Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

792 results about "Copper ore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Following is a list of minerals that serve as copper ores in the copper mining process:

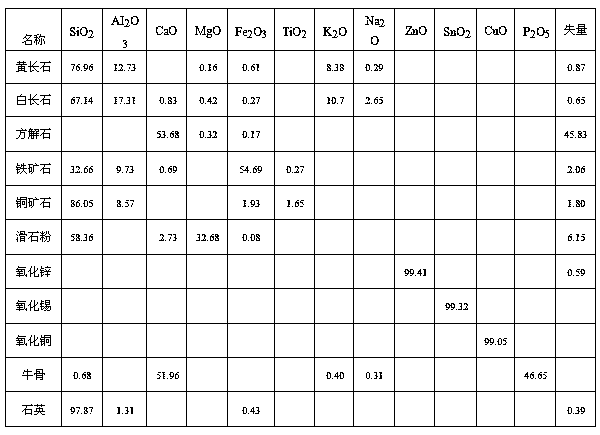

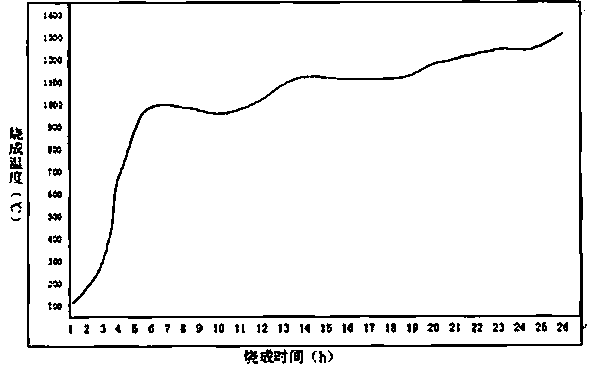

Novel tang-dynasty jun porcelain glaze and manufacturing process thereof

The invention discloses novel tang-dynasty jun porcelain glaze. Yellow feldspar, white feldspar, calcite, quartz, copper ore and iron core are used as glaze raw materials; the yellow feldspar, the white feldspar, the calcite, the quartz, the talcum powder, the copper ore, the zinc oxide, the tin oxide, the copper oxide and ox bone are used as ground coat raw materials; the burnt jun porcelain glaze satisfies the requirement of the tang-dynasty jun porcelain glaze technology, so that the glaze color is natural and variable.

