Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

480 results about "Industrial technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial technology is the use of engineering and manufacturing technology to make production faster, simpler and more efficient. The industrial technology field employs creative and technically proficient individuals who can help a company achieve efficient and profitable productivity.

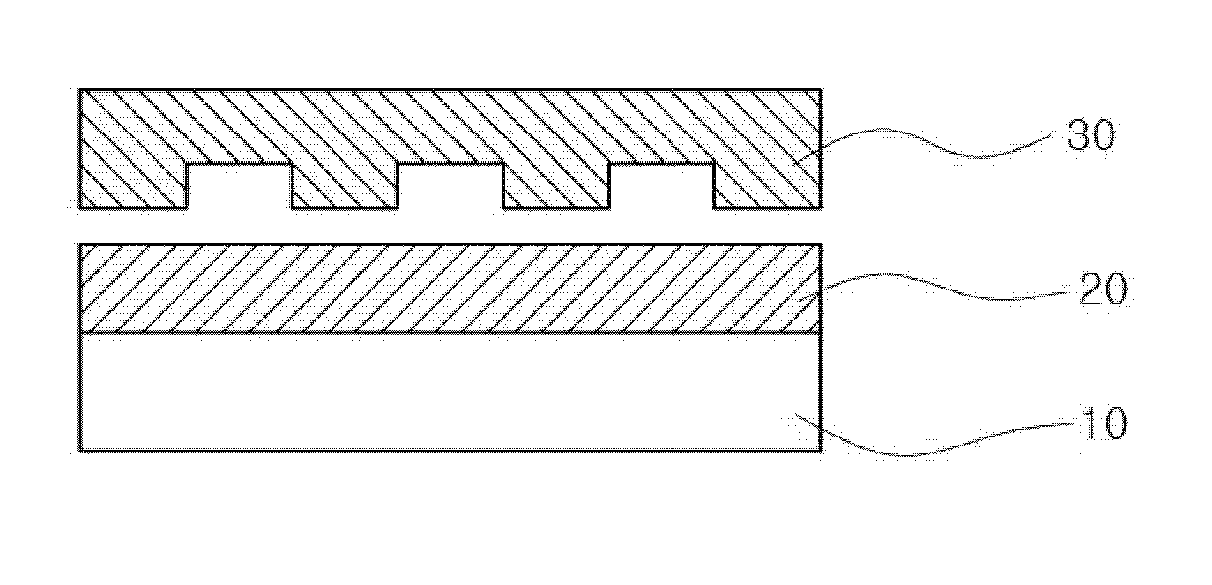

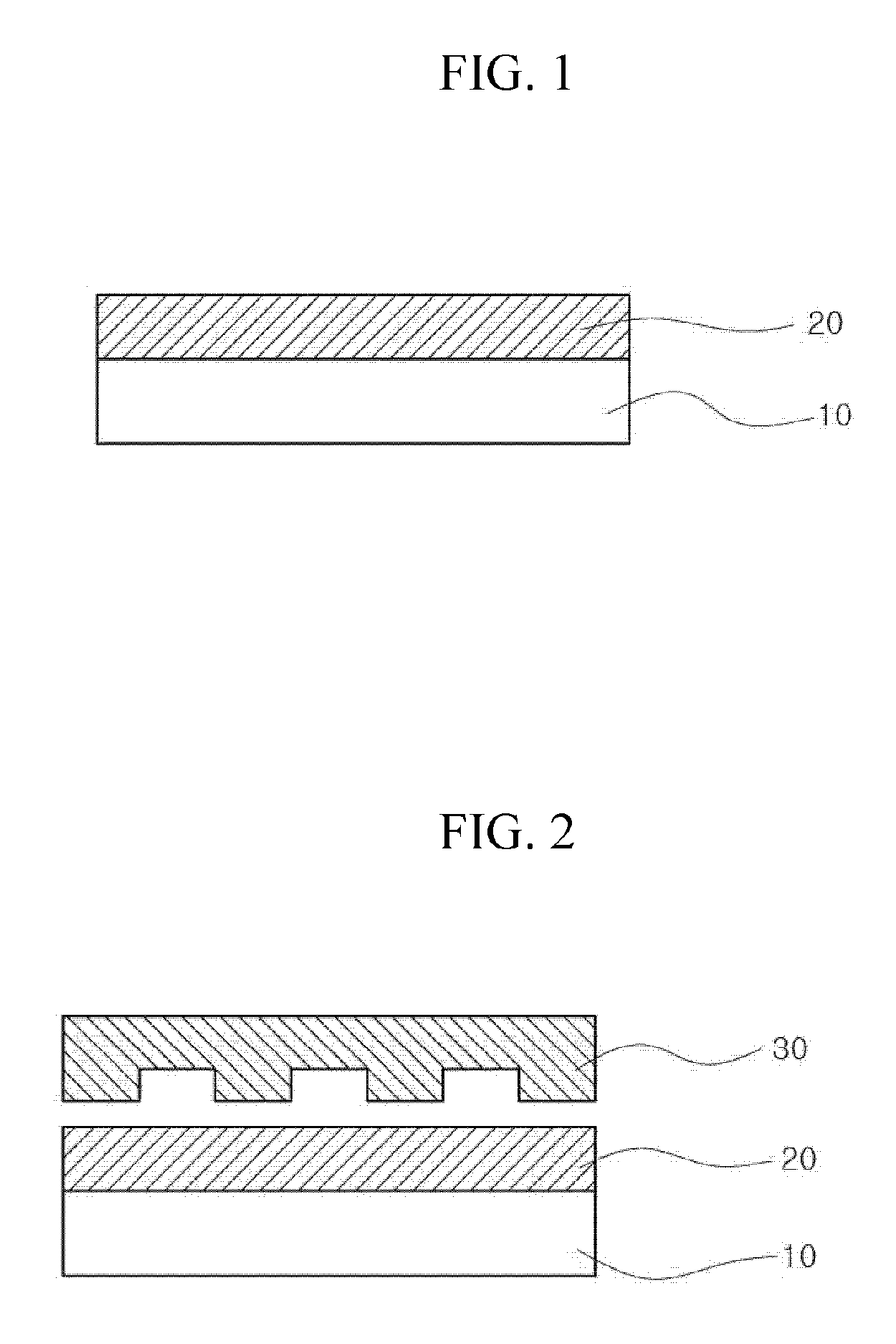

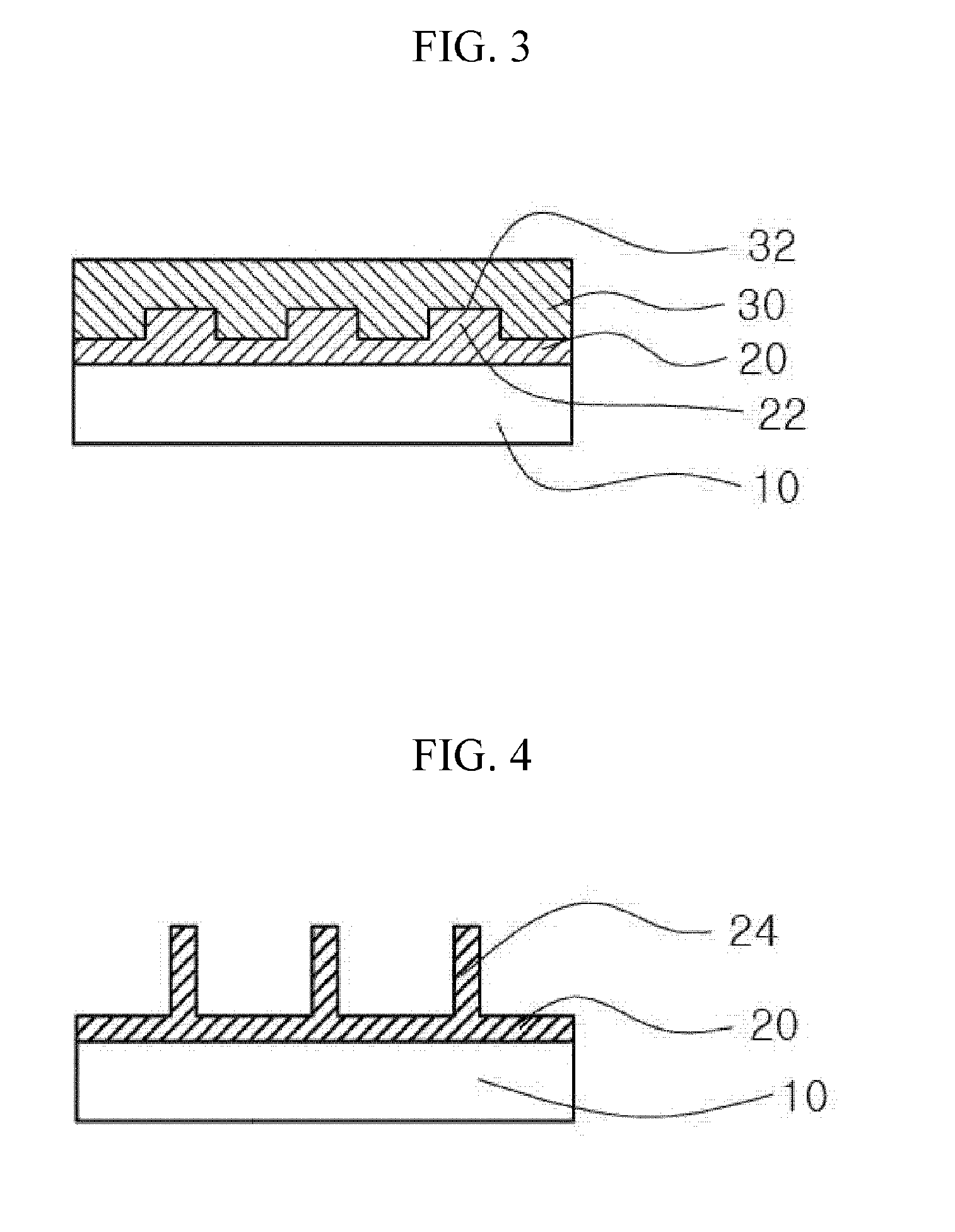

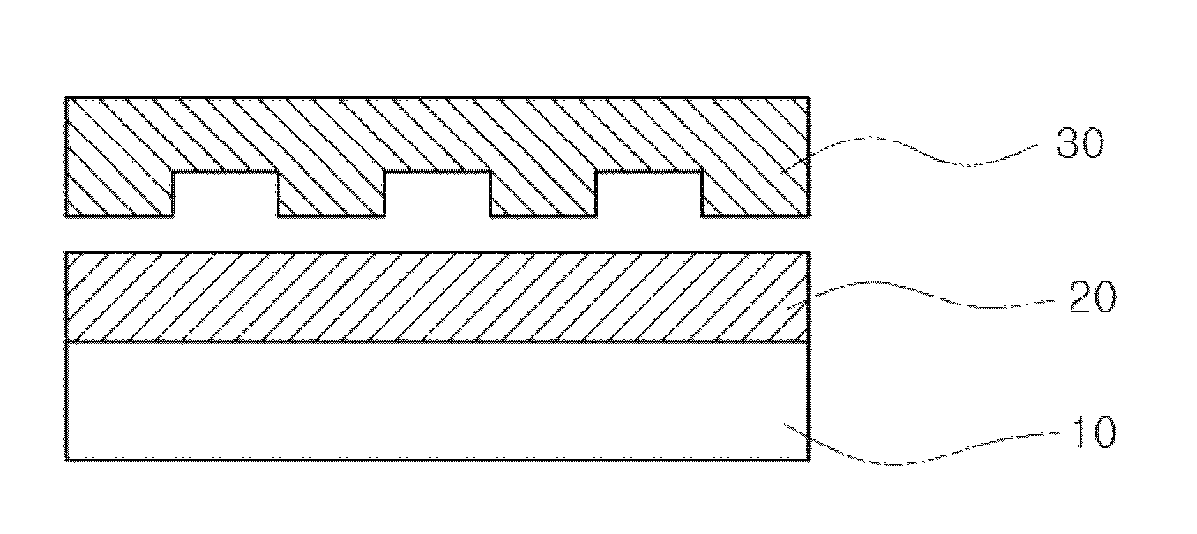

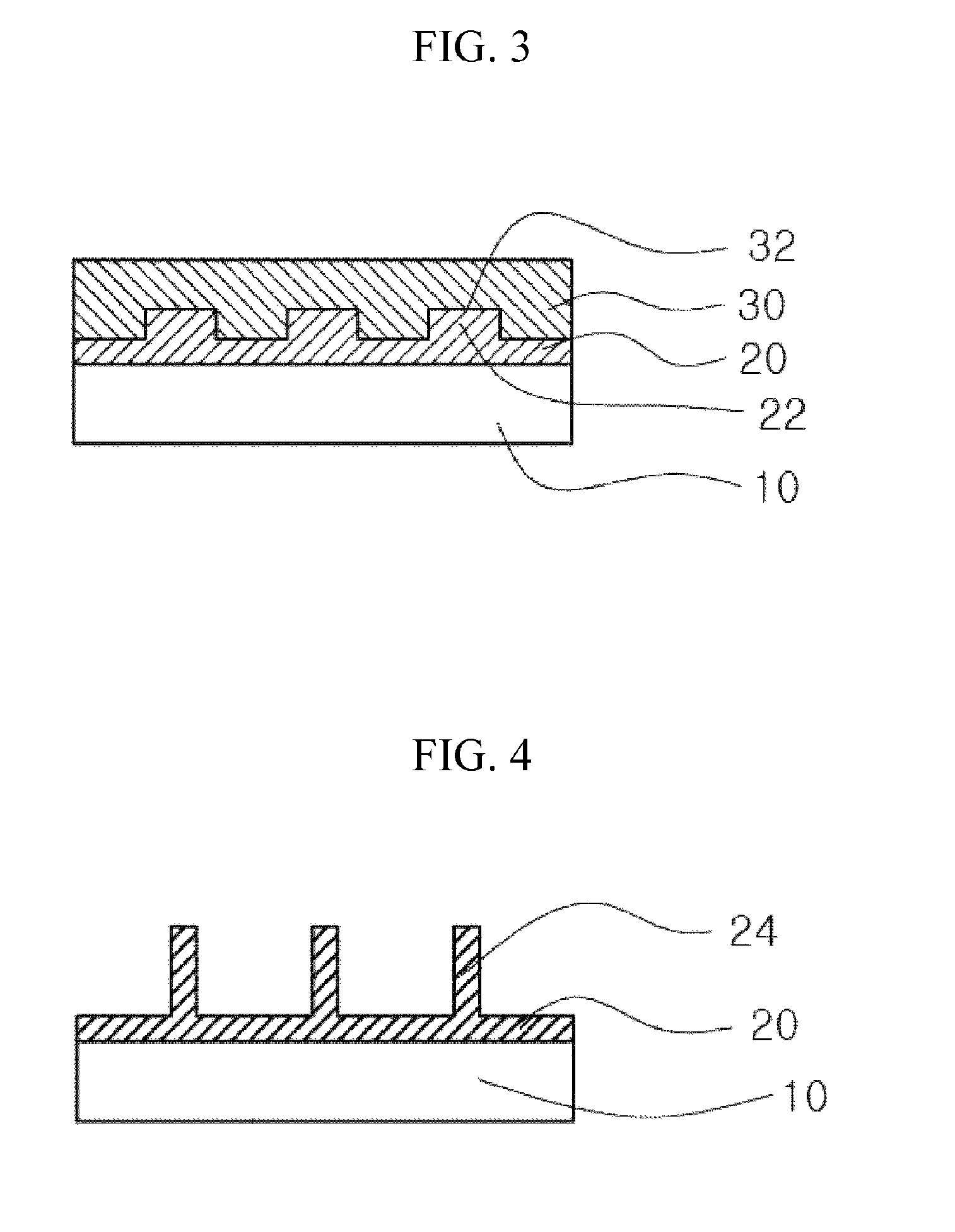

Method for forming nanostructure having high aspect ratio and method for forming nanopattern using the same

InactiveUS20080000871A1Simple and economical processHigh aspect ratioDecorative surface effectsIndividual molecule manipulationPolymer scienceCarbon nanotube

Provided is a method of forming a nanostructure having a nano-sized diameter and a high aspect ratio through a simple and economical process. To form the nanostructure, a polymer thin film is formed on a substrate and a mold is brought to contact the polymer thin film. Then, a polymer patterning is formed to contact the background surface of an engraved part of the mold, and then the polymer pattern is extended out by removing the mold out of the polymer thin film. The nanostructure forming method of the present research can reproduce diverse cilia optimized in the natural world. Also, it can be used to develop new materials with an ultra-hydrophobic property or a high adhesiveness. Further, it can be applied to a nanopattern forming process for miniaturizing electronic devices and to various ultra-precise industrial technologies together with carbon nanotube, which stands in the highlight recently.

