Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

151results about How to "Facilitates component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

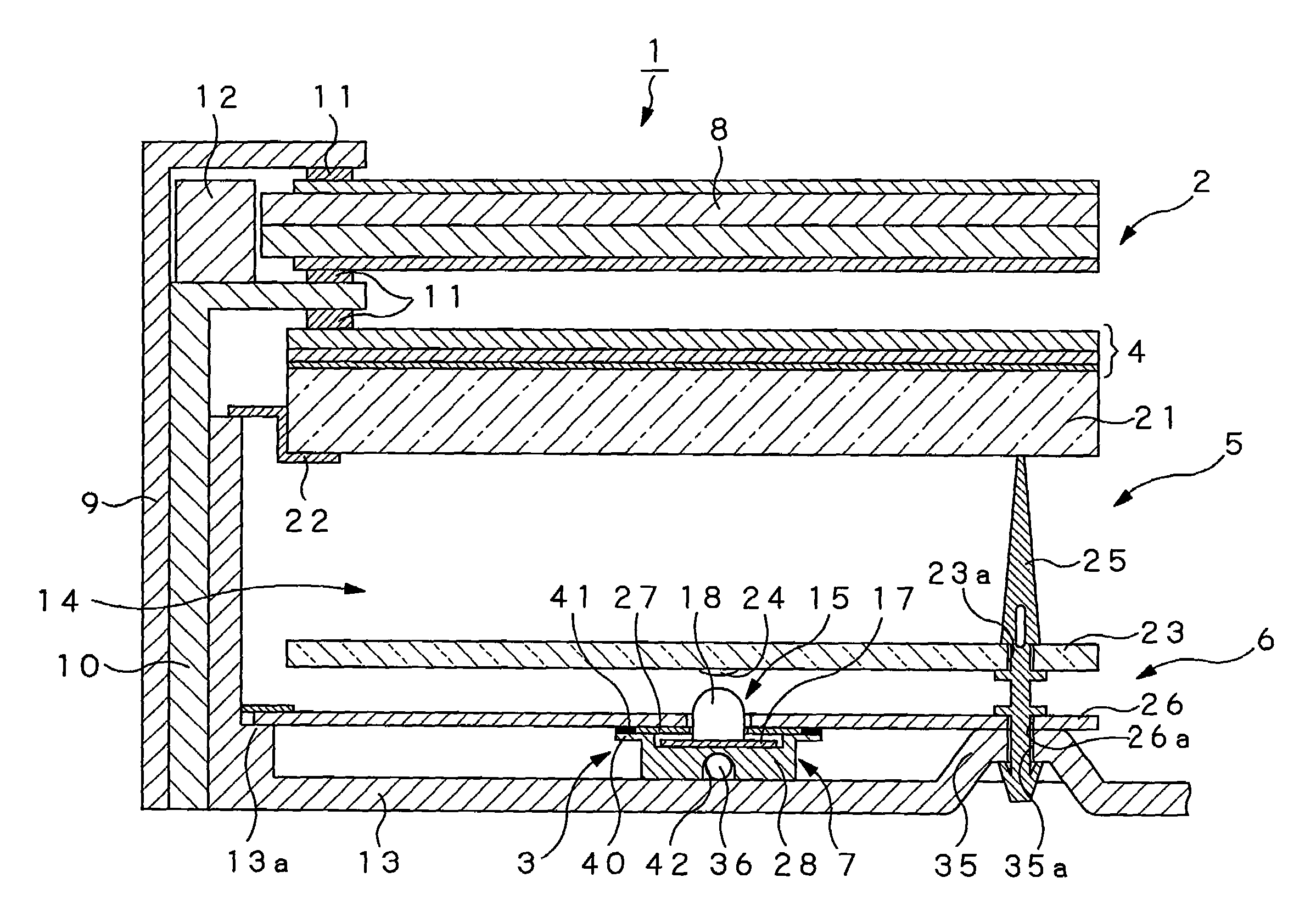

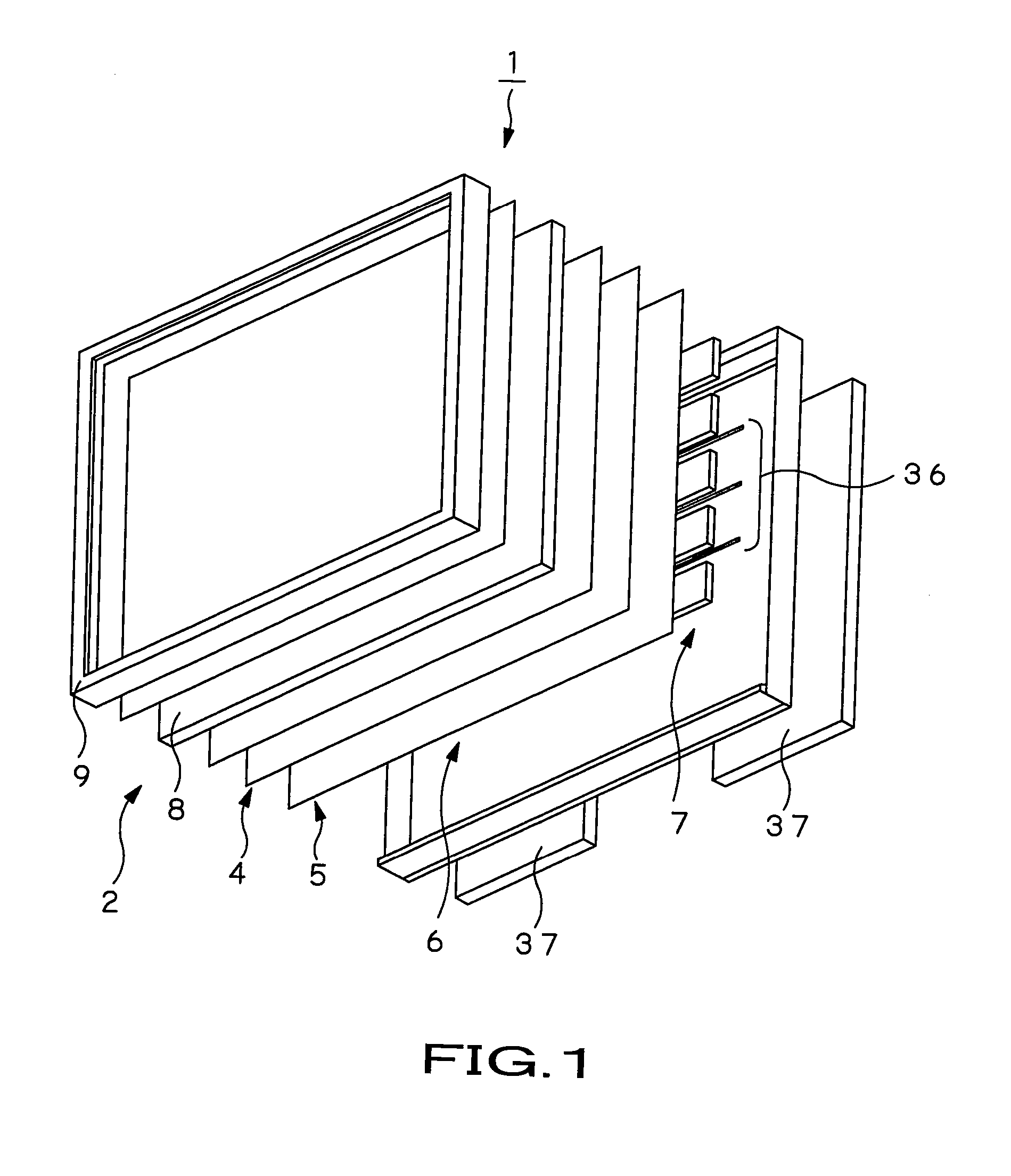

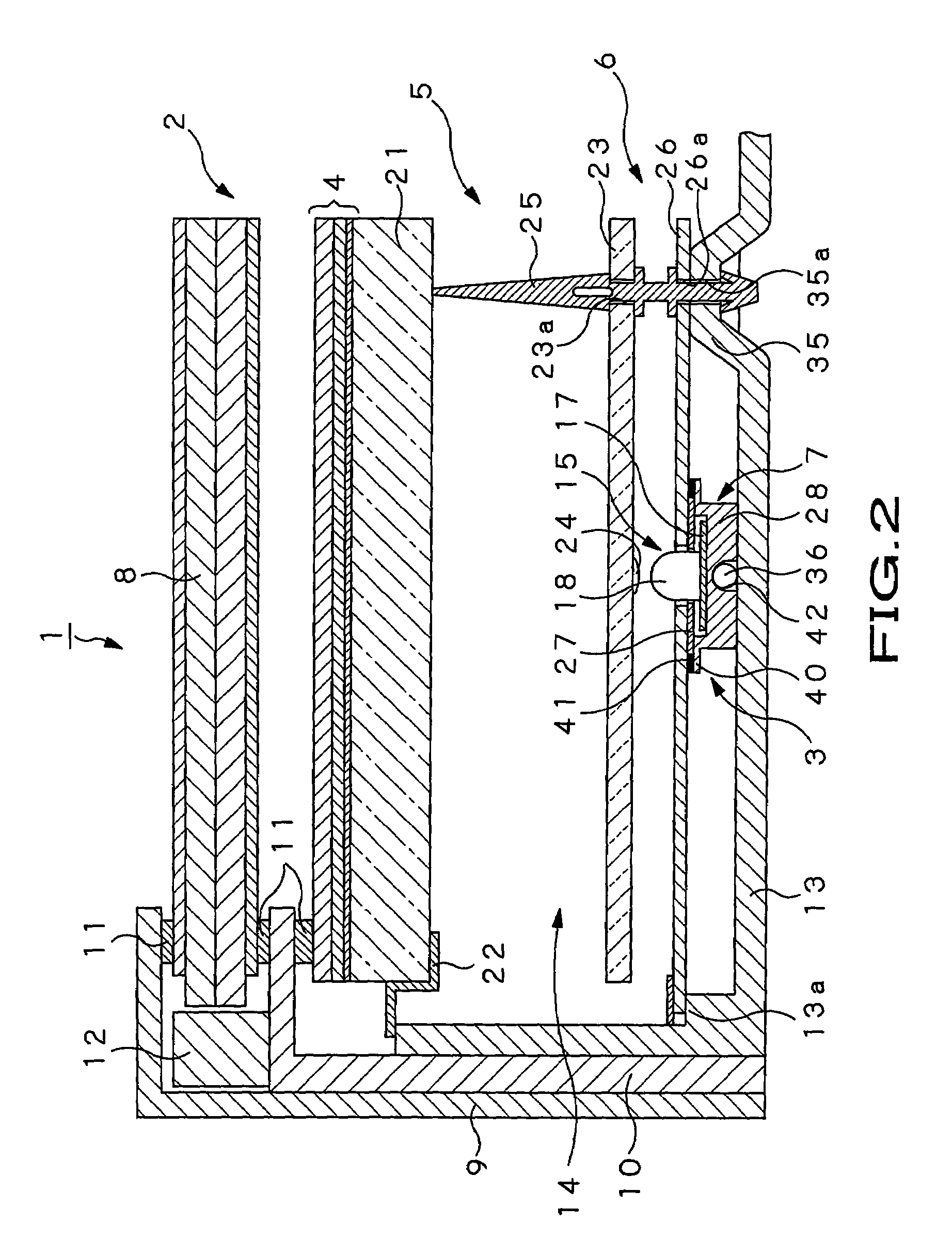

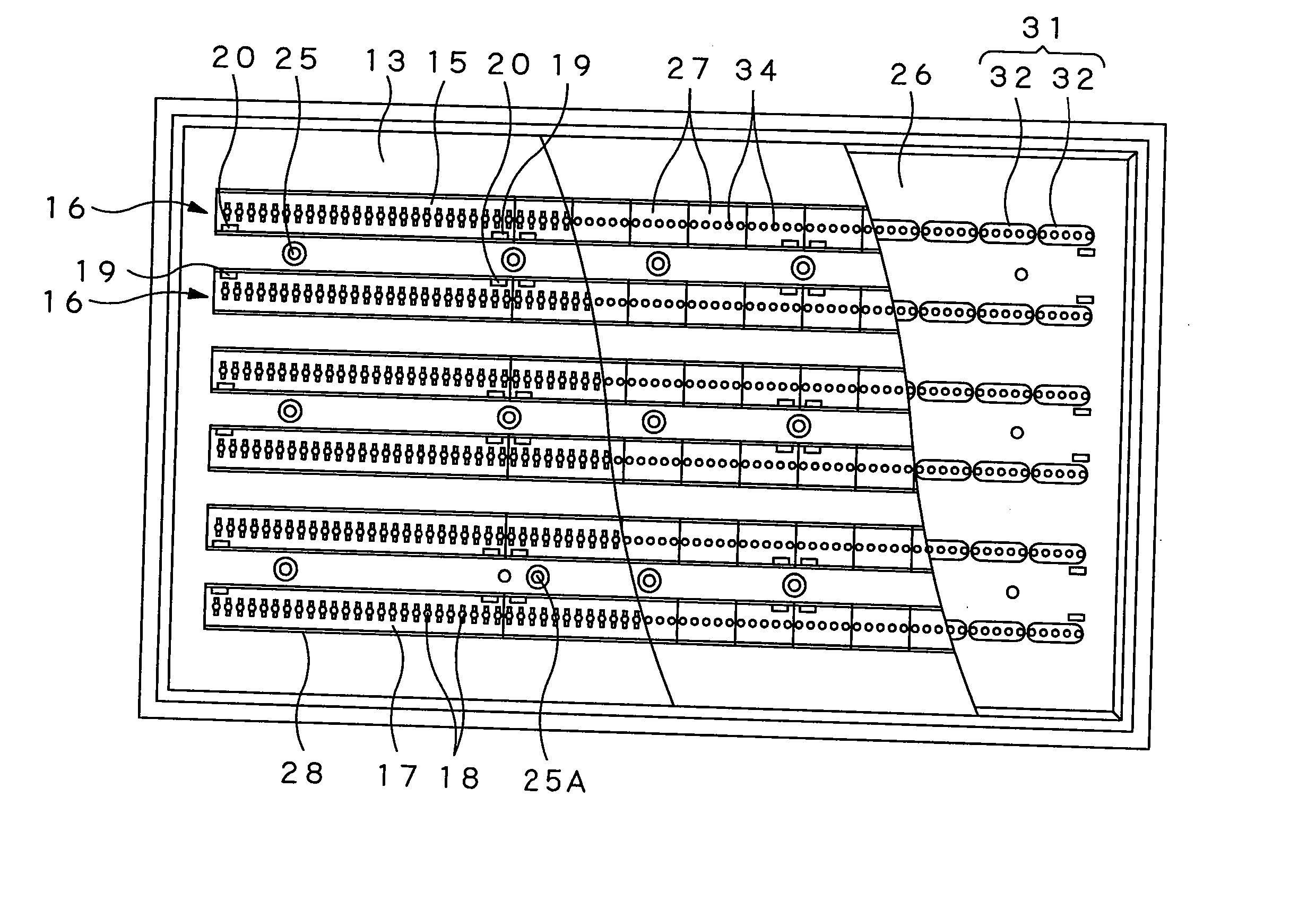

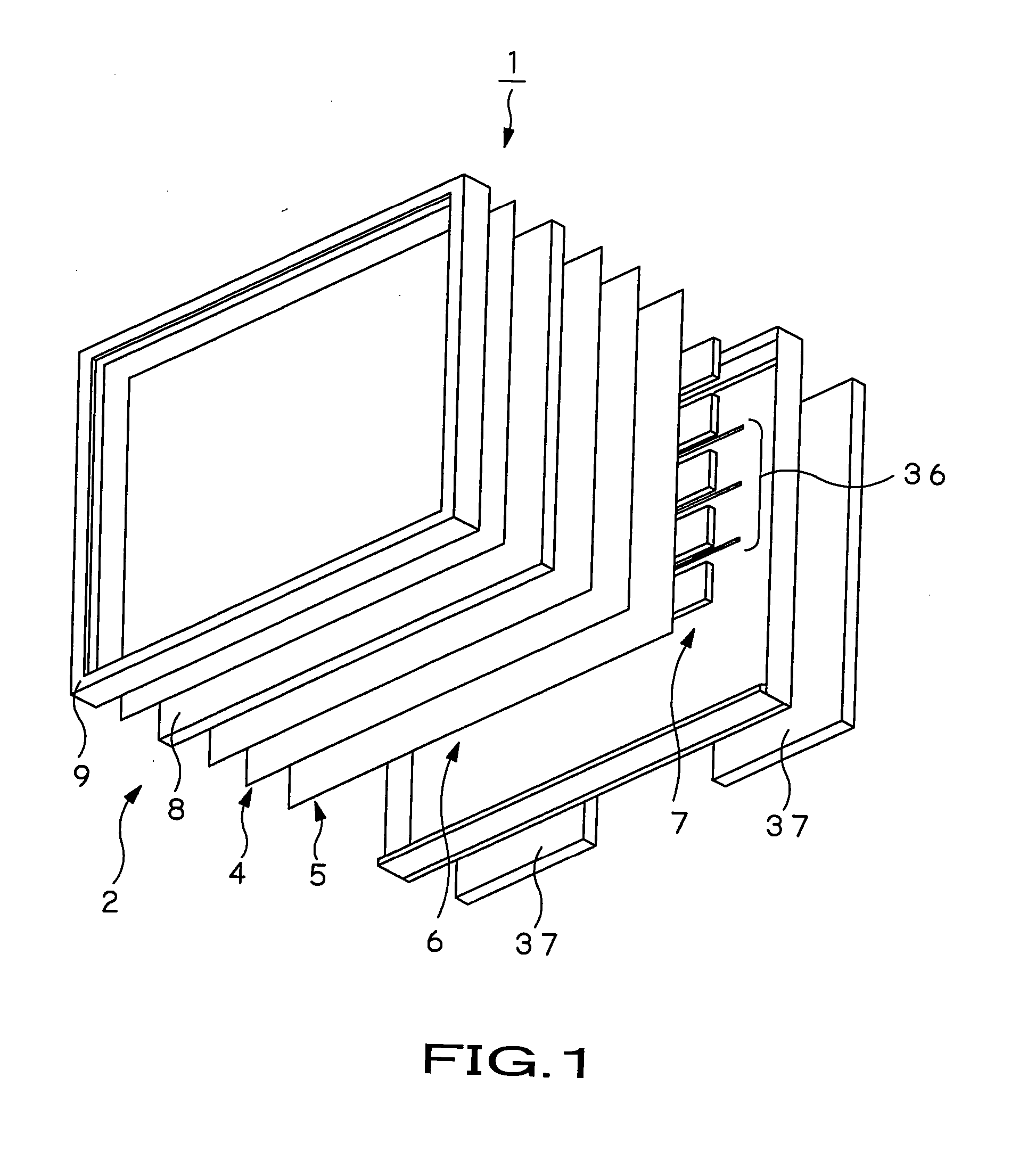

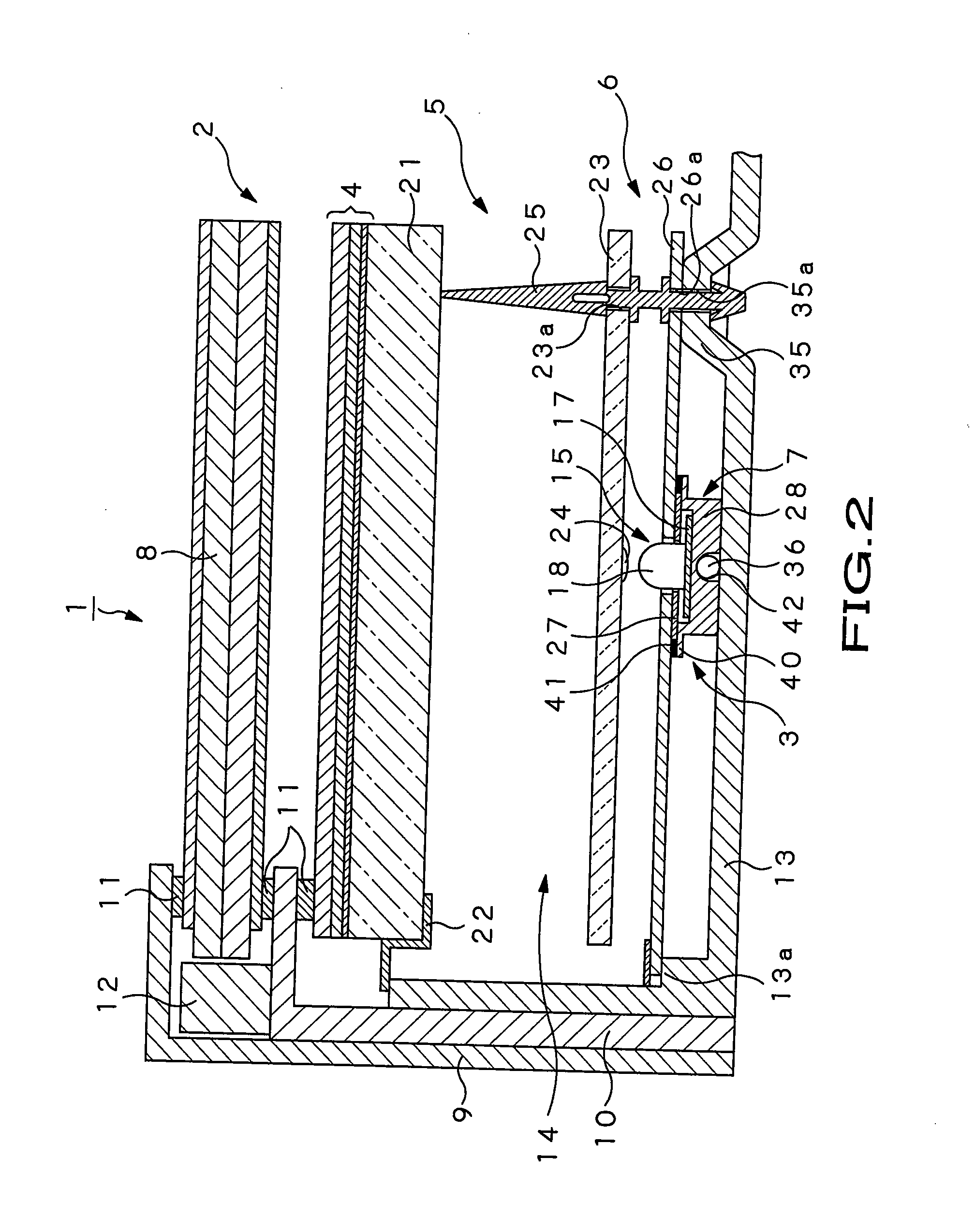

Backlight device and liquid crystal display apparatus

ActiveUS7324174B2Improve lighting efficiencyImprove utilization efficiencyNon-electric lightingPoint-like light sourceLiquid-crystal displayTelevision receivers

Disclosed is a light transmitting liquid crystal display apparatus used with advantage with a television receiver having a large-sized display not less than 30 inch. A backlight section (3) sending out illuminating light is formed by a plural number of rows made up of many light emitting units (15) arranged on the back surface of a liquid crystal display panel (8). Each light emitting unit includes many LED units (18) mounted on an interconnection substrate (17) and is mounted in this state on a heat dissipating plate (28). A reflecting section (6) for reflecting the light radiated from each LED is formed by a large number of reflective sheet pieces (27), assembled from one heat emitting unit to another, and a reflective plate (26) secured to reflecting plate supports (40) formed on the heat dissipating plate.

Owner:SATURN LICENSING LLC

Backlight device and liquid crystal display apparatus

ActiveUS20070103908A1Improve lighting efficiencyImprove utilization efficiencyNon-electric lightingMeasurement apparatus componentsLiquid-crystal displayTelevision receivers

Disclosed is a light transmitting liquid crystal display apparatus used with advantage with a television receiver having a large-sized display not less than 30 inch. A backlight section (3) sending out illuminating light is formed by a plural number of rows made up of many light emitting units (15) arranged on the back surface of a liquid crystal display panel (8). Each light emitting unit includes many LED units (18) mounted on an interconnection substrate (17) and is mounted in this state on a heat dissipating plate (28). A reflecting section (6) for reflecting the light radiated from each LED is formed by a large number of reflective sheet pieces (27), assembled from one heat emitting unit to another, and a reflective plate (26) secured to reflecting plate supports (40) formed on the heat dissipating plate.

