Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

707results about "Bell-and-hopper arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

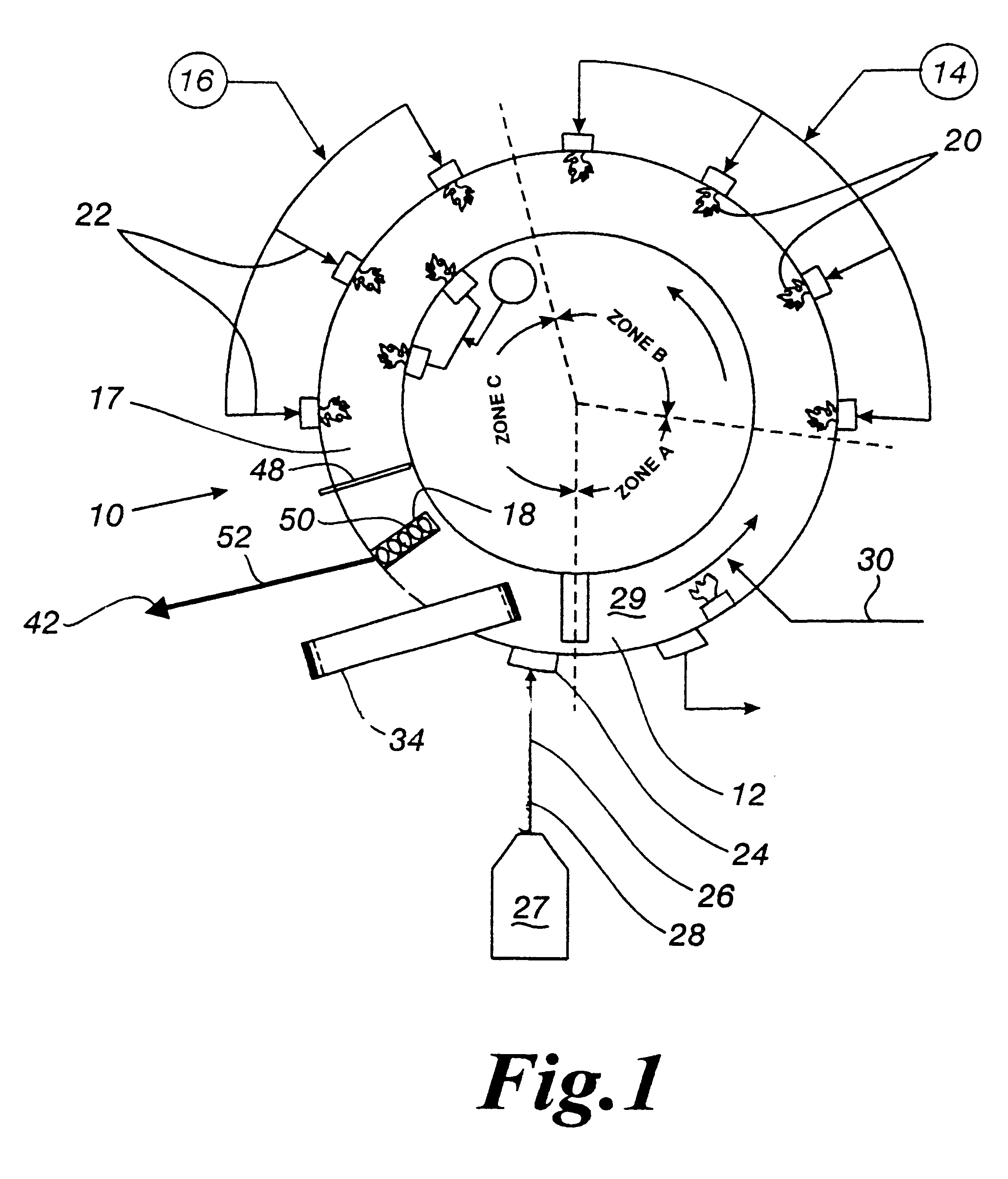

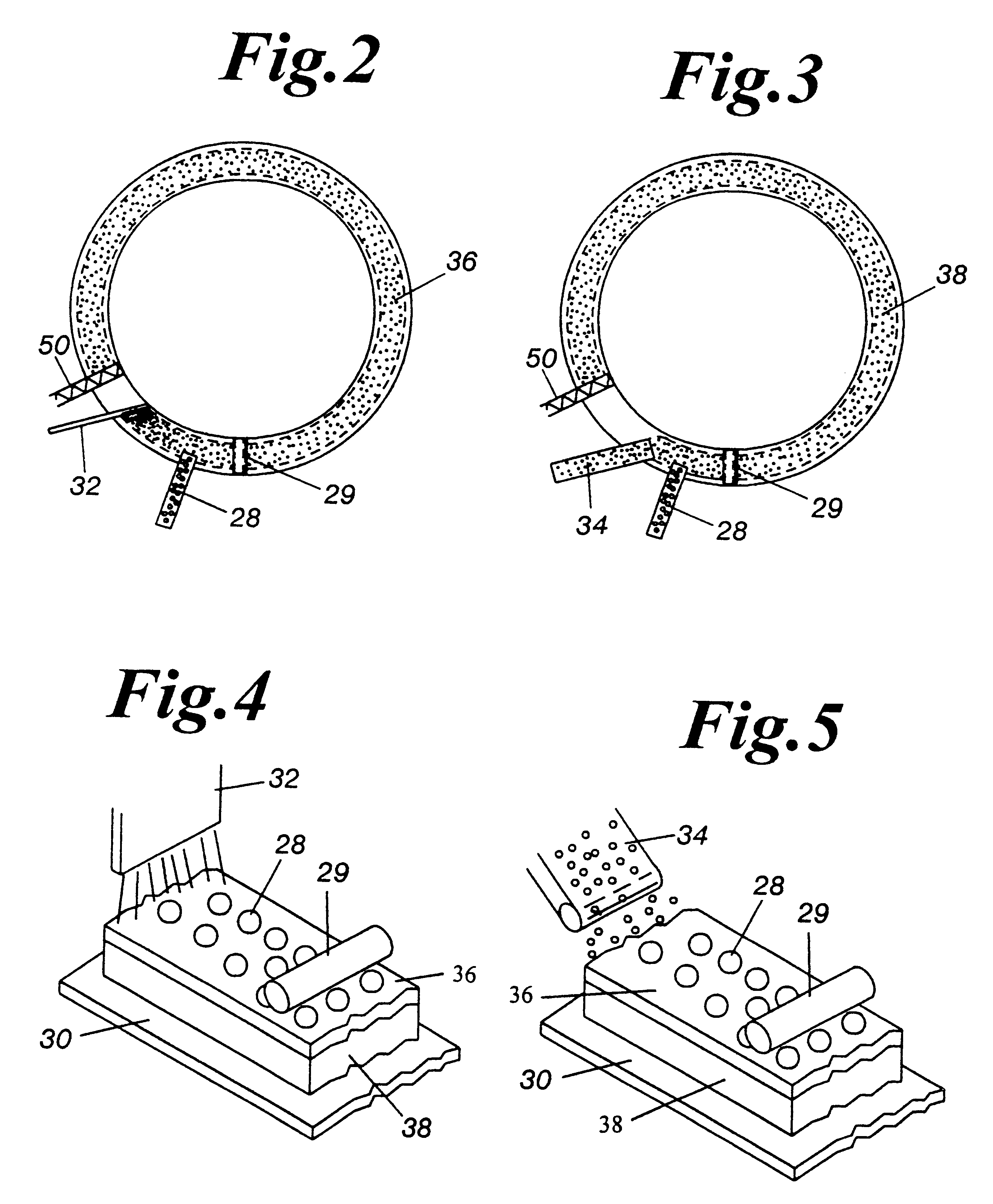

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

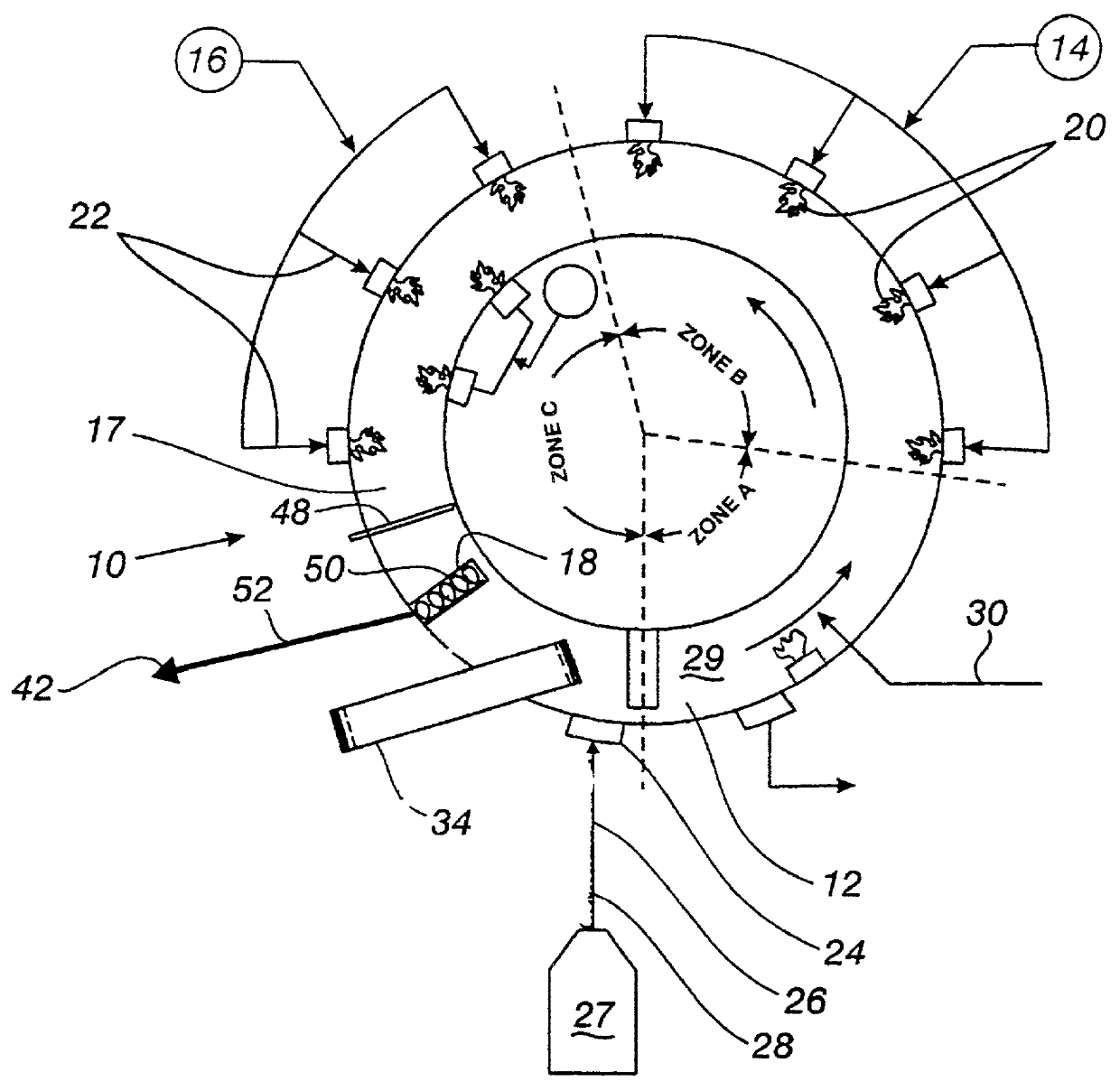

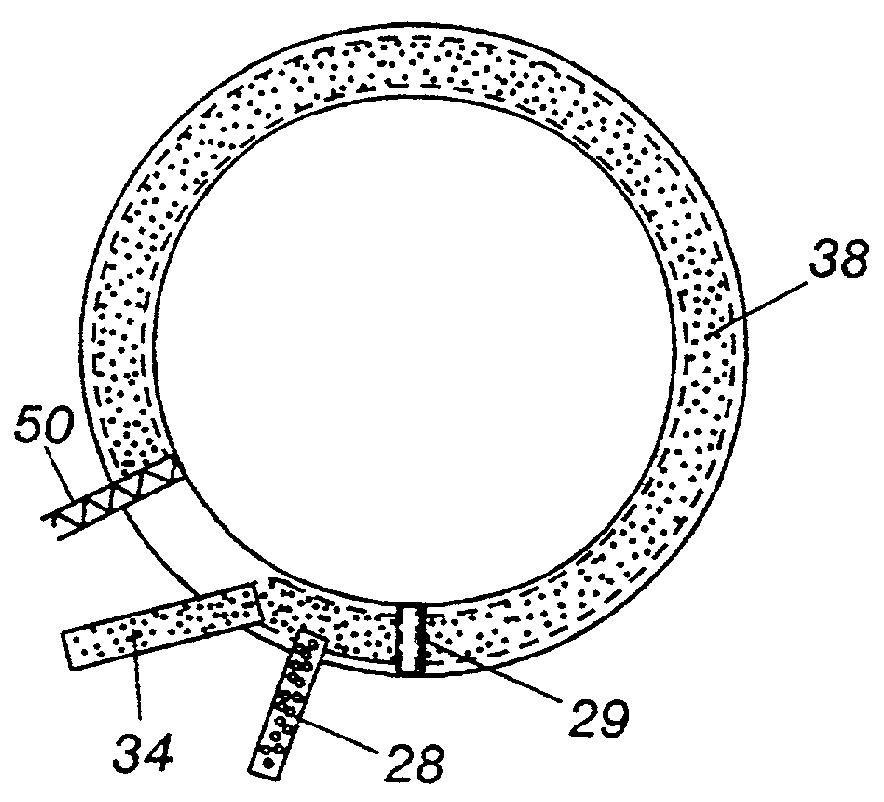

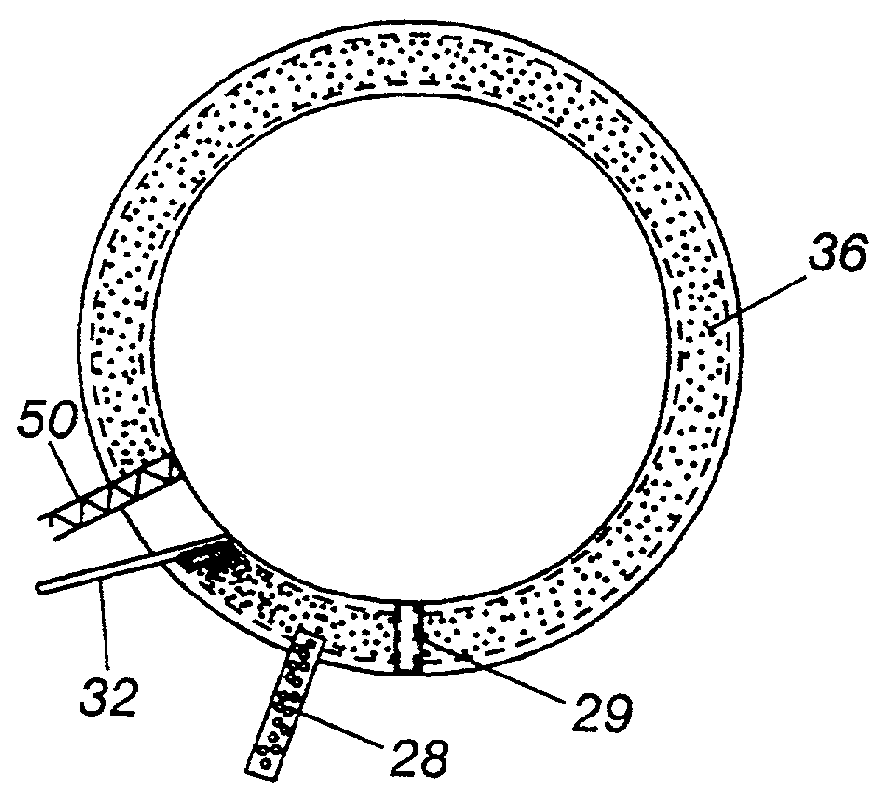

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

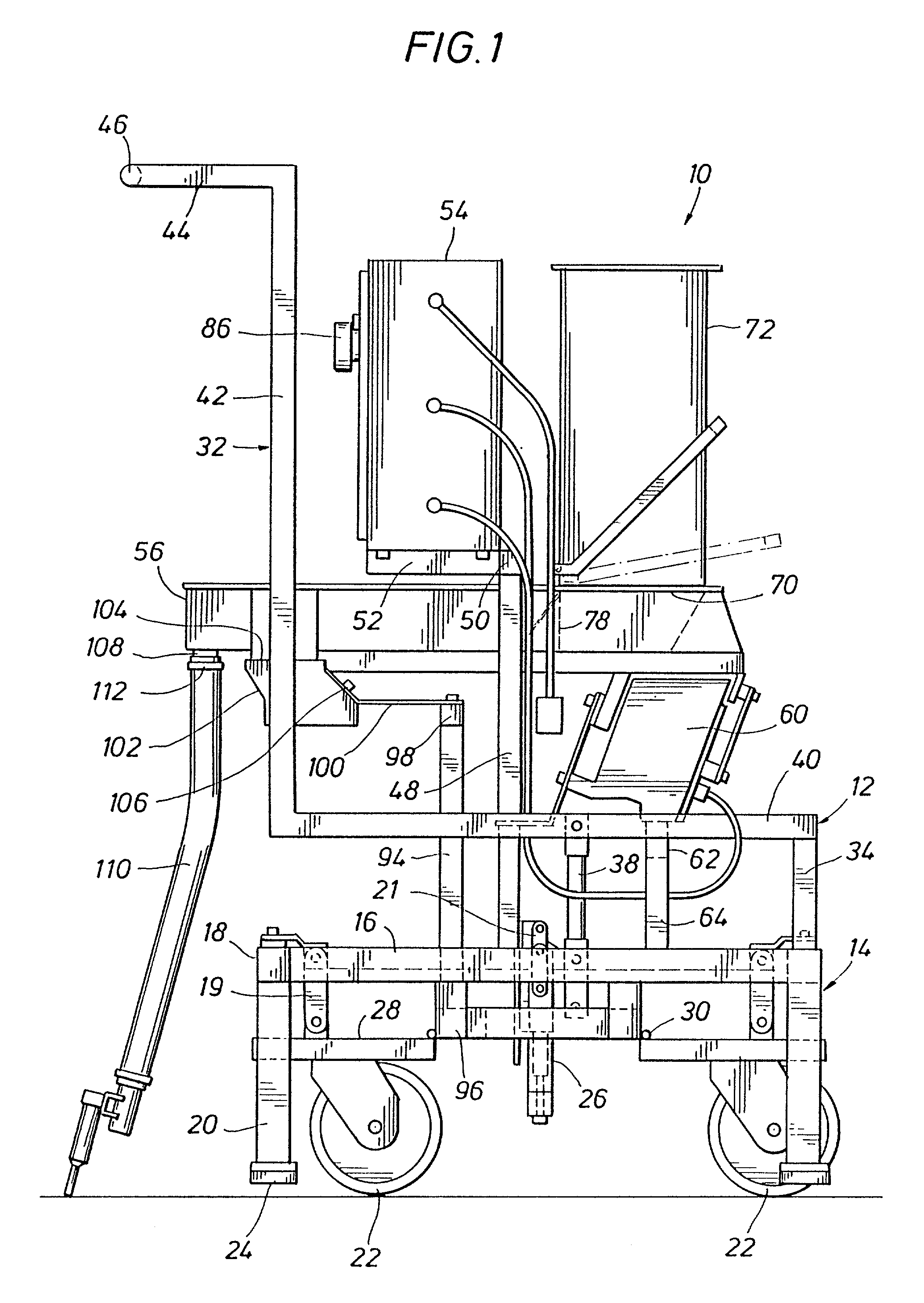

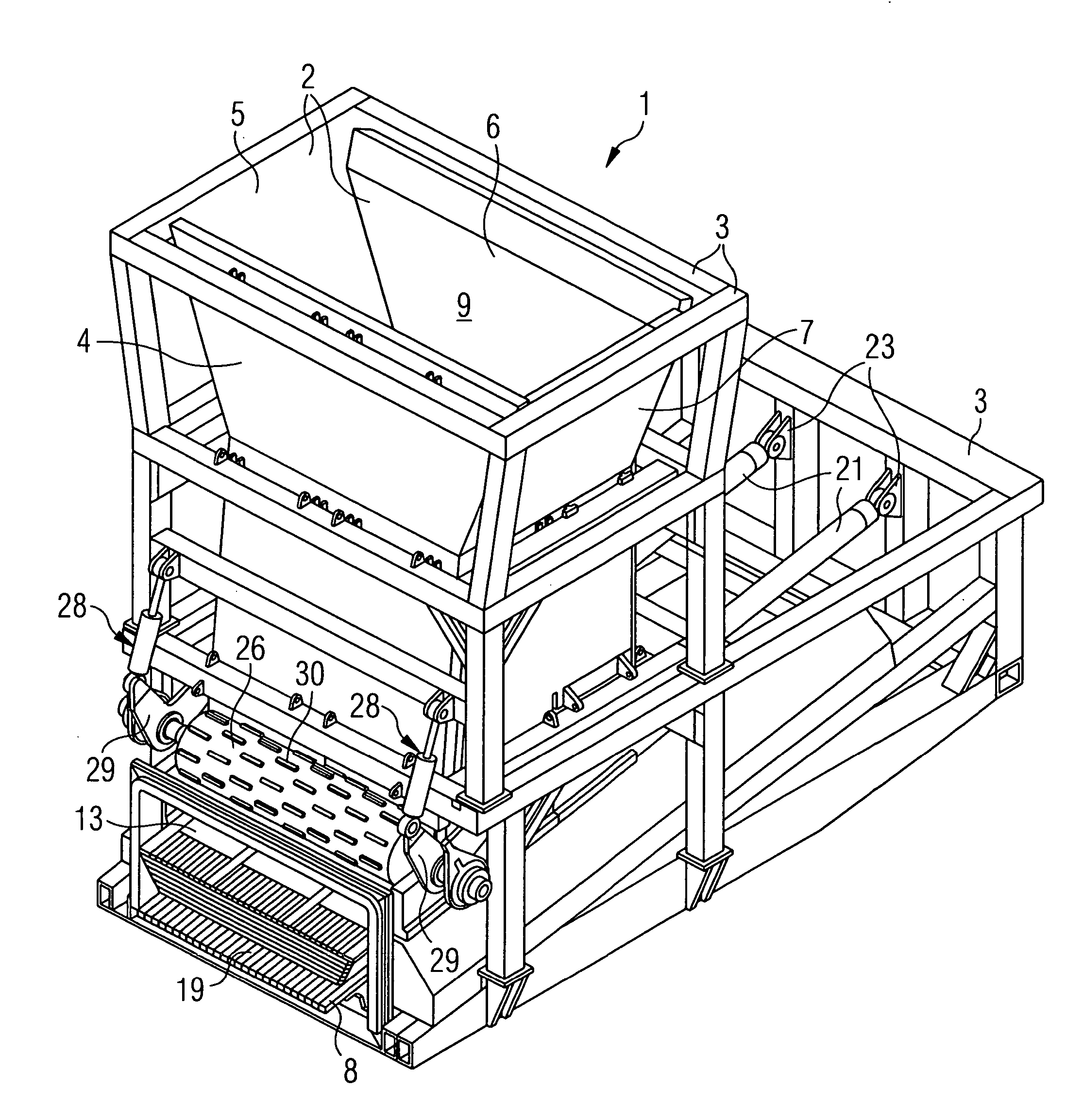

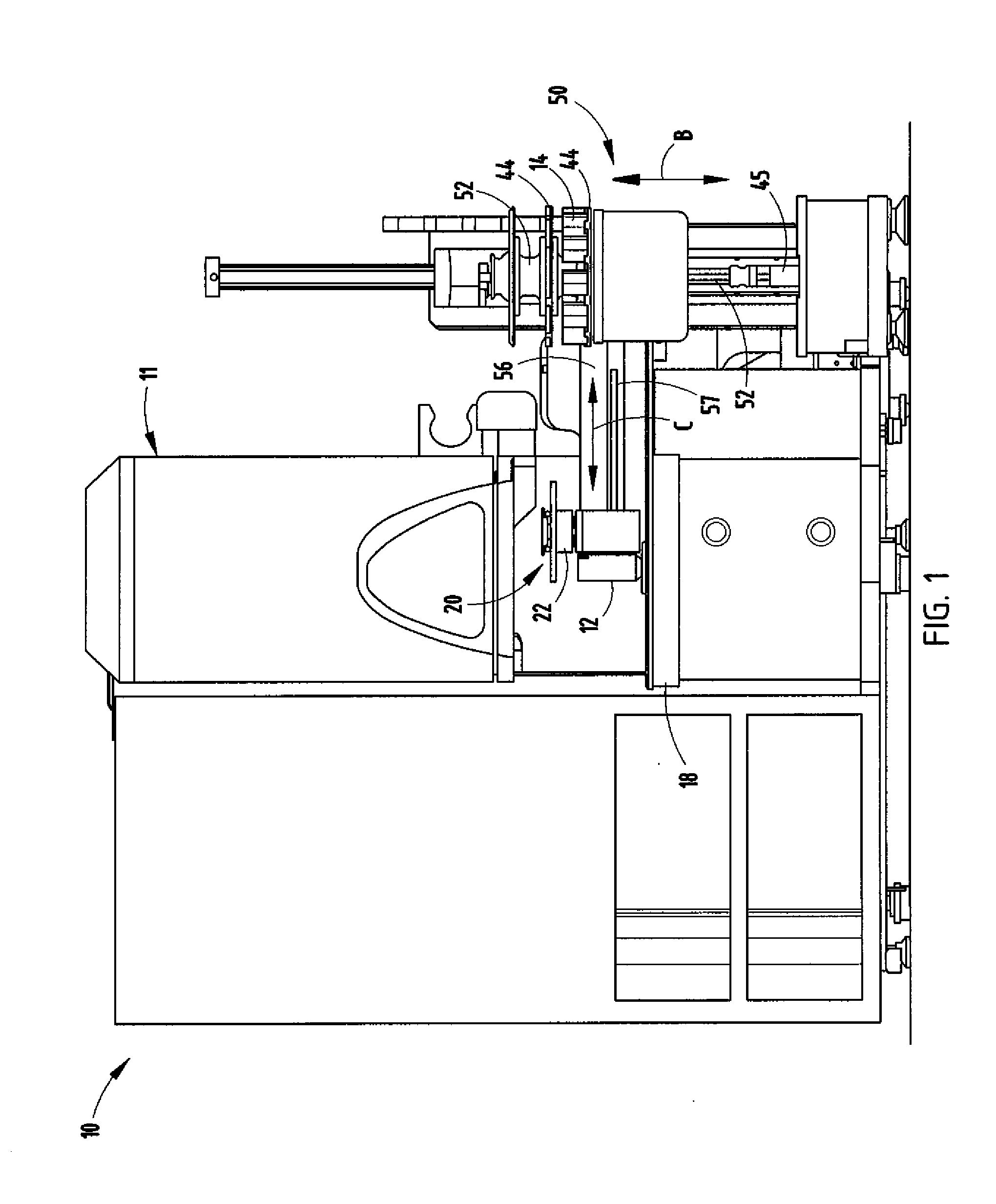

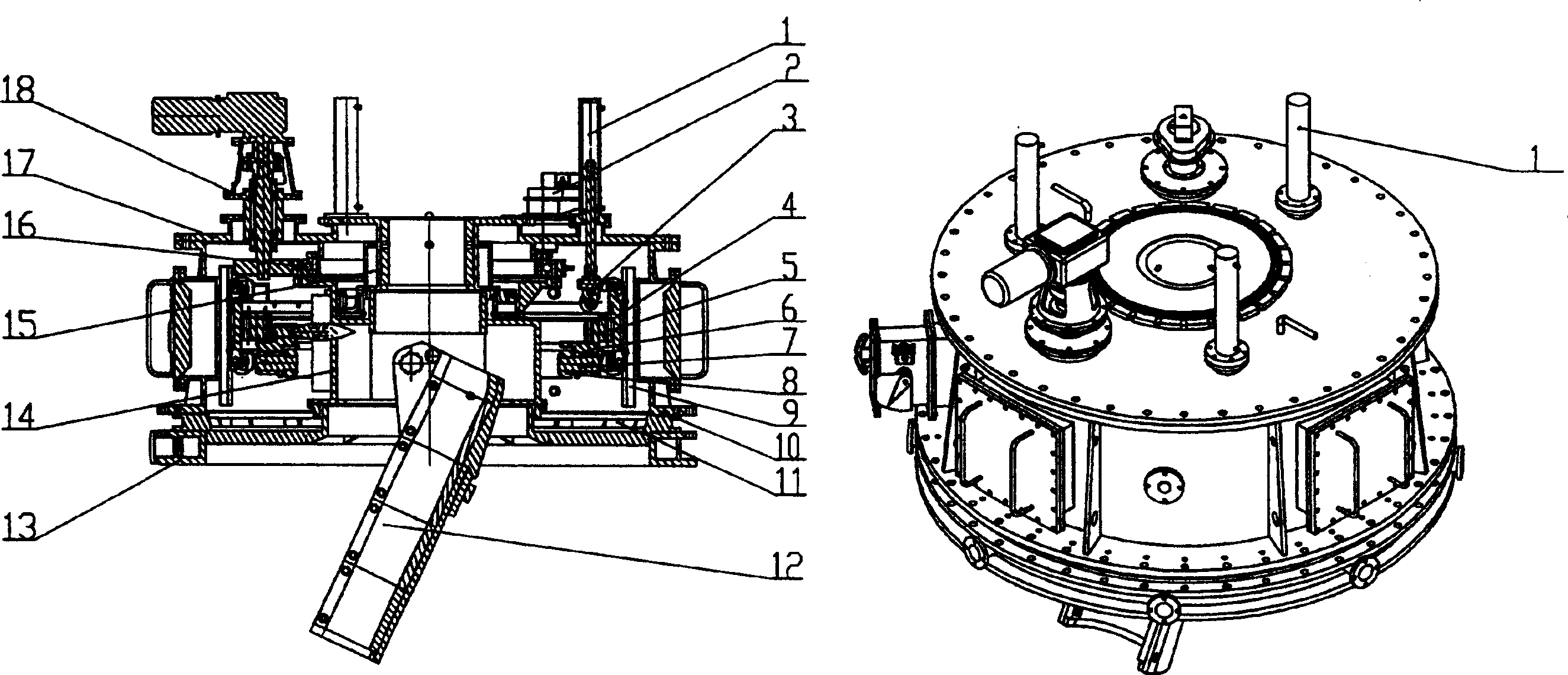

Catalytic reactor charging system and method for operation thereof

InactiveUS20010041117A1Permit accuracyPermit efficiencyTank vehiclesBell-and-hopper arrangementPtru catalystControl system

