Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

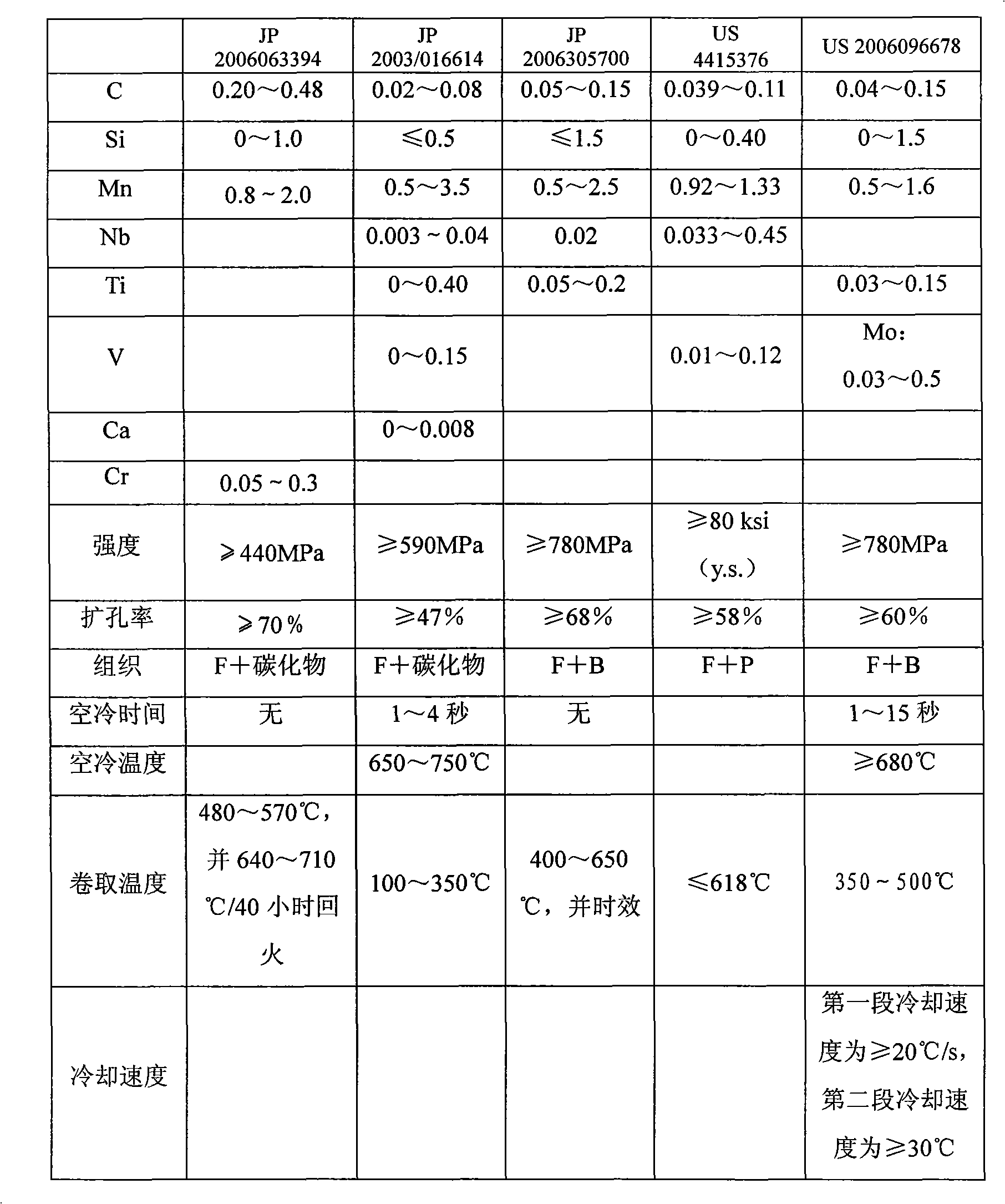

285results about How to "Improved cold working properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot rolling high-chambering steel plate with tensile strength of 590 MPa and manufacturing process thereof

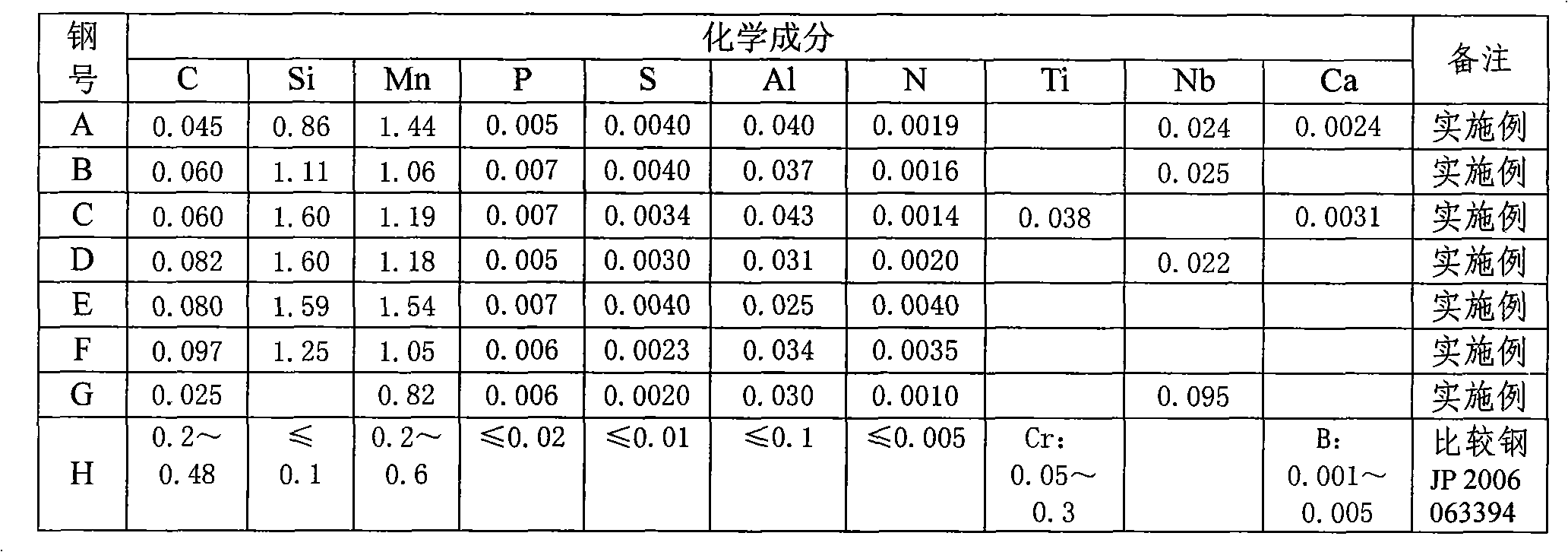

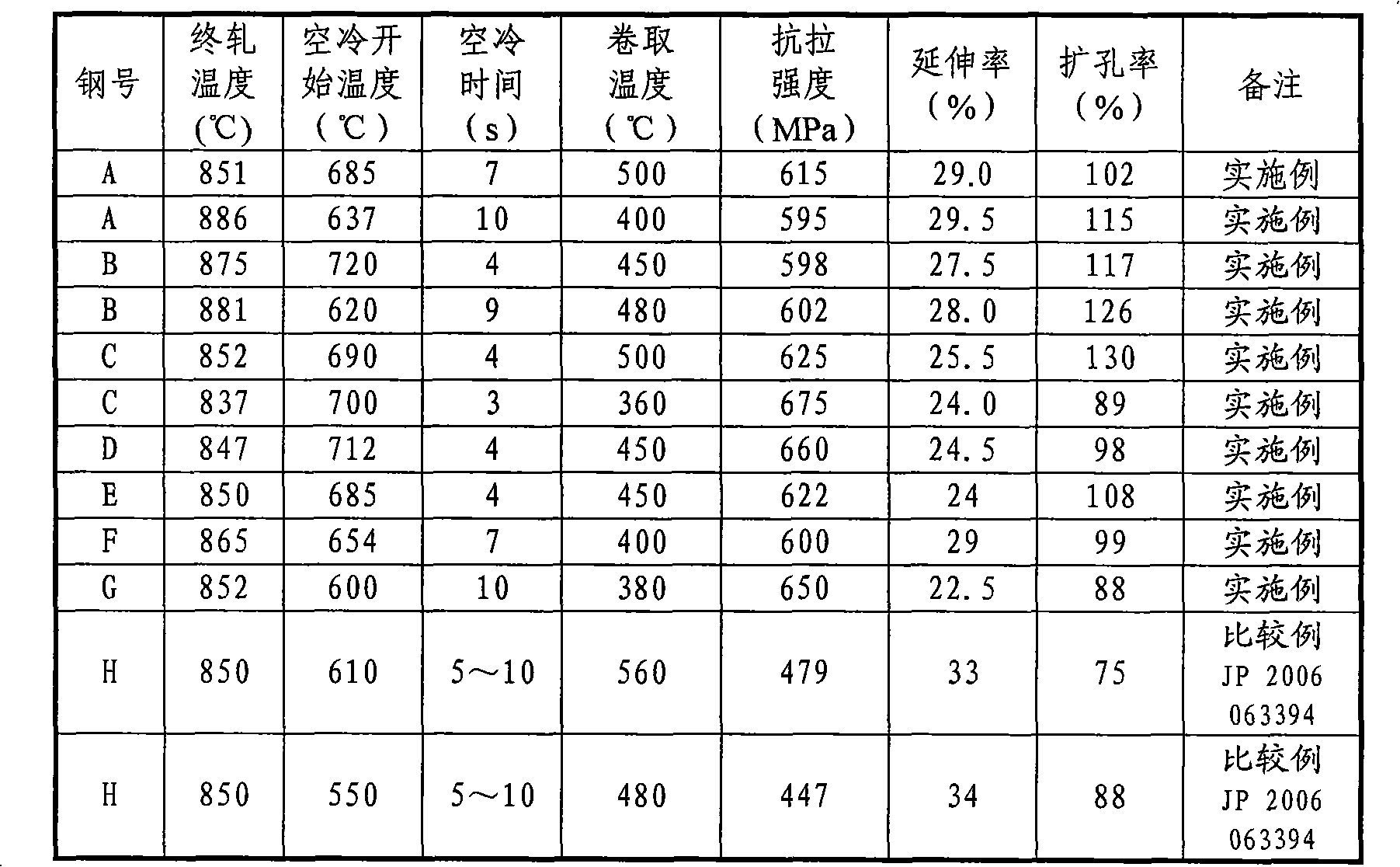

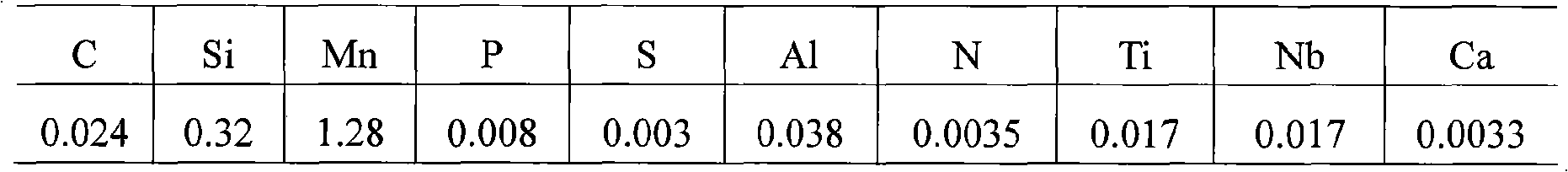

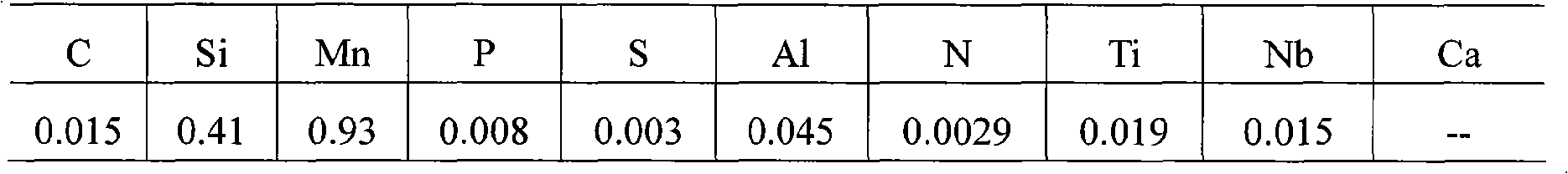

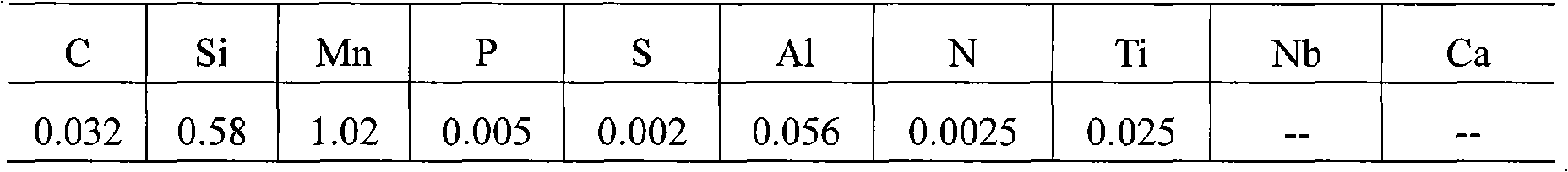

The invention discloses a hot rolling high-chambering steel plate with the tensile strength of 590 MPa. The steel plate comprises the following chemical compositions in percentage by weight: 0.02-0.10 percent of C, 0-1.6 percent of Si, 0.8-2.0 percent of Mn, smaller than or equal to 0.035 percent of P, smaller than or equal to 0.010 percent of S, 0.025-0.060 percent of Al, smaller than or equal to 0.0060 percent of N, 0-0.10 percent of Nb, 0-0.04 percent of Ti, 0-0.0050 percent of Ca and the balance of Fe and unavoidable impurities. The manufacturing process of the hot rolling high-chambering steel plate comprises the following steps of: heating a steel billet at 1,150-1,250 DEG C, and then rolling in an austenitic area, wherein the rolling deformation is larger than 80 percent, and the finish rolling temperature is 830-900 DEG C; cooling the steel plate after finish rolling to 600-750 DEG C at a cooling speed of 50-100 DEG C / s; cooling for 3-10 seconds in the air at a cooling speed of 5-15 DEG C / s; then cooling the steel plate to 350-500 DEG C at a cooling speed of 70 DEG C / s and reeling; and then cooling in the air to room temperature. The steel plate is particularly suitable for manufacturing a chassis component of a car.

Owner:BAOSHAN IRON & STEEL CO LTD

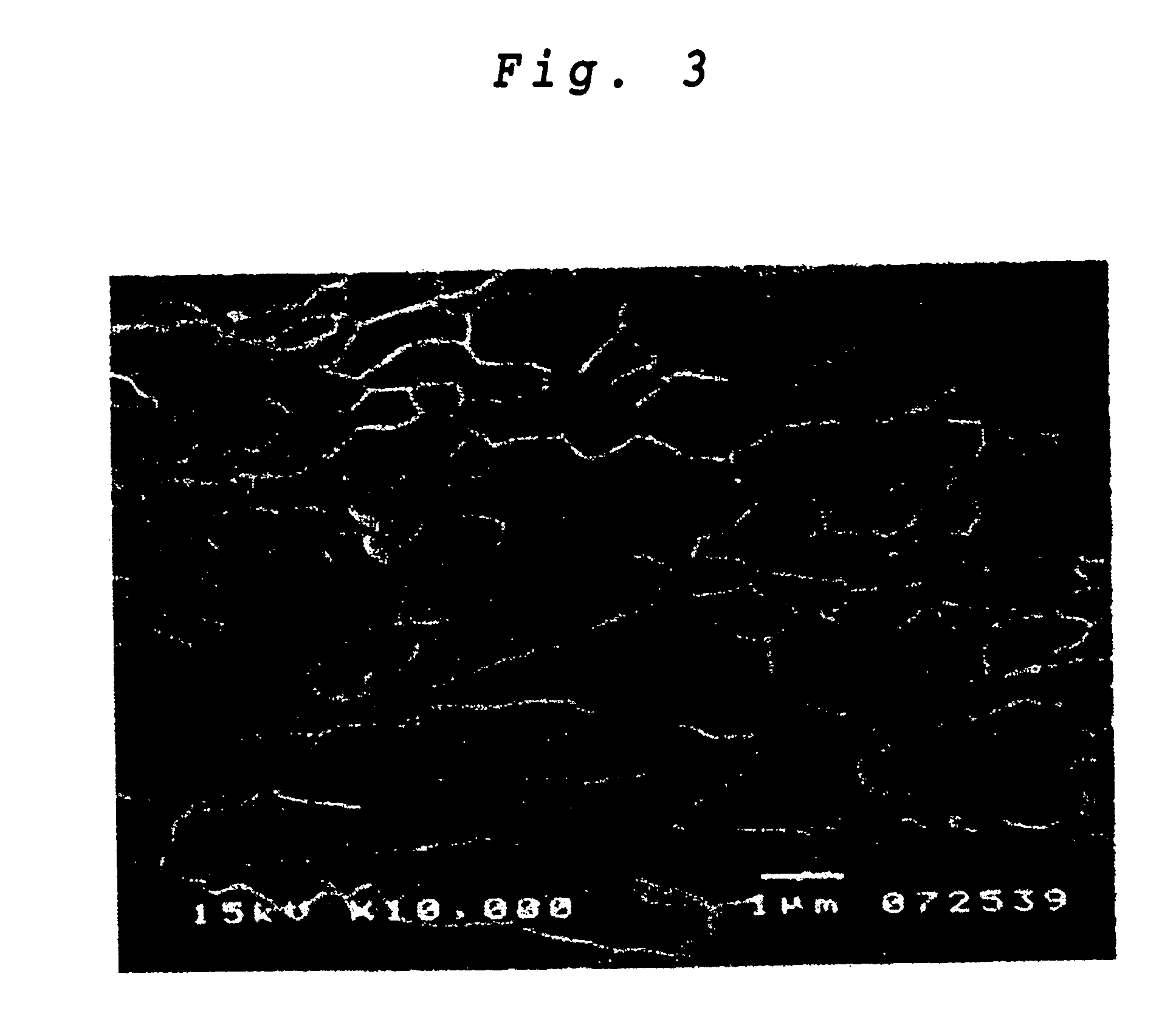

Method for processing metastable beta-type titanium alloy plate

The invention relates to a method for processing a metastable beta-type titanium alloy plate and belongs to the technical field of titanium alloy processing. The invention aims to overcome defects in the prior art, provides technology for processing a Ti-15-3 alloy plate and improves the cold working performance of alloy. The method for processing the metastable beta-type titanium alloy plate comprises the following steps of: smelting the titanium alloy plate into an ingot, charging at the temperature of between 800 and 850 DEG C and keeping the temperature for 100 to 150 minutes, raising the temperature to between 1,100 and 1,150 DEG C and keeping the temperature for 240 to 360 minutes, and finishing the first fire by repeatedly upsetting and drawing; drawing unidirectionally until cogging is finished so as to obtain a blank; sawing and rolling the plate blank into a hot-rolled plate blank with the thickness of 4 to 10 mm at the temperature of between 850 and 1,000 DEG C; and cold rolling to obtain a plate with the thickness of 1 to 3 mm after annealing and alkaline and acid washing. By controlling the rolling temperature, the deformation degree and the cooling speed after deformation, the method controls the structure of a forging stock to fully break the forging stock, and effectively suppresses phase precipitation resulting in a brittle alloy. Therefore, the cold working plasticity and cold working performance are improved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Hot rolling high reaming steel plate having 440MPa grade of tensile strength and manufacturing method thereof

InactiveCN101353757AExcellent hole expandabilityGood formabilityRoll mill control devicesMetal rolling arrangementsChemical compositionSheet steel

The invention provides a hot-rolled high reaming steel sheet with tensile strength of 440MPa, comprising the following chemical composition (weight percent): C: 0.01 to 0.06 percent, Si: 0 to 0.6 percent, Mn: 0.8 to 1.3 percent, P: less than or equal to 0.035 percent, S: less than or equal to 0.010 percent, Al: 0.025 to 0.060 percent, N: less than or equal to 0.0060 percent, Nb: 0 to 0.25 percent, and the rest are Fe and inevitable impurities. The invention also provides a preparation method of the hot-rolled high reaming steel sheet, and the method does not need heat treatment, can reduce the cost, and needs no complicated control of cooling technology after hot rolling, which is convenient for production. The steel sheet provided by the invention has good reaming performance, moldability and cold processing performance, and is mainly used for the molding and processing of parts with complicated shapes for automobile chassis.