Owner:SATURN LICENSING LLC

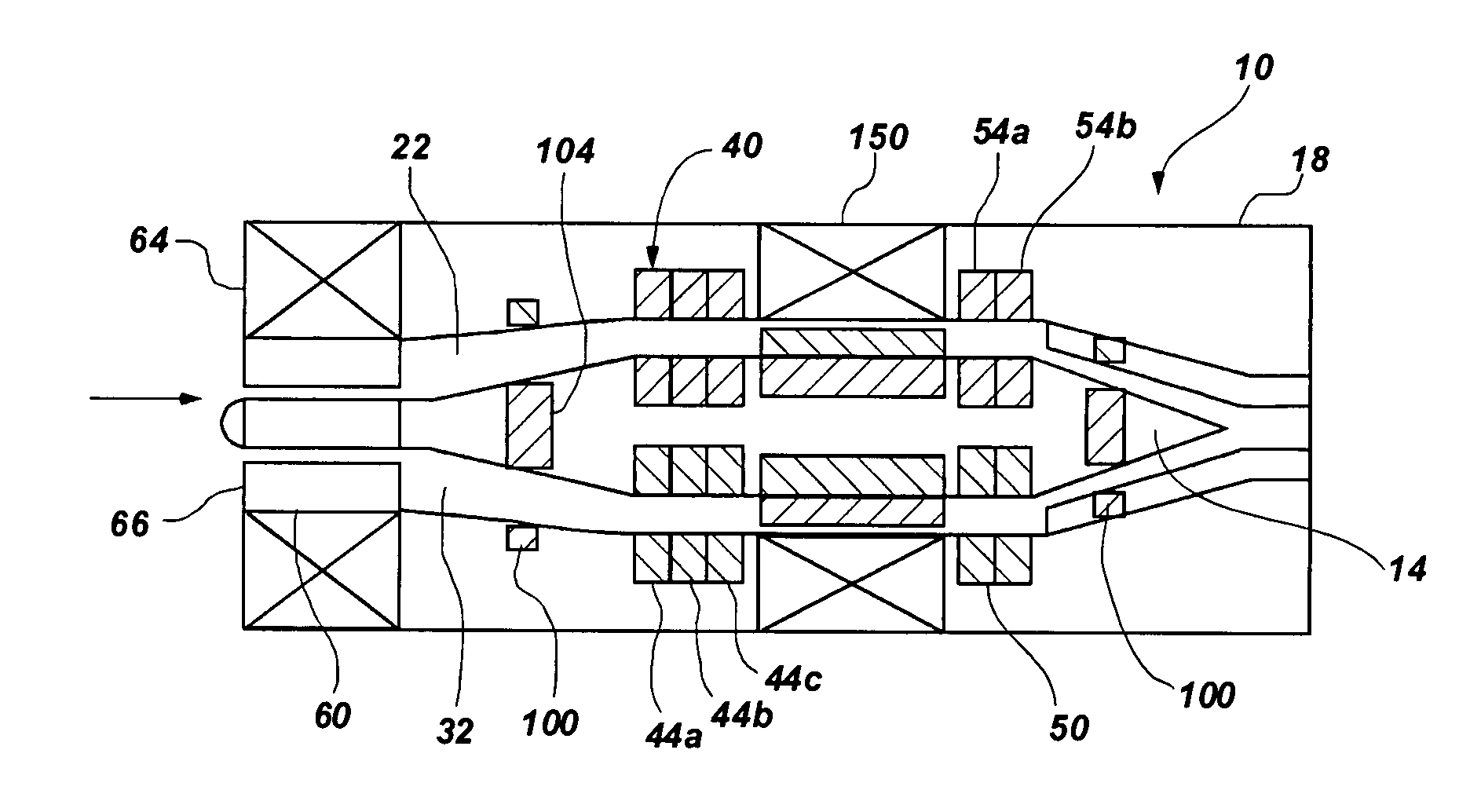

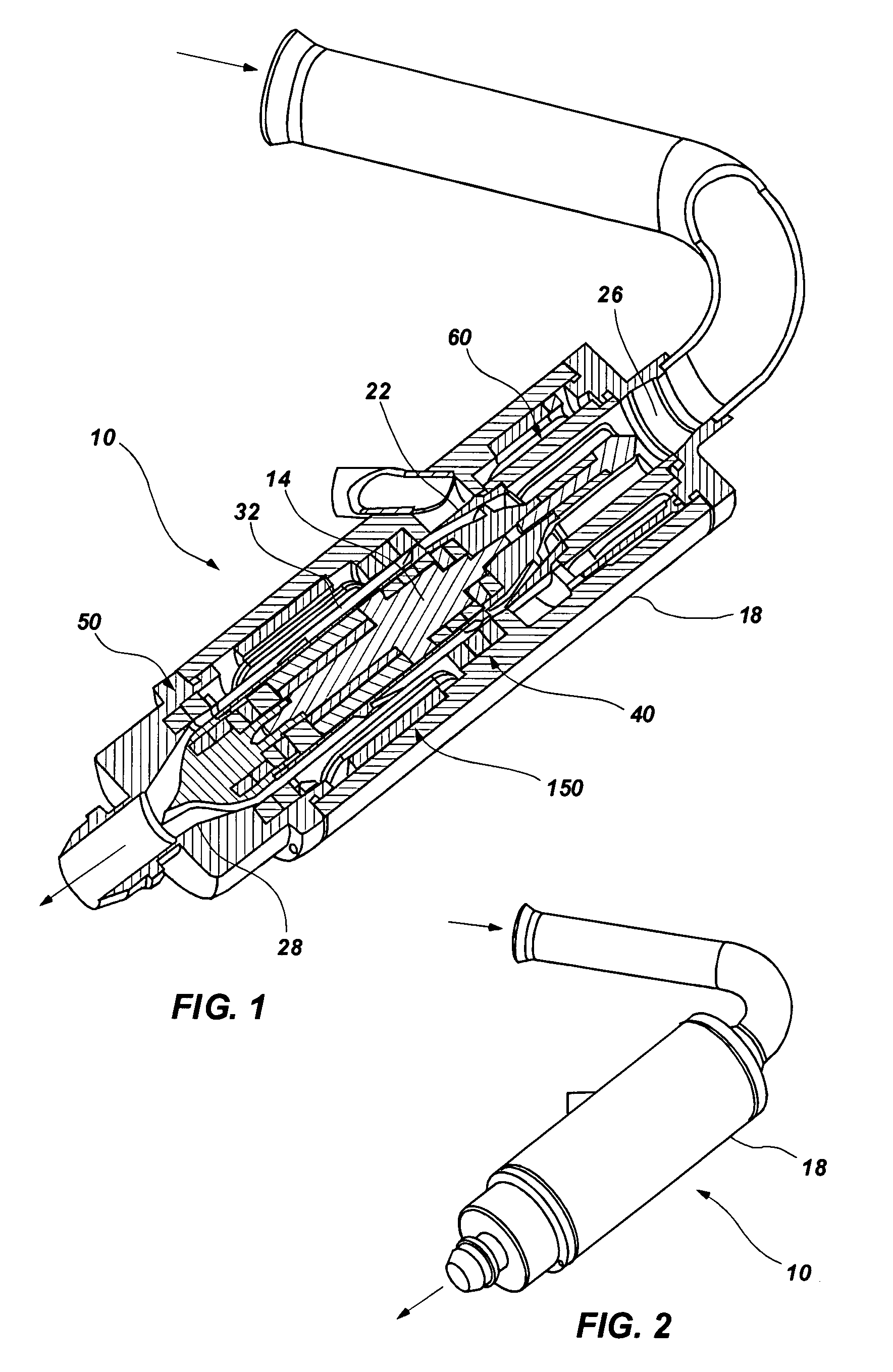

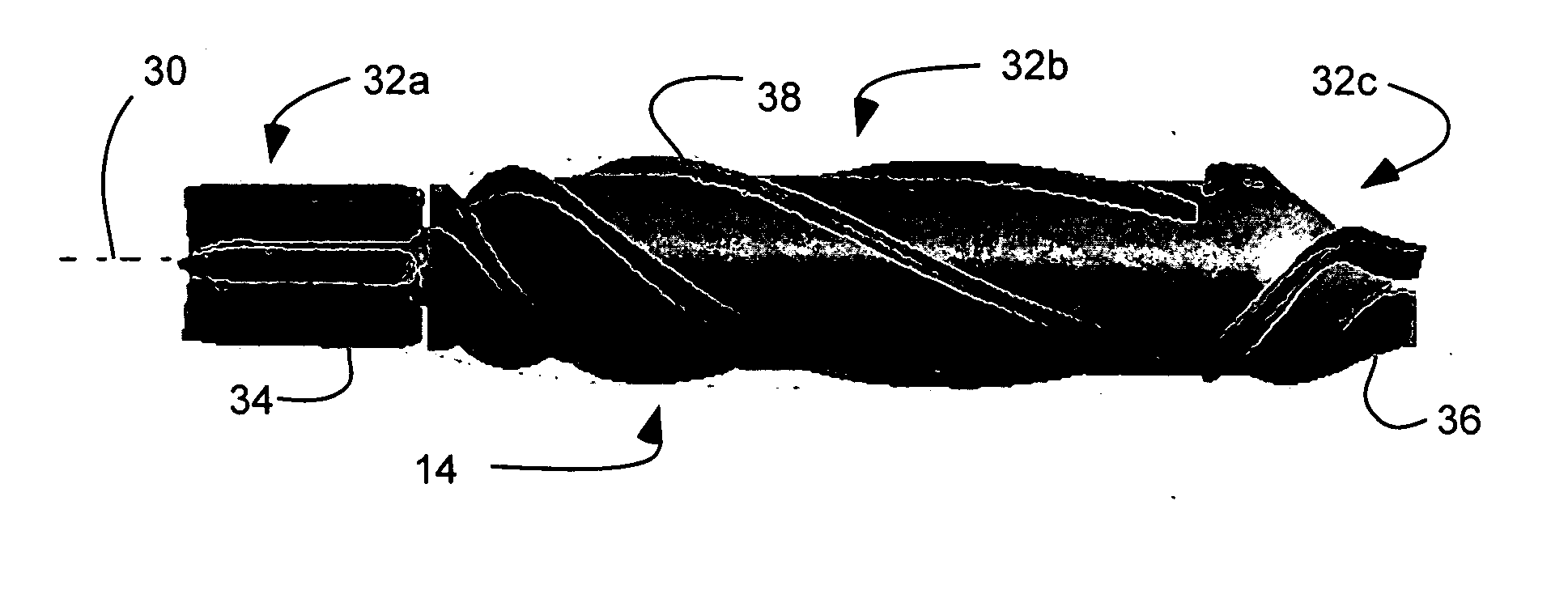

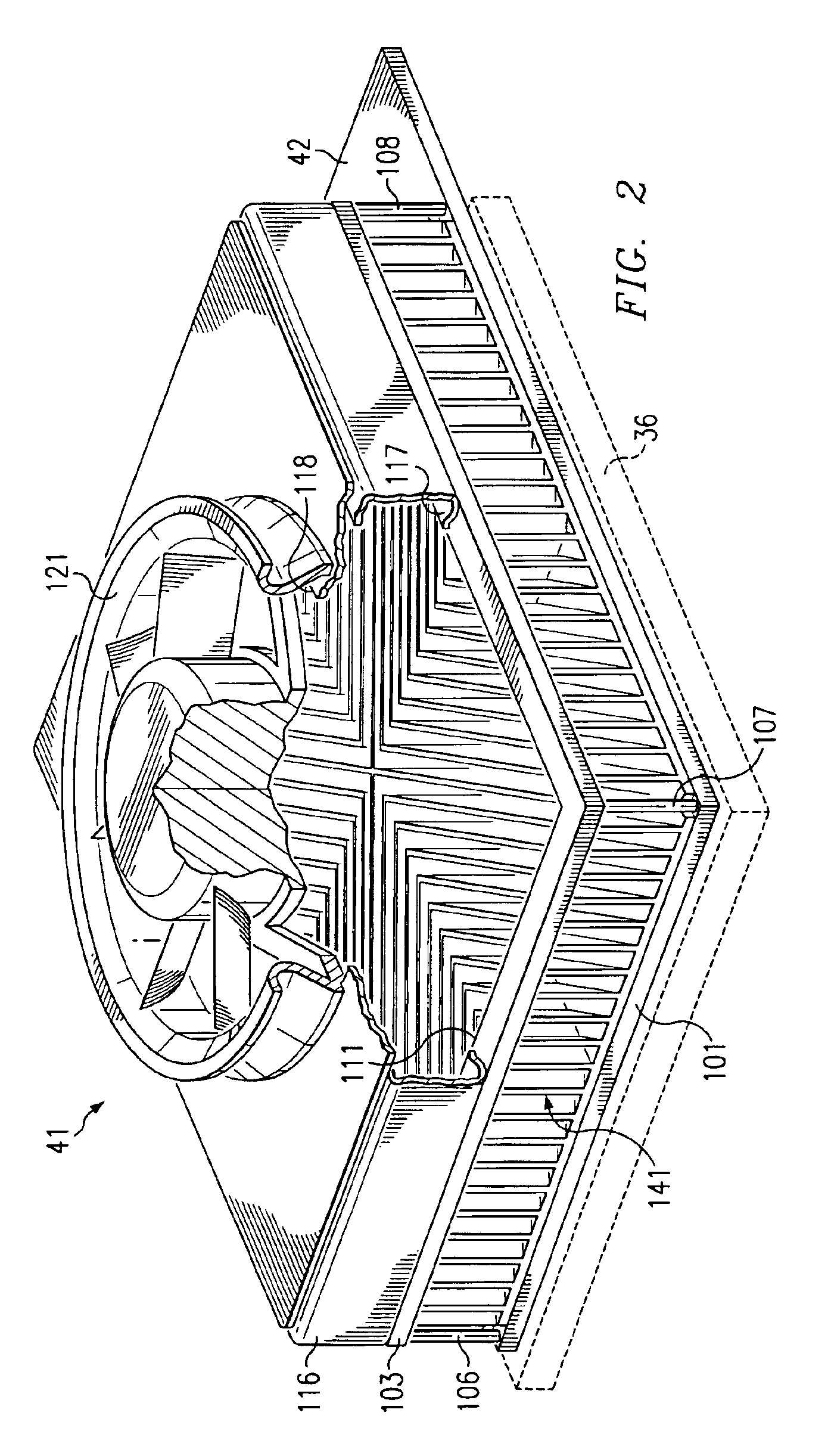

Streamlined unobstructed one-pass axial-flow pump

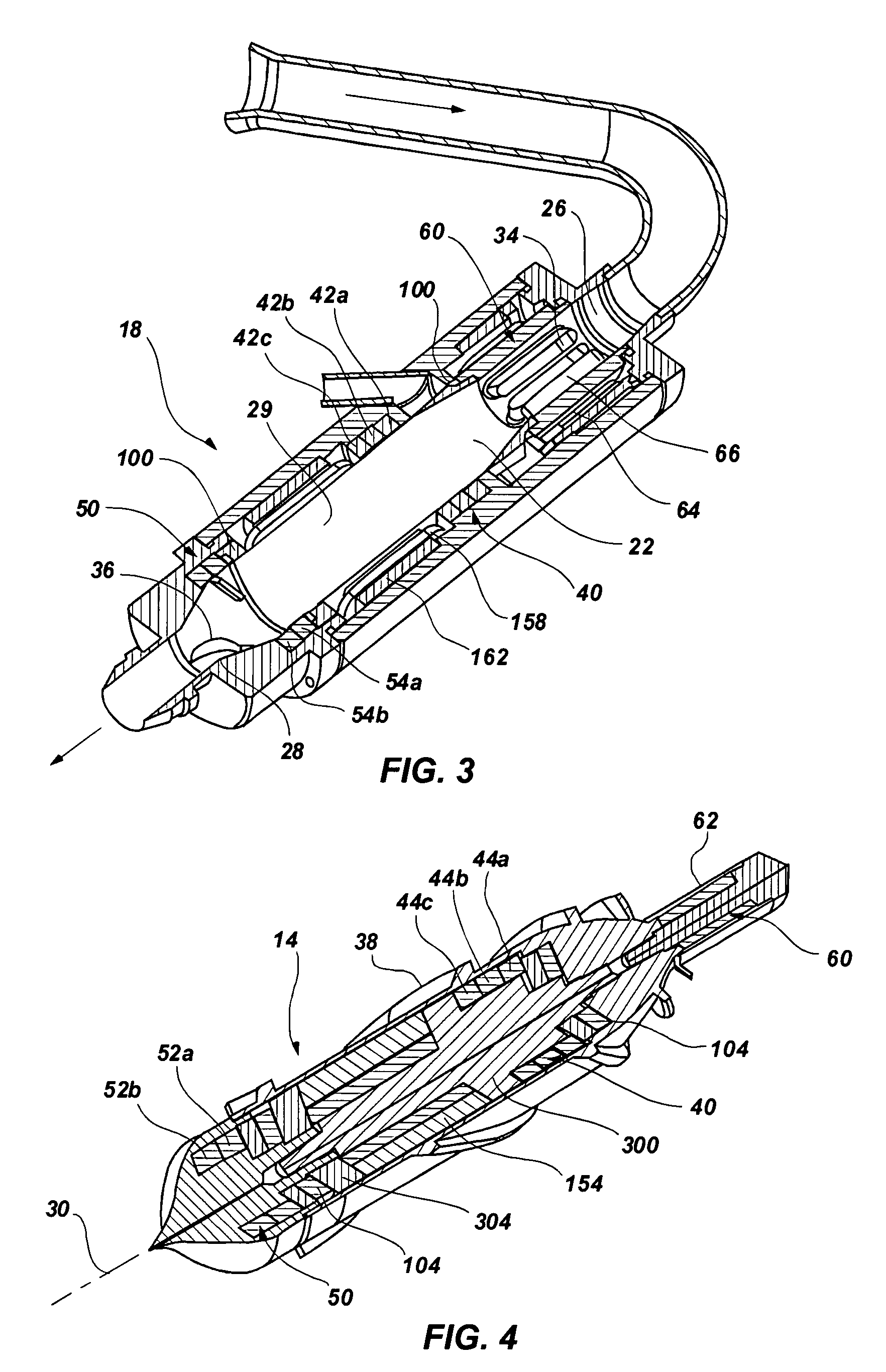

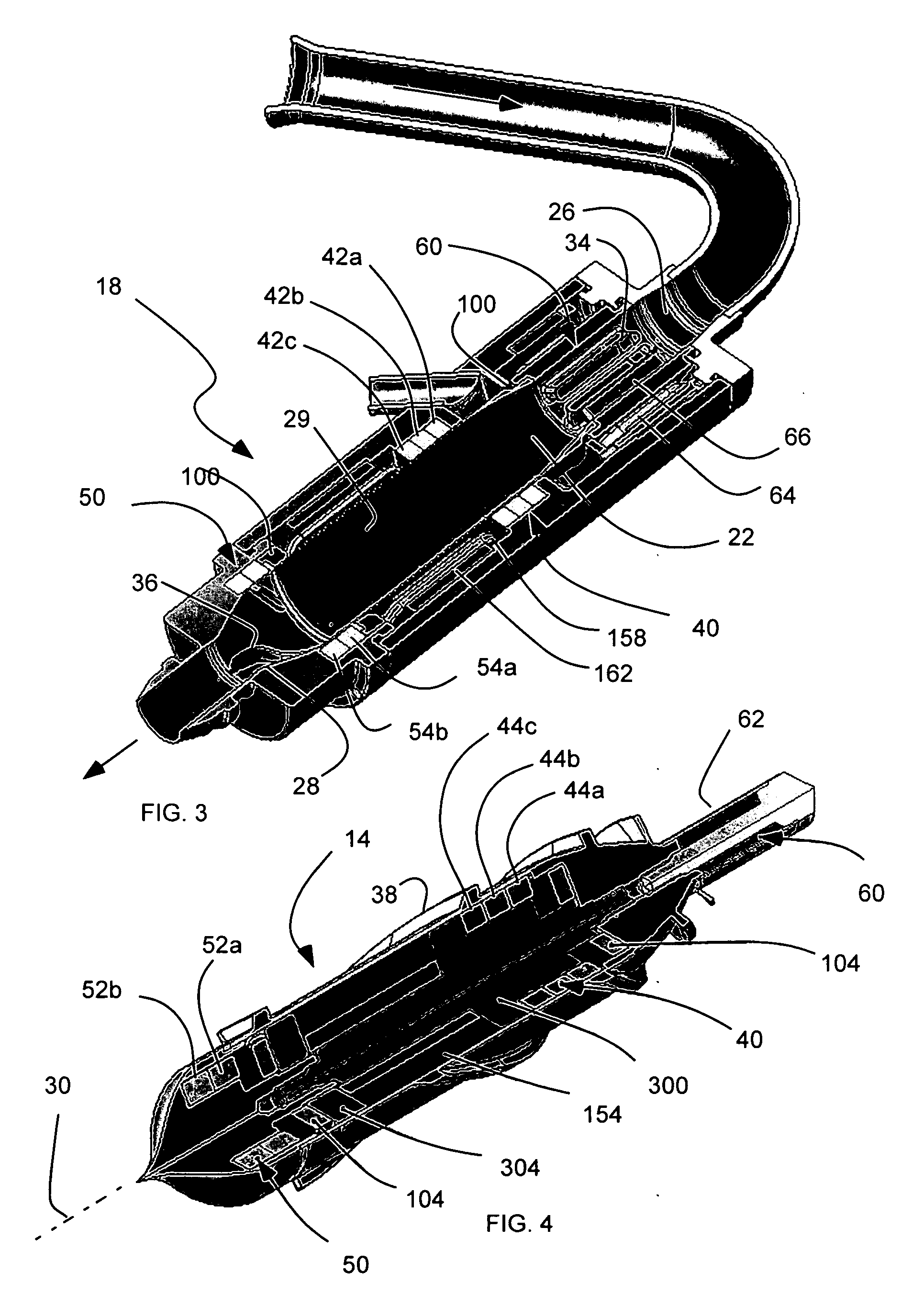

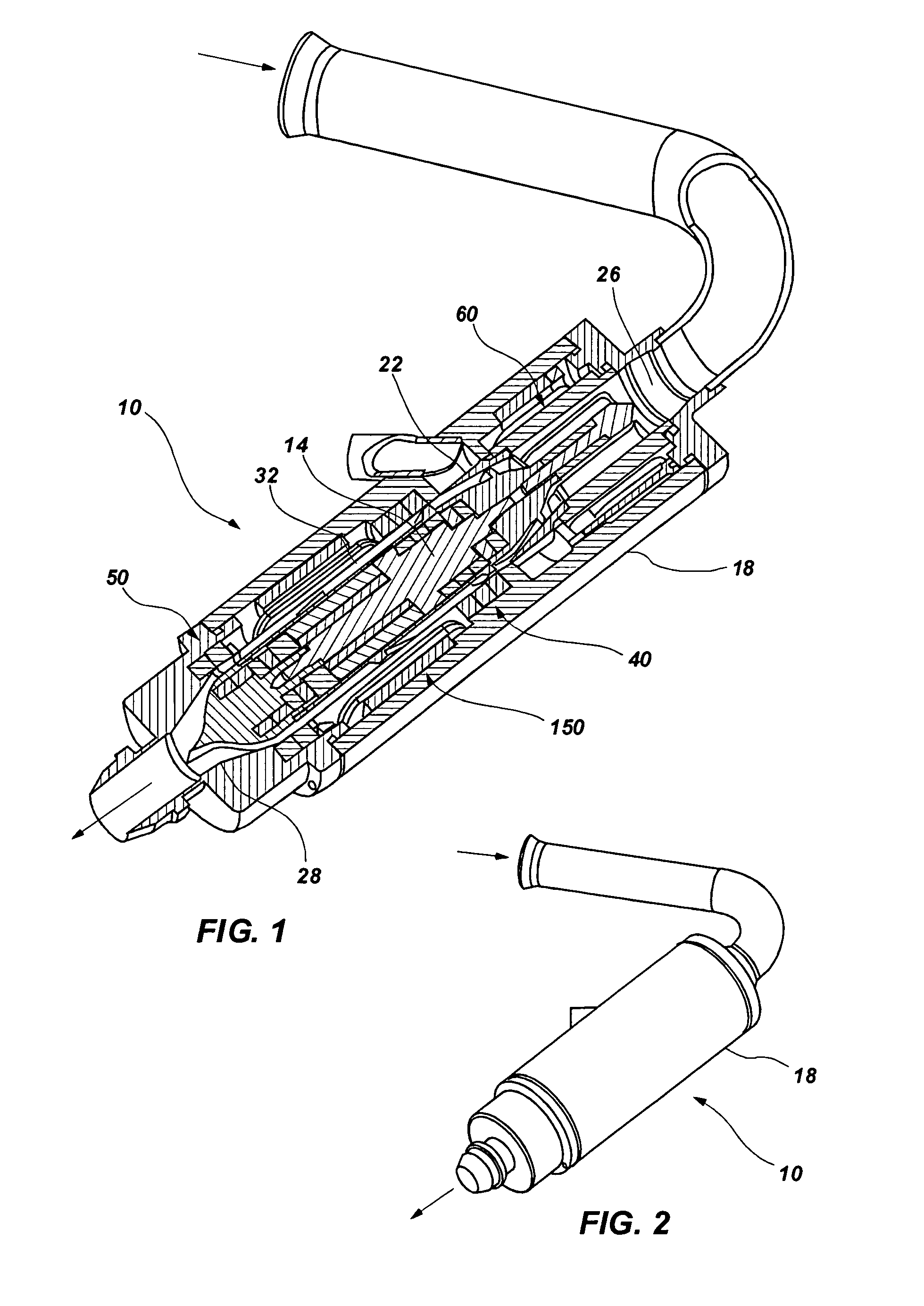

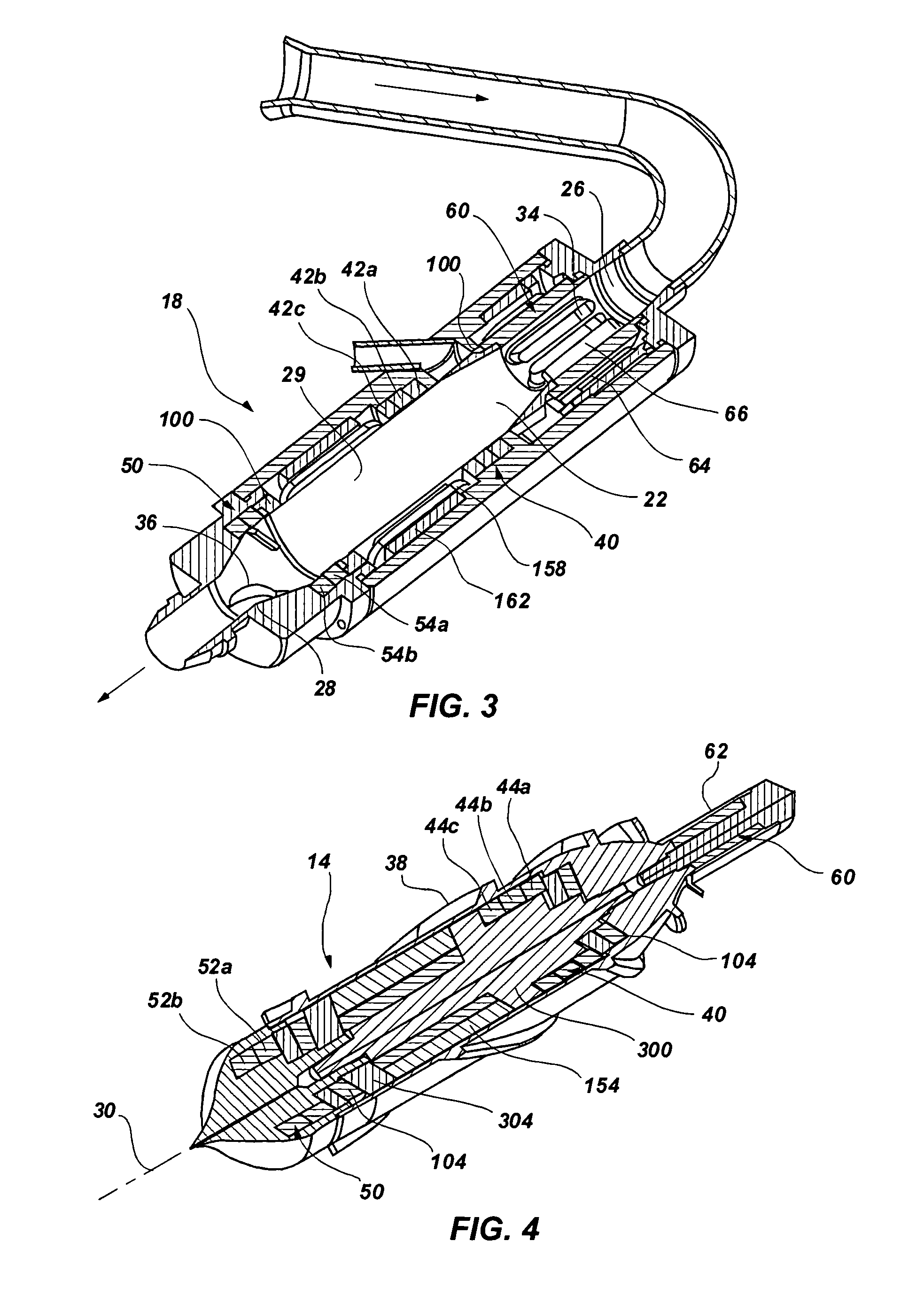

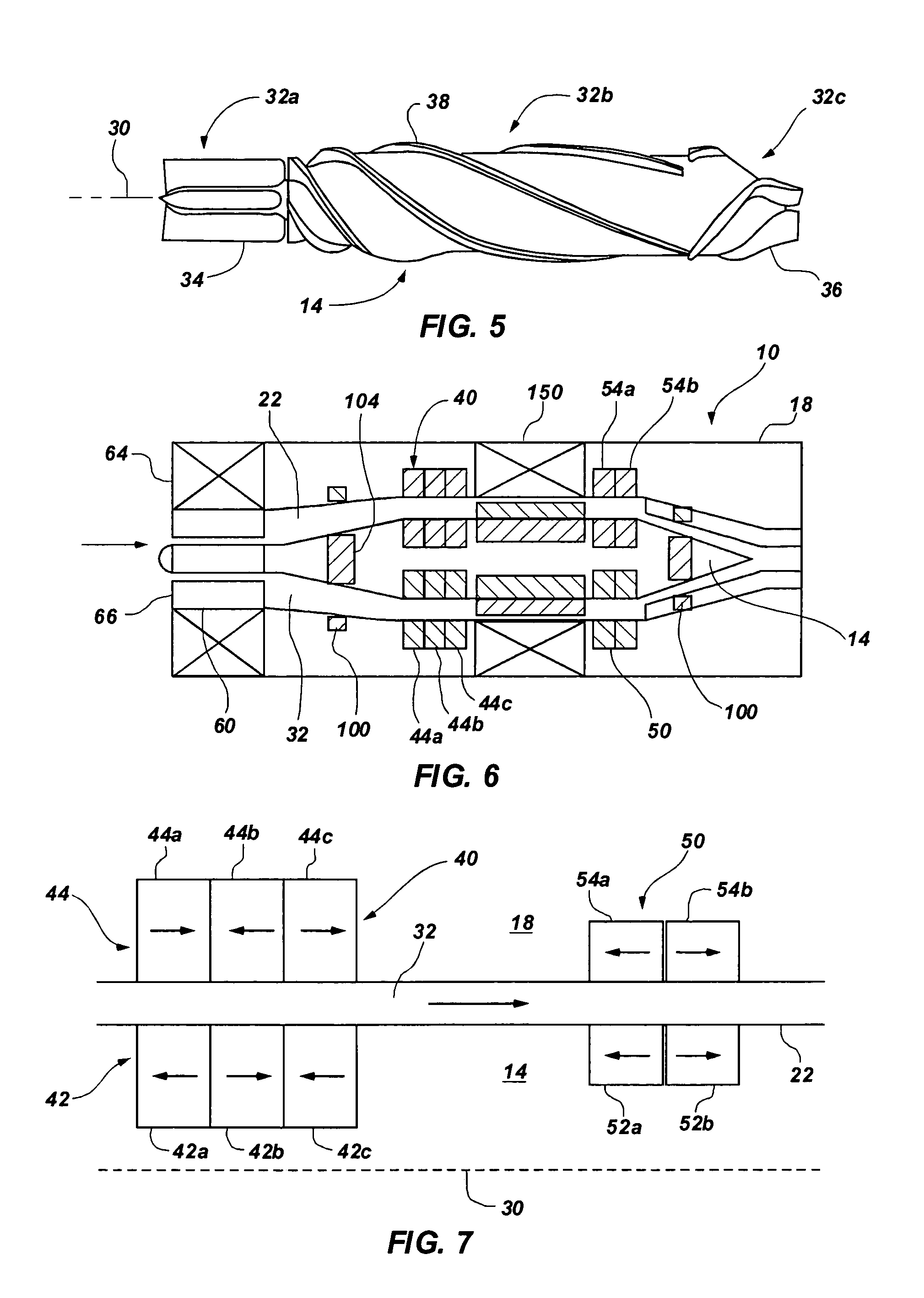

InactiveUS7229258B2Small sizeIncreased operating lifeBlood pumpsIntravenous devicesAxial-flow pumpOne pass

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings (passive permanent and active electromagnetic) having impeller magnets on the impeller and stator magnets or coils / poles on the stator. A motor includes impeller magnets on the impeller and coils / poles associated with the stator. A single, annular blood flow path extends axially through the cavity between the impeller and the stator, and between the impeller magnets on the impeller and the stator magnets or the coils / poles on the stator.

