Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

473results about How to "Easy to condense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

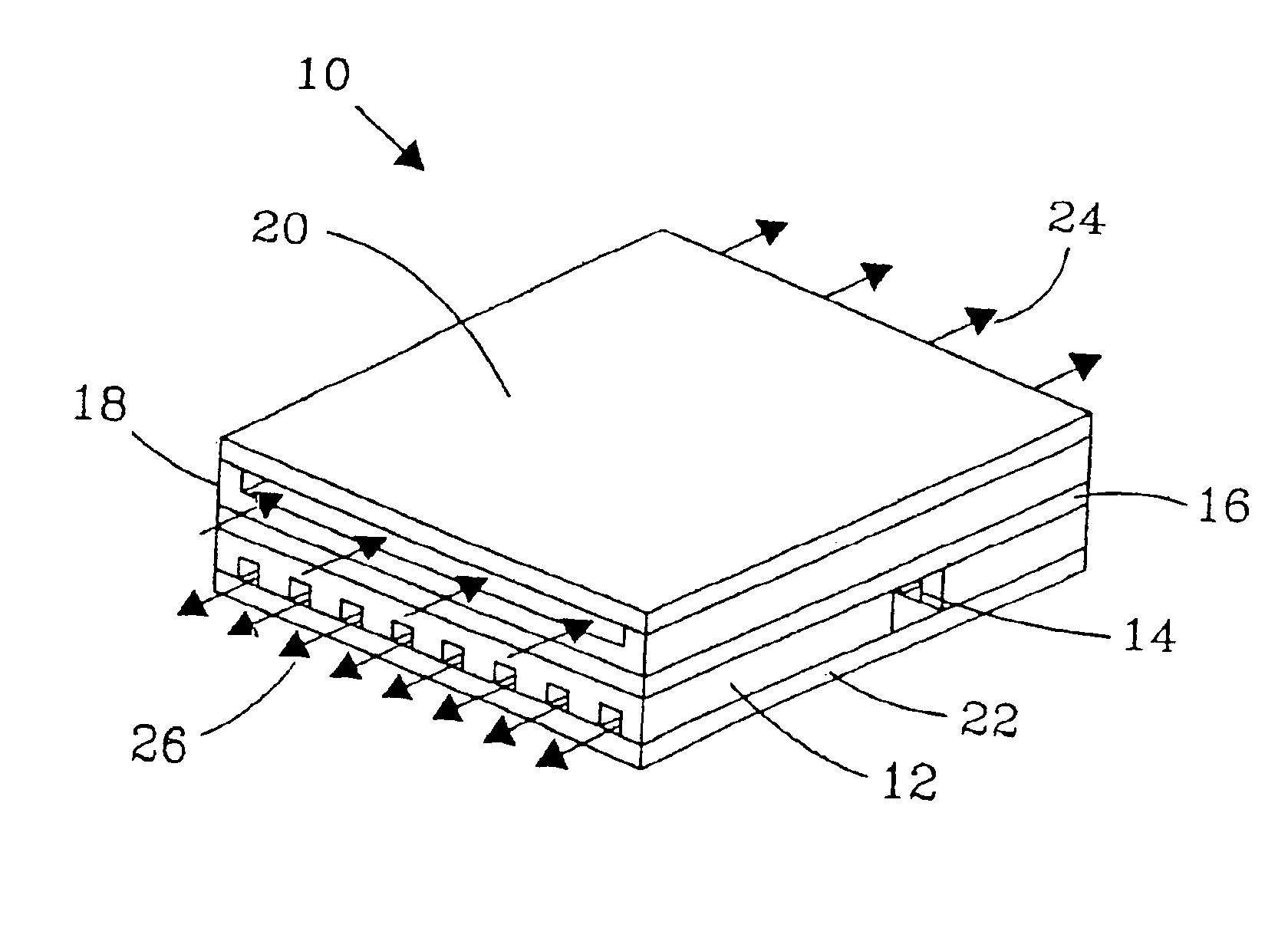

Carbon nanotube-containing structures, methods of making, and processes using same

InactiveUS7011760B2Large specific surface areaImprove conductivityCarbon compoundsChemical/physical/physico-chemical microreactorsPre treatmentSURFACTANT BLEND

Carbon nanotube structures are disclosed in which nanotubes are disposed over a porous support such as a foam, felt, mesh, or membrane. Techniques of making these structures are also disclosed. In some of these techniques, a support is pretreated with a templated surfactant composition to assist with the formation of a nanotube layer.

Owner:BATTELLE MEMORIAL INST

Plasma curing process for porous silica thin film

InactiveUS20010038919A1High elastic modulusLow dielectric constantSilicaPretreated surfacesSilicon dioxideMaterials science

Low dielectric constant films with improved elastic modulus. The method of making such coatings involves providing a porous network coating produced from a resin containing at least 2 Si-H groups and plasma curing the coating to convert the coating into porous silica. Plasma curing of the network coating yields a coating with improved modulus, but with a higher dielectric constant. The coating is plasma cured for between about 15 and about 120 seconds at a temperature less than about 350° C. The plasma cured coating can optionally be annealed. Rapid thermal processing (RTP) of the plasma cured coating reduces the dielectric constant of the coating while maintaining an improved elastic modulus as compared to the plasma cured porous network coating. The annealing temperature is typically less than about 475° C., and the annealing time is typically no more than about 180 seconds. The annealed, plasma cured coating has a dielectric constant in the range of from about 1.1 to about 2.4 and an improved elastic modulus.