Owner:BAOSHAN IRON & STEEL CO LTD

Corrosion resistant niobium-titanium alloy, and method for manufacturing plates and pipes with the same

InactiveCN102703757AImprove corrosion resistanceExpand the range of corrosion resistanceSolid solution strengtheningTitanium alloy

The invention relates to a corrosion resistant niobium-titanium alloy, and a method for manufacturing plates and pipes with the corrosion resistant niobium-titanium alloy, wherein the corrosion resistant niobium-titanium alloy contains the following components by weight: 0.1-4.9% o Nb, not more than 0.08% of C, not more than 0.03% of N, not more than 0.012% of H, not more than 0.1% of O, not morethan 0.1% of Fe, and the balance of Ti. In Ti-(0.8-6%) Nb alloy pipes disclosed by the invention, titanium is as a matrix; little niobium is added; mechanical property of the niobium is improved by asolid-solution strengthening way; shearing strength and tensile strength of the alloy are higher than pure titanium; the tensile strength is increased by 10-20%; good plasticity and formability are kept; cold working performance is excellent; the niobium is added to further increase corrosion resistance of titanium and enlarge corrosion resistant range of titanium, so that the corrosion resistantniobium-titanium alloy is a good easily-formed corrosion resistant material.

Owner:NINGXIA ORIENT TANTALUM IND

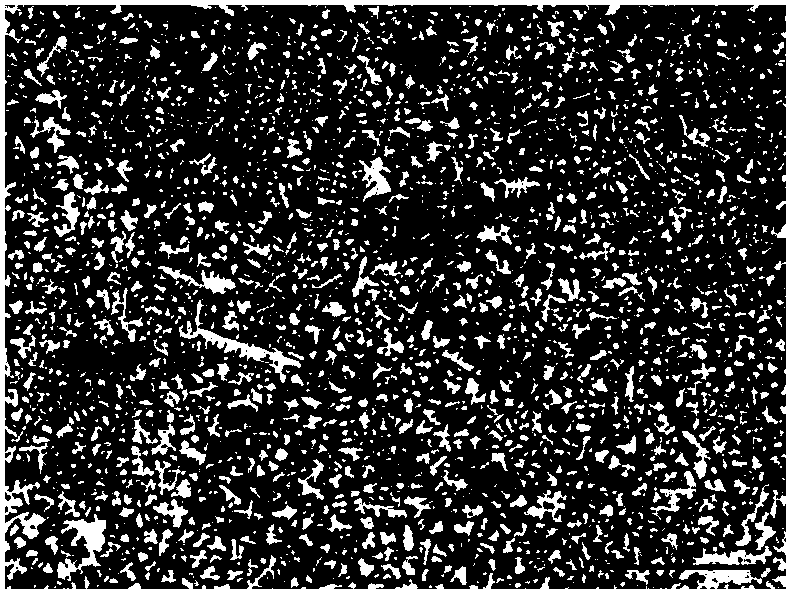

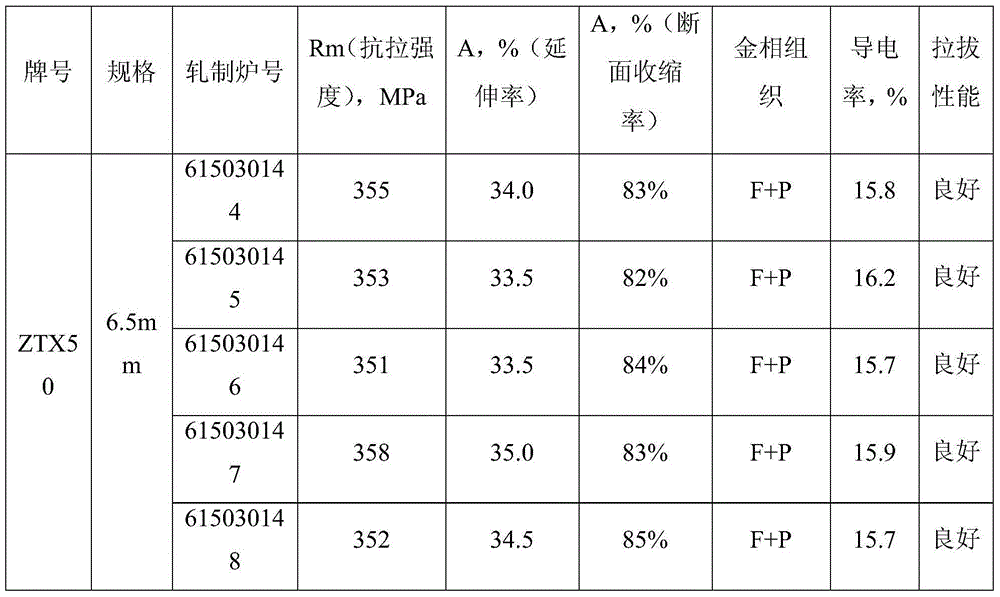

Medium carbon steel on-line balling rolling tech.

ActiveCN100999775AExcellent cold workabilityQuality improvementTemperature control deviceHeat treatment process controlMechanical componentsRoom temperature

The present invention discloses on-line medium carbon steel nodularizing and rolling process. The process includes low temperature finish rolling at 680-850 deg.c and accumulated cross section deformation of 50 %-80 %, controlled cooling after rolling at 3-15 deg.c / s to 660-720 deg.c, isothermal course, and naturally cooling to room temperature. The said technological scheme results in metallographic structure of the rolled piece with high ferrite component, less pearlite component, small and dispersed pearlite and granular cementite, lowered strength and hardness, raised plasticity and excellent cold machining performance.

Owner:MAANSHAN IRON & STEEL CO LTD

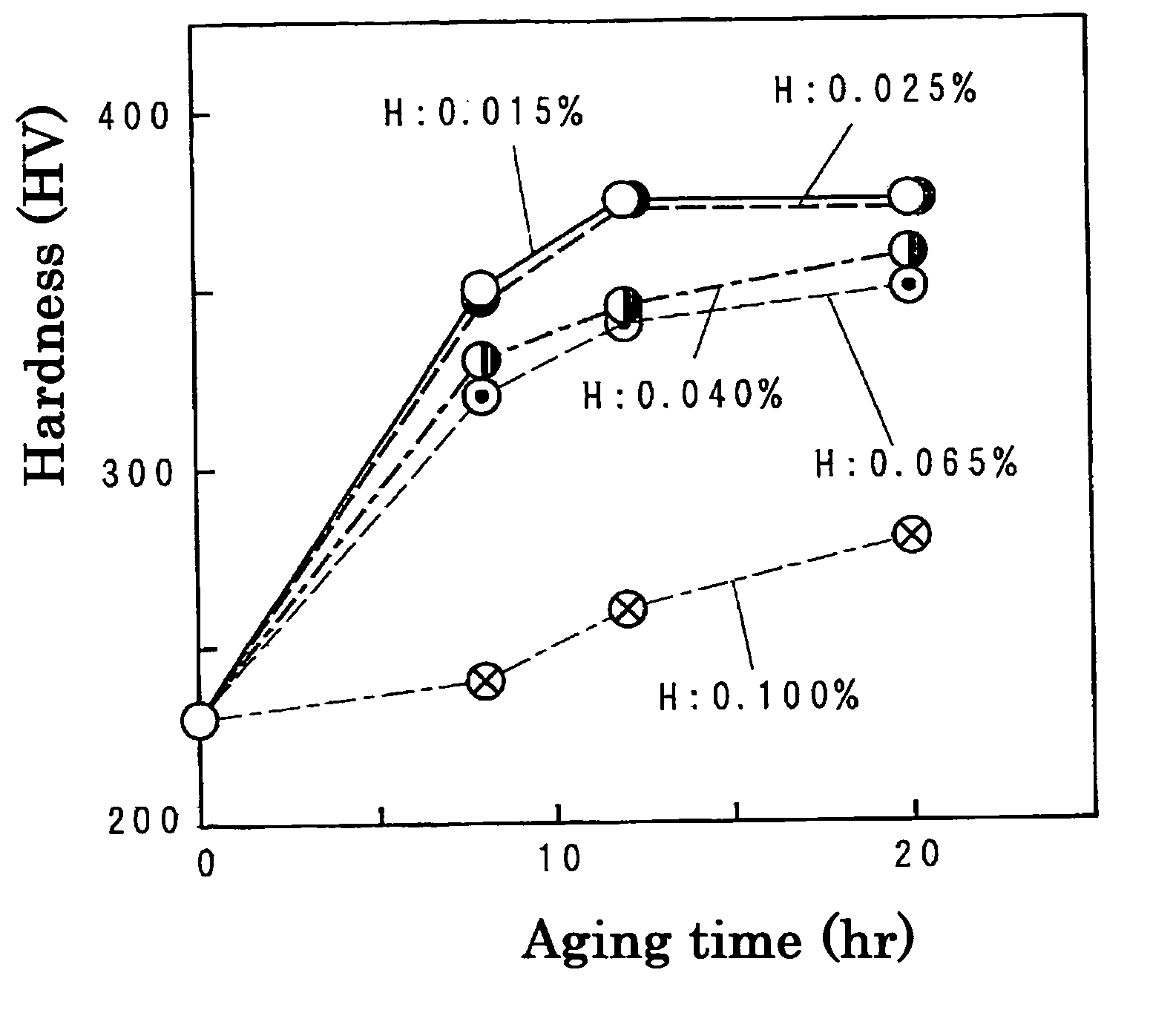

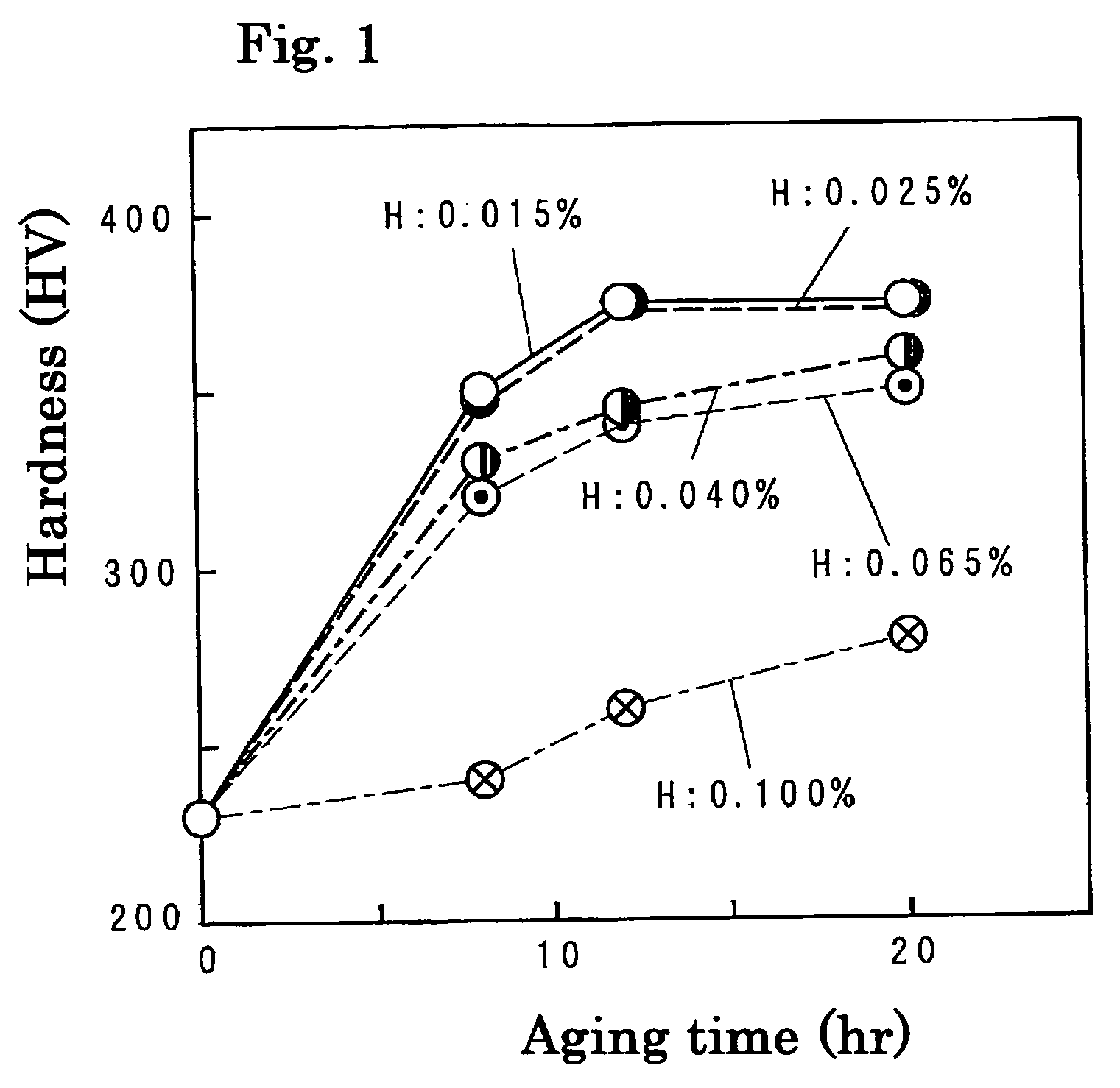

Steel for high-speed cold working and method for production thereof, and high-speed cold working part and method for production thereof

InactiveCN101210298AGuaranteed StrengthExcellent cold workabilityFurnace typesHeat treatment process controlHardnessImpurity

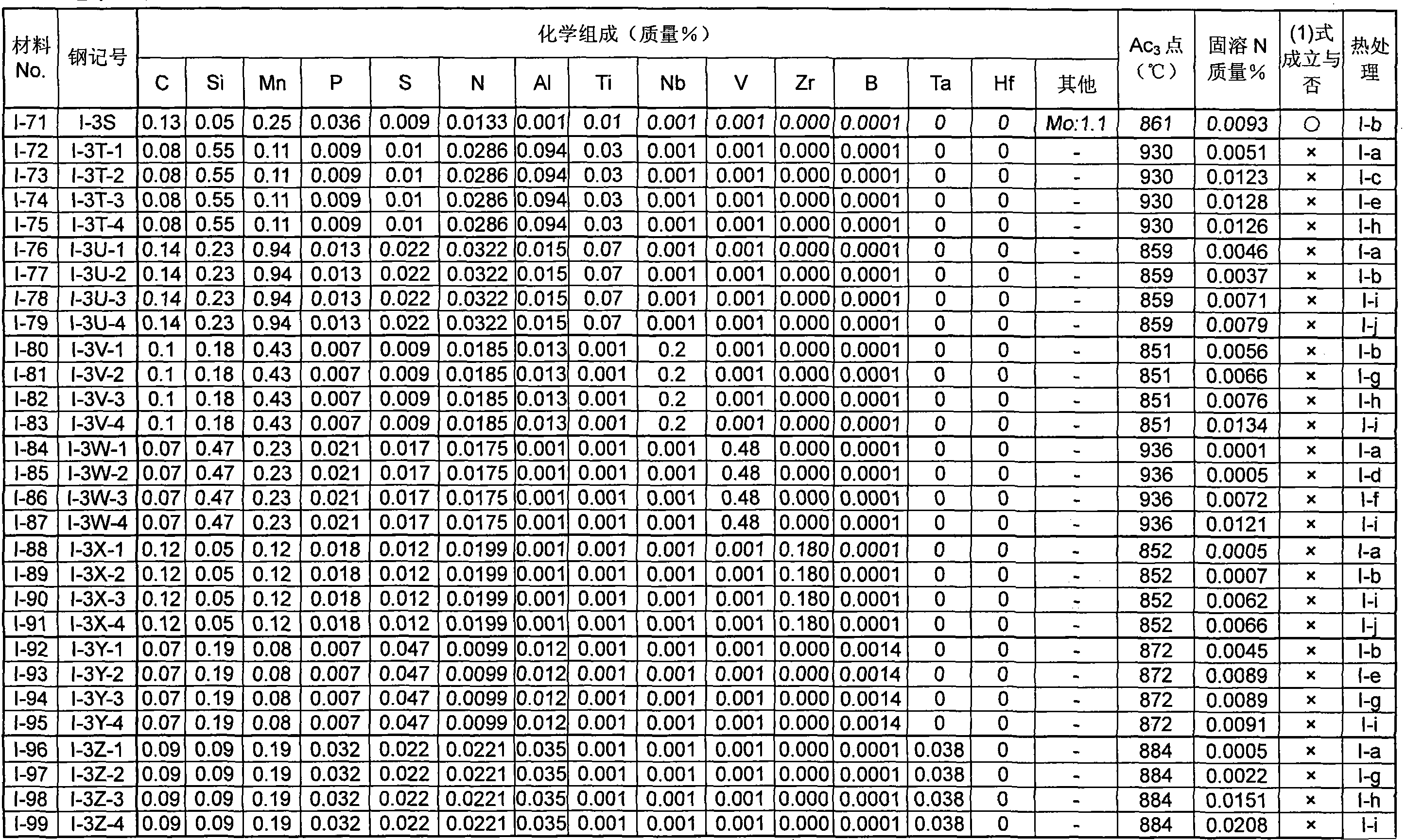

Disclosed herein is a steel for high-speed cold working which exhibits good cold workability during working and also exhibits high hardness after working. The steel for high-speed cold working contains C : 0.03 to 0.6% (by mass), Si : 0.005 to 0.6%, Mn : 0.05 to 2%, P : no more than 0.05% (excluding 0%), S : no more than 0.05% (excluding 0%), and N : no more than 0.04% (excluding 0%), with the remainder being iron and inevitable impurities and the amount of dissolved nitrogen in the steel being no less than 0.006%.

