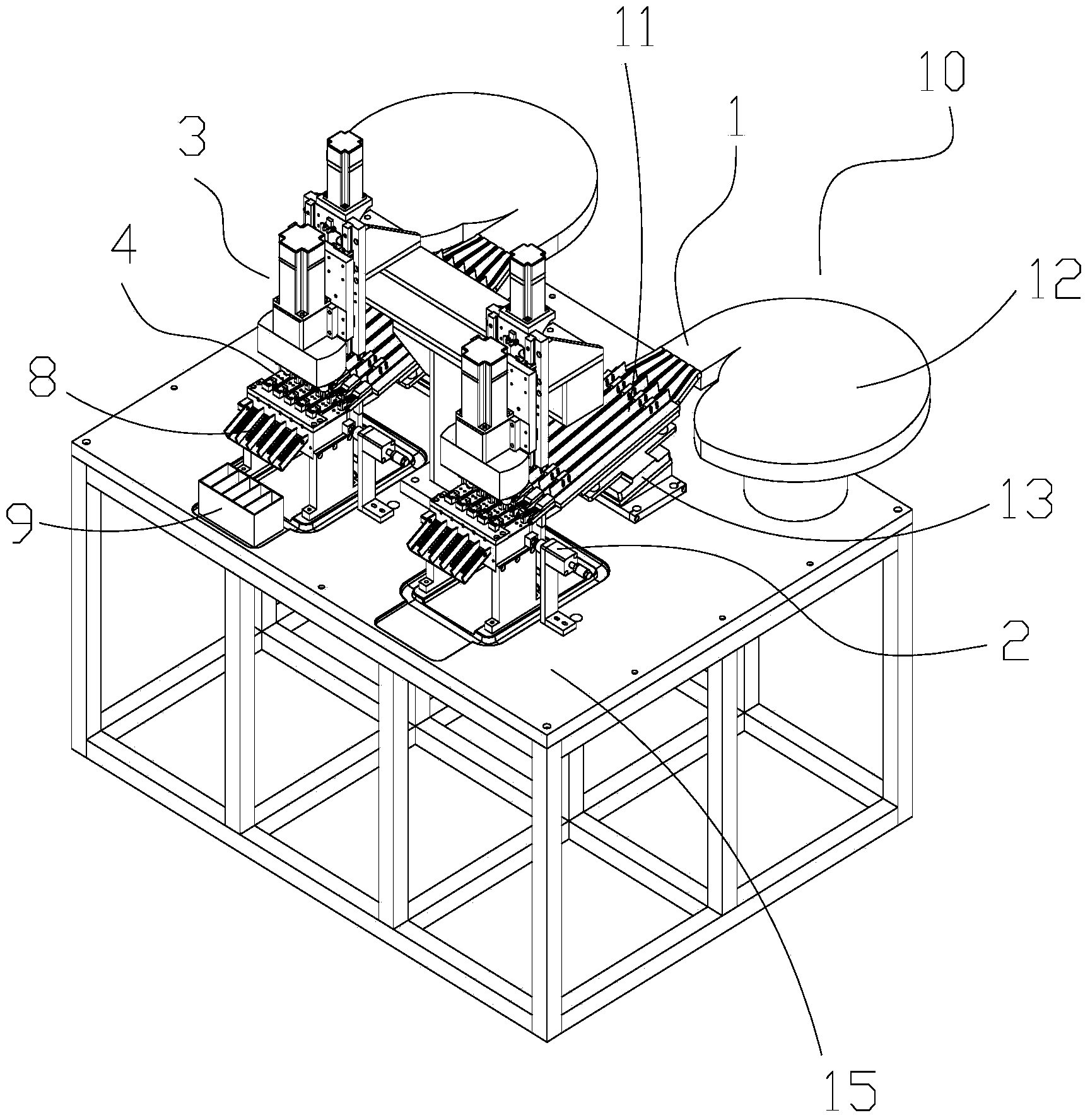

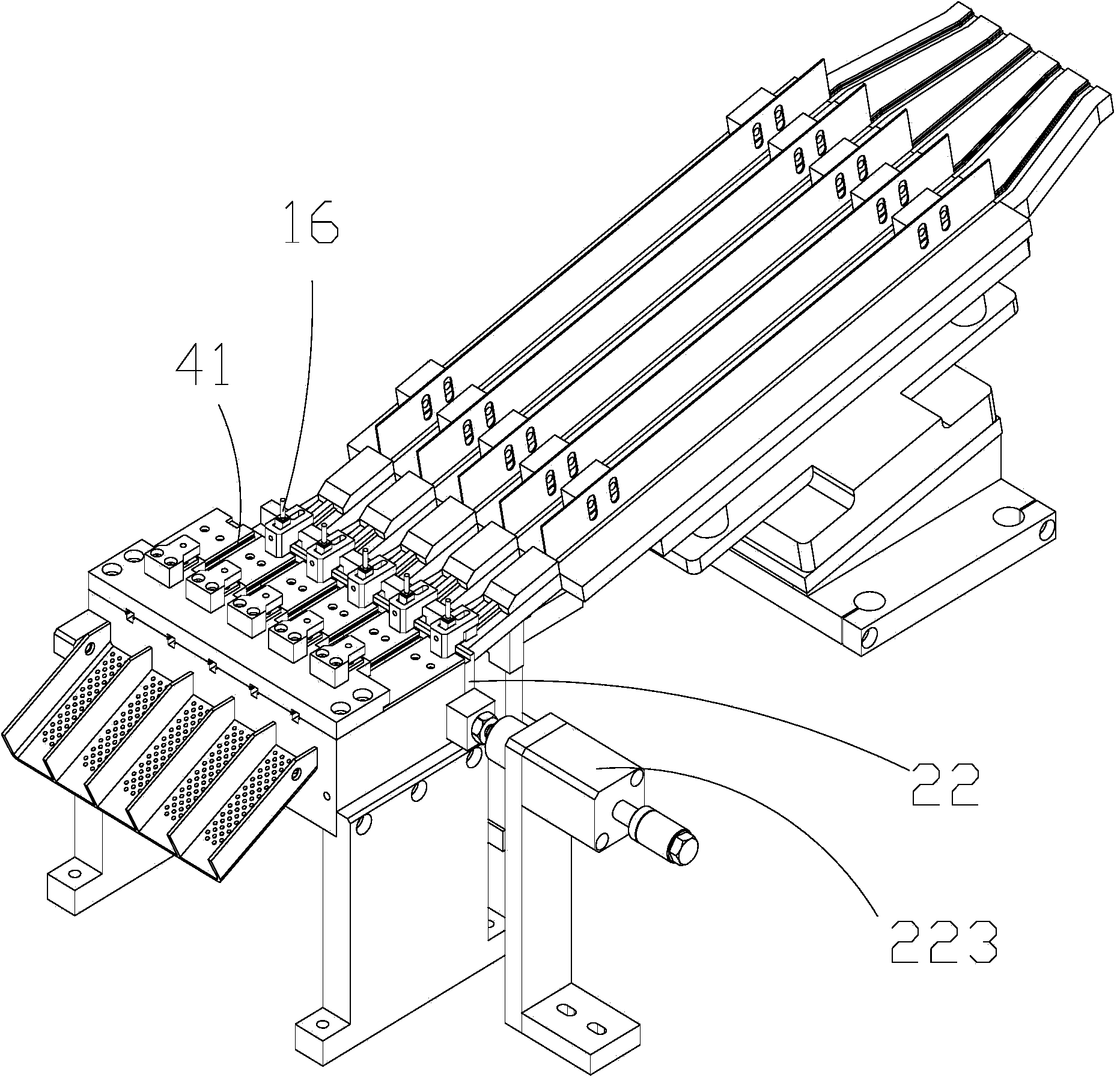

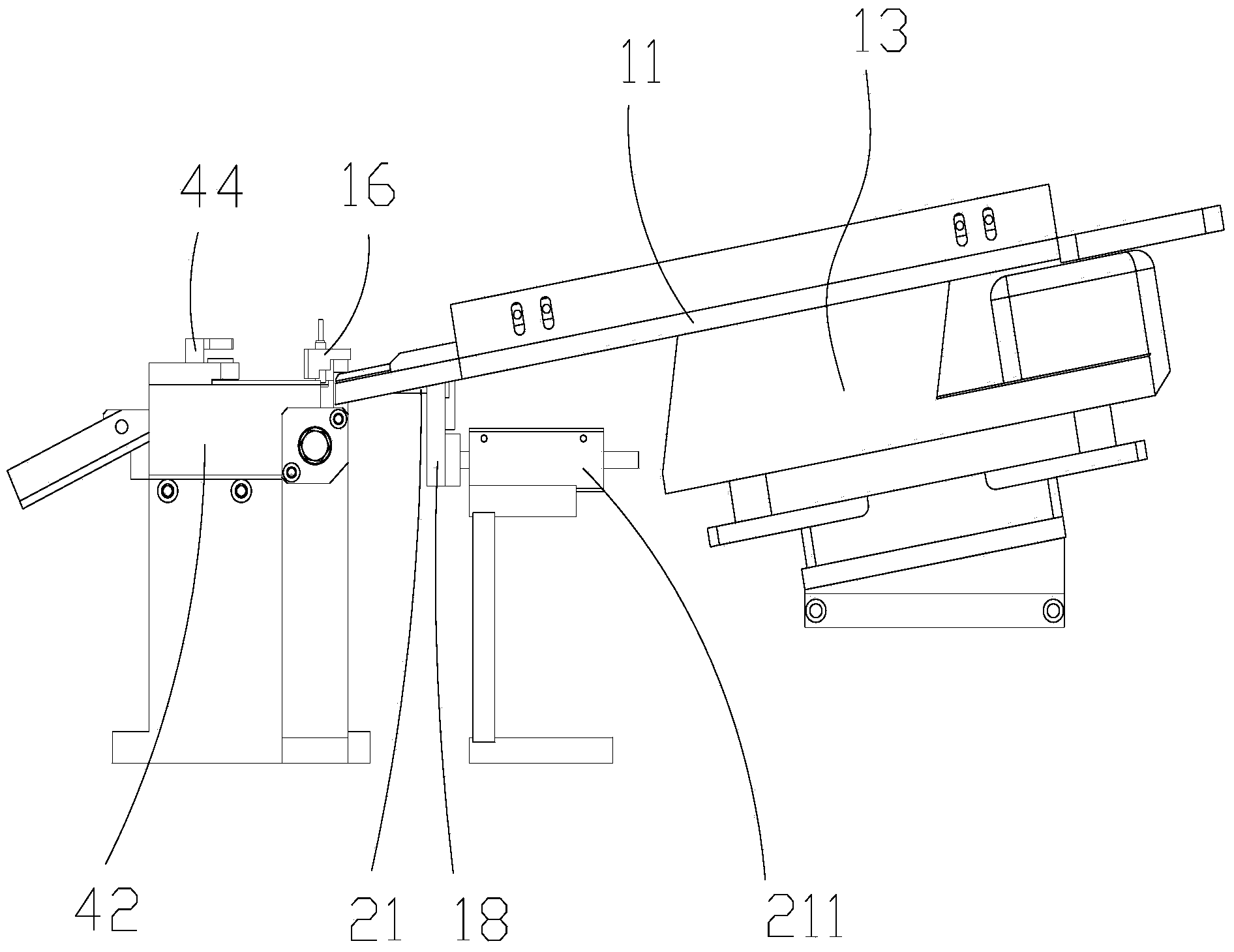

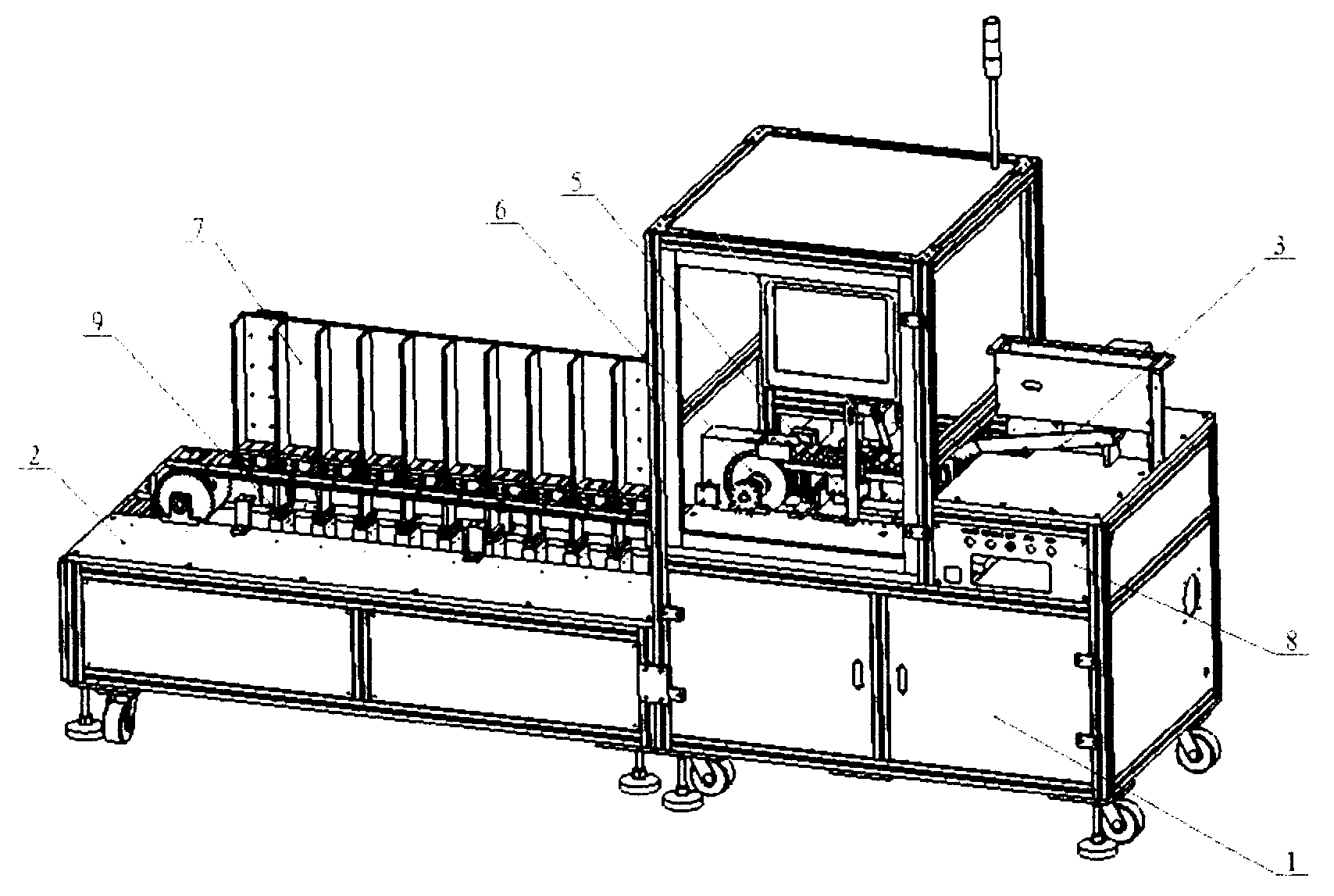

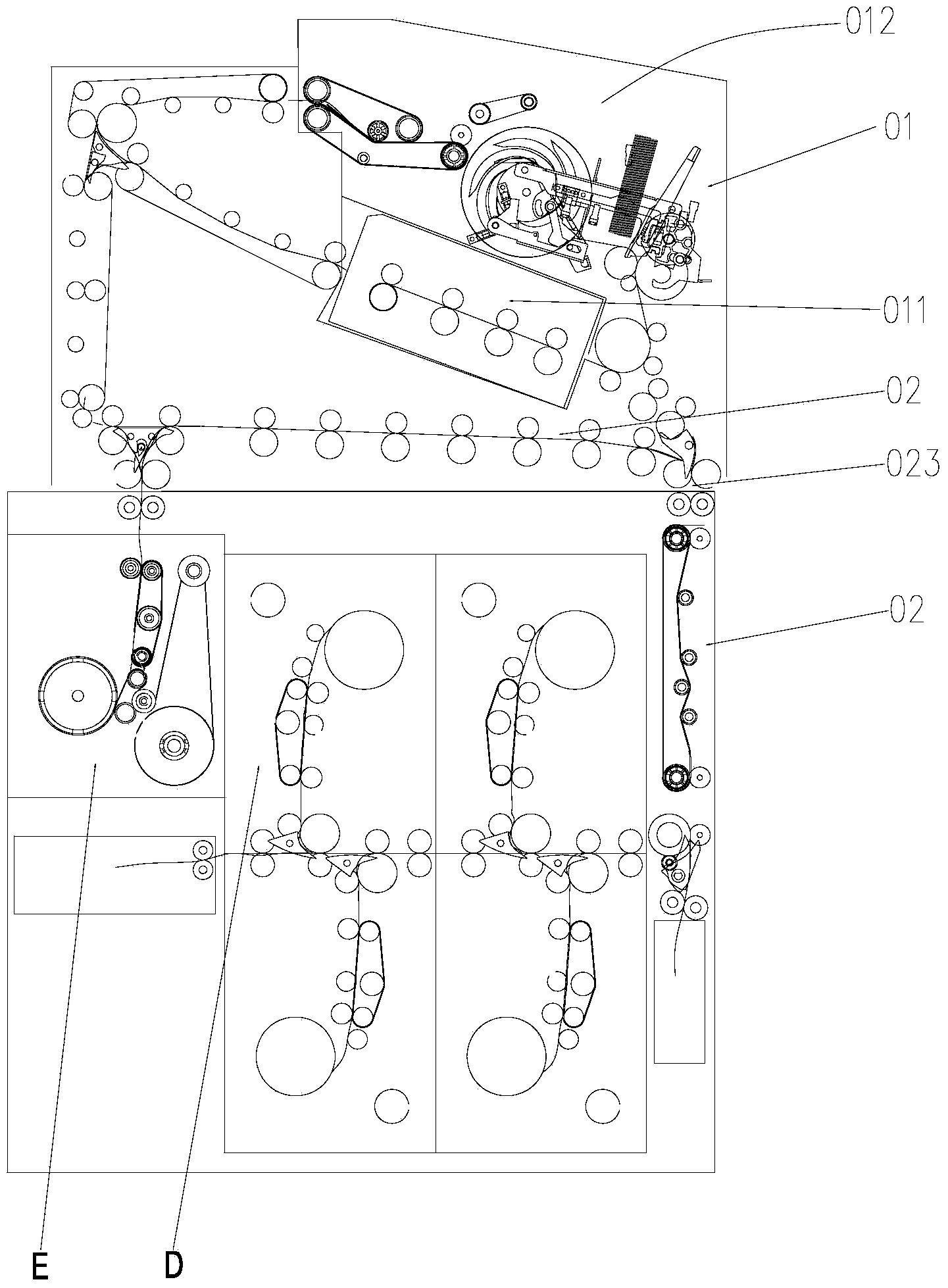

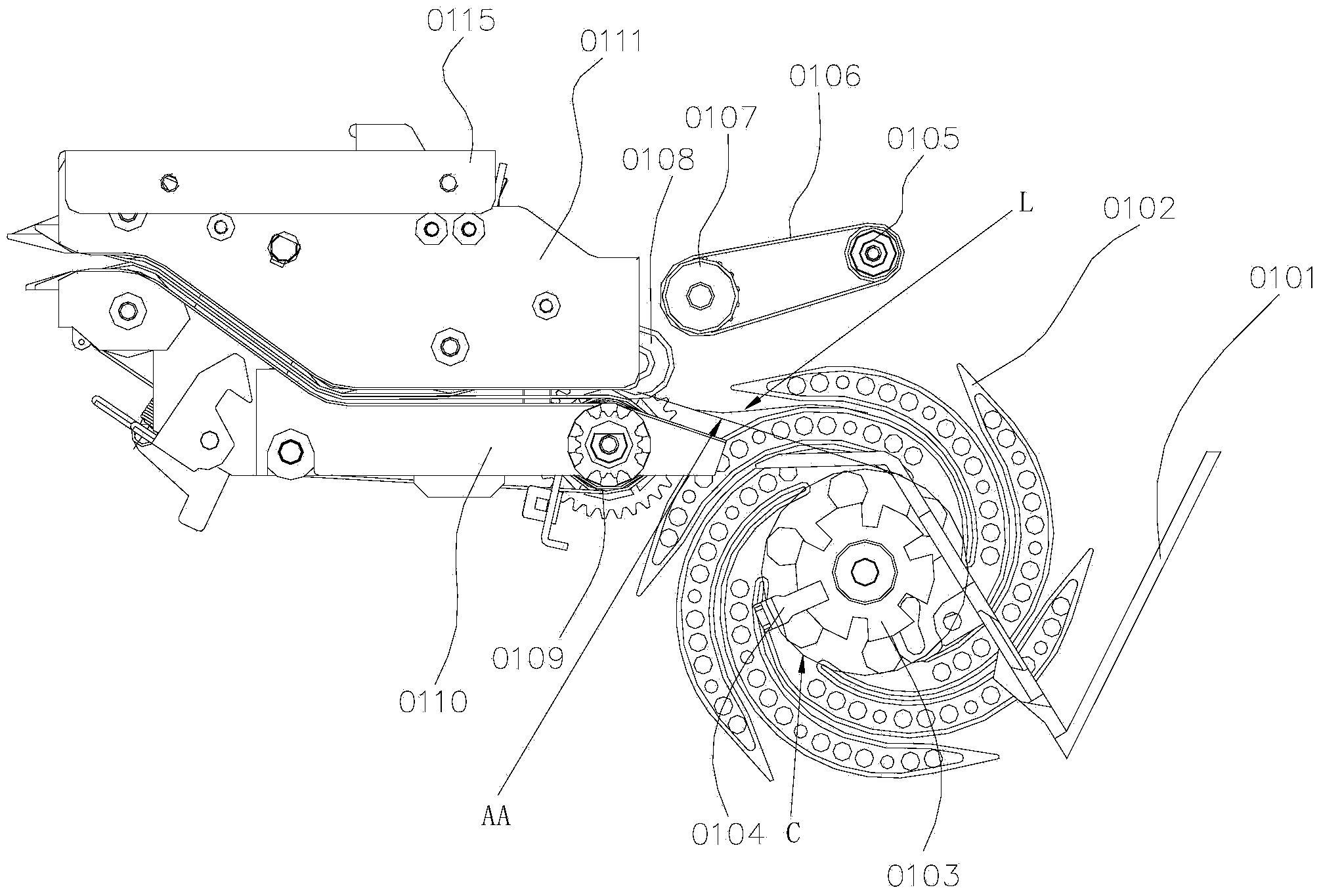

Automatic nut tapping machine

ActiveCN103406606AQuality assuranceAchieve positioningThread cutting feeding devicesThread cutting machinesProduction rateEngineering

The invention discloses an automatic nut tapping machine which comprises a conveying device (1), a feeding device (2), a head tapping assembly (3) and a nut positioning device (4). The nut positioning device (4) is provided with a tapping channel (41), the conveying device (1) is provided with a conveying rail (11), the feeding device (2) comprises a feeding push rod (21), a cutting push rod (22) and a sensor, the cutting push rod is provided with a nut storage space (221) and can reciprocate, so that the nut storage space (221) can be aligned with the conveying rail (11) or the feeding push rod (21) and the tapping channel (41), a single nut to be tapped is consistently pushed to the lower side of a screw tap for tapping by the feeding push rod, materials cannot be frequently plugged in the feeding link and are more orderly and stably fed, and productivity is improved.

Owner:申乐股份有限公司

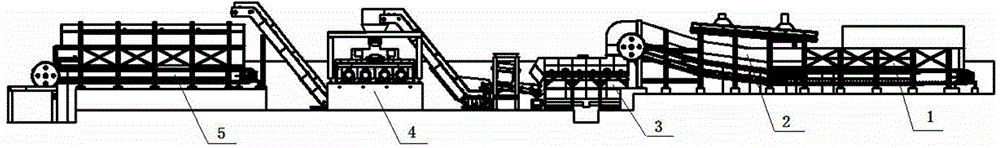

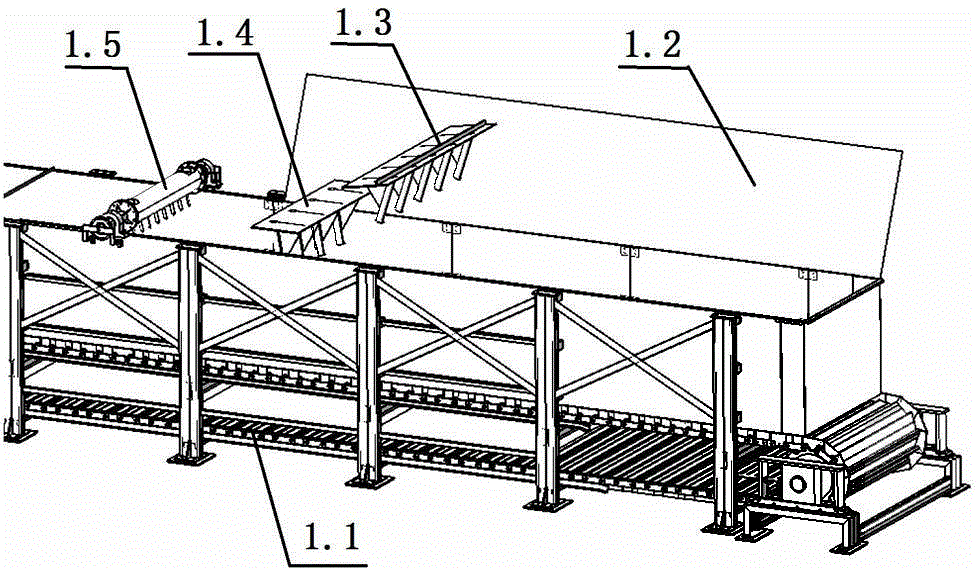

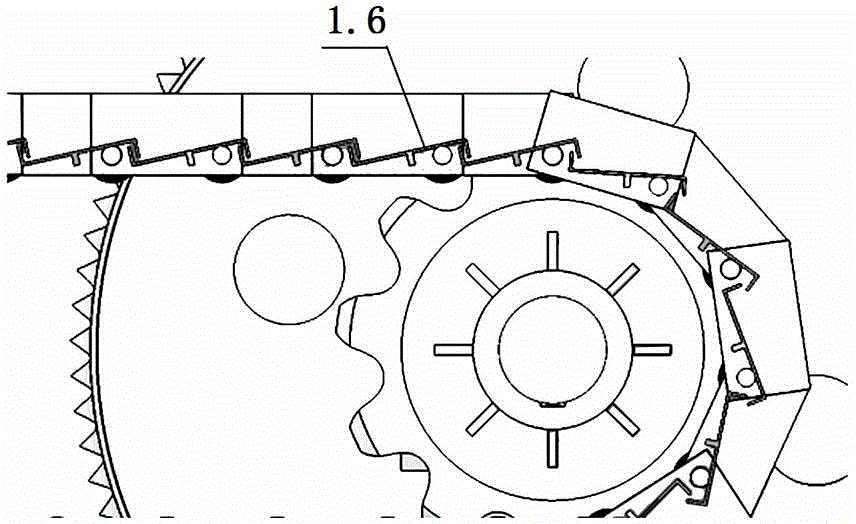

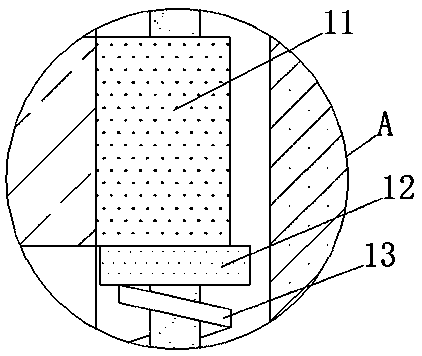

Continuous straw crushing system

The present invention discloses a continuous straw crushing system, which sequentially comprises a material feeding system, a pre-powder system, an impurity removing system, a fine powder system, and a material storage system along a material operation direction, wherein the impurity removing system is connected with the pre-powder system and the fine powder system, the material feeding system comprises a chain plate conveyor, a first-stage leveling grille, a second-stage leveling grille and a material turning roller, the pre-powder system is provided with a leveling device arranged at the foremost end, a first-stage coarse powder device and a second-stage coarse powder device, the cutter shaft of the leveling device is provided