Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2469results about How to "Short preparation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

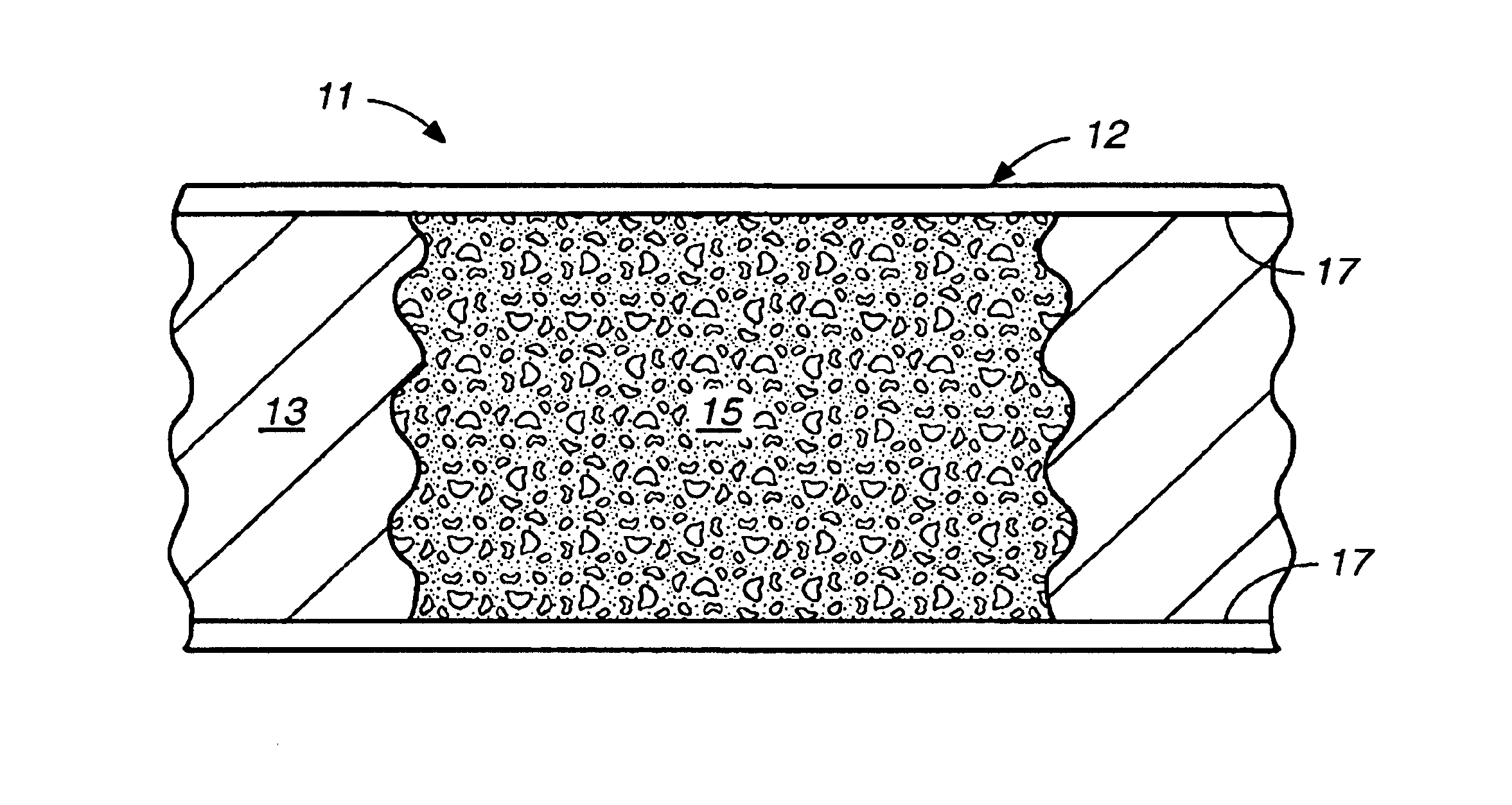

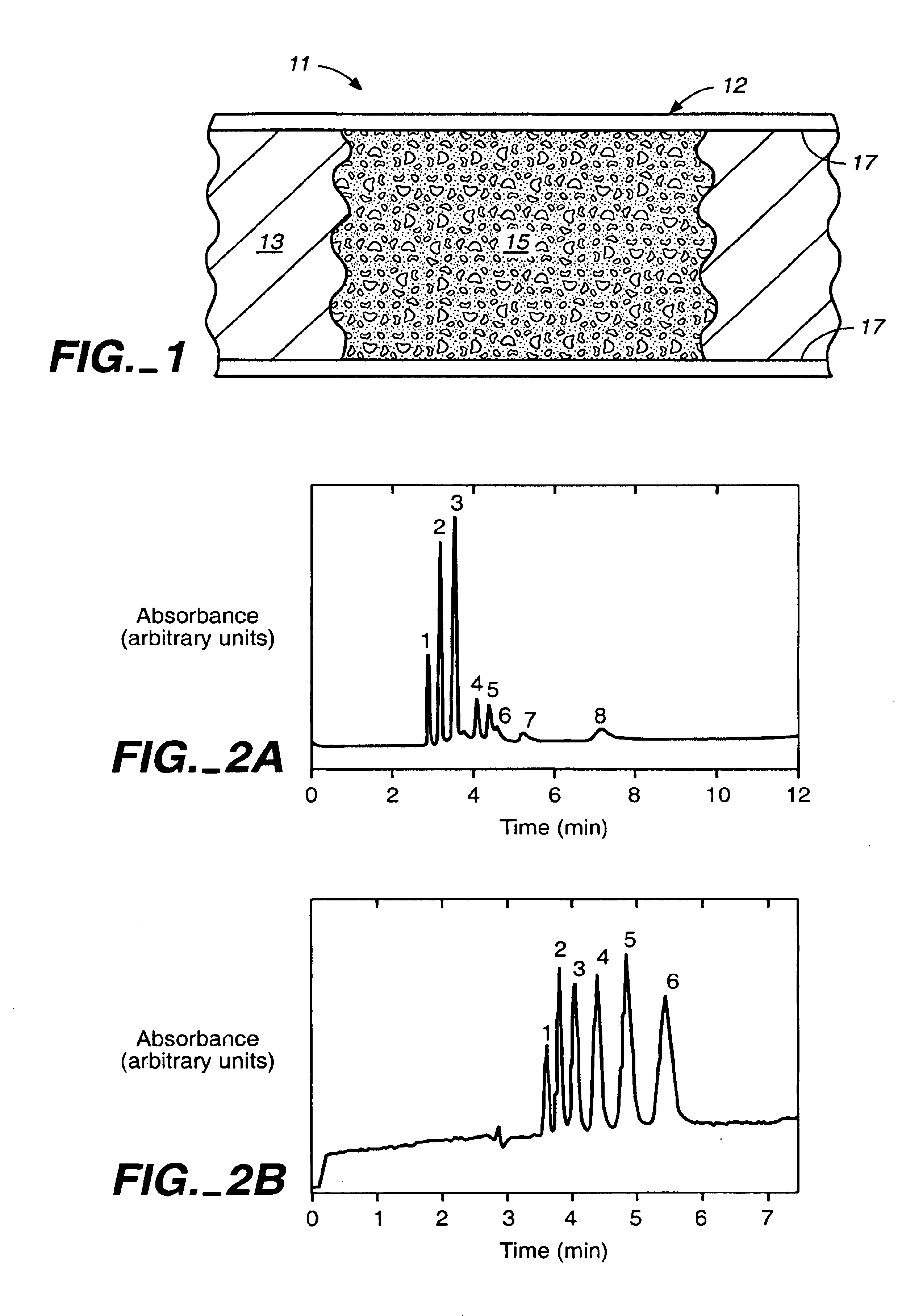

Photopolymerized sol-gel column and associated methods

InactiveUS6866785B2Simple preparationShort preparation timeIon-exchange process apparatusComponent separationChemistrySol-gel

A separation column and a method of making the separation column are provided. The separation column includes a separation channel and fritless separation medium in the channel. The separation medium includes a porous matrix, and the porous matrix includes a metal organic polymer, such as a photopolymer. The separation medium can be used to separate a sample of analytes.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Method for obtaining release agent layer on base plate and composite material containing base plate and release agent layer

ActiveCN105238216AAvoid stickingPlay an isolation roleLayered productsEpoxy resin coatingsTitaniumMaterials science

The invention relates to the field of release agents, in particular to a method for obtaining a release agent layer on a base plate and a composite material containing the base plate and the release agent layer. The method for obtaining the parting agent layer on the base plate comprises coating a release agent on the base plate, and drying to form the parting agent layer on the base plate. The method is characterized in that the release agent comprises water, alcohol, epoxy resin and Al2O3 powder, wherein relative to 100g of Al2O3 powder, the dosage of the water is 300-600mL, the dosage of the alcohol is 300-600mL, and the dosage of the epoxy resin is 5-15mL. The release agent can be online directly sprayed on the surface of a composite titanium board, and can be quickly cured to form a self-drying type coating to achieve a parting effect, so that in a 4-6h constant-temperature process at 800-1000 DEG C and a rolling process of a titanium steel composite board, adhesion and surface roughness increase phenomena of a titanium-titanium interface are avoided, and the yield and the production efficiency for titanium steel composite board processing are improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

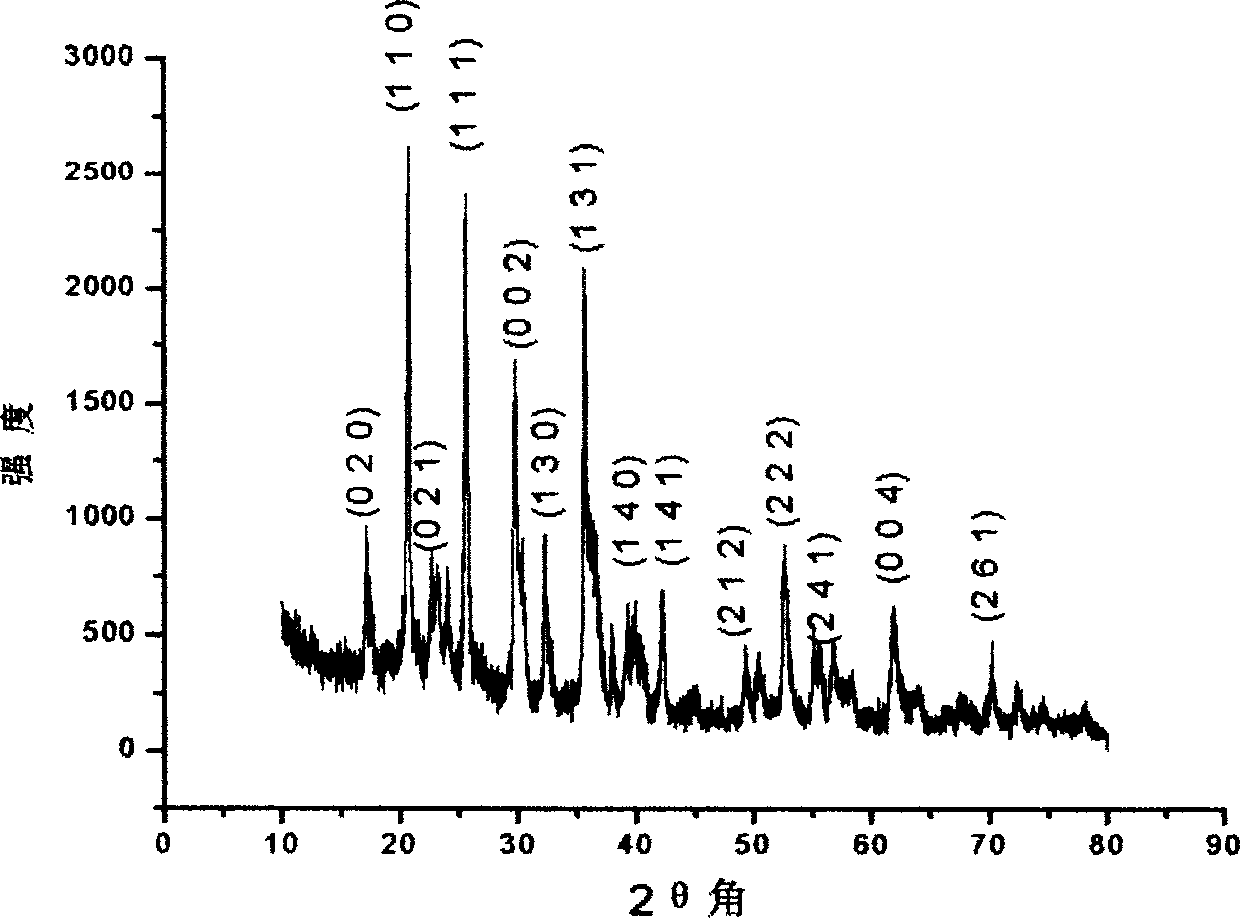

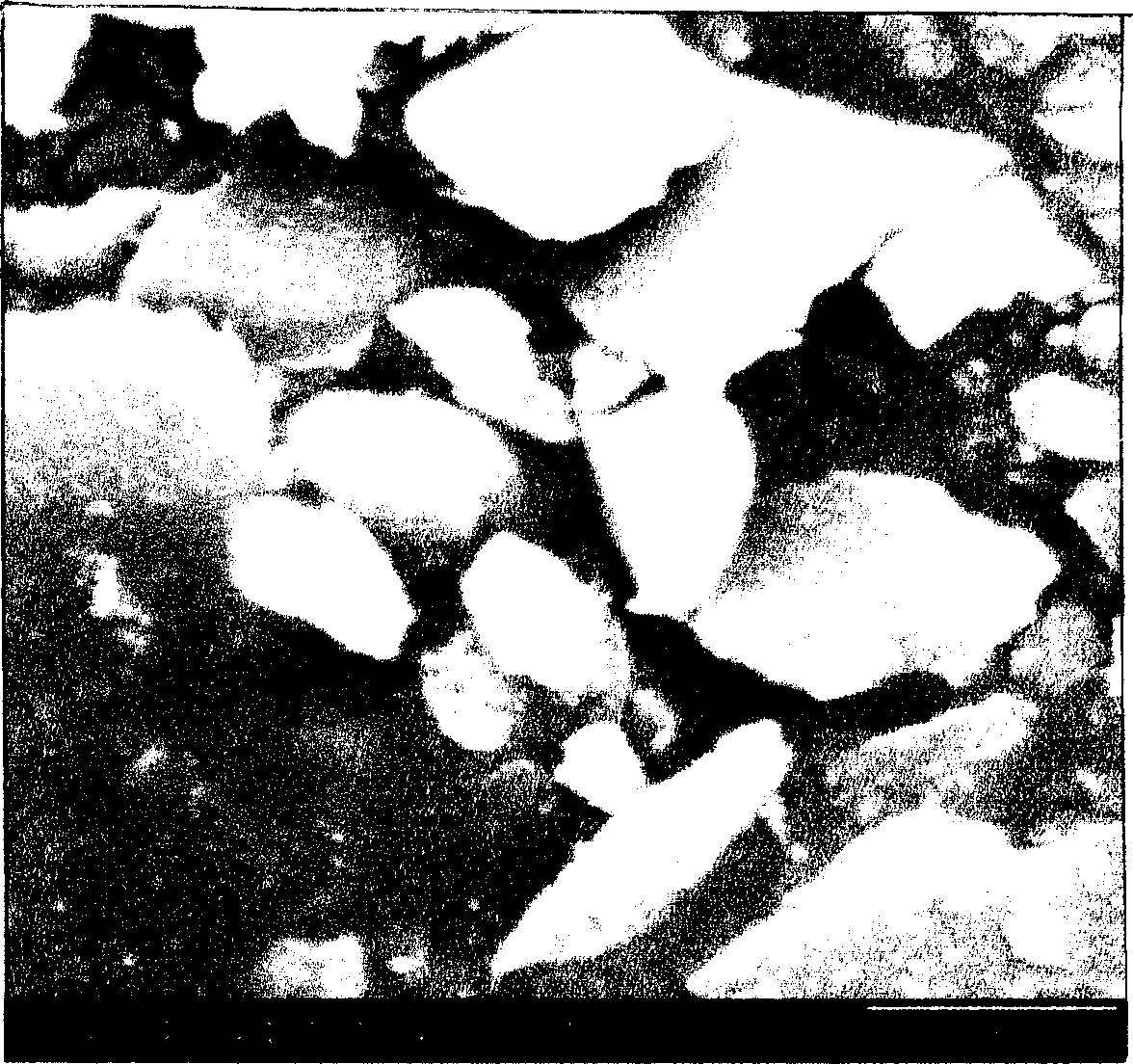

Preparation method of multicrystal LiFePO4 powder having olivine structure

InactiveCN1410349ASolve easy oxidationSolve precipitationCell electrodesRare earth metal compoundsOrganic acidGranularity

A polycrystalline LiFePO4 powder with olivine structure is prepared from Fe(Ac)2, FeSO4.7H2O, Ba(Ac)2 and organic acid by the sol-gel method. Its advantages are short period, low burning temp., low energy consumption, high purity and electric conductivity, and high granularity uniformity. It is suitable for making Li-ion battery.