Owner:KOBE STEEL LTD

Steels for high-strength springs excellent in cold workability and quality stability

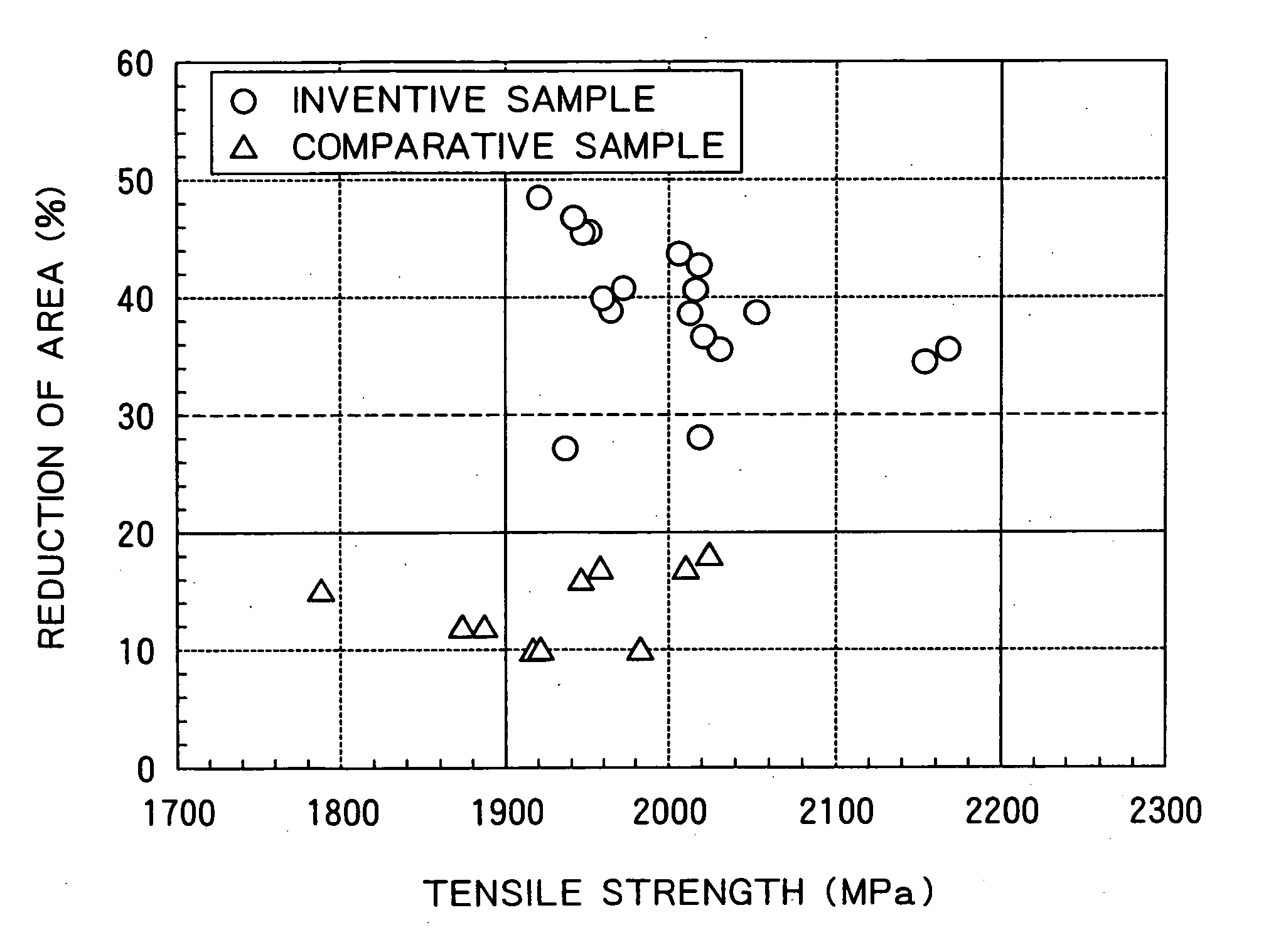

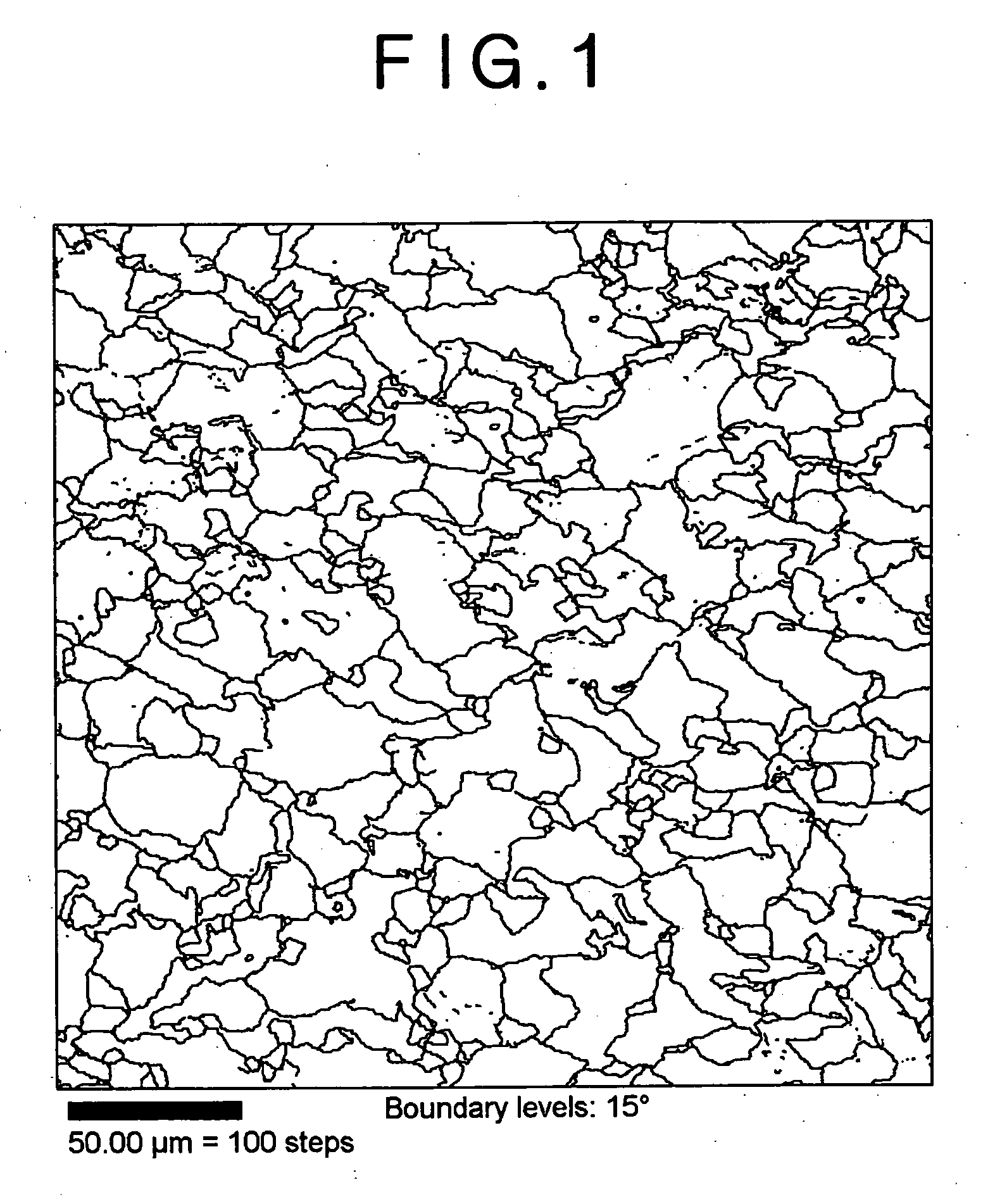

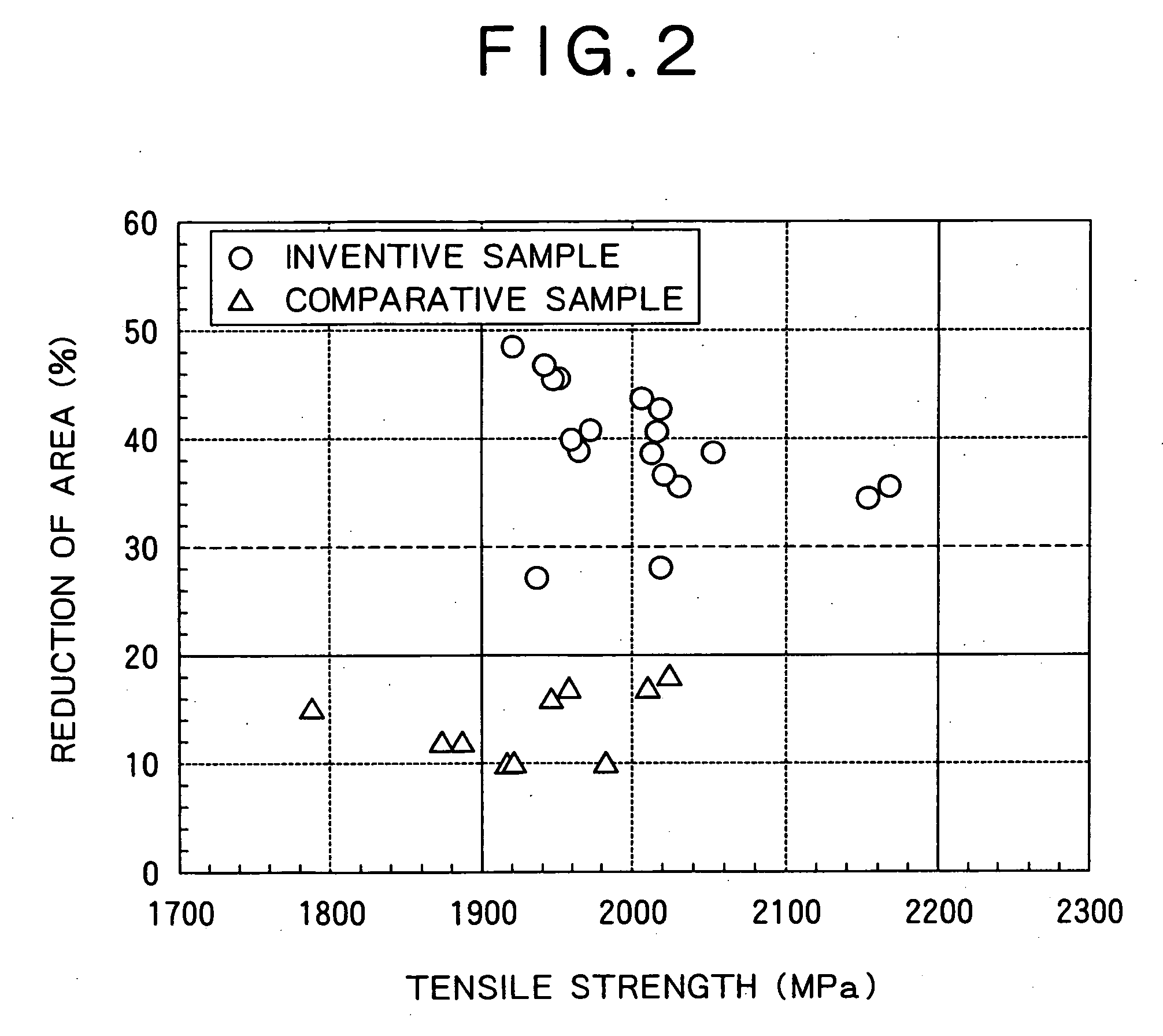

InactiveUS20060196584A1Improved cold working propertiesMaintain stable propertiesSpringsFurnace typesUltimate tensile strengthMaterials science

A steel for high-strength springs contains, on the mass basis, 0.35% to 0.65% of C, 1.4% to 2.5% of Si, 0.1% to 1.0% of Mn, 2.0% or less (exclusive of 0%) of Cr, 1.0% or less (exclusive of 0%) of Ni, 1.0% or less (exclusive of 0%) of Cu, 0.020% or less (exclusive of 0%) of P, 0.020% or less (exclusive of 0%) of S, 0.006% or less (exclusive of 0%) of N:, and 0.1% or less (exclusive of 0%) of Al, with the remainder being iron and inevitable impurities, in which Wp(Fe) and W(C) satisfy the following condition: Wp(Fe)>5×W(C), wherein Wp(Fe) is the content of Fe (percent by mass) constituting Fe-containing precipitates in the steel; and W(C) is the carbon content (percent by mass) of the steel. The steel is excellent in cold workability and quality stability.

Owner:KOBE STEEL LTD

1000Mpa-grade high-strength hot-rolled anti-bullet steel plate and making method

ActiveCN1814845ALow manufacturing costAnti-ballistic performance does not decreaseFurnace typesHeat treatment furnacesSteel platesHigh intensity

This invention relates to a kind of high strength hot-rolled bulletproof steel of 1000Mpa in the following weight percentage: C 0.17-0.21%, Si 1.5-2.2%, Mn 1.5-2.0%, P<=0.035%, S<=0.010%, Al 0.015-0.060%, N<=0.0060%, Nb 0.010-0.050%, Ti 0.010-0.060%, Ca<=0.0050%, Fe and unavoidable impurities, which is processed in the following steps: a, smelting according to the above mentioned components, casting to form slabs, b, heating the slabs to 1100-1250DEG C, hot-rolling the slabs in the austenitic area and over 80% of them are deformed and the final temperature is 800-900DEG C, d, the final rolled steel is cooled to 650-780DEG C in the speed of 50deg.C / s and air cooled for 6-15 seconds, e, cooling them to 350-450deg.C in the speed over 50deg.C / s, f, rolling them and air cooling them to room temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

Biomedical titanium-niobium-based shape memory alloy as well as preparation method, processing method and application method thereof

The invention relates to a biomedical titanium-niobium-based shape memory alloy as well as a preparation method, a processing method and an application method thereof. The alloy comprises the following chemical compositions by weight percent: 28-39% of niobium, 0.35-5.5% of tin, 0.3-5.5% of aluminum, 0.5-5.5% of silicon, 0.2-5.5% of zirconium and the allowance of titanium. The alloy has the advantages of low elasticity modulus, good biocompatibility and mechanics compatibility, no toxic nickel element, good mechanical property and corrosion resisting property, excellent cold working property and low cold-working hardening ratio; the alloy can be used for cold working with large deformation such as cold rolling, cold wire drawing and the like, and the working cost is low. The titanium-niobium-based shape memory alloy is of the ideal and novel biological shape memory alloy material that replaces the TiNi shape memory alloy and can be widely used for an ultra-flexible bracket, an orthodontics dental arch wire and an orthopedics implantation instrument and the like in the fields of the medical treatment, the sports goods and the like.

Owner:GRINM MEDICAL INSTR BEIJING CO LTD

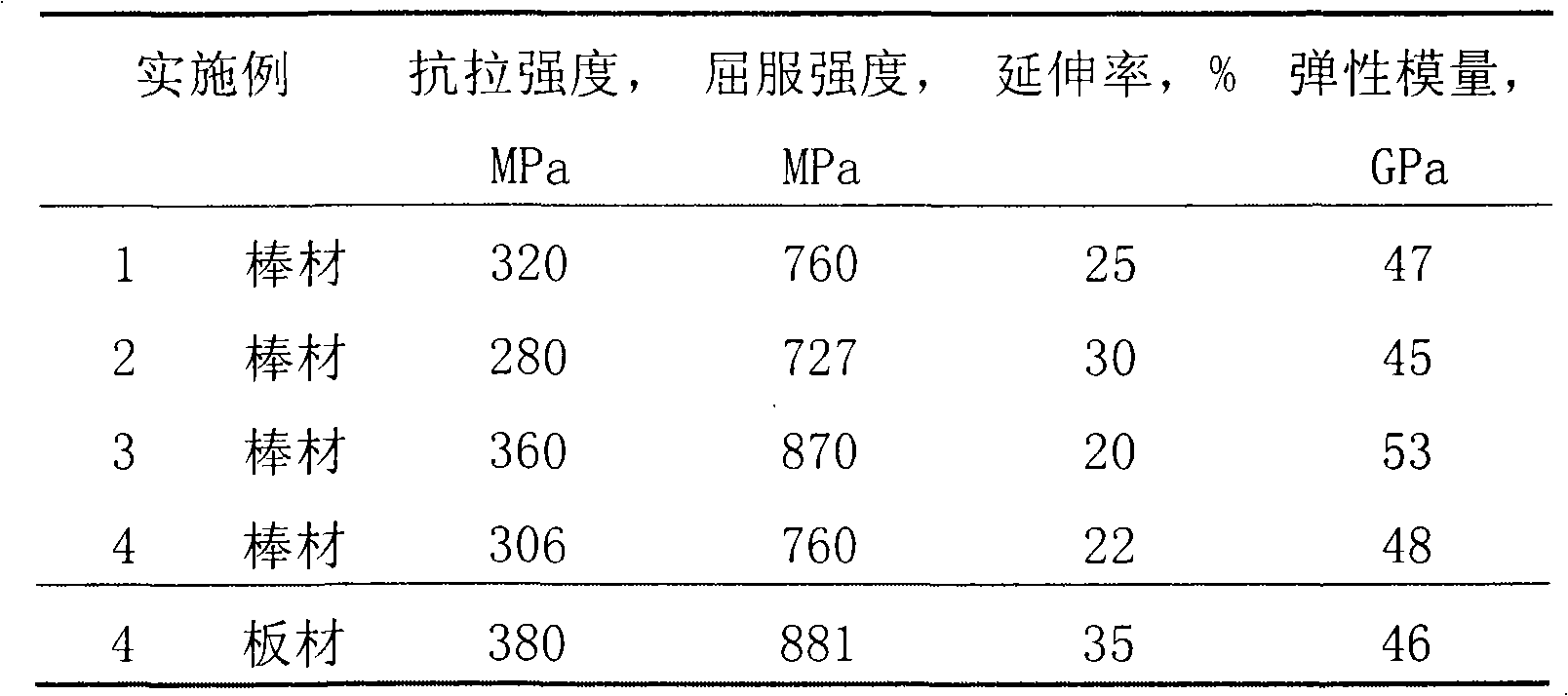

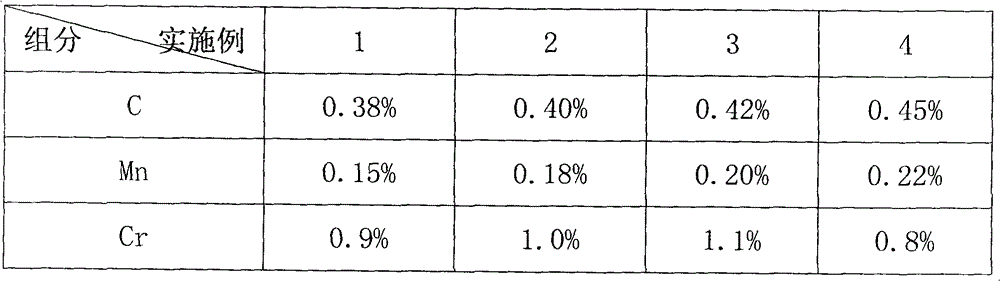

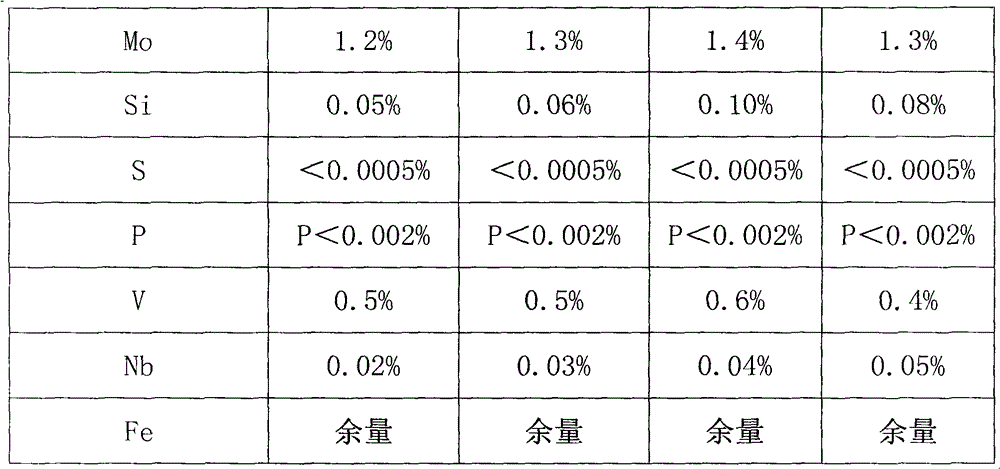

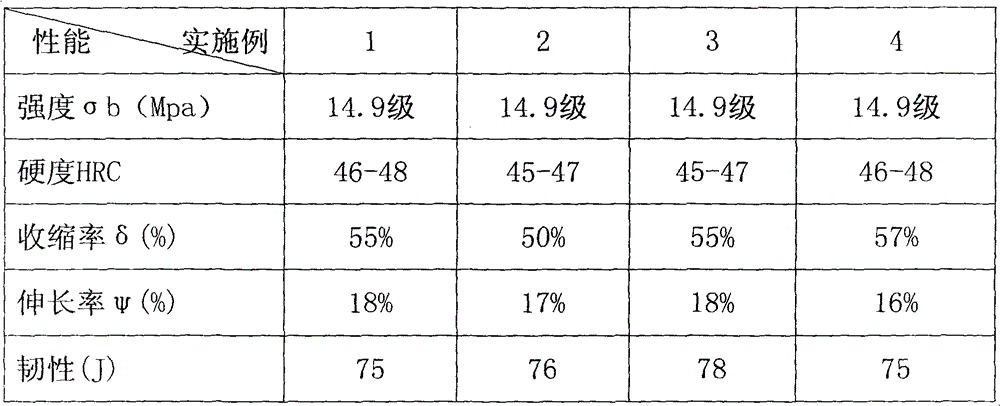

High-strength bolt and processing method thereof

InactiveCN102943210AImproved cold working propertiesReduce contentScrewsChemical compositionUltimate tensile strength

The invention belongs to the technical field of bolt processing and relates to a high-strength bolt and a processing method thereof. The high-strength bolt solves the problem that the present bolt is low in strength and hardness. The high-strength bolt is formed by processing the high-strength bolt steel, wherein the high-strength bolt steel comprises the following chemical components by mass percent: 0.38%-0.45% of C, 0.15%-0.25% of Mn, 0.8%-1.2% of Cr, 1.1%-1.4% of Mo, 0.05%-0.15% of Si, less than 0.001% of S, less than 0.004% of P, 0.4%-0.6% of V, 0.01-0.05% of Nb and the balance of Fe. The high-strength bolt has the advantages of high strength and hardness.