Owner:SEOUL NAT UNIV R&DB FOUND

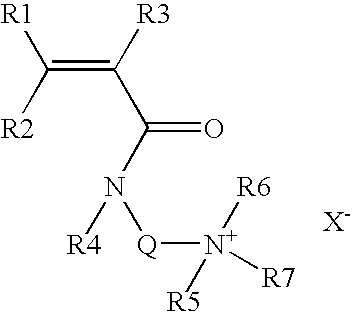

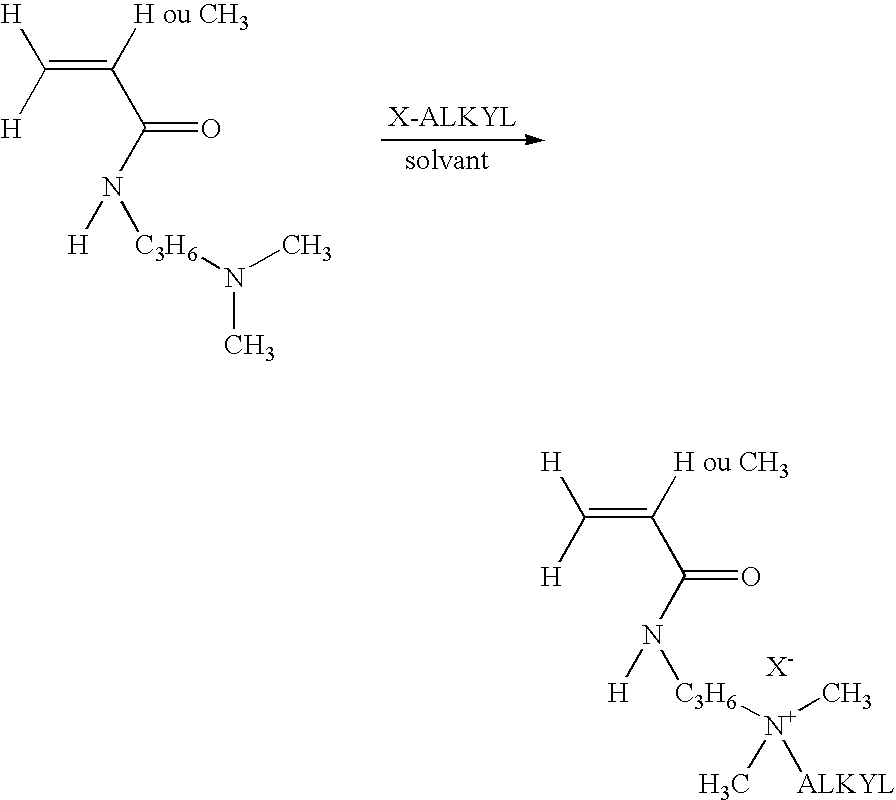

High molecular weight associative amphoteric polymers and uses thereof

High molecular weight associative amphoteric polymers for increasing the viscosity of aqueous solutions, comprise: at lease one cationic monomer derived from acrylamide bearing at least one hydrophobic chain of 8 to 30 carbon atoms; 1 to 99.9 mole % of at least one anionic monomer; and 1 to 99 mole % of one or several non-ionic water-soluble monomers. Aqueous solutions containing said polymers find uses in industry, in particular the oil, paper, water treatment, mining, cosmetics, textile, detergency industries and generally in all industrial techniques using thickened solutions.

Owner:S P C M SA

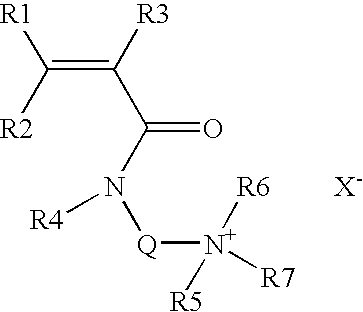

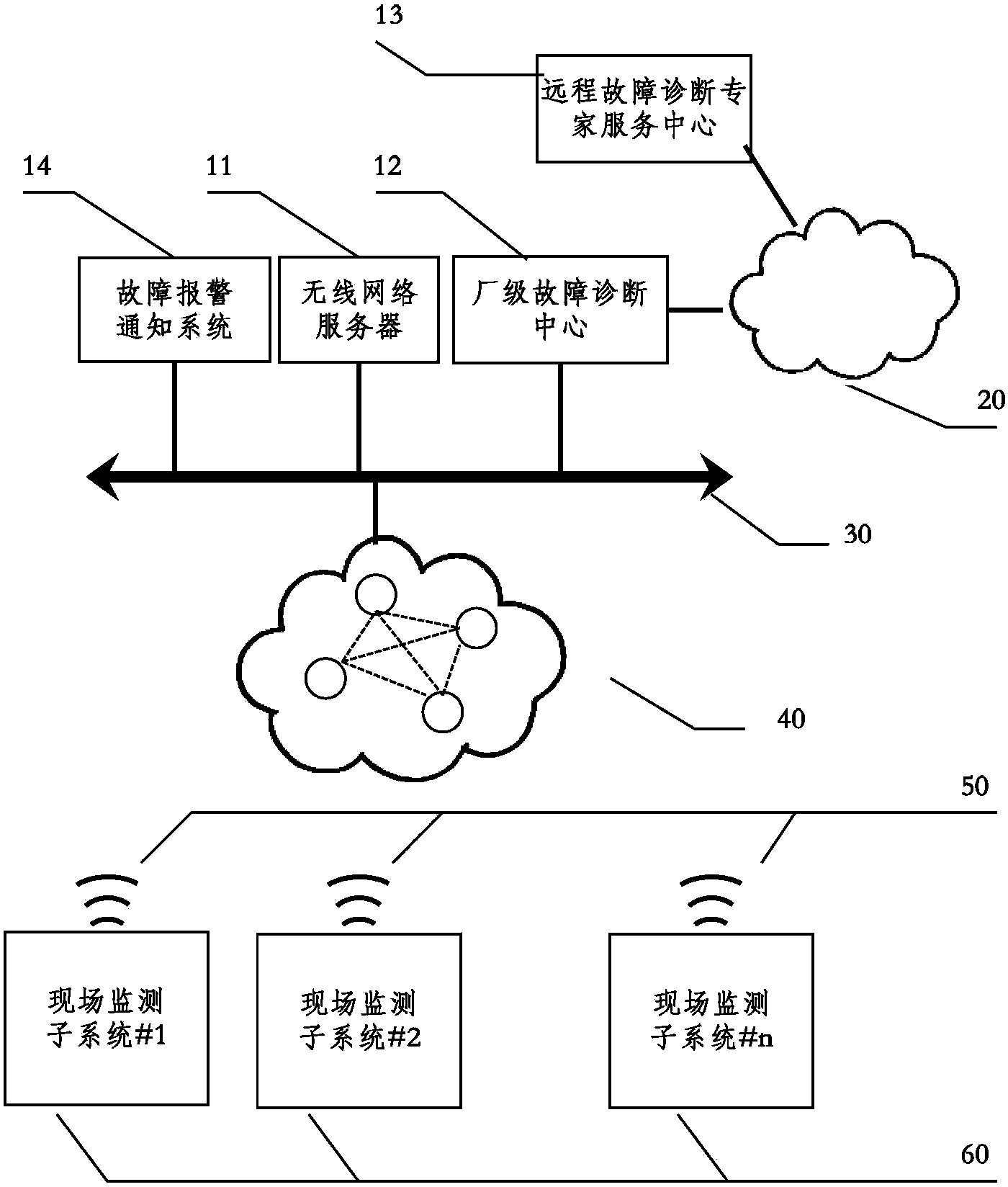

Device fault pre-maintenance method based on industrial wireless technology

InactiveCN103913193AEliminate dead endsIncrease flexibilityMeasurement devicesTransmission systemsIndustrial EthernetMonitor equipment

The invention relates to a device fault pre-maintenance method based on an industrial wireless technology. In the method, through data communication of an industrial wireless network and an industrial Ethernet, real-time monitoring and fault pre-maintenance are performed on an on-site device. The method includes the following steps: an upper computer performs parameter configuration on on-site instruments, which are used for monitoring the device, through the industrial Ethernet and the industrial wireless network; the instruments acquire sensor information of the on-site device according to the parameter configuration and upload result data, which is obtained after local processing of the sensor information, to the upper computer through the industrial wireless network and the industrial Ethernet; the upper computer performs fault diagnosis according to the result data and judges the operation state of the device; and if the fault diagnosis result is obtained, on-site maintenance personnel are notified through a fault alarm so as to maintain the device.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

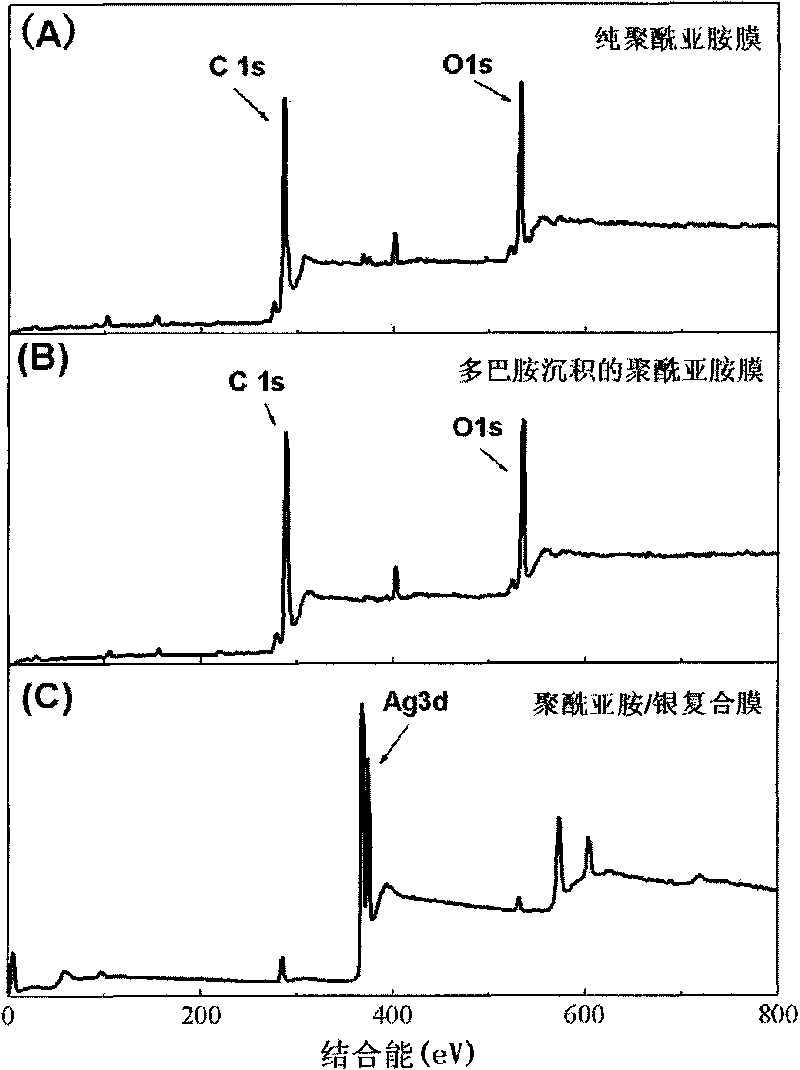

Method for preparing polymer/silver composite membrane by depositing dopamine

InactiveCN101724841ASimple and fast operationShort timeLiquid surface applicatorsSuperimposed coating processPolymeric surfaceChemical industry

The invention discloses a method for preparing a polymer / silver composite membrane by depositing dopamine, which belongs to the field of surface medication for the polymer. The prior polymer surface metallization art has the problems of long time, bad electric conductivity and the like. The method comprises the following steps of: depositing dopamine on the surface of the polymer membrane under an alkaline condition; arranging the polymer membrane, on which the dopamine is deposited, in silver plating solution; and adding reducer glucose solution into the mixture to prepare the polymer / silver composite membrane with high electric conductivity and high reflectivity. The method has simple and convenient operation, short time and low cost, and is applicable for all shapes and performance of polymer membranes. The prepared composite membrane has excellent electric conductivity and high reflectivity, and is applicable for chemical industry, metallurgy, new materials, microelectronic devices, military industrial technology and life system.

Owner:BEIJING UNIV OF CHEM TECH

Negative ion flame-retardant anti-bacterial fiber and preparation method thereof

InactiveCN101586267ASimple manufacturing methodWith mechanical propertiesFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberPolyester

The invention provides negative ion flame-retardant anti-bacterial fiber belonging to the field of textile industry technique and a and preparation method thereof, the weight percentages and components thereof are as follows: polyester fibre 92-99%, compound combustion inhibitor 0.6-6.4%, antimicrobial powder 0.1-1.6% and negative ion generating agent 0.1-1.6%. The method provided by the invention can prepare negative ion flame-retardant anti-bacterial fiber which can simultaneously reach national architectural material flame-retardant performance B1 grade standard and conform to national antimicrobial material specification, with 6140 / cm of negative ion generating number density.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