Owner:TSINGHUA UNIV

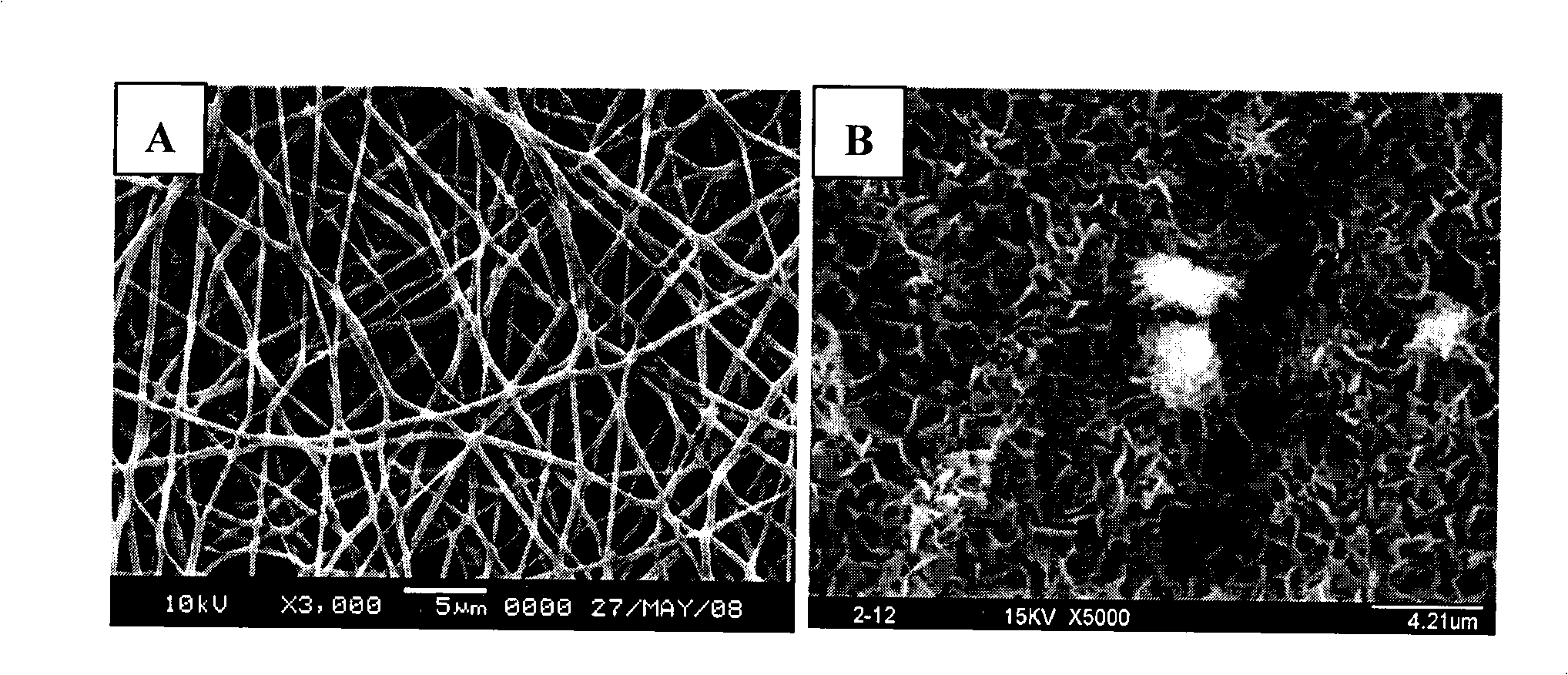

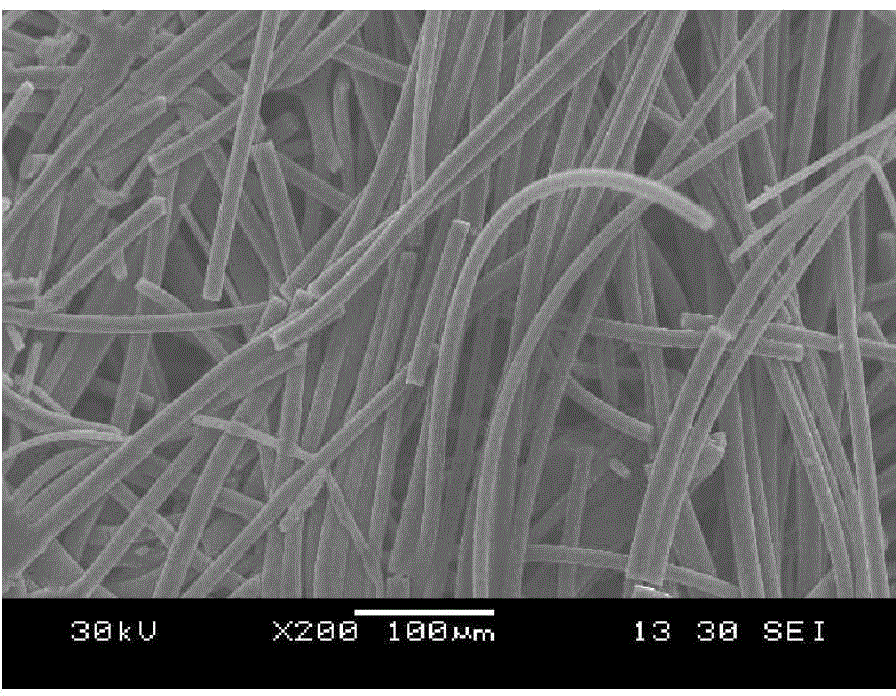

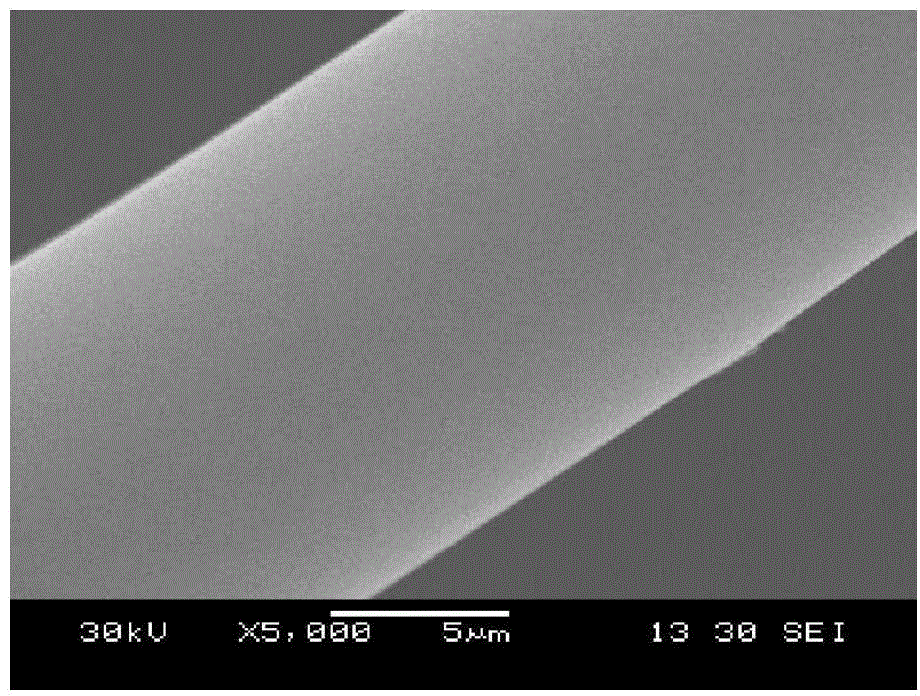

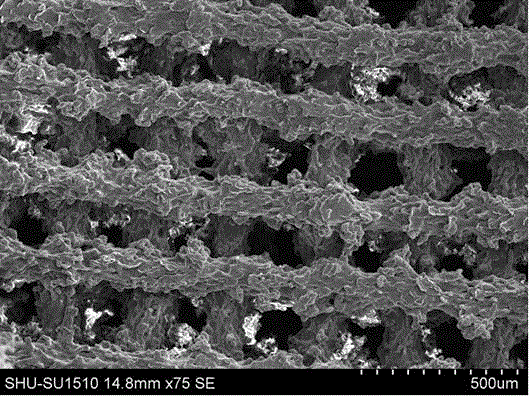

Method for preparing galvanic deposit calcium phosphorus mineralized layer superfine fibre bone material

The invention relates to a method for preparing superfine fiber bone materials of an electrodeposition calcium phosphate mineralized layer, which comprises the following steps: firstly, high-polymer superfine fibers are prepared on the surface of a metal electrode by adoption of electrostatic spinning and taken as an electrochemical deposition template; a layer of bone salt ingredients which are rich in calcium and phosphor is deposited on the surface of the fibers by the constant-voltage or constant-current deposition technology; mineralized superfine fibers are soaked into 0.1 to 1.0 mol per liter of NaOH solution for 1 to 24 hours; mineralized electro spinning fibers are subjected to die stamping into blocks under the pressure of between 10 and 40 MPa; and the porous bone materials with a porosity between 50 and 90 percent and a pore diameter between 50 and 500 micrometers are processed by the salt particle leaching / gas foaming technology, and are used for bone defect restoration after freeze-drying sterilization. The porous bone materials prepared by the method have better biocompatibility; and the electrochemical deposition technology can prepare organic-inorganic composite materials with higher bone salt content within a shorter period; and the preparation time is short and the preparation conditions are mild.

Owner:DONGHUA UNIV

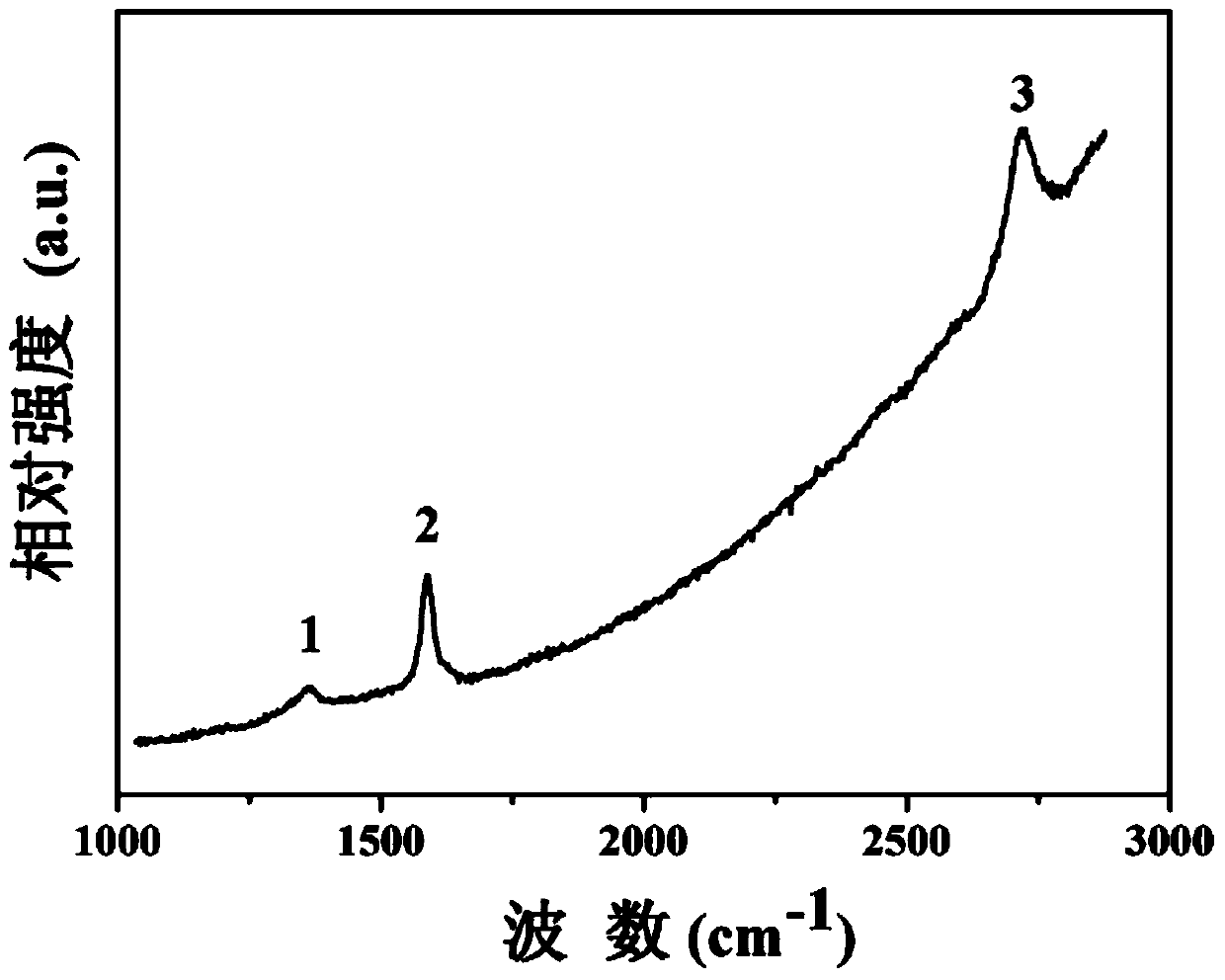

Efficient in-situ preparation method of graphene reinforced copper-based composite material

The invention discloses an efficient in-situ preparation method of a graphene reinforced copper-based composite material, and relates to a method for preparing a graphene reinforced copper-based composite material and the method can be used for solving the problems of poor uniform dispersion, poor structure integrity of grapheme and complex process in the existing preparation method of the graphene reinforced copper-based composite material. The efficient in-situ preparation method of the graphene reinforced copper-based composite material comprises the following steps: putting copper powder in a plasma reinforced chemical vapor deposition vacuum device, introducing hydrogen, preserving heat at high temperature, then introducing argon and carbon source gas, depositing, stopping introducing the carbon source gas after ending the deposition, and finally, cooling below the room temperature to obtain grapheme / copper composite powder, and then primarily pressing, sintering and secondarily pressing the grapheme / copper composite powder to obtain the graphene reinforced copper-based composite material. The method is an efficient in-situ preparation method of a graphene reinforced copper-based composite material.

Owner:HARBIN INST OF TECH

Oily high-temperature resistant protective coating material, application thereof and titanium ingot production method

The invention discloses an oily high-temperature resistant protective coating material. The oily high-temperature resistant protective coating material is obtained after a raw material mixture is uniformly mixed, wherein the raw material mixture contains an oxidation protecting agent and an oily film forming agent; the oxidation protecting agent contains Al powder and Fe powder which are in the weight ratio of 1: (0.01-0.1). The invention further discloses an application of the oily high-temperature resistant protective coating material in titanium ingot production and a titanium ingot production method. The oily high-temperature resistant protective coating material disclosed by the invention has the advantages that the condition that the surface of a titanium ingot is not subjected to oxidation cracking under the condition that the titanium ingot undergoes constant temperature for 8 hours at the high temperature of 1,000 DEG C can be guaranteed, the forming possibility of an oxygen dissolved layer can be greatly reduced, and the yield and production efficiency of a titanium material are increased; the construction environment is not affected; the preparation process is simple; a variety of coating manners, such as pneumatic spraying, vacuum spraying and brushing, can be adopted. The titanium ingot production method disclosed by the invention has good economic and social benefits and has relatively broad popularization and application prospects in titanium plate and titanium tube production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Preparation method of polylactic acid/nano-cellulose composite material

The invention provides a preparation method of a polylactic acid / nano cellulose composite material. The composite material comprises the following components in percentage by weight: 55 to 99.8% of polylactic acid, 0.1 to 15% of nano cellulose, and 0.1 to 30% of polyethylene glycol. The method comprises the following steps of: preparing a 5 to 15% an aqueous solution of microcrystalline cellulose, dripping concentrated sulfuric acid until the concentration of sulfuric acid reaches 40 to 60%, stirring and reacting for 1 to 2hours, carrying out centrifugation, ultrasound treatment and adjusting pH value to be neutral to obtain a nano cellulose suspension; dissolving polyethylene glycol, mixing with the nano cellulose suspension, stirring for 1 to 3hours at the temperature of 90 DEG C and carrying out vacuum drying to obtain a polyethylene glycol / nano cellulose comixture; and carrying out melt blending on the polyethylene glycol / nano cellulose comixture and polylactic acid for 5 to 8minutes at the temperature of 120 to 170 DEG C to obtain the composite material. The method is convenient and simple to operate, short in the time of the preparation process and solves the problem of uniform dispersion of nano-cellulose in the polylactic acid.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

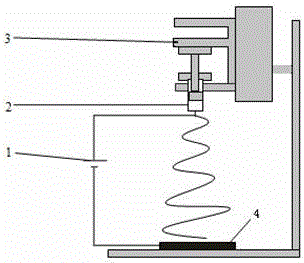

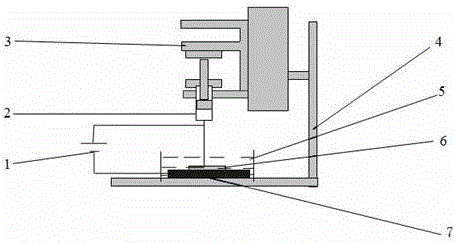

Preparation method of inorganic/organic multi-drug controlled release composite nano fiber scaffold

InactiveCN103751851ASimple and fast operationEase of mass productionOrganic active ingredientsPharmaceutical non-active ingredientsFiberBiocompatibility Testing

The invention relates to a preparation method of inorganic / organic multi-drug controlled release composite nano fiber scaffold, which includes the steps of preparing drug loading nanoparticle with particle size of 5-500 nm, preparing mixed solution of high molecular polymer and drug, adding multiple drug loading nanoparticles into the polymer solution, ultrasonically stirring, and carrying out electrostatic spinning to obtain inorganic / organic multi-drug controlled release composite nano fiber scaffold with diameter of 50-800 nm. The preparation method provided by the invention has the advantages of mild reaction conditions, simple operation, and easy experimental apparatus, and is in favor or large-scale production; the obtained multi-drug controlled release composite nano fiber scaffold has good stability and good biocompatibility and biodegradability, and can be stored for a long period of time, and the degradation product is non-toxic. The inorganic / organic multi-drug controlled release composite nano fiber scaffold can be widely applied in the fields of tissue engineering, biomedical engineering, drug therapy and the like.