Owner:谢亚平

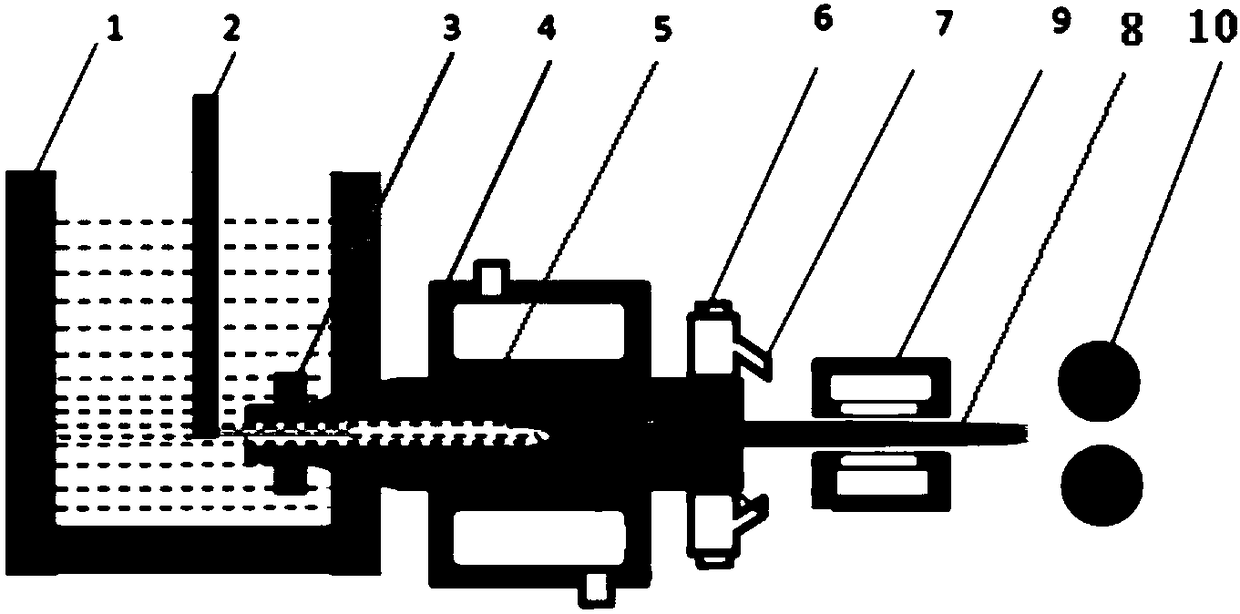

CuNiSn series alloy and strip billet composition external field horizontal continuous casting preparation method and device

The invention discloses a CuNiSn series alloy and strip billet composition external field horizontal continuous casting preparation method and device. A CuNiSn series alloy is in a Cu matrix, and meanwhile contains microalloying elements comprising B, Sr and V. The content sum of the microalloying elements comprising B, Sr and V is smaller than or equal to 0.3% of the mass of a CuNiSn series elastic copper alloy matrix. The preparation method comprises the steps of alloy melting and horizontal continuous casting. The technological process of horizontal continuous casting comprises stretching,primary standstill, reverse push, secondary standstill and stretching. The outlet end of a crystallizer of the horizontal continuous casting equipment is provided with a nitrogen nozzle which forms agas curtain on the periphery of a strip billet. An ultrasonic generator sealed by a boron nitride ceramic casing pipe with high heat resistance and low ultrasonic attenuation is further arranged in aheat insulation furnace. The inlet of the crystallizer is annularly sleeved with an electromagnetic induction coil. The prepared CuNiSn series elastic copper alloy has the characteristics of super strength, high stress relaxation resistance and the like, and is applicable to high-performance conductive elastic devices for spaceflight, aviation and microelectronics industry.

Owner:CENT SOUTH UNIV +1

Preparation method of high-strength corrosion-resistant copper pipe for heat exchanger

The invention discloses a preparation method of a high-strength corrosion-resistant copper pipe for a heat exchanger. The high-strength corrosion-resistant copper pipe comprises a copper matrix and alloy metals. The alloy metals comprise, by weight, 0.5-0.6% of magnesium, 0.08-0.09% of silver, 0.2-0.4% of tin. 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.05-0.06% of nickel, 0.005-0.008% of titanium and 0.02-0.04% of mischmetal. The mischmetal comprises yttrium, berkelium and lanthanum according to a mass ratio of 1: (0.15-0.2): (0.4-0.5). The preparation method utilizes upward continuous casting, rolling and drawing processes to replace casting, sawing, heating, extrusion and pickling processes of the traditional preparation method so that processes are greatly simplified, continuous production is realized, a period is short, and efficiency is high. A copper pipe prepared by the preparation method has oxygen content satisfying the oxygen-free copper level standard, has fine grains, and has mechanical strength, high temperature resistance, corrosion resistance and wear resistance obviously superior to the same performances of the existing copper pipe.

Owner:山东兴鲁有色金属集团有限公司

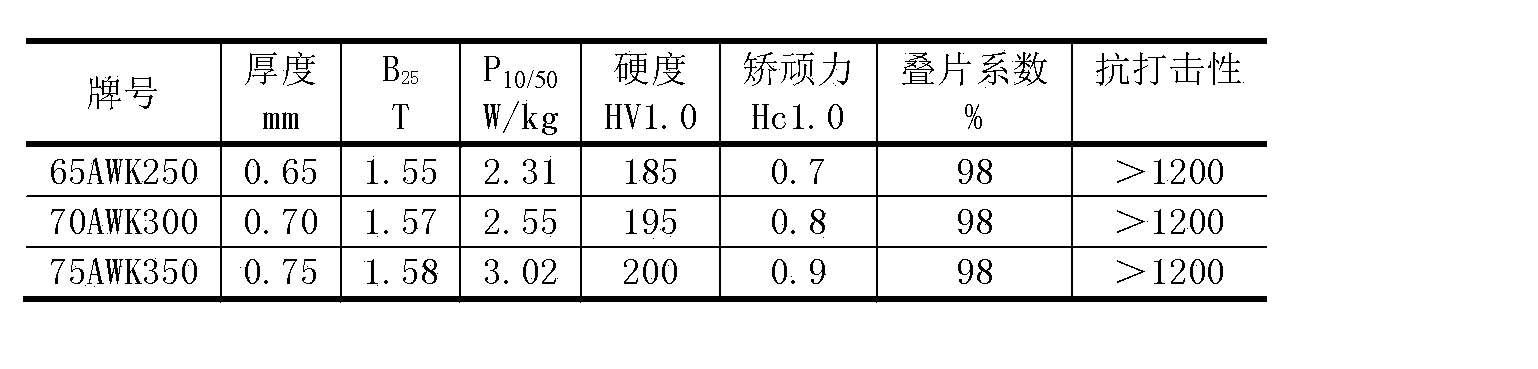

High-strength special-purpose cold-rolled non-oriented electrical steel and producing method thereof

The invention provides high-strength special-purpose cold-rolled non-oriented electrical steel and a producing method thereof. The steel comprises following chemical components by weight: not more than 0.0030% of C, 2.5-3.0% of Si, 0.10-0.5% of Mn, 0.005-0.20% of P, not more than 0.0015% of S, not more than 0.0040% of N and 0.140-1.10% of Als, with the balance being Fe and other unavoidable residual elements. The producing method includes smelting, continuous casting, hot rolling, normalizing, cold rolling and annealing. The electrical steel is low in coercive force, high in hardness, free of magnetic aging, high in strength and high in impact resistance. The product is flexible in production and can be produced in the same line with a high-grade product. The electrical steel has excellent electromagnetic performances, and can be widely used for manufacturing iron core materials of electromagnetic switches. The application field of the electrical steel is broadened.

Owner:ANGANG STEEL CO LTD

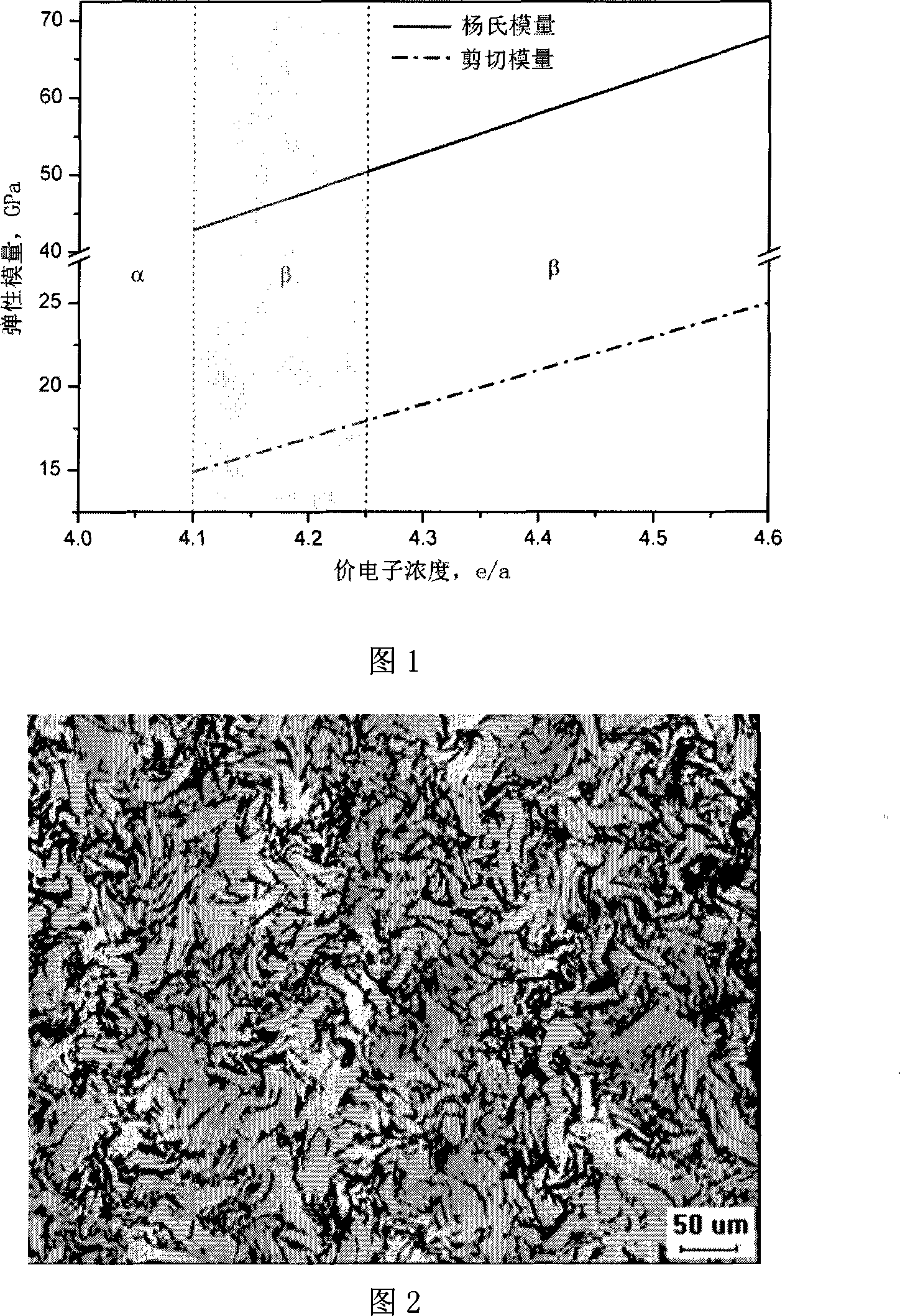

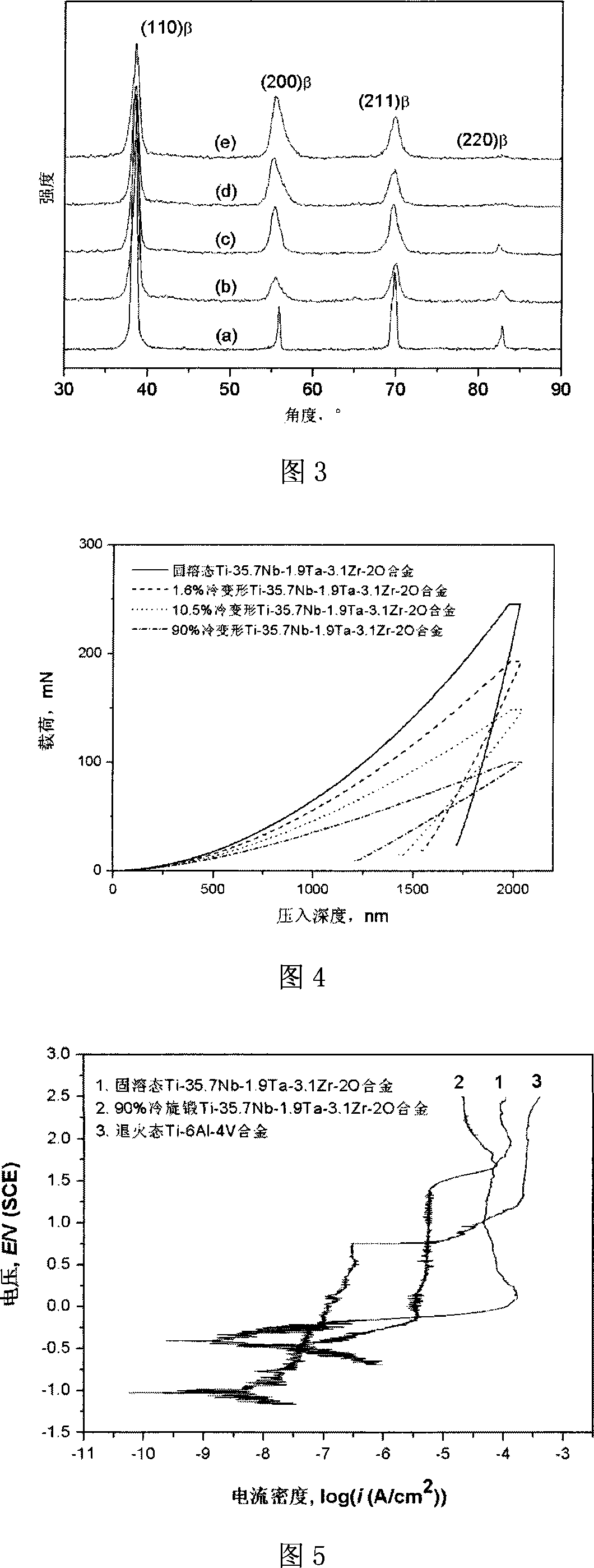

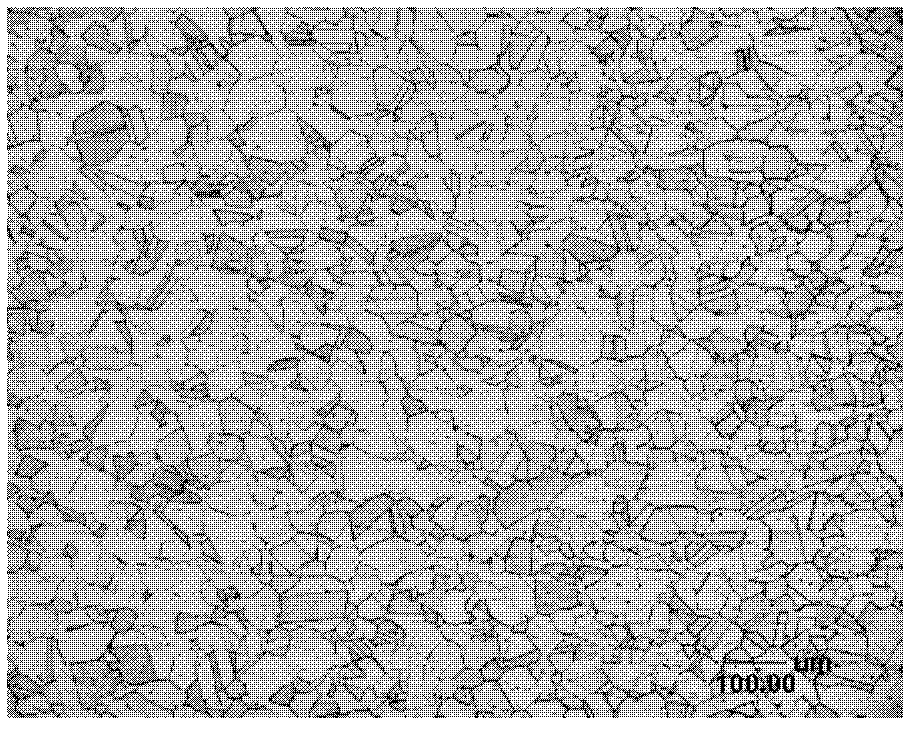

Metastable beta type Ti-Nb-Ta-Zr-O alloy and preparation method thereof

InactiveCN101215655AGood processing performanceLow work hardening rateProsthesisSingle phaseCorrosion

The invention relates to a metastable beta-type Ti- Nb-Ta-Zr-O alloy and a method for preparation, wherein the components of the alloy are that Nb is 35-38 percent by weight, Ta is 0-3 percent by weight, Zr is 2-4 percent by weight, O is 0.2-0.8 percent by weight, and the other content is Ti. The method comprises V1ing, the Ti- Nb-Ta-Zr-O alloy whose components are uniform is obtained through the vacuum consumable electrode arc furnace melting method. V2ing, Ti- Nb-Ta-Zr-O alloy ingots are done by heat processing treatment in the temperature range of 800-100 DEG C. V3ing, after being done by the solid solution quenching treatment, the Ti- Nb-Ta-Zr-O alloy which is treated in the temperature range of 1000-1200 DEG C is cooled, thereby obtaining a single-phase beta tissue. V4ing, solid solution state Ti- Nb-Ta-Zr-O alloy is done by cold processing treatment in room temperature, thereby obtaining various alloy bars and plates. The alloy of the invention has super elasticity, low modulus, high strength, no biological toxicity, corrosion resistance, excellent biocompatibility and easy processing forming, and the alloy is capable of being widely used on biological implantation materials and other medical devices.

