Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

945results about "Hydrogen separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

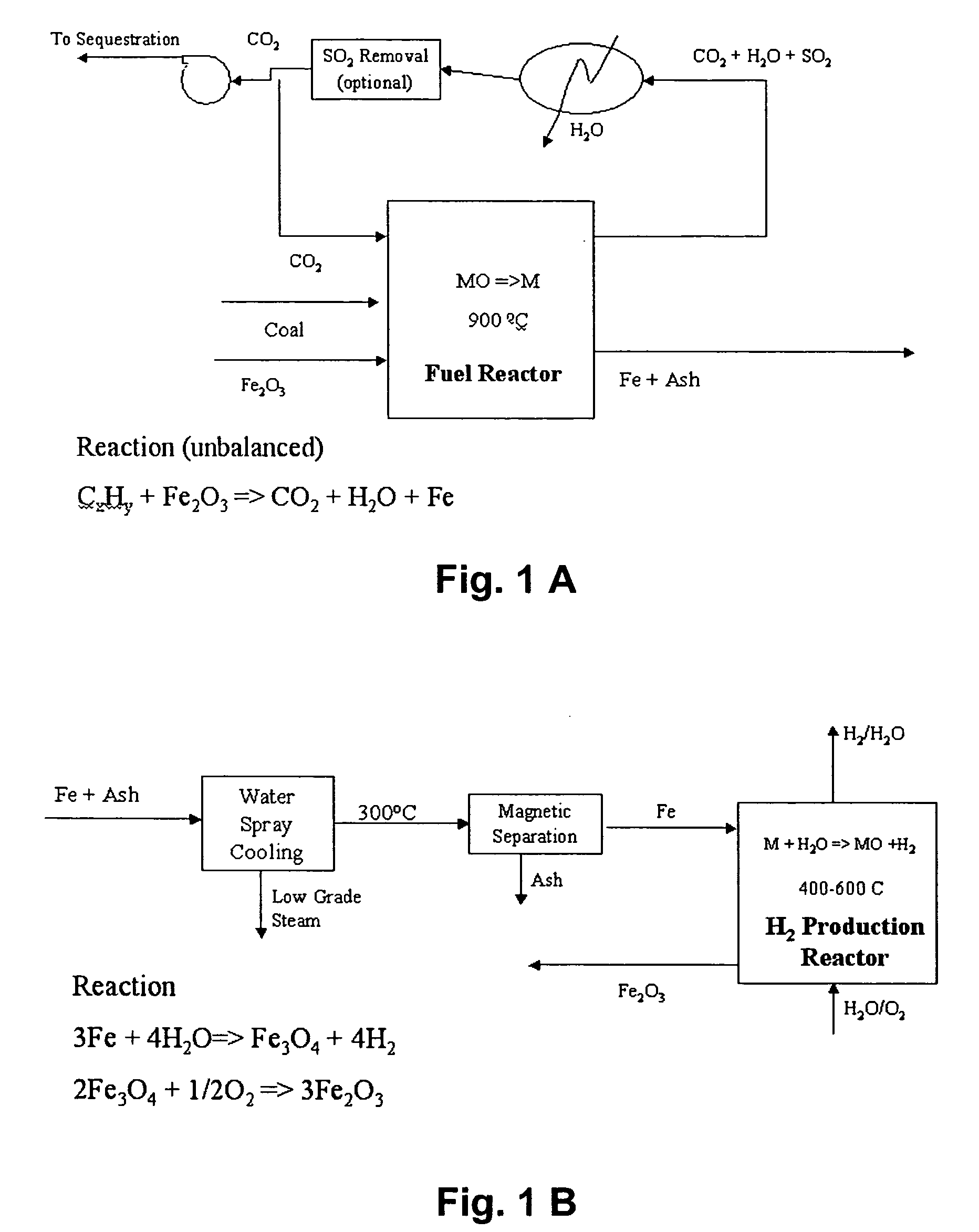

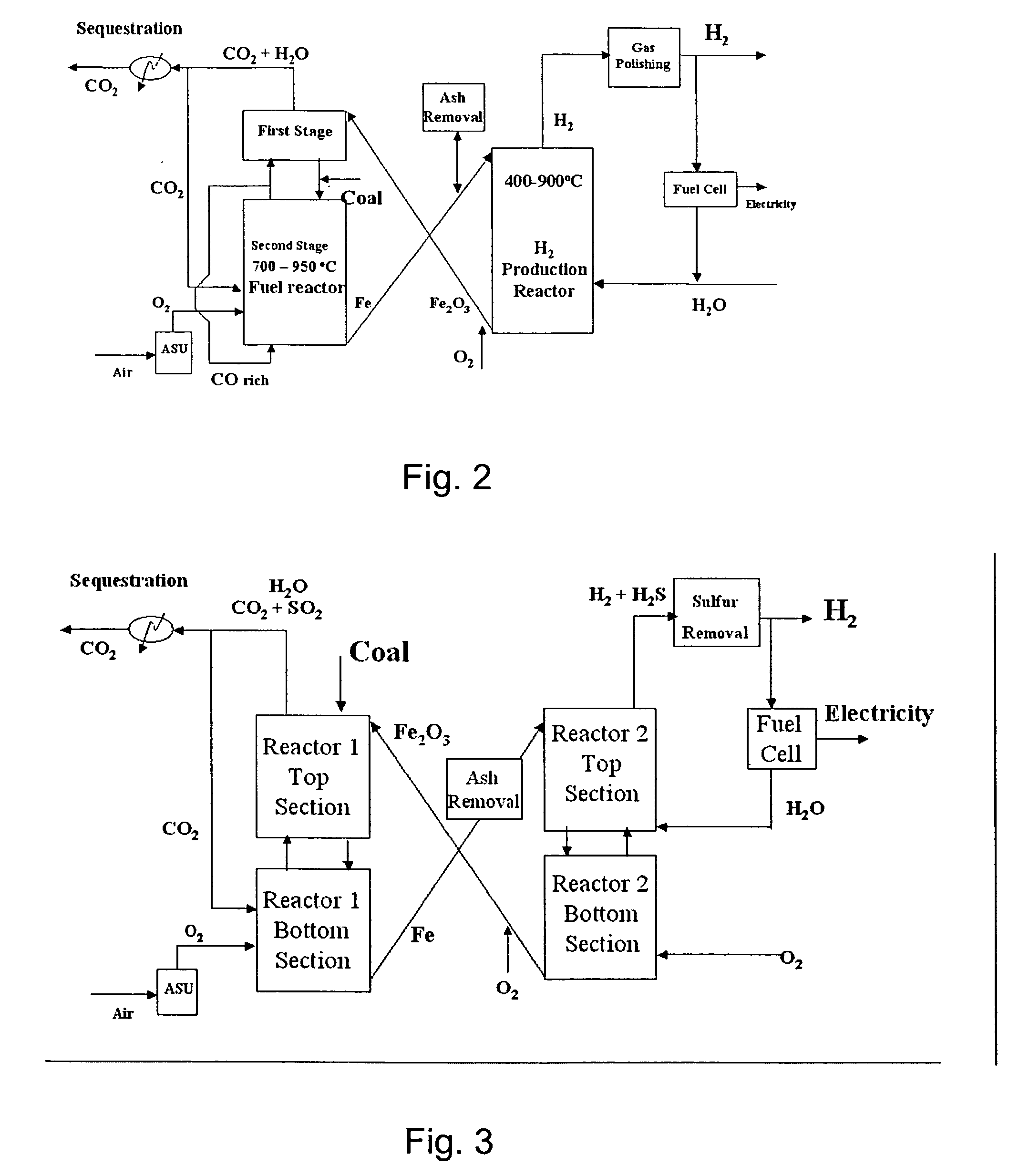

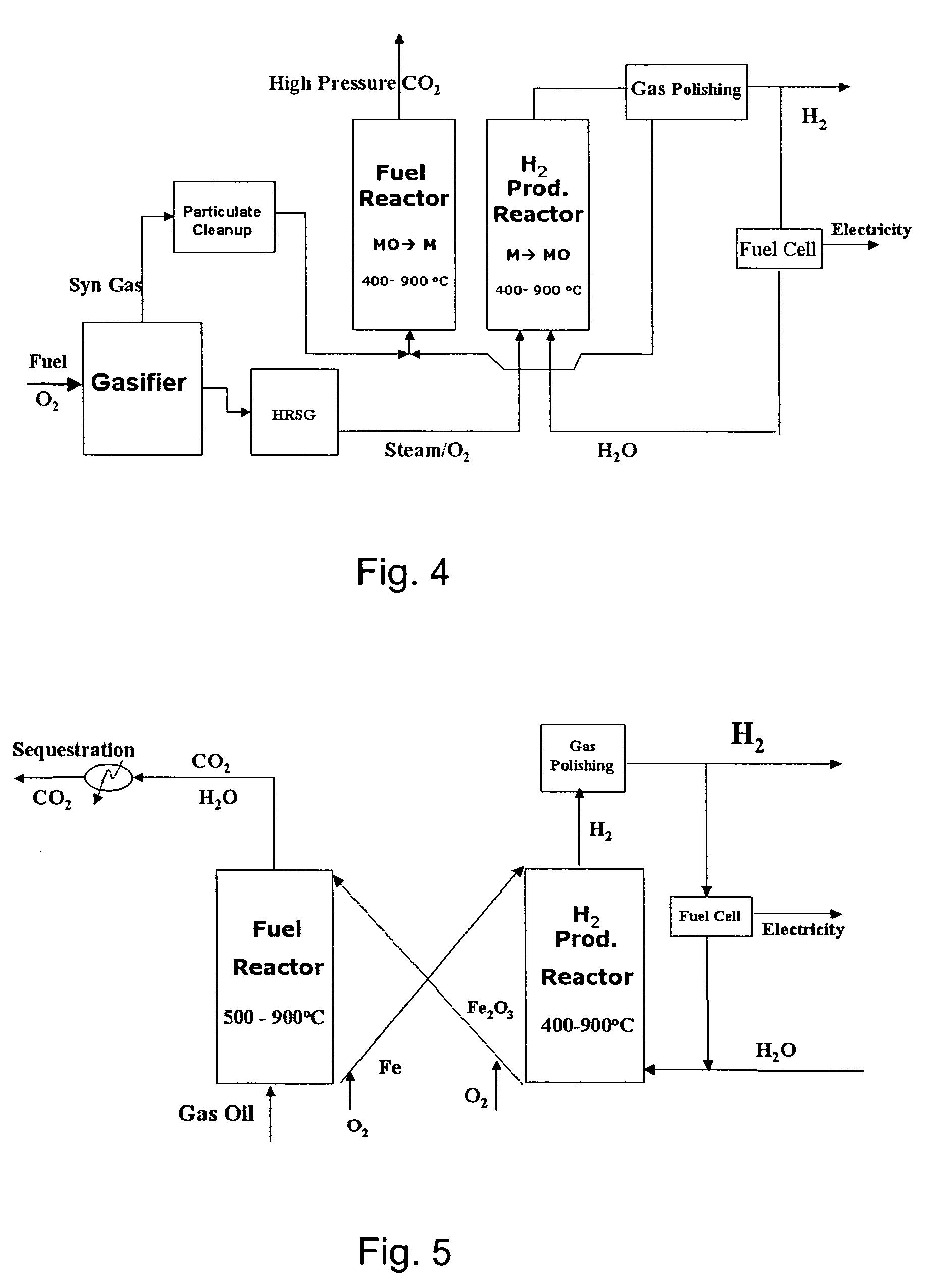

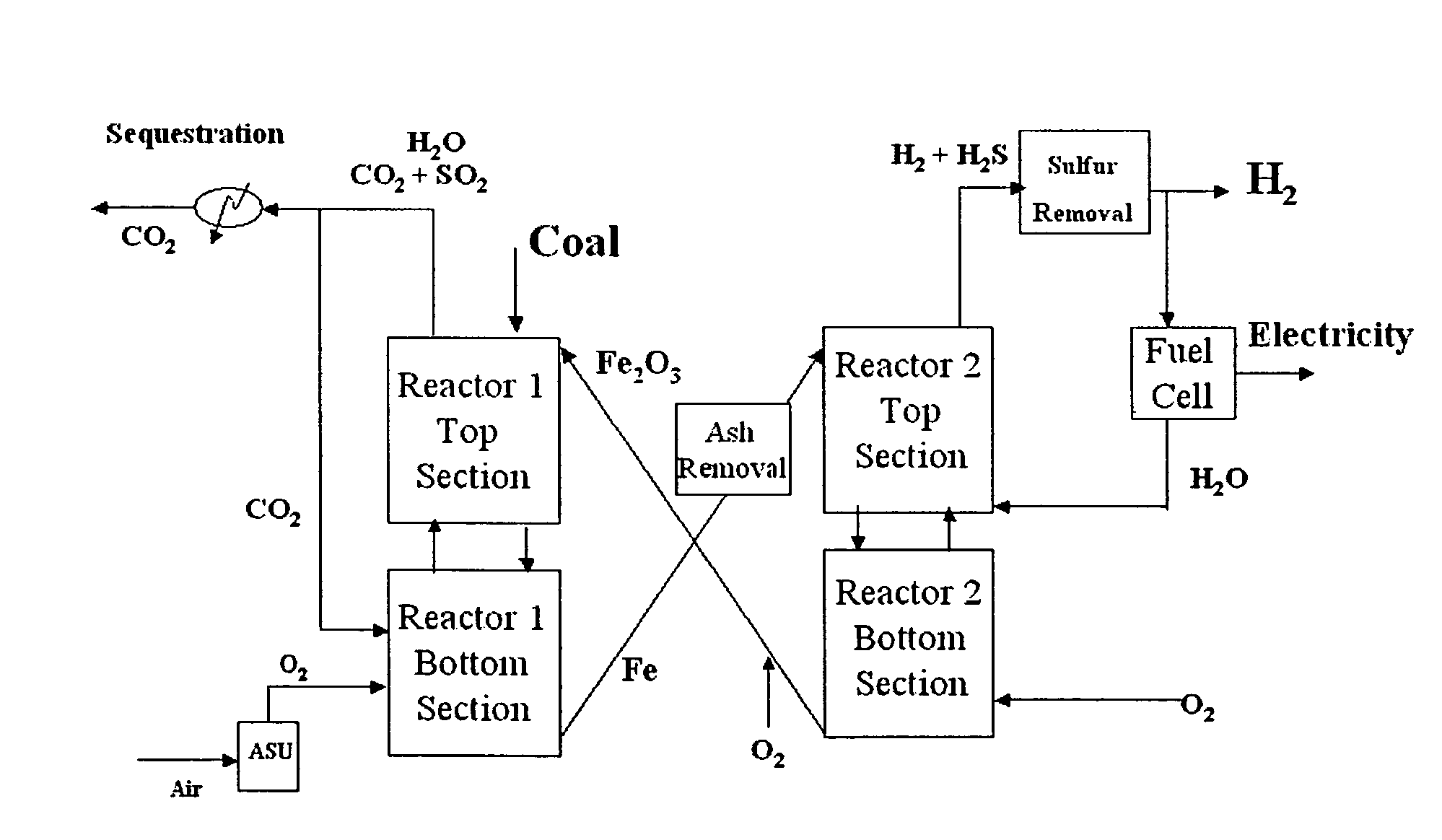

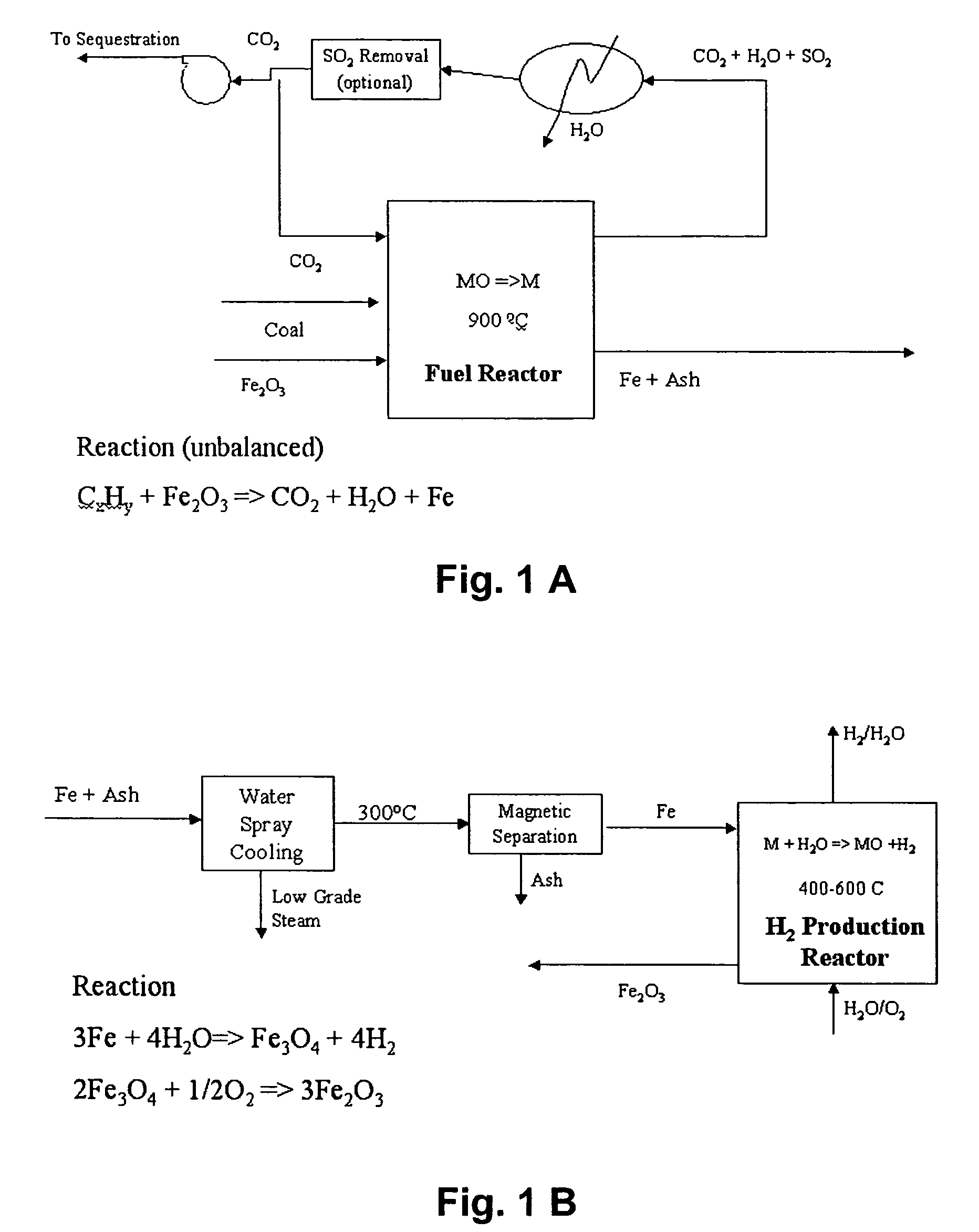

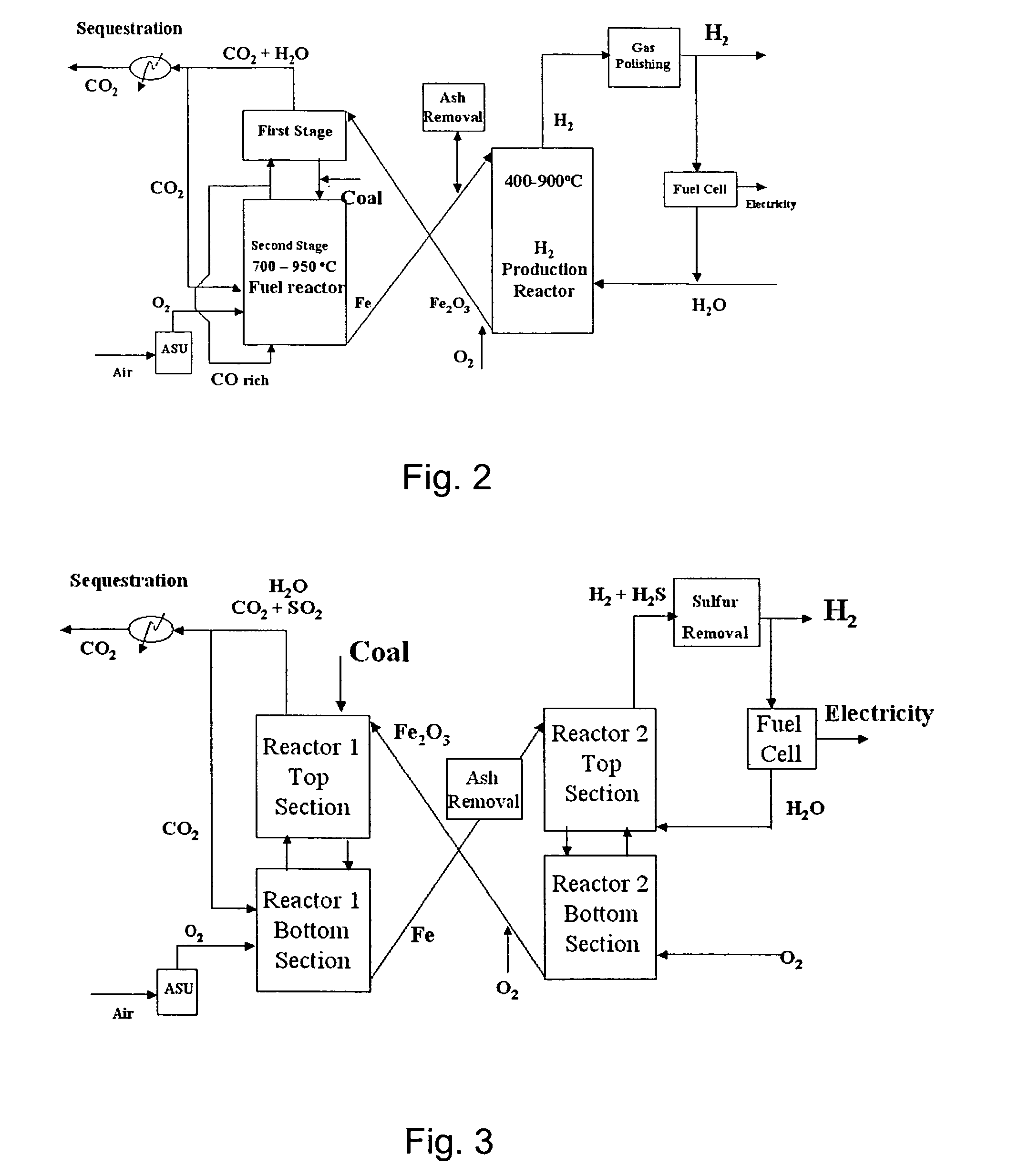

Combustion looping using composite oxygen carriers

ActiveUS20050175533A1Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

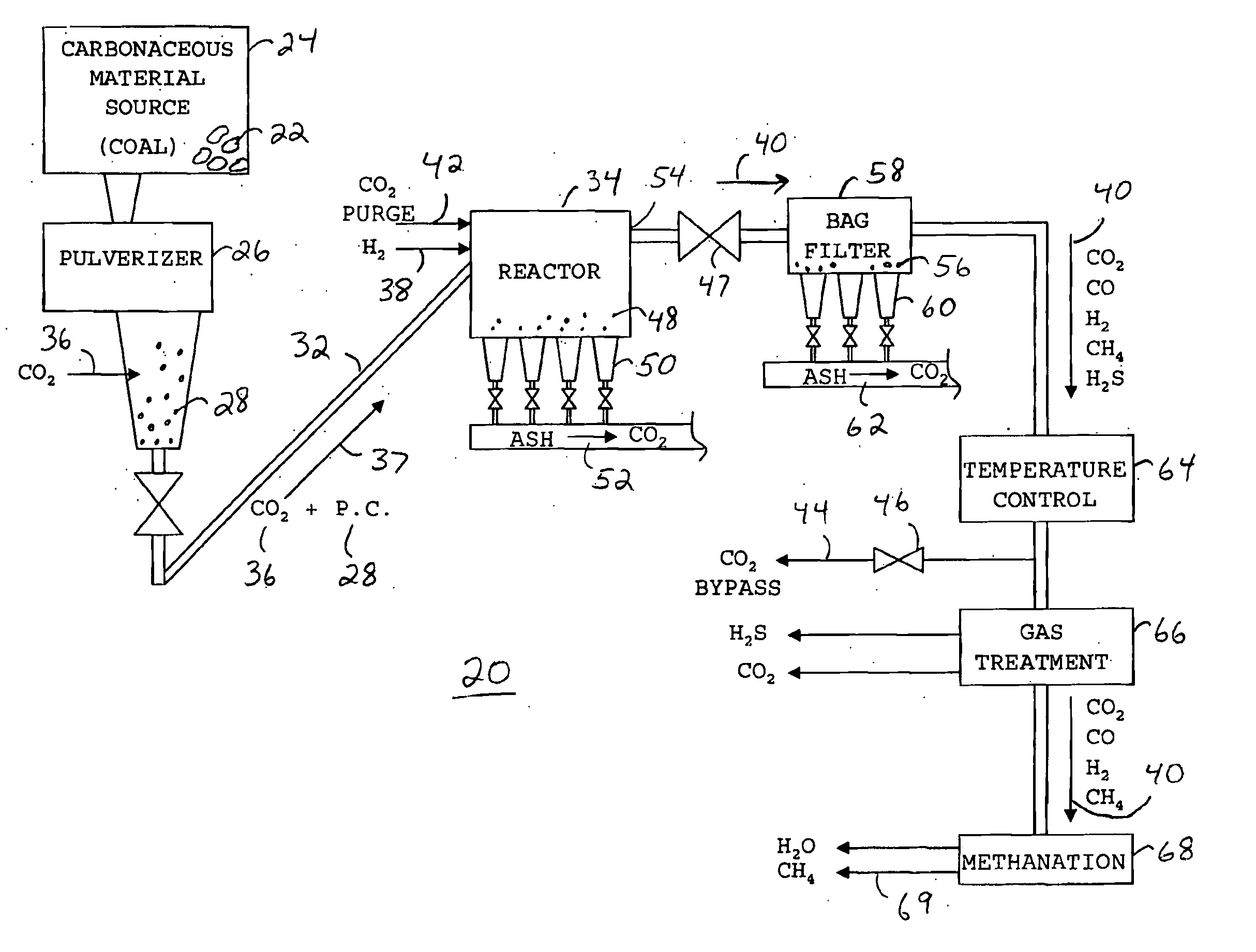

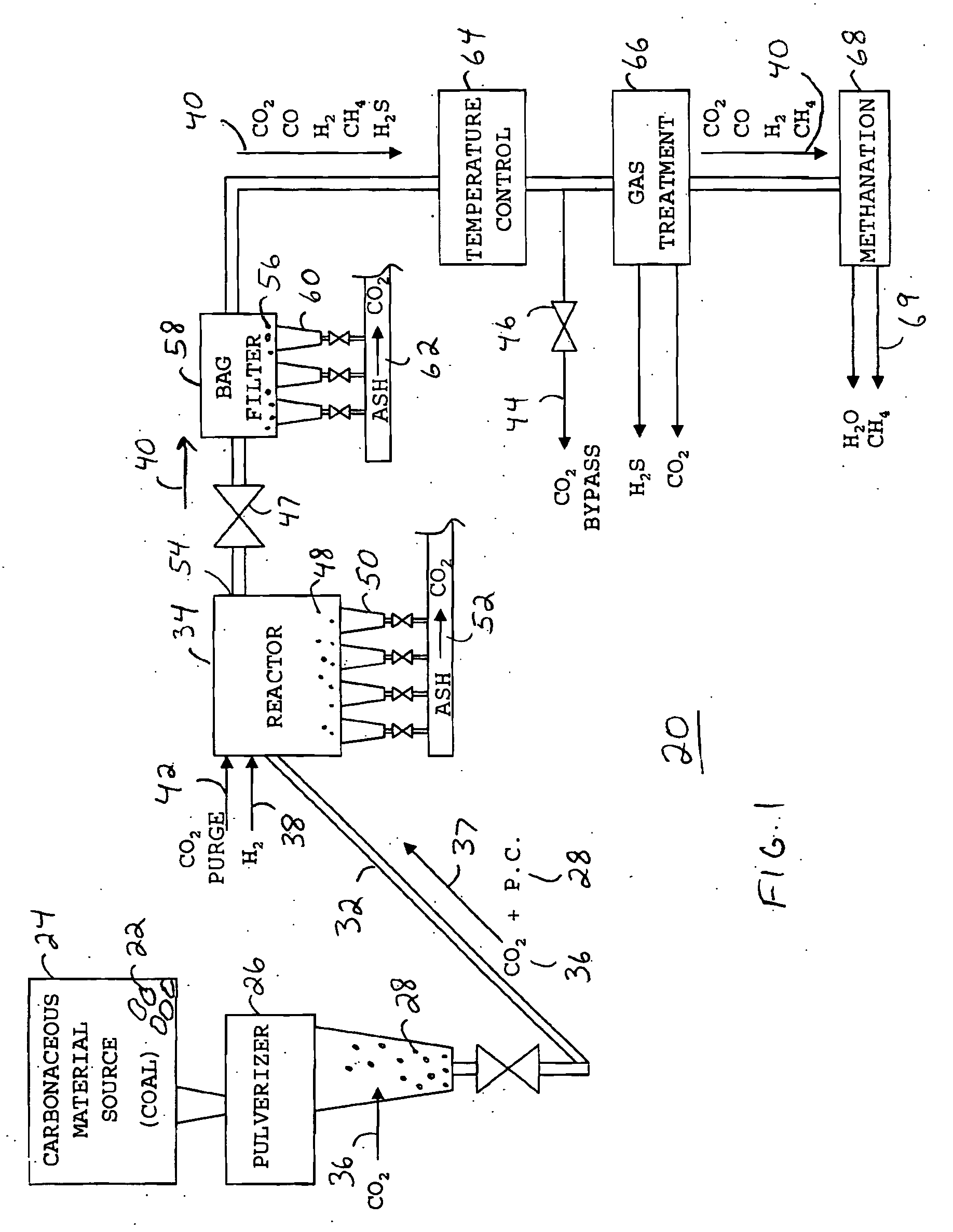

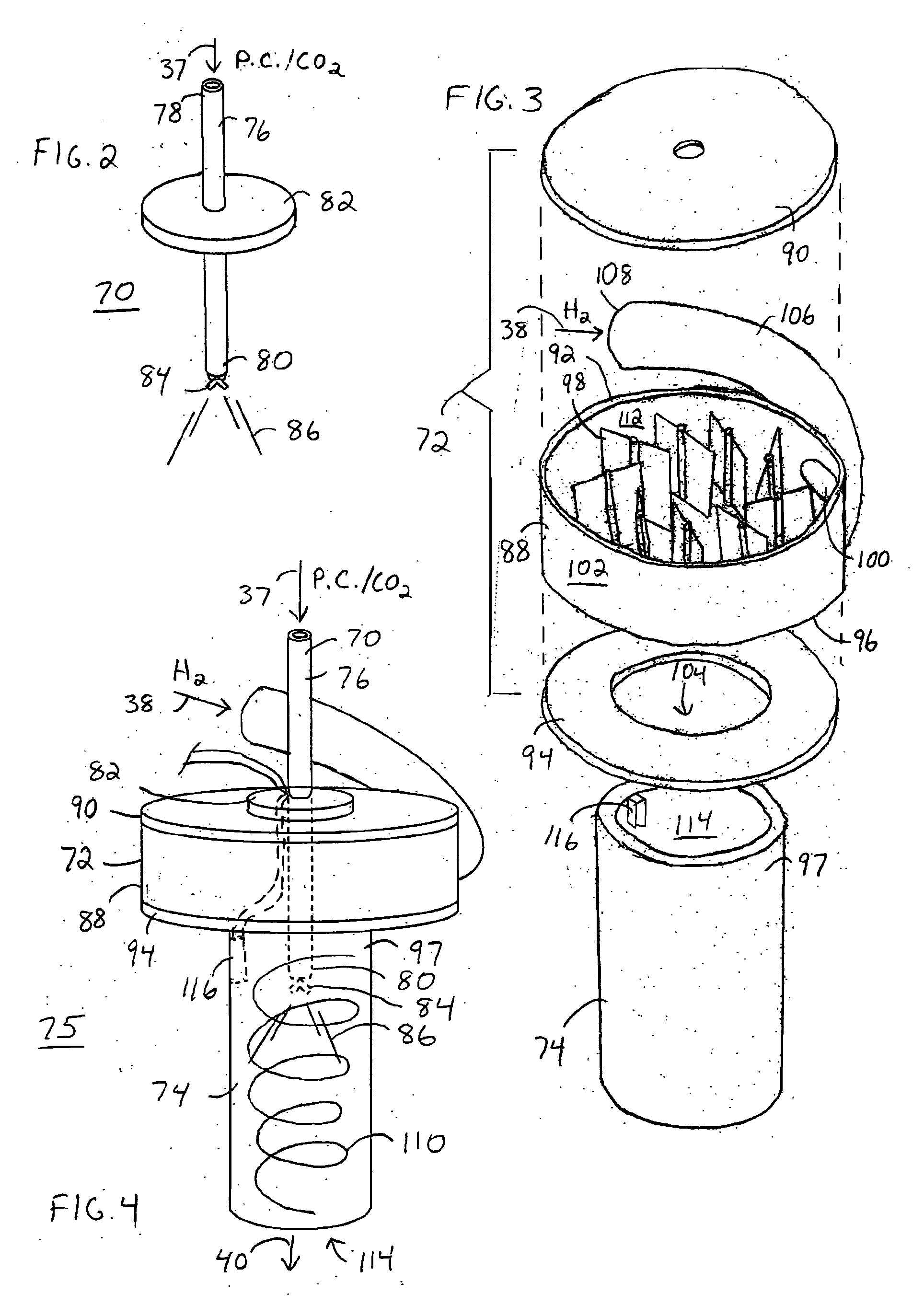

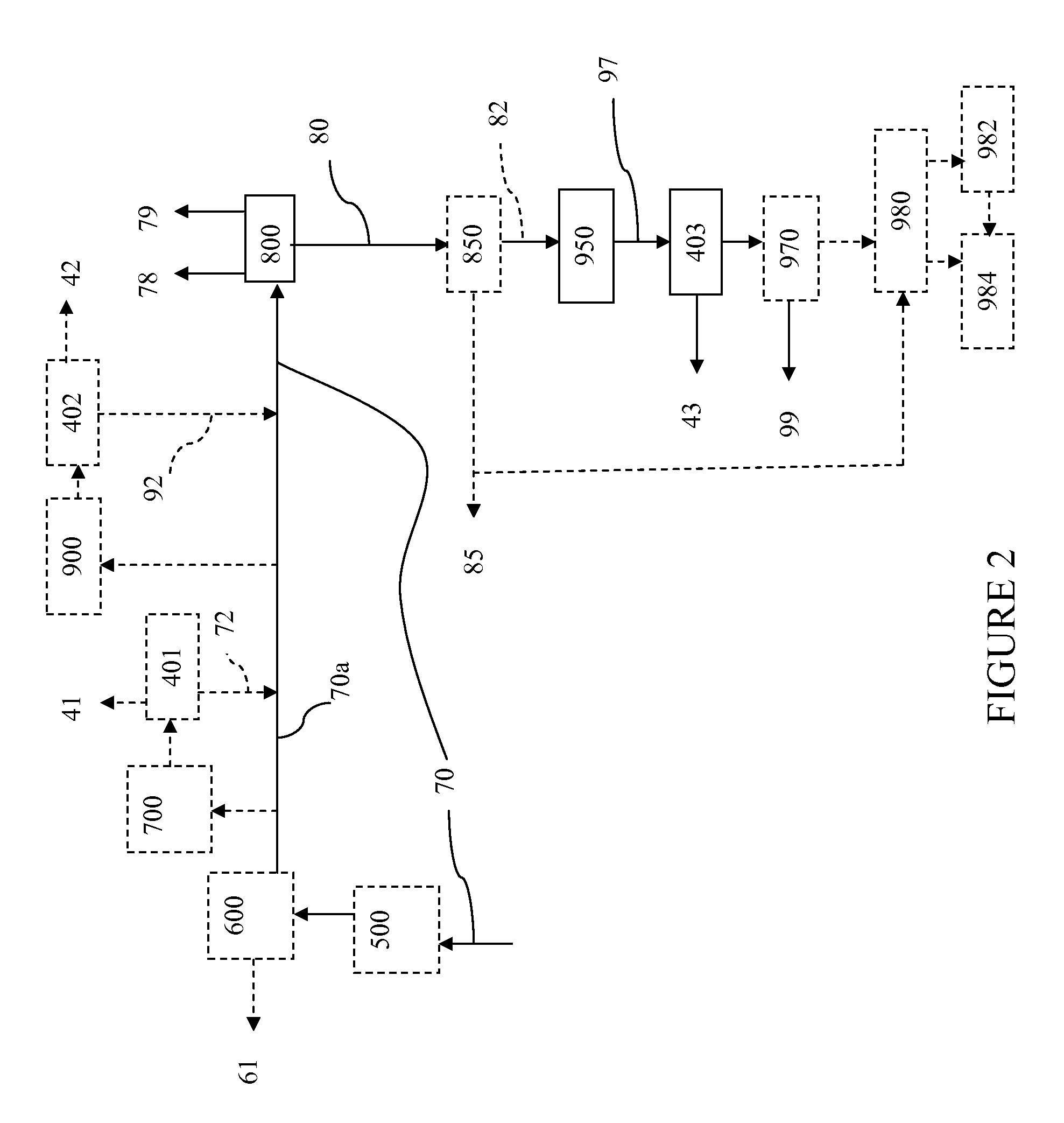

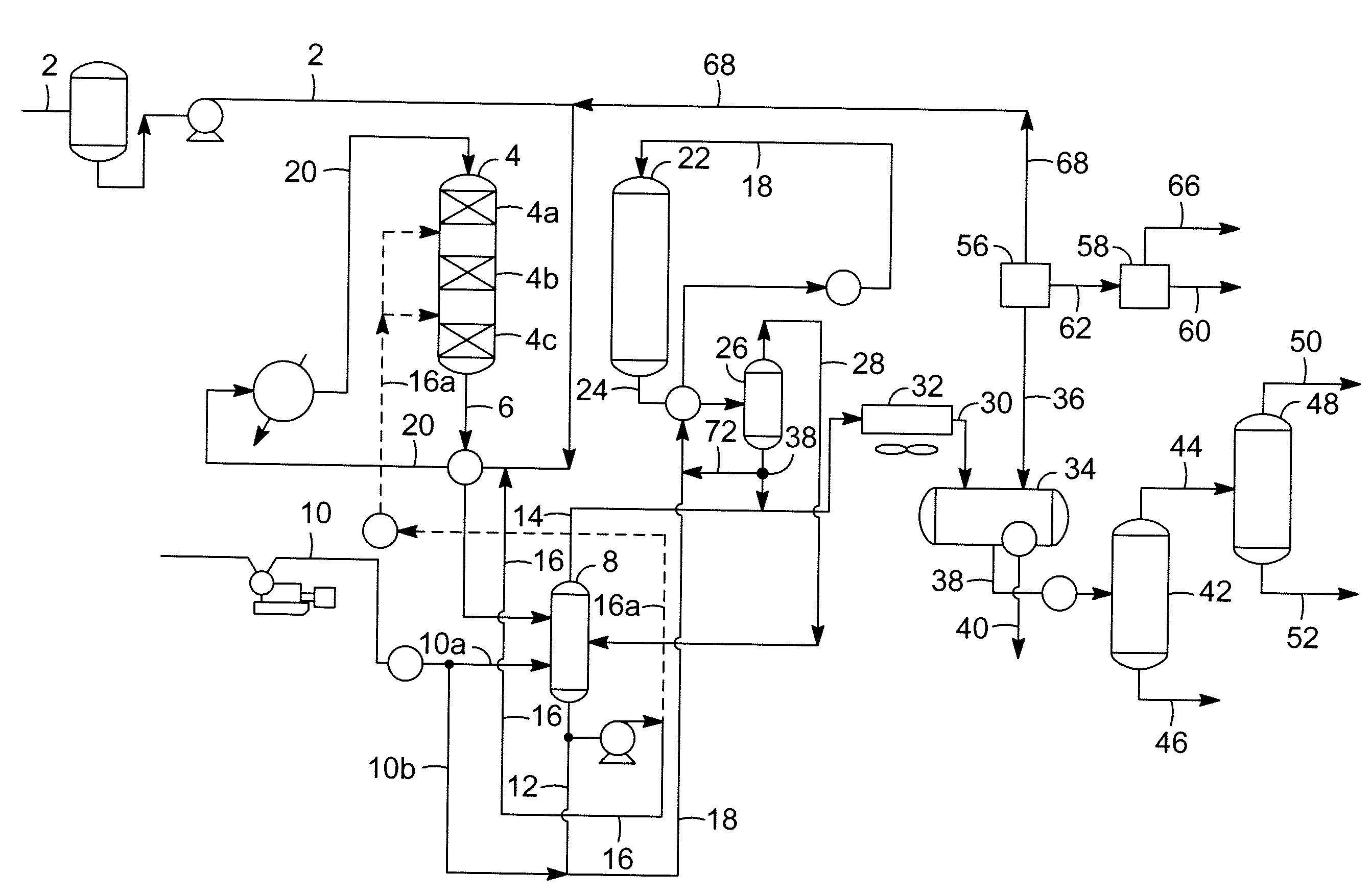

Method and apparatus for producing methane from carbonaceous material

InactiveUS20060265953A1Efficient productionEfficient deliveryHydrogen separationGaseous fuelsHydrogenReaction zone

A method for producing methane (69) from a carbonaceous (22) material includes conveying pulverized carbonaceous material (28) entrained in an inert carrier fluid, such as carbon dioxide (36), into a reactor (34). The reactor (34) includes a vortex region (72) for receiving hydrogen gas (38) and imparting a swirling motion to the hydrogen gas (38). The pulverized carbonaceous material (28) is exposed to the swirling stream of hydrogen gas (38) in a first reaction zone (114) within the reactor (34) to form an exit gas (40) that includes methane (69). Remaining unreacted carbonaceous material (28) is further exposed to the hydrogen gas (38) in a second, low velocity, reaction zone (120). The methane rich exit gas (40) is subsequently extracted from the reactor (34) for further processing.

