Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "High properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

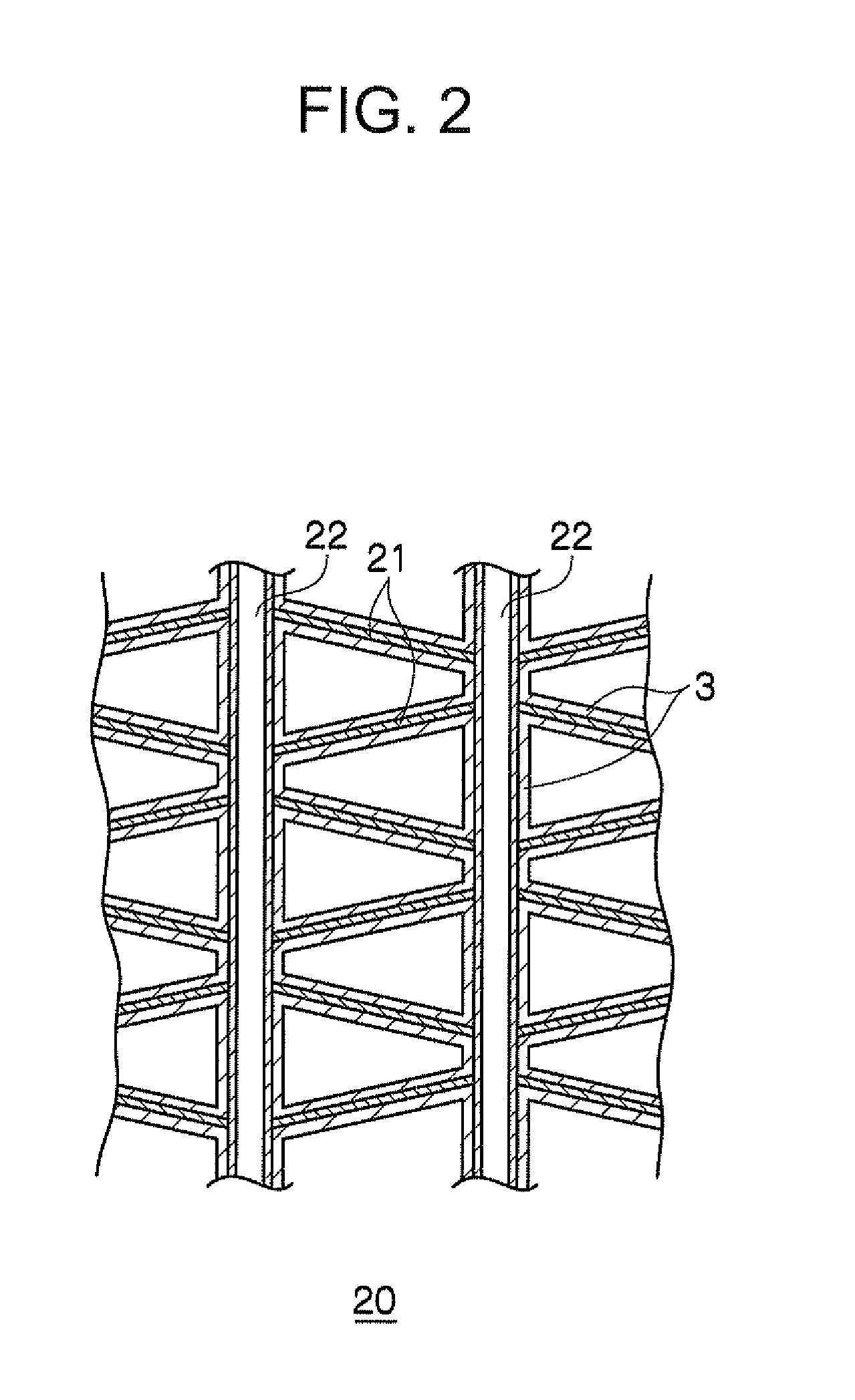

Carbon nanotube-containing structures, methods of making, and processes using same

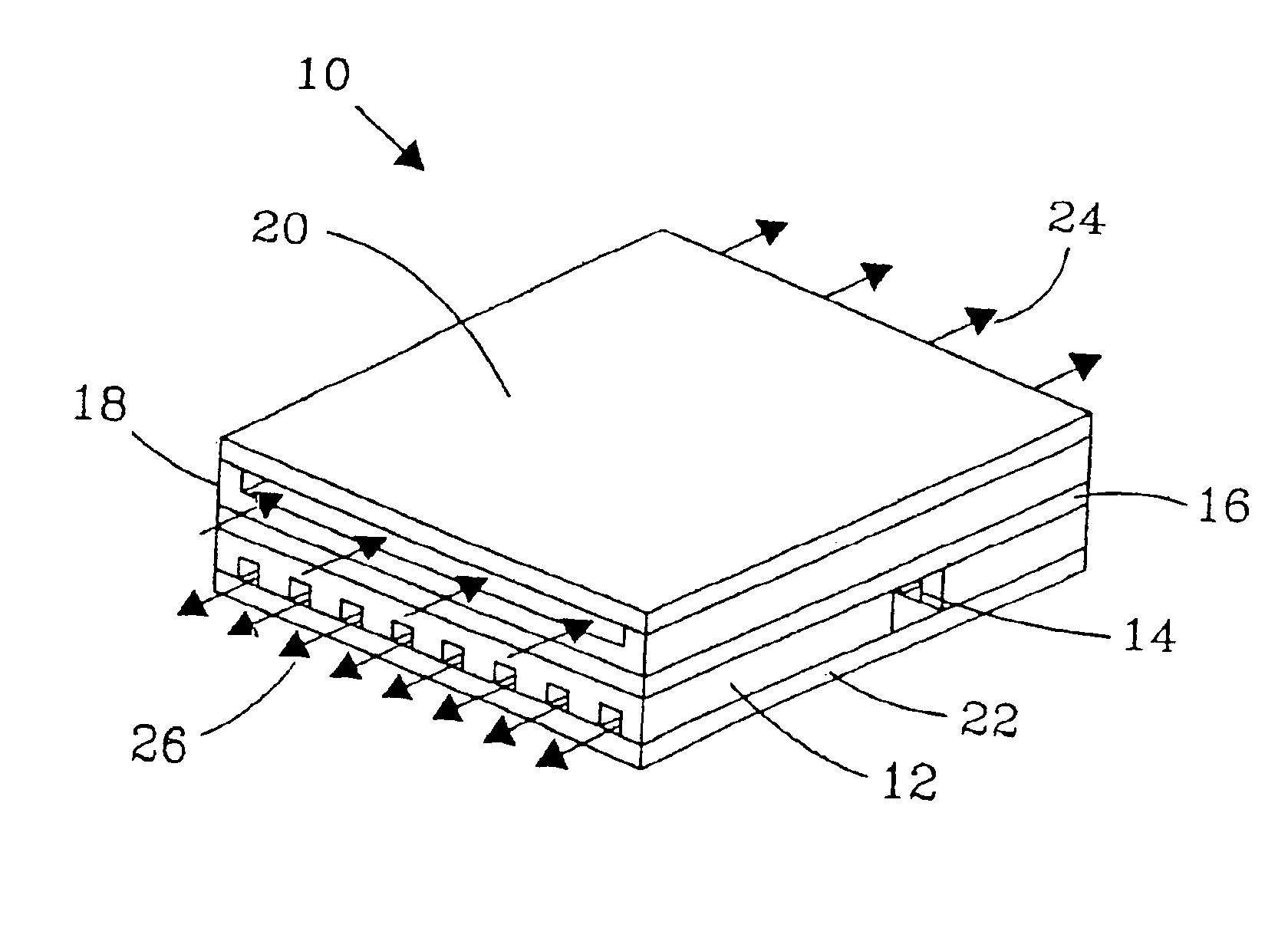

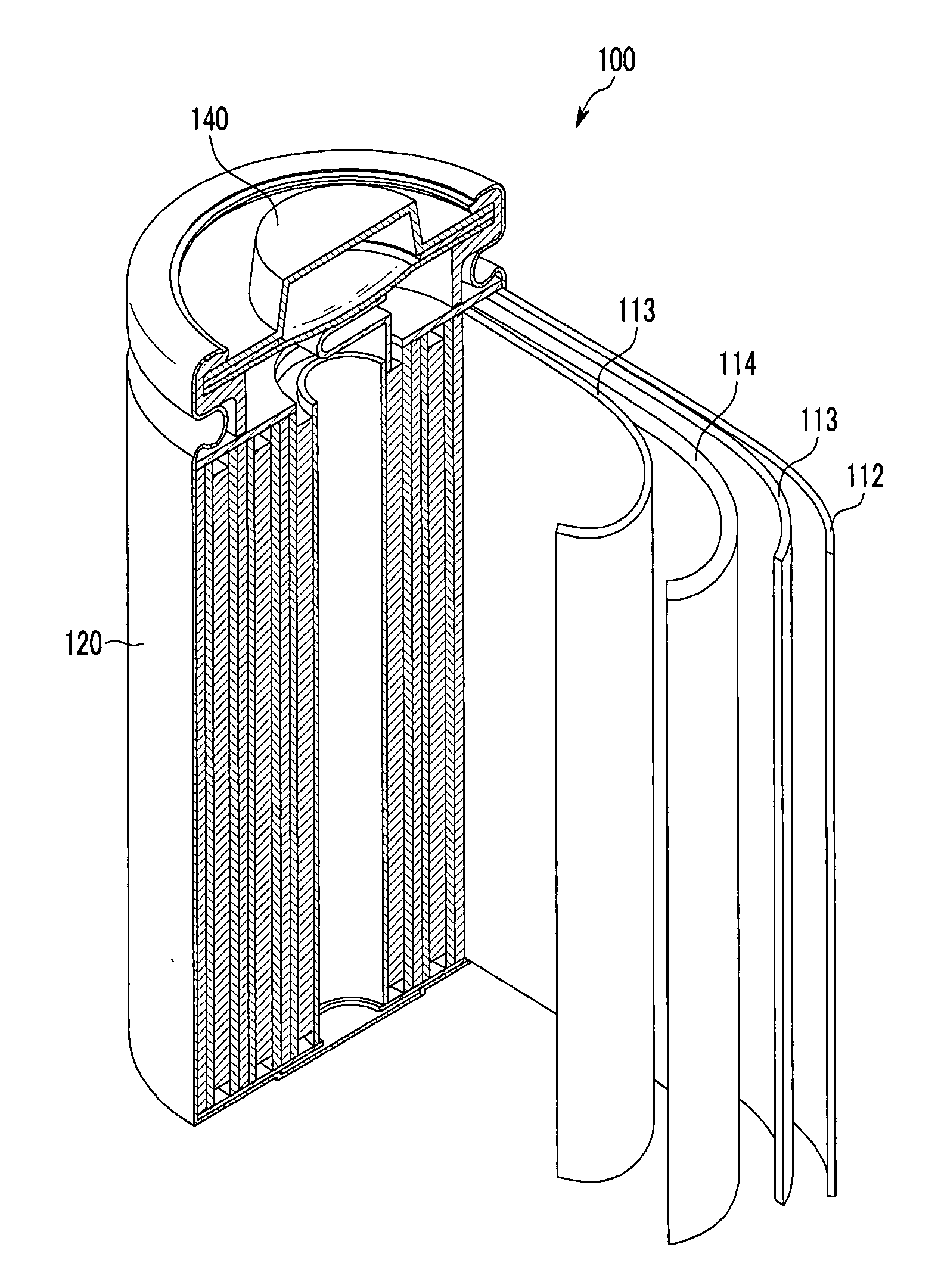

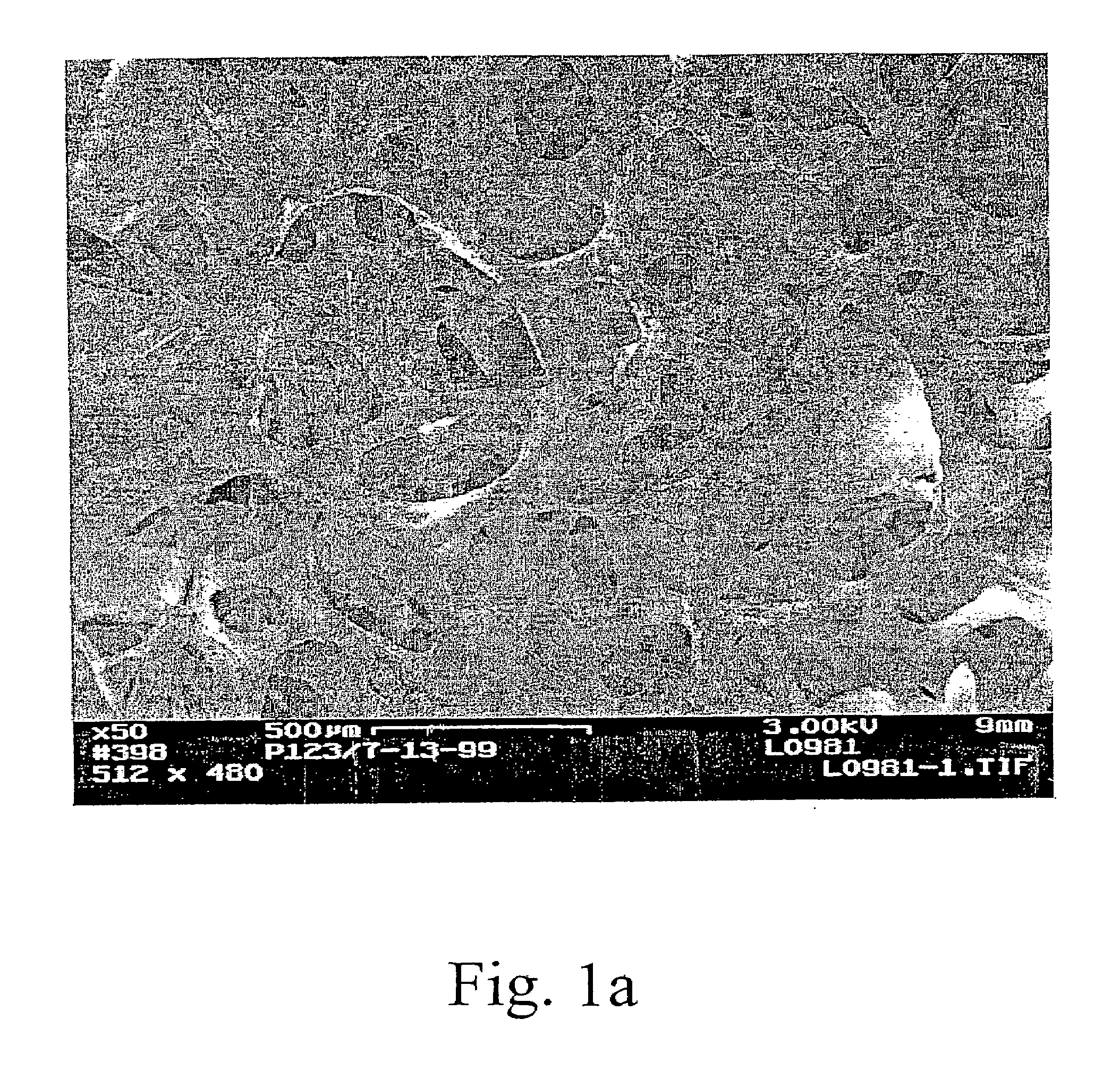

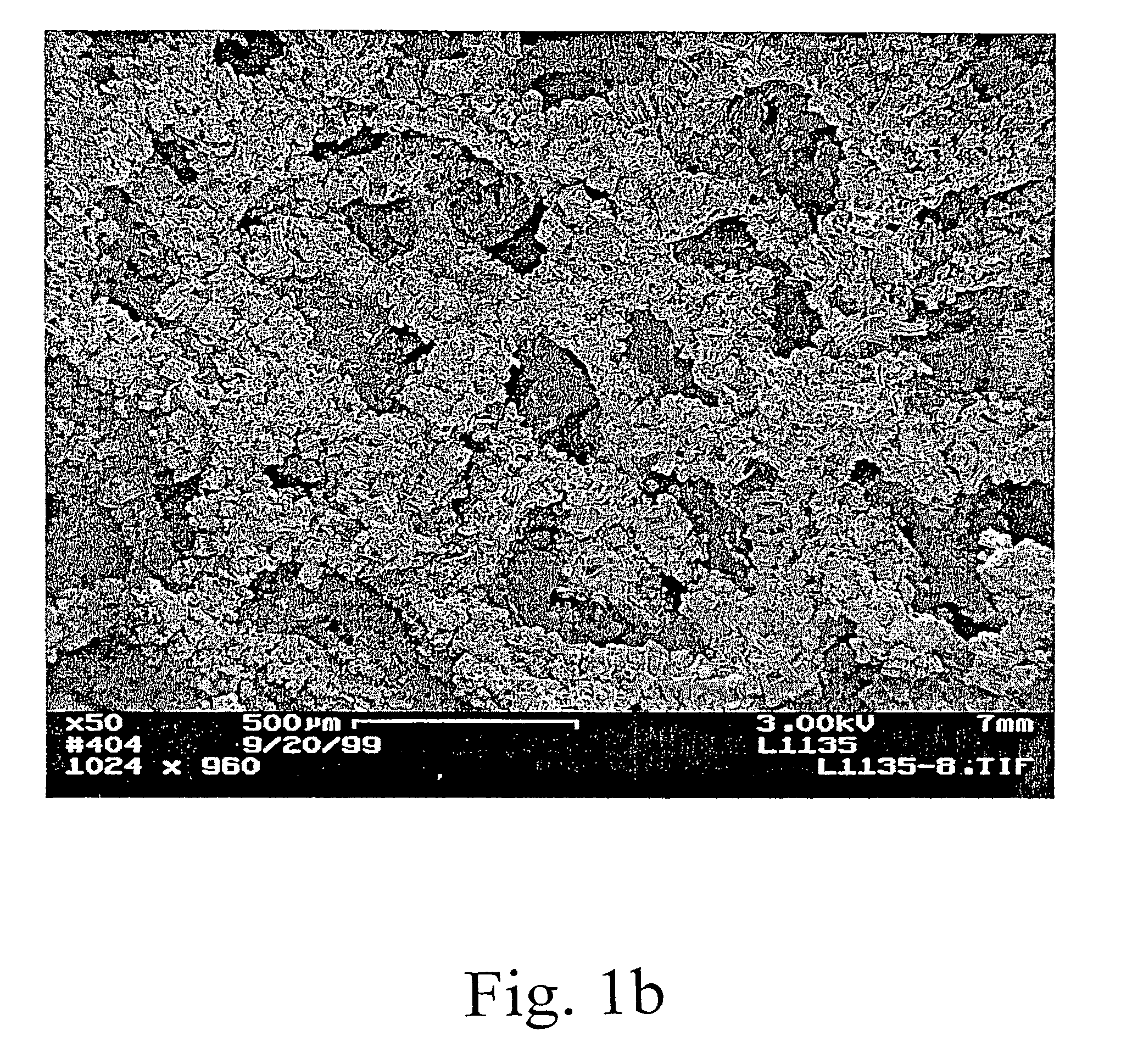

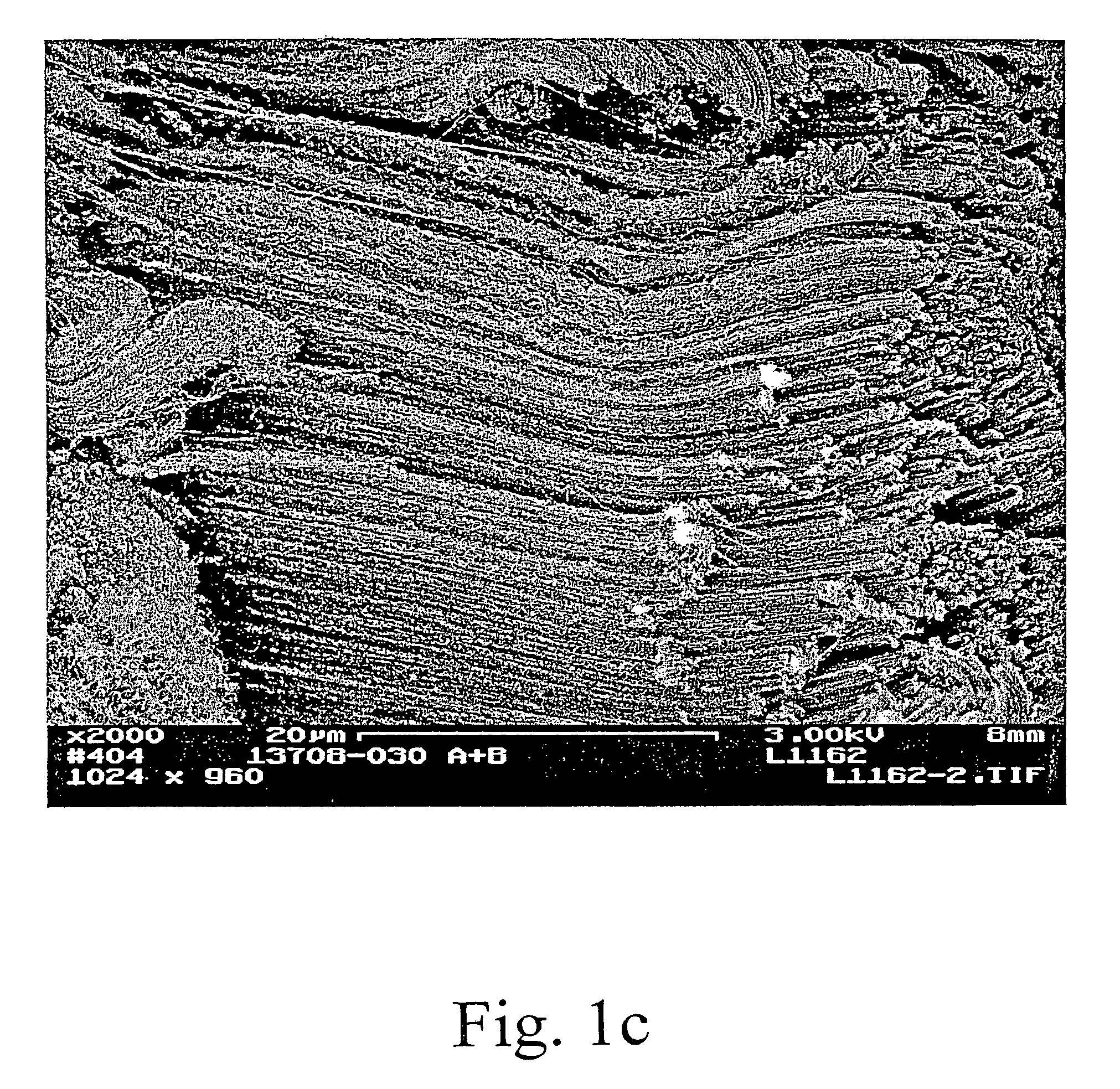

InactiveUS7011760B2Large specific surface areaImprove conductivityCarbon compoundsChemical/physical/physico-chemical microreactorsPre treatmentSURFACTANT BLEND

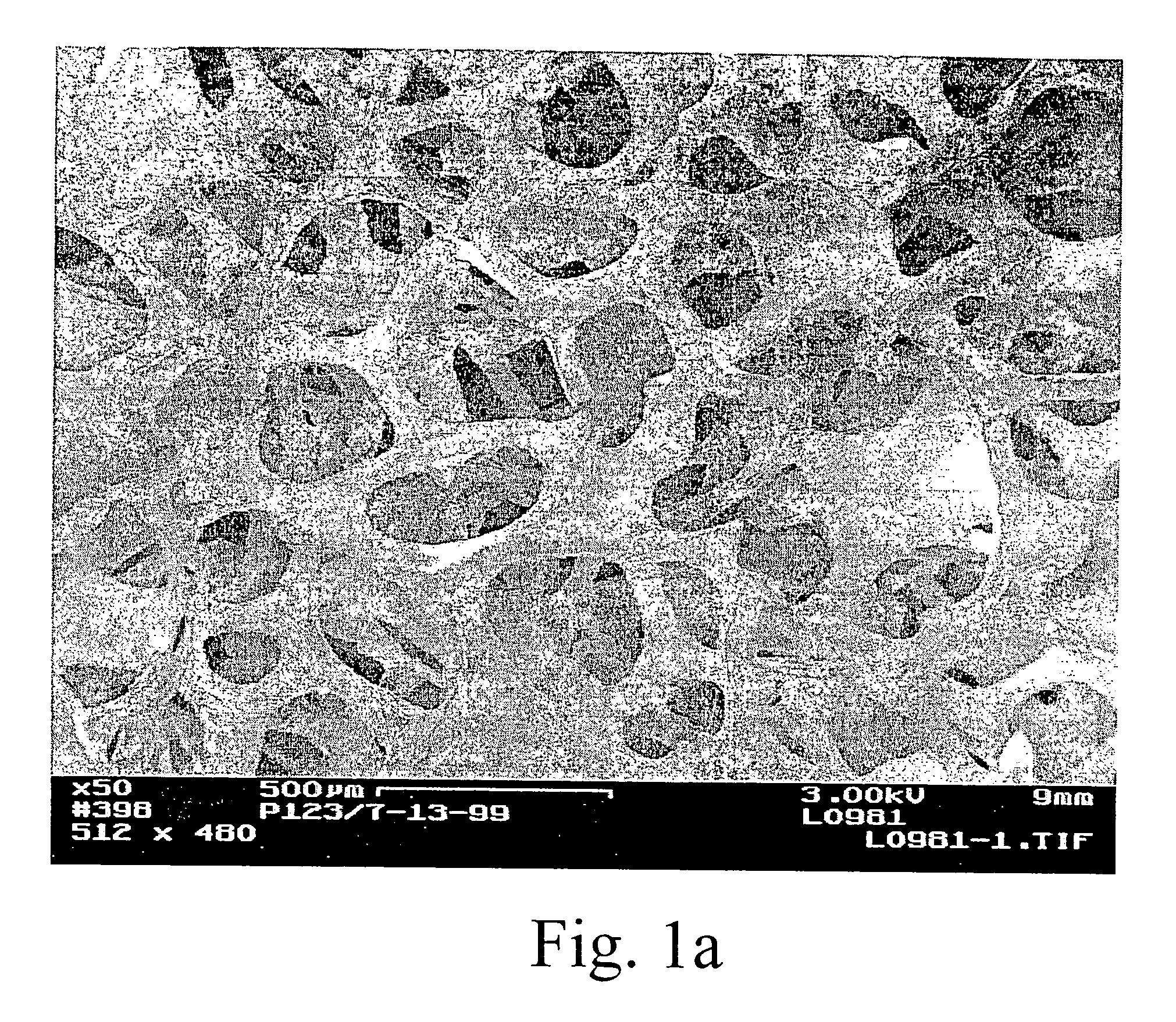

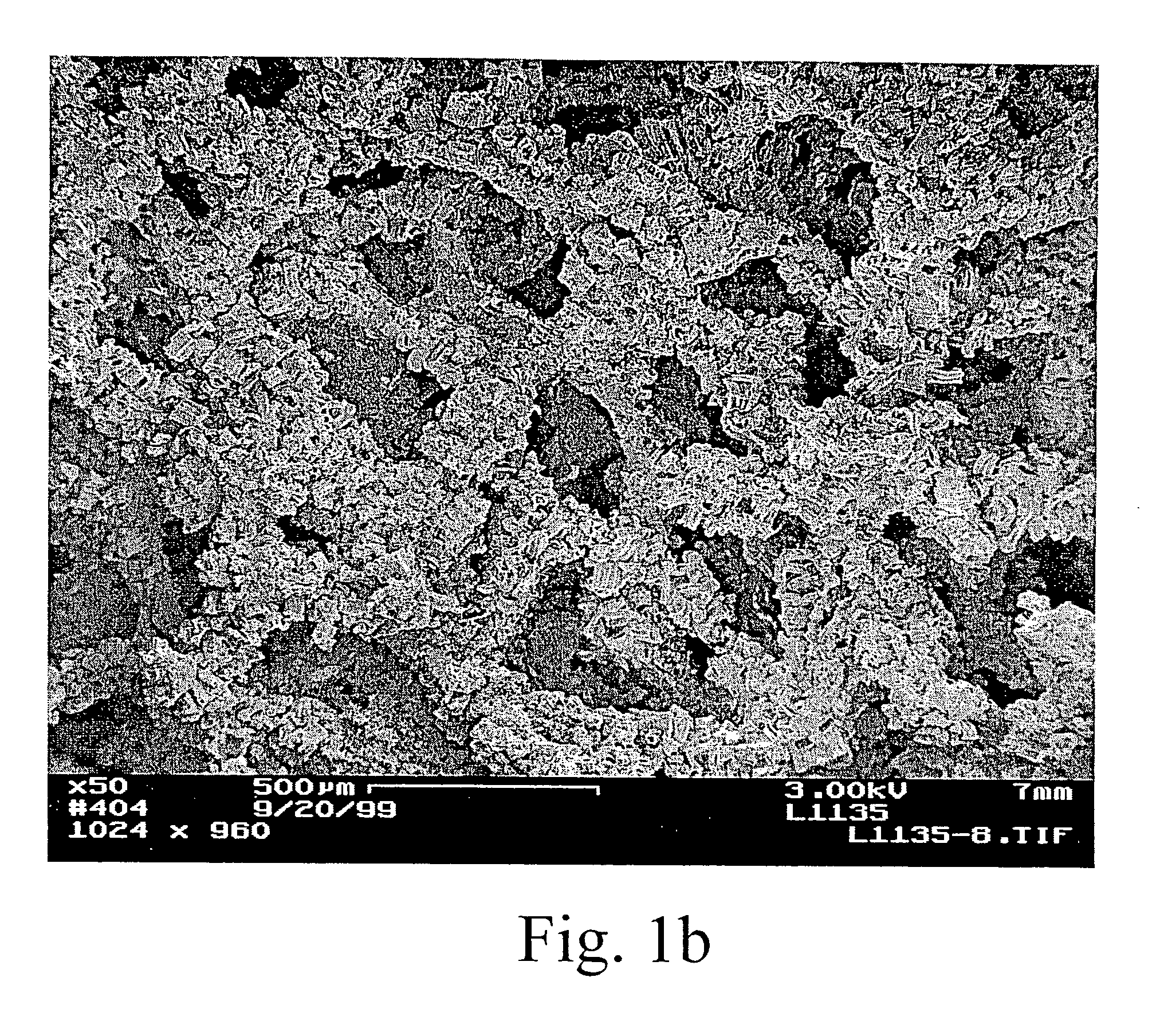

Carbon nanotube structures are disclosed in which nanotubes are disposed over a porous support such as a foam, felt, mesh, or membrane. Techniques of making these structures are also disclosed. In some of these techniques, a support is pretreated with a templated surfactant composition to assist with the formation of a nanotube layer.

