Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2412results about "Volume/mass flow by thermal effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

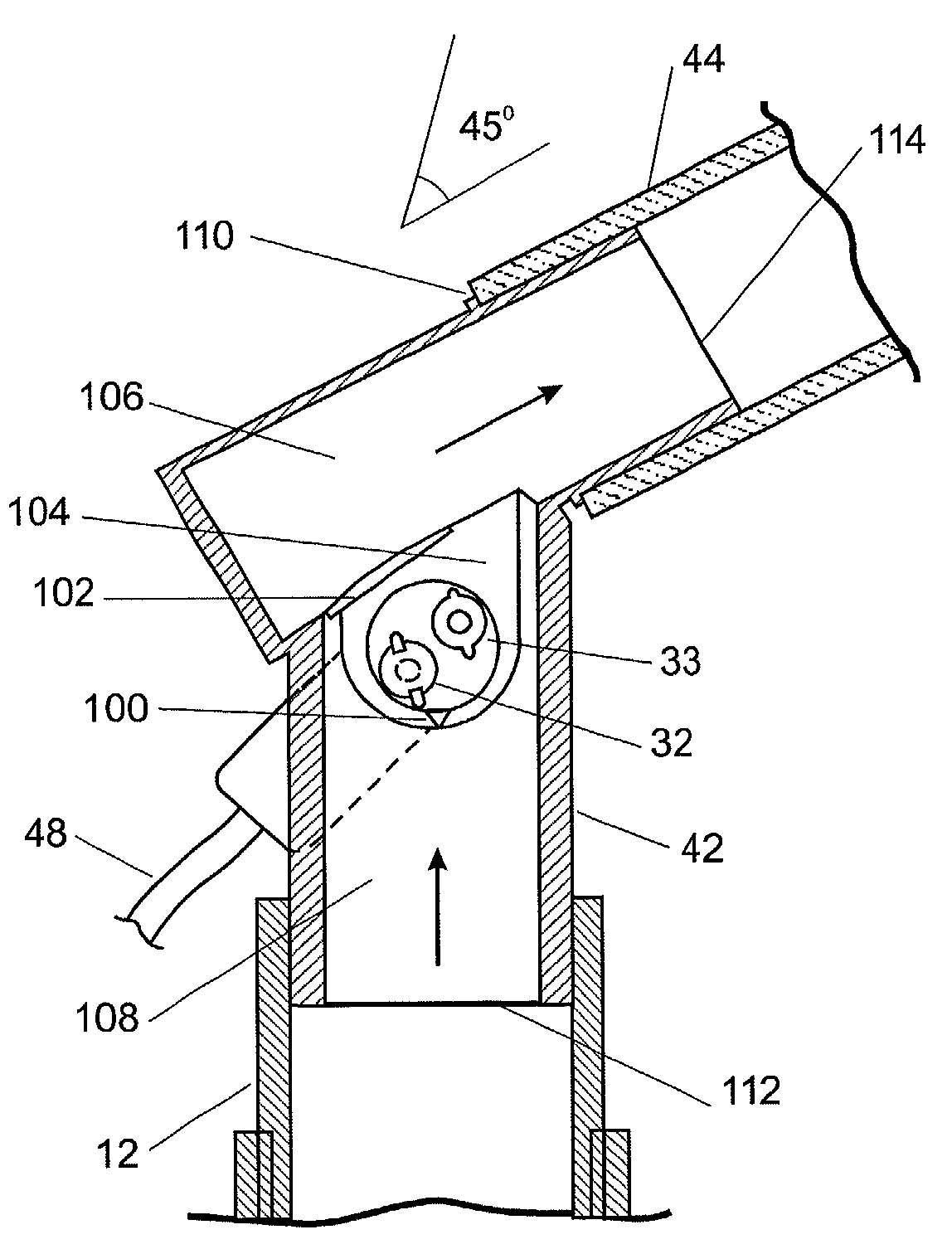

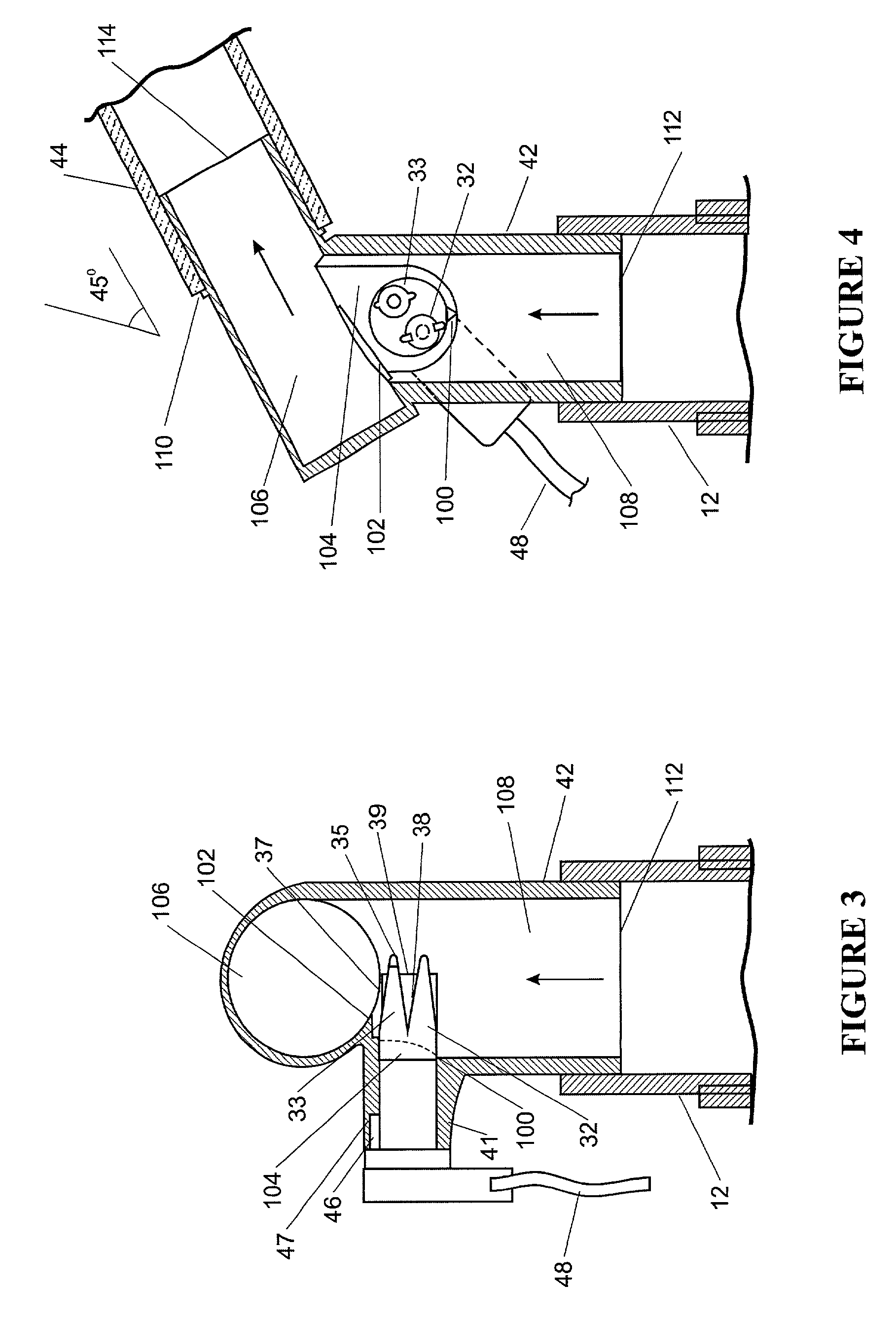

Immersible thermal mass flow meter

ActiveUS6971274B2Quality improvementImprove measurement qualityVolume/mass flow by thermal effectsThin film sensorEngineering

Owner:SIERRA INSTR

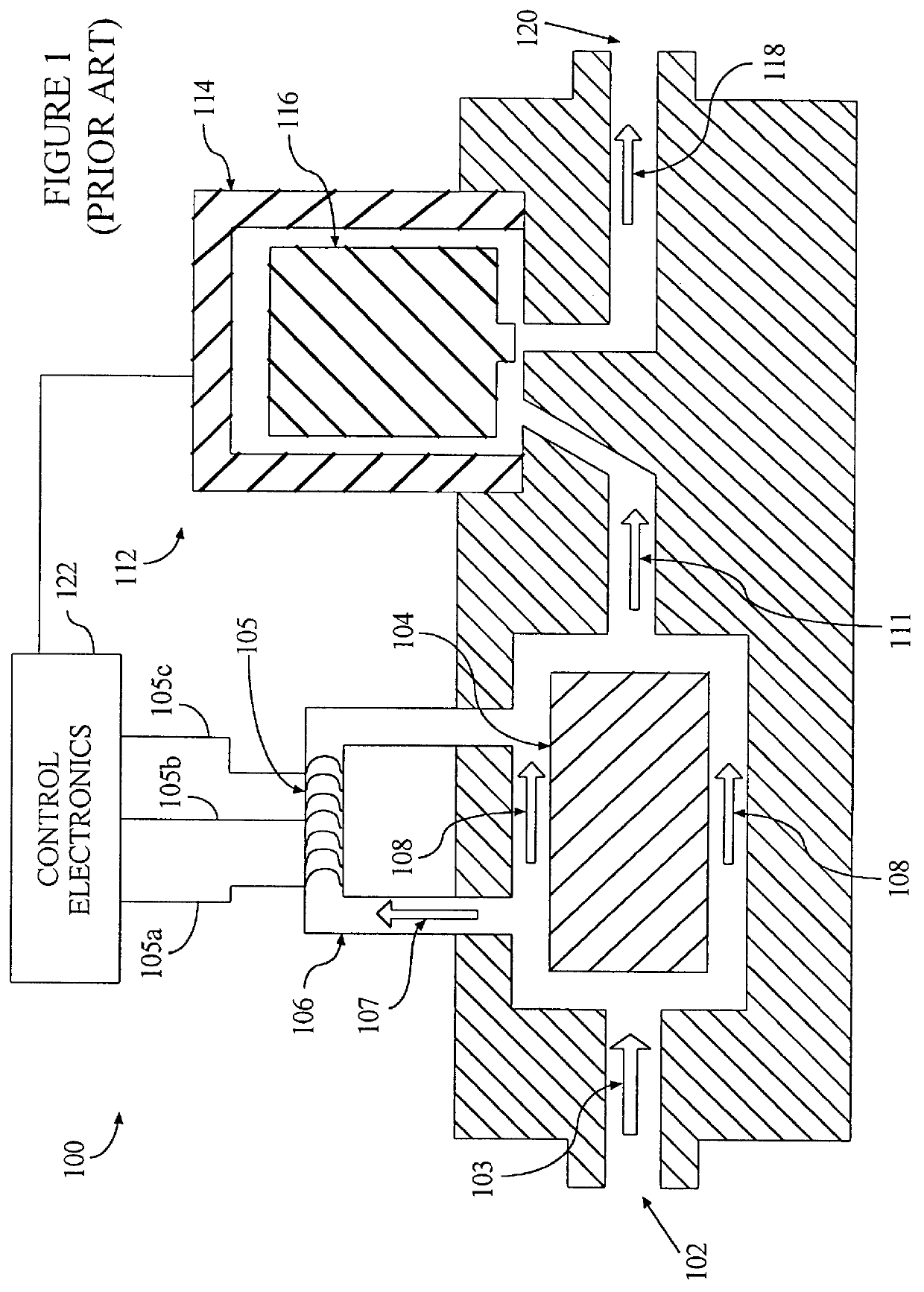

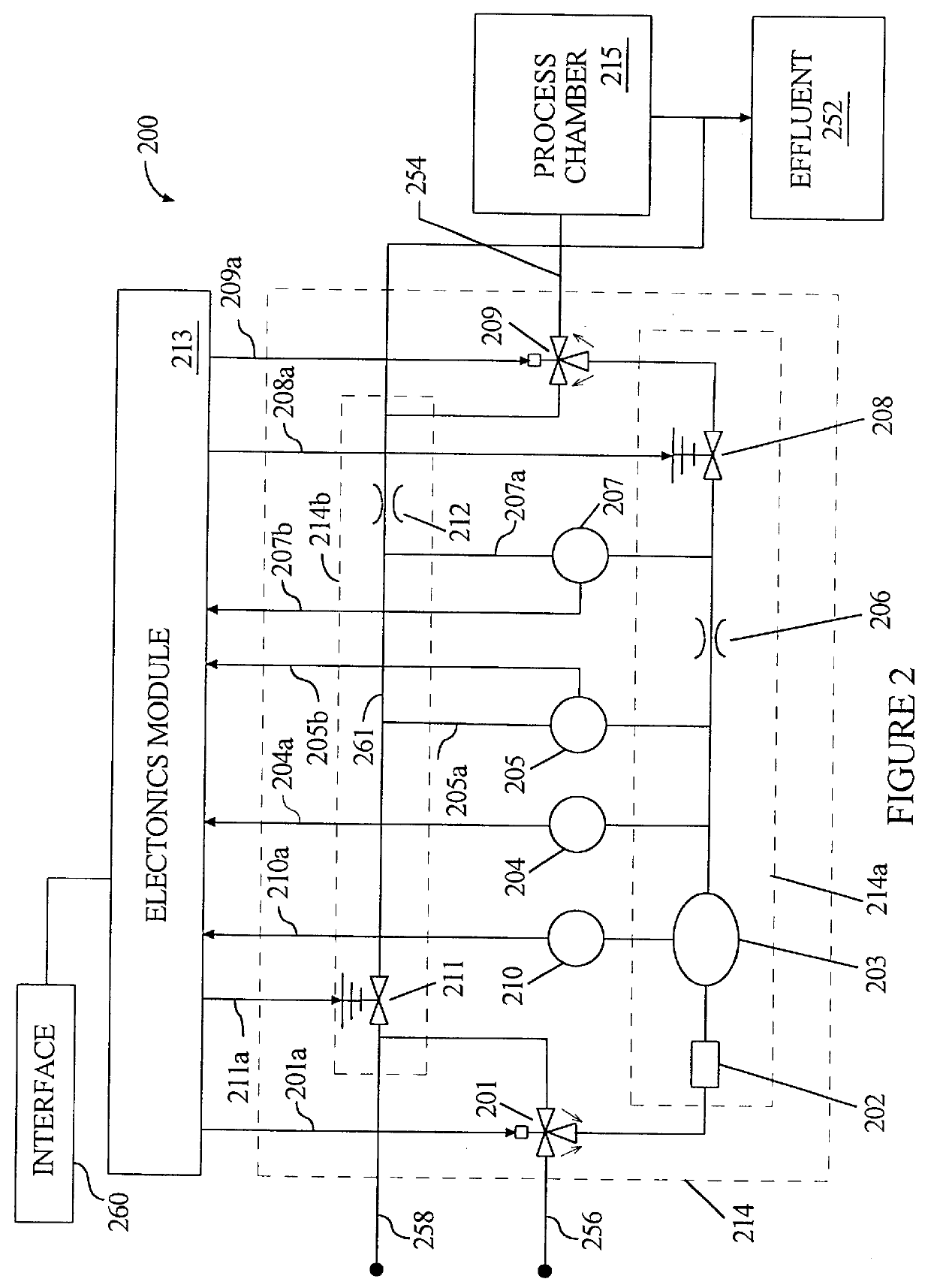

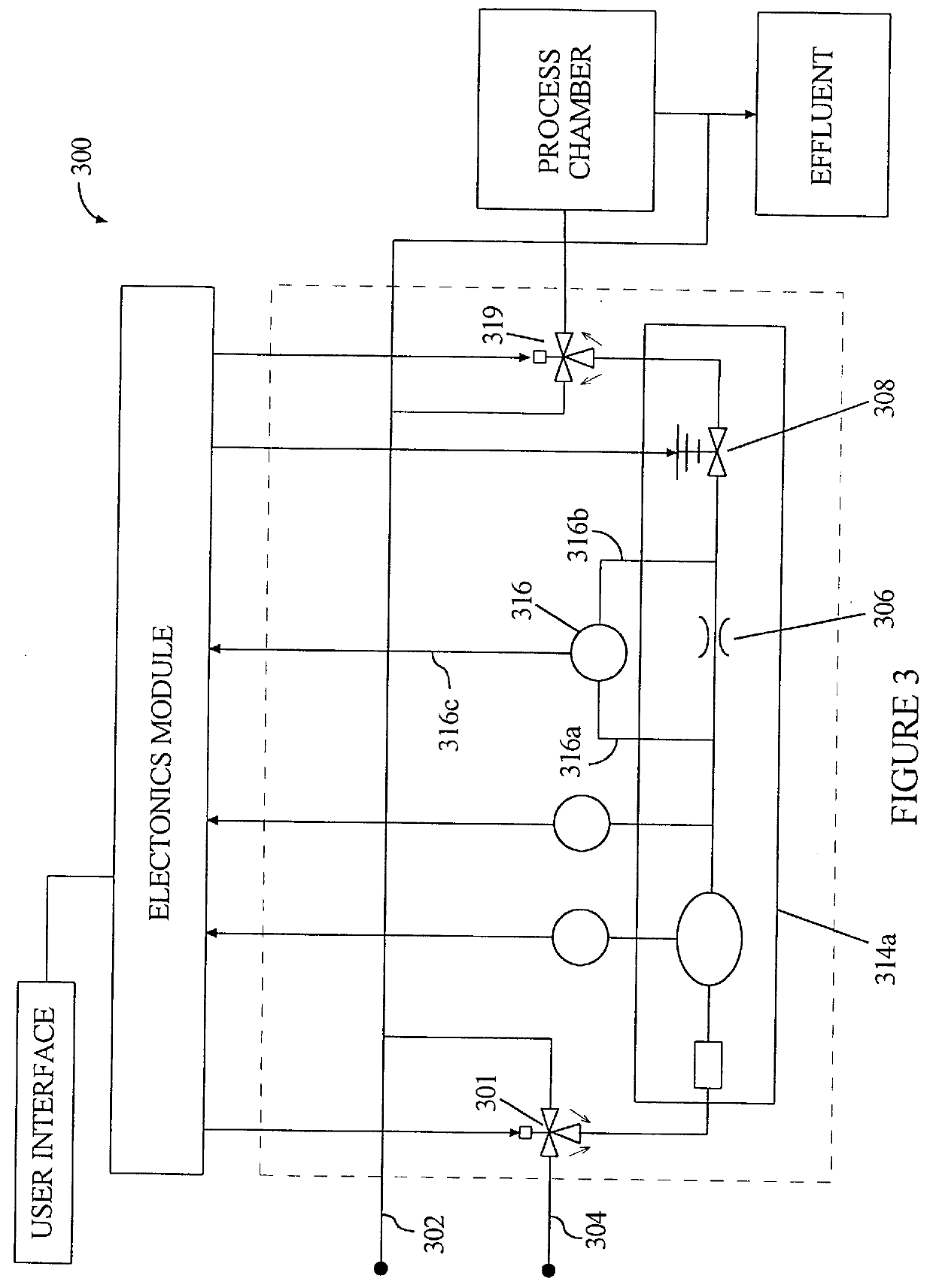

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

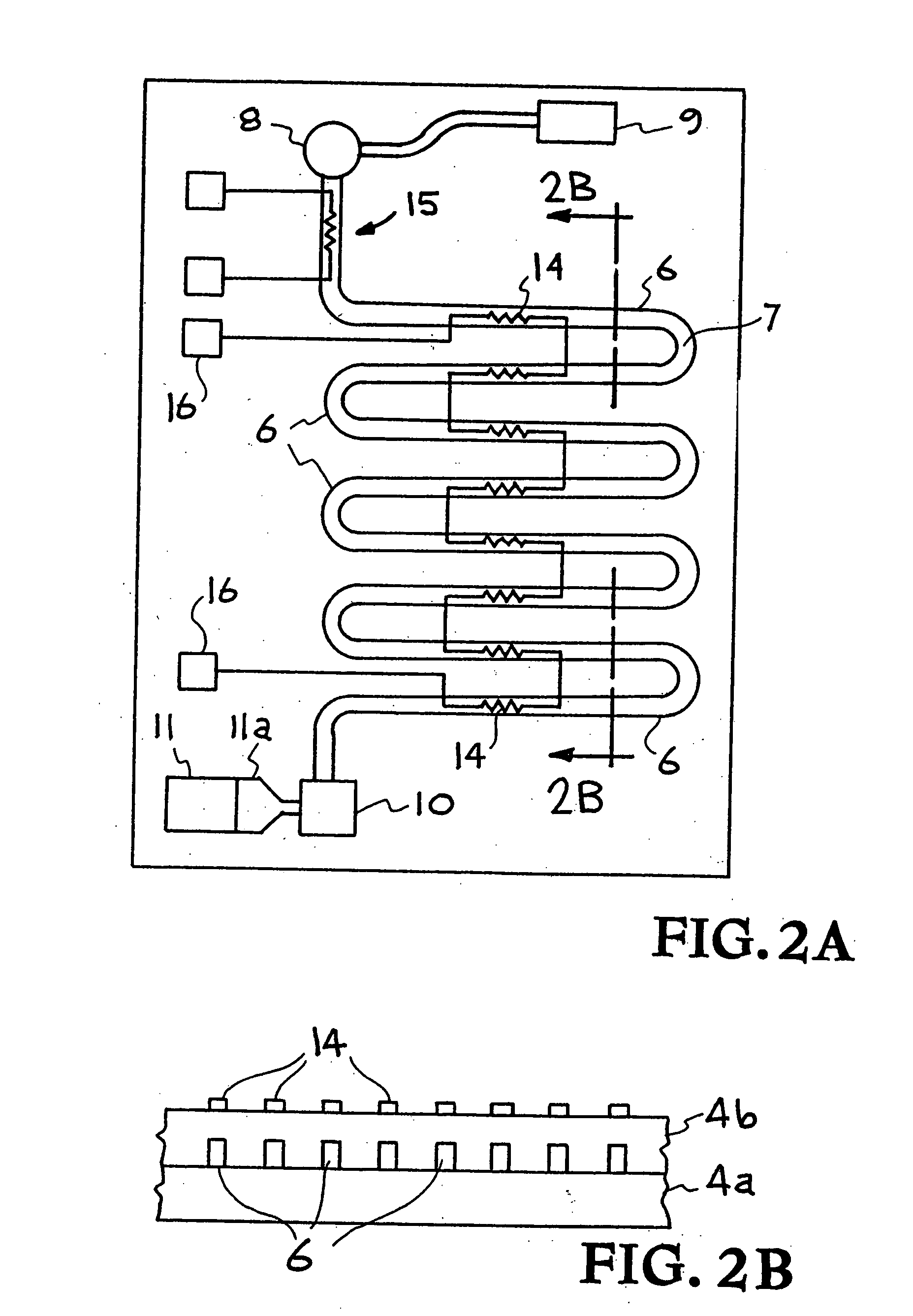

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

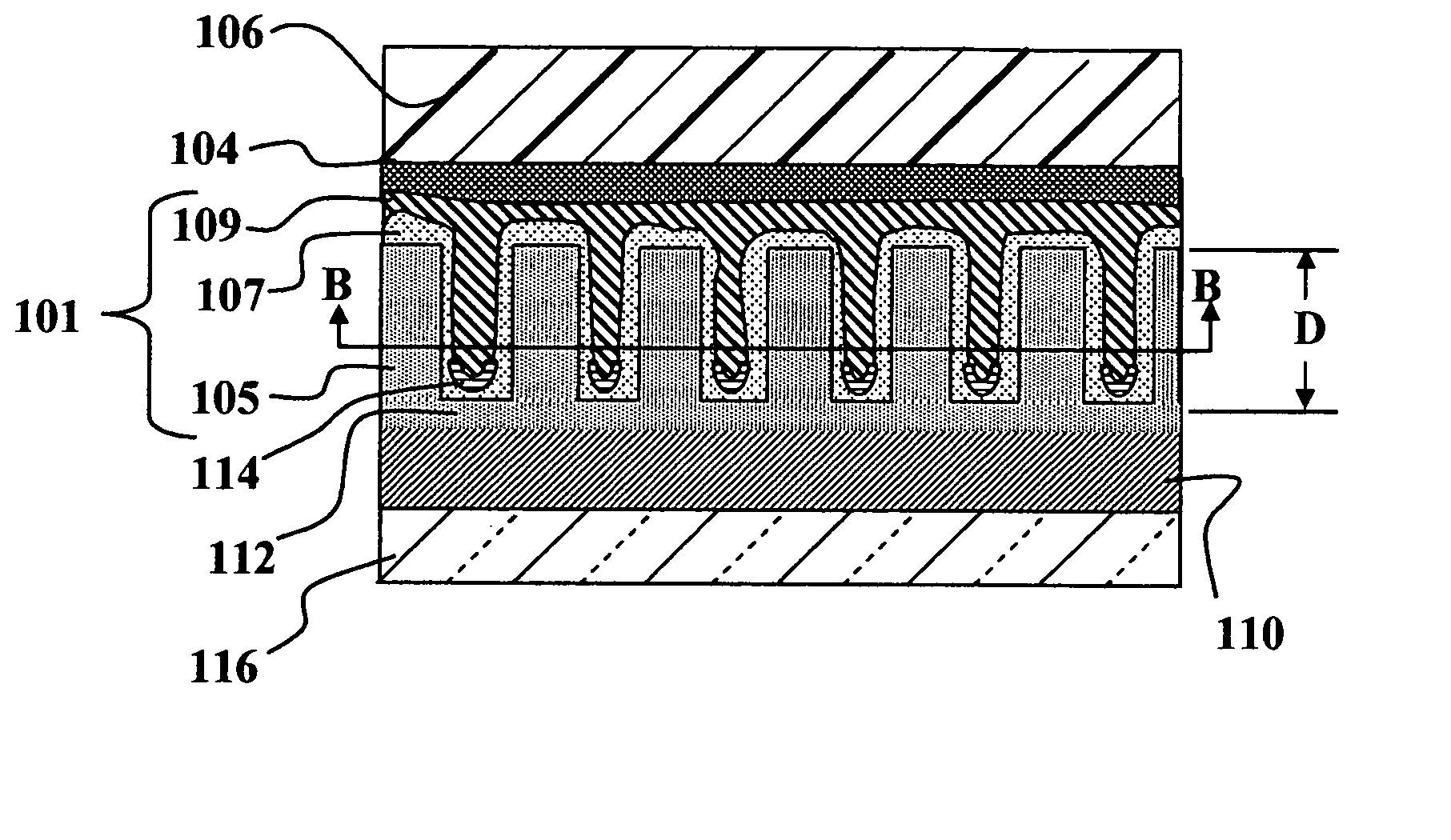

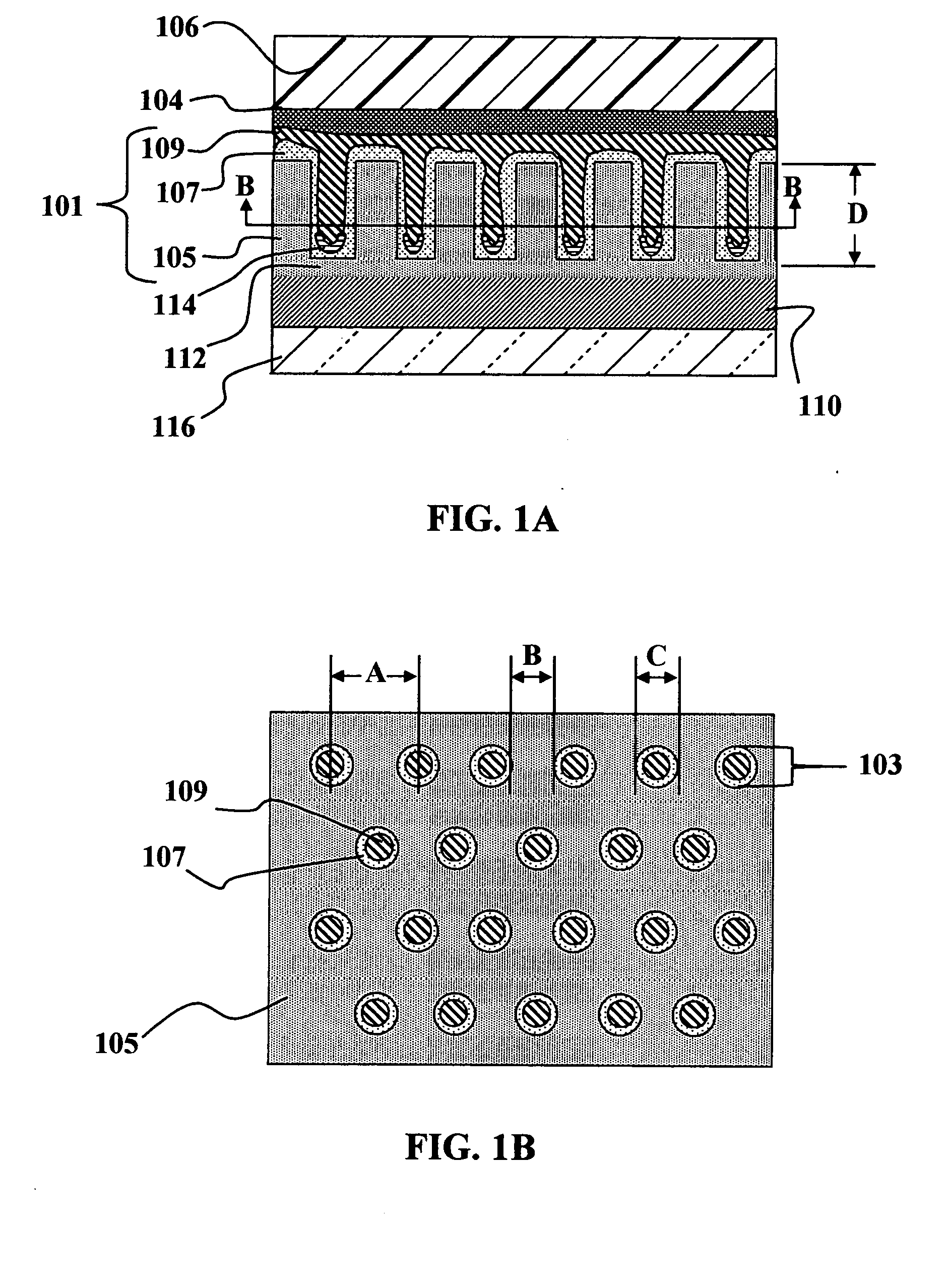

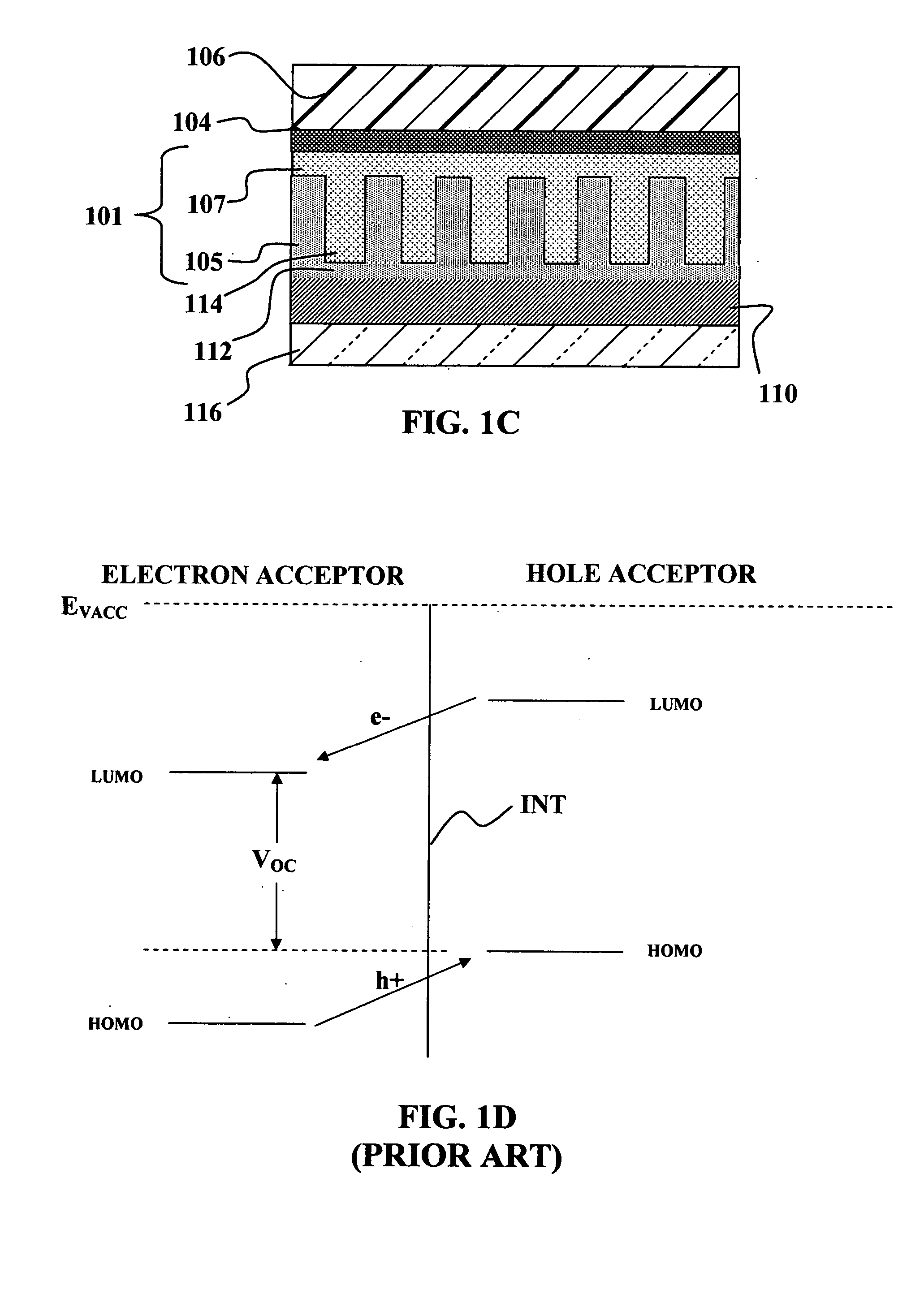

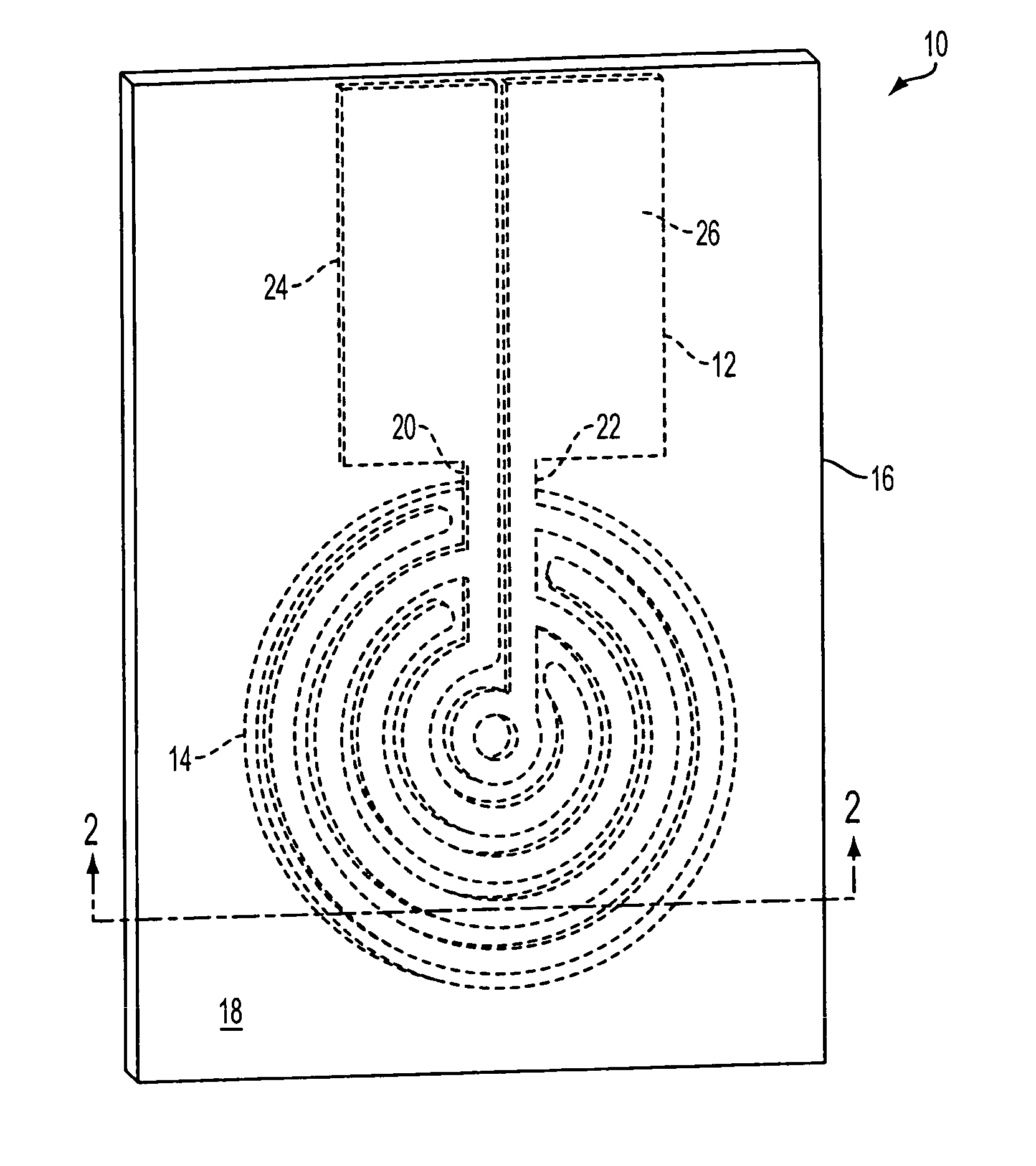

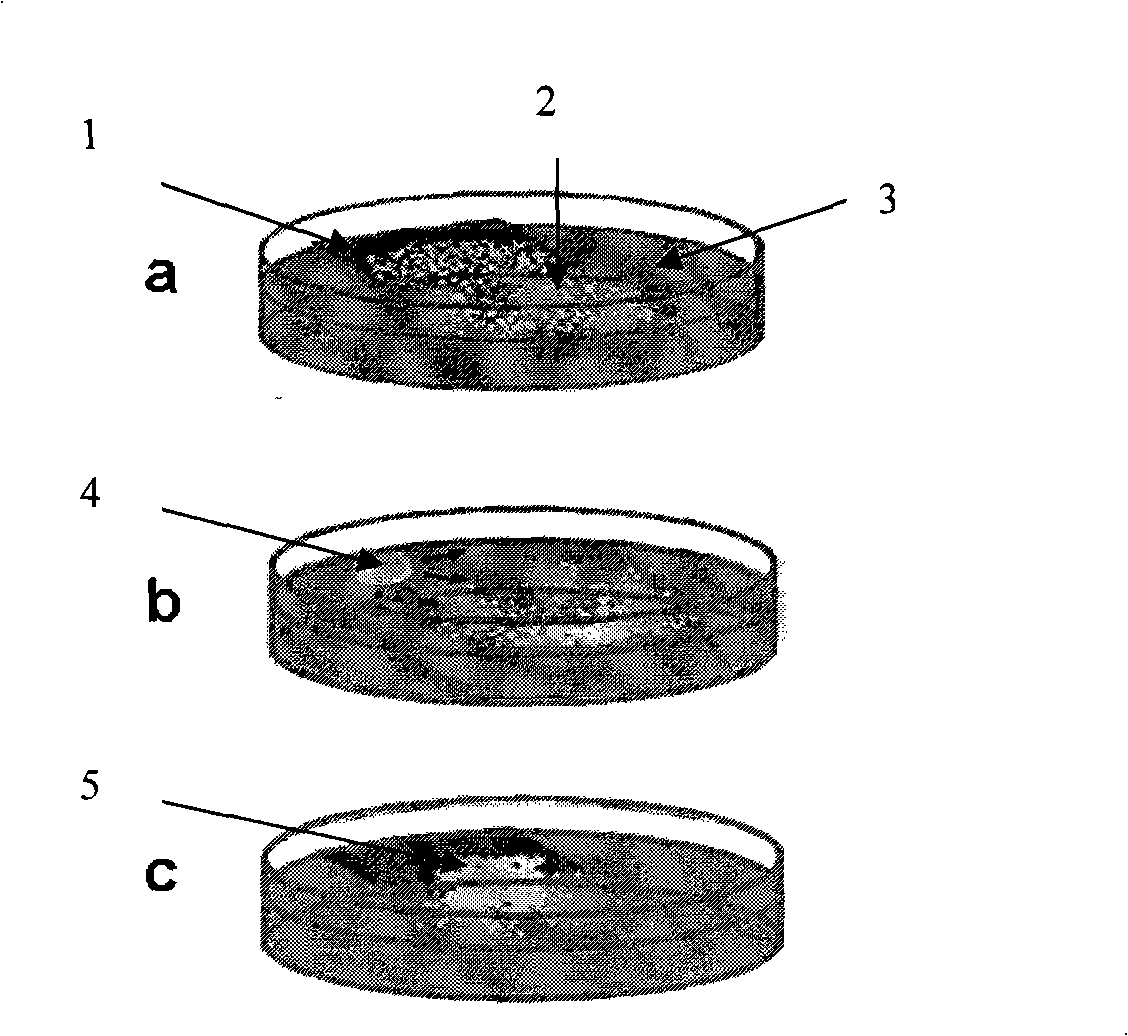

Photovoltaic devices fabricated from nanostructured template

Photovoltaic devices, such as solar cells, and methods for their manufacture are disclosed. A device may be characterized by an architecture having a nanostructured template made from an n-type first charge transfer material with template elements between about 1 nm and about 500 nm in diameter with about 1012 to 1016 elements / m2. A p-type second charge-transfer material optionally coats the walls of the template elements leaving behind additional space. A p-type third charge-transfer material fills the additional space volumetrically interdigitating with the second charge transfer material.

