Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7161 results about "Hydrogen sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen sulfide is the chemical compound with the formula H₂S. It is a colorless chalcogen hydride gas with the characteristic foul odor of rotten eggs. It is very poisonous, corrosive, and flammable.

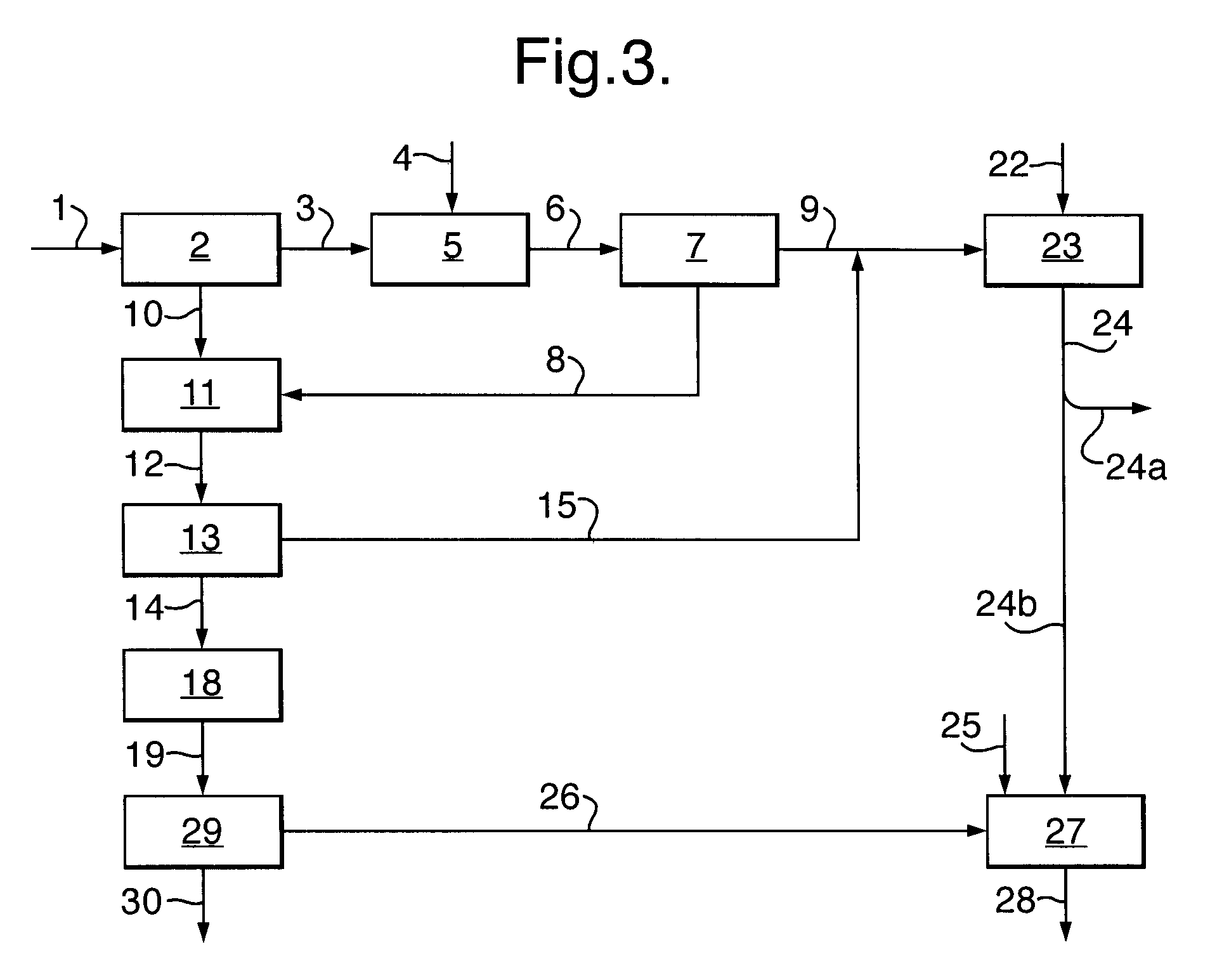

Pre-passivation process for a continuous reforming apparatus, and passivation process for a continuous reforming apparatus during the initial reacation

ActiveUS20100282645A1Reduce operational riskReduce contentThermal non-catalytic crackingPhysical/chemical process catalystsLiquid productReaction temperature

The present invention relates to a pre-passivation process for a continuous reforming apparatus prior to the reaction, or a passivation process for a continuous reforming apparatus during the initial reaction, comprising loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, injecting sulfide into the gas at a reactor temperature ranging from 100-650° C., controlling the sulfur amount in the recycle gas within a range of 0.5-100×10−6 L / L so as to passivate the apparatus.The process of the present invention may also comprise the following steps:(1) loading a reforming catalyst into the continuous reforming apparatus, starting the gas circulation and raising the temperature of a reactor, feeding the reforming feedstock into the reaction system when the temperature of the reactor is increased to 300-460° C., introducing sulfide into the reaction system while or after the reforming feedstock is fed, controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.5 μg / g-50 μg / g, reducing the content of sulfide introduced into the system when hydrogen sulfide concentration in the recycle gas reaches to 2.0 μL / L˜30 μL / L; and(2) maintaining the reforming reactor at a temperature of 460-490° C., controlling the ratio of the total sulfur amount introduced into the system to the reforming feedstock within the range of 0.2 μg / g-0.5 μg / g, adjusting the amount of the reforming feedstock to the design value of the apparatus, increasing the reforming reaction temperature to 490-545° C. according to the requirements on the octane number of the liquid product, and letting the reforming apparatus run under normal operating conditions.

Owner:CHINA PETROCHEMICAL CORP +1

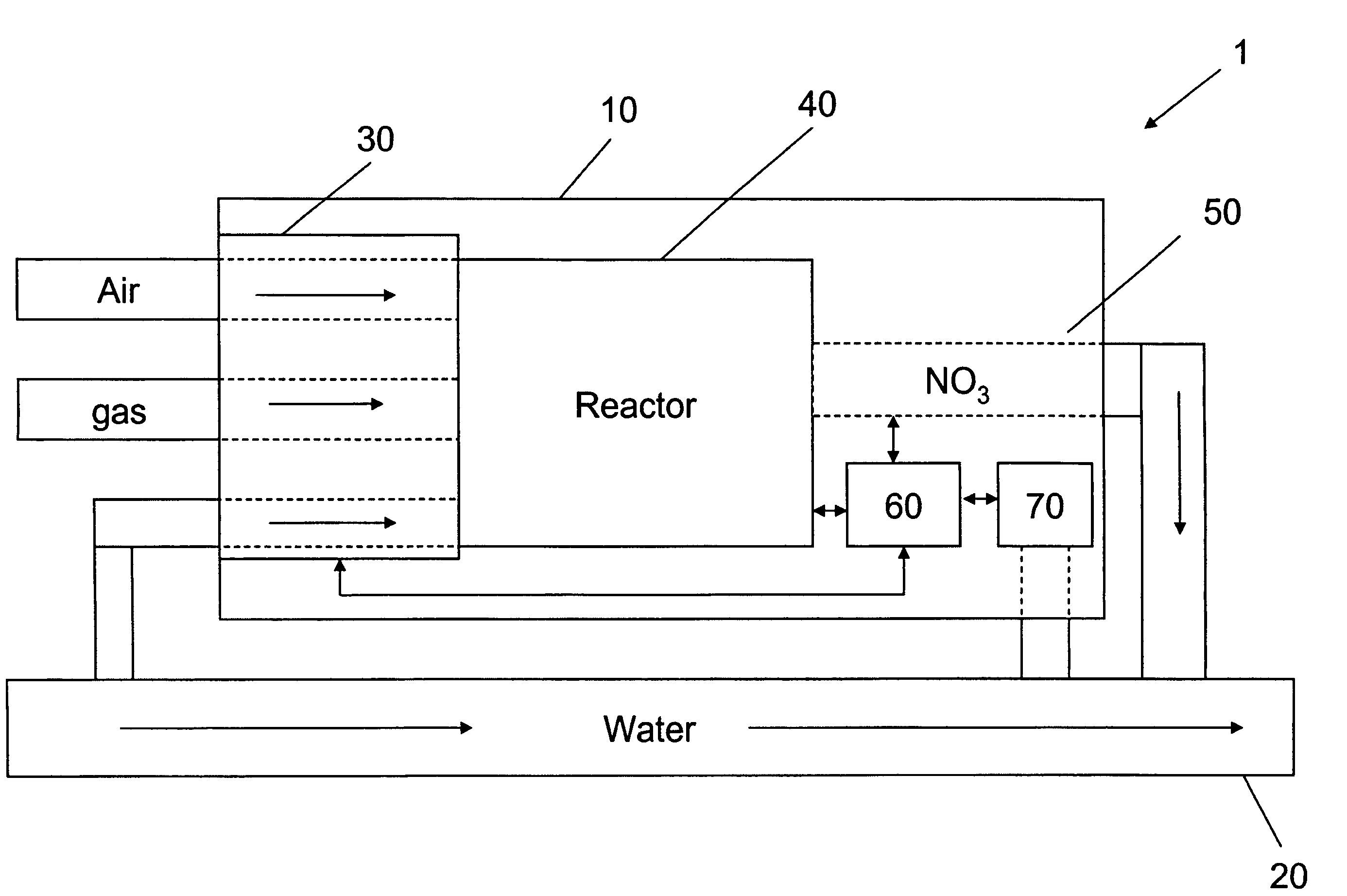

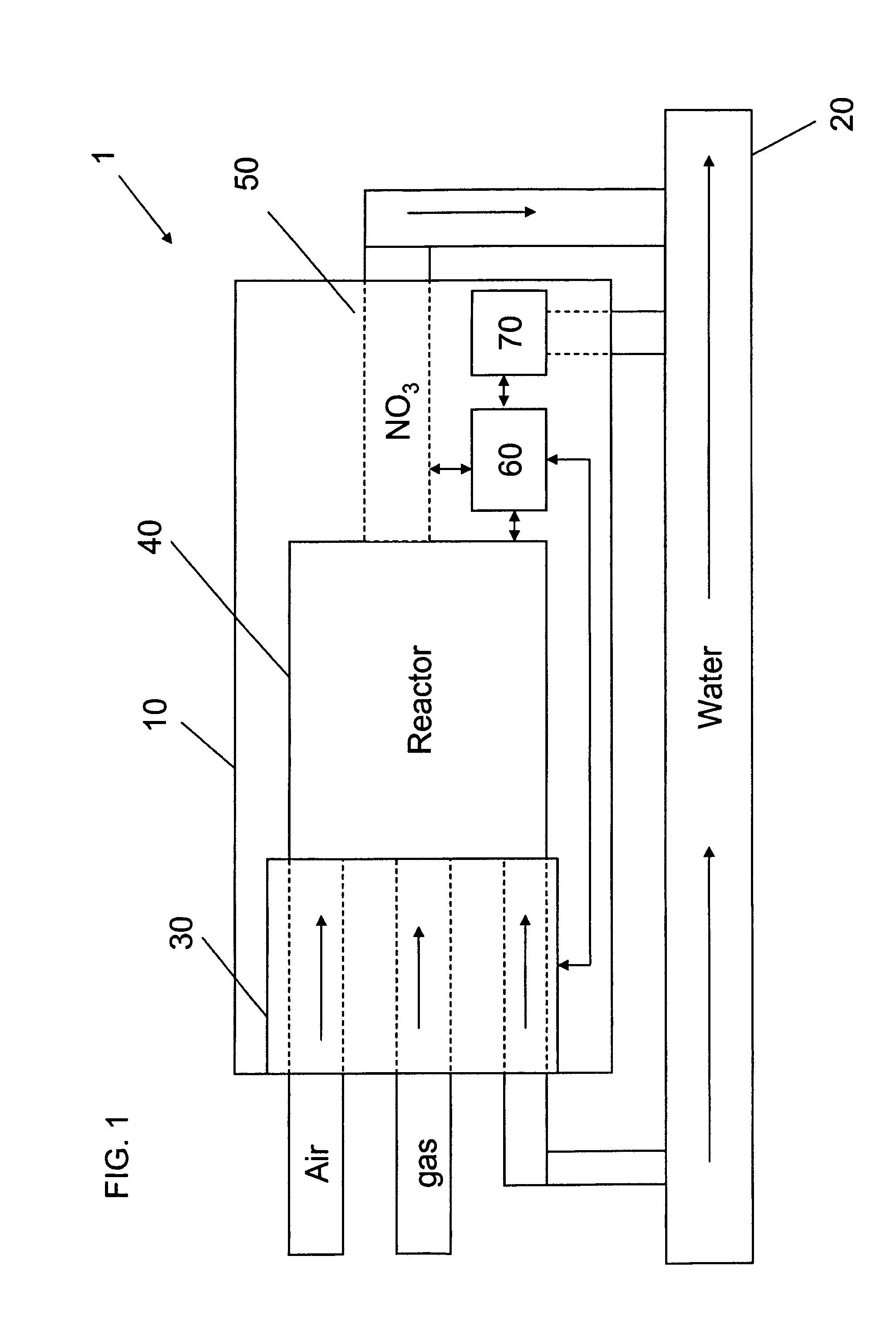

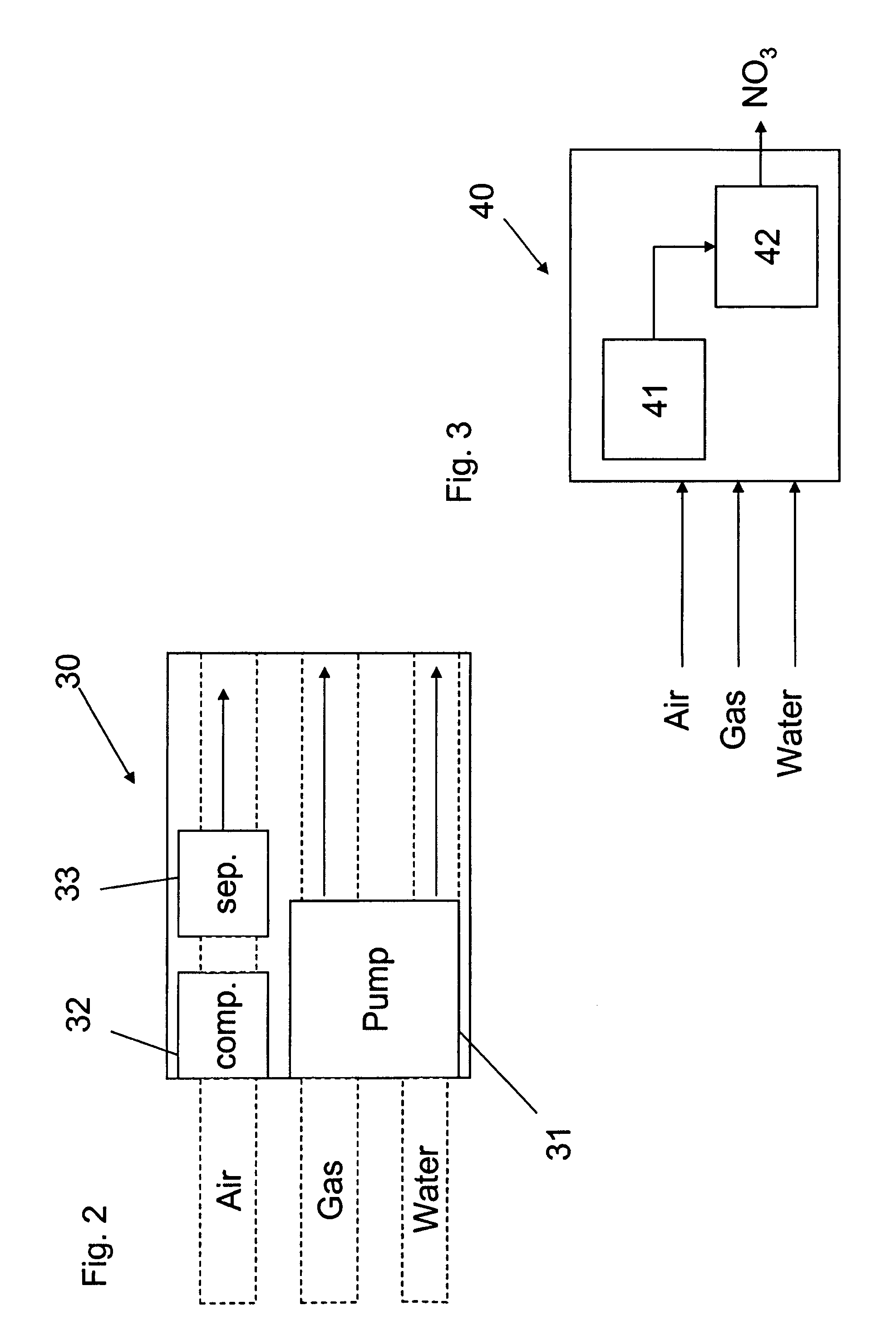

Apparatus for on-site production of nitrate ions

InactiveUS7514058B1Enhanced overall recoveryWater treatment parameter controlWater treatment compoundsMicrobial enhanced oil recoverySulfate-reducing bacteria

An apparatus and method produces nitrate ions on-site from water, natural gas and air extracted in proximity to the apparatus. The apparatus generates nitrate ions and brings the nitrate ions into contact with an aqueous system. Hydrogen sulfide present in the aqueous system is removed and the production of hydrogen sulfide by sulfate-reducing bacteria (SRB) is eliminated by introducing into the system nitrate ions, whereby denitrifying microorganisms, using nitrate, outcompete the sulfate-reducing bacteria for the available carbon nutrients, thus preventing the SRB from producing hydrogen sulfide. Nitrate ions generated by the apparatus and added to the aqueous system which contains the denitrifying microorganisms can enhance oil recovery by means of microbial enhanced oil recovery mechanisms.