Owner:BATTELLE MEMORIAL INST

Carbon nanotube-containing structures, methods of making, and processes using same

InactiveUS20050040090A1Function efficientlyReduce concentrationCarbon compoundsChemical/physical/physico-chemical microreactorsPre treatmentMembrane configuration

Carbon nanotube structures are disclosed in which nanotubes are disposed over a porous support such as a foam, felt, mesh, or membrane. Techniques of making these structures are also disclosed. In some of these techniques, a support is pretreated with a templated surfactant composition to assist with the formation of a nanotube layer.

Owner:BATTELLE MEMORIAL INST

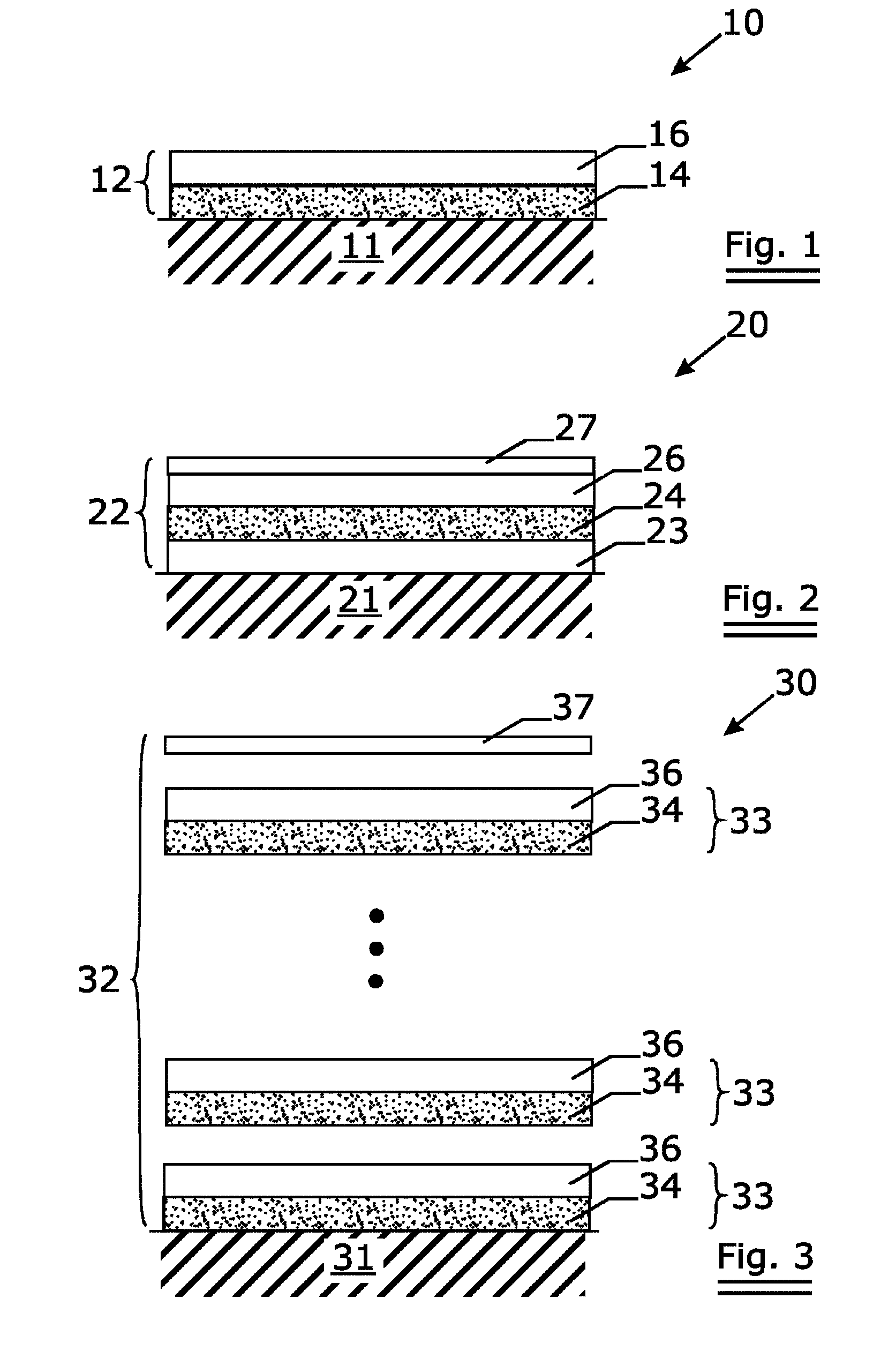

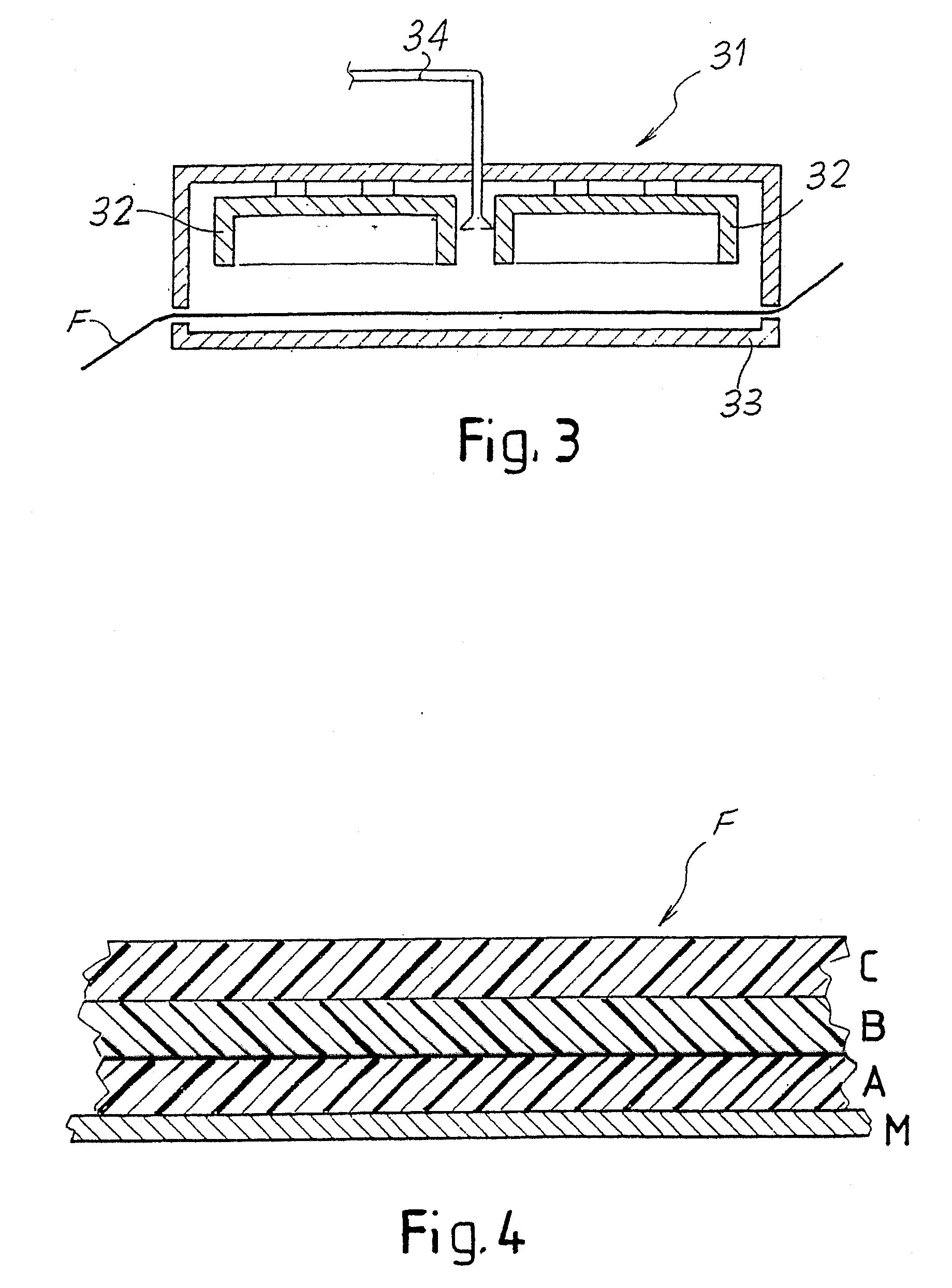

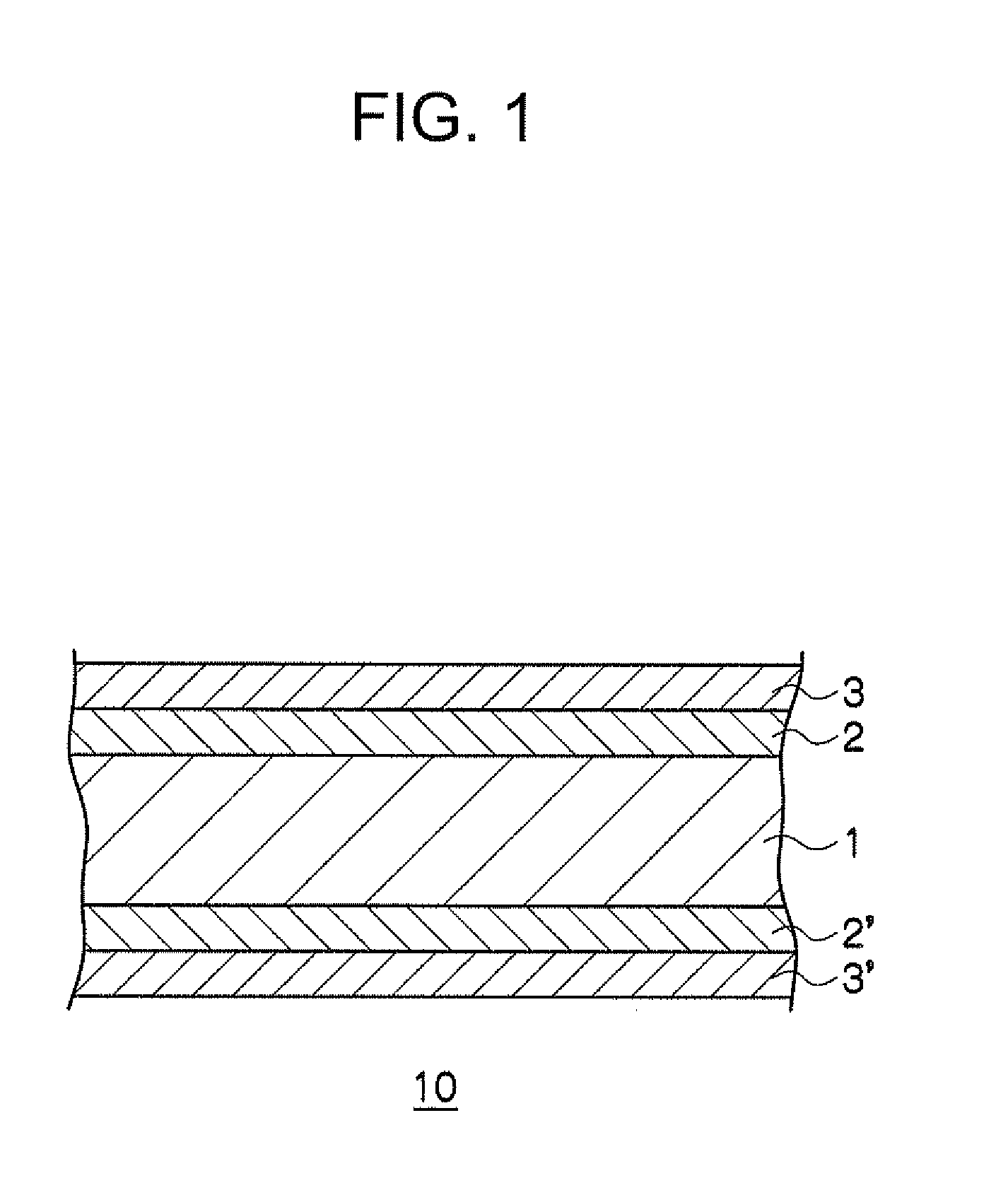

Substrate Coated with a Layered Structure Comprising a Tetrahedral Carbon Layer and a Softer Outer Layer

ActiveUS20080220257A1Easy to wearReduce wearNatural mineral layered productsChemical vapor deposition coatingCarbon coatingCarbon layer

The invention relates to a metal substrate coated at least partially with a layered structure. The layered structure comprises an intermediate layer deposited on the metal substrate and an amorphous carbon layer deposited on the intermediate layer. The amorphous carbon layer has a Young's modulus lower than 200 GPa. The intermediate layer comprises a tetrahedral carbon layer having a Young's modulus higher than 200 GPa. The invention further relates to a method to reduce the wear on a counterbody of a metal substrate coated with a tetrahedral carbon coating.

Owner:SULZER METAPLAS

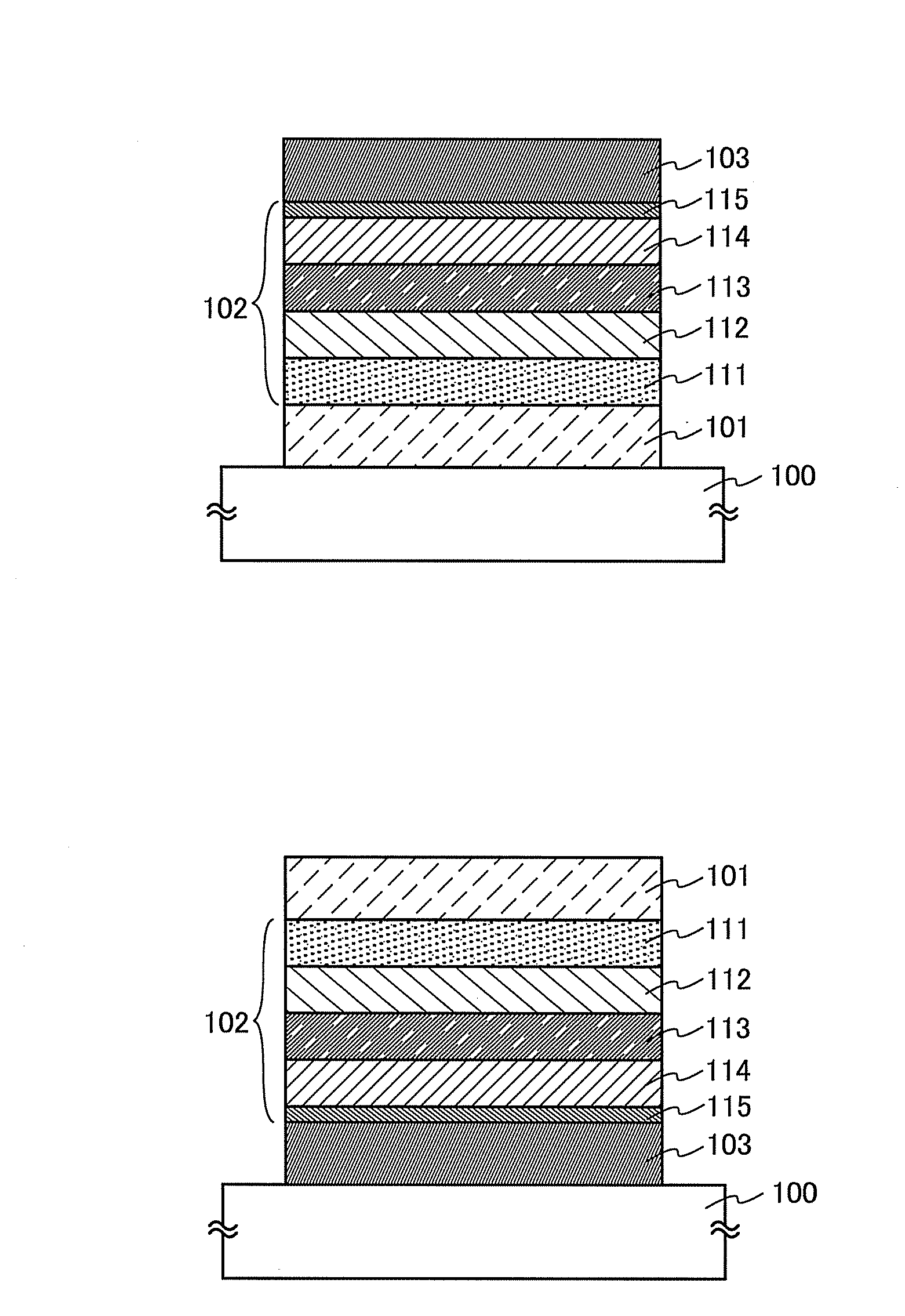

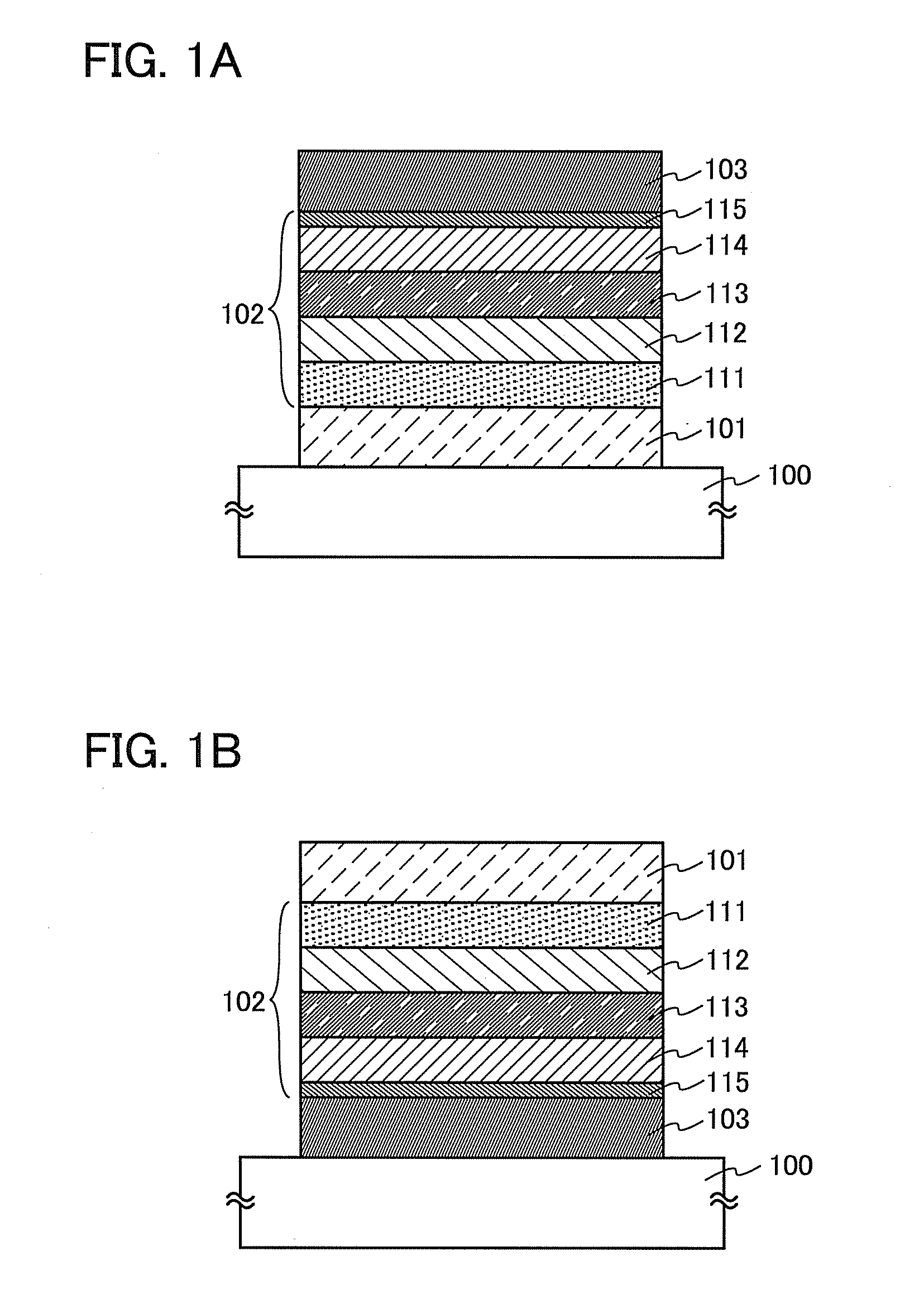

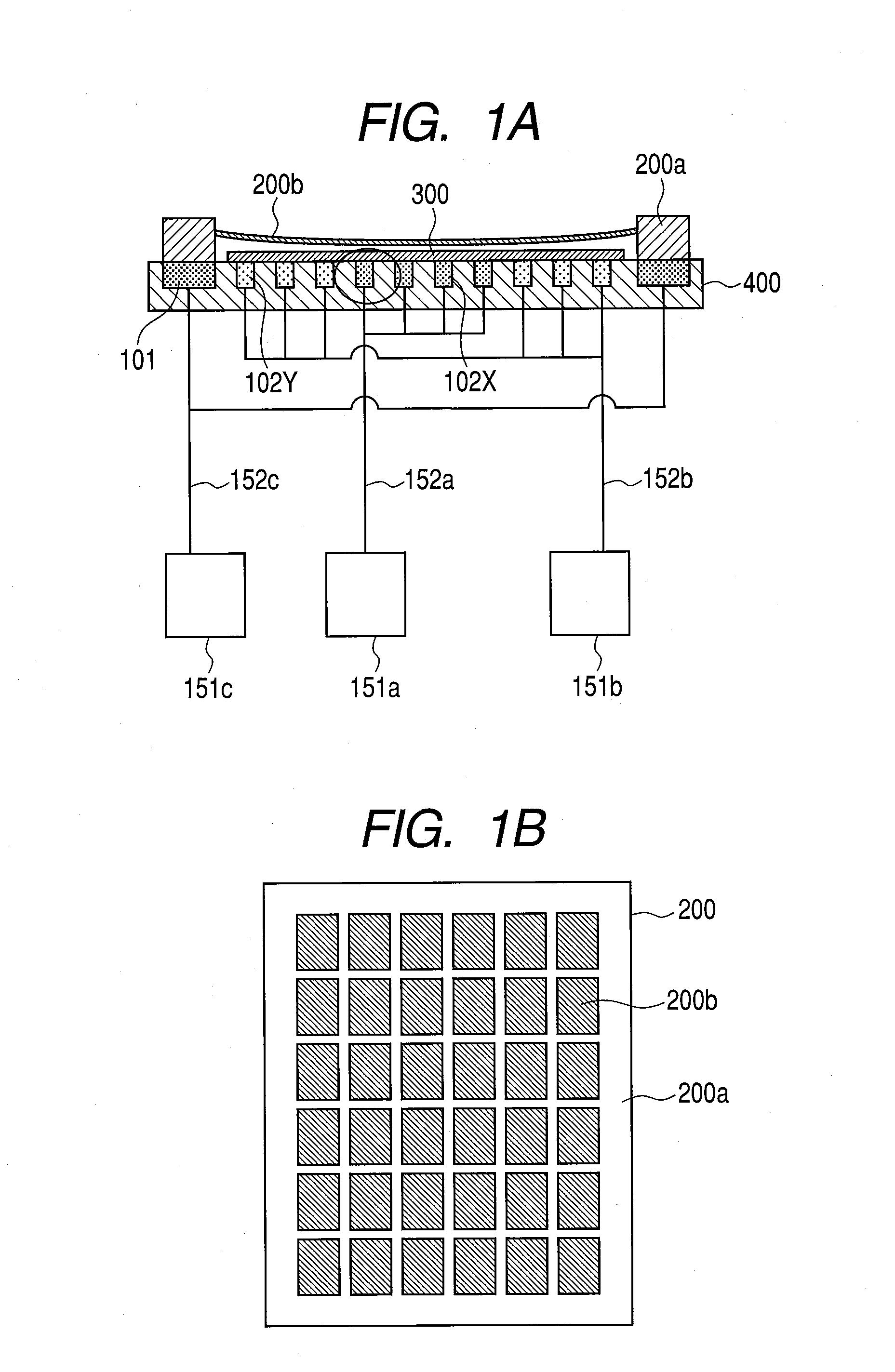

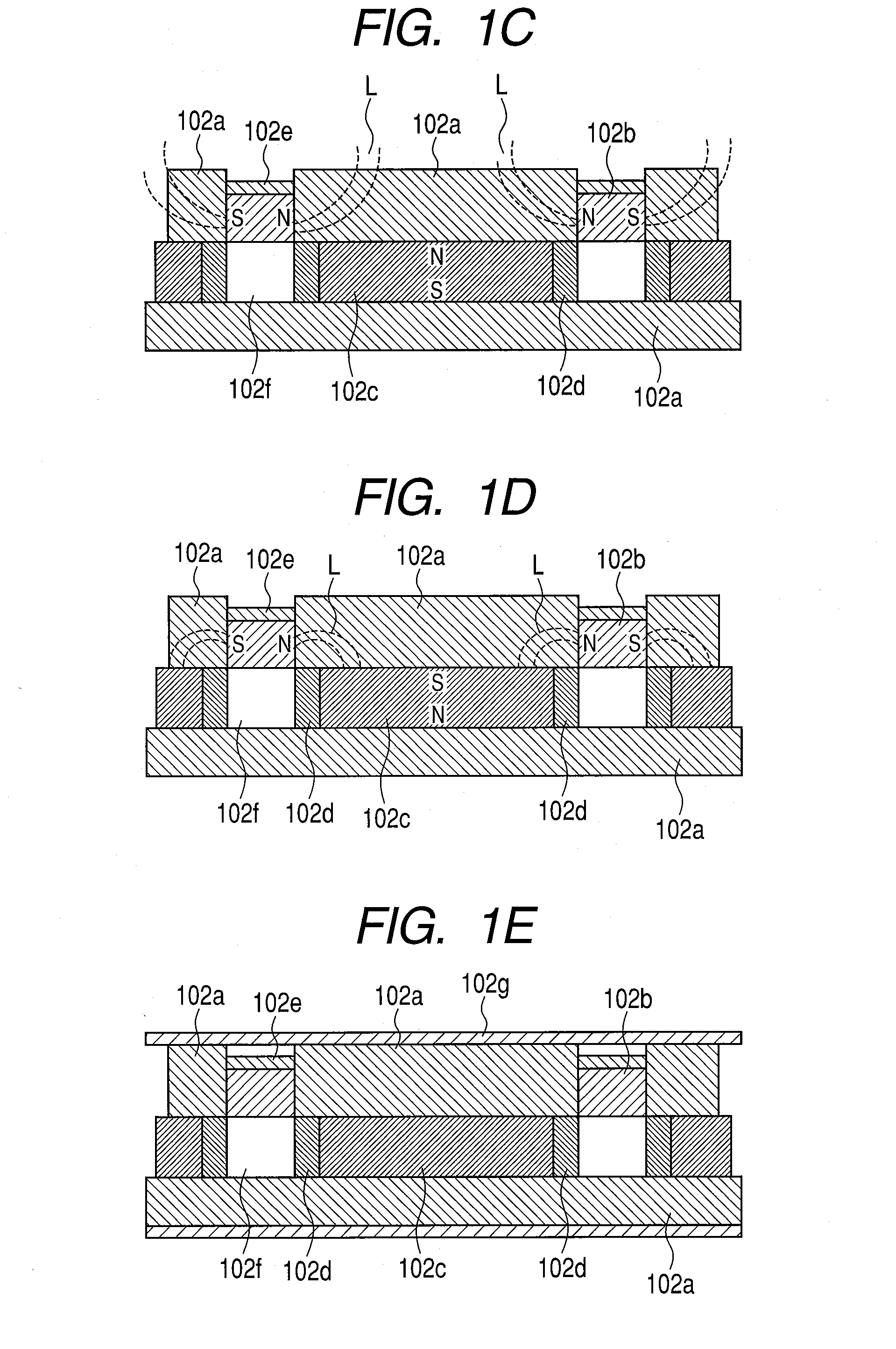

Triazole Derivative, and Light-Emitting Element, Light-Emitting Device, Electronic Device and Lighting Device Using the Triazole Derivative

InactiveUS20110285276A1Excellent hole injectionHigh triplet excitation energyOrganic chemistryDischarge tube luminescnet screensTriazole derivativesOxygen

Objects are to provide the following: a substance that facilitates hole injection and has high triplet excitation energy; a light-emitting element having high emission efficiency using the substance that facilitates hole injection and has high triplet excitation energy; a light-emitting element having low driving voltage; and a light-emitting device, an electronic device, and a lighting device having low power consumption. Provided is a triazole derivative in which a dibenzothiophen-4-yl or dibenzofuran-4-yl group represented by General Formula (G2) is bonded to any one of Ar1 to Ar3 of a triazole derivative represented by General Formula (G1). In the formulae, A represents oxygen or sulfur, Ar1 to Ar3 separately represent a substituted or unsubstituted aryl group having 6 to 13 carbon atoms, and R1 to R7 separately represent hydrogen, an alkyl group having 1 to 4 carbon atoms, or a substituted or unsubstituted aryl group having 6 to 13 carbon atoms.

