Method for using low-temperature plasma to prepare supported metal sulfide catalyst

A technology of metal sulfide and low-temperature plasma, which is applied in the field of material science, can solve problems such as increased operating costs, agglomeration of active phases, and reduced dispersion, and achieves the effects of short preparation time, small particle size, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

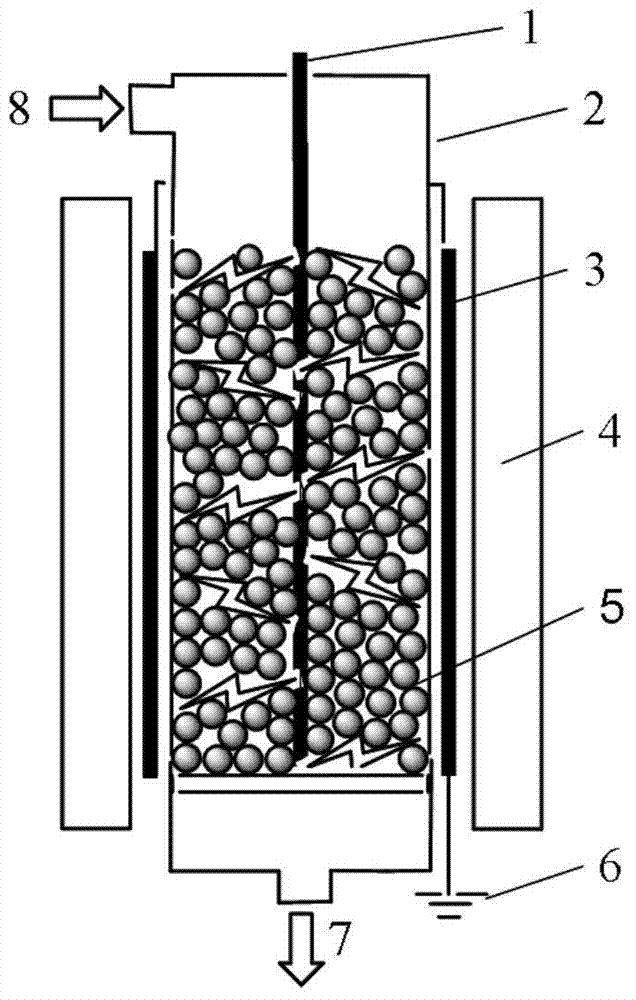

Method used

Image

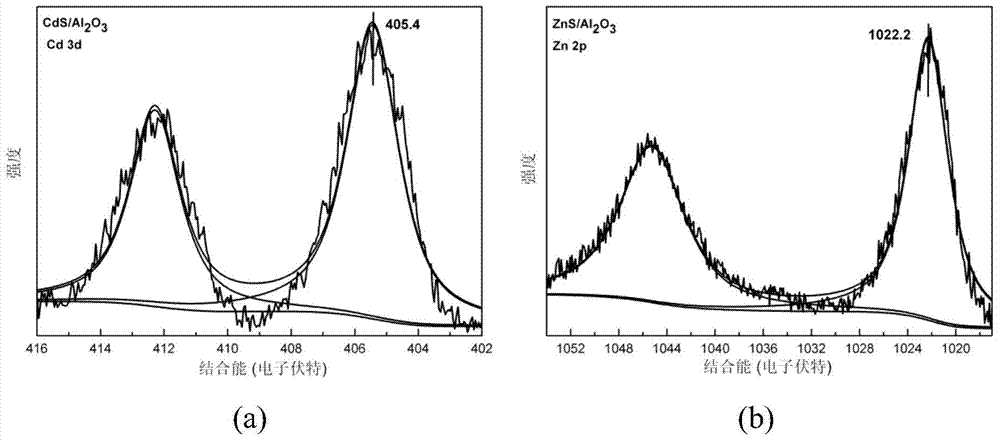

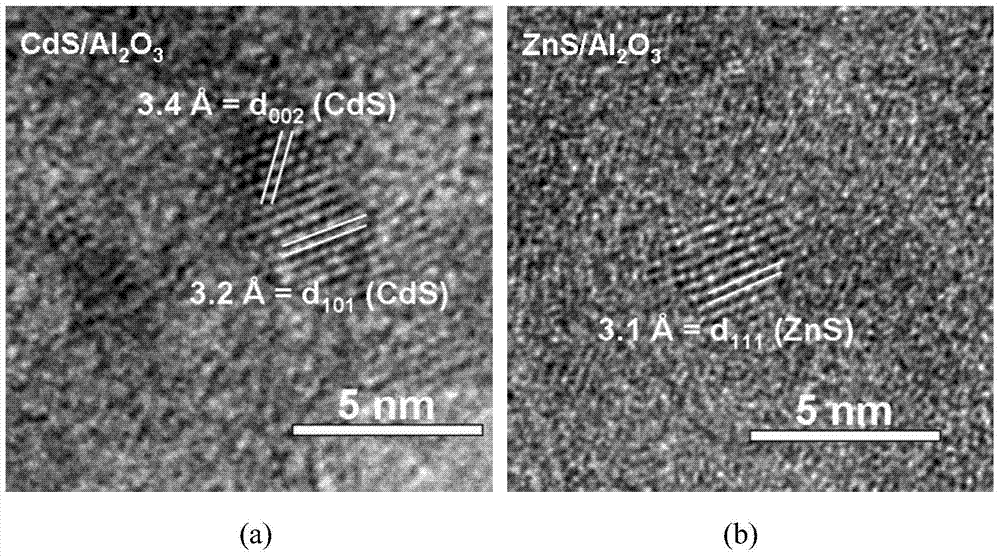

Examples

Embodiment 1

[0026] Weigh 3 grams of γ-Al with a particle size of 40-60 mesh 2 o 3 carrier, take 0.80 g of Cd(NO 3 ) 2 4H 2 O was dissolved in 3 ml of deionized water, the solution was slowly dropped into the carrier and stirred evenly, impregnated at room temperature for 8 hours, and then dried in an oven at 120 °C for 12 hours, the obtained catalyst precursor was marked as Cd(NO 3 ) 2 / Al 2 o 3 .

Embodiment 2

[0028] Weigh 3 grams of SiO with a particle size of 40-60 mesh 2 carrier, take 0.80 g of Cd(NO 3 ) 2 4H 2 O was dissolved in 3 ml of deionized water, the solution was slowly dropped into the carrier and stirred evenly, impregnated at room temperature for 8 hours, and then dried in an oven at 120 °C for 12 hours, the obtained catalyst precursor was marked as Cd(NO 3 ) 2 / SiO 2 .

Embodiment 3

[0030] Take by weighing 3 grams of particle size and be the gac carrier of 40-60 purpose, get 0.80 gram of Cd(NO 3 ) 2 4H 2 O was dissolved in 3 ml of deionized water, the solution was slowly dropped into the carrier and stirred evenly, impregnated at room temperature for 8 hours, and then dried in an oven at 120 °C for 12 hours, the obtained catalyst precursor was marked as Cd(NO 3 ) 2 / C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com