Owner:AXCELIS TECHNOLOGIES +1

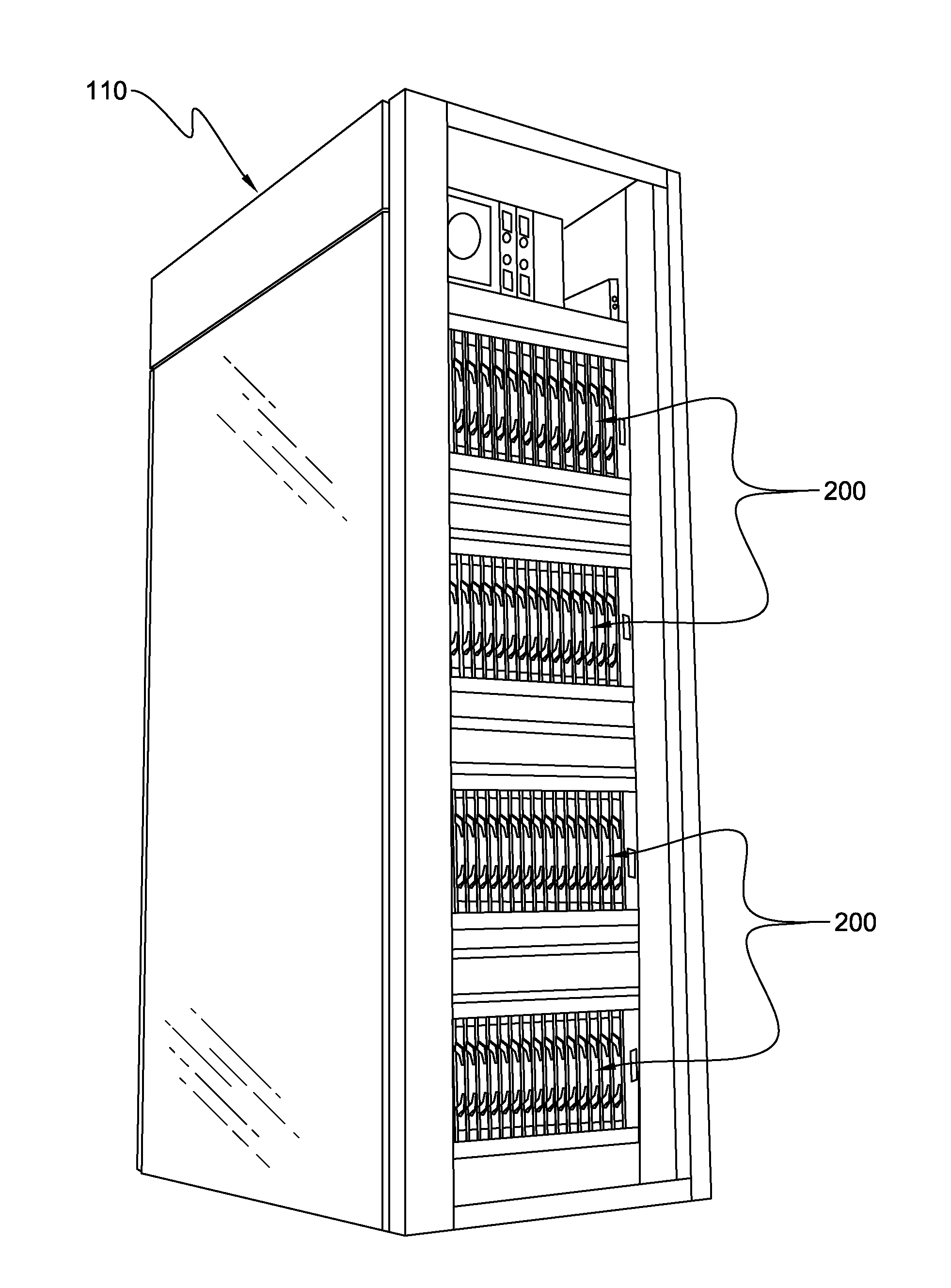

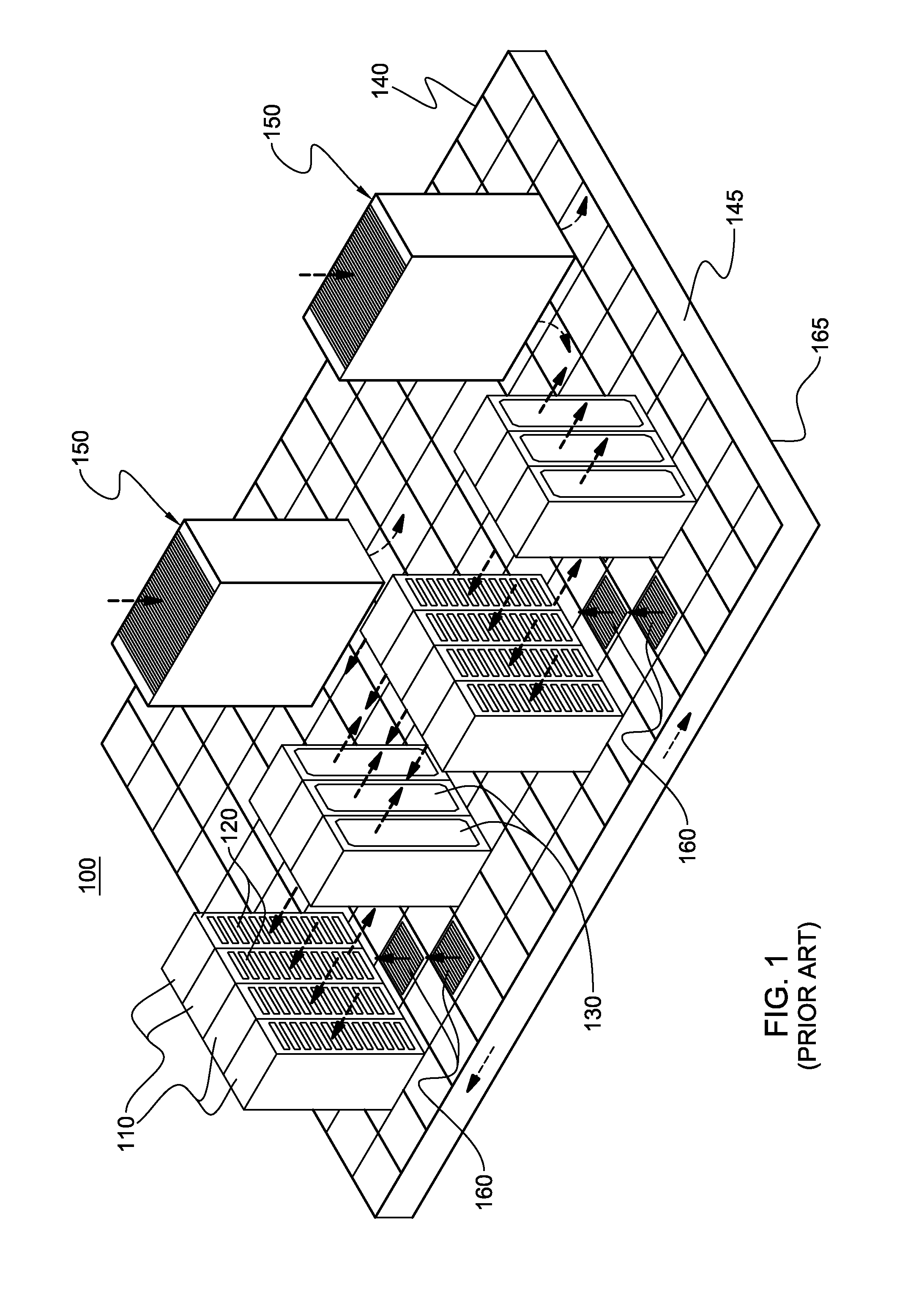

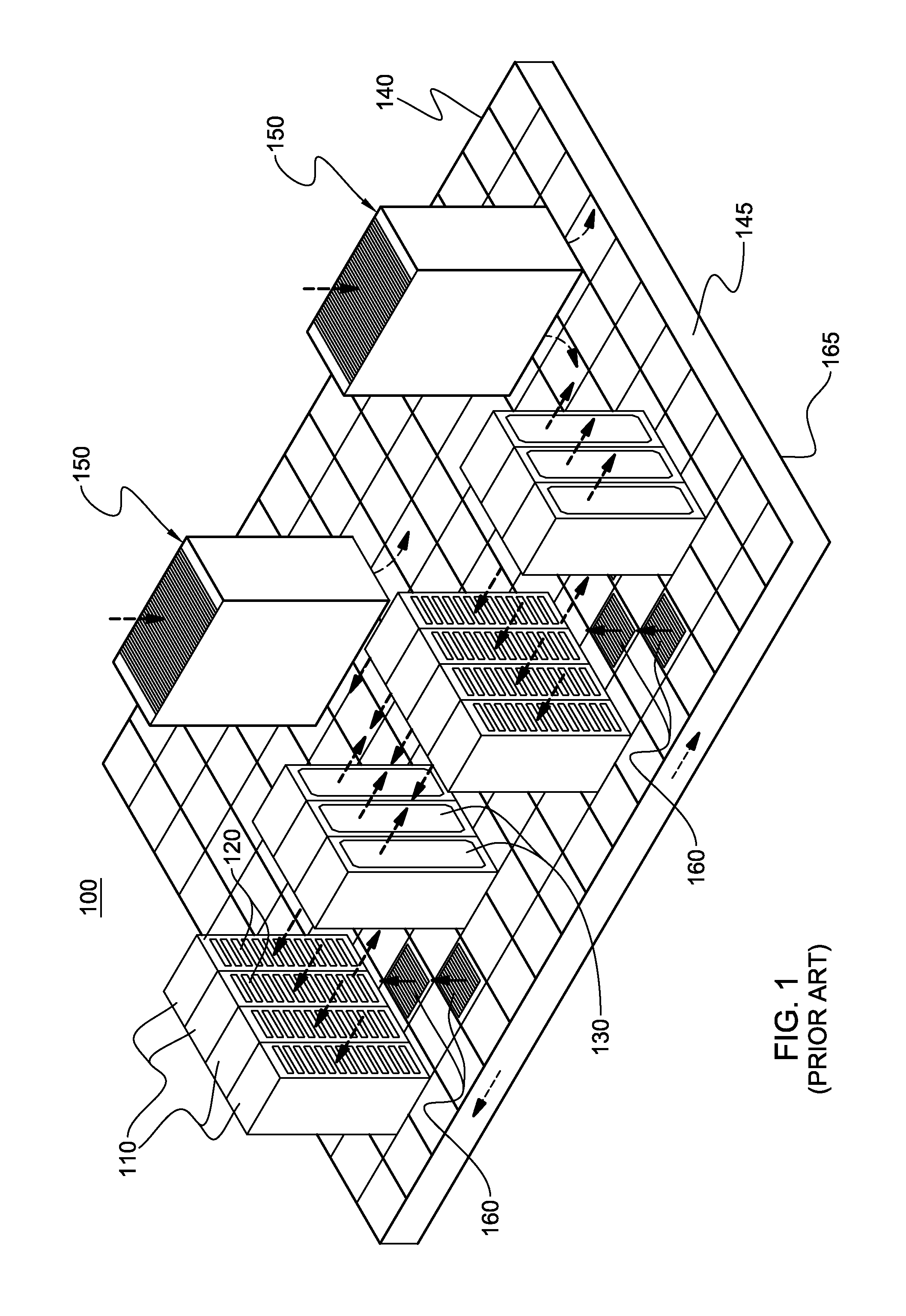

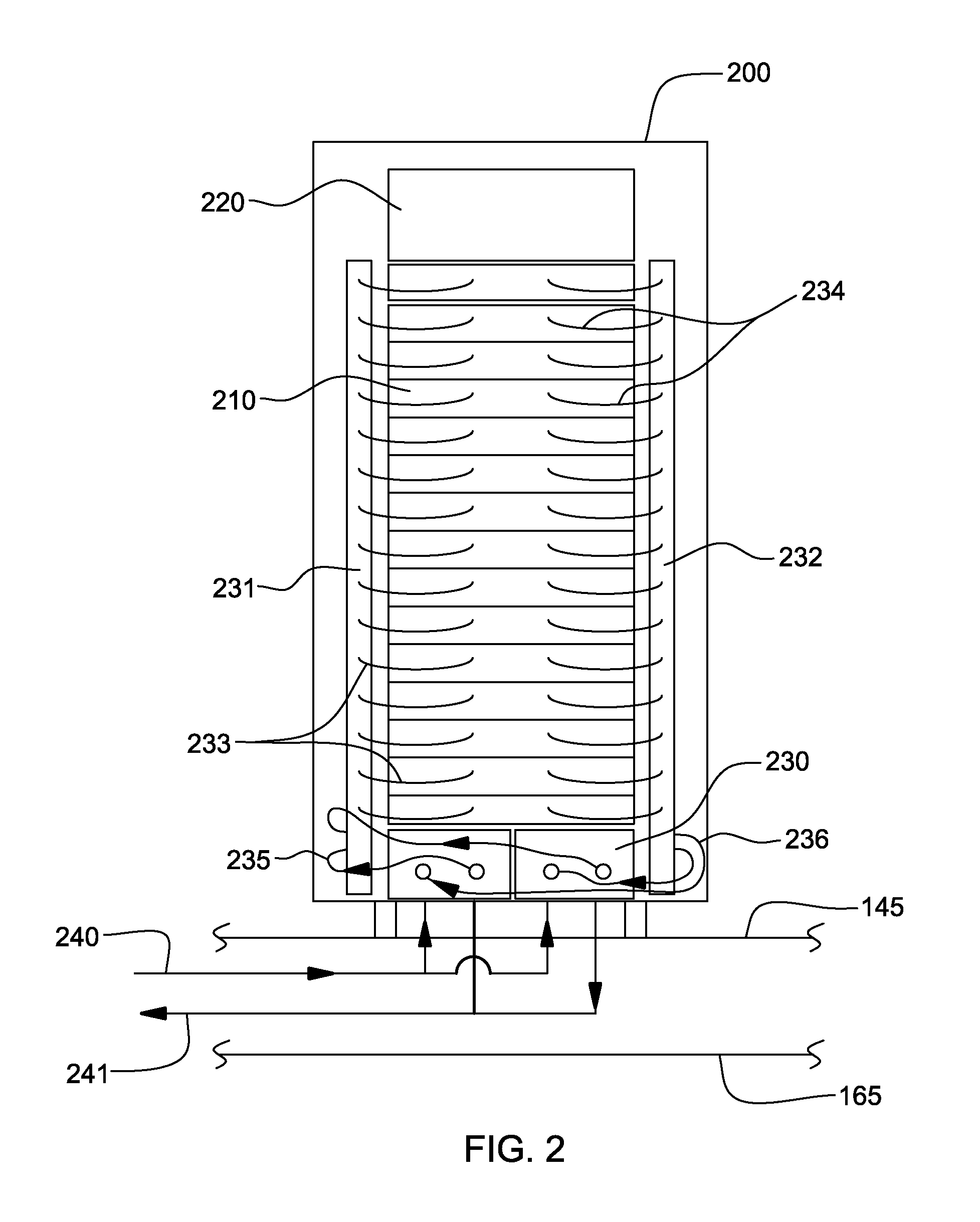

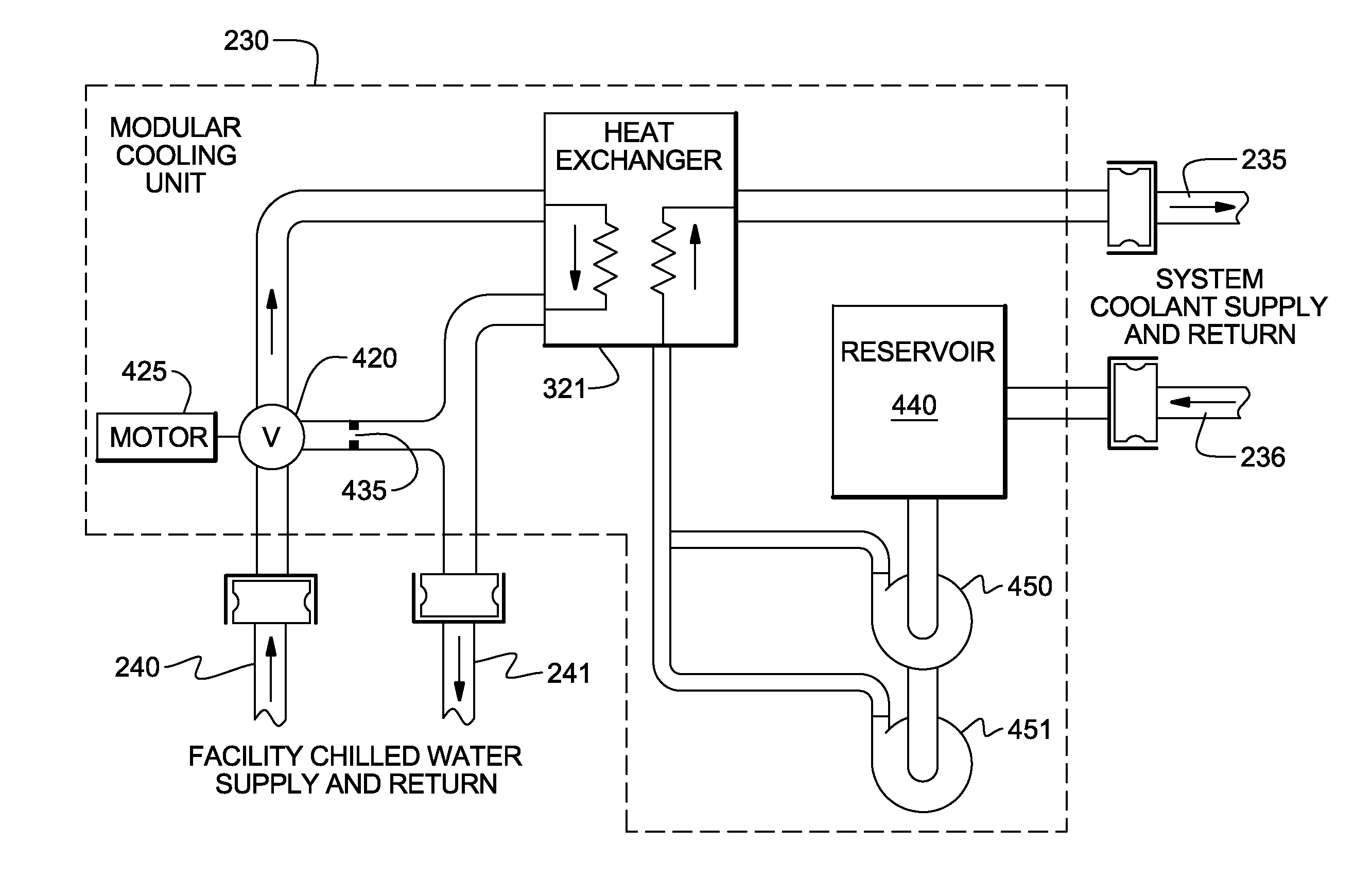

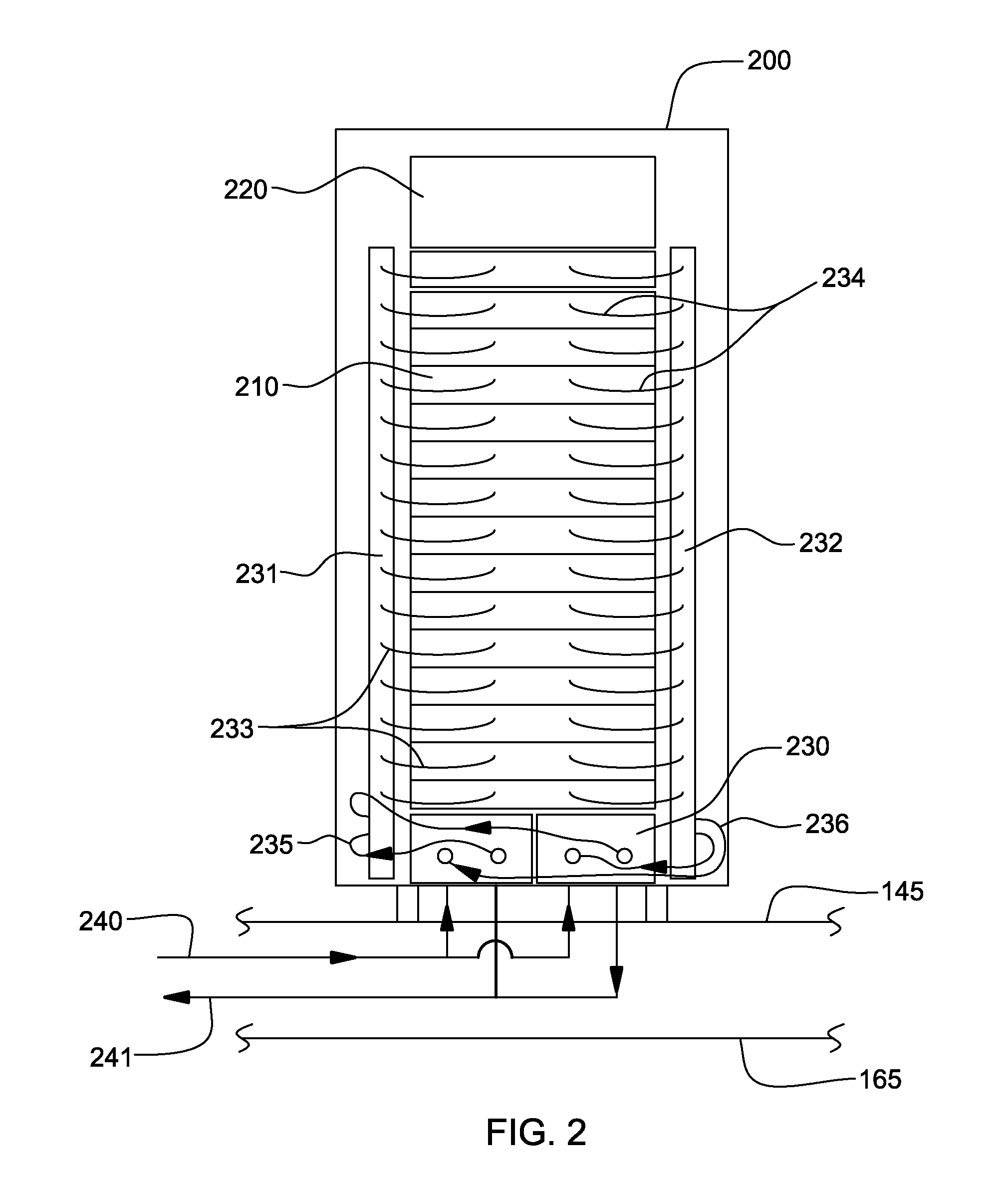

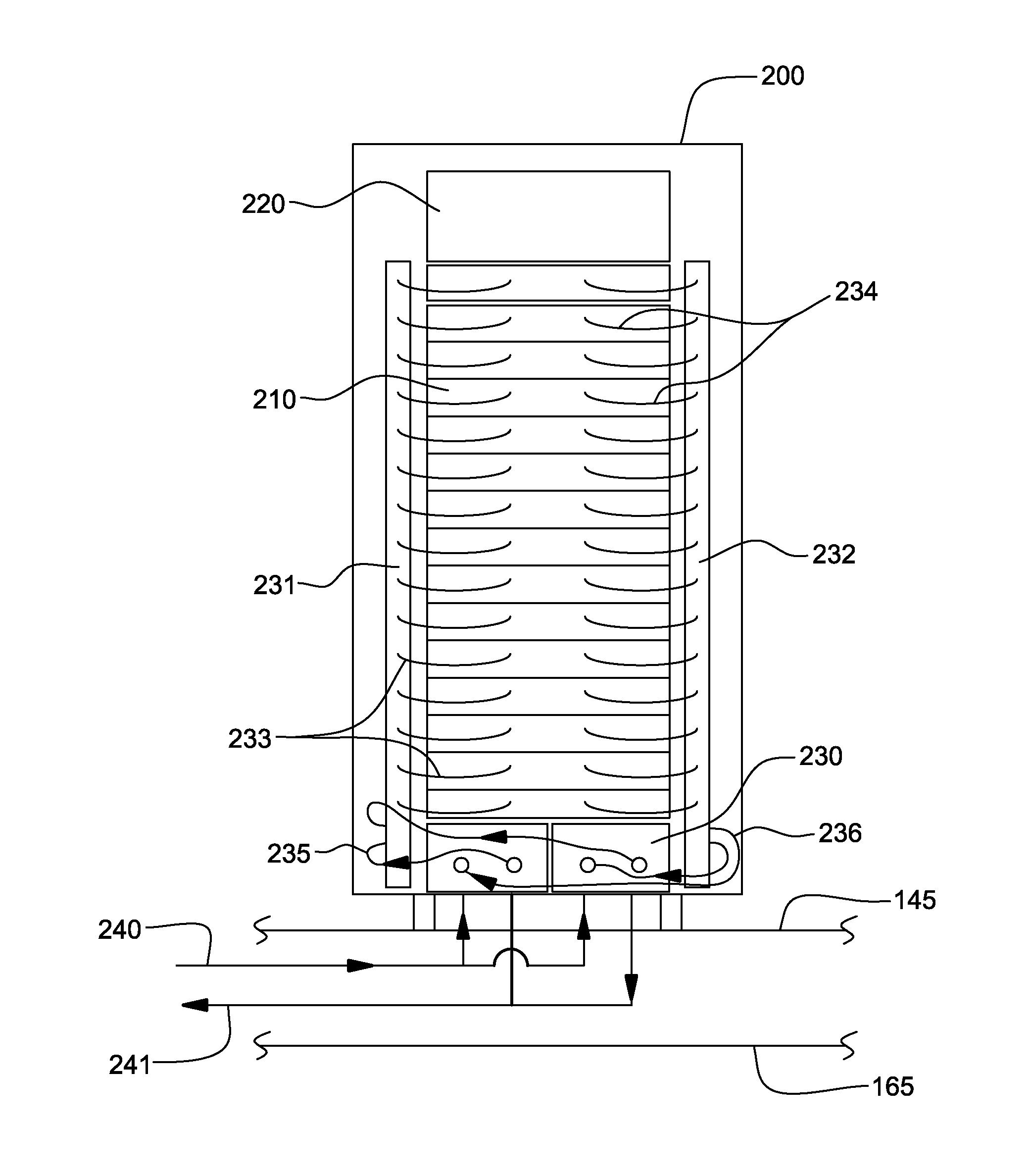

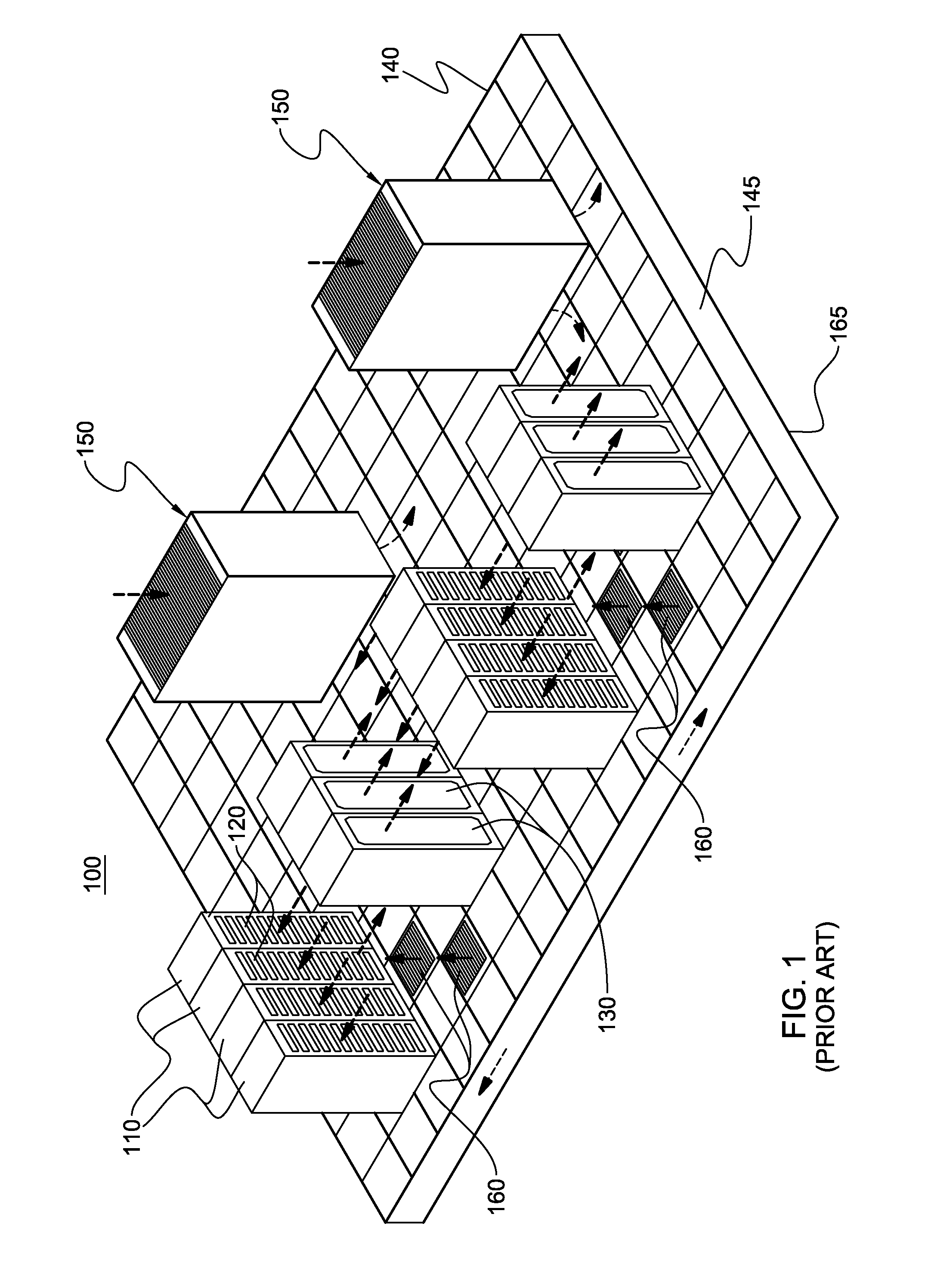

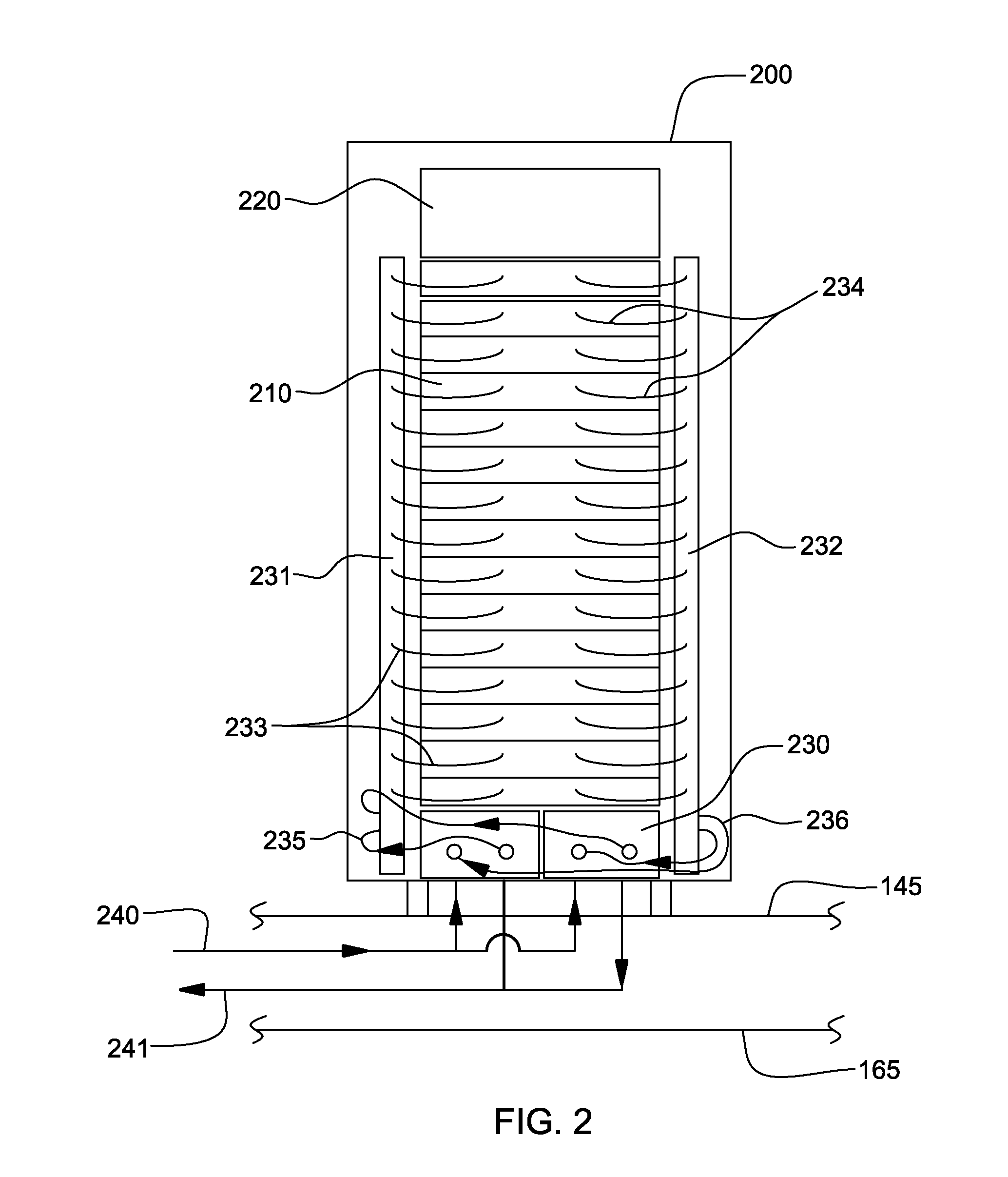

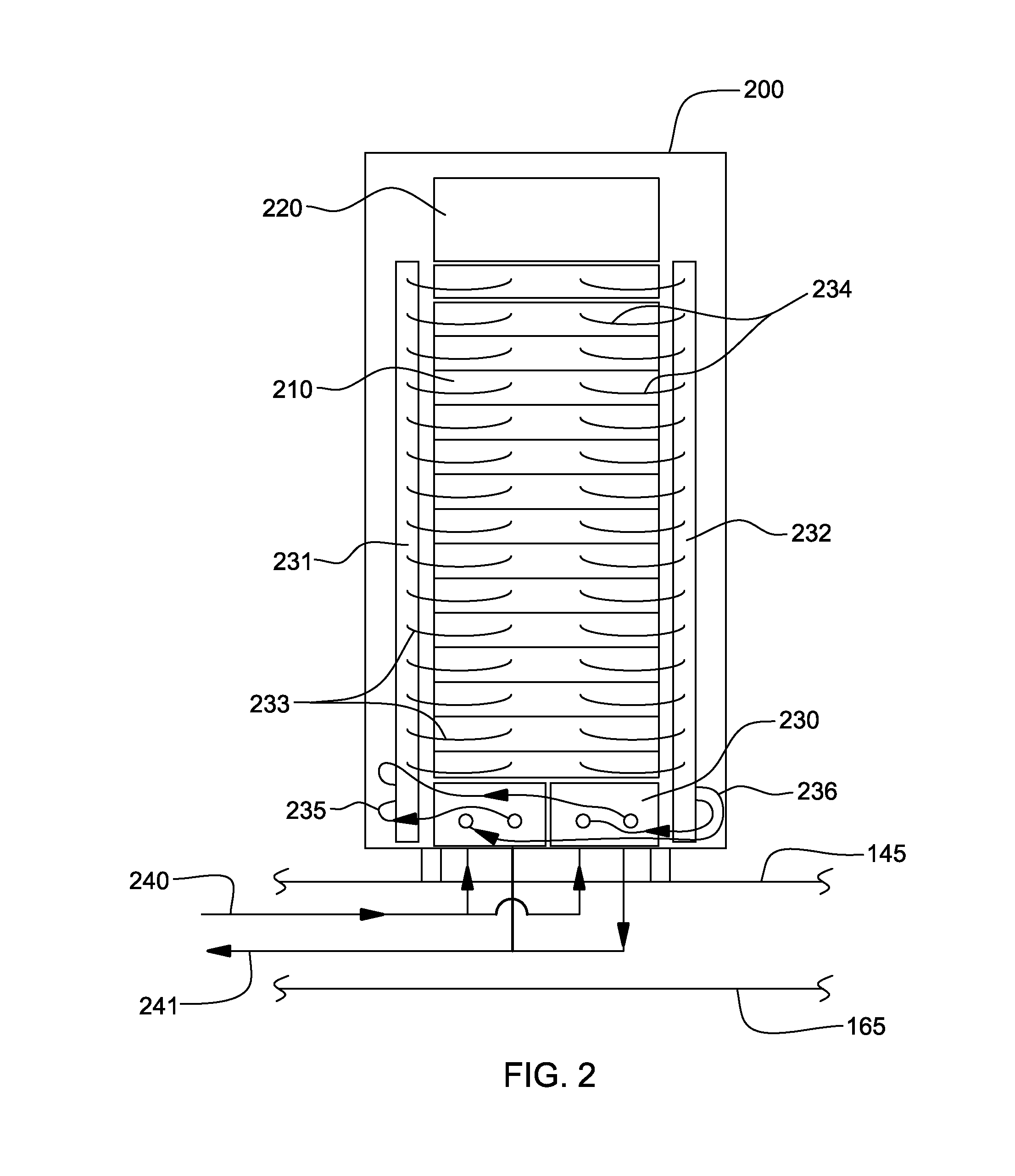

Liquid-cooled electronics rack with immersion-cooled electronic subsystems and vertically-mounted, vapor-condensing unit

InactiveUS20110315353A1Overcomes shortcomingEnhanced advantageDomestic cooling apparatusIndirect heat exchangersDielectricLiquid state

Liquid-cooled electronics racks are provided which include: immersion-cooled electronic subsystems; a vertically-oriented, vapor-condensing unit facilitating condensing dielectric fluid vapor egressing from the immersion-cooled subsystems, the vertically-oriented, vapor-condensing unit being sized and configured to reside adjacent to at least one side of the electronics rack; a reservoir for holding dielectric fluid, the reservoir receiving dielectric fluid condensate from the vertically-oriented, vapor-condensing unit; a dielectric fluid supply manifold coupling in fluid communication the reservoir and the dielectric fluid inlets of the immersion-cooled electronic subsystems; and a pump associated with a reservoir for pumping under pressure dielectric fluid from the reservoir to the dielectric fluid supply manifold for maintaining dielectric fluid in a liquid state within the immersion-cooled electronic subsystems.

Owner:IBM CORP

Carbon nanotube-containing structures, methods of making, and processes using same

InactiveUS20050040090A1Function efficientlyReduce concentrationCarbon compoundsChemical/physical/physico-chemical microreactorsPre treatmentMembrane configuration

Carbon nanotube structures are disclosed in which nanotubes are disposed over a porous support such as a foam, felt, mesh, or membrane. Techniques of making these structures are also disclosed. In some of these techniques, a support is pretreated with a templated surfactant composition to assist with the formation of a nanotube layer.

Owner:BATTELLE MEMORIAL INST

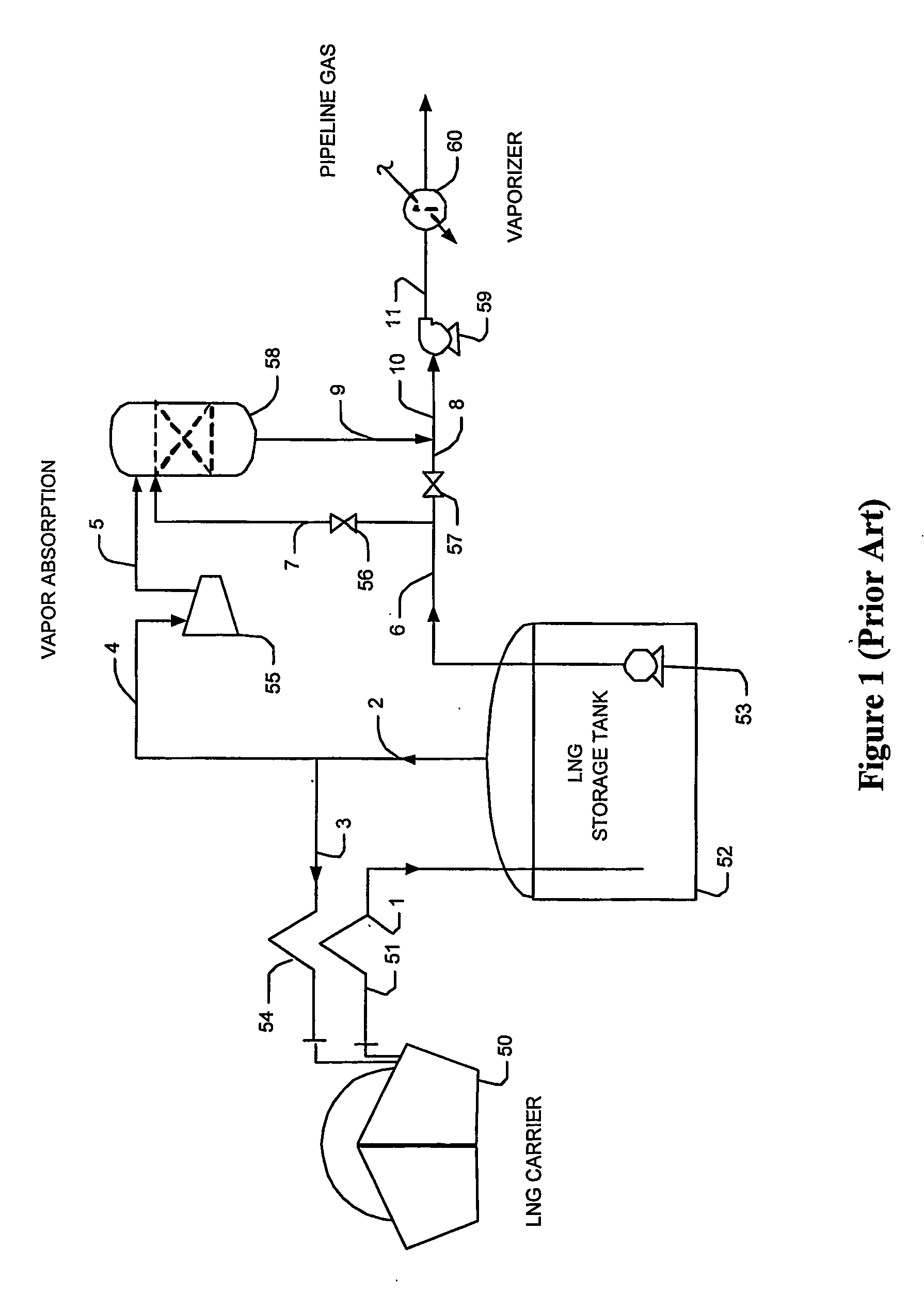

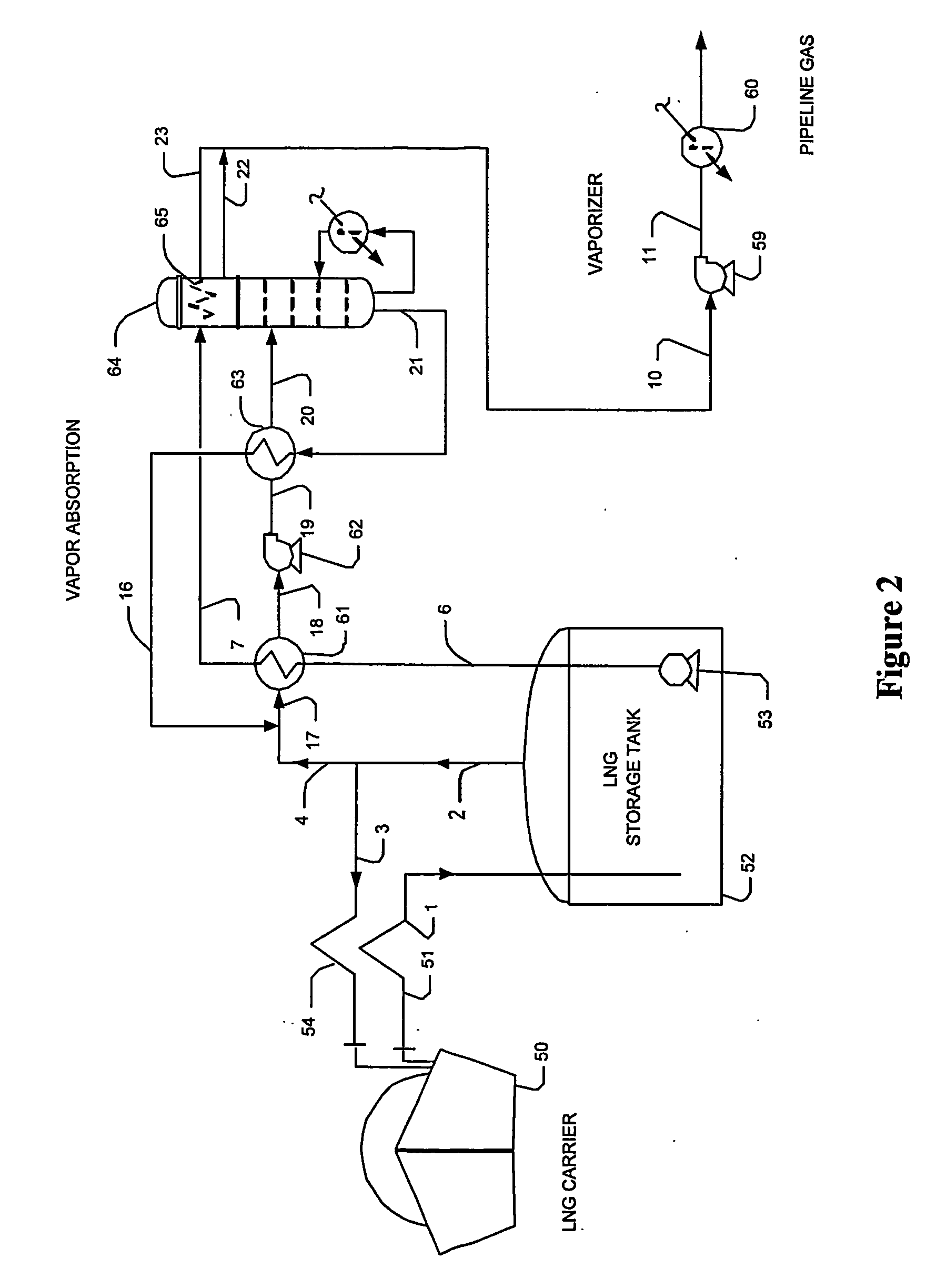

Lng vapor handling configurations and methods

InactiveUS20070125122A1Easy to condenseSolidificationLiquefactionProcess engineeringComponents of crude oil

LNG vapor from an LNG storage vessel is absorbed using C3 and heavier components provided by a fractionator that receives a mixture of LNG vapors and the C3 and heavier components as fractionator feed. In such configurations, refrigeration content of the LNG liquid from the LNG storage vessel is advantageously used to condense the LNG vapor after separation. Where desired, a portion of the LNG liquid may also be used as fractionator feed to produce LPG as a bottom product.