Owner:MEDFORTE RES FOUND +1

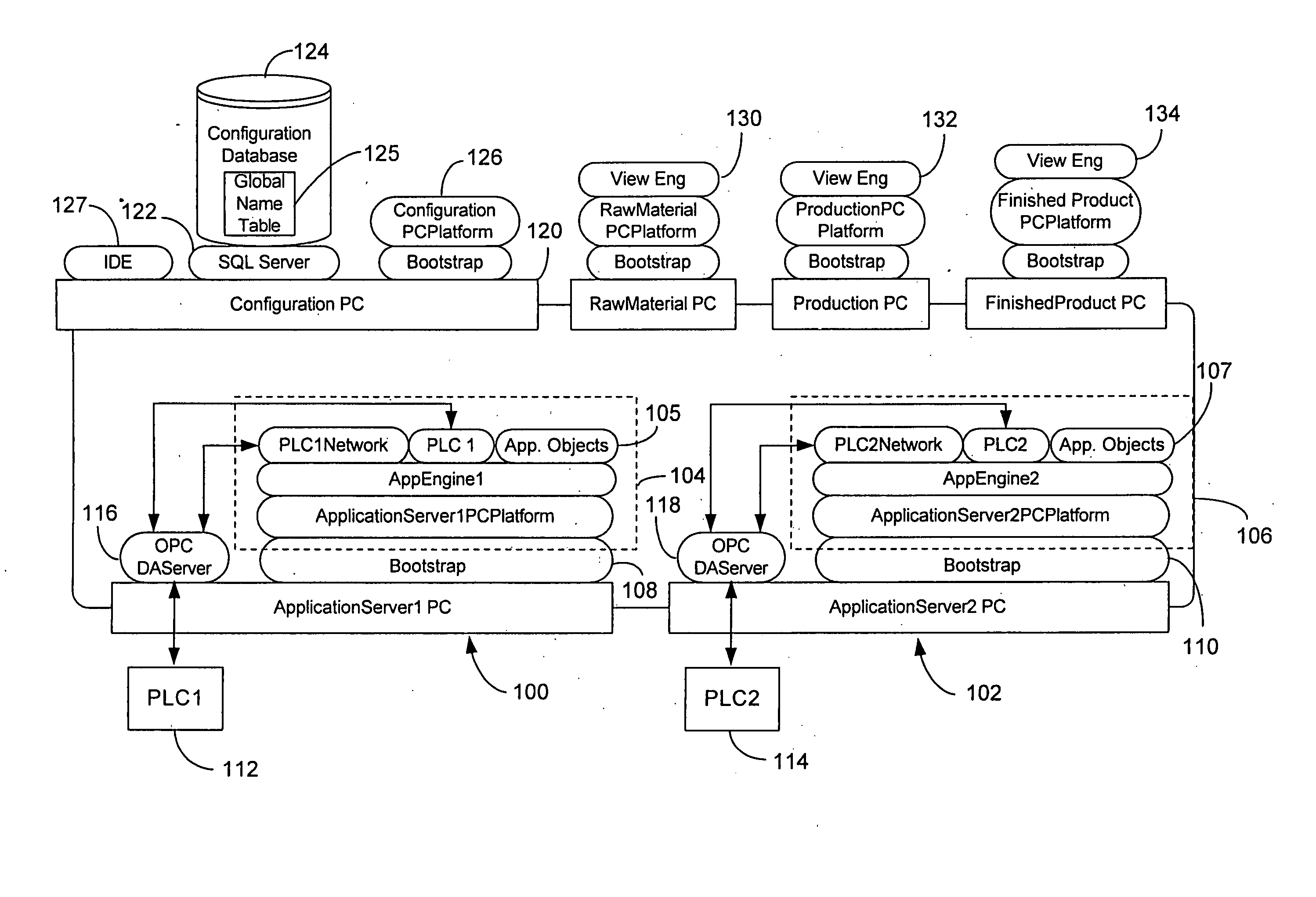

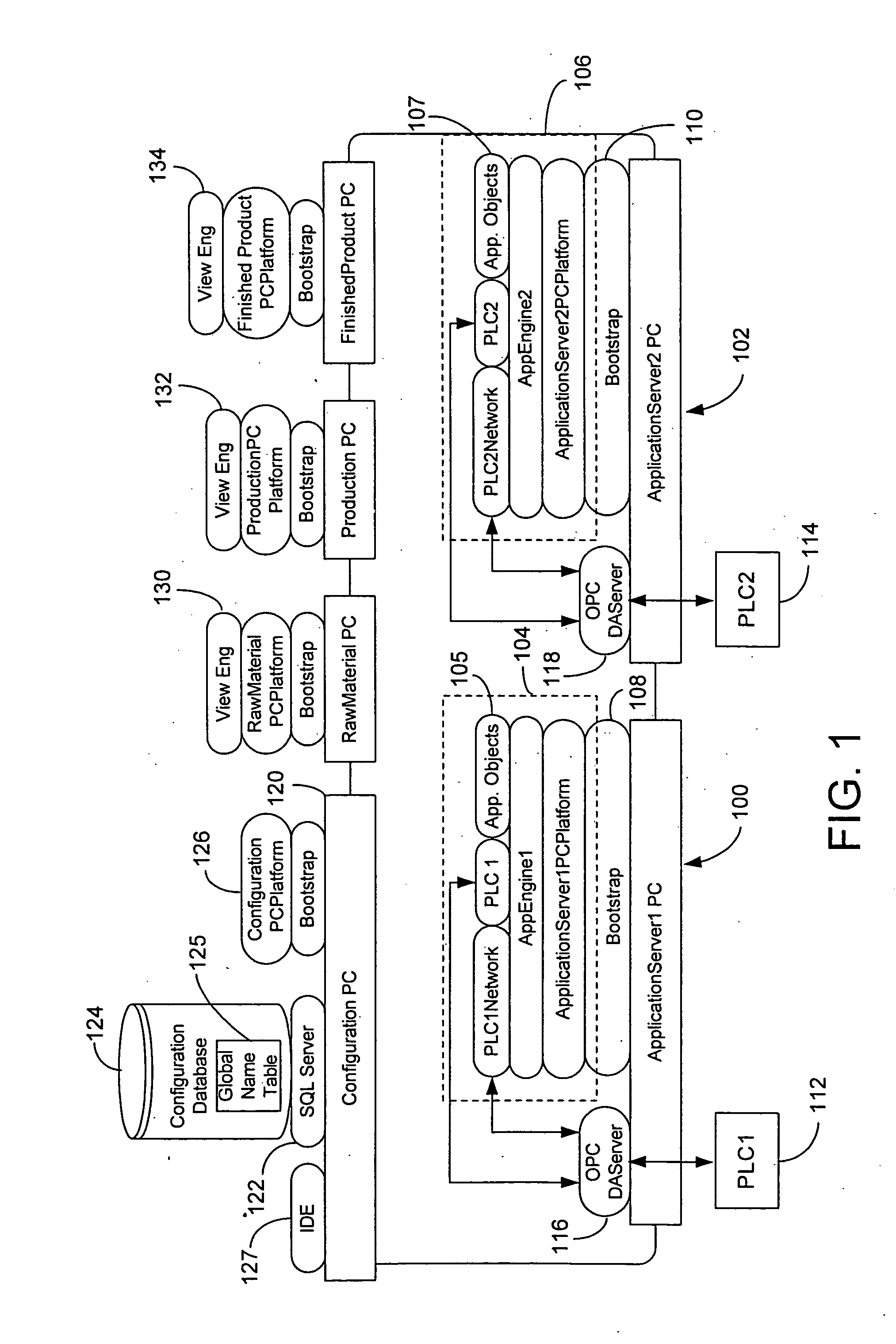

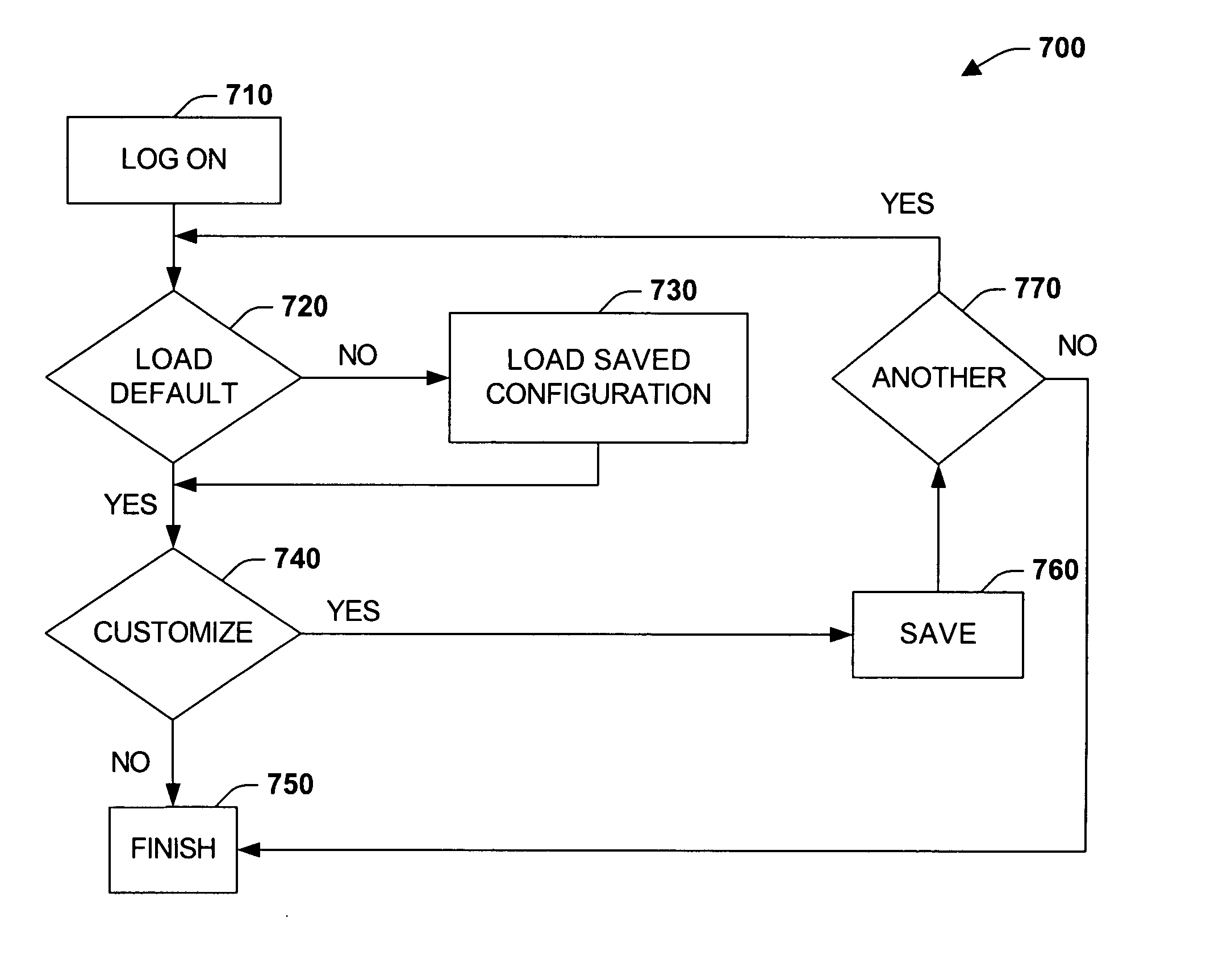

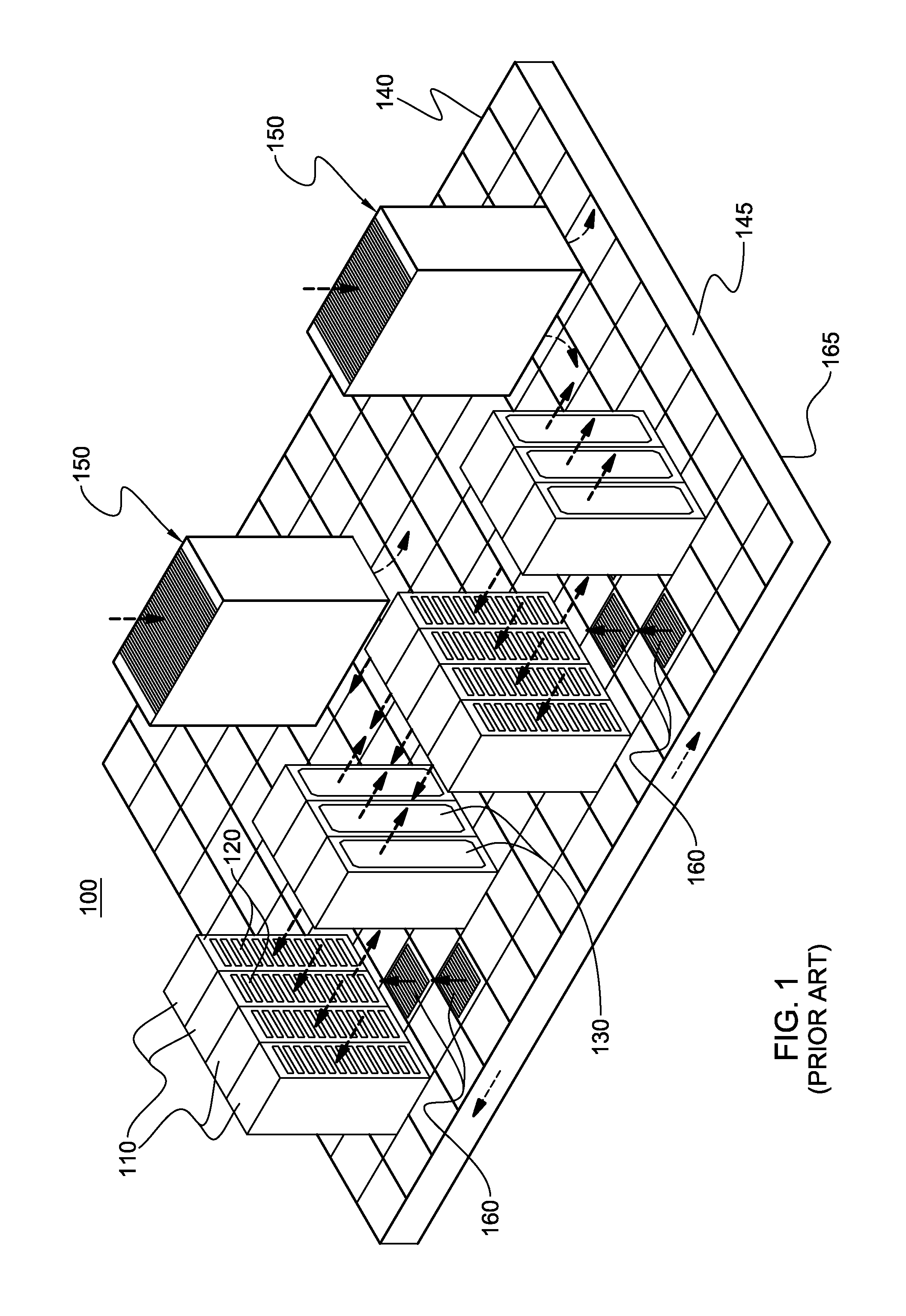

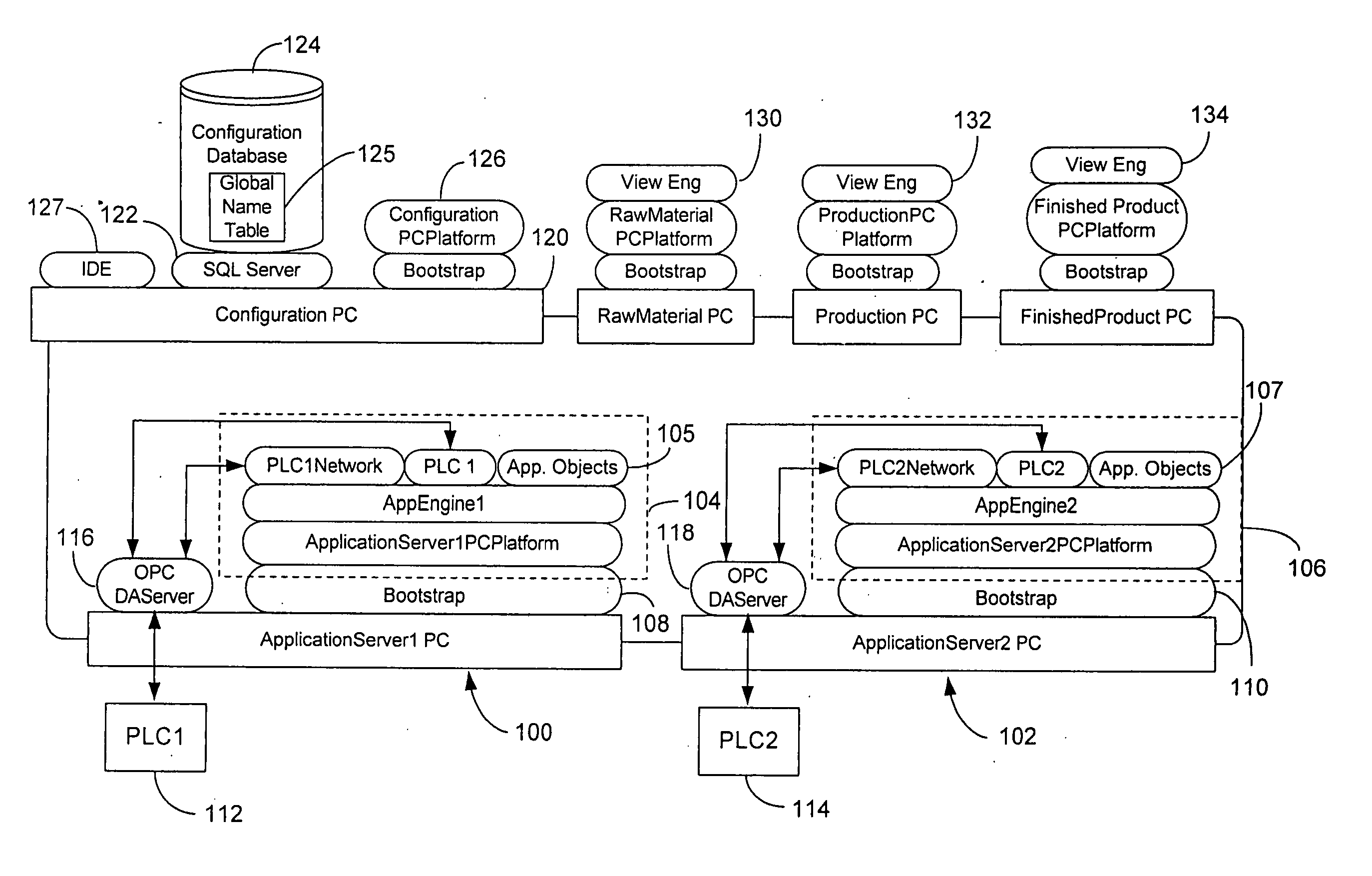

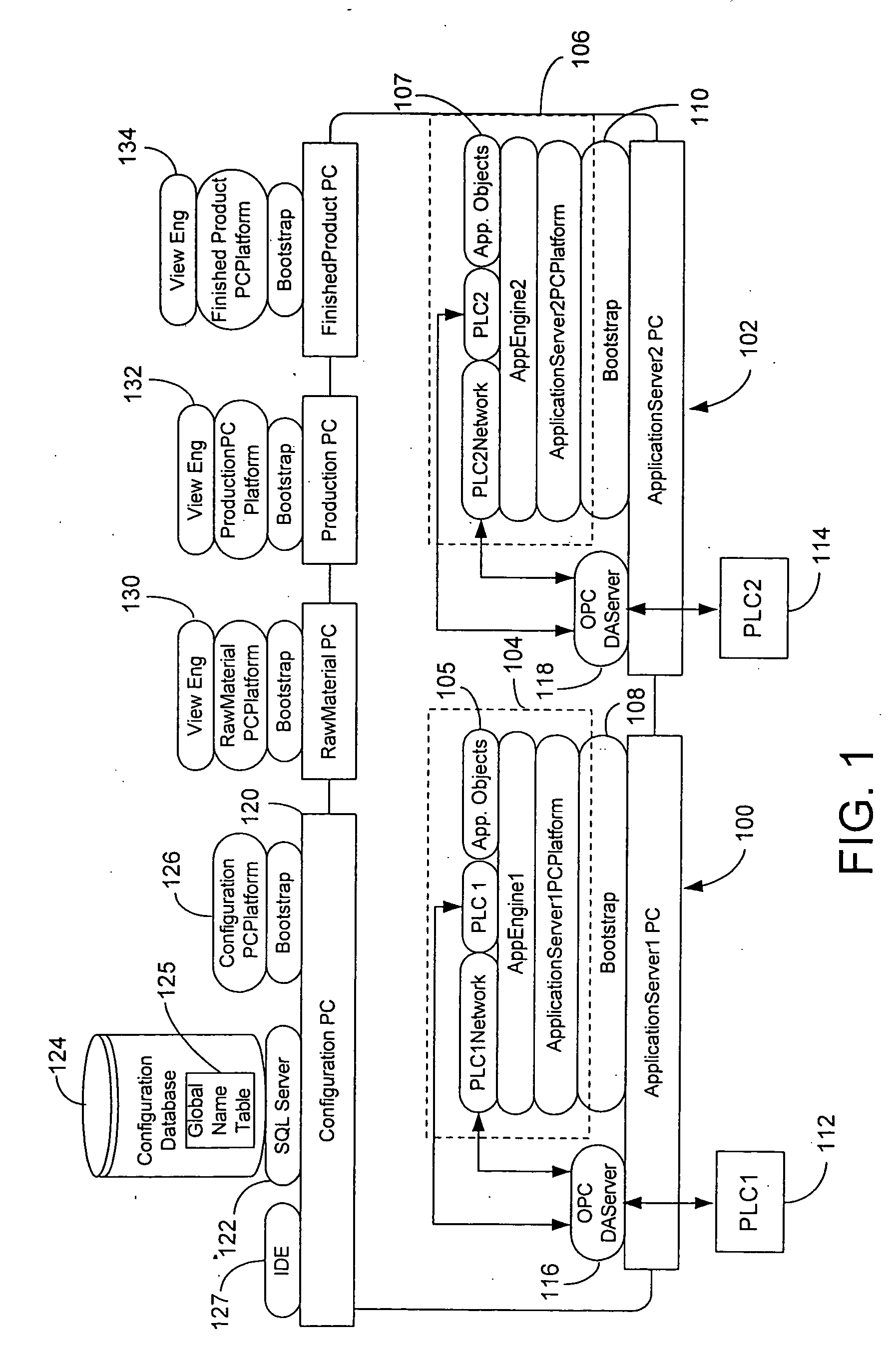

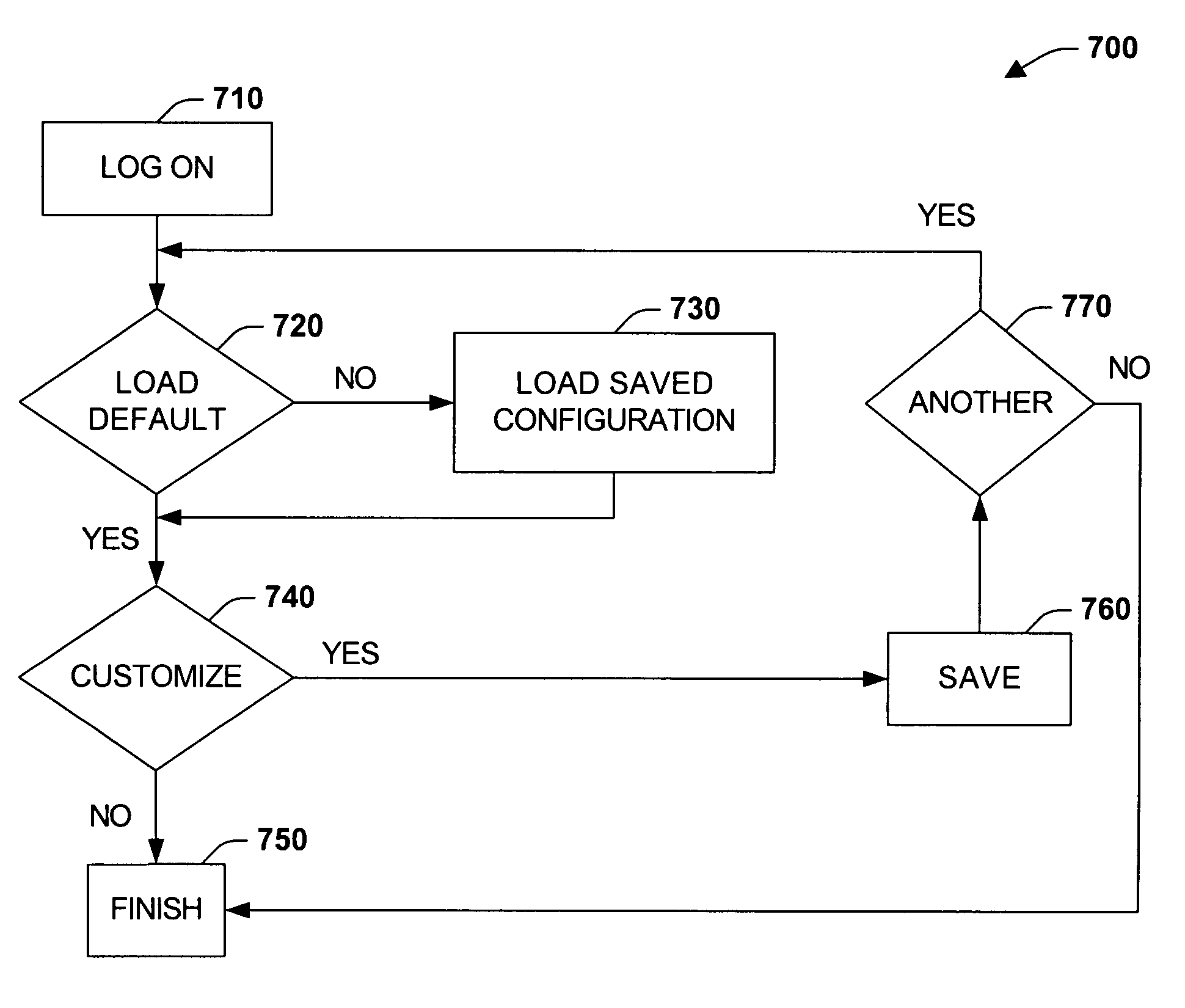

Remotely monitoring/diagnosing distributed components of a supervisory process control and manufacturing information application from a central location

InactiveUS20050060408A1Facilitates componentAmplifier modifications to reduce noise influenceComputer controlGraphicsManagement tool

A centralized diagnostics management tool is disclosed that facilitates centralized monitoring of distributed components of a supervisory process control and manufacturing information application. The centralized diagnostics management tool includes a diagnostics management console shell that is customized according to a set of software modules that interface to data sources to populate views supported by the console shell. The console shell includes a set of view templates including controls for manipulating graphically displayed representations of data rendered by the distributed components. The console shell also includes an interface for exchanging requests and data with an extensible set of software modules that provide data links to ones of the set of distributed components. The software modules also define the customizable portions of the view rendered by the console shell.

Owner:SCHNEIDER ELECTRIC SOFTWARE LLC

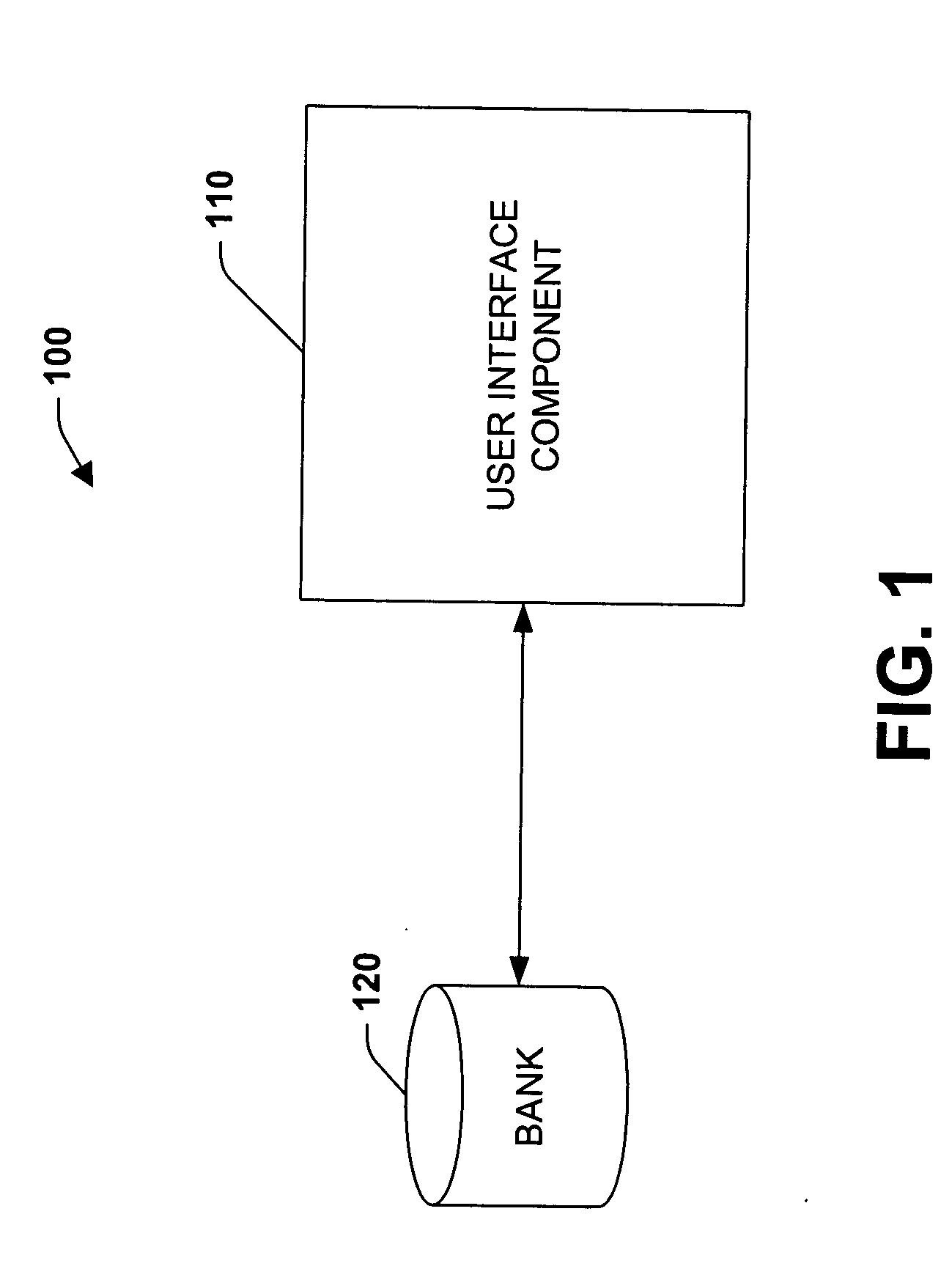

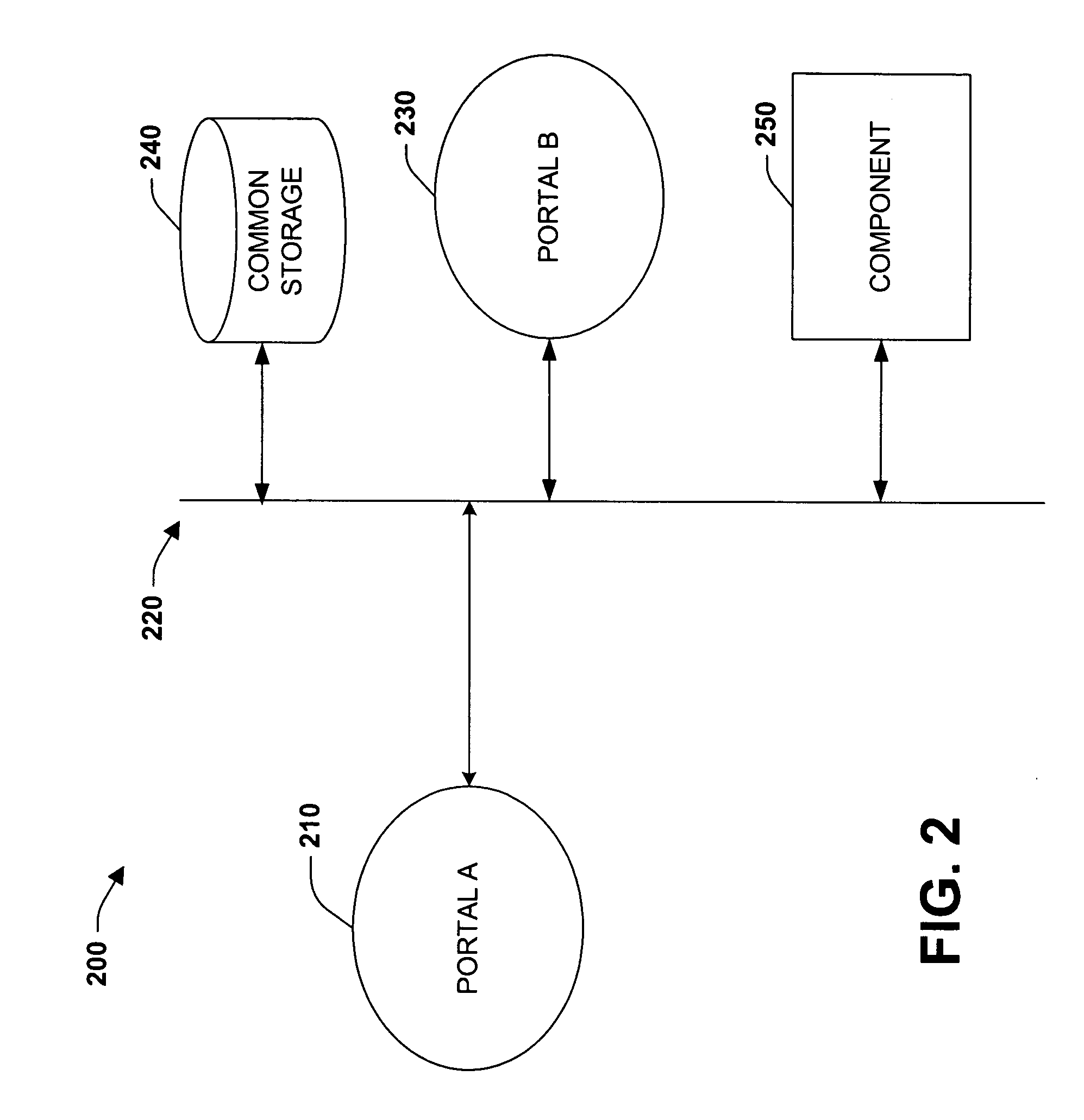

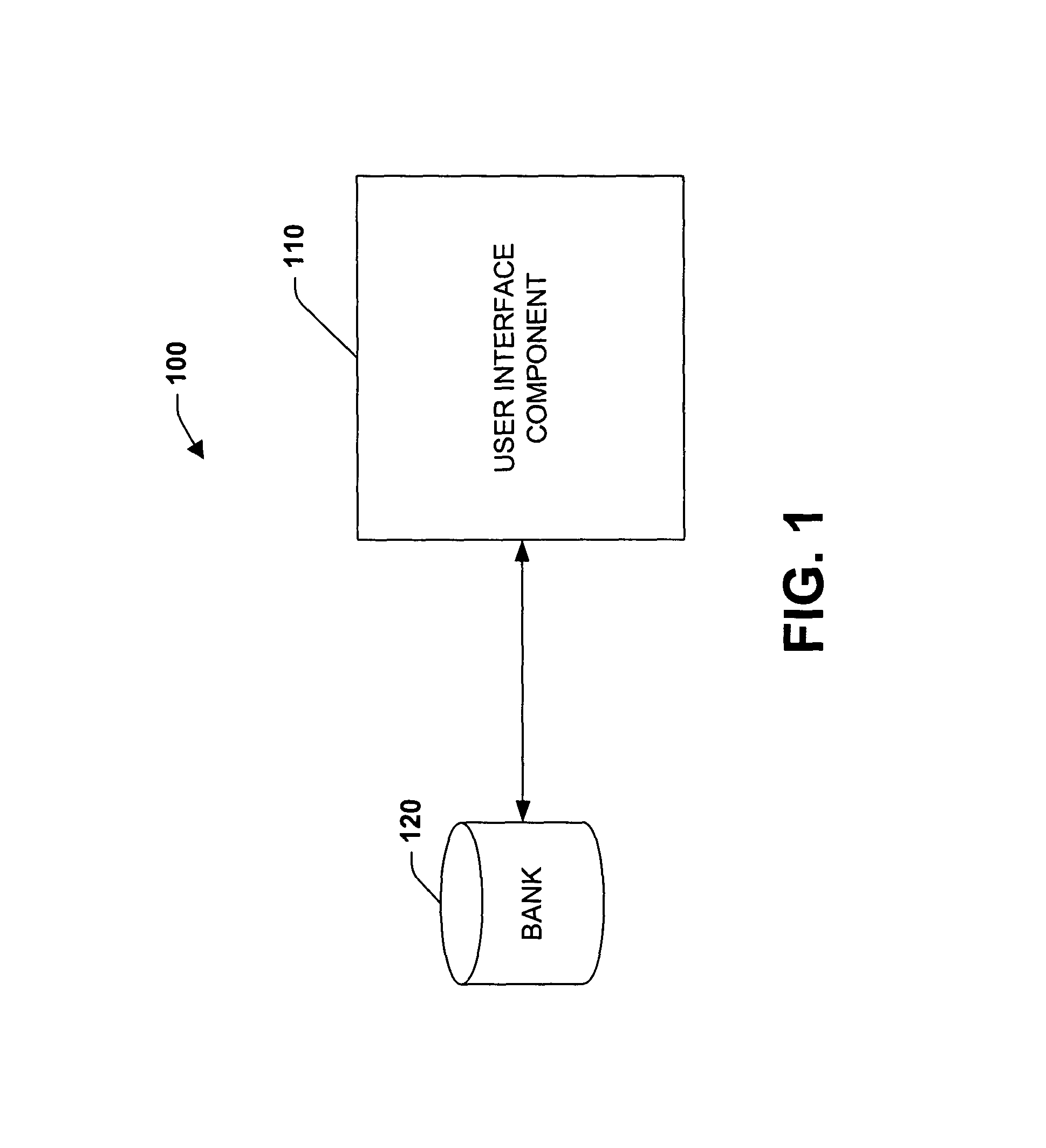

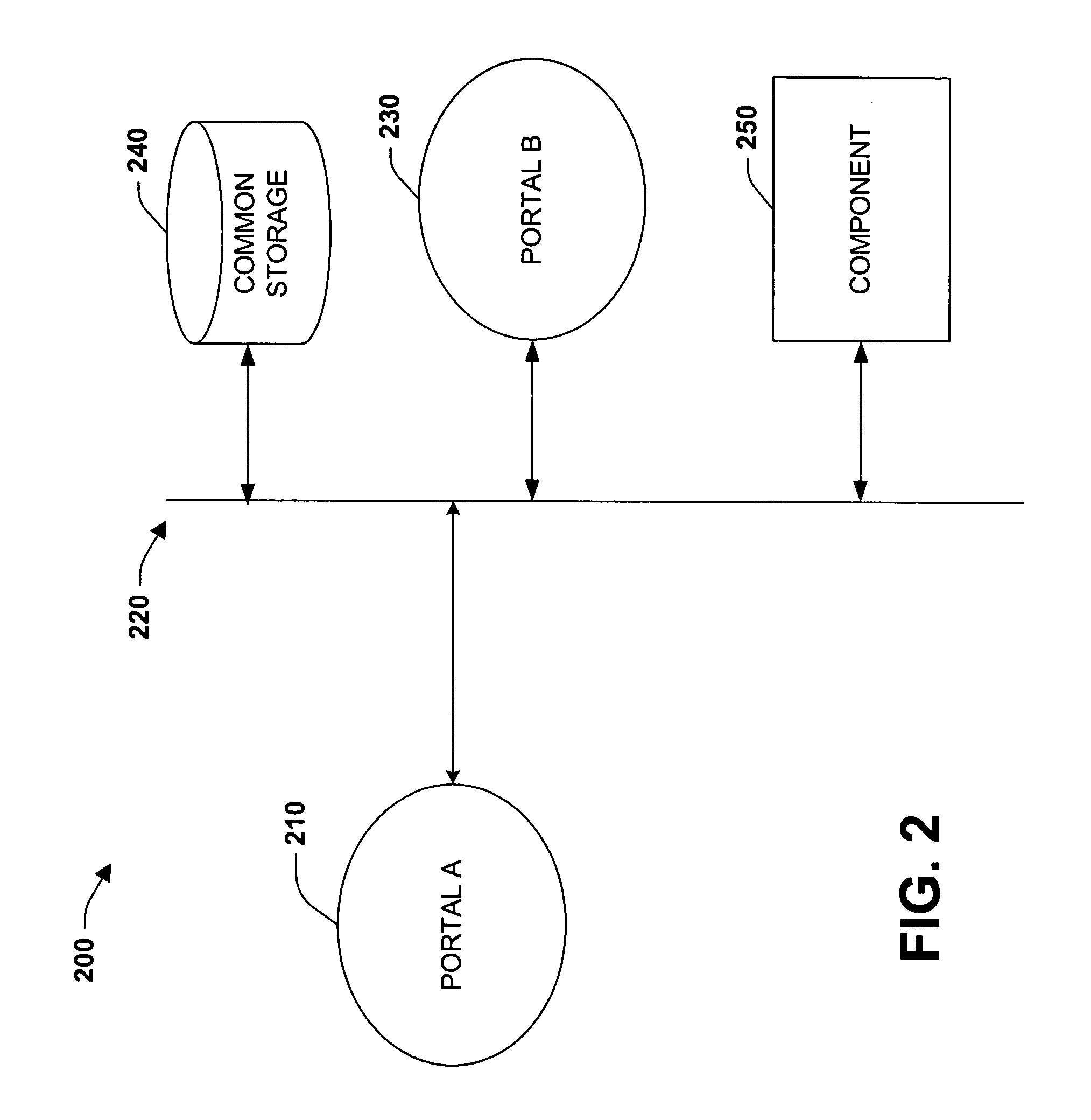

Systems and methods for sharing portal configurations

ActiveUS20050065913A1Improve developmentEasy to determineDigital data processing detailsMultiple digital computer combinationsPortletApplication server

Owner:INTELLECTUAL VENTURES ASSETS 190 LLC

Streamlined unobstructed one-pass axial-flow pump

InactiveUS20050135942A1Reduce coagulationSmall sizeBlood pumpsIntravenous devicesAxial-flow pumpImpeller

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings (passive permanent and active electromagnetic) having impeller magnets on the impeller and stator magnets or coils / poles on the stator. A motor includes impeller magnets on the impeller and coils / poles associated with the stator. A single, annular blood flow path extends axially through the cavity between the impeller and the stator, and between the impeller magnets on the impeller and the stator magnets or the coils / poles on the stator.

Owner:MEDFORTE RES FOUND +1

Axial-flow blood pump with magnetically suspended, radially and axially stabilized impeller

InactiveUS7070398B2Small sizeIncreased operating lifeBlood pumpsIntravenous devicesImpellerMagnetic bearing

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings including an axial bearing to support the impeller axially in the cavity. The axial bearing includes adjacent impeller magnets and adjacent stator magnets with axially aligned polarities and reverse polarities with respect to adjacent magnets. A motor includes impeller magnets on the impeller and coils and poles associated with the stator. Radial permanent magnet and electromagnetic bearings are also included. The magnetic bearings and the motor have stator magnets or coils and poles disposed radially across the fluid passage from corresponding impeller magnets to define an annular gap positioned radially between the impeller and the stator, and positioned radially between all of the plurality of magnetic bearings, creating a straight through blood path without secondary flow paths.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND +1

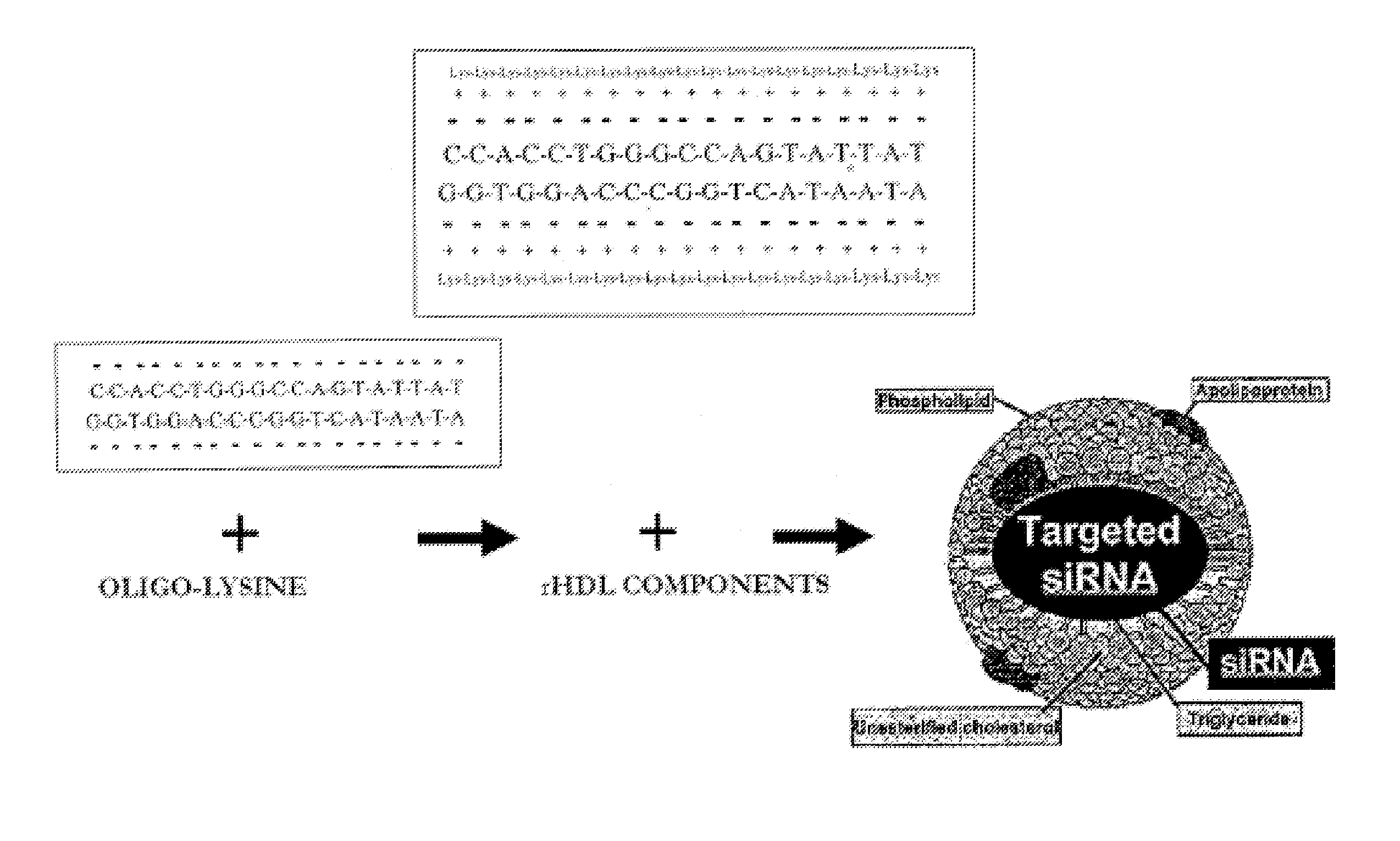

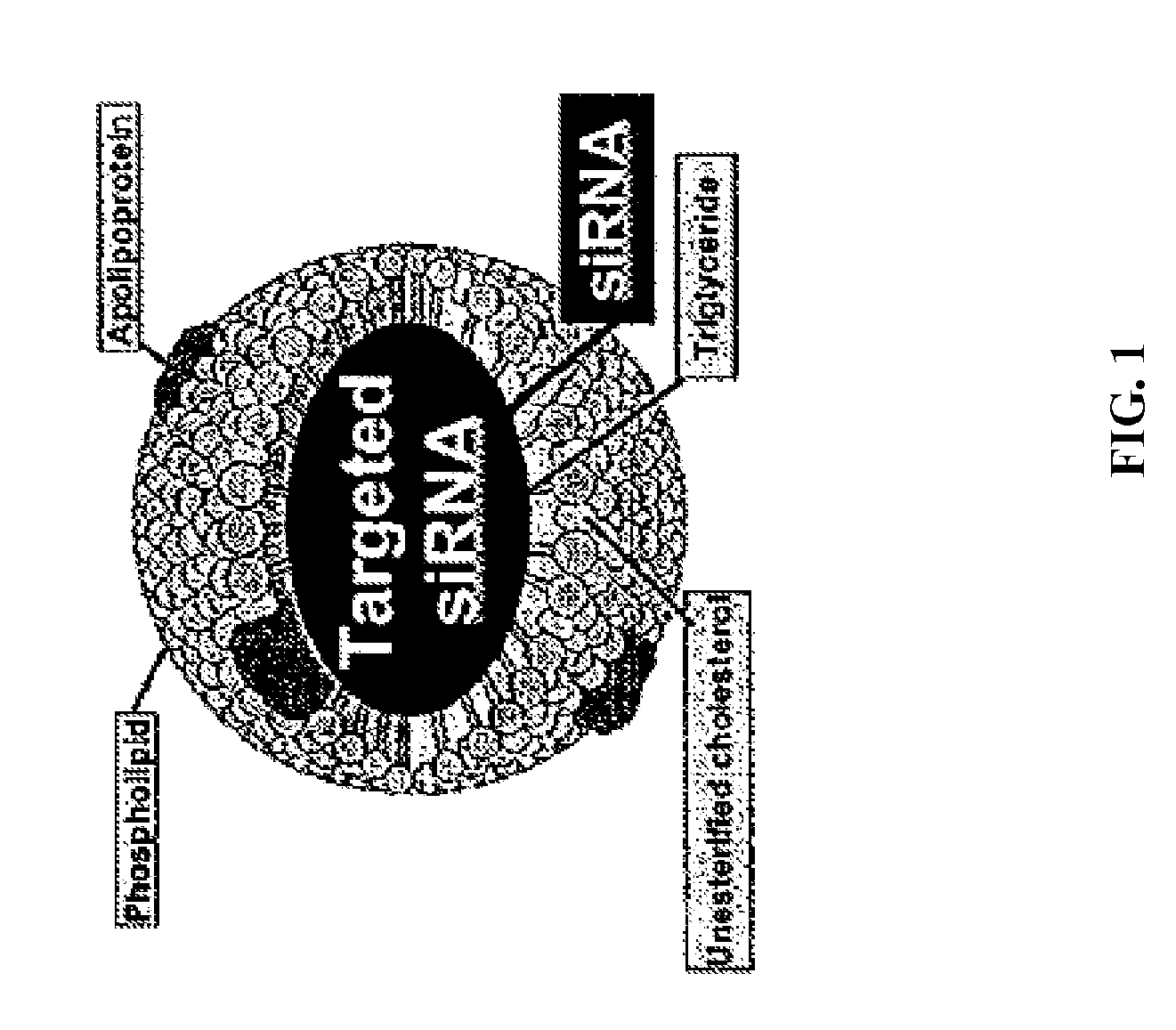

HDL particles for delivery of nucleic acids

InactiveUS8734853B2Efficient deliveryHigh densityPowder deliveryOrganic active ingredientsApolipoproteins EHDL particle

Disclosed are high density lipoprotein-nucleic acid particles, wherein the particles include (a) an apolipoprotein; (b) a nucleic acid component comprising a therapeutic nucleic acid segment; and (c) a polypeptide comprising a positively charged region, wherein the positively-charged region of the polypeptide associates with the nucleic acid component. Also disclosed are pharmaceutical compositions that include a) an apolipoprotein; (b) a nucleic acid component comprising a therapeutic nucleic acid segment; and (c) a polypeptide comprising a positively charged region. Methods that concern the particles and pharmaceutical compositions of the present invention are also set forth, as well as kits.