with a vibration detector, an impurity removing grille is arranged above the rear of the leveling device, the impurity removing system comprises a crushed stone removing device and an iron remover positioned on the rear portion, the fine power system is provided with two crushing bins, the material inlet position is provided with a quantification roller, and a row of material separation rollers are arranged on the lower portion of the quantification roller. With the continuous straw crushing system of the present invention, the continuous and efficient crushing operation can be performed on straws, the problems of high impurity content in straws and large material feeding operation strength are solved, the crushing efficiency is high, the operation is safe and stable, and the large-batch and continuous production requirement can be met.

Owner:河南上源精工机械有限公司

Electronic product placing frame with damping effect

InactiveCN108458043APrevent accidental slippingReduce shockMachine framesNon-rotating vibration suppressionEngineering

The invention discloses an electronic product placing frame with a damping effect. The electronic product placing frame comprises a fixing base, a first groove is formed in the upper surface of the fixing base, two symmetric second grooves are formed in the inner side wall of the first groove, a sliding rod is fixedly connected inside each second groove, and a sliding ring matched with the corresponding sliding rod sleeves the outer surface of each sliding rod. According to the electronic product placing frame with the damping effect, sliding grooves are formed and sliding blocks are used cooperatively so that the two ends of an elastic plate can be effectively moved, and impact force borne by the elastic plate is buffered; a third spring is arranged so that stretching of the elastic platecan be effectively limited, and then the effect of relieving the impact is achieved; the elastic plate is arranged and a first spring and a second spring are cooperatively arranged, so that the buffering force of a first fixing plate is greatly reduced, the stability of a second fixing plate is improved, and the problem that an existing electronic product placing frame is poor in damping effect is solved.

