Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3917results about "Electronic waste recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secondary market and vending system for devices

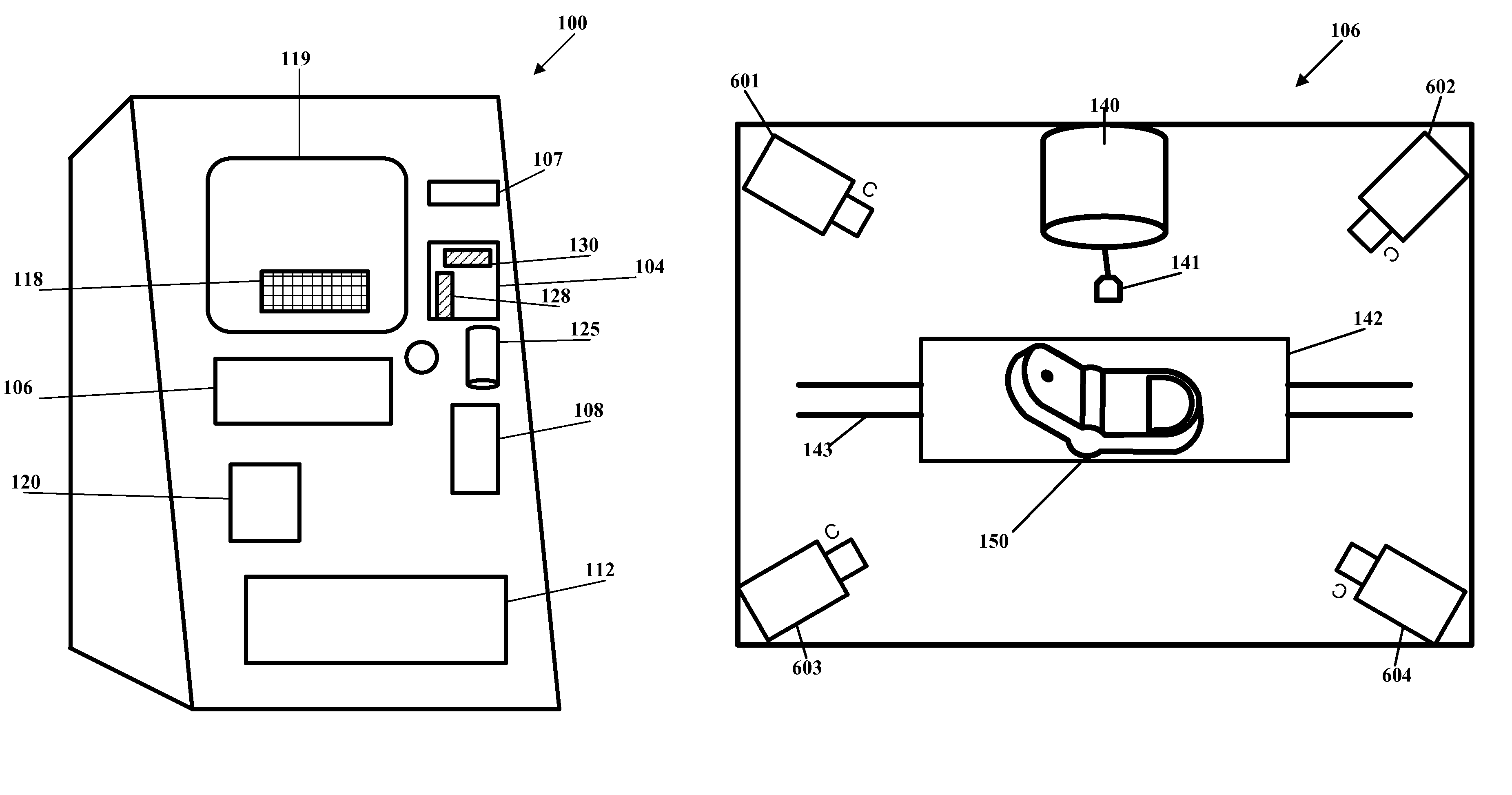

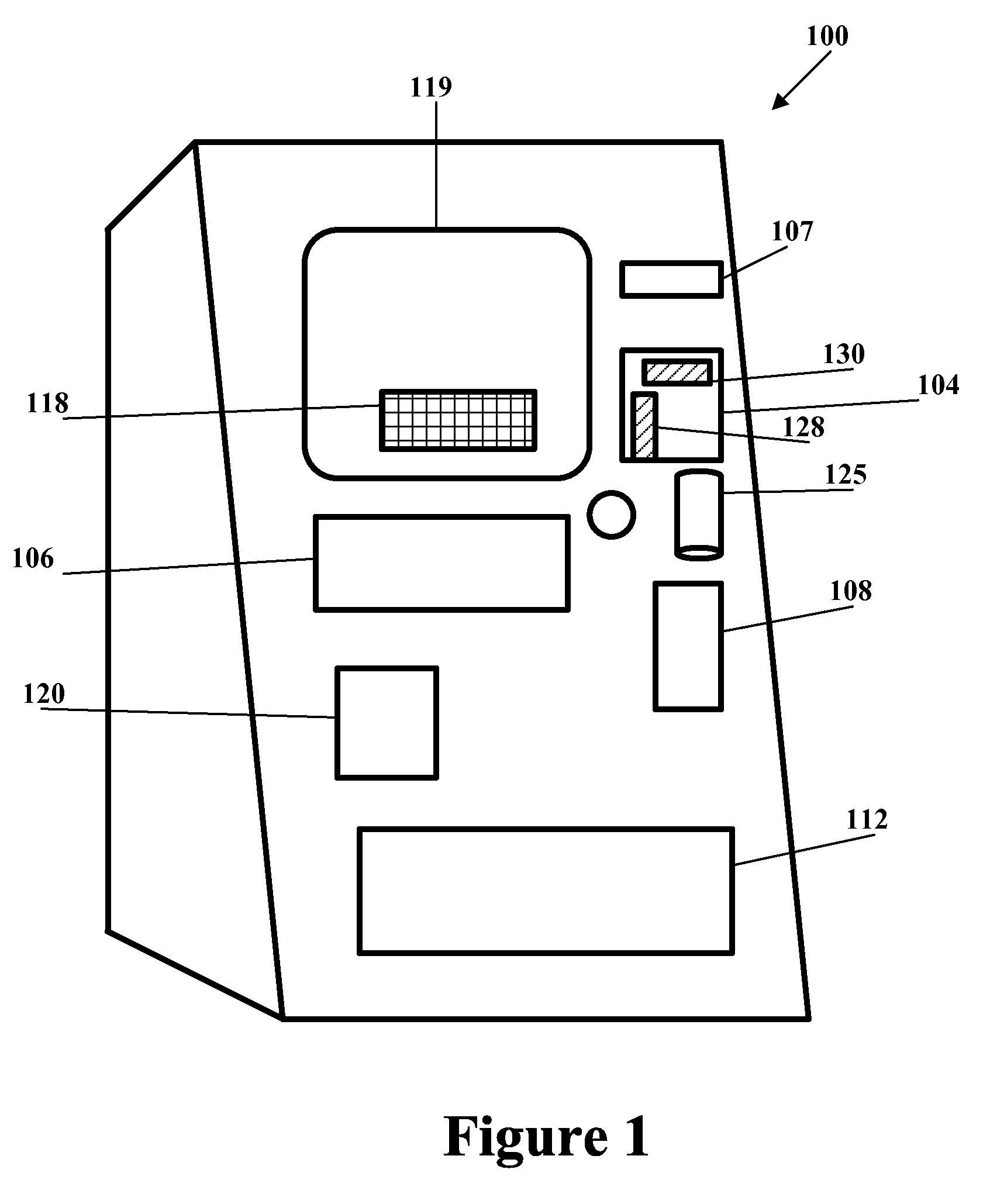

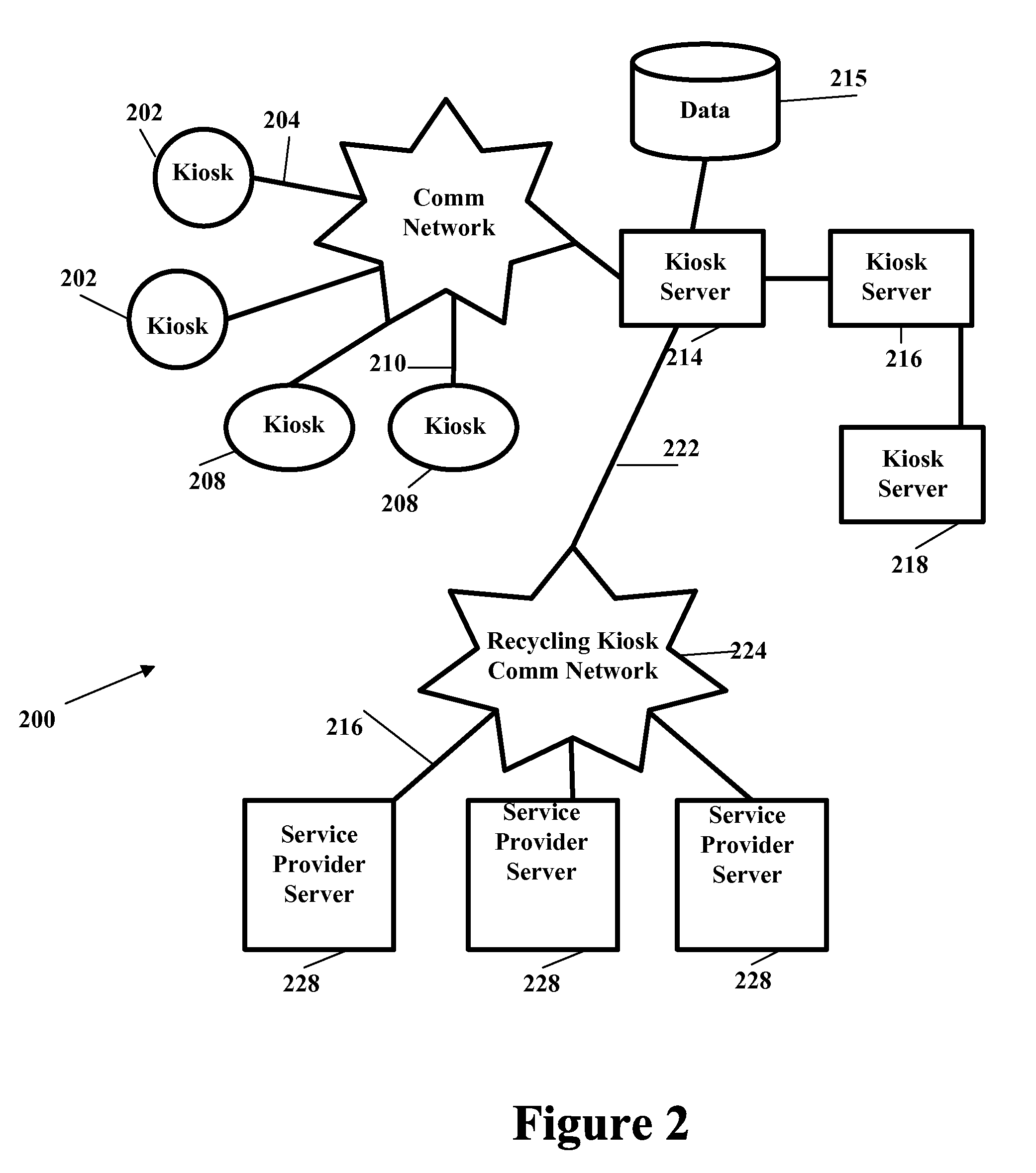

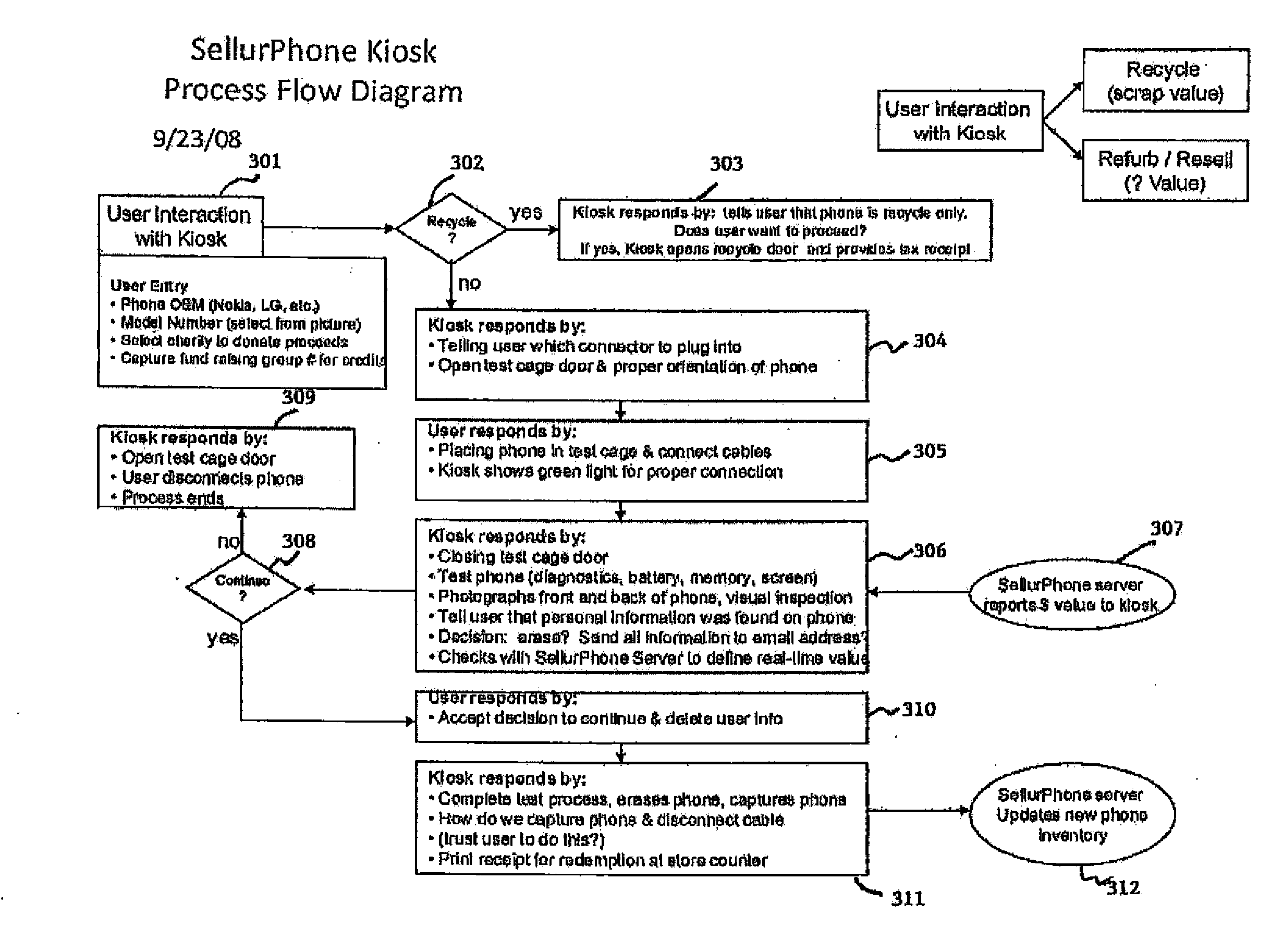

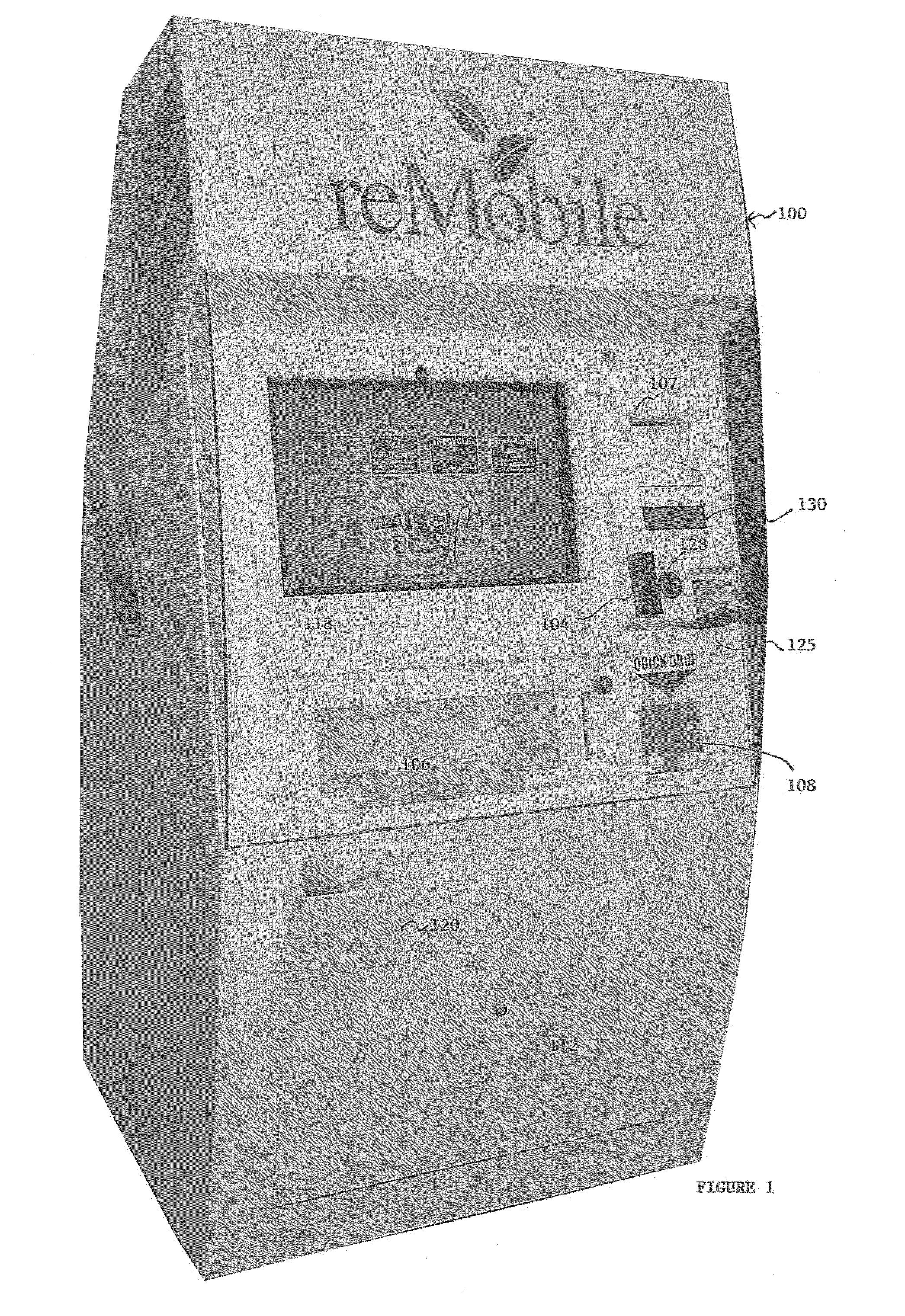

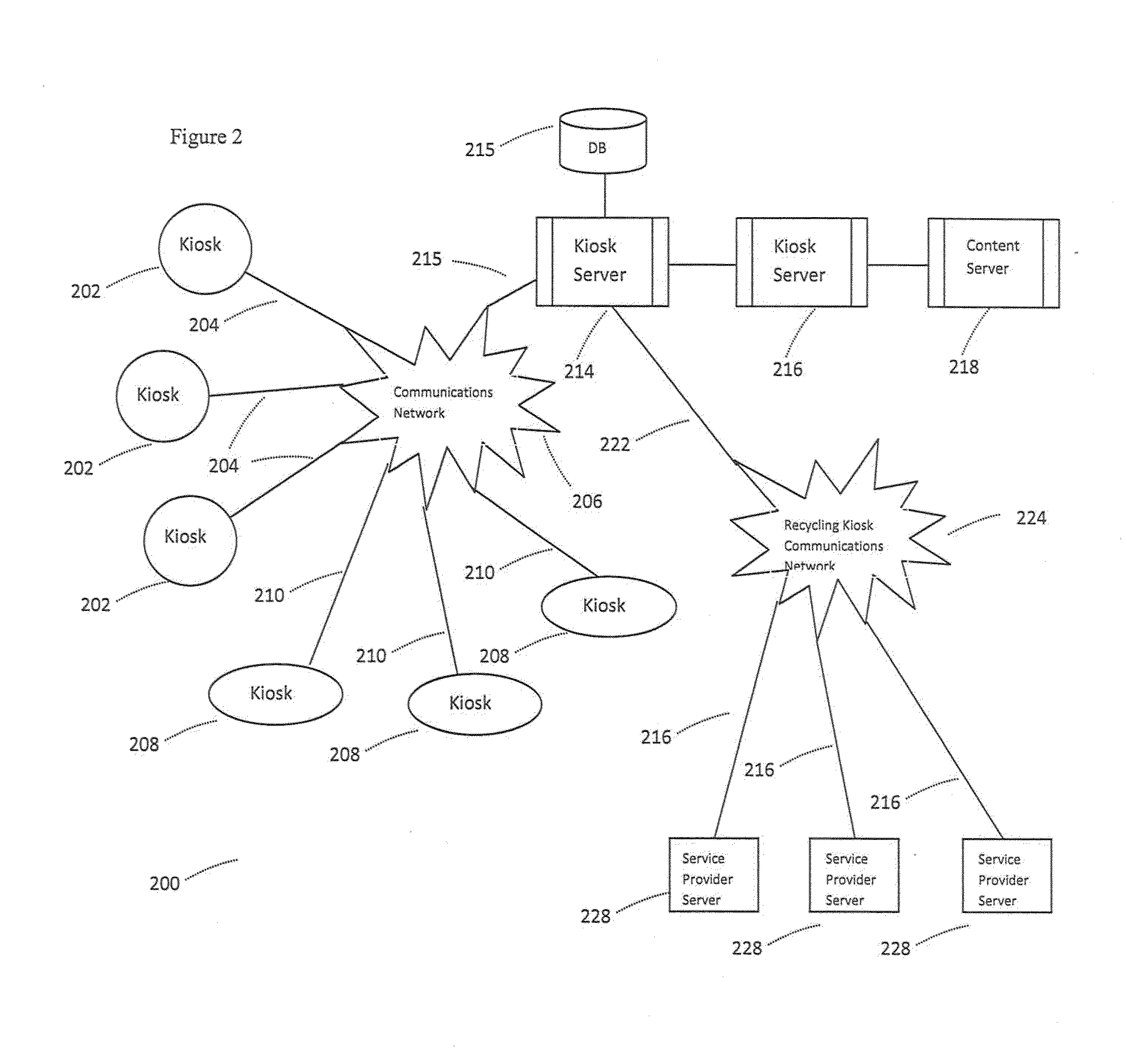

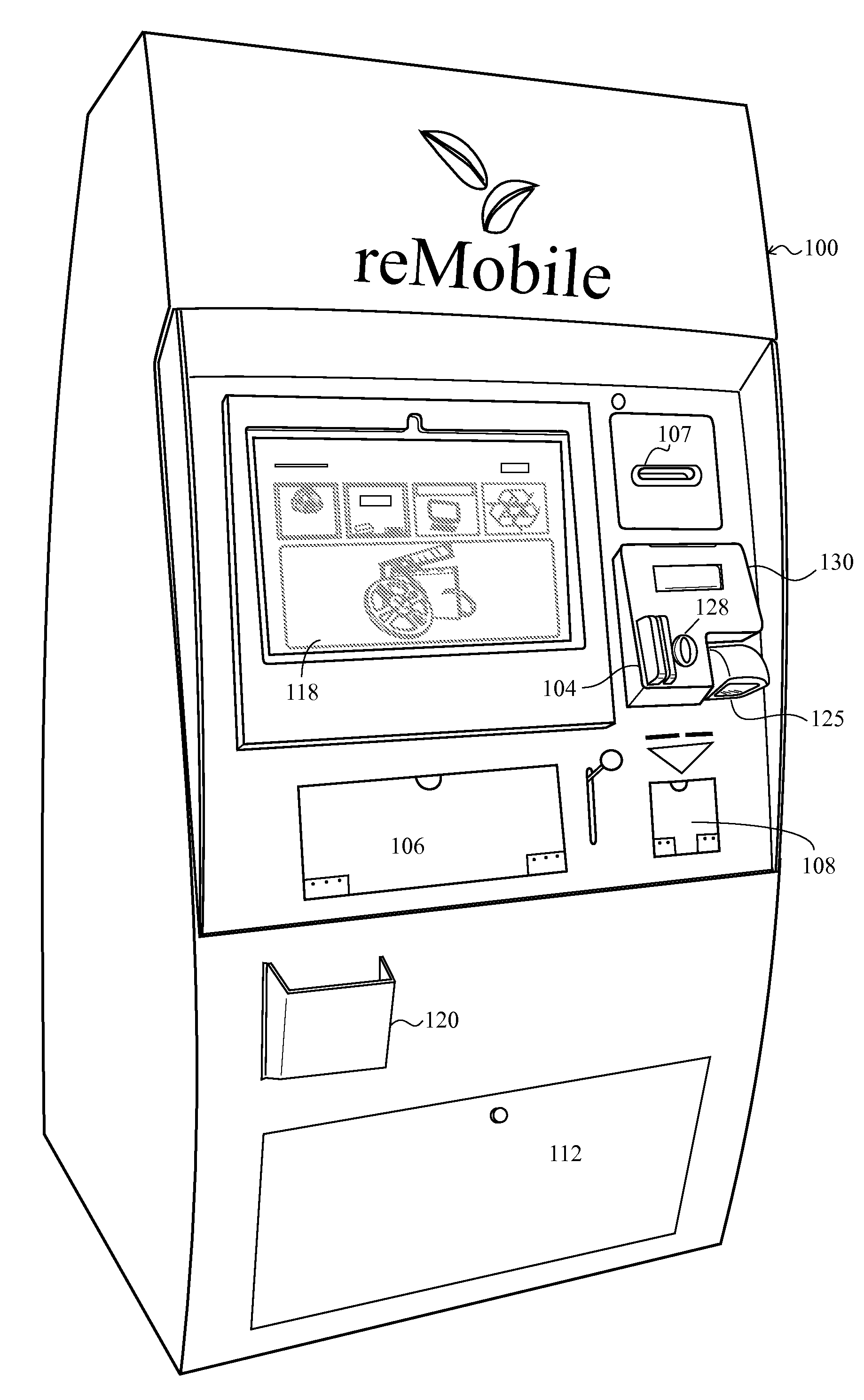

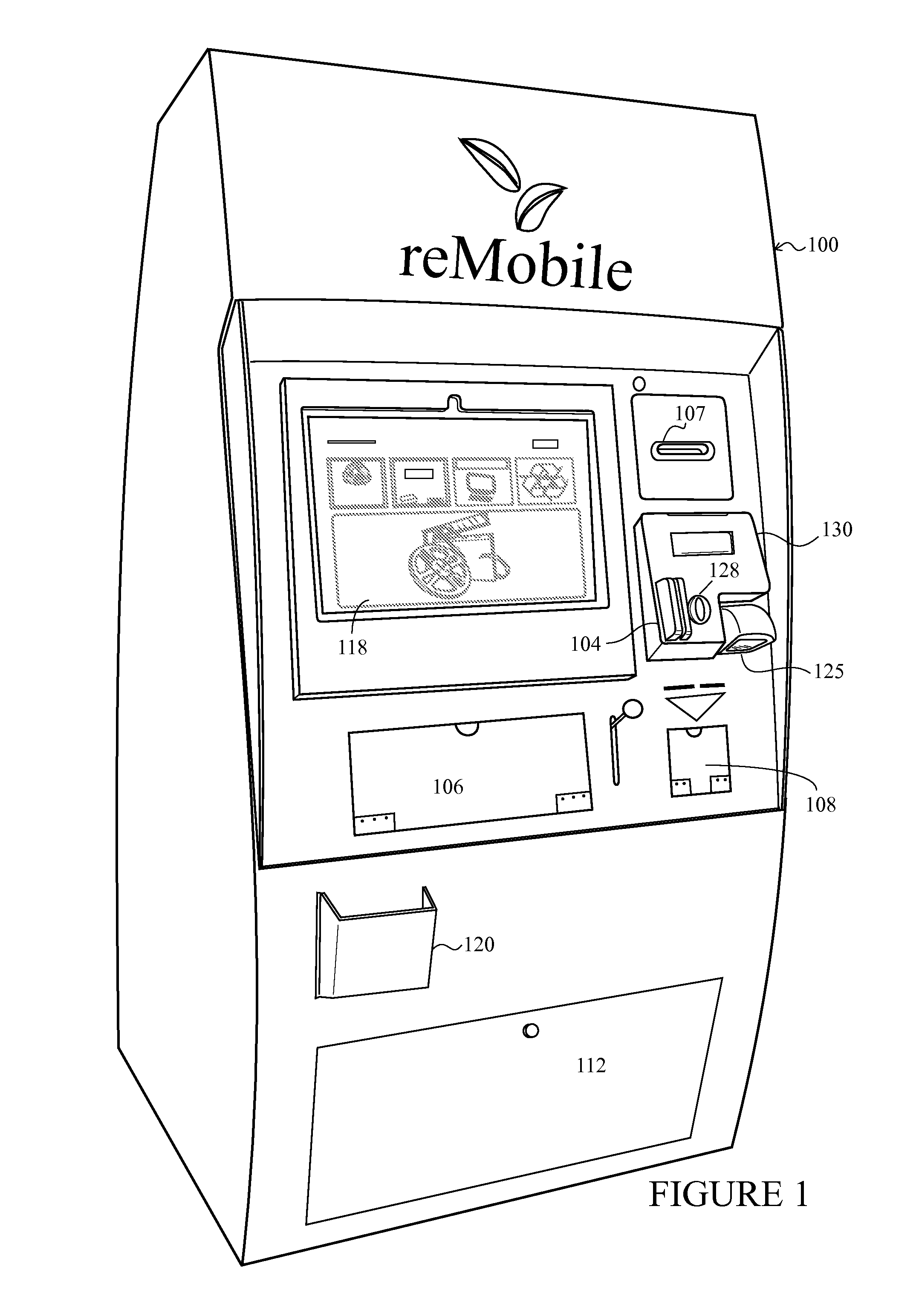

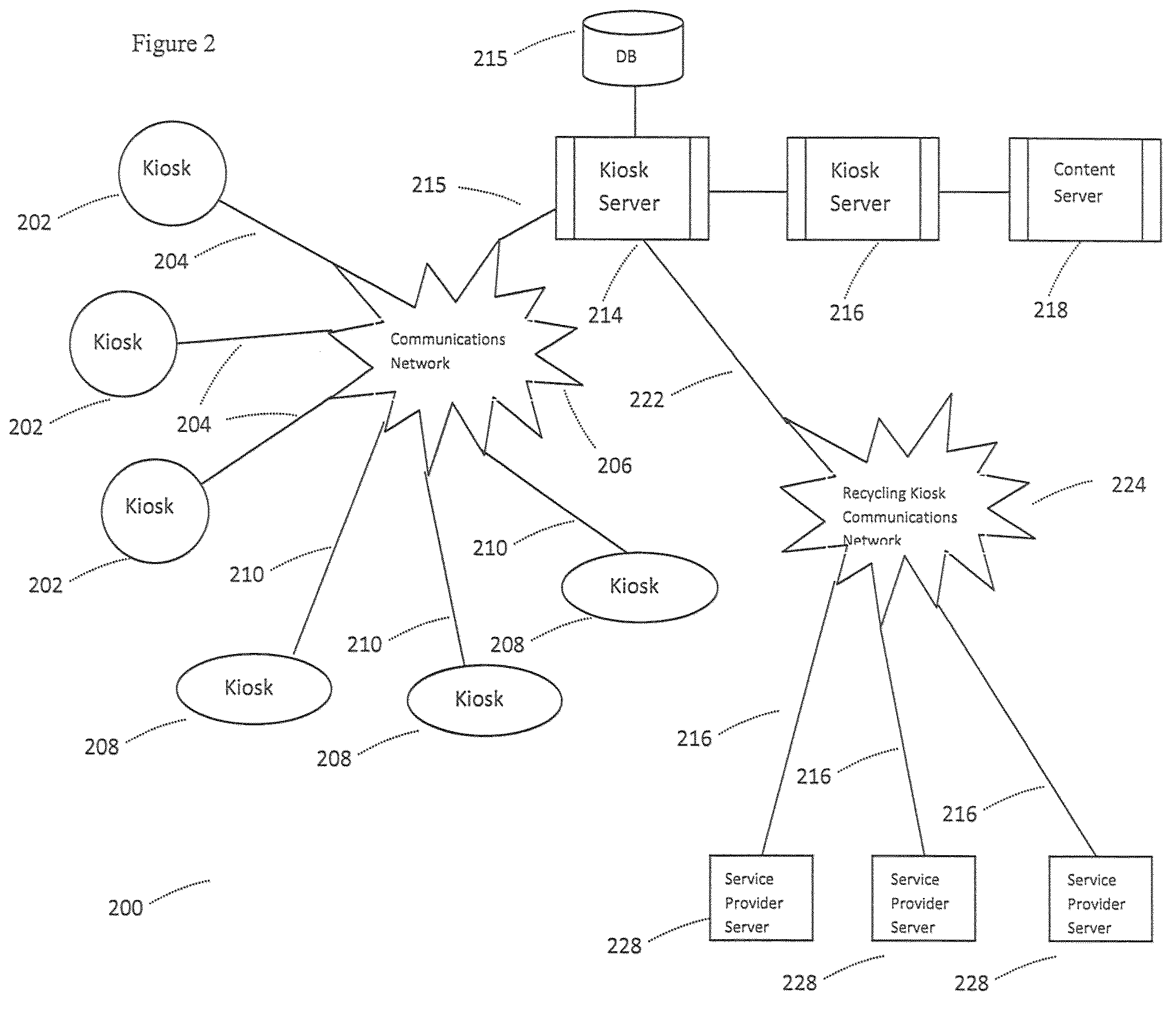

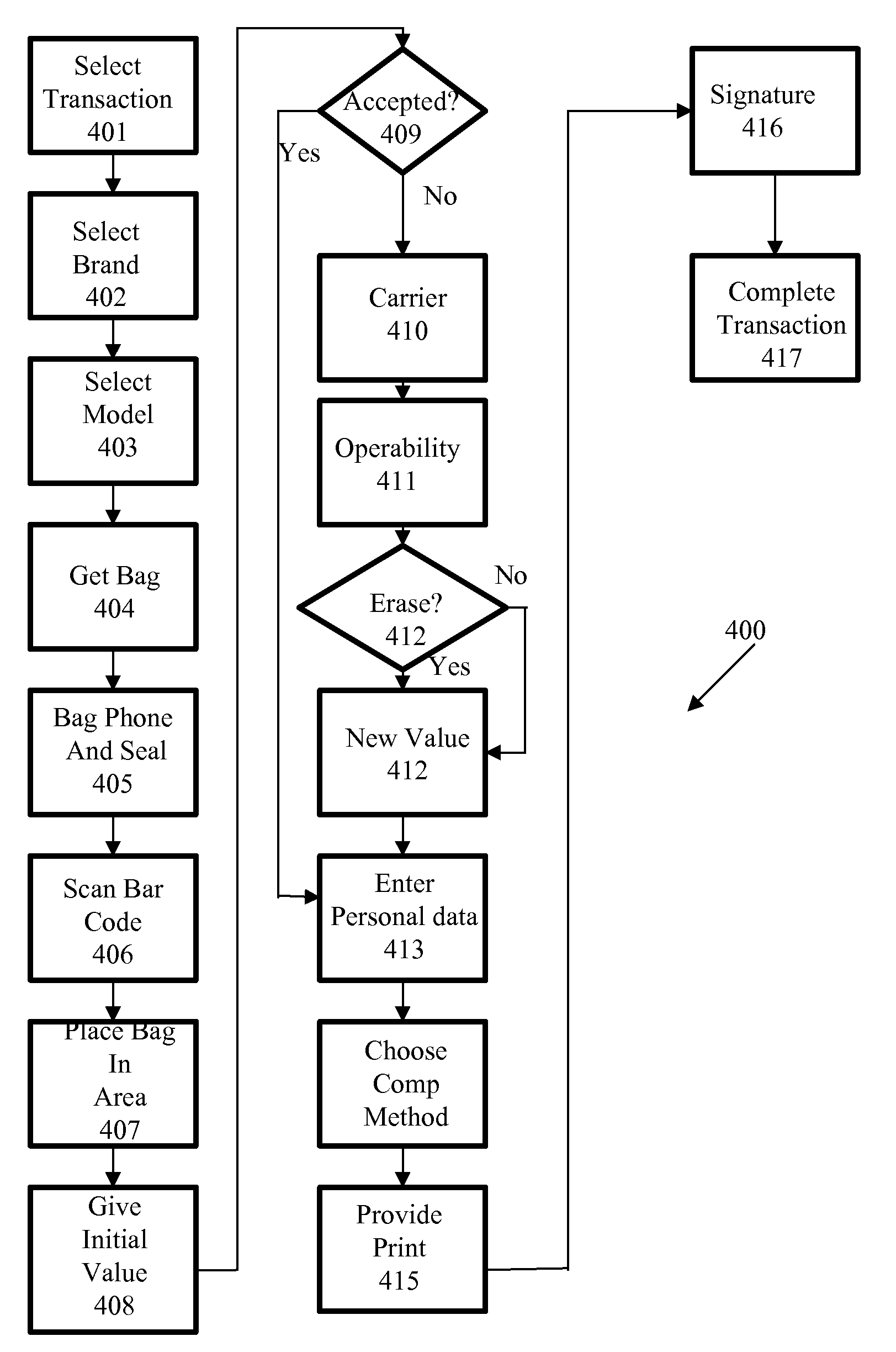

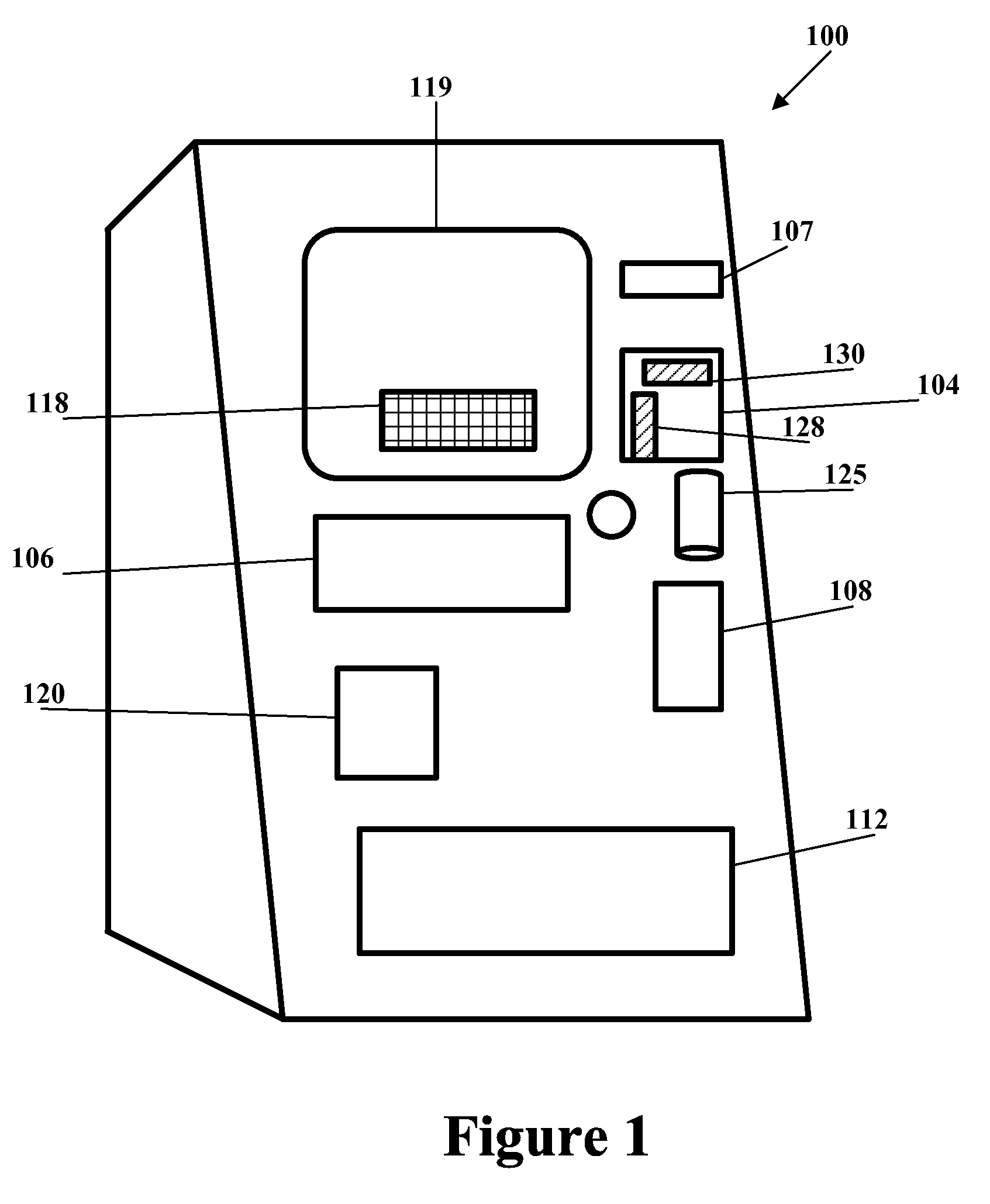

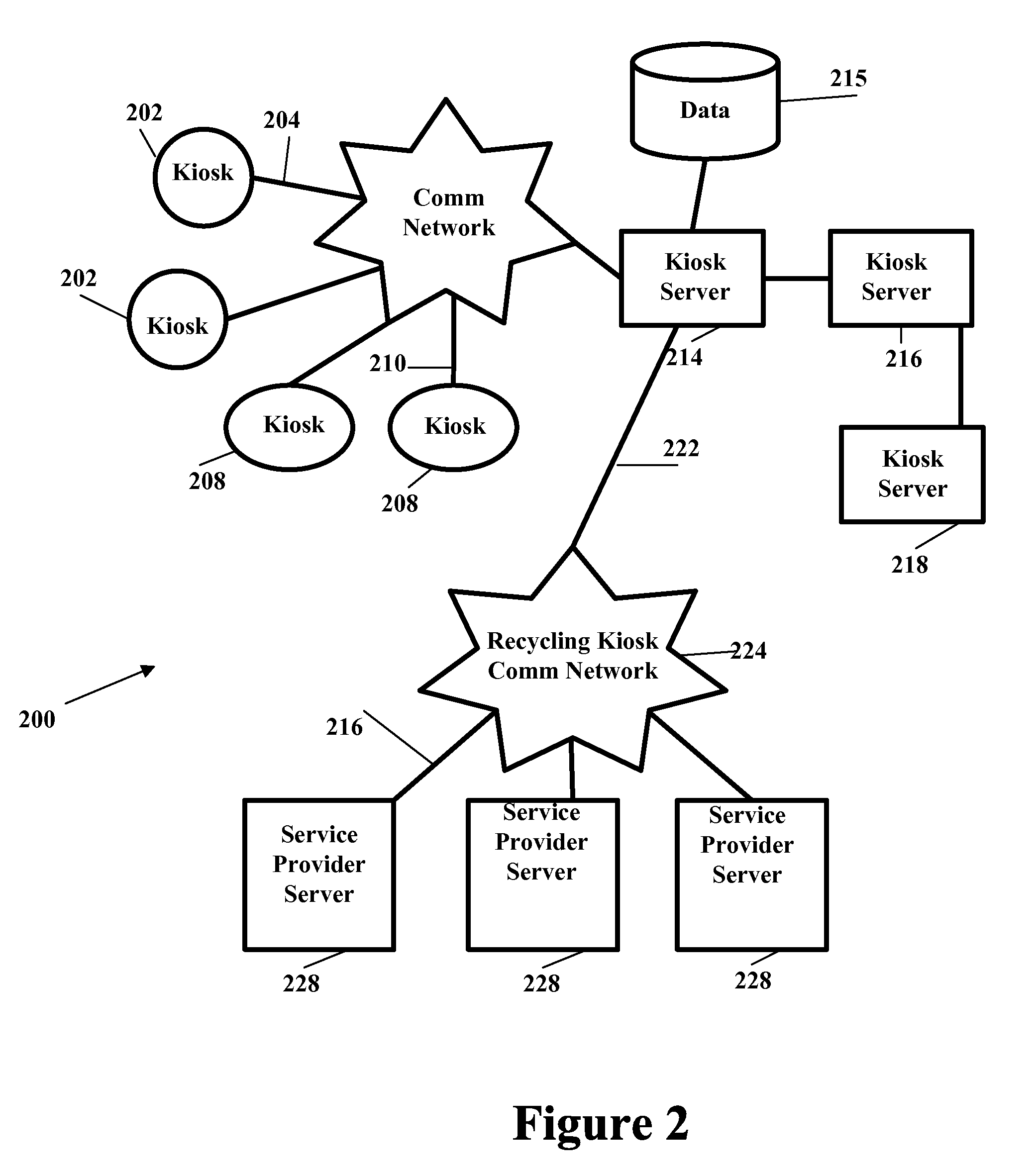

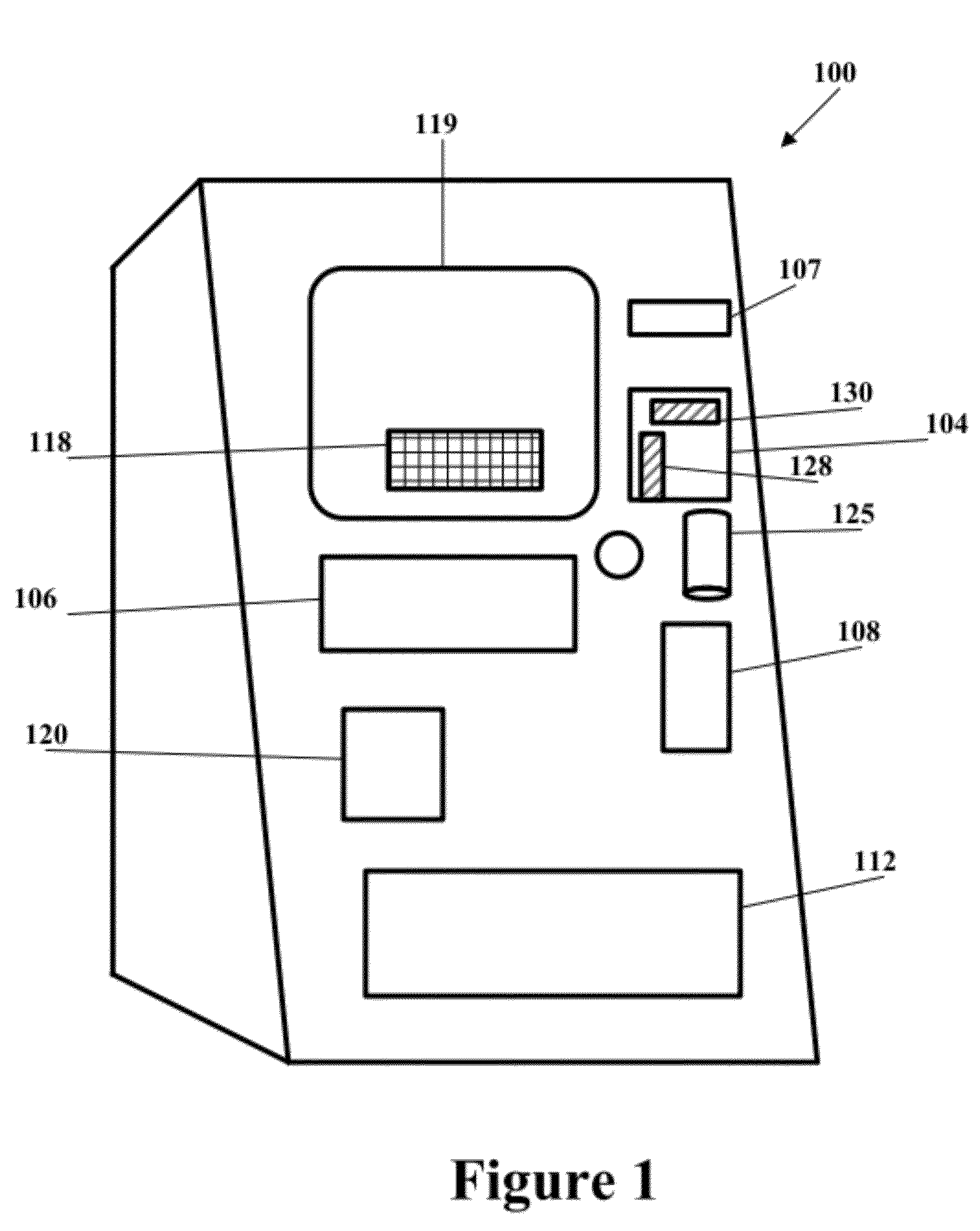