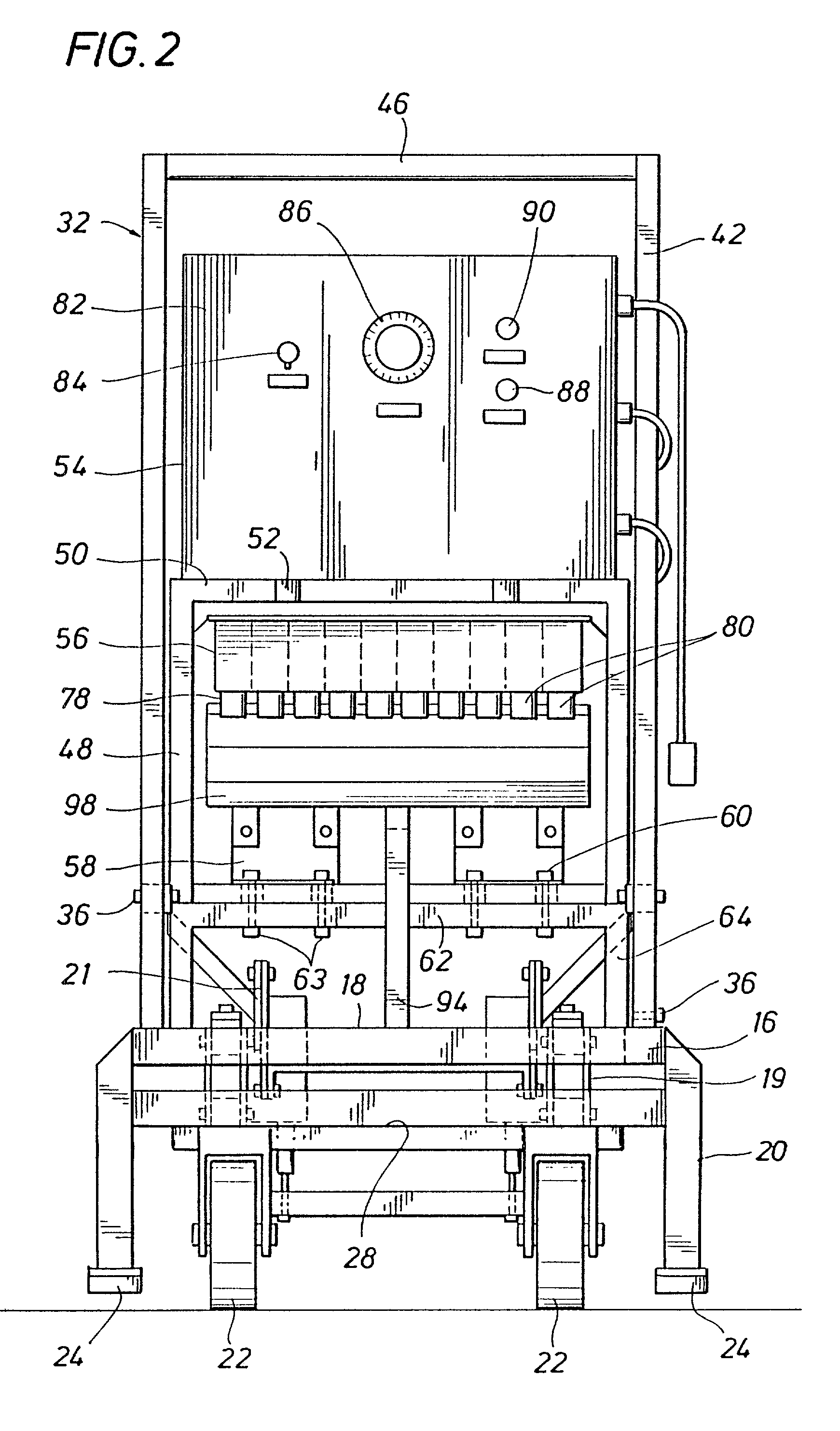

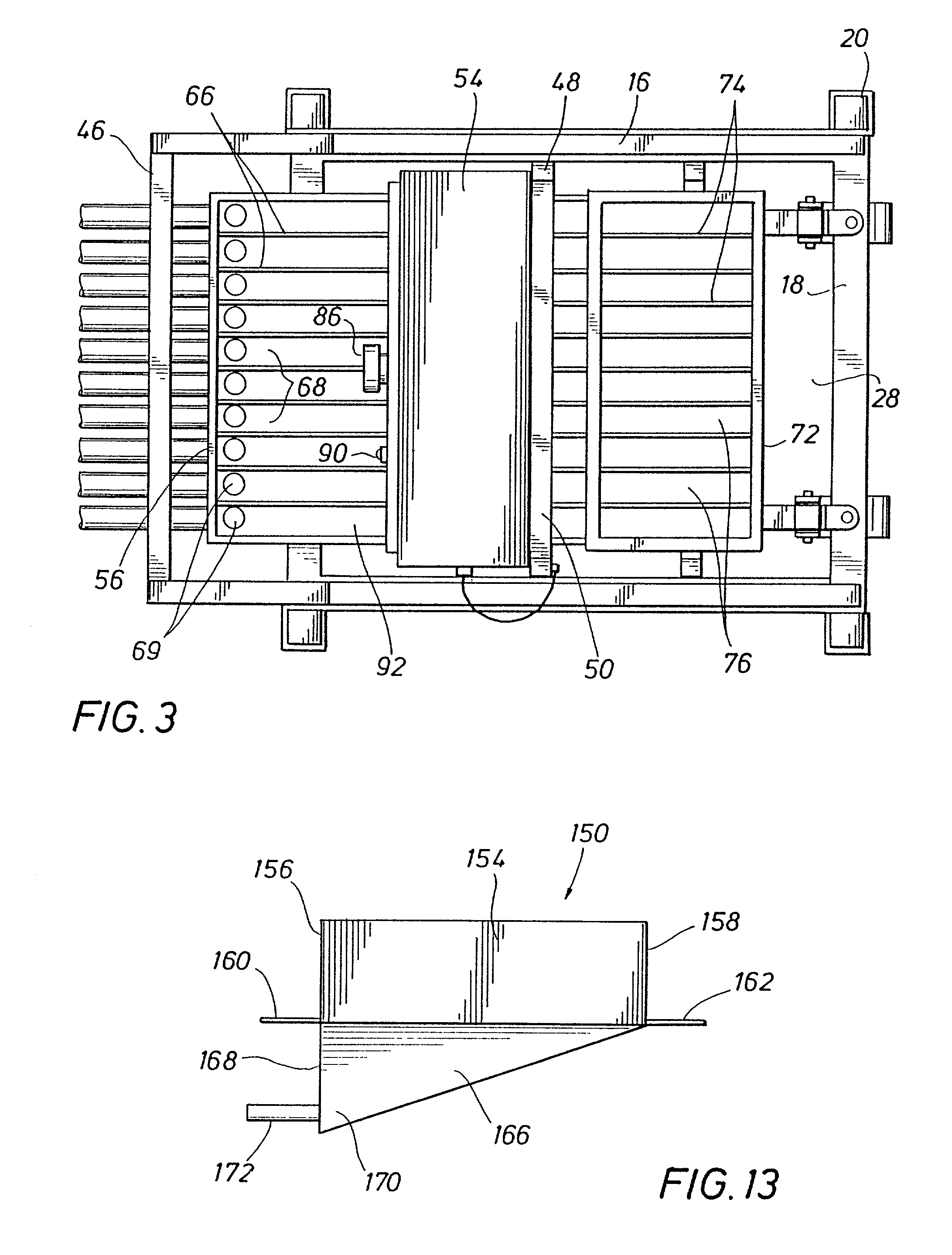

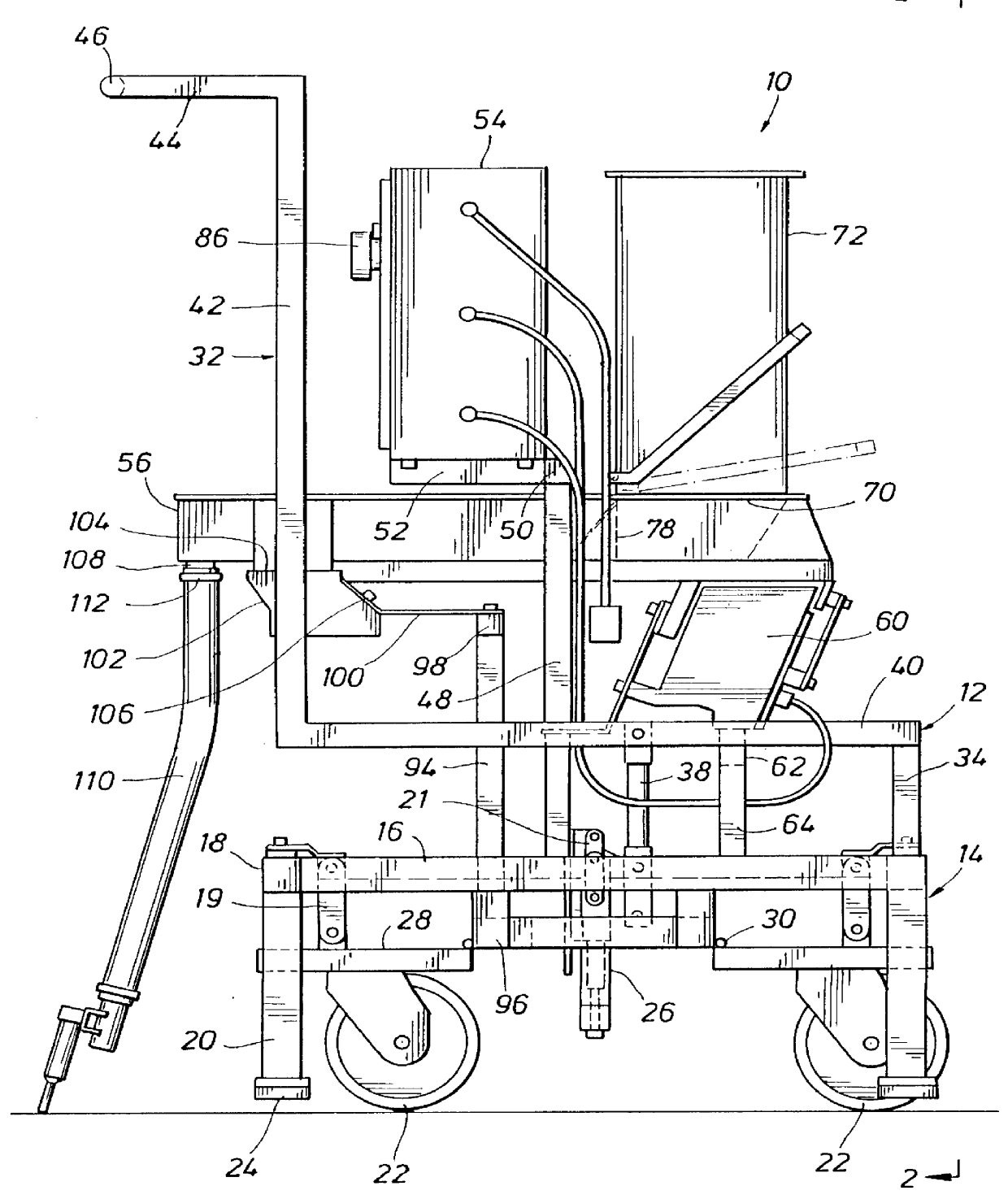

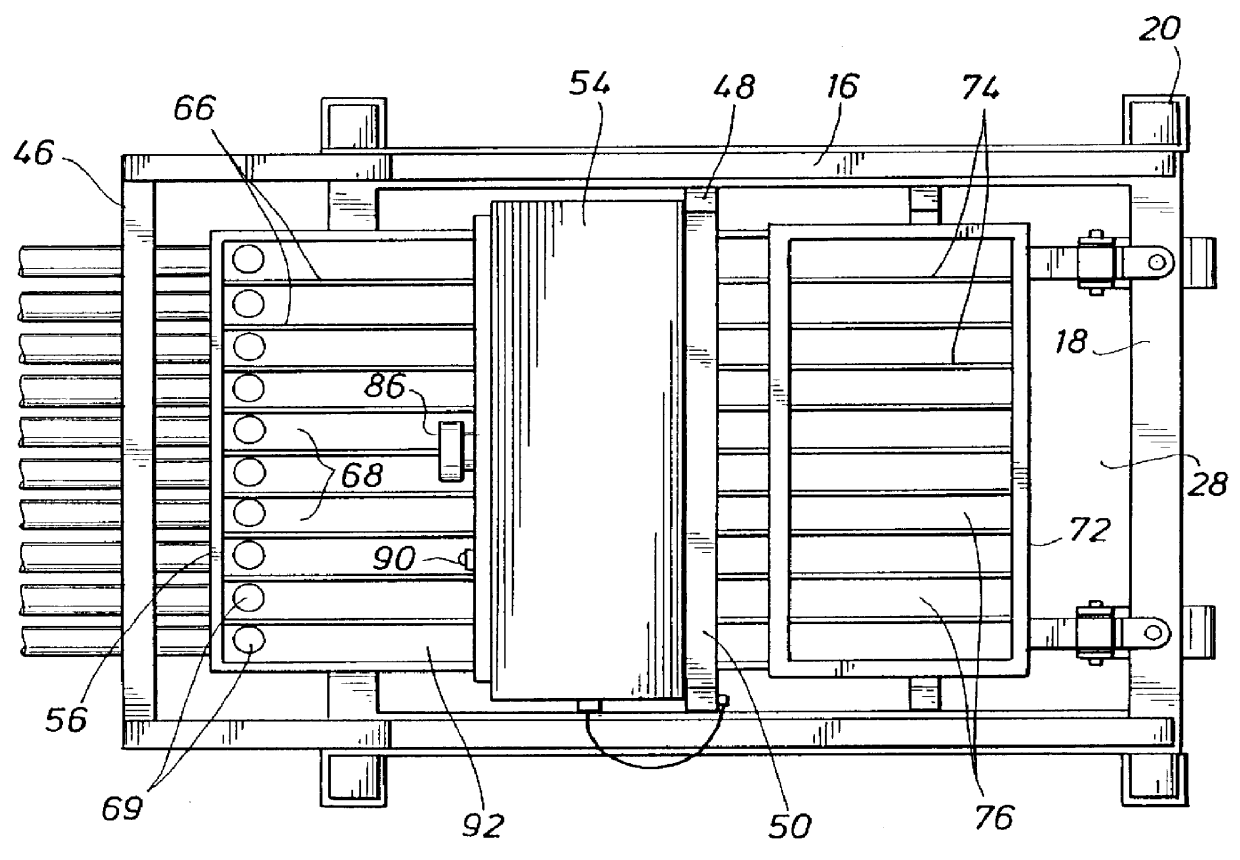

A catalyst loading system for utilizing catalyst from a bulk supply located adjacent but not on the upper tube sheet of a catalytic reactor and for mechanized measuring of multiple identical quantities of catalyst and for mechanized loading of catalyst pellets into the reaction tubes of the reactor to achieve even drop rate, compaction and outage of the reaction tubes. From the bulk supply, multi-compartment catalyst charging hoppers are individually filled in rapid and accurately measured fashion by mechanized filling equipment having a predetermined sequence of operation that ensures accuracy of volumetric catalyst measurement. The charging hoppers are used for delivery of measured volumes of catalyst of a reactor tube loading mechanism which may take the form of a mobile cart framework being selectively positionable relative to the upper tube sheet and reaction tubes of a catalytic reactor to be charged with catalyst pellets. A pair of electronic vibrators are mounted to the cart framework and provide for support and vibratory movement of a vibratory tray having a catalyst feed hopper adapted to feed catalyst pellets to a plurality of generally parallel catalyst transfer troughs along which catalyst pellets are moved by vibration of the vibratory tray to a plurality of drop tubes. A compartmented hopper is fixed to the vibratory tray and controllably feeds catalyst pellets into respective catalyst transfer troughs. A plurality of charging tubes are connected to respective drop tubes by a plurality of elongate flexible tubes and are maintained in fixed, spaced relation by a structural element so as to define a charging manifold for simultaneous, timed delivery of catalyst pellets into a plurality of reactor tubes. The charging manifold has locator pins which are inserted into selected reactor tubes for orienting the charging tubes of the charging manifold with respect to a selected group of reaction tubes. A system is also provided for raising and lowering the charging manifold for efficiency of reactor tube charging operations. An electronic control system is effective for controlling the vibrators to achieve even drop rate from each of the catalyst transfer troughs and to control the vibrators responsive to catalyst weight to achieve even catalyst drop rate during an entire catalyst charging cycle.

Owner:COMARDO MATHIS P

Catalytic reactor charging system and method for operation thereof

InactiveUS6132157APermit accuracyPermit efficiencyTank vehiclesBell-and-hopper arrangementStructural elementProcess engineering

A catalyst loading system for utilizing catalyst from a bulk supply located adjacent but not on the upper tube sheet of a catalytic reactor and for mechanized measuring of multiple identical quantities of catalyst and for mechanized loading of catalyst pellets into the reaction tubes of the reactor to achieve even drop rate, compaction and outage of the reaction tubes. A pair of electronic vibrators are mounted to the cart framework and provide for support and vibratory movement of a vibratory tray having a catalyst feed hopper adapted to feed catalyst pellets to a plurality of generally parallel catalyst transfer troughs along which catalyst pellets are moved by vibration of the vibratory tray to a plurality of drop tubes. A compartmented hopper is fixed to the vibratory tray and controllably feeds catalyst pellets into respective catalyst transfer troughs. A plurality of charging tubes are connected to respective drop tubes by a plurality of elongate flexible tubes and are maintained in fixed, spaced relation by a structural element so as to define a charging manifold for simultaneous, timed delivery of catalyst pellets into a plurality of reactor tubes. The charging manifold which can be raised and lowered has locator pins which are inserted into selected reactor tubes for orienting the charging tubes of the charging manifold with respect to a selected group of reaction tubes. An electronic control system controls the vibrators responsive to catalyst weight to achieve even catalyst drop rate during an entire catalyst charging cycle.

