Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6179results about How to "Avoid easy clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

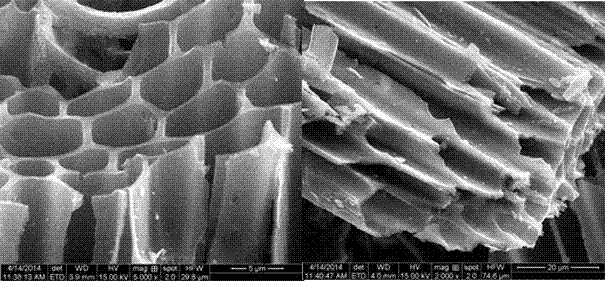

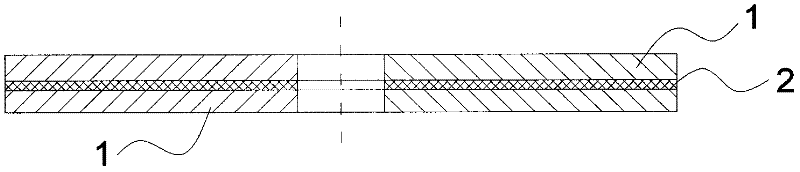

Lignin carbon nanofiber and preparation method thereof

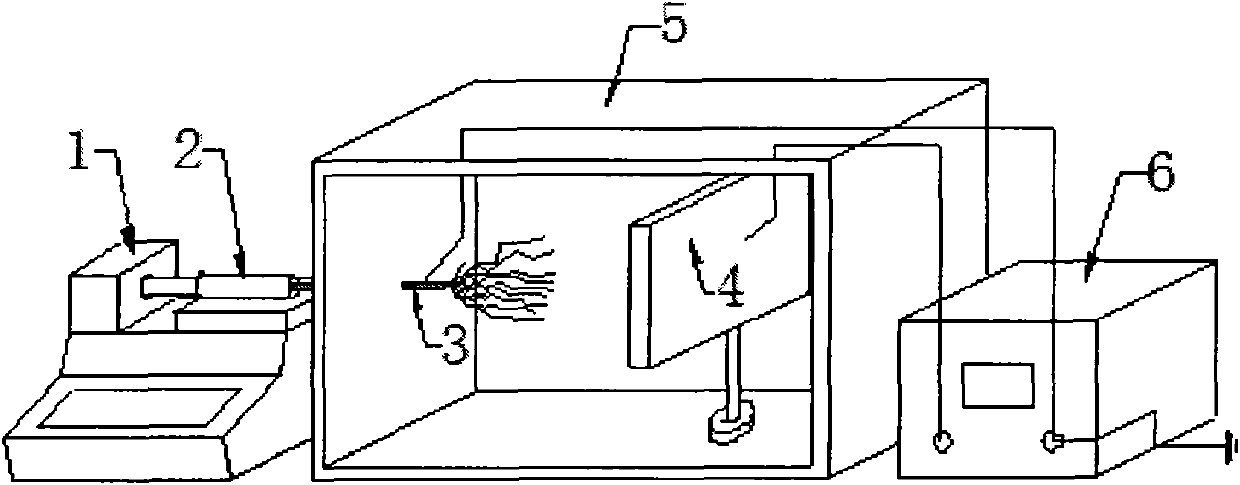

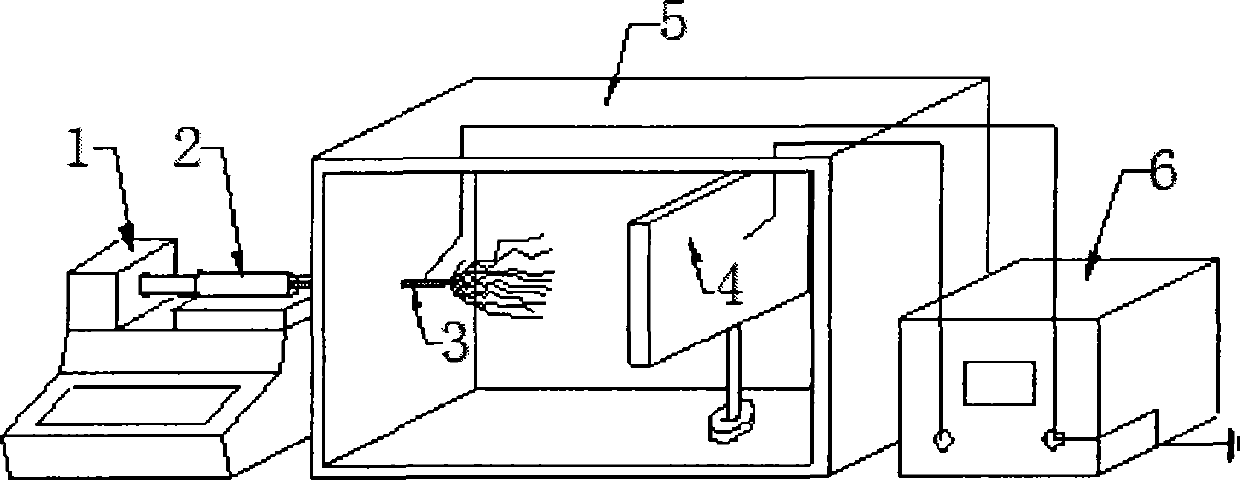

ActiveCN101768799AImprove spinnabilityGuaranteed reliabilityFilament/thread formingFibre chemical featuresFiberCarbon fibers

The invention discloses a lignin carbon nanofiber and a preparation method thereof, belonging to the field of materials. The preparation method comprises 5 steps of lignin pretreatment, preparation of spinning solution, electrostatic spinning, pre-oxidation and carbonization. The preparation method is characterized in that the lignin pretreatment means that lignin with the relative molecular mass within 5,000 to 50,000 is selected, and then the treatment of removing carbohydrate and inorganic salt is respectively carried out on alkali lignin and acetic acid lignin (or formic acid lignin). The diameter of the obtained carbon nanofiber is within 50 to 300nm and the length is within 1 to 10mum. As the obtained lignin has good spinnability, the nanofiber can be spun and further processed into the carbon nanofiber without synthetic macromolecules. In addition, the method adopts simple electrospinning equipment for electrospinning, the diameter of a spinning nozzle is large, the blockage cannot easily occur, and the working reliability of the spinning equipment is ensured.

Owner:SOUTH CHINA UNIV OF TECH

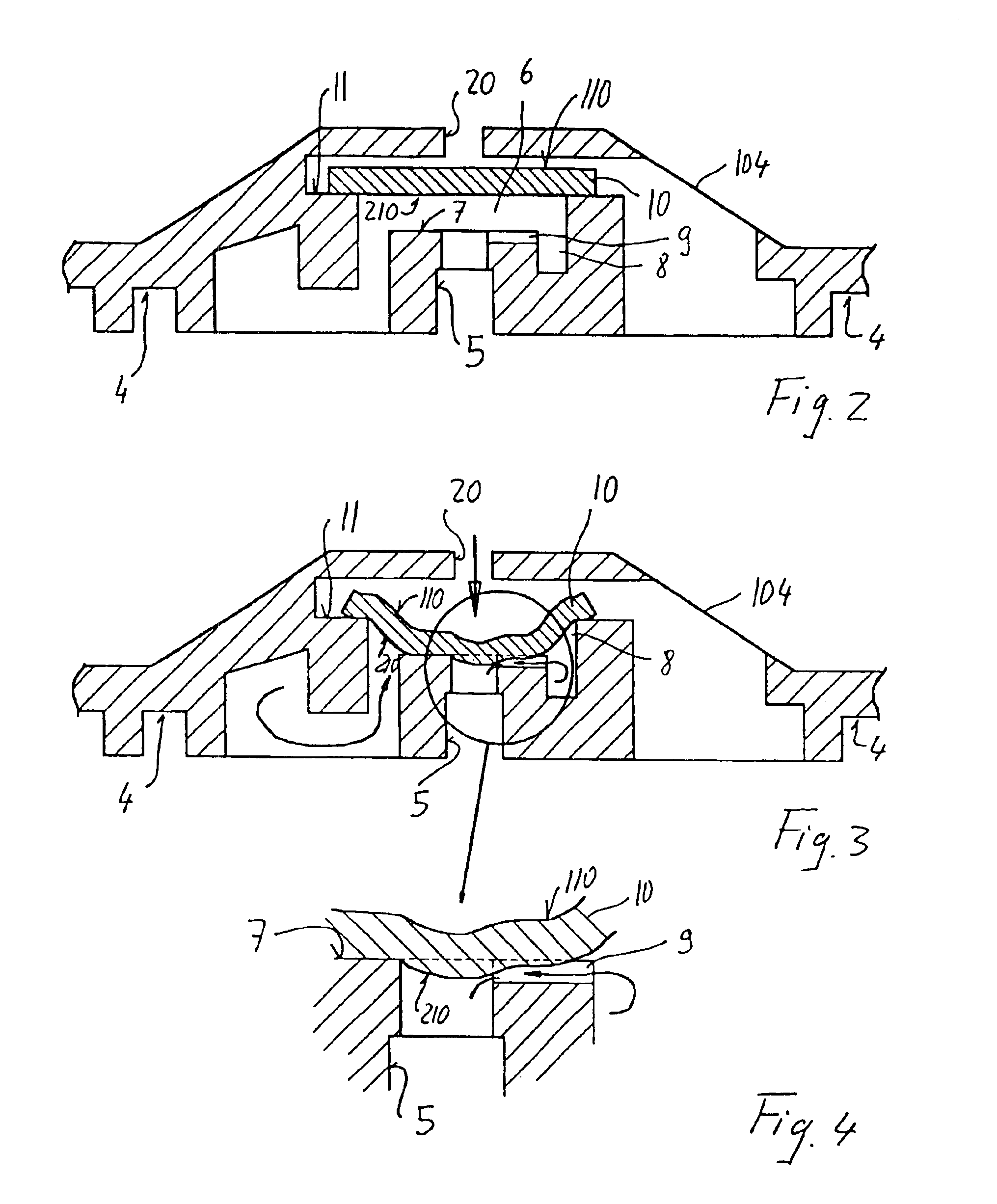

Self-compensating drip irrigation emitter

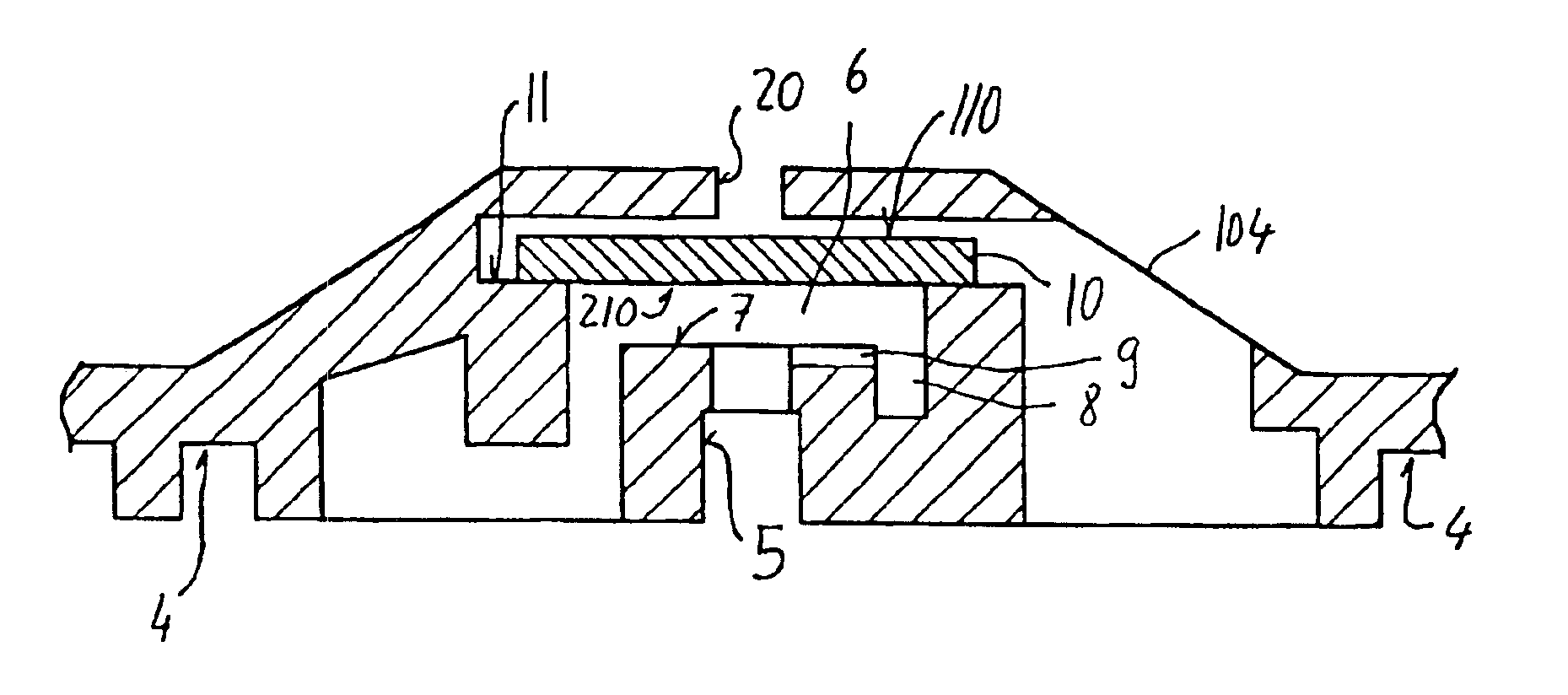

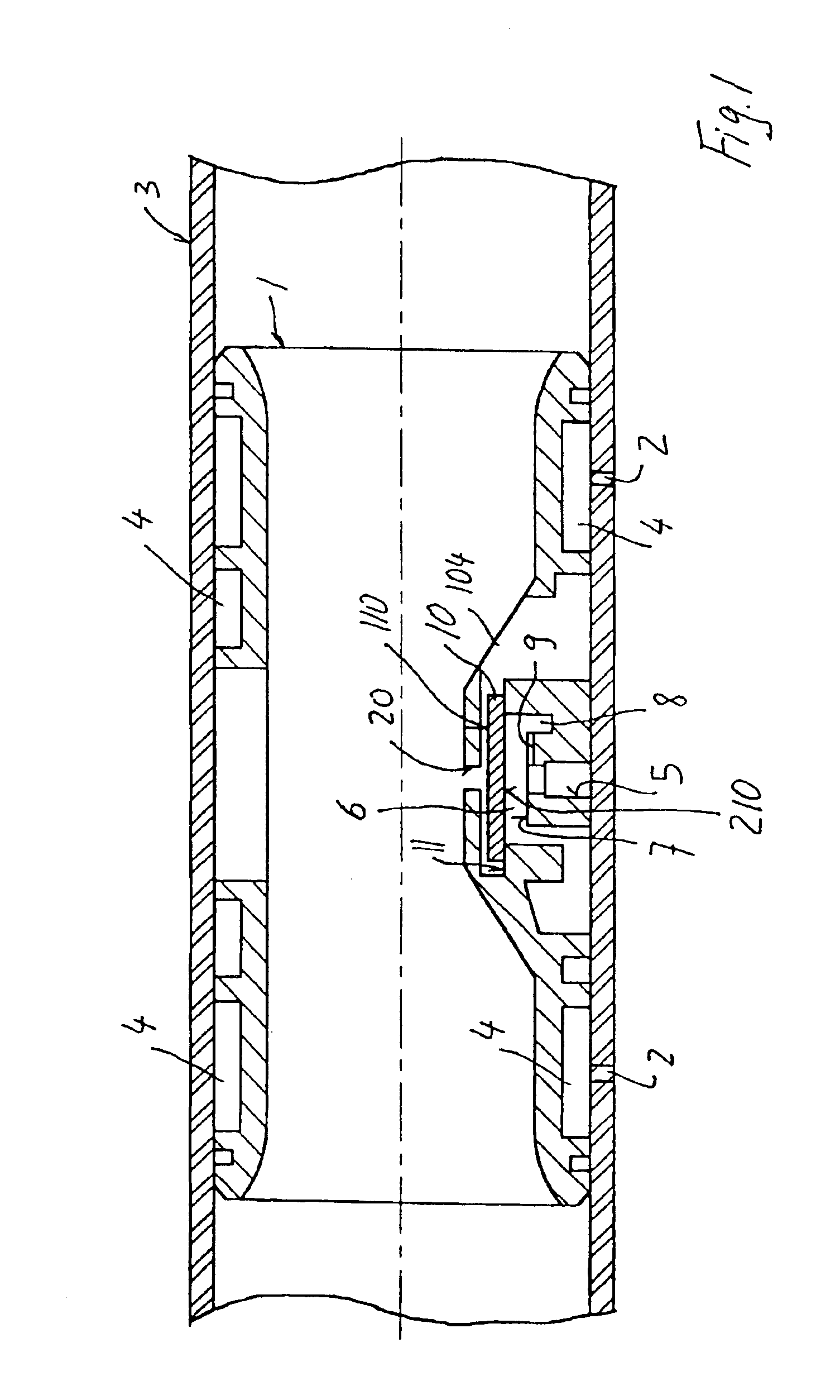

InactiveUS6945476B2Simple and inexpensive arrangementAvoid easy cloggingClimate change adaptationWatering devicesDrip irrigationEngineering

The invention relates to a self-compensating drip irrigation emitter. A plurality of novel embodiments are provided, wherein the emitter of the invention is capable of always supplying a substantially constant flow within a range of pressures of a fluid flowing in a pipe (3), from very low to very high pressures. Furthermore, the emitter of the invention has such characteristics as to prevent any accidental and undesired clogging thereof by sediments or debris.

Owner:IRRITEC

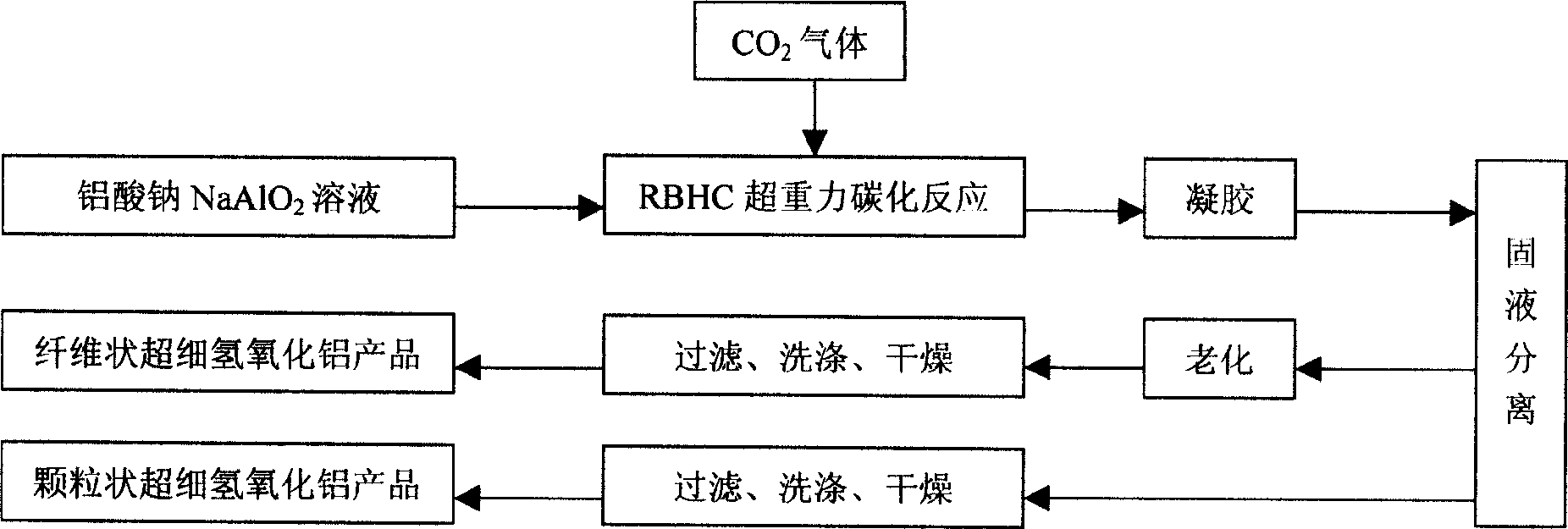

Preparation method of ultrafine aluminium hydroxide

InactiveCN1752006ASolve defects that are prone to clogging equipmentLow miscellaneous crystal contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationNanoparticleAluminium hydroxide

A process for preparing superfine aluminium hydroxide includes such steps as carbonifying reaction between NaAlO2 solution and the gas containing CO2 in gravitation condition to obtain aluminium hydroxide gel, preparing superfine aluminium hydroxide, filtering, washing, and drying. The product (nanofibers or nanoparticles of aluminium hydroxide) can be used as inorganic flame-retarding agent or for preparing catalyst.

Owner:XIANGTAN UNIV

Heavy metals absorbent and method of use

InactiveUS20050029198A1Improved resistance to physical degradationAvoid easy cloggingOther chemical processesWater contaminantsFiberSorbent

A media for removal of heavy metals from an aqueous system comprising a mixture of nano alumina fibers and a ferric or manganic compound selected from the group consisting of hydroxides, oxyhydroxides, oxides and hydroxyoxides and mixtures thereof. The nano alumina is preferably produced by hydrothermal digestion of aluminum hydroxide, is treated with alkaline, followed by the addition of a ferric or manganic salt to form a gel like mass that is dried, heat treated, ground and sieved to form the sorbent. Alternatively a non-woven media is formed by adding mineral fiber such as microglass to the hydrothermal step. The resulting mulch is treated with alkaline and subsequently an iron and / or manganic compound, wet laid and dried to form the fibrous sorbent. Removal of heavy metals from the aqueous system is readily accomplished by contacting the aqueous system with the media until the heavy metal is substantially removed from the aqueous system.