Owner:SHANGHAI JIAO TONG UNIV

Ni-saving austenitic stainless steel cold-rolled sheet with excellent processability and manufacturing method thereof

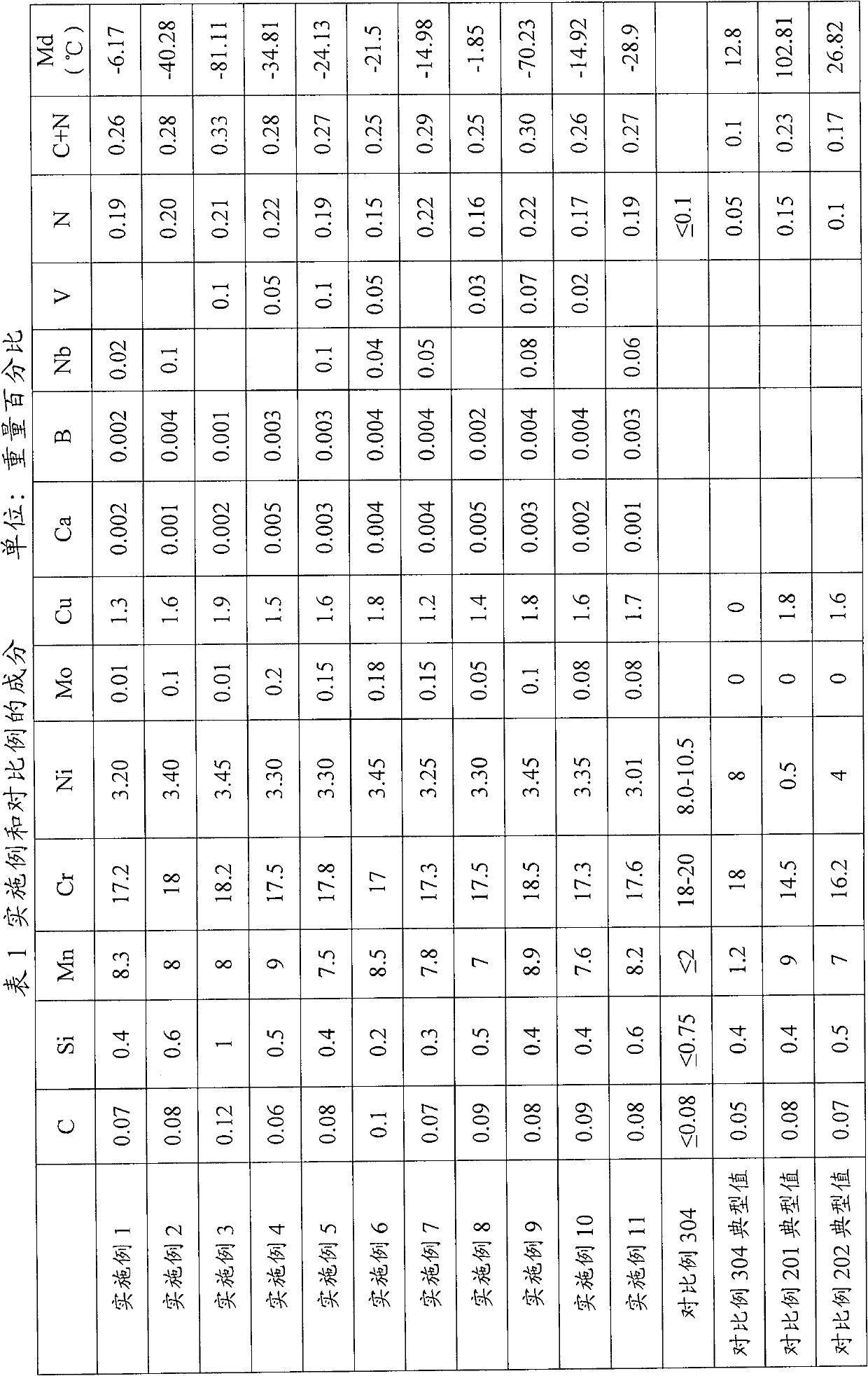

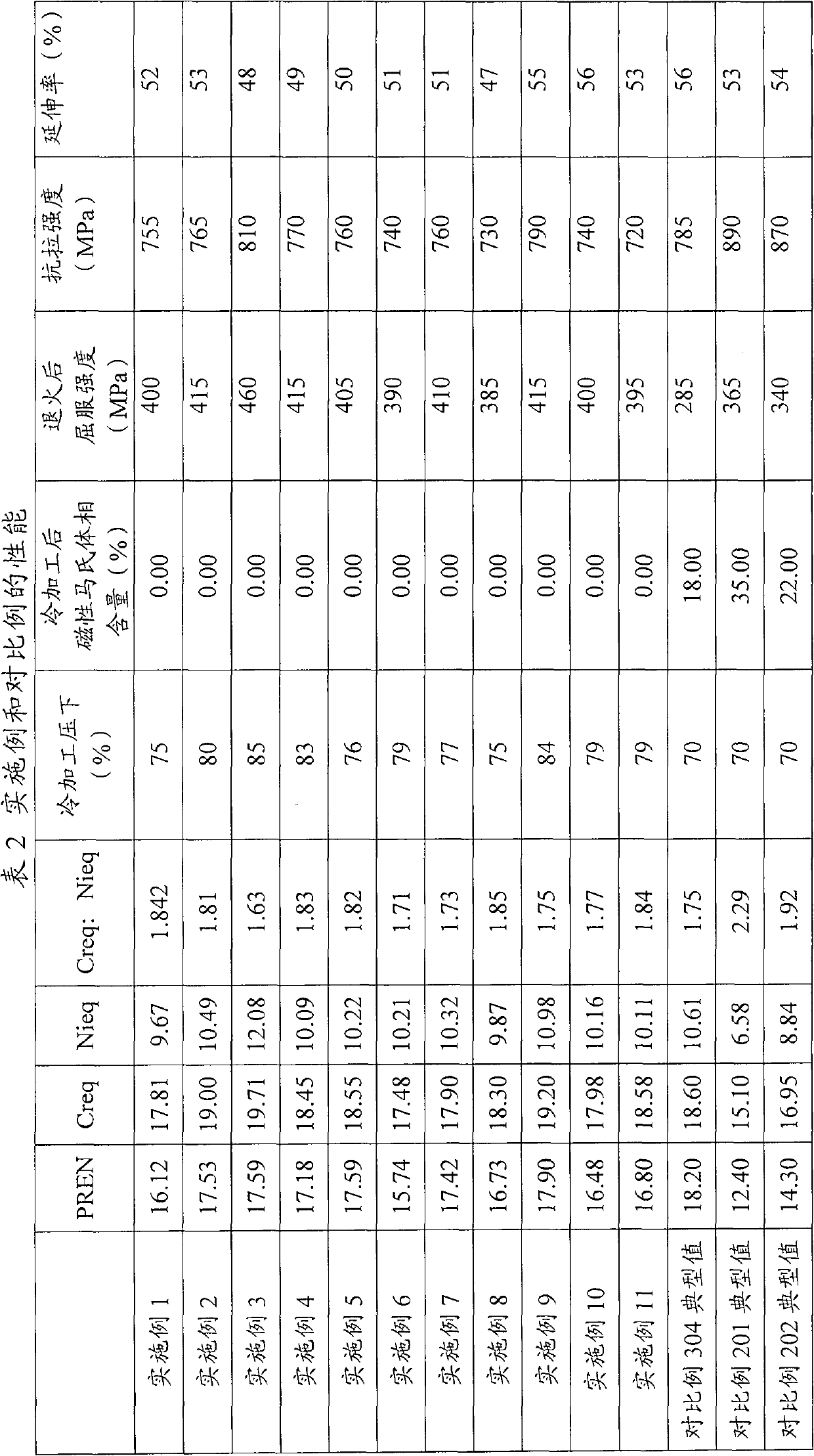

The invention relates to an Ni-saving austenitic stainless steel with excellent processability. The austenitic stainless steel comprises one or two of the following chemical components in percentage by weight: 0.06-0.12 of C, 0.2-1.0 of Si, 7.0-9.0 of Mn, 17.0-18.5 of Cr, 3.01-3.45 of Ni, 0.15-0.22 of N, 0.01-0.2 of Mo, 1.2-1.9 of Cu, B larger than or equal to 0.001% and smaller than or equal to 0.004%, Ca larger than or equal to 0.001% and smaller than or equal to 0.005%, V smaller than or equal to 0.1%, Nb smaller than or equal to 0.1%, and the balance of Fe and unavoidable impurities, wherein the sum of the percentage of C and the percentage of N is larger than or equal to 0.25%. The manufacturing method of the austenitic stainless steel comprises the following steps: heating a smelted and poured casting blank to 1100-1250 DEG C and preserving heat, performing hot working on the casting blank until a needed thickness is obtained, wherein the heat preserving time is more than 30min; after hot working, annealing at a controlled temperature of 980-1100 DEG C and washing the blank with any acid, and performing cold rolling, wherein when Md30 / 50 is larger than or equal to -30 DEG C and smaller than or equal to 0 DEG C, the maximum cold rolling deformation is 75-80%; or when Md30 / 50 is smaller than or equal to -30 DEG C, the maximum cold rolling deformation is 80-85%. According to the invention, the cold working performance of the Ni-saving austenitic stainless steel is improved; the corrosion resistance is close to that of type 304, and meanwhile the cost is lower than that of the type 304.

Owner:BAOSTEEL STAINLESS STEEL

High-carbon steel wire for superfine steel wire and manufacturing method thereof

InactiveCN101481772AHigh strengthImprove toughnessTemperature control deviceFurnace typesWire rodHigh carbon

The invention discloses a high carbon steel wire used for an ultrathin steel wire and a manufacturing method thereof. The wire has the following compositions in terms of weight percentage: 0.60 to 1.2 of C, 0.10 to 0.50 of Si, 0.01 to 0.60 of Mn, no more than 0.020 of P, no more than 0.020 of S, no more than 0.002 of Ti, no more than 0.005 of Al, no more than 0.006 of N and Fe and the balance of inevitable impurities. The manufacturing method comprises the following steps: smelting, molten iron desulfurisation and converter top and bottom blowing are carried out by adopting an ultrapure steel technique, ladle argon blowing refining and external refining are carried out by adopting low-alkalinity steel slag with 0.5 to 1.6 of CaO / SiO2; square billet is formed by casting; austenitizing with the temperature of 750 DEG C to 850 DEG C is carried out on the square billet by using a heating furnace; control rolling and control cooling treatment is carried out on the high speed wire; the rolling temperature is controlled to be 750 to 900 DEG C; and finally the wire is manufactured. The wire can effectively avoid the filament breakage in the drawing technique, and the drawn filament is not broken at least when drawn for more than 1,200,000 meters; and the wire can produce ultrathin steel wire, which has the diameter of less than 0.50 mm and has high strength and high toughness, and meets the requirements of automotive and rubber industries and the construction of roads and bridges.

Owner:WUHAN IRON & STEEL (GROUP) CORP

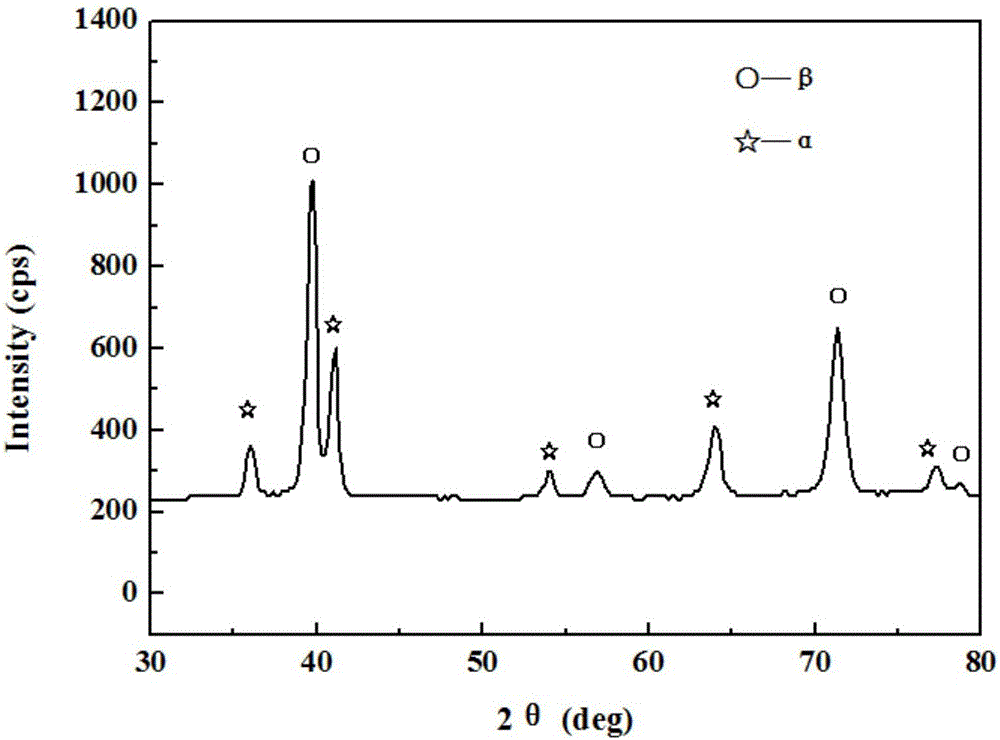

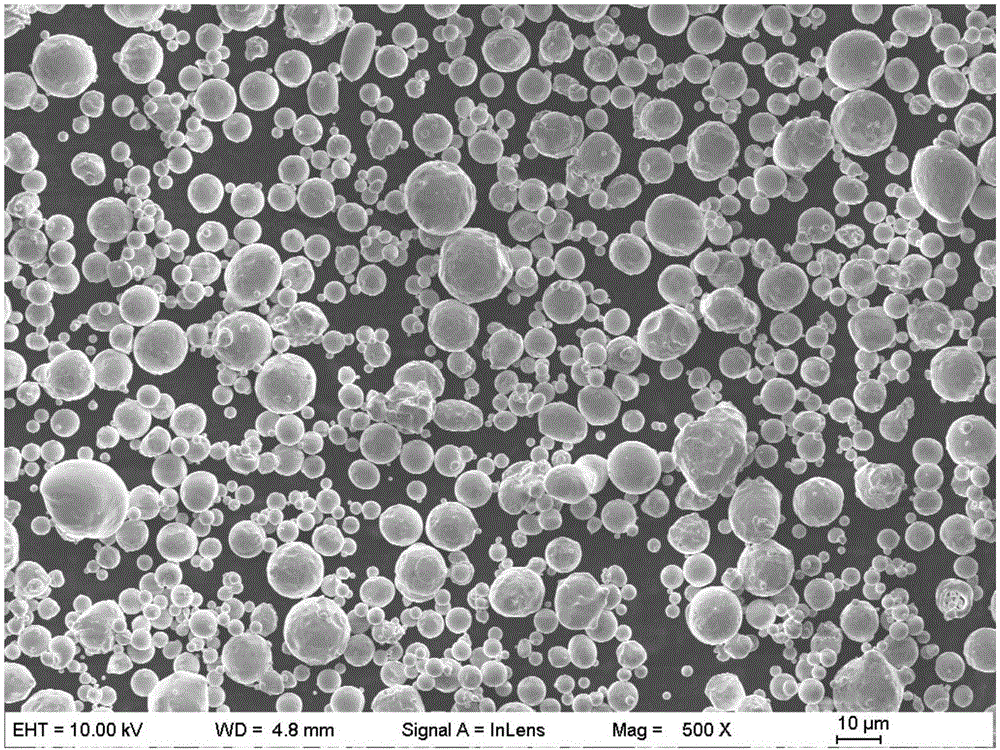

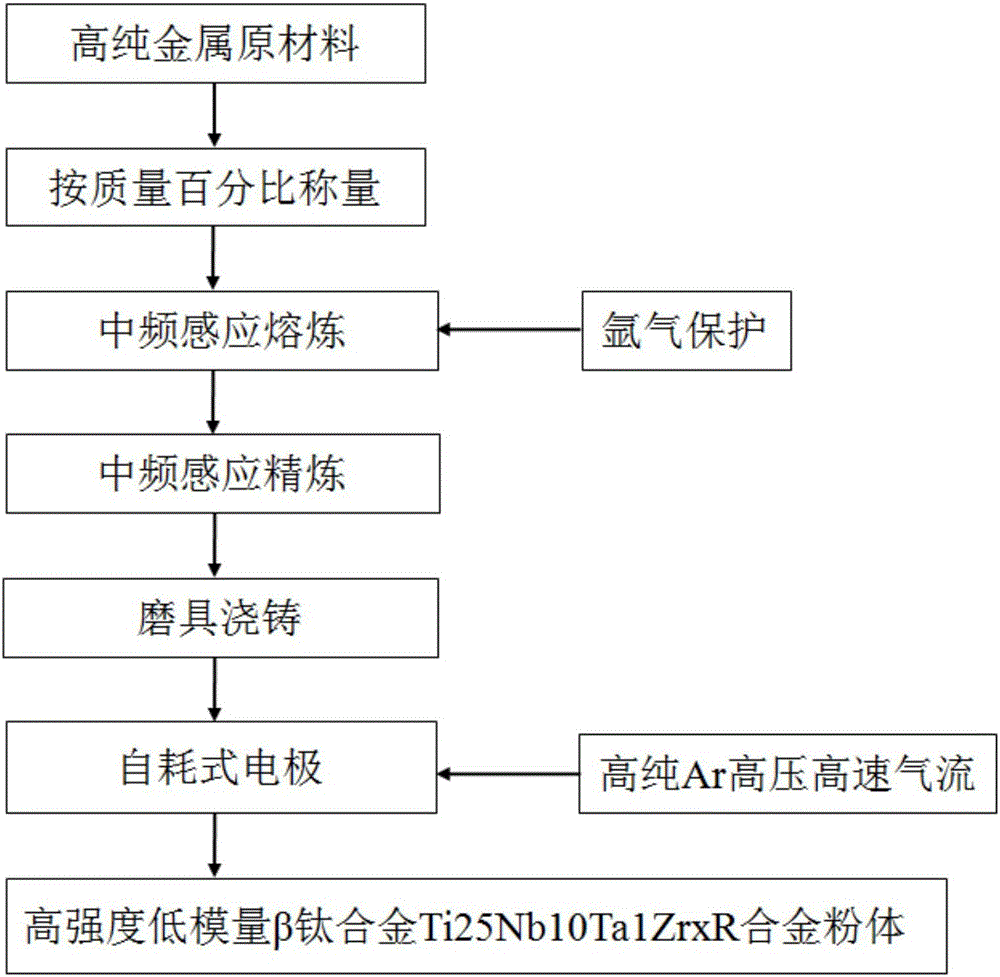

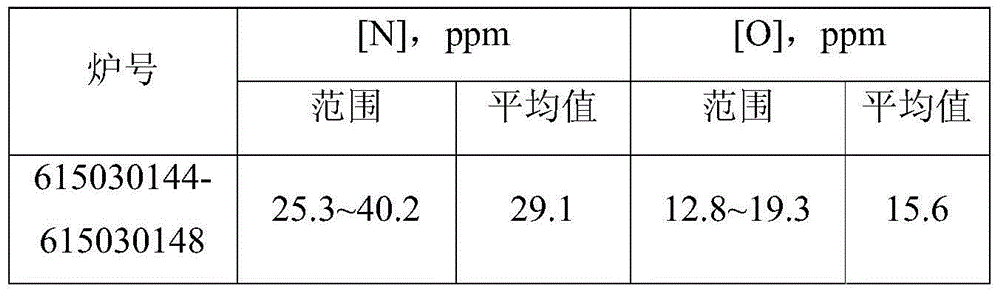

Medical beta-titanium alloy powder material used for 3D printing and preparation method thereof

ActiveCN106148760AGuaranteed purityImproved cold working propertiesAdditive manufacturing apparatusLow modulusElastic modulus

The invention discloses a medical beta-titanium alloy powder material used for 3D printing and a preparation method thereof. The beta-titanium alloy molecular formula is Ti25Nb10Ta1ZrxR, and the medical beta-titanium alloy powder material is composed of, by weight, 25% of Nb, 10% of Ta, 1% of Zr, and the balance Ti, wherein R represents rear earth, the value range of x is 0.05-0.1, R is at least one of Y, La, Ce and Er, and Ta represents Ti20Ta alloy. The titanium alloy powder material is prepared through electrode induction smelting gas atomization, that is, metal liquid subjected to medium-frequency induction smelting and refining is cast into a grinding tool to obtain a metal cast rod, and the metal cast rod serves as a consumable electrode of electrode induction gas atomization; and then the powder material is prepared through an electrode induction atomization method. The high-strength low-modulus powder material Ti25Nb10Ta1Zr0.1R prepared through the method is high in purity, high in sphericity degree and free of toxicity, printed titanium alloy is high in strength (with the yield strength being 800-850 Mpa and the tensile strength being 1100-1250 Mpa) and low in elastic modulus (35-40 Gpa). The preparation method provided by the invention is suitable for large-scale industrial production, does not pollute the environment and is environmentally friendly.

Owner:浙江亚通新材料股份有限公司

Spring steel round steel and production process thereof

The invention belongs to the field of metallurgy and discloses spring steel round steel and a production process thereof. The spring steel round steel comprises the following components in percentage by weight: 0.56 to 0.64 percent of carbon (C), 1.60 to 2.00 percent of silicon (Si), 0.70 to 1.00 percent of manganese (Mn), less than or equal to 0.025 percent of phosphorus (P), less than or equal to 0.025 percent of sulfur (S), 0.15 to 0.35 percent of chromium (Cr), less than or equal to 0.35 percent of nickel (Ni), less than or equal to 0.25 percent of copper (Cu) and the balance of Ferrum (Fe). The production process comprises the following steps of: converter or electric furnace smelting, LF refining, VD degassing, CCM continuous casting and bar rolling. The spring steel round steel of the invention has the characteristics of low alloying element content, low decarburizing tendency, high temper resistance, high hot-working performance, low cost, high performance after heat processing and the like of a common round steel; besides, the spring steel round steel simultaneously has high cold workability under the condition of air cooling after rolling. The process ensures that the rolled spring steel round steel obtains a texture of pearlite and a small number of ferrolites under the condition of air cooling, and has high plasticity and toughness during cold working, and every performance can meet the requirements of GB / T1222 after heat processing.

Owner:NANJING IRON & STEEL CO LTD

Beta-type titanium alloy

Provided is a β-type titanium alloy having excellent cold workability and higher strength than Ti-20V-4Al-1Sn β-type titanium alloy, which contains: V: 5-15%, Fe: 0.5% by weight ~2.5%, Mo: 0.5~6%, Cr: 0.5~5%, and let the weight % of V contained be XV, the weight % of Fe contained be XFe, and the weight % of Mo contained be XMo When the weight % of Cr contained is XCr, the value of XV+2.95XFe+1.5XMo+1.65XCr is 15 to 23%, Al: 1.5 to 5%, and the balance is composed of Ti and impurities.