Owner:NITRA GEN LLC

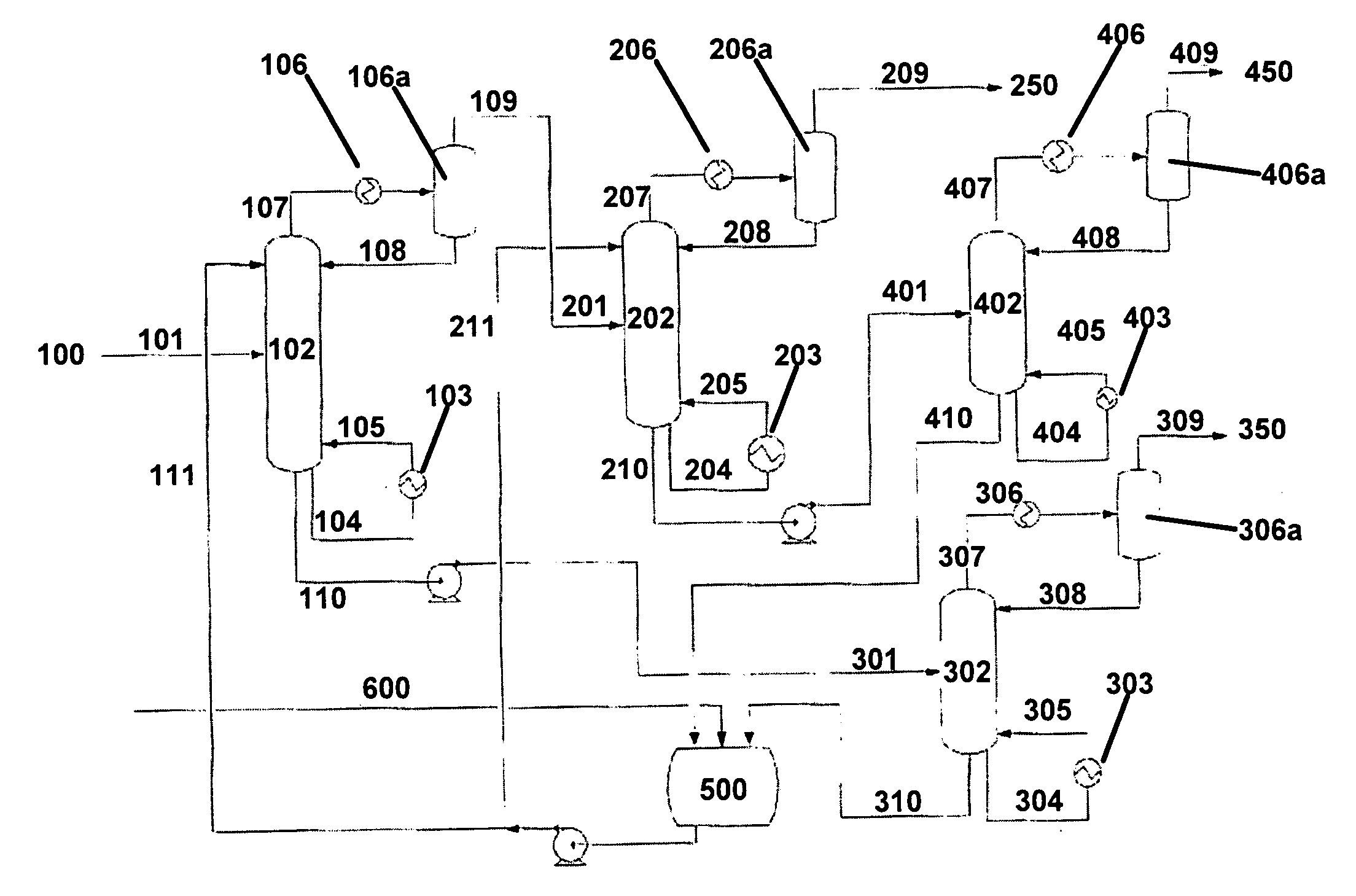

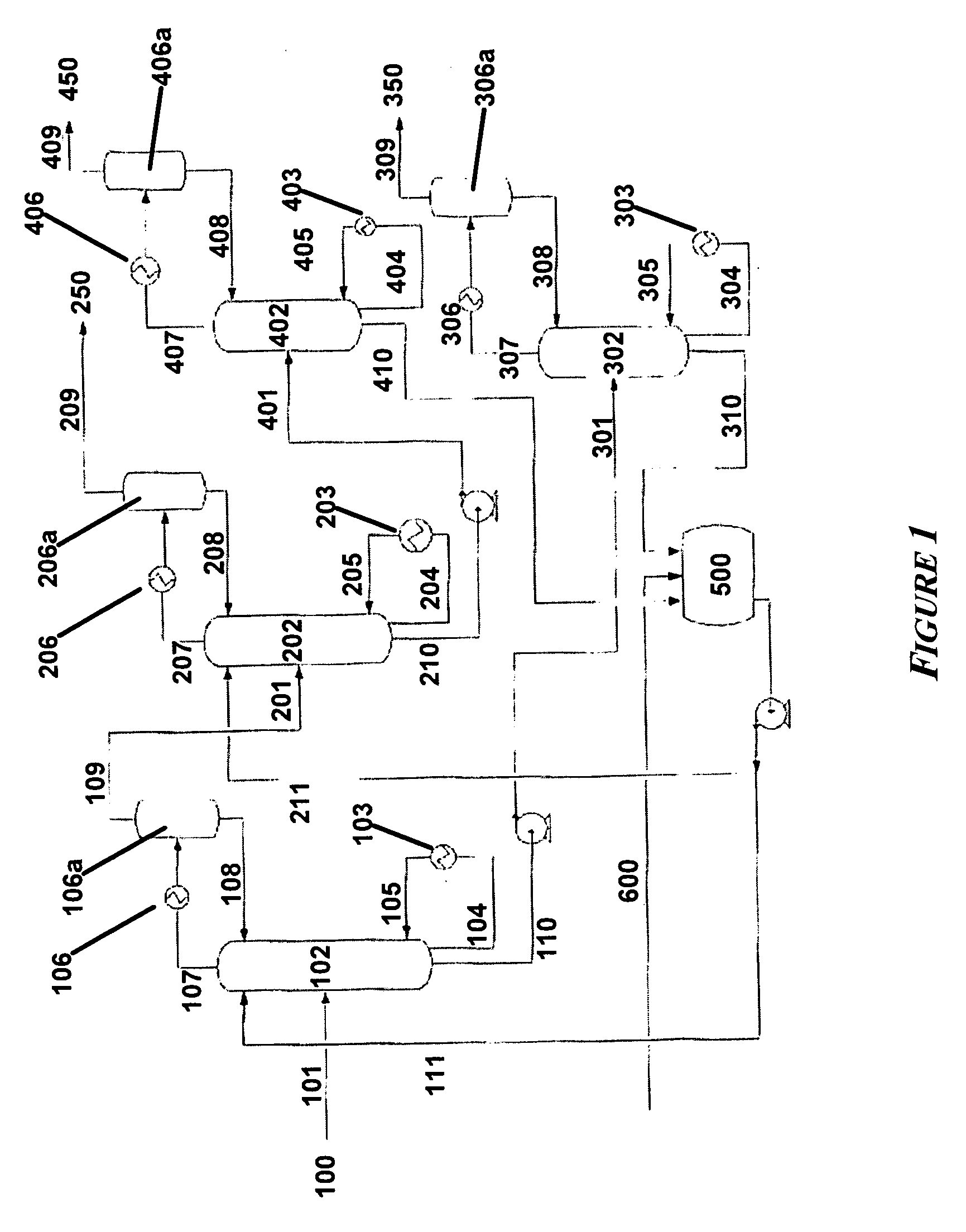

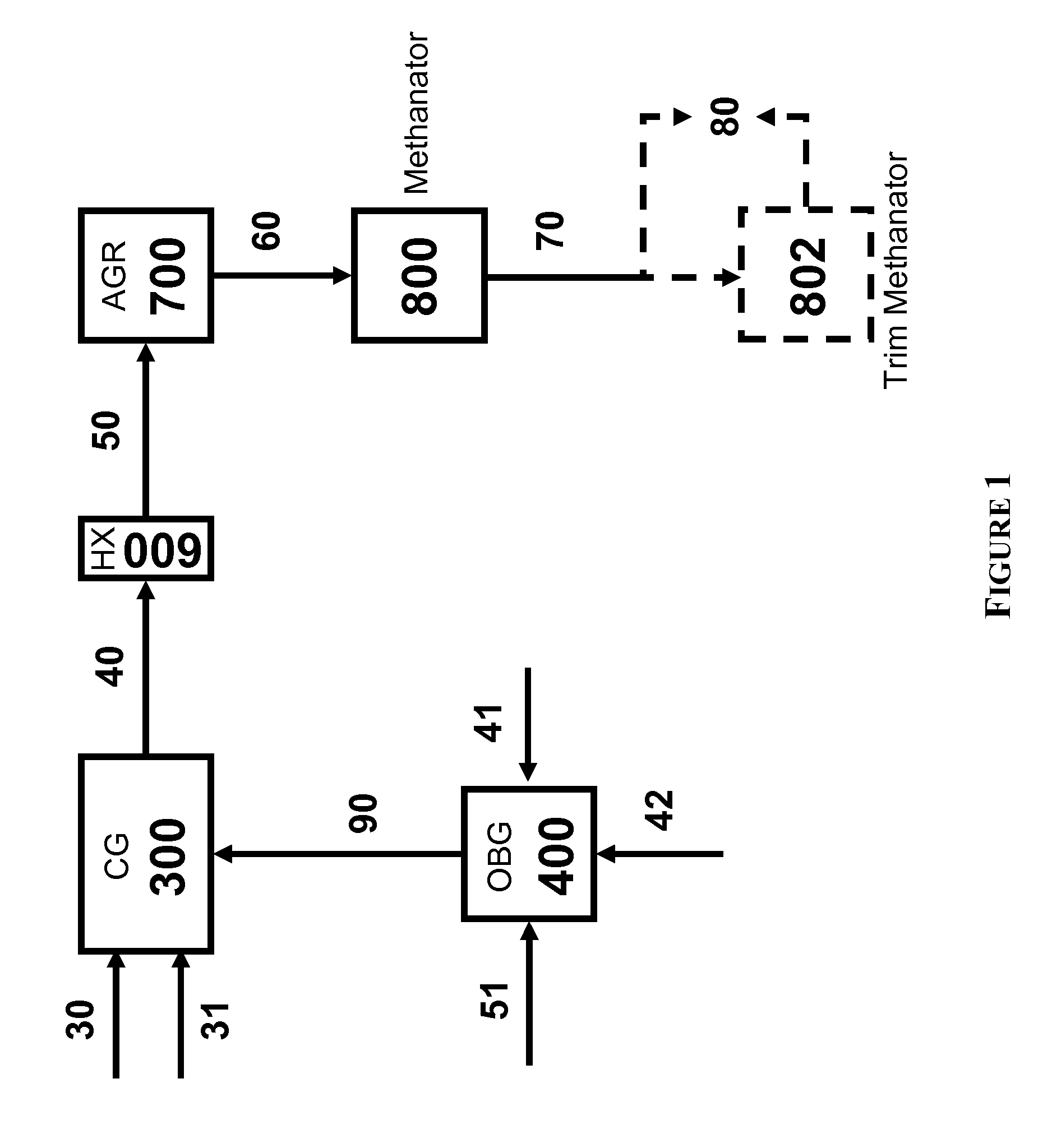

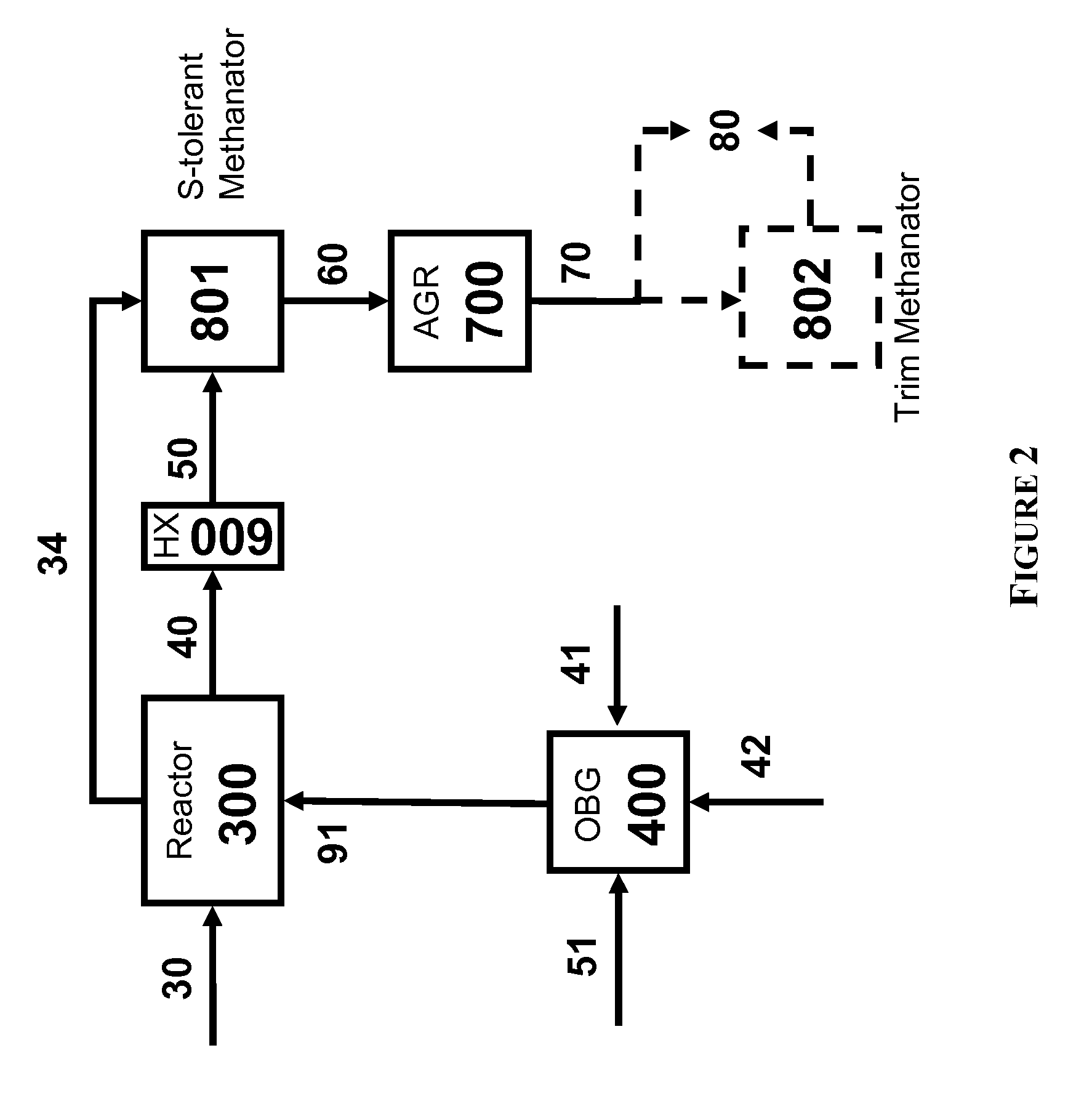

Selective Removal and Recovery of Acid Gases from Gasification Products

Processes and apparatuses are described for the selective removal and recovery of acid gases from a gas source comprising at least hydrogen sulfide and carbon dioxide. A step-wise approach is illustrated wherein hydrogen sulfide may be selectively removed from a gas source by treatment with methanol under conditions where substantially all the hydrogen sulfide may be removed. The partially purified gas source may then be provided with a second treatment with methanol under conditions which selectively remove carbon dioxide from the gas stream. Such methods are generally applicable to any gas source comprising at least hydrogen sulfide and carbon dioxide, for example, a gas source produced from the catalytic gasification of a carbonaceous material, the combustion of a carbonaceous material, or the oxy-blown gasification of a carbonaceous material.

Owner:SURE CHAMPION INVESTMENT LTD

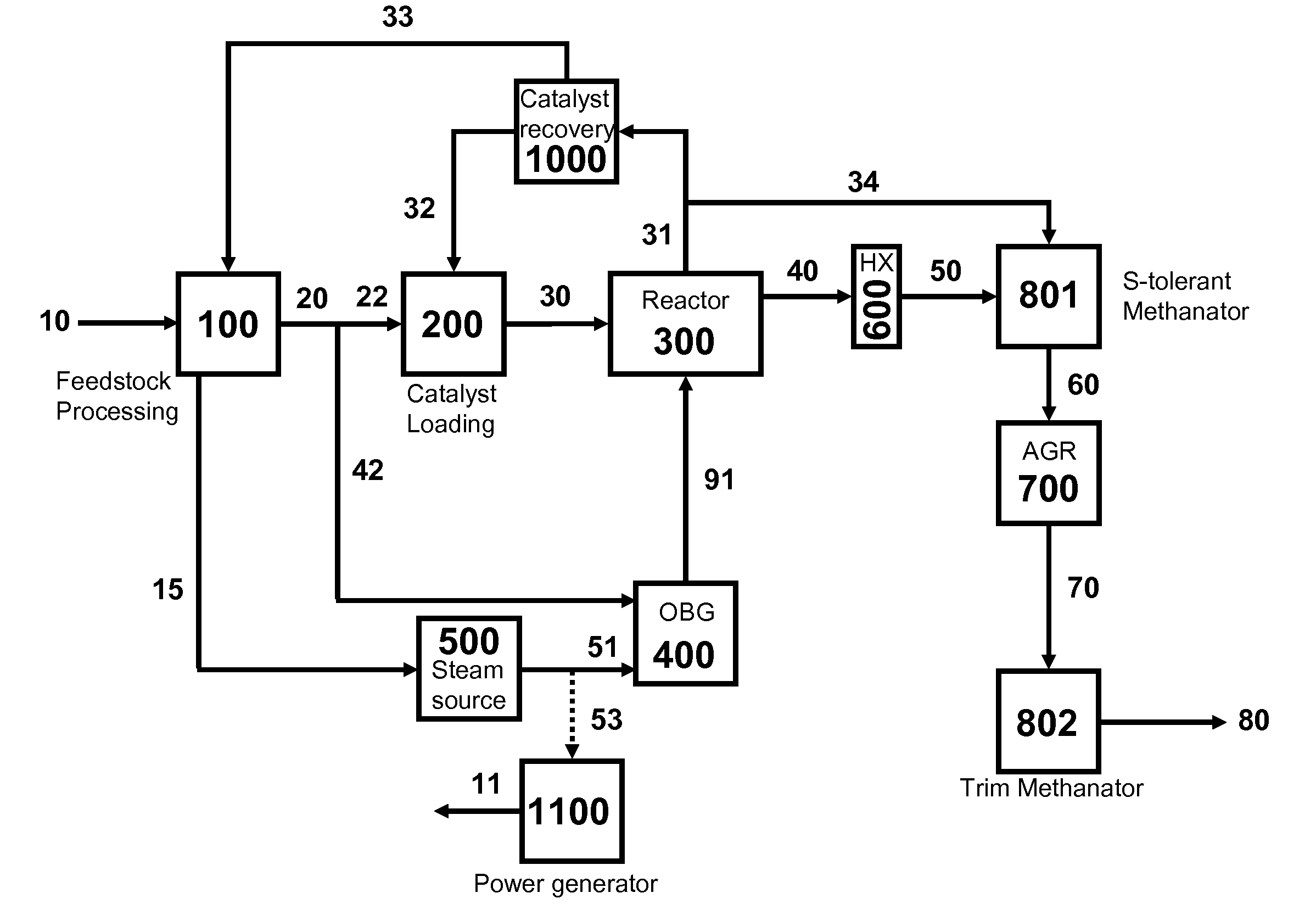

Processes for Gasification of a Carbonaceous Feedstock

The present invention relates to processes and continuous processes for preparing gaseous products, and in particular, methane via the catalytic gasification of carbonaceous feedstocks in the presence of steam. In one aspect of the invention, the processes comprise at least partially combusting a first carbonaceous feedstock with an oxygen-rich gas stream in an oxygen-blown gasifier, under suitable temperature and pressure, to generate a first gas stream comprising hydrogen, carbon monoxide and superheated steam; and reacting a second carbonaceous feedstock and the first gas stream in a catalytic gasifier in the presence of a gasification catalyst under suitable temperature and pressure to form a second gas stream comprising a plurality of gaseous products comprising methane, carbon dioxide, hydrogen, carbon monoxide and hydrogen sulfide. The processes can comprise using at least one catalytic methanator to convert carbon monoxide and hydrogen in the gaseous products to methane and in certain embodiments do not recycle carbon monoxide or hydrogen to the gasifier.

Owner:SURE CHAMPION INVESTMENT LTD

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Composition and process for well cleaning

Disclosed is a microemulsion well treatment microemulsion that is formed by combining a solvent-surfactant blend with a carrier fluid. In preferred embodiments, the solvent-surfactant blend includes a surfactant and a solvent selected from the group consisting of terpenes and alkyl or aryl esters of short chain alcohols. The disclosed well treatment microemulsion can be used in well remediation, stimulation and hydrogen sulfide mitigation operations. Additionally, the well treatment microemulsion can be used in the production of benzothiophenes through interaction with hydrogen sulfide.

Owner:PNC BANK NAT ASSOC +2

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst. The particulate compositions are gasified in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Coal Compositions for Catalytic Gasification

ActiveUS20090217590A1Drying solid materials with heatGaseous fuelsPtru catalystHydrocotyle bowlesioides

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

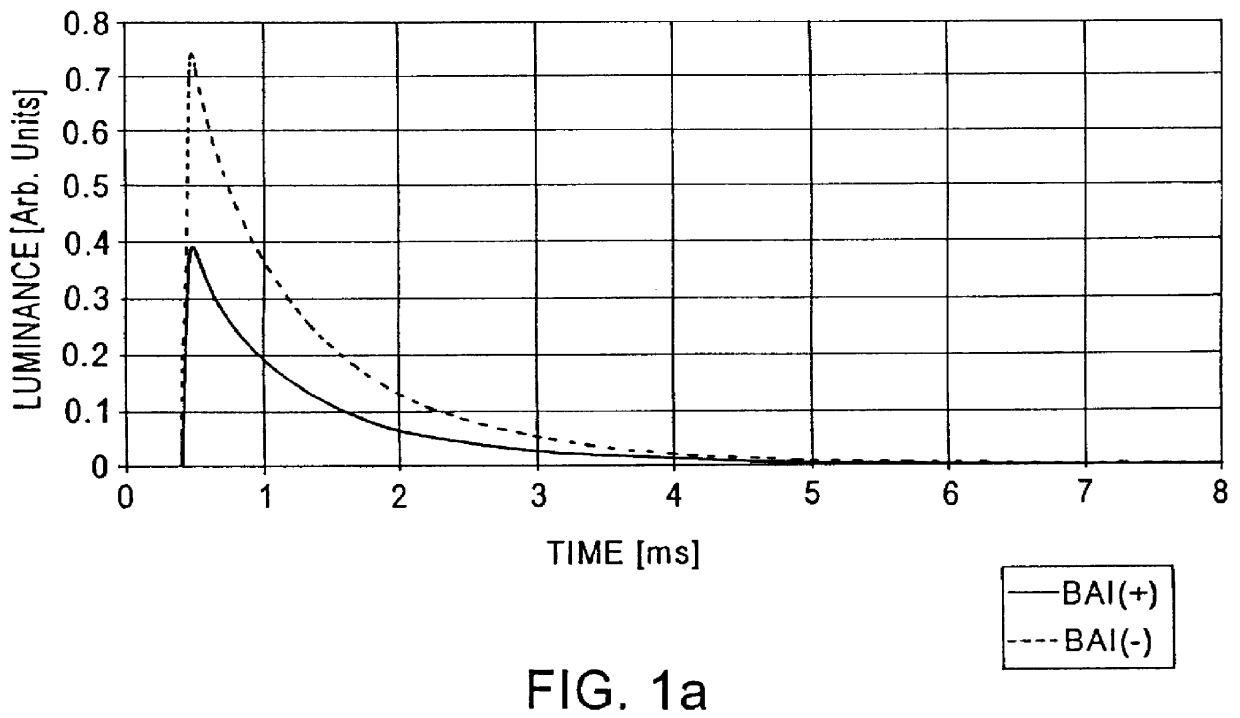

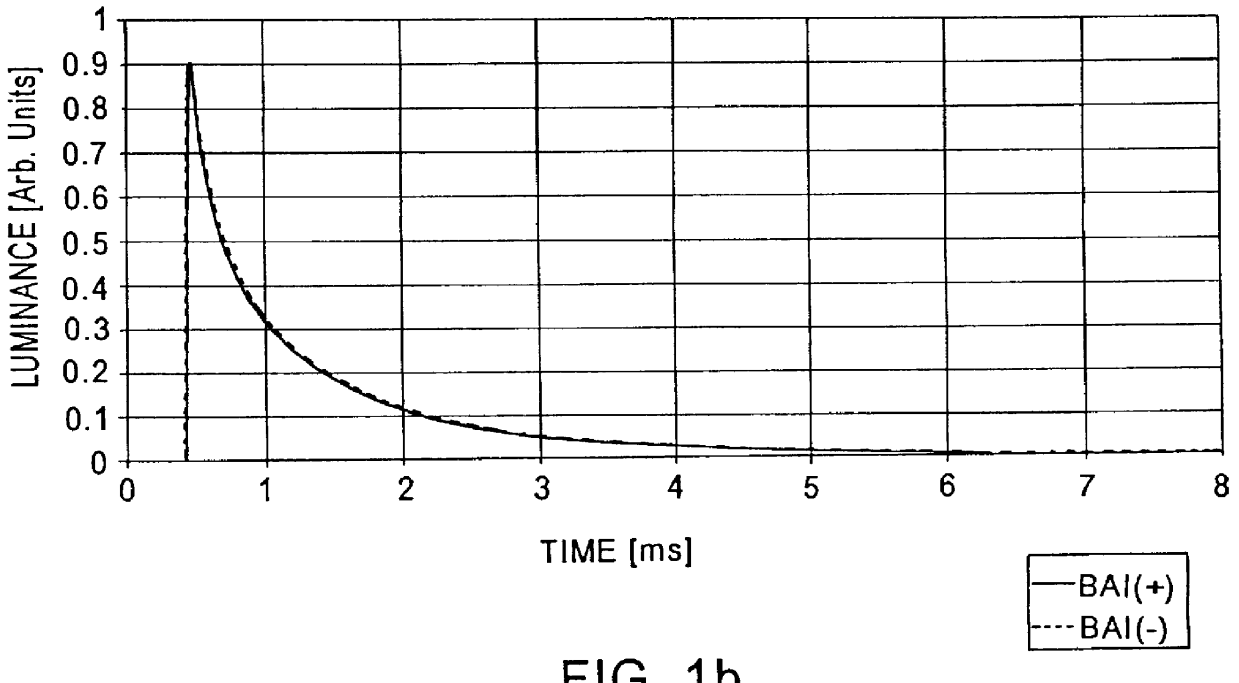

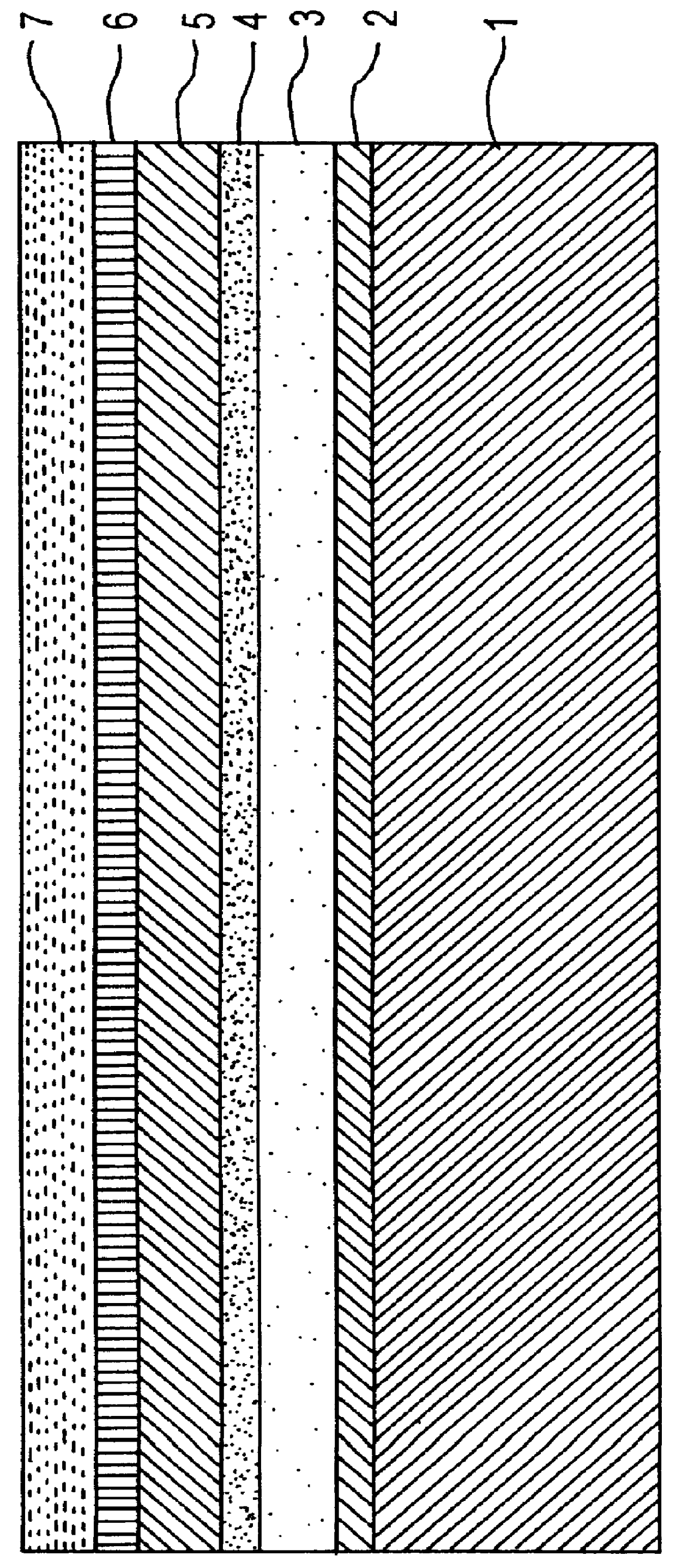

Method of growing a ZnS:Mn phosphor layer for use in thin-film electroluminescent components

InactiveUS6113977AImprove electroluminescence performanceSimple manufacturing processElectrical apparatusElectroluminescent light sourcesOrganozinc compoundFluorescence

The invention relates to a method of growing a ZnS:Mn phosphor layer suitable for use in thin-film electroluminescent components. According to the method, the ZnS:Mn phosphor layer is grown on a substrate by means of the ALE method using volatile zinc, sulfur and manganese compounds as the precursors. According to the invention, an organozinc compound such as diethylzinc or dimethylzinc is used as precursor for zinc, hydrogen sulfide or an organosulfur compound is used as precursor for sulfur, and an organomanganese compound or organic manganese complex compound is used as precursor for manganese. The invention provides a display component with drive-voltage-symmetrical light emission and stable characteristics of luminance level and turn-on voltage.

