Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Cold saw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cold saw is a circular saw designed to cut metal which uses a toothed blade to transfer the heat generated by cutting to the chips created by the saw blade, allowing both the blade and material being cut to remain cool. This is in contrast to an abrasive saw, which abrades the metal and generates a great deal of heat absorbed by the material being cut and saw blade.

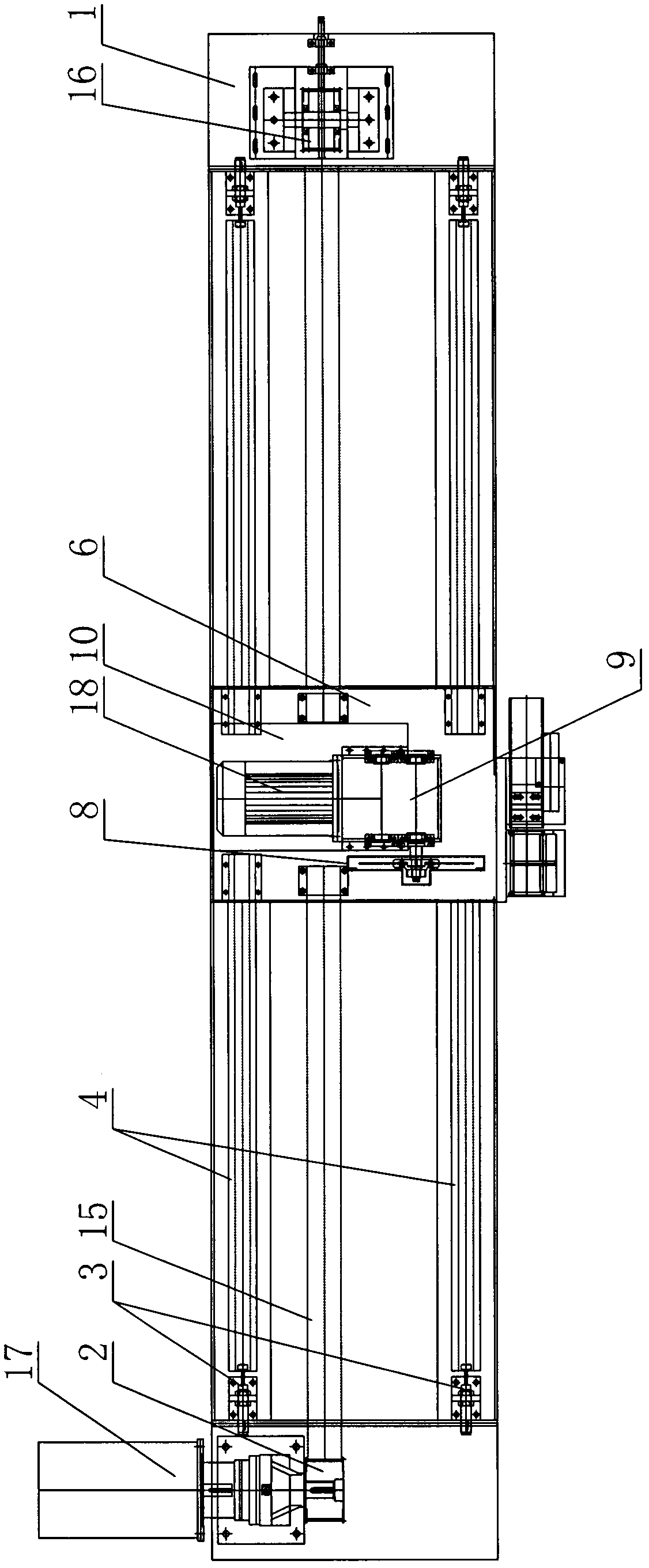

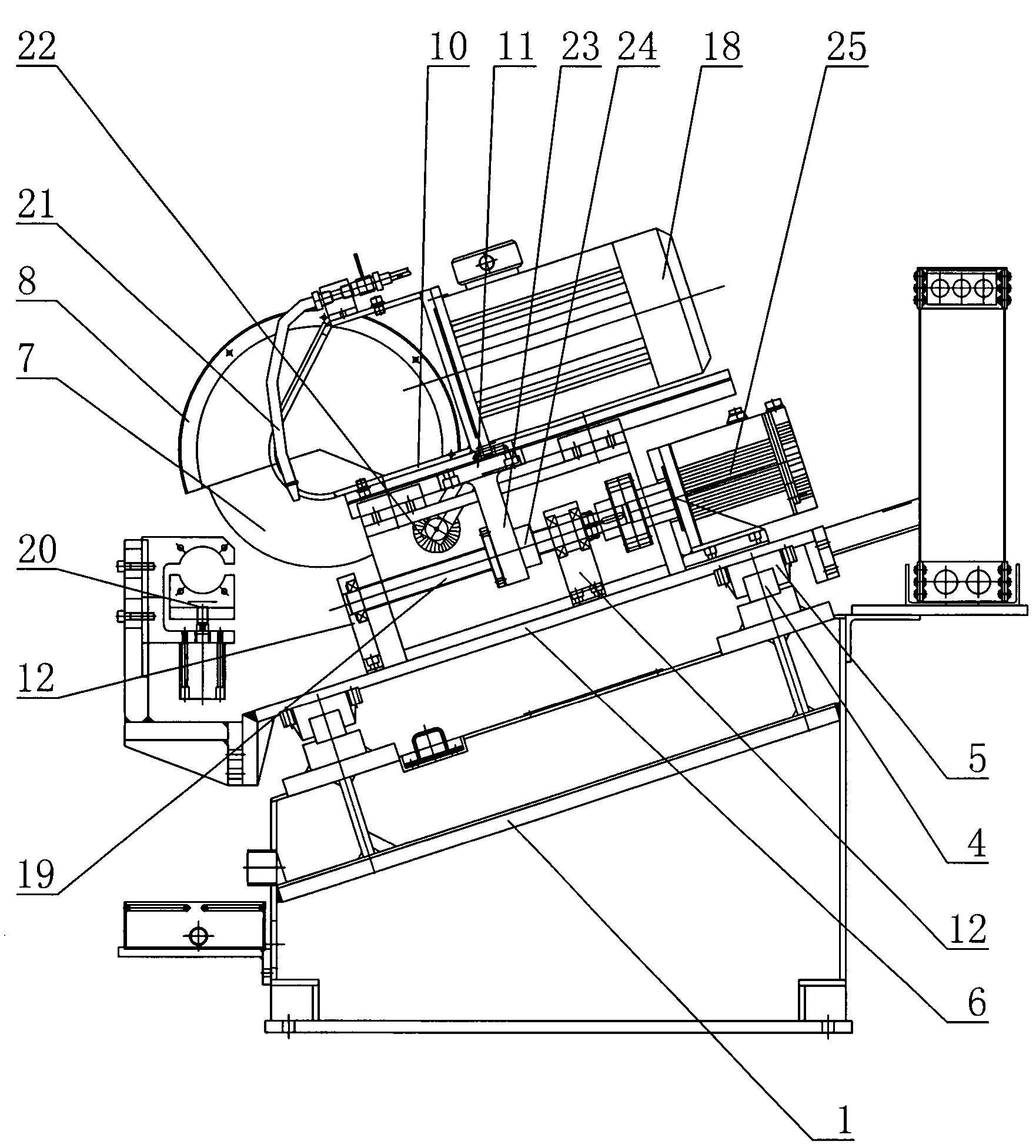

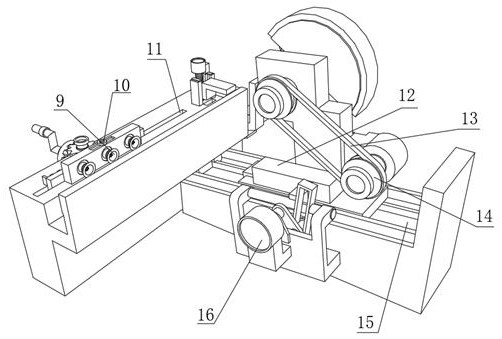

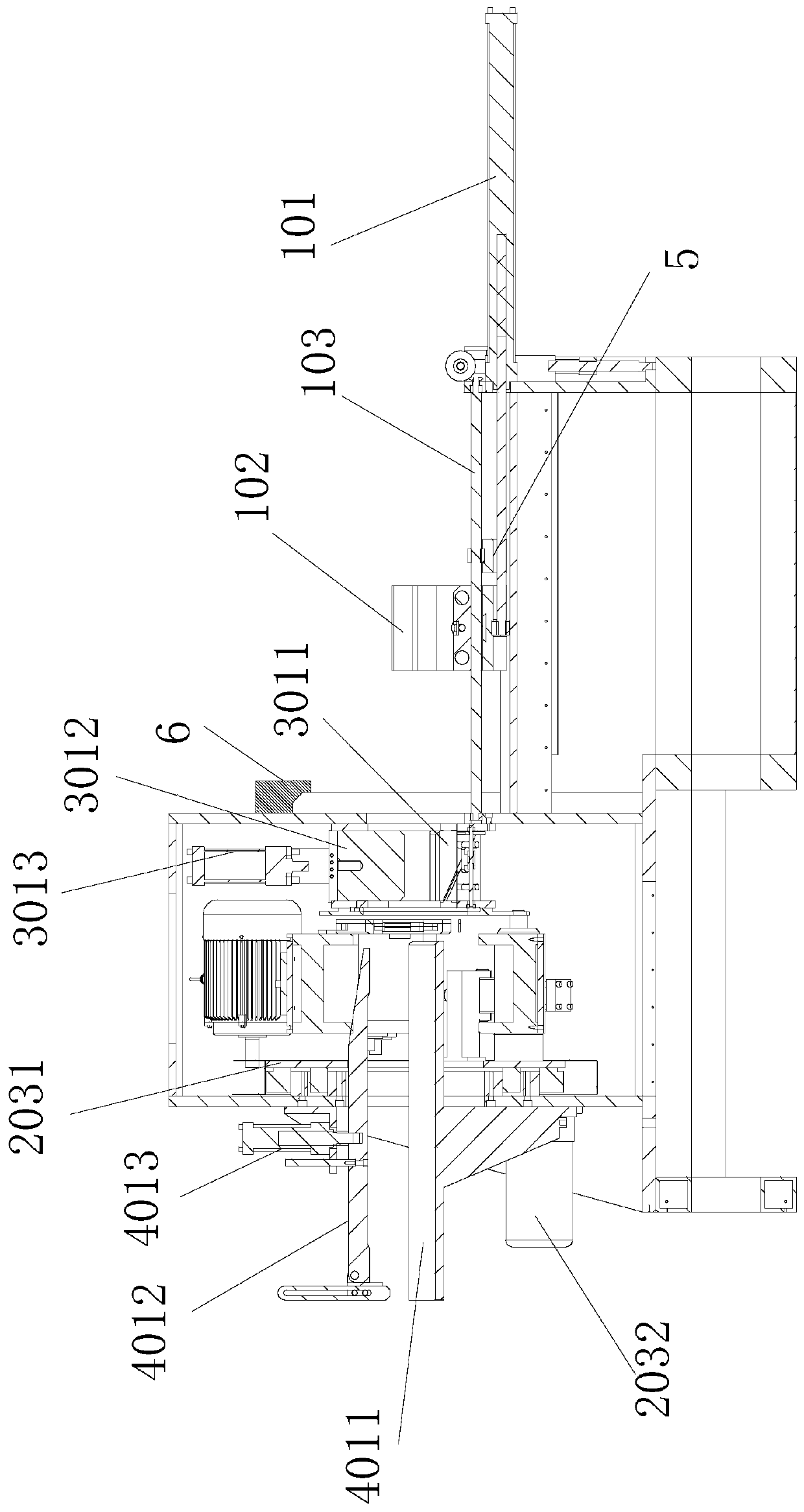

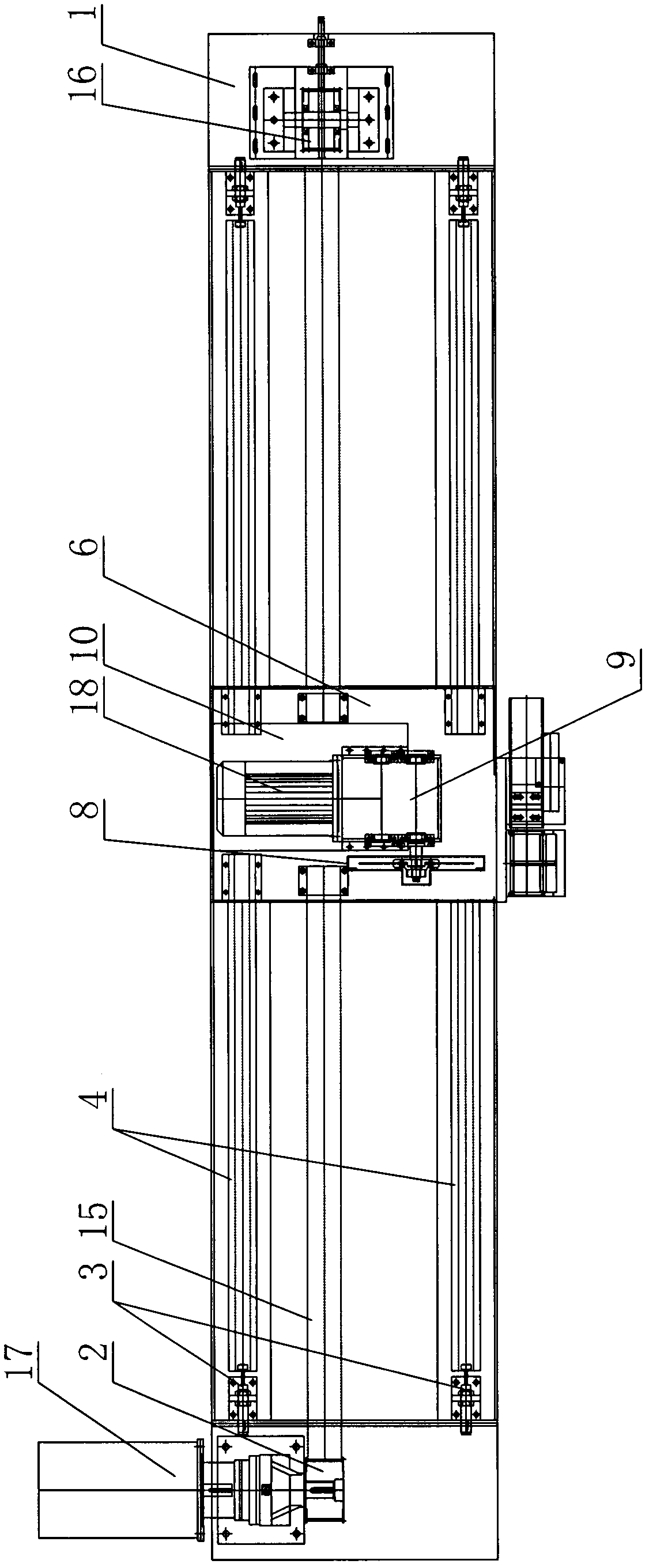

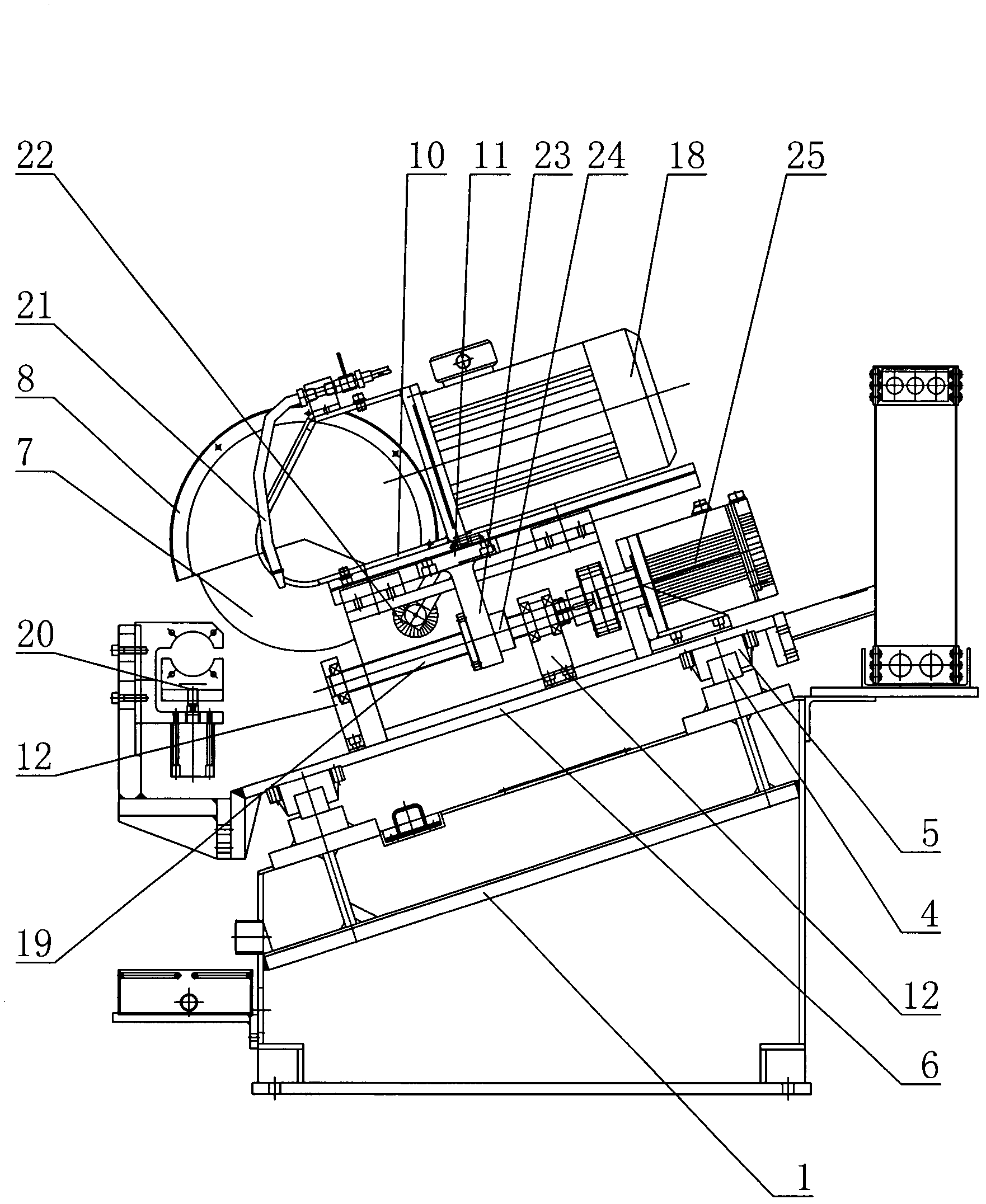

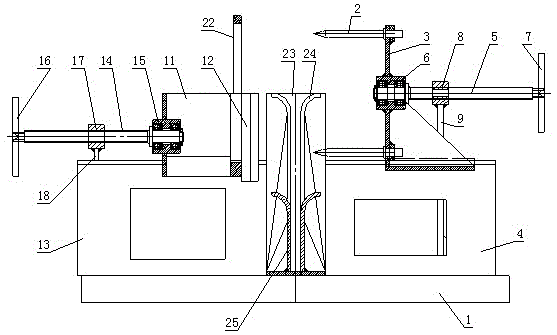

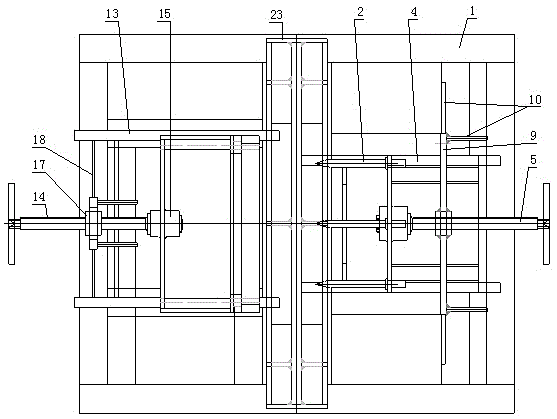

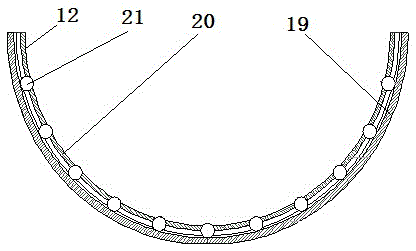

Synchronous cold saw cutting machine

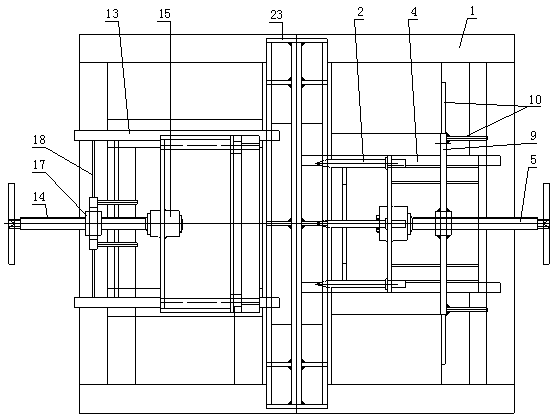

ActiveCN102059486AConvenient blankingAvoid stockpilingMetal sawing devicesMetal sawing accessoriesLinear motionBall screw

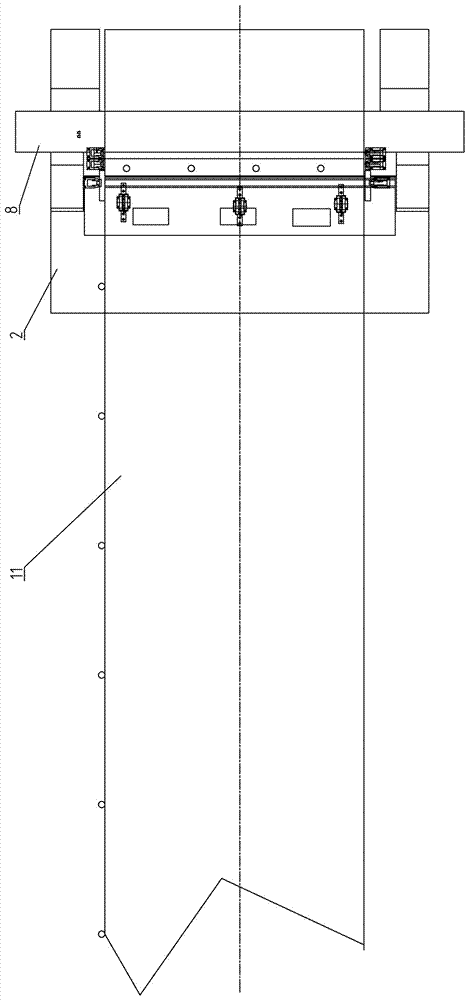

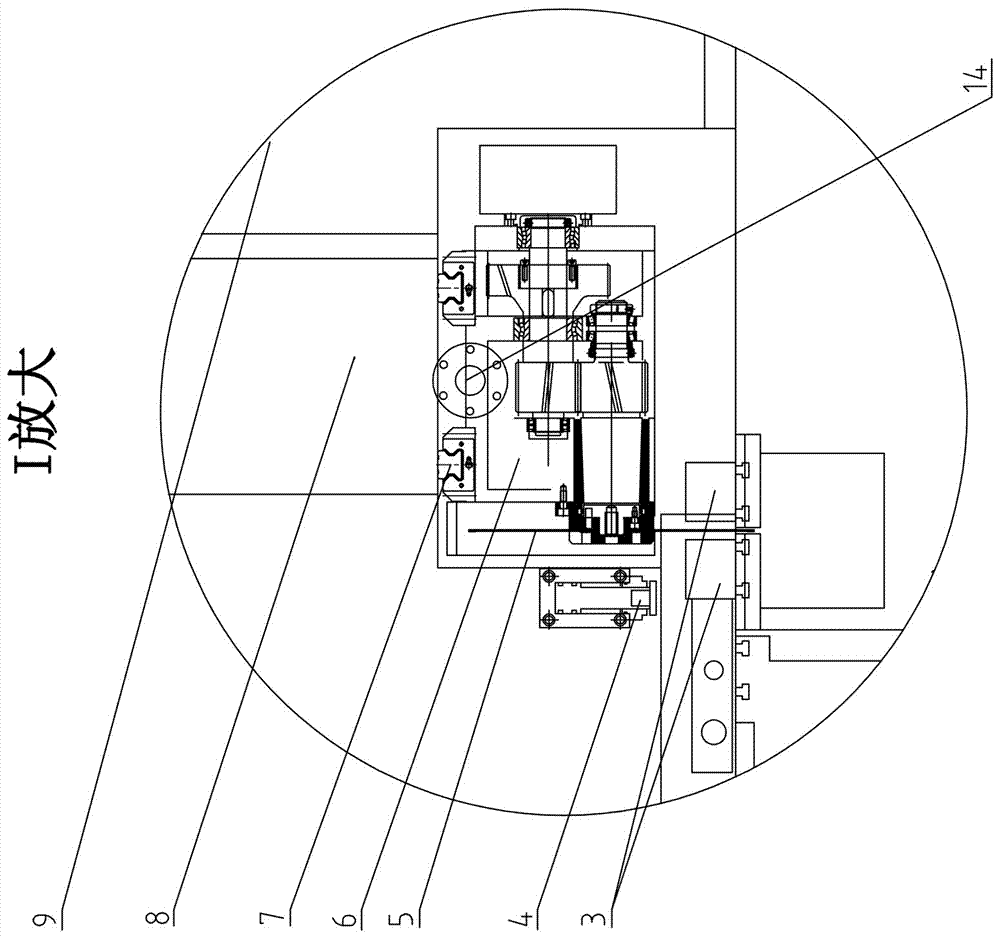

The invention relates to a synchronous cold saw cutting machine in the field of welding pipe automatic production equipment. In the synchronous cold saw cutting machine, a saw cutting motor is connected with a milling saw blade through a transmission box; two parallel main guide rails are horizontally arranged on a machine frame; main sliding blocks are arranged on the main guide rails in a matching way and fixedly arranged on the lower side of a main workbench; a driving mechanism for driving the main workbench to do linear motion is arranged on the machine frame and is in synchronous transmission connection with a main servo motor; an upright column is arranged on the main workbench and is connected with a secondary workbench through a secondary guide rail sliding block mechanism; the transmission box is fixedly arranged on the upper side of the secondary workbench; the lower side of the secondary workbench is in transmission connection with a feed motor through a ball screw mechanism; a