Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180 results about "Heat gun" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heat gun is a device used to emit a stream of hot air, usually at temperatures between 100 °C and 550 °C (200-1000 °F), with some hotter models running around 760 °C (1400 °F), which can be held by hand. Heat guns usually have the form of an elongated body pointing at what is to be heated, with a handle fixed to it at right angles and a trigger, in the same general layout as a handgun, hence the name. A lighter duty heat gun is similar to a portable Hair dryer.

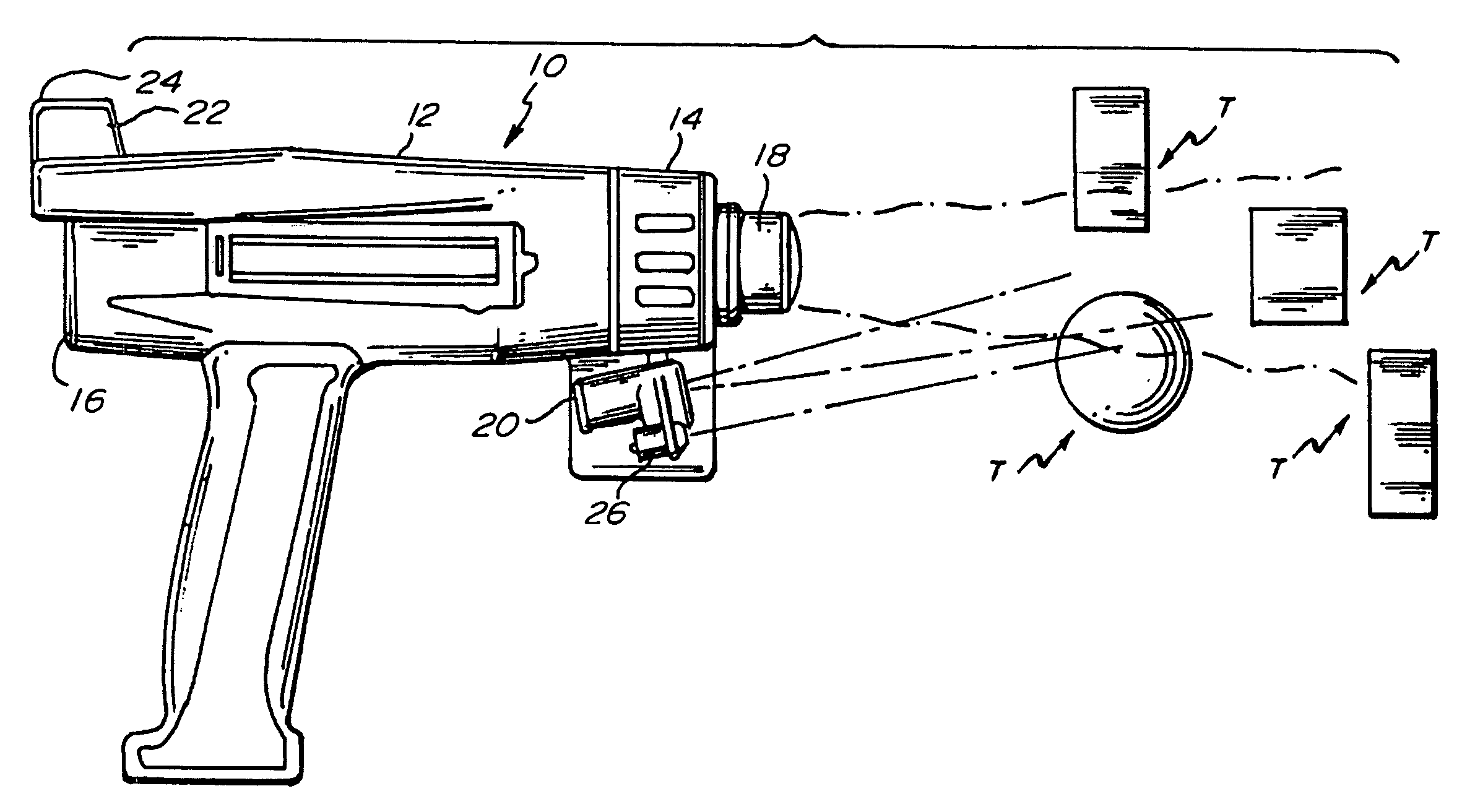

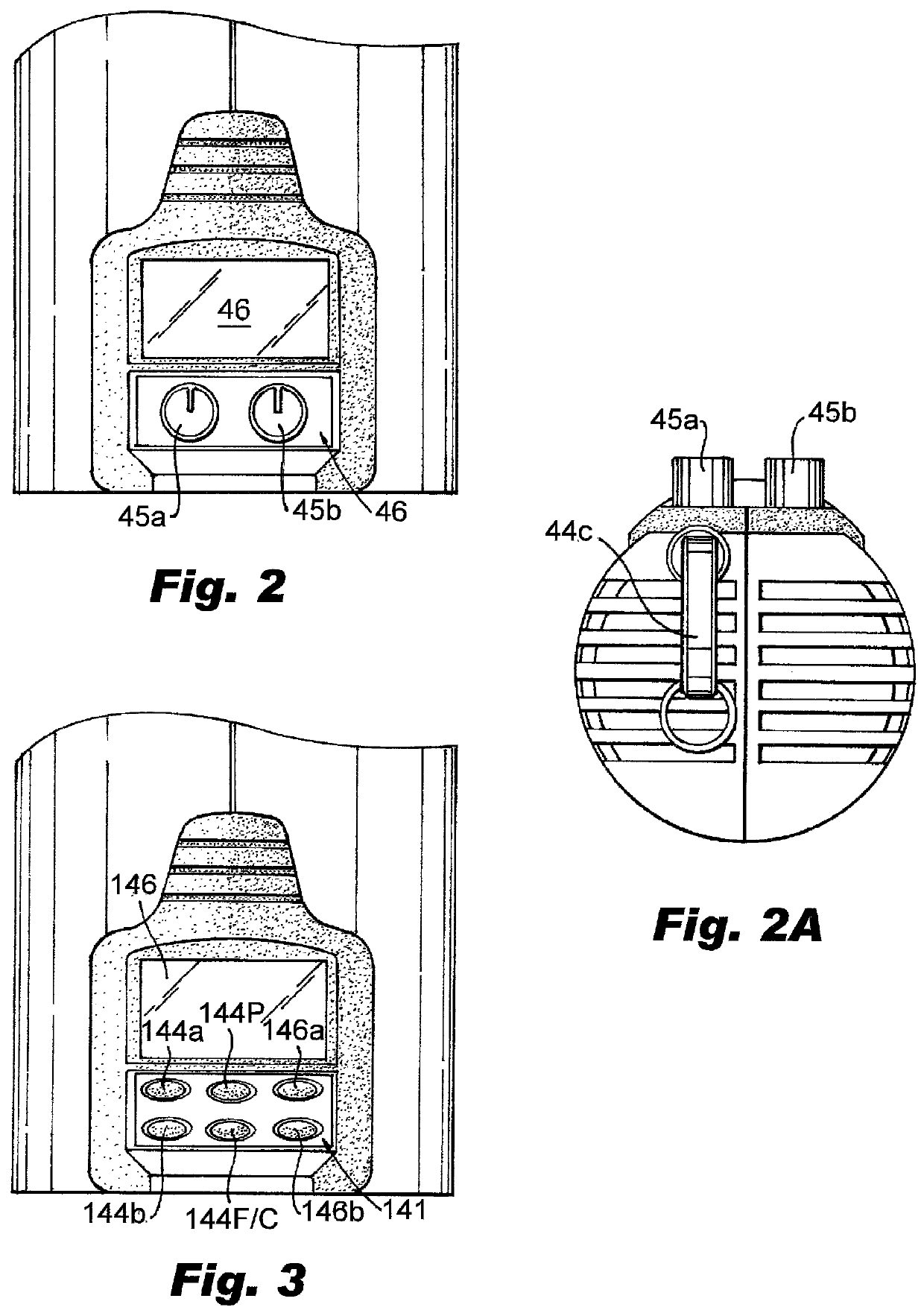

Heat gun with infrared surface thermometer

A heat gun includes an infrared surface thermometer measuring the surface temperature of a target and a surface temperature indicator readable by an operator of the heat gun, and a nozzle directing heated air at the target. The infrared surface thermometer is pivotally mounted on the heat gun adjacent the nozzle, so as to be aimed at targets at varying distances from the nozzle. The surface temperature indicator is mounted on the heat gun at the end of the heat gun nearest the operator. Optionally, a laser mounted on the thermometer is used to aim the thermometer at the target.