Owner:佘峰

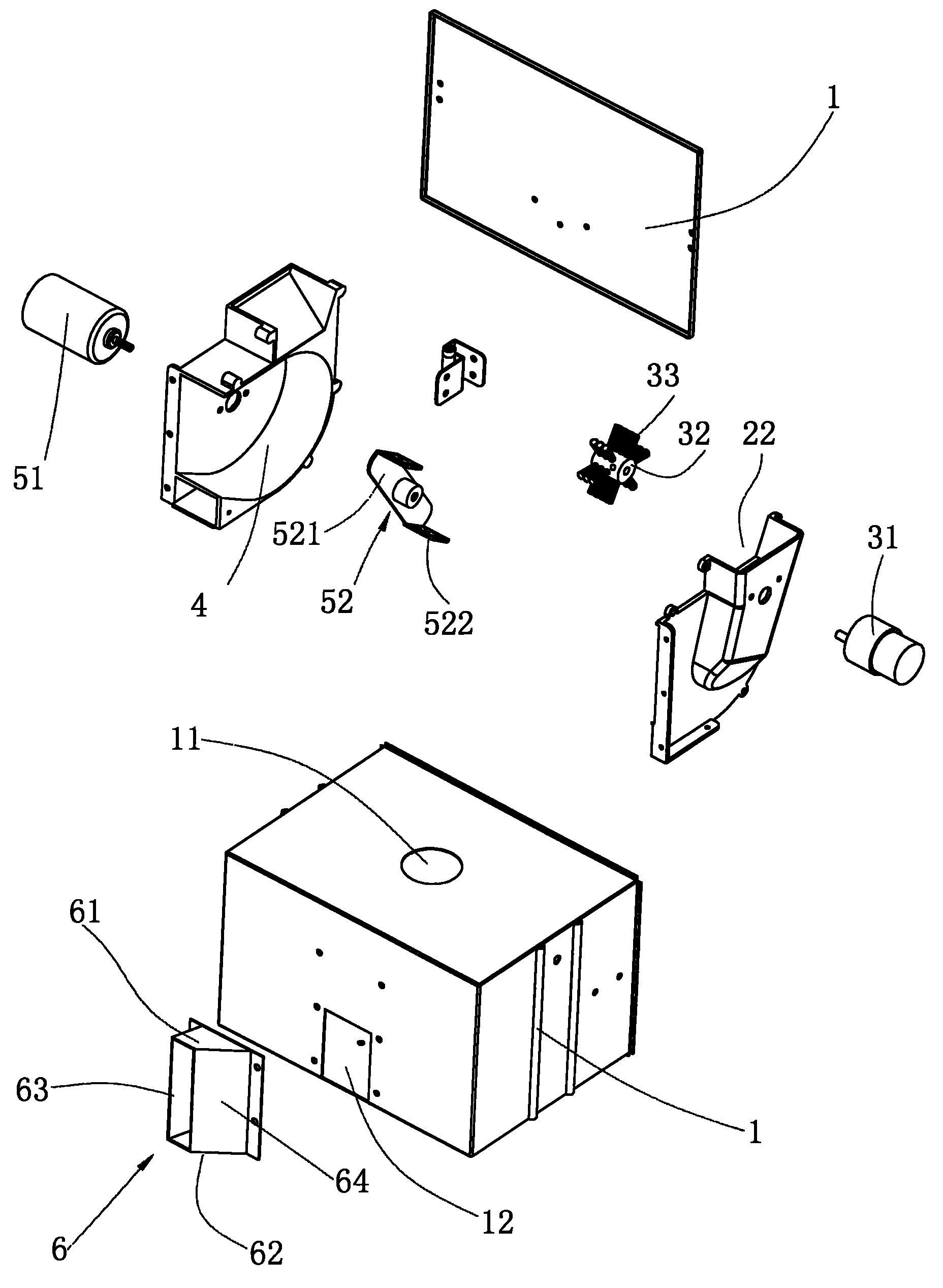

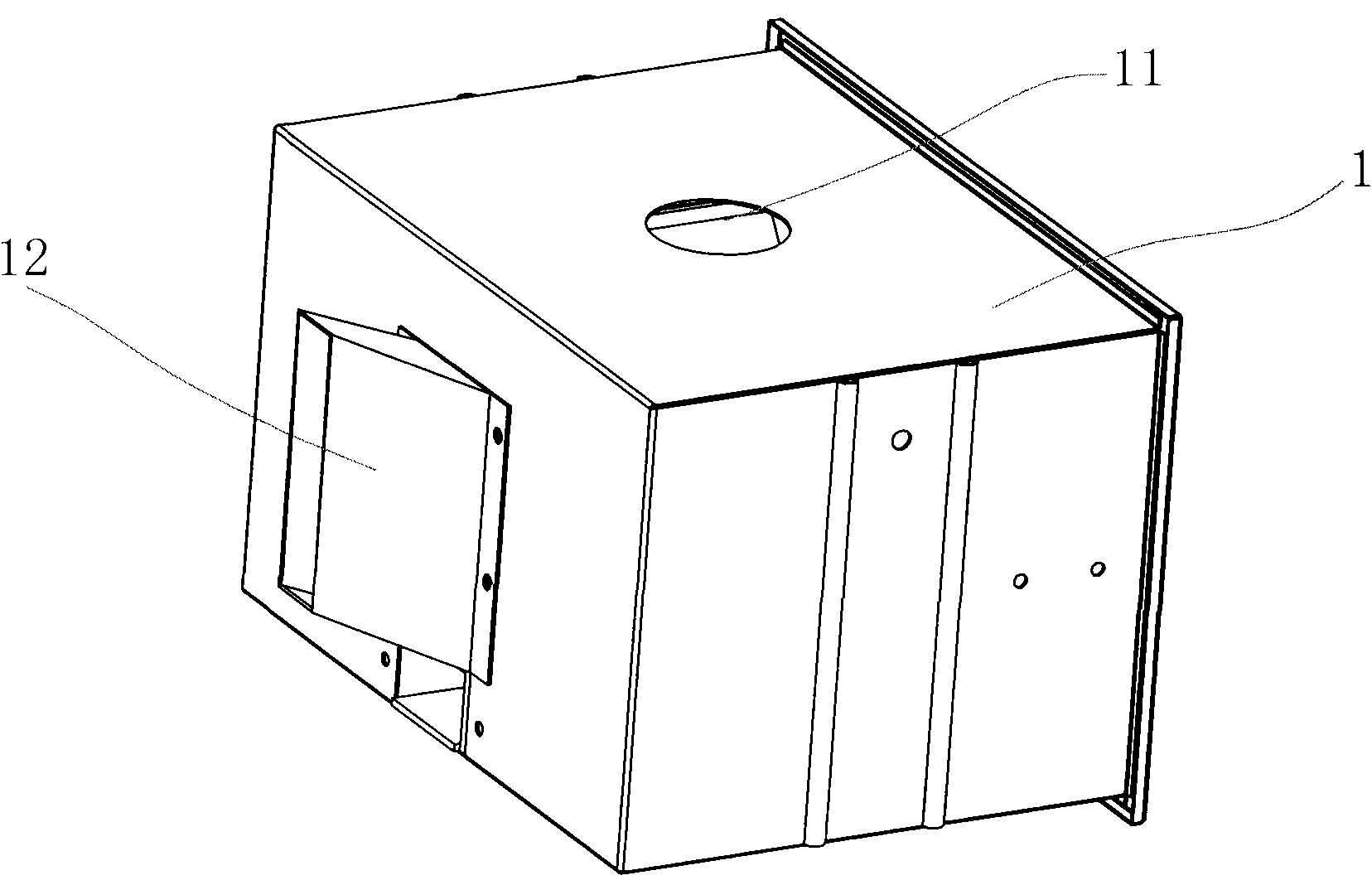

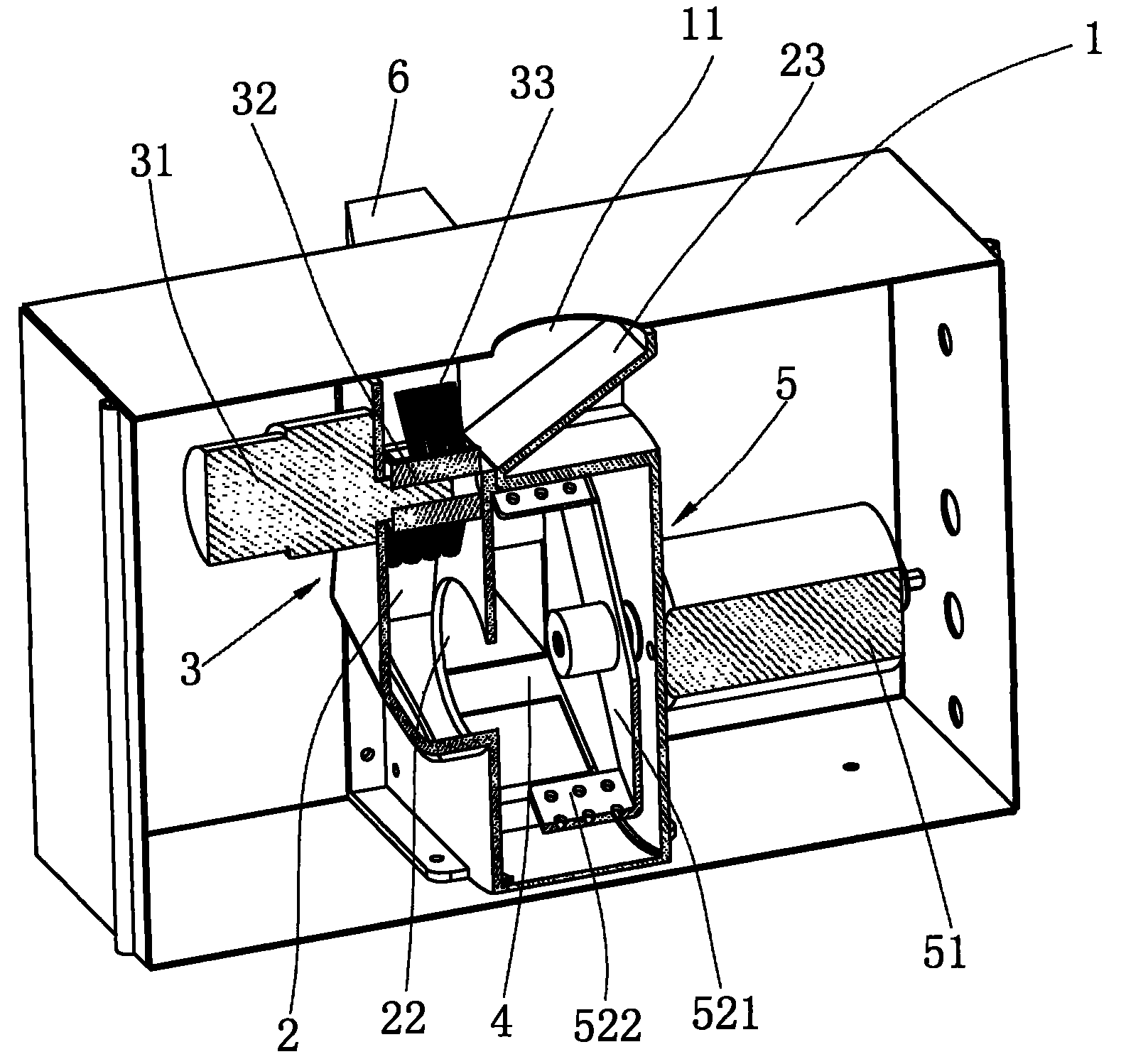

Novel mailbox device

InactiveCN106974537AEasy to fall intoAvoid jammingKitchen equipmentDomestic articlesSlide plateEngineering

A novel mailbox device comprises a mailbox, the right end face of the mailbox is provided with a drop opening, a rainproof plate is arranged on the right end face of the mailbox above the drop opening, a chamber with an upward opening and a push channel with a rightward opening that is positioned below the chamber are arranged in the mailbox, a communicating port is arranged between the chamber and the push channel, a pusher is mounted slidably on in the push channel, the pusher is provided with a pick channel having an upward opening, a bearing plate extended to the right is arranged at the right end of the bottom wall of the push channel, a slide channel having an upward opening is arranged in the bottom wall of the push channel and in the bearing plate, a first slider is mounted slidably in the first slide channel, a screw is fitly mounted in the first slider, the right end of the screw is mounted in the right end wall of the first slide channel in steerable manner, the left end of the screw is connected to the motor in the left end wall of the first slide channel, slide guide channels extended to left and right are arranged in the front and rear end walls of the communicating port, and a slide plate extended to front and rear is mounted slidably in each slide guide channel.