Owner:NIPPON STEEL CORP

Steel disc strip for diode lead and production technology of steel disc strip

The invention relates to steel and a production method of the steel, in particular to a steel disc strip for a diode lead and a production technology of the steel disc strip. The steel disc strip comprises, by weight, 0.03% to 0.06% of C, 0.02% to 0.05% of Si, 0.18% to 0.28% of Mn, larger than or equal to 0.020% of Al, not larger than 0.015% of P, not larger than 0.015% of S, not larger than 0.20% of Cr or Ni or Cu, not larger than 10ppm of Ca, and the balanced Fe and inevitable impurities. The preparation method comprises a converter refining working procedure, an RH carbon-deoxidization working procedure, an LF refining working procedure, a continuous casting working procedure and a rolling working procedure. The technical problems that at present, the steel disc strip for the diode lead is poor in drawing property, cold machining cracks are prone to being generated, the purity is not high, and the quality is unstable are solved.

Owner:ZENITH STEEL GROUP CORP +1

Beta titanium alloy for fastener and manufacturing method

The invention discloses a Beta titanium alloy used for a fastener. The Beta titanium alloy comprises the following components, in weight percentage: molybdenum: 4 to 7 percent, niobium: 4 to 6.5 percent, chromium: 3 to 5 percent, tantalum: 1 to 3 percent, aluminum: 2 to 4 percent, iron: 1.0 percent or less, carbon: 0.1 percent or less, nitrogen: 0.05 percent or less, hydrogen: 0.015 percent or less, oxygen: 0.02 percent or less, balance titanium. A preparation method thereof is characterized in that after sponge titanium, pure aluminum, pure chromium, Ti-0.31Mo, Ti-0.53Nb and Al-0.80Ta are mixed and pressed with a pressing machine into block-shaped electrodes; a plurality of electrodes are welded with an ion welding machine into a long strip-shaped electrode which is taken as a consumable electrode and melted in a vacuum consumable arc furnace, the obtained casting ingot is again taken as the consumable electrode and melted for 2 to 3 times to acquire the product titanium alloy ingot. The invention has the advantages that the intensity is high, the low-cost large-scale production can be realized, the intensity requirements can be satisfied, the processing and modeling are easy, and the energy consumption is reduced.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD +1

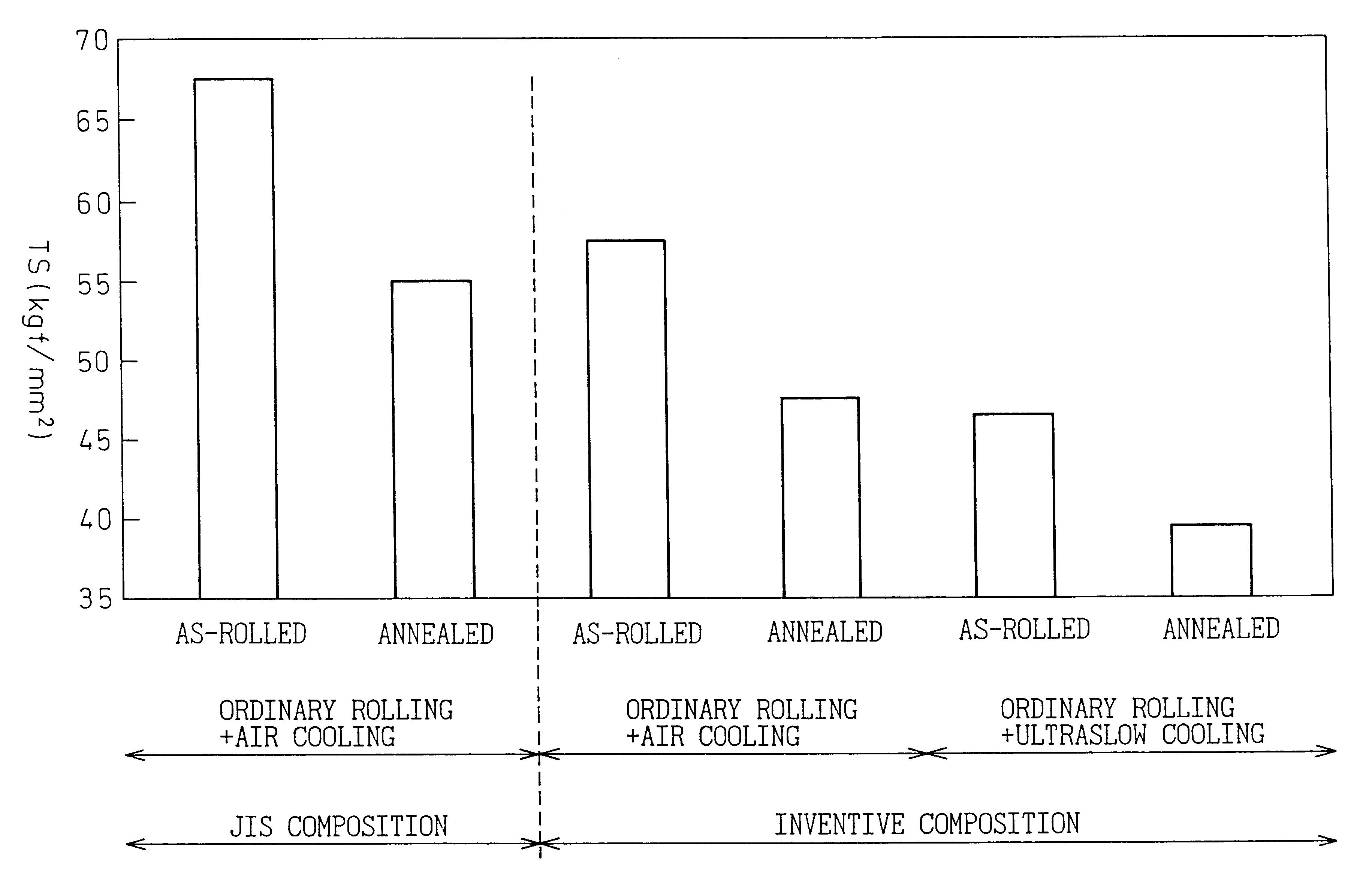

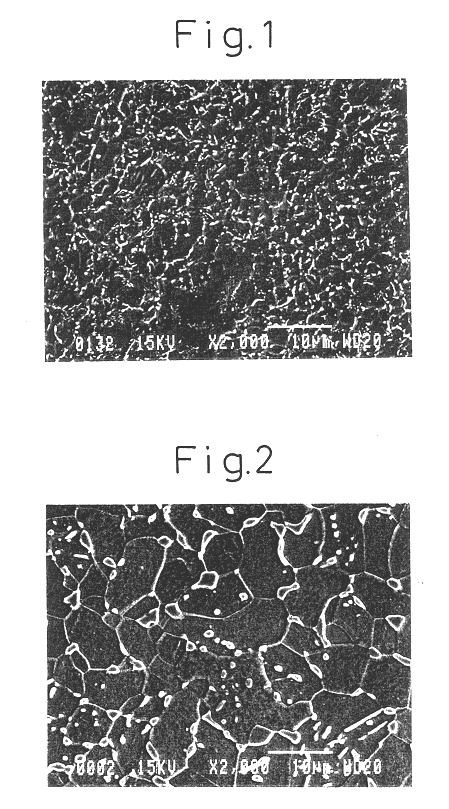

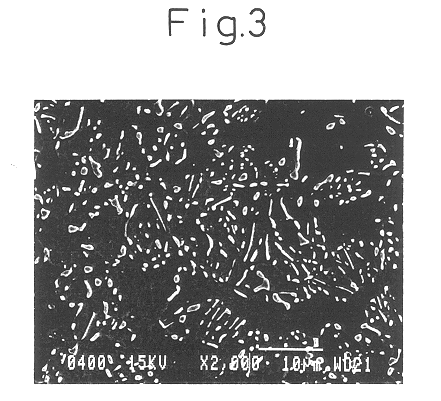

Cold workable steel bar or wire and process

InactiveUS6488787B1Degree of improvementImprove hardenabilityFurnace typesHeat treatment furnacesCarbideSteel bar

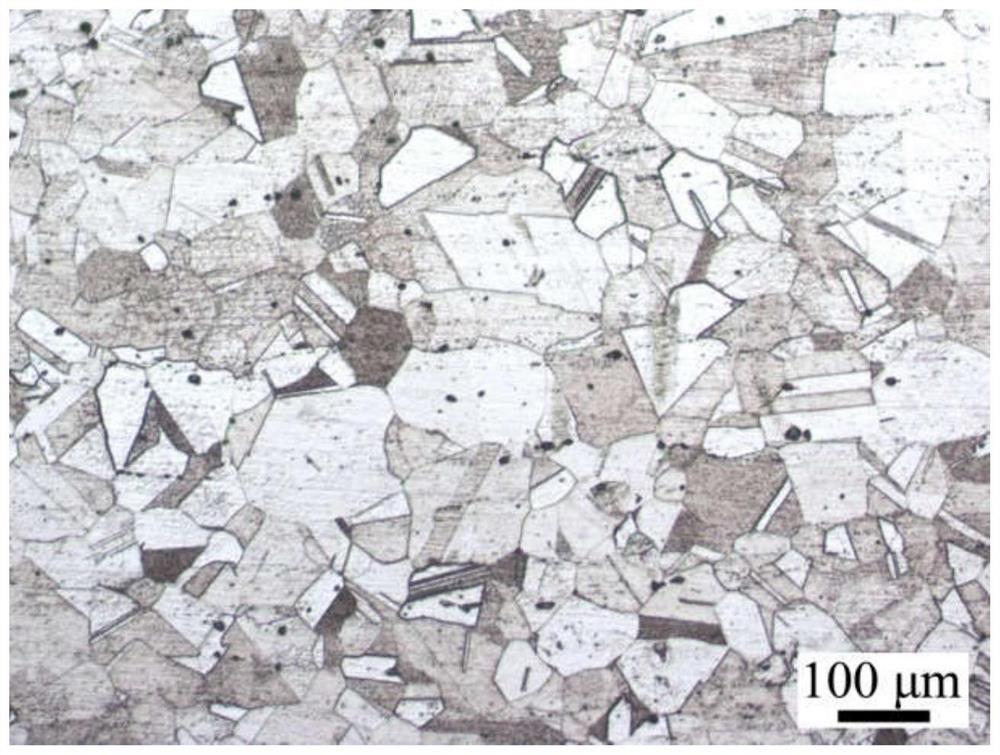

A machine structural steel bar or wire having a softening degree of at least that of the conventional spheroidization-annealed steel material, excellent hardenability, and improved cold workability,comprising 0.1 to 0.5 wt % of C, 0.01 to 0.15 wt % of Si, 0.2 to 1.7 wt % of Mn, 0.0005 to 0.05 wt % of Al, 0.005 to 0.07 wt % of Ti, 0.0003 to 0.007 wt % of B, 0.002 to 0.02 wt % of N and the balance of Fe and unavoidable impurities, the unavoidable impurities including up to 0.02 wt % of P and up to 0.003 wt % of O, andhaving a microstructure comprising ferrite and spheroidal carbides, the ferritic grain size number according to JIS G0522 of the ferrite being at least No. 8 and the number of the spheroidal carbides per unit area mm2 being up to 1.5x106xC wt %.

Owner:NIPPON STEEL CORP

Duplex stainless steel wire material, steel wire, bolt, and method for production of the bolt

ActiveCN101815803AExcellent cold forgeabilityHigh strengthFurnace typesHeat treatment furnacesWire rodMetallurgy