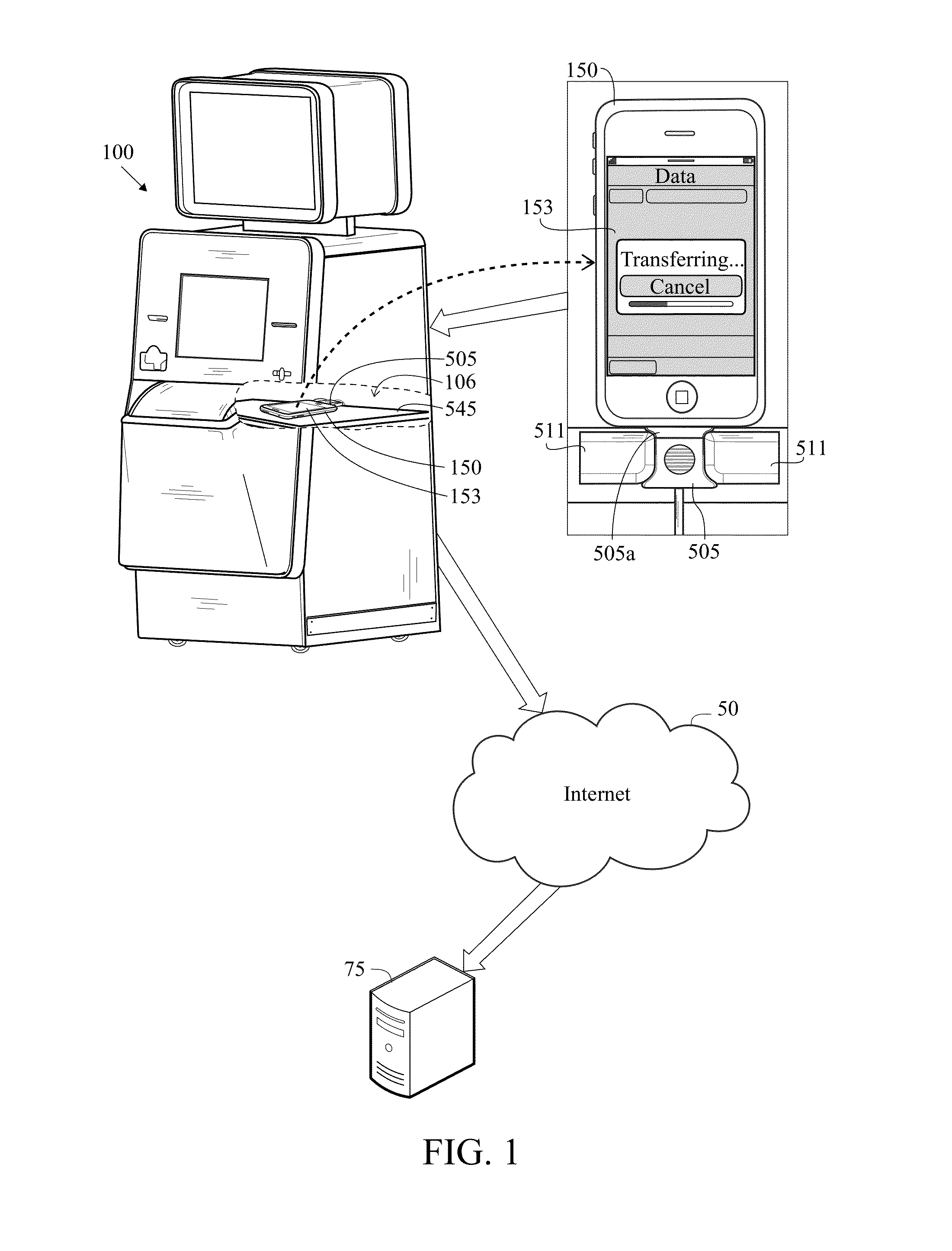

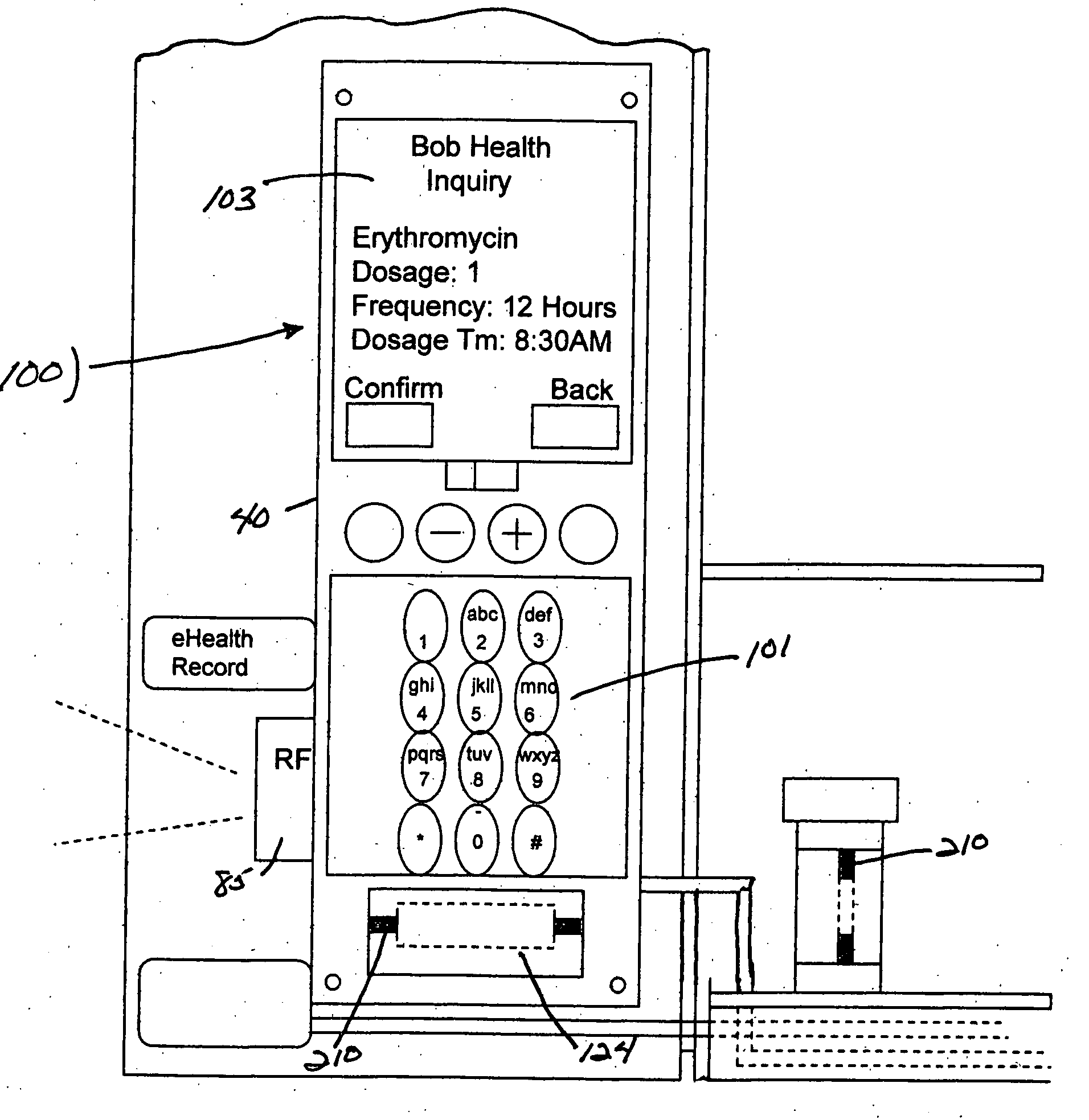

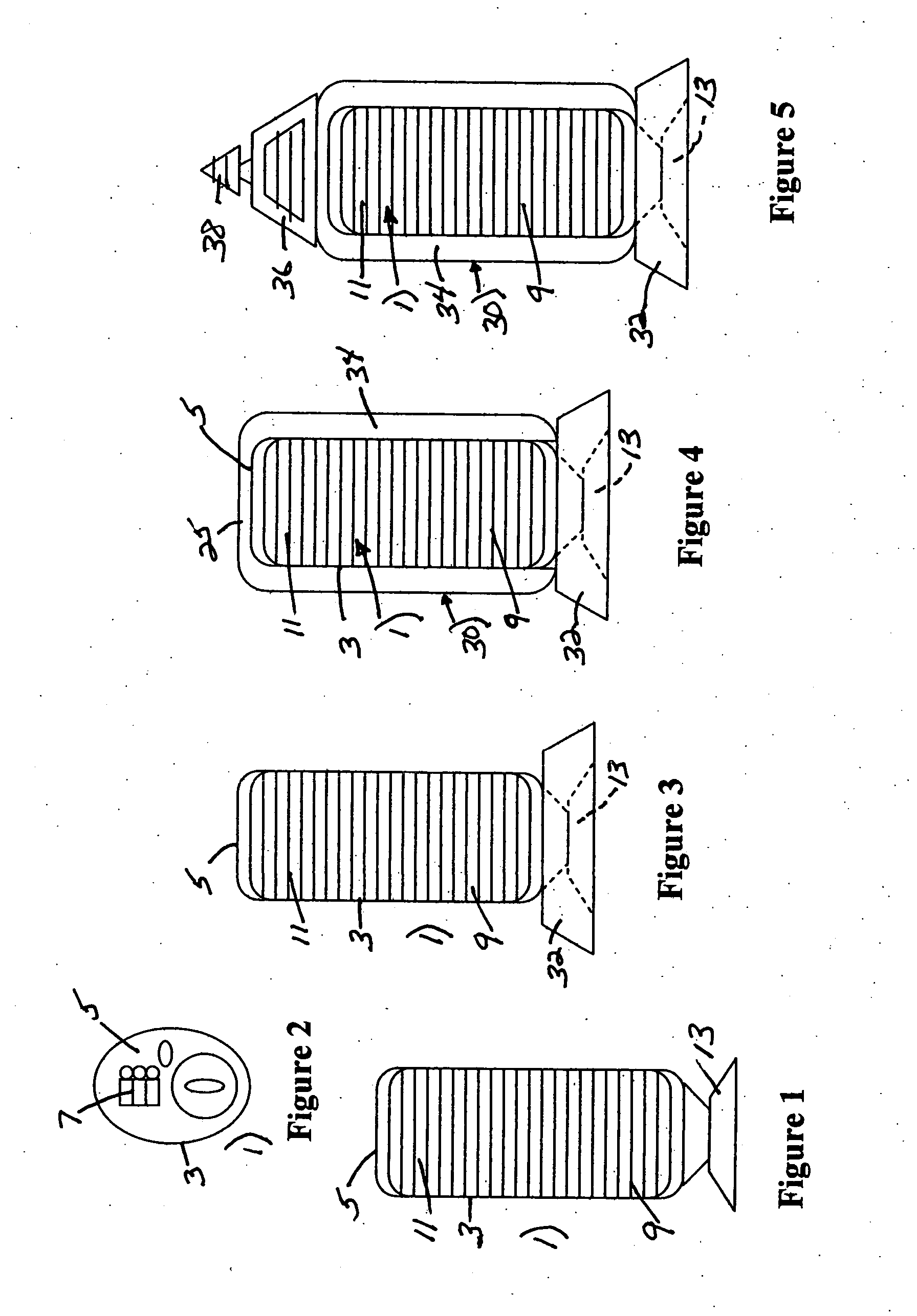

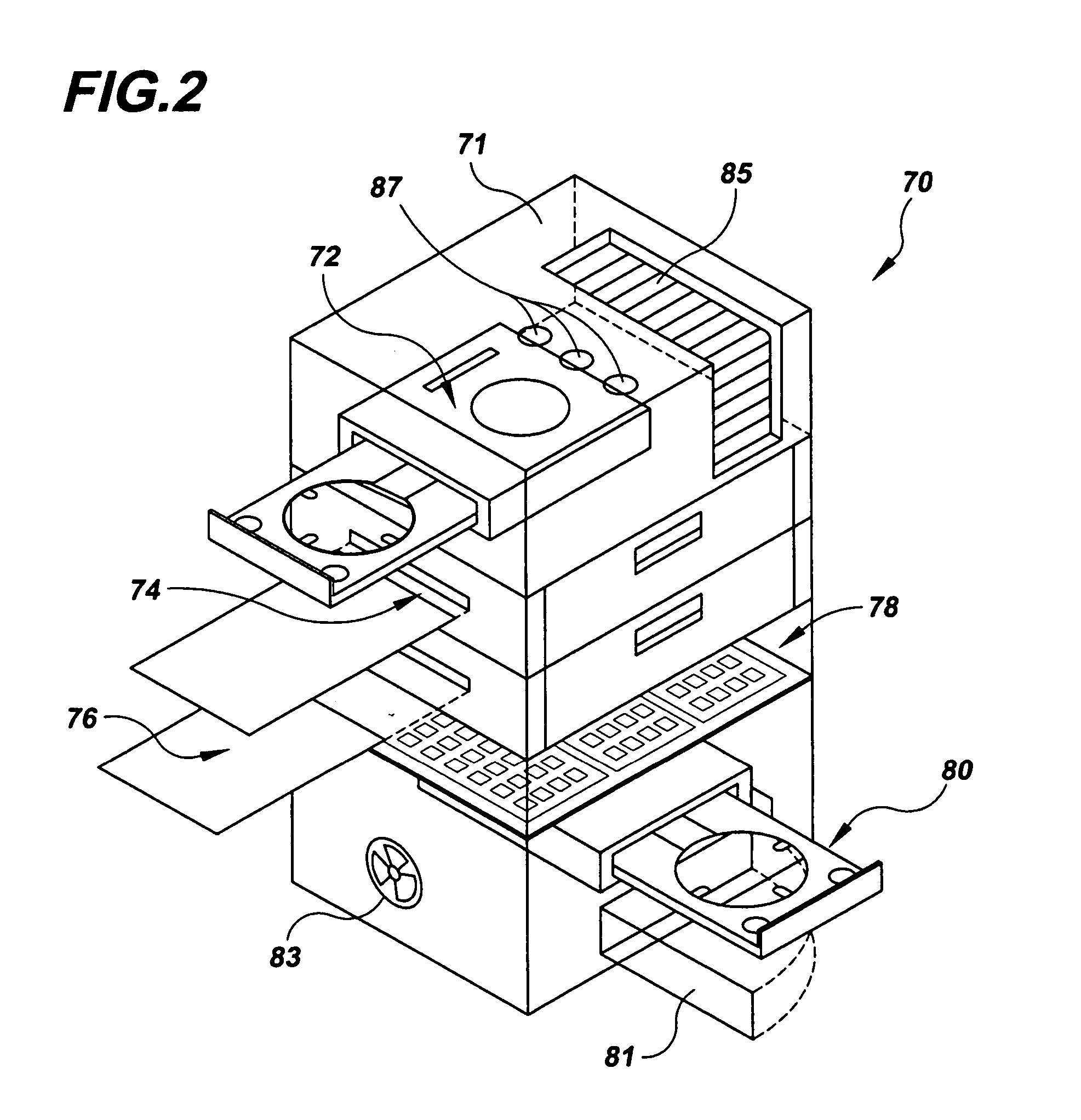

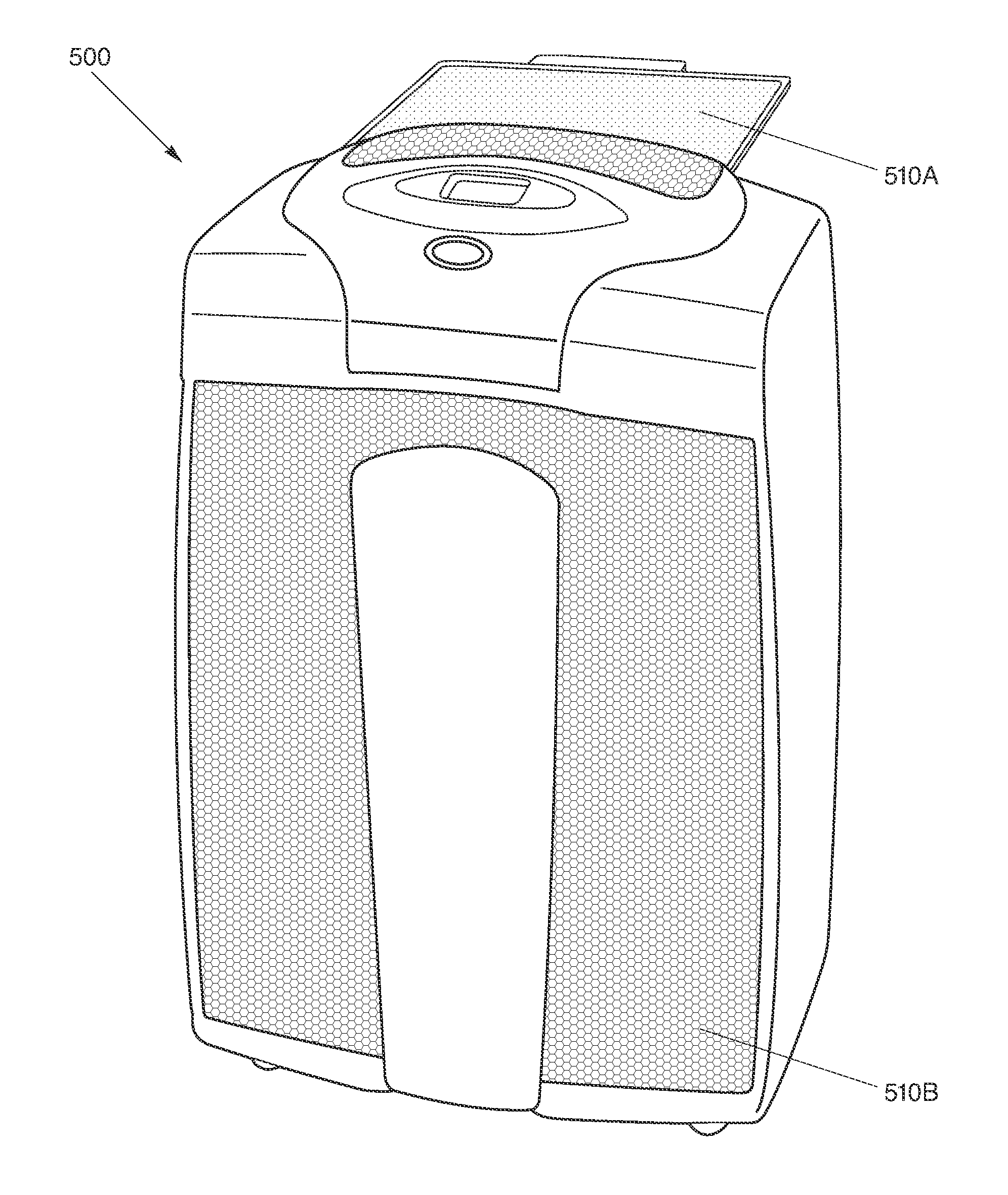

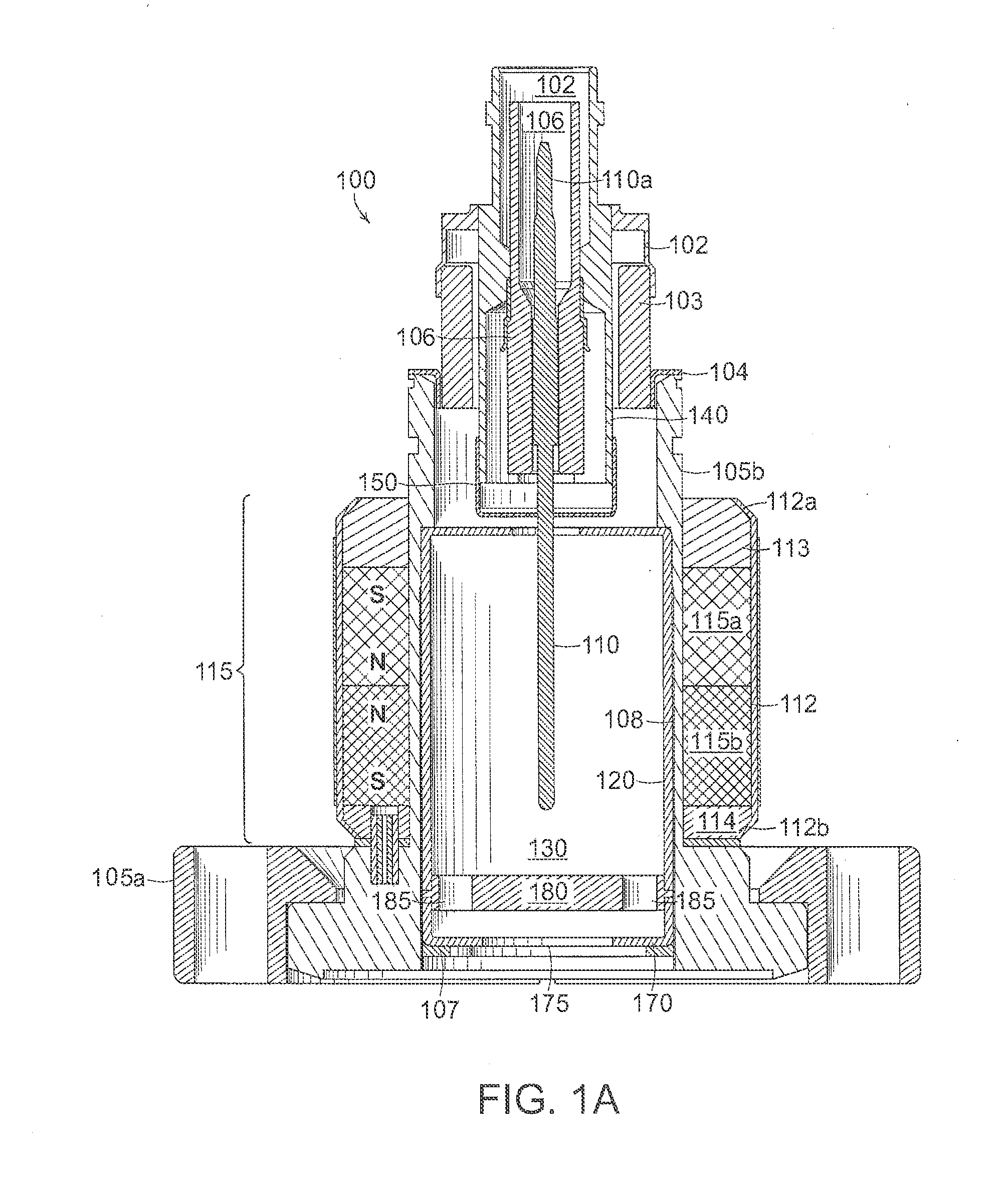

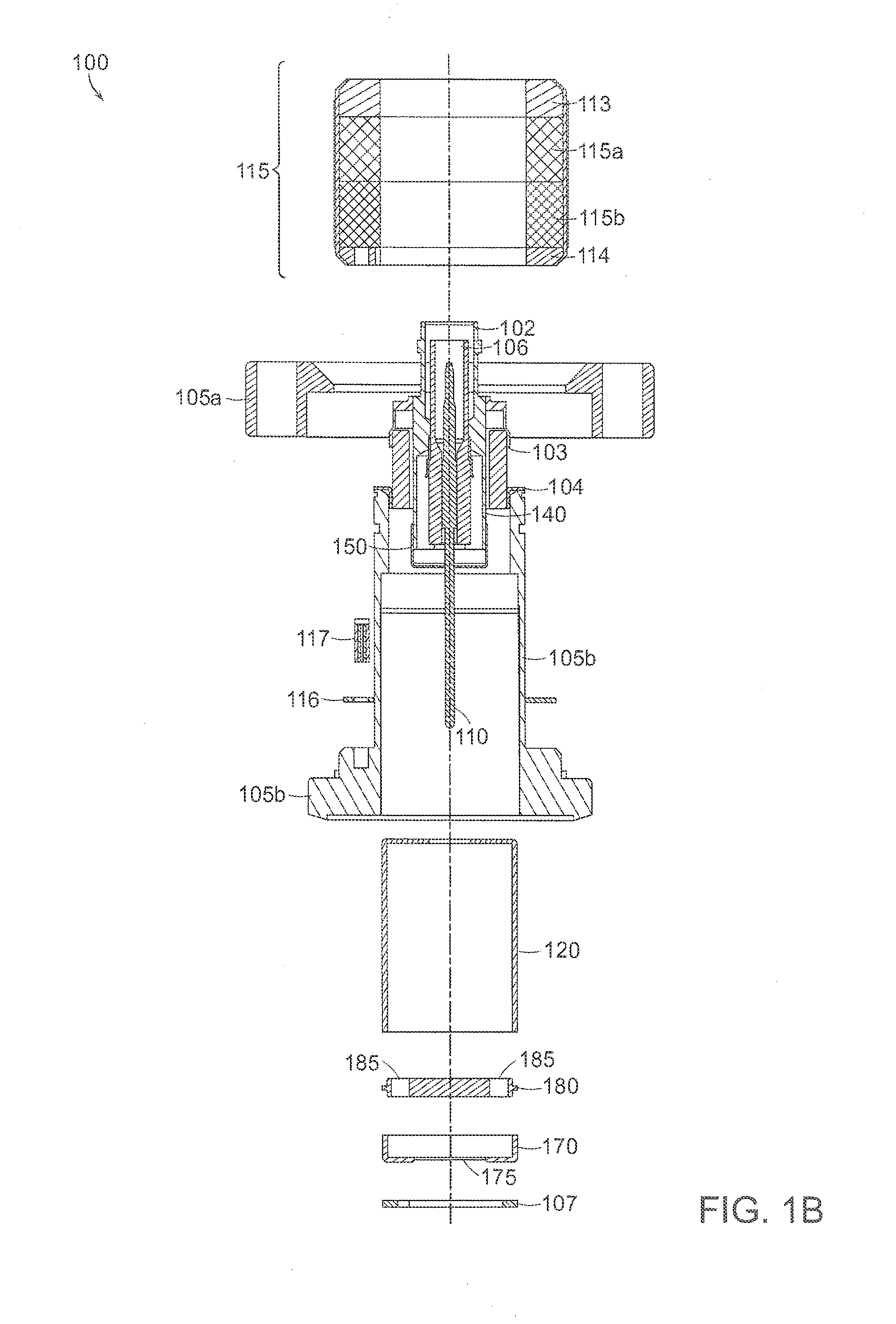

A recycling kiosk for recycling and financial remuneration for submission of a mobile telephone is disclosed herein. The recycling kiosk includes an inspection area with at least one camera and a plurality of electrical connectors in order to perform a visual analysis and an electrical analysis of the mobile telephone for determination of a value of the mobile telephone. The recycling kiosk also includes a processor, a display and a user interface.