Owner:浙江特意电气有限公司

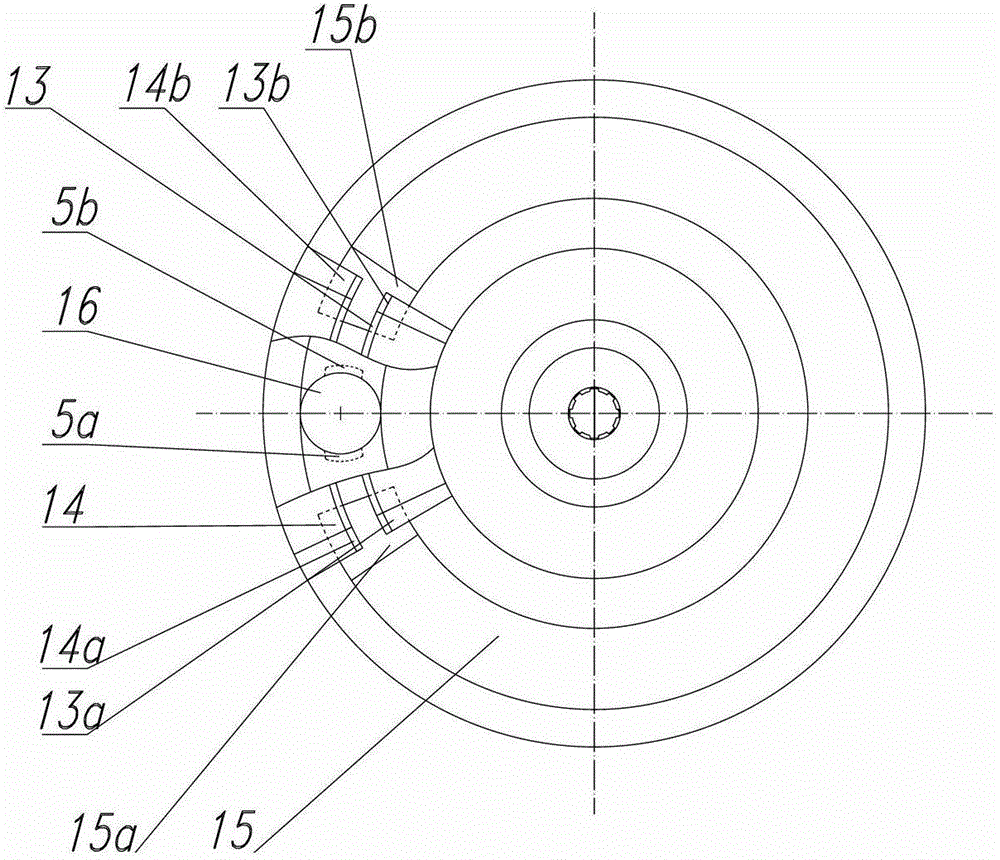

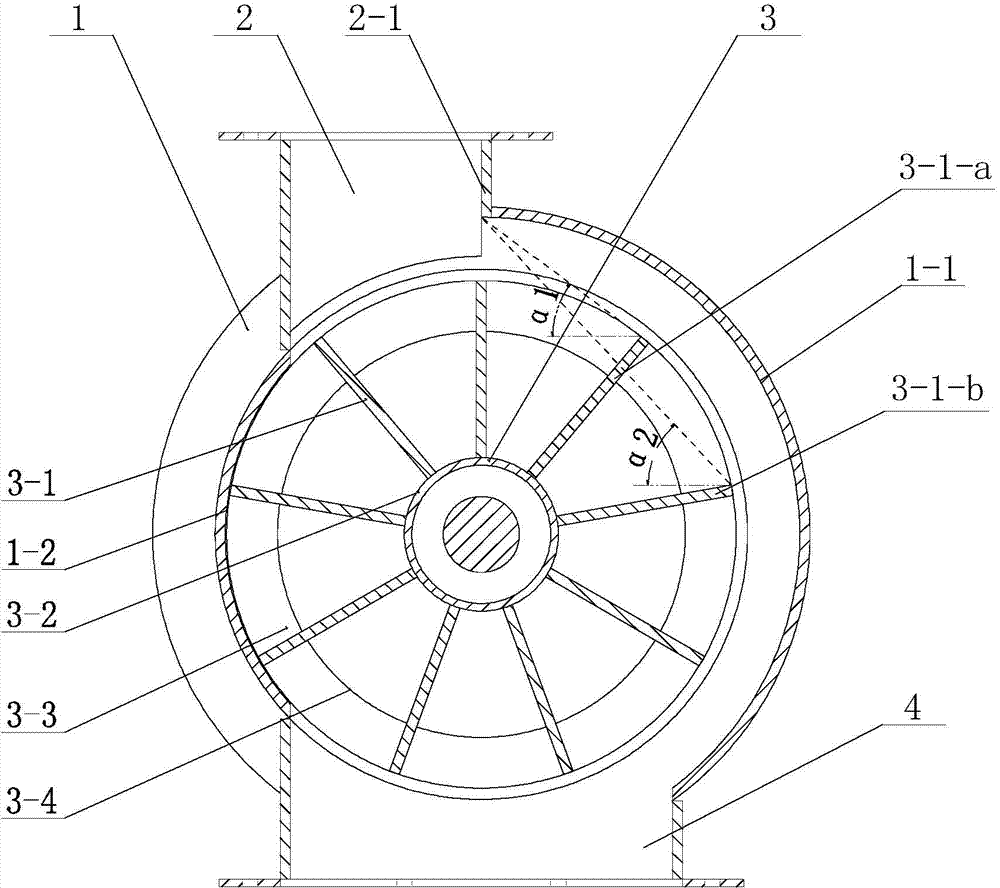

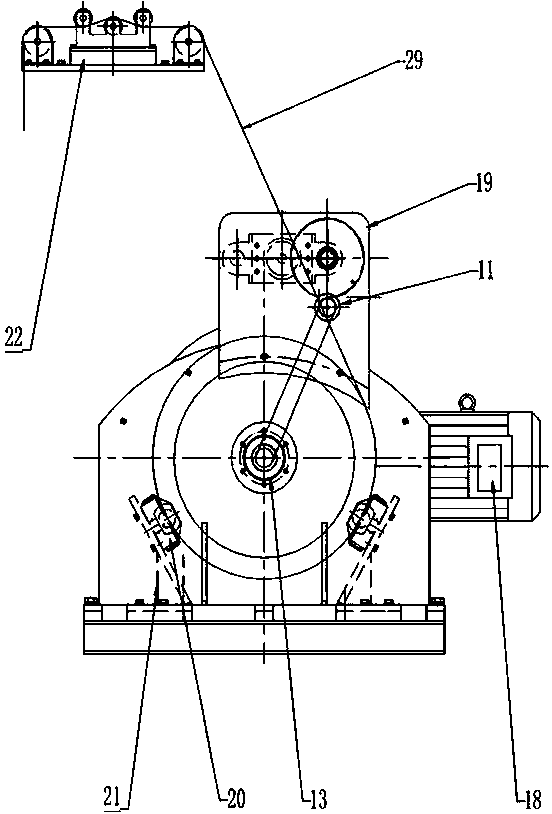

Novel impeller feeder

InactiveCN103896027APrecise control of dischargeEasy to controlRotary conveyorsImpellerMaximum diameter

The invention discloses a novel impeller feeder. The novel impeller feeder comprises a case. A feeding port and a discharge port are formed in the upper portion of the case and the lower portion of the case respectively. An impeller is arranged in the case and comprises a wheel groove bottom with which a rotating shaft is sleeved. A plurality of blades are arranged on the periphery of the wheel groove bottom at intervals in the peripheral direction. N upwardly-inclined blades are arranged in the area, corresponding to the conveying-side inner wall of the case, of the impeller, wherein N is larger than or equal to 2, and the included angle formed between the horizontal plane and the connecting line of the radial edge of at least one of the N blades and the lower end of the conveying-side edge wall of the feeding port is smaller than the angle of repose of materials. The gap between the conveying-side inner wall of the case is 2.5 times larger than the maximum diameter of the materials. The novel impeller feeder is compact in structure, serious abrasion is avoided on the premise that the requirement for full-width feeding is met, blockage caused by the materials can be prevented, control precision can be improved, and the maintenance workload and power consumption of the novel impeller feeder are substantially reduced.

Owner:CHINA UNIV OF MINING & TECH

Directional bait feeder

InactiveCN101773092AImprove applicabilityLarge delivery torquePisciculture and aquariaCause blockageEngineering

The invention relates to a directional bait feeder which comprises a shell. A feeding hole for fodder to enter is arranged on the top surface of the shell. A discharging hole for flinging fodder out of the shell is arranged at one side of the shell which is internally provided with a conveying device and a flinging device, wherein the conveying device bears the fodder entering the shell and conveys the fodder to the next procedure, and the flinging device bears the fodder conveyed by the conveying device and flings the fodder to a set position out of the shell. The directional bait feeder is characterized in that the conveying device comprises a conveying motor with an adjustable speed and a rotating wheel driven by the conveying motor, and the prophetical wall of the rotating wheel is axially and alternately provided with at least two groups of mutually parallel brushes. The invention adopts the brushes to control feeding and can keep feeding evenness and avoid inclined-type discharging during startup to cause blockage. Meanwhile, the deformation amount of the brushes is great, and the sizes of fodder particles are not limited so that the rotating blockage problem can be avoided, and the feeding amount can be adjusted by adjusting the rotating speed of the conveying motor.

Owner:NINGBO UNIV

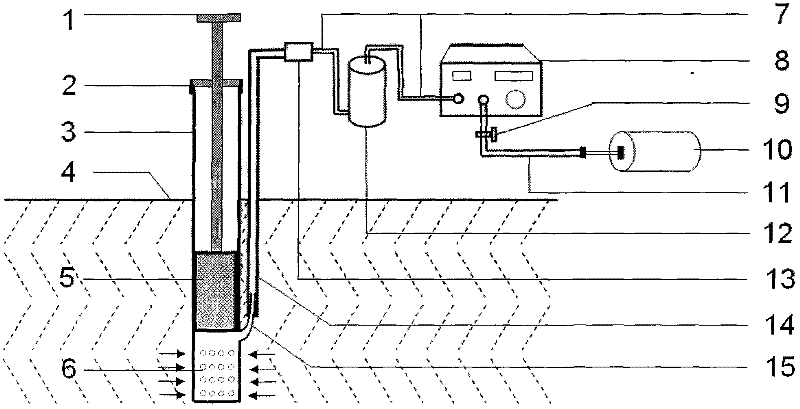

Air cylinder type soil profile gas collector

InactiveCN102680286AAvoid jammingAvoid cloggingWithdrawing sample devicesSuction equipmentMultiple point

The invention relates to an air cylinder type soil profile gas collector. The air cylinder type soil profile gas collector comprises a piston handle, a dust cap, a protective sleeve, a rubber piston, a suction pipe, a miniature vacuum pump, a gas collection bag, a gas outlet pipe with a needle, a replaceable type filter, a single-channel gas outlet valve and a gas collection pipe, wherein a certain range of gas inlet micro pores are uniformly distributed on the wall on the lower part of the protective sleeve, and the top of the gas collection pipe is connected with the single-channel gas outlet valve. According to the air cylinder type soil profile gas collector, blockage interference of soil particles, water and ice to the gas inlet micro pores can be avoided; soil greenhouse gas within a depth range can be collected, and meanwhile, outside atmosphere can be avoided entering the gas collection pipe; and mobile gas suction equipment consisting of the miniature vacuum pump and the like is utilized to suck gas to increase the quantity of collected gas, so that test errors can be further eliminated, and the test precision can be improved. The air cylinder type soil profile gas collectors can be distributed in soil of different depths to collect soil greenhouse gas of different depth ranges so as to regularly monitor greenhouse gas concentrations of soil profiles within various depth ranges. The air cylinder type soil profile gas collector has the advantages of simple structure and convenience in operation and is suitable for simultaneous observation of multiple points.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

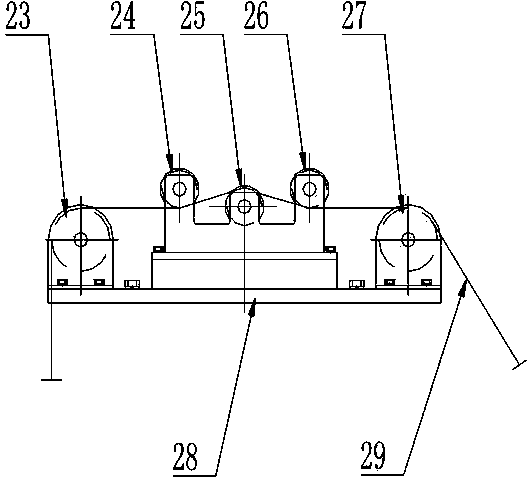

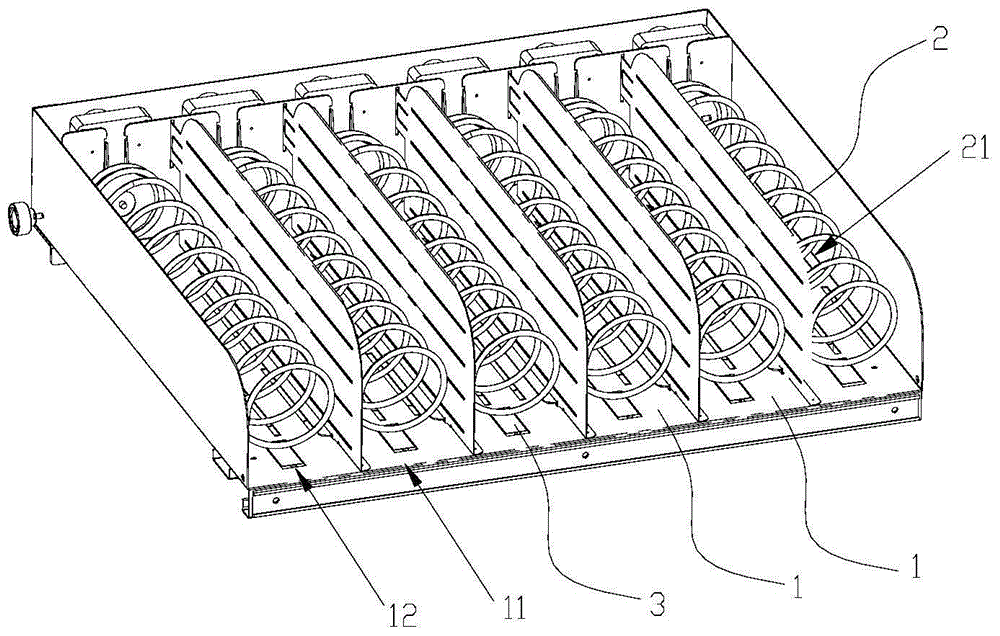

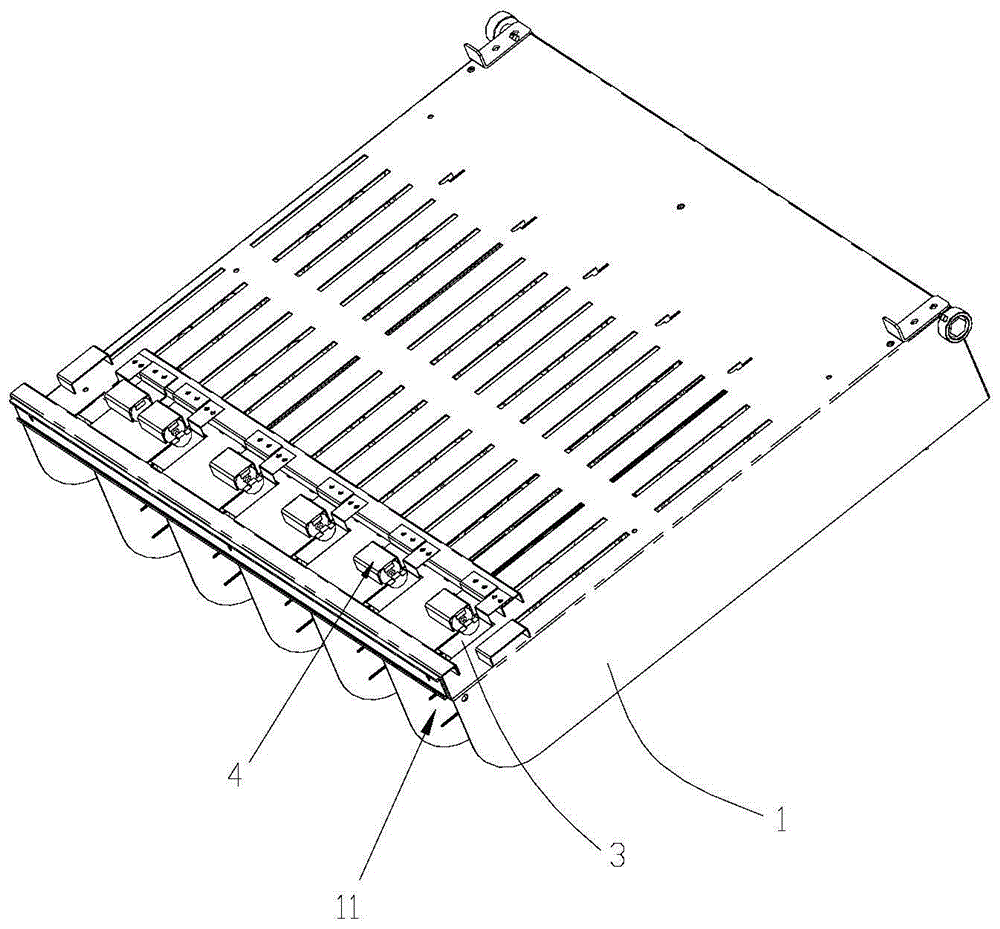

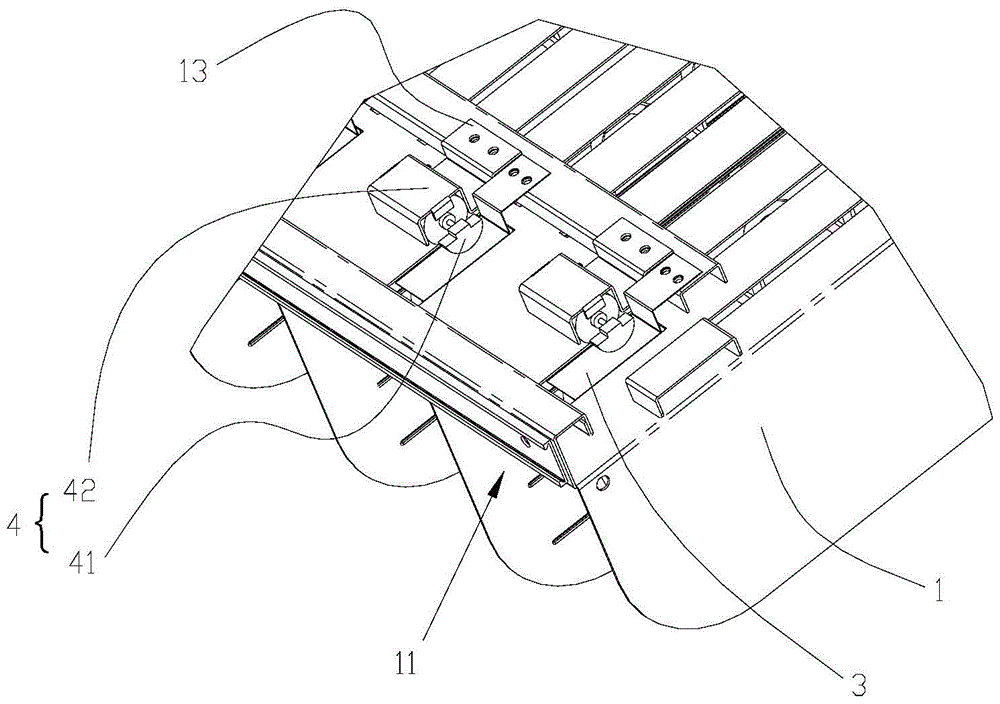

Automatic battery sorting system

The invention provides an automatic battery sorting system, comprising a putting assembly, a battery detection unit, a sorting unit, a drive assembly and a control unit, wherein the putting assembly is used for putting batteries to be sorted; the battery detection unit is used for identifying the marks of the batteries to be sorted and obtaining the electrical properties of the batteries to be sorted; the sorting unit is used for putting the batteries to be sorted in the corresponding positions according to the information obtained by the battery detection unit; the drive assembly is used fortransferring the batteries to be sorted from the putting assembly to the battery detection unit in sequence and transferring the batteries to be sorted from the battery detection unit to the sorting unit on the same horizontal chain; and the control unit is used for controlling each part of the automatic battery sorting system to exchange information and work.