Owner:ARGONIDE CORP

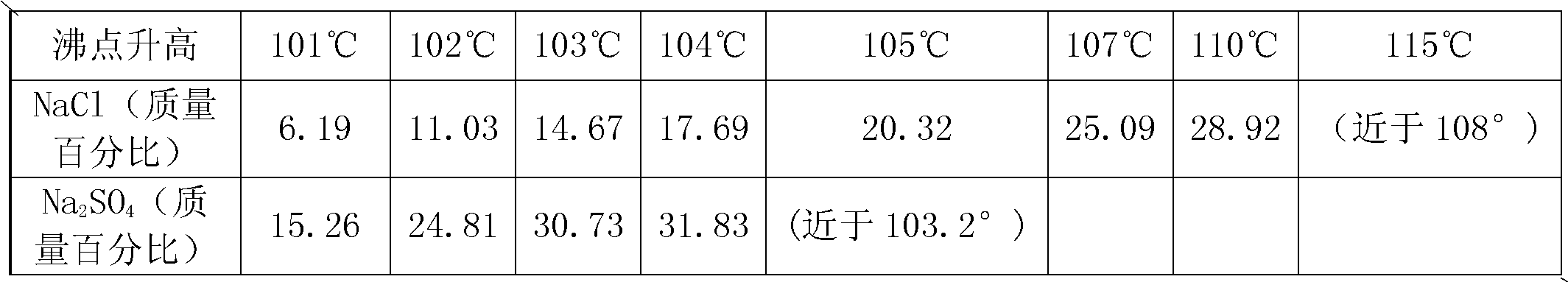

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

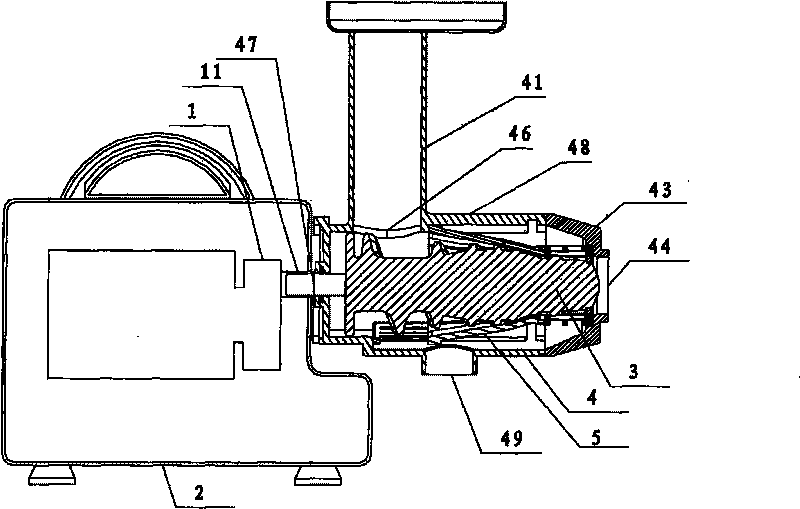

Easy cleaning extrusion type juicer

ActiveCN101697857AOutflow smoothlyImprove Juicing EfficiencyStrainersAgricultural engineeringFruits and vegetables

The invention discloses an easy cleaning extrusion type juicer which comprises an engine base, a motor, a juice collecting chamber, an extruding and crushing part and a filtering part, wherein the extruding and crushing part comprises a push-in screw and an extrusion cylinder matched with the push-in screw. The extrusion cylinder is arranged in the juice collecting chamber, and the filtering part is arranged on the lower part of the extrusion cylinder. The filtering part is characterized in comprising grids, and scum juice filtering gaps are arranged between the grids. The easy cleaning extrusion type juicer of the invention has the advantages that the size of the scum juice filtering gaps can change according to the size of the material under the action of the push-in screw to the material, the juice extrusion rate is high, so that the juicer is especially suitable for lone-term material feed; the juicer is easy to clean after being used, the extruded fruit and vegetable juice has less foam, and the inherent colour and taste of the fruit and vegetable juice can be kept to the maximum extend.

Owner:JOYOUNG CO LTD

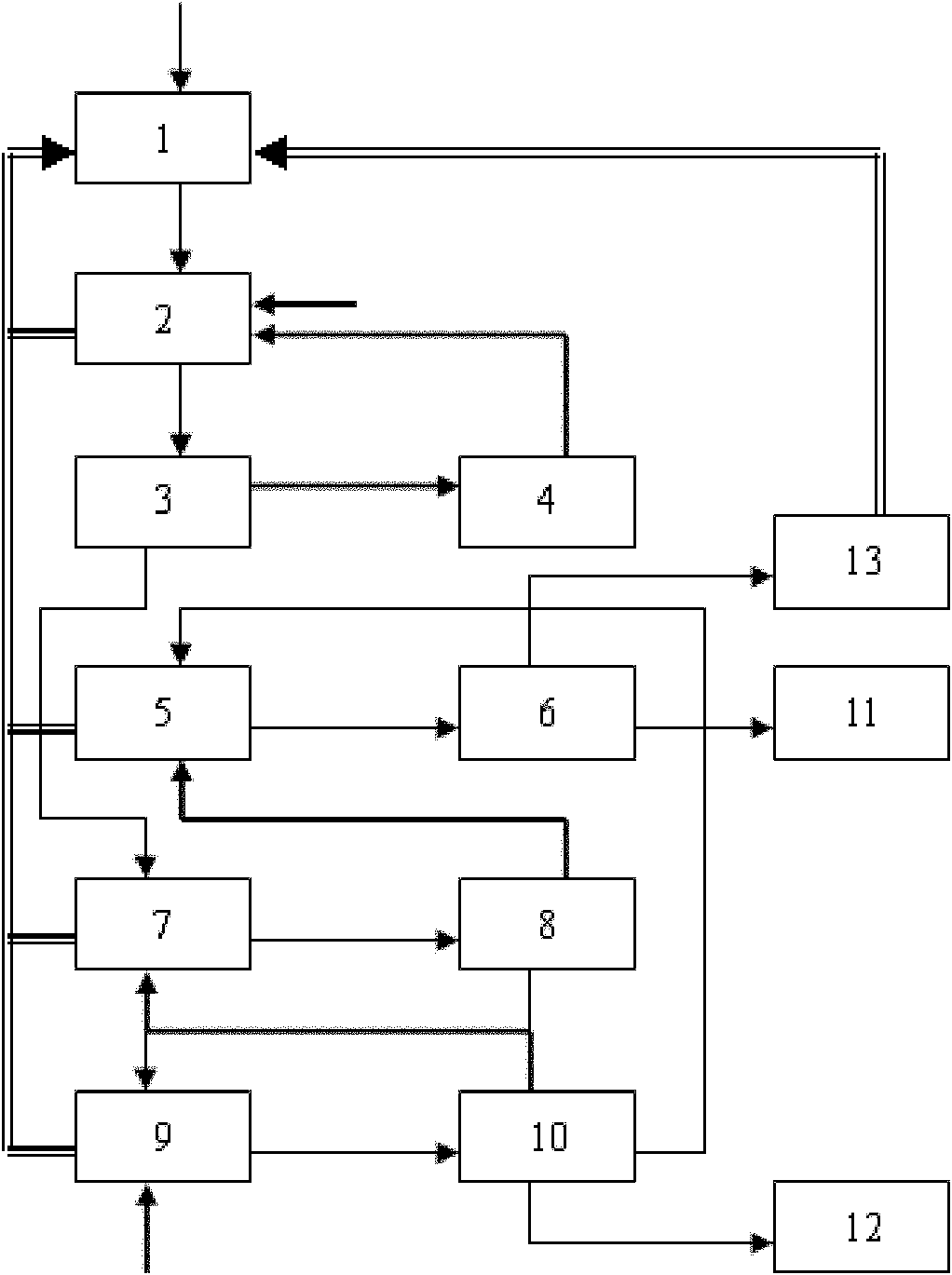

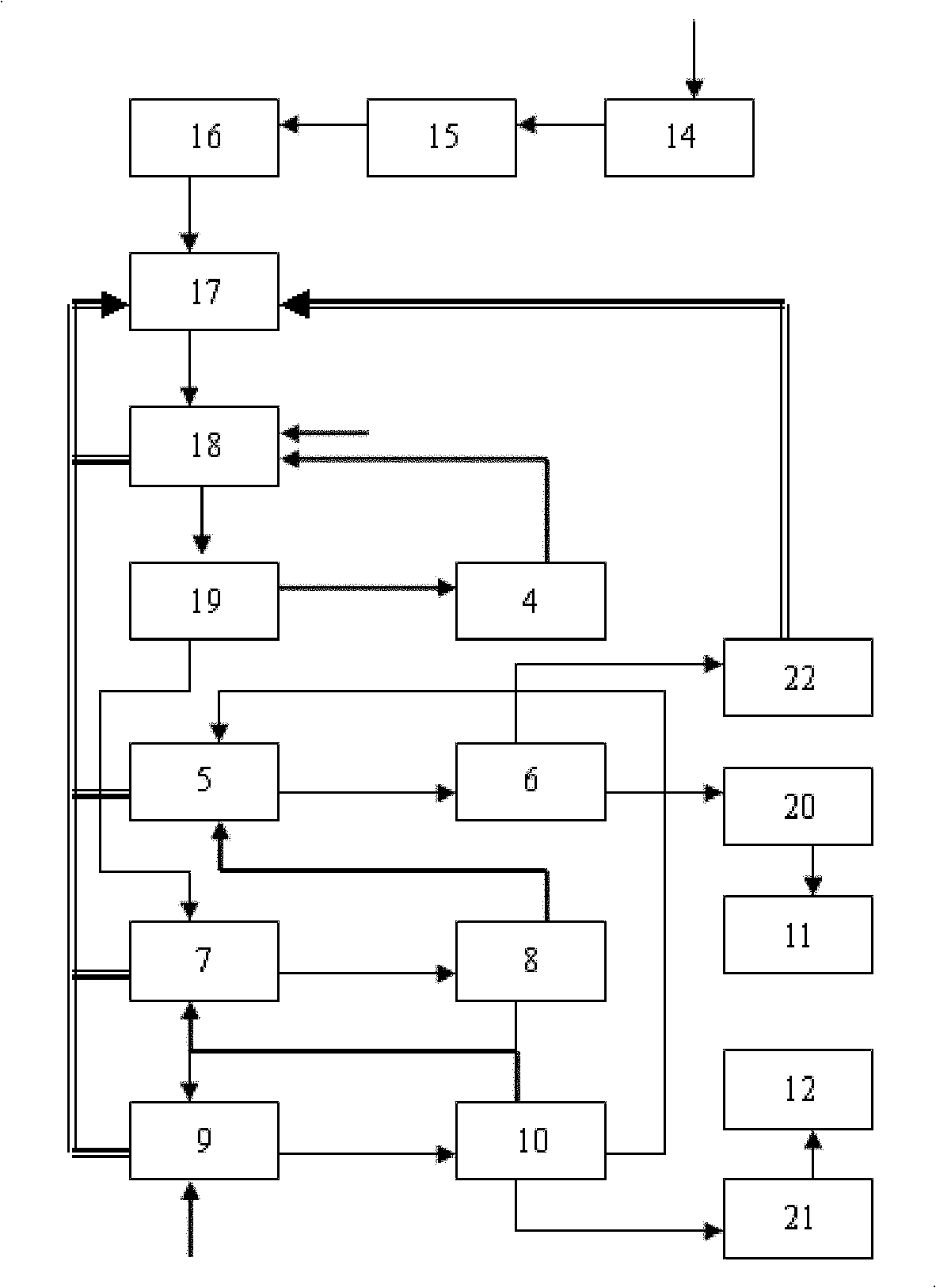

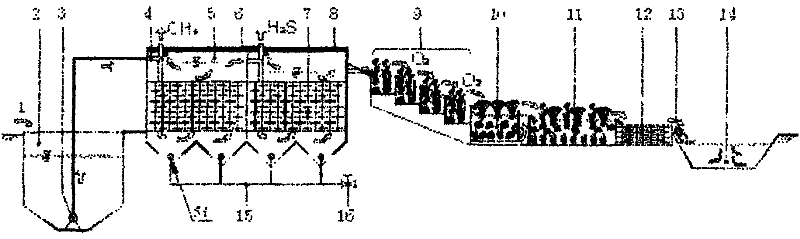

Novel technology for treating domestic sewage in rural area

ActiveCN102219332AIncrease economic benefitsLess investmentWaste based fuelTreatment with anaerobic digestion processesRural areaNitrogen

The invention discloses a system and method for treating domestic sewage in a rural area, which belongs to the technical field of environment-friendly sewage treatment. The domestic sewage enters an aerated grit chamber also serving as an adjusting tank for carrying out appropriate grit setting and adjusting, so that a part of inorganic pollutants is removed; the sewage is conveyed to a concentration type two-stage anaerobic reaction tank through a lifting water pump, suspended matters in the sewage are filtered and intercepted when the sewage passes through a concentration filter layer; contaminated gases, such as CH4, H2S and the like generated in the concentration type two-stage anaerobic reaction tank are discharged through a gas port; a part of concentration liquid is discharged out of the system through a concentration bottom sediment drainage pipe by opening a valve regularly; supernatant fluid from a water outlet of the concentration type two-stage anaerobic reaction tank enters a ladder plunge type wetland, a non-medium wetland, an economic income type wetland, a bacteria filter and a fishpond in turn; and nitrogen and phosphorus eutrophic pollutants in water are filtered, intercepted, adsorbed, decomposed, absorbed and precipitated by rootstocks of aquatic plants and the like. Therefore, according to the novel technology disclosed by the invention, the purpose of water purification can be achieved through regular harvest.

Owner:上海欧保环境科技有限公司

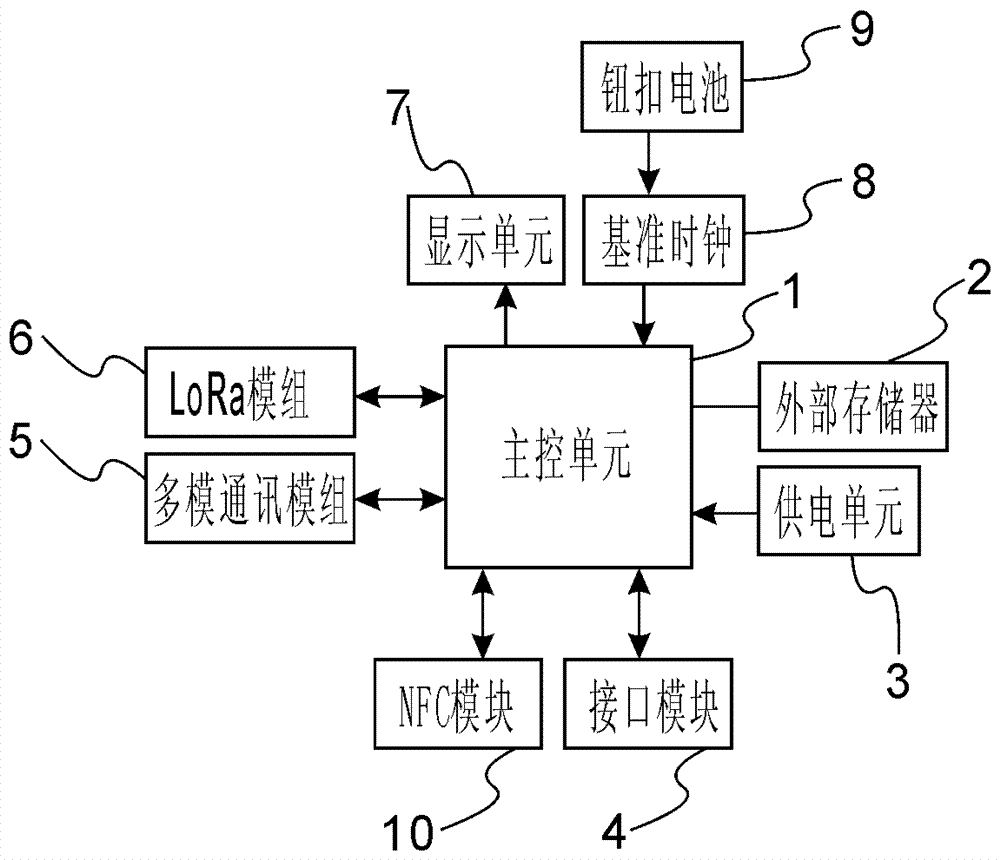

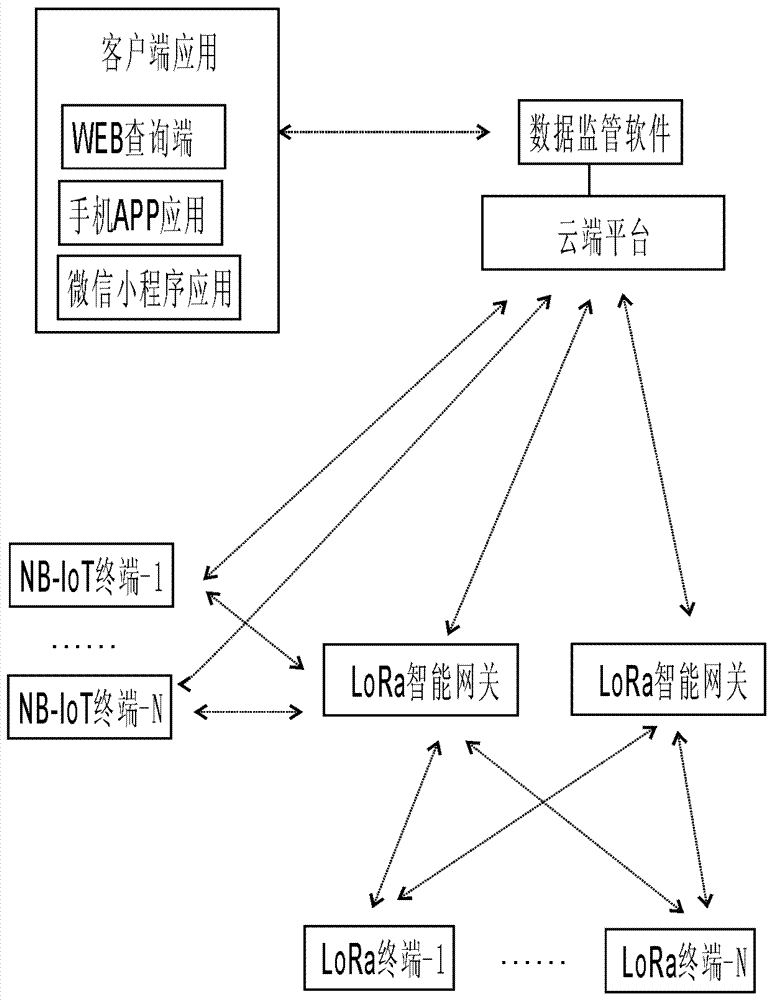

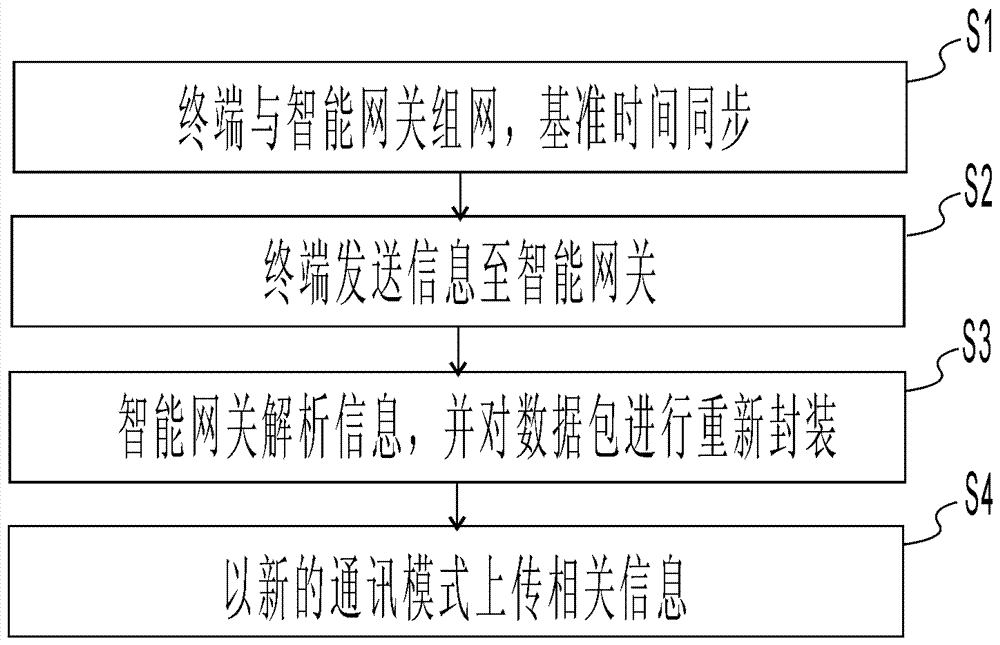

LoRa intelligent gateway, and using method, Internet of Things system thereof

PendingCN107027162AReduce limitationsReduce wastePower managementTransmissionExternal storageRemote communication

The invention discloses a LoRa intelligent gateway, and a using method, Internet of Things system thereof, and a narrow band Internet of Things system. The LoRa intelligent gateway includes a master control unit and also an external memory, a power supply unit, an interface unit, a multi-model communication module, a LoRa module, a display unit, a reference clock, a button clock, and an NFC module which are connected to the master control unit. According to the invention, the LoRa intelligent gateway uses the multi-mode communication module, combines the advantages of low power consumption and remote communication, can reduce limitation of power supplies, and based on actual requirements, uses new terminals as well as old terminals at the maximum, and is compatible with communication modes of new and old Internet of Things systems. The LoRa intelligent gateway can be configured to be in a NB-IoT mode or an eMTC mode directly according to requirements, or uses old GPRS mode. According to the invention, the LoRa intelligent gateway is based on actual requirements, has novel theories, is easy to implement, and has wide application prospect.