Owner:ECOATM LLC

Secondary market and vending system for devices

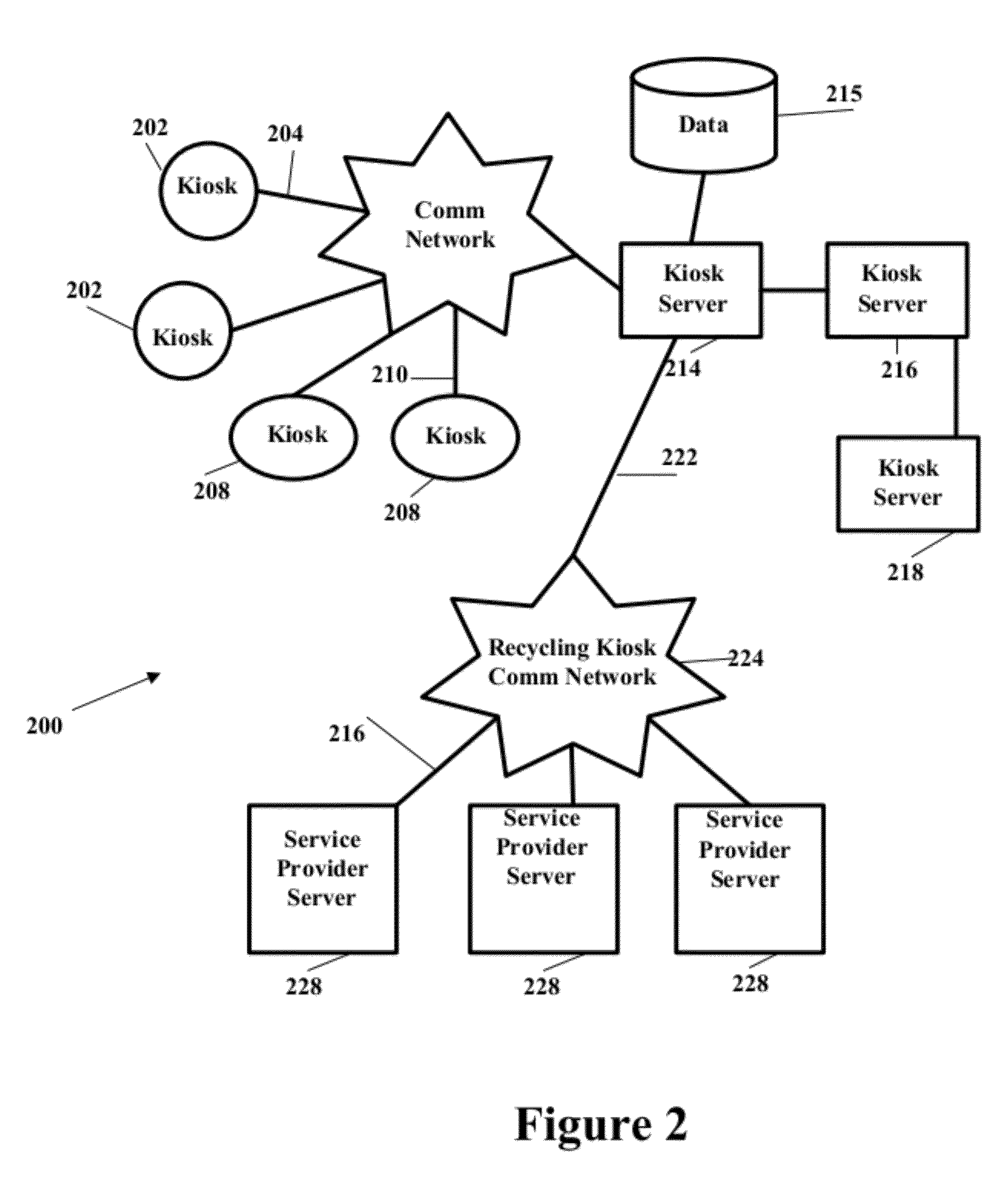

The system enables one to securely recycle an electronic device in a publicly accessible location. In particular, the embodiment described may be used by a mobile phone owner to submit his / her mobile phone for recycling via an electronic kiosk and receive compensation in some form. The compensation might be dispersed via cash, voucher, credit or debit card, or other magnetic or electronic transaction methods.

Owner:ECOATM LLC

Secondary market and vending system for devices

The system enables one to securely recycle an electronic device in a publicly accessible location. In particular, the embodiment described may be used by a mobile phone owner to submit his / her mobile phone for recycling via an electronic kiosk and receive compensation in some form. The compensation might be dispersed via cash, voucher, credit or debit card, or other magnetic or electronic transaction methods.

Owner:ECOATM LLC

Secondary Market And Vending System For Devices

A recycling kiosk for recycling and financial remuneration for submission of a mobile telephone is disclosed herein. The recycling kiosk includes an inspection area with at least one camera and a plurality of electrical connectors in order to perform a visual analysis and an electrical analysis of the mobile telephone for determination of a value of the mobile telephone. The recycling kiosk also includes a processor, a display and a user interface.

Owner:ECOATM LLC

Apparatus and method for recycling mobile phones

A recycling kiosk for recycling and financial remuneration for submission of a mobile telephone is disclosed herein. The recycling kiosk includes an inspection area with a plurality of white walls in order to perform a visual analysis of the mobile telephone for determination of a value of the mobile telephone. The visual analysis inspects the LCD screen of the mobile phone to determine if the LCD screen is damaged. The recycling kiosk also includes a processor, a display and a user interface.

Owner:ECOATM LLC

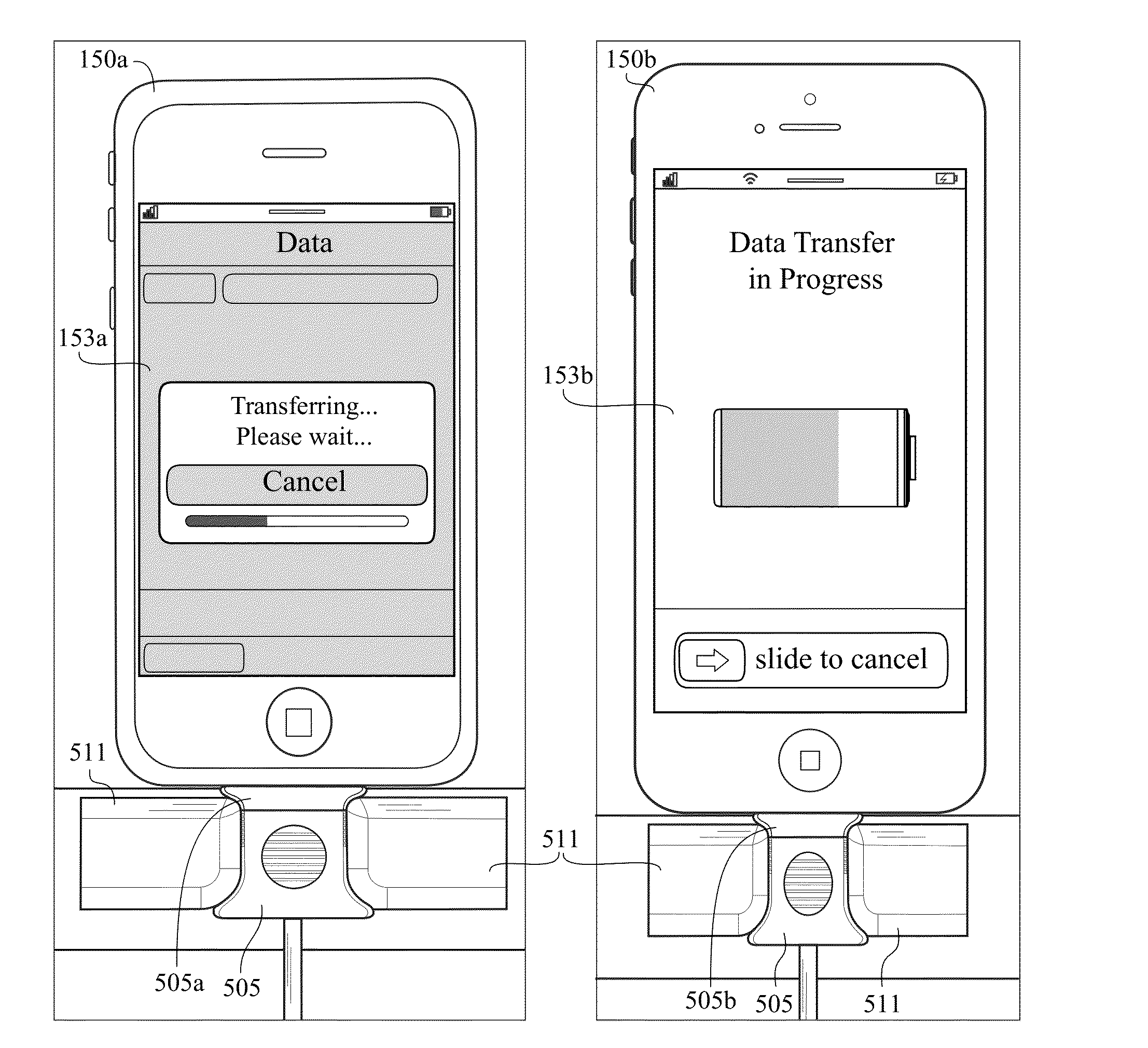

Method And Apparatus For Removing Data From A Recycled Electronic Device

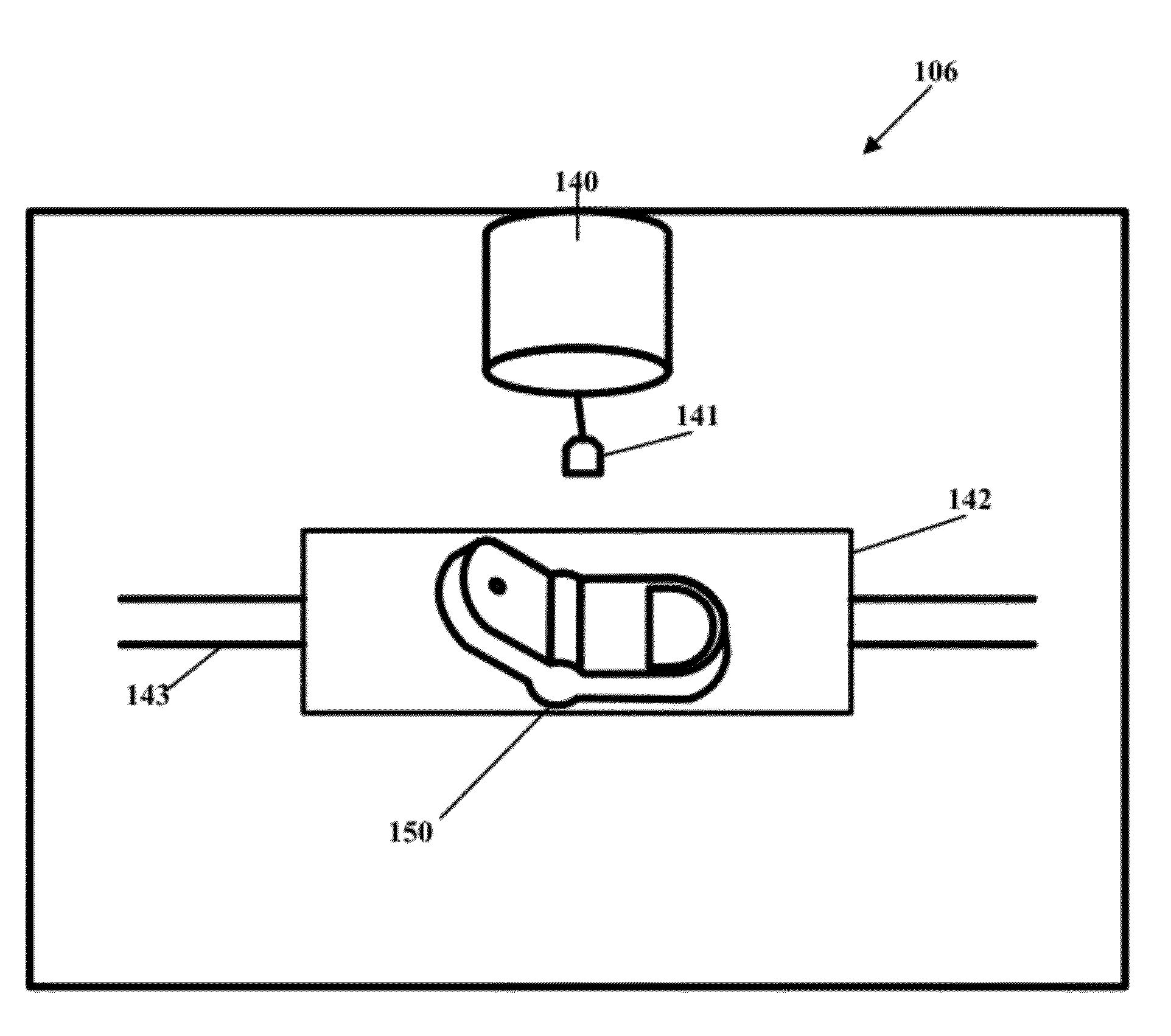

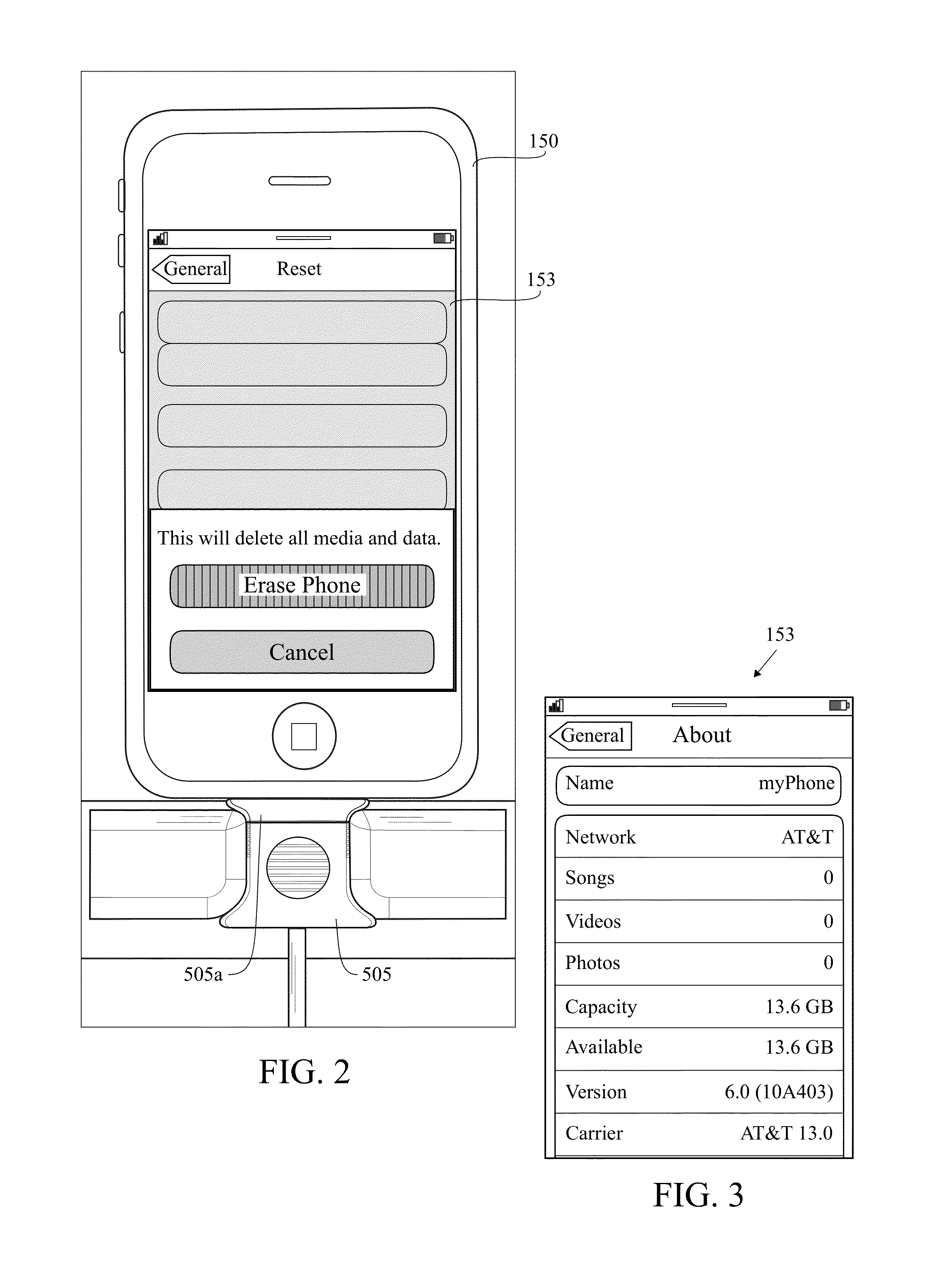

A method and apparatus for transferring data from a recycled electronic device such as a mobile phone is disclosed herein. The apparatus is preferably a recycling kiosk which includes electrical connectors and an inspection area with an upper chamber, a lower chamber, a transparent plate and at least one camera in order to perform a visual analysis and an electrical analysis of the electronic device for determination of a value of the electronic device. The recycling kiosk also includes a processor managing the transfer of data.

Owner:ECOATM

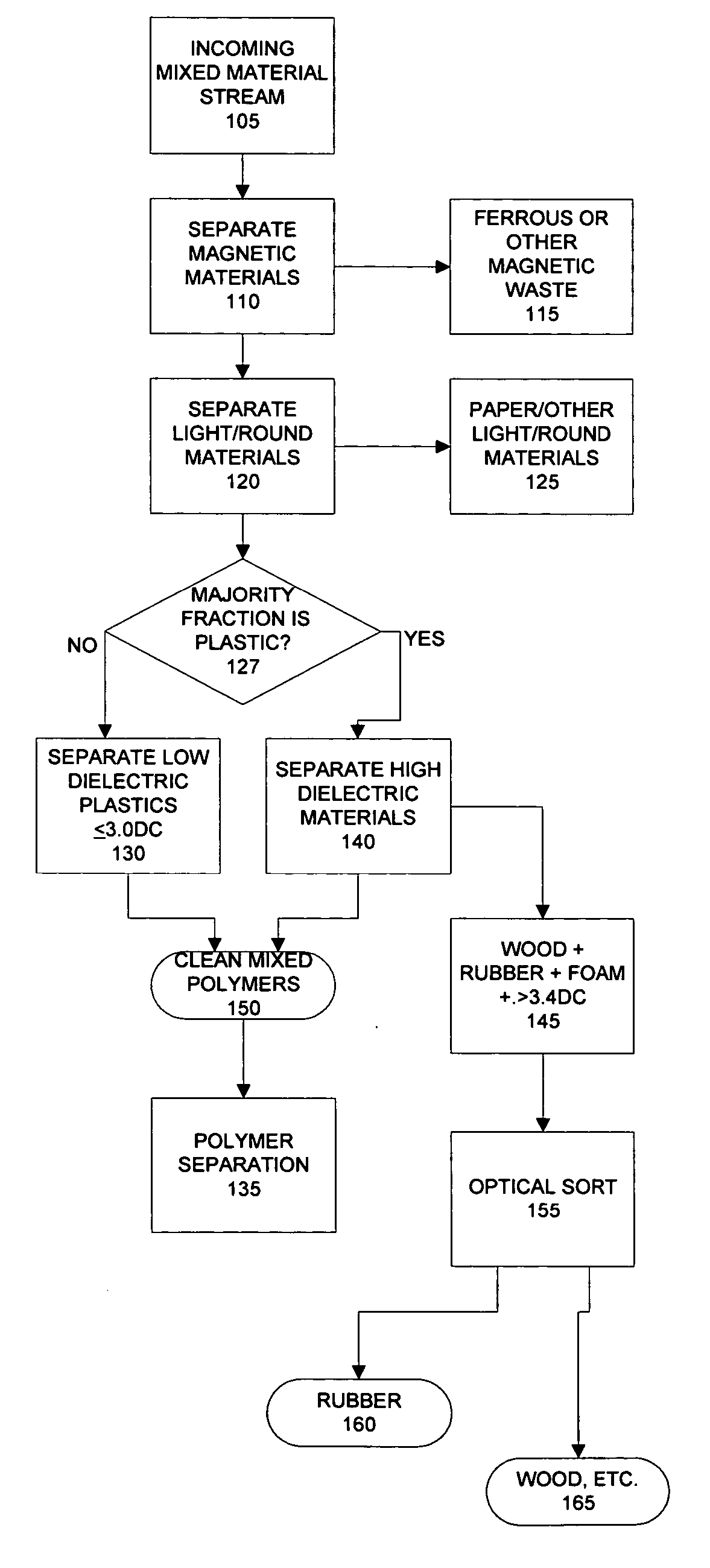

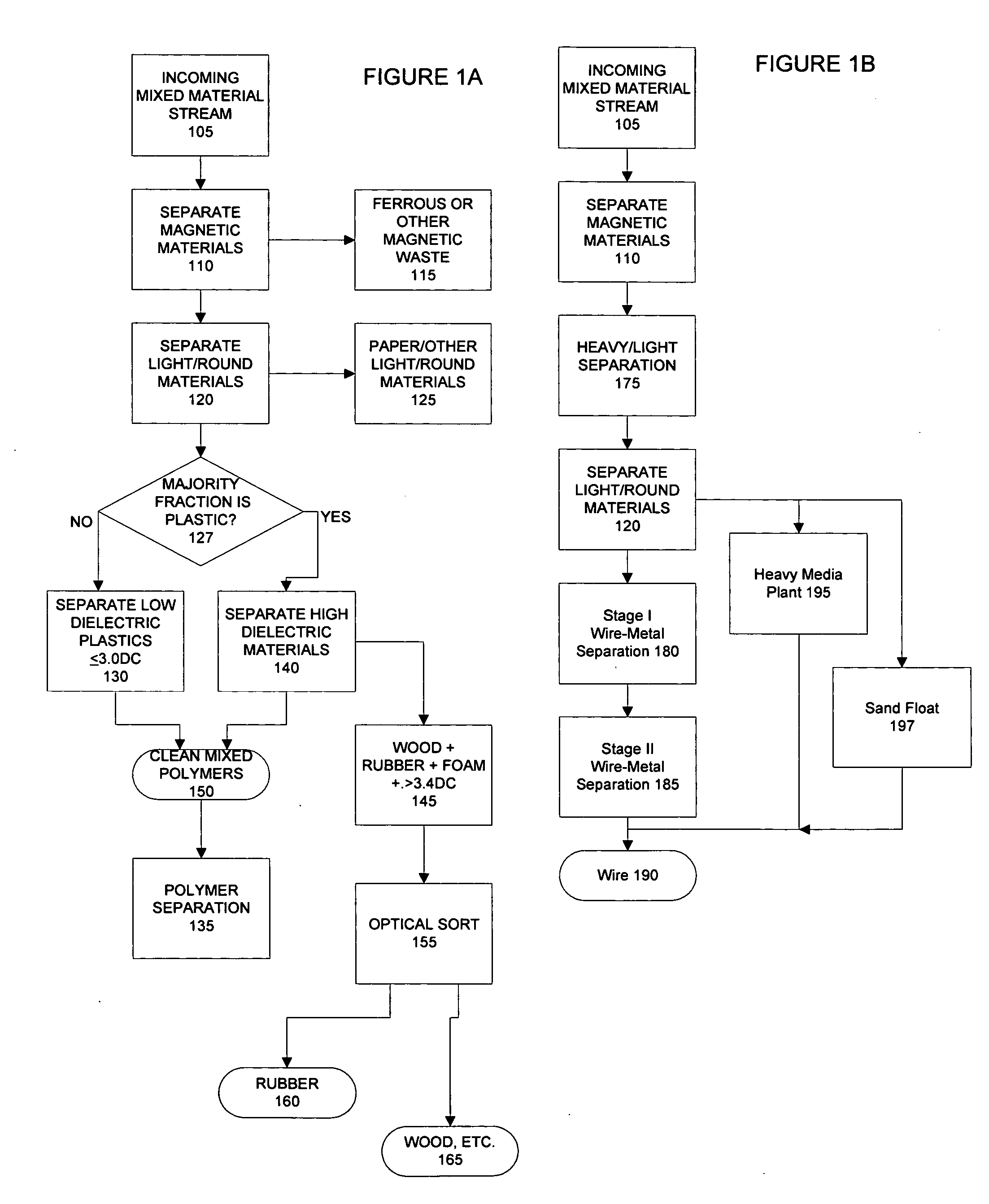

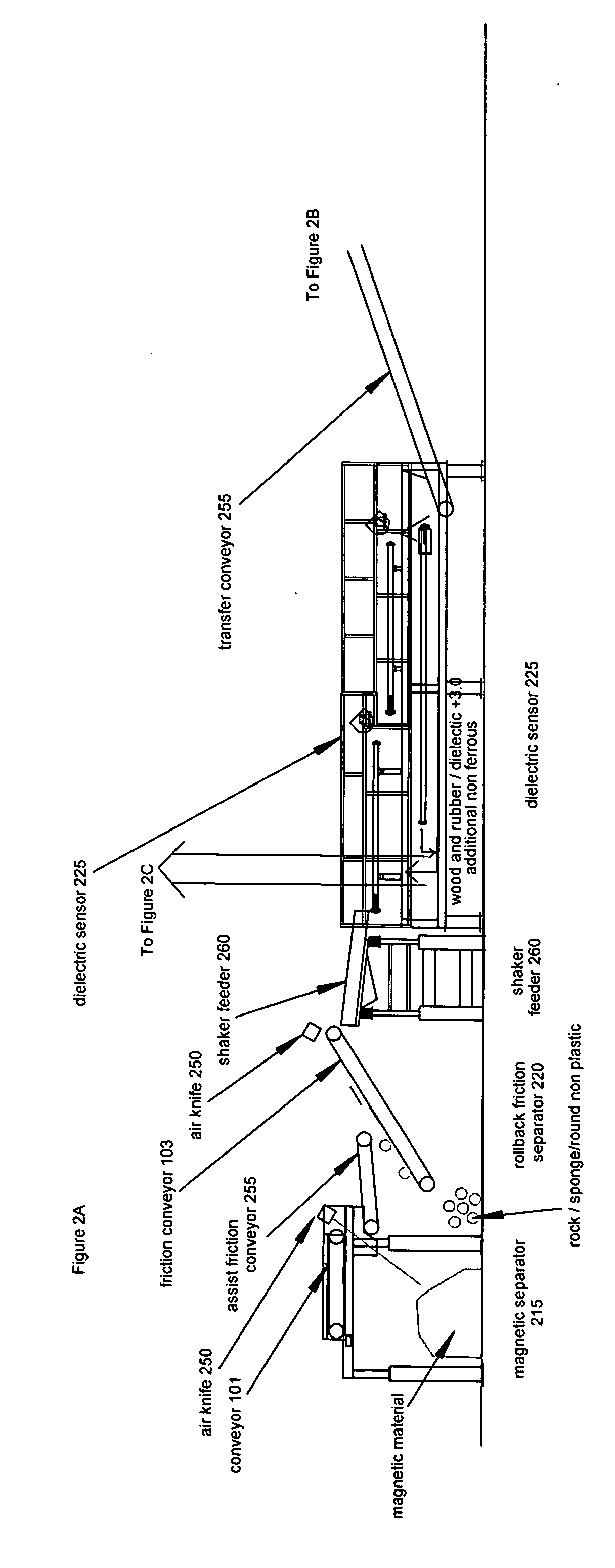

Dissimilar materials sorting process, system and apparata

InactiveUS20070187299A1Improve uniformityUnified operationGas current separationSolid waste disposalElectricityMagnetic separator

An automated system for sorting dissimilar materials, and in particular for sorting plastics from other materials and for sorting different types of plastics from one another comprises, depending upon the embodiment, combinations of a sizing mechanism, a friction separation, an air separator, a magnetic separator, a dielectric sensor sortation bed, shaker screening, a ballistic separator, an inductive sensor sortation system and a float / sink tank. The dielectric sensor sortation system may be either analog or digital, depending upon the particular implementation. One or more float / sink tanks can be used, depending upon the embodiment, each with a media of a different specific gravity. The media may be water, or water plus a compound such as calcium chloride. In addition, multiples of the same general type of module can be used for particular configurations. A heavy media system or a sand float process can be used either alternatively or additionally.