Owner:FLUOR TECH CORP

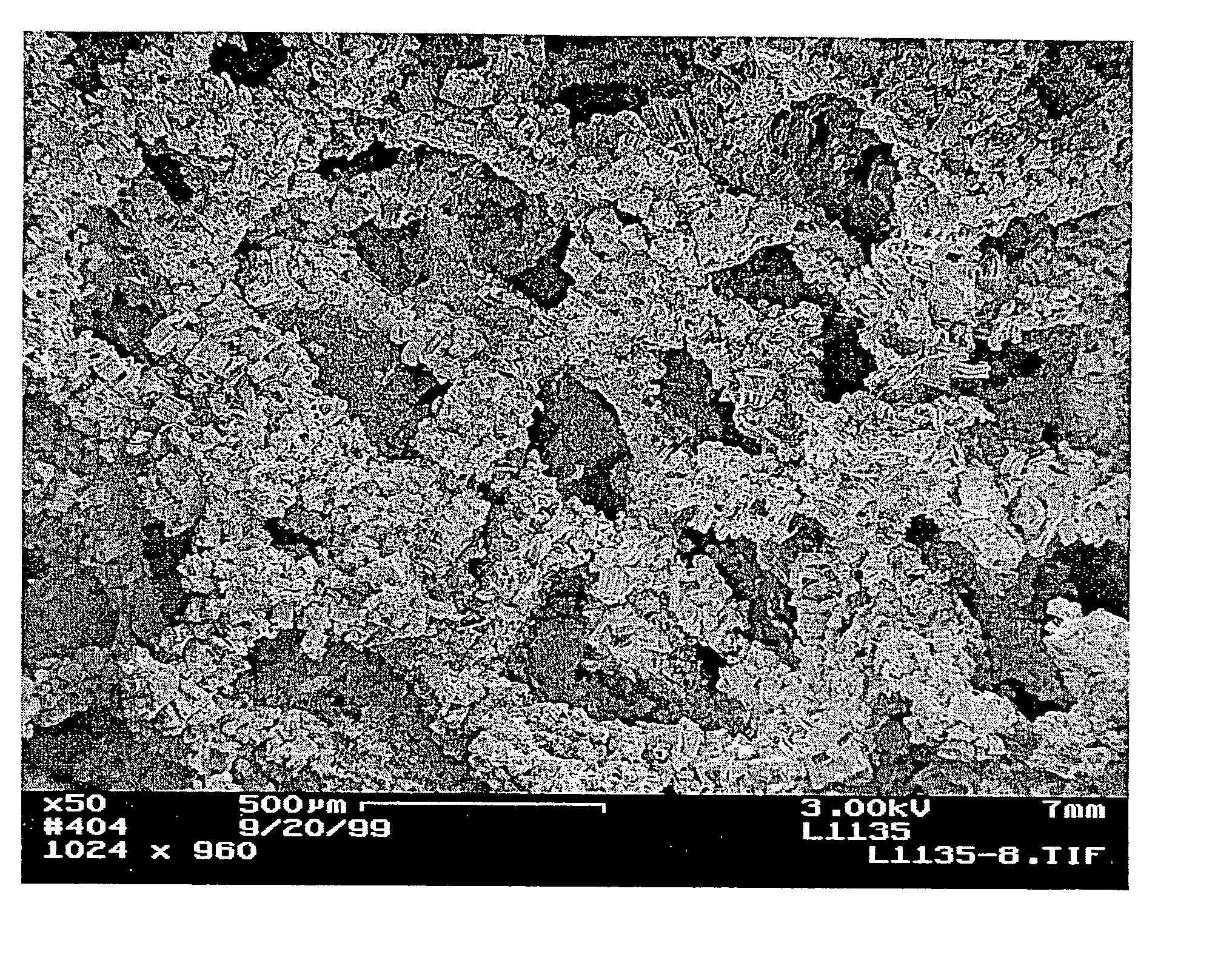

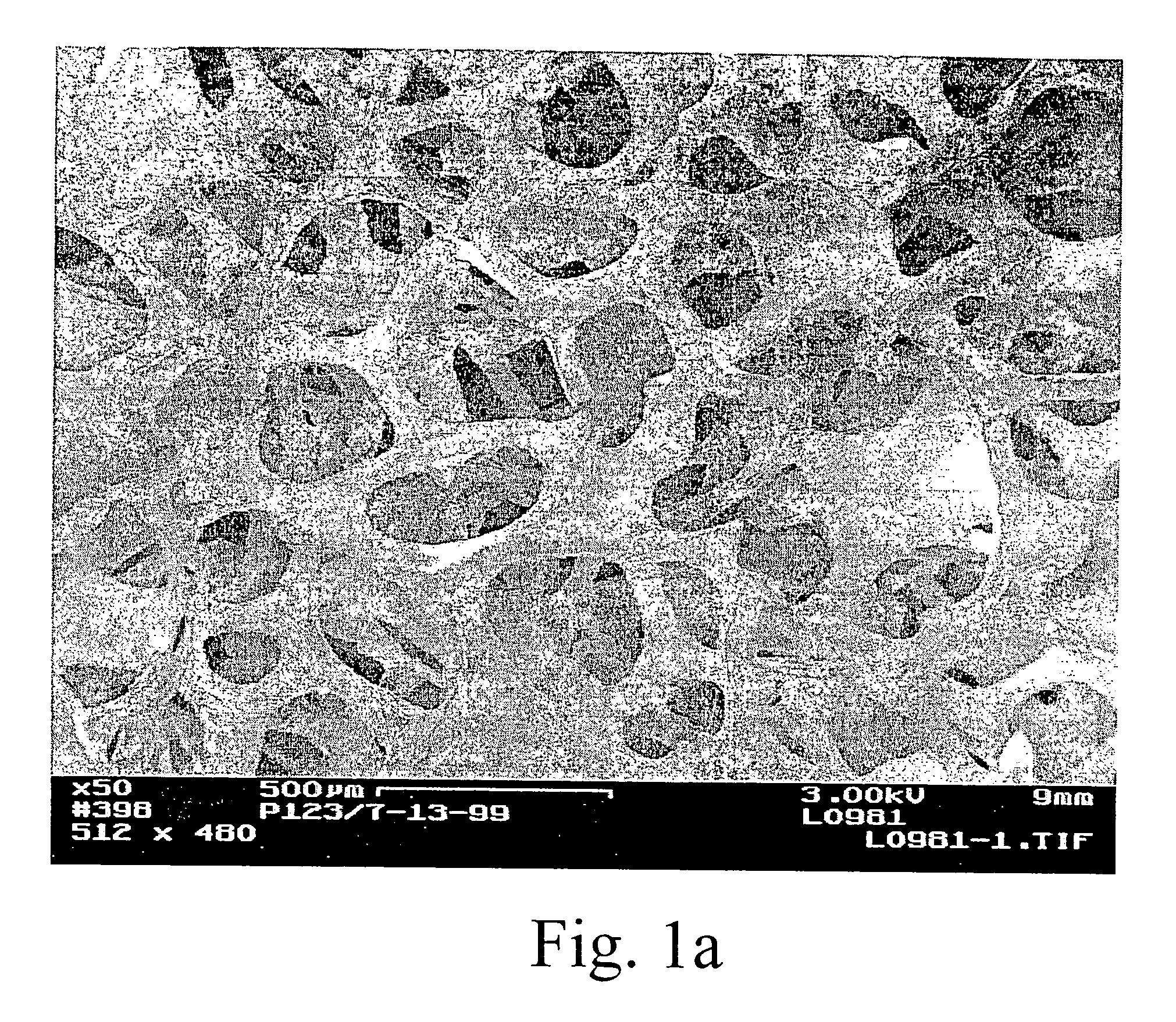

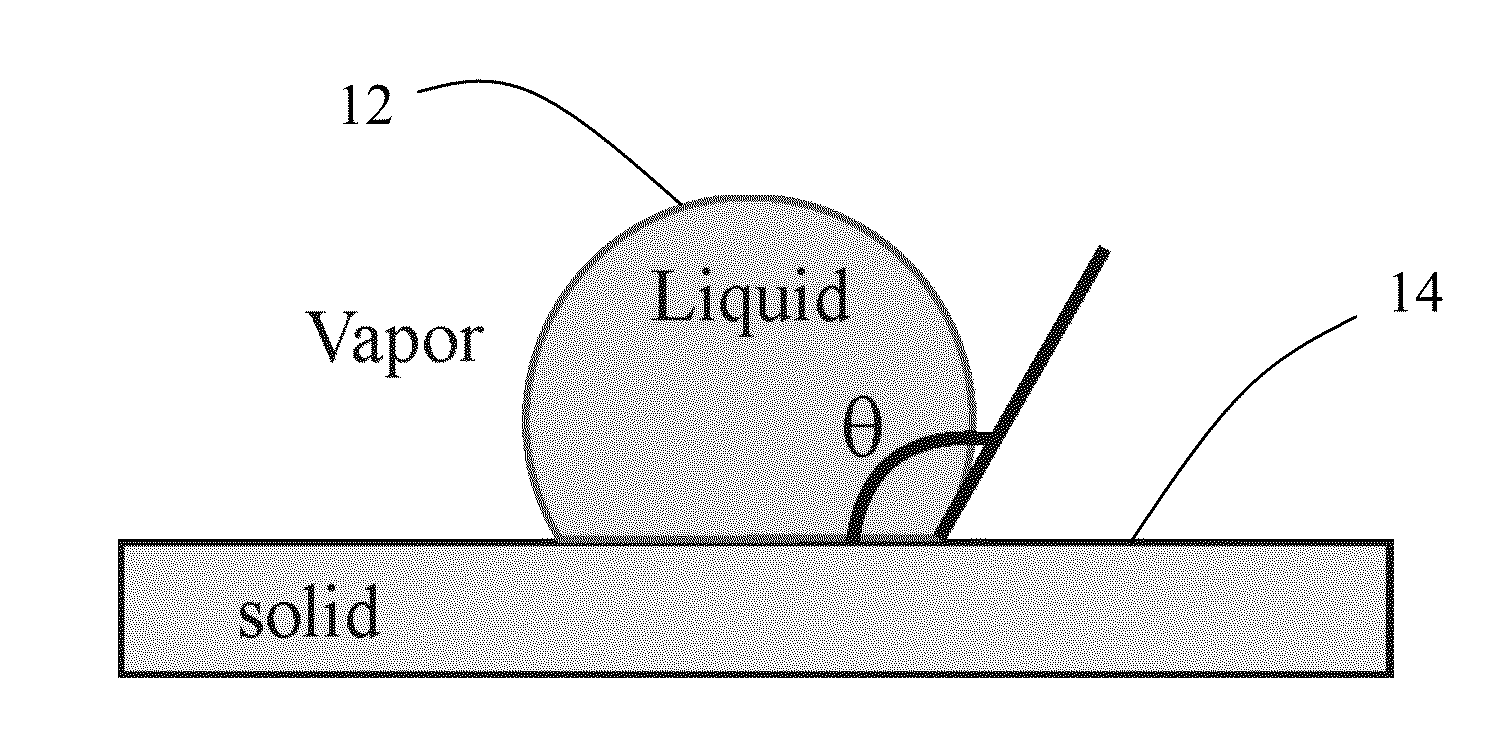

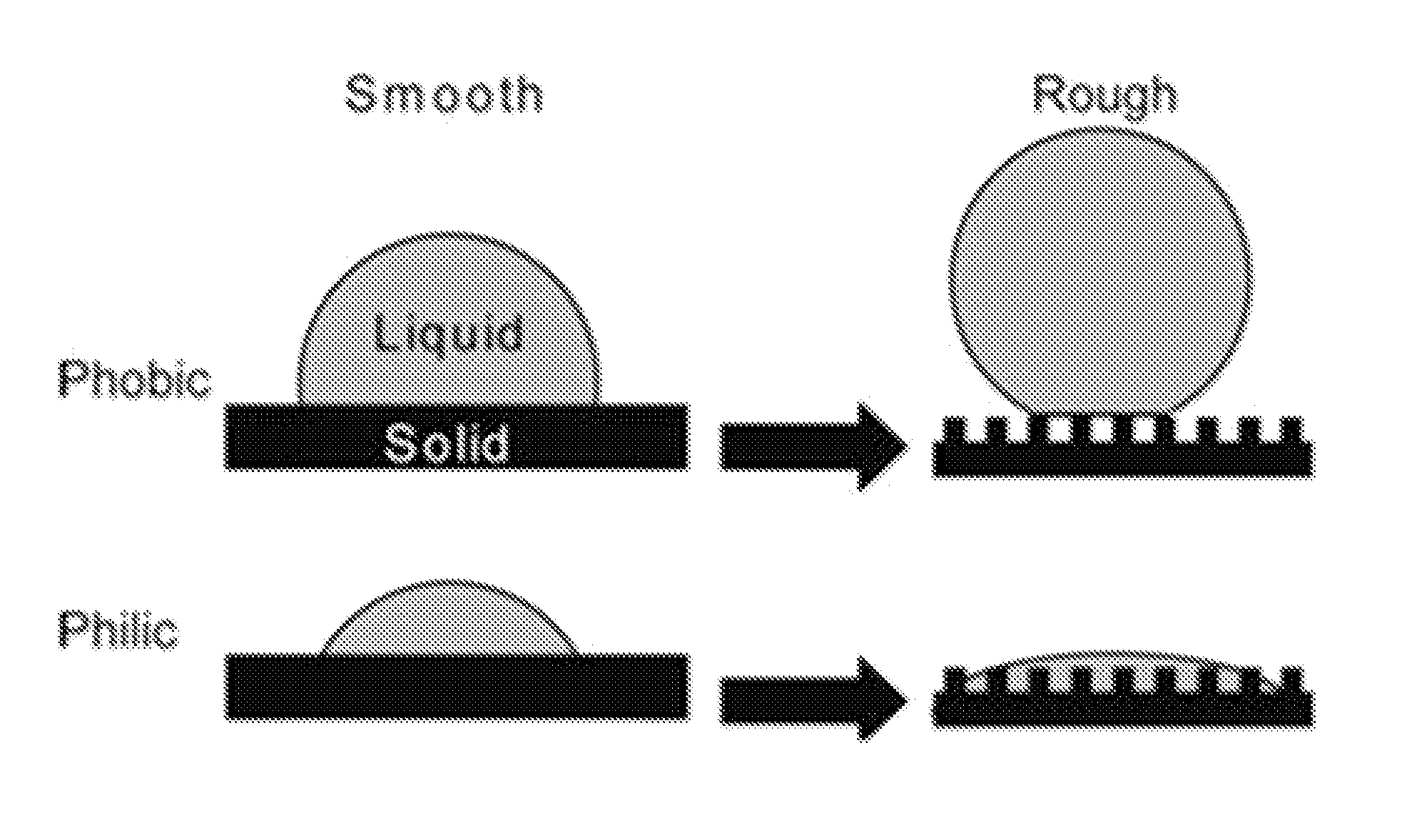

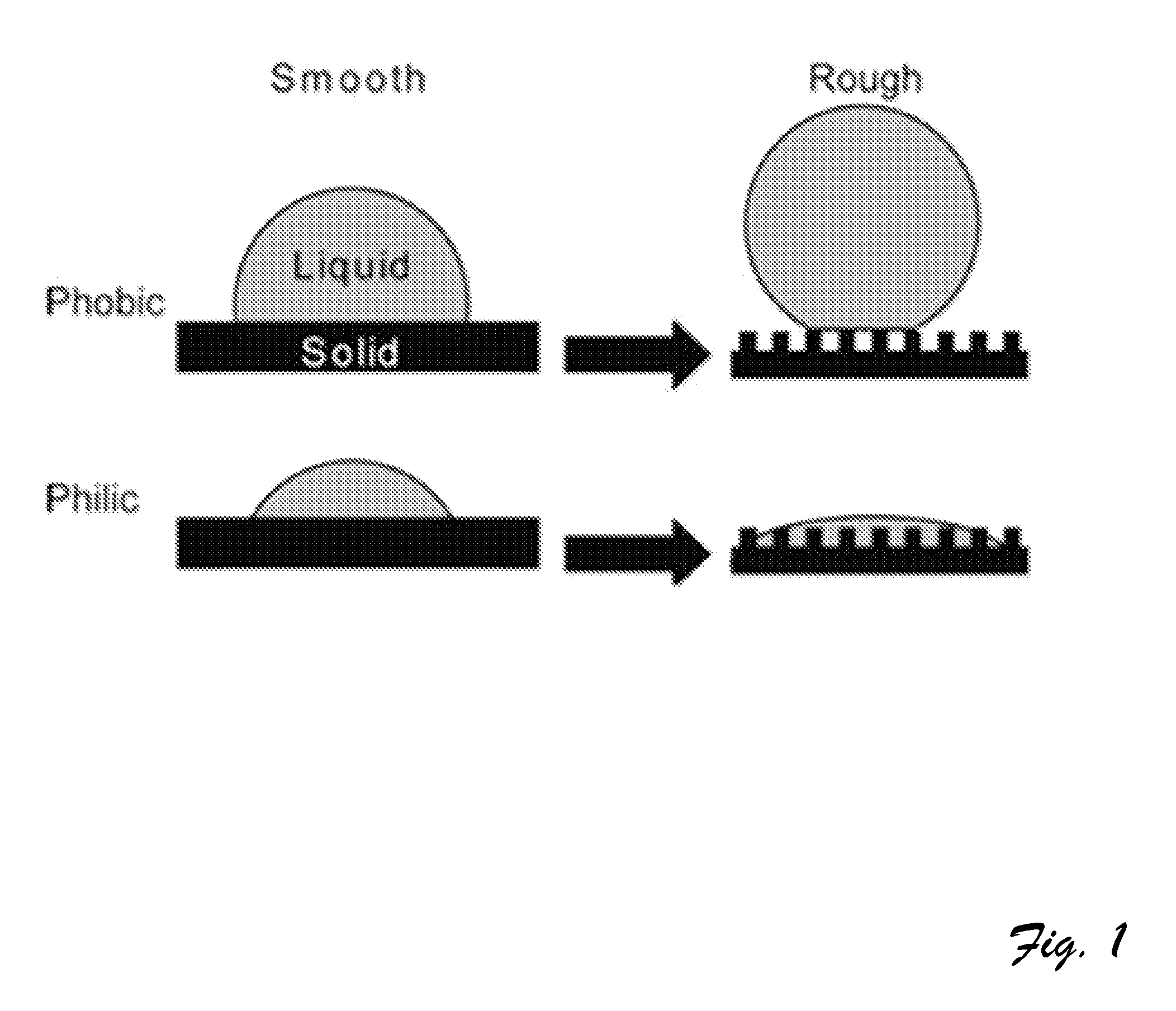

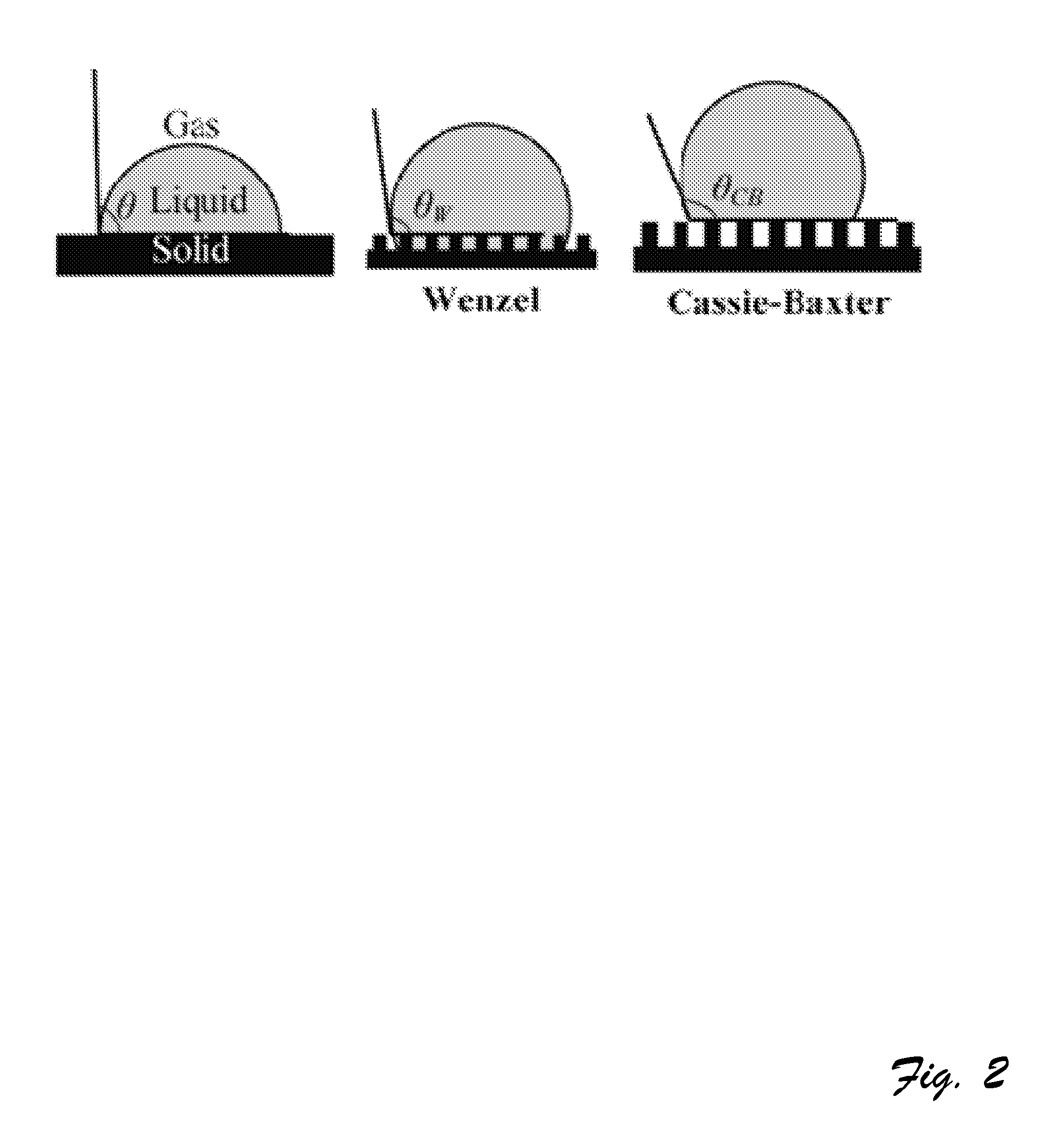

Hydrophobic Materials Incorporating Rare Earth Elements and Methods of Manufacture

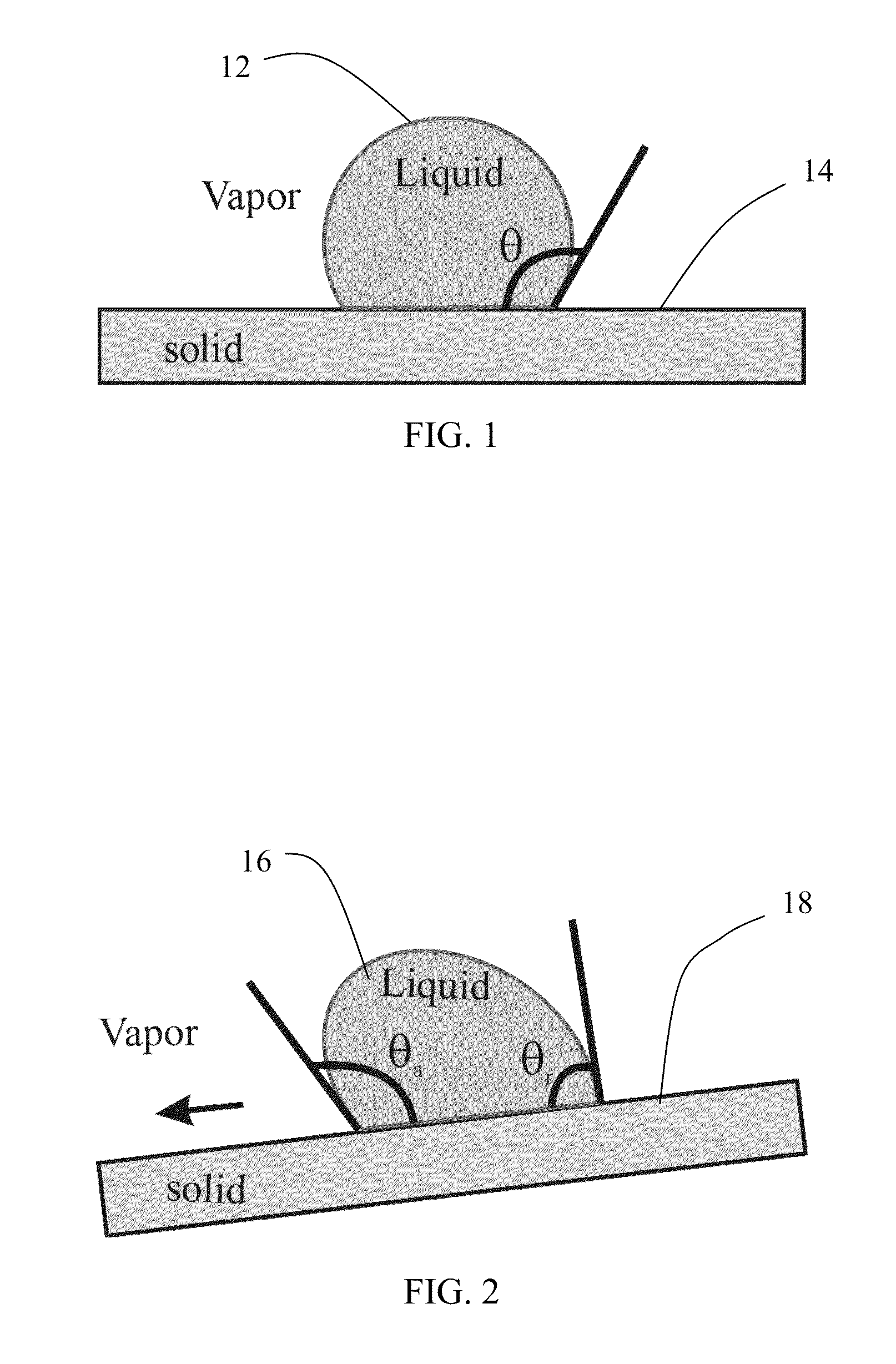

InactiveUS20130251942A1Improve waterproof performanceGood for condensationVacuum evaporation coatingSputtering coatingRare-earth elementBoride

This invention relates generally to an article that includes a base substrate and a hydrophobic coating on the base substrate, wherein the hydrophobic coating includes a rare earth element material (e.g., a rare earth oxide, a rare earth carbide, a rare earth nitride, a rare earth fluoride, and / or a rare earth boride). An exposed surface of the hydrophobic coating has a dynamic contact angle with water of at least about 90 degrees. A method of manufacturing the article includes providing the base substrate and forming a coating on the base substrate (e.g., through sintering or sputtering).

Owner:MASSACHUSETTS INST OF TECH

Multi-fluid, two-phase immersion-cooling of electronic component(s)

InactiveUS8619425B2Easy to condenseImprove cooling effectIndirect heat exchangersHeat exchange apparatusEngineeringElectronic component

Cooling apparatuses and methods are provided for immersion-cooling one or more electronic components. The cooling apparatus includes a housing at least partially surrounding and forming a fluid-tight compartment about the electronic component(s), and a boiling fluid mixture of first and second dielectric fluids within the fluid-tight compartment, with the electronic component(s) immersed within the mixture. A condensing fluid is also provided within the fluid-tight compartment, and is immiscible with the boiling fluid mixture. The condensing fluid has a lower specific gravity and a higher thermal conductivity than the boiling fluid mixture, and facilitates condensing of vaporized boiling fluid mixture. A cooling structure is provided within the compartment, and includes a condensing region and a sub-cooling region, with the condensing region being in contact with the condensing fluid, and the sub-cooling region being in contact with the boiling fluid mixture. The cooling structure facilitates heat removal from the fluid-tight compartment.

Owner:IBM CORP

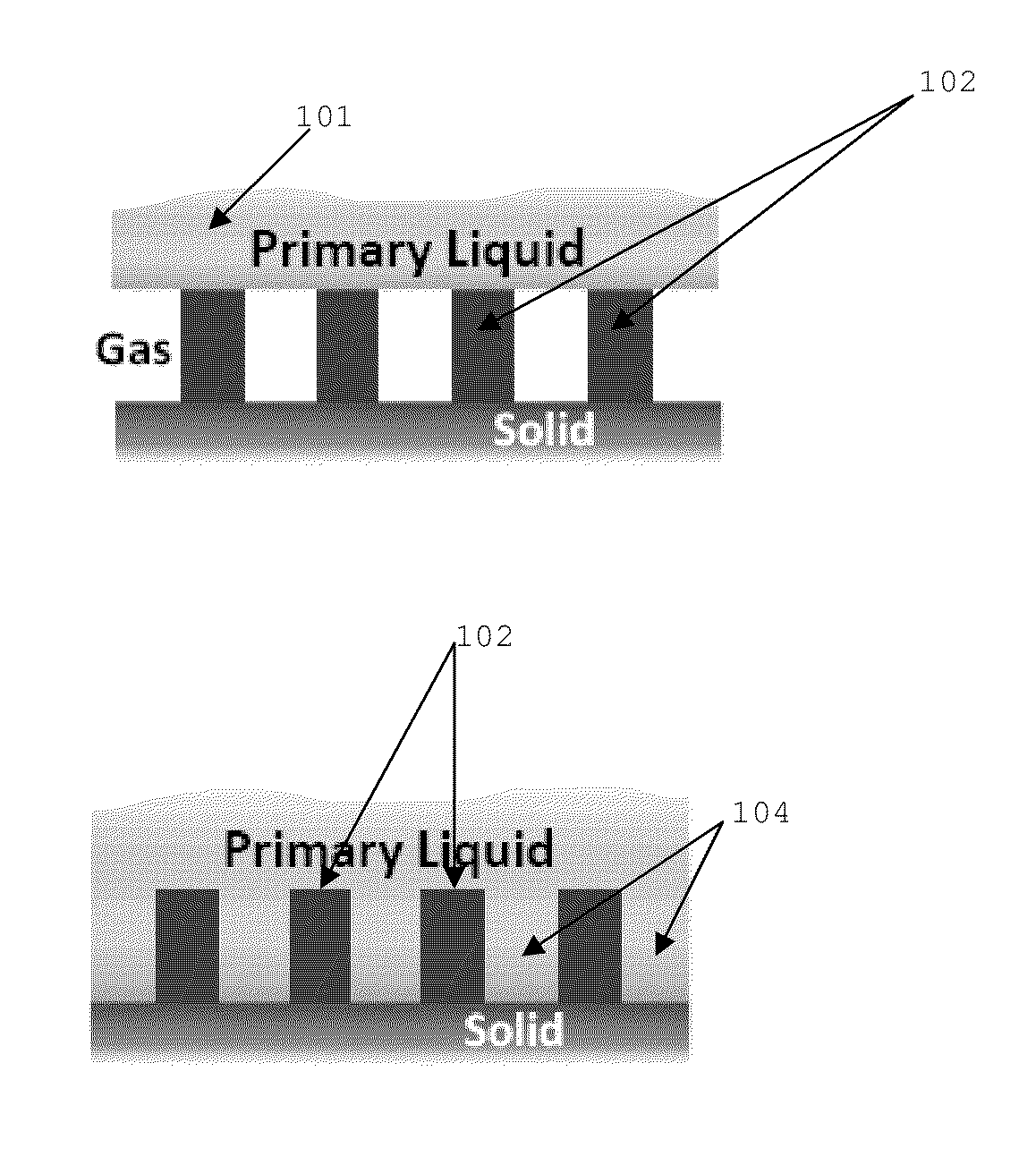

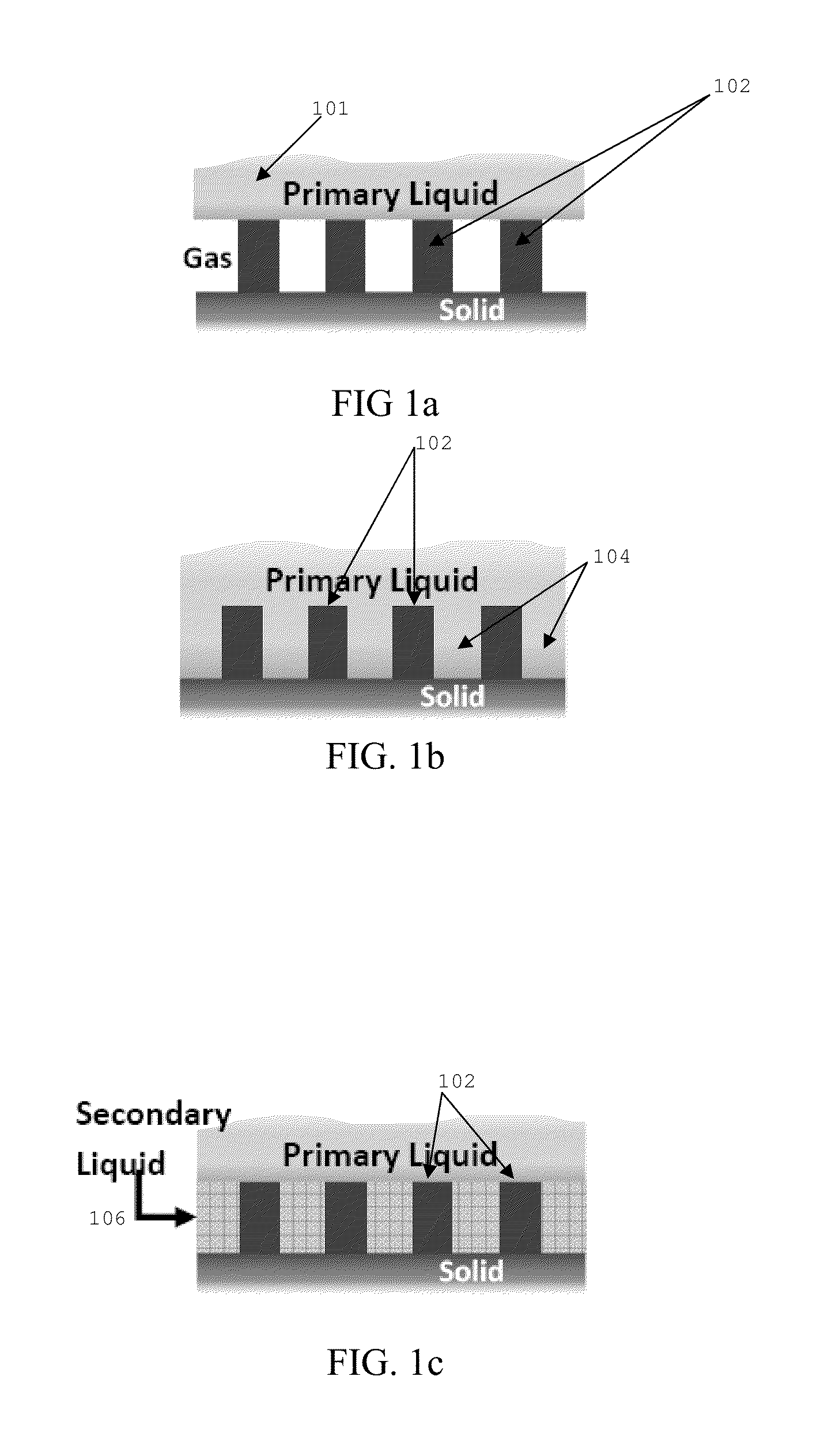

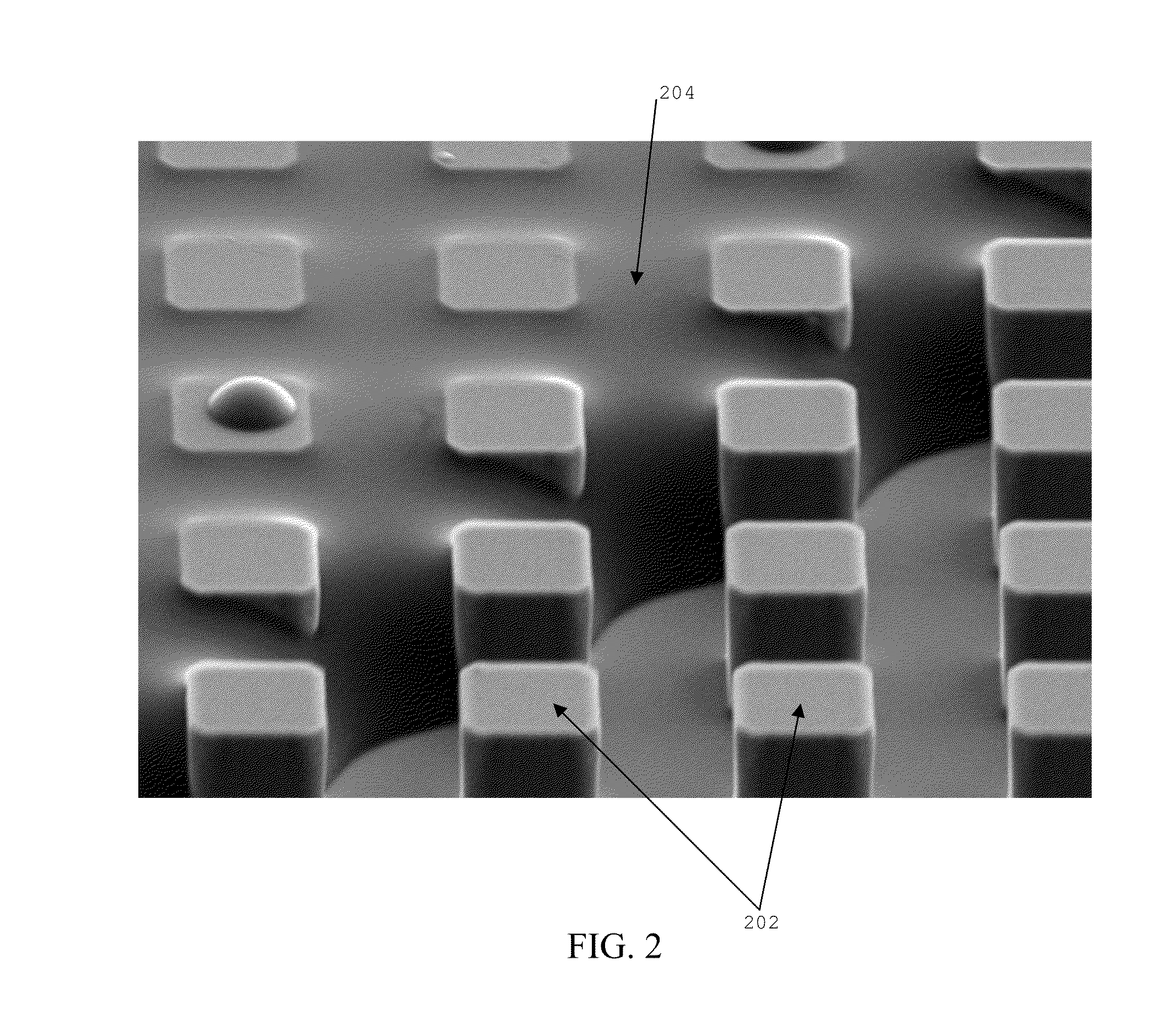

Articles and methods for modifying condensation on surfaces

InactiveUS20130220813A1Enhance heat transfer coefficientEnhance condensationElectrolysis componentsVolume/mass flow measurementChemistryMicrometer

Owner:MASSACHUSETTS INST OF TECH

Silylated thermoplastic vulcanizate compositions

InactiveUS20060235156A1Improve creep resistanceEasy to condenseGraft polymer adhesivesElastomerSilanes

A process for making a thermoplastic vulcanizate includes blending a thermoplastic first polymer, an elastomeric second polymer, a carboxylic anhydride, a free radical generator, and a tackifier to provide a tacky first blend containing the thermoplastic first polymer and grafted elastomeric second polymer with the tackifier dispersed therein; then, reacting the first blend with a silane to provide a non-tacky thermoplastic vulcanizate product.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

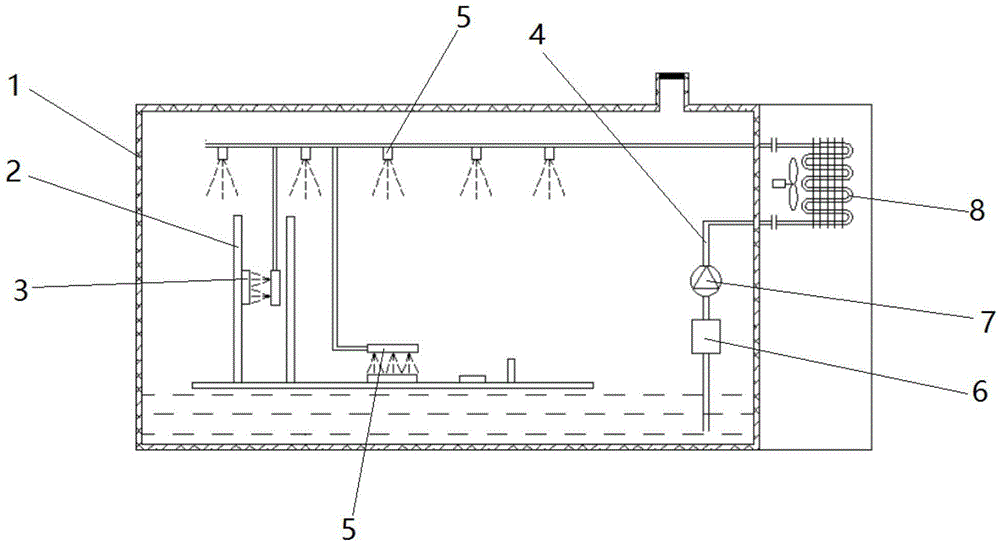

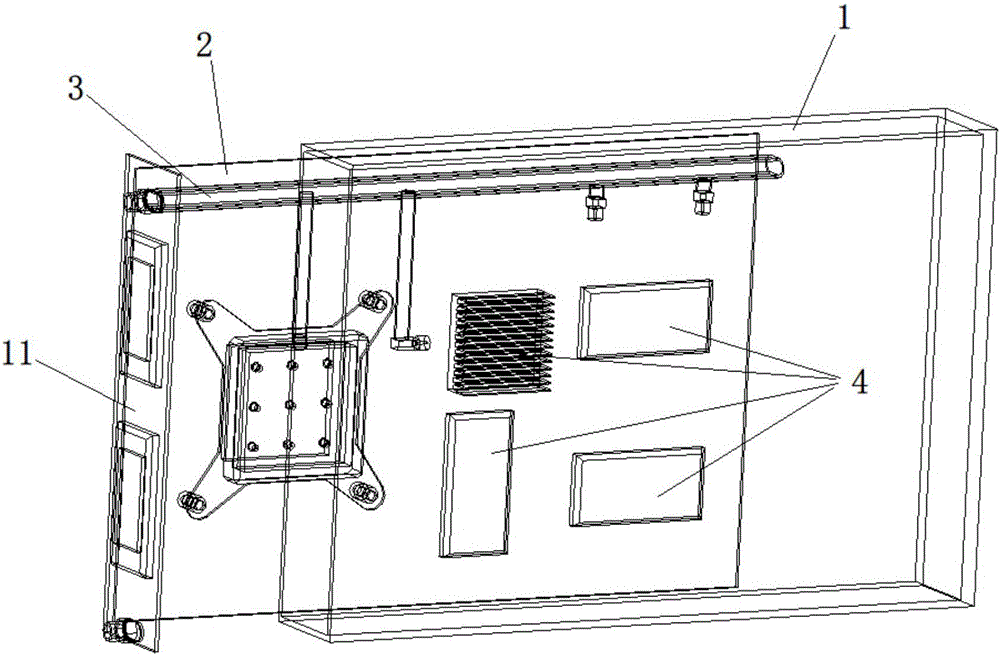

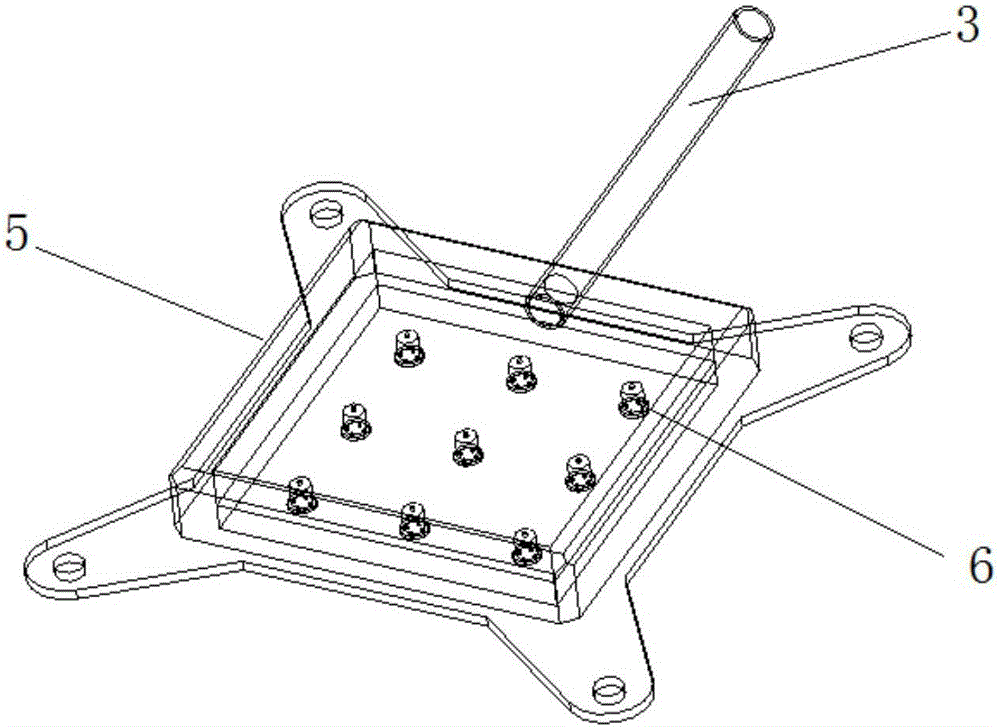

Integrated liquid-cooling heat dissipation case

ActiveCN105658037AImprove heat transfer effectImprove cooling efficiencyCooling/ventilation/heating modificationsCooling fluidCoolant pump

The invention relates to the field of liquid cooling, and provides an integrated liquid-cooling heat dissipation case. The integrated liquid-cooling heat dissipation case comprises a case body, a circuit board and a liquid-cooling heat dissipation system. A closed space composed of a plurality of wall boards is formed in the case body. The circuit board is arranged in the case body, and one or more heat emission devices are arranged on the circuit board. A liquid storage groove is formed in the bottom of the case body and used for storing cooling liquid. The liquid-cooling heat dissipation system comprises a pipeline, a heat dissipation mechanism, a pumping mechanism and a spraying mechanism. The pumping mechanism is used for pumping the cooling liquid in the liquid storage groove into the pipeline, the spraying mechanism is connected to one end of the pipeline and used for spraying the cooling liquid into the case body or directly spraying the cooling liquid to the heat emission devices, and the heat dissipation mechanism is arranged at the position, in front of the spraying mechanism, of the pipeline and used for transferring heat of the cooling liquid to the outside of the case body. By the adoption of the integrated structural design, the integrated liquid-cooling heat dissipation case can be used in hostile environments and is convenient to carry, reasonable in design, light in weight, high in heat exchange capability and low in cost.