Owner:SEMICON ENERGY LAB CO LTD

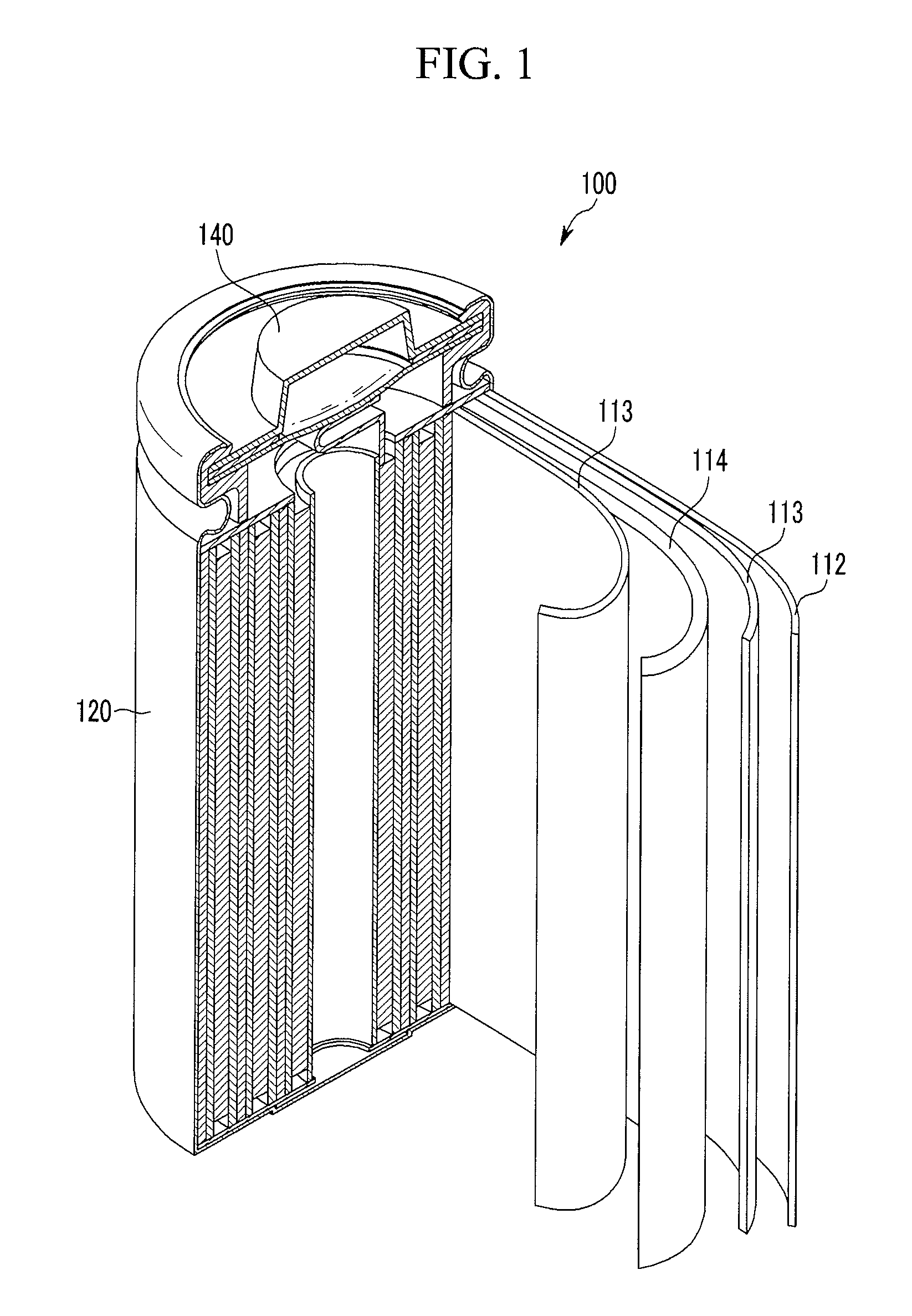

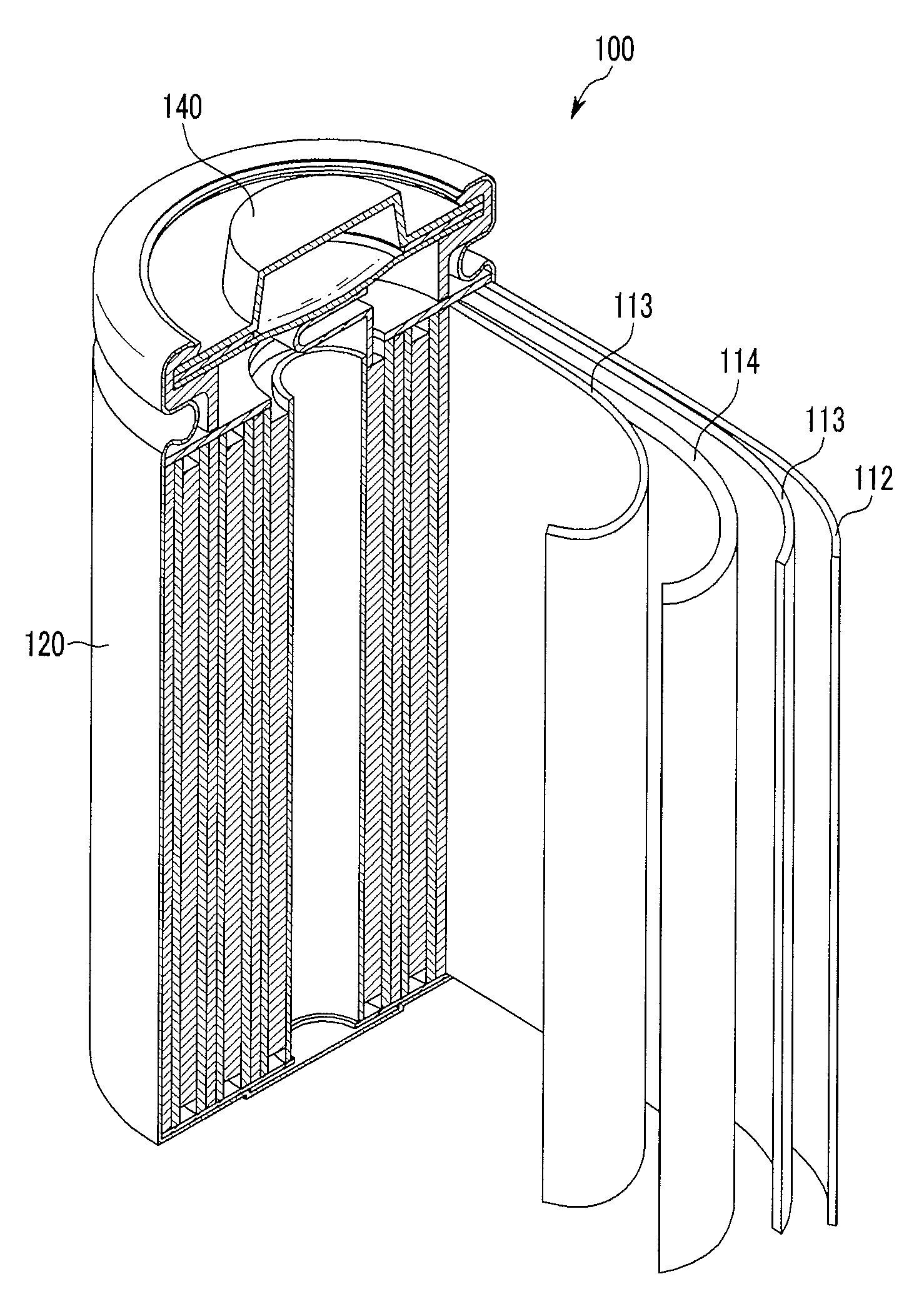

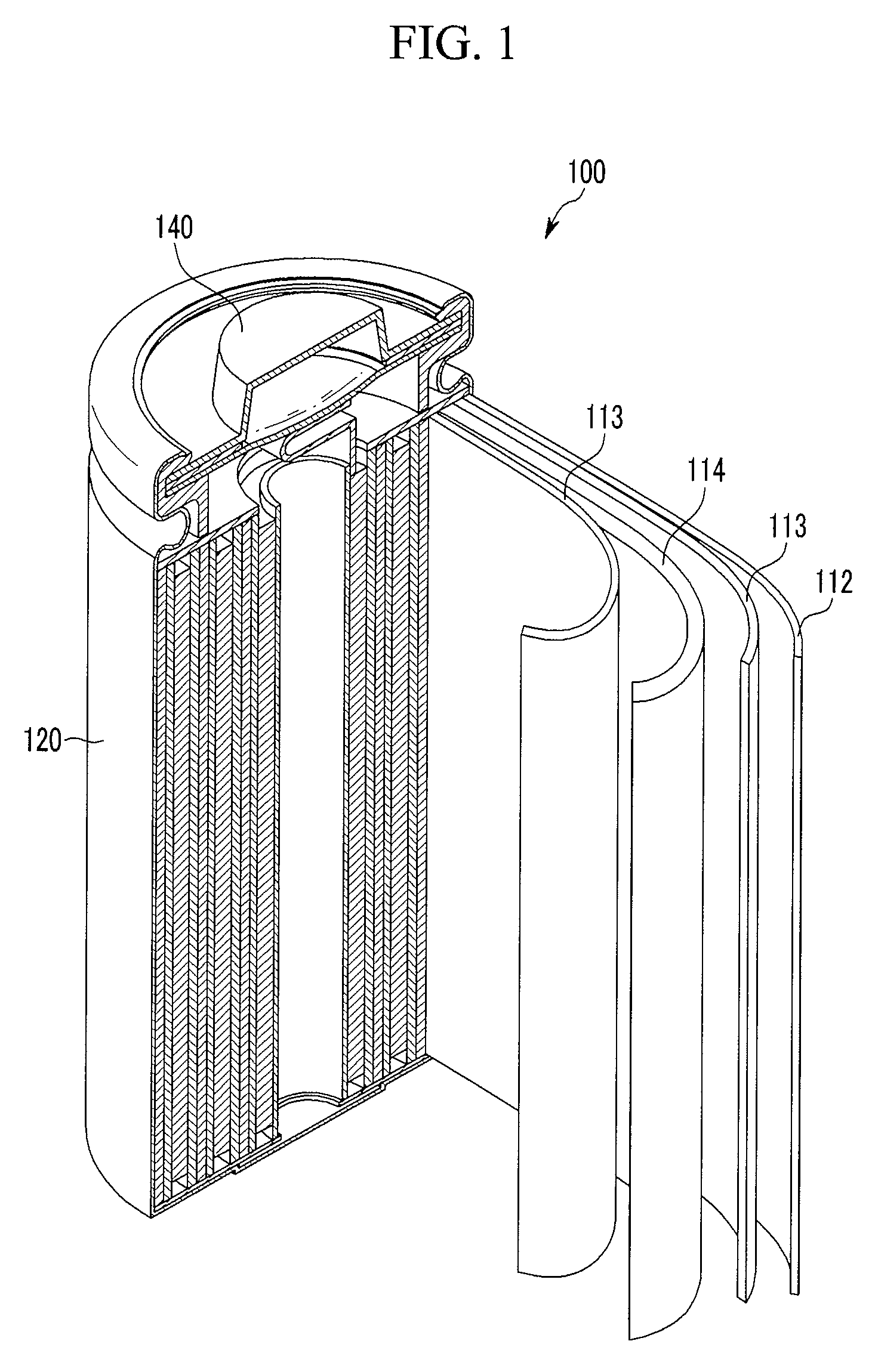

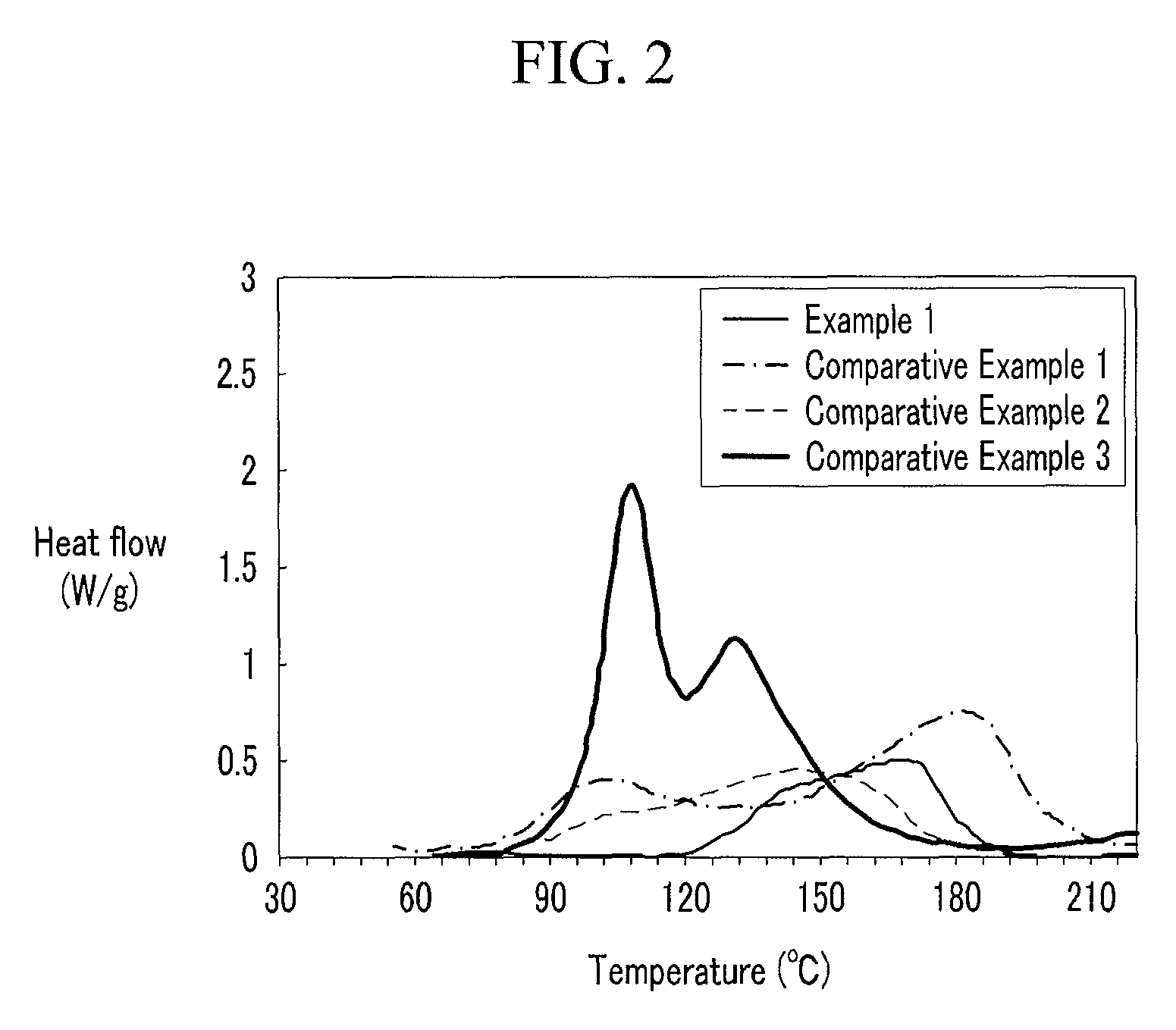

Flame Retardant Electrolyte for Rechargeable Lithium Battery and Rechargeable Lithium Battery Including the Same

ActiveUS20100209782A1Reduce and eliminate decompositionImproved thermal stability and flame retardancyFinal product manufactureElectrode carriers/collectorsSolventAmmonium Cation

Flame retardant electrolyte solutions for rechargeable lithium batteries and lithium batteries including the electrolyte solutions are provided. The flame retardant electrolyte solution includes a lithium salt, a linear carbonate-based solvent, at least one ammonium cation, a phosphoric acid-based solvent, and an additive including oxalatoborate.