Owner:FUJIAN QIANGMIN INFORMATION TECH CO LTD

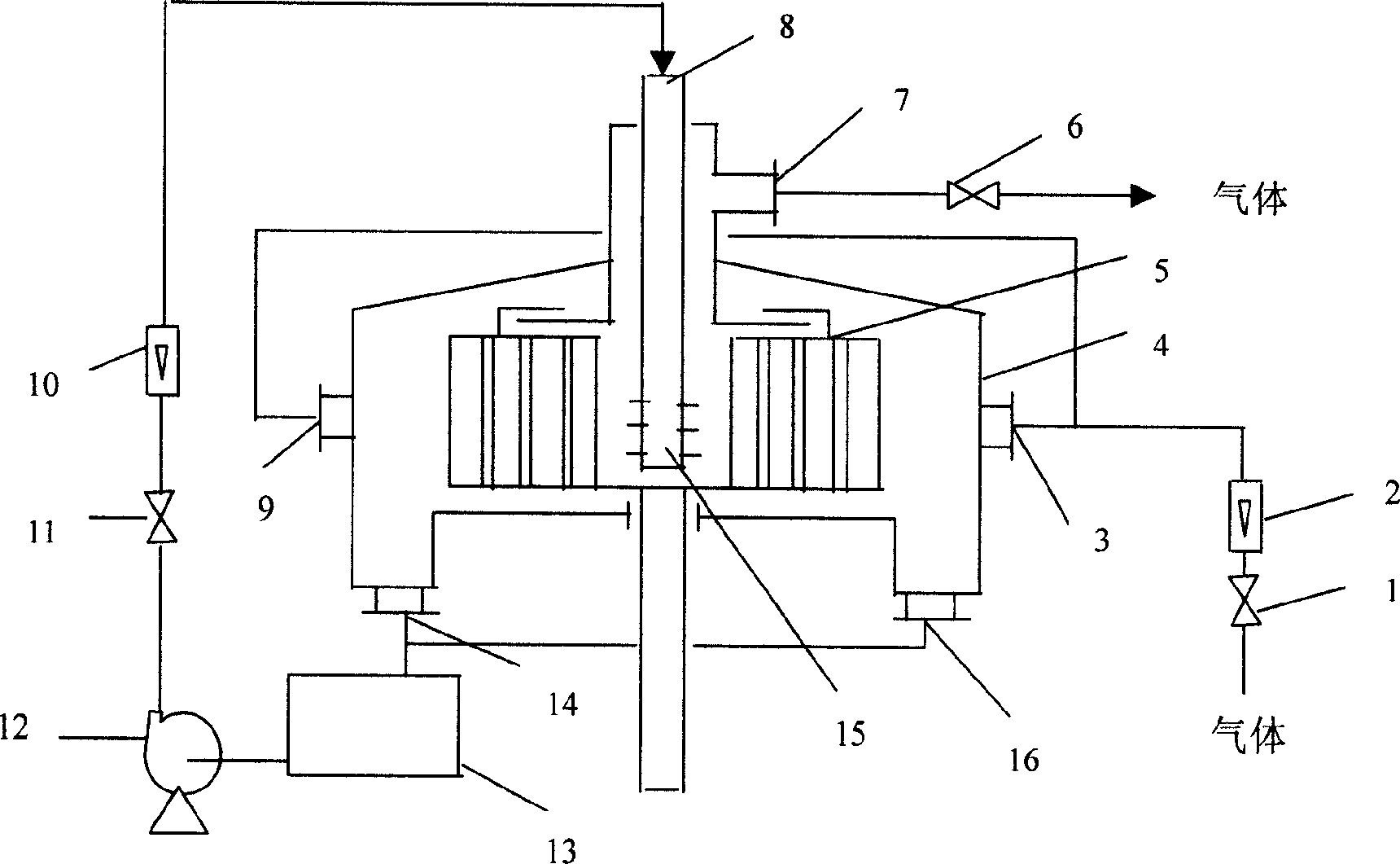

Method of eliminating impurity from gas phase

ActiveCN1608715AGood particle trapping effectGas phase pressure drop is smallUsing liquid separation agentGas phaseProduct gas

The method of eliminating impurity from gas phase includes introducing the eliminating agent for gas phase and the eliminating agent for liquid phase into the super-gravitational rotating bed reactor separately via the gas phase inlet and the liquid phase inlet, eliminating foam from the gas after eliminating impurity with the defoaming unit before exhaust from the reactor, and draining the liquid phase rich in solid powder and / or H2S via the liquid phase outlet. The present invention also sets defoaming section in the outlet end of the reactor to eliminate liquid foam from the gas phase via two-stage defoaming, including the first stage defoaming in the rotary deforaming device and the second stage defoaming in the fixed or rotating defoaming device. The present invention makes it possible to eliminate solid dust and H2S from gas phase simultaneously, and this shortens the technological process, lowers the cost and power consumption, and reduces the covered area.

Owner:CHINA PETROLEUM & CHEM CORP +2

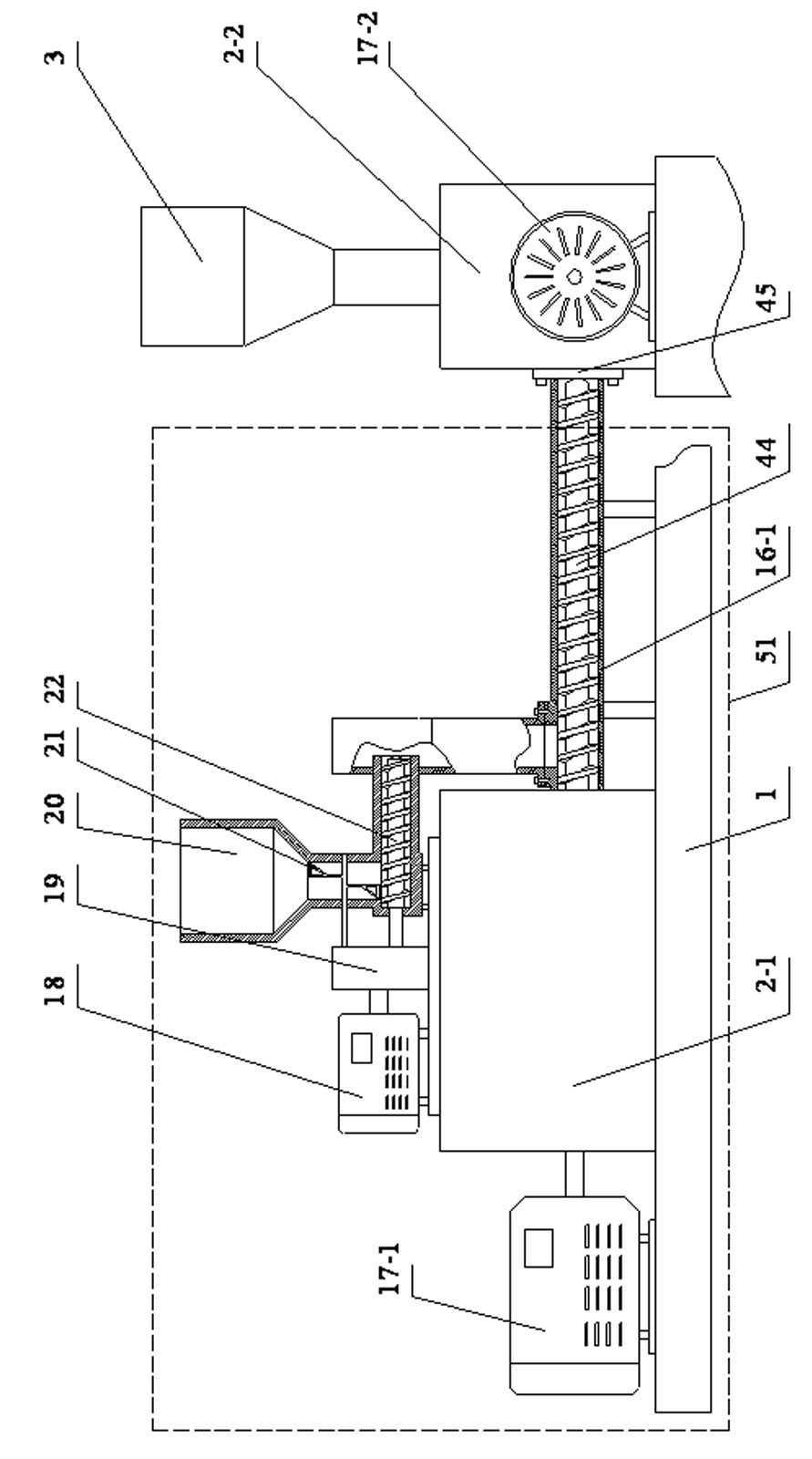

Wood plastic composite foaming material and forming process and equipment thereof

The invention relates to a wood plastic composite foaming material and a forming process and forming equipment thereof. The diameters of foam holes of the wood plastic composite foaming material are 0.01 to 5 millimeters; and the main component of the material is a mixture of thermoplastic plastic and plant fiber powder, or a mixture of thermoplastic plastic, starch and plant fiber powder, or a mixture of thermoplastic plastic, rubber powder and plant fiber powder. The invention also relates to the forming process and the forming equipment for the wood plastic composite foaming material. The wood plastic composite foaming material has the advantages of low density, high strength and low production cost, is suitable to be used as a packing material for various commodities, a buffering member for various devices, an elastic member of a product such as a sofa, a mattress, a sole and the like and a structural component of a household electric appliance, and is used for replacing wood for manufacturing floors, handrails, doors and windows, resting chairs used in gardens and the like.

Owner:佛山市科昌塑料制品有限公司

Multifunctional complete sucking type sweeping car

ActiveCN101003968AEfficient removalClean up thoroughlyRoad cleaningRefuse vehiclesParticulatesAir cleaning

The present invention relates to a multifunctional full-suction type roadsweeper. Said multifunctional fall-suction type roadsweeper includes the following several portions: upper dust-collecting tank, lower settlement negative-pressure tank, air-cleaning chamber, flower fan, air outlet pipe, air-blowing pipe, reverse-flow dust remover, filter dust-remover and power device. Said invention also provides the connection mode of all portions, also provides its working principle and concrete operation method.

Owner:高亚峰

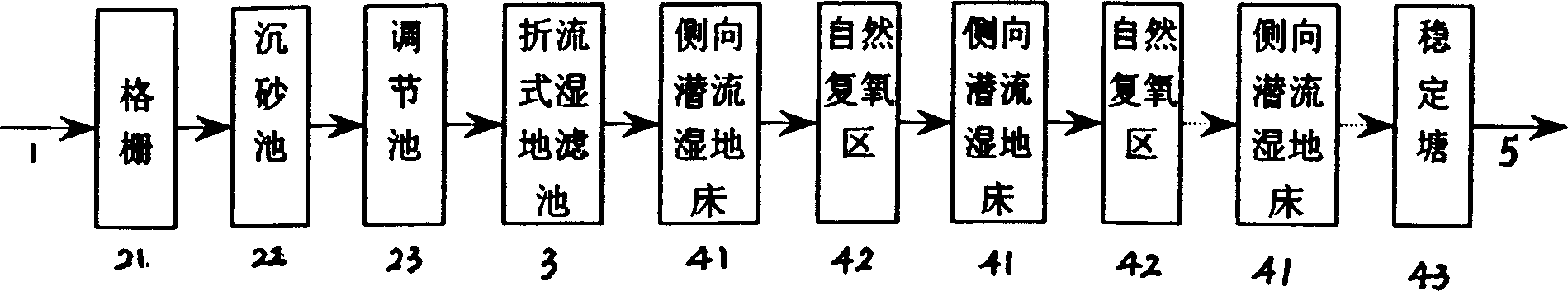

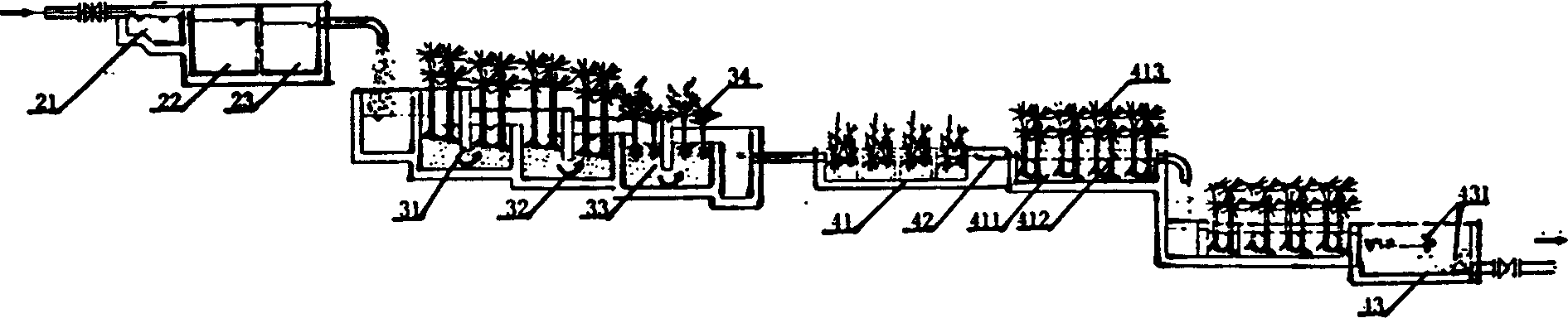

System and process for sawage treating with baffling wet land filtering tank and rateral underflow wet land bed

InactiveCN1693231AImprove biodegradabilityMake full use of interceptionTreatment using aerobic processesTreatment with aerobic and anaerobic processesWater flowExpanded clay aggregate

A system for treating sewage is composed of a pretreating construction, a deflection-type nunja filter pool group and a lateral underflow nunja bed group, which are arranged in gradient mode from high level to low level. Each filter pool contains a vertical retention wall, filler (haydite or zeolite) and aquatic plant. Said lateral underflow nunja bed group consists of multi-stage lateral underflow nunja bed, natural oxygen-aerating area and anaerobic stabilizing pond. Its method is also disclosed.

Owner:CHONGQING UNIV

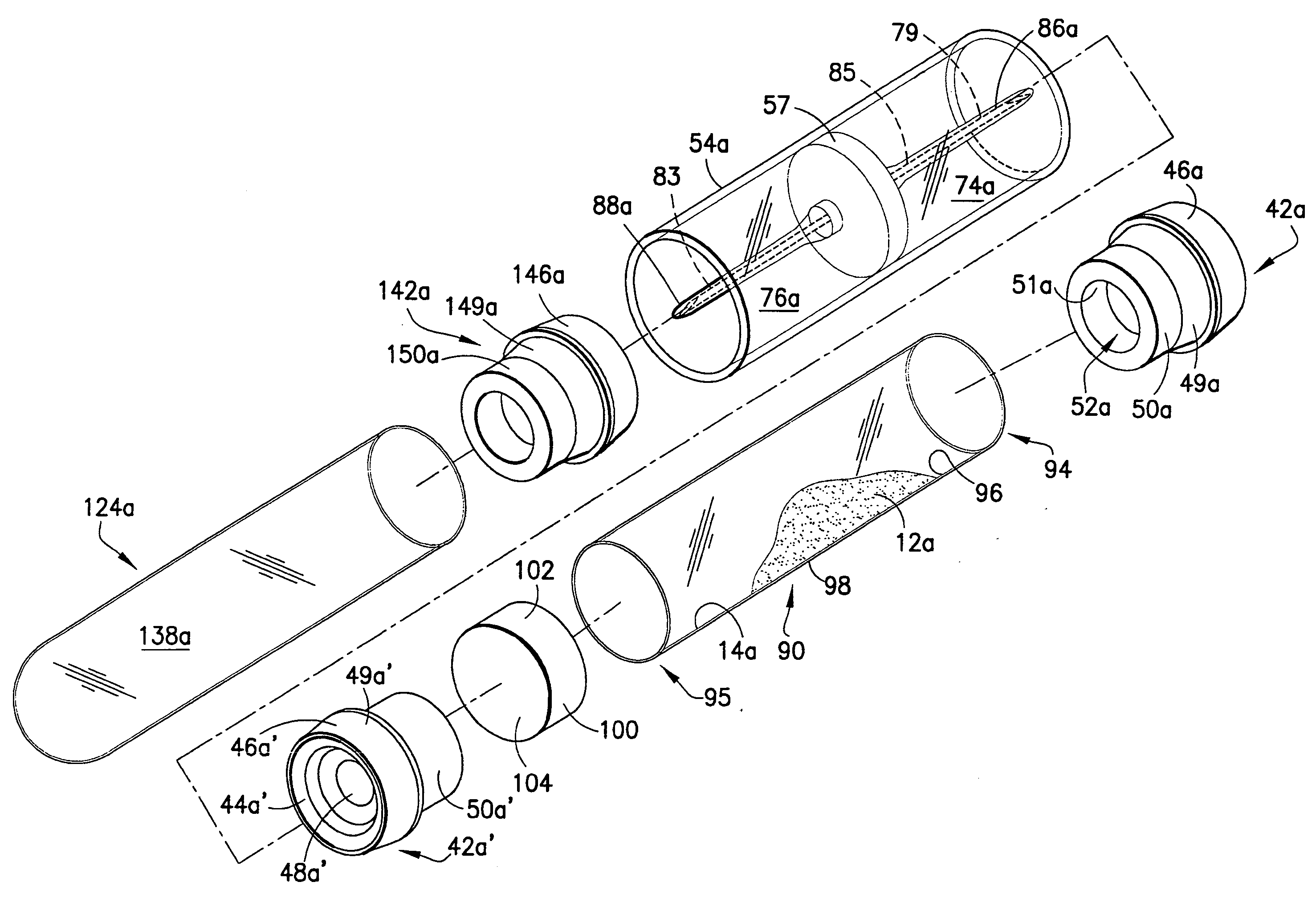

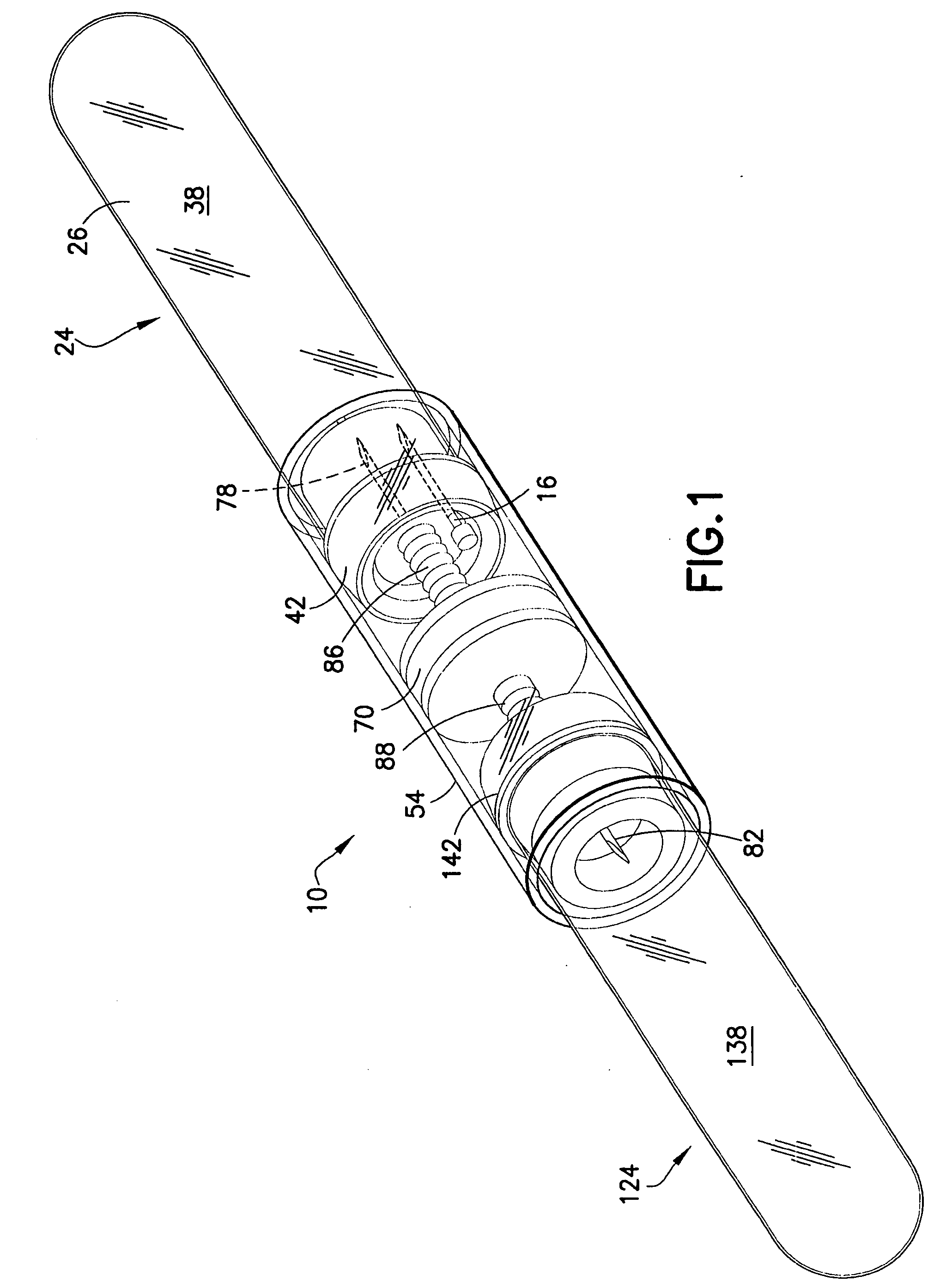

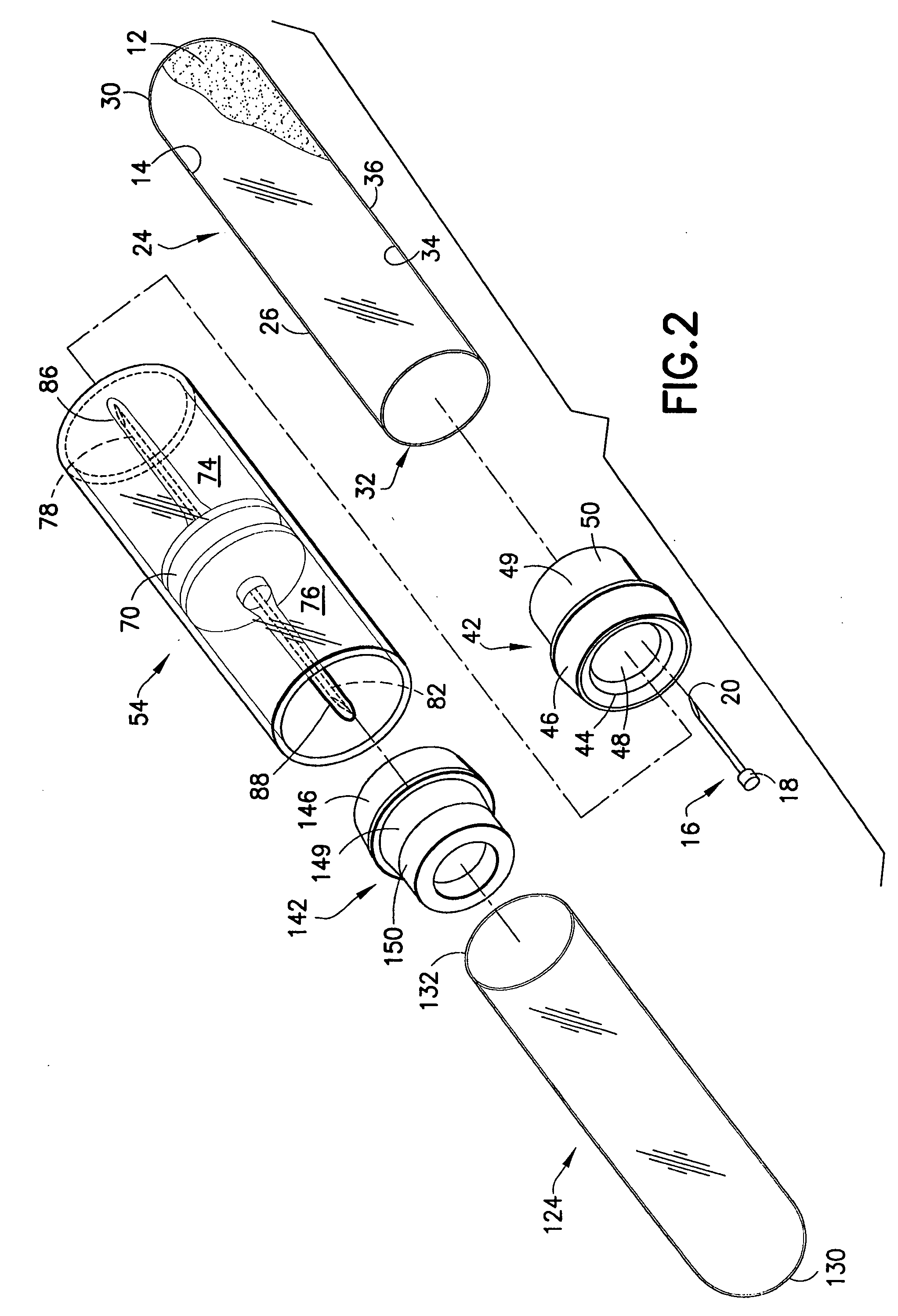

Plasma on demand tube

ActiveUS20050139547A1Avoid easy cloggingEasy to useCapsClosure lidsEvacuated blood collection tubeMedicine

A device for separating plasma from whole blood is provided having an evacuated primary collection chamber capable of fluid communication through a porous filter to an evacuated secondary collection chamber. An agglutinating agent is provided within the primary collection chamber so as to aggregate blood cells within a whole blood sample. The porous filter has a pore size which is small enough to capture the aggregated blood cells therein, yet large enough to permit plasma to transfer therethrough under pressures associated with conventional evacuated blood collection tubes. The primary and secondary collection chambers may be provided in separate containers or tubes, with transfer occurring therebetween through a transfer device including the porous filter therein.