Owner:UNIV OF NORTH TEXAS HEALTH SCI CENT +1

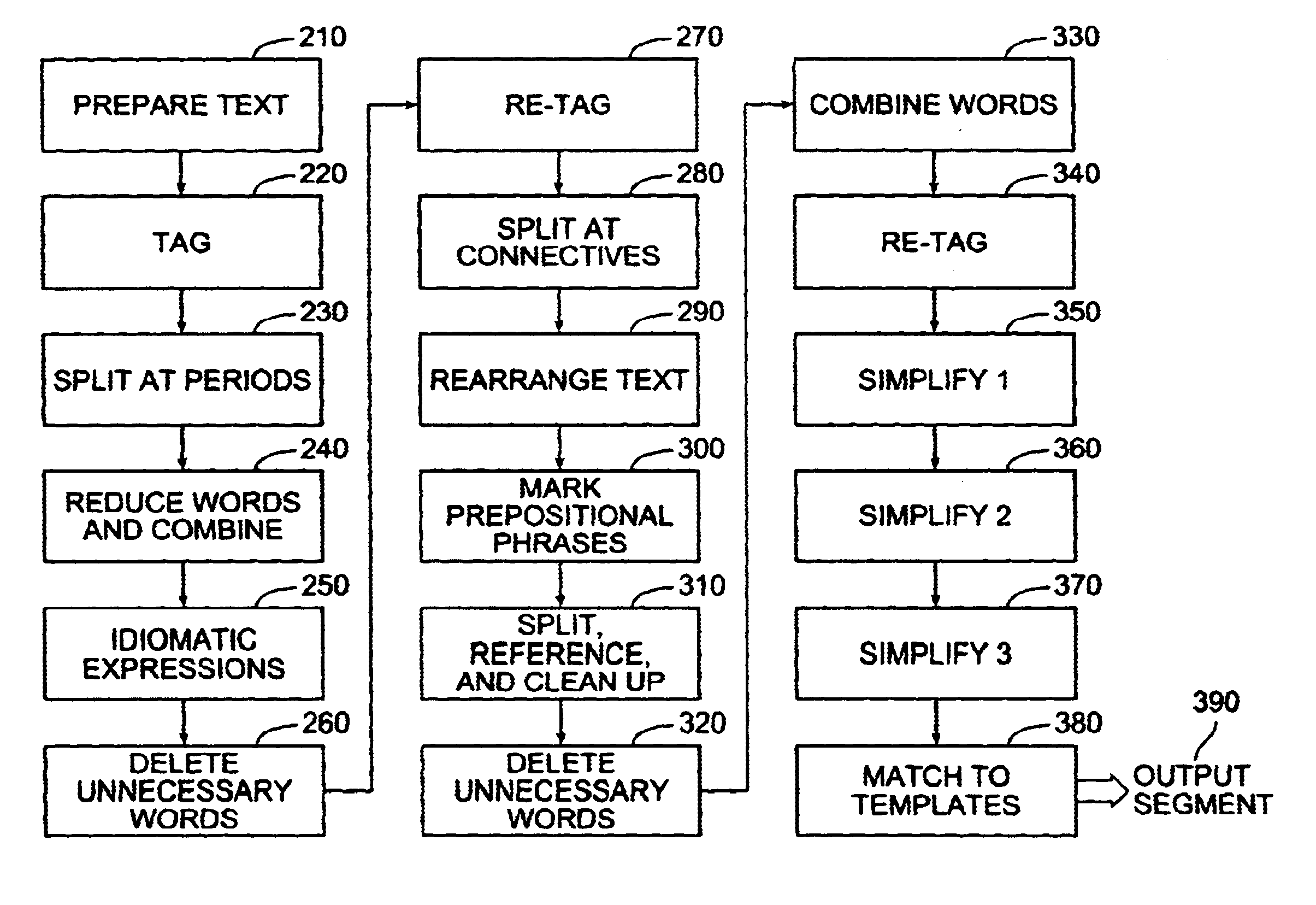

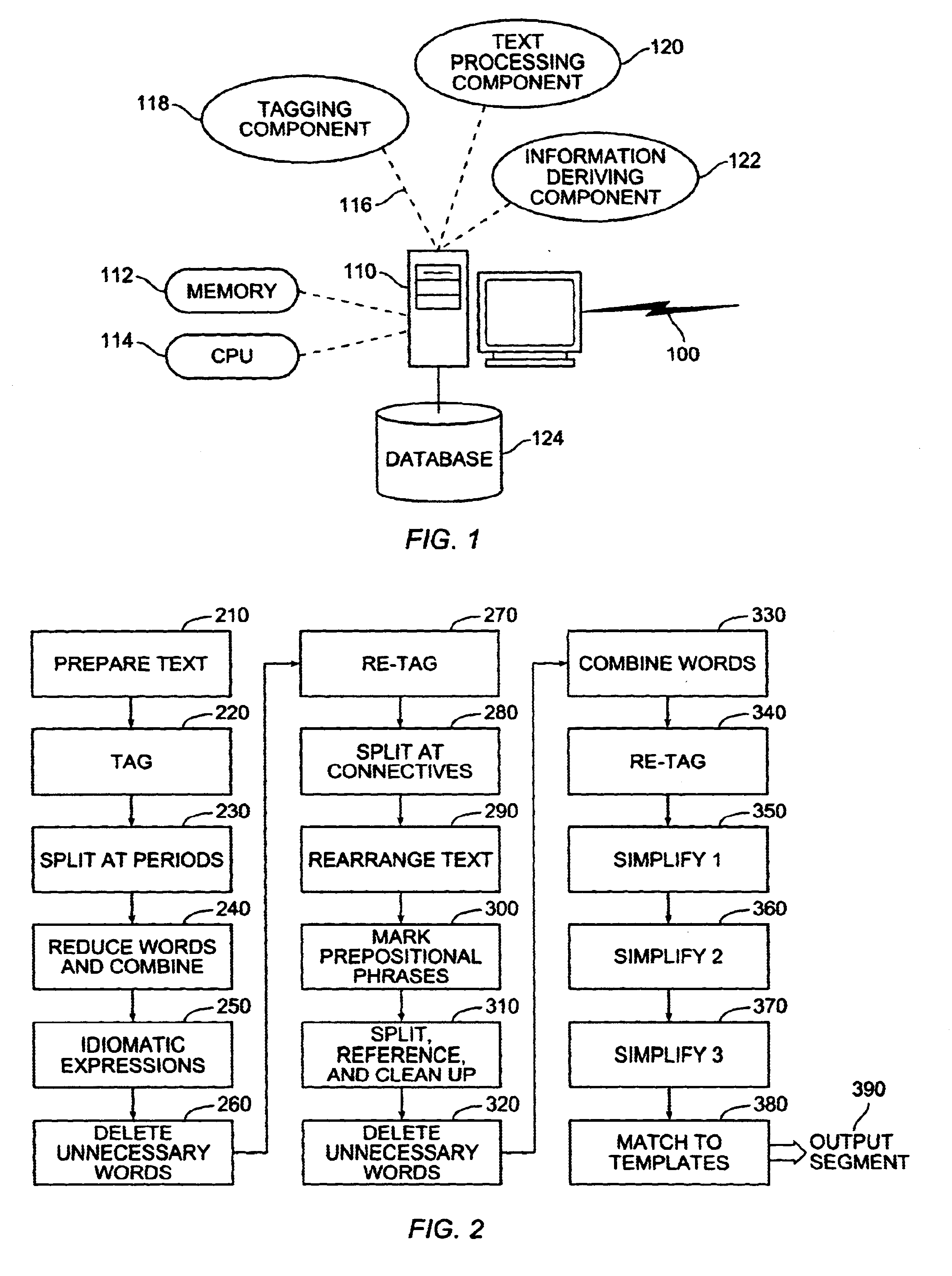

Method and system for text analysis based on the tagging, processing, and/or reformatting of the input text

InactiveUS6658377B1Improve accuracyEasily correlatedNatural language data processingSpecial data processing applicationsInformation retrievalNatural language

A method and system are provided for text analysis. A computer is used to analyze, parse, and manipulate natural language text according to a series of specific steps. Text is decomposed into small, homogenous segments that can be readily correlated to one another, to quantitative data, or to a knowledge database. The segments generated at the completion of the text analysis can then be further processed, for example, by a computer to derive statistical information, to generate a report, or to build a knowledge database.

Owner:BCS SOFTWARE LLC

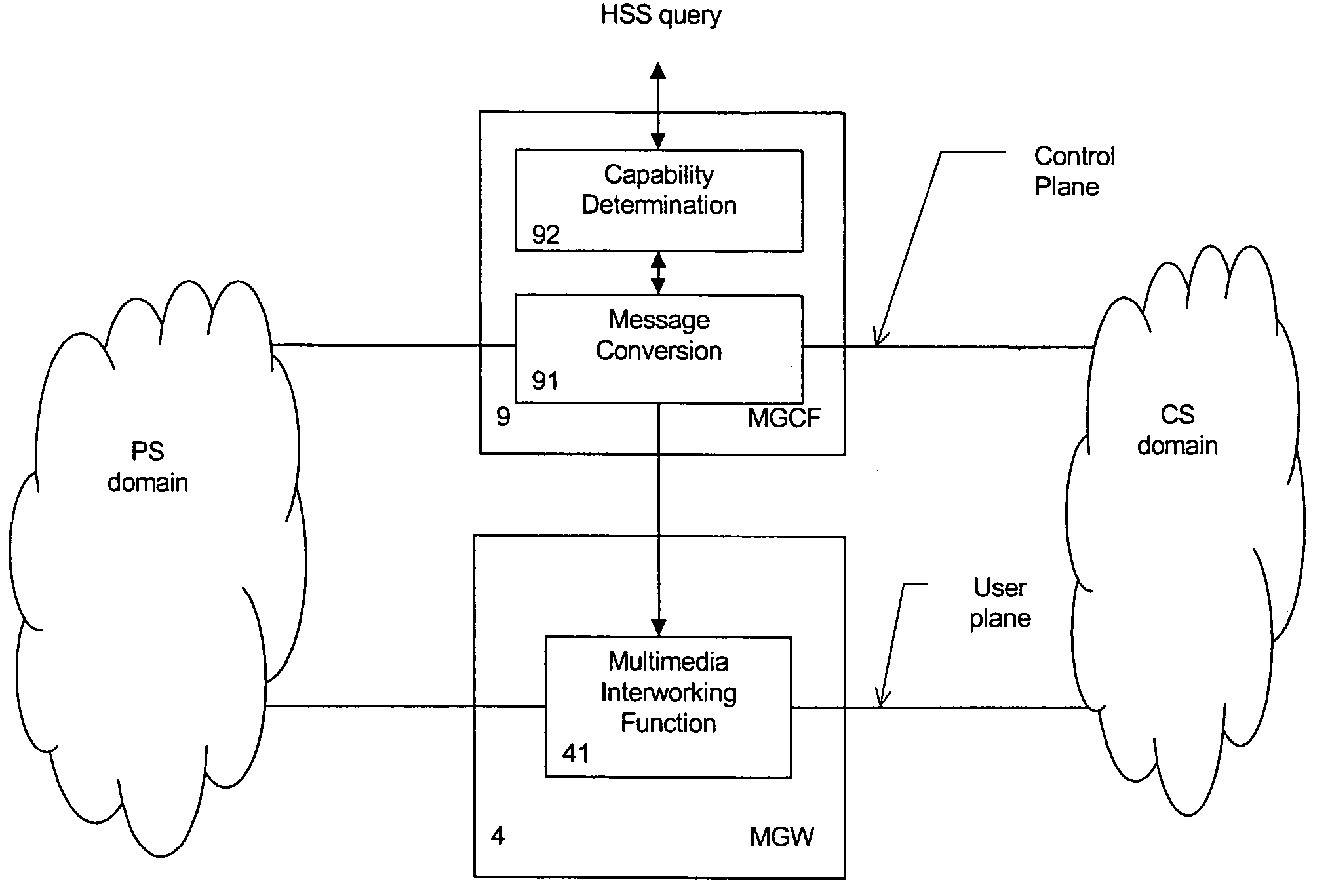

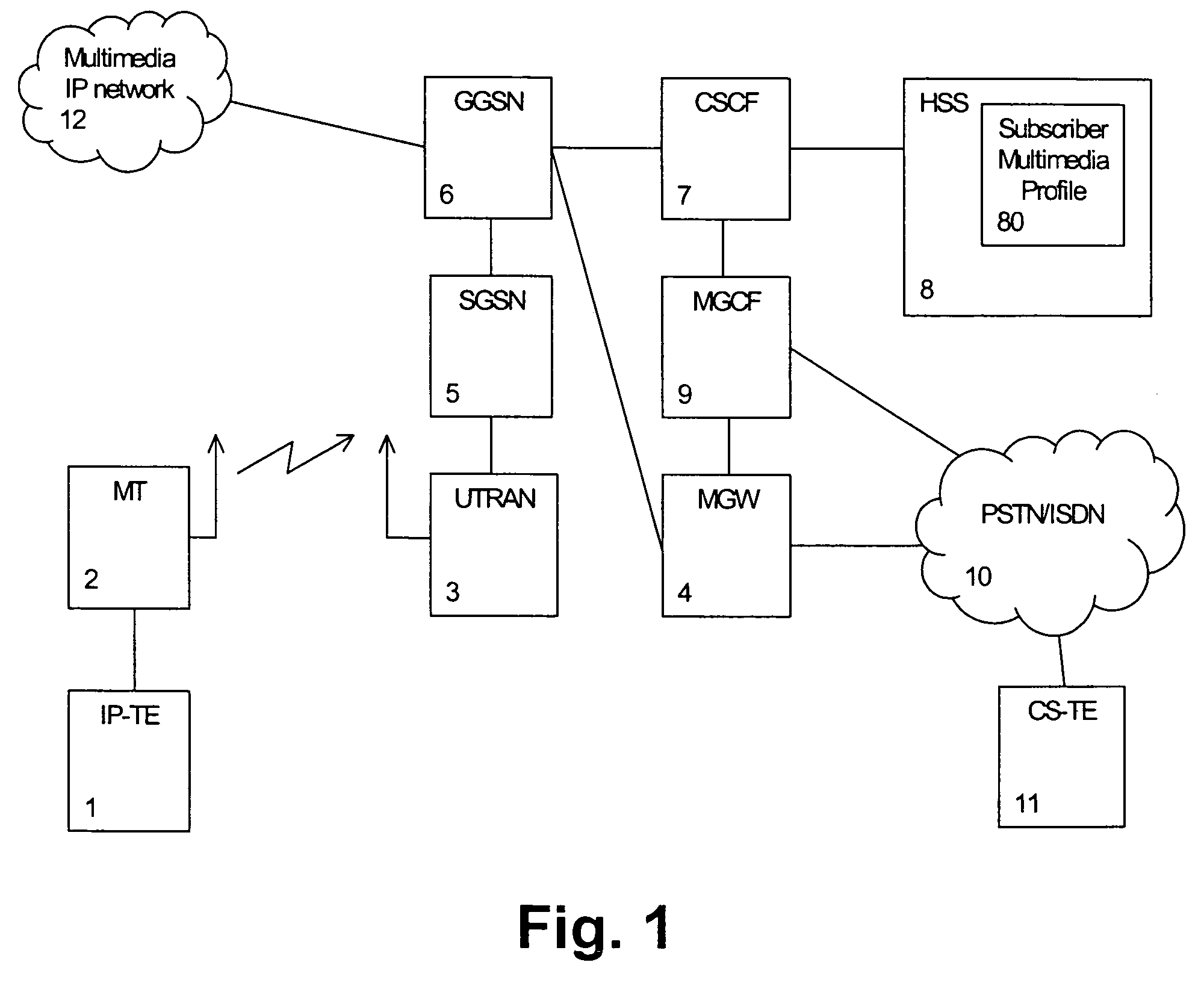

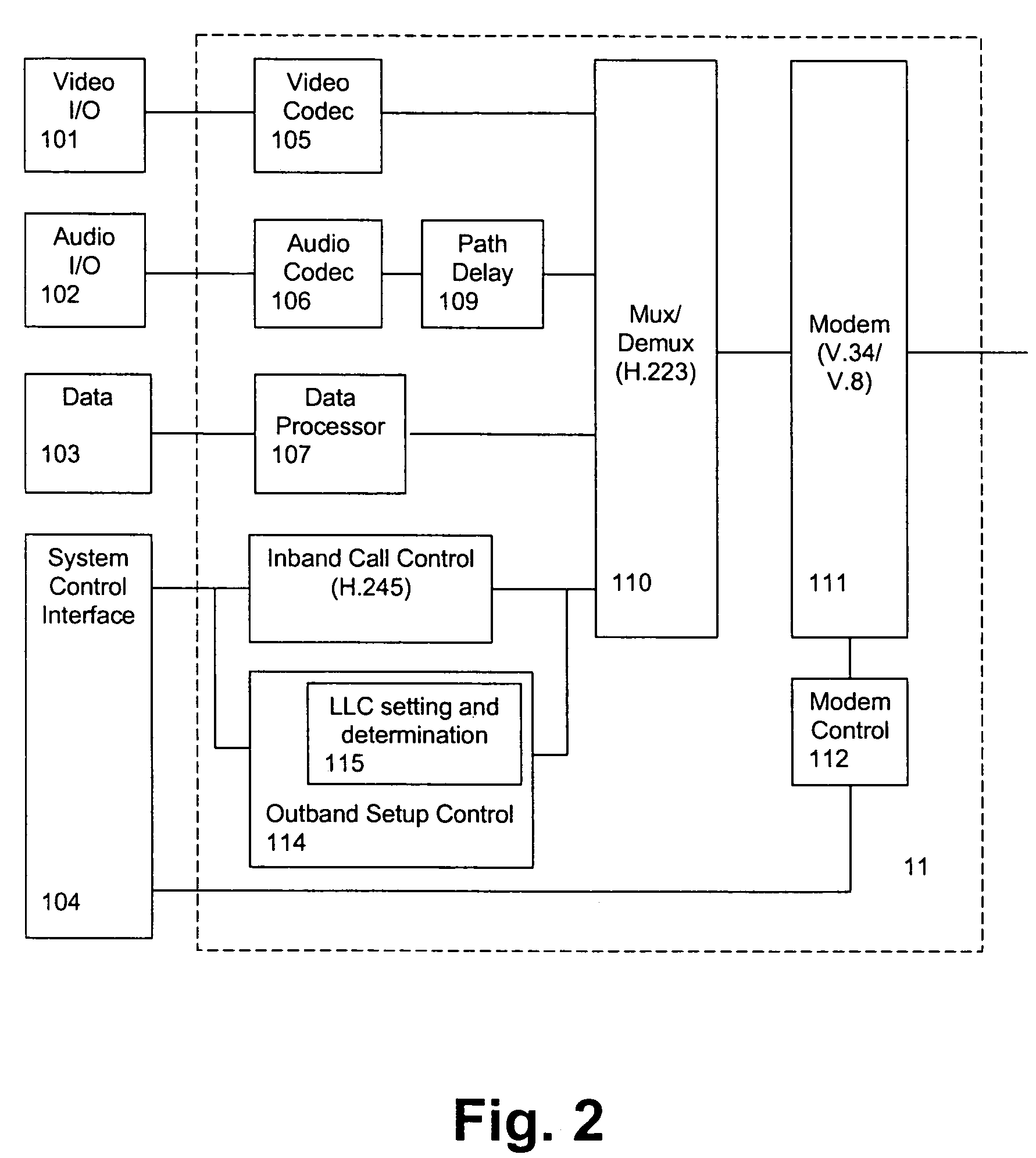

Method and system for establishing a multimedia connection by negotiating capability in an outband control channel

InactiveUS7330542B2Simple componentsNegotiation can be simplifiedMultiplex system selection arrangementsInterconnection arrangementsTerminal equipmentComputer compatibility

The present invention relates to a method and system for establishing a connection to a terminal device, wherein a user capability information defining supported types of information streams is set in a compatibility information element within an outband signaling message, and a capability negotiation is performed by transmitting said outband signaling message via an outband control channel. The code or user capability information may be set at the terminal device or at an intermediate network element based on a subscriber profile information obtained from a subscriber database. Thereby, the user capability, such as a multimedia session composition, can be already negotiated or handled during the outband call setup phase, and a corresponding inband negotiation can be avoided.

Owner:NOKIA TECHNOLOGLES OY

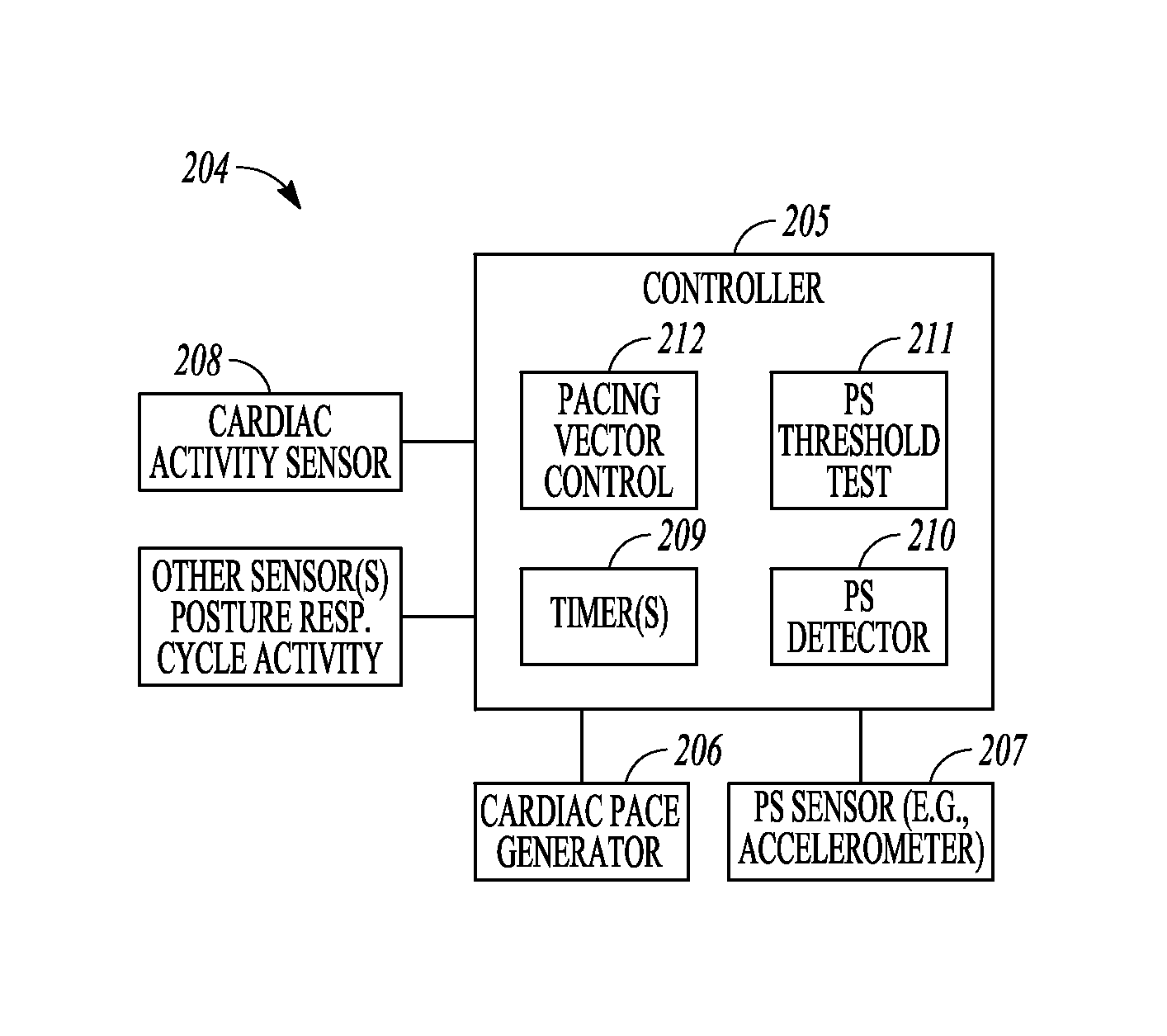

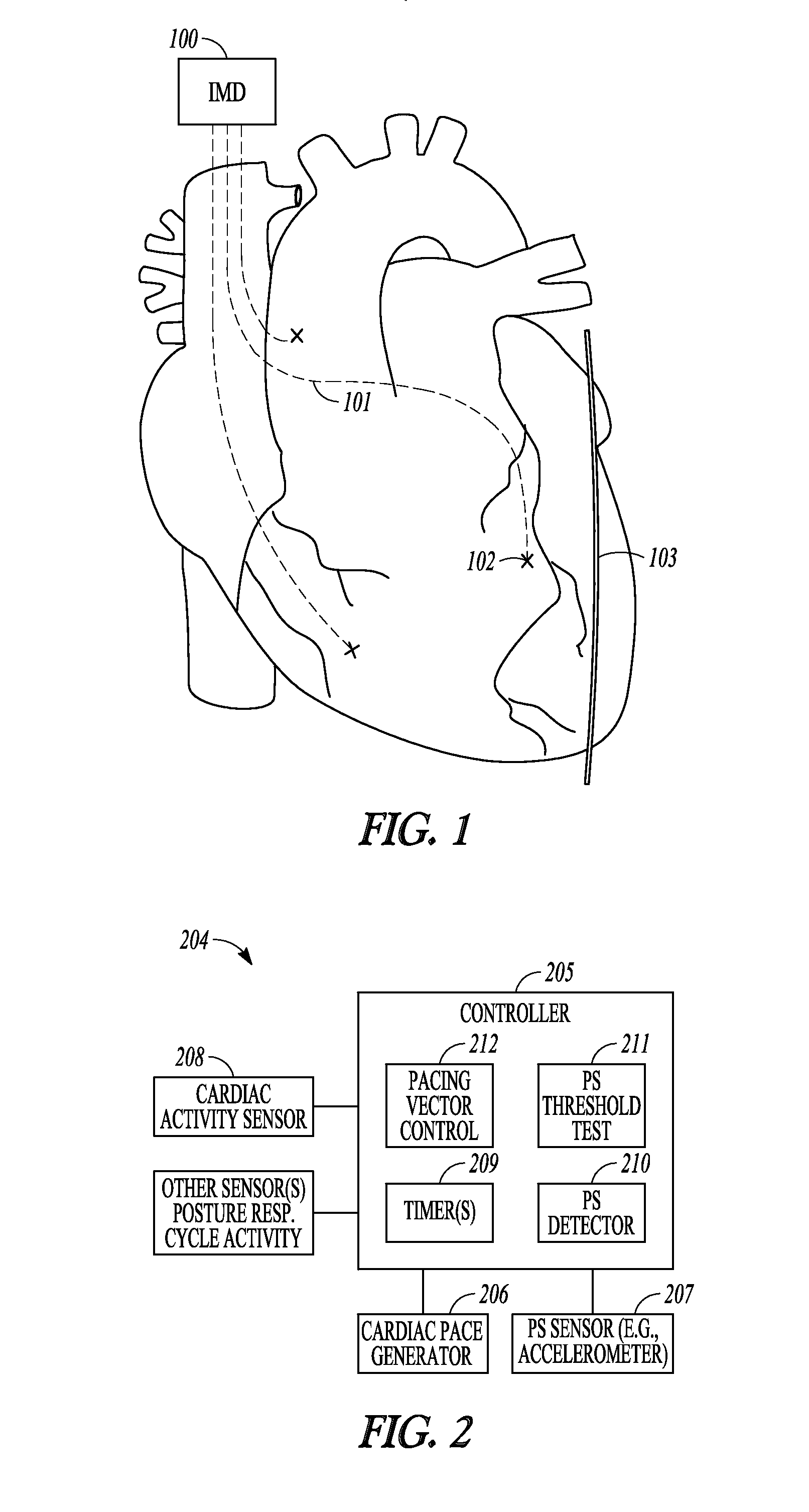

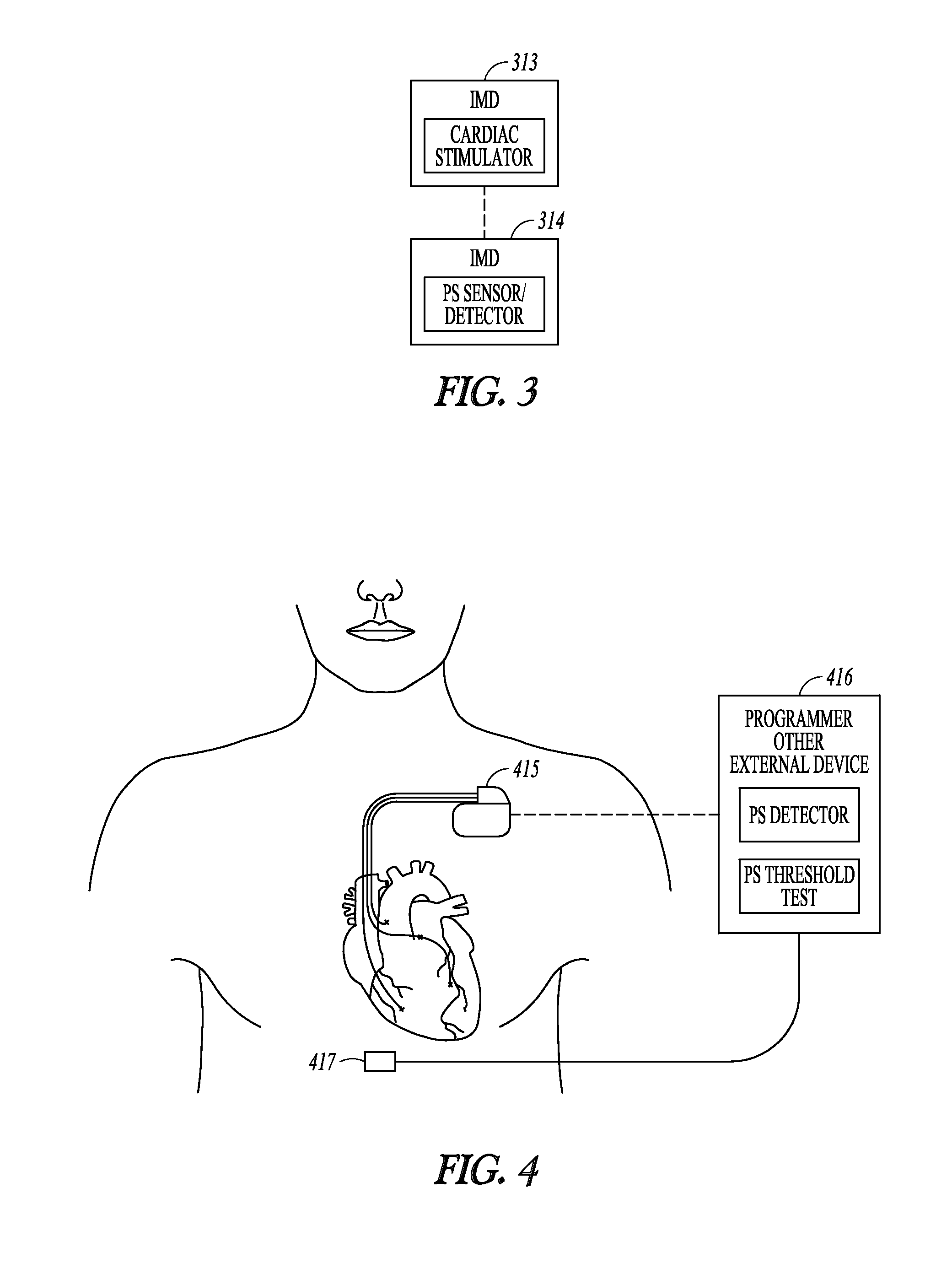

Baseline determination for phrenic nerve stimulation detection

Some method examples may include pacing a heart with cardiac paces, sensing a physiological signal for use in detecting pace-induced phrenic nerve stimulation, performing a baseline level determination process to identify a baseline level for the sensed physiological signal, and detecting pace-induced phrenic nerve stimulation using the sensed physiological signal and the calculated baseline level. Detecting pace-induced phrenic nerve stimulation may include sampling the sensed physiological signal during each of a plurality of cardiac cycles to provide sampled signals and calculating the baseline level for the physiological signal using the sampled signals. Sampling the sensed physiological signal may include sampling the signal during a time window defined using a pace time with each of the cardiac cycles to avoid cardiac components and phrenic nerve stimulation components in the sampled signal.

Owner:CARDIAC PACEMAKERS INC

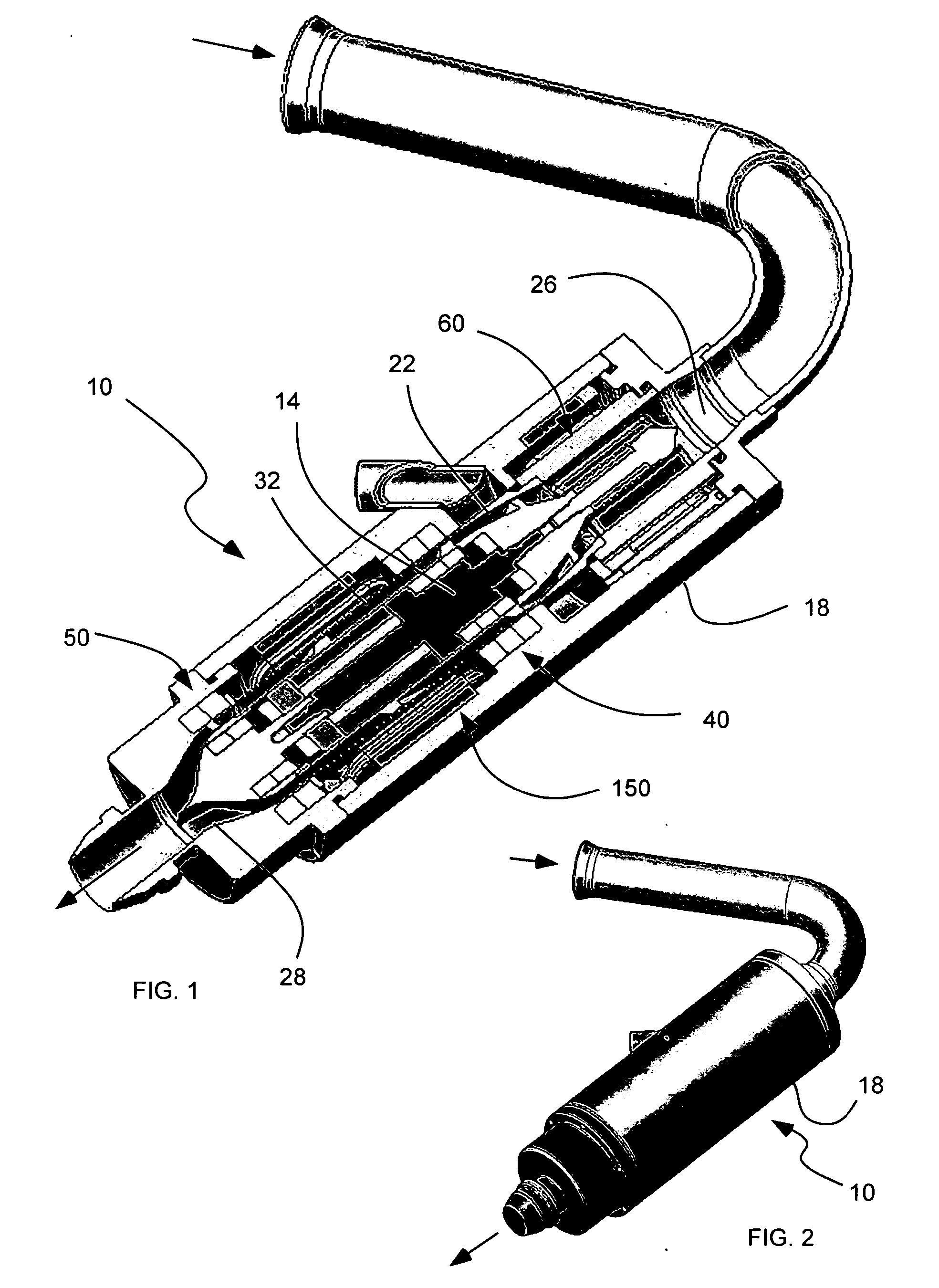

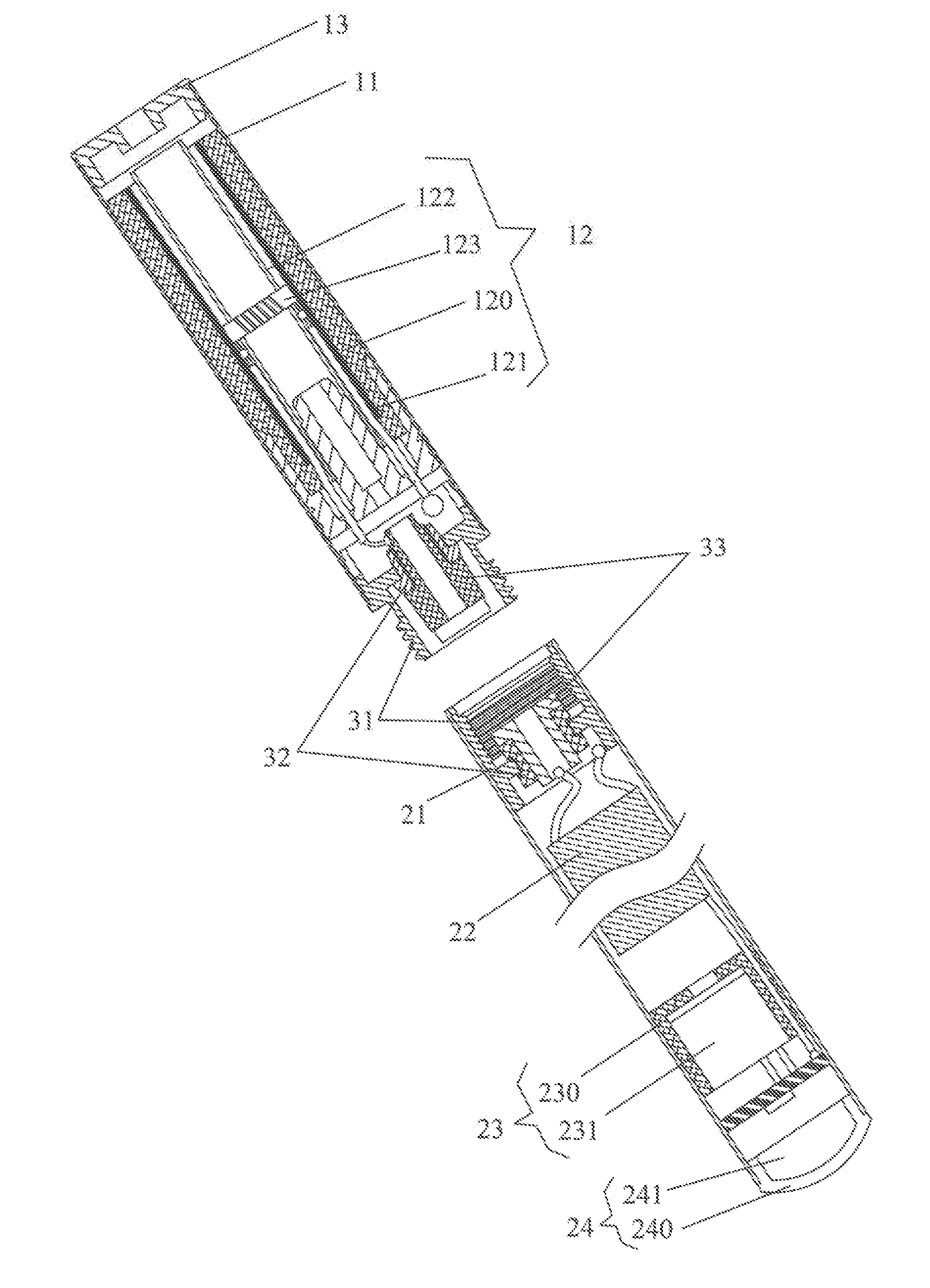

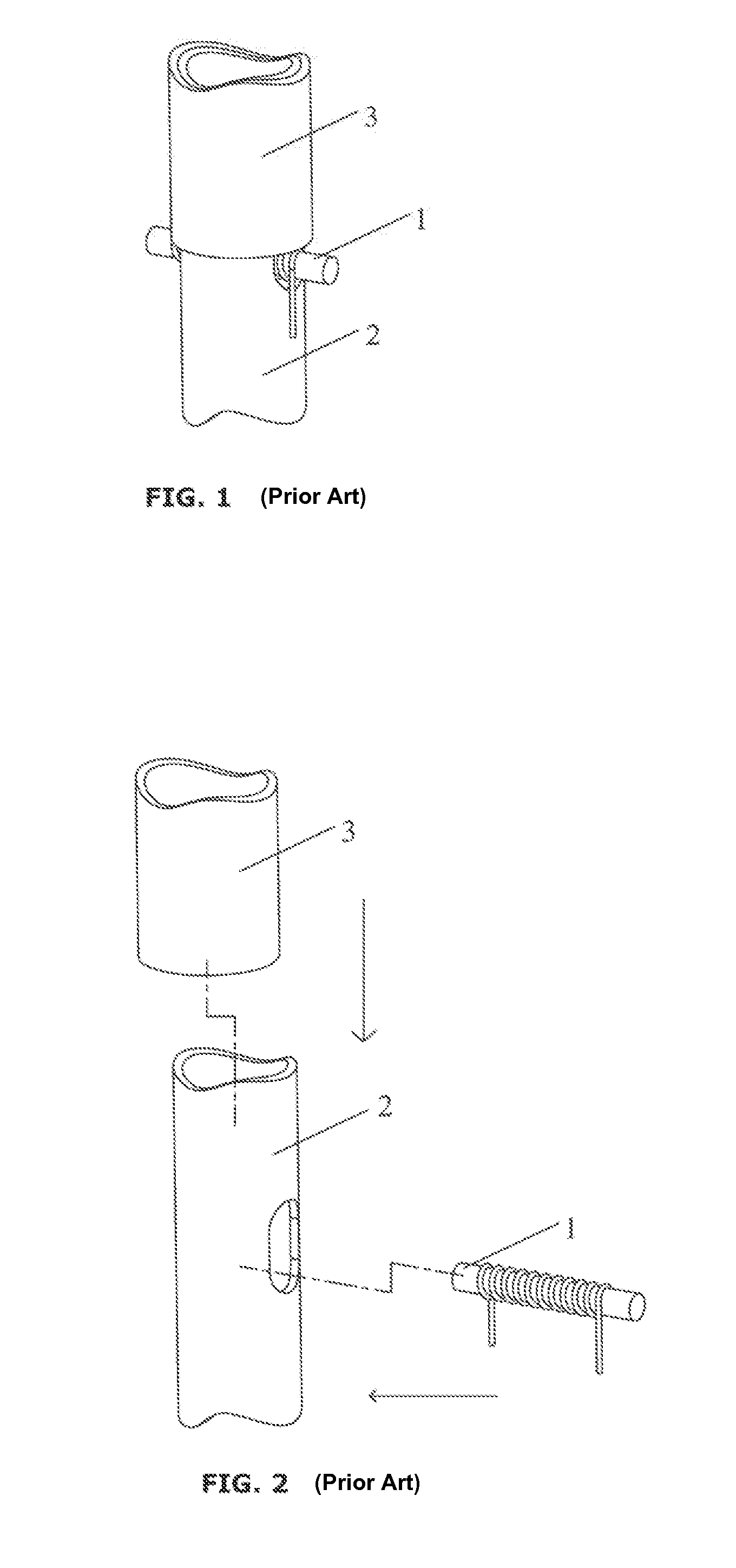

Electronic cigarette and assembly method of atomizer thereof

InactiveUS20150196056A1Simple assemblyHigh efficiencyElectric heatingTobacco pipesCost savingsEngineering

An electronic cigarette and a method for assembling an atomizer thereof. The electronic cigarette comprises a suction rod (10) and a power supply rod (20). The suction rod (10) comprises a suction tube (11) and an atomizer (12) disposed in the suction tube (11) and used for generating smoke. The atomizer (12) comprises an air pipe (122) and a heating assembly (123). The air pipe (122) is provided with a through hole (100) along a radial direction used for accommodating and fixing the heating assembly (123). The air pipe (122) is also provided with a notch (200) which has a bottom communicating with the through hole (100) and is used for assembling the heating assembly. By disposing a notch (200) which has a bottom communicating with the through hole (100) and is used for assembling the heating assembly (123) on the air pipe (122), technical effects of simple assembly, high efficiency, stable quality and cost saving are achieved.