Owner:ARIZONA PUBLIC SERVICE

Chemical microreactor and method thereof

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

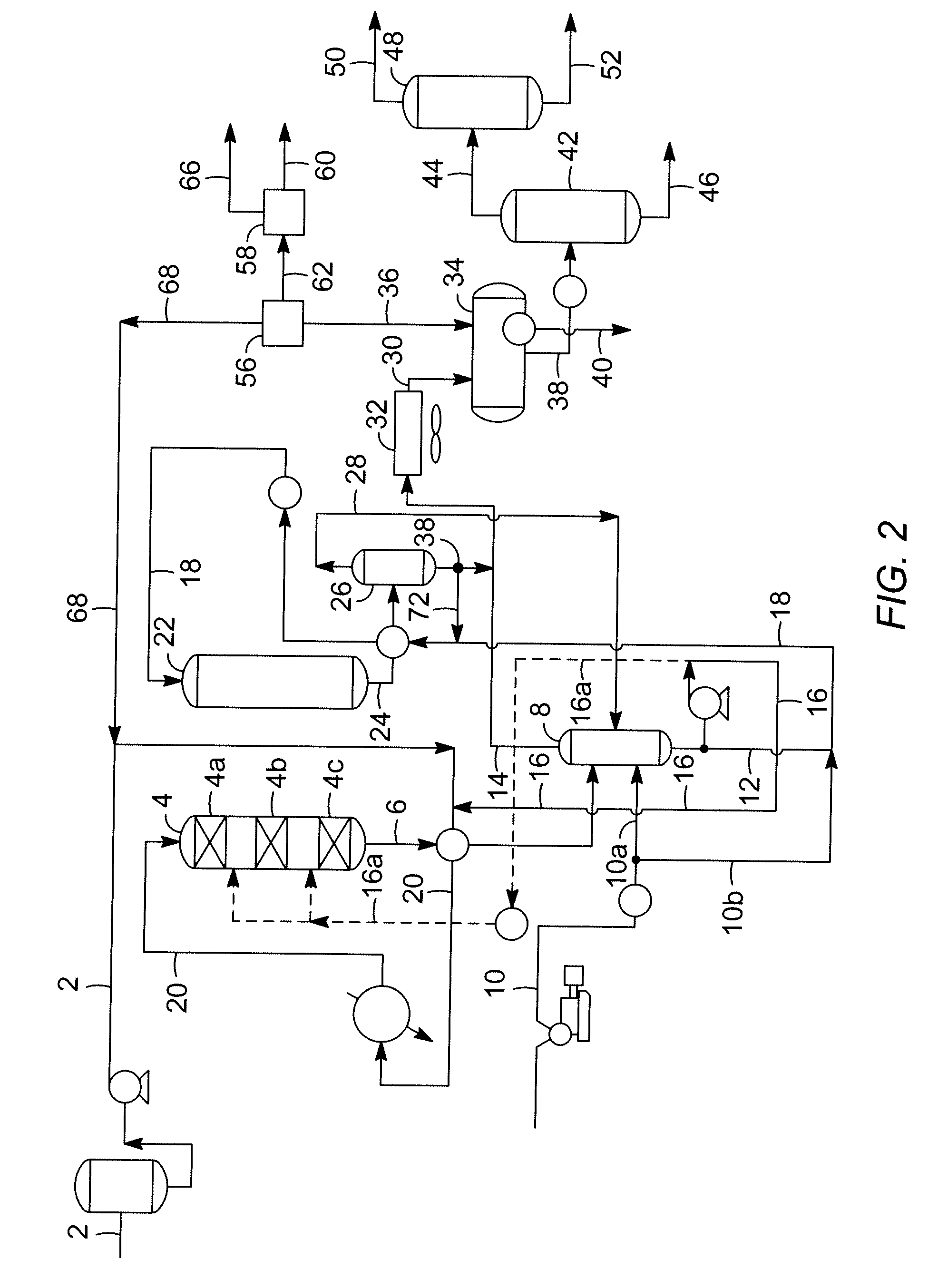

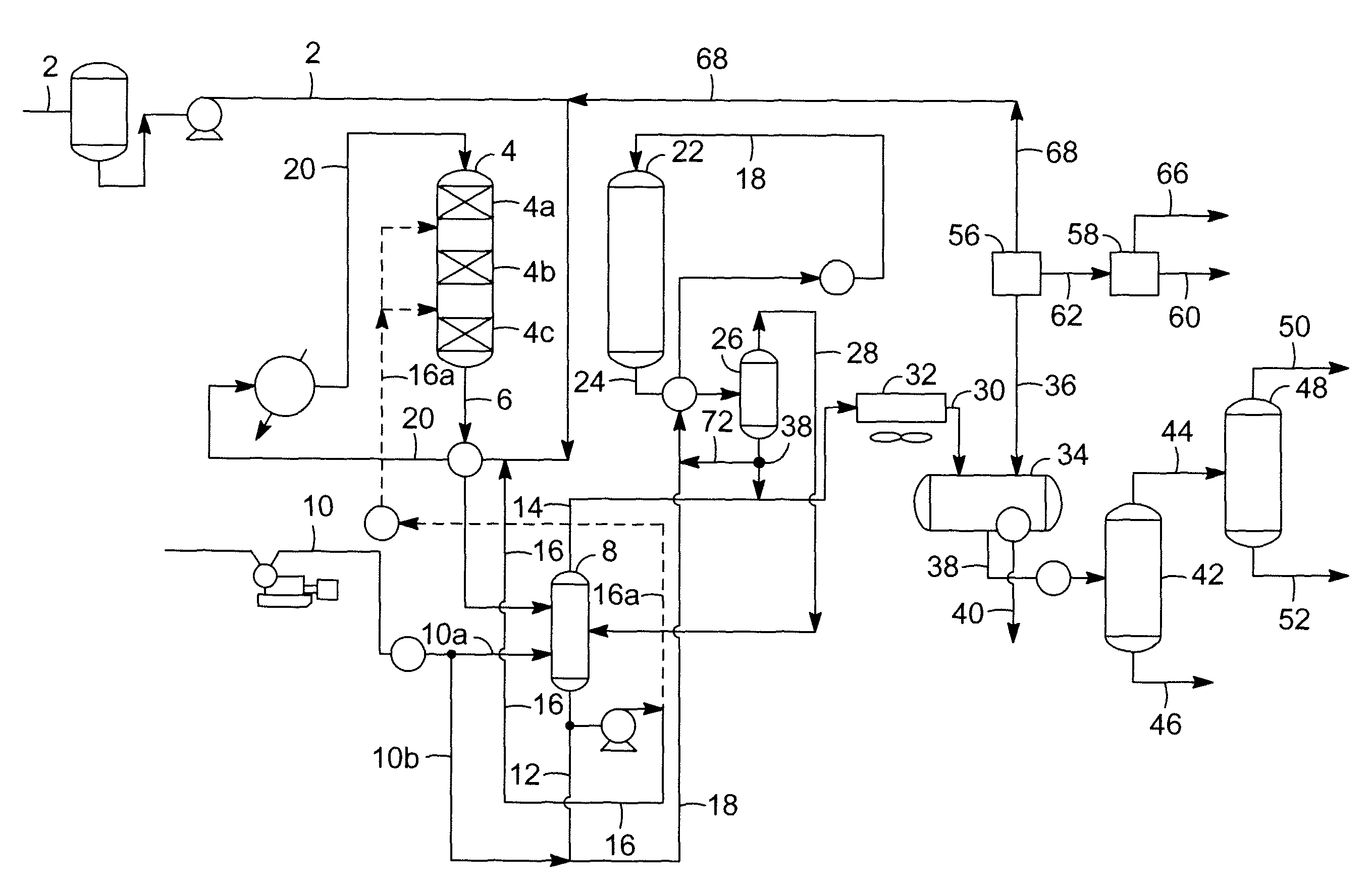

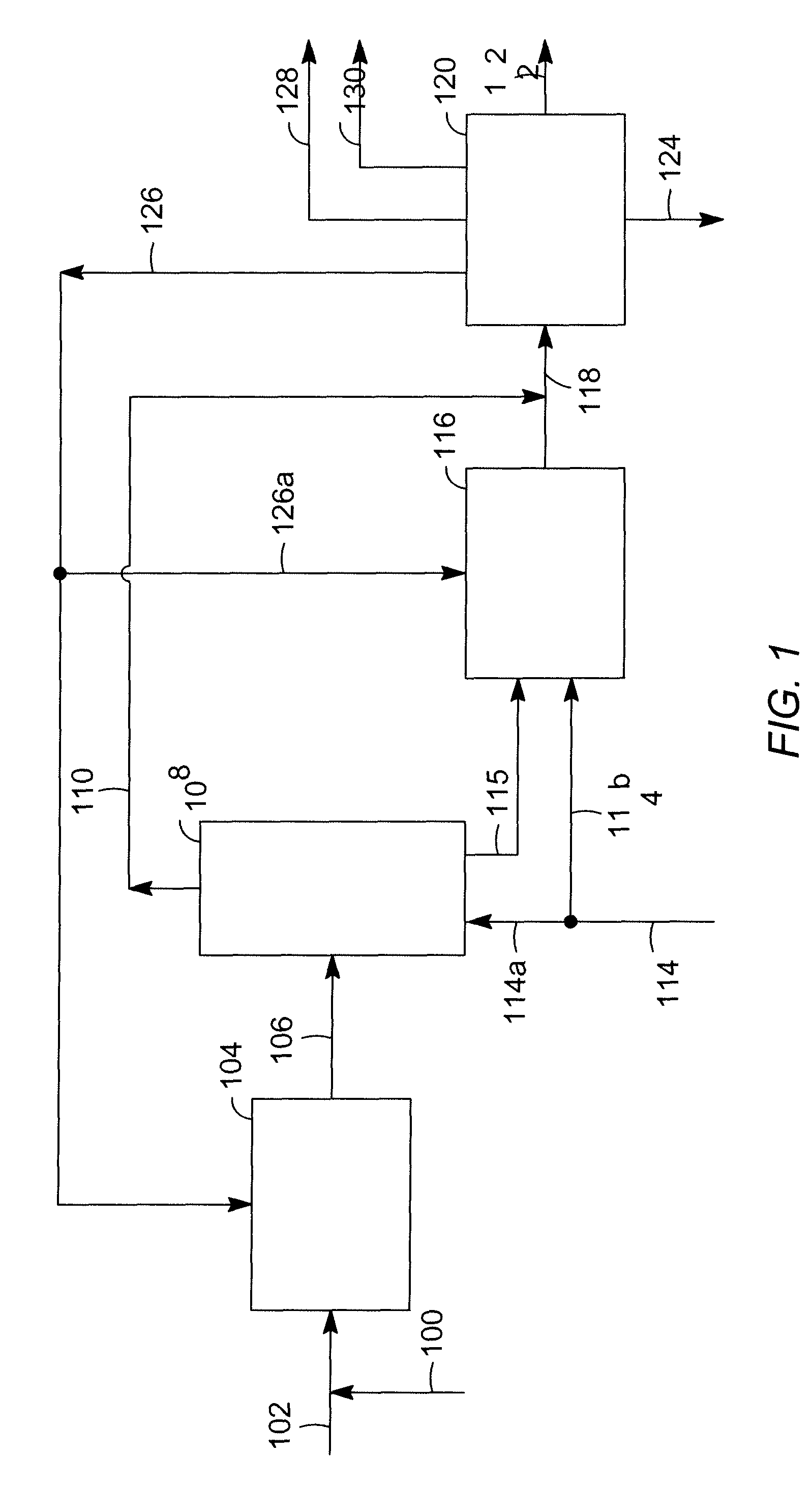

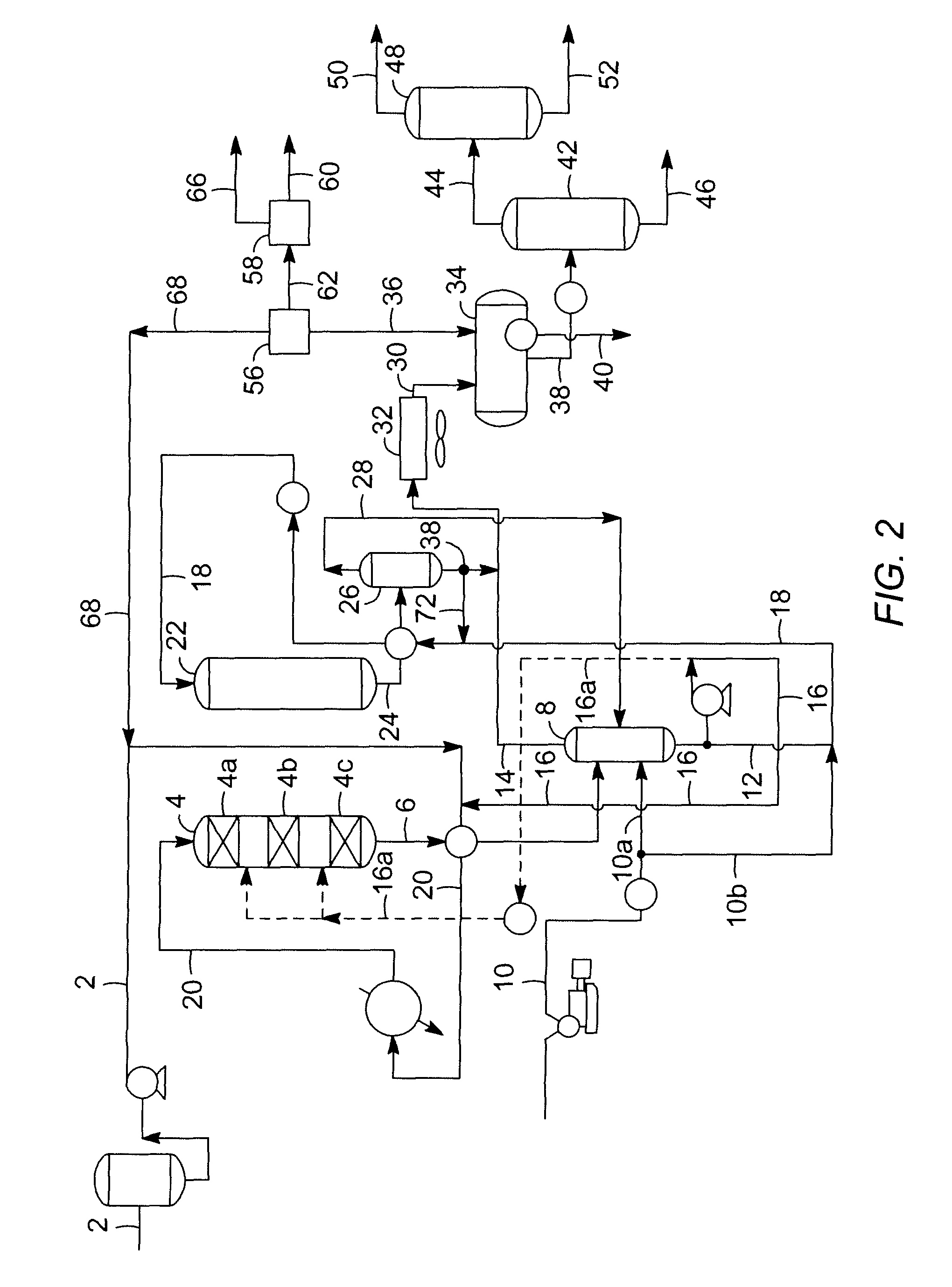

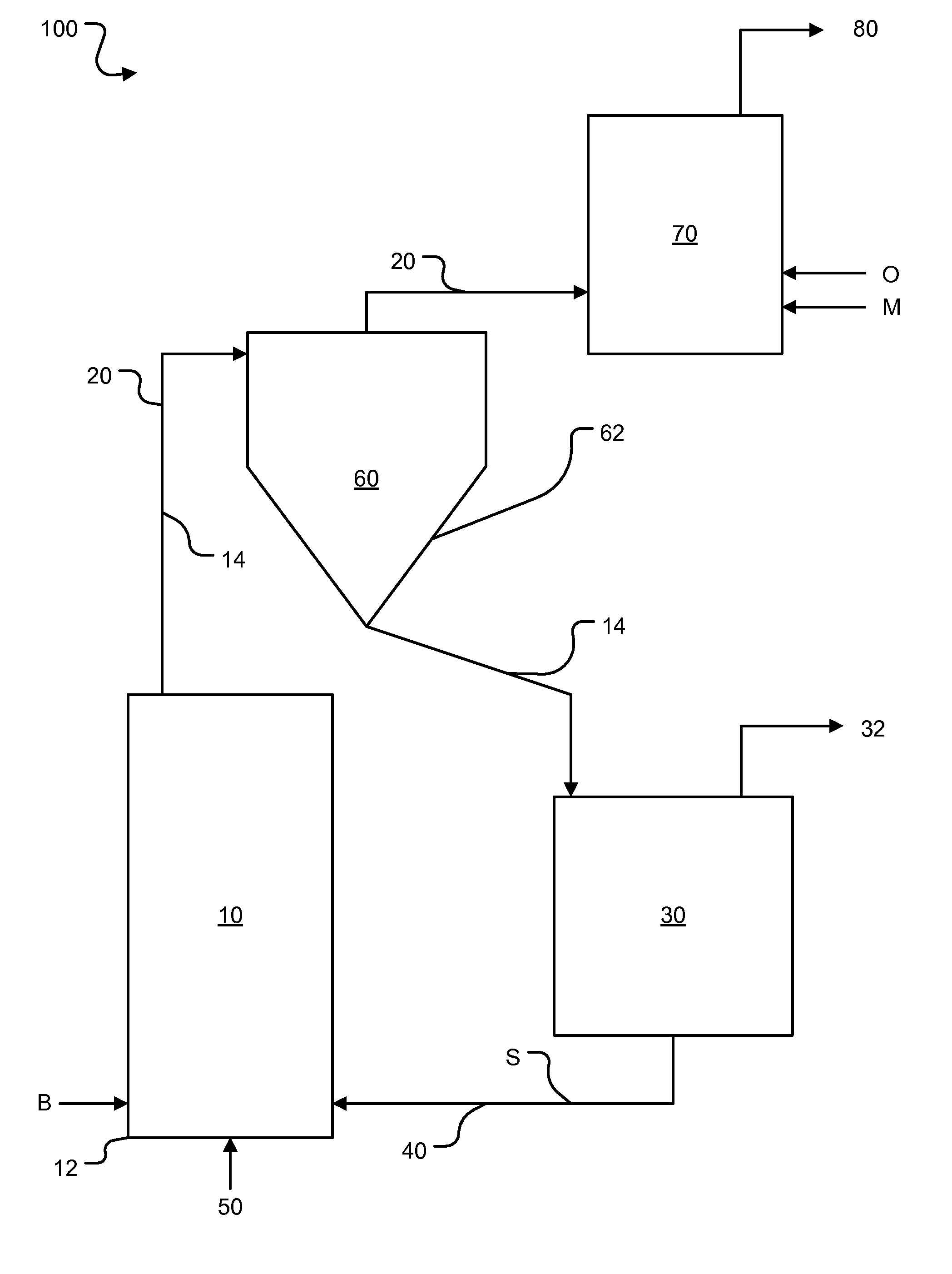

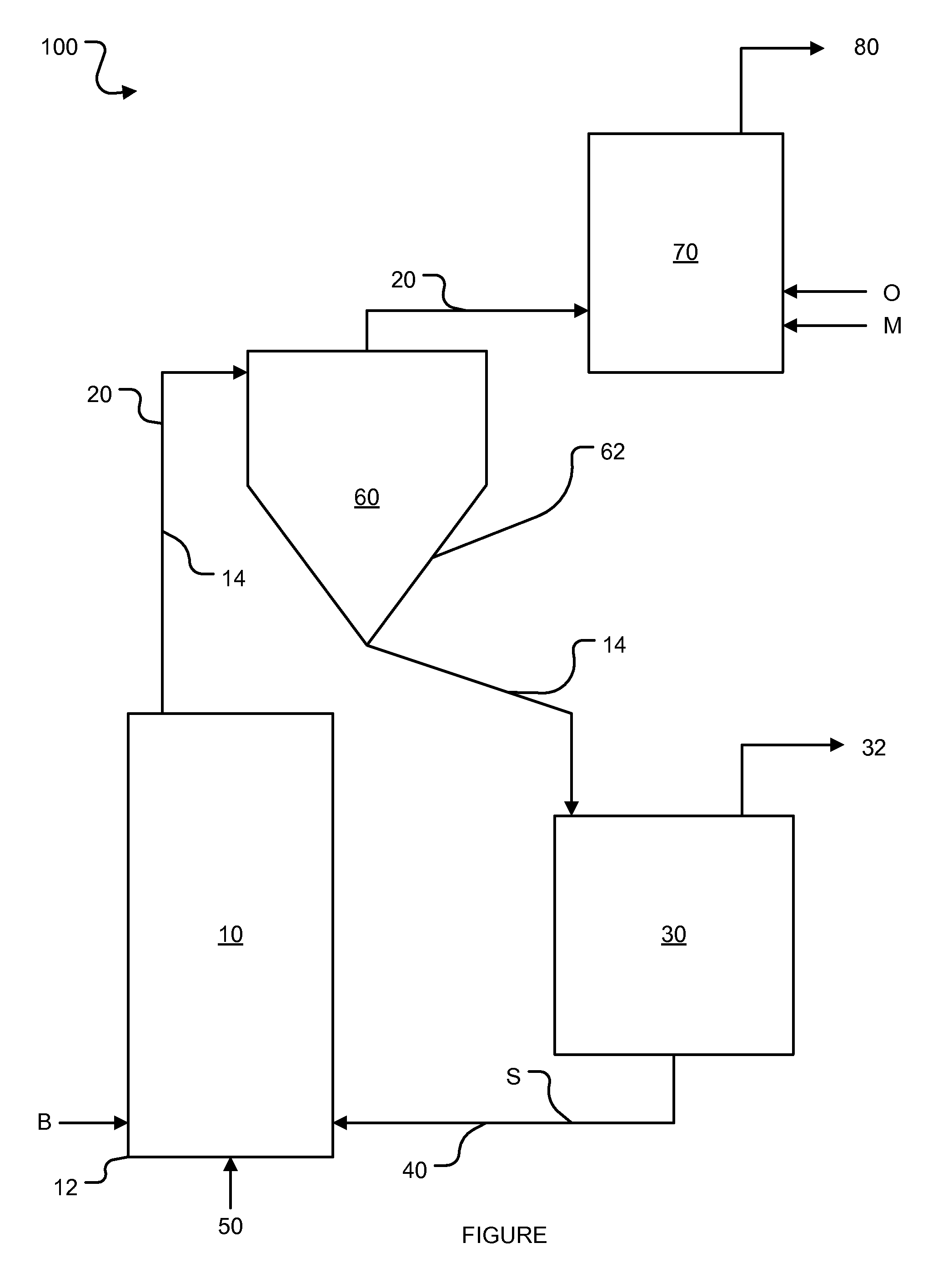

Processes for Hydromethanation of a Carbonaceous Feedstock

ActiveUS20100287835A1Increase the amount of carbonIncrease volumeHydrocarbon by isomerisationHydrogen separationMethanationOrganic chemistry

The present invention relates to processes for preparing gaseous products, and in particular methane, via the hydromethanation of a carbonaceous feedstock in the presence of steam, syngas, a hydromethanation catalyst and an oxygen-rich gas stream.