Owner:BECTON DICKINSON & CO

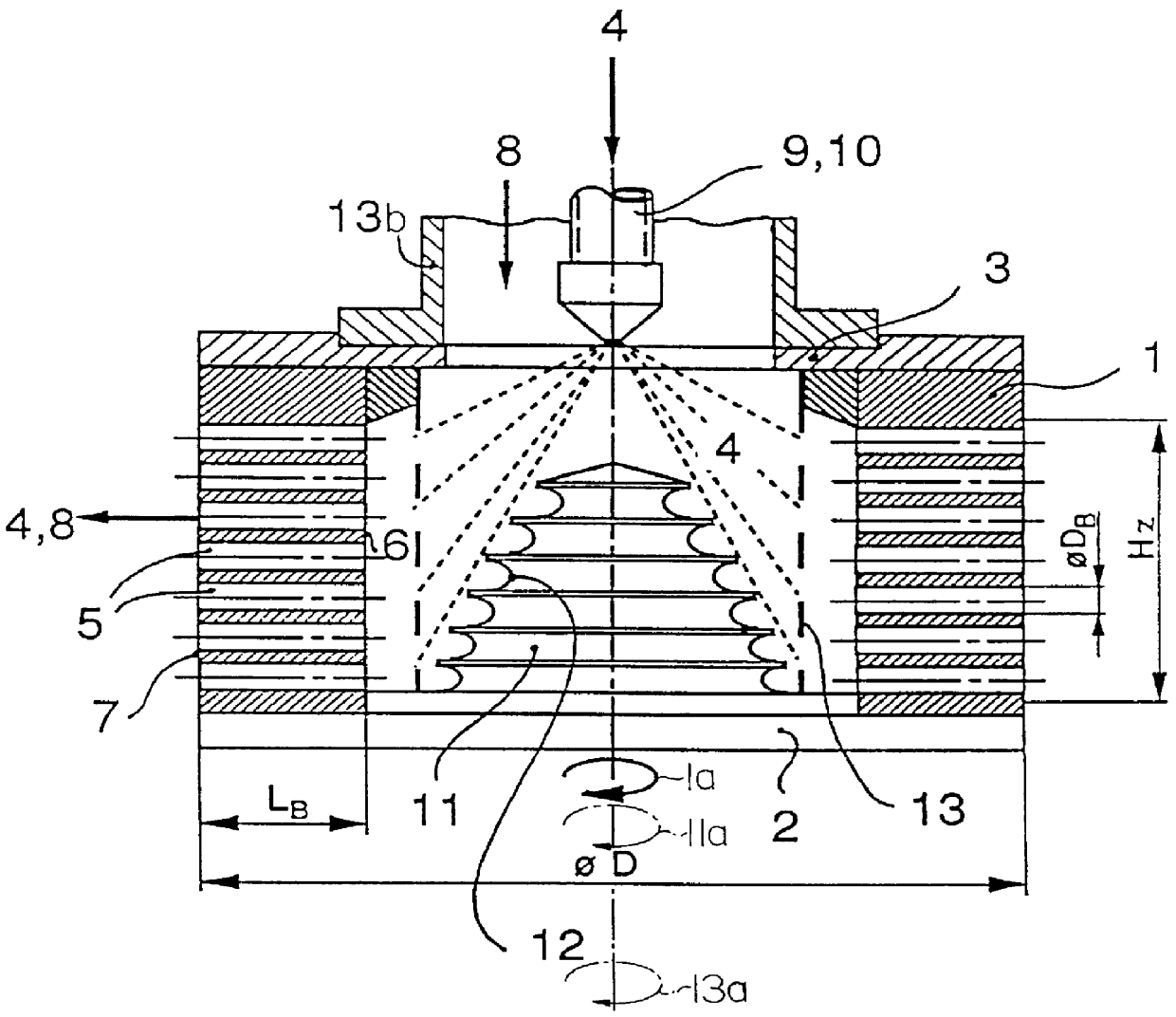

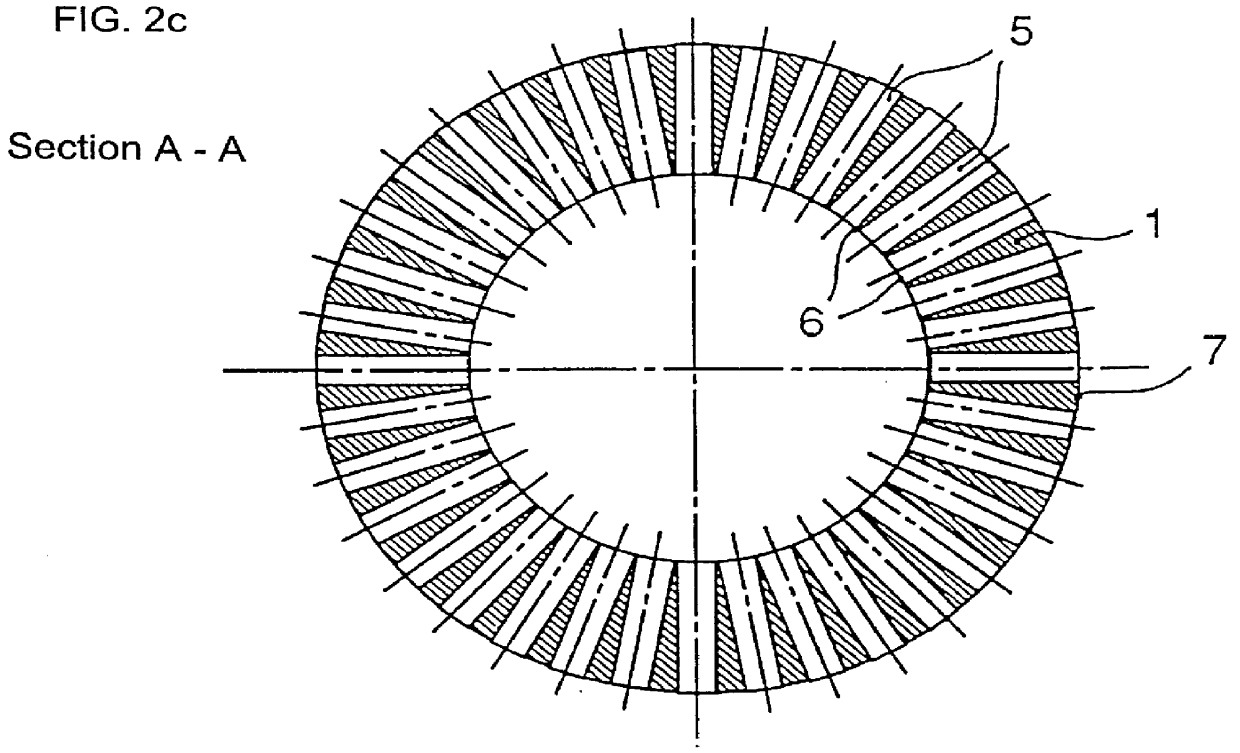

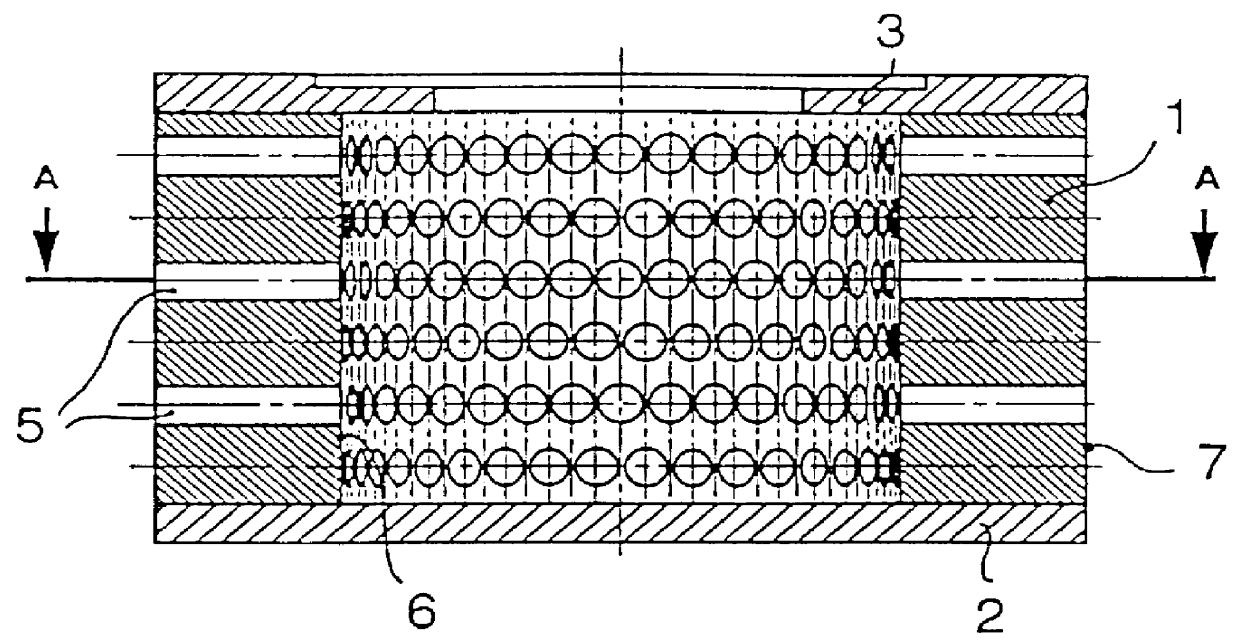

Process and a device for atomizing liquids

InactiveUS6098895ALarge caliberAvoid easy cloggingBurnersMovable spraying apparatusDecompositionEngineering

The liquid to be atomized is uniformly sprayed on the inner surface of a hollow rotating cylinder, for example by means of one- or two-fluid-nozzles and is thus distributed on bores provided in the cylinder wall. The rotation of the cylinder causes the liquid to flow outwards through the bores. Droplets are generated when the liquid flows out of the bores by laminary decomposition of the jet. The flow rate in each bore lies in the range 1.0<+E,dot V+EE B (a3 rho 5 / sigma 5)0.25<16 to prevent the droplets from becoming too large and to satisfy the condition of an adequate flow laminarity, i.e. for the value of the Reynolds number for the continuous liquid flow in the boress not to exceed Re delta 400. +E,dot V+EE B represents the flow rate of the liquid in each bore, a represents the centrifugal acceleration at the outer surface of the cylinder, rho represents the density of the liquid and delta indicates the surface tension of the liquid. The large number N>200 of bores having the diameter DB in the cylinder wall causes the flow rate of liquid through each bore to be relatively low, so that a continuous laminary flow in each bore is ensured even at low viscosities and technically useful total flow rates. Preferably cylindrical bores with a minimum length at least three times larger than the bore diameter are provided in the cylinder wall, with a narrow spacing in the range defined by 1.1<t / DB<5, so that a number of bores as large as possible may be arranged in the wall of the cylinder.

Owner:NIRO

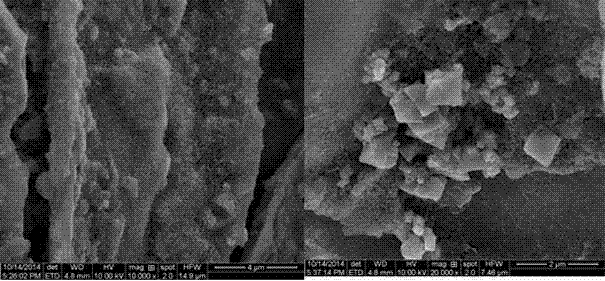

Modified magnetic biochar adsorbing material and application thereof

ActiveCN104258823AStable structureAvoid easy cloggingOther chemical processesAlkali metal oxides/hydroxidesCarbonizationBiochar

The invention discloses a modified magnetic biochar adsorbing material and application thereof. The adsorbing material is prepared through the following steps: taking agricultural waste corn stalks as a raw material, magnetizing and carbonizing the raw material, and adhering chitosan coating to the surface of the raw material. The adsorbing material is wide in raw material source, stable in structure, low in possibility of blocking, high in efficiency of effectively removing typical heavy metal pollutants namely cadmium ions and copper ions in water, convenient to separate, recycle and reuse and free of secondary pollution, achieves resource utilization, and has good environmental benefits and economic benefits.

Owner:UNIV OF JINAN

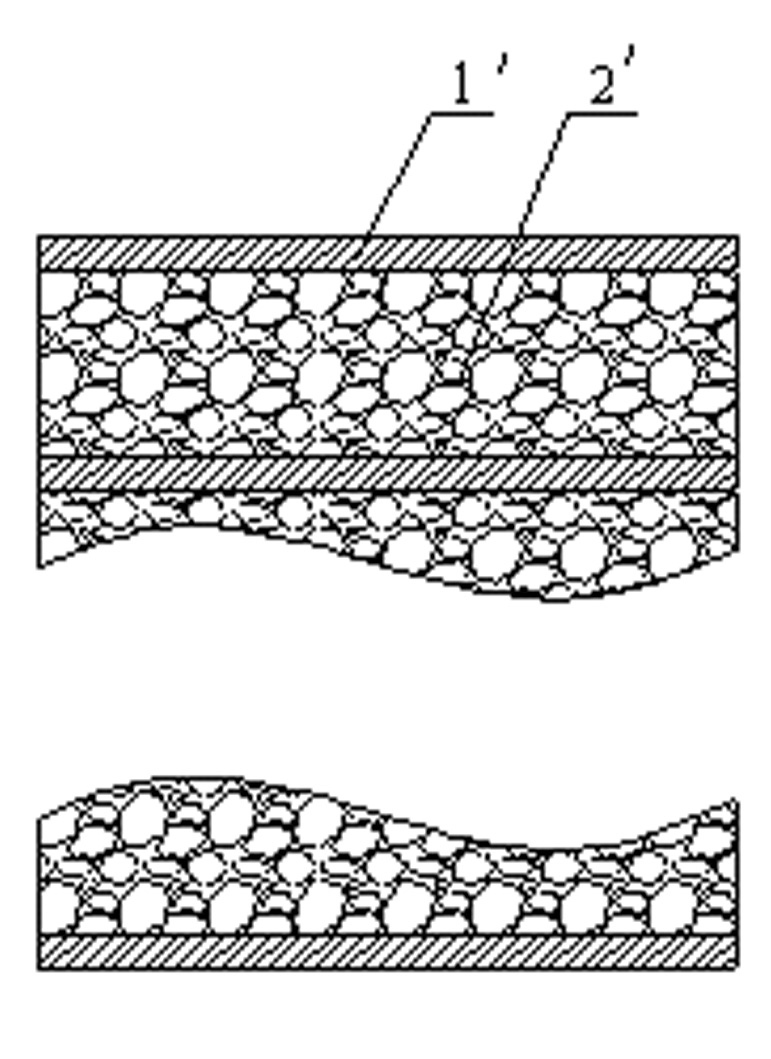

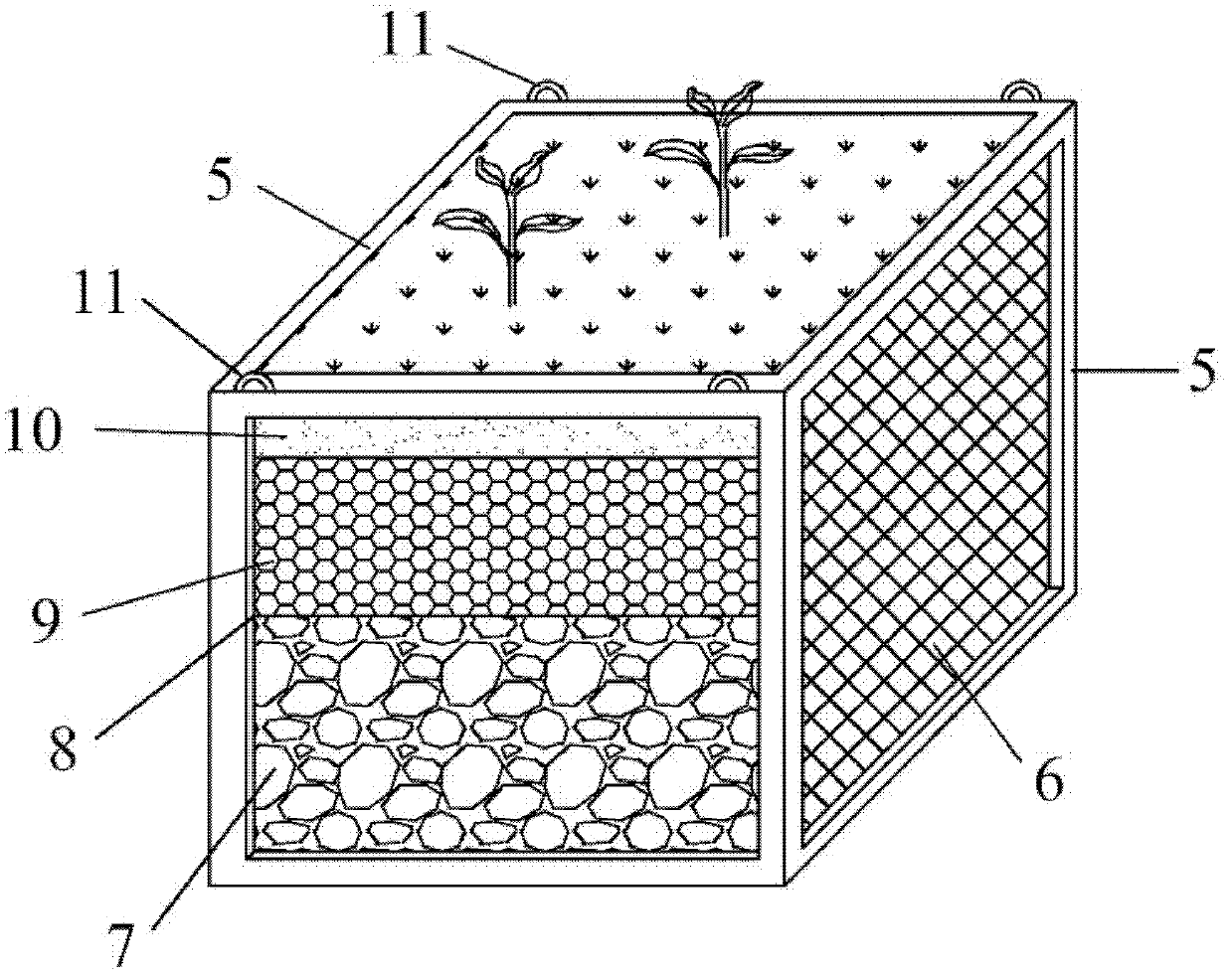

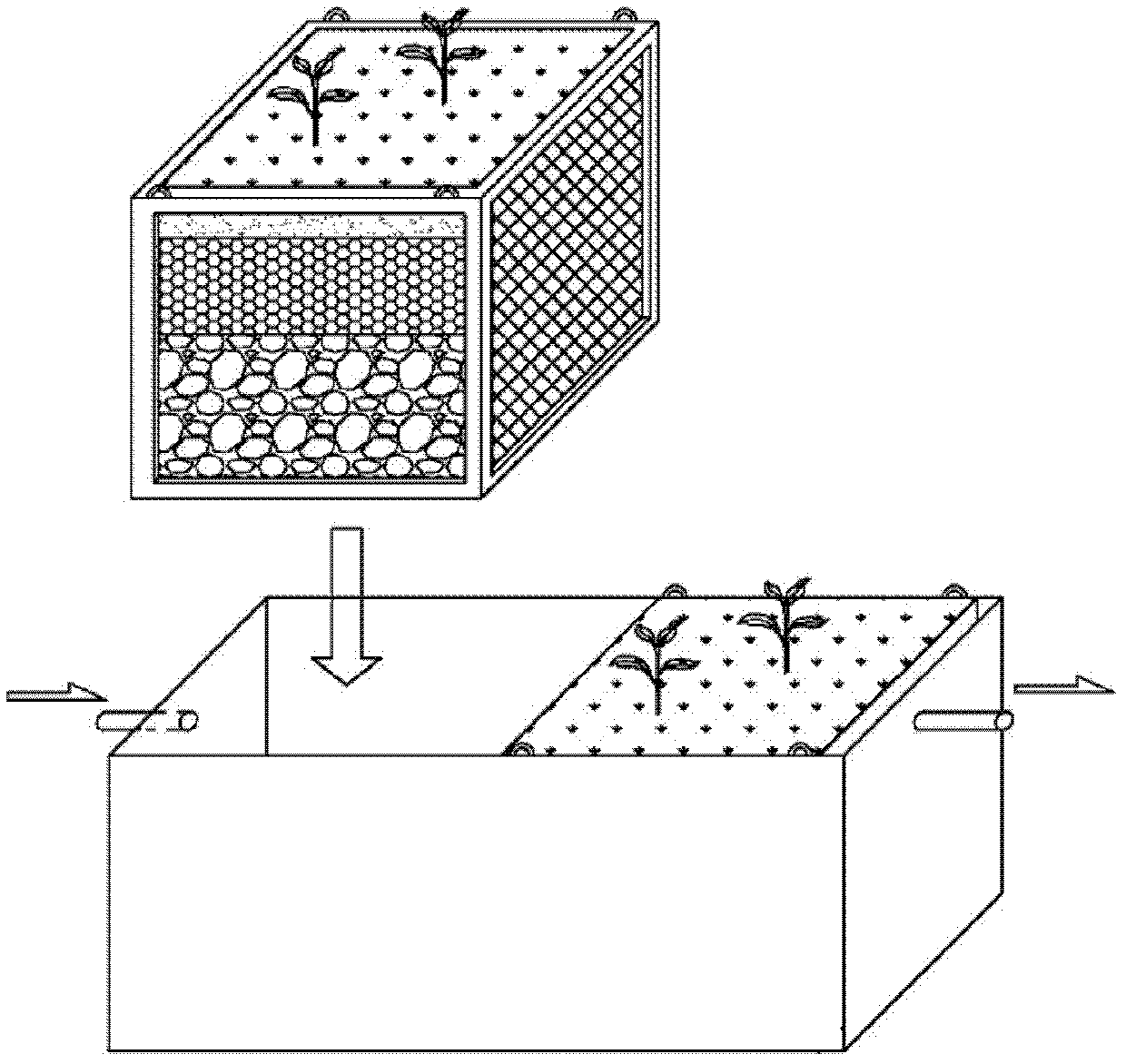

Modularized detachable constructed wetland

InactiveCN102603077ASimple structureEasy to installSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater quality