Owner:AERIS CAPITAL SUSTAINABLE IP

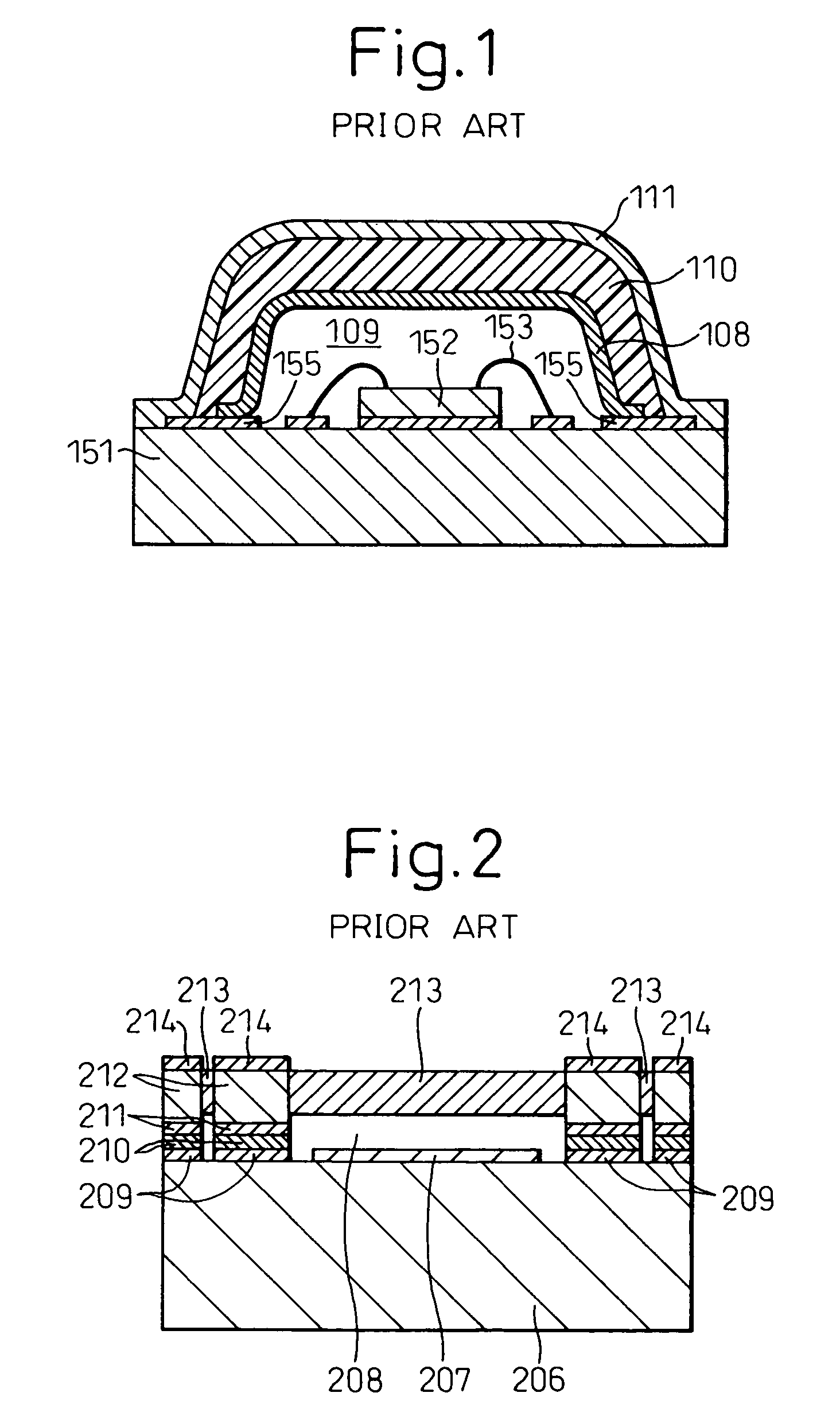

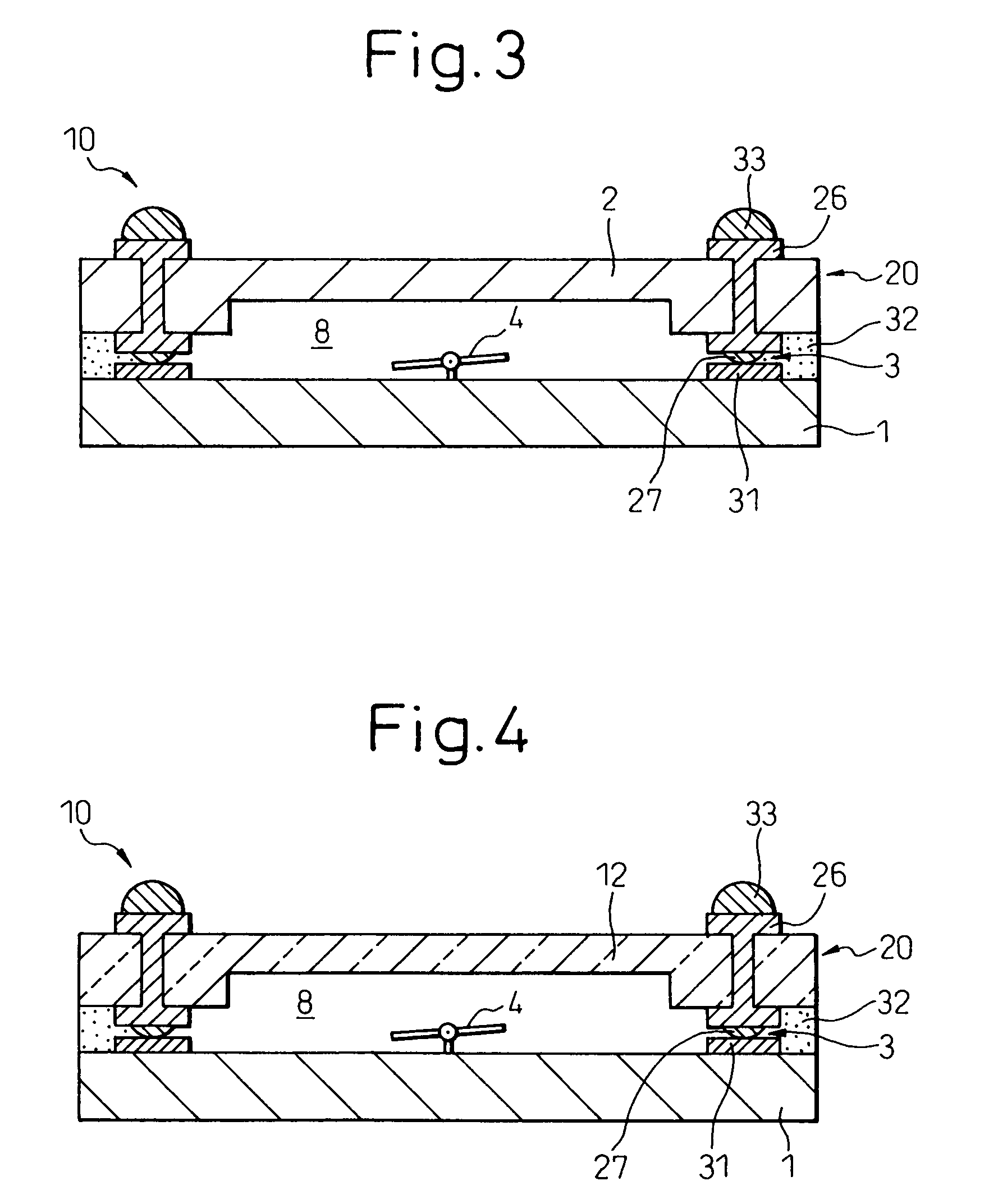

Electronic devices and its production methods

ActiveUS20050167795A1Deterioration of characteristicSmall and compactVolume/mass flow by thermal effectsFixed microstructural devicesSystem elementEngineering

An electronic device having mounted thereon an MEMS element or other functional elements, in which a device body and lid define an element-carrying space, the element-carrying space is sealed air-tight by an ultrasonic bonded part bonding the device body and the lid, and the element-carrying space having arranged inside it a system element secured to the device body and / or the lid by flip-chip connection.

Owner:SHINKO ELECTRIC IND CO LTD

Compact sensor using microcavity structures

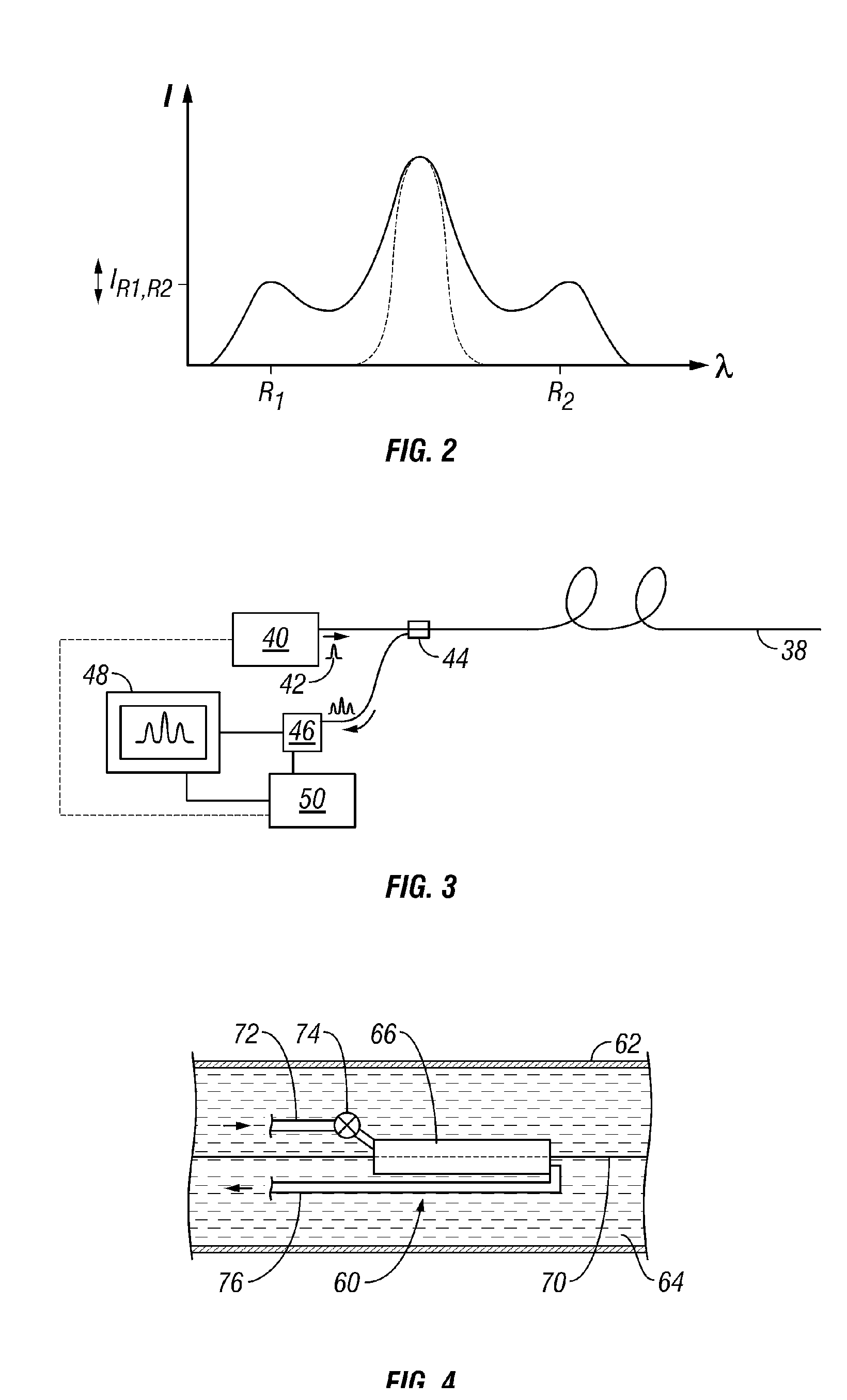

InactiveUS20020068018A1Strong signalStrong reception signalSemi-permeable membranesMaterial analysis by observing effect on chemical indicatorResonanceLight beam

A compact sensor for detection of chemical and / or biological compounds in low concentration. The sensor comprises electromagnetic microcavities. The agent to be detected passes the microcavities, is absorbed and / or absorbed by the microcavities, and modifies the electromagnetic field inside the microcavities. After the agent has been adsorbed and / or absorbed, a probe beam is applied to the microcavities. The change of electromagnetic field is detected by the detector, and the frequency of the probe beam at which the resonance is observed, is indicative of a particular agent being present. A method for detecting chemical and / or biological compounds using the sensor.

Owner:HRL LAB

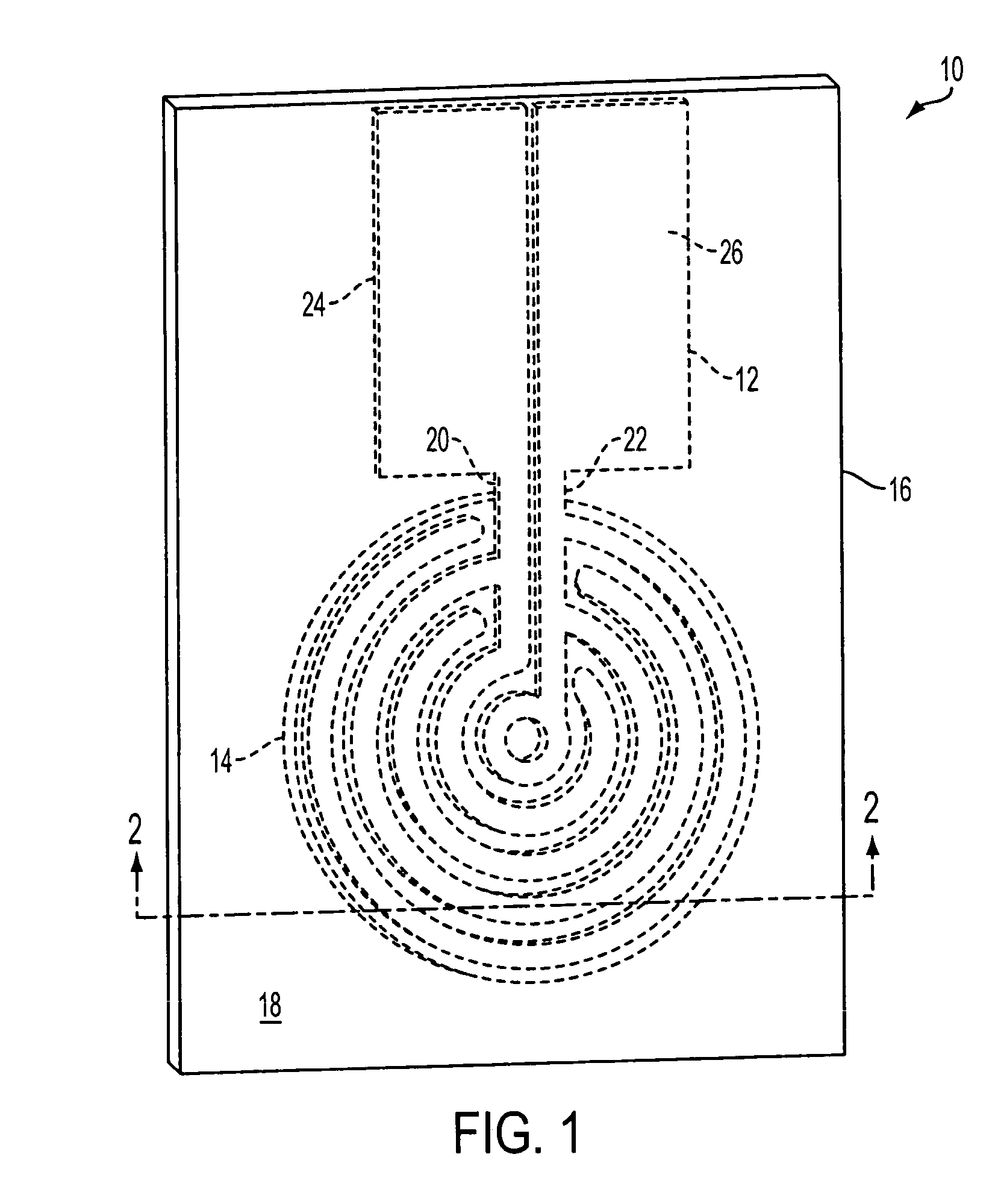

Apparatus and method for heating microfluidic volumes and moving fluids

ActiveUS7049558B2Heating or cooling apparatusVolume/mass flow by thermal effectsTemperature controlElectrical resistance and conductance

A device and method for the temperature control, concentration, volume measurement and transport of microfluidic volumes are provided. The device includes one or more heating elements having a resistive material that varies with temperature. The heating elements are formed into a laminar body that may be formed into a variety of geometries and / or easily married to a second body including micro-well plates, micro-centrifuge tubes and microfluidic circuits.

Owner:LIFE TECH CORP

Compact sensor using microcavity structures

InactiveUS6777244B2Probing the microcavities optically is easierHigh sensitivitySemi-permeable membranesMaterial analysis by observing effect on chemical indicatorResonanceLight beam

A compact sensor for detection of chemical and / or biological compounds in low concentration. The sensor comprises electromagnetic microcavities. The agent to be detected passes the microcavities, is absorbed and / or absorbed by the microcavities, and modifies the electromagnetic field inside the microcavities. After the agent has been adsorbed and / or absorbed, a probe beam is applied to the microcavities. The change of electromagnetic field is detected by the detector, and the frequency of the probe beam at which the resonance is observed, is indicative of a particular agent being present. A method for detecting chemical and / or biological compounds using the sensor.

Owner:HRL LAB

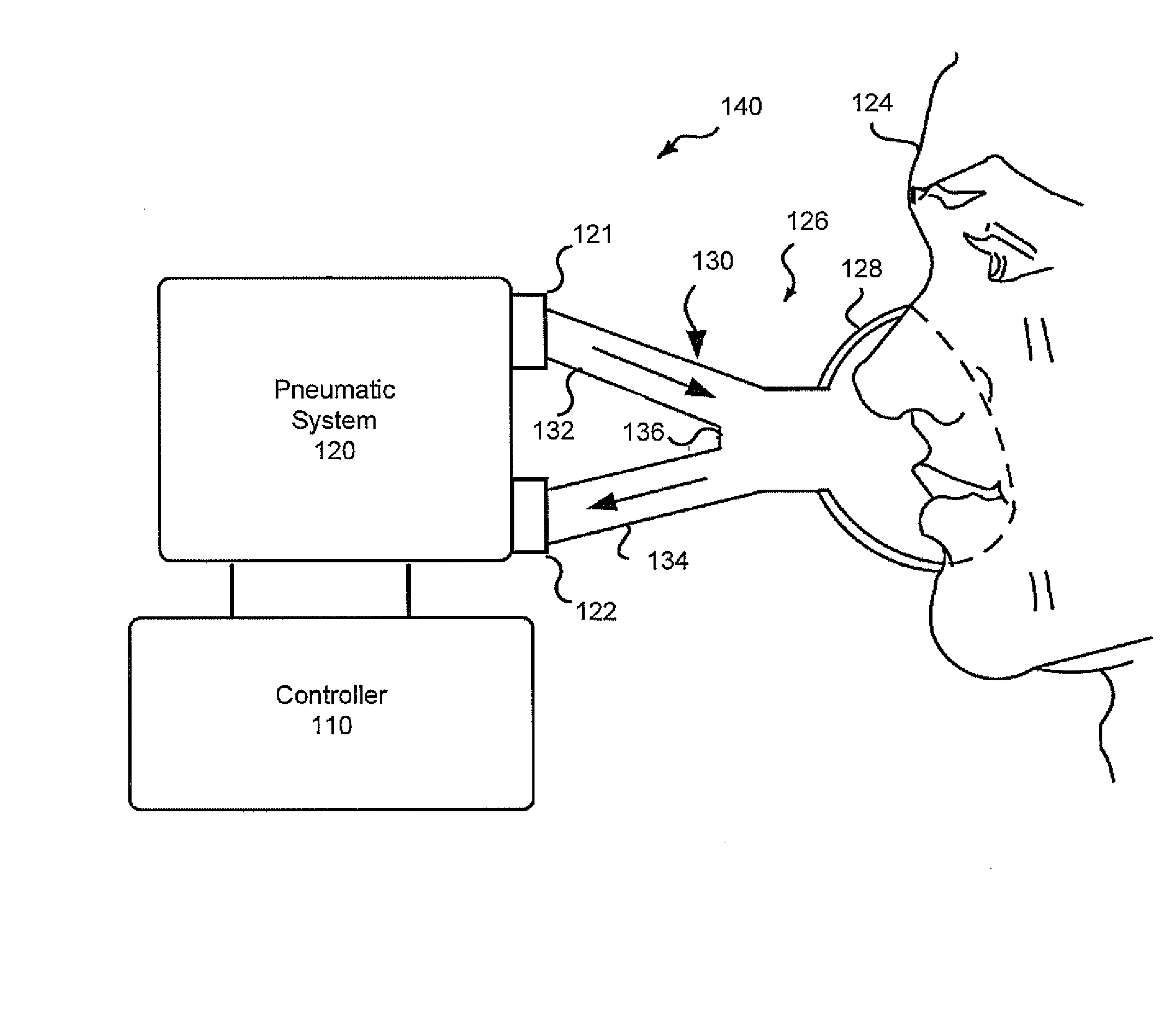

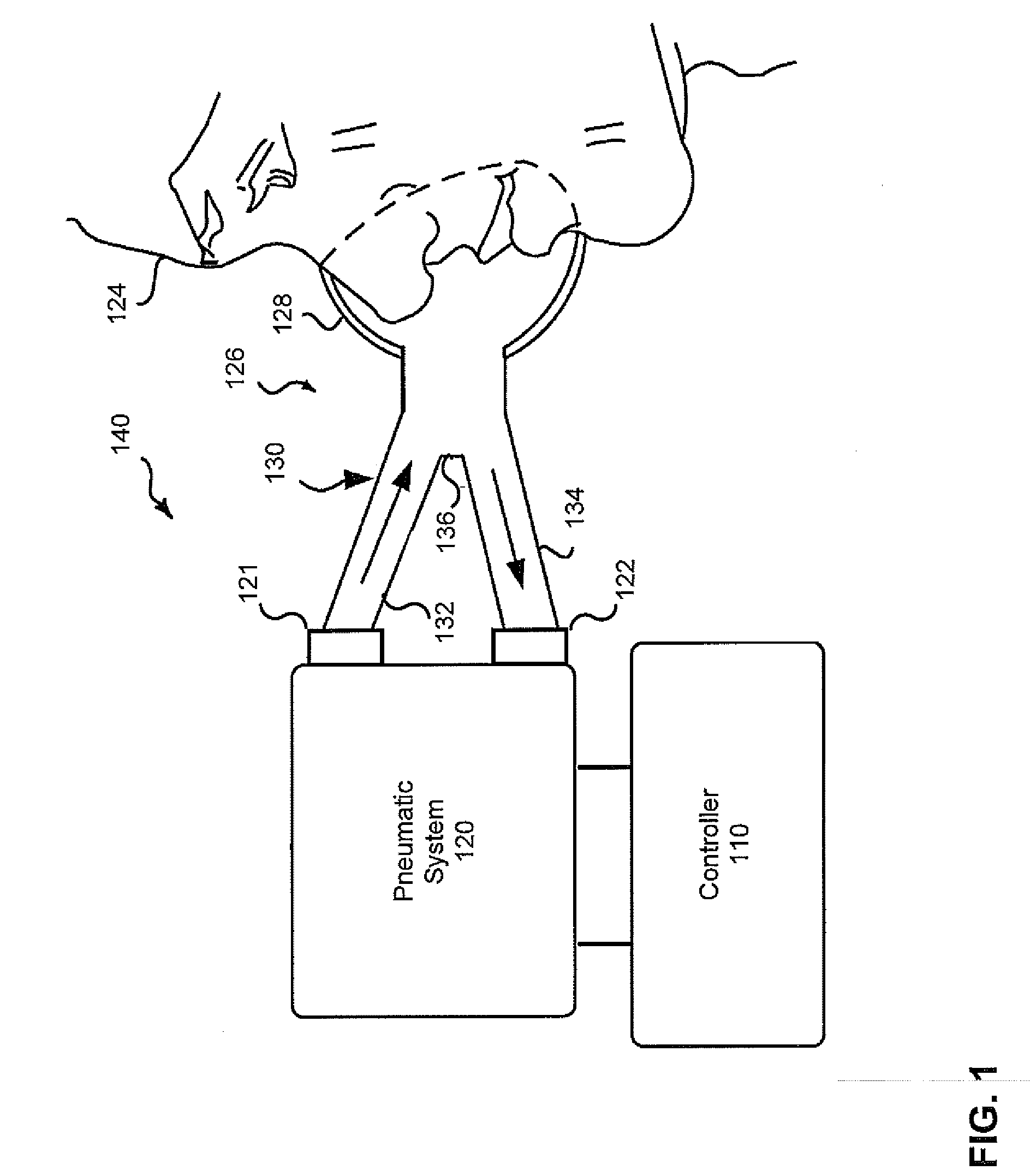

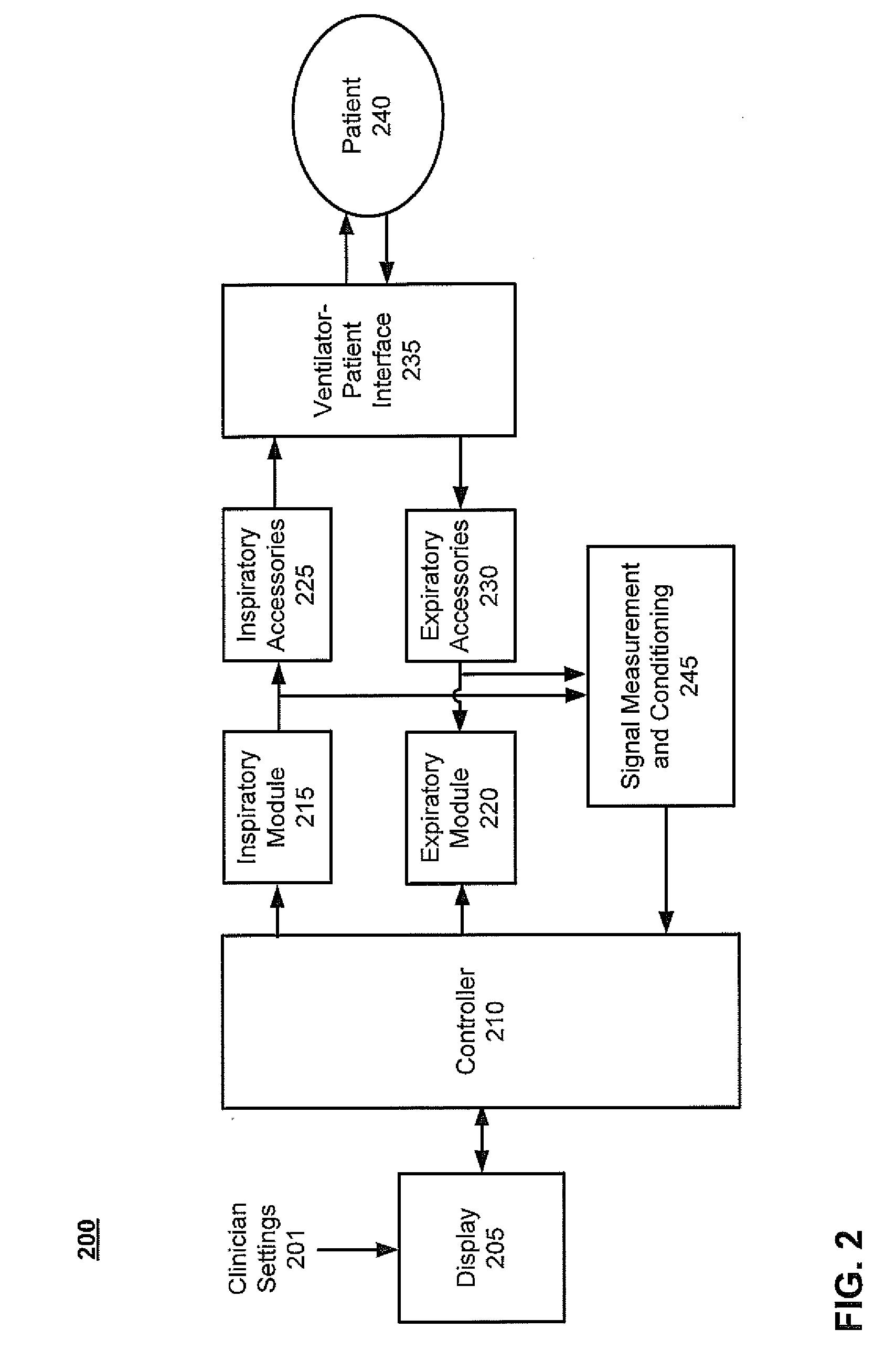

Flow rate compensation for transient thermal response of hot-wire anemometers

ActiveUS20100218765A1Operating means/releasing devices for valvesVolume/mass flow by thermal effectsEngineeringOxygen

Systems and methods are described for application of a transitory corrective modification to a hot-wire anemometer flow voltage and / or calculated flow rate to compensate for transient thermal response of the anemometer during a change in mixture of a mixed gas being measured. According to one embodiment a method of applying the transitory corrective modification is provided. An output signal of an exhalation flow sensor of a medical ventilator is received. The flow sensor includes a hot-wire anemometer. The output signal is indicative of a rate of flow of expired gas by a patient. Transient thermal response of the hot-wire anemometer is compensated for by applying a corrective modification to the output signal or a value based thereon. The corrective modification is based at least in part on a fraction of inspired oxygen (FiO2) being supplied by the medical ventilator to the patient.

Owner:TYCO HEALTHCARE GRP LP

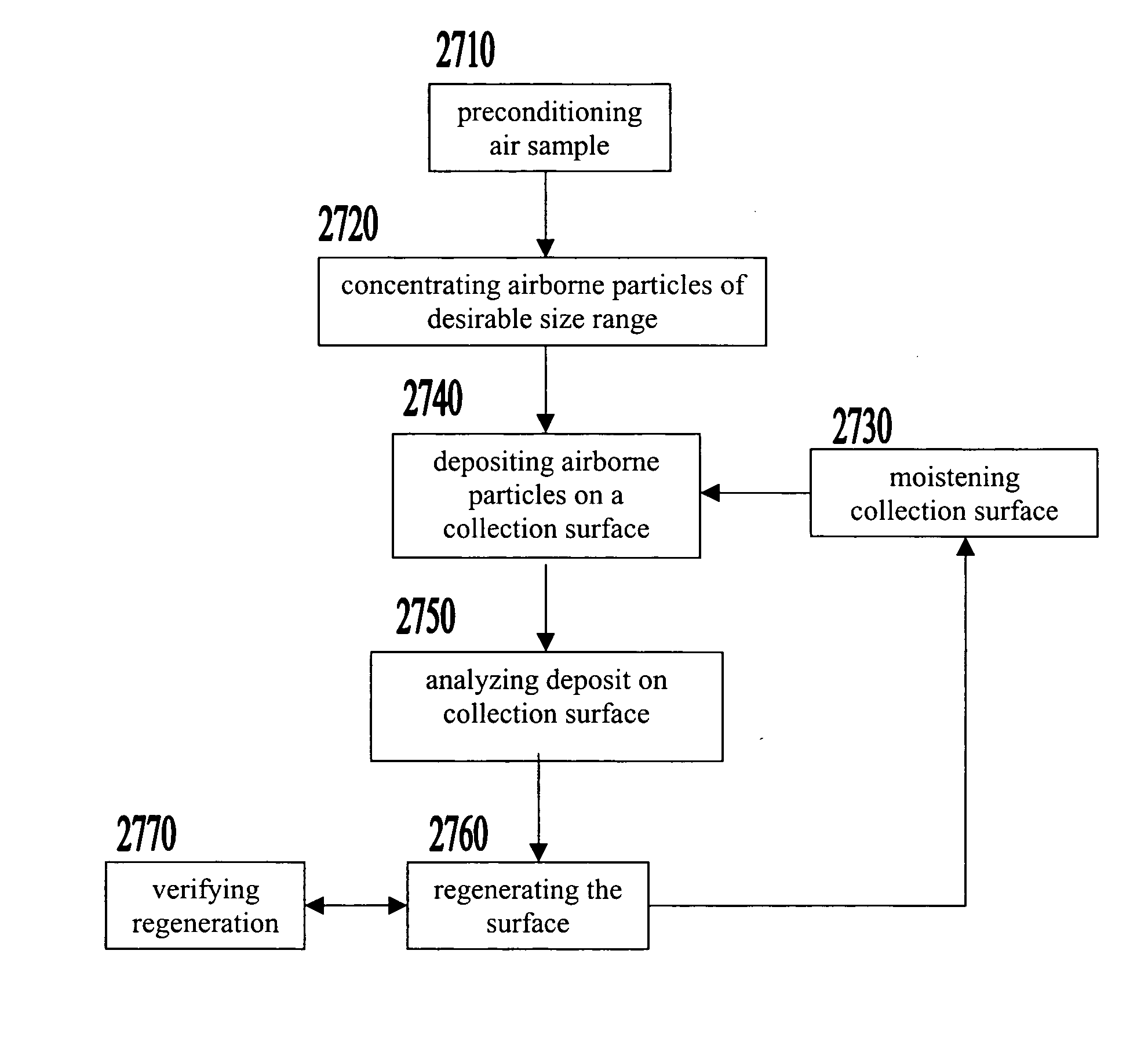

Methods and devices for continuous sampling of airborne particles using a regenerative surface

InactiveUS20040232052A1Increase volume of materialImprove concentrationFixed microstructural devicesVolume/mass flow measurementEngineeringAtmospheric sciences

Airborne particles are impacted on a collection surface, analyzed, and then the collection surface is regenerated. Thus, the same collection surface can be used in numerous cycles. The analysis can be focused on one or more properties of interest, such as the concentration of airborne biologicals. Sensors based on regenerative collection surfaces may be incorporated in many networks for applications such as building automation.

