Method for preparing metal powder with low iron content by treating a waste circuit board component through mechanical physical method

A technology for waste circuit boards and metal powders is applied in the field of electronic waste recycling, which can solve the problems of high cost, serious environmental pollution, and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Use a heat gun to disassemble components from waste desktop computer circuit boards at 450°C. Various components were taken in proportion for component analysis and determination. The comprehensive results are as follows: iron content is 22.93% (nearly one of which is elemental), copper content is 32.65% (of which eight is elemental), aluminum content is 8.53%, silicon The content is 26.92%.

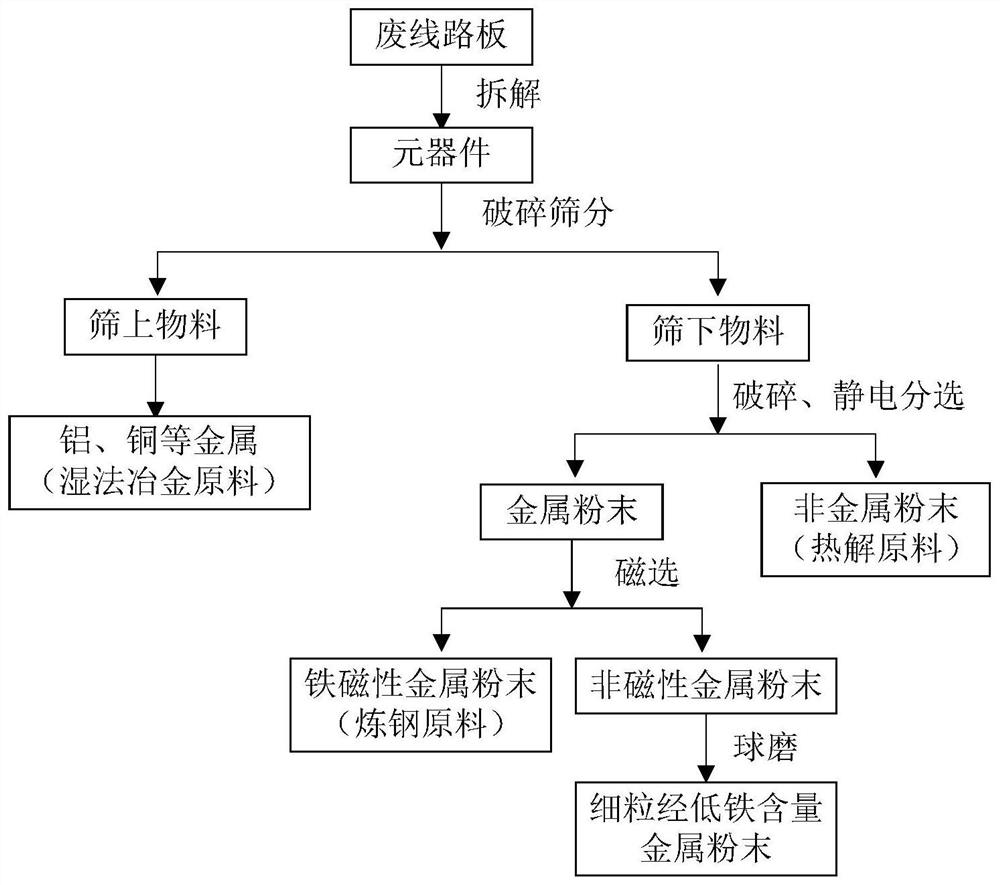

[0027] Such as figure 1 As shown in the process flow, the disassembled desktop computer components are initially crushed with a shear crusher, and then sieved with a 5mm sieve to obtain copper (accounting for 33.49% of the total copper), aluminum (accounting for 85.83% of the total amount of aluminum) mainly on the sieve metal particles, and under the sieve metal and non-metal mixed particles.

[0028] The metal and non-metal mixed particles under the sieve are crushed for the second time by a universal crusher to obtain a mixed powder with a particle size of 0.5mm, and then the...

Embodiment 2

[0030] Use a heat gun to disassemble components from waste laptop circuit boards at 400°C. Various components were taken in proportion for component analysis and determination. The comprehensive results are as follows: iron content is 23.59% (less than one of which is elemental), copper content is 33.28% (nearly nine of which is elemental), and aluminum content is 7.37%. , the silicon content is 29.32%.

[0031] Such as figure 1As shown in the process flow, the dismantled waste notebook computer components are initially crushed by a shear crusher, and then sieved by a 5mm sieve to obtain copper (accounting for 35.37% of the total amount of copper), aluminum ( Accounting for 87.49% of the total amount of aluminum) mainly on the sieve metal particles, and under the sieve metal and non-metal mixed particles. The metal and non-metal mixed particles under the sieve are crushed for the second time by a universal crusher to obtain a mixed powder with a particle size of 0.5mm, and t...

Embodiment 3

[0034] Use a heat gun to disassemble components from waste TV circuit boards at 350°C. Various components were taken in proportion for component analysis and determination. The comprehensive results are as follows: iron content is 20.46% (nearly 10% of which), copper content is 35.71% (nearly 90% of which is elemental), aluminum content is 8.52%, silicon The content is 27.84%.

[0035] Such as figure 1 As shown in the process flow, the dismantled waste TV components are initially crushed with a shear crusher, and then sieved with a 5mm sieve to obtain copper (accounting for 37.72% of the total amount of copper), aluminum ( Accounting for 90.62% of the total amount of aluminum) mainly on the sieve metal particles, and under the sieve metal and non-metal mixed particles.

[0036] The metal and non-metal mixed particles under the sieve are crushed for the second time by a universal crusher to obtain a mixed powder with a particle size of 0.5mm, and then the metal powder and non...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com