Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2840results about How to "Achieving zero emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

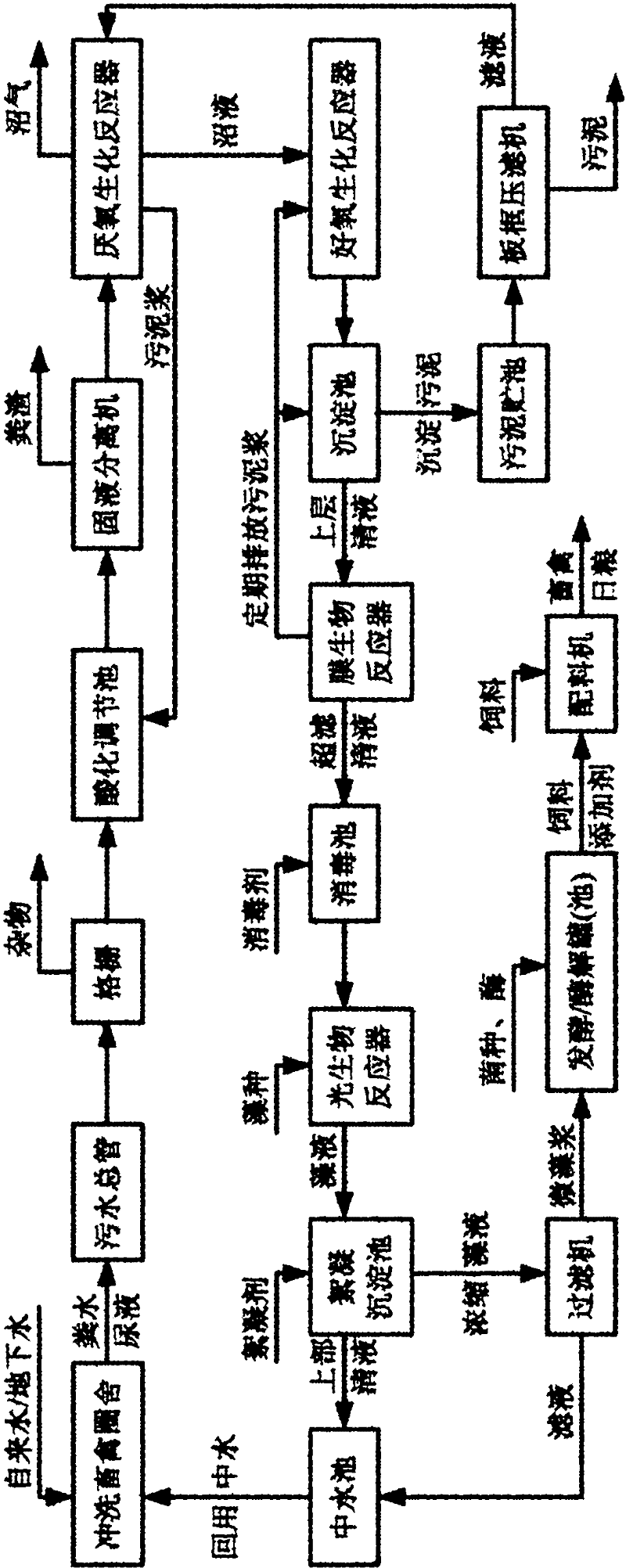

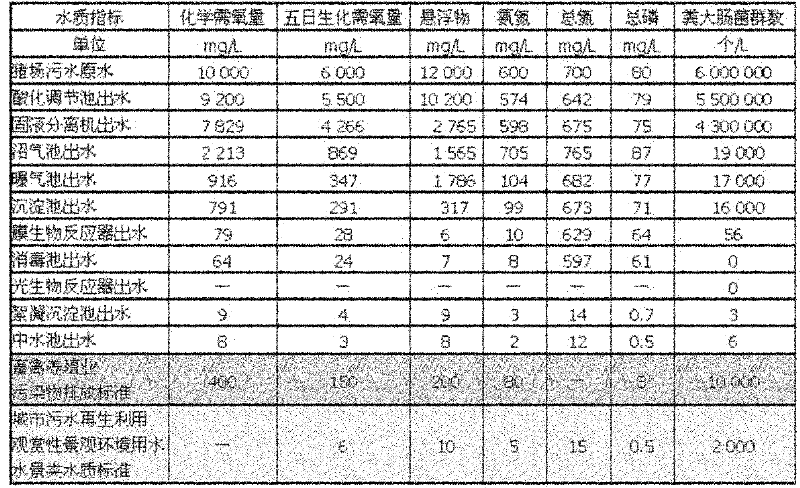

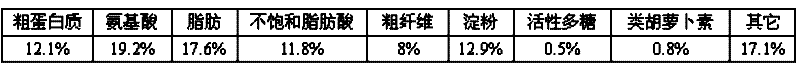

Method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water

InactiveCN102161550AReduce water consumptionAchieving zero emissionsWaste water treatment from animal husbandryAnimal feeding stuffUltrafiltrationSlurry

The invention relates to the fields of environmental technology and the breeding and processing of microalgae, in particular to a method for producing feed additive from livestock and poultry breeding wastewater and purifying breeding wastewater to reclaimed water. The method is characterized by comprising the following steps that: wastewater enters an acidification adjusting tank through a grille, and the acidified wastewater enters an anaerobic biochemical reactor for treatment and then enters an aerobic biochemical reactor; after the aerobic biochemical treatment, the obtained biogas slurry enters a settling tank for settling, the supernatant enters a membrane bioreactor for further aerobic treatment and is filtered by an ultrafiltration membrane, the generated ultrafiltration clear liquid is sterilized and neutralized and then enters a photobioreactor, algae are added into the photobioreactor to perform microalgae cultivation, and the algae liquid is discharged from the photobioreactor and then enters a flocculation and settling tank; and after flocculation and settling, the supernatant is used for water recycling, the concentrated algae liquid at the bottom enters a filter, and the separated microalgae slurry enters a fermentation / enzymolysis pot (tank) to perform fermentation / enzymolysis to be used as the feed additive. The invention has the advantages of high economic adaptability, zero discharge and the like.

