Method of eliminating impurity from gas phase

An impurity and removal technology, applied in separation methods, chemical instruments and methods, use of liquid separation agents, etc., can solve problems such as large investment, dust can not meet the requirements, and the problem of liquid foam entrainment at the gas outlet has not been solved. Reduce equipment investment, good particle trapping effect, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Use the method of the present invention to remove solid dust in the air, wherein the solid dust content in the air: 3-70mg / m 3 , air flow: 300m 3 / h, water as dedusting agent, water volume: 0.5-2.5m 3 / h, high gravity rotary bed reactor speed: 500-1450 rpm, stainless steel wire mesh packing specific surface area: 300-800m 2 / m 3 , Stainless steel wire mesh packing porosity: 96-98%.

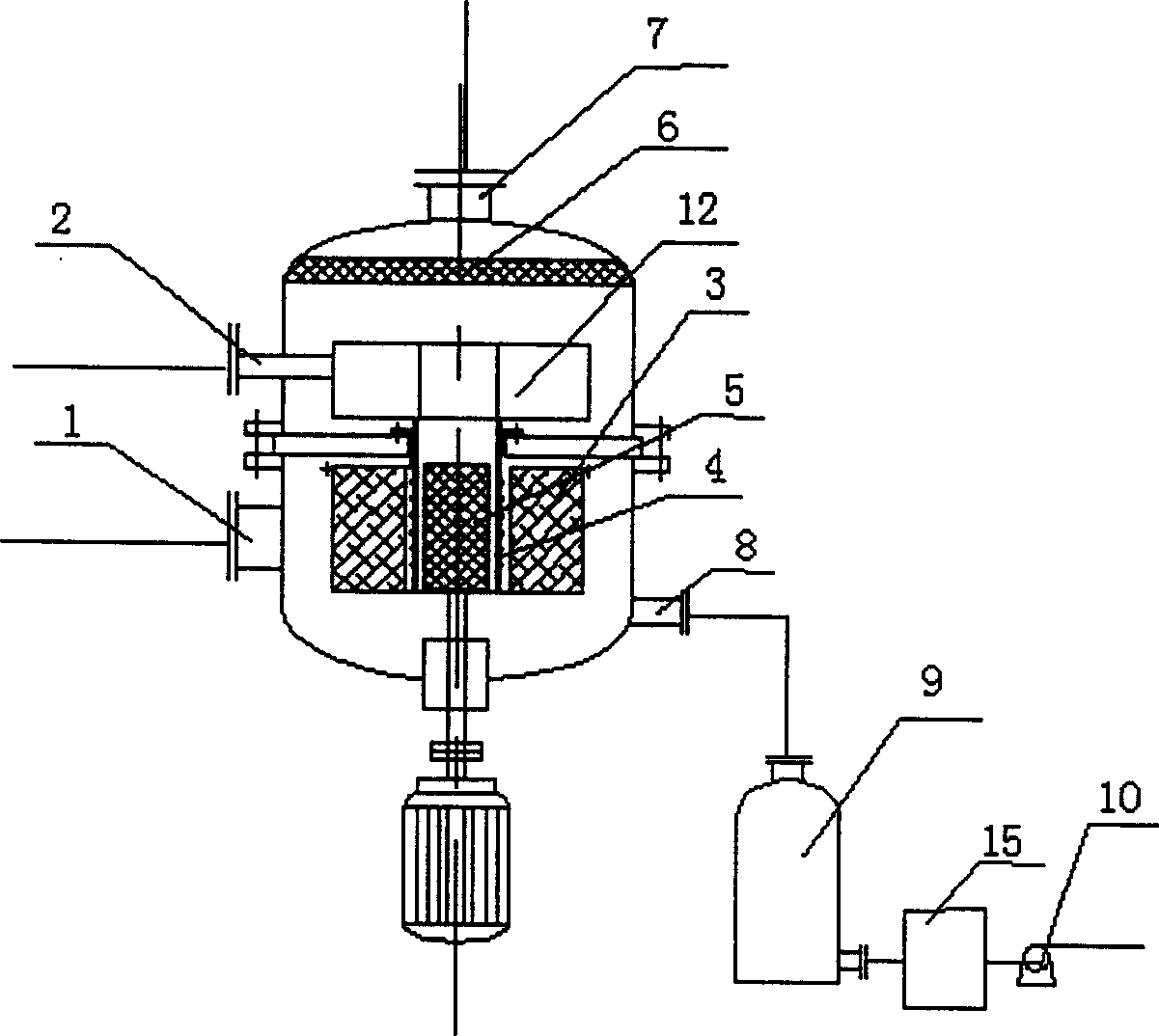

[0041] The schematic diagram of the technological process adopted by the high-gravity rotating bed reactor is as attached figure 1 shown. Air is tangentially introduced into the reactor from the gas phase inlet 1 of the high-gravity rotating bed reactor, water is introduced into the reactor through the liquid phase inlet 2 of the high-gravity rotating bed reactor, and sprayed on the porous packing layer by the liquid distributor 4 3, the specific surface area of 685m2 is filled on the inner edge of the rotor 2 / m 3 , small corrugated packing with a porosity of 96.4% and a radial th...

