Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

484results about How to "Shorten smelting time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preventing electric precipitation detonation discharge of top and bottom blown converter

ActiveCN101619375APrevent explosion ventingShorten smelting timeManufacturing convertersElectricityDetonation

The invention relates to a method for preventing the electric precipitation detonation discharge of a top and bottom blown converter, which aims at protecting an electric precipitation device and saving the melting time and is suitable for a top and bottom blown converter with electric precipitation function. The method for preventing electric precipitation detonation discharge of a top and bottom blown converter comprises the following steps: pumping flue gas generated by charging the converter; normally blowing; controlling the Si content which is not less than 0.15 percent by weight in molten iron when an oxygen lance is firstly lifted to deslag; manually regulating the oxygen flow rate to 50 percent of a normal flow rate so as to blow and smelt when the oxygen lance is secondly deslagged; adding lime about 500kg after the ignition is successful; observing the content variation of CO and O2 in a flue gas analyzer which is arranged on the heat end of a flue on a blowing picture so as to increase the oxygen flow rate step by step; increasing the oxygen flow rate to 450Nm3 / min after the oxygen content is reduced to below 5 percent in volume percentage; maintaining the oxygen flow rate for 10-15 seconds; and finally increasing the oxygen flow rate to 650Nm3 / min so as to normally blow and smelt.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

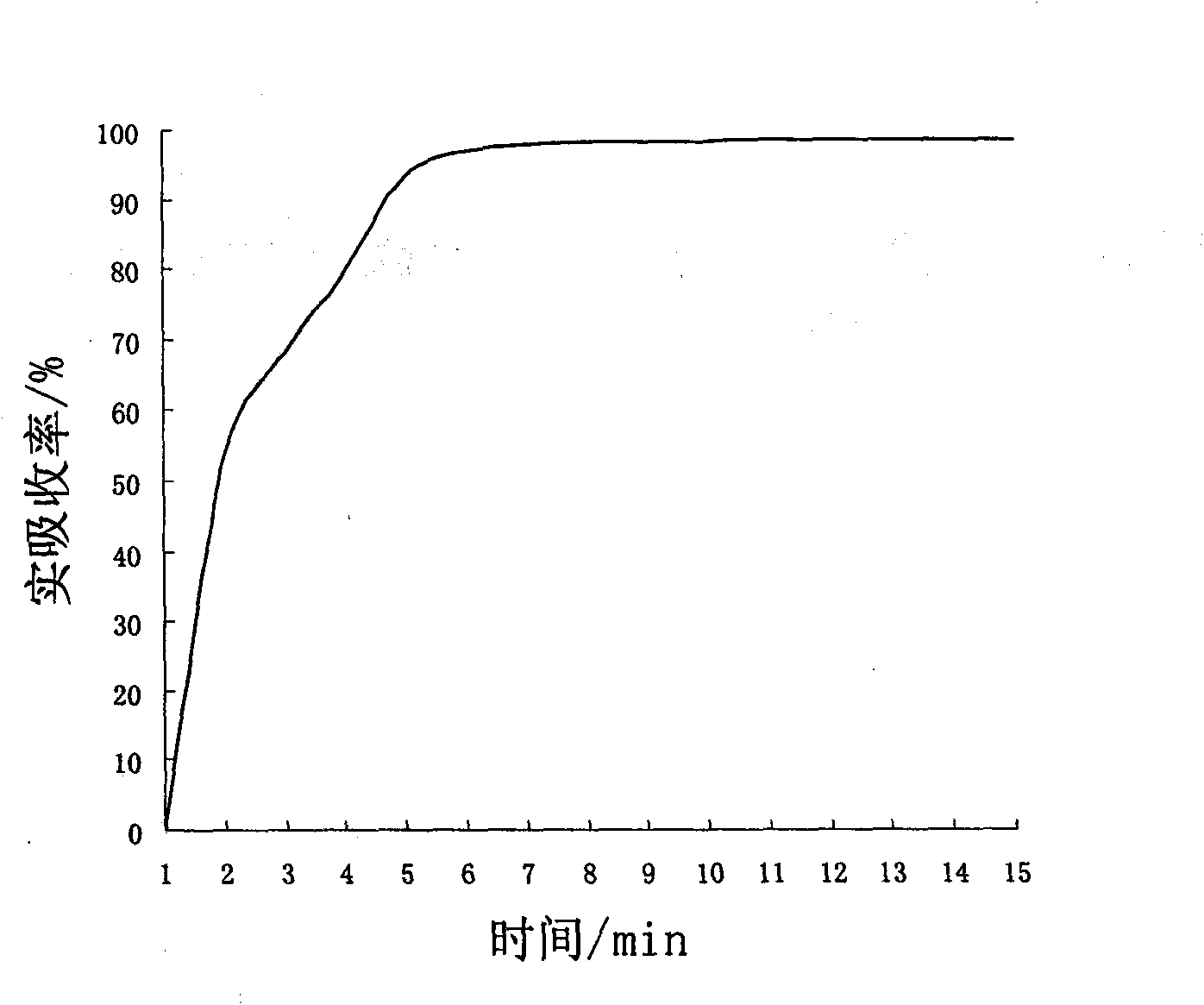

Additive for smelting aluminium alloy and preparation method and application method thereof

The invention relates to an additive for smelting aluminium alloy and a preparation method and an application method thereof, relating to the technical field of nonferrous alloy manufacturing with a special additive. The additive is composed of metal powder, cosolvent, heat-generating agent, detonating agent and moisture proof agent. The preparation method comprises the following steps: raw materials comprising the following by mass percentage, 70-81.5% of metal powder, 15-20% of cosolvent, 2-5% of heat-generating agent, 1-3% of detonating agent and 0.5-2% of moisture proof agent, are fully mixed evenly into compound powder with a ball mill, and the mixture is put into a mould, and is performed with cold pressing by a hydraulic pressure machine so as to obtain the additive for smelting aluminium alloy. The application method of the invention comprises the following steps: a graphite crucible filled with a pure aluminium pig is arranged in a resistance furnace to be heated until the aluminium pig is melted into aluminium liquid, and then the additive is added to react with the aluminium liquid so as to obtain aluminium alloy. Under the condition that the quality of aluminium alloy is not lowered, the additive solves the problems of high dissolving temperature, low absorptivity and unstable absorptivity of the additive.

Owner:HEBEI UNIV OF TECH

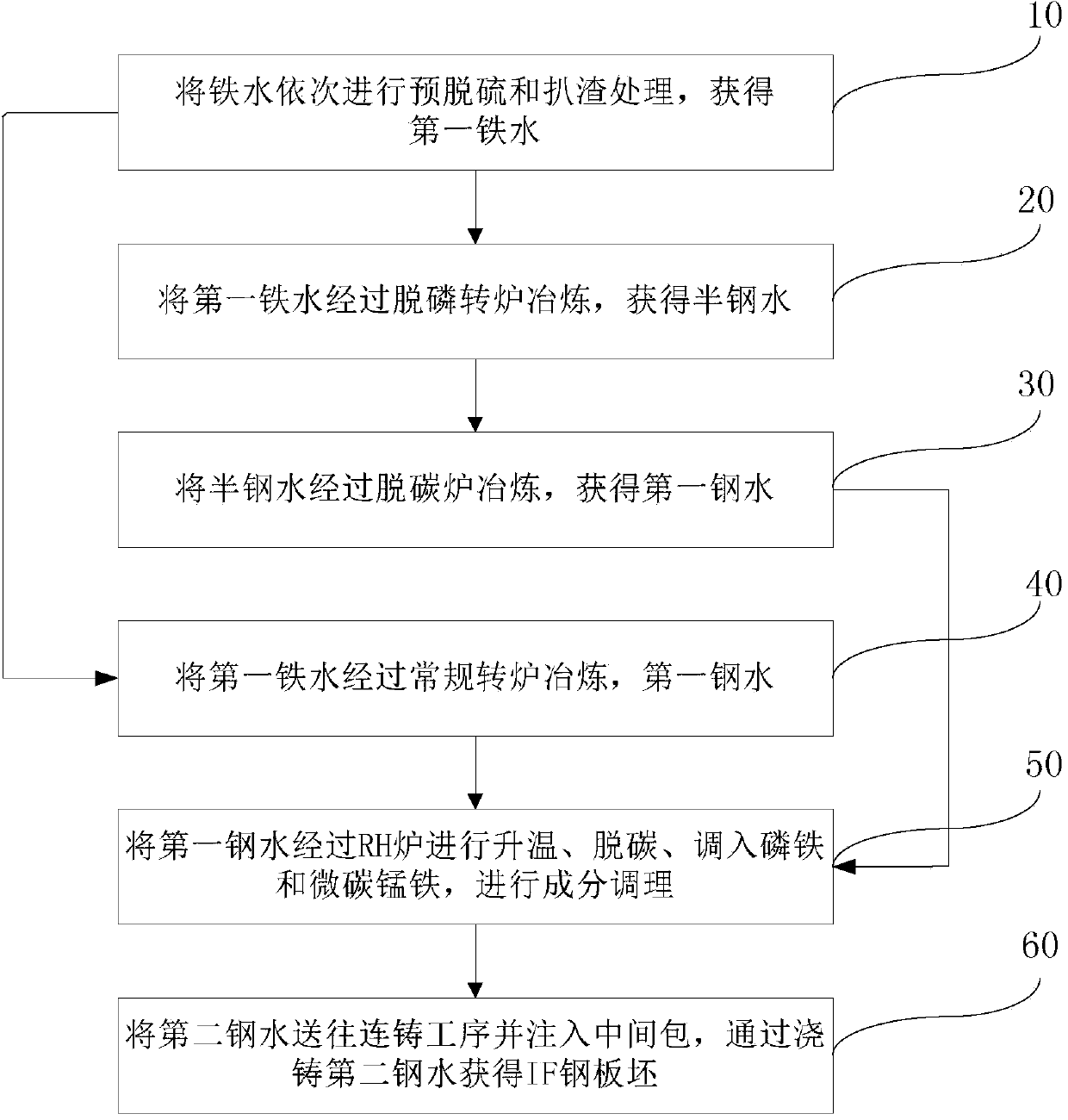

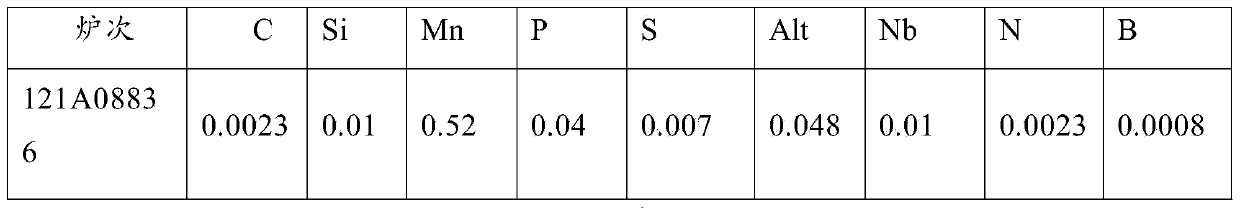

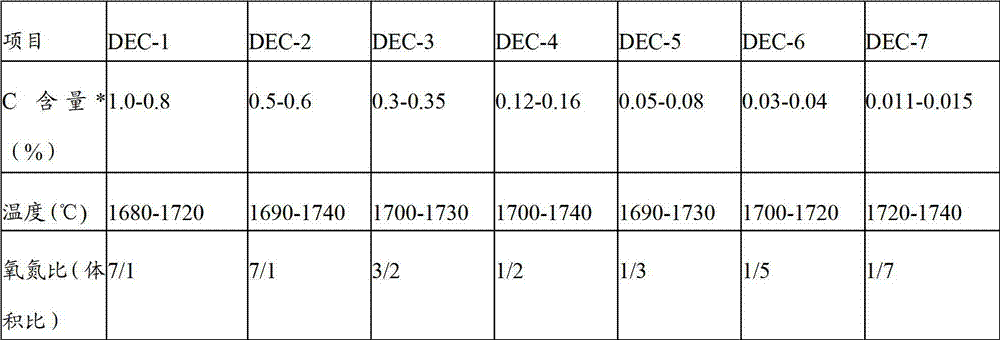

Preparation method of IF (Interstitial Free) steel containing phosphorus, silicon and manganese

The invention relates to the technical field of metallurgy, and in particular relates to a preparation method of IF (Interstitial Free) steel containing phosphorus, silicon and manganese. The preparation method comprises the following steps: sequentially performing predesulfurization and slagging-off treatment on molten iron to obtain first molten iron; performing dephosphorization converter smelting on the first molten iron to obtain semi molten steel; performing decarbonization furnace smelting on the semi molten steel to obtain first molten steel, or, performing conventional converter smelting on the first molten iron to obtain the first molten steel; performing temperature adjustment and decarbonization on the first molten steel by virtue of an RH (Ruhrstahl-Heraus) furnace, and introducing ferrophosphorus and micro carbon ferromanganese; then supplementing ferrophosphorus and micro carbon ferromanganese into the first molten steel, adding a ferro-silicon alloy at the same time, and adjusting components of the first molten steel to obtain second molten steel with qualified carbon content and silicon-manganese-phosphorus content; transferring the second molten steel to a continuous casting process and pouring into a middle ladle, and casting the second molten steel to obtain an IF steel plate slab. The preparation method of the IF steel containing phosphorus, silicon and manganese, disclosed by the invention, can be used for reducing the time and load for adjusting the components, shortening the smelting time in the RH furnace and increasing the production efficiency and the plate slab quality.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