Owner:沈珂

Composite fire resistant pouring material

The invention relates to an organic-inorganic composite combined advanced monolithic refractory which has the formula of 40 to 56 percent of 5-1mm corundum or bauxite, 12 to 30 percent of 1-0.0088mm corundum or bauxite, 16 to 25 percent of corundum or bauxite with d90 less than 0.088mm, 0 to 5 percent of alpha alumina micropowder, 1 to 8 percent of hydratable alumina, 1 to 6 percent of siliceous dust, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of external efficient water reducing agents (polycarboxylic acid plus sulfonation naphthaldehyde polymer plus sulfonation melamine polymer), 1 to 6 percent of latex of the system of external polyacrylic acid, 1 to 6 percent of external water and 0 to 3 percent of external heat-resistant steel fiber. Casting materials of the invention have excellent performances of condensation, hardening, demoulding, drying and heating and are suitable for high-temperature furnace projects with changeful field conditions.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

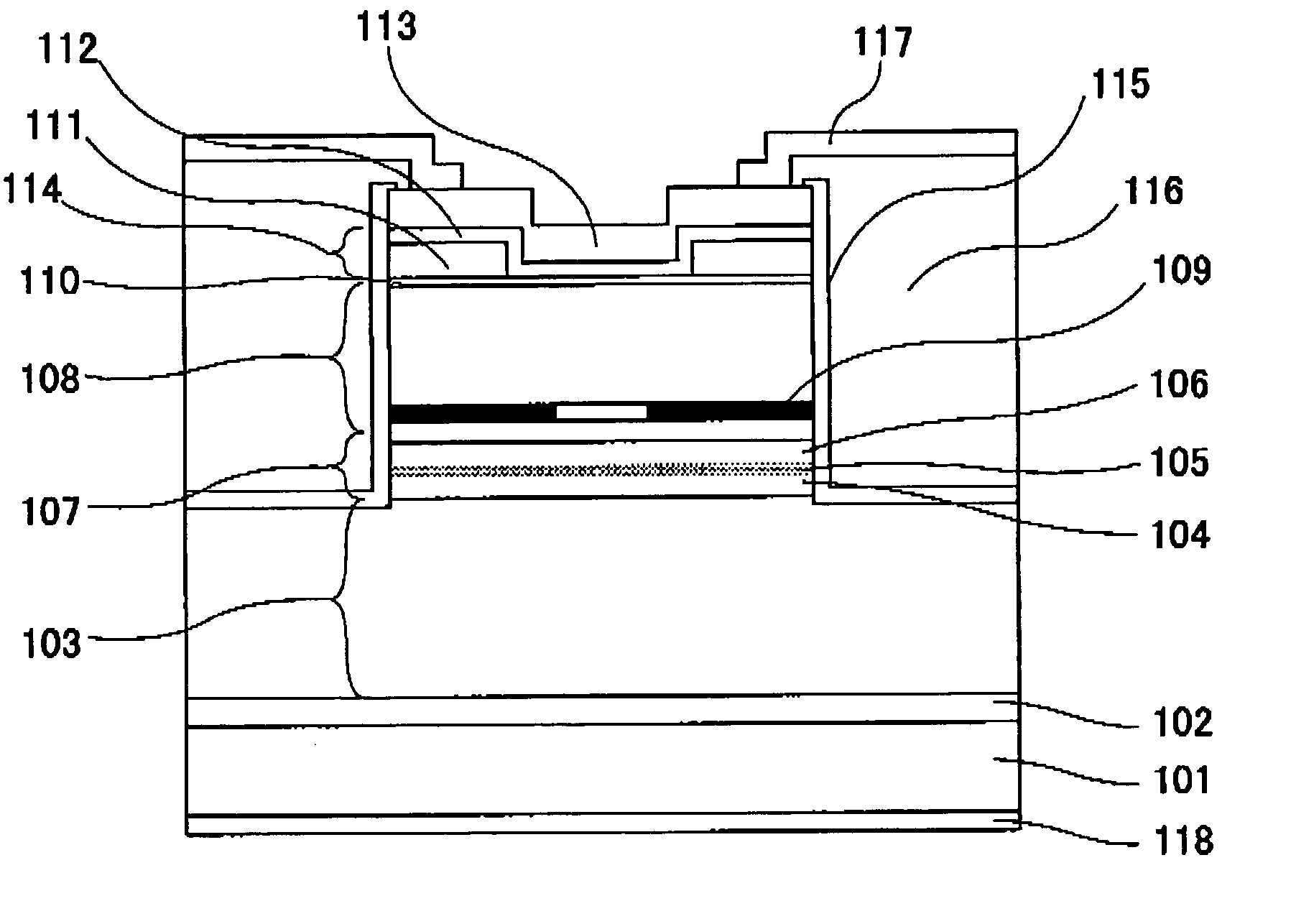

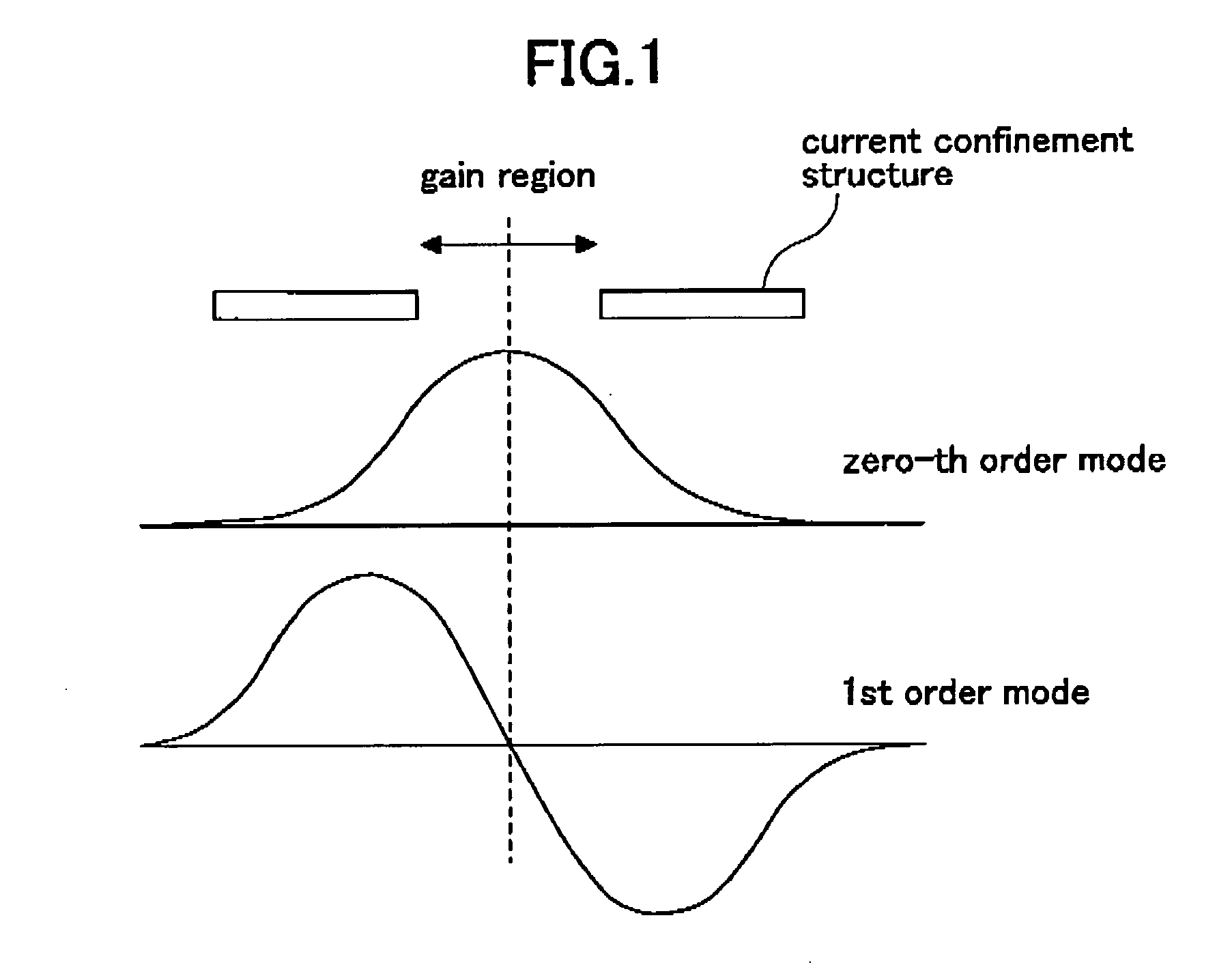

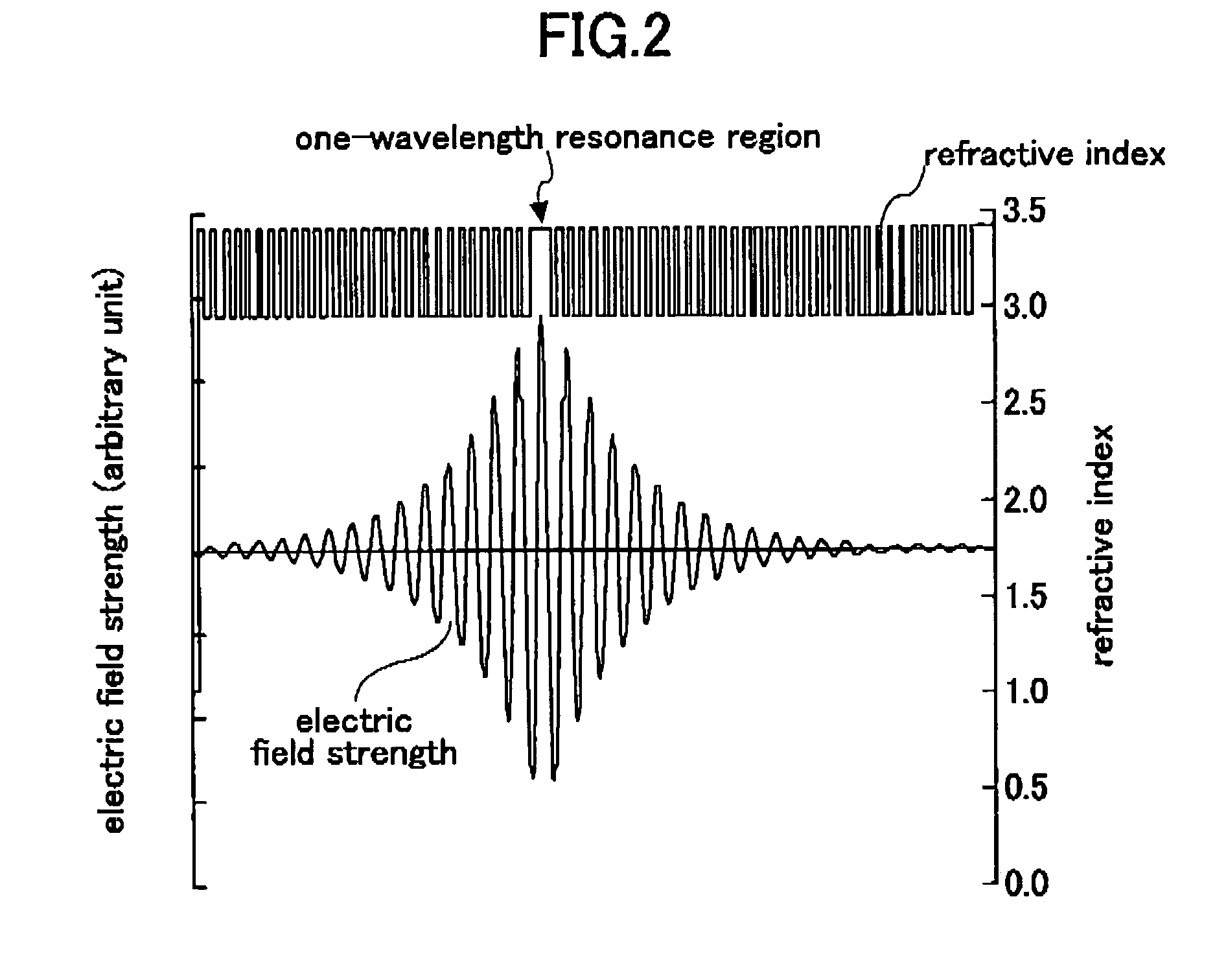

Surface emitting laser device and production method

InactiveUS20060093006A1Well formedIncrease productionLaser detailsSemiconductor lasersCurrent limitingResonance

A surface emitting laser device is disclosed that is able to selectively add a sufficiently large loss to a high order transverse mode so as to efficiently suppress a high order transverse mode oscillation and to oscillate at high output in a single fundamental transverse mode. The surface emitting laser device includes a first resonance region that includes an active layer and spacer layers, two distributed Bragg reflectors that sandwich the resonance region, and a current confinement structure that defines a current injection region for the active layer. At least one of the distributed Bragg reflectors includes a second resonance region arranged in the current injection region excluding a predetermined region surrounding a center of the current injection region.

Owner:RICOH KK

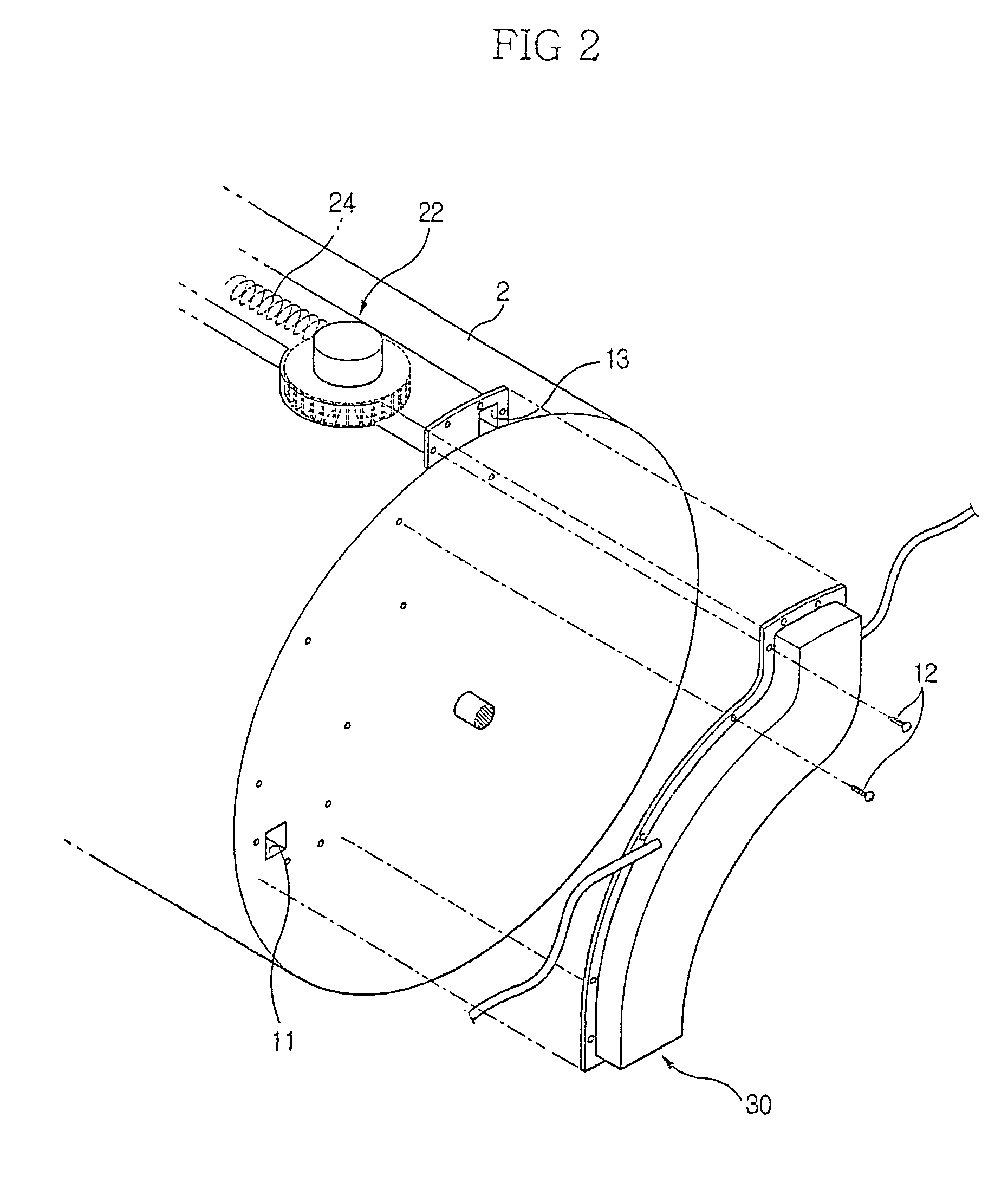

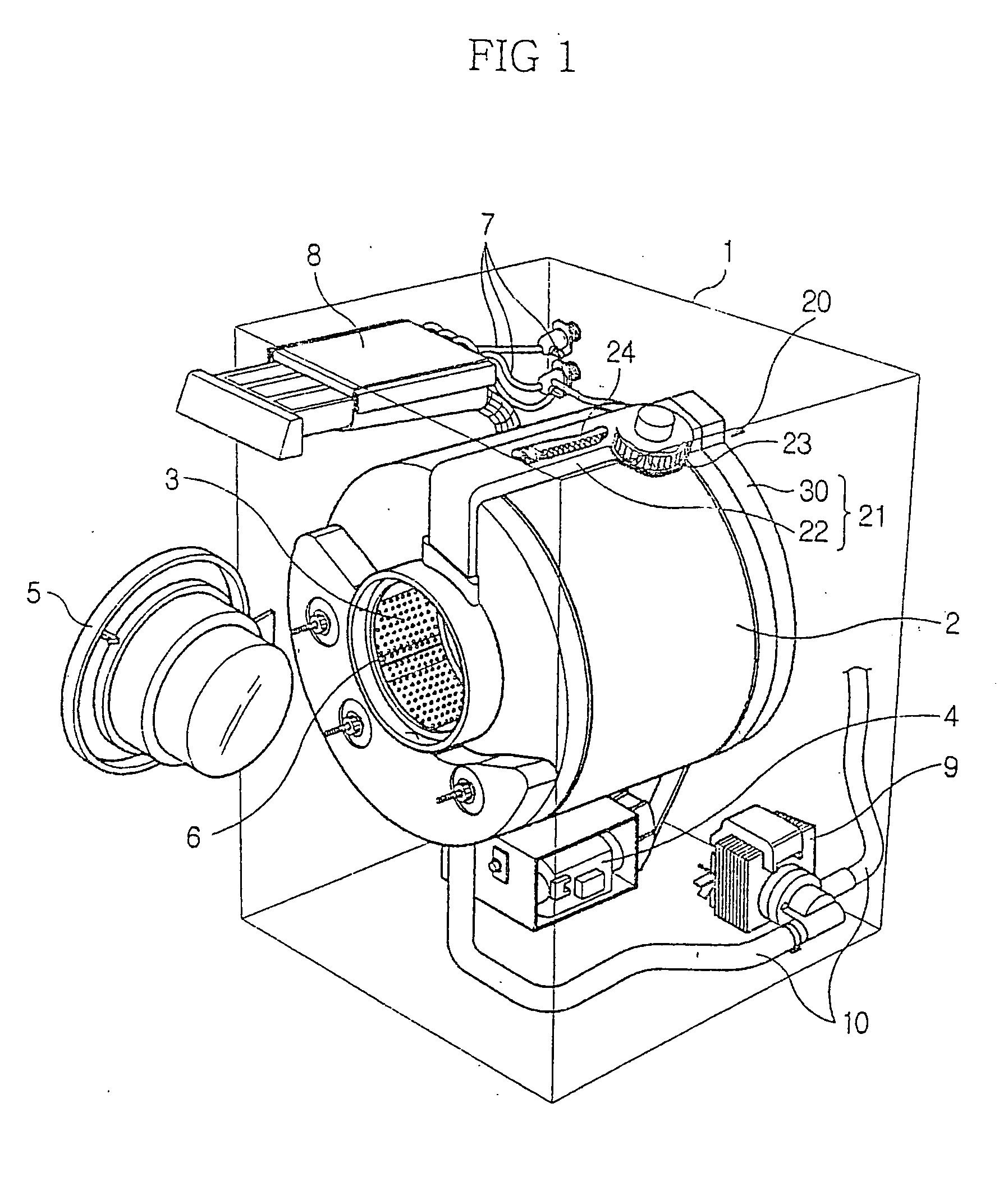

Drying apparatus and washing machine having the same

InactiveUS7017282B2Fast dryingEfficiently condensing and adsorbing vaporDrying machines with non-progressive movementsWashing machine with receptaclesEngineeringLaundry

A washing machine including a drying apparatus. The washing machine including the drying apparatus quickly dries wet laundry by efficiently condensing and adsorbing vapor from humid air of high temperature flowing from a water tub during a drying-mode operation. The drying apparatus includes a condensing duct and a blower duct respectively mounted on a rear surface and an upper surface of the water tub. The condensing duct has an ultrasonic atomizing unit, a condensing unit and a water adsorption unit therein, while the blower duct has a blower fan and a heater therein. An inner space of the condensing duct is partitioned into a first condensing path, a second condensing path and a third condensing path by a first air guide and a second air guide. The ultrasonic atomizing unit, the condensing unit and the water adsorption unit are installed in the first condensing path, the second condensing path and the third condensing path of the condensing duct, respectively, thus condensing and adsorbing vapor from the humid air which sequentially passes through the first to third condensing paths, thereby dehumidifying the air providing dry air which is fed to the water tub to dry the wet laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