Owner:DONGHUA UNIV

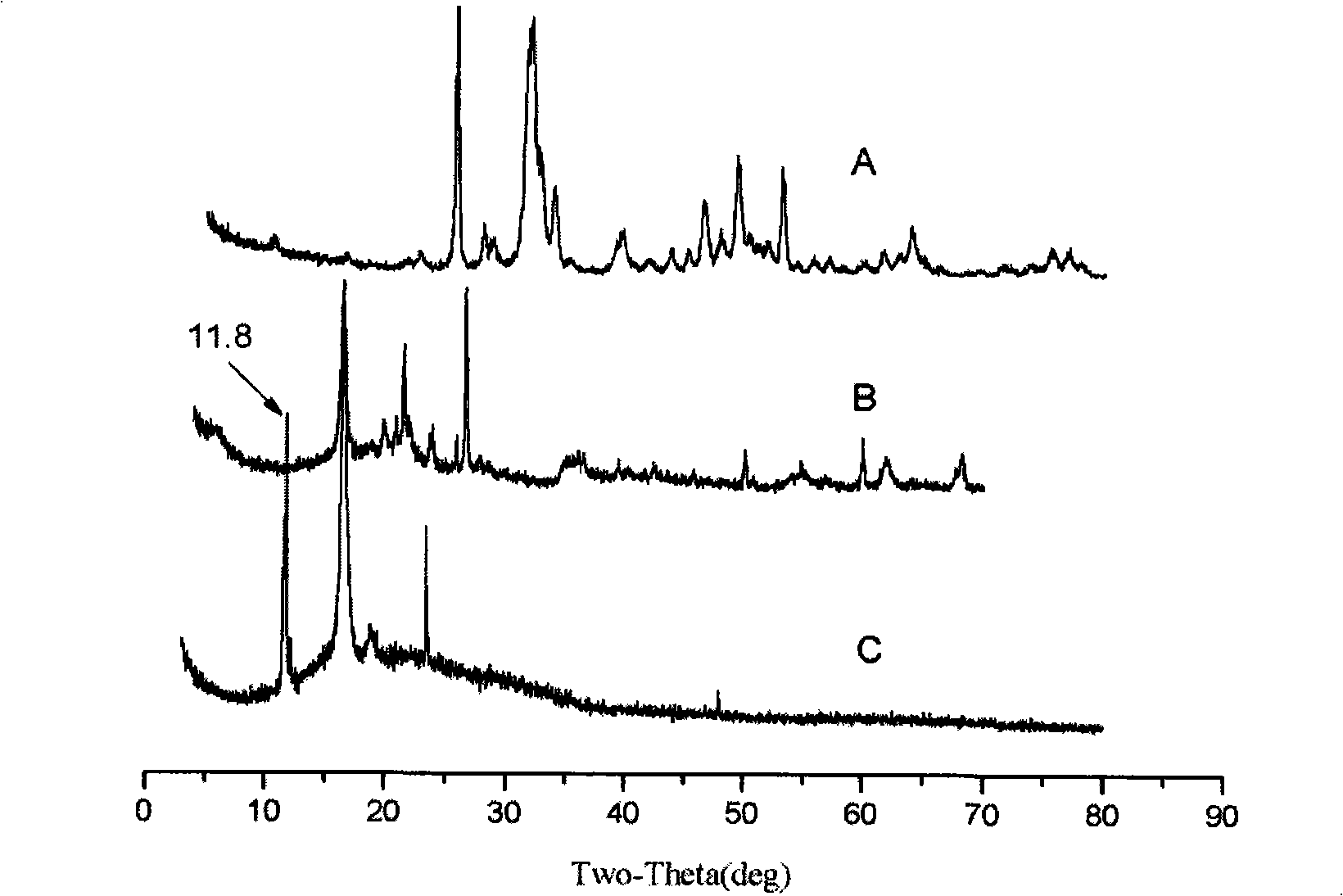

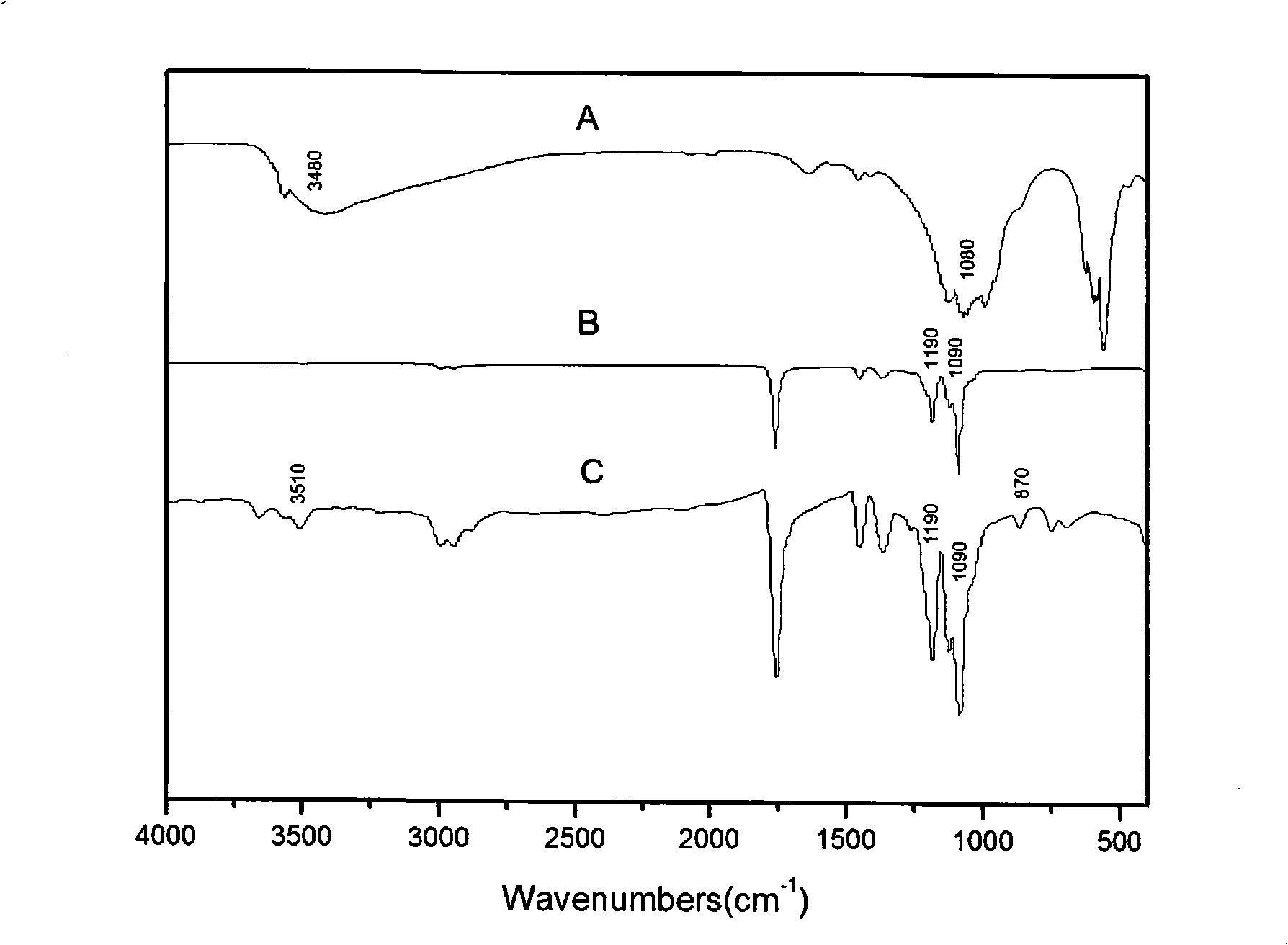

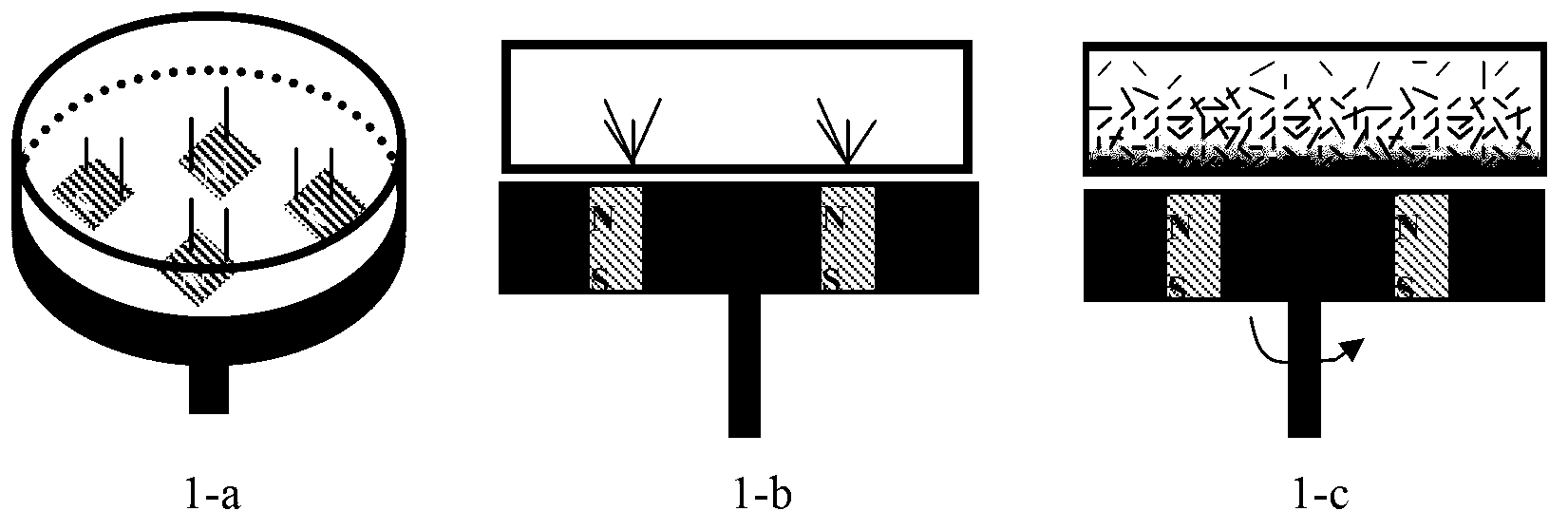

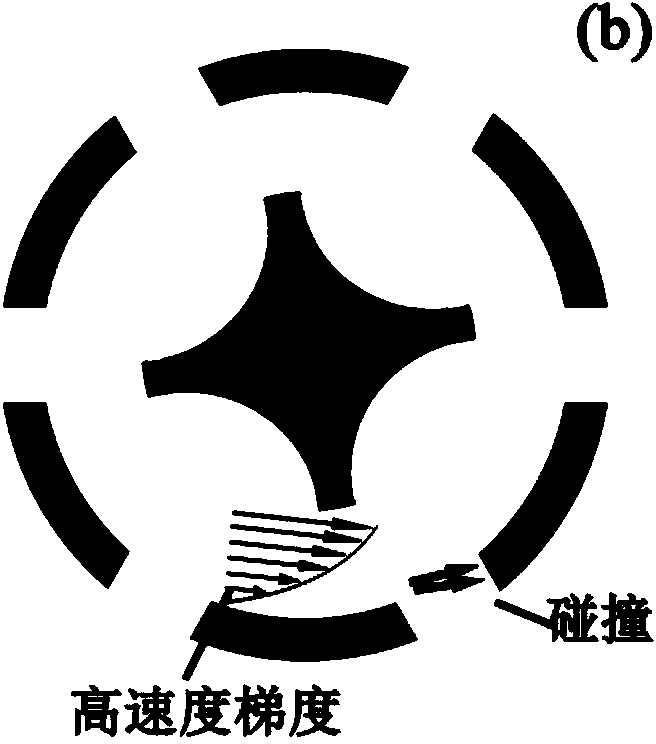

Methods for preparing graphene or graphene oxide

ActiveCN102701193AAvoid damageIncrease the frequency of collisionsMaterial nanotechnologyGrapheneGraphiteSolvent

The invention relates to methods for preparing graphene or graphene oxide, and belongs to the technical field of preparation of nanometer materials. A wet method comprises the following steps of: putting a carbon material, a magnetic steel needle grinding body and a solvent into a grinding container, and closing; putting the container into a space with a changing magnetic field, and peeling to obtain a mixture of graphite nanometer microchip-graphene; and separating the graphite nanometer microchip-graphene from a steel needle, settling, and performing centrifugal separation to obtain transparent suspension of the graphene. A dry method comprises the following steps of: putting a carbon material and a magnetic steel needle grinding body into a grinding container, and closing; and putting the container into a space with a changing magnetic field, and peeling to obtain mixture dry powder of graphite nanometer microchip-graphene. The methods have the characteristics of high collision frequency and grinding efficiency and short preparation time.

Owner:SHANDONG UNIV OF TECH

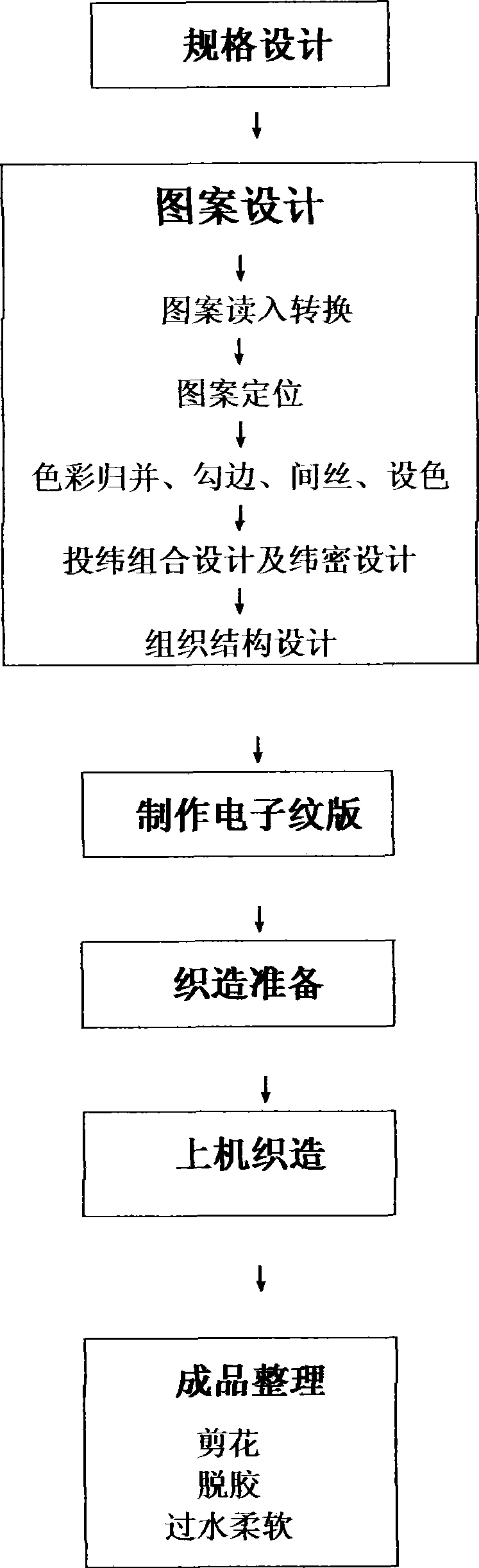

Production method of figured cloth different from embroidery characteristics

ActiveCN101423998AFeel goodStrong three-dimensional senseCard-punching apparatusSwivel-woven fabricsWork in processVolumetric Mass Density

The invention discloses a method for manufacturing jacquard fabrics different from embroidering properties, which comprises the following steps of specification design, pattern design, weaving preparation, weaving on a machine, and sorting of finished products, wherein the step of pattern design is to read target patterns of the jacquard fabrics to be manufactured into a computer, to adjust and position the position of the patterns on the fabrics according to the dimension of the finished products, to set a plurality of colors for the patterns, to merge the colors, and to manufacture an electronic pattern card through picking combinational design, longitude and latitude density design and weave construction design; and the step of sorting of the finished products is to perform trimming on the floating length of weft threads on the reverse side of semifinished products which are off the machine. The jacquard fabrics produced by the method have good hand feeling, strong third dimension, high ornamental value, and distinct contrast between rugged figured pattern and refined bottom plates, achieve the embroidering style after being subjected to two procedures of jacquard weaving and jacquard trimming, is accurate to position the patterns, are more suitable to be used as family spinning fabrics such as curtains and back cushions compared with the prior jacquard fabrics, and have the characteristics of short manufacturing time and low production cost.

Owner:DALI SILK ZHEJIANG

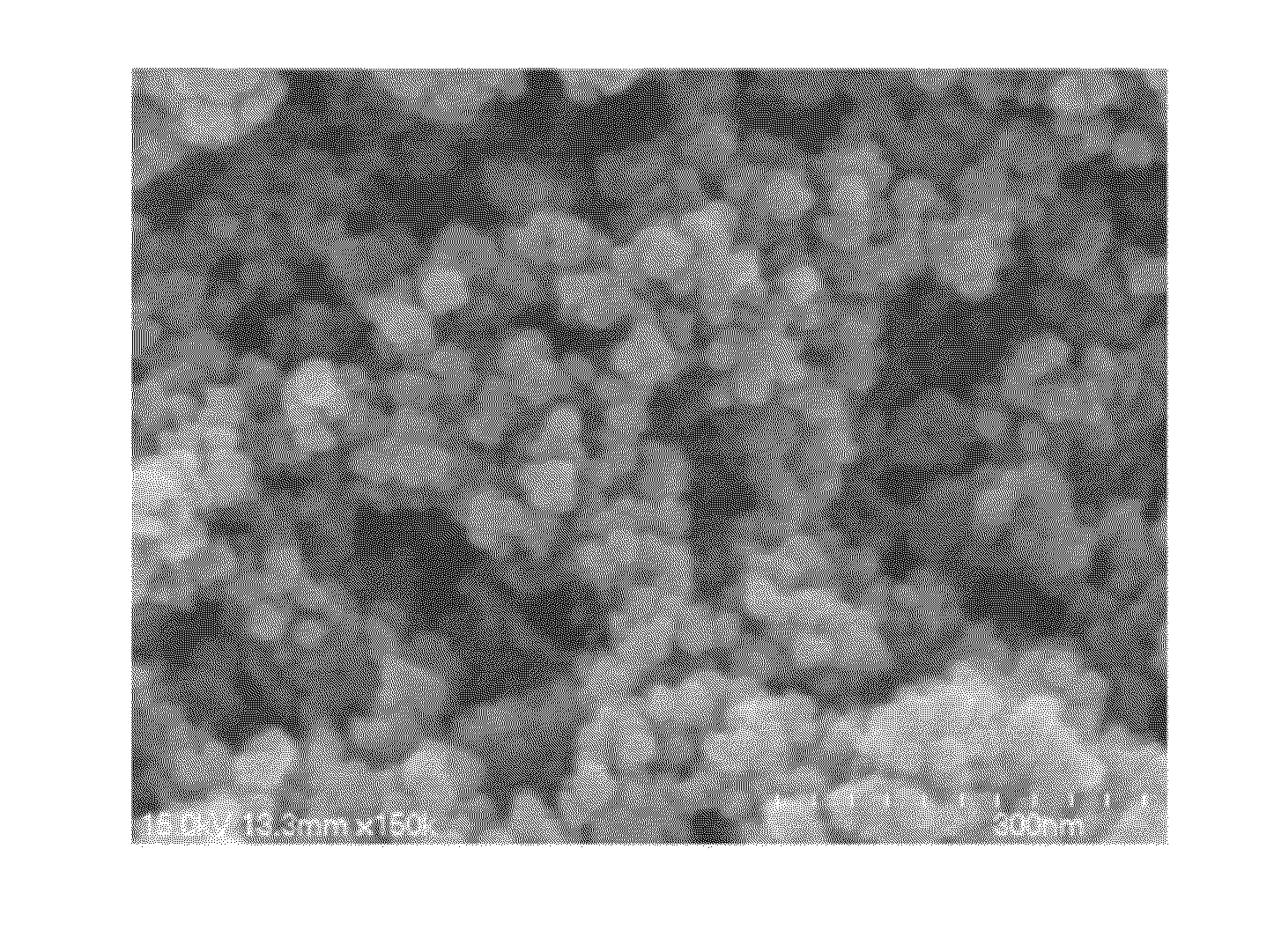

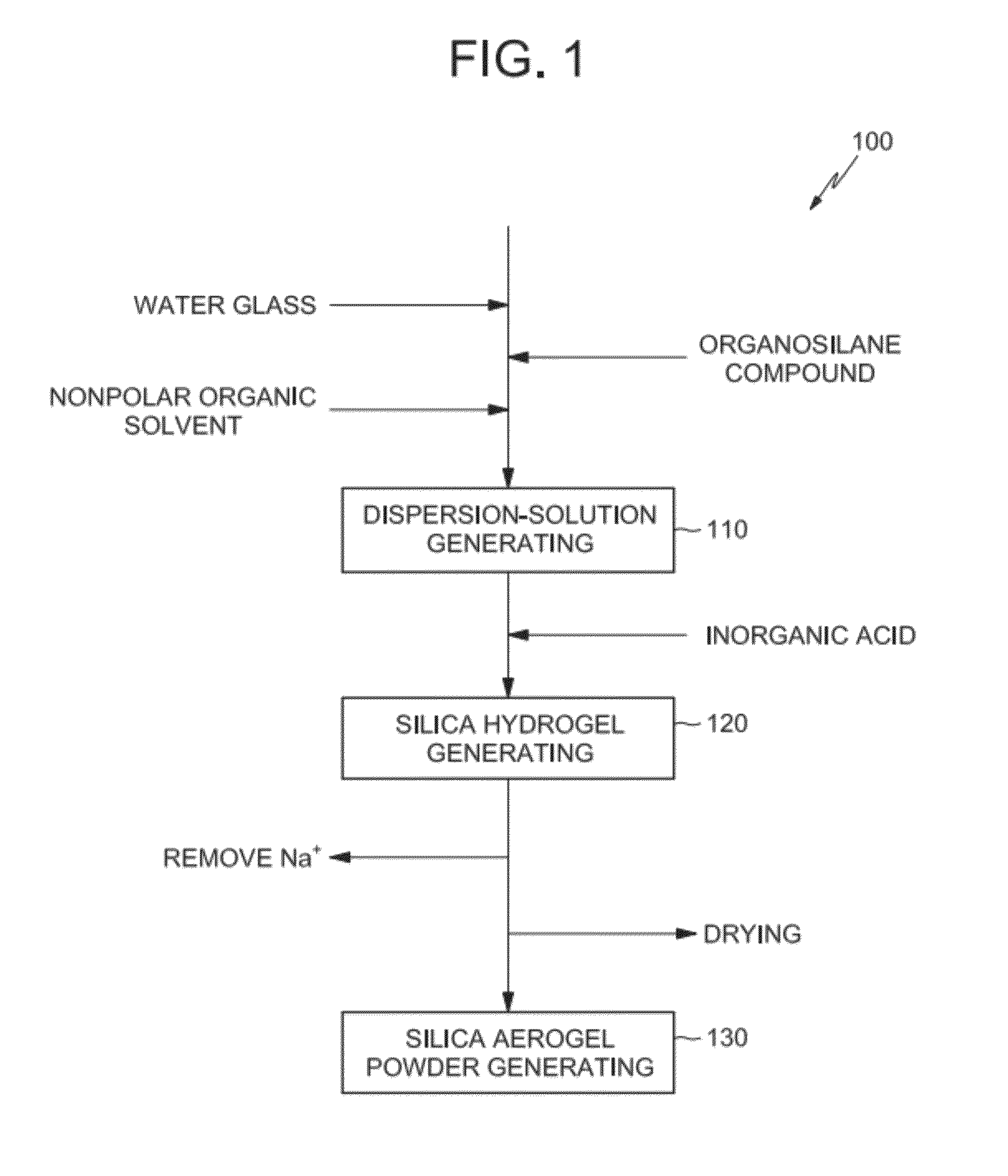

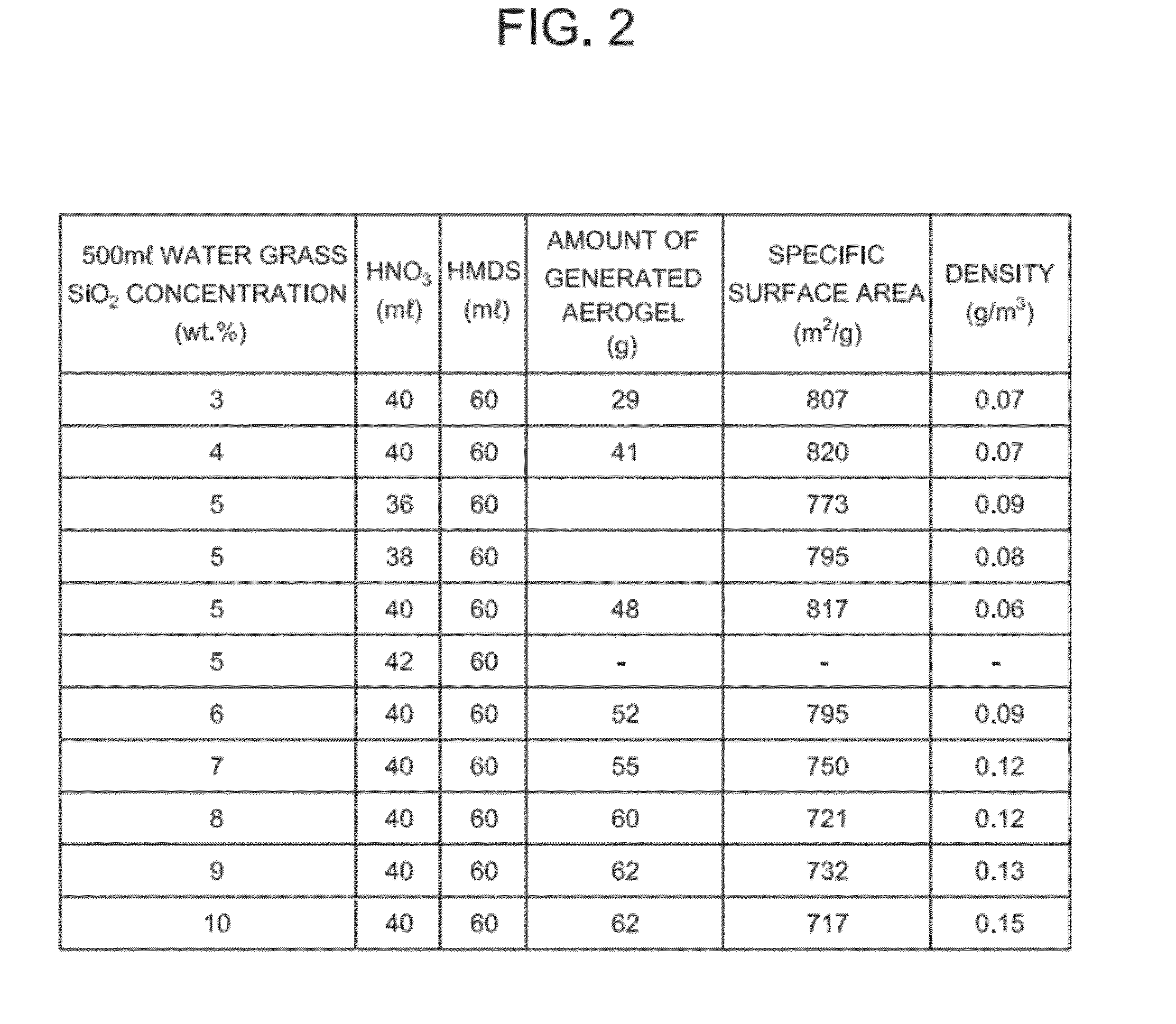

Method of preparing silica aerogel powder

A method of preparing silica aero-gel powders having a short preparation time and stable preparation processes. In the method, the silica aerogel powders are generated by using a water glass solution, an inorganic acid, an organosilane compound and an organic solvent. The method includes dispersion-solution generating, gelating and solvent exchanging and drying. In the dispersion-solution generating, a dispersion solution is generated by dispersing the water glass solution and the organosilane compound in the organic solvent. In the gelating and solvent exchanging, silica hydrogel is generated by adding the inorganic acid to the dispersion solution and simultaneously performing gelating and solvent-exchanging. In the drying, the silica aerogel powders are generated by drying the silica hydro-gel.

