Method and equipment for breaking down and reclaiming electronic components and solder of discarded circuit board

A technology of electronic components and recycling methods, which is applied in the field of dismantling and recycling of electronic components and solder of waste circuit boards, and the field of devices, which can solve problems such as high operating costs, low efficiency of dismantling and recycling, and complex system structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

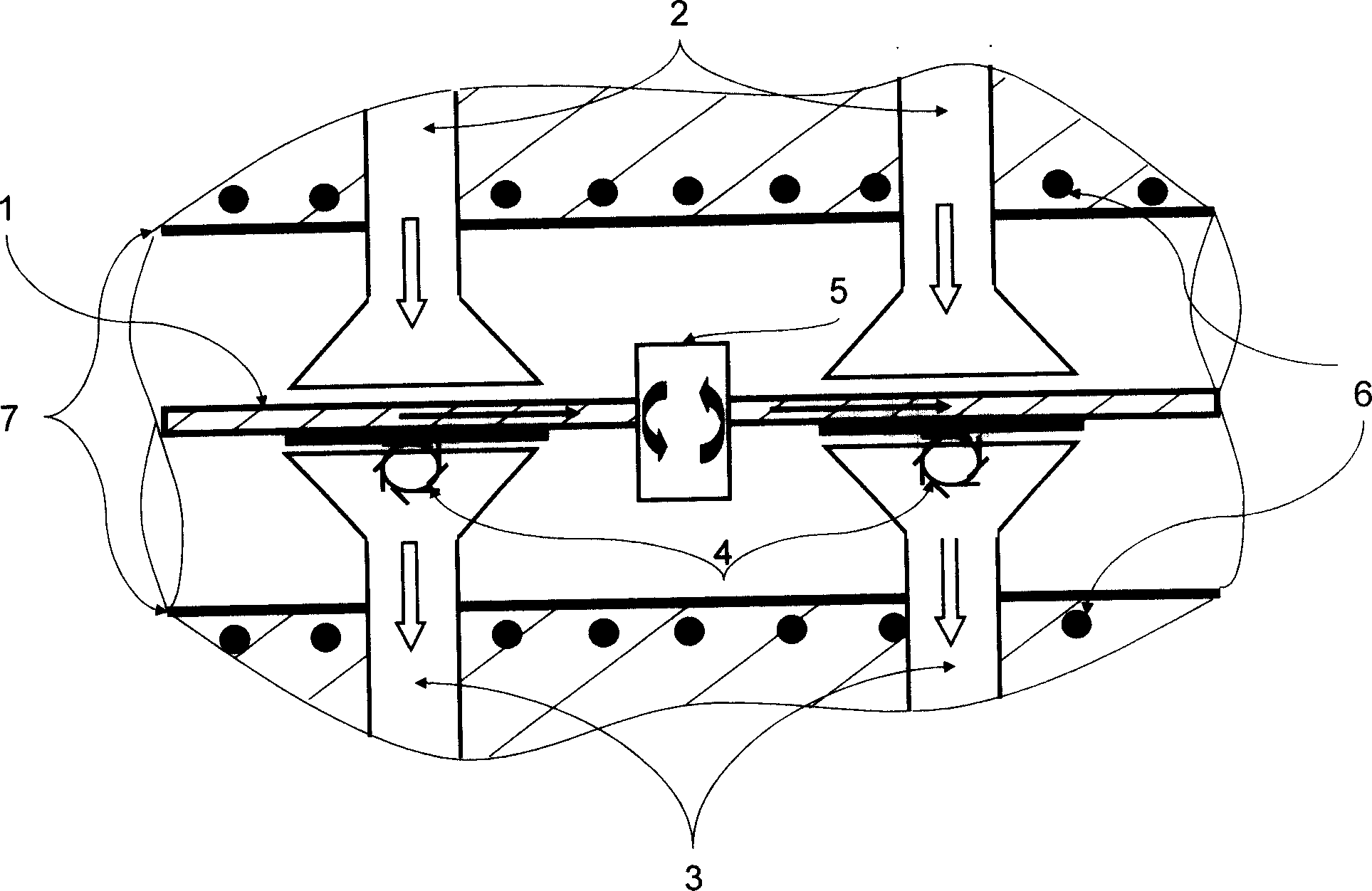

[0014] Description of the main technological process of this set of equipment:

