Method for producing spherical thermal-spraying powder

A technology of thermal spraying powder and production method, which is applied in coating, melting spraying, metal material coating technology and other directions, can solve the problems of difficult to produce thermal spraying powder, low granulation efficiency, large difference in sintering density, etc. Achieve stable and consistent quality, high production efficiency, and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

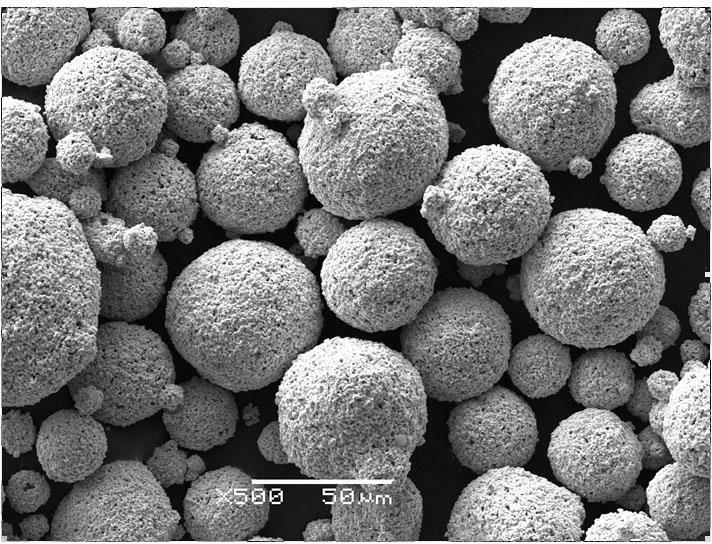

Image

Examples

Embodiment 1

[0018] Embodiment 1: The production method of the spherical thermal spray powder with WC as the base material and Co as the binding phase.

[0019] A. Wet mill preparation slurry: put 413.6kg of WC powder (accounting for 94% of raw material mass percentage) and 26.4kg of Co powder (accounting for 6% of raw material mass percentage) that meet the requirements of the national standard for industrial production into the ball mill, and add 79.2 One liter of deionized water was used as the wet grinding medium (accounting for 18% of the mass percentage of the raw material powder) and 8.8kg of molding agent polyethylene glycol (also known as PEG, accounting for 2.0% of the mass percentage of the raw material powder), and wet milled for 15 hours to make a mixture pulp;

[0020] B. Centrifugal atomization drying and granulation: Send the prepared slurry into the slurry mixing tank of the centrifugal spray drying device, and after stirring evenly, spray the slurry into the drying chambe...

Embodiment 2

[0025] Embodiment 2: The production method of the spherical thermal spray powder with WC as the base material and Ni as the binding phase.

[0026] A. Wet mill preparation slurry: put 295.68kg of WC powder (accounting for 6.27% of the mass percentage of raw materials) and 144.32kg of Ni powder (accounting for 32.8% of the mass percentage of raw materials) that meet the requirements of the national standard for industrial production into the ball mill, and add 149.6 liter of alcohol (accounting for 34.0% of the mass percentage of raw materials) and 22kg of forming agent polyethylene glycol (accounting for 5% of the mass percentage of raw materials), wet milling for 40h to make a mixed slurry;

[0027] B. Centrifugal atomization drying and granulation: Send the prepared slurry into the slurry mixing tank of the centrifugal spray drying device, and after stirring evenly, spray the slurry into the drying chamber for drying and granulation. The diameter of the atomizing disc of the...

Embodiment 3

[0032] Embodiment 3: The production method of the spherical thermal spray powder with WC as the base material and Fe as the binding phase.

[0033] A. Wet mill preparation slurry: put 396kg of WC powder (accounting for 90% of the mass percentage of raw materials) and 44kg of Fe powder (accounting for 10% of the mass percentage of raw materials) that meet the requirements of the national standard for industrial production into the ball mill, and add 132 liters of Ionized water (accounting for 30% of the mass percentage of raw materials) and 13.2kg of forming agent polyethylene glycol (accounting for 3% of the mass percentage of raw materials) were wet milled for 21 hours to make a mixed slurry;

[0034]B. Centrifugal atomization drying and granulation: Send the prepared slurry into the slurry mixing tank of the centrifugal spray drying device, and after stirring evenly, spray the slurry into the drying chamber for drying and granulation. The diameter of the atomizing disc of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com