Owner:KIMREE HI TECH

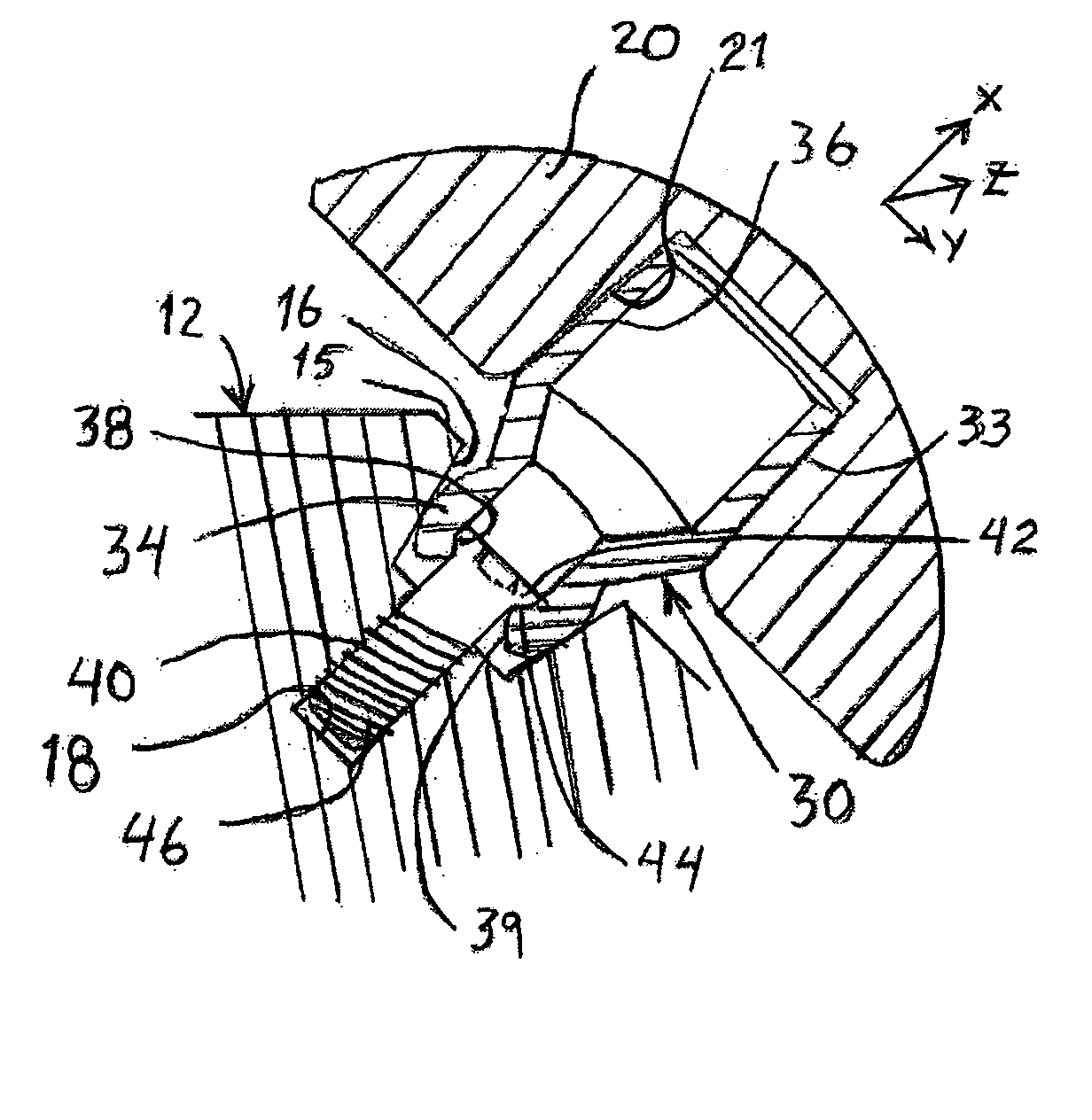

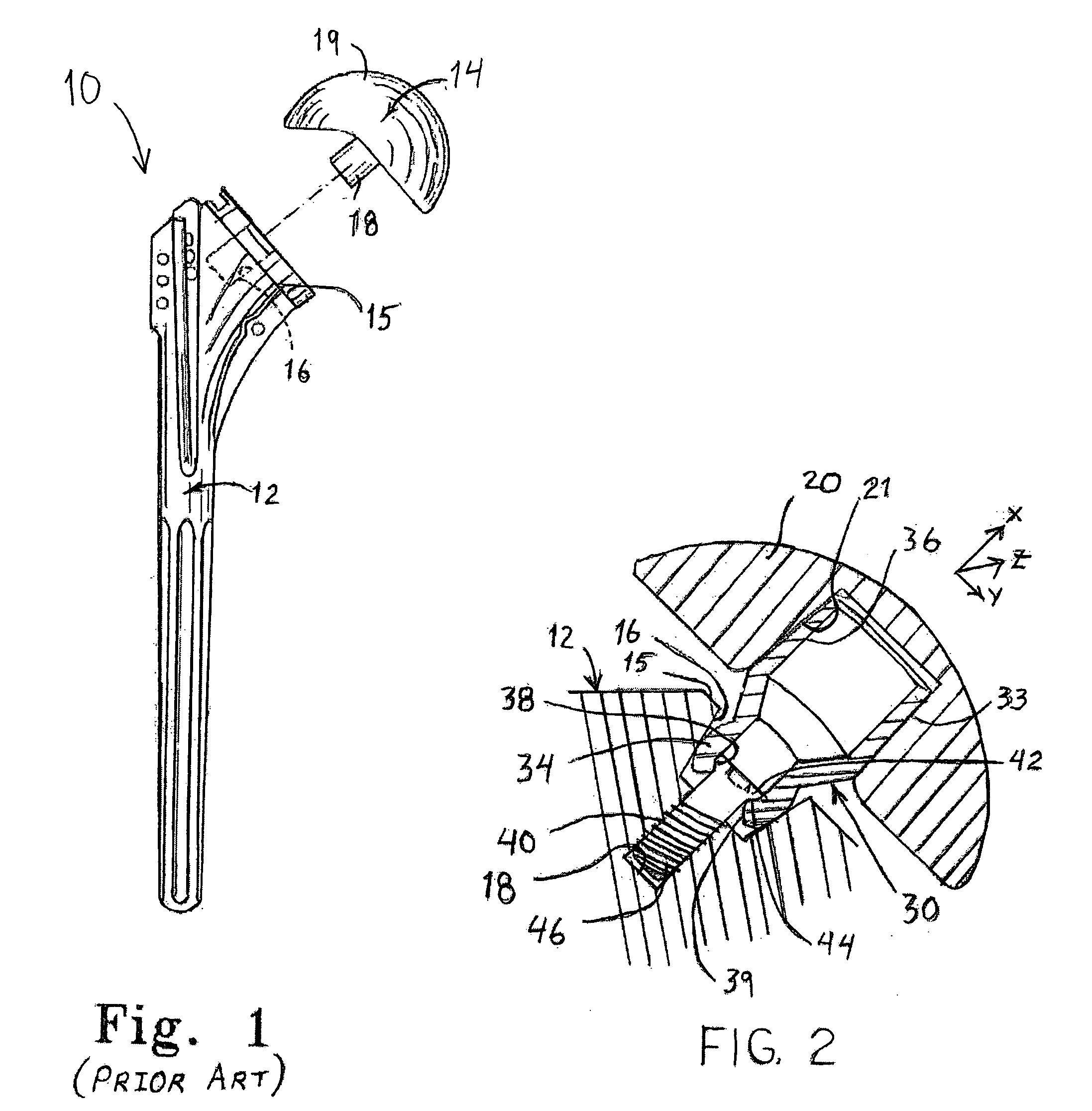

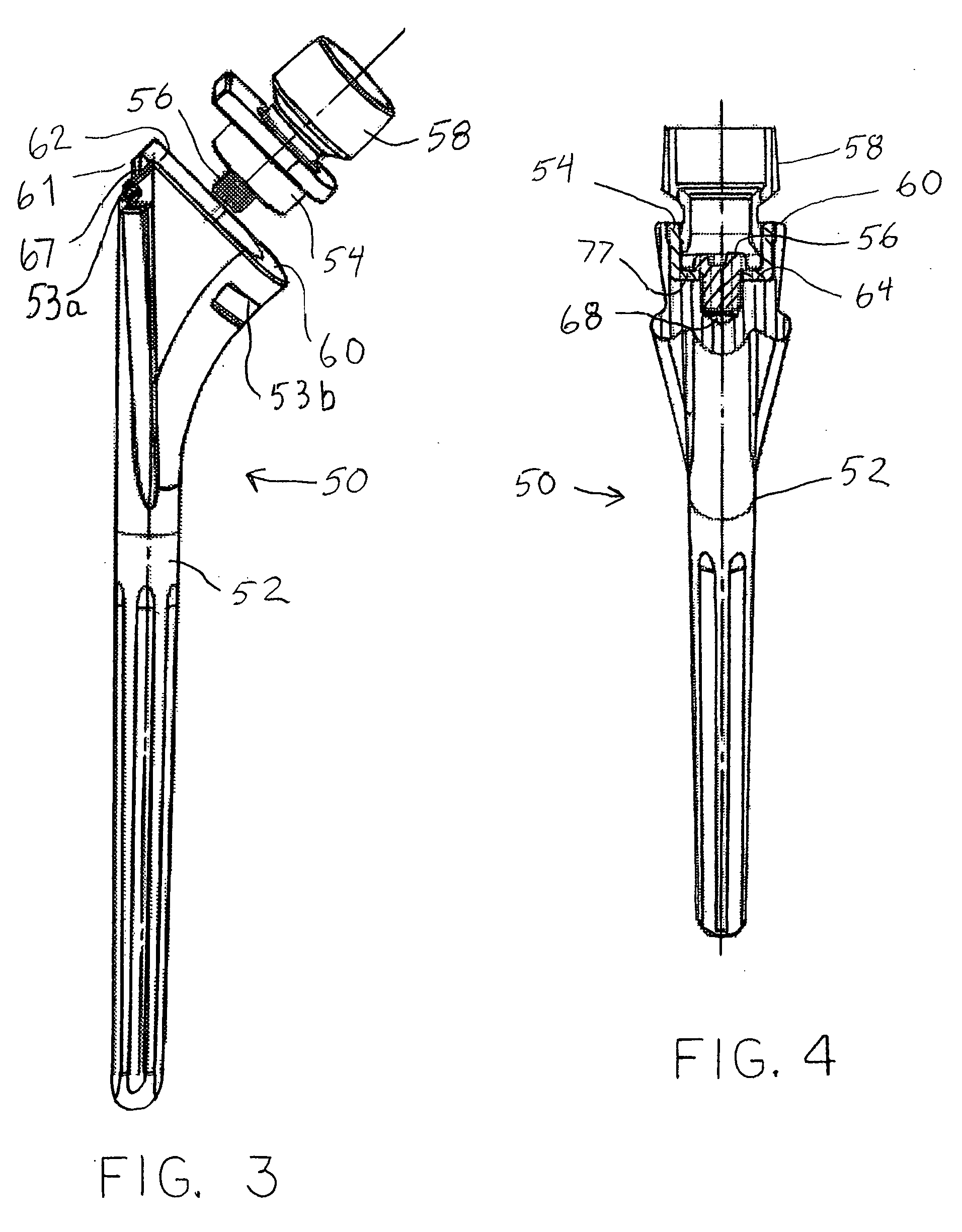

Joint prosthesis with infinitely positionable head

ActiveUS20060142872A1Easy accessFacilitates componentJoint implantsFemoral headsHumeral HeadsAngular orientation

A joint prosthesis includes a bone engaging portion, such as a stem, and articulating component, such as a humeral head, and an insert component that supports the articulating component and is removable from the stem. A mating component mates with the humeral head and is configured to engage the insert component at adjustable angles according to the anatomy of the patient's joint. In a revision surgery, the stem remains within the patient's bone while the insert component is removed with the mating component and humeral head fixed to the insert component. A new insert component may be prepared with the mating component and humeral head oriented to replicate the angular orientation of the previous prosthesis. The new insert component is then mounted within an insert cavity in the implanted stem and rigidly fastened to complete the revision.

Owner:DEPUY SYNTHES PROD INC

Catalyst recover from a slurry

InactiveUS20060135631A1Easy to separateFacilitates componentOther chemical processesOrganic compound preparationWaxParticulates

Embodiments of the invention relate to processes and apparatus for the washing and recovery of metal-containing catalyst solids in a form suitable for reclamation. More specifically, a catalyst recovery process comprises removing an organic residue with a washing medium from a metal-containing catalyst solids, recovering washed solids, and treating the washed solids under oxidative conditions to form non-reactive solids. The treatment oxidative conditions may be effective to convert the metal(s) into an oxide form and / or may facilitate the removal of remaining organic residue from the washed solids. The treatment of the washed solids may comprise calcination. In some embodiments, the metal-containing catalyst solids may be recovered from a slurry stream, and the process further comprises passing the slurry stream though a separation unit to obtain a catalyst-enriched retentate slurry. In some embodiments, the organic residue comprises a hydrocarbon wax, and the solid catalyst is a hydrocarbon synthesis particulate catalyst.