Owner:COMARDO MATHIS P

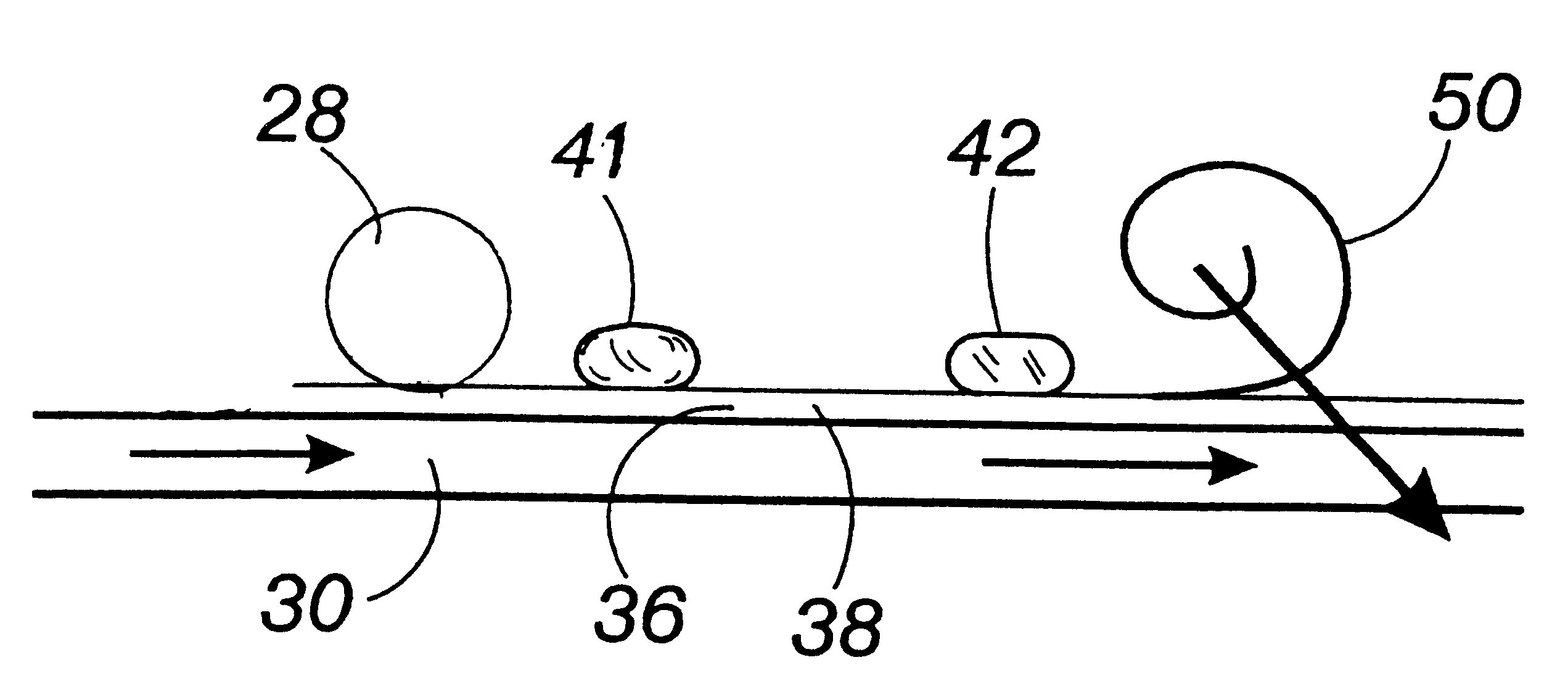

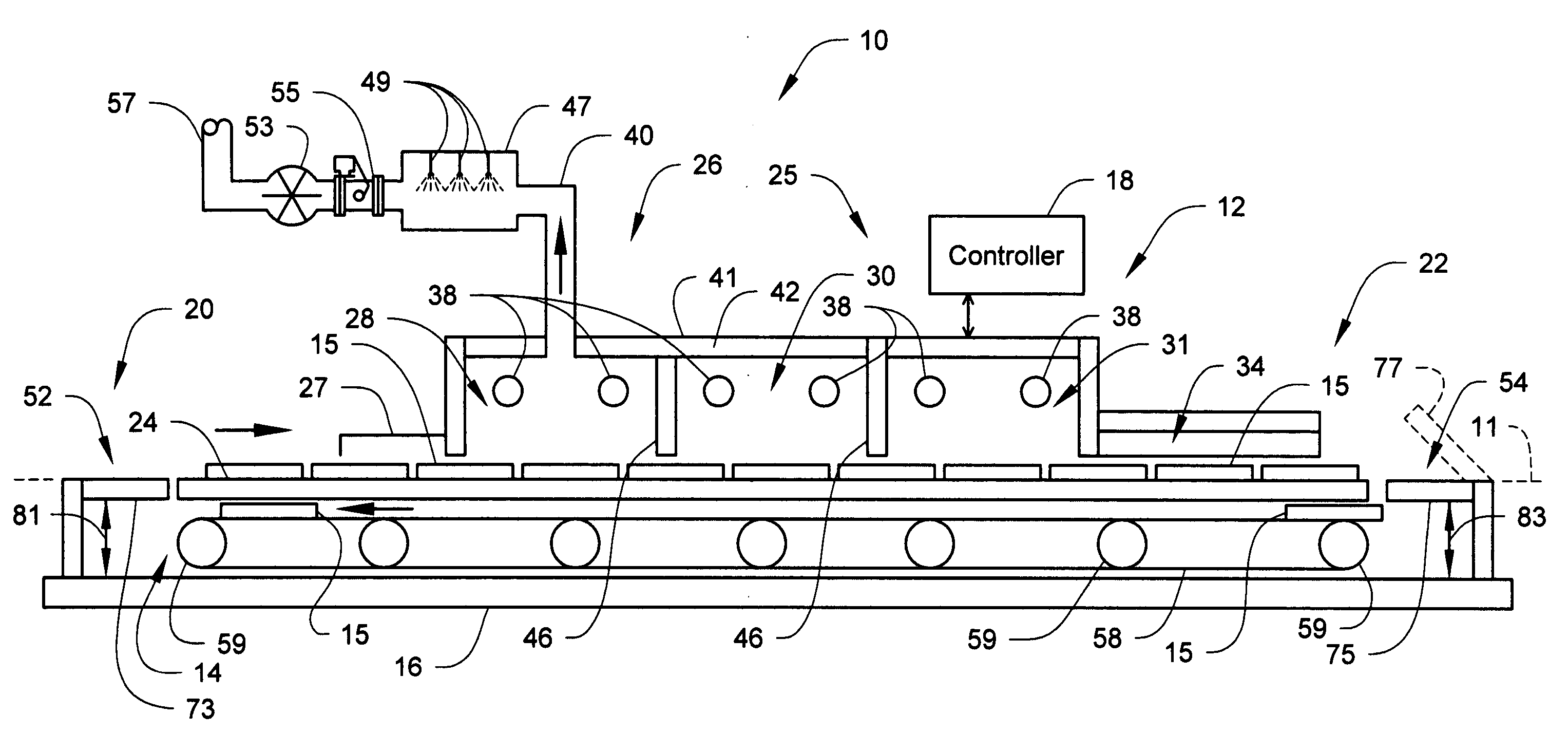

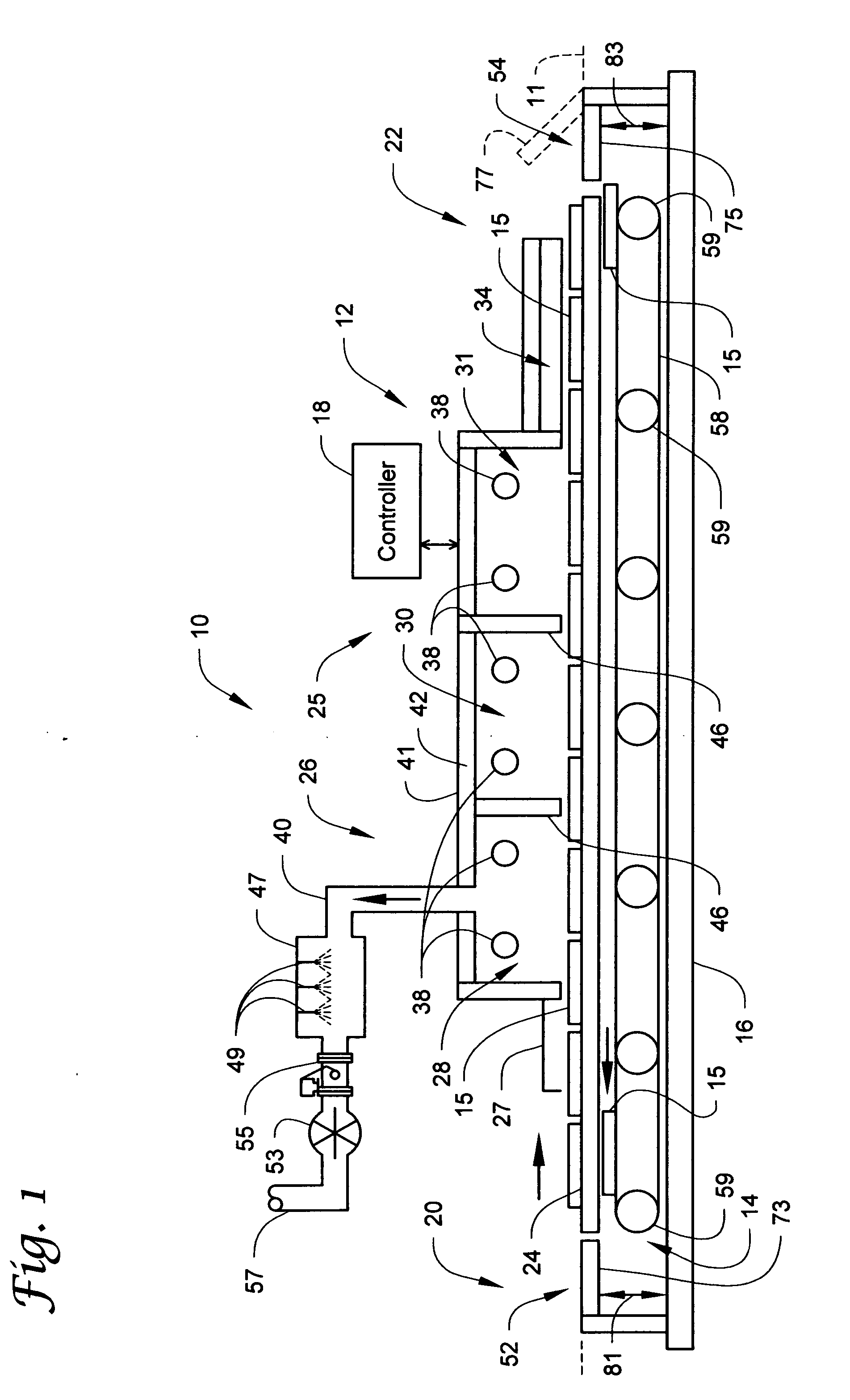

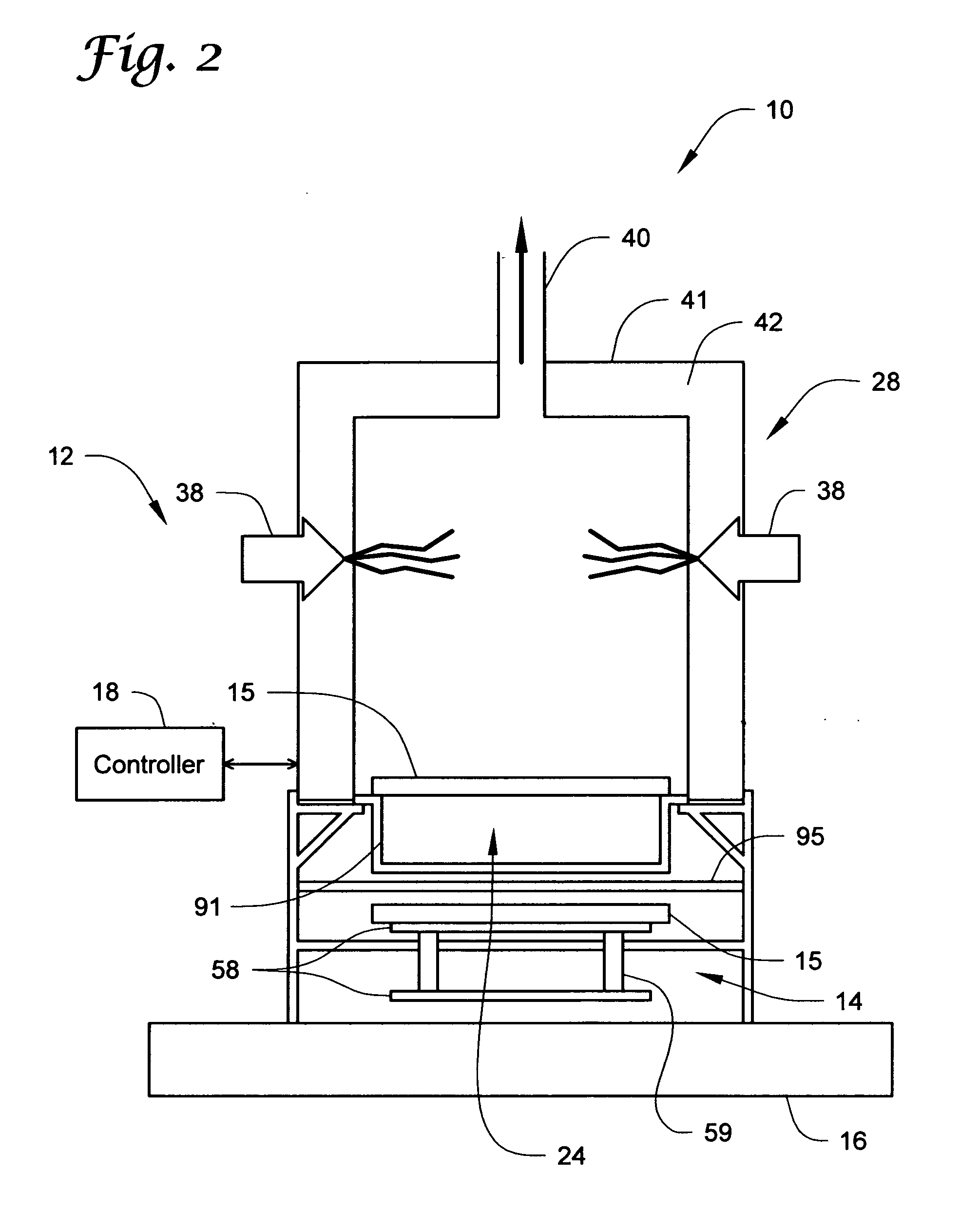

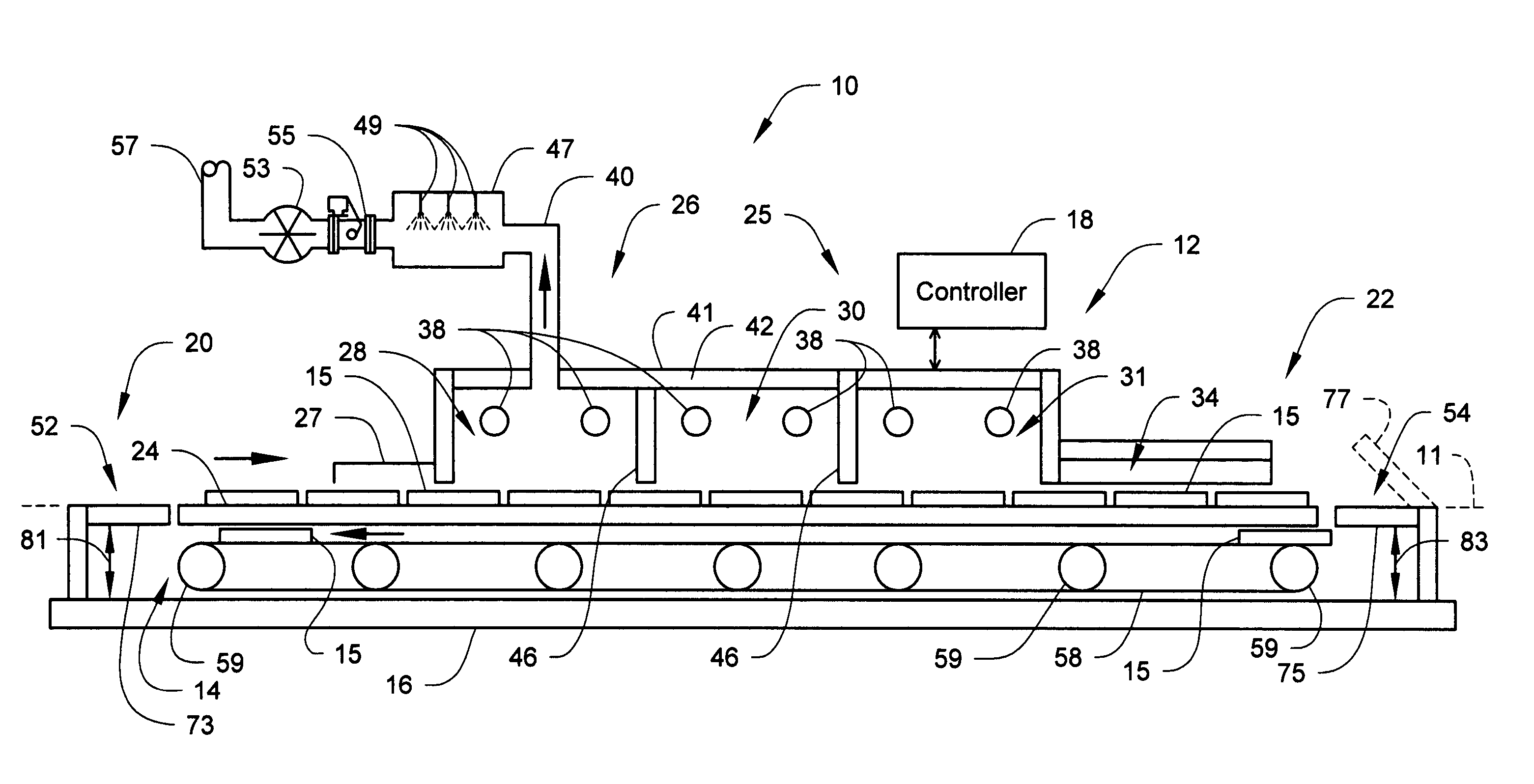

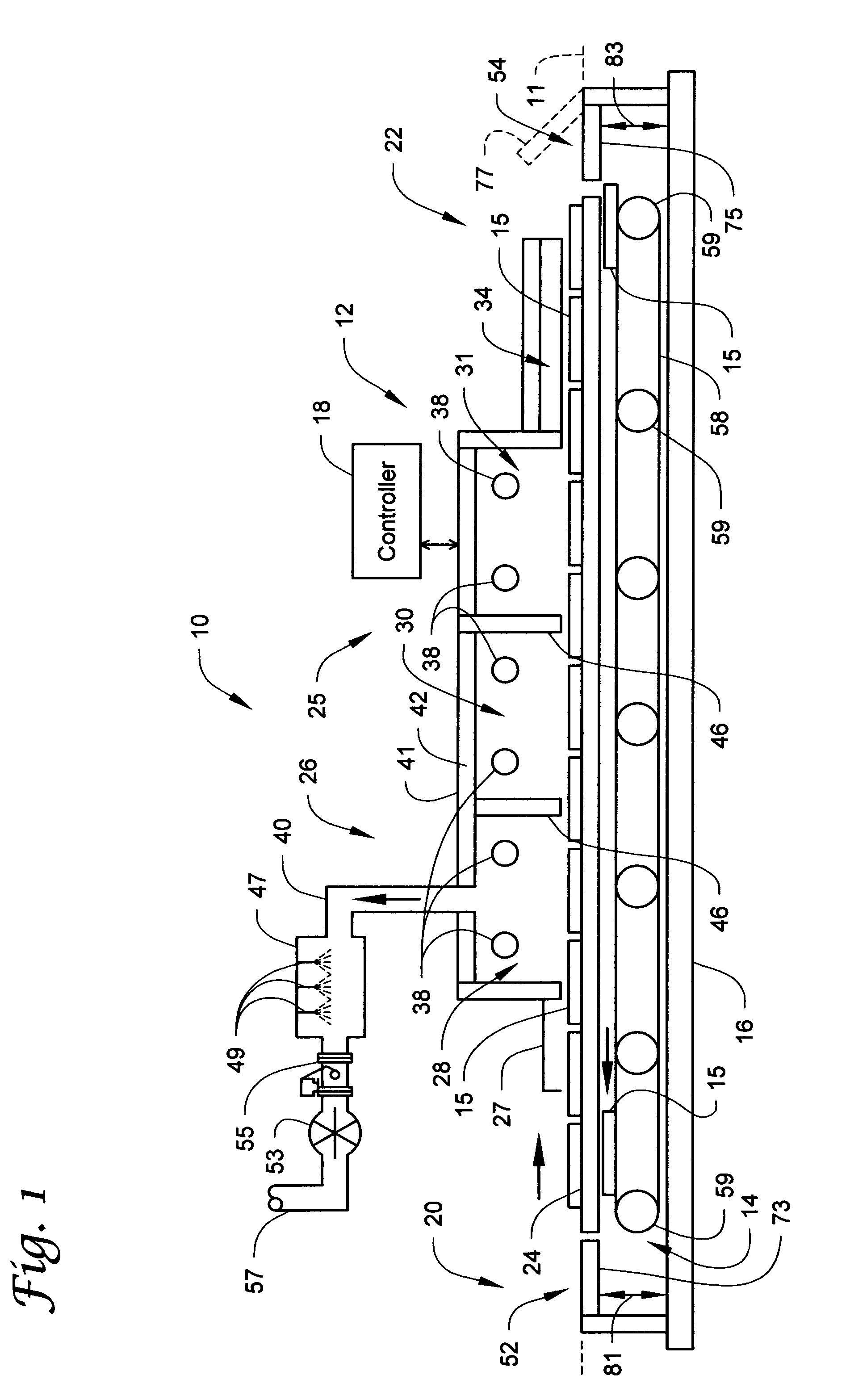

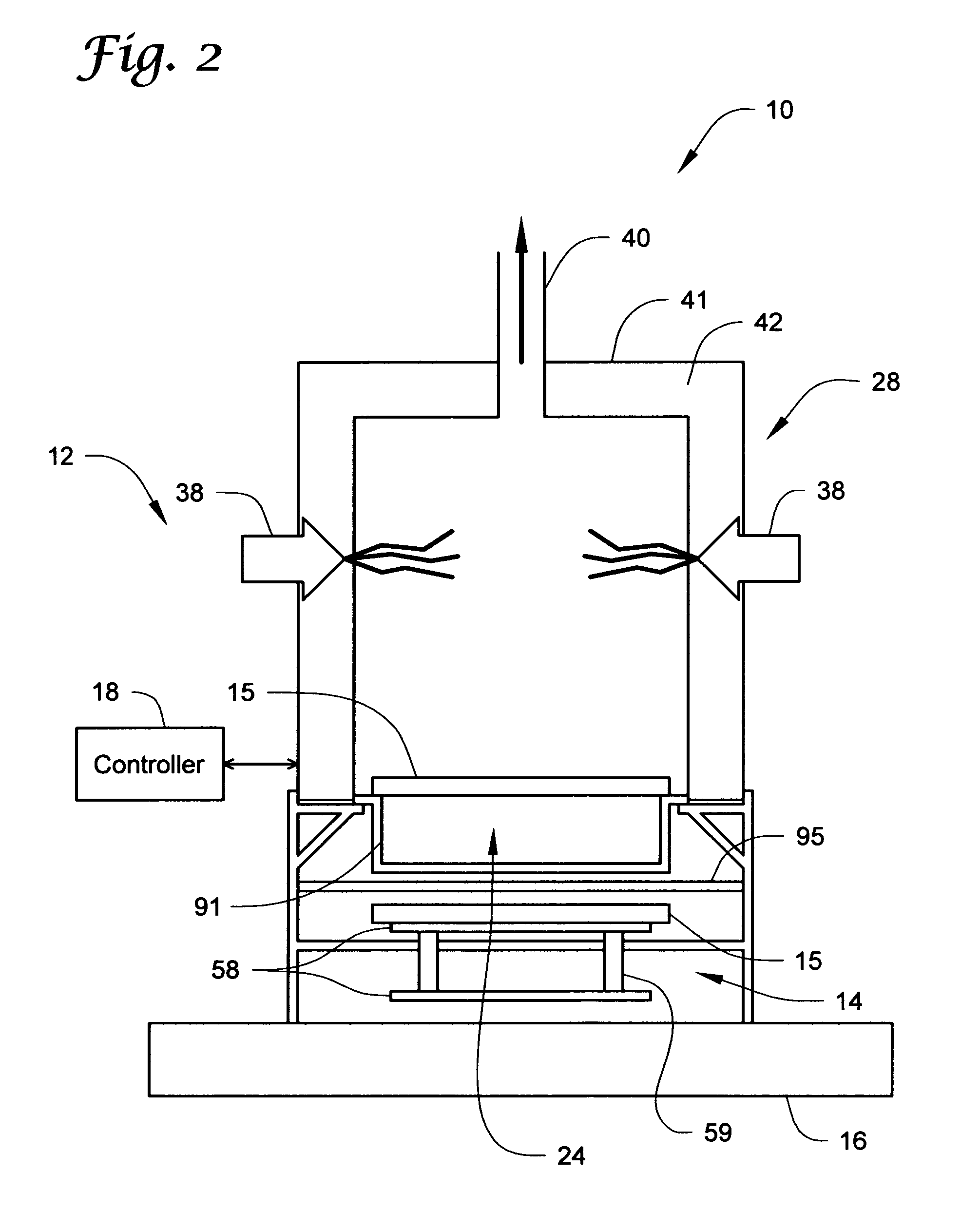

Linear hearth furnace system and methods regarding same

Systems and methods for use in processing raw material (e.g., iron bearing material) include a linear furnace apparatus extending along a longitudinal axis between a charging end and a discharging end (e.g., the linear furnace apparatus includes at least a furnace zone positioned along the longitudinal axis). Raw material is provided into one or more separate or separable containers (e.g., trays) at the charging end of the linear furnace apparatus. The separate or separable containers are moved through at least the furnace zone and to the discharging end where the processed material is discharged resulting in one or more empty containers. One or more of the empty containers are returned to the charging end of the linear furnace apparatus to receive further raw material.

Owner:NU IRON TECH LLC

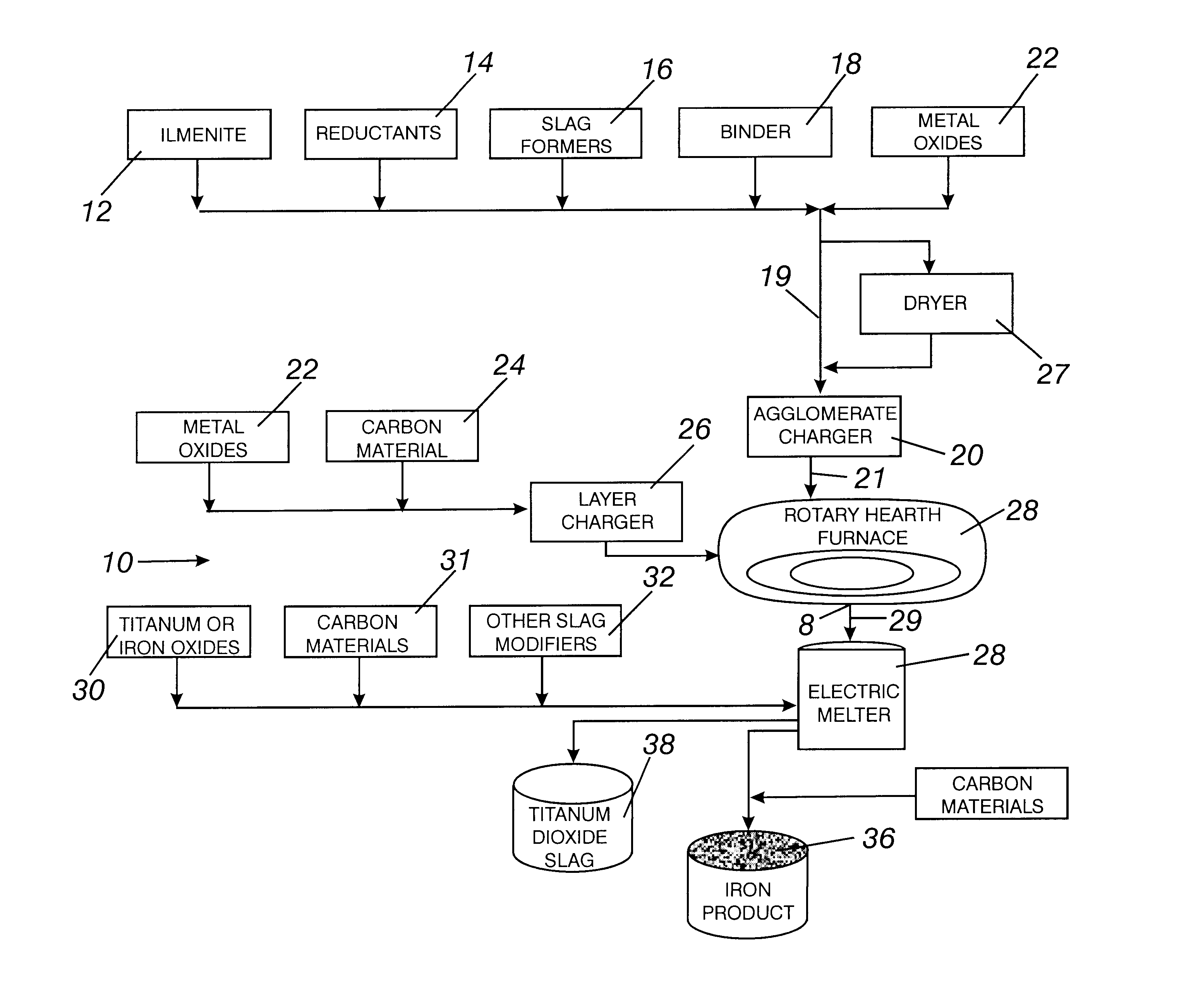

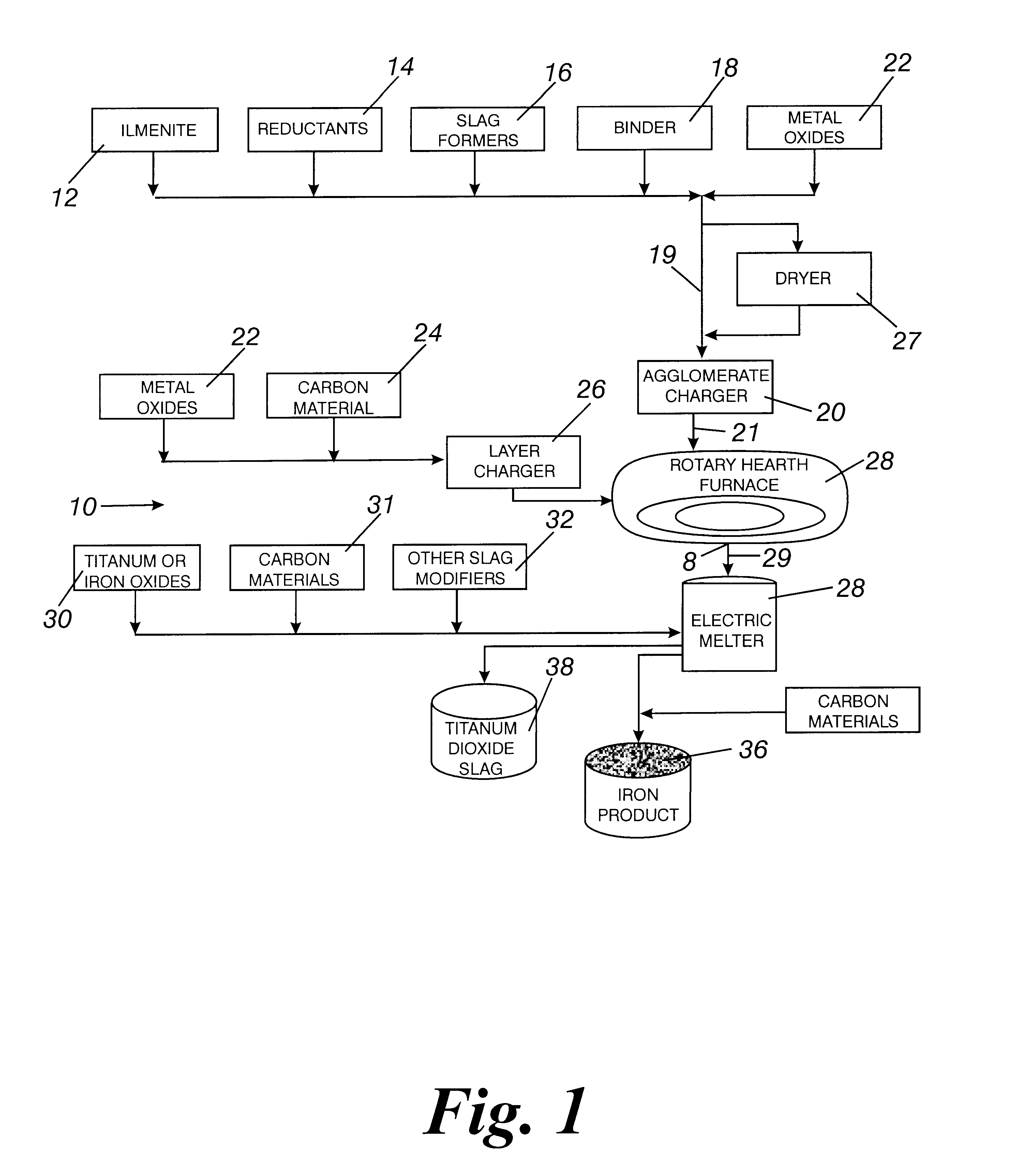

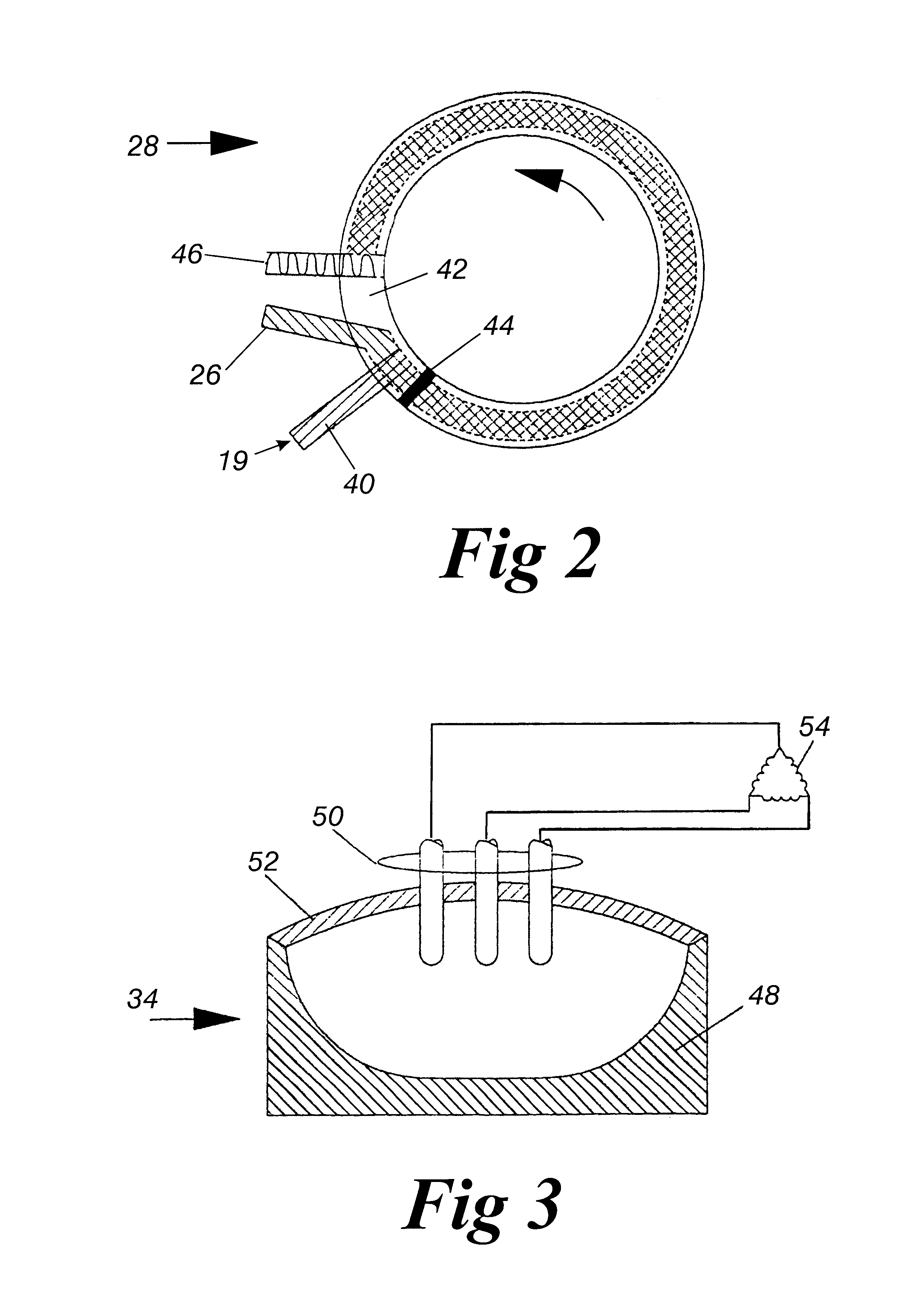

Method for producing beneficiated titanium oxides

The invention is a method and apparatus for producing beneficiated titanium oxides using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced agglomerates. The pre-reduced agglomerates is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Fluid slag and molted iron forms melted agglomerates. The fluid slag is rich in titanium. The melted agglomerates are cooled, and then the melted agglomerates and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the melted agglomerates from the hearth conditioner. The hearth conditioner is recycled, and the melted agglomerates are prepared for sale or for additional treatment in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:MIDREX TECH INC

Charging device, especially charging stock preheater

InactiveUS20070013112A1Raise the discharge heightIncrease heightBagsSacksShaped chargeHorizontal axis

To facilitate a trouble-free charging of scrap metal having differing constitutions, such as light and heavy scrap metal, from a lower discharge opening of a shaft-shaped charging device or a charging stock preheater (1) into a melting vessel by a pusher (13), the lateral surfaces of the pusher (13) are formed so as to converge from the upper side to the lower side and the actuating device (2) of the pusher (13) is pivotably supported in a frame structure (3) about a horizontal axis. In addition, the upper boundary of the discharge opening for the charging stock from the shaft (2) is preferably formed by a horizontal, rotatably supported roller (26), more preferably with engaging elements (30) distributed around the circumferential surface. Sections of the charging device that are severely mechanically stressed are preferably formed by steel billet sections connected to form a structural unit.

