Non-magnetic high manganese steel sheet with high strength and manufacturing method thereof

a high-tensile steel, non-magnetic technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of loss of electrical current high cost of stainless steel, etc., to increase the stability of austenite, high degree of formability, and high stability of austeni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

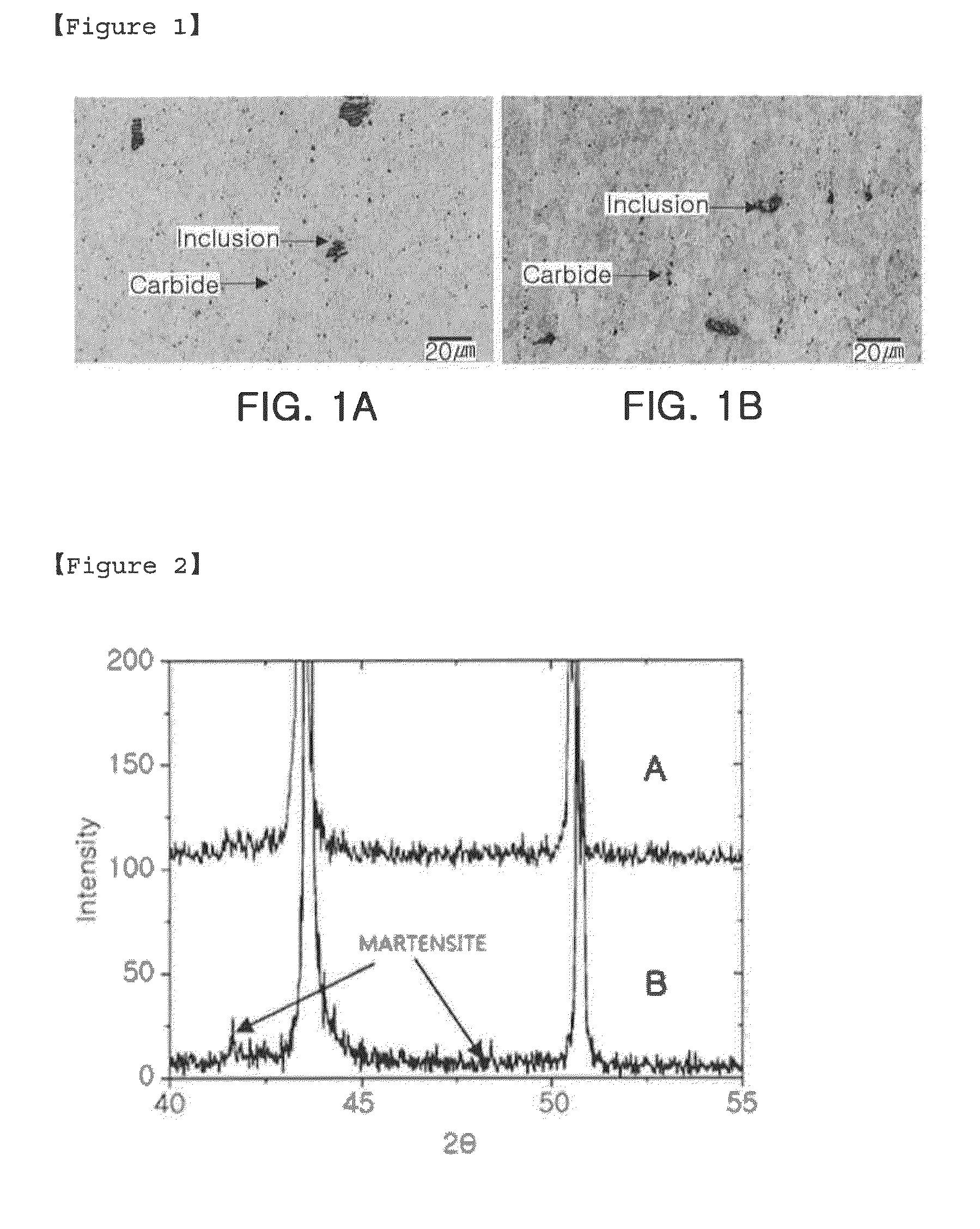

[0048]Steel slabs having the following compositions were reheated to 1200° C., and a finish hot rolling was performed on the steel slabs at 900° C. to form steel sheets. Thereafter, the steel sheets were coiled at 500° C. and then cold-rolled with a reduction ratio of 50%. The cold-rolled steel sheets were continuously annealed at 800° C.

TABLE 1No.CMnSiPSAlTiBN10.6117.960.010.090.0040.010.0660.0020.009720.6118.300.010.090.0031.500.0860.0020.008730.6118.500.010.090.0032.690.0830.0030.006540.6114.540.010.100.0050.010.0770.0020.009850.6115.100.010.090.0061.510.0850.0020.008160.6115.540.010.090.0051.970.0850.0020.006970.6111.580.010.100.0050.010.0680.0020.009580.6111.630.010.100.0061.460.0870.0020.003990.6112.410.010.100.0041.950.0920.0020.0069

[0049]The yield strength, tensile strength, and elongation of each of the steel sheets were measured a shown in Table 2 so as to inspect physical properties of the steel sheets.

