Overflow valve with pressure regulating and safety functions

A safety function and relief valve technology, applied in the field of hydraulic control valves, can solve the problems of damaged hydraulic components, enlarged hydraulic system structure, abnormal system operation, etc., to achieve the effect of increasing stability and preventing clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

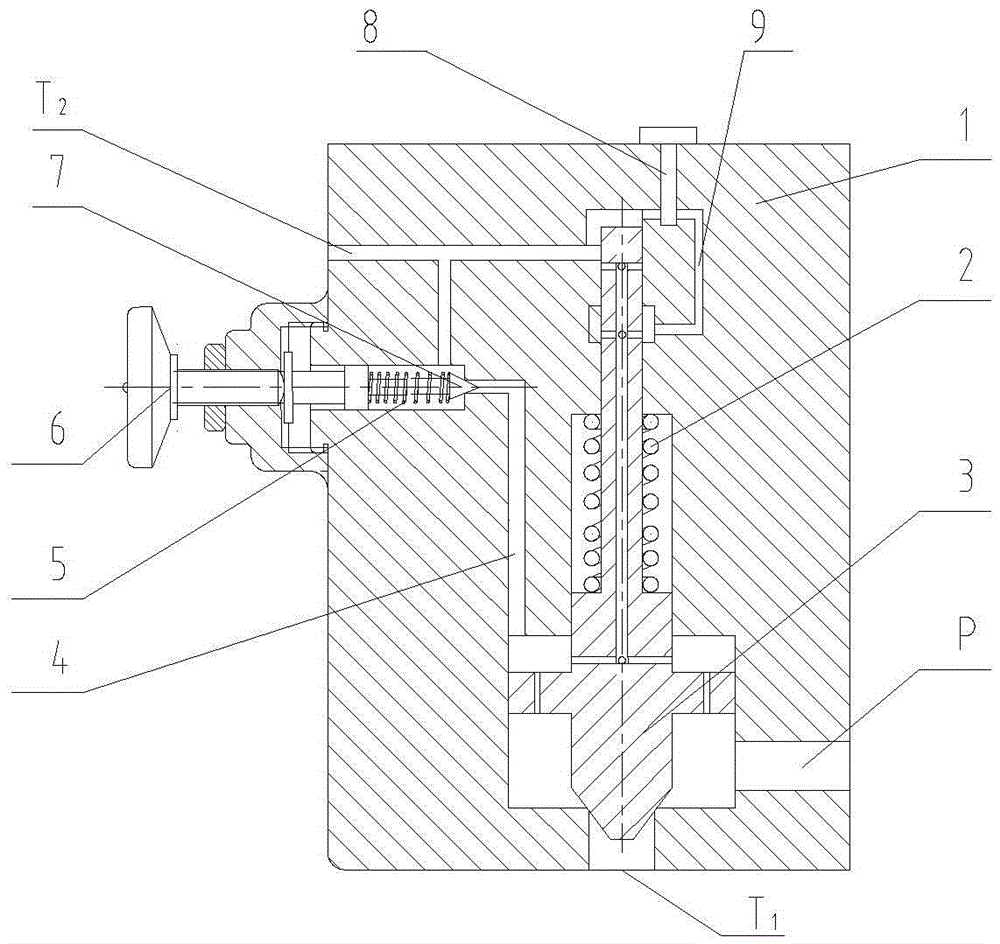

[0026] Such as figure 1 , Figure 4 , Figure 5 and Figure 6 As shown, a relief valve with pressure regulation and safety functions described in the embodiment of the present invention can be divided into three working processes: a pressure stabilization process, a safety process and an emergency process.