The invention discloses a modularized detachable constructed wetland, which is formed by a plurality of wetland modules, each module is relatively independent, and the module comprises a plurality of detachable filler units; each filler unit consists of a filler frame, a net separator and a filler layer, and the filler layer comprises a soil layer, a soil separation layer and a porous light filler layer from top to bottom. According to the water quality, the water yield and the water outlet requirement of the treated sewage, the wetland modules can be connected in series and in parallel or compositely connected to constitute a constructed wetland system. The modularized detachable constructed wetland has a simple structure, is convenient to install, is low in cost, and adapts to industrialized batch production. In the operation process of the wetland, the wetland modules and the filler units can be replaced and repaired at any time, the system is not blocked easily, the treatment effect is good, and the land can be reused.

Owner:王启明

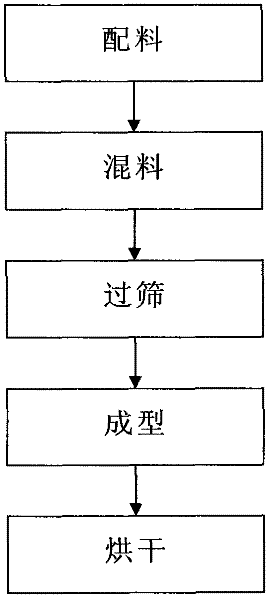

Resin abrasive cutting wheel and manufacturing method thereof

ActiveCN102343558AHigh strengthImprove cutting effectBonded abrasive wheelsGrinding devicesCarbideGrinding wheel

The invention provides a resin abrasive cutting wheel and a manufacturing method thereof, belonging to the field of grinding tools. The resin abrasive cutting wheel solves the problem that the traditional brown corundum resin grinding wheel has low cost but bad cutting performance. The resin abrasive cutting wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body to reinforce the rotation strength of the grinding body, wherein the grinding body comprises the following raw materials in proportions by weight: 62-70% of brown corundum, 4-10% of black silicon carbide, 18-20% of phenolic resin and the balance of packing. The invention also provides a manufacturing method of the resin abrasive cutting wheel. According to the manufacturing method, the cutting performance of the abrasive cutting wheel is increased by increasing a special proportion of black silicon carbide under the condition that the cost is not increased.

Owner:NINGBO DAHUA GRINDING WHEEL

Comprehensive treatment method for garbage leachate

ActiveCN102649616AGuarantees long-term operational stabilityReduce energy consumptionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentMacromolecular SubstancesIon

The invention relates to a comprehensive treatment method for garbage leachate. The comprehensive treatment method for the garbage leachate comprises the following steps: (1) performing foam separation pretreatment; (2) performing coagulation sedimentation pretreatment; (3) performing microfiltration and ultrafiltration treatment; (4) performing gaseous film separation treatment; and (5) performing biochemical treatment. The garbage leachate is subjected to coagulation sedimentation and foam separation pretreatment, so that most of metal ions, floating oil, surfactants and part of organic matters are removed from the garbage leachate and the chemical oxygen demand (COD) and the chromaticity of the garbage leachate are reduced; suspended matters, macromolecular matters and the like are removed from the leachate through the microfiltration and ultrafiltration after pretreatment, so the liquid is clear, the gaseous film is difficult to block and pollute, and long-term operating stabilityof the gaseous film in the subsequence process is guaranteed; and ammonia nitrogen is efficiently removed from the leachate in the gaseous film stabilizing process and the ammonia nitrogen removal rate can be adjusted as required, so that the waste water has the best nitrogen carbon ratio and the successful operation of the subsequence biochemical system is guaranteed.

Owner:天津凯铂能膜工程技术有限公司

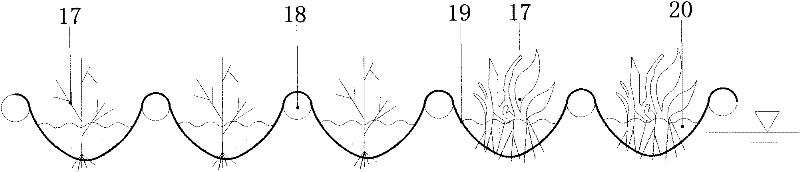

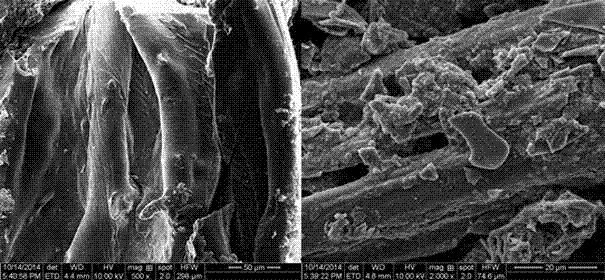

Planting method of famous and precious Chinese herb medicine dendrobium officinale

InactiveCN103004421AConducive to accumulation of emissionsAccelerate evaporationHorticultureFertilizer mixturesPlant rootsEvaporation

The invention relates to a planting method of famous and precious Chinese herb medicine dendrobium officinale, and the method is characterized in that a cultivation bed of a plantation trough with an undulated bottom is established under a certain facility environment, multiple mixed organic matrixes mainly comprising pine bark are paved, a nondestructive planting technology for stretching tissue culture seedling roots is adopted, and scientific and reasonable dendrobium officinale planting method adopting comprehensive cultivation measures such as a photo and temperature control technology, a fertilizer control technology, an insect and harmful organism nuisanceless control technology and a sustainable harvesting technology is adopted in different growth seasons and for different plants according to the biological characteristics of the dendrobium officinale; and due to the adoption of the method, the ventilation, moisture evaporation and moistening functions of a plant root environment can be enhanced, and harmful substances influencing the growth of the plant can be eliminated in time, so that the plant can grow strong, active components are highly concentrated, the resistance is enhanced, a purpose of high yield and excellent quality can be realized, the high yield and stable yield of the dendrobium officinale can be guaranteed, the product quality is excellent, sustainability for harvesting the dendrobium officinale for multiple years can be realized, and super high yield of fresh products about 600kg per Mu every year can be realized after the method is put into production.

Owner:MAOMING HUISHENGYUAN BIOLOGICAL SCI & TECH

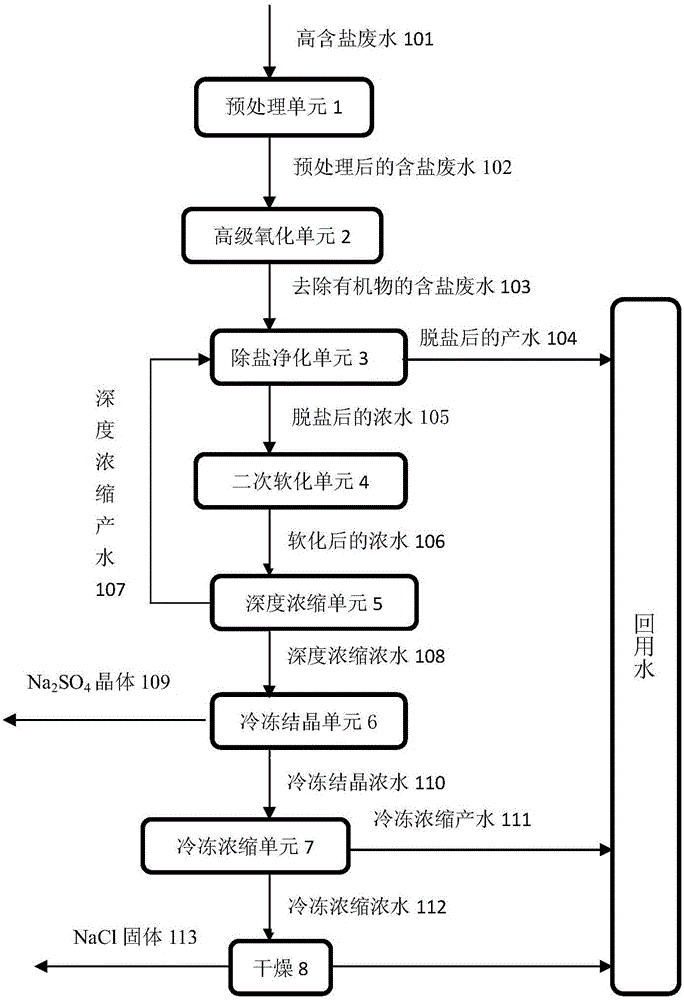

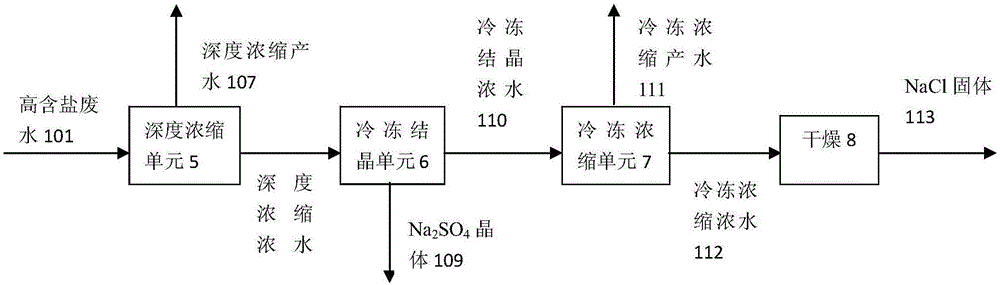

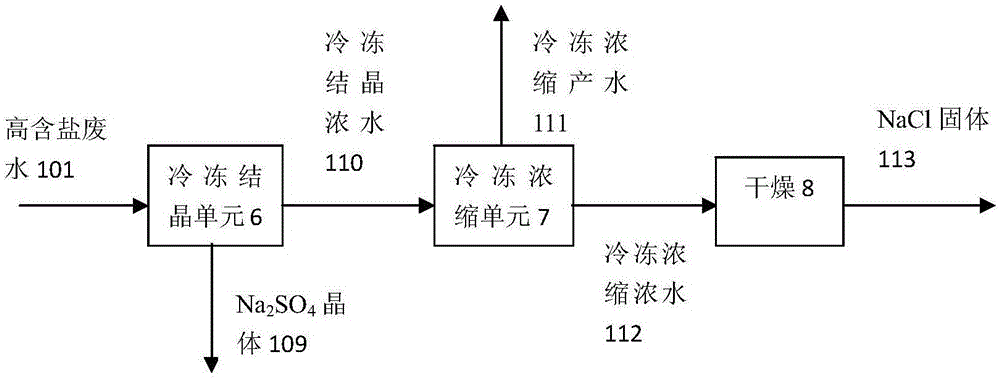

Salt separation and purification recovery method for salt-containing wastewater

ActiveCN106830465AAvoid easy cloggingRealize processingGeneral water supply conservationWater/sewage treatment by ion-exchangeRecovery methodCell separation

The invention discloses a salt separation and purification recovery method for salt-containing wastewater. The method comprises the following steps: performing advanced oxidation treatment on pretreated salt-containing wastewater so as to obtain salt-containing wastewater in which organic matters are removed; desalting and purifying the salt-containing wastewater in which organic matters are removed so as to obtain desalted produced water and desalted concentrated water, performing secondary softening treatment on the desalted concentrated water so as to obtain softened concentrated water; performing deep concentration on the softened concentrated water so as to obtain deeply concentrated produced water and deeply-concentrated concentrated water; performing freezing crystallization on the deeply-concentrated concentrated water so as to obtain sodium sulfate crystals and freezing crystallized concentrated water; performing freezing crystallization on the freezing crystallized concentrated water for at least one time so as to obtain freezing crystallized produced water and freezing crystallized concentrated water; and evaporating or drying the freezing crystallized concentrated water, thereby obtaining the sodium chloride crystal. The traditional evaporative crystallization process is replaced with the freezing crystallization, the process is implemented under low temperature and normal pressure, the equipment is difficultly corroded, the operation is safe and reliable, the energy consumption is effectively reduced, the pipeline is difficultly blocked, and the investment and operating cost can be reduced.