Owner:FLIR DETECTION

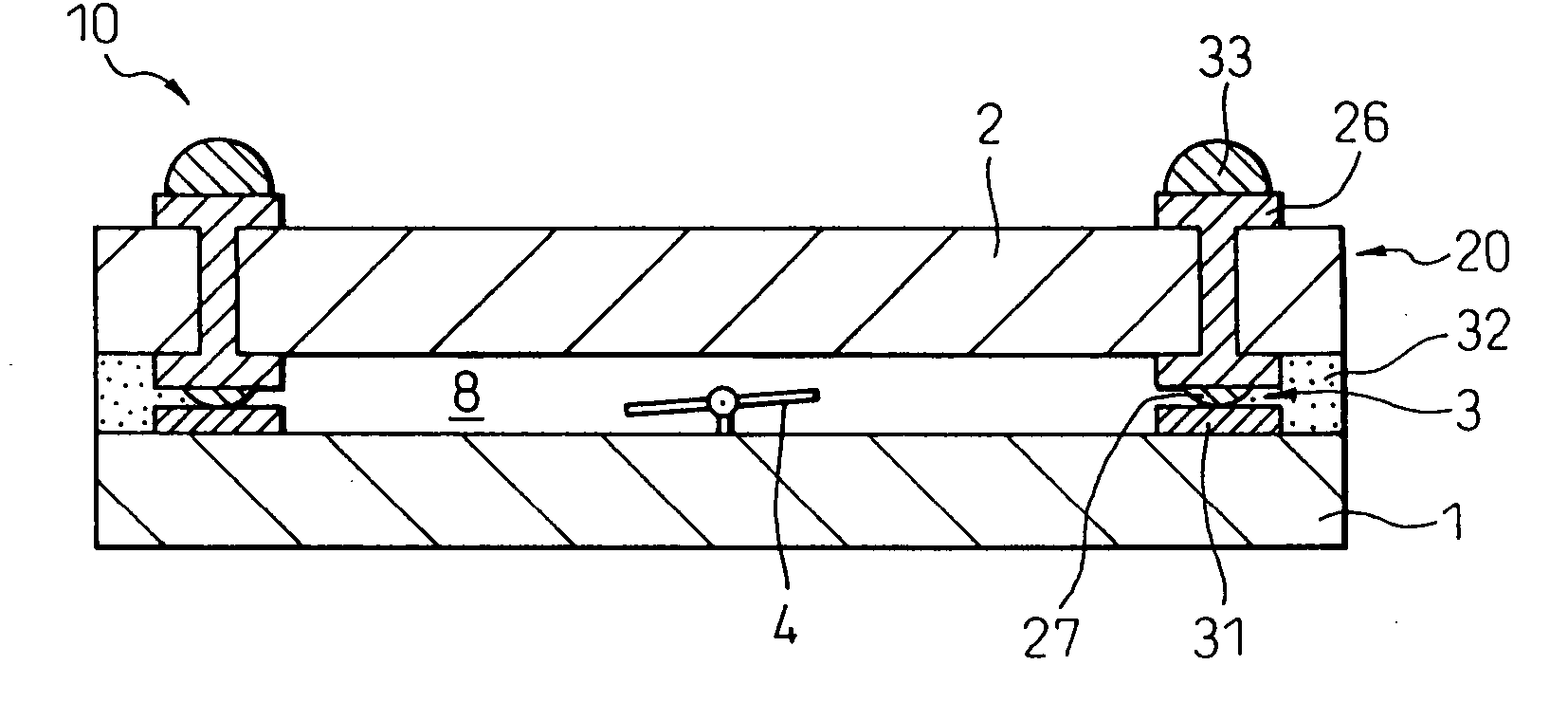

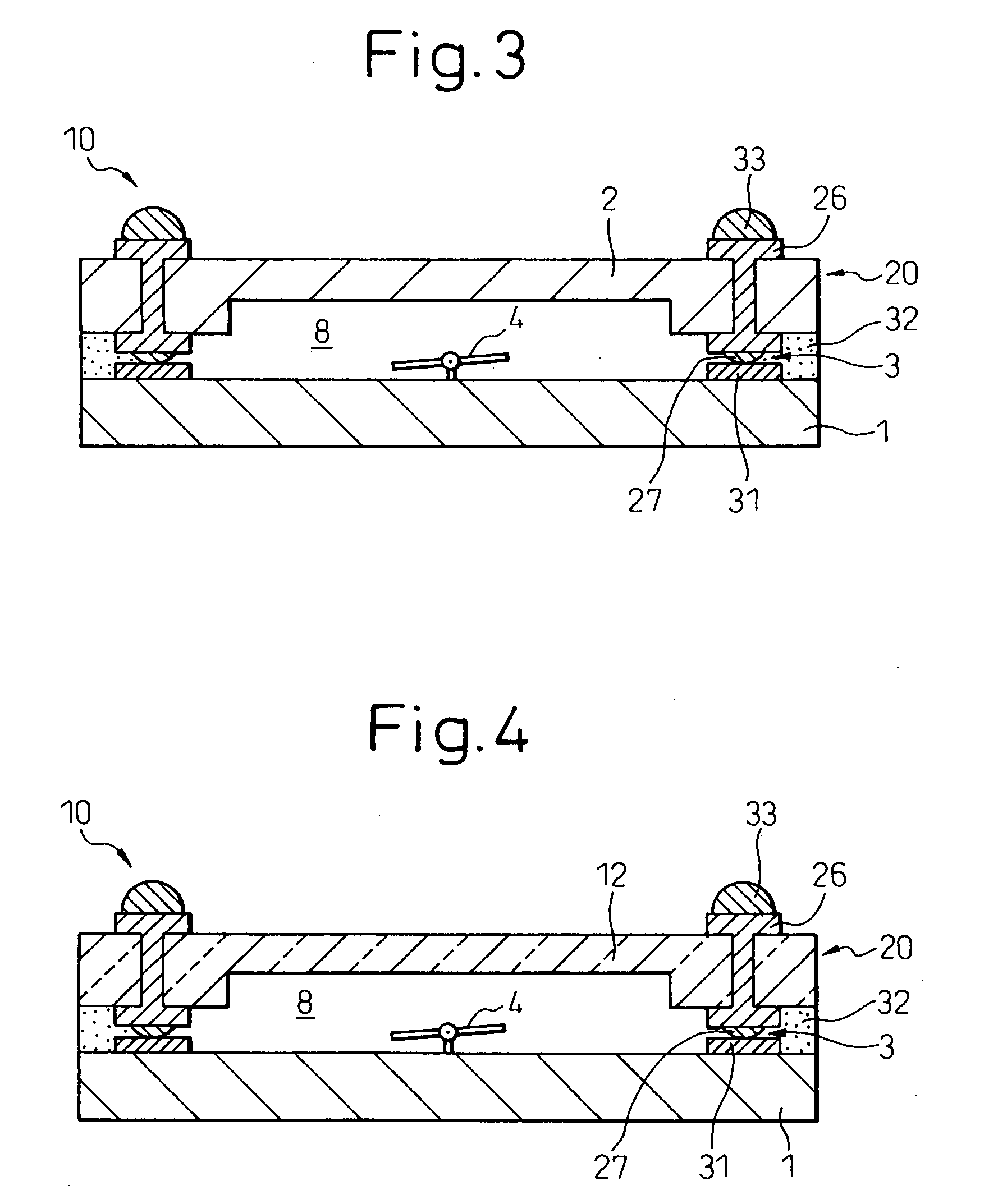

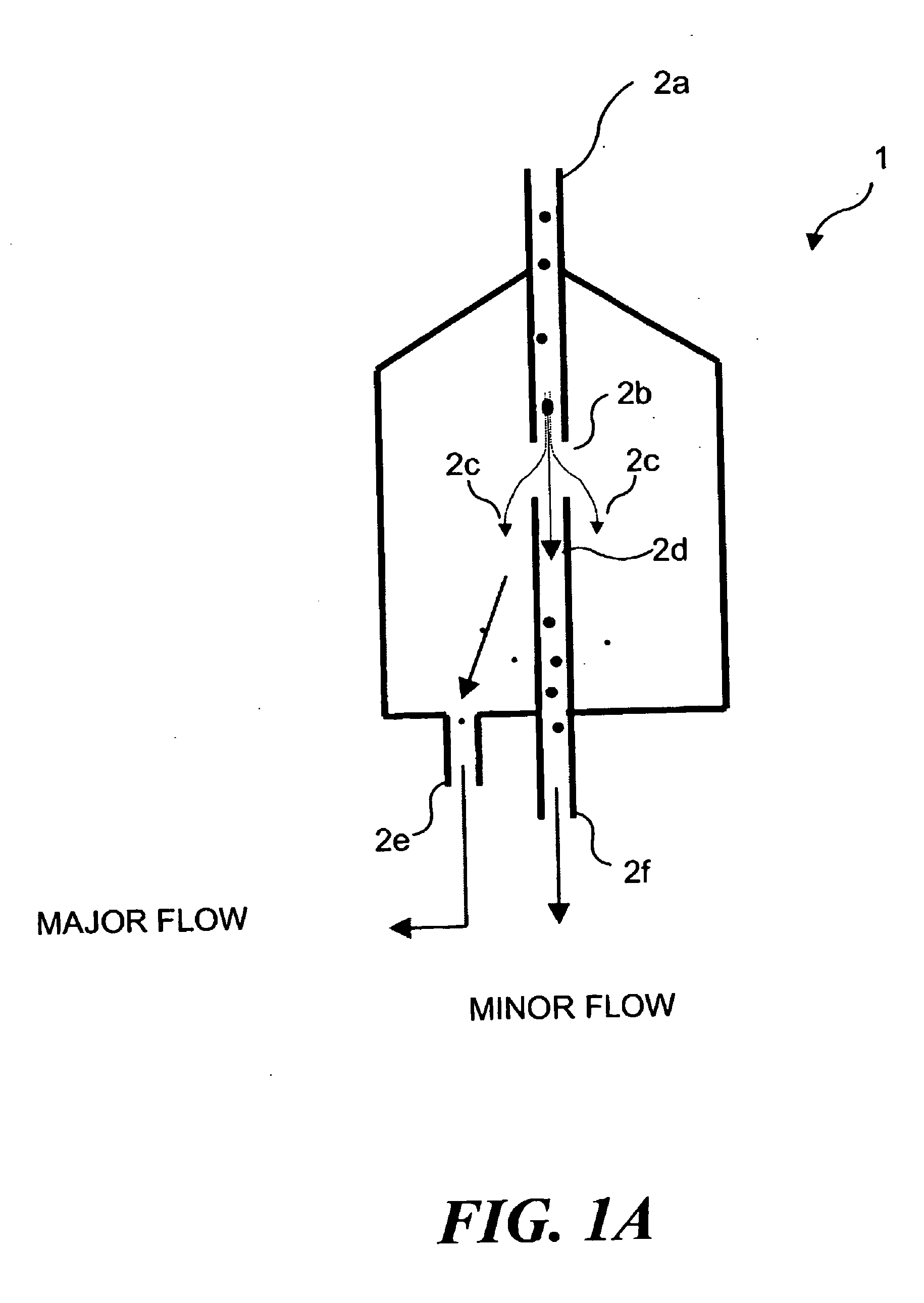

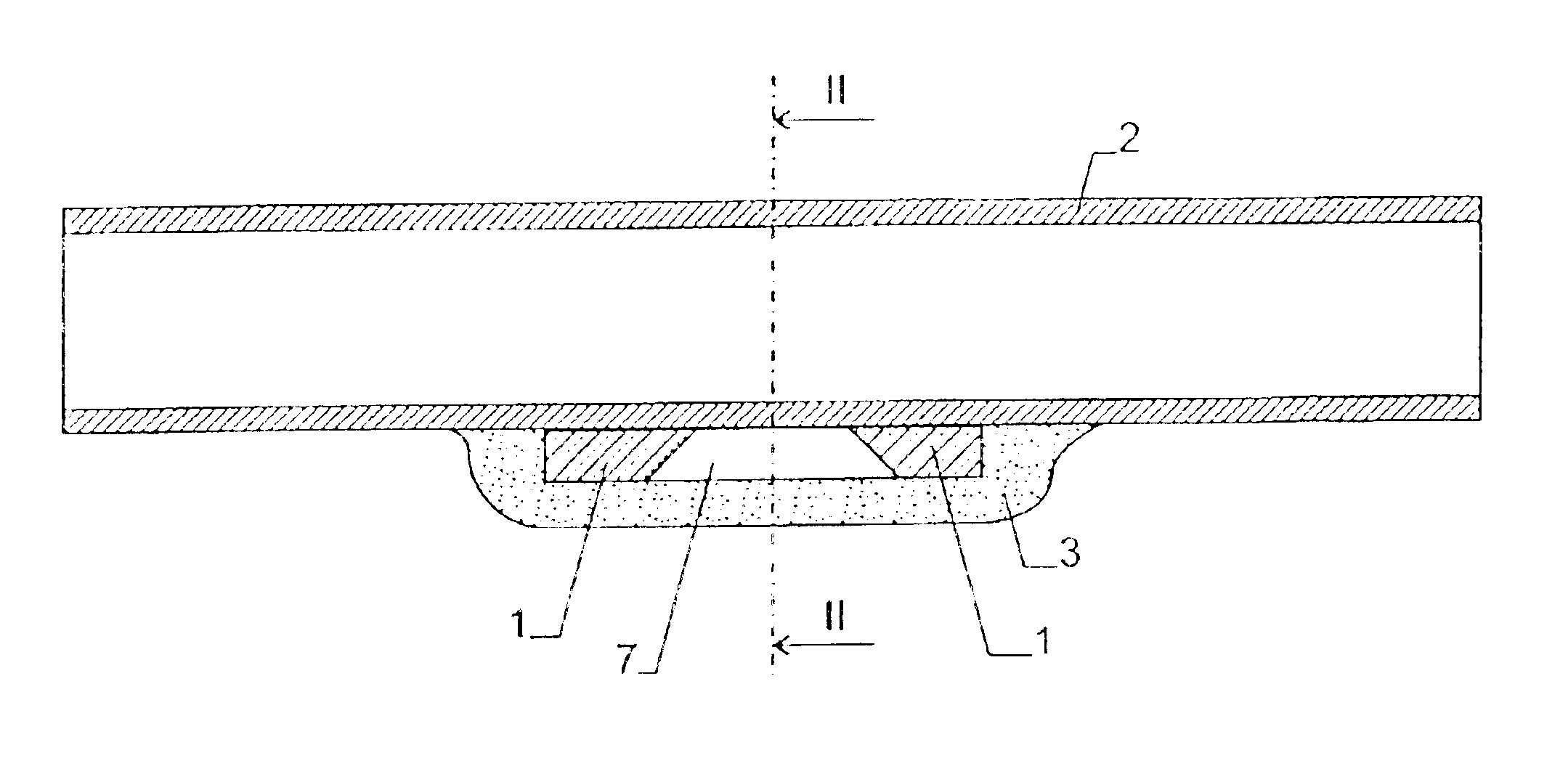

Flow sensor

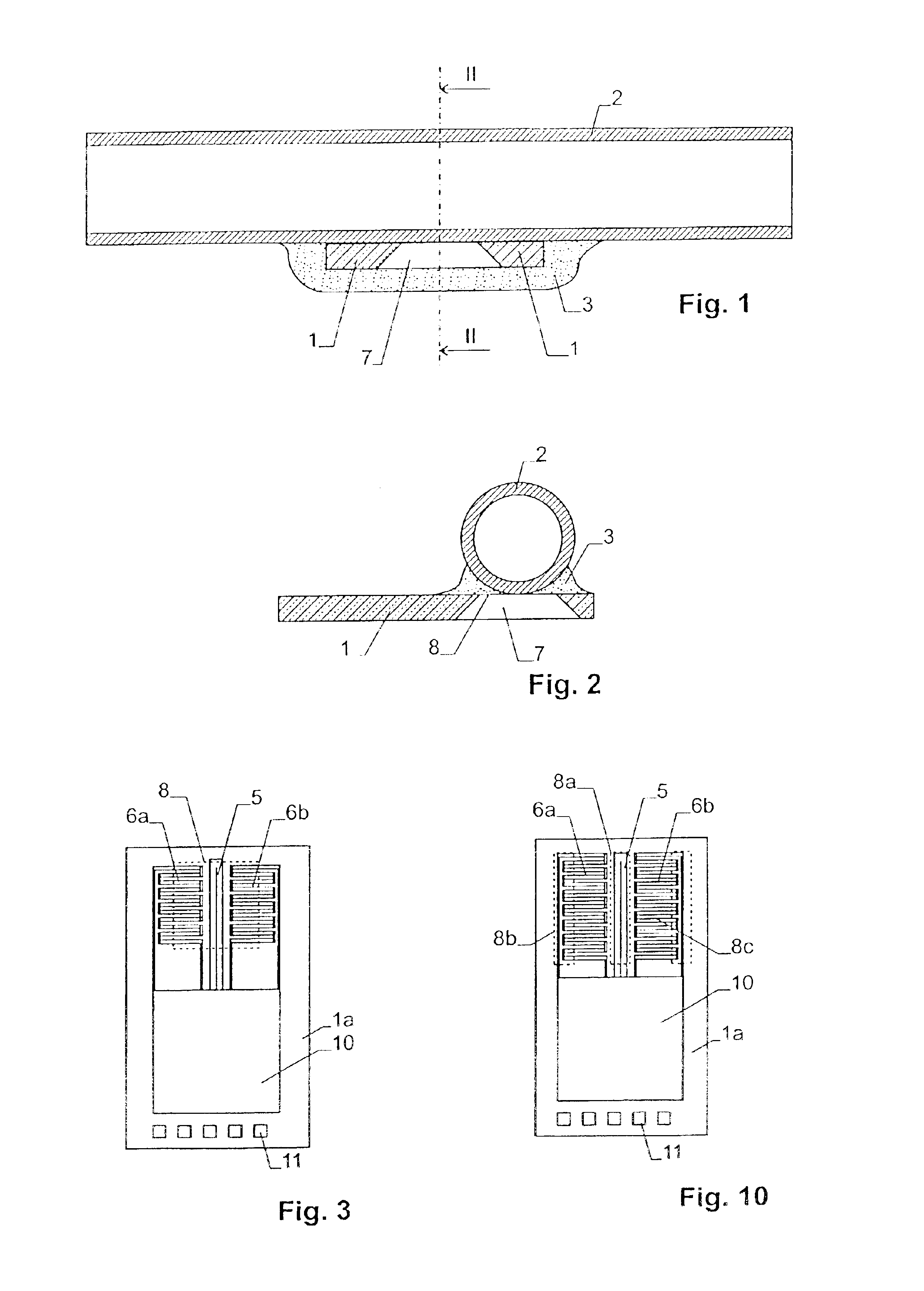

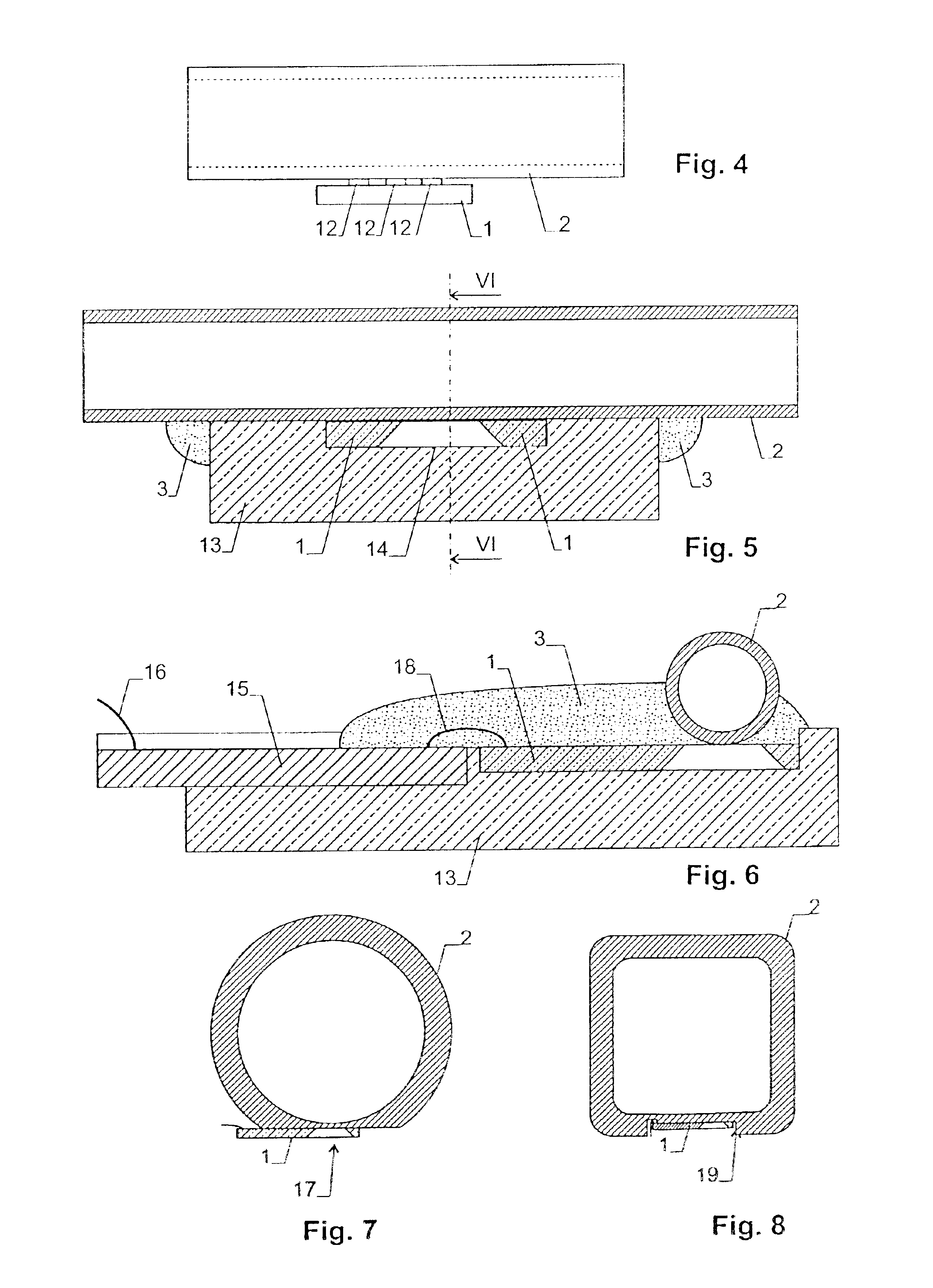

The flow sensor comprises a semiconductor device (1) on which a heat source and, symmetrically thereto, two temperature sensors are arranged. The semiconductor device (1) is arranged on an exterior side of a tube section (2), and a liquid, the flow velocity of which has to be measured, is led through the tube section (2). The temperature sensors and the heat source are in thermal contact with the exterior side of the tube section (2). It has been found that such an assembly allows to carry out flow measurements with high accuracy and sensitivity.

Owner:SENSIRION HLDG

Chemical microreactor and method thereof

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Electronic devices and its production methods

ActiveUS7456497B2Deterioration of characteristicSmall and compactFixed microstructural devicesVolume/mass flow by thermal effectsHermetic sealEngineering

An electronic device having mounted thereon an MEMS element or other functional elements, in which a device body and lid define an element-carrying space, the element-carrying space is sealed air-tight by an ultrasonic bonded part bonding the device body and the lid, and the element-carrying space having arranged inside it a system element secured to the device body and / or the lid by flip-chip connection.