Owner:PLANAR SYSTEMS +1

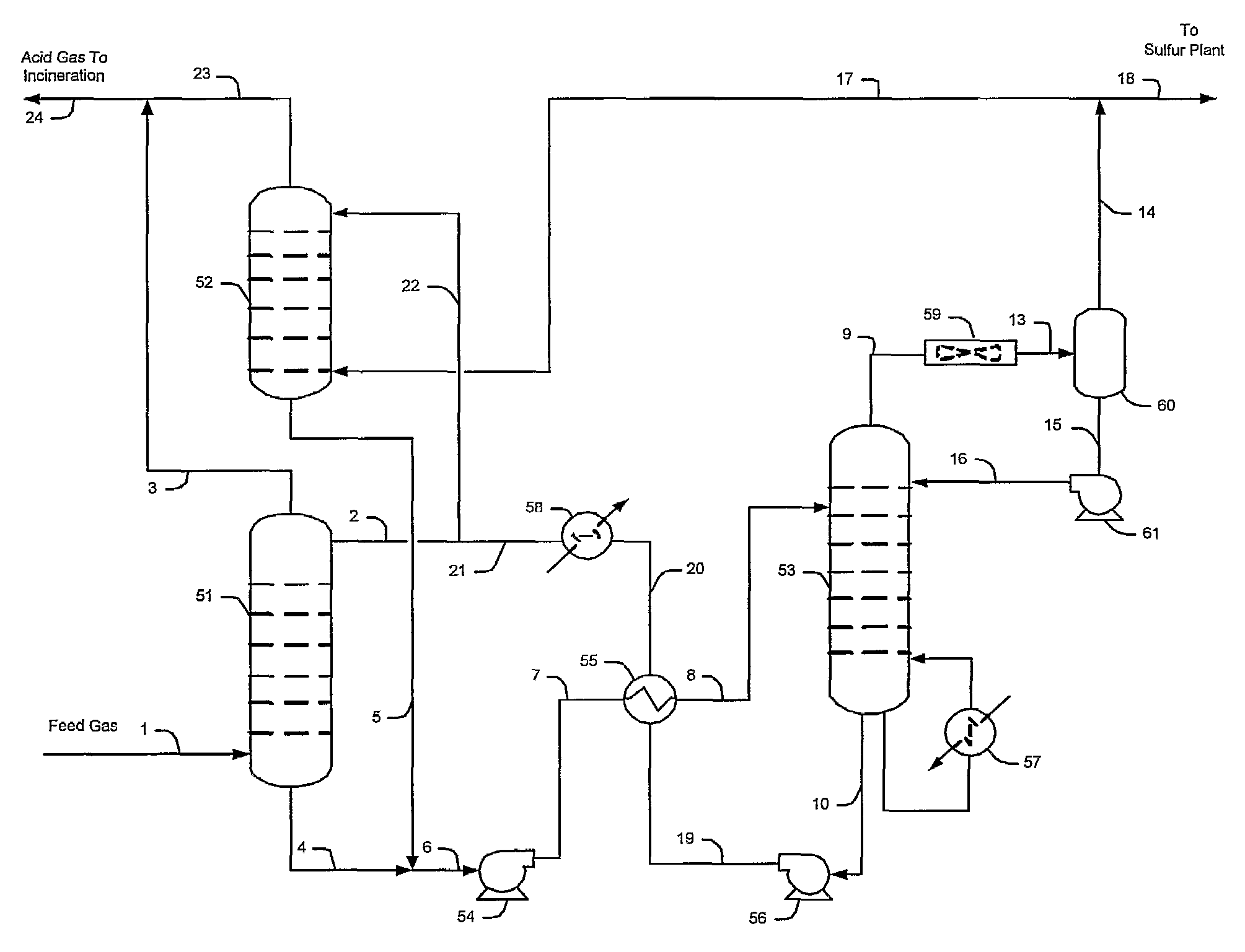

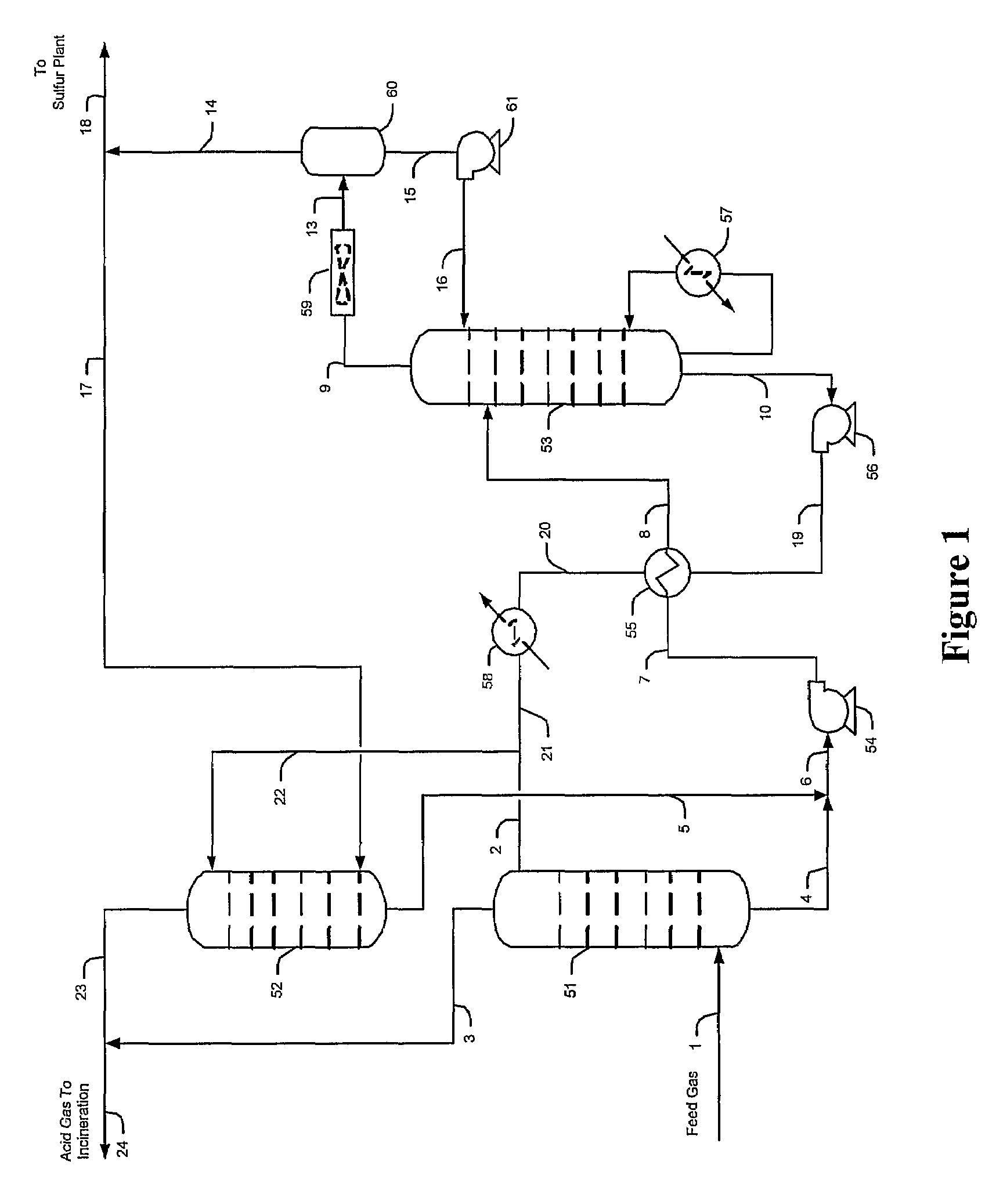

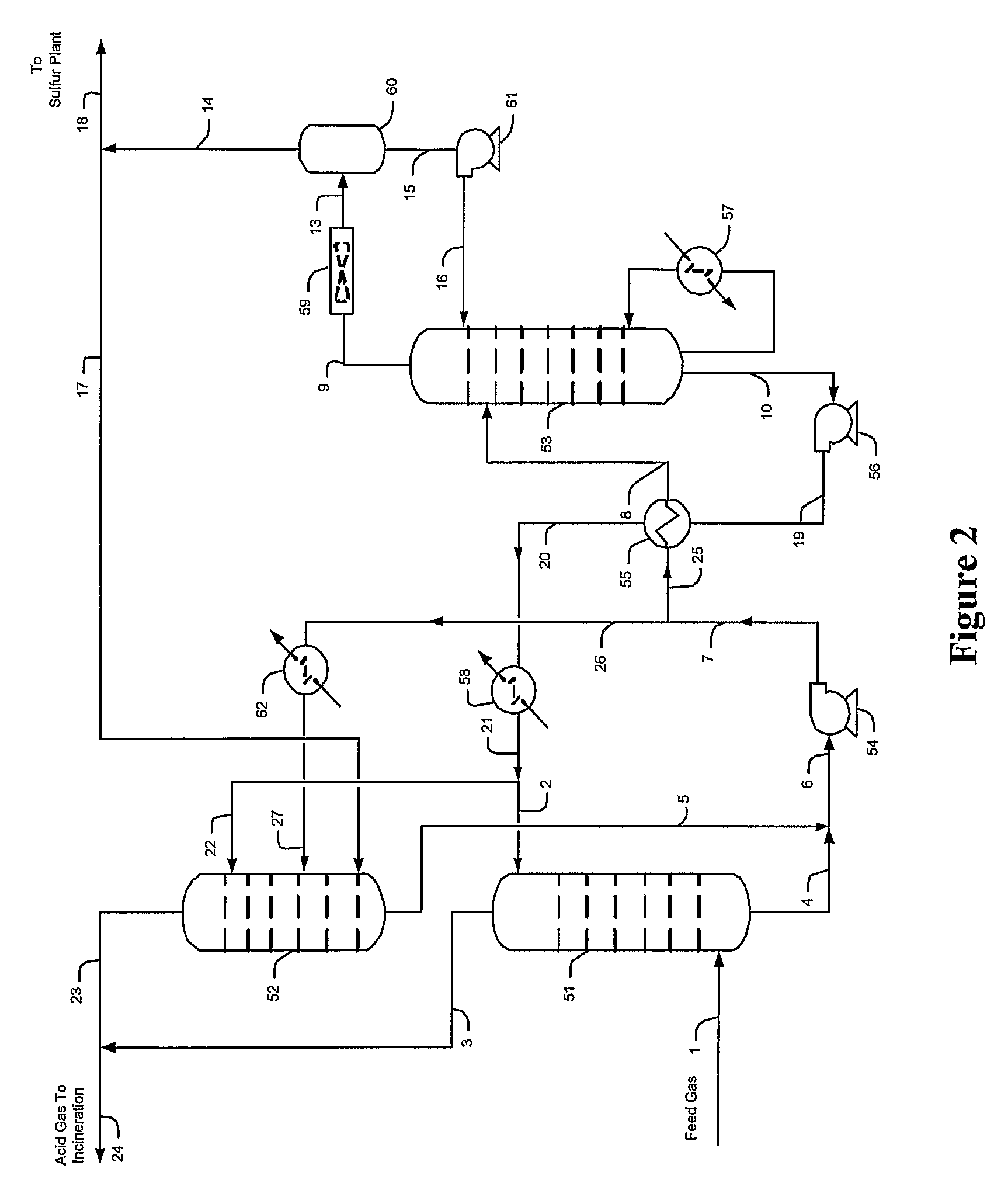

Methods and configurations for acid gas enrichment

ActiveUS7635408B2Increase the concentration of hydrogen sulfideSmall sizeGas treatmentCarbon compoundsSolventCarbon dioxide

Hydrogen sulfide is selectively enriched from an acid gas (1) that comprises relatively large quantities of carbon dioxide using a configuration in which a portion of an isolated hydrogen sulfide stream is introduced into an absorber (51) operating as a carbon dioxide rejecter. The resulting concentrated hydrogen sulfide enriched solvent (4) is then further used (directly or indirectly) to absorb hydrogen sulfide from an acid feed gas.

Owner:FLUOR ENTERPRISES

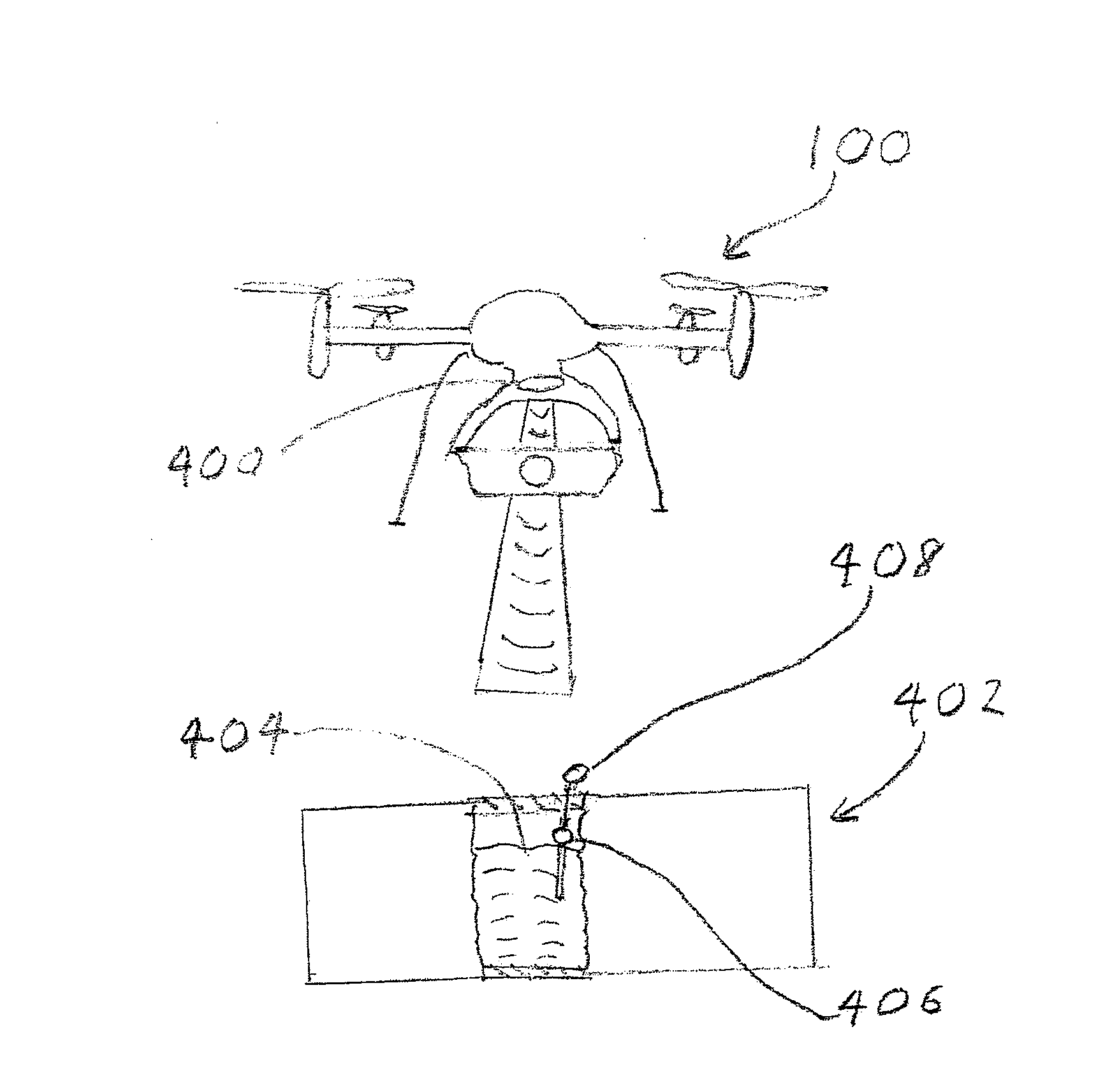

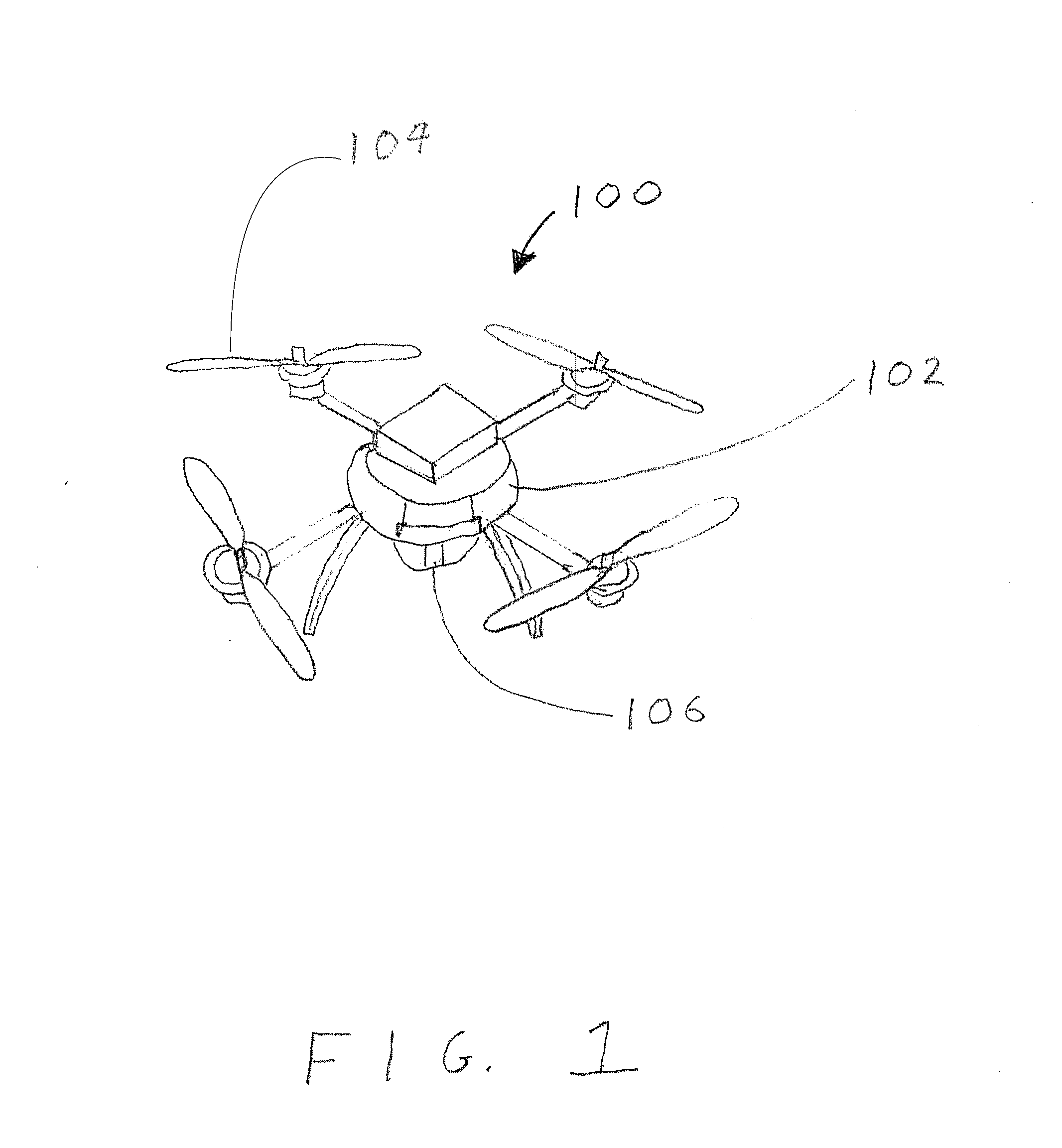

Systems, Methods and Devices for Collecting Data at Remote Oil and Natural Gas Sites

InactiveUS20160214715A1Avoid flyingAccurately determinedAircraft componentsUnmanned aerial vehiclesParticulatesHydrocotyle bowlesioides

Systems, methods and devices are provided for detecting airborne particulates and / or gases at remote oil and natural gas sites, such as wells, and / or processing and refinery plants. One such system comprises an unmanned aerial vehicle (UAV), such as a drone aircraft, configured for aerial dispatch to the remote site and wireless connection to an external processor, cloud apparatus or the like. The UAV includes one or more on-board sensors configured to detect airborne particulates or gases, such as methane gas, hydrogen sulfide, hydrocarbons, weather conditions, ground-based elements or compounds or the like. The on-board sensors may comprise light transmitters, such as lasers, configured for transmitting light or laser pulses into the ambient environment around the remote site and detecting backscatter to detect the concentration and / or velocity vector(s) of the airborne particulates or gases. The UAV is further configured to wirelessly transmit data associated with the airborne particulates or gases to the external processor or cloud apparatus in real-time.

Owner:OIL & GAS IT LLC

Method for preparing high-quality ethylene raw material with petroleum naphtha hydrogenation

ActiveCN101343557AImprove qualityIncrease productionOrganic chemistryBulk chemical productionVegetable oilPetroleum naphtha

The invention relates to a method for generating the high quality ethylene raw material through naphtha hydrogenation. The method takes naphtha fraction and animal and vegetable oil as the raw material oil, under the condition of hydrofining, the raw material oil and hydrogen are mixed and passed through a hydrofining reaction area, the hydrogen-rich gas recycling utilization can be acquired through separating the hydrofining generated oil, and low Sulfur, low hydrogen and low aromatic naphtha can be acquired through removing hydrogen sulfide of the separated liquid with an air stripping tower. Compared with the prior art, the method has the advantages that the oil is mixed in the naphtha hydrogenation raw material, the quality of the product as the ethylene cracking raw material, in particular to aromatic long chain hydrocarbon nC16 to 18 and propane acquired through the animal and vegetable oil hydrogenation, can be remarkably improved, the cracking furnace ethylene output can be increased and the cracking furnace life can be prolonged through adding the aromatic long chain hydrocarbon nC16 to 18 and propane in the ethylene cracking raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for mitigation of wellbore contaminants

InactiveUS6942037B1Lessened potential hazardSimple treatmentCleaning apparatusFluid removalFoaming agentWater flow

A method is disclosed for intermittently mitigating hazardous sulfur compounds, such as hydrogen sulfide, mercaptans and sulfur oxides, from a fluid in the head space of a wellbore. The method comprises contacting the fluid with a foamed aqueous stream comprising an active scavenging agent, such as a triazine, and a stiff foaming agent. The scavenging agent reacts with hazardous sulfur compounds to eliminate the compounds from the fluid stream in the vapor space of the wellbore without withdrawing the hydrocarbon from the wellbore and without releasing hazardous sulfur compounds to the environment.

Owner:CLARIANT INT LTD

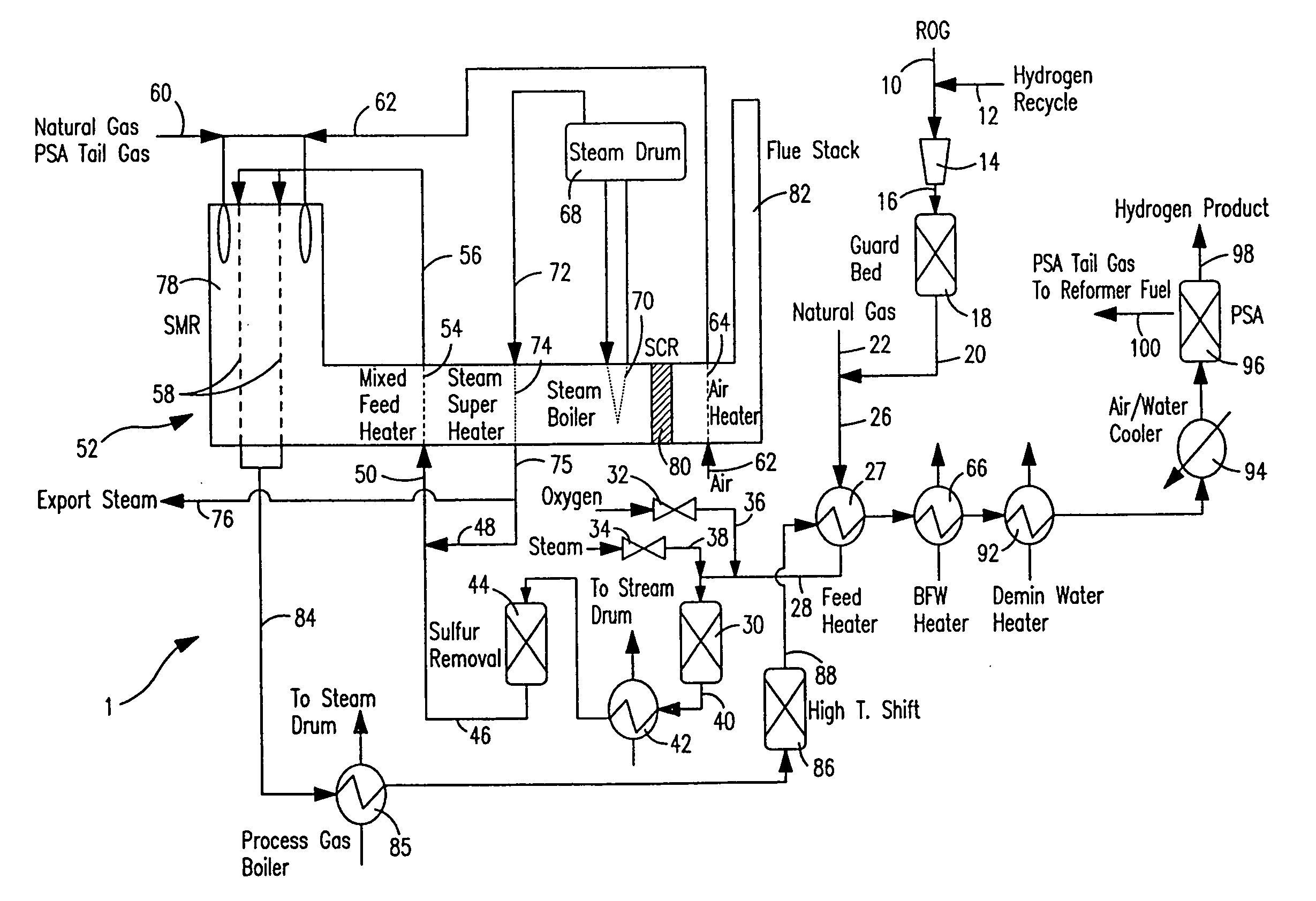

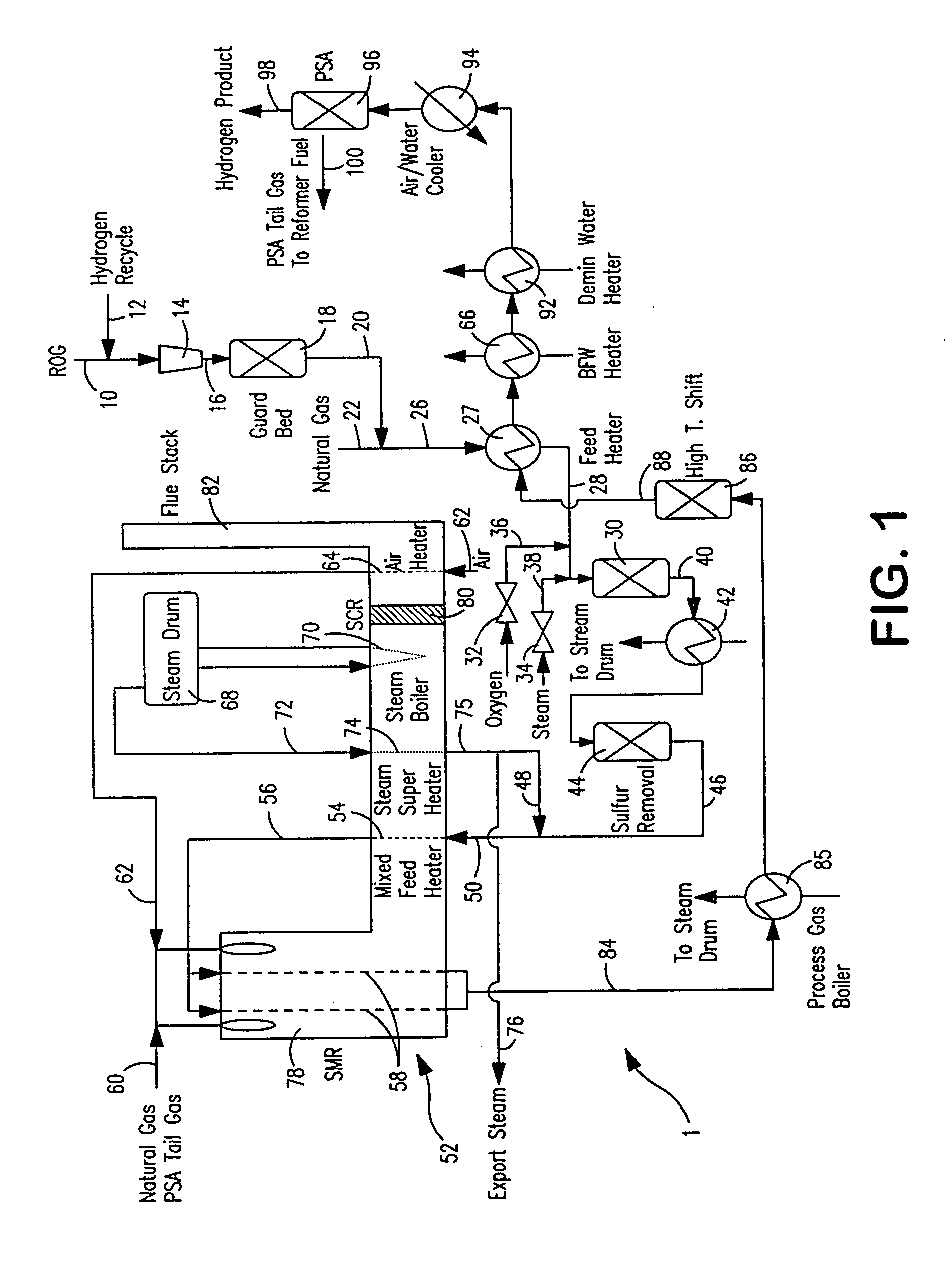

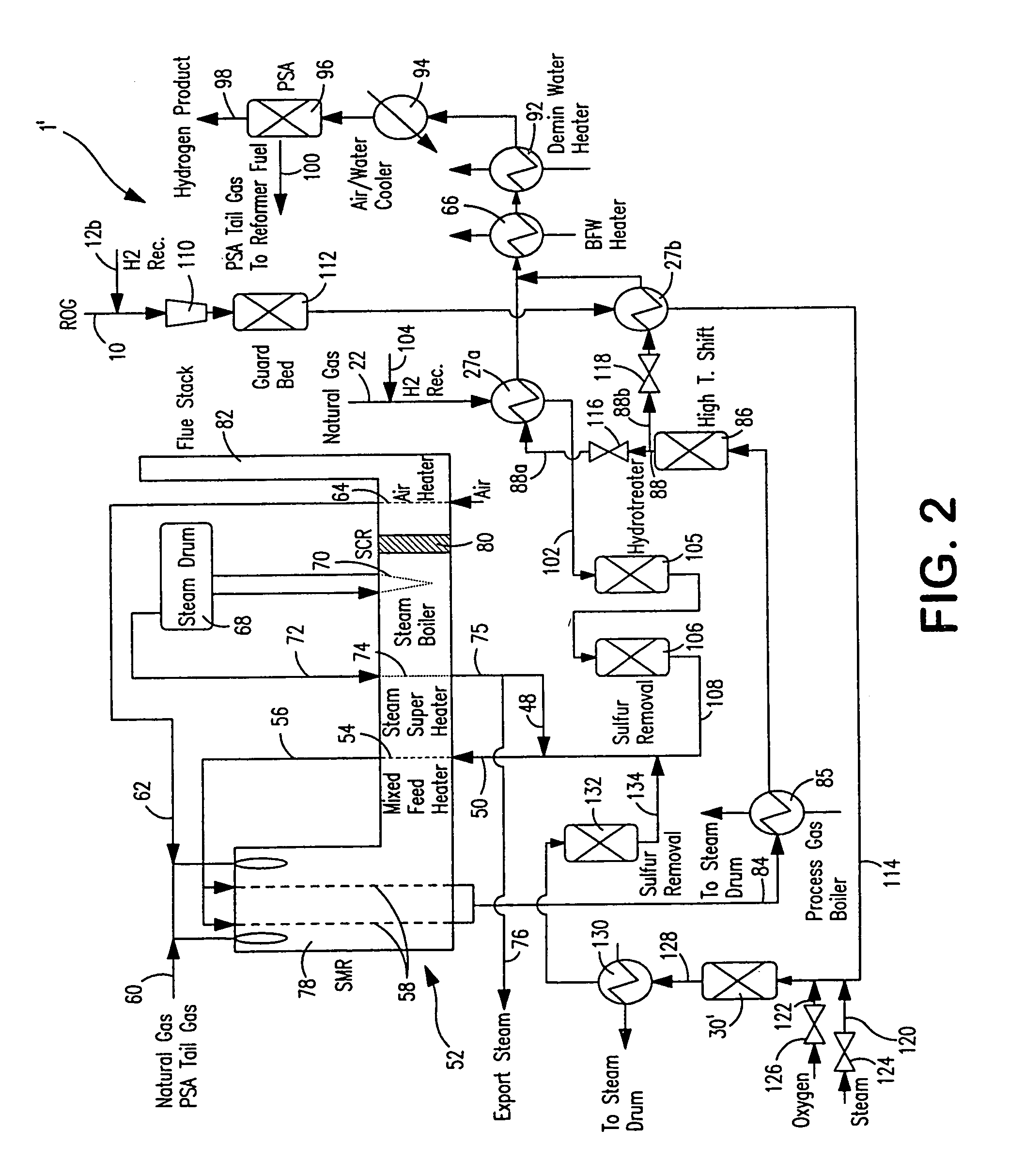

Steam methane reforming method

ActiveUS7037485B1Reduce fuel usageReduce firing rateHydrocarbon from carbon oxidesHydrogen separation using solid contactMethane reformerAlkane

A steam methane reforming method in which a feed stream is treated in a reactor containing a catalyst that is capable of promoting both hydrogenation and partial oxidation reactions. The reactor is either operated in a catalytic hydrogenation mode to convert olefins into saturated hydrocarbons and / or to chemically reduce sulfur species to hydrogen sulfide or a catalytic oxidative mode utilizing oxygen and steam to prereform the feed and thus, increase the hydrogen content of a synthesis gas produced by a steam methane reformer. The method is applicable to the treatment of feed streams containing at least 15% by volume of hydrocarbons with two or more carbon atoms and / or 3% by volume of olefins, such as a refinery off-gas. In such case, the catalytic oxidative mode is conducted with a steam to carbon ratio of less than 0.5, an oxygen to carbon ratio of less than 0.25 and a reaction temperature of between about 500° C. and about 860° C. to limit the feed to the steam methane reformer to volumetric dry concentrations of less than about 0.5% for the olefins and less than about 10% for alkanes with two or more carbon atoms.