Owner:DIVERSIFIED DYNAMICS

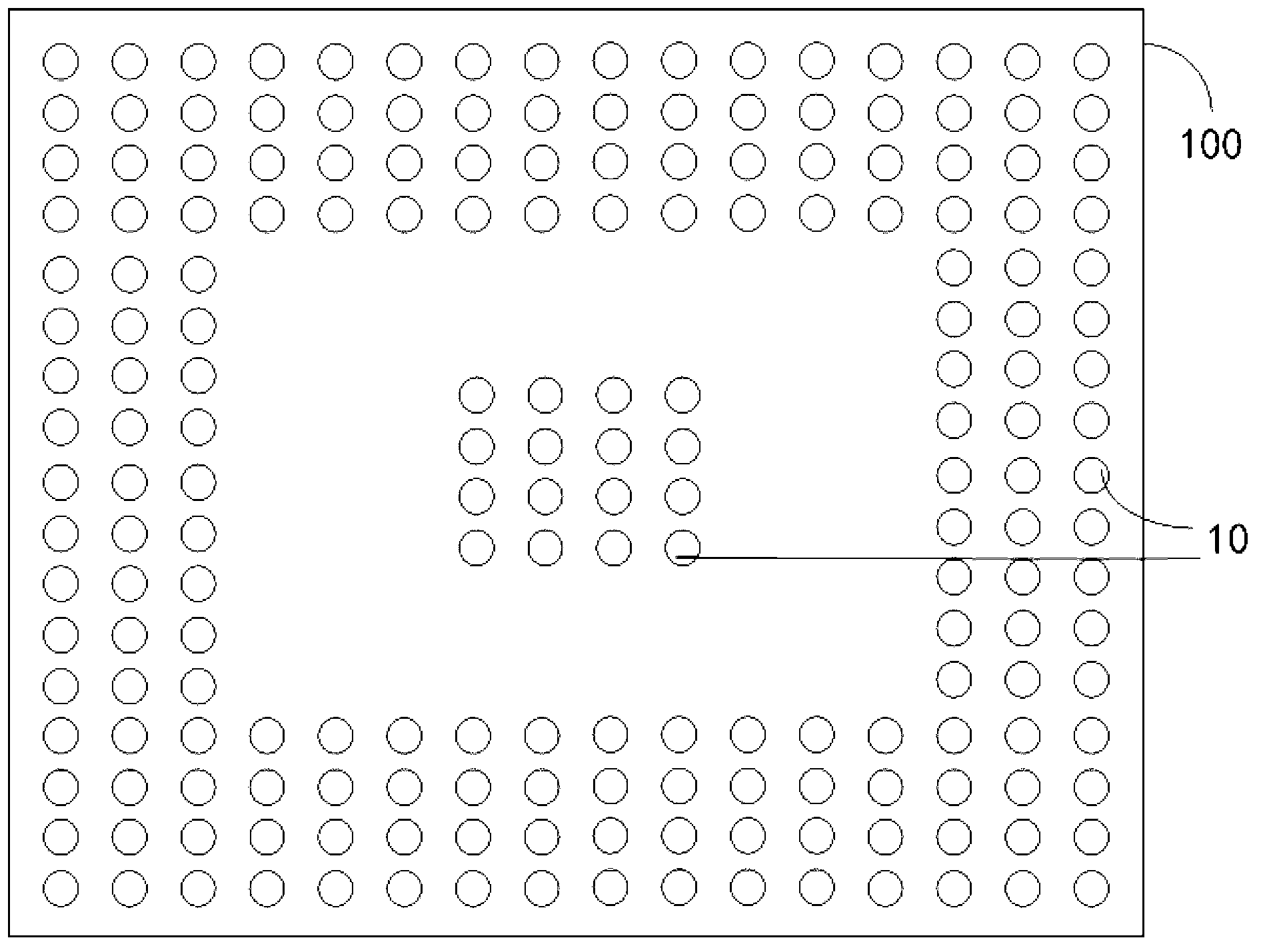

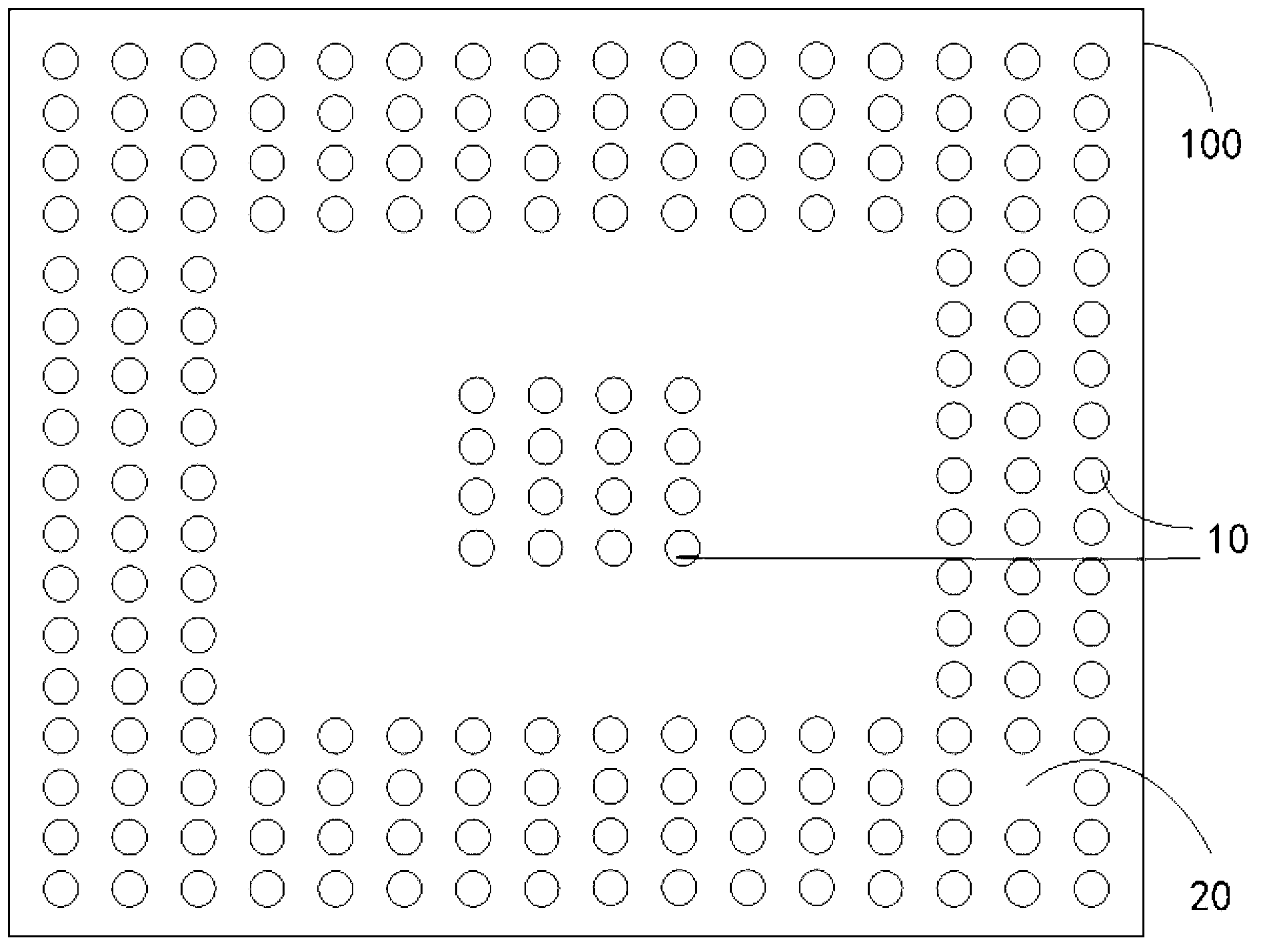

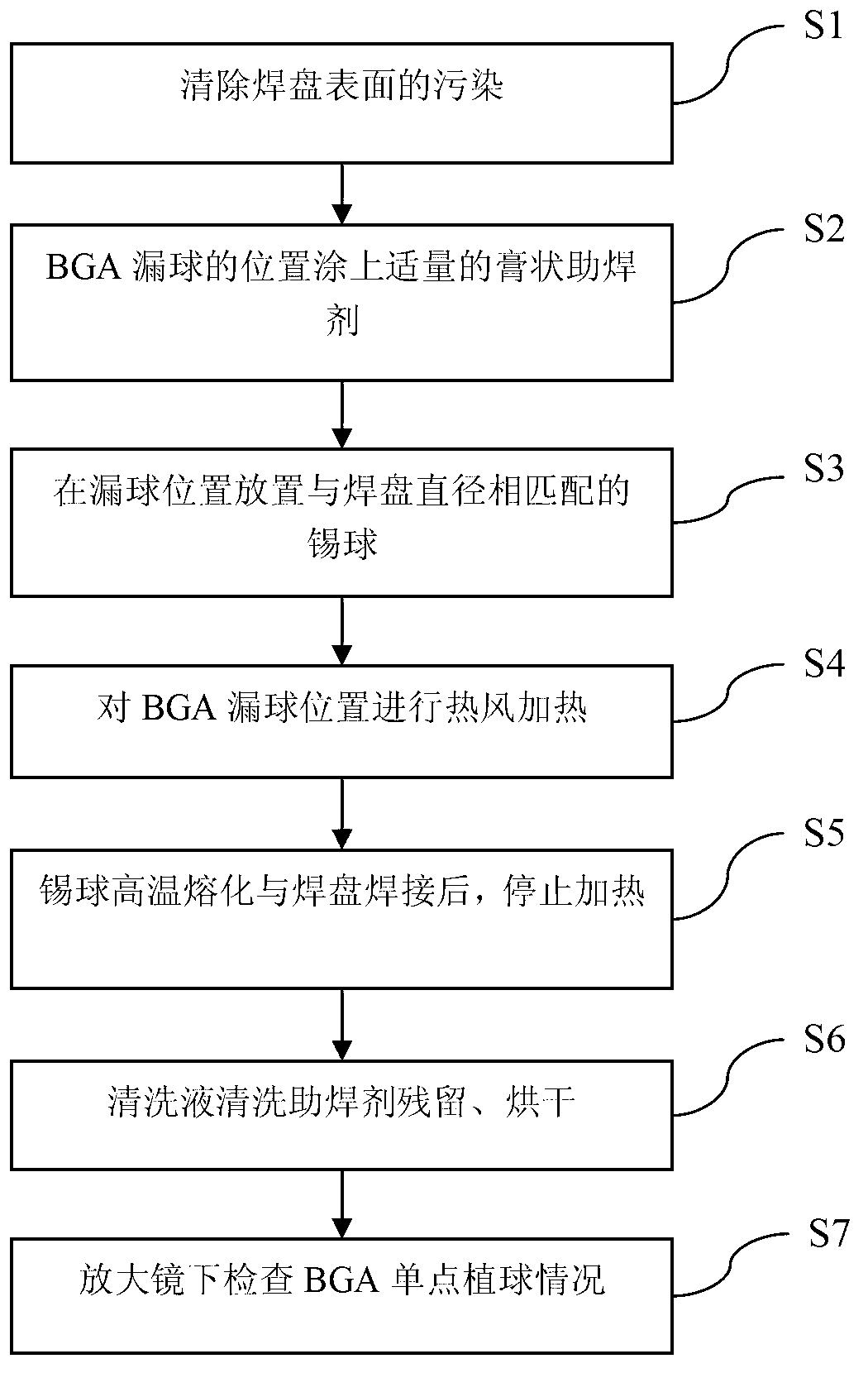

Ball grid array (BGA) balling single-point repair method

ActiveCN103231138AReduce heat exposureLife-span-reducing effectsSoldering apparatusSemiconductor/solid-state device manufacturingSolder ballEngineering

The invention provides a ball grid array (BGA) balling single-point repair method. The BGA balling single-point repair method includes: step one, removing an oxide layer and pollutants on the surface of a ball leaking pad on the bottom surface of a BGA chip; step two, taking paste scaling powder, and spreading the paste scaling powder on the ball leaking pad; step three, placing a solder ball with the diameter matched with that of the pad on the pad coated with the paste scaling powder in the step two; step four, heating the position where the solder ball is placed by using a heat gun in a mode that output air of the heat gun is perpendicular to the bottom surface of the BGA chip; and step five, closing the heat gun after the solder ball is melted, and detecting whether repair is successful after the heat gun is closed.

Owner:JIANGNAN INST OF COMPUTING TECH

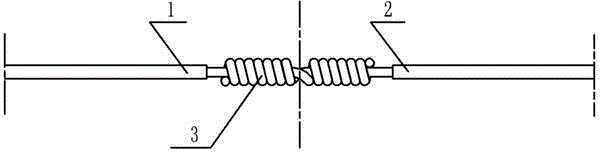

Production method of copper core cable soldered and sealed intermediate joint

The invention relates to a production method of a copper core cable soldered and sealed intermediate joint. The production method comprises the following steps that: 1) a cable, a wire 1 and a wire 2 are skinned, and the wires are made into a fixedly-connected bare joint 3; 2) the bare joint is wound with a solder wire 4; 3) the solder wire 4 is wrapped in aluminum foil paper 5; 4) a heat gun 6 is turned on to uniformly heat the aluminum foil paper, so that the solder wire can be indirectly heated to be soldered on the bare joint; 5) the joint is sleeved with a heat shrinkable sleeve 7, and the heat shrinkable sleeve 7 is uniformly heated with the heat gun; 6) the heat shrinkable sleeve shrinks and attaches to the bare joint; 7) the production of other wire joints of the cable is completed at a place where the above wire joint is not located according the step 1 to step 6; 8) cable sheaths at two ends of the joints are wrapped in hot-melt adhesive tapes 9 by one to two laps; and 9) the hot-melt adhesive tapes are sleeved with a large heat shrinkable sleeve 10, and the large heat shrinkable sleeve is uniformly heated with the heat gun, and therefore, the large heat shrinkable sleeve can shrink, and the hot-melt adhesive tapes in the large heat shrinkable sleeve can be melt, and the heat shrinkable sleeve can be bonded with the cable sheaths by the hot-melt adhesive, so that sealing and waterproof performance can be realized.