Owner:SHINKO ELECTRIC IND CO LTD

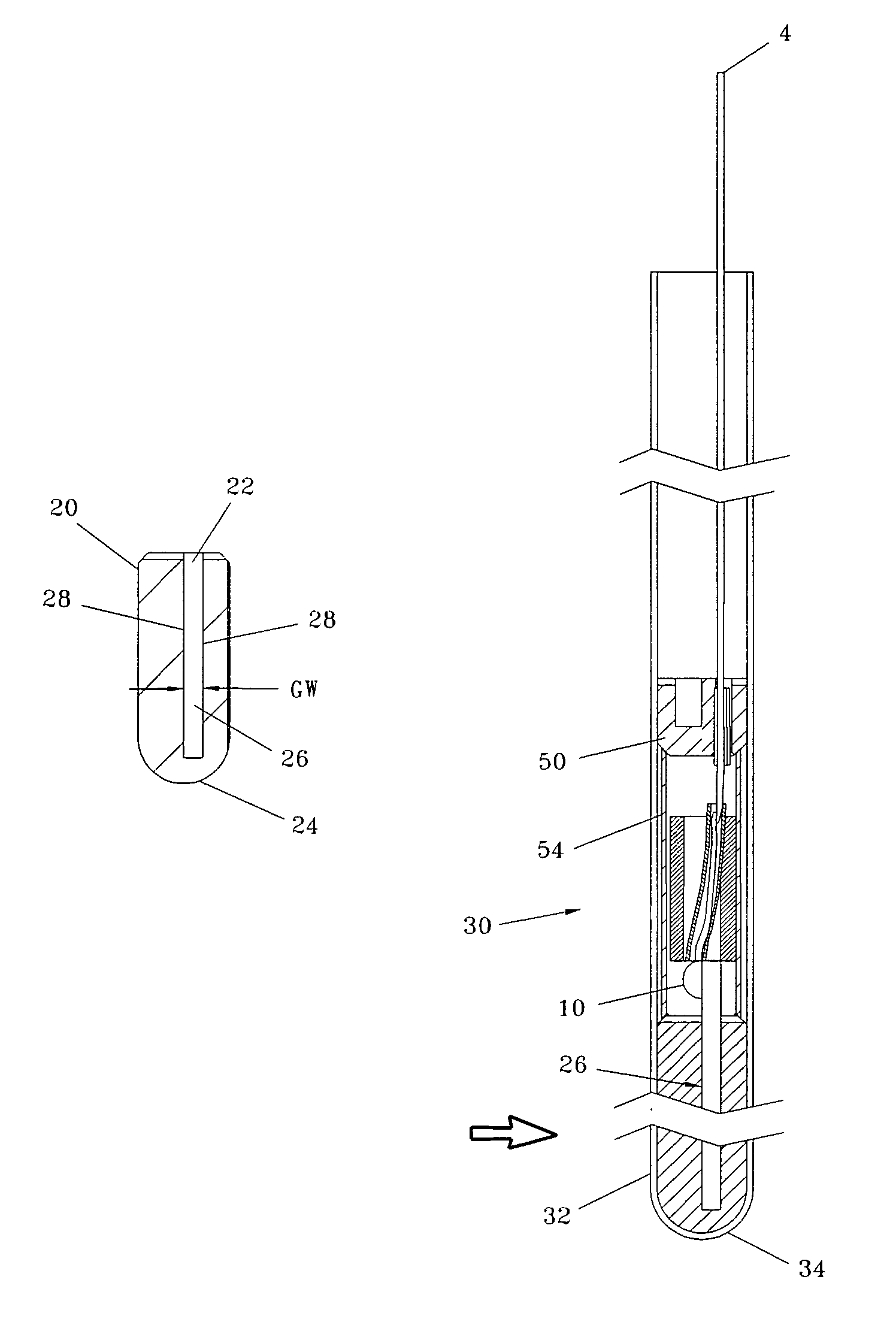

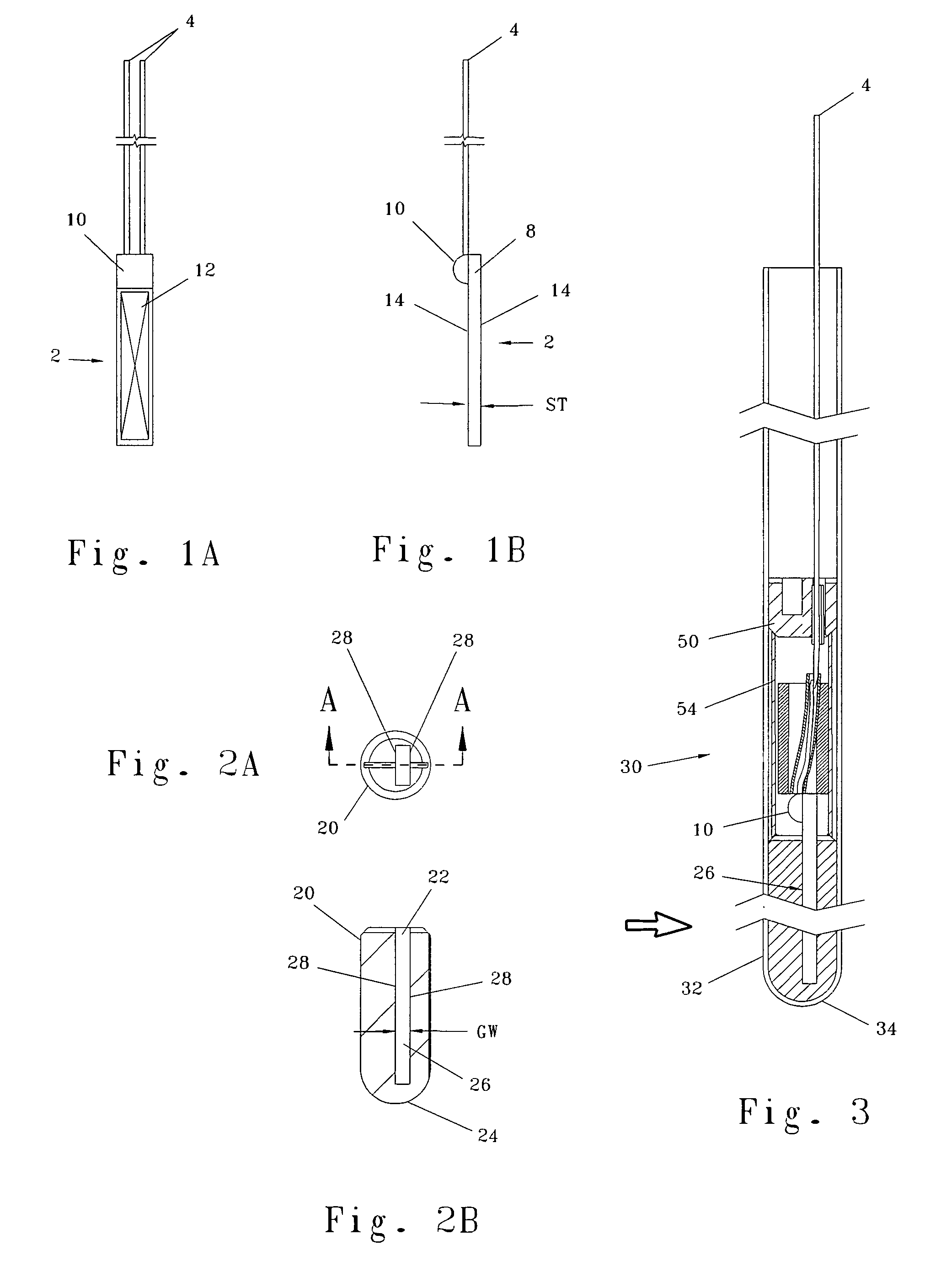

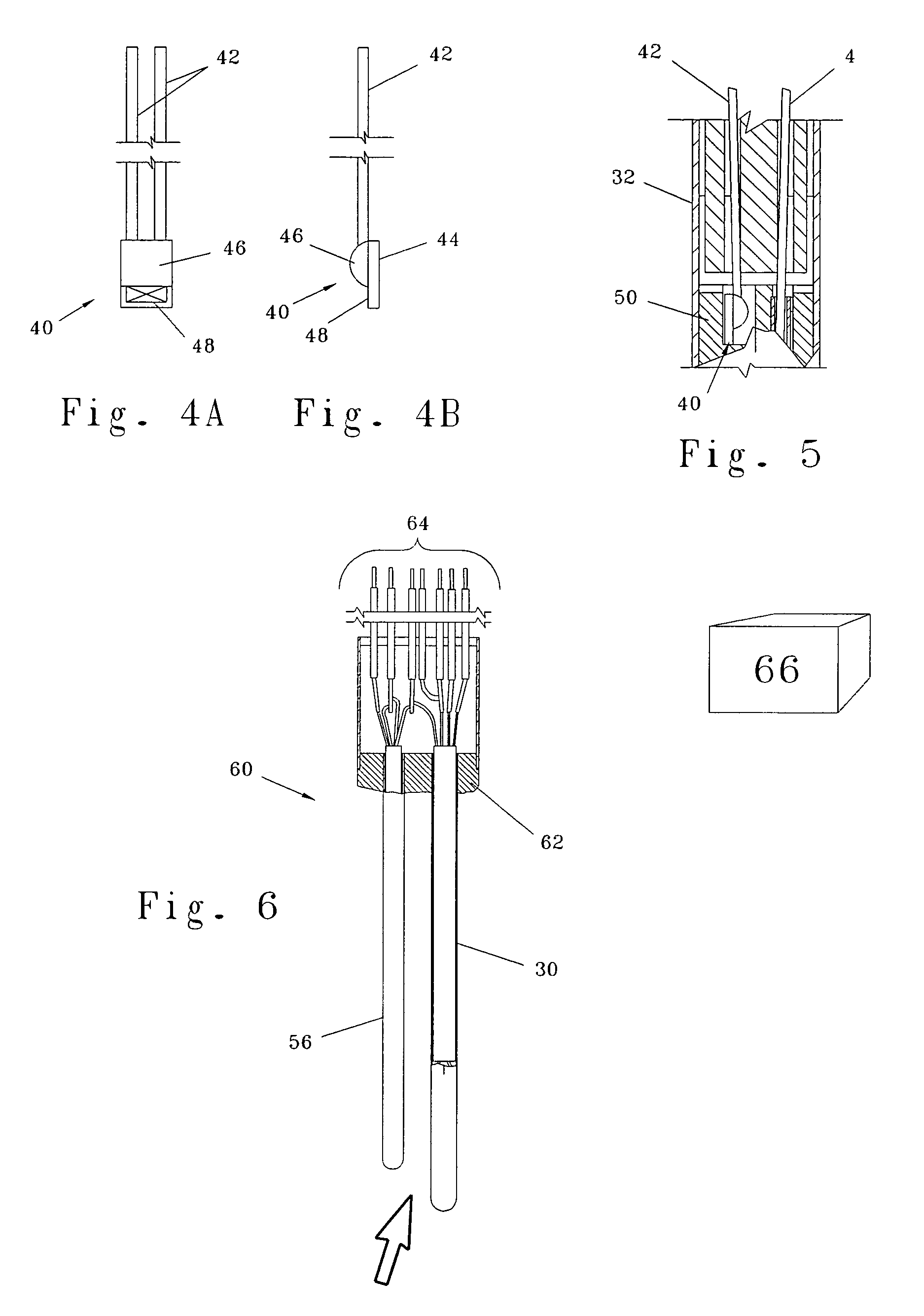

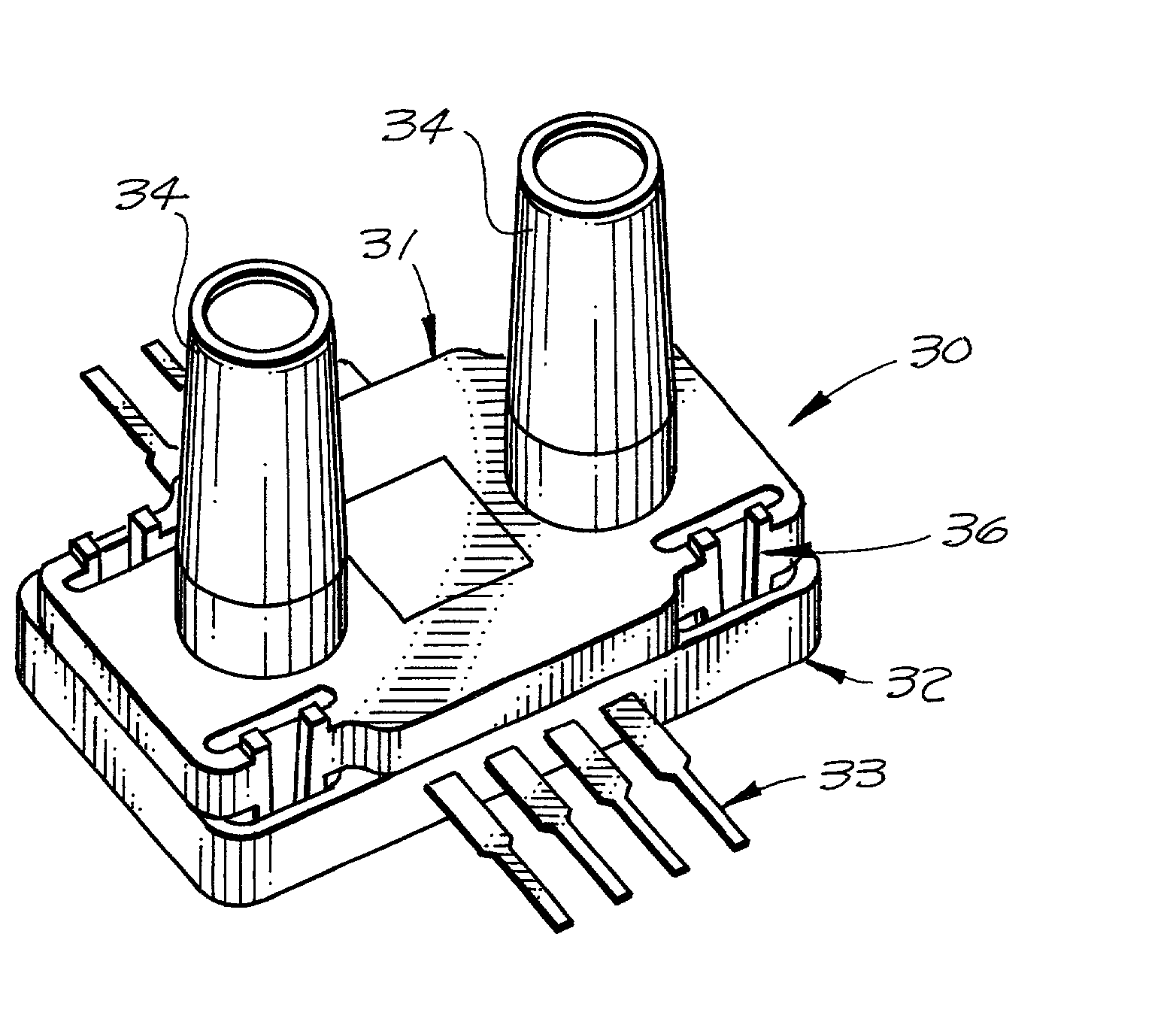

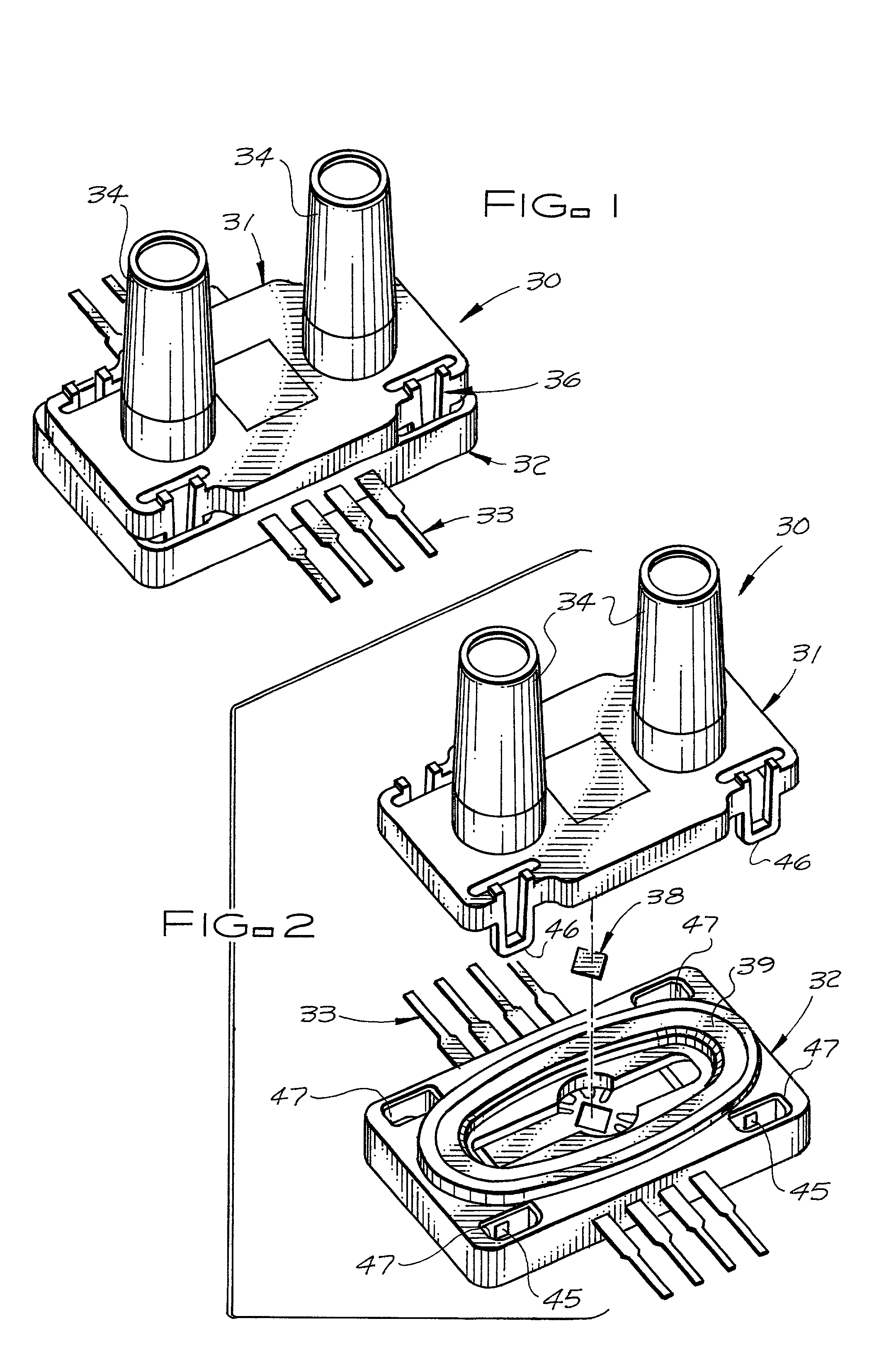

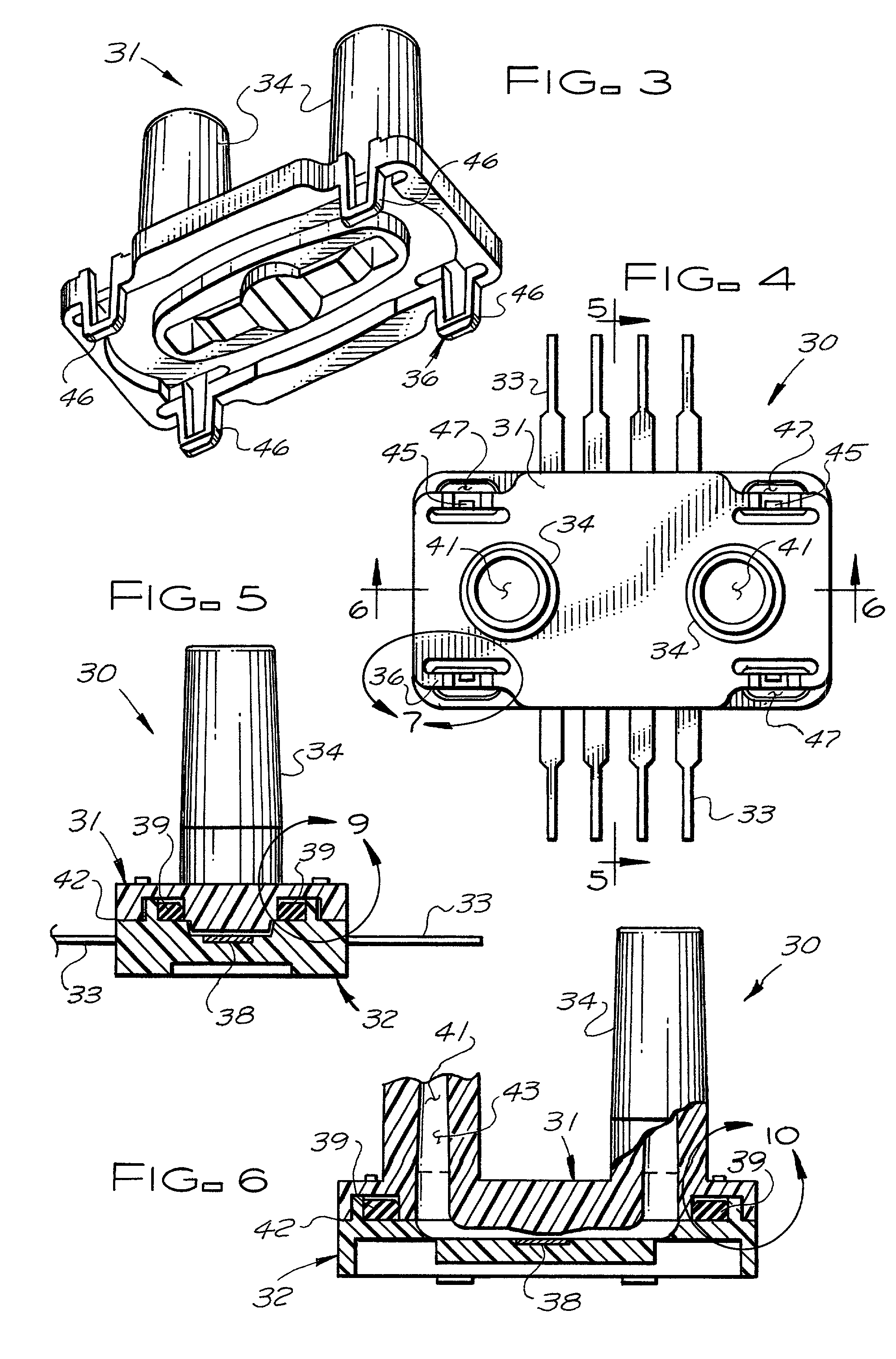

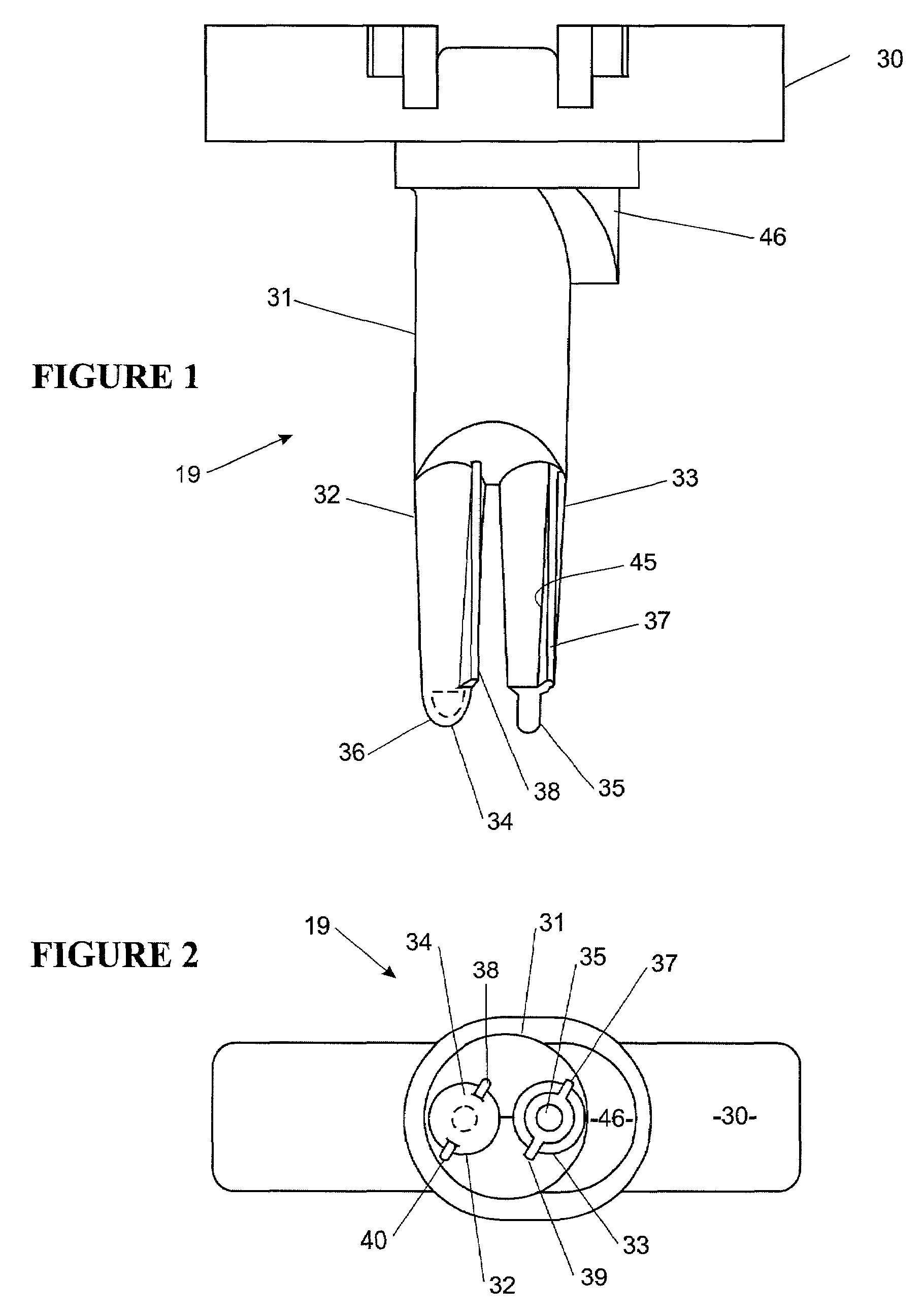

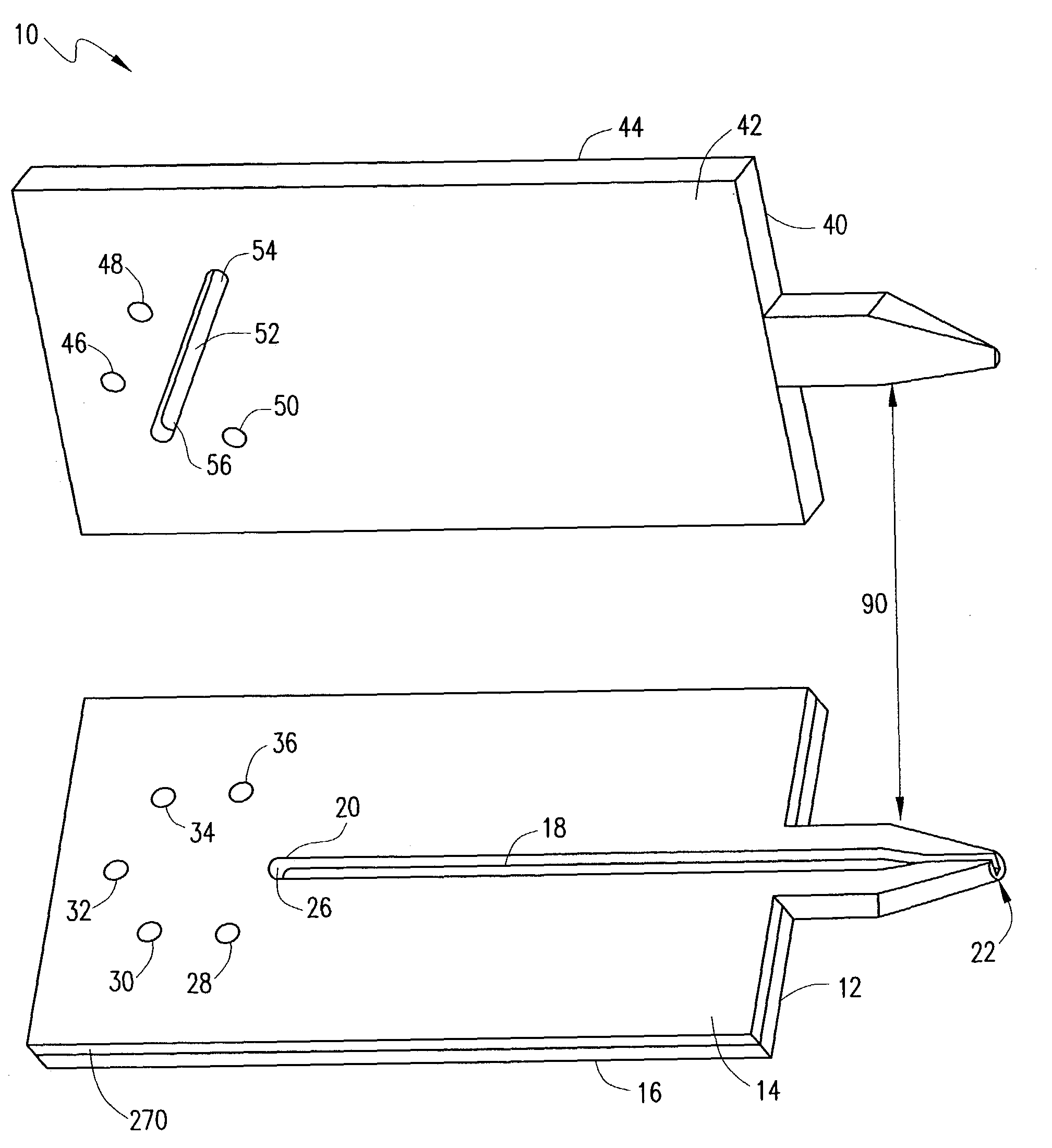

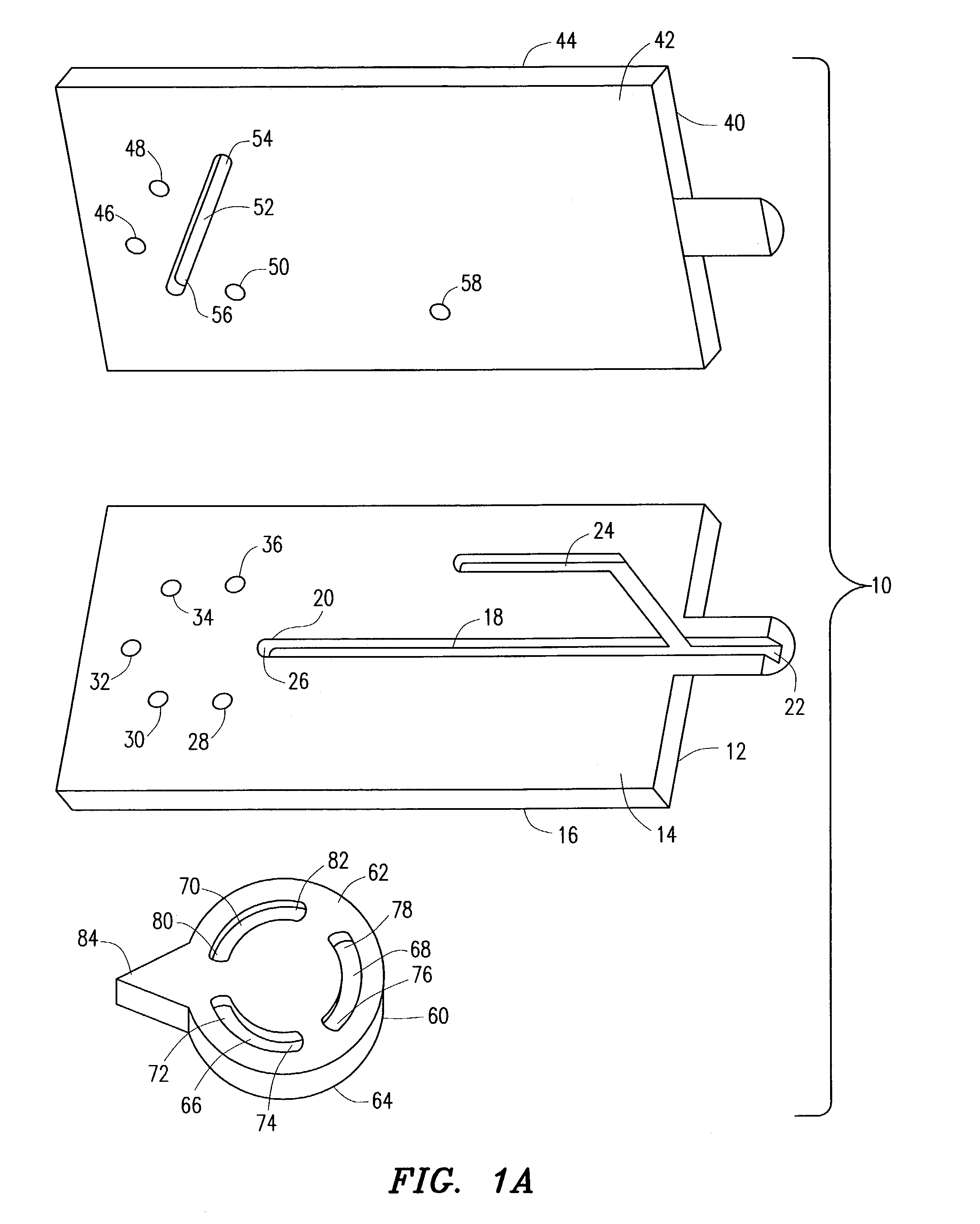

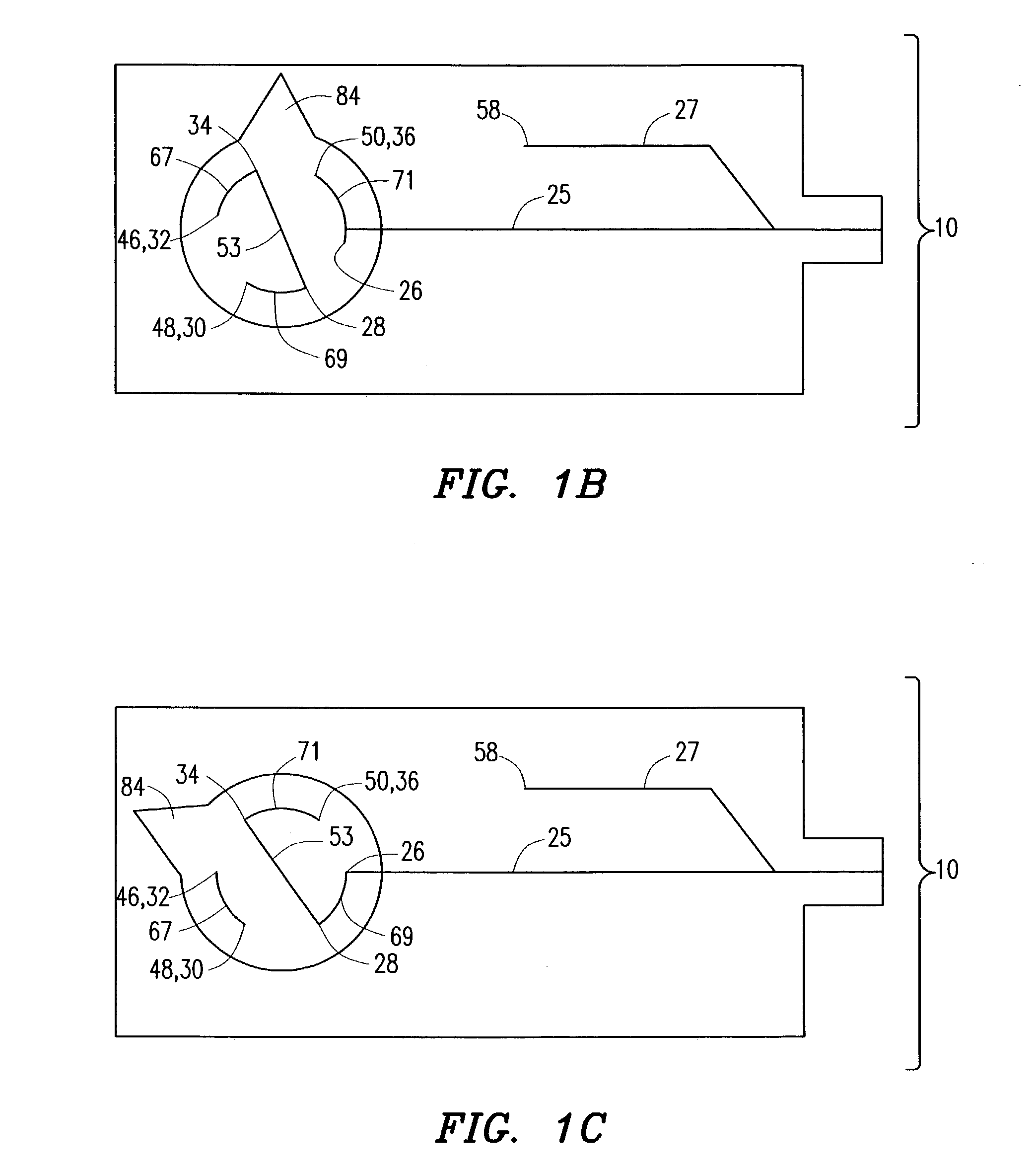

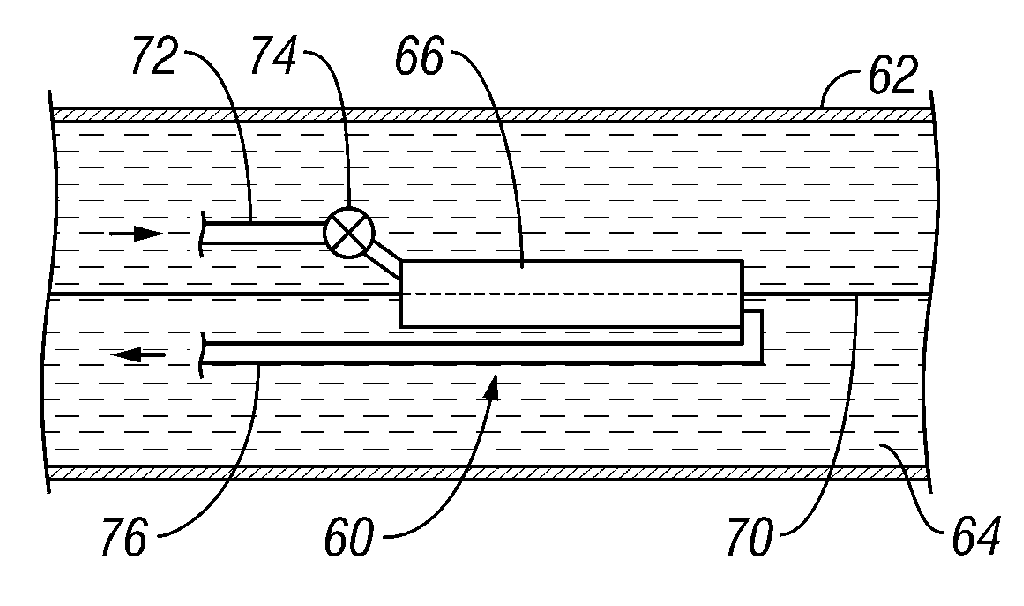

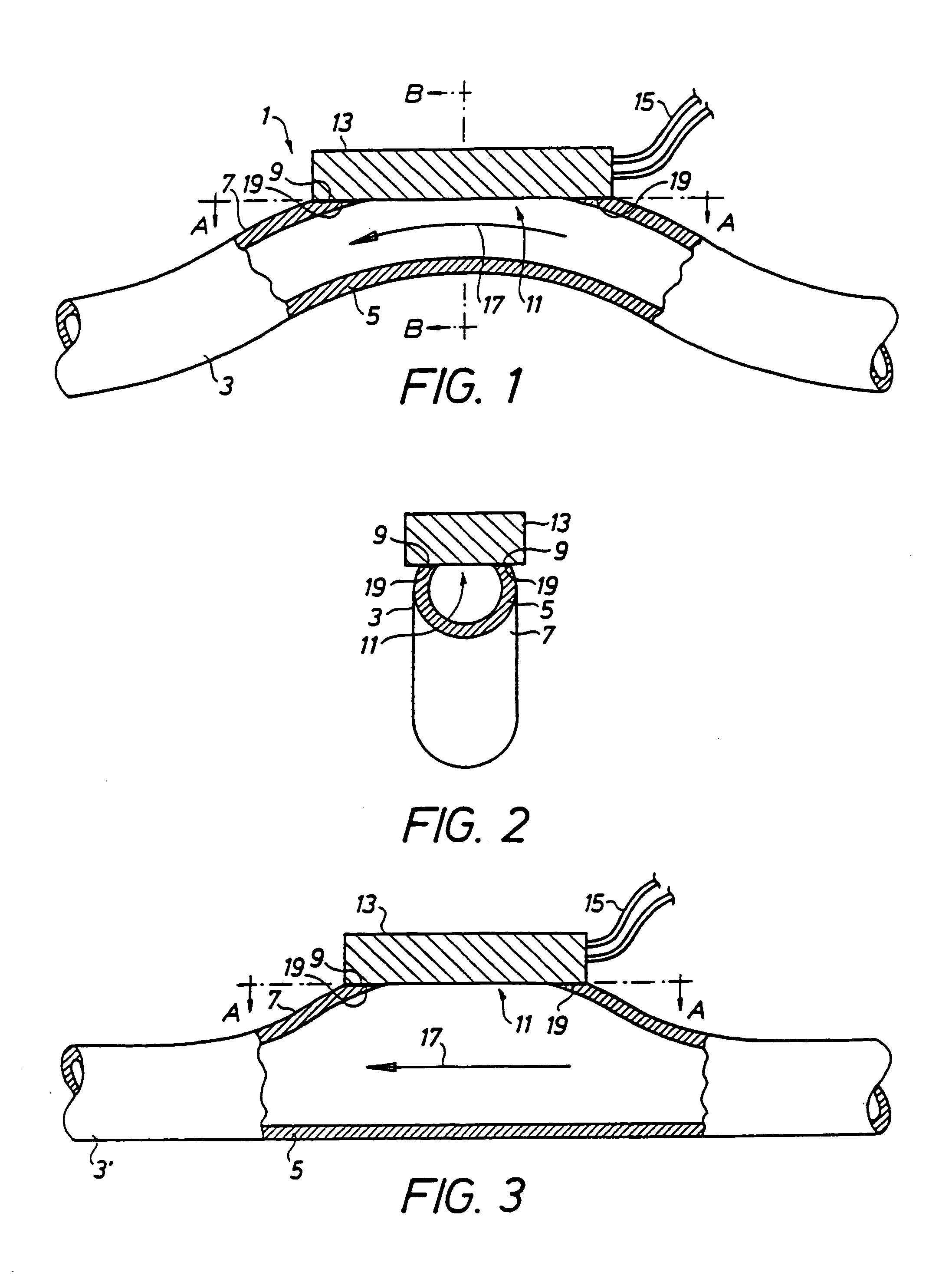

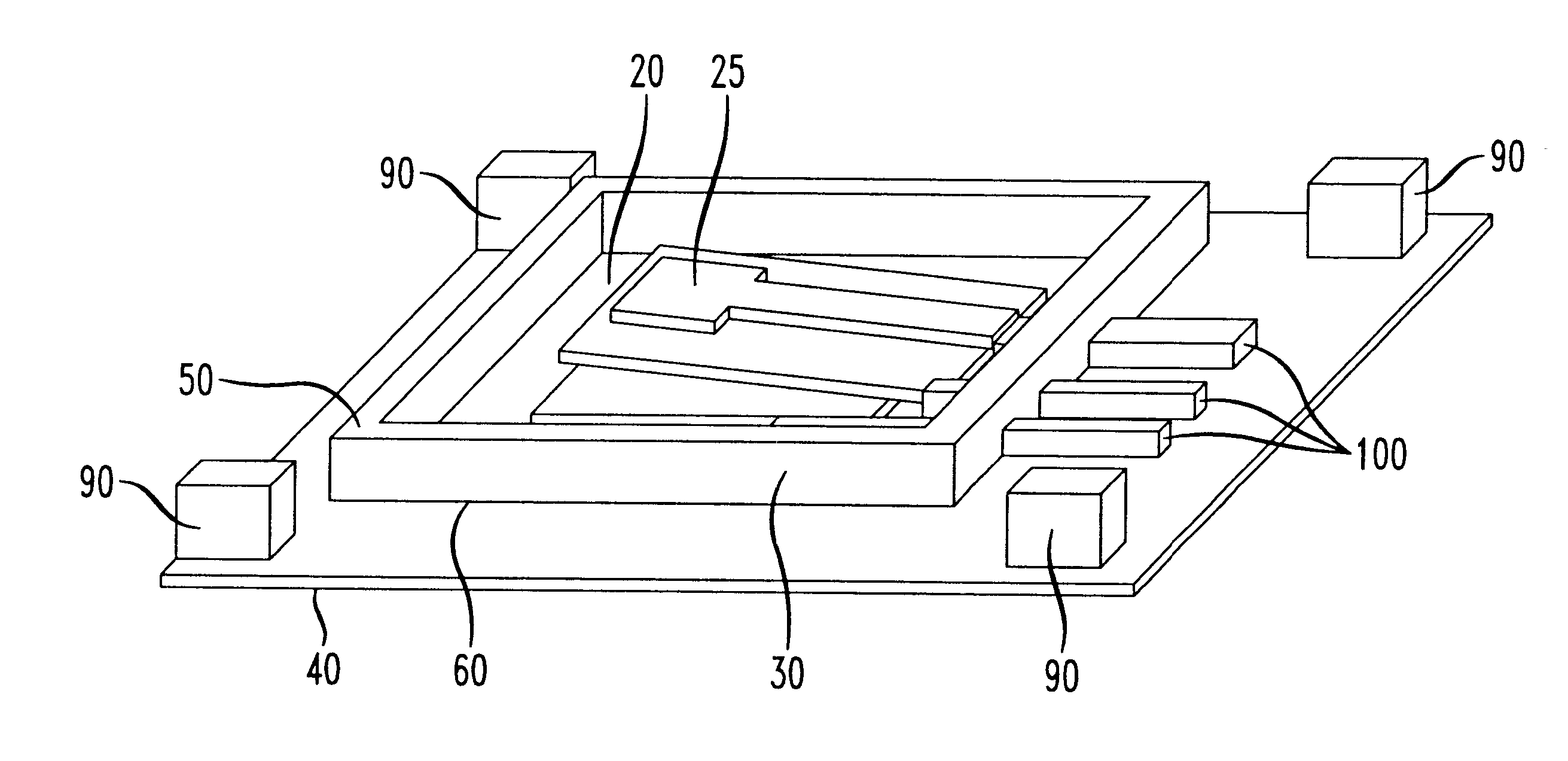

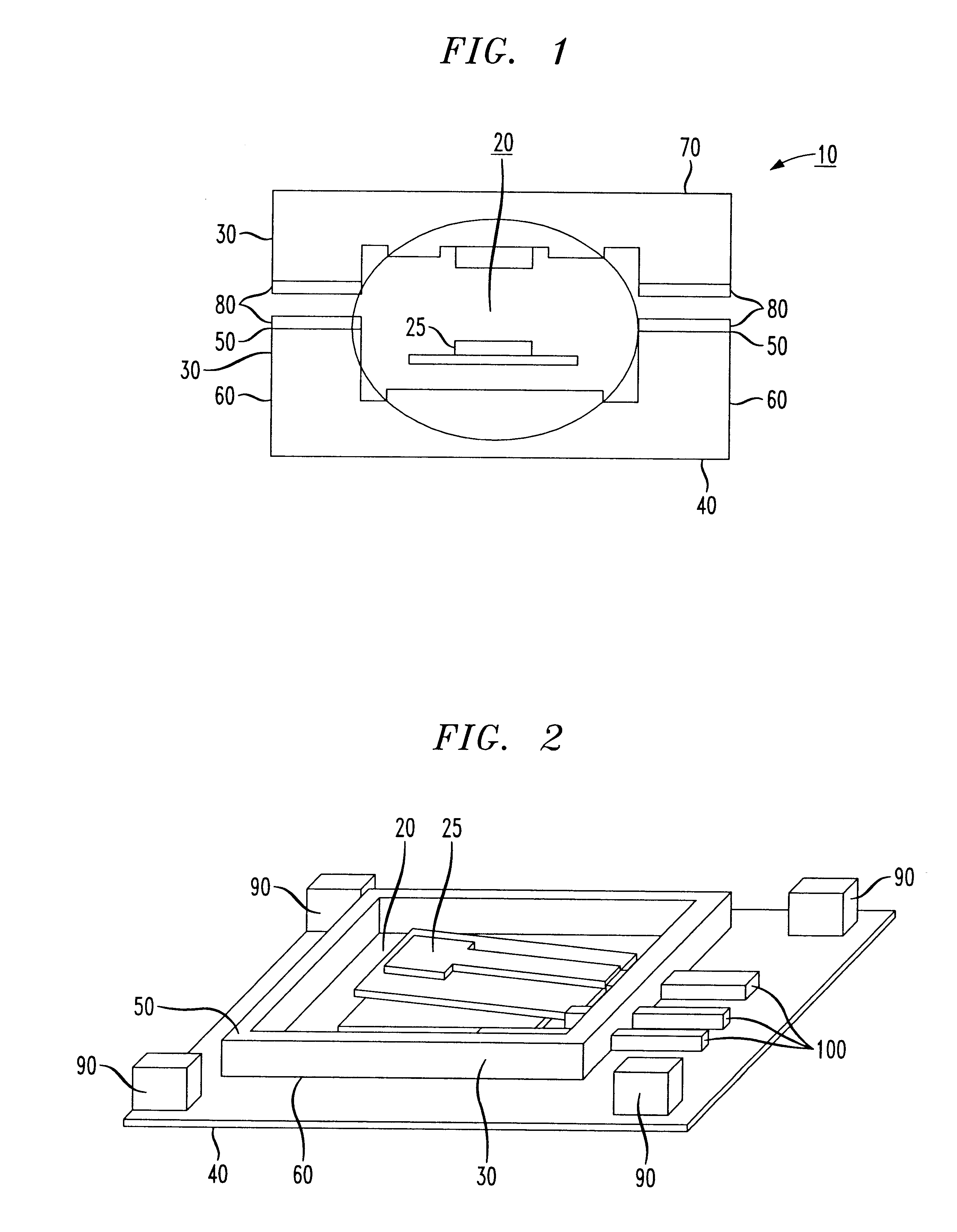

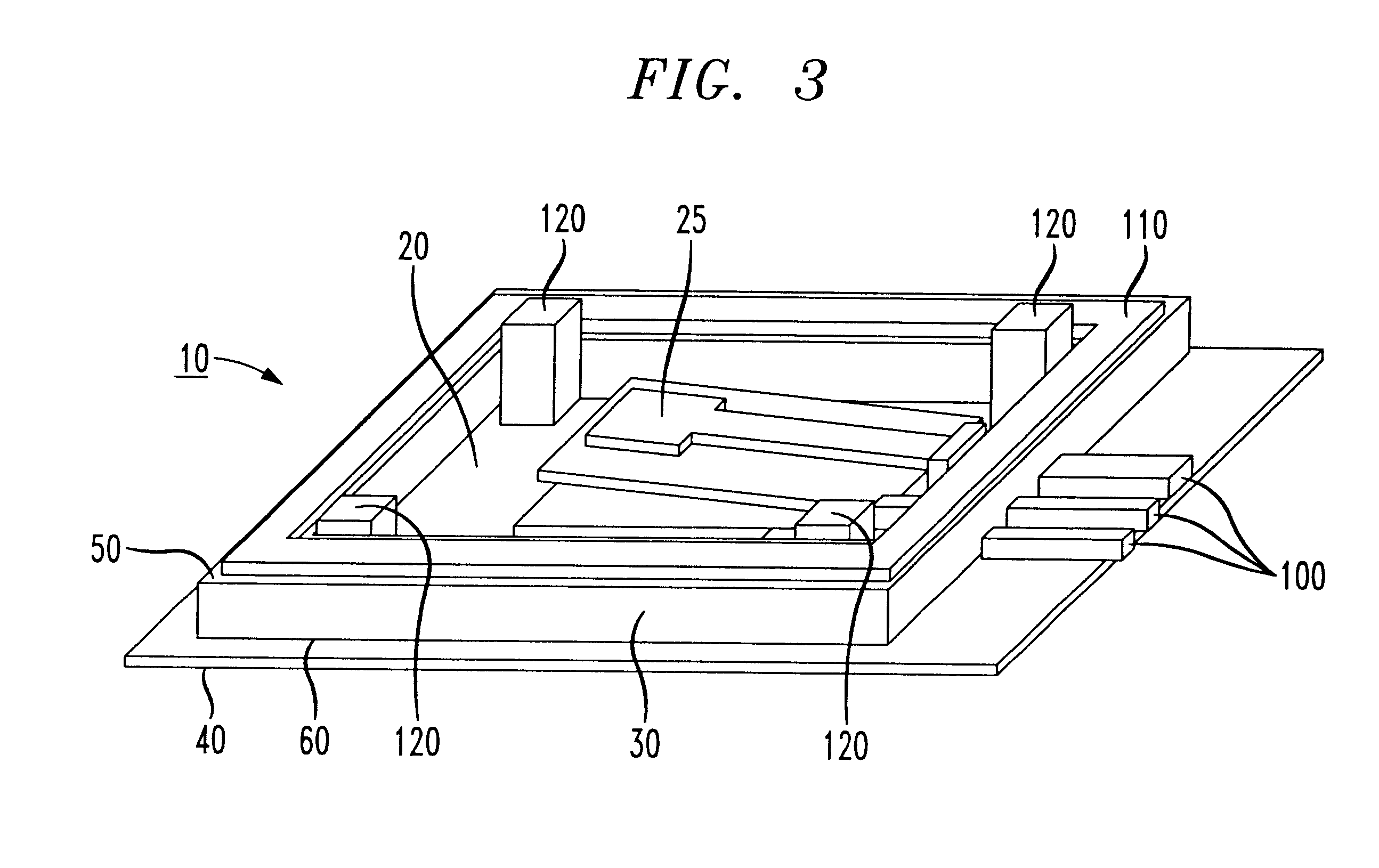

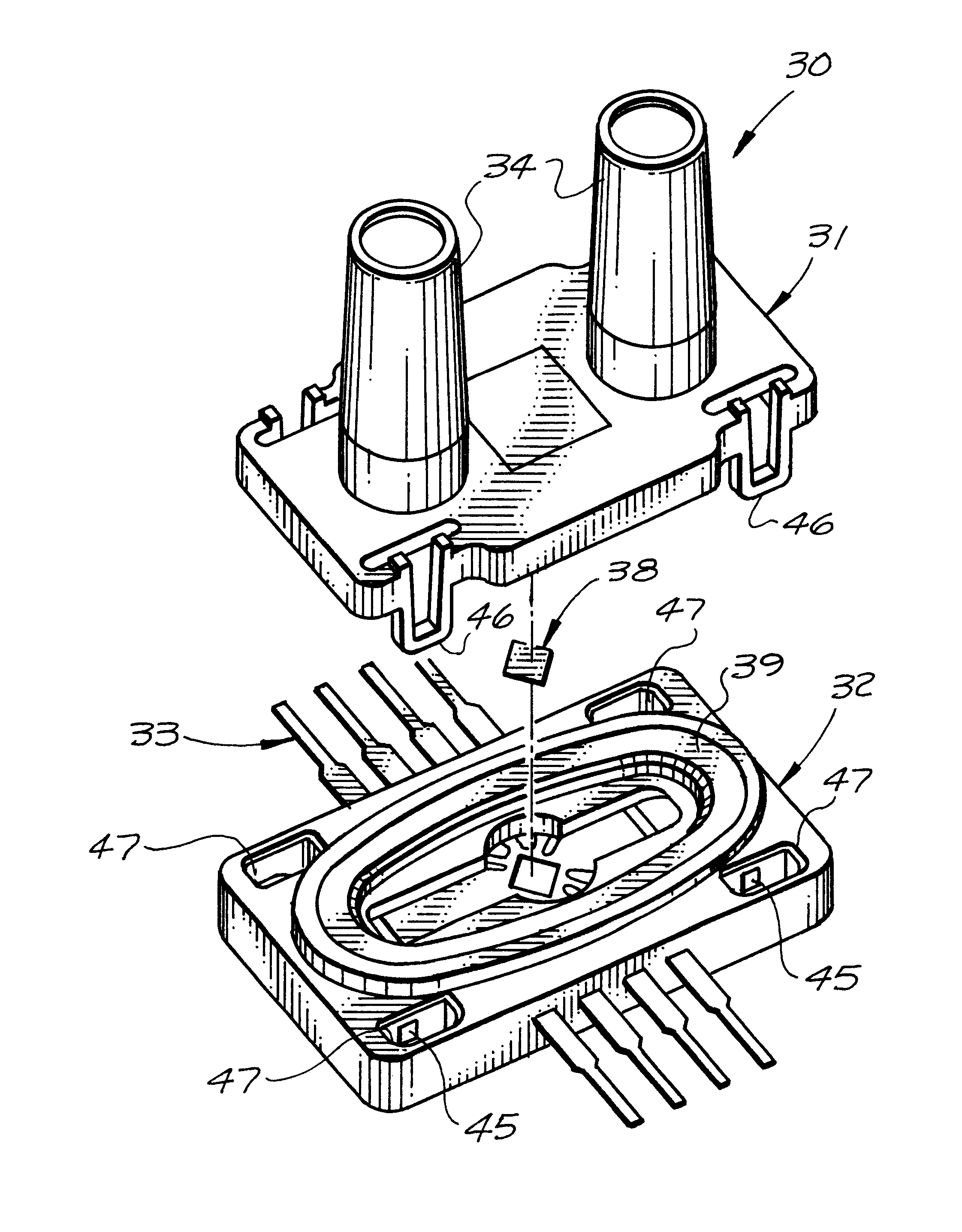

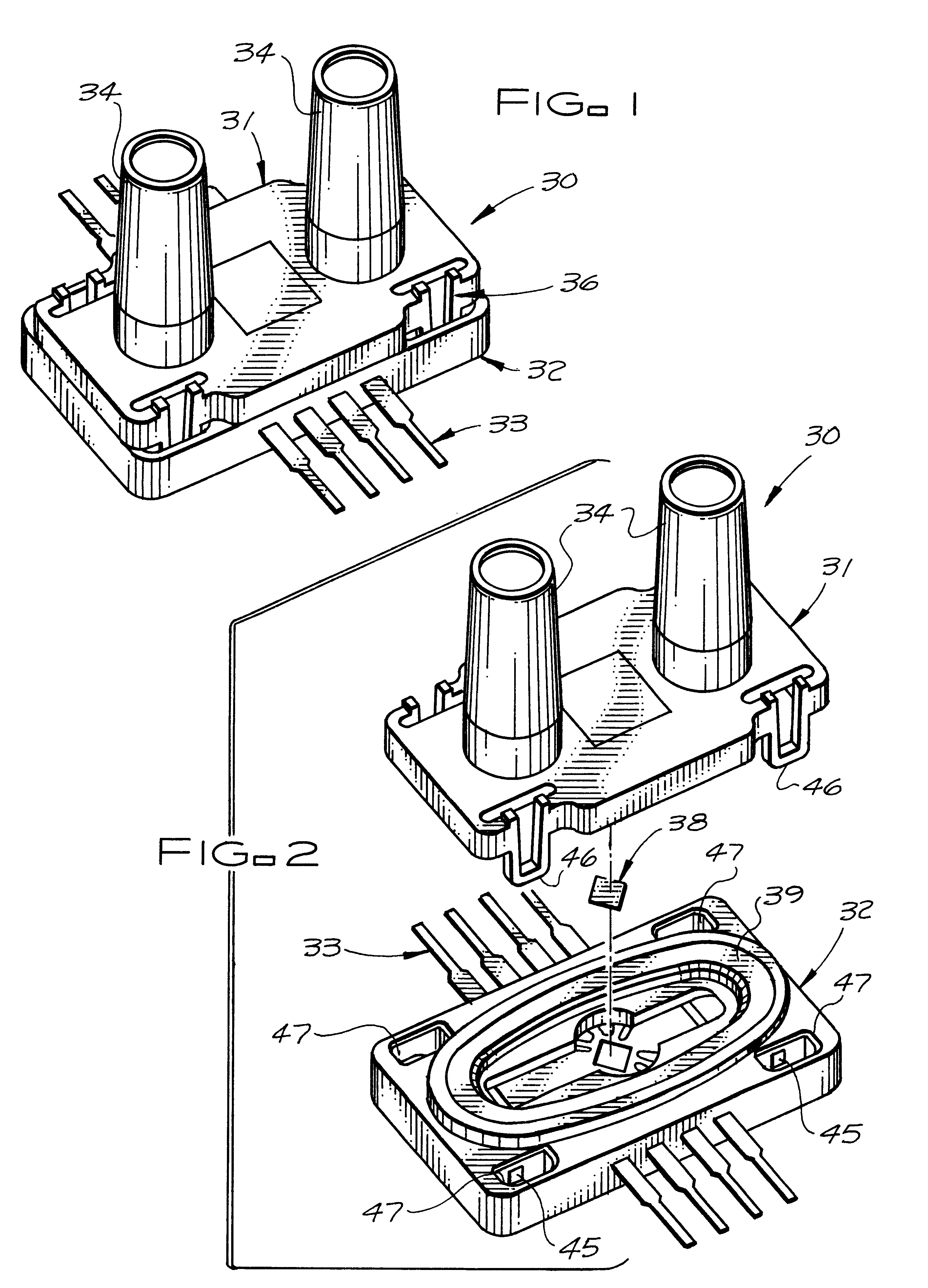

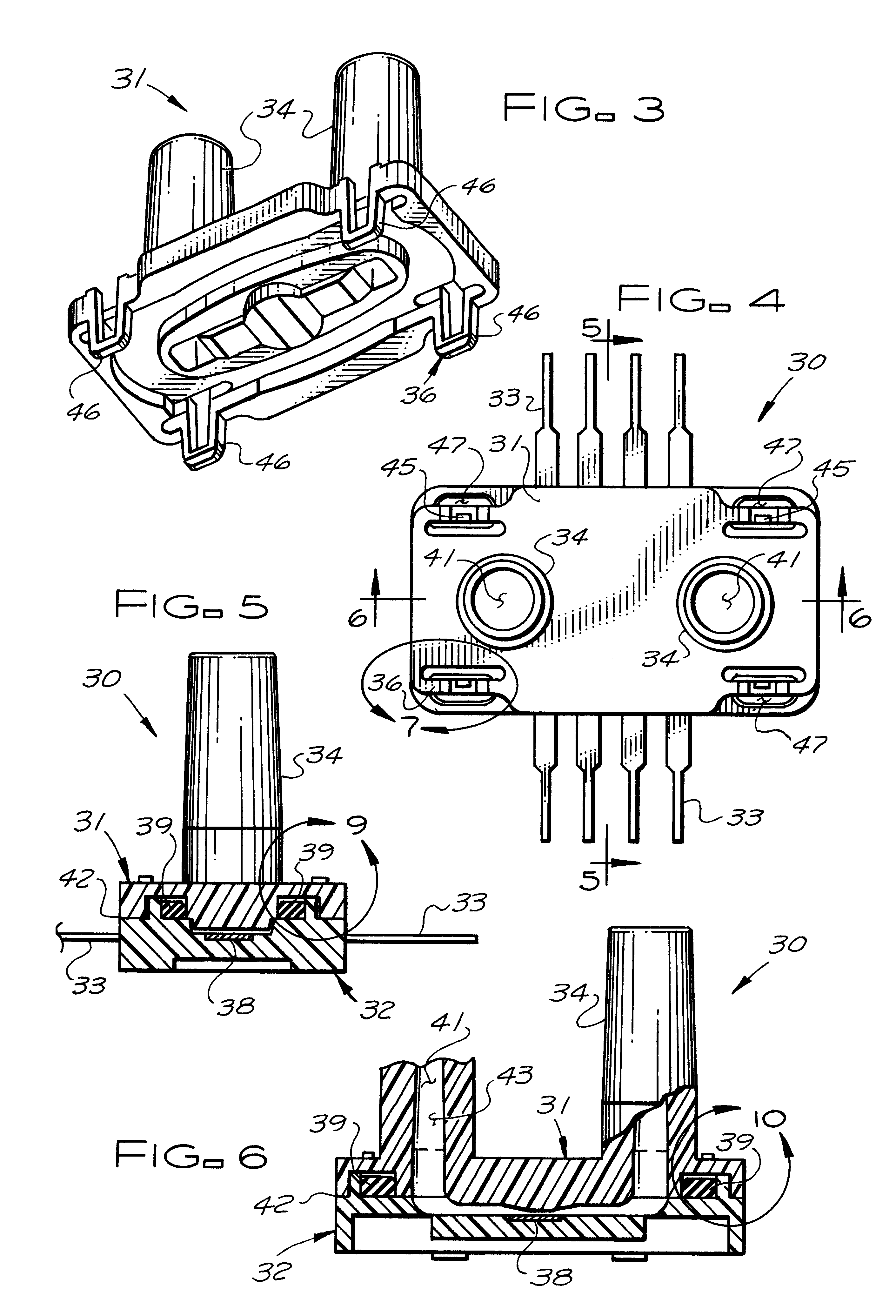

System for sensing the motion or pressure of a fluid

InactiveUS20020078744A1Volume/mass flow by thermal effectsFluid pressure measurementElectricitySurface mounting

A system for sensing or measuring the motion of a fluid such as air. The system typically has a two-part plastic body containing an internal flow passage. The parts of the body may snap together or attach with an adhesive. A transducer or an electronic sensor is typically located within the flow passage, which may measure mass flow rate and may have two resistive thermal devices (RTDs) located on either side of a heat source. The body may have two elongated port tubes configured to attach to tubing. The port tubes may contain venturis, and may be substantially straight and substantially parallel, forming a U shape. A metal lead frame may be provided in electrical communication with the sensor. The lead frame may be integrally molded within the body, and may have a lower coefficient of thermal expansion than the body. The internal flow passage and the sensor may be substantially symmetrical and measure the flow rate of the fluid substantially equally in either flow direction. The system may be configured for surface mounting or for through-hole mounting, and may be a dual in-line type.