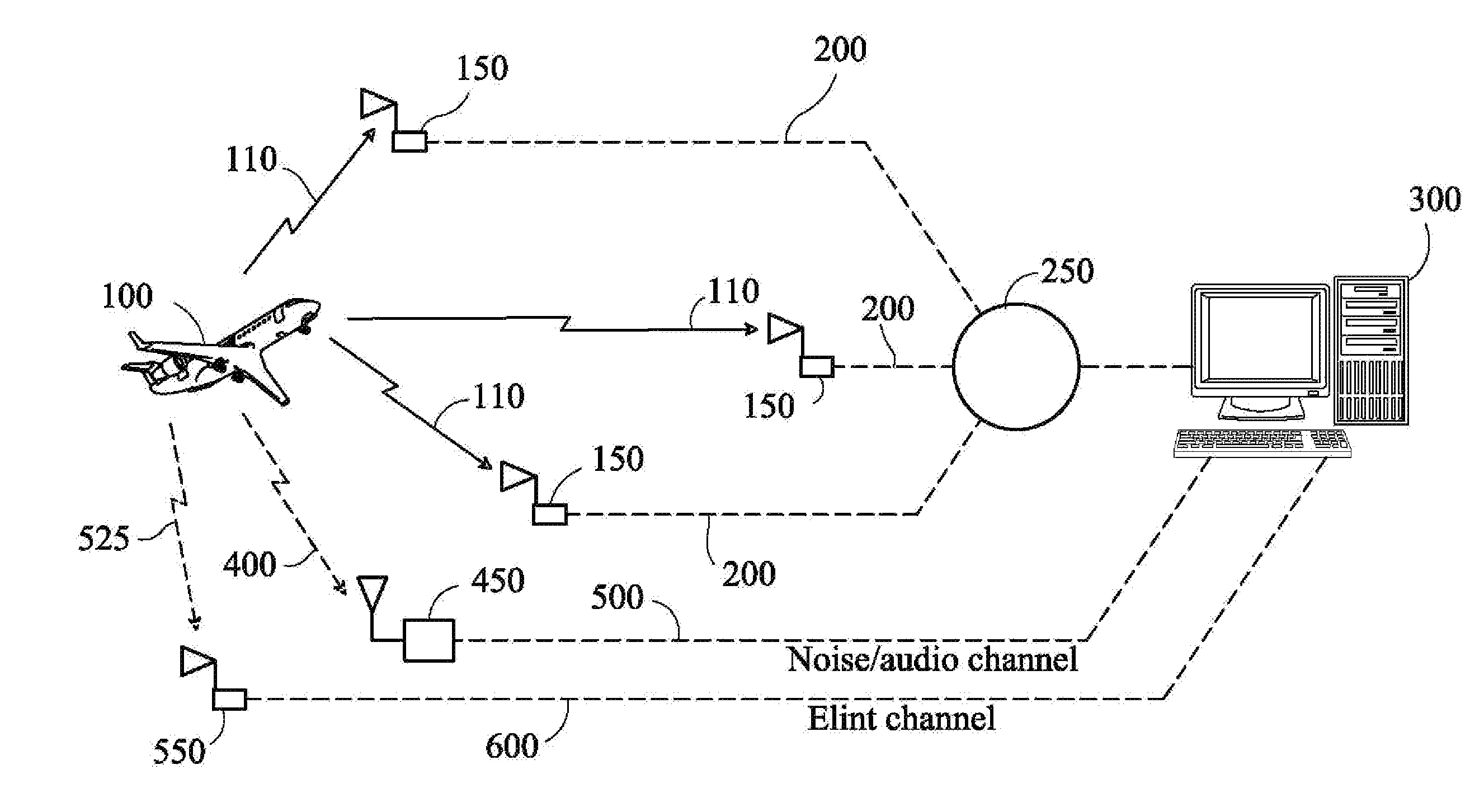

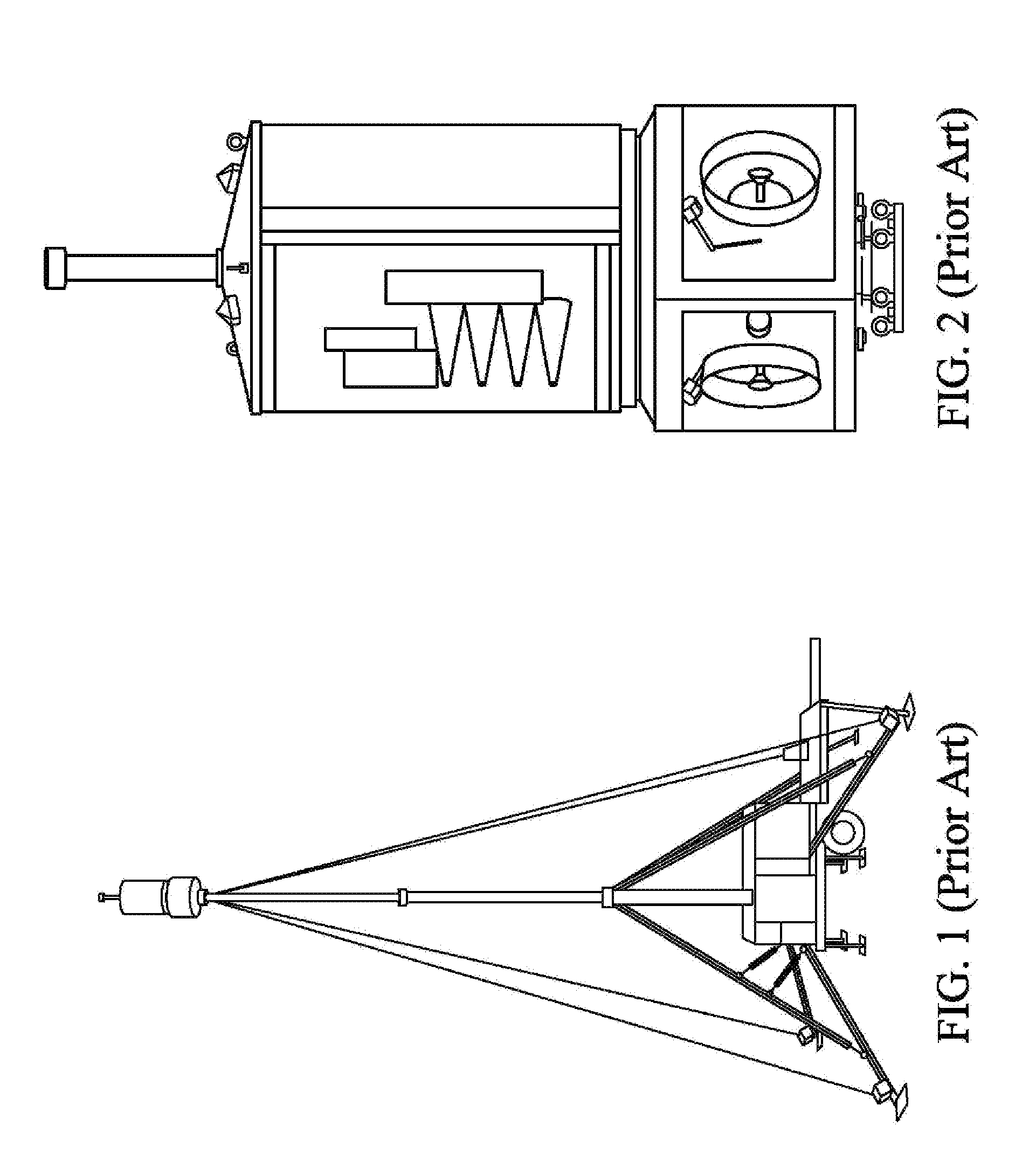

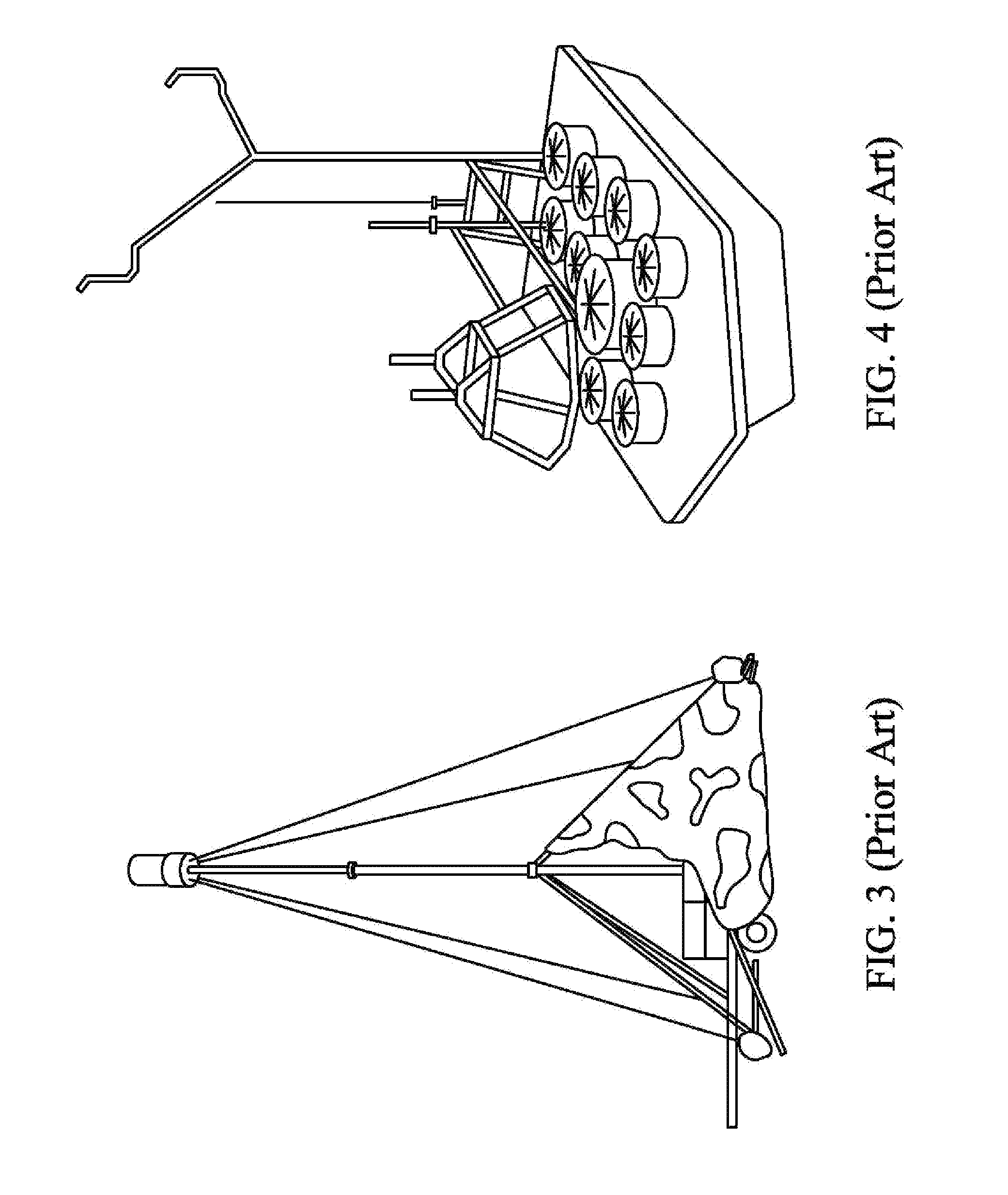

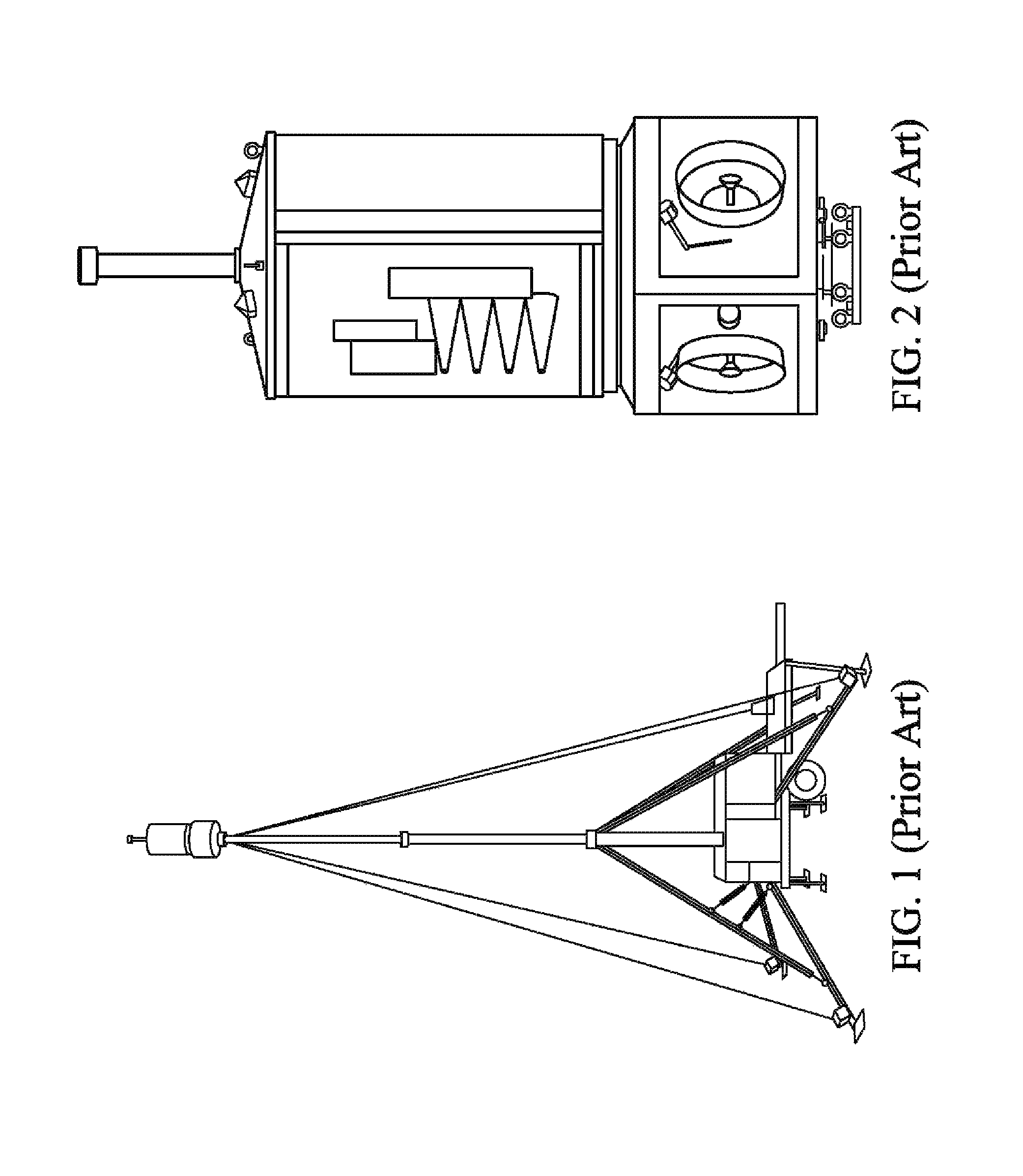

Deployable intelligence and tracking system for homeland security and search and rescue

This invention builds on previous industry techniques to correlate data from a variety of sources for the purposes of tracking and identifying aircraft, vehicles, and marine vessels in real time over a variety of different areas including oceans and mountainous terrain. Passive broadband tracking of aircraft emitters, and electronic fingerprinting of emitters, correlated with audio, video, infrared, primary radar and other information is employed to provide a comprehensive assessment of an aircraft's position, track and identification for a variety of applications including homeland security and search and rescue.

Owner:ERA AS

Propellant depot in space

InactiveUS7559508B1Improve efficiencyLow costLaunch systemsCosmonautic power supply systemsPropellant depotMature technology

A space transportation propellant depot has multiple locations, sources and capabilities. Maximizing known mature technologies coupled with realistic industrial techniques results in the incremental development of a propellant source on the moon. Propellant depots are economically driven locations with defined services, sources of propellant and innovation in the pursuit of transportation related commerce as mankind explores for resources beyond Earth.