Owner:AEROGEL R&D PTE LTD

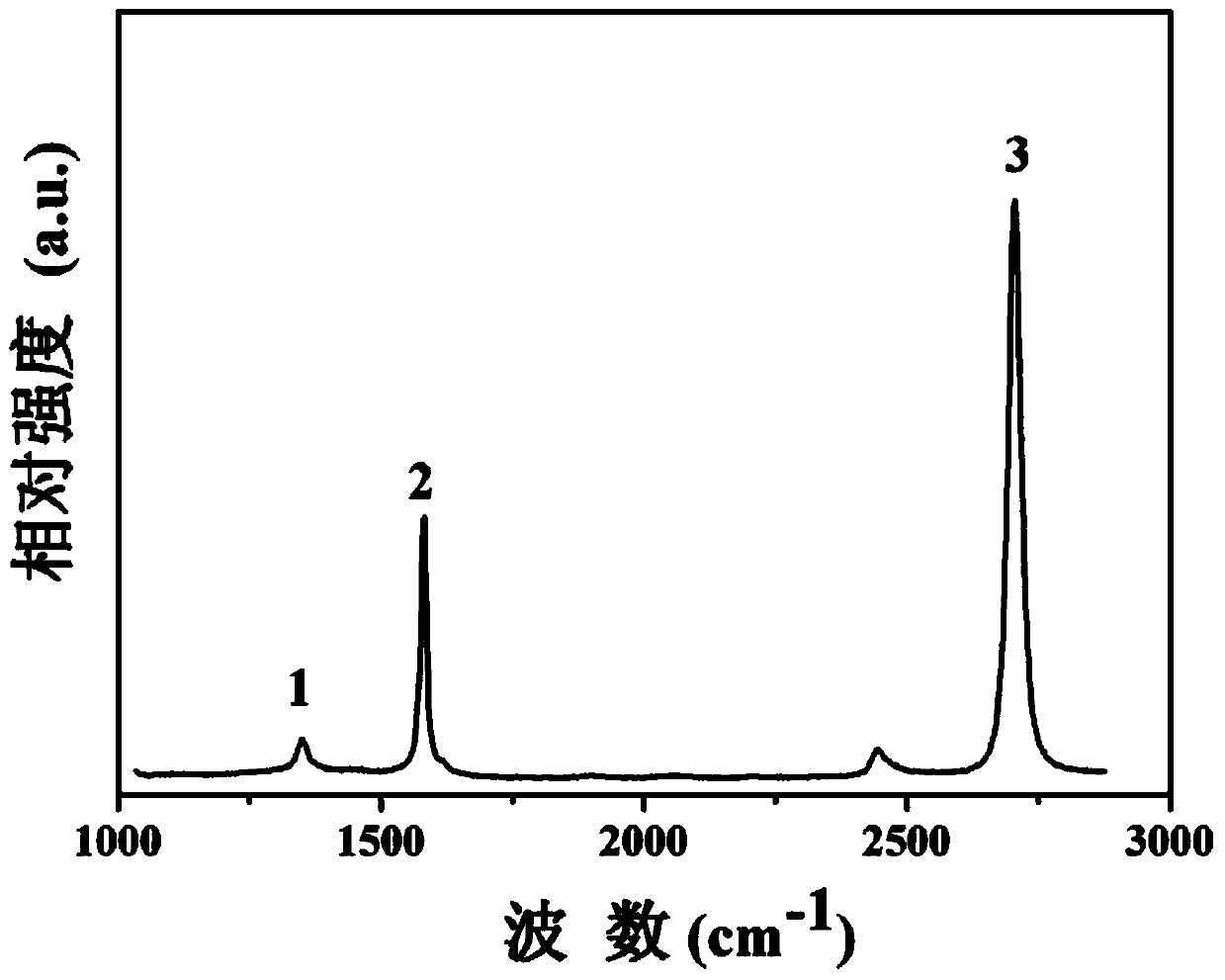

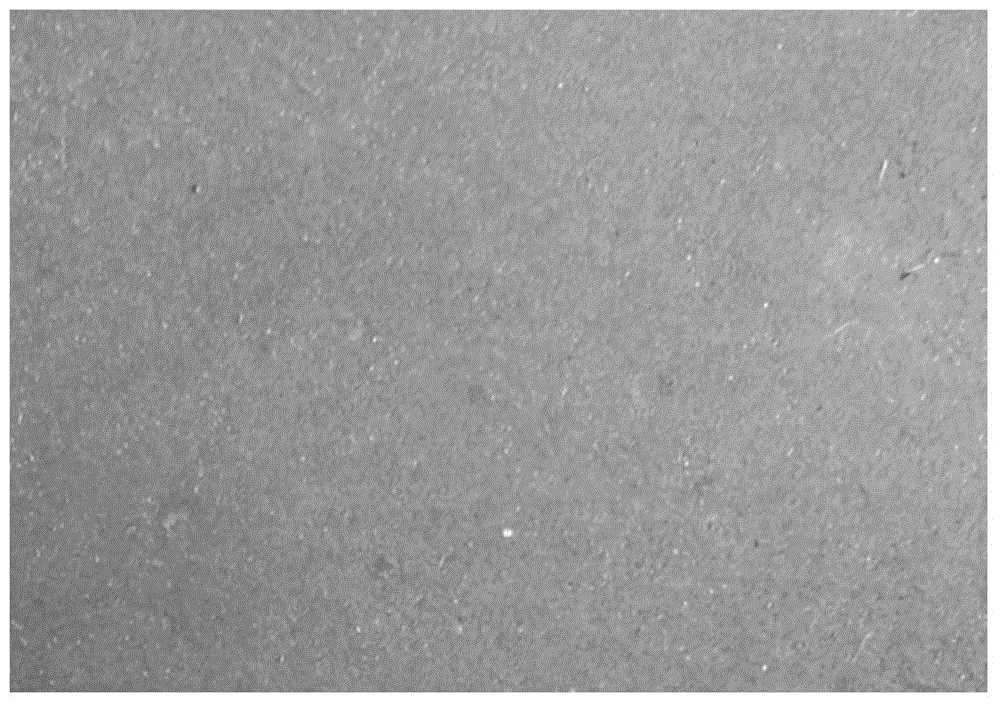

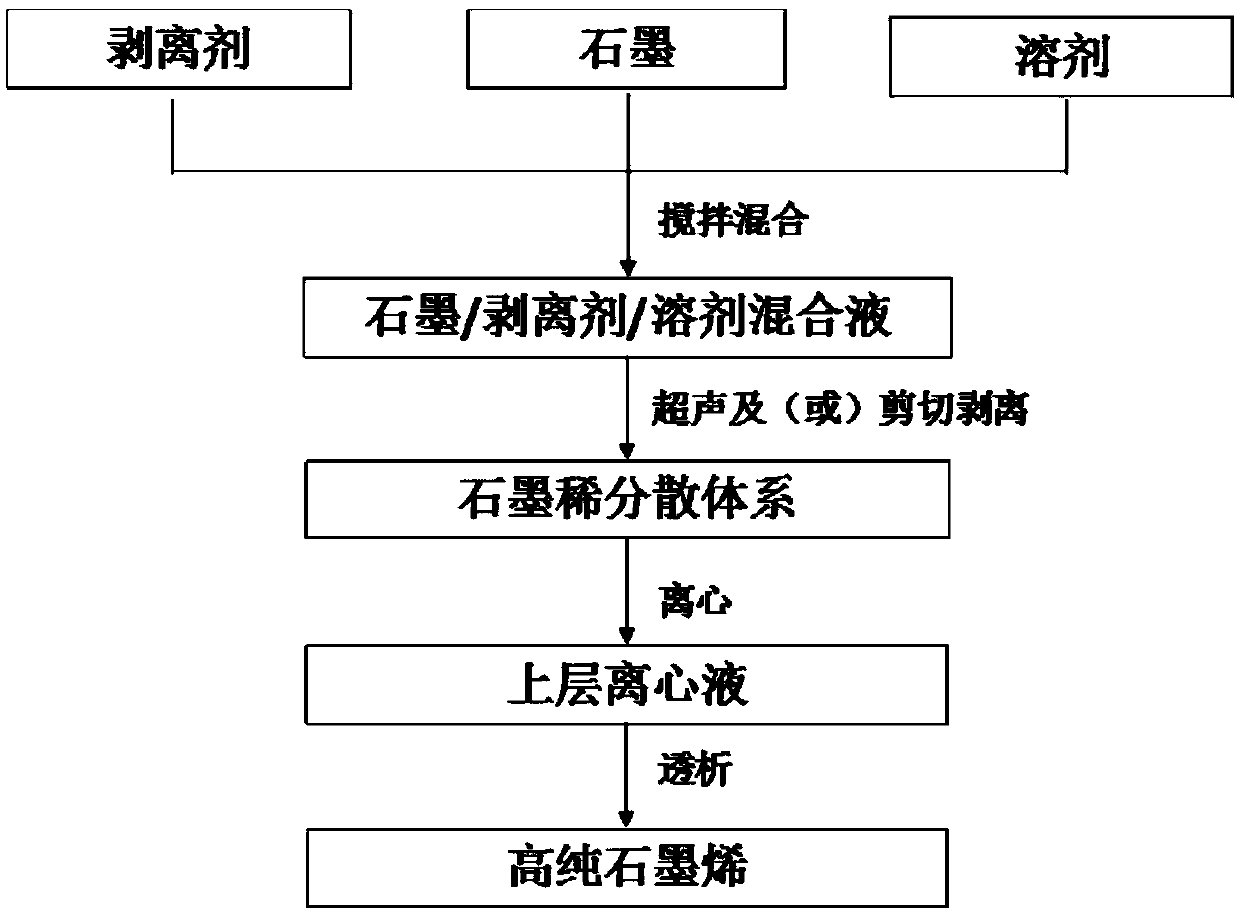

Liquid-phase stripping preparation method of graphene

ActiveCN105502371AReduce the number of layersHigh monolayer ratioSingle layer grapheneGraphiteCvd graphene

The invention provides a liquid-phase stripping preparation method of graphene. The liquid-phase stripping preparation method comprises the steps that first, an aromatic compound is used as a stripping agent to prepare a stripping agent solution, graphite powder is added, and graphite pre-stripping dispersion liquid is obtained after sufficient stirring; second, the graphite pre-stripping dispersion liquid obtained in the first step is subjected to stripping dispersion through ultrasonic and / or mechanical shear to obtain a graphene mixed dispersion system; third, the graphene mixed dispersion system obtained in the second step is centrifuged, the upper-layer solution can be taken for dialysis, and impurities are remove to obtain a pure graphene product. The liquid-phase stripping preparation method can effectively separate graphite flake layers, a large amount of graphene is obtained within a short period of time, and the prepared graphene is single-layer or double-layer graphene and is good in conductive / thermal performance and excellent in comprehensive performances. The liquid-phase stripping preparation method has the advantages of being simple in operation, high in efficiency and green, being environmentally-friendly and the like, and achievement of industrialized graphene preparation is hopeful.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

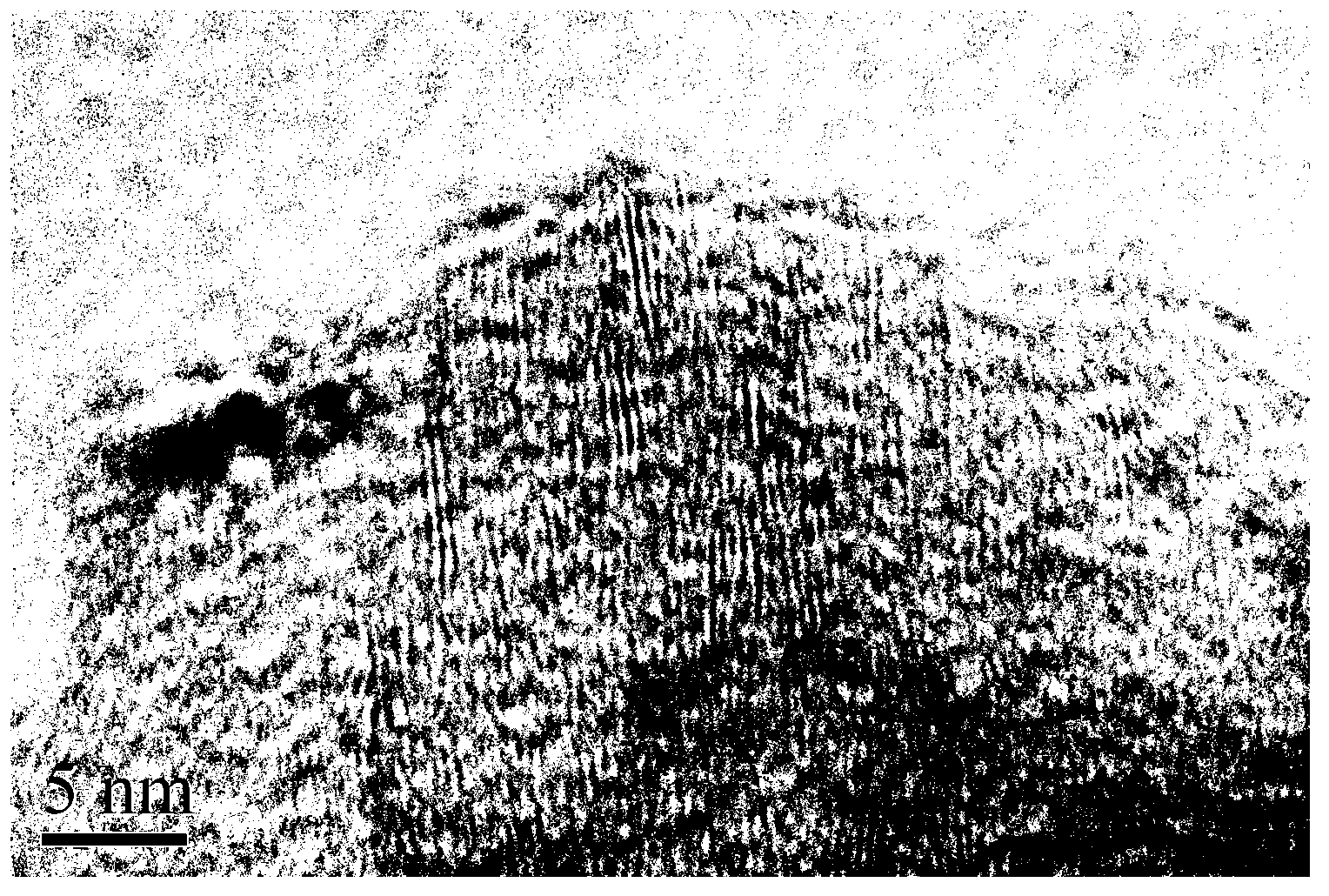

Catalyst for converting alcohols and ethers into aromatic hydrocarbons as well as preparation method and use method thereof

ActiveCN103007985ASmall particle sizeEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrogenAlcohol

The invention discloses a catalyst for converting alcohols and ethers into aromatic hydrocarbons, as well as a preparation method and a use method of the catalyst, and belongs to the technical field of chemical engineering. The preparation method comprises the steps as follows: at first, taking a template agent, kaolin, sodium hydroxide and water as raw materials for preparing a hydrogen type nanoscale ZSM-5 molecular sieve, and then directly preparing the catalyst; or based on the hydrogen type nanoscale ZSM-5 molecular sieve, preparing the two-component, three-component or four-component catalyst with metal and / or a structure enhancer and / or a stabilizing additive. The catalyst comprises the following components in percentage by mass: 30-100% of the needle-like nanoscale ZSM-5 molecular sieve, 0-10% of the metal, 0-50% of the structure enhancer and 0-10% of the stabilizing additive. The invention further provides a method for enabling the catalyst to be used for converting alcohols and ethers into aromatic hydrocarbons. The catalyst is small in particle size, high in catalytic efficiency and low in use cost; the preparation method is simple and efficient; and the use method is reasonable and efficient.

Owner:TSINGHUA UNIV

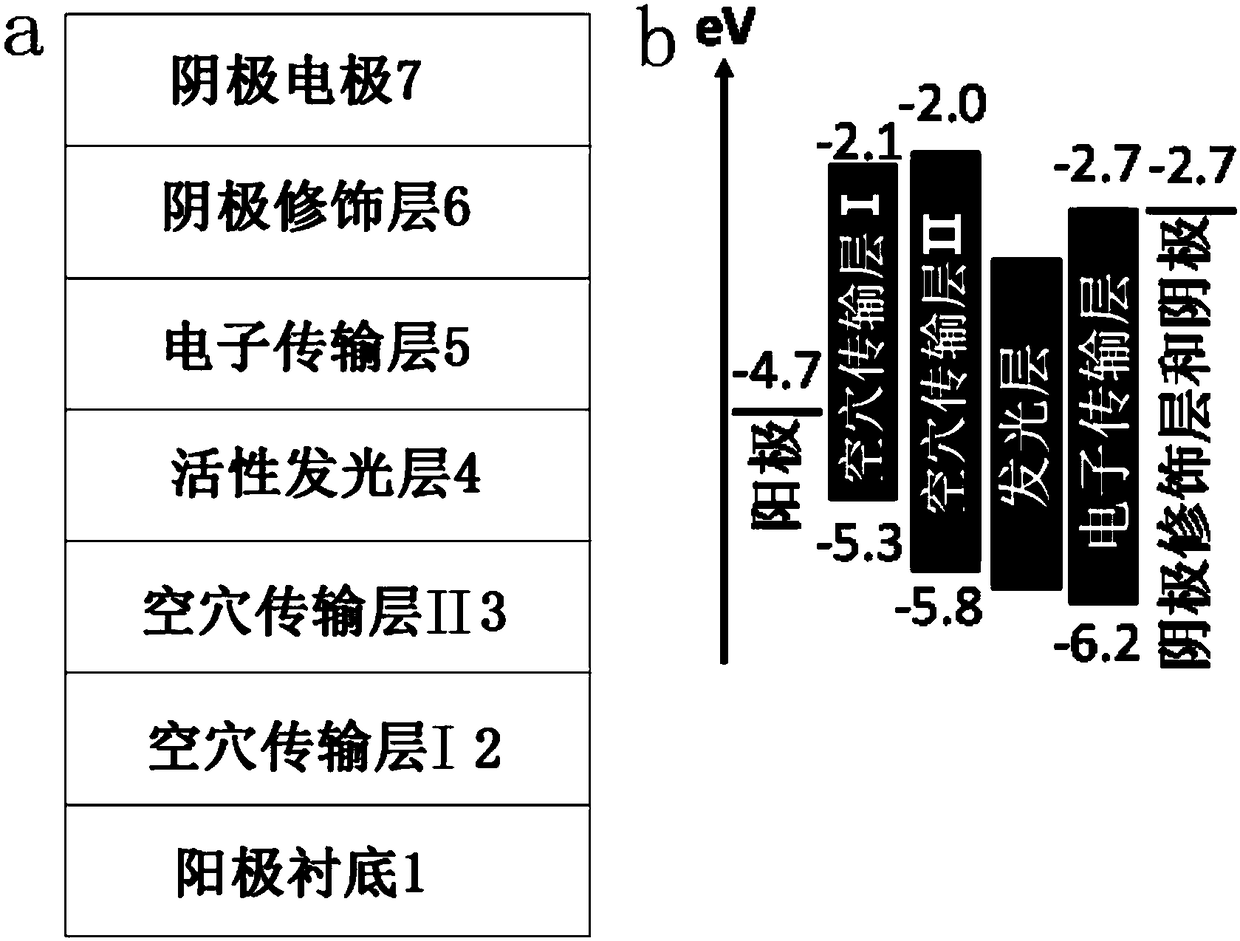

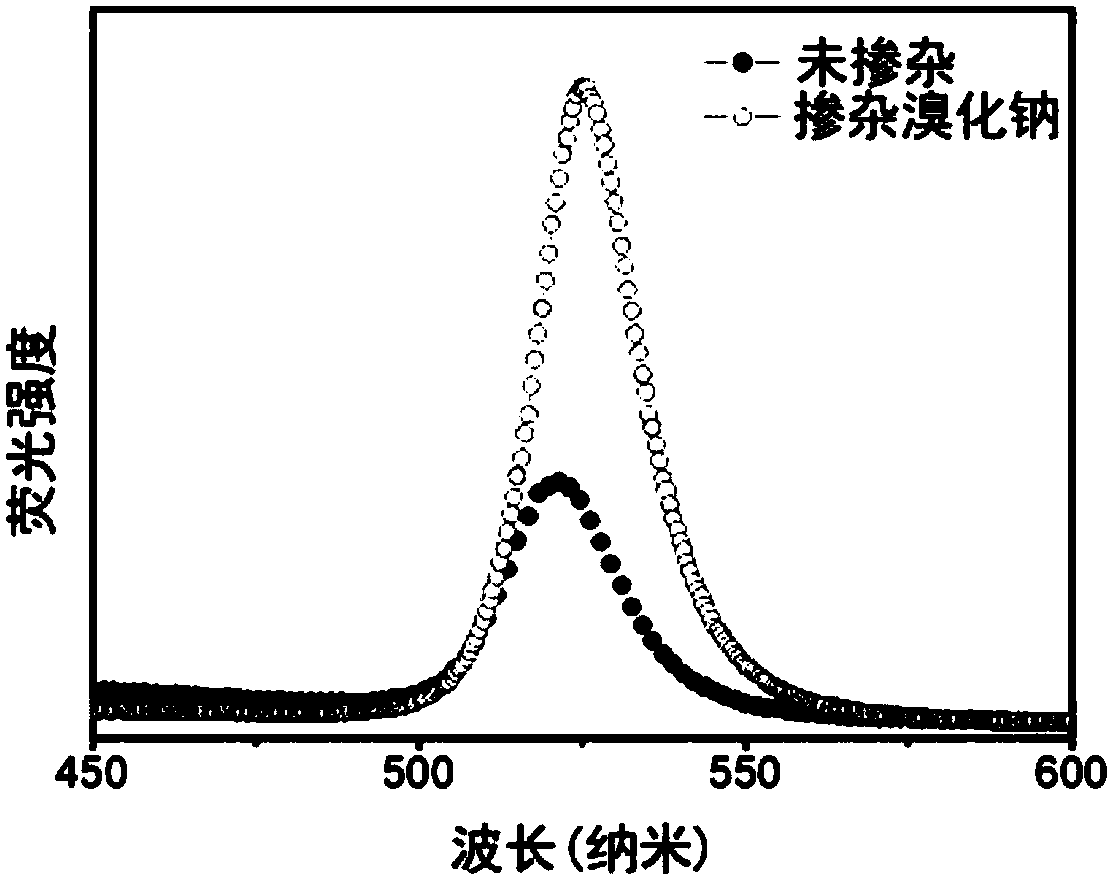

Alkali halide-doped perovskite light-emitting diode and fabrication method thereof

InactiveCN108269940ALow costSimple preparation processSolid-state devicesSemiconductor/solid-state device manufacturingHole transport layerAlkali metal halide

The invention relates to an alkali halide-doped perovskite light-emitting diode. The alkali halide-doped perovskite light-emitting diode comprises a substrate, a hole transmission layer, an active light-emitting layer, an electron transmission layer, an electrode modification layer and an electrode, wherein the thickness of the active light-emitting layer is 5-100 nanometers, the active light-emitting layer comprises perovskite and an alkali halide doped in the perovskite, the molecular formula of the perovskite is one or more of CsPbCl<x>Br<3-x>, CsPbBr<x>I<3-x>, MAPbCl<x>Br<3-x>, MAPbBr<x<I<3-x>, FAPbCl<x>Br<3-x> and FAPbBr<x>I<3-x>, x is equal to 0, 1, 2 or 3, and the alkali halide is one or more of LiCl, NaCl, KCl, RbCl, LiBr, NaBr, KBr, RbBr, LiI, NaI, KI and RbI. The invention also provides a fabrication method of the alkali halide-doped perovskite light-emitting diode. The fabrication method comprises the steps of forming the hole transmission layer or the electron transmissionlayer o the substrate; modifying an alkali halide-containing perovskite precursor solution used as the active light-emitting layer on the hole transmission layer of the electron transmission layer; sequentially forming the electron transmission layer, a negative electrode modification layer and a negative electrode on the active light-emitting layer or sequentially forming the hole transmission layer, a positive electrode modification layer and a positive electrode on the active light-emitting layer; and performing package.