Owner:HONEYWELL INT INC

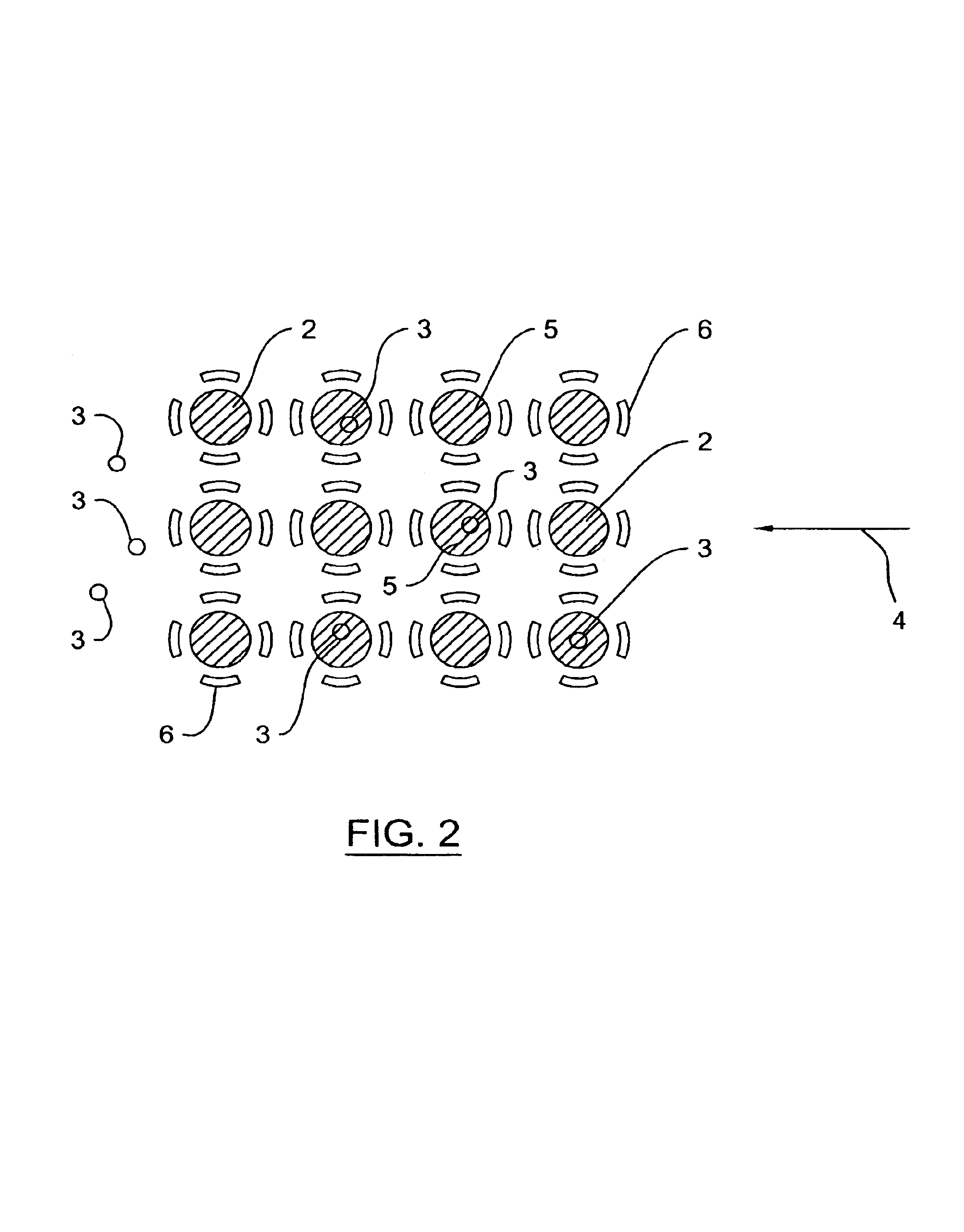

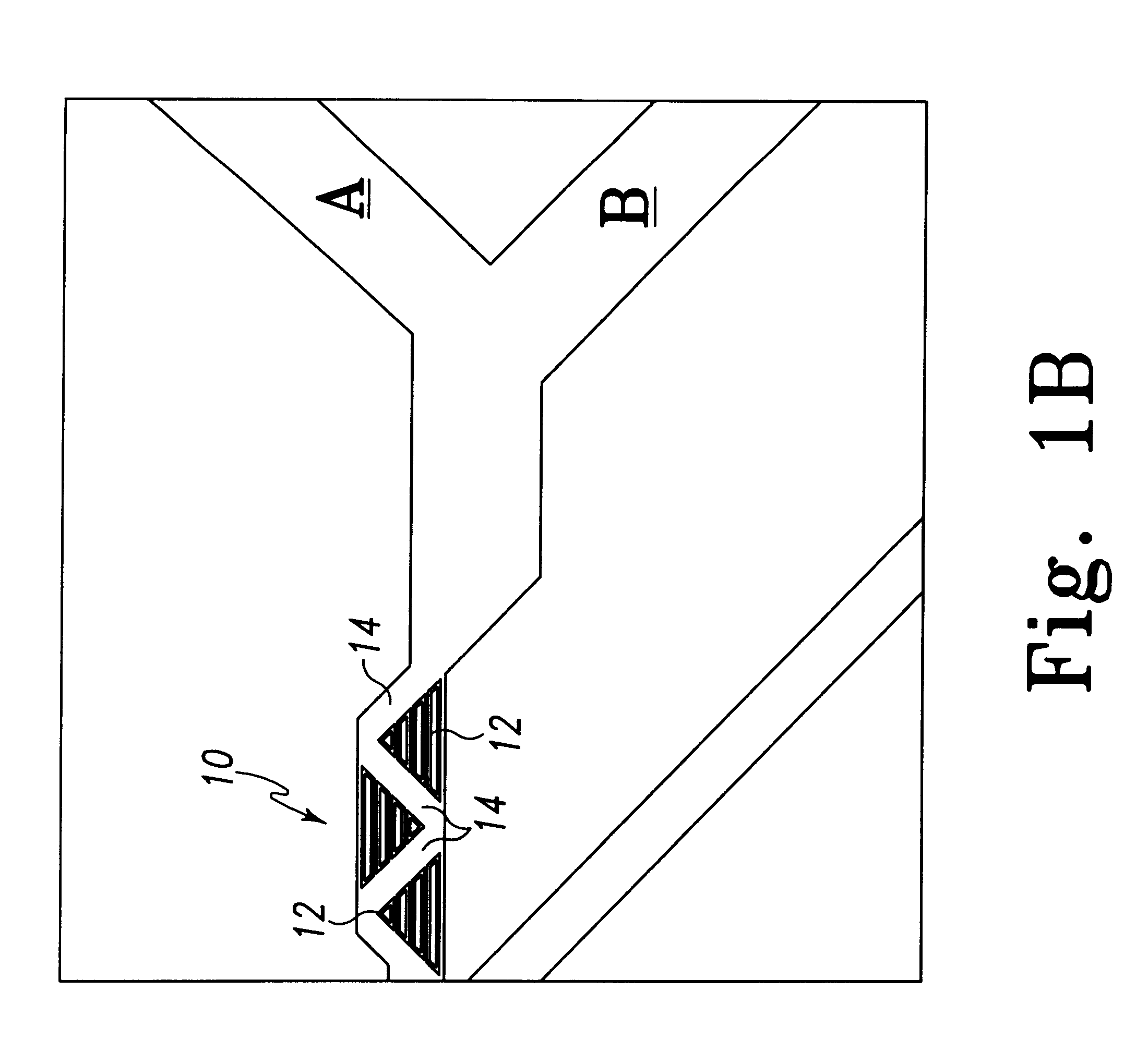

In situ micromachined mixer for microfluidic analytical systems

The present invention relates to an in situ micromachined mixer for microfluidic analytical systems. In a preferred embodiment, a 100 pL mixer for liquids transported by electroosmotic flow (EOF) is described. Mixing was achieved in multiple intersecting channels with a bimodal width distribution and varying lengths. Five .mu.m width channels ran parallel to the direction of flow whereas larger 27 .mu.m width channels ran back and forth through the network at a 45.degree. angle. All channels were approximately 10 .mu.m deep. It was observed that little mixing of confluent streams occurred in the 100 .mu.m wide mixer inlet channel where mixing would be achieved almost exclusively by diffusion. In contrast, mixing was complete after passage through the channel network in the .apprxeq.200 .mu.m length mixer. Solvent composition was altered by varying the voltage on solvent reservoirs. The high efficiency attained in this mixer was attributed to the presence of a 2 pL vortex in the center of the mixer. Video tracking of fluorescent particles with a fluorescence microscope allowed the position and volume of this vortex to be determined.

Owner:PURDUE RES FOUND INC

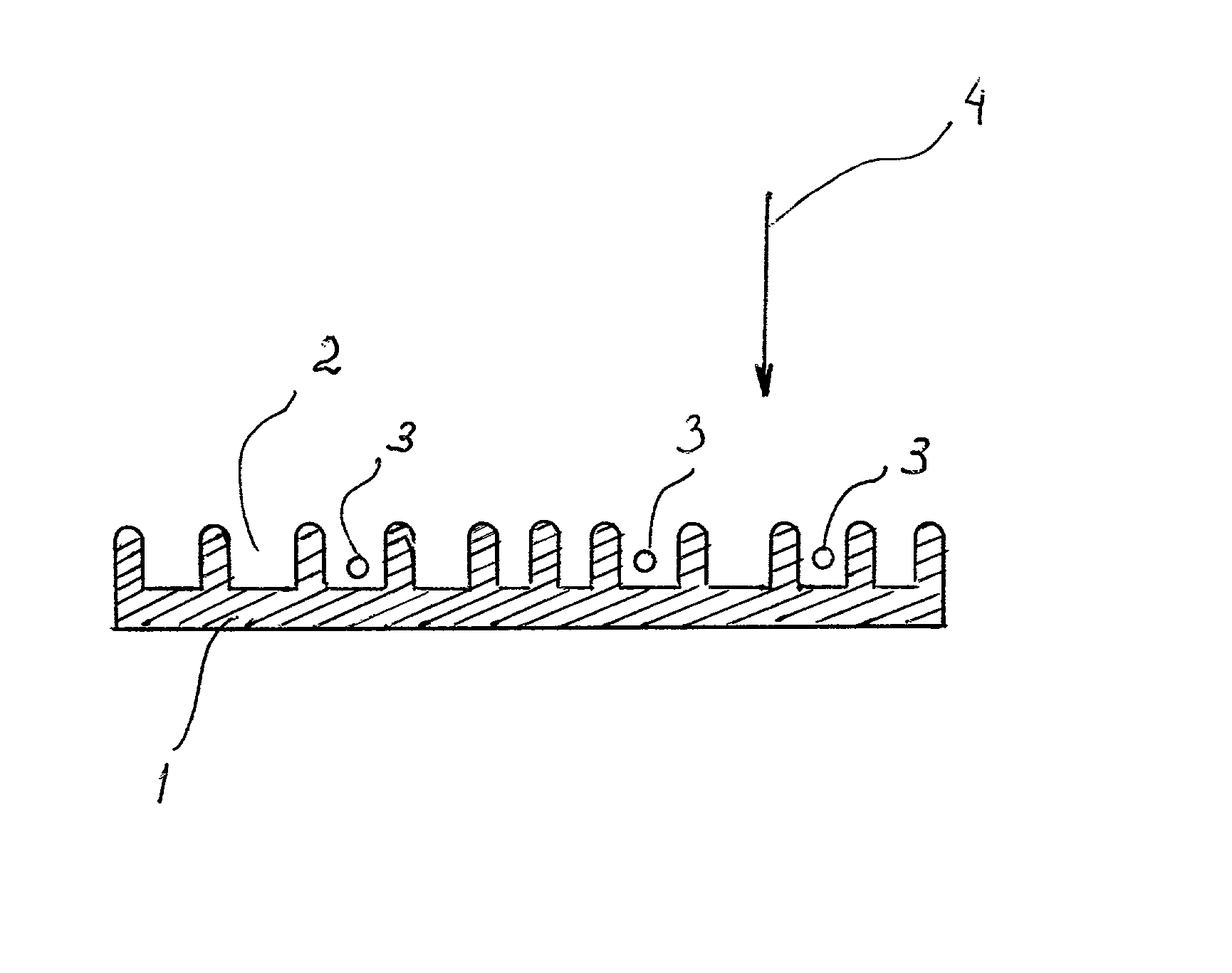

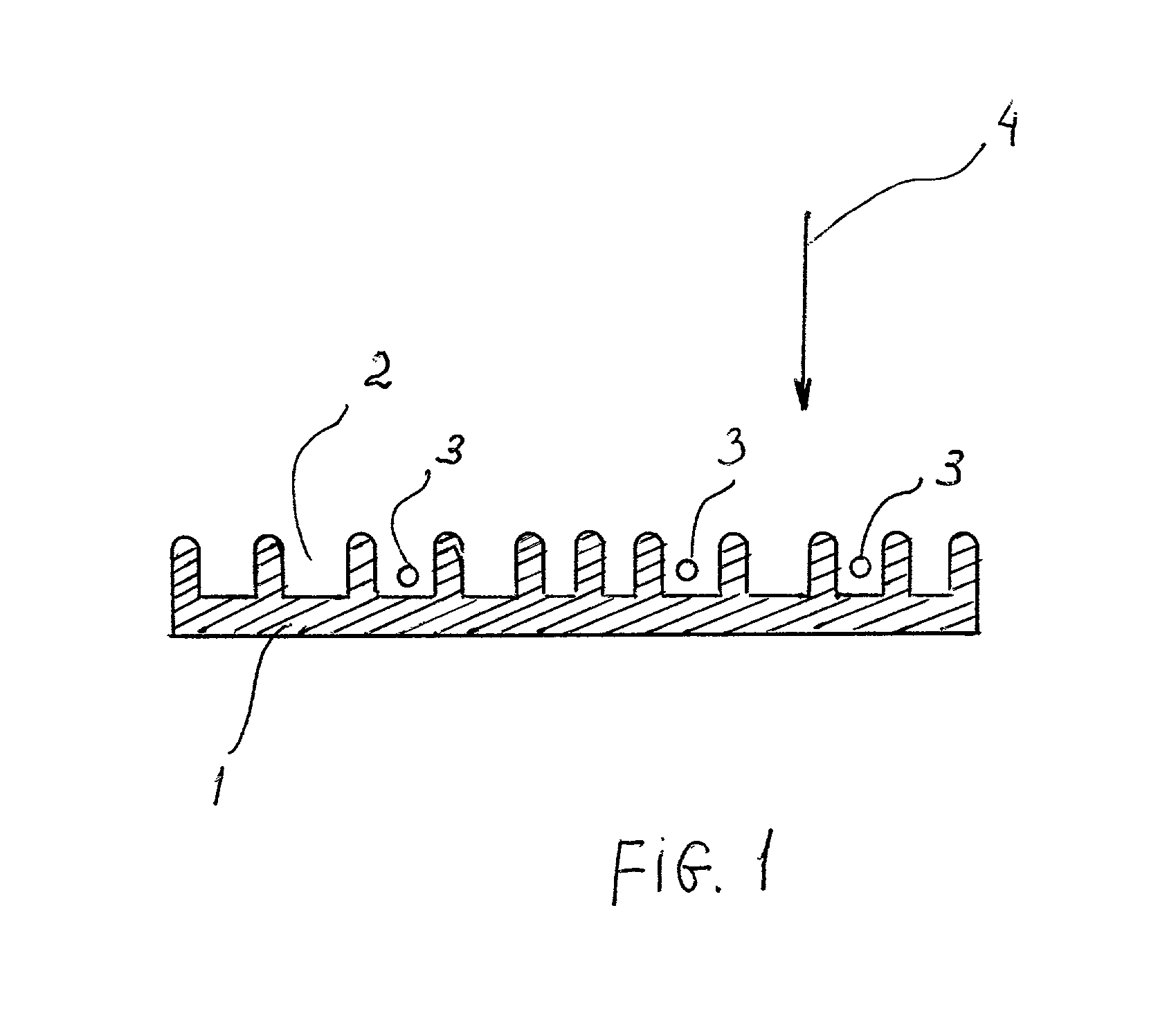

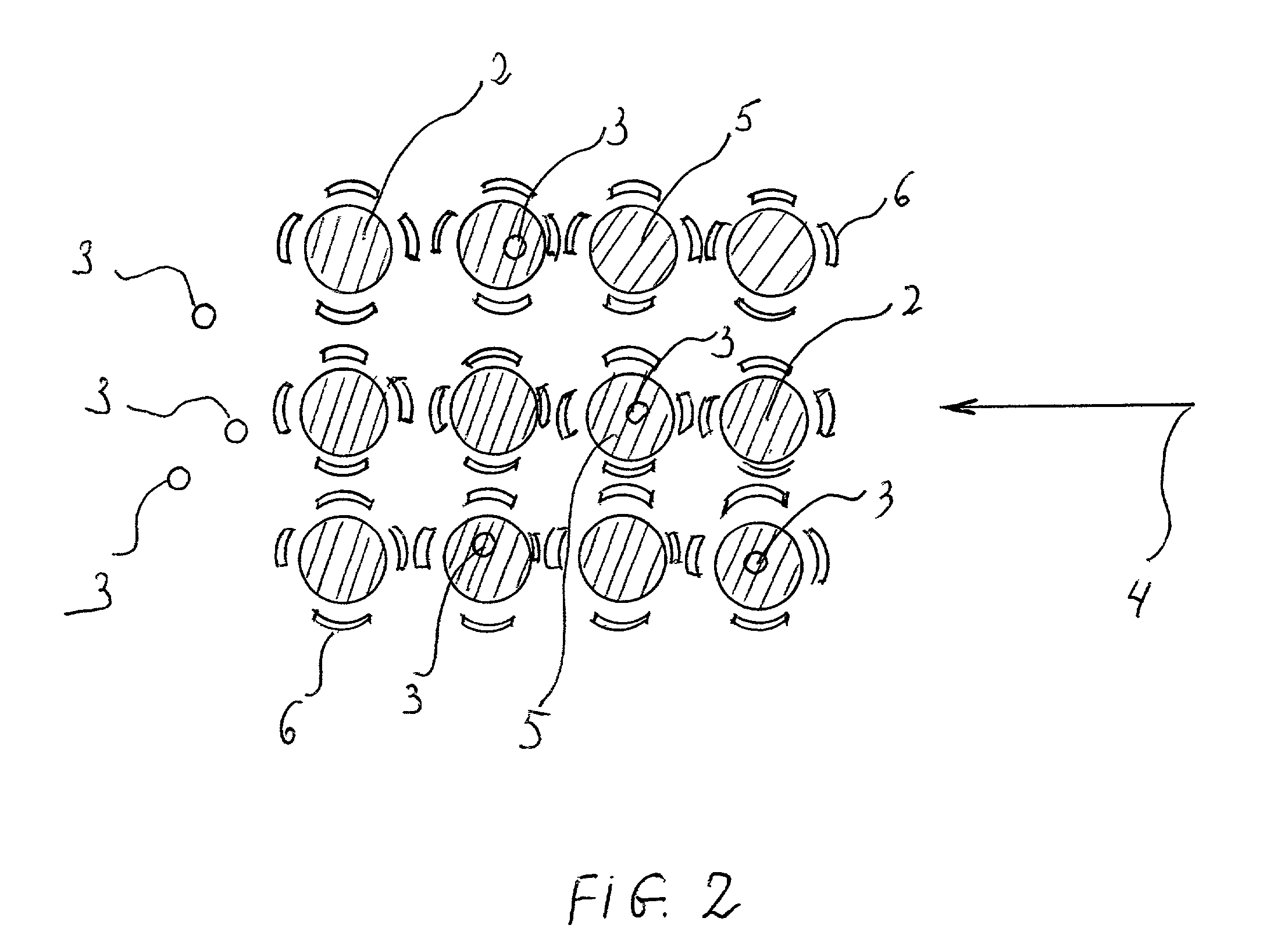

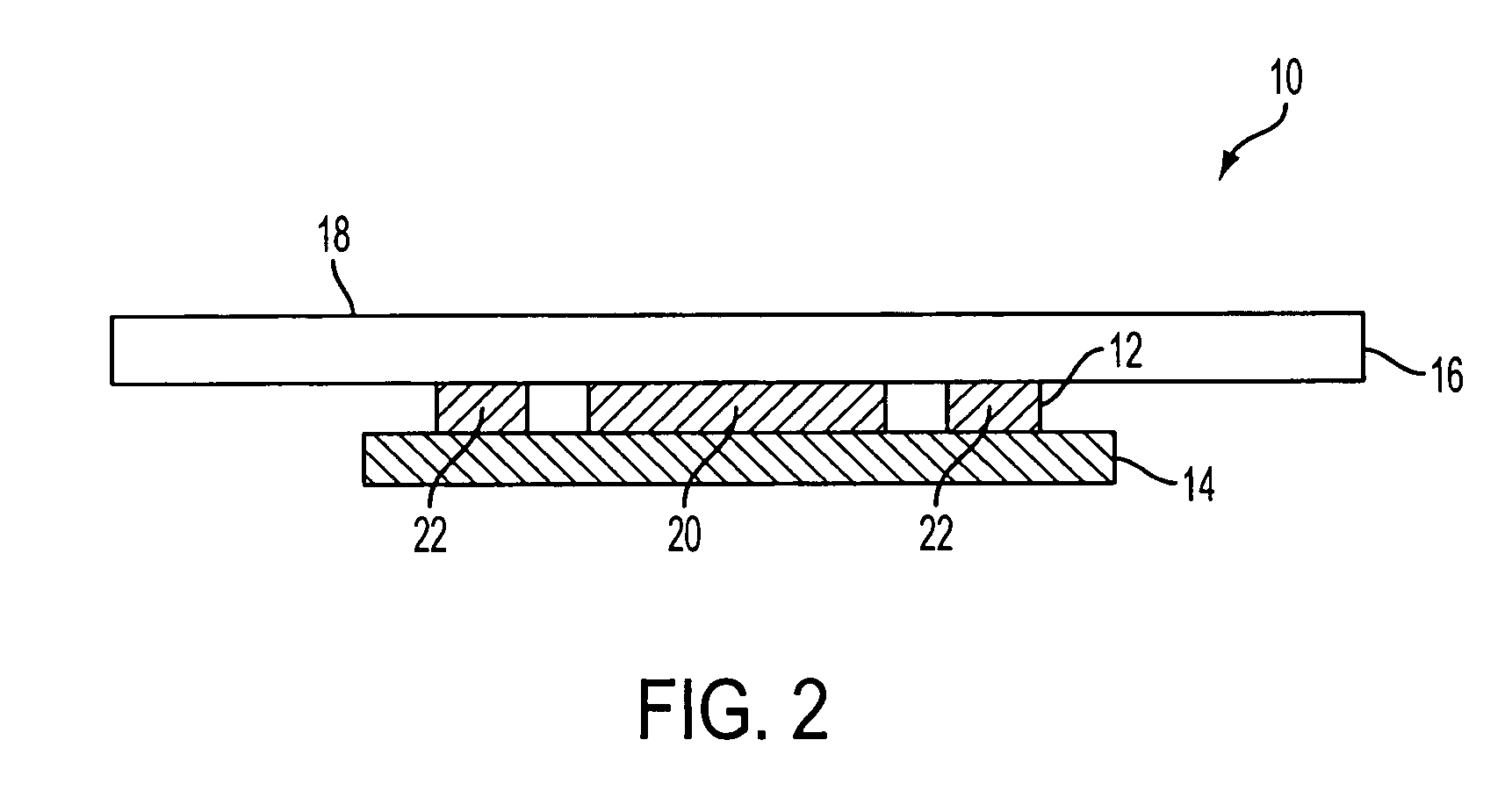

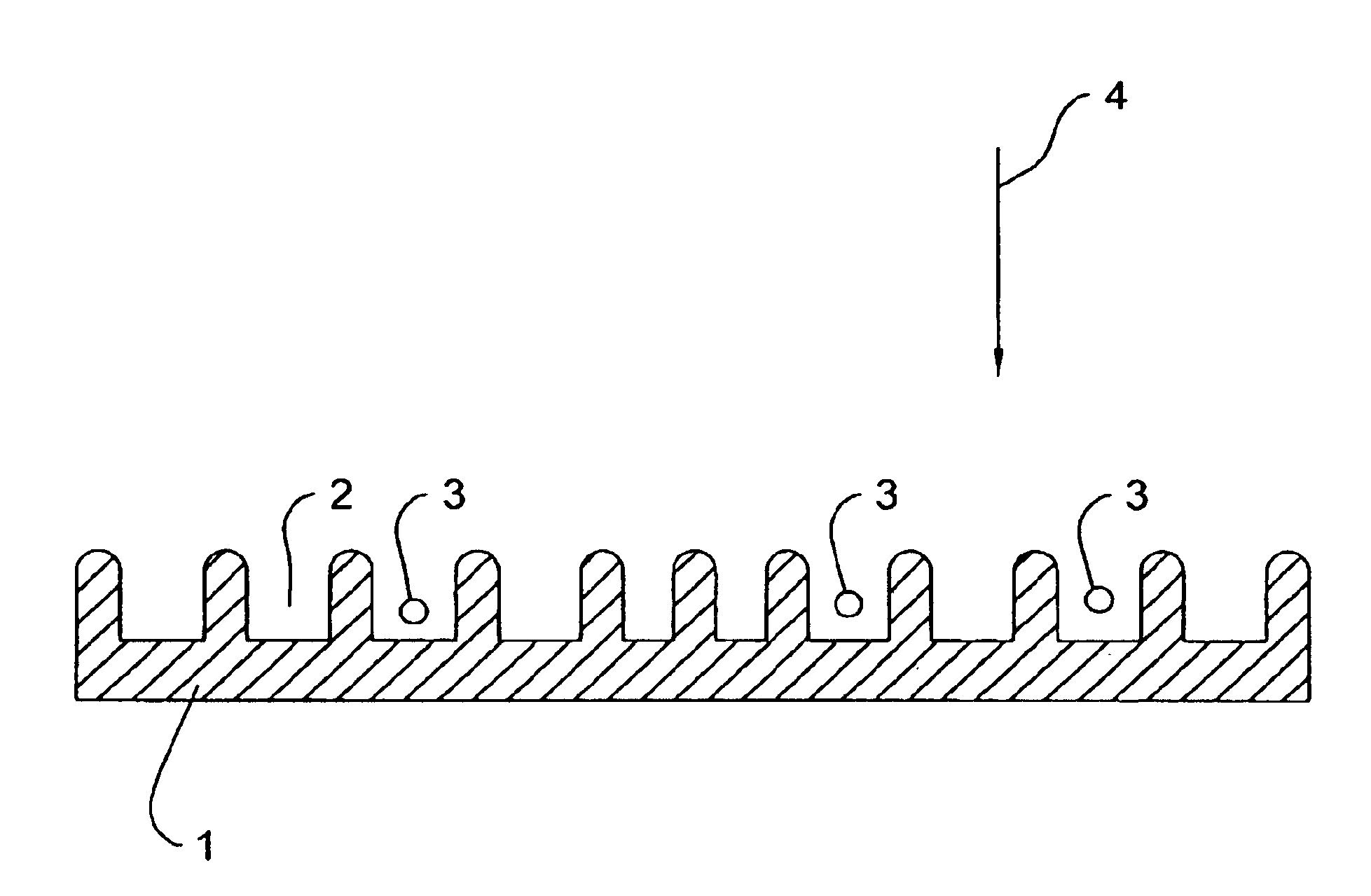

Microneedle structure and production method therefor

InactiveUS7648484B2Fixed microstructural devicesVolume/mass flow by thermal effectsEngineeringDry etching

A method for processing a wafer to form a plurality of hollow microneedles projecting from a substrate includes forming, by use of a dry etching process, a number of groups of recessed features, each including at least one slot deployed to form an open shape having an included area and at least one hole located within the included area. The internal surfaces of the holes and the slots are then coated with a protective layer. An anisotropic wet etching process is then performed in such a manner as to remove material from outside the included areas while leaving a projecting feature within each of the included areas. The protective layer is then removed to reveal the microneedles.

Owner:NANOPASS TECH LTD

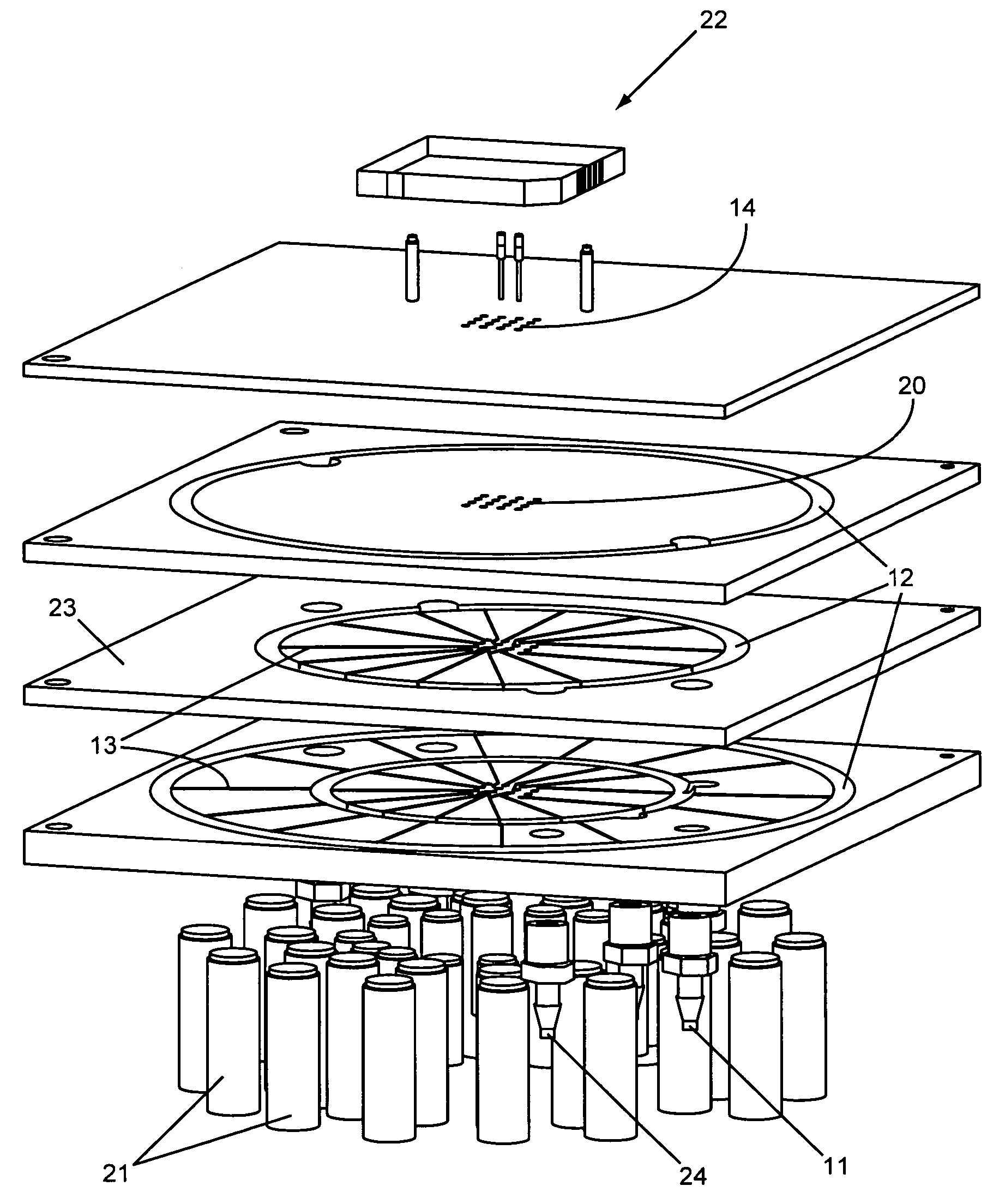

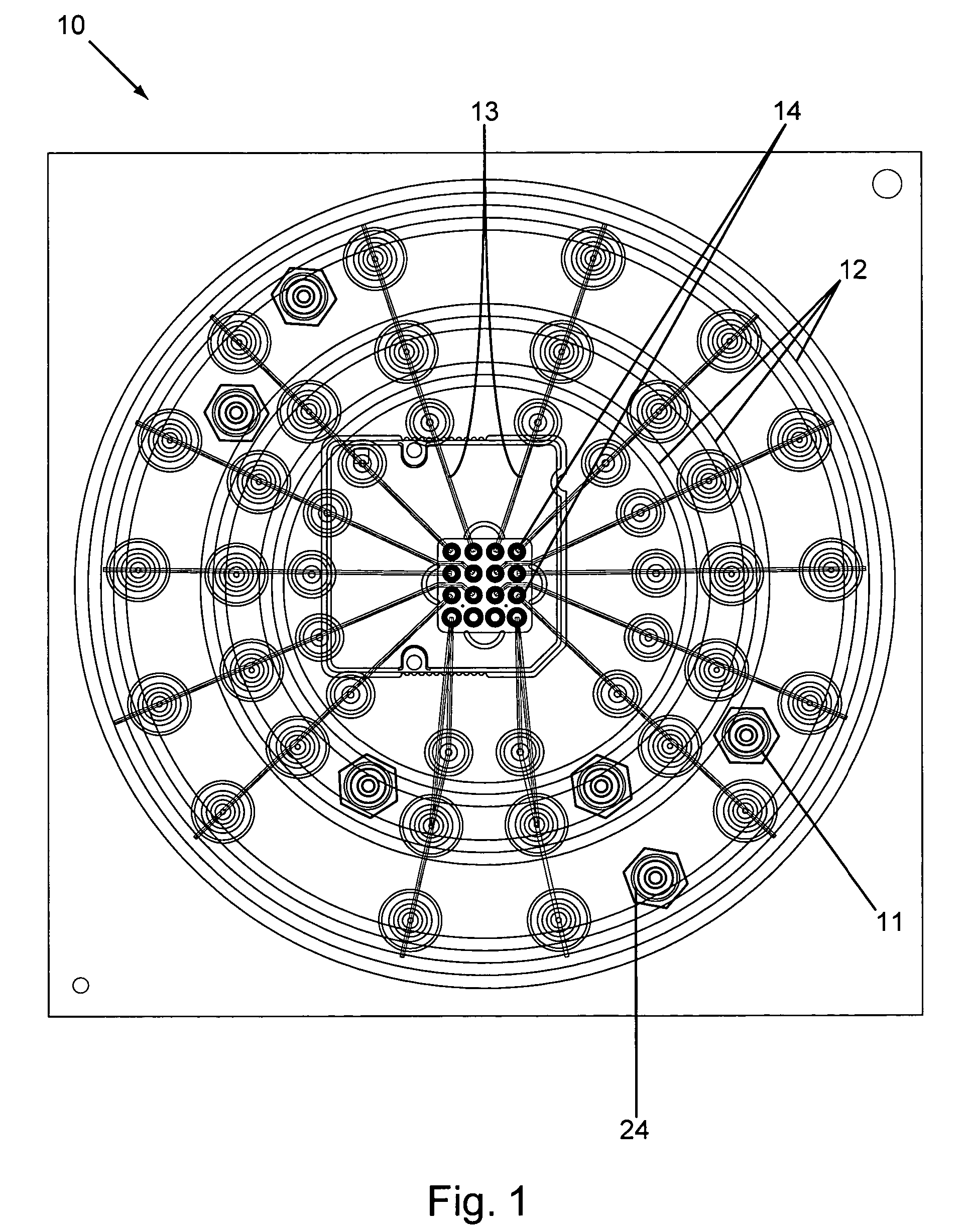

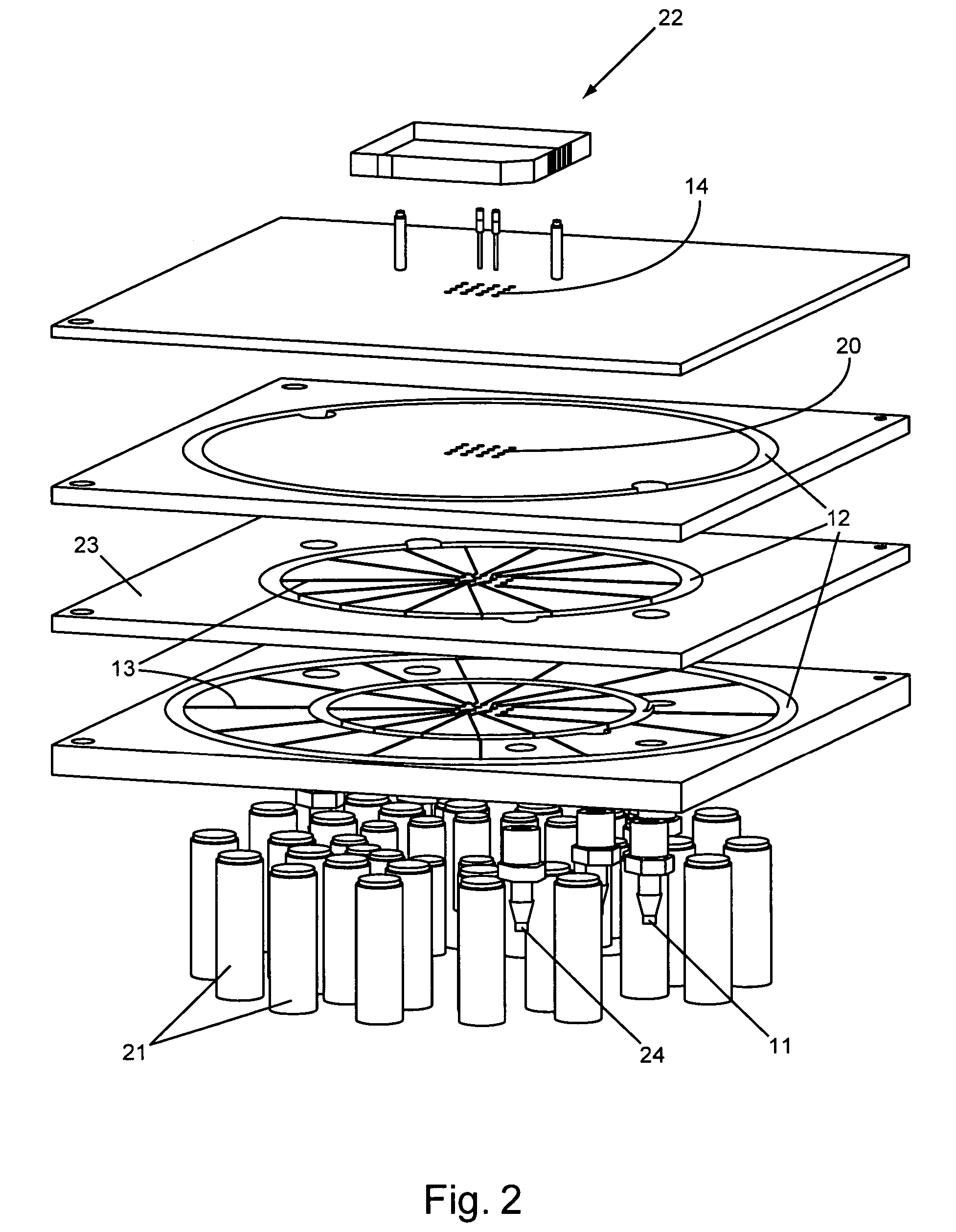

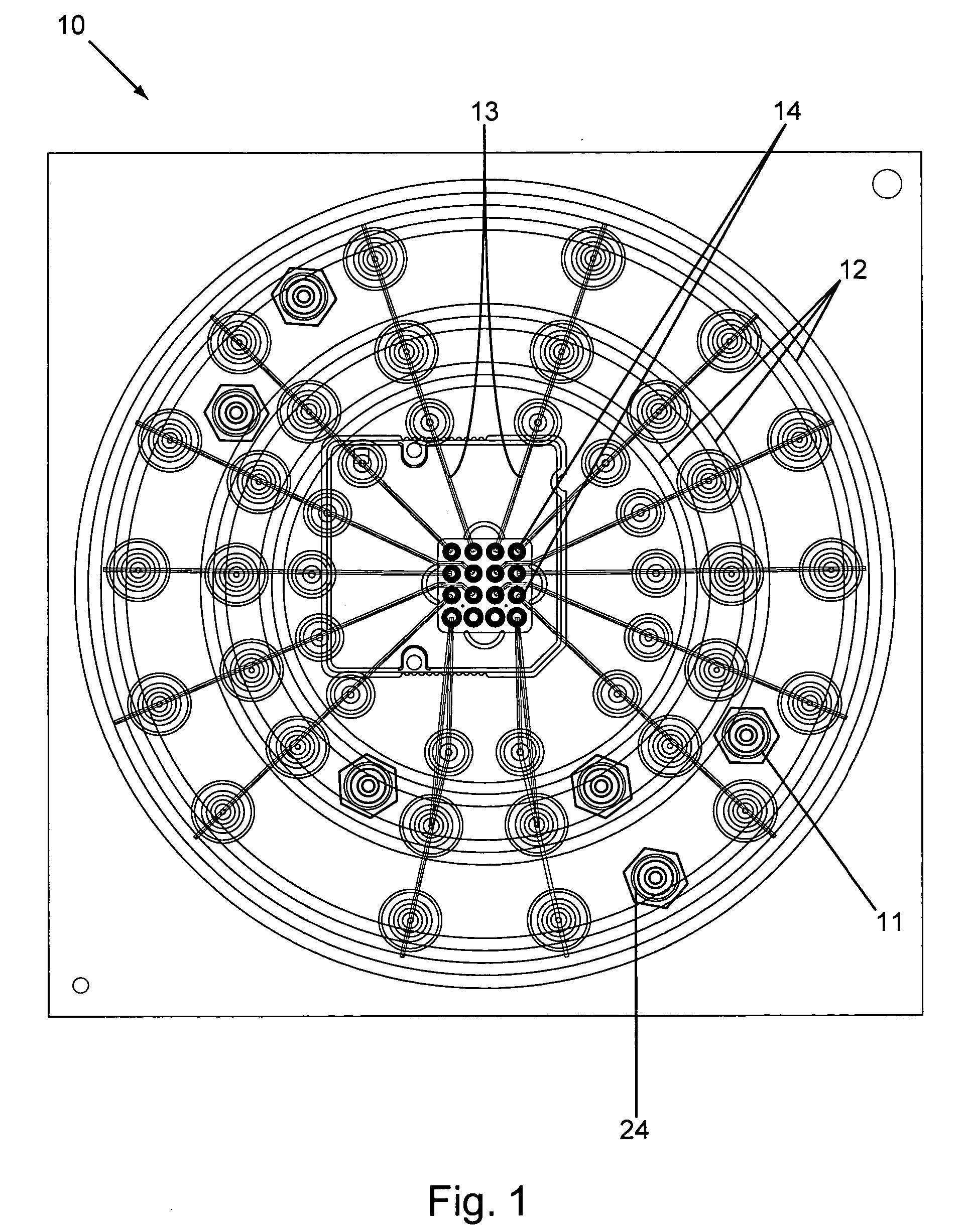

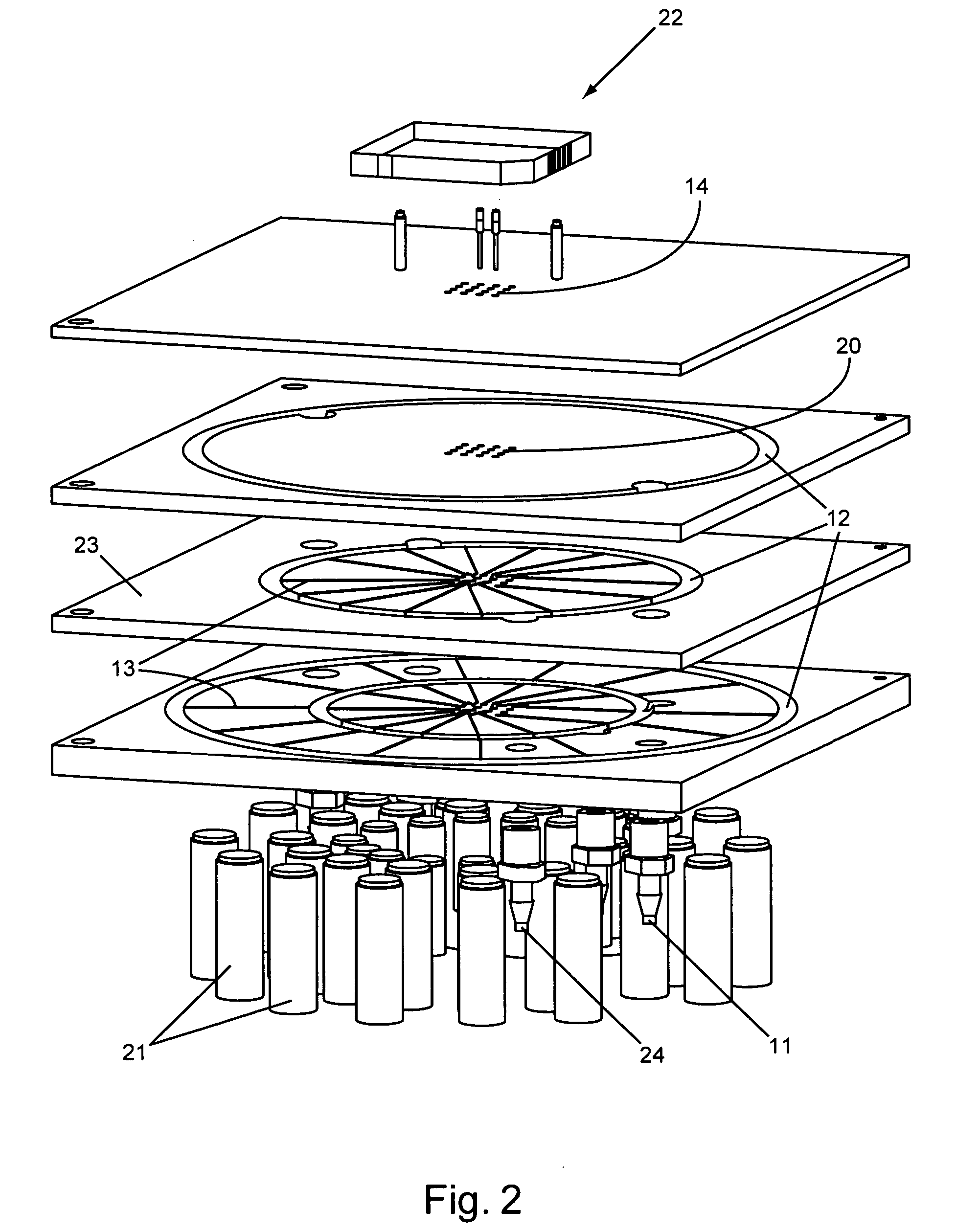

Methods and systems for processing microscale devices for reuse

InactiveUS7514046B2Efficient processingImprove efficiencyFixed microstructural devicesVolume/mass flow by thermal effectsBiomedical engineeringMicrofluidic chip

This invention provides methods and systems for flushing, washing, and priming microscale devices for reuse. Washing and priming methods include flowing solutions from a manifold to flush wells and microchannels of a microfluidic chip. Systems include manifolds adapted to seal and flow solutions or gasses into chip wells. Devices include microfluidic devices with data storage modules to track the reprocessing status of the microscale devices.