screw nut of the ball screw mechanism is fixed with the lower side of the secondary workbench; the two ends of a screw rod of the ball screw mechanism are arranged on the upper side of the main workbench through a screw rod base; and a pipe fixture is arranged on the side of the main workbench. The synchronous cold saw cutting machine can cut off a metal pipe during the linear motion of the metal pipe, does not generate burrs on the cut, and can obviously increase the production speed of a welding pipe production line.

Owner:江苏省南扬机械制造有限公司

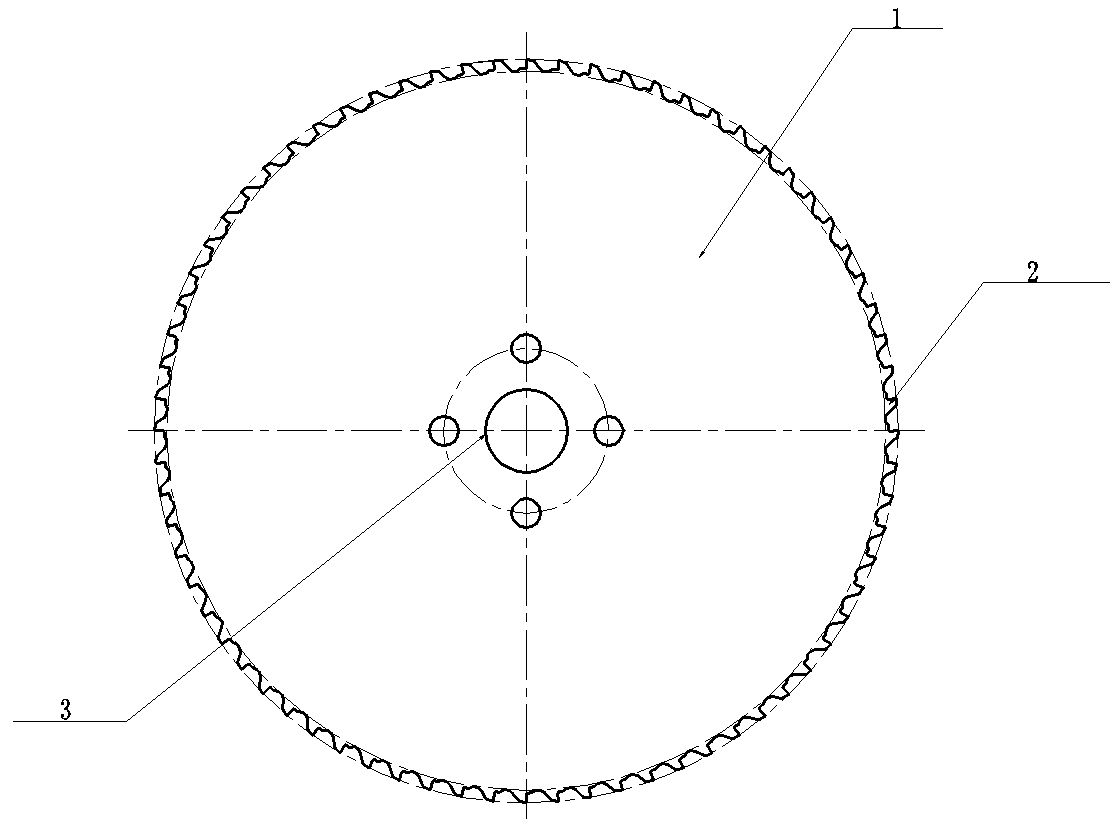

Method for preparing stainless steel cutting cold saw and saw blade of cold saw

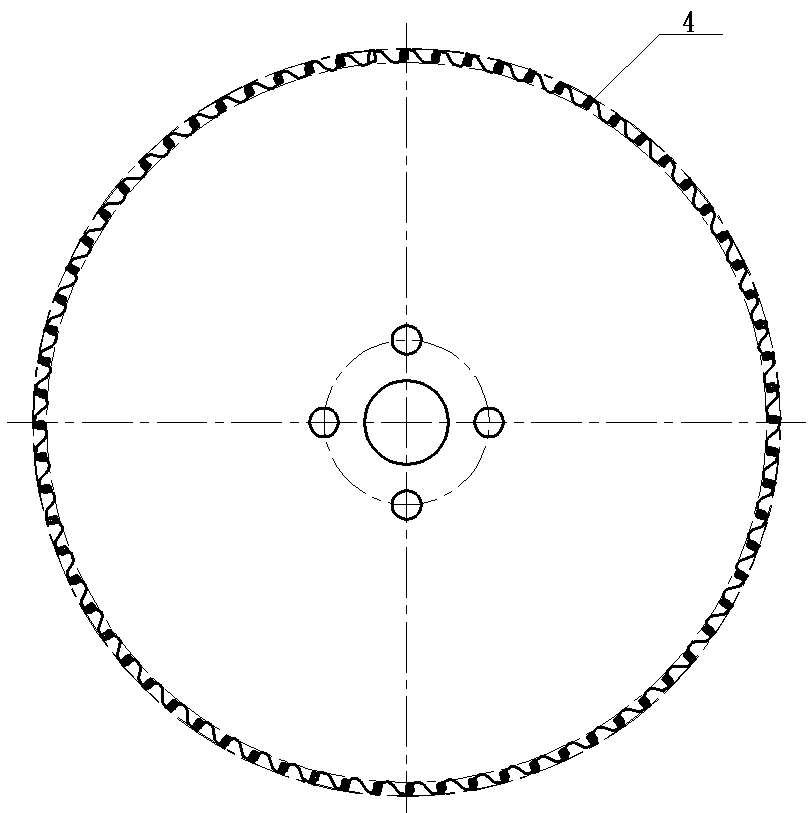

ActiveCN104353898AImprove thermal stabilityImprove wear resistanceMetal sawing tool makingMetal sawing toolsTool bitCircular saw

The invention provides a method for preparing a stainless steel cutting cold saw and a saw blade of a cold saw. The method comprises the following steps: performing stress treatment on a circular saw blade base body; controlling the welding precision of a specially-shaped tool bit; processing a low-friction-coefficient chip guiding slot, a chip breakage slot, a tipping prevention edge, a cutting edge and a low-friction-coefficient side surface on the tool bit; performing cutting edge passivation and TiAlN coating treatment after the tool bit is processed. The saw blade prepared according to the method comprises a saw blade base body, sawteeth arranged on the circumference of the saw blade base body and a mounting hole formed in the saw blade base body, a chip breakage slot is formed in a rear tool face of a sawtooth tool bit, a tipping prevention edge is cut at the intersection of the rear tool face and an upper end main side surface of the sawtooth tool bit, a cutting edge is formed at the junction part of the front tool face and the rear tool face, and a chip guiding slot is formed in the front tool face connected with the cutting edge. The saw blade has the benefits of wear resistance and heat resistance; the chip sticking resistance is improved and the service life is prolonged.