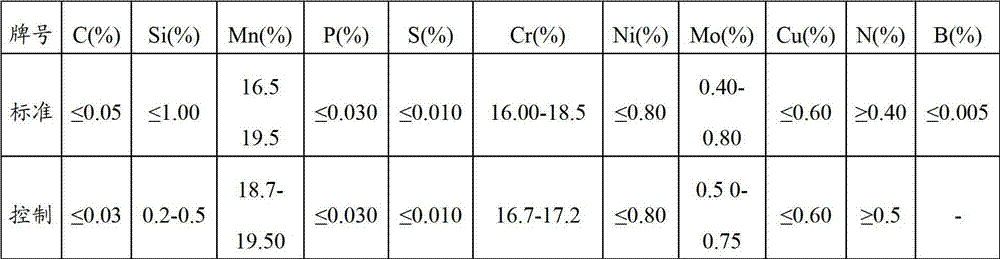

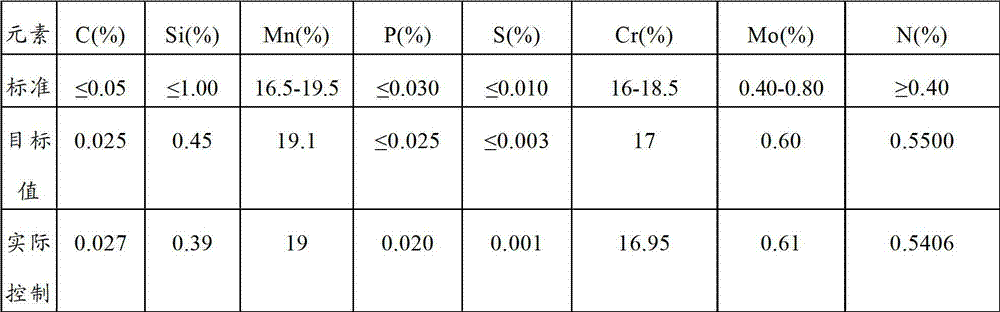

High-nitrogen high-manganese stainless steel and smelting method thereof

The invention discloses a smelting method of stainless steel. The smelting method comprises the following steps: (1) an electric furnace smelting process: adding chromium-containing waste steel and manganese-containing waste steel into an electric furnace for smelting, and tapping after waste steel is molten completely in the electric furnace, wherein the content of manganese is controlled to be 3-6%, and the content of chromium is controlled to be 24-28%; (2) a nitrogen-oxygen decarbonization refining process: transferring molten steel into a refining station of a nitrogen-oxygen refining furnace for refining under the condition that nitrogen is introduced at the flow rate of 2000-2200Nm<3> / h in the whole refining course, decarbonizing at first, adding metal Mn after decarbonizing is completed, raising the temperature, then, reducing, slagging after reducing, adding manganese alloy after slagging under the condition that the flow rate of nitrogen is 900-1100Nm<3> / h at the moment, stirring, and then tapping molten steel into a die casting ladle; (3) a ladle refining process, wherein nitrogen-manganese alloy is added stepwise in a refining process, and then argon blowing treatment is carried out; and (4) a die casting process. The invention further provides stainless steel obtained by using the smelting method. The smelting method disclosed by the invention has the advantages of shortening smelting time, improving nitrogen adding efficiency, reducing nitrogen adding cost and improving the purity degree of the molten steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

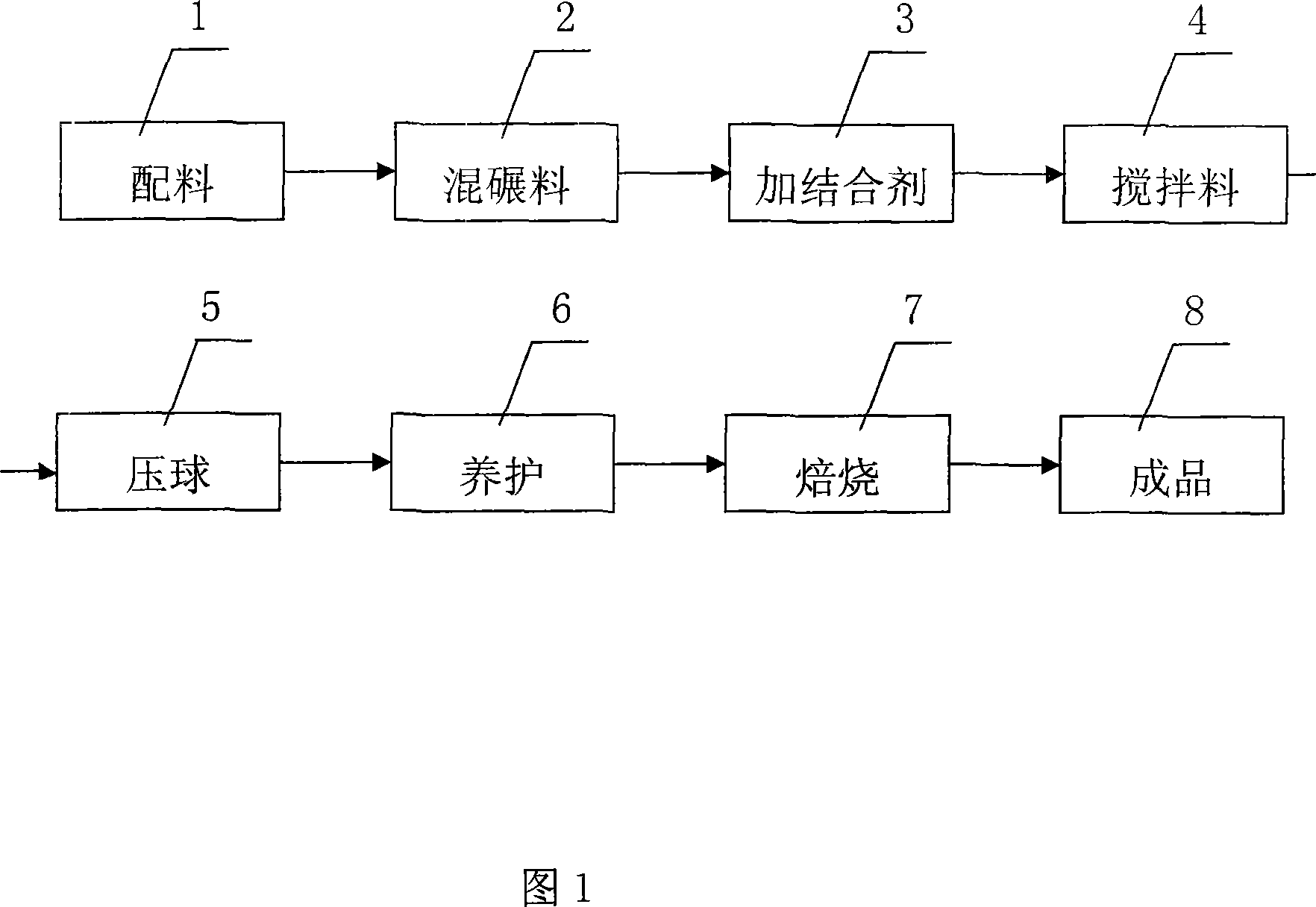

No-fluorine composite slag melting agent for converter steelmaking and its production process

The present invention is one kind of no-fluorine composite slag melting agent for converter steelmaking and its production process. The no-fluorine composite slag melting agent as one kind of steelmaking supplementary material consists of FeO 40-50 wt%, CaO 10-20 wt%, MnO 12-45 wt%, H2O 0.5-1 wt%, MgO 1-8 wt%, Al2O3 and SiO2 1-10 wt%, and impurity for the rest. Its production process includes the steps of compounding, grinding, adding adhesive, stirring, pelletizing, curing and roasting. It is used in no-fluorine steelmaking with less invasion to converter lining, long converter service life, less environmental pollution, low production cost and other advantages.