Owner:CAPLIPER LIFE SCI INC +1

Respiratory humidification system

ActiveUS7043979B2Analysing fluids using sonic/ultrasonic/infrasonic wavesVolume/mass flow by thermal effectsEngineering

Owner:FISHER & PAYKEL HEALTHCARE LTD

PAEK-based microfluidic device with integrated electrospray emitter

A polyaryl-ether-ketone (PAEK)-based microfluidic device having an integrated electrospray emitter is disclosed. Bonding of at least one PAEK substrate forming the microfluidic device is accomplished using a solvent-resistant adhesive, such as a polyimide-based adhesive, in combination with an adhesion enhancement treatment. By providing the PAEK-based microfluidic device with an integrated electrospray emitter, efficient and effective analysis of fluid samples is enabled.

Owner:AGILENT TECH INC

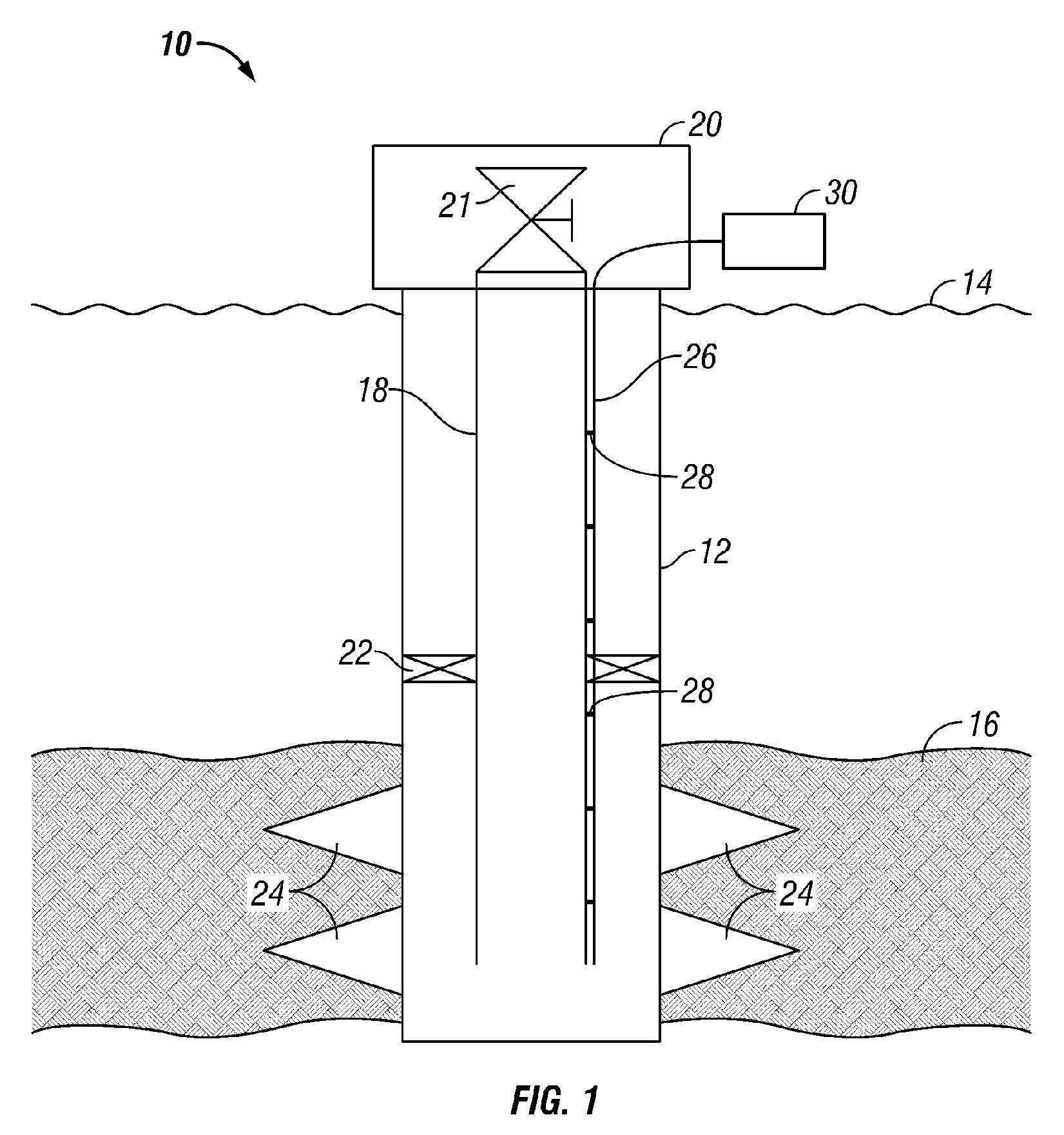

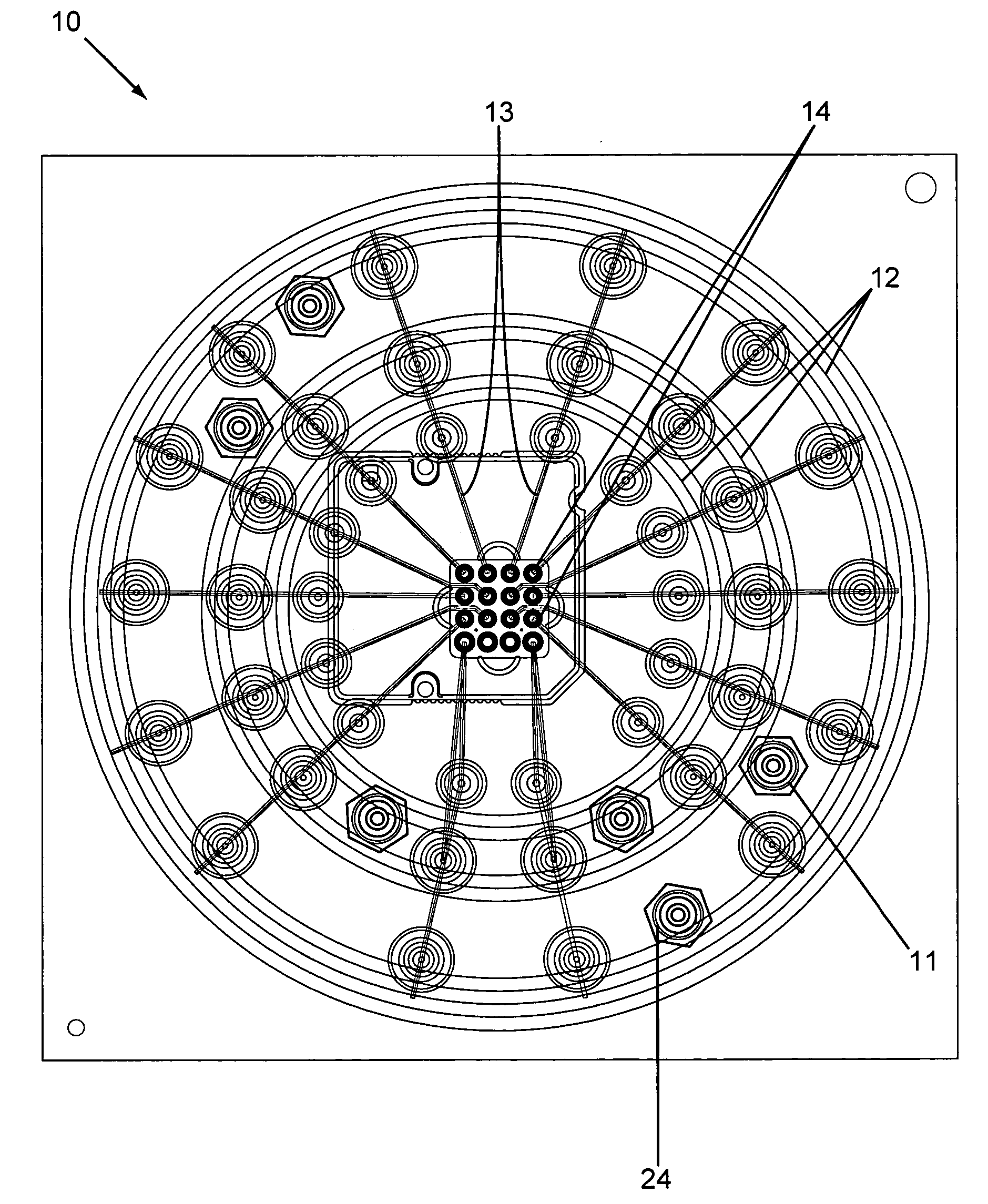

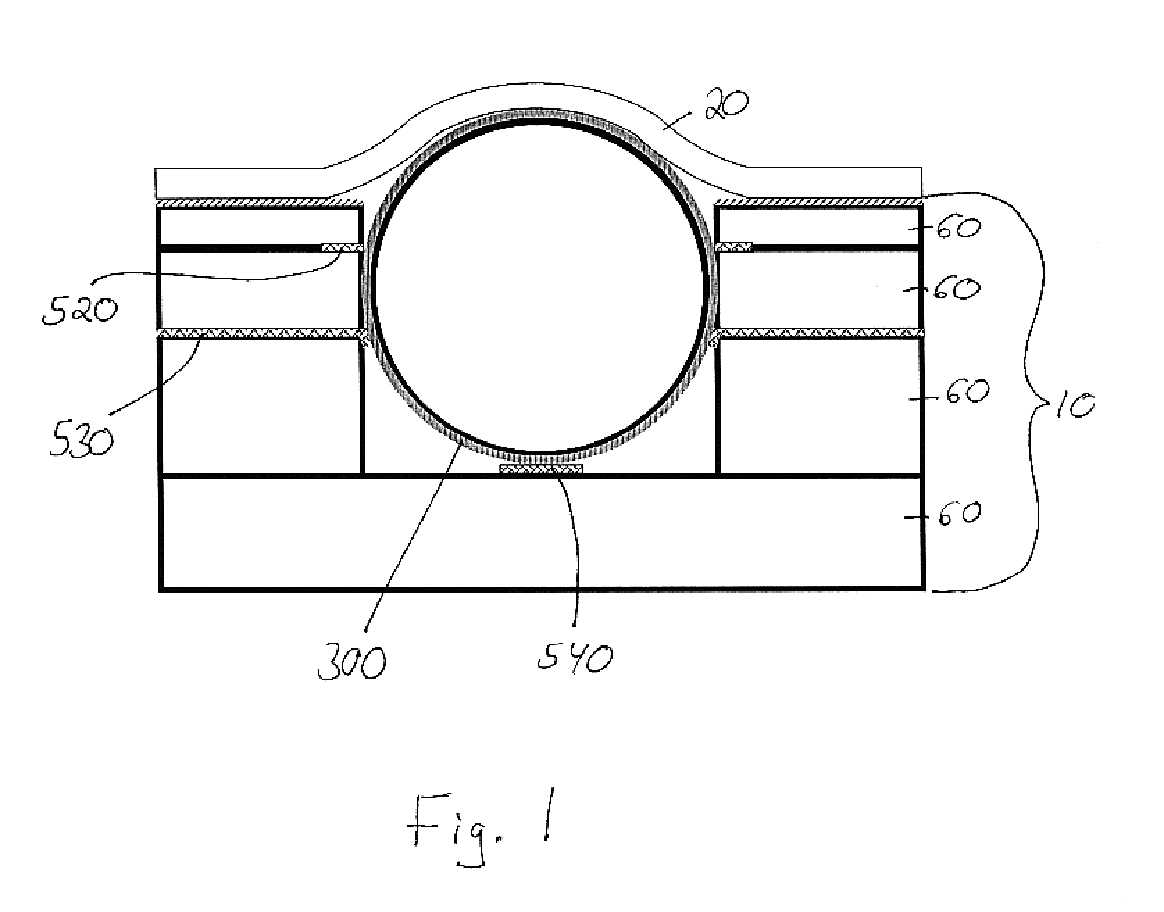

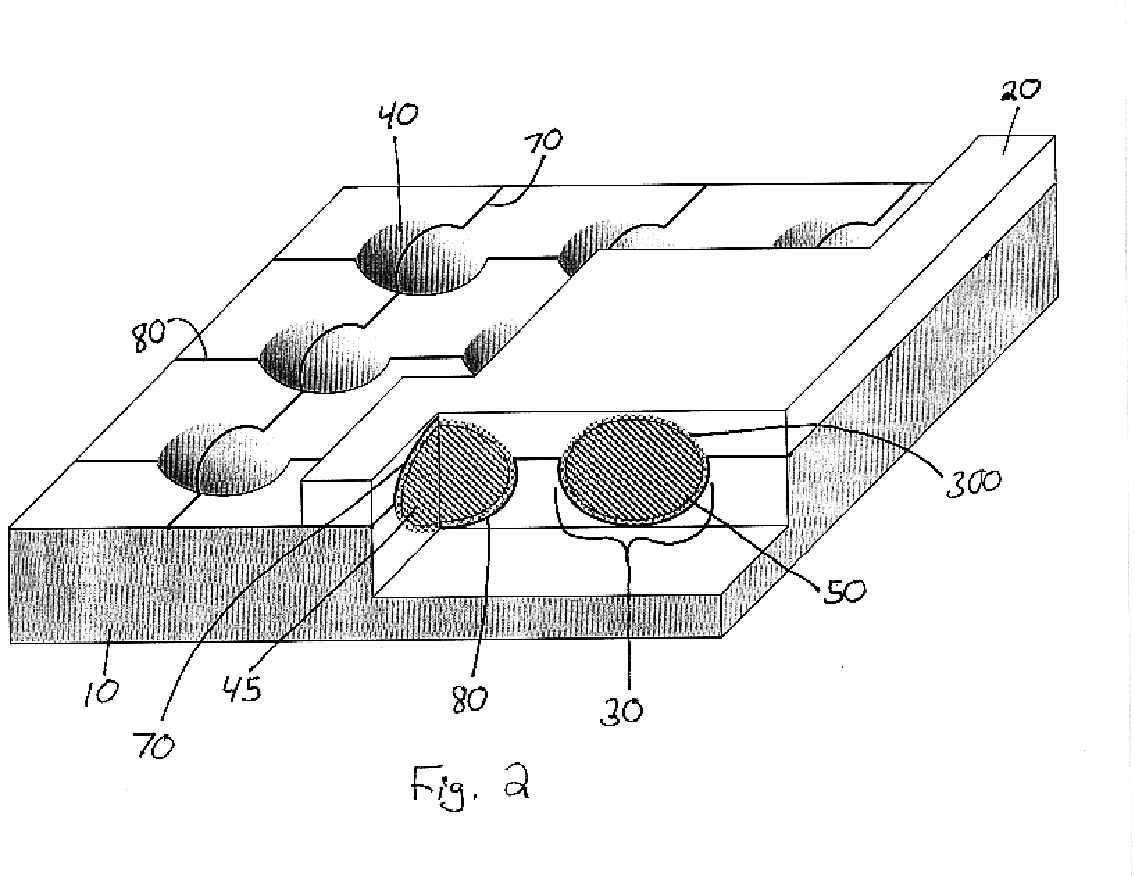

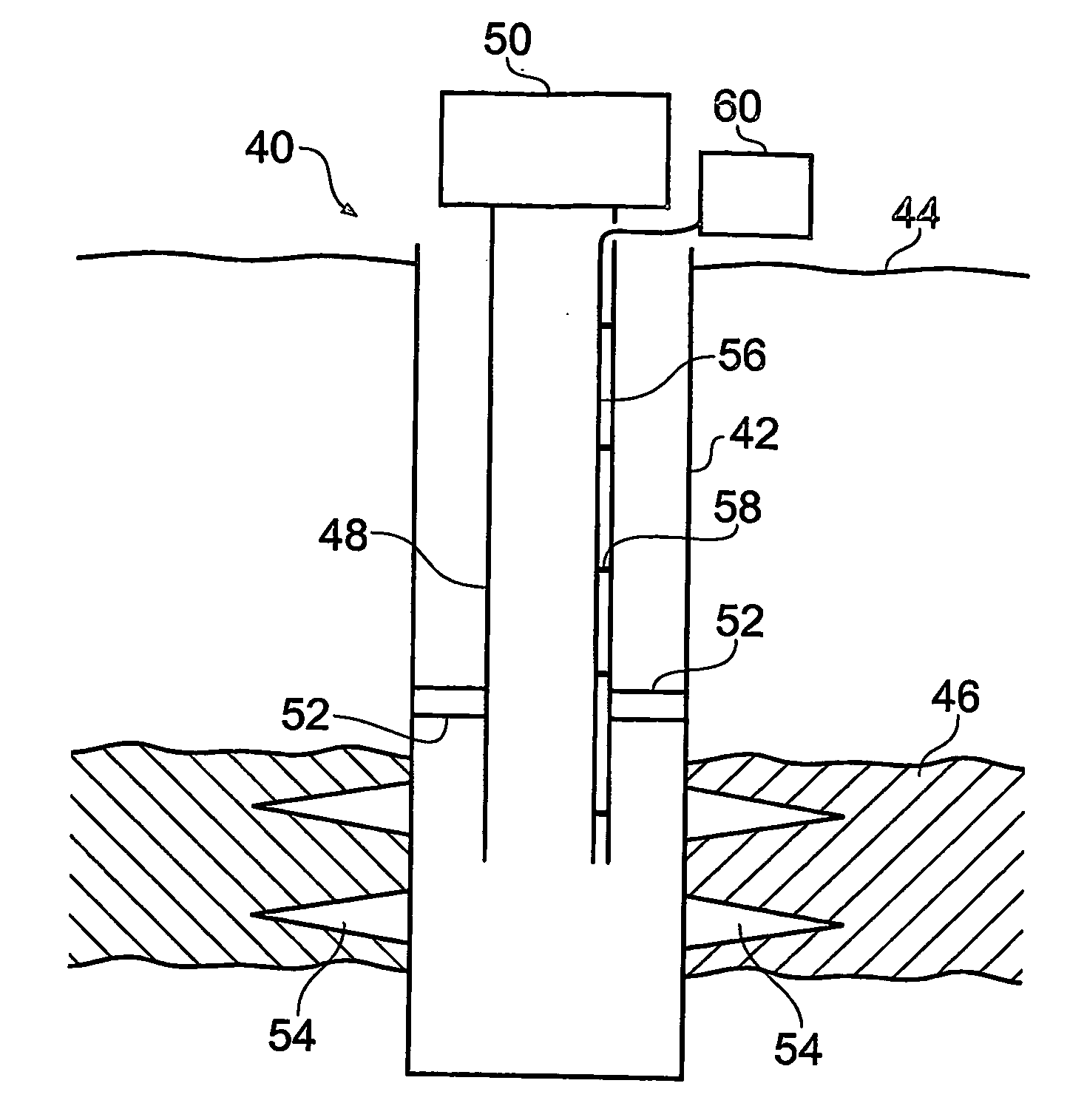

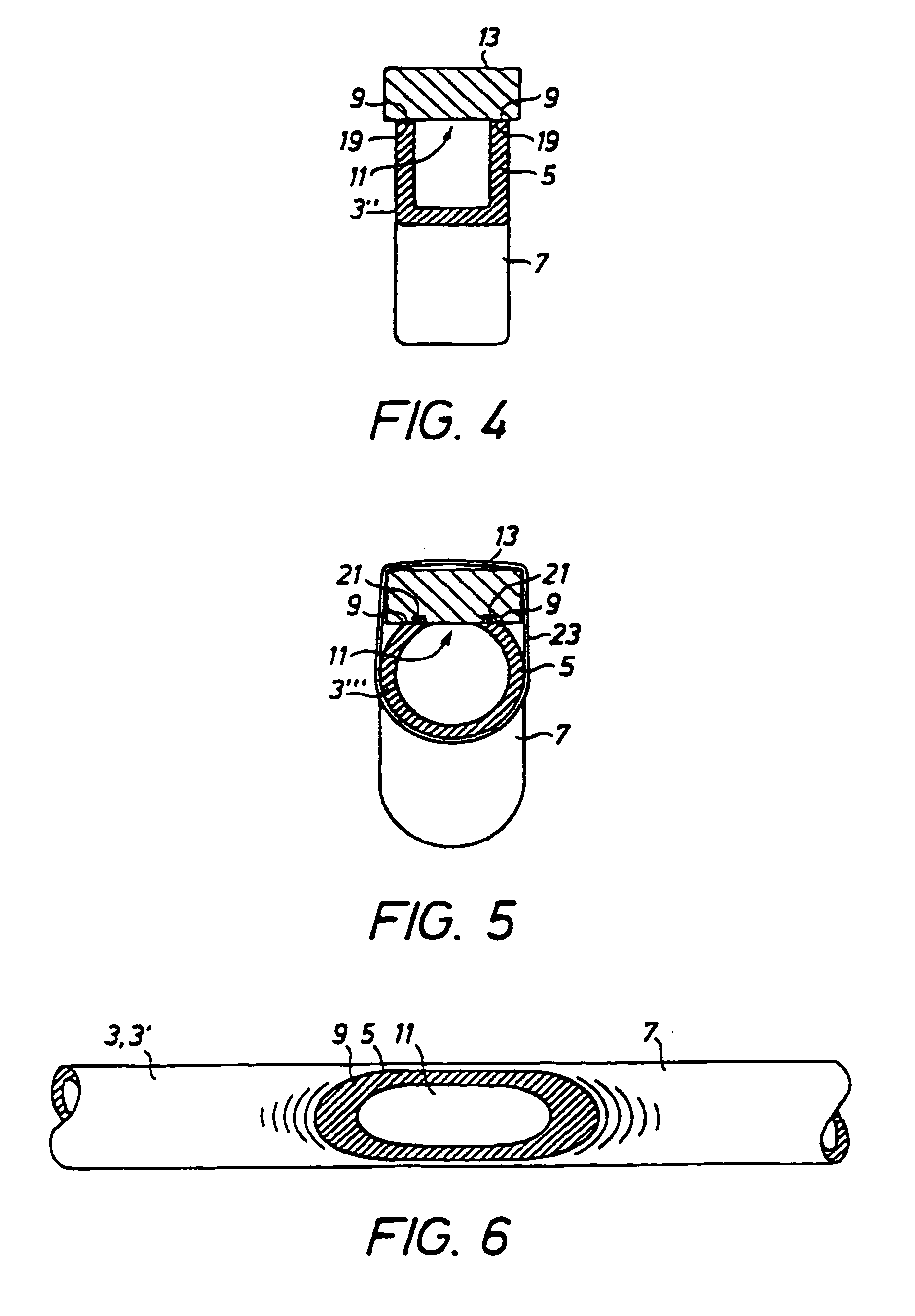

Method and Apparatus for Measuring Fluid Properties

InactiveUS20060010973A1Simple methodEnsure correct executionSurveyConstructionsThermal energyEngineering

A method of measuring fluid properties such as flow velocity, flow rate, and fluid composition comprises positioning a heat exchange element with a temperature sensor, such as an optical fiber temperature sensor, arranged centrally inside the element in thermal contact with a fluid of interest, heating or cooling the heat exchange element to cause a temperature difference and exchange of thermal energy between the element and the fluid, using the temperature sensor to measure the temperature of the heat exchange element during the exchange of thermal energy, and determining properties of the fluid from the temperature measurement. A second temperature sensor can be provided offset from the first sensor to provide additional measurements to improve accuracy, and a plurality of heat exchange elements with temperature sensors can be used together to determine fluid properties over a large region.

Owner:SCHLUMBERGER TECH CORP

Methods and systems for processing microscale devices for reuse

ActiveUS20050019213A1Effective flushingImprove efficiencyFixed microstructural devicesVolume/mass flow by thermal effectsBiomedical engineeringMicrofluidic chip

This invention provides methods and systems for flushing, washing, and priming microscale devices for reuse. Washing and priming methods include flowing solutions from a manifold to flush wells and microchannels of a microfluidic chip. Systems include manifolds adapted to seal and flow solutions or gasses into chip wells. Devices include microfluidic devices with data storage modules to track the reprocessing status of the microscale devices.

Owner:CAPLIPER LIFE SCI INC +1

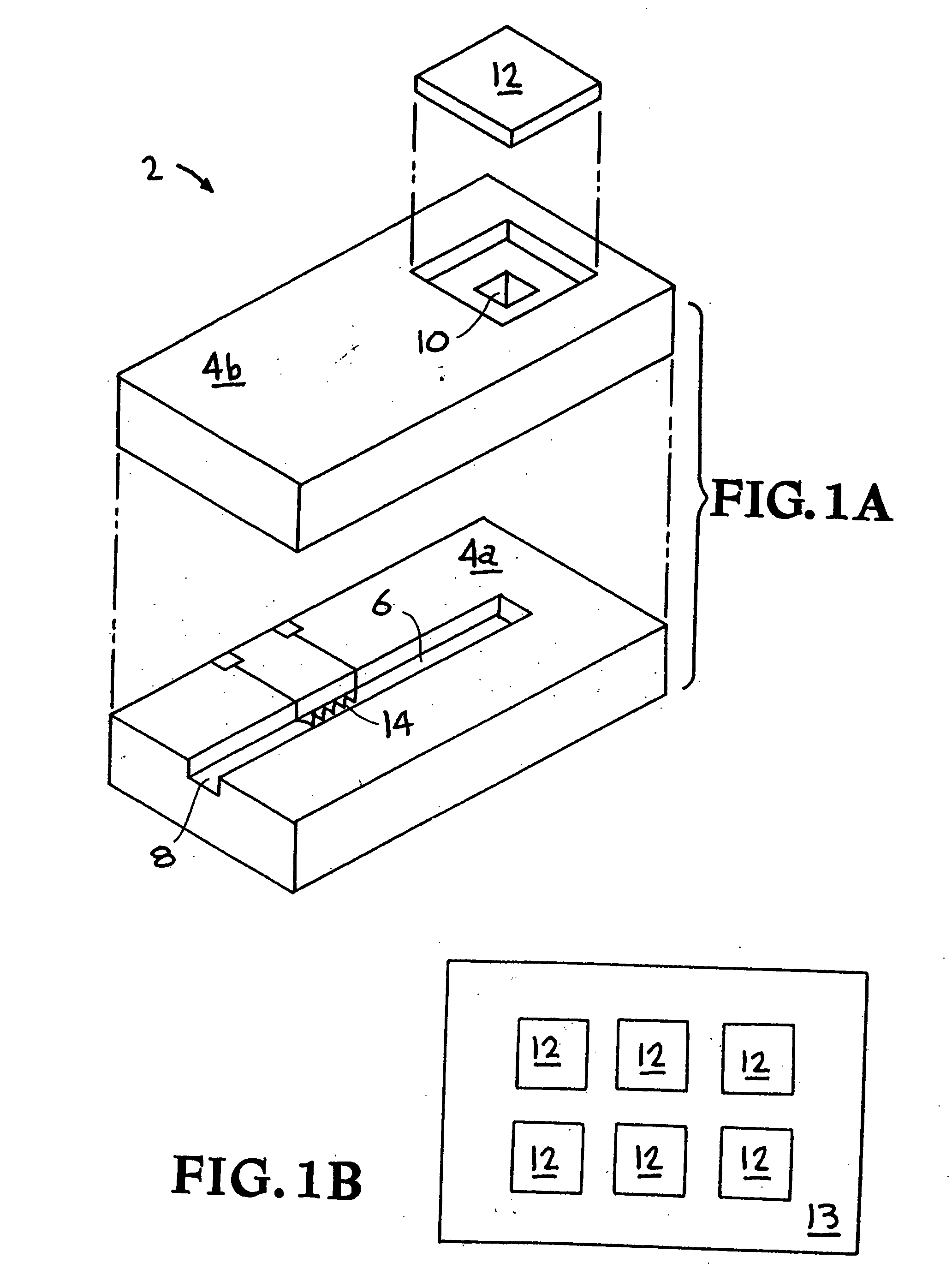

Method of forming a mold and molding a micro-device

A method of forming a device including a plurality of micron or sub-micron sized features is provided. A master having a surface contour defining a plurality of features is provided. The surface contour of the master is coated with at least one layer of material to form a shell. The master is removed from the shell to form a negative image of the surface contour in the shell. The negative image in the shell is filled with material, for example, polycarbonate, polyacrylic, or polystyrene, to form a device having features substantially the same as the master. The negative image may be filled using injection molding, compression molding, embossing or any other compatible technique.

Owner:BECTON DICKINSON & CO

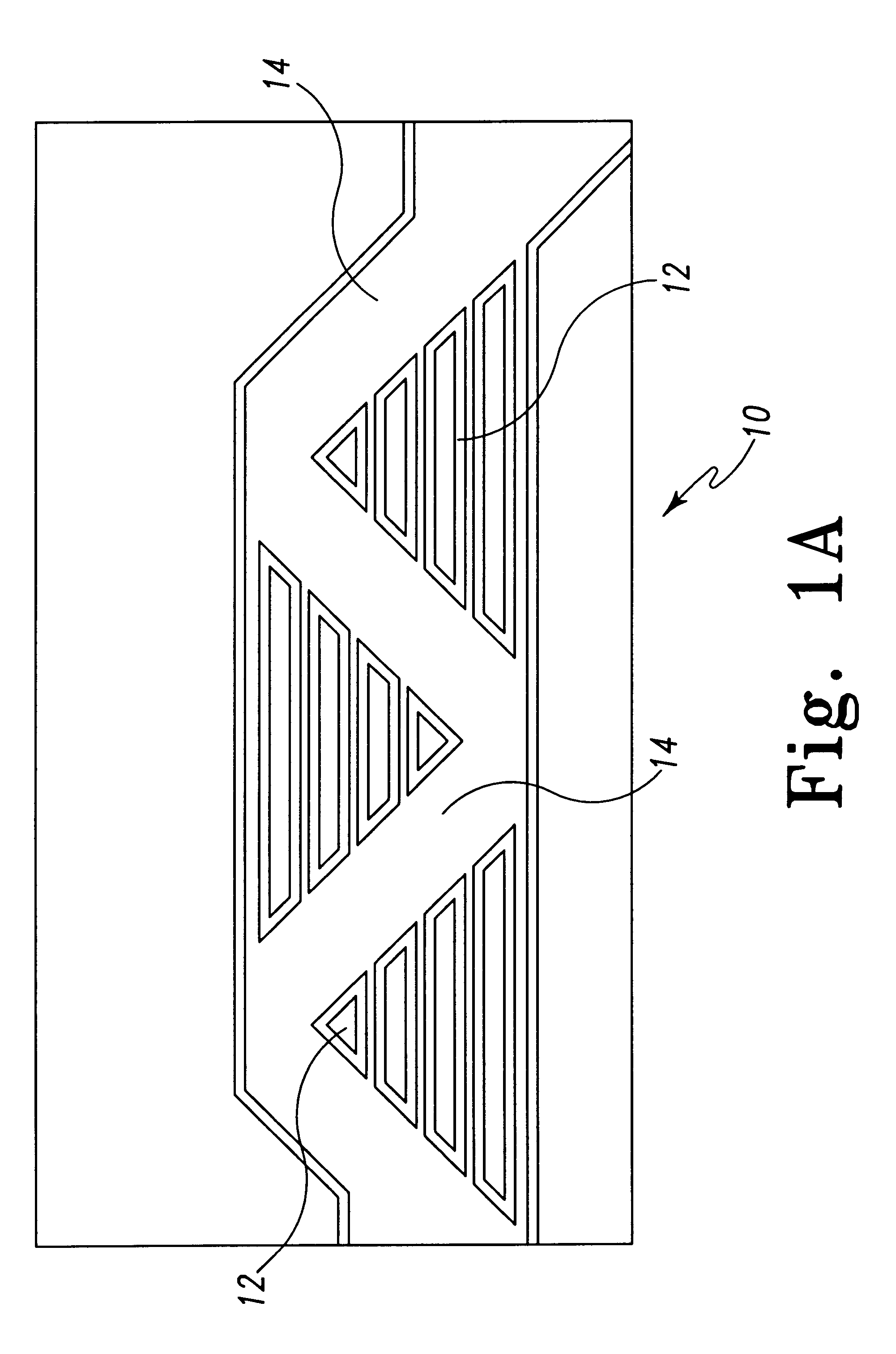

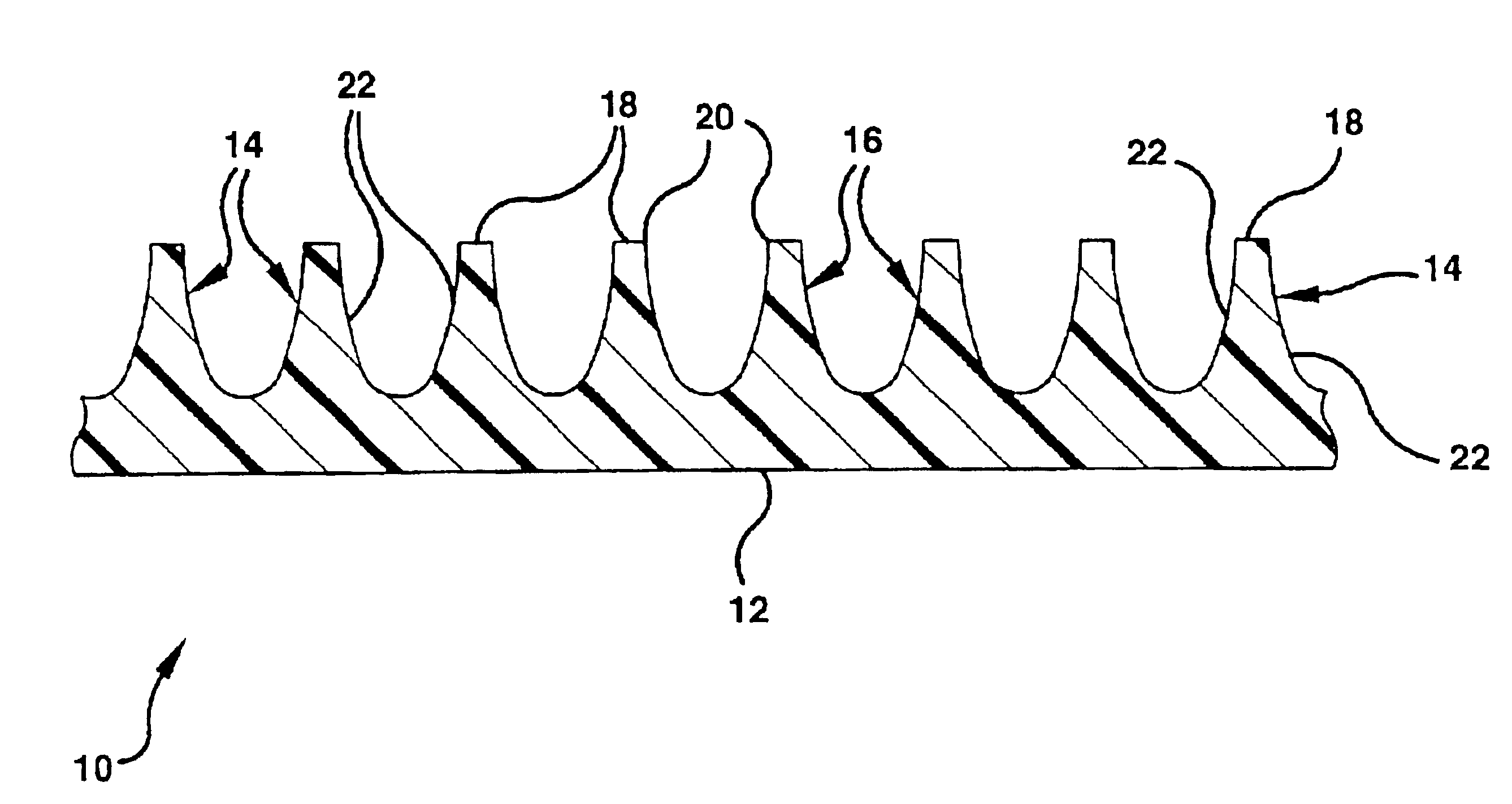

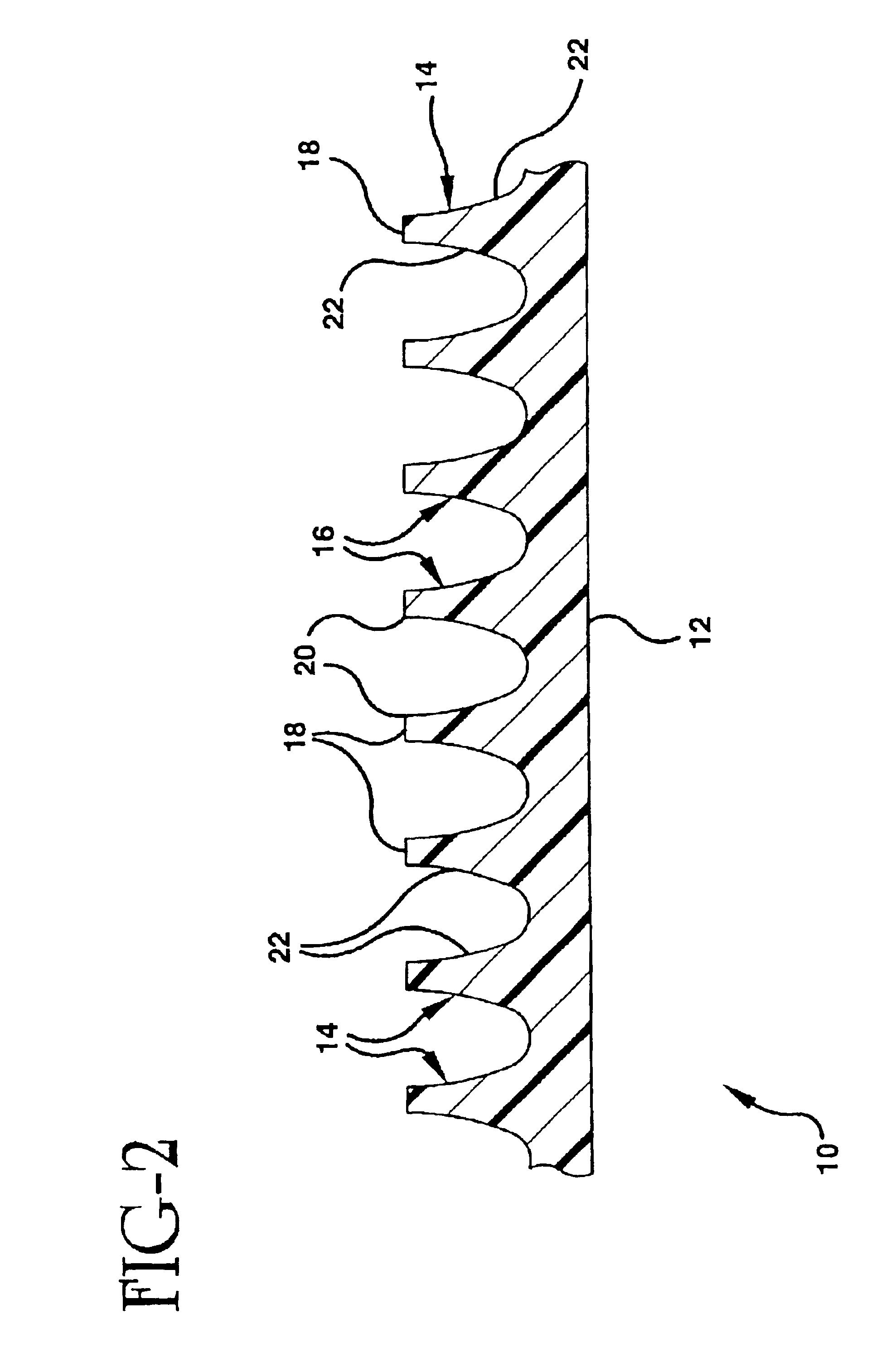

Micro-component for use in a light-emitting panel

InactiveUS6762566B1Sufficient resolutionManufactured very thinMechanical apparatusVolume/mass flow by thermal effectsEngineeringImproved method

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. Several improved methods of forming micro-components are also disclosed.