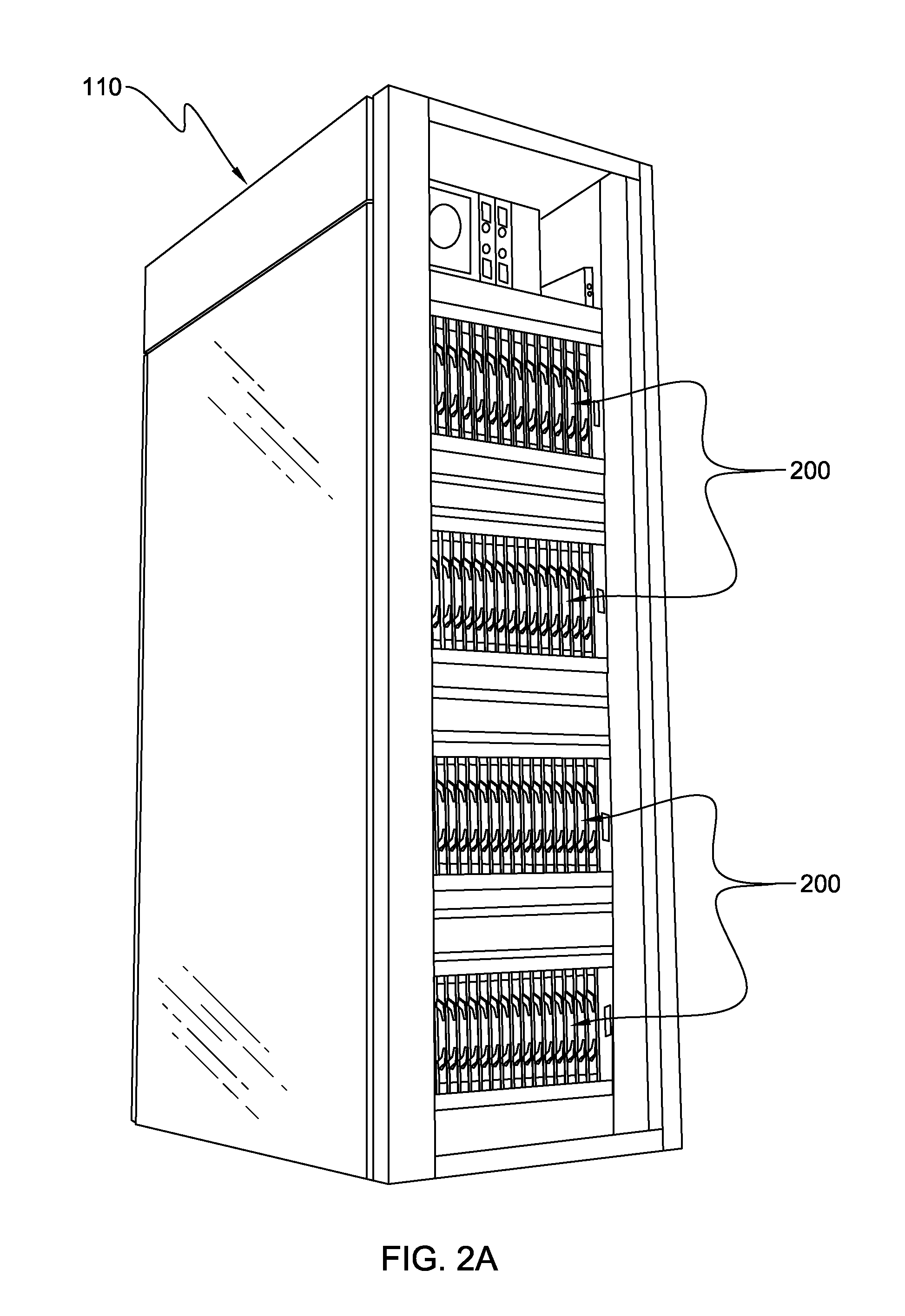

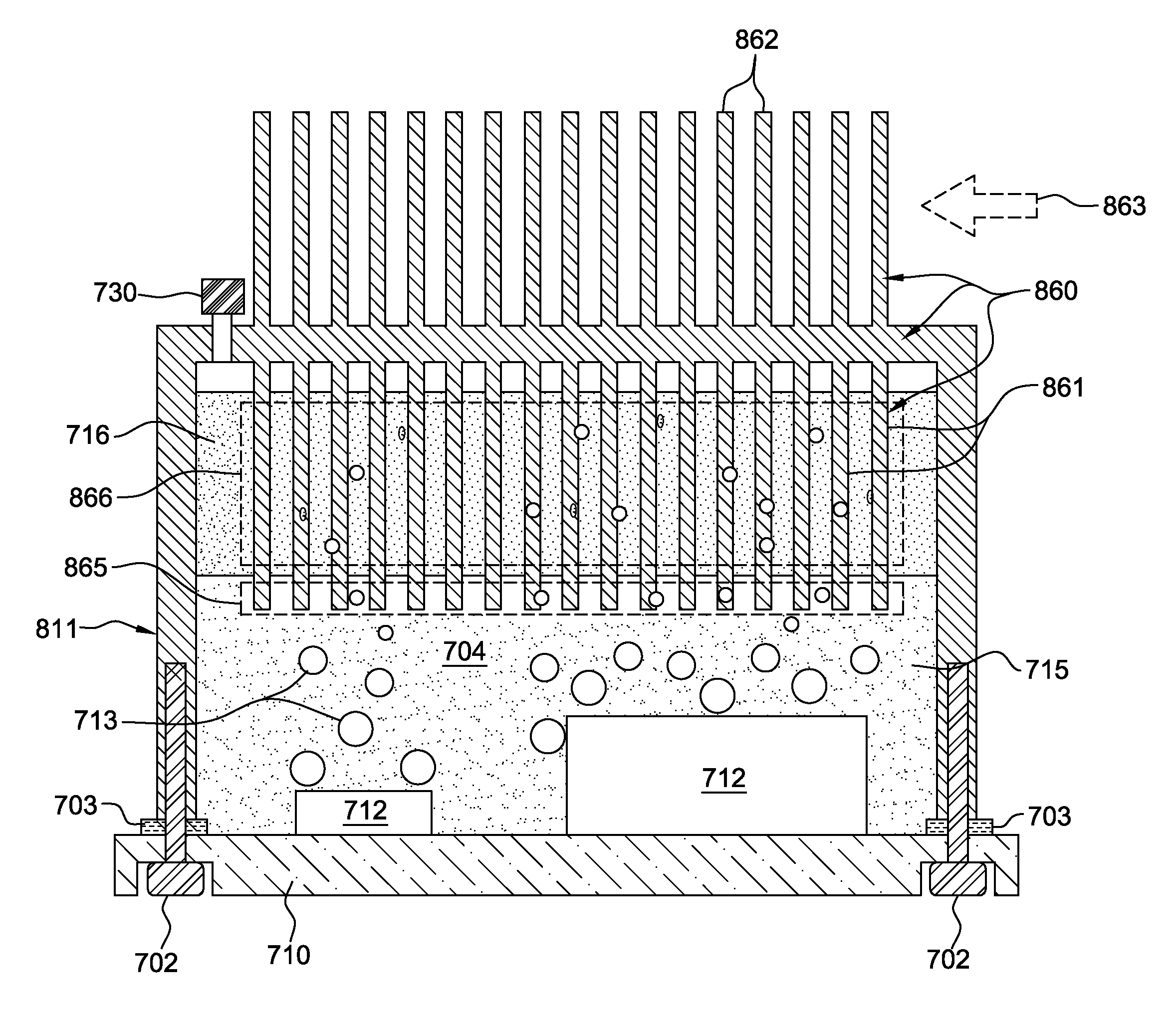

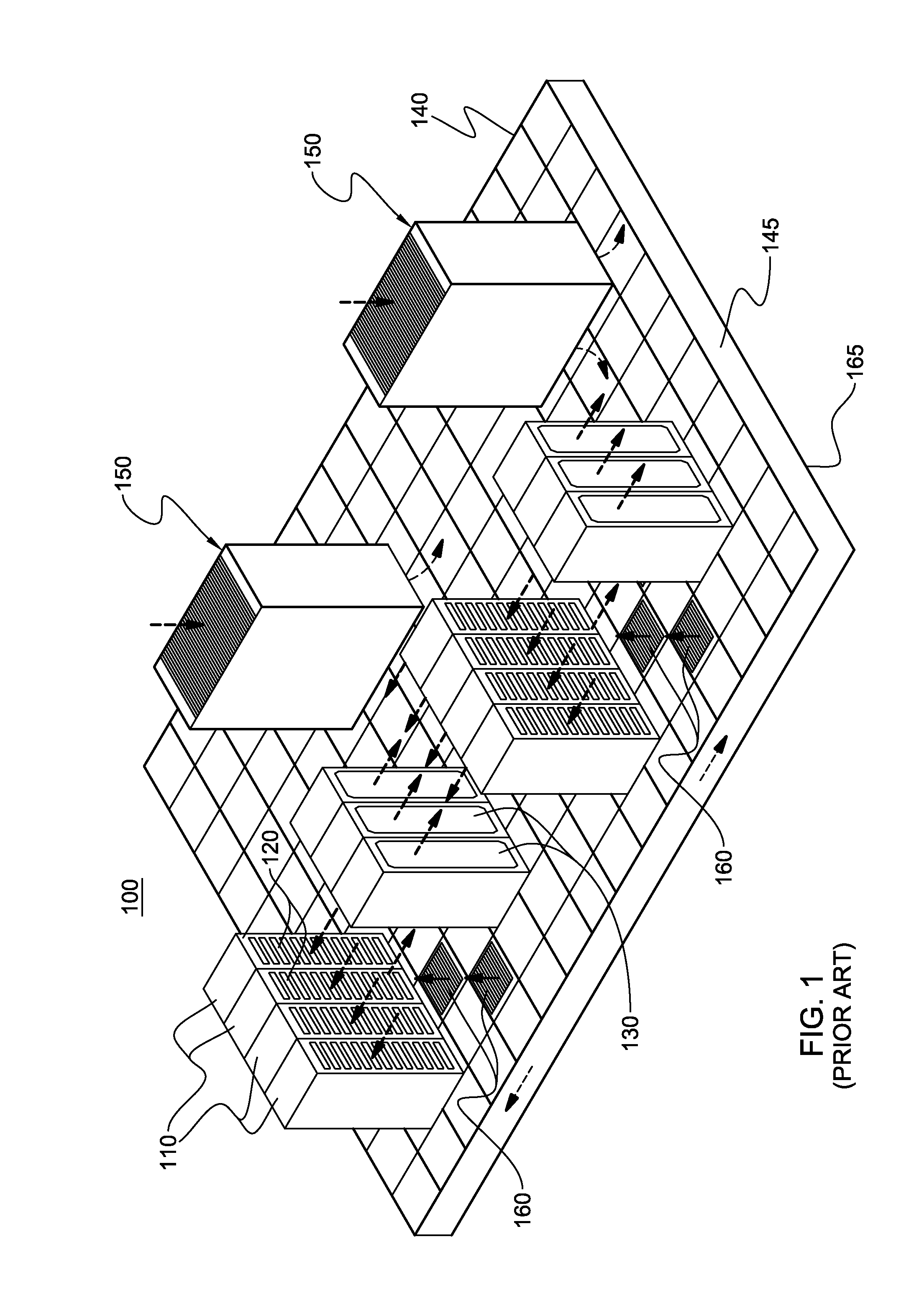

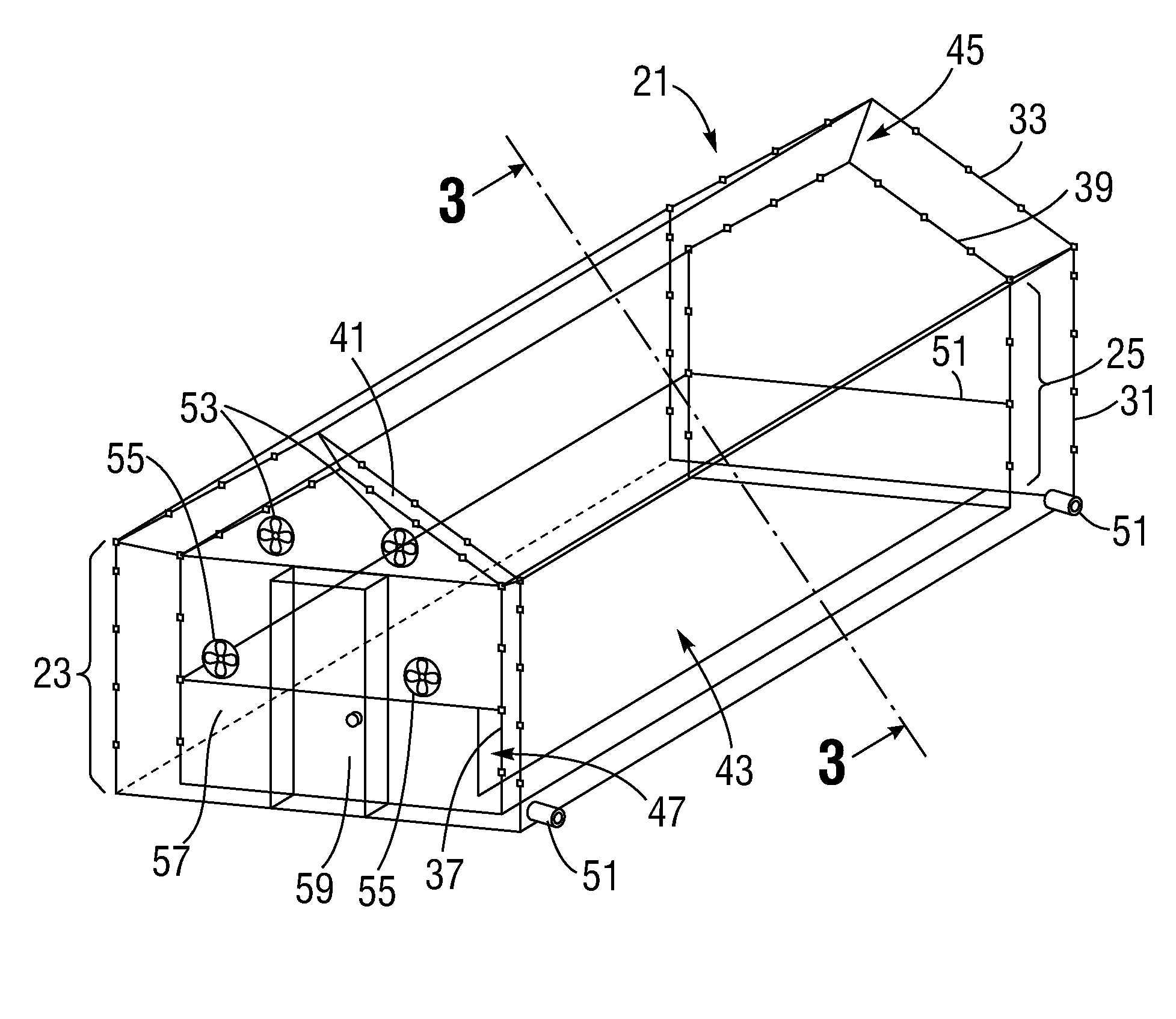

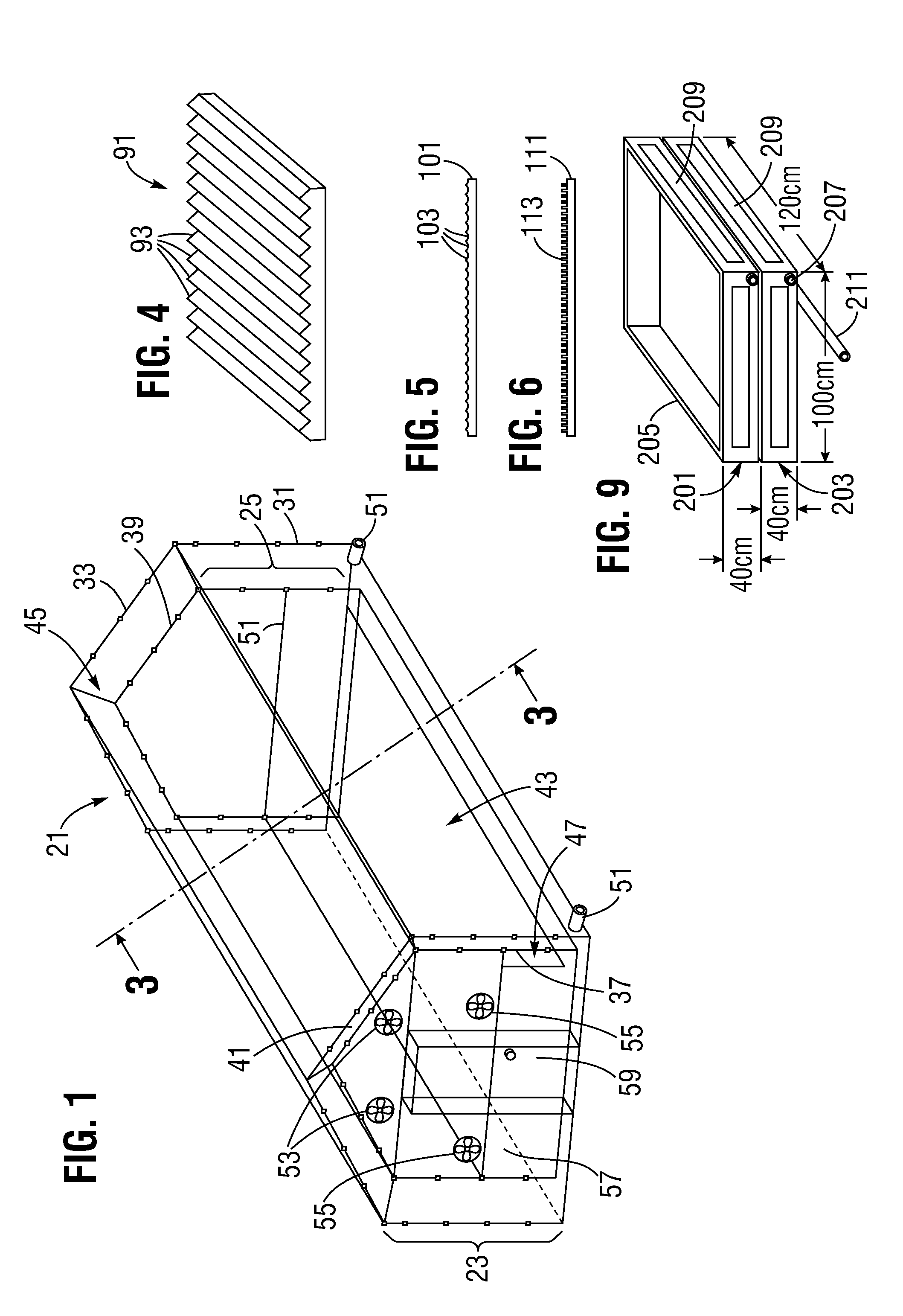

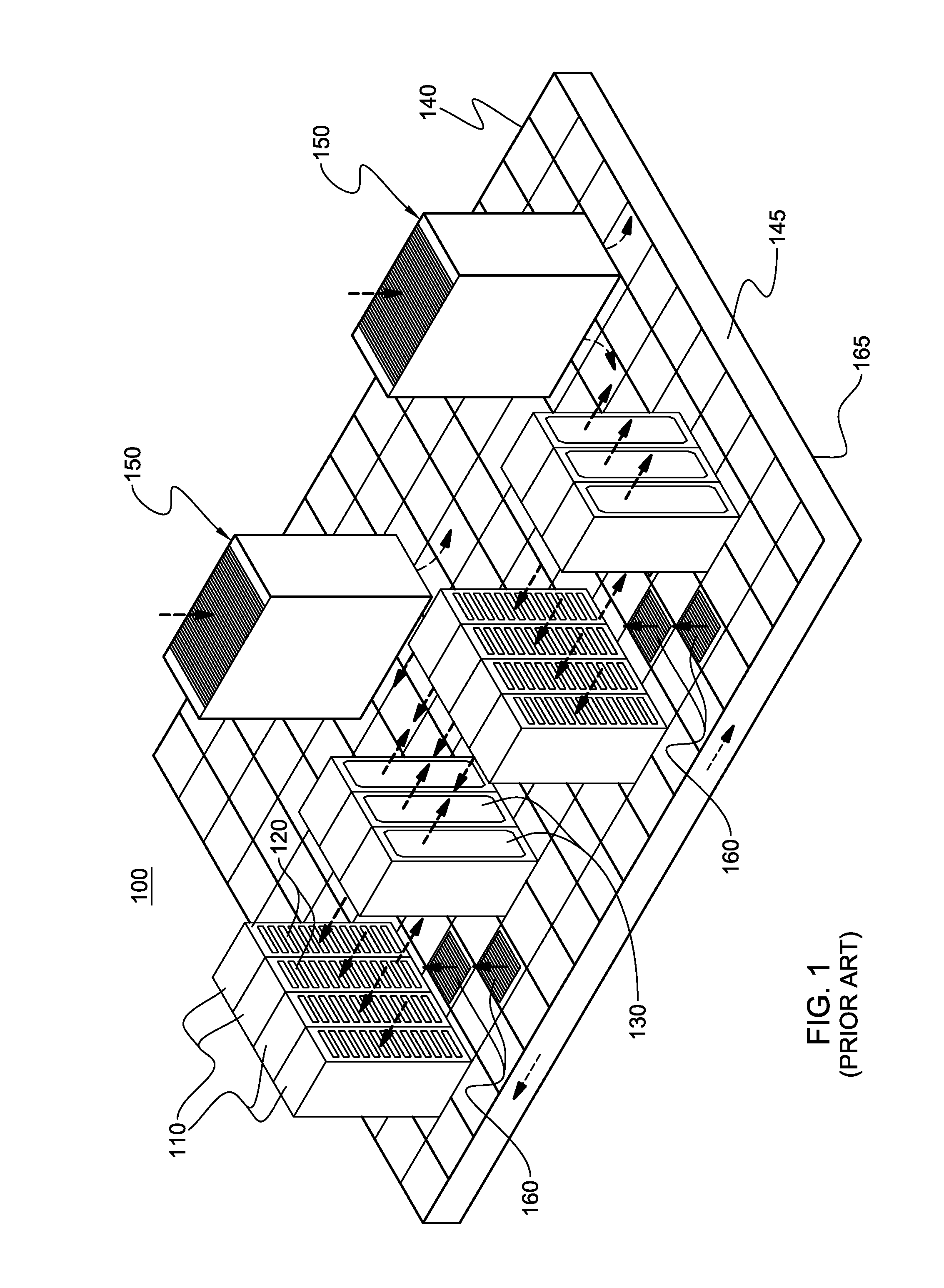

Interleaved, immersion-cooling apparatuses and methods for cooling electronic subsystems

ActiveUS20110315343A1Improve cooling effectFacilitates localized coolingSemiconductor/solid-state device detailsSolid-state devicesDielectricEngineering

Cooling apparatuses and methods are provided for immersion-cooling of an electronic subsystem of an electronics rack. The cooling apparatuses include a housing at least partially surrounding and forming a sealed compartment about the electronic subsystem and a dielectric fluid disposed within the sealed compartment, with the electronic subsystem being immersed within the dielectric fluid. A liquid-cooled vapor condenser is provided which includes a plurality of thermally conductive condenser fins extending within the sealed compartment. The condenser fins facilitate cooling and condensing of dielectric fluid vapor generated within the sealed compartment. Within the sealed compartment, multiple thermally conductive condenser fins are interleaved with multiple fluid-boiling fins of a heat spreader coupled to one or more of the electronic components immersed within the dielectric fluid. The interleaved fins facilitate localized cooling and condensing of dielectric fluid vapor within the sealed compartment.

Owner:LENOVO GLOBAL TECH INT LTD

Composition of materials for production of acid resistant cement and concrete and methods thereof

InactiveUS6749679B2High strengthImprove moisture and high-temperature curing propertySolid waste managementAlkali metal silicate coatingsSlagPortland cement

A cement composition for use in acidic environment containing liquid alkali silicate, vitreous silicate setting agent, lime containing material and inert filler and building materials made therefrom as well as the method of making such building materials. The liquid alkali silicate may include sodium silicate or potassium silicate. The vitreous silicate setting agent may include soda-lime glass powder or coal fly ash. The lime containing material refers to the materials containing more than 20% lime and may include quicklime, hydrated lime, Portland cement, blast furnace slag or steel slag. The inert fillers include ground quartz, ground ceramic, and / or clay.

Owner:ADVANCED MATERIALS TECHNOLOGIES

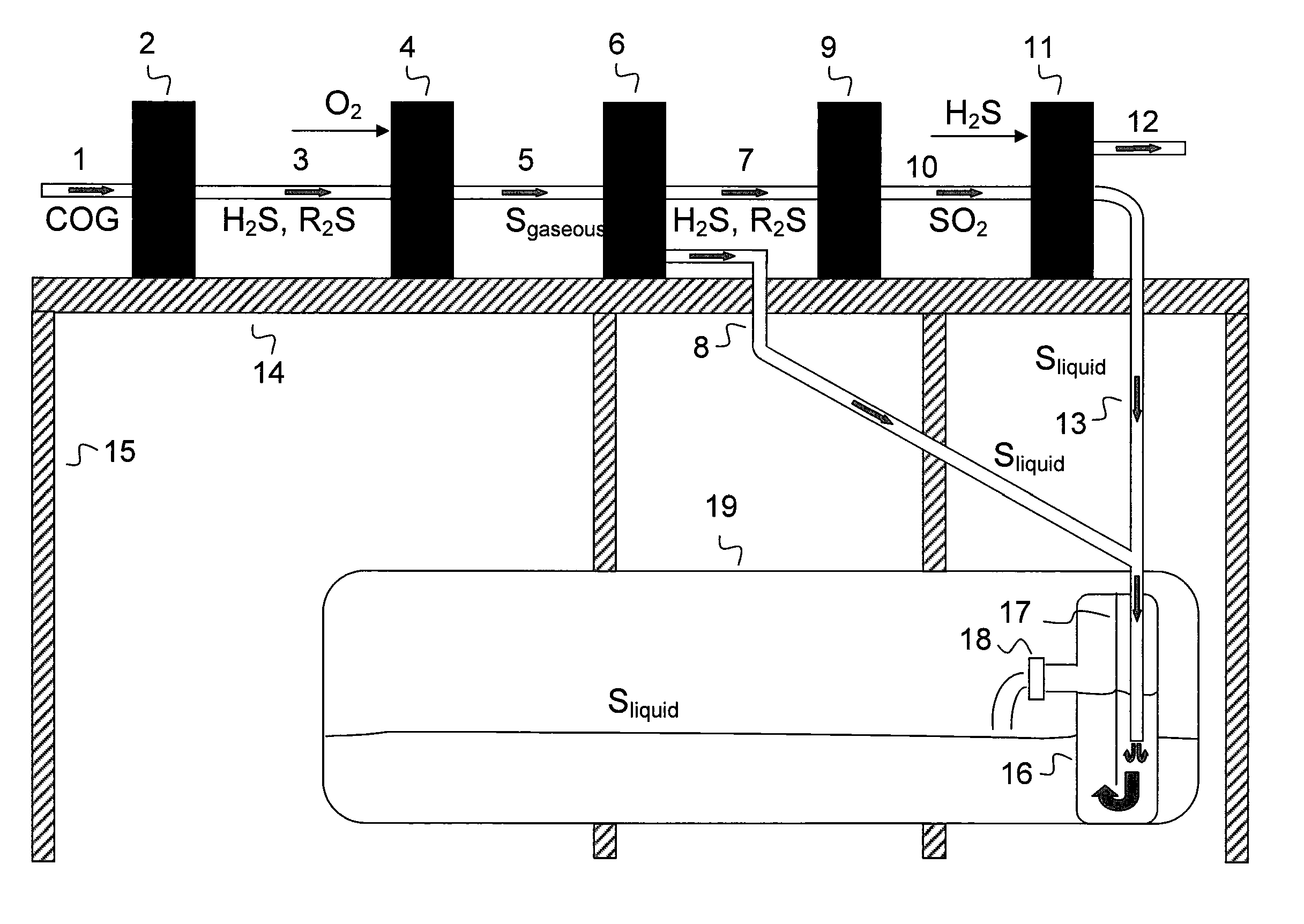

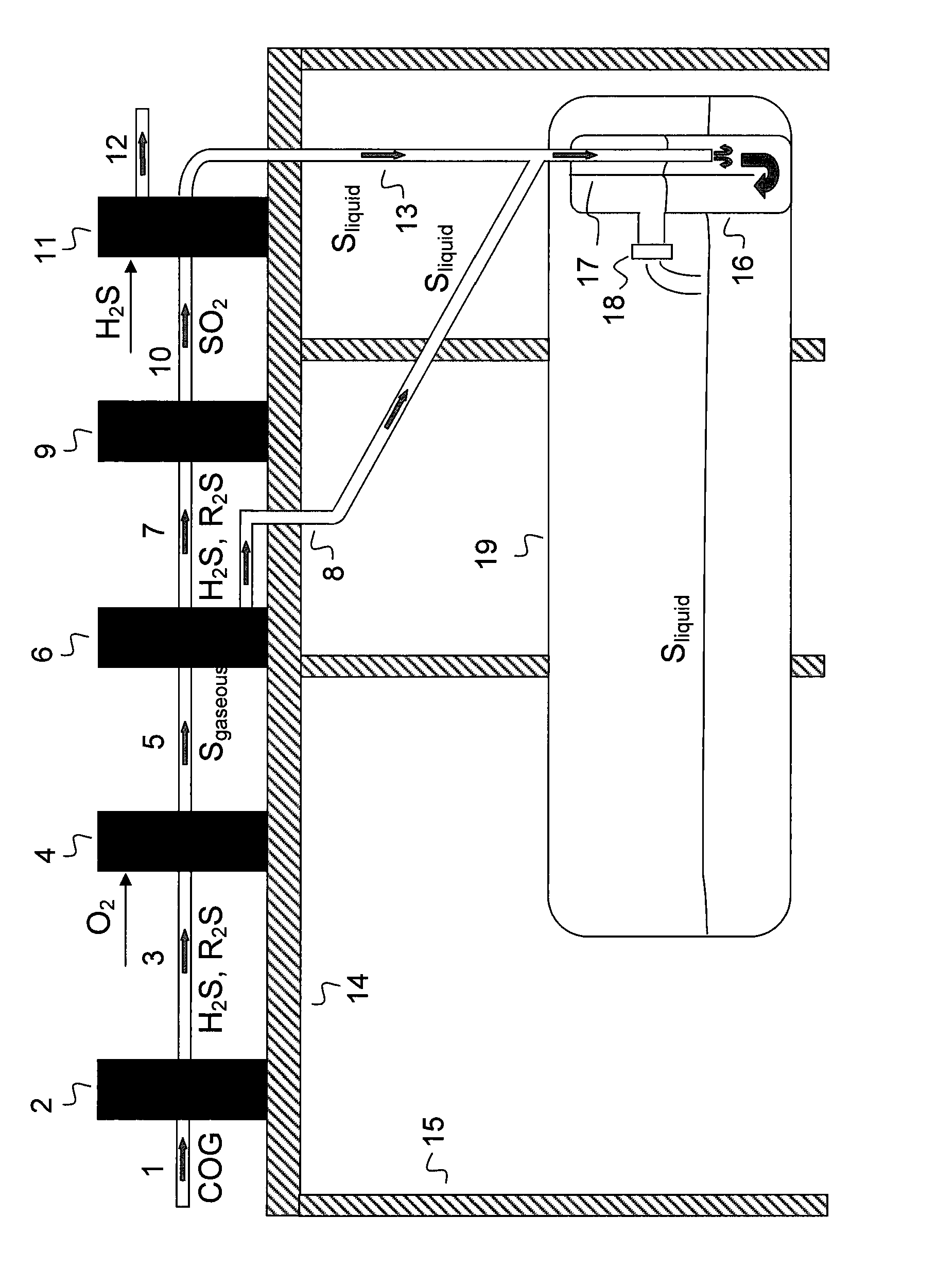

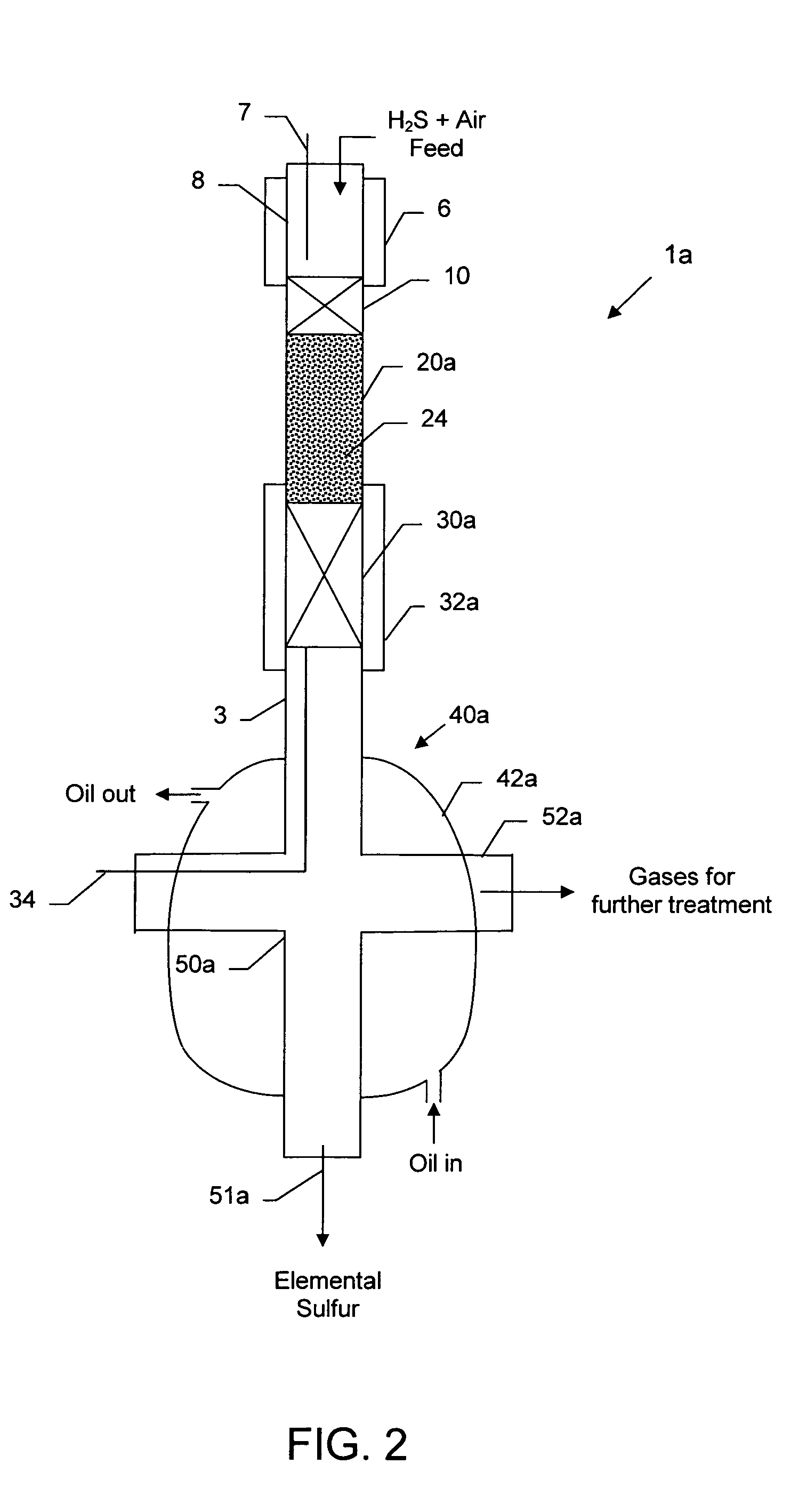

Device and method for condensing, separating, and storing liquid sulfur in a Claus plant

A device for condensing, separating, and storing sulfur in a Claus plant. having a Claus furnace, waste heat boiler, and Claus reactor. Plant parts are supported on a floor or comparable device, and an immersion chamber is provided below the Claus plant and optionally also below a device arranged upstream for gas scrubbing. The immersion chamber receives the sulfur in a siphoning manner, wherein the excess sulfur flows at least 4.00 meters deeper from the immersion chamber into a ground-level container in which the immersion chamber is arranged. The invention further relates to a method, by means of which liquid sulfur is conducted into an immersion chamber, wherein the immersion chamber is arranged at a height level below the waste heat boiler and the Claus reactor so that the liquid sulfur reaches the immersion chamber without further pumping and overcomes a height difference of at least 4.00 meters.