Owner:郎雪 +1

A production system and production method of foamed aluminum

Owner:丹阳翊德炉业有限公司

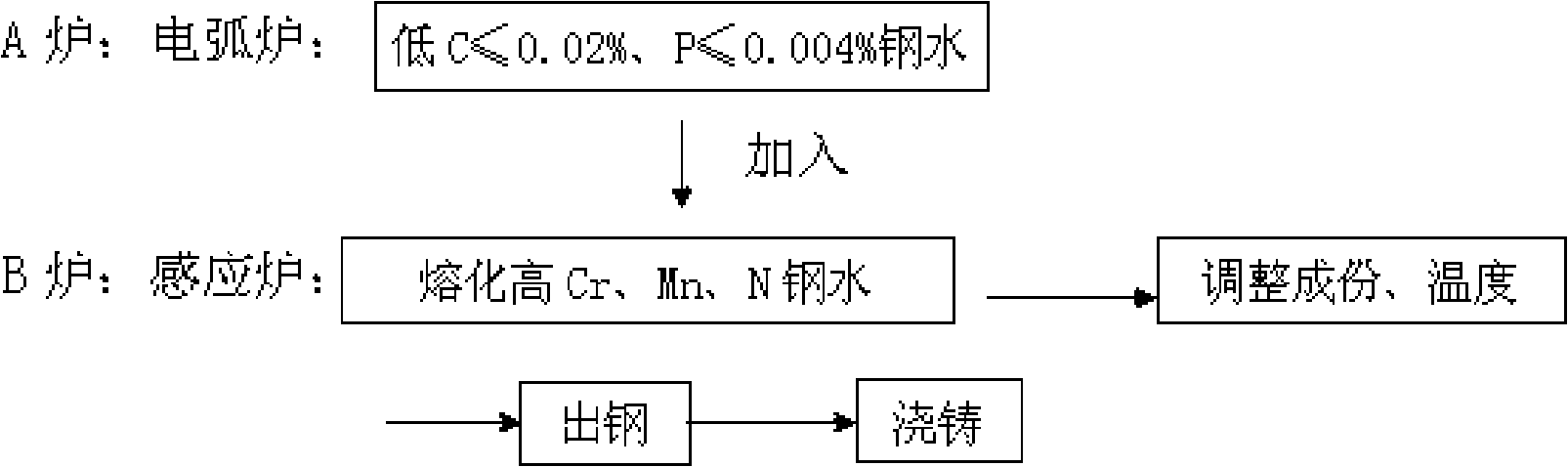

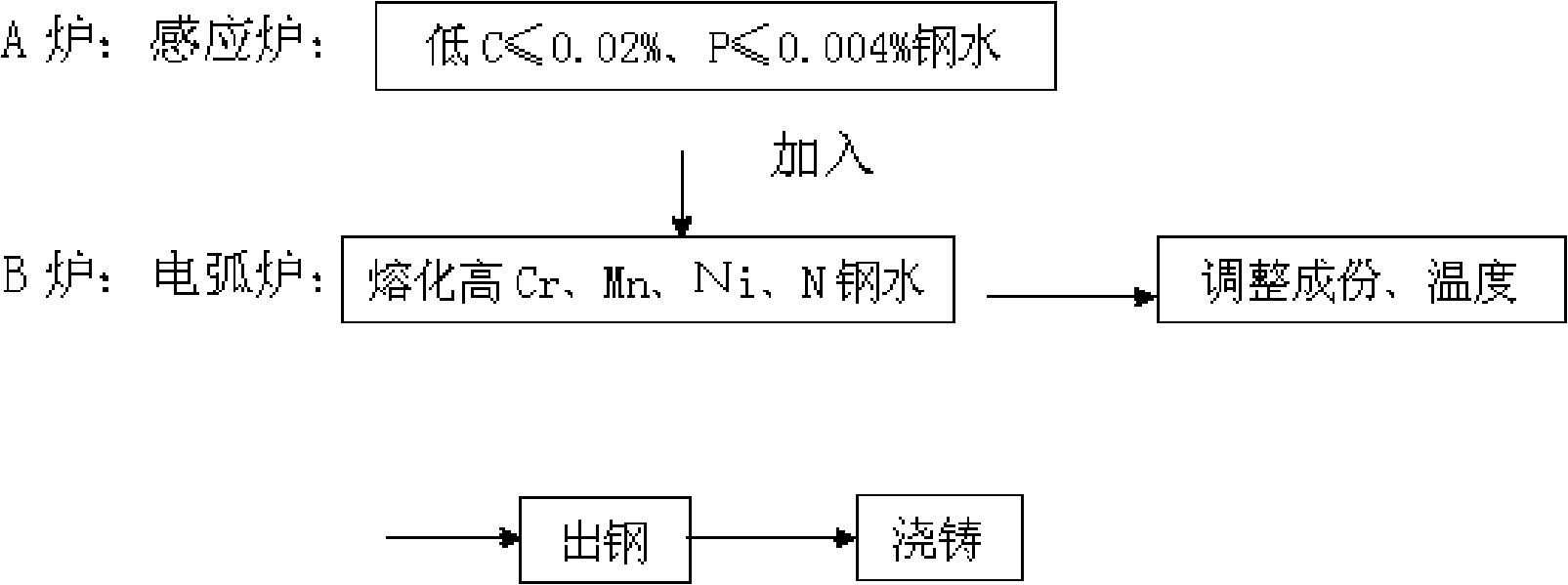

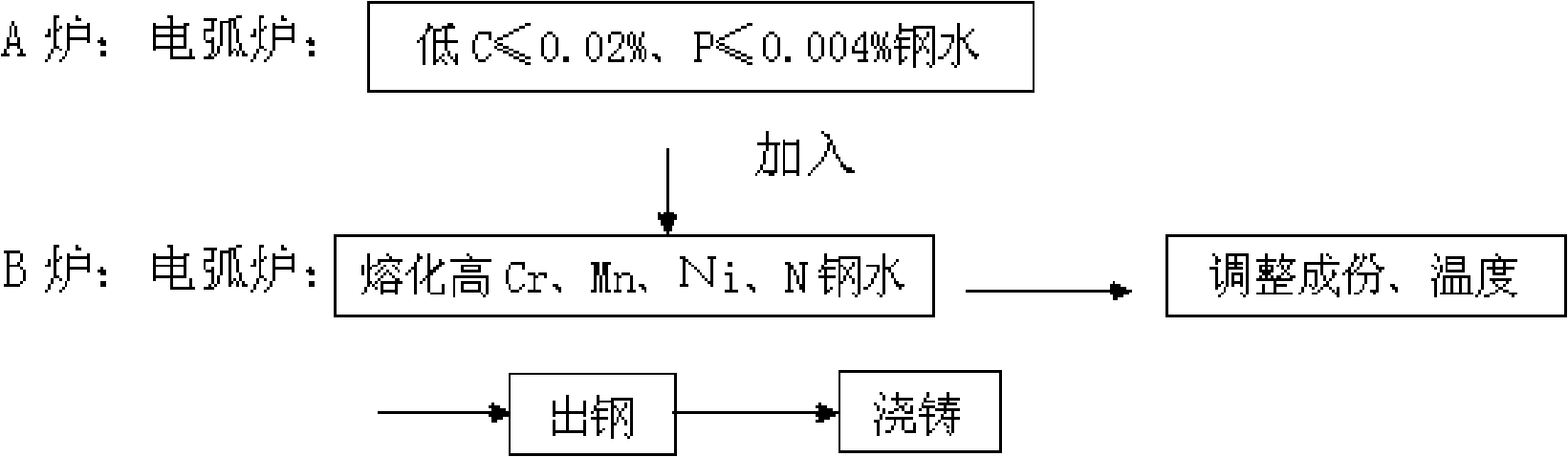

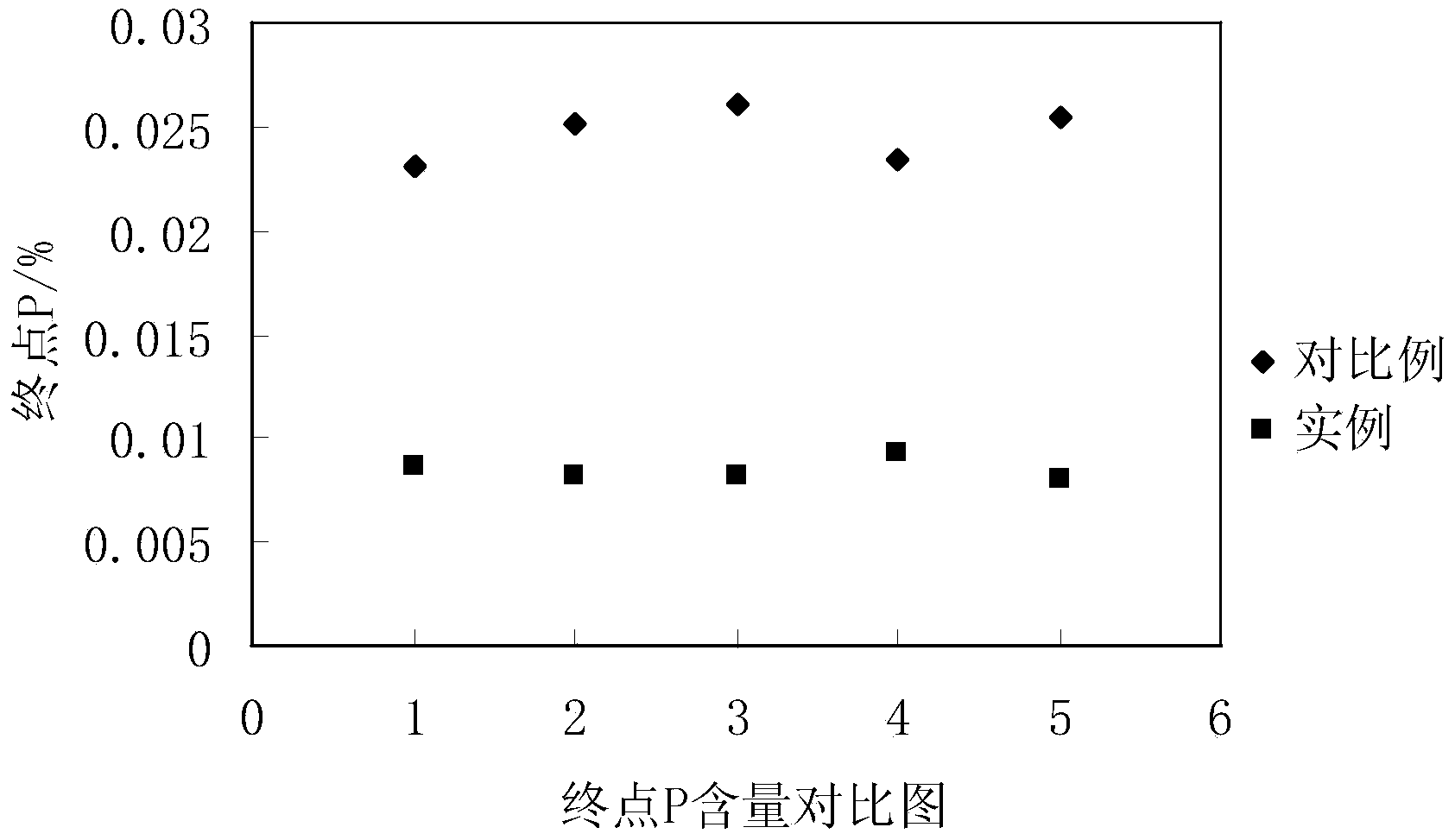

Method for smelting high-nitrogen steel

The invention discloses a method for smelting high nitrogen steel, which comprises a smelting method of a high nitrogen steel which can effectively improve and guarantee the content of N in alloy, the technical proposal which is adopted comprises the following steps: firstly, smelting molten steel with an electric arc furnace or an induction furnace, secondly, simultaneously adopting another electric arc furnace or an induction furnace to smelt nitrogen containing alloy, adapting the sum of molten steel components in the step one and the step two with steel grade, thirdly, adding molten steel which is smelted in nitrogen containing alloy solution, and refining under the protection of nitrogen, and getting high nitrogen steel. The technical proposal of the invention which is adopted by the invention to smelt high nitrogen steel without needing complex pressurization and remelting equipment, the total smelting time is greatly shortened, which is only one half of the time for smelting high nitrogen steel in the prior art, the operation is simple, and chemical components in steel are stable, fluctuation of steel components among furnaces is small, which is beneficial for processing follow-up process. And meanwhile, the number of deoxidation reducing agent is greatly reduced, and smelting cost is lowered.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Efficient dephosphorization method of combined blown converter

ActiveCN104250672AProlong the reaction time at low temperatureGood dephosphorization effectManufacturing convertersProcess efficiency improvementSpray nozzleMaterials science

The invention relates to an efficient dephosphorization method of a combined blown converter. The method comprises the steps of: subjecting molten iron to desulphurization, and adding determined scrap steel cold material to the desulfurized molten iron; adjusting the position of an oxygen lance and open blowing parameters; adding a first batch of material, thoroughly melting, lowering the position of the oxygen lance by lowering the position of the spray nozzle of oxygen lance by 40-50 mm every 20-30 s, and adding 2.14-4.44 kg / t of active lime every time before lowering the position of the spray nozzle of the oxygen lance; lowering the position of the oxygen lance to 1500-1600 mm, fixing, adding all the residual active lime and controlling the open blowing oxygen pressure of the spray nozzle of the oxygen lance at 0.83-0.85 Mpa; converting 6-8 min, adding the remaining sinter and grain steel in molten iron by batches under addition amount of the sinter and grain steel of 3.0-6.22 kg / t respectively each batch and feeding interval of 35-60 s, adding all the sinter and grain steel; continuing converting for 3-5min, using a sublance TSC probe to measure temperature of the hot metal and sampling, after measurement of carbon temperature by the sublance TSC probe, adjusting the oxygen pressure of the oxygen lance to 0.83-0.85 Mpa, continuing lowering the position of the oxygen lance to 1200mm until the end of the blowing, and hoisting the oxygen lance; and tapping.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

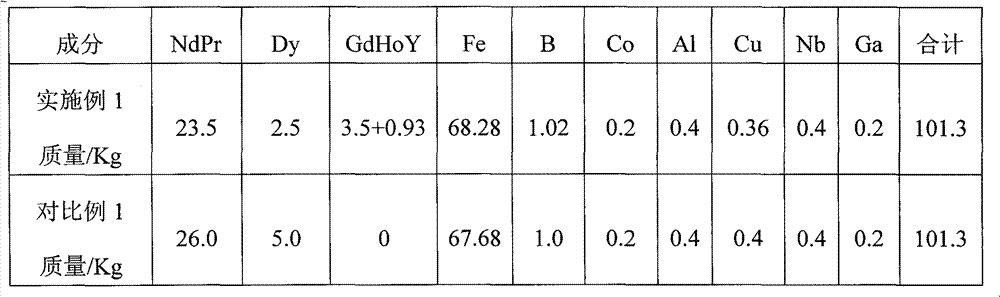

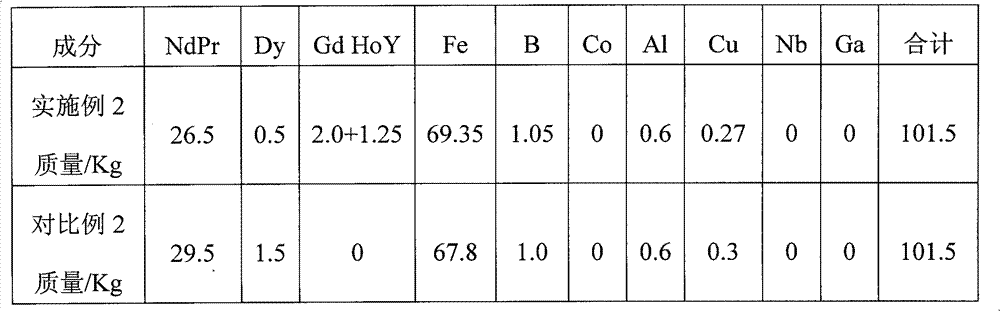

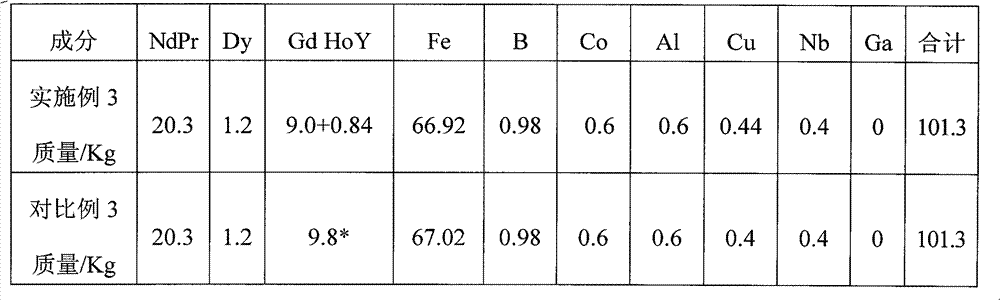

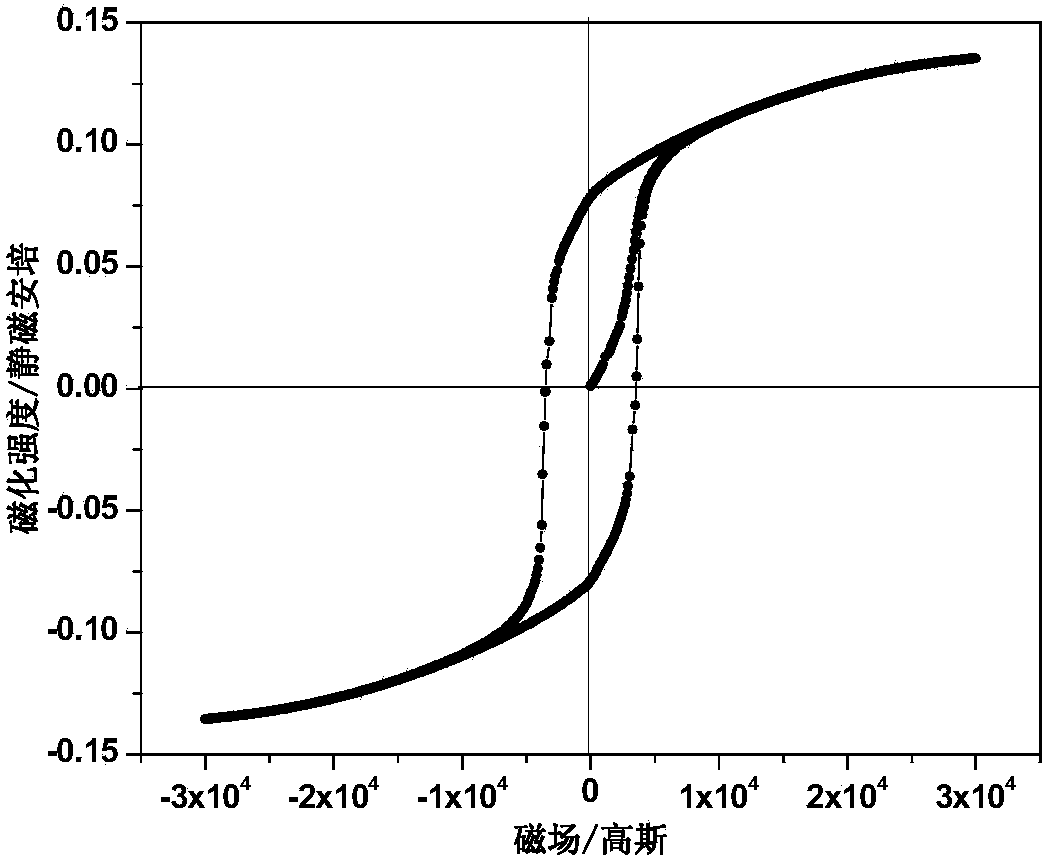

Method for preparing composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium

ActiveCN102956336AImprove remanenceIncrease the maximum energy productInorganic material magnetismRare-earth elementCurie temperature

The invention provides a method for preparing a composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium. The method includes the steps of primary batching, fusion casting, milling, secondary batching, powder mixing, forming, sintering and heat treatment, wherein in the primary batching step, iron alloy added with three rare earth elements of the gadolinium, the holmium and the yttrium is composited, and in the secondary batching step, oxide added with the three rare earth elements of ultrafine gadolinium, holmium and yttrium and cuprous oxide powder are composited. By the method, the relative surplus and cheap gadolinium, holmium and yttrium can be used for partially substituting for rare earth elements of neodymium, praseodymium or dysprosium, and accordingly neodymium, praseodymium or dysprosium consumption can be decreased by 10-30wt.%. Besides, Curie temperature and coercivity force of the prepared neodymium-iron-boron permanent magnet material are increased, corrosion resistance is enhanced, operating temperature and toughness are increased, and processability is improved.