Owner:TAYLOR THOMAS C +2

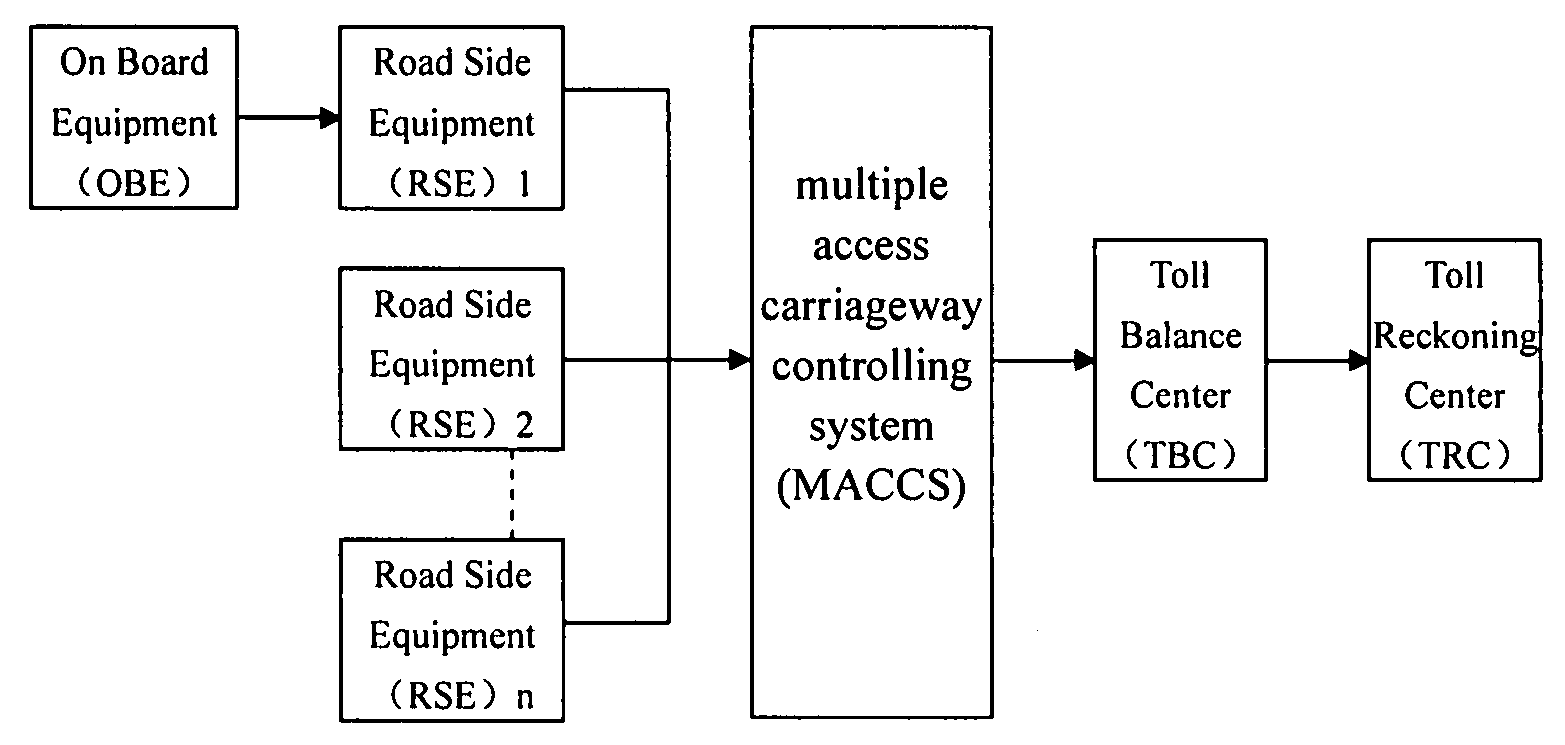

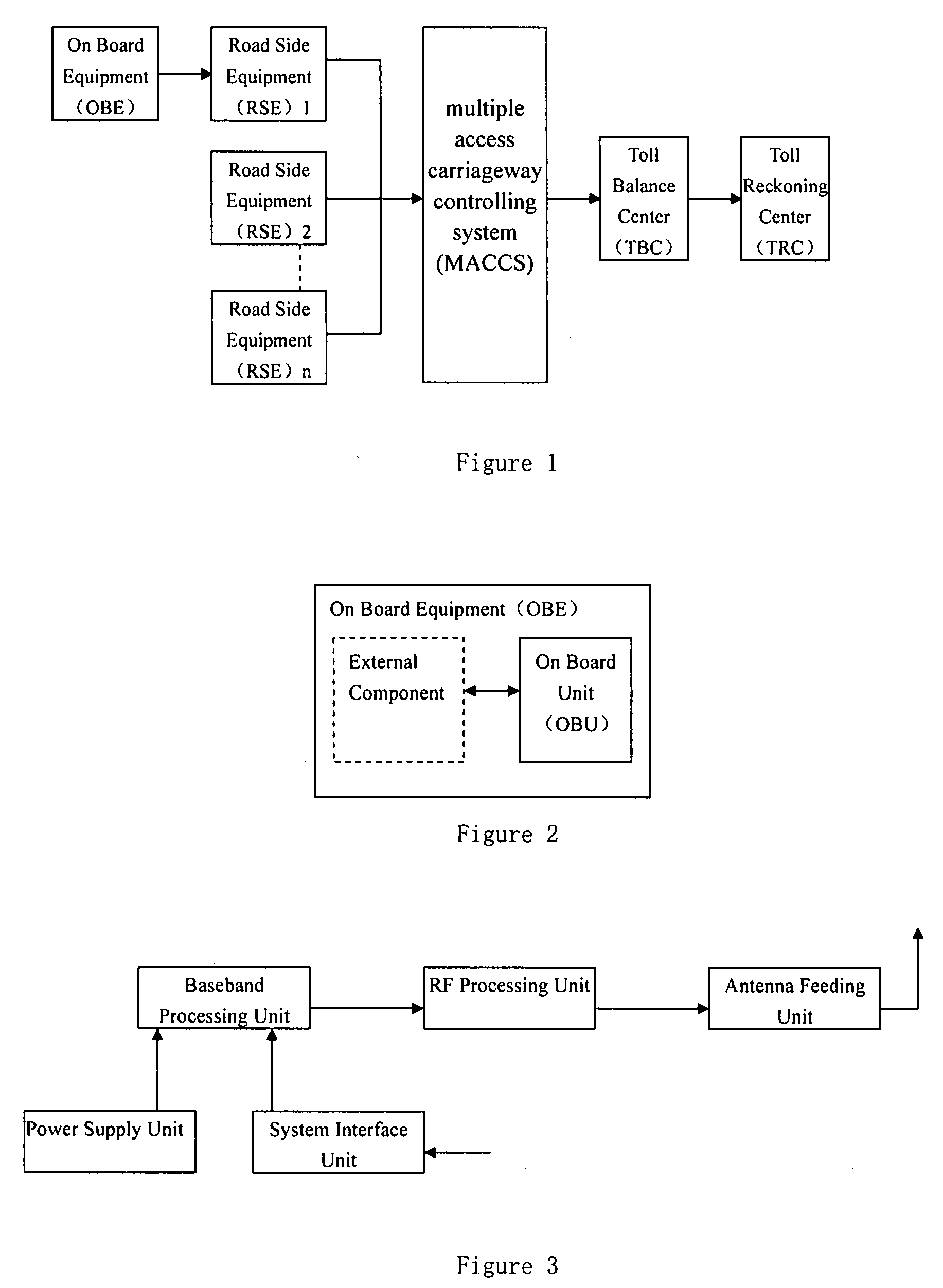

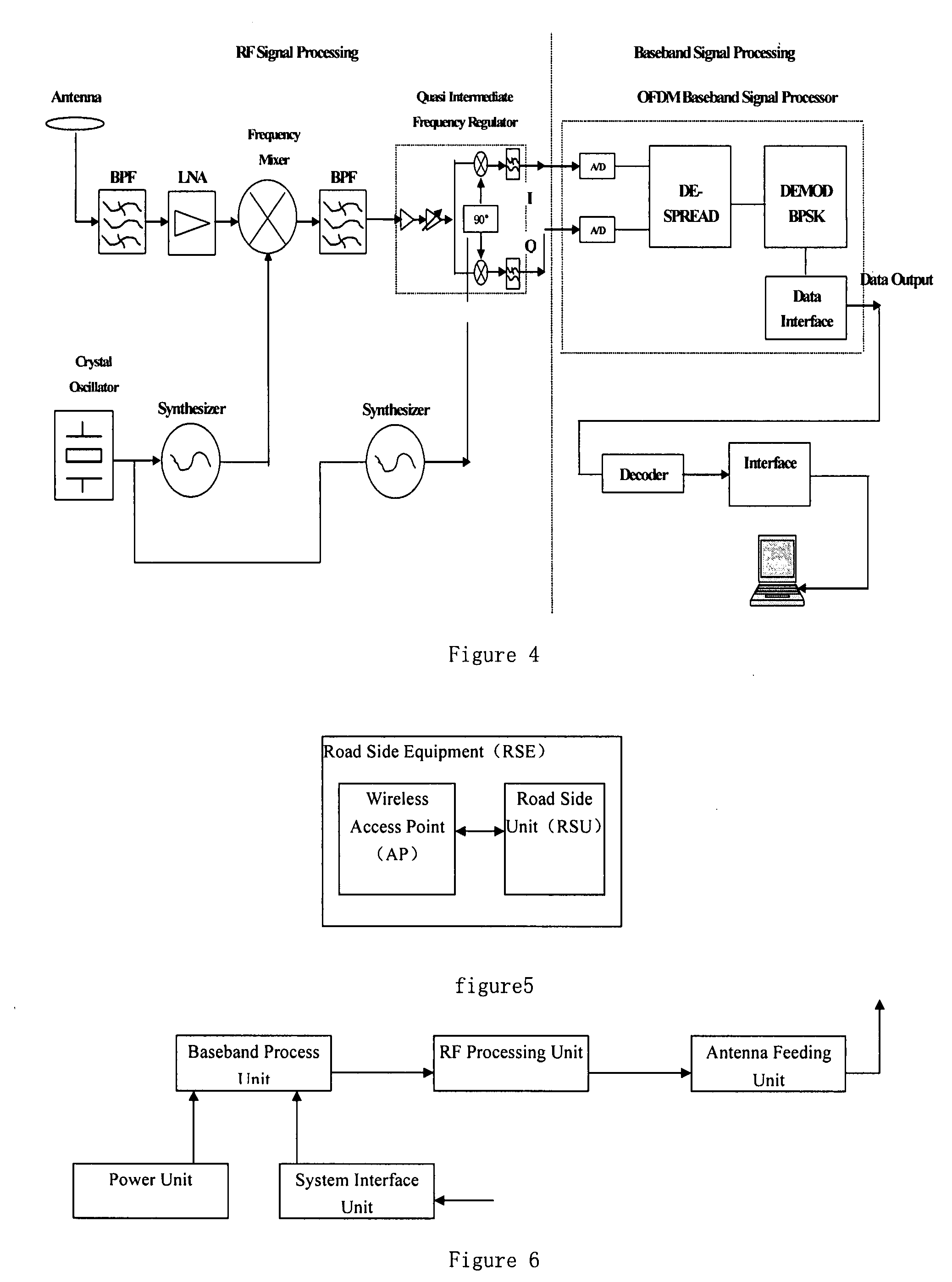

Wlan-Based No-Stop Electronic Toll Collection System and the Implementation Thereof

ActiveUS20090121898A1Effectively overcome technology prejudiceLow costControlling traffic signalsTicket-issuing apparatusComputer networkElectronic toll collection system

A no-stop electronic toll collection (ETC) system based on WLAN is disclosed in the present invention. The system includes an on-board equipment, roadside equipments, a multiple access carriageway control system and a toll balance center. The communication is implemented between the on-board equipment and the roadside equipments according to the demand determined by the wireless local network protocol. The system offered in the present invention applies several technology means to effectively overcome the technology prejudice that the WLAN technology is not suitable for the ETC system. Compared with the existing technology, the present ETC system has the advantages of low cost, high efficiency, complete function and good performance index, therefore the present invention is very meaningful for the application and extension of the ETC system and the improvement of the industrial technology.

Owner:BEIJING WATCH DATA SYST

Method for producing alcohol and feed by utilizing seaweed chemical waste material

InactiveCN101024847AEconomic Industrial TechnologyEnvironmental Industrial TechnologyAnimal feeding stuffMicroorganism based processesLiquid wasteChemical industry

The invention discloses a method for producing alcohol and feed by alga chemical waste, i.e. using the cellulose-containing waste residues as raw materials formed in the course of producing sodium alginate, mannitol, I or trehalose glue products in the alga chemical industry, making enzymatic hydrolysis by cellulase and anaerobic fermentation by brewing yeast or double fermentation by cellulase producing bacteria and brewing yeast, then making solid-liquid separation and obtaining alcohol and feed. And the invention provides economic, environmental protection and effective industrial technique for waste residues and waste liquid in the alga chemical industry, able to turn waste into wealth and provide important technical support for full and high value utilization of alga resources and development of alga circulating economy.

Owner:SHANDONG UNIV

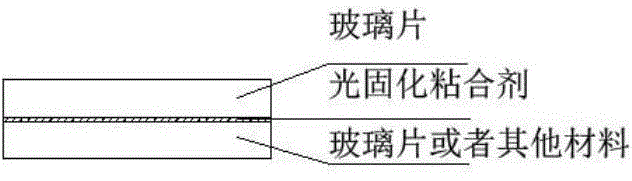

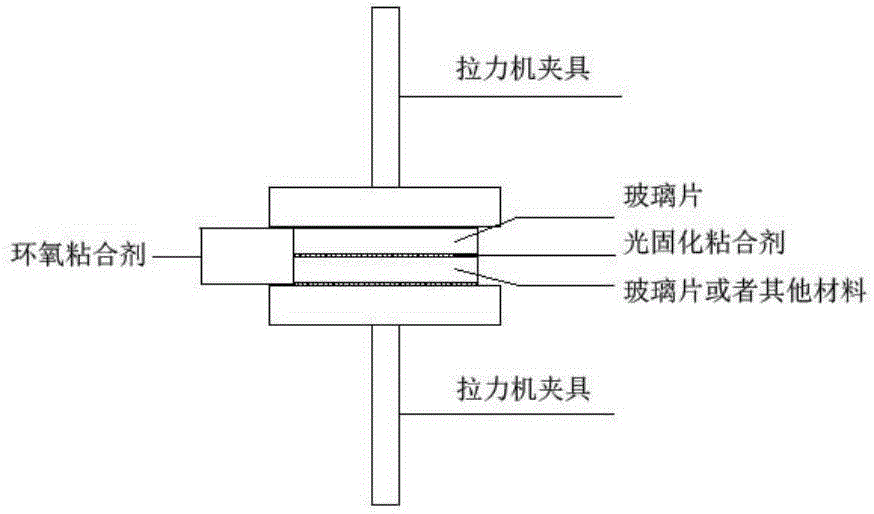

Preparation method of novel dual-cured UV curing binder

InactiveCN104449542AAdhesive processesNon-macromolecular adhesive additivesMetallic materialsDouble bond

The invention relates to a preparation method of a novel dual-cured UV curing binder, and belongs to the technical field of binder industry. The novel dual-cured UV curable binder is prepared by using radical polymerizable resins such as common urethane acrylate, epoxy acrylate and unsaturated polyester as main binding materials, using a double bond-containing reactive diluent as a solvent, and using a UV initiator and a thermal initiator as a compound initiator, supplemented by other binding agents. During curing, a certain initial binding power is firstly obtained by UV curing, and higher binding power is obtained by secondary curing through heating or oxygen isolation. The preparation method provided by the invention not only has the advantages of high curing speed of the traditional light curing binders, but also has the advantages of effectively avoiding the generation of internal stress in the curing process of the traditional light curing binder, and improving the binding strength of the binder; the binder has excellent solvent resistance, high binding strength, and low cost. The binder is widely used for binding glass and glass, glass and metal materials and other transparent materials.

Owner:JIANGNAN UNIV

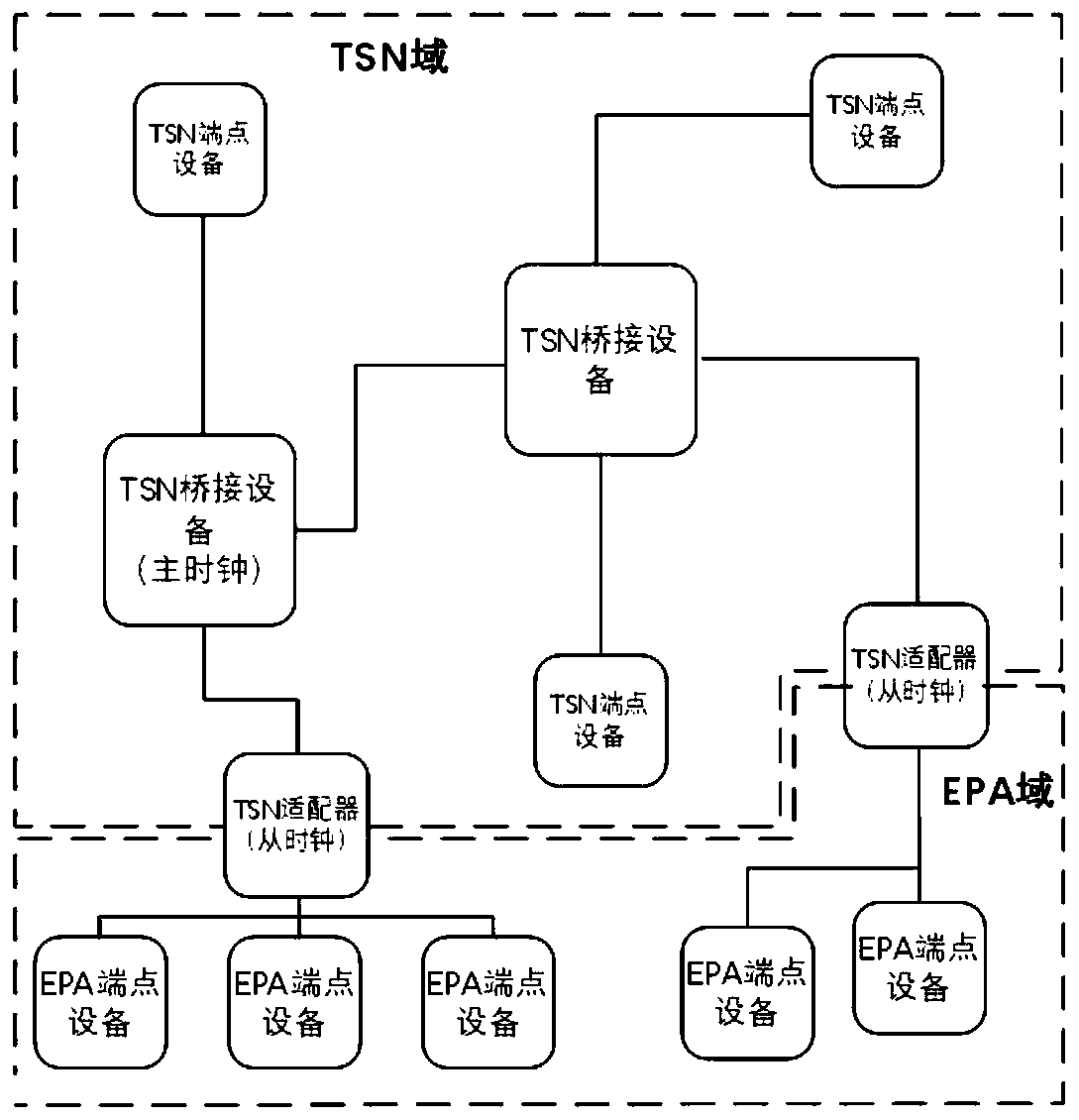

EPA industrial bus and time sensitive network adaptation system and method

ActiveCN110943899AProtect normal transmissionEfficient use ofTime-division multiplexNetworks interconnectionLow jitterLow delay

The invention relates to an EPA industrial bus and time sensitive network adaptation system and method, solves the technical problem that an EPA Ethernet cannot be connected with a time sensitive network in real time to construct a fast channel, and comprises an EPA endpoint device and a TSN endpoint device. The EPA endpoint device is in communication connection with a TSN bridging device througha TSN adapter, and the TSN bridging device is connected with the TSN endpoint device; the TSN adapter receives the time data issued by the main clock from the TSN bridging device, and adds a timestampin the process of receiving or transmitting the clock synchronization data to complete clock synchronization; and the TSN bridging device is used for providing time synchronization, low delay, low jitter and flow bandwidth guarantee, so that the problem is better solved, and the method can be applied to the EPA industrial technology.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

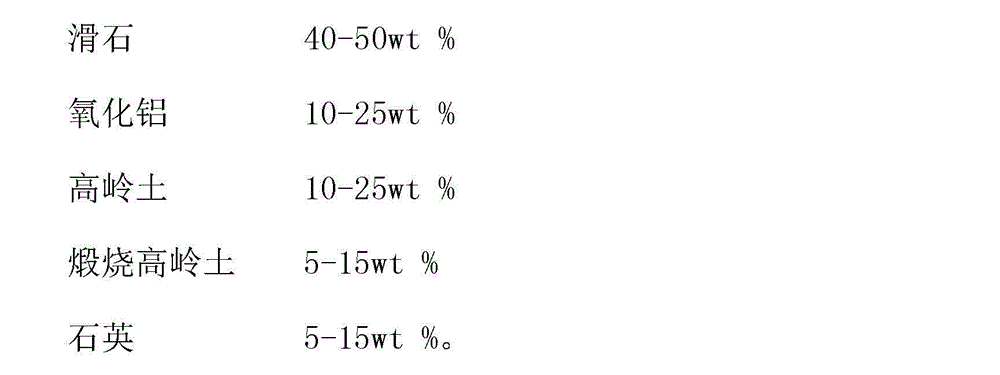

Honeycombed porous ceramic having high thermal conductivity and ultralow expansion coefficient

ActiveCN103145439AGood coating effectImprove mechanical propertiesCeramicwareCeramic moldingCrystal orientation

A honeycombed porous ceramic having a high thermal conductivity and an ultralow expansion coefficient relates to the technical field of the silicate industry. The ceramic having a low even negative thermal expansion coefficient and a high thermal conductivity is obtained through treating a rare earth mixture, potassium phosphotungstate, zirconium oxide and amorphous quartz particles as a sintering aid, and expansion coefficient and thermal conductivity adjustment agents, and the ceramic has a high-orientation sheet iolite structure and has a good catalyst coating performance and good mechanical strengths; and ethylene oxide having different molecular weights are adopted as a ceramic molding binder, rapeseed oil or peanut oil is treated as a primary molding lubrication agent, a paste goes through a high-pressure extruder orientation extruding channel, a crystal orientation carding die and a honeycombed porous die to obtain a green body having high-orientation arranged crystals, and a special sintering curve is adopted to obtain the ceramic. The above whole ceramic preparation process flow and the above formula are economic, stable and environmentally-friendly.

Owner:安徽中鼎美达环保科技有限公司

Cultivation method for good-quality and high-yield peonies

InactiveCN104718940AImprove survival rateEasy to controlBio-organic fraction processingOrganic fertiliser preparationAgricultural engineeringIndustrial technology

The invention discloses a cultivation method for good-quality and high-yield peonies. The method includes the steps that fine soil preparation is conducted; base fertilizer is applied; plant division is conducted; planting is conducted; field management is conducted; harvesting is conducted. The invention provides an artificial cultivation production technology of the good-quality and high-yield peonies. Supported by the base of a modern agricultural science and technology, the survival rate is high, the course can be controlled, the production cycle is short, and the method is easy and convenient to operate by using the plant division method of a modern industrial technological means; the good-quality and high-yield peonies can be obtained, the yield per unit area by 1500-2000 kg of fresh roots is achieved.