Owner:VALERIO THOMAS A

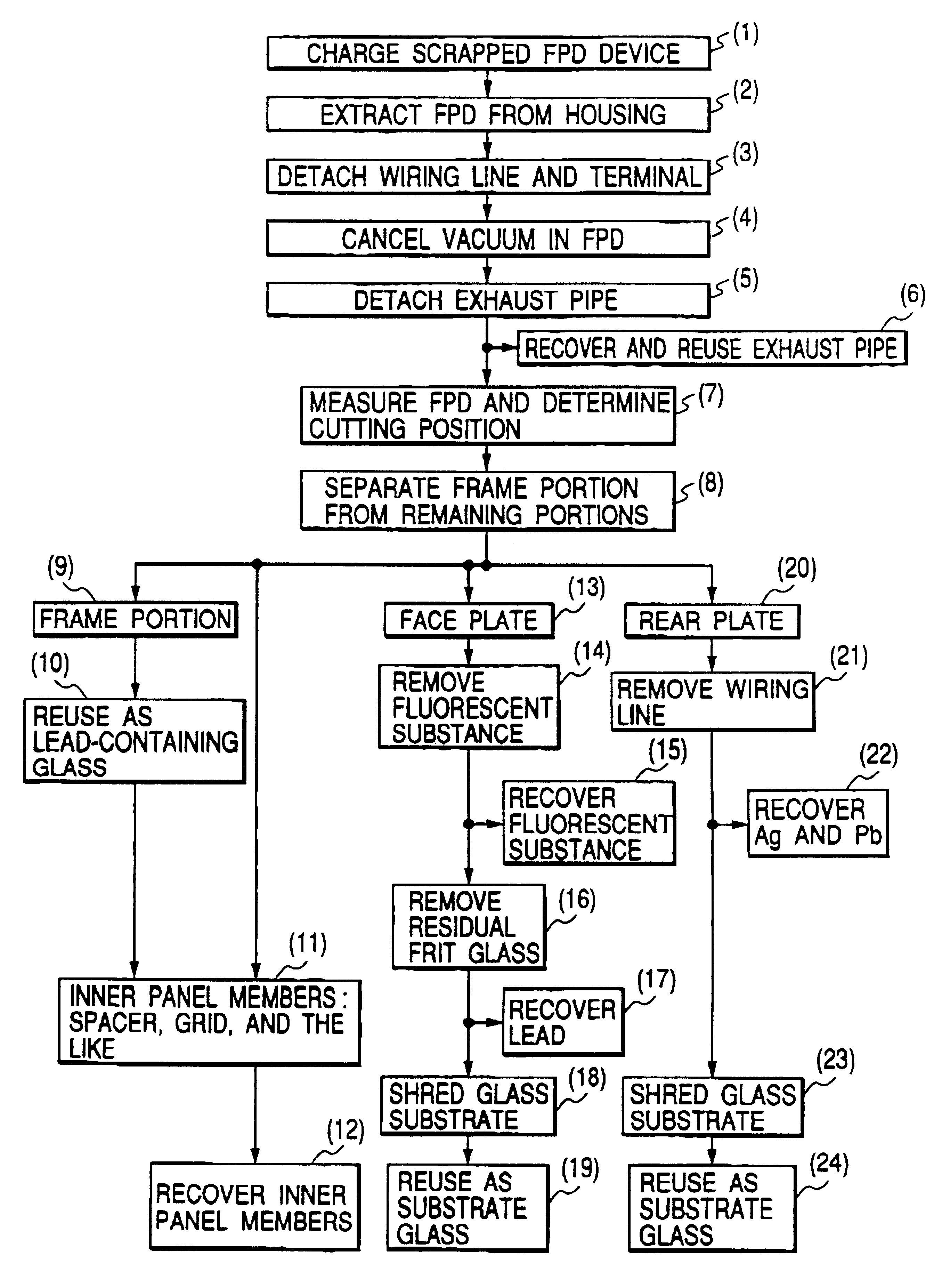

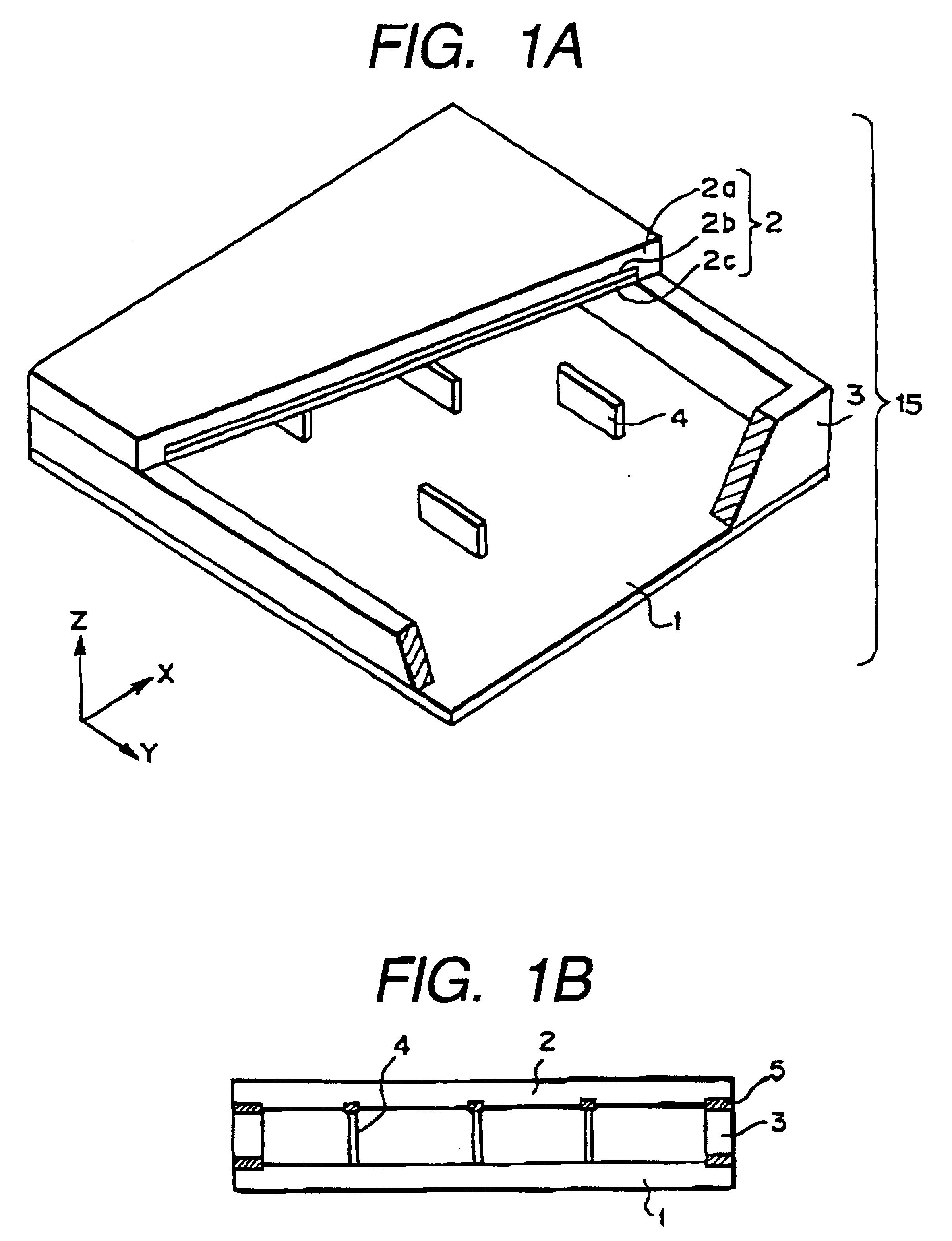

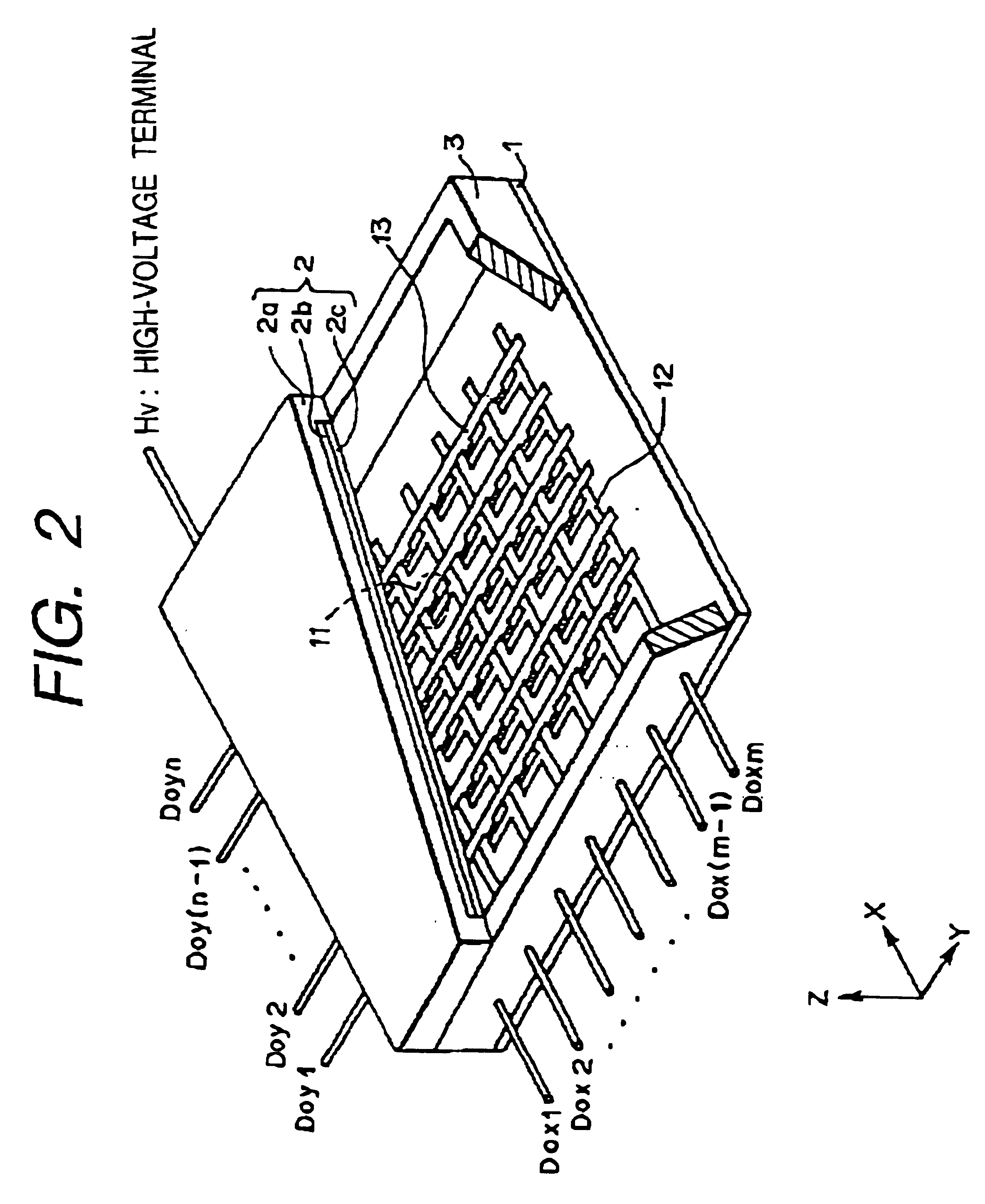

Image display apparatus, disassembly processing method therefor, and component recovery method

InactiveUS6632113B1No pressureAvoid secondary damageElectric discharge tubesGlass recyclingRecovery methodFrit

To reuse glass used in a flat panel display, processing suitable for global environment such as processing of separating a lead component must be realized. A disassembly processing method for a flat panel display having a structure in which a face plate and rear plate mainly containing glass are airtightly joined via a frame with frit glass is characterized by including the step of separating the face plate and rear plate joined with the frit glass. The separation step is characterized by separating the face plate and rear plate by cutting, dissolution, or melting.< / PTEXT>

Owner:CANON KK

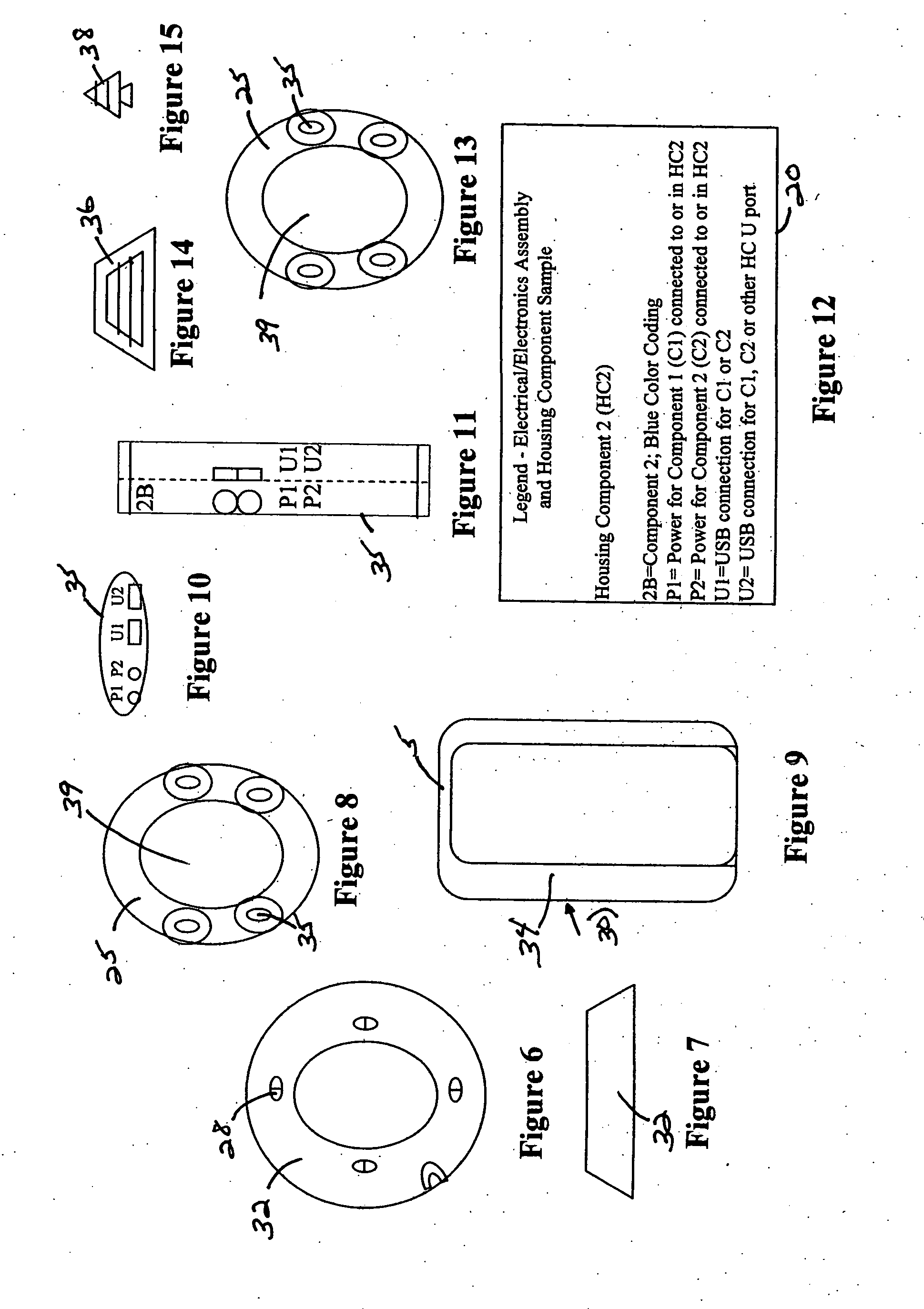

Multifunction-capable health related devices

InactiveUS20050188853A1Low incremental costImprove overall utilizationCombination devicesAuxillary pretreatmentBarcodeEngineering

Health and environmental devices such as air purifiers are adapted with components for multifunctional capabilities that involve electronic devices and associated housings containing at least one processor adapted to operate at least one component selected from the group consisting of air purifiers, sensors, local area and wide area networked components, and entertainment and electronic components. Health and safety related containers, covers and information input, processing, and output devices include one or more coded data readers for use with bar code, radio frequency identification (RFID) and other coded data technologies and comprise components to support at least one of the following: communications; networked sensors; and monitoring applications. Increased efficiencies in the use of coded data reader systems that include such coded readers and the associated items being read are supported by alignment indicia adapted for being on said items being read and on said reading devices.

Owner:SCANNELL ROBERT F JR

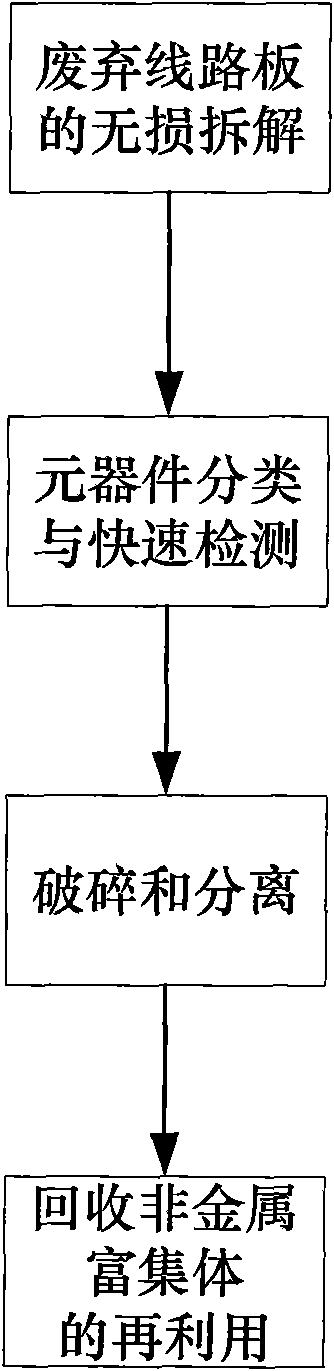

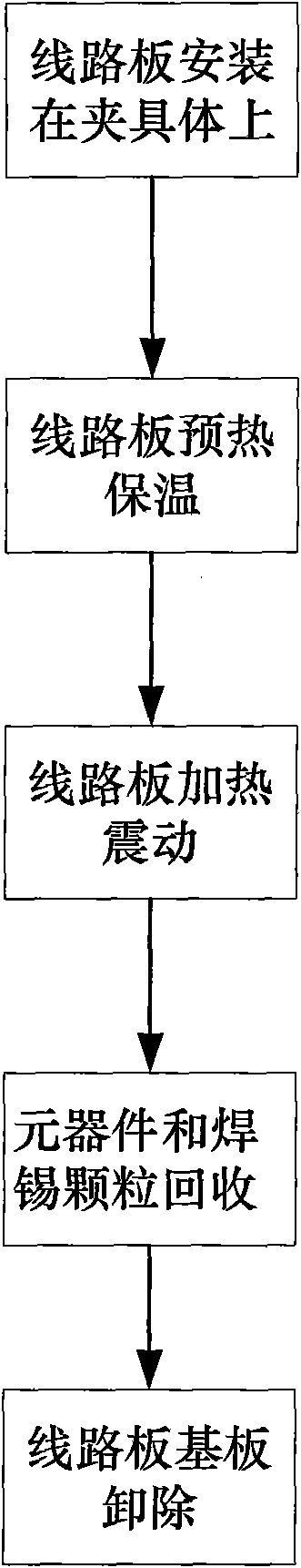

Recycling method of discarded circuit board

InactiveCN101642765ARealize separation and recoverySimplified brokenSolid waste disposalSoldering apparatusEngineeringMetal powder

The invention discloses a recycling method of discarded circuit boards, comprising the following steps: disassembling a discarded circuit board into three parts: a base plate, components and solder, then carrying out sorting and rapid detection on disassembled components; respectively crushing and separating the base plates and various loss-of-function components, and recycling the crushed and separated various powders, wherein the metal powder can be directly reused, and the recycled non-metal powder is used for being prepared into compound material. The method provided by the invention can realize sorting recycling of all resources of the discarded circuit boards; the recycled material can be reused, and therefore, the secondary pollution can not be generated.