Owner:HANGZHOU WAGEN PRECISION TOOLING CO LTD

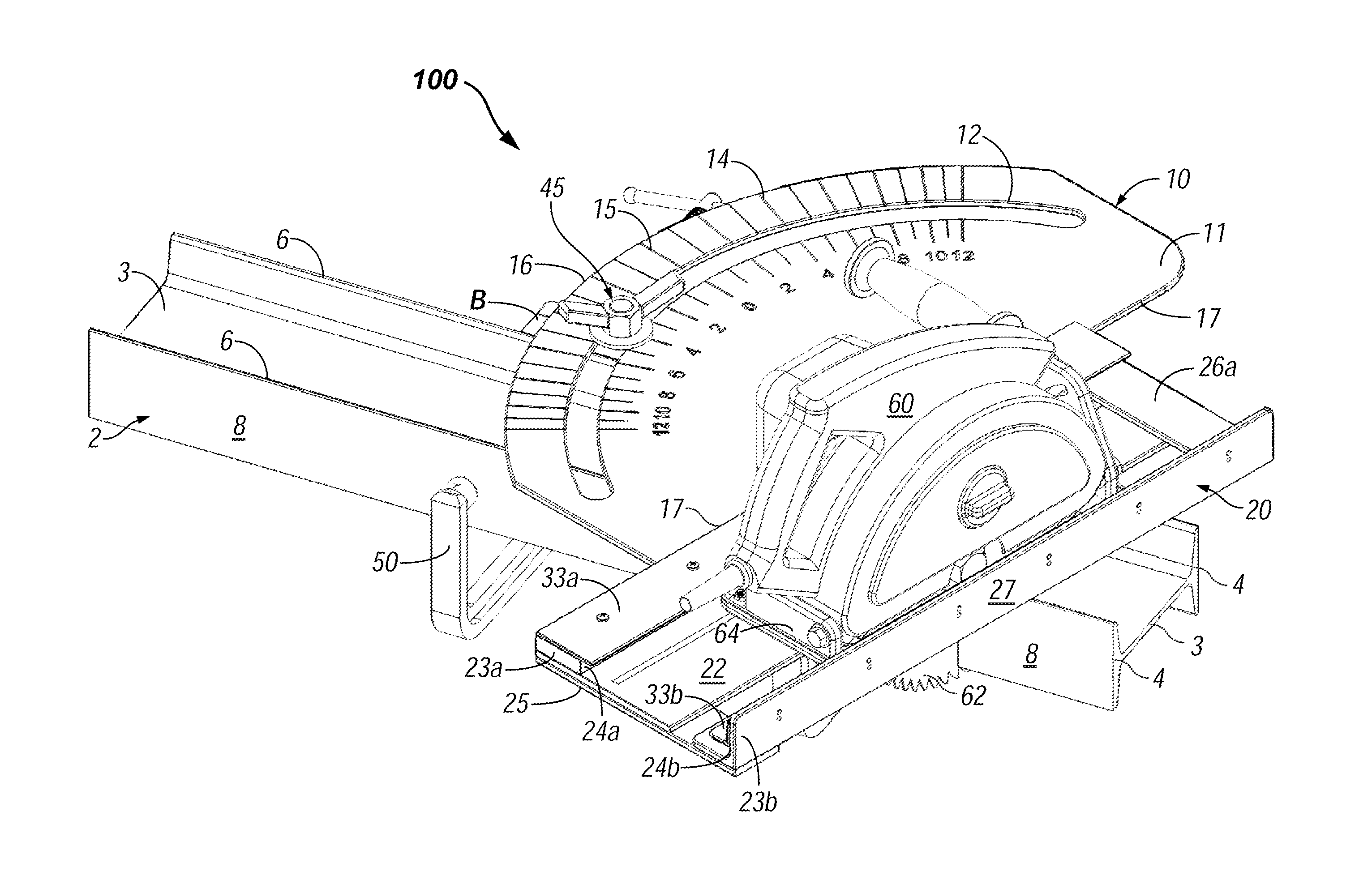

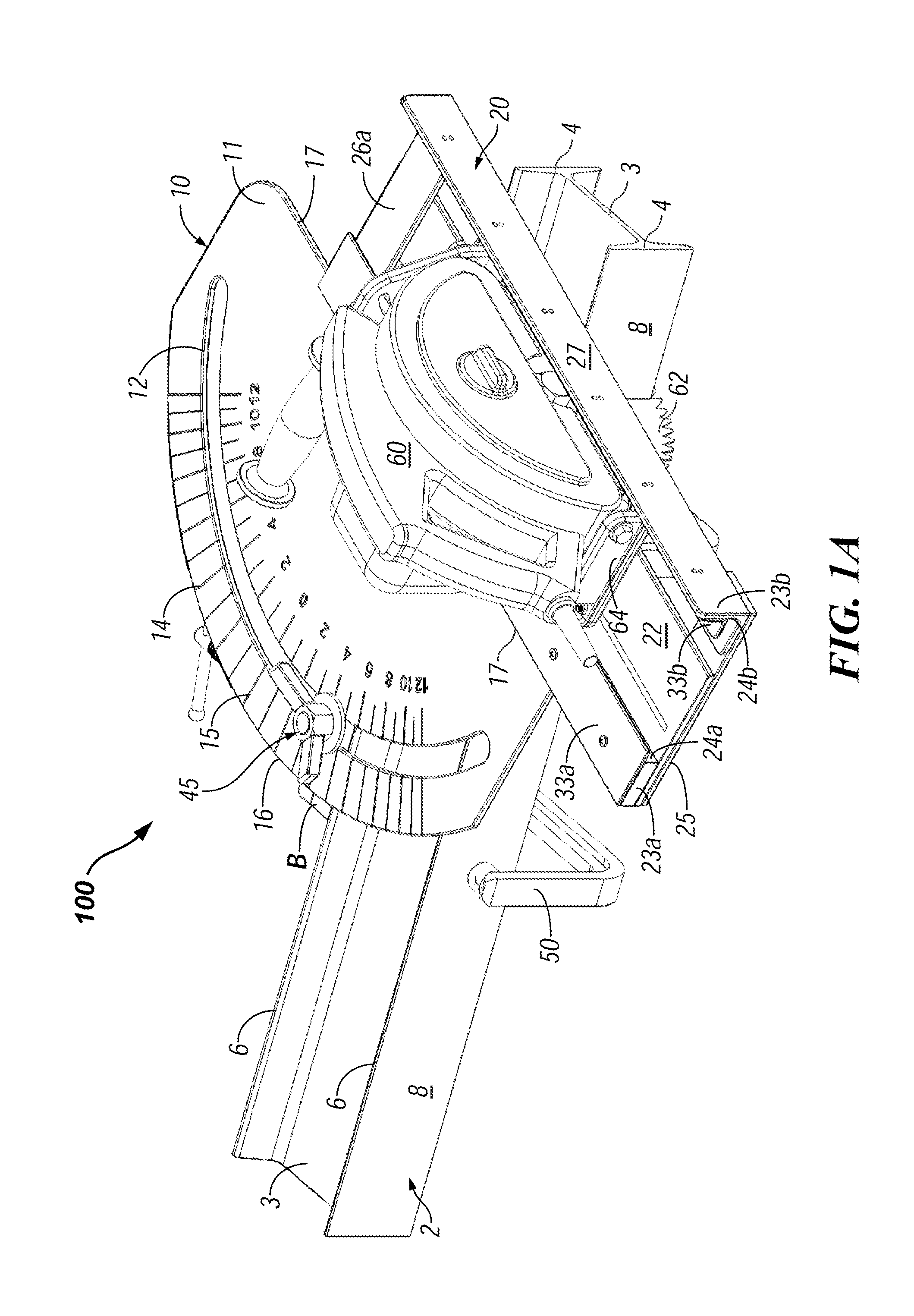

Saw cutting guide

InactiveUS20150047484A1Overcome disadvantagesSafely and accurately guidingMetal sawing devicesMetal sawing accessoriesCold sawDisadvantage

The improved saw cutting guide of the present invention overcomes many of the disadvantages of prior art power cutting tools by providing a portable, mechanical guide for safely and accurately guiding a powered cutting tool along a predetermined cut line in the workpiece that is at a desired angular position relative to the cutting blade of the power cutting tool. The saw cutting guide includes a main baseplate having a top side and an under side, and featuring a guide track on the top side, for receiving and guiding a power cutting tool, and a pivotally mounted alignment fence on the underside for selectively aligning the work piece in relation to the guide track. In a preferred embodiment, the power cutting tool comprises an electric circular saw having a metal cutting blade featuring cold saw metal-cutting technology.