Owner:SUZHOU UNIV

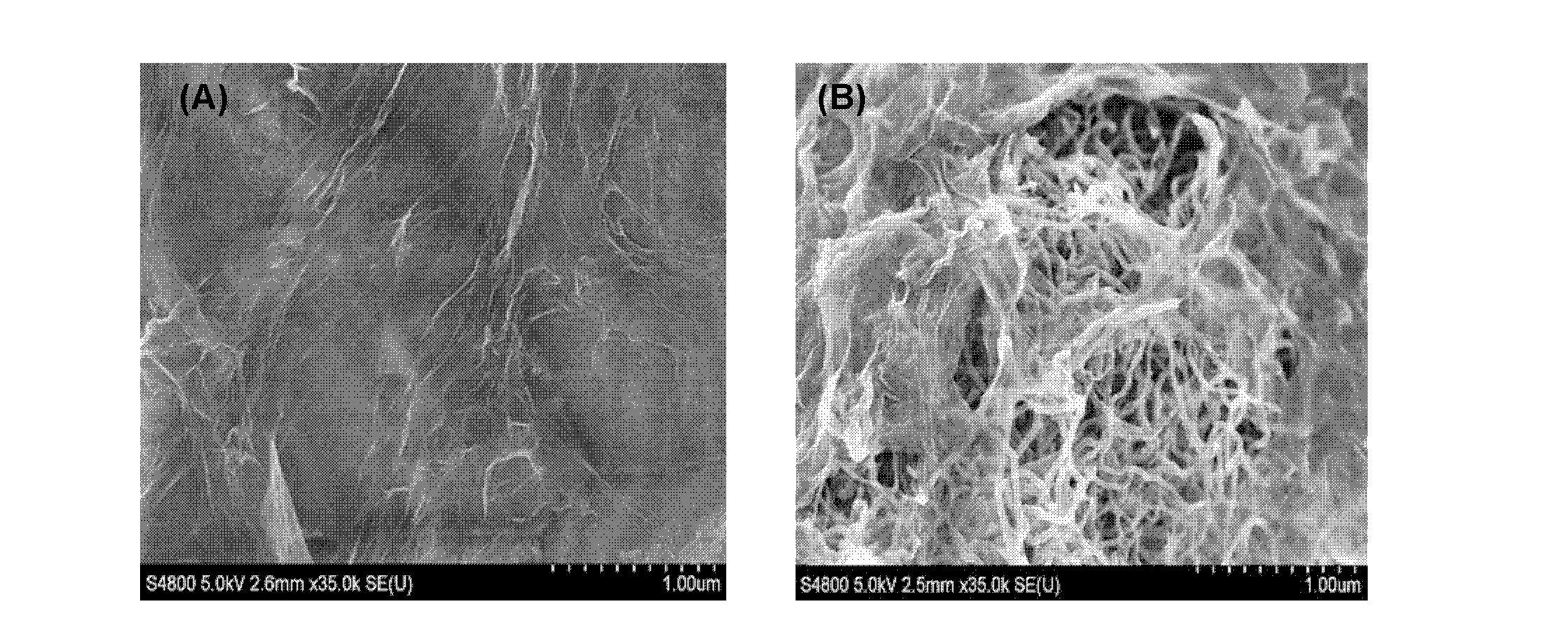

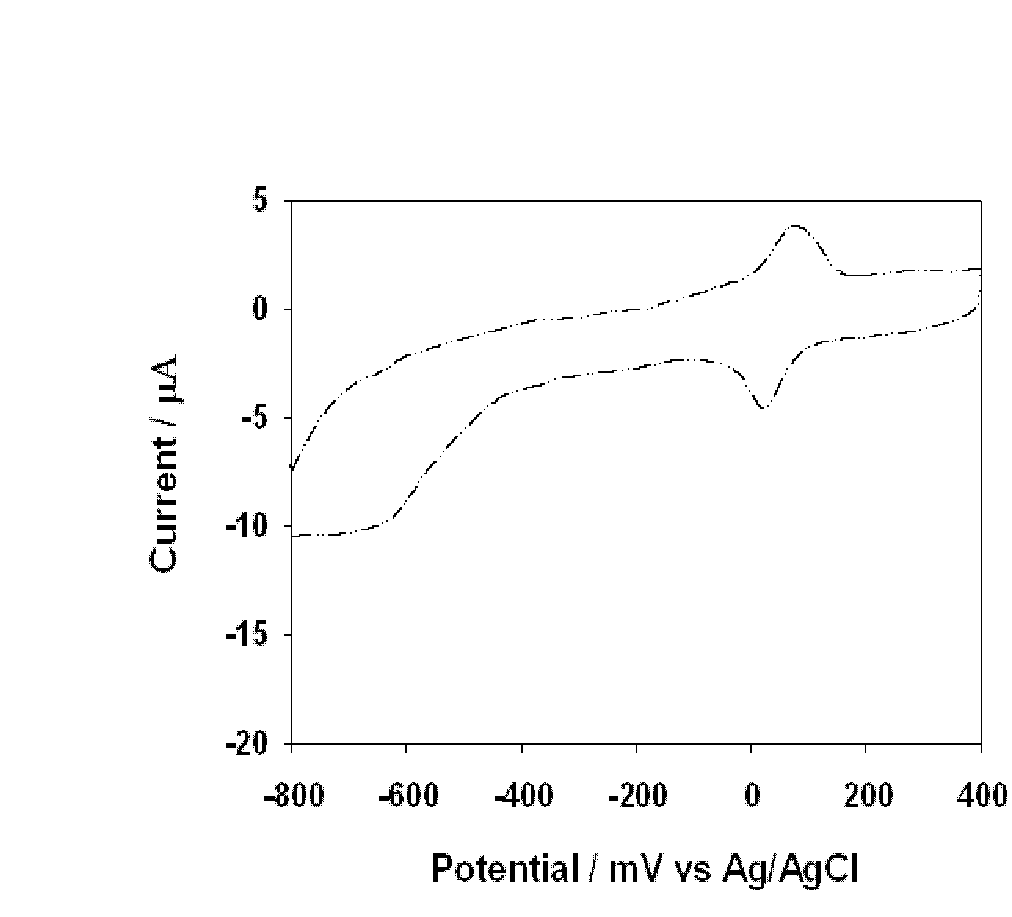

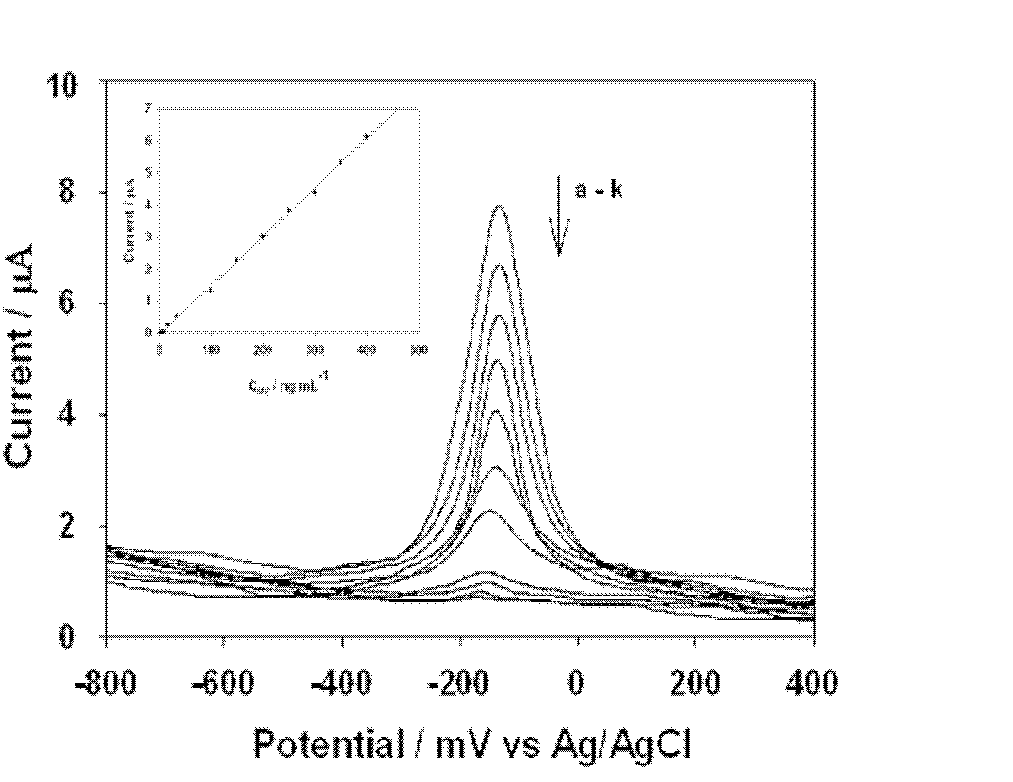

Enzyme-free methyl parathion detection sensor, and preparation and application methods thereof

InactiveCN102636537AHigh Sensitivity DetectionShort preparation timeMaterial electrochemical variablesEnvironmental resistanceCarbon nanotube

The invention discloses an enzyme-free methyl parathion detection sensor, and preparation and application methods thereof. The sensor comprises a three-electrode system, wherein a graphene / carbon nanotube / chitosan deposition modified glassy carbon electrode is used as a working electrode, a platinum sheet is used as a counter electrode, and a calomel electrode is used as a reference electrode. In the detection process, by using the graphene / carbon nanotube / chitosan deposition modified glassy carbon electrode as the working electrode, the platinum sheet as the counter electrode and the calomel electrode as the reference electrode, an electrochemical work station is utilized to determine the content of methyl parathion. The enzyme-free methyl parathion detection sensor disclosed by the invention has the advantages of short preparation time and environment friendliness, is simple to operate, and can be recycled; and the low detection limit is 0.8ng / L. The invention also has the advantages of short sample detection time and simple treatment.

Owner:HUNAN UNIV

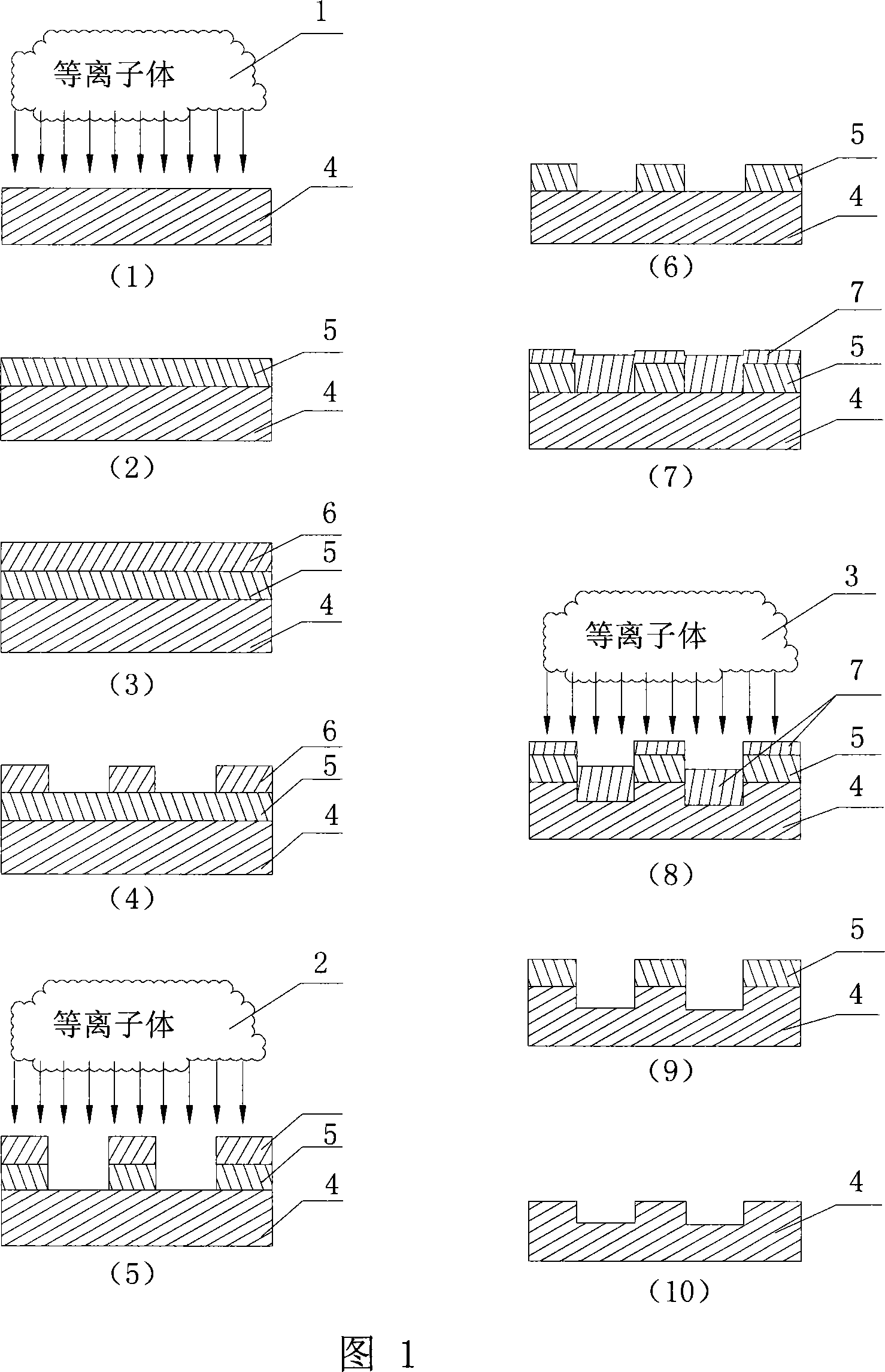

Preparation method of diamond surface graphics

InactiveCN101118378ARealize graphic processingEasy to operatePhotomechanical apparatusOriginals for photomechanical treatmentGraphicsResist

The present invention relates to a preparation method for diamond surface visualization, and is characterized in that the preparation method includes the following steps: firstly, the cleanness of the diamond surface; secondly, the preparation of the insulated layer of the diamond surface; thirdly, the preparation of the photosensitive resist pattern of the insulated layer surface; fourthly, the preparation of the insulated layer pattern of the diamond surface; fifthly, wiping off photosensitive resist remained on the surface of the diamond insulated layer; sixthly, the preparation of a metal folium used for sculpturing the diamond surface; seventhly, the diamond provided with the metal folium on the surface prepared in the sixth step is put in a vacuum chamber, and inlet working gas, a plasma body is produced by blazing the electric energy or the electromagnetic energy, under the temperature of 800 to 900 DEG C, the diamond is sculptured, thus the diamond with visualization surface can be obtained; eighthly, the diamond with visualization surface can be obtained by eliminating the metal folium remained on the diamond surface. The present invention has the advantages of prepared extensively, easy to operate, short time for preparation, and no obvious preferential mechanical erosion to the crystal boundary of the polycrystalline diamond.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

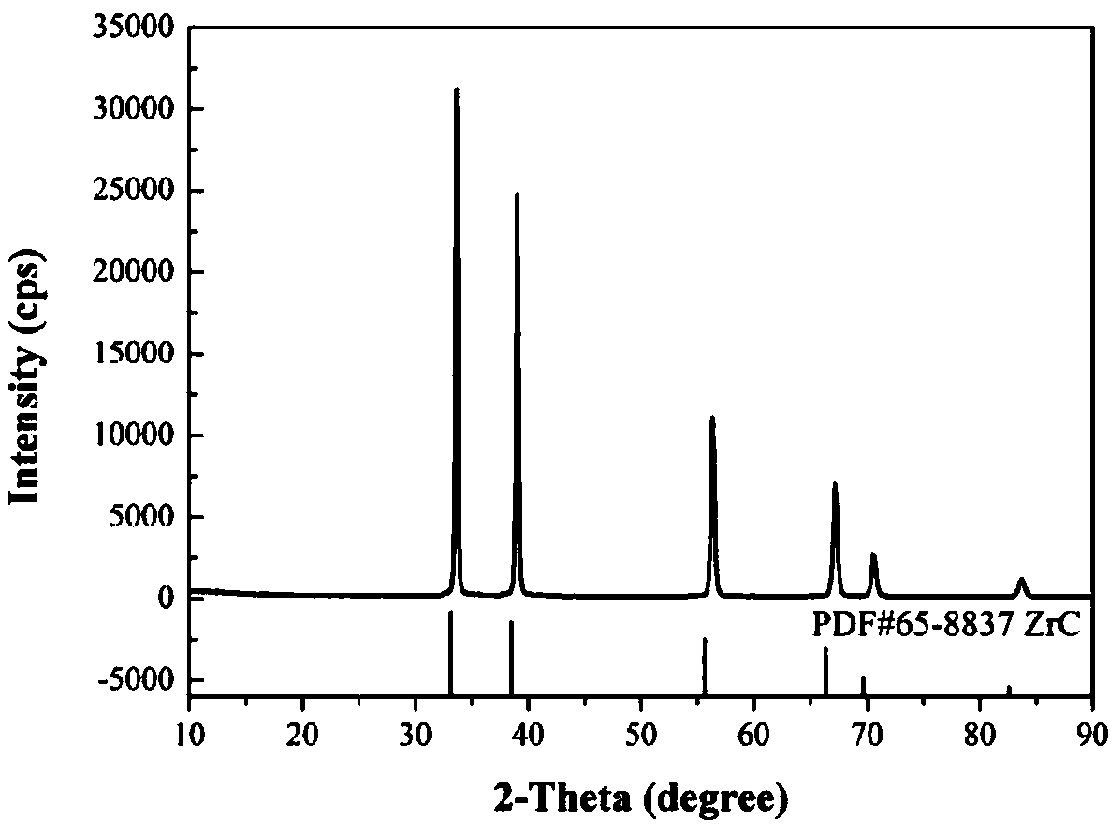

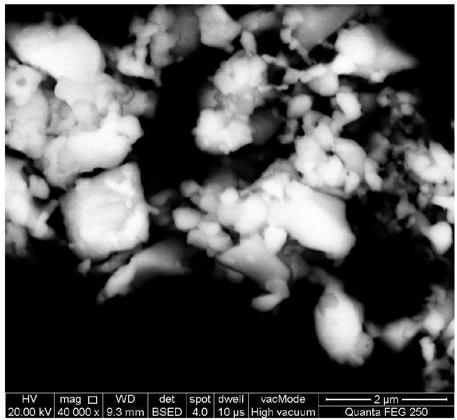

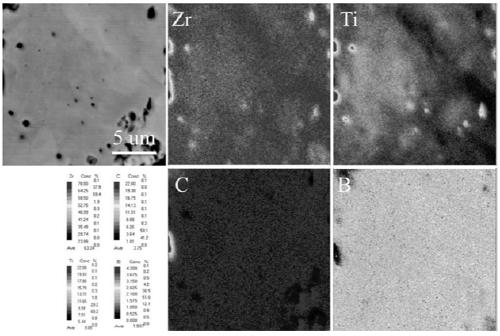

High-entropy boron-containing carbide ultrahigh temperature ceramic powder and preparation method thereof

The invention belongs to the technical field of carbide ceramics, and concretely relates to a high-entropy boron-containing carbide ultrahigh temperature ceramic powder and a preparation method thereof. The molecular formula of the ceramic powder is XCyBz, wherein X is at least two of Zr, Ti, Hf, V, Nb, Ta, Cr, Mo and W, y is equal to or more than 0.6 and less 1.0, z is more than 0 and equal to orless than 0.4, and y + z = 1. The ceramic powder has a single phase face-centered cubic structure. The preparation method comprises the following steps: carrying out ball-milling mixing on at least two metal powders and C powder, carrying out pressureless plasma sintering and crushing to obtain carbide powder, mixing the carbide powder with B2O3 powder and a carbon source, and then performing high temperature sintering and crushing to obtain the ceramic powder. The ceramic powder is a single-phase solid solution, has the face-centered cubic structure, and contains the boron element, so the ceramic powder integrates the high temperature resistance of carbides and the oxidation resistance of borides, and can be used to prepare an ablation and oxidation resistant high-entropy boron-containing carbide ultrahigh temperature ceramic block or composite material.