TABLE 2No.Yield strength (MPa)Tensile strength (MPa)Elongation (%)1484...

embodiment 2

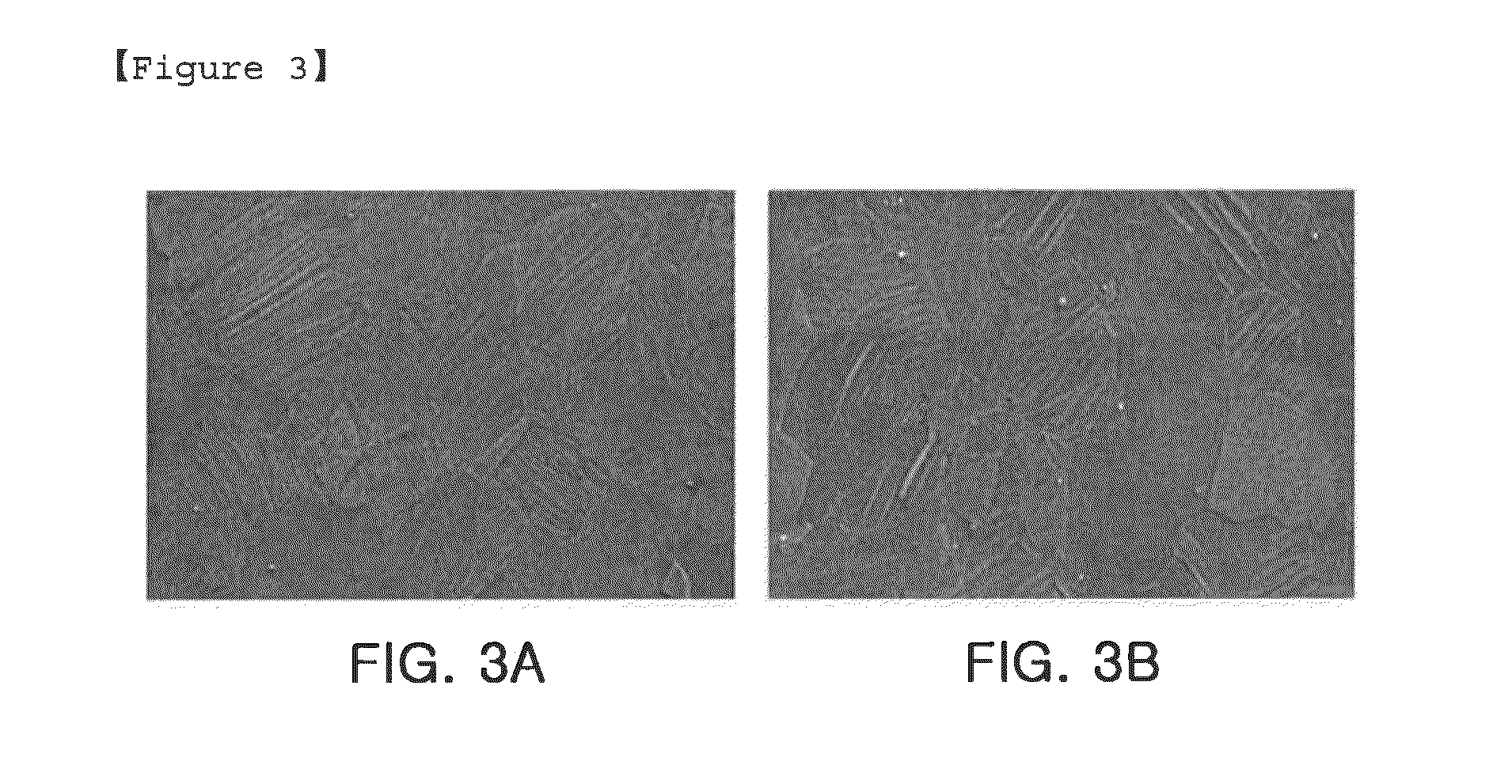

[0055]Steel slabs having the following compositions (weight %) were reheated to 1200° C., and a finish hot rolling was performed on the steel slabs at 900° C. to form steel sheets. Thereafter, the steel sheets were coiled at 500° C. and then cold-rolled at a reduction ratio of 50%. The cold-rolled steel sheets were continuously annealed at 800° C.

TABLE 4Sample No.CMnPSAlSiTiBN10.6118.00.0910.0040.010.010.06620.00210.009720.6118.30.0870.00341.490.010.08570.00230.008730.6018.30.0870.00241.930.010.08560.00230.007840.6118.50.0900.00272.680.010.08330.00250.006550.6114.50.0970.00510.020.010.07660.00210.009860.6115.10.0940.00551.510.010.08540.00240.008170.6115.50.0940.00491.970.010.08460.00240.006980.6111.60.1010.00530.010.010.06840.0020.009590.6111.60.1020.00571.450.010.08680.00230.0039100.6112.40.0980.00391.940.010.09150.00220.0069110.6118.30.0920.00410.510.010.06620.00210.0037120.6218.40.0910.00421.020.010.08570.00230.0087130.6118.20.0930.00411.210.010.08560.00230.0078140.6118.30.0920.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com