Owner:LANE RICHARD P

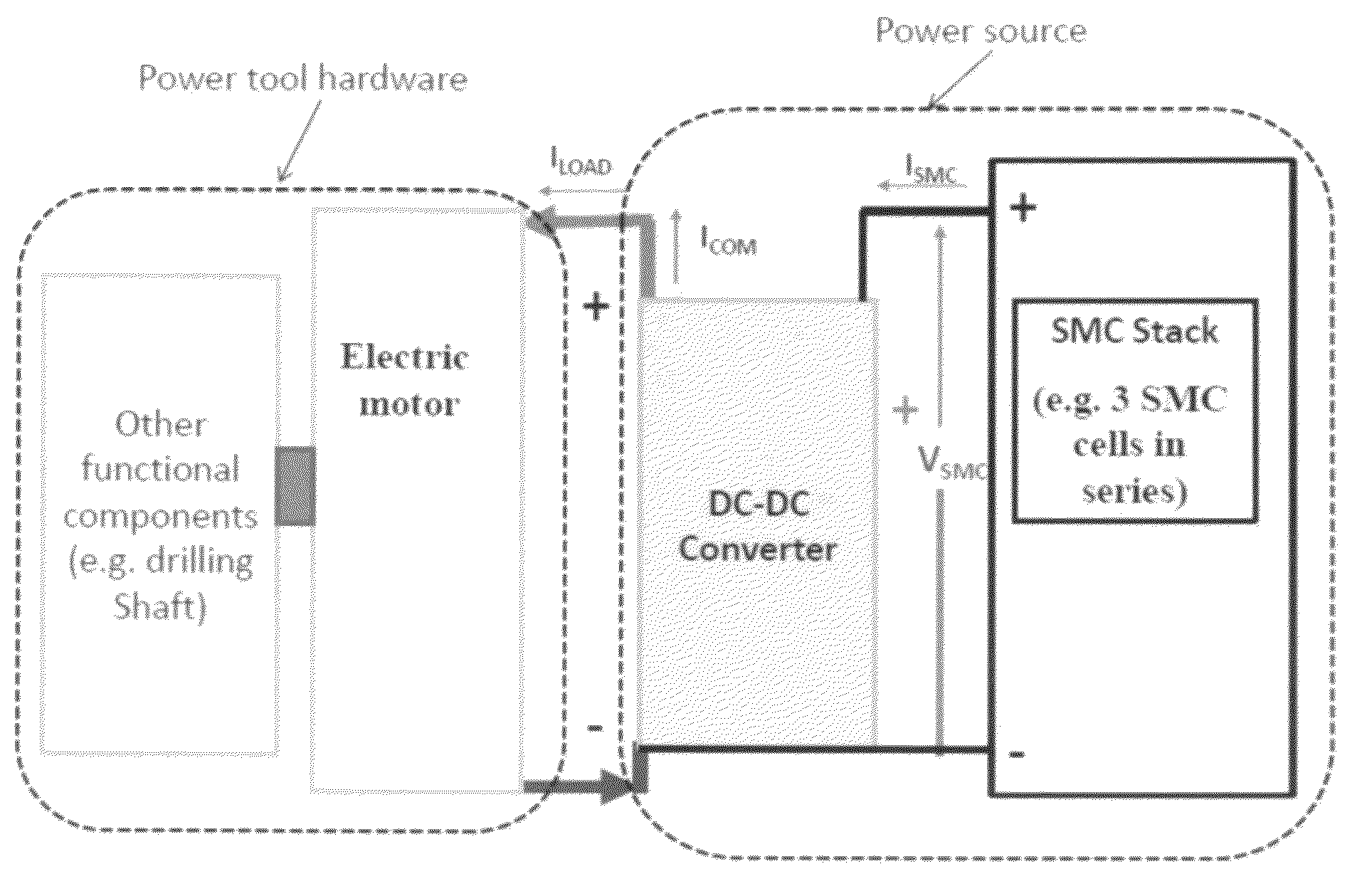

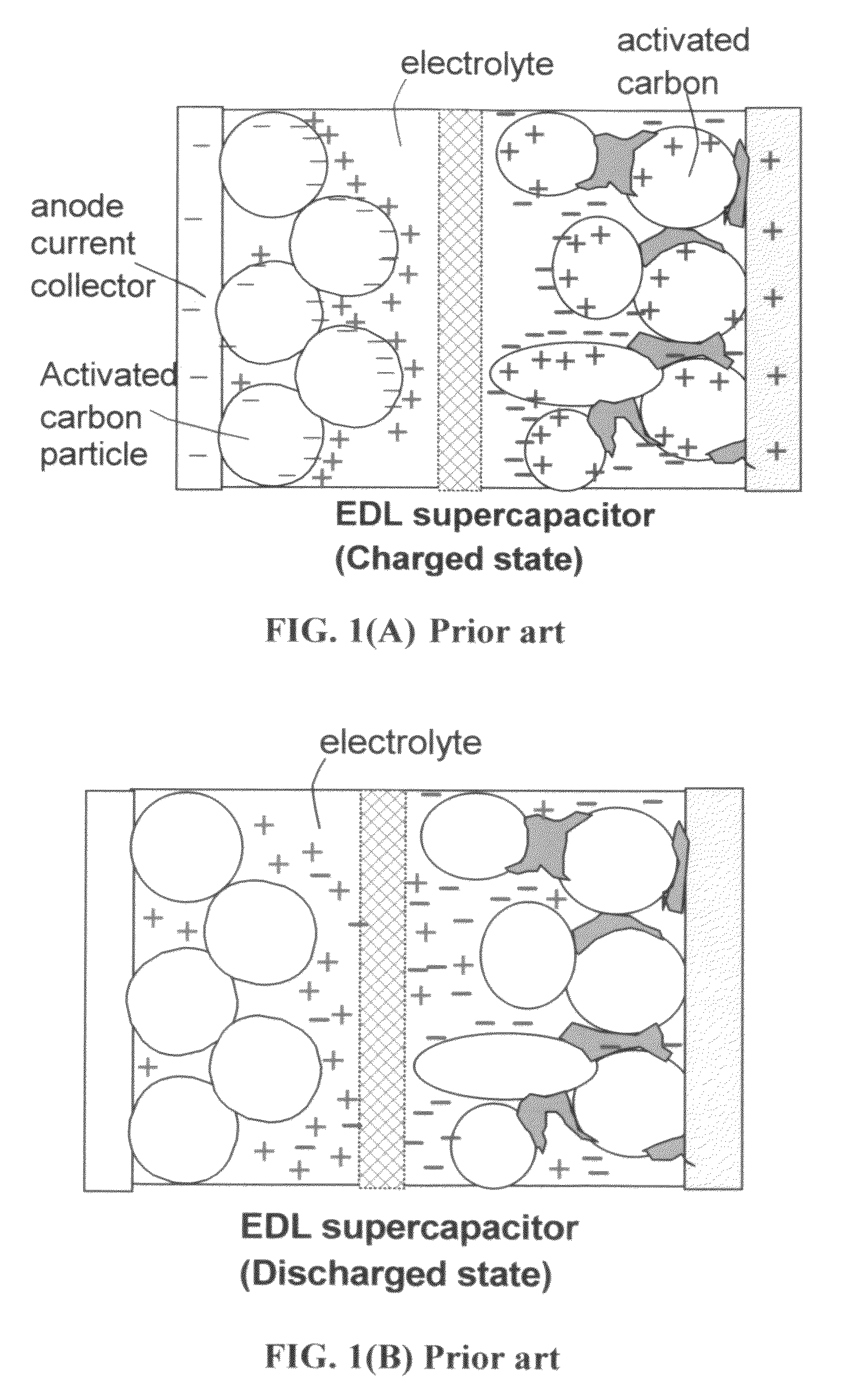

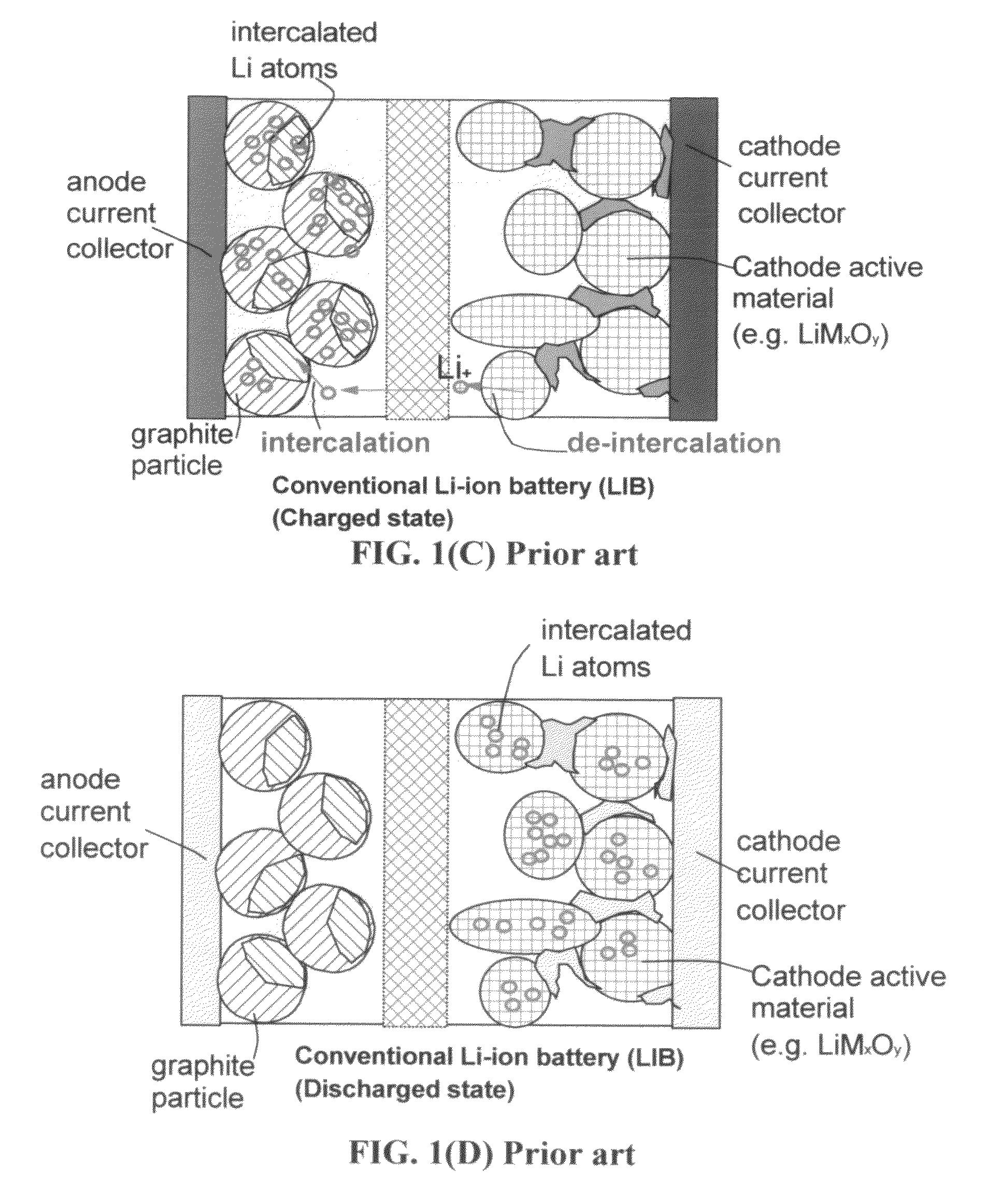

Surface-mediated cell-driven power tools and methods of operating same

ActiveUS9085076B2Increase electrode areaHigh currentDrilling rodsCapacitor and primary/secondary cellsSanderAngle grinder

A portable power tool comprises an electric motor, actuator, or light-emitting hardware and a rechargeable power source connected to the electric motor, actuator, or light-emitting hardware, wherein the power source contains at least a surface-mediated cell (SMC). The power tools include, but are not limited to, impact driver, air compressor, alligator shear, angle grinder, band saw, belt sander, biscuit joiner, ceramic tile cutter tile saw, chainsaw, circular saw, concrete saw, cold saw, crusher, diamond blade, diamond tools, disc sander, drill, floor sander, grinding machine, heat gun, impact wrench, jackhammer, jointer, jigsaw, lathe, miter saw, nail gun, needle scaler, torque wrench, powder-actuated tools, power wrench, radial arm saw, random orbital sander, reciprocating saw, rotary reciprocating saw, rotary tool, sabre saw, sander, scroll saw, steel cut off saw, table saw, thickness planer, trimmer, wall chaser, wood router, or flashlight.

Owner:GLOBAL GRAPHENE GRP INC +1

Symmetric rolling technology for T-shaped elevator guide rail steel

InactiveCN104148381AFix stability issuesSolve for uniformityMetal rolling arrangementsShape changeEngineering

The invention discloses a symmetric rolling technology for T-shaped elevator guide rail steel. The technology comprises loading and heating, rough rolling of five rolling mills, universal continuous rolling of ten rolling mills, cooling bed cooling, straightening, rough cutting of a disc cold saw, clamp bundling, center subdivision, straightening, sizing sawing of a band saw as well as receiving and warehouse storage. According to the symmetric rolling technology for the T-shaped elevator guide rail steel, the universal rolling mills are used for rolling the elevator guide rail steel, and asymmetric rolling is changed into symmetric rolling by shape change during rolling, so that an original rolling hole type system which is more stable can be reasonably used, and simultaneously, the problems that a guide system is instable during rolling and cooling is uninform after rolling are solved. Compared with a conventional production technology, the rolling yield can be increased greatly, rolling quality and accuracy are stabilized, the rolling accident rate is reduced, and roll consumption is reduced.

Owner:CHANGZHOU DONGFANG SPECIAL STEEL

Machining technology for cold saw blade

InactiveCN109317752AGuaranteed cleanlinessHigh flatness precisionMetal sawing tool makingAngle grinderCircular saw

The invention discloses a machining technology for a cold saw blade. The machining technology comprise the following steps that S1, a plate is cut, wherein the plate is cut to obtain a circular saw blade base body with sawteeth; S2, burrs on the surface of the saw blade base body are removed, wherein firstly, the surface of the saw blade base body is de-burred manually by using an angle grinder, and after the relatively large burrs on the surface of the saw blade are removed, a full-automatic de-burring machine is used for carrying out de-burring on the saw blade base body again; and S3, tempering is carried out on the saw blade base body, wherein the saw blade base body undergoes tempering and de-stressing heat treatment, the tempering temperature is 360 DEG C, the tempering time is 4 hours, and the tempering cooling time is 60-72 hours. According to the machining technology, the technological steps are simple, repeated de-burring and cleaning are carried out, the cleanliness degree of the saw blade can be guaranteed during grinding each time, the flatness precision of the saw blade can be improved, through the special angle design of a tool bit, the precision is higher when a workpiece is cut, and the yield of the cold saw blade is improved.

Owner:成都壹佰科技有限公司

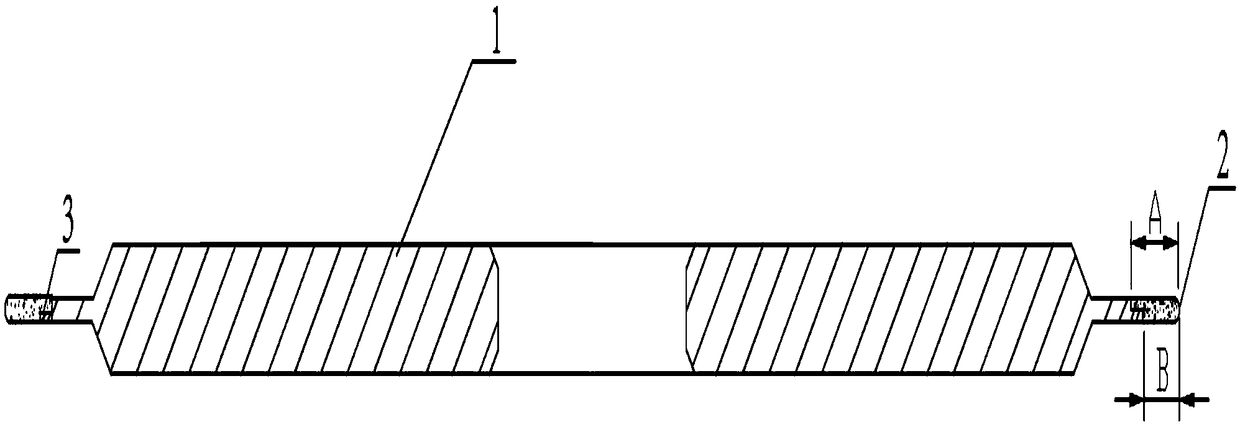

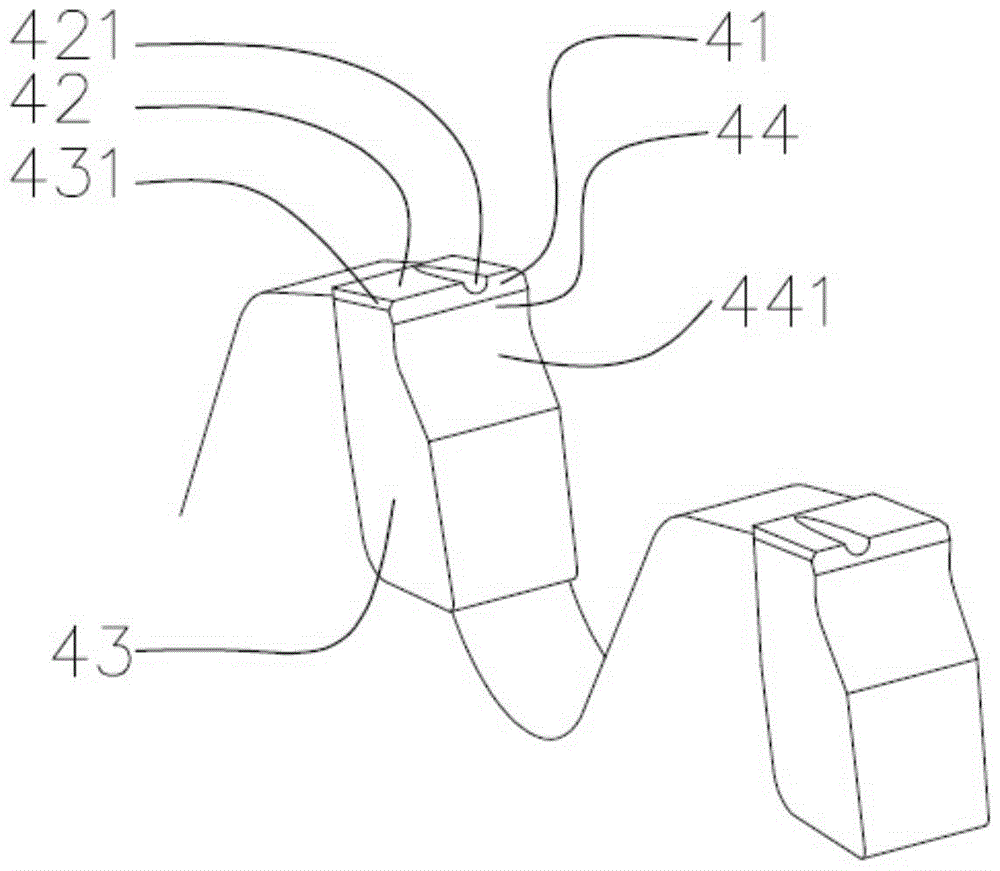

Method for installing profile steel cold saw blade

InactiveCN103921061AImprove installation convenienceImprove securityMetal working apparatusEngineeringCold saw

The invention discloses a method for installing a profile steel cold saw blade. The method is characterized by including the steps that corresponding assembly positioning holes are formed in the saw blade and a fixing disc; the saw blade and the fixing disc are relatively vertically fixed through an auxiliary device; matched positioning pins are inserted into the assembly positioning holes in the saw blade and the fixing disc, and then the saw blade and the fixing disc are relatively positioned; connecting bolts between the saw blade and the fixing bolt are installed and connected, and then installation is finished. The method for installing the profile steel cold saw blade has the advantages that installation convenience and safety of the saw blade can be improved, and labor efficiency is improved; the adopted auxiliary device assists users in installing and connecting the saw blade and the fixing disc, so that the saw blade and the fixing disc can be more quickly, conveniently and safely installed and connected with less effort.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

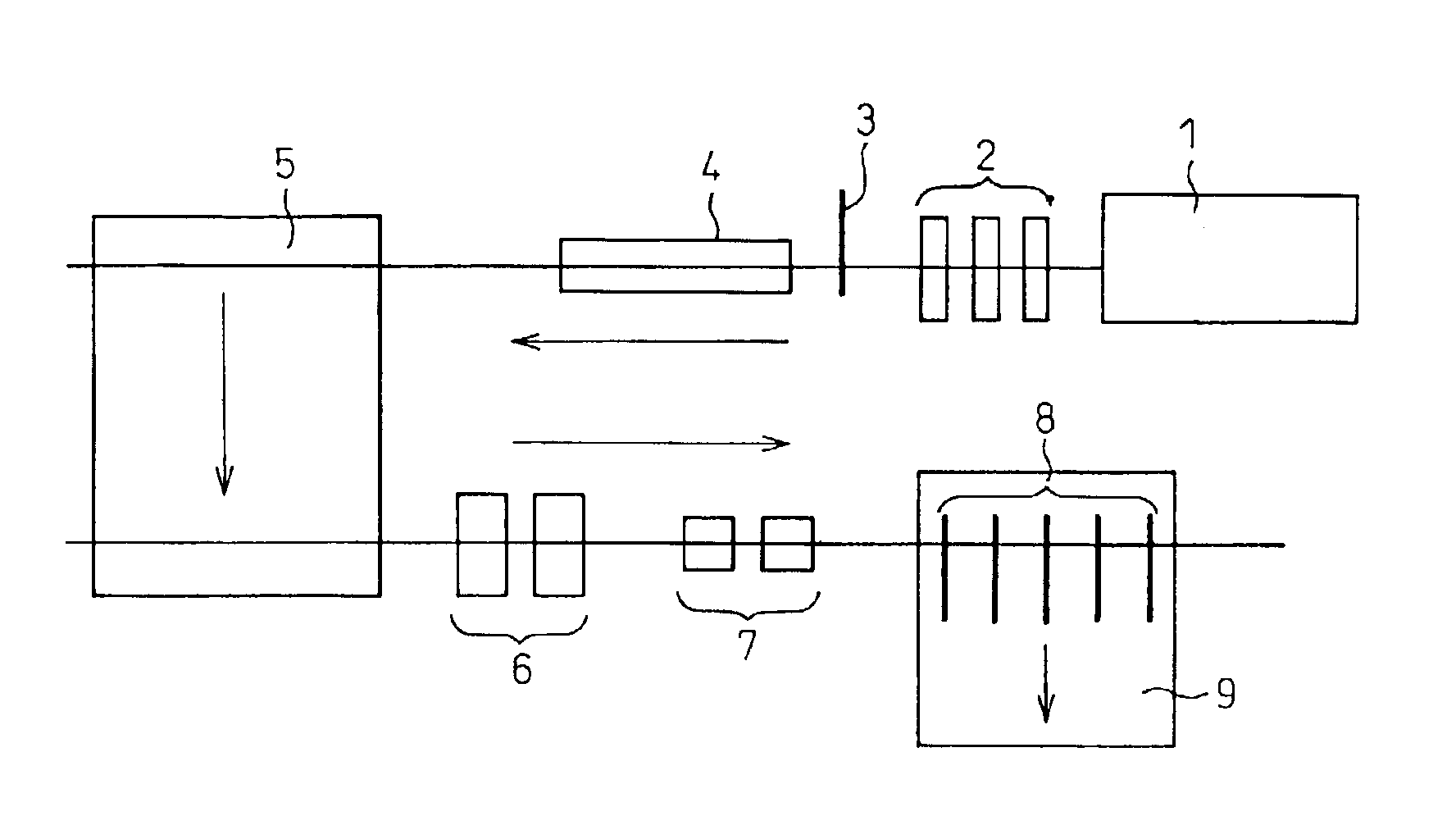

Rail producing method and producing equipment

InactiveUS6931703B2Increase productivityHigh yieldMetal sawing devicesMetal rolling stand detailsEngineeringHot rolled

The present invention provides a method and equipment for producing a rail, the method and equipment being capable of lowering a bend at an end of a rail effectively and the truncation amount thereof. The present invention is a method for producing a rail, characterized by: cooling a hot-rolled mother rail to an ordinary temperature substantially while the length thereof after the hot rolling is maintained; and thereafter cutting the mother rail simultaneously in a predetermined length with at least three cold-sawing machines. Further, the present invention is equipment for producing a rail, characterized by equipped with: a transfer bed capable of moving a mother rail cooled to an ordinary temperature substantially while the length thereof after hot rolling is maintained in the rolling direction and / or in the direction perpendicular to the rolling direction; and at least three cold-sawing machines disposed in parallel with each other on said transfer bed.