Owner:SAMSUNG SDI CO LTD

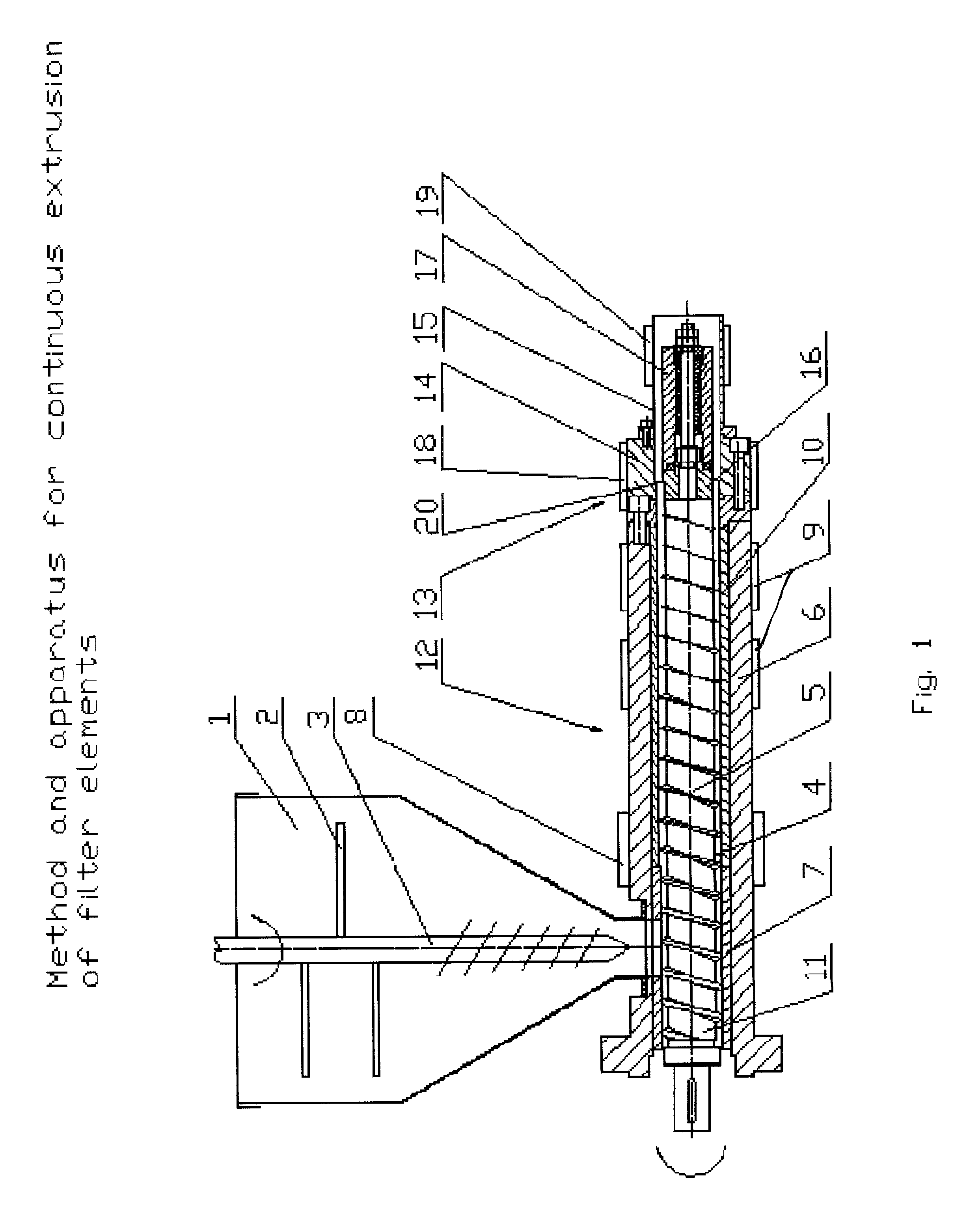

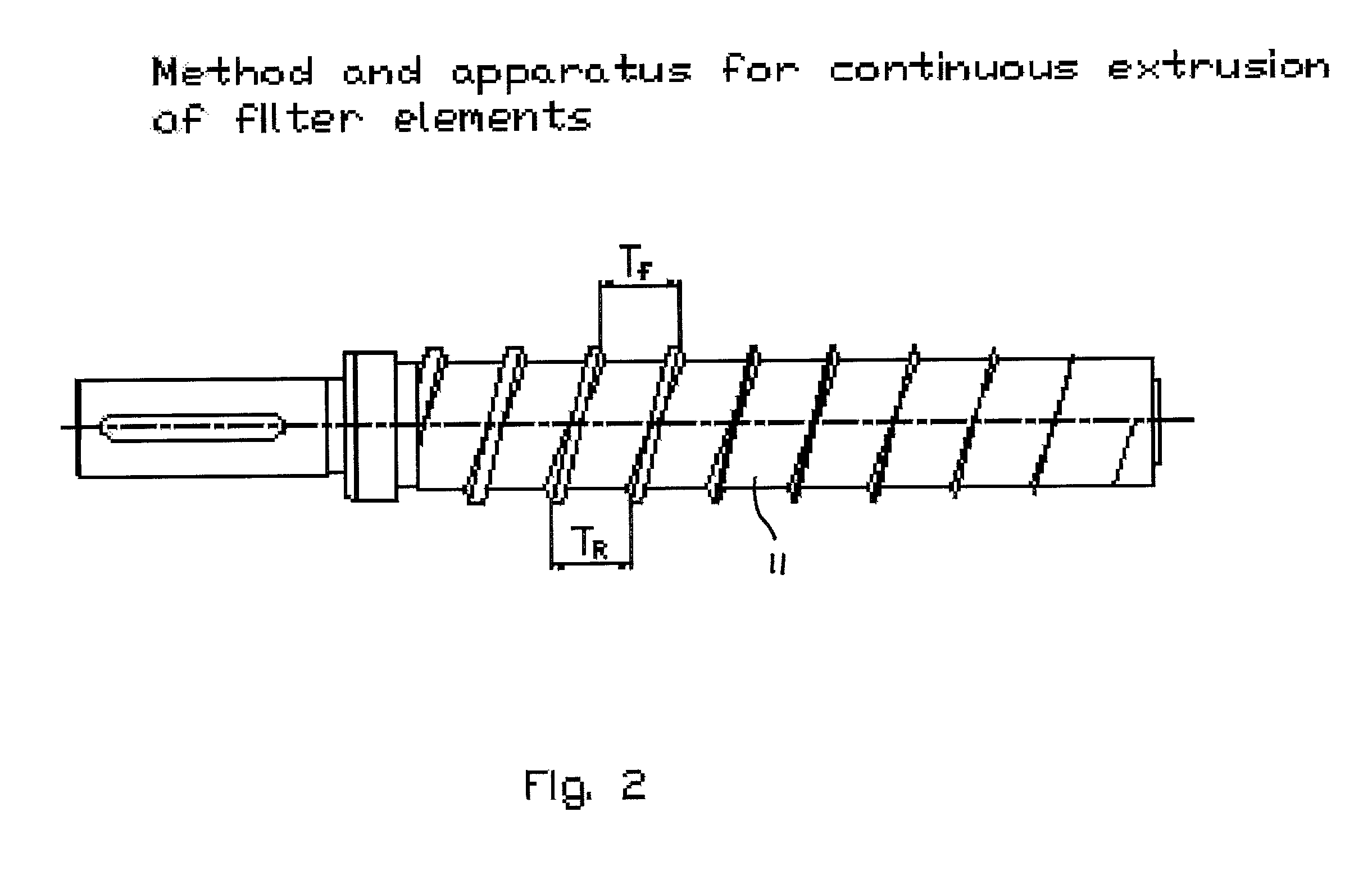

Method and apparatus for continuous extrusion of filter elements

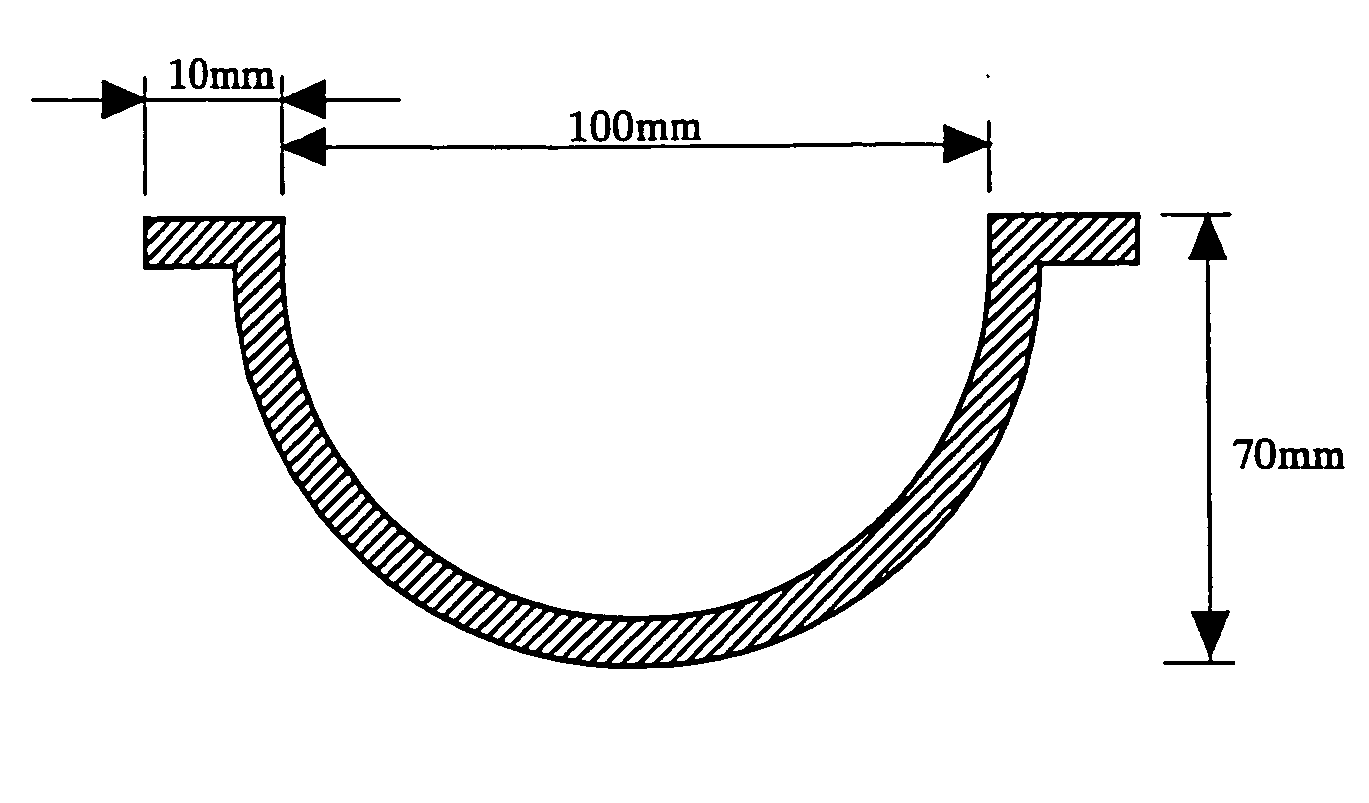

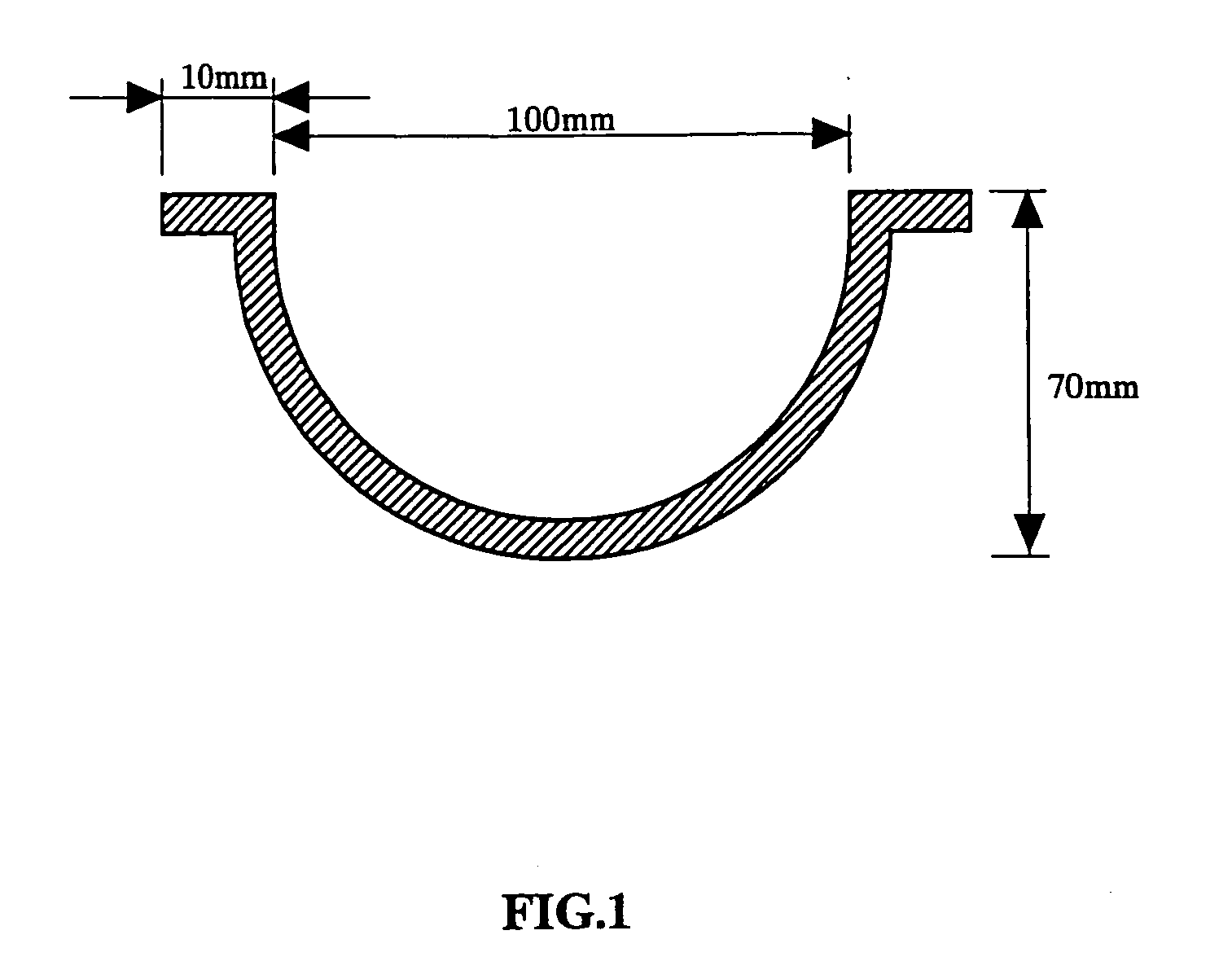

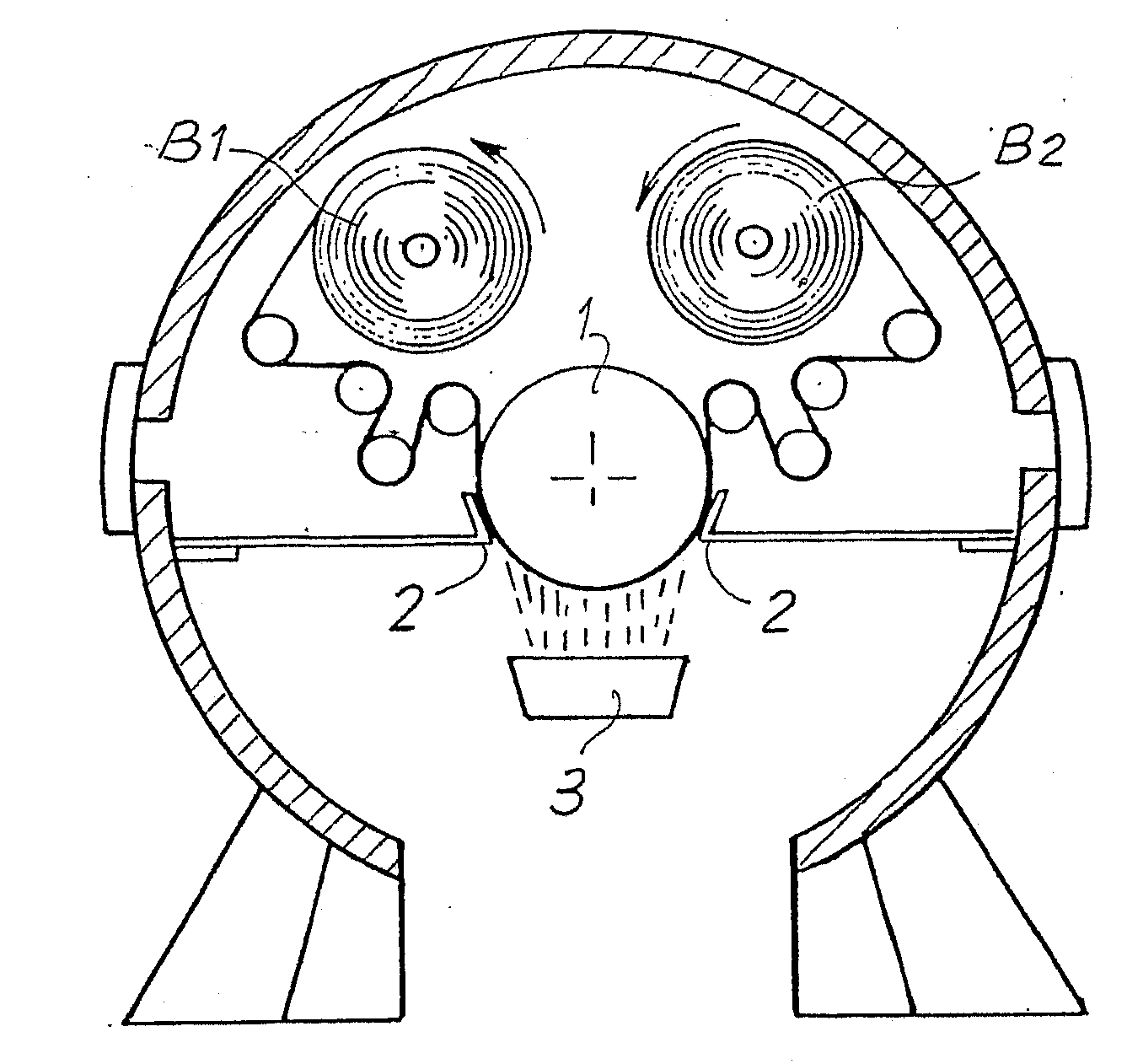

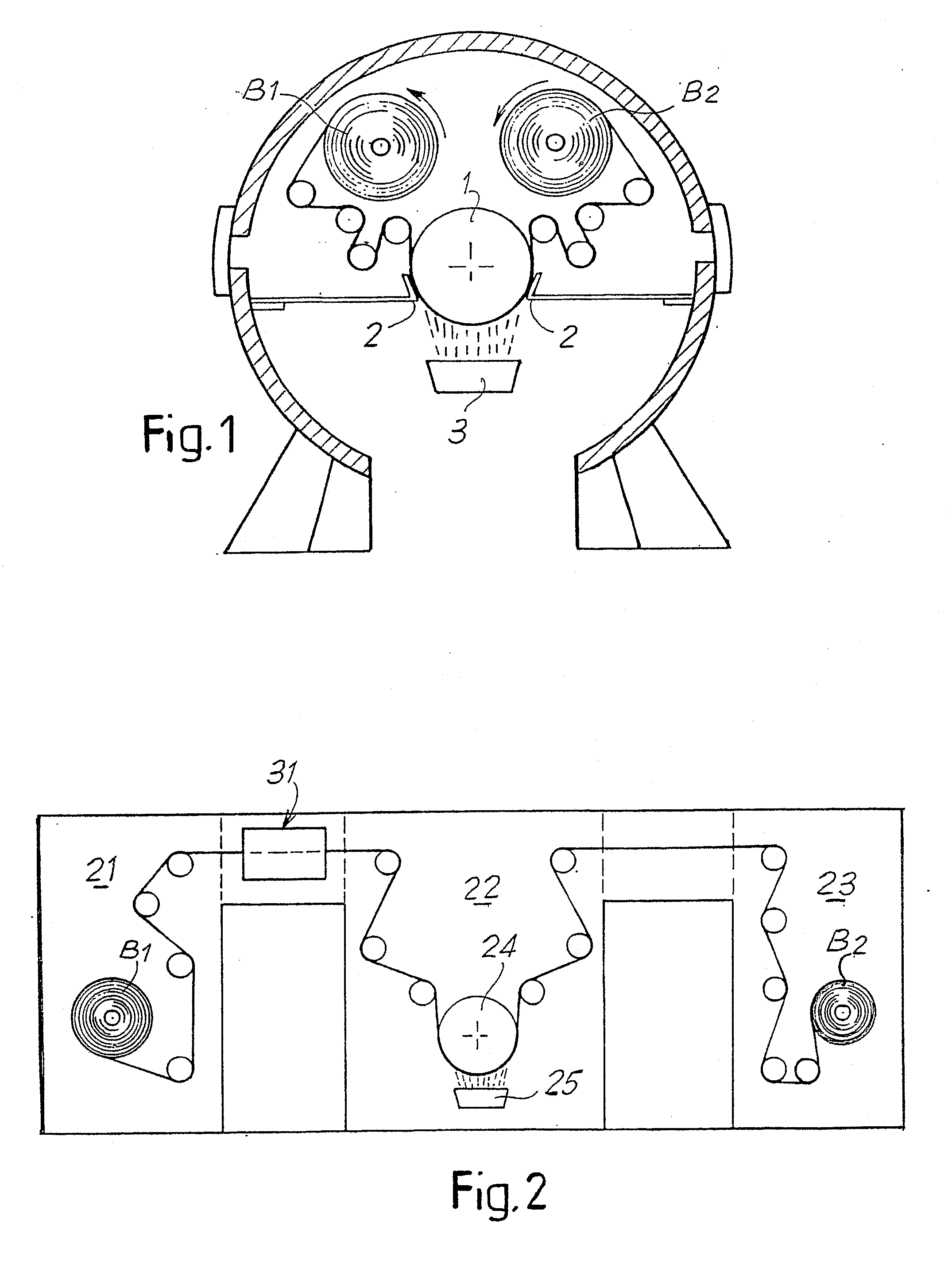

InactiveUS20020062740A1Flight height is reducedHigh densityFrozen sweetsConfectioneryActivated carbonFiber

A method and apparatus for making filter elements in which a mixture of activated carbon granules and fibers are processed with meltable polymer fibers to form a porous element. The density of the porous structure increases in a direction from the periphery thereof to its center. Also, the article formed by the method using the apparatus.

Owner:BRUKOV NIKOLAY V +1

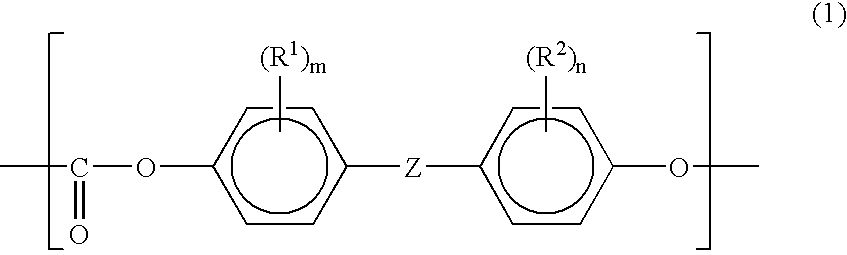

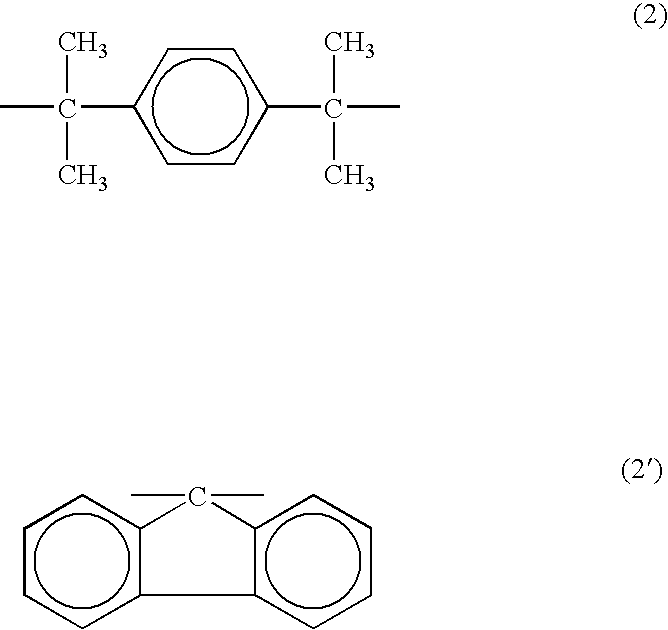

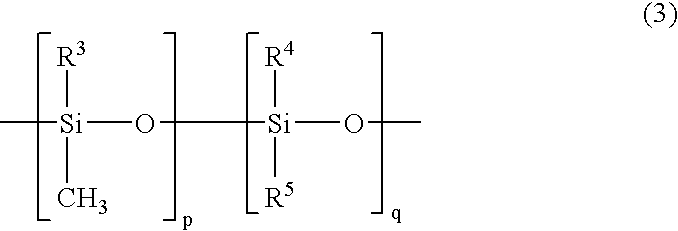

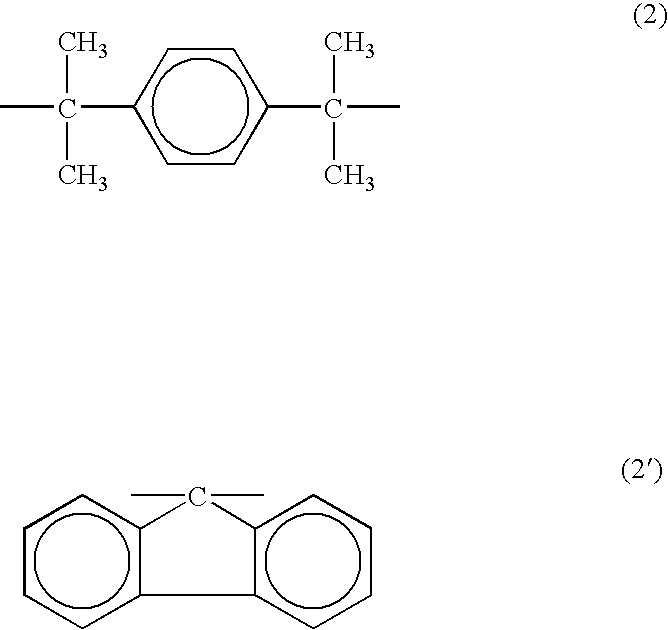

Polycarbonate resin composition and molded object thereof

ActiveUS20060047037A1Improve thermal stabilityHigh propertiesSkin careSheet deliveryTetrafluoroethyleneFiber

A polycarbonate resin composition which has excellent flame retardancy, even when containing neither any phosphorus compound flame retardant nor any halogenated flame retardant, and which is highly reflective and has light-shutting properties and excellent thermal stability. The polycarbonate resin composition comprises 5 to 98 parts by weight of a polycarbonate / polyorganosiloxane copolymer, 0 to 93 parts by weight of a polycarbonate resin, 2 to 50 parts by weight of titanium oxide, 0 to 1.0 parts by weight of a fibril-forming polytetrafluoroethylene, and 0.05 to 2.0 parts by weight of an organosiloxane, the sum of the ingredients (A), (B), and (C) is 100 parts by weight.

Owner:IDEMITSU KOSAN CO LTD

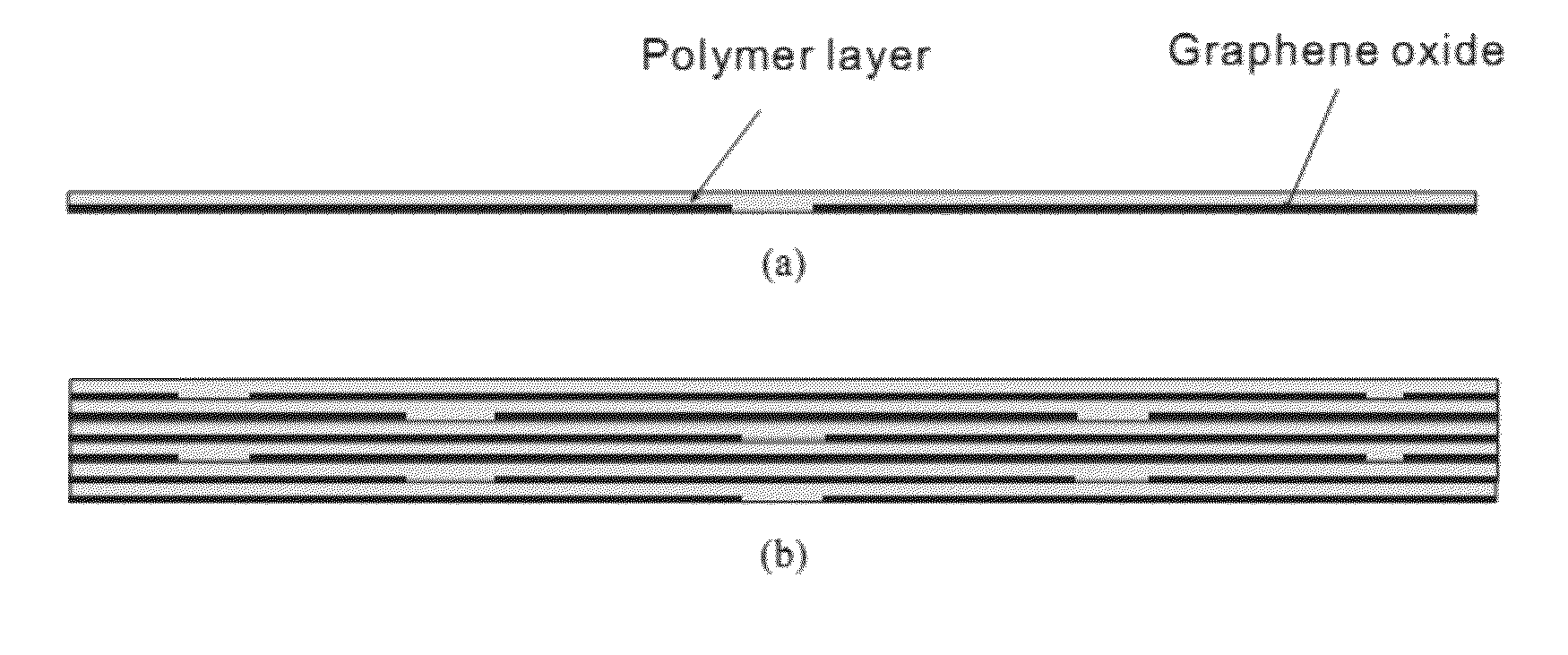

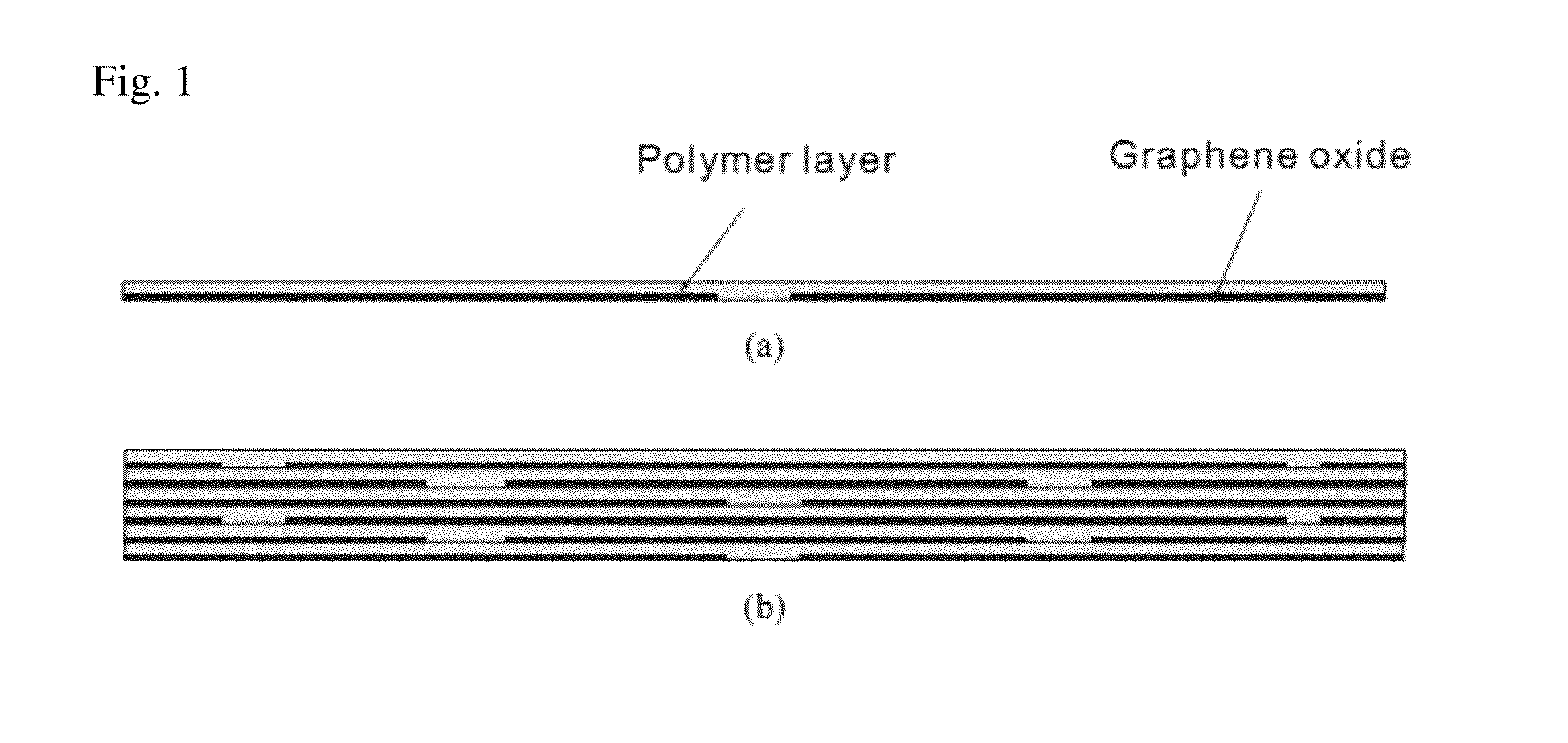

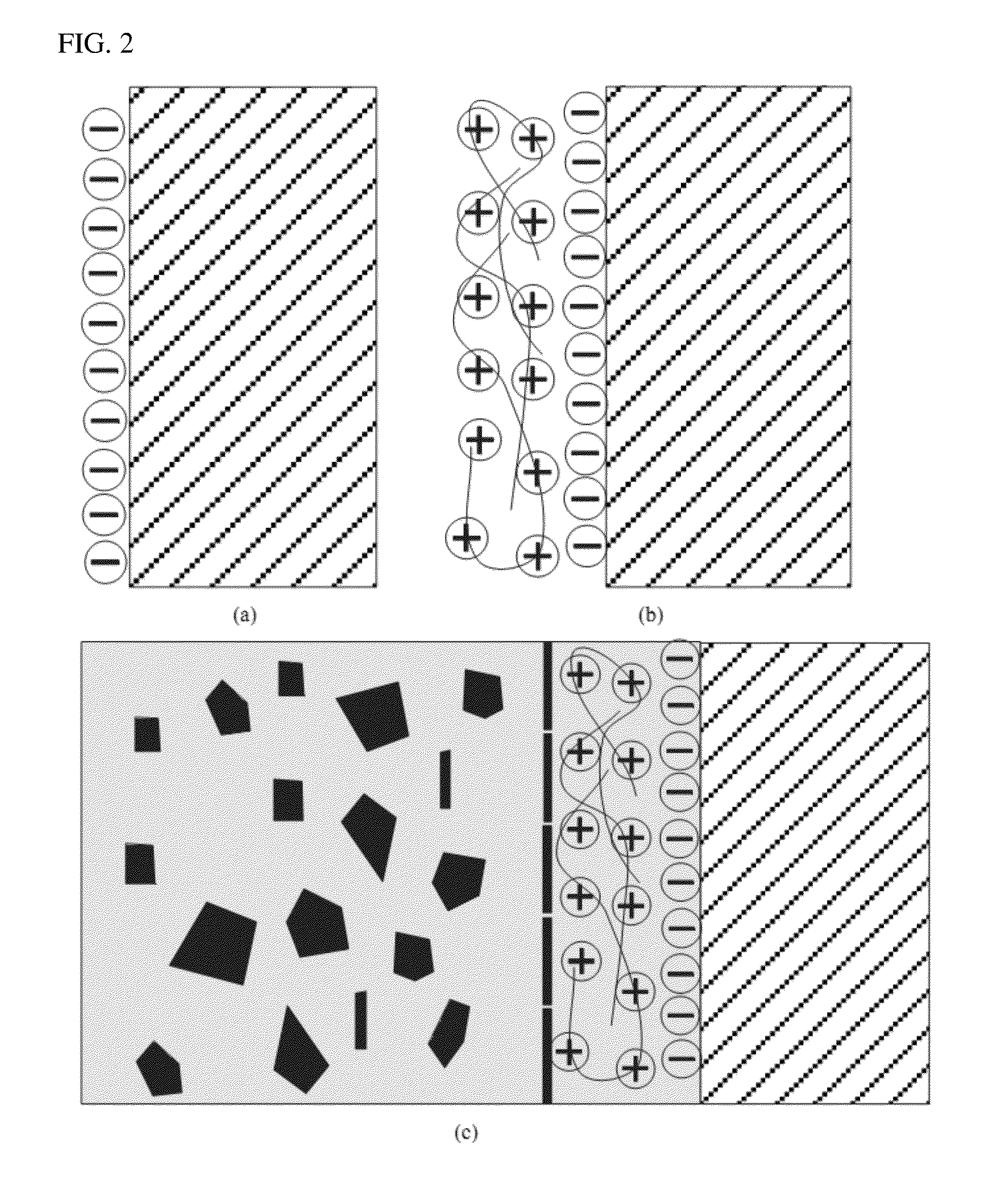

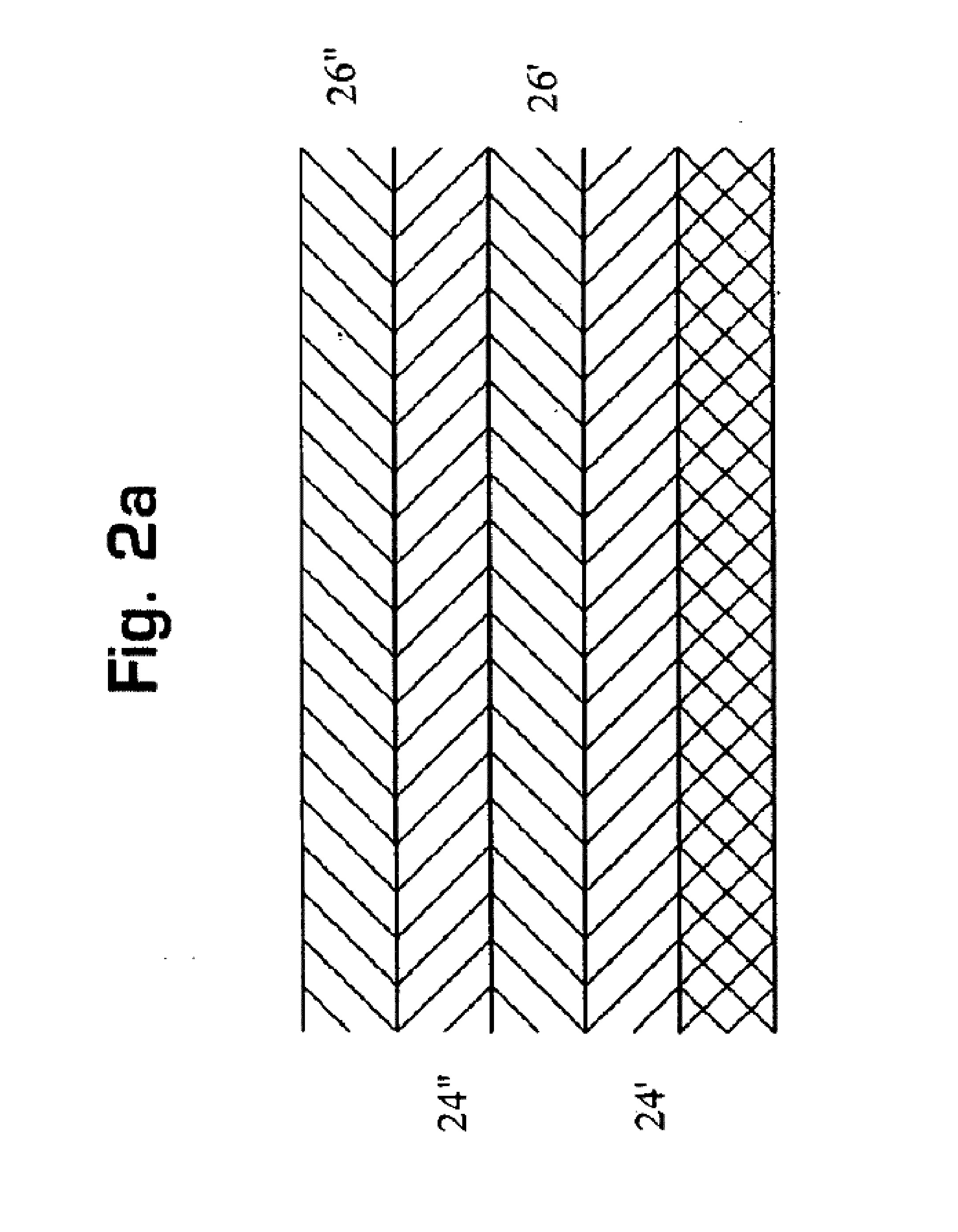

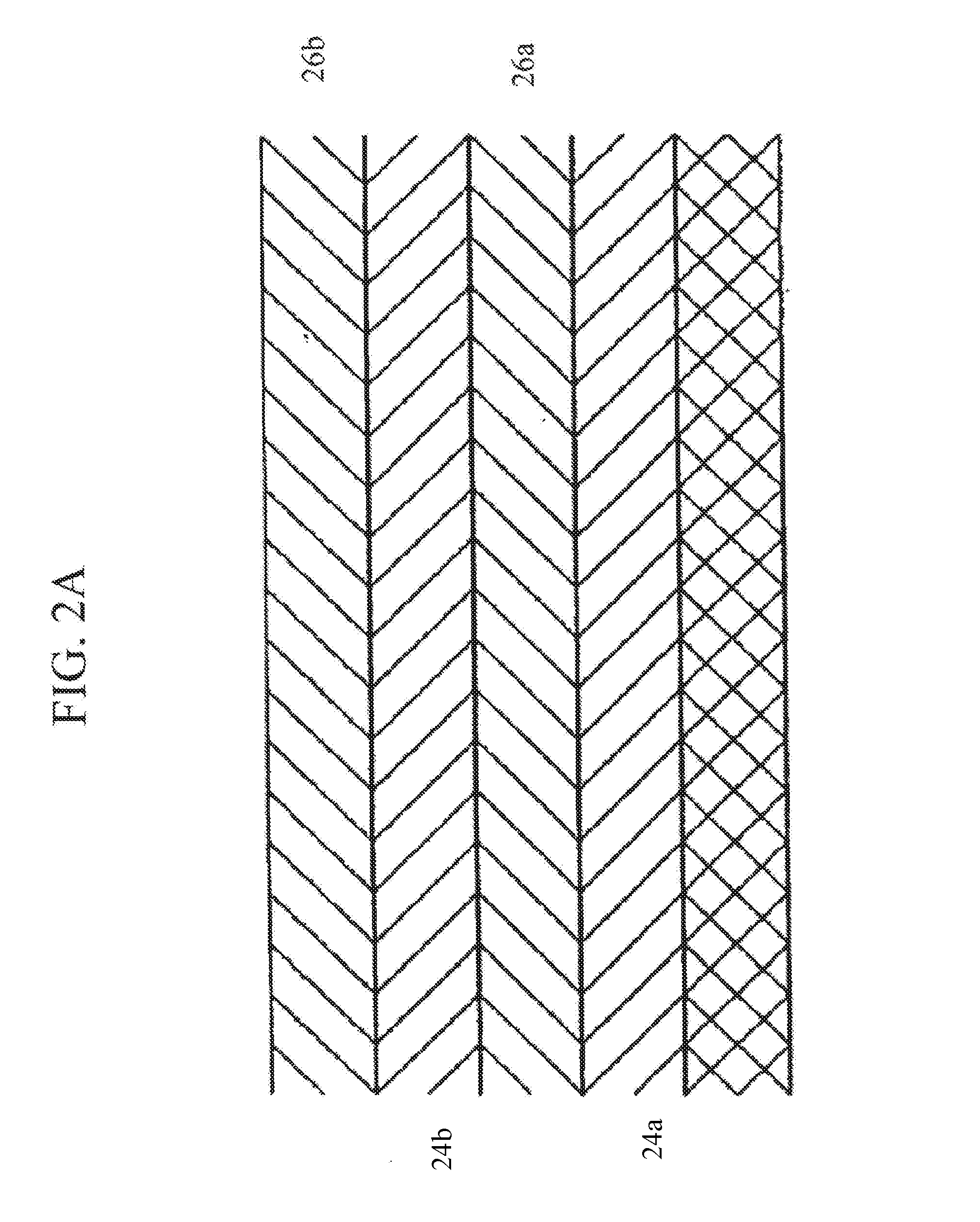

Encapsulation film with thin layer composed of graphene oxide and reduced graphene oxide and method for forming the same

InactiveUS20140242354A1Maximizing thicknessHinder propertyLamination ancillary operationsFinal product manufactureThin layerOptoelectronics

Provided are an encapsulation film formed by stacking at least one bilayer including a thin layer composed of graphene oxide or reduced graphene oxide and an organic polymer layer and a method for forming the same. Since the encapsulation film is formed by stacking at least one bilayer including a thin layer composed of graphene oxide or reduced graphene oxide, the encapsulation film can represent an excellent blocking property with respect to oxygen and moisture. Parallel diffusion of the oxygen and the moisture in the encapsulation film may be significantly limited by maximizing a thickness of the organic polymer layer formed between the thin layers.