Owner:GANZHOU JIATON ADVANCED MATERIALS

Preparation method of copper and magnesium alloy contact wire for railway electrification

ActiveCN103276237AIncrease production capacityReduce the temperatureSingle bars/rods/wires/strips conductorsMetal/alloy conductorsMisch metalNiobium

A copper and magnesium alloy contact wire for railway electrification comprises a copper base and alloy metal, wherein the alloy metal comprises components in percentage by weight as follows: 0.5-0.6% of magnesium, 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.005-0.008% of titanium and 0.02-0.04% of misch metal. A preparation technology adopts an upward continuous casting extrusion-cold rolling-stretching technology. The oxygen content of the prepared contact wire reaches an oxygen-free copper level, the grain is fine, the mechanical property is remarkably improved, the contact wire is uniform in a length direction, the flatness is good, the locomotive picking-up performance is good, the tensile strength, the elongation percentage, the grain size and the toughness are greatly improved when the copper and magnesium alloy contact wire is compared with a conventional wire, and the copper and magnesium alloy contact wire has wide popularization and application values in the high-speed railway electrification field.

Owner:山东维点技术有限公司

Rapid desulfurization refining method for ladle furnace

The invention discloses a rapid desulfurization refining method for a ladle furnace (LF). The method comprises the following steps of: 1) performing desulfurization refining in the LF, wherein the LF treatment starting temperature is between 1,570 and 1,605 DEG C; 2) after a ladle argon blowing device of the LF is turned on, blowing argon from the bottom of the ladle; 3) after finishing adjusting the temperature, inserting a desulfurization powder spraying gun into a molten steel liquid for spraying a desulfurizing agent; 4) after finishing spraying powder, switching the spraying gun to a functional stage of blowing the argon, blowing the argon from the top, simultaneously blowing the argon from the bottom of the ladle, and performing strong stirring desulfurization operation; 5) alloying, namely after desulfurization is finished, lifting the desulfurization powder spraying gun, adjusting a ladle bottom blowing flow, and performing alloy configuration to meet a target requirement on final components of a steel grade; and 6) after finishing adjusting components, performing soft stirring operation, measuring the temperature, sampling, and turning off the ladle argon blowing device to finish treating. The method realizes rapid desulfurization of the LF, and can shorten an overall melting cycle and improve the number of continuous casting furnaces and production efficiency.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for smelting medium ferrovanadium

The invention belongs to the metallurgy field and in particular relates to a method for smelting medium ferrovanadium. The invention aims to solve the technical problem of an electro-aluminothermic process with high vanadium recovery from smelting and is specifically characterized by adopting the mixed materials of V2O5 and V2O3 as the raw materials and using the electro-aluminothermic process to smelt the medium ferrovanadium. The method comprises the following steps: A. preparing bottom materials and main materials; B firstly adding the bottom materials for smelting at the initial stage of smelting; C. then adding the main materials after the bottom materials react steadily; and D. refining. The bottom materials include aluminium, V2O5, iron and lime. The main materials include V2O3, aluminium, V2O5, iron, lime and fluorite. The method not only fully utilizes the reaction heat, but also simplifies the technological process, reduces the viscosity of the slag and ensures the ferrovanadium recovery from smelting to be steadily increased by over 96%.

Owner:SICHUAN CHUANWEI GRP CO LTD +1

Preparation method of high-strength corrosion-resistant copper pipe for heat exchanger

The invention discloses a preparation method of a high-strength corrosion-resistant copper pipe for a heat exchanger. The high-strength corrosion-resistant copper pipe comprises a copper matrix and alloy metals. The alloy metals comprise, by weight, 0.5-0.6% of magnesium, 0.08-0.09% of silver, 0.2-0.4% of tin. 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.05-0.06% of nickel, 0.005-0.008% of titanium and 0.02-0.04% of mischmetal. The mischmetal comprises yttrium, berkelium and lanthanum according to a mass ratio of 1: (0.15-0.2): (0.4-0.5). The preparation method utilizes upward continuous casting, rolling and drawing processes to replace casting, sawing, heating, extrusion and pickling processes of the traditional preparation method so that processes are greatly simplified, continuous production is realized, a period is short, and efficiency is high. A copper pipe prepared by the preparation method has oxygen content satisfying the oxygen-free copper level standard, has fine grains, and has mechanical strength, high temperature resistance, corrosion resistance and wear resistance obviously superior to the same performances of the existing copper pipe.

Owner:山东兴鲁有色金属集团有限公司

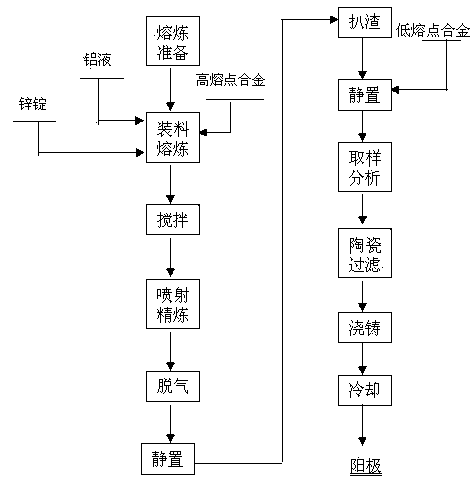

Casting method of aluminum alloy sacrificial anode

The invention belongs to the technical field of corrosion and prevention, and in particular relates to a casting method of an aluminum alloy sacrificial anode. The casting method comprises the following steps: adding basic electrolytic molten aluminum to a resistance furnace; then adding a zinc ingot to obtain molten aluminum alloy; performing jet refining on the molten aluminum alloy by adopting an argon located refining agent; charging argon to refined aluminum alloy melt to degas; drossing oxidizing scum on the surface of the aluminum alloy melt through a drossing tool; adding a low melting point metallic element to drossed aluminum alloy melt; electromagnetically agitating the melt after pressing the low melting point metal; carrying out ceramic filtering; pouring and casting the aluminum alloy melt to a preheated iron anode mould at an even casting speed under the temperature of 700 to 740 DEG C until the mould is full of the aluminum alloy melt; and moving the aluminum alloy melt out of the mould after cooling, solidifying and molding, so as to obtain the aluminum alloy sacrificial anode. The casting method has the characteristics of being short in smelting time, small in loss of iron scale, high in degassing and purifying performances, and low in smelting cost.

Owner:NORTHEASTERN UNIV +1

Method for recycling residual hot steel slag in continuous casted steel ladle

InactiveCN102399917ASimple processNot easy to solidifyManufacturing convertersRecycling and recovery technologiesSlagMolten steel

The invention discloses a method for recycling residual hot steel slag in a continuous casted steel ladle. The method is characterized in that in continuous casting production, after steel ladle molten steel is injected into a tundish, molten residual hot steel slag in a steel ladle is poured into a heavy molten iron pot and then are put into a converter with molten iron for steel making. The method enables heat energy, residual steel and residues of residual hot steel slag in a continuous casted steel ladle to be fully used, and reduces steel-making accessory consumption and a steel-making production cost.

Owner:ANGANG STEEL CO LTD

High-precision valve resistant to abrasion and corrosion and manufacturing method thereof

A high-precision valve resistant to abrasion and corrosion comprises a high-strength valve body resistant to abrasion and corrosion and 3D printed high-precision valve internal parts. The high-strength valve body resistant to abrasion and corrosion is made of raw materials in a cast mode, wherein special element matching is adopted for the raw materials. A 3D printing technology is adopted for manufacturing and assembling all the valve internal parts at the same time; finally, the high-strength valve body resistant to abrasion and corrosion and the 3D printed high-precision valve internal parts are assembled. The high-precision valve has the advantages that valve body is excellent in resistance to abrasion and corrosion; the production efficiency and precision of the valve internal parts are high, and the high-precision valve is convenient to assemble and stable in working.

Owner:ANHUI JINDA INSTR

Smelting method of phosphorus containing steel

ActiveCN1786204AReduce manufacturing costReduce pollutionManufacturing convertersElectric furnaceAlkalinitySlag

The invention discloses a phosphor containing steel smelting method. Converter is adopted fast heating up to eliminate carbon, save phosphor, and make high phosphor slag smelting operation. When the converter is at blowing early stage, oxygen lance positing is between 0.0-1.0meter, diacidic base degree is 1.0-2.5, oxygen supply intensity is 2.8-5.0m3 / t. min, 0.5-45.0kg / ton steel barringerite or phosphate ore is added into the converter; then 1.0-30.0kg / ton is added at the blowing late stage. After scrap steel is melted with iron liquid to form molten steel in electric furnace, slag forming material is add, diacidic base degree is 1.0-2.5, oxygen supply intensity is 1.5-4.5m3 / t.min. 0.5-40.0kg / ton steel barringerite or phosphate ore is added into molten steel at decarbonizing process; and 0.5-30.0kg / ton is added at smelting late stage. This smelting method can make most phosphor enter molted steel to do phosphor alloying.

Owner:LIANYUAN IRON & STEEL GROUP CO LTD

Method for preparing hot rolling strip steel capable of preventing edge crack of extremely thin rolled strip steel

InactiveCN102179407AUniform temperatureReduce temperature differenceTemperature control deviceMetal rolling arrangementsTemperature differenceAlloy

The invention relates to a method for preparing hot rolling strip steel capable of preventing edge crack of extremely thin rolled strip steel. The method comprises the following steps of: (1) smelting, namely desulfurizing molten iron, smelting by using a converter, blowing argon at an argon station, and performing continuous casting to form slabs; (2) performing hot rolling, namely heating the slabs to 1,210 to 1260 DEG C, wherein the temperature difference of the same slab is less than or equal to 30 DEG C; performing rough rolling, and finish rolling, wherein the side pressure delta B when the slab with the width B is subjected to rough rolling is controlled according to the following formula: delta B ranges from 35*B / 1,250*(B-1,050) / (1,250-1,050)+35*B / 1,050*(1,250-B) / (1,250-1,050) to 50; and finally reeling to obtain the hot rolling strip steel. The method is simple and practical, is stable in use and high in uniformity, reduces the alloy cost and shortens the production cycle; and the steel plate heat commercial (SPHC) hot rolling strip steel prepared by the method has the obvious effect of preventing the edge crack of extremely thin cold-rolled sheet.