Owner:FUCHS TECH

Facility for producing reduced iron

In the method of producing reduced iron according to the invention, fine iron oxides and powdery solid reductants are mixed, compacted into sheet-like compacts, and charged onto the hearth of a reduction furnace for reduction while maintaining the temperature inside the furnace at not less than 1100 DEG C. As the sheet-like compacts can be obtained by compacting mixture of raw material by use of rollers or the like, processing time is much shorter than the case of pelletization or agglomeration. A drying step is unnecessary since feeds are placed no the hearth via a feeder chute or the like. The method is carried out with ease by use of the facility according to the invention. High quality hot metal can be produced by charging reduced iron in hot condition obtained by the method described as above into a shaft furnace or a in-bath smelting furnace for melting at high thermal efficiency.

Owner:SUMITOMO METAL IND LTD

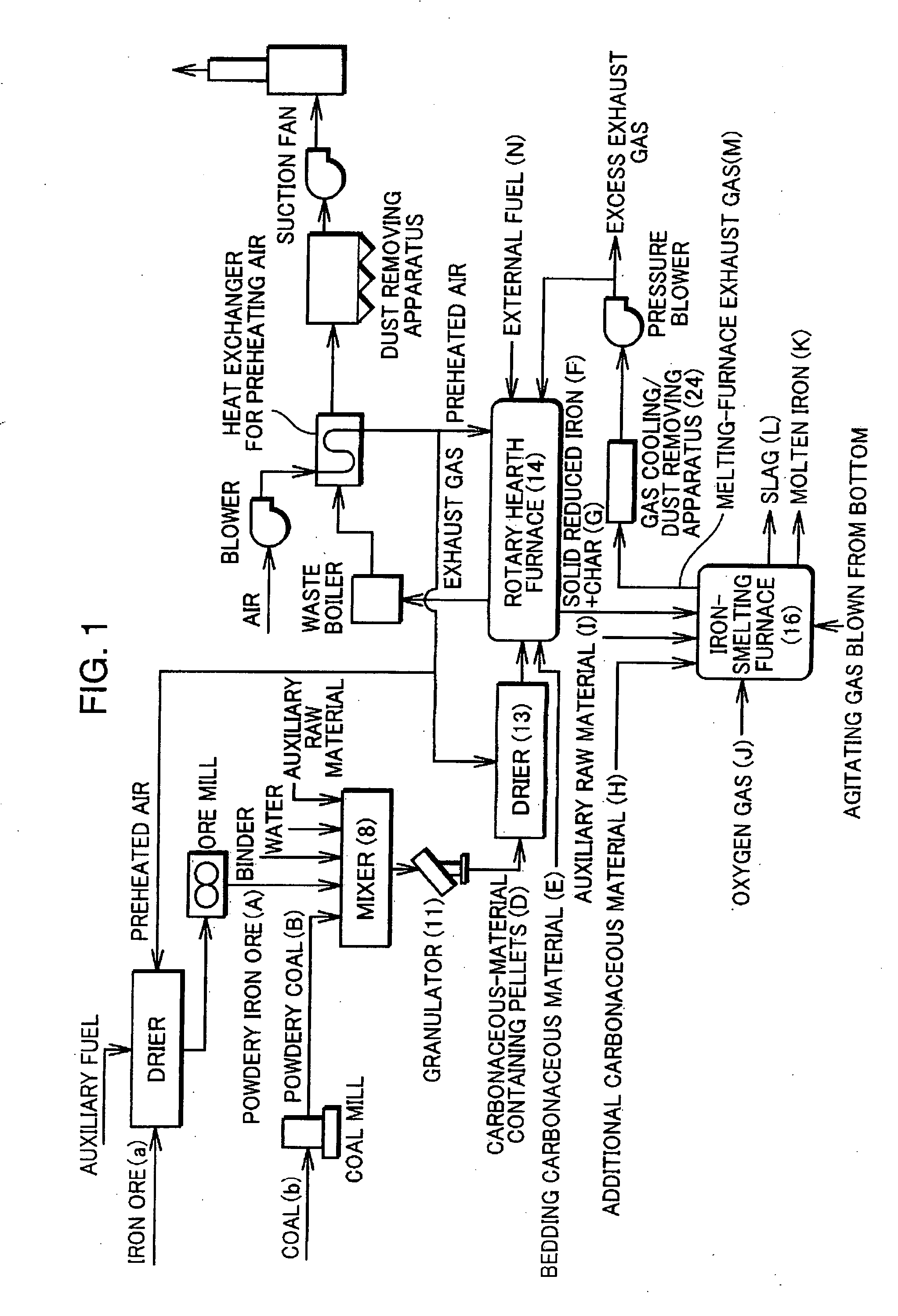

Process for Producing Molten Iron and Apparatus Therefor

A bedding carbonaceous material is charged onto a hearth of a rotary hearth furnace, carbonaceous-material containing pellets containing powdery iron ore and powdery coal are placed on the bedding carbonaceous material, and the hearth is caused to pass inside the rotary hearth furnace to heat and reduce the carbonaceous-material containing pellets to solid reduced iron and to heat and dry the bedding carbonaceous material by distillation into char. Subsequently, the solid reduced iron and the char are charged into an iron-melting furnace without being substantially cooled, and an oxygen gas is blown into the iron-melting furnace to melt the solid reduced iron, thereby obtaining molten iron. At least a part of an exhaust gas from the iron-melting furnace is used as a fuel gas for the rotary hearth furnace after being cooled and having dust removed.

Owner:KOBE STEEL LTD

Iron production method of operation in a rotary hearth furnace and improved furnace apparatus

The present invention is an apparatus and method for the direct reduction of iron oxide utilizing a rotary hearth furnace to form a high purity carbon-containing iron metal button. The hearth layer may be a refractory or a vitreous hearth layer of iron oxide, carbon, and silica compounds. Additionally, coating materials may be introduced onto the refractory or vitreous hearth layer before iron oxide ore and carbon materials are added, with the coating materials preventing attack of the molten iron on the hearth layer. The coating materials may include compounds of carbon, iron oxide, silicon oxide, magnesium oxide, and / or aluminum oxide. The coating materials may be placed as a solid or a slurry on the hearth layer and heated, which provides a protective layer onto which the iron oxide ores and carbon materials are placed. The iron oxide is reduced and forms molten globules of high purity iron and residual carbon, which remain separate from the hearth layer. An improved apparatus includes a cooling plate that is placed in close proximity with the refractory or vitreous hearth layer, cooling the molten globules to form iron metal buttons that are removed from the hearth layer. The improvements due to the present apparatus and method of operation provide high purity iron and carbon solid buttons, which are separate from slag particulates, and discharged without significant loss of iron product to the interior surfaces of the furnace.

Owner:MIDREX INT B V ROTTERDAM

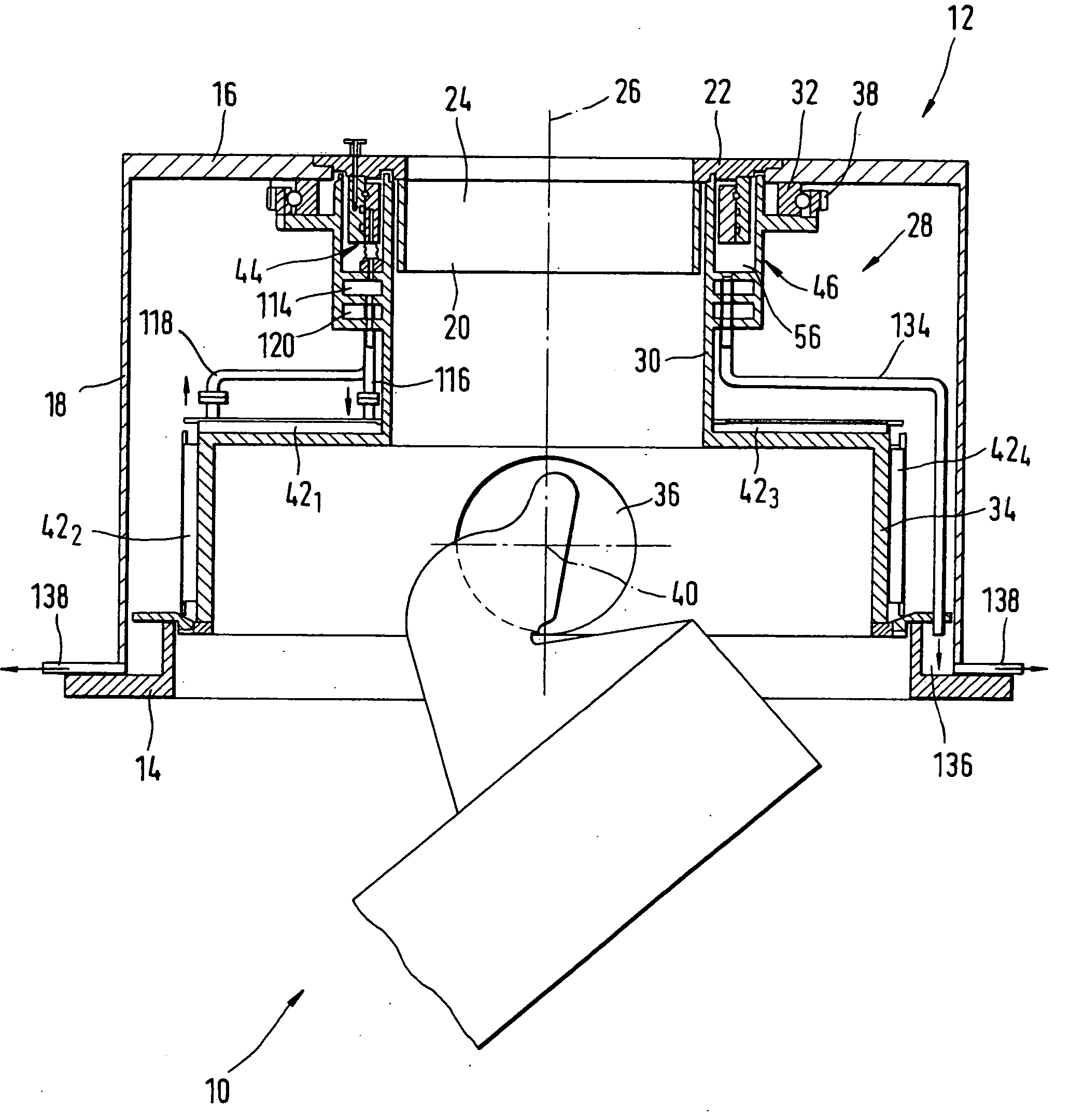

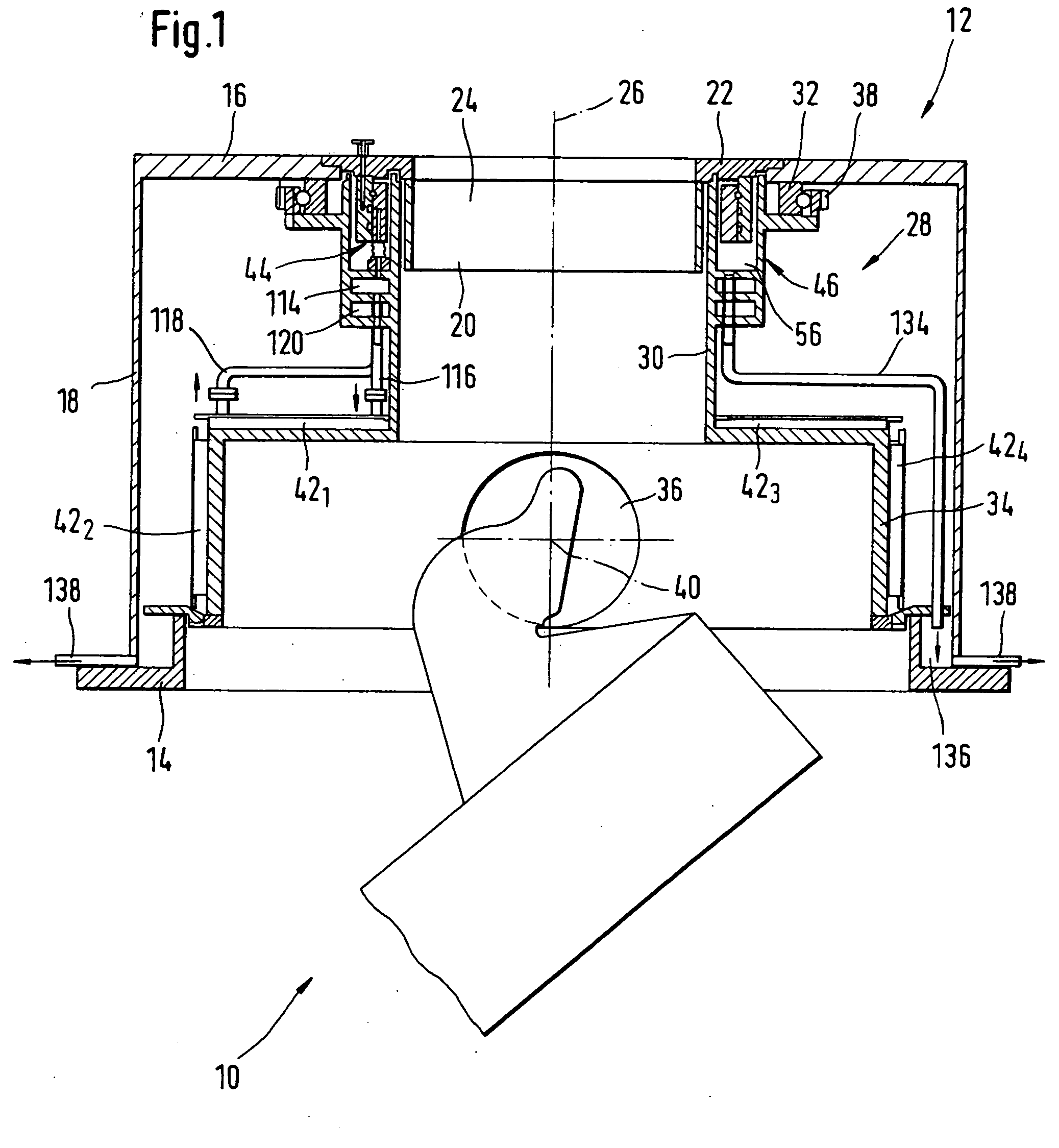

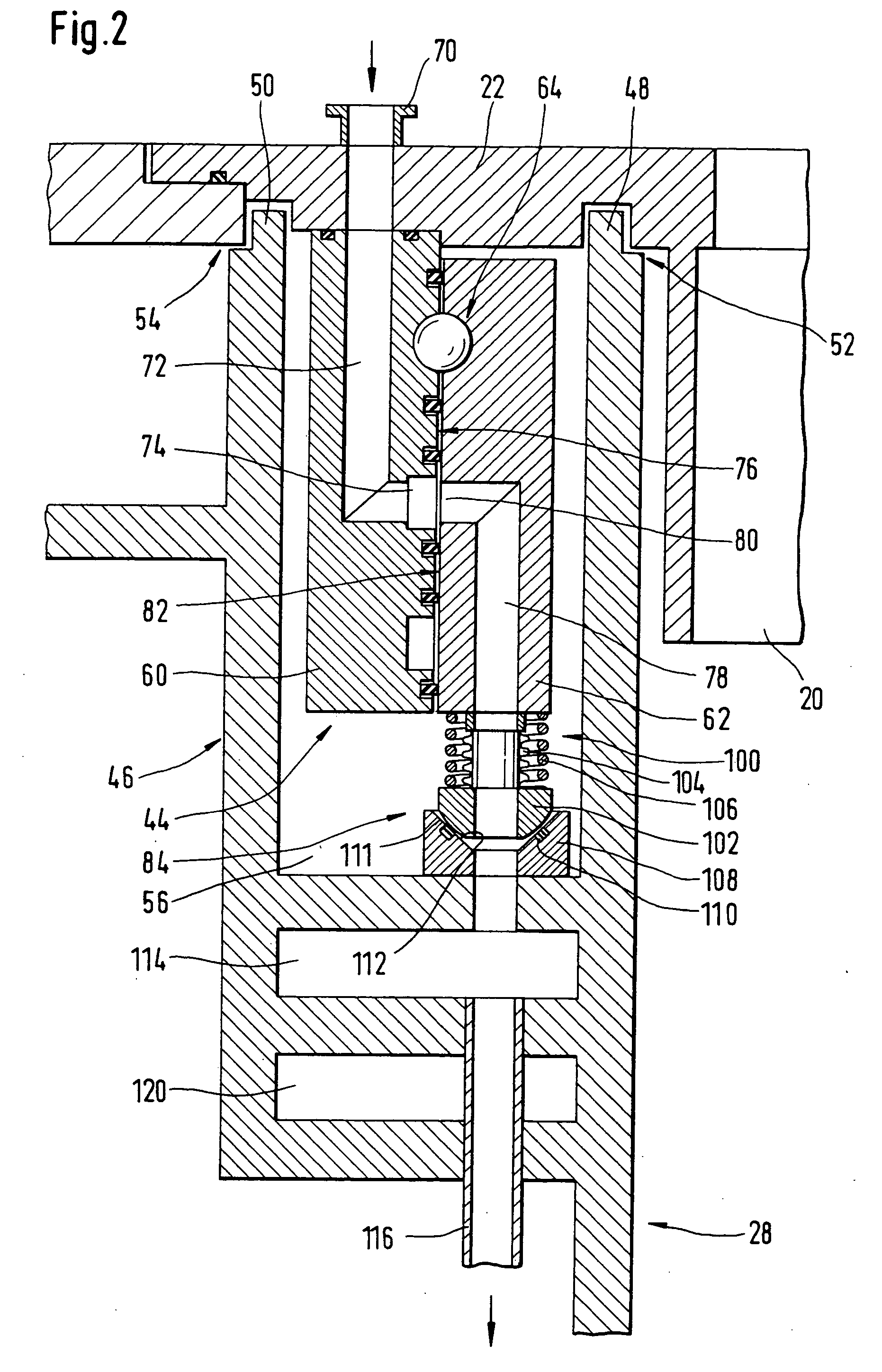

Device for loading a shaft furnace

A loading device for a shaft furnace comprises a chute supported by a suspension rotor (28) in a fixed housing. The rotor (28) is fitted with a cooling circuit, supplied with liquid coolant via a rotating annular joint (44). The latter comprises a fixed ring (60) and a rotating ring (62), and is fitted in an annular leak collecting tank (46) formed by the suspension rotor (28). Fixed ring (60) is supported by the housing (12). Rotating ring (62) is supported entirely by fixed ring (60) via a bearing (64). Selective coupling means (65, 66) connect the rotating ring (62) to the suspension rotor (28) in such a way as to transmit a rotary moment of rotor (28) to rotating ring (62) selectively, while at the same time preventing other forces from rotor (28) being transmitted to rotating ring (62).

Owner:PAUL WURTH SA

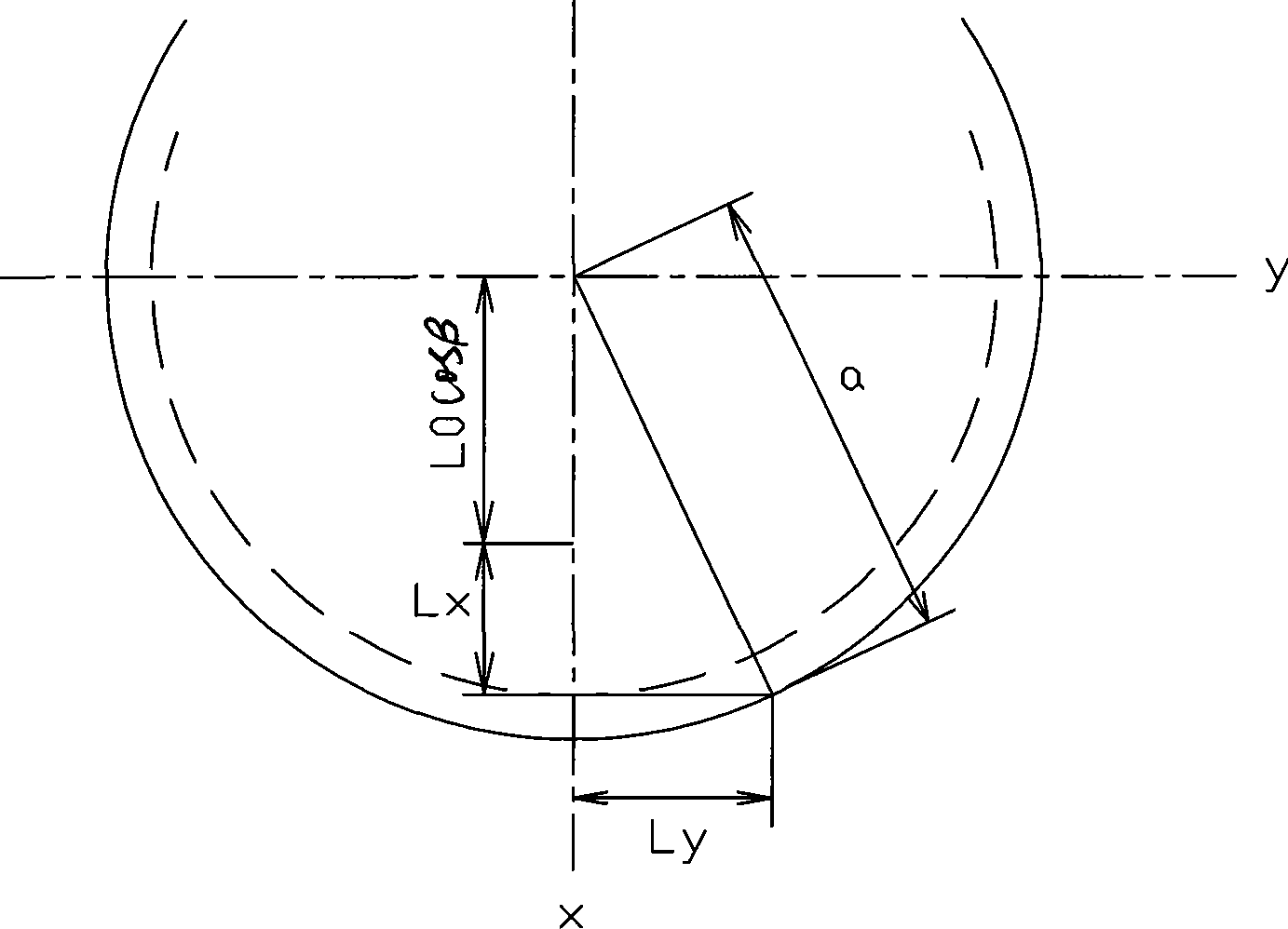

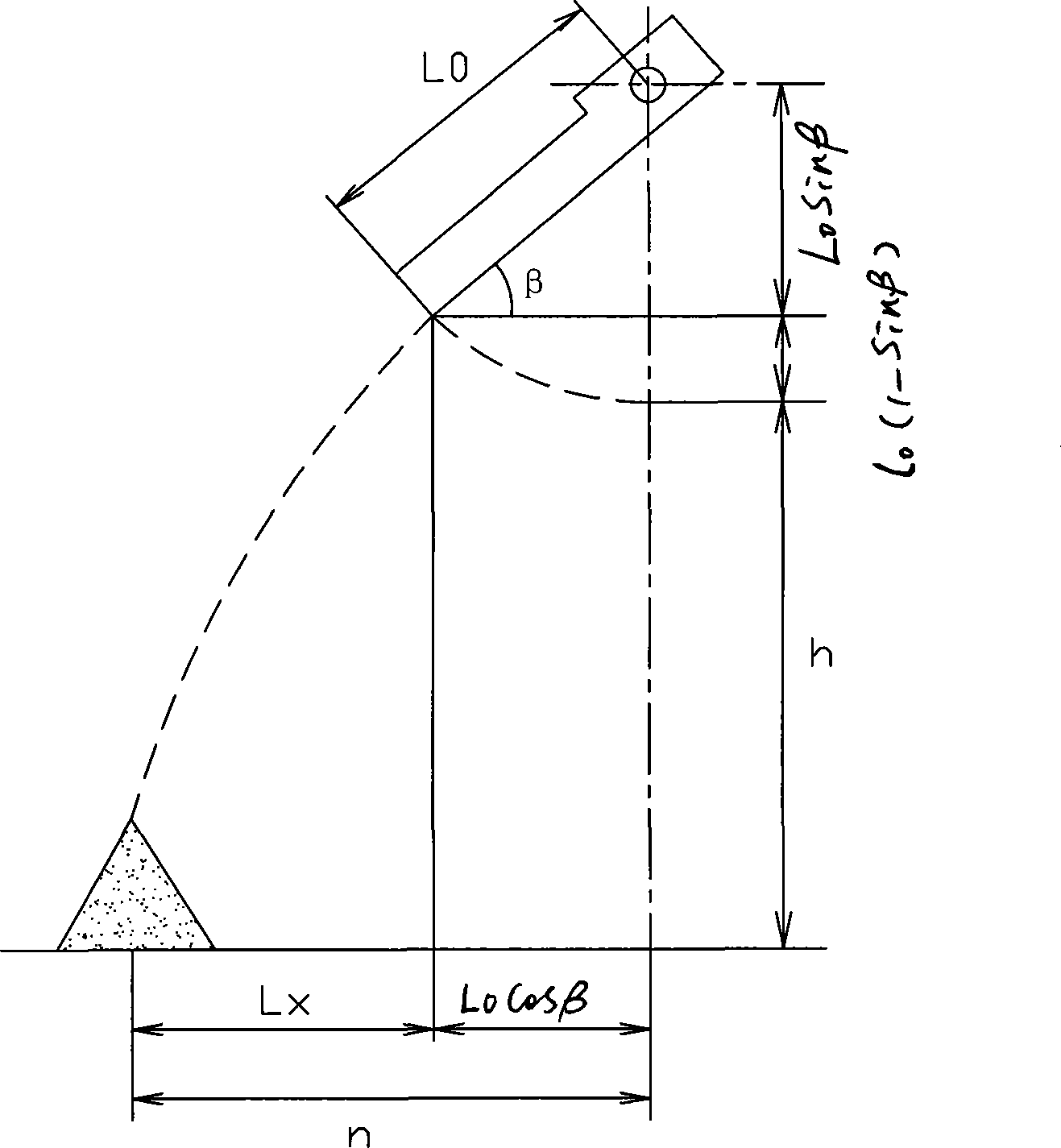

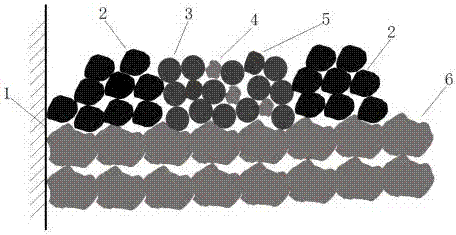

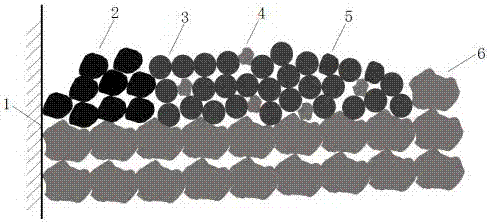

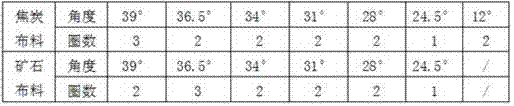

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Blast-furnace burden distribution method for high-proportion pellets

InactiveCN107119163AEfficient control over scrollingEffective control of rolling effectBell-and-hopper arrangementBlast furnace detailsDistribution matrixPresent method

The invention discloses a method for distributing material for a blast furnace with a high proportion of pellets. The process is as follows: the ore to be fed into the furnace includes pellets and sintered ore; the pellets and coke are mixed into the furnace; When the amount of pellets accounts for 30% to 60% of the total ore, the sintered ore is placed at both ends of the cloth stall, and the other ore is placed in the middle of the cloth stall; when the pellets account for more than 60% of the total ore, the sintered ore is placed The stalls on the edge of the furnace throat, and other ores are distributed in other stalls. The method effectively controls the rolling of the pellets by optimizing the material distribution matrix, and stabilizes the forward movement of the blast furnace while increasing the ratio of the pellets into the furnace. This method can effectively control the rolling effect of the pellets in the furnace when the high proportion of pellets is smelted in the blast furnace, which is conducive to stabilizing the two airflows at the edge and center of the furnace, controlling the reasonable operation of the furnace type, and ensuring the stability of the blast furnace. It has the characteristics of strong operability, simple process and easy realization.