Owner:蔡志武 +1

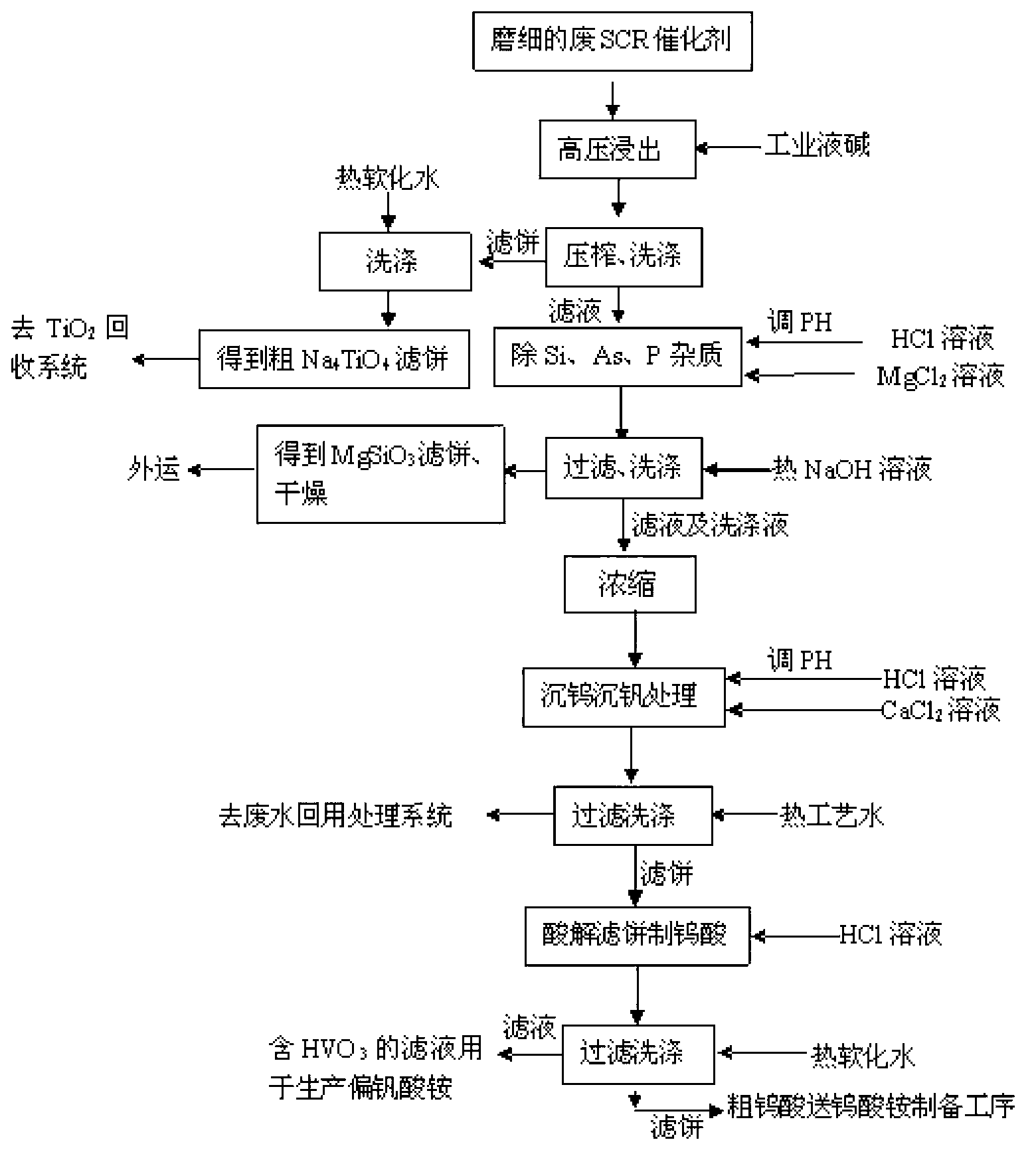

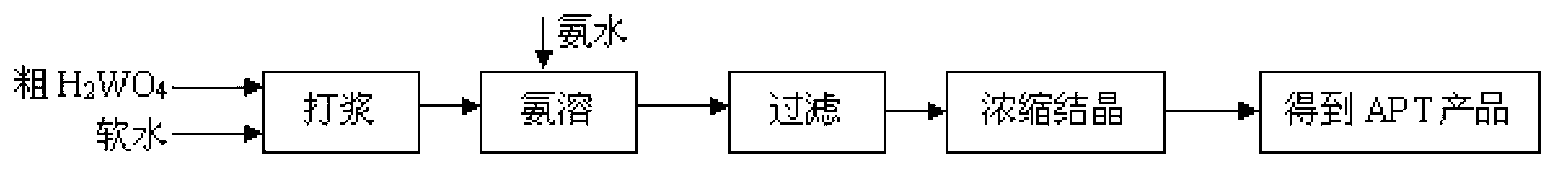

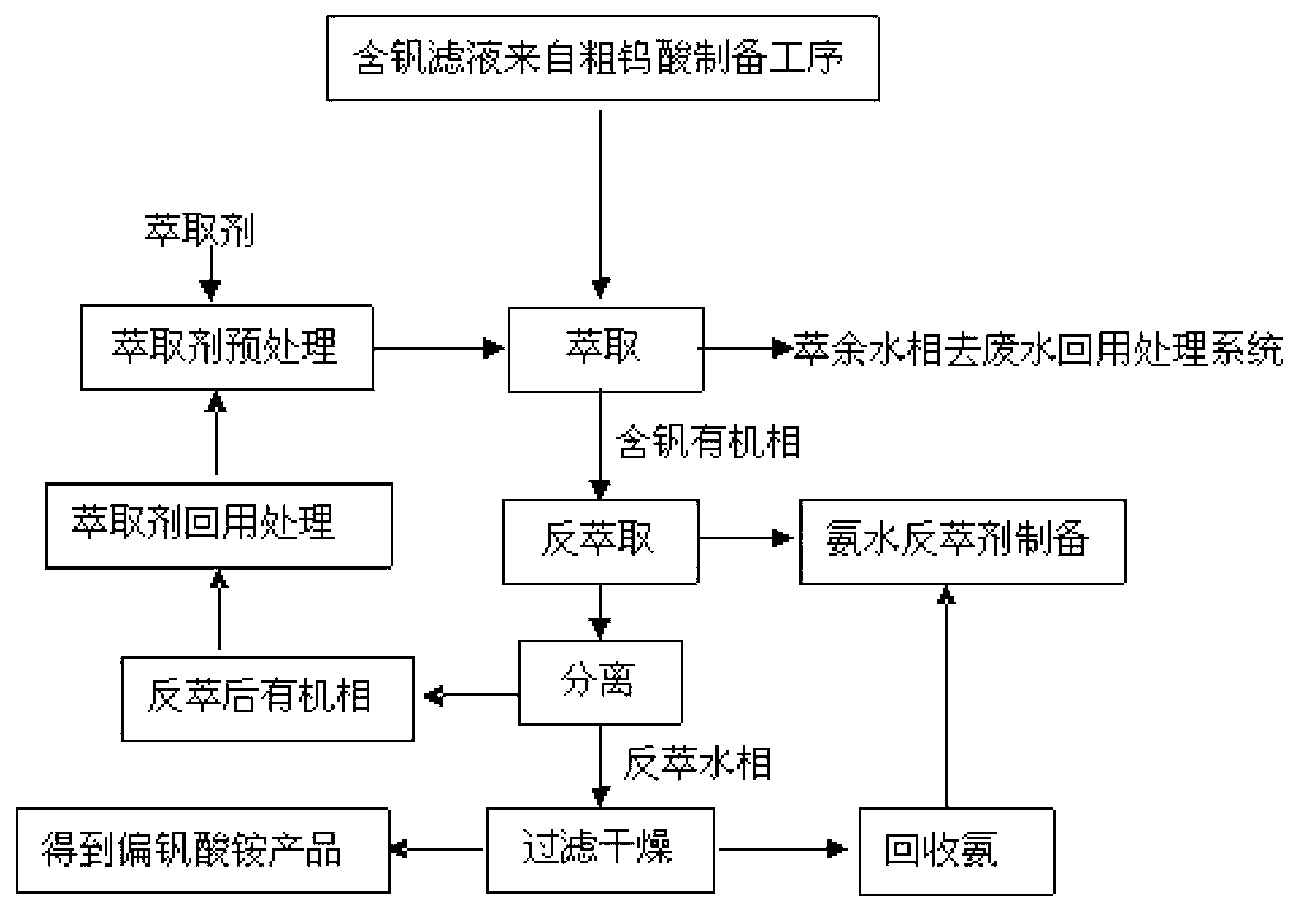

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

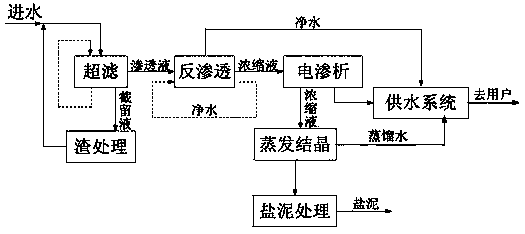

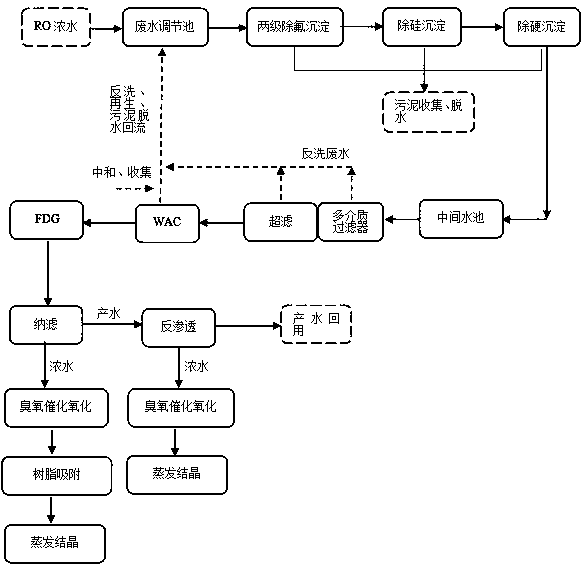

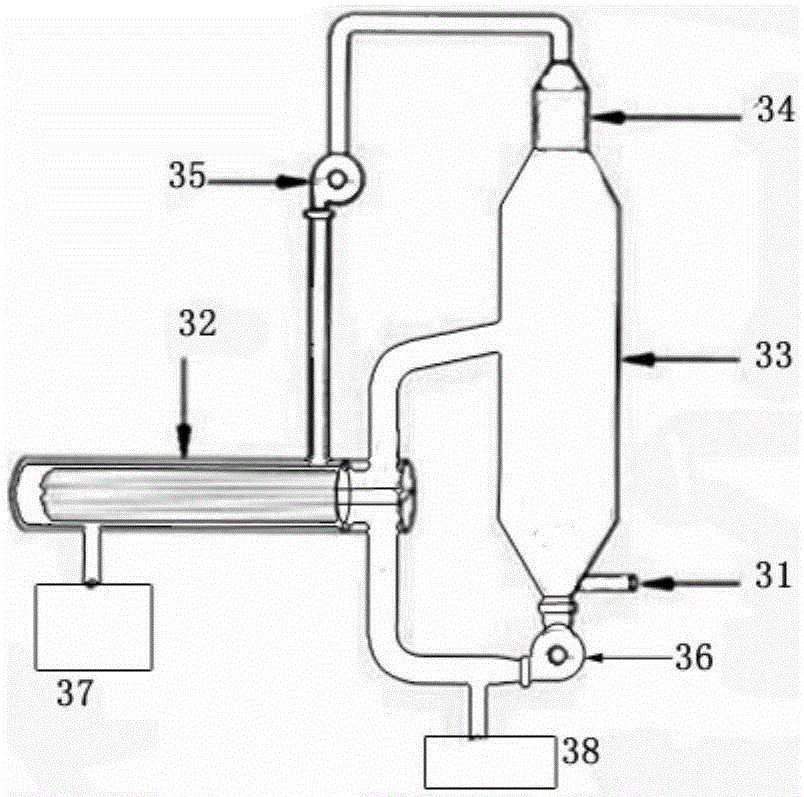

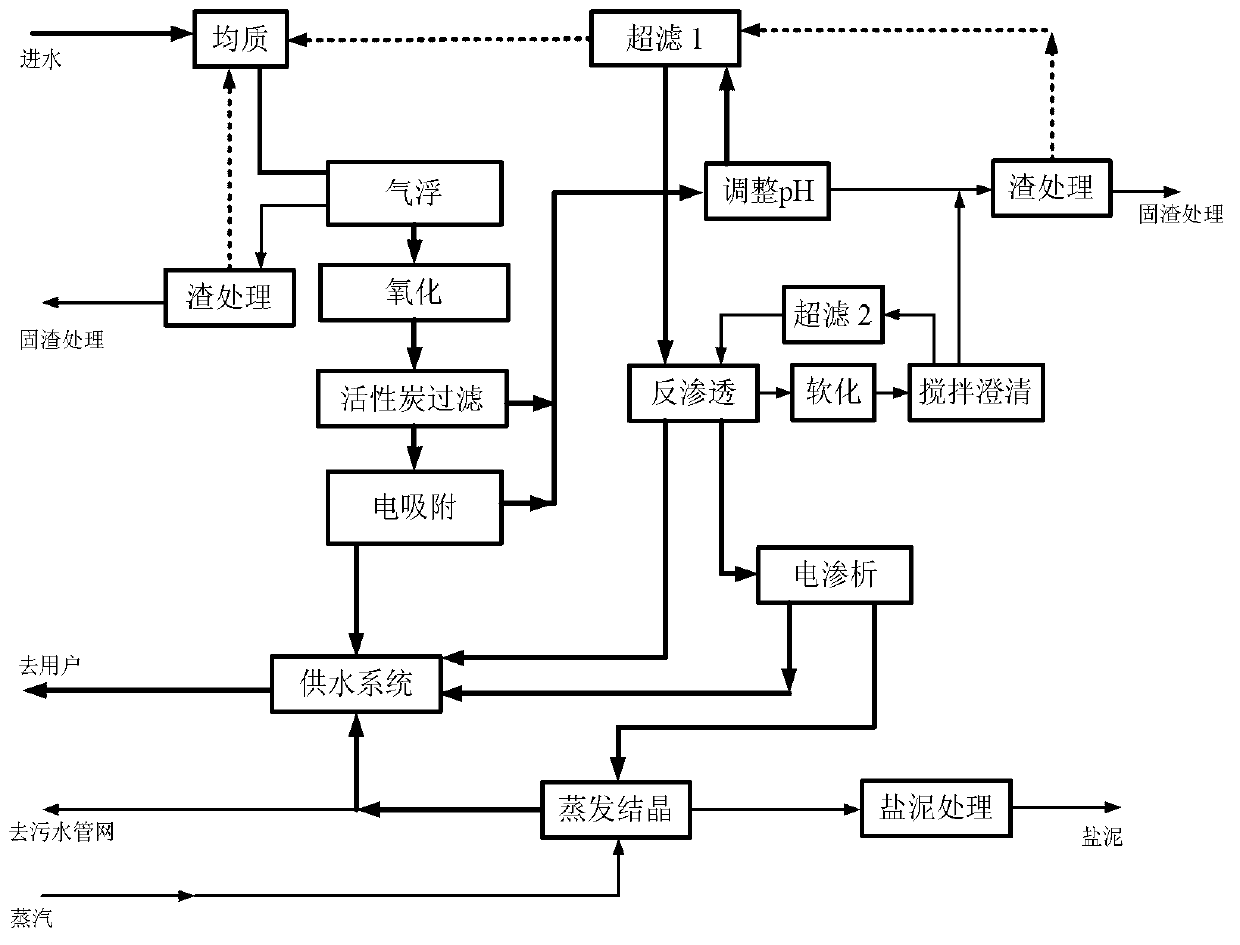

Membrane and evaporation crystallization integrated process with zero discharge of high-salinity industrial wastewater

ActiveCN103508602AAchieving zero emissionsReduce energy consumptionDispersed particle separationWater/sewage treatment bu osmosis/dialysisFiltrationUltrafiltration

The invention relates to a membrane and evaporation crystallization integrated process with zero discharge of high-salinity industrial wastewater. The process is as below: carrying out ultrafiltration pretreatment on industrial wastewater and sending the wastewater to a reverse osmosis process through a high-pressure pump; reusing lateral infiltration water; conducting electrodialysis treatment on a concentrate subjected to several times of filtration; evaporating and crystallizing the materials obtained from electrodialysis concentration to obtain salt slurry and water; carry outing posttreatment on the salt slurry; and reusing condensed water. The process provided by the invention couples membrane and evaporation crystallization, not only can recover high quality purified water from industrial wastewater with high salinity but also can realize zero discharge of wastewater with high salinity, and has the characteristics of low energy consumption, low production cost and advanced process.

Owner:NANJING JIUSI HIGH TECH +1

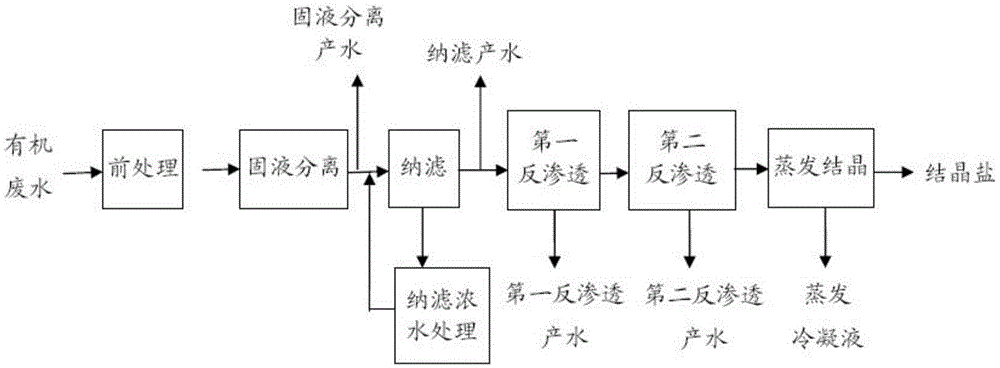

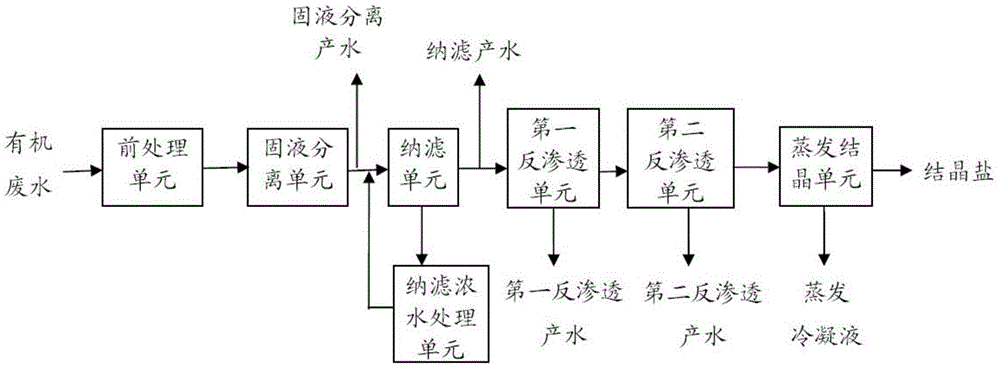

Processing method for reducing and recycling organic waste water and processing system

InactiveCN105540967AReduce foulingReduce the risk of contaminationFatty/oily/floating substances removal devicesWater contaminantsReverse osmosisWastewater

The invention provides a processing method for reducing and recycling organic waste water. The method comprises steps: (1) pre-treating waste water to obtain pre-treated out-water; (2) treating the out-water obtained from the step (1) through solid-liquid separation; (3) nano-filtering the out-water obtained from step (2); (4) treating nano-filtered concentrated water obtained from the step (3) to obtain out-water subjected concentrated water nano-filtering, returning to the step (3) for mixing the out-water subjected to concentrated water nano-filtering with the out-water subjected to solid-liquid separation, and performing nano-filtering; (5) performing first reverse osmosis treatment on out-water obtained from the step (3) through nano-filtering; (6) performing second reverse osmosis treatment on concentrated water obtained from the step (5) through first reverse osmosis treatment; and (7) evaporating and crystallizing a concentrated liquid obtained from the step (6) through second reverse osmosis treatment in order to obtain crystallized salt and evaporated concentrated water. The invention further provides a processing system of the method. Through the method and system, waste water is truly reduced and recycled.

Owner:DATANG INT CHEM TECH RESINST

Interface paint with high hydrophobicity, heat conductivity and adhesion

A high-hydrophobicity, heat conductivity and adhesivity pigment of interface is prepared by taking methyl chloroform and butanone as medium, liquid-phase treating ordinary carbon black by silicone oil to hydrophobic activate, forming coating into dense methyl surface by polyester modified dimethylsilicone and agitation dispersing by supersonic homogenizer. The formed coating (2) is three-dimensional cross-linking network of cured polyphenylene methyl resin, which contains nanometer carbon black and silicon dioxide, and it forms dense methyl thin layer (3) on coating surface. It can be used to treat heat exchanger surface (1) of indoor apparatus and outer tube fin of household air conditioner. It has good hardness and is non- toxic.

Owner:李跃

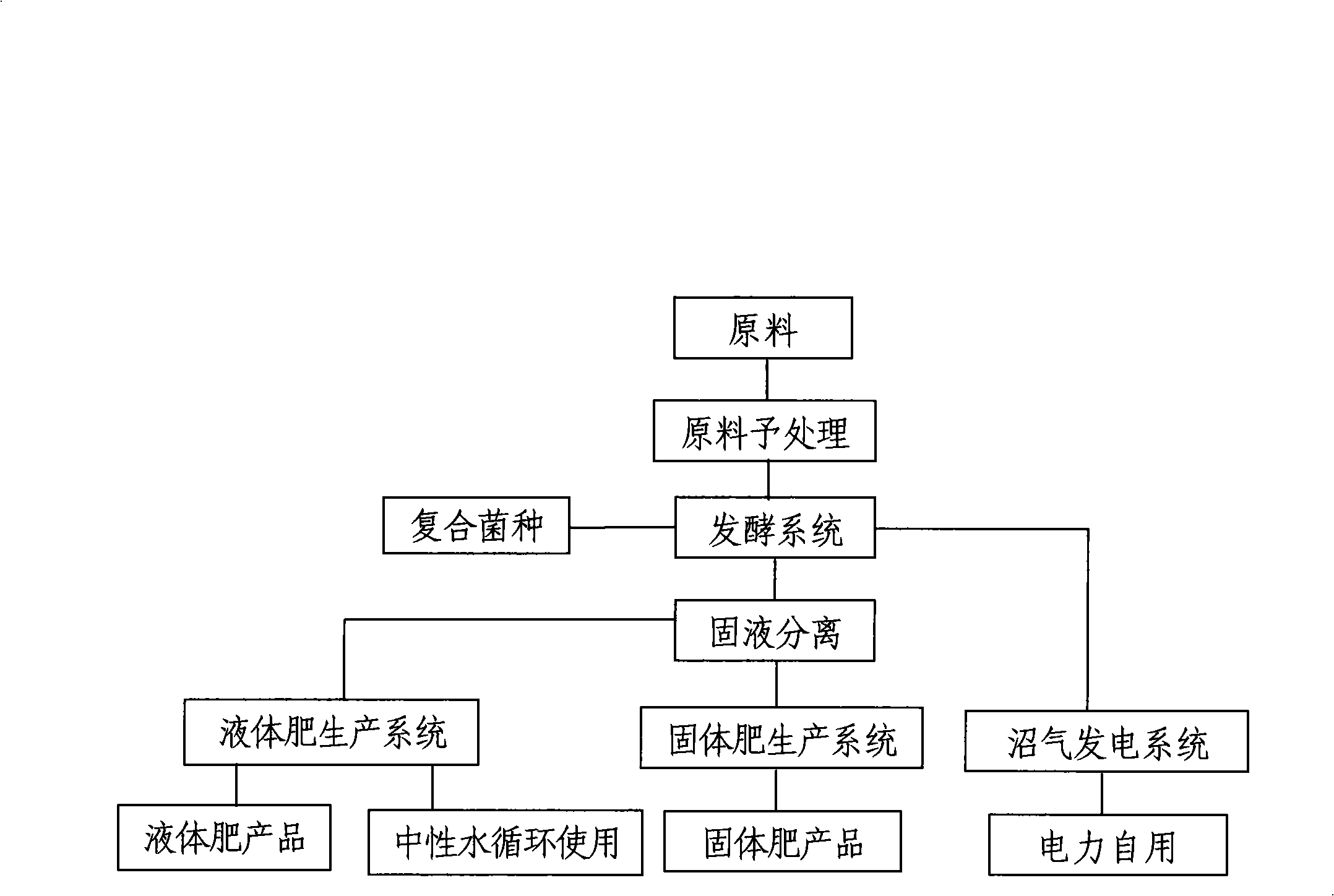

Innocent comprehensive approach method for human feces by biotechnology

InactiveCN101307332AThoroughly deodorizedElectricity for own useBio-organic fraction processingSolid waste disposalElectricityFiltration

The invention relates to a method for realizing harmless comprehensive treatment of human excrements through adopting biotechnology, in particular to a comprehensive technology used for the harmless centralized treatment of human excrements in urban areas. The method comprises the following steps that: (1) human excrements, aquatic plants and terrestrial plants are added in a fermenter, and then a composite strain mixed solution of microzyme, bacillus and lactobacillus is fed into the fermenter so as to carry out aerobic fermentation and anaerobic fermentation in turn; (2) the biogas generated during fermentation is fed into a biogas generating set so as to generate electricity; (3) the products after fermentation undergoes solid-liquid separation, and the solid fermentation products are made into solid organic fertilizer through dewatering, drying, preparation and regranulation; (4) the liquid fermentation products is obtained after solid-liquid separation undergo decoloring, filtration and settlement layering, in the liquid, the sublayer liquid in the solution is made into liquid organic fertilizer through coarse filtration, secondary filtration, sterilization and preparation and the supernatant is made into rinsing meeting effluent standard through aeration and settlement filtration. The method can realize clean, environment-friendly and energy-saving ecological production.

Owner:昆明伽得科贸有限公司

Method and equipment for breaking down and reclaiming electronic components and solder of discarded circuit board

InactiveCN1600458AReduce damage rateHigh split rateSolid waste disposalPrinted circuitsRecovery methodElectronic component