Owner:PHILLIPS 66 CO

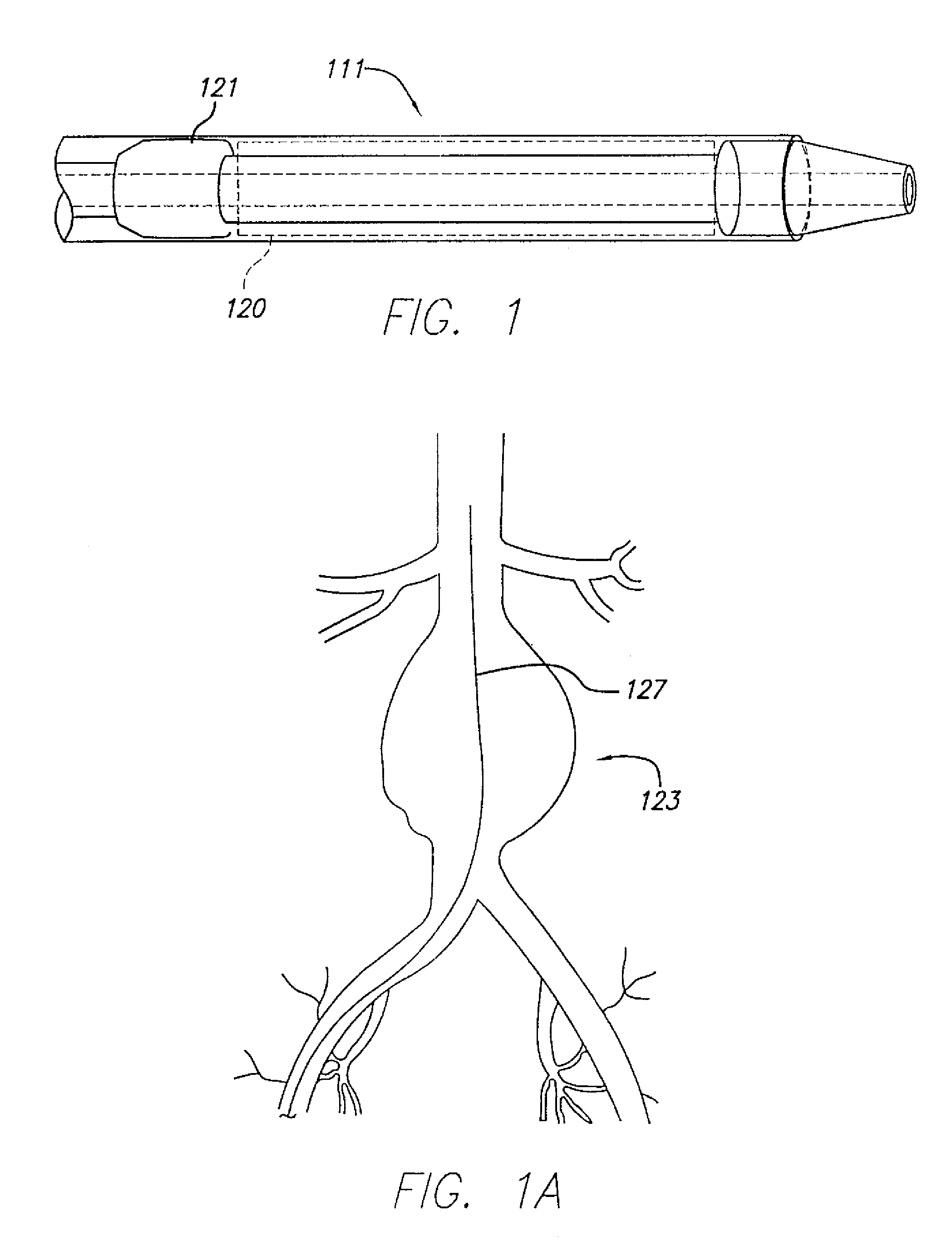

Staged endovascular graft delivery system

Owner:LIFESHIELD SCI

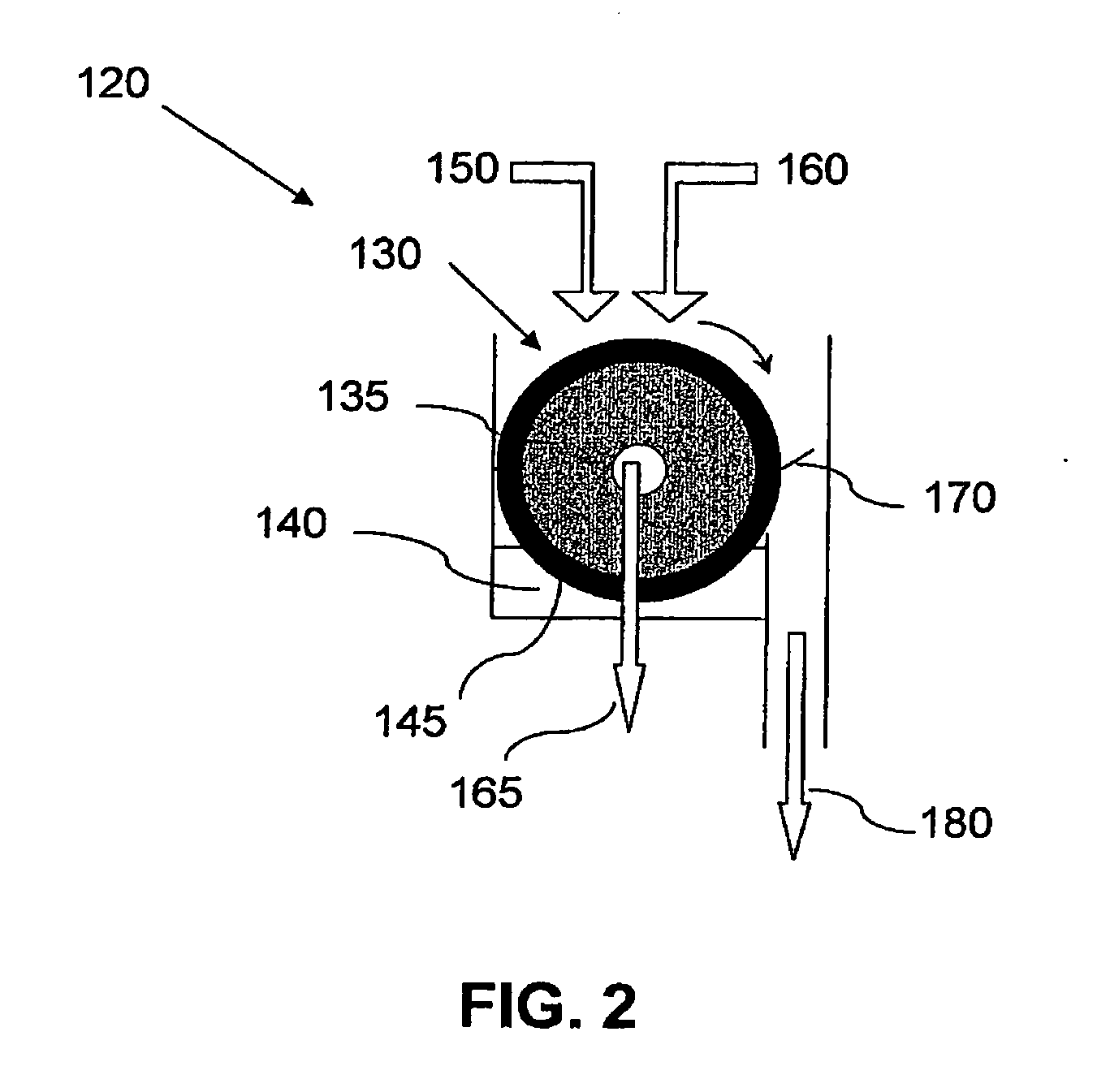

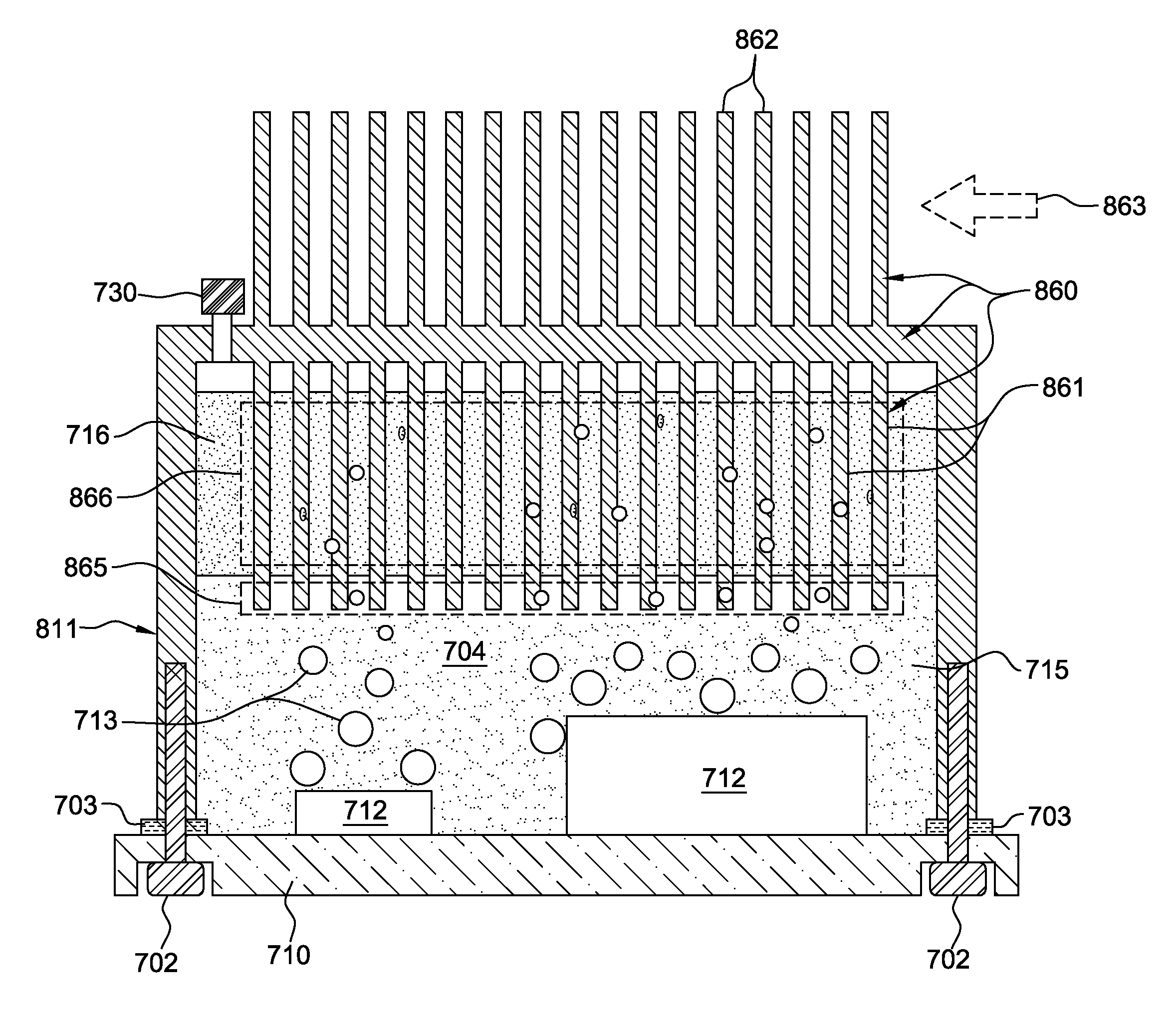

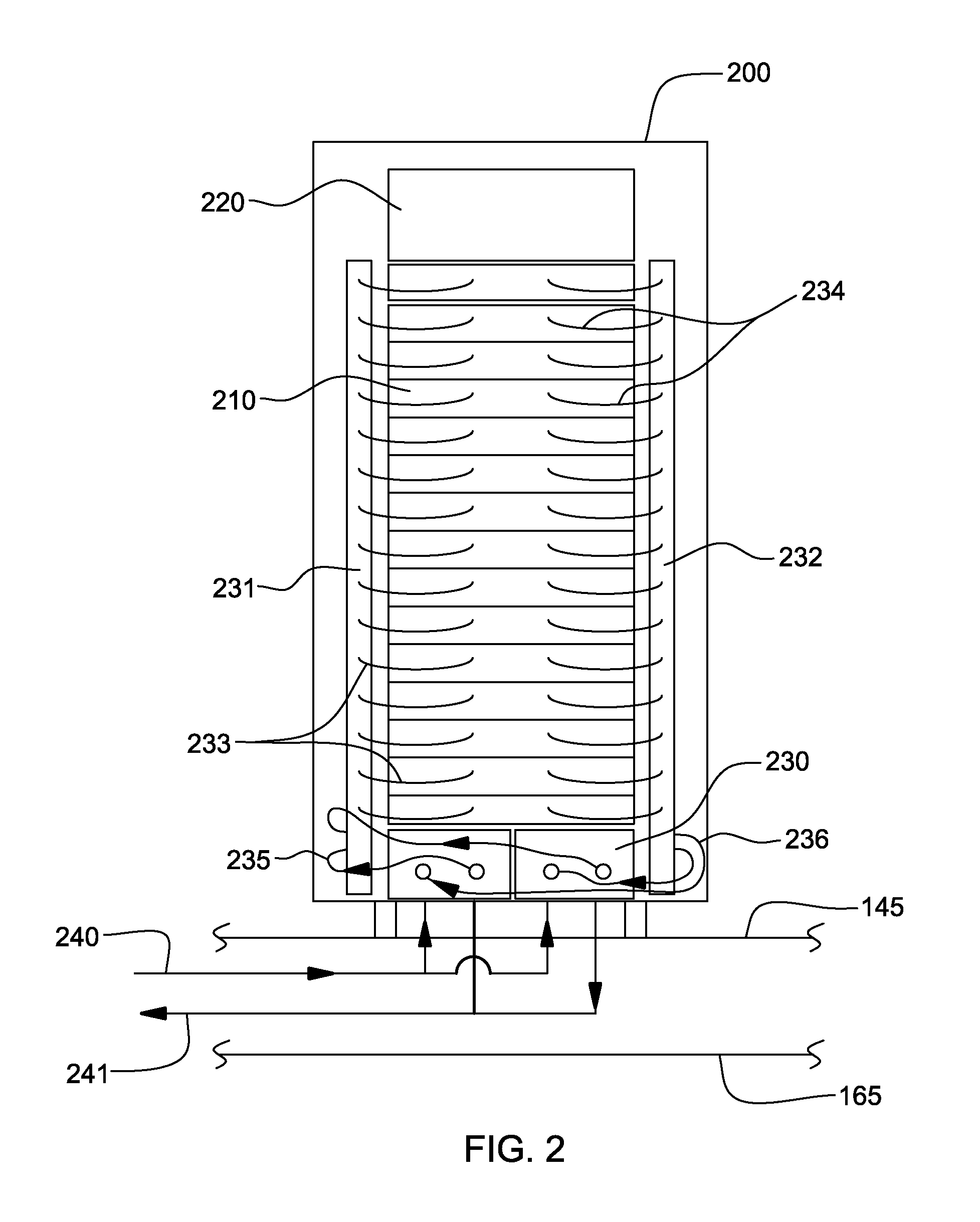

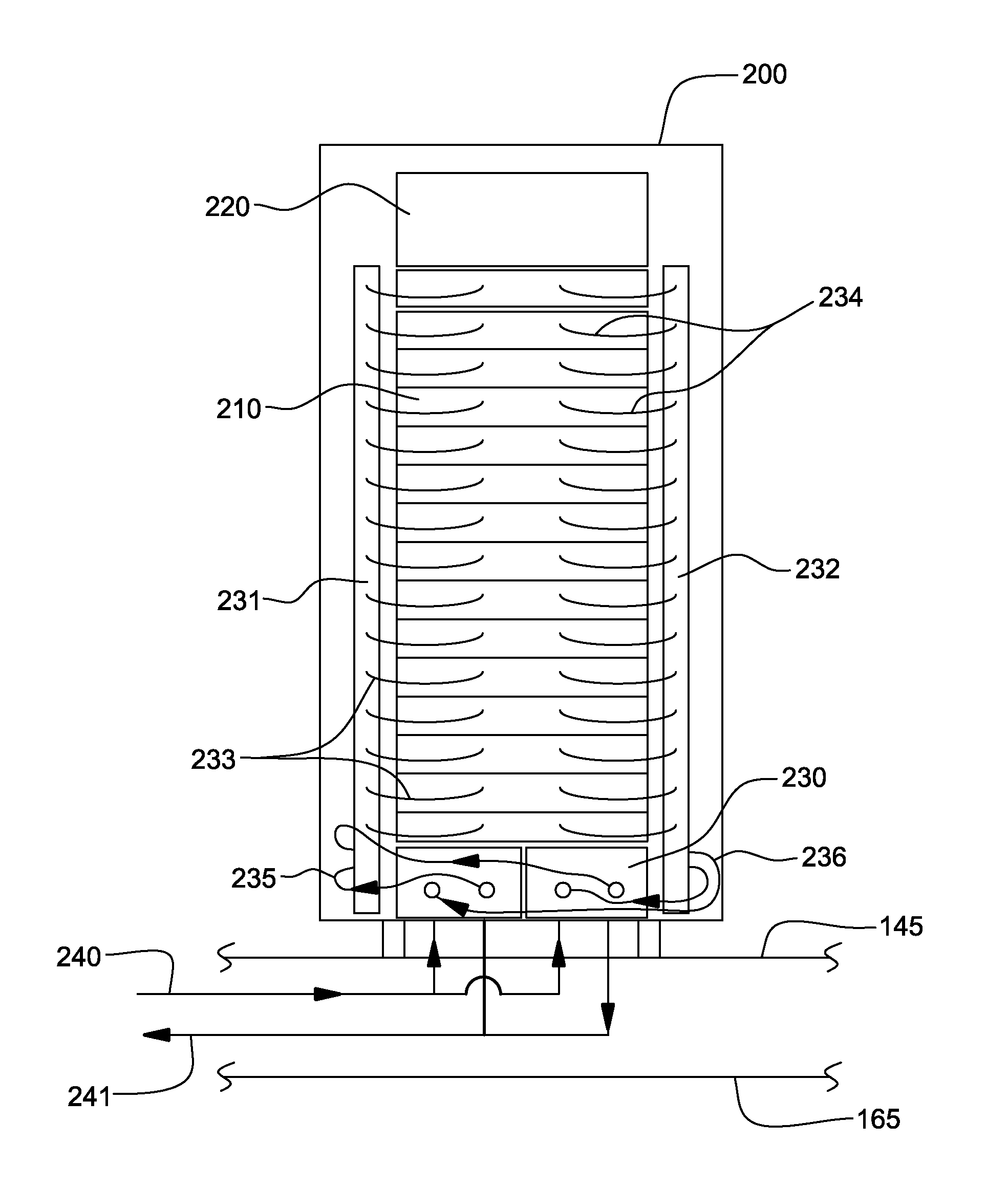

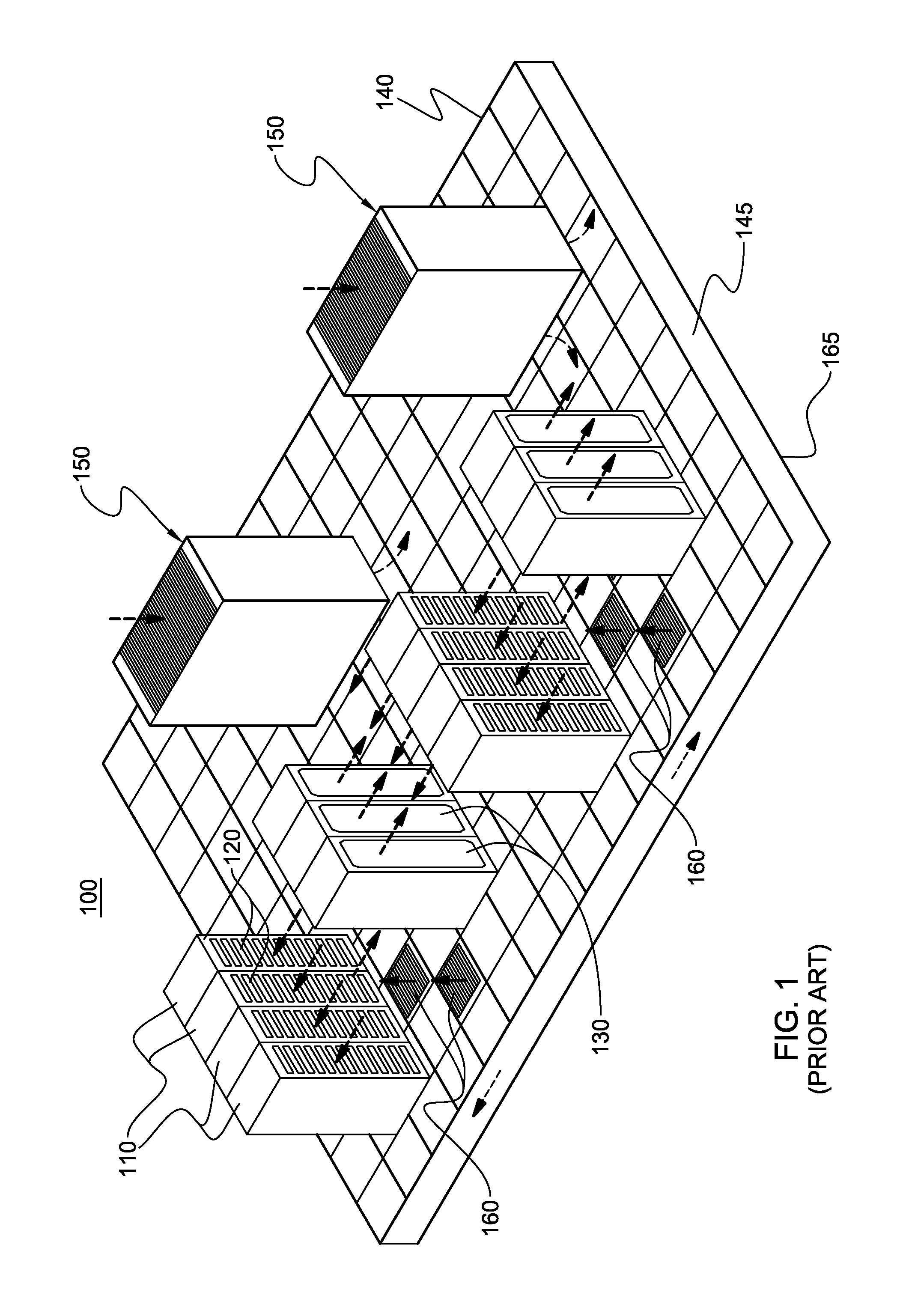

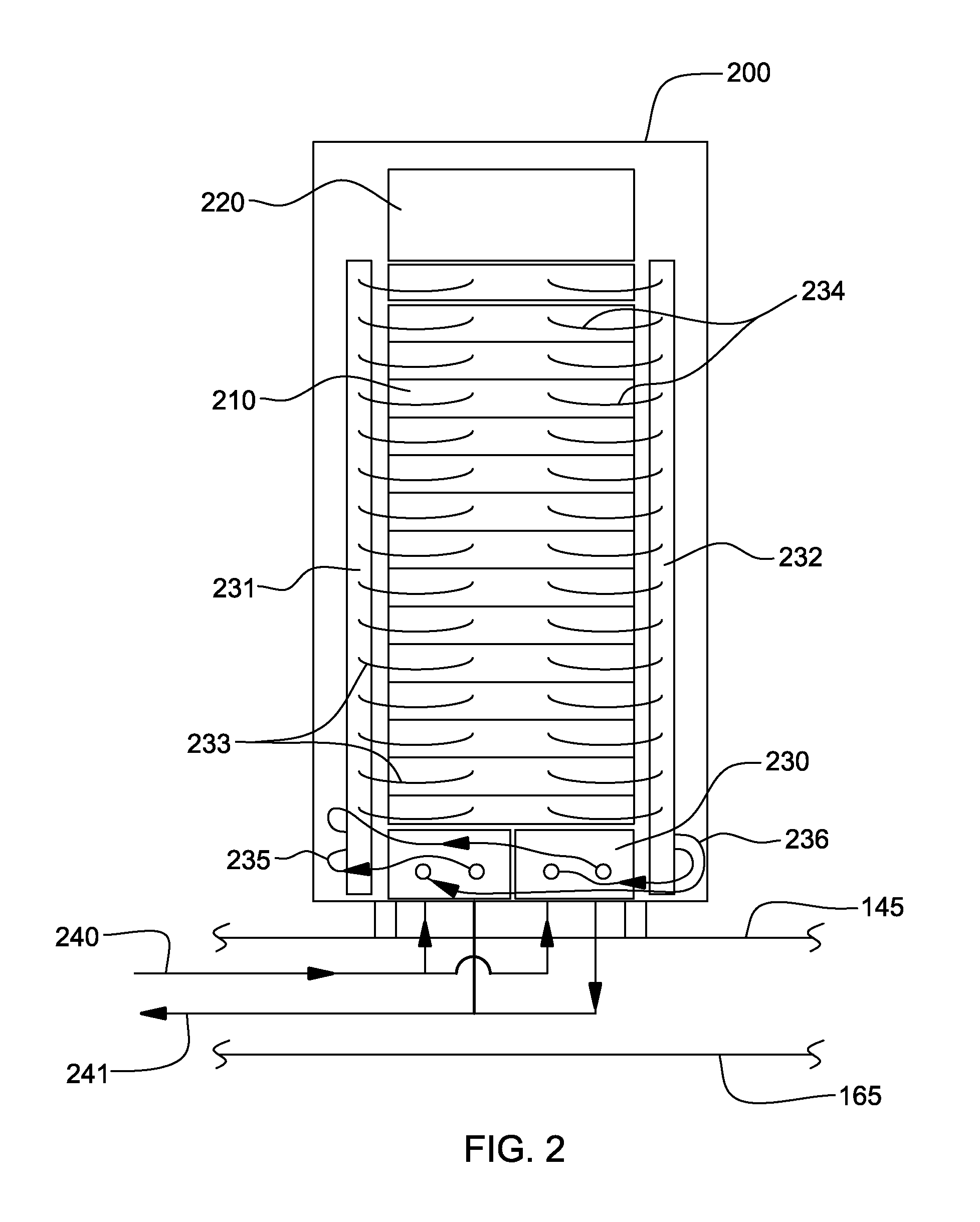

Multi-fluid, two-phase immersion-cooling of electronic component(s)

InactiveUS8619425B2Easy to condenseImprove cooling effectIndirect heat exchangersHeat exchange apparatusEngineeringElectronic component

Cooling apparatuses and methods are provided for immersion-cooling one or more electronic components. The cooling apparatus includes a housing at least partially surrounding and forming a fluid-tight compartment about the electronic component(s), and a boiling fluid mixture of first and second dielectric fluids within the fluid-tight compartment, with the electronic component(s) immersed within the mixture. A condensing fluid is also provided within the fluid-tight compartment, and is immiscible with the boiling fluid mixture. The condensing fluid has a lower specific gravity and a higher thermal conductivity than the boiling fluid mixture, and facilitates condensing of vaporized boiling fluid mixture. A cooling structure is provided within the compartment, and includes a condensing region and a sub-cooling region, with the condensing region being in contact with the condensing fluid, and the sub-cooling region being in contact with the boiling fluid mixture. The cooling structure facilitates heat removal from the fluid-tight compartment.

Owner:IBM CORP

Remotely monitoring/diagnosing distributed components of a supervisory process control and manufacturing information application from a central location

InactiveUS20060224361A1Facilitates componentComputer controlTesting/monitoring control systemsGraphicsManagement tool

A centralized diagnostics management tool is disclosed that facilitates centralized monitoring of distributed components of a supervisory process control and manufacturing information application. The centralized diagnostics management tool includes a diagnostics management console shell that is customized according to a set of software modules that interface to data sources to populate views supported by the console shell. The console shell includes a set of view templates including controls for manipulating graphically displayed representations of data rendered by the distributed components. The console shell also includes an interface for exchanging requests and data with an extensible set of software modules that provide data links to ones of the set of distributed components. The software modules also define the customizable portions of the view rendered by the console shell.

Owner:SCHNEIDER ELECTRIC SOFTWARE LLC

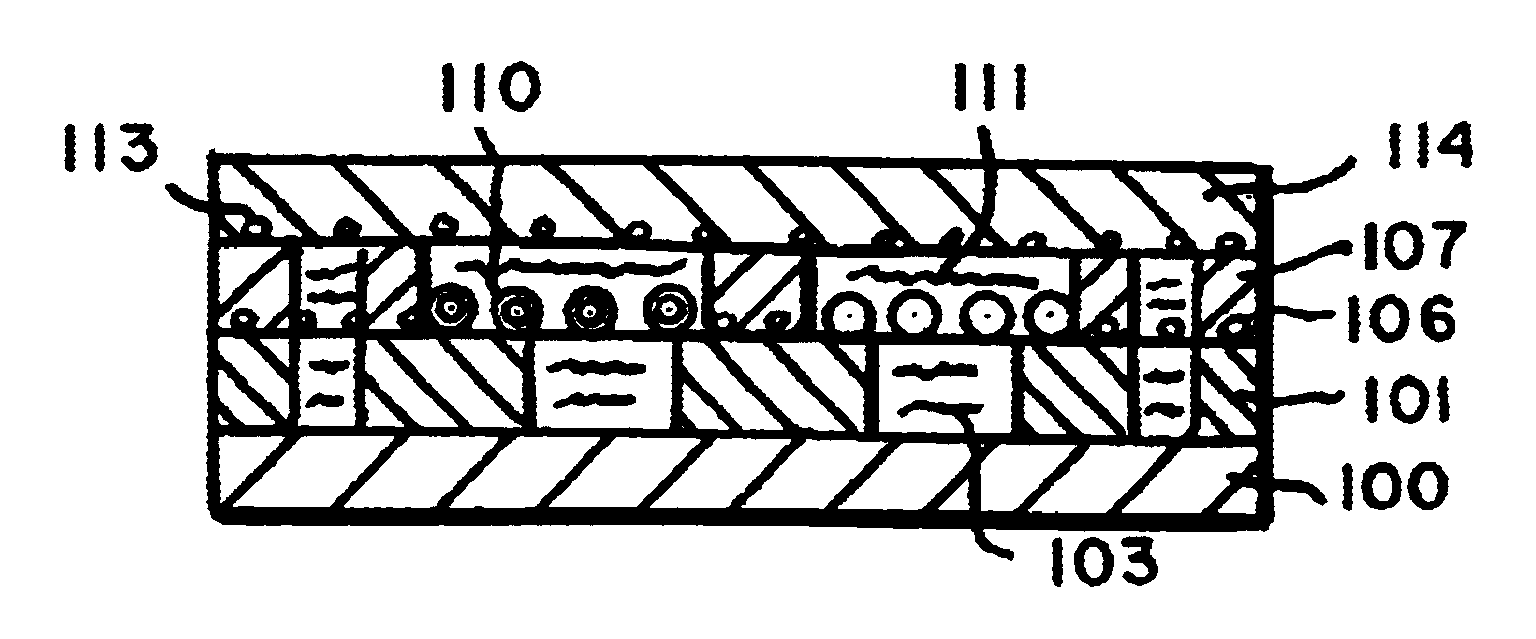

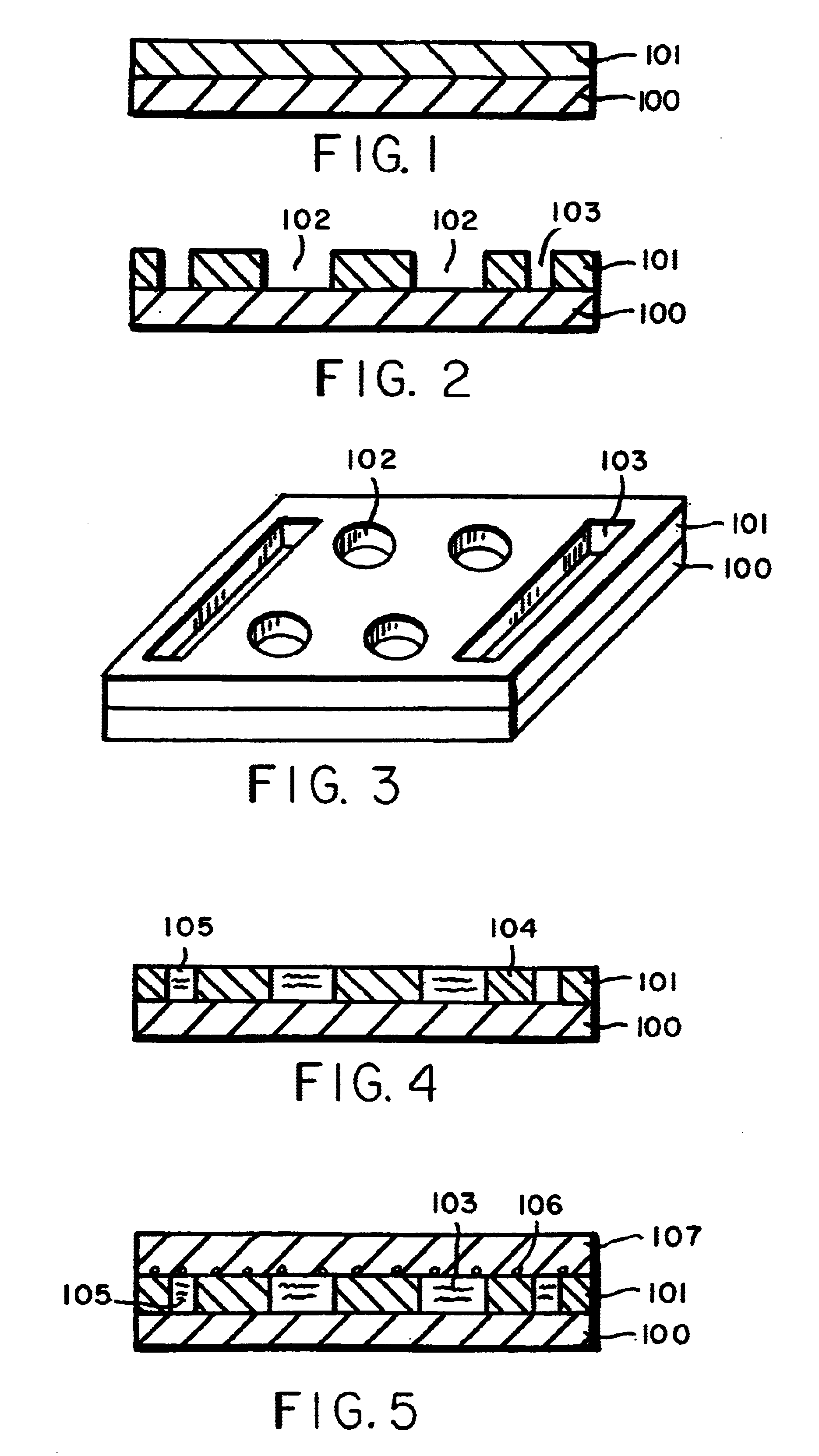

Sequential build circuit board

InactiveUS6944945B1Improve flexural strengthImprove rigiditySemiconductor/solid-state device detailsSolid-state devicesGlass fiberInterconnection

A method for manufacture of a circuit board and the board formed by the novel method. The method comprises selective plating of metallic reinforcing members, solder mount pads, signal and interconnections sequentially. The resultant board is desirably free of glass fiber reinforcement.

Owner:SHIPLEY CO LLC

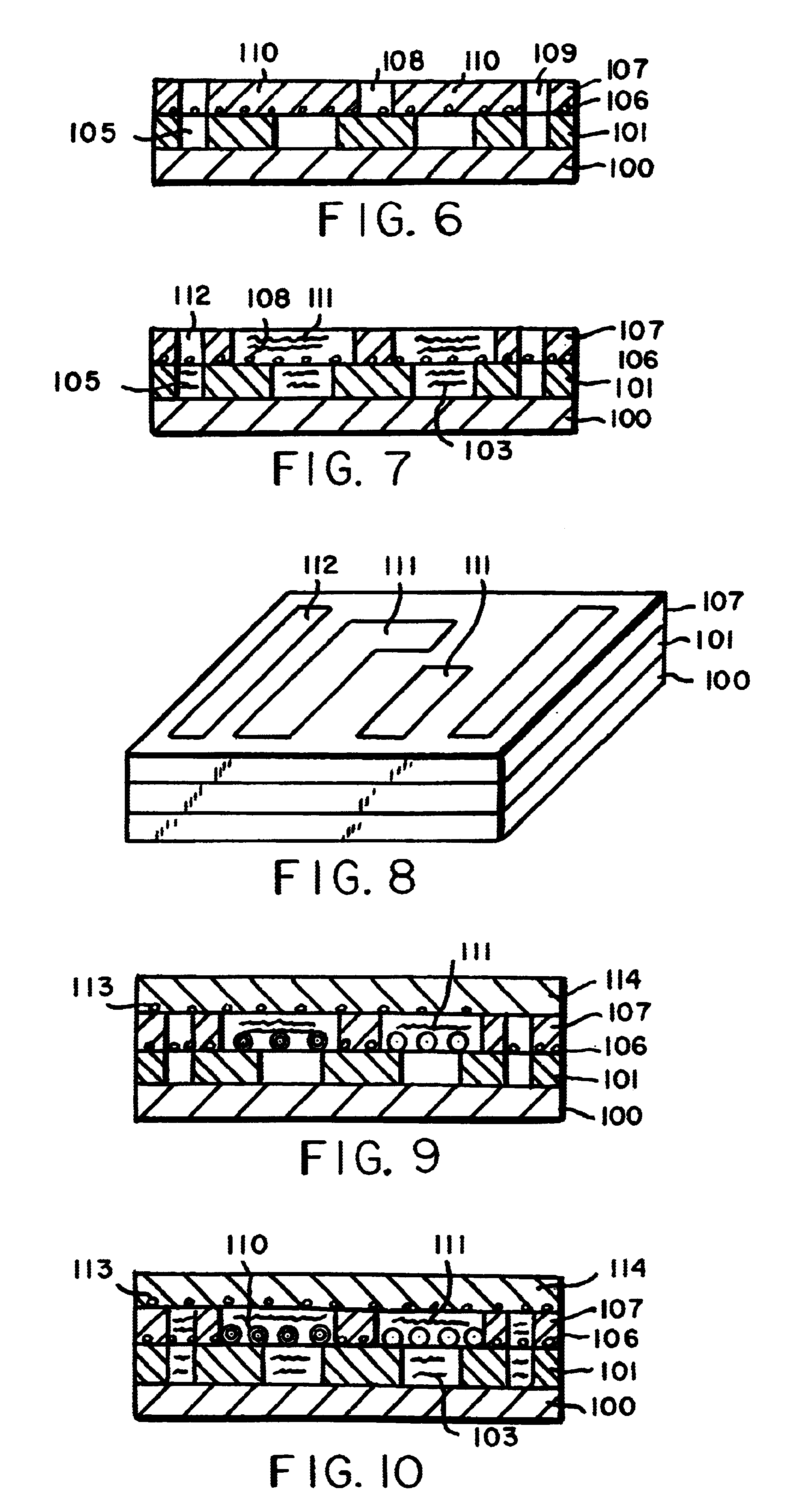

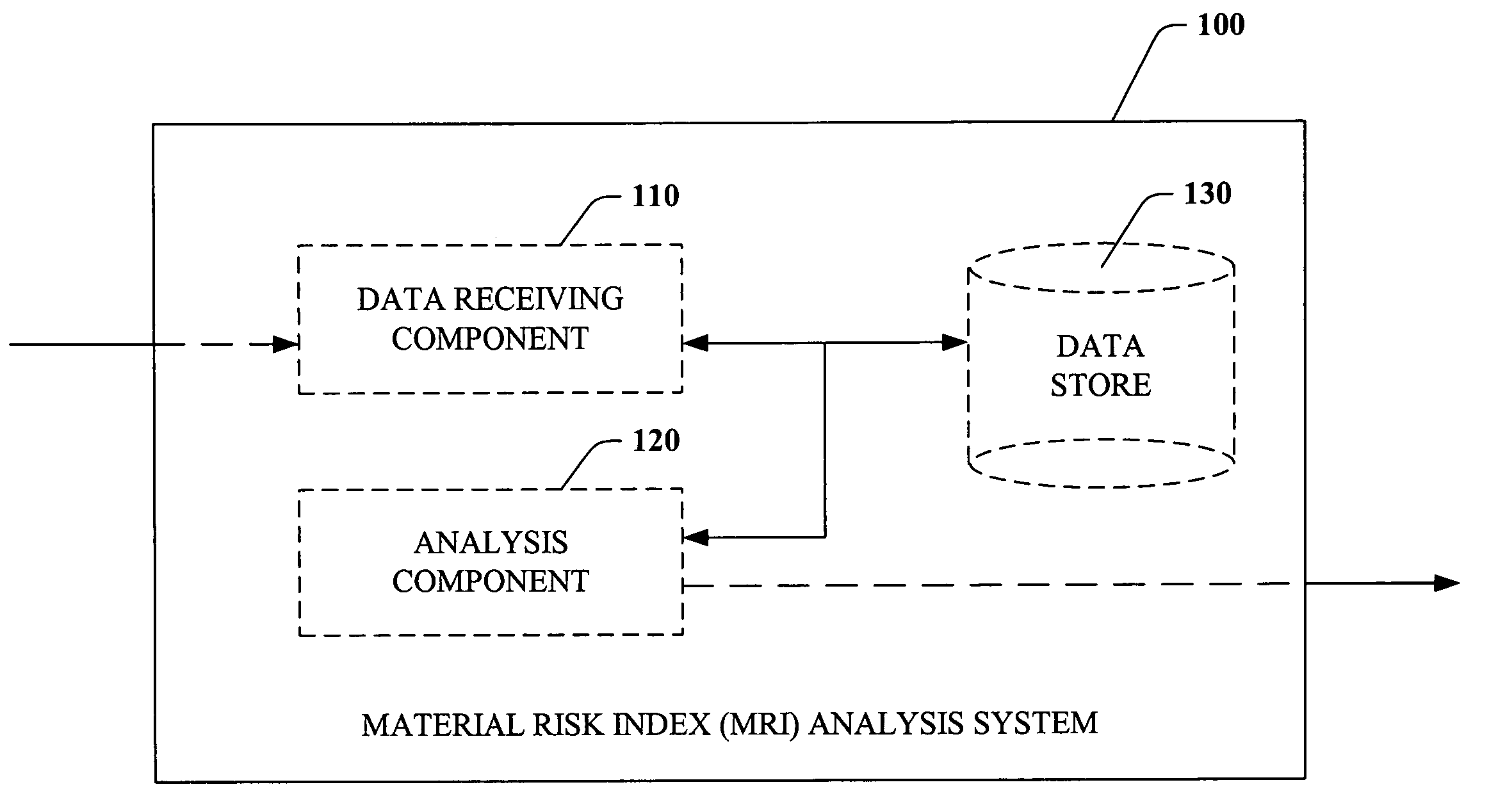

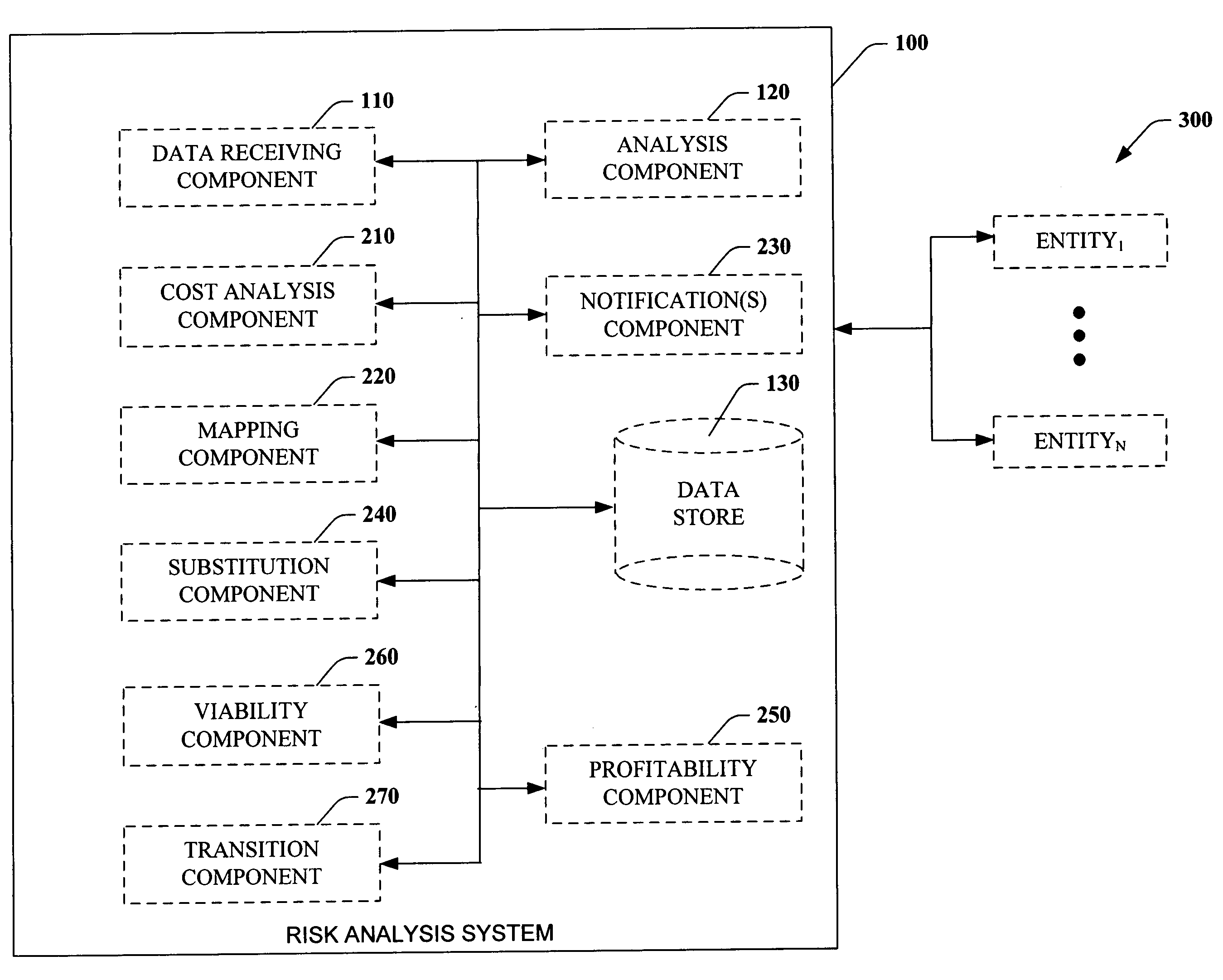

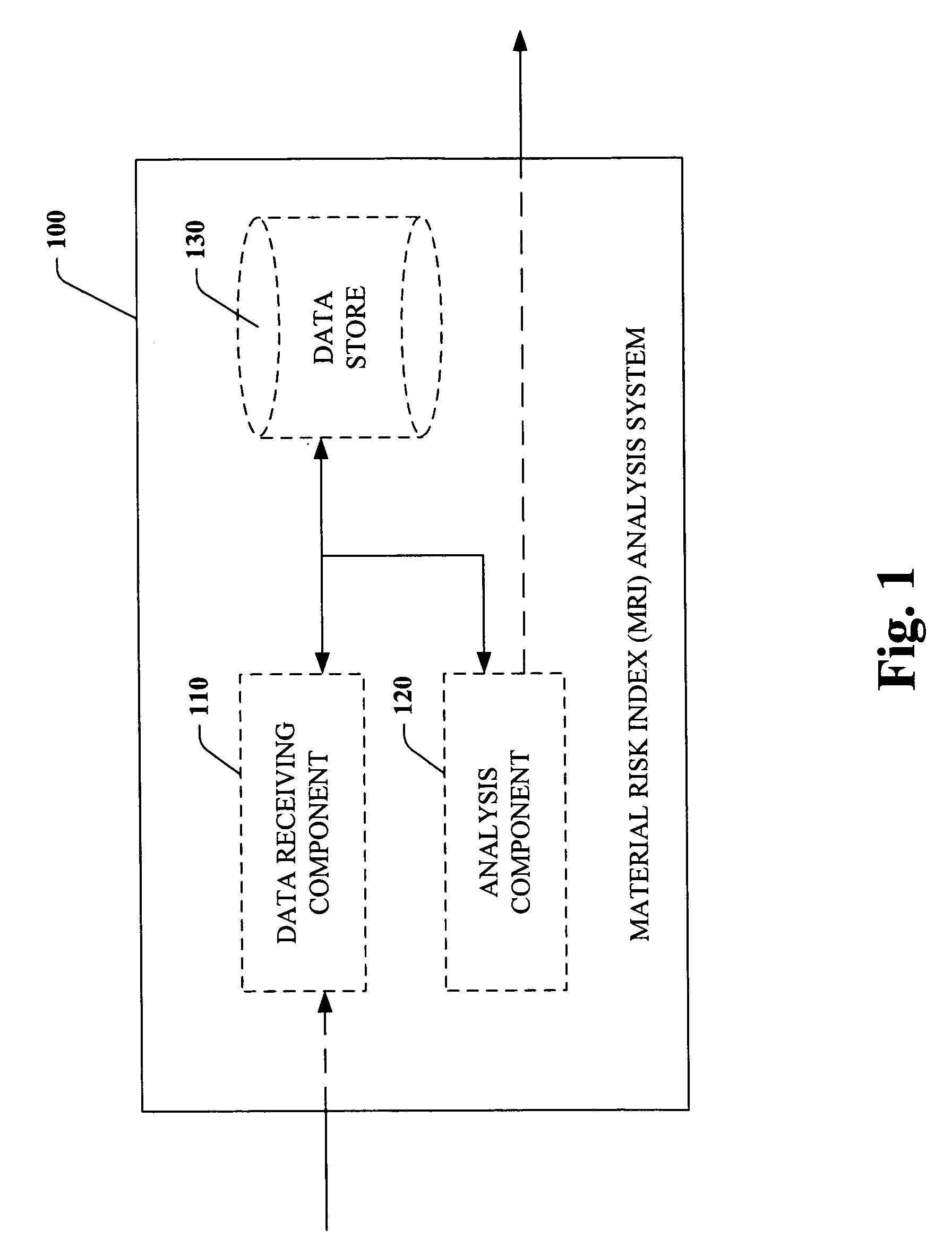

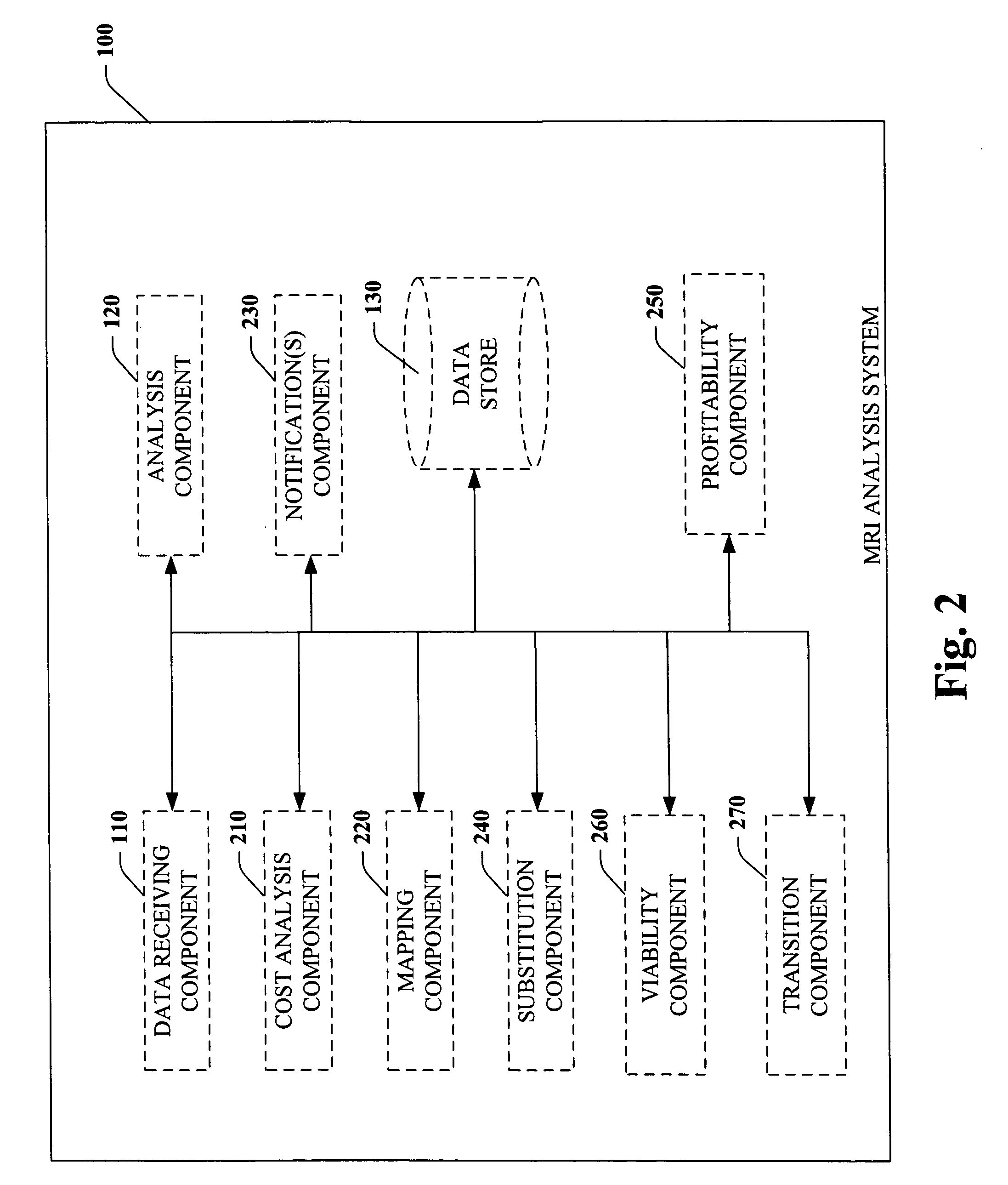

Systems and methods for automatically determining and/or inferring component end of life (EOL)

InactiveUS20050187744A1Facilitates proactively maintaining product life-cyclesFacilitates componentComputation using non-denominational number representationResourcesCost analysisObsolescence

The present invention relates to a system and methodology for facilitating managing product life cycle. A component that determines relevance of components to a product; an analyzing component that determines, infers or predicts obsolescence, level of risk to EOL of a subset of the components. A substitution component that identifies replacement components and suppliers for the subset of components. A cost analysis component that determines material / components cost savings, and redesign cost implementation and / or redesign cost avoidance.

Owner:ROCKWELL AUTOMATION TECH

Production and use of paraffin inhibitor formulations

InactiveUS20100130385A1Avoid disadvantagesFacilitates componentFluid removalLiquid carbonaceous fuelsParaffin waxAlkane

A process for preparing a paraffin inhibitor formulation comprising (a) preparing a mixture comprising a waxy paraffin inhibitor component having a melting point of >0° C. and an emulsifier component, wherein the mixture is prepared at a first temperature range above the melting point of the waxy paraffin inhibitor; (b) adding water to the mixture to produce an o / w emulsion; and (c) cooling the o / w emulsion to a temperature in a second temperature range which is below the melting point of the waxy paraffin inhibitor. The mixture prepared in step (a) may further comprise water to produce a w / o emulsion, the water being present in a proportion by weight that is lower than the sum of the proportions by weight of the paraffin inhibitor and the emulsifier component. The process may further comprise (d) adding an at least partially water-miscible organic solvent in which the paraffin inhibitor is insoluble.