Owner:PRAXAIR TECH INC

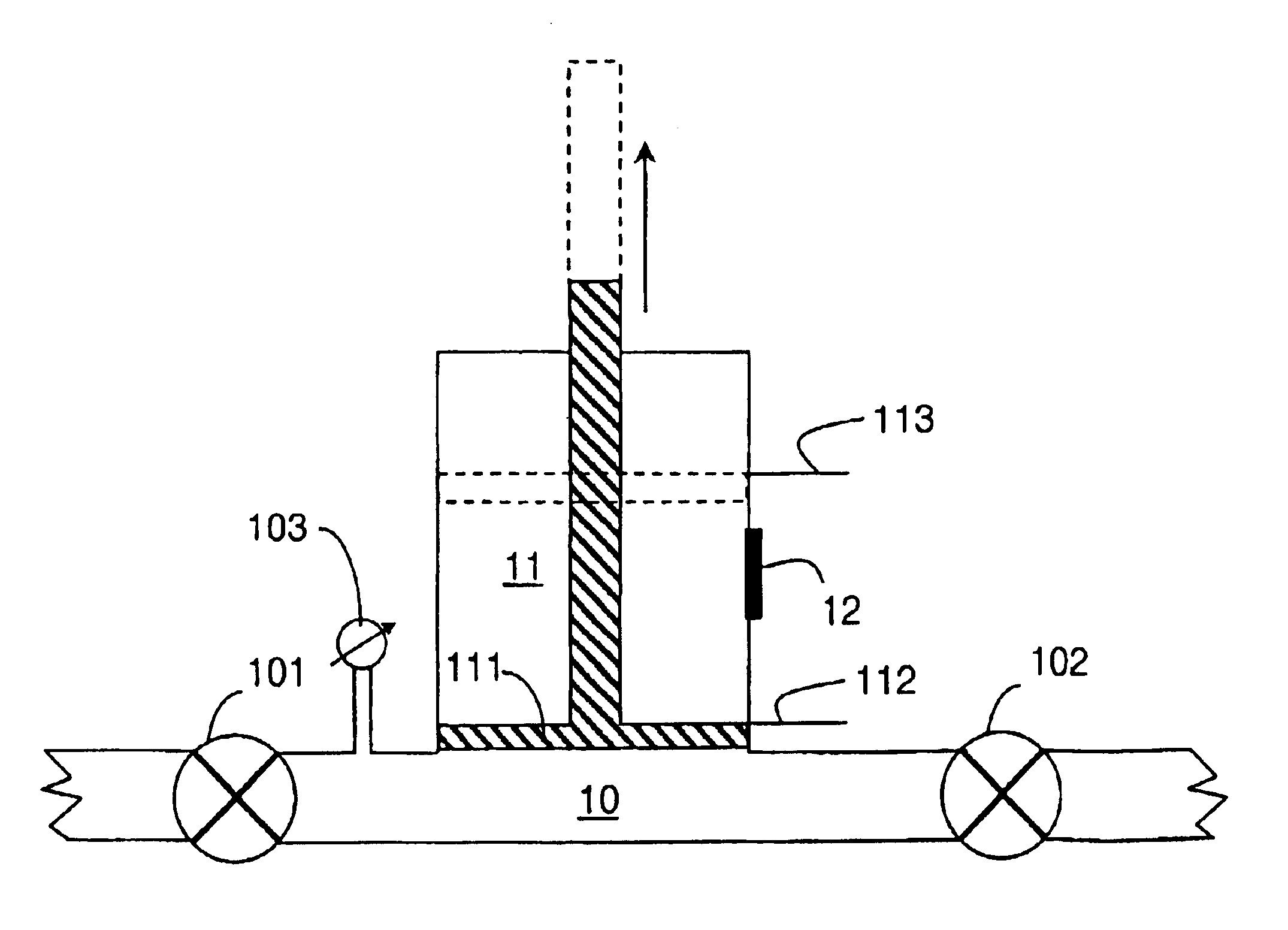

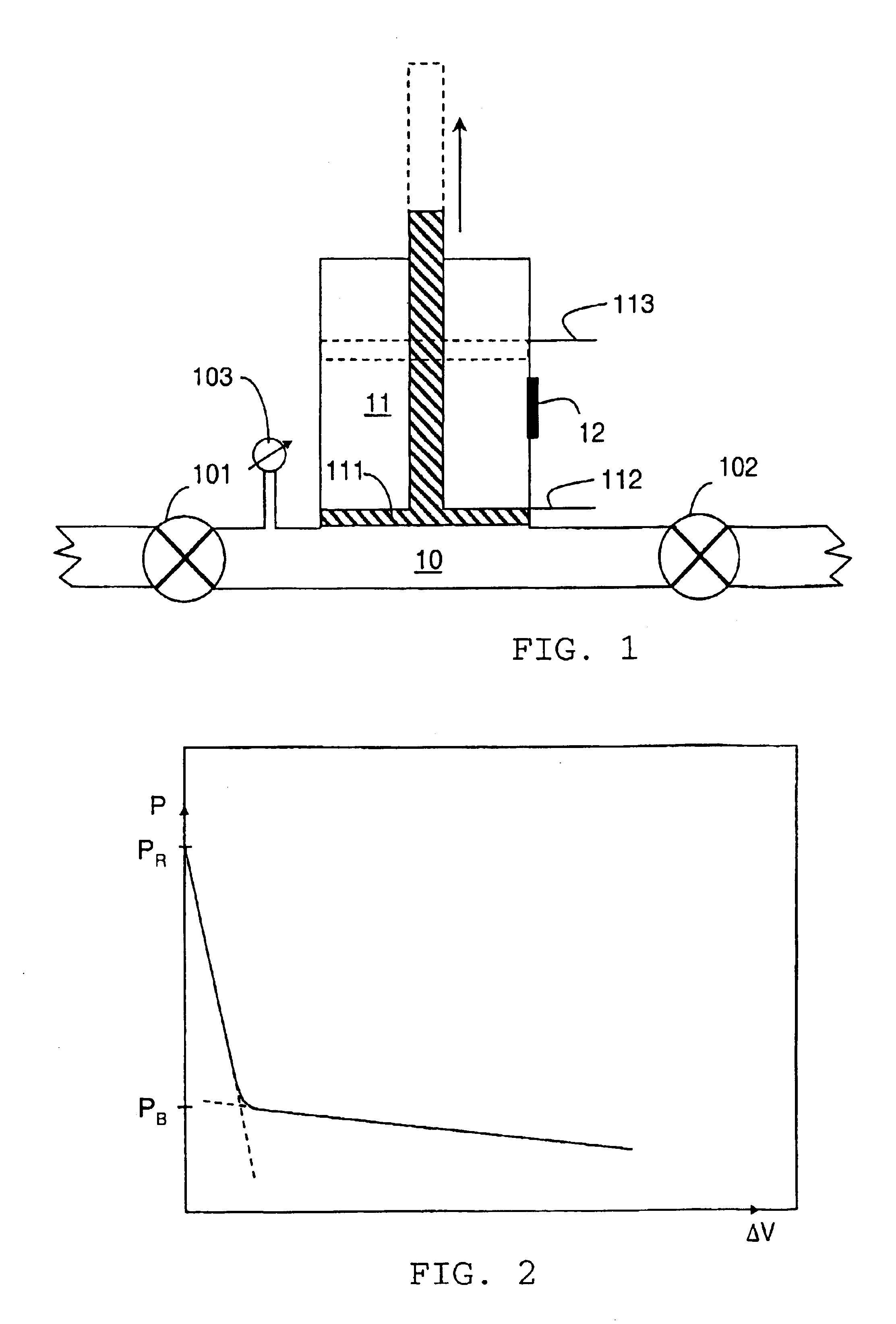

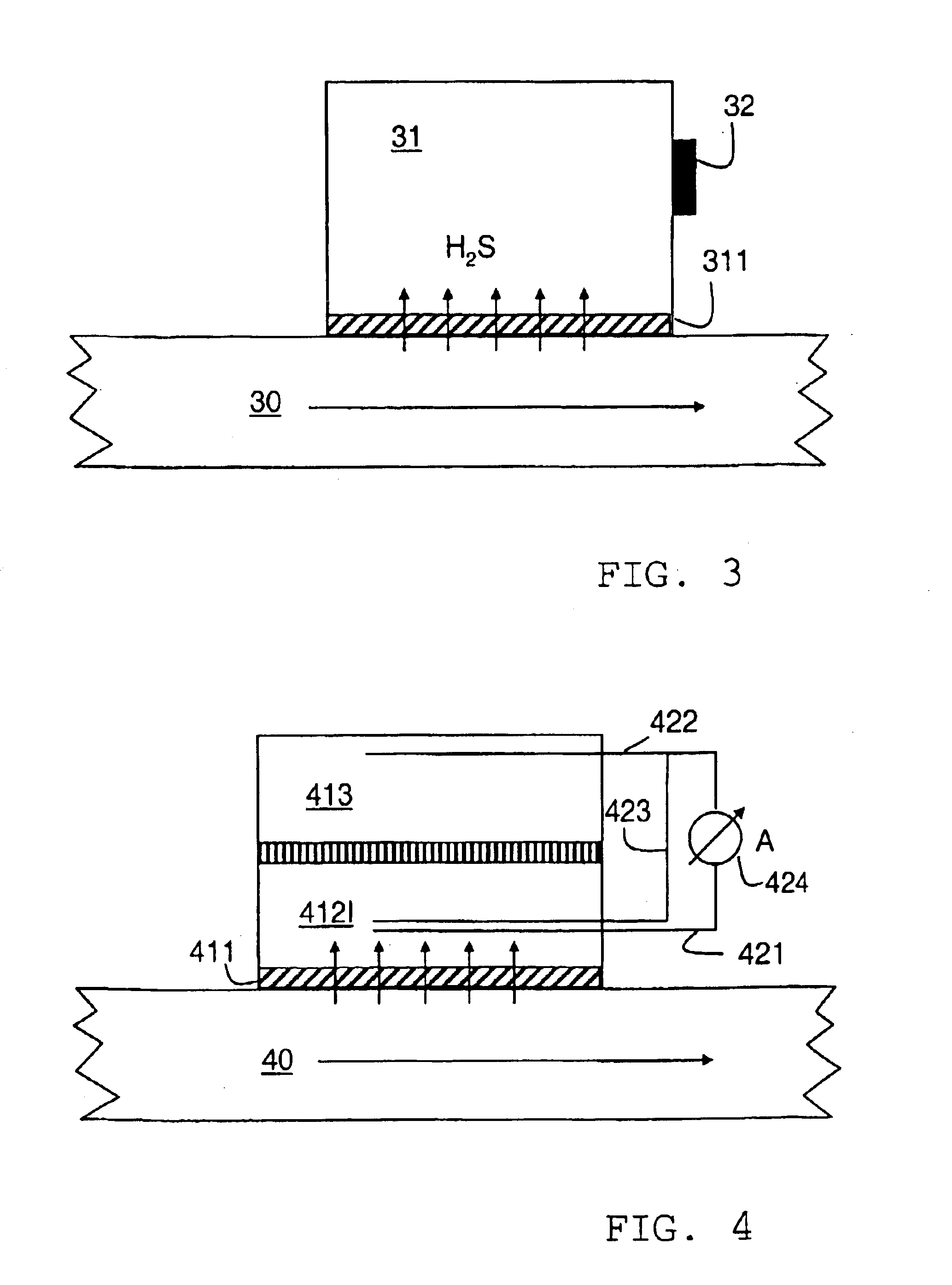

Hydrogen sulphide detection method and apparatus

Described is a downhole method and apparatus for detecting hydrogen sulphide in formation fluids produced in a hydrocarbon well. The sensor system is located within or in communication with an extraction chamber used to extract hydrogen sulphide in a gaseous state from the formation fluid and preferably equipped with renewable sensing elements.

Owner:SCHLUMBERGER TECH CORP

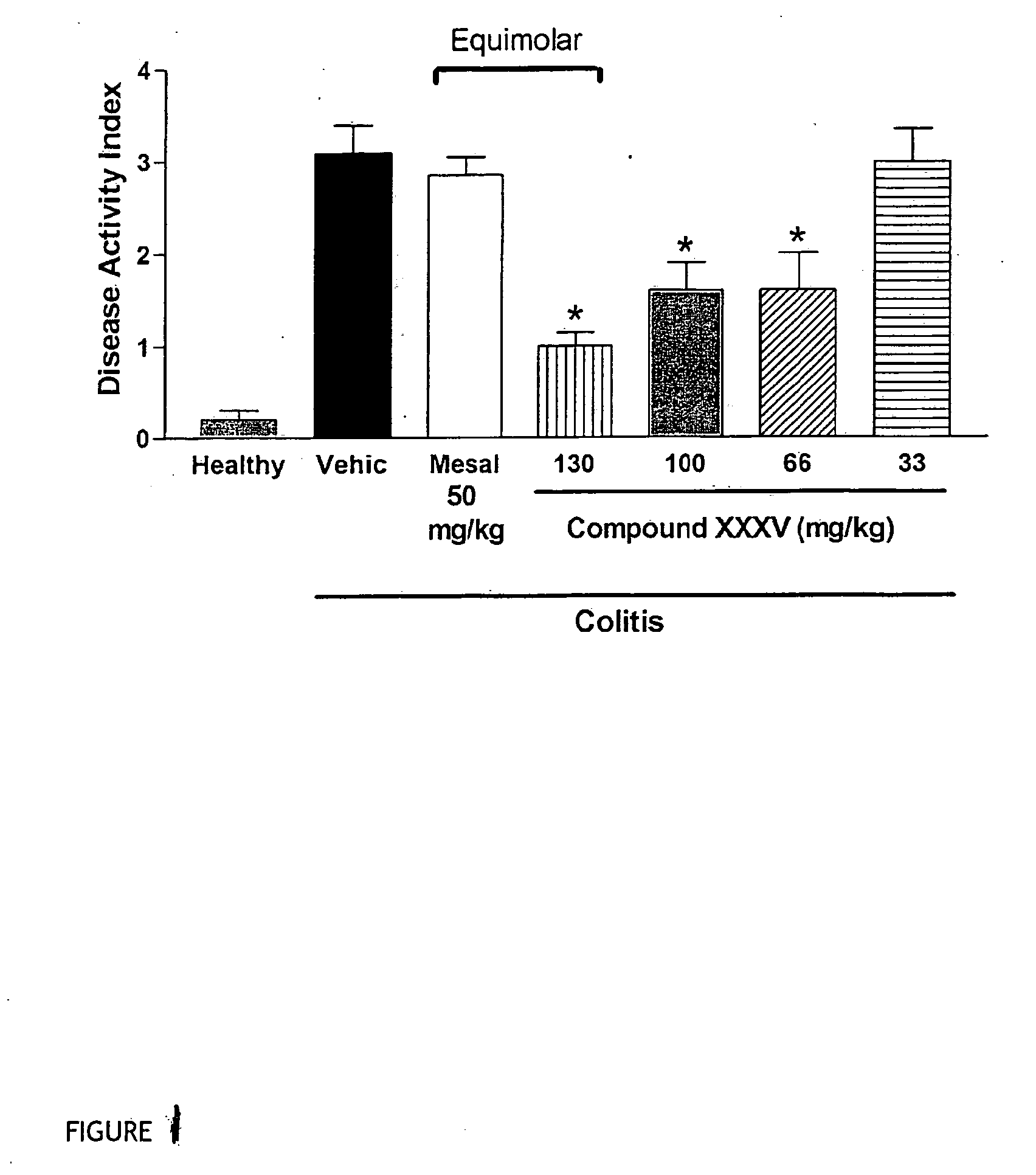

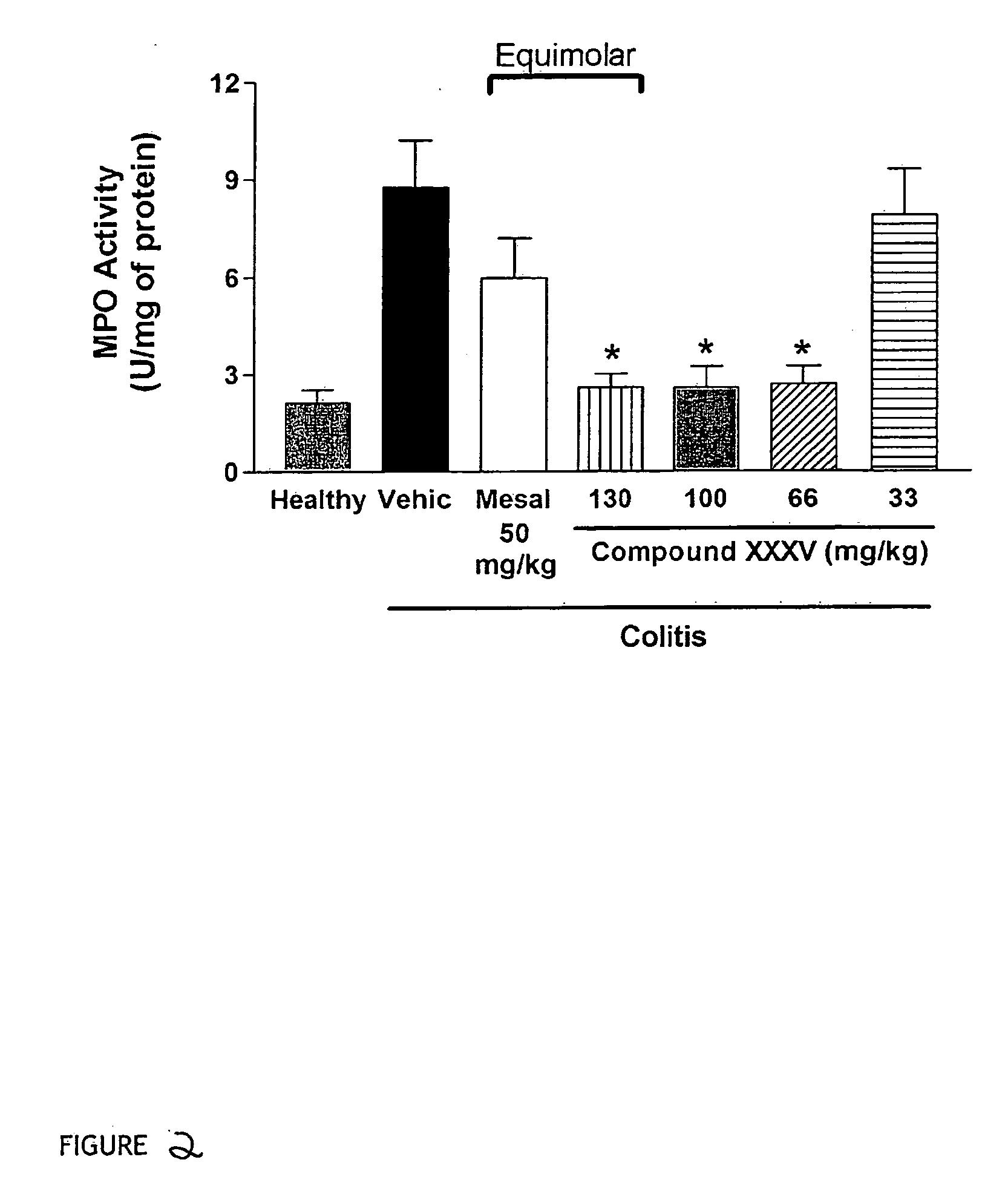

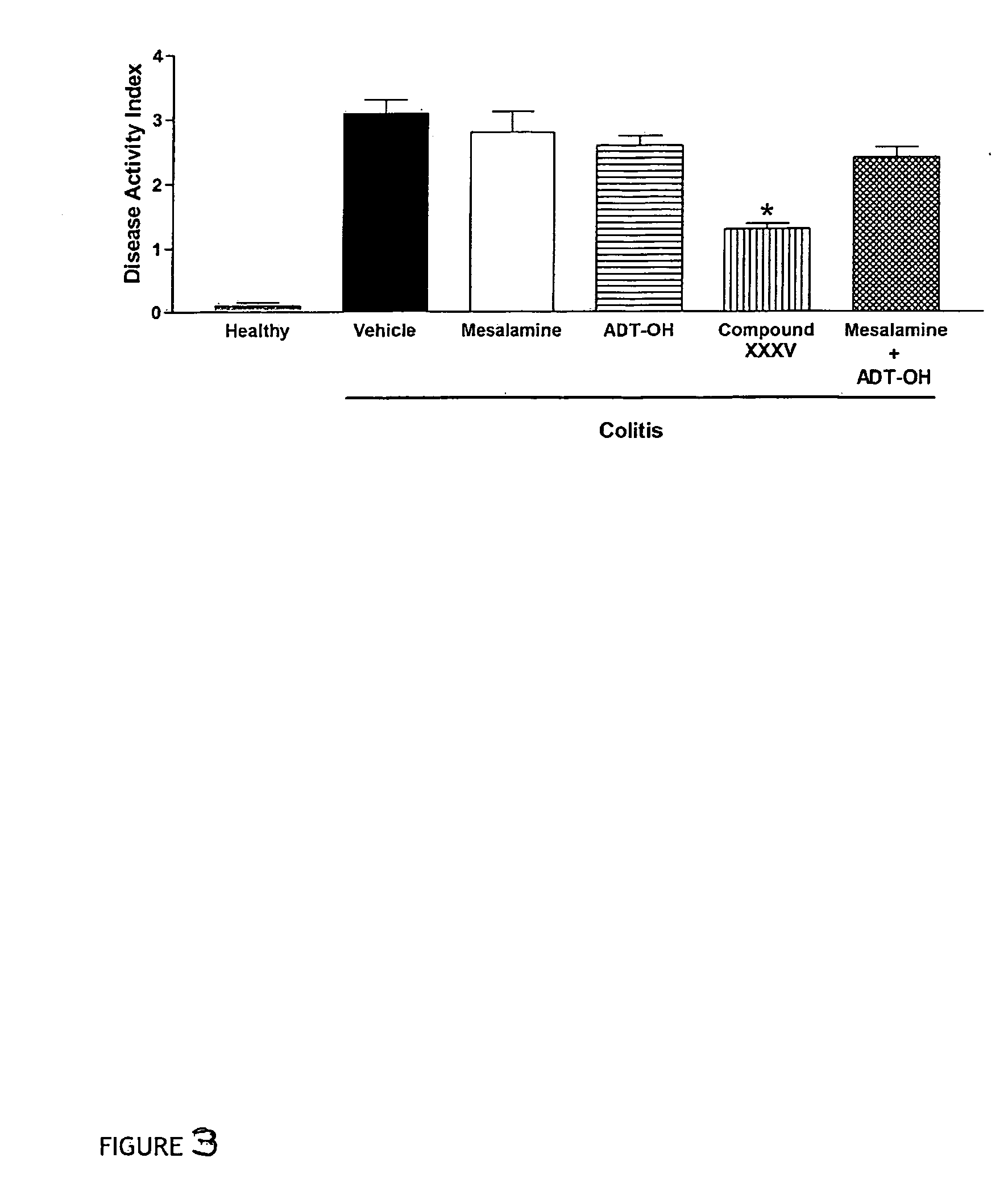

Derivatives of 4- or 5-aminosalicylic acid

InactiveUS20060270635A1Less readily absorbedEasily reach colonBiocidePhosphorous compound active ingredientsThioester synthesisSalicylic acid

The present invention provides new derivatives of 4- or 5-aminosalicylic acid, and a pharmaceutical composition containing these derivatives of 4- or 5-aminosalicylic acid as active ingredients, useful for the treatment of intestinal diseases such as inflammatory bowel disease (IBD) and irritable bowel syndrome (IBS) and for the prevention / treatment of colon cancer. More particularly, these derivatives comprise a hydrogen sulfide releasing moiety linked via an azo, an ester, an anhydride, a thioester or an amide linkage to a molecule of 4- or 5-aminosalicylic acid. Furthermore, the present invention provides a process for preparing these compounds and their use for treating IBD and IBS and the prevention / treatment of colon cancer.