Owner:RO JAE SANG +1

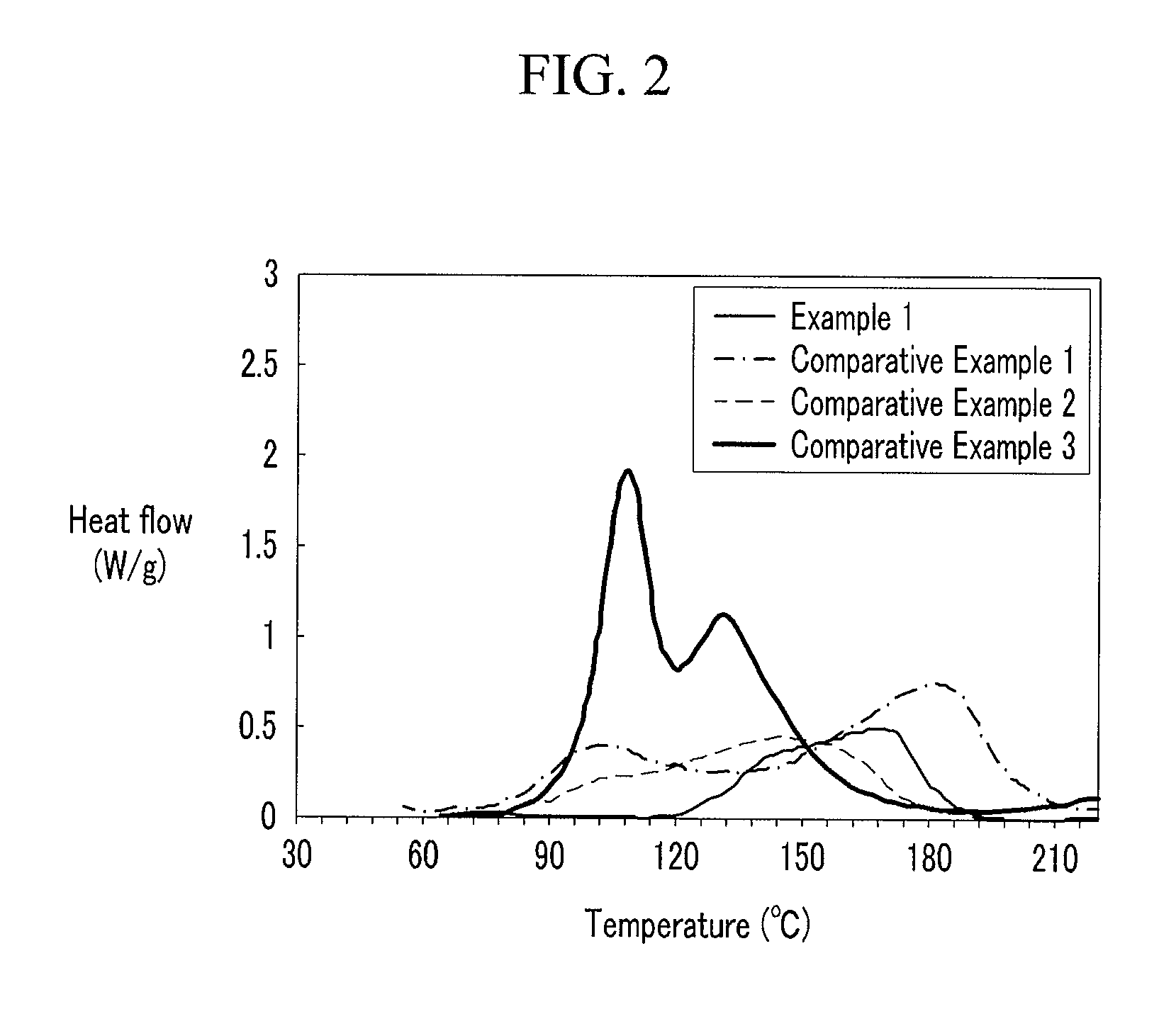

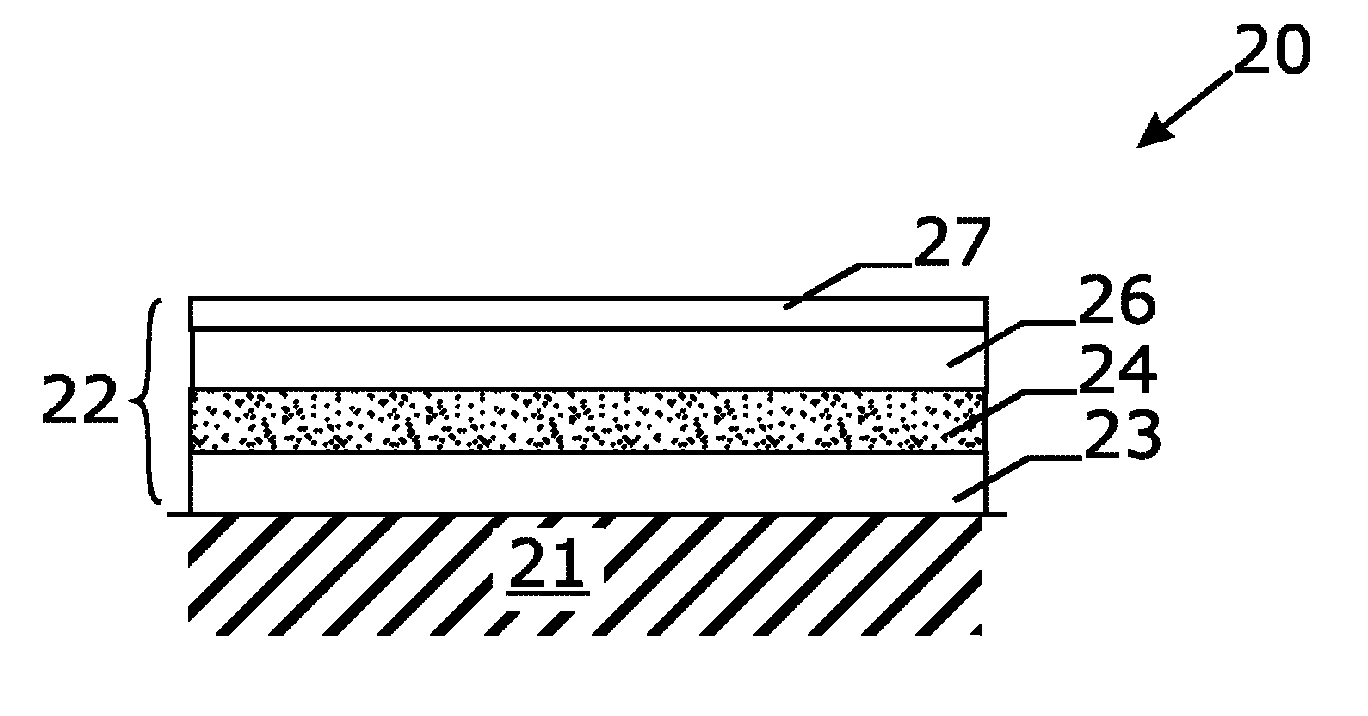

Ethylene resin composition, sealing material for solar cell, and solar cell module utilizing the sealing material

ActiveUS20120073631A1Good adhesion to glassImprove productivityPV power plantsSynthetic resin layered productsSolar cellMetal

The purpose of the present invention is to provide an ethylene resin composition which has excellent properties including adhesion properties, electrically insulating properties, transparency, moldability and process stability and can be produced without requiring any cross-linking procedure if necessary to improve productivity; and others. The ethylene resin composition contains a modified product produced by modifying an ethylene polymer (A) that meets all of the requirements a) to e) mentioned below with an ethylenically unsaturated silane compound (B). a) The density is 900 to 940 kg / m3. b) The melting peak temperature is 90 to 125 DEG C as determined by DSC. c) The melt flow rate (MFR2) is 0.1 to 100 g / 10 minutes as measured at 190° C. and a load of 2.16 kg in accordance with JIS K-6721. d) The Mw / Mn ratio is 1.2 to 3.5. e) The content of metal residues is 0.1 to 50 ppm.