Owner:ANHUI YIYUAN PHARMA CO LTD

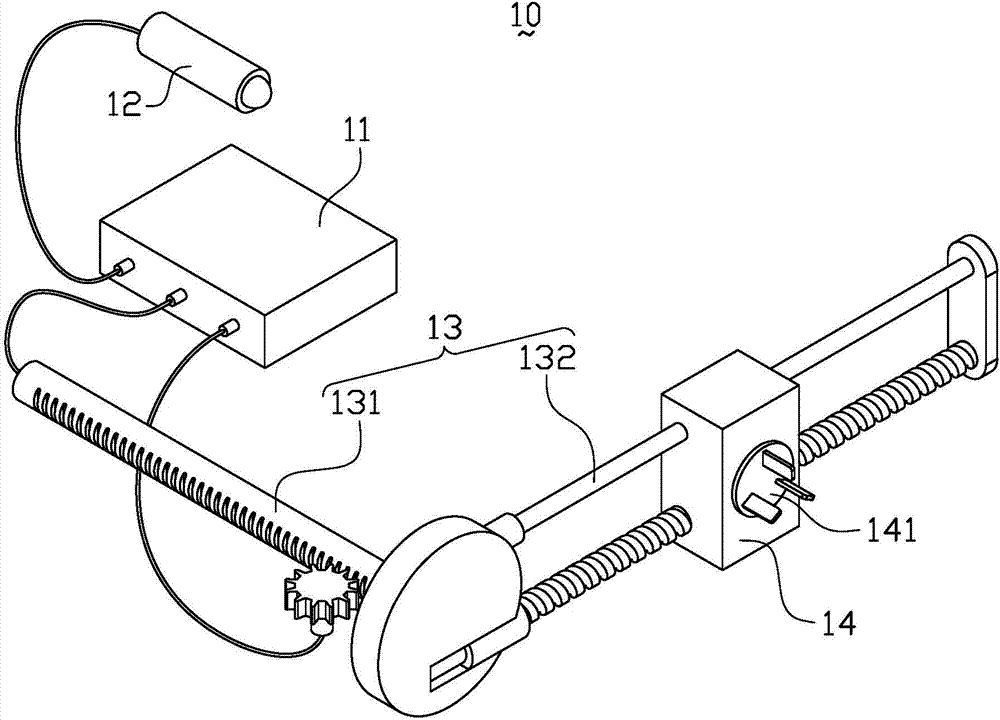

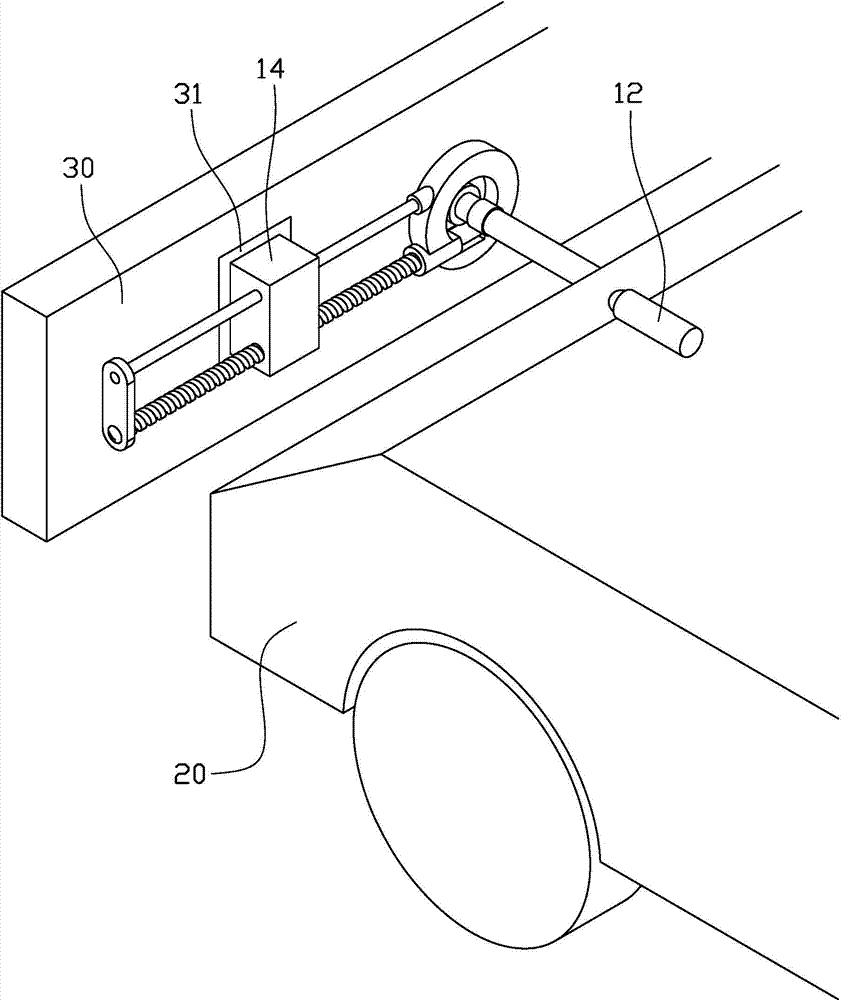

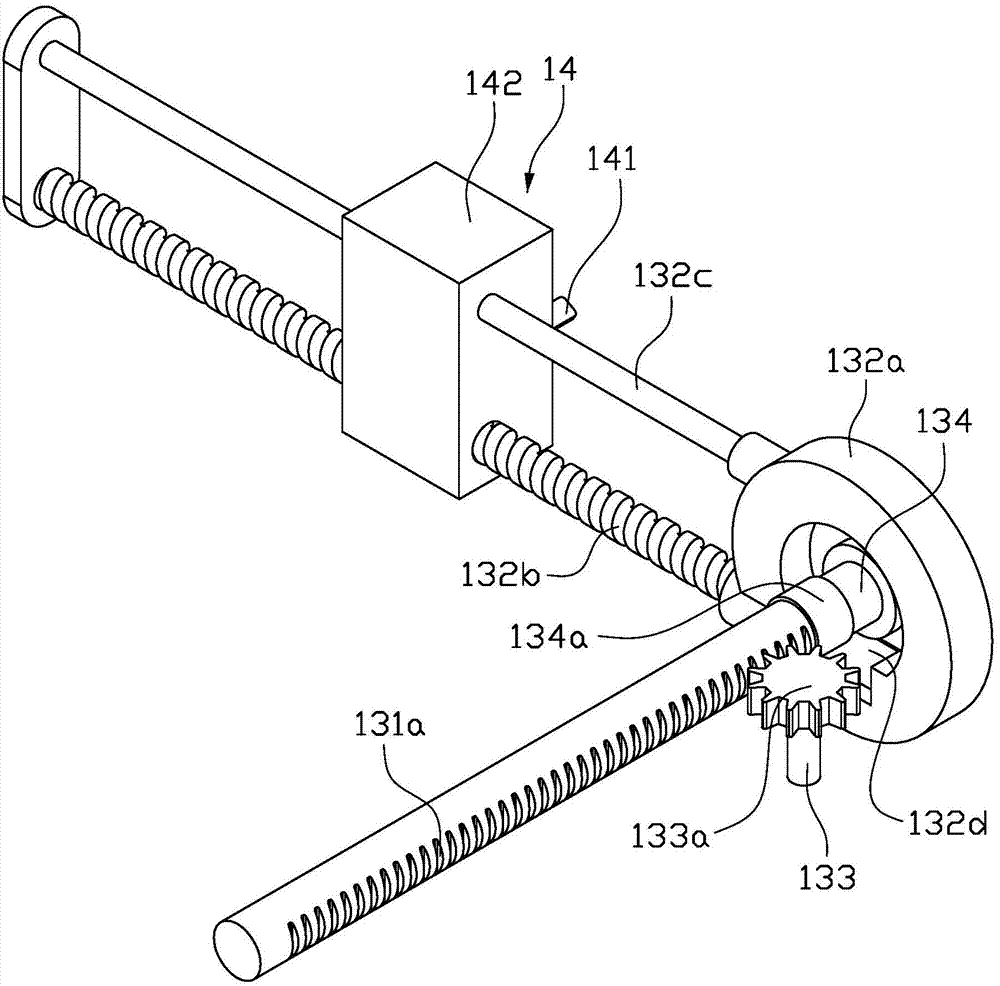

On-board charging unit and automatic charging method applying the same

ActiveCN104124736ALow costEasy to useBatteries circuit arrangementsSecondary cells charging/dischargingIn vehicleOn board

Disclosed is an on-board charging unit. The on-board charging unit comprises a controller, a position detector, a mechanical arm and a charging mechanism, wherein the controller is connected the position detector, the mechanical arm and the charging mechanism through signals respectively, the position detector is used for collecting charging jacks around a vehicle body and position information of the mechanical arm and the charging mechanism, the mechanical arm is connected with the vehicle body, the charging mechanism is slidingly arranged on the mechanical arm, the front end of the charging mechanism is provided with a charging plug, and the controller controls the charging mechanism to slide on the mechanical arm to a position enabling the charging plug to correspond to the charging jacks and controls the mechanical arm to drive the mechanism to plug the charging plug into the charging jacks. The on-board charging unit can automatically determine the position of the charging jacks through the cooperation of the controller, the position detector and the mechanism arm, can automatically extend the mechanical arm to connect the jacks for charging and automatically retract the mechanical arm after charging, integrates existing mature industrial technologies and is low in costs and convenient to use.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

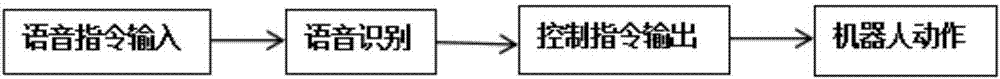

Deep learning-based intelligent industrial robot speech interaction and control method

InactiveCN106898350AChange the way of productionReduce labor intensitySpeech recognitionSpeech identificationSpeech sound

The invention discloses a deep learning-based intelligent industrial robot speech interaction and control method. The method comprises the following steps that: 1) speech is converted into a speech spectrum: original speech is converted into an image through FFT (Fast Fourier Transformation), wherein the image can be used as input; 2) modeling is performed on the whole speech sentence: the speech spectrum, adopted as input, is utilized to perform unsupervised training on a convolutional neural network; 3) the output sequence O of the convolutional neural network is compared with a tag T, and the convolutional neural network is adjusted in a supervised manner through the BP algorithm; and 4) specific text information is inputted into a robot as a control command. According to the deep learning-based intelligent industrial robot speech interaction and control method of the invention, the speech recognition technology and the industrial robot are combined together, and therefore, a traditional production mode is changed, the labor intensity of workers is decreased, labor productivity is enhanced, and the intelligentization development of industrial technologies can be promoted.

Owner:SOUTH CHINA UNIV OF TECH

Plant cultivation methods, cultivation modules and commercial uses thereof

InactiveCN103026888AAvoid churnReduced leak-tight requirementsCultivating equipmentsHorticulturePlant cultivationIndustrial technology

The invention discloses various plant cultivation methods for getting rid of the constraint of natural conditions as much as possible and utilizing the industrial technology. Plants are cultivated in cultivation modules; and the various cultivation methods are formed by combining the characteristics of no leakage, full and tight covering, medium layering, enhanced mobility and the like, and the reference basis for the capacities and the shapes of the cultivation modules is defined. The invention further discloses the various cultivation modules used for the methods, and the various cultivation modules are formed by combining the characteristics that a main part does not leak, a covering part can be fully and tightly covered, the growth of the plants to the outside of the cultivation modules can not be limited, no obvious adverse effect on root system growth is generated, the cultivation measures aiming at a wrapping part are conveniently implement, a breathable material structure, a device for preventing water accumulation and the like are adopted. The invention further discloses three commercial uses of the plant cultivation methods and the cultivation modules: determining a production and sales supervising mode, carrying out fresh-keeping or rooting cultivation and producing plant cultivation goods easy to treat.

Owner:倪龙

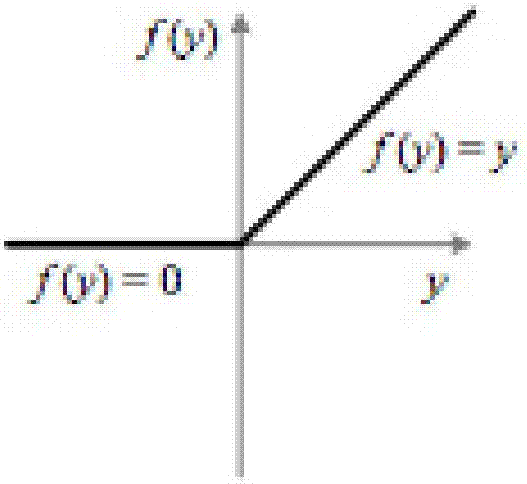

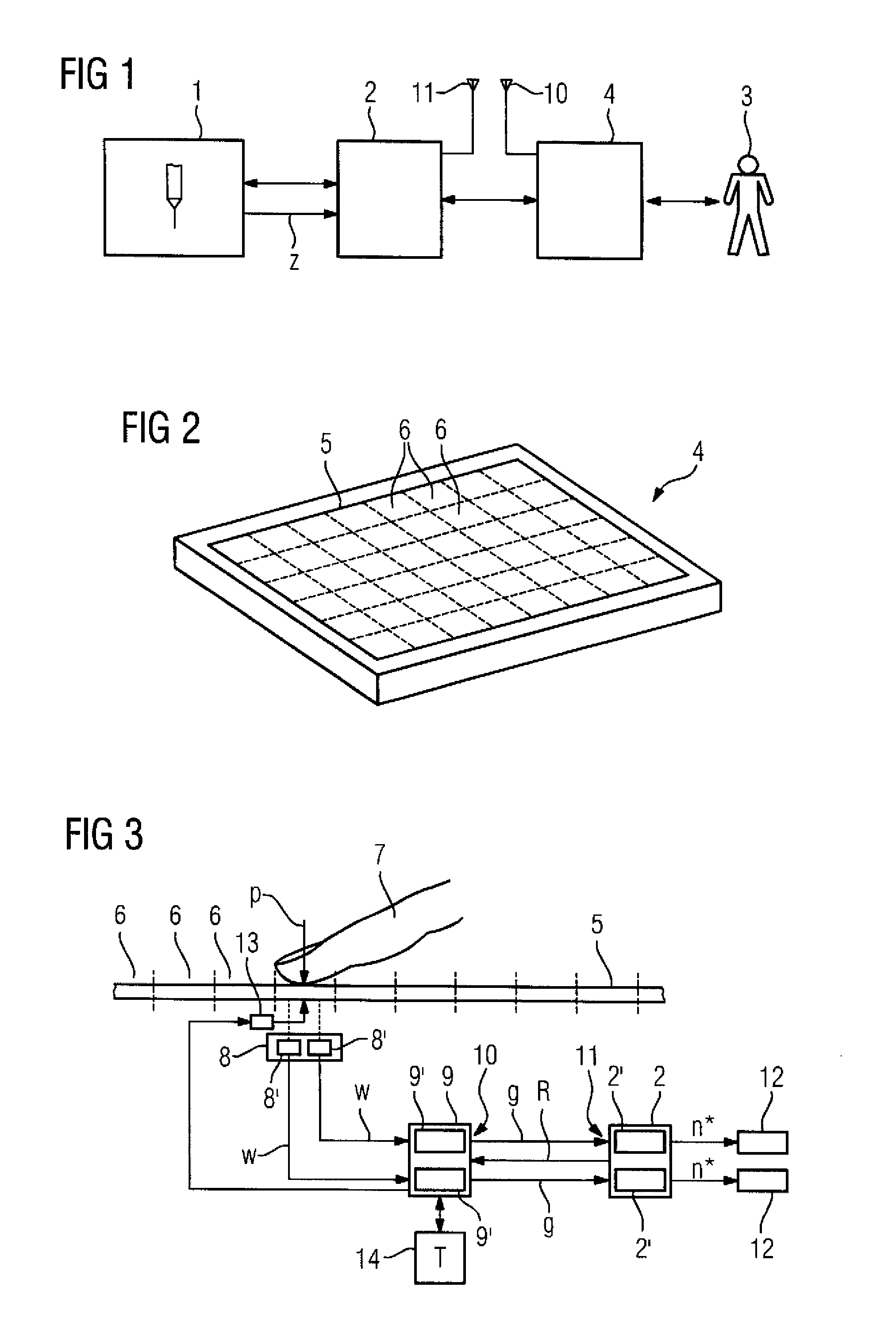

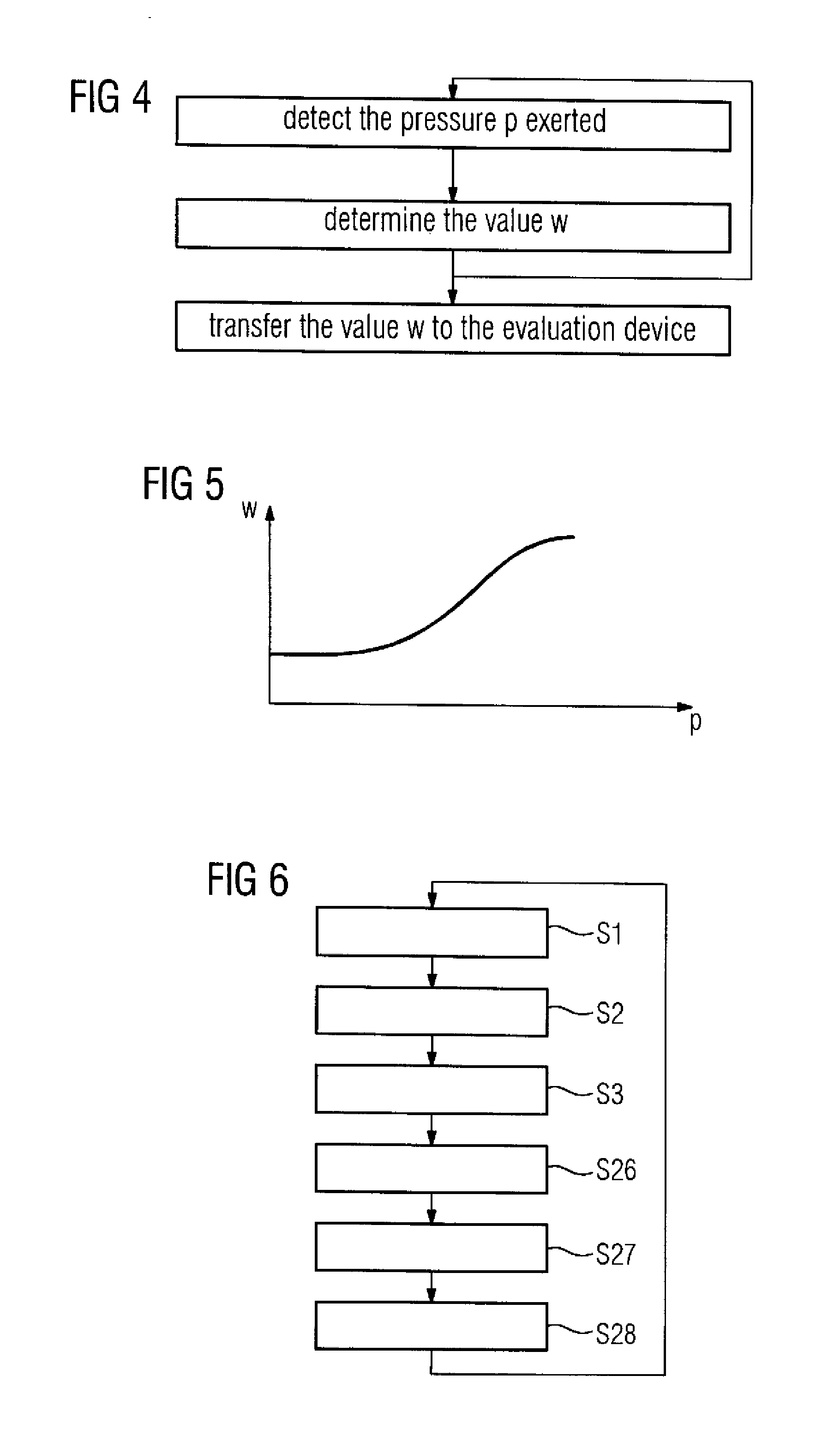

Touchscreen with analog pressure detection as user interface for industrial technical device

InactiveUS20130307799A1Avoid high pressureIncrease valueProgramme controlInput/output processes for data processingOperation modeTouchscreen

Pressure is applied to an area of a touchscreen by an operator of an industrial technical device. A value dependent on the applied pressure is generated by a sensor device associated with the area and supplied to an evaluation device. In a normal operating mode, a variable dependent on the applied pressure is transmitted by the evaluation device to a control device. The control device activates an element of the industrial technical device and outputs to the element a setpoint value dependent on the applied pressure, when the pressure defined by the transmitted variable exceeds a first threshold value. The setpoint value is a monotonously increasing function of the pressure and has the value zero until the pressure exceeds a second threshold value greater than the first threshold value.