Owner:张杰

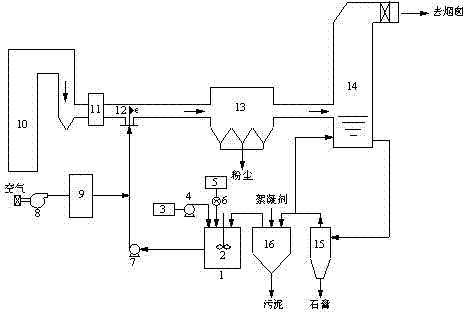

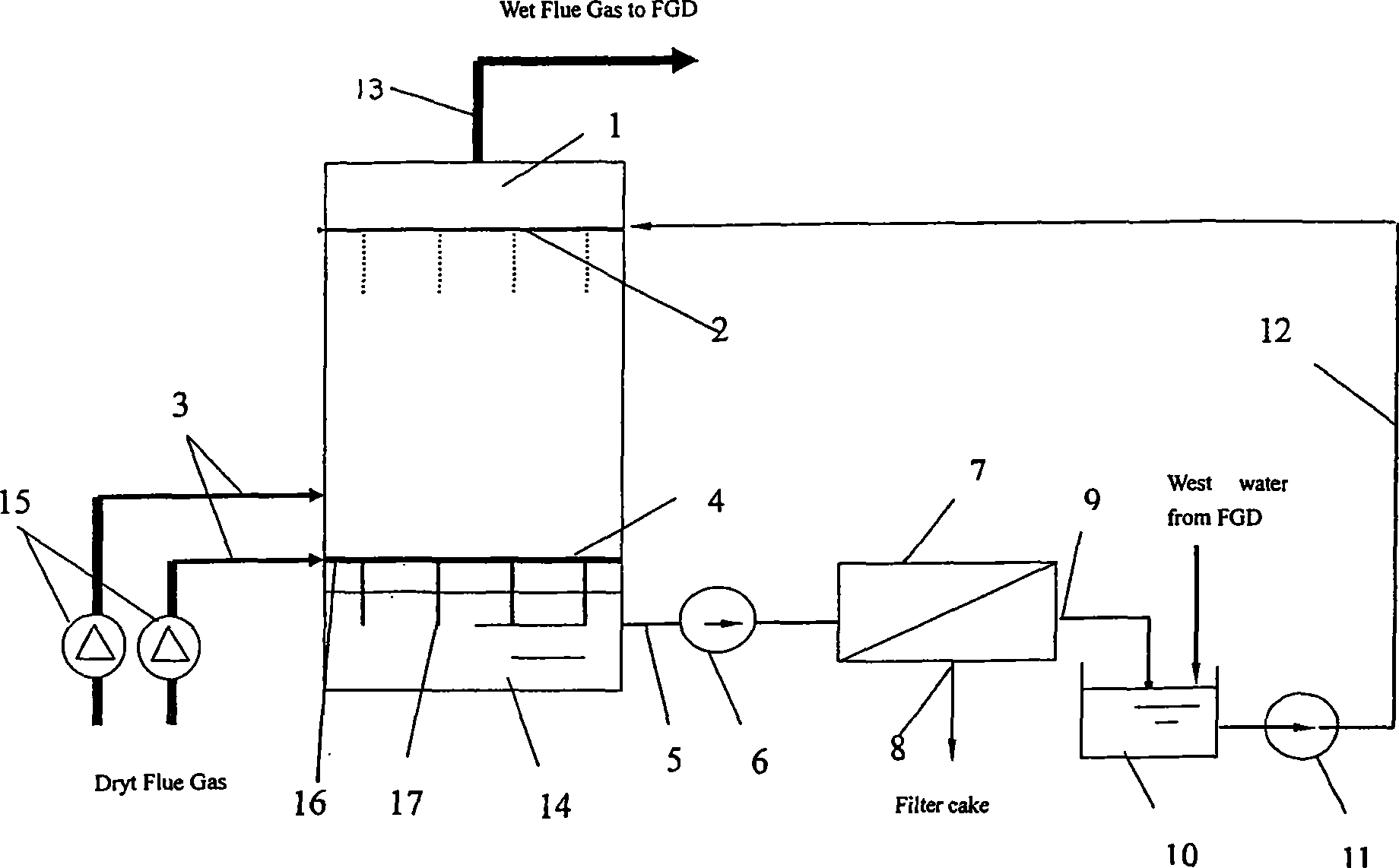

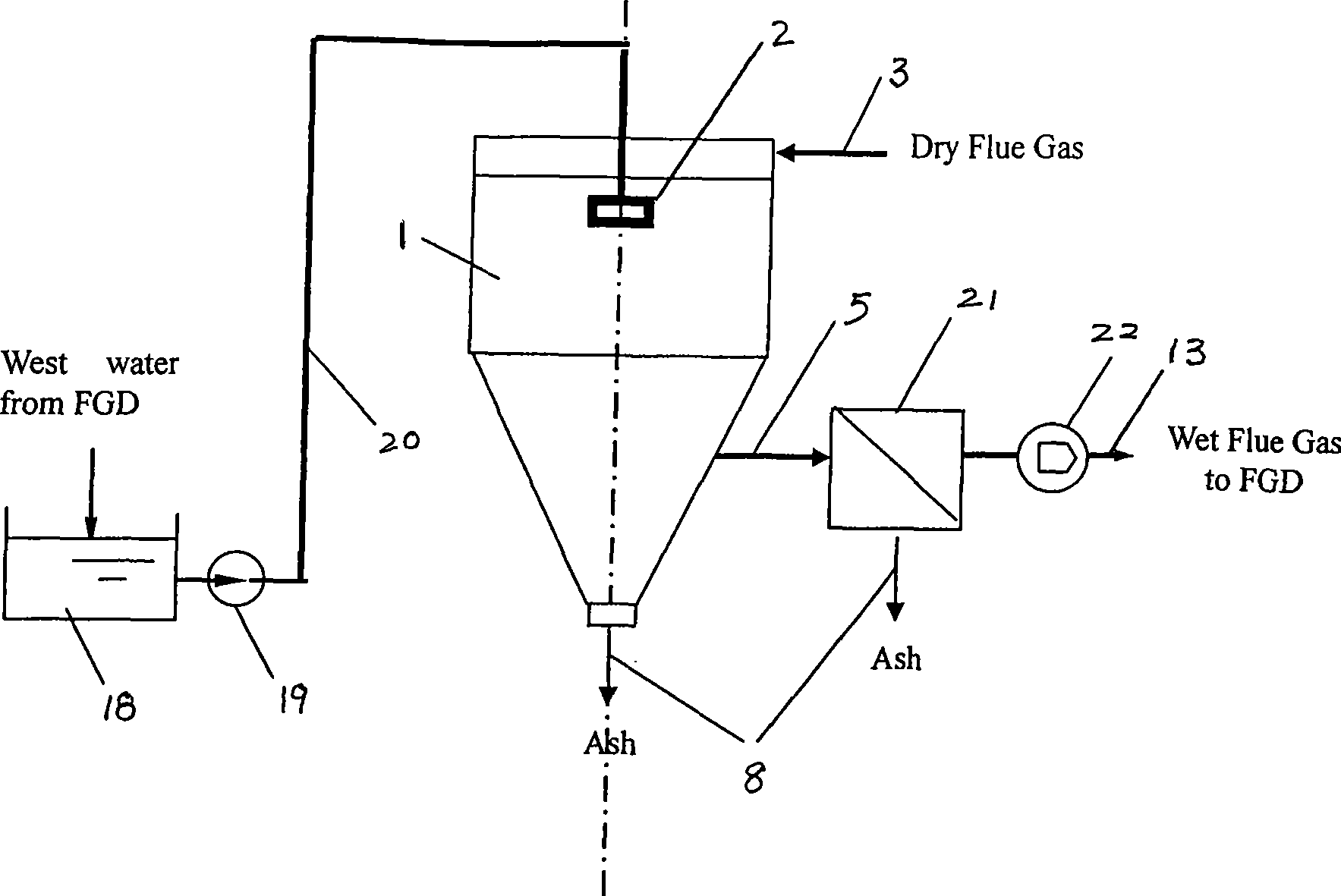

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

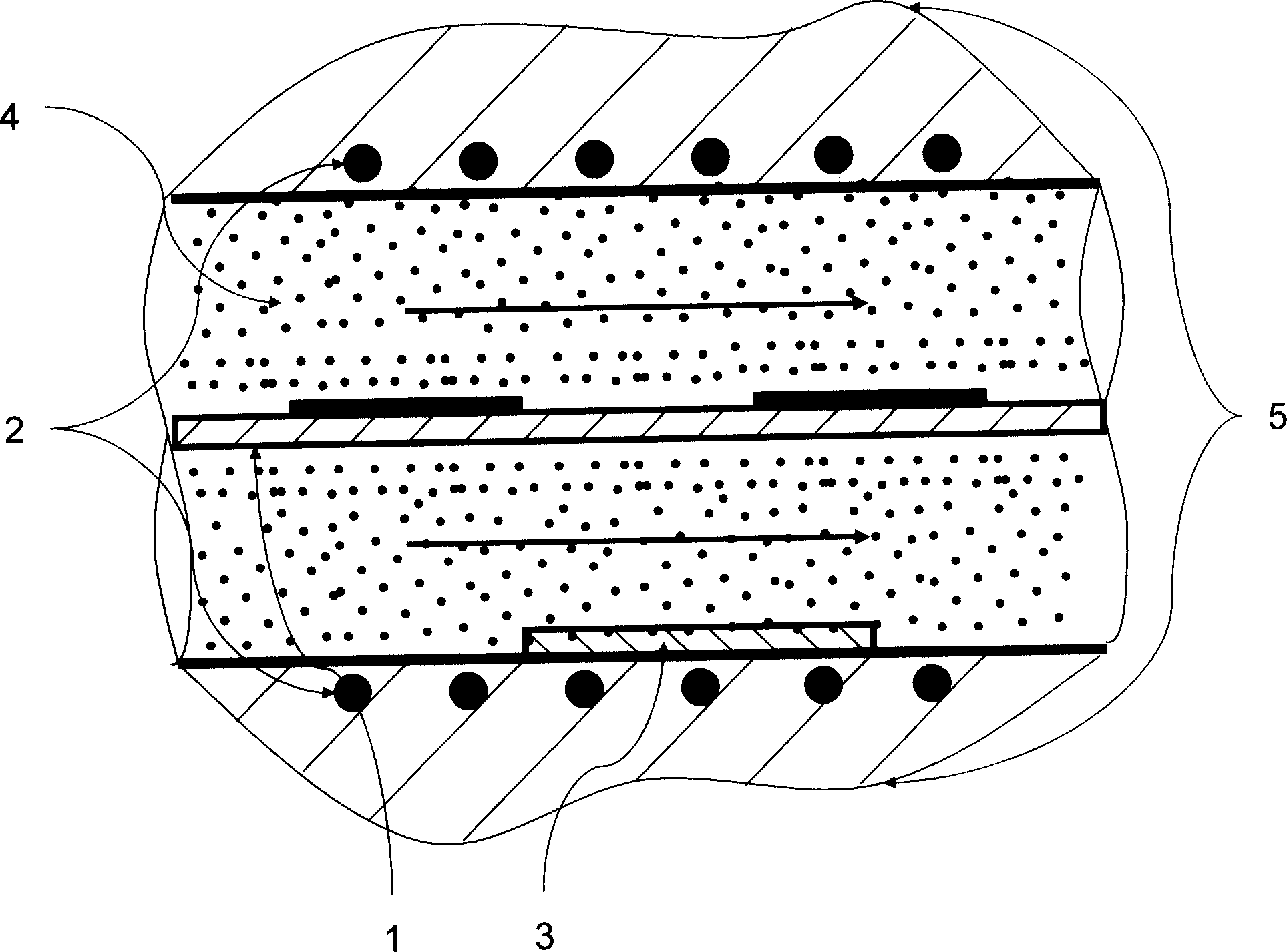

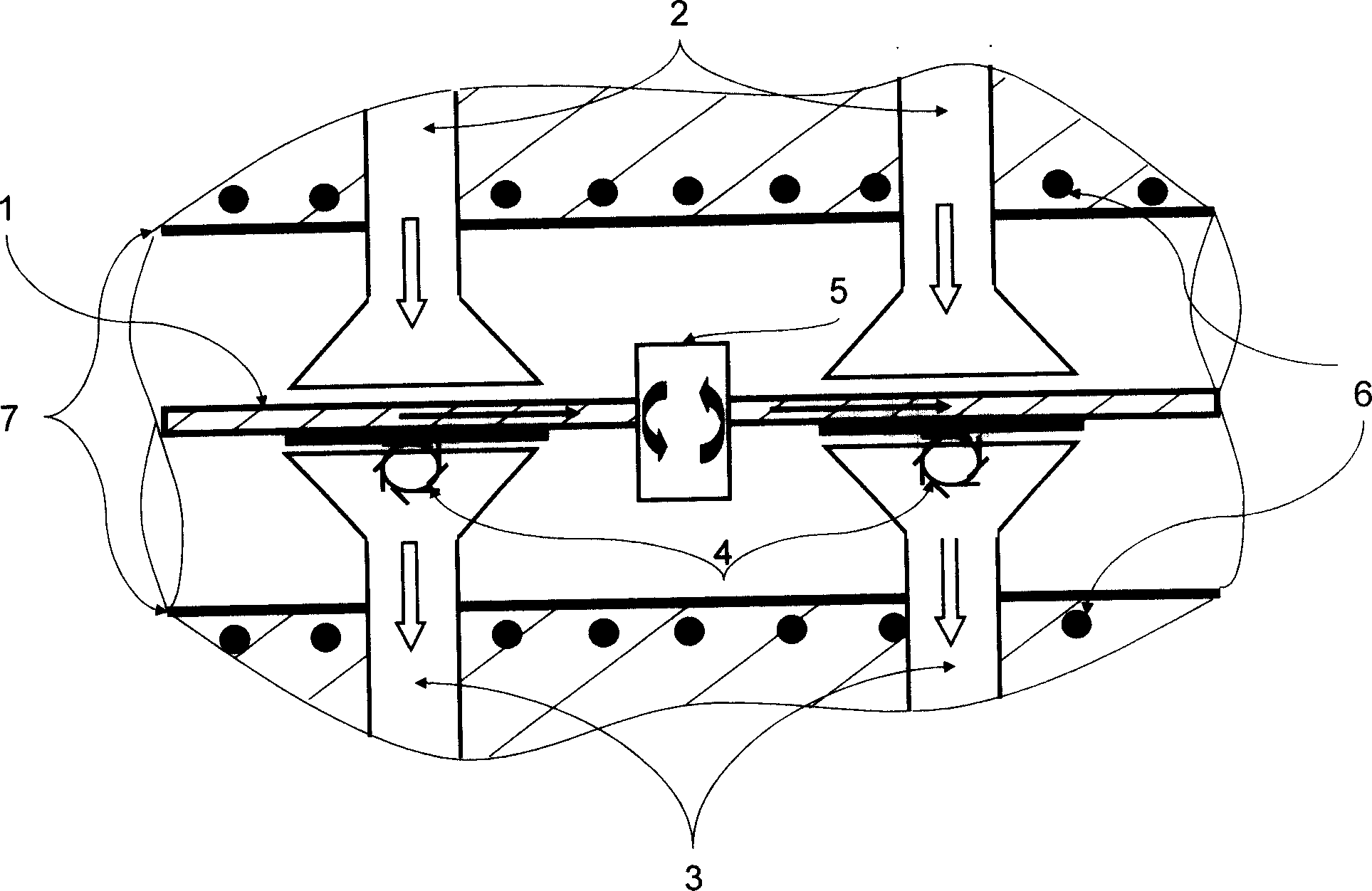

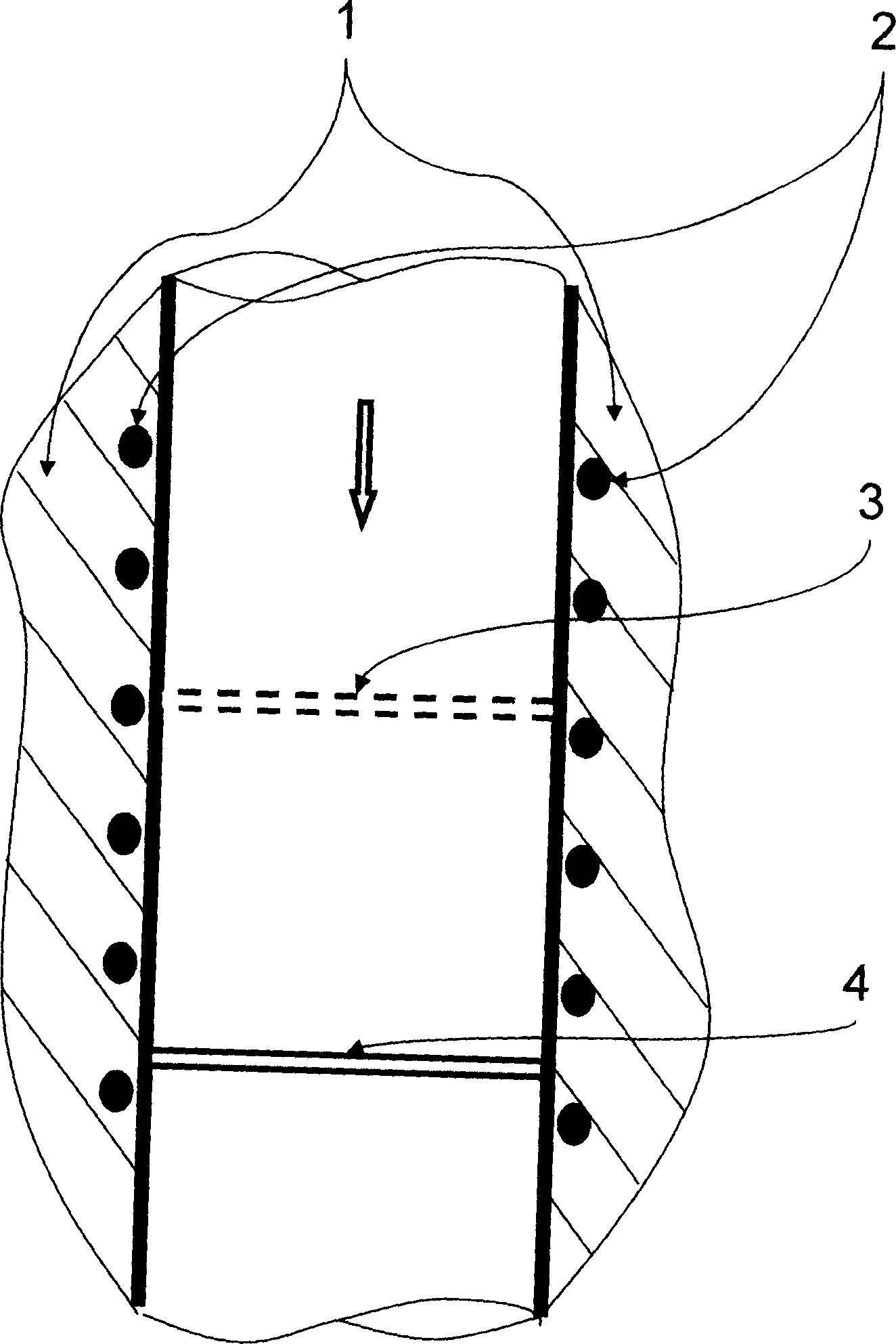

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

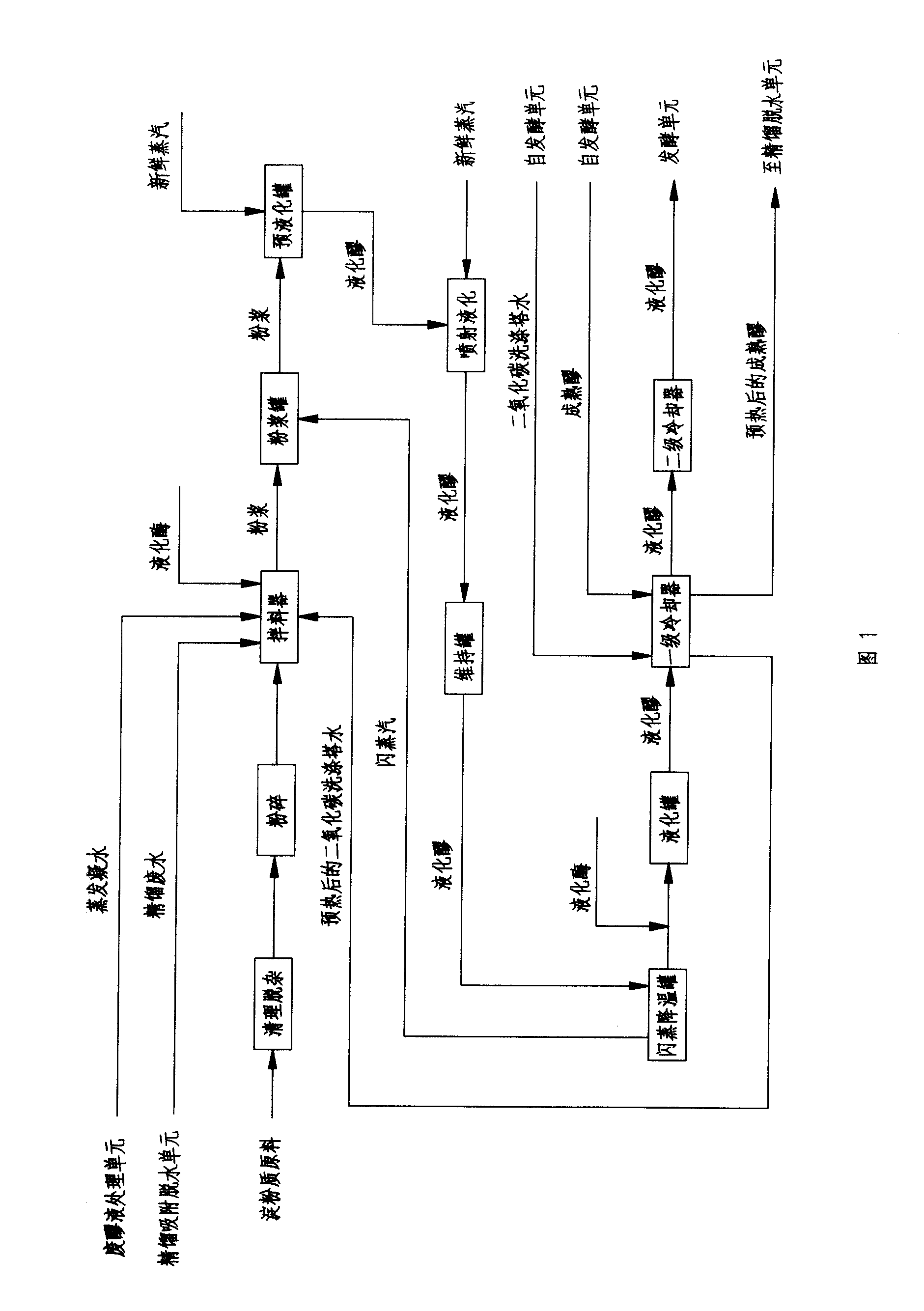

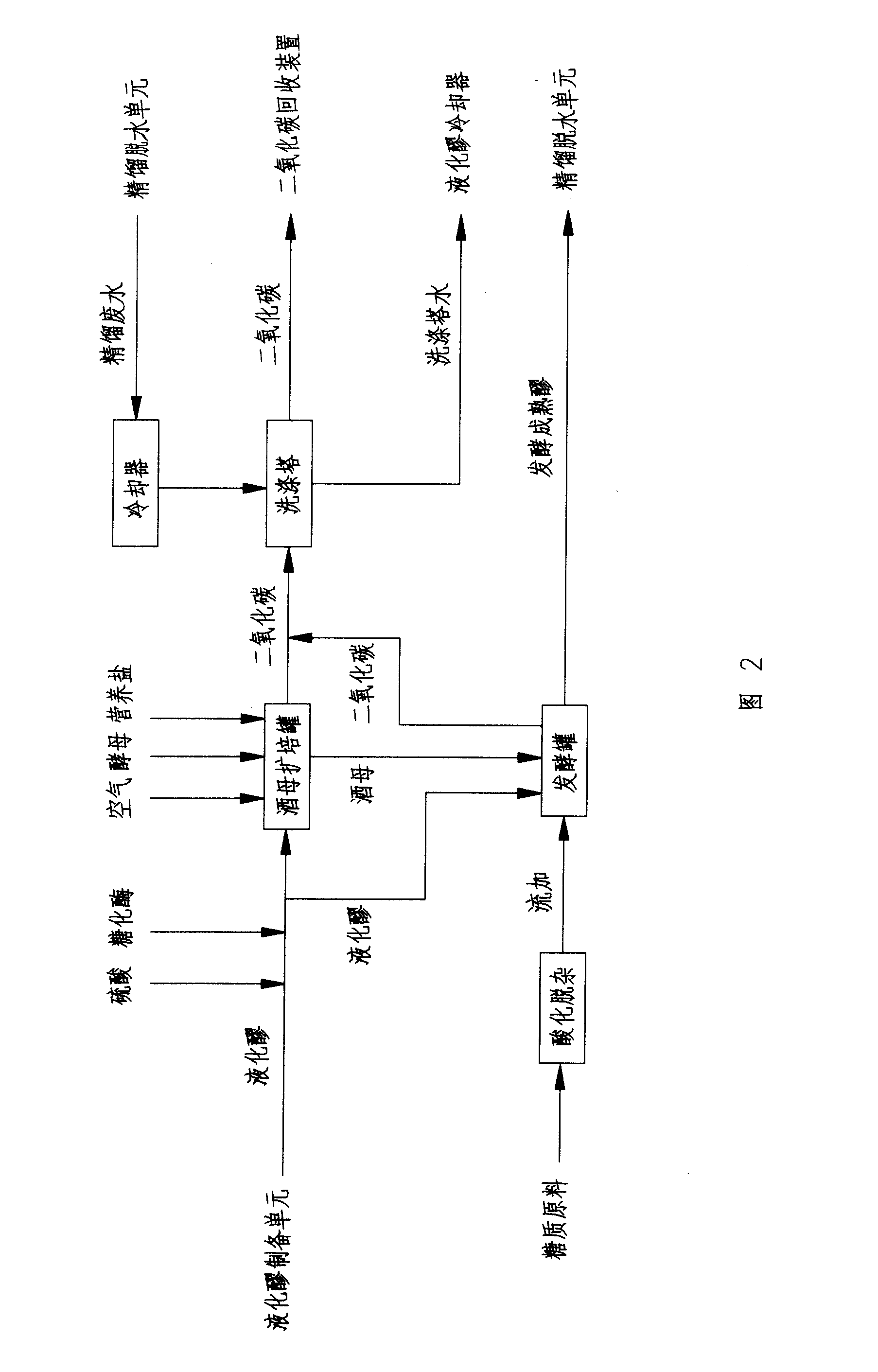

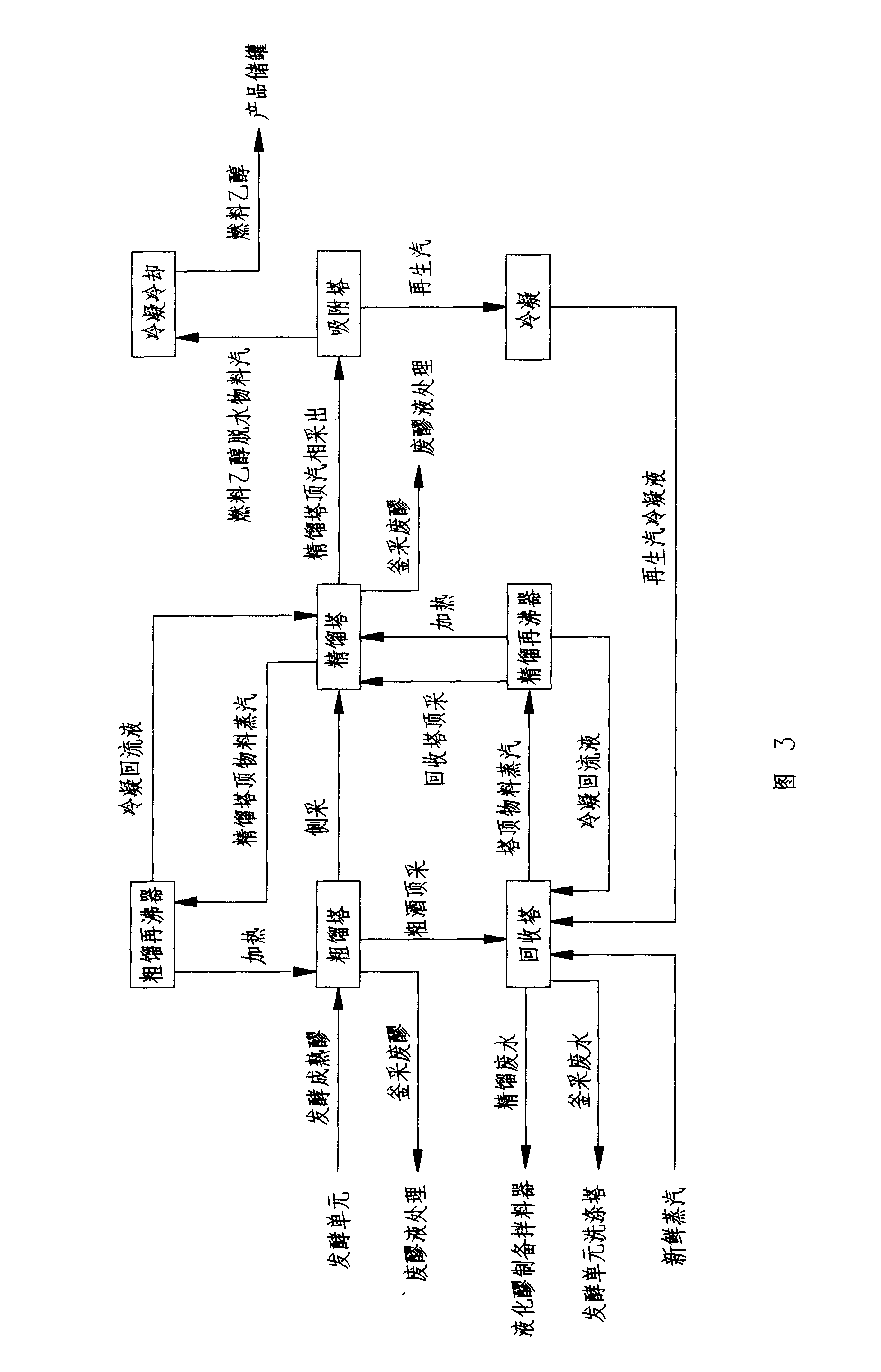

Fuel ethanol production equipment and method

InactiveCN101157890ASolve process problemsSolve problems such as large emissionsBioreactor/fermenter combinationsBiological substance pretreatmentsUltrafiltrationAlcohol production process

The invention relates to a novel equipment and a method of ethanol fuel production. The water resource in a preparation unit of liquefied wort is the washing water in a CO2 washing tower. A recovery tower pot collects waste water and a portion of liquor condensate by vaporing when waste water is dealt with to send to a mixing machine of the preparation unit of liquefied wort. And the consumption of fresh water is zero. The process of rectification and dehydration adopts technology of multieffect thermal coupling rectification. Only when the recovery tower pot uses fresh vapor to heat, the energy consumption of the process of rectification and dehydration is reduced largely. The waste wort solution produced by the alcohol production process which is dealt with by the device for pneumatic drying, multieffect evaporation of clear liquid, being anaerobic and oxygen consumption of the vapored condensate liquor and purifying by using ultrafiltration membrane etc, can be recovered with the valuable product. The reasonable treatment plan realizes zero discharge of technique waste water when in the ethanol fuel production.