Owner:LEYARD LIGHTING CO LTD

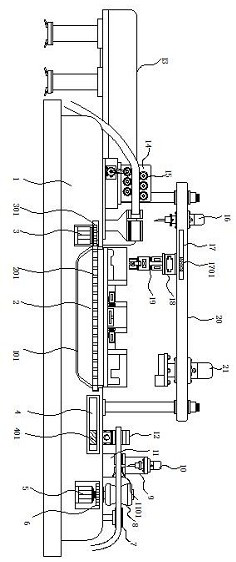

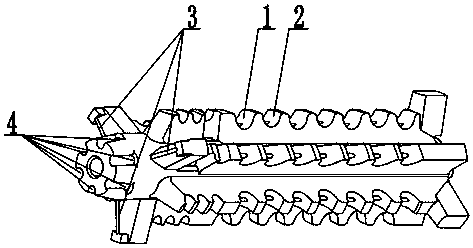

VCM coil winding system

A VCM coil winding system comprises a rack, a three-dimensional driving mechanism, a wire lifting clamping mechanism, a tinning mechanism, a winding mechanism, a hot air mechanism and a control module. The control module controls the three-dimensional driving mechanism to drive a wire so as to enable the wire lifting clamping mechanism to clamp the wire. After the wire lifting clamping mechanism clamps the wire, the control module controls the tinning mechanism to tin the wire between the wire lifting clamping mechanism and the three-dimensional driving mechanism. After the wire is tinned, thecontrol module controls the wire lifting clamping mechanism and the three-dimensional driving mechanism to enable the wire to be close to a VCM coil framework together and wind the wire at the corresponding position of the VCM coil framework while a main shaft assembly rotates. The control module controls the hot air gun to always aim at the winding position of the VCM coil framework to blow hotair after the wire is tinned and before the wire is wound. According to the VCM coil winding system, under the control of the control module, full-process winding of a VCM coil can be automatically completed.

Owner:TANAC AUTOMATION

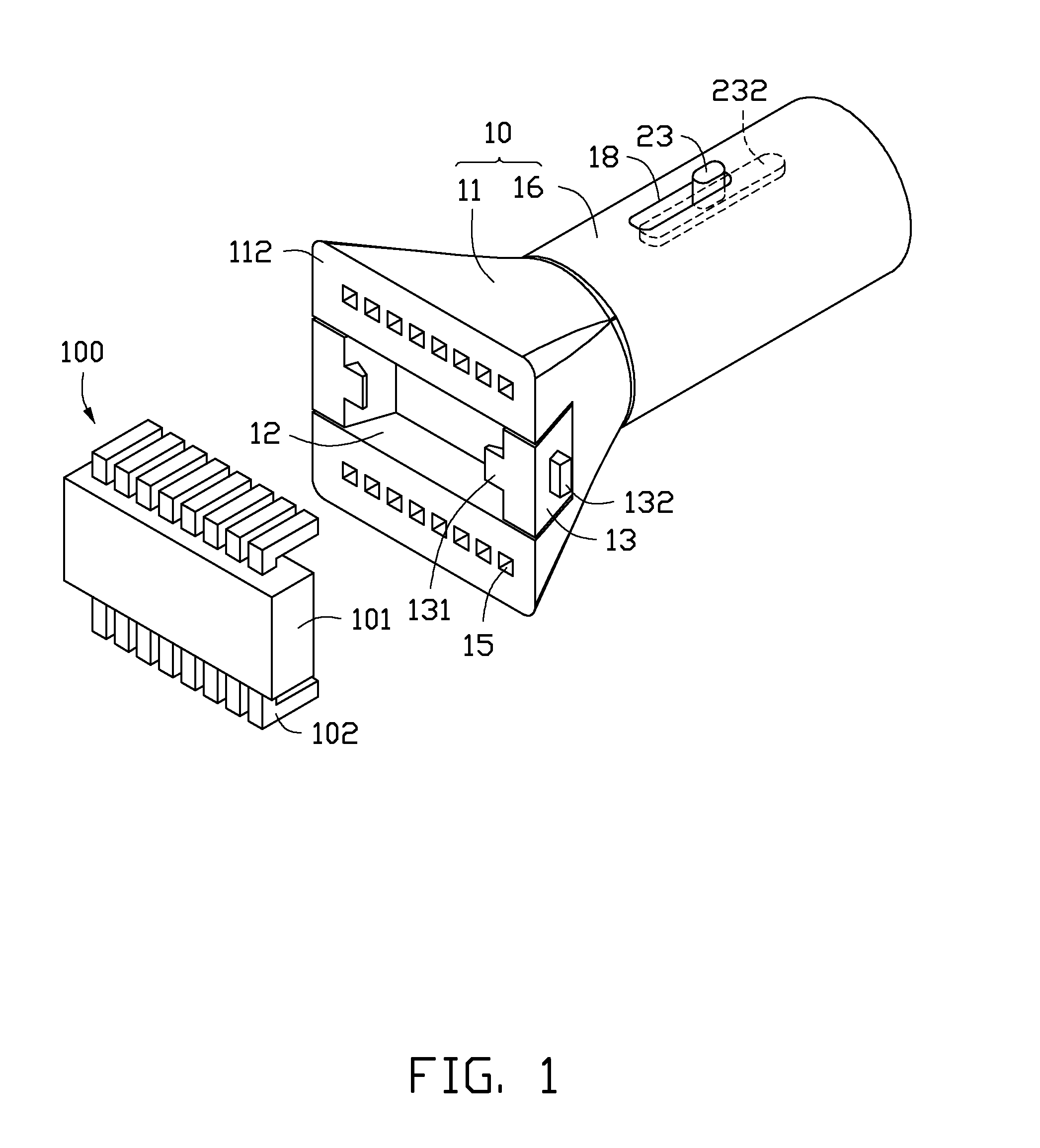

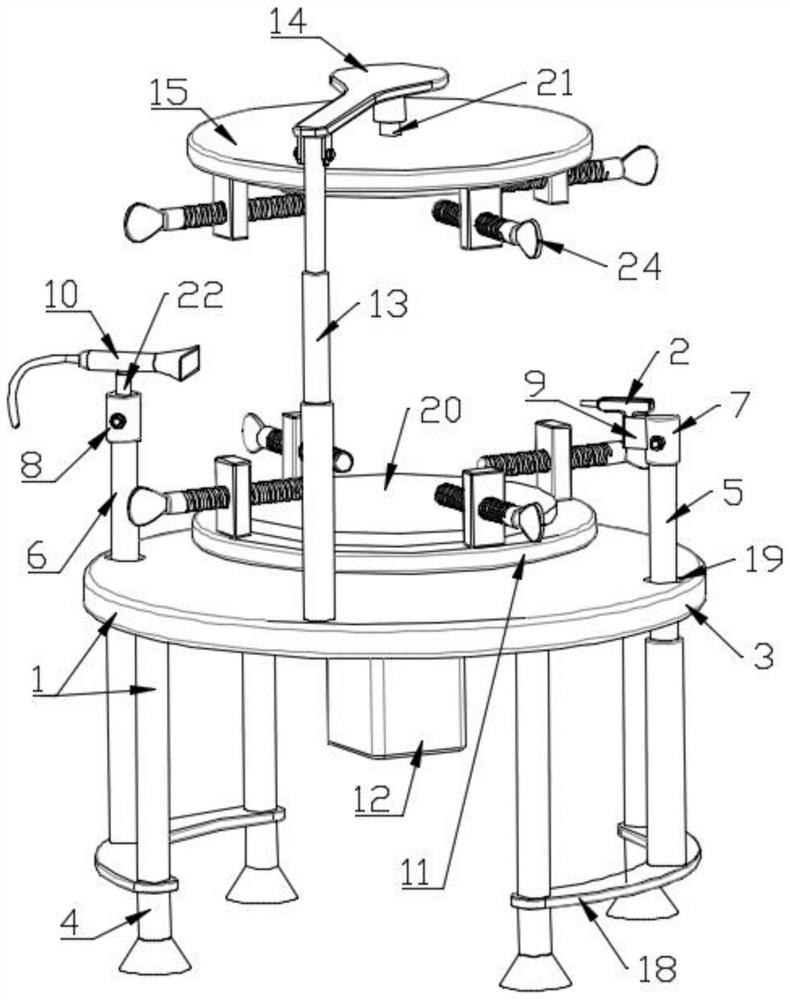

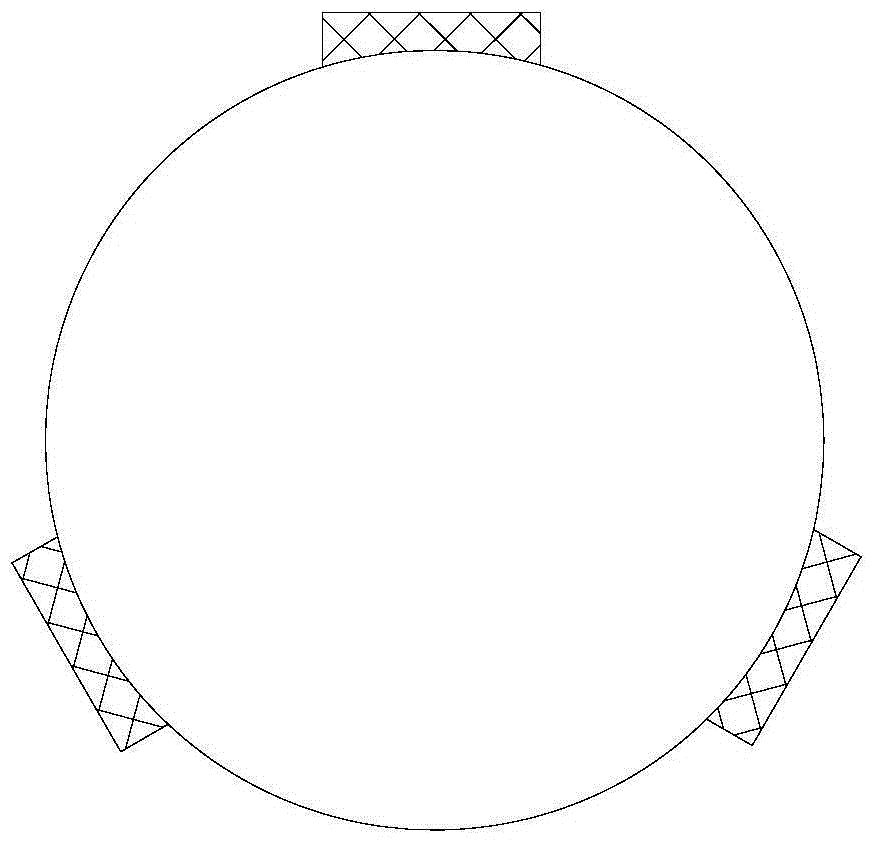

Paint spraying device for irregular curved surface metal

InactiveCN111804481AFull area coverage sprayed wellImprove drying efficiencyPretreated surfacesCoatingsElectric machineryStructural engineering