[0027] Pressure stabilization process: The fluid enters the main valve cavity from the liquid inlet P, enters the flow channel 4 on the upper side of the main valve core 3 through the damping hole Ia, and acts on the pilot valve core 7, and at the same time, the fluid flows into the center hole through the peripheral hole Ib In c, the emergency pin 8 acts on the emergency pin 8 through the drainage hole 9. At this time, the notch 81 on the emergency pin 8 is closed, and the drainage hole 9 and the liquid outlet IIT 2 Not connected. When the fluid pressure on the upper side of the main spool 3 is lower than the opening pressure of the pilot valve, the pilot spool 7 is c...

Embodiment 2

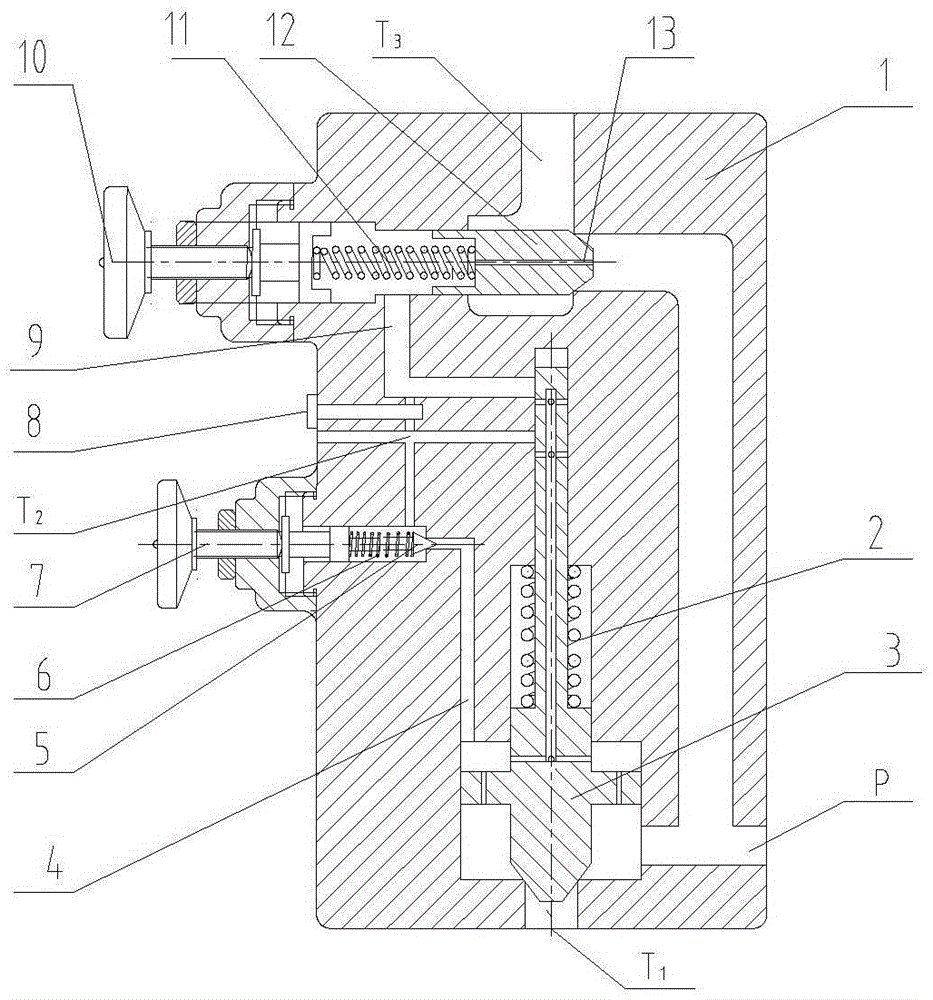

[0031] Such as figure 2 , Figure 4 , Figure 5 and Figure 6 As shown, a relief valve with pressure regulation and safety functions described in the embodiment of the present invention has a working process similar to that of embodiment 1. A safety valve is added to the valve body 1, and a damping hole is opened on the safety valve core 12. II13. In the safety process, compared with the first solution, the safety valve core 12 in the second solution will be opened, so that the fluid flows from the liquid outlet IIIT 3 The outflow increases the overflow volume, and the safety protection performance is reliable.