Owner:SURE CHAMPION INVESTMENT LTD

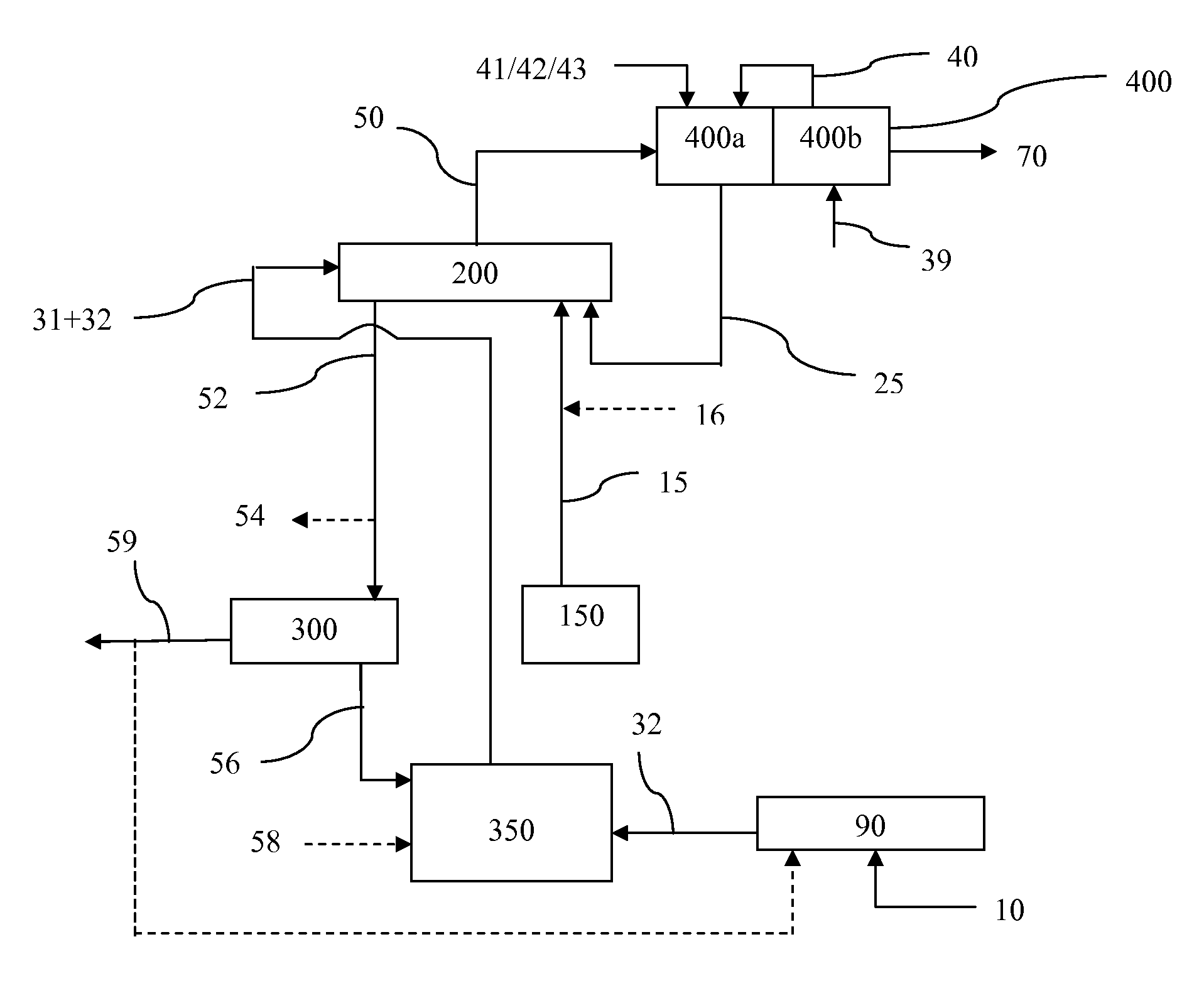

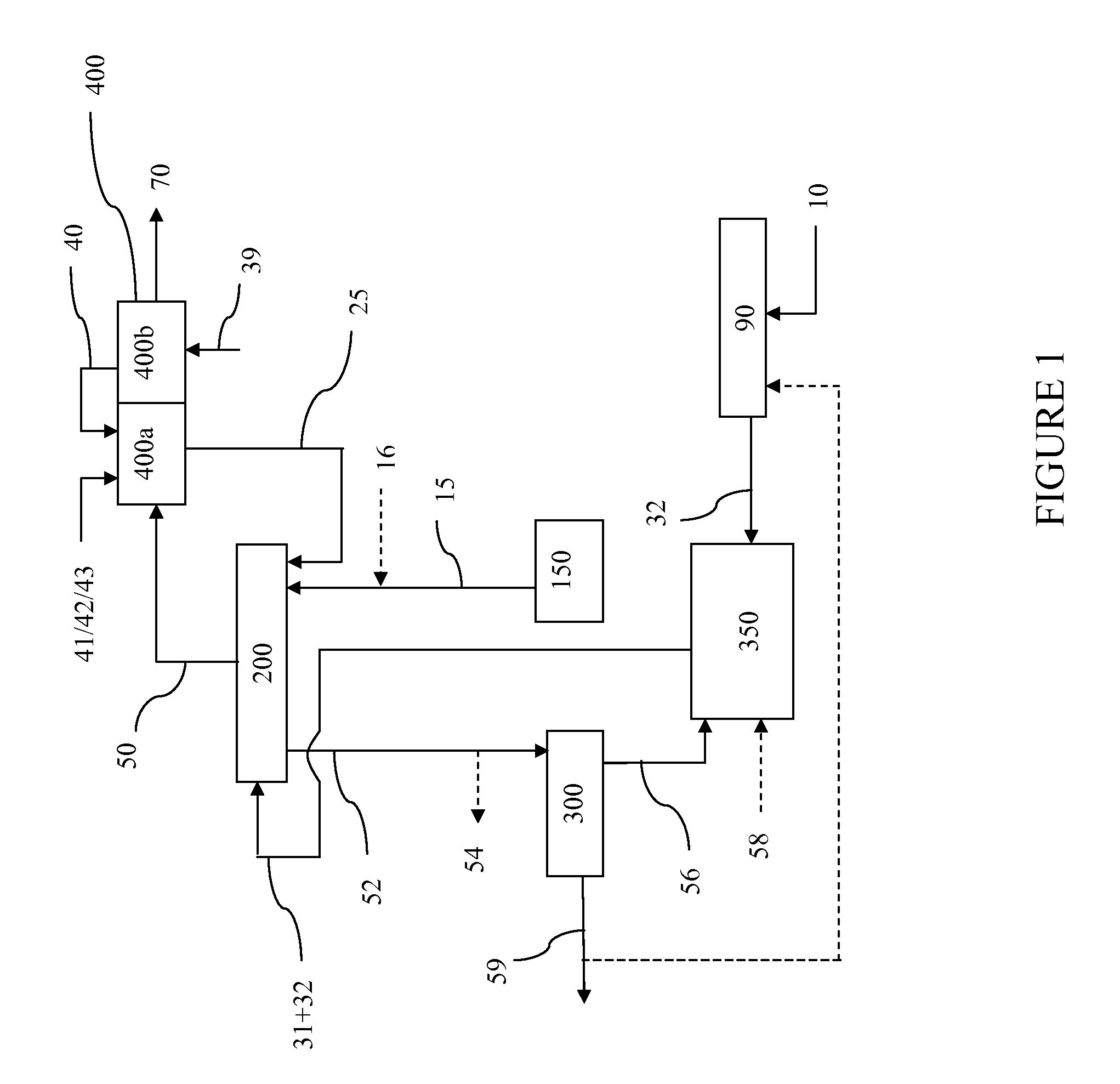

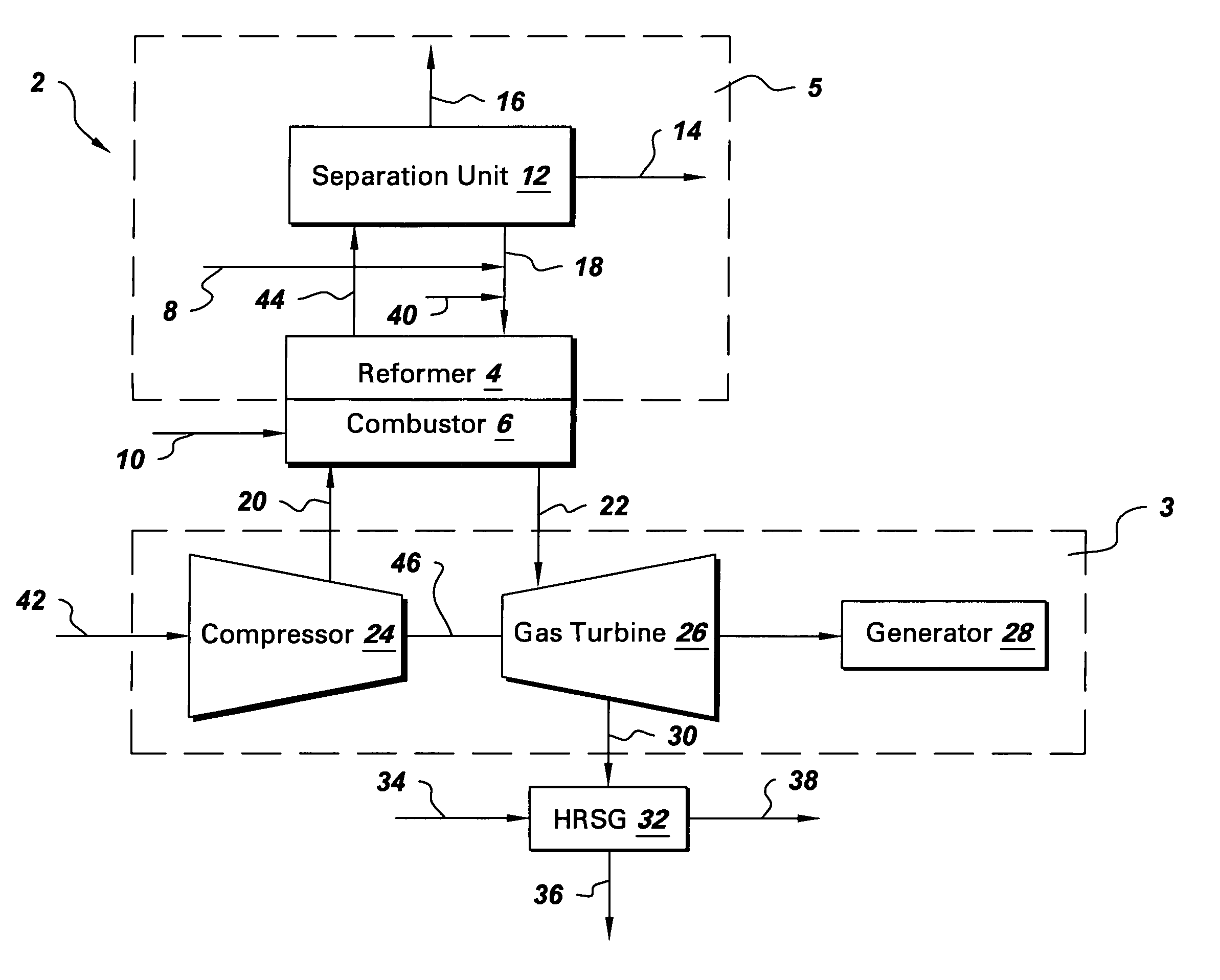

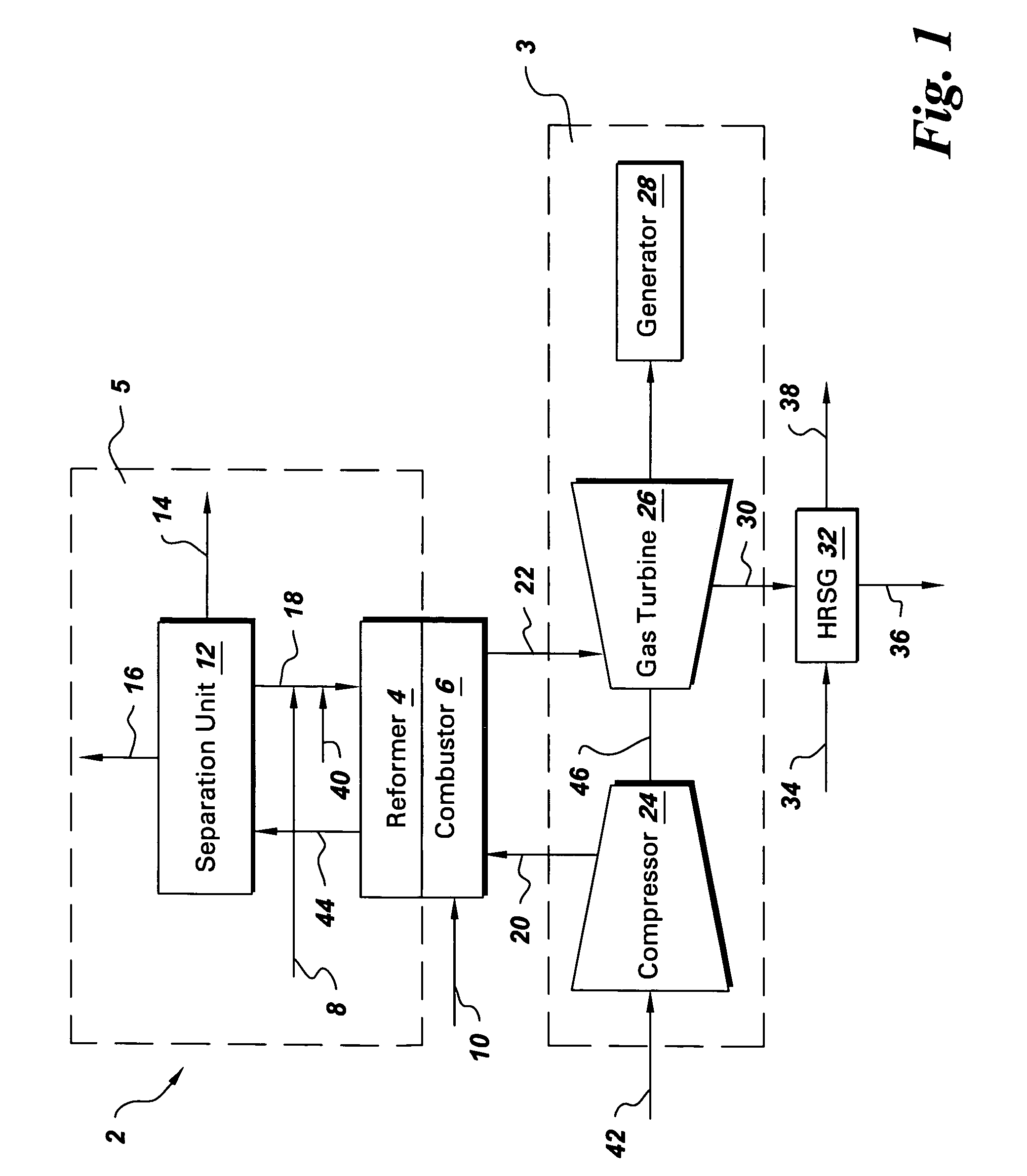

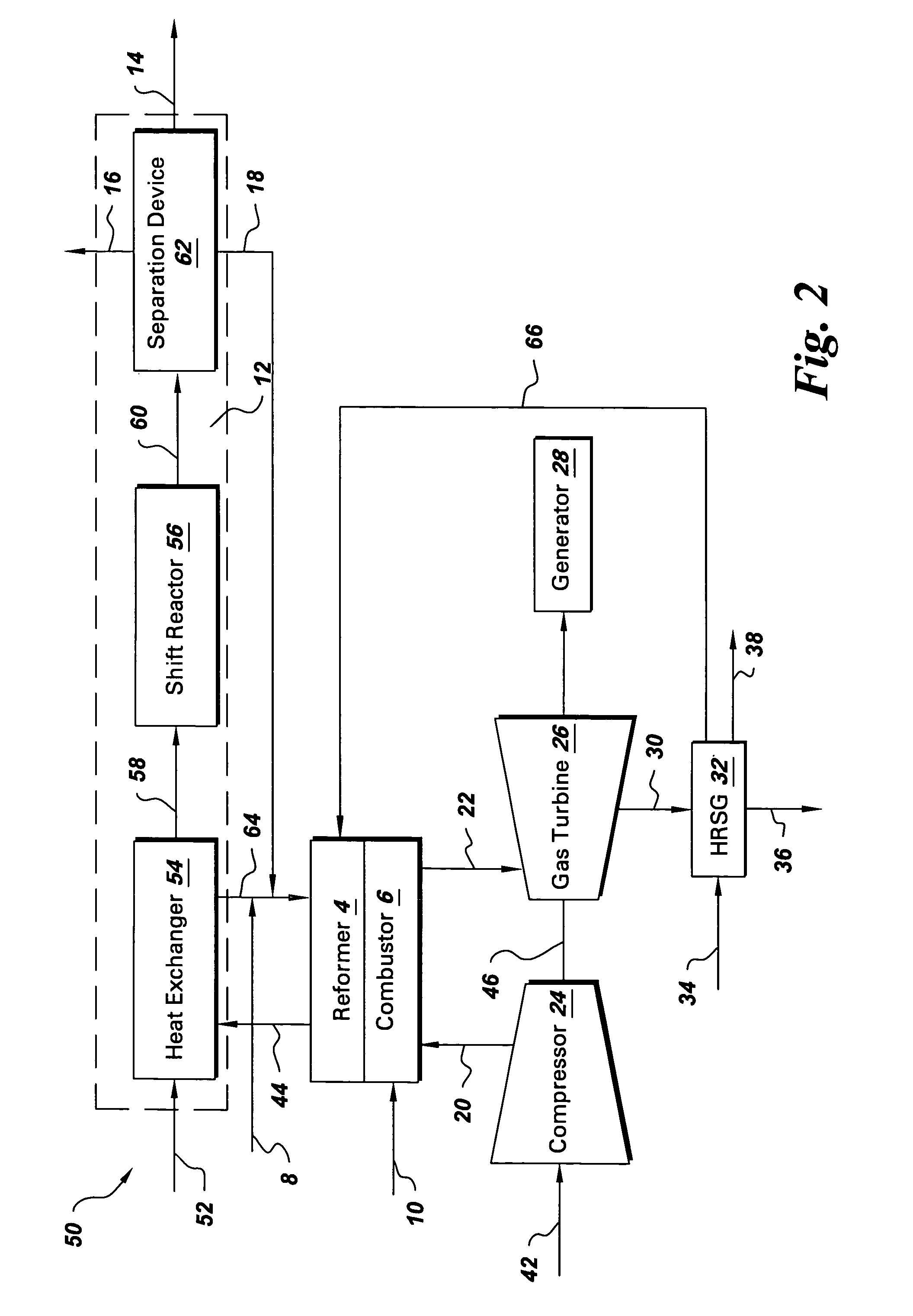

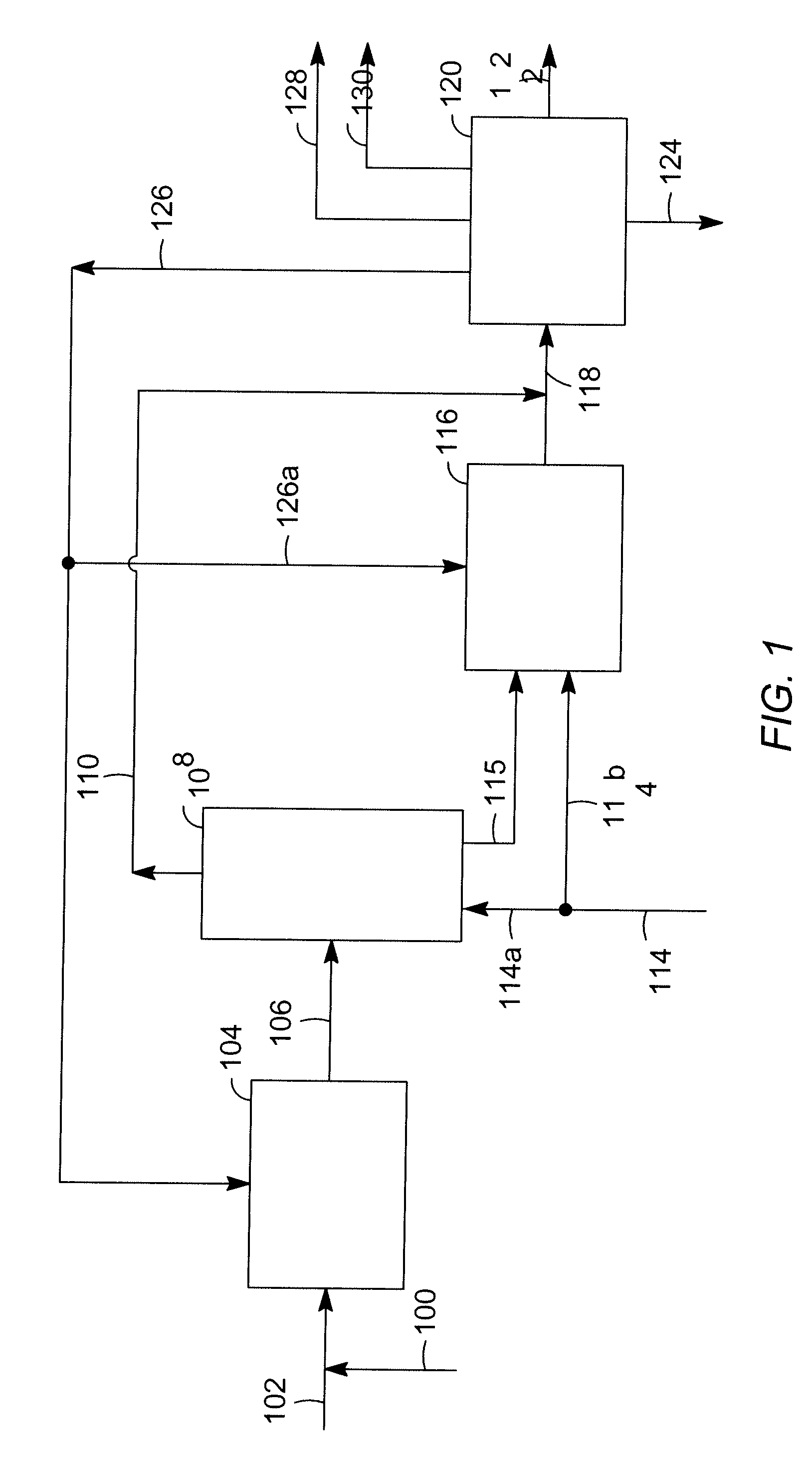

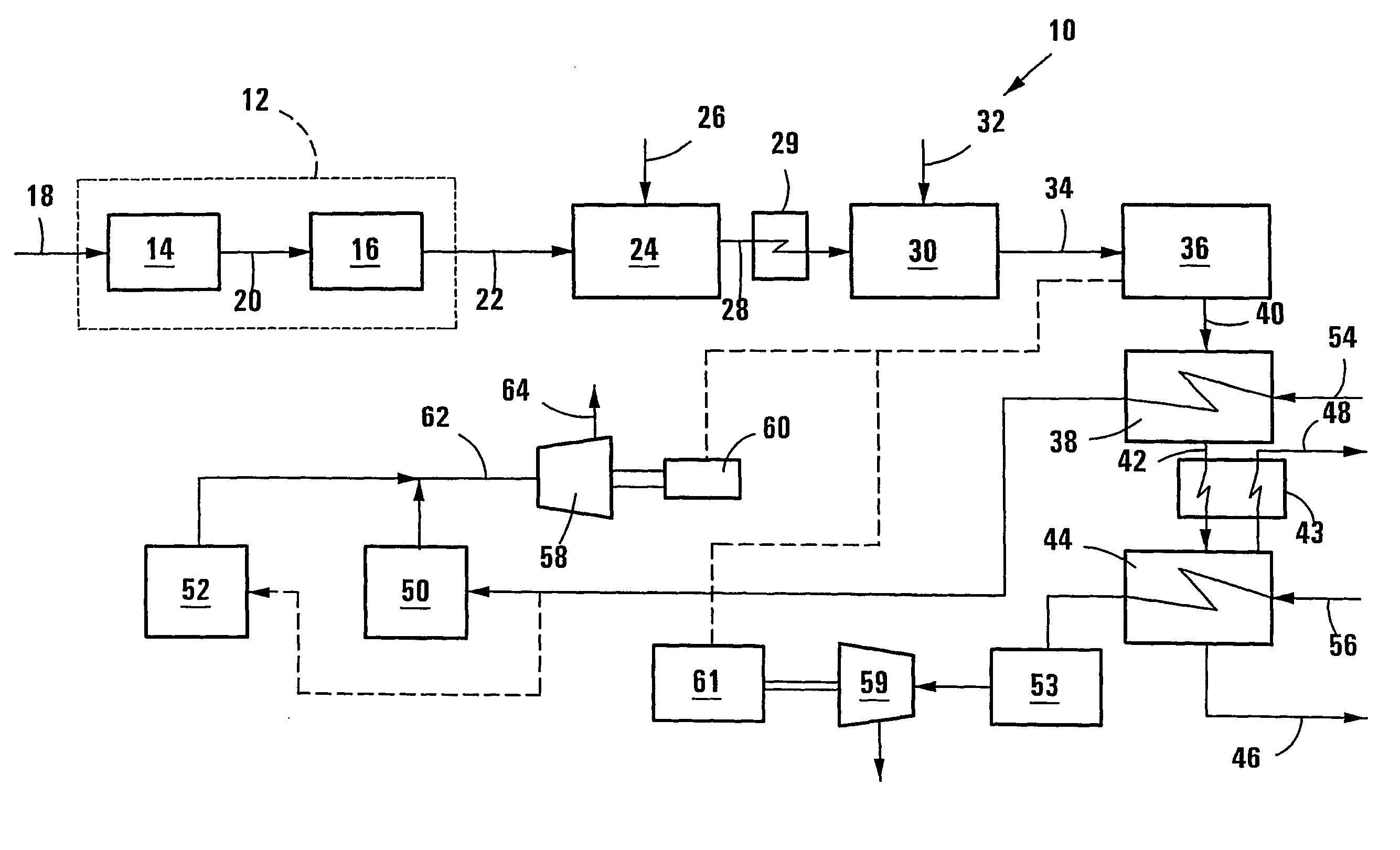

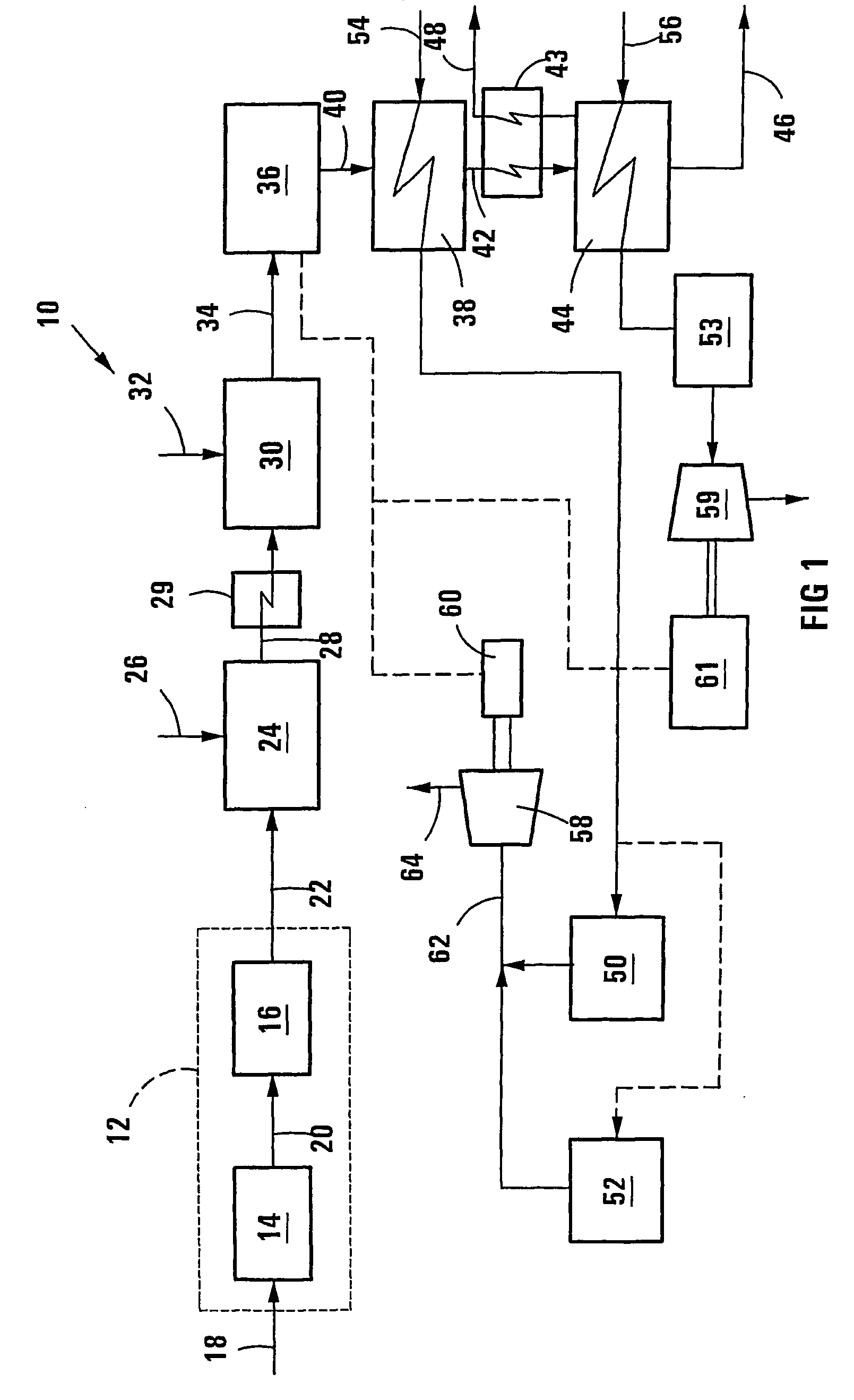

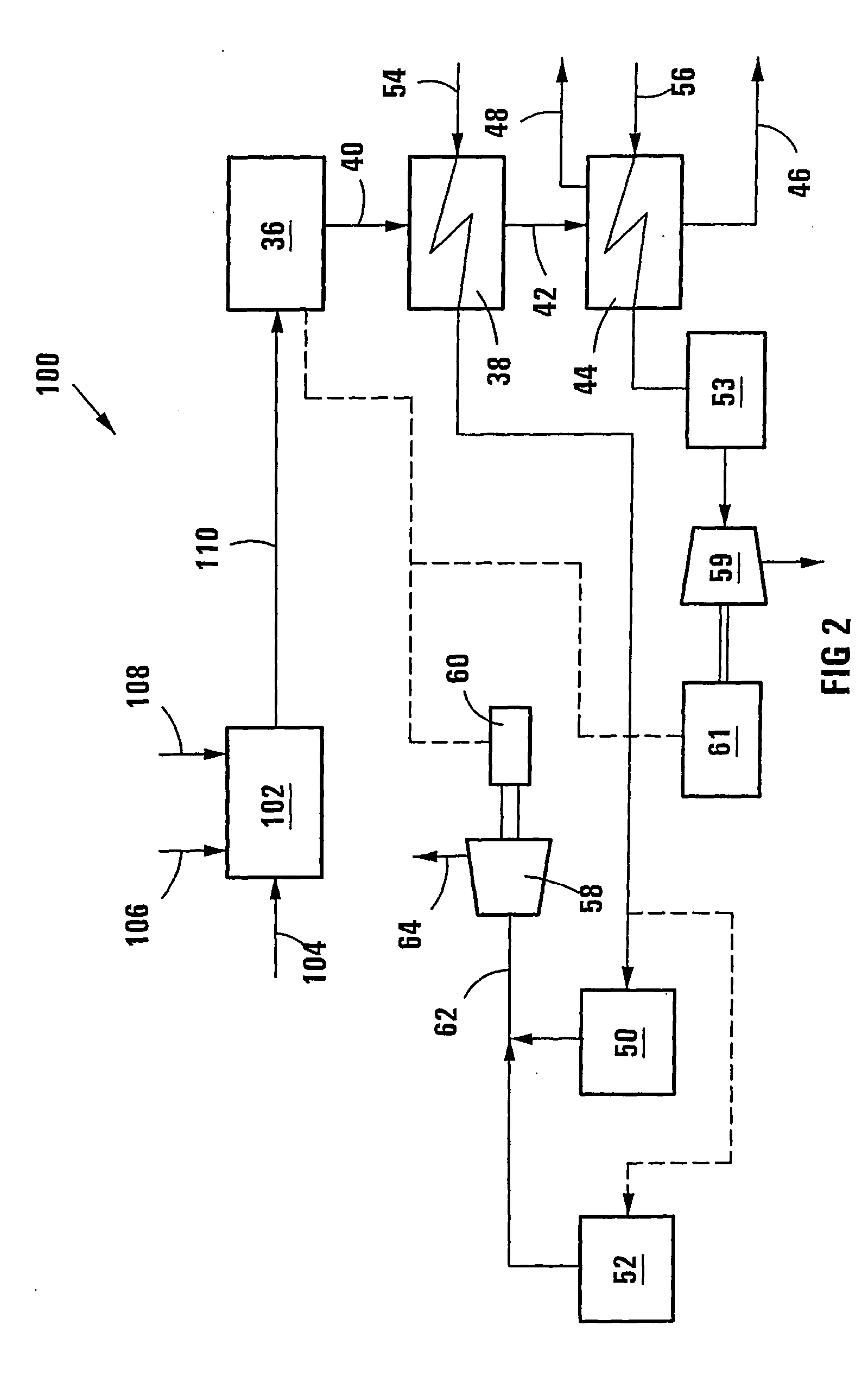

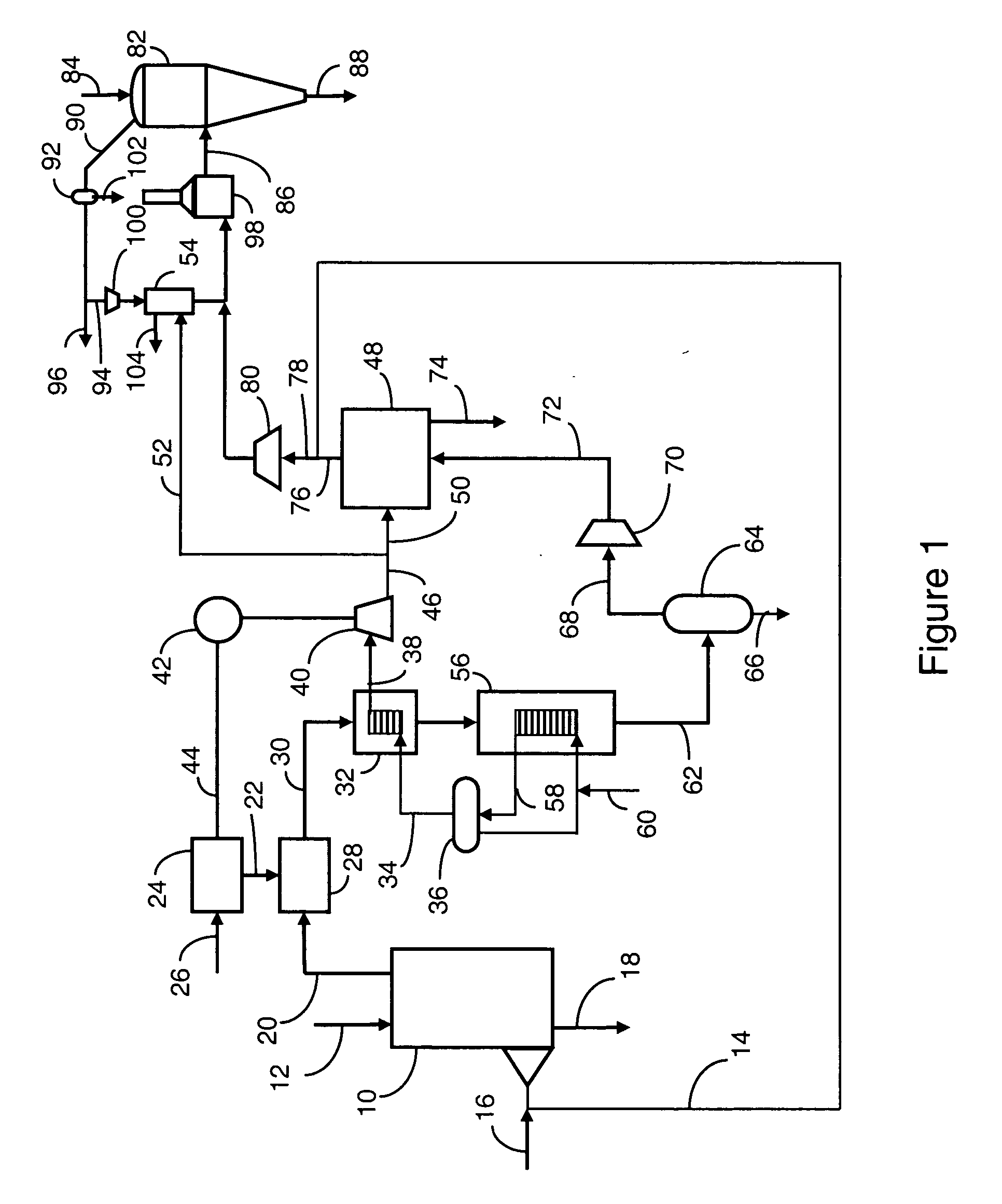

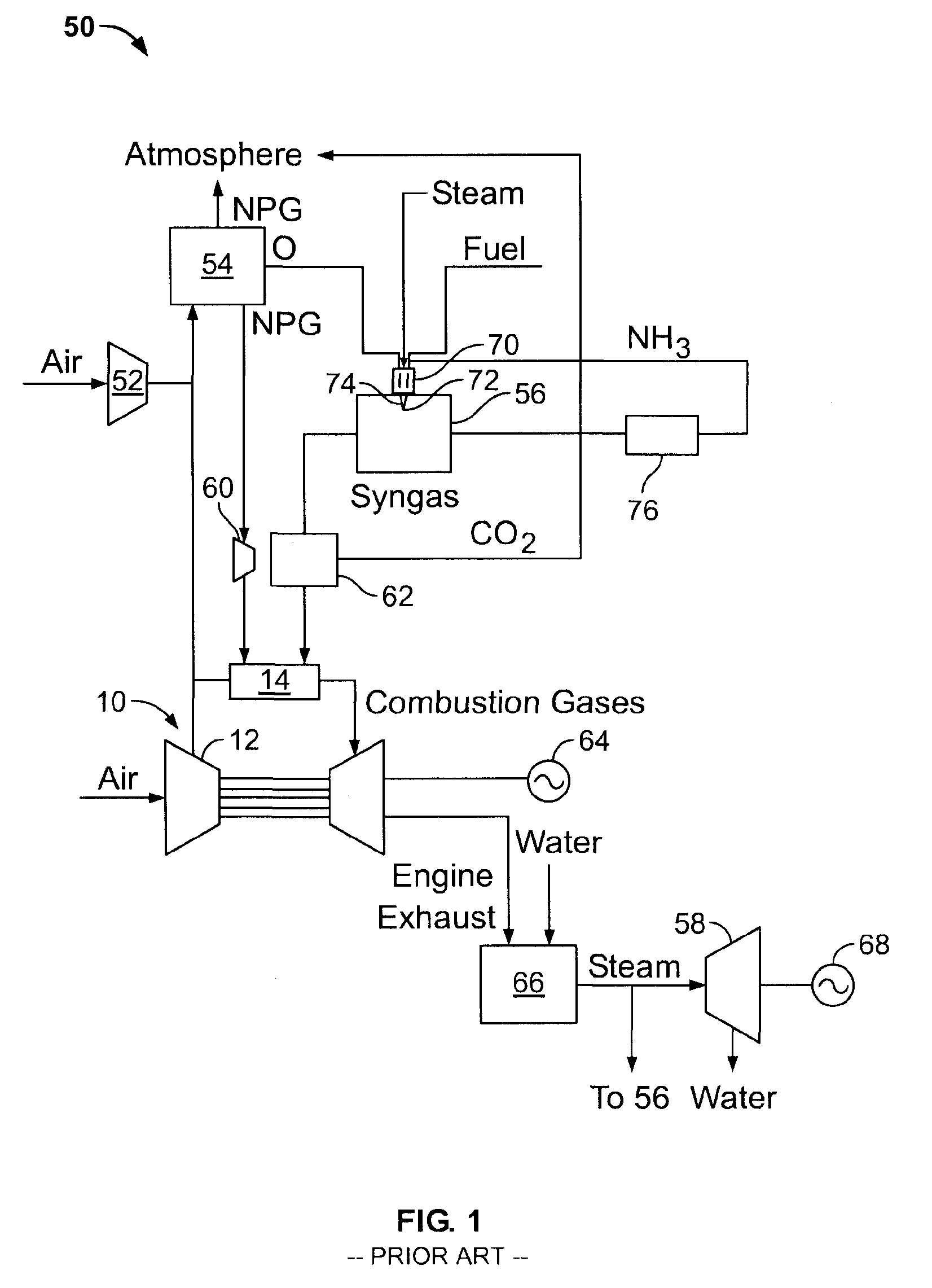

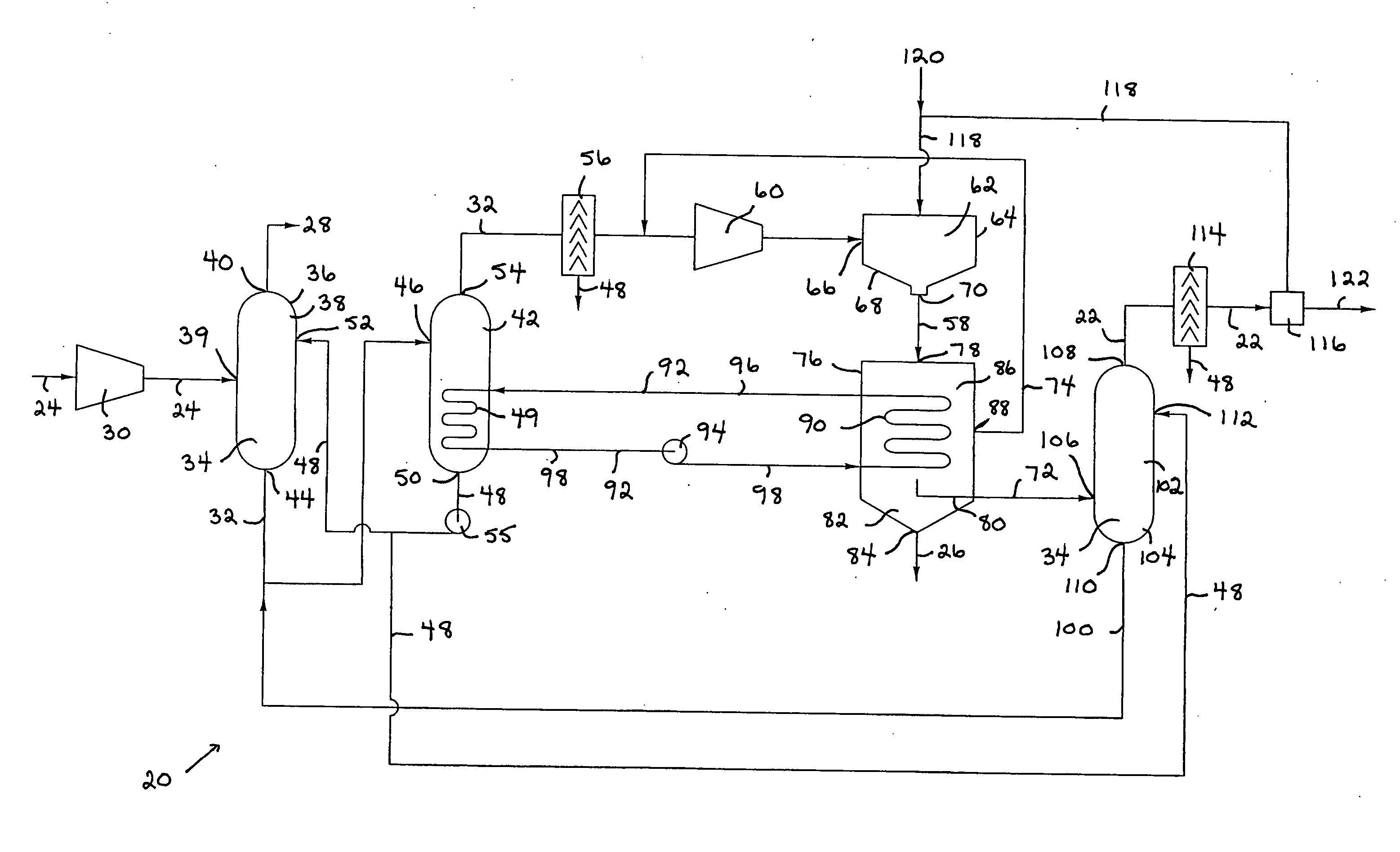

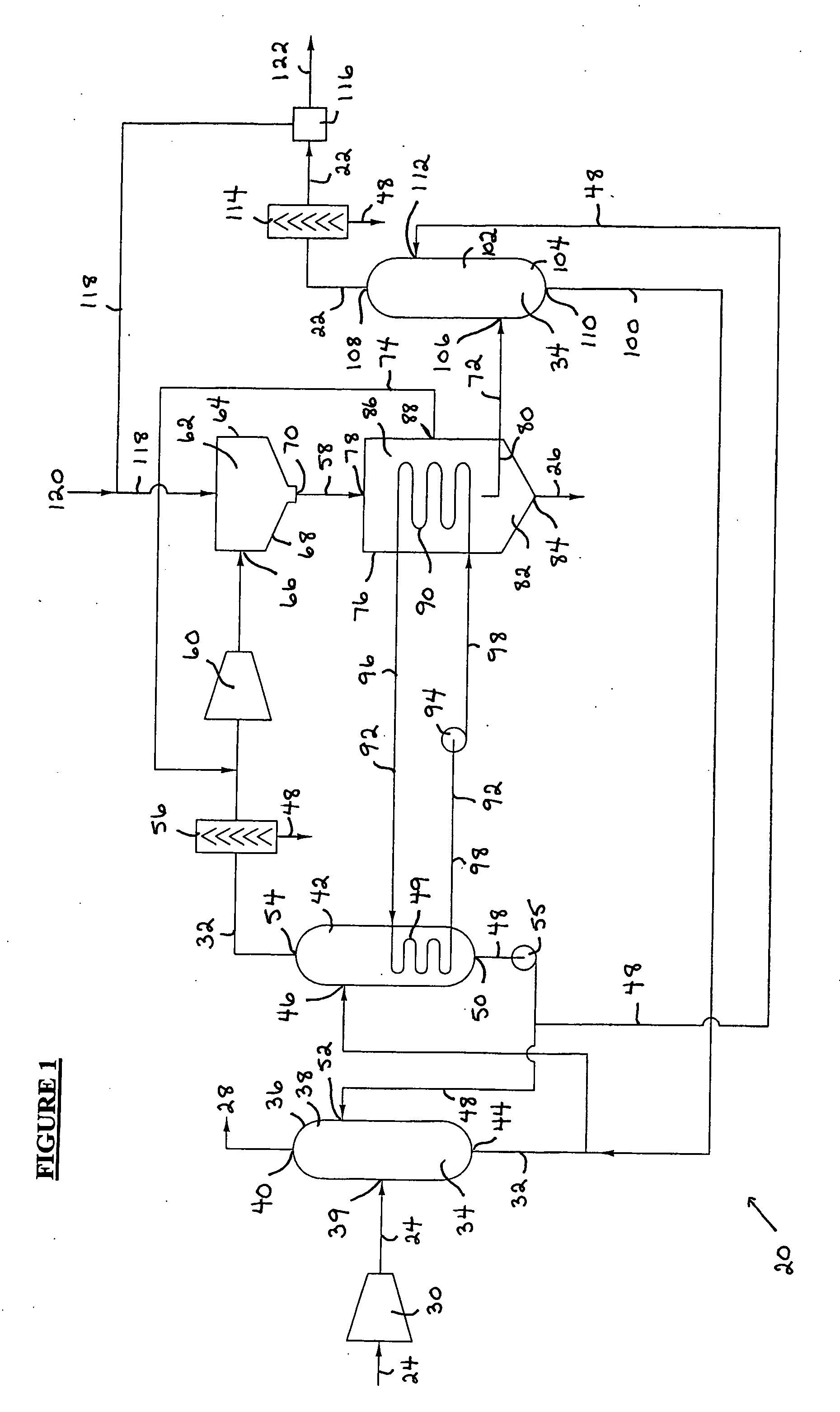

System and method for co-production of hydrogen and electrical energy

A system for co-production of hydrogen and electrical energy comprising a reformer configured to receive a reformer fuel and steam and produce a reformate rich in hydrogen. The system further comprises a separation unit in fluid communication with the reformer wherein the separation unit is configured to receive the reformate to separate hydrogen from the reformate and produce an off gas. The system also includes a combustor configured to receive a fuel for combustion and produce heat energy and a hot compressed gas, wherein the combustor is coupled with the reformer. A gas turbine expands the hot compressed gas and produces electrical energy and an expanded gas; wherein at least a part of the heat energy from the combustor is used to produce the reformate in the reformer.

Owner:GENERAL ELECTRIC CO

Combustion looping using composite oxygen carriers

ActiveUS7767191B2Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

Production of Diesel Fuel from Renewable Feedstocks with Reduced Hydrogen Consumption

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel. Water is added to the deoxygenation reaction to drive carbon monoxide and water to react to form hydrogen and carbon dioxide. The hydrogen is then consumed by the reactions. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties.

Owner:UOP LLC

Production of diesel fuel from renewable feedstocks with reduced hydrogen consumption

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel. Water is added to the deoxygenation reaction to drive carbon monoxide and water to react to form hydrogen and carbon dioxide. The hydrogen is then consumed by the reactions. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties.

Owner:UOP LLC

Production of synthesis gas and synthesis gas derived products

A process for upgrading raw synthesis gas comprising at least CH4, CO2, CO and H2, includes heating the raw synthesis gas by addition of energy derived from electricity to provide an upgraded synthesis gas comprising less CH4 and CO2 and more CO and H2 than the raw synthesis gas. The invention extends to a process for producing synthesis gas, which process includes reforming a hydrocarbonaceous gas feedstock which includes CH4 to raw synthesis gas comprising at least CH4, CO2, CO and H2, and upgrading the raw synthesis gas in a process which includes heating the raw synthesis gas by addition of energy derived from electricity to provide an upgraded synthesis gas comprising less CH4 and CO2 and more CO and H2 than the raw synthesis gas.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

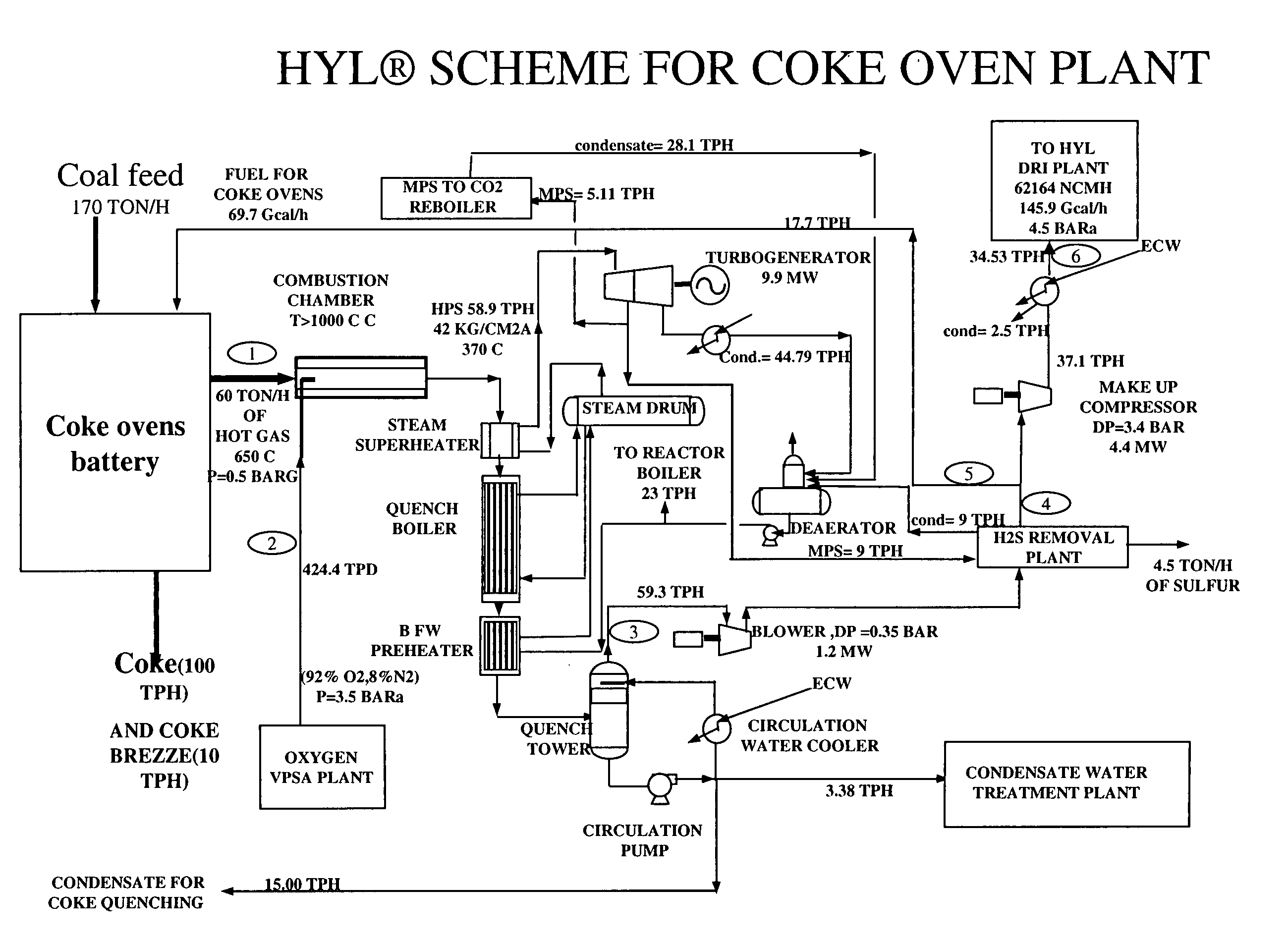

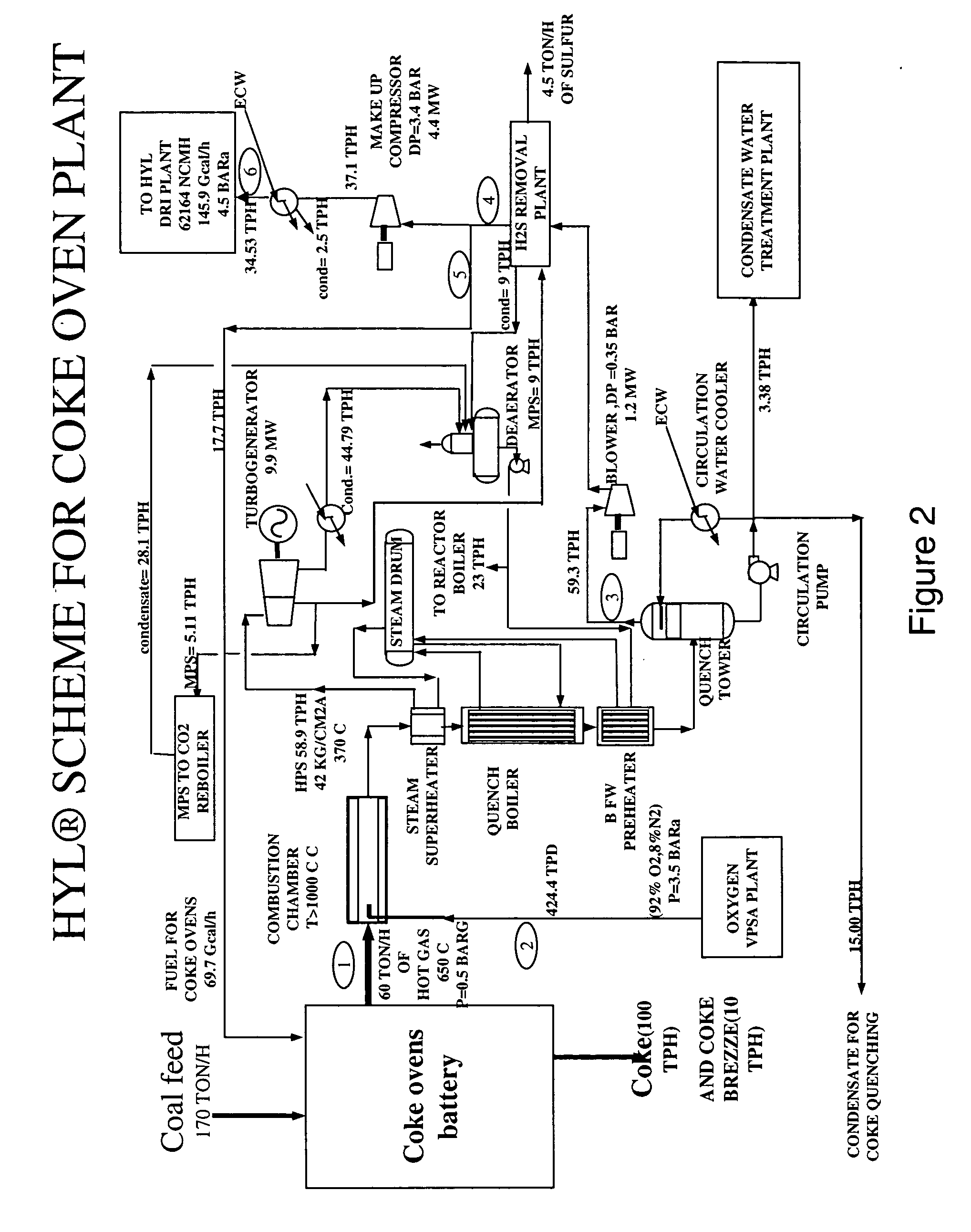

Method and apparatus for producing clean reducing gases from coke oven gas

InactiveUS20060027043A1Avoiding complex and expensiveOxygen/ozone/oxide/hydroxideHydrogen separationProcess engineeringCoke oven

A process and system for producing reducing gases are disclosed, wherein volatile components derived from coal are transformed into reducing gases suitable for utilization as synthesis gas, as a reducing agent for the direct reduction of iron ores and / or as a clean fuel.