Owner:TANGSHAN IRON & STEEL GROUP +1

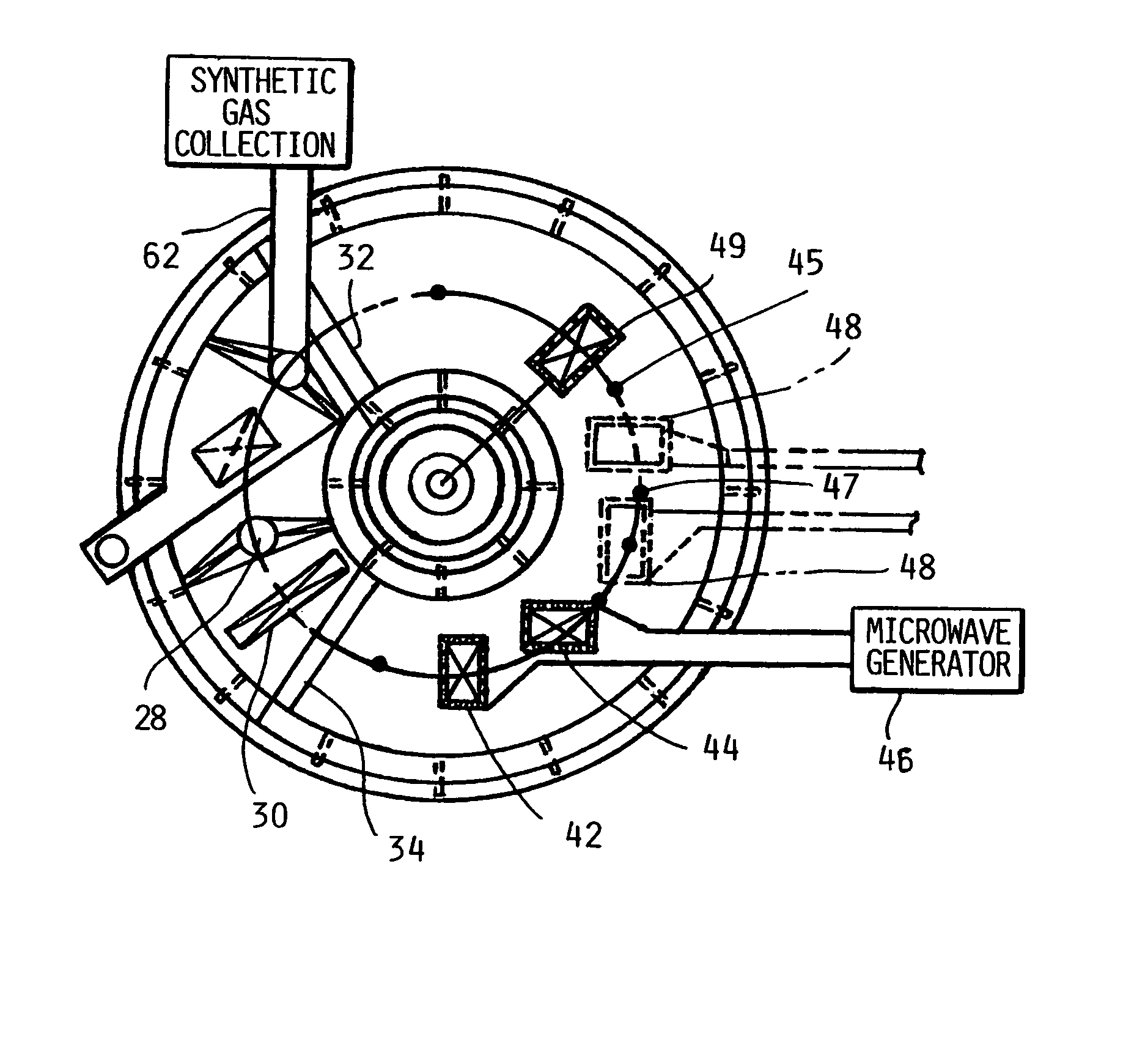

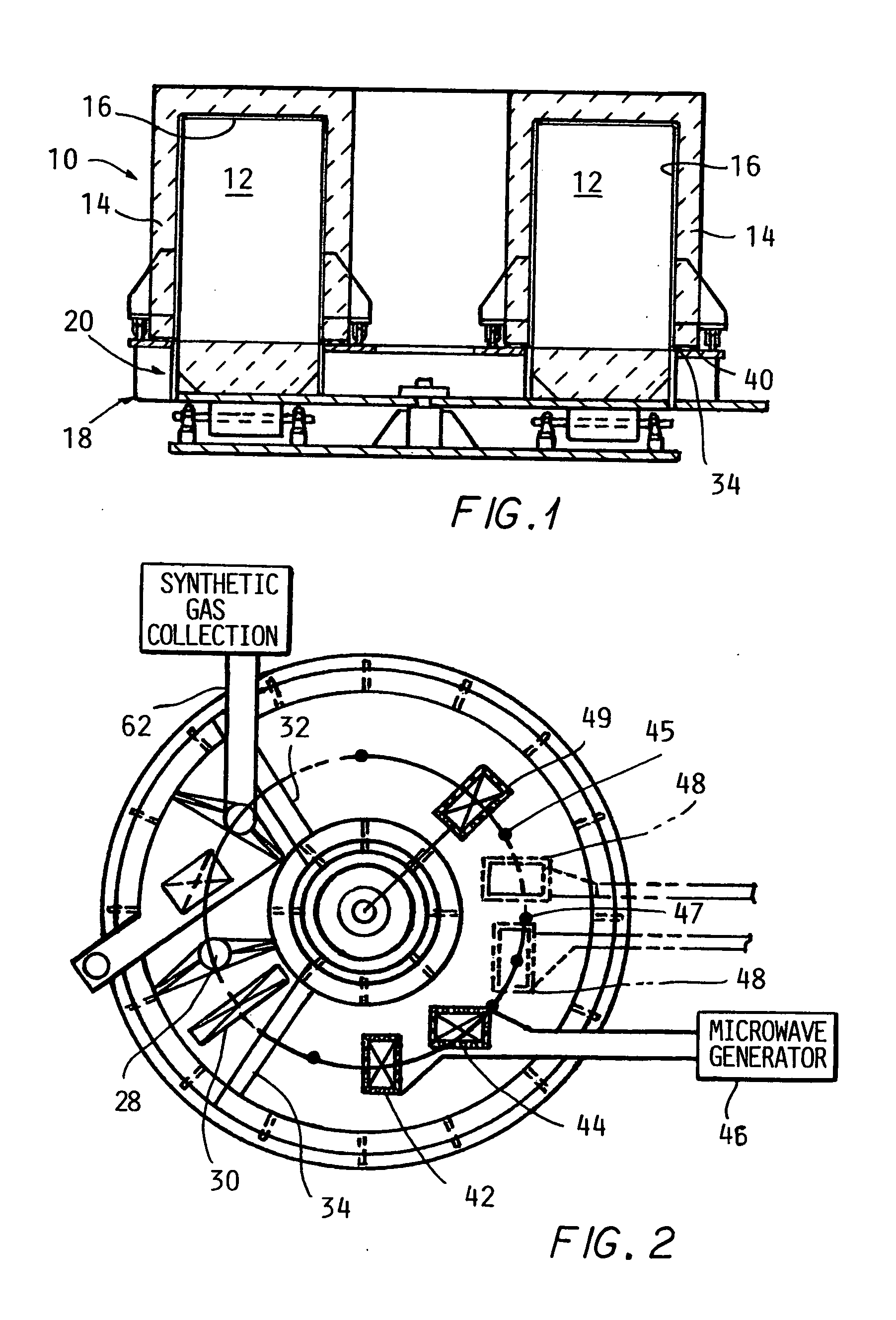

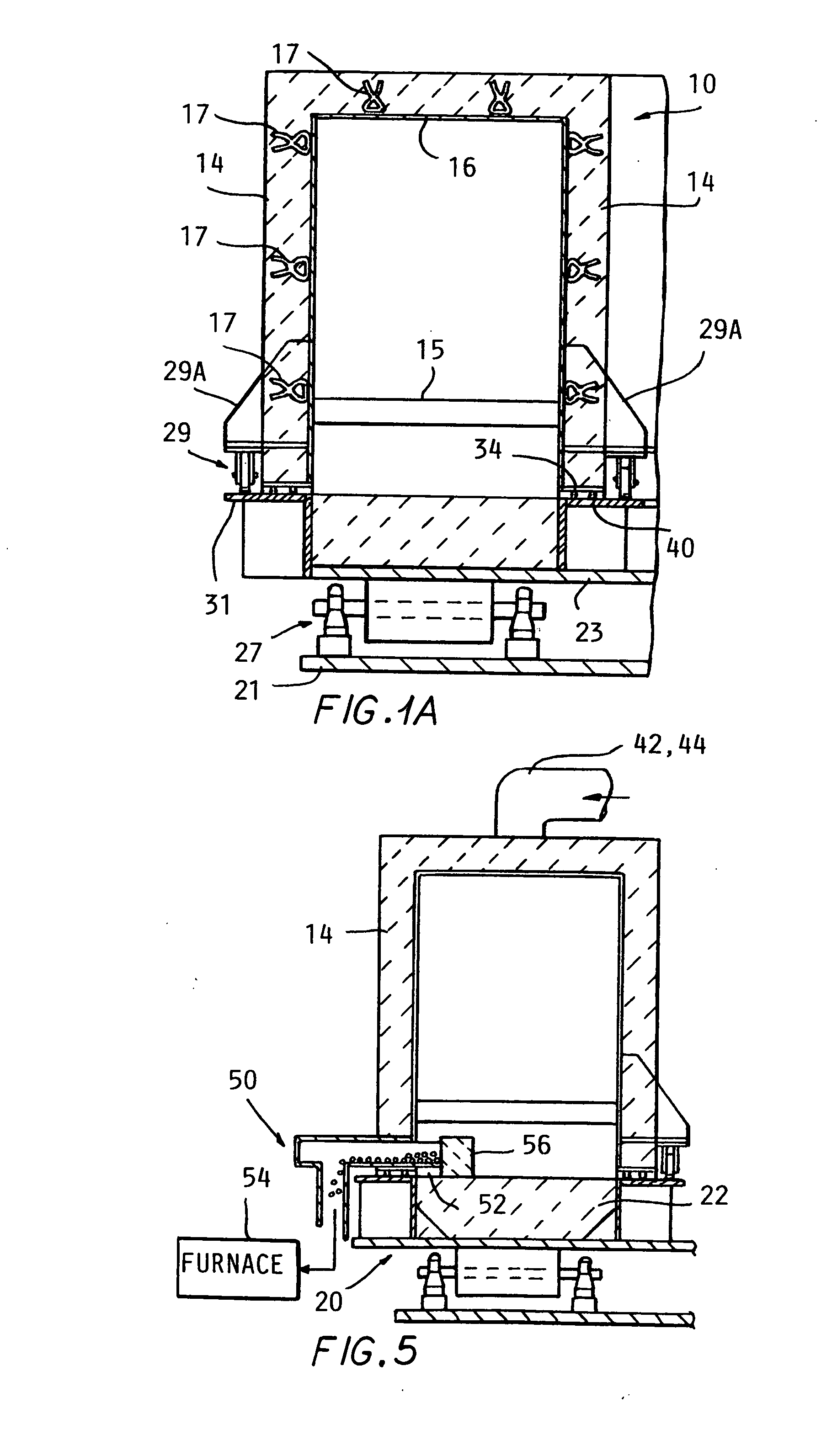

Microwave heating method and apparatus for iron oxide reduction

A method and apparatus for reducing iron oxides using microwave heating in a furnace chamber which is sealed against the entrance of air reduces the energy required and produces a low temperature reduction and allows the recovery of combustible synthetic gas as a byproduct of the process. Avoidance of the reduction of sulfur, phorphorus and silica is also insured, as is the need to reduce the silica content of the feed material prior to reducing the ore. A continuous rotary hearth furnace, a rotary kiln, a linear conveyor and vertical shaft furnace chamber configurations are described. A secondary heating zone can also be included to process the reduced iron into iron nuggets or liquid metallic iron.

Owner:HWANG JIANN YANG +1

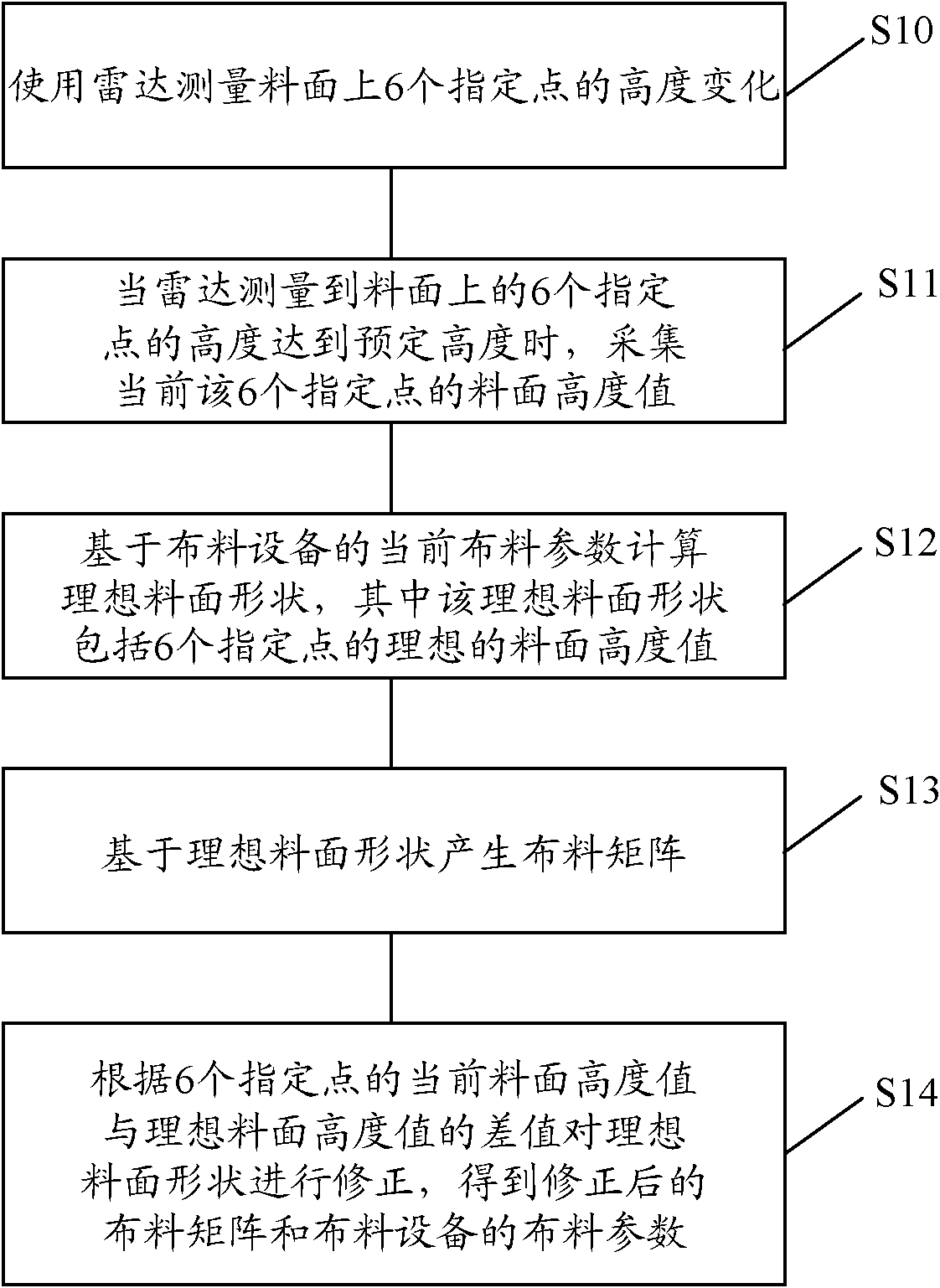

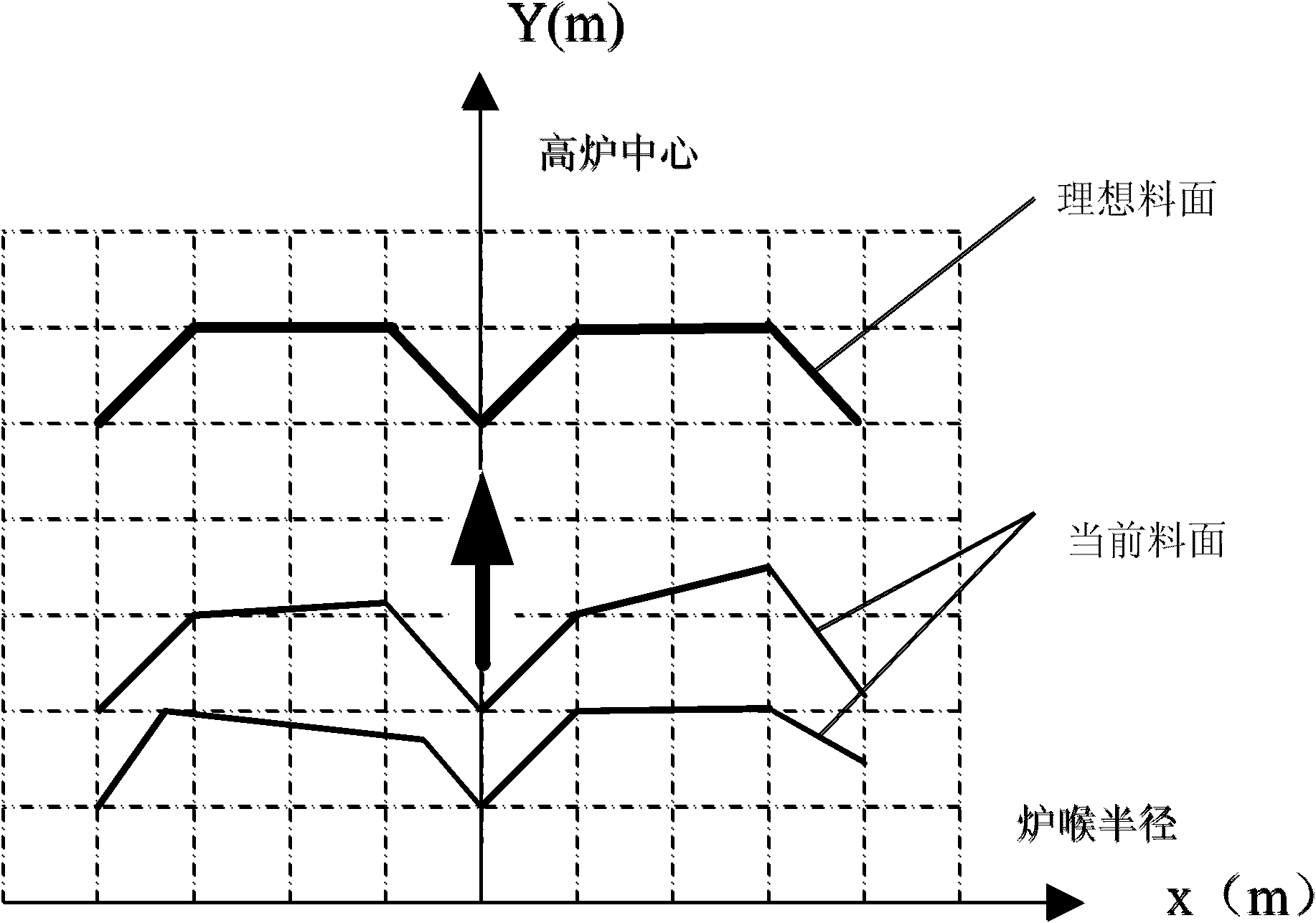

Burden surface profile control method of blast furnace burden distribution and control system

InactiveCN102732659AAccurate detectionFabric Process OptimizationBell-and-hopper arrangementChecking devicesDistribution matrixControl system

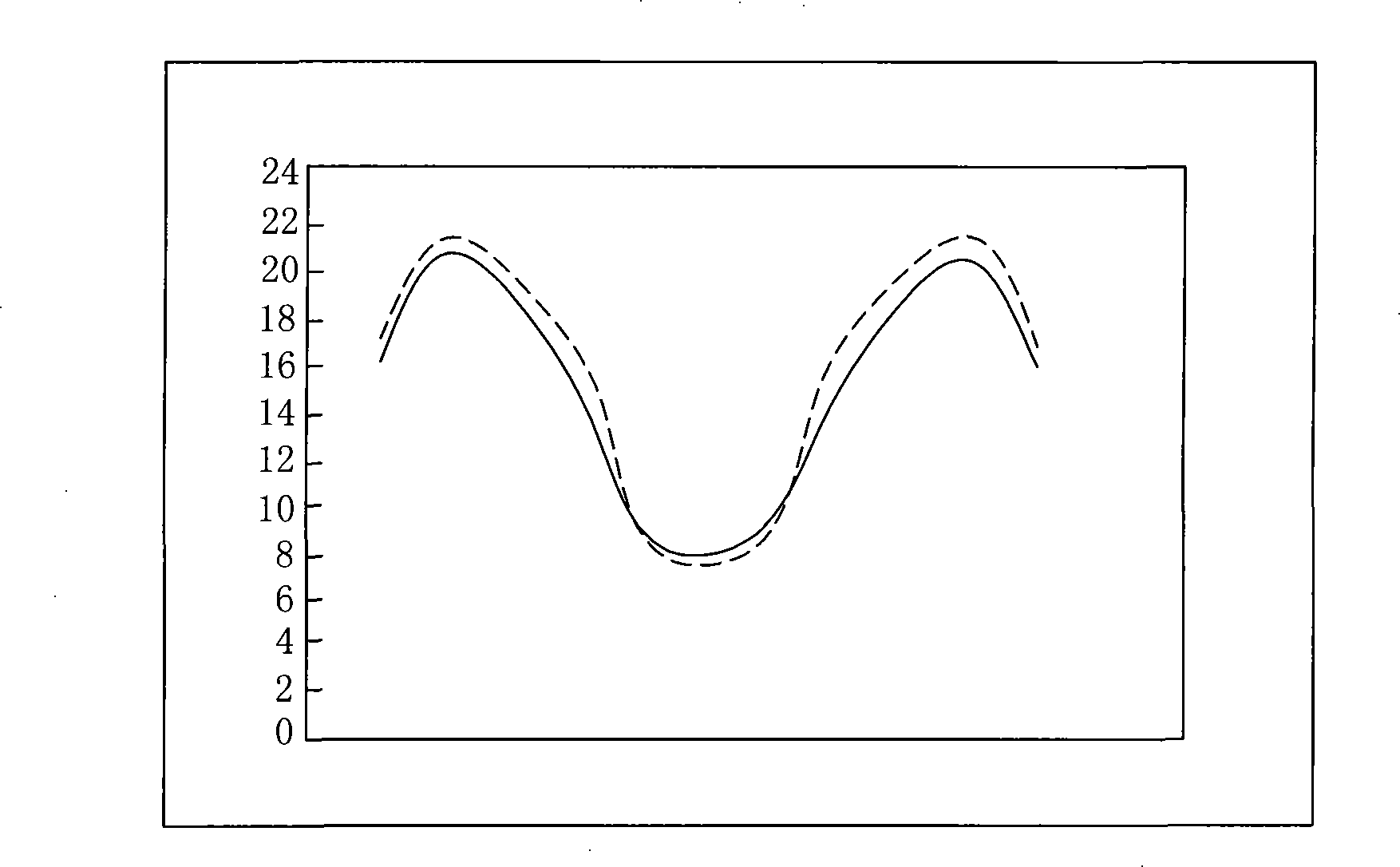

The invention discloses a control method of a burden surface profile control method of blast furnace burden distribution, and the method comprises: measuring the height variation of 6 specified points on the burden surface by radars; measuring the burden surface height values of the 6 specified points when the radars measure that the heights of the 6 specified points on the burden surface reach predetermined heights; calculating an ideal burden surface profile on the basis of current burden distribution parameters of burden distribution equipment, with the ideal burden surface profile containing the ideal burden surface height values of the 6 specified points; generating a burden distribution matrix based on the ideal burden surface profile; on the basis of the 6 specified points, revising the ideal burden surface profile according to the differences between the current burden surface height values and the ideal burden surface height values of the 6 specified points, thus obtaining a revised burden distribution matrix and revised burden distribution parameters of the burden distribution equipment; conducting burden distribution equipment based on the revised burden distribution parameters of the burden distribution equipment. The burden surface profile control method and control system of blast furnace burden distribution of the invention can realize more accurate detection of the burden surface, enable more optimized burden distribution process, reduce burden surface fluctuation, and achieve stable production, energy saving as well as consumption reduction.