Owner:ANTIBE THERAPEUTICS INC

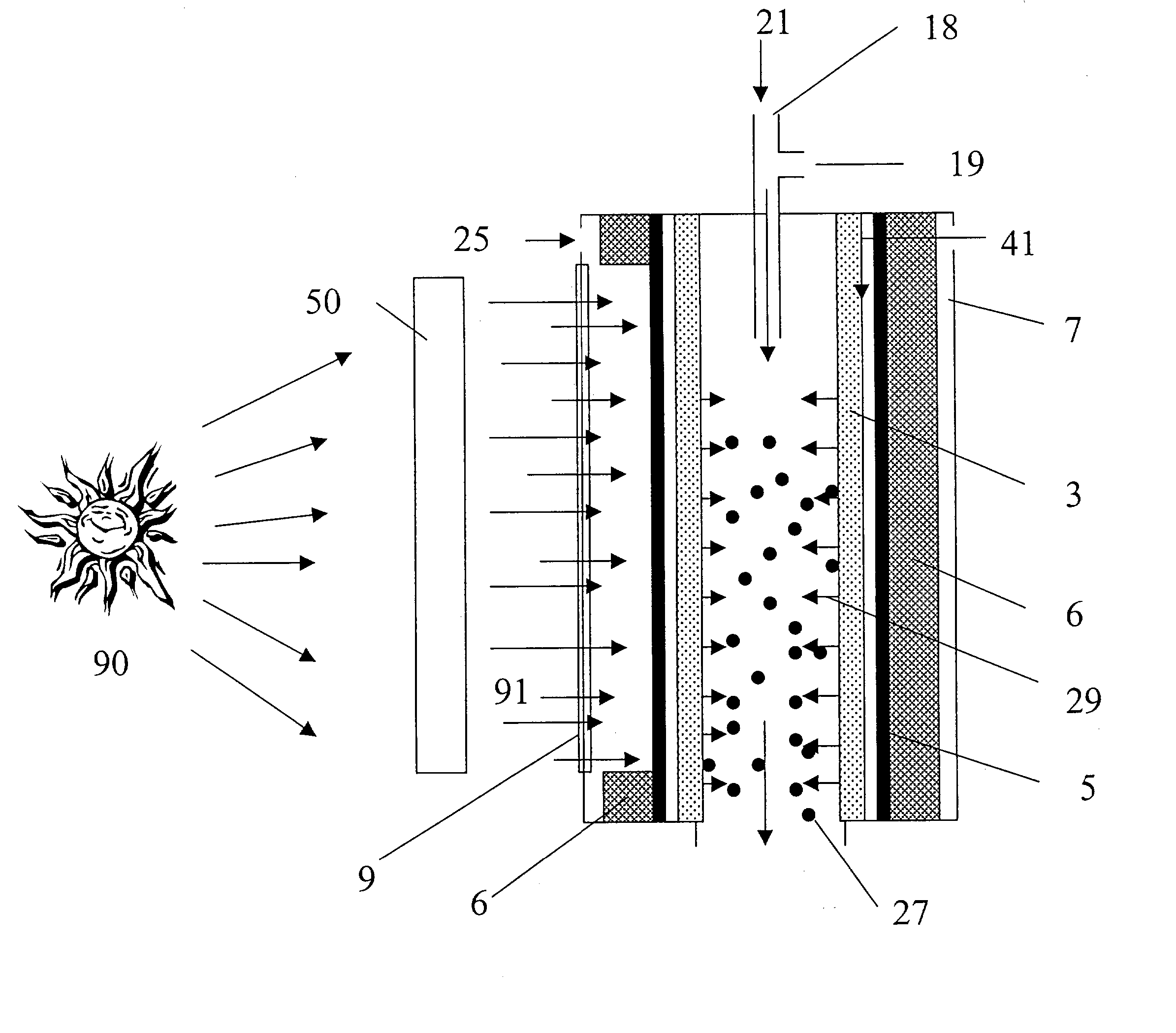

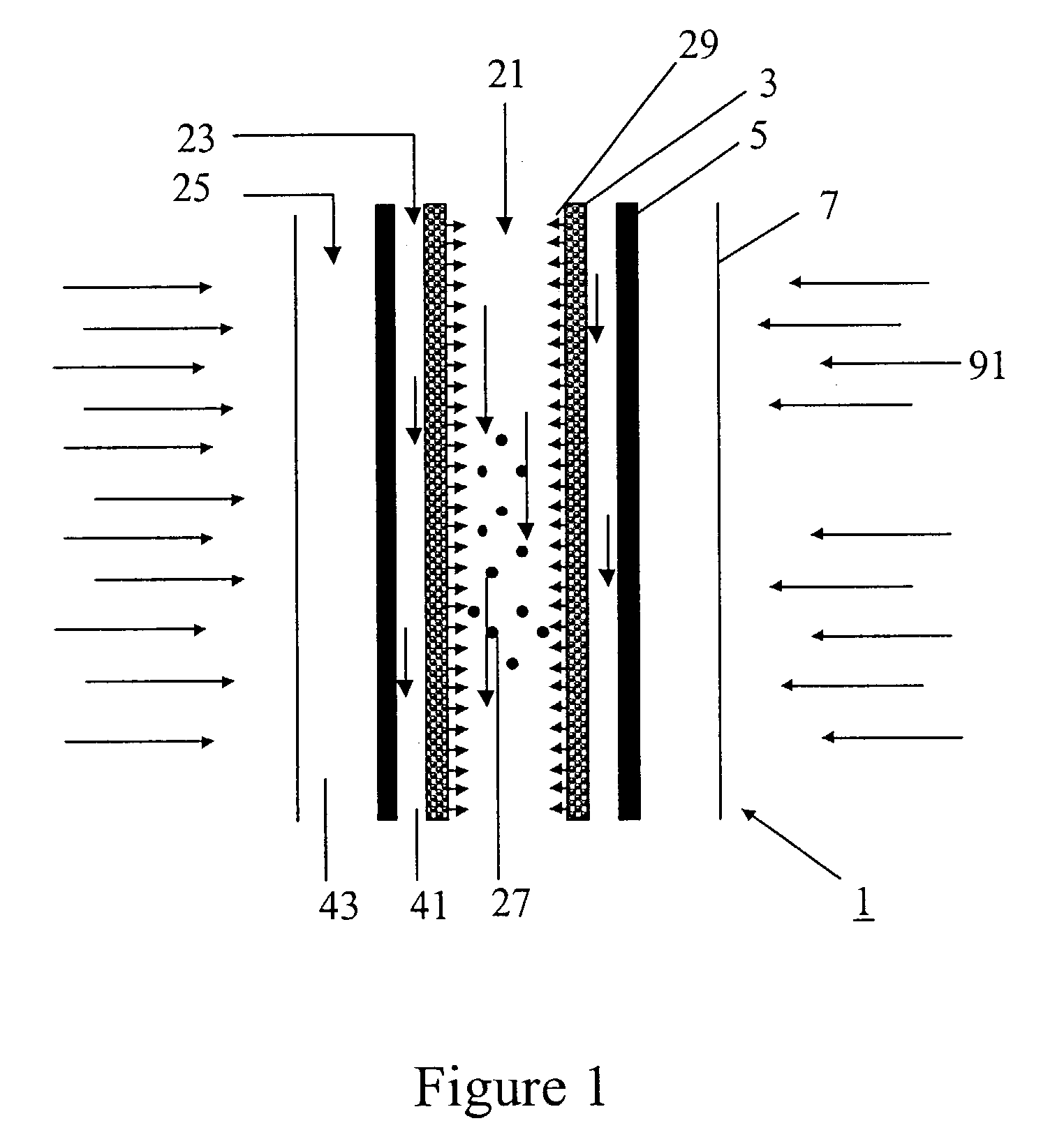

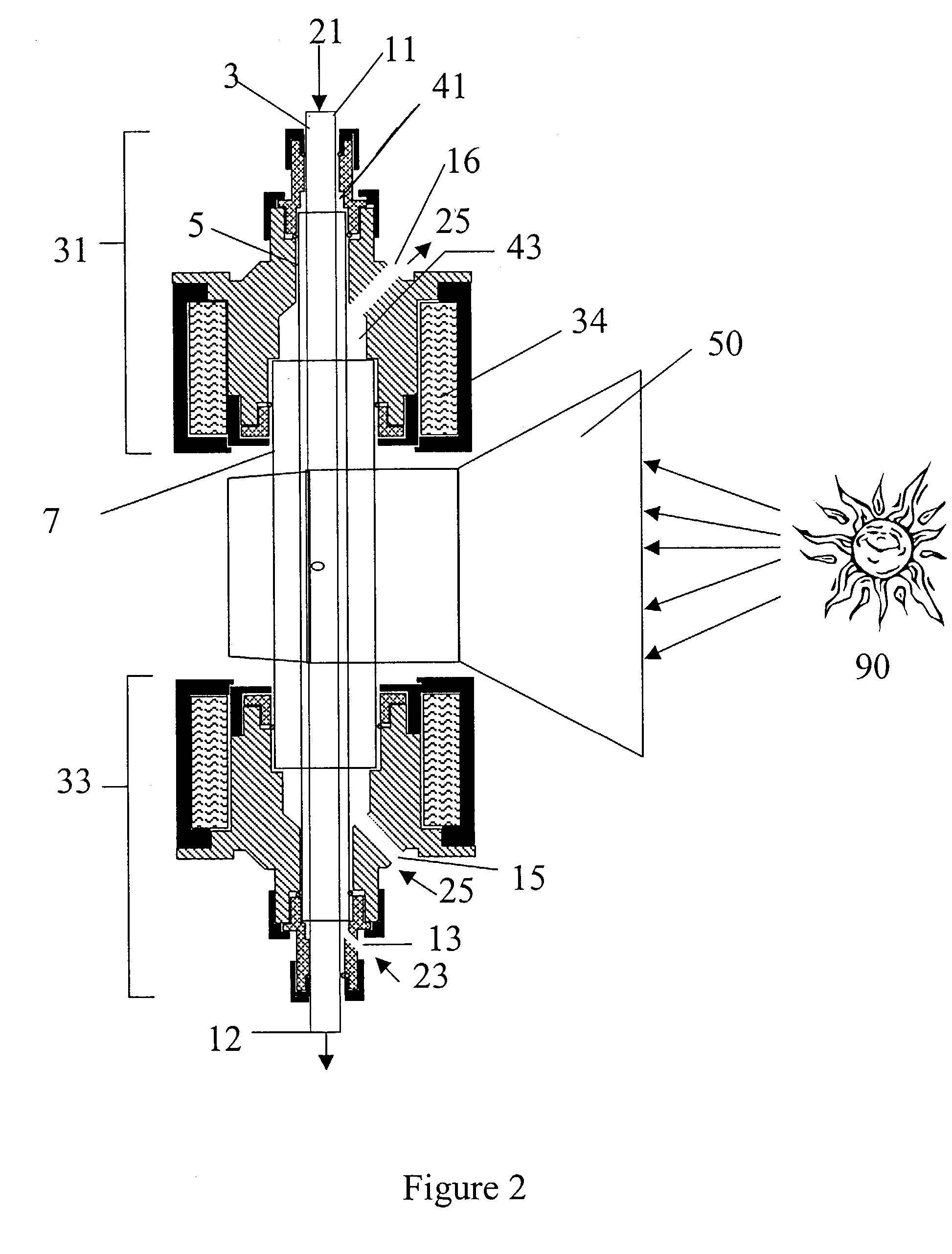

Solar-thermal fluid-wall reaction processing

InactiveUS7033570B2Reduce and preventShort stayThermal non-catalytic crackingSolar heating energyHydrogenReactor system

The present invention provides a method for carrying out high temperature thermal dissociation reactions requiring rapid-heating and short residence times using solar energy. In particular, the present invention provides a method for carrying out high temperature thermal reactions such as dissociation of hydrocarbon containing gases and hydrogen sulfide to produce hydrogen and dry reforming of hydrocarbon containing gases with carbon dioxide. In the methods of the invention where hydrocarbon containing gases are dissociated, fine carbon black particles are also produced. The present invention also provides solar-thermal reactors and solar-thermal reactor systems.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

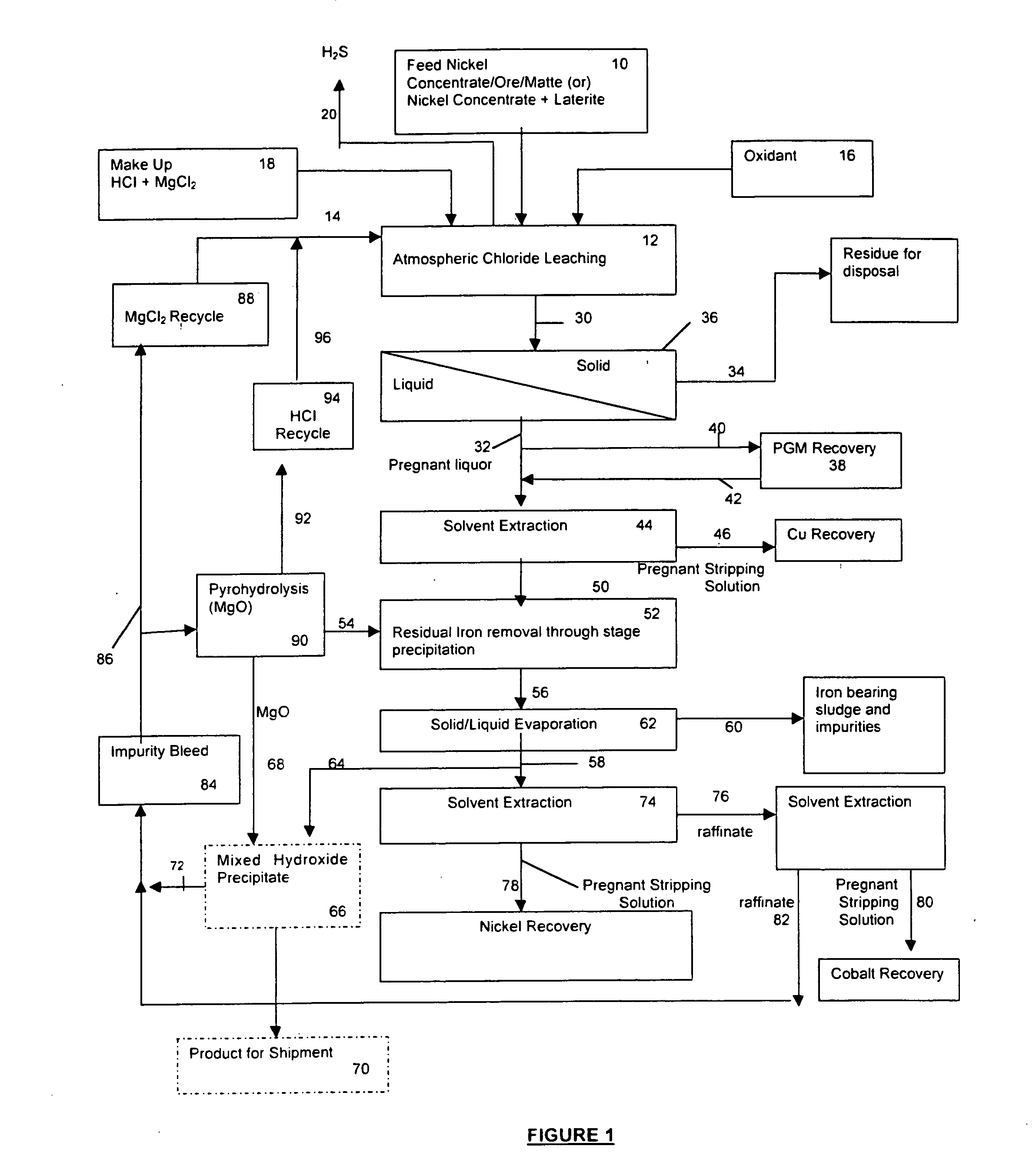

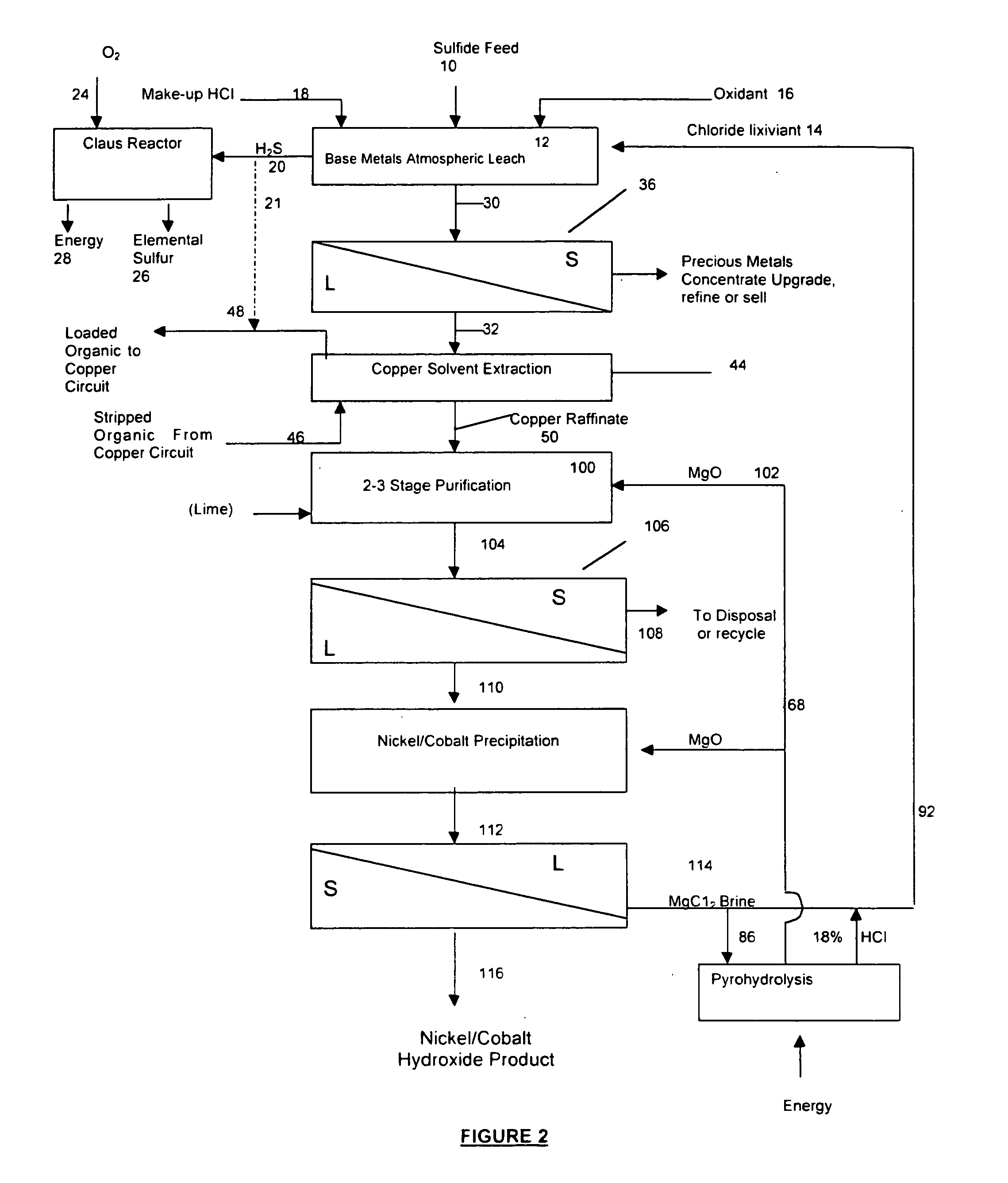

Process for the recovery of value metals from base metal sulfide ores

InactiveUS20050118081A1Simple gas/liquidReduce the amount requiredSulfur compoundsSolid sorbent liquid separationSulfideDissolution

A process for leaching a value metal from a base metal sulfide ore, comprising the step of leaching the ore with a lixiviant comprising a chloride, an oxidant and hydrochloric acid is disclosed. The leaching is controlled, by use of low concentrations of hydrochloric acid and a redox potential, to effect formation of hydrogen sulfide from the base metal sulfide ore. The hydrogen sulfide is stripped from the leach solution, thereby reducing the amount of sulfate generated in the leach to very low levels. The leaching may also be conducted to limit the co-dissolution of platinum group metals and gold with the base value metals. The leach forms a value metal-rich leachate and a solids residue. The solids residue may be subsequently leached to recover the platinum group metals and gold. The value metal-rich leachate can be is oxidized and neutralized to recover the value base metals. In an embodiment, the chloride is magnesium chloride and lixiviant solution is regenerated.

Owner:JAGUAR NICKEL INC

Nanomaterial-based gas sensors

InactiveUS20100089772A1High sensitivityLow detection limitWeather/light/corrosion resistanceVolume/mass flow measurementWater vaporCarbon nanotube

A gas sensing device (nanosensor) includes a substrate with at least a pair of conductive electrodes spaced apart by a gap, and an electrochemically functionalized semiconductive nanomaterial bridging the gap between the electrodes to form a nanostructure network. The nanomaterial may be single-walled carbon nanotubes (SWNTs) functionalized by the deposition of nanoparticles selected from the group consisting of an elemental metal (e.g., gold or palladium), a doped polymer (e.g., camphor-sulfonic acid doped polyaniline), and a metal oxide (e.g. tin oxide). Depending on the nanoparticles employed in the functionalization, the nanosensor may be used to detect a selected gas, such as hydrogen, mercury vapor, hydrogen sulfide, nitrogen dioxide, methane, water vapor, and / or ammonia, in a gaseous environment.

Owner:RGT UNIV OF CALIFORNIA

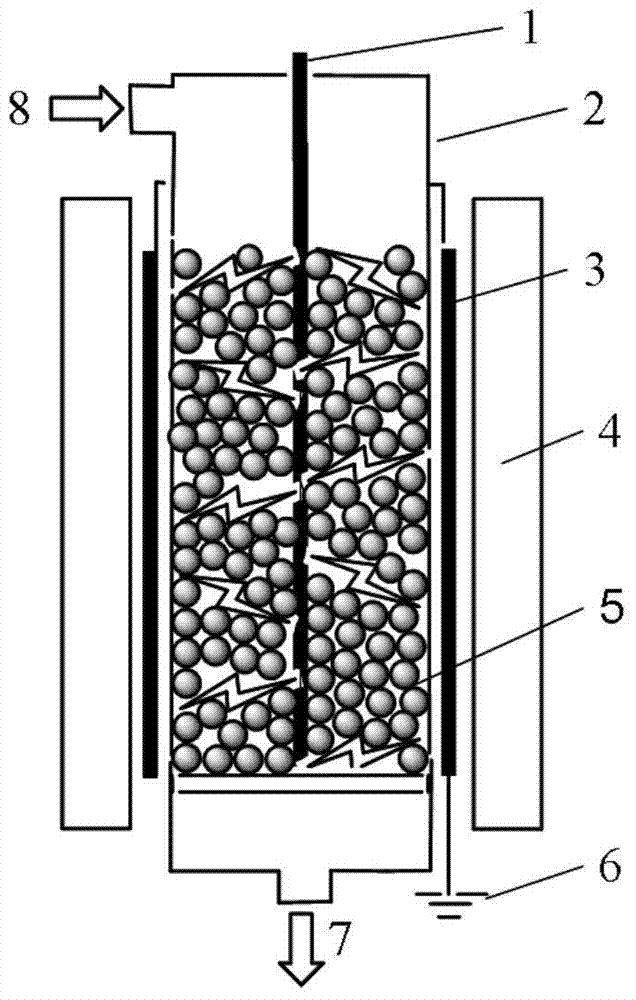

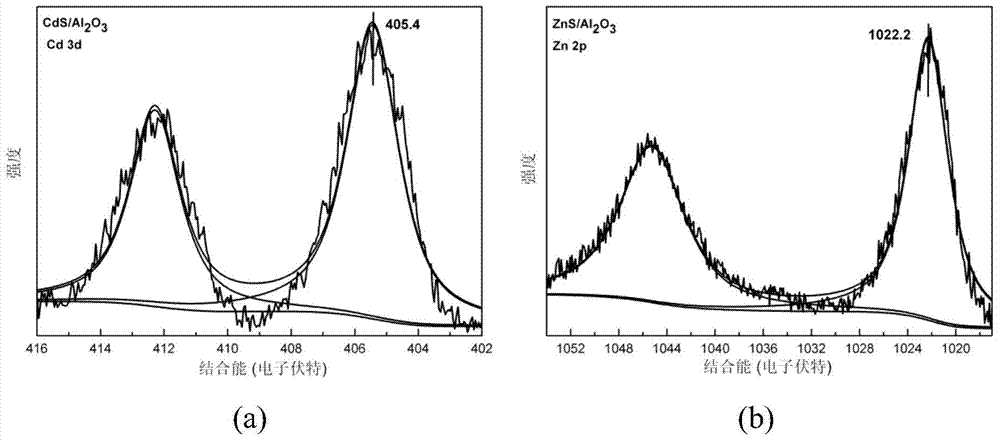

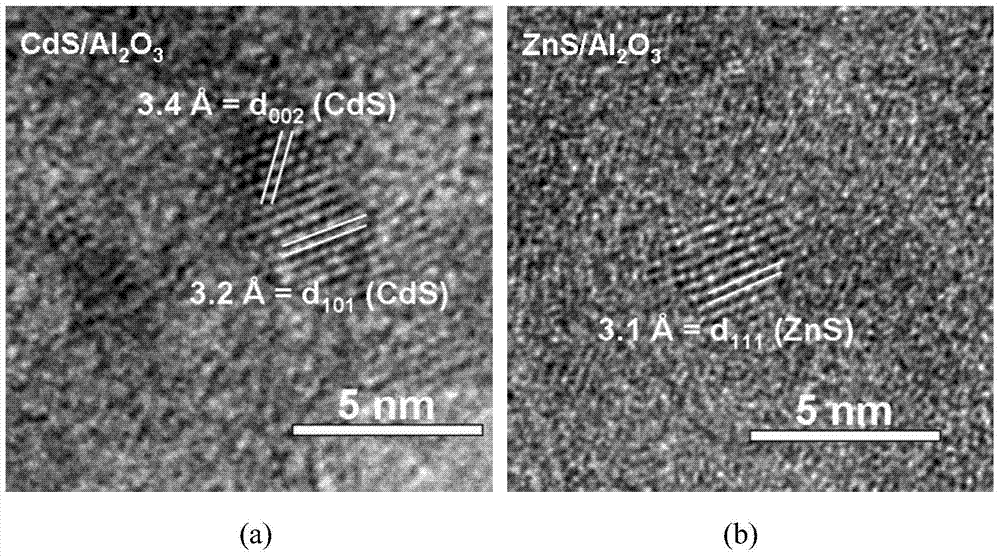

Method for using low-temperature plasma to prepare supported metal sulfide catalyst

InactiveCN103495427AGood dispersionAvoid exposureMaterial nanotechnologyMolecular sieve catalystsDispersityReaction temperature

The invention discloses a method for using low-temperature plasma to prepare a supported metal sulfide catalyst and belongs to the technical field of material science. The method is characterized by including: allowing ionization of hydrogen sulfide gas or gas containing hydrogen sulfide through gas discharge to form the low-temperature plasma distributed evenly, and using the low-temperature plasma to interact with supported metal salt precursor to generate metal sulfide. Due to the fact that the catalyst is avoided from being exposed in excessively high temperature, the prepared catalyst is free of thermal agglomeration, so that the catalyst is smaller in particle size and higher in dispersity. The method is suitable for preparation of various sulfide catalysts, metal sulfide can be supported on different materials to prepare various supported catalysts. The method has the advantages of low reaction temperature, low energy consumption, short preparation time and the like. In addition, processing objects are common metal salt, wide involve range is achieved, and the prepared catalyst is applicable to various common heterogeneous reactions.