Owner:GEESUN AUTOMATION TECH

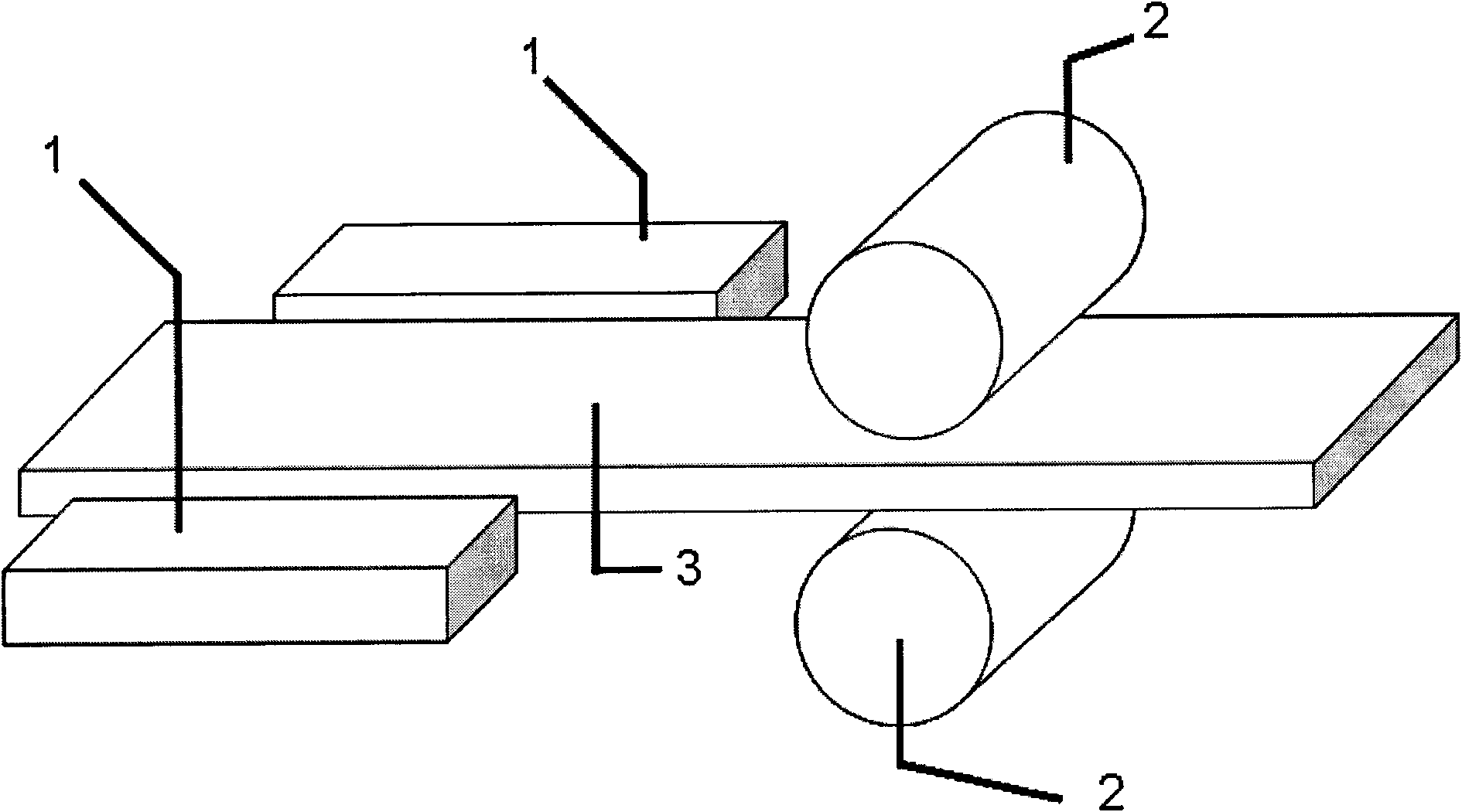

Method for controlling quality of edges of intermediate slabs

The invention discloses a method for controlling the quality of edges of intermediate slabs. Controlling equipment comprises a slab sizing press machine, a four-roll invertible roughing No.2 stand with a vertical roll and a finishing vertical roll. The method comprises the following steps: 1) according to the width of strip steel finished products, determining a finishing target width FET; 2) determining a finishing natural spread FS; 3) determining the maximum effective edging of the finishing vertical roll Wf; 4) according to values calculated in steps 1 to 3, obtaining a roughing outlet target width RET; 5) determining a roughing No.2 stand multi-pass natural spread alpha; 6) determining a roughing No.2 stand multi-pass total rolling reduction RW, and distributing a reduction gradient of each pass; 7) according to values calculated in steps 4 to 6, obtaining a slab target width WB; and 8) according to the value of the slab target width WB, setting the edging of the slab sizing pressmachine as 0, idling first two passes of the four-roll invertible roughing No.2 stand, and making the reduction gradient in subsequent passes gradually increased, wherein the finishing vertical rolladopts the maximum effective edging.

Owner:BAOSHAN IRON & STEEL CO LTD

Concavely-embedded hidden stamp system

ActiveCN102873998BImprove securityPrevent theftCharacter and pattern recognitionStampingEngineeringFingerprint

The invention provides a concavely-embedded hidden stamp system, which comprises a control unit and an executing unit, wherein the executing unit comprises a shell, a stamp arranged inside the shell, a motor and a transmission frame; the shell is provided with an acquisition window; a finger induction sensor and a fingerprint sensor are arranged in the acquisition window; a revolving shaft of the motor is connected with a screw rod; the transmission frame is provided with a threaded hole; the screw rod is in threaded connection in the threaded hole; the transmission frame is in sliding connection with the shell; the stamp is fixed on the transmission frame; when a finger extends into the acquisition window, a trigger signal is transmitted to the control unit through the finger induction sensor, the control unit is used for starting the fingerprint sensor for acquiring the fingerprint information of a user, and the motor rotates to drive the stamp to extend out of the shell if the fingerprint information of the user is matched; and when a finger is separated from the acquisition window, the finger induction sensor stops transmitting the trigger signal, the motor rotates reversely, the stamp is automatically moved into the shell, and the stamp is hidden in the shell in a concave embedding way for protecting, so that the safety of the concavely-embedded hidden stamp system is improved.