Owner:BAOSHAN IRON & STEEL CO LTD +1

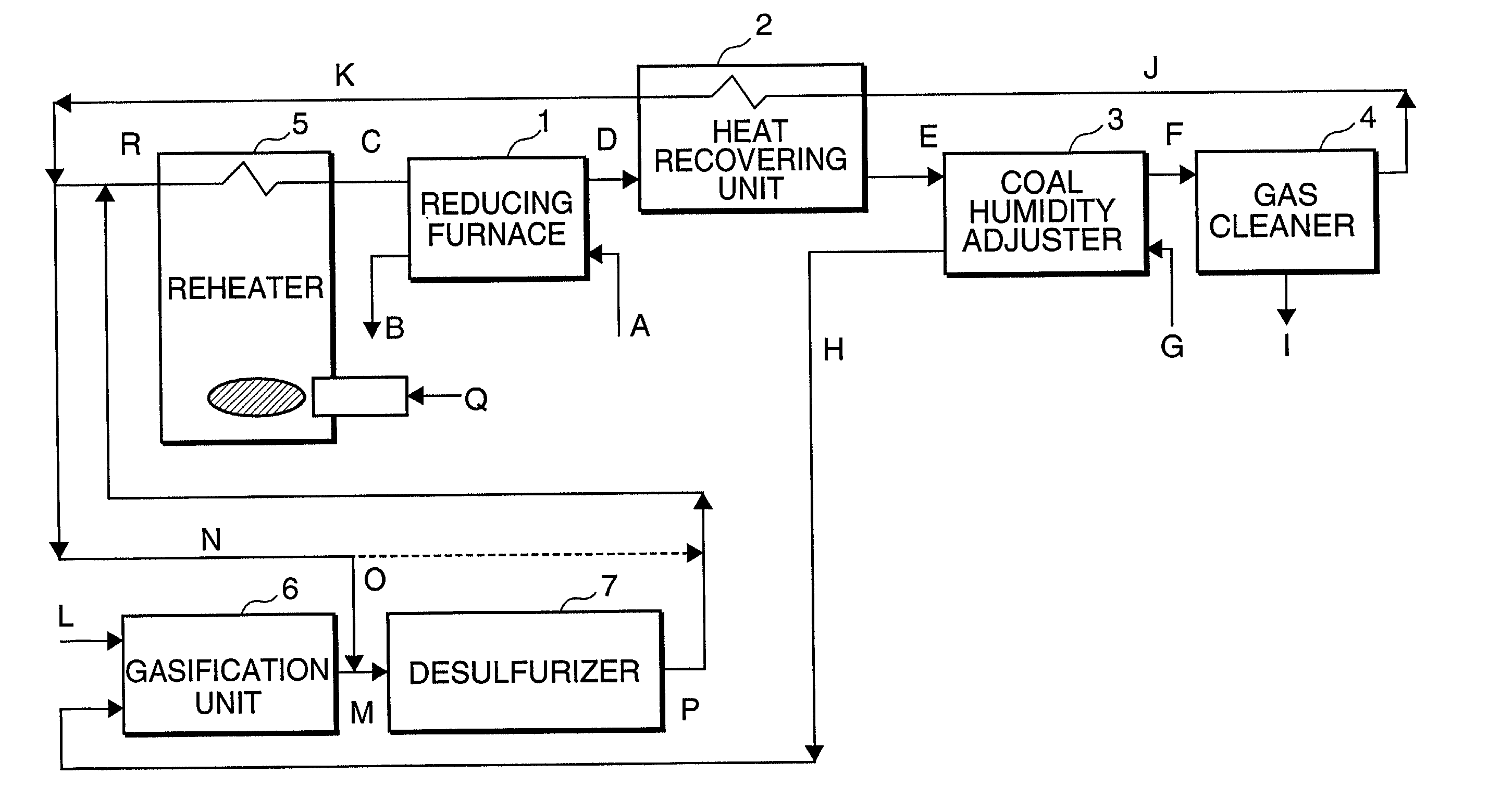

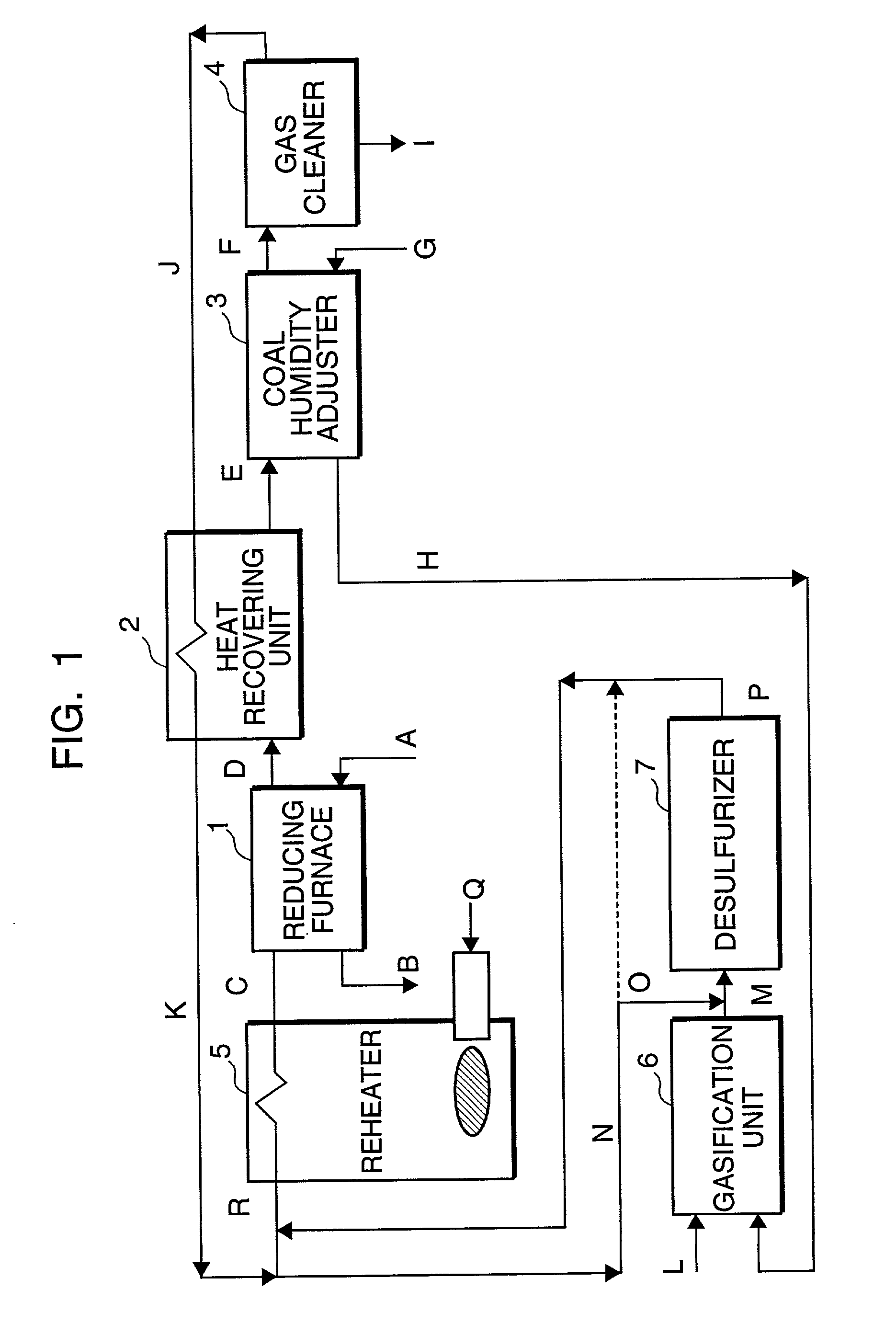

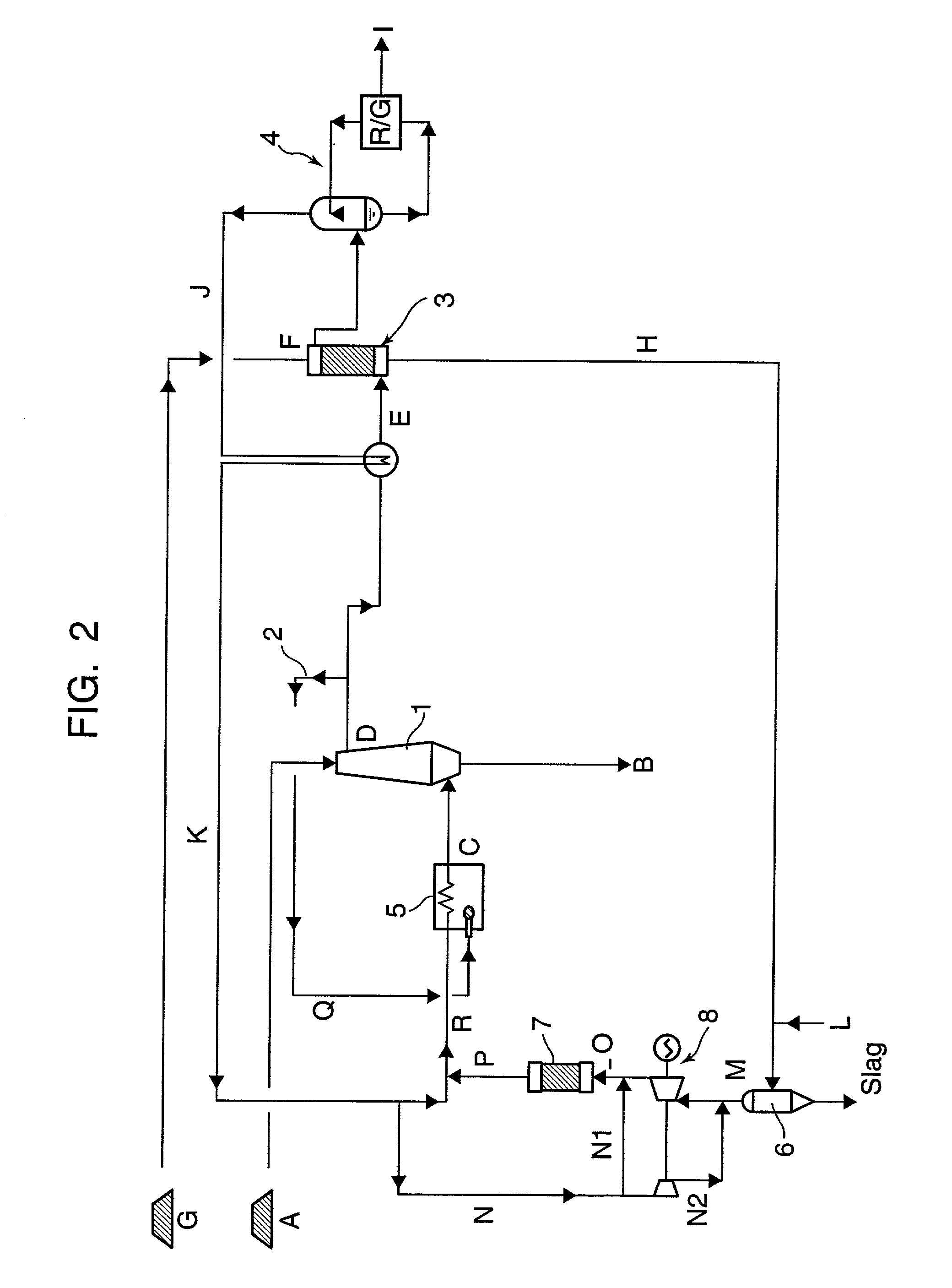

Method of producing direct reduced iron with use of coal-derived gas

InactiveUS20020078795A1Efficient use ofLow degreeTuyeresBell-and-hopper arrangementProduct gasCoal gasifier

In a method of producing direct reduced iron with use of a coal-derived gas, coal is heated to lower the moisture thereof, and the moisture-lowered coal is gasified in a coal gasification furnace to produce a coal-derived gas containing a reducing gas. The reducing gas is then utilized to reduce iron ore in an iron ore reducing furnace. With use of an exhaust gas from the iron ore reducing furnace, the coal is heated in the step of heating coal.

Owner:KOBE STEEL LTD +1

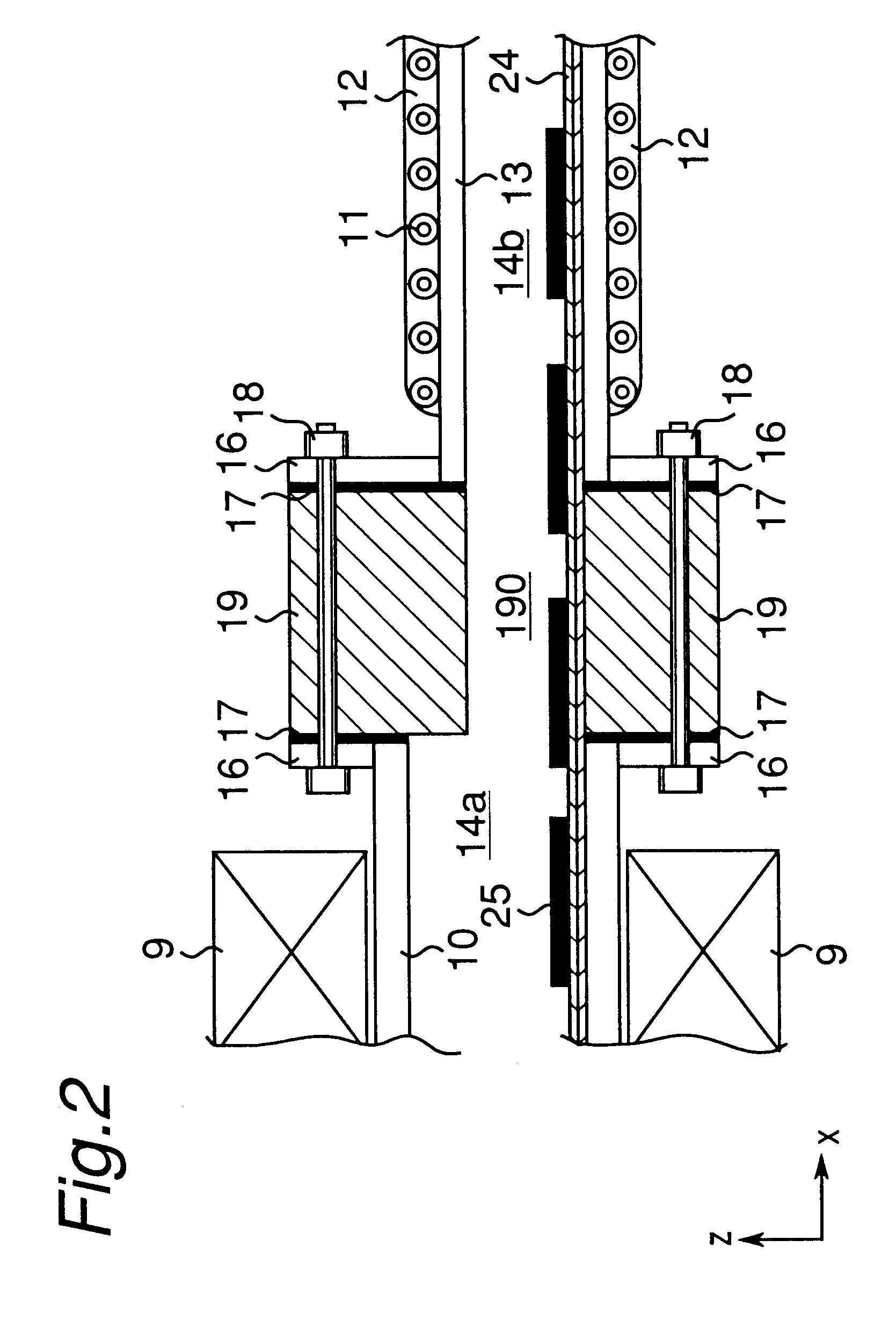

Substrate processing apparatus and manufacturing method for semiconductor devices

ActiveUS20080134483A1Smooth transferSimple structureConveyorsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A substrate processing apparatus comprises a storage container for storing multiple substrates and whose substrate loading and unloading opening is shut by a lid, a loading and unloading port for carrying the storage container into and out of the case, a placement unit for placing the storage container in the loading and unloading port, a storage chamber provided adjacent to the loading and unloading port for storing the storage container, an opening and closing device for opening and closing the substrate loading and unloading opening of the storage container placed in the placement unit, a transfer device containing a holding mechanism for supporting the bottom of the storage container and transferring the storage container supported in the holding mechanism, over the opening and closing device between the inside and outside of the storage chamber, and an elevator mechanism for raising and lowering the placement unit between the placement unit height position where the opening and closing device opens and closes the storage container, and a height position where the transfer device gives and receives the storage container.

Owner:KOKUSA ELECTRIC CO LTD

Substrate treating apparatus with inter-unit buffers

ActiveUS8545118B2Quality improvementLiquid surface applicatorsConveyorsEngineeringMechanical engineering

The invention provides coating units, heat-treating units, and a first main transport mechanism for transporting substrates to each of these treating units. The substrates are transferred from the first main transport mechanism to a second main transport mechanism through a receiver. When a substrate cannot be placed on the receiver, this substrate is placed on a buffer. Thus, the first main transport mechanism can continue transporting other substrates. The other substrates in the treating units are transported between the treating units without delay, to receive a series of treatments including coating treatment and heat treatment as scheduled. This prevents lowering of the quality of treatment for forming film on the substrates.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

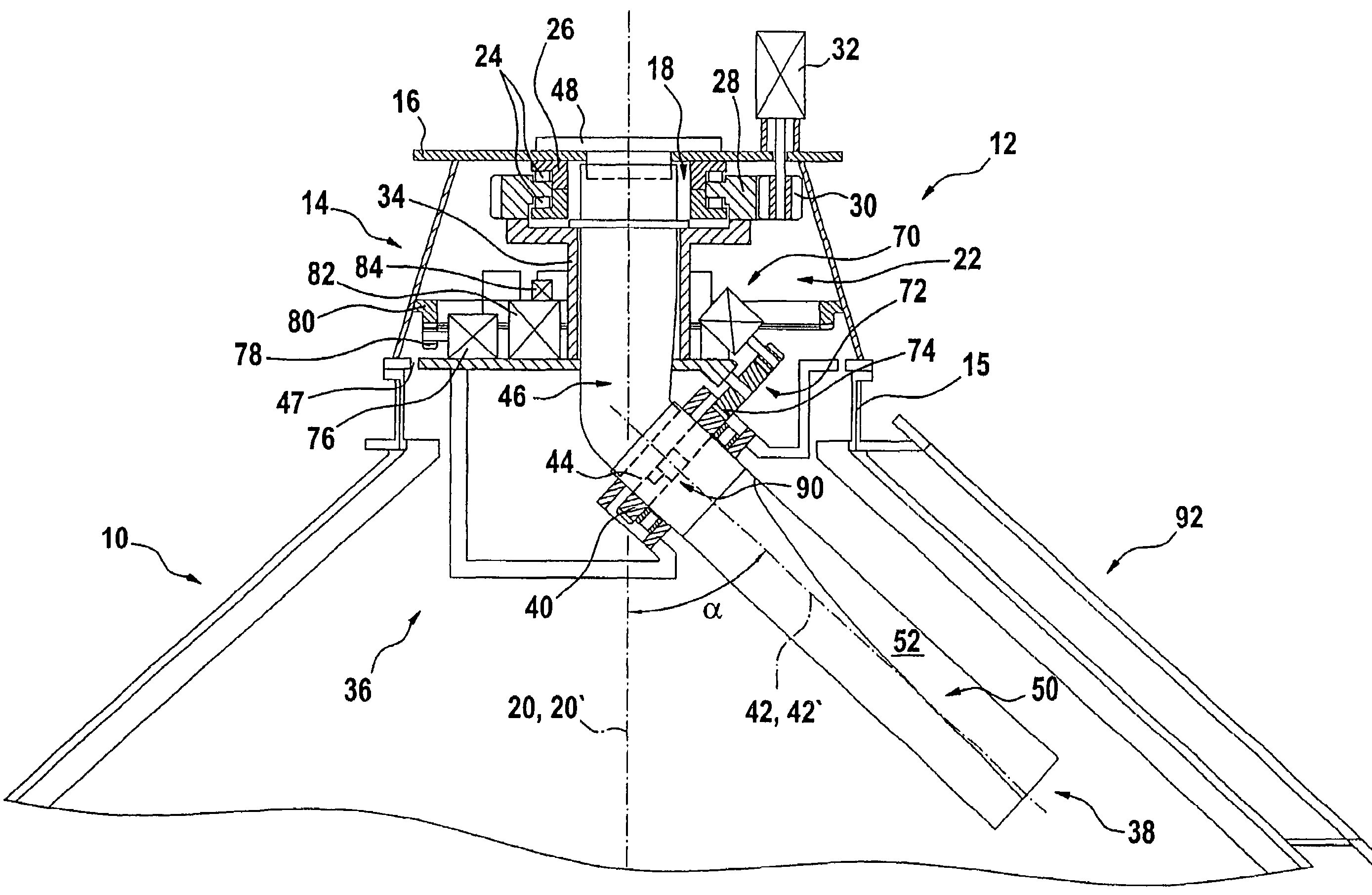

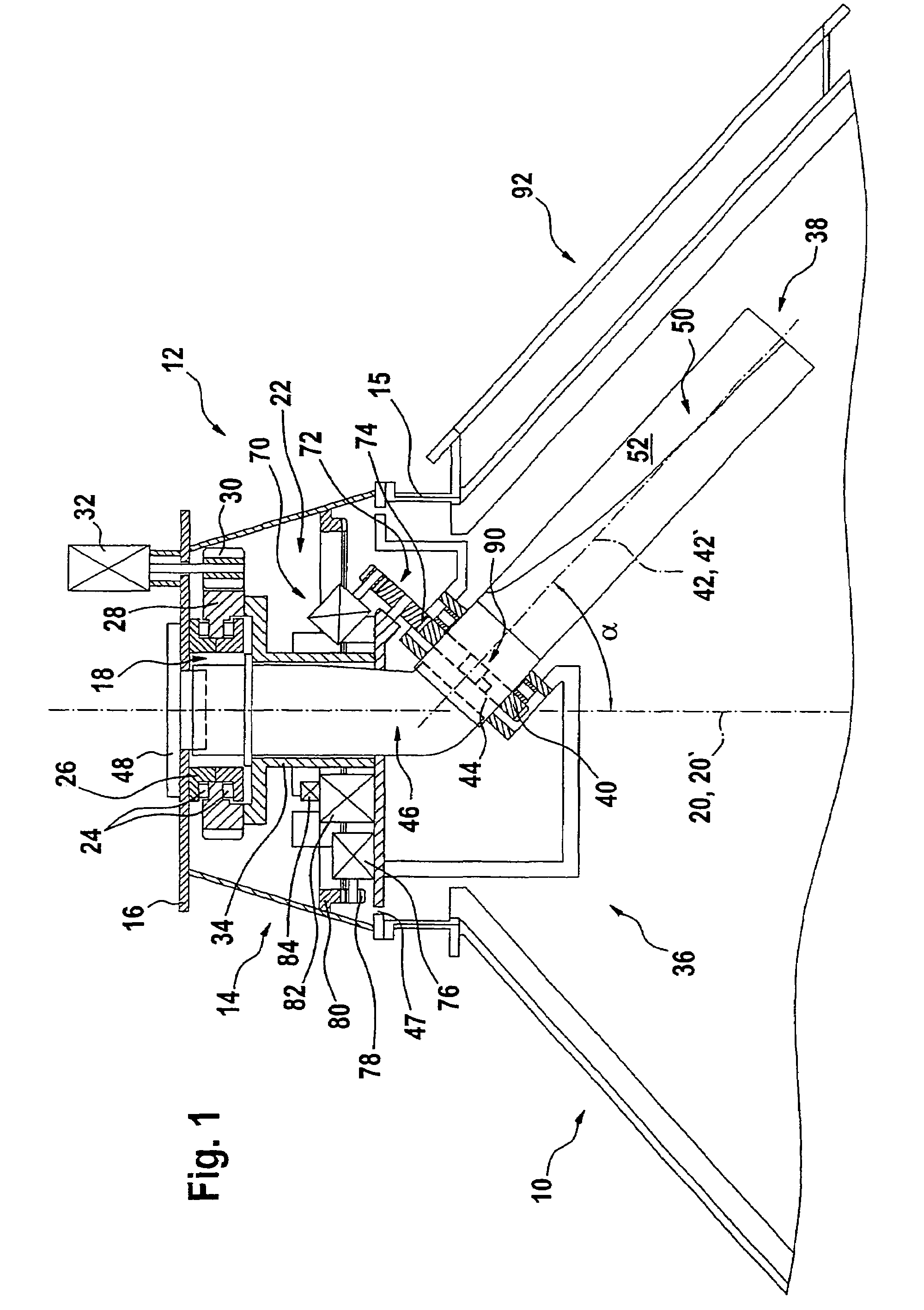

Charging device with rotary chute

InactiveUS7311486B2Simple driveEasy mounting and dismountingThrowing machinesConveyorsMechanical engineeringVertical axis

A charging device for bulk material comprises a rotor having a substantially vertical axis of rotation a first drive for rotating the rotor and a chute supported by the rotor so as to be rotated with the latter. The chute can be rotated about its longitudinal axis. Its concavely curved sliding surface has a width that is diminishing from the top end to the bottom end of the chute, so that it is possible to vary the location where bulk material sliding down the chute channel leaves the latter by rotating the chute about its longitudinal axis.

Owner:PAUL WURTH SA

Substrate treating apparatus with inter-unit buffers

ActiveUS20090142162A1Limit quality of treatmentQuality improvementLiquid surface applicatorsConveyorsEngineeringMechanical engineering

The invention provides coating units, heat-treating units, and a first main transport mechanism for transporting substrates to each of these treating units. The substrates are transferred from the first main transport mechanism to a second main transport mechanism through a receiver. When a substrate cannot be placed on the receiver, this substrate is placed on a buffer. Thus, the first main transport mechanism can continue transporting other substrates. The other substrates in the treating units are transported between the treating units without delay, to receive a series of treatments including coating treatment and heat treatment as scheduled. This prevents lowering of the quality of treatment for forming film on the substrates.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