Owner:NINGBO IRON & STEEL

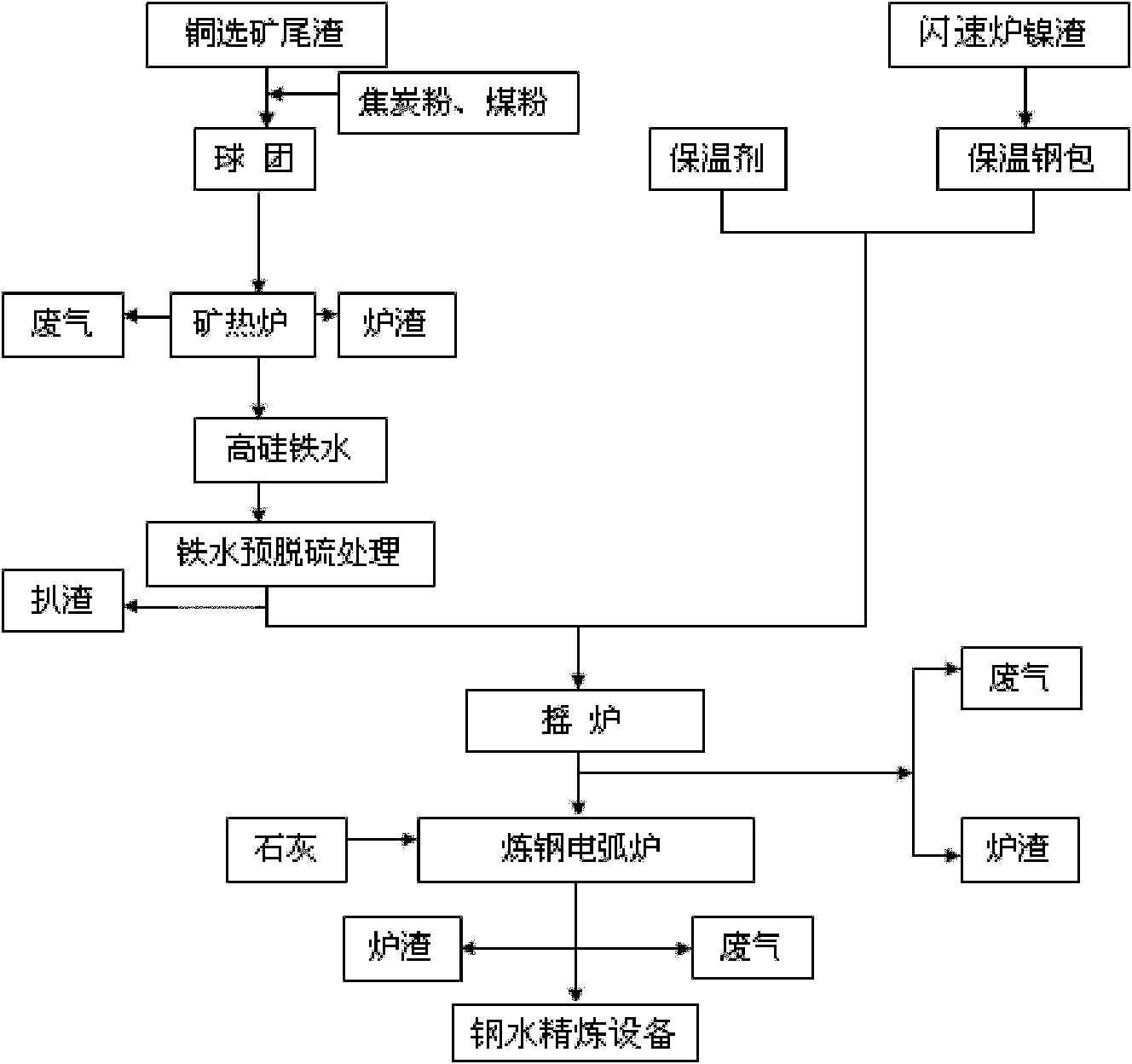

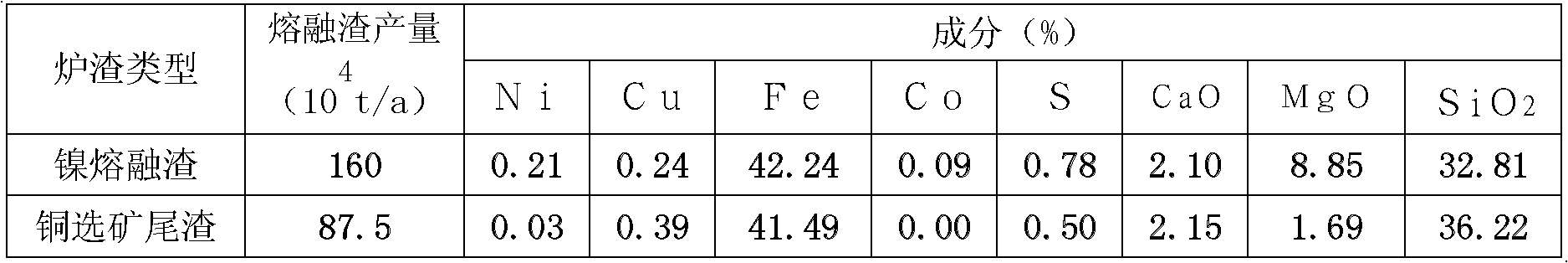

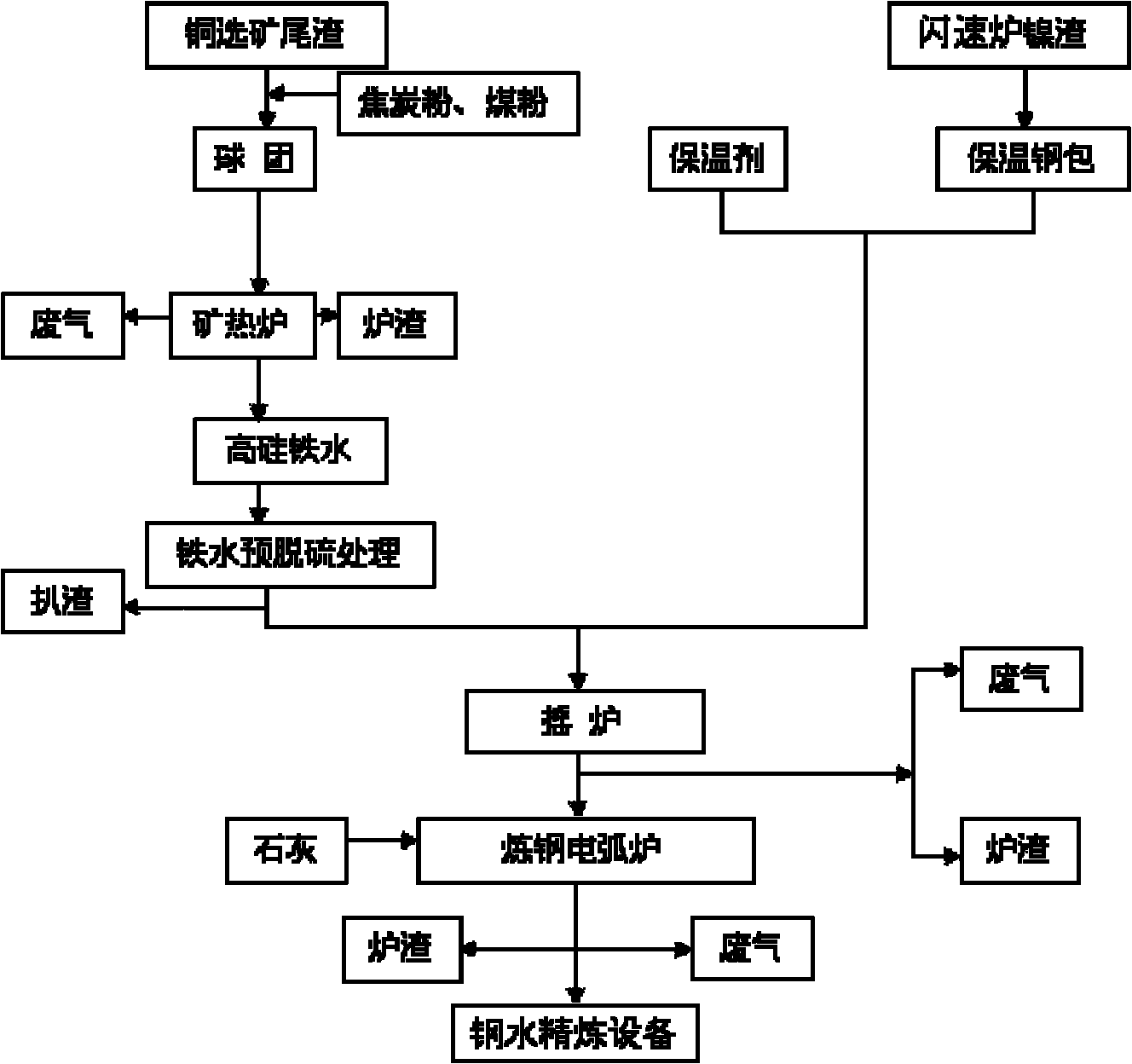

Iron extracting and steelmaking process for comprehensively treating copper ore tailing and nickel molten slag

InactiveCN102051428AGood reduction kinetics conditionsImprove smelting efficiencySteelmakingProcess equipment

The invention discloses an iron extracting and steelmaking process for treating copper ore tailing and nickel molten slag by an ore heating furnace, a shaking furnace, a steelmaking electric arc furnace and a refining furnace. The iron extracting and steelmaking process comprises the following steps of: (1) uniformly mixing copper ore tailing and a carbonaceous reducing agent and granulating into pellet lump ore; (2) charging the pellet lump ore into the ore heating furnace and smelting to obtain silicon-contained molten iron; (3) desulfurating and deslagging the silicon-contained molten iron to obtain low-sulphur-silicon molten iron or confirming whether sulphur is removed according to the sulphur content of the silicon-contained molten iron; (4) transporting the nickel molten slag to an iron extracting station in a heat preserving way; (5) charging the nickel molten slag into the shaking furnace, adding lime and low-sulphur-silicon molten iron, mixing and stirring to obtain reduced molten iron; and (6) conveying the reduced molten iron into the electric arc furnace and adding lime for desulfurating, decarbonizing and dephosphorizing to obtain molten steel. The process reasonably utilizes the components of the copper ore tailing, fully recovers valuable metals in the copper ore tailing and the nickel molten slag, achieves the aim of comprehensive utilization, has reasonable design, is convenient for mastering and construction and is suitable for industrialized application.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

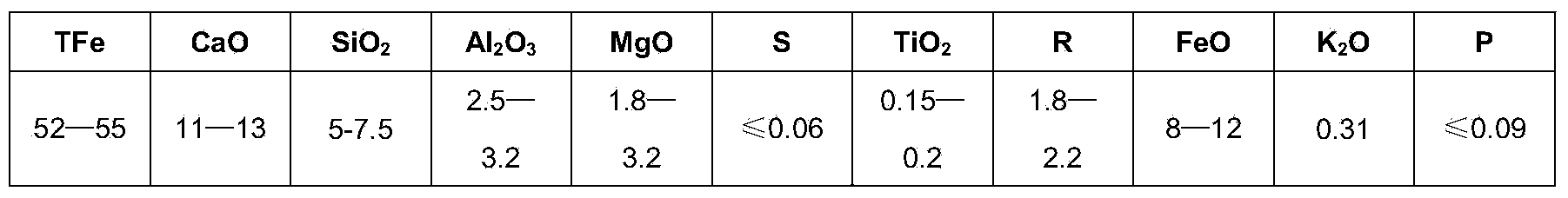

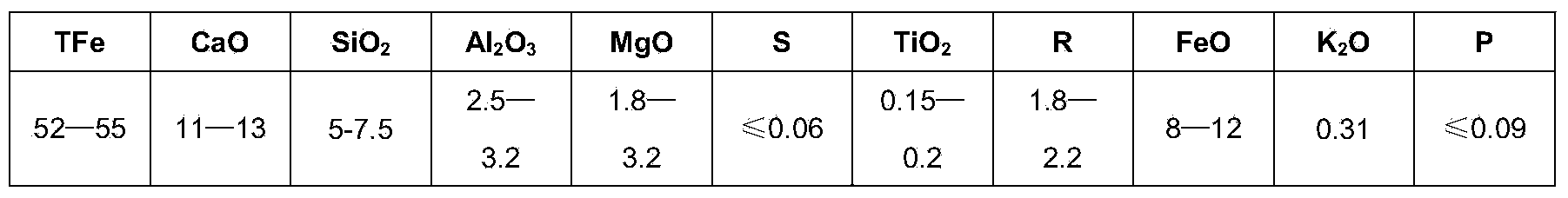

Electroslag remelting premelted slag for improving purity of GH4169 alloy return scraps and preparing method

The invention belongs to the technical field of high-temperature alloy purifying smelting and relates to an electroslag remelting premelted slag for improving the purity of GH4169 alloy return scrapsand a preparing method. According to the ranges of composition proportions of the premelted slag, CaF2 accounts for 40-55%, CaO accounts for 20-25%, Al2O3 accounts for 18-22%, MgO accounts for 3-6%, TiO2 accounts for 2-3%, and MgF2 accounts for 1-2%; and in the premelted slag at 600 DEG C or lower, moisture is smaller than or equal to 0.06%, SiO2 is smaller than or equal to 0.5%, C is smaller thanor equal to 0.03%, P is smaller than or equal to 0.01%, and S is smaller than or equal to 0.005%. Prepared ceramic materials are subjected to ball milling mixing, smelting through an electric arc furnace, quick cooling and crushing screening, then dried for 2-3 h at the high temperature of 950 DEG C + / -20 DEG C and finally sealed and packaged under the protection of the inert gas (Ar). The premelted slag can ensure the internal metallurgical quality and the surface quality of GH4169 alloy return scrap ingots for aircraft engines, the alloy purity is high, and the premelted slag has the advantages of energy conservation and environmental friendliness, and has wide market prospects and application value.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Finegrained aluminium-chromium composite fireproof materials

The invention relates to a novel fire-resistant raw material for preparing periclasite magnesium aluminate spinel fireproof material and high grade fusion-cast AZS fireproof material whose formulation is, desiliconisation zirconium 30-73%, commercial alumina 27%-70%, magnesite 0-10%, wherein the content of zirconium dioxide in desiliconisation zirconium is 85-92%, the content of magnesium oxide in magnesite is 97%, the total content of magnesium oxide in the formulation is 0.2-10%, the total content of silicon oxide is 0.5-1.5%, the total content of zirconium oxide is 30-60%, the total content of alumina is 30-65%. The raw material can be used to prepare periclasite-magnesium aluminate spinel material with substantial improvement on heat and shock resistance, thermal conductivity.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

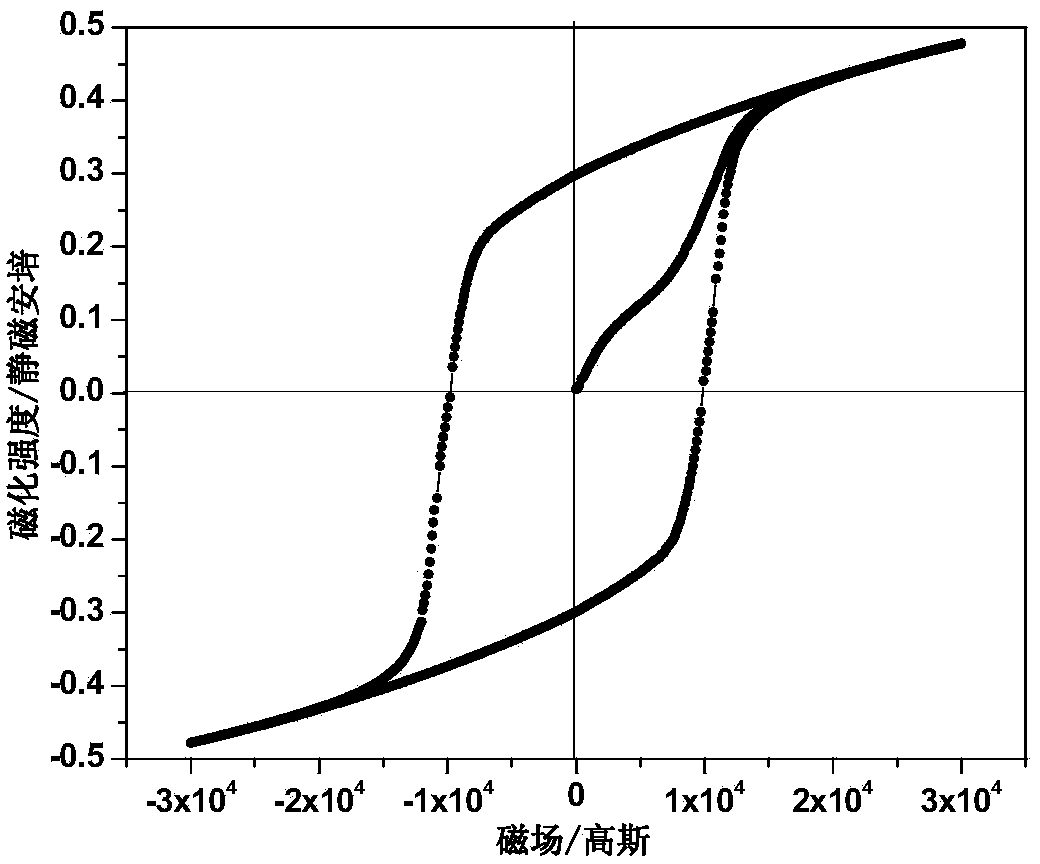

Ferro-cerium-based rapid quenching permanent magnet powder and preparation method of ferro-cerium-based rapid quenching permanent magnet powder

ActiveCN103714928ALower melting temperatureShorten smelting timeInorganic material magnetismCeriumEngineering production

The invention relates to ferro-cerium-based rapid quenching permanent magnet powder and a preparation method of the ferro-cerium-based rapid quenching permanent magnet powder. The alloy composition chemical formula of the ferro-cerium-based rapid quenching permanent magnet powder is [Ce100-x, Rex]aFe100-a-b-cBbTMc, wherein the x is the mass percent of the rare earth gross, the a, the b and the c show the mass percents of corresponding elements respectively, 0<=x<=50%, 27.5%<=a<=32%, 0.8%<=b<=1.5%, 0.5%<=c<=5%, the Re is one or more of Nd, Pr, Dy and Tb, and the TM is one or more of Ga, Co, Cu, Nb and Al. According to the preparation method, the ferro-cerium-based rapid quenching permanent magnet powder and Re'-Fe-B without Ce can be prepared with a water-cooling electromagnetic roller (a copper alloy roller or a molybdenum roller), and a ferro-cerium-based hot-pressing magnet with double hard magnetic principal phases or multiple hard magnetic principal phases can be prepared with the two kinds of magnetic powder. The ferro-cerium-based rapid quenching permanent magnet powder fills up blanks of middle-grade magnet powder and lower-grade magnet powder on the market at present, the product performance cost ratio is high, and the ferro-cerium-based rapid quenching permanent magnet powder and the preparation method are suitable for engineering production.