Owner:MITSUI CHEM TOHCELLO INC

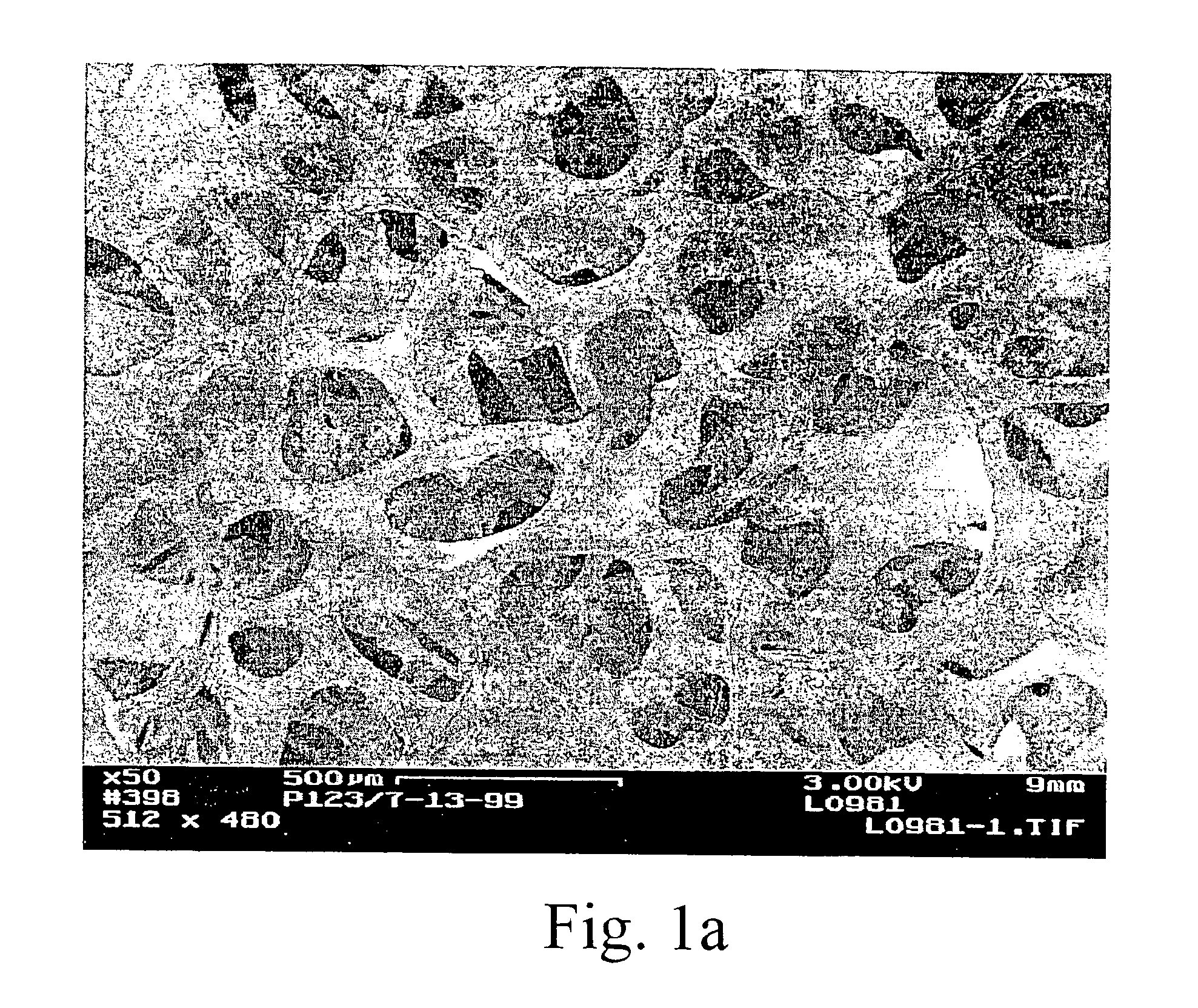

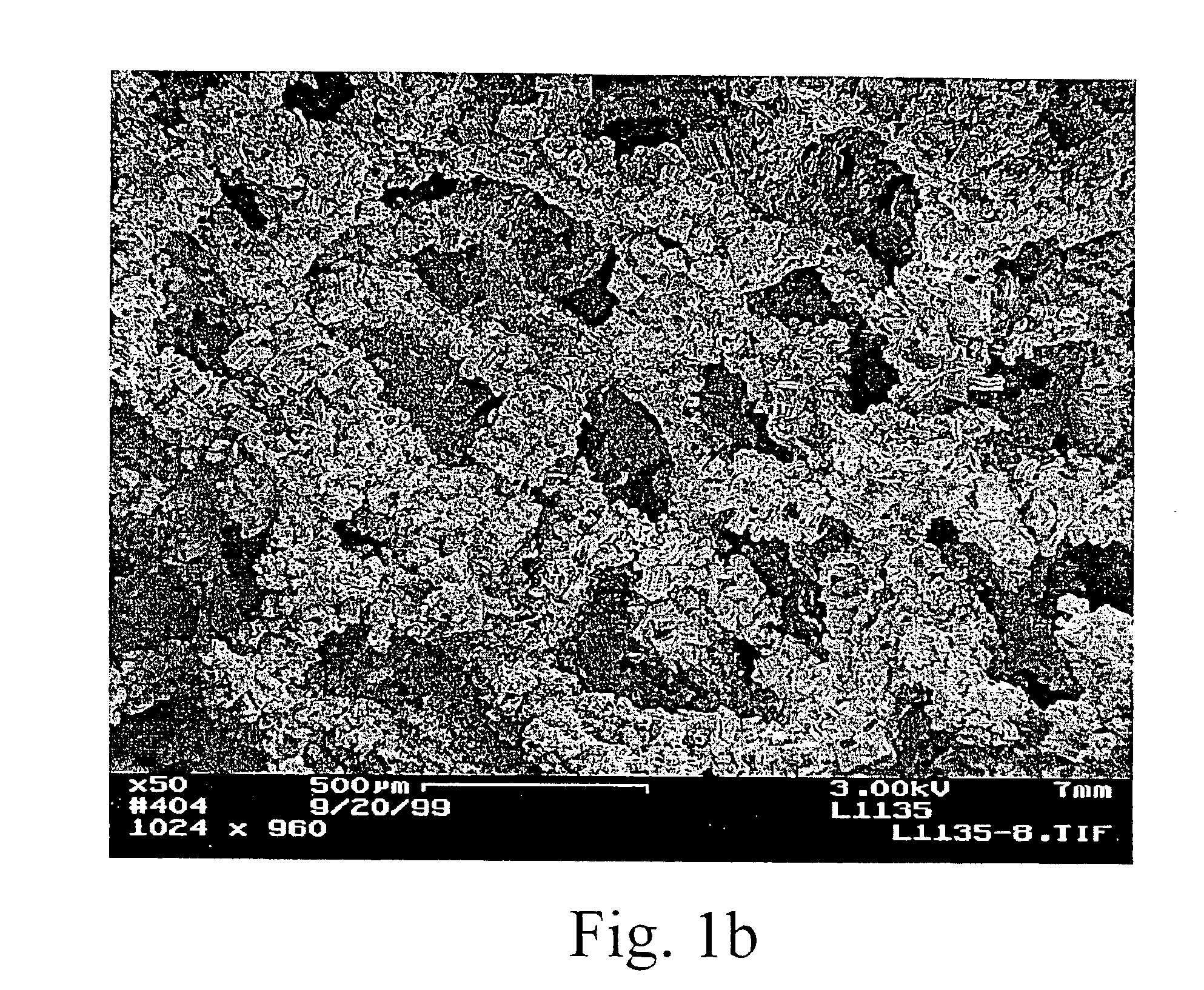

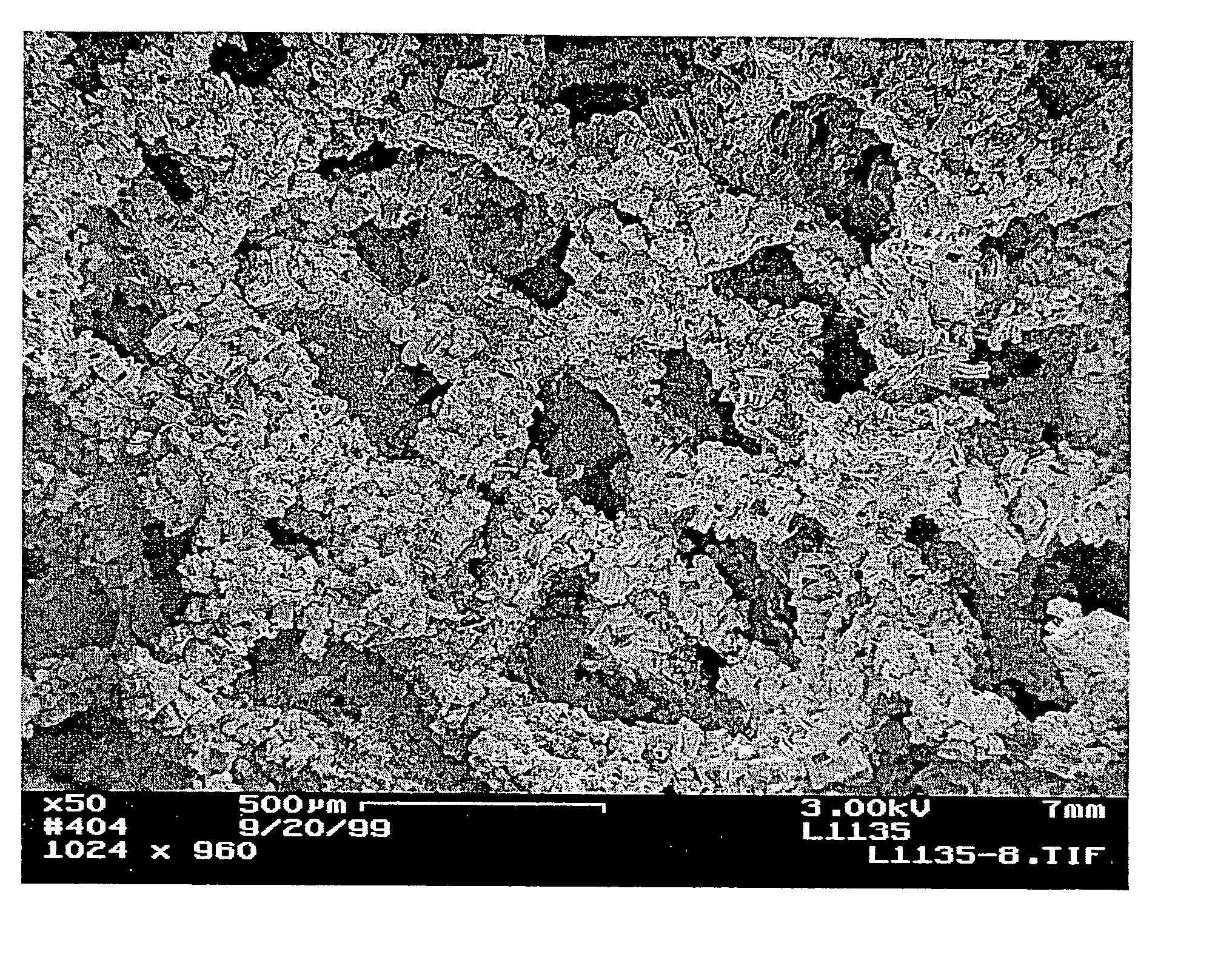

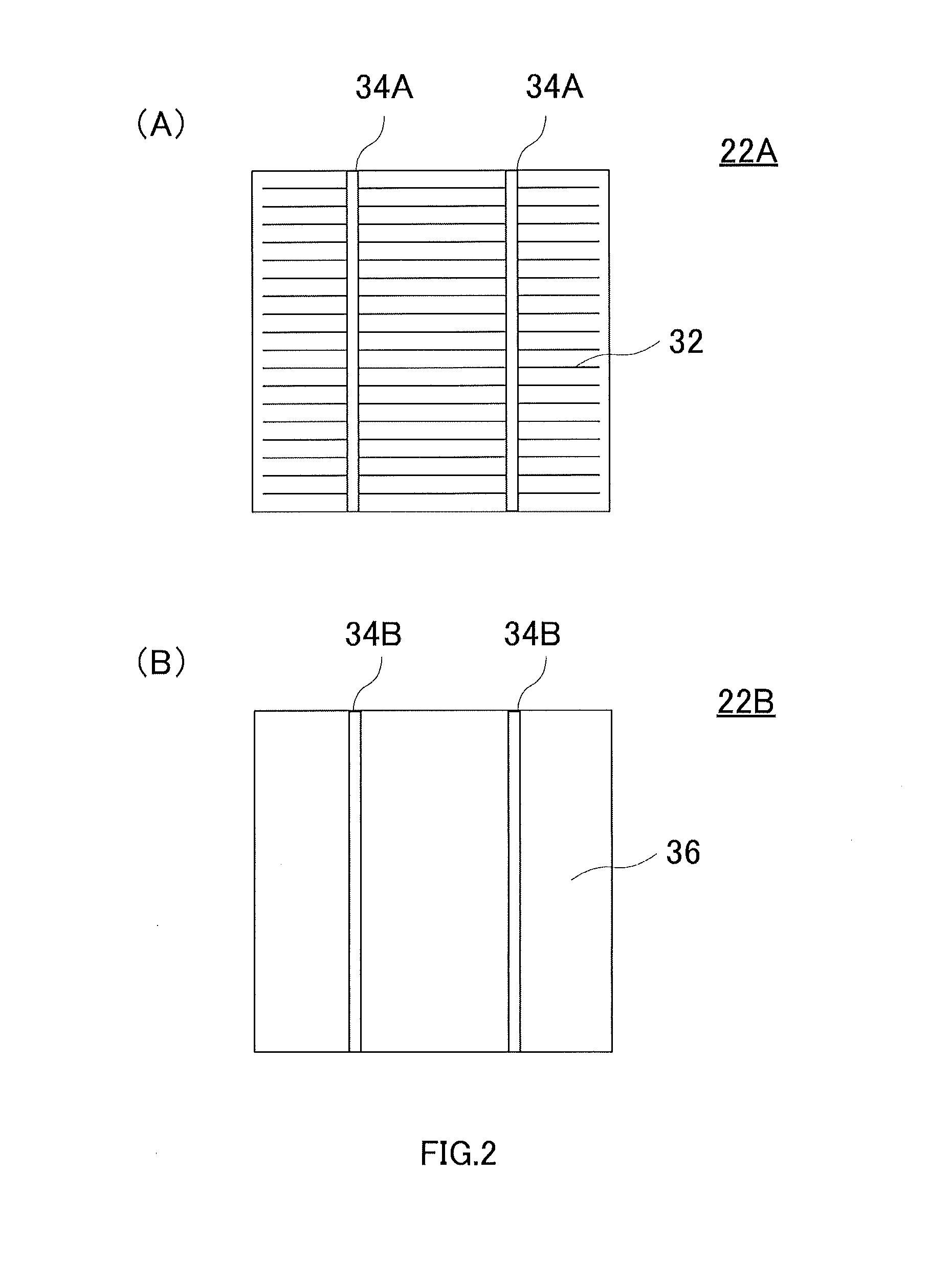

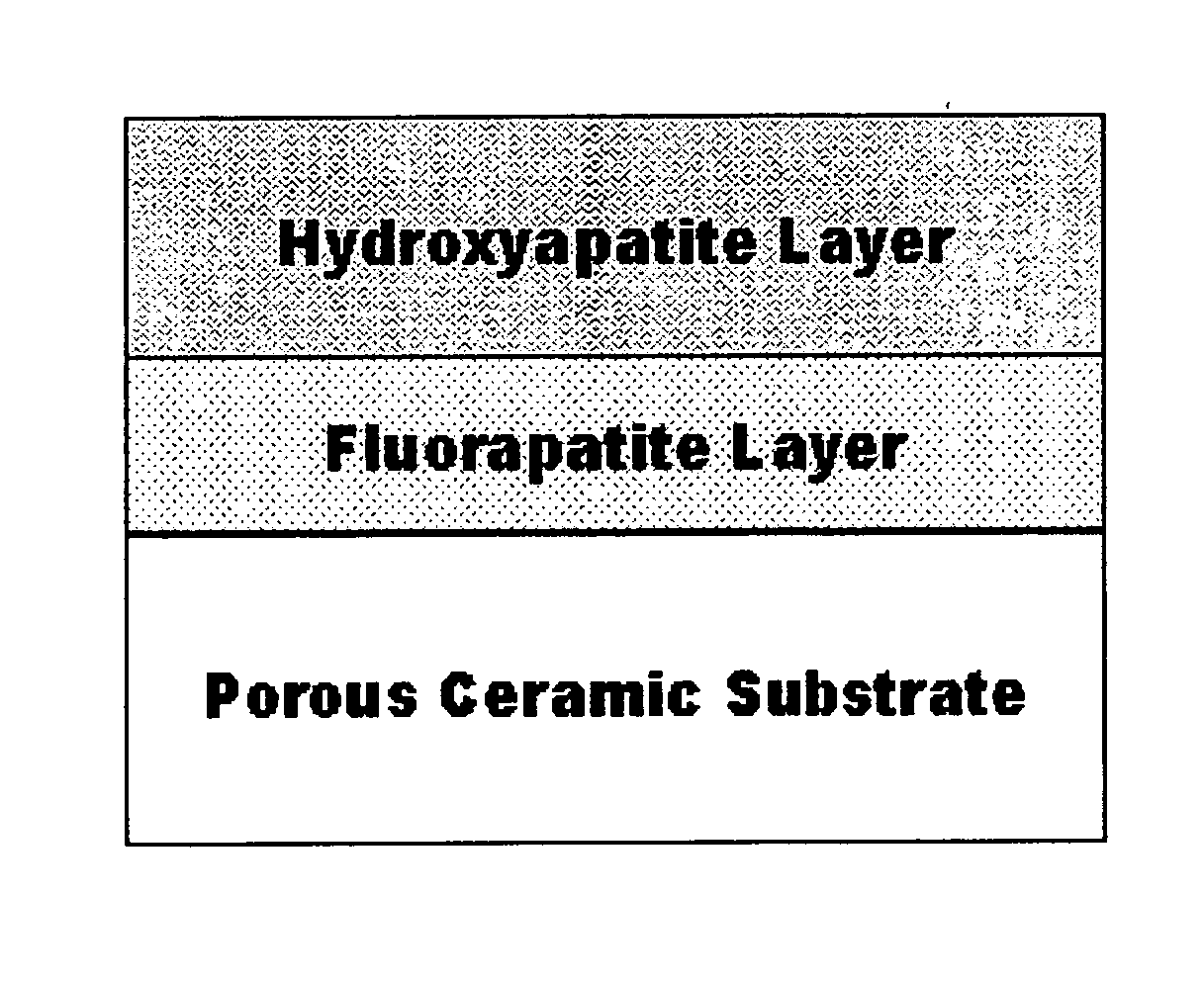

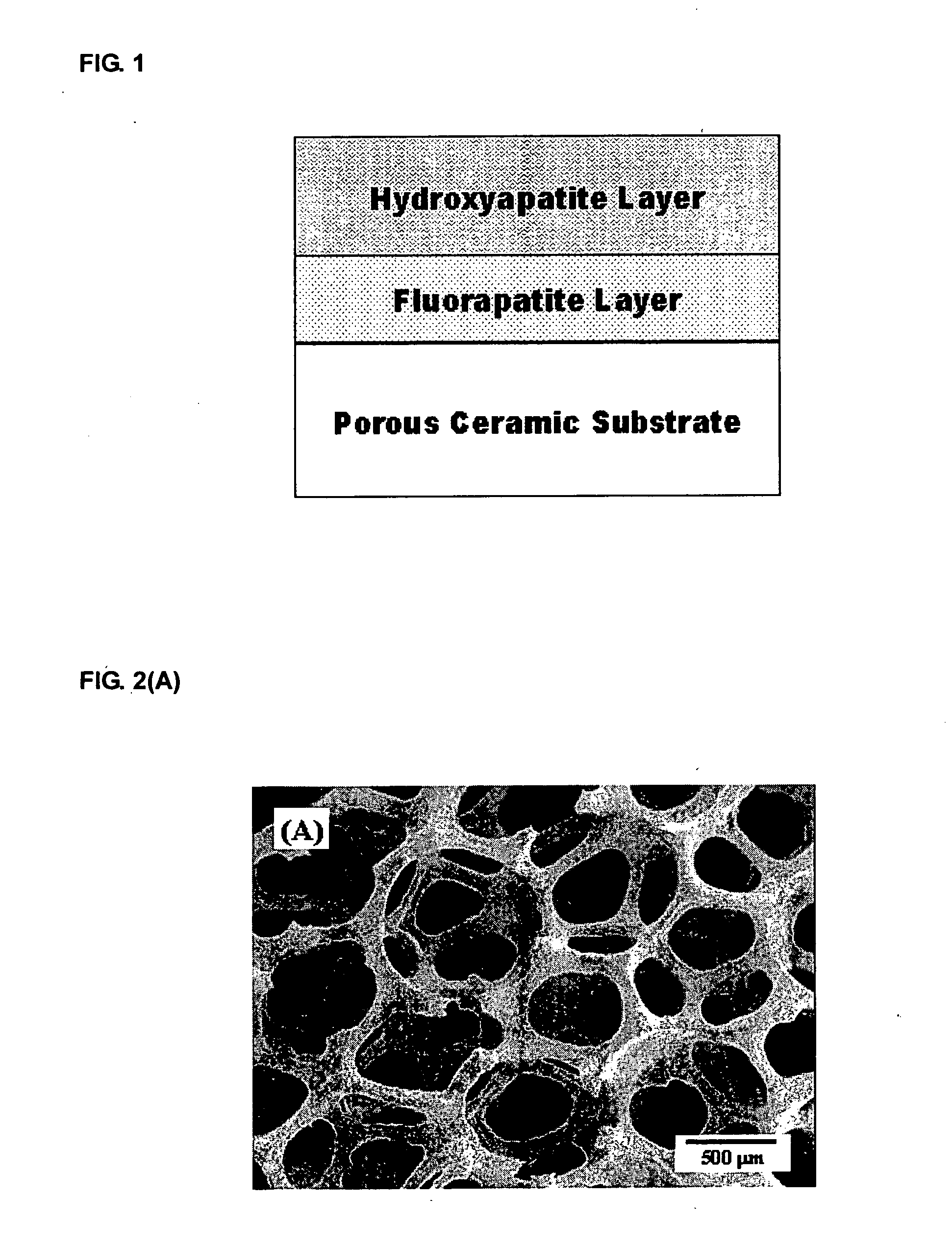

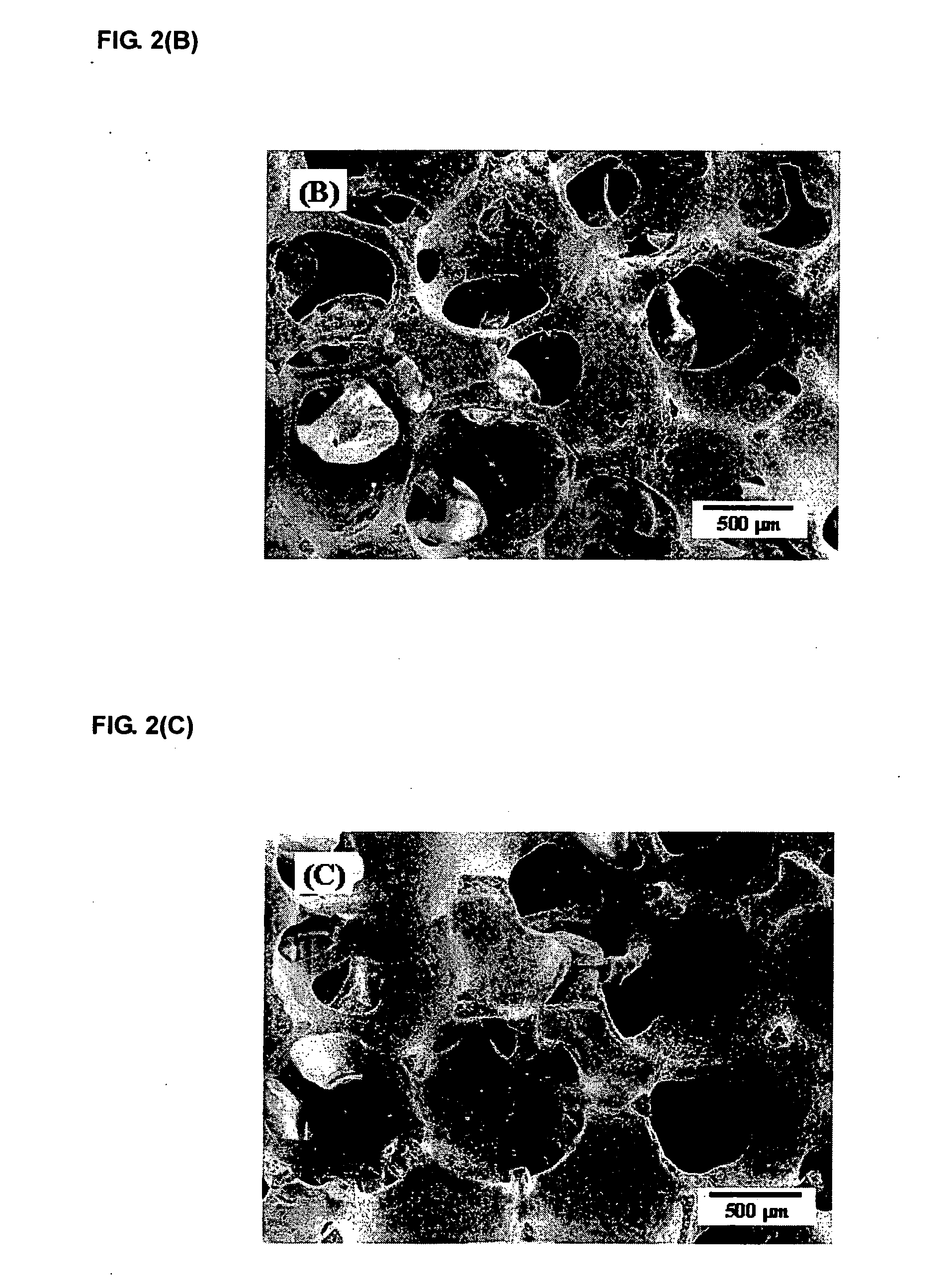

Porous bioceramics for bone scaffold and method for manufacturing the same

InactiveUS20050113934A1High of bioactivityHigh propertiesBone implantPretreated surfacesOsseointegrationBiocompatibility Testing

The present invention provides a porous bioceramics for bone scaffold. The porous bioceramics according to the present invention comprises a biocompatible porous ceramic substrate having the property to thermal-decompose hydroxyapatite in contact with it; a fluorapatite (FA) inner layer formed on said porous ceramic substrate; and a hydroxyapatite (HA) outer layer formed on said fluorapatite inner layer. The insertion of FA intermediate layer can prevent the thermal reaction between ZrO2 and HA. Therefore, the present invention can provide the implant material into human body having excellent mechanical properties of zirconia as well as the biocompatibility, bioaffinity and bioactivity of HA. The present invention can also provide the implant material to promote osteoconduction and osteointegration in human body.

Owner:SEOUL NAT UNIV R&DB FOUND

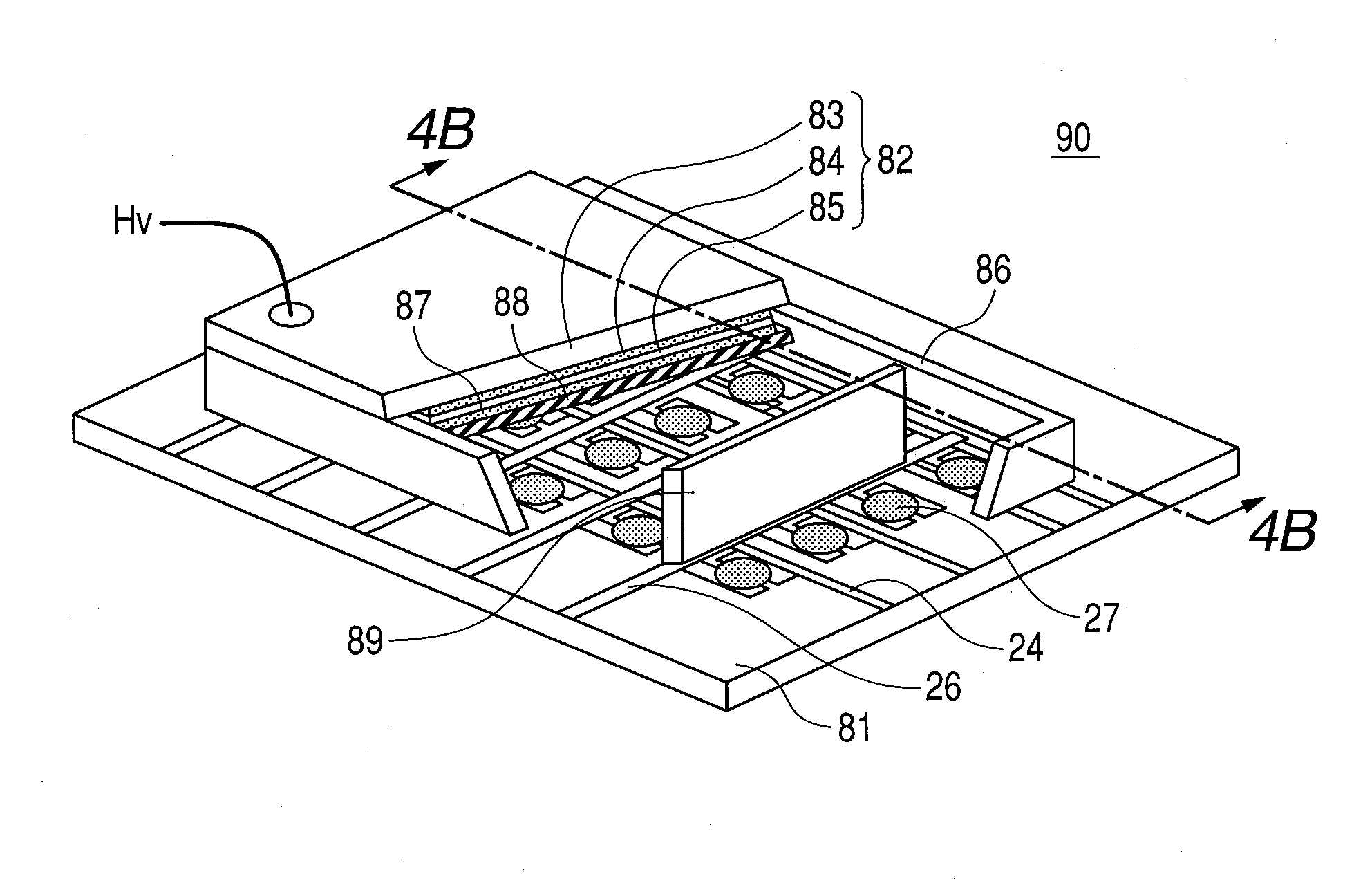

Mask fixing device in vacuum processing apparatus

A vacuum processing apparatus which processes an object to be processed with the use of a mask membrane plane of magnetic material and a mask frame of the magnetic material is characterized in that the mask of the magnetic material is attracted by an electro-permanent magnet that is disposed in an opposite side of the mask with respect to the surface having the object to be processed mounted thereon.

Owner:CANON ANELVA CORP

Substrate coated with a layered structure comprising a tetrahedral carbon layer and a softer outer layer

ActiveUS7947372B2Inhibit wearHigh hardnessNatural mineral layered productsChemical vapor deposition coatingCarbon coatingCarbon layer

The invention relates to a metal substrate coated at least partially with a layered structure. The layered structure comprises an intermediate layer deposited on the metal substrate and an amorphous carbon layer deposited on the intermediate layer. The amorphous carbon layer has a Young's modulus lower than 200 GPa. The intermediate layer comprises a tetrahedral carbon layer having a Young's modulus higher than 200 GPa. The invention further relates to a method to reduce the wear on a counterbody of a metal substrate coated with a tetrahedral carbon coating.

Owner:SULZER METAPLAS

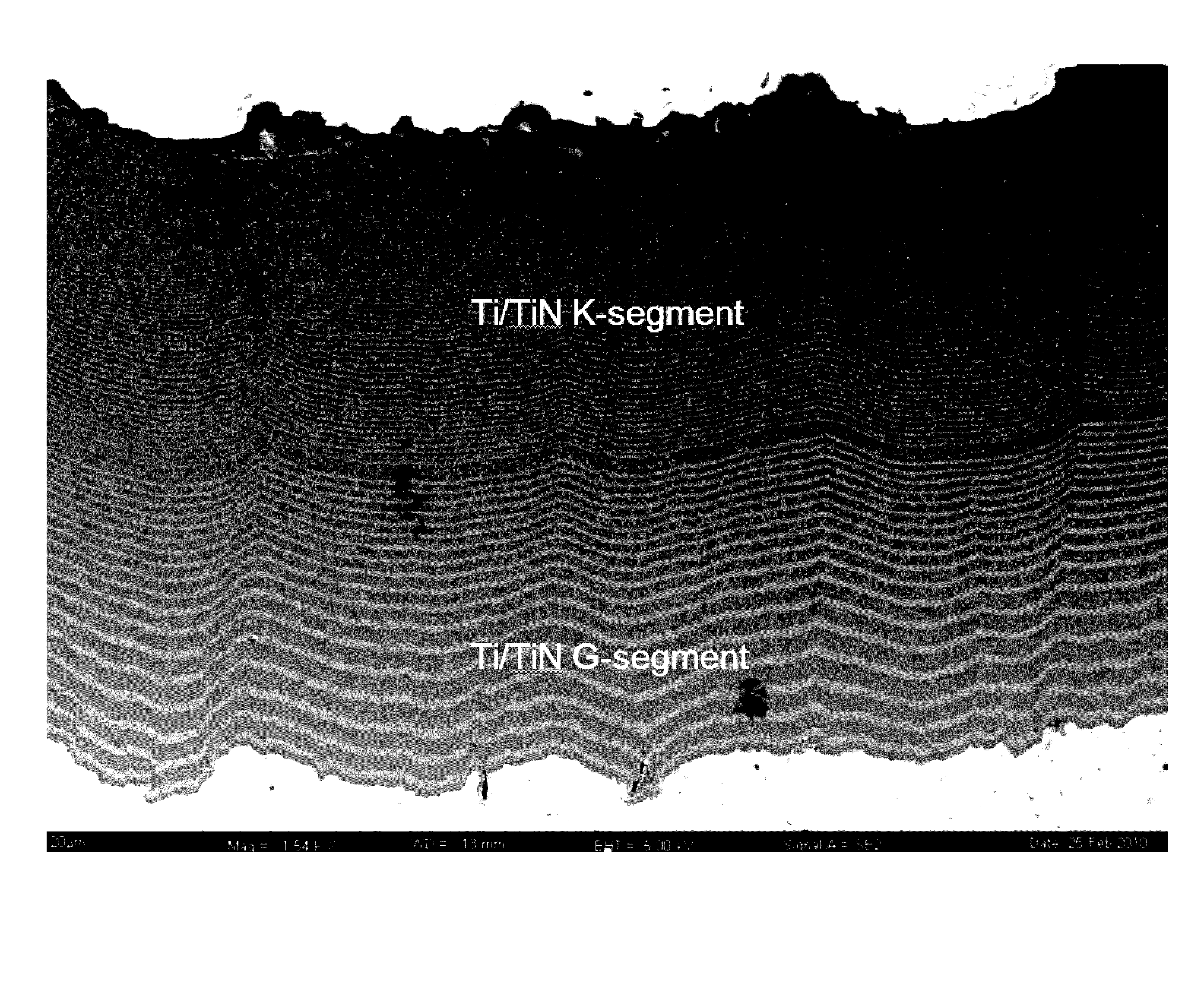

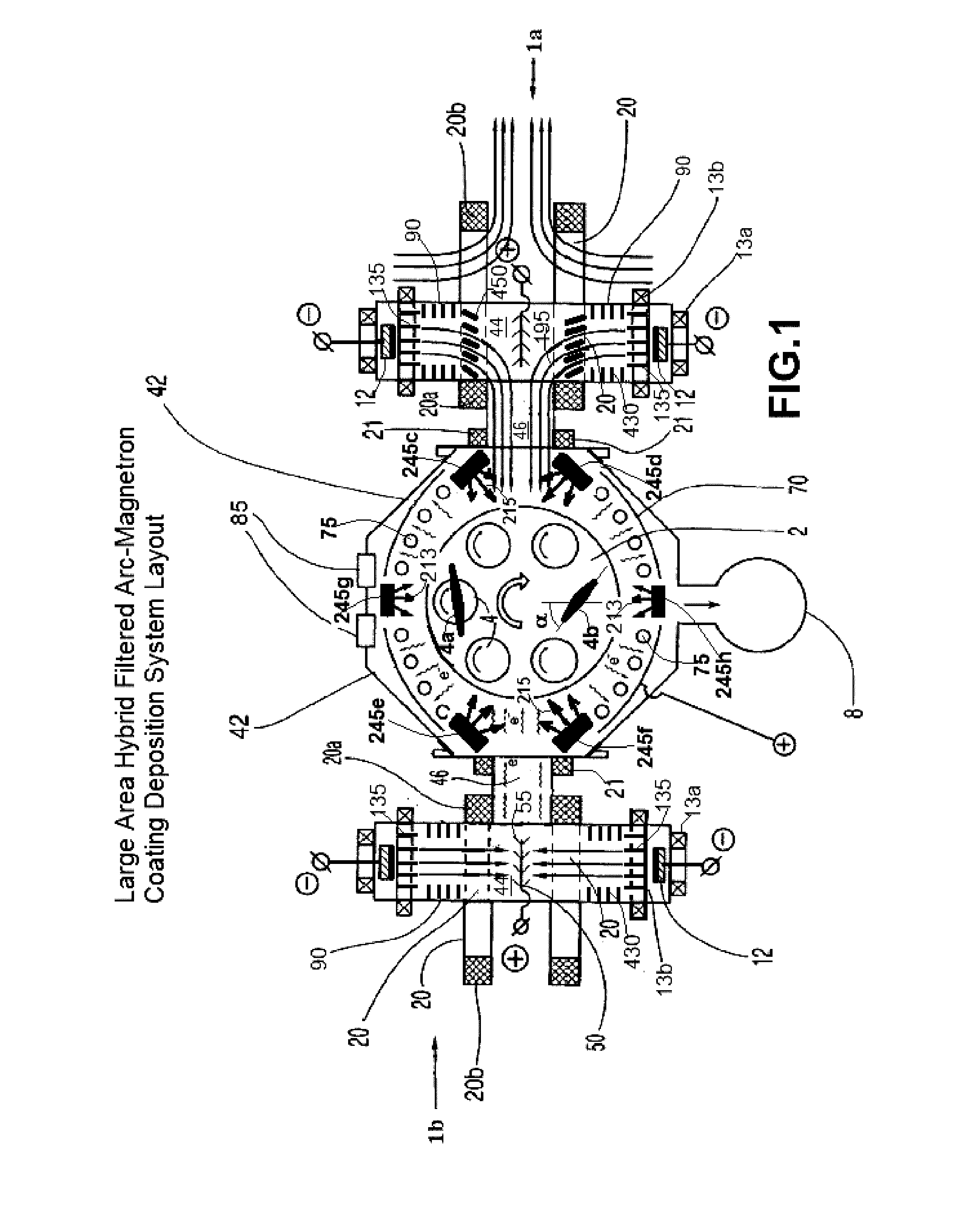

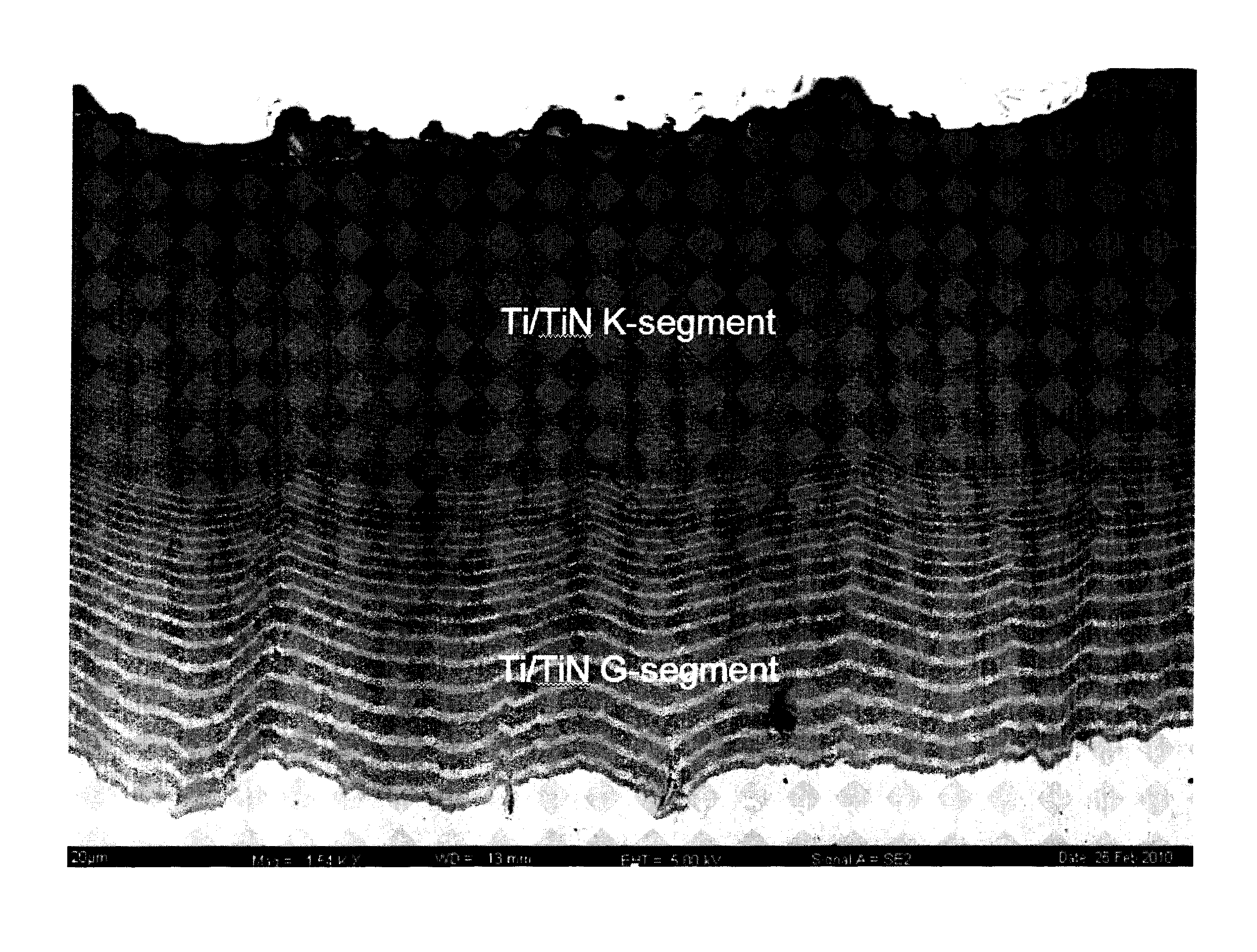

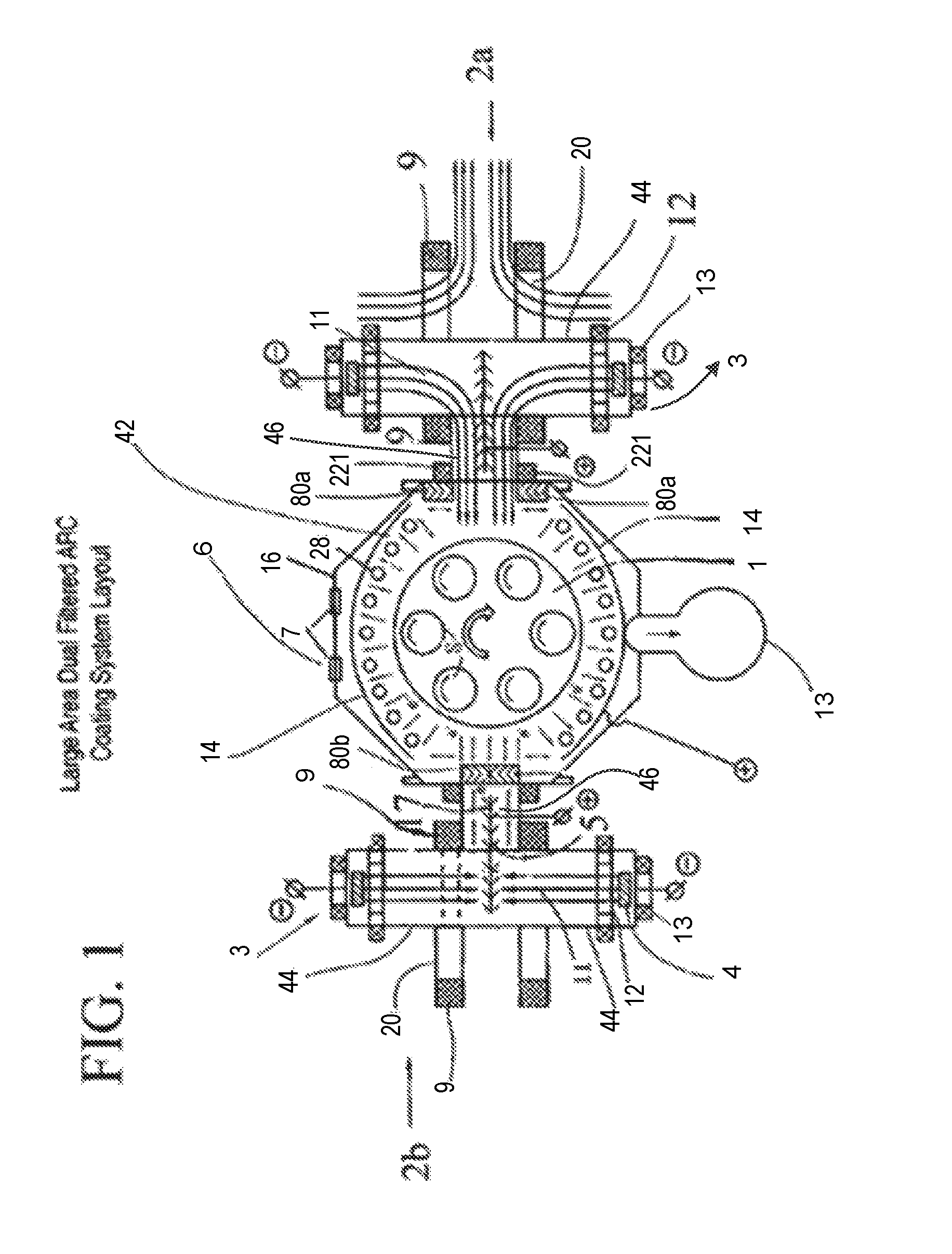

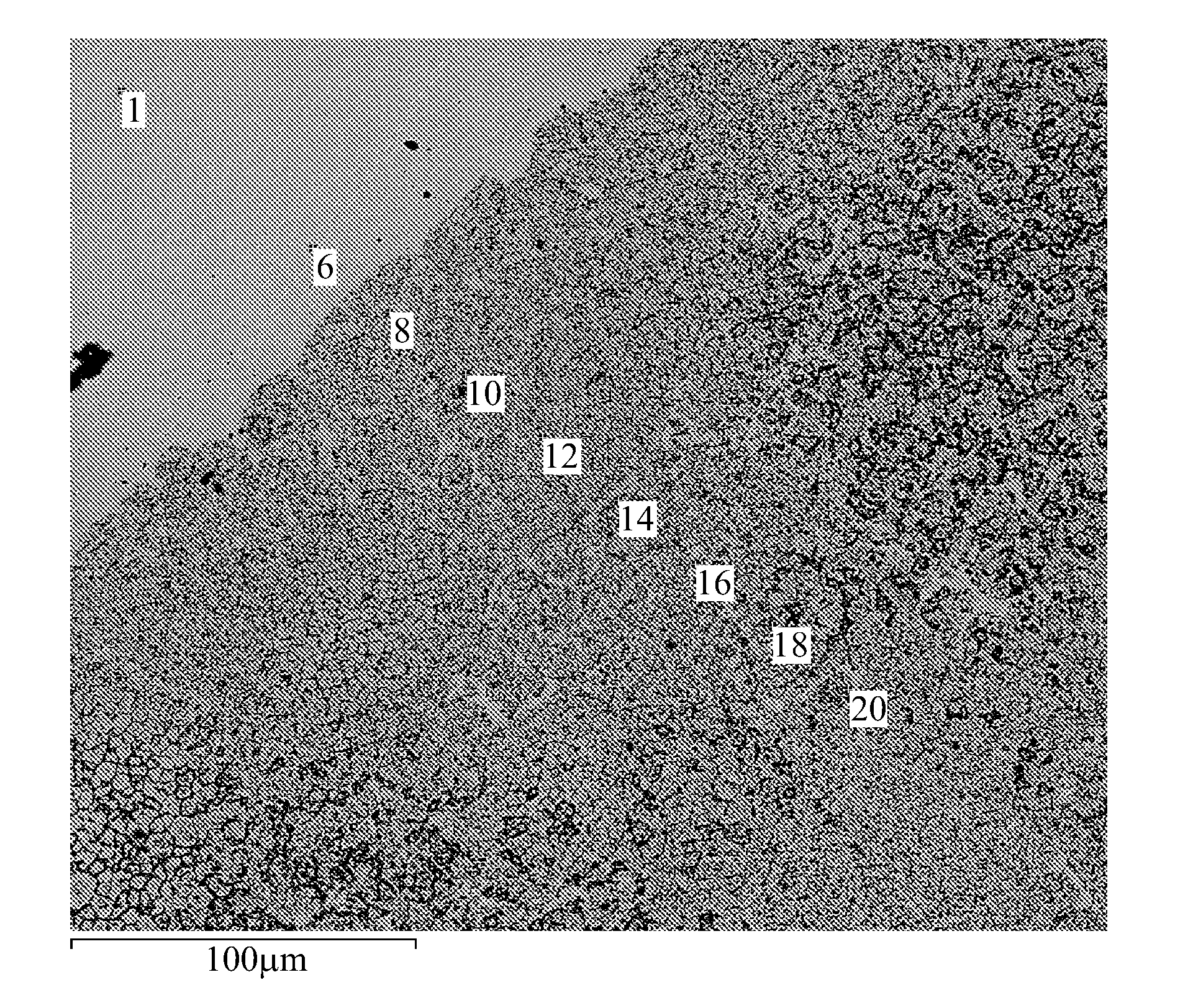

Erosion And Corrosion Resistant Protective Coatings For Turbomachinery

InactiveUS20170030204A1Increase flexibilityImprove reflectivityEngine manufactureBlade accessoriesCeramic coatingPlasma flow

An erosion and corrosion resistant protective coating for turbomachinery application includes at least one ceramic or metal-ceramic coating segment deposited on surface of a conductive metal substrate subjected to a pre-deposition treatment by at least blasting to provide the surface with texture. The erosion and corrosion resistant coating has a plurality of dome-like structures with dome width between in range from about 0.01 μm to about 30 μm. The at least one coating segment is formed by condensation of ion bombardment from a metal-gaseous plasma flow, wherein, at least during deposition of first micron of the coating segment, deposition rate of metal ions is at least 3 μm / hr and kinetic energy of deposited metal ions exceeds 5 eV.