The invention relates to the technical field of paint spraying equipment, in particular to a paint spraying device for irregular curved surface metal. The paint spraying device comprises a supportingtable and a spray gun; the supporting table comprises a circular supporting plate and supporting legs evenly arranged at the bottom of the circular supporting plate in the circumferential direction, and a first electric push rod and a second electric push rod are fixedly arranged on the two sides of the circular supporting plate correspondingly; the tops of the first electric push rod and the second electric push rod are fixedly connected with a first mounting sleeve body and a second mounting sleeve body correspondingly, a mounting block used for mounting the paint spraying gun is arranged atthe top of the first mounting sleeve body, and a hot air gun is mounted at the top of the second mounting sleeve body; and a motor connected with the bottom of a circular rotary table is arranged atthe bottom of the circular supporting plate, and a third electric push rod is fixedly arranged at the top of the circular supporting plate. By means of the paint spraying device, irregular curved surface metal can be well sprayed, a paint film attached to the surface of the irregular curved surface metal can be rapidly dried, and the paint spraying efficiency of the irregular curved surface metalis improved.

Owner:郭猛

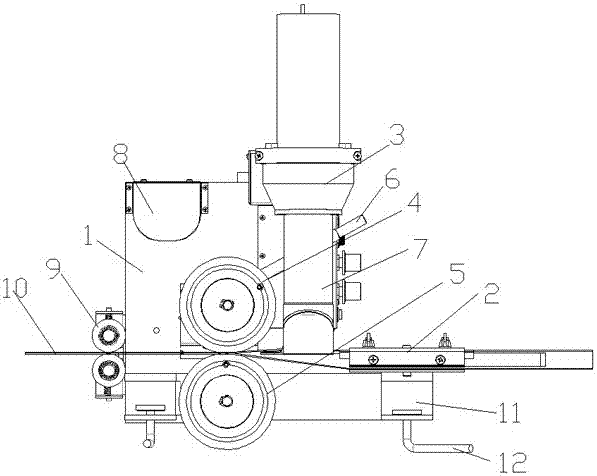

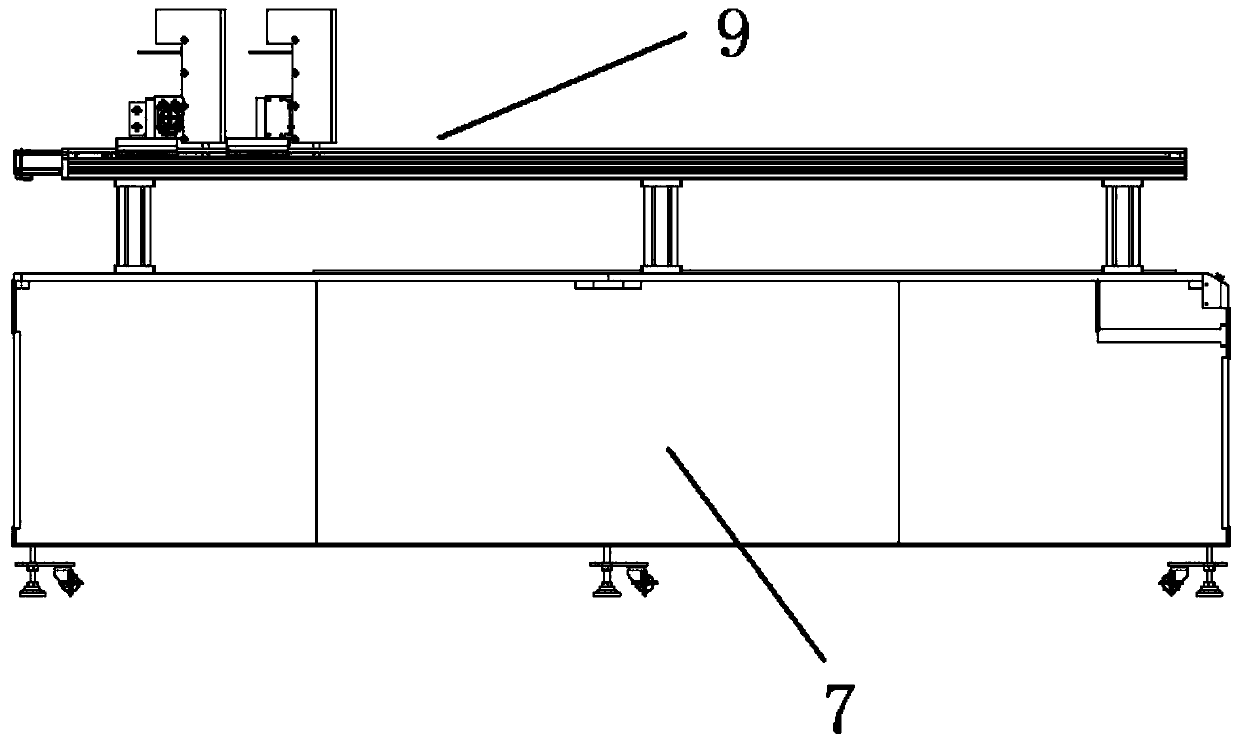

Edge folding and rope stringing welding machine and application method thereof

The invention relates to an edge folding and rope stringing welding machine and an application method thereof. The edge folding and rope stringing welding machine comprises a rack. The rack is sequentially provided with an edge folding and rope stringing guider, a hot air gun, an edge pressing welding structure and auxiliary cooling press rollers. The edge pressing welding structure comprises an upper pressing wheel and a lower pressing wheel. The rack is provided with a speed adjusting motor for driving the upper pressing wheel and the lower pressing wheel to rotate. The lower pressing wheel is arranged at the front end of a lower rotation shaft, and the rear end of the lower rotation shaft is provided with a chain wheel A. The upper pressing wheel is arranged at the front end of an upper rotation shaft. A reversing shaft is arranged above the upper rotation shaft. A planet gear is arranged at the front portion of the upper rotation shaft. A sun gear in engaged transmission with the planet gear is arranged at the front portion of the reversing shaft. A chain wheel B is arranged at the tail end of the reversing shaft. The chain wheel A and the chain wheel B are in chain transmission with the speed adjusting motor through a transmission chain. The rear end of the upper pressing wheel and the rear end of the lower pressing wheel are sleeved with rope rollers. By means of the edge folding and rope stringing welding machine and the application method thereof, landing edge butt welding, closed type edge folding welding, opening type edge folding welding and rope stringing welding operation can be conducted on welding materials, suitability is good, and cloth and a rubber rope can be effectively prevented from contracting and disengaging through the arrangement of the auxiliary cooling press rollers.

Owner:FUZHOU LESITE PLASTIC WELDING TECH

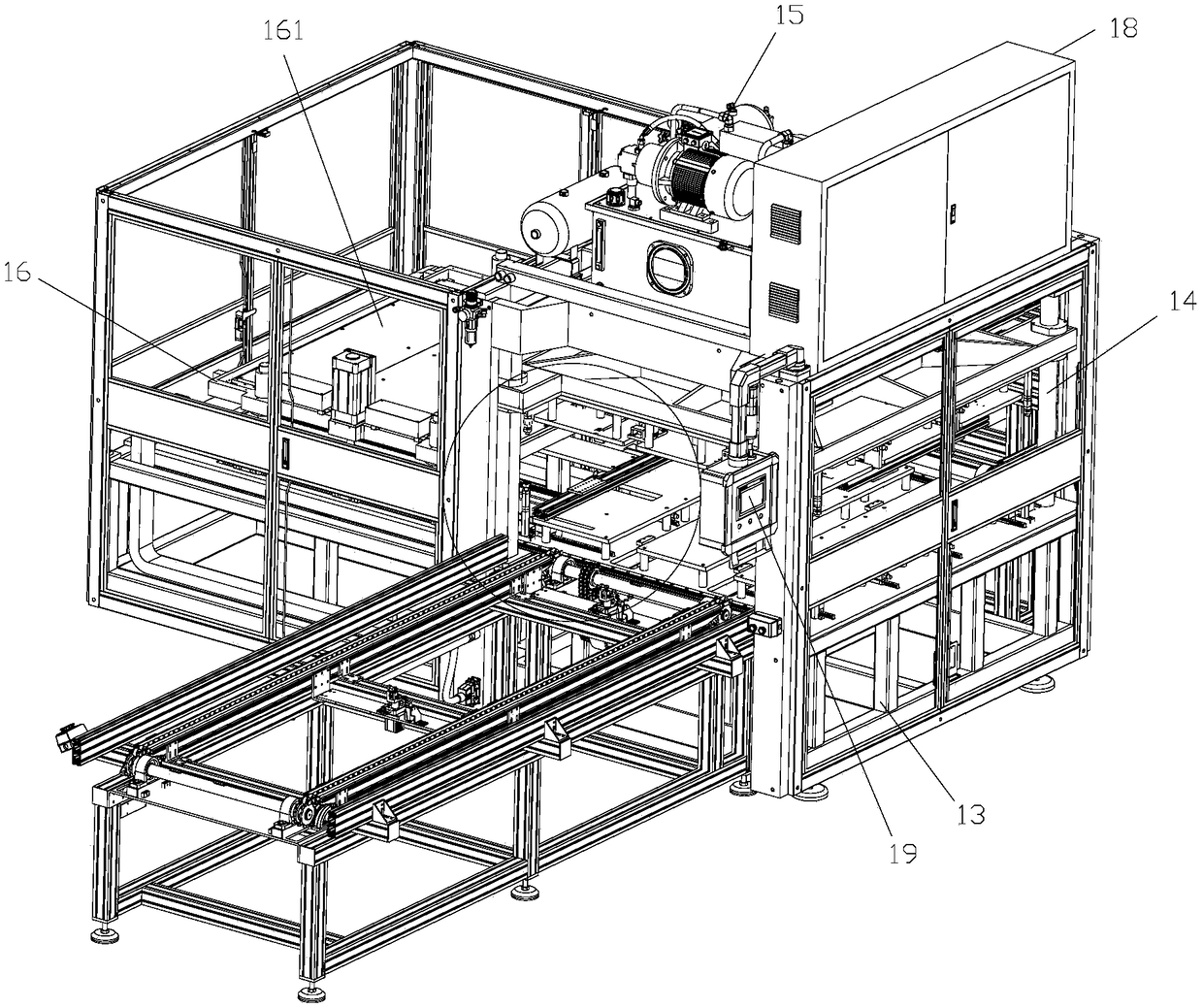

Tray welding assembly line

The invention discloses a tray welding assembly line, and relates to the field of heat plate welding assembly line equipment for plastic trays. The tray welding assembly line is sequentially providedwith a material distribution working station, a heat plate welding working station, an edge milling working station, a hot air welding working station, a splitting working station and a material discharge working station; after the tray raw material is welded by a heat plate, the tray is sent into a second chain group to perform edge milling, and a milling knife is used for treating the spilled material at the welding edge of the tray; then, the tray is sent into a third chain group to perform hot air welding on antislip strips, and a hot air gun is used for performing heat melting welding onthe crossing part of the antislip and the tray; after the welding is completed, the synchronous splitting is performed; finally, the single tray after splitting is sent into the material discharge working station on a fourth chain group, and the trays are sequentially stacked up; after ten trays are overlapped, the trays are fetched out and delivered out by an operator. The tray welding assembly line has the advantages that the automation degree is high; a plurality of processing structures are integrated into one assembly line; on the basis of heat melting welding of the plastic tray, each procedure is performed on the sustained running material delivery line, and the working efficiency of the tray welding assembly line is outstanding.