Embodiment 2

[0046] Coking dry gas in refineries contains a certain amount of carbon powder and hydrogen sulfide as well as a large amount of hydrogen, nitrogen, C 1 、C 2 and a small amount of C 3 , this dry gas will enter the subsequent hydrogen production workshop to produce hydrogen, so the content of carbon powder, hydrogen sulfide and gas liquid entrainment are required to be as low as possible, and the method of the present invention is used to remove the carbon powder and carbon powder contained in the coking dry gas. hydrogen sulfide. The coking dry gas flow rate mentioned therein: 10 tons / hour, H 2 S content: 8300-22000mg / Nm 3 , Toner content: 5g / Nm 3 , particle size range: 0.2-20μm, pressure: 1MPa; both desulfurizer and dedusting agent are 30% MDEA (methyldiethanolamine) solution, liquid flow rate: 20 tons / hour, H 2 S content: 1.56g / l; the rotating speed of the high-gravity rotating bed reactor is 960 rpm.

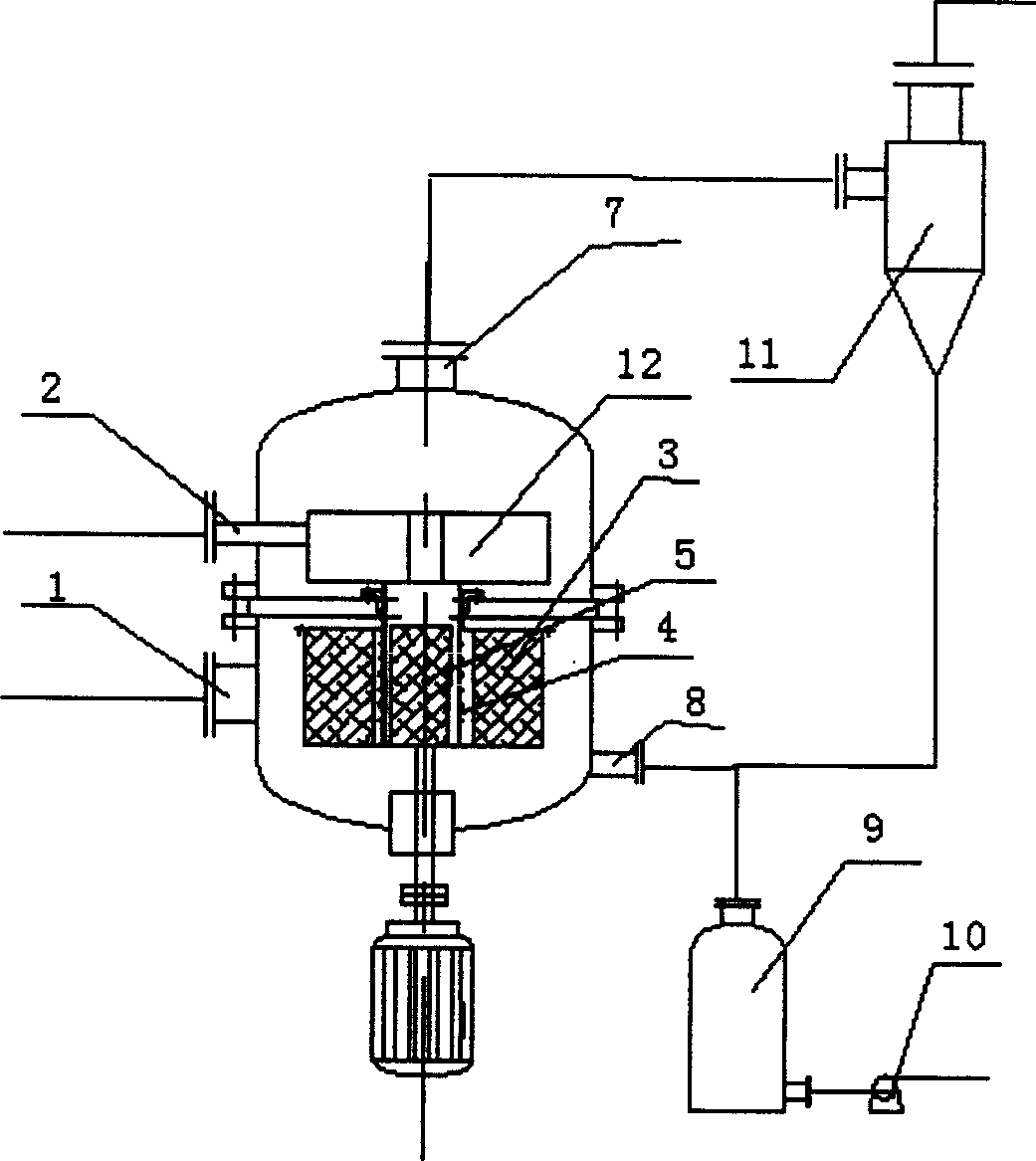

[0047] The schematic diagram of the technological process adopted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com