Owner:BASF AG

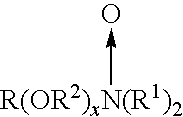

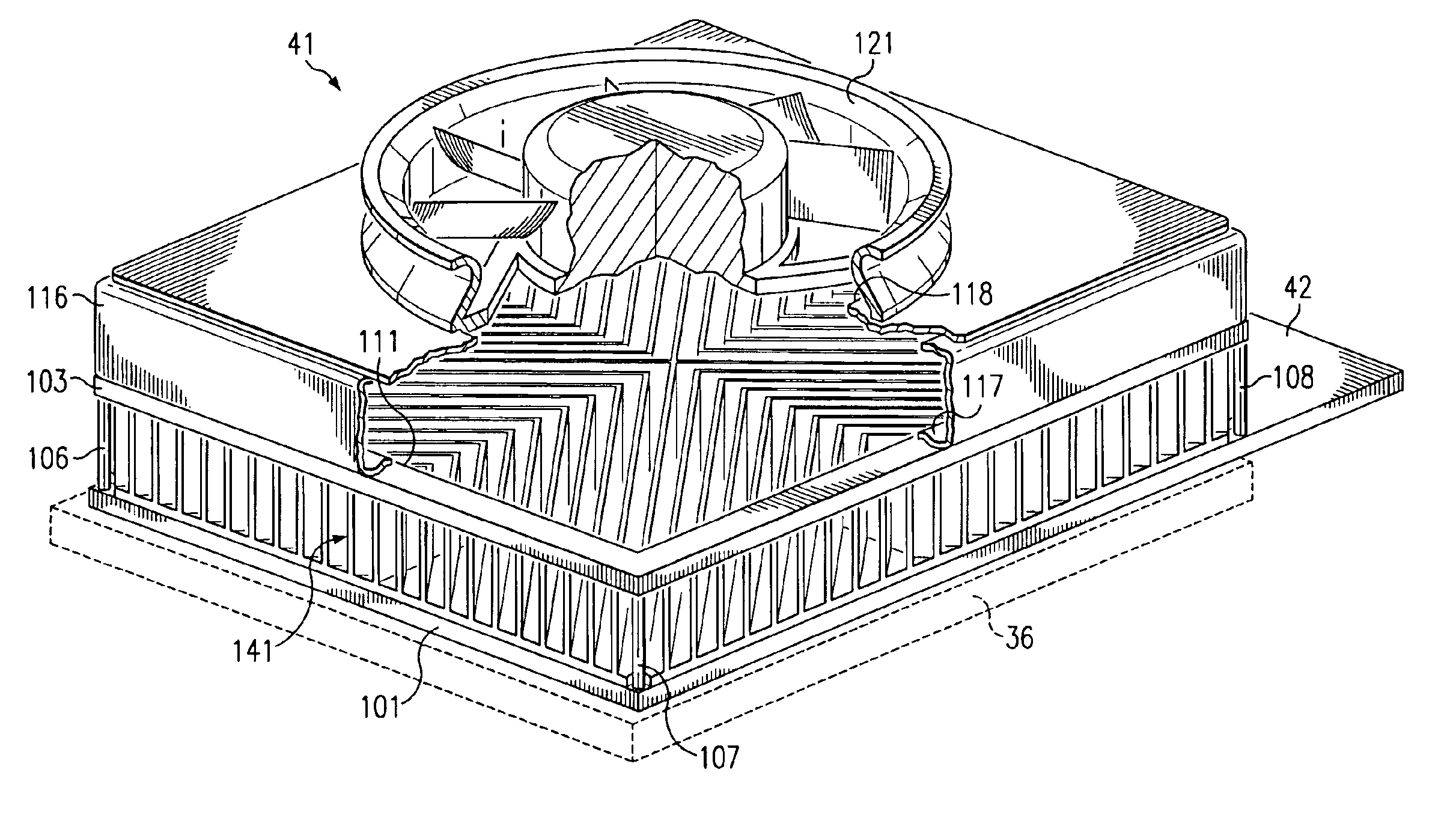

Method and apparatus for cooling a circuit component

InactiveUS7046515B1Components is relatively effectiveMinimal audible noiseDigital data processing detailsSemiconductor/solid-state device detailsEngineeringFluid supply

An apparatus includes a thermally conductive section with a side facing approximately parallel to an axis and adapted to be thermally coupled to a circuit component, and includes a fluid supply section which directs a fluid flow along the axis toward an opposite side of the thermally conductive section. The thermally conductive section splits the fluid flow into a plurality of flow portions which each flow through the thermally conductive section in a direction approximately parallel to a plane perpendicular to the axis, the flow portions exiting the thermally conductive section at a plurality of respective locations disposed along a substantial portion of the periphery of the thermally conductive section.

Owner:OL SECURITY LIABILITY CO

Systems and methods for automatically determining and/or inferring component end of life (EOL)

InactiveUS7672921B1Facilitates proactively maintaining product life-cyclesFacilitates componentDigital computer detailsResourcesCost analysisObsolescence

The invention relates to a system and methodology for facilitating managing product life cycle. A component that determines relevance of components to a product; an analyzing component that determines, infers or predicts obsolescence, level of risk to EOL of a subset of the components. A substitution component that identifies replacement components and suppliers for the subset of components. A cost analysis component that determines material / components cost savings, and redesign cost implementation and / or redesign cost avoidance. A viability component that measures reliability of a component. A transition component that identifies components that require updating or replacement. A profitability component that determines the expected revenue derived from a component over its projected remaining life.

Owner:ROCKWELL AUTOMATION TECH

Multi-fluid, two-phase immersion-cooling of electronic component(s)

InactiveUS20130105120A1Easy to condenseLow specific gravityIndirect heat exchangersHeat exchange apparatusEngineeringElectronic component

Cooling apparatuses and methods are provided for immersion-cooling one or more electronic components. The cooling apparatus includes a housing at least partially surrounding and forming a fluid-tight compartment about the electronic component(s), and a boiling fluid mixture of first and second dielectric fluids within the fluid-tight compartment, with the electronic component(s) immersed within the mixture. A condensing fluid is also provided within the fluid-tight compartment, and is immiscible with the boiling fluid mixture. The condensing fluid has a lower specific gravity and a higher thermal conductivity than the boiling fluid mixture, and facilitates condensing of vaporized boiling fluid mixture. A cooling structure is provided within the compartment, and includes a condensing region and a sub-cooling region, with the condensing region being in contact with the condensing fluid, and the sub-cooling region being in contact with the boiling fluid mixture. The cooling structure facilitates heat removal from the fluid-tight compartment.

Owner:IBM CORP

Peptides For Skin Rejuvenation And Methods Of Using The Same

ActiveUS20140309173A1Improvement factorMore lipophilicCosmetic preparationsOrganic active ingredientsDiseaseCell-Extracellular Matrix

The invention provides compositions for stimulating the formation of one or more extracellular matrix components that contain a lipoaminoacid derivative of the tripeptide carnosine such as N-Octanoyl Carnosine. Also provided are compositions containing N-Octanoyl Carnosine in combination with selected tripeptide and / or tetrapeptides as well as pharmaceutical and / or cosmetic compositions containing such compositions. The invention further provides methods of using the compositions and compositions of the invention to treat, alleviate, and / or ameliorate a symptom, condition, disorder, or disease of the skin or mucosa, wherein the symptom, condition, disorder, or disease is associated with changes in extracellular matrix components.

Owner:ANTEIS SA

Systems and methods for sharing portal configurations

ActiveUS7895234B2Improve experienceImprove efficiencyDigital data processing detailsMultiple digital computer combinationsPortletWeb site

Owner:AI CORE TECH LLC

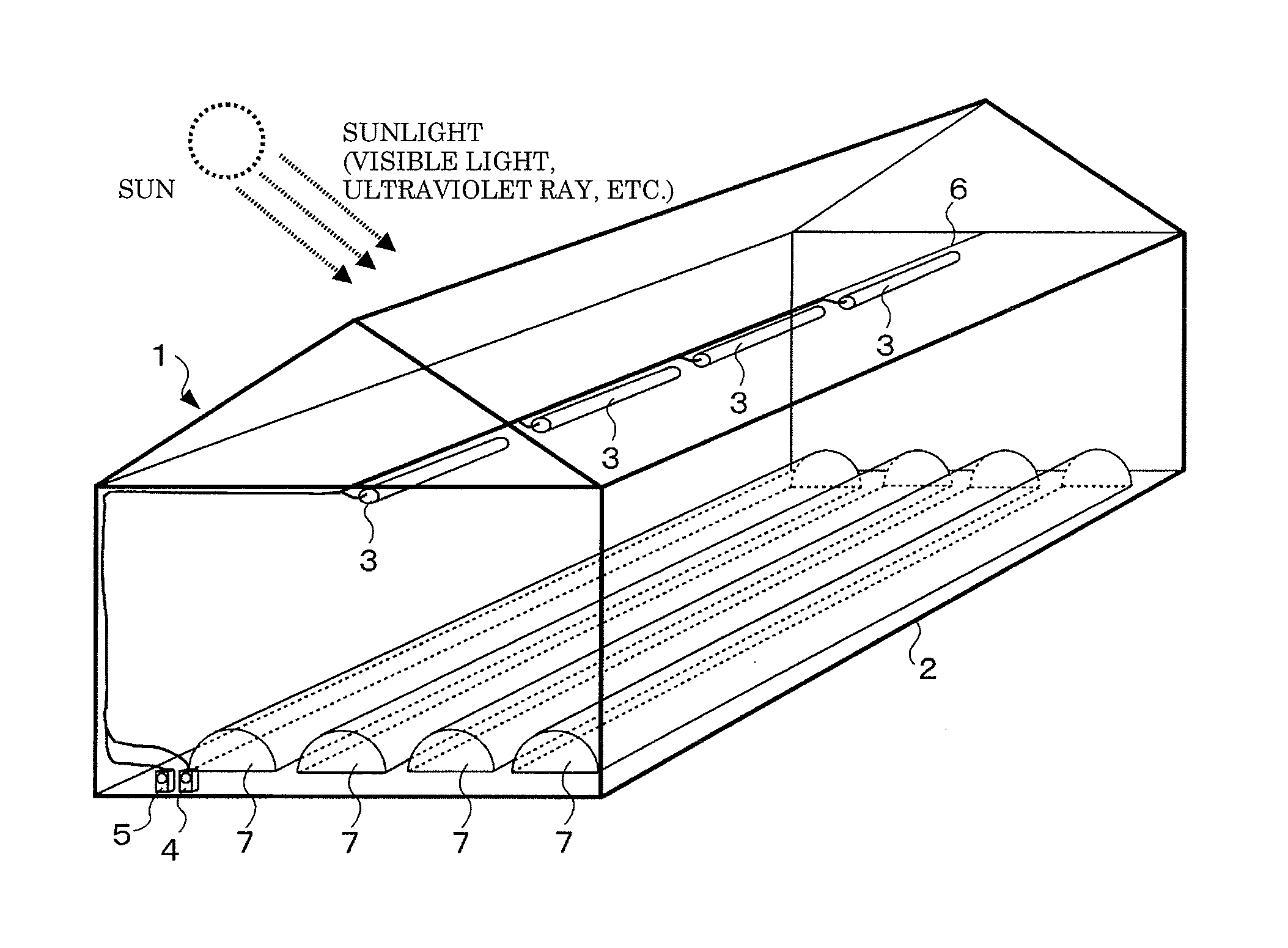

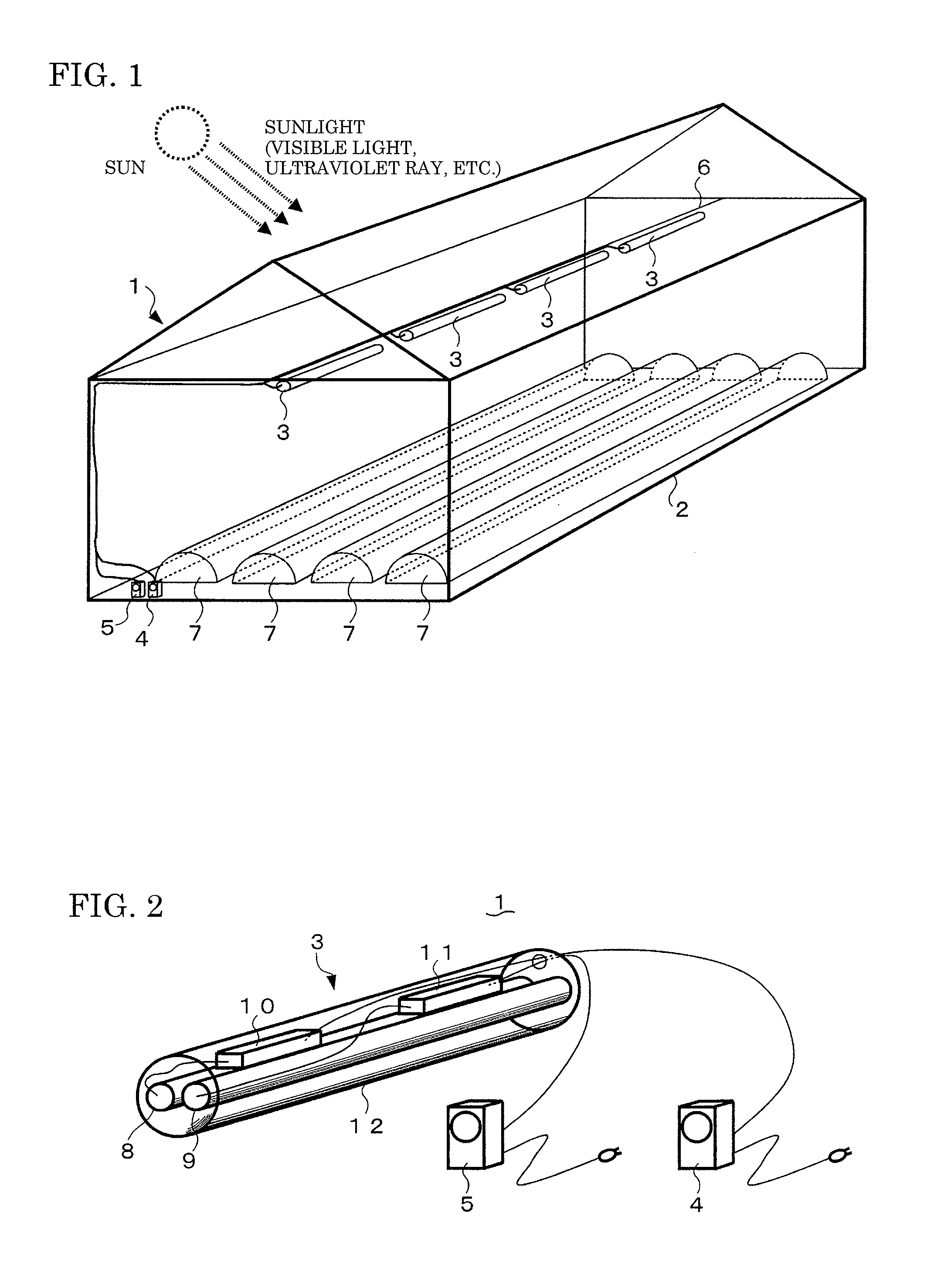

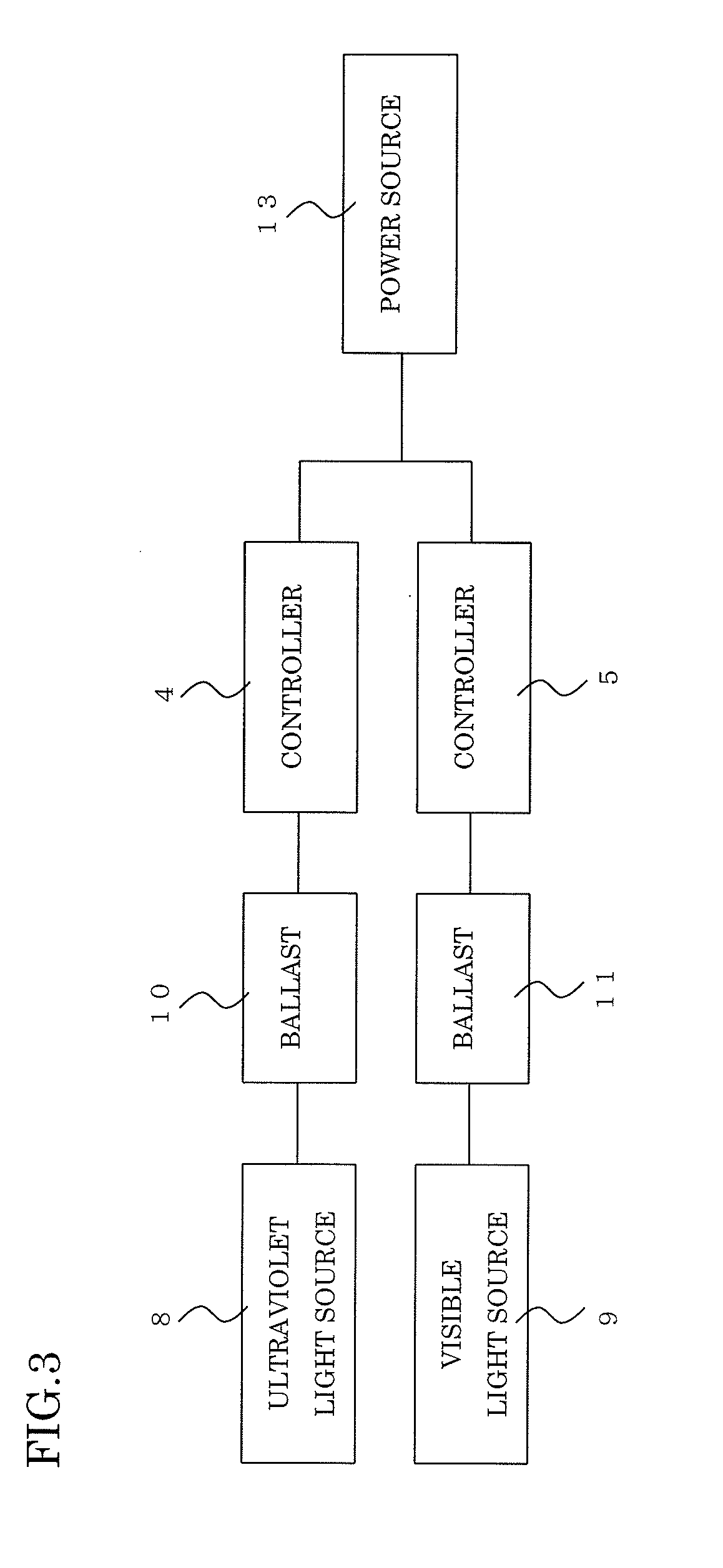

Lighting system for preventing plant disease damage

InactiveUS20110163246A1Suppress manufacturing costAdditional componentElectrical apparatusSaving energy measuresDiseaseEffect light

A lighting system for preventing a plant disease damage is provided with an ultraviolet light source which emits ultraviolet ray including UV-B in a wavelength region of 255 to 340 nm, a visible light source which emits visible light, and controllers which control a lighting of the ultraviolet light source and the visible light source. The controller controls the lighting of the ultraviolet light source so that a horizontal irradiance on a canopy surface of a plant is 50 μW / cm2 or less during a predetermined daytime period. The controller controls the lighting of the visible light source so that a horizontal illuminance on a canopy surface of a plant is 10 lux or less during a predetermined nighttime period. The lighting system promotes a component change of the plant effectively by a stimulation by the UV-B irradiation and the prolonged irradiation time of the visible light which is associated with a vegetative growth, so that a nutritional component of the plant can stably be increased. Moreover, the lighting of the ultraviolet light source and the visible light source is controlled by the controllers, thus a user effort is reduced and efficiency is achieved.

Owner:PANASONIC CORP

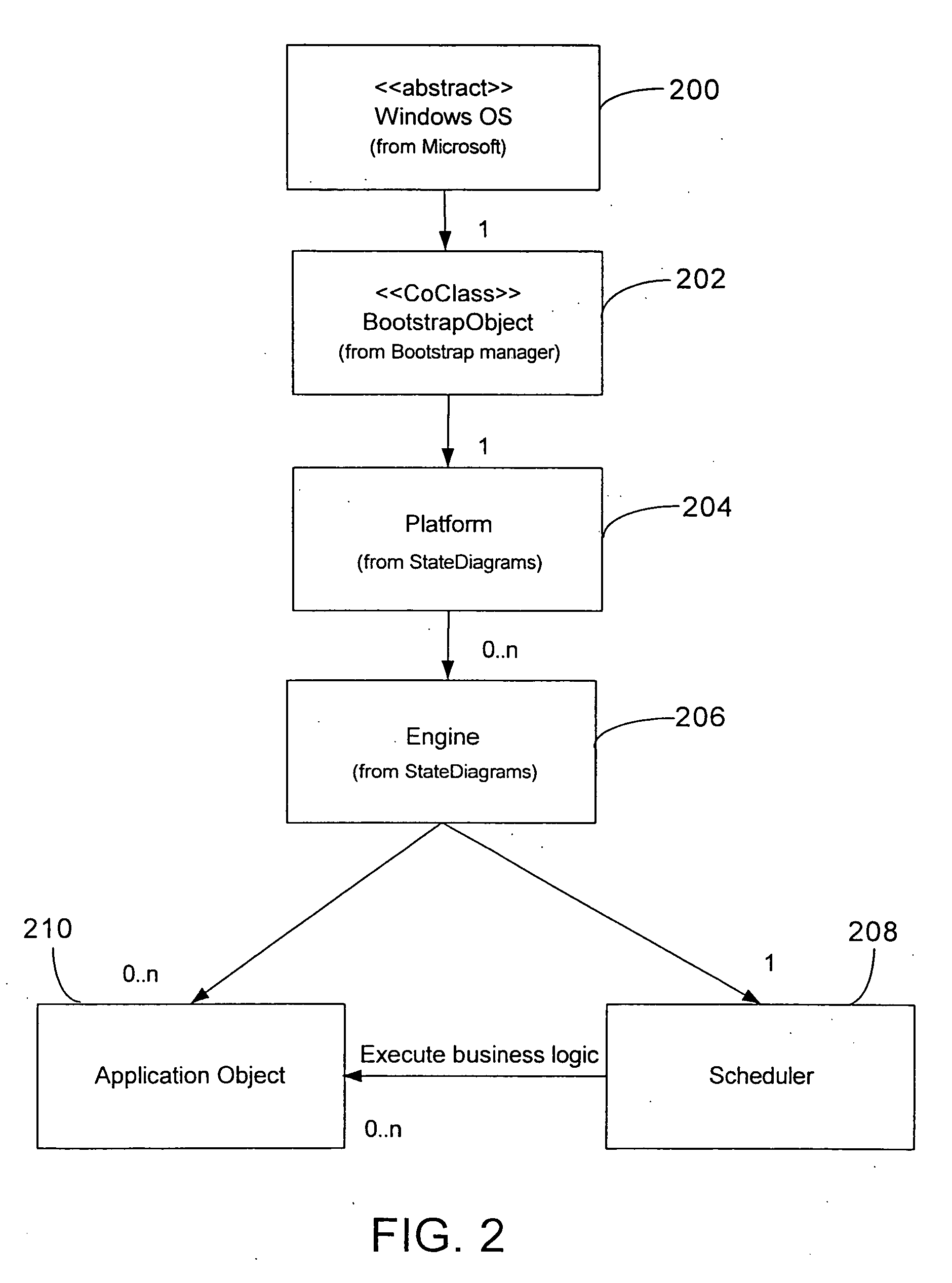

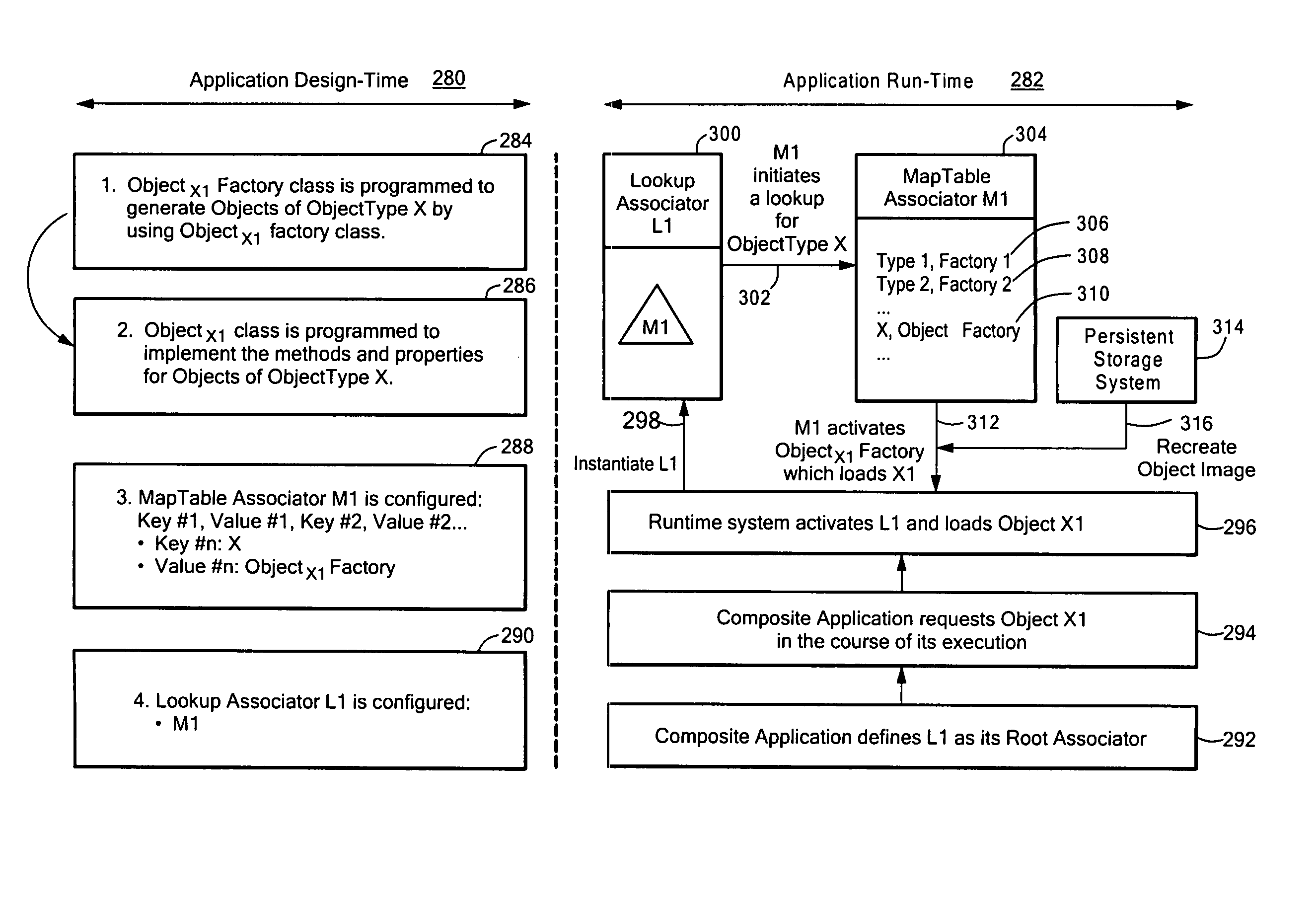

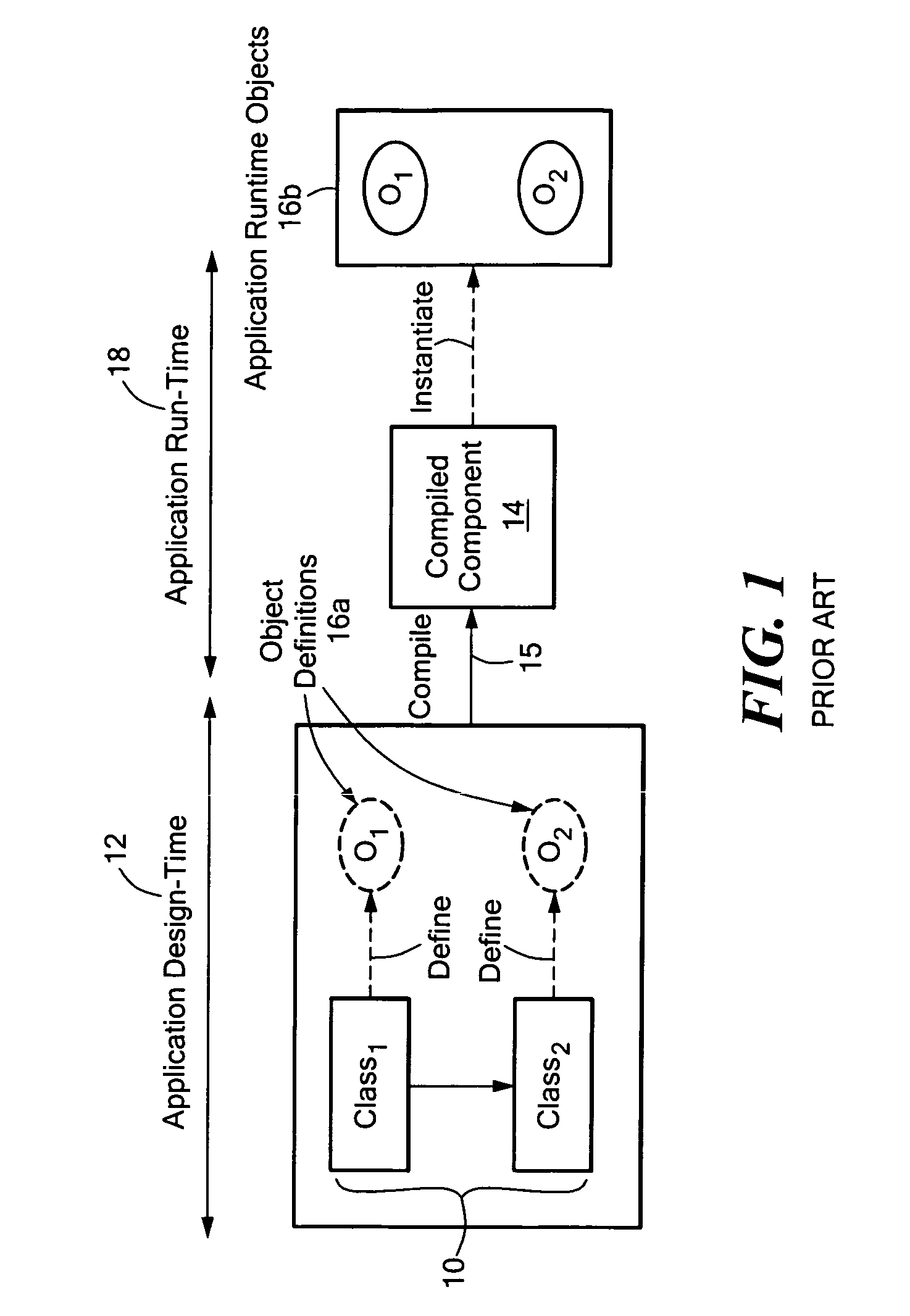

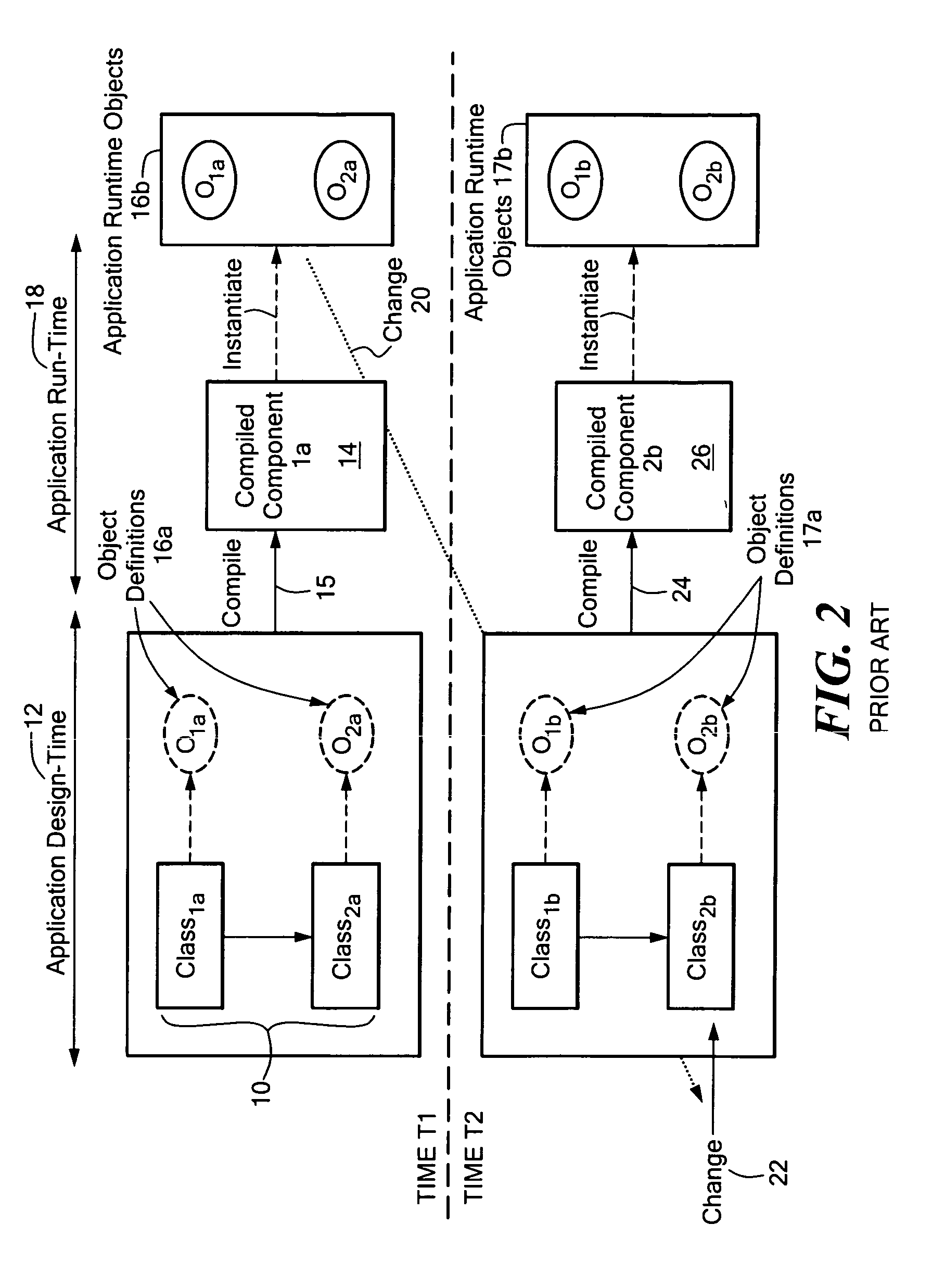

System and method for providing composite applications

InactiveUS7421716B1Easy to reuseEasy to integrateProgram controlSoftware deploymentGeneral purposeComposite application

A system and method for providing composite applications for software-based systems that uses a built-in application model having at least one general purpose object type, and providing dynamic late-binding of object implementations through an object typing system decoupled from pre-run time program code, using persistently stored objects. The application model may require that program objects in a conformant application be instances of a predefined active object type, or optionally instances of a predefined reactive object type. The application model enables integration of applications into composite applications, and further integration of composite applications into subsequently defined systems. The run-time object typing system for persistently stored objects is independent of the class typing system that is defined at compile-time or link-time, and enables convenient and practical modifications during development, deployment and maintenance of composite applications.