Owner:CENT SOUTH UNIV

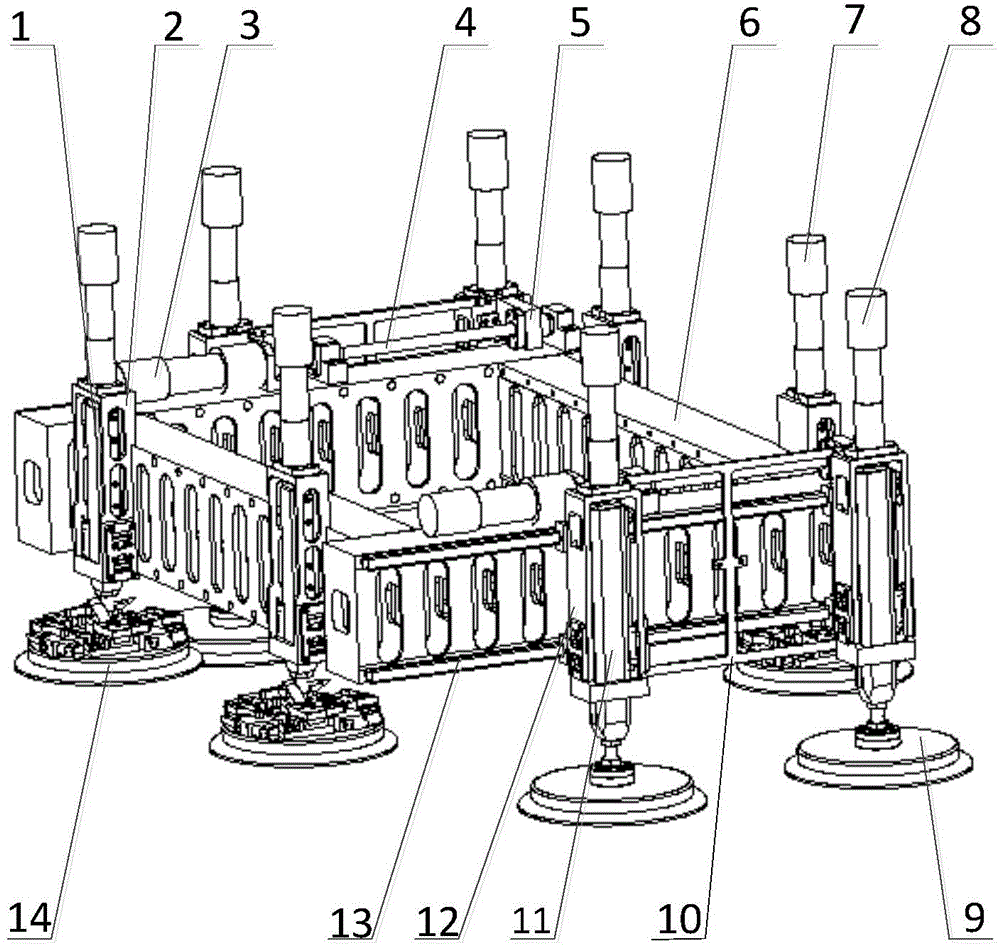

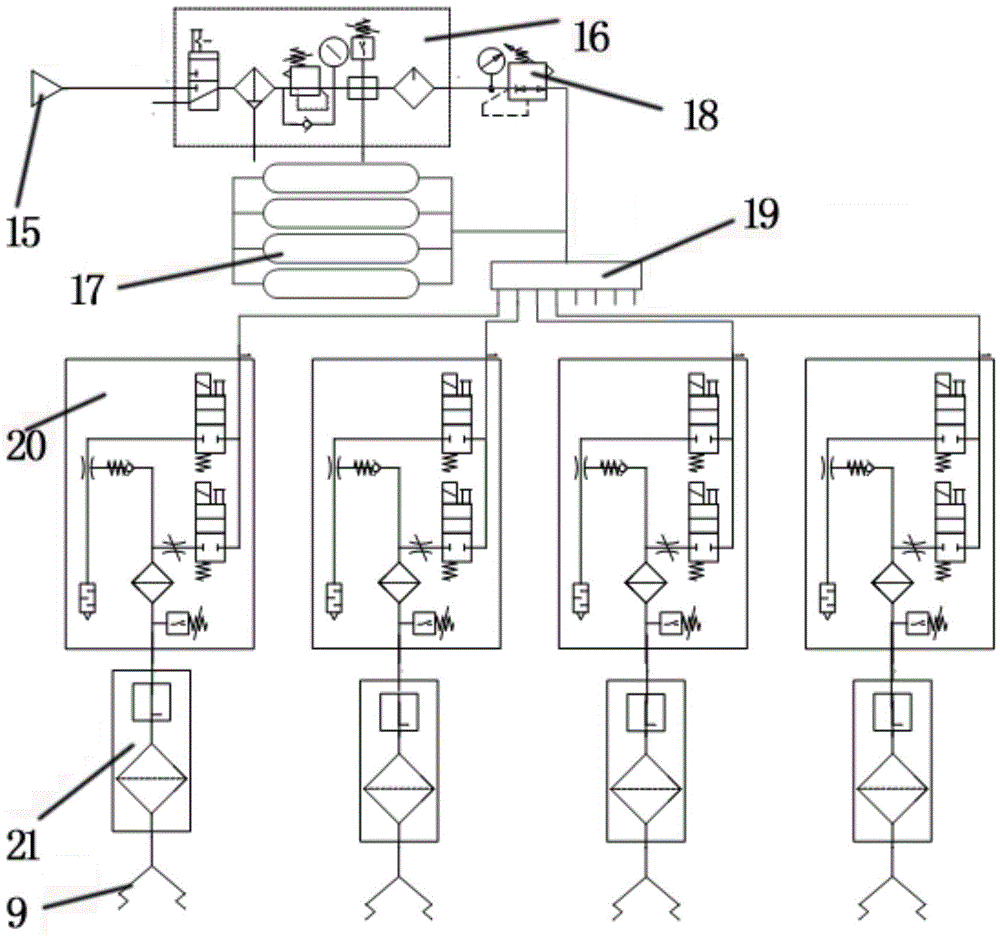

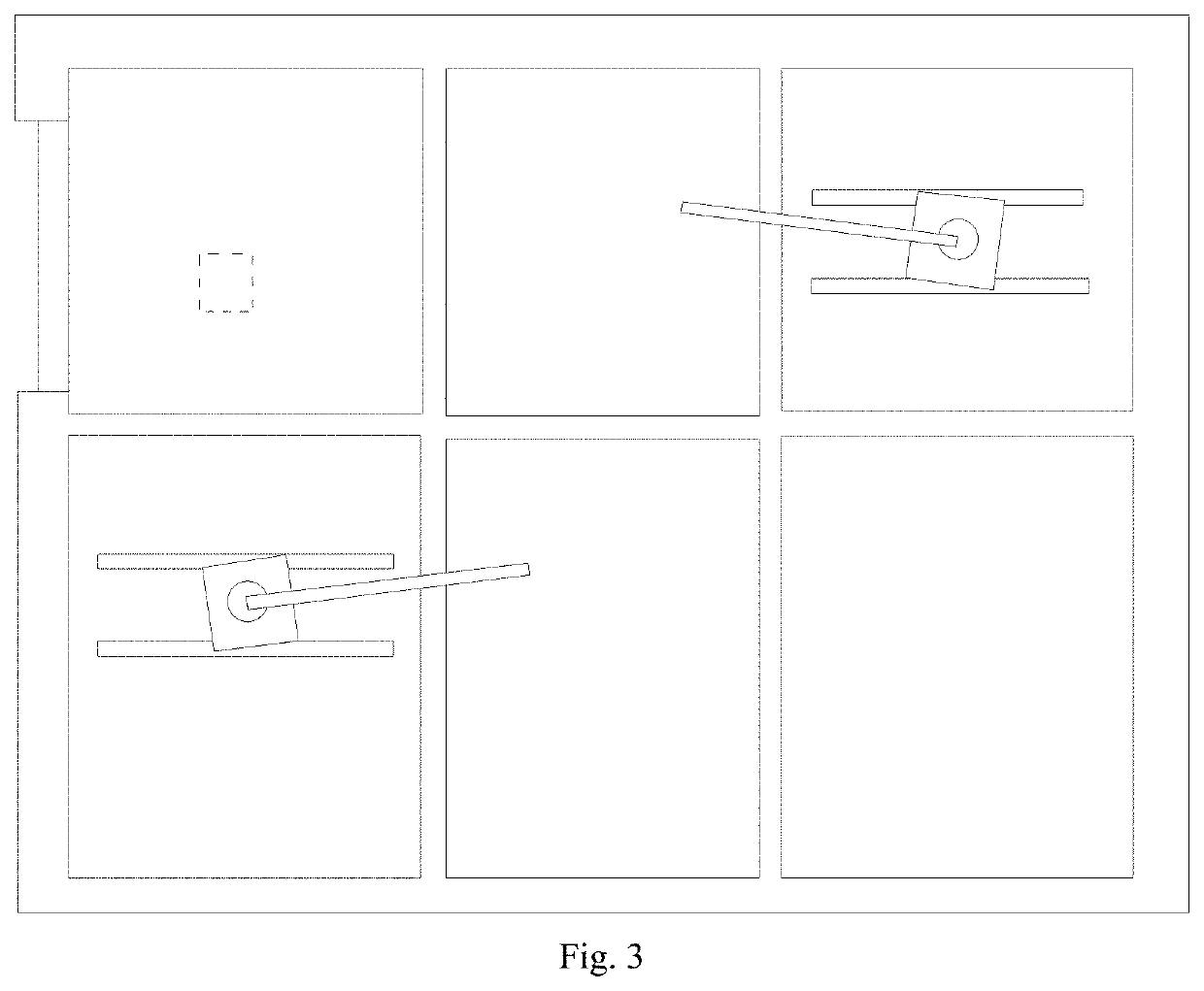

Walking mechanism and walking method of crawling robot

The invention discloses a walking mechanism of a crawling robot. The walking mechanism is characterized by comprising a moving frame, a plurality of outer legs and a plurality of inner legs, wherein the moving frame is rectangular; the outer legs are symmetrically mounted on two symmetrical lateral sides of the moving frame, and the inner legs are symmetrically mounted on the other two symmetrical lateral sides of the moving frame; each outer leg comprises an outer-leg frame and a telescopic leg arranged in the outer-leg frame; each inner leg comprises an inner-leg frame and a telescopic leg arranged in the inner-leg frame; suction cups are mounted at the bottoms of the outer legs and the inner legs; the telescopic legs of the outer legs are connected with the moving frame, and the moving frame ascends and descends with the telescopic legs of the outer legs; the inner-leg frames are rigidly connected with the moving frame, and the inner-leg frames ascend and descend with the moving frame; the outer-leg frames are mounted on the moving frame through guide rails; transverse feed motors are mounted on the moving frame, and the transverse feed motors drive transverse feed screws; the inner legs and the outer legs are both provided with longitudinal feed motors, and the longitudinal feed motors drive longitudinal feed screws.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

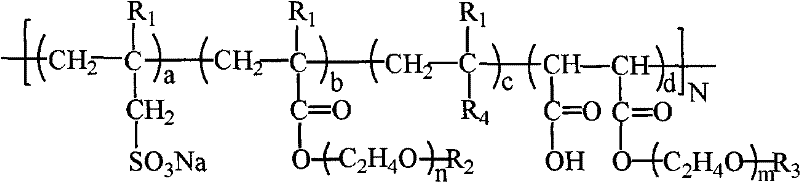

Preparation method for polycarboxylic acid series comb-shaped surface active agent

InactiveCN102199298AEnergy savingShort preparation timeTransportation and packagingMixingSolventSurface-active agents

The invention discloses a preparation method for a polycarboxylic acid series comb-shaped surface active agent, which comprises the following steps of: mixing two comonomers, an initiator, a chain transfer agent and a solvent under the protection of nitrogen, heating to a reacting temperature for polymerization to obtain an intermediate polymer; adding a graft compound, a catalytic agent and a dissolvant into the intermediate polymer, carrying out graft reaction at graft temperature, decompressing and removing part of solvent in a reaction system after reaction, and then precipitating the product with a precipitator; dissolving filter cakes with the solvent; precipitating the dissolved solution with the precipitator again, dissolving repeatedly, precipitating again and then refining, and finally decompressing and drying the product to the constant weight. The preparation method has the advantages of reasonable technology, simple operation, low preparation cost, mild reacting conditions and good product quality.