Owner:孟友新

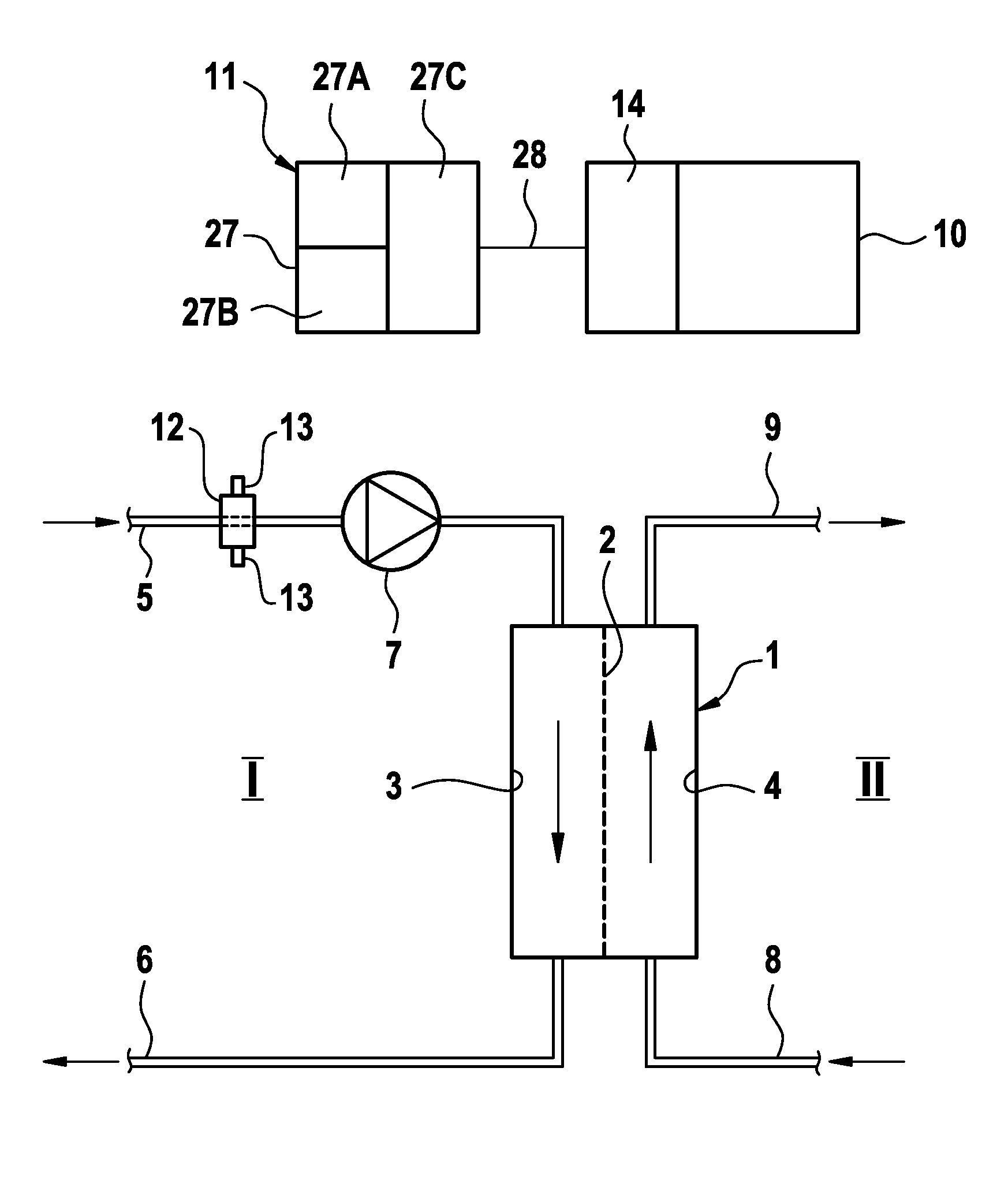

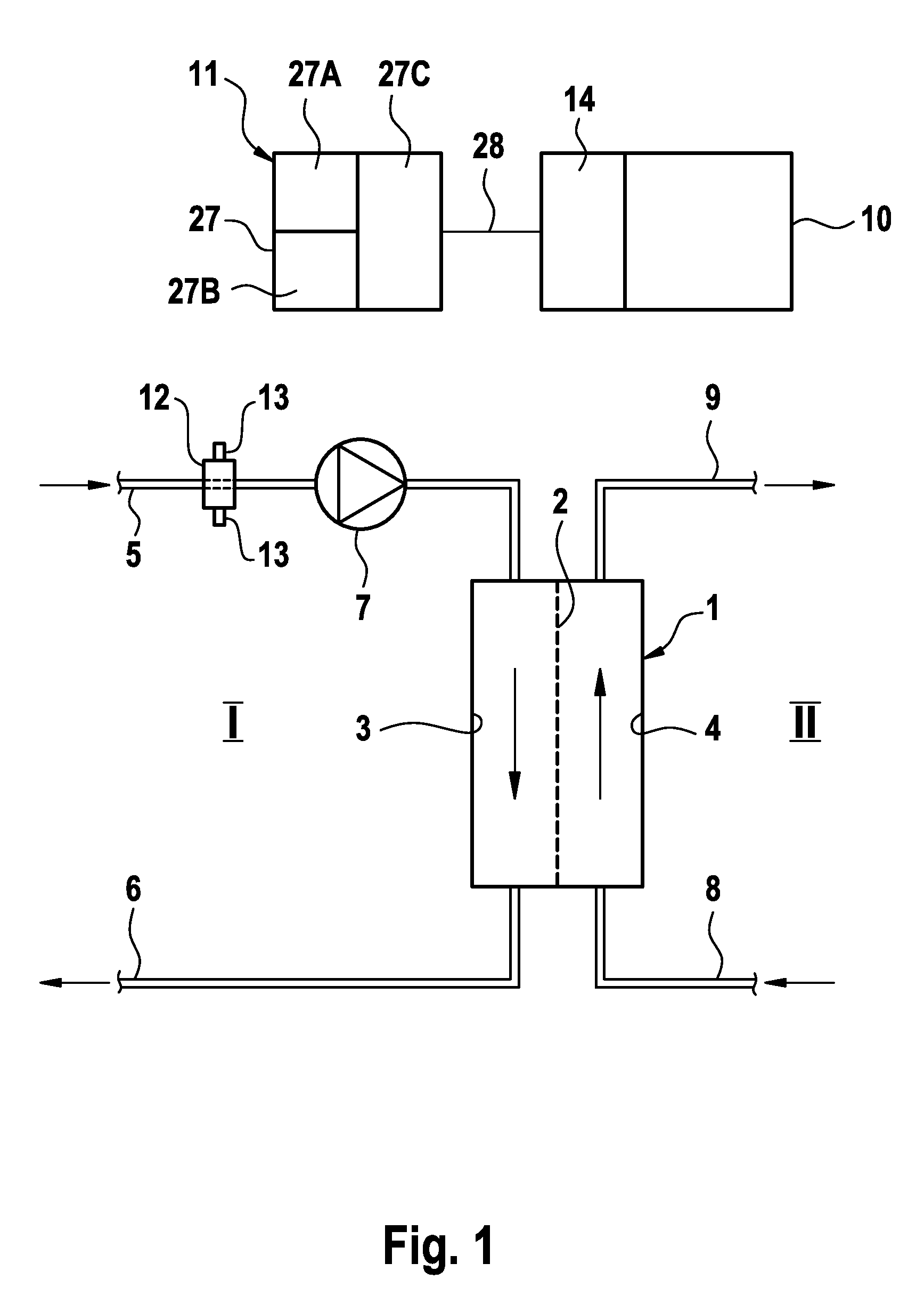

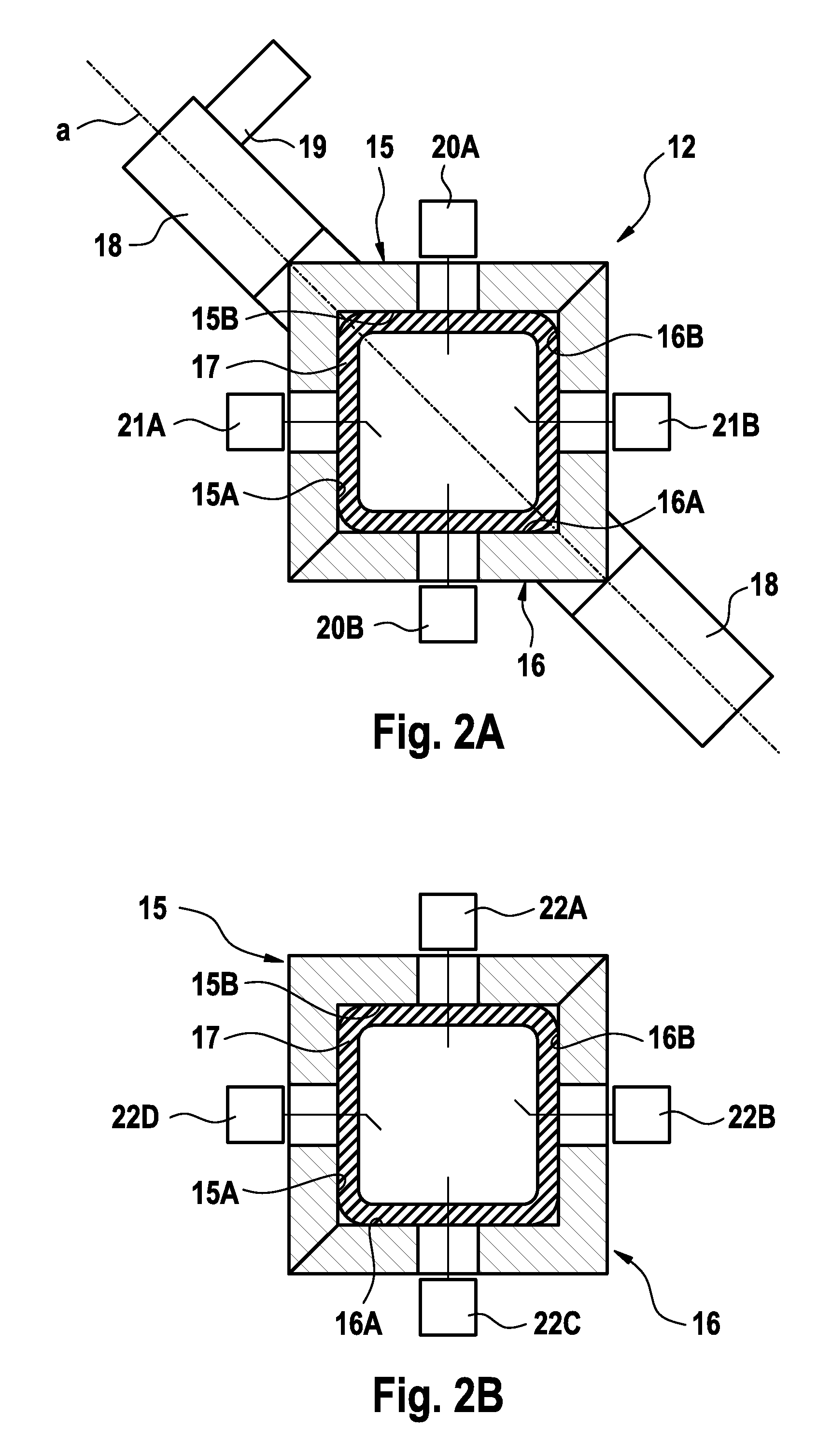

Device for determining a concentration of a constituent of blood in a hose line

InactiveUS8792089B2Uniform applicationIncrease ratingsMedical devicesDiagnostic recording/measuringBlood treatmentsBlood component

A device for determining the concentration of a constituent of blood in a hose line, in particular in the hose line of an extracorporeal blood circuit of an extracorporeal blood treatment apparatus, includes a clamping unit having an actuation mechanism configured to apply a clamping force such that first and second receiving elements are moved towards one another from a first position releasing the hose line into a second position clamping the hose line, in which the drive of the actuation mechanism takes place with an electric motor, and a monitoring unit configured to detect a hose line inserted into the receiving elements. A method for detecting a hose line in a clamping unit of a device for determining the concentration of a blood constituent in the hose line is also described. Automation of the measurement of the blood parameters is thus possible.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

Hot wheel bill stacking device

ActiveCN103646466AMake sure to insertPrevent Flying MoneyFunction indicatorsCoin/currency accepting devicesTransmission beltEngineering

The invention provides a hot wheel bill stacking device. The hot wheel bill stacking device comprises a power pinch wheel set, a hot wheel, a bill stacking plate, a conveying channel and a floating wheel, wherein the power pinch wheel set is arranged at an inlet of the hot wheel bill stacking device, comprises a transmission belt wheel and a conveying belt which is sleeved on the transmission belt wheel, and is used for inputting or outputting paper money; the hot wheel is erected on an installation side plate through a rotary shaft, is linked with the power pinch wheel set, and is used for conveying the paper money in a mode of rotating at high speed while carrying the paper money; the bill stacking plate is positioned below the hot wheel and is used for stacking bills; the conveying channel consists of an upper channel plate and a lower channel plate and is used for providing a path for paper money transmission; the floating wheel is arranged above the power pinch wheel set and is tangential to the transmission belt wheel; a tangential line formed by the transmission belt wheel and the floating wheel is parallel to the linked tail end plane between the conveying channel and the hot wheel and is tangential to a root base circle of the hot wheel.

Owner:GRG BAKING EQUIP CO LTD

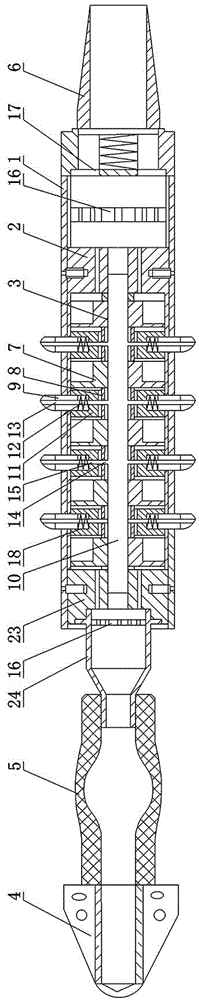

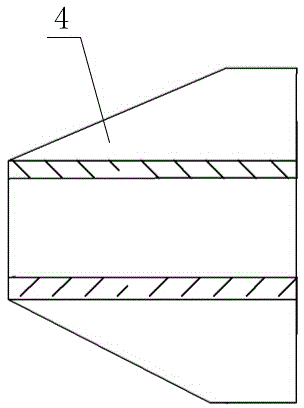

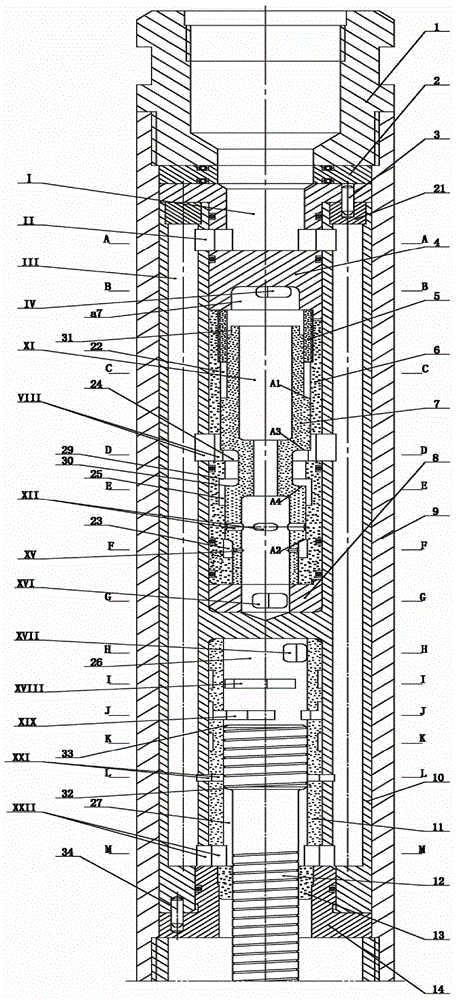

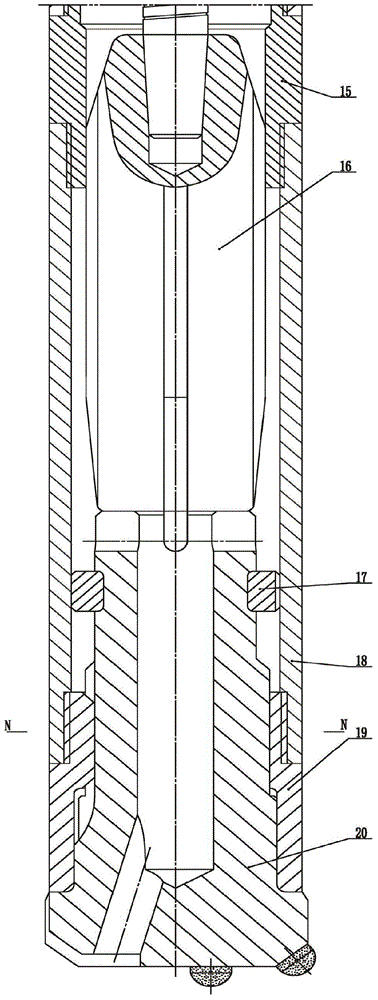

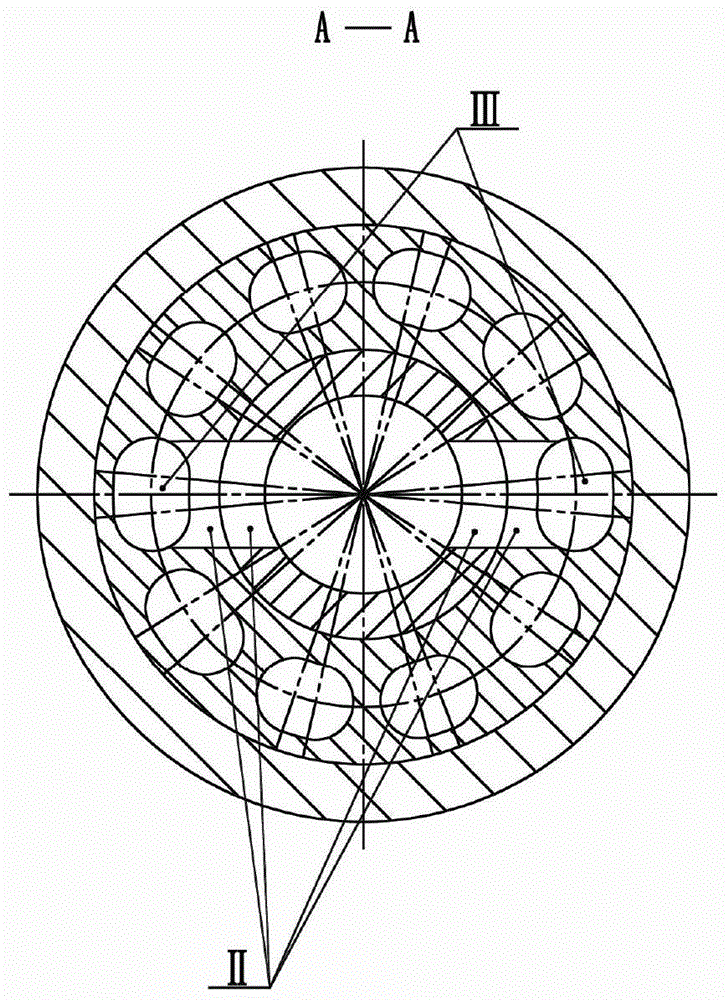

Stroke differential type high-energy hydraulic drive down-hole hammer

The invention relates to a stroke differential type high-energy hydraulic drive down-hole hammer. A spline on a drill bit is in sliding fit with a spline groove, a valve cover sleeve is in interference fit with a valve sleeve to be installed into the upper end of the valve sleeve. A valve cover is inserted into a cylinder body upper end hole and is radially provided with low-pressure emptying channels, hole channels corresponding to the radial channels are radially formed in the radial direction of a cylinder body and are communicated with axial hole channels. The upper portion of the high-energy hydraulic drive down-hole hammer is in threaded connection with an outer cylinder through an upper connector and a middle connector respectively to form a whole through package. The axial size of a piston of the hammer is small, matching surfaces are few, the leakage area is greatly decreased, and the hammer is easy to assemble, not prone to abrasion, long in service life and high in sensitivity. A differential loop is adopted for a stroke, so that the piston quickly obtains large impact end speed within a shorter stroke, and the hard rock drilling efficiency is remarkably improved. The hammer is provided with a novel empty hammering preventing mechanism, high-pressure slurry flows into a cavity through the channels and then flows into the bottom of a hole, the hammer is not driven, it is ensured that the down-hole hammer does not work when a drilling tool is lifted to be away from the down-hole hammer, and accordingly the safety of the drilling tool is ensured.

Owner:JILIN UNIV

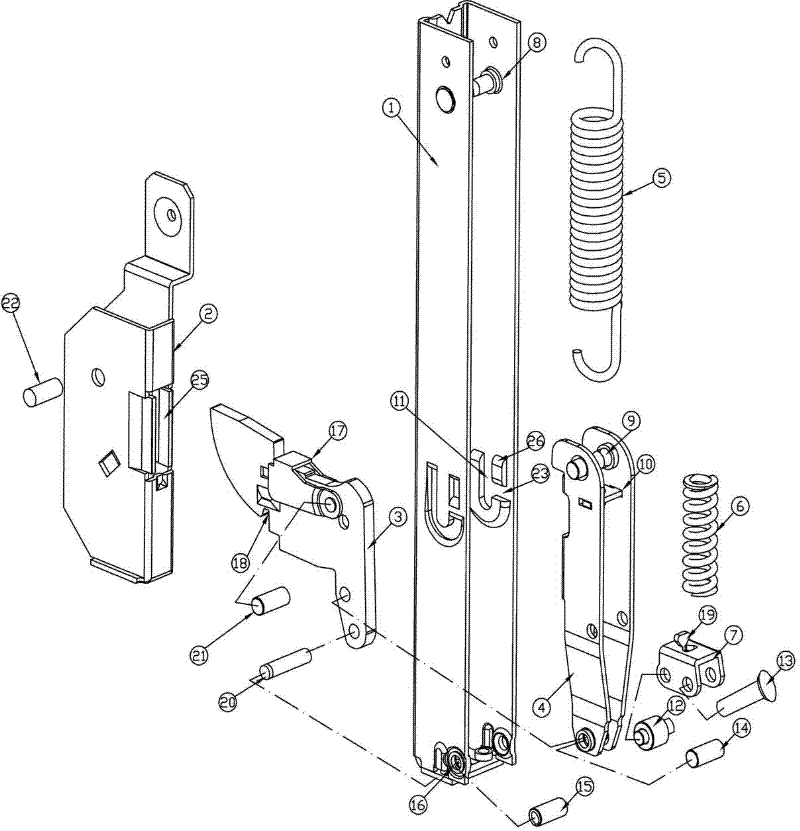

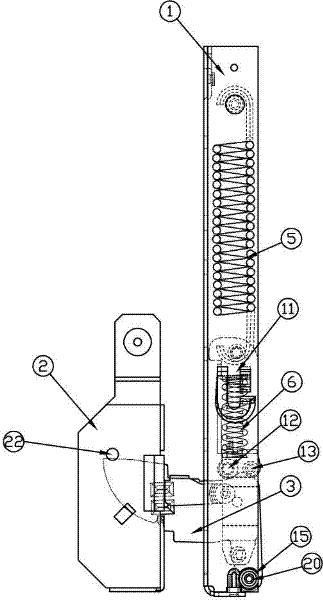

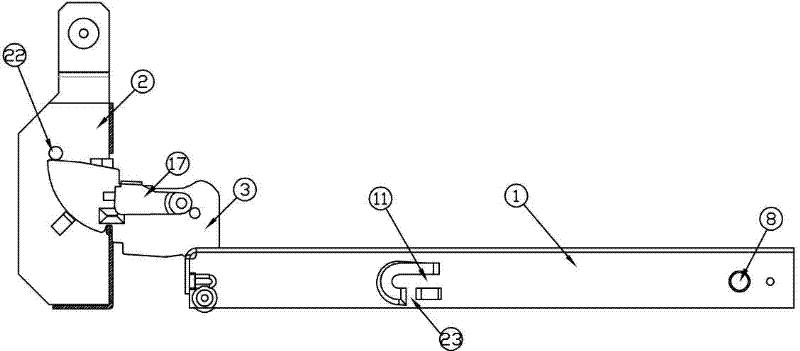

Hinge

ActiveCN102400623ASufficient expansion spaceAvoid scalding accidentsCooking vesselsPin hingesNatural stateTorsion spring

The invention relates to a hinge, in particular to a hinge used between a furnace door and a furnace body of an electric steaming furnace. The hinge comprises a hinge rotating component, a hinge fixing seat (2) and a hinge positioning sheet (3), wherein the hinge rotating component comprises a shell (1), a positioning sheet connecting component (4) and a tension spring (5); the lower end of the positioning sheet connecting component (4) is connected with the hinge positioning sheet (3); the upper end of the positioning sheet connecting component (4) is connected with one end of the tension spring (5) through a tension spring lower end fixing rod (9); the side wall of the positioning sheet connecting component (4) is in sliding fit with a limit groove (11) on the shell (1) through a bulge; and the other end of the tension spring (5) is connected with a tension spring upper end fixing rod (8) on the shell (1). The hinge is characterized in that: a distance between the tension spring upper end fixing rod (8) and the tension spring lower end fixing rod (9) is greater than the length of the tension spring (5) in a natural state. The hinge for the electric steaming furnace has a reasonable structure and is higher in sealing property.