Owner:SUZHOU KEBER PRECISION MACHINERY

Retort oven with adjustable floor

ActiveUS20090107830A1Combustible gas coke oven heatingCharging-discharging device combinationsDecompositionRetention time

A retort oven for decomposition of waste materials through pyrolysis employing a deck with a variable angle of inclination for adjusting the retention time and processing rate of waste material flowing unassisted through the oven interior. The oven includes an outer shell lined with a refractory material and houses an inner oven chamber. The deck is adjustably hinge mounted to the inner chamber supporting sidewalls extending in a decline from a waste material entrance to a charred material exit. The deck is operated in a preferred angle range of inclination between 28°-50° from the oven floor normal. A controlled heat source is positioned within the oven to heat a first outer volume whose heated gases are transferred into a second inner volume of the inner chamber using an array of heat gun tubes heating the deck and material as it descends along the declined deck. The deck can be adjusted for varying the retention time of material within the oven for varied exposure to heat and charring efficiency.

Owner:SIMEKEN

Pulverized coal suspension combustion characteristic trial furnace for cement kiln

The invention discloses a pulverized coal suspension combustion characteristic trial furnace for a cement kiln. The pulverized coal suspension combustion characteristic trial furnace comprises an air source system, a hot air gun, an L-shaped quartz tube, a furnace body heating system and a suspension furnace body temperature monitoring and collecting system, wherein air with proper pressure flow velocity is supplied through the air source system, and is pre-heated through the hot air gun and then the pre-heated air is introduced into the furnace body heating system from the L-shaped quartz tube, so that the input pulverized coal is combusted in a suspension state; the data of temperature changingalong with timein a pulverized coalcombustion process can be acquired by virtue of the suspension furnace body temperature monitoring and collecting system; a curve of the temperature changing along with time of the pulverized coal in the suspension and combustion state is drawn, so that the combustion thermal characteristic of the pulverized coal can be evaluated according to the curve. Compared with the general thermoanalysis technology of the pulverized powder, the trial furnace has the advantages that when the required testing temperature is reached and the heat balance is achieved,the test and calculation of samples to be tested can be completed for only 10 minutes, so that the trial furnace is quick and convenient to operate, and high in accuracy; meanwhile, continuous experiment can also be carried out without generally needing to wait the reduction of the temperature to the room temperature like thermogravimetric analysis, and therefore, a large amount of time can be saved.

Owner:GUANGXI UNIV

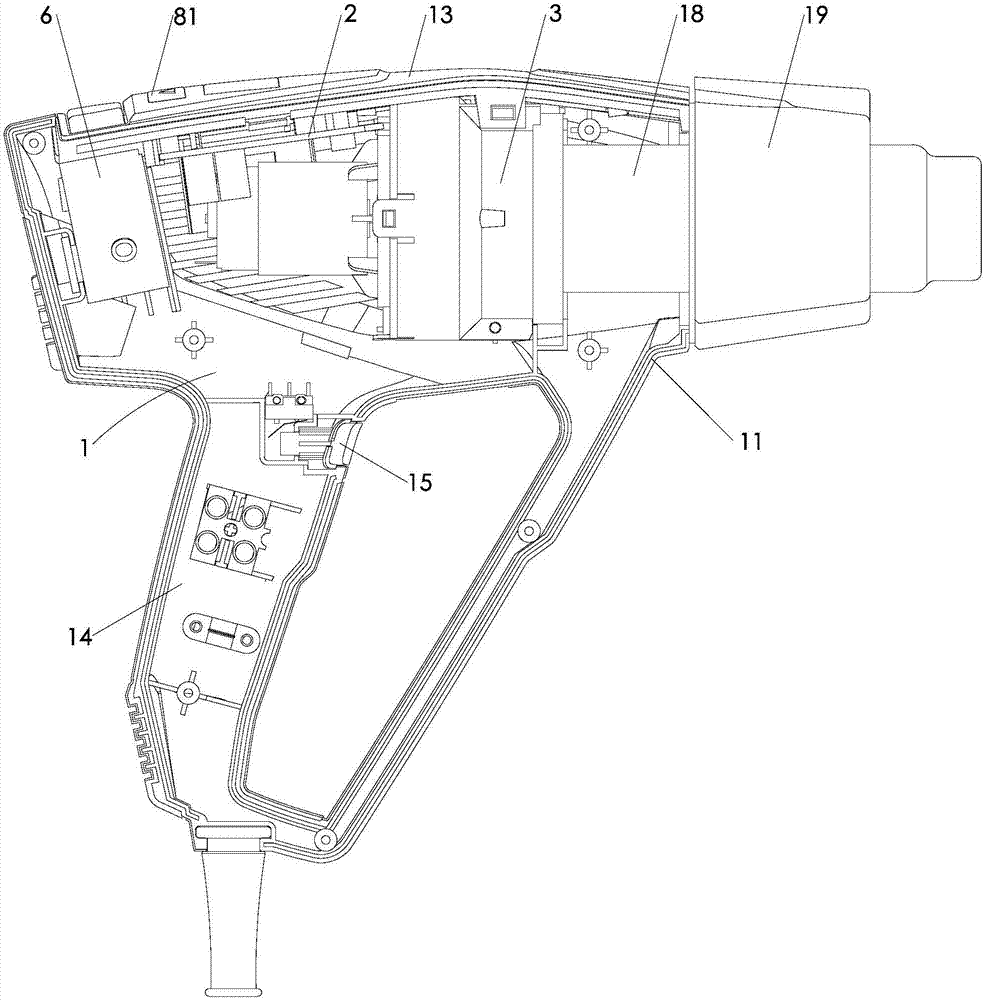

Heat gun

The invention discloses a heat gun, and belongs to the technical field of mechanical heating equipment. The heat gun comprises a shell, a main control board and a heat device; the heat device comprises a heating module, a fan and a motor; the shell is provided with a heat tube; the heating module is arranged in the heat tube; the heating module and the motor are both electrically connected to the main control board; a temperature detecting device and a heating indication device are arranged in the shell; the temperature detecting device comprises a detecting circuit board and an infrared detecting head; the heating module is provided with a detecting channel for enabling the infrared detecting head to receive external infrared radiation energy; and the heating indication device comprises a control substrate and an indicating lamp. Through the effects of the temperature detecting device and the heating indication device, a proper distance can be kept between the heat gun and a heated object, so that the heated object is located in a proper heated state, the potential safety hazard of melting or firing of the heated object caused by unknown or uncontrollable heating temperature is prevented, the heating effect is guaranteed, and the use safety is improved.

Owner:ZHEJIANG PRULDE ELECTRIC APPLIANCE CO LTD

Metal pipe chamfering equipment and working method thereof

ActiveCN111002148AQuick removalQuickly remove the burr of the nozzleEdge grinding machinesGrinding drivesEngineeringPipe

The invention discloses metal pipe chamfering equipment and a working method thereof. According to the chamfering equipment, on one hand, burrs at the pipe opening can be rapidly removed, and a largenumber of metal scraps cannot be generated; in the chamfering process, the positions of an inner circle chamfering disc and an outer circle chamfering disc are actively adjusted, so that the chamfering work can be completed without spending a lot of time to position the metal pipe, and production efficiency is greatly improved; in addition, after the chamfering procedure of the metal pipe is completed, hot air is sprayed out through a hot air gun to dry the surface of the round pipe; after the surface of the round pipe is dried, the round pipe is wrapped by a thermal shrinkage film sent out bya packaging film feeding device; after wrapping is completed, the thermal shrinkage film is cut off through a cut-off device; and then, the thermal shrinkage film is heated through hot air sprayed out of the hot air gun to make thermal shrinkage film shrink and tightly wrap the surface of the round pipe, so that the chamfering and packaging integrated procedure of the metal pipe is completed, andthe round pipe machining efficiency is further improved.

Owner:宁波创青腾达机械有限公司

Method for repairing polypropylene filter plate of plate-and-frame filter press

The invention relates to a method for repairing a polypropylene filter plate of a plate-and-frame filter press, which effectively solves the repairing problem of the polypropylene filter plate of the plate-and-frame filter press. The method comprises the following steps: in a dustfree environment, placing the polypropylene filter plate in a level degree smaller than or equal to 0.05mm / m; with a wound hole as a center, and with a surface with the area being 4-10 times that of the wound hole as a cementing surface, vertically welding polypropylene welding rods on the periphery of the cementing surface to form a closed surface; roughening the closed surface, cleaning the closed surface with clear water, and finally quickly drying the closed surface by using a hot air gun; and putting tin foil paper under the bottom of the wound hole and flattening, pouring modified high-strength epoxy resin structural adhesive into the cementing surface to enable the adhesive-poured liquid level to be leveled with the upper edge of the closed surface, and placing in a dustproof, ventilated, dry and dark place for natural curing. The method is easy to operate and master and is straightforward. A cold bonding process is adopted for automatic binding repair, the original structure of the filter plate is not destroyed, and the method is safe and feasible. The wound repair gas tightness is good, the mechanical strength is high, and the chemical stability is good. The repair method is low in cost.

Owner:HENAN DONGDA TECH CO LTD

Automatic terminal riveting machine capable of carrying out sleeve processing on terminal

ActiveCN112397967AEasy to limitEasy to cut offContact member assembly/disassemblyOptically investigating flaws/contaminationIntelligent machineHeat gun

The invention discloses an automatic terminal riveting machine capable of carrying out sleeve processing on a terminal. The machine specifically comprises a base, a rotating disc, a functional clamp,a grabbing mechanism and a wiring terminal, a conveyor belt is mounted at one end of one side of the top of the base, and a heat shrink tube feeding mechanism is fixed at the other end of one side, close to the conveyor belt, of the top of the base; a rotating groove is formed in the middle of the top end of the interior of the base, the rotating disc is arranged in the rotating groove, limiting bases are evenly arranged at the edge of the top of the rotating disc, and hydraulic ejector rods are arranged in the portions, below the limiting bases, of the rotating disc. According to the automatic terminal riveting machine capable of carrying out sleeve processing on the terminal, by arranging the heat shrink tube feeding mechanism and the heat shrink tube limiting base, intelligent mechanical operation is achieved, manual tube penetrating or handheld hot air gun working is not needed, the machining efficiency is higher, the potential safety hazard that the hands of staff are scalded is avoided, and the use safety is higher.