Owner:CHINA RES INST OF DAILY CHEM IND

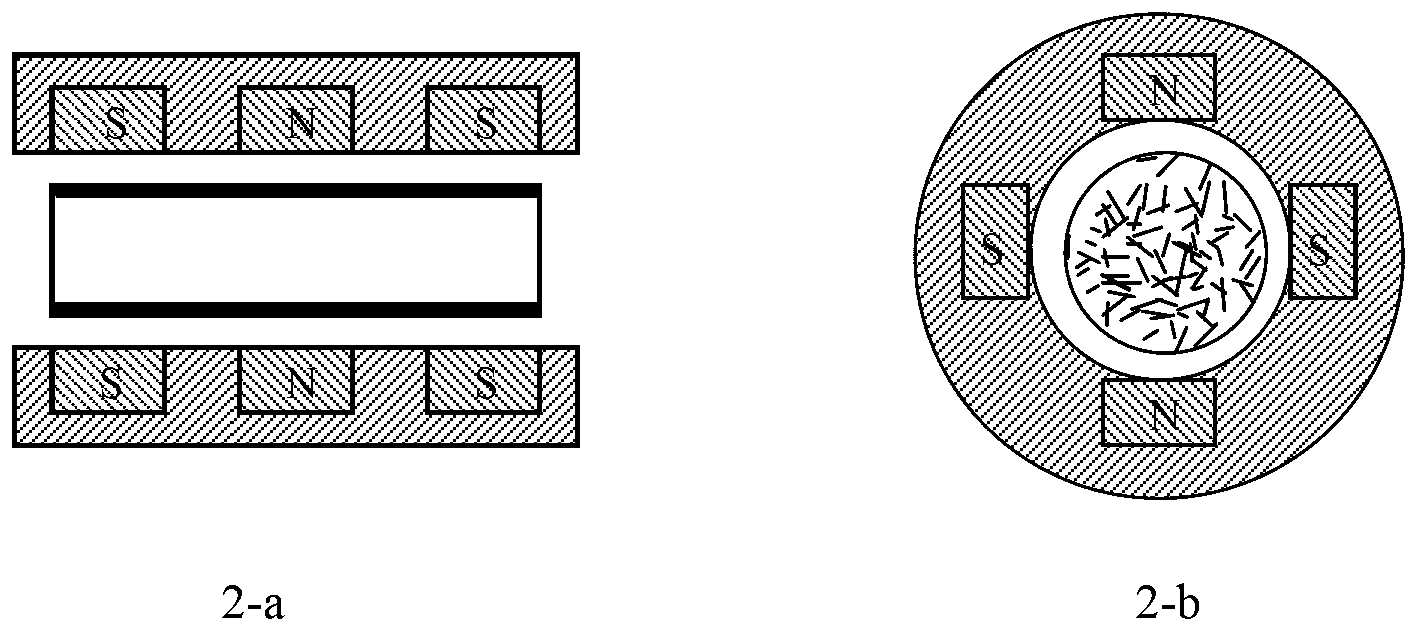

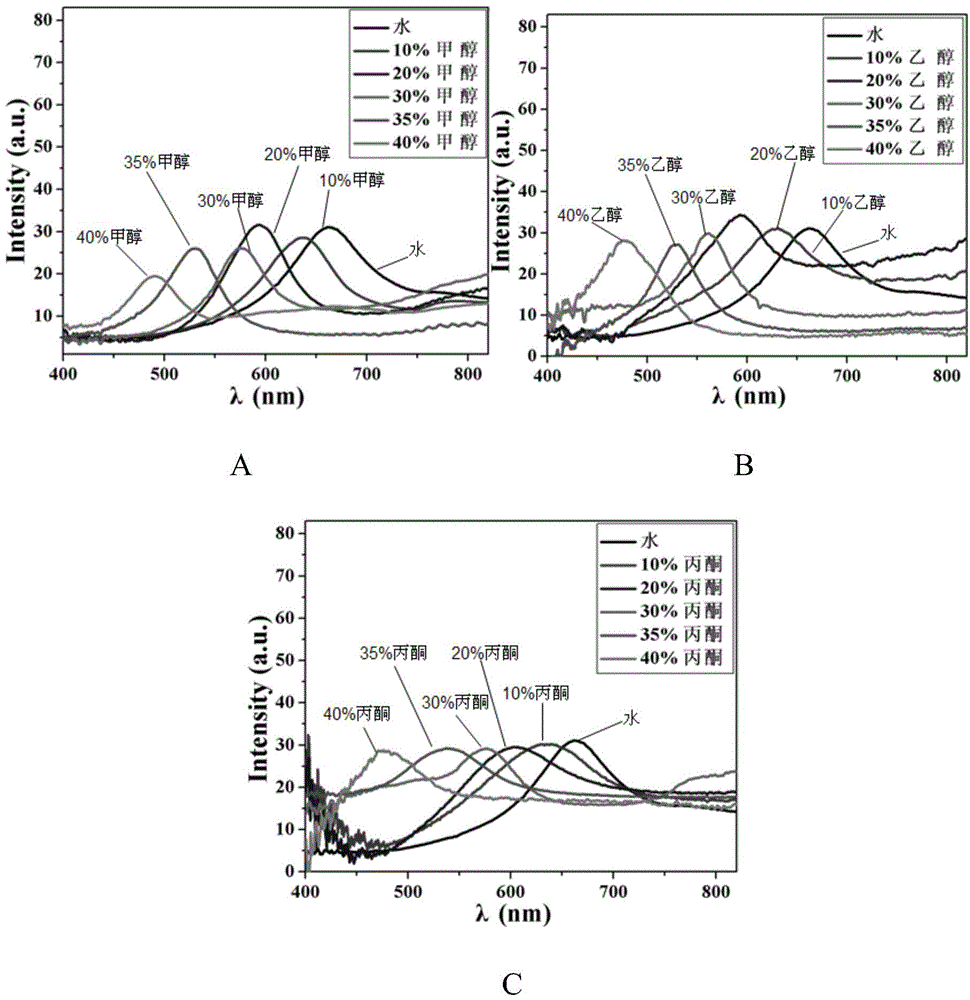

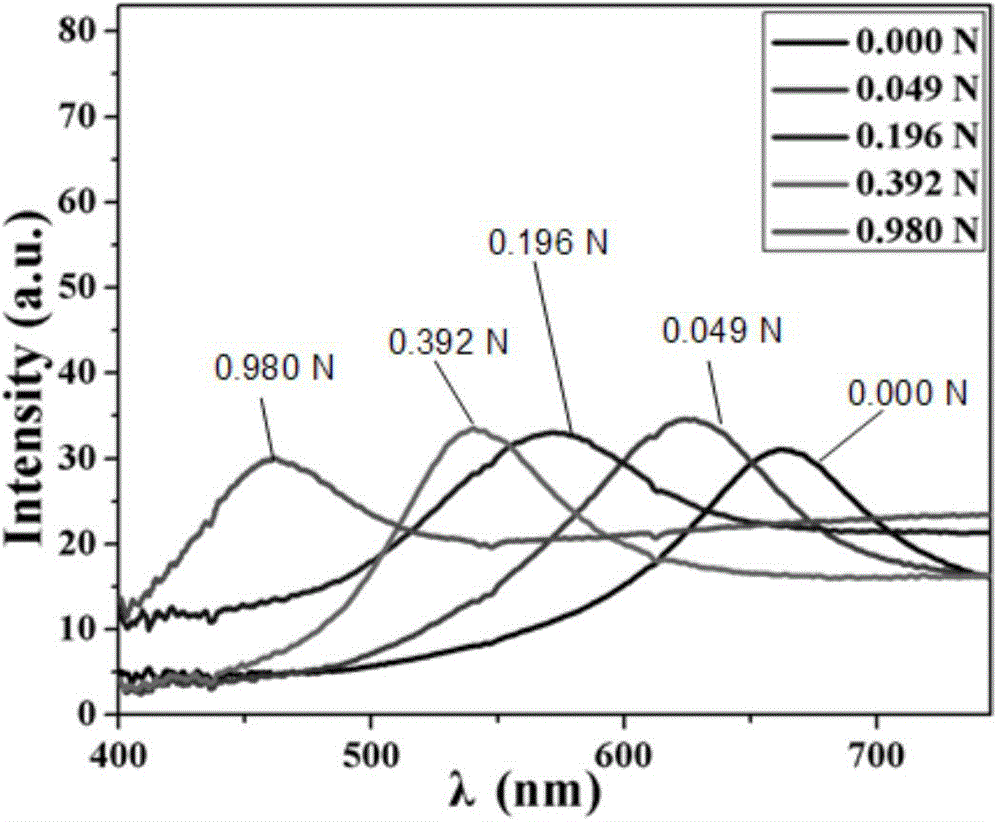

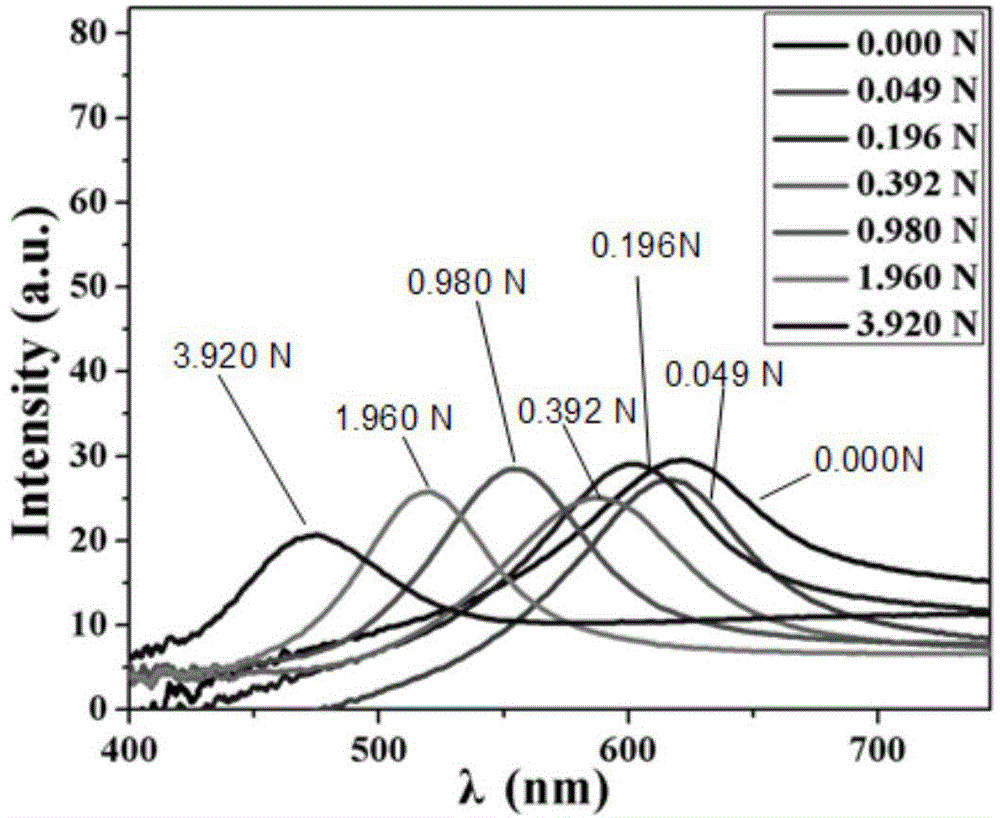

Photonic crystal thin film as well as preparation method and application thereof

ActiveCN104672485AOrdered structure fixationSuitable for naked eye detectionForce measurement by measuring optical property variationFerroso-ferric oxidesPhotonic crystalOrganic solvent

The invention discloses a photonic crystal thin film as well as a preparation method and application thereof. The photonic crystal thin film comprises Fe3O4 nanoparticles and polyacrylamide hydrogel, and the Fe3O4 nanoparticles are uniformly dispersed in the 1mg / ml-50 mg / ml polyacrylamide hydrogel. The preparation method comprises the following steps: (1) uniformly dispersing Fe3O4 nanoparticles, acrylamide, methene acrylamide and photon initiator into an organic solution, to obtain a hydrogel photon crystal suspension; (2) paving the hydrogel photon crystal suspension into a 150-300mu m thin film, loading a magnetic field of 300-2000 gaussian so as to develop the thin film, and then curing; and (3) soaking the cured crystal thin film in water, and replacing the organic solvent, thus obtaining the photonic crystal thin film. The thin film has sensitive solvent response and mechanical response capability, the preparation is fast, and the photonic crystal thin film can be used for naked-eye detection.

Owner:HUAZHONG UNIV OF SCI & TECH

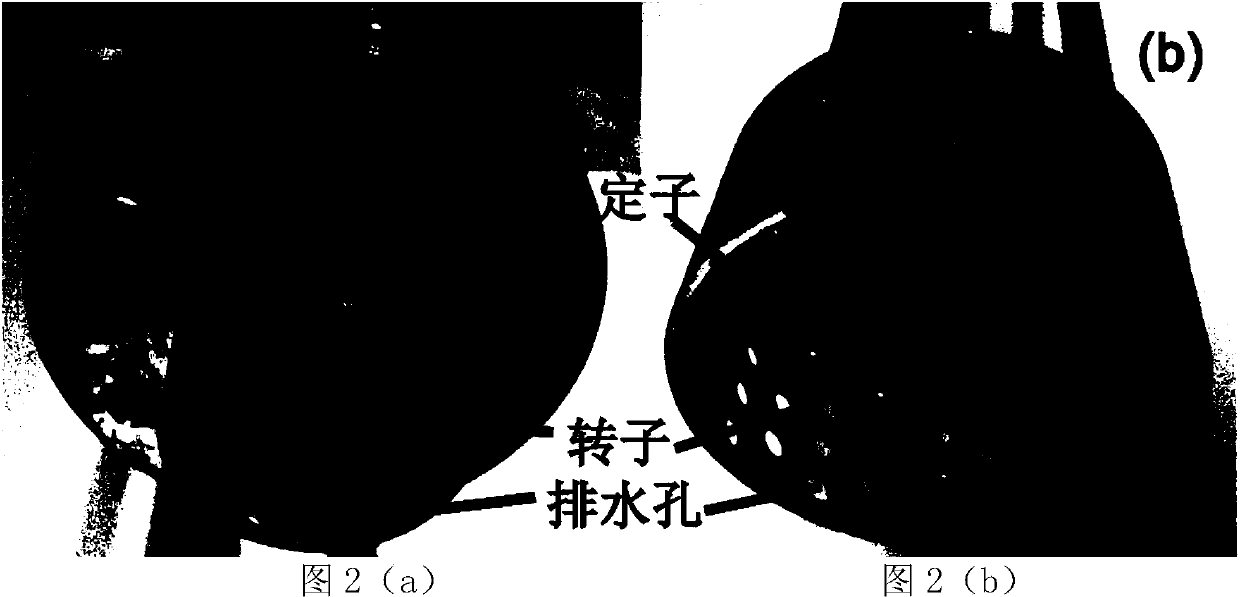

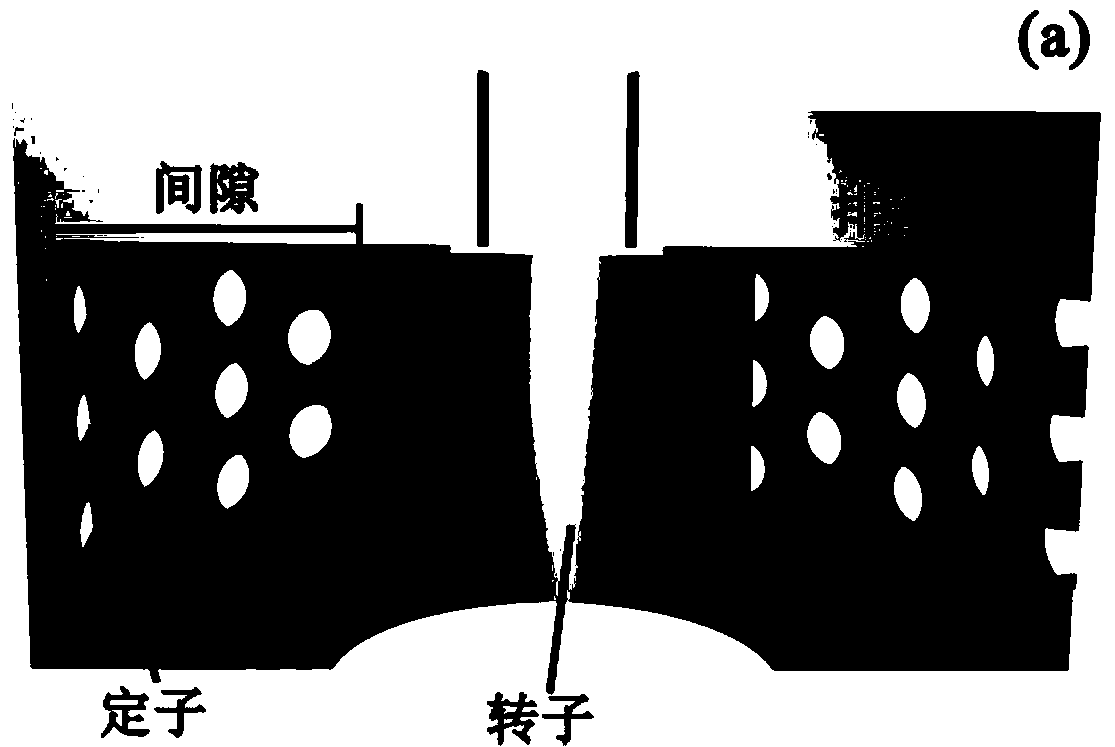

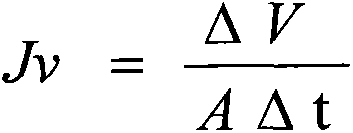

Preparation method for small-size graphene

ActiveCN104003375AHigh monolayer ratioAvoid destructionMaterial nanotechnologyGrapheneCentrifugationGraphite

A disclosed preparation method for small-size graphene comprises the steps: step 1, mixing a graphite powder raw material and a solvent to obtain a graphite mixed solution; step 2, putting the solution in a container, and fixedly arranging a homogenizing head of a stator-rotor apparatus of a stator-rotor mixer below the liquid level; step 3, starting a cooling system and the stator-rotor mixer for processing; and step 4, performing standing processing or centrifugation separation on the prepared solution to remove incompletely-peeled particles, and collecting the supernatant to obtain a stable dispersion solution of small-size graphene. According to the preparation method, a rotor rotating with a high speed drives a fluid to have a high-speed motion, so that high velocity gradient and high shear force are generated, and also graphite sheets are subjected to peeling and refining because the high-speed fluid bumps bosses of a hole wall of a stator, and the prepared graphene is small in dimension, concentrated in distribution and high in single-layer ratio. The method has the characteristics of small equipment investment, low raw material cost, simple, easy and practicable operation and impressive output, and is suitable for large-scale industrialized production as well as laboratory research.

Owner:BEIHANG UNIV

Preparation method of layer-by-layer self-assembling forward osmosis membrane and layer-by-layer self-assembling forward osmosis membrane prepared by method

InactiveCN104524984AEasy to separateSimple preparation processSemi-permeable membranesCationic polyelectrolytesDeposition process

The invention relates to a preparation method of a layer-by-layer self-assembly forward osmosis membrane and a layer-by-layer self-assembling forward osmosis membrane prepared by the method. The preparation method comprises the steps of carrying out modified treatment on a basic membrane, preparing a cationic polyelectrolyte solution, preparing an anionic polyelectrolyte and preparing a multilayer self-assembling membrane. By adopting the method, the deposition process in the prior art for adsorption only by virtue of an electrostatic effect can be changed, and a coordination effect better than the electrostatic effect is used as the driving force of the deposition process, so that the membrane has the characteristics of high water flux and low salt reverse osmotic quantity, other subsequent processes such as GA cross-linking and UV radiation are not needed, and thus the time for the preparation process can be greatly reduced.

Owner:OCEAN UNIV OF CHINA

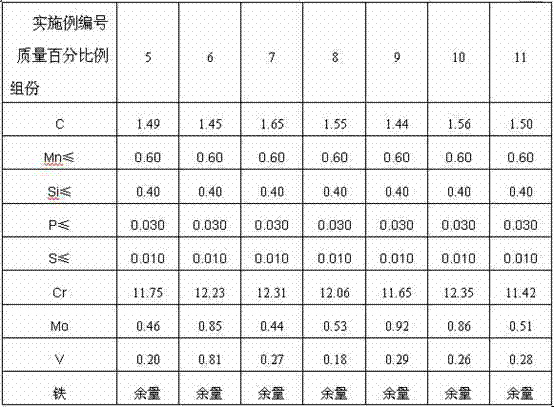

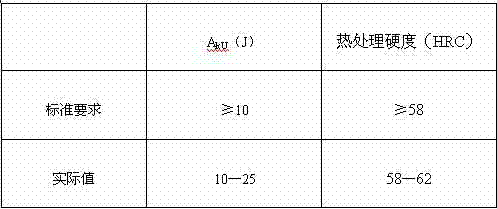

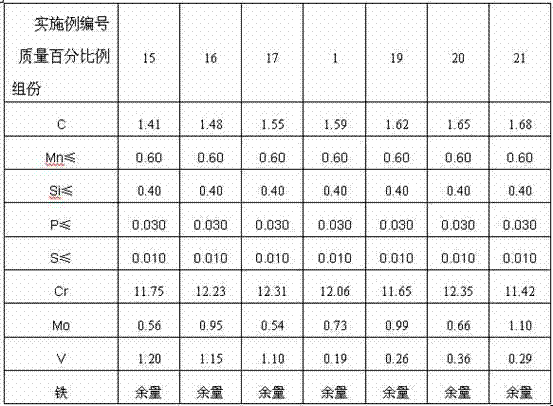

Method for manufacturing large cake forgings of high-carbon and high-chromium cold working die steel

The invention discloses a method for manufacturing large cake forgings of high-carbon and high-chromium cold working die steel. The method is characterized by comprising the following steps of: obtaining Cr12MoV or Cr12Mo1V1 steel by adopting primary smelting with an electric furnace, ladle refining and vacuum degassing process smelting; pouring the tapped steel to form a 6 to 9t octangular ingot; conveying the octangular ingot to a press at the temperature of more than or equal to 300 DEG C, forging the octangular ingot to a blank with the diameter of 300 to 700 millimeters, removing surface defects by annealing, polishing or turning and local grinding, performing cold saw cutting on the end face and blanking to form a cake blank; and heating the cake blank to the temperature of between 1,150 and 1,190 DEG C, upsetting and forging the cake blank by using the press, annealing and turning, and thus obtaining the large cake forgings of the high-carbon and high-chromium cold working die steel. By adopting the method, the yield is improved to 40 to 60 percent; and the manufactured large cake forgings of the high-carbon and high-chromium cold working die steel can comprehensively meet the requirements of hardness, impact toughness and the like and ultrasonic flaw detection quality.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Method for preparing high-entropy alloy coating

InactiveCN103556146AHigh hardnessImprove wear resistanceArc welding apparatusMetallic material coating processesHigh entropy alloysGas tungsten arc welding

The invention relates to the field of multi-principal element high-entropy alloy materials and in particular relates to a method for preparing a high-entropy alloy coating, belonging to the field of coating preparation. The method for preparing the high-entropy alloy coating comprises the following steps: pretreating a substrate, so that the surface of the substrate is clean and flat; preparing high-entropy alloy powder, uniformly mixing, and adding 3-6wt% of organic solution in the alloy powder; uniformly mixing the organic solution and the high-entropy alloy powder, and preparing into paste; uniformly coating the pasty alloy powder on the treated substrate, wherein the thickness of the coating layer is 0.3-6mm; baking the treated coating layer and substrate in an oven at the temperature of 55-80 DEG C for 20-30 hours; cladding the coating layer on the surface of the substrate through gas tungsten arc welding. According to the method for preparing the high-entropy alloy coating, the high-entropy alloy coating with the thickness of 0.3-6mm can be prepared, a heat affected zone to the substrate in the preparation process is small, and the coating is uniform in distribution and firmly bound to the base material.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

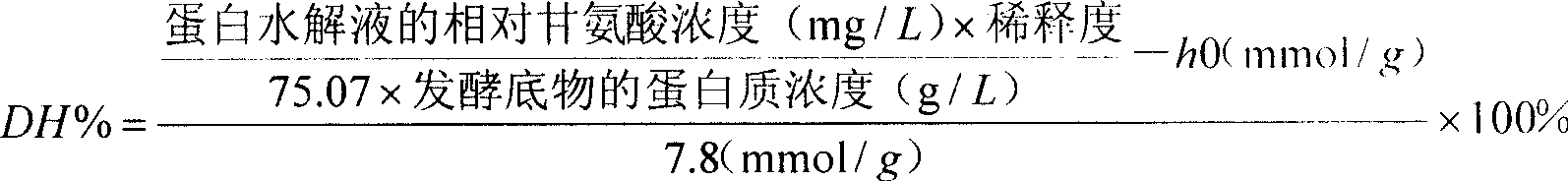

Preparation method of novel protein feed additive

ActiveCN101530162AIncrease egg productionExtend peak egg productionAnimal feeding stuffAccessory food factorsBiotechnologyAnimal science

The invention relates to a preparation method of a hydrolyzed protein mixture and a protein peptide powder feed additive, wherein a multienzyme complex enzyme method is used for hydrolyzing vegetable protein to prepare the hydrolyzed protein mixture and protein peptide powder. The technology of the method is simple, and a non-starch polysaccharide enzyme and a proteinase are compounded so as to be capable of improving the hydrolyzation rate and degree of protein as well as the utilization rate of feed and reducing the production cost. Products prepared by the preparation method can be used as the feed additive to be capable of significantly improving the laying rate of egg-laying poultry, improving the weight increment of meat poultry, reducing the feed-meat rate and improving the production performance of table poultry as well as reducing the incidence rate of diarrhea in young animals and the feed-meat rate of piggy; and the preparation method is applied to aquatic livestock to be capable of improving the weight increment of fish and reducing the bait coefficient and content viscosity in the intestinal tract.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