Owner:NIPPON STEEL CORP

Polymeric diamond saw blade and manufacturing process thereof

InactiveCN105149686AExtended service lifeImprove cutting accuracyMetal sawing tool makingMetal sawing toolsTool bitMaterials science

The invention discloses a polymeric diamond saw blade and a manufacturing process thereof. According to the polymeric diamond saw blade and the manufacturing process thereof, silver solder wires and single-layer silver solder plates are adopted as main solders for welding a saw blade body and sawteeth, polymeric diamond tool bits are arranged on the sawteeth, the sawteeth are welded on an L-shaped toothholder of the saw blade body, and a PVD coating further coats the rear cutter surfaces of the sawteeth. The polymeric diamond saw blade is long in service life, is particular suitable for saw cutting of materials including phosphor-copper alloy, silver-copper alloy and conventional ceramic through a metal cold saw, and has relatively high cutting precision; through comparison, the service life of the polymeric diamond saw blade is 4.23 times of that of the original conventional cold saw blade, and is obviously prolonged compared with the service life of the conventional polymeric diamond tool bit.

Owner:HANGZHOU HIRONO TOOLS

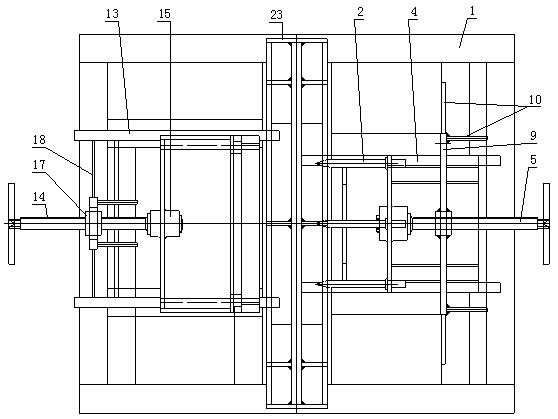

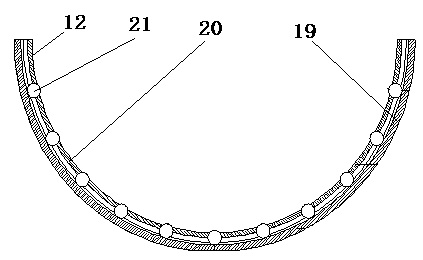

Cold saw grinding wheel of single-bevel edge structure and preparation method for cold saw grinding wheel

ActiveCN108942712AIncrease contact surfacePrevent decouplingBonded abrasive wheelsGrinding devicesCopper platingEdge structure

The invention discloses a cold saw grinding wheel of a single-bevel edge structure and a preparation method for the cold saw grinding wheel. The cold saw grinding wheel comprises a steel substrate andan annular grinding layer; on the steel substrate, a contact surface of the steel substrate and the annular grinding layer is of a horizontal Z-shaped structure; in the horizontal Z-shaped structure,an upper vertical surface is higher than a lower vertical surface; thus, from the appearance of the whole grinding wheel, the grinding layer is thick in one side and thin in the other side; by takinga grinding wheel mounting hole as the inside, a grinding surface bearing large stress is thick by a structure of which the outside is thick and the inside is thin; and the grinding layer is preparedfrom a resin binder and a grinding material. According to the cold saw grinding wheel disclosed by the invention, in order to increase a holding force between the binder and the substrate, an outer circle is knurled, the end face of the inner side of the outer circle is slotted and the joint of a grinding material layer and the substrate is plated with copper, thereby avoiding that the grinding wheel is liable to run off. Moreover, the structure is capable of using the grinding wheel to the maximum degree, thereby reducing cost; and moreover, the shape of the grinding wheel can be adjusted according to the shape of a to-be-processed object, and is suitable for industrial production.

Owner:江苏赛扬精工科技有限责任公司

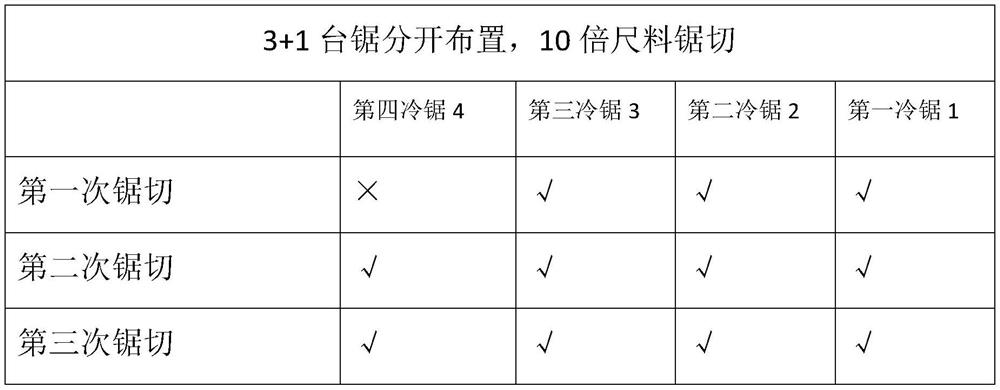

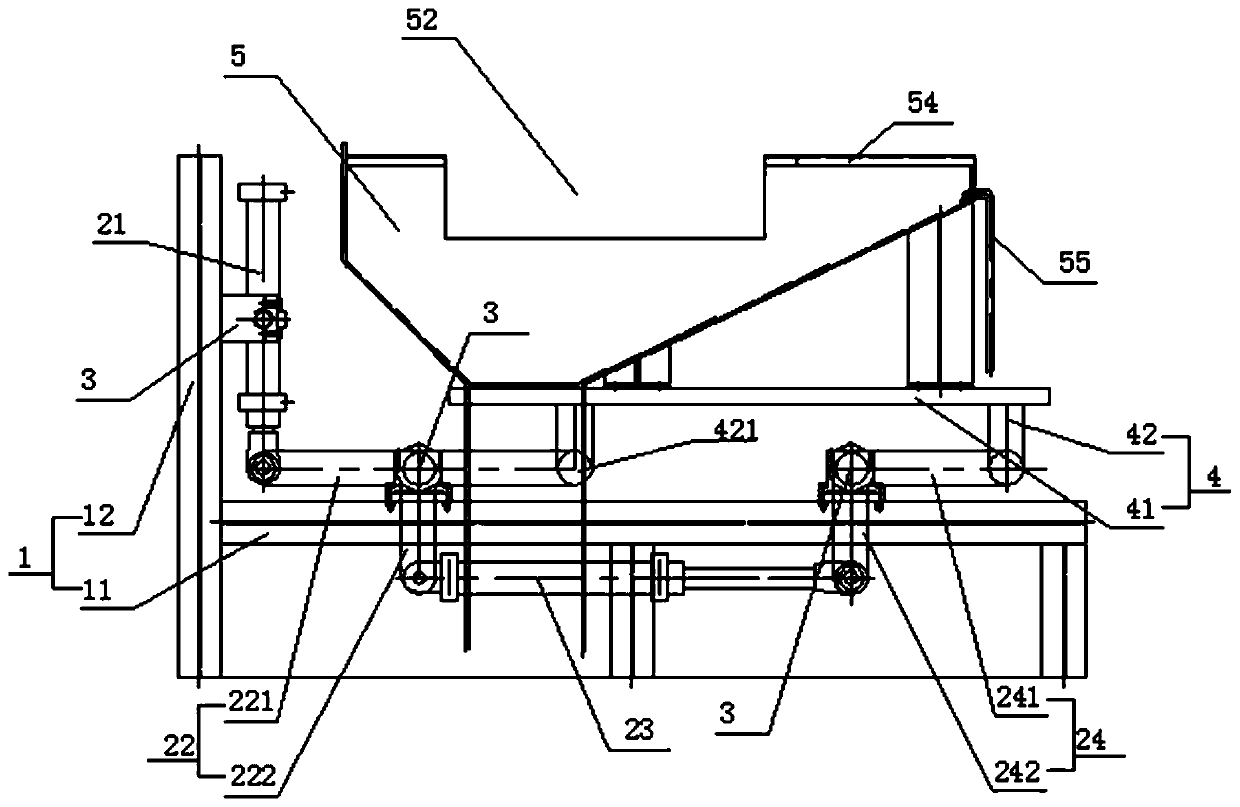

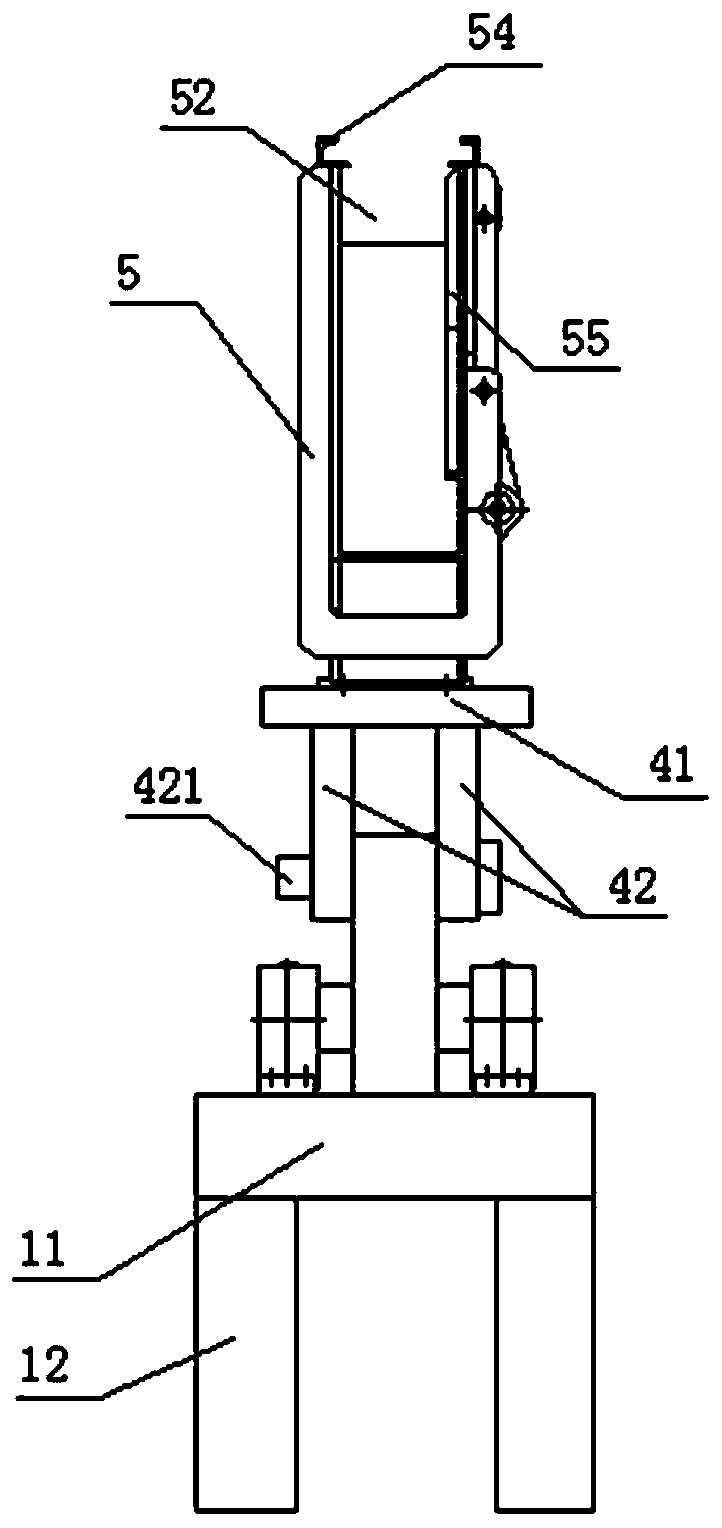

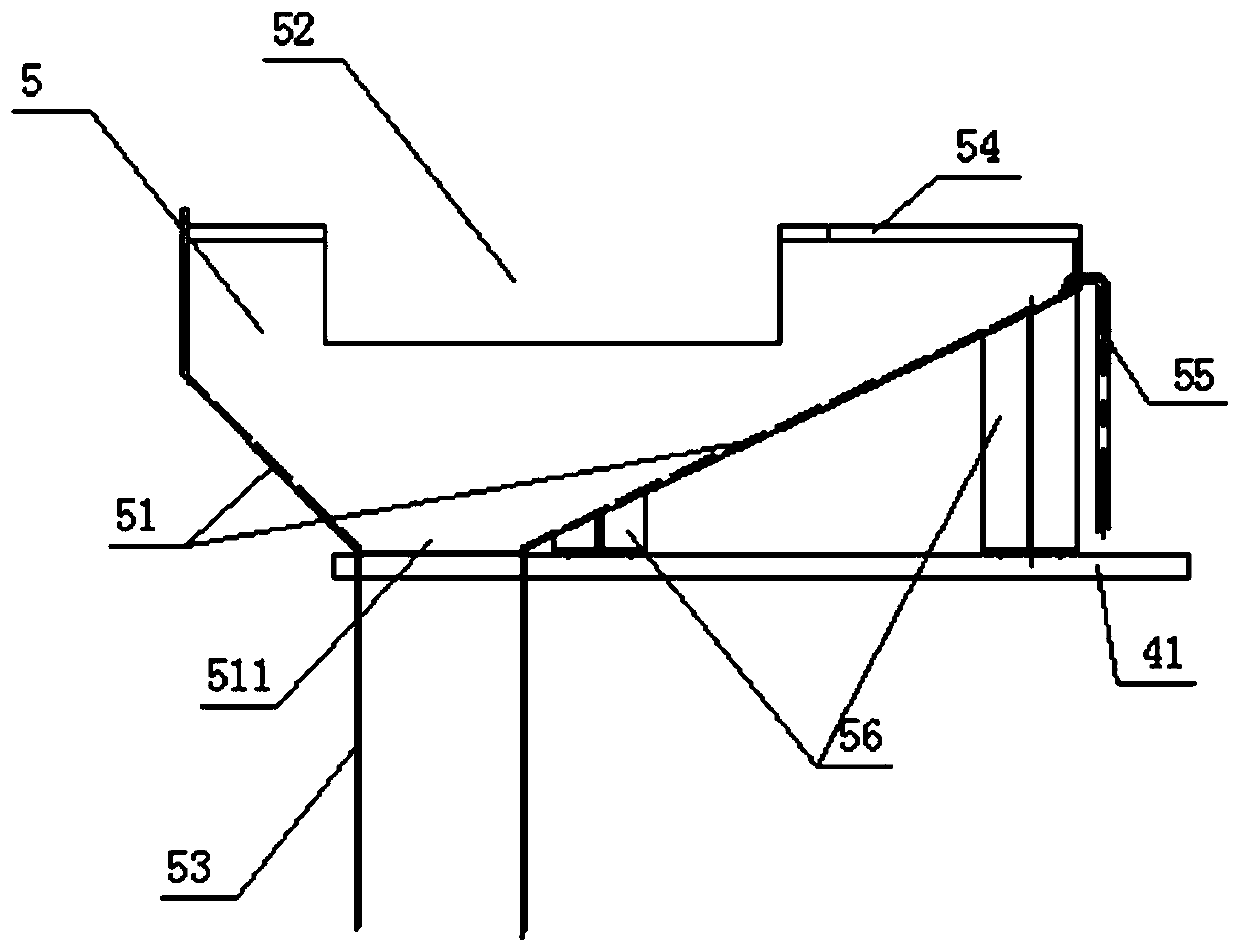

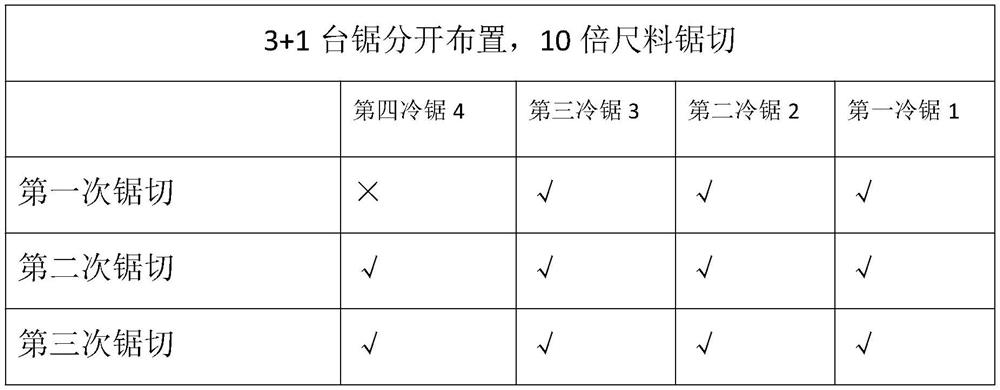

Section steel cold saw cutting process

ActiveCN112756692AIncrease production capacityImprove work efficiencyMetal sawing devicesStructural engineeringIndustrial engineering