Owner:CENT IRON & STEEL RES INST

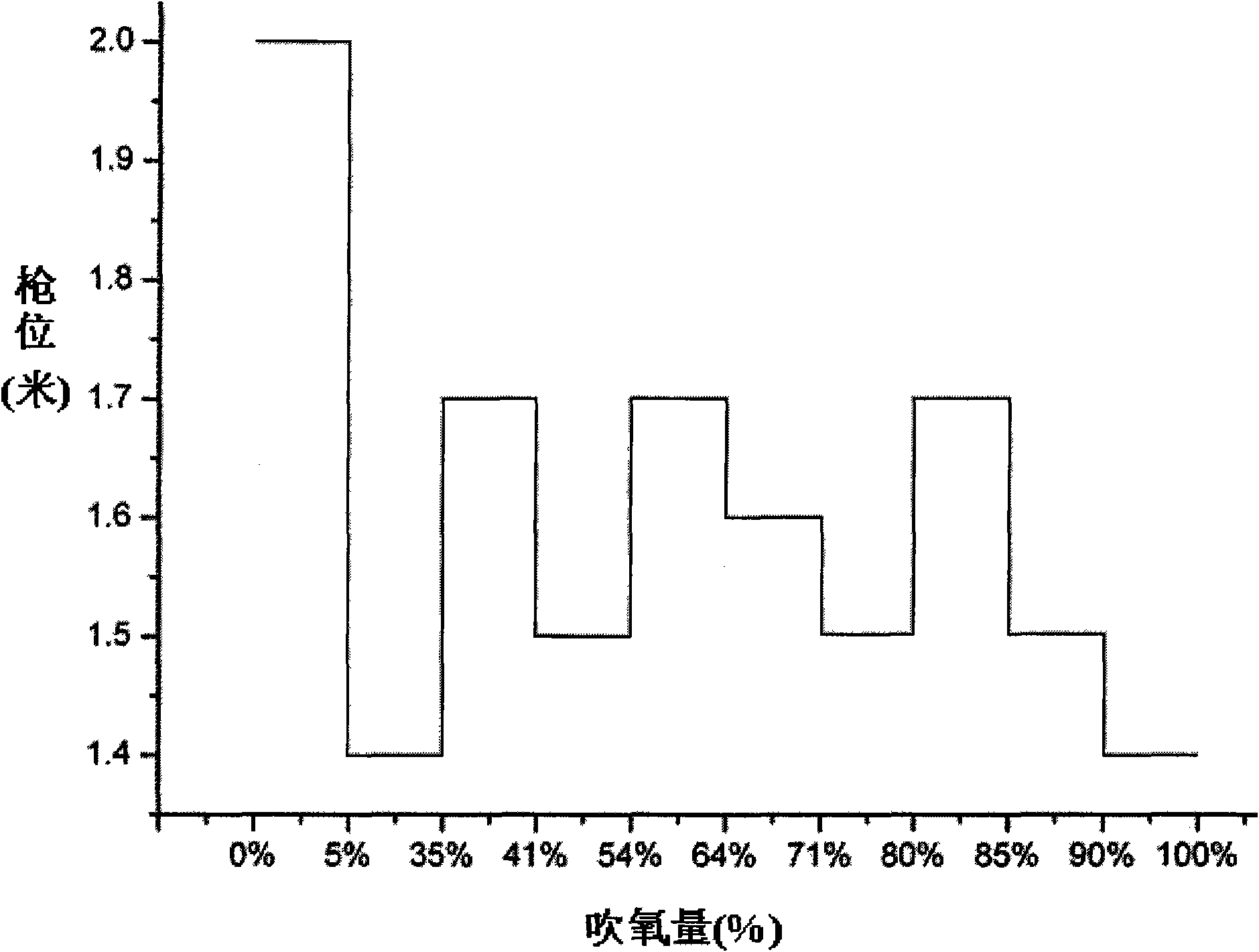

Oxygen top blown converter steel making method

The invention relates to an oxygen top blown converter steel making method, comprising the following steps: the steel material is added to a converter, oxygen is blown into the converter by an oxygen lance and auxiliary materials are added into the furnace by stages in the process of oxygen blowing; wherein the steel material comprises molten iron containing vanadium and titanium; lance position of the oxygen lance moves within 1.4-2.2m above molten steel liquid surface in the converter, wherein blowing beginning lance position is 1.9-2.1m, blowing lance position is 1.4-1.7m and catch carbon lance position is 1.4-1.5m; wherein the auxiliary materials comprise compound slag, lime and high-magnesium lime; with the total content of the blown oxygen as a benchmark, the first batch of auxiliary materials are added when the oxygen blowing content is 0.5-5%; the method of the invention is suitable for smelting high-level steel grade which has high requirements on P and S in a manner of large quantity of slag by molten iron which has relatively high content of P and S after being pretreated. The method can effectively lower consumption of auxiliary materials for molten iron smelting in Panxi Area, shortens smelting time and improves metal yield.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

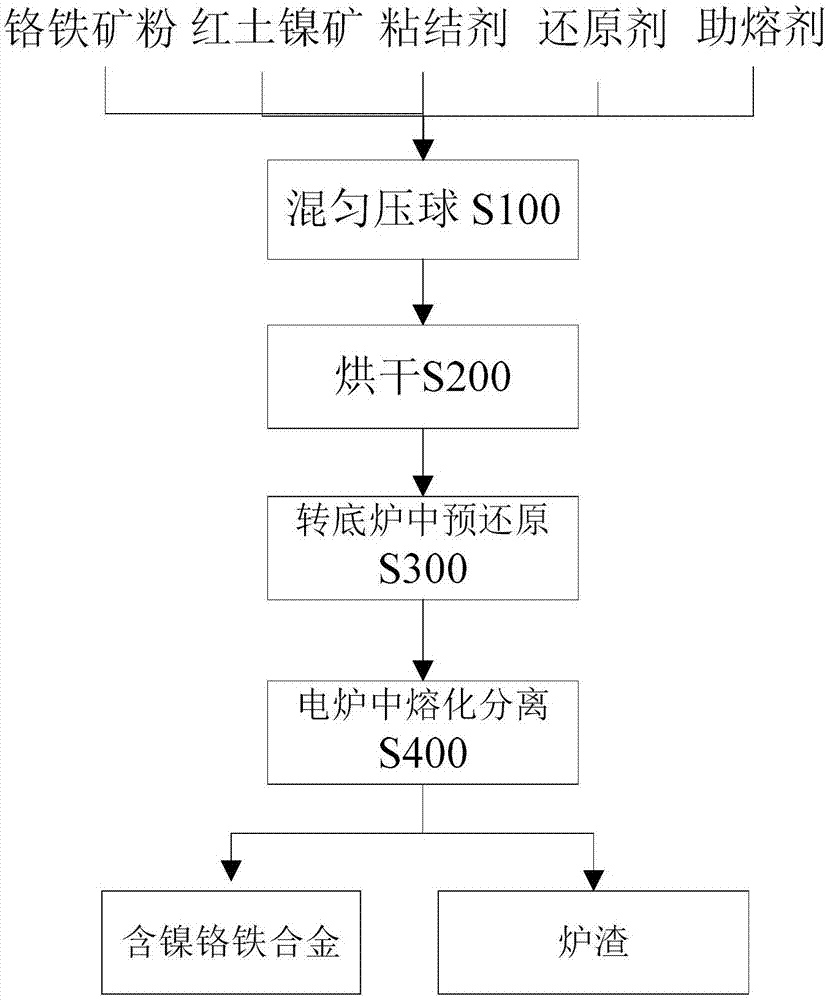

Method for smelting nickel-containing ferrochrome alloy

The invention relates to a method for smelting nickel-chromium ferroalloy, which comprises the following steps: uniformly mixing the ground laterite nickel ore with chromite powder, reducing agent, binder and fluxing agent to prepare balls The pellets are placed in a rotary hearth furnace for high-temperature reduction to obtain metallized pellets; the metallized pellets are sent to an electric furnace for high-temperature melting and separation to obtain nickel-chromium-iron alloys. The present invention uses the easy-to-form characteristics of laterite-nickel ore by mixing ingredients with chromite ore and high-magnesium laterite-nickel ore, reduces the addition of binders, and molds cheap and difficult-to-form chromite powder ore, reducing the Production cost; all raw materials are pre-mixed, the ingredients are relatively uniform, and the smelting time is shortened; the pellets are pre-reduced at high temperature in the rotary hearth furnace, which effectively reduces the power consumption of the electric furnace smelting; at the same time, due to the introduction of Ni in the laterite nickel ore, nickel-containing The ferrochrome alloy further obtained low-cost raw materials for smelting stainless steel.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Coherent jet oxygen blowing method for electric furnace steel making

InactiveCN101684512AAvoid damageImprove adaptabilityProcess efficiency improvementElectric furnaceSteelmakingOxygen

The invention discloses a coherent jet oxygen blowing method for electric furnace steel making, effectively solving the problem of burner damage in the oxygen blowing process of electric furnace steelmaking and enhancing the stirring to a weld pool through the combination of equipment and process improvement. The coherent jet oxygen blowing method for electric furnace steel making comprises the following step: selecting a coherent jet oxygen blowing device and process conditions, wherein the device consists of a primary oxygen spraying and blowing system, a secondary oxygen spraying and blowing system and a fuel gas spraying and blowing system. A primary oxygen spraying hole has a pressure regulation range of 0.8-1.2MPa and an oxygen flow range of 10,000-60,000Nm<3> / h; a secondary oxygenspraying hole has a pressure regulation range of 0.12-0.8MPa and an oxygen flow range of 2,000-10,000Nm<3> / h; and a fuel gas spraying hole has a pressure regulation range of 0.12-0.2MPa, an outlet Mach number of 0.5-1.0 and a fuel gas flow range of 100-2000Nm<3> / h. The invention not only solves the problem of burner damage, but also has important meaning for improving the adaptability of waste steel quality and the internal quality of steel products.

Owner:UNIV OF SCI & TECH LIAONING

Preparation method of copper-silver alloy contact wire for trunk line electrification

ActiveCN103320642AShorten smelting timeIncrease production capacitySingle bars/rods/wires/strips conductorsMetal/alloy conductorsNiobiumMetal

The invention relates a preparation method of a copper-silver alloy contact wire for trunk line electrification. The copper-silver alloy contact wire consists of a copper base and alloy metal, wherein the alloy metal comprises the following components in percentage by weight: 0.08-0.09% of silver, 0.008-0.010% of zirconium, 0.008-0.01% of niobium, 0.005-0.008% of titanium and 0.018-0.020% of mixing rare earth. The preparation process comprises up-drawn continuous casting, continuous extrusion, cold rolling and drawing sequentially. The oxygen content of the prepared contact wire is on a level of oxygen-free copper, and the contact wire is small in crystalline grain, high in mechanical performance, uniform in a length direction, good in flatness, excellent in locomotive getting performance, and higher in tensile strength, ductility, grain size and flexibility in comparison with an existing lead wire; the contact wire has an application value of being popularized in a large range in the high-speed trunk line electrification field.