Owner:TIANJIN UNIV

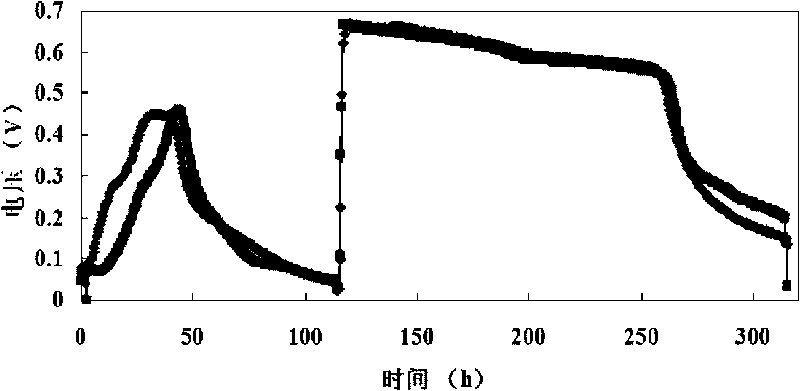

Double-chamber alga microbial fuel cell and method thereof for treating waste water and realizing zero carbon emission

ActiveCN101719555AAchieving zero emissionsAchieving zero carbon emissionsCell electrodesBiochemical fuel cellsPhotosynthesisZero emission

The invention discloses a double-chamber alga microbial fuel cell and a method thereof for treating waste water and realizing zero carbon emission, which relates to a microbial fuel cell and a method for treating waste water. The invention solves the problem that the traditional microbial fuel cell can generate a large amount of CO2 in the process of treating waste water. In the invention, a cation exchange membrane is vertically arranged in a box body of a reactor; an anode chamber and a cathode chamber are formed in the box body of the reactor; an anode is arranged in the anode chamber; a cathode is arranged in the cathode chamber; leads are connected with the anode and the cathode; one end of a gas duct is hermetically connected with a gas collecting chamber, and the other end of the gas duct is arranged at the bottom of the cathode chamber; and a gas collecting device is hermetically installed at a gas outlet. The method comprises the following steps: (1) starting the reactor; and (2) introducing the waste water into the cathode chamber and the anode chamber, catabolizing organic matters by microbes at room temperature, simultaneously obtaining electrical energy, and introducing the CO2 generated in the anode chamber into the cathode chamber to be used by the alga at the cathode for photosynthesis. The invention realizes zero emission of CO2 and simultaneously can recover electrical energy, thereby really changing waste into resources.