Owner:DALIAN UNIV OF TECH

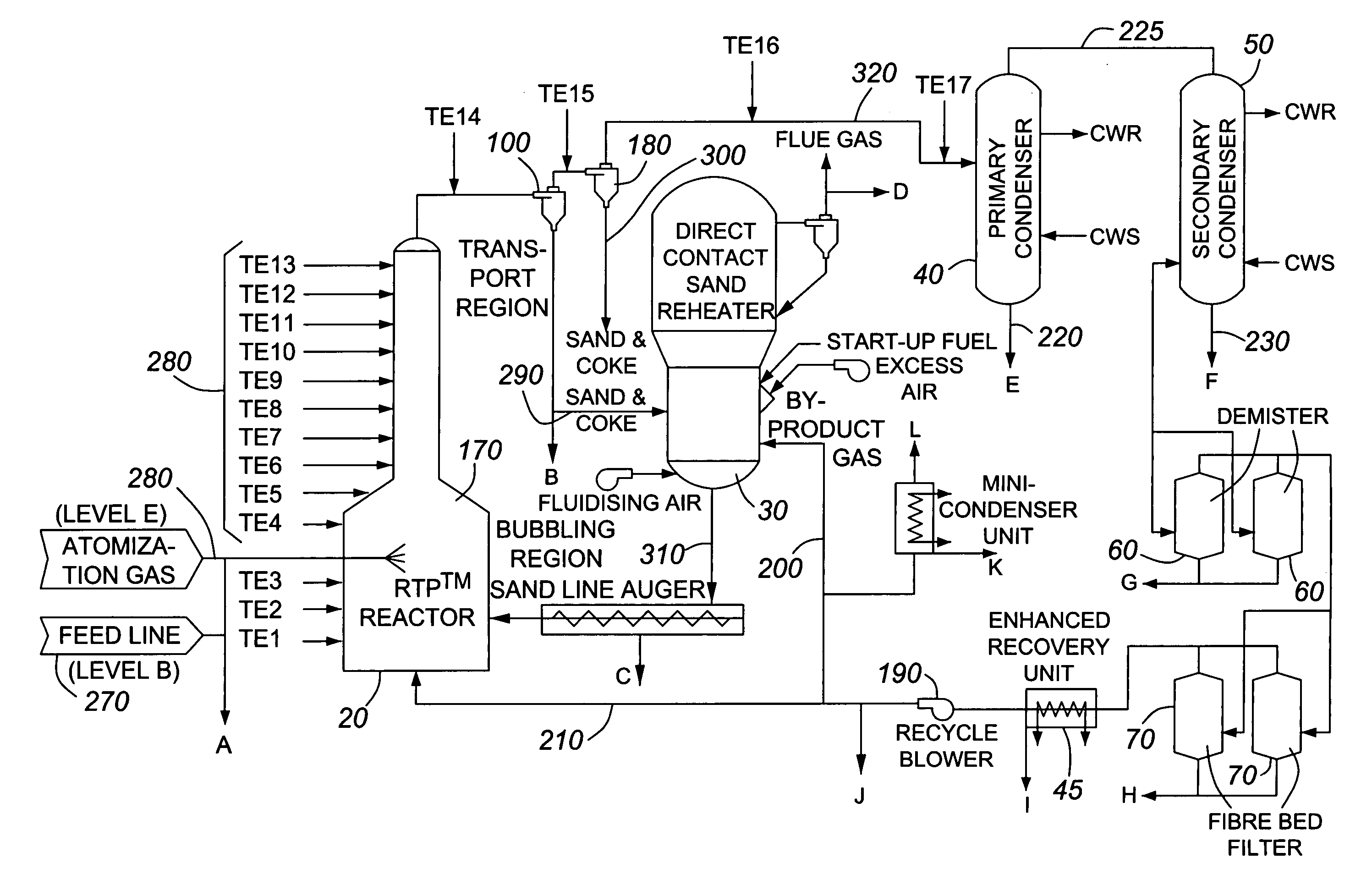

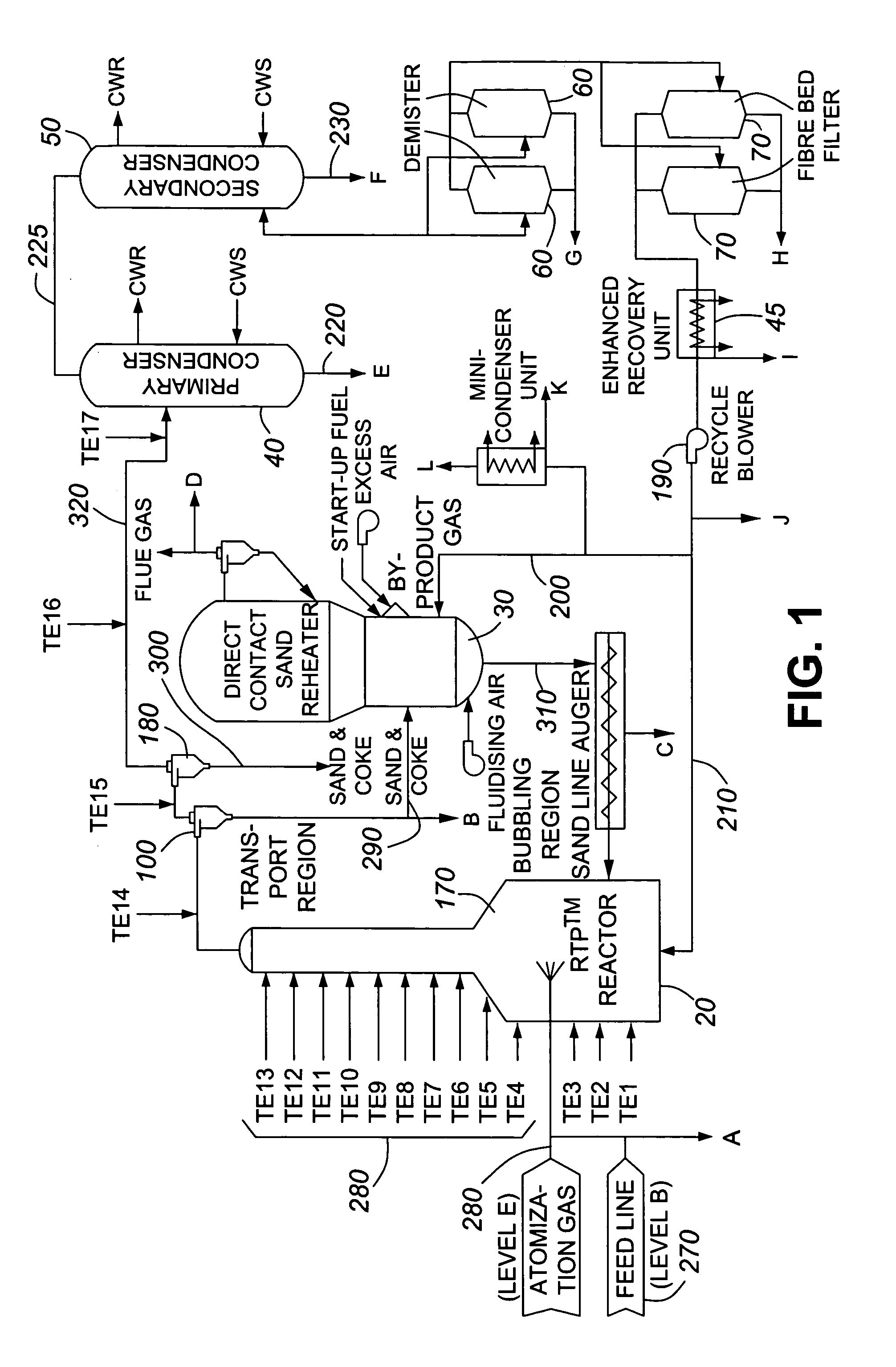

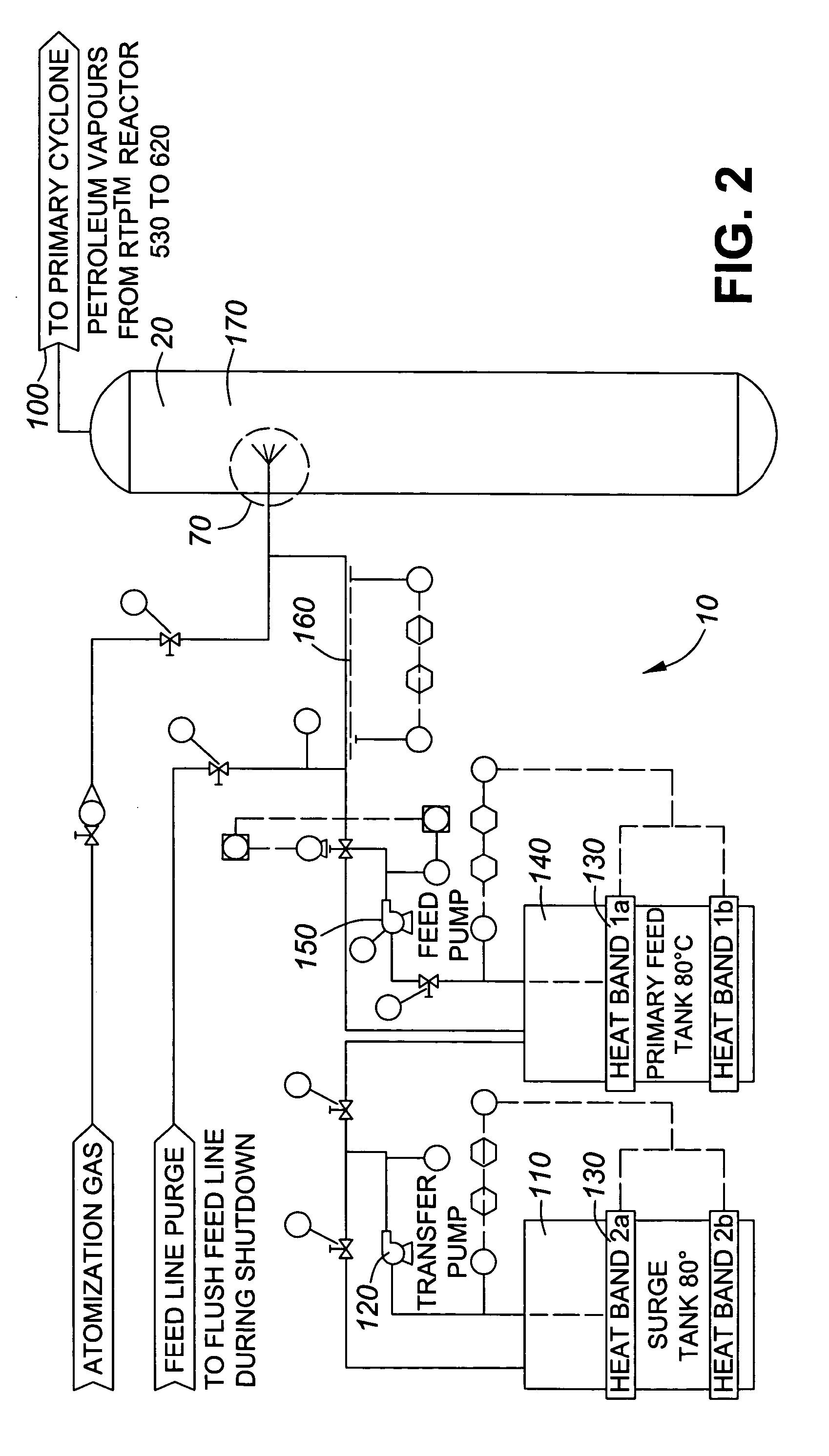

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

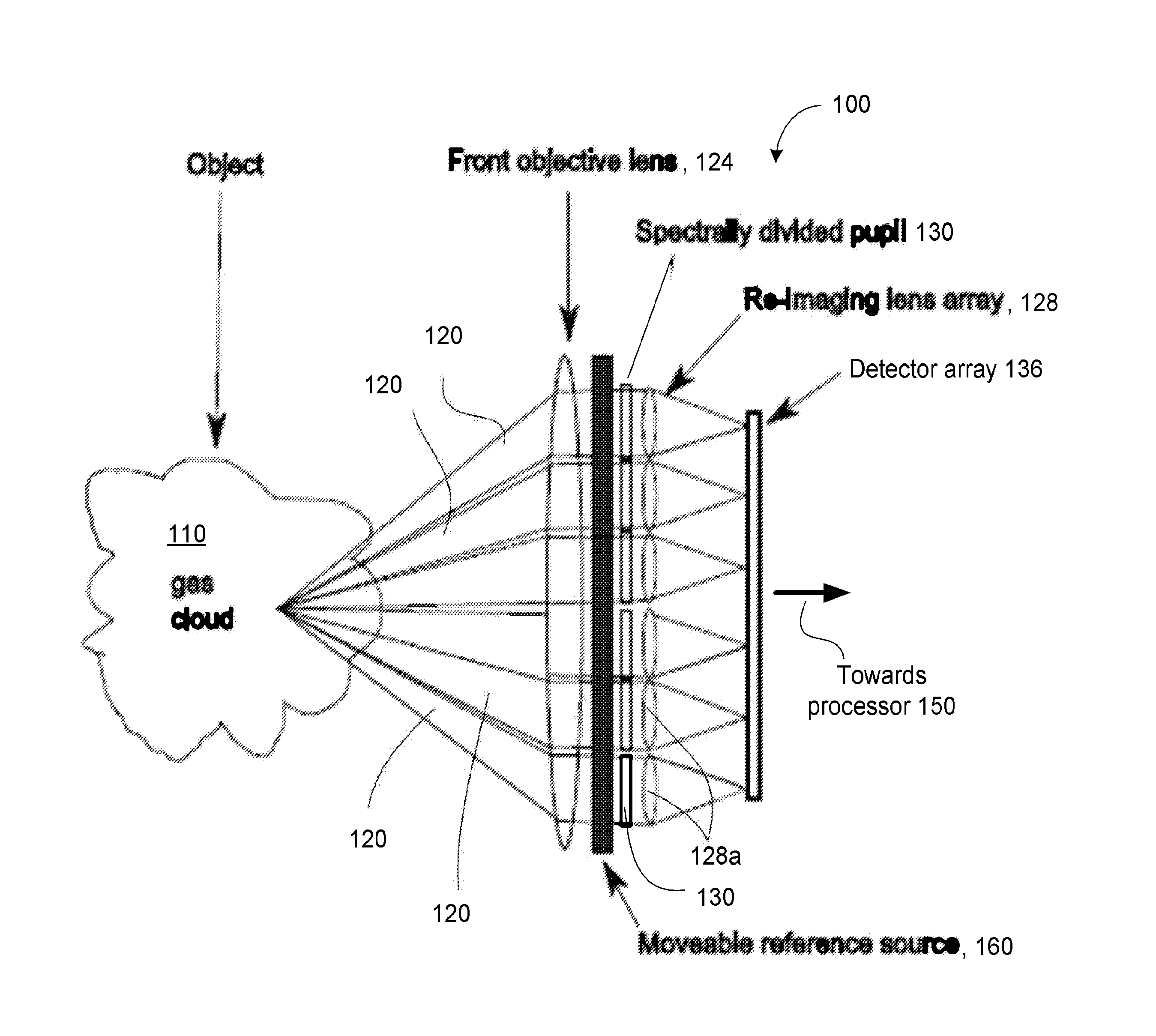

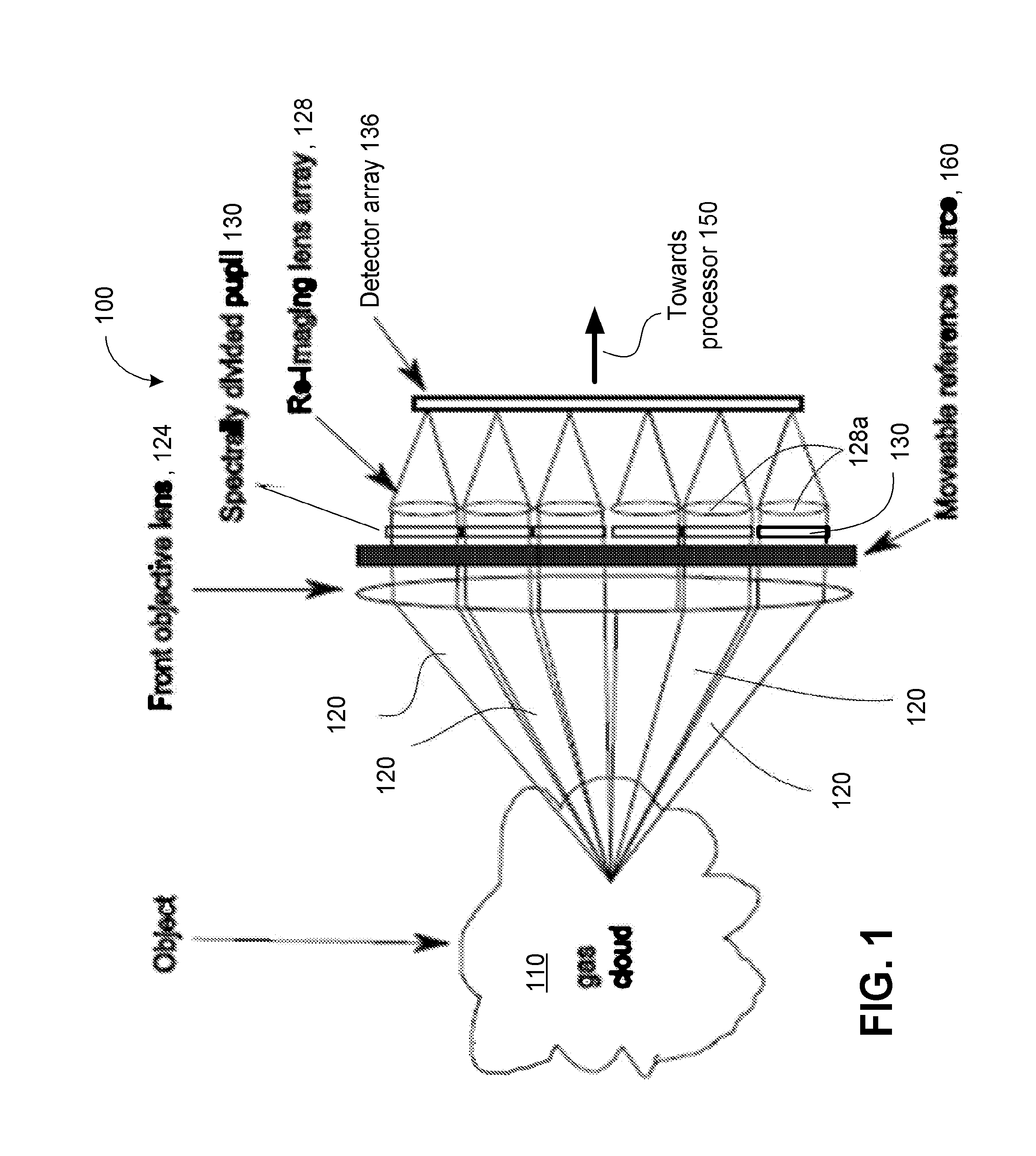

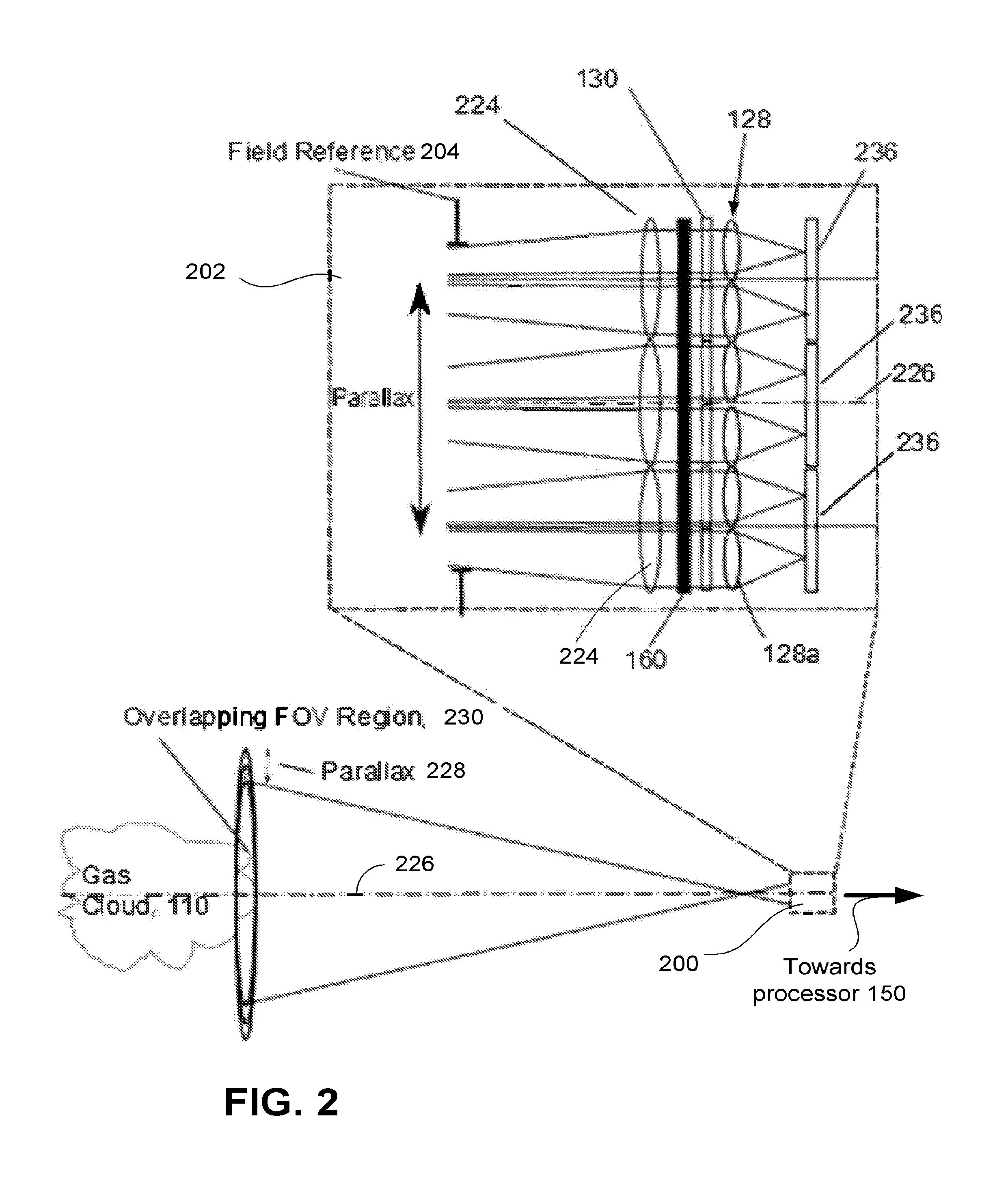

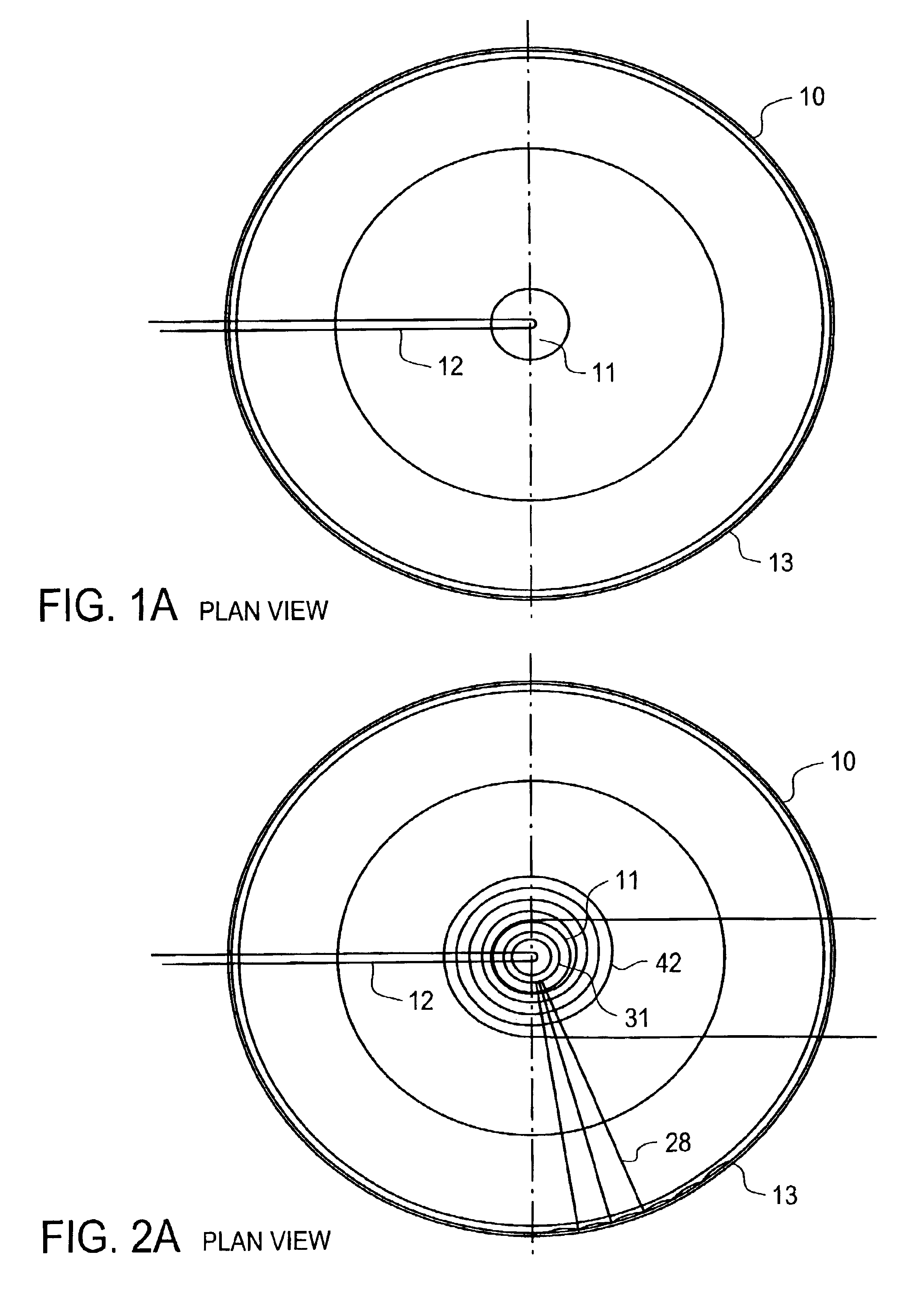

Hydrogen sulfide imaging system

ActiveUS20160349228A1Television system detailsSensing radiation from gases/flamesLength waveOptical detector

Various embodiments disclosed herein describe an infrared (IR) imaging system for detecting a gas. The imaging system can include an optical filter that selectively passes light having a wavelength in a range of 1585 nm to 1595 nm while attenuating light at wavelengths above 1600 nm and below 1580 nm. The system can include an optical detector array sensitive to light having a wavelength of 1590 that is positioned rear of the optical filter.