Owner:宁波欧燕电器有限公司

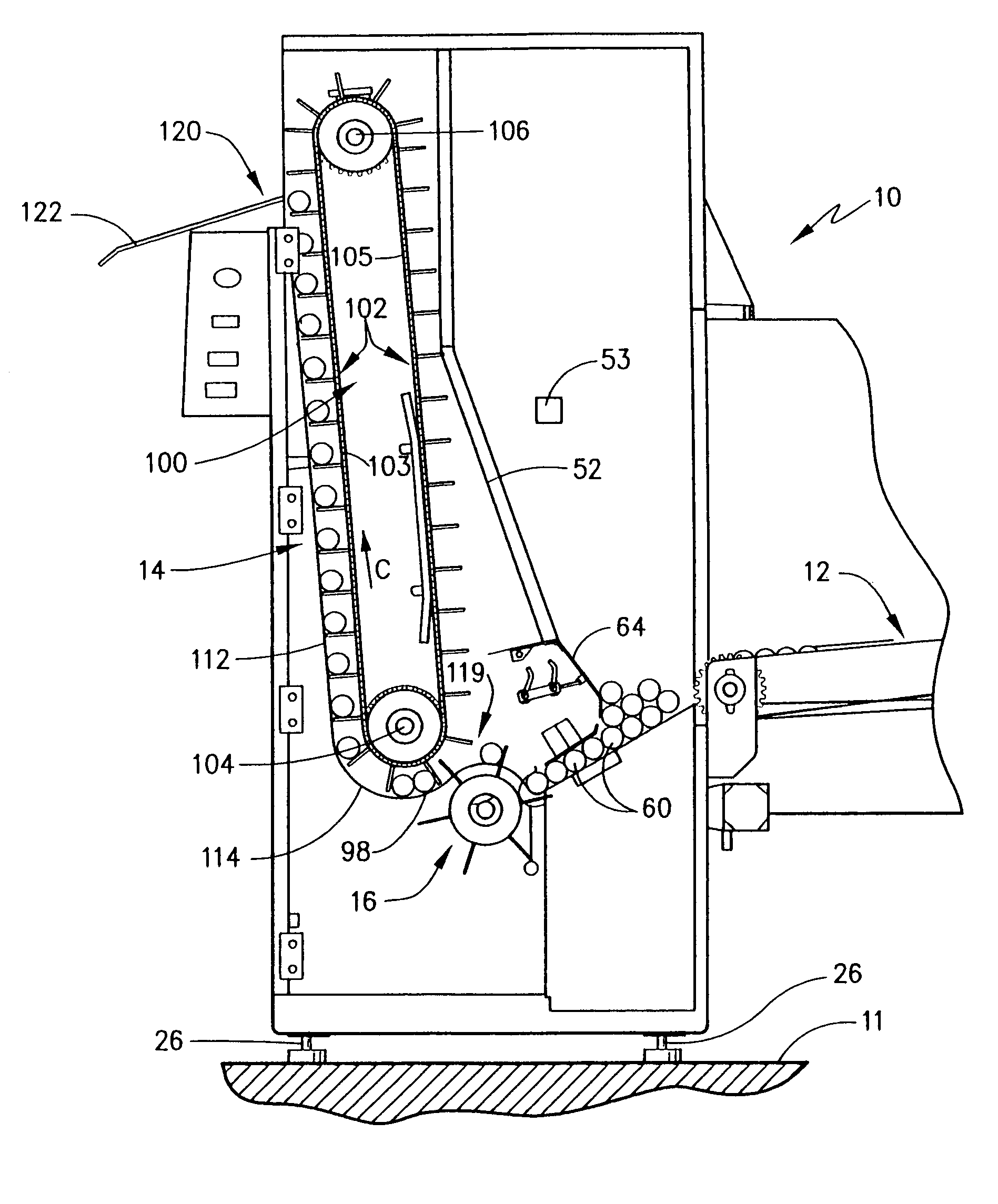

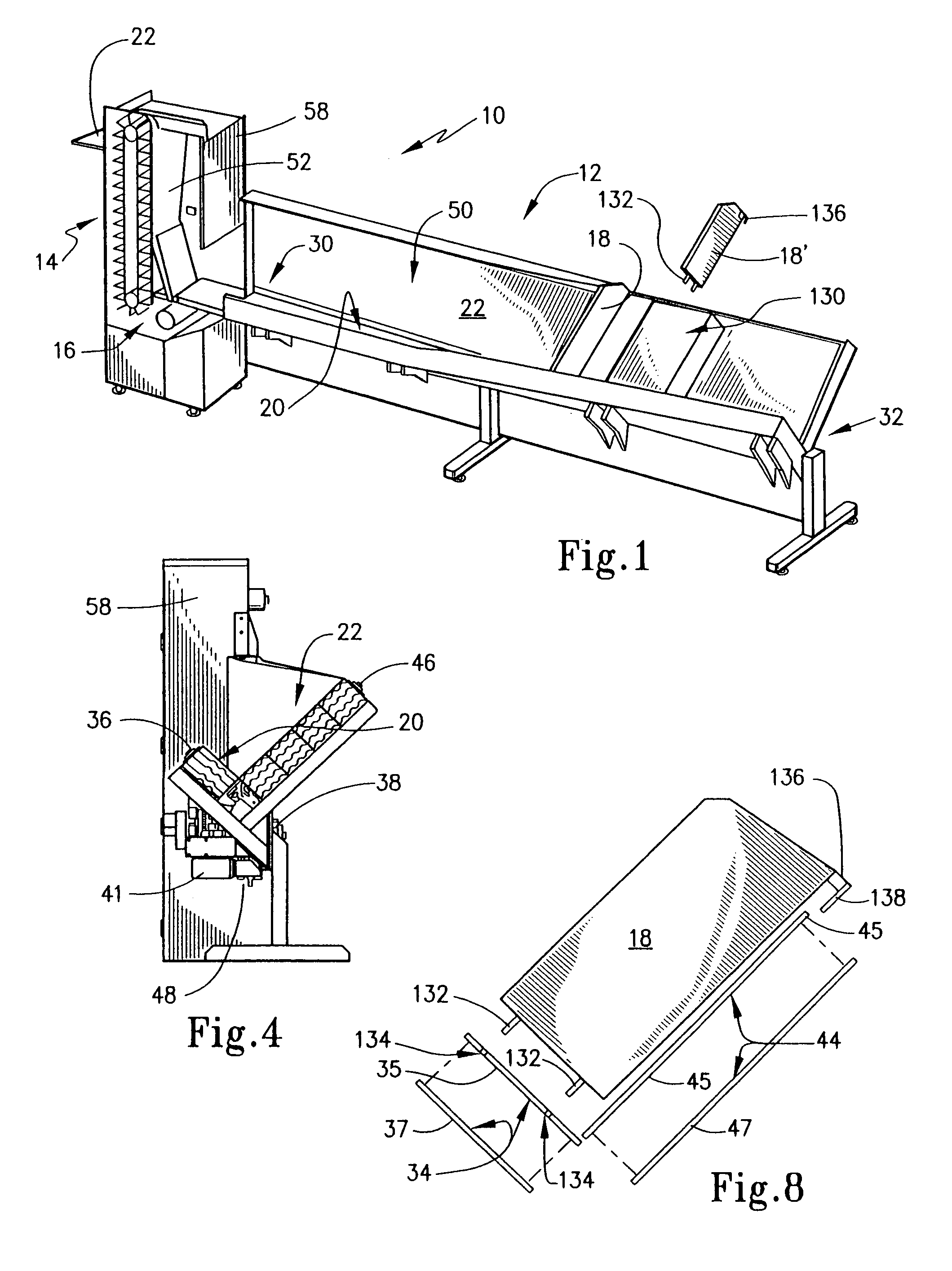

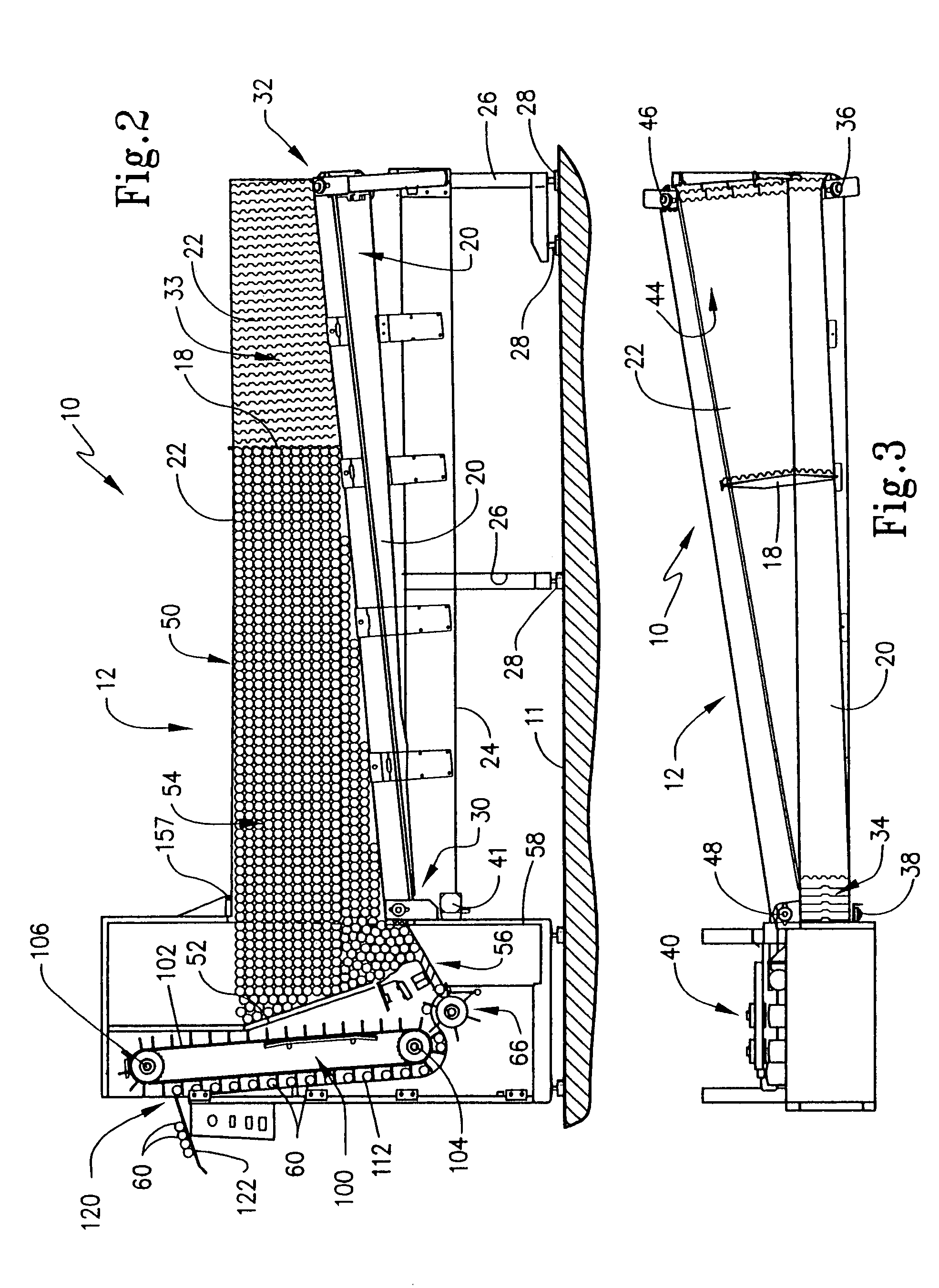

Container transport and organizing apparatus for use in manufacturing operations and method thereof

InactiveUS7222719B2Simple designEasily employedConveyorsConveyor partsEngineeringMechanical engineering

An apparatus and method for transporting containers to be processed in a manufacturing operation includes a transfer assembly that transfers containers from a load area on an upstream conveyor assembly to a discharge on downstream conveyor assembly for further processing. The upstream conveyor assembly may include longitudinally extending first and second conveyors oriented at an angle to one another. The transfer assembly may include a rotating wheel that picks containers from a chute and moves them, one at a time, to the downstream conveyor assembly. The downstream conveyor assembly may be in the form of an elevator that has bays that are sized to receive individual containers. The bays are formed by vanes on a moving belt. The method includes steps inherent in the structure, including receiving a bulk supply of containers, moving them horizontally, columnizing them into a single file, elevating them and thereafter discharging them.

Owner:REAGENT CHEM & RES

Intelligent deep hole rope winch driven by variable frequency motor

ActiveCN103407920AImprove efficiencyReduce energy consumptionWinding mechanismsElectric machineryDeep hole

The invention discloses an intelligent deep hole rope winch driven by a variable frequency motor. The intelligent deep hole rope winch comprises the variable frequency motor, a winch rack, a roller rack, a hydraulic disk brake, a rope arranging mechanism and a monitoring system. The variable frequency motor and the roller rack are arranged on the left side and the right side of the winch rack respectively; the roller rack is horizontally provided with a winch central shaft which is connected with the roller rack through a bearing, and the inside of the roller rack is provided with a roller which is connected with the radial outside of the winch central shaft; the left end of the winch central shaft extends out of the roller rack and is connected with the driven plate of an electromagnetic clutch through a connection board, the output shaft of the variable frequency motor is connected with the input shaft of a reducer gearbox, and the output shaft of the reducer gearbox is connected with the driving plate of the electromagnetic clutch through a shaft sleeve; the rope arranging mechanism is arranged above the roller rack, and ropes are wound onto the roller through the rope arranging mechanism; the monitoring system comprises a rope length and rope speed sensor, a tension testing mechanism and a monitoring computer. The intelligent deep hole rope winch driven by the variable frequency motor has the advantages of high efficiency, safety, intelligent control, energy saving and environmental protection.