Owner:山东维点技术有限公司

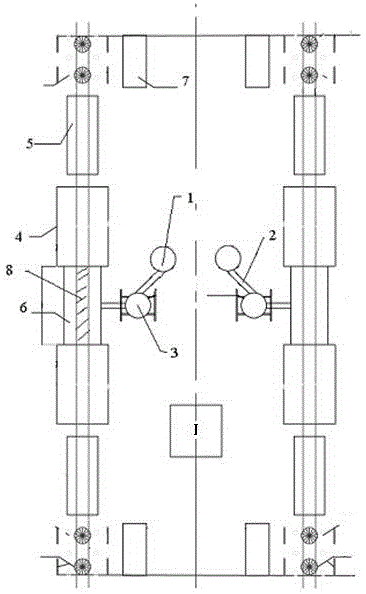

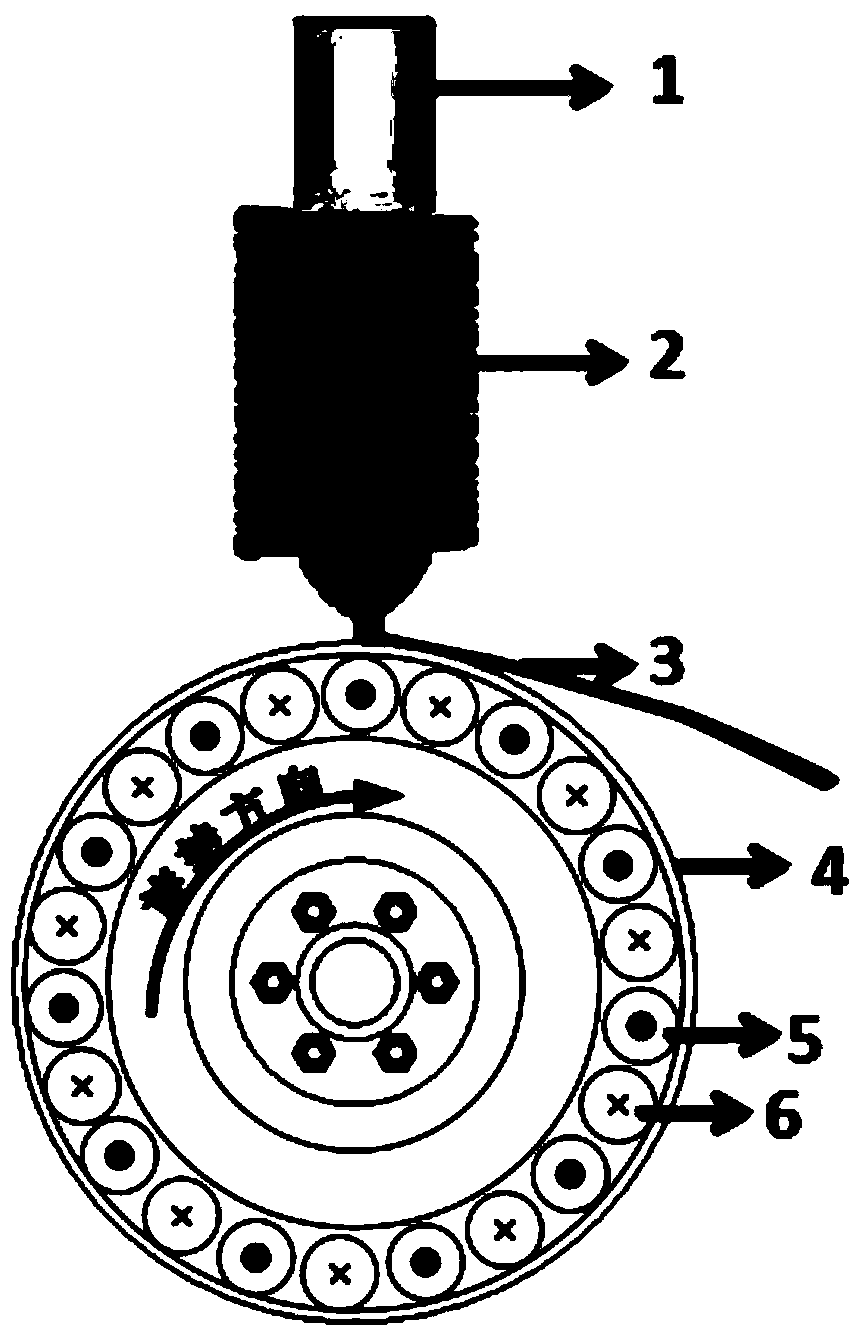

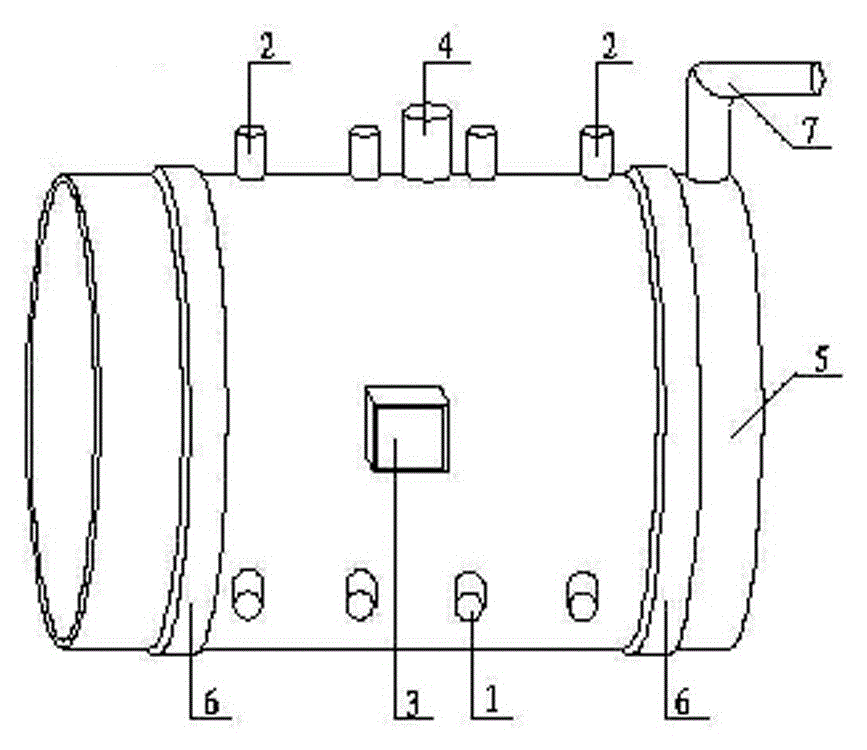

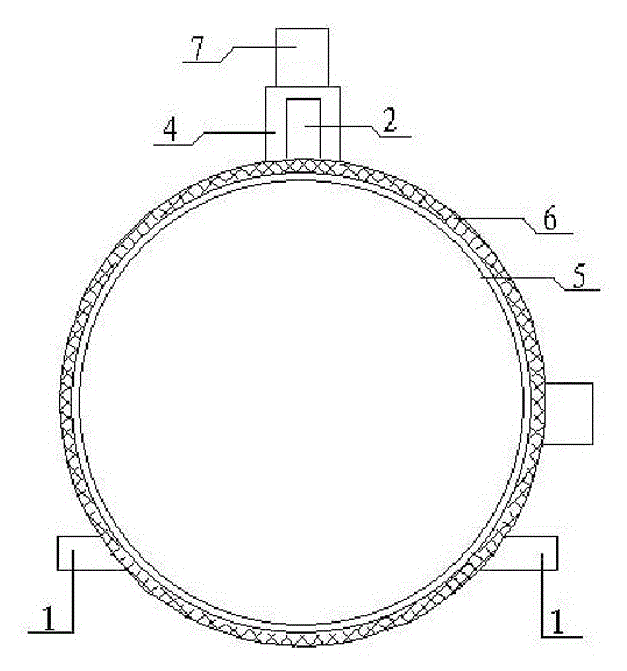

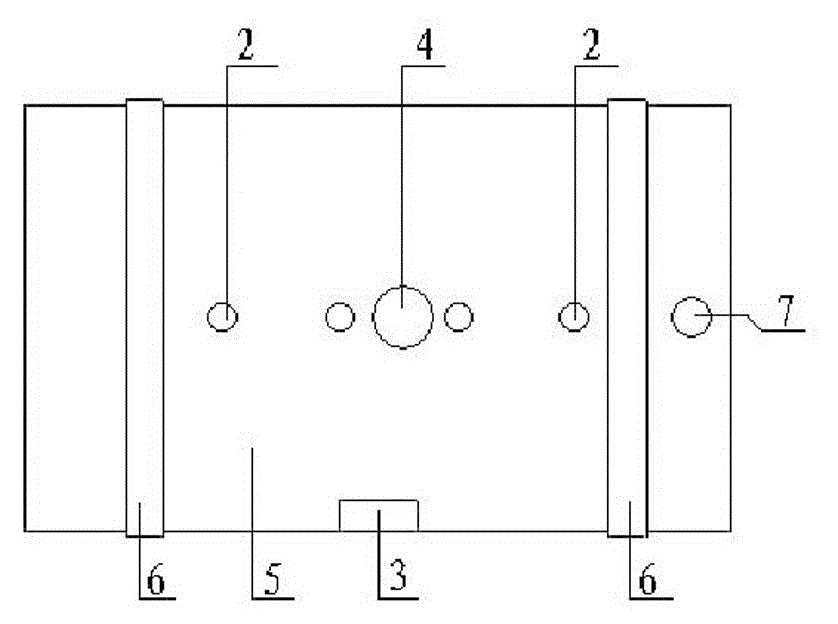

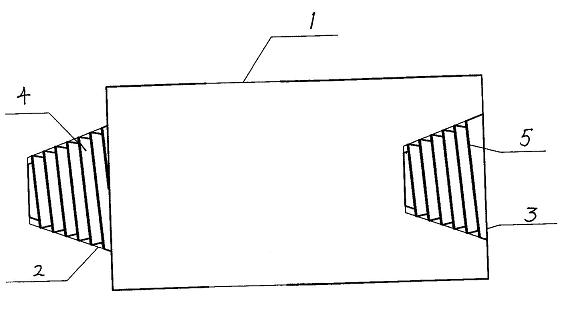

Method and device for preparing crude silver alloy through anode slime

ActiveCN105063363AReduce moistureReduce soot rateProcess efficiency improvementAlloyEnergy consumption

The invention discloses a method and device for preparing crude silver alloy through anode slime. According to the method for preparing crude silver alloy through anode slime, the anode slime is used as the raw material, and the crude silver alloy with the silver content being 80-95 wt% is obtained after the steps of pelletizing, charging and melting, slagging and emission, oxidizing slagging and crude silver alloy discharging. The device is a side-top-combined smelting converter which comprises a plurality of side blowing spray guns (1), a plurality of top blowing spray guns (2), a discharging opening (3), a feed inlet (4), a converter body (5), two rotating racks (6) and a smoke duct (7). According to the method for preparing the crude silver alloy through the anode slime, reduction smelting and oxidizing refining are finished through the side-top-combined smelting converter; compared with traditional two furnaces, the heat efficiency is good, energy consumption is lowered by 20-40%, and cost is reduced; smelting time is shortened to be within 4 days from 6.5 days, and the smelting efficiency is improved; the crude silver alloy can be prepared without additional reducing agents and flux, operation is simple and convenient, and cost is reduced.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