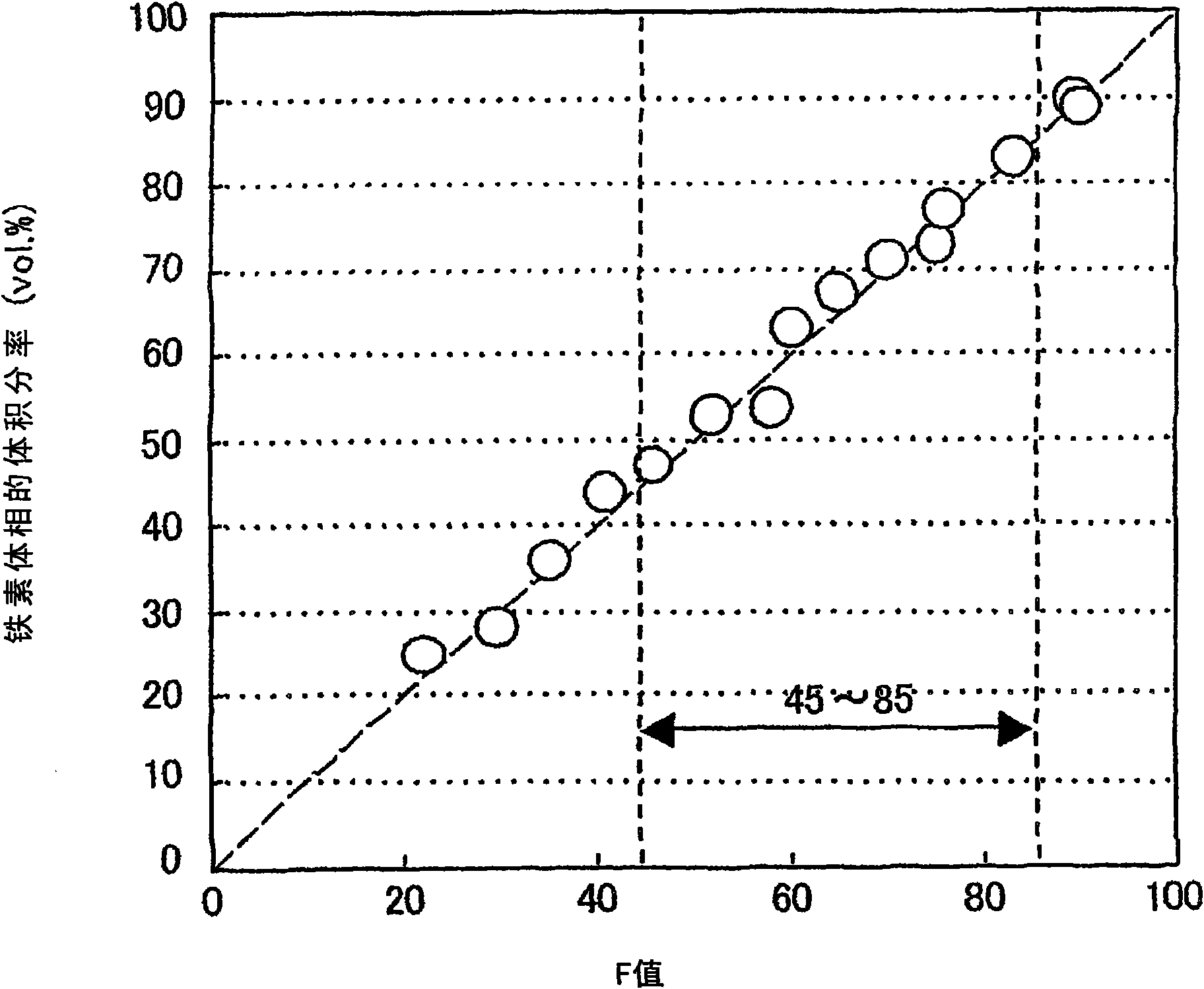

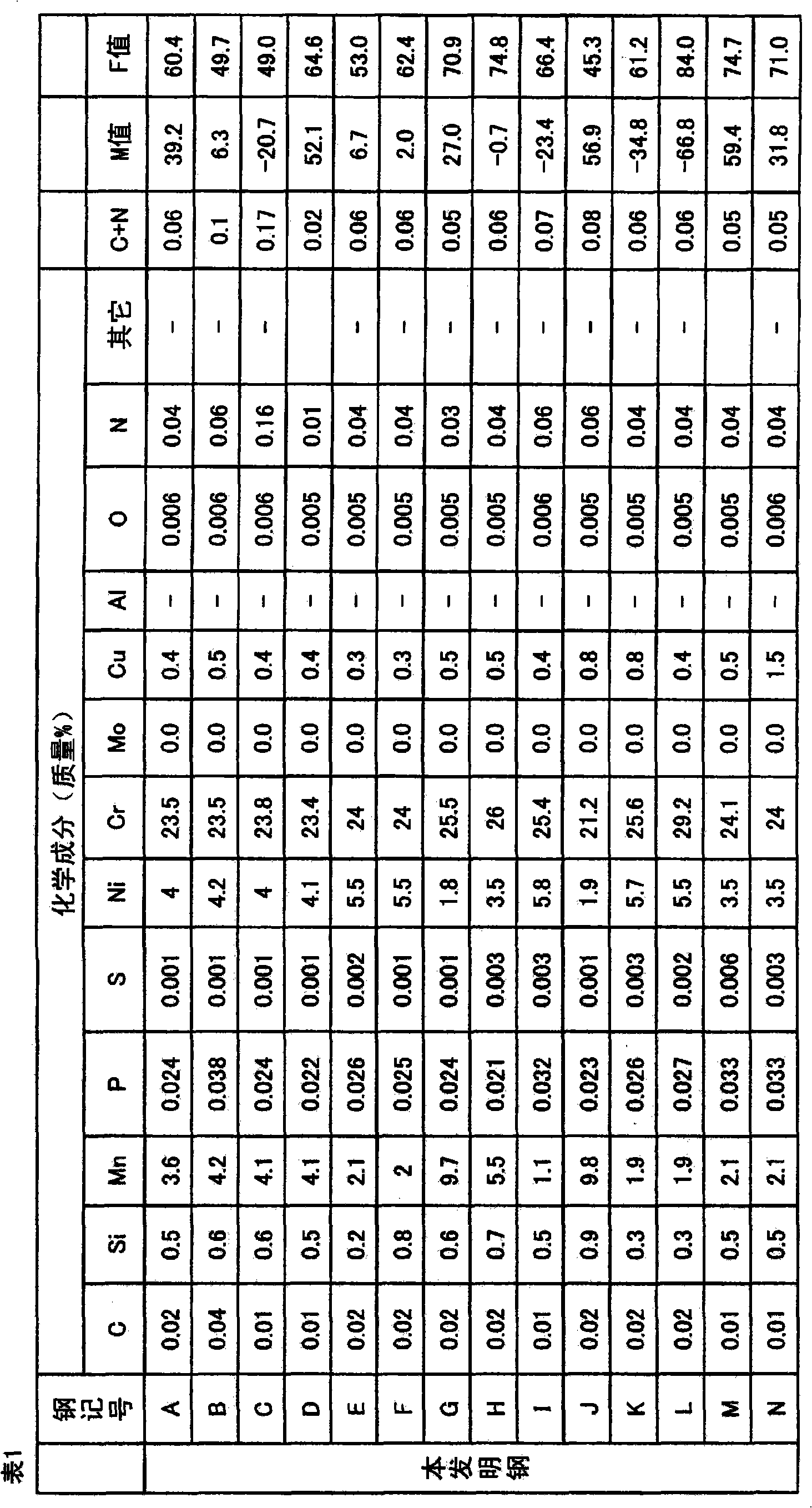

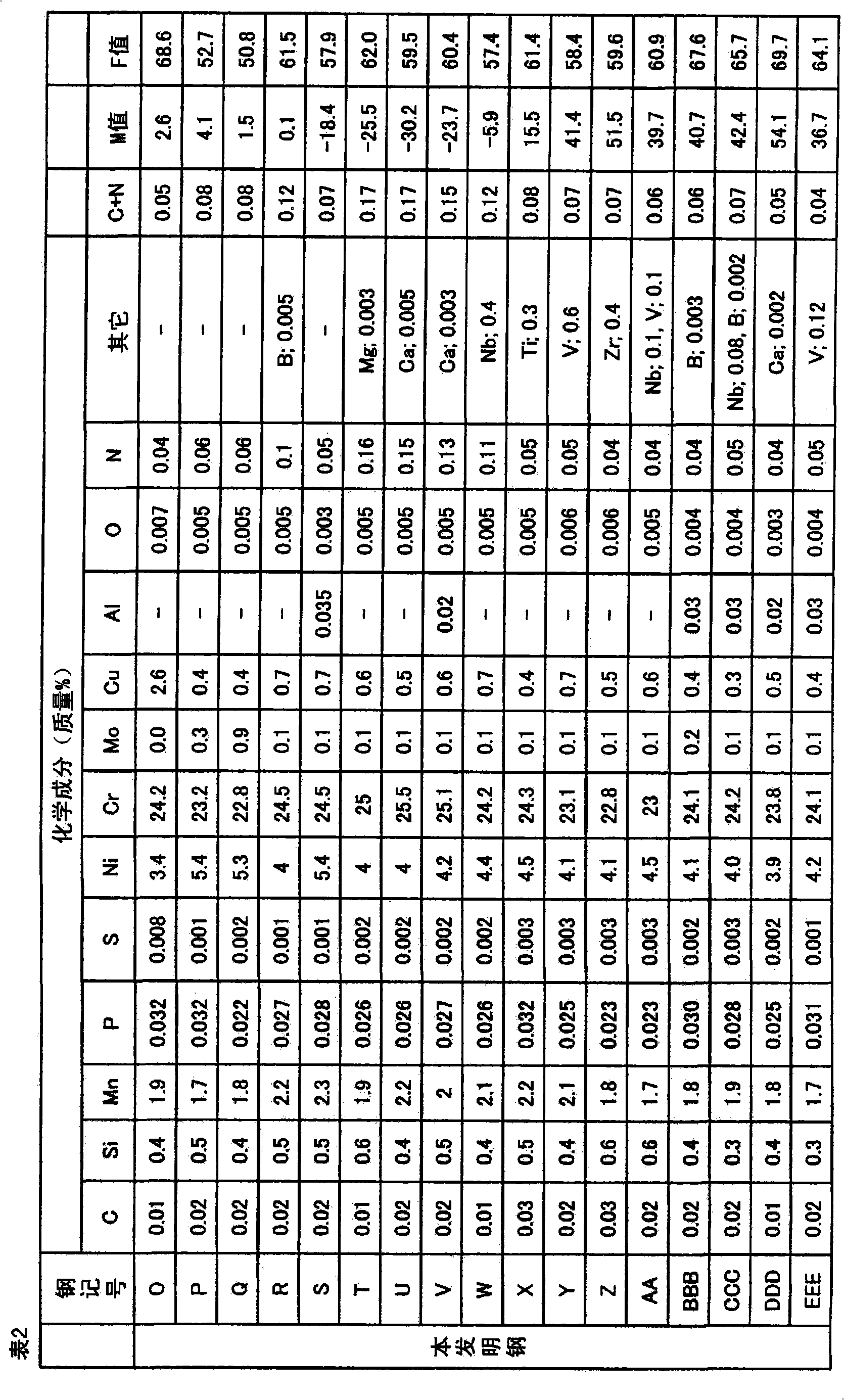

Disclosed is an austenite-ferrite duplex steel wire material for a high-strength, high-corrosion-resistant bolt, which has excellent cold forgeability. The steel wire material comprises the following components (by mass): C: 0.005-0.05%, Si: 0.1-1.0%, Mn: 0.1-10.0%, Ni: 1.0-6.0%, Cr: 19.0-30.0%, Cu: 0.05-3.0% and N: 0.005-0.20%, with the remainder being Fe and substantially unavoidable impurities, wherein the total content of C and N is 0.20% or less, the M value represented by the formula (a) below is 60 or less, the F value represented by the formula (b) is 45 to 85, and the tensile strength is 550 to 750 N / mm2. M = 551-462(C+N)-9.2Si-8.1Mn-29(Ni+Cu)-13.7Cr-18.5Mo (a) F = 5.6Cr-7.1Ni+2.4Mo+15Si-3.1Mn-300C-134N-26.6 (b).

Owner:NIPPON STEEL STAINLESS STEEL CORP

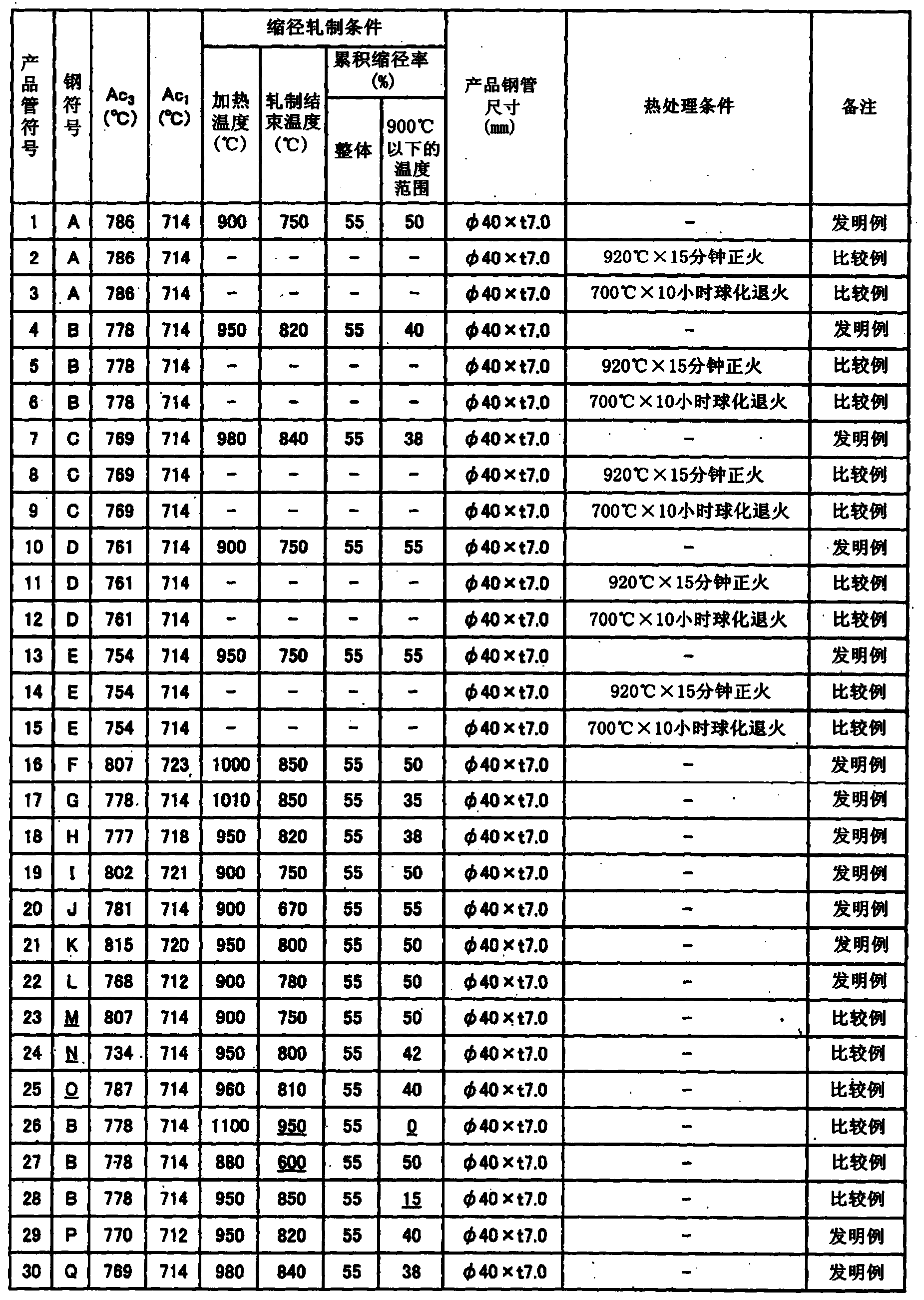

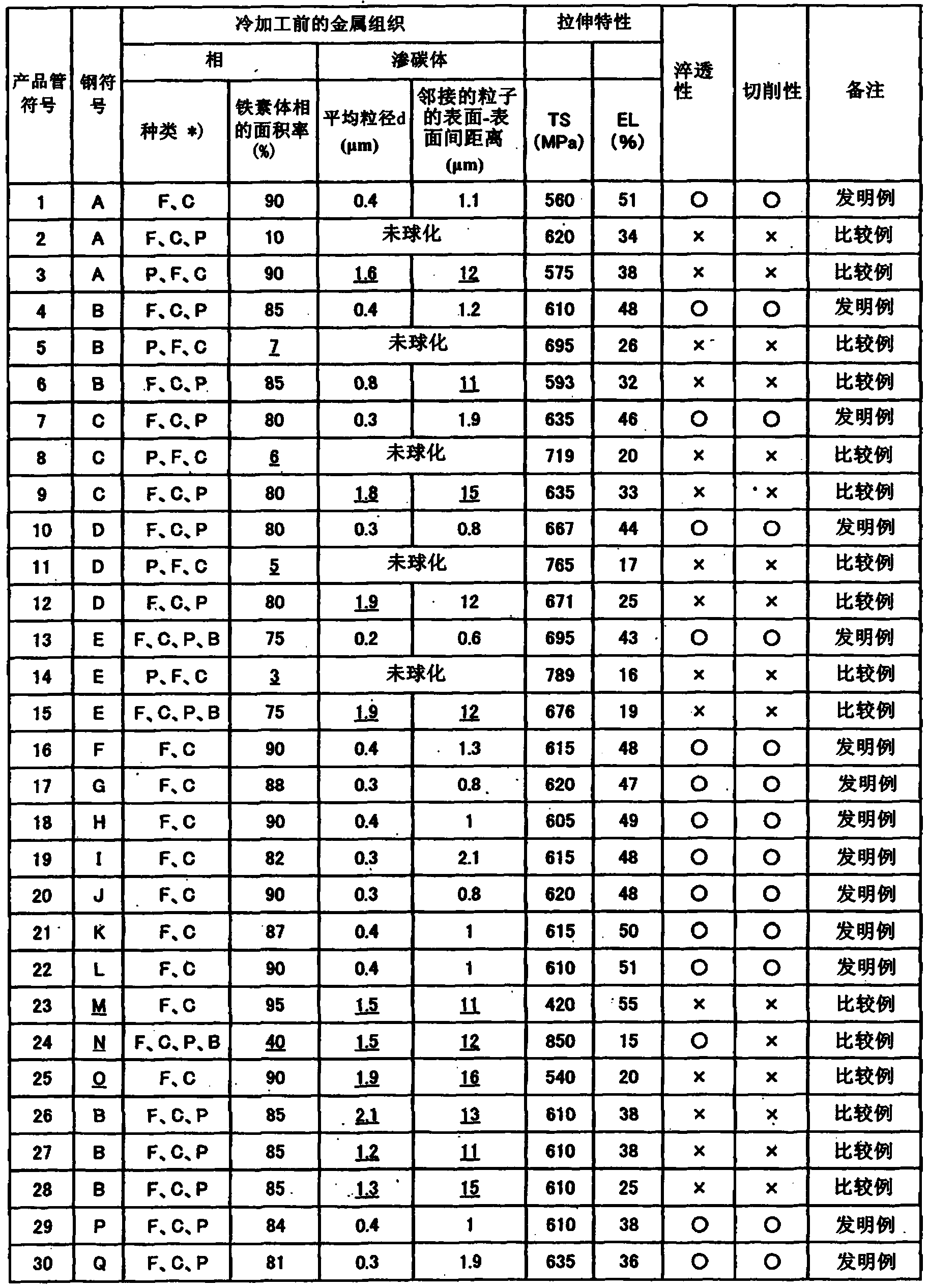

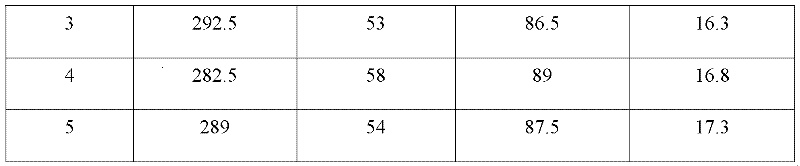

High carbon steel pipe having excellent cold workability, machinability, and quenching properties, and method for manufacturing same

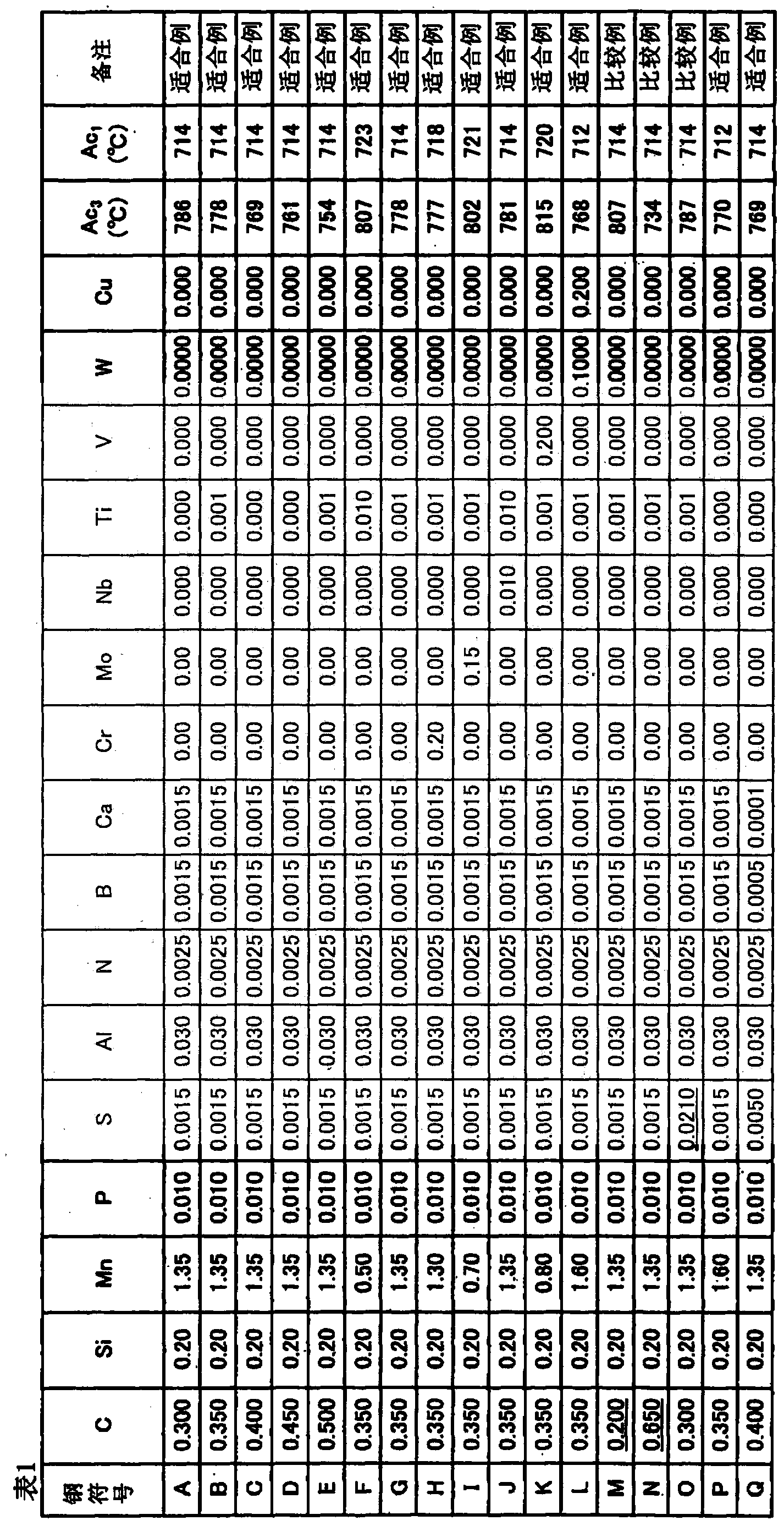

ActiveCN104411846AHelps to reduce weightSimple and cheap to manufactureFurnace typesHigh frequency current welding apparatusMetallurgy% diameter reduction

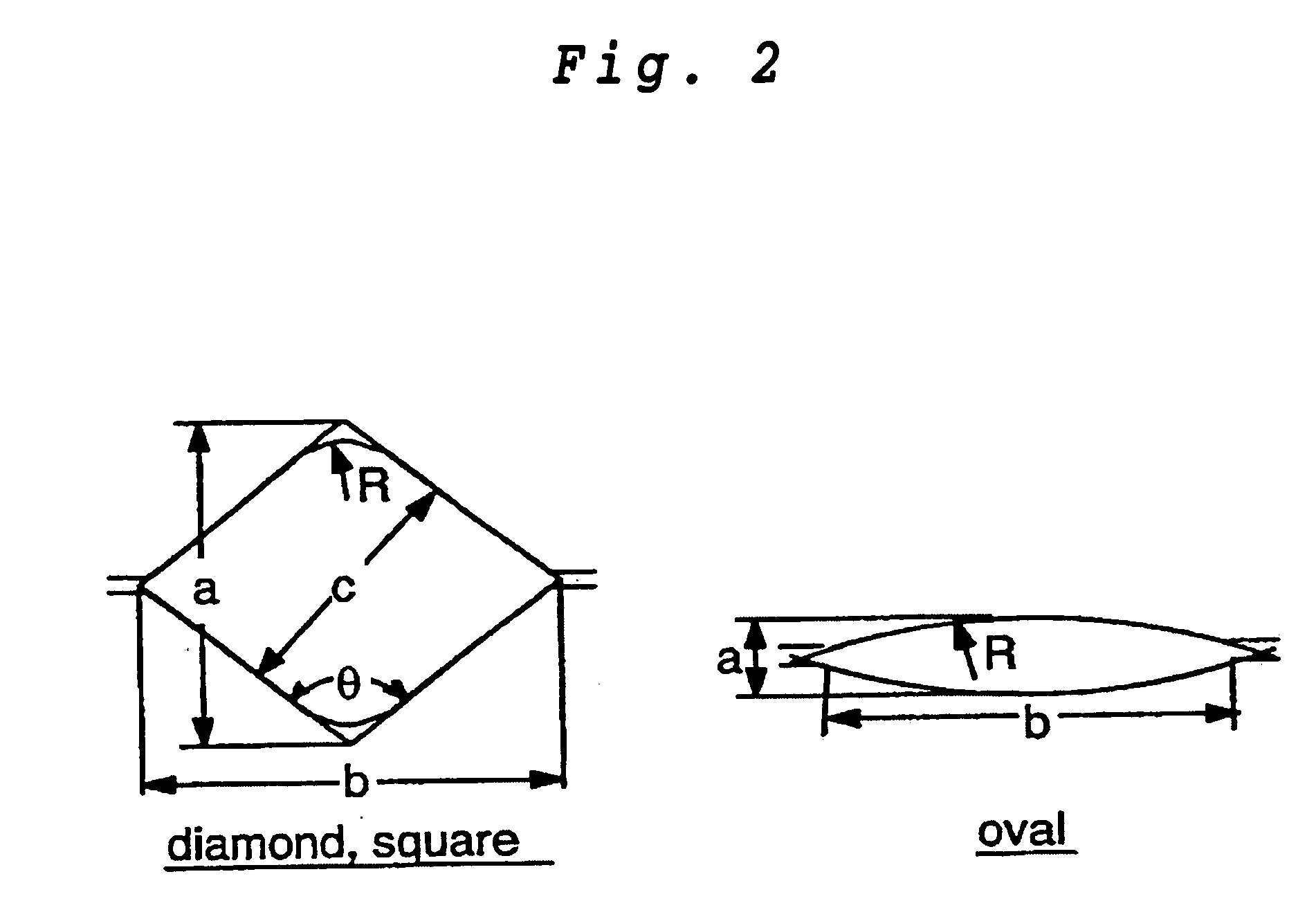

Provided are a high carbon resistance-welded steel pipe having excellent cold workability, machinability, and quenching properties; and a method for manufacturing the same. Specifically, a high carbon steel pipe having a composition containing, by mass, 0.25 to 0.60% of C, 0.01 to 2.0% of Si, 0.2 to 3.0% of Mn, 0.001 to 0.1% of Al, 0.001 to 0.05% of P, 0.02% or less of S, 0.0010 to 0.0100% of N, 0.0003 to 0.0050% of B, and 0.0001 to 0.0050% of Ca, with the remainder made up by residual Fe and unavoidable impurities, is used as a material steel pipe. Heating and soaking is performed to Ac3 transformation point or above, and diameter-reducing rolling is subsequently performed at a rolling finishing temperature of 900°C or above (Ac1 transformation point) and a cumulative diameter reduction ratio of 30 to 70% in a temperature range no greater than 900°C. This makes it possible to obtain, without performing spheroidizing annealing, a structure in which cementite particles having an average particle diameter (d) from 0.1 mum to less than 0.5 mum and in which the average distance (L) between the surfaces of adjacent cementite particles is 0.5 to 10 mum are dispersed in a ferrite phase. In particular, machinability is significantly improved.