Owner:CHINA GEOLOGICAL EQUIP GRP +1

Spring-type vending machine, cargo outlet device thereof and cargo blocking preventing mechanism

ActiveCN105046819AFalling smoothlySales impactCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringMechanical engineering

The invention provides a spring-type vending machine, a cargo outlet device thereof and a cargo blocking preventing mechanism. Cargo blocking can be prevented in the cargo vending process, and continuous and stable vending of cargoes is achieved. The cargo blocking preventing mechanism is used for the cargo outlet device of the spring-type vending machine. The cargo outlet device comprises material channels with cargo outlets in the front ends and cargo outlet springs extending along the material channels. Cargo containing space is formed between adjacent rings of the cargo outlet springs. The cargo blocking preventing mechanism comprises a vibration piece and a power source for driving the vibration piece to vibrate. The vibration piece is arranged at the position corresponding to the corresponding cargo outlet spring and can be in contact with the corresponding cargo outlet spring to drive the cargo outlet spring to vibrate to vibrate the cargoes blocked at the front end of the cargo outlet spring down. The vibration piece of the cargo blocking preventing mechanism can vibrate the cargoes blocked at the front end of the corresponding cargo outlet spring down by driving the cargo outlet spring to vibrate so that cargo blocking can be prevented; meanwhile, vending of the next cargoes can not be influenced, and continuous and stable vending of the cargoes can be achieved.

Owner:青岛澳柯玛自动售货机股份有限公司

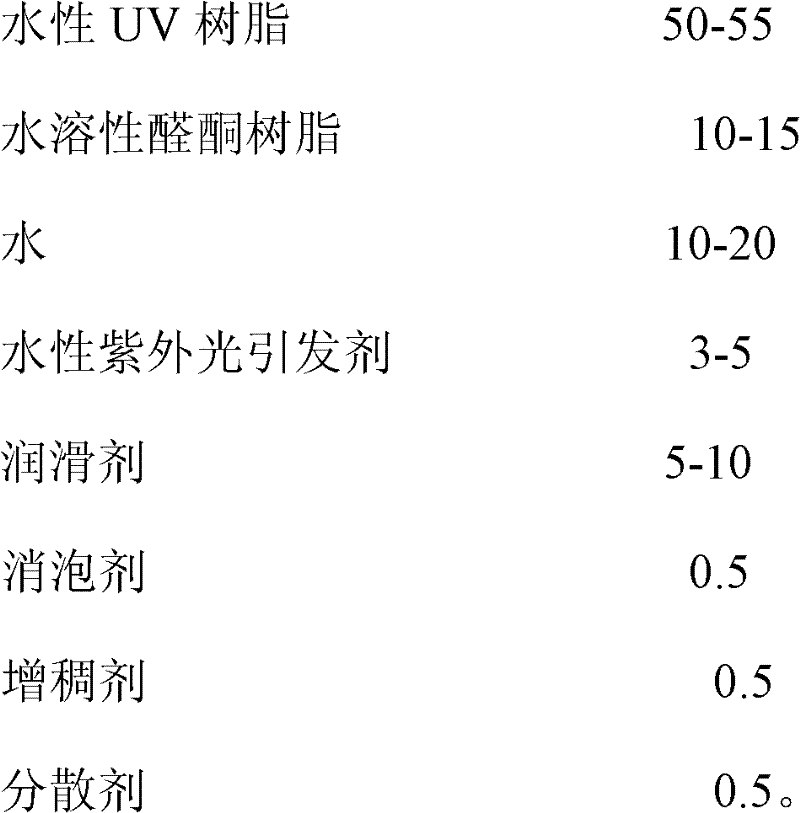

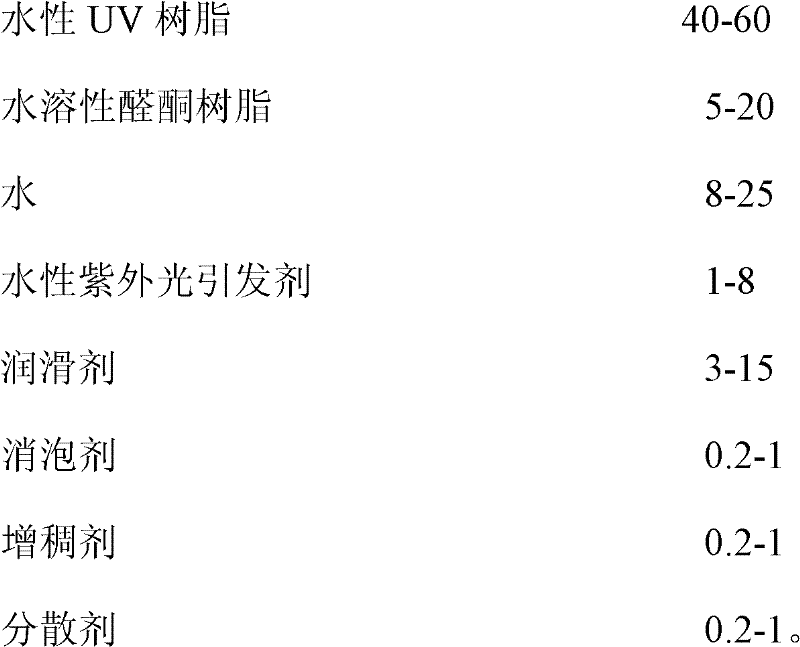

Water-based ultraviolet (UV) curing silk screening snowflake ink

The invention discloses water-based ultraviolet (UV) curing silk screening snowflake ink, which is prepared from the following raw materials in part by weight: 40 to 60 parts of water-based UV resin, 5 to 20 parts of water-soluble aldehyde ketone resin, 8 to 25 parts of water, 1 to 8 parts of water-based UV initiator, 3 to 15 parts of lubricating agent, 0.2 to 1 part of defoaming agent, 0.2 to 1 part of thickening agent and 0.2 to 1 part of dispersant. The invention provides the environment-friendly water-based UV curing silk screening snowflake ink for obviously reducing the peculiar smell of presswork due to ink.

Owner:SHENZHEN KECAI PRINTING

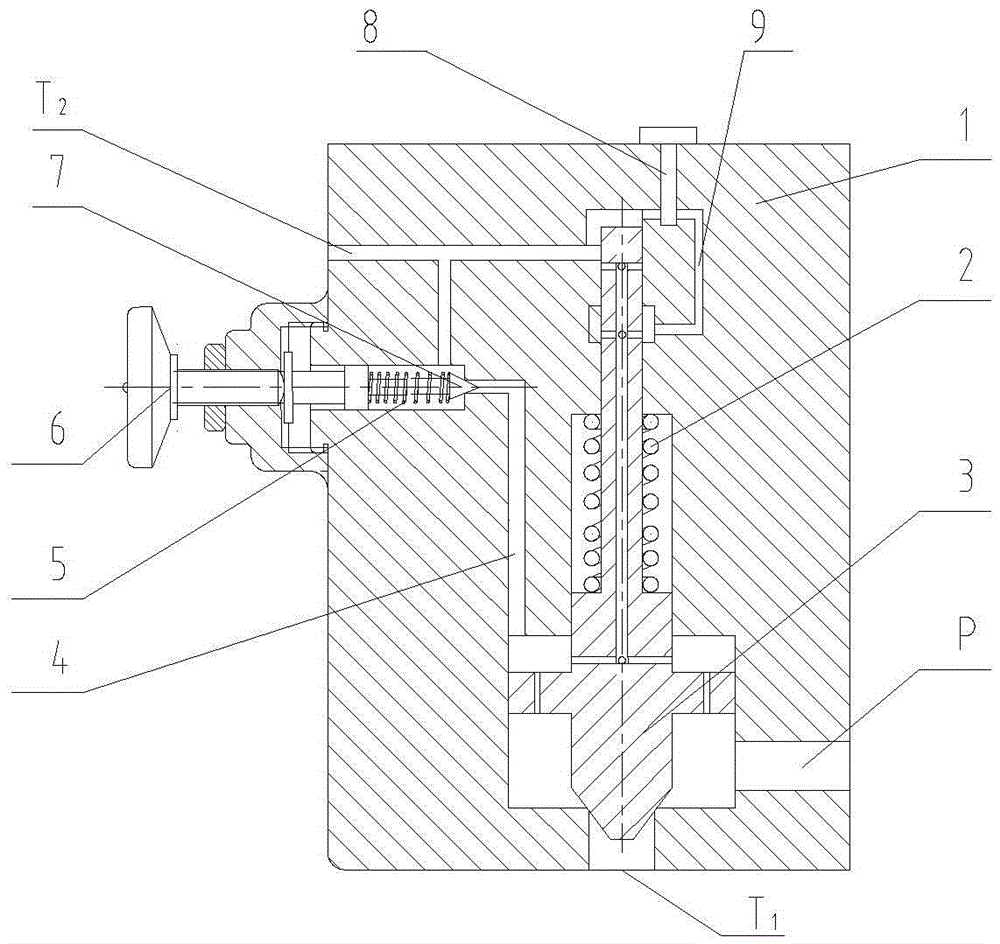

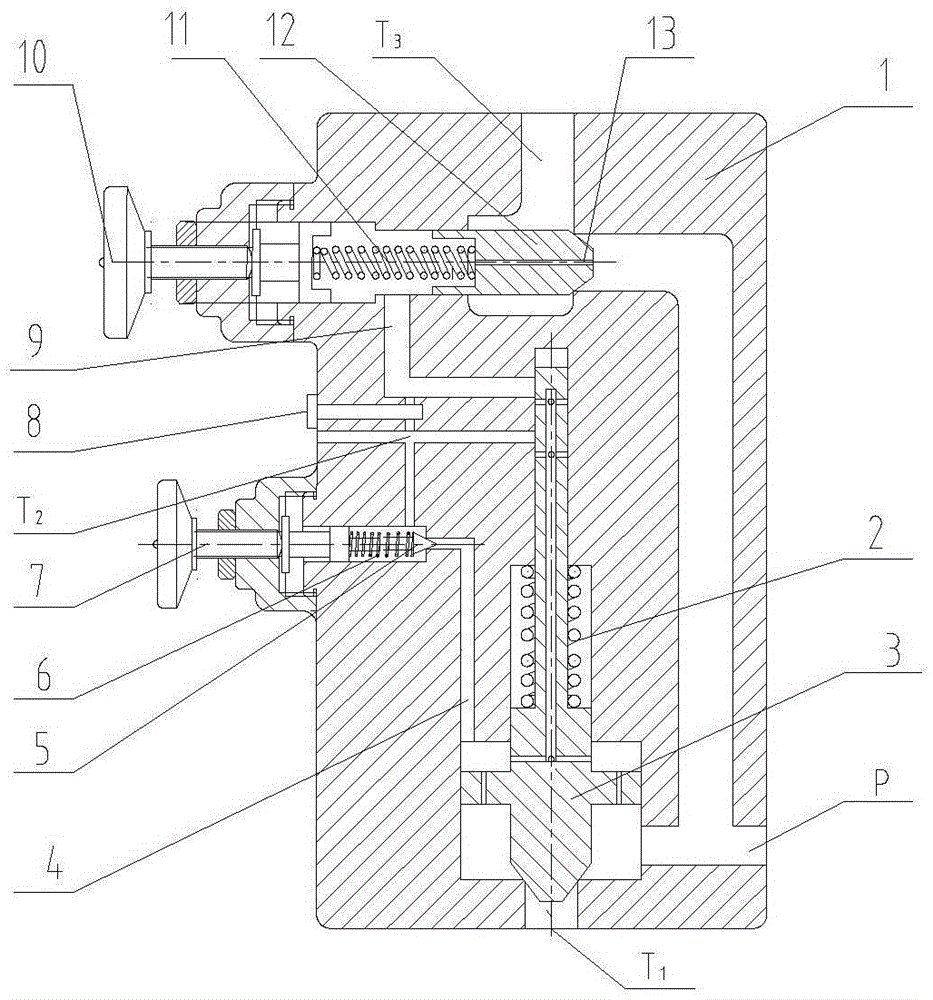

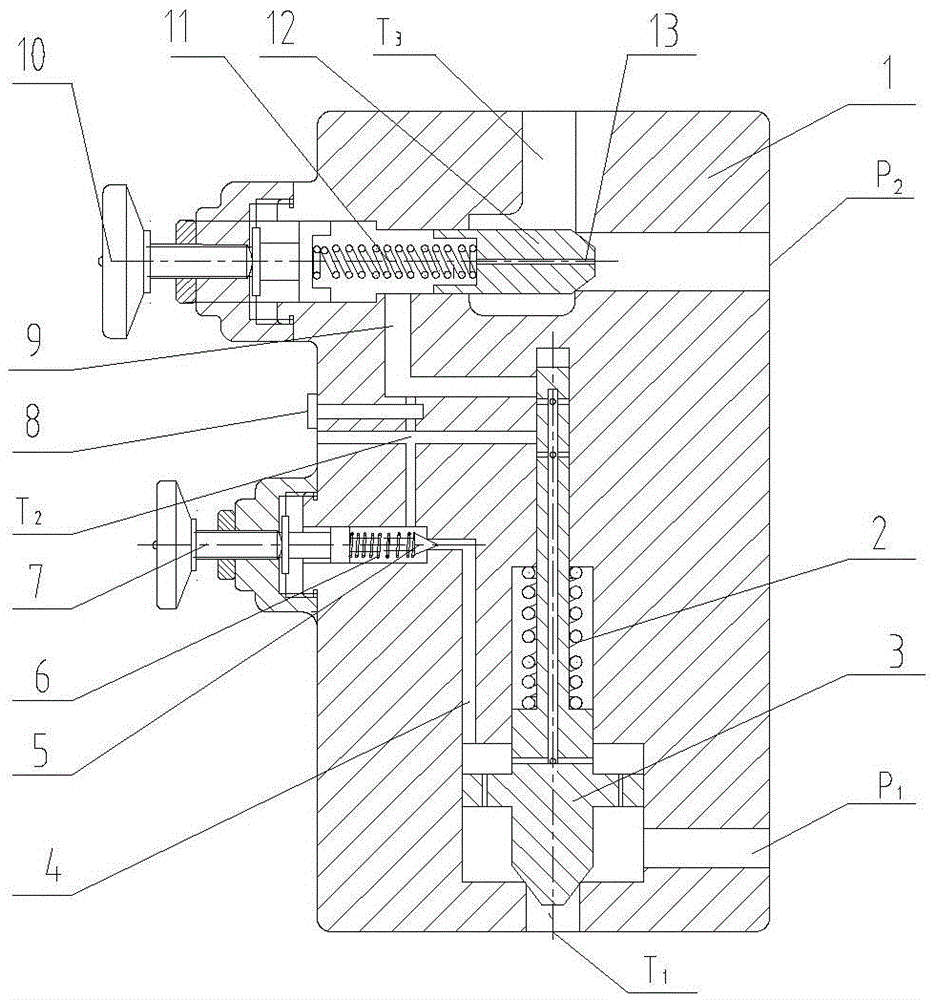

Overflow valve with pressure regulating and safety functions

The invention discloses an overflow valve with pressure regulating and safety functions, and relates to the technical field of hydraulic control valves. The overflow valve comprises a valve body, a main valve, a pilot valve and an emergency pin; the valve body is provided with a runner, a drainage hole, a liquid inlet, a first liquid outlet and a second liquid outlet; one side of the main valve is communicated with the liquid inlet, the other side of the main valve is connected with the pilot valve through the runner, the lower end of the main valve is communicated with the first liquid outlet, and the upper end of the main valve is communicated with the second liquid outlet through the drainage hole; and the emergency pin is connected with the drainage hole. The problem that resonance is caused by a traditional dual overflow valve is effectively solved; the stability of a main valve element is improved; centering of the main valve element is facilitated, and clamping of the valve element is prevented; the balance of the safety valve element is achieved through hydraulic pressure at the two ends, once the pressure is released from one end, the safety valve element can be rapidly opened, and the pressure of the safety valve element is released; when emergency circumstances occur in a system, one end of a pressure limiting valve element is opened to be subject to pressure releasing by rotating a safety pin, and safety and stability of the pressure of the system are guaranteed.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com