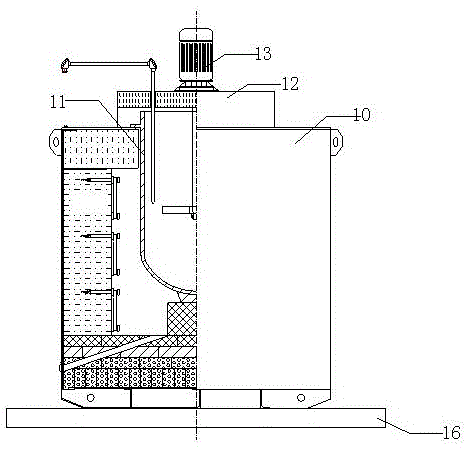

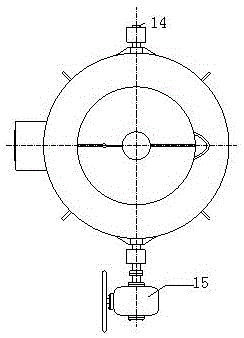

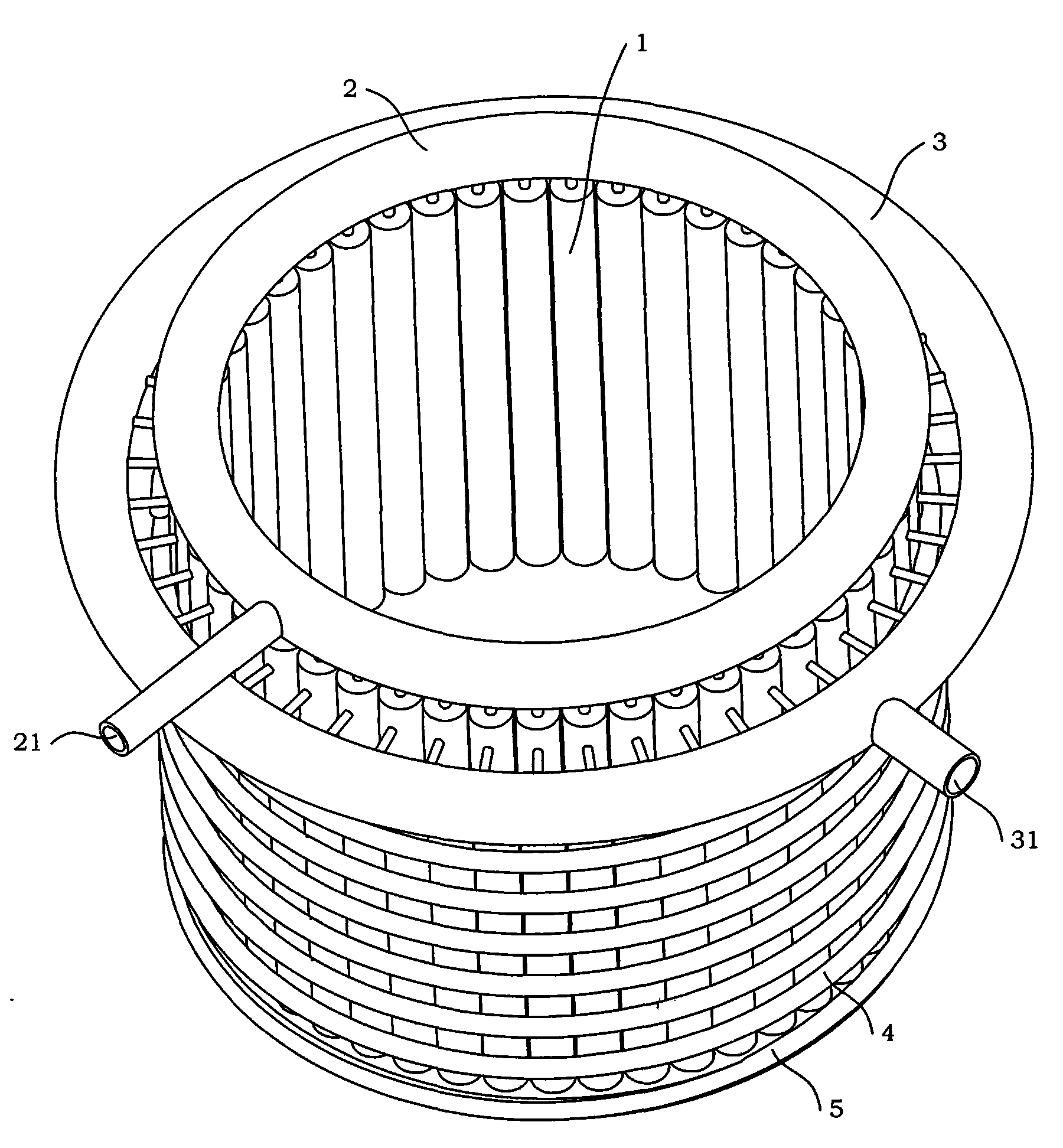

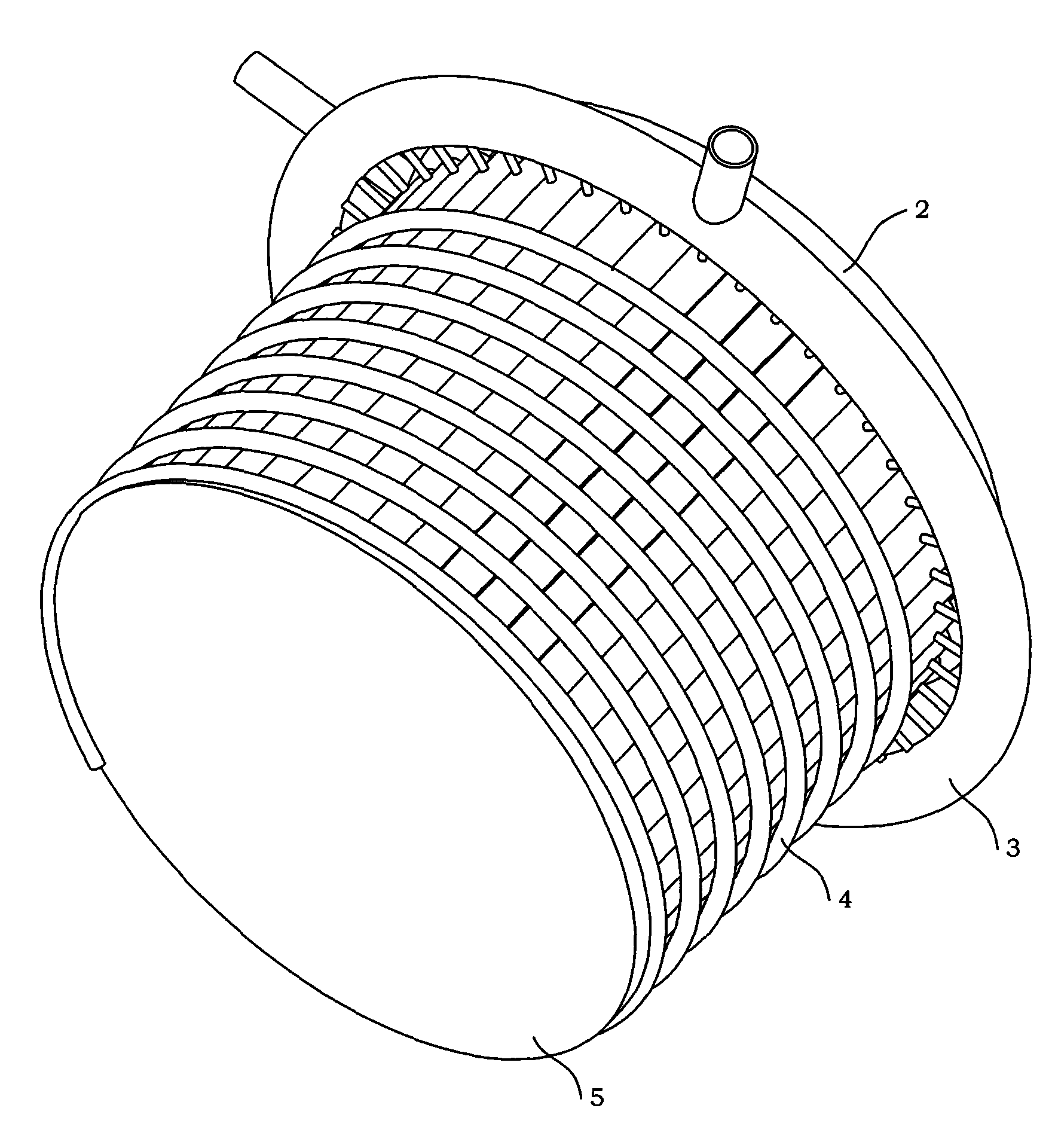

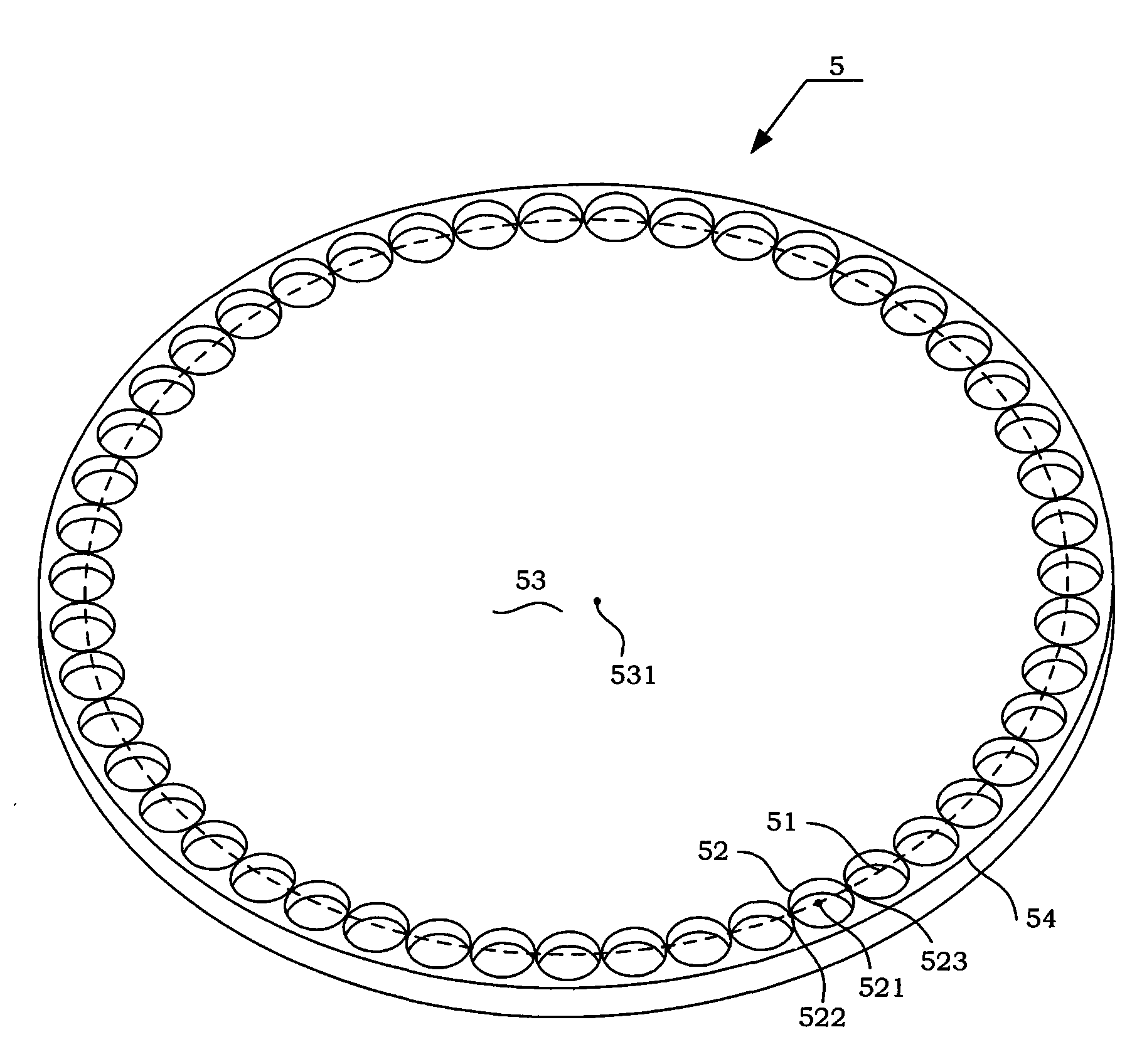

Induction melting cold crucible

The invention discloses an induction melting cold crucible. The induction melting cold crucible comprises a cooling water tube-in-tube(1), a base(5), a water inlet pipeline(2), a water outlet pipeline (3) and an induction coil(4), wherein the lower part of the cooling water tube-in-tube(1) is arranged on the base(5); the water inlet pipeline (2) and the water outlet pipeline (3) are arranged on the upper part of the cooling water tube-in-tube(1) respectively; and the induction coil(4) is wound around the outer part of the cooling water tube-in-tube(1). The induction melting cold crucible formed by the combination of the design idea of discrete components and the base positioning has the advantages of simple processing of parts, low production cost, further low smelting cost of certain rare metals and alloy, and big application range.

Owner:BEIHANG UNIV +1

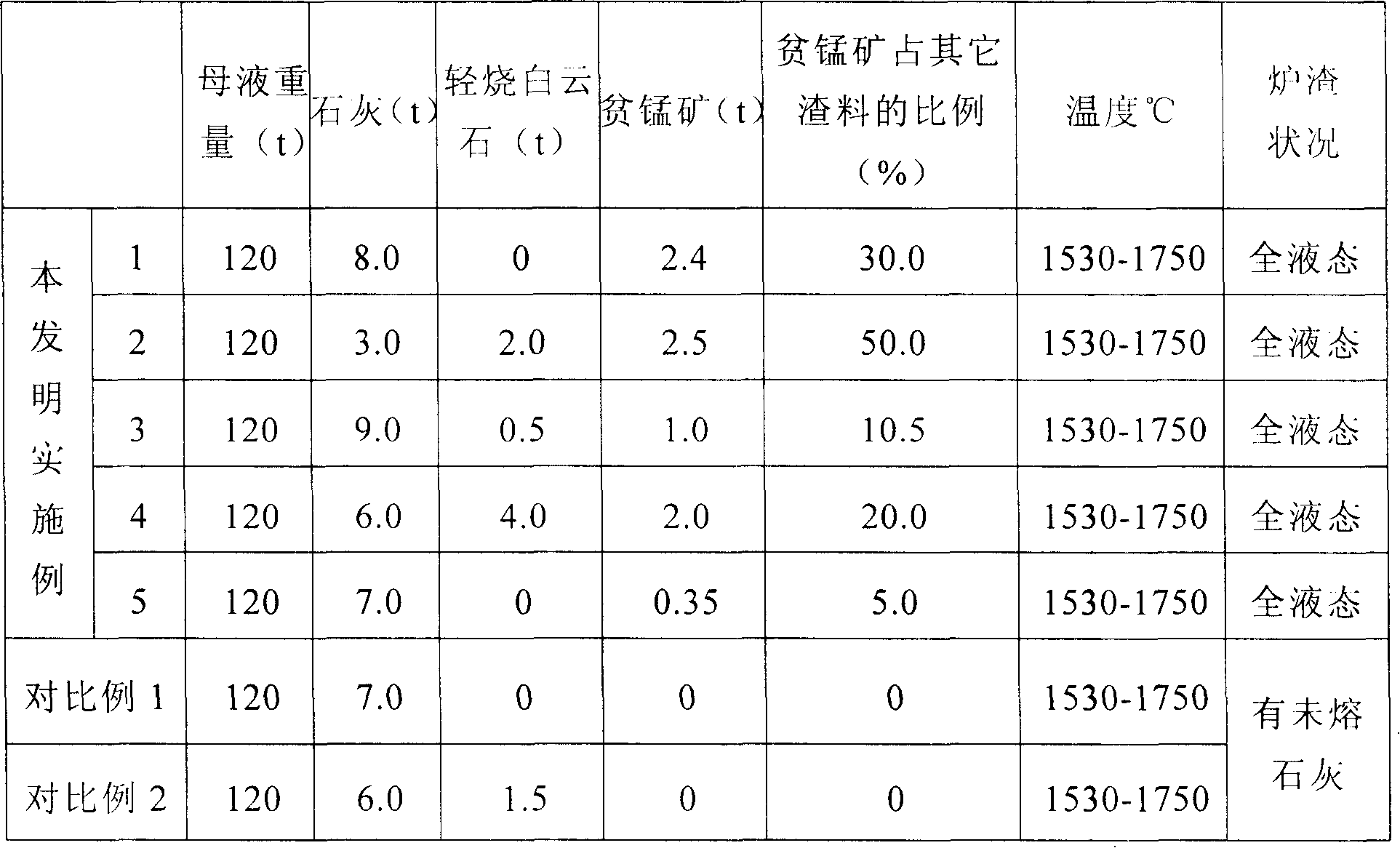

Method for smelting stainless steel oxidizing slag by using argon oxygen furnace

The invention discloses a slag melting method for Argon-Oxygen furnace smelting stainless steel oxidized dross, comprising the procedures that, 1) mass percentage chemical compositions of the crude stainless steel liquid are; 1.5 to 3.5 percent of C, 0 to 0.40 percent of Si, 0 to 0.40 percent of Mn, 8.0 to 30.0 percent of Cr, 0 to 20.0 percent of Ni, no more than 0.03 percent of S, no more than 0.04 percent of P, the balance Fe and incidental impurities; 2) oxidation phase, 3) reduction phase, 4) refining phase. The 2) Oxidation phase is that: lime is added before charging crude stainless steel liquid into Argon-Oxygen furnace to increase the degree of basicity of initial dross. The temperature of steel liquid increases gradually as blowing refinement processes; lime and low-grade manganese ore are added in batches to form complete liquid dross. The 3) reduction phase is that: silicon iron is added to reduce steel liquid and slag, during which only argon gas is used for blowing refinement. The 4) refining phase is that: components are adjusted to target components, during which argon or nitrogen gas is used for blowing refinement. The invention has good slag melting effect during oxidation phase with the Argon-Oxygen furnace, increases decarburization speed, decreases smelting period, thereby improving manufacture efficiency, extending the service life of furnace lining and reducing consumption and cost.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Special carbon electrode for smelting of titanium slag and preparation method thereof

InactiveCN101983002AHigh resistivityLow high resistivityElectric discharge heatingCooking & bakingPetroleum coke

The invention belongs to the technical field of carbon electrodes and discloses a special carbon electrode for smelting of titanium slag and a preparation method thereof. The preparation method is mainly technically characterized by screening solid raw materials comprising electrically calcined coal, petroleum coke and graphite scrap after calcination, proportioning the materials by an electronic proportioning system, then adding into a mixing and kneading pot, stirring and dry-mixing, then adding coal asphalt, mixing and kneading, and further molding, baking and machining for producing a special carbon electrode finished product for smelting of the titanium slag. The special carbon electrode for the smelting of the titanium slag has the advantages of no asphalt volatile matters, high volume density, low ash content and good oxidation resistance; and the the special carbon electrode is used for replacing a self-baking electrode, thus flue gas volatile matters emitted during baking is avoided, the power consumption during the baking process of the self-baking electrode is saved, energy conservation and environmental friendliness are realized, the installation is simple and convenient, the accidents of soft breakage and hard breakage of the electrode caused by careless operation are avoided, and the safety is greatly improved.

Owner:JIZHOU CHANGAN ELECTRODE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com