Owner:BEIHANG UNIV

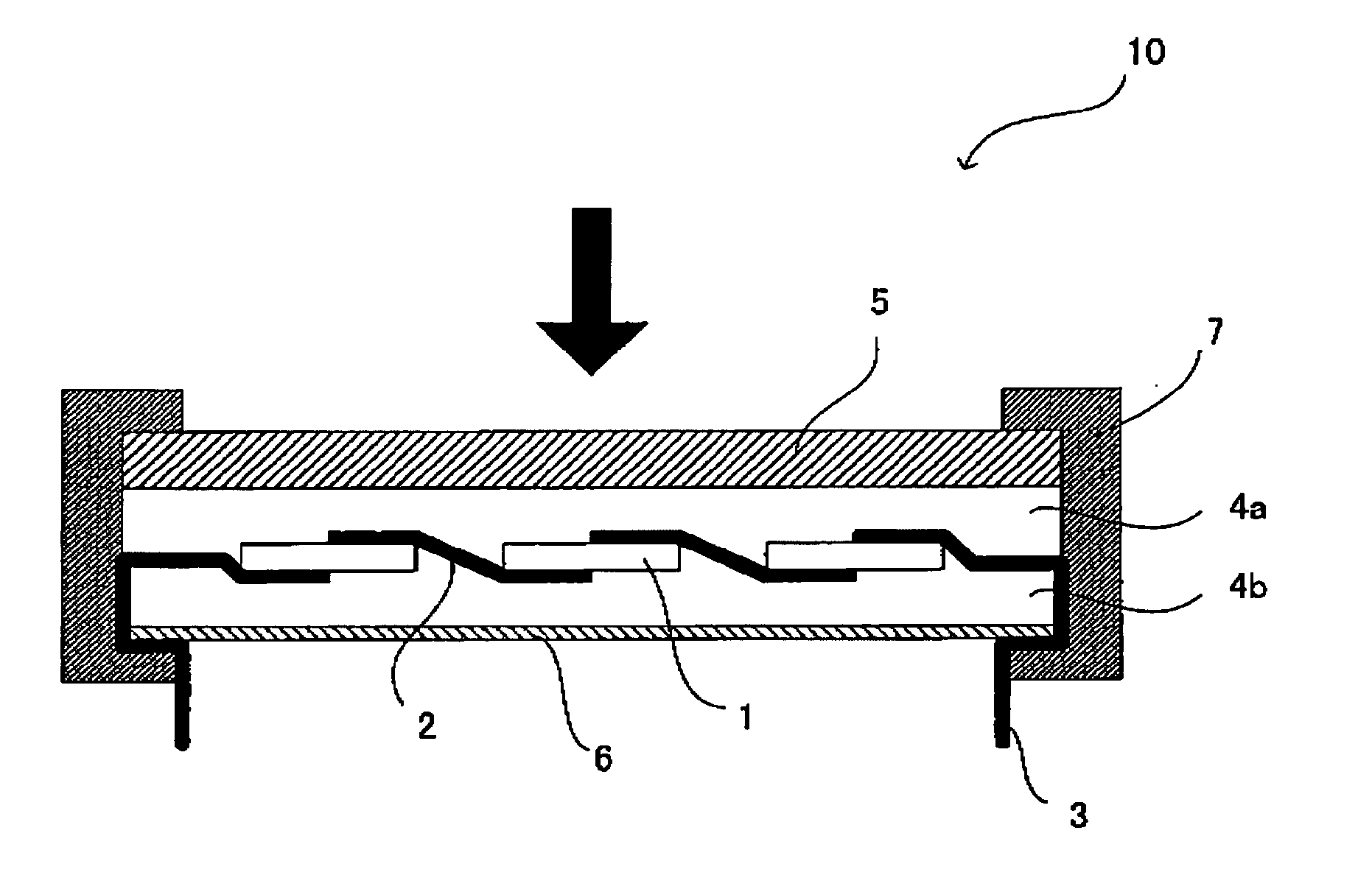

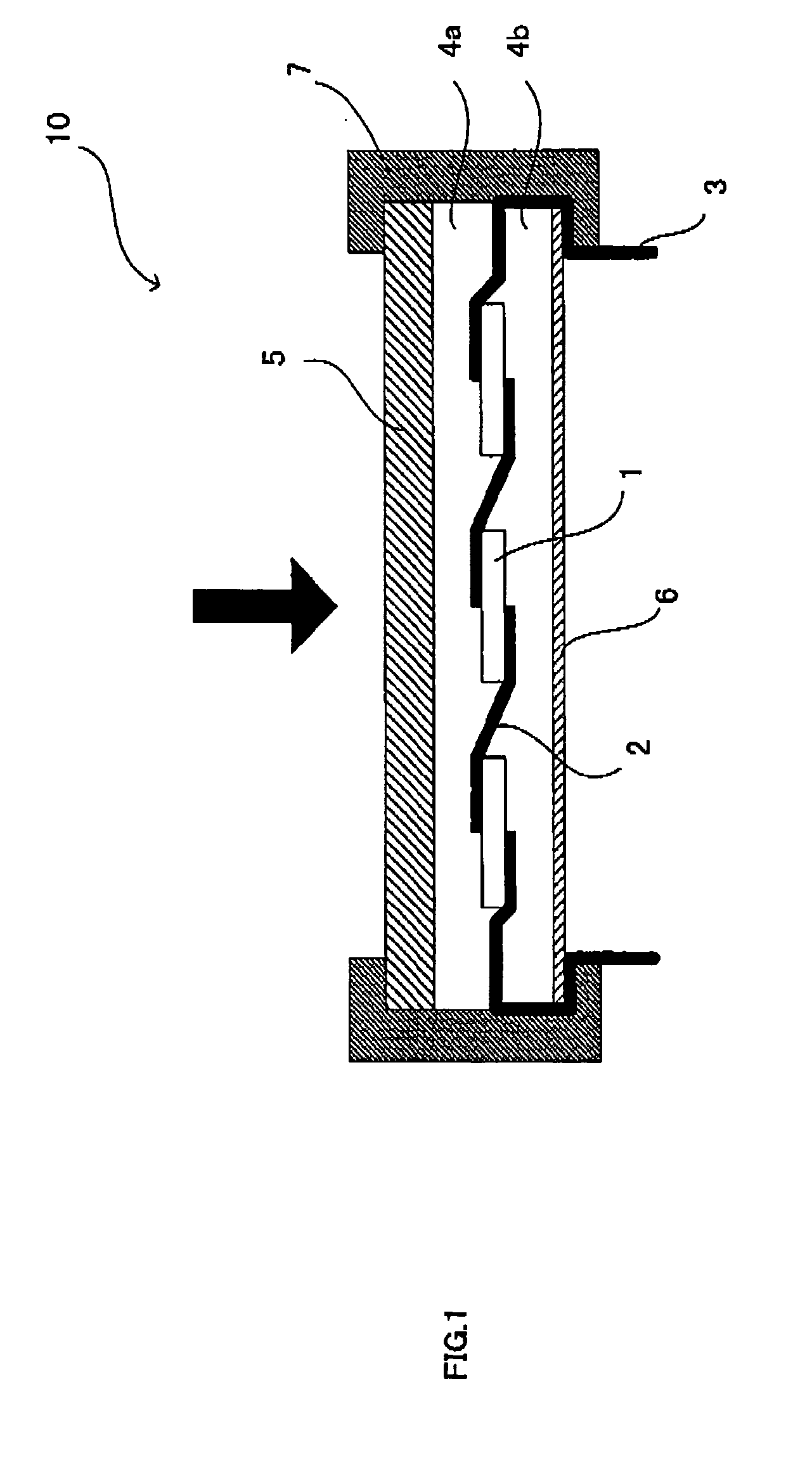

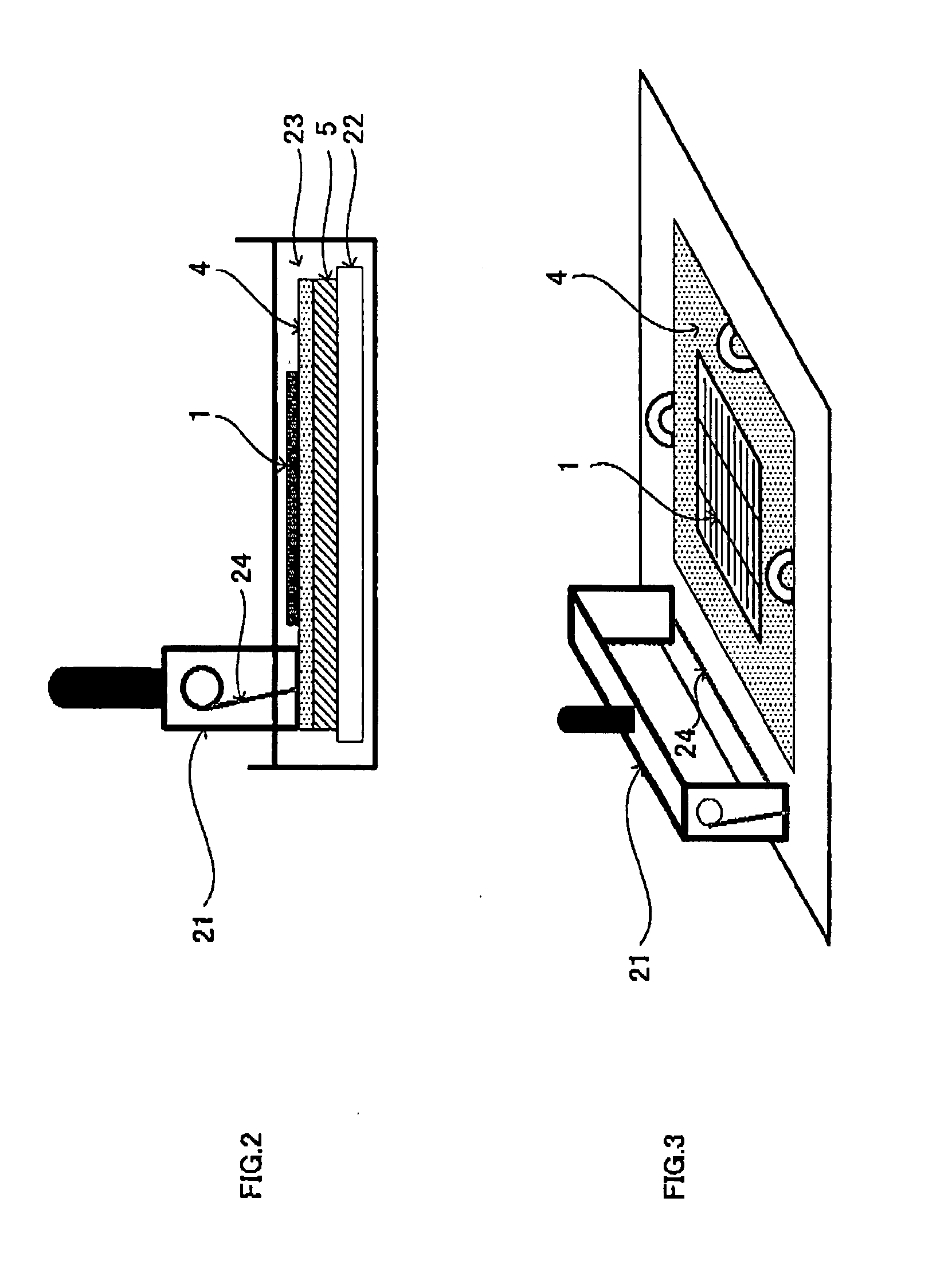

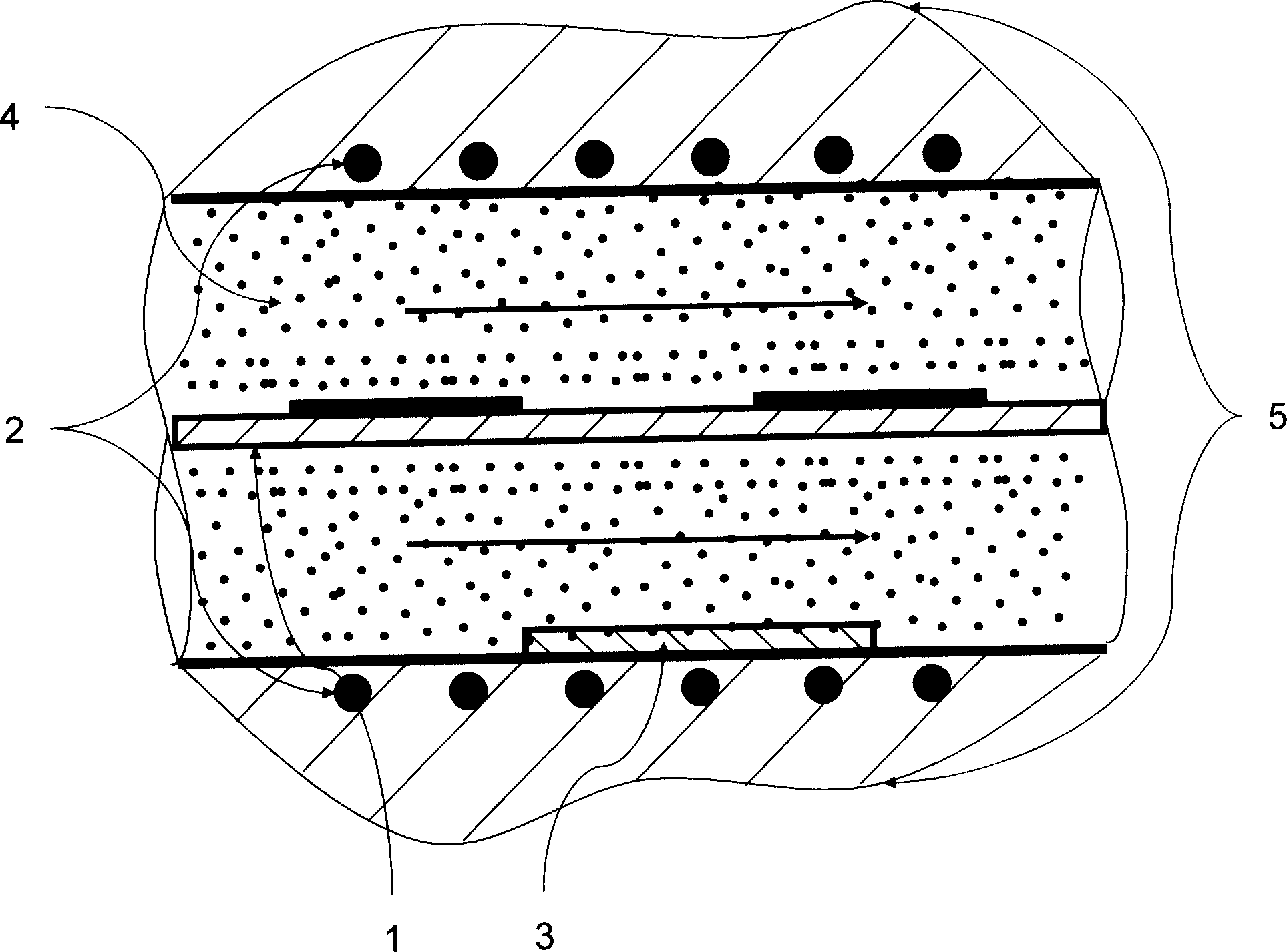

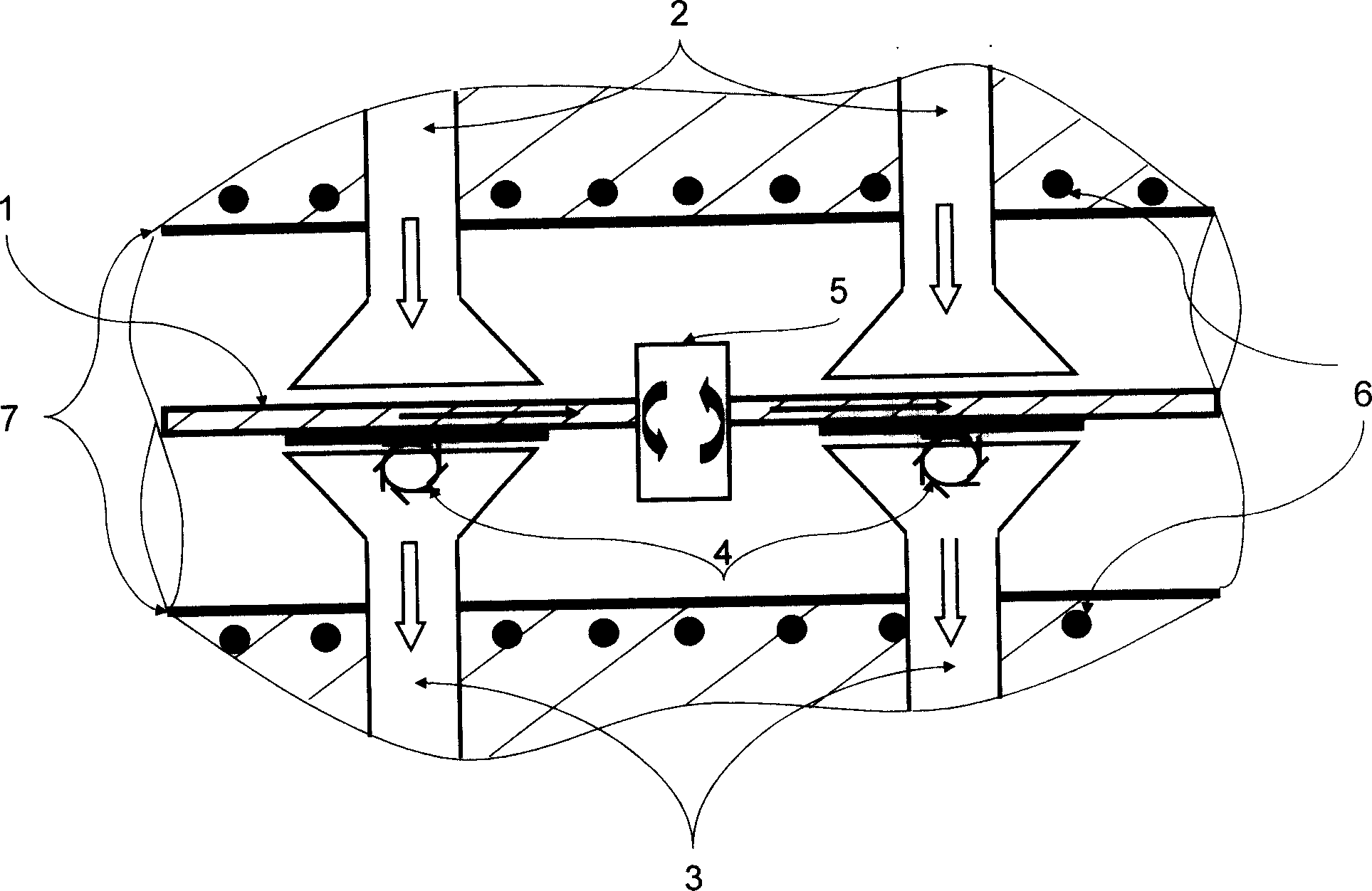

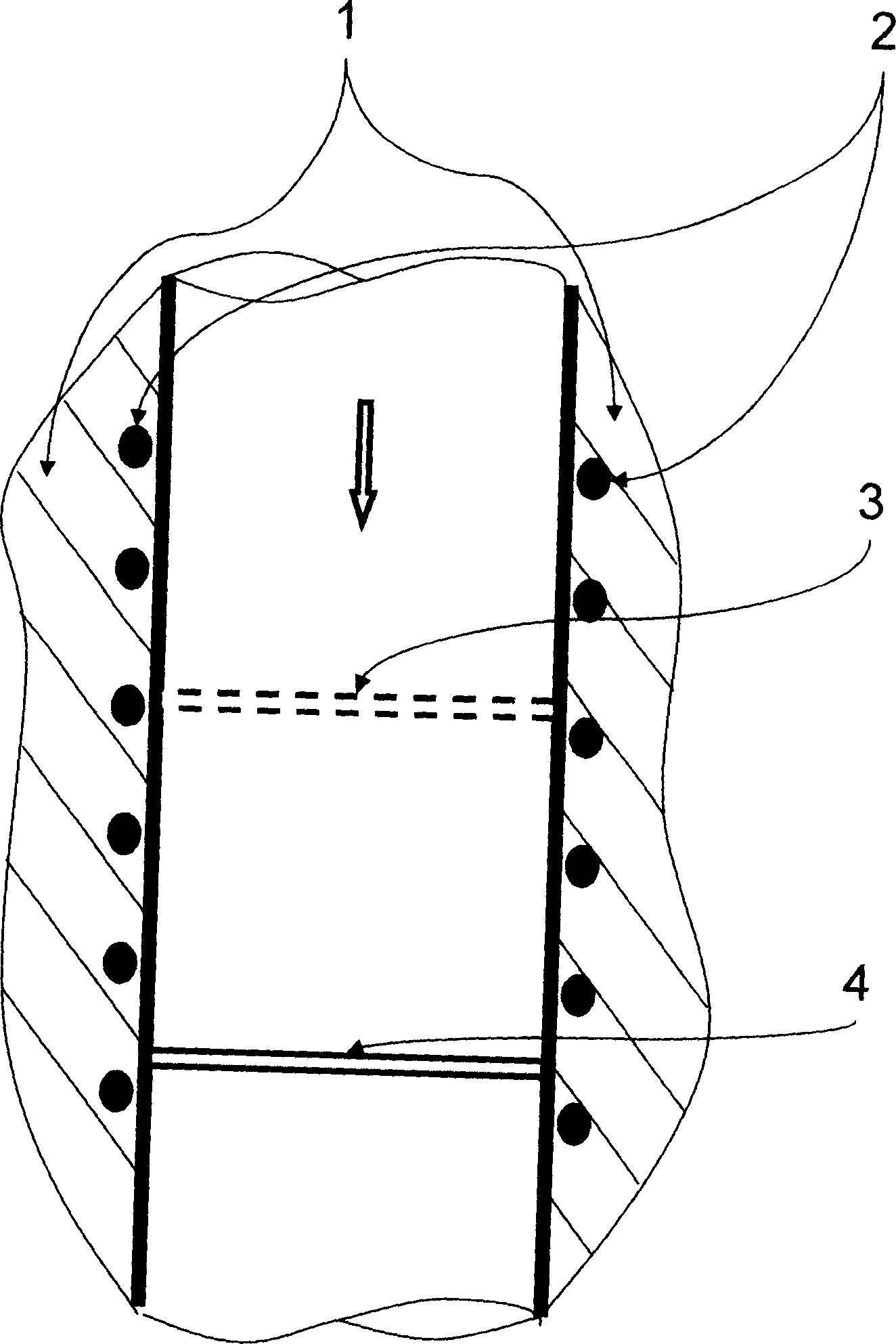

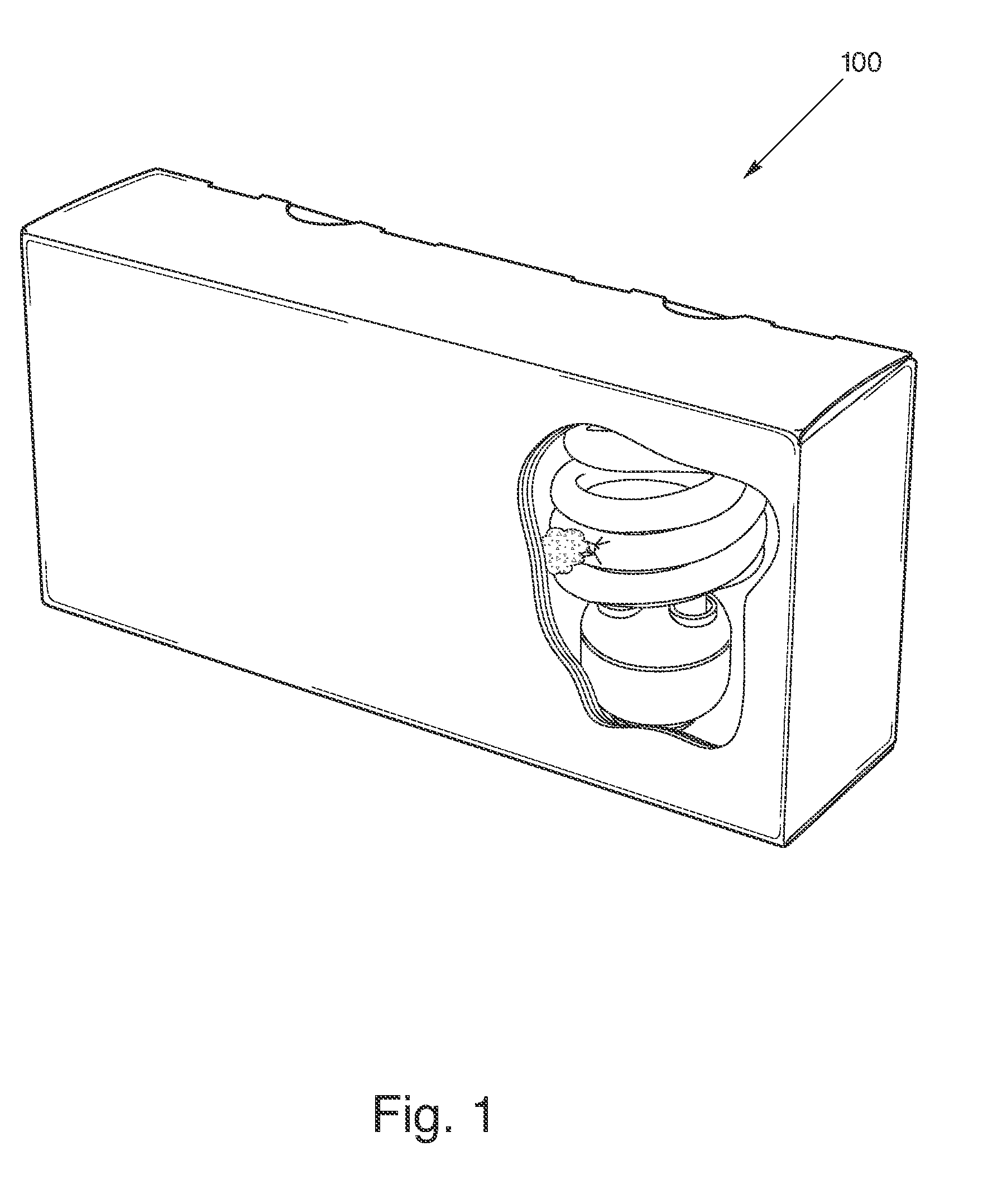

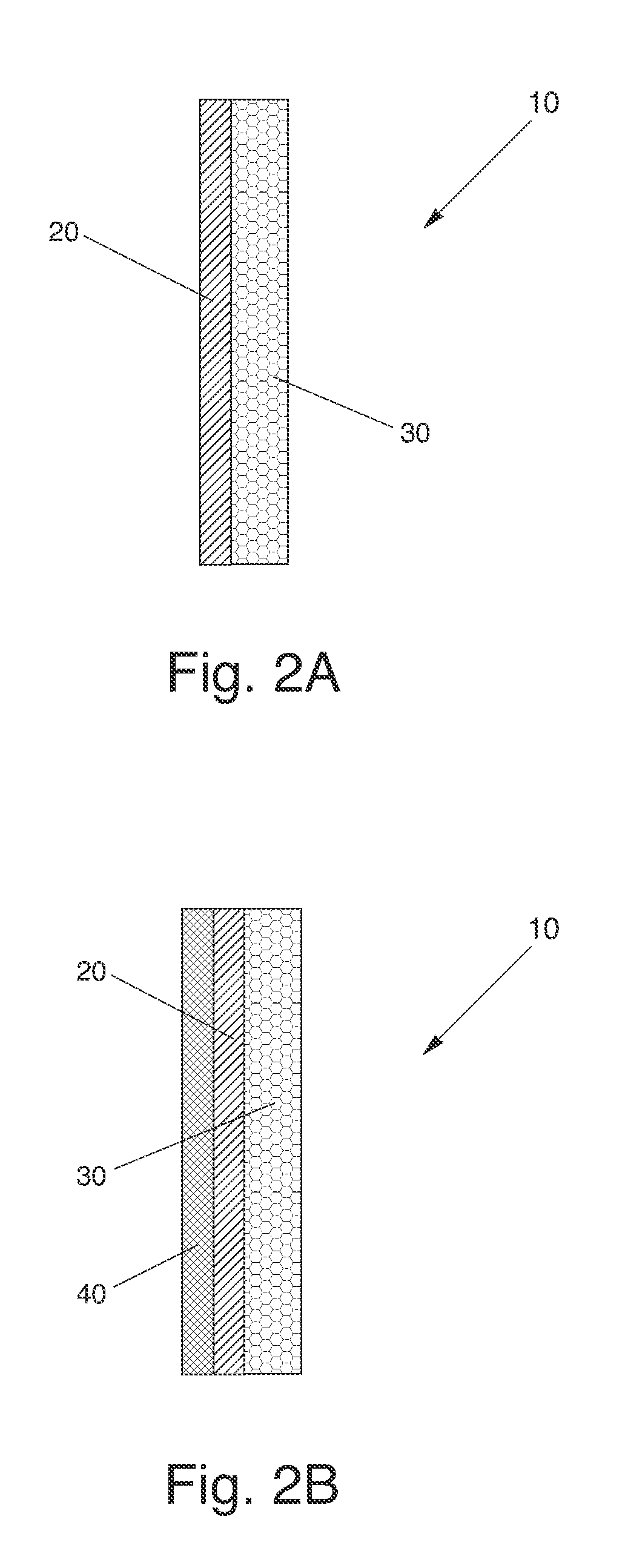

Encapsulant layer for photovoltaic module, photovoltaic module and method for manufacturing regenerated photovoltaic cell and regenerated transparent front face substrate

ActiveUS20050051204A1Low costEasy to separatePV power plantsSolid waste disposalSolar cellBattery bank

The main object of the present invention is to provide an encapsulant layer for photovoltaic module used in a photovoltaic module enabling recovering and recycling or reusing of reutilizeable resources such as a transparent front face substrate and photovoltaic cell and the like among constituents of a photovoltaic module, and to provide a method for manufacturing a regenerated photovoltaic cell and a regenerated transparent front face substrate. The present invention attains the above mentioned object by providing an encapsulant layer for photovoltaic module, wherein the encapsulant layer for photovoltaic module is used in a photovoltaic module formed by laminating: a transparent front face substrate; a photovoltaic cell carrying a wiring electrode and a takeoff electrode, and an encapsulant layer is placed on at least one surface; and a rear face protecting sheet, in this order, comprising a separable layer formed mainly of a thermoplastic resin (a) having a peeling strength from the transparent front face substrate, measured in a 180° peeling test under a 25° C. atmosphere, in a range of 1 N / 15 mm width to 150 N / 15 mm width, (b) having a Vicat softening temperature, measured based on JIS standard K7206, in a range of 60° C. to 128° C., and (c) having a melt mass flow rate, measured based on JIS standard K7210, in a range of 0.1 g / 10 min to 50 g / 10 min, and wherein (d) an output maintenance factor of photoelectronic power, before and after a test measured based on a standard, of the photovoltaic module using the encapsulant layer is in a range of 80% to 100%.

Owner:DAI NIPPON PRINTING CO LTD

Method and equipment for breaking down and reclaiming electronic components and solder of discarded circuit board

InactiveCN1600458AReduce damage rateHigh split rateSolid waste disposalPrinted circuitsRecovery methodElectronic component

Owner:张杰

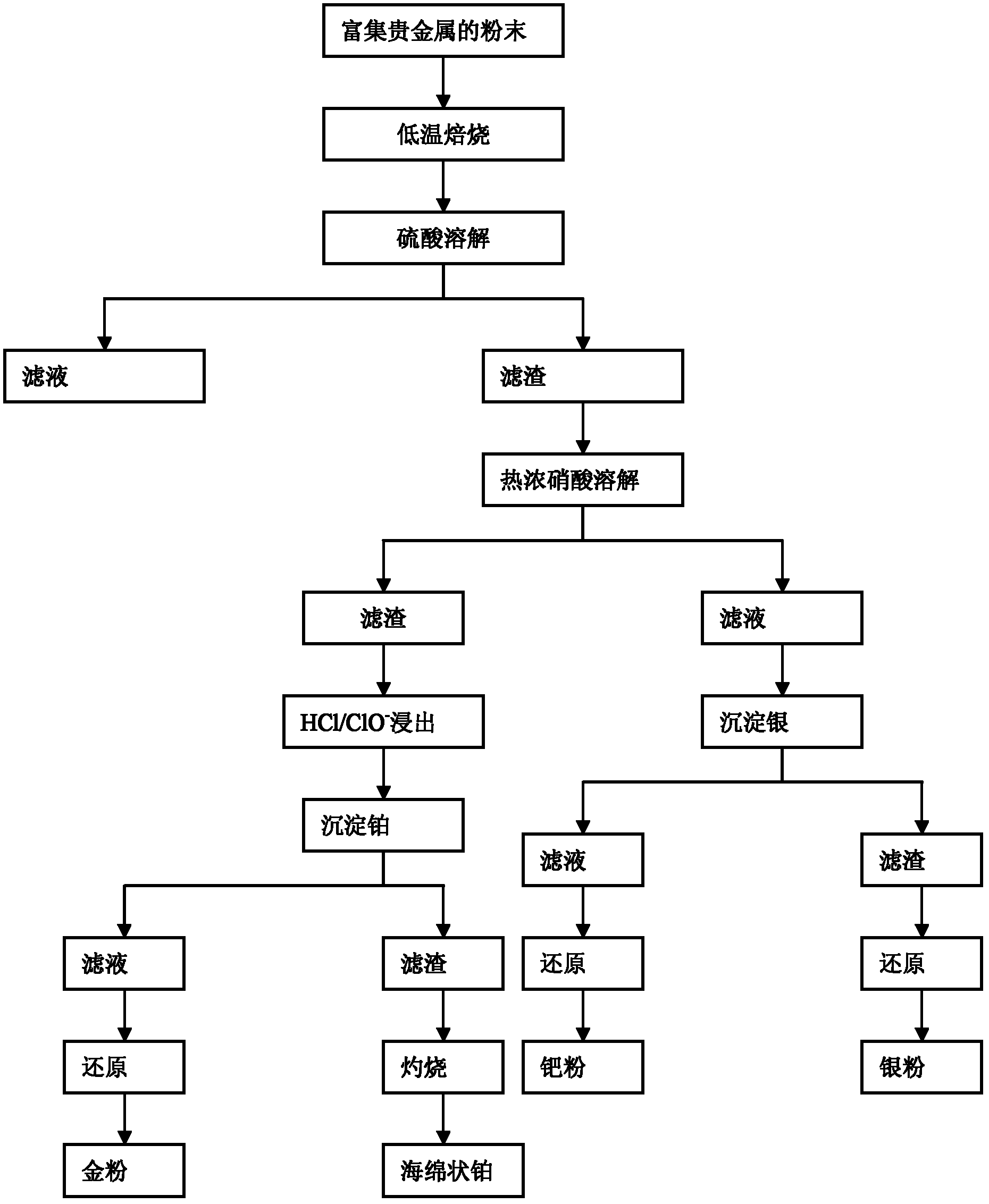

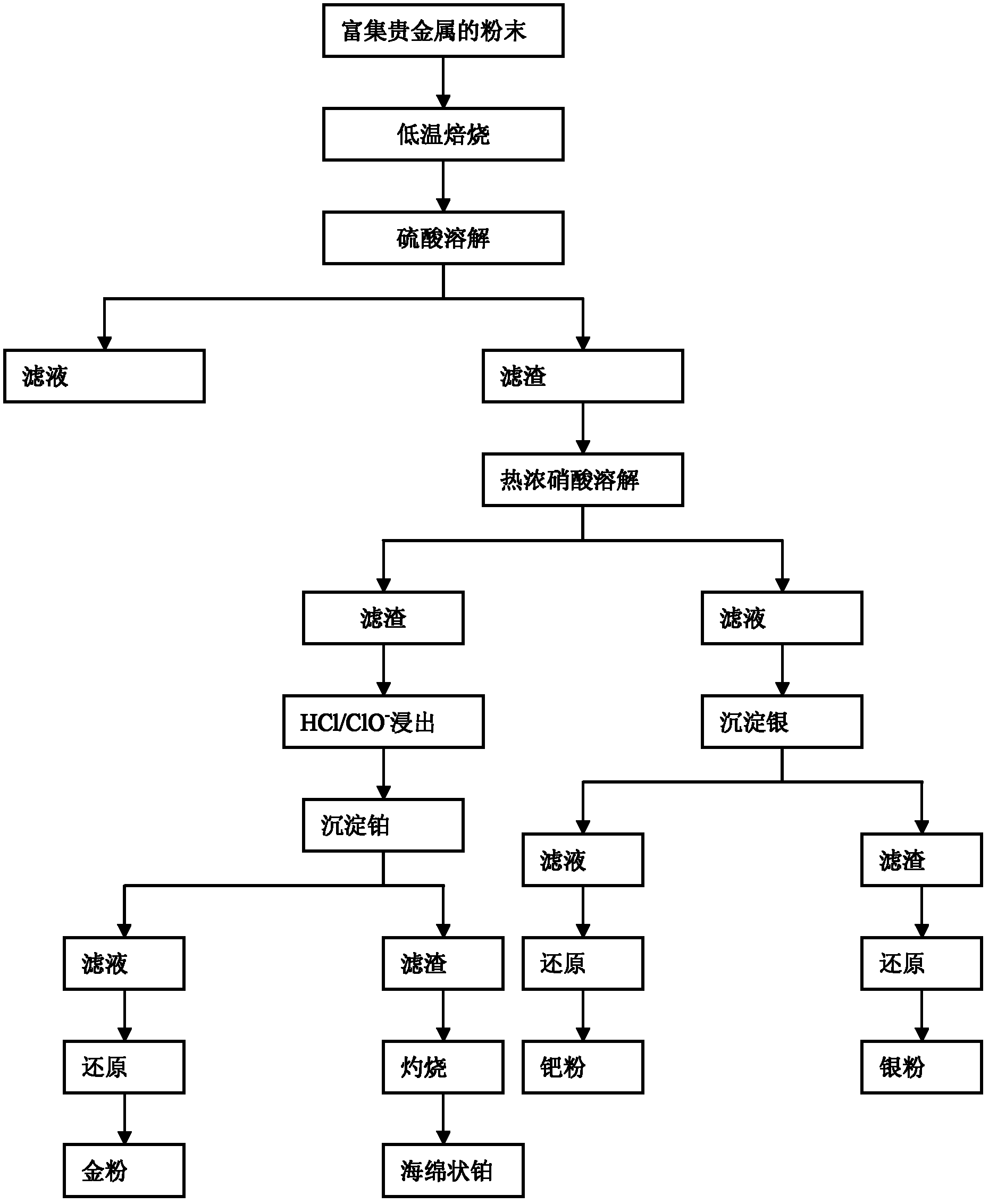

A method for recovering gold, palladium, platinum and silver from waste circuit boards

ActiveCN102277497AEmission reductionIncrease profitProcess efficiency improvementElectronic waste recyclingPlatinumCopper

The invention relates to the field of industrial waste recycling and in particular relates to a method of reclaiming gold, palladium, platinum and silver from a waste circuit board. The method comprises the following steps: (1) removing impurities of a waste circuit board which is subjected to extraction of copper, nickel, lead and tin; (2) separating and reclaiming palladium and silver; and (3) separating and reclaiming platinum and gold. Compared with the prior art, the method provided by the invention has the advantages of lower reclaiming cost, higher recycling rate and higher purity of the reclaimed metals.

Owner:荆门格林循环电子废弃物处置有限公司

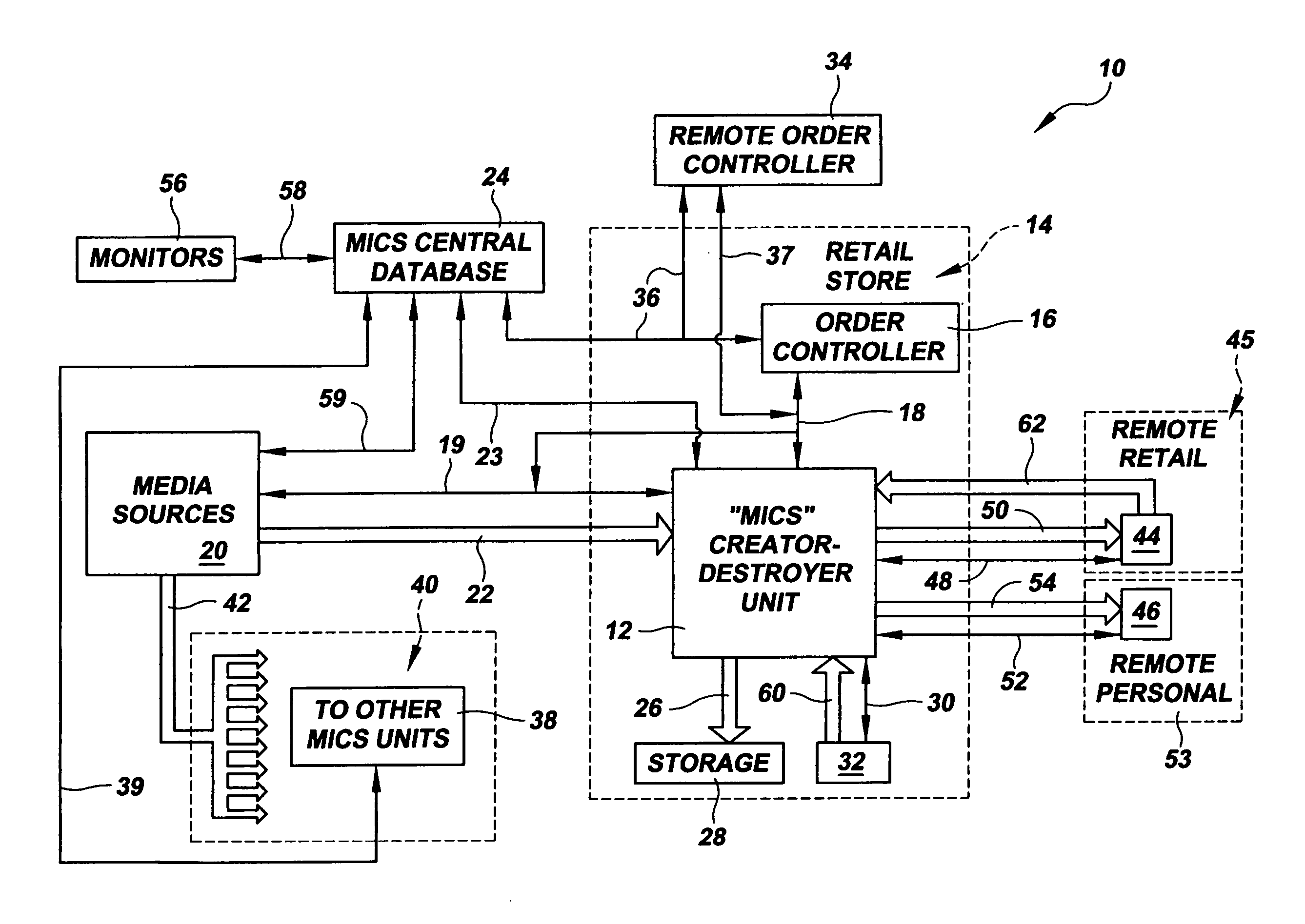

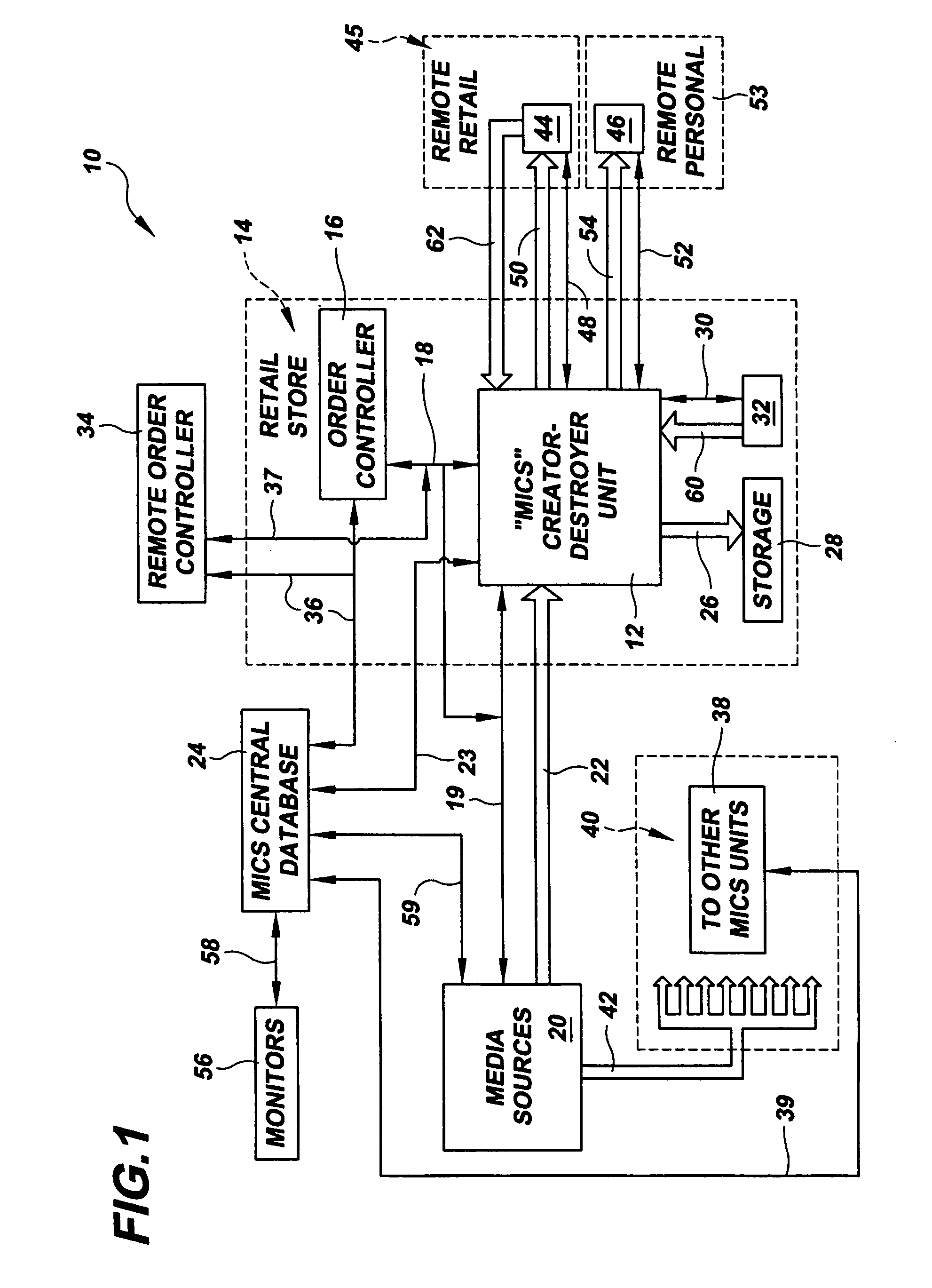

Digital media inventory control, distribution and destruction system

ActiveUS20050125355A1Removal costImprove securityCommerceProgram/content distribution protectionDigital videoComputer software

The system (10) includes a digital media creator-destroyer apparatus (12) for receiving and storing digital media from a remote digital media source (20), for generating multiple transferable copies of the digital media, and for destroying unused copies of the digital media. The digital media creator-destroyer apparatus (12) is housed within a retail store (14) or similar outlet that displays transferable copies of digital media to end-user purchasers. The system (10) provides retailer control at a single store (14) level, regional or national (38) level of inventory, distribution and destruction of digital media, such as music, movies, video games, computer software, ring tones for cell phones, etc., stored on compact disks, digital video disks or other apparatus capable of storing and transferring digital media. Destroying unused copies eliminates cost inefficiencies of the retailer having to return unused copies.

Owner:XYLON LLC

Nanostructured sorbent materials for capturing environmental mercury vapor

InactiveUS20110049045A1Precise positioningAvoid contactMaterial nanotechnologyGas treatmentFluorescenceSorbent

The present invention is a method and material for using a sorbent material to capture and stabilize mercury. The method for using sorbent material to capture and stabilize mercury contains the following steps. First, the sorbent material is provided. The sorbent material, in one embodiment, is nano-particles. In a preferred embodiment, the nano-particles are unstabilized nano-Se. Next, the sorbent material is exposed to mercury in an environment. As a result, the sorbent material captures and stabilizes mercury from the environment. In the preferred embodiment, the environment is an indoor space in which a fluorescent has broken.

Owner:BROWN UNIVERSITY

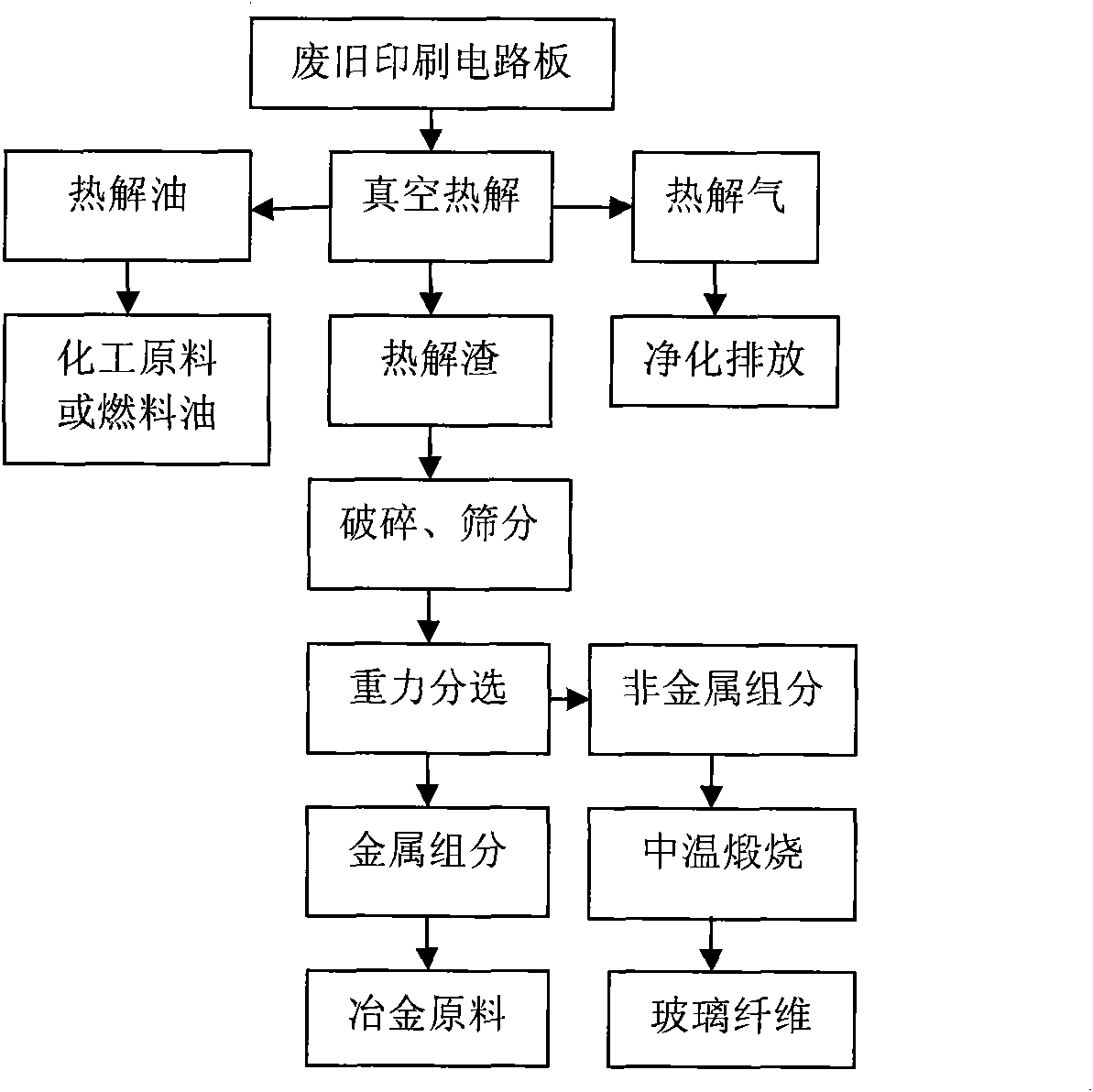

Method for separating and recycling materials of each component in waste printed circuit board

InactiveCN101612628AEasy to separateEfficient recyclingGlass making apparatusSolid waste disposalRecovery methodGlass fiber

The invention discloses a method for separating and recycling the materials of each component in a waste printed circuit board (PCB), and is characterized by subjecting the waste PCB to vacuum pyrolysis, shear breakage, screening classification, gravity separation and medium-temperature calcination, so that all materials of components in the waste PCB can be separated and recycled to obtain organic pyrolytic oil, metal mixtures and glass fiber; wherein, the recycled organic pyrolytic oil can be used as fuel oil or chemical materials, the recycled metal mixtures can be used as metallurgical materials, and the recycled glass fiber can be used as glass fiber processing materials or fillers, thereby achieving the purpose of recycling all resources. The method of the invention can effectively separate and recycle all materials of components in the waste PCB, and has the characteristics that the technological method is simple, feasible, efficient and pollution-free. Therefore, the invention is of great social, economic and environmental benefits.