Owner:HARBIN INST OF TECH

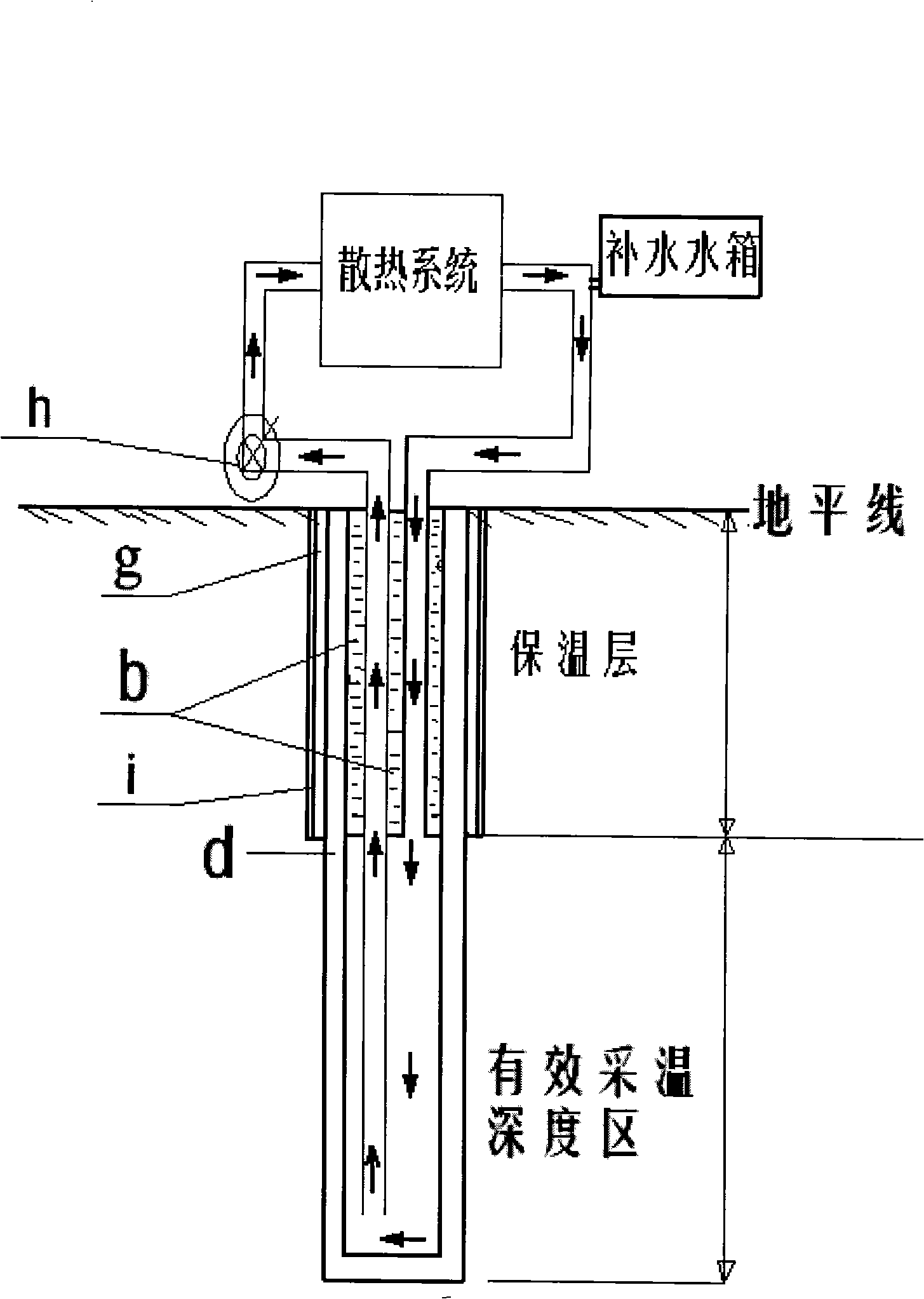

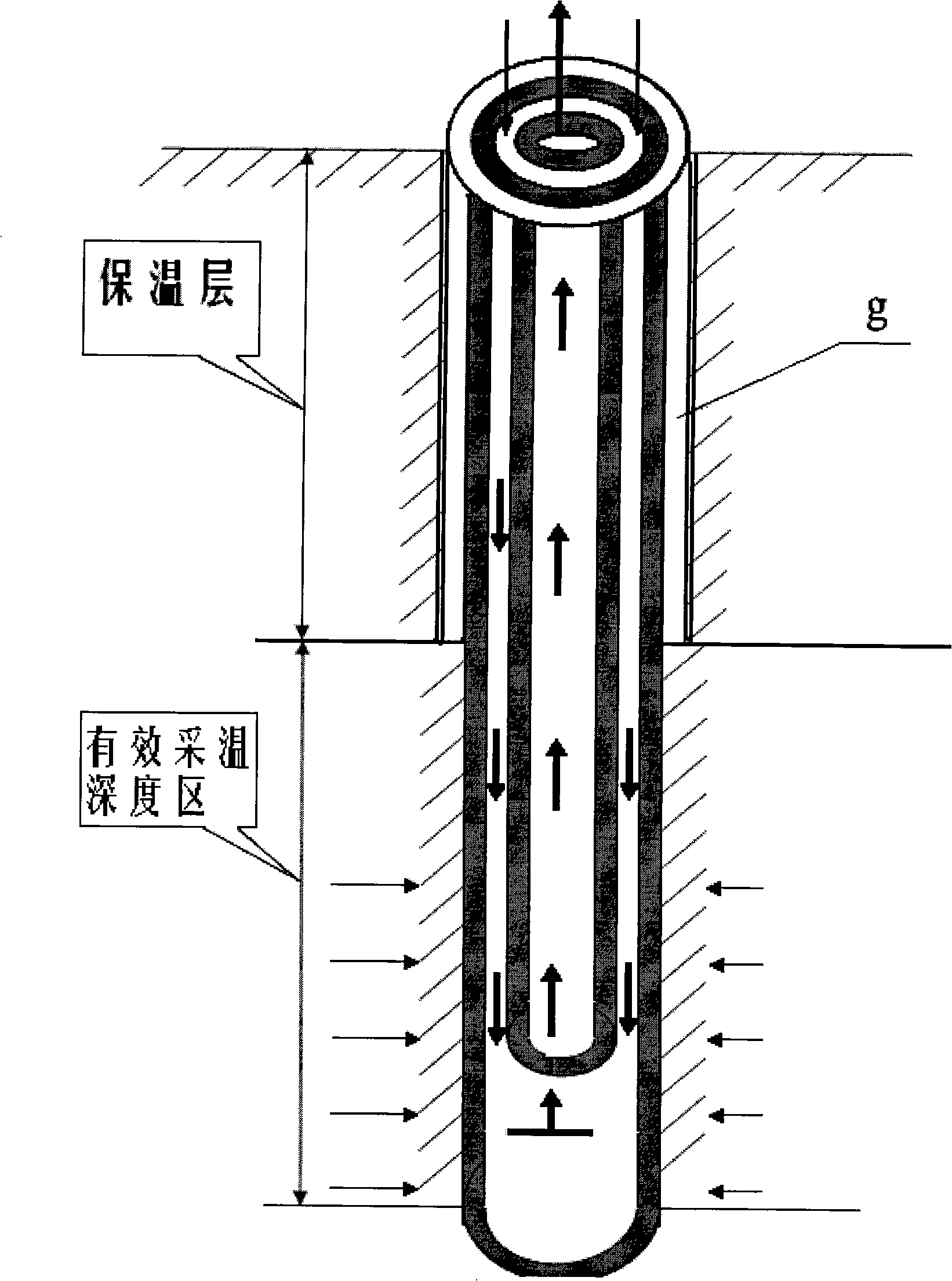

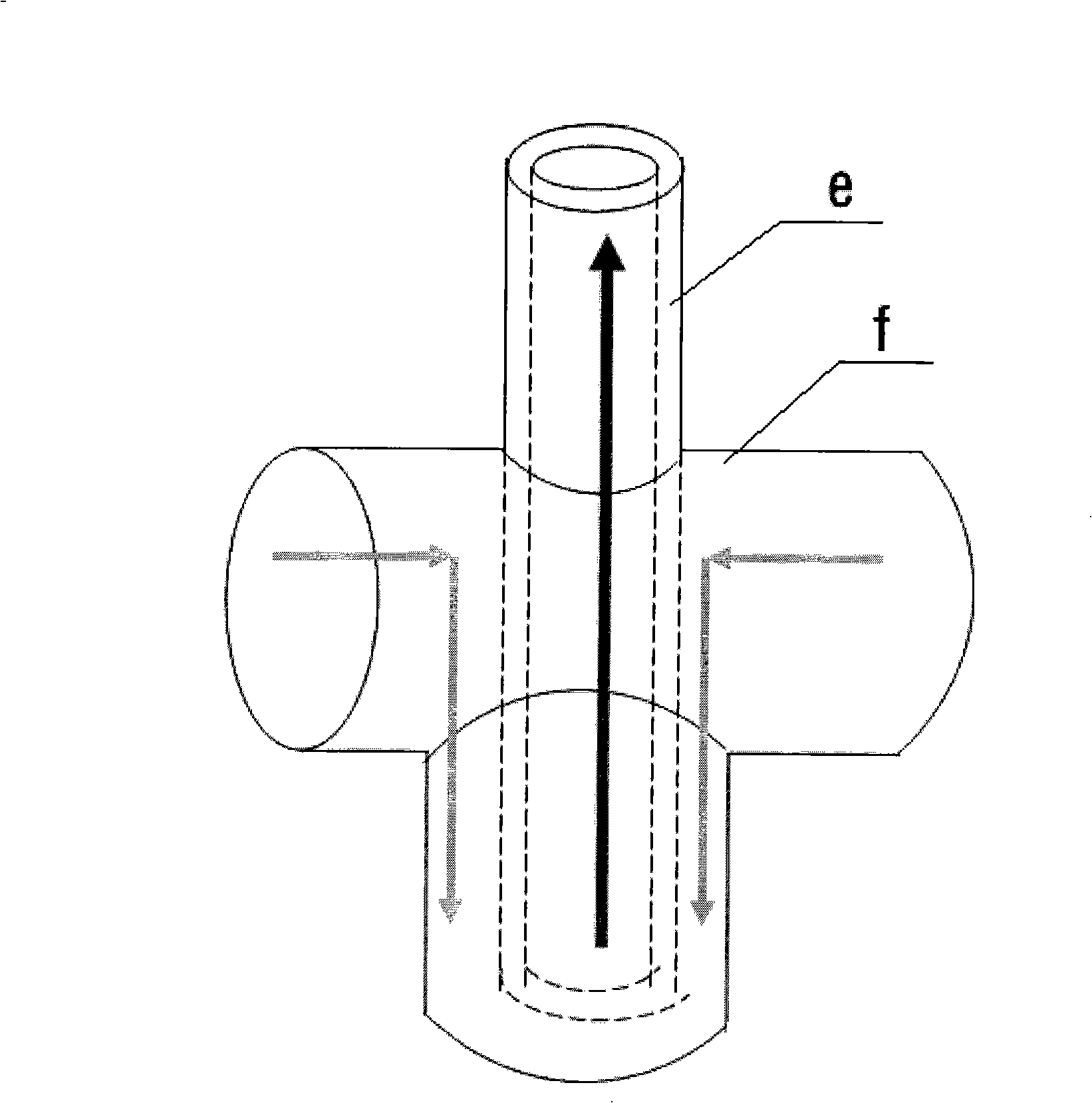

Deep layer terrestrial heat renewable energy source winter heating method

InactiveCN101349450ARich in reservesInexhaustibleLighting and heating apparatusGeothermal energy generationWater circulationRenewable energy

The invention relates to a heating method of deep geothermal renewable energy sources in winter, which is pollution-free, zero-emission, clean, renewable and low-cost. The technical scheme comprises drilling a deep well under the ground, driving sleeve pipes, insulation treating for the sleeve pipes in a non-effective heating depth area under the well, employing circulating water to collect heat energy contained in underground deep rock in an effective heating depth area through the walls of the sleeve pipes, and employing insulation suction pipes to transmit the heat energy to the ground through water circulation to heat targeted users, after radiation, returning low-temperature water to underground via the insulation suction pipes, and collecting the heat energy contained in underground deep rock in the effective heating depth area through the walls of the sleeve pipes again to form a circulating heating system. The heating method for winter has the advantage that the heating method can realize zero-emission, is renewable with extremely low running cost and simple operation, and can benefit people for a lifetime after once investment. The heating method is a key breakthrough of the present heating and energy-saving method, which can largely ease the present supplying situation of winter heating energy, and really realizes energy conservation and emission reduction.

Owner:赵铭

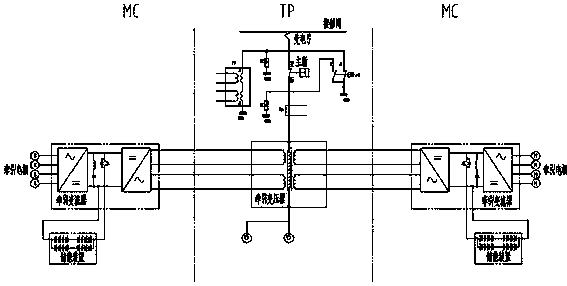

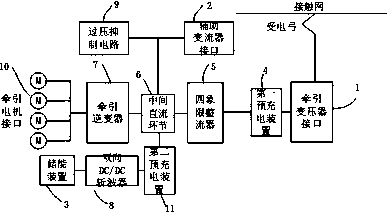

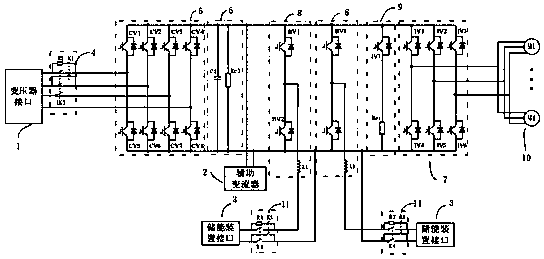

Motor train unit traction system adopting catenary and energy storing devices for hybrid power supply

ActiveCN103350647ARun across the lineAdapt to different transportation needsRailway vehiclesAc-ac conversionTraction systemEmergency rescue

A motor train unit traction system adopting a catenary and energy storing devices for hybrid power supply is characterized by mainly comprising a traction transformer, the energy storing devices, traction converters and traction motors, wherein the catenary is connected with a primary side of the traction transformer through a pantograph, and two secondary side windings of the traction transformer are directly connected with the traction converters which are connected with the traction motors; and the energy storing devices are connected with direct current buses in the middles of the traction converters. The motor train unit traction system can simultaneously operate on an electrification line and a non-electrification line, and the braking energy is absorbed through the energy storing devices under the working condition without the catenary, so that cyclic utilization of the energy is realized, and a green energy saving idea is reflected. Under special rainy or snowy weather or when the catenary is damaged, the motor train unit traction system has emergency rescue and readiness functions, and the energy storing devices can also be used as portable power sources.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

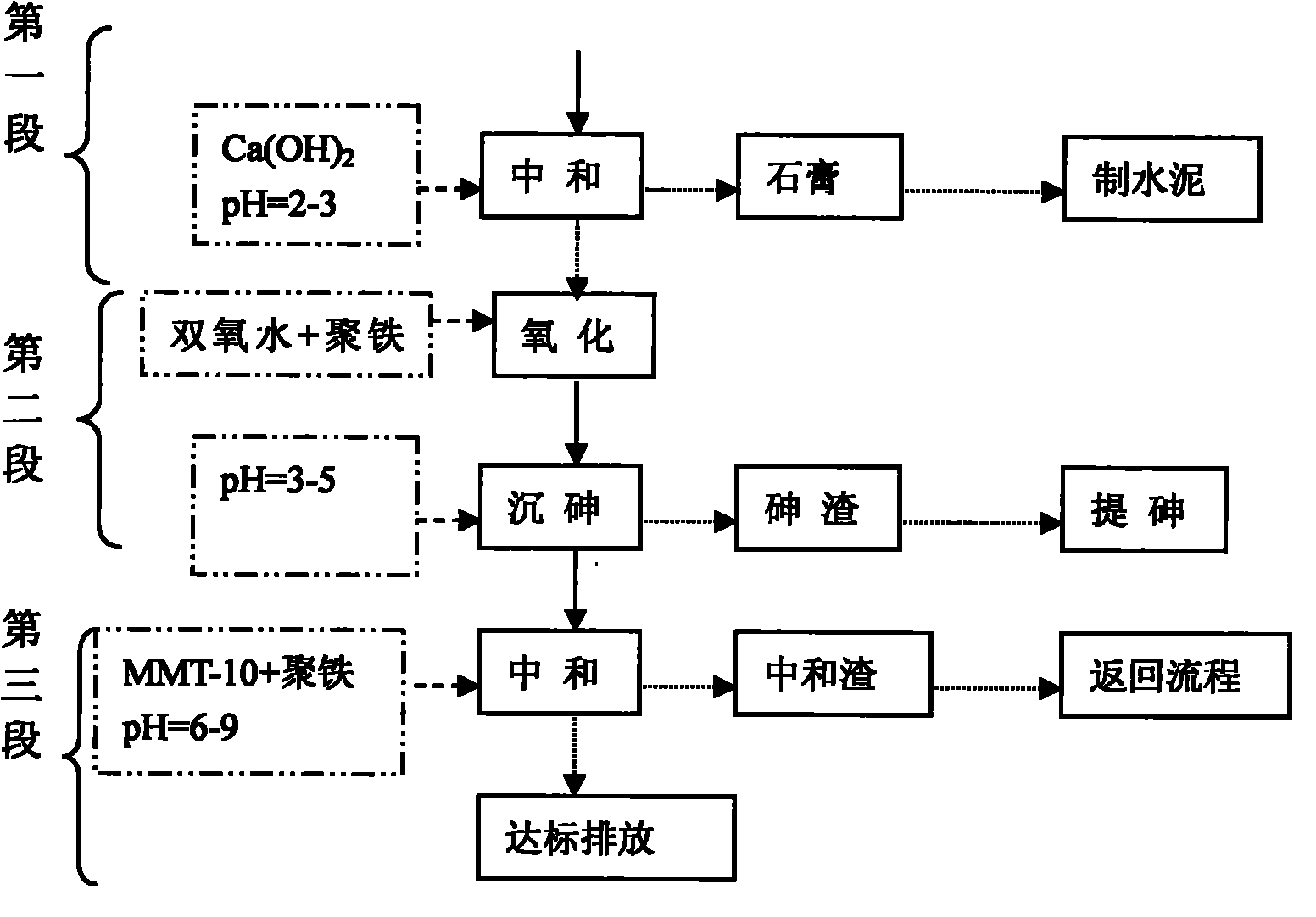

Method for treating waste acid by gypsum sedimentation, arsenic oxidizing sedimentation and iron salt neutralization and co-precipitation

ActiveCN101830583AAchieving zero emissionsRealize resource utilizationWater contaminantsMultistage water/sewage treatmentIron saltsSlag

The invention discloses a method for treating waste acid by gypsum sedimentation, arsenic oxidizing sedimentation and iron salt neutralization and co-precipitation. The method comprises the following steps of: the first section: gypsum sedimentation, namely putting lime cream into the waste acid, and removing most sulfuric acid from the waste acid through neutralization reaction to generate CaSO4sediment and gypsum; the second section: arsenic oxidizing sedimentation, namely performing solid-liquid separation after the gypsum reaction, adding polymeric iron into supernate, adding hydrogen peroxide oxidant into the supernate to oxidize Fe2+ into Fe3+ and oxidize As3+ into As6+ under the condition of low pH, and removing most arsenic from the waste acid through oxidizing sedimentation reaction so as to enrich the arsenic in the waste acid and produce arsenic slag; and the third section: iron salt neutralization and co-precipitation, namely performing solid-liquid separation after the arsenic reaction, adding polymeric iron and heavy metal ion hunting agent into the supernate, and removing residual arsenic and heavy metal ions from the waste acid to generate neutralized slag and water meeting the national discharge standard. The method has the advantages of short flow, simplicity, practicability, good pollution control effect and good gypsum byproduct, and the removal rate of arsenic is up to 99.999 percent.

Owner:YUNNAN COPPER CO LTD

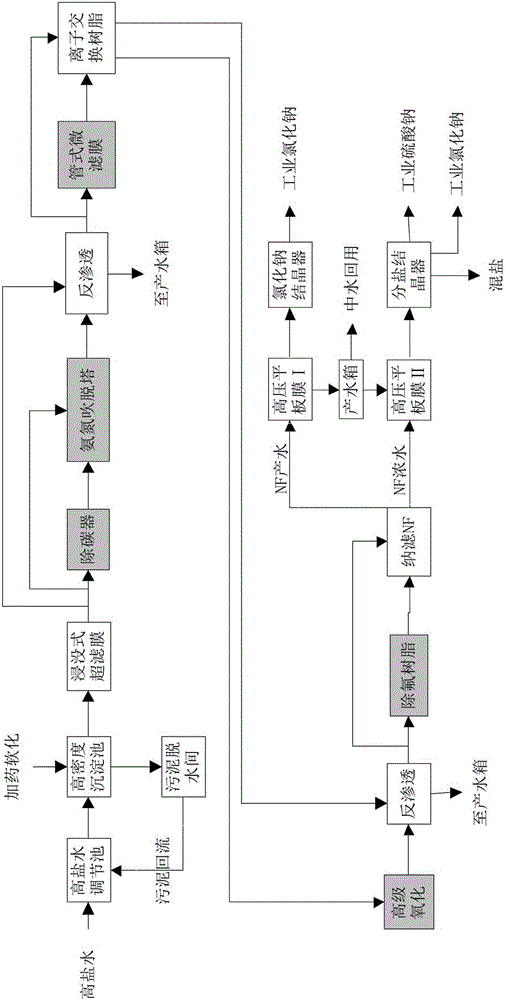

Recycling treatment process for coal coking high-salinity wastewater

PendingCN110606612AAchieving zero emissionsImplement resourcesWater contaminantsTreatment involving filtrationUltrafiltrationResource utilization

The invention relates to a recycling treatment process for coal coking high-salinity wastewater. The process comprises the following steps: (1) fluorine removing; (2) silicon removing; (3) softening;(4) treatment with a multi-medium filter; (5) ultrafiltration; (6) resin softening; (7) FDG; (8) nanofiltration and salt separation; (9) reverse osmosis concentration; (10) advanced oxidation; (11) resin adsorption; and (12) evaporative crystallization. The process has the advantages that the process of pretreatment, nanofiltration salt separation, reverse osmosis concentration, advanced oxidationand evaporative crystallization is adopted, so that zero emission and quality-divided resource utilization of the coal coking high-salinity wastewater are realized.