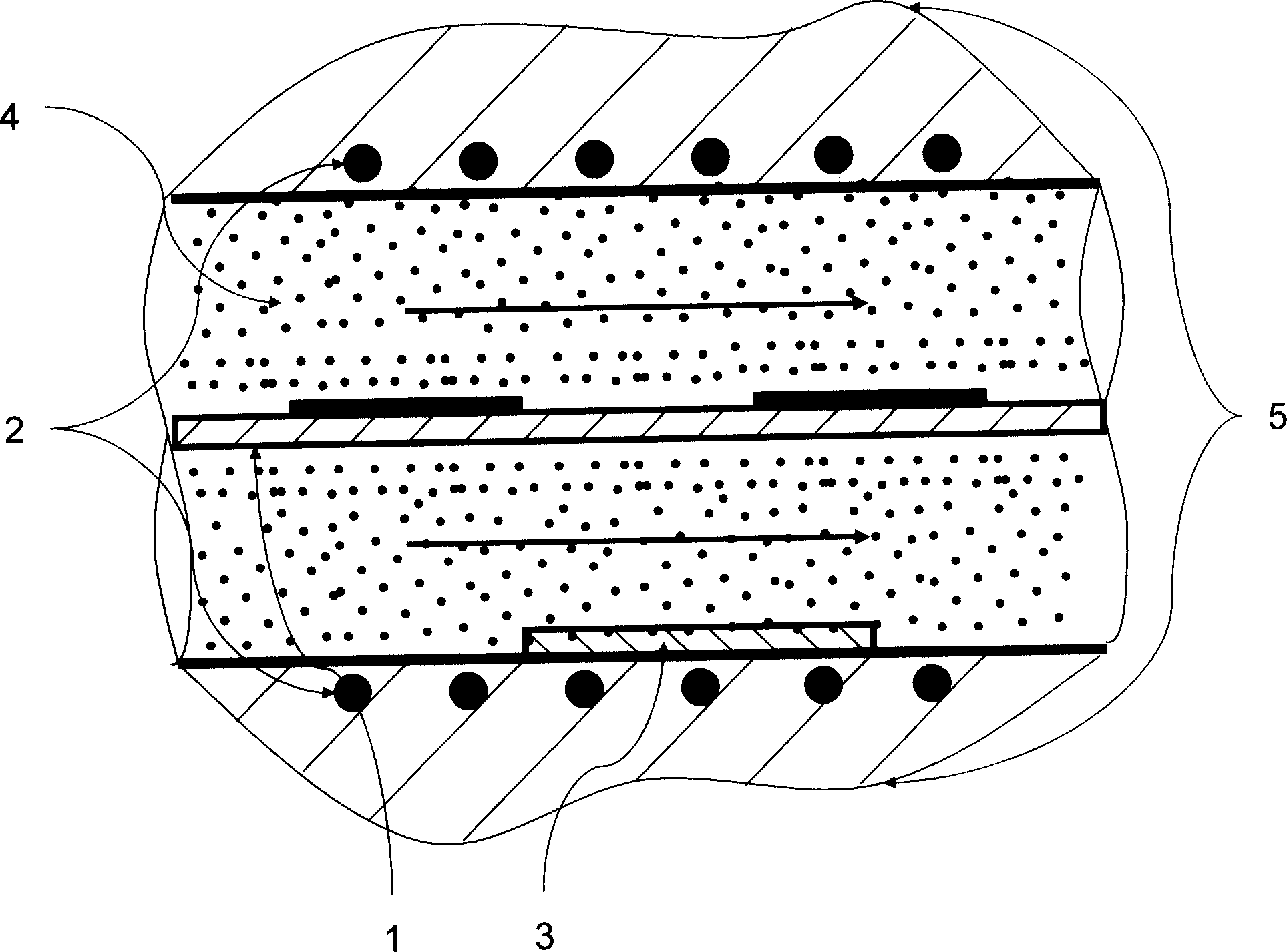

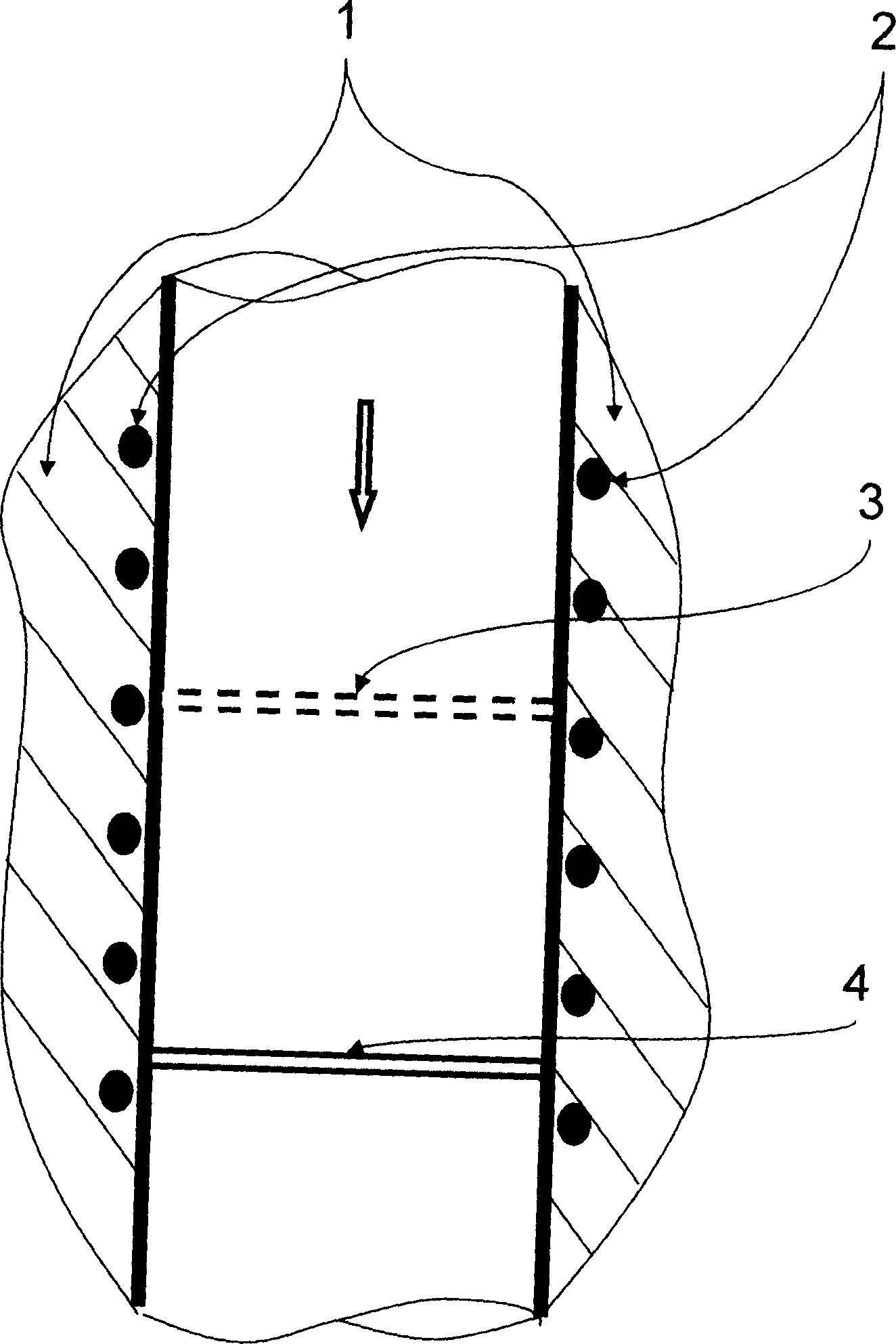

[0015] Discarded circuit boards are screened and sorted through a series of pre-processing mechanisms (not shown), some sundries are removed, and the circuit boards are cleaned and dried as necessary before entering Figure 1 The shown preheating and heating device. The purpose of setting up the device is to melt and bond the solder alloy of the electronic components, so as to carry out the subsequent component disassembly and recovery of components and solder. The heating method of the device is not particularly limited, as long as the circuit board can be uniformly heated at the end of the device to a temperature above the melting point of the solder (when the solder contains eutectic components, the temperature is 183°C) and maintained, so that the solder is evenly melted and kept in a molten state That's it. The temperature setting of the preheating and heating device should be adjustable, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com