Owner:HYLSA SA DE CV

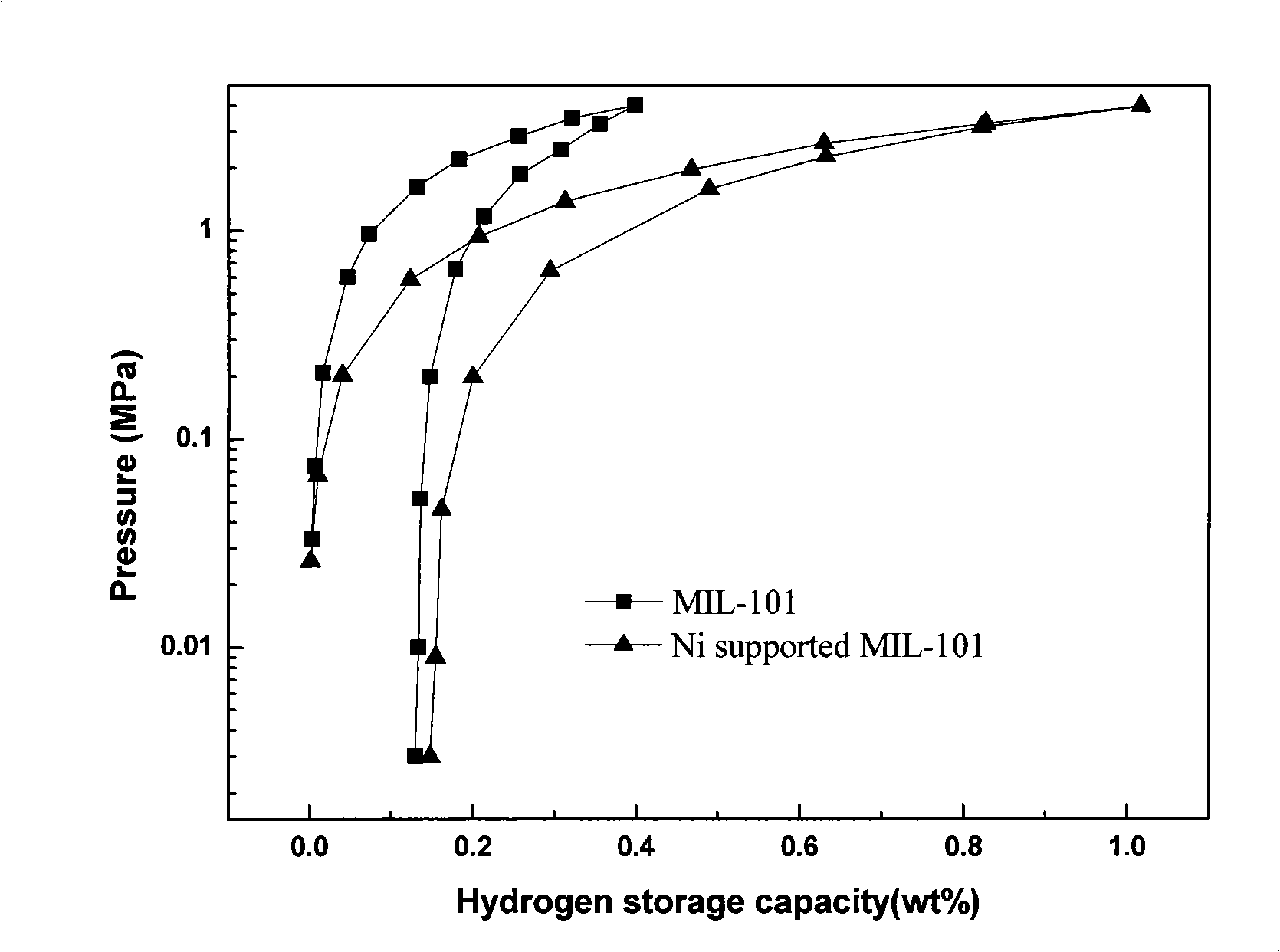

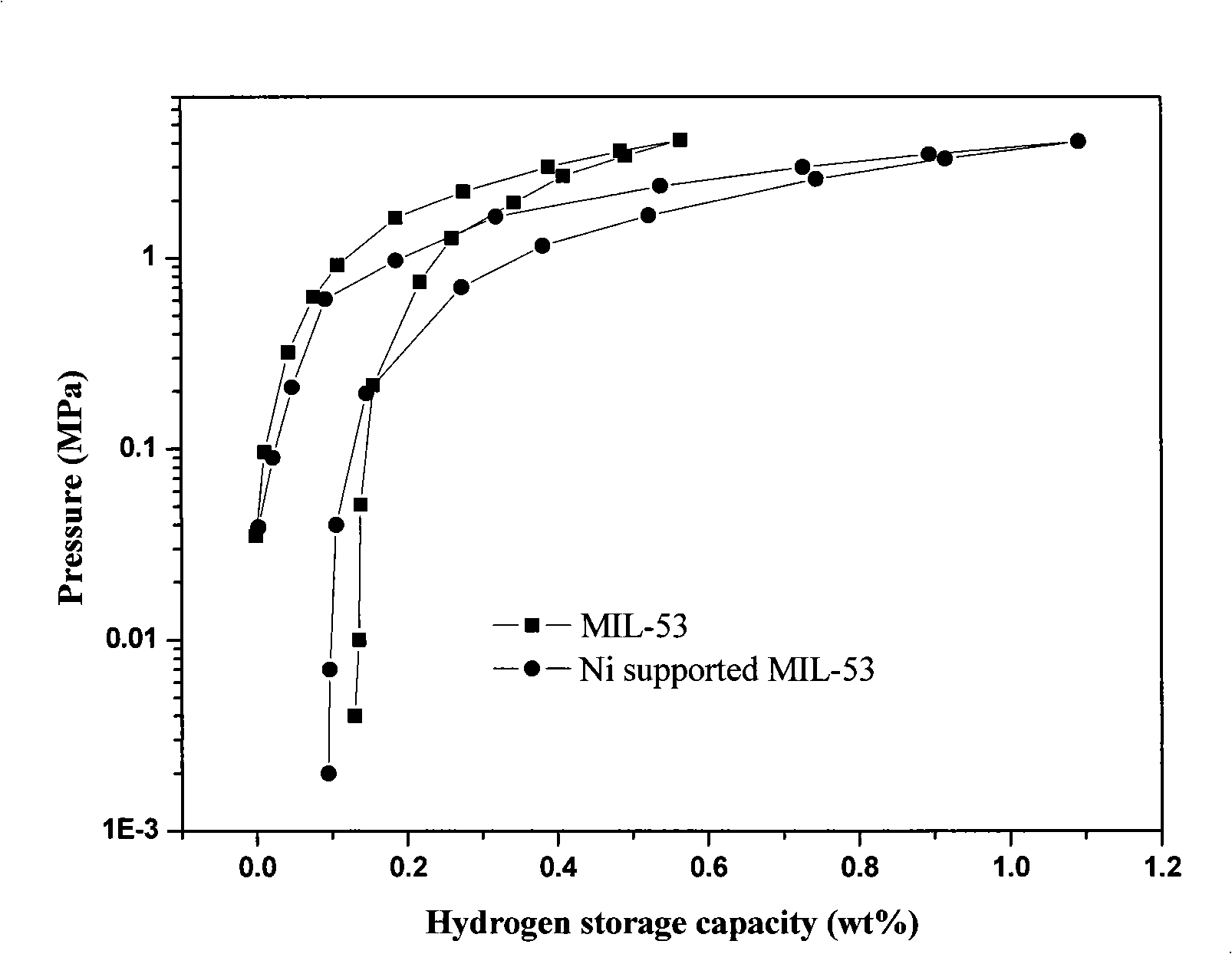

Load type stephanoporate metal organic compound hydrogen storing material

ActiveCN101269317AHigh yieldImprove hydrogenation activityHydrogen separationOther chemical processesSynthesis methodsCarboxylic acid

The invention relates to a hydrogen storage material, in particular to a load porous metal organic hydrogen storage material, being a load metal-porous metal organic compound composite material. The hydrogen storage material is made according to the following steps: (1) inorganic salt and organic acid are used as reagents, water or an organic solvent is adopted, a porous metal organic compound is prepared by a hydro-thermal synthesis method or a solvent-thermal synthesis method; (2) the porous material is loaded by soluble metal salt; the load metal-porous metal organic compound composite material is made by adopting a liquid phase method or a hydrogen reducing method; the loading amount of the metal is 2 to 20 percent of the mass of the composite material. The hydrogen storage material has simple preparation process and low cost; the chemical modification of the organic frame material of the porous metal can effectively improve the hydrogen absorbing and releasing performance of the material under a moderate condition, thereby providing a novel hydrogen storage material which realizes good hydrogen absorbing and releasing under the moderate condition.

Owner:KAILING CHEM ZHANGJIAGANG CO LTD

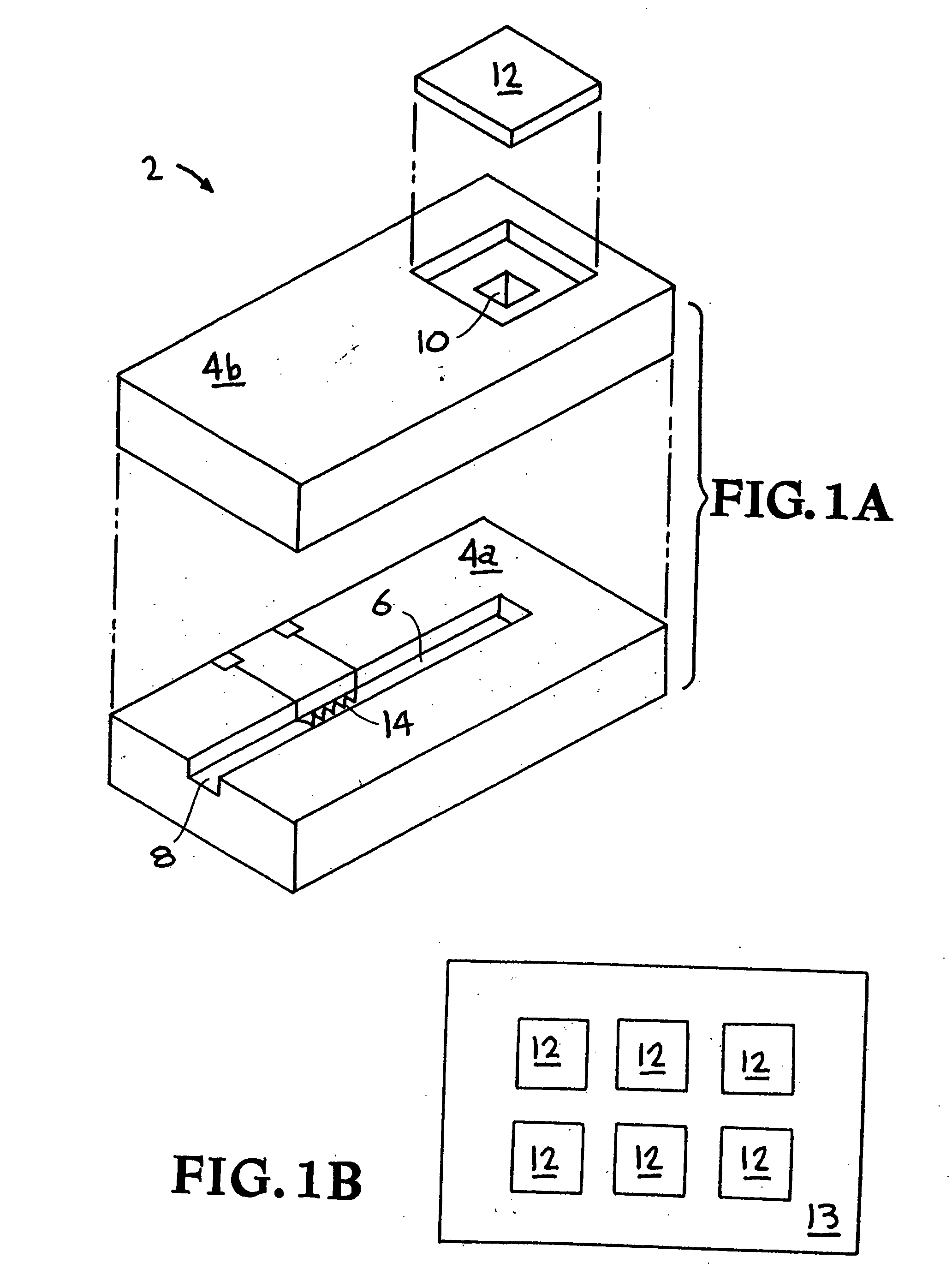

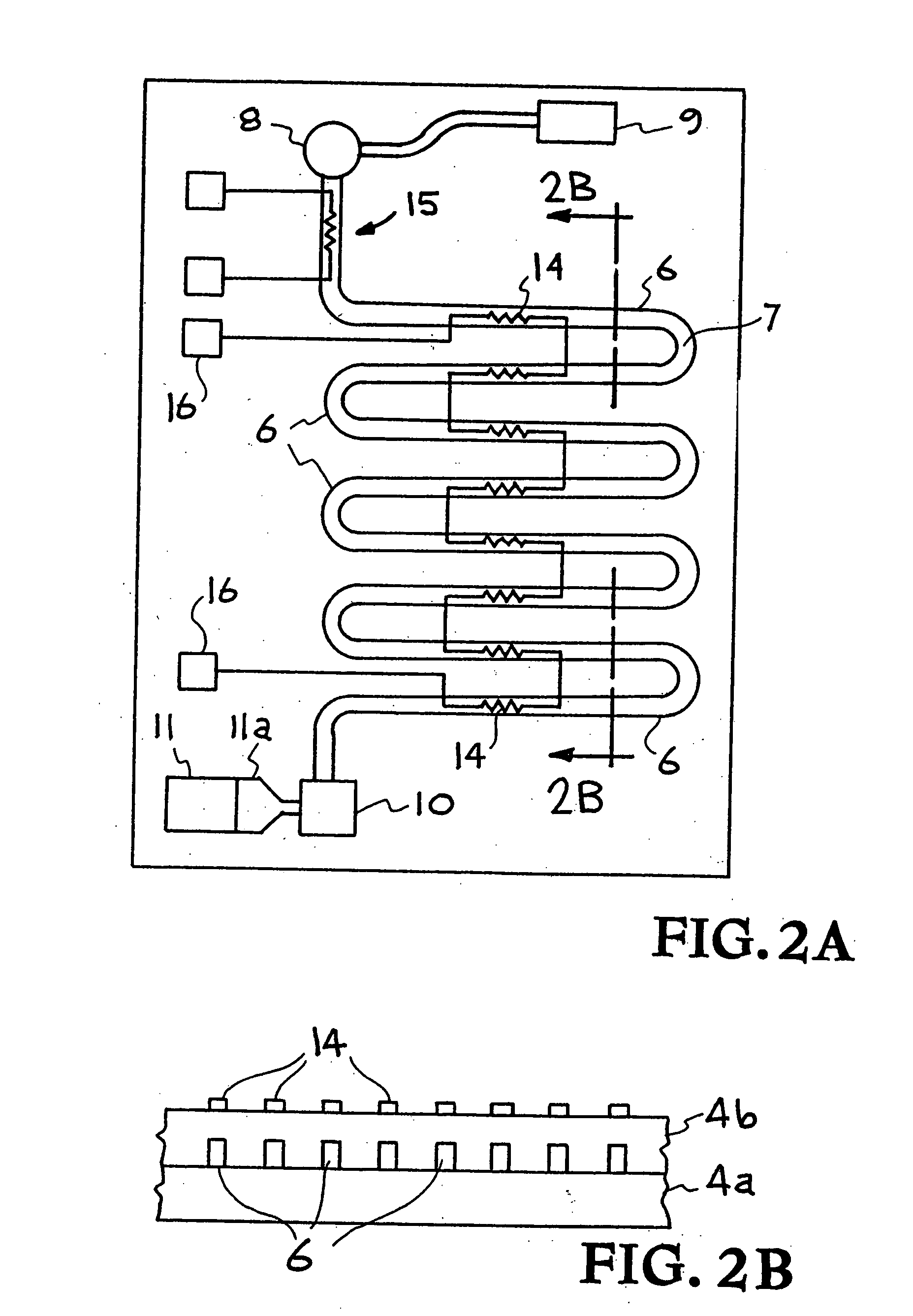

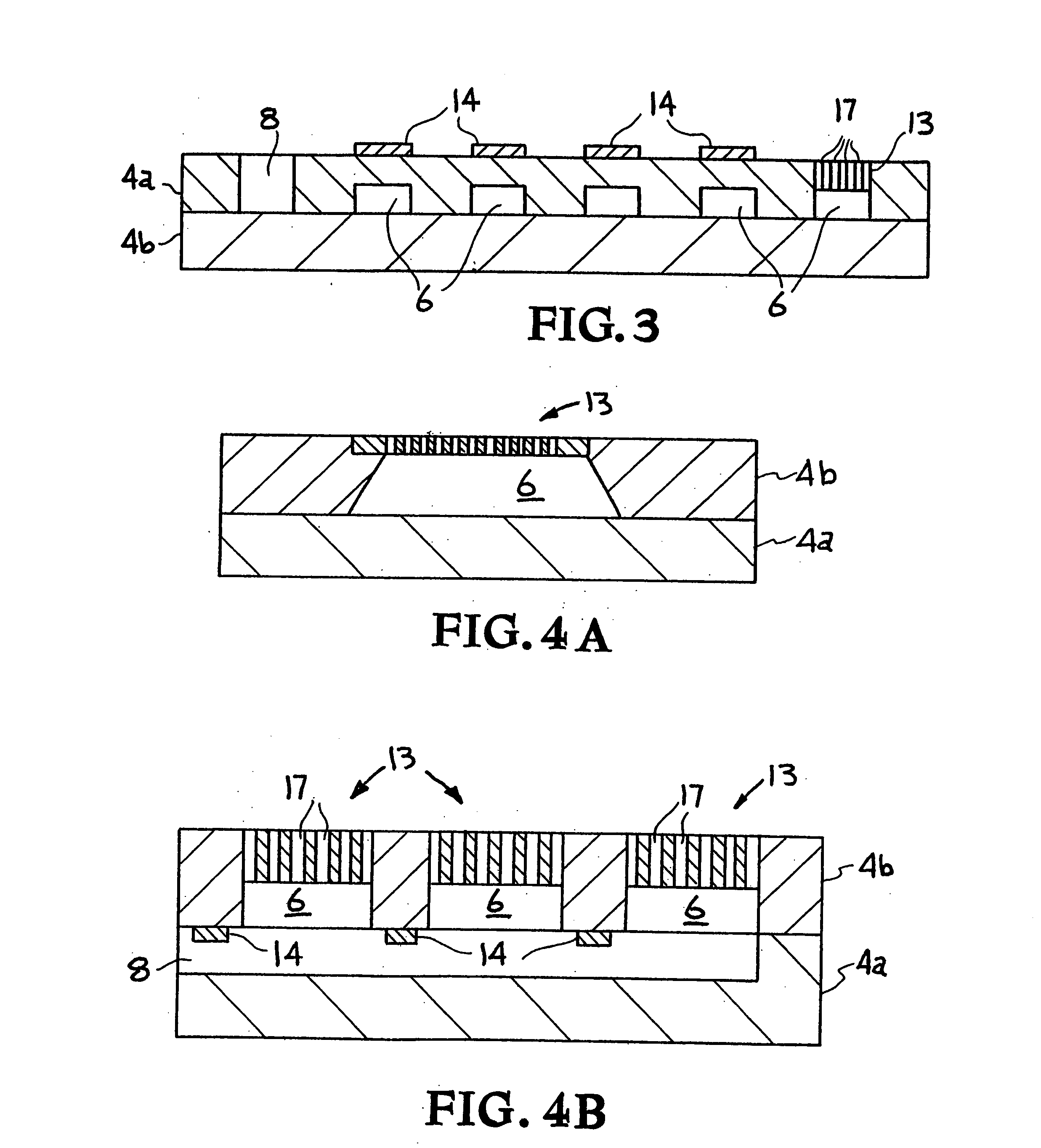

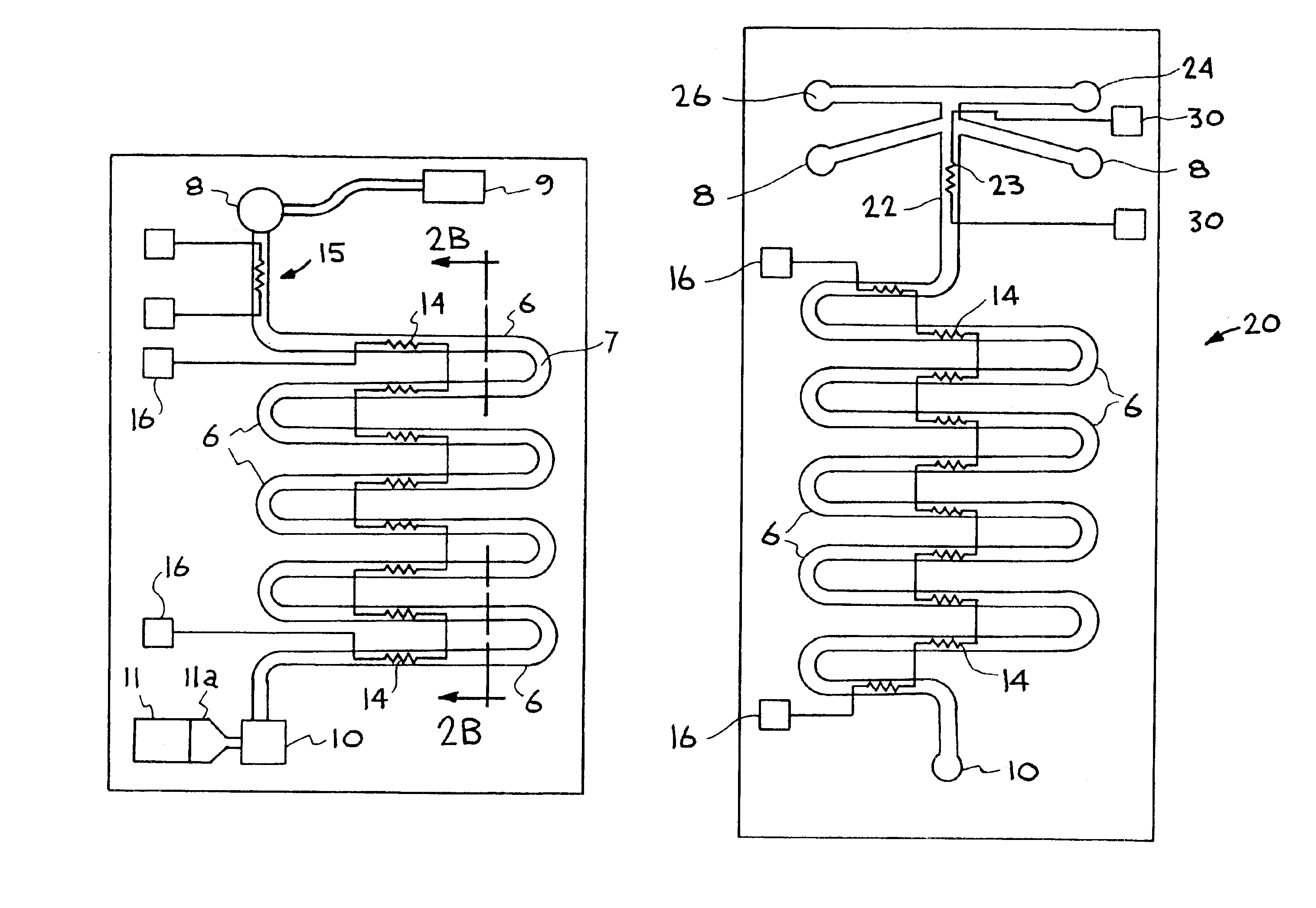

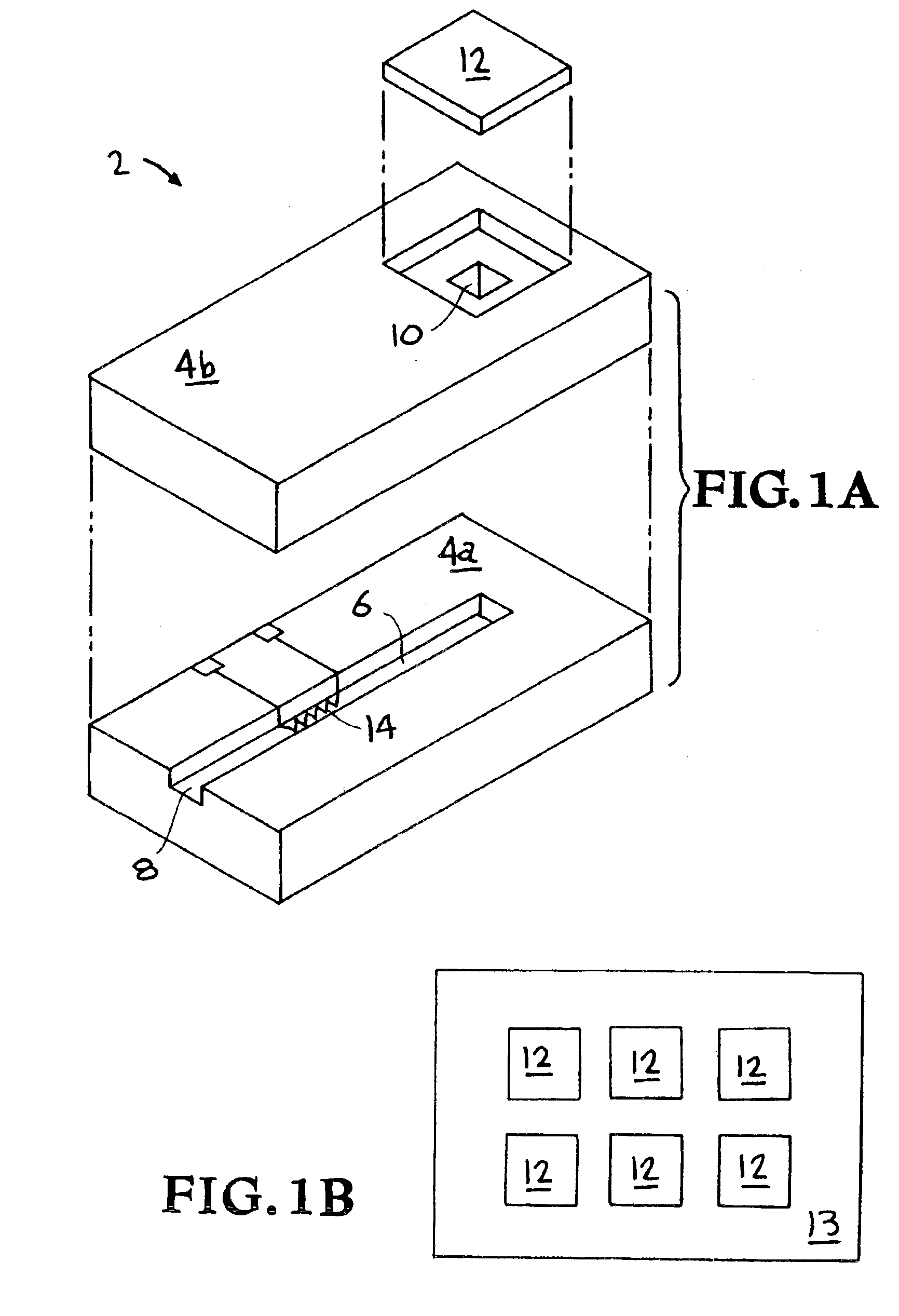

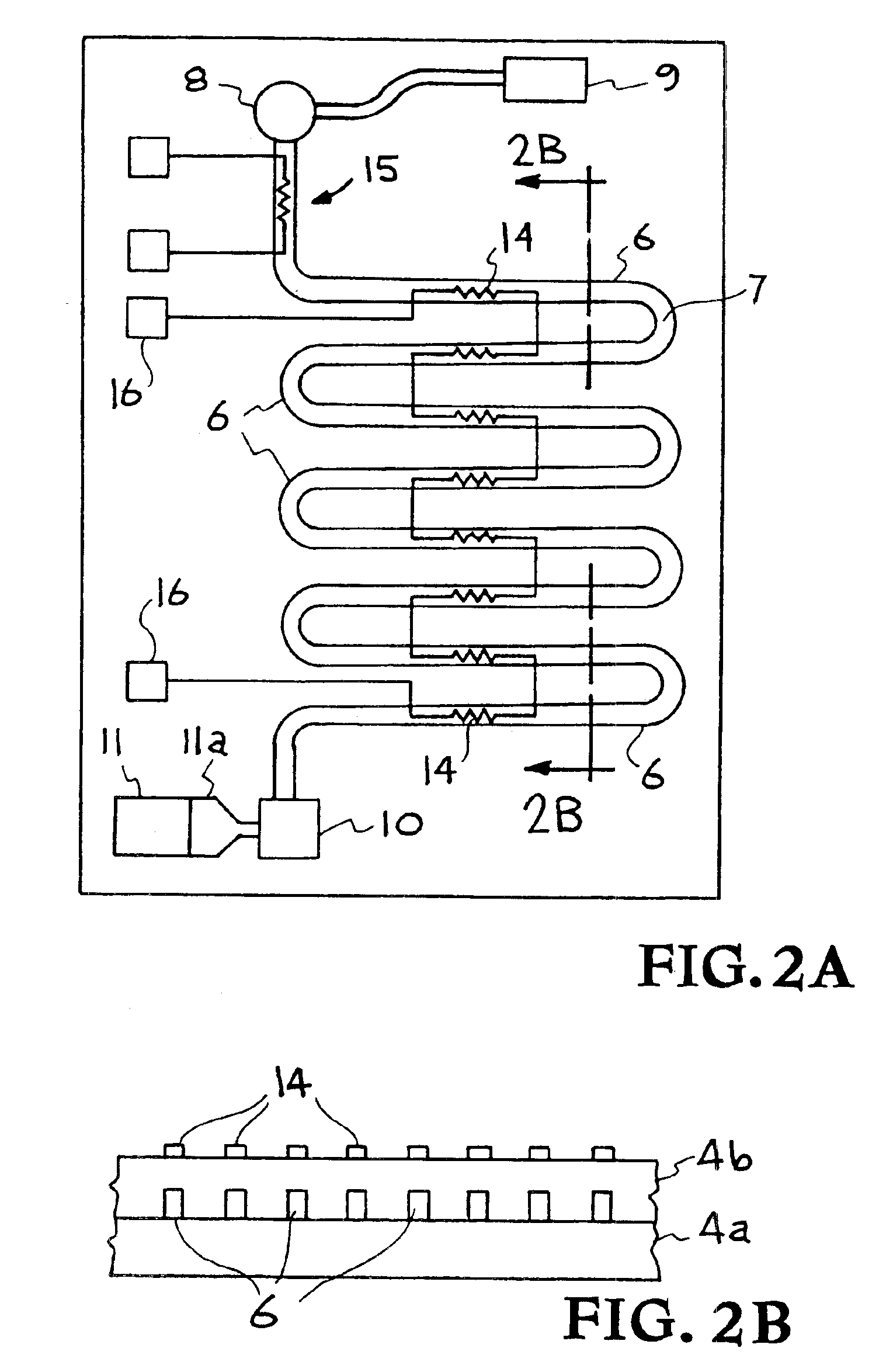

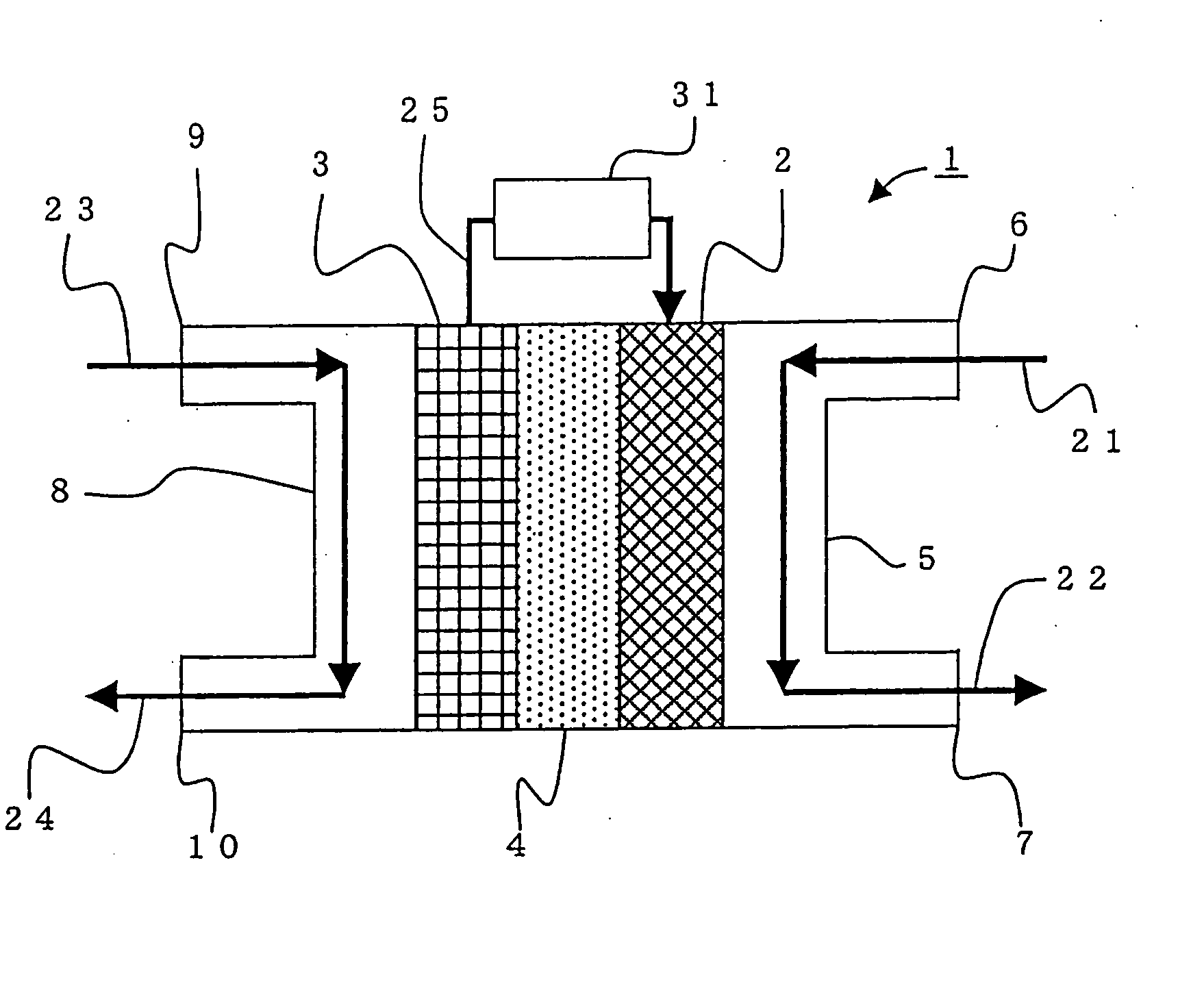

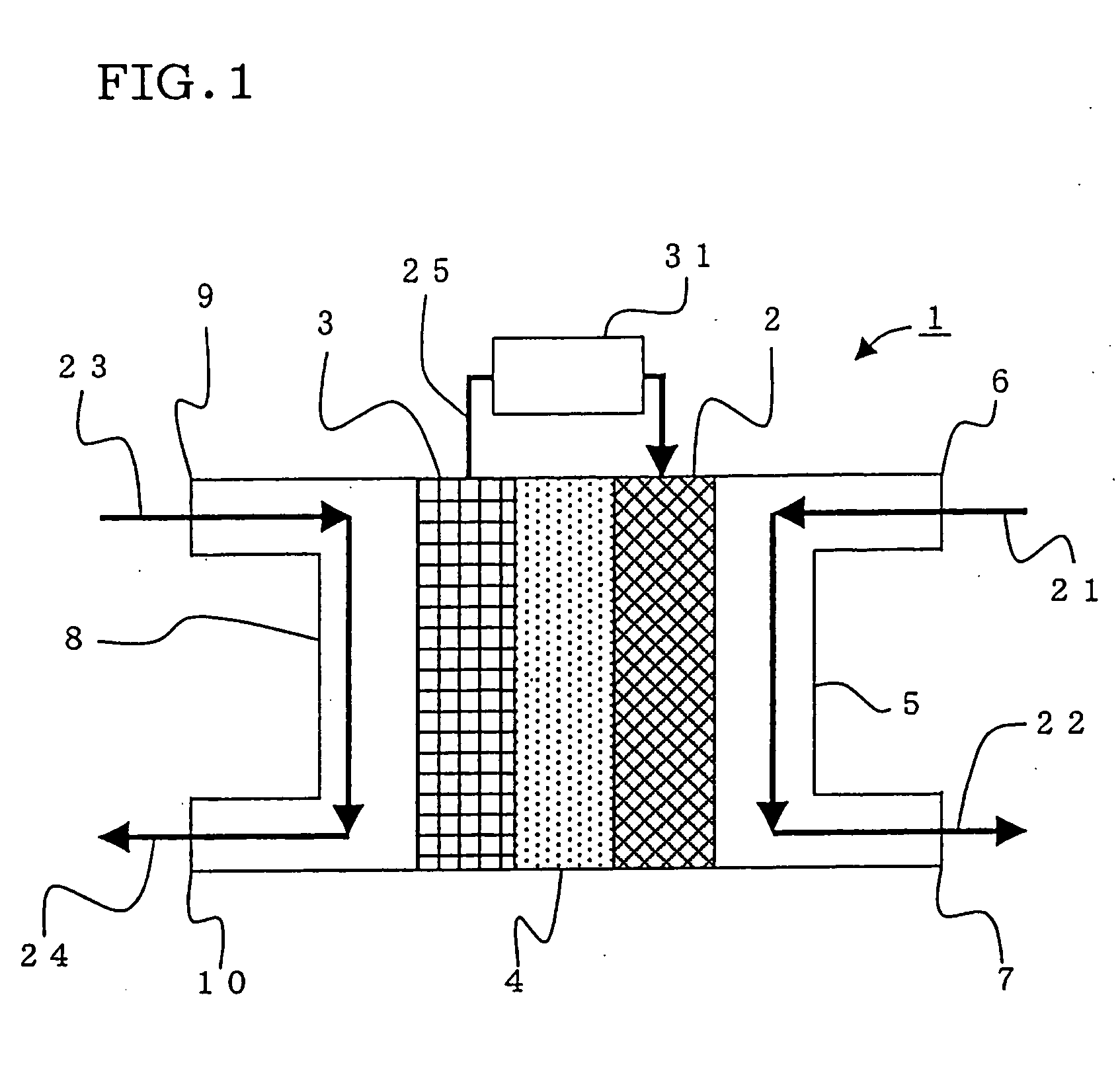

Chemical microreactor and method thereof

InactiveUS6960235B2Physical/chemical process catalystsHydrogen separationMicroreactorSteam reforming