Owner:CHINA ELECTRONICS INNOVATION ENVIRONMENTAL TECH CO LTD +2

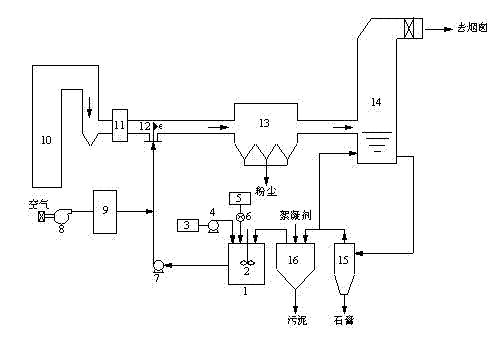

Technique method for processing desulphurization waste water

ActiveCN101417827ALow costReduce energy consumptionWater/sewage treatmentEnergy based wastewater treatmentSalt contentFlue gas

The invention discloses a technology method for treating desulfurization wastewater, which are applicable to treating the wastewater generated from limestone-plaster wet flue gas desulfurization and other wastewater with high salt content. The method uses the flue gas of heat-engine plants to carry out evaporation and solidification treatment to the desulfurization wastewater or other wastewater with high slat content which is hard to be recovered. The method is characterized by low cost, little area occupation and low energy consumption, which can provide help to the original limestone-plaster wet flue gas desulfurization treatment technology and realize zero discharge of the wastewater of the limestone-plaster wet flue gas desulfurization technology.

Owner:CHENGDU RAISE ENVIRONMENTAL PROTECTION TECH CO LTD

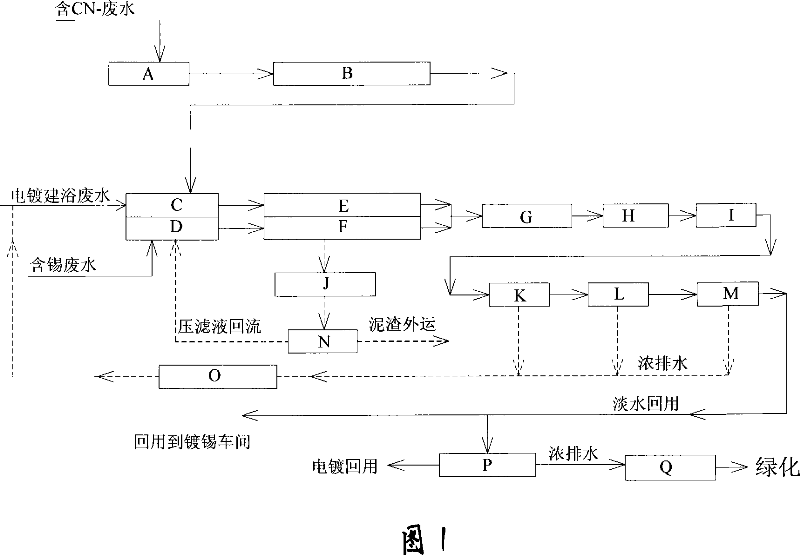

Electroplating wastewater treatment reclaiming technique

ActiveCN101041534AReduce contentHigh desalination rateTreatment using aerobic processesGeneral water supply conservationFiltrationUltrafiltration

The invention discloses a reclaimed craft to dispose electroplating waste water, which comprises the following steps: adopting oxidation-reduction and chemical precipitation disposing method and film technology (fold filtration, hyperfiltration, Na filtration and reverse osmosis desalination) deep purifying method; avoiding accumulation of salt effectively; reverse osmosis sloughing monovalent salt at last grade; trapping bivalent salt in innocent treatment system; proceeding depositing treatment continually; removing accumulating BOD and COD in water body through biochemical treatment effectively; realizing zero discharge of waste water.

Owner:JINAN JINGHENG ELECTRONICS

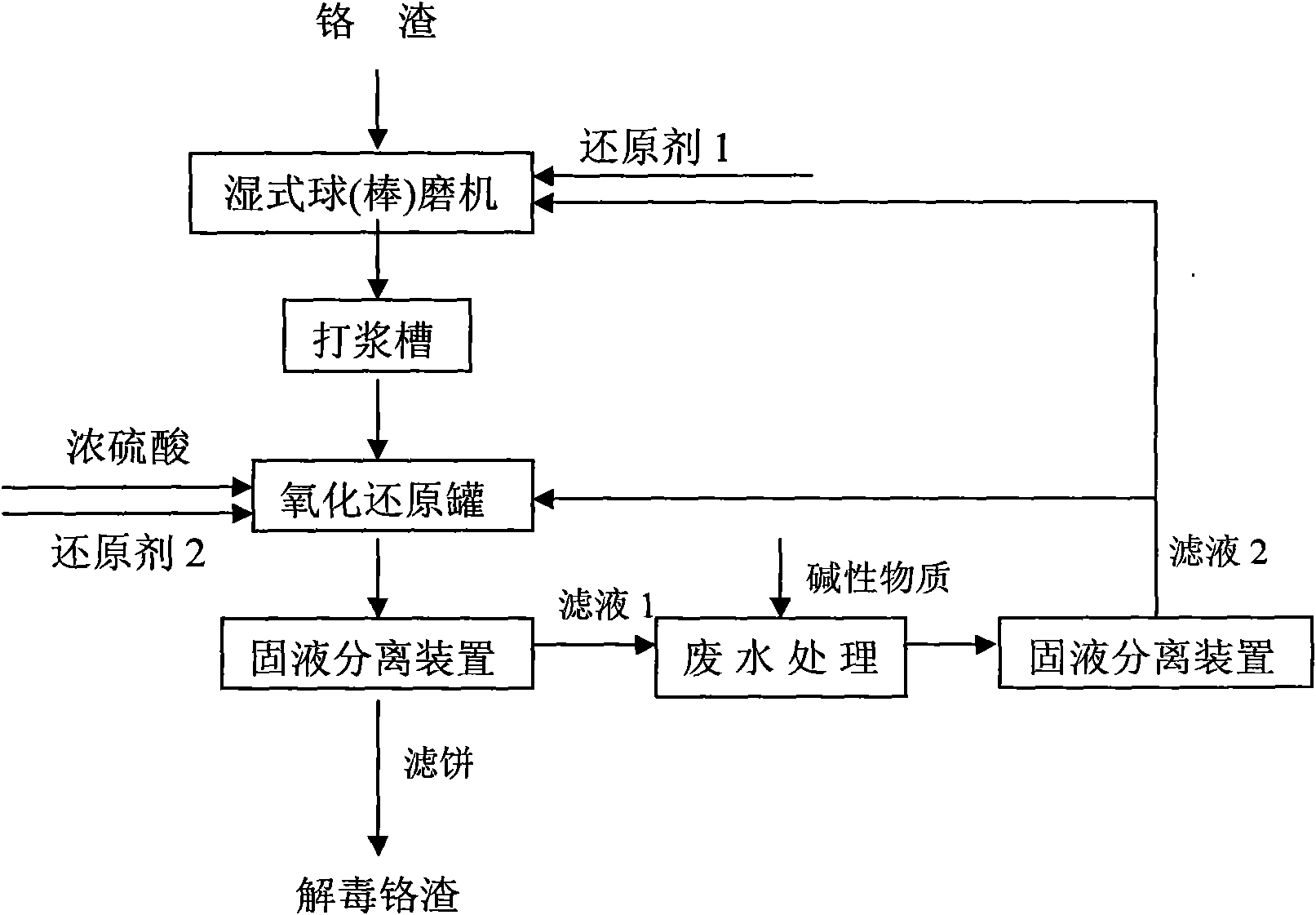

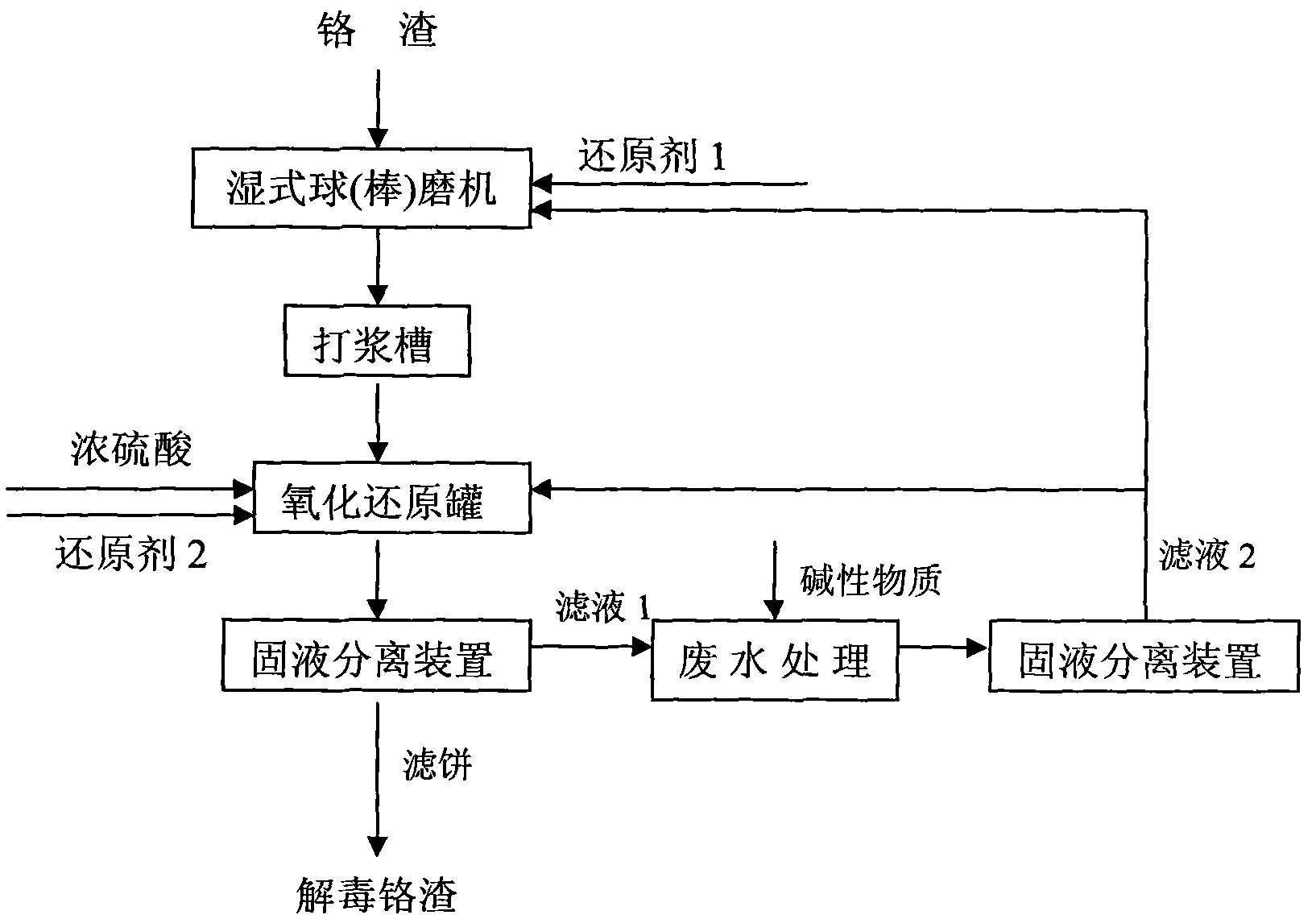

Chromium residue detoxifying process

InactiveCN101816829AReduce dosageImprove mixing uniformityChemical protectionSodium hydrosulfideSlurry

The invention belongs to the technical field of chromium residue detoxifying, and discloses a chromium residue detoxifying process. The process comprises the following steps of: performing wet grinding on chromium residue, adding water into the chromium residue to prepare chromium residue slurry; and after being subjected to acid-leaching reduction reaction, performing solid-liquid separation on the chromium residue slurry to obtain a filter cake, namely the detoxified chromium residue. The process is characterized in that: under the condition of not changing the original alkaline environment of the chromium residue, a reducing agent 1 is added into the chromium residue directly, and then the reducing agent and the chromium residue are subjected to wet grinding to form particles with 100 to 300 meshes; and the water is added to prepare the chromium residue slurry with 30 to 45 baume degrees, wherein the reducing agent 1 is sodium sulphide, sodium bisulfide, sodium thiosulfate or sodium pyrosulfite. The process has simpleness, thorough detoxification, no chromium return phenomenon and easy implementation of mass production; and the process prolongs effective reduction reaction time, improves reaction efficiency, saves the using amount of acid during the acid-leaching reduction, and has low processing cost because Cr6+ in the chromium residue is subjected to two times of dissolution and reduction.

Owner:河南金谷环保工程设备有限公司

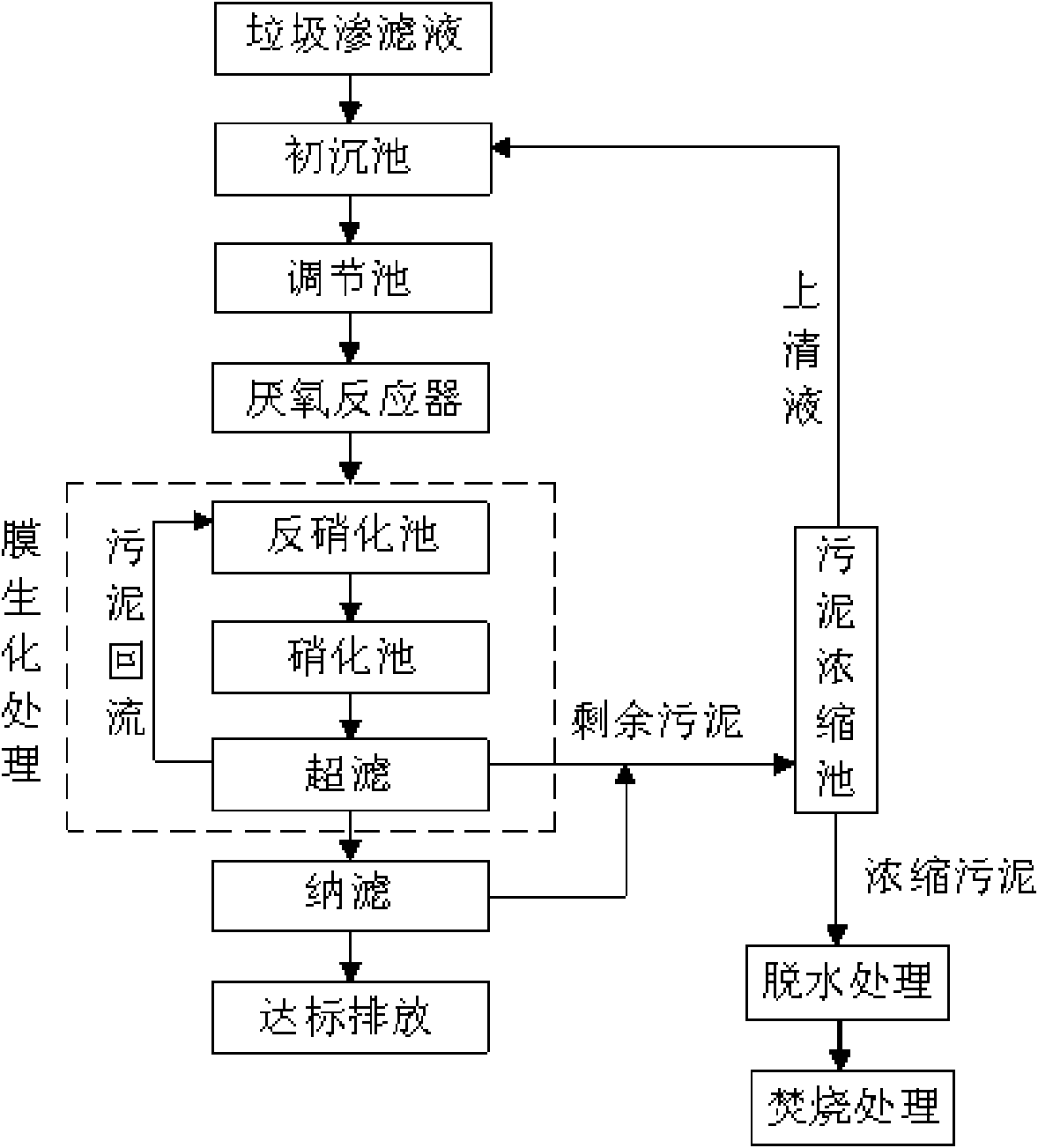

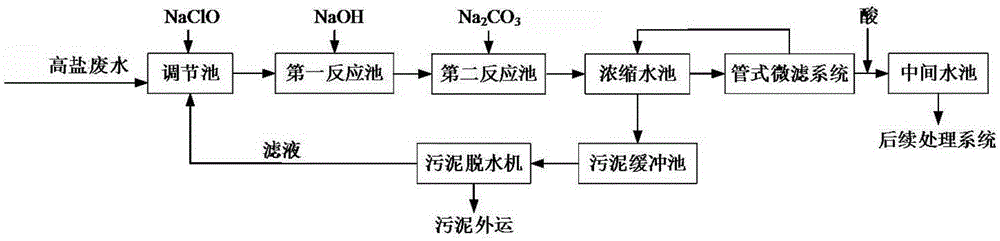

Method and device for treating garbage percolate

ActiveCN101597131AAchieving zero emissionsRelieve stressSludge treatment by de-watering/drying/thickeningTreatment with aerobic and anaerobic processesHigh concentrationAfter treatment

The invention discloses a method and a device for treating garbage percolate, wherein the method comprises the steps of pretreatment, anaerobic treatment, membrane biochemical treatment, nanofiltration treatment, sludge treatment and the like; the device comprises a primary sedimentation tank (1) and an adjusting tank (2), the adjusting tank (2) is connected with an anaerobic reactor (3), the anaerobic reactor (3) is connected with a denitrification tank (4), and the denitrification tank (4) is communicated with a nitrification tank (5); and the nitrification tank (5) is connected with an ultrafiltration apparatus (6), and the ultrafiltration apparatus (6) is connected with a nanofiltration device (7). The method and the device achieve COD degradation of high-concentration wastewater so that the COD of high-concentration COD of 50,000 reaches about 50 after treatment and reaches the standard of industrial reuse water, thus the method and the device achieve zero discharge of the percolate, initiate a new attempt to treat high-concentration percolate, and fill up the domestic blank.