Owner:THYSSENKRUPP IND SOLUTIONS AG

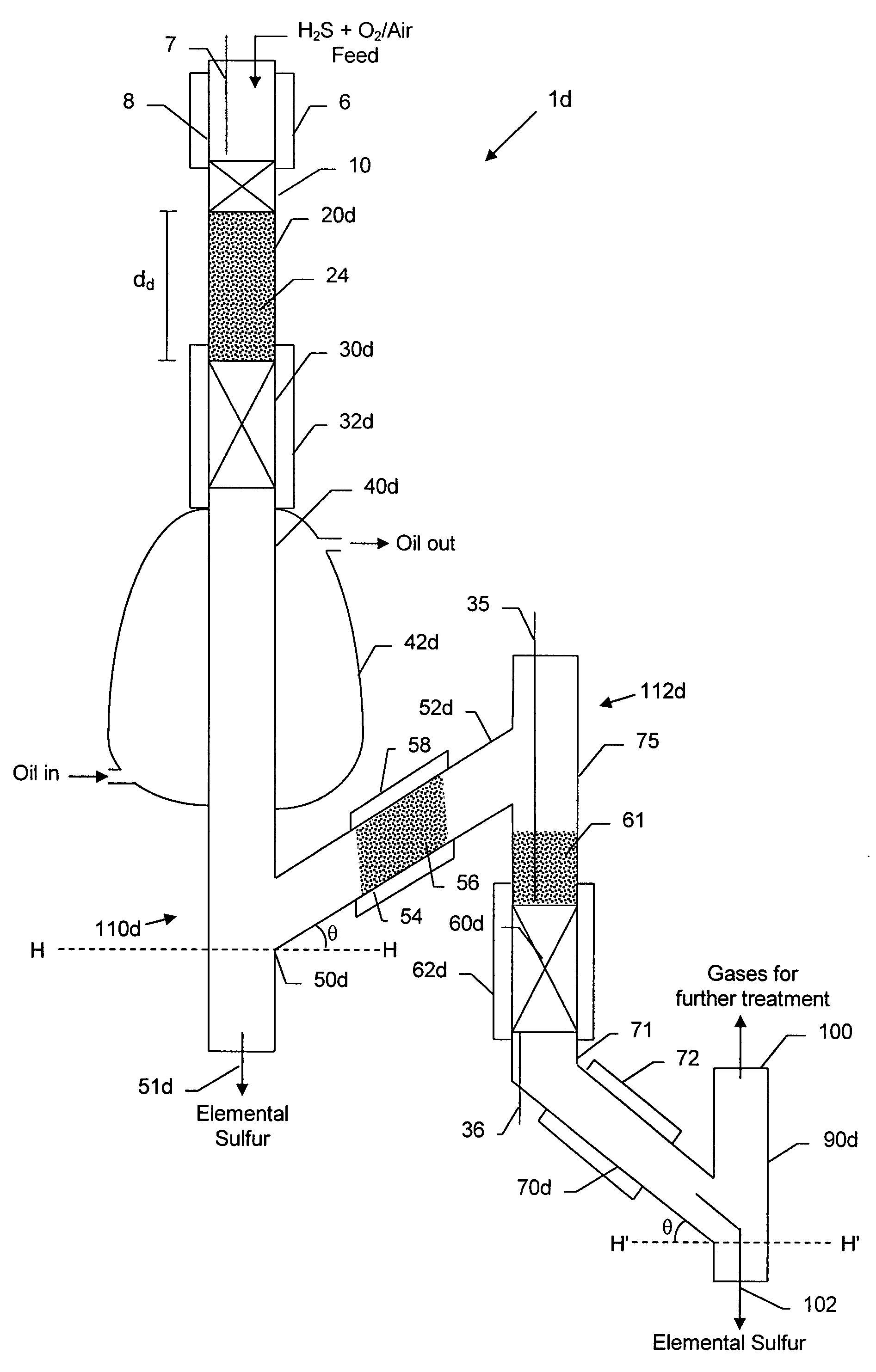

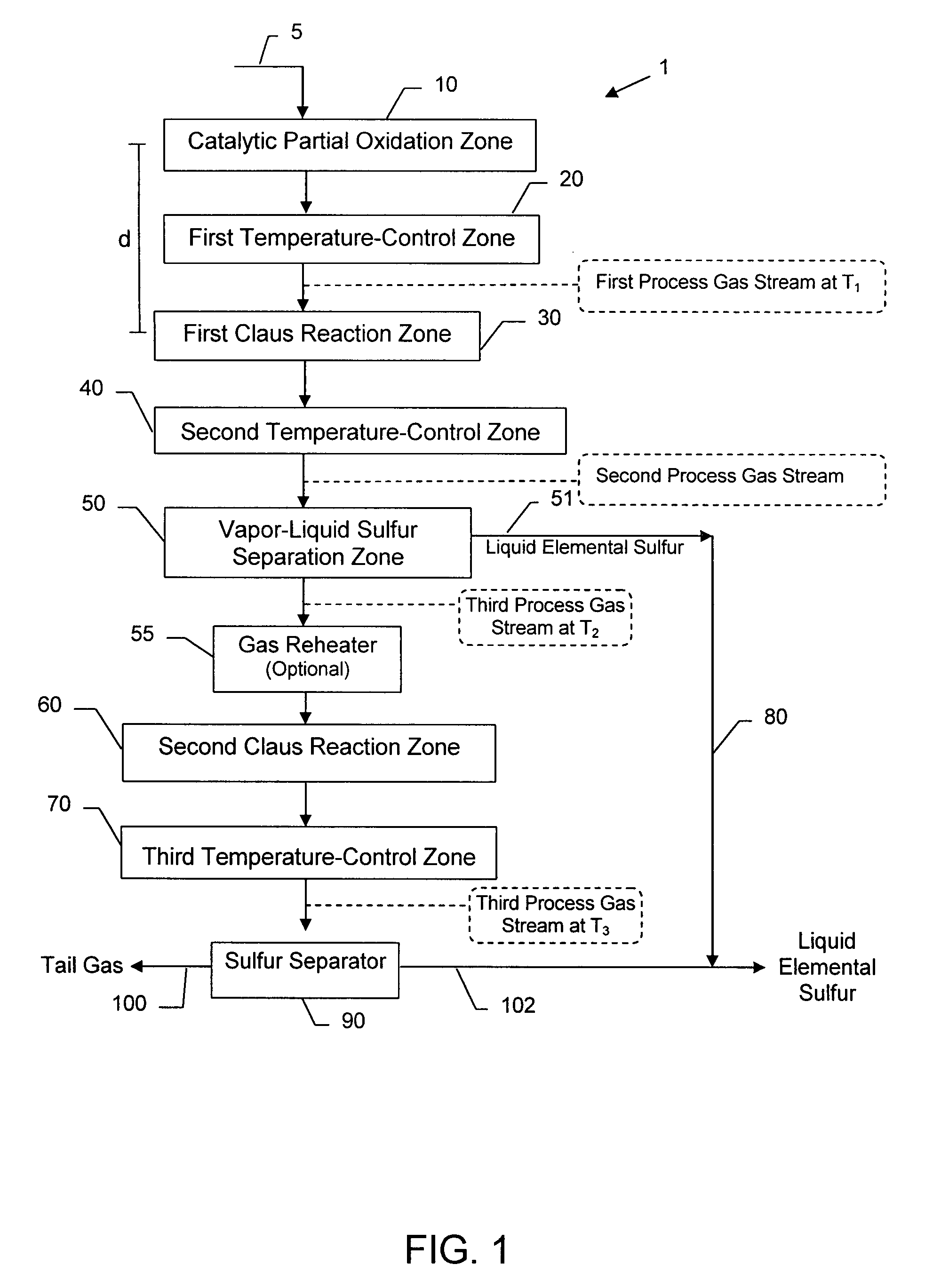

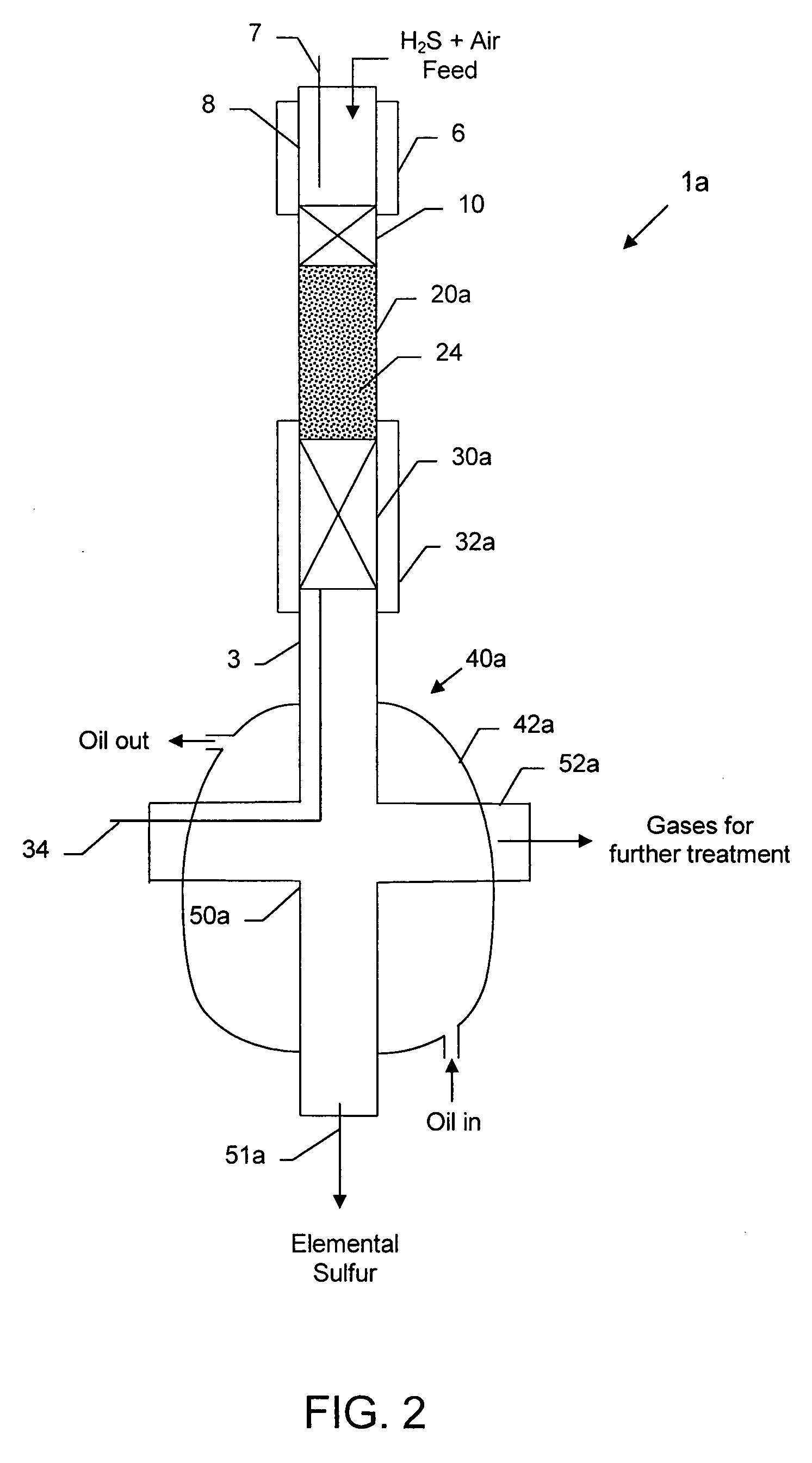

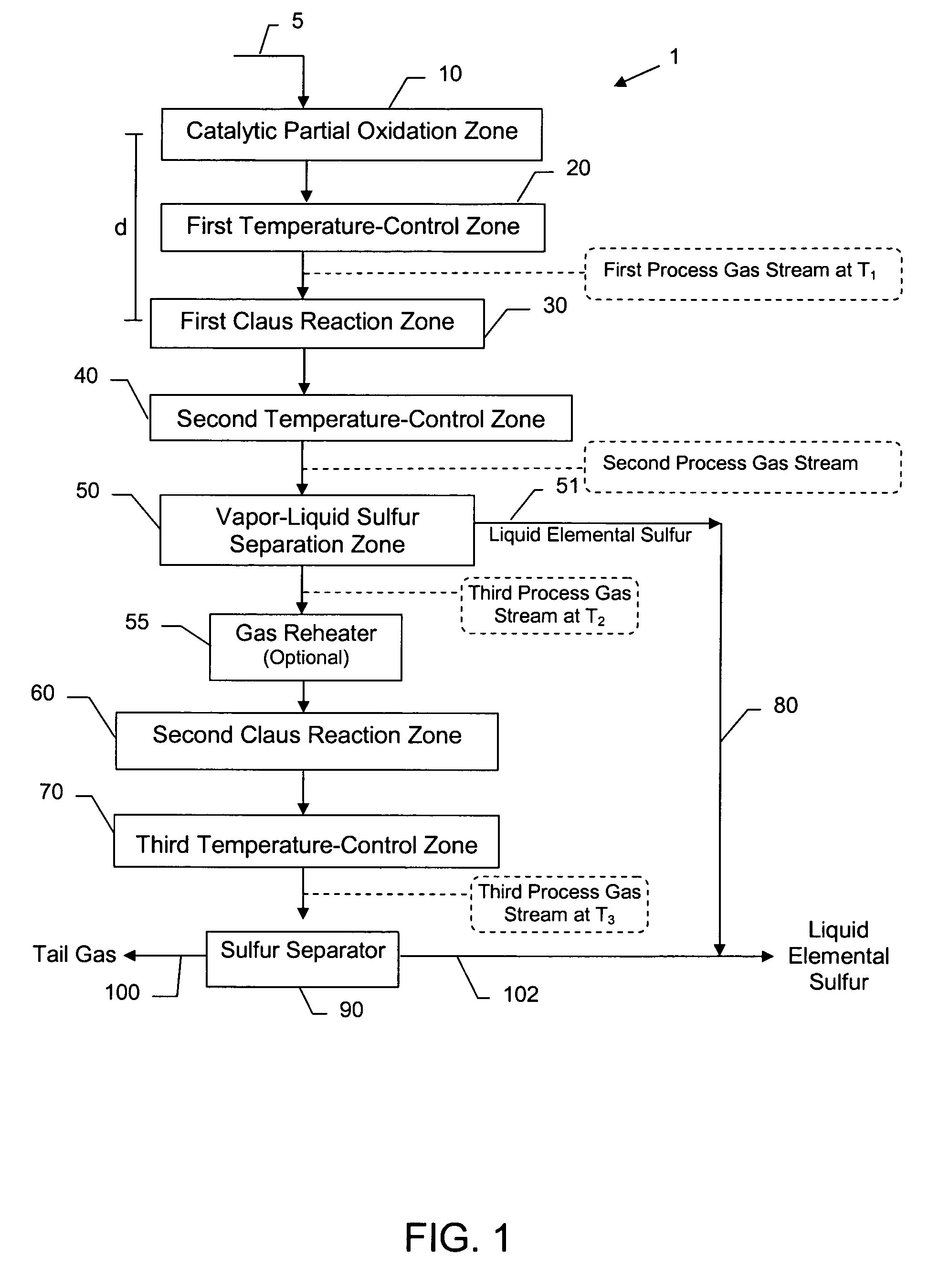

Compact sulfur recovery plant and process

ActiveUS7560088B2Less-costly to buildEasy to controlCombination devicesExhaust apparatusTemperature controlPartial oxidation

A compact sulfur recovery system is disclosed which includes an upflow orientation for the gases through a primary structure including a catalytic partial oxidation reaction zone, a first temperature-control zone, a first Claus catalytic reaction zone, a second temperature-control zone, a first liquid sulfur outlet, and a first effluent gas outlet. The upward flow of the gases puts the hottest gases in contact with the tubes and tube sheet in the waste heat boiler where there is greater confidence in having liquid water in most continuous therewith.

Owner:PHILLIPS 66 CO

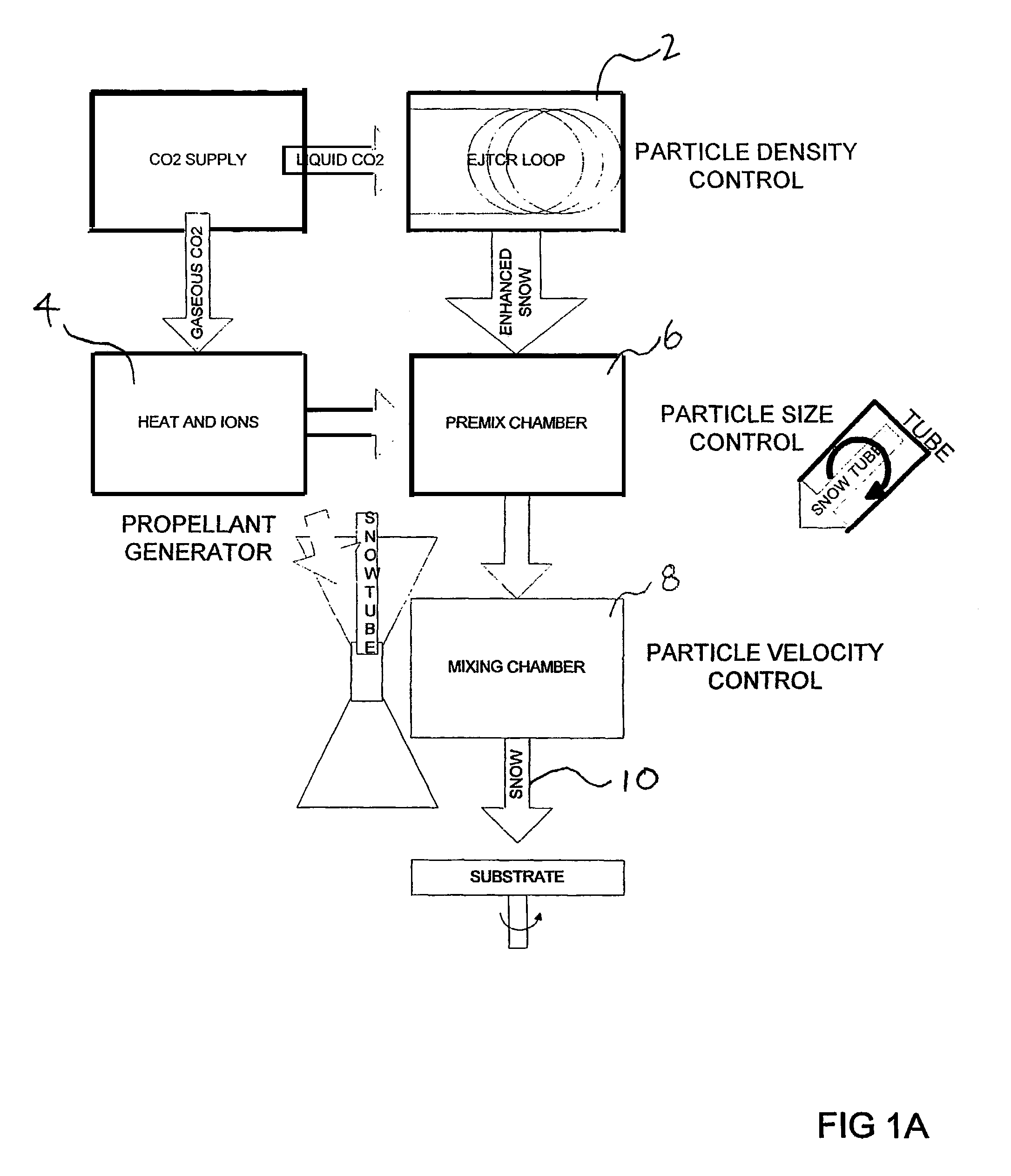

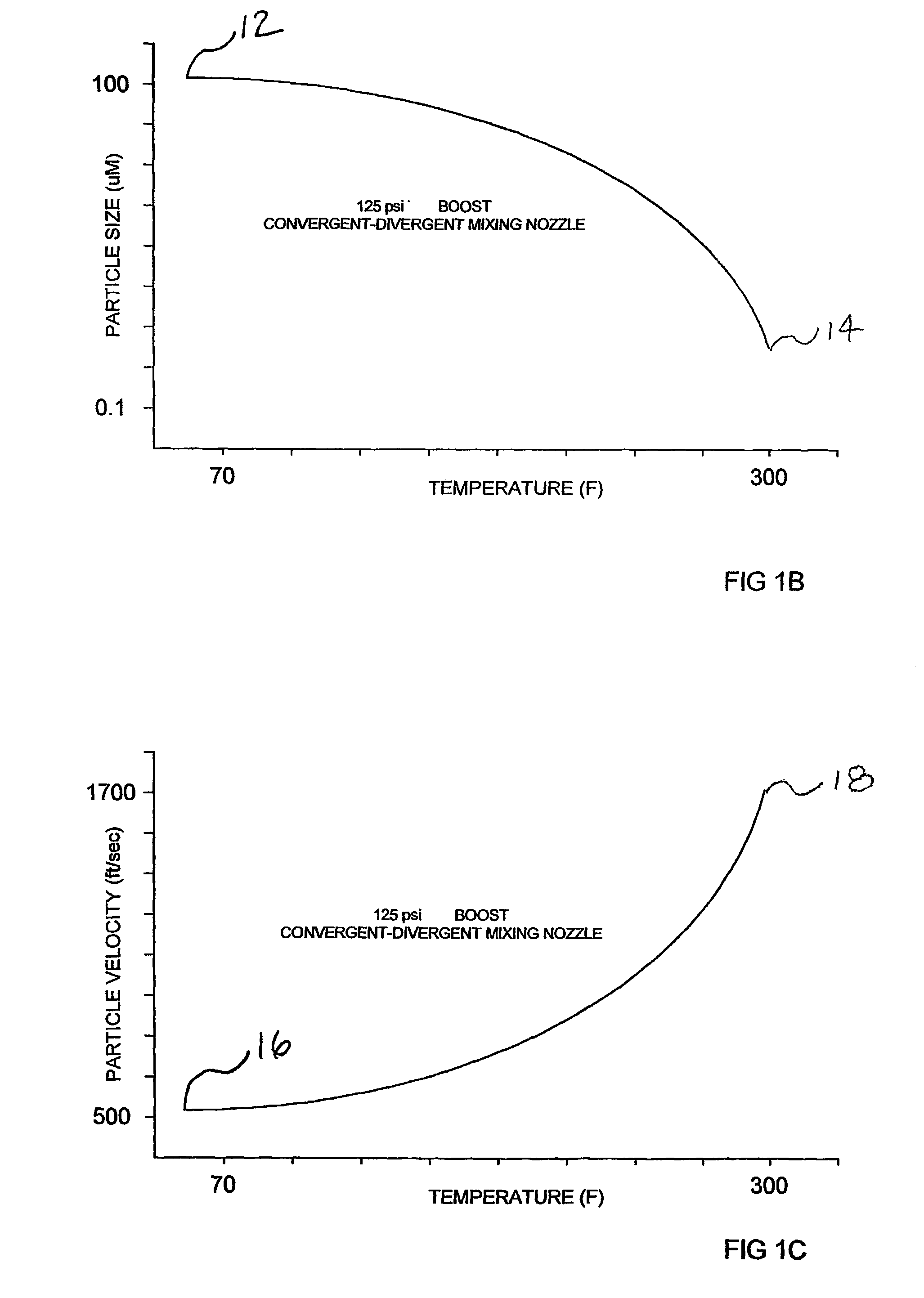

Dense fluid spray cleaning process and apparatus

ActiveUS7451941B2Improve conversion performanceImprove adaptabilitySolid-state devicesAbrasion apparatusParticulatesProcess engineering

Disclosed is a dense fluid spray cleaning apparatus comprising a gas supply (3) for providing a predetermined amount of a gas to an enhanced joule-thompson condensation reactor (2) and for providing gas to a propellant generator (4), a premix chamber (6) for receiving a solid particulate from the enhanced joule thompson condensation reactor and heated gas from the propellant generator, and a mixing chamber (8) for receiving the solid particulate and the heated gas and producing a spray stream containing the solid particulate.

Owner:HITACHI HIGH-TECH CORP

Interleaved, immersion-cooling apparatus and method for an electronic subsystem of an electronics rack

InactiveUS20110315344A1Improve cooling effectFacilitates localized coolingDigital data processing detailsSemiconductor/solid-state device detailsDielectricEngineering

Cooling apparatus and method are provided for immersion-cooling of an electronic subsystem of an electronics rack. The cooling apparatus includes a housing at least partially surrounding and forming a sealed compartment about the electronic subsystem and a dielectric fluid disposed within the sealed compartment so that the electronic subsystem is immersed within the dielectric fluid. A liquid-cooled vapor condenser is provided which includes a plurality of thermally conductive condenser fins extending within the sealed compartment. The condenser fins facilitate cooling and condensing of dielectric fluid vapor generated within the sealed compartment. Within the sealed compartment, multiple thermally conductive condenser fins are interleaved with multiple electronic components immersed within the dielectric fluid to facilitate localized cooling and condensing of dielectric fluid vapor between the multiple electronic components.

Owner:IBM CORP

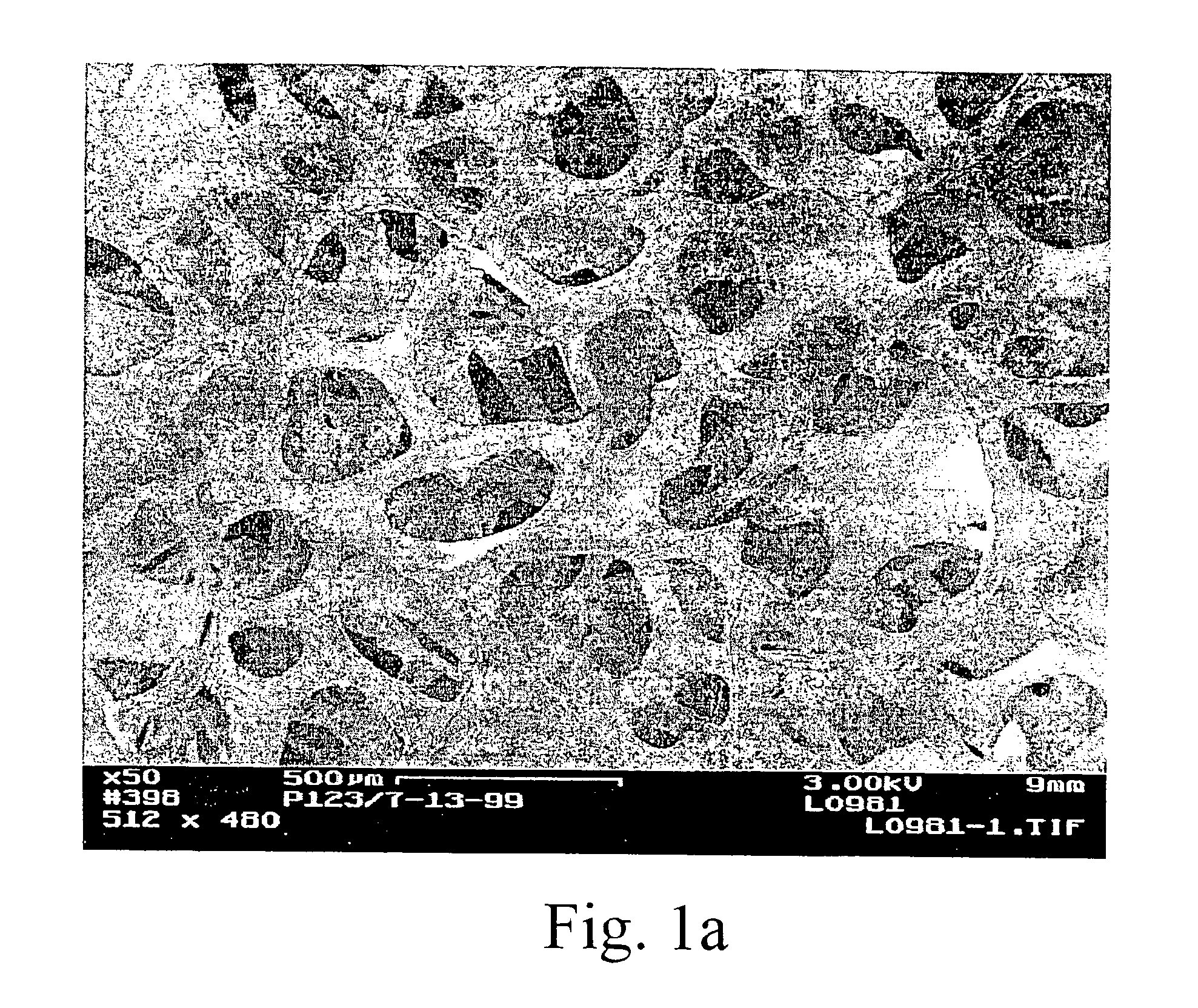

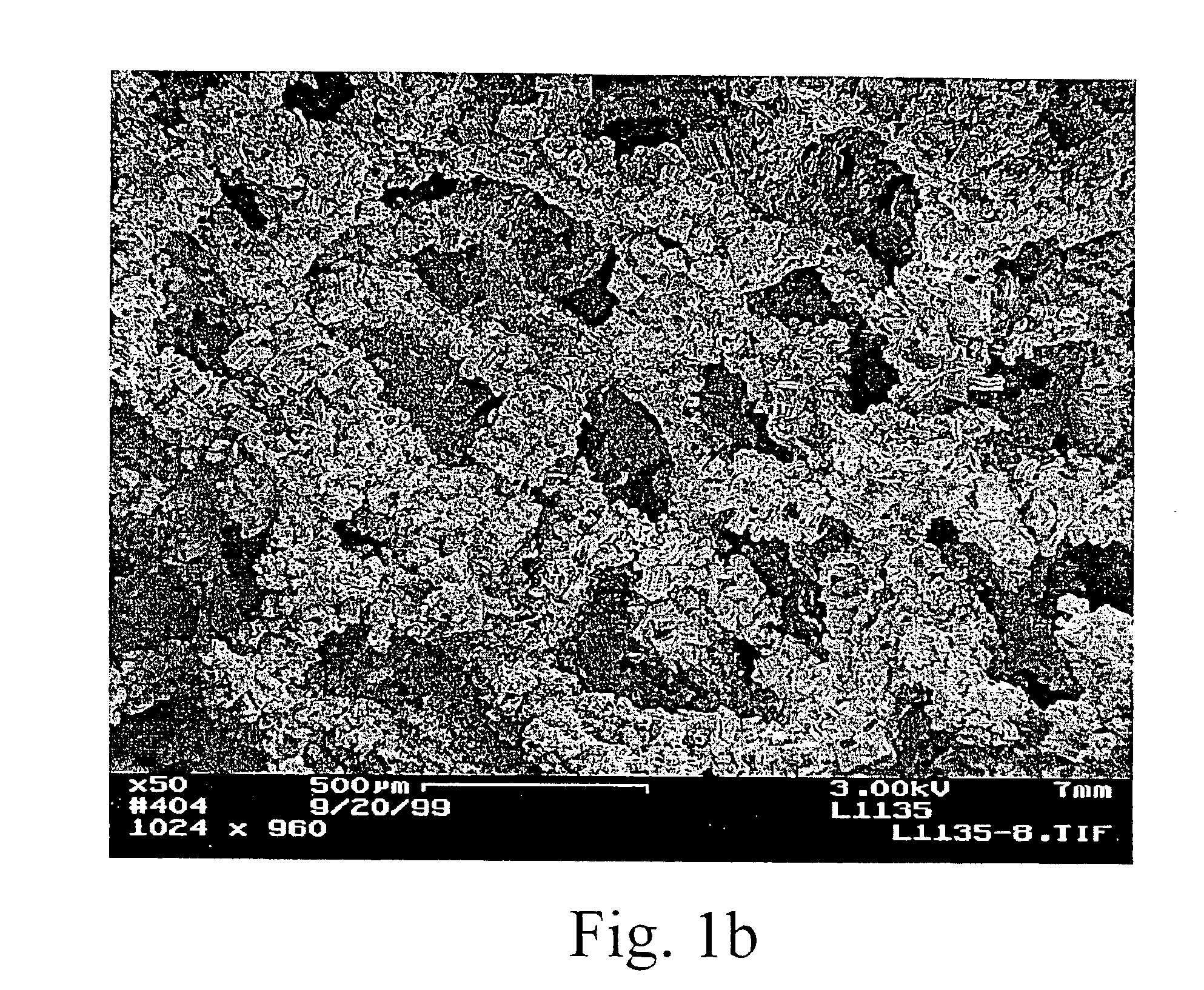

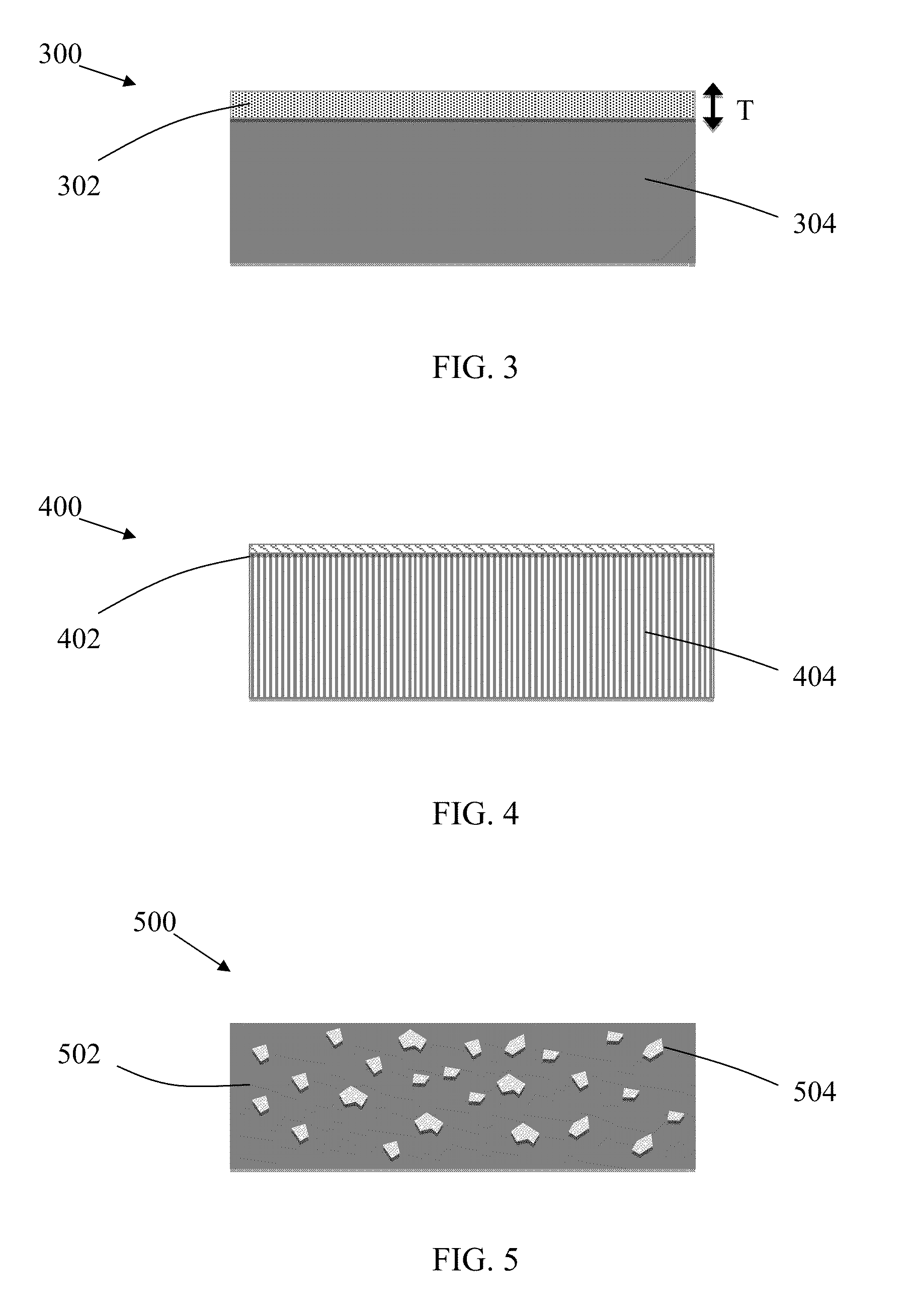

Multi-scale, multi-functional microstructured material

InactiveUS20110311764A1Reduce frictionIncrease frictionLayered productsRecord information storageMaterials scienceMicrostructure

A microstructure disposed on a surface carried by an object comprising: a first set of microfeatures carried by the object wherein said first set of microfeatures causes the surface of the object to exhibit physical properties differing from physical properties exhibited by a non-microstructured surface; and, a second set of microfeatures carried by said surface wherein said second set of microfeatures causes the surface of the object to exhibit physical properties differing from physical properties exhibited by the non-microstructured surface and by said first set of microfeatures.