The invention provides a section steel cold saw cutting process. Equipment of saw cutting areas is arranged in an N+1 type, wherein the first saw cutting area and the second saw cutting area are arranged, the first saw cutting area comprises N cold saws and a fixed-length baffle, and the second saw cutting area comprises a cold saw and a fixed-length baffle; section steel is conveyed through a conveying mechanism and is firstly subjected to saw cutting in the first saw cutting area, and the fixed-length material number of saw cutting in the first saw cutting area is a multiple of N; and when the number of the remaining fixed-length materials to be subjected to saw cutting is smaller than N, the materials enter the second saw cutting area to be subjected to saw cutting. Compared with the prior art, the section steel cold saw cutting process has the following advantages that the working efficiency of a bench saw and the utilization rate of the cold saws are improved, the number of times of saw cutting is reduced, and the production capacity of the cold saws is also improved to a certain degree.

Owner:中重科技(天津)股份有限公司

Extrusion-without-leaving-billet processing method of nonferrous metal section bars

An extrusion-without-leaving-billet processing method of nonferrous metal section bars comprises the following steps: long rod thermal shearing, thermal peeling and prepositioned die extrusion. The method overcomes the influences of secondary pollution of the surfaces of short rods and the secondary generation of oxide skins on the performances and the quality of section bars after extrusion processing, caused by cold sawed saw kerf loss, cold turning, manual carrying and heating processes, shortens the extrusion time, increases the extrusion efficiency, reduces the processing cost of magnesium alloy, aluminum alloy and titanium alloy section bars, reduces the energy consumption and the material loss, saves electric energy, and obviously increases the economic benefit.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Steel plate high-speed cold-cutting rotary sawing machine

InactiveCN107470708AGuaranteed uptimeLow failure rateMetal sawing devicesMetal sawing toolsFailure rateSheet steel

The invention relates to a steel plate high-speed cold-cutting rotary sawing machine. The steel plate high-speed cold-cutting rotary sawing machine comprises a rack part, a feeding part, a saw cutting part and an automatic control part. The feeding part comprises a feeding movable assembly, a size-fixed feeding sliding table, a steel plate fixing clamp and a feeding bracket, the size-fixed feeding sliding table and the feeding movable assembly are assembled, a to-be-machined steel plate is placed on the size-fixed feeding sliding table and the feeding bracket, and the automatic control part controls the feeding movable assembly to work and further drives the size-fixed feeding sliding table to feed forwards; and the saw cutting part comprises a saw cutting feed assembly, a high-speed circular-saw gear case and a saw web, the high-speed circular-saw gear case is assembled below the saw cutting feed assembly, and the automatic control part controls the saw cutting feed assembly to work and further drives the high-speed circular-saw gear case to conduct saw cutting in an advancing and retreating mode. According to the steel plate high-speed cold-cutting rotary sawing machine, a thread driving pay-off and feeding structure is adopted, operation is smooth, and the failure rate is low. The thin type circular saw web is adopted to conduct high-speed cold saw cutting, secondary machining of a saw-cut material is not needed, energy is saved, and further consumables are saved.

Owner:娄底市良台机床有限公司

Cold saw sizing equipment for steel structure production and machining

InactiveCN111843035AMove quicklyImprove stabilityMetal sawing devicesMetal sawing accessoriesRotational axisElectric machine

The invention discloses cold saw sizing equipment for steel structure production and machining, and relates to the technical field of cold saw sizing. The cold saw sizing equipment solves the problemof stability of square steel sawing work, and specifically comprises an inclined base and a material containing base, wherein a guide groove is formed in the outer wall of the top of the inclined base, limiting strips are welded to the outer walls of the two sides, close to the guide groove, of the inclined base, a fixing plate is slidably connected into the guide groove, a first motor is arrangedon the outer wall of the back face of the fixing plate, an output shaft of the first motor is provided with a first rotating shaft, a second rotating shaft is fixed to the outer wall of one side of the fixing plate through a bearing, the circumferential outer walls of the first rotating shaft and the second rotating shaft are sleeved with belt wheels, the circumferential outer walls of the two belt wheels are sleeved with the same belt, one end of the second rotating shaft is sleeved with an alloy saw blade, the same cold saw cover is fixed to the two ends, close to the alloy saw blade, of the second rotating shaft through bearing seats. According to the cold saw sizing equipment, the cutting integrity and burr-free effect of the alloy saw blade are guaranteed, and the translation stability of the alloy saw blade is promoted.

Owner:六安伟宏钢结构有限公司

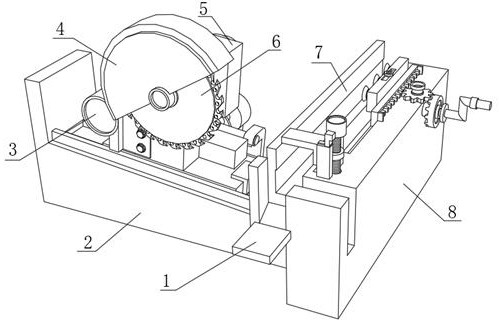

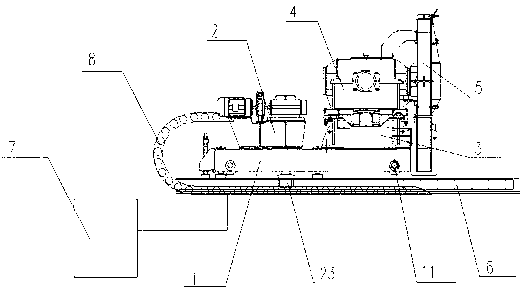

Cold sawing machine

ActiveCN102699425AGuarantee personal safetyLow costMetal sawing devicesMaintainance and safety accessoriesAgricultural engineeringLubrication

The invention discloses a cold sawing machine, which comprises a frame (1), wherein a transmission device (2) and a hydraulic station (9) are arranged on one side of the frame (1); a base (3) is arranged on the other side of the frame (1); a saw blade transmission device (4) is arranged on the base (3); a saw blade device (5) is connected to the saw blade transmission device (4); a lubrication oil station (7) is arranged outside the frame (1); and the lubrication oil station (7) is connected with the frame (1) through a drag chain (8). The cold sawing machine is small in size, the transmission design is compact, bidirectional movable cutting can be realized, the cost is low, and damage to the personal safety of operator workers can be avoided.

Owner:JIANGYIN DADI EQUIP

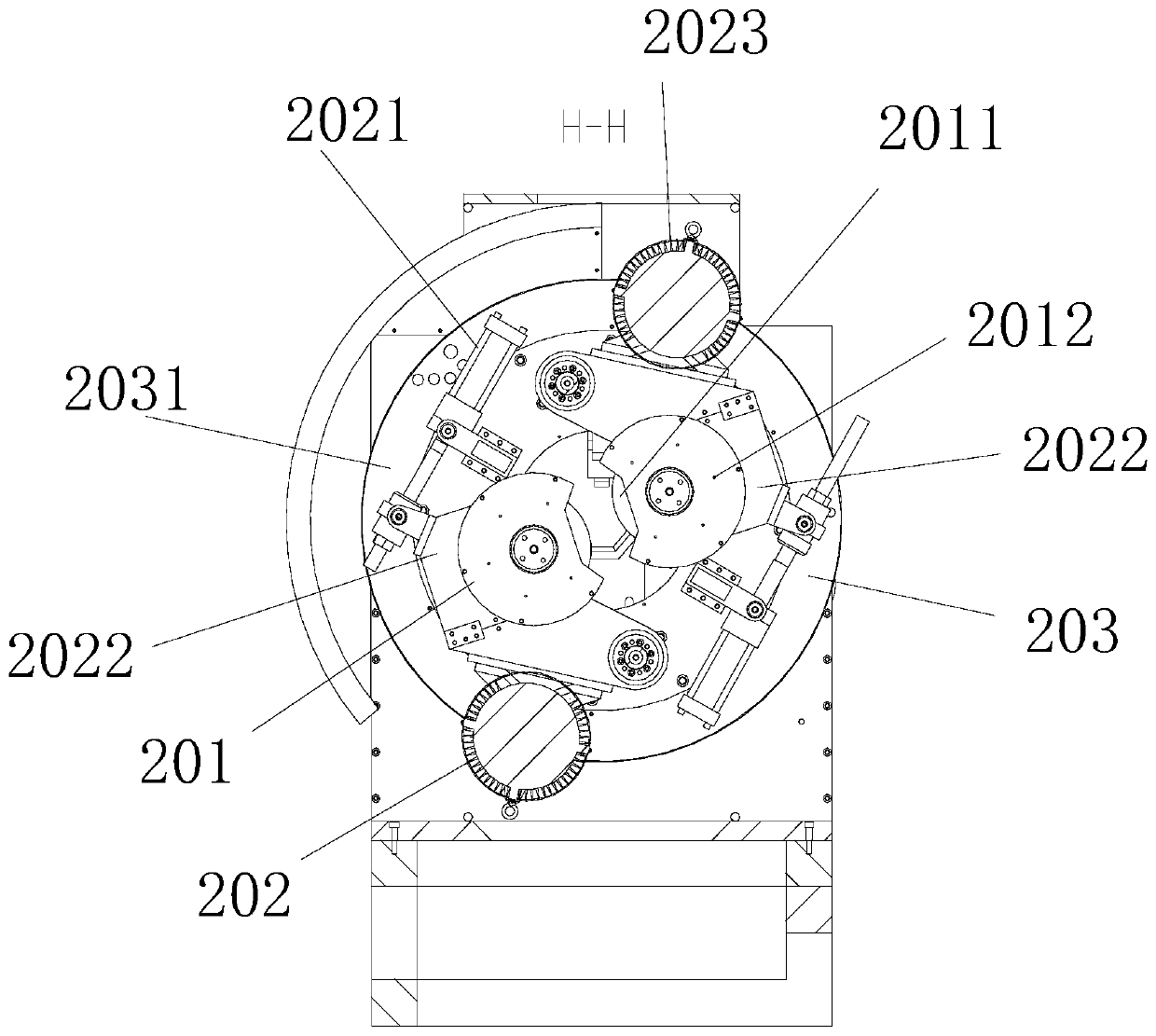

Iron pipe cutting machine

PendingCN110625186AAchieve reductionFlat cutting sectionMetal sawing devicesReciprocating motionCold saw

The invention relates to an iron pipe cutting machine. The machine comprises a feeding part, a cutting part and a clamping part, wherein the feeding part comprises a driving part and a feeding clamping piece, the driving part drives the feeding clamping piece to reciprocate, the cutting part comprises cutting pieces, a cutting driving part and a rotating part, the cutting driving part is arrangedat one side of the cutting pieces, the cutting pieces are driven to operate through the cutting driving part, the two cutting pieces are arranged, the rotating part comprises a rotary cutter disc anda rotary driving part, the cutting pieces are arranged on the rotary cutter disc, the rotary cutter disc is driven to rotate through the rotary driving part, the clamping part comprises a front clamping part and a rear clamping part, the two cutting pieces simultaneously cut an iron pipe, and the cutting pieces can be rotated by 180 degrees, so that the 360-degree cutting on the iron pipe is achieved, a cutting section is flat and smooth, the iron pipe is cut by adopting a cold saw blade, and the cutting section is free of burrs; and the machine can be used for cutting the iron pipe with the diameter of 110-220 mm and the wall thickness of 10-30 mm, and the cutting can be completed within 1 minute.

Owner:扬州一水机械科技有限公司

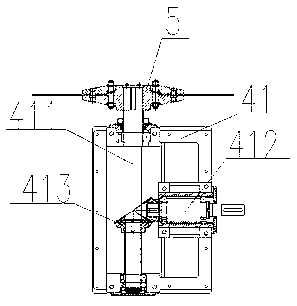

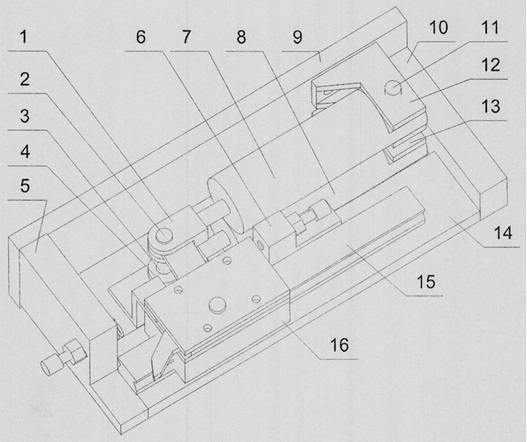

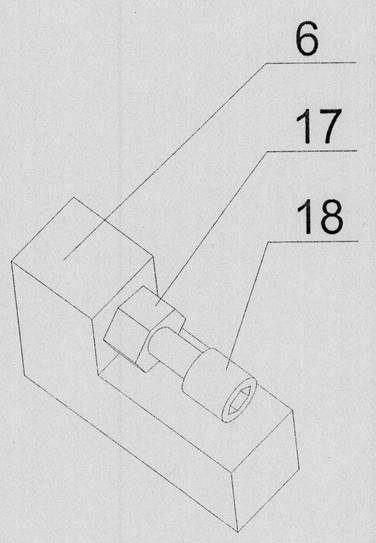

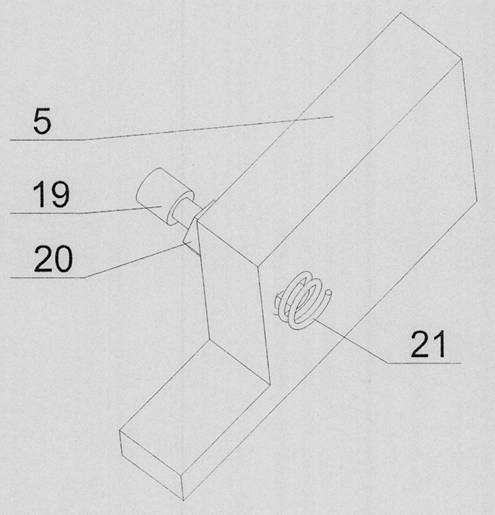

Saw blade installation auxiliary equipment of profile steel cold saw

InactiveCN103921254ARealize the installation connectionQuick and easy installationMetal-working hand toolsCold sawEngineering

The invention discloses saw blade installation auxiliary equipment of a profile steel cold saw. The saw blade installation auxiliary equipment is characterized by comprising a bottom plate and a saw blade positioning base arranged on the bottom plate, wherein the saw blade positioning base is provided with a positioning groove opened upwards and allowing saw blades to be vertically positioned, a saw blade insertion positioning mechanism is arranged on the bottom plate on one side of the saw blade positioning base, a fixing disk installation mechanism is arranged on the bottom plate on the other side of the saw blade positioning base and comprises several positioning pins horizontally installed corresponding to the saw blades on the upper portion of the positioning groove and can drive the positioning pins to be inserted into the saw blades on the upper portion of the positioning groove in the horizontal direction, a fixing disk is installed on the side, close to the saw blades on the upper portion of the positioning groove, of the fixing disk installation mechanism, and the fixing disk after installation and the saw blades installed in the position groove are on the same axis. The equipment is used for assisting in installation and connection between the saw blades and the fixing disk, the saw blades and the fixing disk can be rapidly and conveniently installed and connected through the equipment, labor is saved, safety is achieved, and labor efficiency is greatly improved.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

Cold saw dust collecting device

PendingCN110653418AFlexible adjustmentEasy to collectMetal sawing accessoriesStructural engineeringSawdust

The invention belongs to the technical field of rolling mill auxiliary equipment, and particularly relates to a cold saw dust collecting device. The device comprises a support, a connecting rod mechanism, a bracket and a collecting basket, wherein the bracket is mounted above the support through the connecting rod mechanism, the connecting rod mechanism can drive the bracket to move up and down and can drive the bracket to incline to one side, the collecting basket is fixedly mounted on the bracket, the top of the collecting basket is completely open, the upper edge shape of a top opening of the collecting basket is matched with the outer contour of the bottom of a cold saw blade cover, the bottom of the collecting basket is provided with a dust collecting opening, the bottom surface of the collecting basket is a funnel-shaped structure surrounded by a plurality of inclined plates inclined towards the dust collecting opening, the upper edges of the two opposite side plates of the collecting basket are respectively provided with a matching notch, and the shape of the matching notches is matched with the shape of a cutting rolled piece. The cold saw dust collecting device can inhibitsplashing of the saw dust and can collect the saw dust together, thereby protecting the device and protecting the environment.