A chemical microreactor suitable for generation of hydrogen fuel from liquid sources such as ammonia, methanol, and butane through steam reforming processes when mixed with an appropriate amount of water contains capillary microchannels with integrated resistive heaters to facilitate the occurrence of catalytic steam reforming reactions. One such microreactor employs a packed catalyst capillary microchannel and at least one porous membrane. Another employs a porous membrane with a large surface area or a porous membrane support structure containing a plurality of porous membranes having a large surface area in the aggregate, i.e., greater than about 1 m2 / cm3. The packed catalyst capillary microchannels, porous membranes and porous membrane support structures may be formed by a variety of methods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

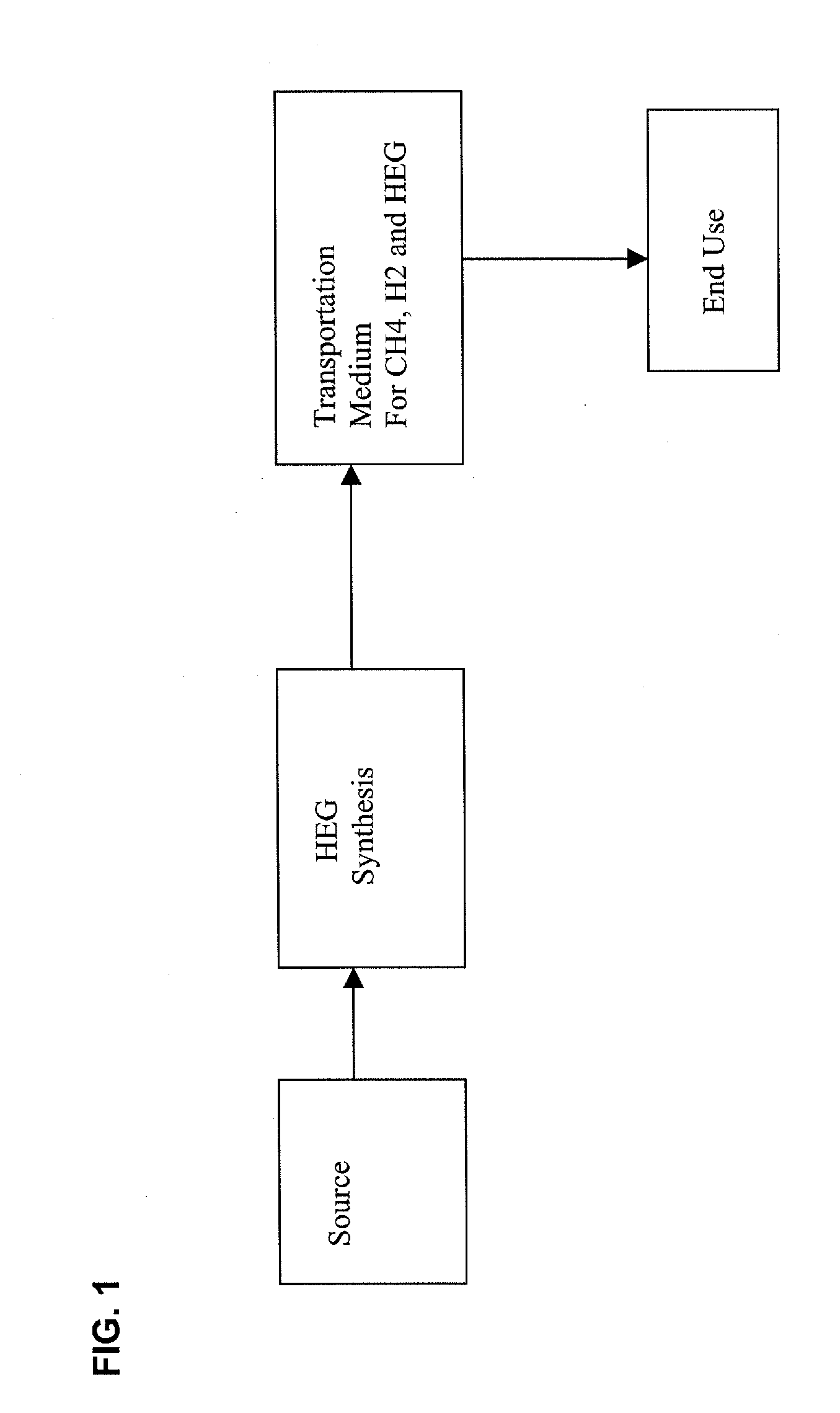

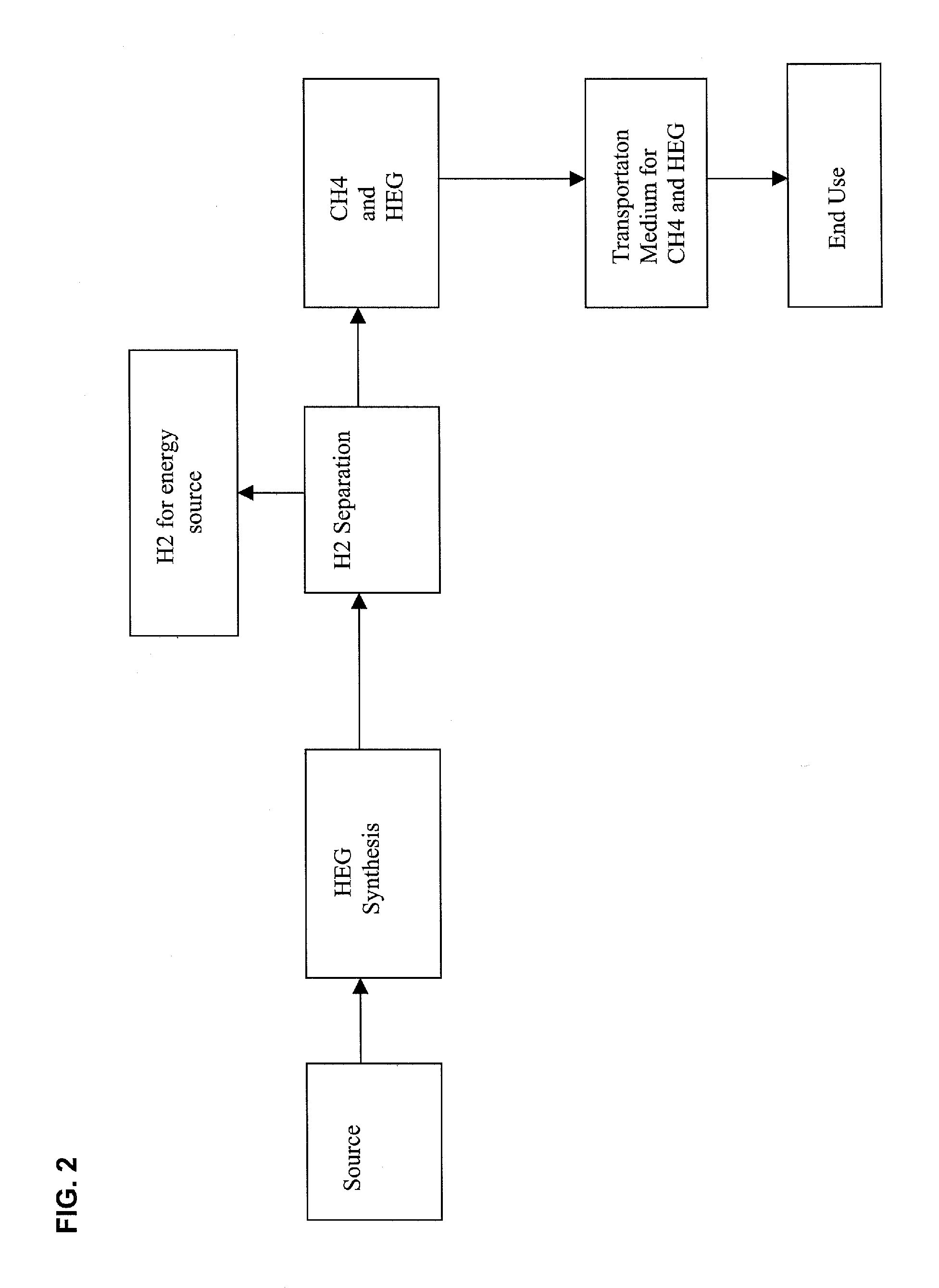

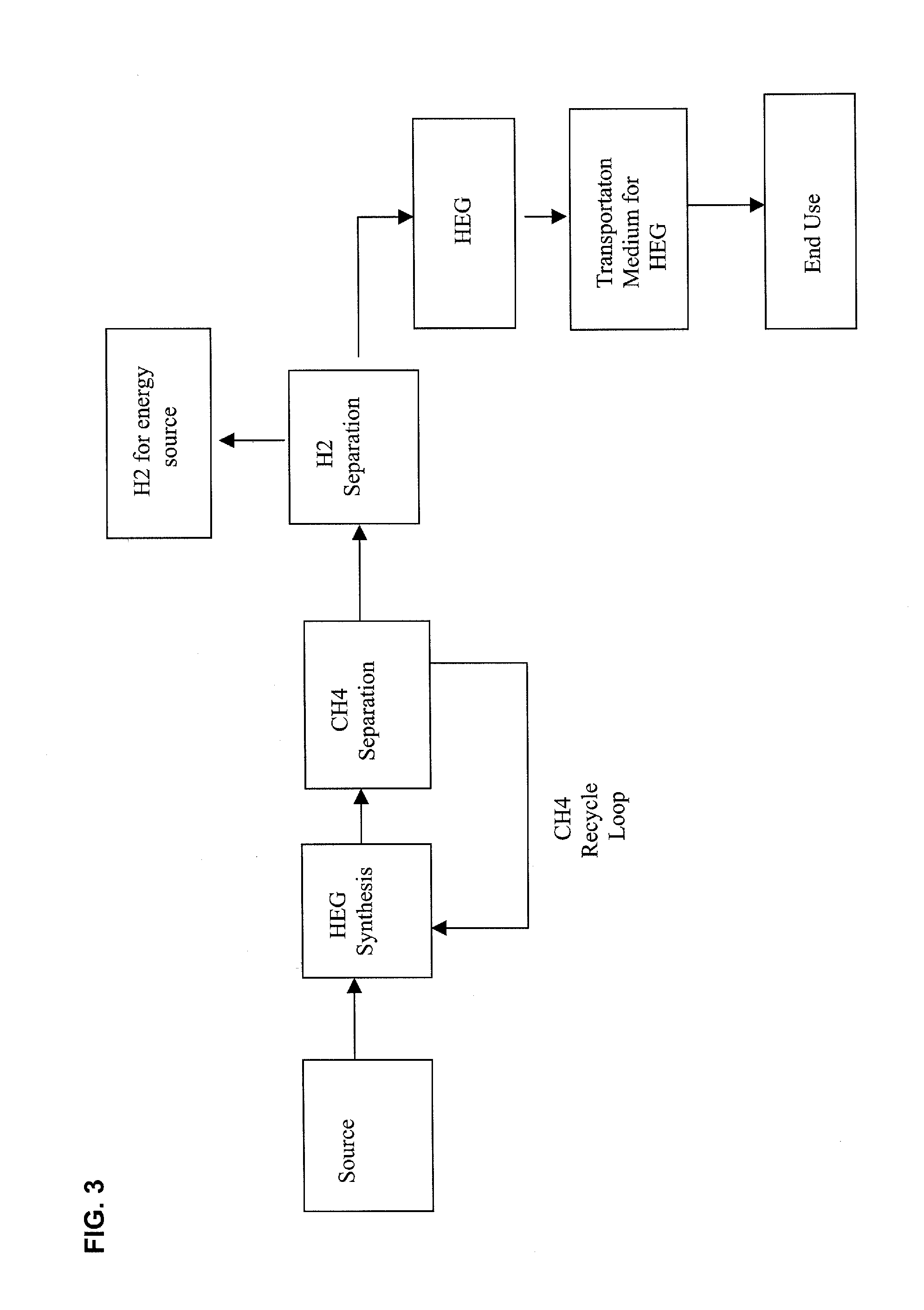

High energy transport gas and method to transport same

A high energy transport gas and a method to transport the high energy transport gas are used to increase the energy content of a pipeline and other vessels that are designed to carry natural gas under ambient conditions, in a compressed state or in a liquefied state. Methane and other gases are used as the feedstock, with methane from natural gas fields, coal beds or derived from hydrogen reacting with coal being primary energy sources. Also, this gas and method can provide an abundant source for hydrogen production, and the energy from hydrogen can be used for fuel cell applications that generate electricity and power motor vehicles. This gas and method are capable of increasing the energy capacity of current natural gas pipelines and other storage and transport vessels.

Owner:DALTON ROBERT C

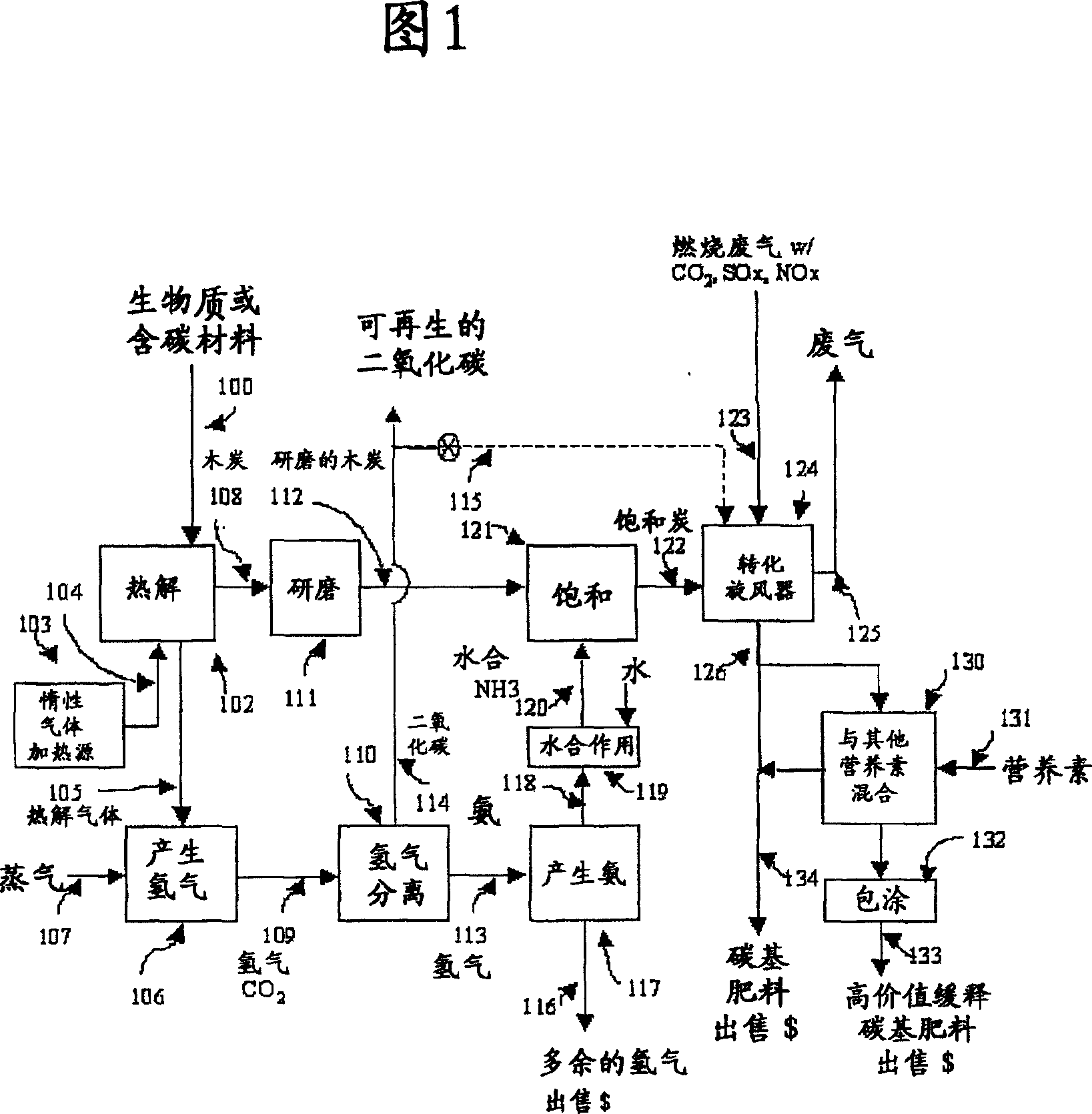

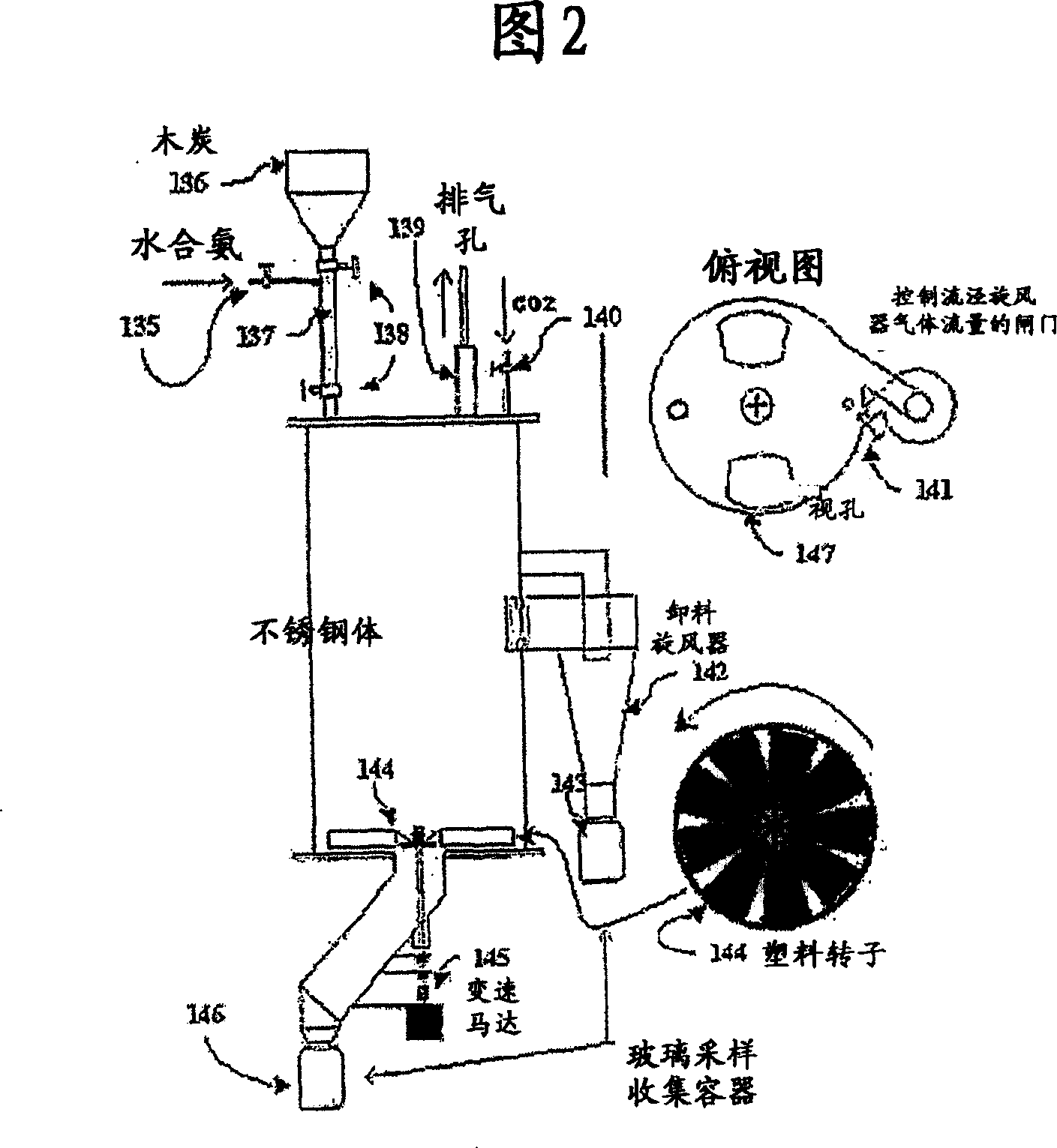

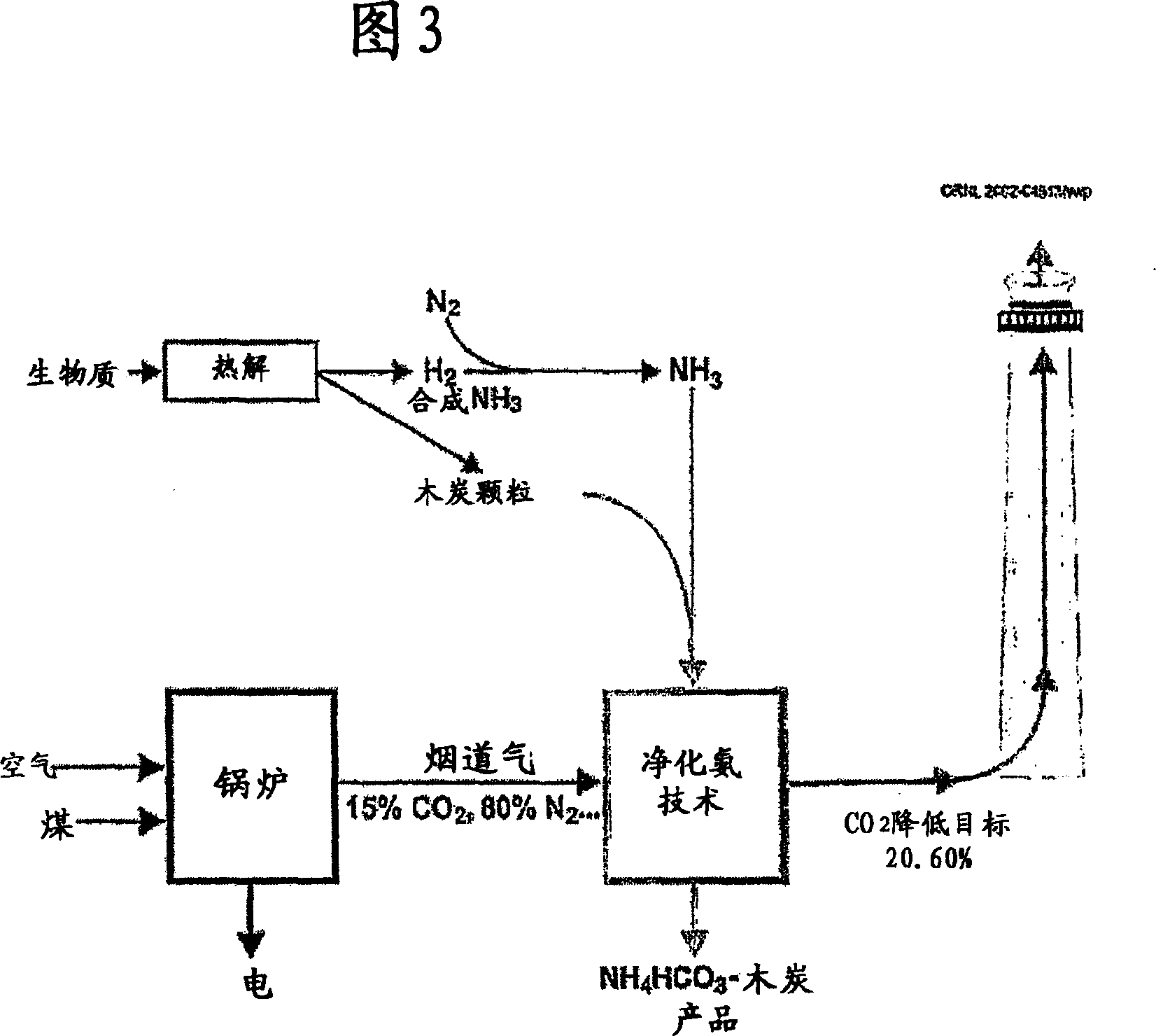

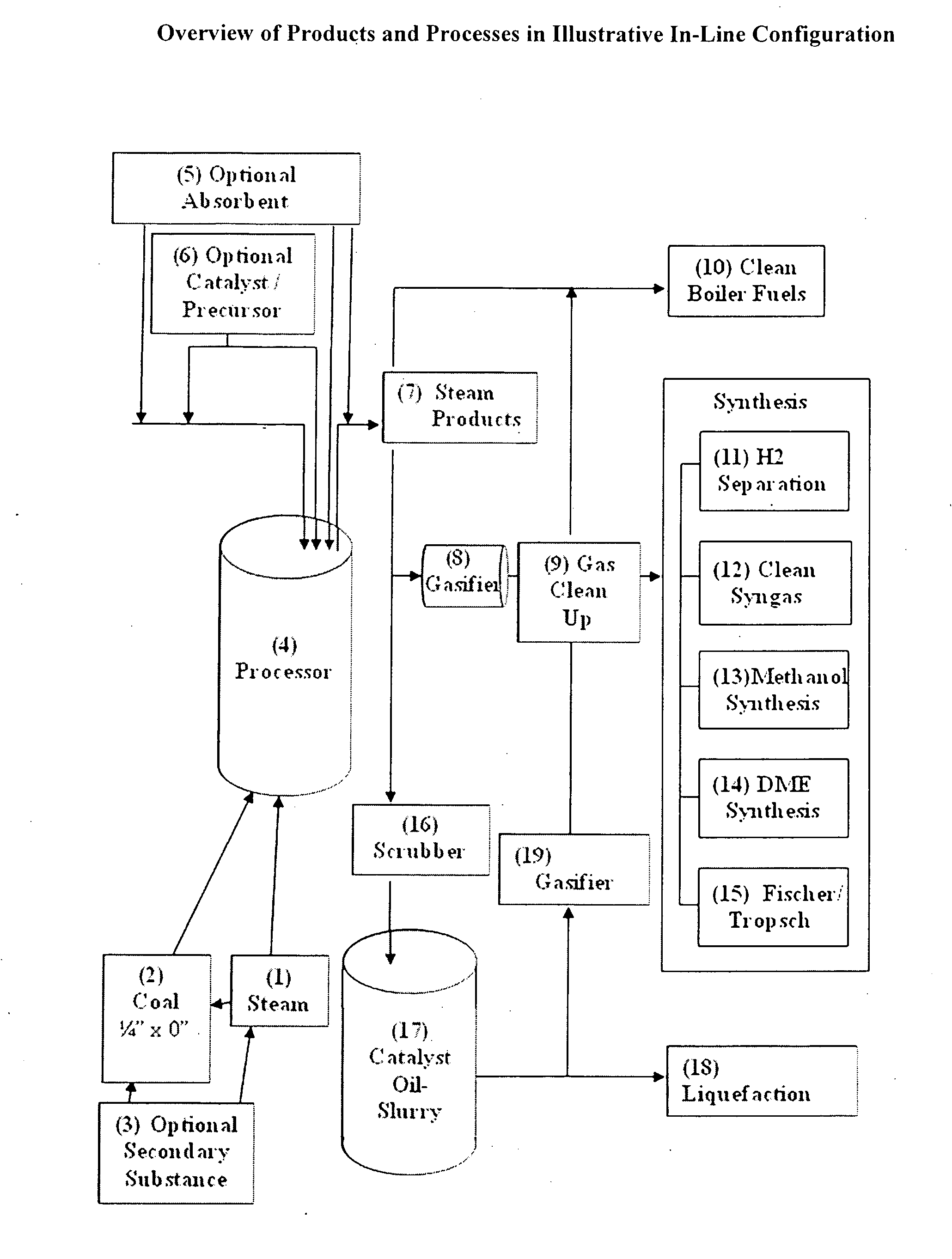

Production and use of a soil amendment made by the combined production of hydrogen, sequestered carbon and utilizing off gases containing carbon dioxide

InactiveCN1997590AHigh carbon contentReduce churn rateNitrous oxide captureMethane captureBiofuelCo product

This invention relates a series of steps to provide an economical production of a carbon based fertilizer and soil amendment made during the capture of greenhouse gases from the combustion of fossil and non fossil fuels. The invention uses biomass and other carbonaceous sources through pyrolytic conversion to gases and charcoal, to allow for the further production of co-products, such as hydrogen and ammonia. The invention also relates to the combination of hydrated ammonia, combustion flue gas exhaust, and charcoal, provide for the conversion of the charcoal into a valued added soil amendment to return essential trace minerals and plant nutrients to the soil. The ability to produce a large volume carbon co-product while removing mandated emissions and producing renewable based hydrogen provides an economic gain to a large number small and large businesses and increase the chance of achieving significant reductions in greenhouse gas emissions.

Owner:丹尼·马歇尔·戴 +1

Fuel cell, operating method thereof, sintering furnace, and power generator

InactiveUS20060127718A1Increase carbon dioxide concentrationEfficient heatingHydrogen separationChemical industryFuel cellsMetallurgy

A molten carbonate fuel cell, operating method of the fuel cell, sintering furnace equipped with the fuel cell, and power generator, wherein a cathode gas with a high carbon dioxide concentration can be obtained without a process of increasing the carbon dioxide concentration, and the heat of furnace exhaust gas can be effectively reclaimed and the fuel consumption can be reduced. The cathode gas is a gas containing a furnace exhaust gas discharged from an industrial furnace for heating materials, a mixed gas of the furnace exhaust gas and a gas for cathode use or a preheated gas for cathode use, which is a gas for cathode use preheated using the furnace exhaust gas as a heating source, or the preheated gas for cathode use, and the carbon dioxide concentration of the cathode gas is 0.1-50 vol %.

Owner:NGK INSULATORS LTD

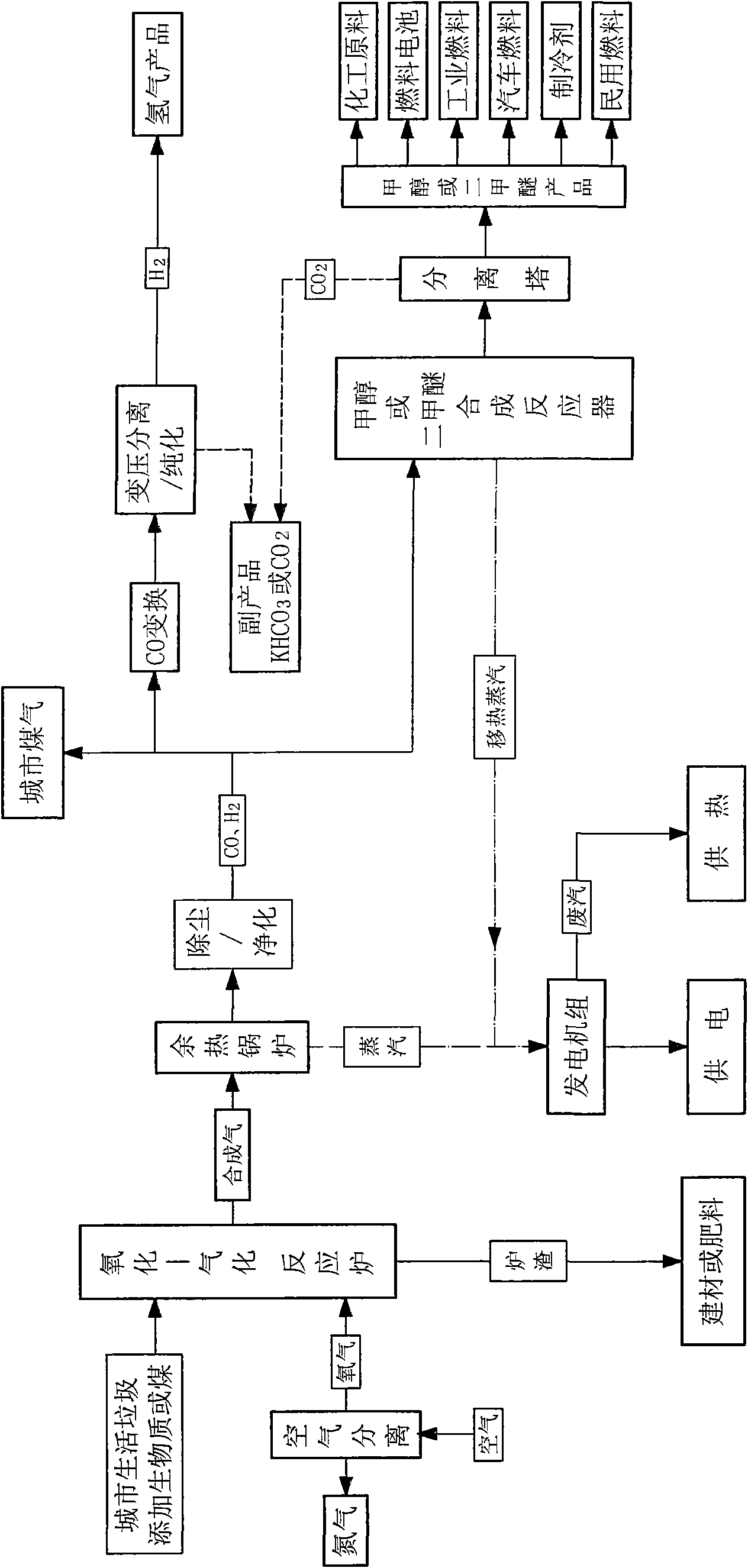

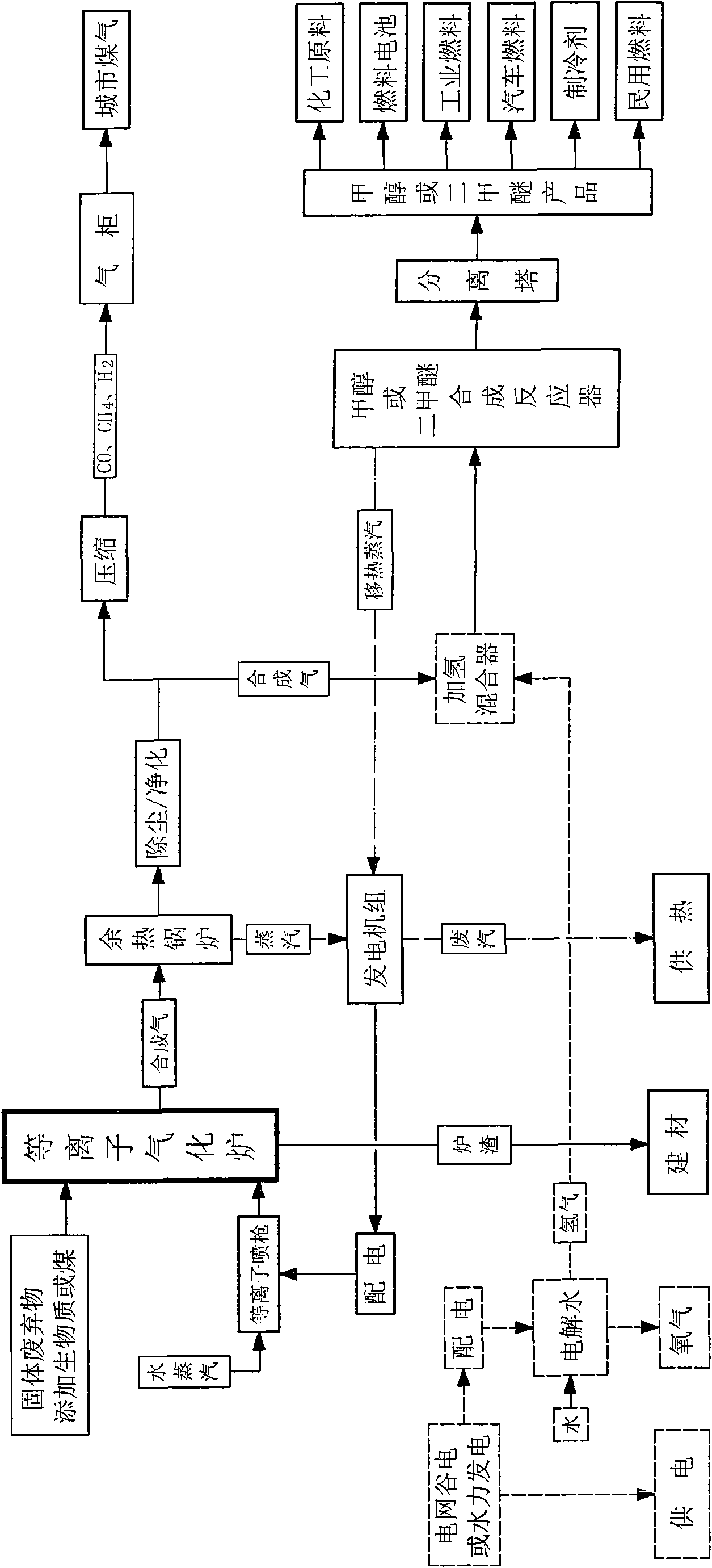

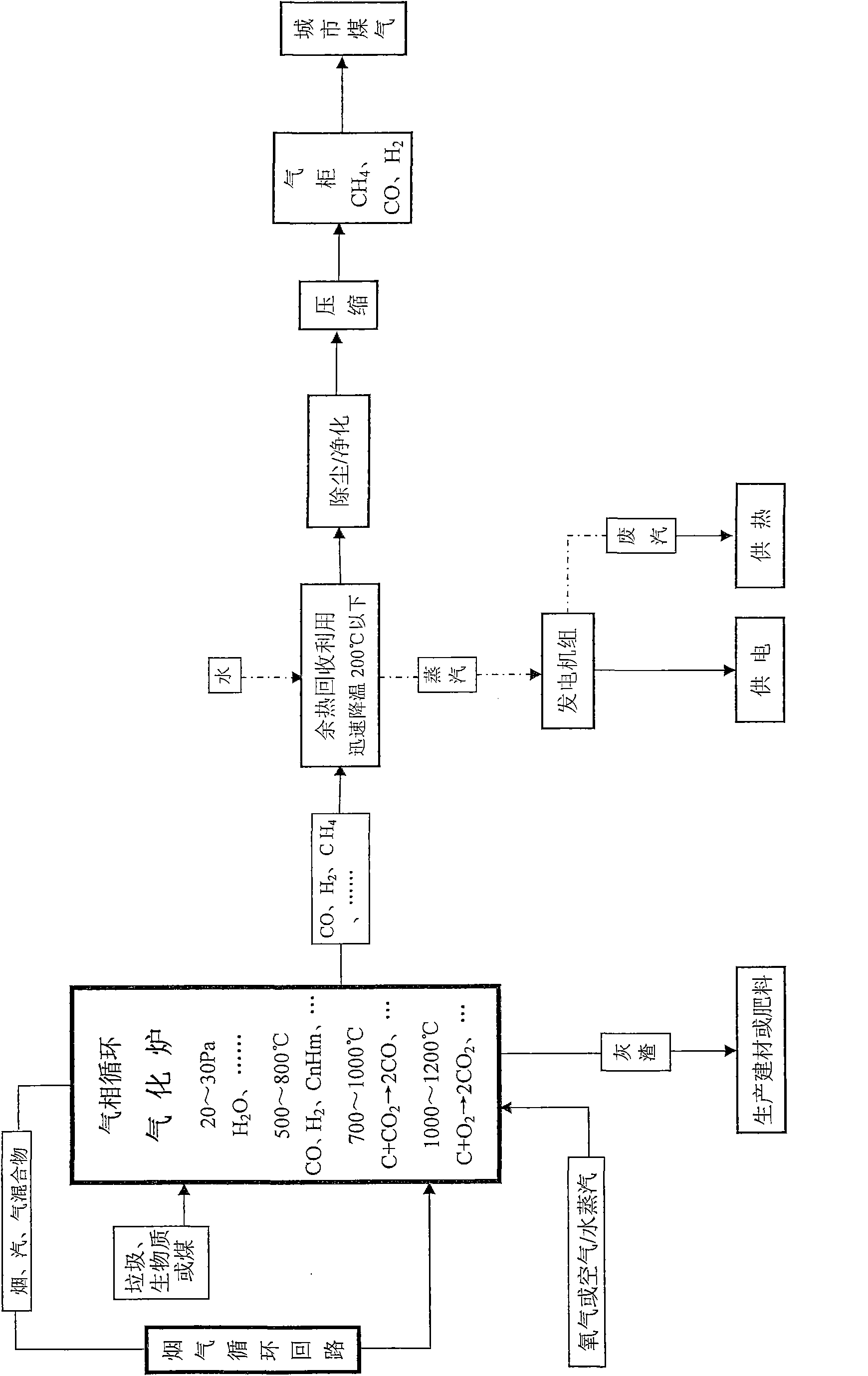

Process, system and device for waste biomass multi-production processing

ActiveCN101565629AEliminate pollutionHarmlessHydrogen separationCombustible gas catalytic treatmentEcological environmentGas phase

The invention relates to a process, a system and a device for waste biomass multi-production processing, in particular to a waste biomass gasification and liquefaction treatment system. The gasification treatment is performed to the waste biomass, the gas is used for producing clean energy and chemical raw materials, the furnace slag is used for producing building materials or fertilizer and the waste heat is used for electric power generation and heat supply so as to realize the environmental-friendly municipal solid waste treatment and the ecological environment protection. The system mainlycomprises a gas-phase circulation gasification furnace, a flue gas circulation air tube, a flue gas circulation fan, a dust-removal / purifying tower and a synthesis reactor and is characterized in that the gas-phase circular reaction is performed to the flue gas in the gasification furnace, the water vapor and the gaseous matter generated during the pyrolysis to obtain hydrogen-rich synthetic gas,and meanwhile, the dioxin (violent in toxicity) is broken up; and the post treatment is performed to the hydrogen-rich synthetic gas to generate city gas, methanol, dimethyl ether or hydrogen. The system has the advantages of full gasification of the solid raw material, no pollutant discharge, extremely low exhaust emission and easy purifying treatment, and the device is flexible in size and is feasible for popularization.