Owner:SIEMENS AG

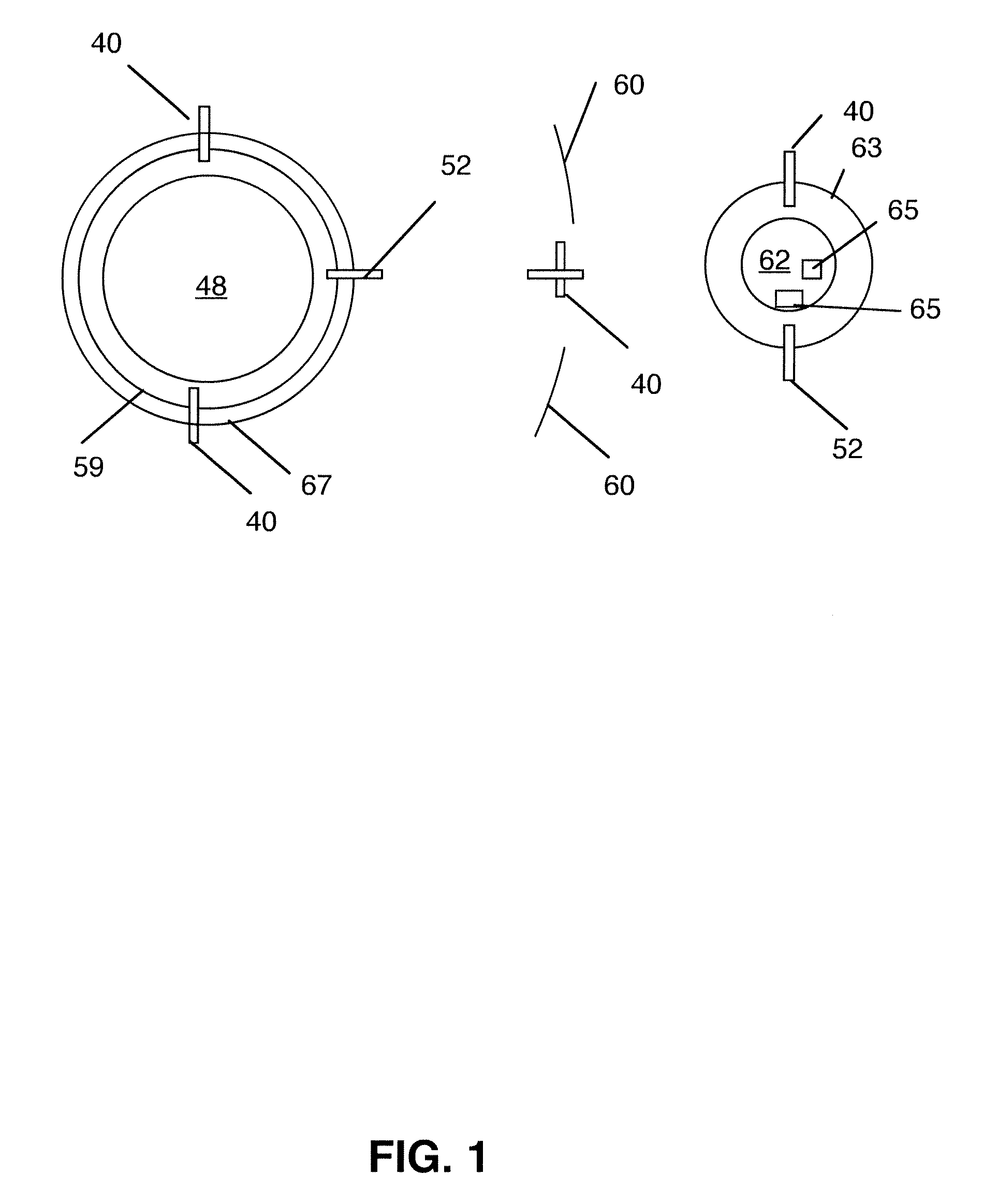

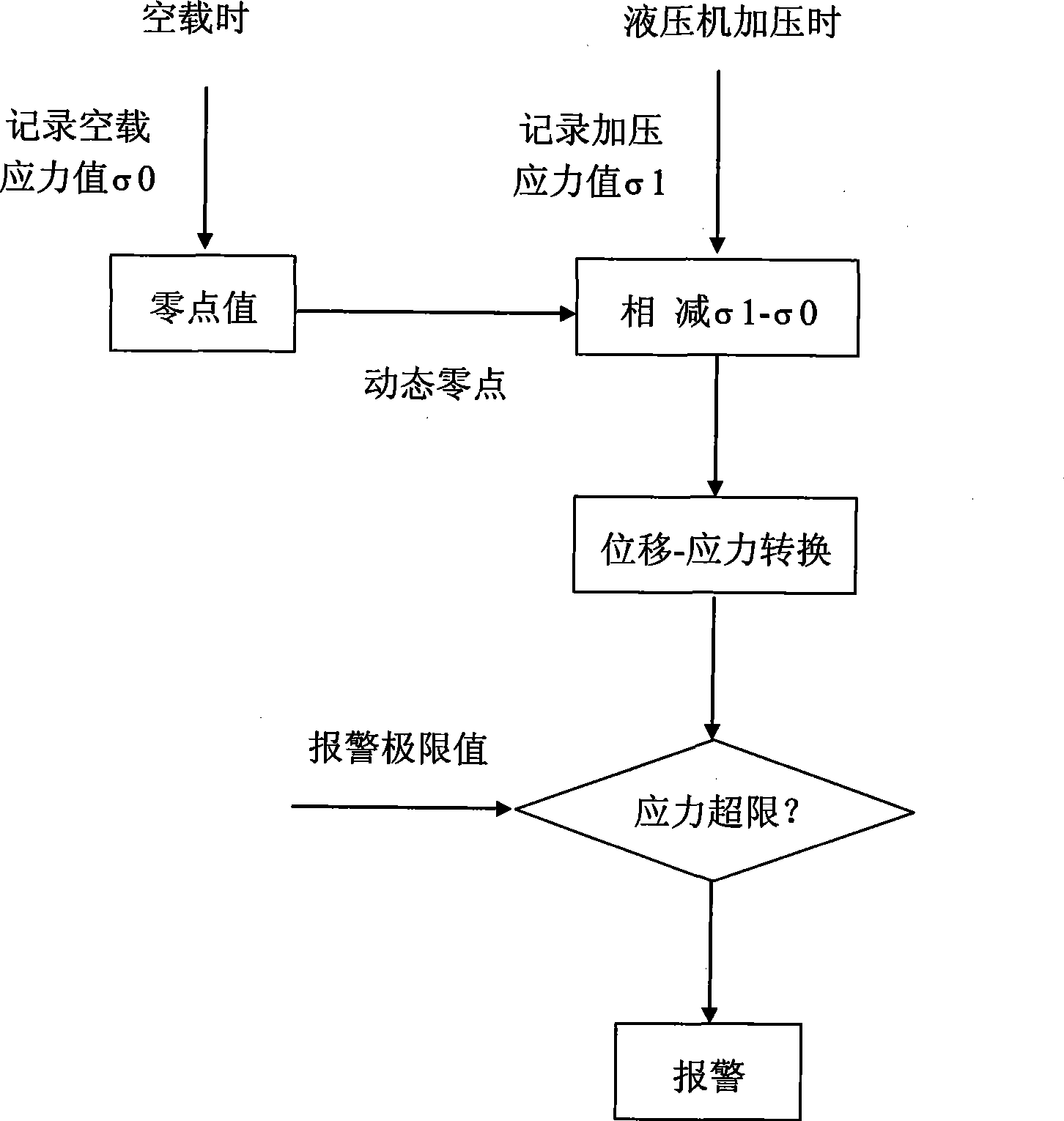

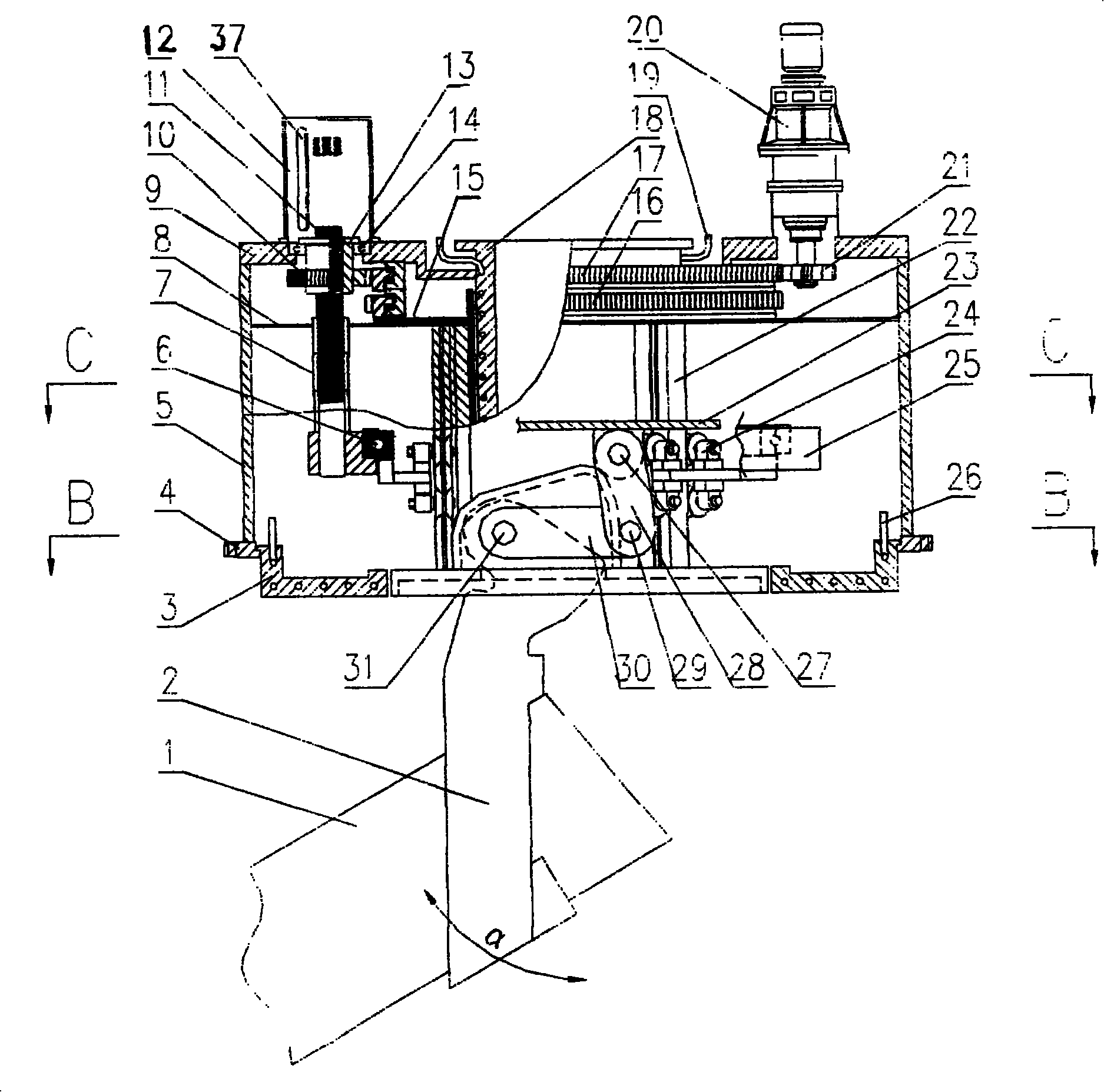

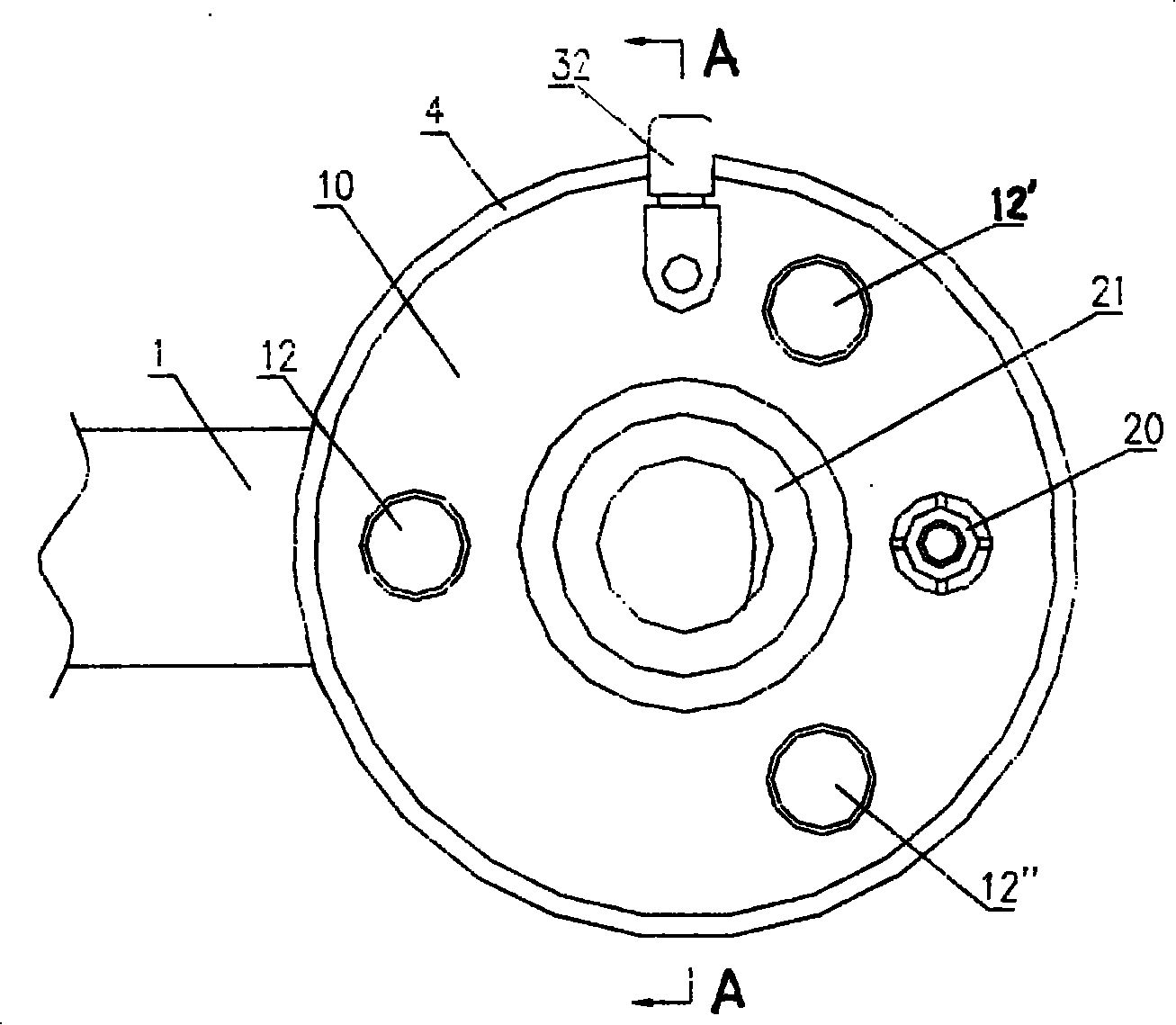

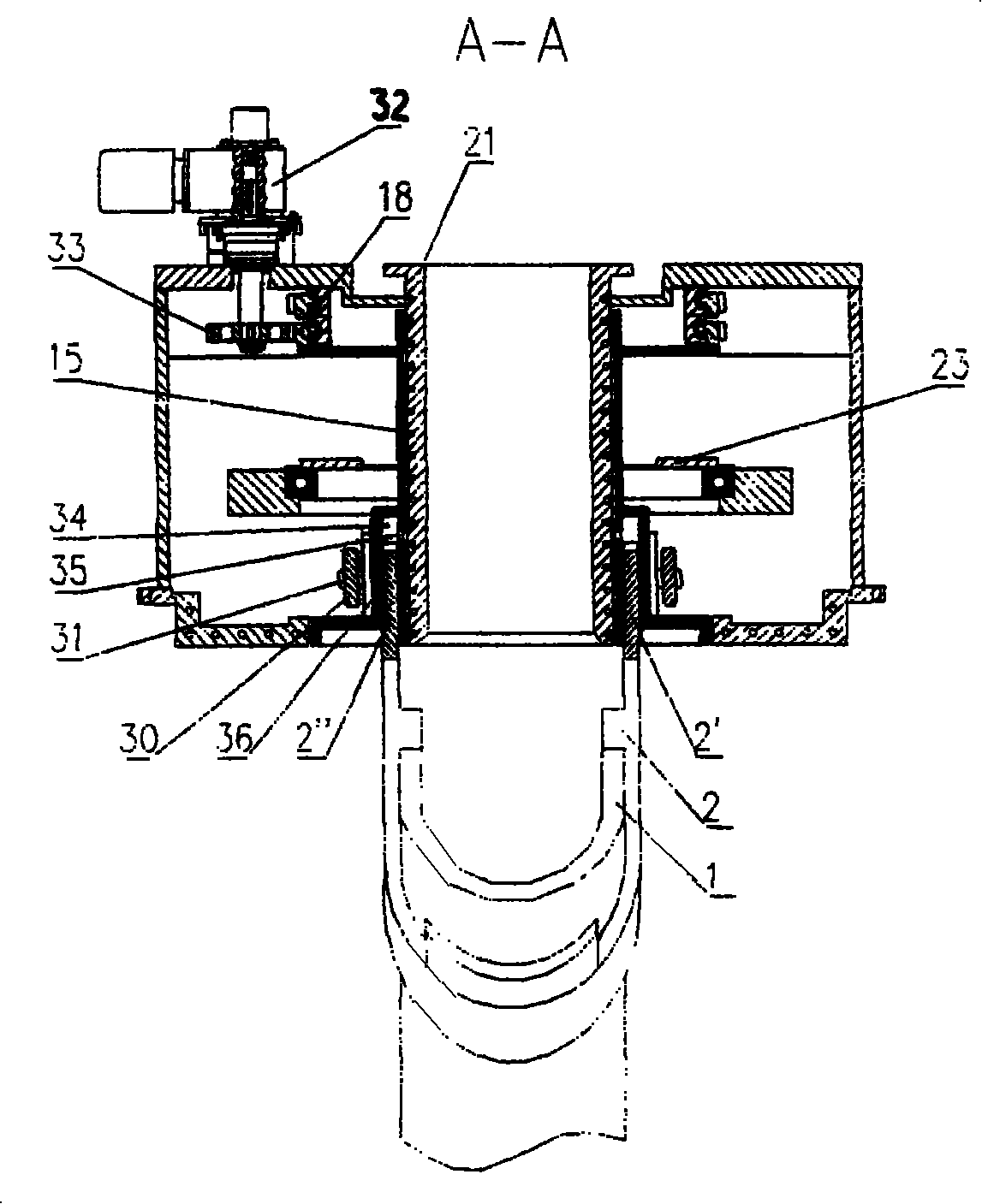

Giant stamp forging hydraulic press upright post stress harvester and stress monitoring system