Owner:REBELLION PHOTONICS

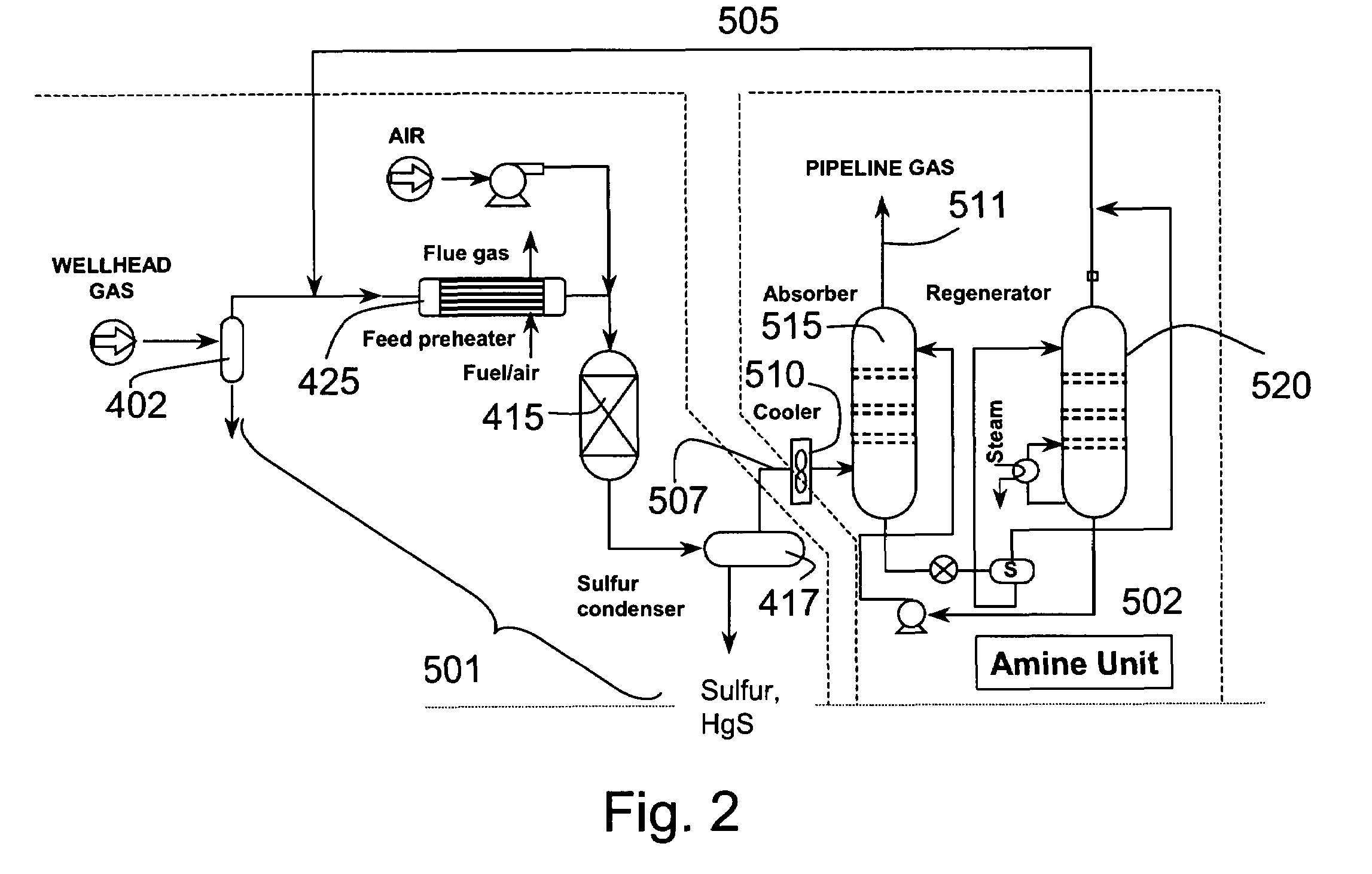

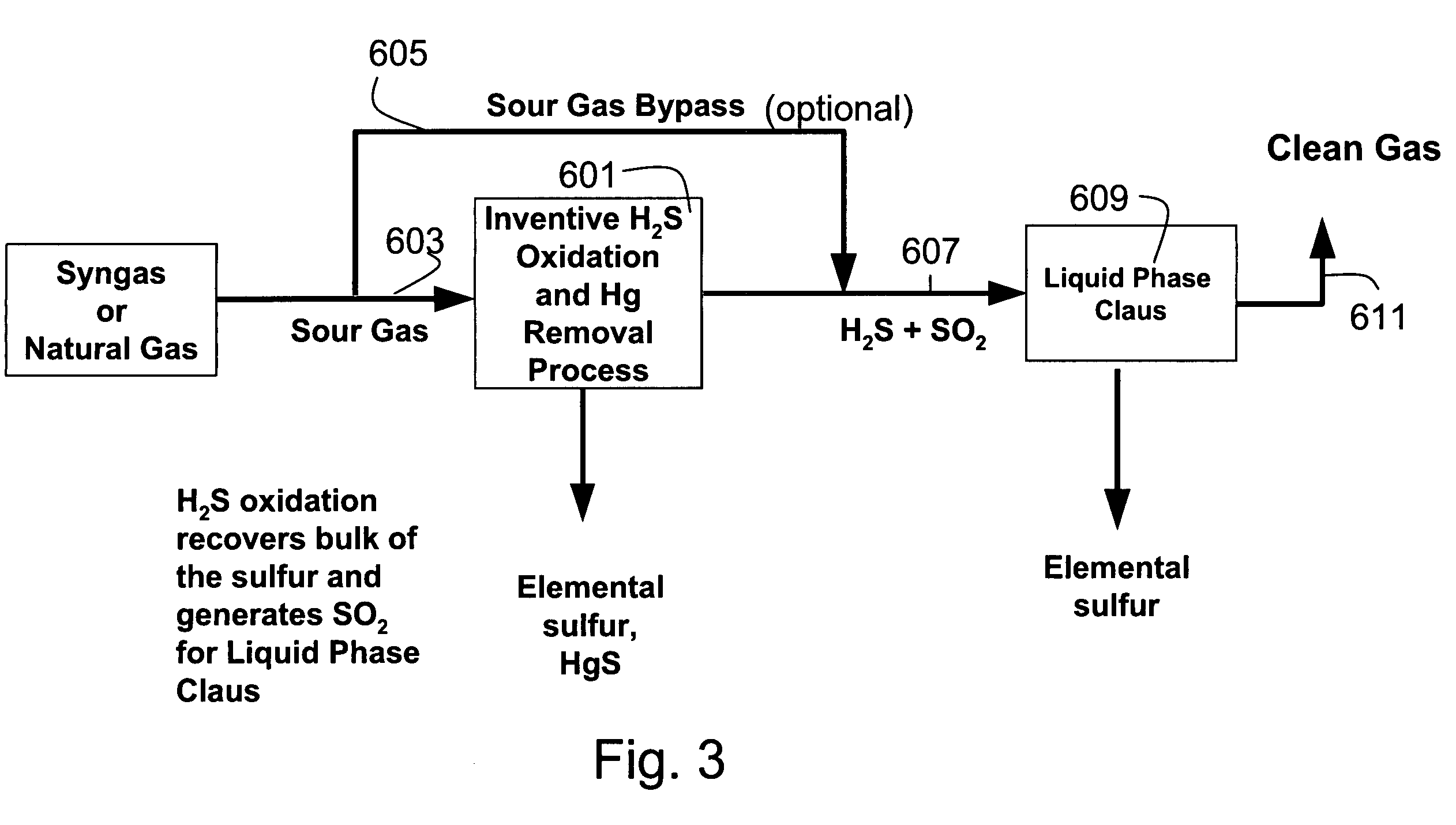

Process for the simultaneous removal of sulfur and mercury

InactiveUS7060233B1Lower capitalReduce operating costsGas treatmentUsing liquid separation agentSulfur containingInorganic sulfide

A process for removing hydrogen sulfide, other sulfur-containing compounds and / or sulfur and mercury from a gas stream contaminated with mercury, hydrogen sulfide or both. The method comprises the step of selective oxidation of hydrogen sulfide (H2S) in a gas stream containing one or more oxidizable components other than H2S to generate elemental sulfur (S) or a mixture of sulfur and sulfur dioxide (SO2). The sulfur generated in the gas stream reacts with mercury in the gas stream to generate mercuric sulfide and sulfur and mercuric sulfide are removed from the gas stream by co-condensation.

Owner:TDA RES

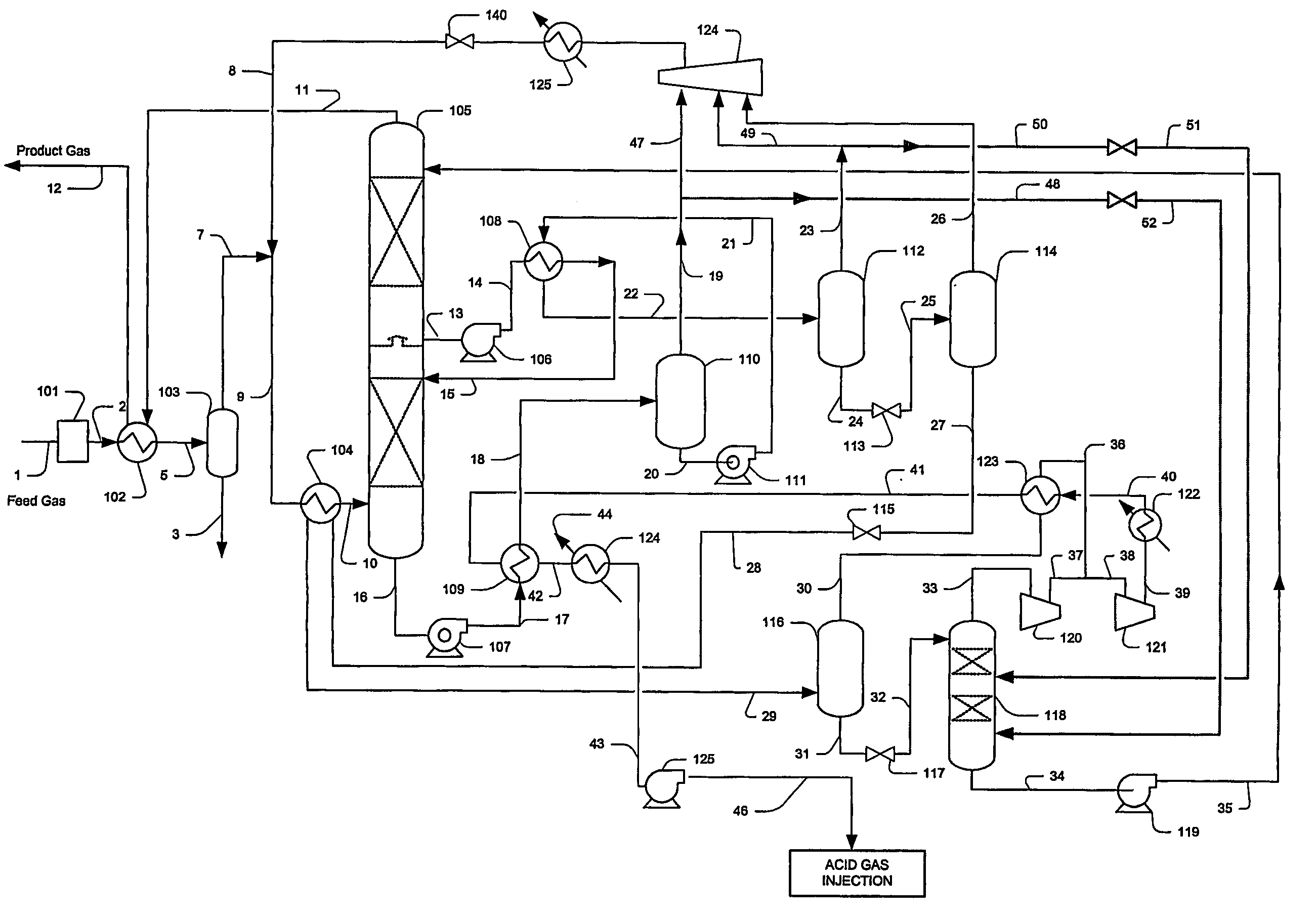

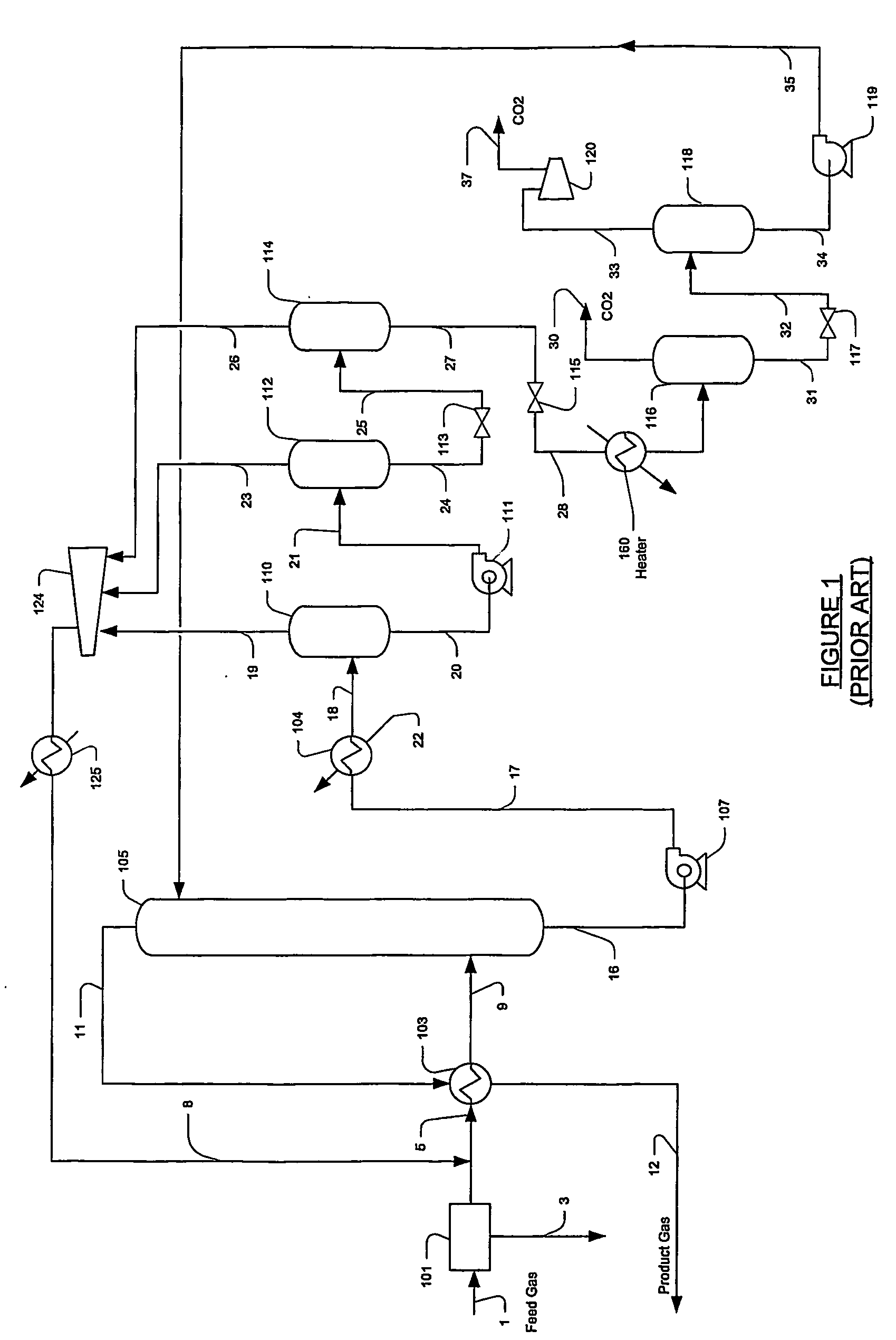

Configurations and methods of acid gas removal

A plant includes a vacuum stripper (118) that receives a lean hydrogen sulfide-containing physical solvent (32) and in which substantially hydrogen sulfide-free stripping gas (51,52) is provided by at least one of a high-pressure flash vessel (110) and a medium pressure flash vessel (112). Contemplated configurations advantageously extend the range of use for physical solvents to treat sour gas comprising carbon dioxide and hydrogen sulfide, and can be used to meet most pipeline specification of 4 ppm hydrogen sulfide.

Owner:FLUOR TECH CORP

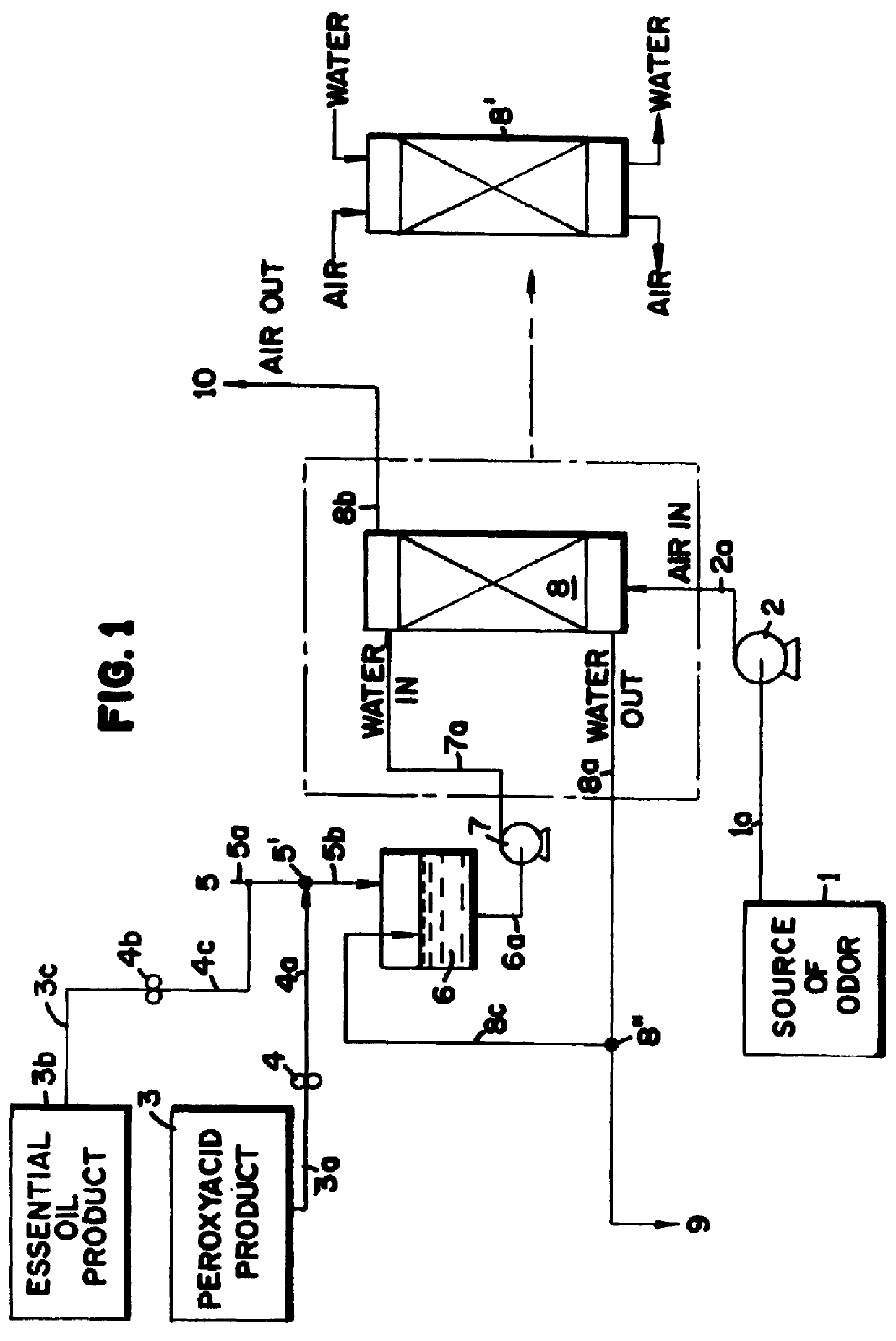

Simultaneous use of peroxygen and olefin compound in odor reduction

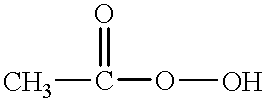

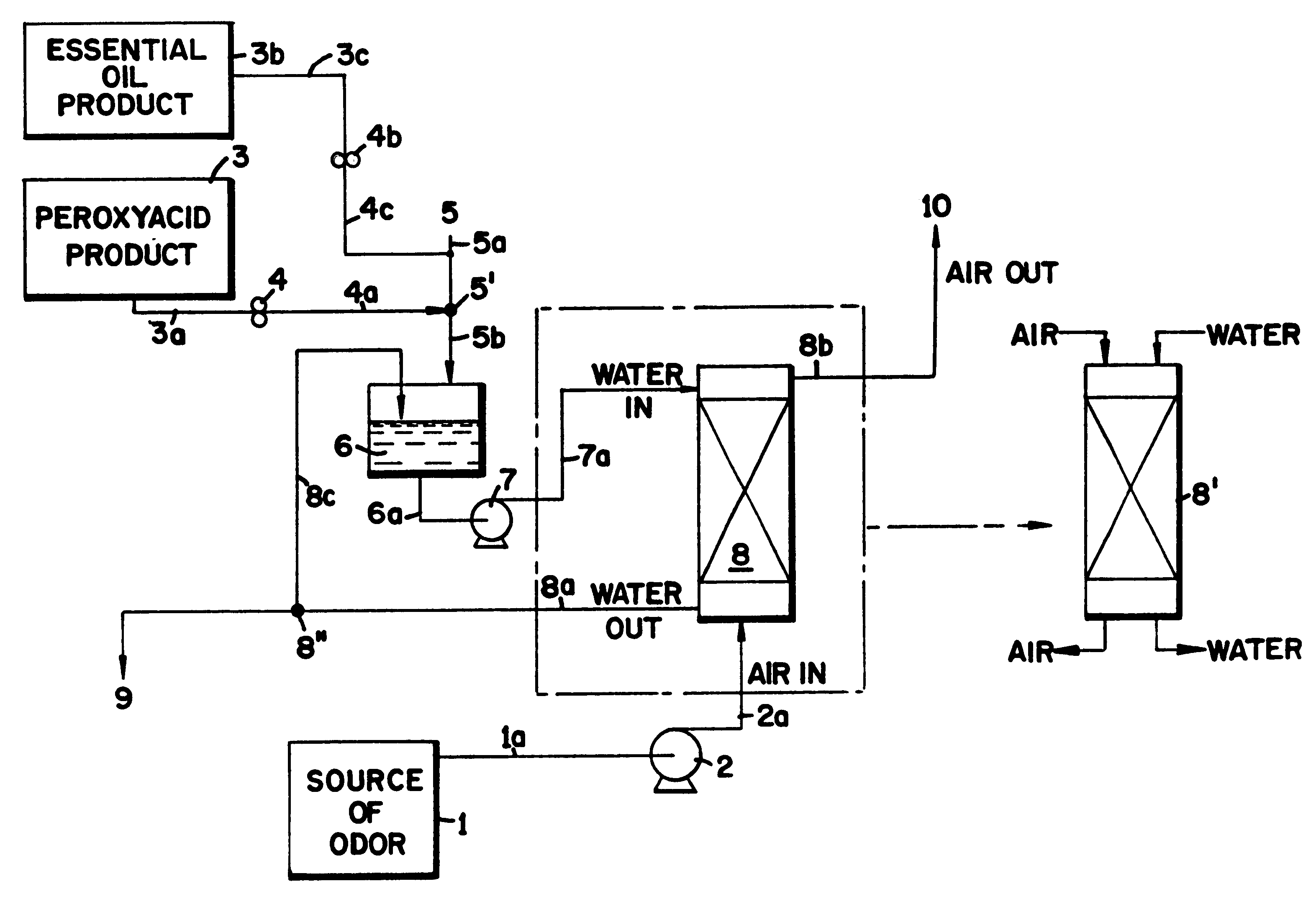

InactiveUS6277344B1Improved malodor removalEnhanced mass transferCyanogen compoundsOrganic chemistryGas phasePeroxy acid

Disclosed is a process for the treatment of a plant fluid effluent containing odor compounds including an alkyl mercaptan or an alkyl thiol, an amine compound, ammonia, hydrogen sulfide and mixtures thereof by contacting the plant effluent in either a counterflow or cocurrent flow process. In the process, the effluent is contacted with an aqueous solution comprising a peroxyacid compound and one or more essential oils. When contacted with the peroxyacid, odor compounds in the effluent are oxidized and converted from the gaseous phase into a chemically modified highly aqueous soluble phase in the aqueous treatment. In this way, odor removal from the gas is preferred and odor compounds are efficiently transferred into the aqueous treatment solution. The use of such a process produces a significant improvement in odor quality index as measured by a conventional process using an expert panel when compared to conventional treatment methods.