Owner:中重科技(天津)股份有限公司

A kind of steel cold sawing process

ActiveCN112756692BIncrease production capacityImprove work efficiencyMetal sawing devicesMaterials scienceIndustrial engineering

The invention provides a cold sawing process for section steel. The equipment in the sawing area is arranged in an N+1 type: a first sawing area and a second sawing area are set, and the first sawing area includes N cold saws and a fixed Ruler baffle, the second sawing area includes a cold saw and a fixed-length baffle; the section steel is transported by the transmission mechanism, and is first sawed in the first sawing area, and the number of cut-to-length materials in the first sawing area is N multiples; when the number of remaining cut-to-length materials to be sawed is less than N, enter the second sawing area for sawing. Compared with the prior art, the section steel cold sawing process of the present invention has the following advantages: the work efficiency of the table saw and the utilization rate of the cold saw are improved, the times of sawing are reduced, and the production capacity of the cold saw is also improved.

Owner:中重科技(天津)股份有限公司

Cold sawing wheel with single bevel structure and preparation method thereof

ActiveCN108942712BMeet the requirements of uneven forceGood for single-sided forceBonded abrasive wheelsGrinding devicesKnurlingEngineering

The invention discloses a cold sawing grinding wheel with a single hypotenuse structure and a preparation method thereof, comprising a steel substrate and an annular grinding layer; on the steel substrate, the contact surface between the steel substrate and the annular grinding layer is a horizontal Z-shaped Structure; in the horizontal Z-shaped structure, the upper vertical surface is higher than the lower vertical surface; in this way, the whole grinding wheel is observed from the appearance, the grinding layer is thick on one side and thin on the other side, with the grinding wheel installation hole as the inside, the outer thickness is thicker and the inner thickness is thinner The structure makes the grinding surface thick; the grinding layer is made of resin bond and abrasive. In order to increase the holding force between the bonding agent and the substrate, the present invention adopts knurling of the outer circle, grooves on the inner side of the outer circle, and copper plating at the connection between the abrasive layer and the substrate, so as to prevent the grinding wheel from being easily detached under force. In addition, this structure can maximize the use of the grinding wheel and save costs. And its shape can be adjusted according to the shape of the processing object, which is suitable for industrial production.

Owner:江苏赛扬精工科技有限责任公司

Wire cutting cold saw alloy tool bit tooth shifting mechanism

PendingCN111975149ASimple structureHigh repeat positioning accuracyElectrical-based auxillary apparatusTool bitWire cutting

The invention relates to a wire cutting machine tool, in particular to a wire cutting cold saw alloy tool bit tooth shifting mechanism. The mechanism is characterized in that a power cylinder frame and a damping cylinder frame are arranged on a front mounting plate; a left baffle plate and a right baffle plate are arranged at two ends of the front mounting plate; a power cylinder connected with acylinder swing shaft is arranged on the power cylinder frame; a power cylinder Y joint is arranged on the power cylinder; a rotating shaft above the power cylinder Y joint is connected with a tooth shifting head; a damping cylinder connected with the cylinder swing shaft is arranged on the damping cylinder frame; a damping cylinder Y joint is arranged on the damping cylinder; a rotating shaft below the damping cylinder Y joint is connected with a damping cylinder connecting frame; a bottom plate is arranged between the left baffle plate and the right baffle plate; a guide rail and a stop blockare arranged on the bottom plate; and a sliding block is arranged on the guide rail. Through the above arrangement, when a cold saw alloy is processed by wire cutting, the requirements that the wirecutting cold saw alloy tool bit tooth shifting mechanism is simple in structure, convenient to apply, high in repeated positioning accuracy and free of water are met.

Owner:临沂和通精密机械设备有限公司

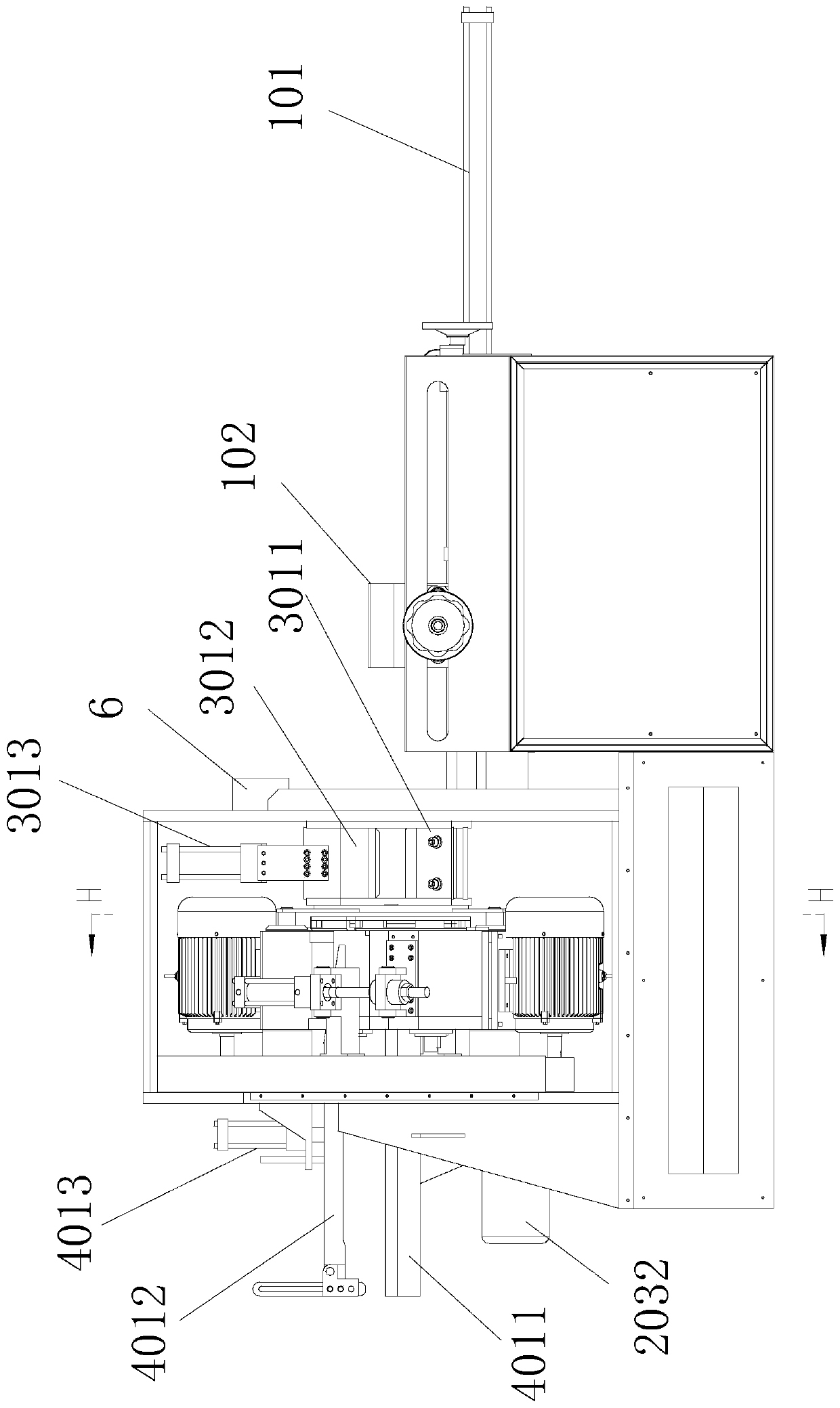

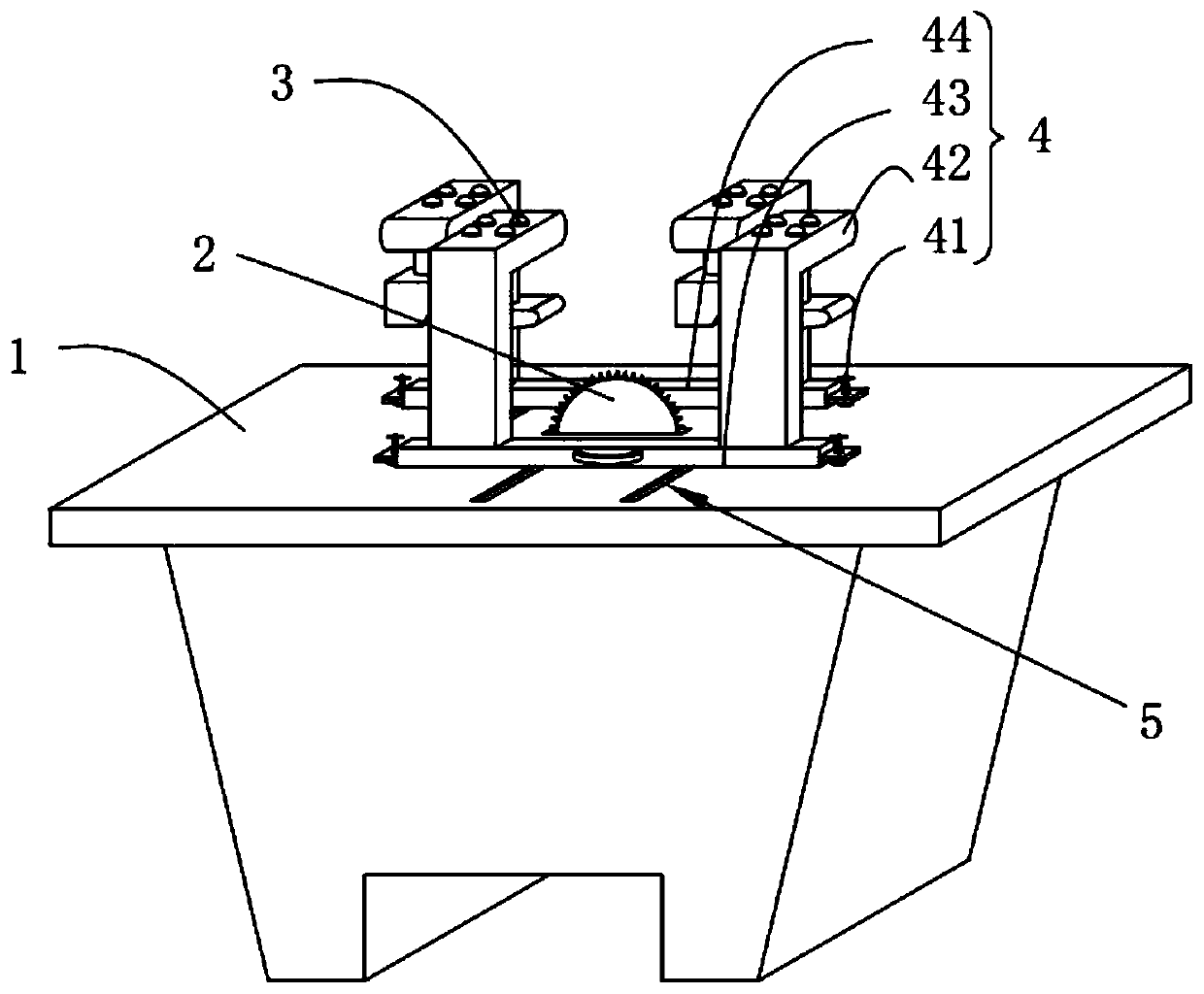

An automatic high-speed cold sawing system for superhard metal

ActiveCN109226878BAvoid vibrationThe cutting surface of the workpiece is flushMetal sawing devicesMachinePhysics

The invention relates to the field of cold sawing machines, in particular to an automatic high-speed cold sawing system for superhard metal. The system comprises a machine body, a saw blade, fixing mechanisms, supporting mechanisms, an installation mechanism, a connecting mechanism, a sealing mechanism and a limiting mechanism; the supporting mechanisms are installed at the two ends of the saw blade respectively, the fixing mechanisms are installed at the two ends of each supporting mechanism, the supporting mechanisms slide on the top surface of the machine body, the two ends of workpieces make contact with the supporting mechanisms, the side walls of the workpieces are fixed, and the workpieces slide at the bottoms of the fixing mechanisms; the fixing mechanisms extrude the workpieces, the saw blade cut the workpieces between the adjacent fixing mechanisms, the top surfaces of uncut workpieces and cut workpieces are fixed by the multiple fixing mechanisms, the workpiece are preventedfrom shaking, and then the workpiece cutting faces are flush and free of burrs; the installation mechanism is arranged between the supporting mechanisms and the surface of the machine body and slidably connected with the sealing mechanism, when the supporting mechanisms slide on the top surface of the machine body, the supporting mechanisms drive the sealing mechanism to move to close the installation mechanism, and the phenomenon that workpiece chippings fall into the installation mechanism is prevented.

Owner:SHANDONG TECHGONG GEOTECHN ENG EQUIP CO LTD

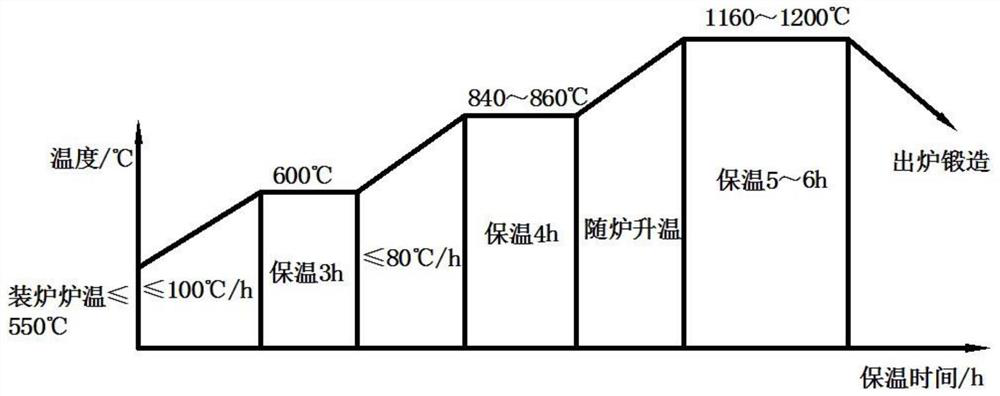

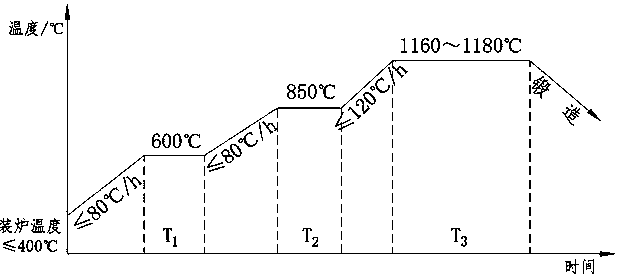

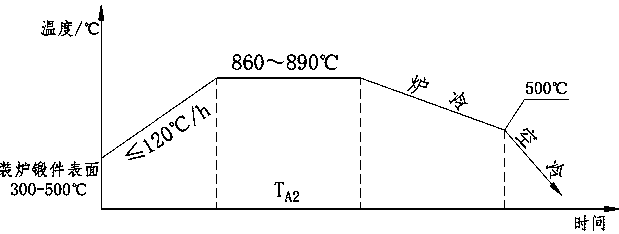

A high-strength and high-toughness large martensitic stainless steel ring forging and its manufacturing method

ActiveCN112442634BOptimize chemical compositionNo crackFurnace typesEngine componentsTemperingMartensitic stainless steel

The invention provides a high-strength and high-toughness large-scale martensitic stainless steel ring forging. In terms of weight percentage, the martensitic stainless steel includes C: 0.14-0.22%, Mn: 0.45-1.5%, and P: ≤0.030% , S: ≤0.020%, Si: ≤0.60%, Cr: 15~15.5%, Mo: ≤0.20%, Ni: 2.0~2.5%, Cu: ≤0.20%, V: ≤0.10%, Nb: ≤0.050% , Ti: ≤0.020%, and the balance is Fe; at the same time, the gas composition meets: H: ≤3ppm, O: ≤40ppm, N: 200-400ppm; the corresponding manufacturing method, the steel ingot is passed through the cold saw nozzle, the riser, the heat Cut the riser, then perform three upsetting and two pulling, horse frame reaming, ring rolling, preliminary heat treatment, rough turning, quenching and tempering, body sampling, physical and chemical testing, and processing according to the drawing. The invention can solve the problems that large-scale ring forgings produced by adopting the martensitic stainless steel X17CrNi16-2 are prone to cracking after forging and unstable impact energy.