Owner:佛山市顺德区恒沃电器有限公司

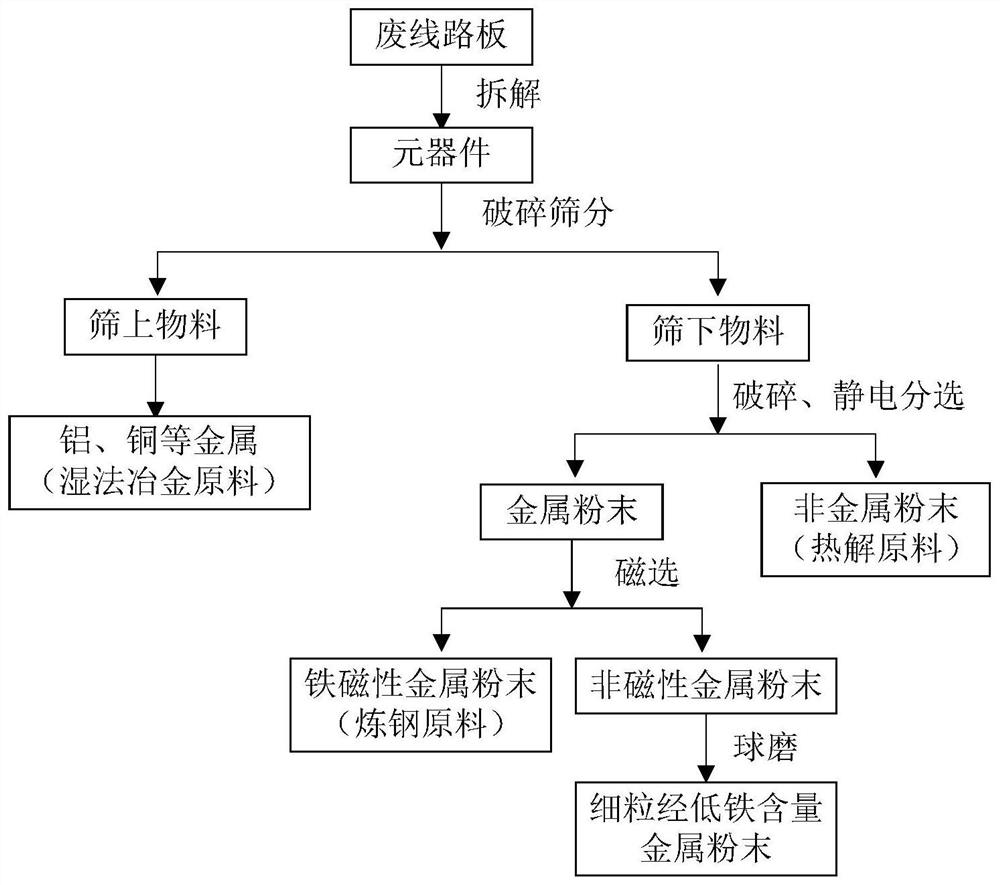

Method for preparing metal powder with low iron content by treating a waste circuit board component through mechanical physical method

InactiveCN113020219AEasy to separateEfficient separationSolid waste disposalElectronic waste recyclingElectrostatic separationCopper

The invention discloses a method for preparing metal powder with low iron content by treating a waste circuit board component through a mechanical physical method, and belongs to the technical field of electronic waste recycling. According to the method, firstly, a heat gun is used for disassembling the component, a small part of nonmetal is carbonized in the process, and therefore a part of metal and nonmetal in the component are separated to facilitate subsequent metal dissociation; then, primary crushing and screening are carried out by utilizing the metal ductility difference, and a part of copper with high ductility and most aluminum are separated from iron with low ductility; next, secondary crushing and screening are conducted on materials obtained through primary crushing and screening, and therefore metal is completely dissociated; high-grade metal powder and non-metal powder are efficiently separated through electrostatic separation; then, ferromagnetic metal and non-magnetic metal are separated from the metal powder with high iron content through a magnetic separation process; and finally, the ferromagnetic metal powder is ball-milled to obtain fine-grained metal powder with low iron content (mainly containing copper and precious metal).

Owner:BEIJING UNIV OF TECH

Portable hot melting repairing device and method for outer sheath of high-voltage cable

ActiveCN112186659AQuick fixSimple structureClimate change adaptationApparatus for repairing insulation/armouring cablesEngineeringStructural engineering

The invention discloses a portable hot melting repairing device and method for a high-voltage cable outer sheath, and the device comprises an adjustable electric temperature hot air gun, a material injection cylinder, a gluing gun, and a heating and melting device. Wherein the material injection cylinder can be assembled on the gluing gun and can be arranged in the heating and melting device. Theportable hot melting repairing device for the outer sheath of the high-voltage cable can quickly repair the outer sheath of the cable, and is simple in structure, convenient to carry and good in repairing effect; the portable hot melting repair method for the outer sheath of the medium-high voltage cable is applied to repair of the cable, is convenient and rapid, can fuse the same materials, and enables the repaired cable to reach a good state without difference from a brand-new cable in sealing and insulating properties.

Owner:CHONGQING TAISHAN CABLE

Plastic composite pipe end sealing device of steel skeleton

The invention discloses a plastic composite pipe end sealing device of a steel skeleton. The plastic composite pipe end sealing device comprises a car body (12), wherein a thermo-extrusion gun (6) and a heat gun (5) are arranged on the car body (12); a stock mold (8) of a bar groove is arranged at the plastic outlet of the thermo-extrusion gun (6); micro-adjusting mechanisms are arranged on the thermo-extrusion gun (6) and the heat gun (5). Compared with the prior art, the plastic composite pipe end sealing device is simple in structure, has a good sealing effect, and can seal the end part of a plastic composite pipe of the steel skeleton without a corresponding annular cover plate manufactured in advance, the production cost can be greatly reduced, and the production efficiency is greatly improved.

Owner:新疆登煌管业有限公司

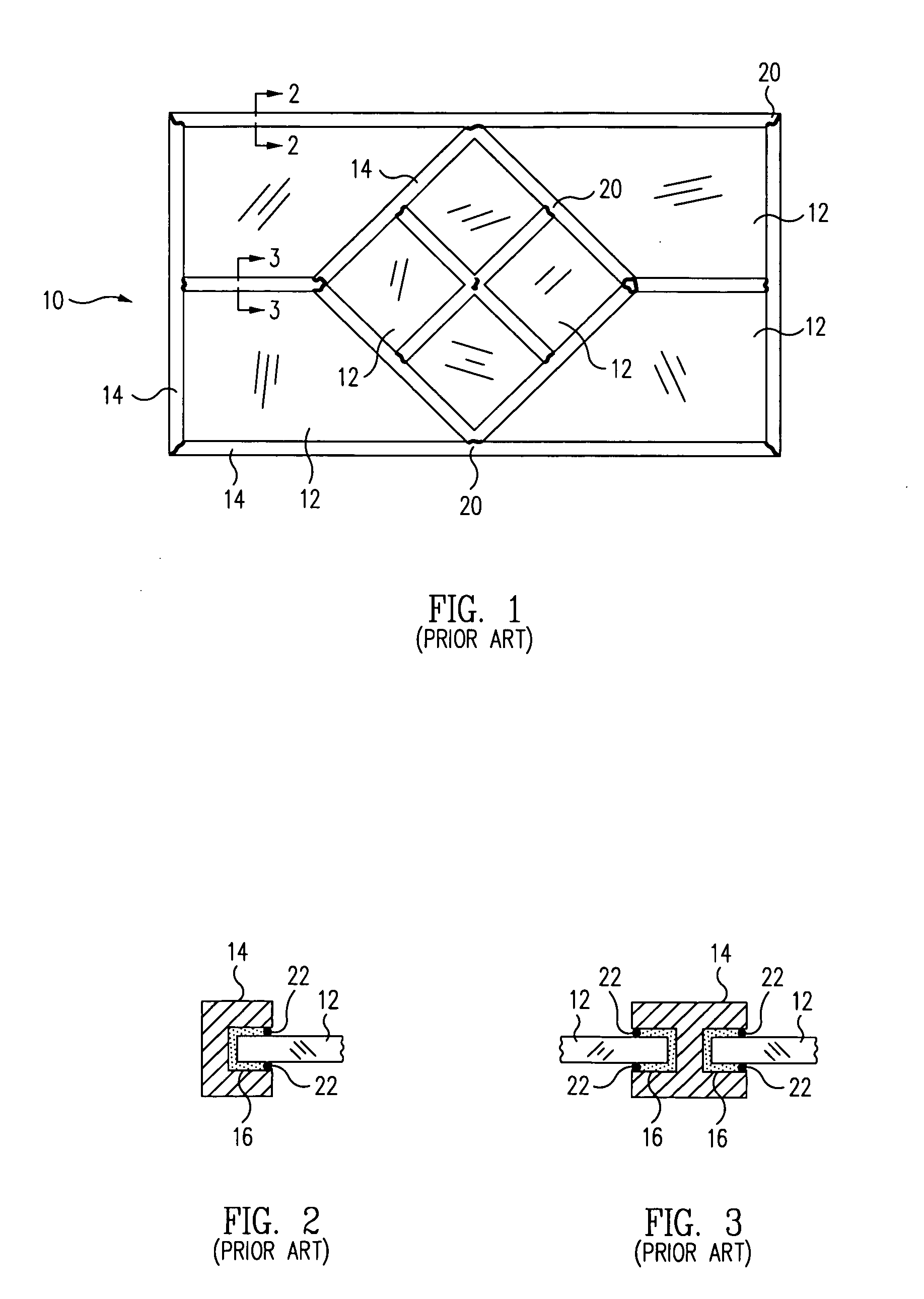

Making glazed panels puttied with hot melt adhesive

InactiveUS20070292694A1Eliminate needCeramic layered productsGlass/slag layered productsHot meltColor glass

A method for making a glazed panel, such as a stained glass window, using a hot melt adhesive instead of a conventional, noisome, slow-drying putty, includes the provision of a glass pane, such as a leaded or stained glass pane, having a peripheral margin, a soft metal came, such as a lead came, having a U-shaped channel configured to receive the peripheral margin of the glass pane, and an elongated strip of a hot melt adhesive disposed in the channel of the came. The glass pane is heated, e.g., with a hot air gun, to a temperature above the melting point of the adhesive and its peripheral margin is then inserted into the channel of the came such that the heated peripheral margin of the glass causes the adhesive to melt and adhere the peripheral margin of the glass pane to the interior surface of the channel of the came.