Owner:CERYLION

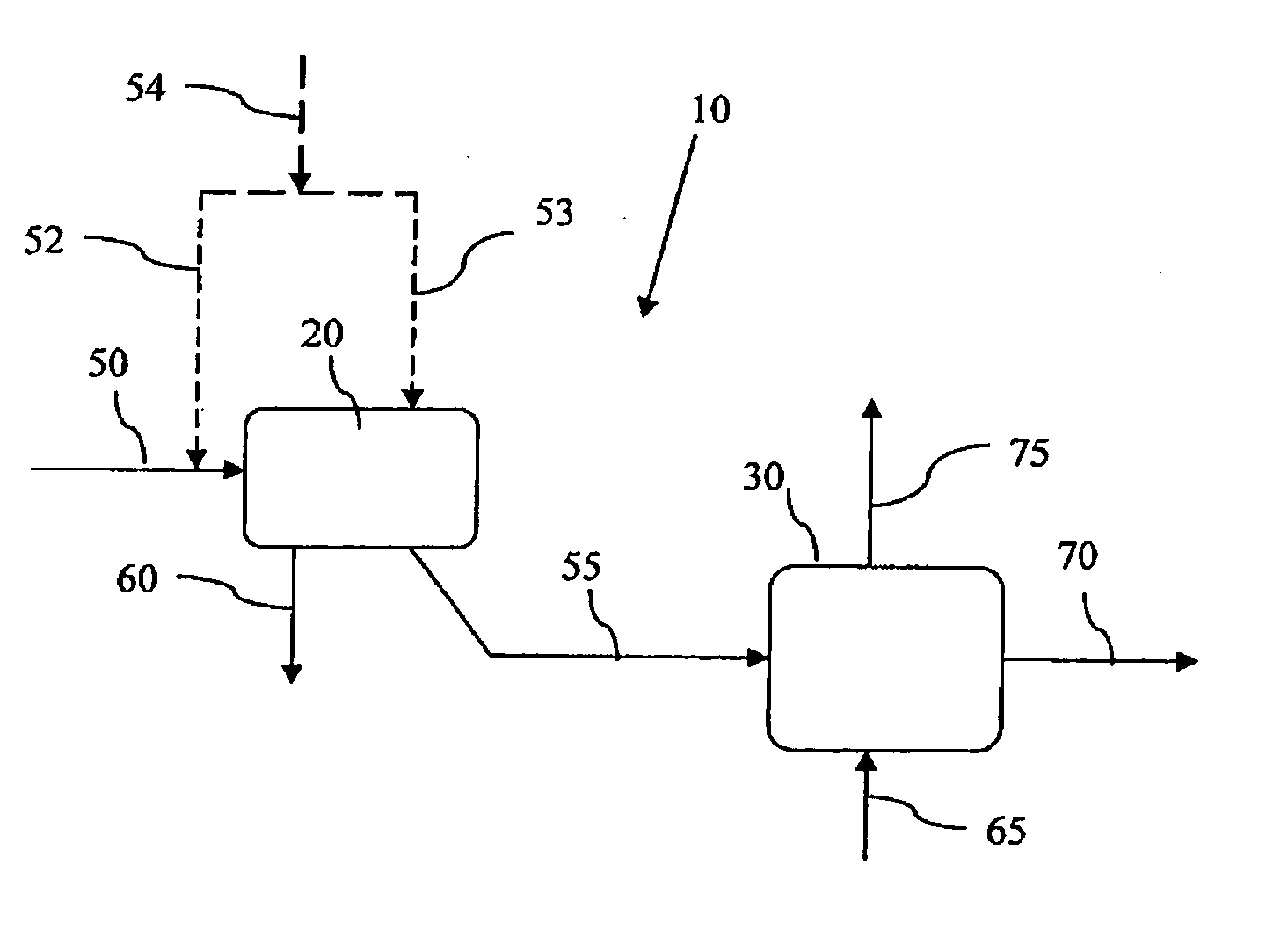

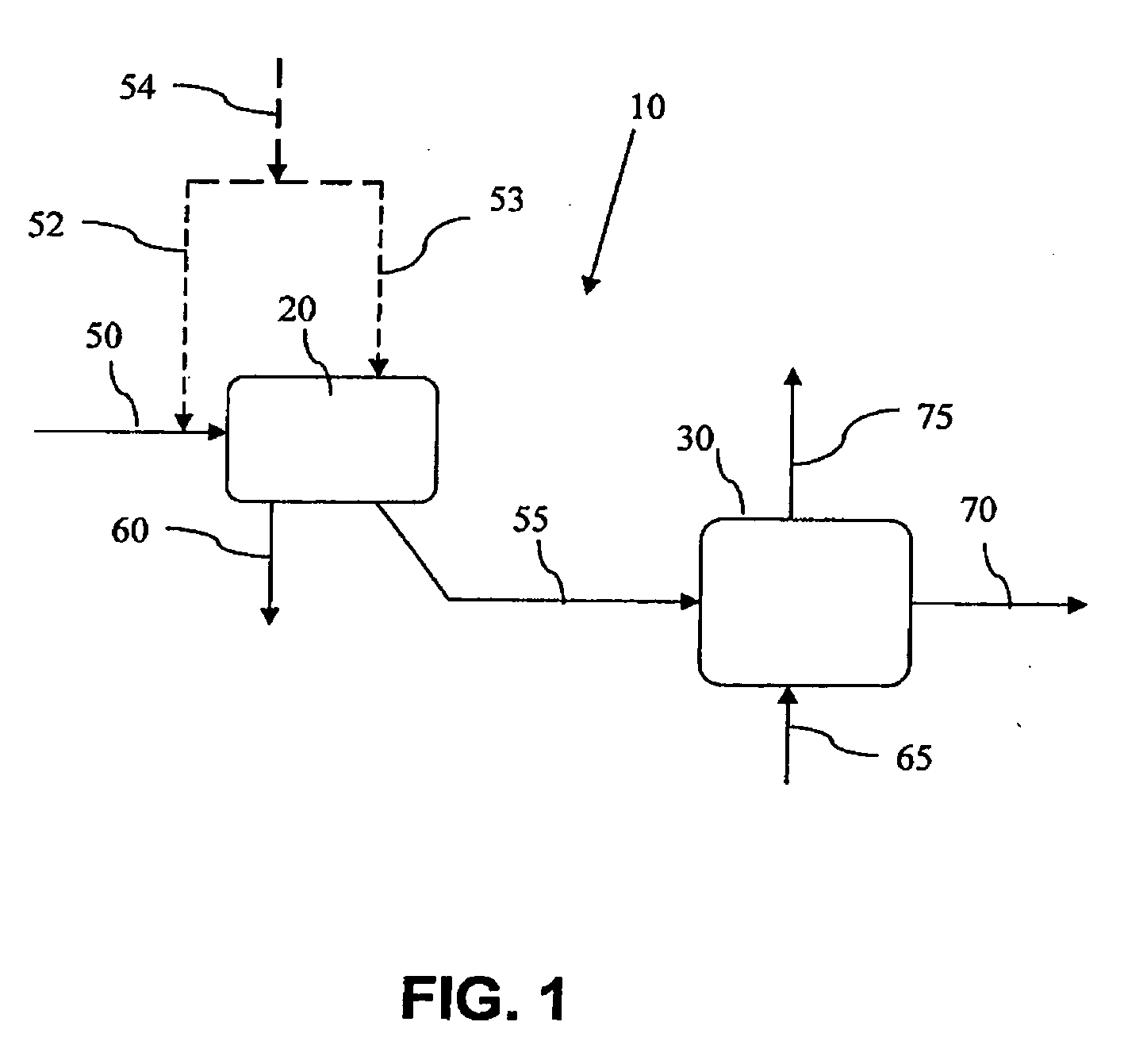

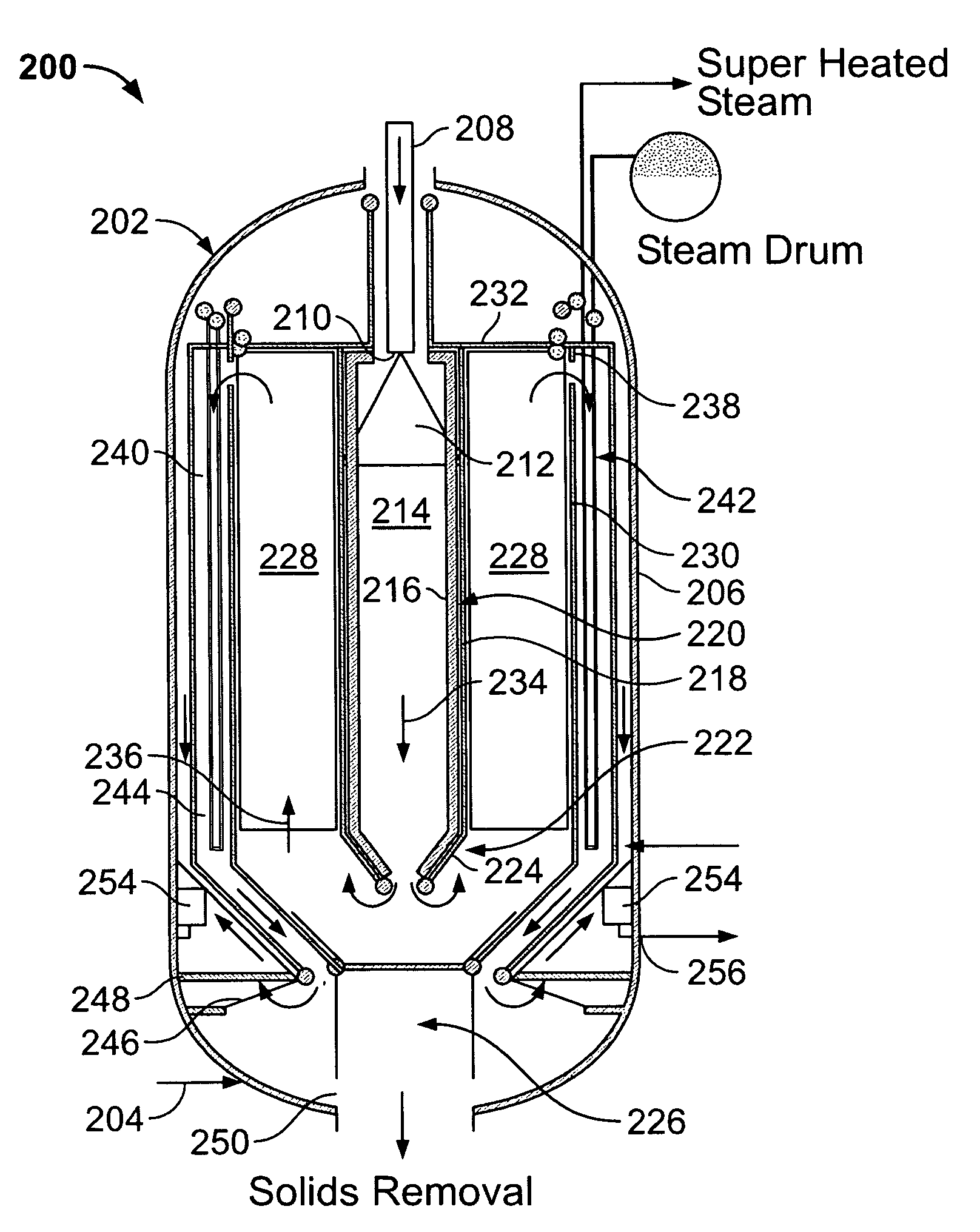

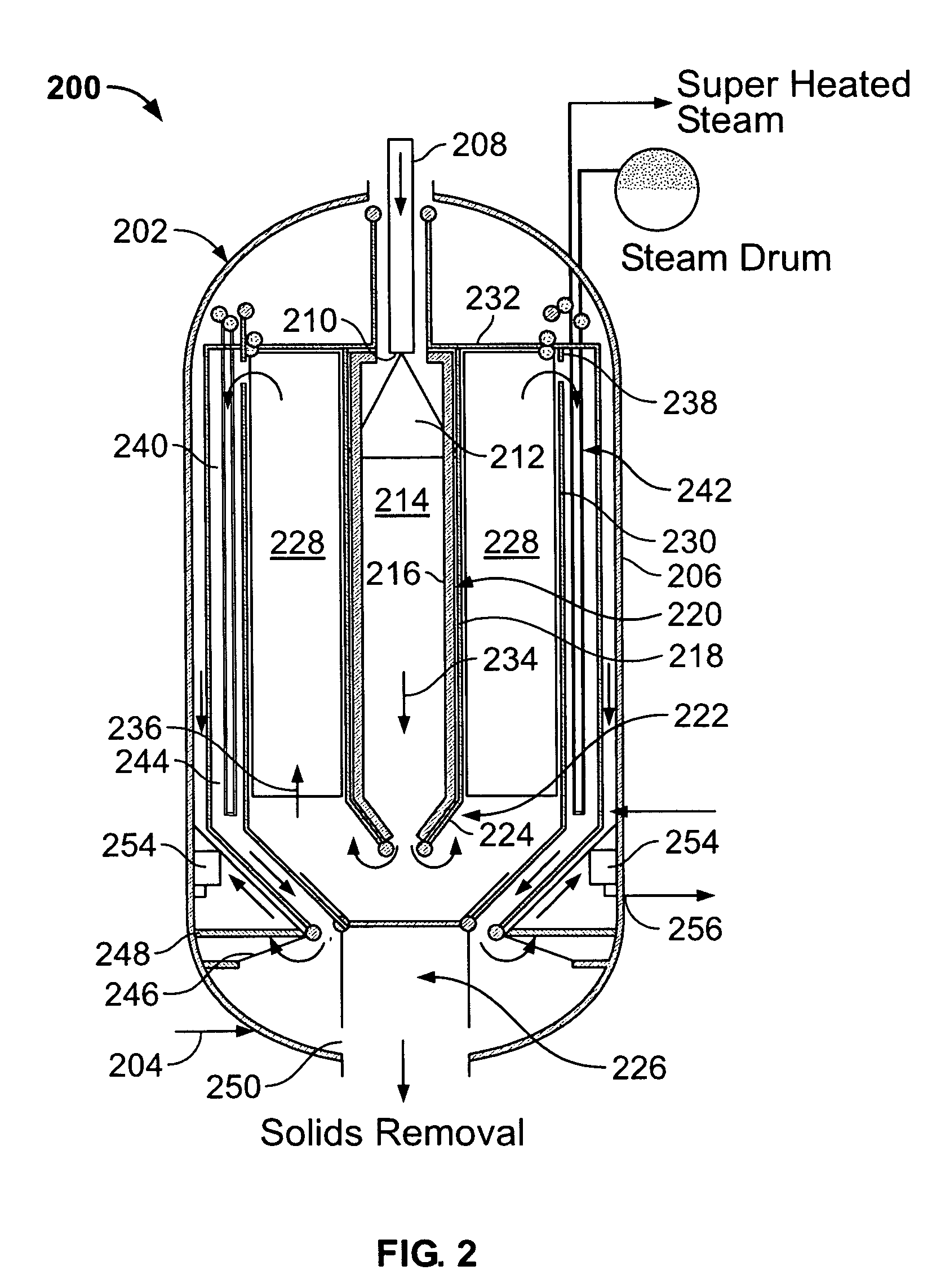

Methods and systems for advanced gasifier solids removal

ActiveUS7744663B2Facilitates componentGasifier mechanical detailsHydrogen/synthetic gas productionSyngasCombustor

Methods and systems for a gasifier solids removal system are provided. The system includes a down flow combustor including an inlet and an outlet and a combustion zone extending therebetween, the combustor configured to direct a flow of process material including syngas, flowable slag, and particulates in a first downward direction, a plurality of flow passages in serial flow communication including a first flow passage and a second flow passage, wherein the process material flow reverses direction flowing from the first passage to the second passage, and a plurality of entrainment separation stages in serial flow communication with at least one of the plurality of flow passages.

Owner:AIR PROD & CHEM INC

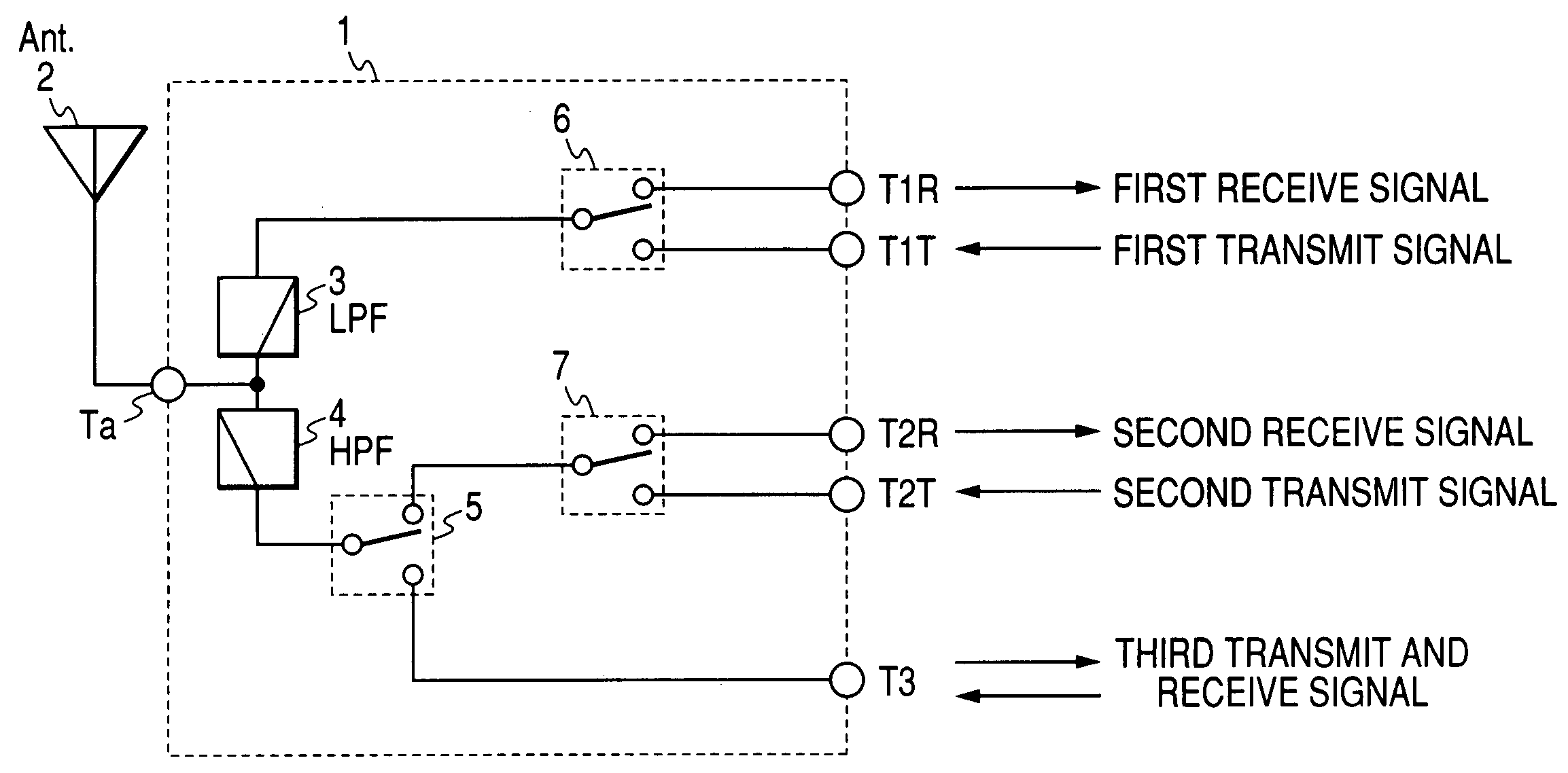

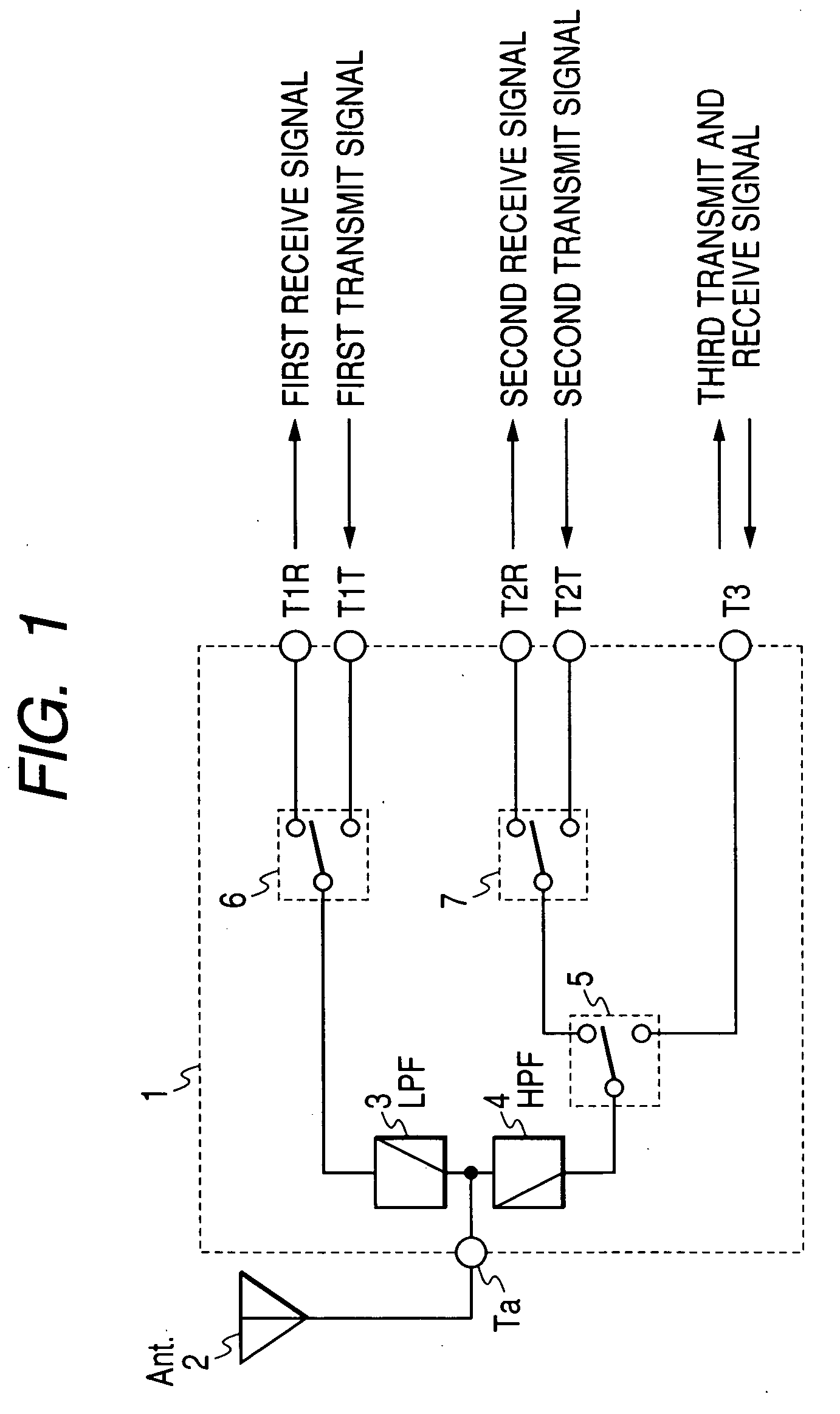

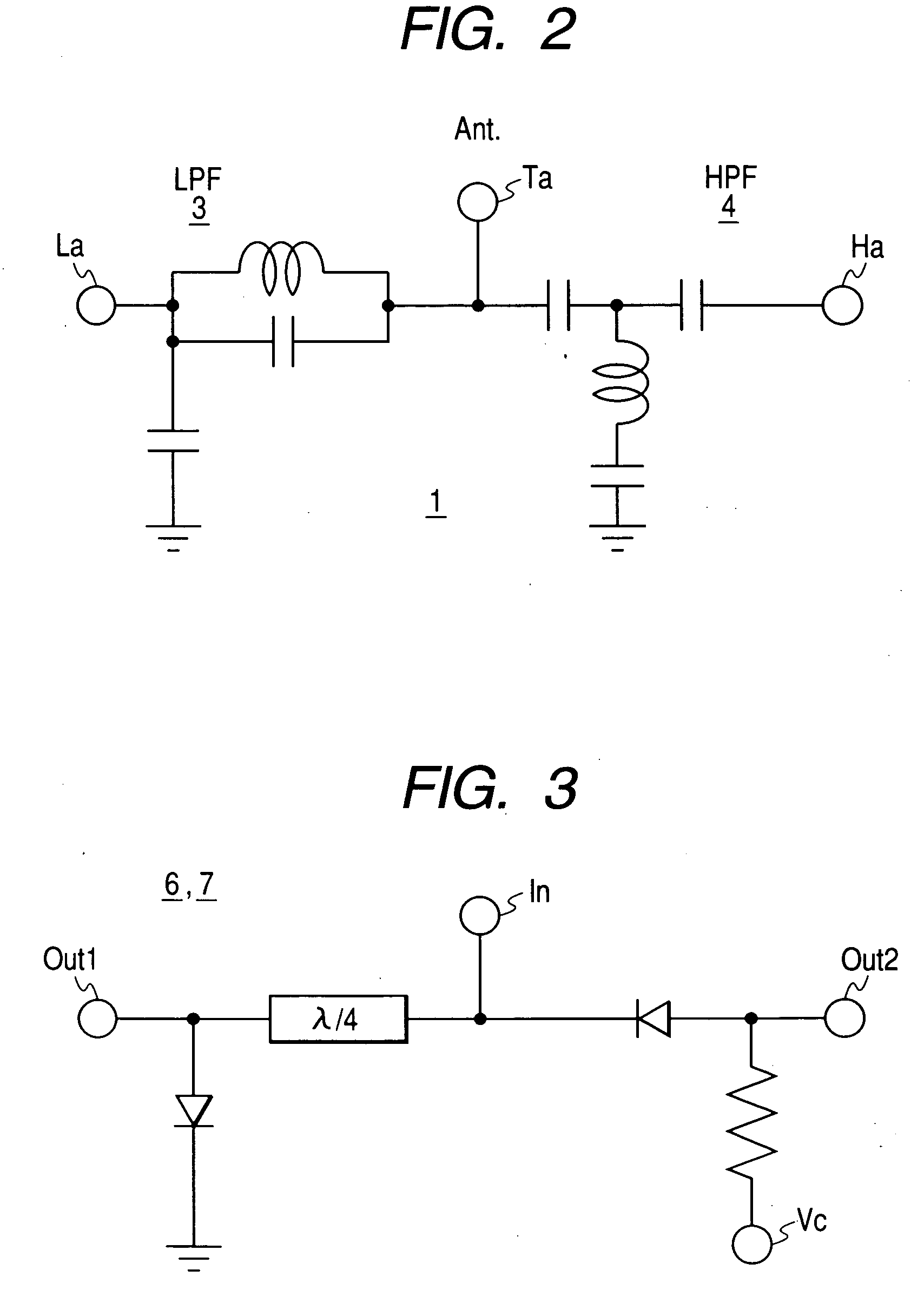

Antenna sharing device and wireless communication terminal using the same

InactiveUS20060141944A1Circuit more complicatedIncrease the number ofTransmission monitoringRadio transmissionDiplexerPIN diode

A compact, inexpensive antenna sharing device meeting requirements in terms of transmitter distortion characteristic and ESD characteristic is provided which separates and combines signals transmitted and received in first to third signal bands and which thereby enables an antenna terminal to be shared as a common terminal. It includes a diplexer realizing an attenuation characteristic for protection against ESD, a compound semiconductor switch with an IIP3 of 66 dBm or more, and an inexpensive PIN diode switch.

Owner:HITACHI MEDIA ELECTORONICS CO LTD

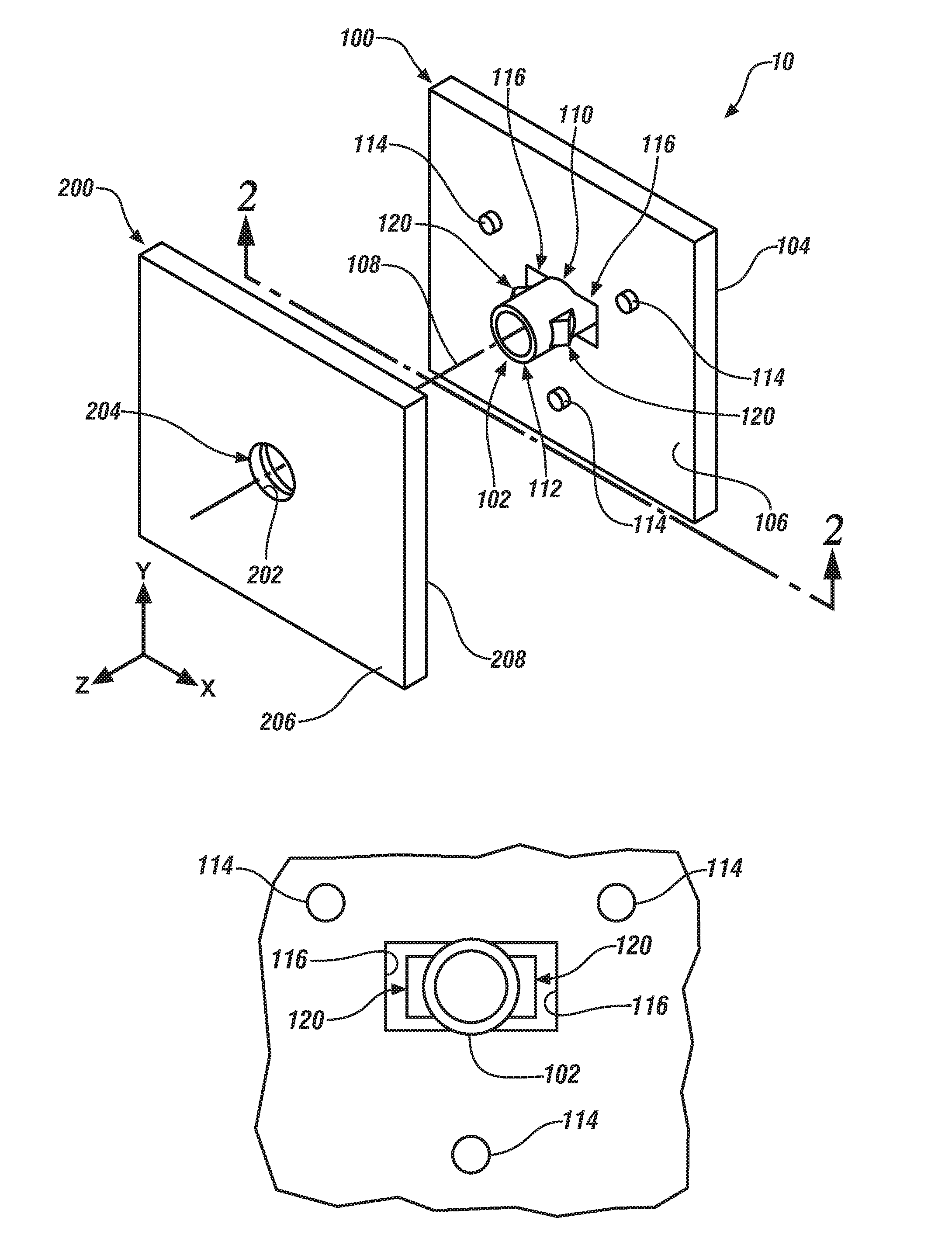

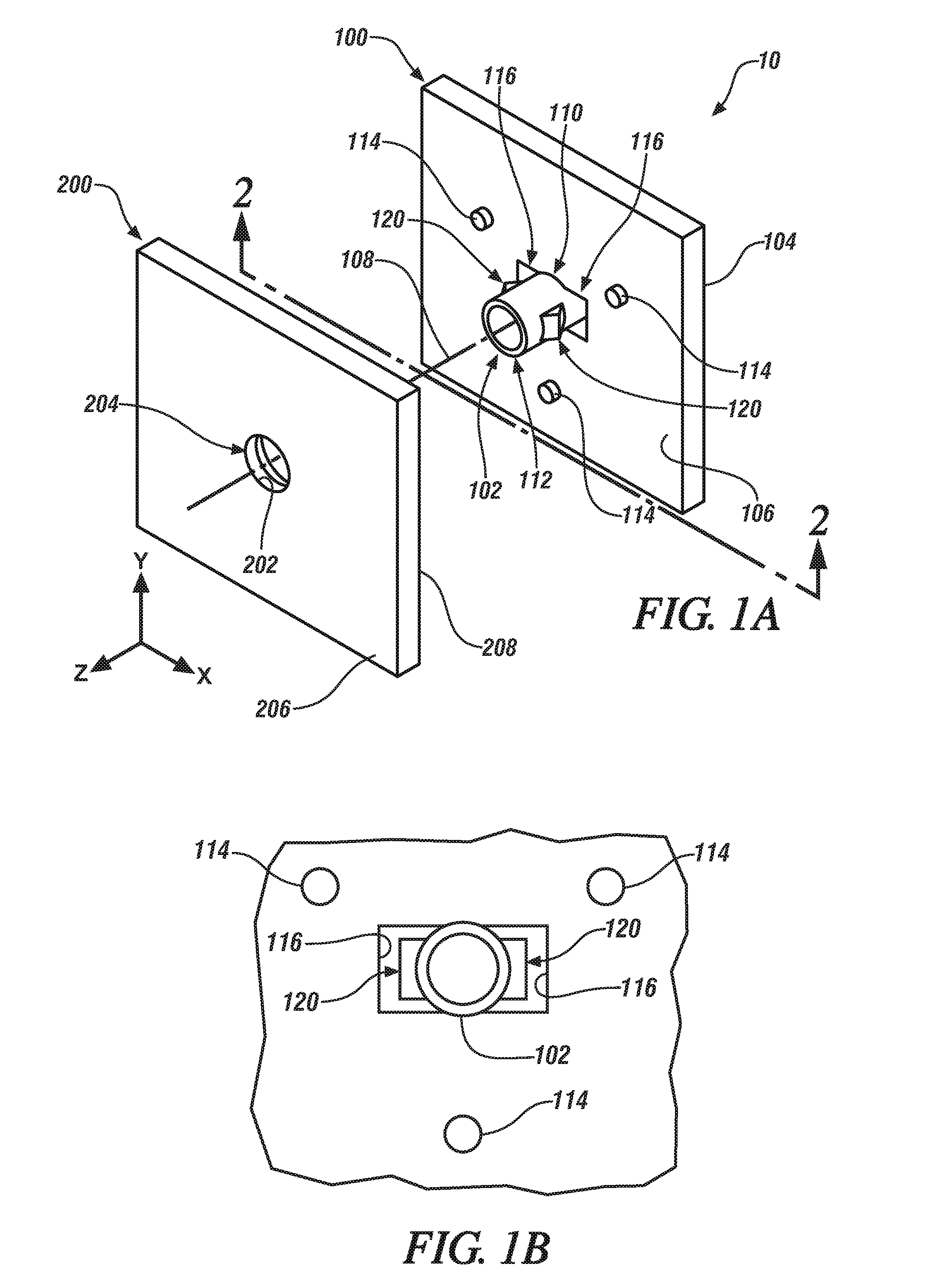

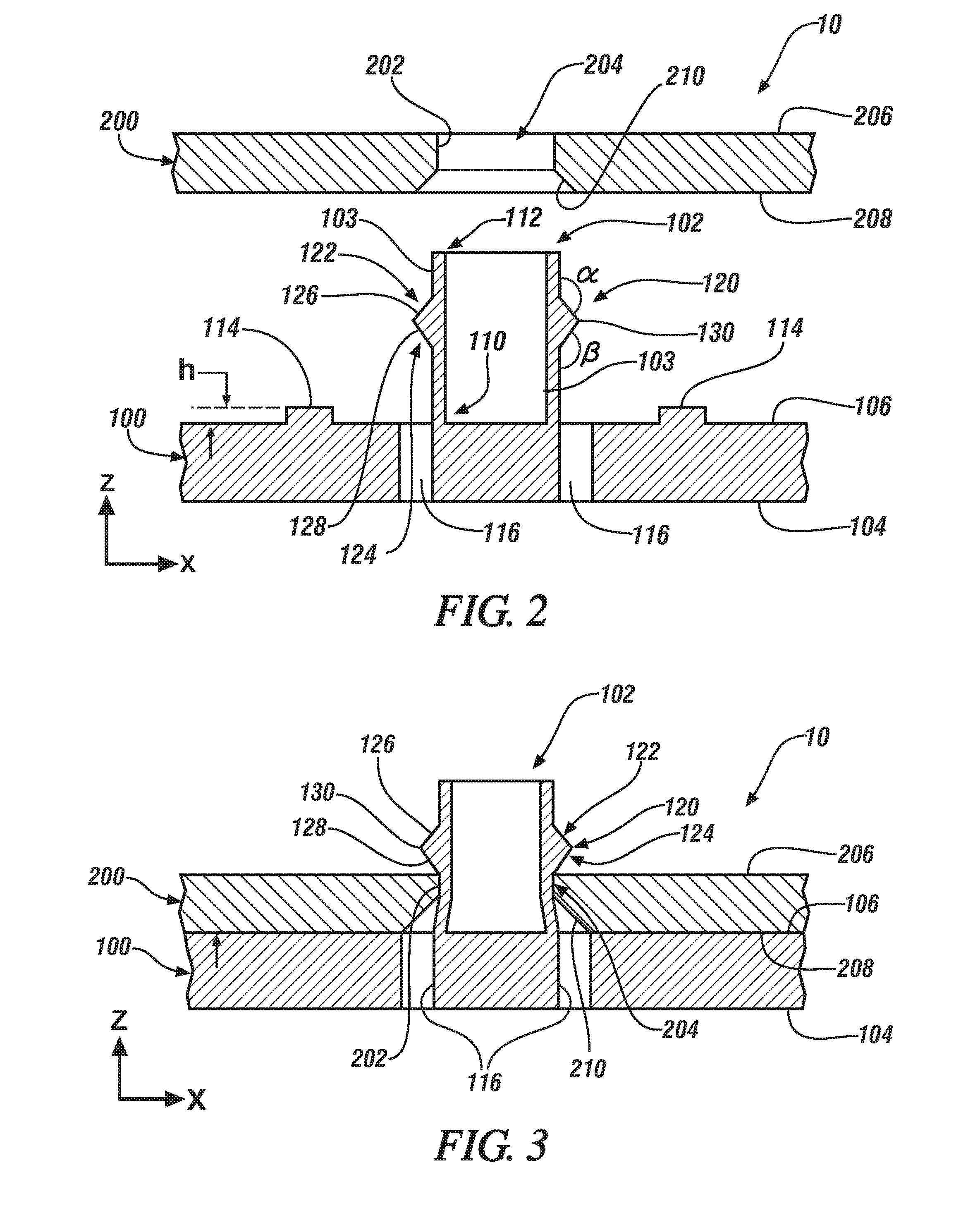

Elastically averaged alignment systems and methods

In one aspect, an elastically averaged alignment system is provided. The alignment system includes a first component having an alignment member, and a second component having an inner wall defining an alignment aperture. The alignment aperture is configured to receive the alignment member to couple the first component and the second component. The alignment member includes at least one retention member configured to engage the second component to facilitate retaining at least a portion of the alignment member within the alignment aperture. The alignment member is an elastically deformable material such that when the alignment member is inserted into the alignment aperture, the alignment member elastically deforms to an elastically averaged final configuration to facilitate aligning and stiffening the first component and the second component in a desired orientation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com