ActiveCN101368856AExtended service lifeRealize long-distance transmissionForce measurementPressesStress conditionsAnalog-to-digital converter

The invention discloses a giant die forging hydraulic press column stress acquisition device, which is characterized in that a sensor bracket is arranged on an upright column; a displacement sensor is arranged on the sensor bracket; one end of a displacement connecting rod is sleeved in a through hole of the sensor bracket and positioned below the displacement sensor; and the other end of the displacement connecting rod is fixedly arranged on the upright column. The invention also discloses a giant die forging hydraulic press column stress monitoring system, which comprises the giant die forging hydraulic press column stress acquisition device, an analog-to-digital converter and a microprocessor; and the industrial fieldbus technology is adopted to achieve fully digital communication of the detection system. By effectively monitoring the hydraulic press working column stress conditions in a real-time manner, the invention greatly improves the safety, reliability, application and maintenance efficiency, thus extending the service life of the giant die forging hydraulic press.

Owner:CENT SOUTH UNIV

Method for producing high strenght flyash ceramic sand

InactiveCN1900008ALight weightHas high strengthCeramic materials productionClaywaresGranularityHigh intensity

The high strength fly ash haydite producing process belongs to the field of fly ash utilizing and new building material technology. The high strength fly ash haydite is produced with fly ash, clay, saw dust and coal powder, and through mixing in a stirrer, adding certain amount of water glass and controlling water content of about 20 %, pelletizing, sintering and cooling. The high strength fly ash haydite product has granularity of 3-5mm, bulk density of 800-900kg / cu m, and compression strength of 10-20 MPa, and may be used as aggregate of wall board.

Owner:JILIN ACAD OF AGRI MACHINERY

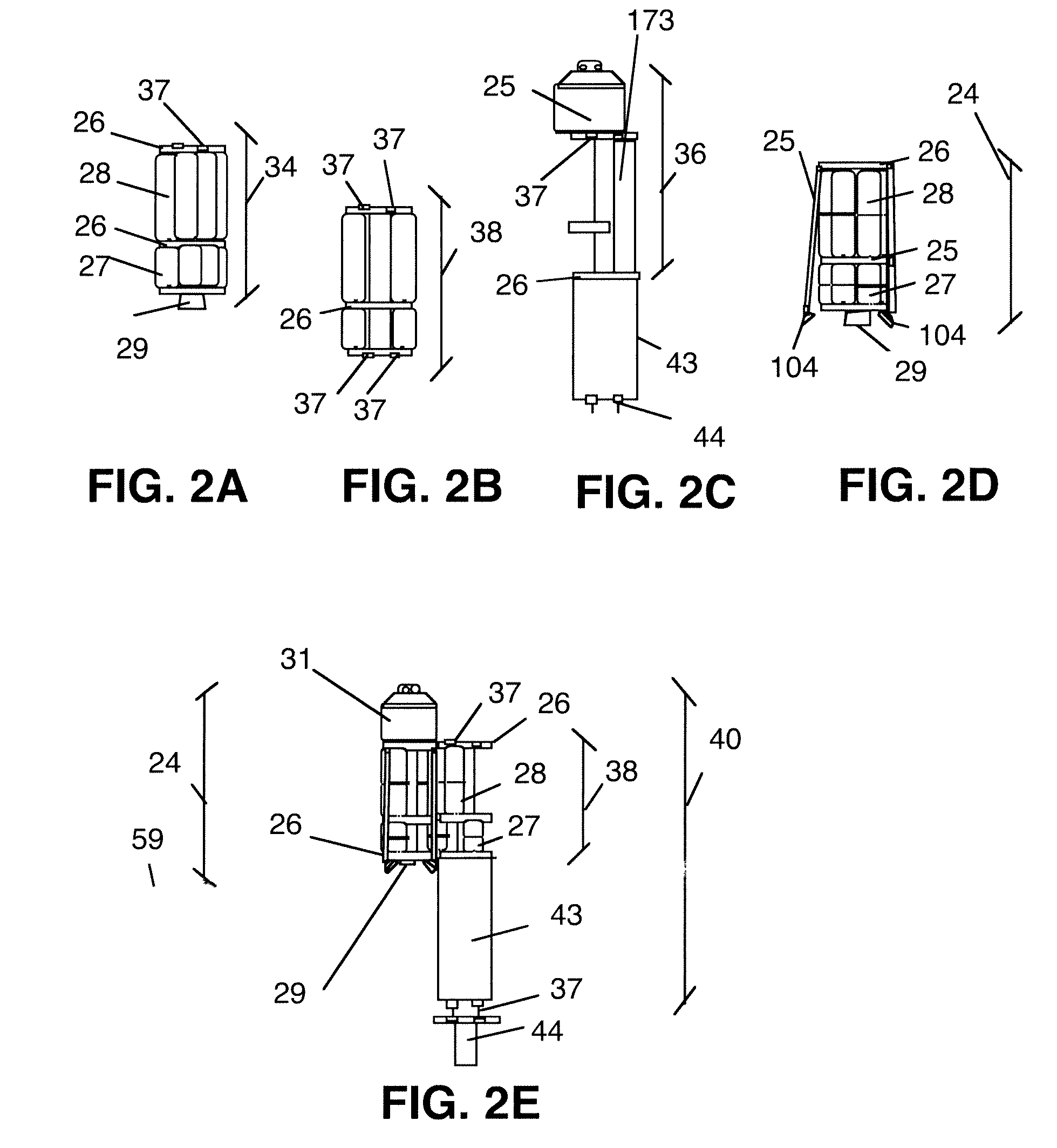

Blast furnace bellless furnace top distributor

ActiveCN101173321AExtended service lifeFully lubricatedBell-and-hopper arrangementBlast furnace detailsEngineeringShaft furnace

The invention discloses a bell-less top distributing gear of furnace, belonging to technical field of metallurgical industry. The invention adopts sealed cooling, a water-cooling venturi tube with pipe laying and a water-cooling chassis. A motor drives a chute to rotate and tilt; wherein, the motor drives the nut of the ball screw assembly to rotate and then drives the lead screw and the lifting rotary frame connected with the lead screw to move up and down in order to achieve chute to tilt for Alpha angle. The invention has the advantages of high coaxiality, high transmitting precision, long service life of the critical component, easy manufacture, light weight and low cost. The tilting Alpha angle of the chute and the stationarity of the tilting movement of the chute can be checked during the producing process of the furnace by the invention. The invention can be used in charging operation of furnace roof and also is suitable for shaft furnace or smelting reduction furnace which need to feed from the roof to the closed space and distribute regularly.

Owner:CISDI ENG CO LTD

Deployable intelligence and tracking system for homeland security and search and rescue

This invention builds on previous industry techniques to correlate data from a variety of sources for the purposes of tracking and identifying aircraft, vehicles, and marine vessels in real time over a variety of different areas including oceans and mountainous terrain. Passive broadband tracking of aircraft emitters, and electronic fingerprinting of emitters, correlated with audio, video, infrared, primary radar and other information is employed to provide a comprehensive assessment of an aircraft's position, track and identification for a variety of applications including homeland security and search and rescue.

Owner:ERA AS

Method for forming nanostructure having high aspect ratio and method for forming nanopattern using the same

InactiveUS7632417B2Simple and economical processHigh aspect ratioDecorative surface effectsIndividual molecule manipulationPolymer scienceCarbon nanotube

Provided is a method of forming a nanostructure having a nano-sized diameter and a high aspect ratio through a simple and economical process. To form the nanostructure, a polymer thin film is formed on a substrate and a mold is brought to contact the polymer thin film. Then, a polymer patterning is formed to contact the background surface of an engraved part of the mold, and then the polymer pattern is extended out by removing the mold out of the polymer thin film. The nanostructure forming method of the present research can reproduce diverse cilia optimized in the natural world. Also, it can be used to develop new materials with an ultra-hydrophobic property or a high adhesiveness. Further, it can be applied to a nanopattern forming process for miniaturizing electronic devices and to various ultra-precise industrial technologies together with carbon nanotube, which stands in the highlight recently.

Owner:SEOUL NAT UNIV R&DB FOUND

Multi-purpose gelatin fiber and preparation method thereof

InactiveCN101643947AImprove thermal stabilityHigh strengthWigsArtificial filament washing/dryingPolymer scienceEmulsion

The invention relates to a multi-purpose gelatin fiber and a preparation method thereof, in particular to the preparation of amphipathy polymer and emulsion thereof, the preparation of spinning solution, fiber spinning, after-treating of the fiber and the like, wherein firstly free radical polymerization or polyurethane prepolymer is adopted for compounding amphipathy polymer which is prepared into emulsion in water, and then the emulsion is added into a gelatin solution to prepare spinning solution with certain viscosity; the spinning solution is prepared in to fiber by a wet spinning; and finally in order to increase the intensity of the fiber, the fiber is needed to be post-treated. The gelatin fiber and the preparation method thereof belong to the textile industry technical field; andthe formed fiber can be used for clothing material, biology medical material and hairpiece products.

Owner:UNIV OF SCI & TECH OF CHINA

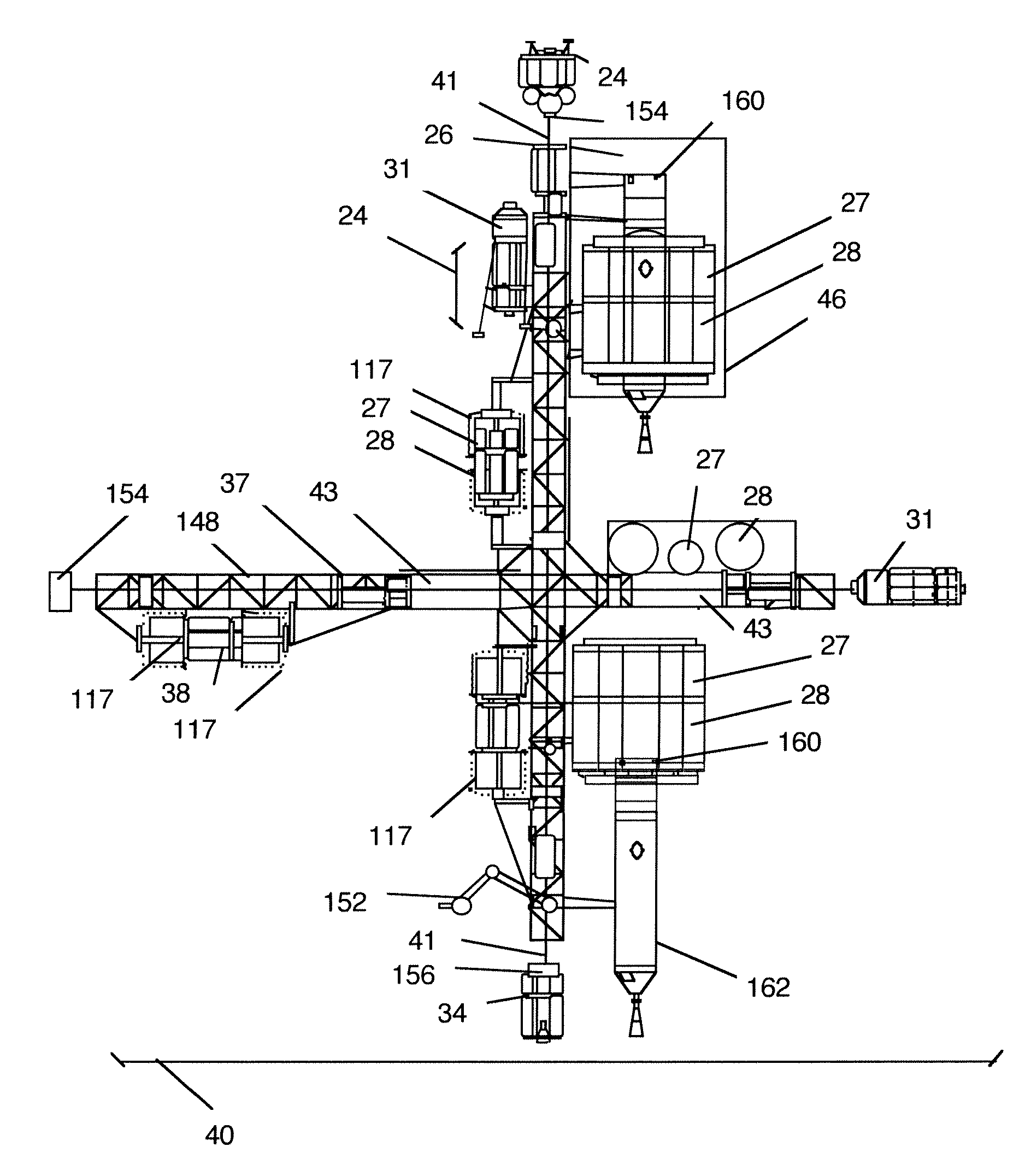

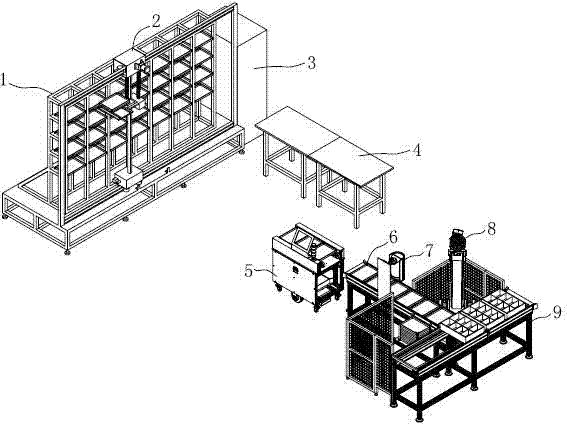

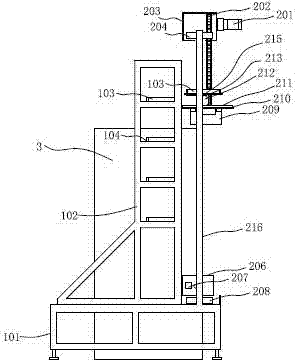

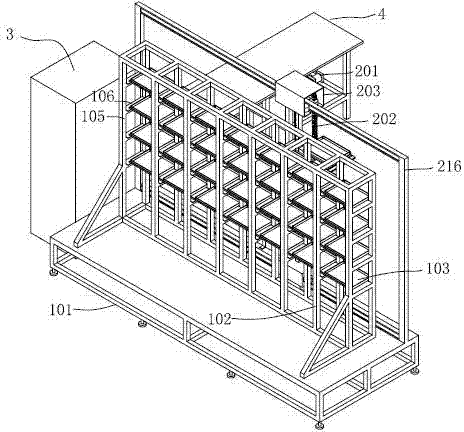

Practical training system of industrial robot technology

The invention relates to a practical training system of an industrial robot technology. The practical training system comprises a stereoscopic warehouse system, a control cabinet and a worktable, wherein a stacker crane capable of moving in an X axis and a Y axis and storing and fetching trays is arranged on the stereoscopic warehouse system; the practical training system further comprises a first conveying mechanism and a second conveying mechanism; the first conveying mechanism travels to and fro between the stereoscopic warehouse system and the second conveying mechanism through a guide rail; a mechanical arm and a camera are arranged on the two sides of the second conveying mechanism respectively; a third conveying mechanism is further arranged at the end part of the second conveying mechanism. A tray frame of the practical training system can accommodate a plurality of trays; meanwhile, a tray positioning block is arranged on the tray frame and used for preventing the trays from dropping out of the tray frame in storage; by setting the stacker crane on a sliding framework and by using an X axis or Y axis code reader, the accurate positioning and storing and fetching of each tray on the tray frame are realized; the product identification is realized by the camera; the articles are grabbed by the mechanical arm; therefore, the practical training system of the industrial robot technology is high in automation; the working efficiency of the practical training system is greatly improved.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

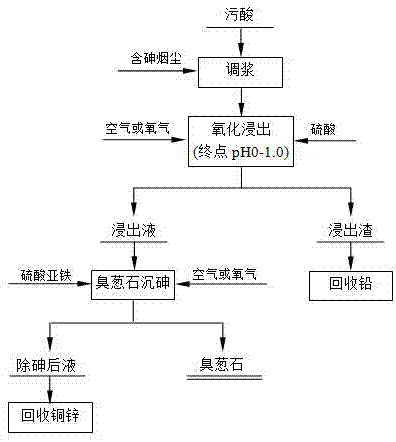

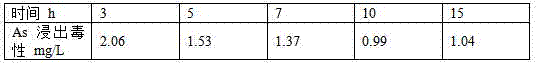

Acid recycling and arsenic curing method for acidic waste water

InactiveCN107459166AImprove resource utilizationRealize synchronous processingGas treatmentWater contaminantsNon-ferrous extractive metallurgyOxygen

The invention relates to an acid recycling and arsenic curing method for acidic waste water and belongs to the technical field of the non-ferrous metallurgical industry. The acid recycling and arsenic curing method comprises the following steps: performing size mixing on arsenic soot and acidic waste water, then pumping in air or oxygen to perform oxidation leaching, controlling the pH value of a leaching end point, and performing normal-pressure scorodite arsenic curing on an arsenic-containing leaching agent. According to the acid recycling and arsenic curing method, arsenic-containing soot and acidic waste water mixed size mixing, oxidation leaching and scorodite arsenic curing technologies are adopted to treat acidic waste water, a new thought is provided for recycling of acidic waste water and harmless arsenic treatment of the non-ferrous metallurgical industry, and the acid recycling and arsenic curing method mainly focuses on efficient utilization of acid in acidic waste water and harmless arsenic treatment. Arsenic-containing soot generated in the non-ferrous metal smelting process is taken as a neutralizer, and arsenic-containing soot and arsenic-containing acidic waste water are synchronously treated, so that effective utilization of acid in acidic waste water is realized, meanwhile, obtained scorodite crystals are convenient to pile up, and the characteristics of complete arsenic and acid separation, low treatment cost and the like are achieved.