Owner:GUANGDONG UNIV OF TECH

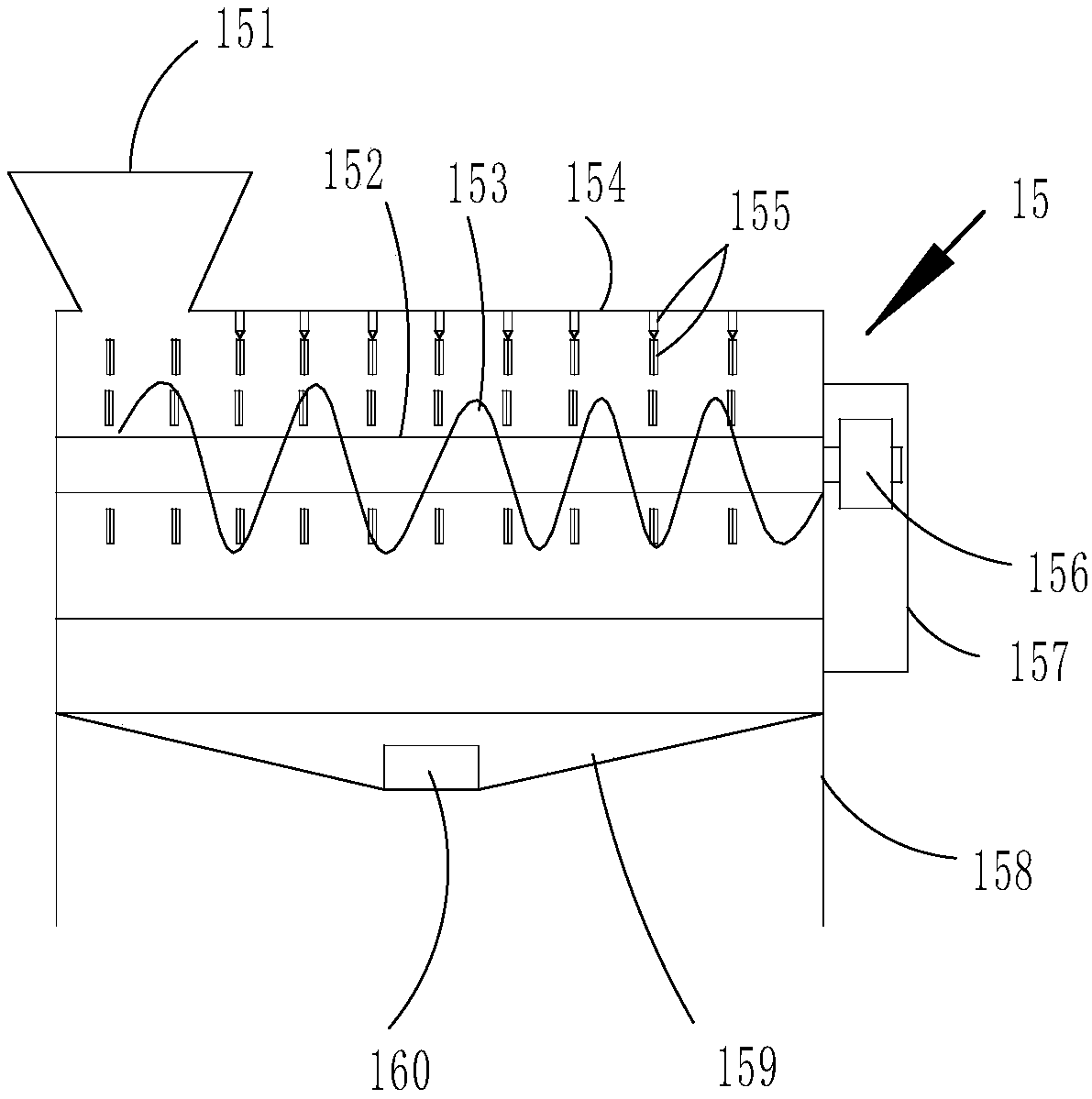

Waste Cable Recovery System

ActiveCN109036736AImprove recycling effectAvoid stickingBasic electric elementsApparatus for removing/armouring cablesEngineeringCopper

The invention provides a waste cable recovery system and belongs to the technical field of waste cable reuse. The system includes frame, pay-off roll, straightening device, cutting device, cop core winding roller, two cooling devices, two cutting devices and crushing device. A let-out roller, a straightening device, a cutting device and a cop core winding roller are arranged in sequence from one end of that frame, two cooling device and two cutting devices are arranged between the cutting device and the cop core winding roller and are symmetrically arranged on both sides of the frame, the cooling device is close to the frame, and the cutting device is far away from the frame. The invention provides a waste cable recovery system, by carrying out straightening first, and Cutting, Cut off thecable sheath after cooling, the cable sheath after the cutting-off falls into the lower crushing device for crushing, copper core is wound on the copper core winding roller along a straight line, after straightening the cable sheath, adhesion and incessant cutting of the cable sheath can be avoided, thereby avoiding scratching the copper core, the cable sheath is cut off after cooling, and is easy to cut and crushing.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

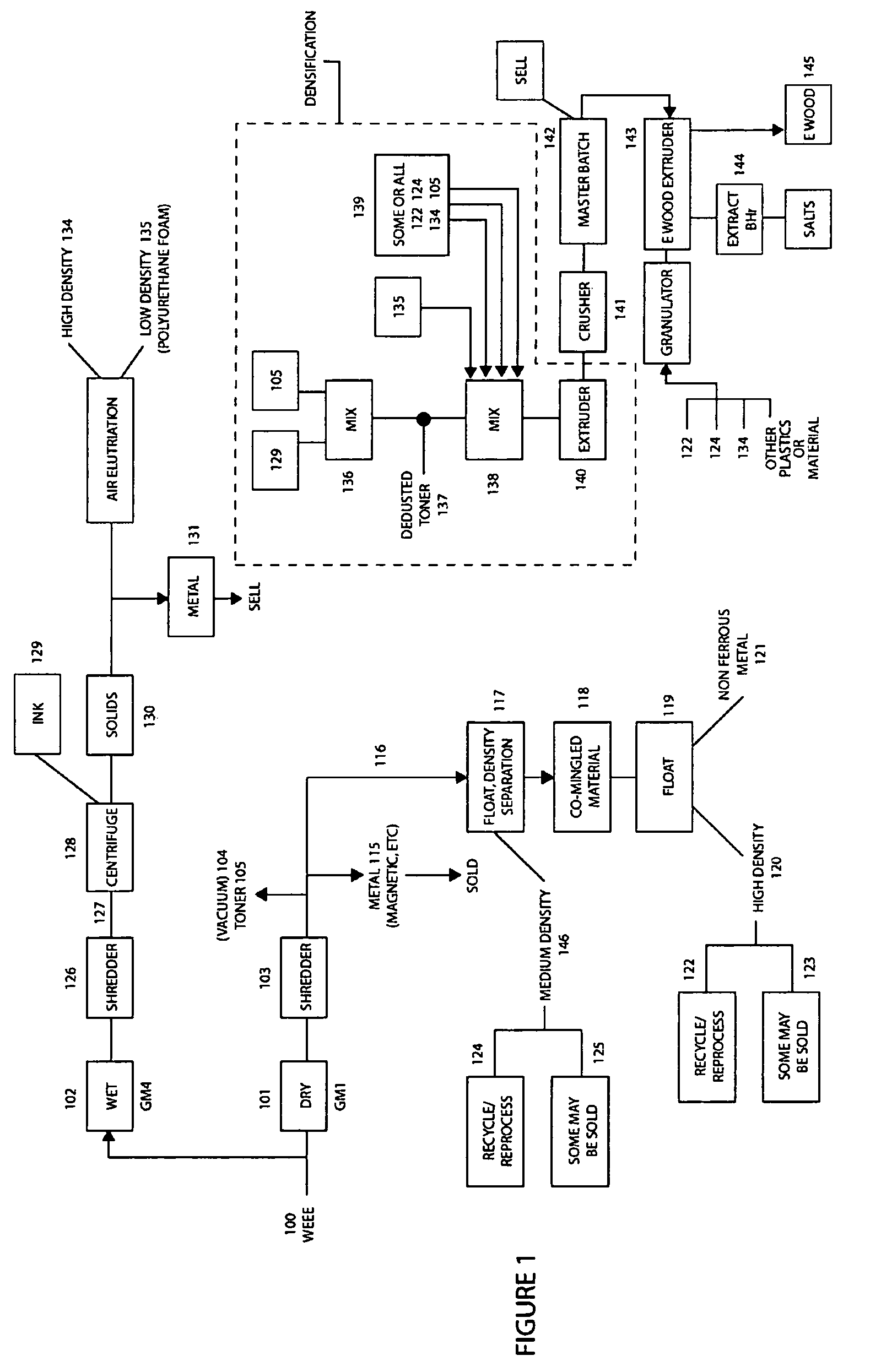

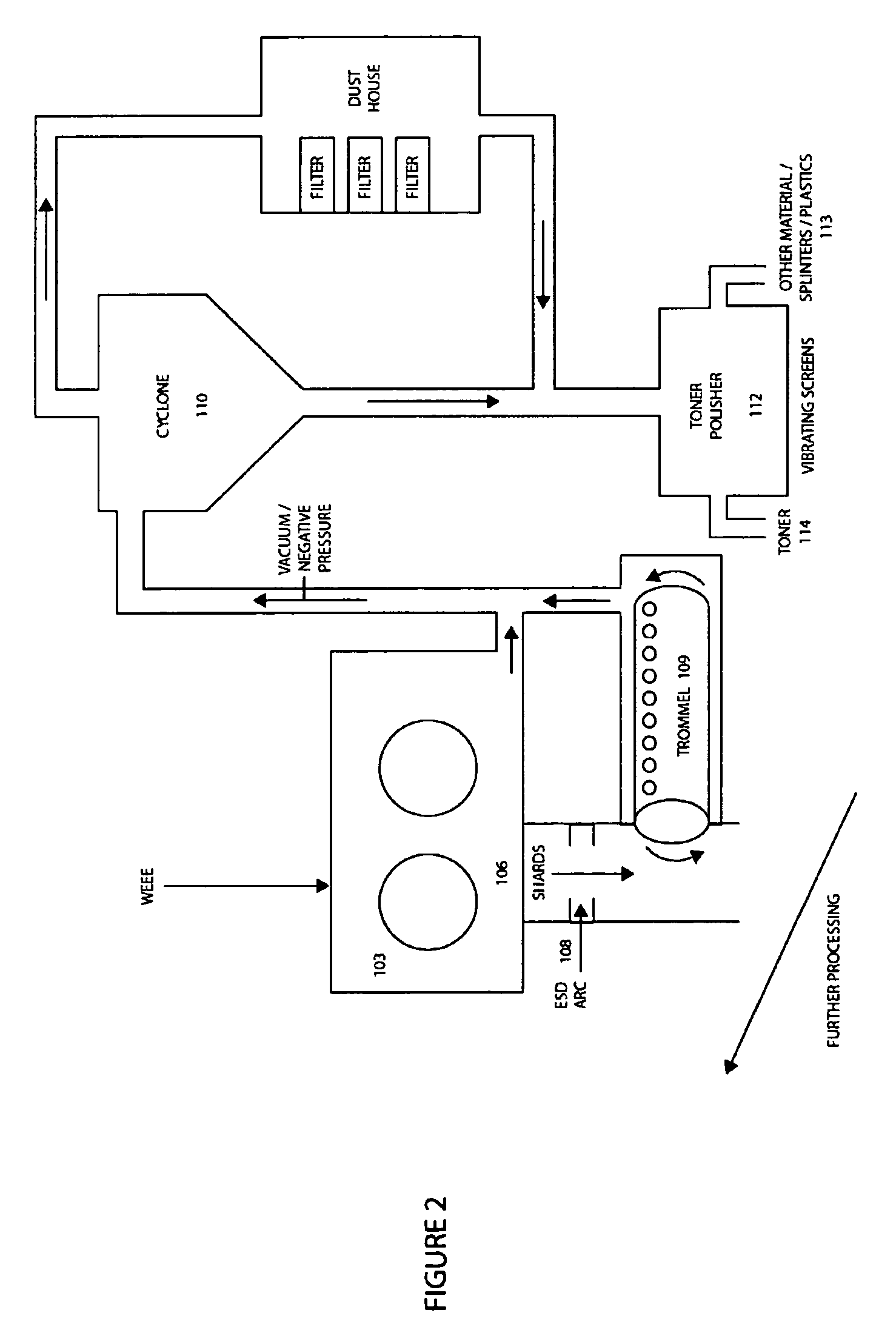

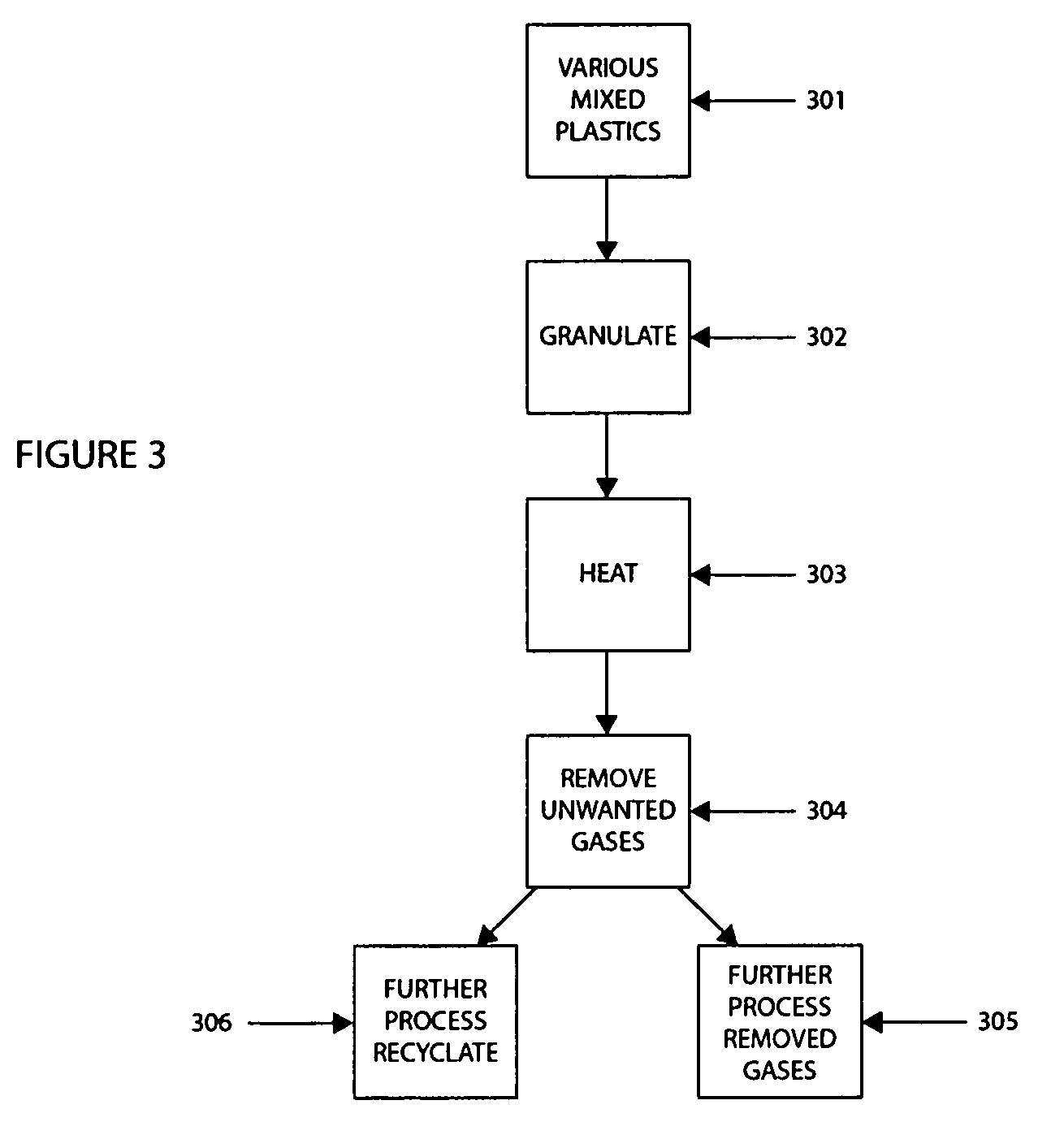

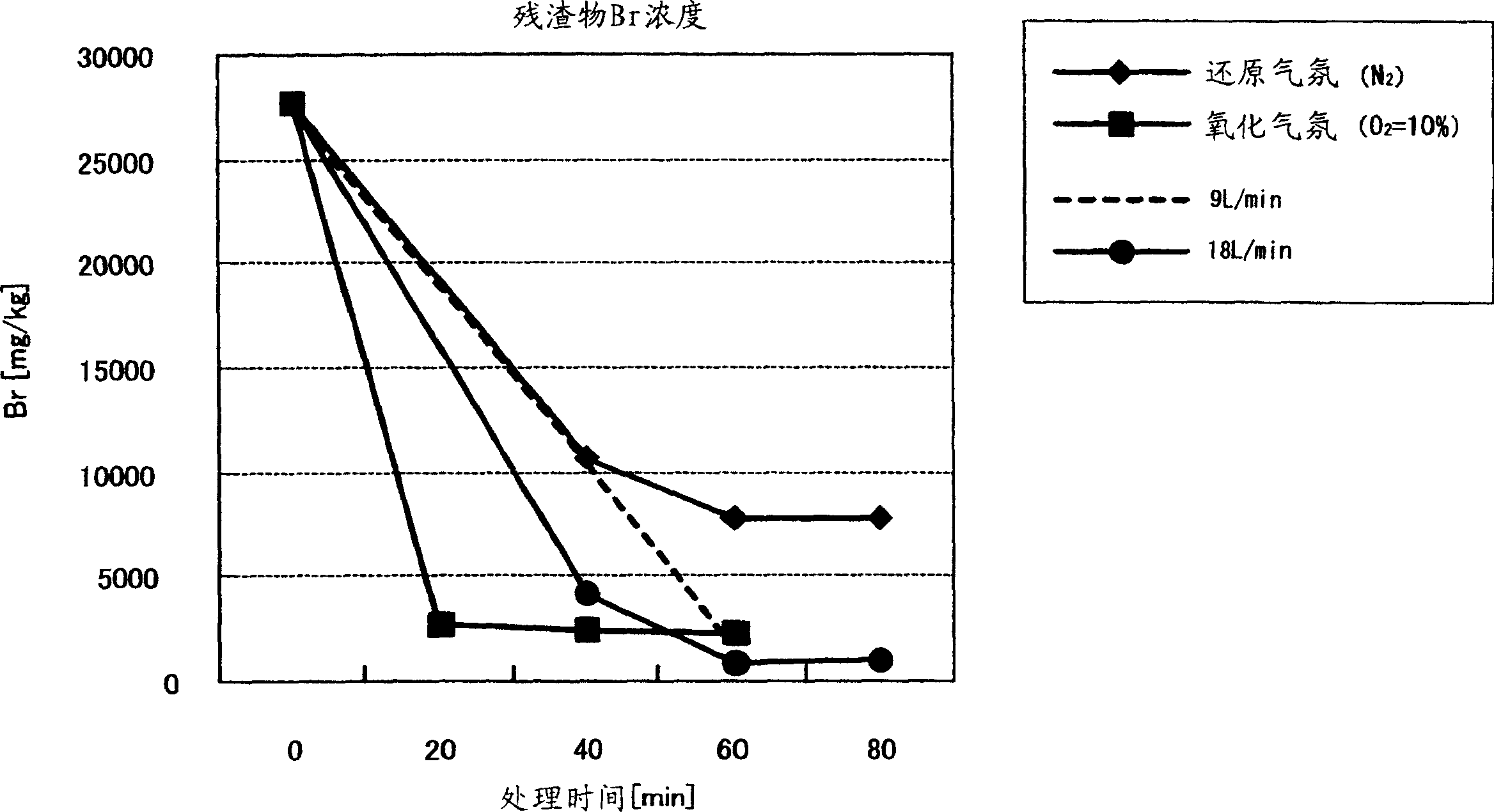

Method of recycling mixed streams of ewaste (WEEE)

The present invention relates to the recycling of waste electrical and electronic equipment (WEEE). Preferably, the present invention relates to the substantial recycling of all material forming the WEEE, thus providing substantially zero landfill. In yet another form, the invention relates to an additive and / or method of providing an additive. In still another form, the invention relates to recycling ink, toner, and / or PU foam from imaging consumables, forming part of the WEEE. In another form, the invention relates to the recycling of plastic materials containing flame retardants, including the recycling of plastics materials, such as plastics materials containing brominated flame retardants generally based on styrenics (e.g. PS, HIPS, ABS, PPO / PS, PPE / PS, ABS / PC) and polyamides (Nylon 6, nylon 6,6, nylon 12) and other engineering plastics such as polyacetal, polycarbonate, PET, PBT, liquid crystal polymers.

Owner:CLOSE THE LOOP TECH

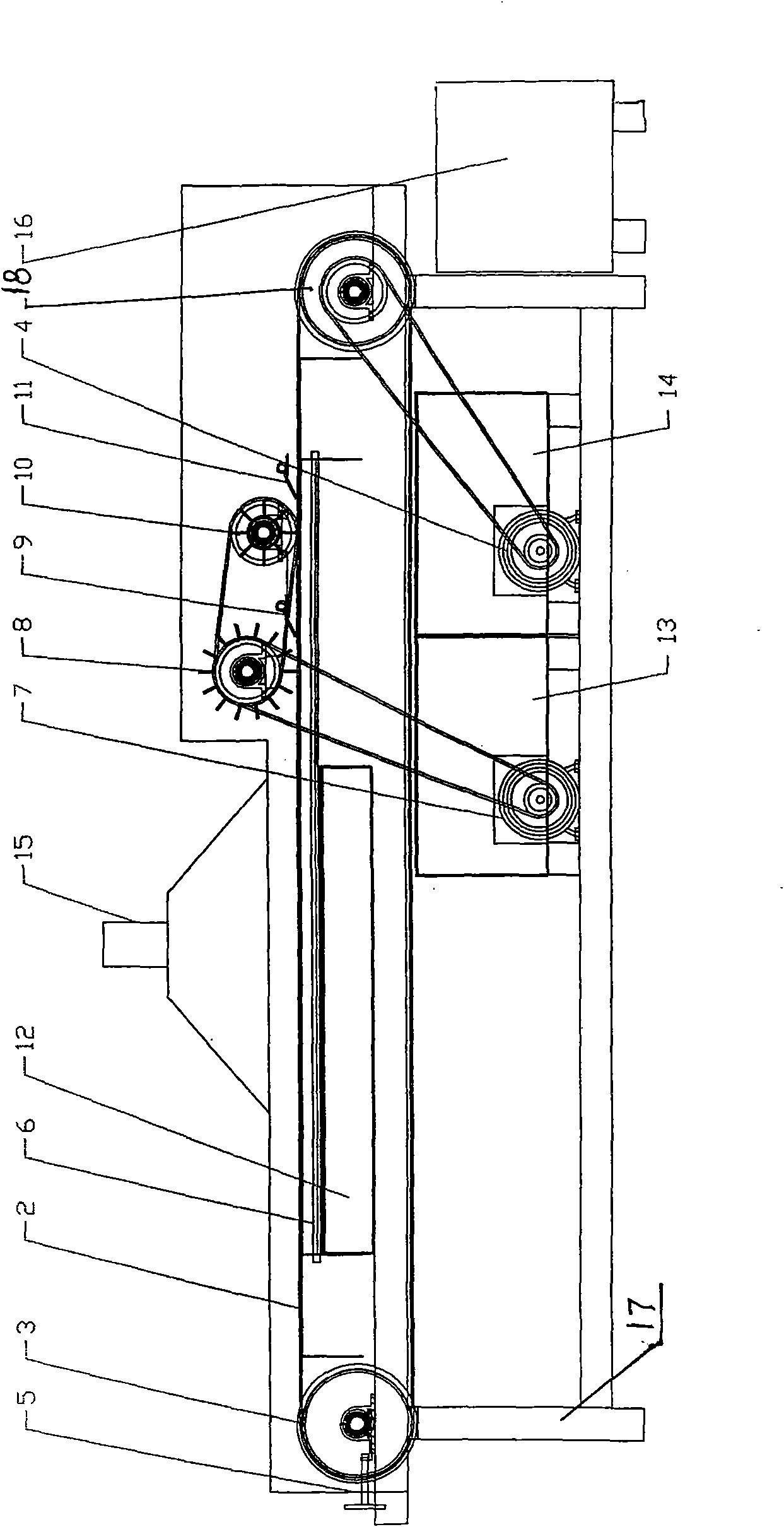

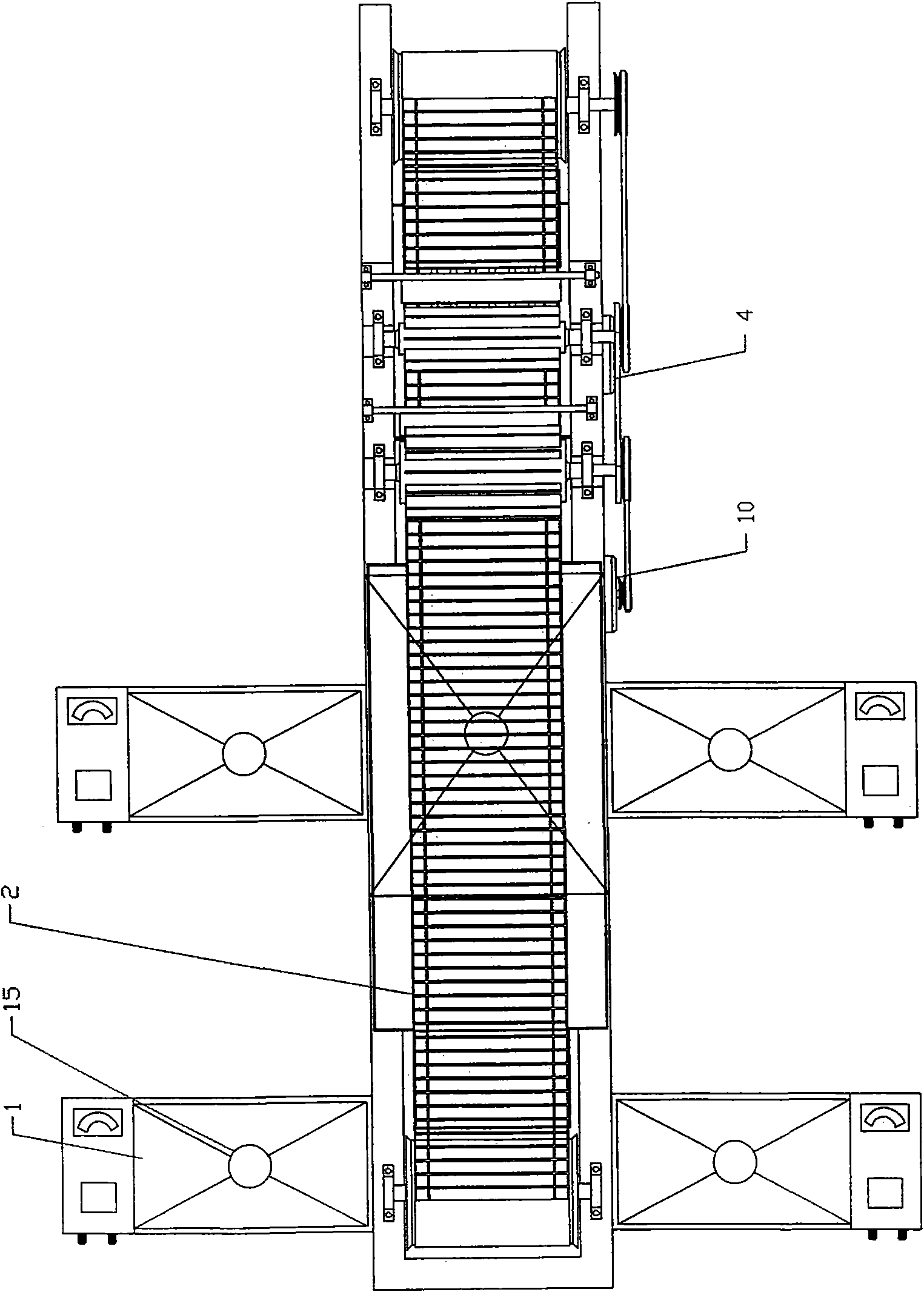

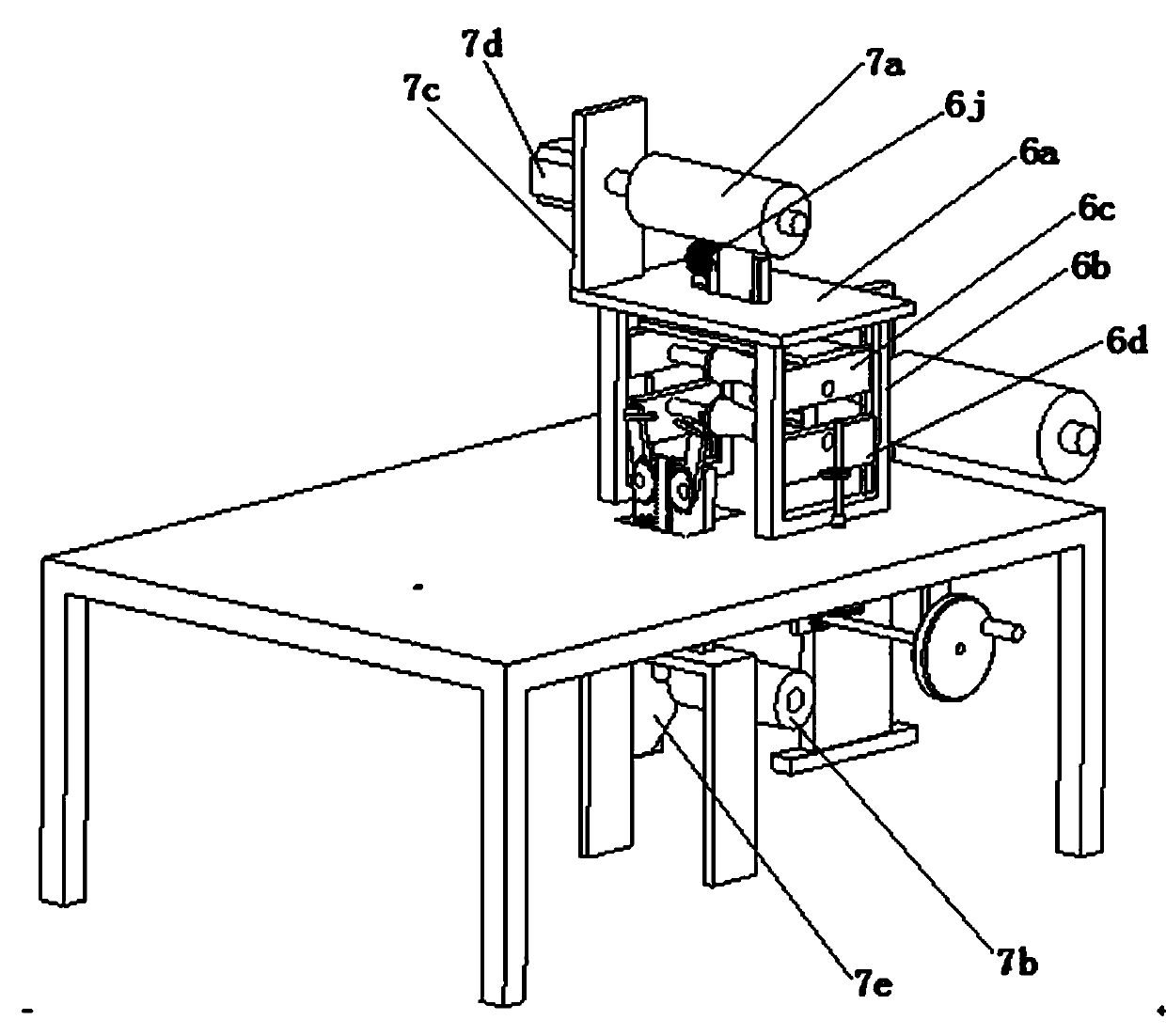

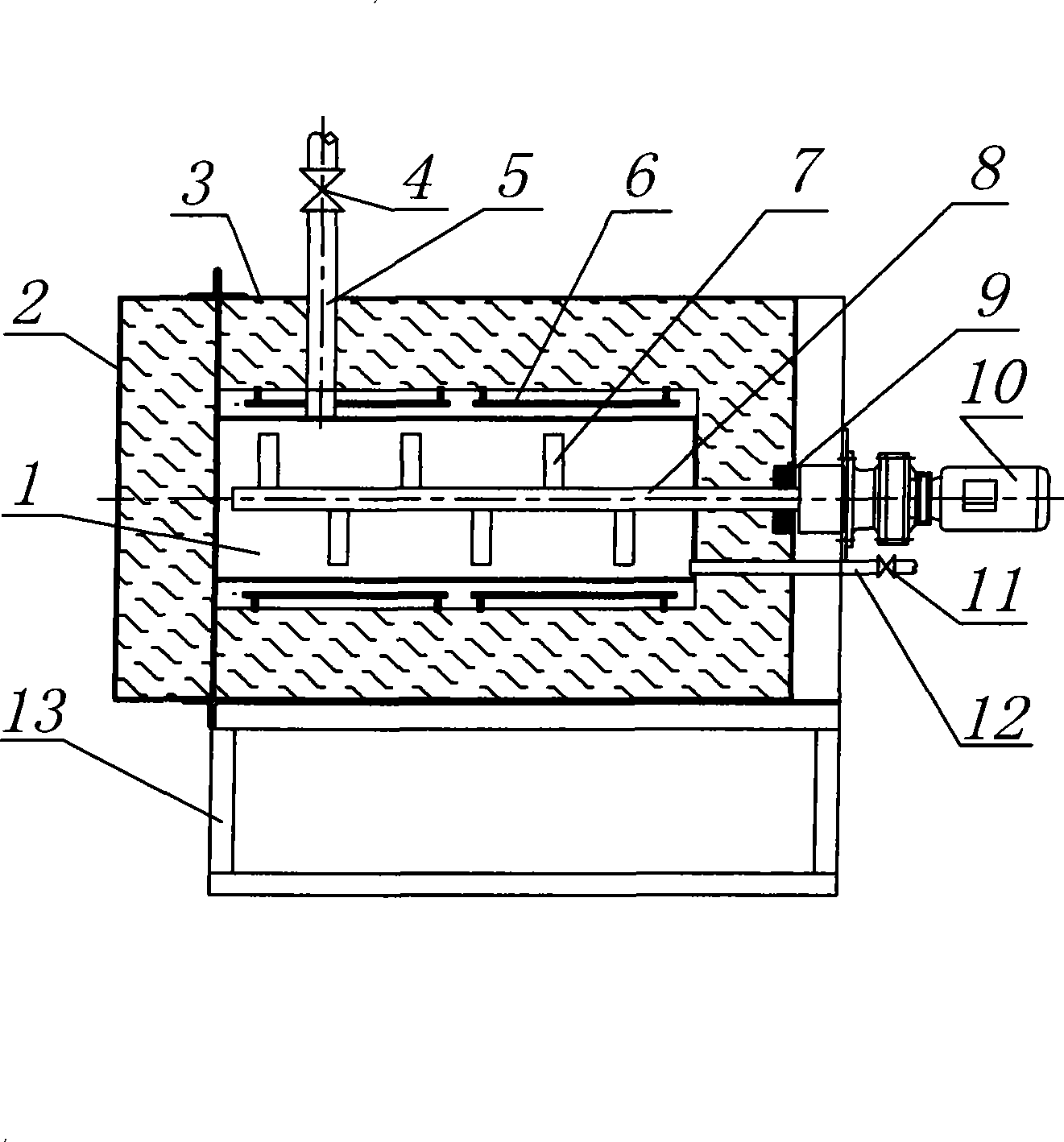

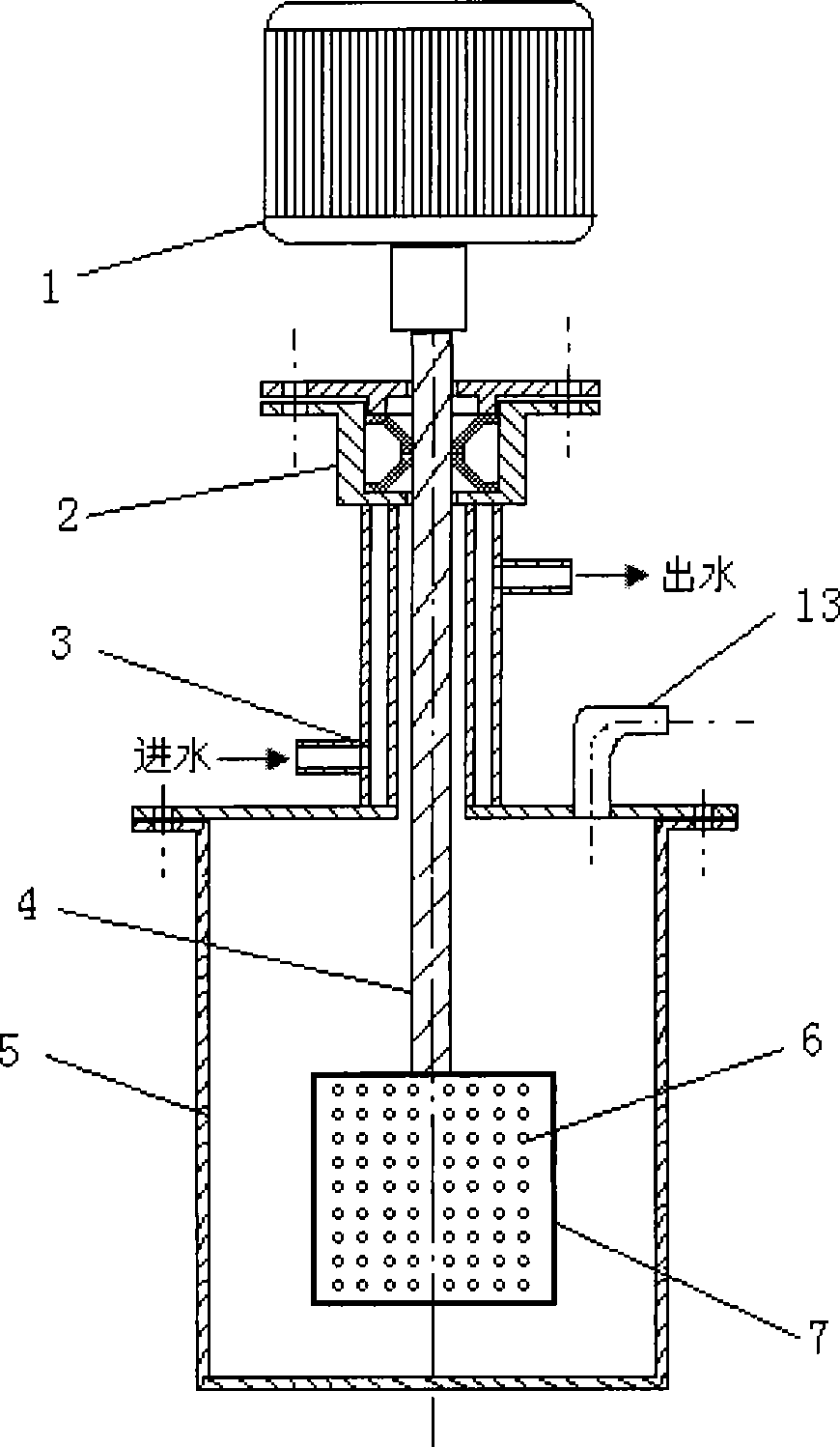

Method and device for disassembling electronic components from waste printed circuit boards and recovering soldering tin

InactiveCN101537522AAchieve separationSpeed up circulationSolid waste disposalElectronic waste recyclingElectricityAutomatic control

The invention provides a method and a device for disassembling electronic components from waste printed circuit boards (PCB) and recovering soldering tin. The method comprises the following steps: placing the PCB with the electronic components in a temperature-setting tin-melting furnace in a manner that the PCB faces up; grabbing larger electronic components manually and feeding the PCB containing smaller electronic components and soldering tin to the conveyor belt after the soldering tin is melted by heat, wherein, an automatic-control electrical heating and warming device is additionally arranged at the bottom of the conveyor belt; pinning down the PCB by a hob and forwarding the PCB, and eliminating the electronic components and the soldering tin by a scraper arranged on the rear side of the hob, so that the soldering tin can be separated from the electronic components on the PCB through the successive coordinating operation of hobs and scrapers in a plurality of groups; recovering the soldering tin by a material-receiving pot; and subjecting the peculiar smell and harmful gases generated by heating the PCB to negative-pressure air draft and absorption treatment and discharging the gases until the discharge standards are met. The invention is suitable for treating PCBs with various thicknesses and recovering electronic components of various types and models; the invention has the advantages of high speed, high efficiency, no pollution, high operability and advanced technology; and the invention contains a novel and environment-friendly method and an equipment for disassembling the waste printed circuit boards and recovering treatment of soldering tin.