Owner:汕头市澄海洁源垃圾发电厂有限公司

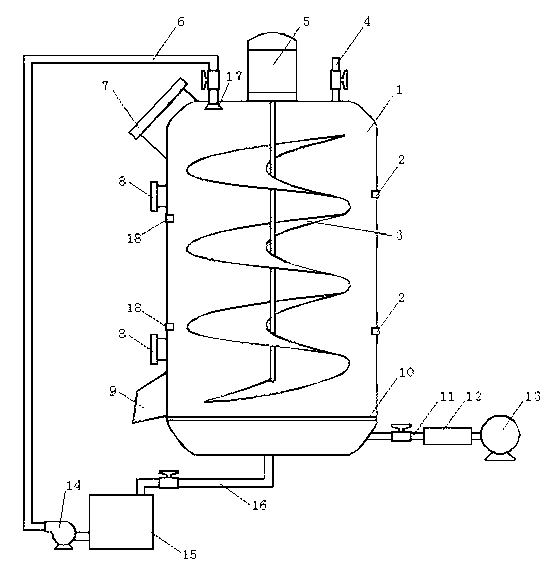

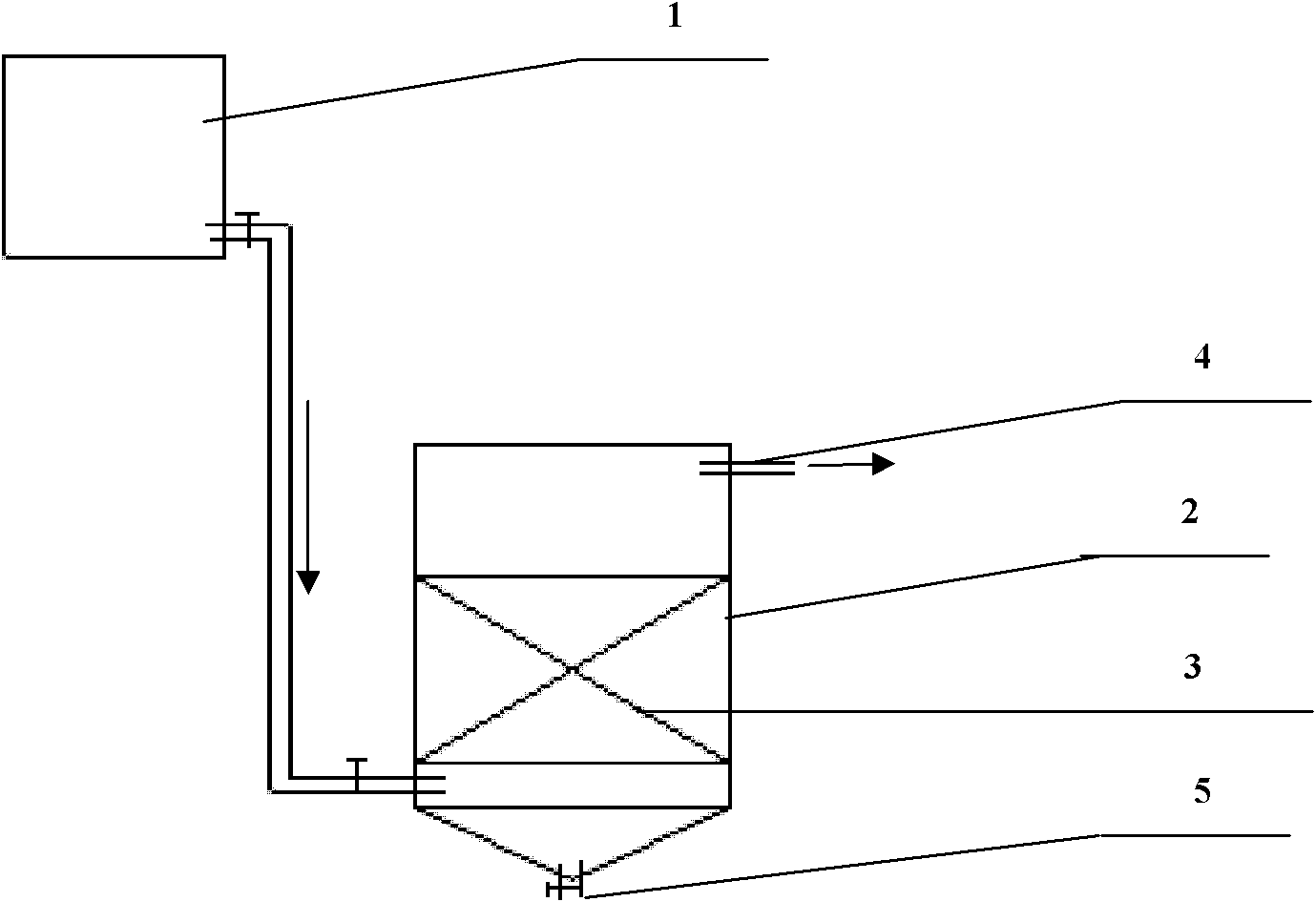

Biomass tower type compost treatment device and method

ActiveCN103011927ALarge change in volume compressionNo pollution in the processBio-organic fraction processingOrganic fertiliser preparationOrganic farmingMicrobial agent

The invention discloses a biomass tower type compost treatment device and method. The device and method have the advantages of enhancing the function of a microbial ecosystem, accelerating the decomposition of organic substances, promoting the maturity of composts, improving the composting efficiency and effectively preventing the spread of pathogenic bacteria and the diffusion of peculiar smells by using an efficient microbial agent through a closed composting operation method. Pollution-free organic farming is realized; lots of enzymes and active substances secreted by funguses while composting can be used as the best metabolic enhancer for crops, so that the disease and insect resistances can be increased; and the soil can be improved and activated for permanent farming so as to create a basis for pesticide-free organic farming and realize zero-emission and no pollution in the agricultural industry.

Owner:湖南绿心科技有限公司

Method for extracting high-quality soybean germ oil by using subcritical butane

ActiveCN102161932AAccelerate the speed of desolvationResidue reductionFatty-oils/fats productionEdible oils/fatsBiotechnologySoy germ

The invention relates to a method for extracting high-quality soybean germ oil by using subcritical butane and relates to the field of grain fine and deep processing. The method comprises: cutting purified soybean germs into slices which are 0.3 to 0.4 millimeters thick; placing the slices in an extraction kettle; performing 1 to 5 times of countercurrent leaching of the cut soybean germs by using liquefied butane as a solvent, wherein the extraction time is 10 to 120 minutes, the material to liquid ratio is 1:(1-6), the extraction temperature is 10 to 90 DEG C, and the extraction pressure is0.2 to 0.1MPa; delivering extracted mixed oil and wet dregs into an evaporation system and desolventizing under reduced pressure; and subjecting the obtained soybean germ crude oil to normal winterization, alkali refining and decolorization processes to obtain a soybean germ oil product with high beta-sitosterol content. In the invention, the soybean germ oil is extracted by using subcritical butane, the manufacturing cost of equipment is reduced considerably, the operation cost is low, the production period is shorter, the yield is high, and the method represents a low-consumption and environment-friendly practical technique for producing soybean germ oil.

Owner:江苏鸿祺生物科技有限公司

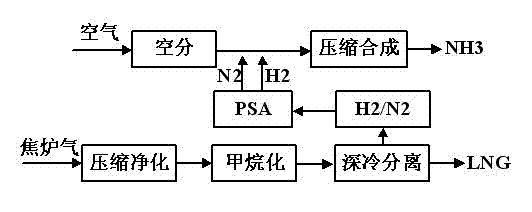

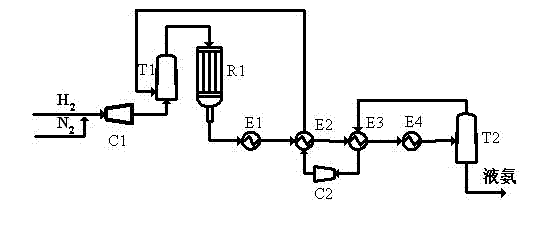

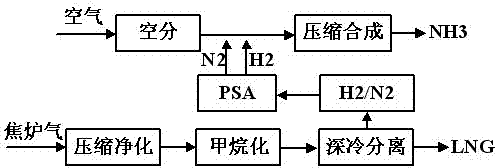

Technology for preparing liquefied natural gas and liquid ammonia by using coke oven gas

InactiveCN102517108AIncrease added valueReduce in quantityGaseous fuelsBulk chemical productionMethanationCoke oven

The invention discloses a technology for preparing liquefied natural gas and liquid ammonia by using coke oven gas. The coke oven gas is subjected to the steps of compression, purification, methanation, cryogenic separation and liquefaction of synthetic natural gas, variable pressure adsorptive separation and liquid ammonia preparation with hydrogen rich gas, so that the liquefied natural gas (LNG) of which methane purity is more than 99 percent and the liquid ammonia reaching national first level standard are obtained. By the technology, the hydrogen byproduct of the coke oven gas for preparing the LNG is fully utilized; effective ingredients of the coke oven gas such as H2, N2, CH4, CO and CO2 are furthest utilized; the CO and the CO2 are methanated, so that the yield of the CH4 is improved by about 1 / 3; the liquefied CH4 is used as the LNG and sold; and the rest nitrogen-containing hydrogen-rich gas is used as a raw material for synthesizing ammonia, so that the additional value of the coke oven gas is improved, and reliable raw material guarantee is provided for developing downstream products with high additional values and prolonging the product chain.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

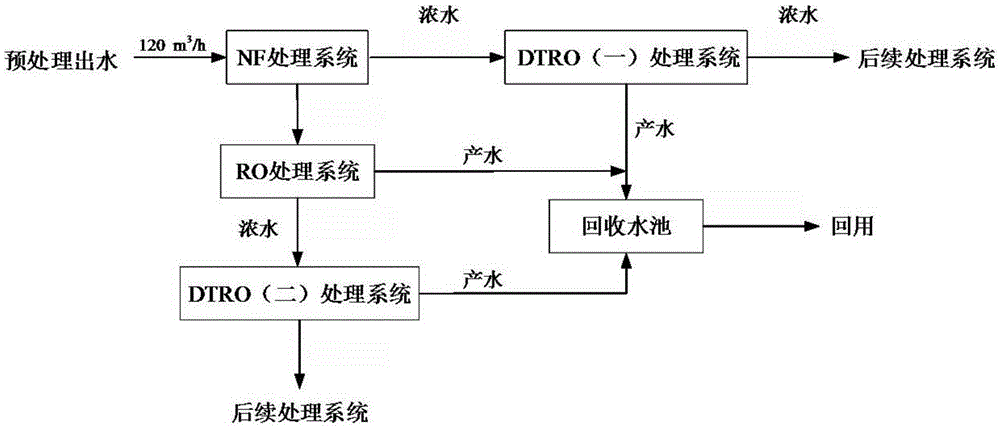

High-salt waste water zero emission and salt separation processing method and device

ActiveCN105254106AShort processReduce doseWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemistryPre treatment

The invention discloses a high-salt waste water zero emission and salt separation processing method and device. The method includes the following steps of 1, waste water preprocessing, 2, waste water decrement and concentration and 3, crystallization. By means of the high-salt waste water zero emission and salt separation processing method and device, waste water can be processed efficiently, liquid and salt ingredients in the waste water are effectively separated, a product obtained after waste water can be recycled or sold as other industrial products, so that zero emission of waste water is achieved. The method is simple and easy to implement, high in processing efficiency and small in energy consumption; by the adoption of the method, pollution to the environment is avoided, an active function is played on improvement of regional water environment quality, the utilization rate of waste water is raised, production cost is saved, and environmental and social benefits are quite remarkable. The device is high in operation efficiency, convenient to assemble, low in cost and small in energy consumption.

Owner:华电水务工程有限公司 +1

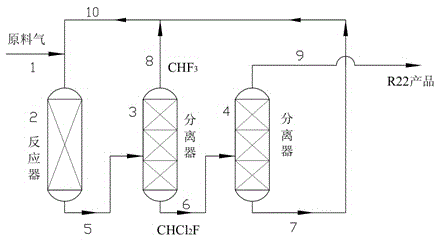

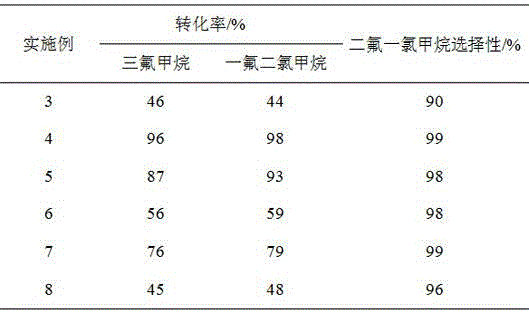

Method for resource utilization of fluoroform

ActiveCN104628513AReduce processing costsReduce equipment investmentPreparation by halogen replacementChemical recyclingHalohydrocarbonResource utilization

The invention discloses a method for resource utilization of fluoroform. The method is characterized by mixing fluoroform with one or a plurality of halohydrocarbon, converting the mixture into a product containing monochlorodifluoromethane in the presence of a catalyst, and reacting unreacted fluoroform with other reaction products in a reactor. According to the method, chlorofluorocarbon containing chlorine or bromine or chlorofluorocarbon which contains chlorine or bromine and needs to be processed during a production process is utilized as reaction material to perform chlorine / fluorine exchange reaction with fluoroform to prepare monochlorodifluoromethane, better economic benefits and social benefits are provided; and in products, monochlorodifluoromethane can be recycled though separation, remained waste gas does not need to be processed, and can still enter the reactor as gas reacted with fluoroform, the conversion rate of reactants is improved, and zero-discharge is realized.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

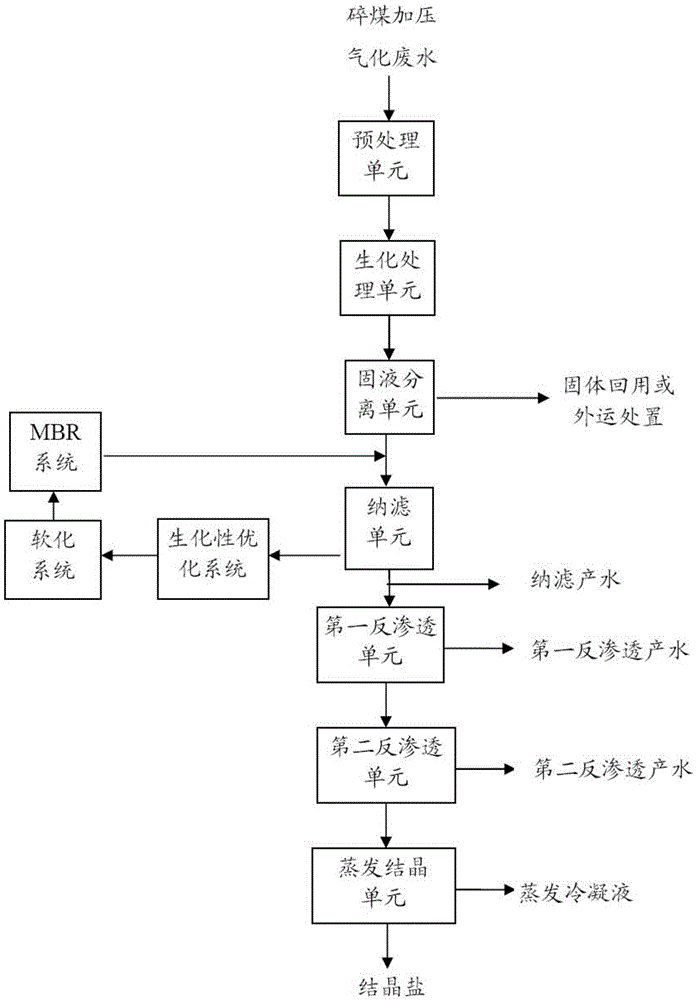

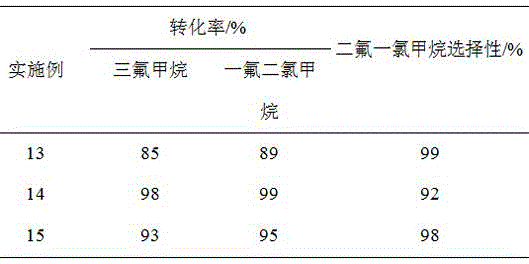

Coal chemical strong brine zero emission and salt screening technology

InactiveCN105540976ASimple processHigh degree of automationScale removal and water softeningTreatment involving filtrationChemistryZero emission

The invention discloses a coal chemical strong brine zero emission and salt screening technology. Strong brine enters a first special reverse osmosis process pack after being treated by an adjusting pond and a pre-treatment device, freshwater of the strong brine is reused, water produced on the thick water side passes through a softening process pack to remove calcium ions and magnesium ions in wastewater and then enters a first-stage special nanofiltration process pack, water produced on the thick water side of the first-stage special nanofiltration process pack passes through a first evaporation crystallization process pack to obtain industrial-grade sodium sulfate, water produced on the fresh water side enters a second-stage special nanofiltration process pack, water produced on the thick water side of the second-stage special nanofiltration process pack returns to the adjusting pond, water produced on the fresh water side enters a reverse osmosis membrane process pack, the fresh water is reused, water produced on the thick water side enters a second special reverse osmosis membrane process pack, water produced on the fresh water side of the second special reverse osmosis membrane process pack flows back to the adjusting pond or is reused according to water quality, and water produced on the thick water side passes through a second evaporation crystallization process pack to obtain industrial-grade sodium chloride. The technology is simple, cost is low, the automation degree is high, long-time stable operation can be achieved, and secondary pollution is not caused.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