Owner:JFE STEEL CORP

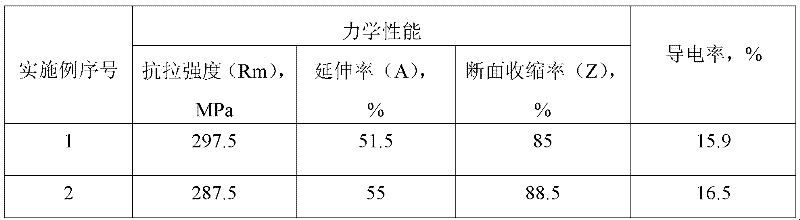

Steel for copper-clad steel and method for producing the same

The invention relates to copper clad steel and a production method thereof. The copper clad steel comprises the following components by weight percent: less than or equal to 0.01% of C, less or equal to 0.009%of Si, 0.05-0.12% of Mn, 0.008-0.015% of Als, less than or equal to 0.015% of P, less than or equal to 0.010% of S and the balance of iron and inevitable impurities. The production method comprises the following steps: smelting, performing continuous casting to obtain a billet; heating the continuous casting billet; performing rough rolling on a high-speed line; performing finish rollingon another high-speed line; silking; performing delay chilling on a Stelmor line; and performing air cooling to the room temperature for standby. The production method solves the problems of the existing SWRM6 wire rod that the work hardening of the wire rod is easy to cause, the electrical conductivity is low and the requirements of the high-end copper clad steel can not be met. The invention provides the copper clad steel product which has good cold workability and high electrical conductivity and completely meets the user requirement.

Owner:武汉钢铁有限公司

Beta type titanium alloy and manufacturing method thereof

InactiveUS20060062685A1Easily and stably realizingImproved cold working propertiesDecorative surface effectsMetallurgyOxygen

The present invention provides a β type titanium alloy characterized by consisting of, by mass %, V: 15 to 25%, Al: 2.5 to 5%, Sn: 0.5 to 4%, O (Oxygen): not more than 0.20%, H: not more than 0.03%, Fe: not more than 0.40%, C: not more than 0.05% and N: not more than 0.02%, and the balance Ti and impurities. The present invention also provides a method of manufacturing a β type titanium alloy characterized by comprising the following steps (a) to (c): (a) Preparing a β type titanium alloy consisting of, by mass %, V: 15 to 25%, Al: 2.5 to 5%, Sn: 0.5 to 4%, O (Oxygen): not more than 0.20%, H: not more than 0.03%, Fe: not more than 0.40%, C: not more than 0.05% and N: not more than 0.02%, and the balance Ti and impurities. (b) Pickling the B type titanium alloy in an aqueous solution including 3 to 40 mass % of HF, and (c) Further pickling the B type titanium alloy in an aqueous solution including 3 to 6 mass % of HF and 5 to 20 mass % of HNO3.

Owner:SUMITOMO METAL IND LTD

Austenitic stainless steel and manufacturing method thereof

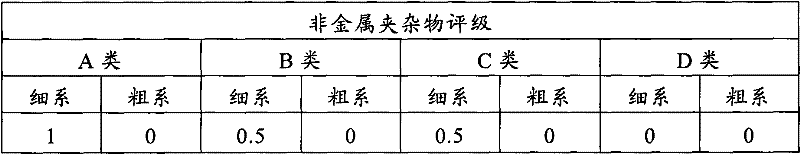

The invention relates to low-nickel austenitic stainless steel with high polishing performance, which comprises the following chemical ingredients in percentage by weight: 0.05 to 0.12 percent of C, more than 0.3 percent and less than 1 percent of Si, 9.2 to 11.0 percent of Mn, 14.0 to 16.0 percent of Cr, less than or equal to 0.4 percent of Ni, 0.12 to 0.25 percent of N, less than 0.08 percent of P, less than 0.01 percent of S, 1.5 to 3.5 percent of Cu, more than or equal to 10*10<-4> and less than or equal to 30*10<-4> percent of B, more than or equal to 30*10<-4> and less than or equal to 60*10<-4> percent of Ca and the balance of Fe and inevitable impurities. A single austenite structure is obtained at room temperature by reasonable ingredient design on the premise of reducing the consumption of noble metal Ni substantially, so that the stainless steel has the high mechanical performance and a certain corrosion resistance. In addition, the purity of molten steel is improved by a scientific manufacturing method, and the defects of peeling, sand holes and the like of the stainless steel in the polishing process are overcome effectively by utilizing the technology of inclusion modification; and the grain size level of cold rolling products is controlled to avoid polishing stripes, so that the polishing performance is high. The low-nickel austenitic stainless steel can better meet the using requirement of the stainless steel with high polishing performance in fields of decoration, products and the like, and the cost is reduced greatly.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

High-strength and high-toughness nickel-base high-temperature alloy foil and preparation method thereof

ActiveCN111850348AHigh strengthImprove high temperature mechanical propertiesChemical elementOxidation resistant

The invention discloses high-strength and high-toughness nickel-based high-temperature alloy foil and a preparation method thereof, and belongs to the technical field of nickel-based high-temperaturealloy materials. The foil comprises the following chemical elements of, by mass, 0.01-0.05% of C, 16-18% of Cr, 4-6% of Al, 3-7% of Fe, 0.001-0.02% of Y, 0.01-0.8% of Ti, 0.05-2% of Mn, 0.001-0.03% ofCe, 0.001-0.8% of Si, 0.001-0.01% of B, less than or equal to 0.20% of W, less than or equal to 0.10% of Co, less than or equal to 0.10% of Mo, less than or equal to 0.03% of Zr, and the balance Ni and inevitable impurities. The nickel-based high-temperature alloy foil for a honeycomb sealing structure can service at 980 DEG C or below with low density, low linear expansion coefficient, high temperature wear resistance, high temperature corrosion resistance, oxidation resistance, high strength, high toughness, easiness in processing and molding and easiness in welding, and the problems of long process flow, low yield and poor surface quality and plate shape of the finished product foil of an existing nickel-based high-temperature alloy foil are solved.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

Excellent Cold-Workability Exhibiting High-Strength Steel Wire or Steel Bar or High-Strength Shaped Article, and Process for Producing Them

InactiveUS20080041503A1Improved cold working propertiesFurnace typesHeat treatment furnacesHigh intensityIngot

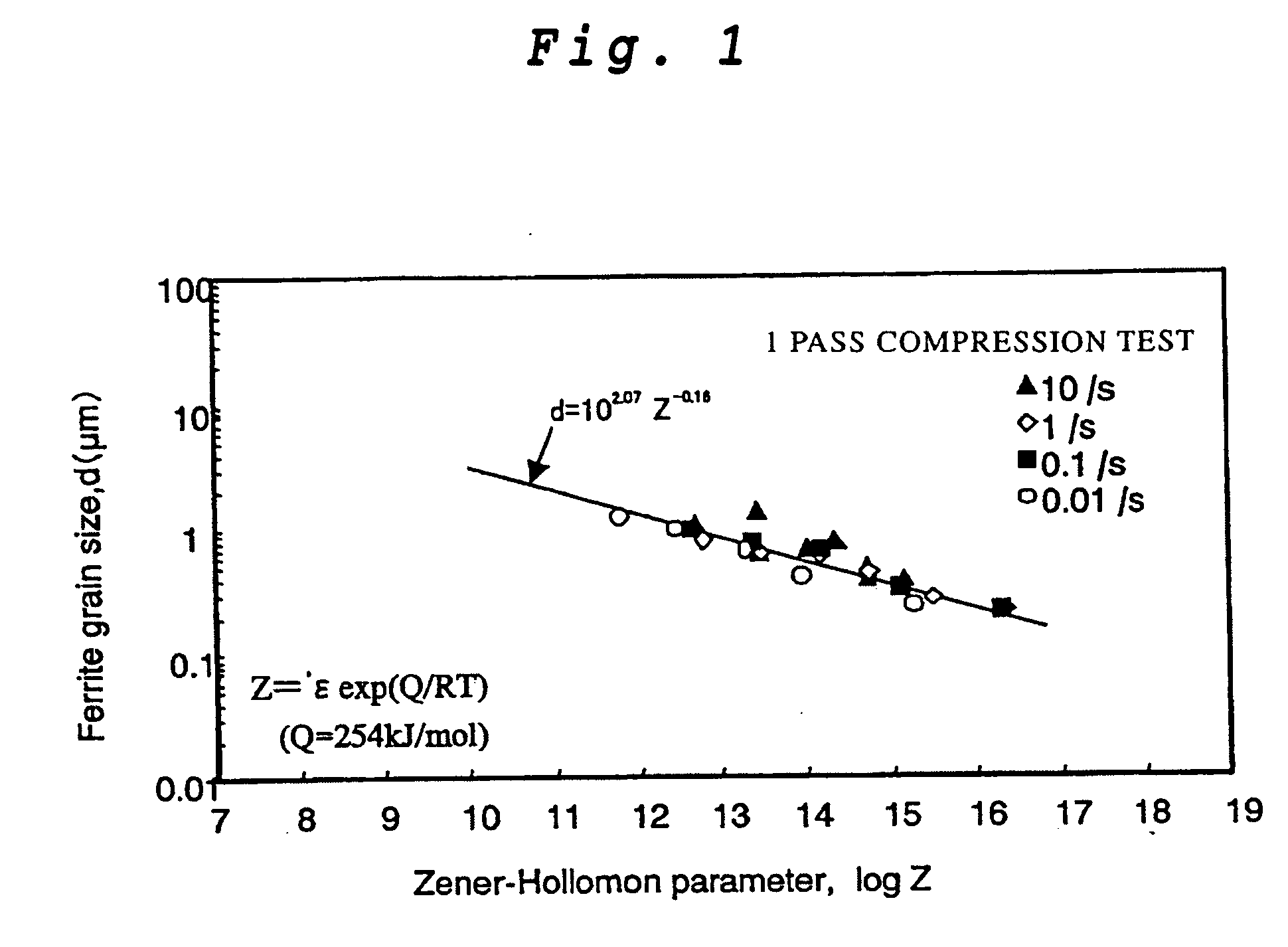

There are provided an excellent cold-workability exhibiting high-strength steel wire or steel bar, or high-strength shaped article and a process for producing them. In particular, there is provided a process comprising carrying out hot working at 350 to 800° C. of a steel ingot, cast slab, steel slab or steel semifinished product having a C content of not greater than the solid solution limit of carbon of ferrite phase at Ael point and not greater than 0.010 mass % and being free of any cementite, or having a C content of >0.01 to 0.45 mass % to thereby obtain a material whose average crystal grain diameter in a cross section perpendicular to the longitudinal direction is ≦3 μm, and thereafter carrying out cold working of the material to thereby attain formation of a ferrite structure whose average crystal grain diameter in a cross section perpendicular to the longitudinal direction is ≦500 nm.

Owner:NAT INST FOR MATERIALS SCI

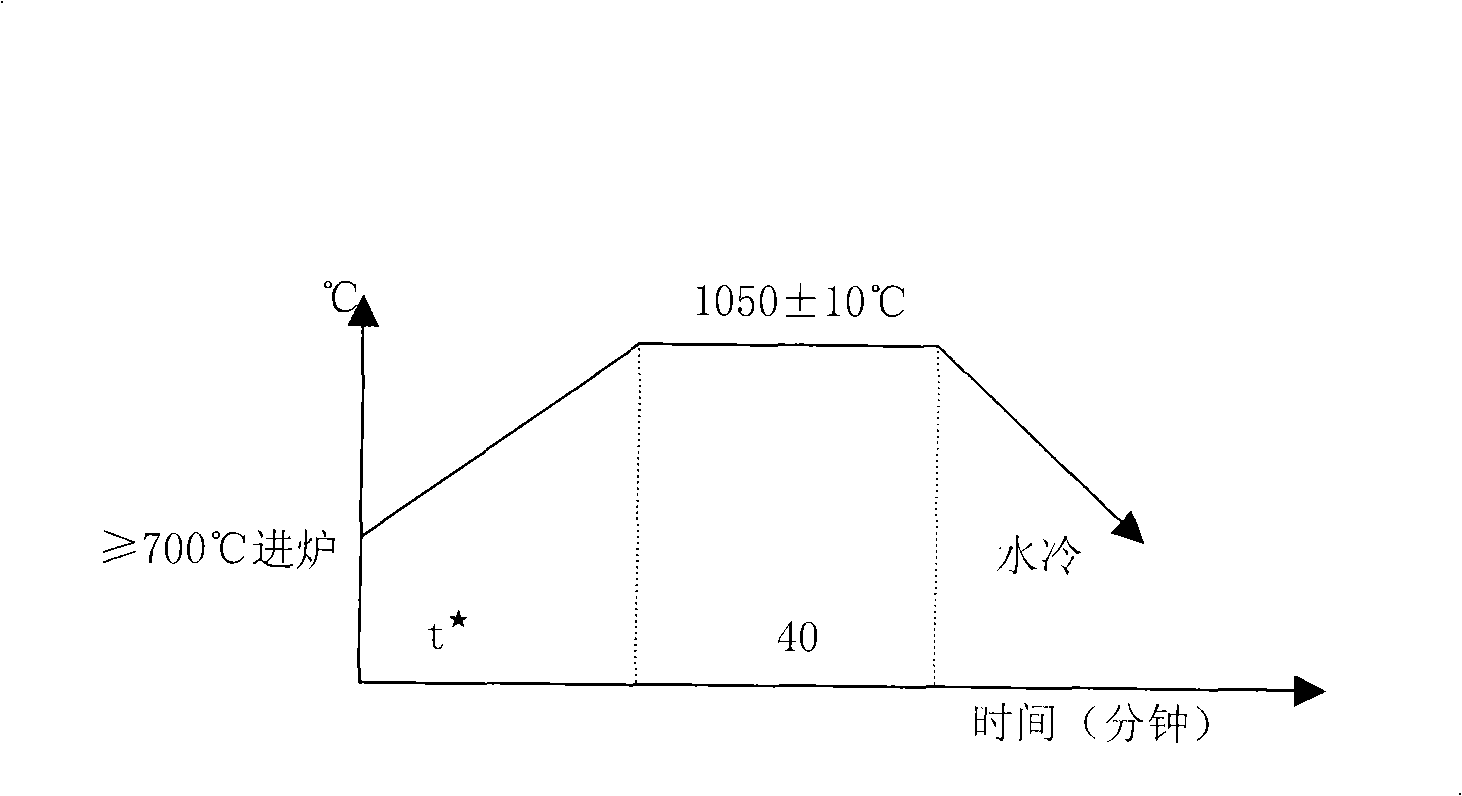

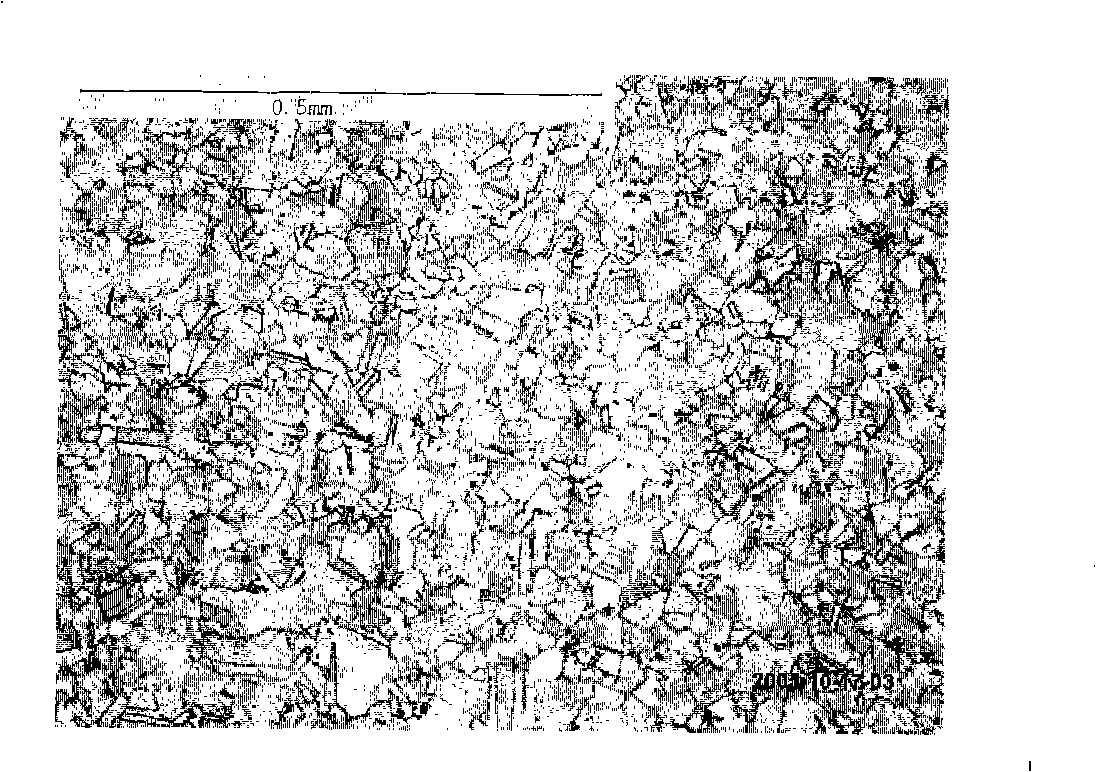

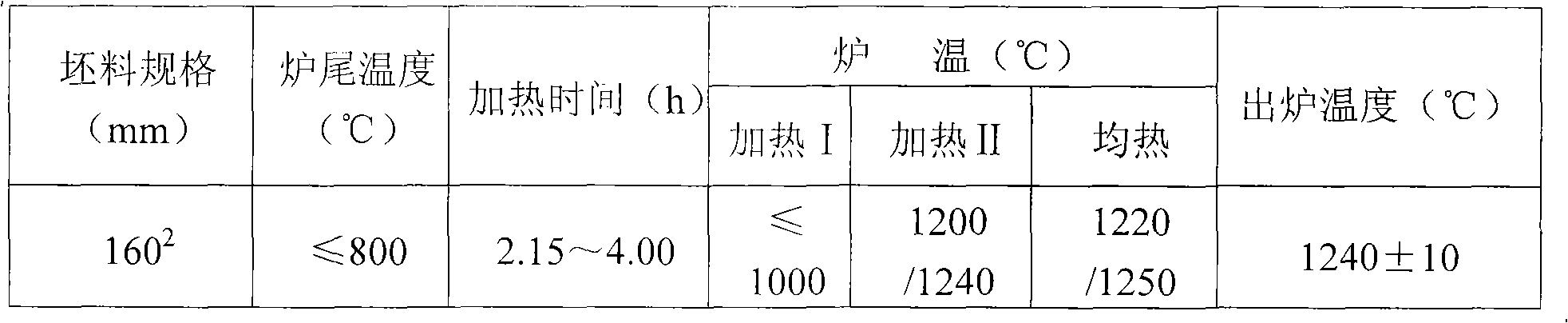

Stainless steel wire rod for standard parts and method for manufacturing same

The invention discloses a stainless steel wire rod used on a standard part as well as a manufacturing method, the stainless steel wire rod comprises the compositions, in weight percent: C: 0.03 to 0.08, Si<=0.55, Mn: 13.50 to 15.50, P<0.045, S <0.020, Cr: 12.50 to 14.00, Ni: 0.80 to 1.45, Cu: 1.75 to 3.50, balance Fe and unavoidable impurities. The manufacturing method includes the following steps of: 1. adopting an electric furnace plus an AOD secondary refining process for smelting, and continuous casting to form billet, 2. rolling, with a soaking temperature of between 1220DEG C and 1250DEG C, an initial rolling temperature >=1180DEG C, and a finishing temperature of between 950DEG C and 1050DEG C; 3. solid solution heat treatment, with a solid solution temperature of 1050DEG C+-10DEG C, the heat preservation time of 40 minutes, and the heating time of 30 to 60 minutes, and water cooling after exiting the furnace; and 4. acid washing. The wire rod and the manufacturing method reduce the nickel and chromium content and effectively save the nickel resource, and have greatly reduced costs of steel per ton compared with 304HC, and have excellent cold working performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com