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD +1

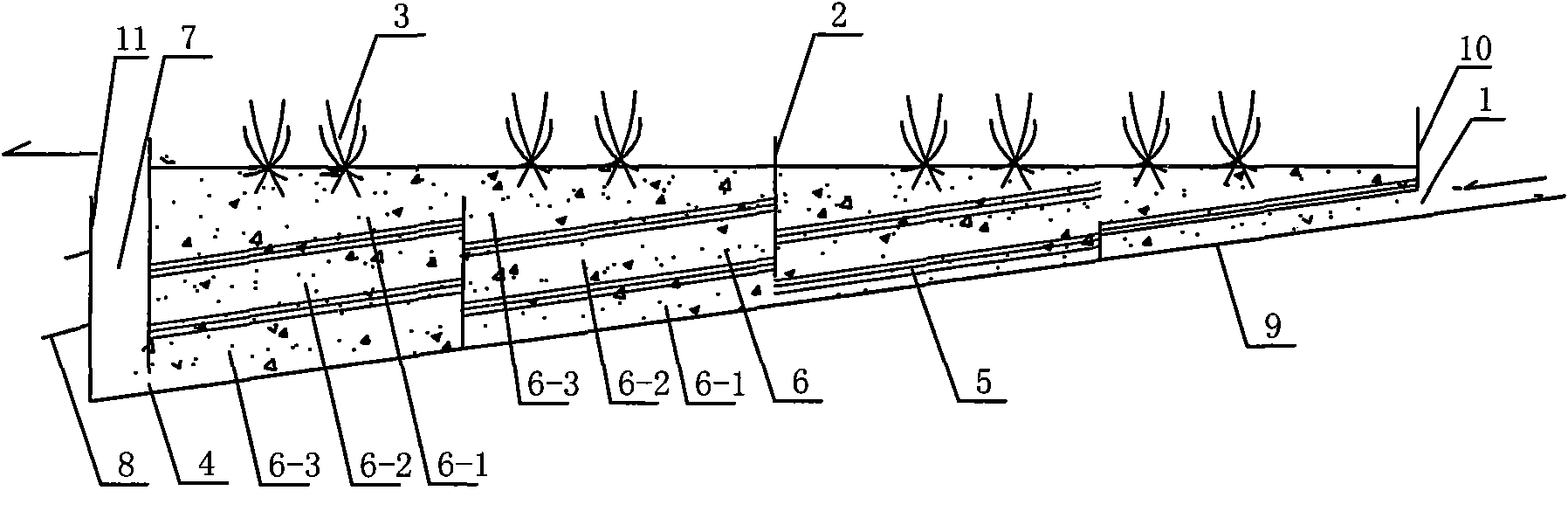

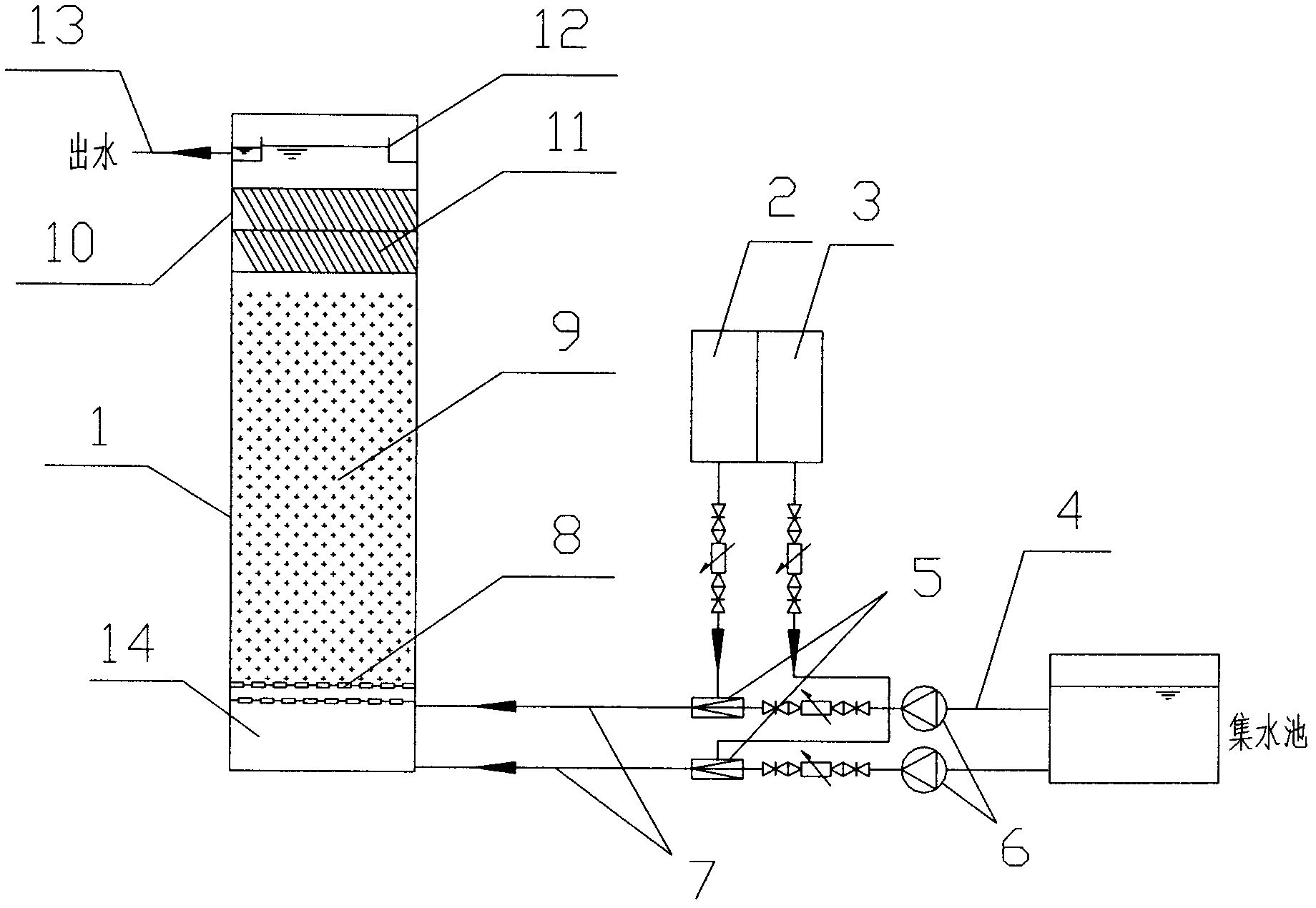

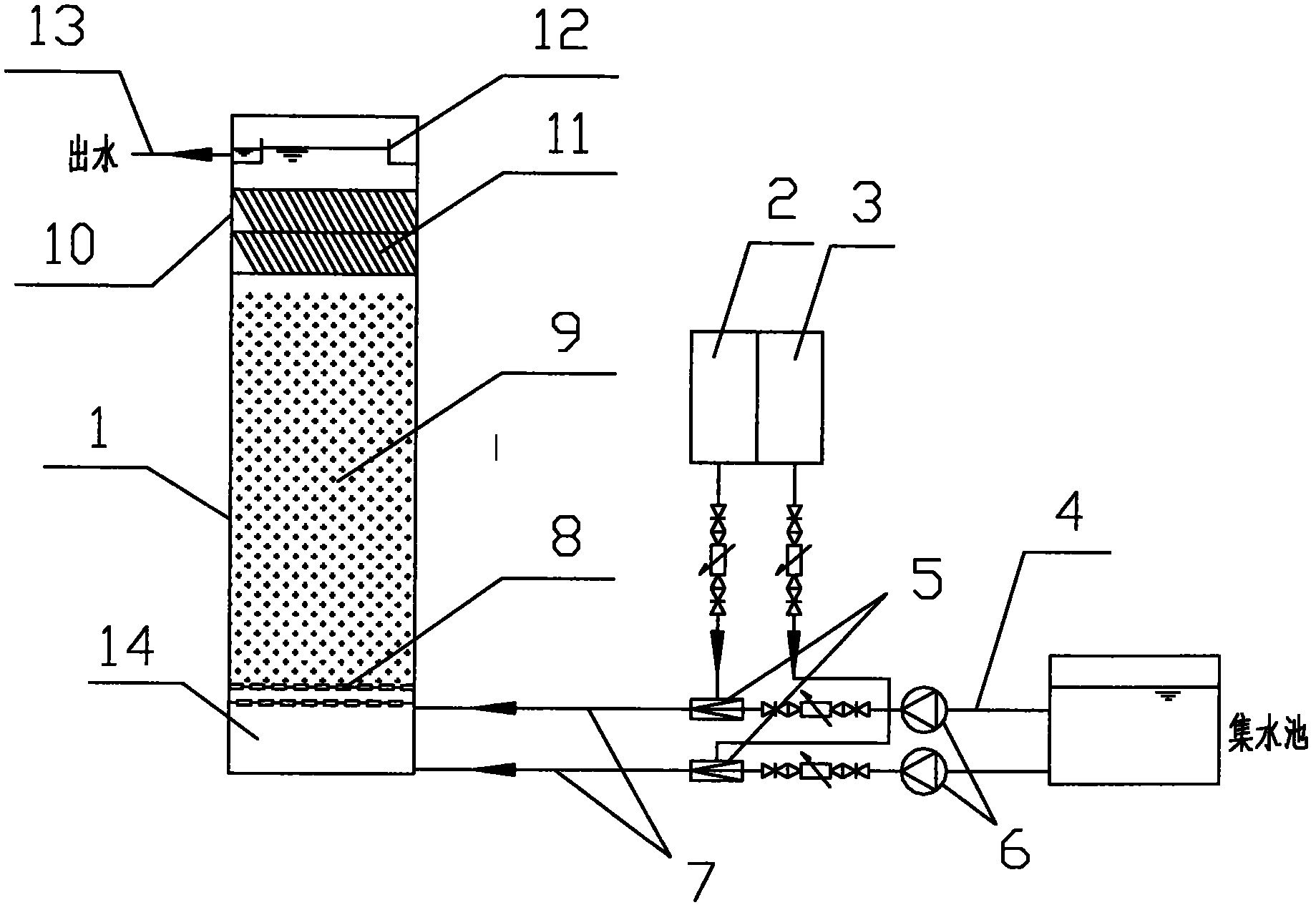

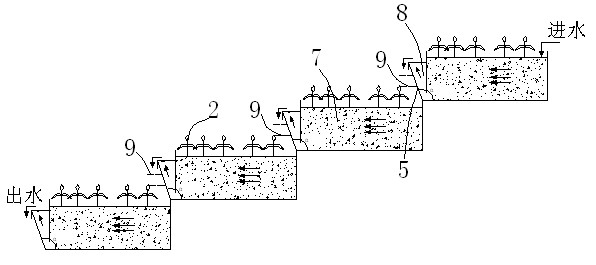

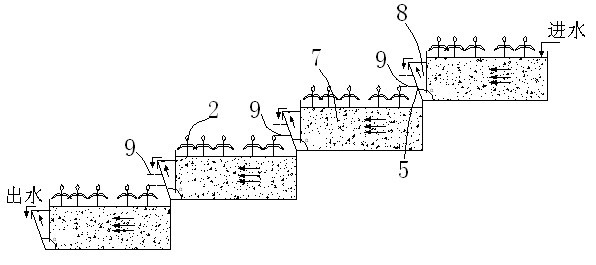

Subsurface flow constructed wetland sewage treatment system by drop water aeration oxygenation

InactiveCN101643278AExtended stayPromote biodegradationSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater quality

The invention relates to a subsurface flow constructed wetland sewage treatment system by drop water aeration oxygenation, composed of drop water aeration subsurface flow constructed wetlands in one stage or multistage series. Each stage of drop water aeration subsurface flow constructed wetland comprises a bed body, an inflow barricade, an outlet barricade and a drop water baffle; wherein a plurality of deflectors, gravel fillers and emergent aquatic plants are arranged in the bed body between the inflow barricade and the outlet barricade. The invention is even in water distribution, small inwake space and uniform in water impact, residence time of sewage in the bed body is extended, blocking is difficult, thus being beneficial to improving effluent quality and biodegradation of microorganism on nutrient such as nitrogen, phosphor and the like in the sewage, and construction and running cost is low. The invention, under the joint action of the effects, can effectively degrade pollutant of urban and town domestic sewage, a small amount of industry waste water and farm drainage and is applicable to mountain land and hilly country with certain gradient.

Owner:CHONGQING UNIV

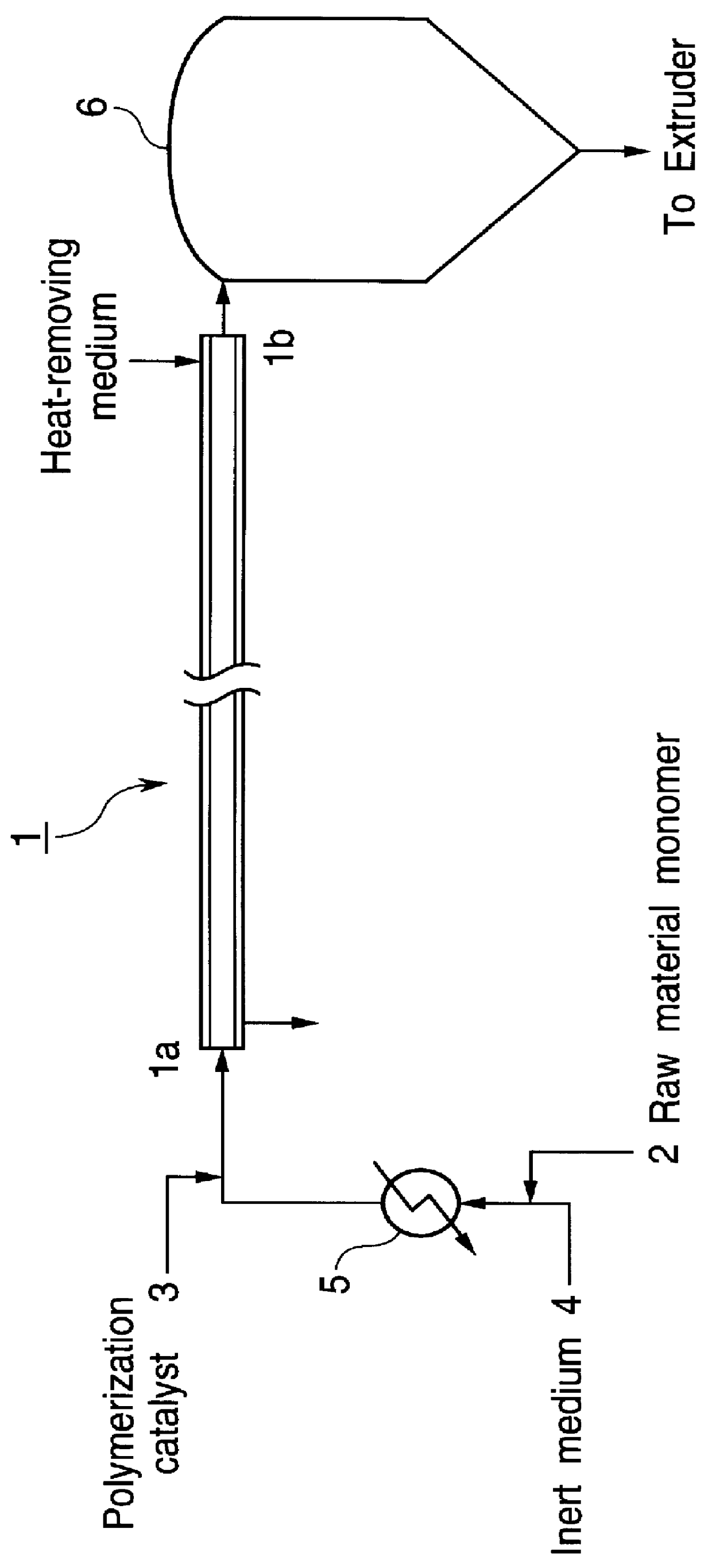

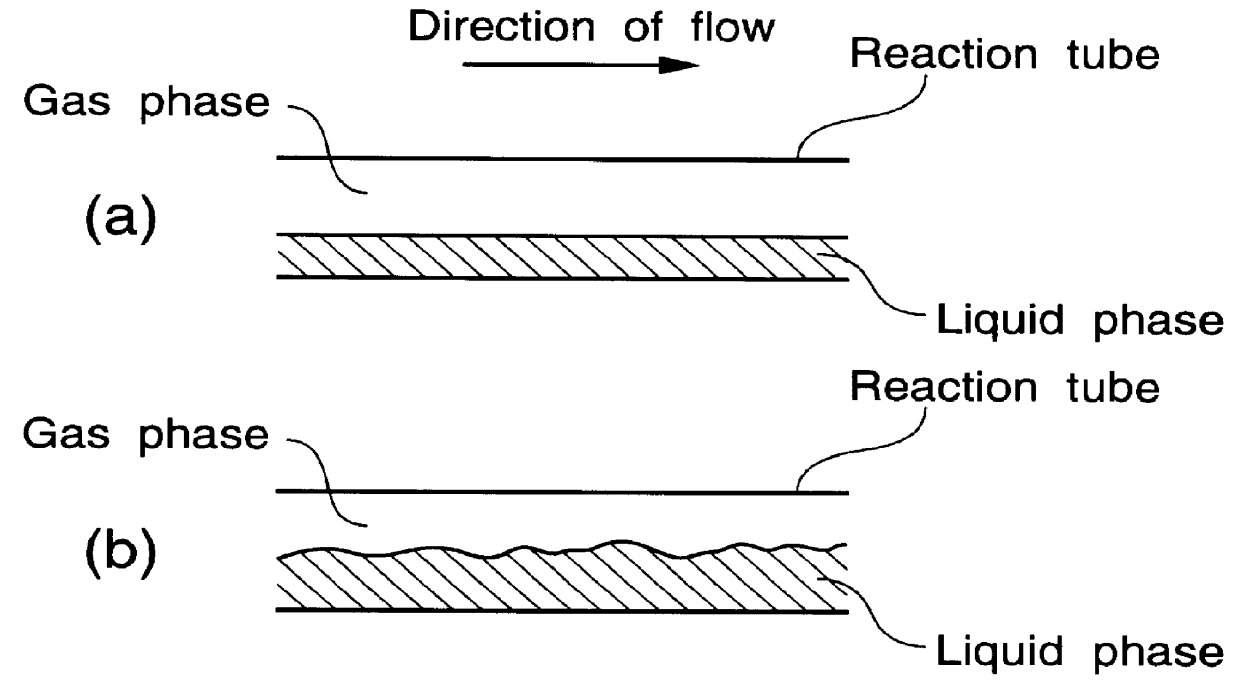

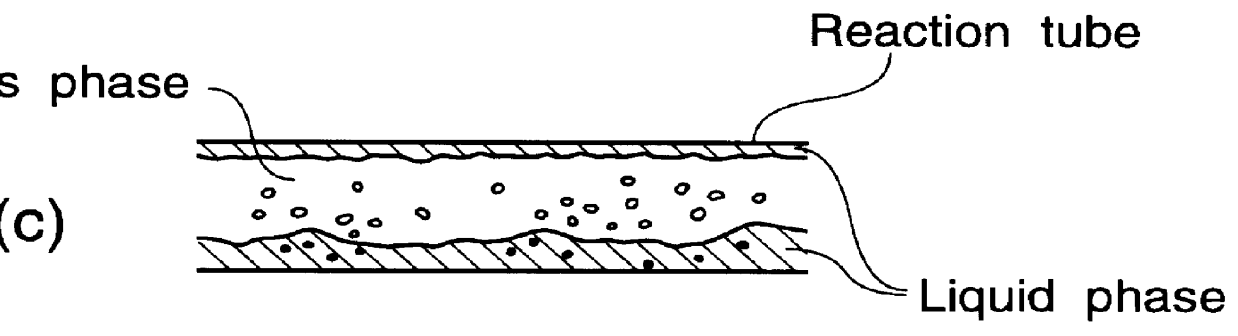

Polymerization process using separated flow

InactiveUS6111035ALow costEasy to controlChemical/physical/physico-chemical stationary reactorsPressure vessels for chemical processGas phasePolymerization catalysts

Disclosed is a polymerization process comprising feeding a monomer as a raw material, a polymerization catalyst, and optionally, an inert medium to a tubular reactor in a pressurized state; permitting a part of the raw material monomer and the inert medium fed to the reactor to form a gas phase and the remainder to form a liquid phase, so that both of the gas phase comprising the raw material monomer and / or the inert medium and the liquid phase comprising the raw material monomer and / or the inert medium are present in the reactor, wherein said liquid phase may contain a resulting polymer as a solid, and so that a gas-liquid separated flow or a gas-liquid-solid separated flow has the gas phase that is continuous in the direction of flow is formed in the reactor; and polymerizing the raw material monomer while carrying the liquid phase by the gas phase flow, wherein the ratio of a volume flow rate of the liquid phase to a volume flow rate of the gas phase at the outlet of the reactor is 0.00001 to 100,000. According to the polymerization process, polymerization can be accomplished with excellent thermal efficiency and small power energy, and besides various polymers almost free from restrictions on their properties such as viscosities and melting points can be produced.

Owner:MITSUI CHEM INC

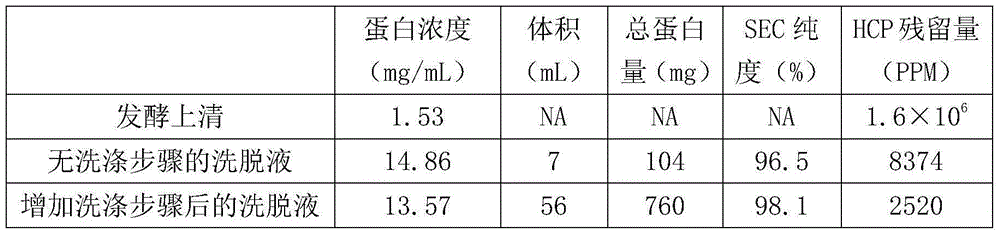

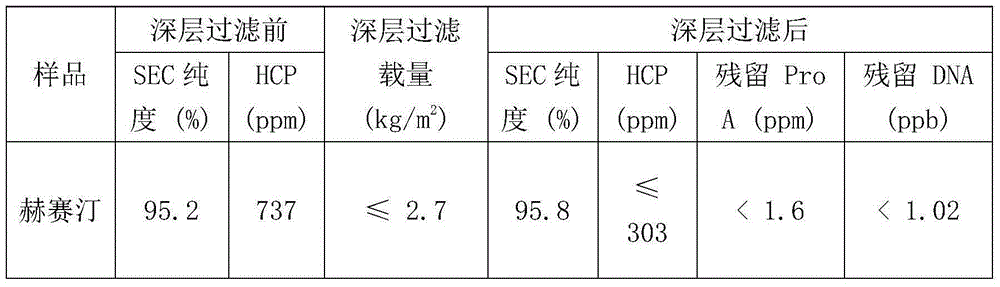

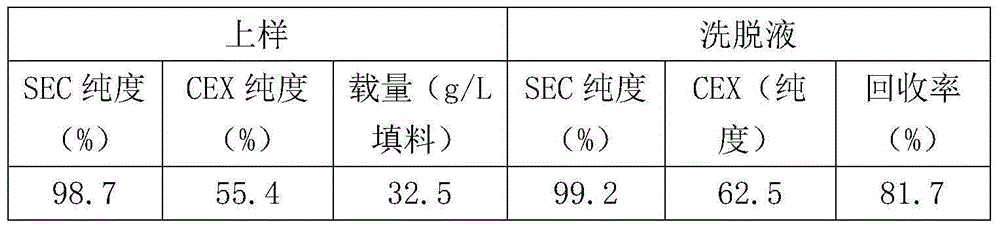

Monoclonal antibody purification process

ActiveCN105017418AAntibody purity is highHigh purityImmunoglobulins against animals/humansPeptide preparation methodsChemistryNeutral ph

The present invention discloses a monoclonal antibody purification process, which comprises: 1) carrying out affinity chromatography; 2) adjusting the pH value of the affinity chromatography eluent to 3.3-3.8, and carrying out virus inactivation; 3) adjusting the pH value to a neutral pH value, and carrying out deep filtration; 4) carrying out anion exchange chromatography; and 5) carrying out cation exchange chromatography. According to the present invention, the low-pH value and high-salt washing step is added to the affinity chromatography to remove the host protein and DNA while the deep filtration is used after the low-pH value virus inactivation to carry out the clarifying treatment, such that the separation effect of the affinity chromatography on the antibody monomer and the polymer is improved so as to increase the purity of the monoclonal antibody product.

Owner:上海药明生物医药有限公司

Advanced oxidation treatment device and advanced oxidation treatment process of refractory organic wastewater

InactiveCN102642911AReduced power unitWell mixedWater/sewage treatment by oxidationChemical oxygen demandRefractory

The invention aims at providing an advanced oxidation treatment device and an advanced oxidation treatment process of refractory organic wastewater, which are low in energy consumption, rapid in reaction speed, high in pollutant removal rate and low in operation cost. The device comprises a Fenton oxidizing tower, an oxidant feeding system and a catalyst feeding system, the Fenton oxidizing tower is a main device of the advanced oxidation treatment device, and the oxidant feeding system and the catalyst feeding system are respectively connected with multifunctional ejectors on two water inlet pipes of the Fenton oxidizing tower. The advanced oxidation treatment device and the advanced oxidation treatment process can treat refractory substances thoroughly, and chemical oxygen demand (COD) concentration of outlet water can reach below 50mg / L stably.

Owner:山东绿泉环保科技股份有限公司

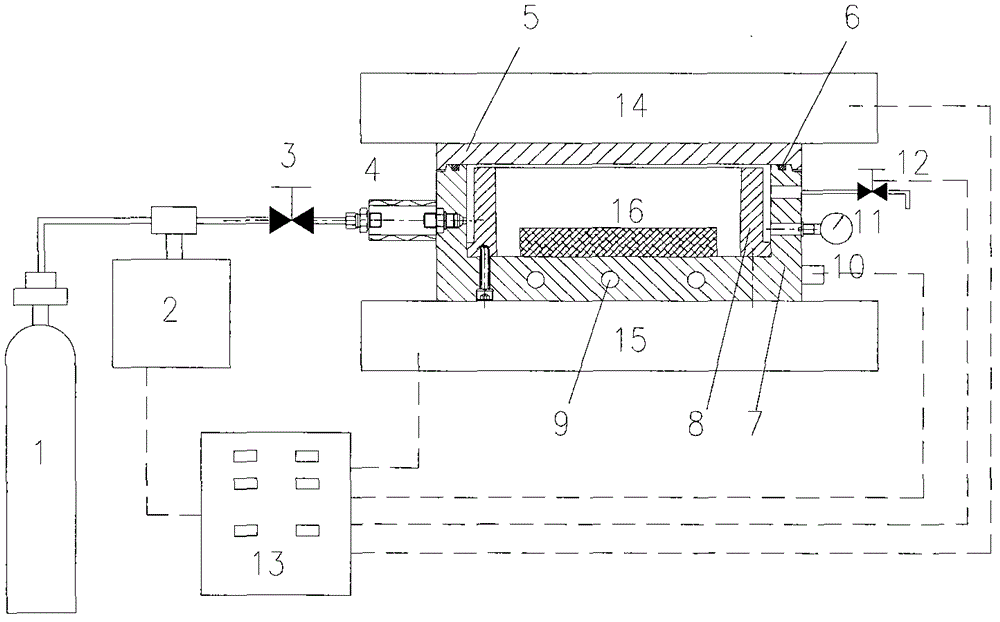

Supercritical fluid-assisted polymer mould foaming apparatus

The invention provides a supercritical fluid-assisted polymer mould foaming apparatus, comprising a supercritical fluid conveying system, a mould system, a temperature measuring device, a pressure measuring device, a pressure relief device, a display and control system, etc., wherein the supercritical fluid conveying system is connected with the mould system, the temperature measuring device, the pressure measuring device and the pressure relief device are respectively connected with the mould system, and the mould system carries out heating by using upper and lower hot plates of a moulding press. In virtue of ultra-strong penetration and diffusion capability of a supercritical fluid, the supercritical fluid gradually diffuses into a polymer matrix under the action of a certain temperature and supercritical fluid pressure in a certain period of time, and then pressure is rapidly released so as to obtain a foamed material with a certain shape. The apparatus can be used for supercritical fluid foaming of thermoplastic plastics, thermoplastic elastomer, rubber materials and the like, is applicable to free foaming or controlled foaming and has the advantages of a simple structure, low cost and convenient operation.