Owner:KUNMING UNIV OF SCI & TECH

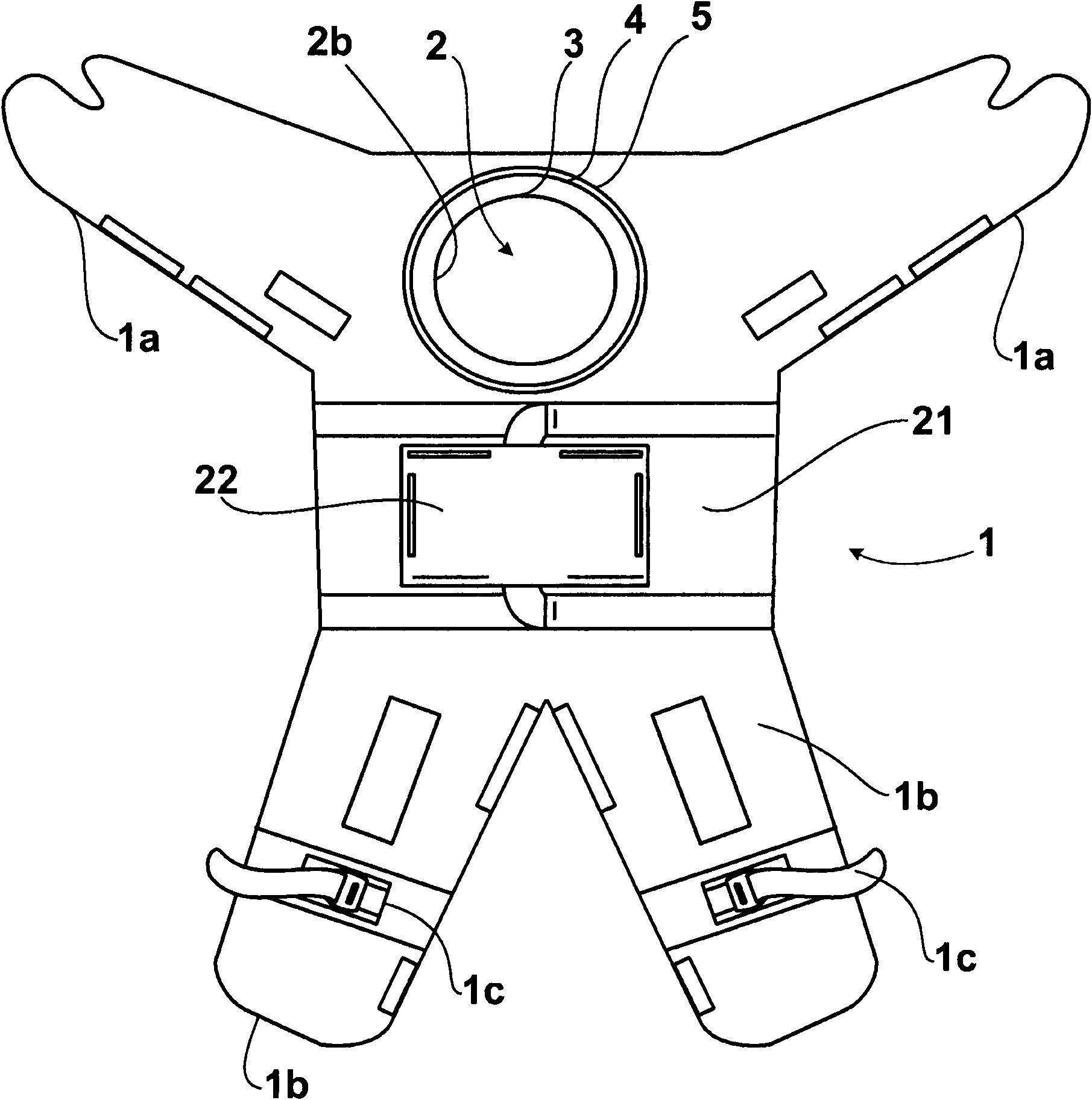

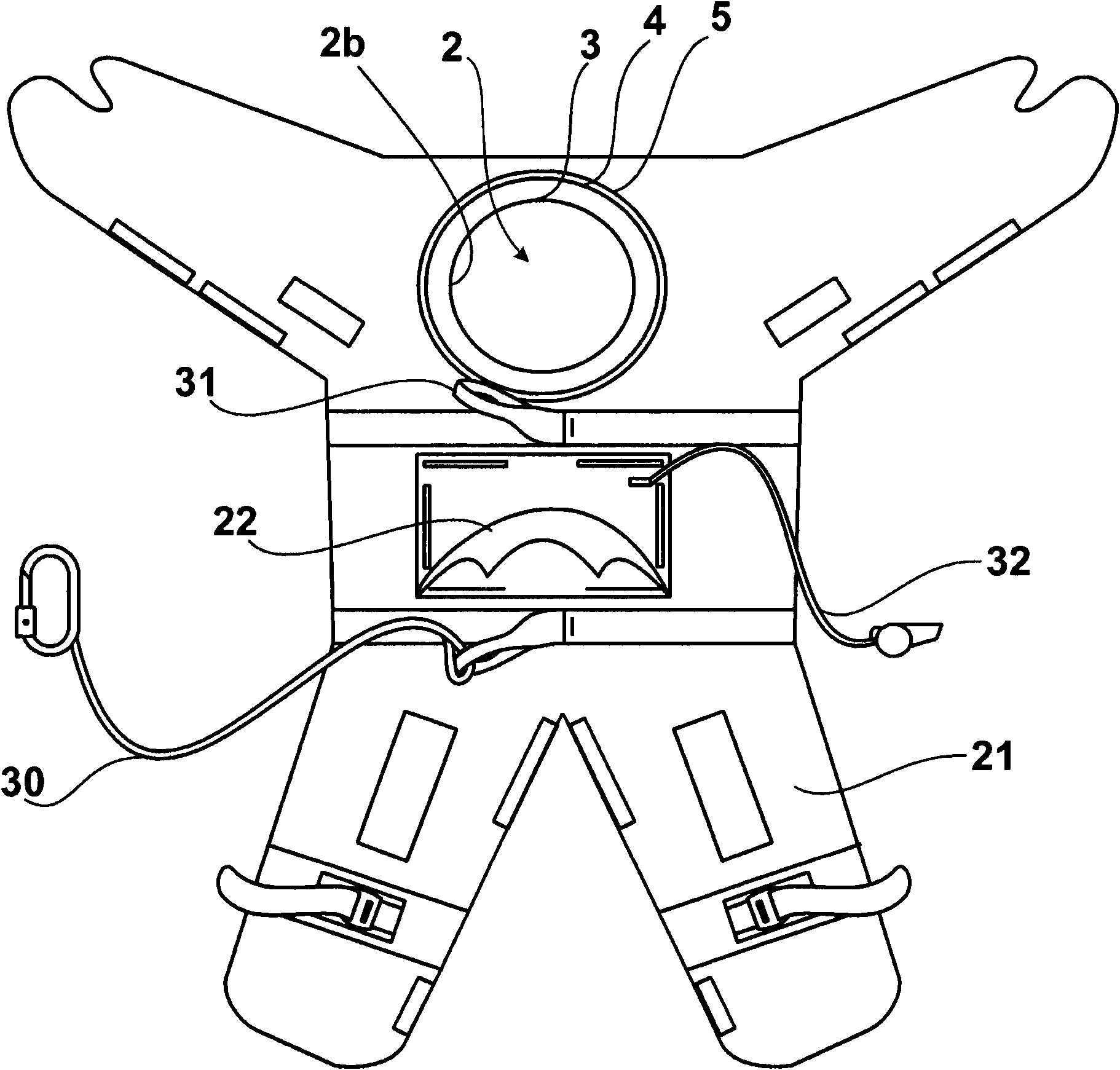

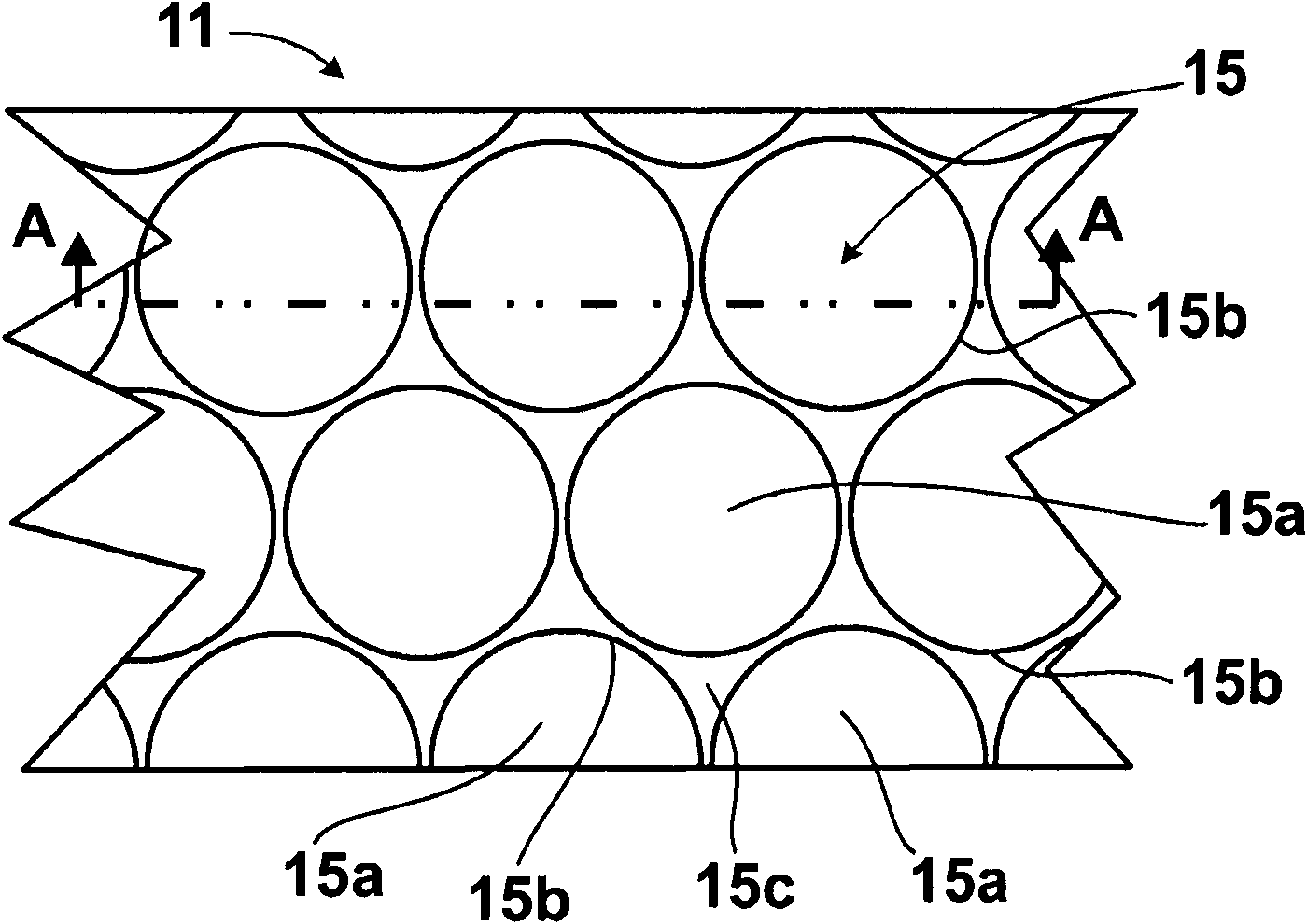

Salvage suit for shipwrecks

Owner:马里奥·凯撒·维尼奥拉

Industrial technology for quickly extracting high-purity chlorogenic acid from sweet potato leaf

InactiveCN101613278AHigh yieldReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationChlorogenic acidOrganic solvent

The invention relates to a production method for extracting high-purity chlorogenic acid from sweet potato leaves. Fresh sweet potato leaves of which the water ratio is about 80 percent are extracted at normal temperature by using 0.1mol / L of hydrochloric acid solution and 20 percent of ethanol without any drying processing; the obtained product is filtered to obtain extracting solution; active carbon is added into the extracting solution; the mixture is discolored and absorbed by KLFC-150 macroporous resin; and an eluent is concentrated to obtain a chlorogenic acid product. The operating technology has the main characteristics of lixiviating of the hydrochloric acid solution along with direct use for raw materials without drying, less energy consumption, less use of organic solvents, environmental protection, safety, low production cost and high yield.

Owner:湖南大拇指生物药业有限公司

Two-step process chlorine-alkali electrolytic method and device adopting double electrolytic cells based on three-electrode system

The invention belongs to the technical field of the chlorine-alkali industry, and specifically discloses a two-step process chlorine-alkali electrolytic method and device adopting double electrolytic cells based on a three-electrode system. The device comprises two independent electrolytic cells (a cell-A and a cell-B), a hydrogen evolution catalytic electrode, a chlorine evolution catalytic electrode and a sodium storage electrode capable of reversibly storing sodium ions. According to the method, a process of electrolyzing a salt solution or seawater is divided into a step of producing hydrogen gas / sodium hydroxide and a step of producing chlorine, which are separately completed in the two independent electrolytic cells (cell-A and cell-B). An electrolytic process in the electrolytic cell-A and an electrolytic process in the electrolytic cell-B are alternately carried out in a circulating manner. According to the method, a step of simultaneously producing hydrogen gas / sodium hydroxide and producing chlorine during conventional electrolysis of the salt solution or the seawater is divided, so that the step of producing hydrogen gas / sodium hydroxide and the step of producing chlorine are separately completed in different electrolytic cells while the desalination of the salt solution or the seawater is realized; and furthermore, the cost of the chlorine-alkali industry is further reduced, the safety is greatly improved and the purity of the generated sodium hydroxide is effectively guaranteed while the desalination of the salt solution or the seawater is realized.

Owner:FUDAN UNIV

Preparation method of high-tenacity flame-retardant polyester filament

InactiveCN105177754AHigh strengthEasy to operateFilament forming substance formingArtificial filament heat treatmentPolymer scienceAntistatic agent

The invention relates to a preparation method of a high-tenacity flame-retardant polyester filament, which comprises the following steps: adding PTA and EG into a charging opening at the front part of a double-screw device for copolymerization to obtain PET; adding a flame retardant and an anti-static agent into a charging opening at the middle part of the double-screw device, blending with PET, and shearing at high temperature to obtain spinning melt; extruding the spinning melt into a spinning component, circularly blowing in the constant temperature and humidity environment, and cooling to obtain nascent fiber; and carrying out first-grade drafting on the nascent fiber through hot oil at 180-200 DEG C, carrying out second-grade drafting on the nascent fiber through boiling water, thermoforming, washing, drying and winding to obtain the high-tenacity flame-retardant polyester filament. The polyester filament obtained by the preparation method provided by the invention has the tenacity of 9-12CN / dtex and the fiber oxygen index of more than 35.9 and is applied to underground coal mines. The device used by the preparation method provided by the invention is simple, convenient in operation and low in price, and the preparation method provides guarantee for technical revolution of the polyester industry.

Owner:DONGHUA UNIV +1

Indoor industrial solid earthworm breeding method

The invention relates to an indoor industrial solid earthworm breeding method. The method comprises the step of arranging breeding baskets in a room with constant temperature and constant humidity, the step of paving base materials, the step of feeding fodders and the like. Effective industrial solid earthworm breeding is realized by combining the modern industrial technology according to the biological nature of earthworms, and wastes serve as the main fodder, so that low cost and high efficiency are realized, an important technical breakthrough for earthworm breeding industry is made, the reproductive rate of earthworms is high and the growing speed of the earthworms is high.

Owner:王庆革

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com