Owner:LEIDOS

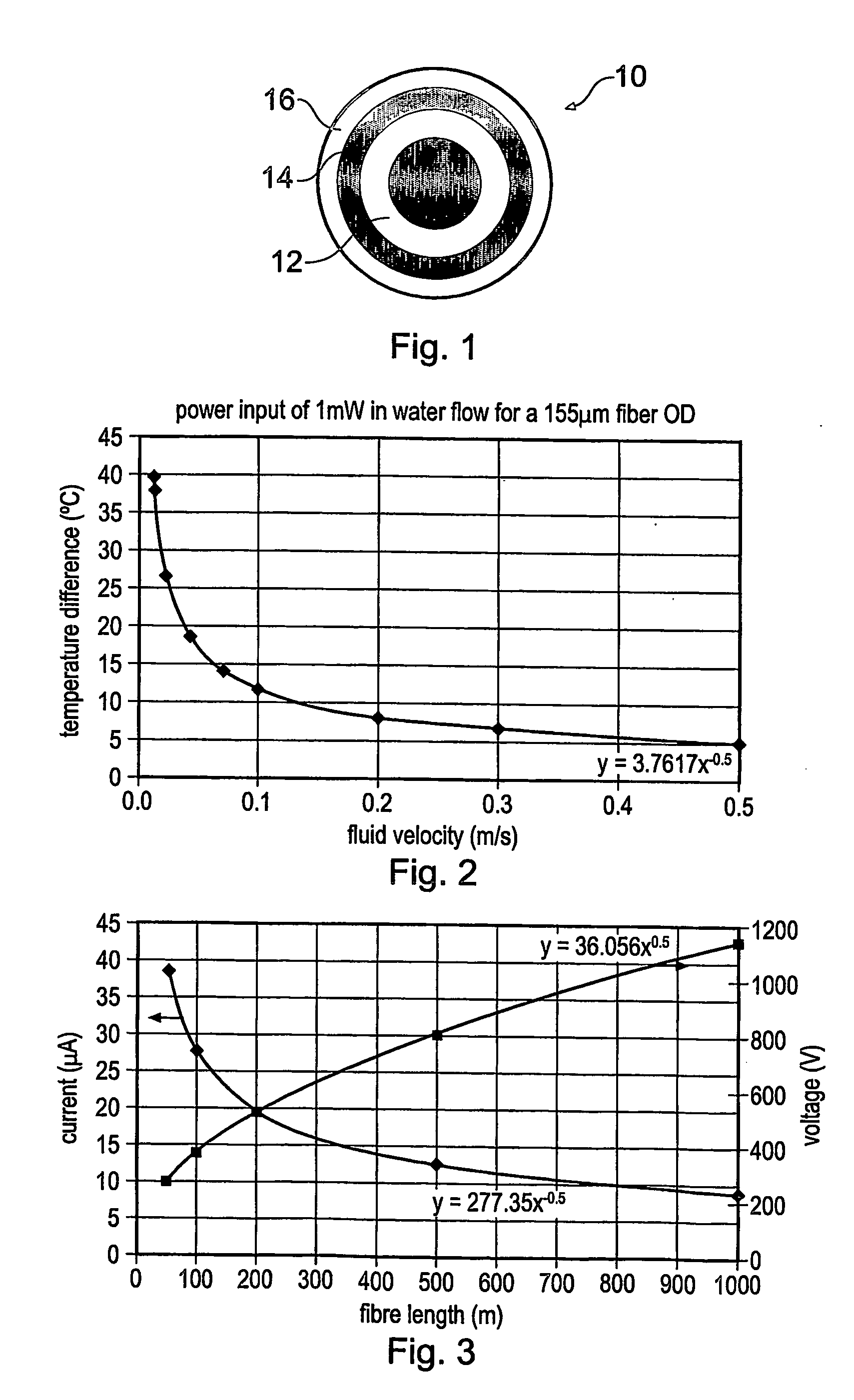

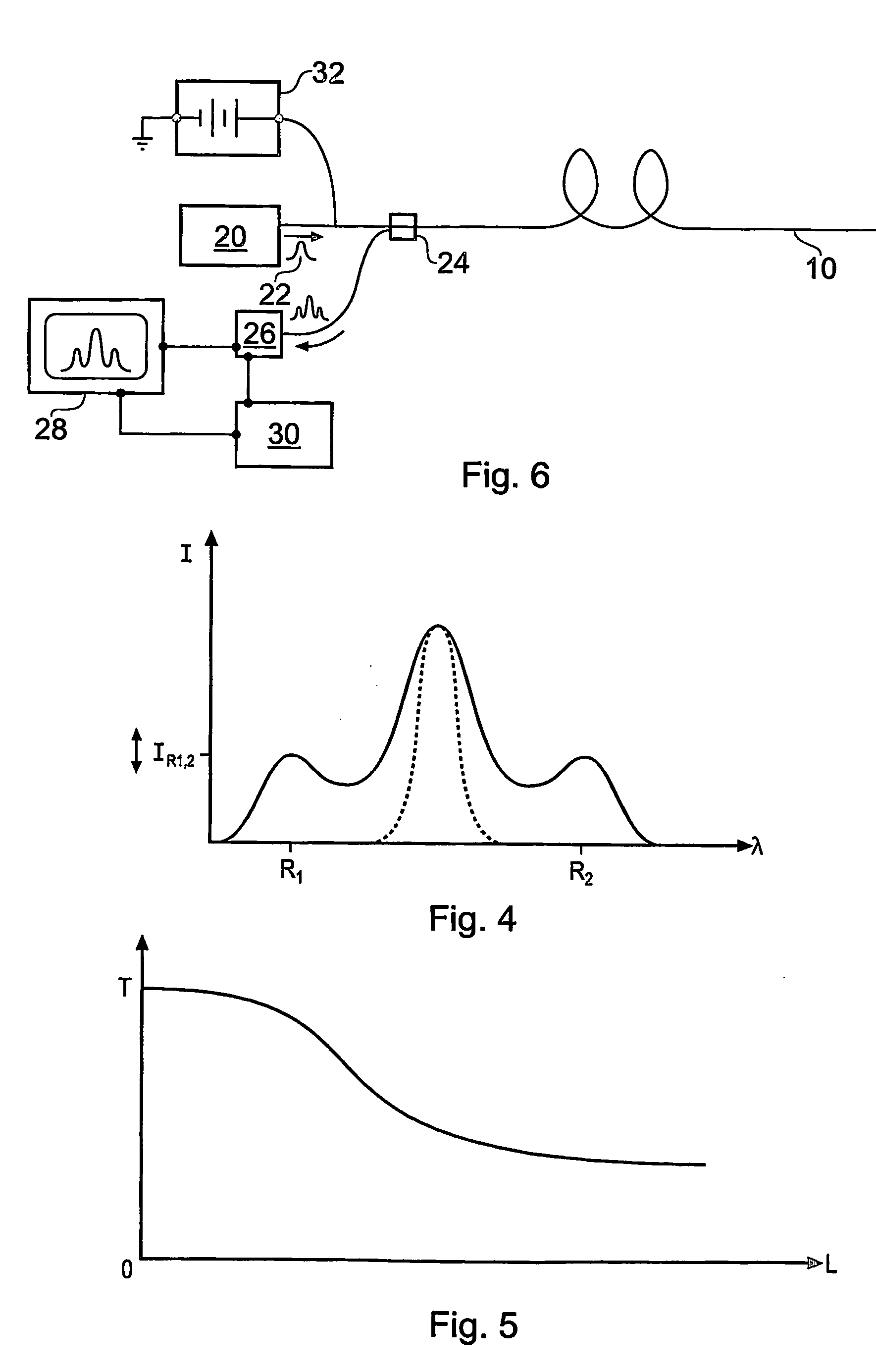

Fluid flow measurement using optical fibres

InactiveUS20060214098A1Easy to manufactureConvenient ArrangementSurveyConstructionsFiberElectrical resistance and conductance

A method of monitoring fluid flow uses an optical fibre having a heatable coating. The fibre is disposed within flowing fluid, and the heatable coating heated so that heat is transferred from the coating to the fluid. Optical measurements of the temperature of the heatable coating are made, where the temperature of the heatable coating depends on the flow velocity of the flowing fluid, and the temperature measurement is used to derive information about the flow. The coating may be an electrically resistive layer on the outer surface of the fibre, that is heated by passing electric current through it. This allows distributed flow measurements to be made. Alternatively, discrete measurements can be made if the coating is provided as a thin film layer on an end facet of the fibre. The coating is heated by directing light at a wavelength absorbed by the thin film material along the fibre.

Owner:SCHLUMBERGER TECH CORP

Arrangement for measuring a property of a fluid present in a tube

InactiveUS7168334B1Readily brought into direct contactSimple andVolume/mass flow by thermal effectsFluid pressure measurement by mechanical elementsEngineering

Owner:GAMBRO LUNDIA AB

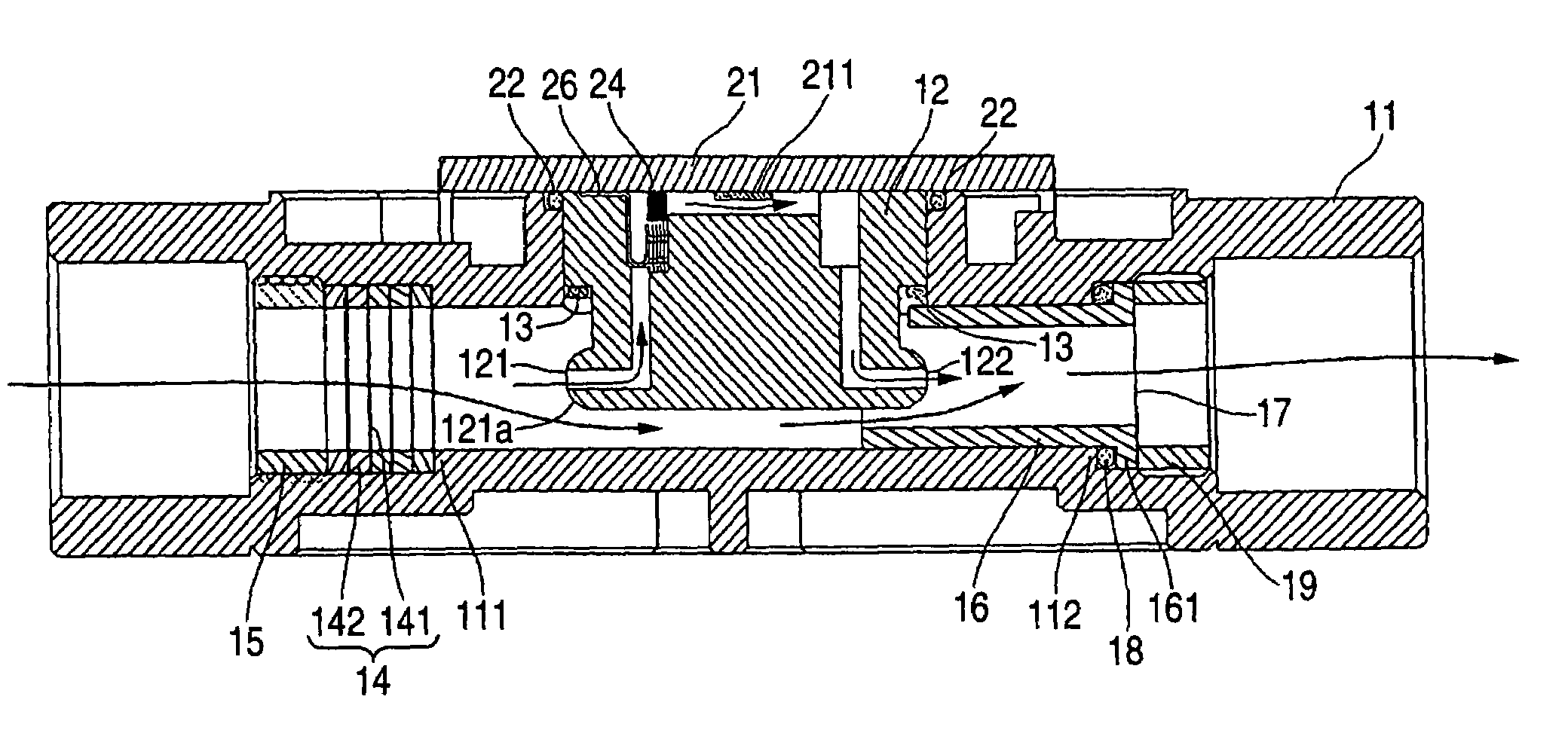

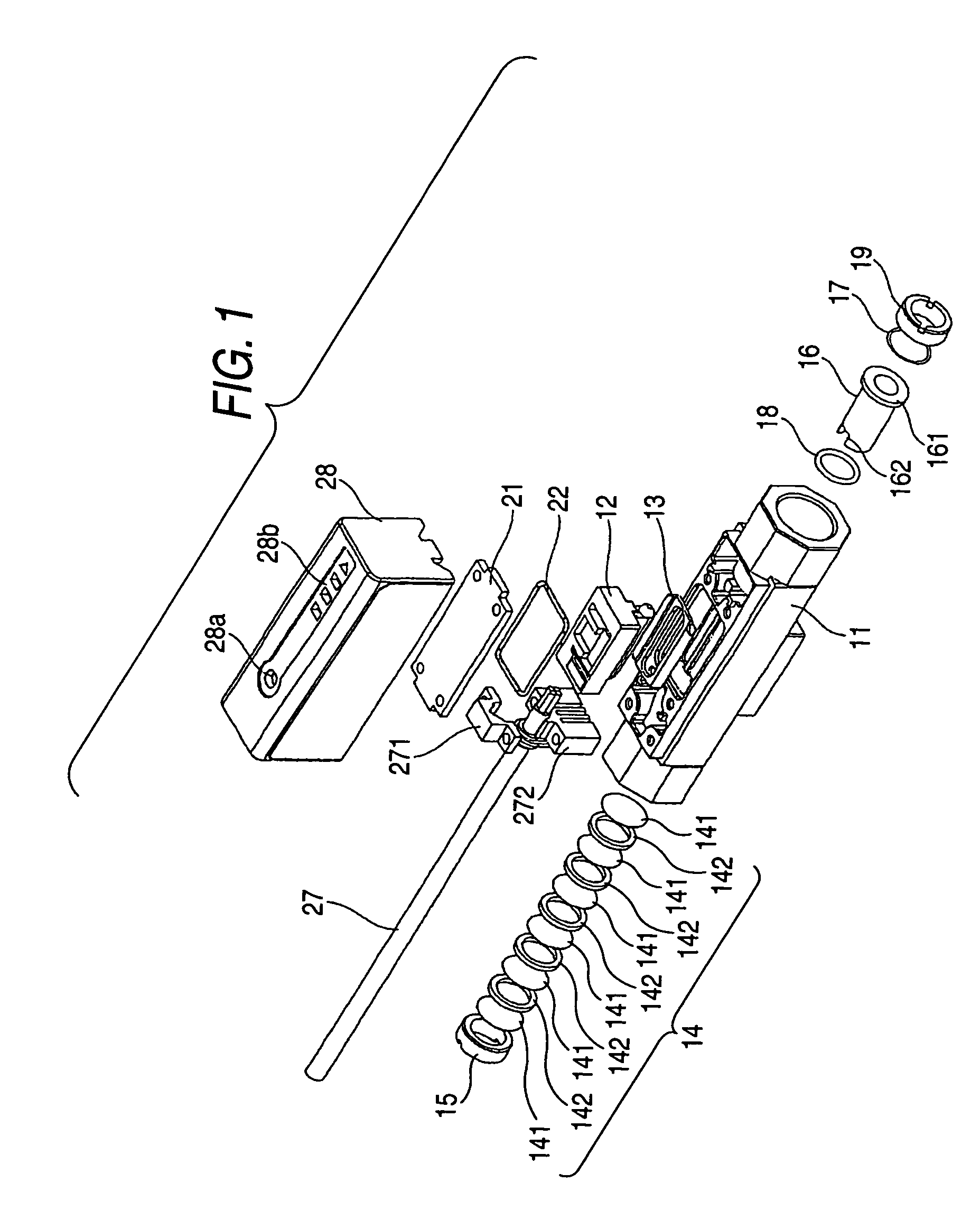

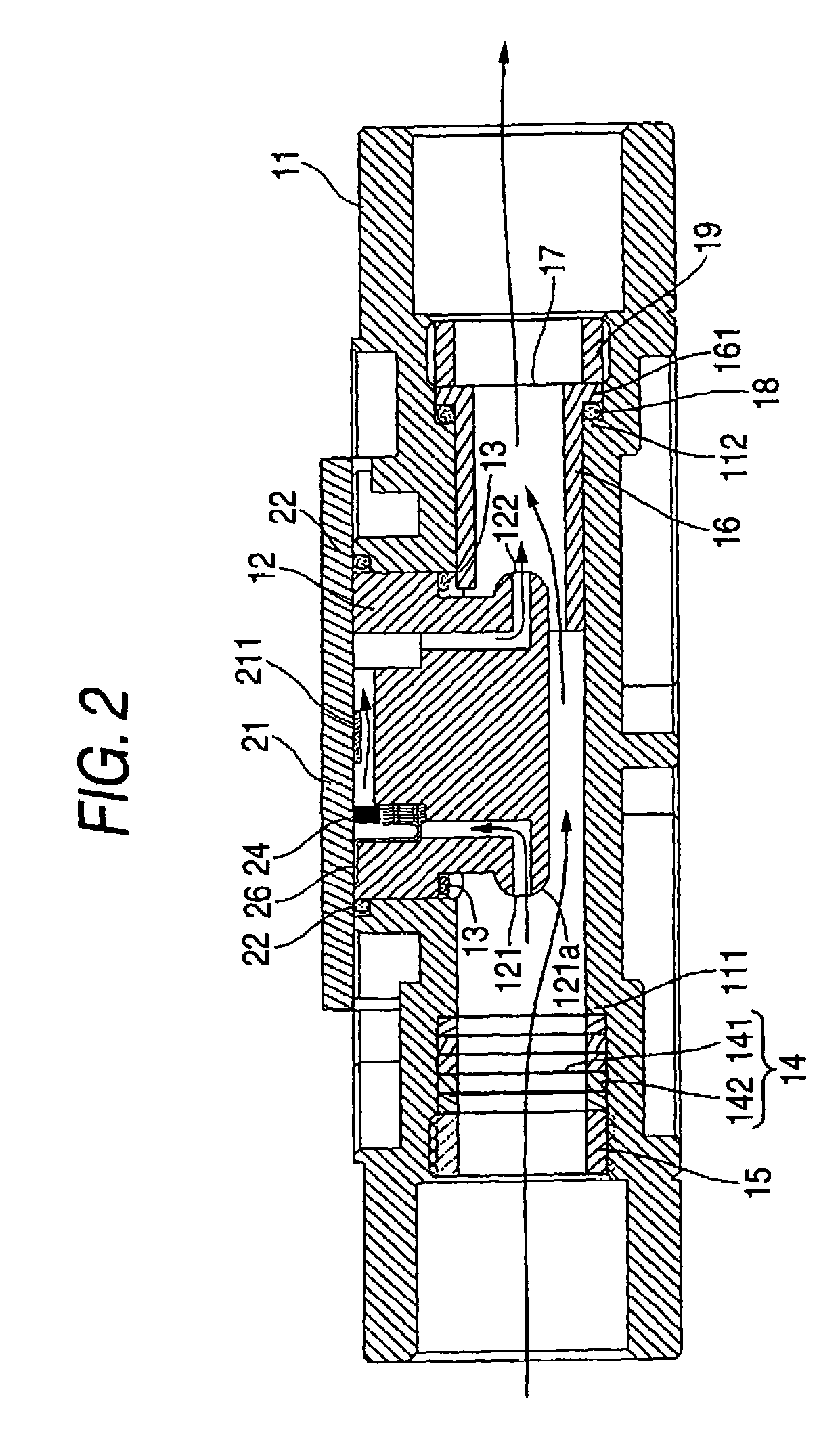

Split-flow-type flow sensor device

InactiveUS7059184B2Low costImprove accuracyVolume/mass flow by thermal effectsVolume flow proportion measurementMechanical engineeringEngineering

Owner:KEYENCE

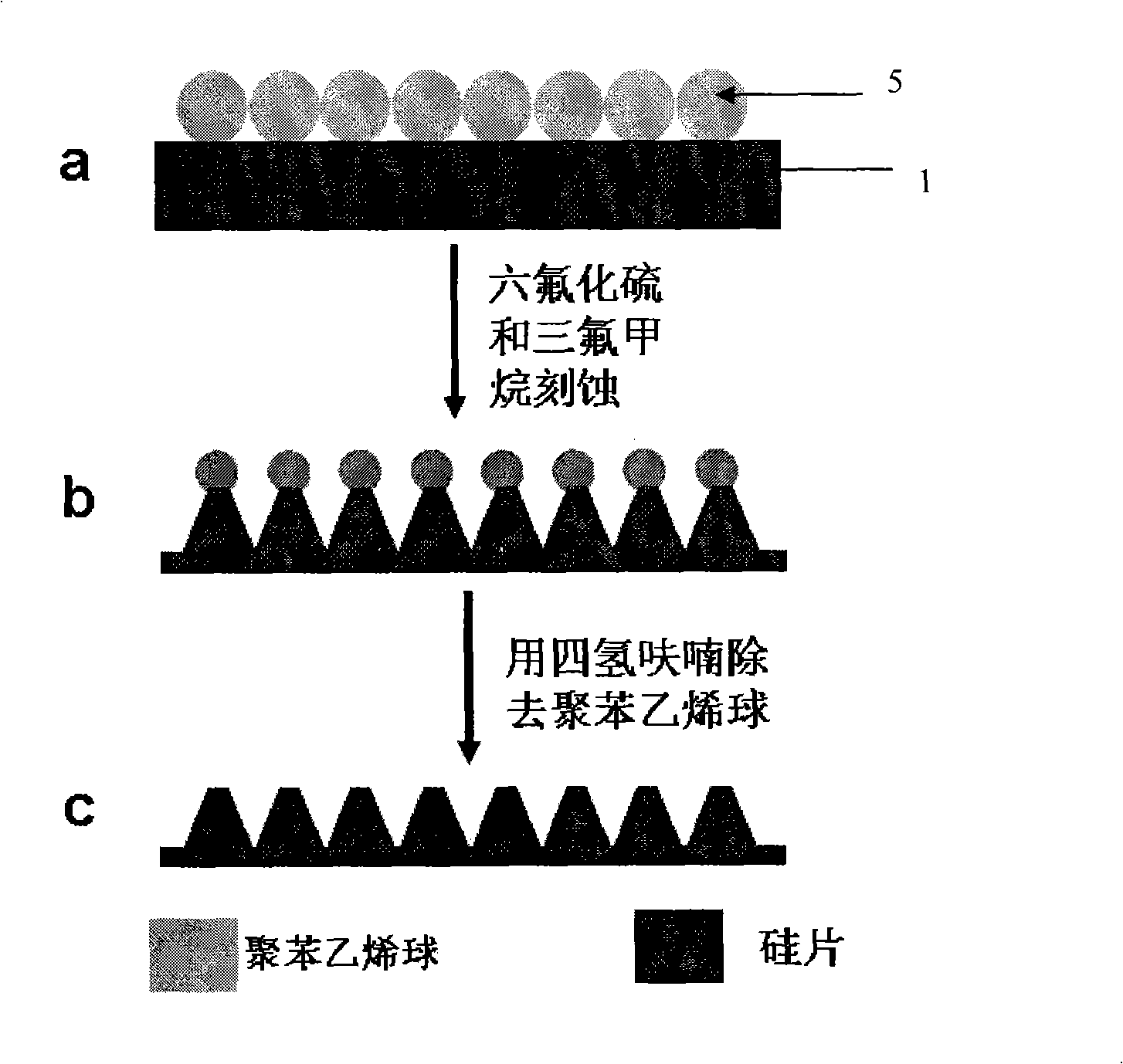

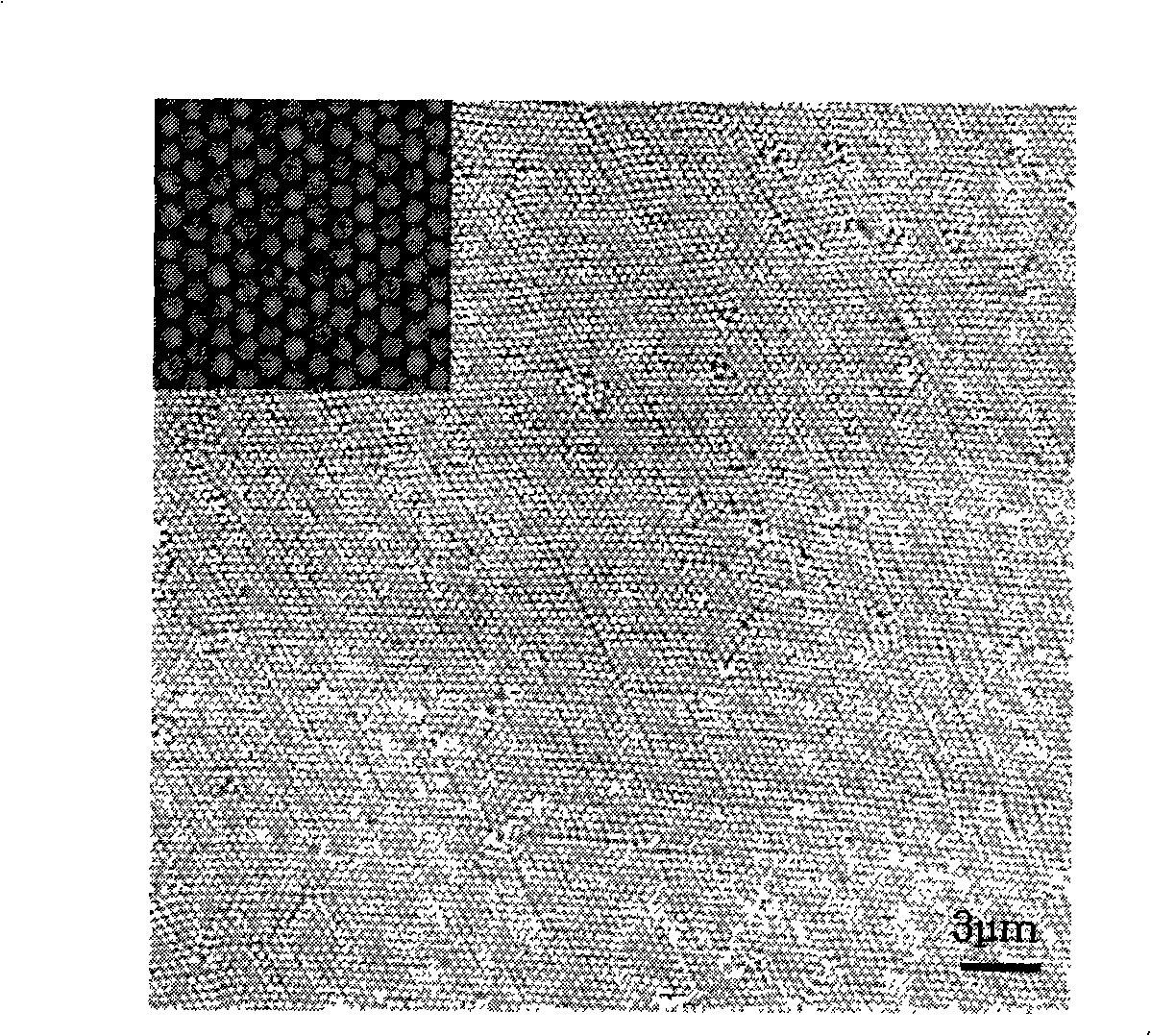

Method for constructing anti-reflection microstructure using single layer nanometer particle as etching blocking layer

InactiveCN101308219ASimple methodBase variableSemi-permeable membranesVolume/mass flow by thermal effectsSurface patternLight energy

The invention belongs to the surface patterning microstructure construction technique, which relates to a method for constructing a microstructure with anti-reflection performance on a foundation base by combining the self-assembly technique with the reactive ion beam etching technique. The method is to take monolayer polymeric micro-spheres, silicon dioxide micro-spheres and nano-particles of metal or metal oxides as a barrier layer and implement the RIE etching to the foundation base, then an approximate cone-shaped microstructure is constructed on the foundation base, and the structure has extreme high anti-reflection performance, thereby effectively improving the light energy utilization rate, reducing the interference of veiling glare in an optical system, increasing the optical transmittance, and further improving the sensitivity and stability of the optical system, and the method can be used for constructing large-area anti-reflection structures. The method of the invention has advantages of simple operation, changeable foundation base, strong applicability, good repeatability, low cost, high efficiency, adjustable anti-reflective applied wavelength and conformity to industrialized standards, and can be used for making photoelectric devices such as solar batteries and white light sensors.