Owner:上海格灵迈环境科技有限公司

Systems and methods for oxidation of synthesis gas tar

Owner:RES USA LLC

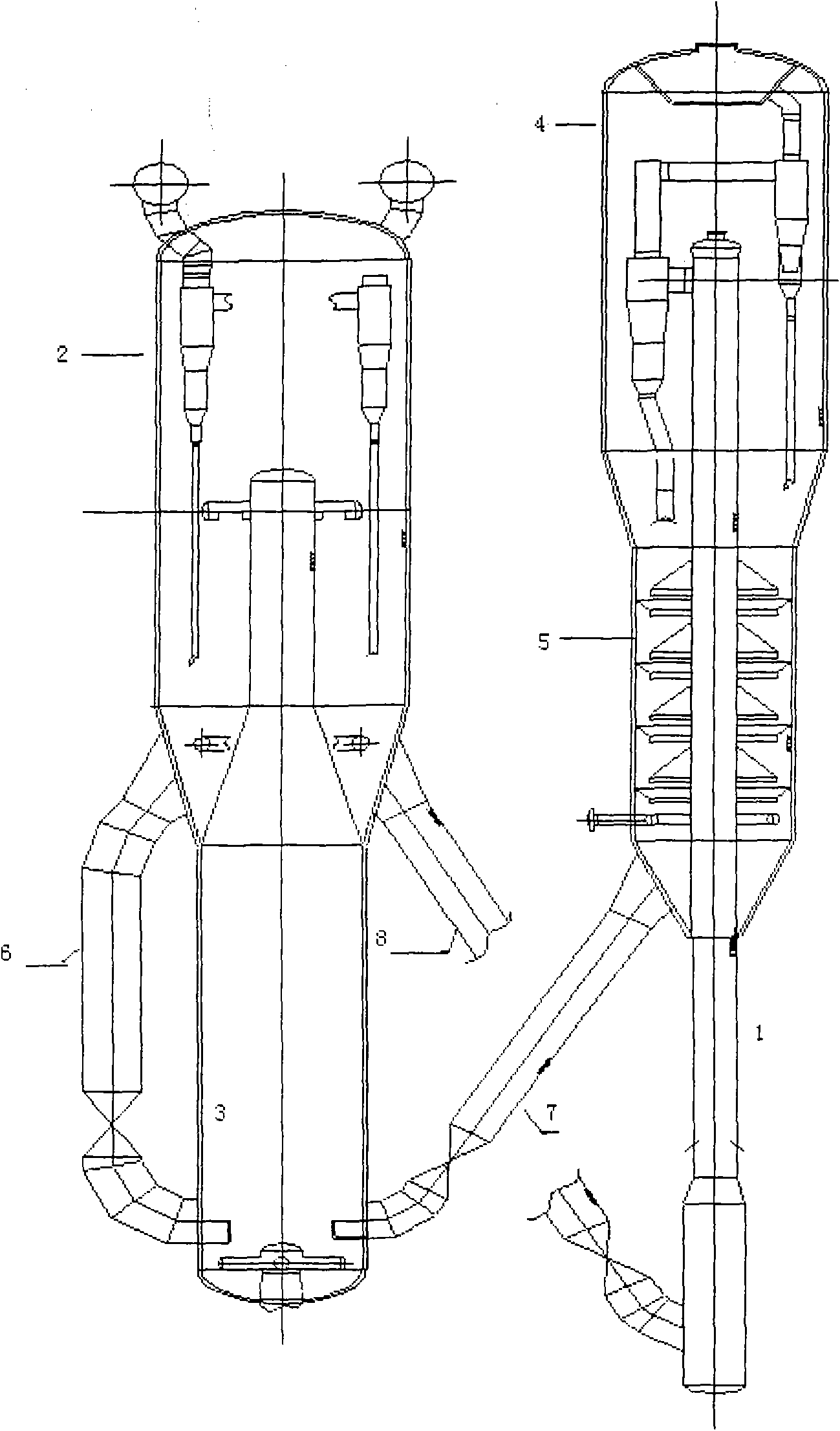

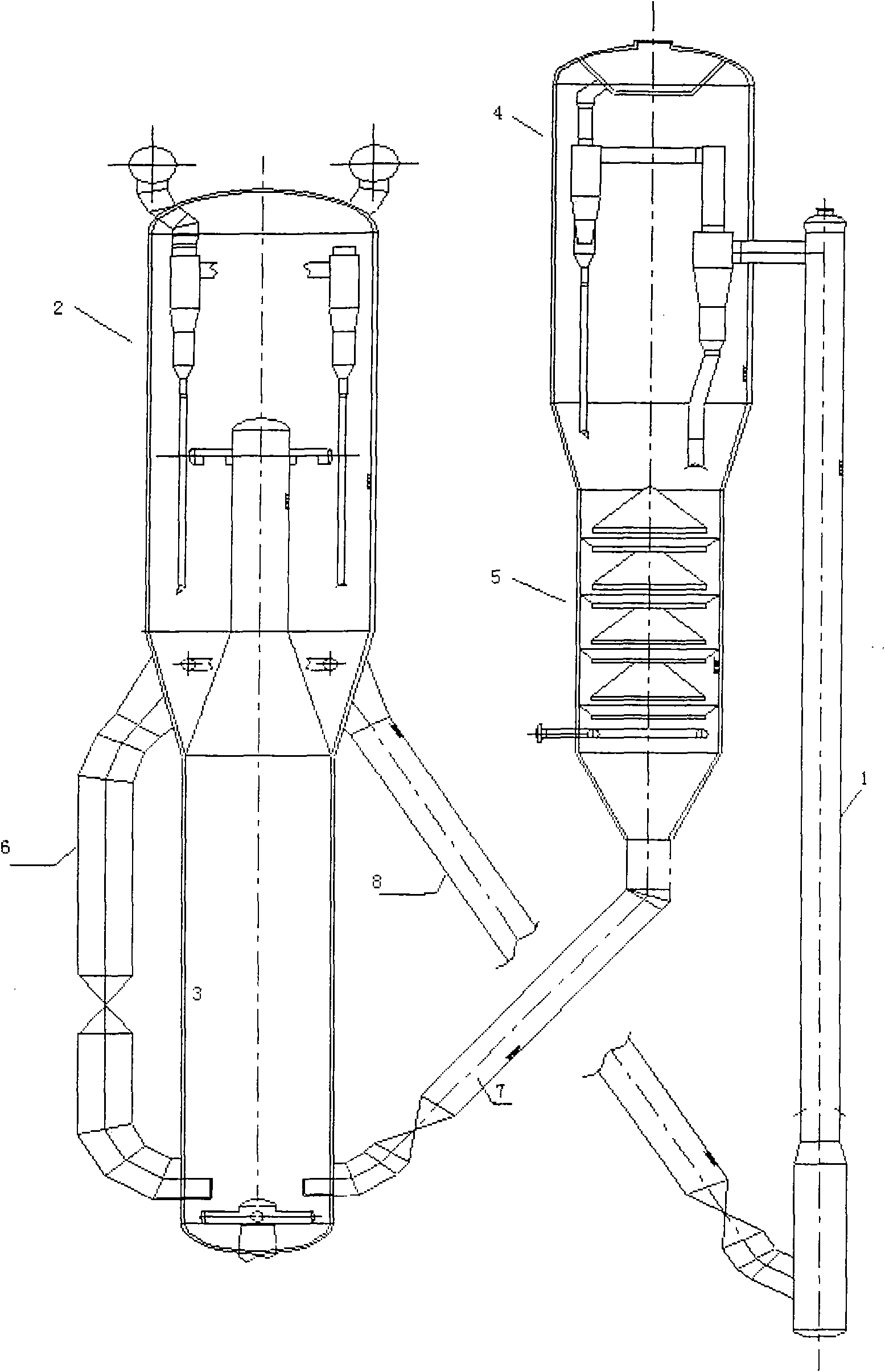

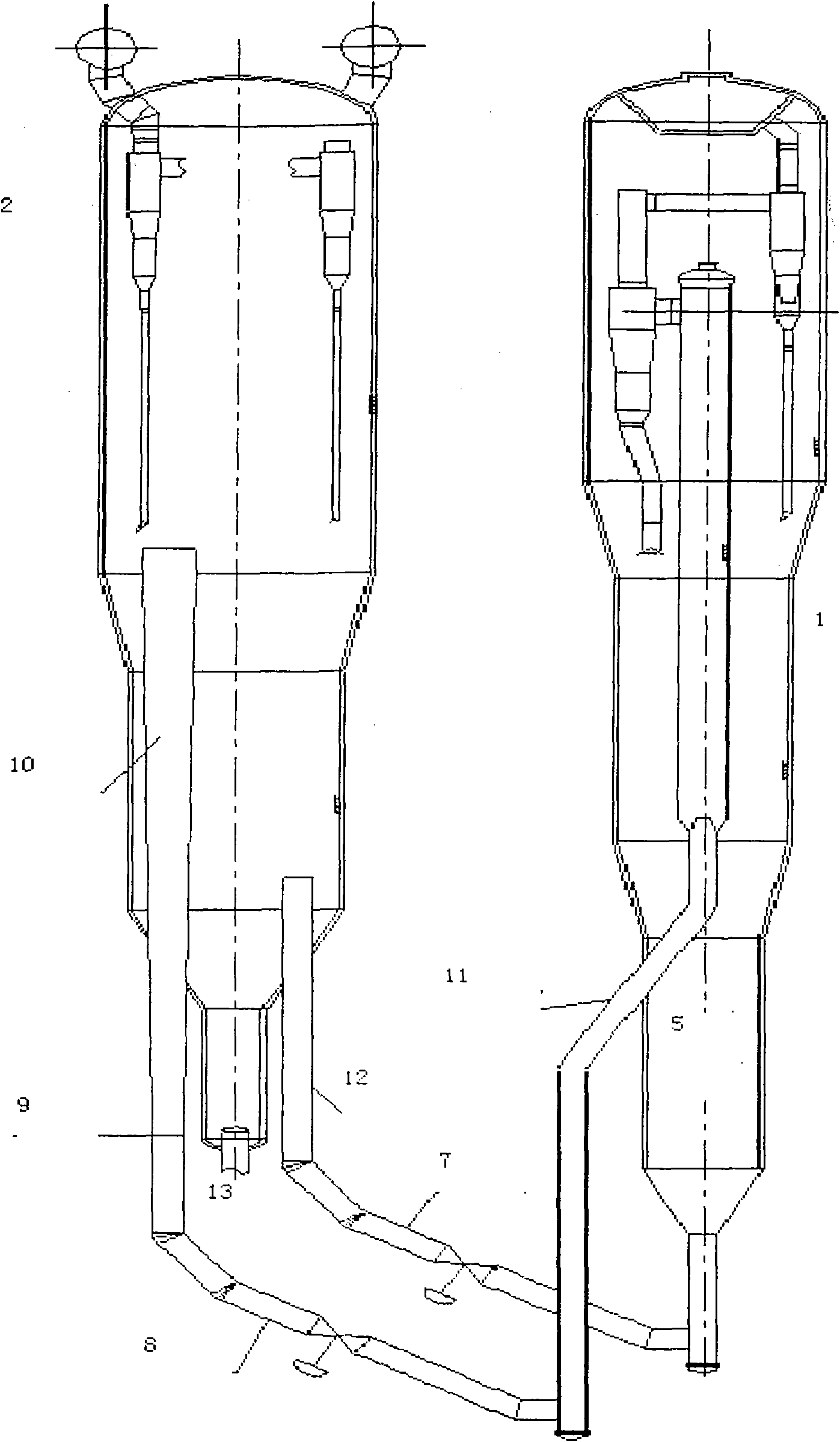

Technology device and method for preparing propylene by dehydrogenating propane or propane-enriched low carbon hydrocarbon

ActiveCN102040445AReduce energy consumptionLow unit priceHydrogen separationDistillation purification/separationGas phaseAlkali metal oxide

The invention provides a technology device and method for preparing propylene by dehydrogenating propane or propane-enriching low carbon hydrocarbon. The device comprises a reacting / regenerating part and a product fractionating part. A reacting / regenerating system is divided into a parallel type arrangement scheme and a coaxial type arrangement scheme by a fluidized bed reacting / regenerating technology, wherein a raising pipe of the parallel type reacting / regenerating system is an internal or external raising pipe, and a raising pipe of the coaxial type reacting / regenerating system is an external raising pipe. The method comprises the steps: leading raw materials and reaction products to enter into a raising pipe reactor after heat exchange; performing a dehydrogenating conversion reaction under the conditions that the reaction temperature is 500-700 DEG C, the pressure is 0.1-0.4MPa, and the ratio of a microspherical catalyst to oil is 5-60, wherein the microspherical catalyst consists of chromium, rare earth oxides, alkali metal oxides and a gamma-Al2O3 carrier, preferably, the temperature is 550-670 DEG C, the pressure is 0.1-0.15MPa, and the ratio of the microspherical catalyst to oil is 6-14; leading the reaction products and the raw materials to enter into a gas-oil separator to separate a gas phase, a liquid phase from a water phase after heat exchange and cooling; leading the separated gas to enter into a gas compressor to be compressed and be transported to an absorbing / stabilizing part; pumping the liquid to an absorbing tower; transporting the liquefied gas from a return tank at the top of a stabilizing tower to a propylene / propane separating tower by a charging pump of a propylene tower; discharging the fine propylene separated from the top of the tower out of the device as a product; discharging the separated byproduct hydrogen out of the device; and returning products at bottom of the tower to the reacting / regenerating part to be recycled.

Owner:卓润生 +1

Systems and methods for oxidation of synthesis gas tar

InactiveUS20090090053A1Improve propertiesMuffle furnacesGas purification by catalytic conversionTarProduct gas

Owner:RES USA LLC

Processing device for improved utilization of fuel solids

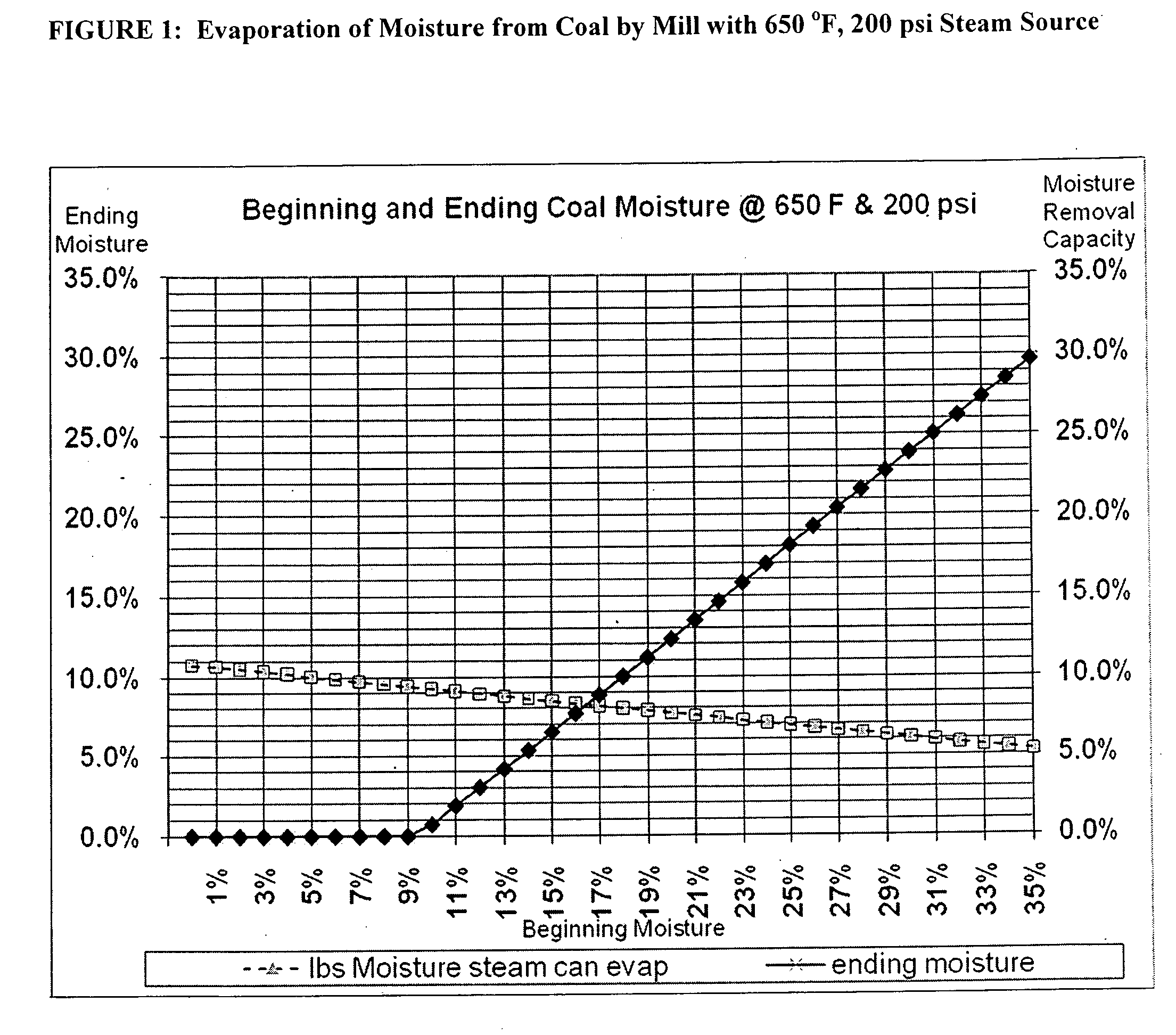

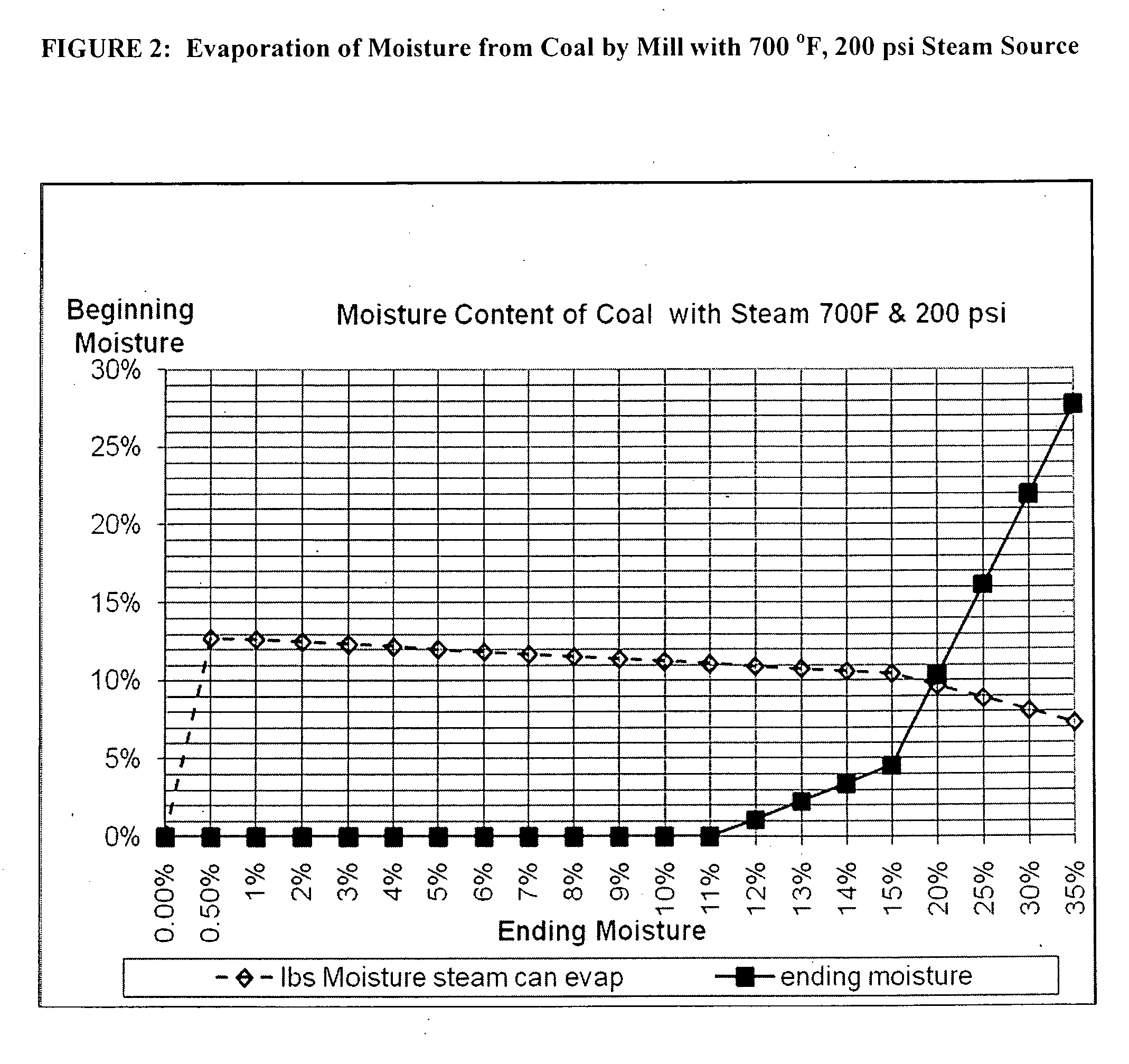

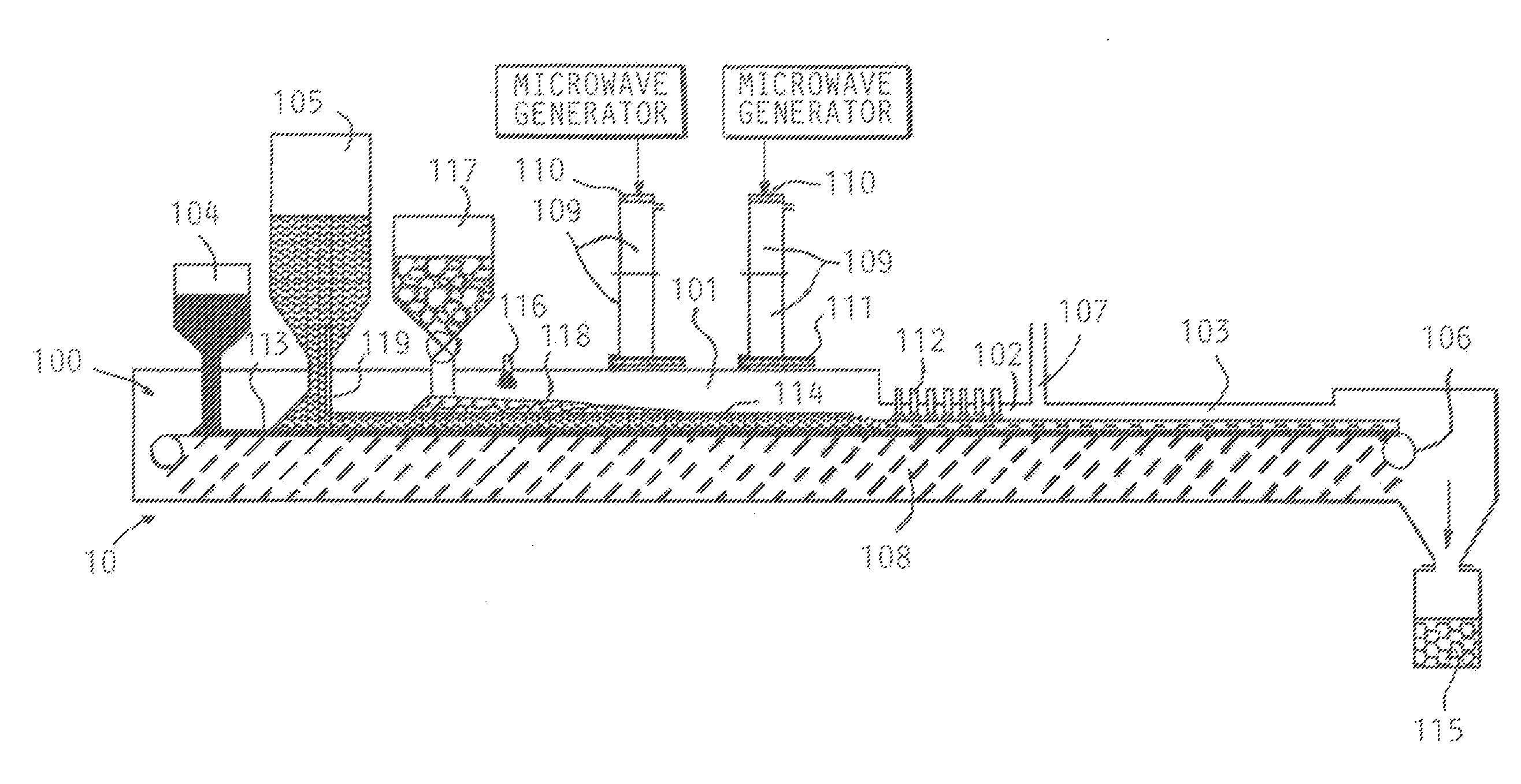

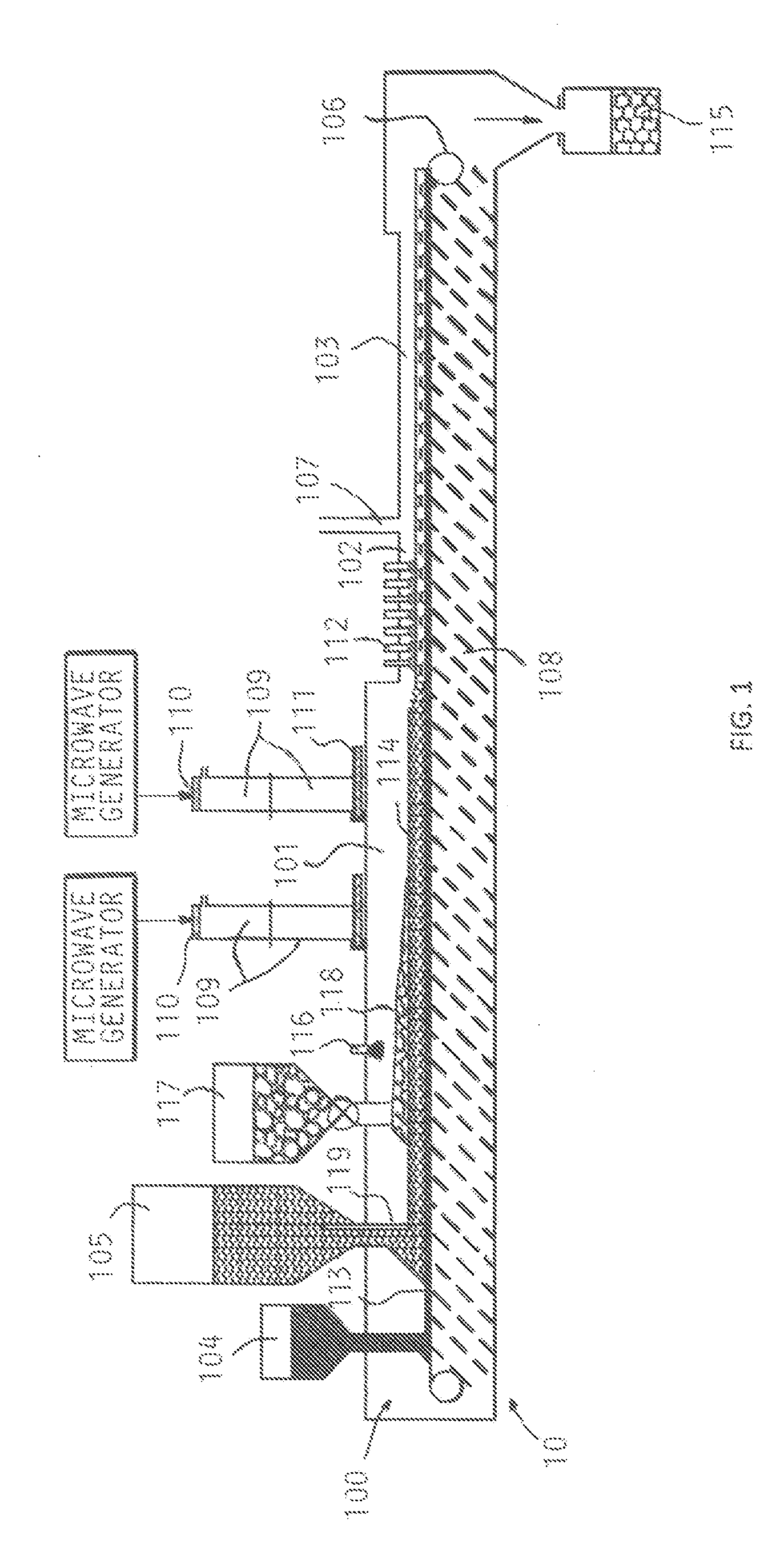

InactiveUS20090199425A1Little wearRapid and uniform and fuel efficient gasificationDrying gas arrangementsWaste based fuelCombustionNitrogen oxides

The invention provides an apparatus for comminuting coal or other fuel solids in a shear field, and for optionally coating the solids with catalysts for combustion, liquefaction, and or gasification during the milling process. The apparatus further provides for control of water content in the solids may be controlled before, during and after the milling in order to obtain micronized solids with fine hydration layers. The output fuel solids of the apparatus can burn at low temperatures, avoiding emissions of nitrogen oxides, and they also have improved properties for surfactant-free suspension in either water or oil media, as well as for liquefaction and gasification.

Owner:HYDROCOAL TECH

Method and Apparatus For Coproduction of Pig Iron and High Quality Syngas

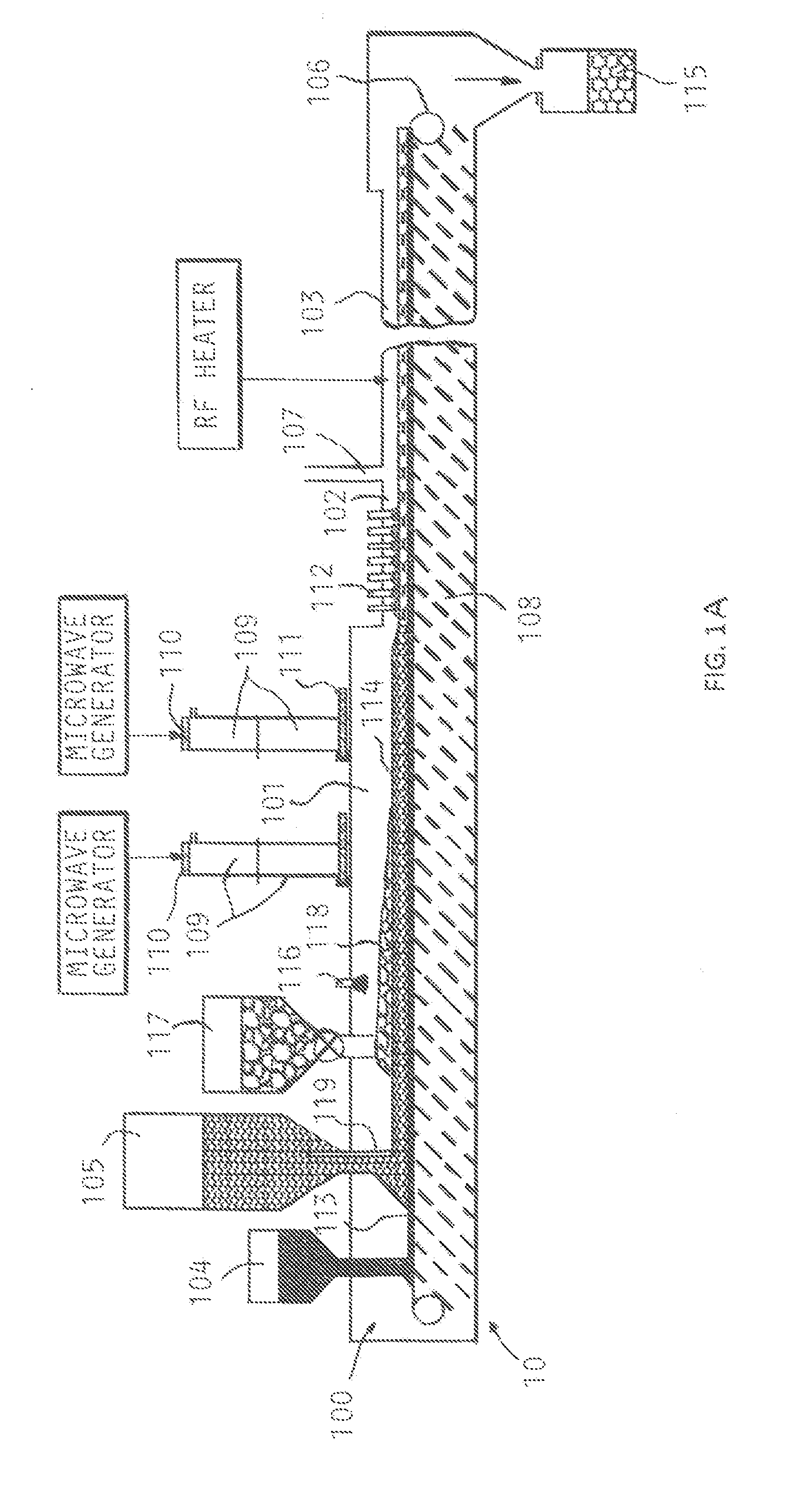

ActiveUS20120031232A1Improve microwave absorption performanceHeating up fastBlast furnace detailsCharge manipulationSludgeLiquid fuel