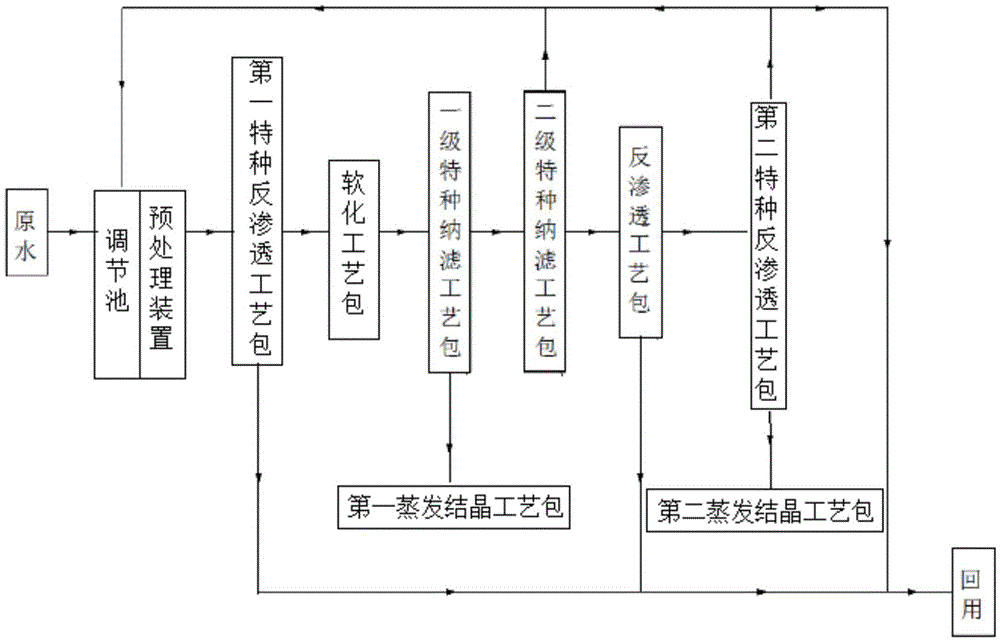

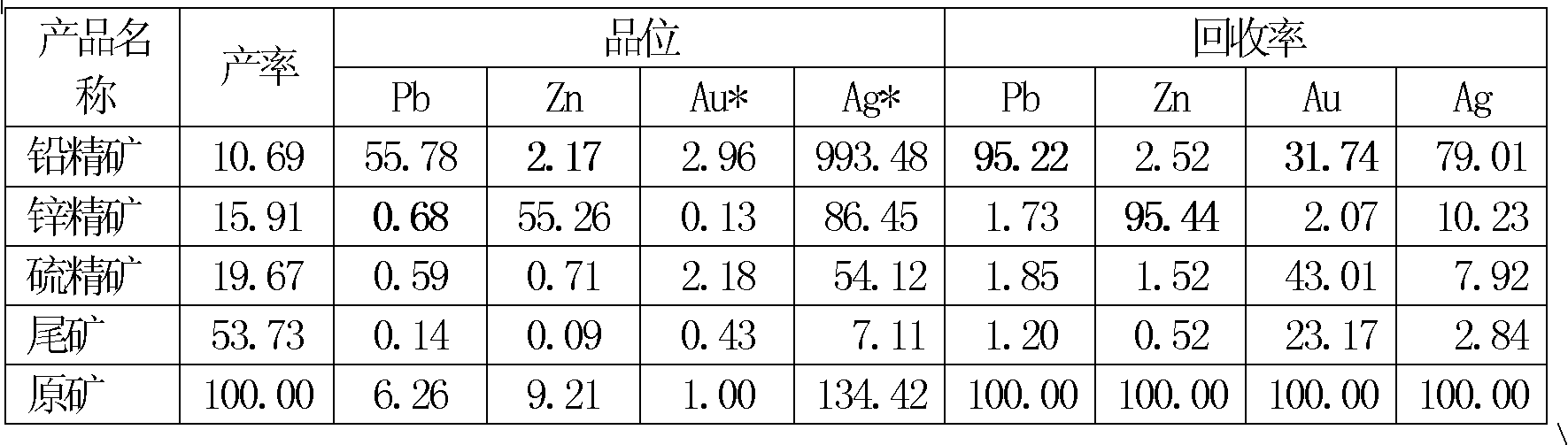

Method for treating and recycling lead-zinc sulfide ore dressing wastewater

ActiveCN101913720AEliminate the effects ofExtended service lifeWaste water treatment from quariesMultistage water/sewage treatmentActive carbonNovel technique

The invention provides a technique for treating and recycling lead-zinc ore dressing wastewater and aims to solve the problems of influence on the ore dressing index due to the recycling of the ore dressing wastewater for production and environmental pollution caused by drainage. The novel technique for treating and recycling the lead-zinc sulfide ore dressing wastewater comprises the steps of: adjusting the pH value of the total wastewater of an ore dressing plant; adding ferrous sulfate and flocculant into the wastewater to perform oxidation-coagulation treatment; and oxidizing the treated water by using chlorine dioxide, and performing catalytic oxidation and adsorption by using an active carbon bed, so that the treated water reaches the relevant discharge standard of China; and totally recycling the treated water by adopting the combined application of potential-controlled flotation and an environmental-protection collector. Compared with the field process technique, the method saves the cyanide flotation process and improves the recovery rates of lead, zinc and gold. The method provides whole technical integration of the combined application technique of the potential-controlled flotation and the environmental-protection collector and the wastewater treatment technique for the treatment and recycling of the lead-zinc ore dressing wastewater, and realizes recycling of the ore dressing wastewater.

Owner:HUNAN HERMES SAFE ENVIRONMENT PROTECTION SCI

Near zero emission process of salt-containing waste water

ActiveCN103342432AHigh recovery rateReduce processing costsDispersed particle separationWater/sewage treatment bu osmosis/dialysisChemical oxygen demandUltrafiltration

The invention relates to a near zero emission process of salt-containing waste water. The process specifically comprises the following steps of: 1) pretreatment, namely, removing part of COD (Chemical Oxygen Demand), suspended solids, hardness and the like from raw water; 2) electric absorption, namely, removing inorganic salt in pretreated partial water, wherein concentrated water generated in the process and part of oxidized waste water which is not subjected to electric adsorption treatment enter into a membrane filtering system together; 3) treatment in a membrane treatment system, wherein the membrane treatment system mainly comprises ultrafiltration, reverse osmosis and electroosmosis processes; and 4) evaporative crystallization and salty mud treatment process, namely, evaporating and crystallizing concentrated salty water generated by electroosmosis, wherein fresh water generated in the process enters into a water supply system while solids generated in the process enter into the salty mud treatment system. The comprehensive water recovery rate of the near zero emission process can reach 99.5%, so that resource and harmful treatment of the salt-containing waste water is realized.

Owner:NANJING UNIV OF TECH +1

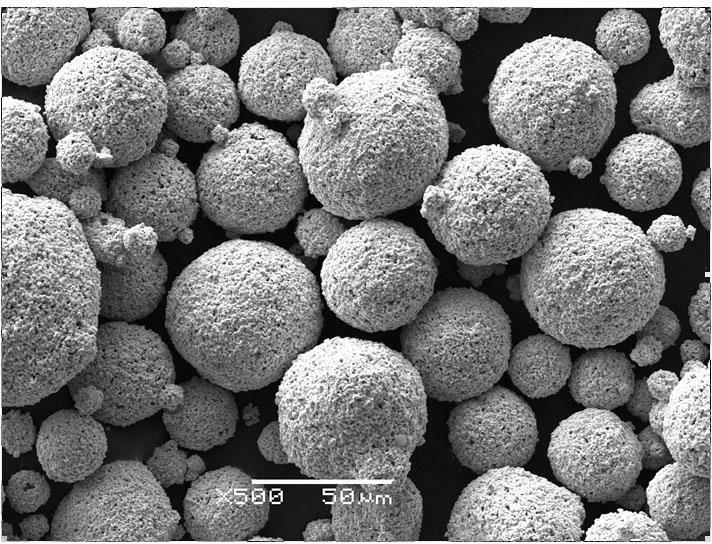

Method for producing spherical thermal-spraying powder

The invention discloses a method for producing spherical thermal-spraying powder. The method sequentially comprises the steps of: A, firstly, adding 55-95% of tungsten carbide powder, 5-33% of metal nickel powder or cobalt powder or iron powder, and 0-22% of chromium carbide powder into a ball grinding mill in terms of mass percentage, meanwhile, adding 15-35% of wet-grinding media and 2-5% of a forming agent in terms of the total mass of raw material powder, and performing wet grinding for 12-40h to obtain mixed slurry; B, centrifuging, atomizing and pelleting to obtain spherical mixed powder; C, placing the spherical mixed powder into a dewaxing and sintering integrated furnace, removing the forming agent, sintering for 20-70min in vacuum at the temperature of 800-1350 DEG C, cooling to below 50 DEG C and discharging out of the furnace; and D, crushing and sieving agglomerate materials obtained in the step C to obtain the spherical thermal-spraying powder. The method disclosed by the invention has wide applicability, and is not only suitable for producing the tungsten-carbide-based spherical thermal-spraying powder but also suitable for producing the thermal-spraying powder of other metal, nonmetal and mixtures of metal and nonmetal; and a production process is nonhazardous, the quality is stable and consistent, and the thermal-spraying powder smaller than 30 micrometers can be produced.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

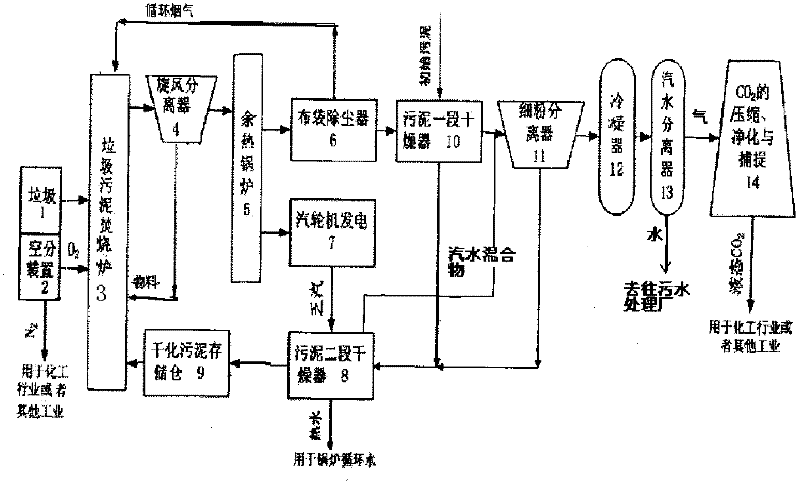

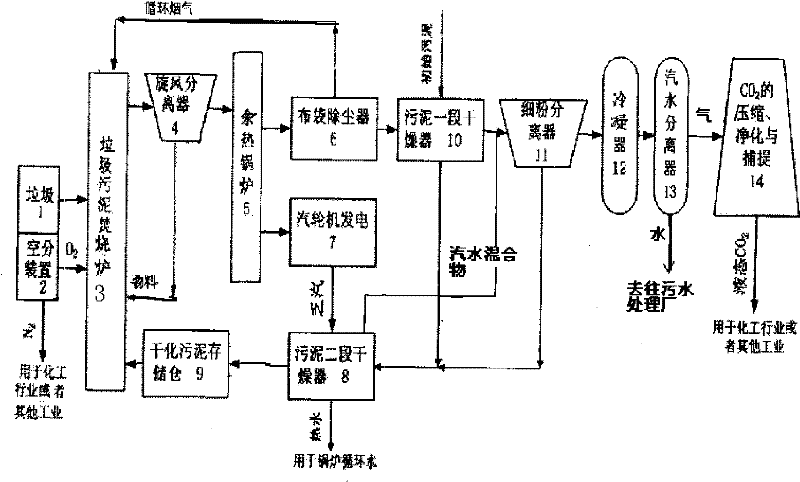

Sludge drying and incinerating integrated zero-discharge treatment system and treatment process

InactiveCN102531318AGood effectLow running costSludge treatment by de-watering/drying/thickeningIndirect carbon-dioxide mitigationSludgeToxic material

The invention discloses a sludge drying and incinerating integrated zero-discharge treatment system and treatment process, belonging to the technical field of harmless treatment of sludge. The treatment system is composed of a garbage storage pit, an air separation device, a garbage-sludge incinerator, a cyclone separator, a waste heat boiler, a bag-type dust remover, a turbo-generator set, a two-stage drier, a dried sludge storage bin, a fine powder separator, a condenser, a steam-water separator, and a carbon dioxide purifying and catching system. According to the invention, the dried sludge burns sufficiently in oxygen-rich atmosphere, the auxiliary fuel is saved, the incinerating waste heat is efficiently recovered and utilized, CO2 in discharged flue gas is cooled, purified, compressed and liquefied to ultimately obtain high-purity CO2 which can be used for industrial application, other impurities are recovered, dioxin and other extremely toxic substances are collected separately and conveyed to qualified divisions for unitized treatment, the purposes of treating a waste with another waste and promoting harmless treatment with resource treatment are realized, the waste treatment cost is lowered and the energy utilization rate is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for producing water-soluble citrus peel fibres

InactiveCN101797037AAchieve full utilizationAchieving zero emissionsFood preparationFiberFood material

The invention relates to a method for producing water-soluble citrus peel fibres. Fresh citrus peels are taken as raw materials and are subjected to the technology such as colour preserving, drying and crushing, CO2 supercritical bitter and color removal, superfine pulverizing and enzymolysis, concentration, high-pressure homogenization, filling and sterilizing to convert cellulose, hemicellulose, pectin and the like in the citrus peels into the water-soluble citrus peel fibres which can be eaten directly and also can be taken as raw materials of high-carbohydrate fibre functional foods. Aromatic oil and pigments of the citrus are obtained in the production process. Therefore, the full use of the citrus and zero emission of peel residue are realized in the citrus processing process.

Owner:SHAOYANG UNIV

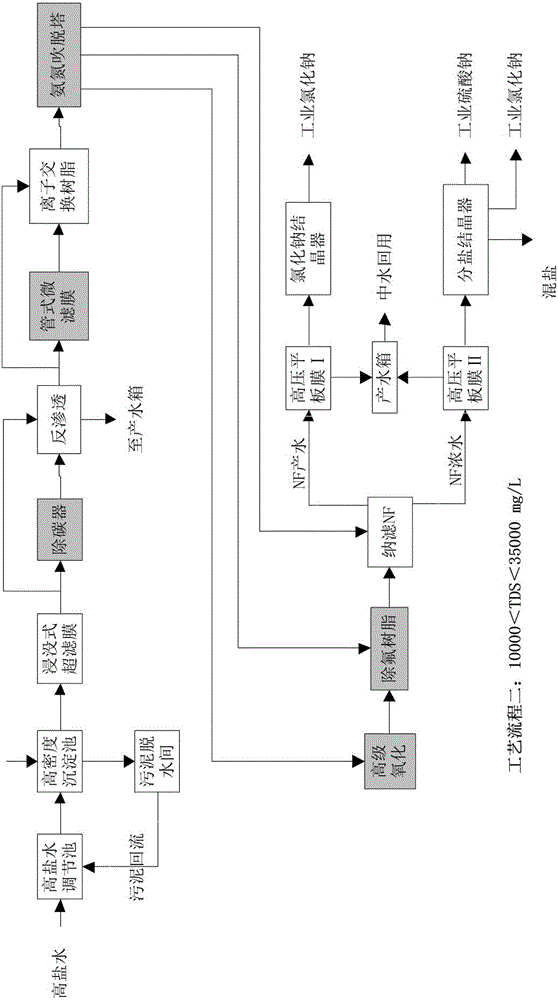

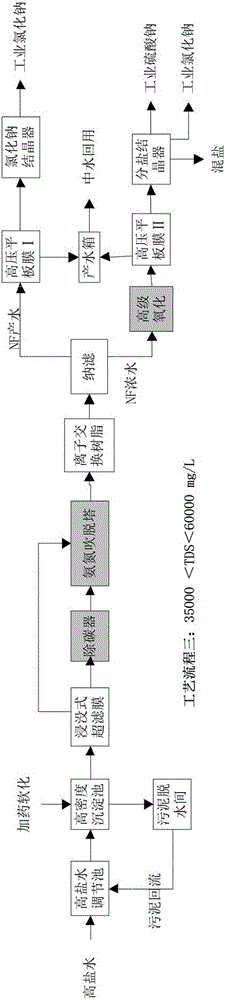

Device and method for treating industrial wastewater with high salt content

InactiveCN106396228AHigh recovery rateAchieving zero emissionsGeneral water supply conservationWater/sewage treatment by ion-exchangeFiltrationIon exchange

The invention provides a method for treating industrial wastewater with a high salt content. The method includes steps of pretreating the industrial wastewater with the high salt content, to be more specific, regulating and homogenizing the industrial wastewater with the high salt content by the aid of a high-salinity water regulating tank, then feeding the industrial wastewater into a high-density sedimentation tank, carrying out chemical softening treatment and flocculation sedimentation on the industrial wastewater, simultaneously removing most silicon dioxide and suspended matters, feeding water treated by the high-density sedimentation tank into an immersed ultra-filtration tank and further removing suspended matters and colloidal impurities in the water; carrying out separation and concentration, to be more specific, concentrating and separating the industrial wastewater with the high salt content after the industrial wastewater is pretreated at the pretreatment step, or carrying out ion exchange treatment on the industrial wastewater; recycling crystals, and to be more specific, separating the sodium chloride crystals and the sodium sulfate crystals from the water by the aid of crystallizers. The invention further provides a device for treating the industrial wastewater with the high salt content.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com