Owner:QINGDAO UNIV OF SCI & TECH

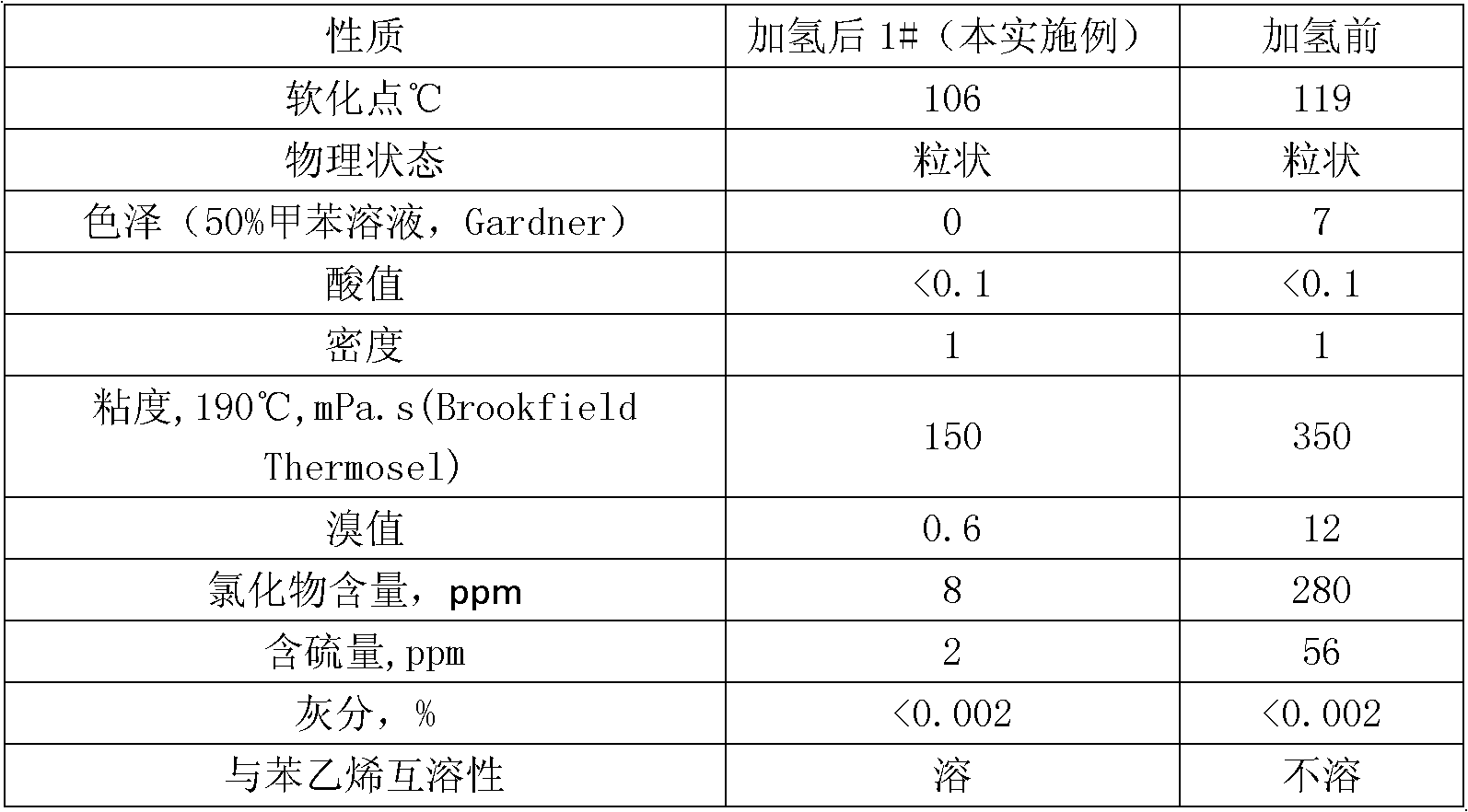

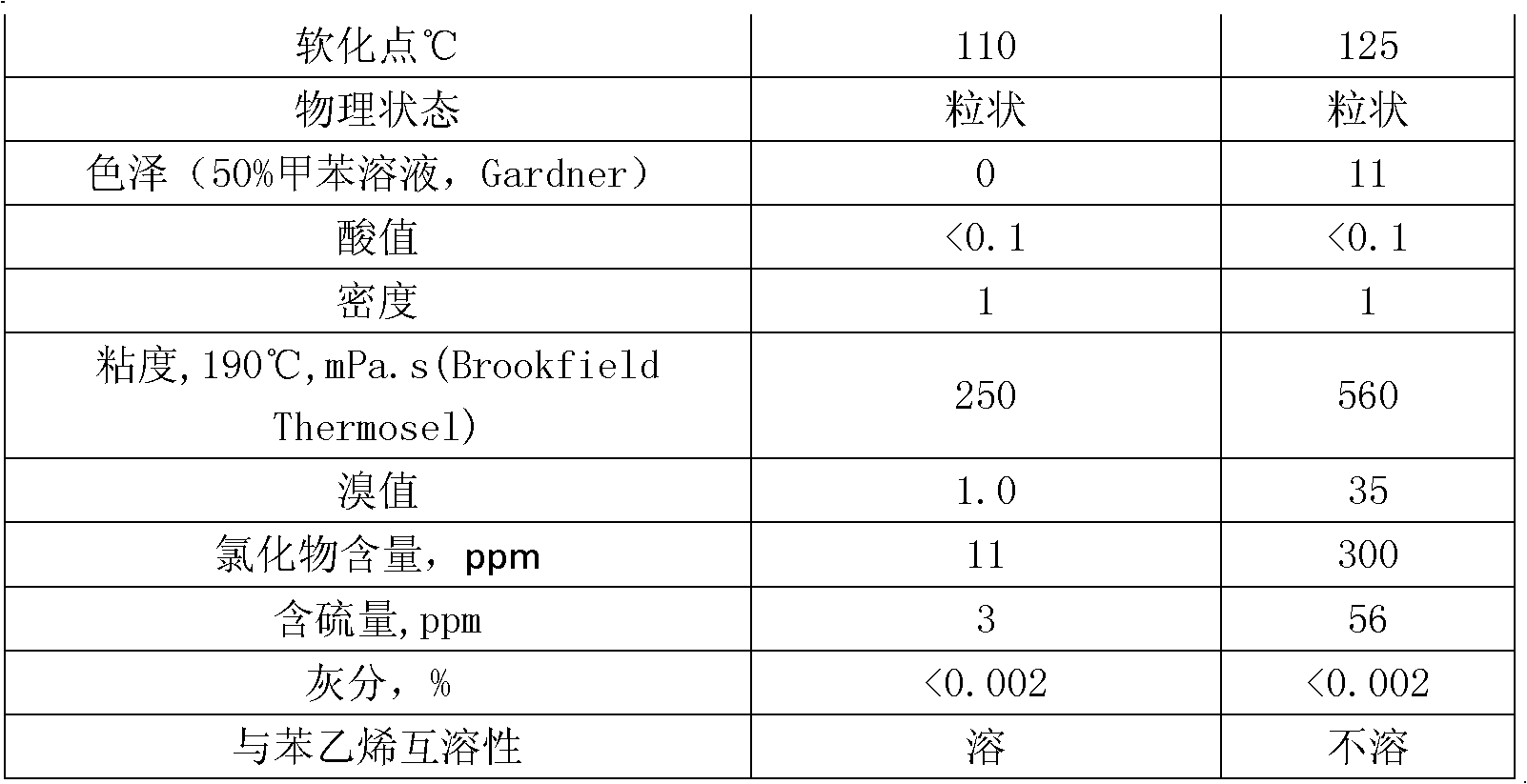

Preparation method for Carbon 5/Carbon 9 hydrogenated petroleum resin

The invention discloses a preparation method for Carbon 5 / Carbon 9 hydrogenated petroleum resin. In the existing preparation methods, certain methods have extremely high requirements on devices and high cost, and catalysts used by certain methods are not ideal for aromatic ring hydrogenation effect or easily cause intoxication. The preparation method comprises the following steps: firstly dissolving Carbon 5 / Carbon 9 petroleum resin by a dissolvent, then carrying out centrifugal sedimentation on the carbon 5 / Carbon 9 petroleum resin so as to remove most insoluble gel and asphaltenes, filtering the carbon 5 / Carbon 9 petroleum resin in an absorption tower filled with fillers so as to remove remained insoluble gel, asphaltenes and heavy metals; carrying out medium pressure hydrogenation reaction on liquid obtained through filtration in a static bed filled with secondary hydrogenation catalyst; and finally, carrying out flash evaporation and steam stripping so as to remove solvent in the product. The preparation method adopts a macroporous catalyst carrier; fluids are not easily blocked in holes, thereby greatly reducing fluid pressure drop and increasing effective catalytic area; and secondary hydrogenation can be completed in medium pressure, thereby greatly reducing requirements on devices and investment cost of the devices and obtaining hydrogenated petroleum resin with high quality.

Owner:杭州腾王网络科技有限公司

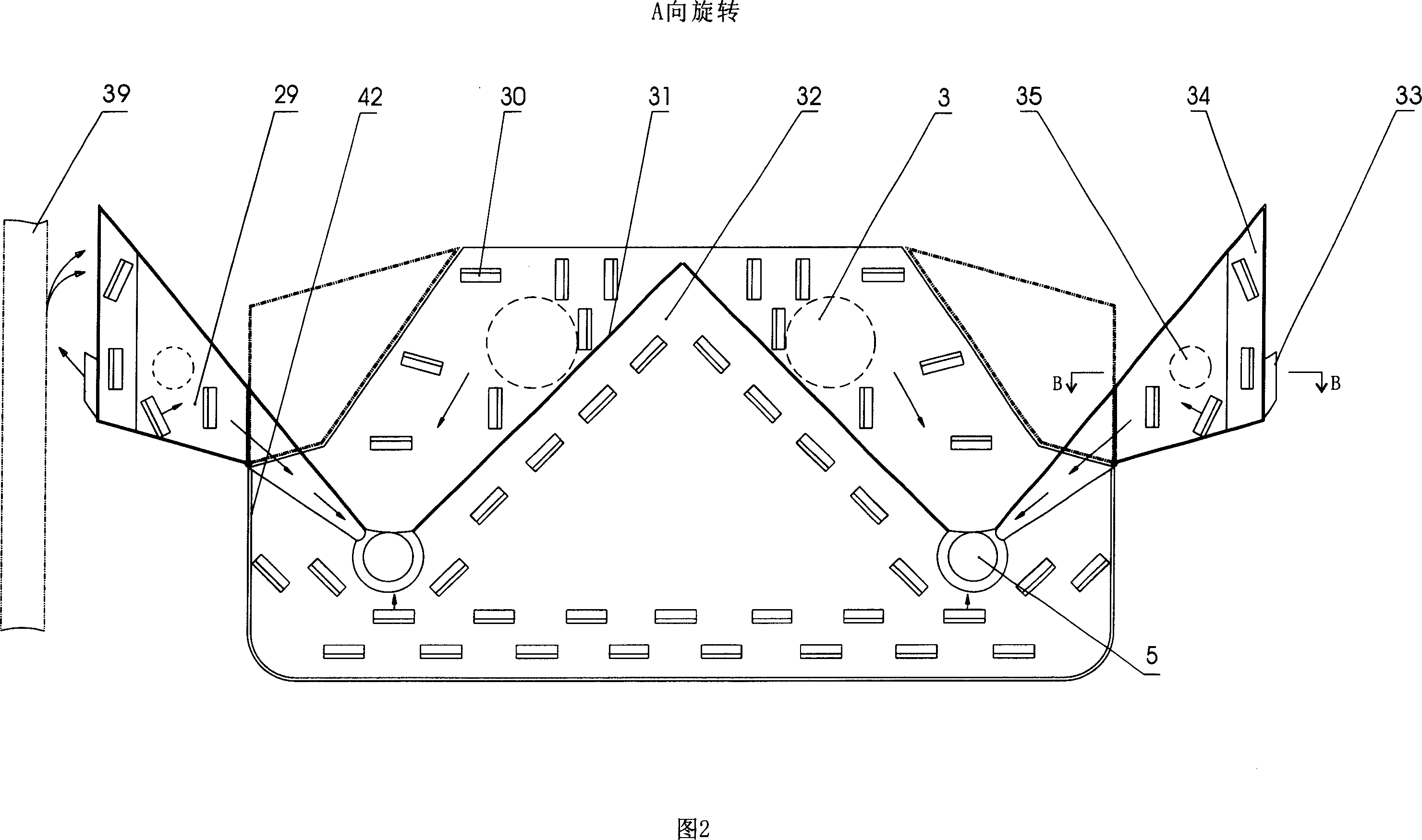

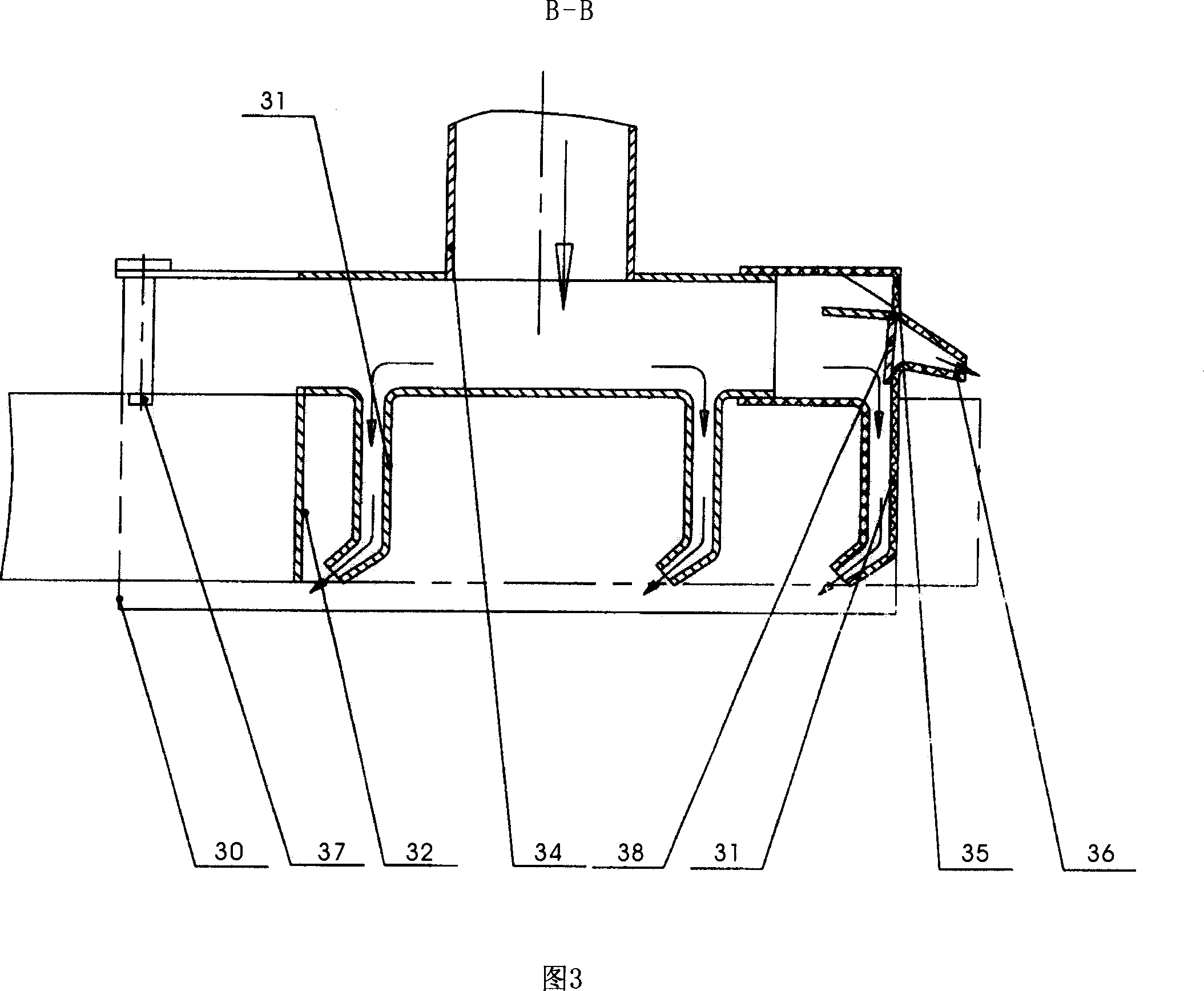

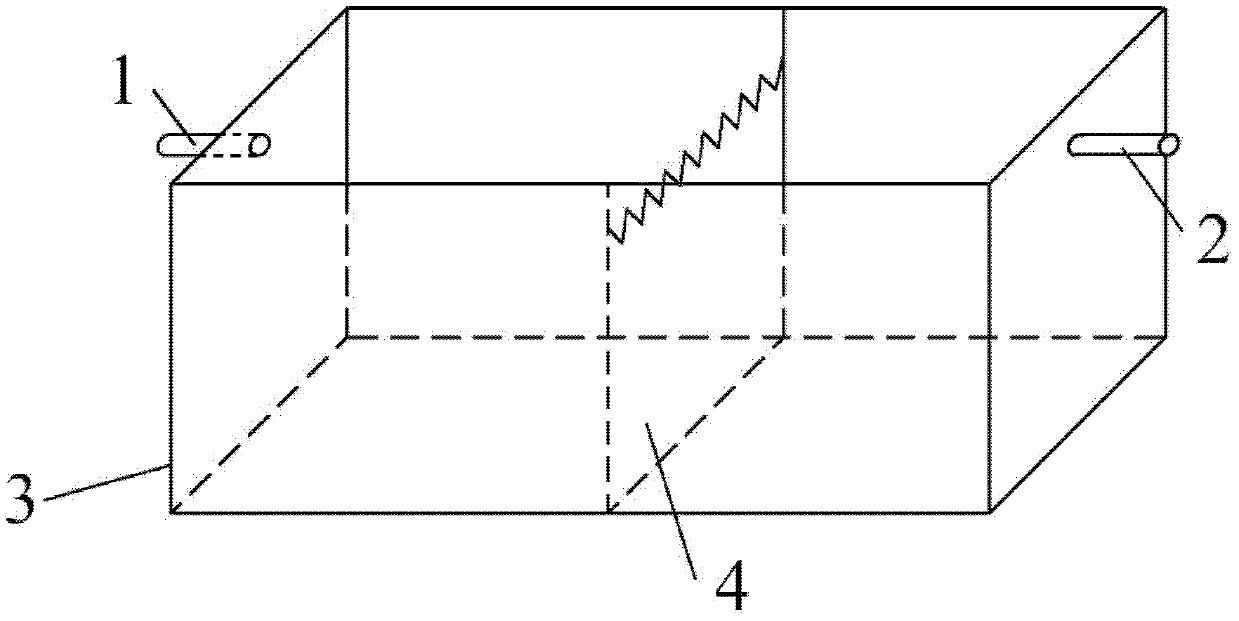

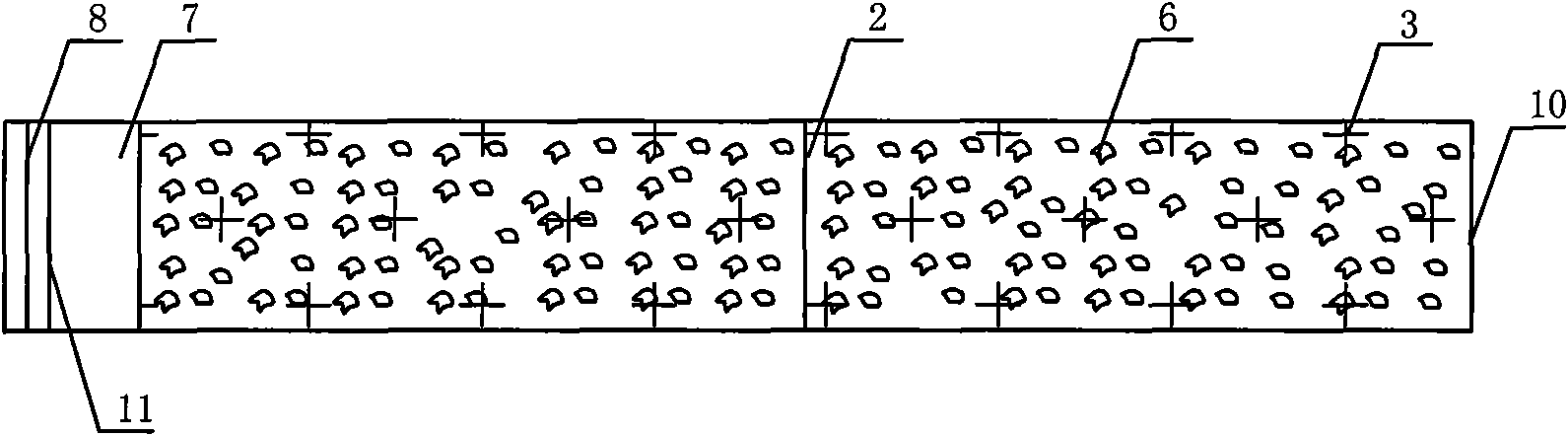

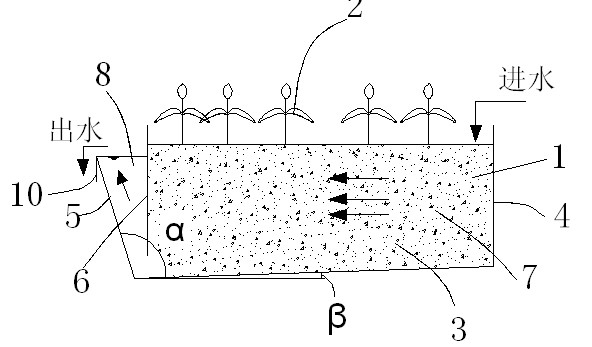

Artificial wetland purifying system for free waterfall aeration

InactiveCN102126794AZero energy consumptionObvious advantage of energy savingSustainable biological treatmentBiological water/sewage treatmentTerrainConstructed wetland

The invention discloses an artificial wetland purifying system for free waterfall aeration. The system consists of multiple stages of stepped artificial wetlands, wherein the gradient of a bed bottom (3) of each stage of wetland bed is between 3 percent and 6 percent; the included angle between a back side wall (5) and the bed bottom (3) is alpha which is more than 90 degrees and less than or equal to 120 degrees; a guide plate (10) is vertically arranged at the upper end of the back side wall (5); a baffle plate (6) with equal width to the wetland bed is vertically arranged on the middle back part of the wetland bed, and partitions the wetland bed into a filler pool (7) and a collecting basin (8); a water flow channel is reserved between the lower end of the baffle plate (6) and the bed bottom (3); and the top end of the back side wall (5) is lower than the top end of the baffle plate (6). The system makes full use of free waterfall aeration and oxygenation, has the characteristics of small floor area, high dissolved oxygen level, good treatment effect, difficulty in causing dead angles and the like, and is particularly suitable for special terrains with gradients.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