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

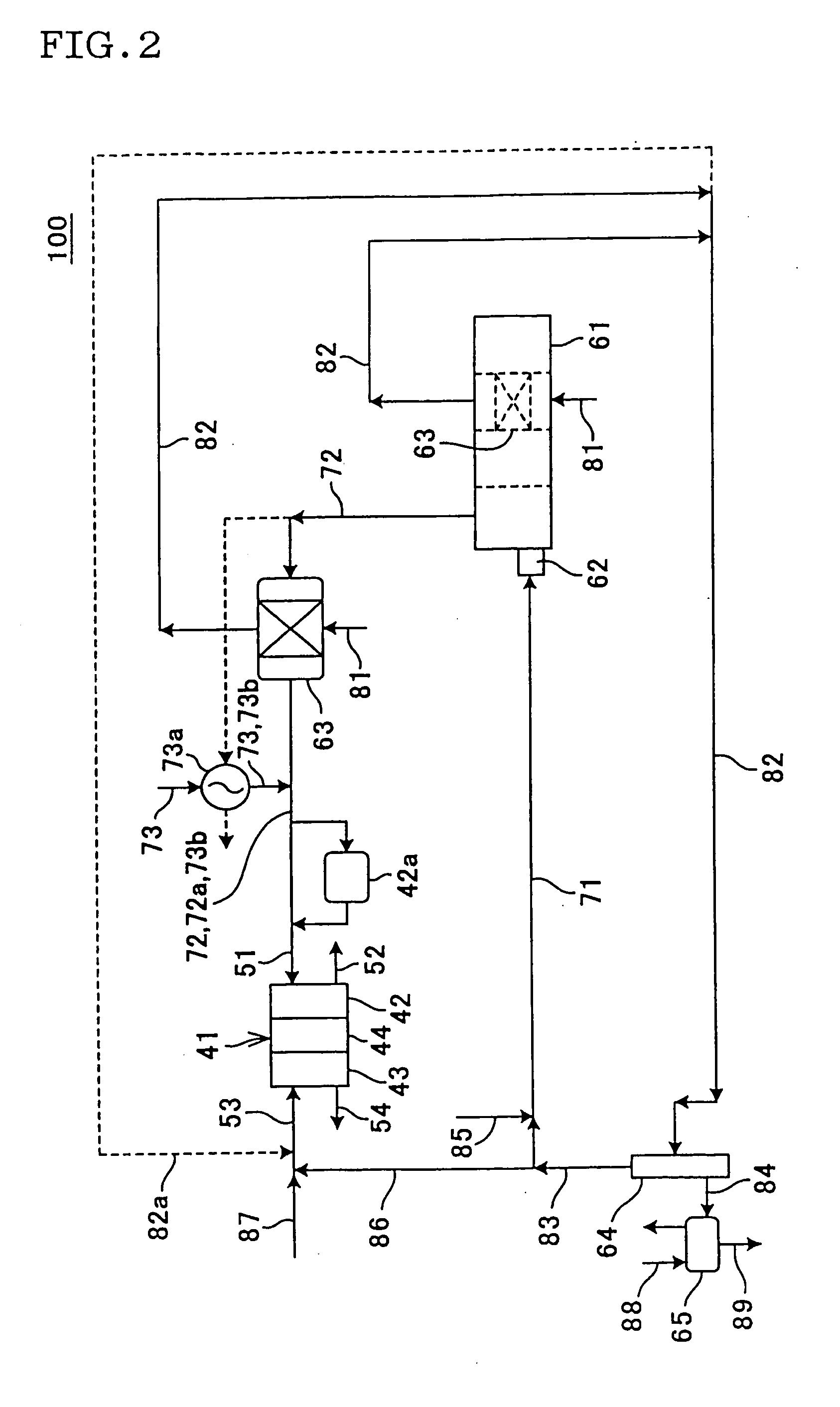

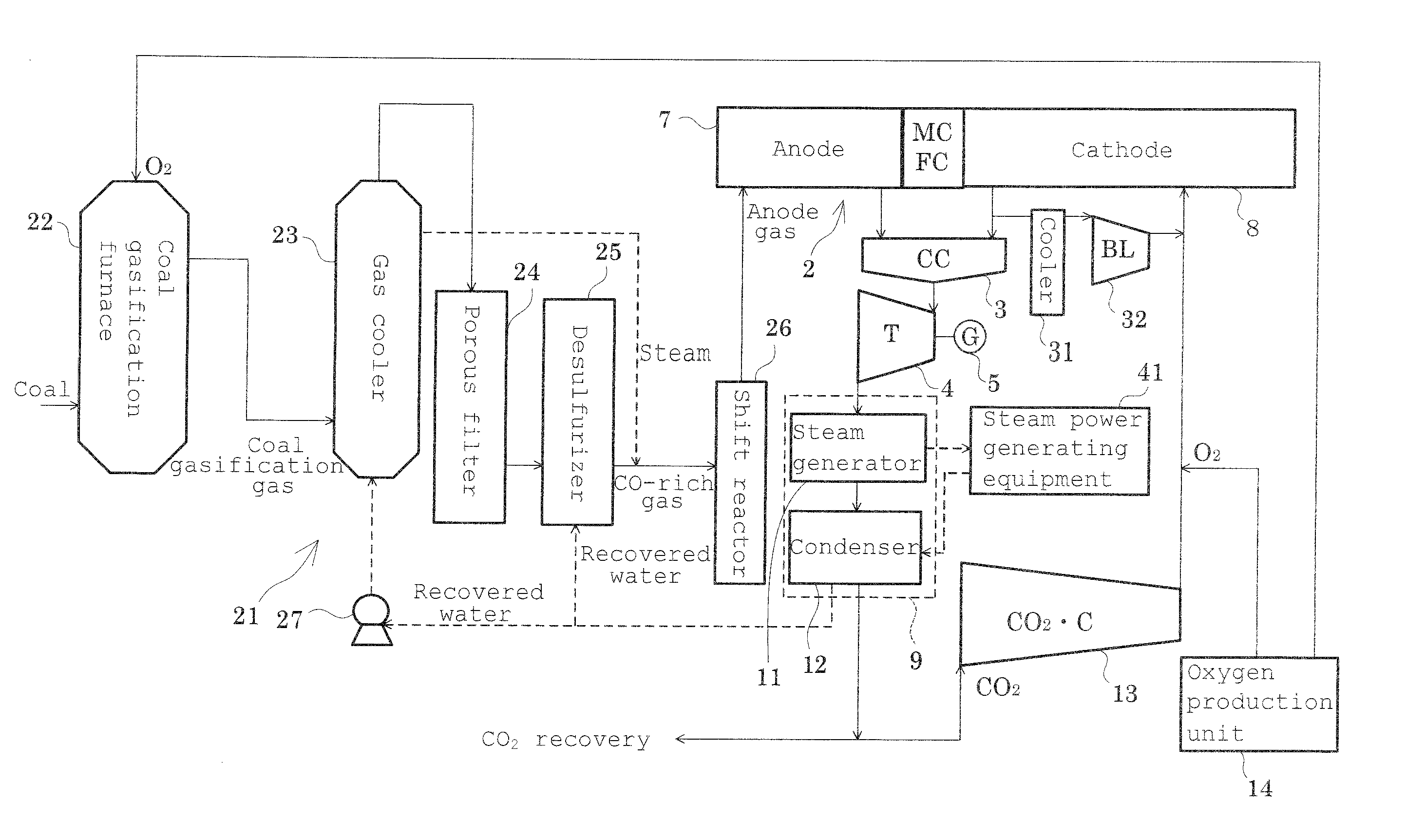

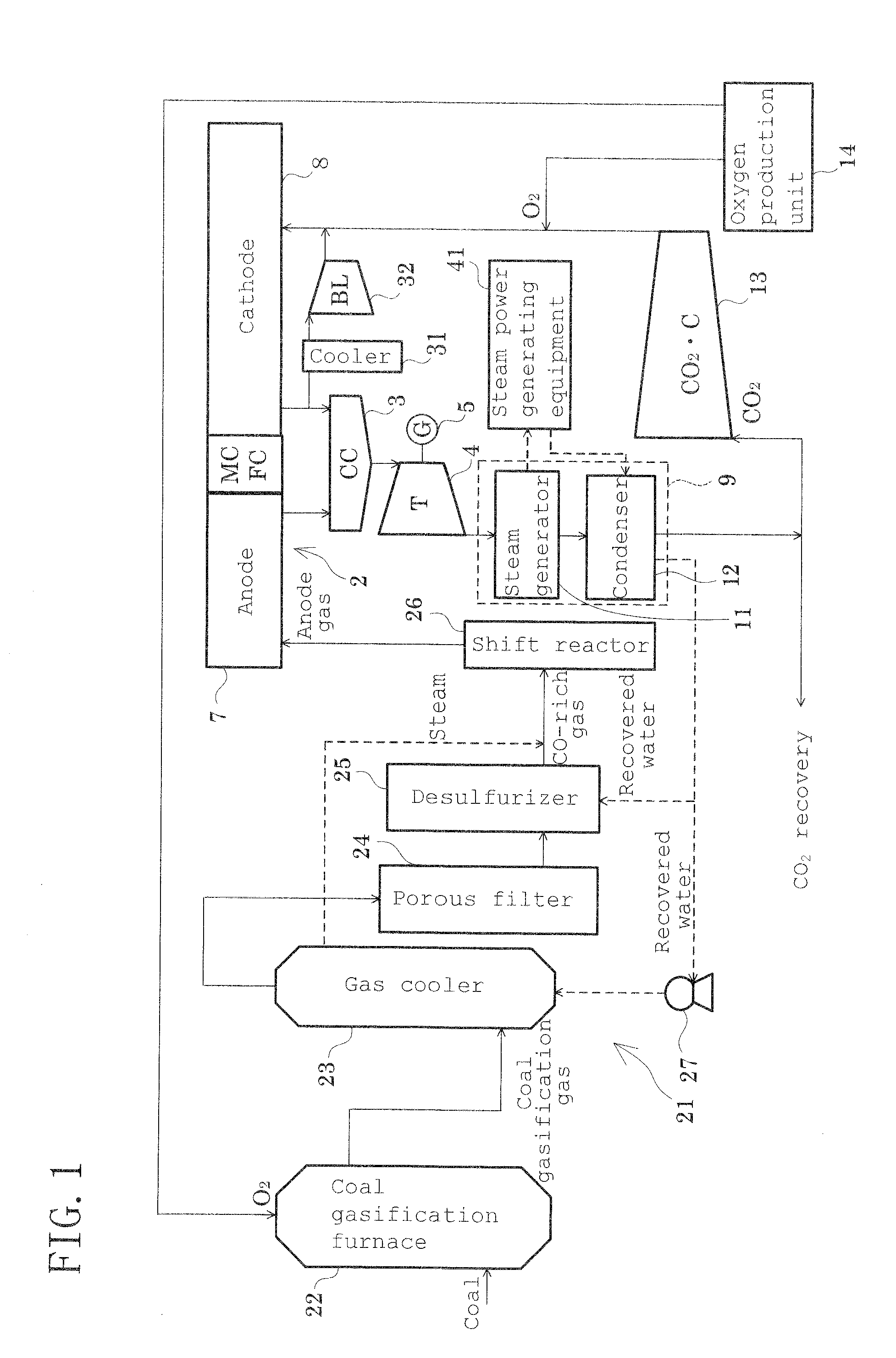

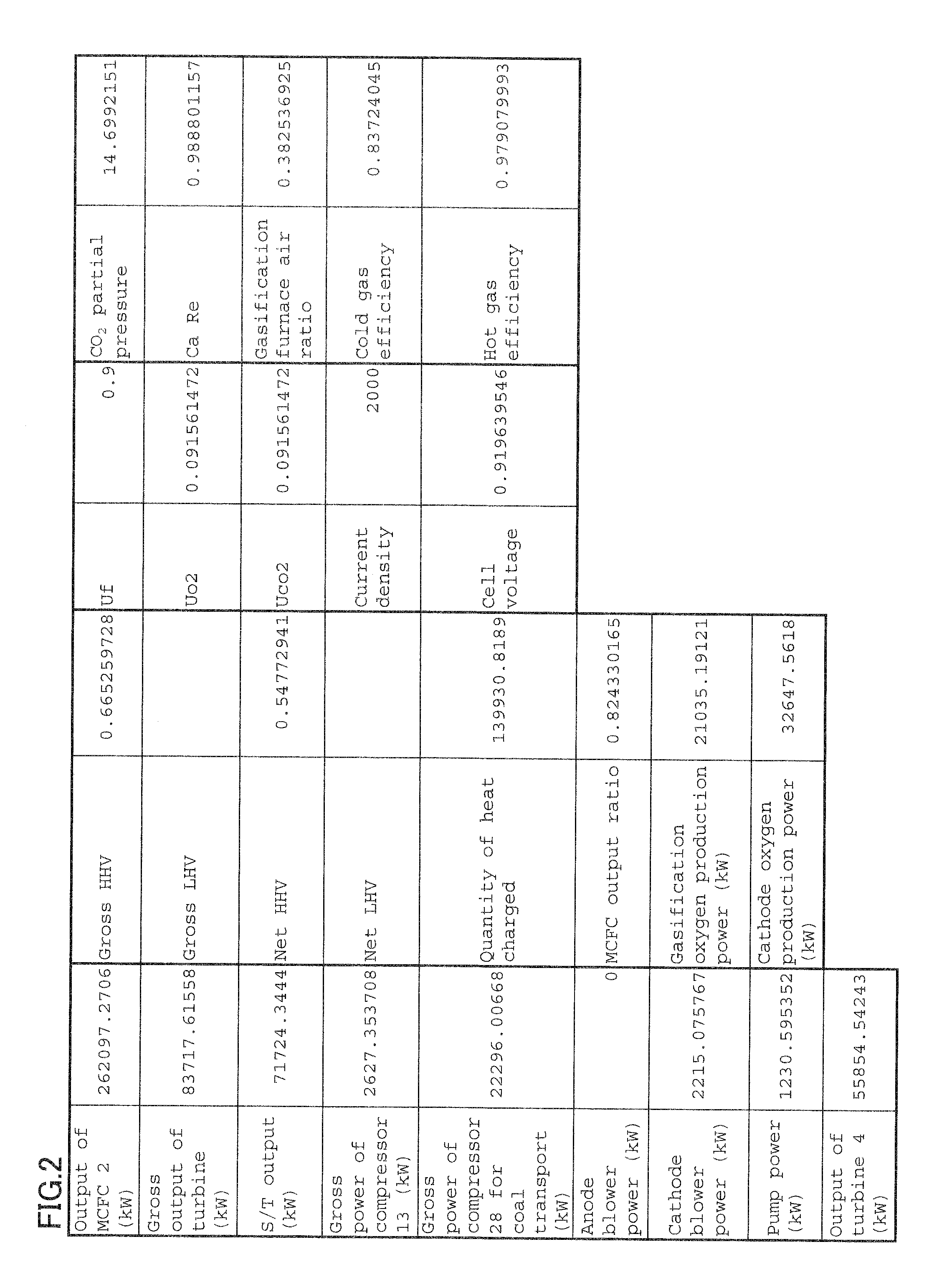

Power generating plant

InactiveUS20100015486A1Maintain performanceElectricity cogenerationFuel cell heat exchangePower stationGas cooler

Coal is reacted in a furnace 22 to obtain a coal gasification gas. The coal gasification gas is cooled by a gas cooler 23, passed through a porous filter 24, and desulfurized by a desulfurizer 25 to produce a CO-containing gas as an anode. The CO gas-containing gas is subjected to an exothermic reaction in a shift reactor 26 to form H2 and CO2, and the anode gas containing H2 is supplied to an anode 7 of MCFC 2. Thus, in the absence of an extra heat source and a heat exchange source, a desired anode gas is obtained from the coal gasification gas, and with heat buildup of the MCFC 2 being inhibited and its performance being maintained, reduction of CO2 is taken into consideration. A power generating plant equipped with the MCFC 2 capable of using a coal gasification fuel substantially containing a CO gas is thus achieved.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

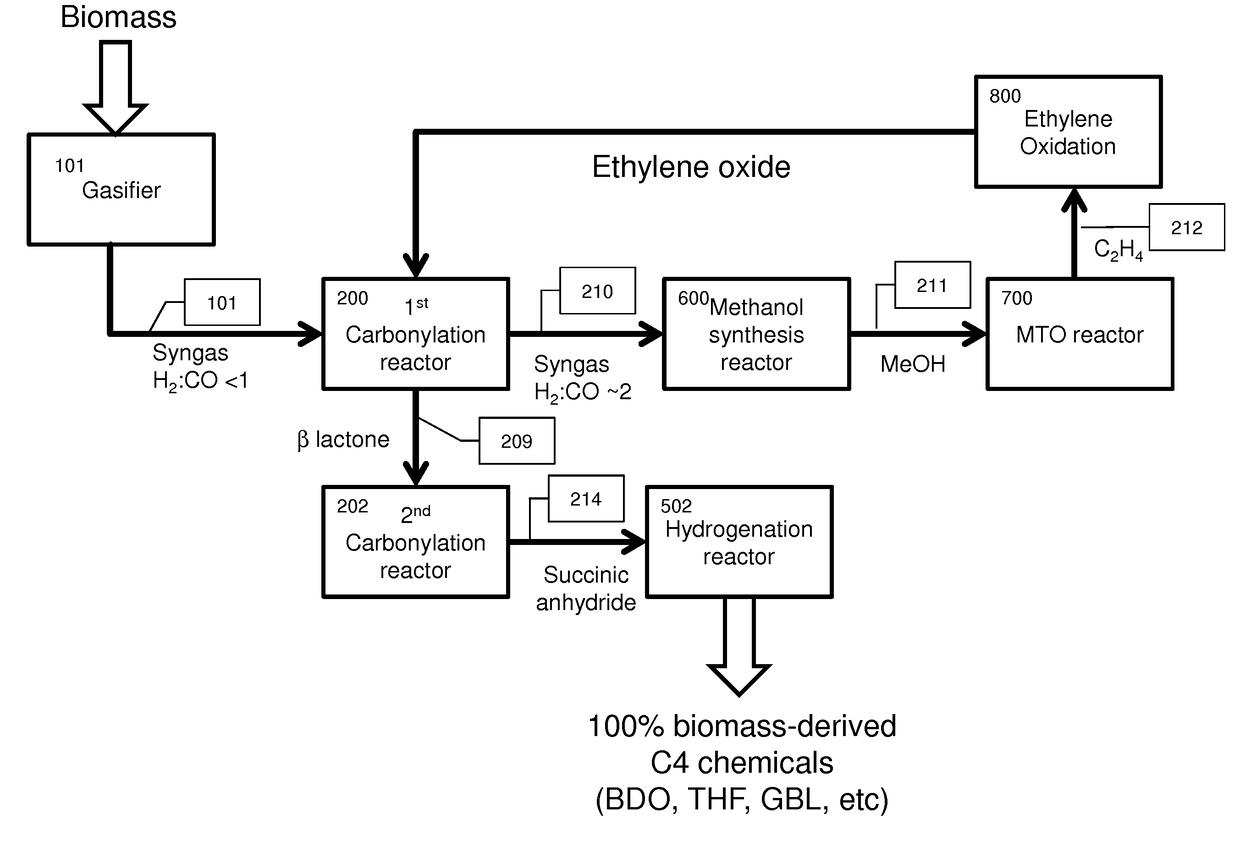

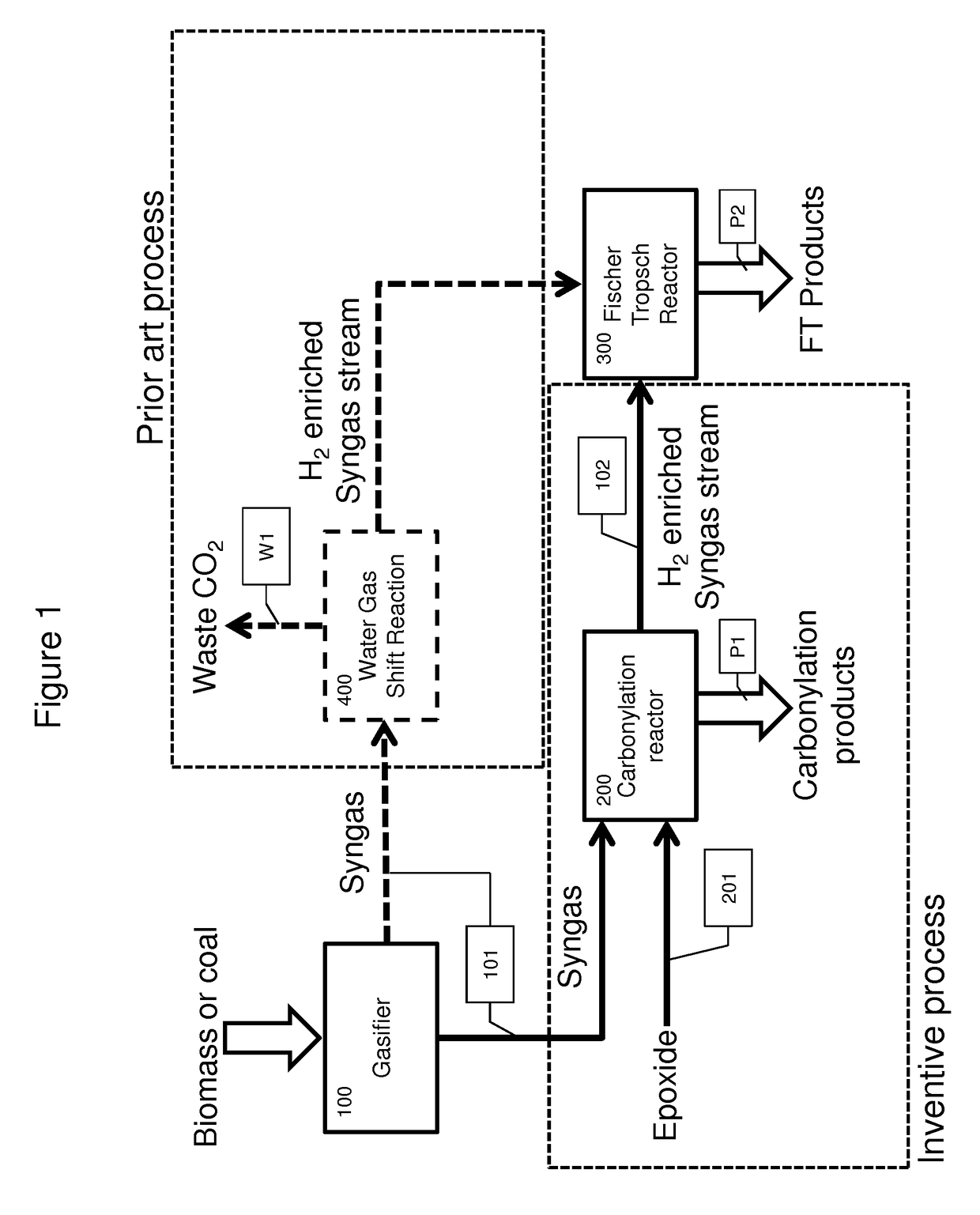

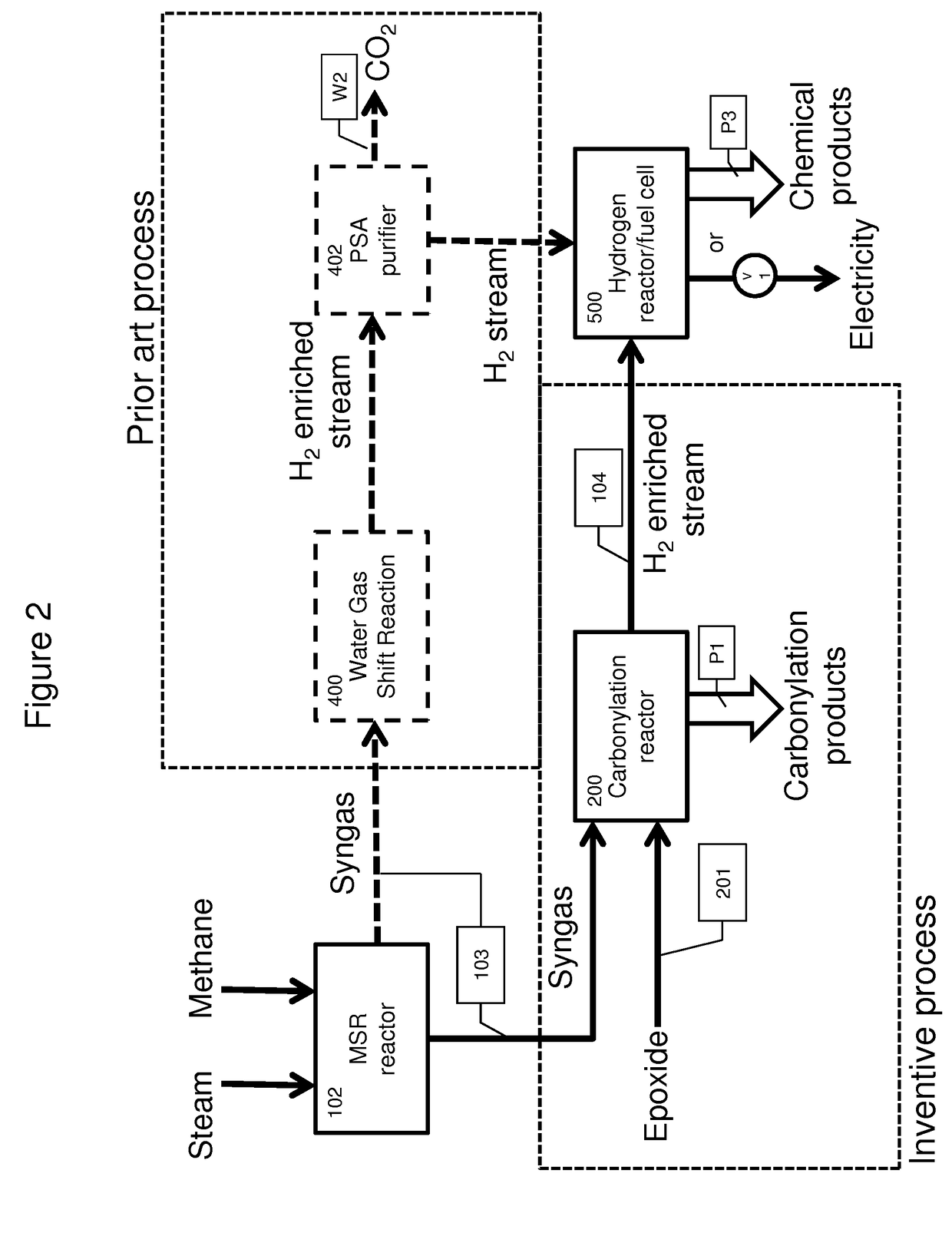

Integrated methods for chemical synthesis

ActiveUS20170107103A1Improve carbon efficiencyQuantity maximizationBiofuelsPreparation from carboxylic acid esters/lactonesChemical synthesisSyngas

Among other things, the present invention encompasses the applicant's recognition that epoxide carbonylation can be performed industrially utilizing syngas streams containing hydrogen, carbon monoxide and varying amounts carbon dioxide. Contrary to expectation, the epoxide carbonylation reaction proceeds selectively in the presence of these mixed gas streams and incorporates excess CO in the syngas stream into valuable chemical precursors, resulting in hydrogen streams substantially free of CO. This is economically and environmentally preferable to performing WSGR which releases the excess carbon as CO2. The integrated processes herein therefore provide improved carbon efficiency for processes based on coal or biomass gasification or steam methane reforming.

Owner:NOVOMER INC

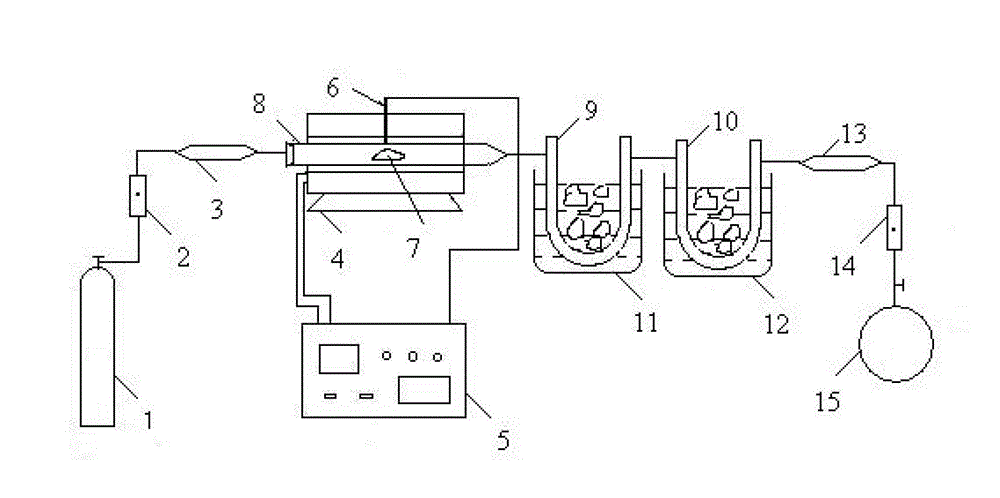

Method for making hydrogen through pyrolytic gasification of biomass and coke under microwave field

InactiveCN102874750AFavorable for pyrolysis gasification reactionHeating up fastHydrogen separationChemical industryIce waterNitrogen gas

The invention discloses a method for making hydrogen through the pyrolytic gasification of biomass and coke under a microwave field, which is characterized by comprising the following steps of: by using fresh biomass as a raw material, zinc chloride as a catalyst and the coke as a microwave-absorbing medium and a gasifying material, carrying out the pyrolytic gasification of the raw material, the catalyst and the coke by using a microwave source as a heating source after uniformly mixing the raw material, the catalyst and the coke, collecting a volatile product which is formed through the pyrolytic gasification through nitrogen purging, then removing tar, water and ash through a water-ice mixture-cooling system, and then entering a hydrogen-gas separating system to obtain hydrogen gas. The fresh biomass required by the method disclosed by the invention is cheap and easy to obtain, the raw material is reproducible, and the integrated sustainable utilization of resources, energy sources and environments can be realized.

Owner:ANHUI UNIV OF SCI & TECH

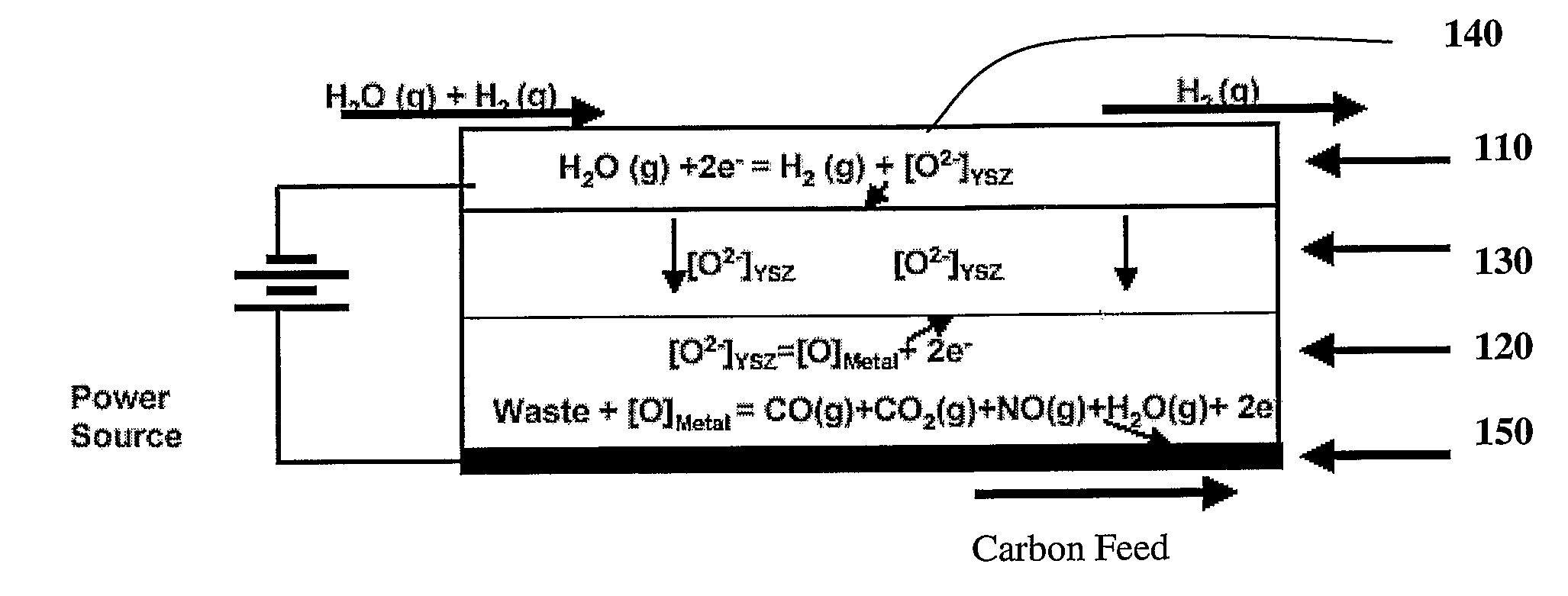

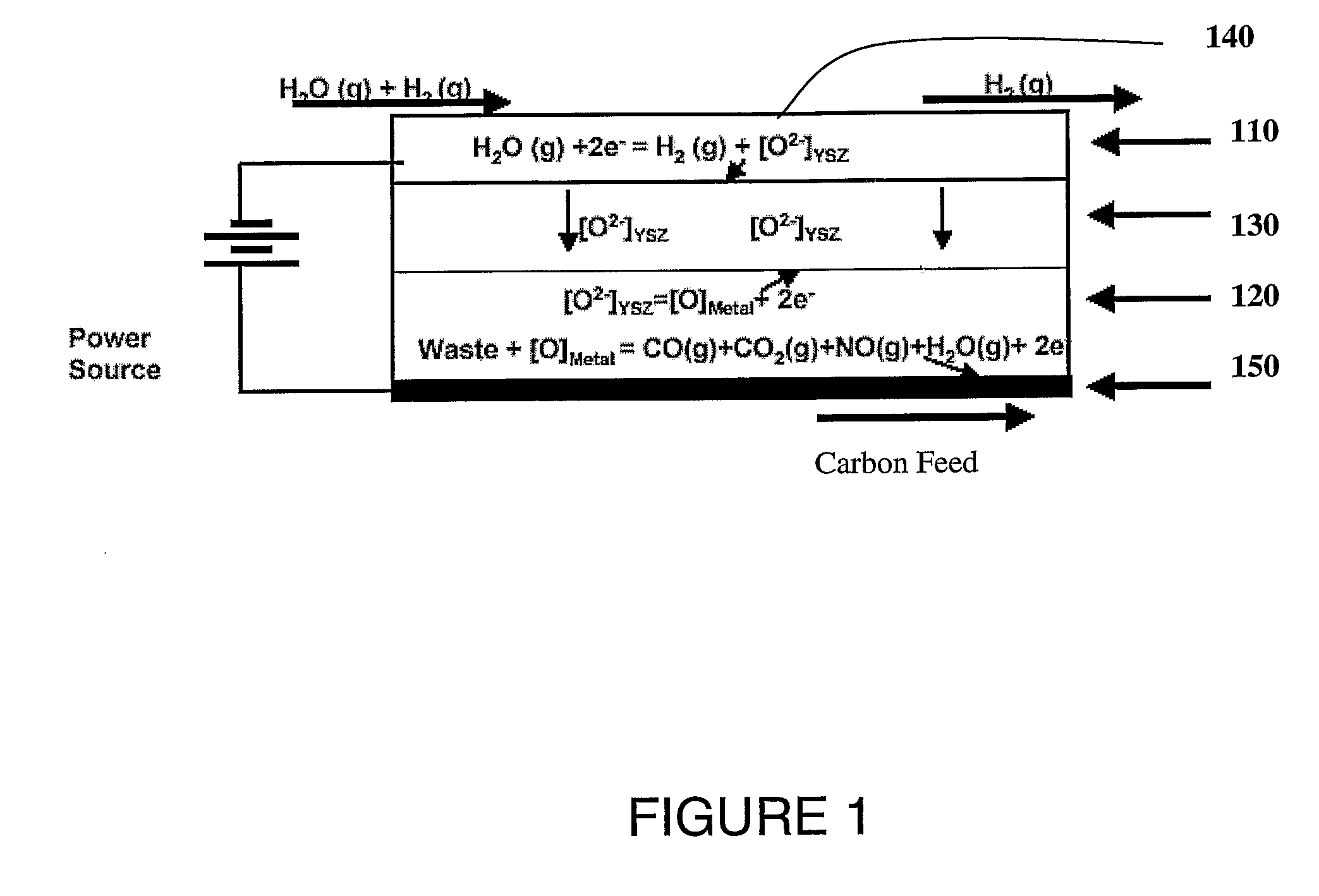

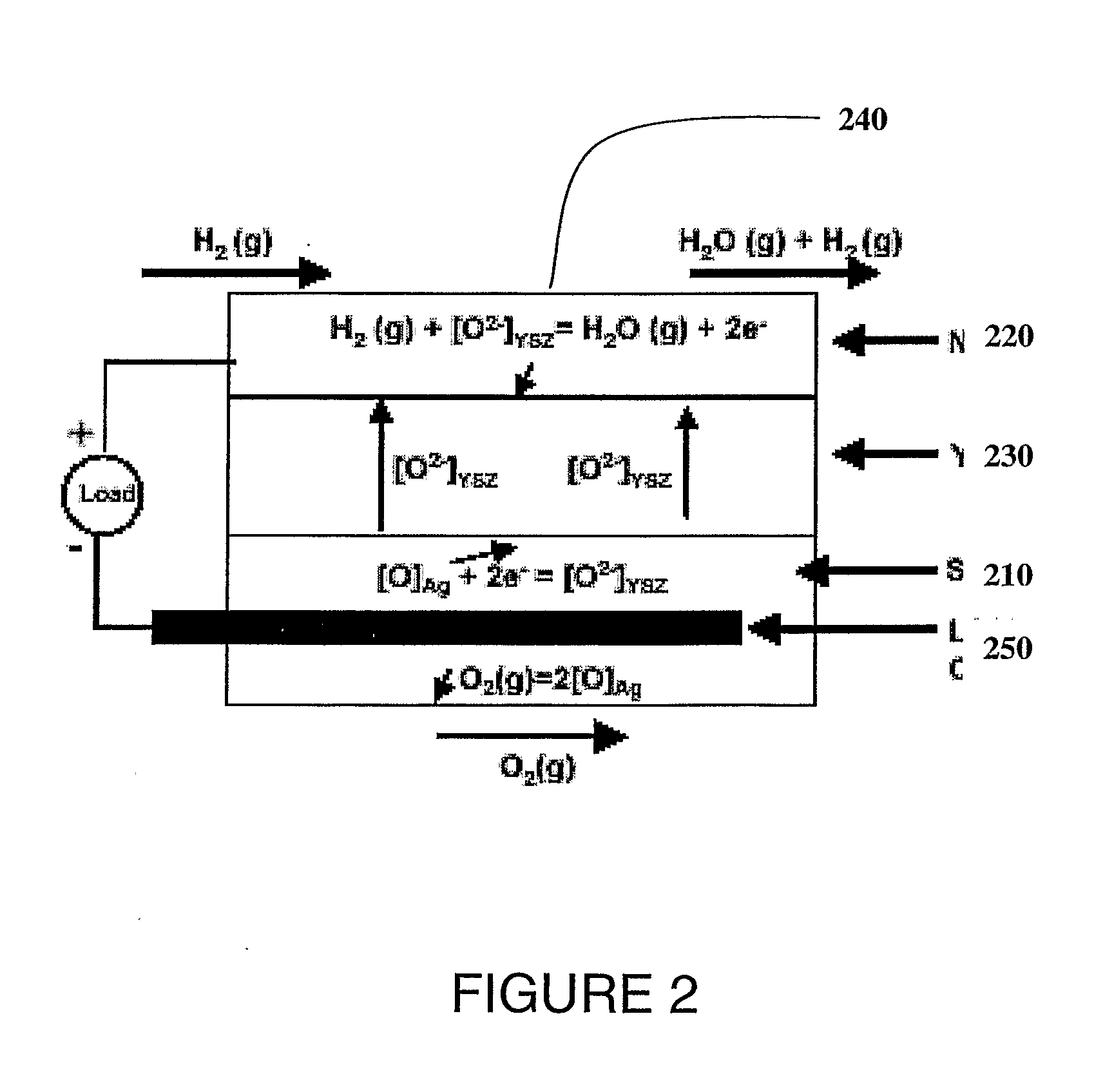

Waste to hydrogen conversion process and related apparatus

InactiveUS20090071841A1Efficiently reduce steamEfficient decompositionCellsHydrogen separationElectrolysisSilver electrode

A reversible electrochemical system includes a first electrode comprising liquid silver metal and a second electrode, said first and second electrodes separated by a oxygen ion-conducting solid electrolyte; a conduit for directing a first reactive material across the second electrode; and a conduit for contacting second reactive material with the first liquid silver electrode, wherein the cell is capable of steam electrolysis when the polarity of the electrodes is selected such that the liquid silver is an anode and the cell is capable of electrical energy generation when the polarity of the electrodes is selected such that the liquid silver is a cathode.