Owner:HOOWAKI

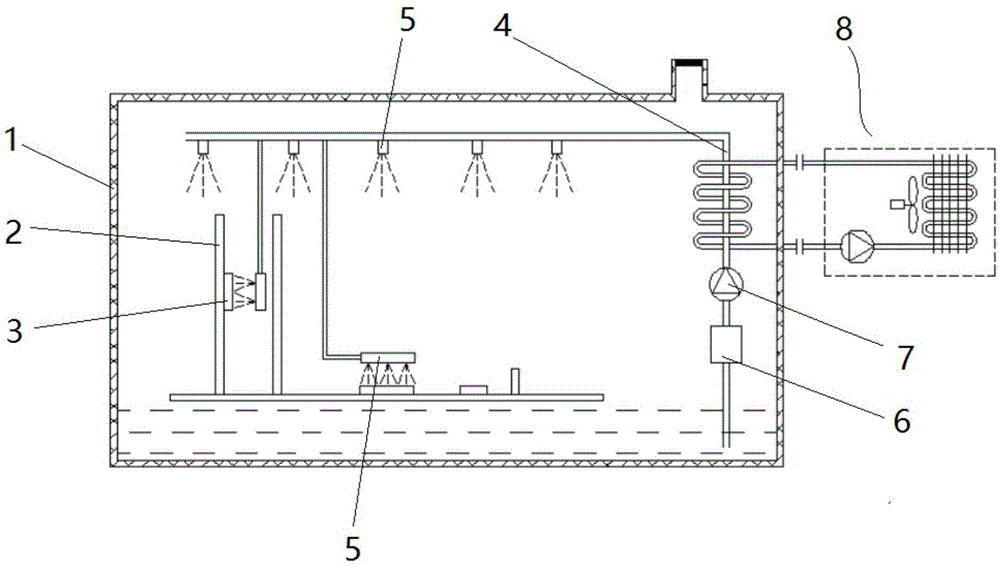

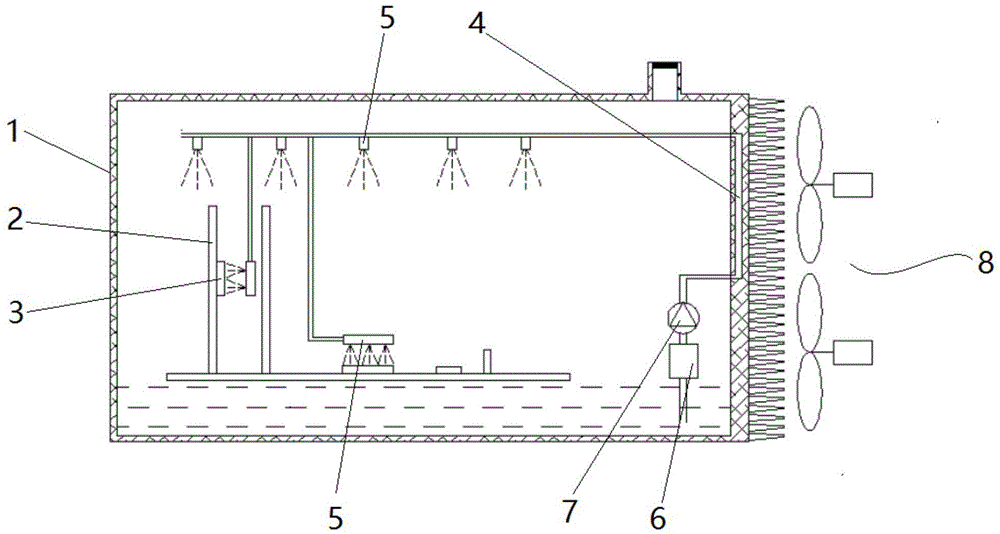

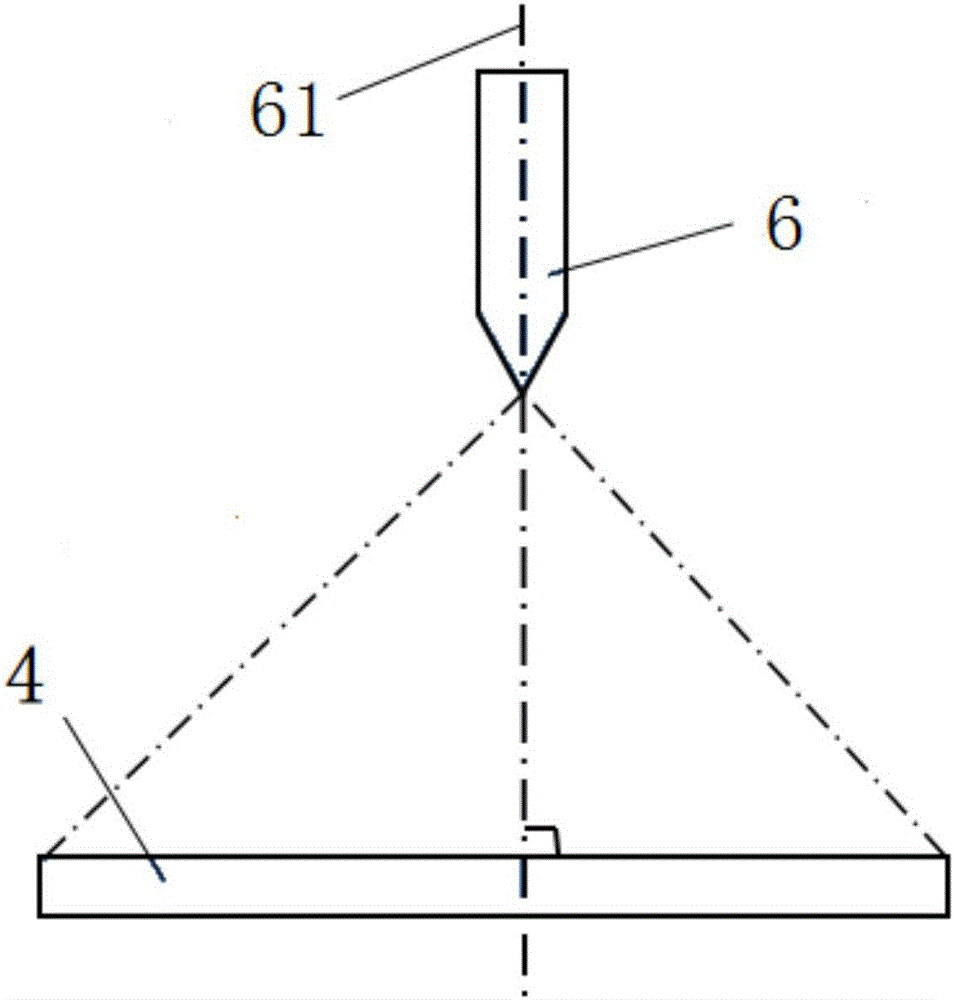

Electronic device and heat radiation device utilizing liquid cooling heat radiation and cooling method thereof

ActiveCN105025691AEnhanced heat transferImprove cooling efficiencyDigital data processing detailsCooling/ventilation/heating modificationsSystem structureNuclear engineering

The invention provides an electronic device utilizing liquid cooling heat radiation. The electronic device comprises a shell, a circuit board and a liquid cooling heat radiation module. The circuit board and the liquid cooling heat radiation module are arranged in the shell. The circuit board is provided with one or multiple heating devices. The liquid cooling heat radiation module comprises a liquid inlet pipeline and nozzles which are arranged on the liquid inlet pipeline. Cooling liquid is conducted into the shell from the outside of the shell by the liquid inlet pipeline. Cooling liquid is sprayed in a space formed by the shell by the nozzles to cool the heating devices. Cooling liquid steam after heat exchange is mixed with cooling liquid sprayed by the nozzles so that the cooling liquid steam is enabled to be condensed. Compared with an existing direct liquid cooling heat radiation device, the electronic device utilizing liquid cooling heat radiation has advantages of being low in demand for cooling liquid, low in weight, simple in system structure, high in heat exchange capability and high in environmental adaptability and has quite high application potential.

Owner:沈珂

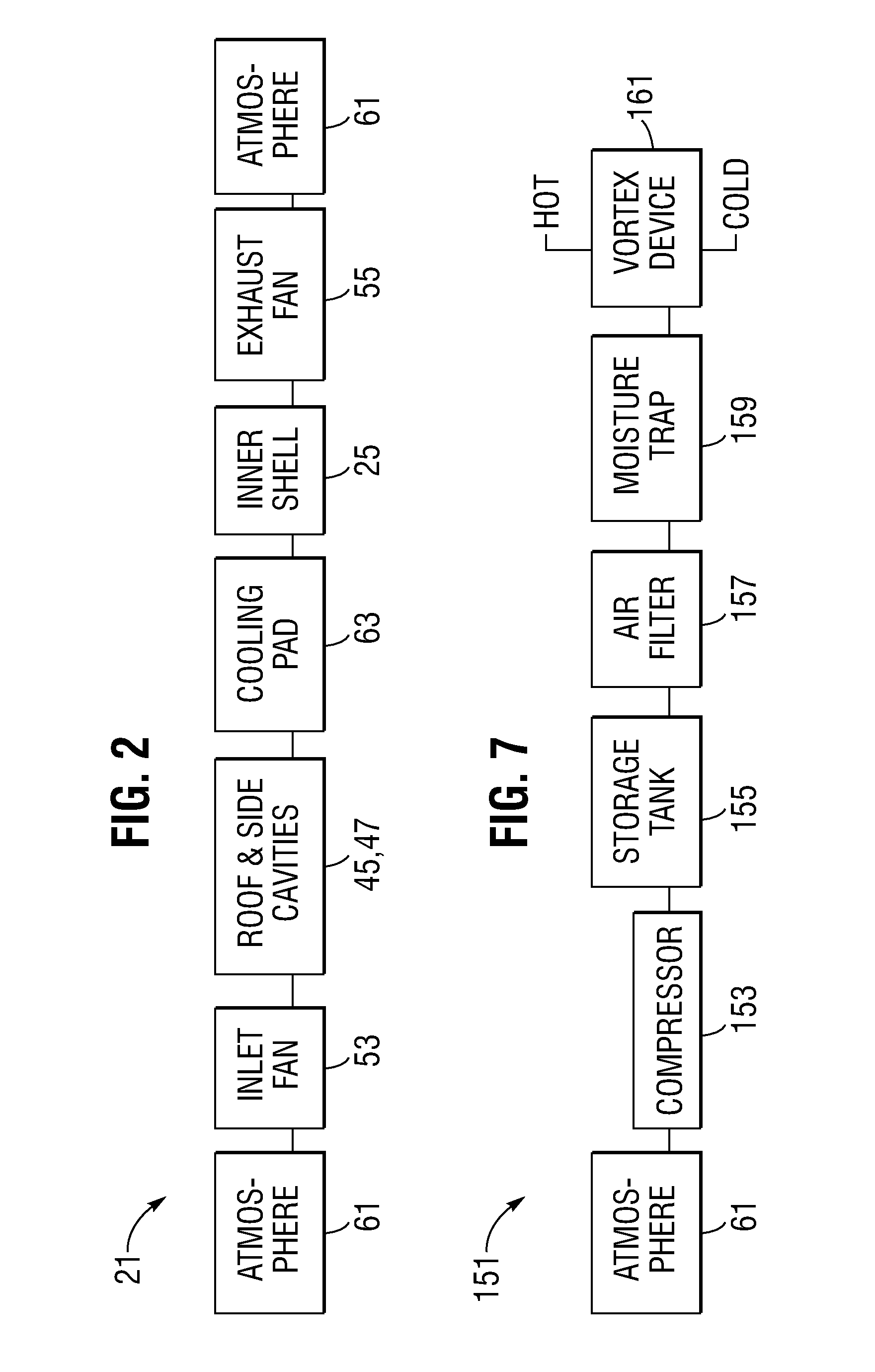

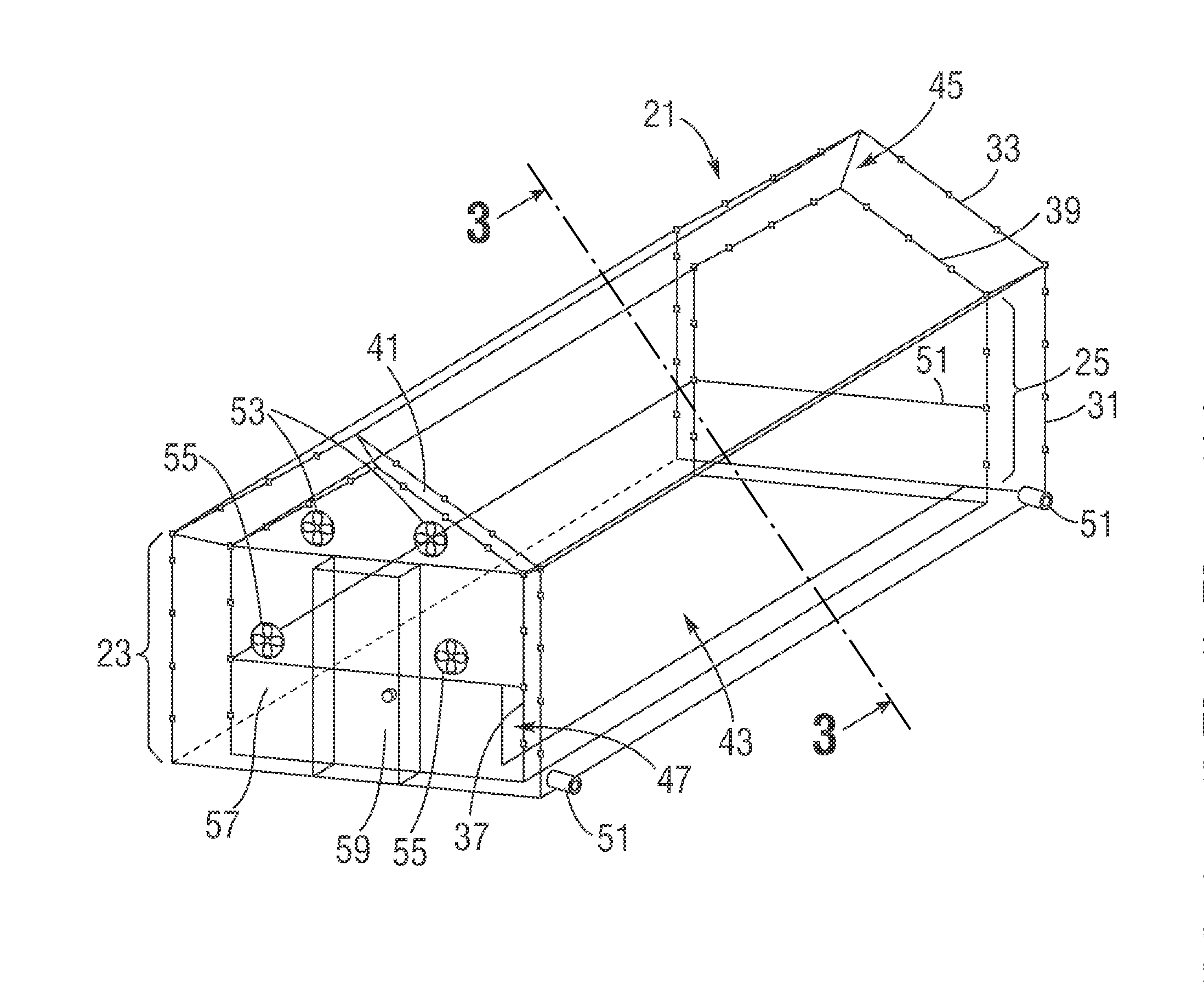

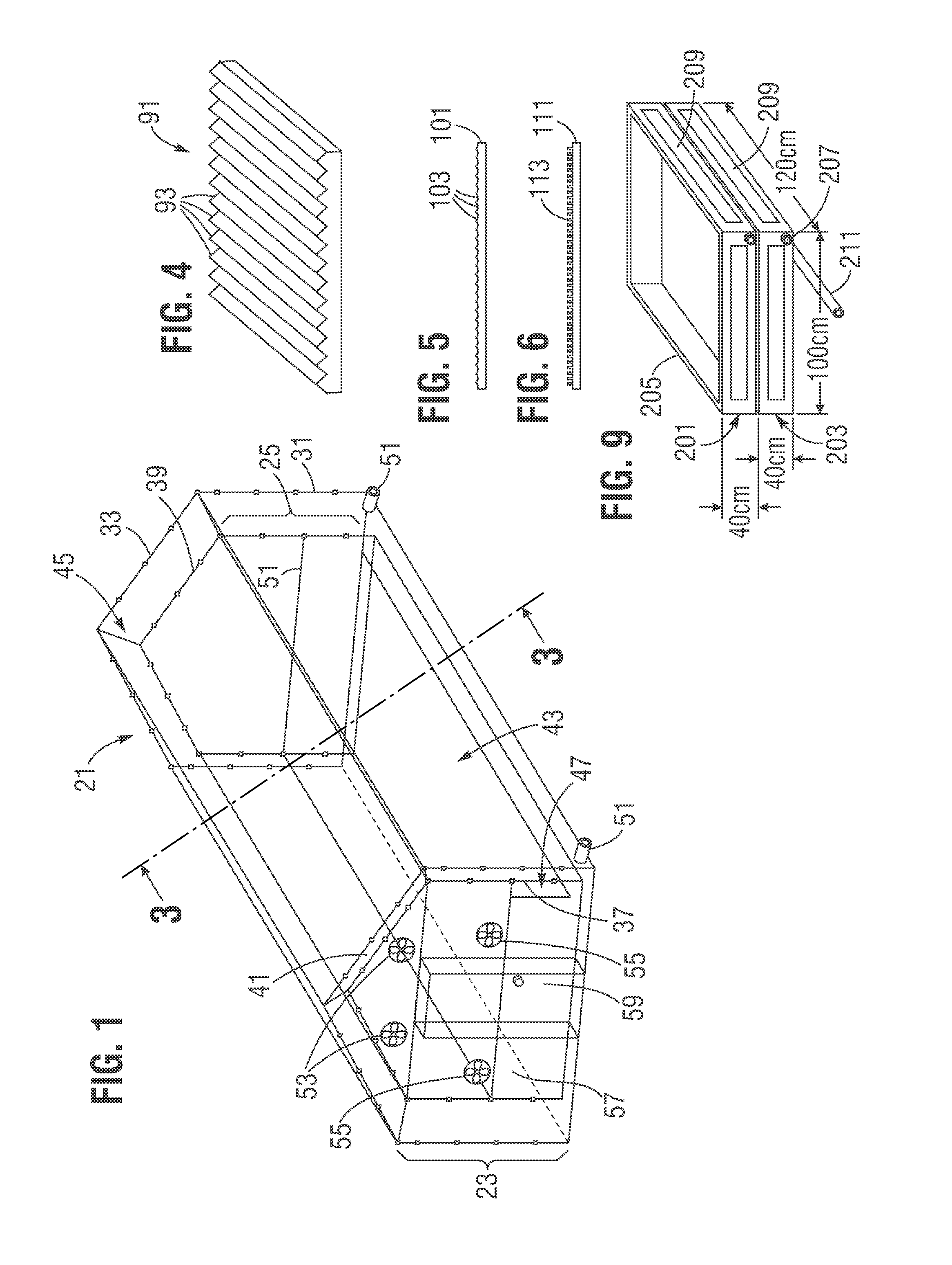

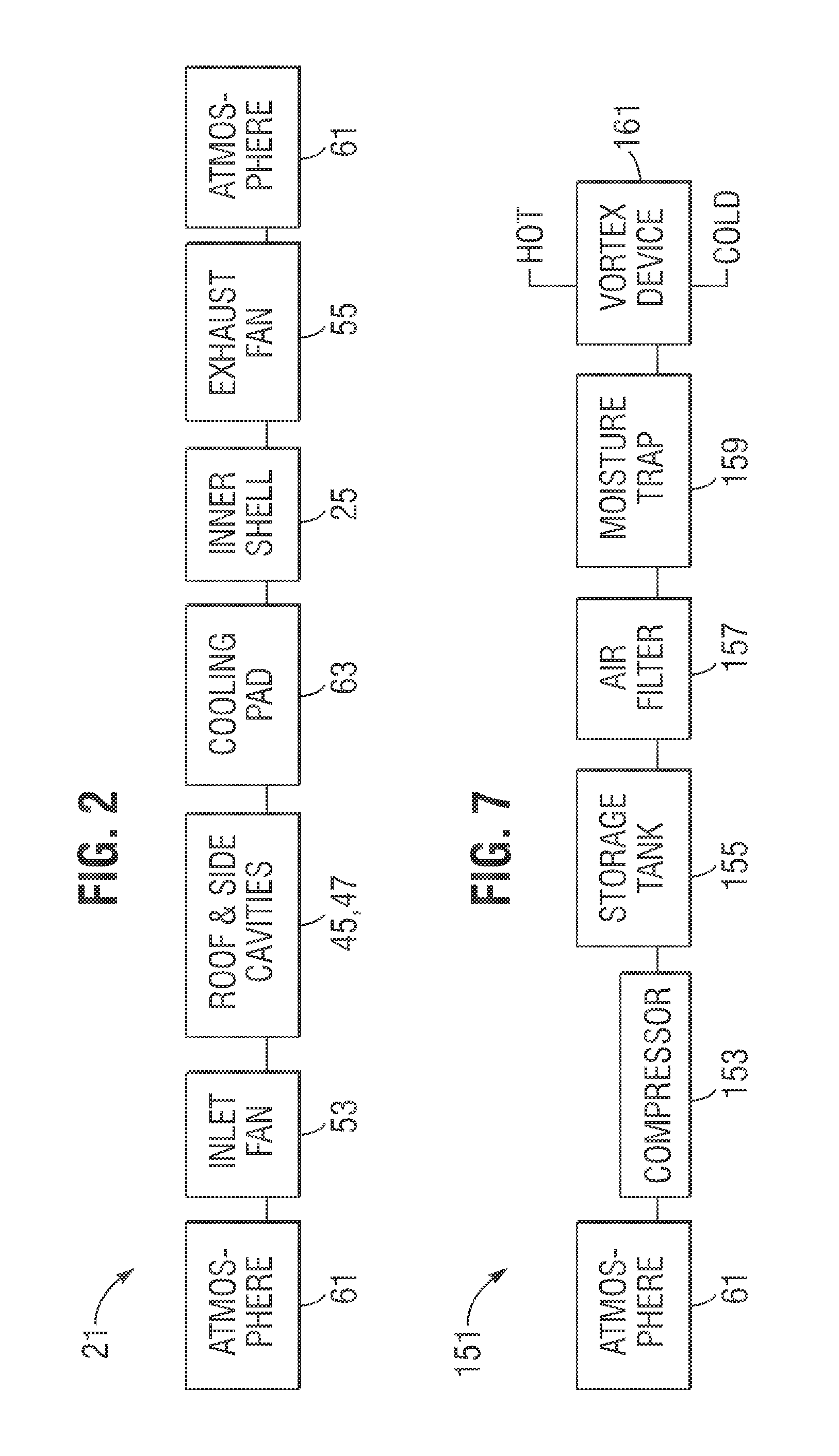

Desalination greenhouse

InactiveUS20130192131A1High purityLow production costClimate change adaptationGreenhouse cultivationWater useWater source

A desalination greenhouse of the invention provides both winter and summer crop growing operations and to produce a source of potable water given an input of only brackish or sea water. A consistency of temperature is produced by insulation and compensating absorption of heat in summer, with the release of heat in winter to keep crops more isothermal, but without obstructing natural light transmission to the crops. A very thin layer of brackish or salt water is evaporated from an inner shell and condensed onto an outer shell. Supplemental heat exchange can be applied to cool water used for crop irrigation.