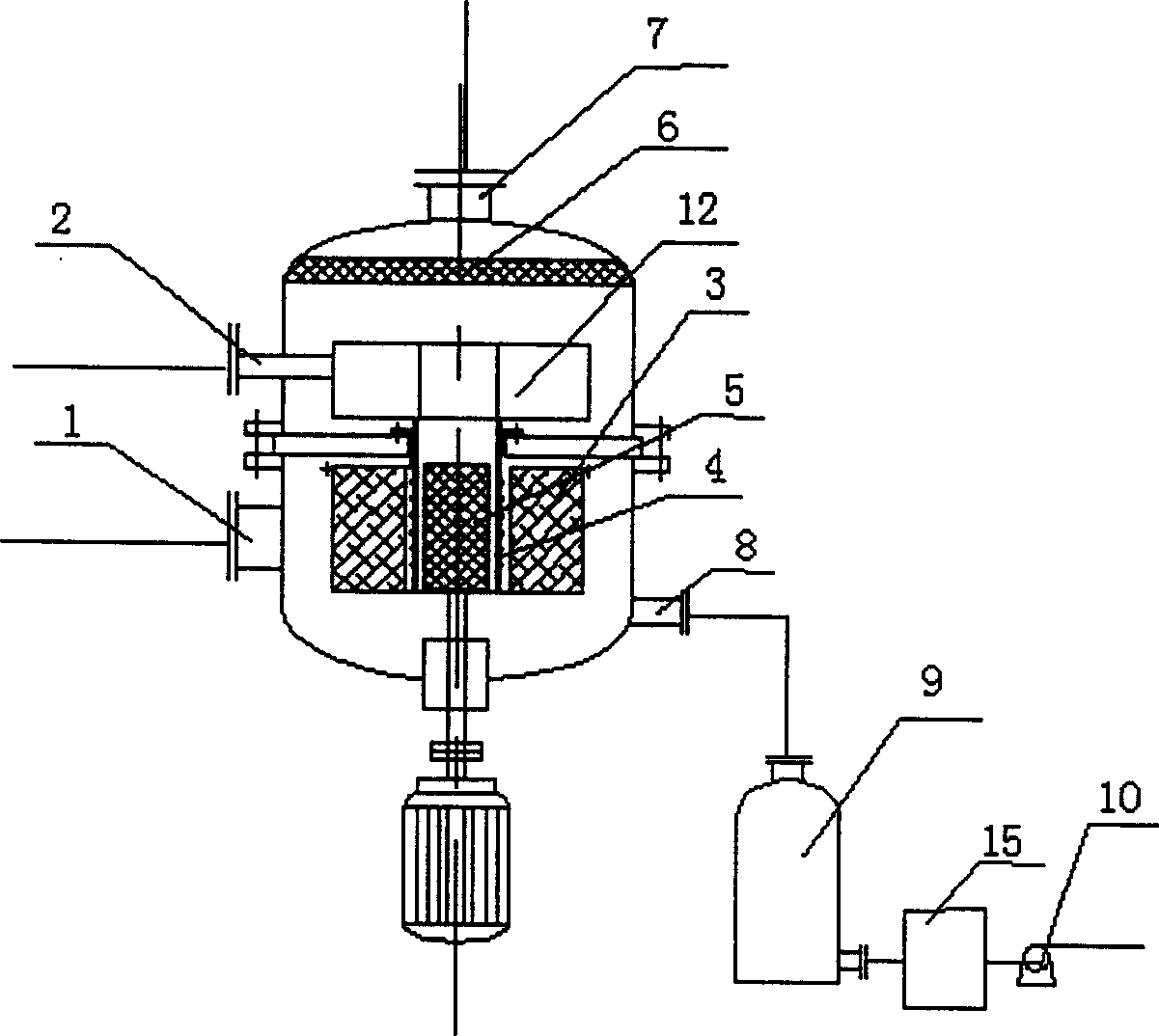

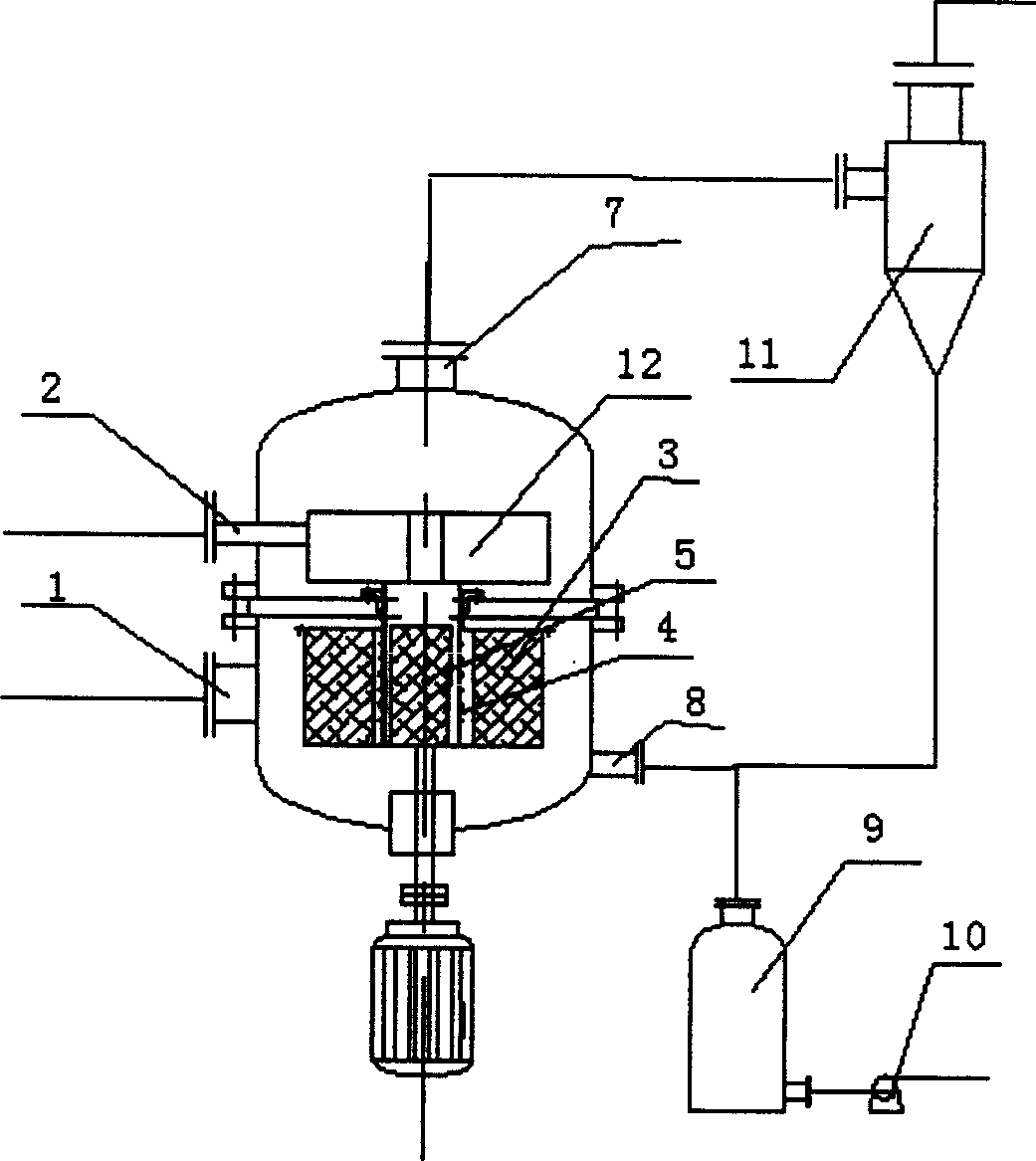

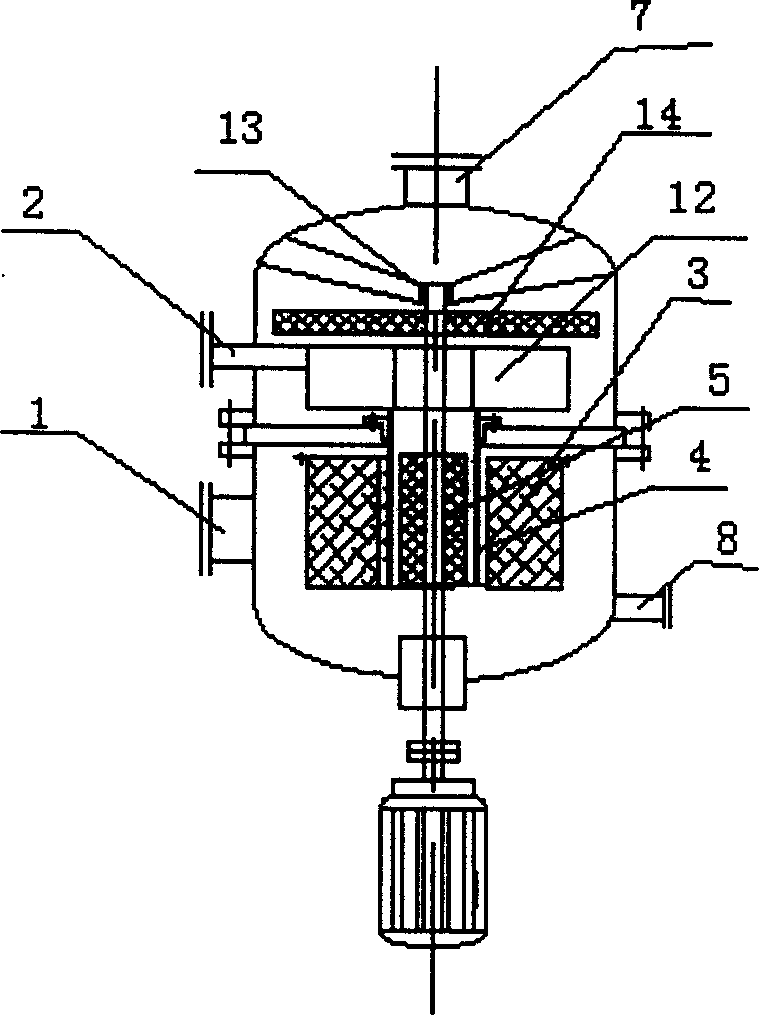

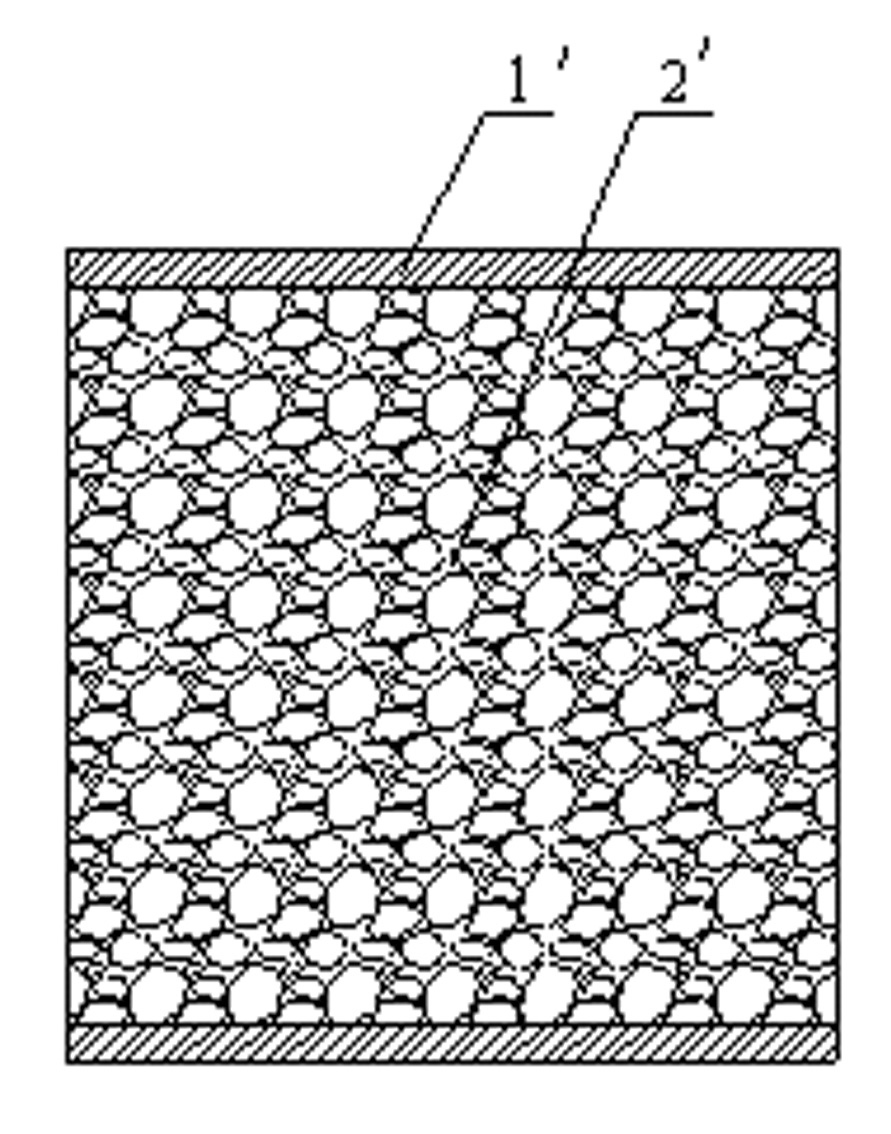

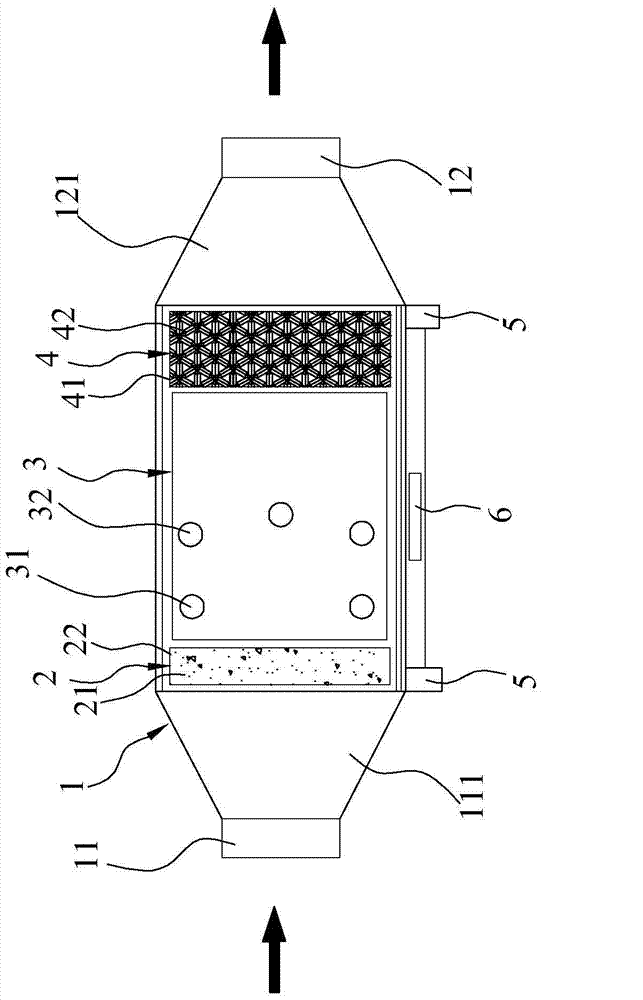

Highly effective slurry phase bed reactor

InactiveCN1593740AEasy to operateAvoid easy cloggingChemical/physical processesNuclear engineeringSpray nozzle

The invention relates to a kind of efficient reactor with paddle bed, which belongs to the chemical machinery field. It is composed mainly with the solid and liquid separator, the inner tube that the track is changeable, the reactor cover, the heat exchanger with an internal component, the riser with the spray nozzle, the inner-tube tank that has the heating and gas distribution function, the spray nozzle for protecting from choking, the mounting plate of the spray nozzle, the heat exchanger, the outlet of the heating coil, the quadratic distribution plate, the heating coil and so on. The beneficial effictiveness of the invention can be described as follows: the reactor and the distributor can't block up easily; the gas and the liquid can be mixed evenly; the reactive efficiency is high; the carrying amount of the catalyst and the solvent is so bit that it can not occur the bias current, channeling and dead bed; the size running quickly, and the viscosity of the size in the reactor is identical generally; the reactor can be shifted out in time, and especially in the stage of the catalytic, reducing and intensifying, it can realize to operate the reactor steadily; otherwise, the distribution of the virgin gas in the reactor along the axle is in agreement on the concentration of the catalyst, so that can make the catalyst have the most activity, and then it can be make the full use of the reactor space.

Owner:TAIYUAN UNIV OF TECH

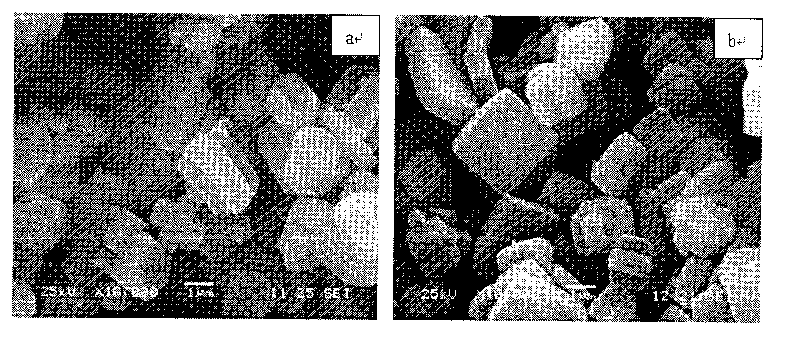

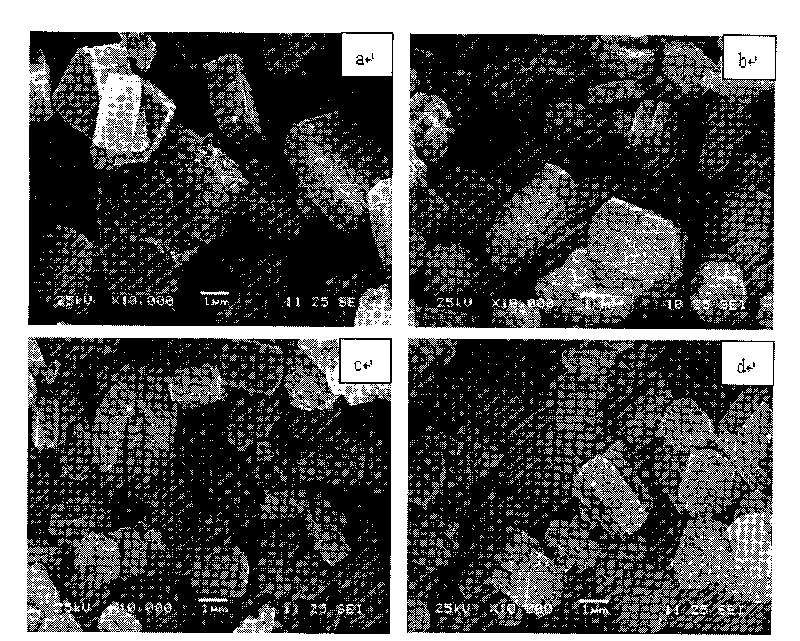

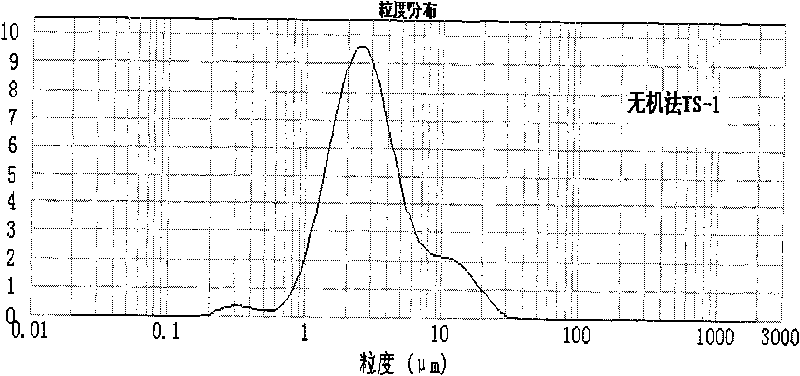

Titanium-silicon molecular sieve TS-1 catalyst for catalyzing ketone oximation reaction

InactiveCN101757945AHigh activityHigh reuse rateMolecular sieve catalystsCatalyst activation/preparationKetoneLarge particle

The invention relates to a titanium-silicon molecular sieve TS-1 catalyst for catalyzing ketone oximation reaction. In order to solve the problems of small particles, difficult separation and reutilization, high synthesis cost, strict and complex requirements in the process of gluing, poor repeatability and stability and the like in the prior art, the invention provides a new titanium-silicon molecular sieve TS-1 catalyst for the catalyzing ketone oximation reaction, which is prepared from the following steps: mixing the titanium-silicon molecular sieve TS-1 with one or more solutions of organic amine, ammonium salt, ammonia water and urea, carrying out crystallization again under the self-generating hydro-thermal pressure, and filtering, washing, drying and roasting to obtain the product. The prepared titanium-silicon molecular sieve TS-1 catalyst has large particles and easy separation and recovery after reaction, can improve the reutilization ratio, is especially suitable for ketone oximation reaction using hydrogen peroxide as an oxidizing agent, and can not produce byproducts, thereby protecting the environment and being beneficial to industrial application.

Owner:XIANGTAN UNIV

Compound type cooking fume purifier with coupling function

ActiveCN103900132AEfficient purificationImprove purification effectCombination devicesDomestic stoves or rangesActive componentCoupling

The invention provides a compound type cooking fume purifier with a coupling function. The compound type cooking fume purifier comprises a shell, wherein the shell is provided with an air inlet and an air outlet; a gas channel is formed between the air inlet and the air outlet; the gas channel is internally provided with a static electricity capturing unit and a catalytic absorption unit in sequence from the air inlet to the air outlet; the static electricity capturing unit comprises an ionization region and a capturing region; the catalytic absorption unit comprises a catalyst and a carrier for loading the catalyst; the catalyst comprises an active component and an auxiliary component; the active component is an oxide of a transition metal element; the auxiliary component is Al2O3 or TiO2. The cooking fume purifier is simple in structure, low in manufacturing cost, high in purification efficiency, compact in structure and long in service life and does not need to be frequently maintained; the catalytic absorption unit can be used for purifying upper-state cooking fume molecules stimulated by the static electricity capturing unit under a room temperature.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com