Owner:NANO PROD ENG

Iron-based soft magnetic powder for dust core, method for producing the same and dust core

ActiveUS20100051851A1Improve heat resistanceReduce the amount requiredMetal-working apparatusInorganic material magnetismElectricityO-Phosphoric Acid

Disclosed herein is an iron powder for dust cores which effectively keeps insulation among iron powder particles and excels in mechanical strength even though the amount of insulating material is reduced to achieve high-density forming and which also exhibits good thermal stability necessary for electrical insulating properties even after heat treatment at high temperatures.The iron-based magnetic powder has layers of phosphoric acid-based film and silicone resin film sequentially formed on the surface thereof, said phosphoric acid-based film containing at least one element selected from the group consisting of Co, Na, S, Si, and W.

Owner:KOBE STEEL LTD

Flame retardant electrolyte solution for rechargeable lithium battery and rechargeable lithium battery including the same

ActiveUS20110123869A1Reducing and eliminating decompositionHigh characteristicsNon-aqueous electrolyte accumulatorsCell electrodesPhosphoric acidPhysical chemistry

Disclosed are a flame retardant electrolyte solution for a rechargeable lithium battery including a lithium salt, a linear carbonate-based solvent, an ionic liquid including ammonium cations, and a phosphoric acid-based solvent, and a rechargeable lithium battery including the same.

Owner:SAMSUNG SDI CO LTD

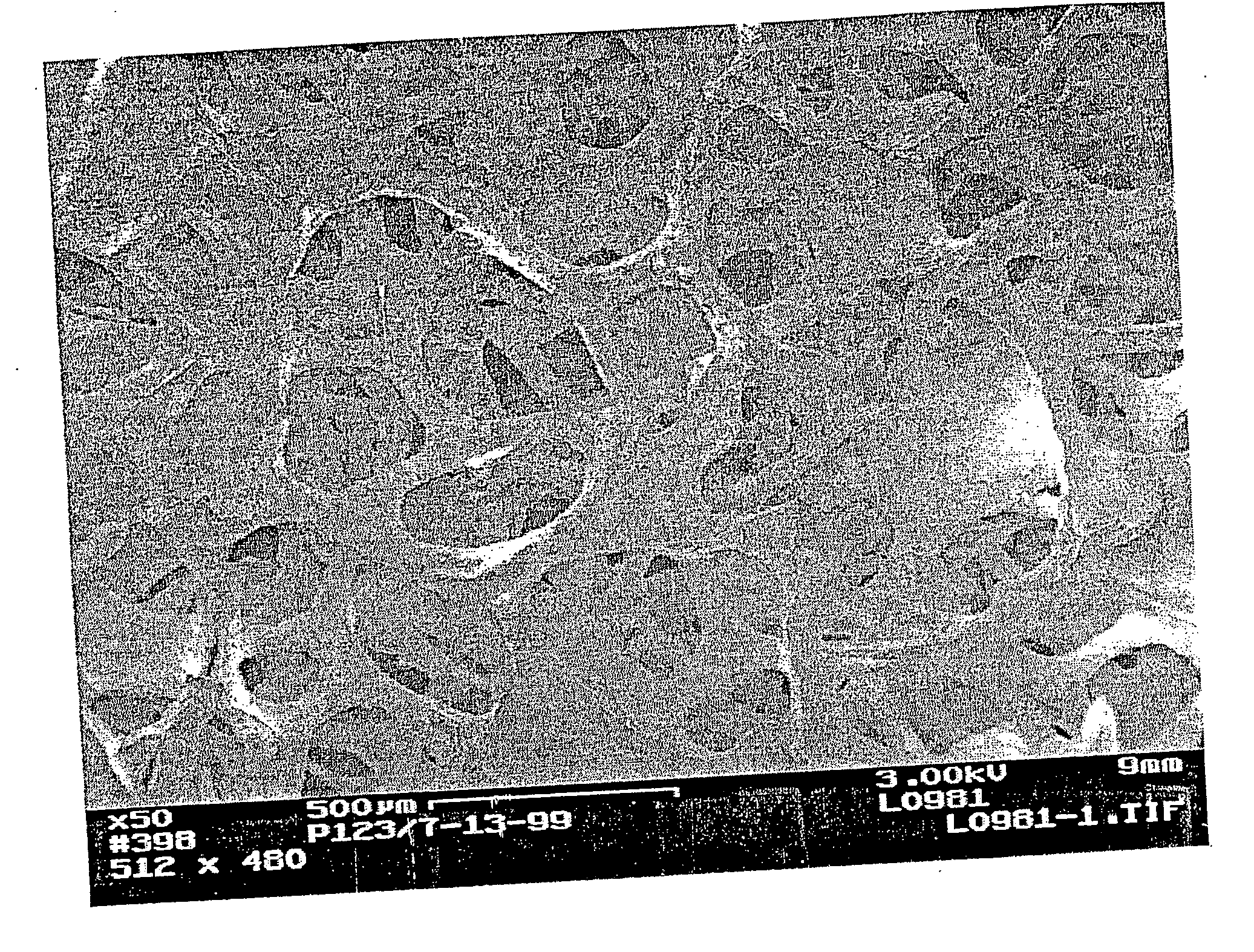

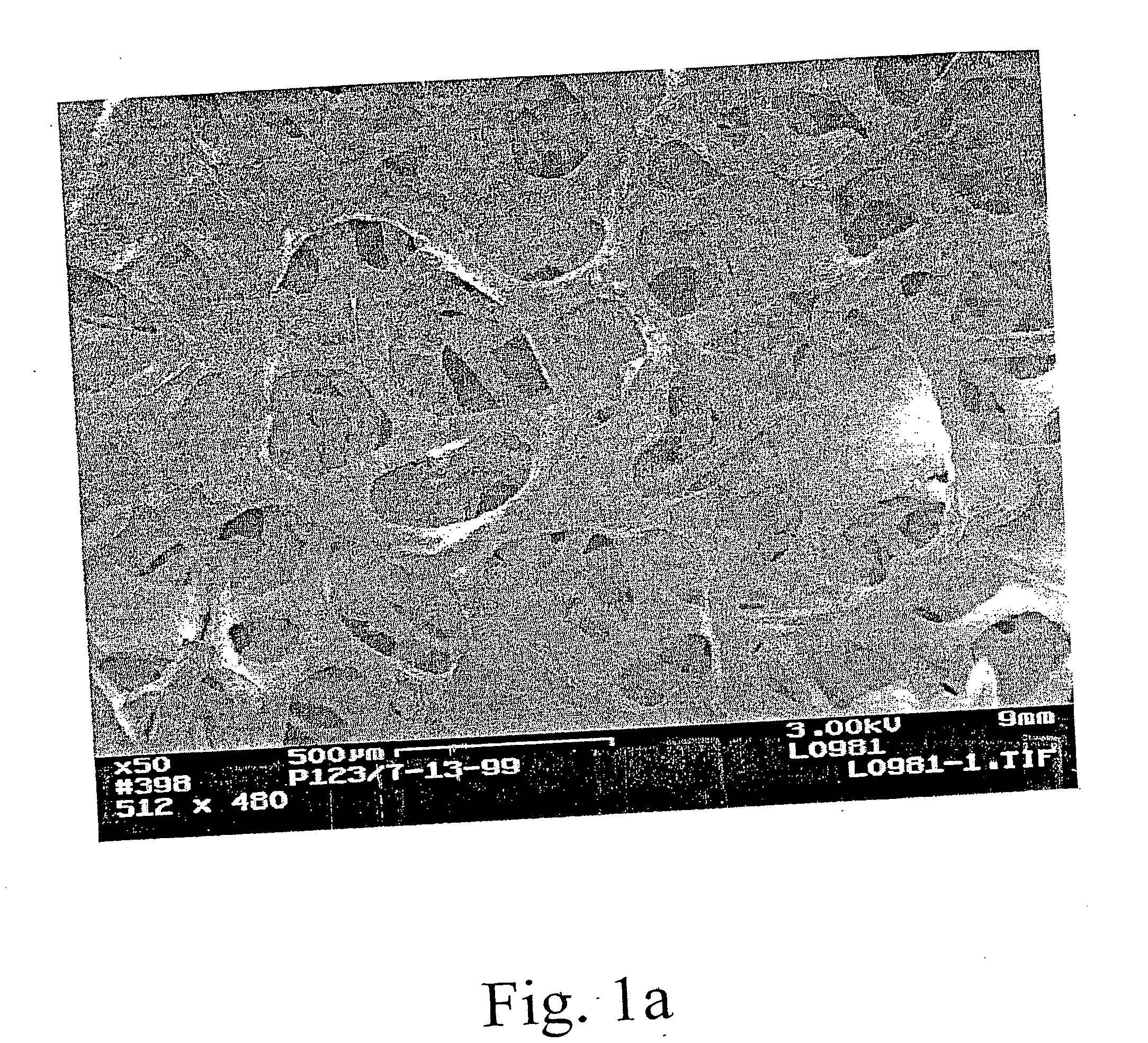

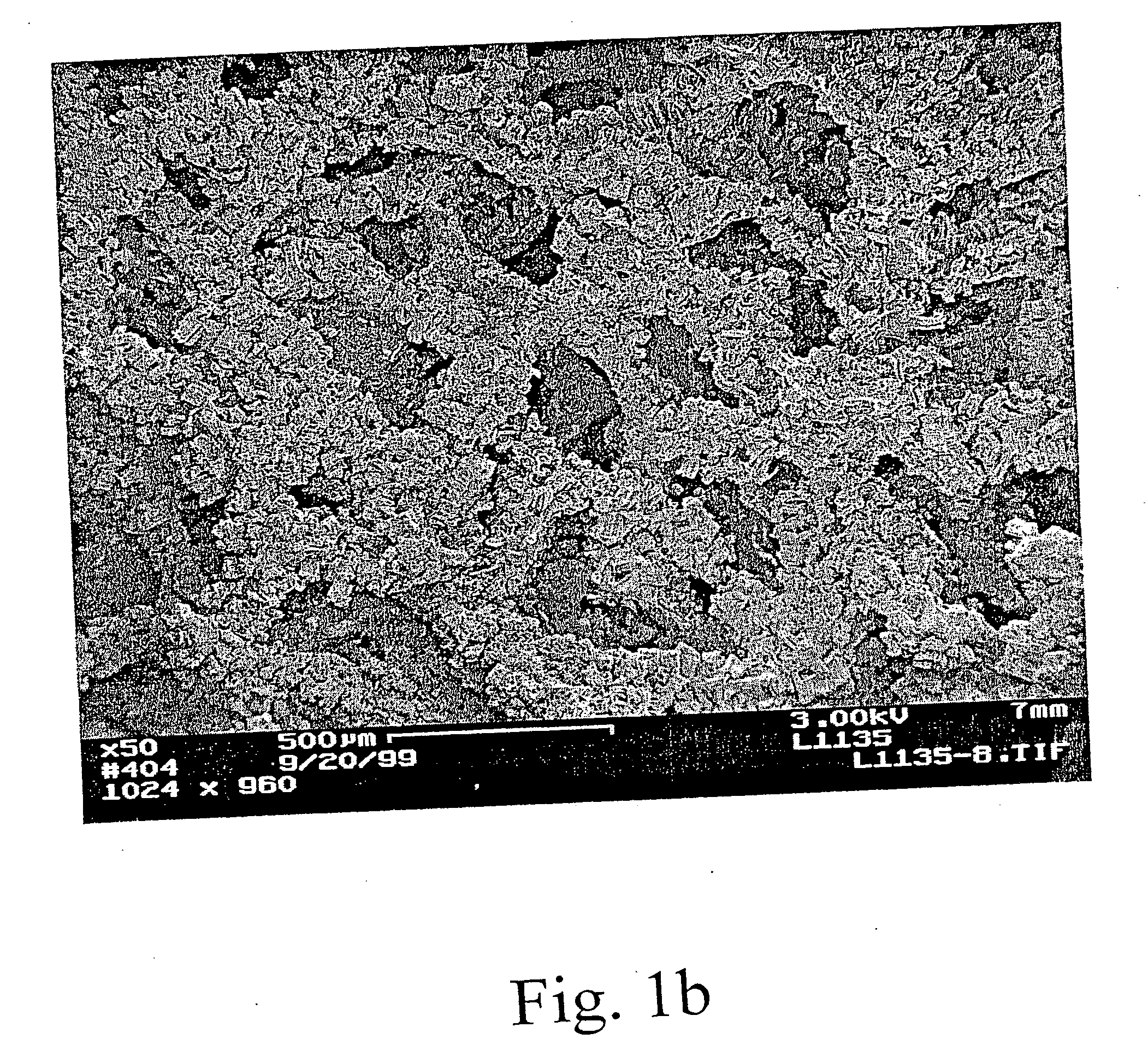

Carbon nanotube-containing catalysts, methods of making, and reactions catalyzed over nanotube catalysts

InactiveUS7008969B2Improve performanceImprove reaction speedMaterial nanotechnologyCarbon compoundsPerformance resultsOxide

Methods have been developed to form catalysts having active metals disposed on a carbon nanotube coated porous substrate. Catalysts and reactions over nanotube-containing catalysts are also disclosed. Results are presented showing enhanced performance resulting from use of the inventive catalyst. Mesoporous oxide layers can be utilized to improve catalyst properties.

Owner:BATTELLE MEMORIAL INST

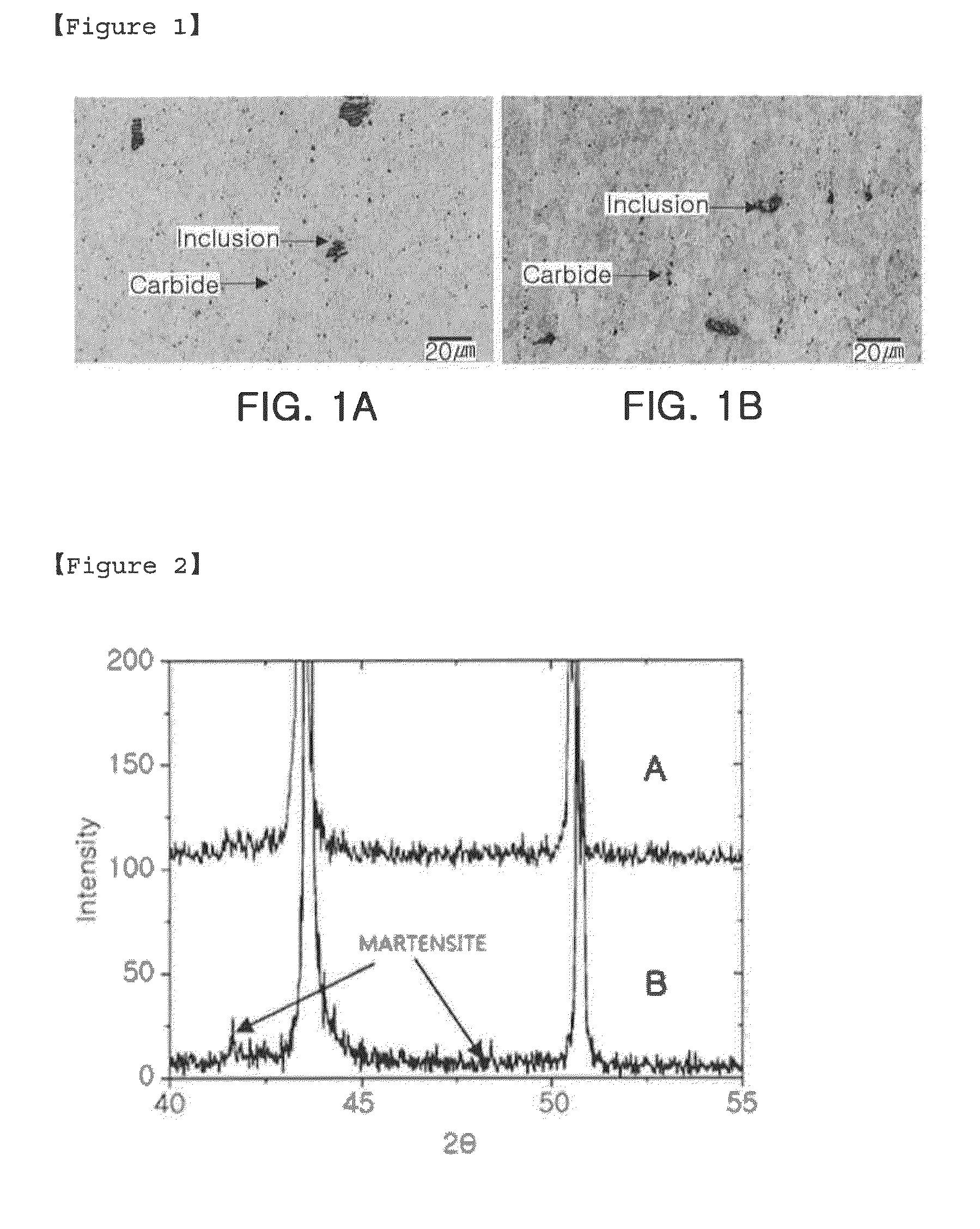

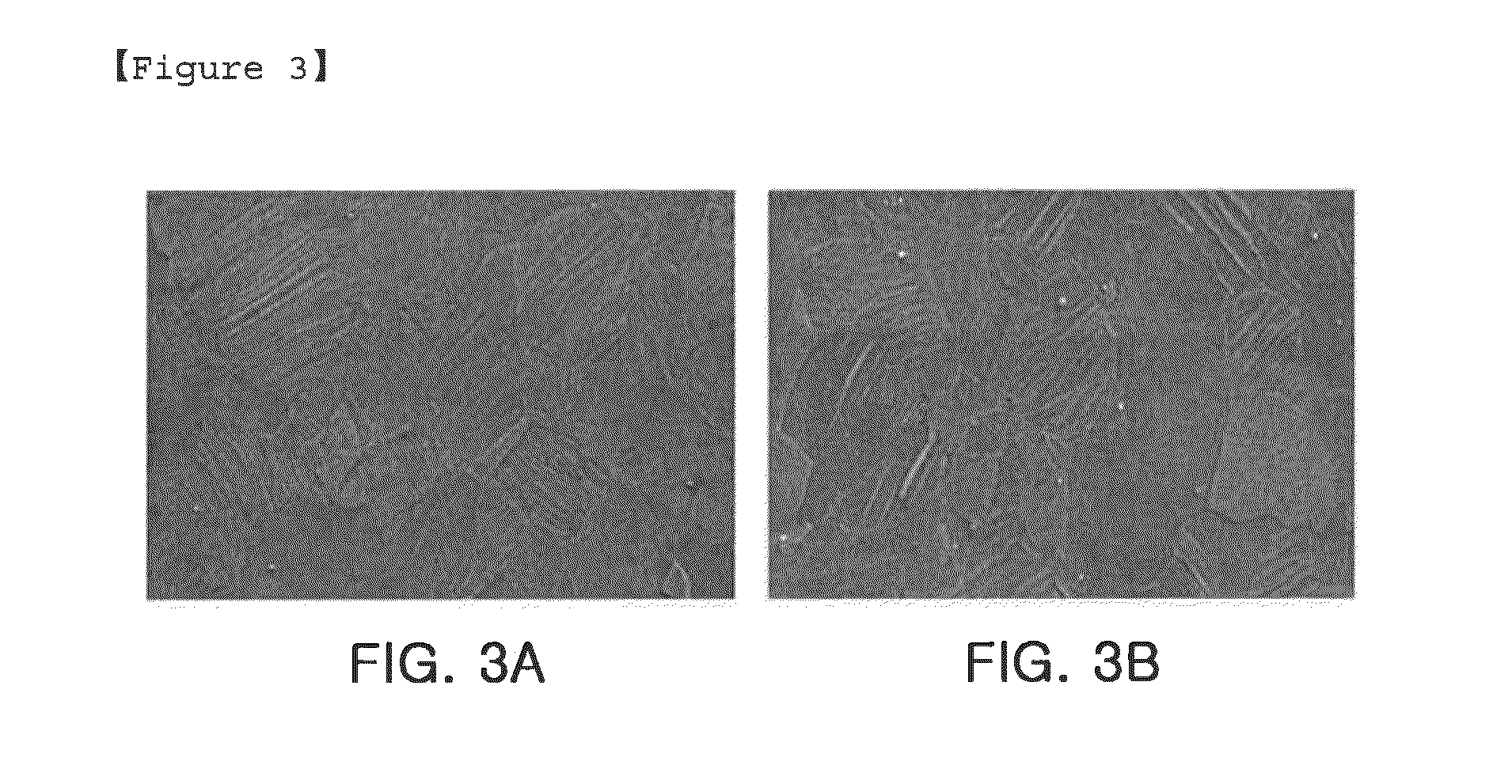

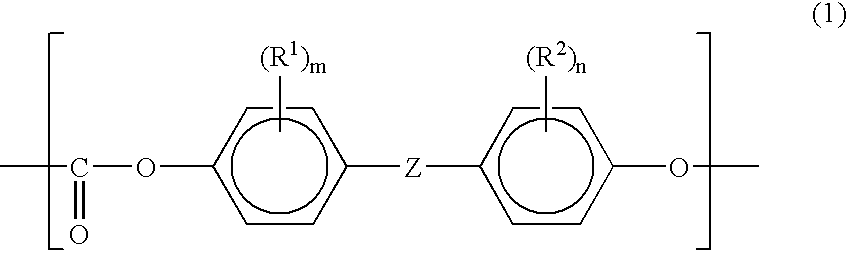

Non-magnetic high manganese steel sheet with high strength and manufacturing method thereof

InactiveUS20150211088A1Increased austenite stabilityHigh degreeFurnace typesHeat treatment furnacesHigh intensityNon magnetic

The present invention relates to a non-magnetic high manganese steel sheet with high-strength, which has superior strength and moldability, and at the same time, can obtain superior non-magnetic characteristics, and a method for manufacturing the same.

Owner:POHANG IRON & STEEL CO LTD

Polycarbonate resin composition and molded object thereof

Owner:IDEMITSU KOSAN CO LTD

Adhesive composition and bonding method

ActiveUS20100236716A1Improve retentionImprove productivityAdhesive processesLaminationLiquid compositionAldehyde

To provide an adhesive composition having high adhesion and quick curing properties on the second time scale, and having a high retention in a durability test such as a high temperature and high humidity test.A two-part type adhesive composition which comprises a first agent comprising (A) a nitrile butadiene rubber having an acrylonitrile content of from 10 to 30%, (B) a polymerizable (meth)acrylic liquid composition, (C) an organic peroxide and (D) a basic compound having an amine structure, and a second agent comprising (E) a reaction condensate of an amine and an aldehyde and (F) a reducing agent containing copper, preferably, an adhesive composition wherein the first agent contains a photopolymerization initiator, and a bonding method using it.

Owner:DENKA CO LTD

Conductive tin oxide sol and process for producing same

ActiveUS20100207076A1High propertiesHigh transparencyPigmenting treatmentMaterial nanotechnologyHYDROSOLOptical path length

There is provided a conductive tin oxide sol having a high transparency, and a process for producing the sol, a coating composition by use of the sol and a material coated with the coating composition. The conductive tin oxide sol containing phosphorus-doped conductive tin oxide colloidal particles (A), wherein a sol prepared so as to have the colloidal particles (A) in a concentration of 10 mass % in the sol has a transmittance of 30% or more at a wavelength of 600 nm in an optical path length of 10 mm. The particle diameter of the conductive tin oxide sol by observation with transmission electron microscope is 2 to 25 nm. The molar ratio of the doped phosphorus (P) to the tin oxide (SnO2) in the colloidal particles (A) is 0.005 to 0.2. The conductive tin oxide sol is produced by mixing a phosphorus compound in a tin oxide sol, and then subjecting to a hydrothermal treatment. The coating composition contains the conductive tin oxide sol and a binder. The material having a coating film formed from the coating composition is also provided.

Owner:NISSAN CHEM IND LTD

Erosion and corrosion resistant protective coating for turbomachinery methods of making the same and applications thereof

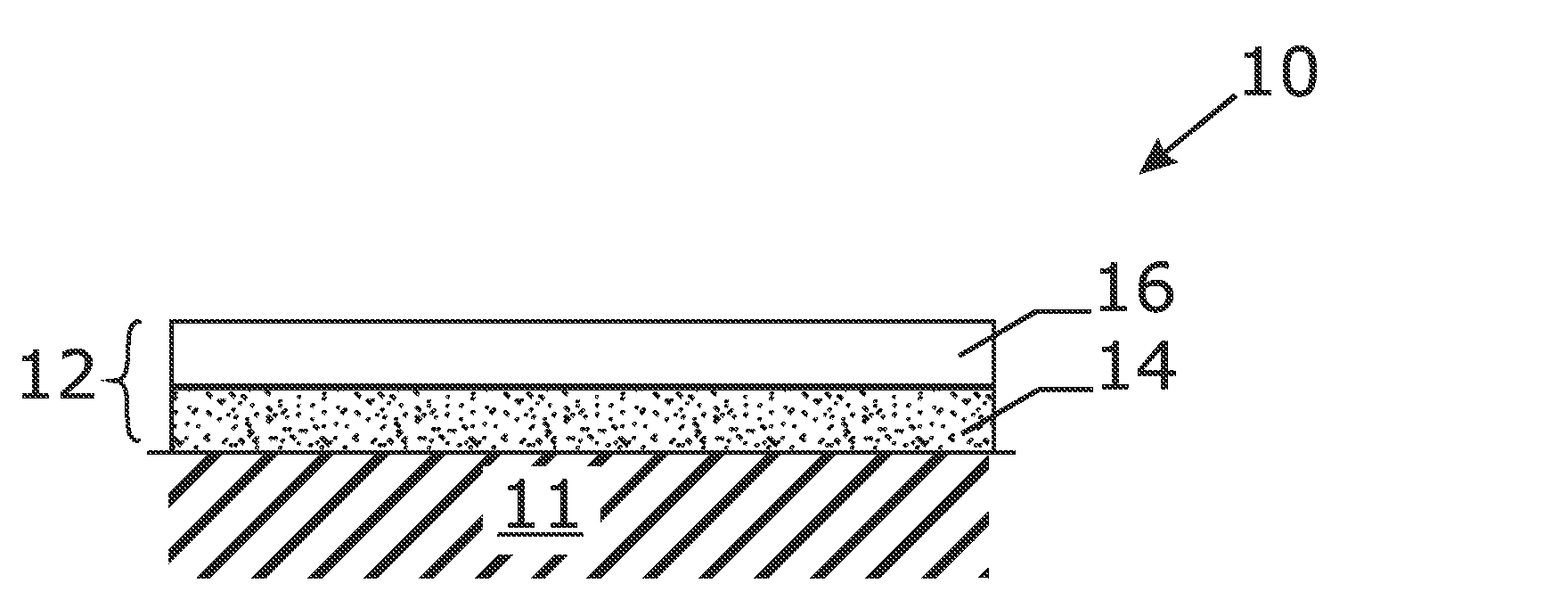

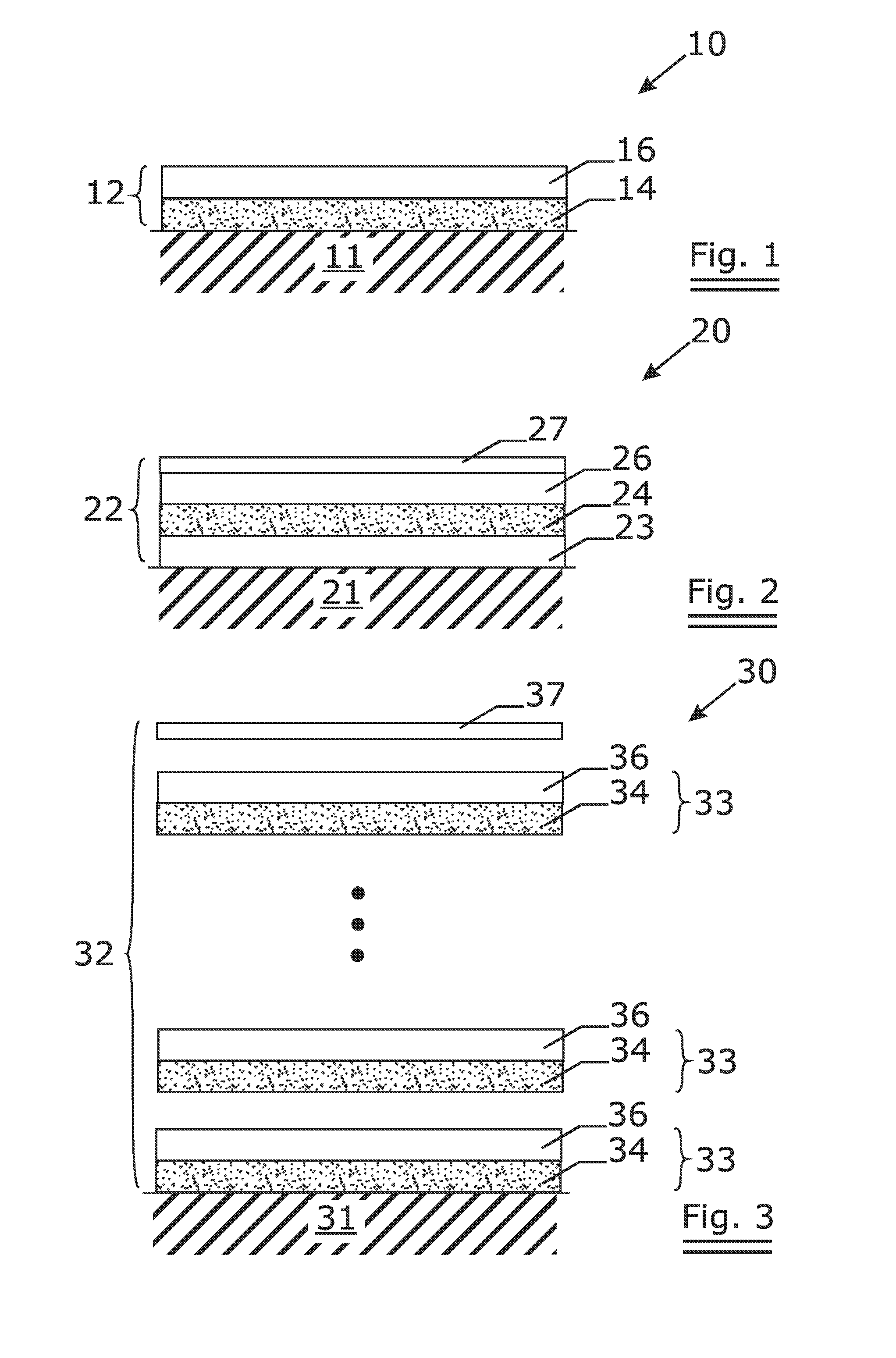

ActiveUS9482105B1Increase flexibilityImprove reflectivityBlade accessoriesEfficient propulsion technologiesThin metalWear resistant

A wear resistant coating protects against corrosion and erosion of the thin metal protective sheath on turbomachinery applications. The coating has a metal layer overlaid by a ceramic layer. Multiple metal and ceramic layers can make up the coating with the layers varying in thickness allowing the layers nearer the substrate to remain more malleable to bend with the sheath and those layers nearer the top of the coating to be more brittle and resistant to wear. A cold spray metallic layer applied to the substrate provides a lightweight, flexible layer beneath the corrosion and erosion resistant protective multilayer coating.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY +1

Thermoplastic Resin Foam

A thermoplastic resin sheet which has both a high reflectance ratio and excellent shape-holding property suitable for backlights and illumination boxes for use in illumination signboards, illumination fixtures and displays and illumination boxes. The thermoplastic resin foam is manufactured by a manufacturing method including a process for containing inert gas by holding thermoplastic resin sheet containing metallic oxide in a pressurized inert gas atmosphere and a process for heating the thermoplastic resin sheet in which the inert gas is contained at a temperature higher than the softening temperature of the thermoplastic resin, under normal pressure, and foaming the resin.