Owner:STREUTER TECH

Respiratory therapeutic electric heat source face mask

A therapeutic face mask apparatus for wearers with resistant respiratory viruses, is connected to a heat gun that provides adjustable heated and humidified air for inhalation. The heat gun heats ambient air that is breathed in through the face mask during normal breathing, which is worn over the nose and mouth of a person. A temperature gauge monitors temperature for future adjustment of the amount of heat generating current to raise the heat to a predetermined temperature to deactivate resistant viruses in compromised upper and / or lower respiratory systems of the wearer. The air in the chamber is heated for inhalation by a resistive element in the heat gun. The temperature of the resistive material (and by extension the warm air generated), is regulated / adjusted by increasing or decreasing the current output settings on the power source, so that heated and pressured air is produced.

Owner:SABIN ROBERT

Method for installing ultrahigh frequency RFID label on metal tool

InactiveCN105069501ASo as not to damageEasy to installRecord carriers used with machinesForeign matterEngineering

The invention provides a method for installing an ultrahigh frequency RFID label on a metal tool. The method is characterized by comprising the following steps that S100) the surface of the tool is cleaned by sand paper or a polisher to ensure that the surface of the tool does not include foreign matters or corrosion; S200) the back side of the RFID label tightly clings to the surface of the tool, and an electrical engineering adhesive plaster winds and the fixes the RFID label; and S300) a thermoplastic tube sleeves the RFID label, it is ensured that the thermoplastic tube completely covers the RFID label, and a heat gun heats the thermoplastic tube uniformly so that the thermoplastic tube is compressed when being heated and wraps the RFID label tightly and fixes the RFID label to the surface of the tool. Thus, the RFID label can be firmly installed.

Owner:GUANGZHOU HUAWEI TOMORROW SOFTWARE TECH

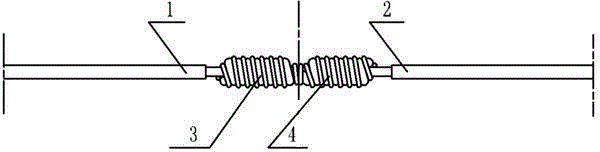

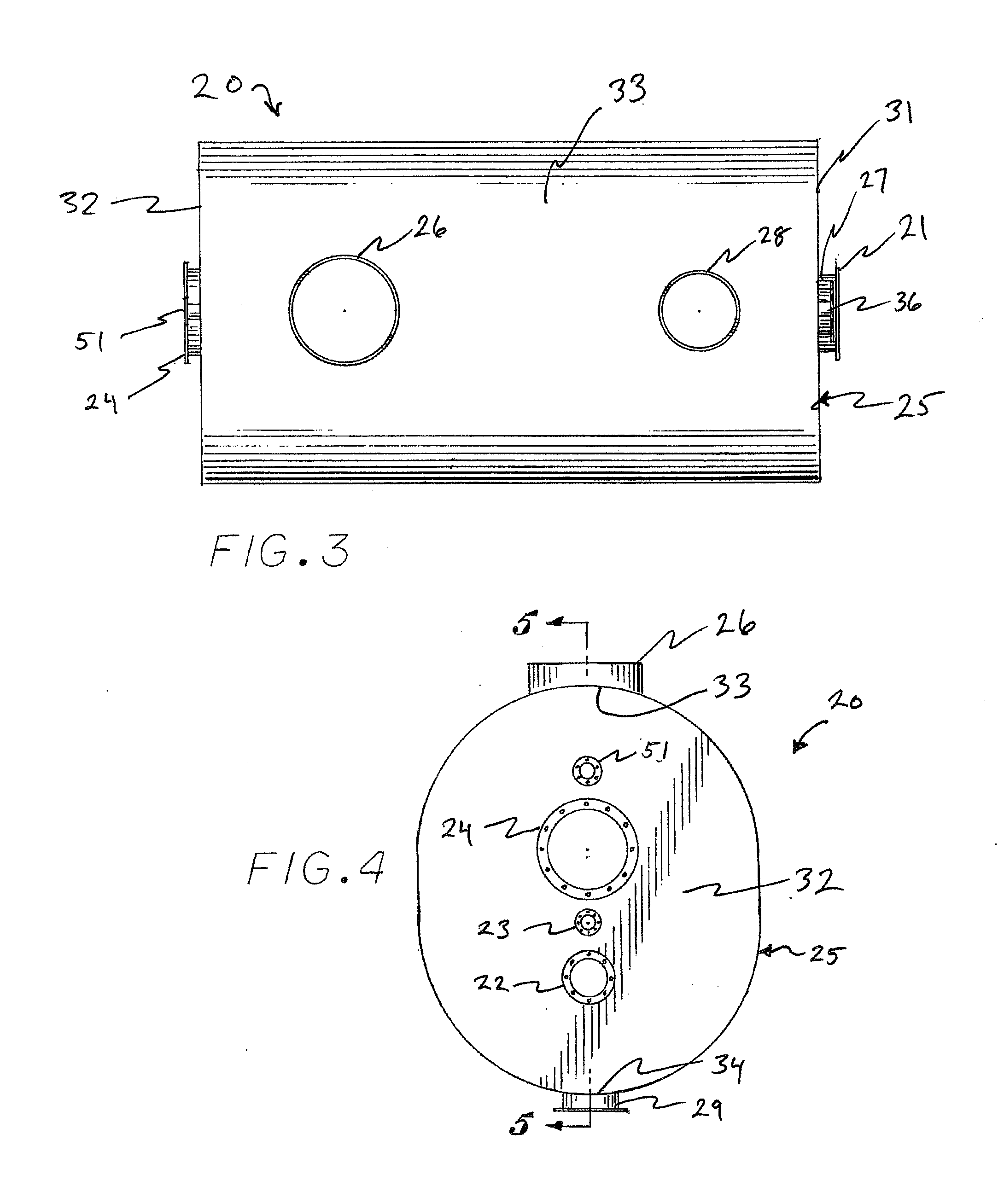

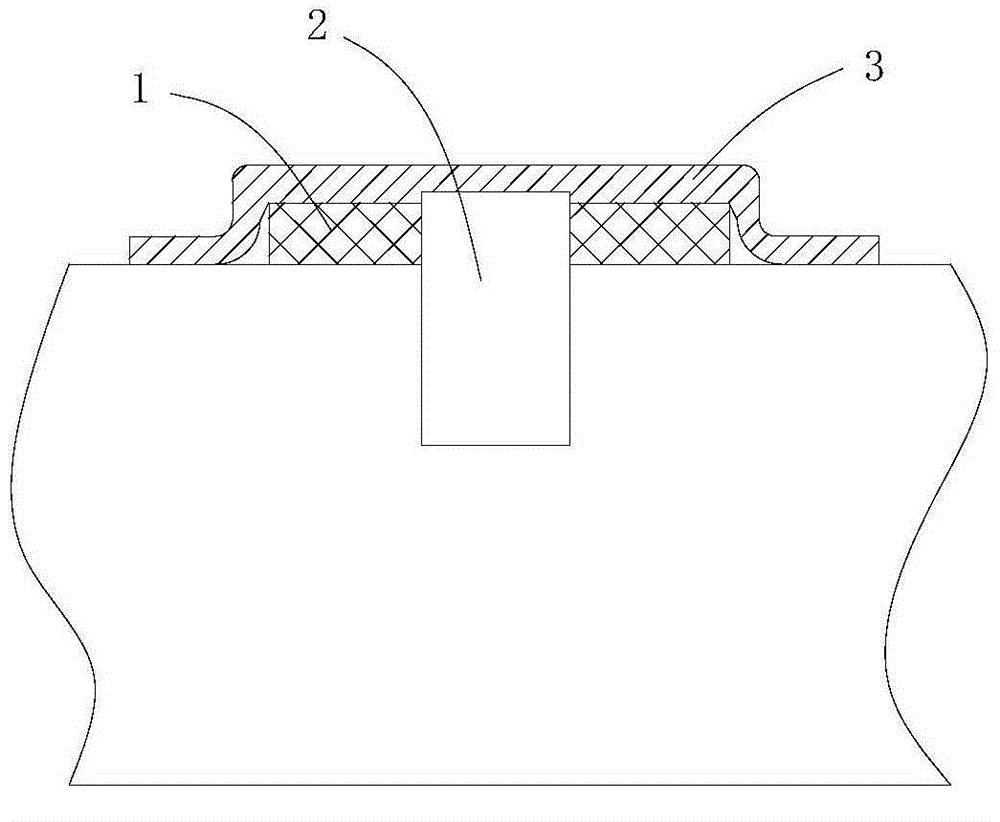

Heat gun

A heat gun includes a canister, a first outlet pipe, and an assistant member. The canister includes a columnar sidewall bounding a receiving space and an installation board mounted in the receiving space. The assistant member includes a first vent pipe, and a second vent pipe communicating with the first vent pipe and slidably mounted to the first vent pipe. Top ends of the first outlet pipe and the first vent pipe extend through the installation board and communicate with an upper portion of the receiving space. Bottom ends of the first outlet pipe and the second vent pipe function as outlets of the heat gun.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

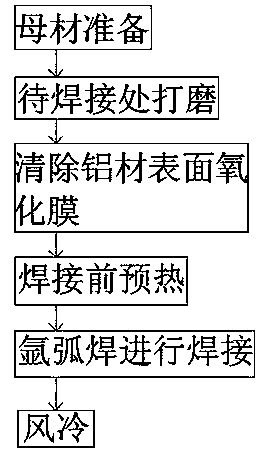

Welding process for aluminum profile processing

InactiveCN111037060AEfficient removalSlow down the rate of secondary oxidationArc welding apparatusWelding/soldering/cutting articlesSurface oxidationCerium

The invention discloses a welding process for aluminum profile processing. The welding process for the aluminum profile processing comprises the following steps of preparing a base material, namely, preparing two aluminum profiles with the diameters of fifteen to thirty millimeters, and adding a silicon material when the aluminum profiles are produced; grinding the positions to be welded, namely,grinding and brushing the surfaces to be ground of the aluminum profiles by using stainless steel wires until the aluminum profiles present metallic luster; removing oxide films from the surfaces of the aluminum profiles, namely, treating the surfaces of the aluminum profiles by a chemical method, and removing the oxide films from the surfaces of the aluminum profiles; preheating before welding, namely, preheating the welded positions of the aluminum profiles by using an hot-air blower; and welding by argon arc welding, adopting a tungsten electrode material in argon arc welding, adding 1.5 to2.6 percent of cerium oxide to pure tungsten, and welding and simultaneously blowing the welded surfaces by using a heat gun. According to the welding process for the aluminum profile processing, first, the welded surfaces of the aluminum profiles are ground and brushed by using the stainless steel wires, and then, the ground and brushed aluminum profiles are subjected to secondary treatment by the chemical method, so that the oxide films on the welded surfaces can be removed effectively, which ensures the strength during welding, and is beneficial to welding.

Owner:ANHUI GAODE ALUMINUM

Heat gun

The invention relates to a heat gun (10) having: a housing (12) with an air duct (20) opening into an air outlet (18); a hot air device (22) arranged in the housing (12) for generating a hot air flowand for guiding the hot air flow through the air duct (20) via the air outlet (18) onto a workpiece; and a thermometer (36) with a temperature sensor (34) for contactless measurement of a surface temperature of the workpiece. According to the invention, a measuring tube (28) is arranged in the air duct (20), the forward end (30) of which tube is open and faces the air outlet (18) and in the rear end (32) of which tube the temperature sensor (34) is arranged.