Owner:ABAHUSAYN MANSUR

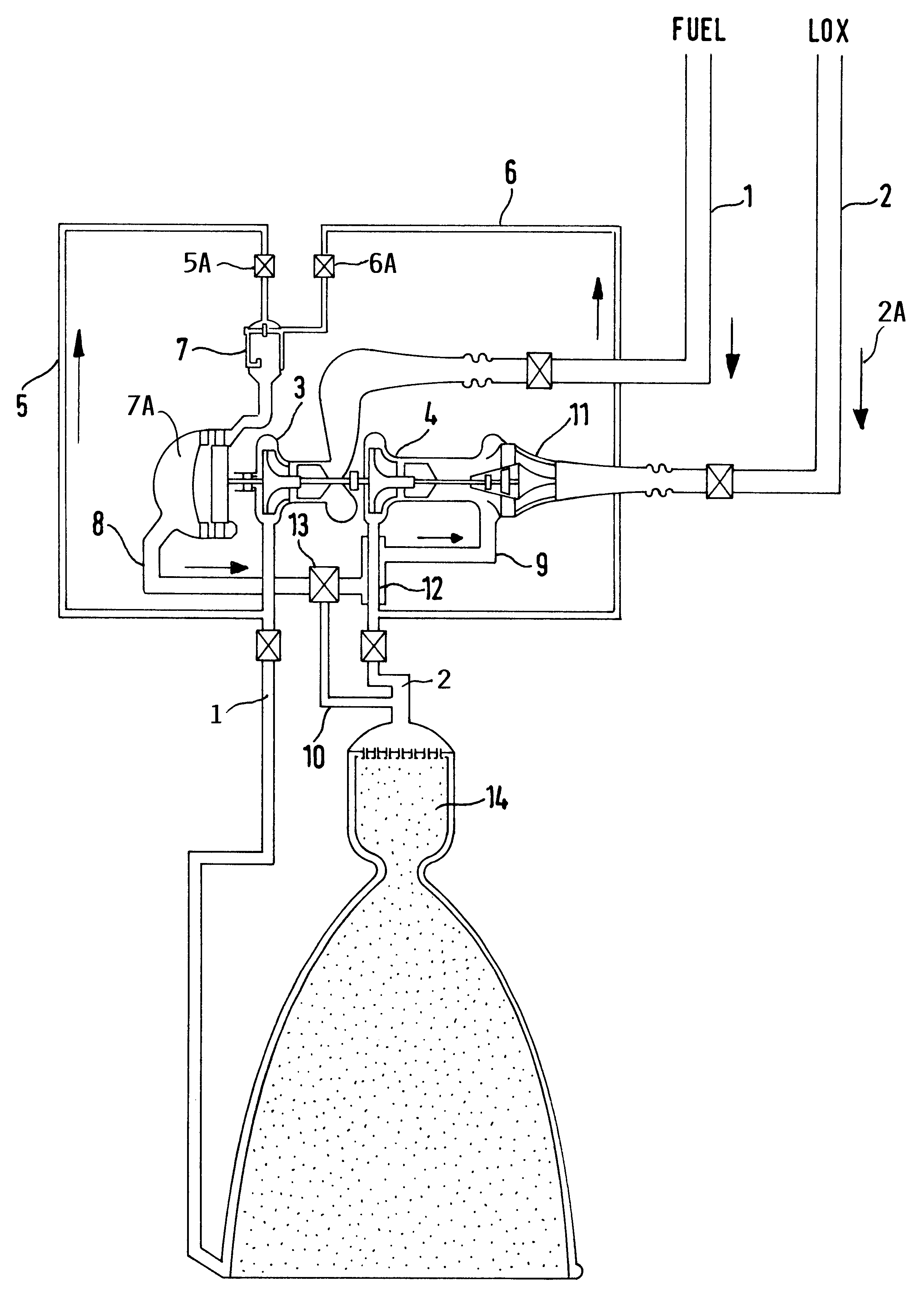

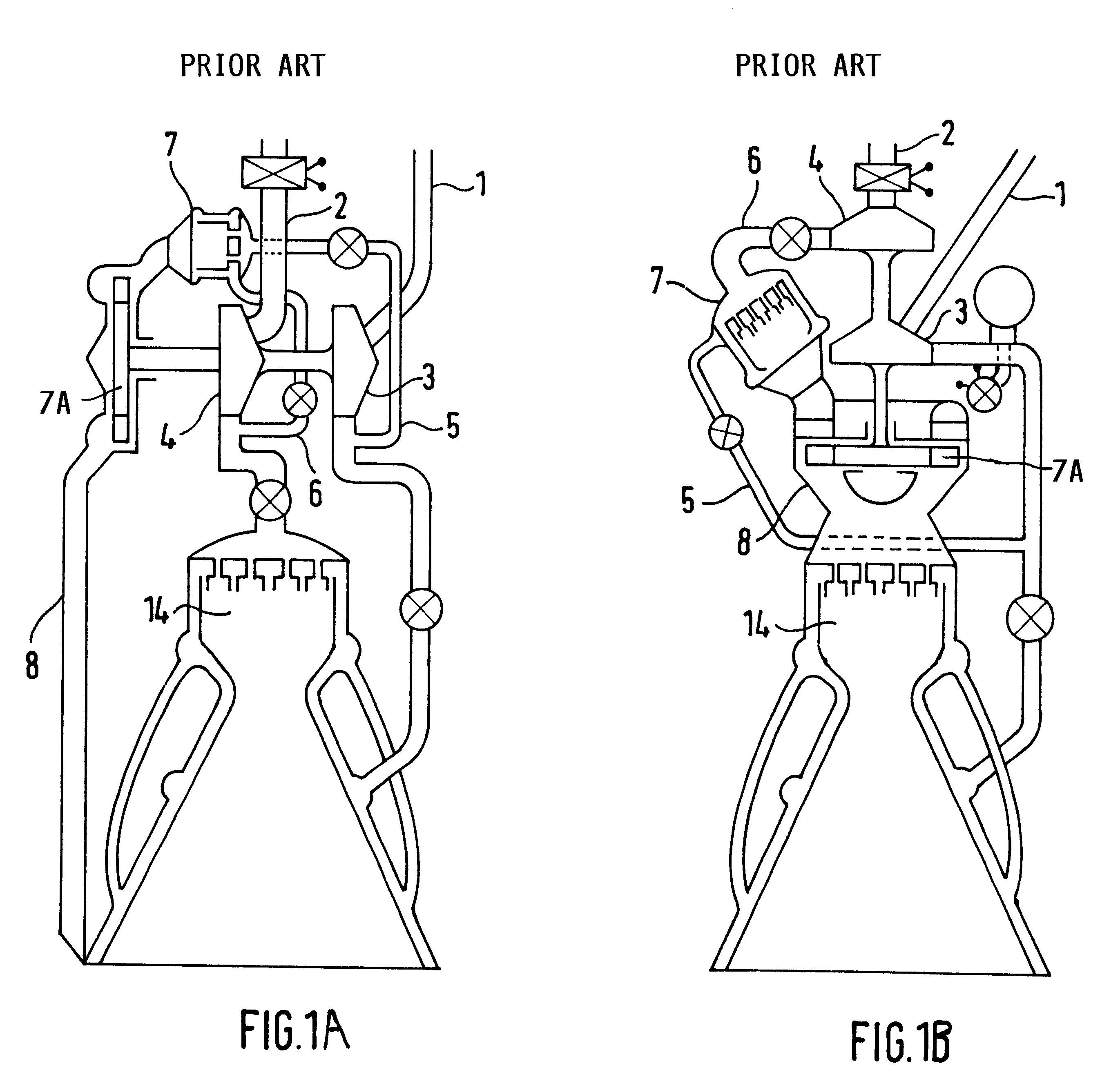

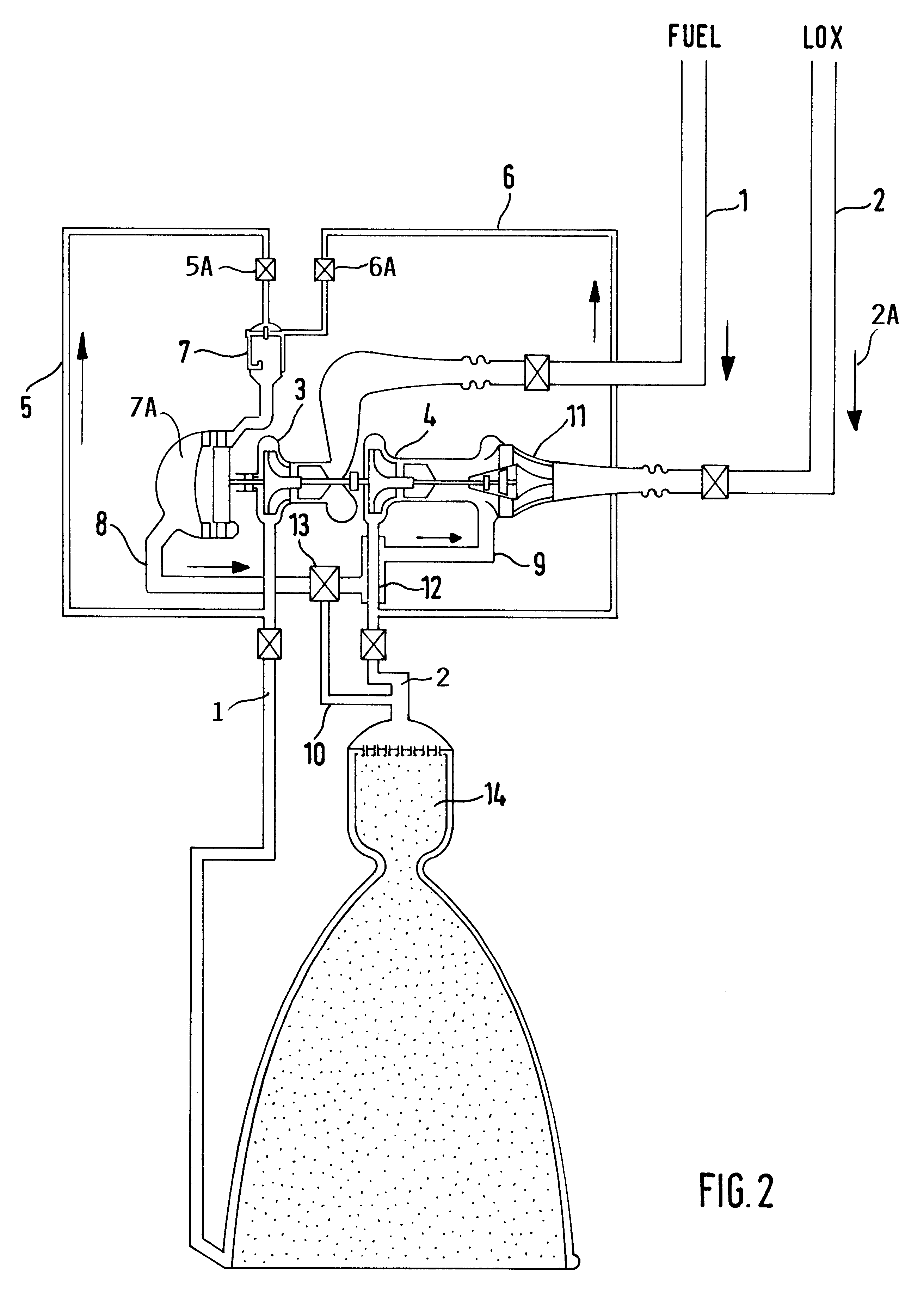

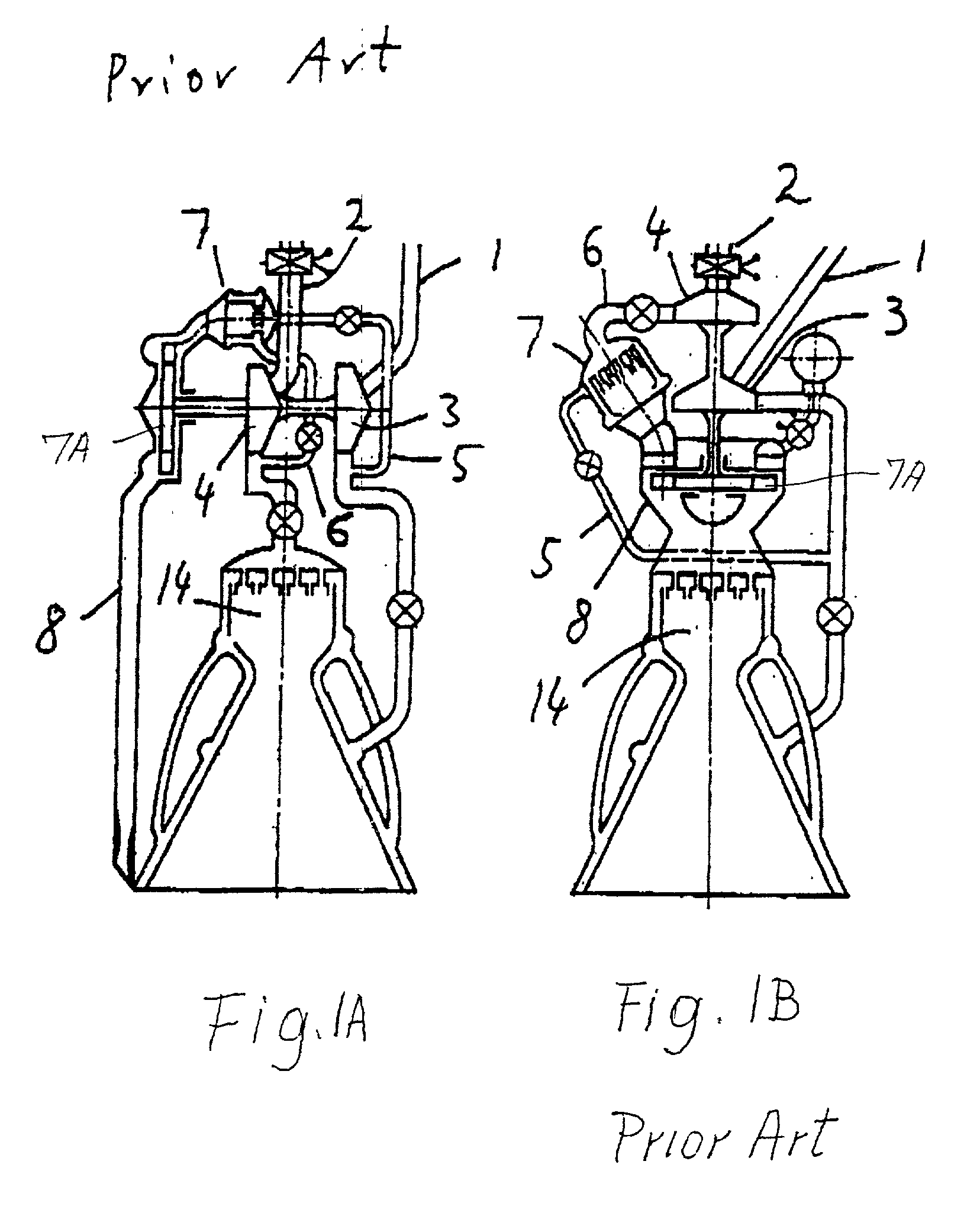

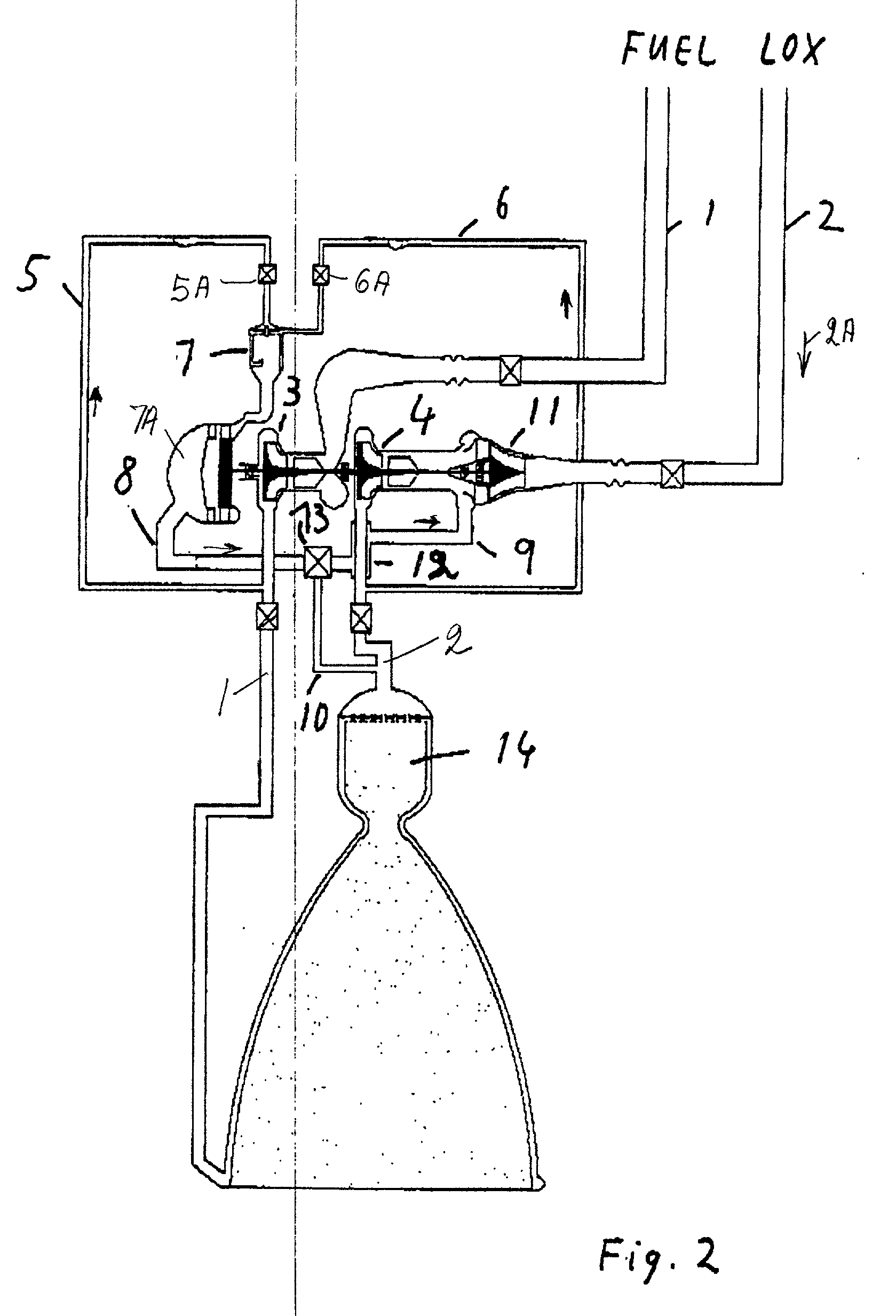

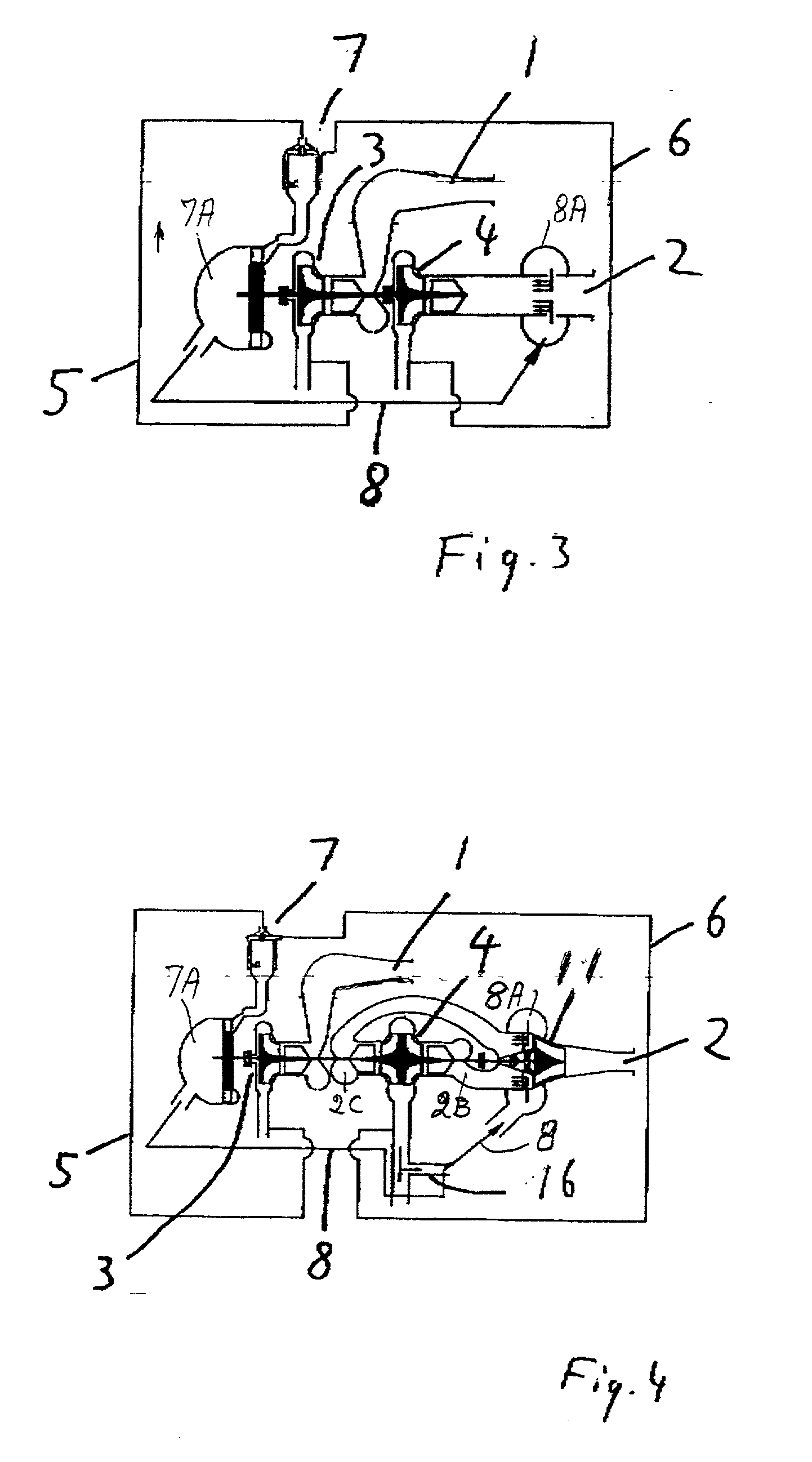

Liquid fuel rocket engine with a closed flow cycle

InactiveUS6470670B2Easy constructionReduce the temperatureRocket engine plantsCombustion chamberProduct gas

A liquid fuel rocket engine with a closed direct auxiliary flow cycle has a combustion chamber connected to each liquid fuel source through a respective main liquid fuel supply line. A turbo pump is provided in each main fuel supply line. The turbo pump is driven by a gas generator which is connected to a first bypass fuel supply line for supplying fuel to the gas generator. An exhaust gas duct (8, 9, 10) leads from the gas generator into at least one main fuel supply line for feeding gas generator exhaust gas into the main fuel supply line upstream of the turbo pump.

Owner:ASTRIUM GMBH

Direct coolant contact vapor condensing

InactiveUS9313920B2Optimize workflowFacilitates ingress of the coolantDigital data processing detailsSubstation/switching arrangement cooling/ventilationLiquid layerWorking fluid

Cooling apparatuses and methods are provided facilitating transfer of heat from a working fluid to a coolant. The cooling apparatus includes a vapor condenser which includes a condenser housing with a condensing chamber accommodating the working fluid and coolant, which are in direct contact within the condensing chamber and are immiscible fluids. The condensing chamber includes a working fluid vapor layer and a working fluid liquid layer; and a working fluid vapor inlet facilitates flow of fluid vapor into the condensing chamber, and a working fluid vapor outlet facilitates egress of working fluid liquid from the condensing chamber. A coolant inlet structure facilitates ingress of coolant into the working fluid vapor layer of the condensing chamber in direct contact with the working fluid vapor to facilitate condensing the vapor into working fluid liquid, and the coolant outlet structure facilitates subsequent egress of coolant from the condensing chamber.

Owner:IBM CORP

Liquid fuel rocket engine with a closed flow cycle

InactiveUS20010015063A1Easy constructionReduce the temperatureRocket engine plantsCombustion chamberProduct gas

A liquid fuel rocket engine with a closed direct auxiliary flow cycle has a combustion chamber connected to each liquid fuel source through a respective main liquid fuel supply line. A turbo pump is provided in each main fuel supply line. The turbo pump is driven by a gas generator which is connected to a first bypass fuel supply line for supplying fuel to the gas generator. An exhaust gas duct (8, 9, 10) leads from the gas generator into at least one main fuel supply line for feeding gas generator exhaust gas into the main fuel supply line upstream of the turbo pump.

Owner:ASTRIUM GMBH

Desalination greenhouse

InactiveUS20150223409A1Increase temperatureReduce humidityClimate change adaptationRenewable energy machinesWater desalinationMoisture

A desalination greenhouse includes a method of fresh water production hybridized with growth and production of a crop. The co-location of a growing crop can provide additional economic incentive to a hybrid system, and provide a moisture enhancement to an internal atmosphere which can be utilized to more efficiently produce and yet benefit from the production of water without the salt content, and as well to concentrate the salt content of brine which is used in another salt production operation. A further substantial achievement could be obtained by desalinization of water by using renewable energy economically and saving 95% of water normally used in open field irrigation of crops.

Owner:ABAHUSAYN MANSUR

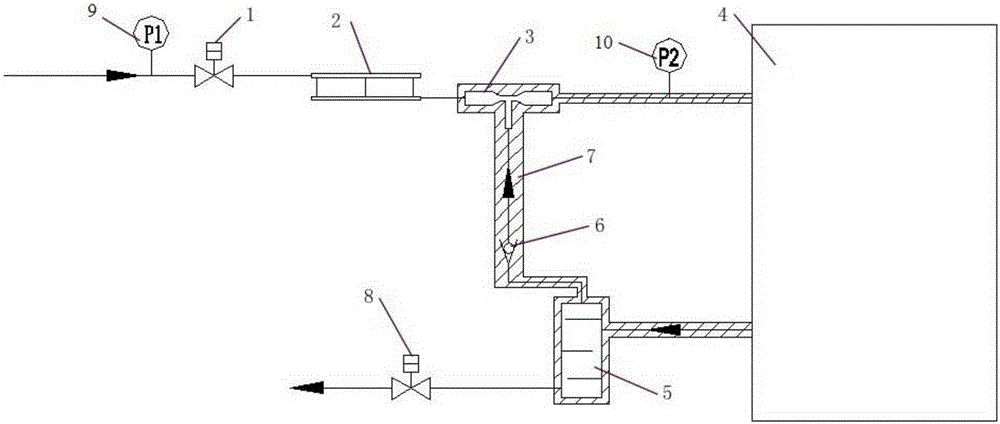

Electrically controlled hydrogen-spraying pressure regulating device of fuel cell system

InactiveCN105186016AImprove working environmentImprove working conditionsFuel cell auxillariesIntake pressureElectric energy

The invention relates to an electrically controlled hydrogen-spraying pressure regulating device of a fuel cell system, which is used for controlling air inflow at the hydrogen side of the fuel cell system. The electrically controlled hydrogen-spraying pressure regulating device comprises a fuel cell stack which is used for performing reaction of a hydrogen fuel cell to generate electric energy; a hydrogen side inlet pressure control component which is connected with a hydrogen inlet pipe of the fuel cell stack and is used for controlling an inlet pressure of the hydrogen and backflow of the hydrogen; a draining component which is connected with a hydrogen drain pipe of the fuel cell pack and is used for draining wastewater; and a controller which is respectively connected with the hydrogen side inlet pressure control component and the hydrogen draining component and is used for controlling the hydrogen side inlet pressure control component and the hydrogen draining component and regulating the hydrogen inlet side pressure. In comparison with the prior art, the electrically controlled hydrogen-spraying pressure regulating device of the fuel cell system has the advantages of improving the working environment of the fuel cell, being safe and reliable, being capable of preventing backflow, keeping the temperature of the returned hydrogen and the like.

Owner:TONGJI UNIV

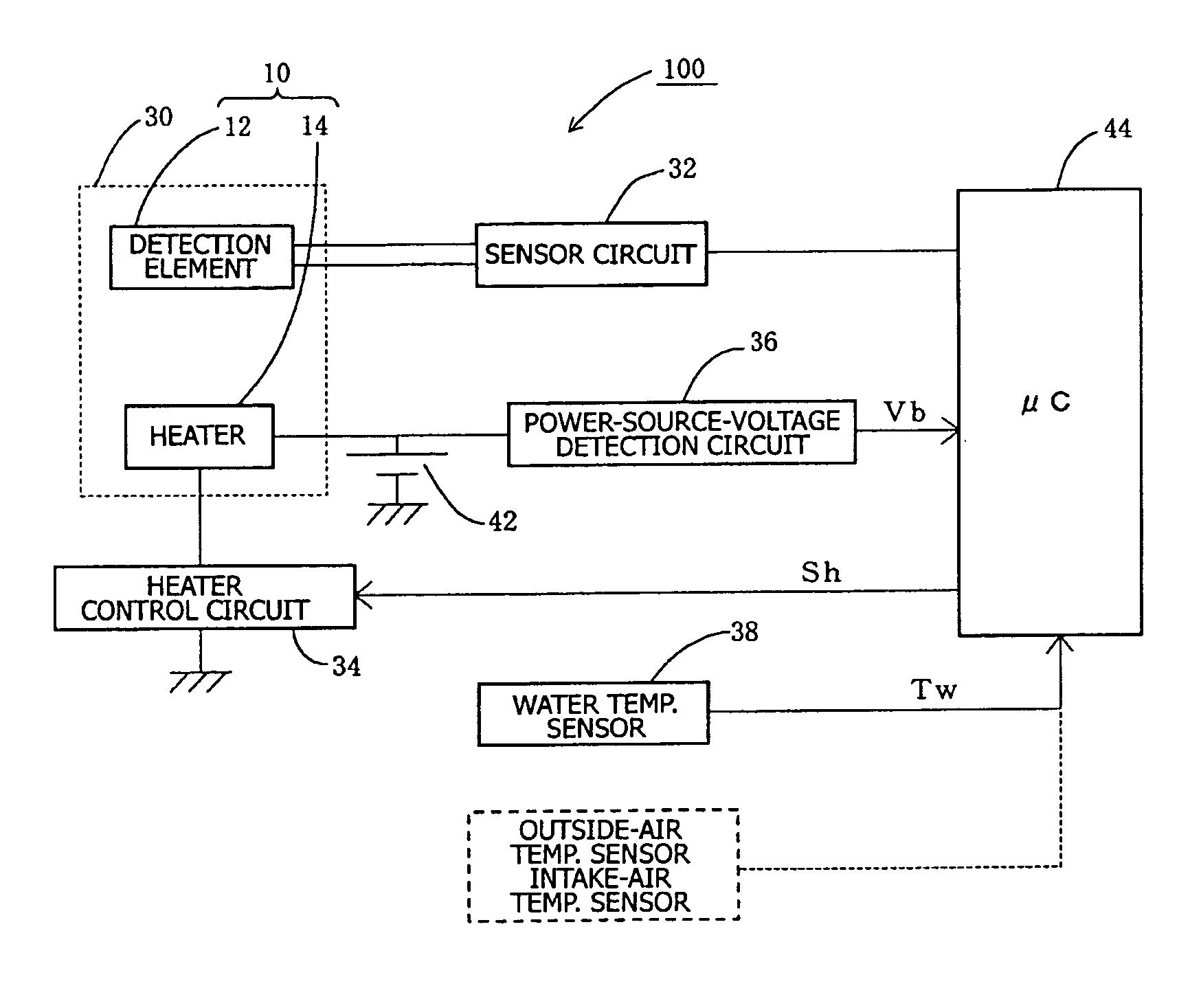

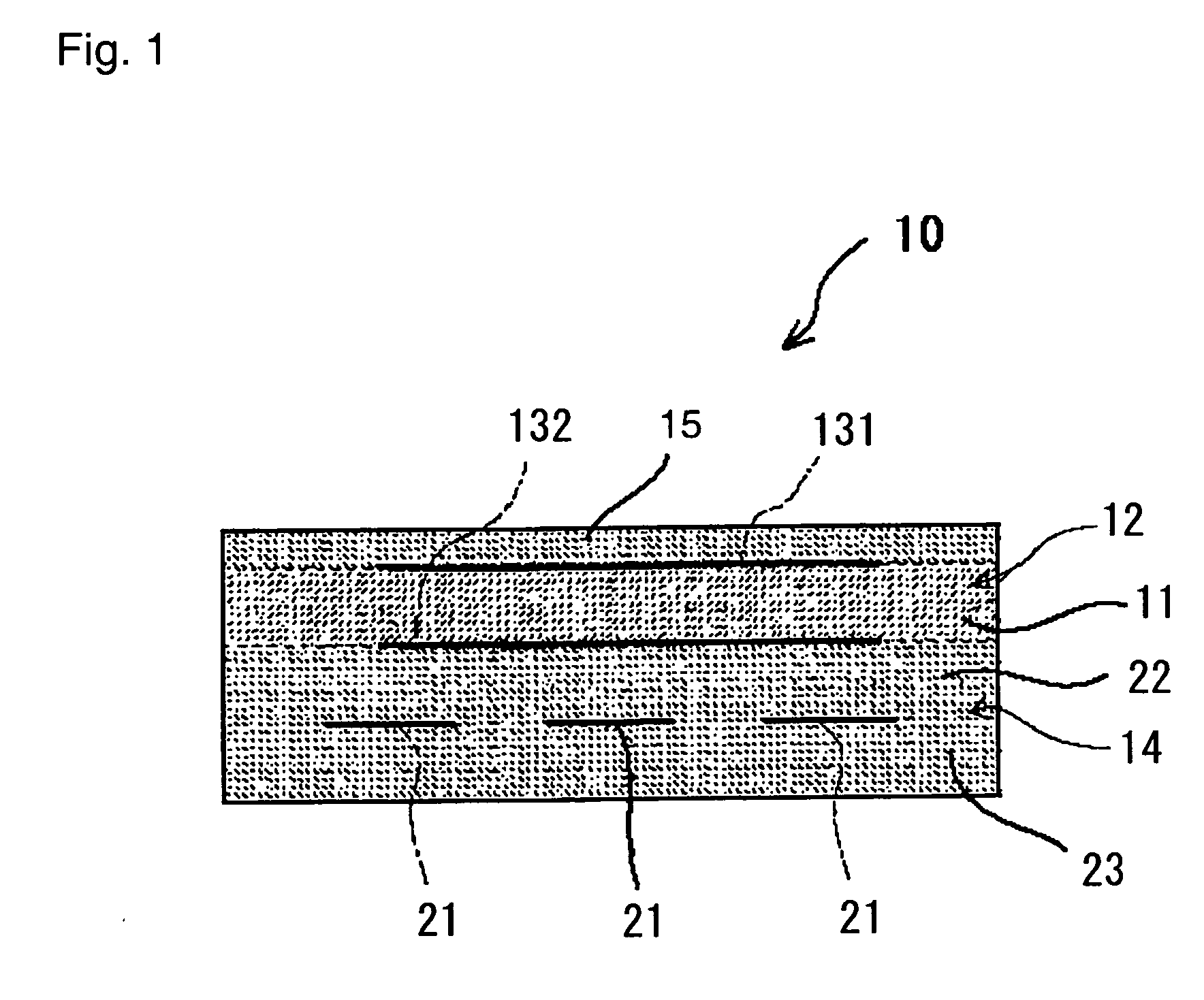

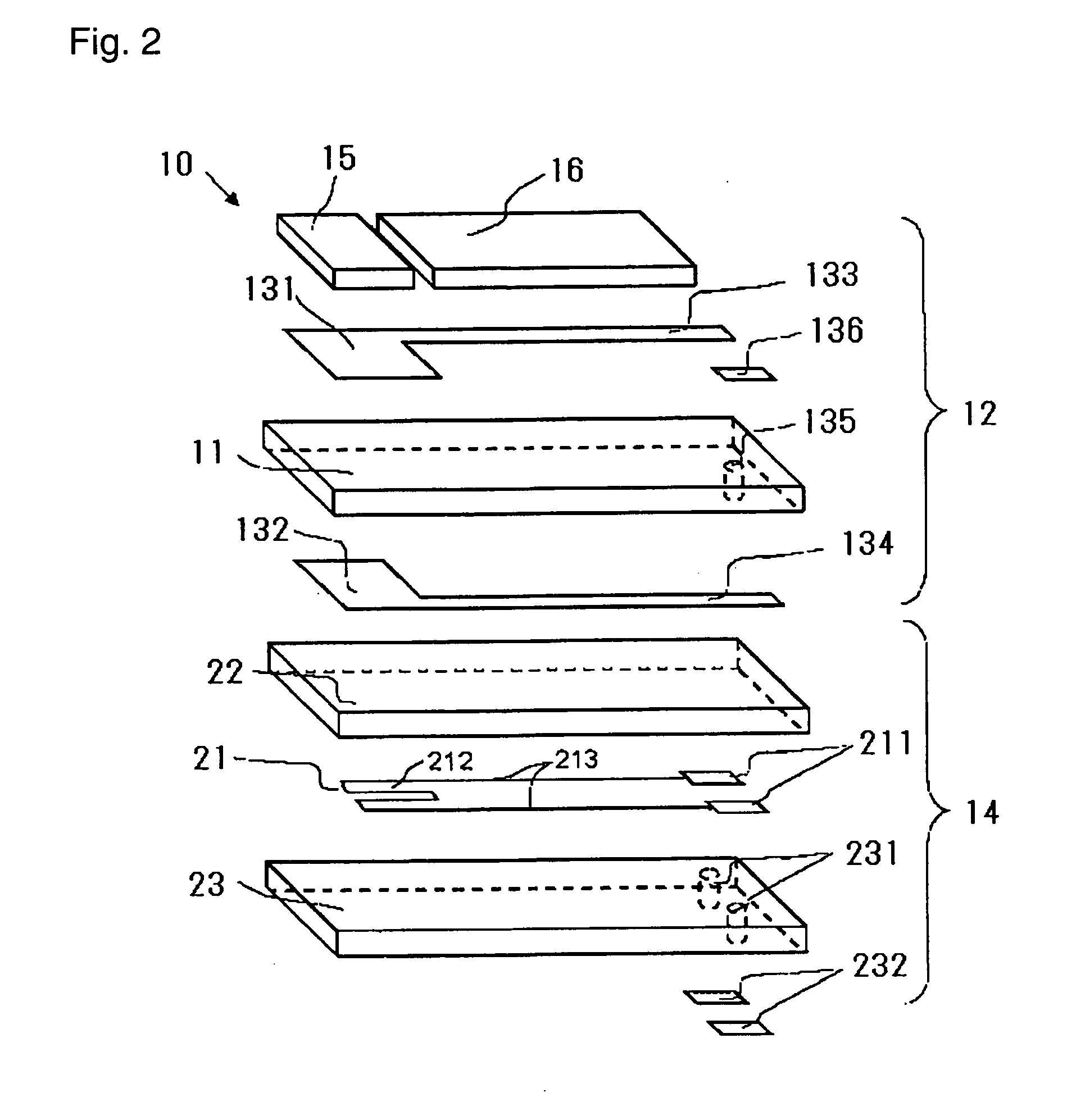

Control apparatus for gas sensor

ActiveUS20050205550A1Reliable preventionLimited supplyRadiation pyrometryElectrical controlMicrocomputerOxygen sensor

A control apparatus for a gas sensor, wherein a microcomputer 44, which is connected to an oxygen sensor 30 including a detection element 12 and a heater 14, detects the cooling water temperature Tw of the engine. The control apparatus determines that condensation water within the exhaust pipe is being generated when the cooling water temperature Tw is equal to or lower than 0° C. When equal to or lower than 0° C., the microcomputer 44 supplies to the heater 14 electrical power for maintaining the temperature of the detection element 12 within the range of 100° C. to a splash-water-cracking generation temperature (e.g., about 300° C.) at or above which cracking can occur in a laminated-type oxygen sensor element 10 due to splash of condensation water. Electrical power is supplied to the heater 14 such that a pulse signal Sh is output from the microcomputer 44, and the heater 14 is pulse-driven by use of a heater electrification control circuit 34.

Owner:NGK SPARK PLUG CO LTD

Compact sulfur recovery plant and process

ActiveUS7226572B1Less-costly to buildEasy to controlCombination devicesExhaust apparatusTemperature controlPartial oxidation

A compact sulfur recovery system is disclosed which comprises a primary structure including a catalytic partial oxidation reaction zone, a first temperature-control zone, a first Claus catalytic reaction zone, a second temperature-control zone, a first liquid sulfur outlet, and a first effluent gas outlet. In some embodiments, a secondary structure follows the primary structure and comprises a second Claus catalytic reaction zone, a third temperature-control zone, a second liquid sulfur outlet, and a second effluent gas outlet. One or more components of the system employ heat transfer enhancement material in the temperature-control zones, and one or more components deter accumulation of liquid sulfur in the Claus catalytic reaction zones. A process for recovering elemental sulfur from hydrogen sulfide-containing gas streams comprises regulating the temperature of certain components to favor the partial oxidation reaction, and the Claus reaction, as appropriate, and deters pooling of liquid sulfur on the Claus catalyst(s).

Owner:PHILLIPS 66 CO

Drying apparatus and washing machine having the same

InactiveUS20050016010A1Fast dryingEfficiently condensing and adsorbing vaporDrying machines with non-progressive movementsWashing machine with receptaclesInterior spaceEngineering

A washing machine including a drying apparatus. The washing machine including the drying apparatus quickly dries wet laundry by efficiently condensing and adsorbing vapor from humid air of high temperature flowing from a water tub during a drying-mode operation. The drying apparatus includes a condensing duct and a blower duct respectively mounted on a rear surface and an upper surface of the water tub. The condensing duct has an ultrasonic atomizing unit, a condensing unit and a water adsorption unit therein, while the blower duct has a blower fan and a heater therein. An inner space of the condensing duct is partitioned into a first condensing path, a second condensing path and a third condensing path by a first air guide and a second air guide. The ultrasonic atomizing unit, the condensing unit and the water adsorption unit are installed in the first condensing path, the second condensing path and the third condensing path of the condensing duct, respectively, thus condensing and adsorbing vapor from the humid air which sequentially passes through the first to third condensing paths, thereby dehumidifying the air providing dry air which is fed to the water tub to dry the wet laundry.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com