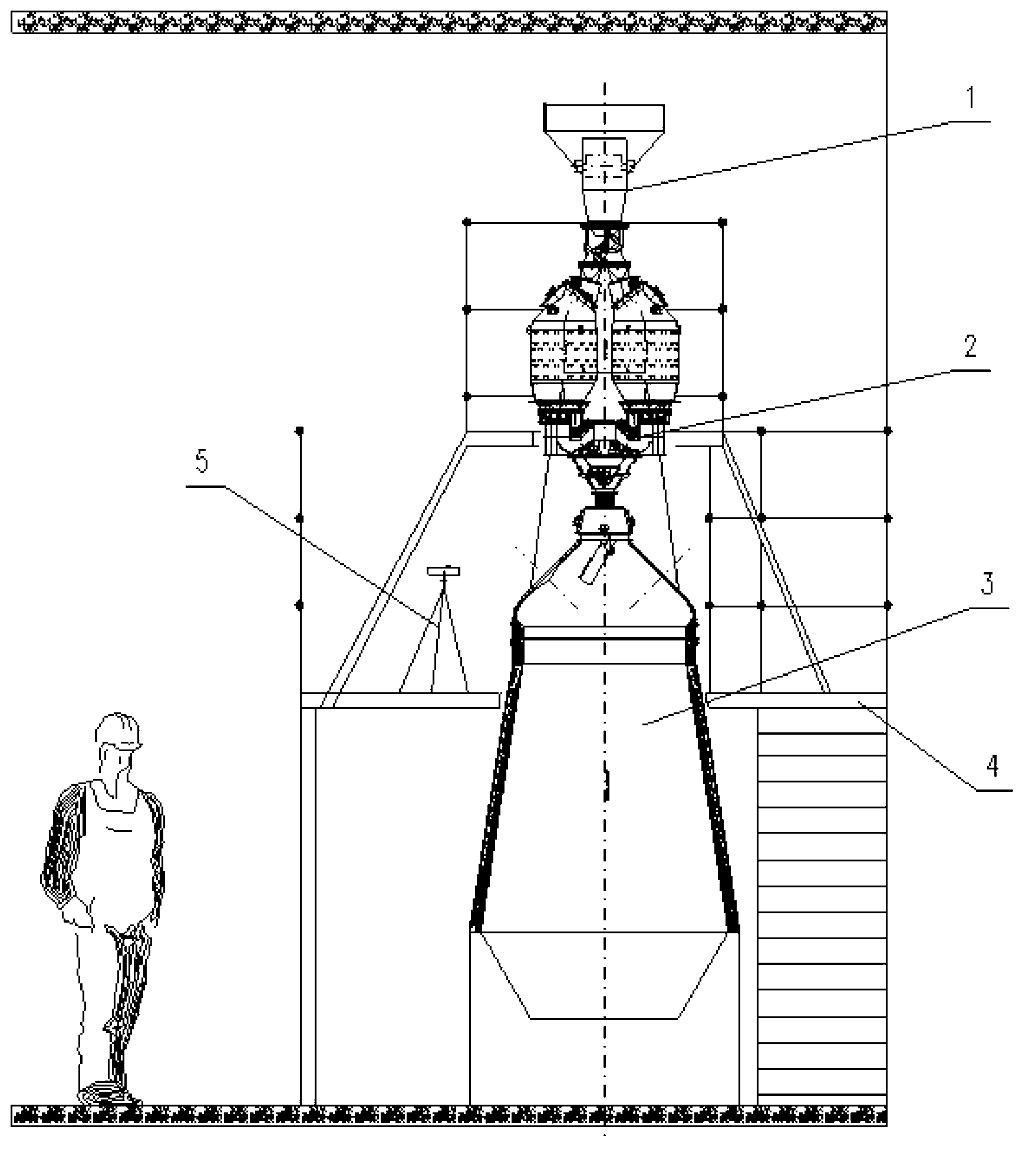

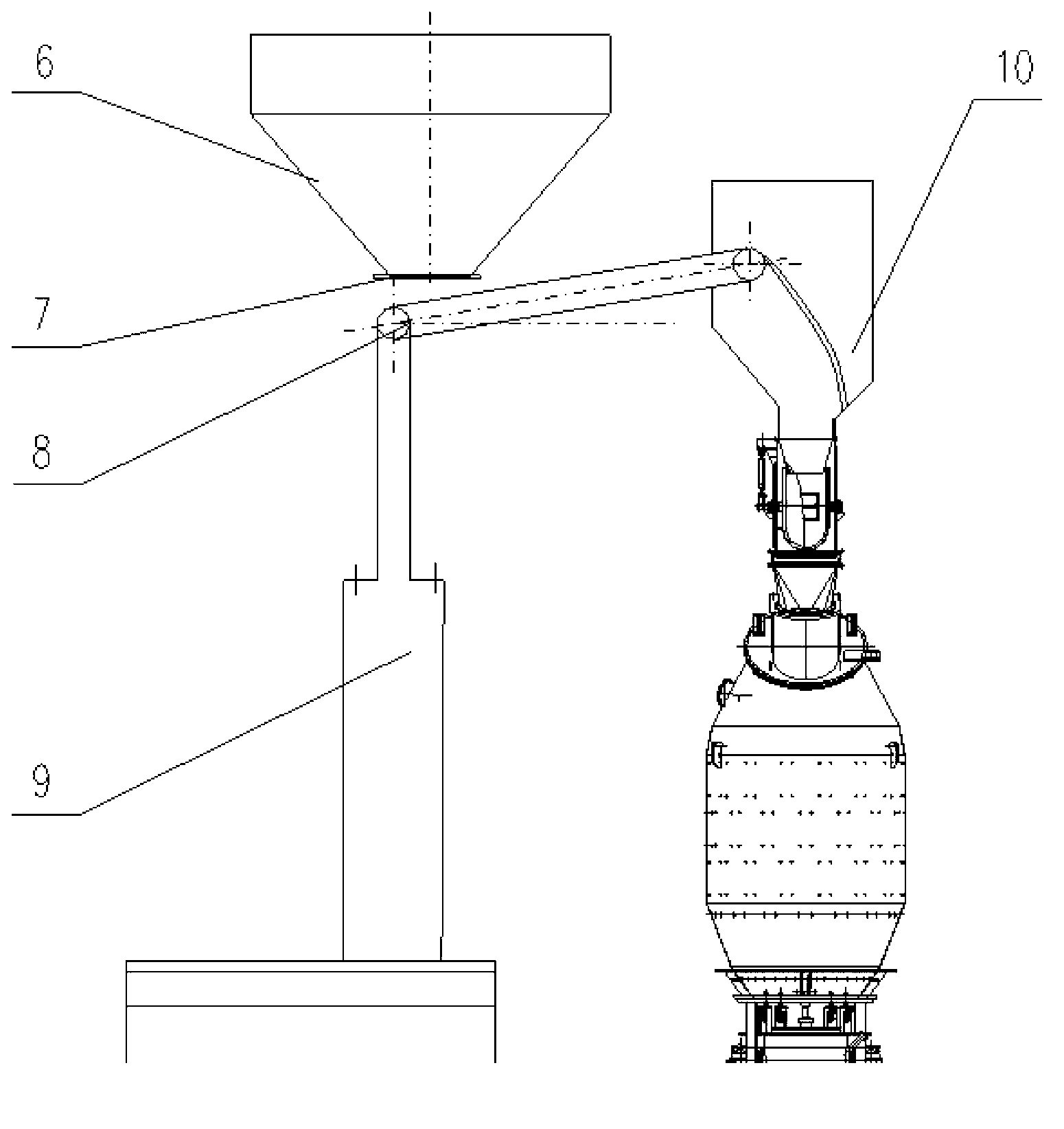

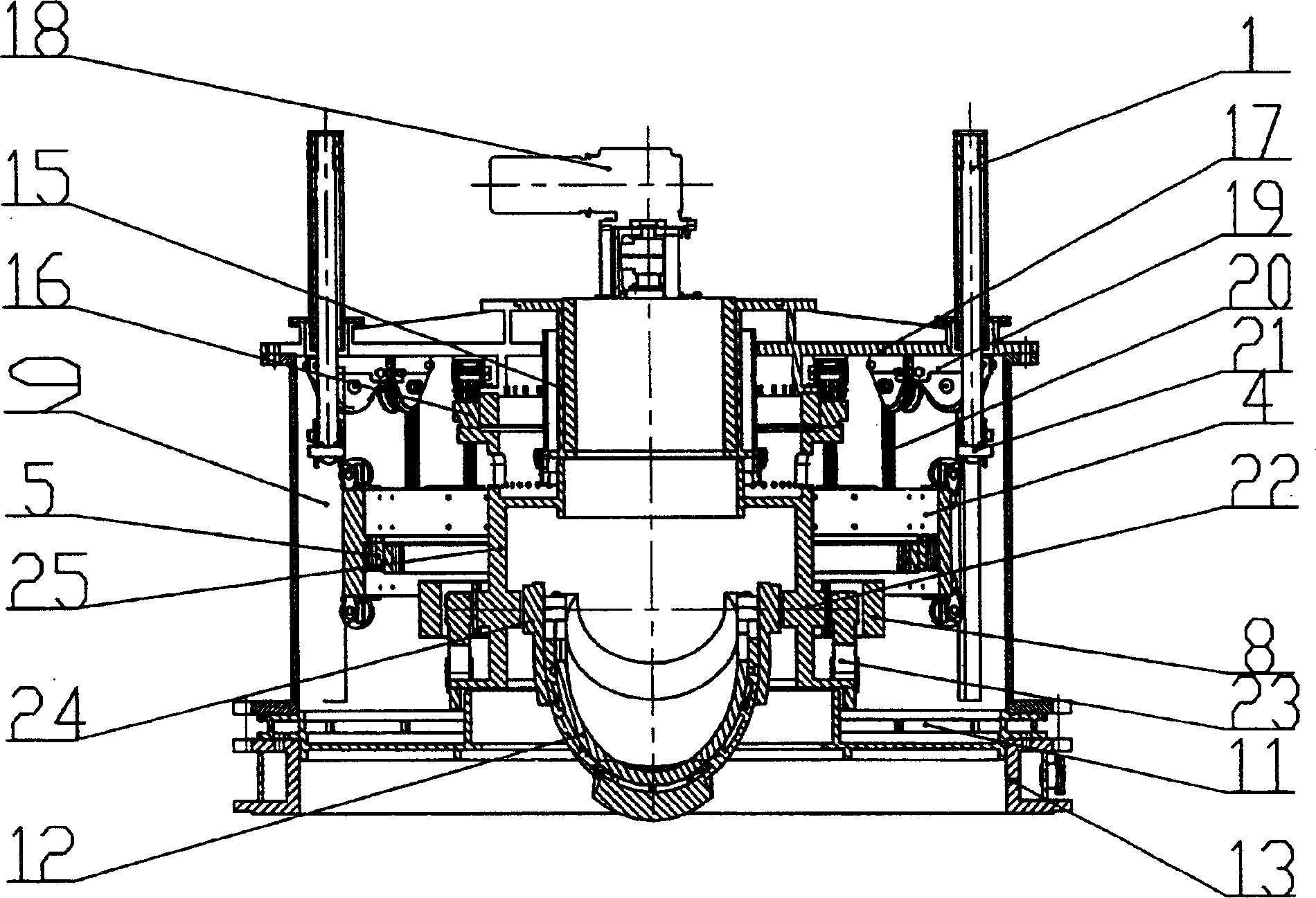

System for researching material distribution rule of furnace top equipment

ActiveCN103194555ASimplified protocolReliable resultsBell-and-hopper arrangementEducational modelsResearch modelTest platform

The invention relates to a system for researching a material distribution rule of furnace top equipment and belongs to the technical field of smelting. The system comprises a fully-emulational belt machine loading system, a fully-transparent furnace top material distribution equipment whole model, a fully-transparent furnace body partition research model, an enterprise-level high-speed camera shooting and analysis system and a test platform, wherein the fully-emulational belt machine loading system (1) is arranged at the top end of the whole set of system and is connected with a second layer of platform of the test platform (4) through a moveable bracket; a lower opening of the fully-emulational belt machine loading system (1) is connected with the fully-transparent furnace top material distribution equipment whole model (2); the lower end of the fully-transparent furnace top material distribution equipment whole model (2) is mounted on the fully-transparent furnace body partition research model (3); and a shooting terminal of the enterprise-level high-speed camera shooting and analysis system (5) is generally placed on a first layer of platform of the test platform (4). The invention has the advantages that the research system is comprehensive, complete, intuitive and accurate; and the test scheme is simple and practical, reliable in result and is a new breakthrough in the field of research on a blast furnace material distribution rule.

Owner:BEIJING SHOUGANG INT ENG TECH

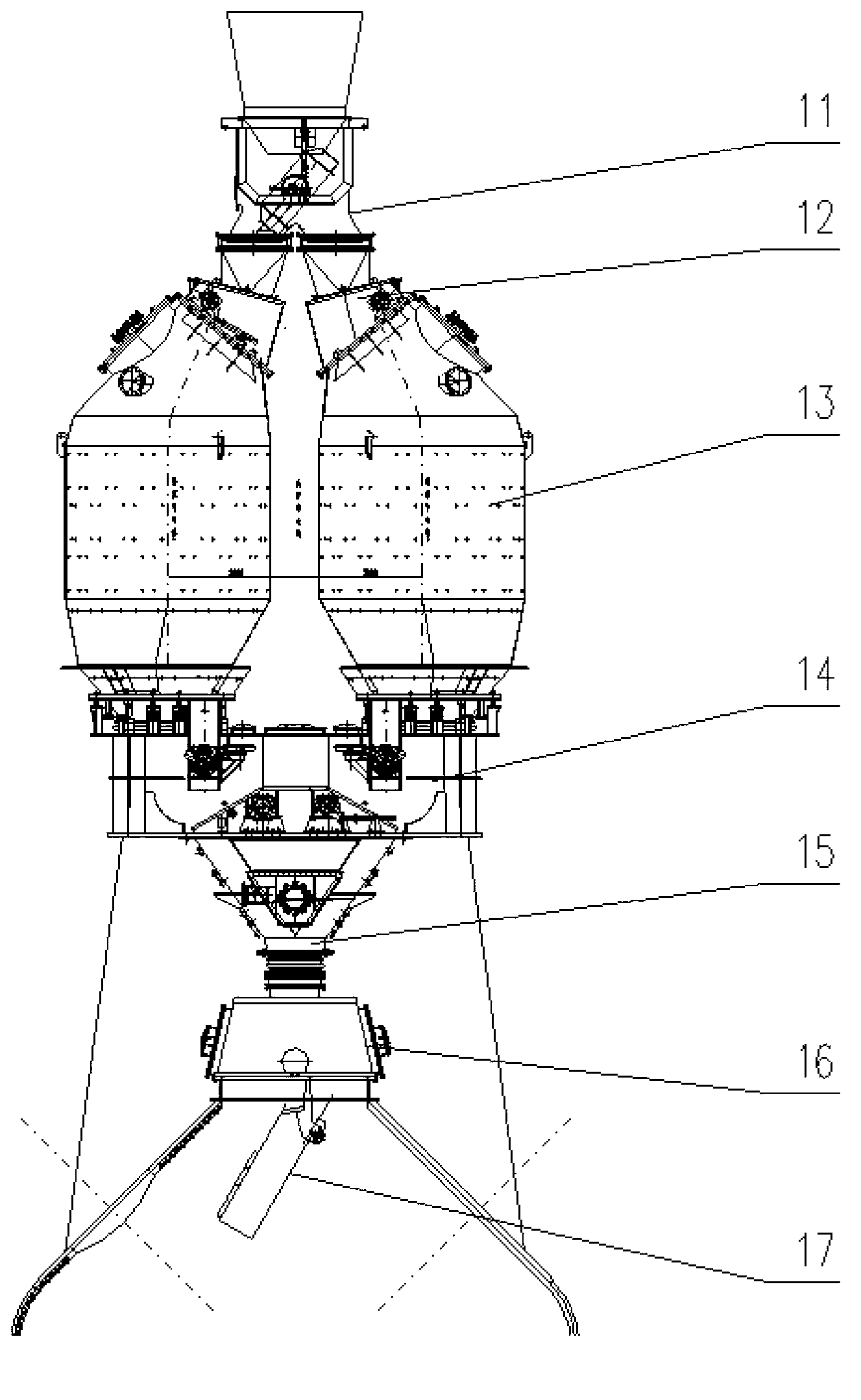

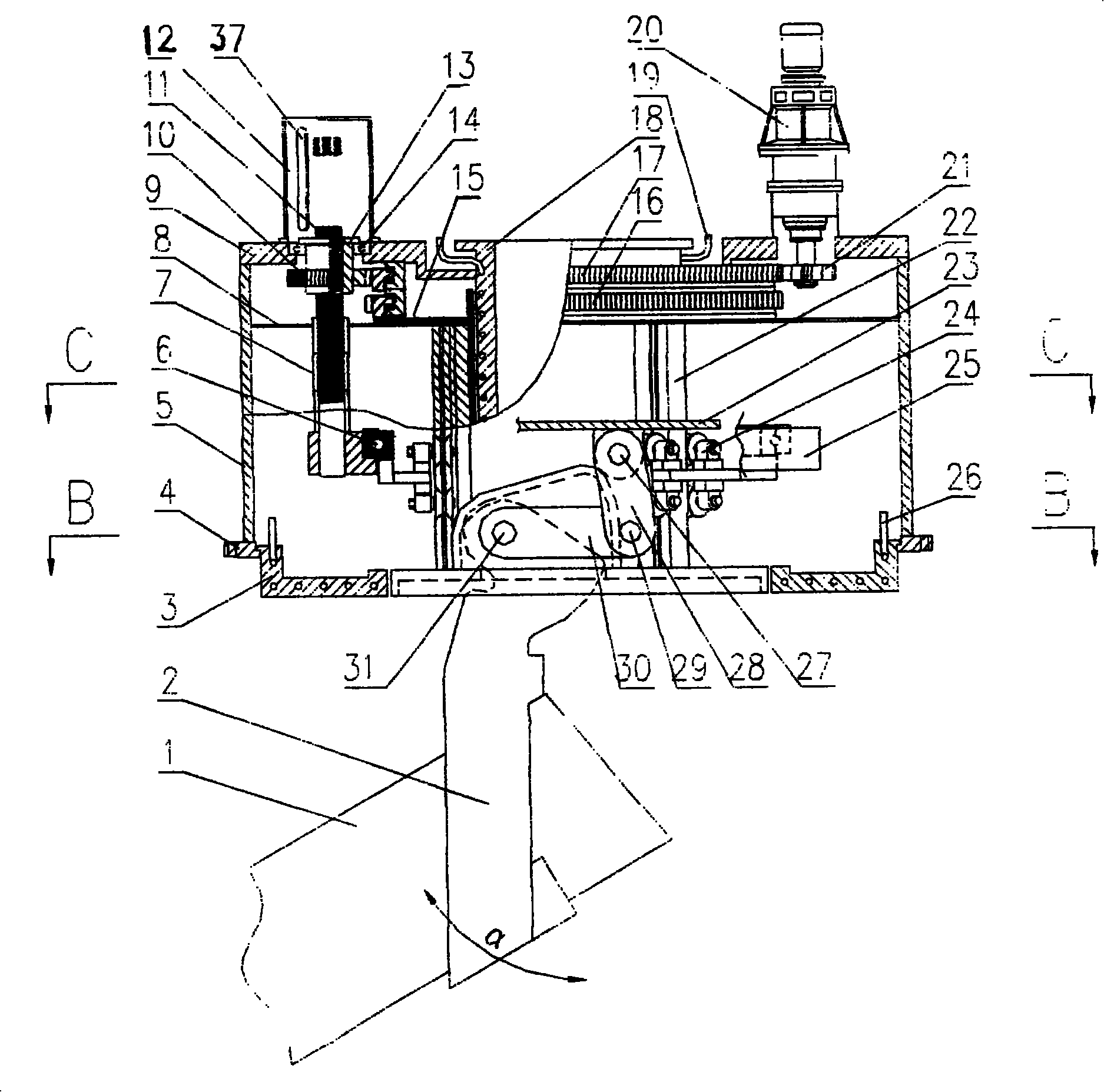

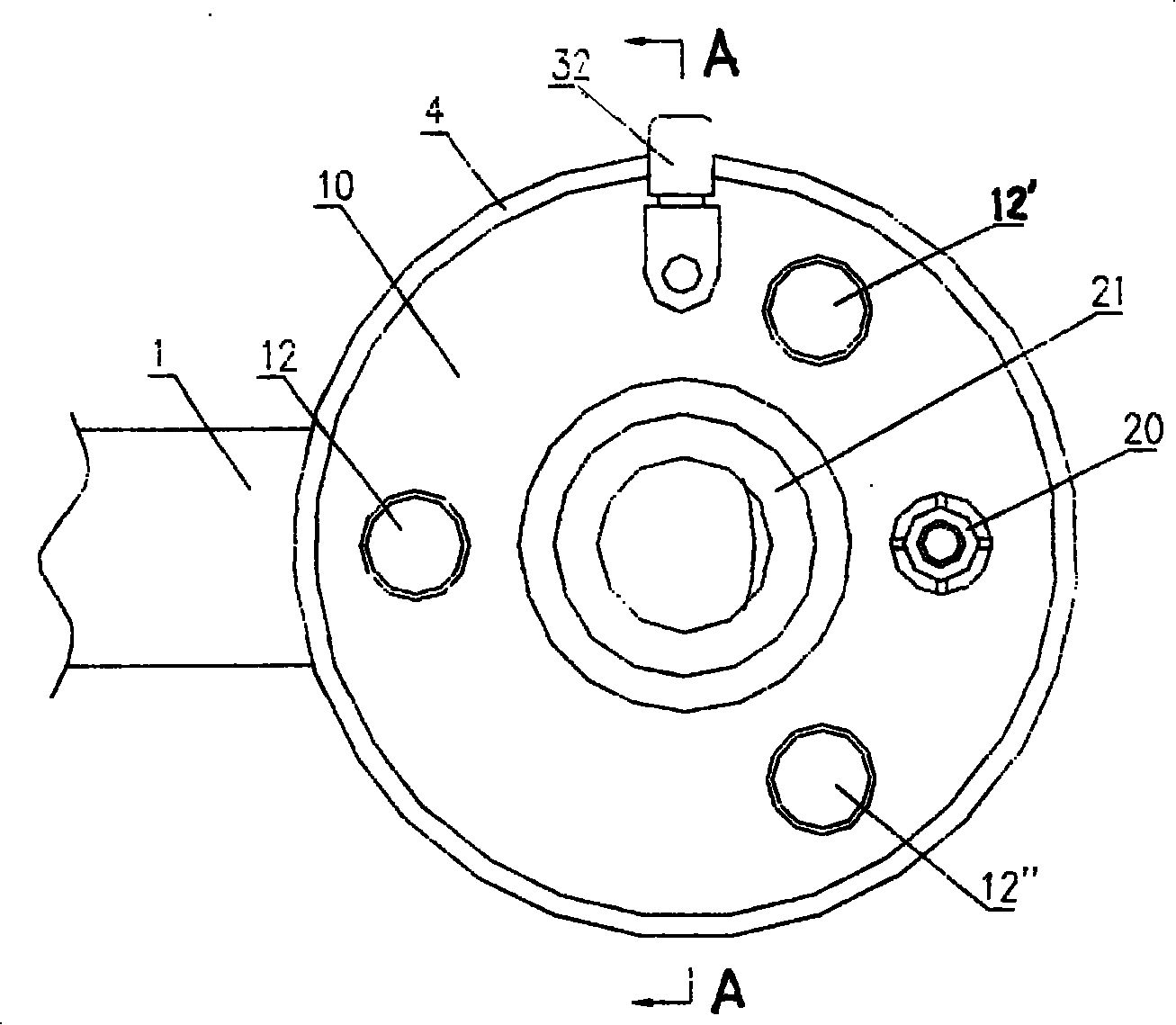

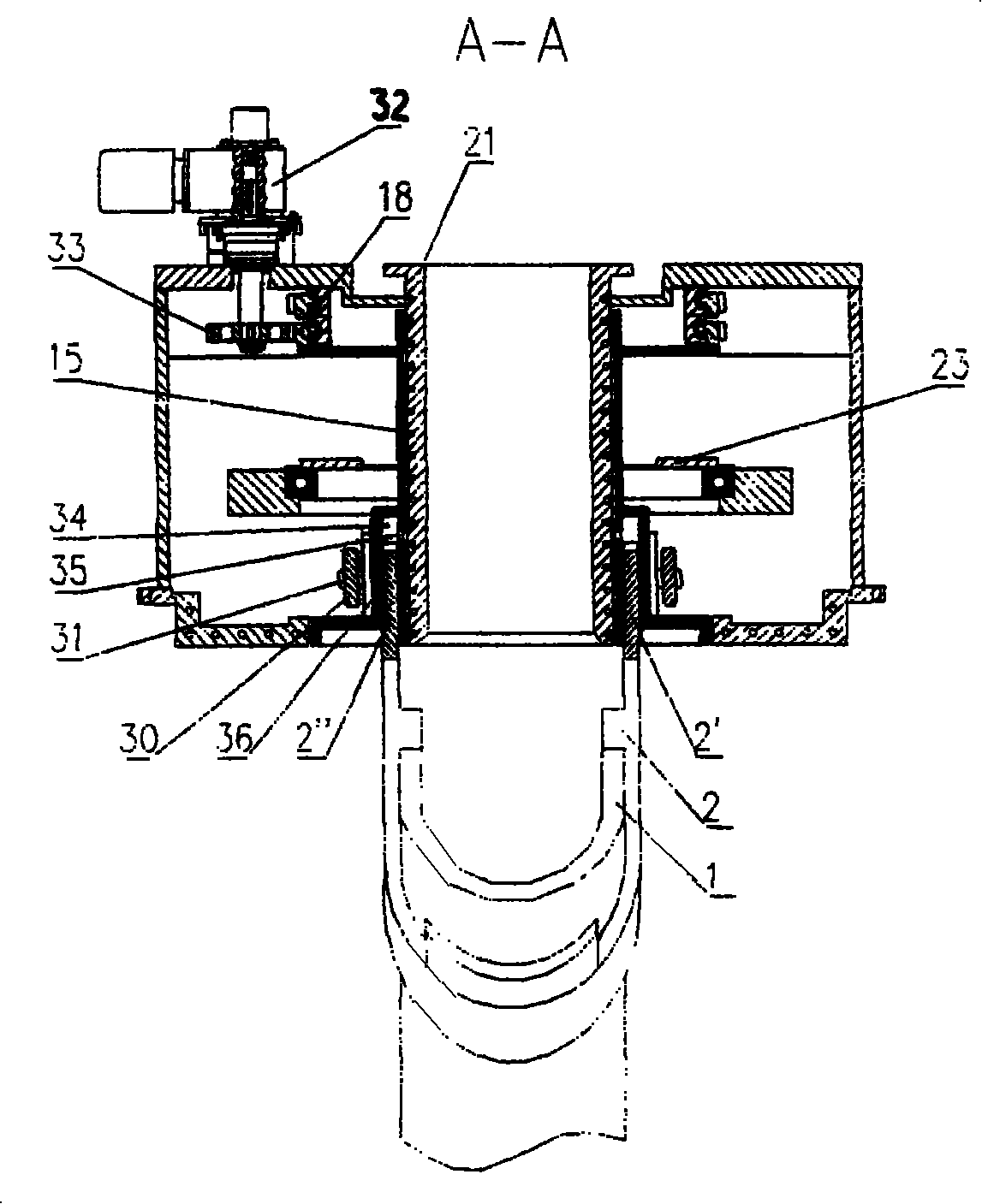

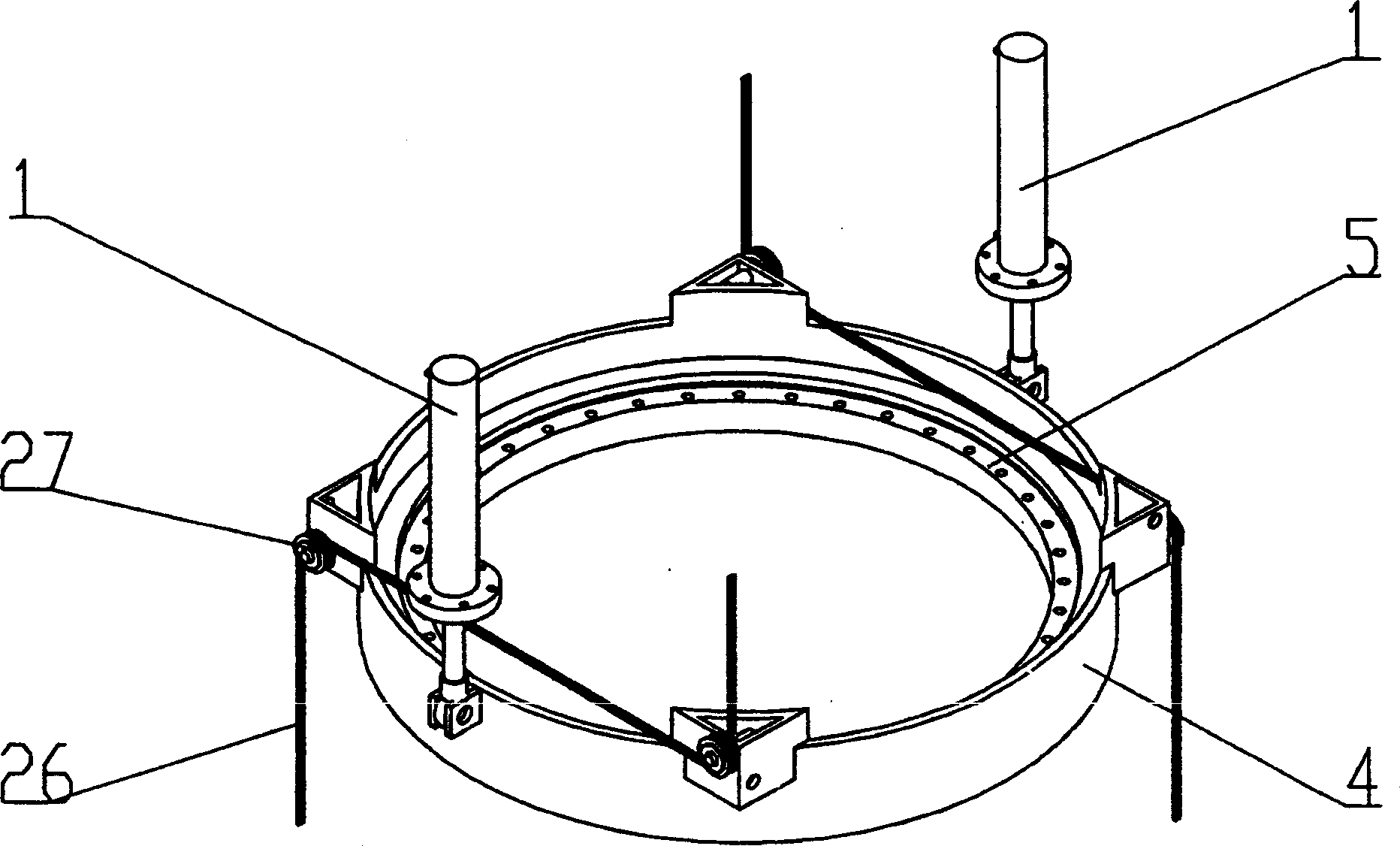

Blast furnace bellless furnace top distributor

ActiveCN101173321AExtended service lifeFully lubricatedBell-and-hopper arrangementBlast furnace detailsEngineeringShaft furnace

The invention discloses a bell-less top distributing gear of furnace, belonging to technical field of metallurgical industry. The invention adopts sealed cooling, a water-cooling venturi tube with pipe laying and a water-cooling chassis. A motor drives a chute to rotate and tilt; wherein, the motor drives the nut of the ball screw assembly to rotate and then drives the lead screw and the lifting rotary frame connected with the lead screw to move up and down in order to achieve chute to tilt for Alpha angle. The invention has the advantages of high coaxiality, high transmitting precision, long service life of the critical component, easy manufacture, light weight and low cost. The tilting Alpha angle of the chute and the stationarity of the tilting movement of the chute can be checked during the producing process of the furnace by the invention. The invention can be used in charging operation of furnace roof and also is suitable for shaft furnace or smelting reduction furnace which need to feed from the roof to the closed space and distribute regularly.