Owner:ISABERG RAPID

Rolling welding method for roller

The invention discloses a rolling welding method for roller and achieves the effect of synchronously welding a plurality of linear welding materials. According to the scheme, a soldering bit adopts the roller; the roller is arranged at the front end of a soldering iron through a rotating shaft; the roller rolls the linear welding materials and a base plate and can implement rolling and welding at the same time; an electric heating device and a temperature sensor are arranged in the roller; a power line and a signal line are respectively communicated with each other through a sliding ring arranged on the rotating shaft; or a hot air gun and flame are used for heating the roller; the temperature sensor is arranged in the roller, so that the temperature of the roller can be controlled by controlling the power of the hot air gun or the degree of the flame.

Owner:王锐

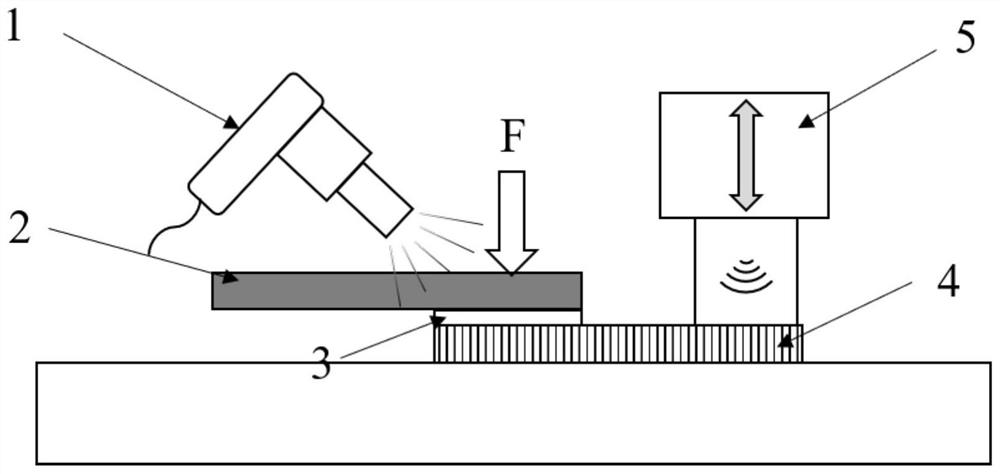

Hot-gas welding method for resin-based composite and light alloy

The present invention provides a hot-gas welding method for a resin-based composite and a light alloy. The hot-gas welding method includes the following steps: step 1, constructing a welding joint: putting a thermoplastic resin film into a joint area of a resin-based composite and a light alloy which are to be welded; step 2, performing ultrasonic-assisted hot-gas welding: applying a pressure to the upper portion of the joint area, starting a heat gun to adjust the temperature to enable the highest temperature in a welding area to be 160-500 DEG C for welding, and meanwhile, applying ultrasonic vibration in the welding process; and after welding is ended, performing cooling to obtain a resin-based composite-light alloy welded joint. Ultrasonic waves are applied to a hot-gas welding process of the composite and the light alloy through ultrasound, ultrasonic vibration is adopted for assisting hot-gas welding of the resin-based composite, the flowing and joint filling capacities of thermoplastic resin are improved by virtue of ultrasonic wave energy, and then, a composite welding joint with higher mechanical properties is constructed.

Owner:SHENYANG AEROSPACE UNIVERSITY

Film laminating mechanism

The invention relates to the technical field of photovoltaic module production equipment, in particular to a film laminating mechanism which aims at solving the problem that in the prior art, a film belt is inconvenient to cut. The film laminating mechanism is technically characterized by comprising a fixing plate which is a cuboid plate, wherein a film belt guide assembly, a film belt pressing mechanism, a mounting frame, a film belt temporary storage assembly and a cutter assembly are arranged on the fixing plate, the film belt guide assembly is used for guiding the film belt, the film beltpressing mechanism is used for straightening the film belt, the mounting frame is used for fixedly arranging the film belt pressing assembly, a hot air gun assembly and an air outlet are further arranged at the bottom of the fixing plate, and the hot air gun assembly and the air outlet are fixedly arranged. Through arrangement of the hot air gun assembly, hot air is conveyed to the air outlet, sothat the film belt can be conveniently cut off; and meanwhile, through the arrangement of air blowing assemblies, the situation that the film belt deforms due to the influence of the ambient temperature is avoided.

Owner:LAPLACE (WUXI) SEMICON TECH CO LTD

Device and method for pre-coating metal solder on vacuum glass

PendingCN110963716AImprove packaging success rateThickness is easy to controlEnergy converterRadial vibration

The invention relates to a device and a method for pre-coating metal solder on vacuum glass, the device for pre-coating the metal solder on the vacuum glass comprises an ultrasonic electric solderingiron and an adsorption motion platform, the ultrasonic electric soldering iron comprises an ultrasonic generator, an electric soldering iron head, a wire feeding device and a hot air gun, an energy converter of the ultrasonic generator is connected with the electric soldering iron head to drive the electric soldering iron head to generate radial vibration; the hot air gun is set near the solderingiron head, the wire feeding device conveys welding wires to the electric soldering iron head, and before the welding wires make contact with the electric soldering iron head, the hot air gun preheatsthe welding wires. The adsorption platform comprises a rack, and an adsorption plate is arranged on the rack; a moving assembly is further arranged on the rack; the metal solder is prefabricated intoa welding wire and conveyed to the electric soldering iron head through the wire feeding device; mechanical vibration generated by an the energy converter of the ultrasonic generator is used for driving the electric soldering iron head to generate radial vibration, and a the welding wire is molten under the heat effect of the electric soldering iron head and is combined with a metalized layer ofglass. And the solder thickness is controllable, and the packaging success rate of the vacuum glass is greatly improved.

Owner:深圳理大科技产业有限公司

Handheld type special-shaped edge bonding machine

InactiveCN112140277AEasy and quick edge bandingImprove processing efficiencyOther plywood/veneer working apparatusDomestic articlesHand heldStructural engineering

The invention provides a handheld type special-shaped edge bonding machine which is characterized in that the edge bonding machine comprises a hot air gun, a fixed part, a fixed cover and a movable part, the fixed part comprises a part C and a part D, the part C and the part D are in a bent corner shape, the upper edge and the lower edge of the part C of the fixed part are connected with an arc-shaped sleeve, and a gun head of the hot air gun is wrapped in together. The upper edge of the part D of the fixed part is fixedly connected with one side of the fixed cover, a roller shaft penetrates between the other side of the fixed cover and the part D, a roller is installed on the roller shaft, the movable part is arranged below the fixed cover, the movable part and the part D of the fixed part are arranged side by side, the part D is connected with the movable part through a connecting rod, and bearing plates are arranged below the part D and the movable part. The two bearing plates are splayed. According to the handheld type special-shaped edge bonding machine, edge bonding at an included angle of a special-shaped plate is more convenient and faster through edge strips, errors are reduced, and therefore the plate machining efficiency is improved.

Owner:ZHONGSHAN XIWEI KITCHEN EQUIP MFG

Automatic joint device and process for one-step forming of inner rib pipe

The invention provides an automatic joint device and process for one-step forming of an inner rib pipe. The device comprises a hot air gun, transmission rollers, a discharge die, a spray water pipe, pinch rollers, an extruder, an electric three-jaw chuck and a rolling frame. The process comprises the following steps: S1, producing a PE melt by the extruder; S2, extruding the PE melt to a gap between the inner rib pipe and a bell and spigot by the discharge die, and melting the contact surface of the inner rib pipe and the chuck by the PE melt playing a role of a 'welding rod'; S3, flattening the melt at the gap between the inner rib pipe and the bell and spigot by using the pinch rollers; and S4, spraying water by the spray water pipe to cool the welding position for completing welding. Less manpower and time are required, and the working efficiency is high.

Owner:广州枫叶管业有限公司

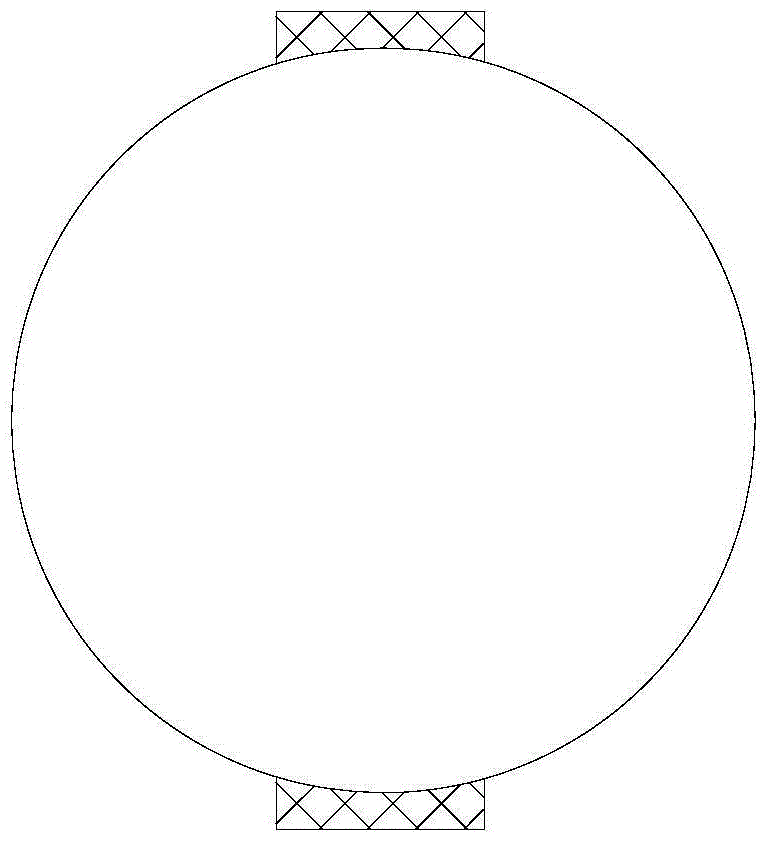

Ceramic support of heat gun heating core

PendingCN107949079AIncrease temperatureReduce surface temperatureHeater elementsCeramic bracketsEngineering

The invention discloses a ceramic support of a heat gun heating core, and relates to the field of electric tools. The ceramic support is of a cylinder structure, wherein a plurality of installation supports are uniformly arranged on the cylinder, a spiral installation groove is arranged on each installation support, a heating wire is wound on the spiral installation grooves of the installation supports in a spiral manner, one end of the cylinder is an air inlet, an air ducting plane that is an inclined surface with tapered edges is arranged at the air inlet, a wire introduction hole is formedin the air inlet, and the electric heating wire enters the installation supports via the wire introduction hole. The ceramic support of the heat gun heating core provided by the invention has the advantages of improving the temperature of the air outlet of the heat gun, and meanwhile also reducing the surface temperature of the electric wire at the air outlet and reducing the difference between previous and after temperatures of the heating wire and prolonging the service life.

Owner:上海捷科工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com