Owner:JILIN UNIV

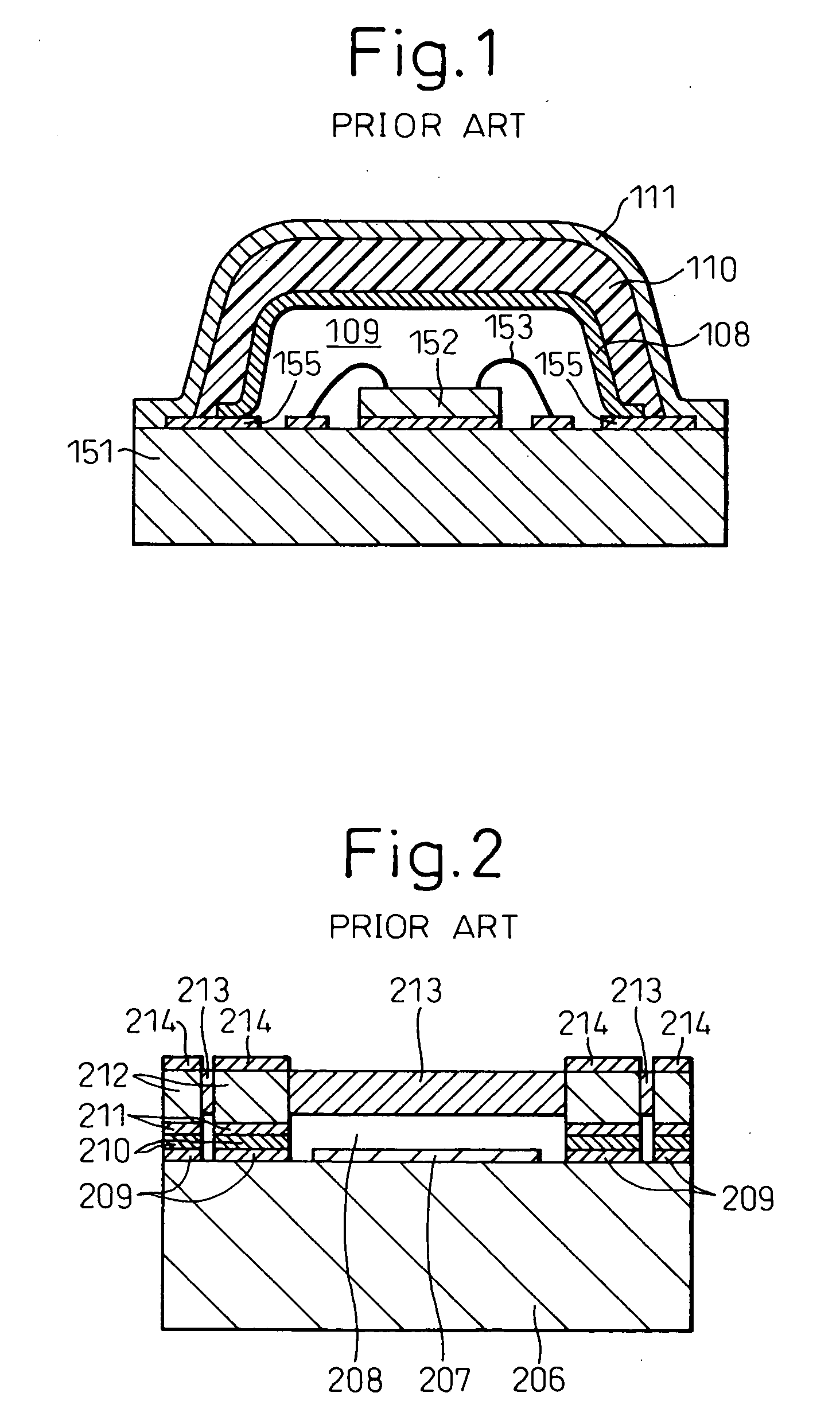

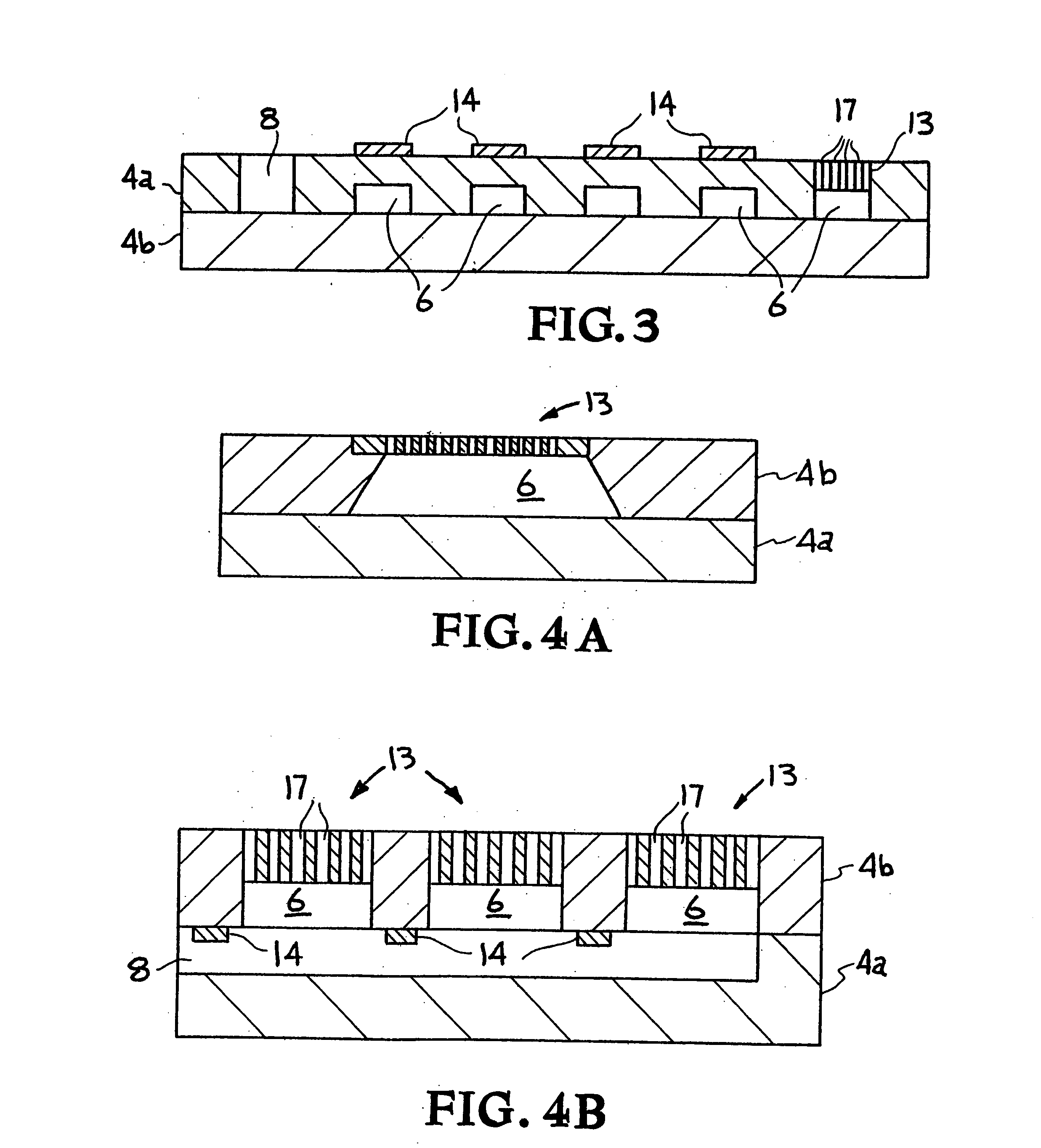

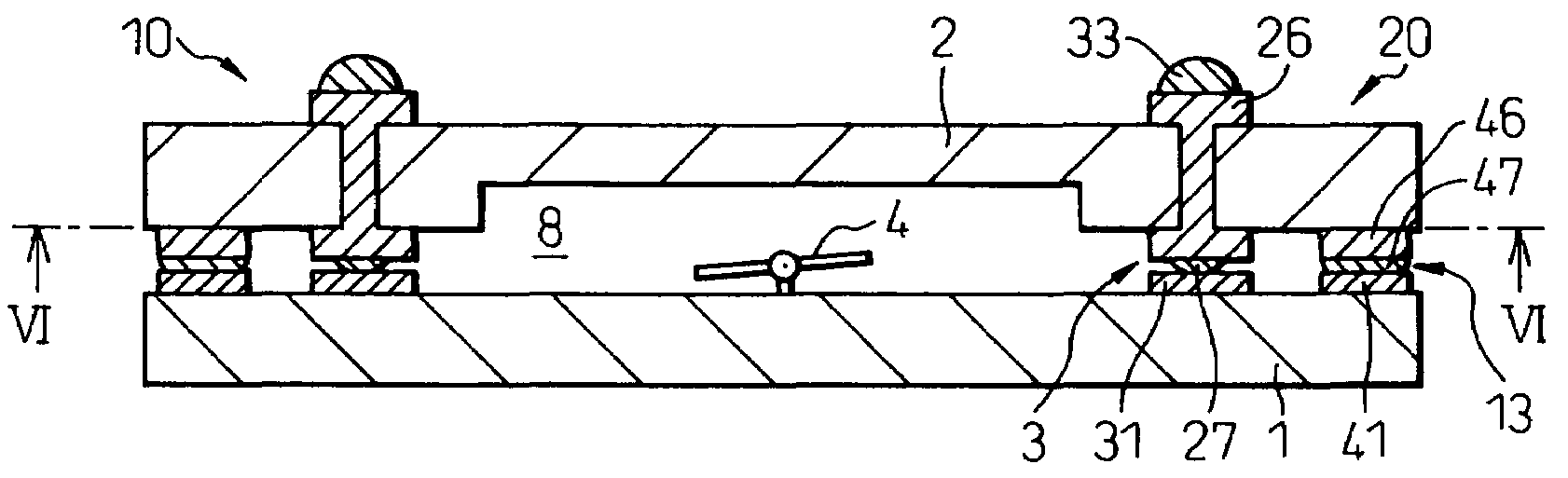

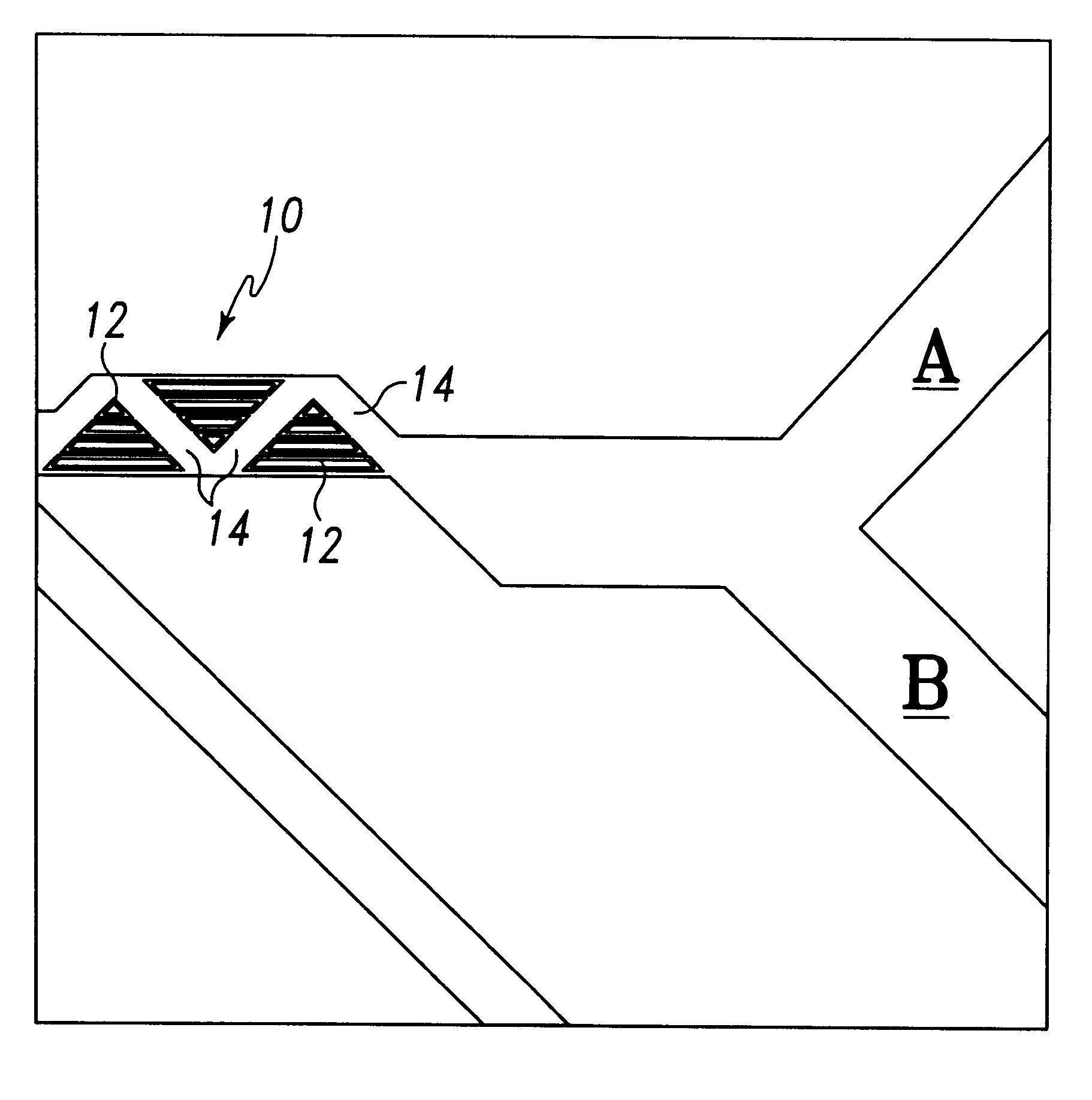

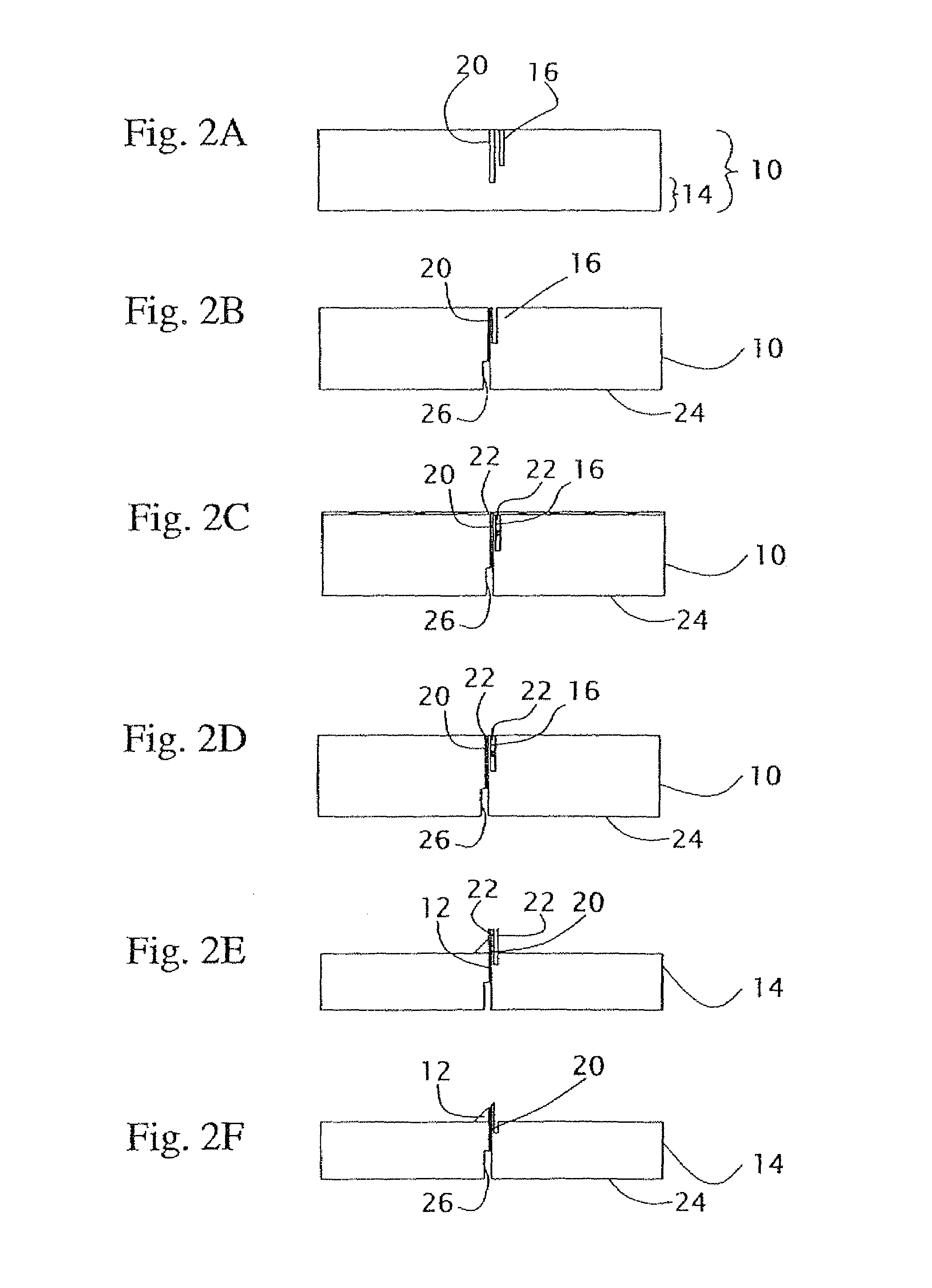

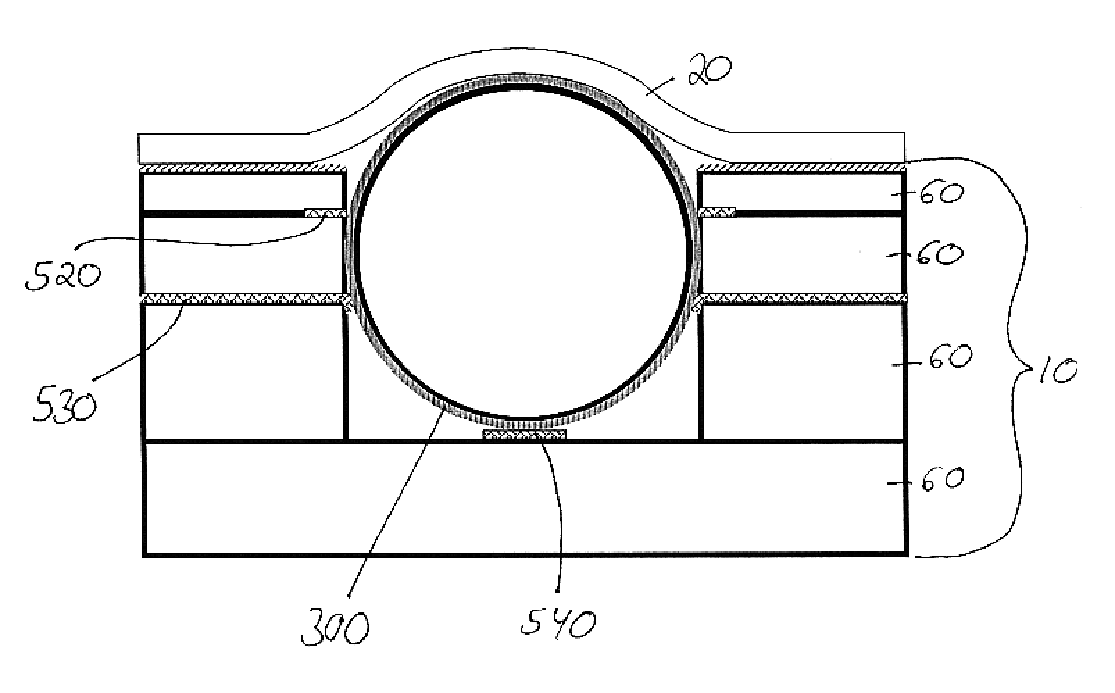

Hermatic firewall for MEMS packaging in flip-chip bonded geometry

InactiveUS6400009B1Easy to implementEffective protectionSemi-permeable membranesFixed microstructural devicesCMOSHermetic seal

A package for hermetically sealing a micro-electromechanical systems (MEMS) device in a hybrid circuit comprise a firewall formed on a substrate for the MEMS device and which has a height defining a cavity of the package in which the MEMS device will be sealed. A second substrate spaced from the first substrate hermetically seals the cavity when the second substrate is flip-chip bonded to the first substrate and soldered to the first substrate with a thin film metal material placed on at least a top portion of the firewall. The resulting firewall MEMS device package can be further packaged using conventional CMOS packaging techniques. By hermetically sealing the cavity, the enclosed MEMS device is protected from deleterious conditions found in the environment of conventional CMOS packaging techniques which is often detrimental to MEMS device function.

Owner:LUCENT TECH INC

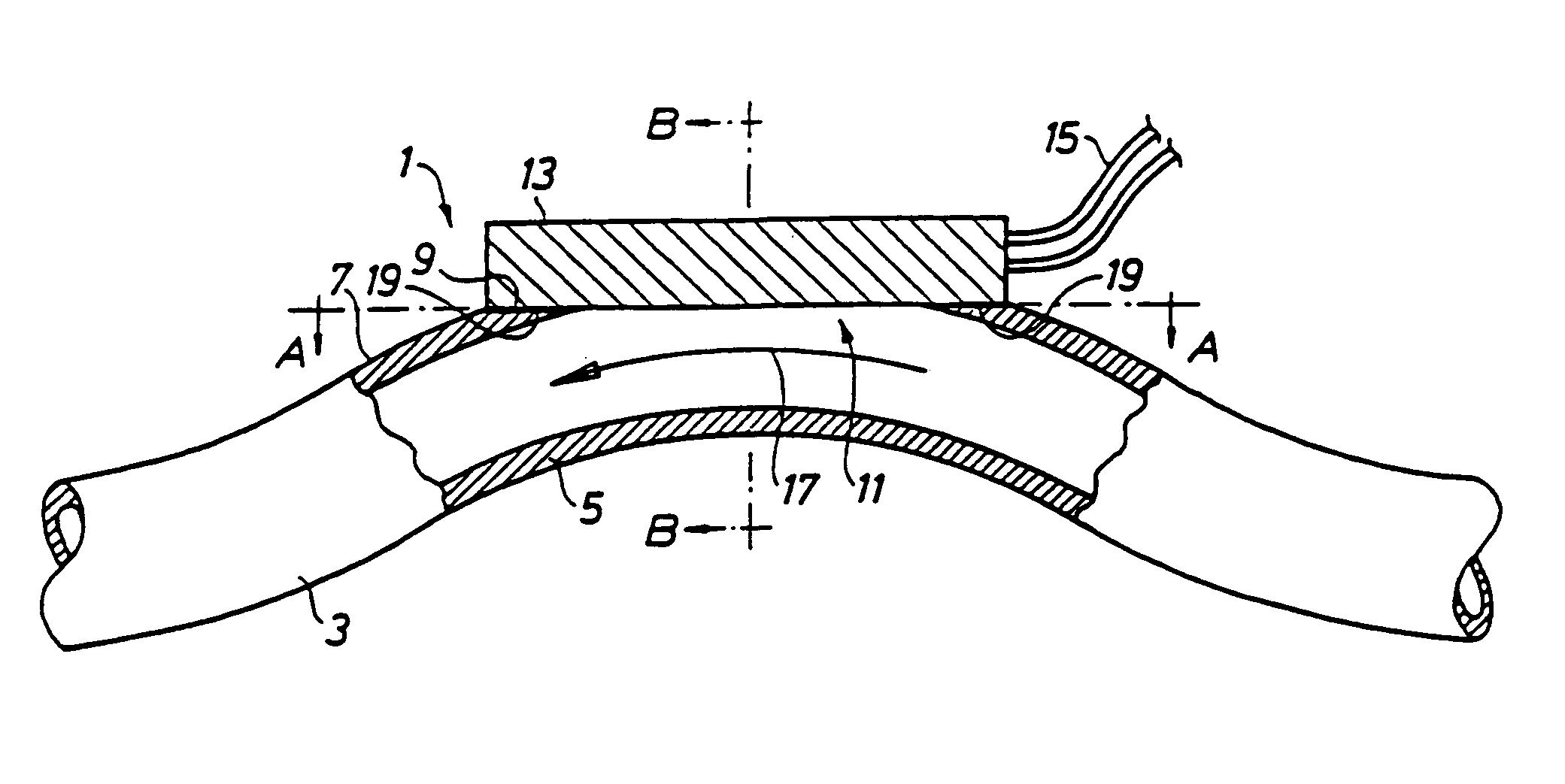

System for sensing the motion or pressure of a fluid, the system having dimensions less than 1.5 inches, a metal lead frame with a coefficient of thermal expansion that is less than that of the body, or two rtds and a heat source

InactiveUS6591674B2Volume/mass flow by thermal effectsFluid pressure measurementElectricityElectrical resistance and conductance

A system for sensing or measuring the motion of a fluid such as air. The system typically has a two-part plastic body containing an internal flow passage. The parts of the body may snap together or attach with an adhesive. A transducer or an electronic sensor is typically located within the flow passage, which may measure mass flow rate and may have two resistive thermal devices (RTDs) located on either side of a heat source. The body may have two elongated port tubes configured to attach to tubing. The port tubes may contain venturis, and may be substantially straight and substantially parallel, forming a U shape. A metal lead frame may be provided in electrical communication with the sensor. The lead frame may be integrally molded within the body, and may have a lower coefficient of thermal expansion than the body. The internal flow passage and the sensor may be substantially symmetrical and measure the flow rate of the fluid substantially equally in either flow direction. The system may be configured for surface mounting or for through-hole mounting, and may be a dual in-line type.

Owner:HONEYWELL INT INC

Thermal Flow Meter

ActiveUS20100116048A1Volume/mass flow by thermal effectsSuction devicesThermodynamicsPhase difference

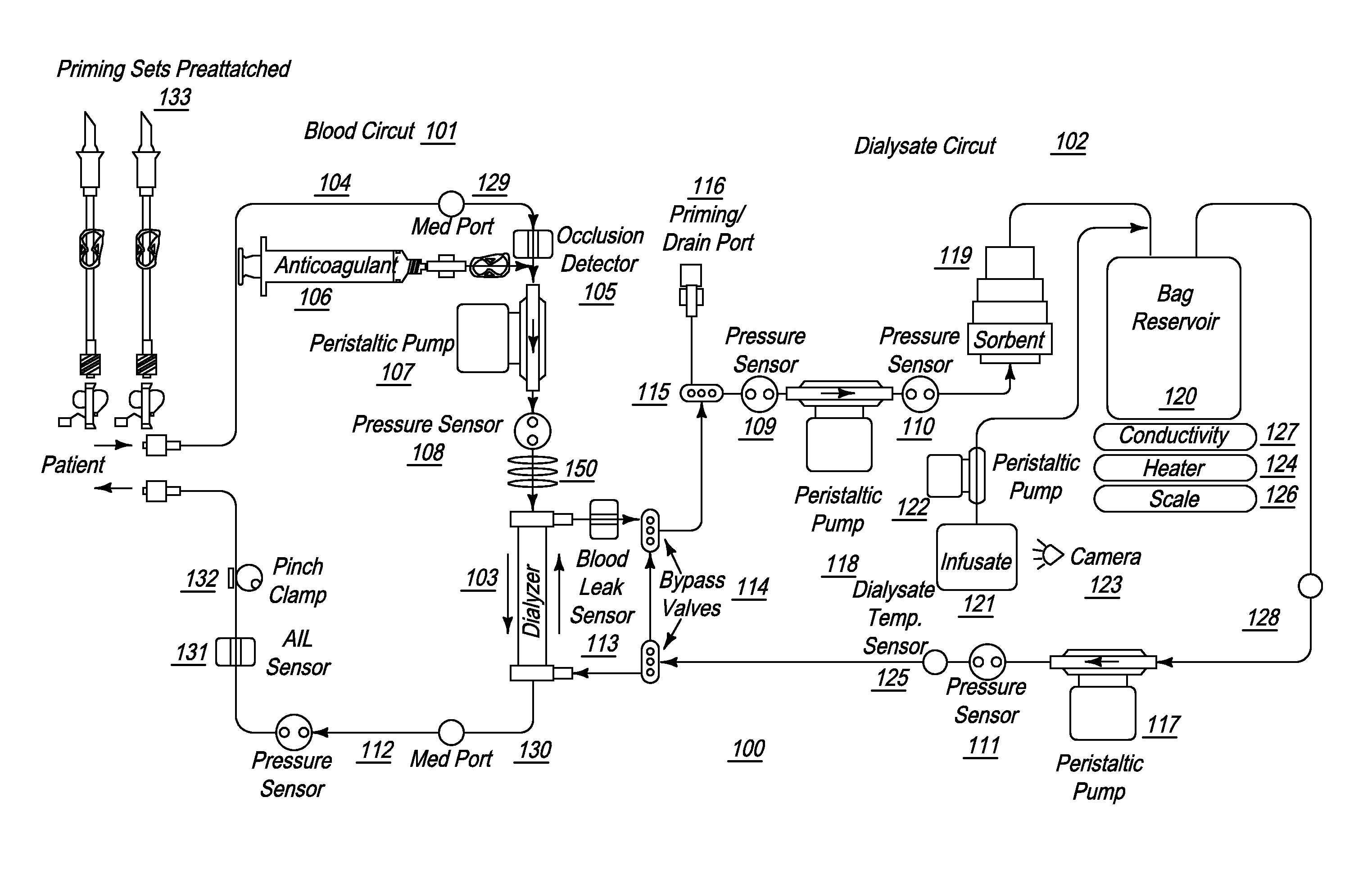

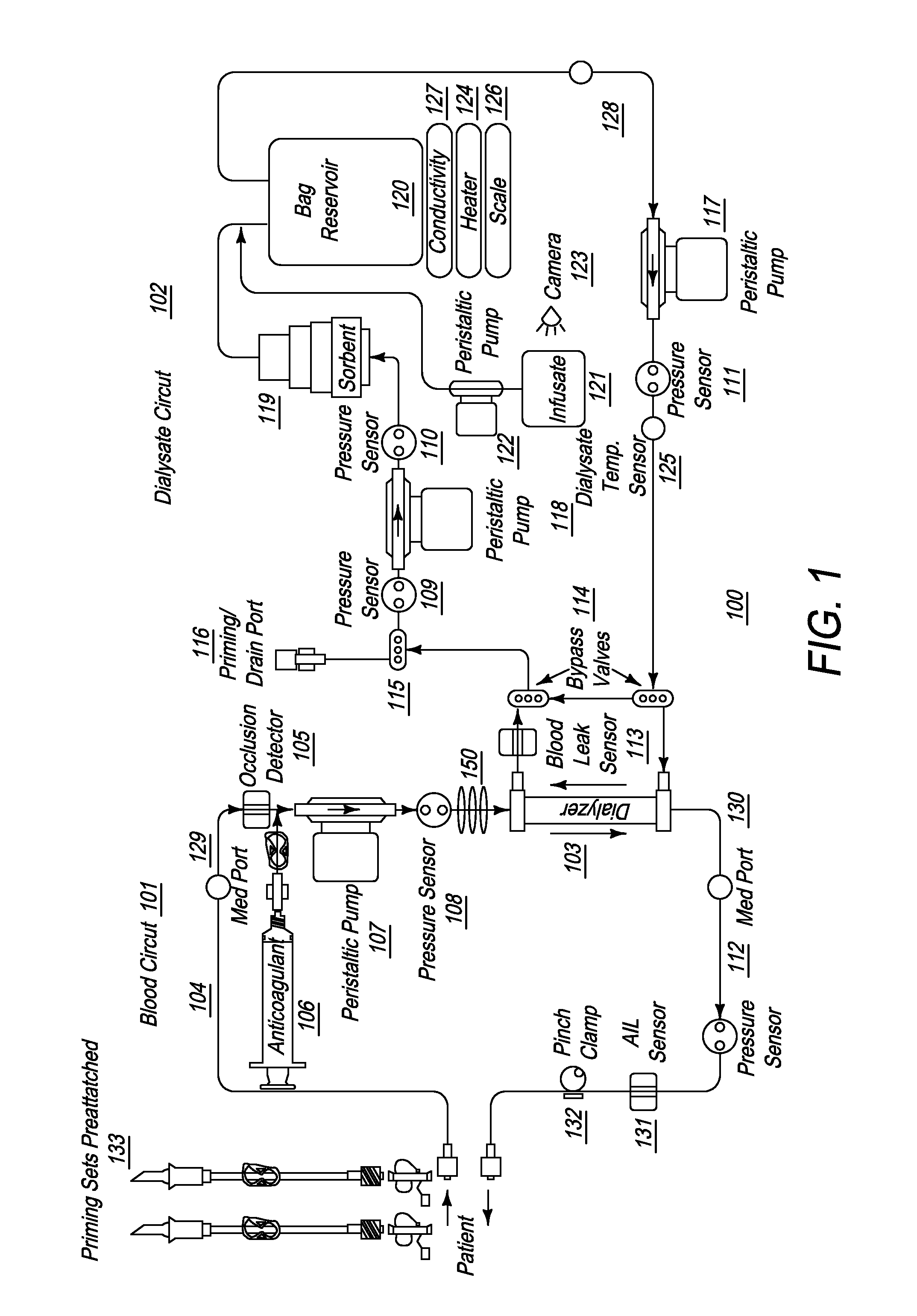

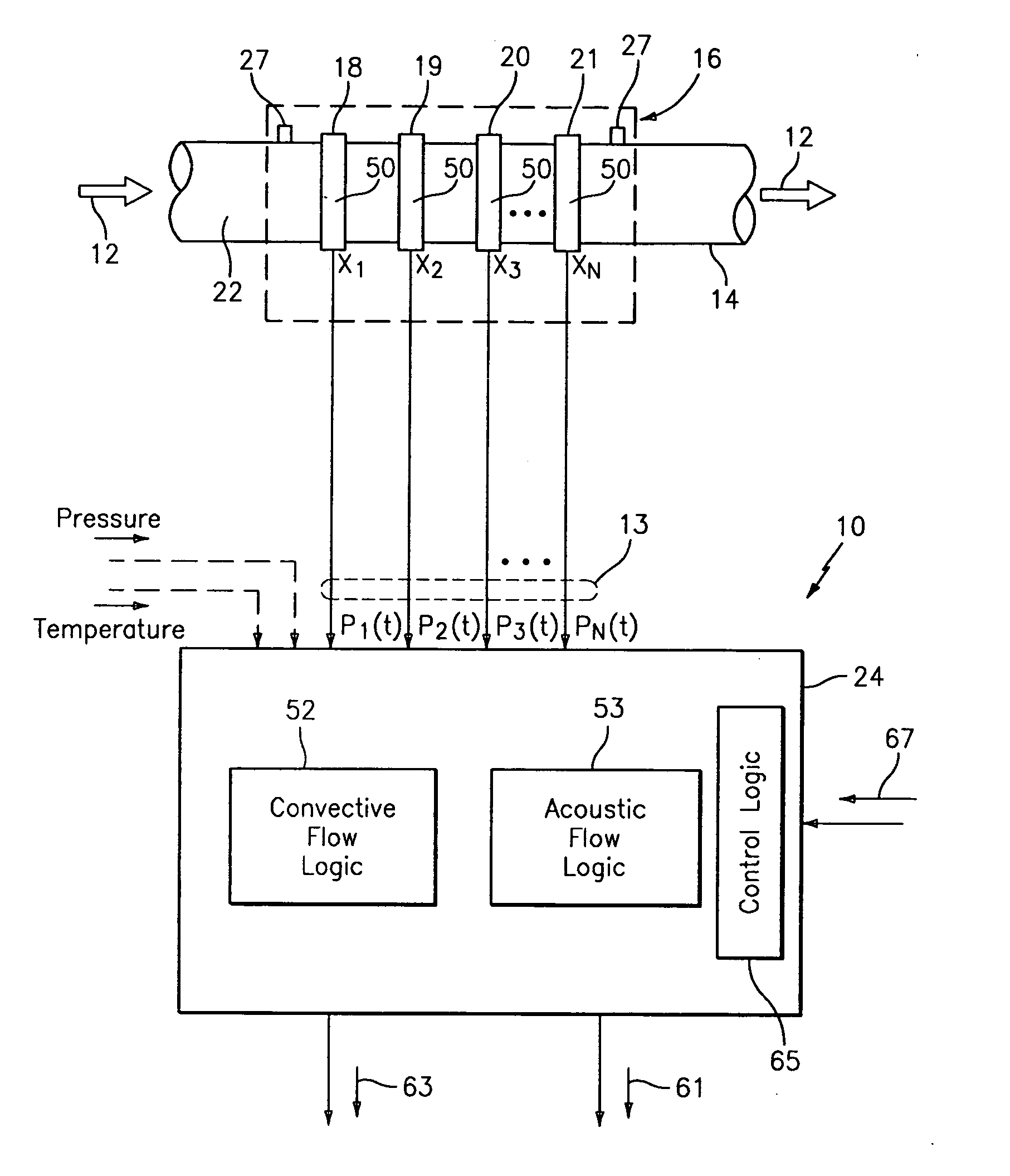

A thermal flow meter for use in dialysis is described, that uses a thermal wave to generate a signal in the fluid for which the flow rate is to be measured. The phase angle of the thermal wave signal changes when traversing downstream. The phase difference between the signals received downstream, compared with a reference excitation source signal is measured, and used to determine the flow rate of the fluid.

Owner:FRESENIUS MEDICAL CARE HLDG INC

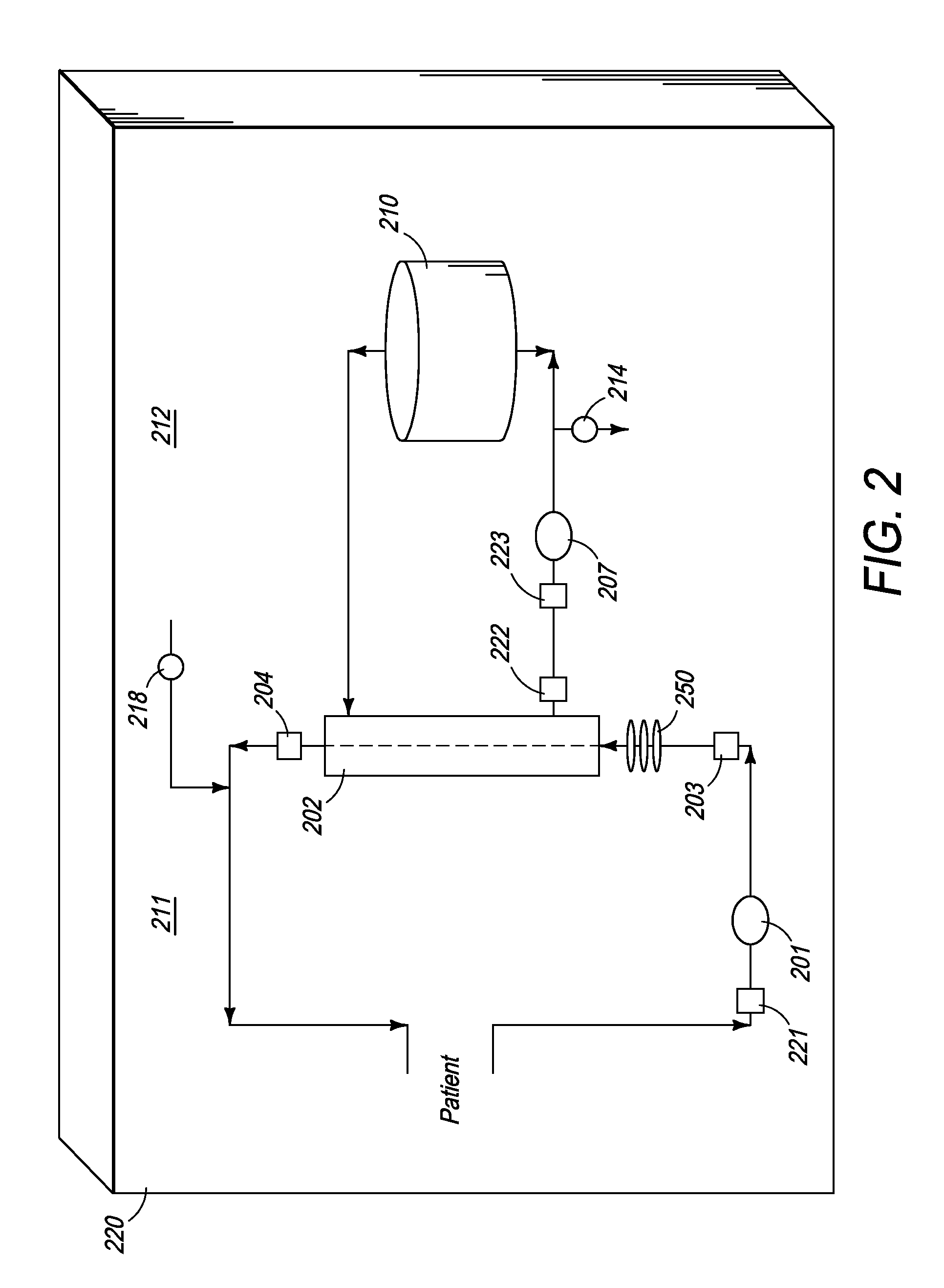

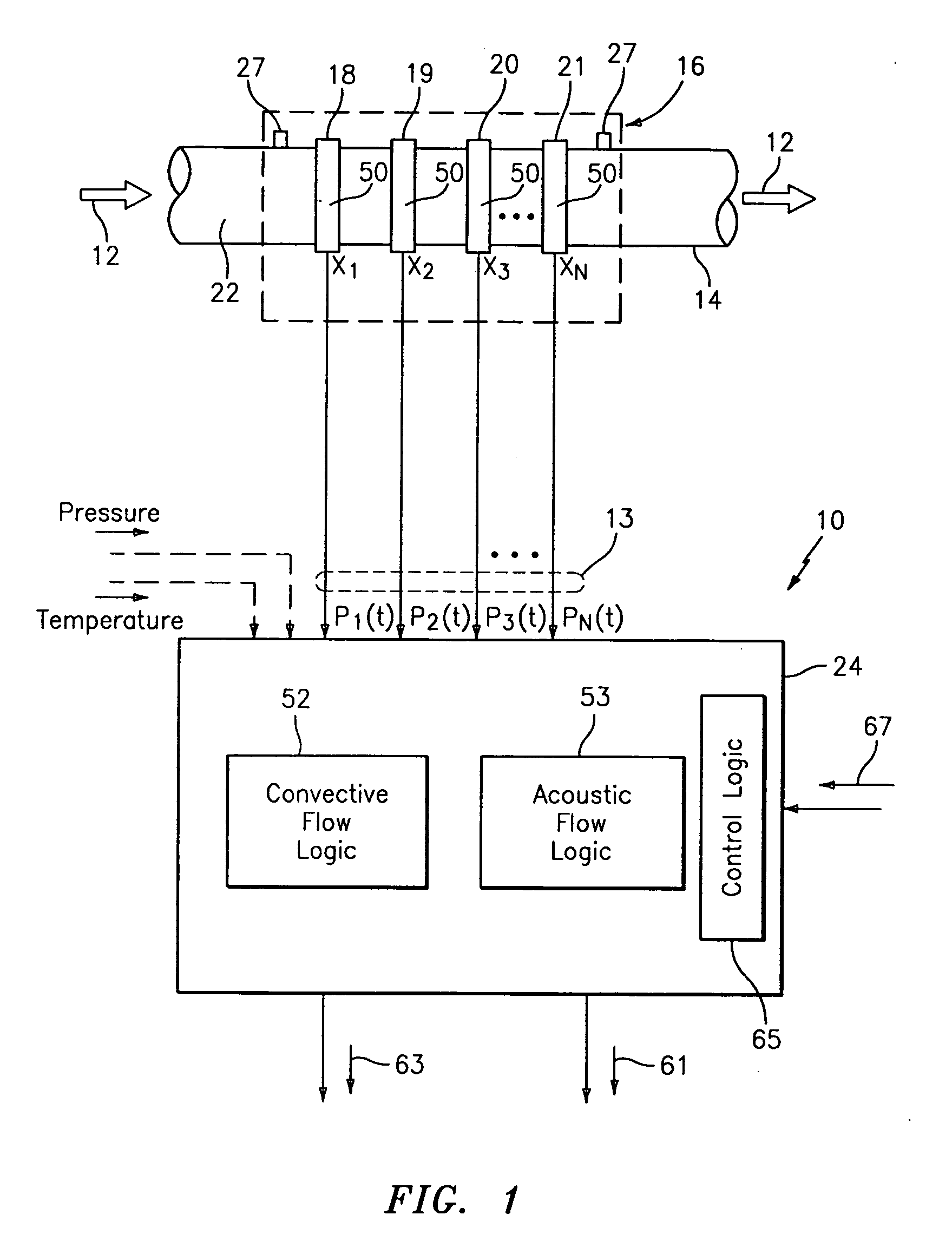

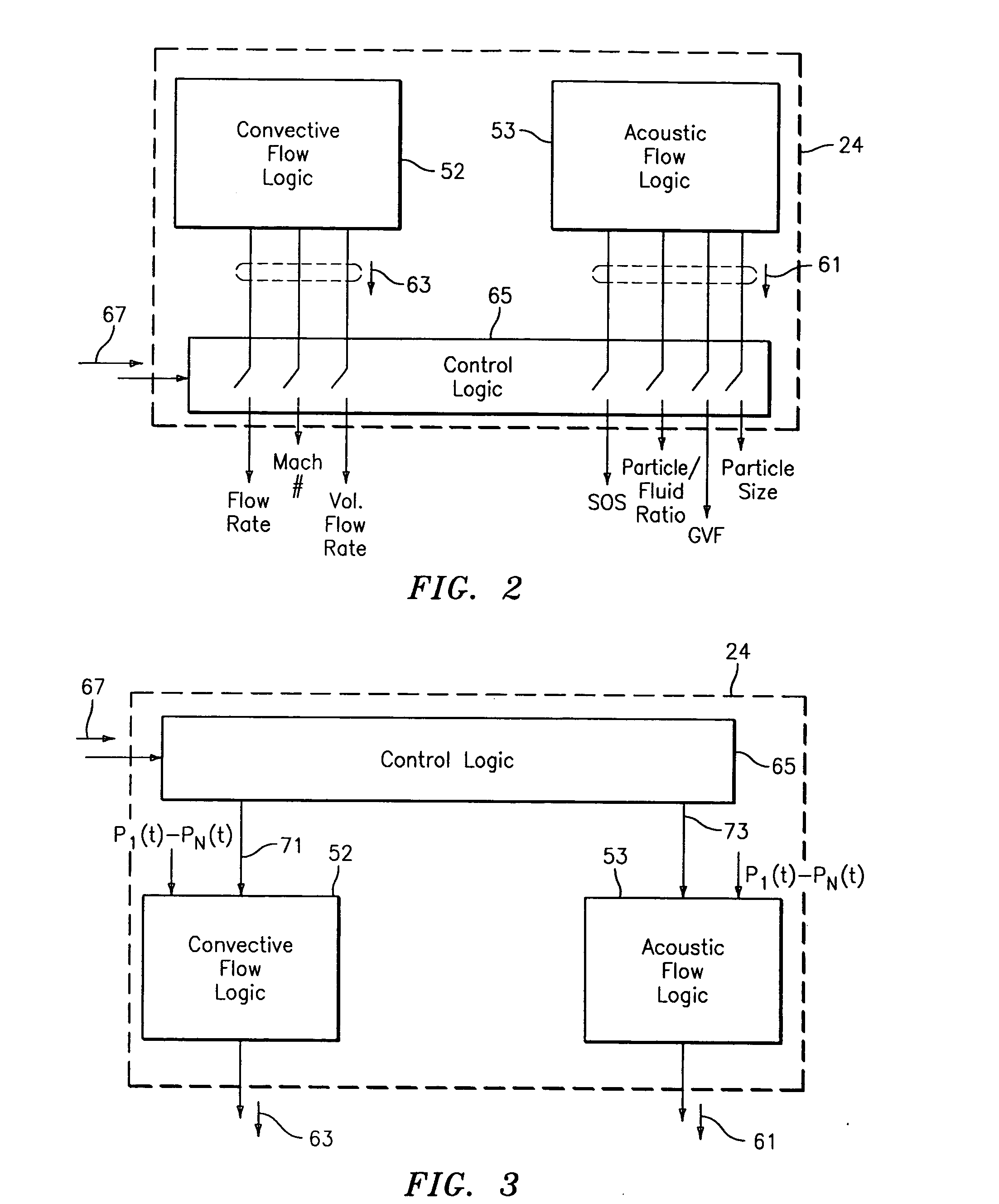

Configurable multi-function flow measurement apparatus having an array of sensors

ActiveUS20050011283A1Testing/calibration apparatusVolume/mass flow by thermal effectsSensor arrayMeasurement device

A configurable multi-function flow measurement apparatus is provided that can selectably function to measure the speed of sound propagating through a fluid flowing within a pipe and / or to measure pressures disturbances (e.g. vortical disturbances or eddies) moving with a fluid to determine respective parameters of the flow propagating through a pipe and detects the health of an industrial process. The configurable flow measurement device can also be selectable to function as a system diagnostic meter that provides a diagnostic signal indicative of the health of the industrial process, namely health of pumps, valves, motors and other devices in an industrial flow loop. The apparatus includes a sensing device that includes an array of strained-based or pressure sensors used to measure the acoustic and convective pressure variations in the flow to determine desired parameters. In response to a remote or local configuration signal, a control logic selects the desired function of the flow measurement apparatus.

Owner:EXPRO METERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com