Embodiment 3

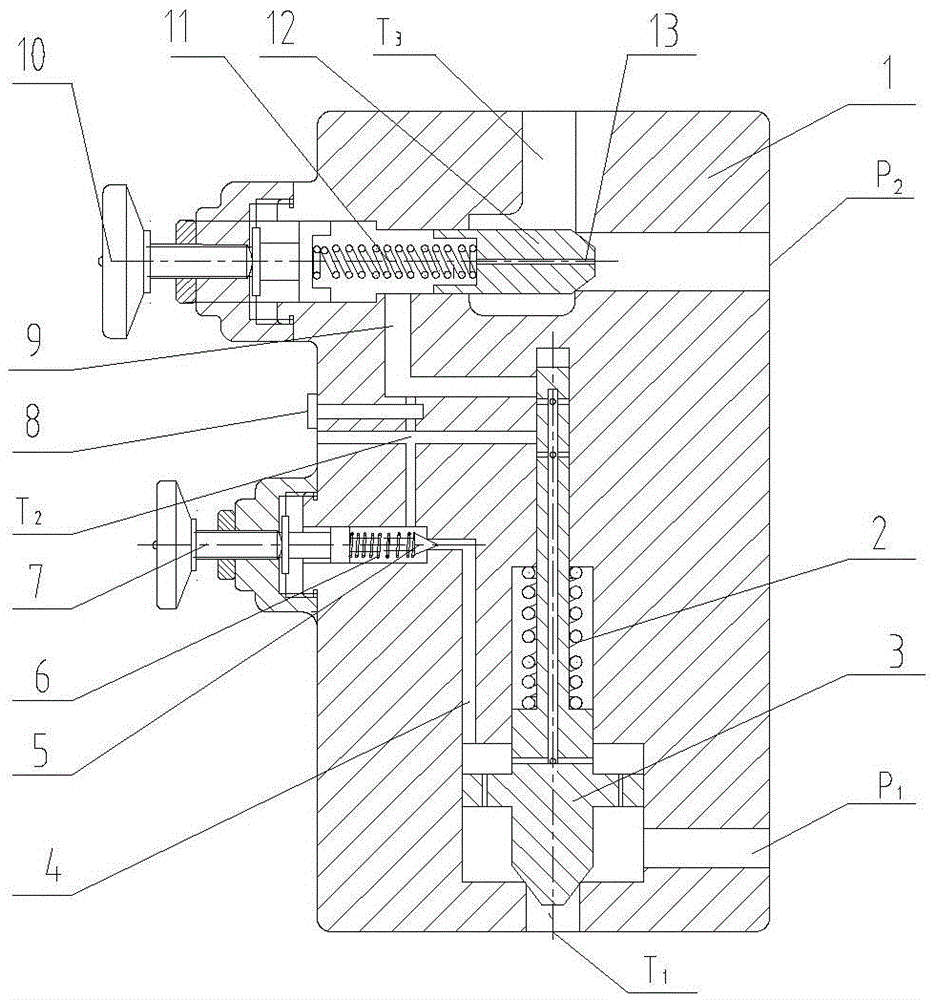

[0033] Such as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the relief valve with pressure regulation and safety functions described in the embodiment of the present invention has a working process similar to that of embodiment 1, and can limit the working states of the two-way actuators. When one of the actuators controlled by the P port works normally, the P 1 The executive components of the port control also work normally. When the system pressure controlled by port P exceeds the safety pressure, the spool 3 moves up to release the two control pressures at the same time.

[0034]In summary, the present invention discloses a relief valve with pressure regulation and safety functions, and establishes a coordination mechanism between the two functions of pressure regulation and pressure limitation. Compared with the combination of traditional double relief valves, there are five Advantages: First, the spool spring of the safety limiting pressure is relatively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com