Owner:HUNAN VARY TECH

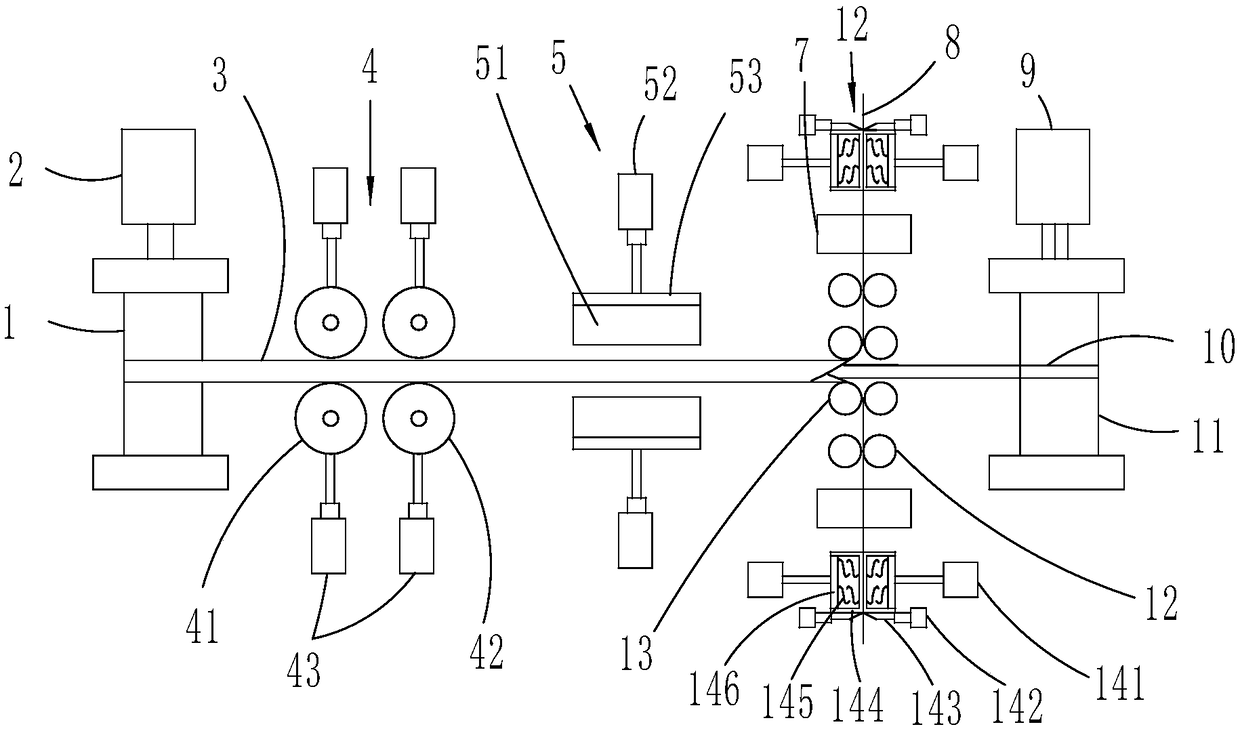

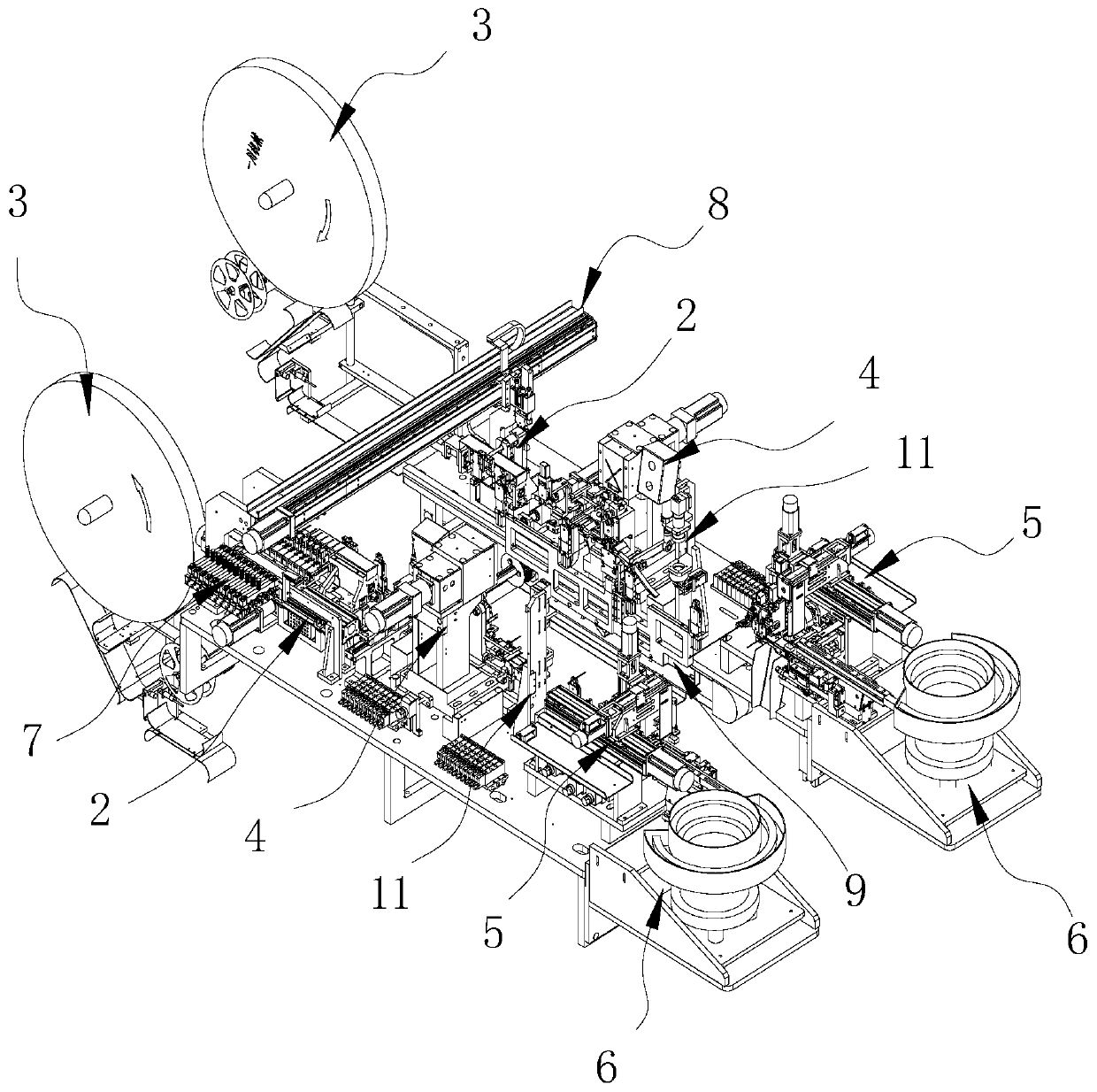

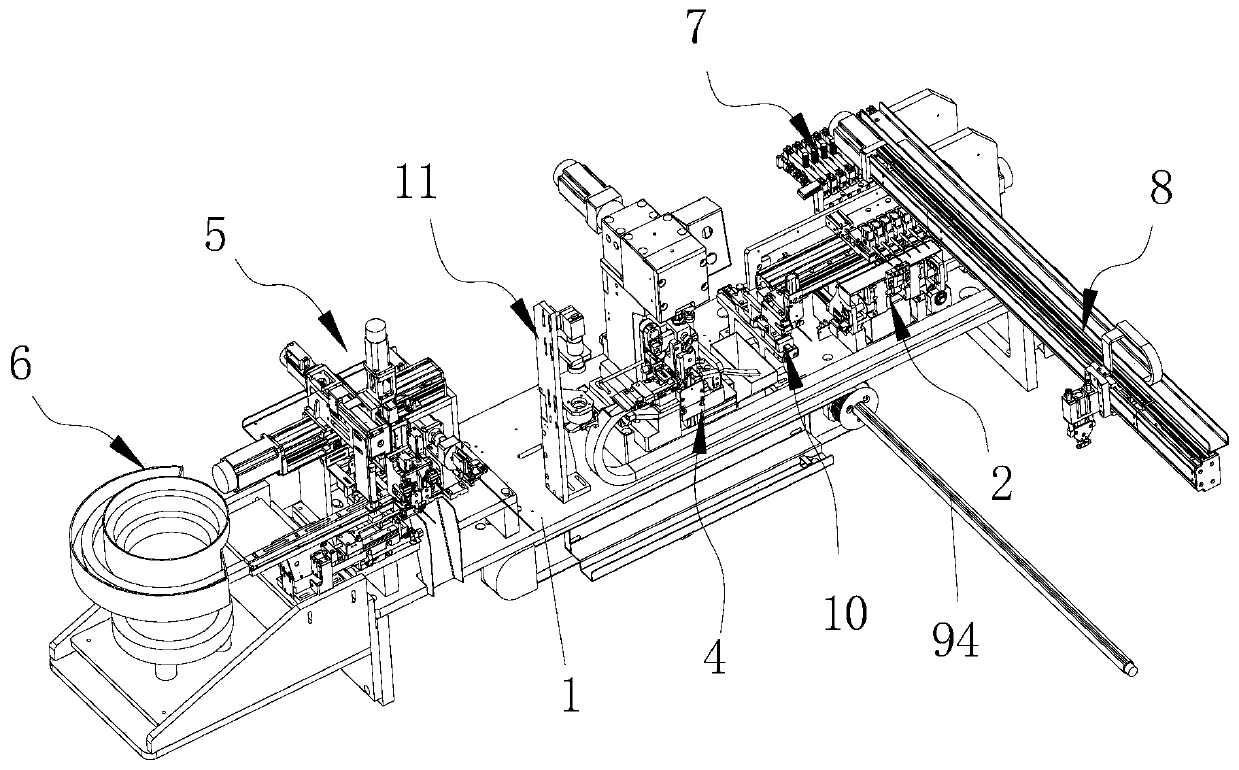

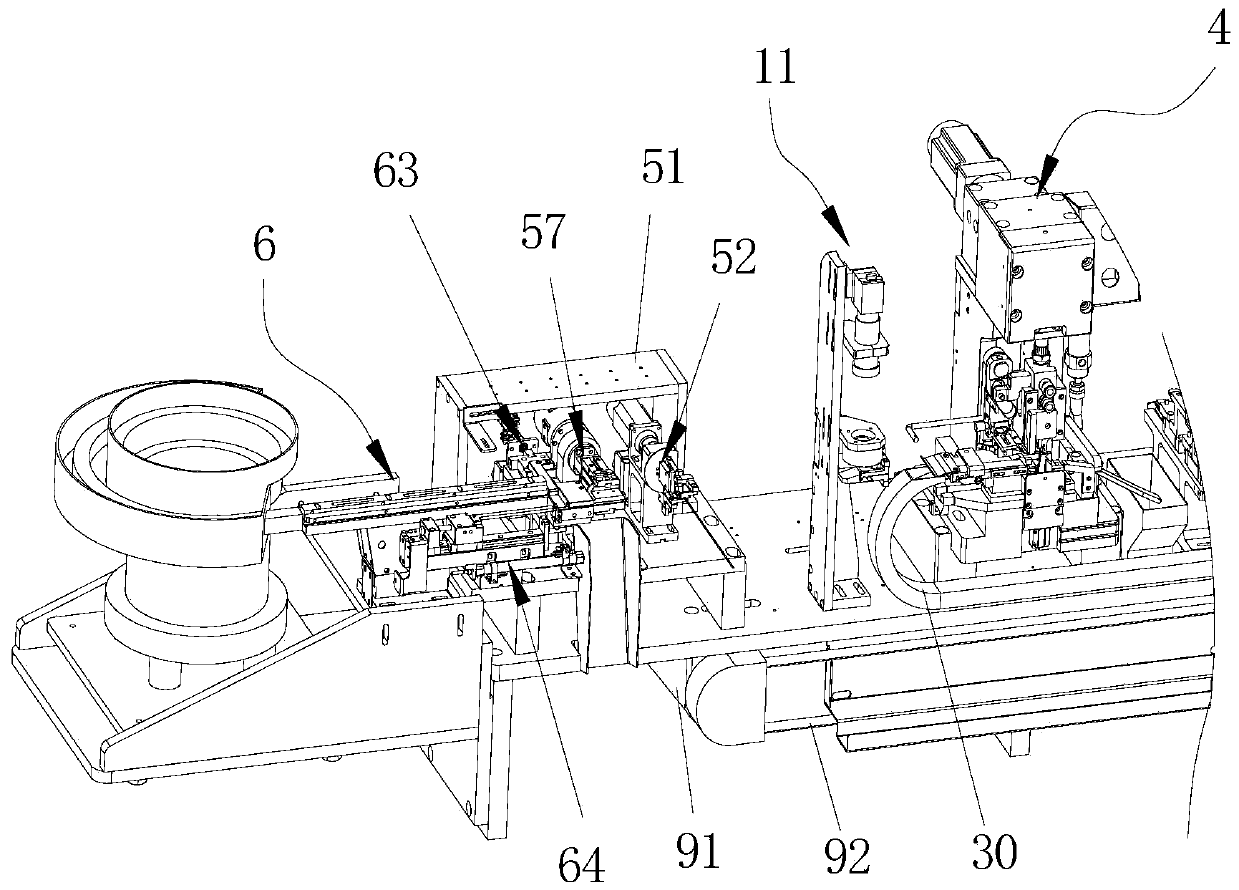

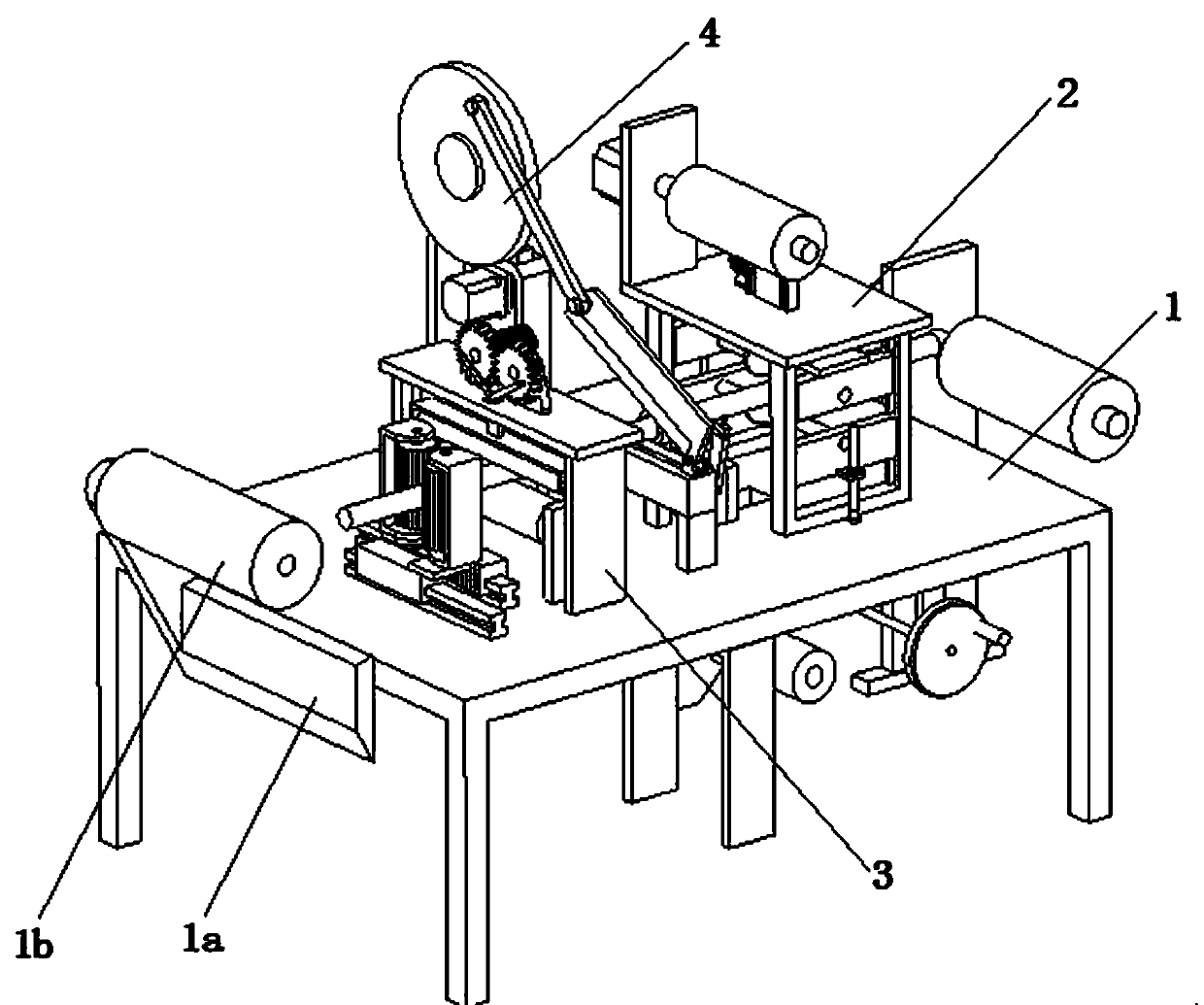

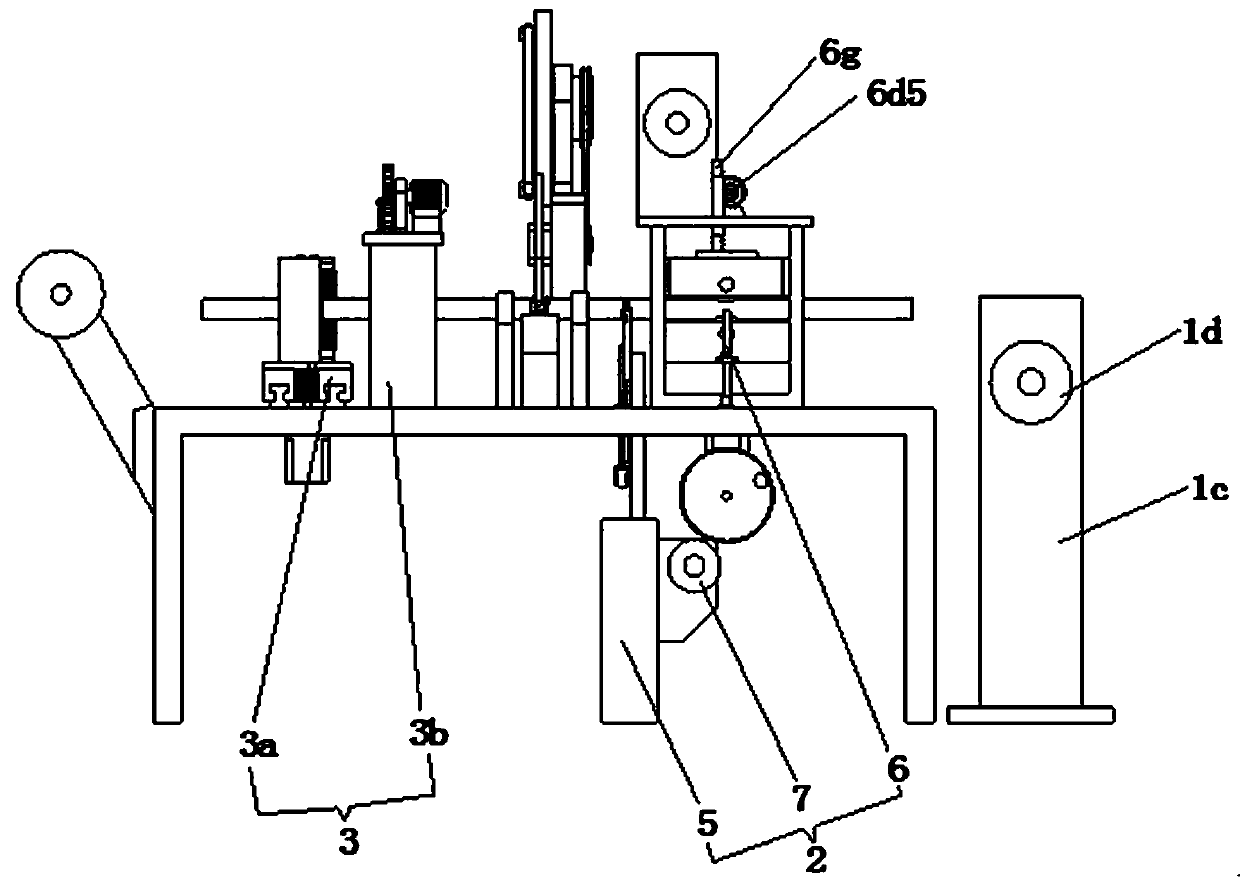

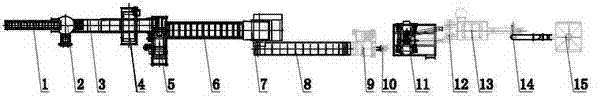

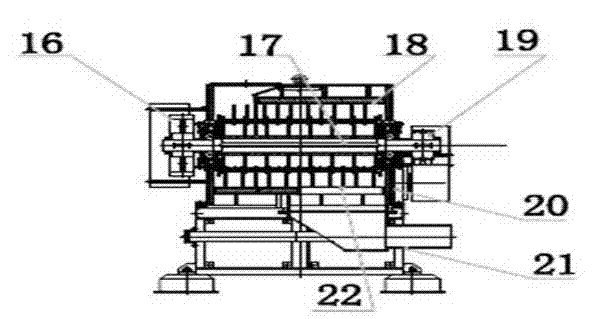

Double-end terminal-pressing and housing-inserting machine for automatically assembling wire harness

PendingCN109888591ARealize automated assembly operationsMeet the requirements of large-scale productionContact member manufacturingContact member assembly/disassemblyPunchingAutomation

The invention discloses a double-end terminal-pressing and housing-inserting machine for automatically assembling a wire harness. The double-end terminal-pressing and housing-inserting machine comprises a wire harness front end assembly unit and a wire harness rear end assembly unit; each of the two units comprises a bracket, a stripping mechanism, a terminal feeding mechanism, a terminal punchingassembly mechanism, a wire-inserting housing mounting mechanism, and a plastic housing feeding mechanism; the terminal feeding mechanism, the stripping mechanism, the terminal punching assembly mechanism, the wire-inserting housing mounting mechanism and the plastic housing feeding mechanism are orderly arranged on the bracket; the wire harness front end assembly unit is further provided with a wire feeding mechanism; and a wire drawing mechanism and a station switching wire shifting mechanism are arranged between the wire harness front end assembly unit and the wire harness rear end assemblyunit. The double-end terminal-pressing and housing-inserting machine provided by the invention integrates the functions of wire feeding, wire drawing, double-head wire stripping, double-head terminalfeeding, double-head terminal punching and wire mounting, double-head plastic housing feeding and double-head wire-inserting housing mounting and the like; the action coordination of various mechanisms can realize the automatic assembly operation of a double-head wire harness, the degree of automation is high the speed is fast, the operation is stable and reliable, the precision is high, and theproduction efficiency and the product quality are improved.

Owner:湖北一川金品机械有限公司

Resourceful treatment method of waste thin film transistor liquid crystal monitor

InactiveCN101690936ALow running costHigh recovery rateSolid waste disposalElectronic waste recyclingHazardous substanceFluorescence

The invention relates to a resourceful treatment method of waste thin film transistor liquid crystal monitors. The method comprises the following steps: sending liquid crystal display panels in a semi-sealed disassembly table to disassemble and remove mercury-containing fluorescent tubes so as to classify and separately recycle metal materials, plastics and glass and reach the aim of recycling resources; at the same time separating mercury-containing fluorescent tubes, organic polarizing film and liquid crystal and separately collecting and processing so as to realize the harmless and safe disposal of hazardous substances. The invention can be widely used for the resourceful recovery treatment of TFT-LCD computer monitors, LCD TVs and other liquid crystal products with similar structure and functions and is characterized by low operating cost and high recovery rate.

Owner:TSINGHUA UNIV

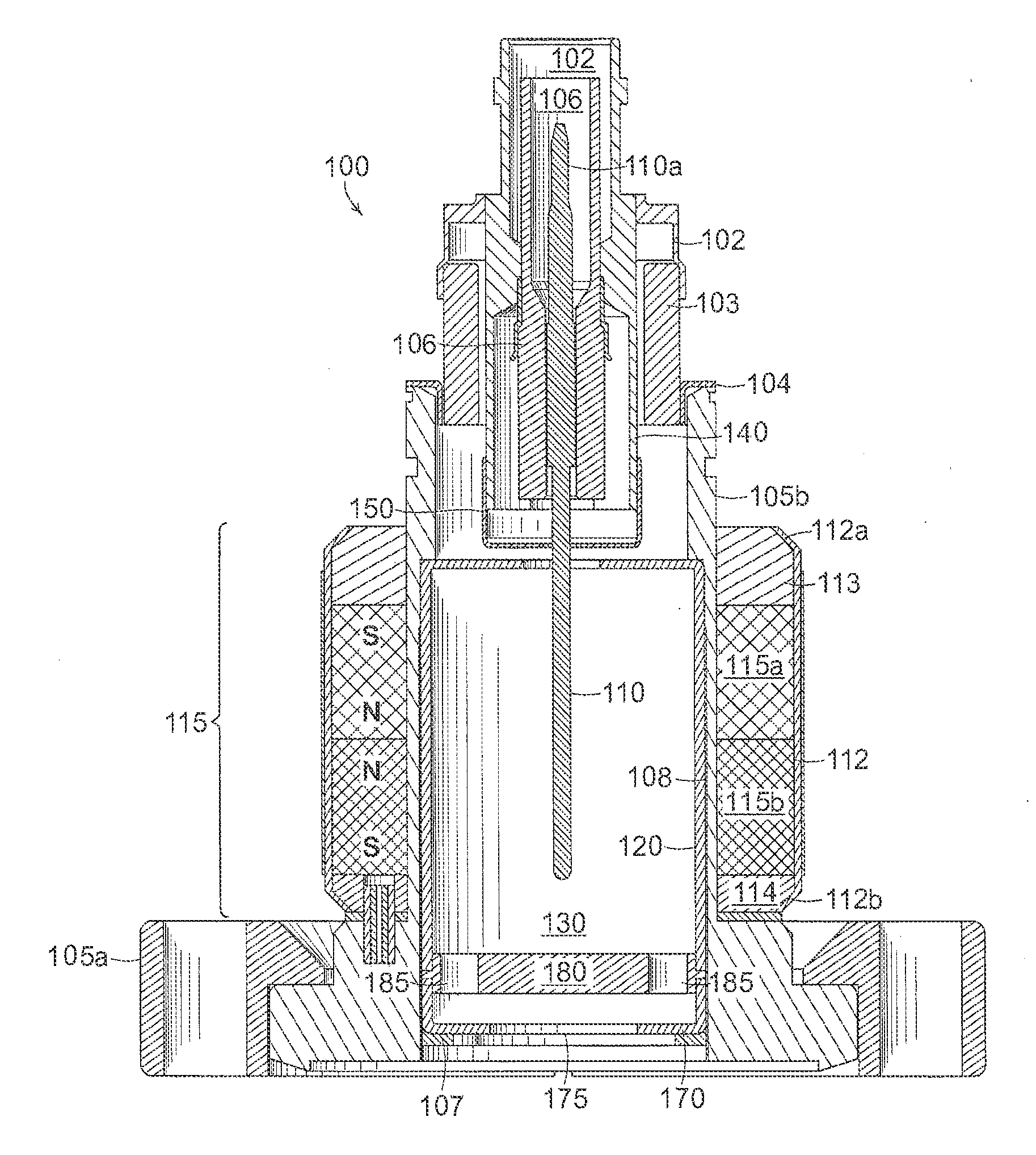

Cold cathode ionization vacuum gauge

ActiveUS20150091579A1Long-term stabilityStart fastVacuum gauge using ionisation effectsManufacture of electrical instrumentsCold cathodeIonization

A cold cathode ionization vacuum gauge includes an extended anode electrode and a cathode electrode surrounding the anode electrode along its length and forming a discharge space between the anode electrode and the cathode electrode. The vacuum gauge further includes an electrically conductive guard ring electrode interposed between the cathode electrode and the anode electrode about a base of the anode electrode to collect leakage electrical current, and a discharge starter device disposed over and electrically connected with the guard ring electrode, the starter device having a plurality of tips directed toward the anode and forming a gap between the tips and the anode.

Owner:MKS INSTR INC

Automatic stripping and recycling device for waste cable

ActiveCN109842061AReduce laborTroubleshoot technical issues with strippingBasic electric elementsApparatus for removing/armouring cablesFixed frameConductor Coil

The invention discloses an automatic stripping and recycling device for waste cables. The automatic stripping and recycling device belongs to the technical field of cable stripping equipment, and comprise a workbench, wherein the top part of the workbench is provided with a cable stripping mechanism, a cable straightening mechanism and a cable cutting mechanism, the cable stripping mechanism comprises a cable limiting assembly, a transverse cutting assembly and a waste sheath winding assembly, the cable straightening mechanism comprises a transverse straightening assembly and a longitudinal straight-pressing assembly, the left end of the workbench is provided with a left fixing frame and an unwinding roller, and the right end of the workbench is provided with a right fixing frame and a material collecting roller. The automatic stripping and recycling device can strip cable sheathes of different diameters by means of the cable stripping mechanism, so that the sheathes of the cables aredivided into two sections and the winding operation can be automatically completed by means of the waste sheath winding assembly, and the cable straightening mechanism can automatically straighteningthe passing cables, so as to avoid the transverse cutting assembly from cutting bent cables and damaging the cables.

Owner:ANHUI HUATENG AGRI TECH CO LTD

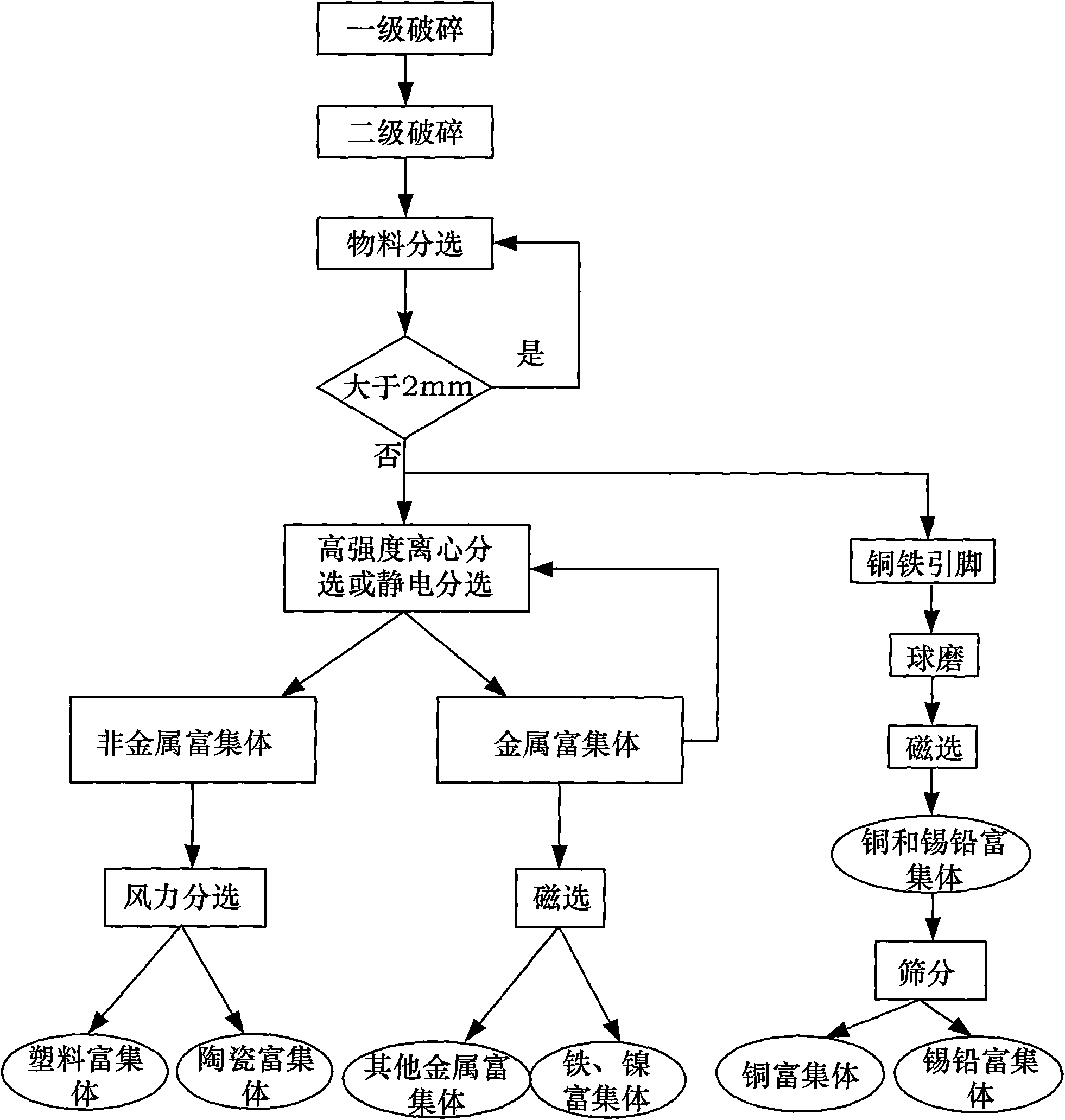

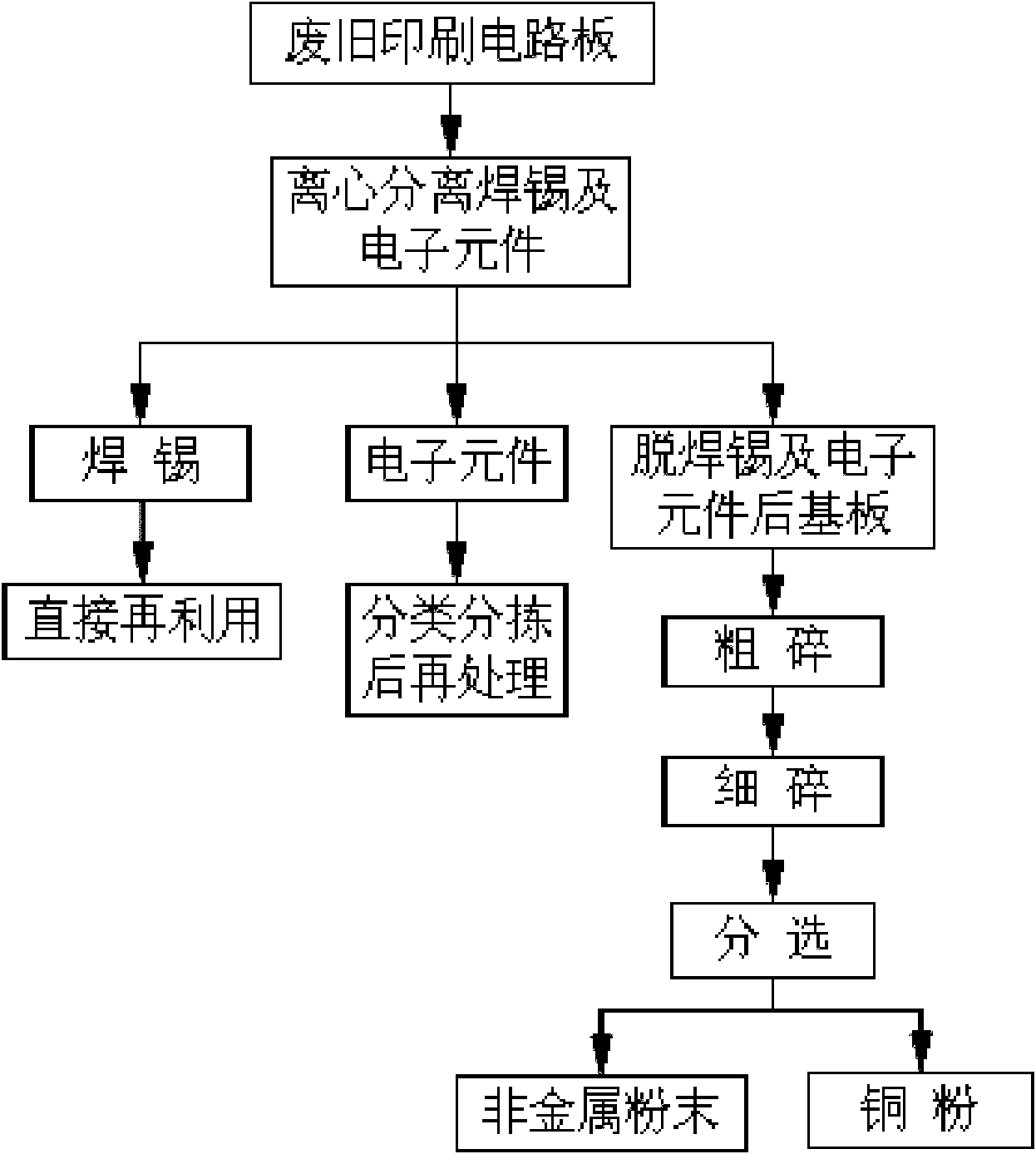

Method for synthetically recycling waste printed circuit board

InactiveCN101623698AAffect purificationImprove efficiencySolid waste disposalSoldering apparatusCrusherCopper

The invention provides a method for synthetically recycling a waste printed circuit board. The method comprises the following steps: (1) the waste printed circuit board with electronic elements is placed in a rotary drum and dipped in a liquid heating medium to melt soldering tin on the waste printed circuit board, the rotary drum is rotated, and the melted soldering tin can be filtered by passing through filtering holes on the wall of the rotary drum under the centrifugal effect of the rotation of the rotary drum; (2) the falling electronic elements are classified, sorted and further processed; and (3) the waste printed circuit board is coarsely crushed by adopting a cutting type crusher after the soldering tin and the electronic elements are removed, a fine crusher is adopted to fine crush the coarsely crushed printed circuit board to ensure that metal and nonmetal are mutually dissociated, and the dissociated mixing materials are separated by a pneumatic separator or a static separator to respectively obtain copper powder and nonmetal powder. The invention realizes scale treatment of the waste printed circuit board with low cost and high efficiency, and ensures that valuable substances such as nonmetal, soldering tin, copper and other metal are synthetically recycled.