Owner:TRUSTEES OF BOSTON UNIV

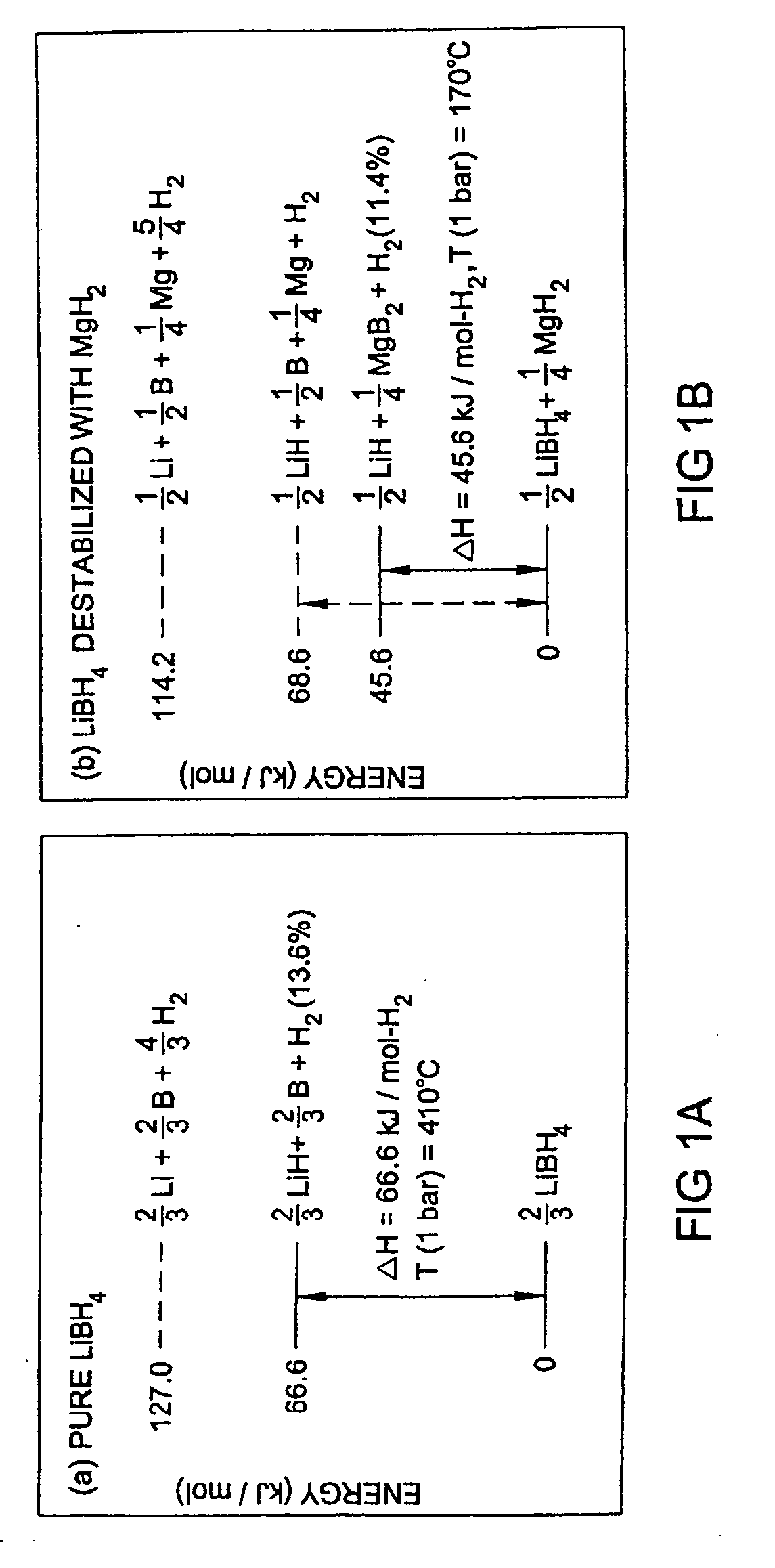

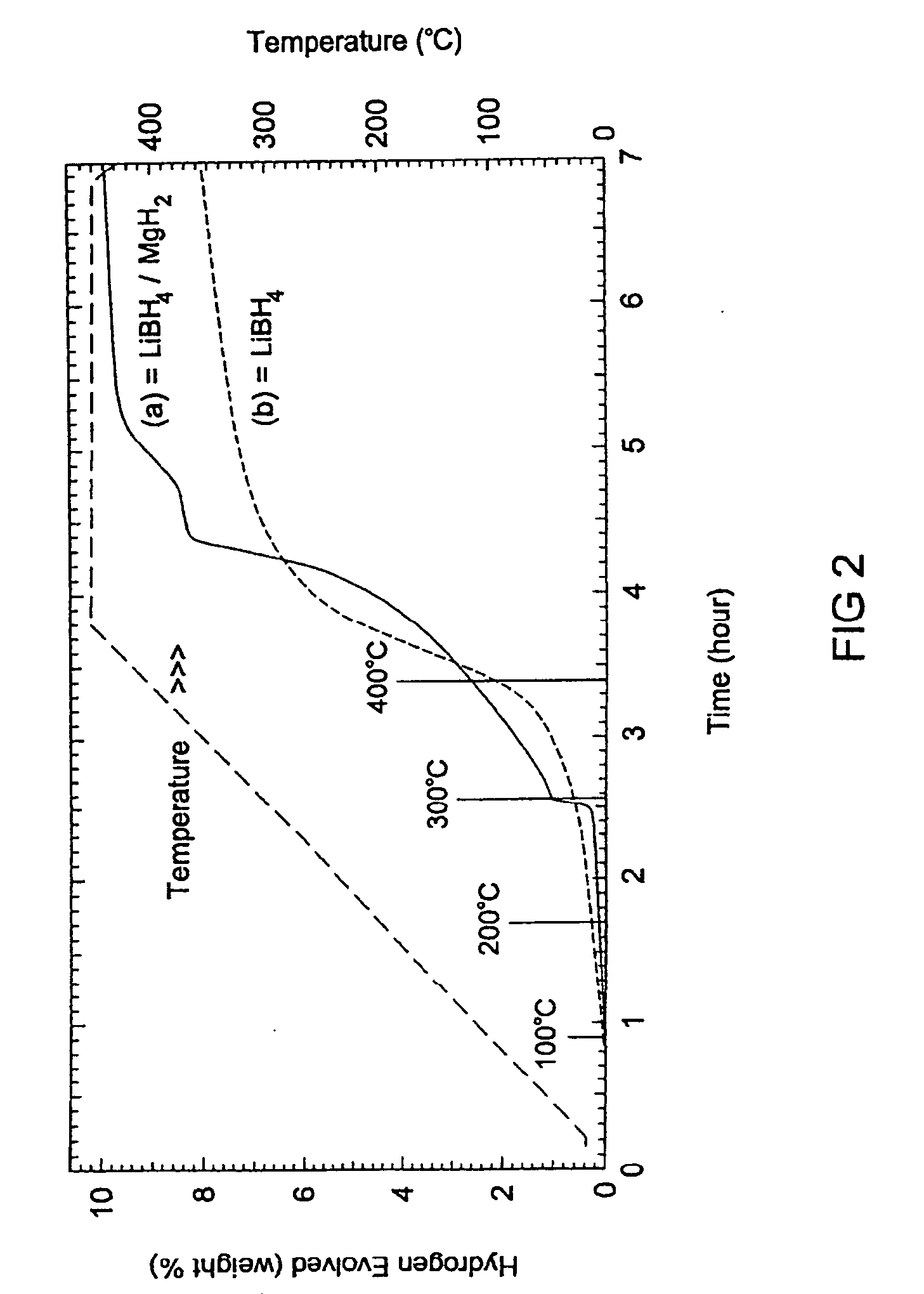

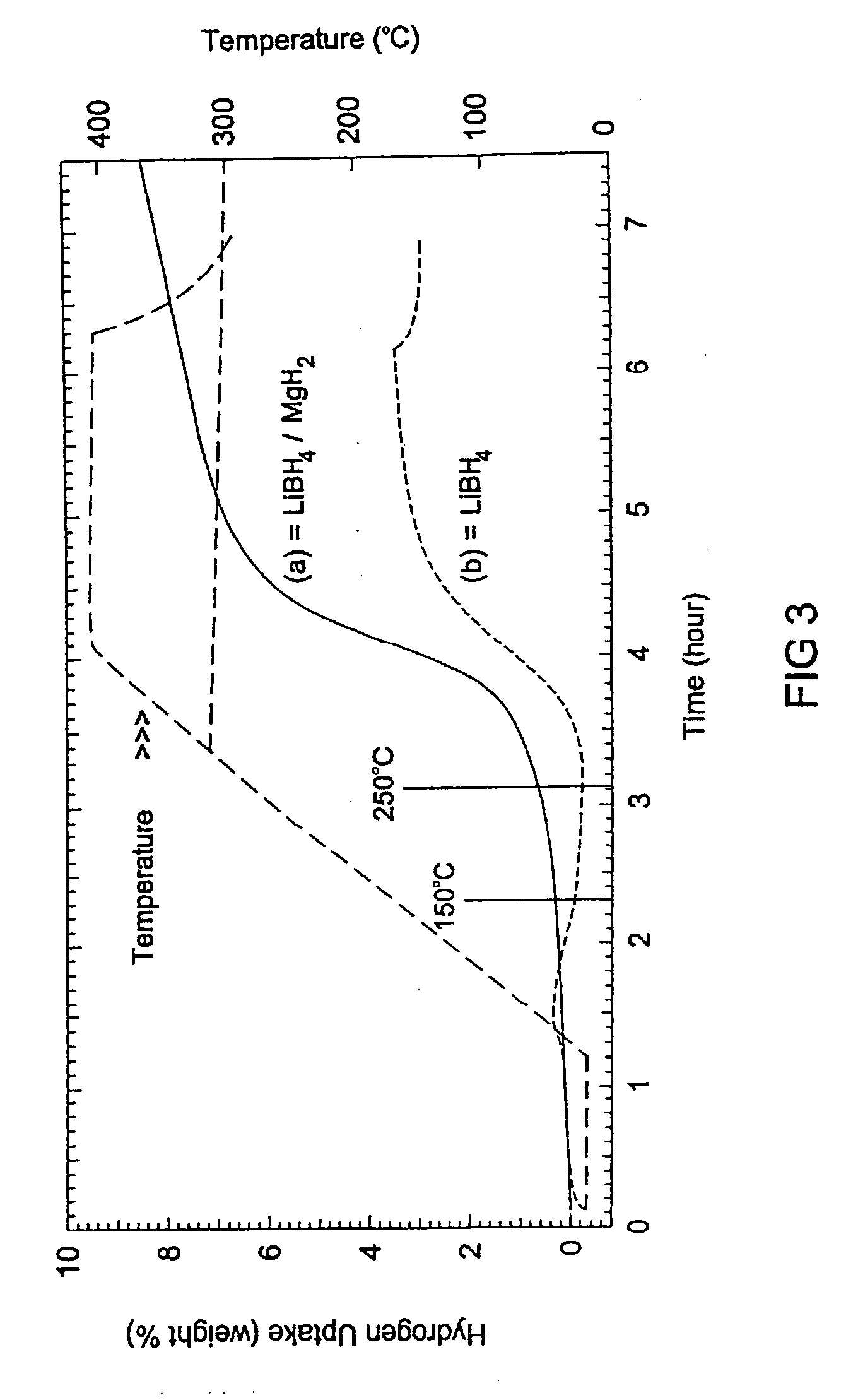

Reversible hydrogen storage systems

InactiveUS20060013753A1Maintain electroneutralityRelease of hydrogenAlkali/alkaline-earth/beryllium/magnesium hydridesHydrogen separationHydrogen storage systemMaterial system

The invention provides compositions for reversible storage of hydrogen at industrially practicable temperature and pressure conditions. Hydrogen storage material systems comprising stable hydrides and destabilizing hydrides. When the stable hydride is in the presence of the destabilizing hydride, the stable hydride releases hydrogen at a lower energy level than it would in the absence of the destabilizing hydride.

Owner:GM GLOBAL TECH OPERATIONS LLC

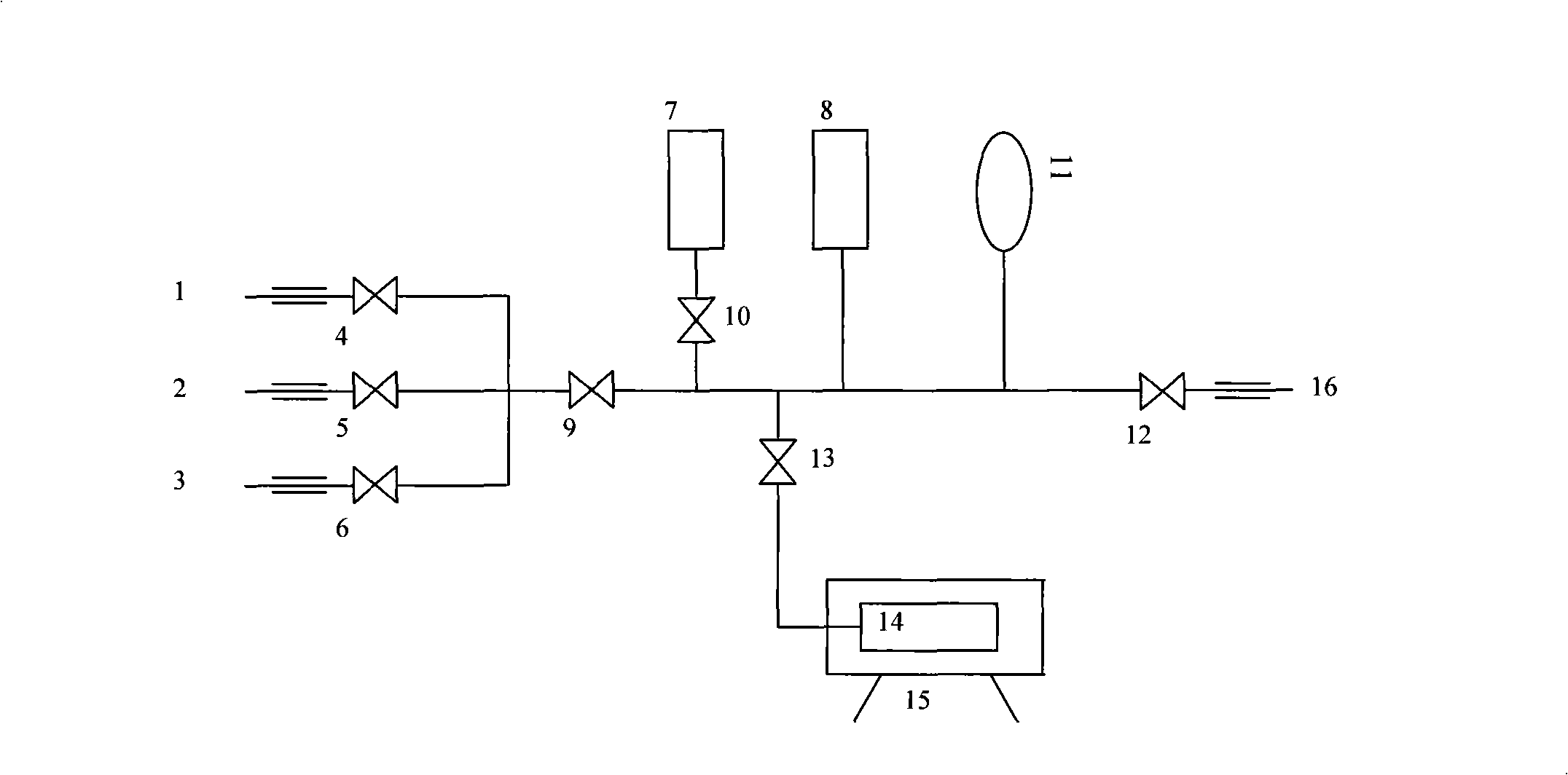

Technological method of purifying hydrogen of hydrogen enriched gas source

ActiveCN1903703AReduce contentImprove product qualityHydrogen separationDispersed particle separationSorbentNitrogen gas

The present invention relates to a technological process for purifying hydrogen gas by using hydrogen-rich gas source. Said process includes the following several procedures: a), raw material gas compression; b), decarbonization and dehydration; c), membrane separation; d), catalytic reaction to make deoxidation; and e), pressure swing adsorption.

Owner:TONGJI UNIV +2

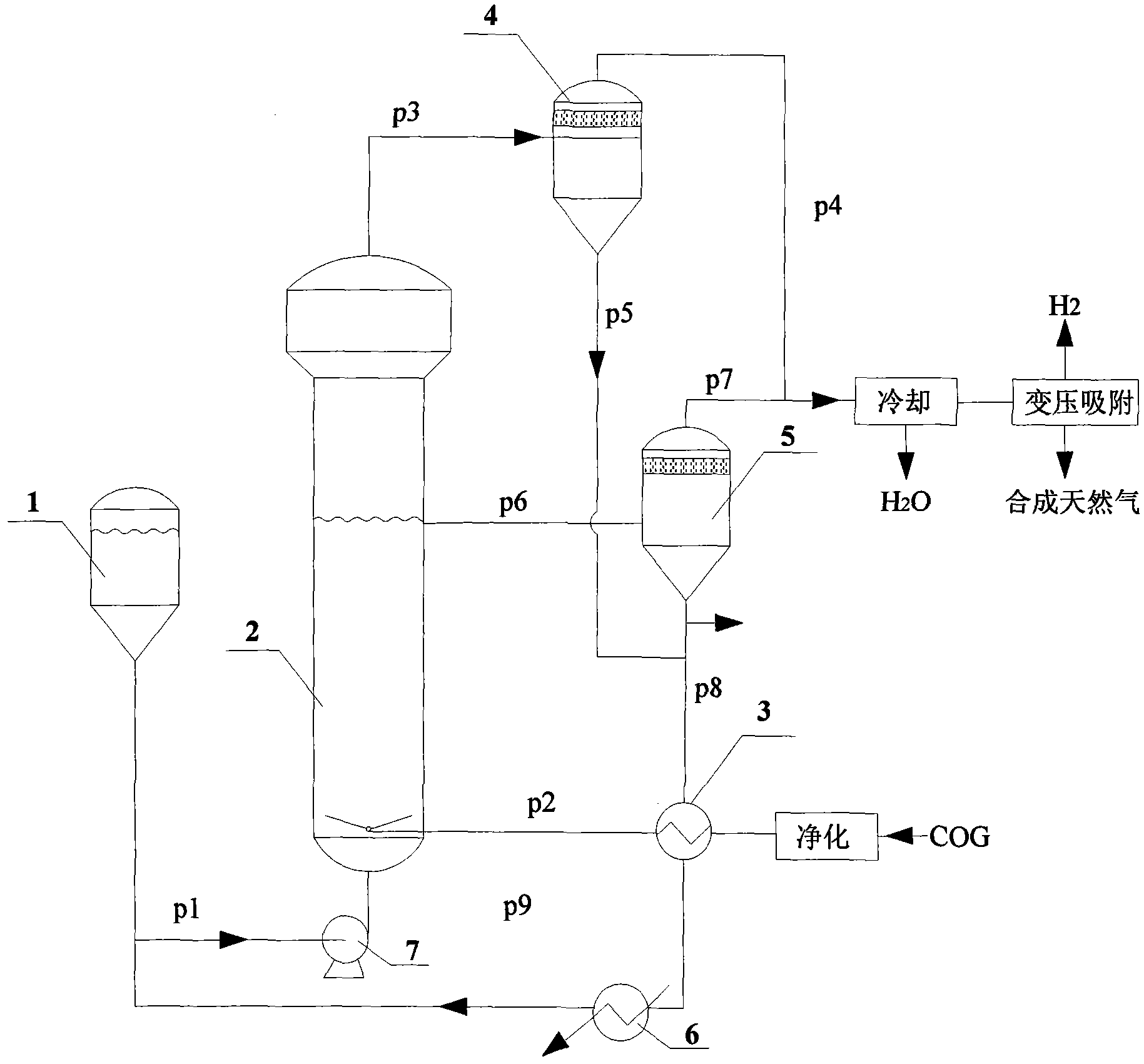

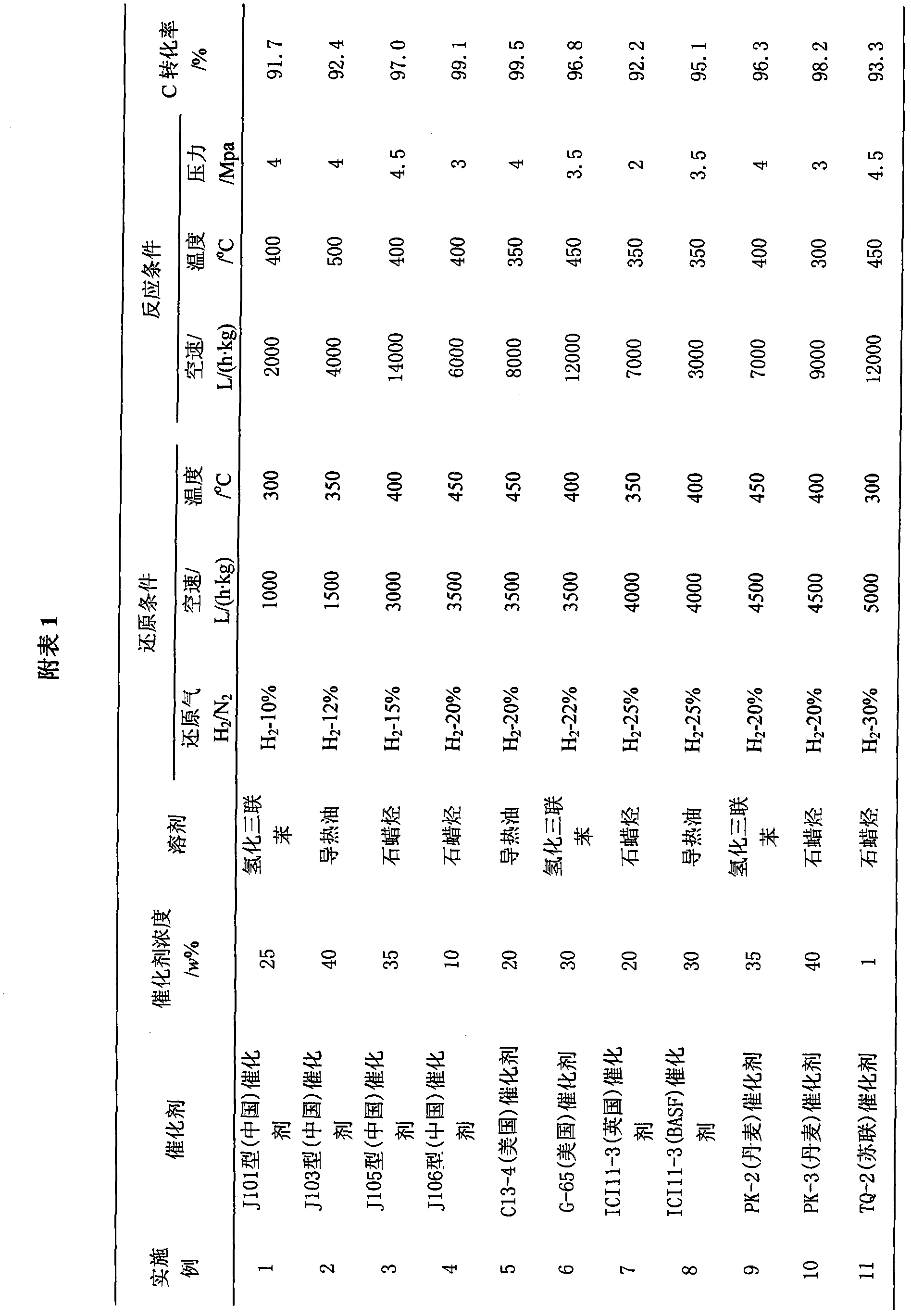

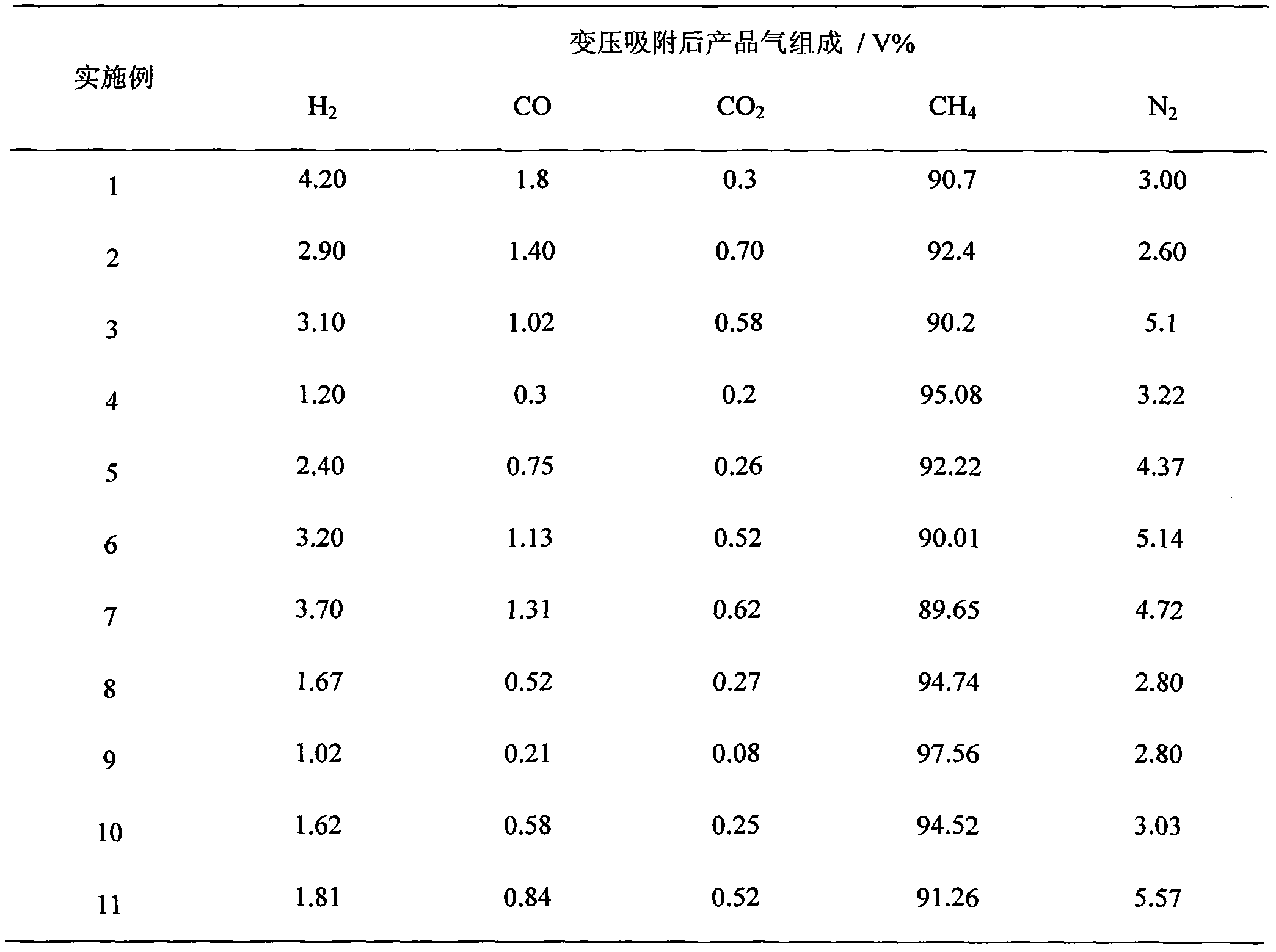

Process for synthesizing natural gas by performing methanation on coke oven gas

The invention relates to a process for synthesizing natural gas by performing methanation on coke oven gas. The process comprises the following steps of: dispersing a fresh methanation catalyst into an inert liquid-phase medium and putting the mixture into a slurry bed methanation reactor for reducing; performing a methanation reaction on the reduced coke oven gas, introducing tail gas into a gas-liquid separator I, discharging a slurry liquid-phase component in the tail gas and the catalyst from the bottom of the gas-liquid separator I and exhausting a gas phase in the tail gas from the top of the gas-liquid separator I; introducing a part of catalyst-containing inert liquid-phase media into a gas-liquid separator II, exhausting a gas phase from the top of the gas-liquid separator II, combining the gas phase with the gas phase exhausted from the top of the gas-liquid separator I, cooling and performing pressure swing adsorption so as to obtain H2 and synthetic natural gas; and discharging a methanation catalyst-containing inert liquid-phase medium from the bottom, combining the methanation catalyst-containing inert liquid-phase medium with the slurry liquid-phase component and the catalyst which are discharged from the bottom of the gas-liquid separator I, filtering a large-particle catalyst of less than 300 meshes out, separating a fine catalyst of more than 300 meshes from the inert liquid-phase medium and discharging, mixing the separated inert liquid-phase medium and the large-particle catalyst, exchanging heat between the mixture and raw material gas, cooling, and introducing the mixture into the slurry bed methanation reactor together with the methanation catalyst which is newly dispersed into the inert liquid-phase medium for the methanation reaction. The process has the advantages that: the process has low energy consumption and small equipment investment, is easy to operate and can replace the catalyst on line.

Owner:河北华丰能源科技发展有限公司

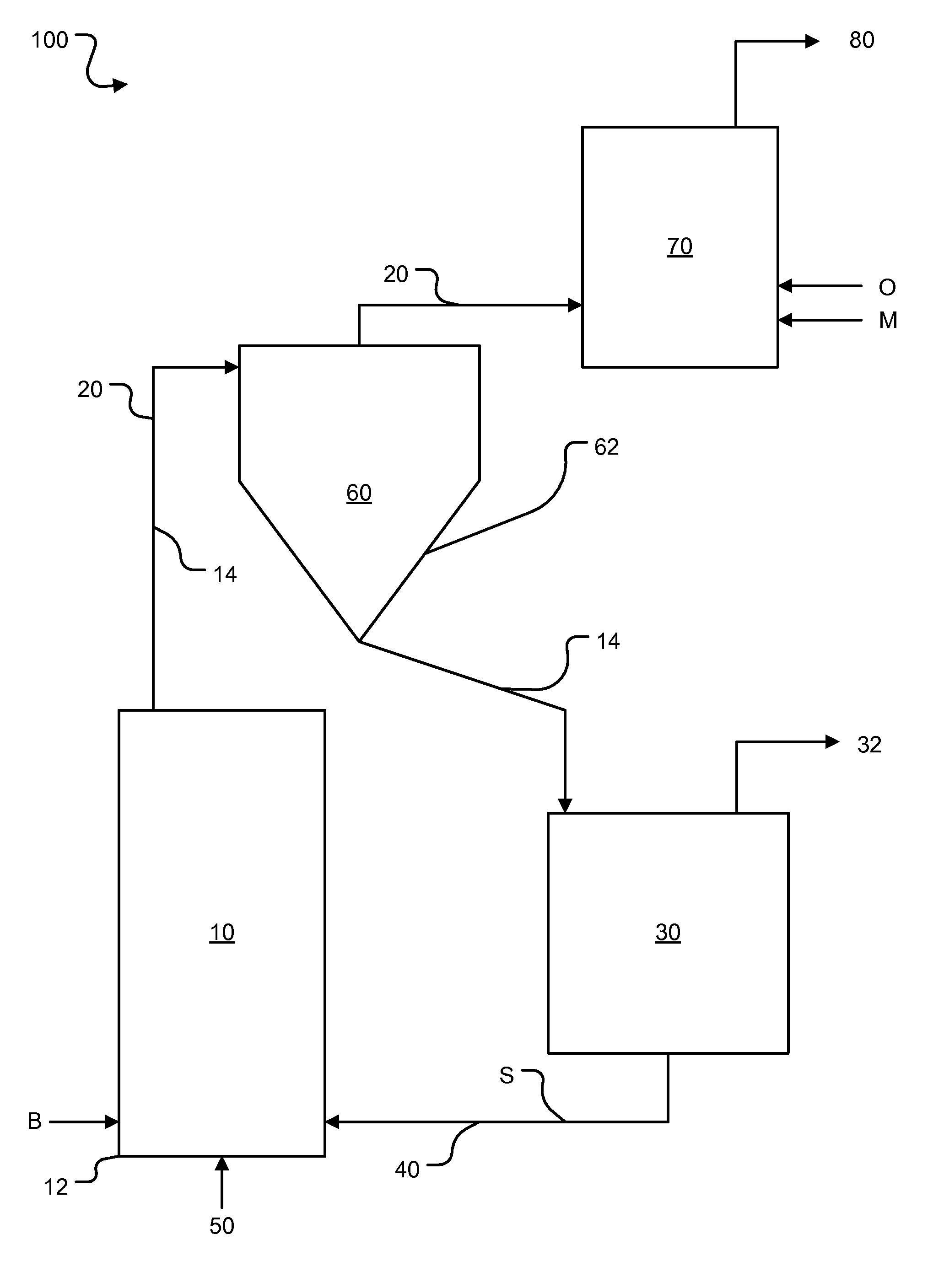

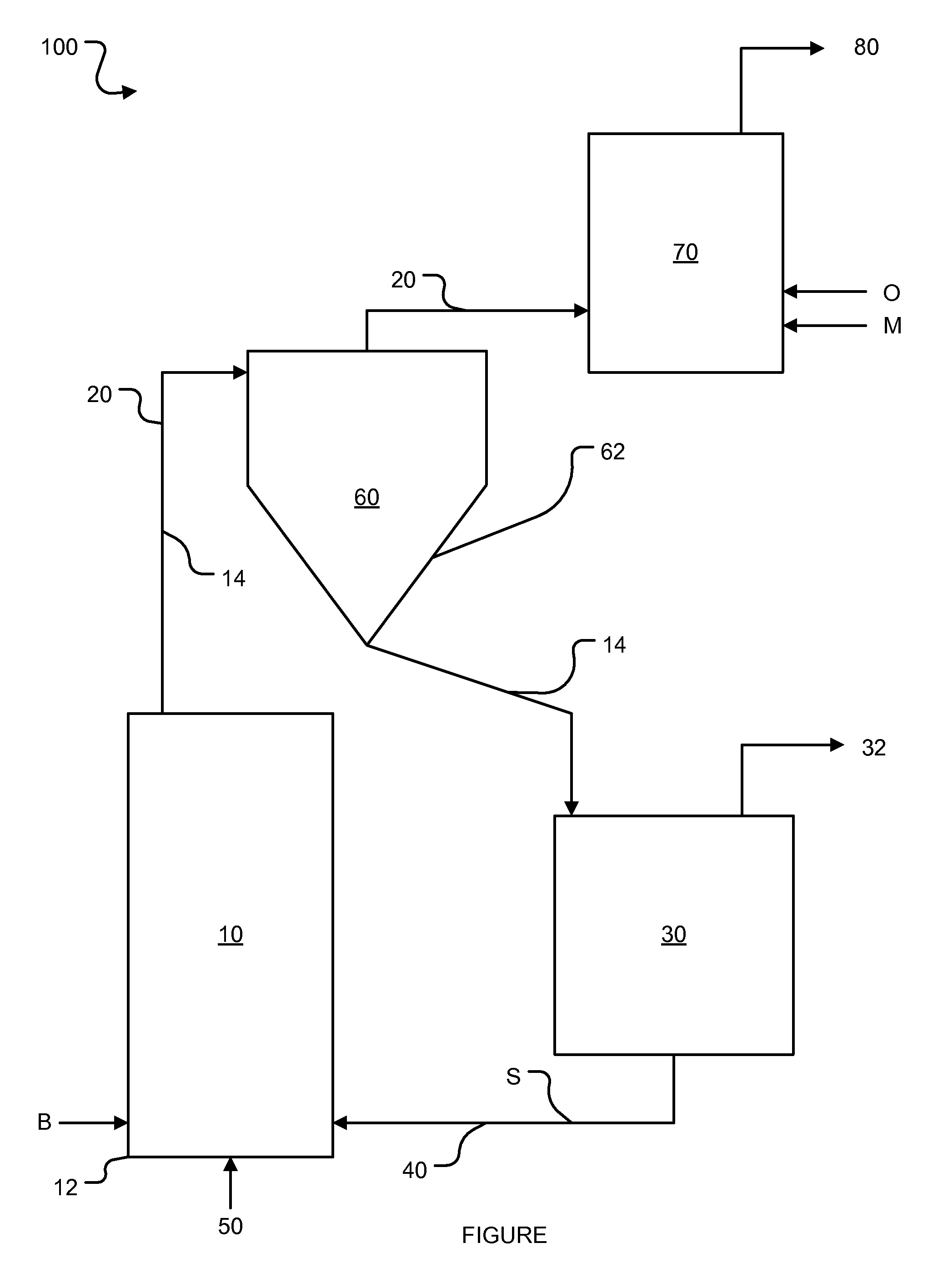

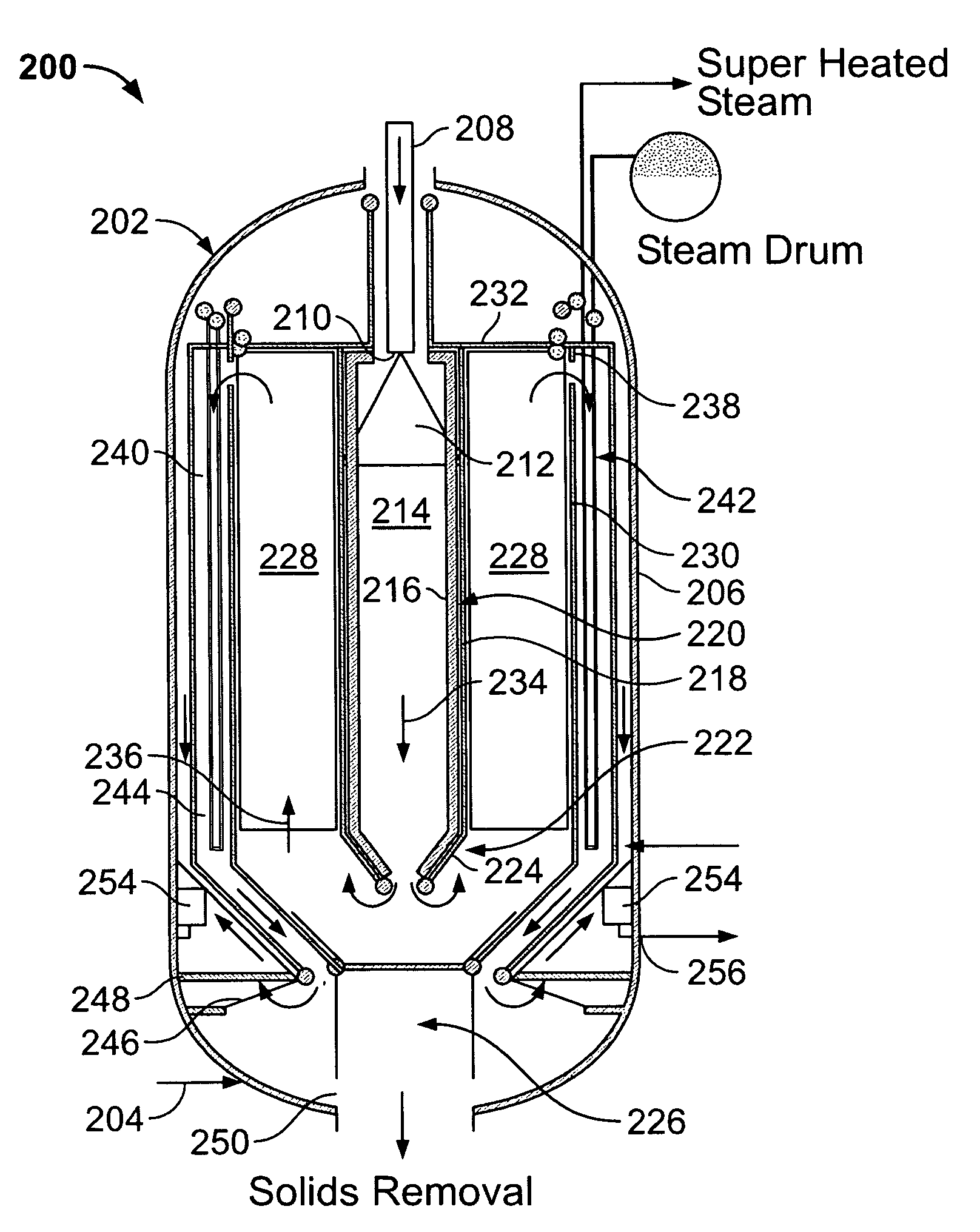

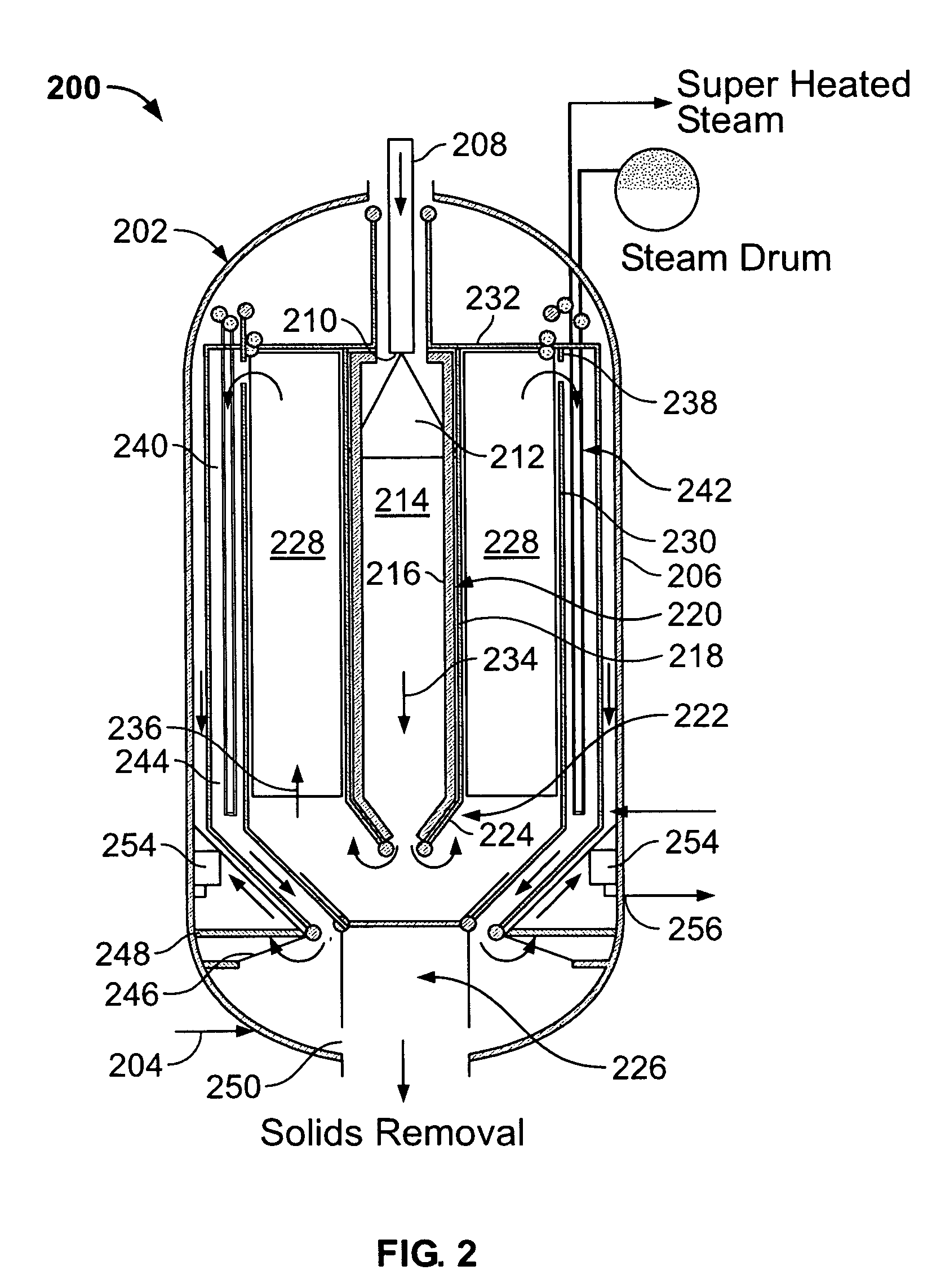

Methods and systems for advanced gasifier solids removal

ActiveUS7744663B2Facilitates componentGasifier mechanical detailsHydrogen/synthetic gas productionSyngasCombustor

Methods and systems for a gasifier solids removal system are provided. The system includes a down flow combustor including an inlet and an outlet and a combustion zone extending therebetween, the combustor configured to direct a flow of process material including syngas, flowable slag, and particulates in a first downward direction, a plurality of flow passages in serial flow communication including a first flow passage and a second flow passage, wherein the process material flow reverses direction flowing from the first passage to the second passage, and a plurality of entrainment separation stages in serial flow communication with at least one of the plurality of flow passages.

Owner:AIR PROD & CHEM INC

Process and apparatus for converting hydrogen sulfide into hydrogen and sulfur

ActiveUS20050191237A1Improve efficiencyIncrease attractivenessHydrogen productionFuel cellsHydrogenSulfur product

A process and an apparatus for obtaining a hydrogen product and a sulfur product from a feed gas. The feed gas is comprised of hydrogen sulfide, the hydrogen product is comprised of elemental hydrogen and the sulfur product is comprised of elemental sulfur. In the process, a first separating step separates the feed gas to obtain a first purified hydrogen sulfide fraction comprised of at least about 90 percent hydrogen sulfide by volume. A dissociating step dissociates hydrogen sulfide present in the first purified hydrogen sulfide fraction to convert it into a dissociated first purified hydrogen sulfide fraction comprised of elemental hydrogen and sulfur. A second separating step separates the dissociated first purified hydrogen sulfide fraction to obtain a hydrogen rich fraction comprised of elemental hydrogen. The sulfur product may also be obtained from the dissociated first purified hydrogen sulfide fraction. Finally, the hydrogen product is obtained from the hydrogen rich fraction. The apparatus is provided for performing the process.

Owner:H2S TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com