Owner:CISDI ENG CO LTD

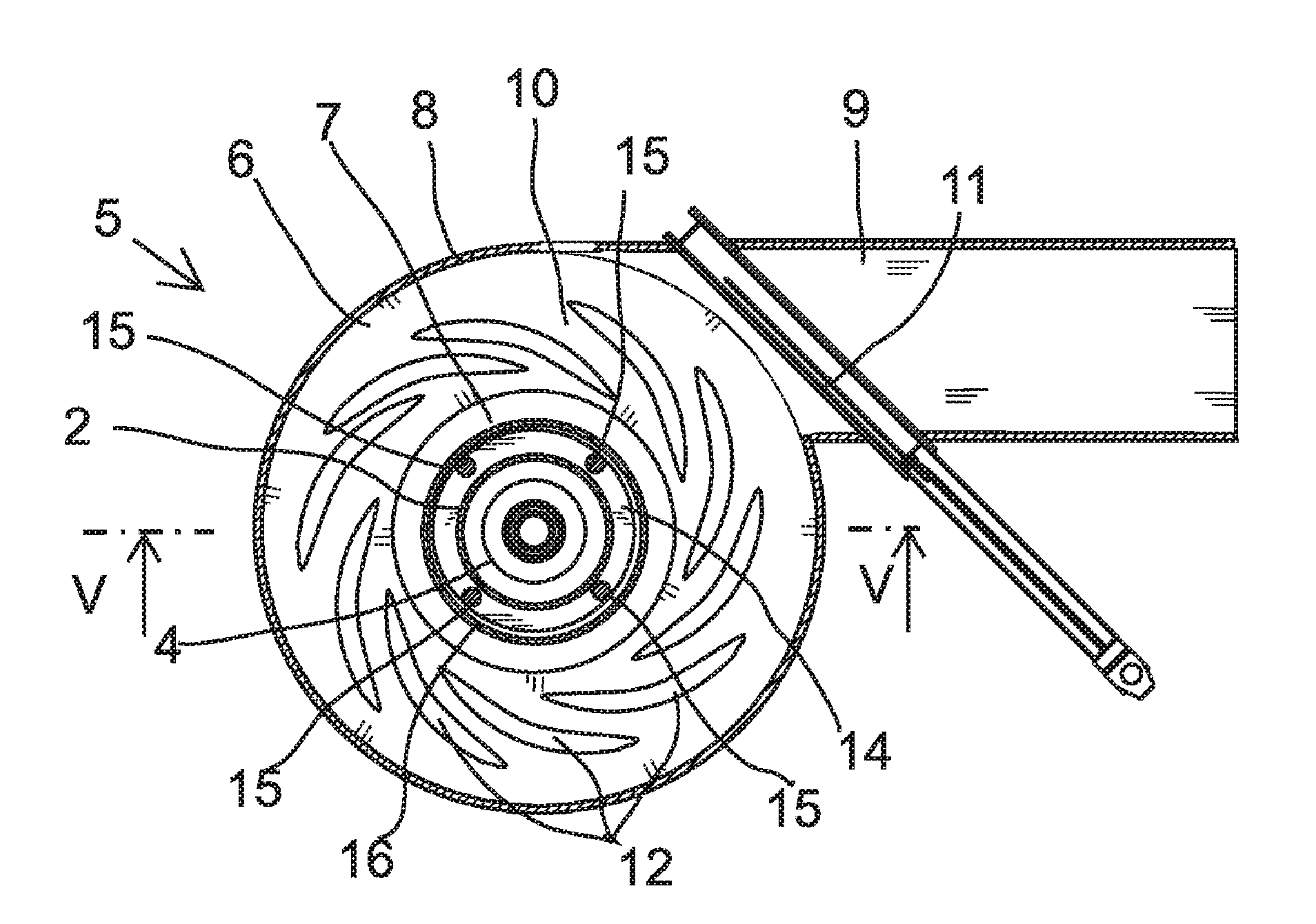

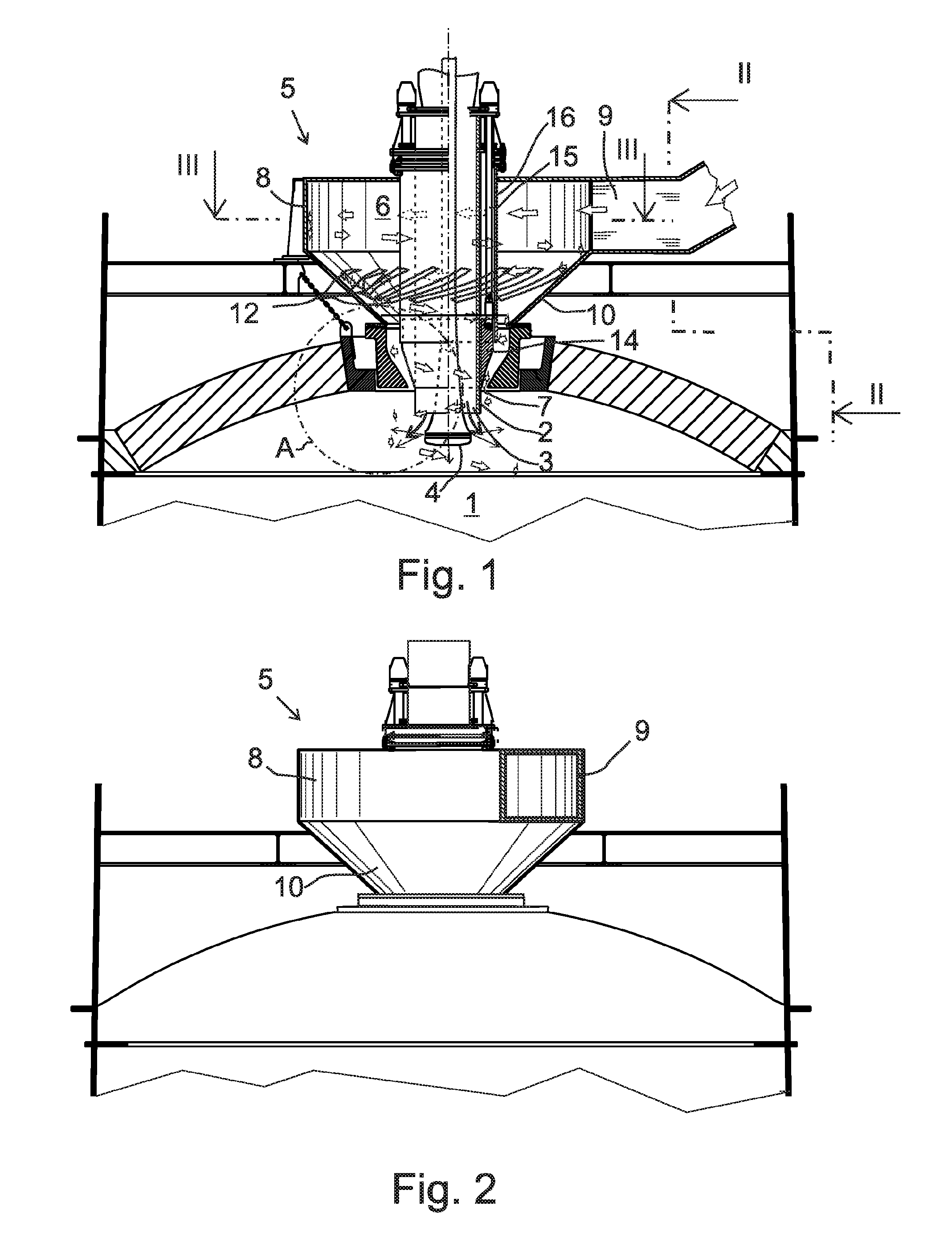

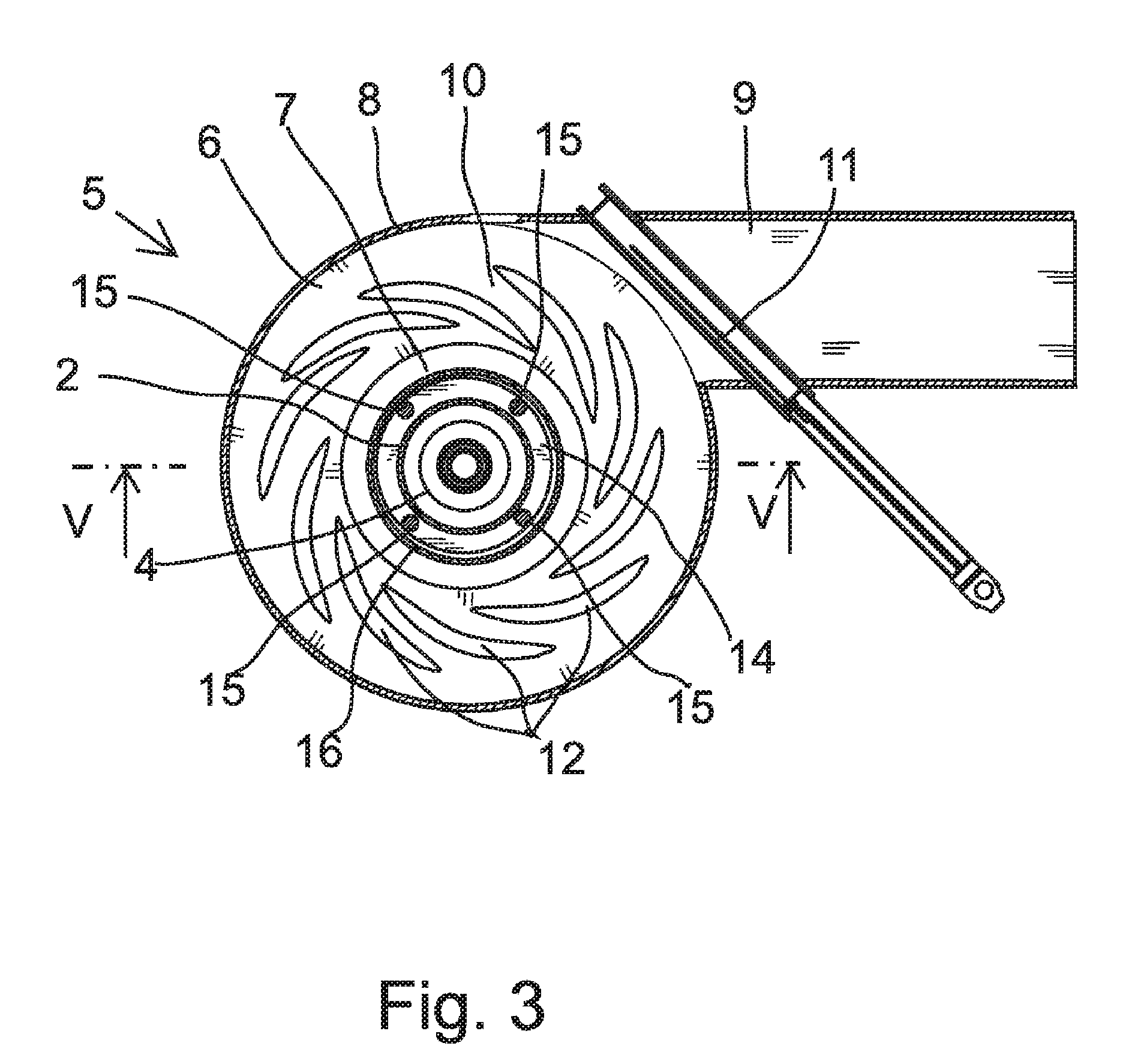

Concentrate burner

InactiveUS20100207307A1Easy to disassembleOptimal swirl angleTuyeresBell-and-hopper arrangementCombustorInlet channel

A concentrate burner for feeding a pulverous concentrate mixture and reaction gas into the reaction shaft (1) of a flash smelting furnace. The concentrate burner includes a feeder pipe (2) for feeding the concentrate mixture into the reaction shaft (1), the orifice (3) of the feeder pipe opening to the reaction shaft, a dispersing device (4), which is arranged concentrically inside the feeder pipe (2) and which extends to a distance from the orifice inside the reaction shaft (1) for directing dispersing gas to the concentrate mixture flowing around the dispersing device. For feeding the reaction gas into the reaction shaft (1), a gas supply device (5) includes a reaction gas chamber (6), which is located outside the reaction shaft and opens to the reaction shaft (1) through an annular discharge orifice (7) that surrounds the feeder pipe (2) concentrically for mixing the reaction gas discharging from the discharge orifice with the concentrate mixture discharging from the middle of the feeder pipe, the concentrate mixture being directed to the side by means of the dispersing gas. The reaction gas chamber (6) comprises a turbulent flow chamber, to which an inlet channel (9) opens tangentially for directing the reaction gas to the reaction gas chamber in a tangential direction. In the inlet channel (9), an adjusting member (11) is arranged for adjusting the cross-sectional area of the reaction gas flow.

Owner:OUTOTEC OYJ

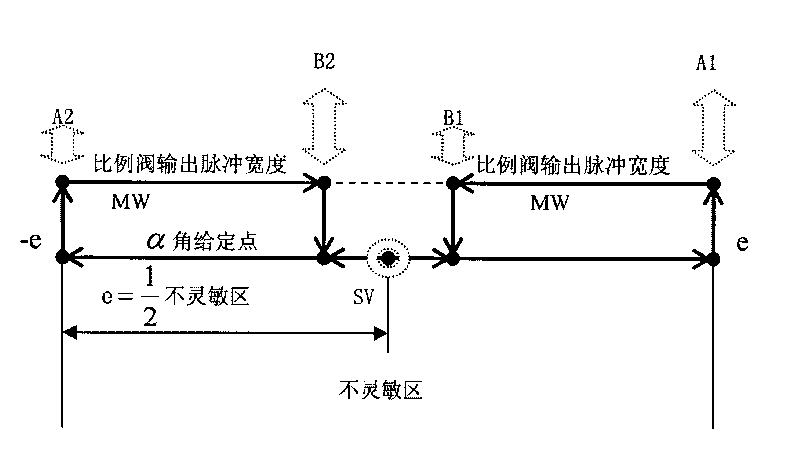

Automatic control device and method of rotary chute pair transmission tilt angle of blast furnace bell-less top

InactiveCN101714001AEliminate the effects ofGive full play to the superiority of ideal fabricsBell-and-hopper arrangementControl without using feedbackAutomatic controlControl signal

The invention provides automatic control device and method of a rotary chute pair transmission tilt angle of a blast furnace bell-less top for automatically controlling the tilt angle of a chute. The automatic control device comprises information collection equipment, a PLC control system and transmission equipment, wherein the information collection equipment is used for collecting the tilting angle position information of the chute and the position information of the chute and transmitting the information to the PLC control system; the PLC control system is used for analyzing the information collected by the information collection equipment, generating a control signal and transmitting the control signal to the transmission equipment; and the transmission equipment is used for controlling the tilting angle of the chute according to the control signal of the PLC control system. The device and the method eliminate the influence brought by deviations caused by the angle alignment control of the stroke of a chute pair transmission tilt angle drive linear oil cylinder on the material distribution of the blast furnace, sufficiently give play to the ideal material distribution superiority of the bell-less material distributor and guarantee the stability of a smelting process. In addition, the invention can prevent the frequent switchover of an electromagnetic directional valve of the chute pair transmission tilt angle drive linear oil cylinder and keep the stable output characteristics of a hydraulic system.

Owner:BERIS ENG & RES CORP

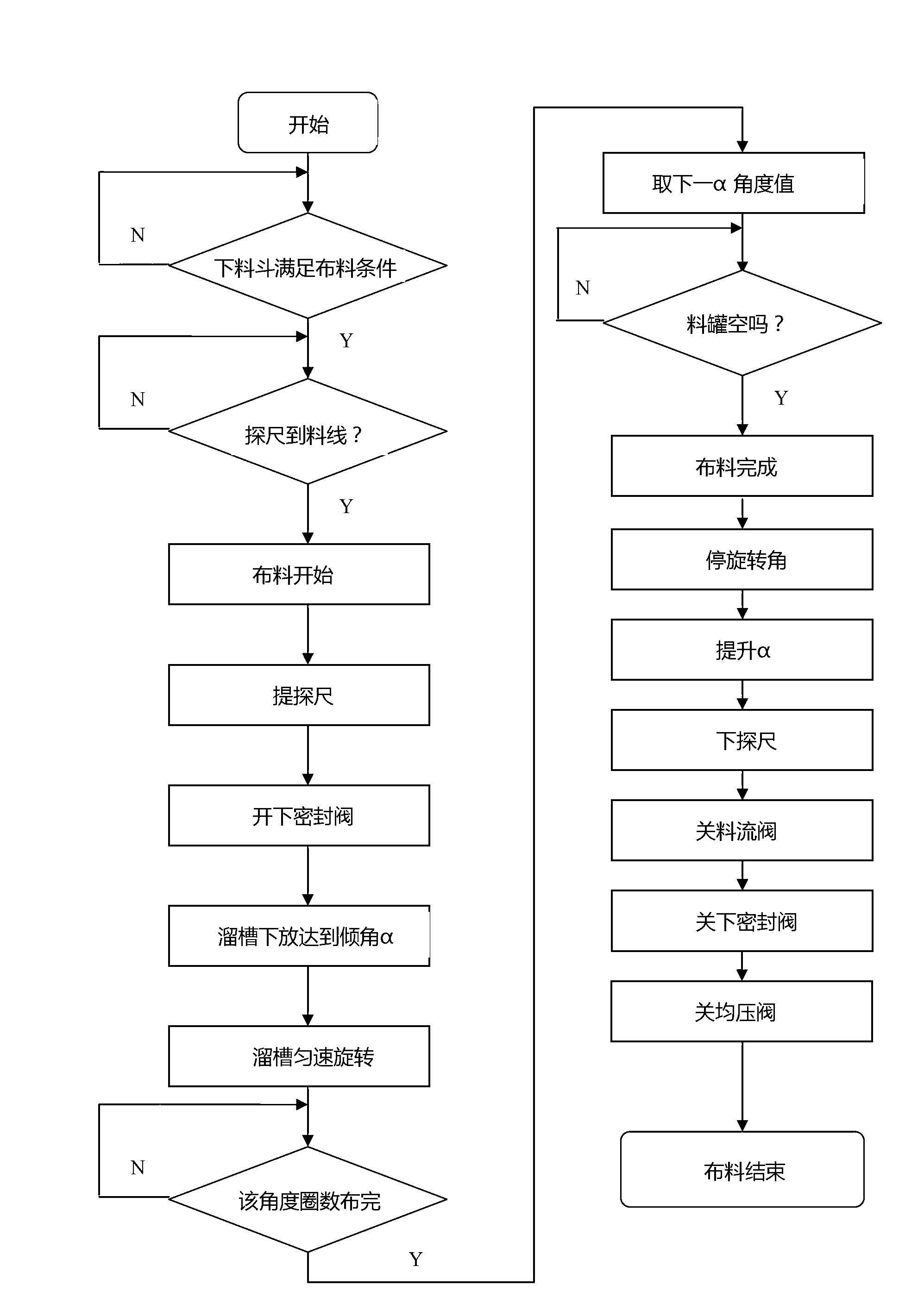

Top distribution device and distribution method for blast furnace

InactiveCN103014210ALarge openingReduce openingBell-and-hopper arrangementBlast furnace detailsProgrammable logic controllerDistribution method

The invention discloses a top distribution device for a blast furnace, which comprises a material flow regulating valve, a rotary drum, a chute, two stock rods and a PLC (programmable logic controller), wherein the material flow regulating valve is arranged at the bottom of a blanking hopper; the roller is arranged at the lower part of the material flow regulating valve; the chute is formed below the rotary drum by a roller device; the stock rods are arranged below the chute and oppositely arranged on the two sides of a blast furnace wall at 180 DEG; and the PLC is connected with the material flow regulating valve and the chute, and controls an opening angle gamma of the material flow regulating valve, an inclination angle alpha of the chute, and an angle beta for uniform speed rotation of the chute. With the adoption of the device and the method, manual intervention is reduced greatly, the number of turns of distribution is automatically controlled in deed, and the device and the method have a very positive effect on continuous and stable operation of the blast furnace.

Owner:JIANGSU YONGGANG GROUP CO LTD

Crucible shuttle assembly and method of operation

ActiveUS20080253870A1Improve throughputConveyorsMaterial analysis by optical meansCrucibleEngineering

A crucible handling shuttle includes a pair of opposed dual crucible-gripping arms mounted on a rotatable head and moves between an induction furnace pedestal and a crucible loading station, such that one pair of arms pick up a crucible loaded with a preweighed sample, the shuttle moves to the induction furnace, where the other pair of arms grip and remove a spent crucible. The shutter head then rotates to deposit the new sample-holding crucible onto the pedestal and subsequently moves out of the furnace area to a sample disposal chute positioned between the crucible loading station and the furnace, whereupon the spent crucible is dropped for disposal. The shuttle head is then rotated and moved to the loading station to pick up a new crucible.

Owner:LECO CORPORATION

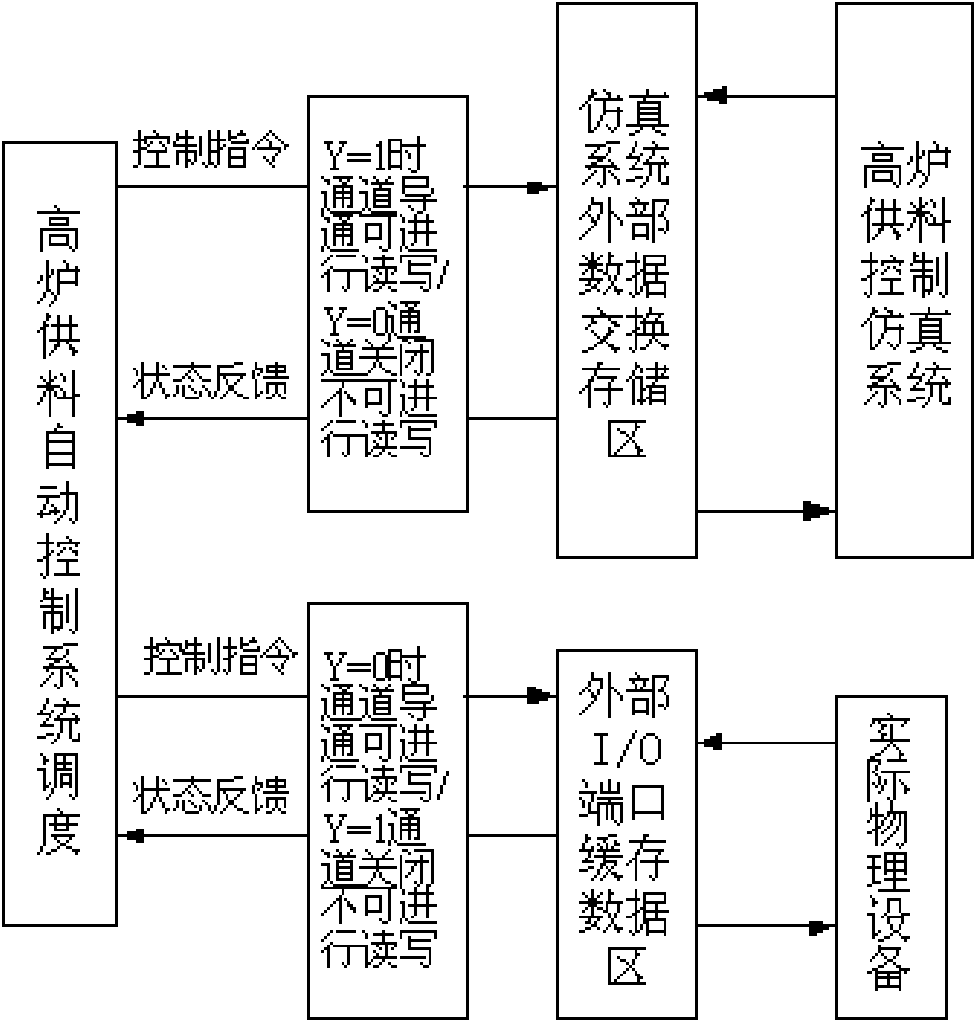

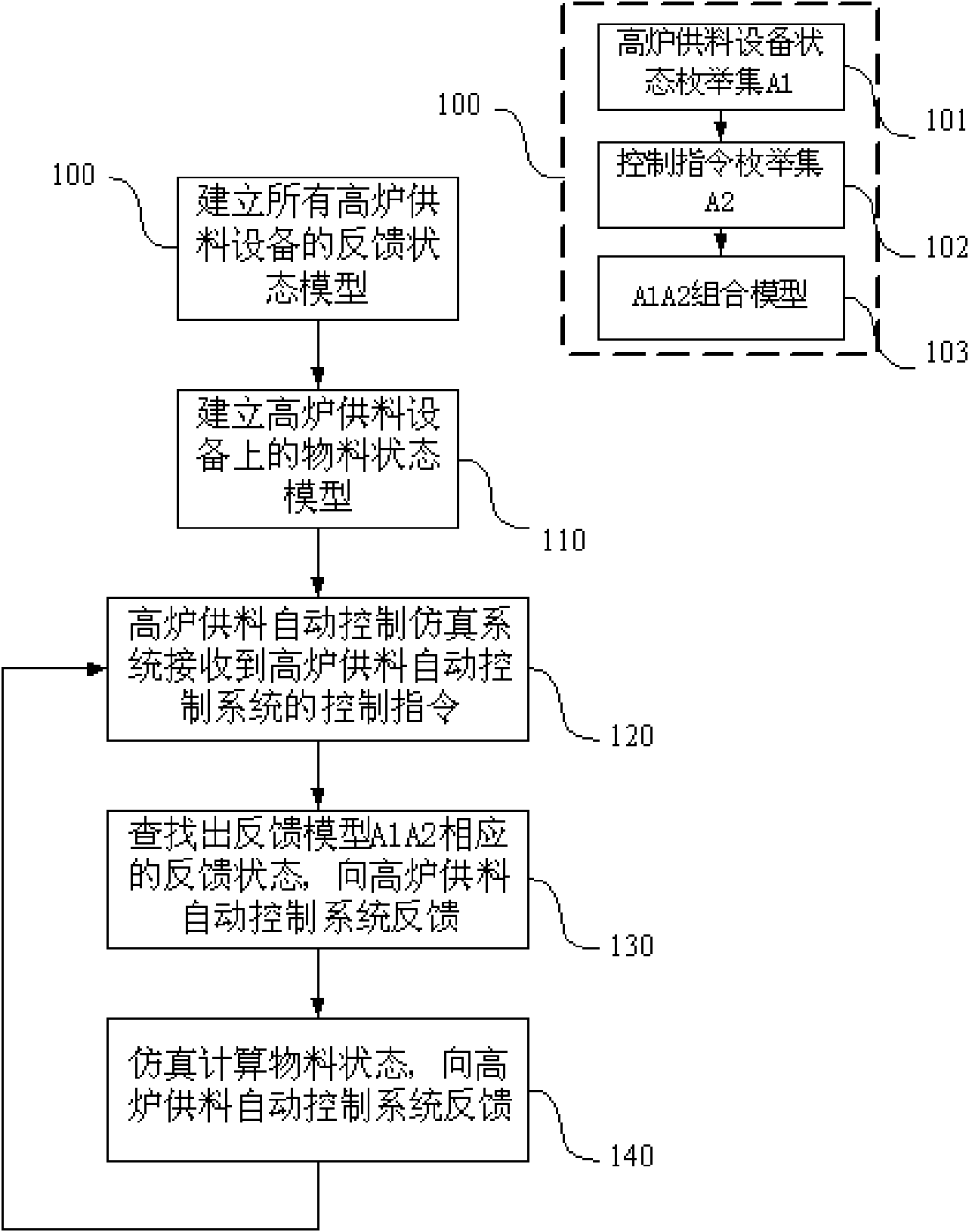

Automatic control system for blast furnace feeding

ActiveCN101604146ARealize simulationAdvanced technologySimulator controlBell-and-hopper arrangementProcess systemsProcess equipment

The invention relates to an automatic control system for blast furnace feeding, which sends a control instruction to blast furnace feeding equipment through a cache data area of an external I / O port thereof and receives the state feedback of the blast furnace feeding equipment. The system is characterized in that the system is also connected with an automatic control simulation system for blast furnace feeding through an external data exchange storage area thereof and sends a control instruction to the automatic control simulation system for blast furnace feeding, and the automatic control simulation system for blast furnace feeding simulates a state feedback signal which is under the control instruction and comprises the operation state of the blast furnace feeding equipment and the state of movement position of materials, and feeds back the state feedback signal to the automatic control system for blast furnace feeding. The automatic control system for blast furnace feeding can completely break away from actual process equipment through the simulation and integrally simulate the production state of an actual feeding process system of a blast furnace, can also control the actual technological production process, and can conveniently switch between the operation simulation and the control of the actual technological production process.

Owner:WISDRI ENG & RES INC LTD

Sealing valve arrangement for a shaft furnace charging installation

InactiveUS8568653B2Avoid easy cloggingLess-time-consuming installationConveyorsOperating means/releasing devices for valvesShaft furnaceValve seat

A sealing valve arrangement for a shaft furnace charging installation includes a shutter-actuating device for moving a shutter between a closed position in sealing contact with a valve seat and an open position remote from the valve seat. The shutter-actuating device is of the dual-motion type and includes a primary tilting arm on a first tilting shaft defining the first axis and is equipped with bearings supporting the primary tilting arm. A secondary tilting arm carries the shutter is connected to a second tilting shaft that defines a second substantially parallel axis and has bearings that support the secondary tilting arm on the primary tilting arm. The shutter-actuating device has a mechanism configured to tilt the secondary tilting arm when the primary tilting arm is tilted.The first tilting shaft is configured as hollow sleeve shaft and the shutter-actuating device includes a reference rod extending through the first tilting shaft.

Owner:PAUL WURTH SA

Blast-furnace channel distributor

InactiveCN1896285APrevent rotationAvoid verticalBell-and-hopper arrangementEngineeringControl theory

The present invention relates to a blast furnace chute distributor that controls the obliquity of the rotating chute via the resultant motion of rotation and rectilinear motion for the advisable distribution on the burden surface. This blast furnace chute distributor mainly contains: box body, top cover, hollow throat, upper slewing ring, turning sleeve, trunnion, crank, crank tail drum, chute bracket, chute, frame, lower slewing ring, support ring, guide rail, drive device of horizontal rotation, digital servo cylinder. One or three digital servo cylinders are combined with the steel wire rope, pulleys, parallel ruler, lever and guide rail to realize the vertical translation of the support ring controlling the chute obliquity. Via the blast furnace chute distributor driven by the digital servo cylinders, the structure is simplified and the accuracy is enhanced. The effect is similar with transmission by steel wire ropes but the setting and debugging are much more convenient.

Owner:僧全松

Thermal treatment apparatus

InactiveUS6623269B2Small heat lossAvoid heat conductionLining supportsGlass transportation apparatusThermal energyHeat losses

A thermal treatment apparatus has a plurality of thermal treatment chambers in which an object to be treated is thermally treated while being transported, and at least one pair of two adjacent thermal treatment chambers of which inside temperatures are different from each other. The thermal treatment chambers are connected through a thermal insulating structural member, whereby thermal conduction between the chambers, such as muffles, is prevented to reduce a heat loss caused in the thermal treatment apparatus. Therefore, input thermal energy which is necessary to carry out a predetermined thermal treatment is significantly reduced without affecting quality and yield of the object.

Owner:PANASONIC CORP

Linear hearth furnace system and methods regarding same

Systems and methods for use in processing raw material (e.g., iron bearing material) include a linear furnace apparatus extending along a longitudinal axis between a charging end and a discharging end (e.g., the linear furnace apparatus includes at least a furnace zone positioned along the longitudinal axis). Raw material is provided into one or more separate or separable containers (e.g., trays) at the charging end of the linear furnace apparatus. The separate or separable containers are moved through at least the furnace zone and to the discharging end where the processed material is discharged resulting in one or more empty containers. One or more of the empty containers are returned to the charging end of the linear furnace apparatus to receive further raw material.

Owner:NU IRON TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com