Owner:CENT SOUTH UNIV

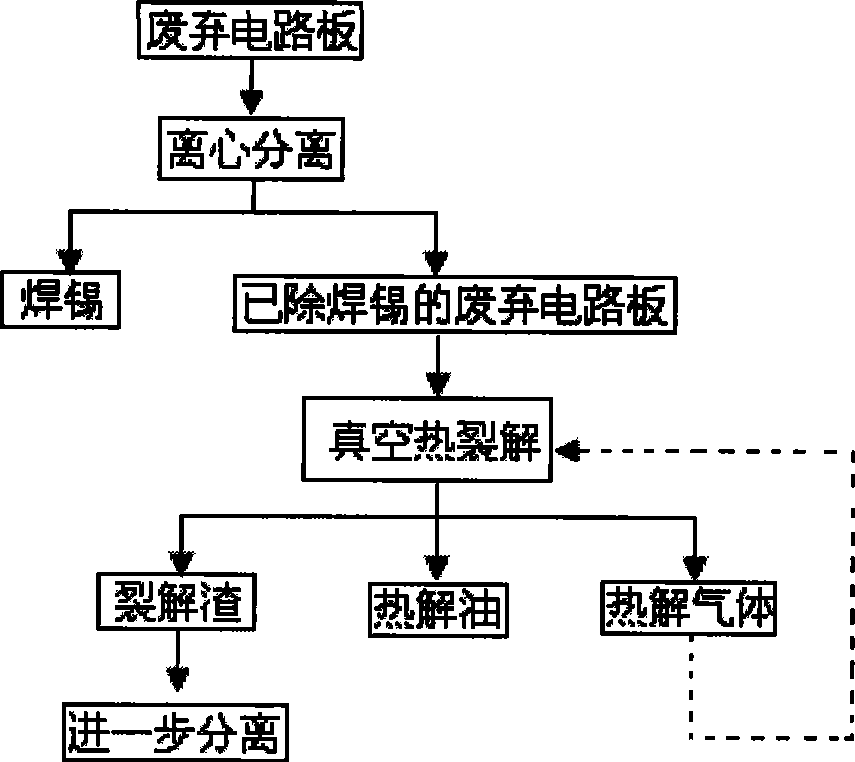

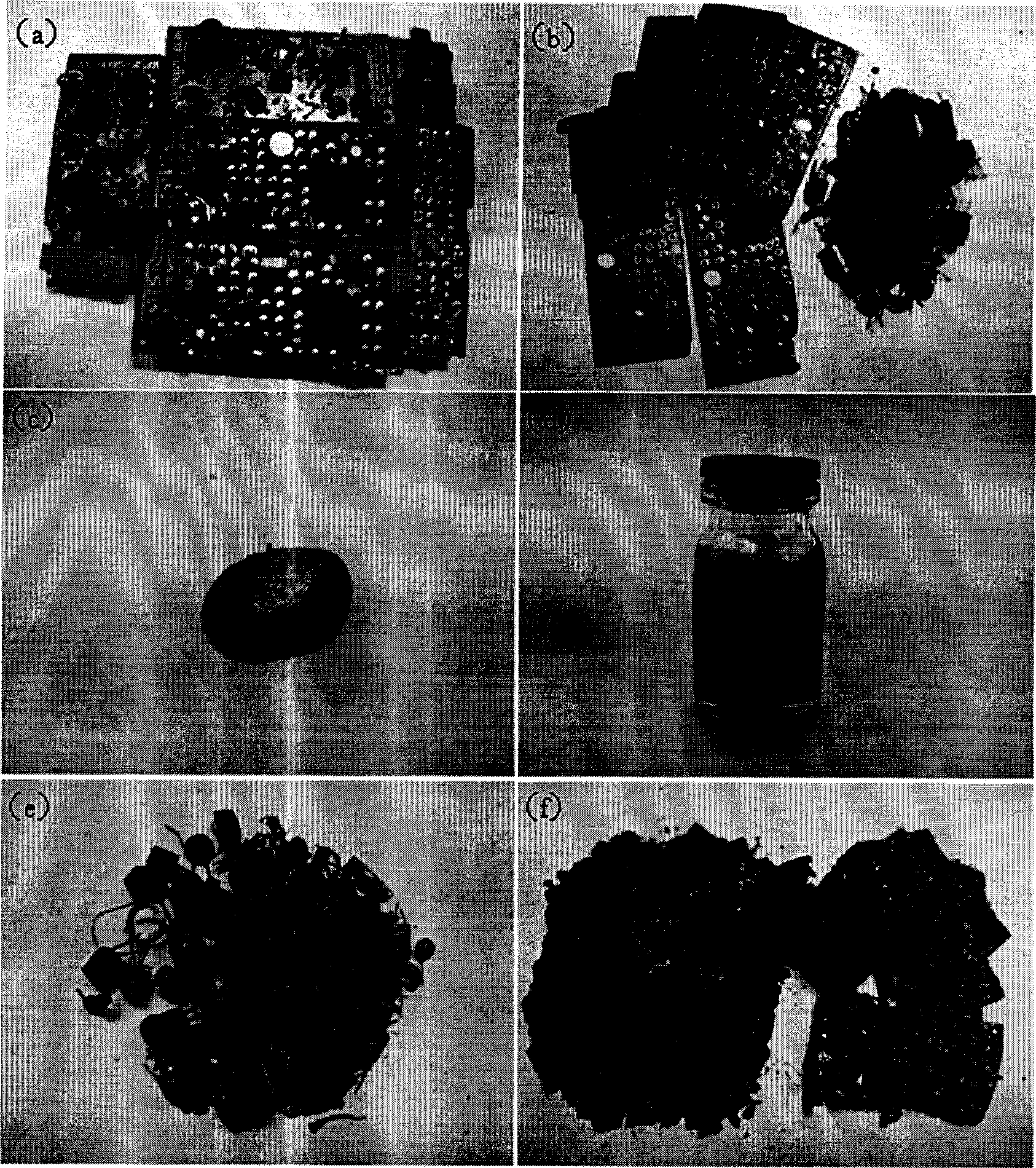

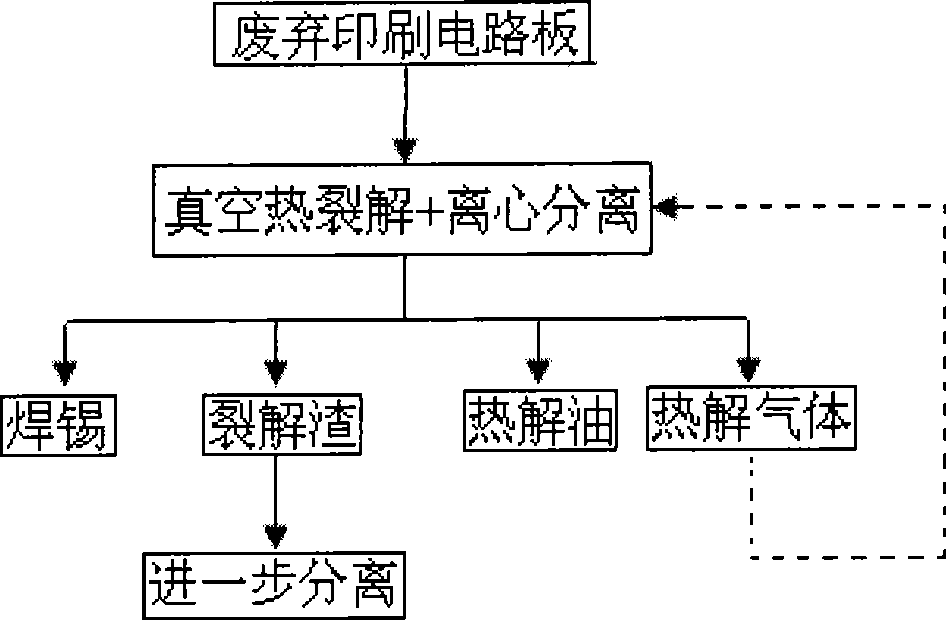

Recovery method of waste circuit board

InactiveCN101423898AEfficient separationOptimizationSolid waste disposalLiquid hydrocarbon mixture productionRecovery methodGlass fiber

The invention provides a method for recovering waste circuit boards. The method comprises the following: 1. a step of heating and centrifugally separating, which is to put the waste circuit boards in an oil bath, heat to melt solder and pass the waste circuit boards with the solder melted through a centrifugal machine so as to efficiently separate the solder from the waste printed circuit boards; 2. a step of cracking in vacuum, which is to put waste circuit board substrates with the solder removed, as well as an electron component in a vacuum cracking device, heat for thermal cracking, collect thermal-cracking volatile products and condense the volatile products into fluid oil; and 3. a step of collecting solid matter after vacuum cracking, which is to classify and collect the electron component and the circuit board substrates after thermal cracking, so as to recover precious metals and other valuable metals of the electron component, as well as copper foil, glass fiber and other substances on the circuit board substrates. The method performs treatment by stages according to the structural characteristics of the waste circuit boards, has the advantages of simplicity, no pollution, low cost, high efficiency and high rate of recovering waste resources of the waste circuit boards, and is suitable for industrial application and the large-scale recovery of the waste circuit boards.

Owner:CENT SOUTH UNIV

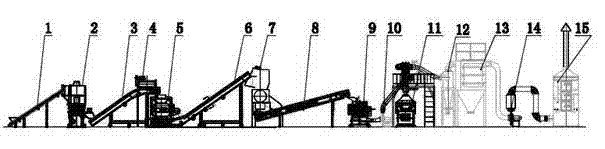

Harmless treatment and resource recovery method and harmless treatment and resource recovery equipment for waste circuit board with components

InactiveCN102962242AScientific recycling processReasonable recycling processSolid waste disposalElectronic waste recyclingActivated carbonEddy current separator

The invention relates to harmless treatment and resource recovery method and harmless treatment and resource recovery equipment for waste circuit boards with components. The equipment comprises a first-level conveyor belt, a compound crusher, a two-level conveyor belt, a permanent magnet deironing separator, an eddy current separator, a three-level conveyor belt, a two-level hammer crusher, a four-level conveyor belt, a three-level hammer flake type crusher, a material conveying fan, a vibrating separator, a cyclone separator, a bag type dust collector, a draught fan and activated carbon adsorption tower. The method comprises the steps that: crushing the waste circuit boards with components into fragments in the compound crusher, separating out irons through the permanent magnet deironing separator, and separating out copper, aluminum and other nonferrous metals on a belt of the eddy-current separator; entering the two-level hammer crusher for further dissociation and crushing, and separating out irons; and driving the balance of materials to enter the three-level hammer flake type crusher, and fully crushing the materials into powder with 60-100 meshes to the vibrating separator. The method and equipment have the advantages that the investment is few, the energy consumption is low, the running cost is low, and the process and the operation are simple, and the production efficiency can be greatly improved and no secondary pollution is caused.

Owner:汨罗万容电子废弃物处理有限公司

Metal and non-metal pyrogenation separation method on waste printed plate board

InactiveCN101386015AEfficient separationHigh recovery rateSolid waste disposalElectronic waste recyclingLiquid wasteLiquid product

The invention discloses a pyrolysis and separation method of metals and non-metals in waste printed circuit boards. The method comprises the following steps: waste printed circuit boards are placed into a furnace cavity of a pyrolysis device, after the furnace door is tightly closed, nitrogen gas is introduced; the material in the furnace cavity is heated at the heating rate of 15-20 DEG C per minute, the temperature thereof is raised to 600-700 DEG C and kept for 20-30min, then the furnace is shut down, micro-positive pressure is kept in the furnace cavity in the process of heating the material, and the material are stirred irregularly; (3) the pyrolysis product is discharged from the pyrolysis device, and a liquid product and a gaseous product are separated after the pyrolysis product exchanges heat with a cooling medium. The method can realize effective separation of the metals and non-metals in the waste PCB, and realize harmless thermal separation of solid wastes; and the method avoids environmental pollution caused by waste water, waste gas, waste liquid, and the like, produced in the treatment process of the prior art; and the recovery purity of the metals is higher.

Owner:TIANJIN UNIV

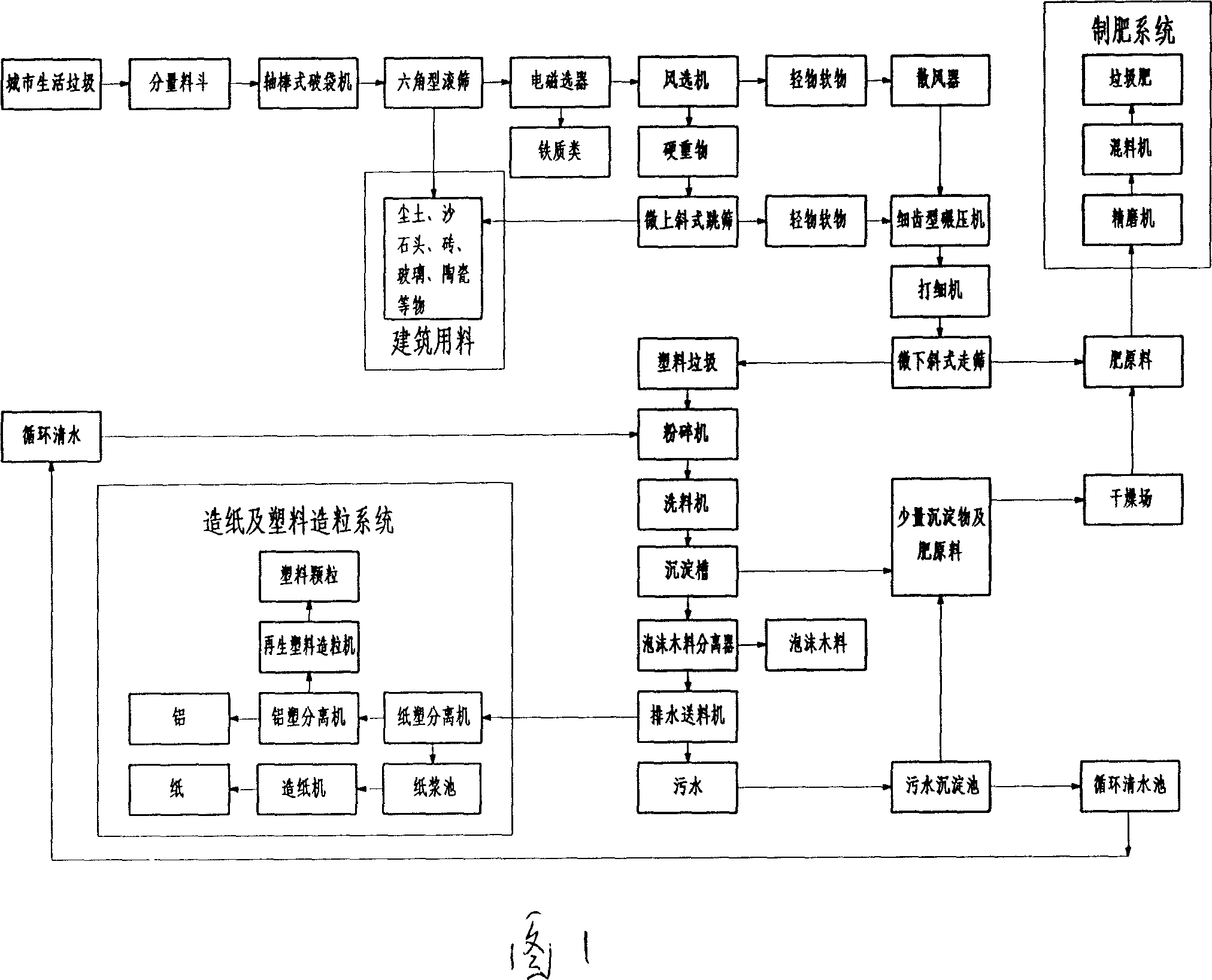

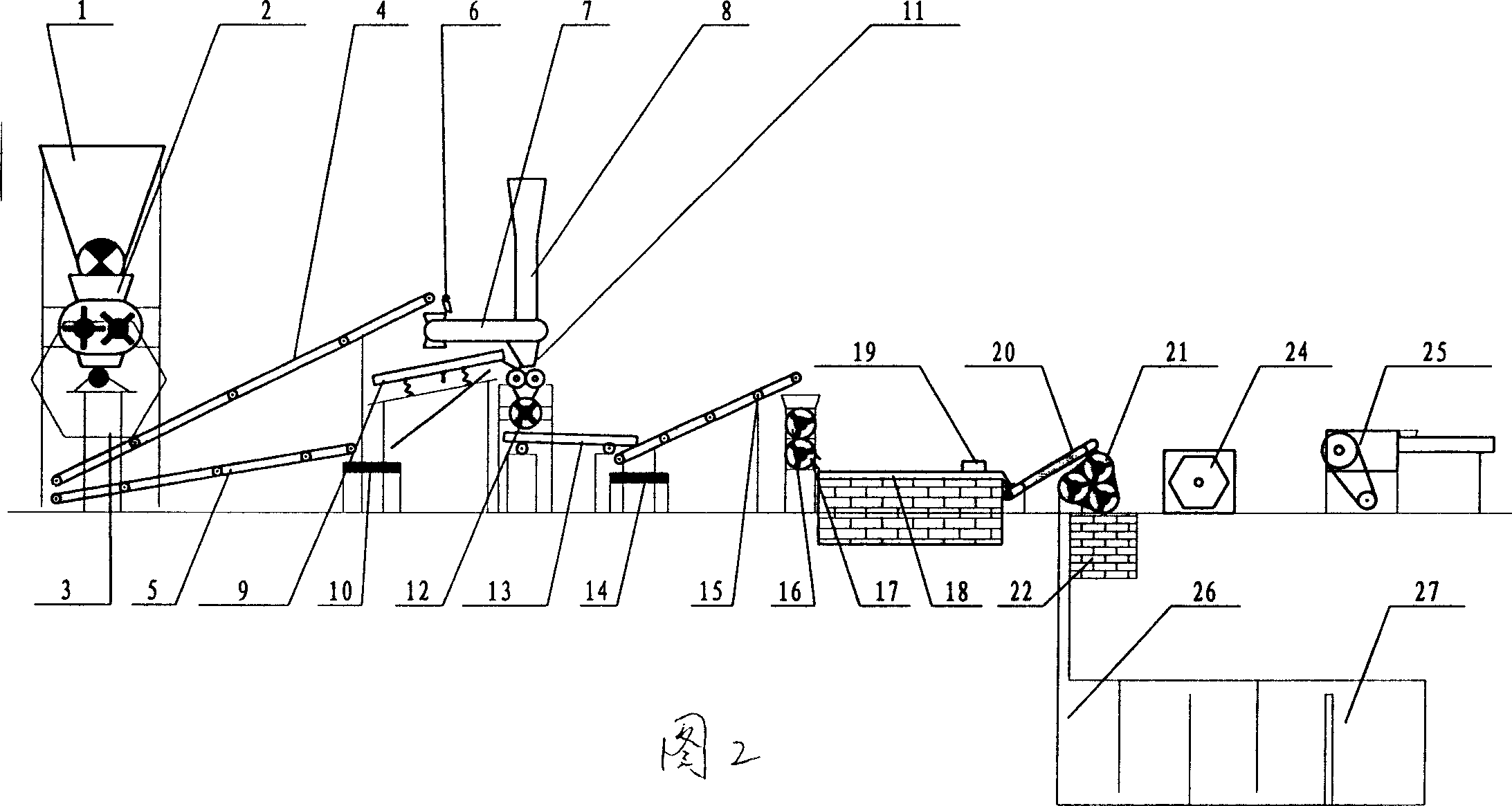

Method and apparatus for treating urban domestic refuse

InactiveCN101028627AReduce consumptionEliminate pollutionGas current separationSolid waste disposalLitterEngineering

An apparatus for reclaiming the city life garbage is composed of feeding hopper, rod-type bag breaker, hexagonal rolling sieve, conveying belt, electromagnetic separator, drum-type pneumatic separator, wind distributor, jump sieve, fine-teeth rolling machine, beater, moving sieve, pulverizer, washing unit, paper-plastics separator, Al-plastics separator, granulating unit, grinder, mixer and paper-making machine. Its method is also disclosed.

Owner:邵道德

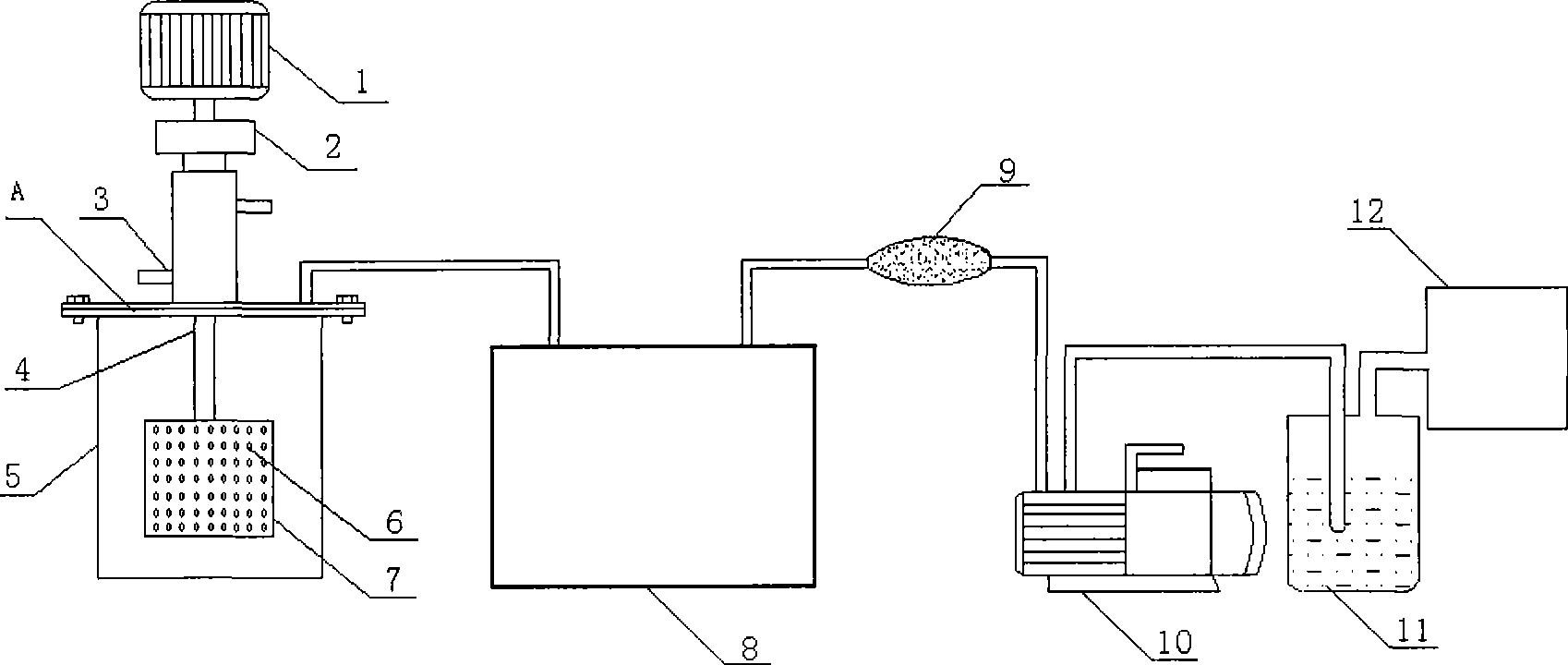

Method and device for high-efficiency recovery of waste circuit boards in vacuum

InactiveCN101444784ANo secondary pollutionSuitable for recyclingSolid waste disposalElectronic waste recyclingEngineeringPrinted circuit board

The invention discloses a method and a device for high-efficiency recovery of waste circuit boards in vacuum. The method comprises the following steps: the waste circuit board is arranged in a vacuum vessel and heated for pyrolysis, wherein, most of pyrolysis volatile matter is cooled and liquefied into liquid oil, and the rest is taken into a gas collector; a centrifuge device separates soldering tin from the circuit board during the pyrolysis; substrates and electronic components of the pyrolyzed circuit board are assorted and collected to be further separated and recovered. The device comprises a compound vacuum pyrolysis and centrifuge device, a cold trap, the gas collector and a vacuum pump. The vacuum vessel of the compound vacuum pyrolysis and centrifuge device is sequentially connected with the cold trap, the vacuum pump and the gas collector by pipelines. The device has the advantages of simple process, no pollution, low cost, high efficiency, and high recovery ratio of waste resources of the waste circuit boards. The soldering tin and organic substances of the waste circuit boards are synchronously recovered, and the soldering tin is separated from other metals at a high efficiency, thus creating a good condition for high-efficiency recovery of other metals. The method and the device are suitable for industrialized application and can help achieve large-scale recovery of the waste circuit boards.

Owner:CENT SOUTH UNIV

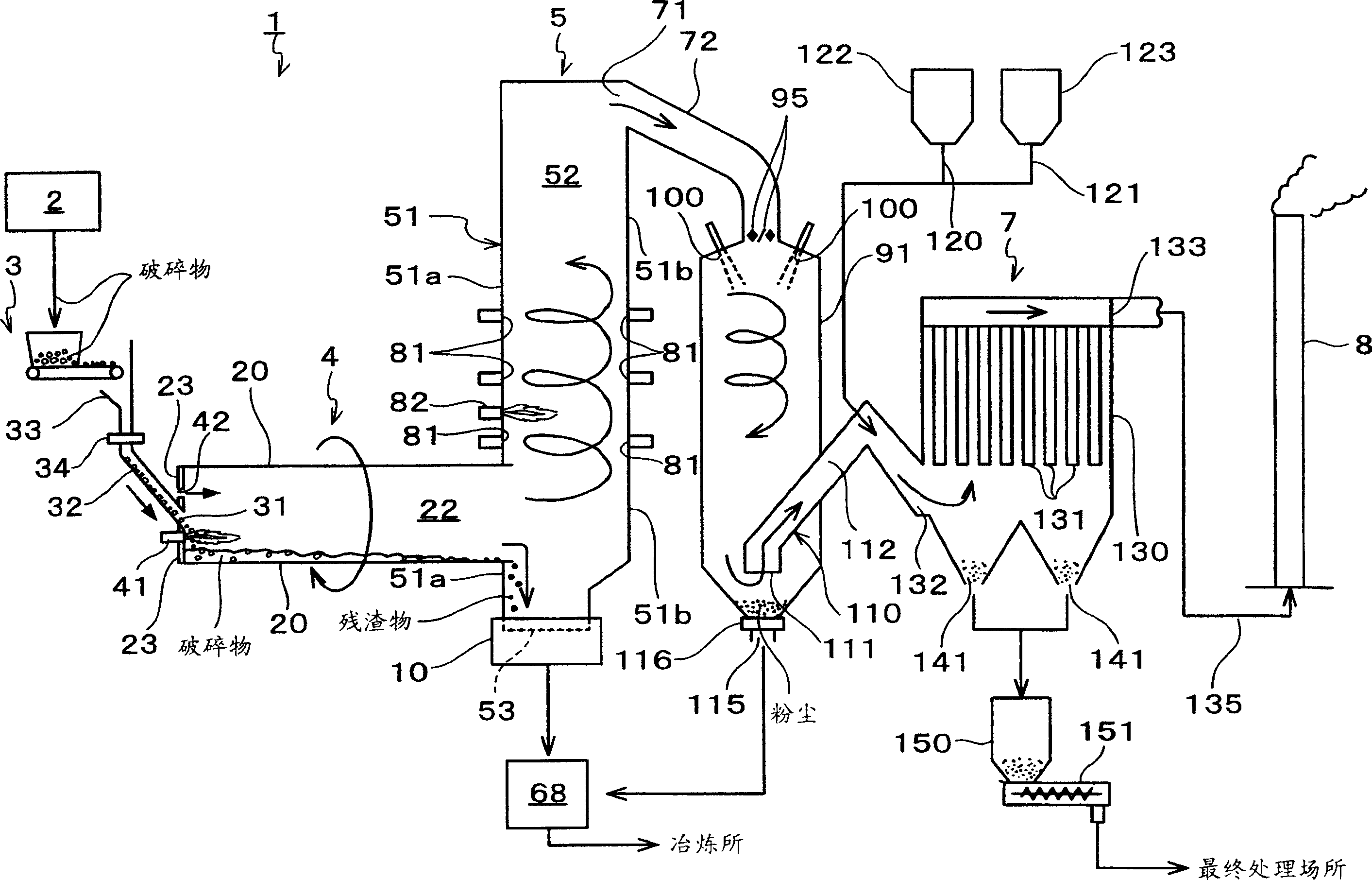

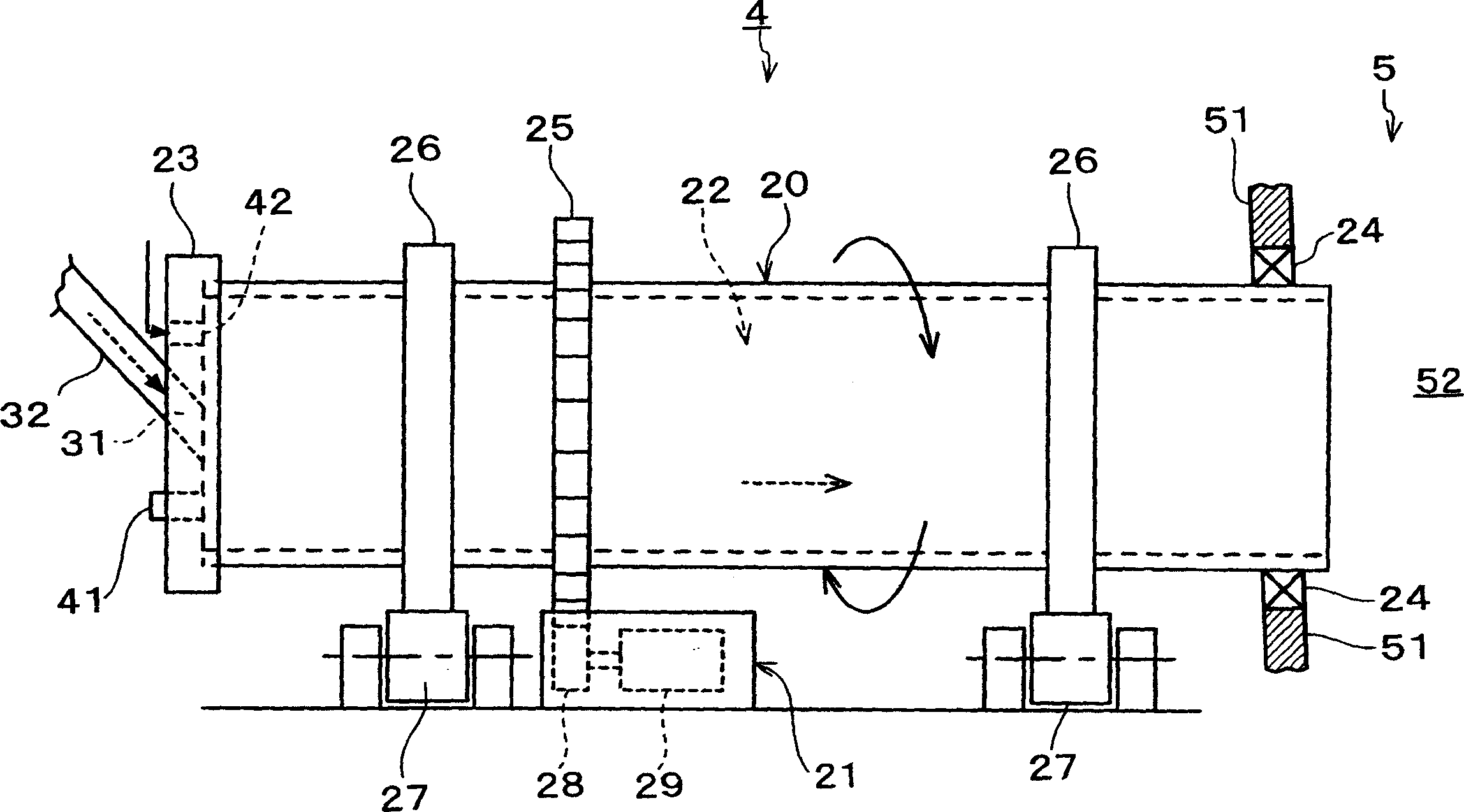

Castoff processing method and system

ActiveCN1834537AEfficient combustionEfficient gasificationProcess efficiency improvementIncinerator apparatusWaste processingHazardous substance

The invention relates to a waste processing method and a waste processing system which can avoid discharging harmful material as dioxins and effectively attain the slag of value metal. Wherein, the method for recycling value metal comprises: burning the waste, recycling the slag that containing value metal, and fully burning generated gas , and cooling said burning gas with the cooling speed that avoiding generating dioxins. With said method, the invention can gasify the resin component in the waste via burning waste, to obtain the slag of value metal in short time.

Owner:DOWA METALS & MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com