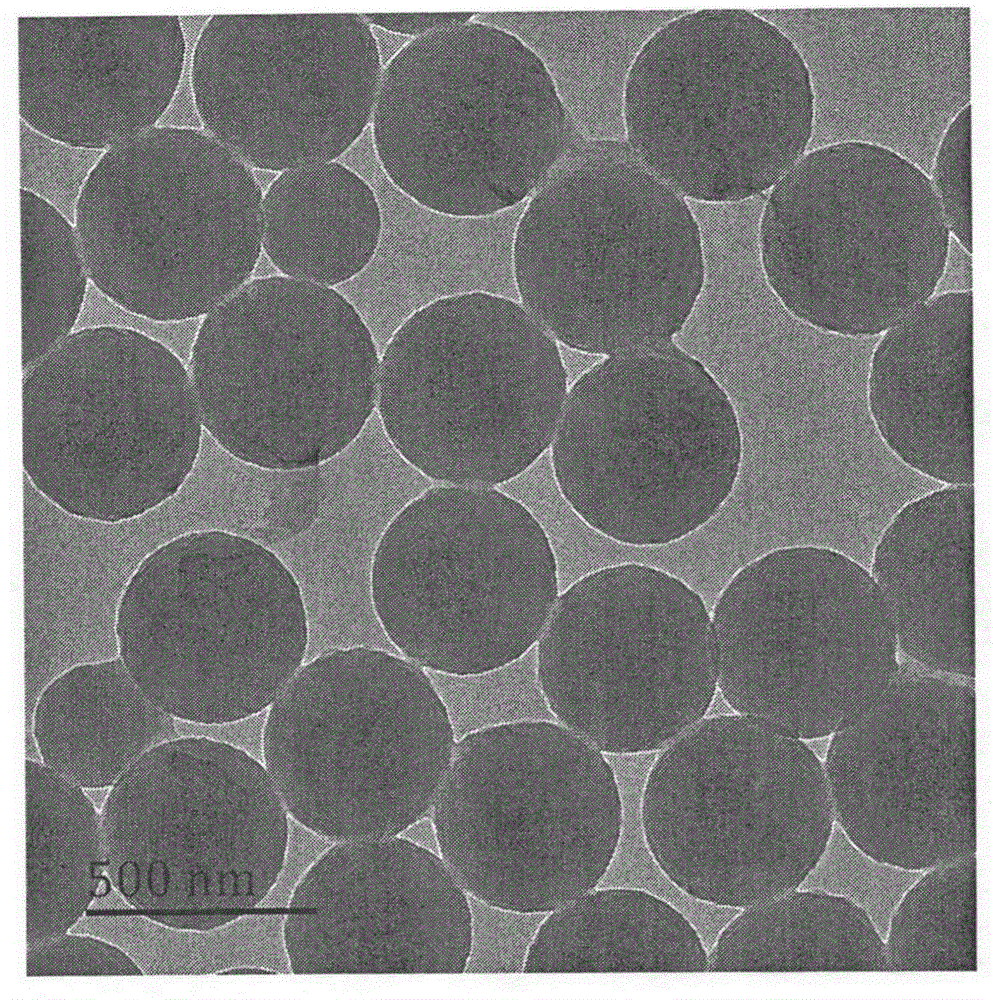

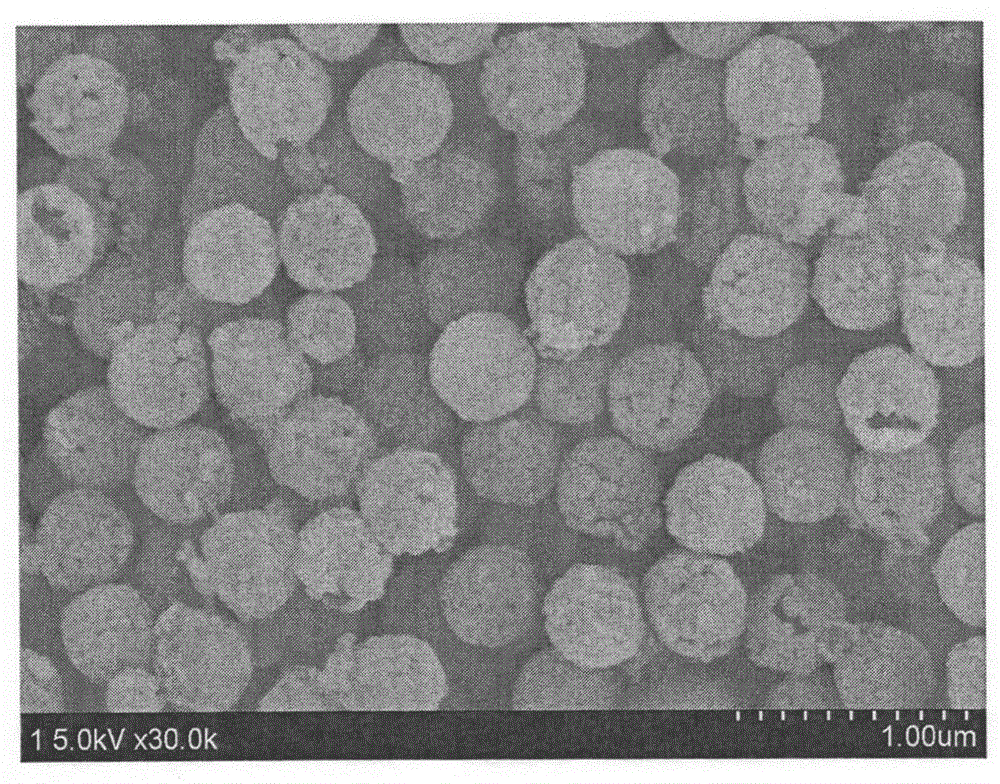

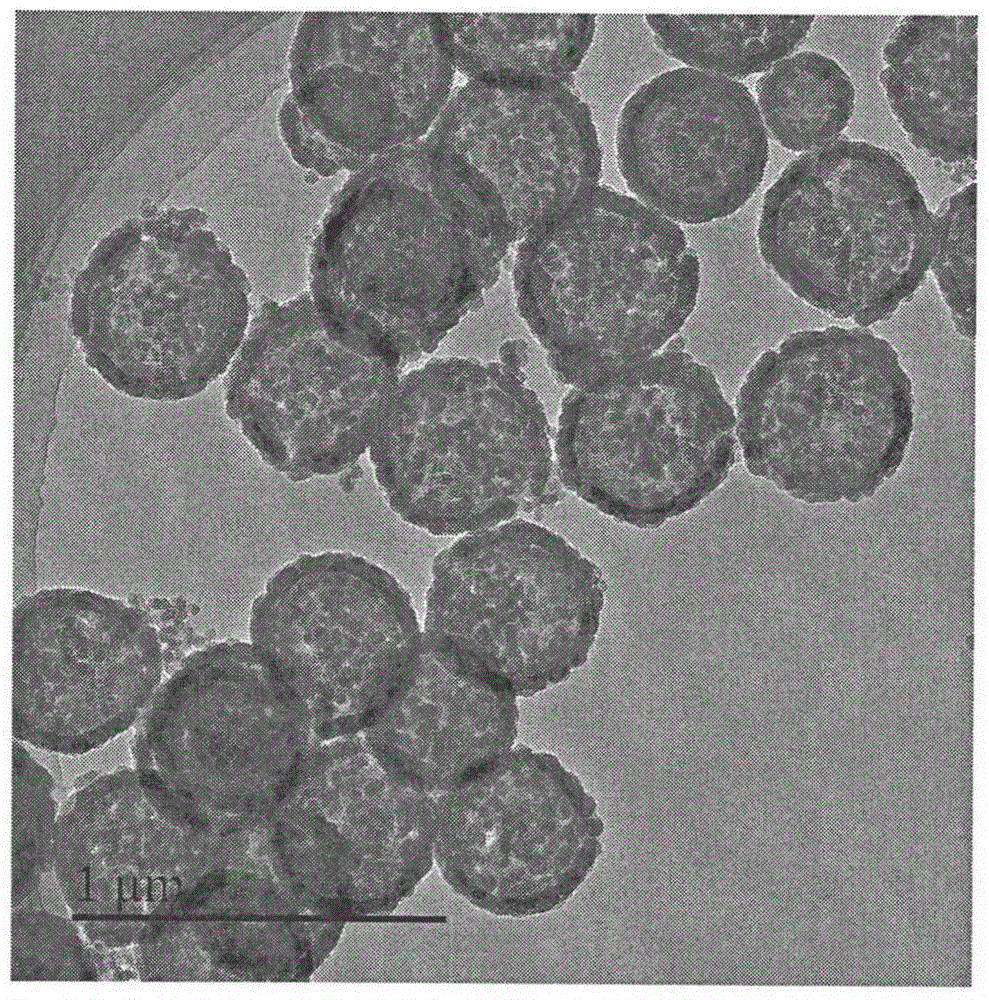

Mesoporous silica nano hollow sphere and preparation method thereof

InactiveCN104445214ALow priceEasy to operateMaterial nanotechnologySilicaBiocompatibility TestingMesoporous silica

The invention provides a mesoporous silica nano hollow sphere and a preparation method thereof. The mesoporous silica nano hollow sphere is characterized by comprising a spherical shell in which a cavity is formed; the spherical shell is formed by aggregating mesoporous silica nano particles with the grain size being 5-50nm, and amino is contained on the inner and outer surfaces of the spherical shell. The novel mesoporous silica nano hollow sphere prepared in the invention is rich in amino on the surface and has the characteristics of being great in specific surface area, good in biocompatibility, high in stability, great in drug loading capacity and the like.

Owner:DONGHUA UNIV

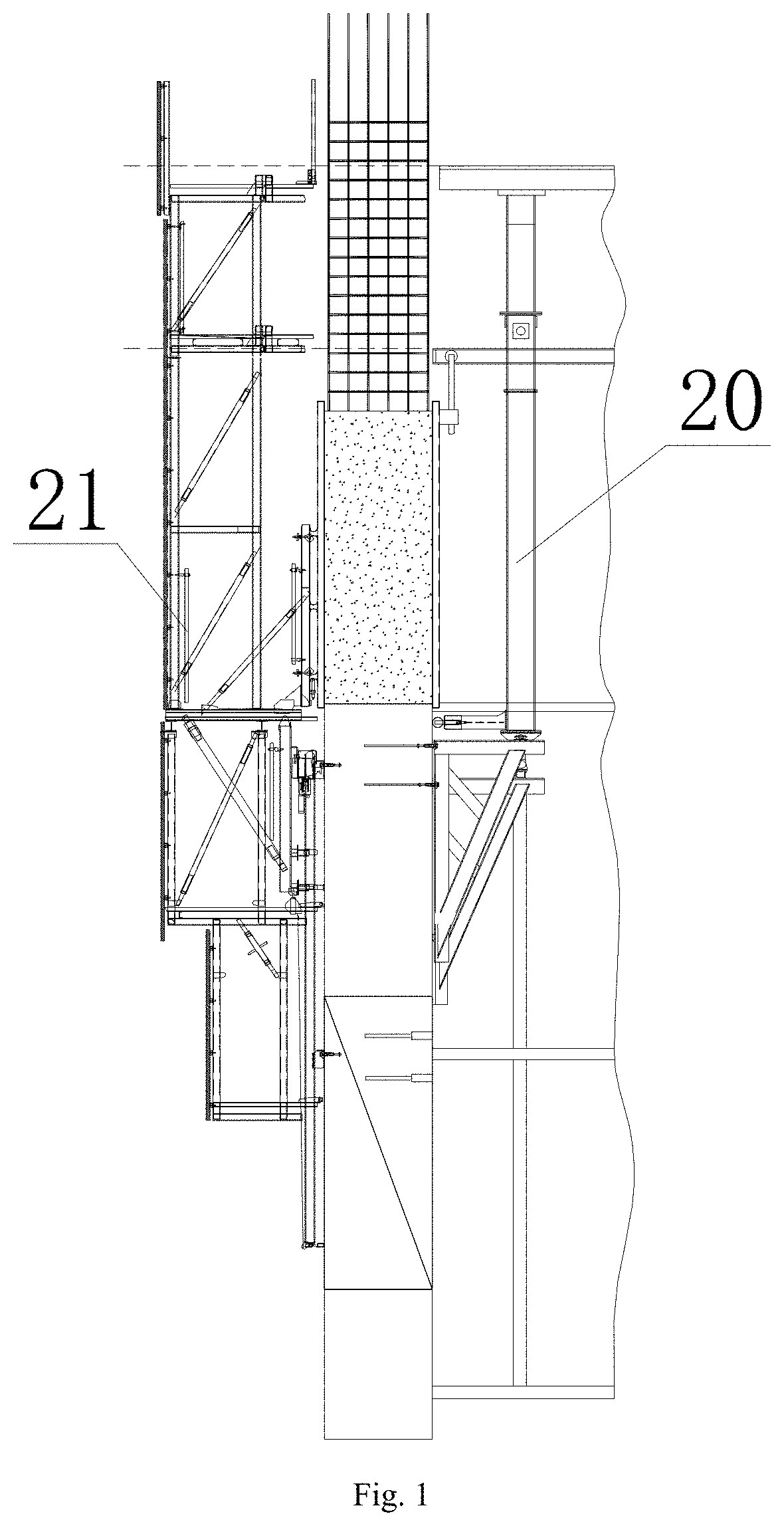

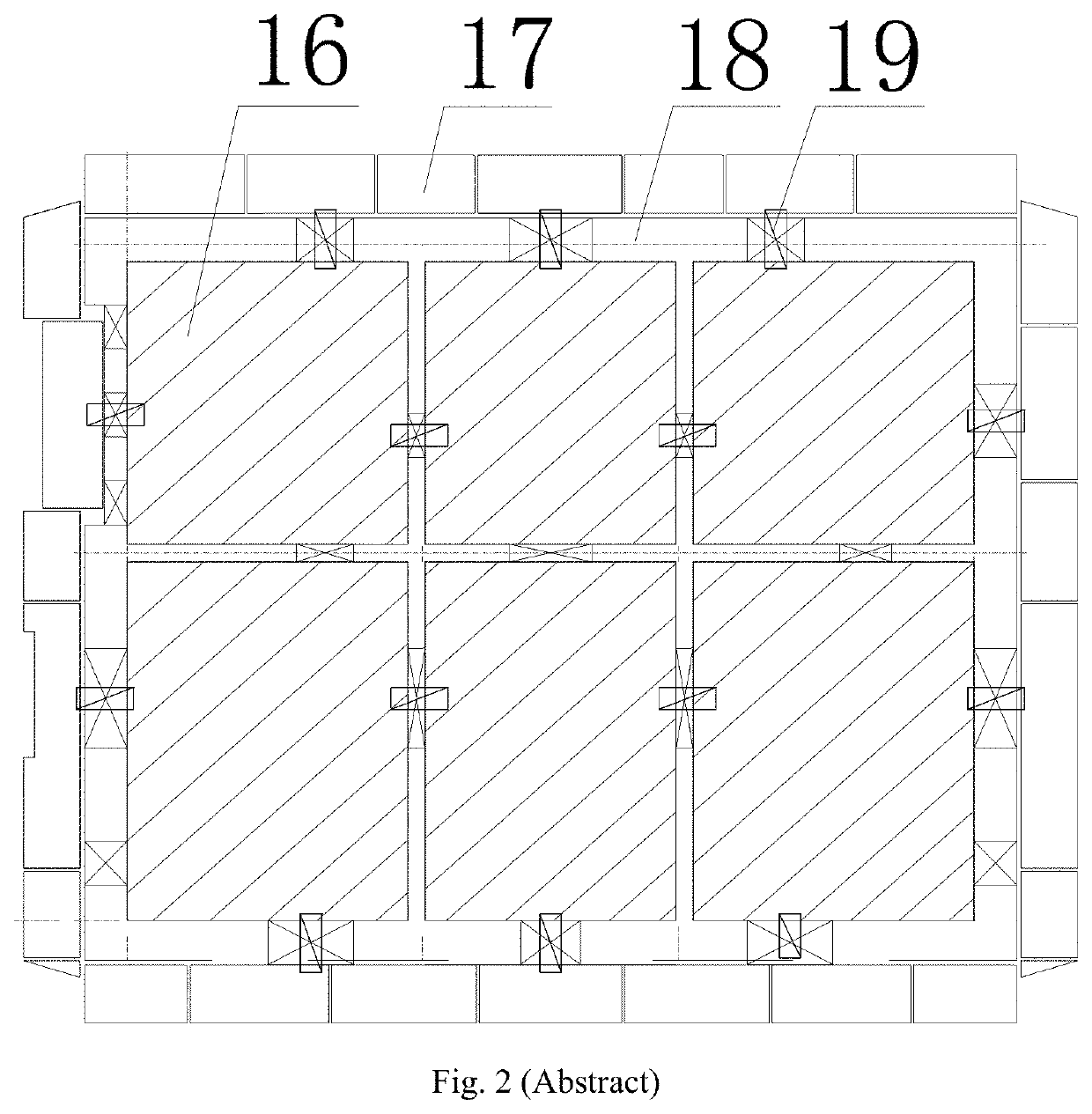

Integrated formwork system for construction of super high-rise building

InactiveUS20200002958A1Improve carrying capacityLight weightForms/shuttering/falseworksBuilding material handlingArchitectural engineeringStructural safety

An integrated formwork system for construction of a super high-rise building, comprising a climbing system in a stereoscopic structure formed by a successive enclosure of a plurality of climbing formwork units, a jacking system formed by a plurality of jacking units arranged side by side being disposed in the stereoscopic structure, and a working space formed between the climbing system and the jacking system, wherein the climbing formwork units located at a same side wall of the stereoscopic structure all correspond to the jacking units adjacent to the side wall and are capable of moving synchronously or separately, the jacking units are provided thereon with a vertical adjusting device and a horizontal adjusting device, and a plurality of groups of tensioning devices are disposed in each of the jacking units. Such formwork has light deadweight, a low gravity center, good structural safety, a broad construction work plane.

Owner:SICHUAN HUASHI GRP CO LTD +1

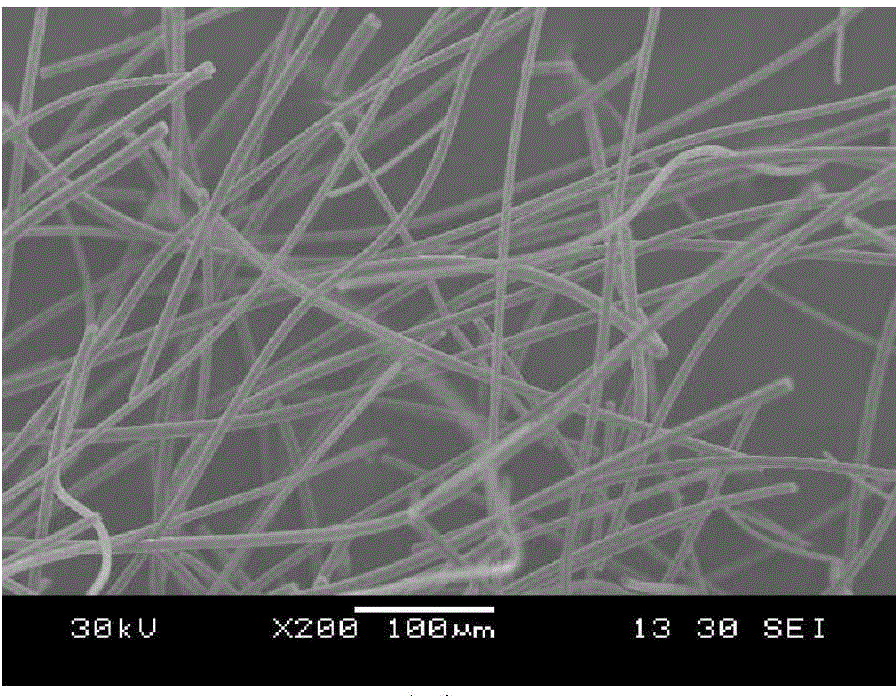

Preparation method of mullite fiber

The invention discloses a preparation method of high-purity continuous mullite fiber. The mullite fiber is prepared by adopting a sol-gel method and a centrifugal spinning technology through taking anhydrous aluminum chloride and aluminum powder as an aluminum source, tetraethylorthosilicate as a silicon source, and glacial acetic acid as a colloid stabilizer and spinning auxiliary. The preparation method comprises the following steps: firstly, preparing a mullite fiber precursor sol according to raw materials, preparing gel fibers through the centrifugal spinning technology, and finally drying and sintering at high temperature to obtain the mullite fiber. In order to improve the room-temperature and high-temperature mechanical performance of mullite, 0-2wt% of oxide second phase is added. Compared with the prior art, the mullite fiber prepared by adopting the method has the advantages that the consumed time is short, raw materials are low in price, and industrial production can be considered; the mullite fiber is higher in high-temperature resistance degree and better in physical and chemical properties compared with aluminum silicate fiber and high-purity alumina fiber; the mullite fiber can also be used as base fibers of mullite fiber felts and fiberboards, and can be further processed.

Owner:南京理工宇龙新材料科技股份有限公司 +1

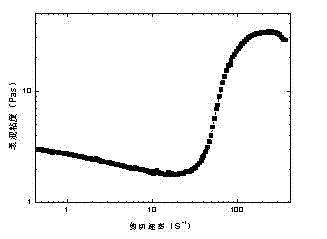

Preparation method and use of shear thickening fluid

The invention relates to the technical field of organic silicon polymer application and provides a preparation method of a shear thickening fluid. The preparation method realizes compatible matching of micro / nano-particles and a dispersion medium and improves system shear thickening effects and system storage stability. The shear thickening fluid is prepared by mixing micro / nano-particles and an organic silicon polymer, wherein a mass ratio of the micro / nano-particles to the organic silicon polymer is (1-3): (2-4). The preparation method is simple and has short preparation time. The shear thickening fluid obtained by the preparation method has stable quality, can be mass-produced easily, has low energy consumption, produces less three wastes and has a low cost. The invention also provides a use of the shear thickening fluid in a liquid protection composite material. The liquid protection composite material prepared from the shear thickening fluid has no toxicity and no pollution and is suitable for a human body and industrial production.

Owner:HANGZHOU NORMAL UNIVERSITY

Micro-nano composite dual-layer skin framework and manufacturing method thereof

ActiveCN106110401AGood biocompatibilityImprove mechanical propertiesAdditive manufacturing apparatusProsthesisPorosityFiber

The invention discloses a micro-nano composite dual-layer skin framework and a manufacturing method thereof which are applied to the skin regenerative tissue engineering. The manufacturing method includes the steps of firstly, preparing a nanofiber membrane layer by the electrospinning technique and utilizing the same as a surface layer of skin; secondly, preparing a three-dimensional framework by direct writing on the nanofiber membrane layer by an electrohydrodynamic inkjet printing method and utilizing the same as dermis. Specifically, the nanofiber membrane refers to a layer of nanofibers uniform in diameter; the nanofibers provide suitable surface morphology for cell adhesion and growth, thereby facilitating cell adhesion and growth; the three-dimensional framework refers to a three-dimension space composed of nanofibers by the electrohydrodynamic inkjet printing method, provides a microenvironment for growth of cells, and facilitates cell infiltration and proliferation; both the nanofiber membrane and the three-dimensional framework are made from biodegradable high-polymer material. Compared with the conventional artificial skin framework, the micro-nano composite dual-layer skin framework has the advantages of high plasticity, good mechanical property, three-dimension structure with high porosity, and high biocompatibility.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com