Owner:ECOLAB USA INC

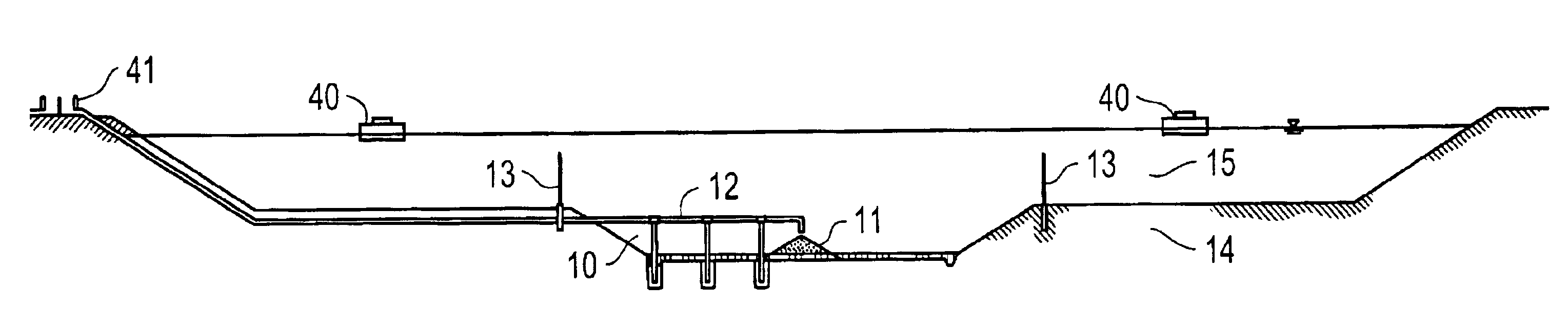

Methods and apparatus for reducing nitrate demands in the reduction of dissolved and/or atmospheric sulfides in wastewater

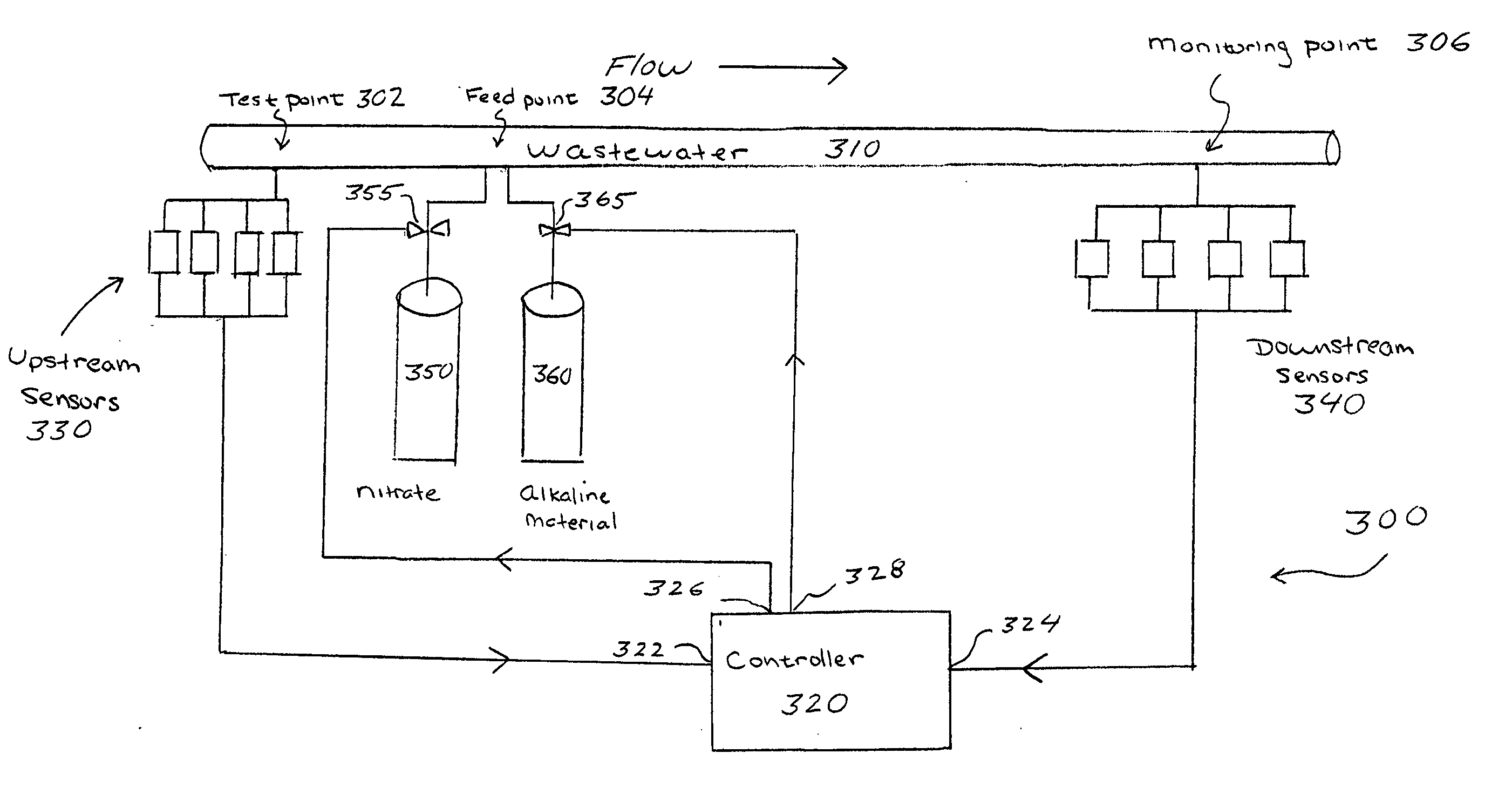

ActiveUS20040173525A1Reduce the amount requiredEasy to adaptWater treatment parameter controlOther chemical processesNitrateAtmospheric air

A method and apparatus for treating wastewater streams by adding, either separately or as a mixture, a nitrate containing compound and an alkaline material in an amount sufficient to achieve a lower concentration of atmospheric hydrogen sulfide and dissolved sulfides downstream of the addition as compared to the atmospheric hydrogen sulfide and dissolved sulfides present in the wastewater stream prior to the addition. By adding alkaline material in addition to a nitrate containing compounds, the amount of nitrate containing compound added can be reduced by at least 10% as compared to the amount of nitrate that would theoretically need to be added in the absence of alkaline material to achieve a comparable lower concentration of atmospheric hydrogen sulfide and dissolved sulfides in the wastewater stream.

Owner:EVOQUA WATER TECH LLC

Process for the manufacture of carbon disulphide

InactiveUS7763227B2Significant costSignificant designCarbon disulfideHydrocarbon from carbon oxidesHydrogenCarbonyl sulfide

A process for the manufacture of carbon disulfide comprising the following steps: (a) reacting carbon monoxide with hydrogen sulfide to form carbonyl sulfide and hydrogen; (b) contacting the carbonyl sulfide formed in step (a) with a catalyst effective for disproportionating carbonyl sulfide into carbon disulfide and carbon dioxide.

Owner:SHELL OIL CO

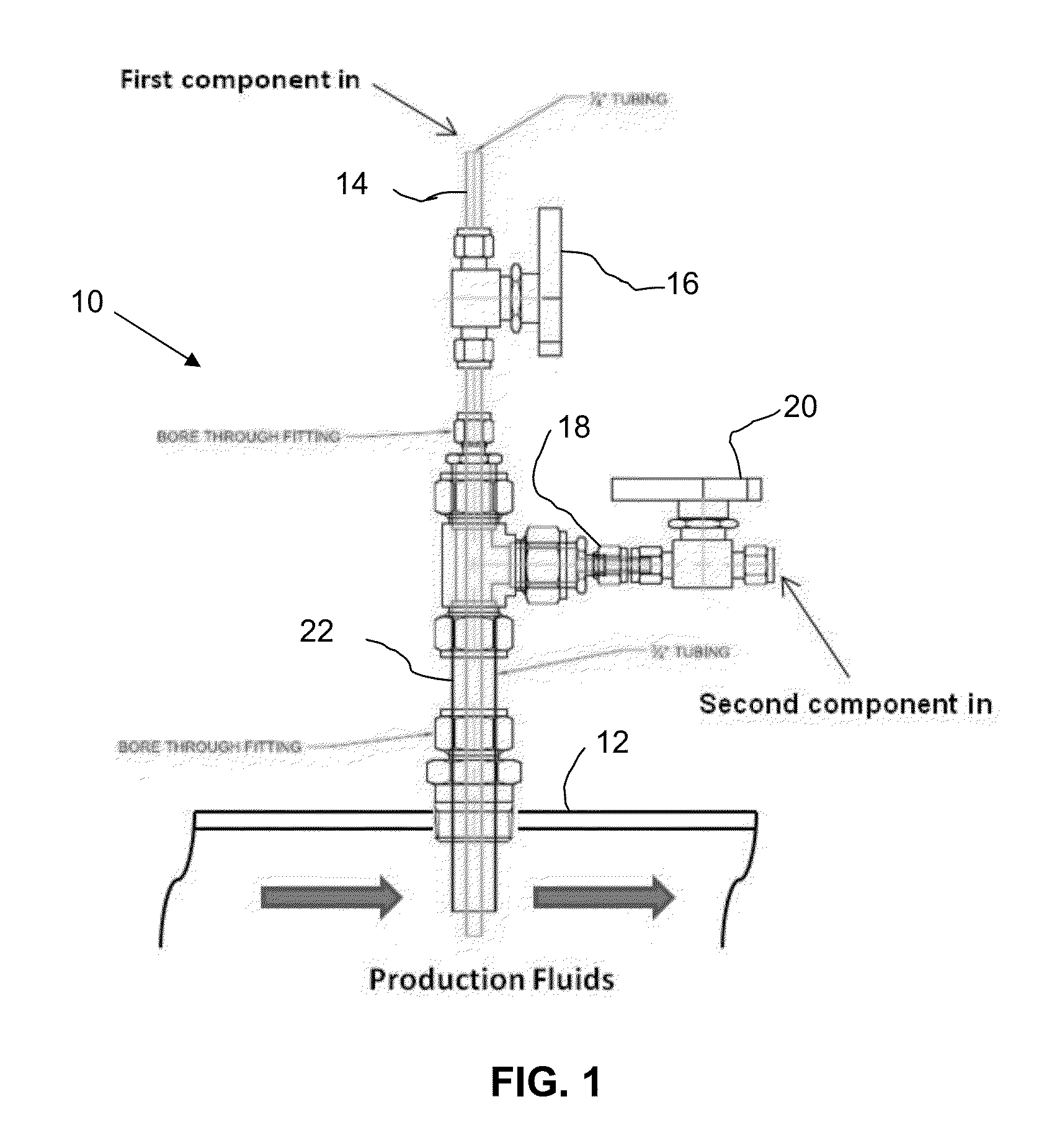

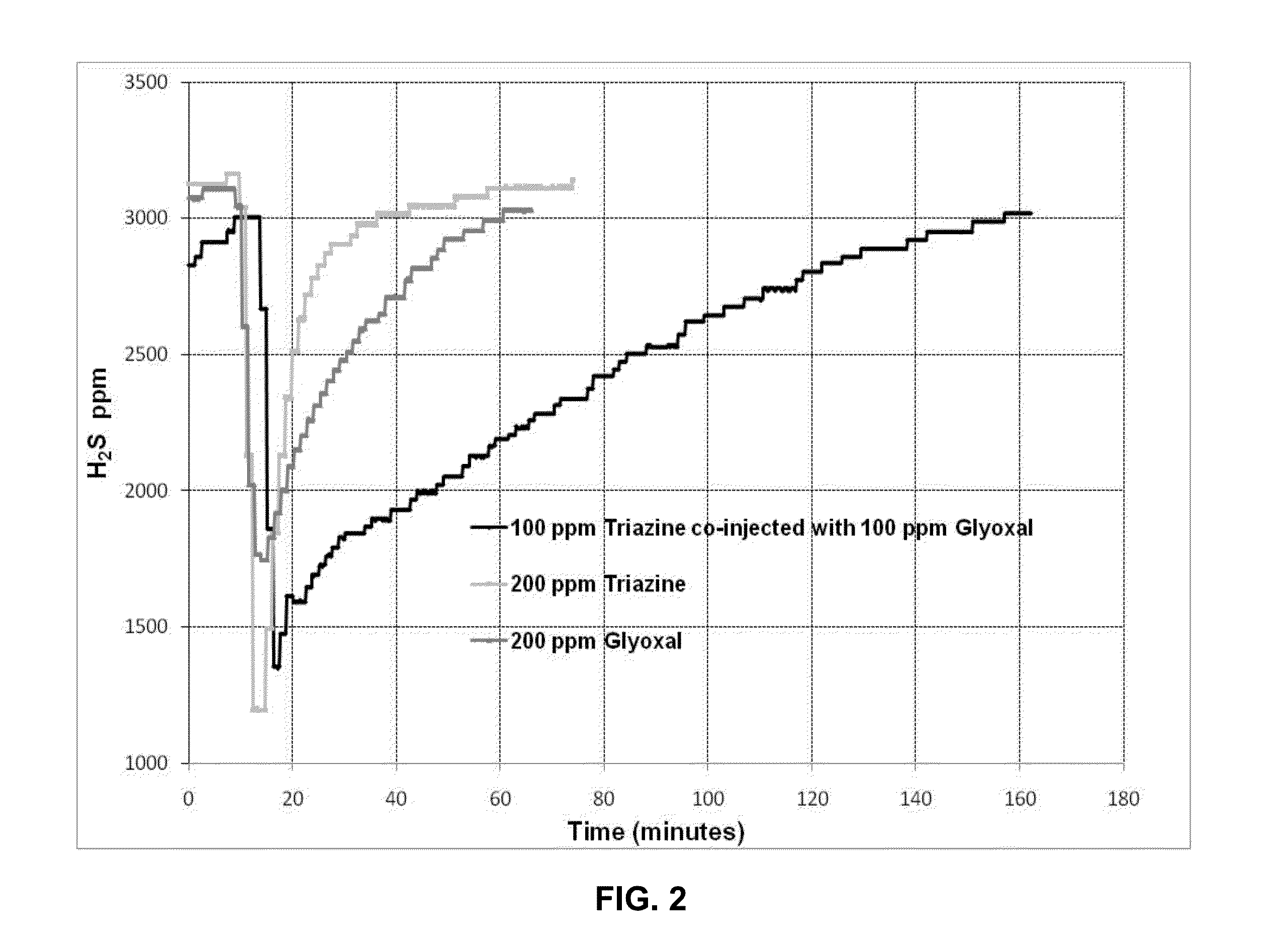

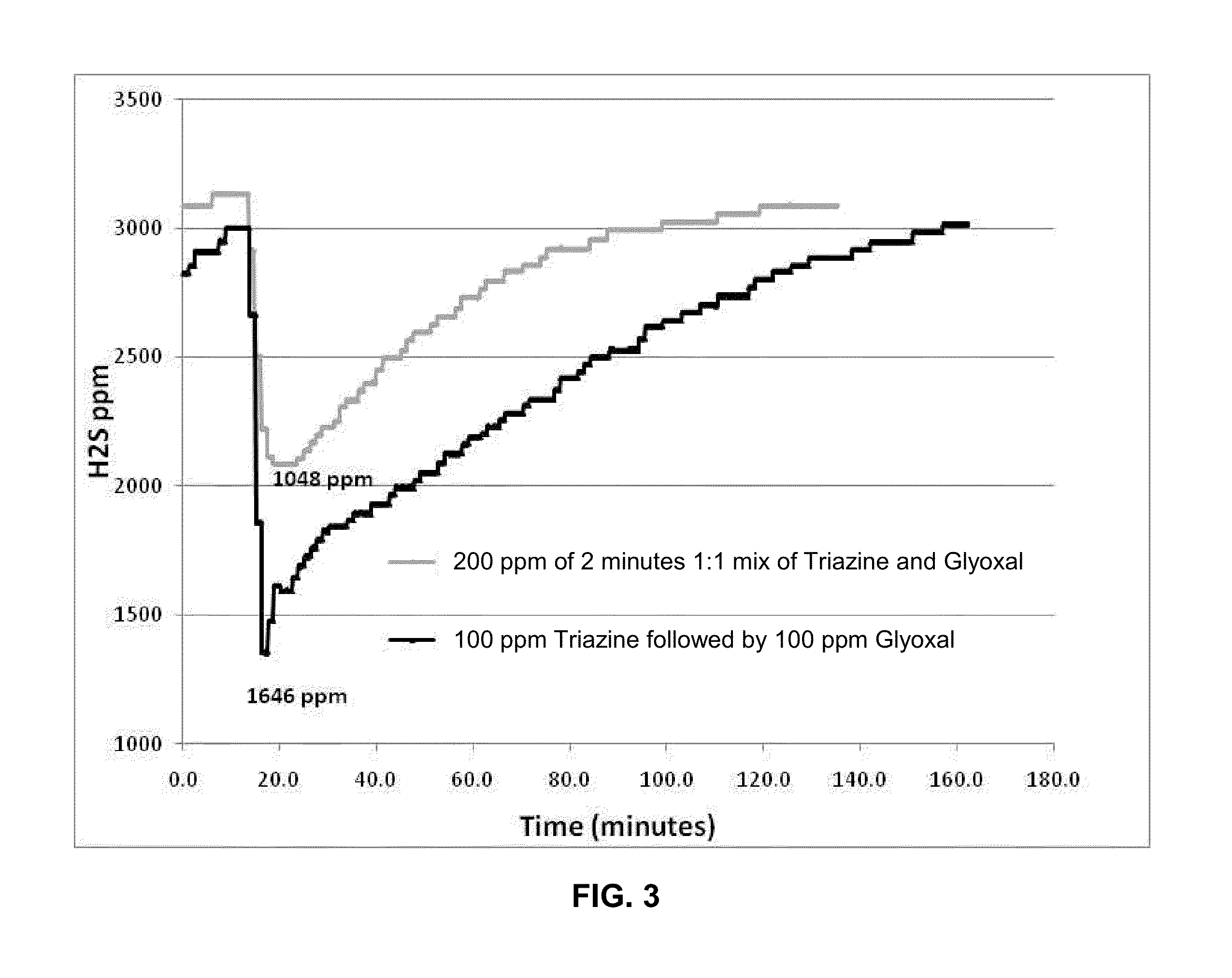

Synergistic Method for Enhanced H2S/Mercaptan Scavenging

The use of a dialdehyde (e.g. glyoxal) and a nitrogen-containing scavenger (e.g. a triazine) when injected separately in media containing hydrogen sulfide (H2S) and / or mercaptans to scavenge H2S and / or mercaptans therefrom gives a synergistically better reaction rate and overall scavenging efficiency, i.e. capacity, over the use of the dialdehyde or the nitrogen-containing scavenger used alone, but in the same total amount of the dialdehyde and nitrogen-containing scavenger. The media may include an aqueous phase, a gas phase, a hydrocarbon phase and mixtures of a gas and / or hydrocarbon phase with an aqueous phase.

Owner:BAKER HUGHES INC

Peroxyacid compound use in odor reduction

InactiveUS6015536AReduce concentrationLess objectionable odor levelUsing liquid separation agentChemical/physical processesGas phasePeroxy acid

Disclosed is a process for the treatment of a plant fluid effluent containing odor compounds including an alkyl mercaptan or an alkyl thiol, an amine compound, ammonia, hydrogen sulfide and mixtures thereof by contacting the plant effluent in either a counterflow or cocurrent flow process. In the process, the effluent is contacted with an aqueous solution comprising a peracid compound. When contacted with the peracid, odor compounds in the effluent are oxidized and converted from the gaseous phase into a chemically modified highly aqueous soluble phase in the aqueous treatment. In this way, odor removal from the gas is preferred and odor compounds are efficiently transferred into the aqueous treatment solution. The use of such a process produces a significant improvement in odor quality index as measured by a conventional process using an expert panel when compared to conventional treatment methods.

Owner:ECOLAB USA INC

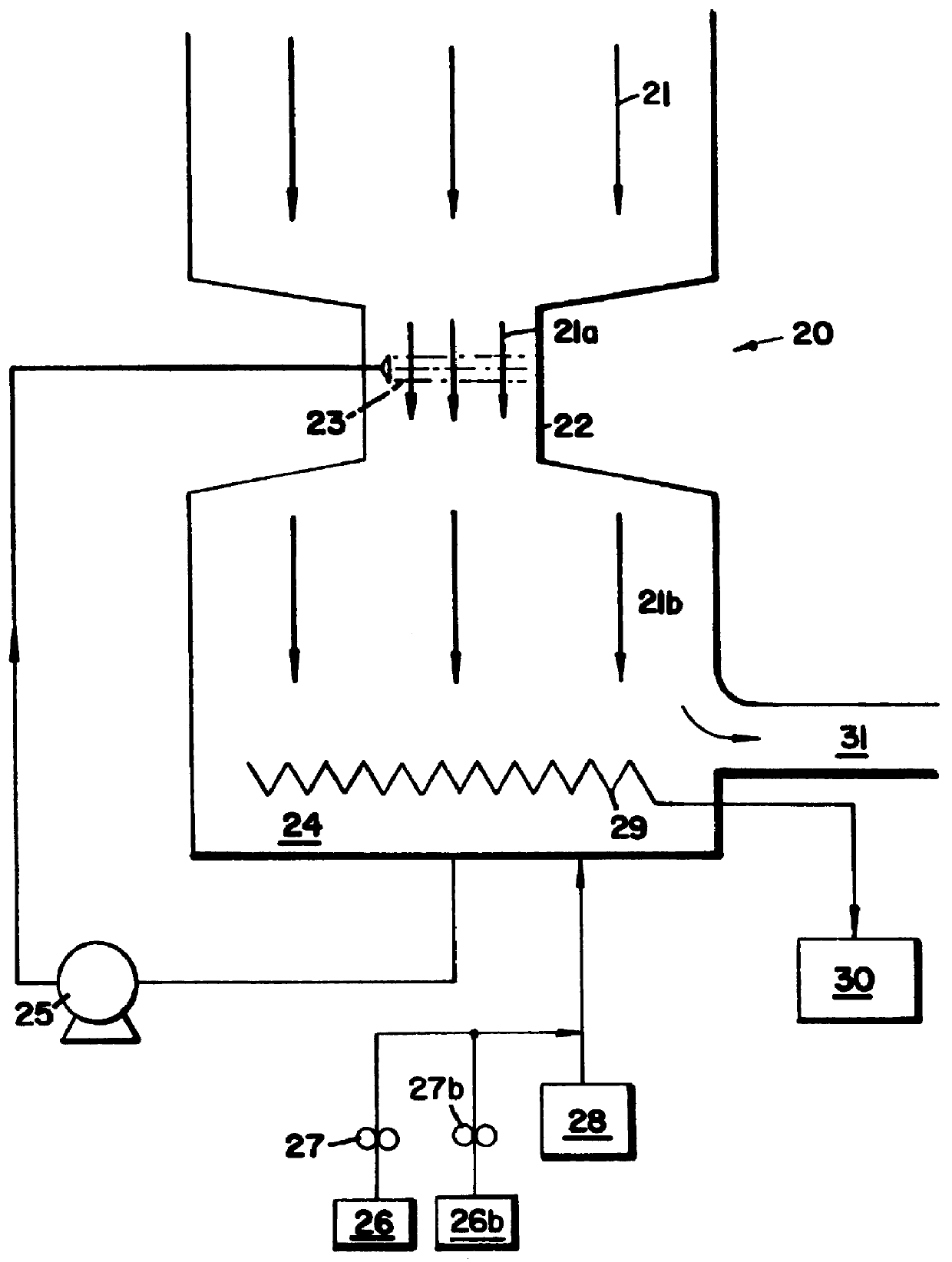

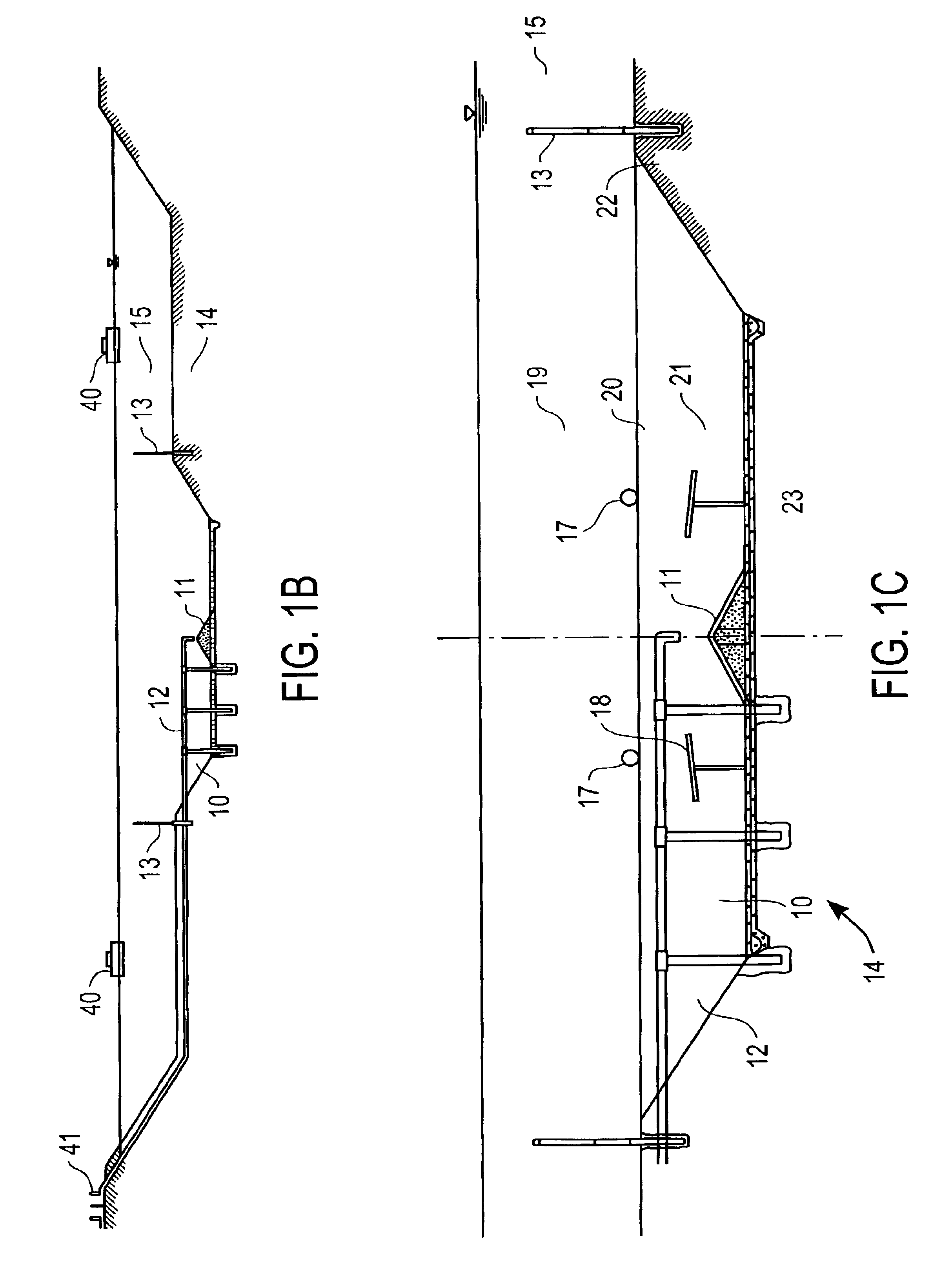

Apparatus to establish and optimize sedimentation and methane fermentation in primary wastewater ponds

InactiveUS6923906B2Raise the pHIncreases the rate of die-away of pathogenic bacteriaLiquid degasificationMixing methodsSludgeIncrease ph

Owner:GREEN FRANKLIN BAILEY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com