Owner:FURUKAWA ELECTRIC CO LTD

Multilayer Metallized Film and Production Method Description

InactiveUS20080318036A1Improve adhesionHigh oxygen and water vapor barrier effectFilm/foil adhesivesSynthetic resin layered productsButeneFlame treatment

To increase the barrier effect of a metallized film intended for use I the packaging, in particular of food products, a particular composition of the plastic layer (A) is suggested, on which the metal layer (M) is deposited by vacuum evaporation. The plastic layer comprises a polypropylene and butene copolymer and is subjected to a preliminary surface activation treatment, preferably to a flame treatment, and to a subsequent plasma treatment under partial vacuum conditions prior to metallization.

Owner:SYROM 90

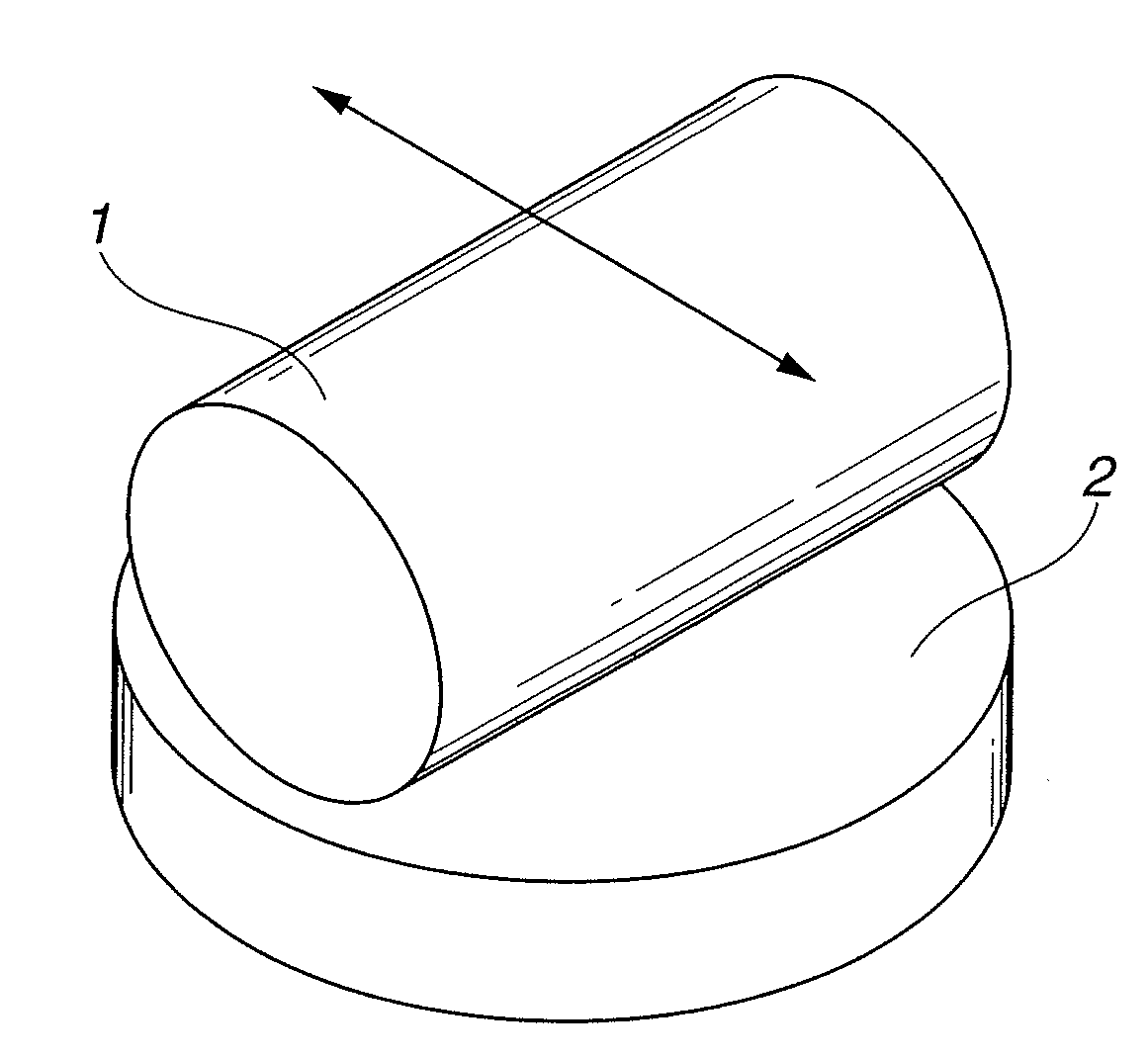

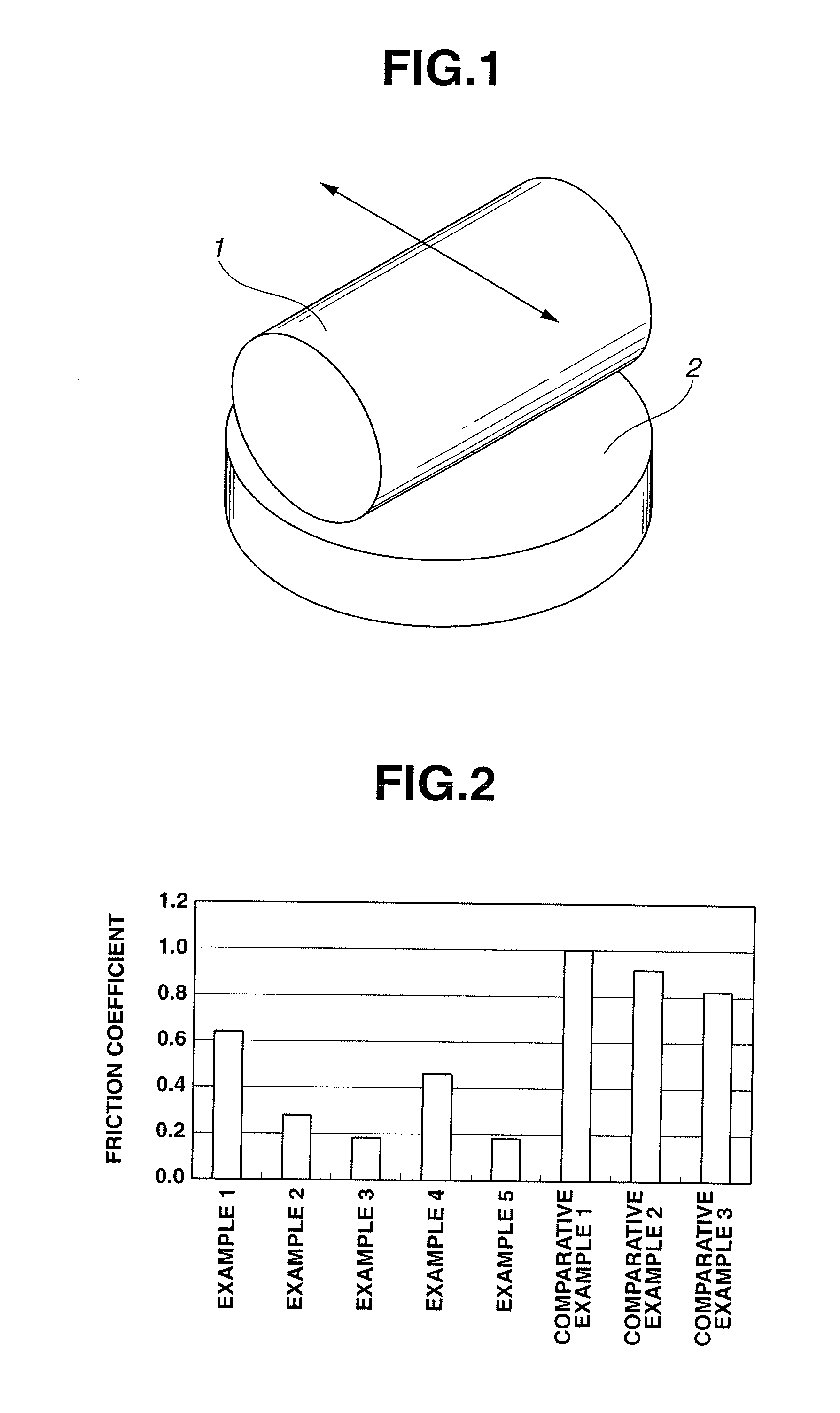

Low- friction sliding mechanism and uses thereof

InactiveUS20080076684A1Maintain good propertiesLow viscosityCamsPiston ringsDiamond-like carbonRoom temperature

A low-friction sliding mechanism includes a pair of sliding members having respective sliding surfaces slidable relative to each other and an ionic liquid applied to the respective sliding surfaces. At least one of the sliding surfaces has a coating of either a diamond-like carbon material, a diamond material or a combination thereof. The ionic liquid consists of cation and anion components and exists in liquid or gel form at room temperature.

Owner:NISSAN MOTOR CO LTD

Porous bioceramics for bone scaffold and method for manufacturing the same

InactiveUS7416564B2High of bioactivityHigh propertiesBone implantPretreated surfacesHuman bodyOsseointegration

The present invention provides a porous bioceramics for bone scaffold. The porous bioceramics according to the present invention comprises a biocompatible porous ceramic substrate having the property to thermal-decompose hydroxyapatite in contact with it; a fluorapatite (FA) inner layer formed on said porous ceramic substrate; and a hydroxyapatite (HA) outer layer formed on said fluorapatite inner layer. The insertion of FA intermediate layer can prevent the thermal reaction between ZrO2 and HA. Therefore, the present invention can provide the implant material into human body having excellent mechanical properties of zirconia as well as the biocompatibility, bioaffinity and bioactivity of HA. The present invention can also provide the implant material to promote osteoconduction and osteointegration in human body.

Owner:SEOUL NAT UNIV R&DB FOUND

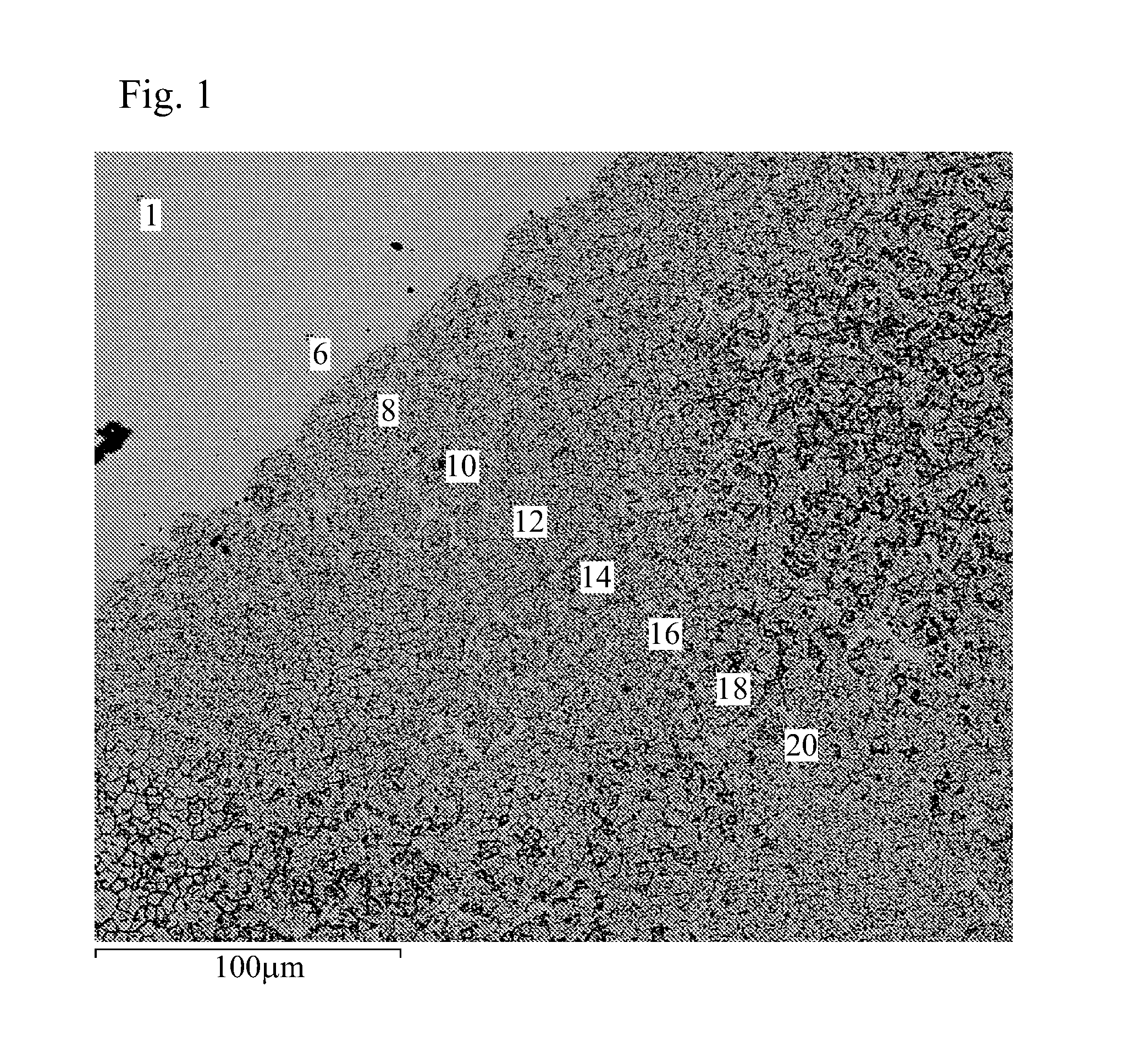

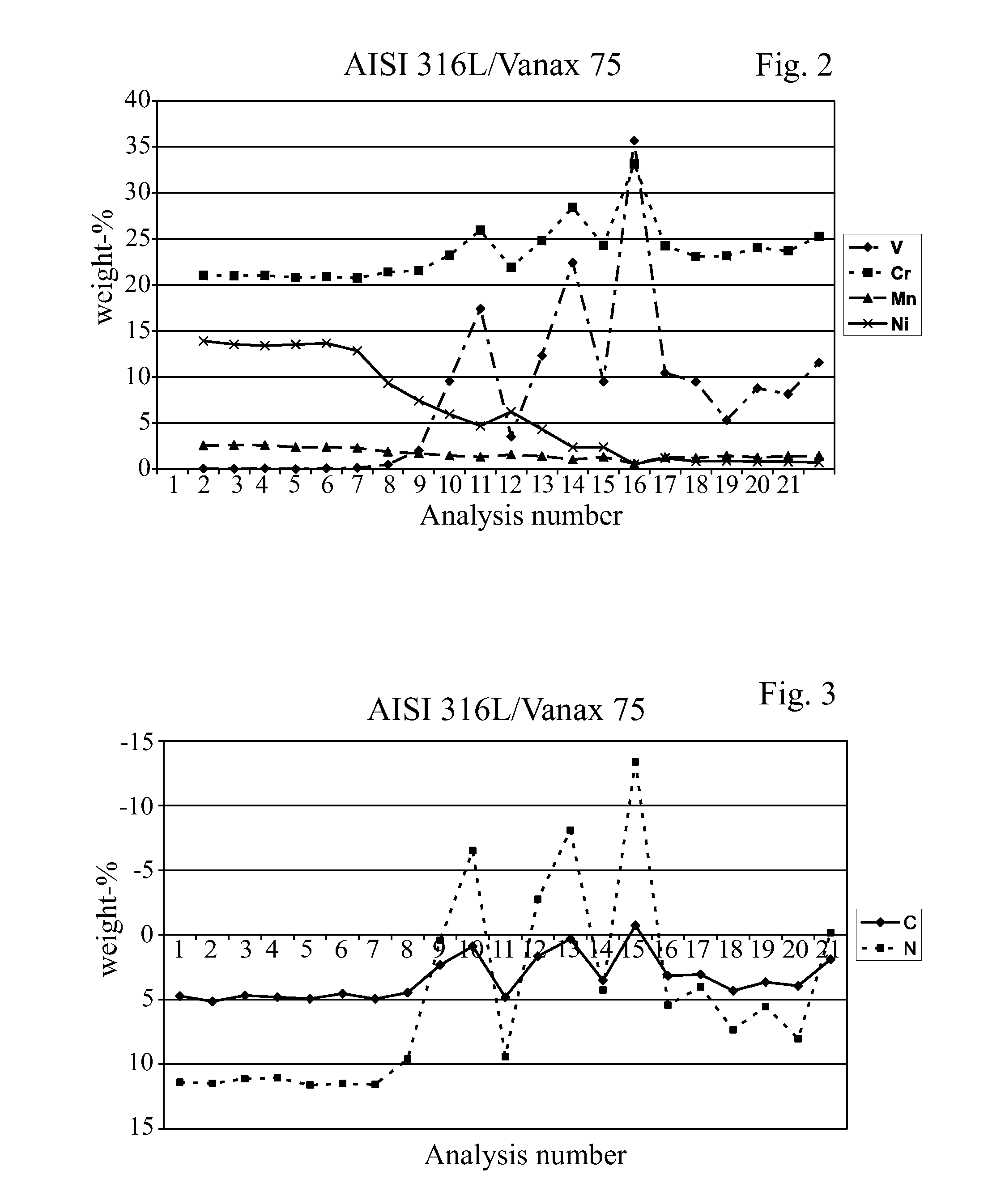

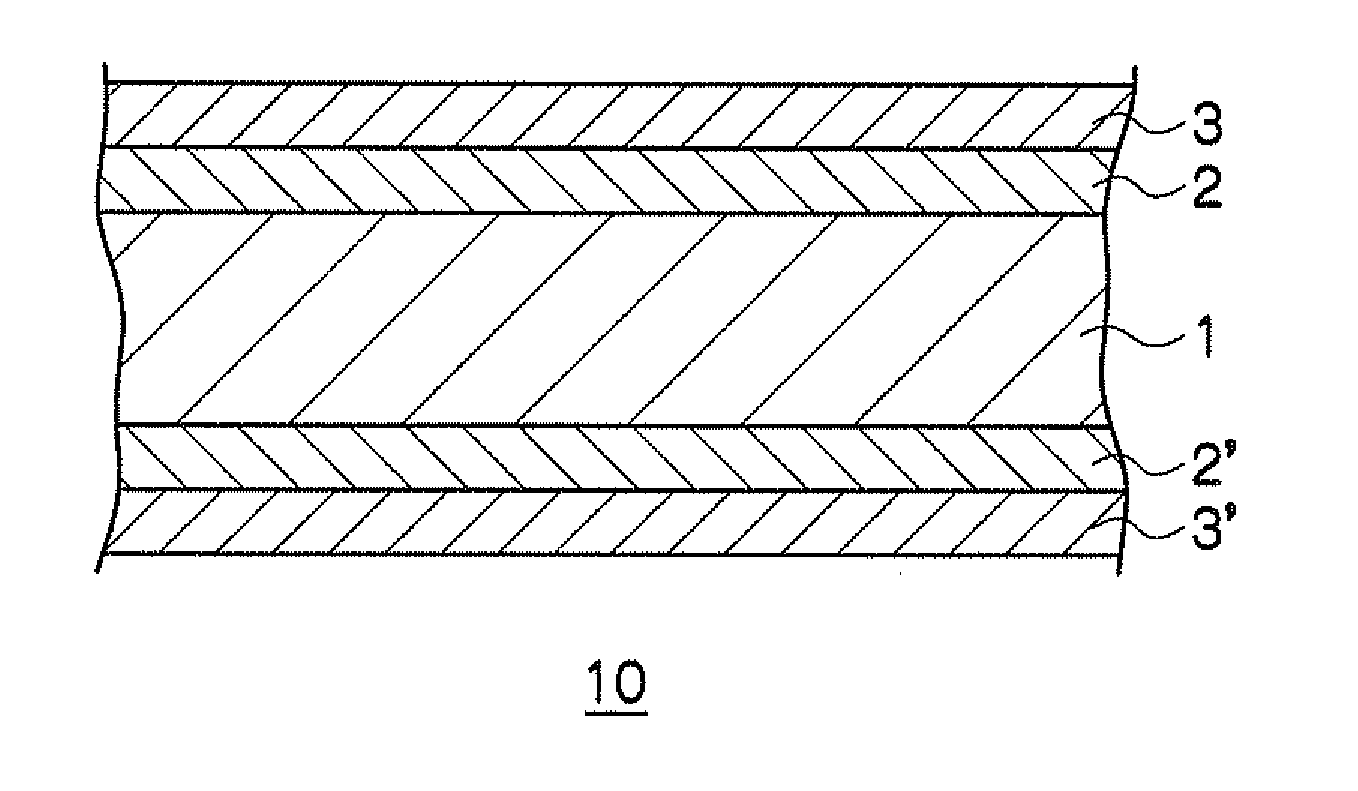

Method for the manufacture of a compound product with a surface region of a wear resistant coating, such a product and the use of a steel material for obtaining the coating

InactiveUS20110217567A1Improve wear resistanceRisk of to minimizedFurnace typesThin material handlingNuclear powerWear resistant

A wear resistant steel material, produced in a powder metallurgical manner, has the following composition in weight-%: and, further, 0.5 to 14 of (V+Nb / 2), wherein the contents of N, on one hand, and of (V+Nb / 2), on the other hand, are balanced in relation to each other so that the contents of said elements are within a range A, B, G, H, A in a perpendicular plane coordinate system, where the content of N is the abscissa and the content of V+Nb / 2 is the ordinate, and where the coordinates for said points are: and max 7 of any of Ti, Zr, and Al; balance essentially only iron and unavoidable impurities. This steel is excellent for obtaining a wear resistant surface region on a substrate of a metallic material by hot isostatic pressing of the steel material of the substrate. Especially when the wear resistant steel is void of Co, the compound body obtained is especially suitable for use in e.g. valves for nuclear power plants.

Owner:UDDEHOLMS AB

Aluminum or aluminum alloy material having surface treatment coating film, and method for treating a surface thereof

ActiveUS20130034743A1Improve applicationImprove heat exchanger efficiencyPretreated surfacesPaints with biocidesHydrophilic polymersSide chain

Provided is an aluminum or aluminum alloy material having a surface treatment coating film on a surface of a substrate formed by an aluminum or aluminum alloy. The aluminum or aluminum alloy material has: a substrate formed by an aluminum or aluminum alloy; and a first protective layer and a second protective layer in the order on a surface of the substrate, wherein the first protective layer is a conversion coating film including vanadium and at least one or more types of metals selected from titanium, zirconium, and hafnium, the second protective layer is an organic coating film having a composition that includes (1) a chitosan derivative and a solubilizing agent, (2) a modified polyvinyl alcohol formed by graft polymerization of a hydrophilic polymer to a side chain of polyvinyl alcohol, and (3) a water-soluble crosslinking agent.

Owner:NIHON PARKERIZING +1

Carbon nanotube-containing catalysts, methods of making, and reactions catalyzed over nanotube catalysts

InactiveUS20060167120A1Large specific surface areaImprove conductivityMaterial nanotechnologyCarbon compoundsPorous substratePerformance results

Methods have been developed to form catalysts having active metals disposed on a carbon nanotube coated porous substrate. Catalysts and reactions over nanotube-containing catalysts are also disclosed. Results are presented showing enhanced performance resulting from use of the inventive catalyst. Mesoporous oxide layers can be utilized to improve catalyst properties.

Owner:BATTELLE MEMORIAL INST

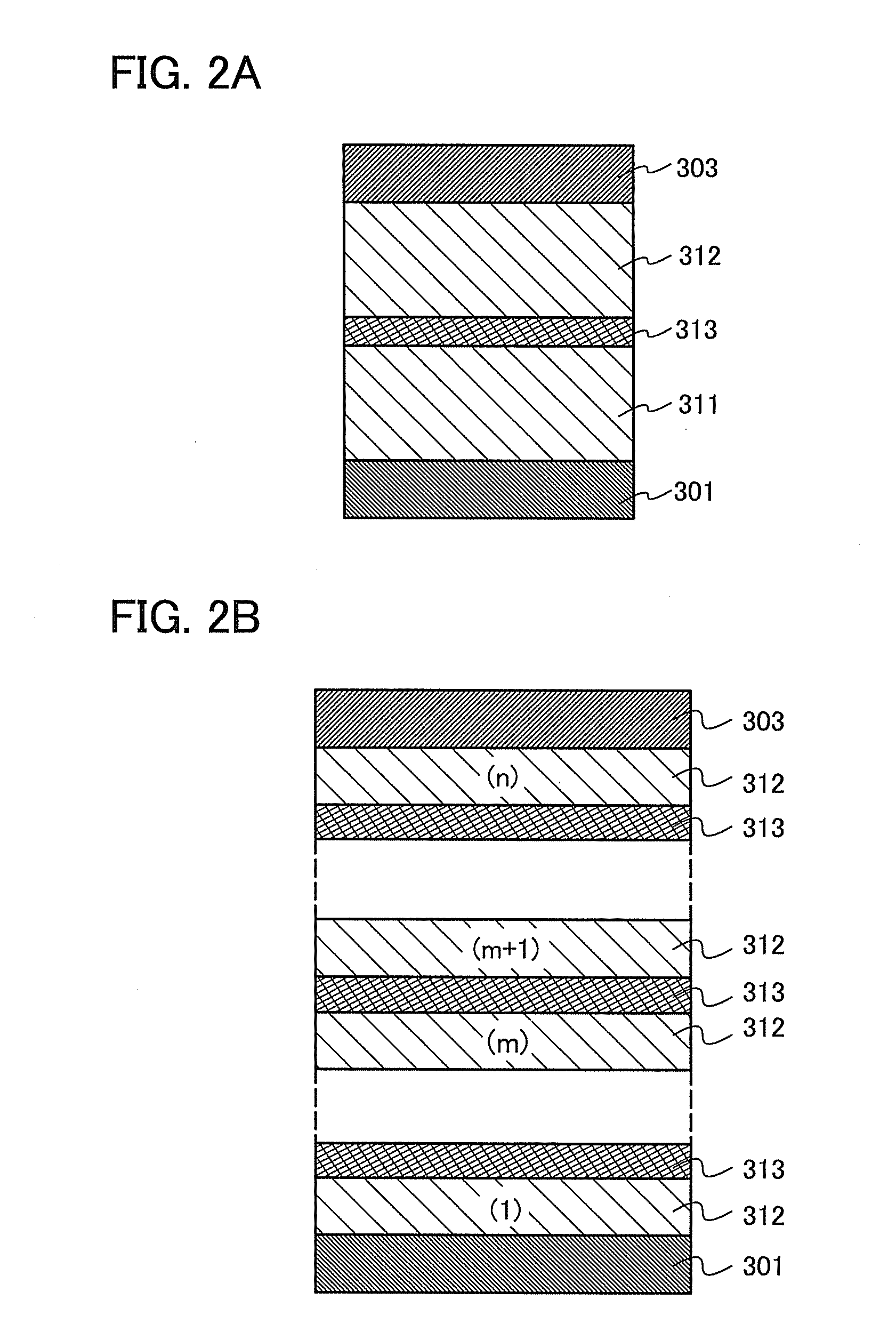

Flame retardant electrolyte for rechargeable lithium battery and rechargeable lithium battery including the same

ActiveUS9099756B2Improved thermal stability and flame retardancyHigh rate and cycle-life characteristicElectrode manufacturing processesFinal product manufacturePhosphoric acidPhysical chemistry

Flame retardant electrolyte solutions for rechargeable lithium batteries and lithium batteries including the electrolyte solutions are provided. The flame retardant electrolyte solution includes a lithium salt, a linear carbonate-based solvent, at least one ammonium cation, a phosphoric acid-based solvent, and an additive including oxalatoborate.

Owner:SAMSUNG SDI CO LTD

Composite reverse osmosis membrane and preparation method thereof

ActiveUS20200122092A1High energyImprove thermal stabilityMembranesReverse osmosisPolyvinyl alcoholPolyamide

The present application discloses a composite reverse osmosis membrane and a preparation method thereof. The method includes: uniformly mixing fluorine-containing polyaryletherketone of a certain concentration and silane-modified polyaryletherketone as a casting solution; coating a non-woven fabric, i.e., a substrate, with the casting solution to form a support layer; then coating the surface of the support layer with a solution A and a solution B sequentially for reaction to form a polyamide desalination layer; and coating the polyamide desalination layer with a modified polyvinyl alcohol anti-pollution layer. By means of the method, the composite reverse osmosis membrane is prepared. Compared with the prior art, the present application can prepare a composite reverse osmosis membrane with high temperature resistance and high strength by using the composite modified polyaryletherketone as the support layer, and moreover, uses polyvinyl alcohol as a component of the anti-pollution layer, and has good anti-pollution properties.

Owner:JIANGSU BANGTEC ENVIRONMENTAL SCI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com