Owner:AVIC EXCELLENCE FORGING WUXI

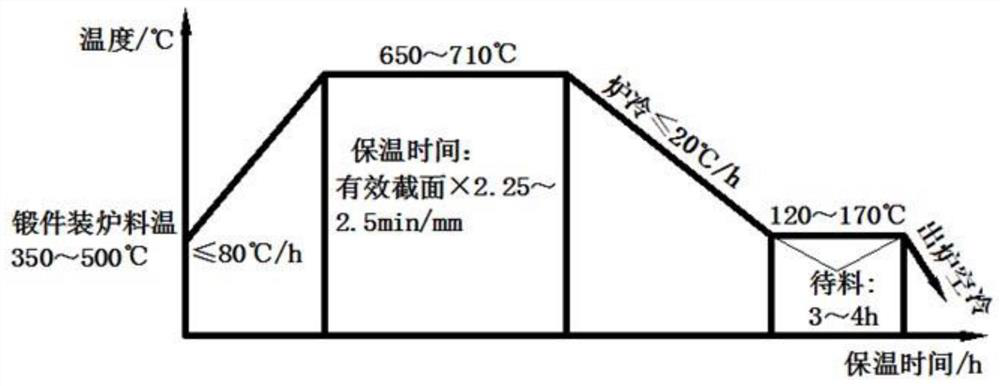

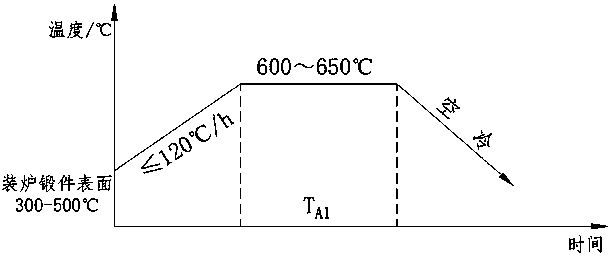

Low-strength martensitic stainless steel ring forging and its forging method

ActiveCN108893684BReduce intensityLow "zero" breakoutMartensitic stainless steelManufactured material

The invention discloses a low strength martensitic stainless steel ring forge piece and a forging method thereof. The martensitic stainless steel is prepared from the following components in percentage by weight: less than or equal to 0.05% of C, less than or equal to 0.05% of Si, 0.50-1.00% of Mn, less than or equal to 0.030% of P, less than or equal to 0.015% of S, 12-14% of Cr, 0.30-0.70% of Mo, 4.00-4.50% of Ni, 0.020-0.040% of N, less than or equal to 0.08% of V, less than or equal to 0.03% of Nb, less than or equal to 0.03% of Ti and the balance of Fe and impurities. The forging processcomprises the following steps: firstly, carrying out drawing-out and pre-forging; and then, carrying out cold saw blanking for upsetting for three times and drawing for two times, chambering a mandrelsupporter and rolling a ring, wherein the initial forging temperature is 1160-1180 DEG C, the finish forging temperature is 900 DEG C, and the finishing temperature can be properly reduced by 30-60 DEG C. In this way, according to the low strength martensitic stainless steel ring forge piece and the forging method thereof, an X3CrNiMo13-4 / QT650 forge piece meeting the demand on standard performance is developed by optimizing the chemical components of raw materials and matching with a reasonable thermal treatment system, so that zero breakthrough of low strength and low hardness products canbe achieved by means of the material, the primary qualification pass rate of the product is 100%, and energy source waste caused by rework and repair is avoided.

Owner:AVIC EXCELLENCE FORGING WUXI

A kind of preparation method of cutting stainless steel cold saw and saw blade thereof

ActiveCN104353898BImprove thermal stabilityImprove wear resistanceMetal sawing tool makingMetal sawing toolsHeat resistanceCircular saw

Owner:HANGZHOU WAGEN PRECISION TOOLING CO LTD

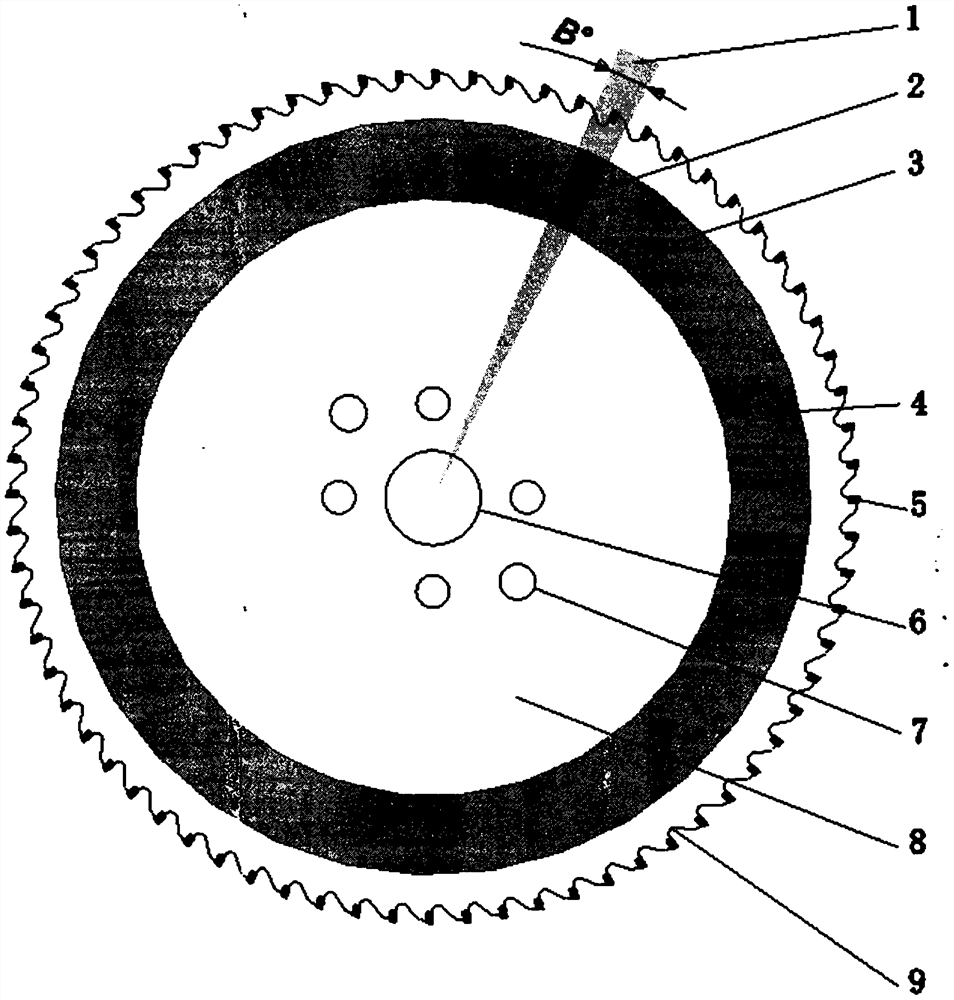

Efficient circular saw blade of cold saw

The invention relates to a cutting tool for section bars such as steel pipes and round steel, in particular to an efficient circular saw blade of a cold saw. The efficient circular saw blade of the cold saw is characterized in that the circular saw blade 8 is not provided with an expansion groove, a tool bit 5 and silencing lines 4 are arranged on the outer side of the circular saw blade 8, the silencing lines 4 are of a double-face penetrating and radial centripetal strip structure of the circular saw blade 8, the multiple silencing lines 4 are distributed on the circular saw blade 8 in the circumferential direction, the radial range of the silencing lines 4 is larger than 2 / 3 of the radius of the circular saw blade 8, and the inward range of the silencing lines 4 is a circumferential range 3 which is larger than 10 mm away from a tooth bottom 9; the circumferential range of each silencing line is within a silencing line area 2 formed by overlapping a sector with an included angle B1 of 10 degrees between two radial centripetal rays of the circular saw blade 8 and the circumferential range. Through the arrangement above, good flatness of the section of a cut workpiece can be achieved, lines of each cutter are clear and visible, friction between the side face of the tool bit and a cutting gap is eliminated, so that power loss of a sawing machine is reduced; heat generated by the workpiece and the saw blade is little, so that the saw blade can keep the optimal cutting performance for a long time.

Owner:浙江科诚工具有限公司

H-shaped steel hot rolling production method

ActiveCN102974609BHelp clearAdd purge stepWork treatment devicesMetal rolling arrangementsStrip millHigh pressure water

The invention relates to an H-shaped steel hot rolling production method. The method comprises the following steps of heating steel billets, descaling by high pressure water, carrying out cogging rolling, rolling by a reversible universal rolling mill, carrying out saw cutting by a hot saw, cooling by a cold bed, carrying out long fixed-length straightening, carrying out length fixing by a cold saw and stacking and bundling, wherein in the step of heating the steel billet, the soaking temperature of a heating furnace is 1,250 to 1,320 DEG C and billets in the furnace are arranged at intervals of 500 to 1,500mm; in the cogging rolling process, 1 to 3 passes of vertically rolling under the light press condition are increased; before and after the process of rolling by the reversible universal rolling mill, a compressed gas purging step is increased and rolled metals are H-shaped steels with specifications of H700*300, H800*300 and H900*300. According to the invention, scales on the surfaces of the large-specification H-shaped steels can be well removed in the hot rolling process and the surface quality of products is improved.

Owner:LAIWU IRON & STEEL GRP

Synchronous cold saw cutting machine

ActiveCN102059486BConvenient blankingAvoid stockpilingMetal sawing devicesMetal sawing accessoriesProduction lineLinear motion

The invention relates to a synchronous cold saw cutting machine in the field of welding pipe automatic production equipment. In the synchronous cold saw cutting machine, a saw cutting motor is connected with a milling saw blade through a transmission box; two parallel main guide rails are horizontally arranged on a machine frame; main sliding blocks are arranged on the main guide rails in a matching way and fixedly arranged on the lower side of a main workbench; a driving mechanism for driving the main workbench to do linear motion is arranged on the machine frame and is in synchronous transmission connection with a main servo motor; an upright column is arranged on the main workbench and is connected with a secondary workbench through a secondary guide rail sliding block mechanism; the transmission box is fixedly arranged on the upper side of the secondary workbench; the lower side of the secondary workbench is in transmission connection with a feed motor through a ball screw mechanism; a screw nut of the ball screw mechanism is fixed with the lower side of the secondary workbench; the two ends of a screw rod of the ball screw mechanism are arranged on the upper side of the main workbench through a screw rod base; and a pipe fixture is arranged on the side of the main workbench. The synchronous cold saw cutting machine can cut off a metal pipe during the linear motion of the metal pipe, does not generate burrs on the cut, and can obviously increase the production speed of a welding pipe production line.

Owner:江苏省南扬机械制造有限公司

A method for installing a steel cold saw blade

InactiveCN103921061BEasy to insert and fixSimple structureMetal working apparatusEngineeringCold saw

The invention discloses a method for installing a profile steel cold saw blade. The method is characterized by including the steps that corresponding assembly positioning holes are formed in the saw blade and a fixing disc; the saw blade and the fixing disc are relatively vertically fixed through an auxiliary device; matched positioning pins are inserted into the assembly positioning holes in the saw blade and the fixing disc, and then the saw blade and the fixing disc are relatively positioned; connecting bolts between the saw blade and the fixing bolt are installed and connected, and then installation is finished. The method for installing the profile steel cold saw blade has the advantages that installation convenience and safety of the saw blade can be improved, and labor efficiency is improved; the adopted auxiliary device assists users in installing and connecting the saw blade and the fixing disc, so that the saw blade and the fixing disc can be more quickly, conveniently and safely installed and connected with less effort.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

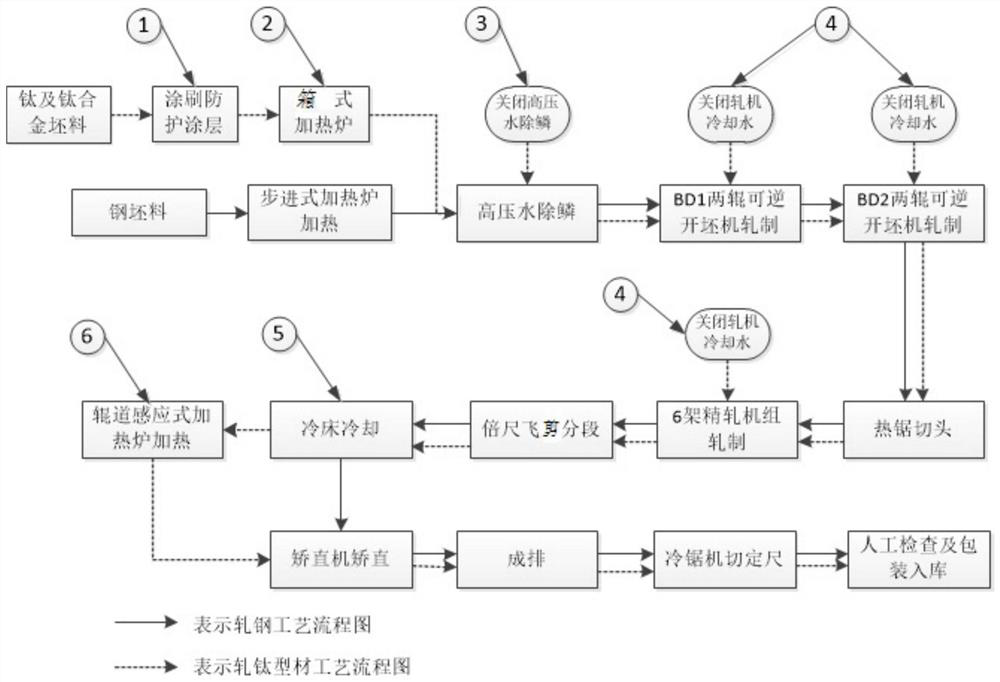

A kind of collinear production method of titanium and titanium alloy profile and profile steel

ActiveCN110883086BSolve production technical problemsHigh quality mass productionTemperature control deviceWork heating devicesTitaniumHeating furnace

The invention discloses a collinear production method for titanium and titanium alloy profiles and profile steel. In the collinear production method, the method for producing titanium and titanium alloy profiles is to firstly coat titanium or titanium alloy blanks with protective coating, After being heated by the first heating furnace, rolling through the first two-roller reversible blanking machine, the second two-roller reversible billeting machine, hot sawing head, finishing rolling unit rolling, double-size flying shear in the section steel production line Segmentation and cooling on the cooling bed, and then heating by the second heating furnace, and then through the straightening machine in the section steel production line to straighten, line up and cold saw machine to cut to length to obtain profiles. Realize the production of titanium and titanium alloy profiles on the small and medium-sized section steel production line, solve the technical problem of steel-titanium collinear production, and provide methods for the economical production of titanium and titanium alloy profiles.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com