Owner:JIA COUNTY RENSHI CERAMIC IND CO LTD

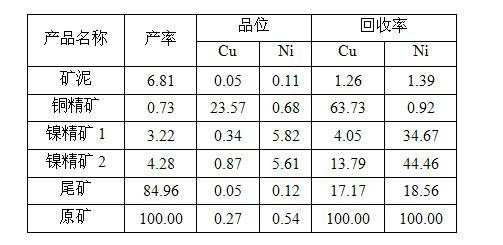

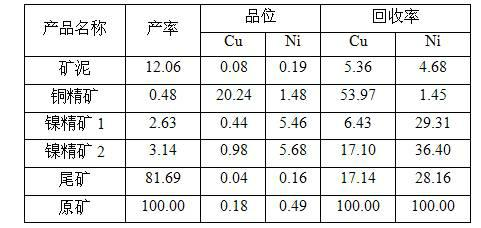

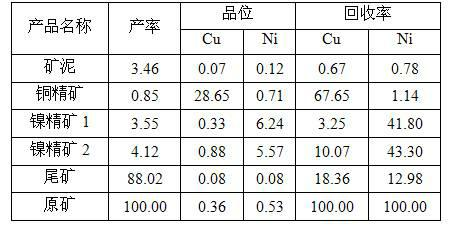

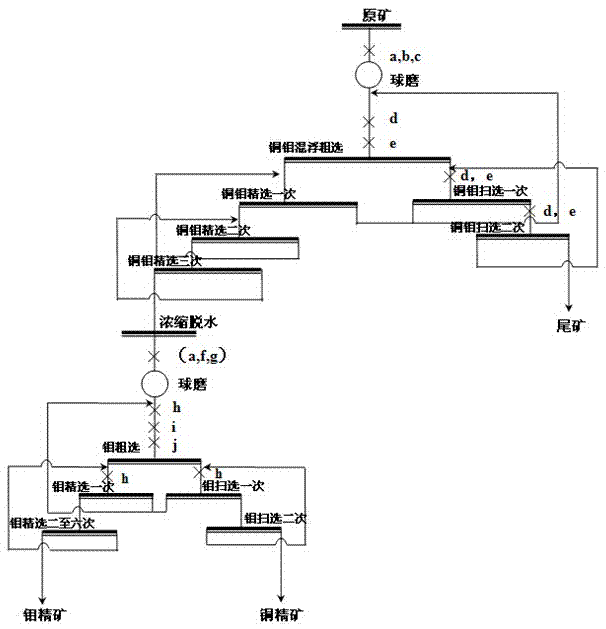

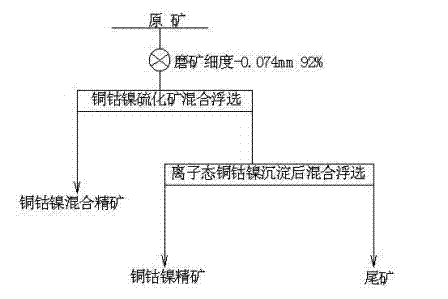

Benefication method for copper nickel

The invention relates to a benefication method for copper nickel. The benefication method for the copper nickel is characterized by comprising the following steps of: (1) finely grinding and desliming on raw copper nickel; (2) performing copper ore flotation on the deslimed raw ore; (3) performing copper concentration on mixed copper rough concentrate obtained in the step (2); (4) performing copper scavenging on copper middling ore I in the step (3); (5) regrinding the mixed copper nickel concentrate of copper and part of nickel in the step (3) and then performing copper nickel separation; (6) performing copper concentration on the copper rough concentrate in the step (5) and performing copper scavenging on the nickel rough concentrate in the step (5); (7) performing copper scavenging II on the nickel concentrate in the step (6); and (8) performing nickel roughing on the reground copper tailings in the step (4). In the benefication method for the copper nickel of the invention, the adaptability of a flotation separation process is high; complex low-grade particle-embedded copper and nickel minerals can be recycled; flotation separation of the copper and nickel minerals can be realized; and the quality and the recovery rate of copper and nickel concentrate are obviously improved.

Owner:西部矿业集团科技发展有限公司

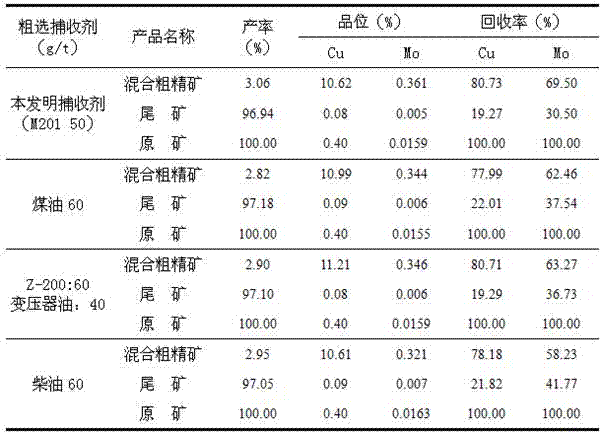

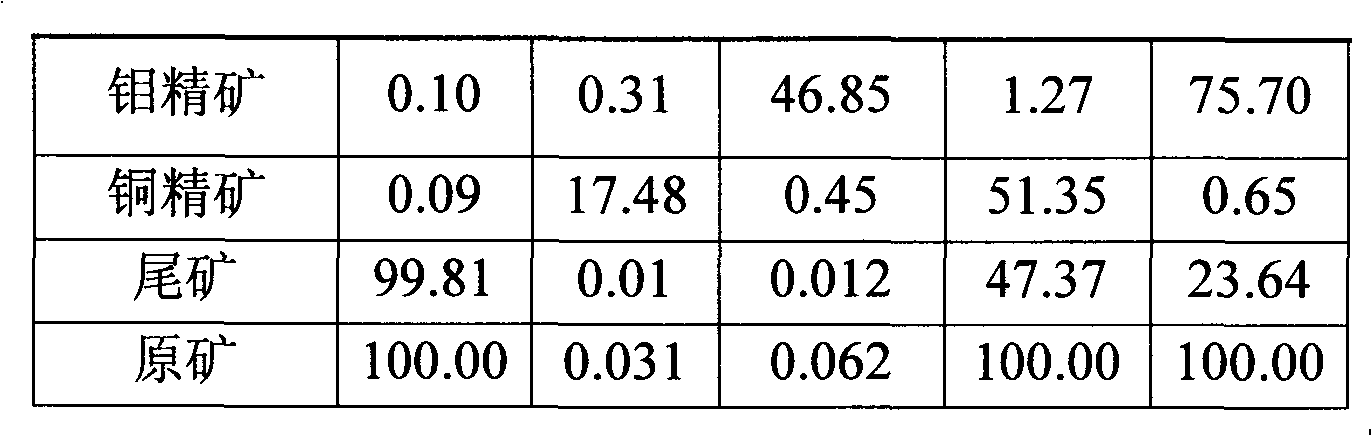

Beneficiation method for low-grade mixed copper ore containing molybdenum

ActiveCN105435953AReduce mutual inclusionHarvestingFlotationWet separationMineral SourcesLower grade

The invention discloses a beneficiation method for low-grade mixed copper ore containing molybdenum. According to the properties and characteristics of the low-grade mixed copper ore containing molybdenum, the copper and molybdenum bulk floatation and re-separation principle technological process is adopted, and high-efficiency concentration of minerals is achieved by using a combination of butyl xanthate and a high-efficiency collector M201 during copper and molybdenum bulk floatation operation; high-efficiency reagent removal of bulk concentrates is achieved through a concentration dewatering and fine grinding method during copper and molybdenum separation operation so that the impact of a large number of reagents existing in copper-lead bulk concentrates on copper and molybdenum separation can be reduced; and moreover, copper minerals are suppressed by means of suppressant F-6, so that separation of copper and molybdenum is effectively realized, and the copper content and molybdenum content of the concentrates are effectively reduced. Meanwhile, in order to stabilize the floatation indexes, the floatation process is optimized for site production, namely, branching and streaming floatation; accordingly, the purpose of comprehensive recovery and utilization of mineral resources is achieved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

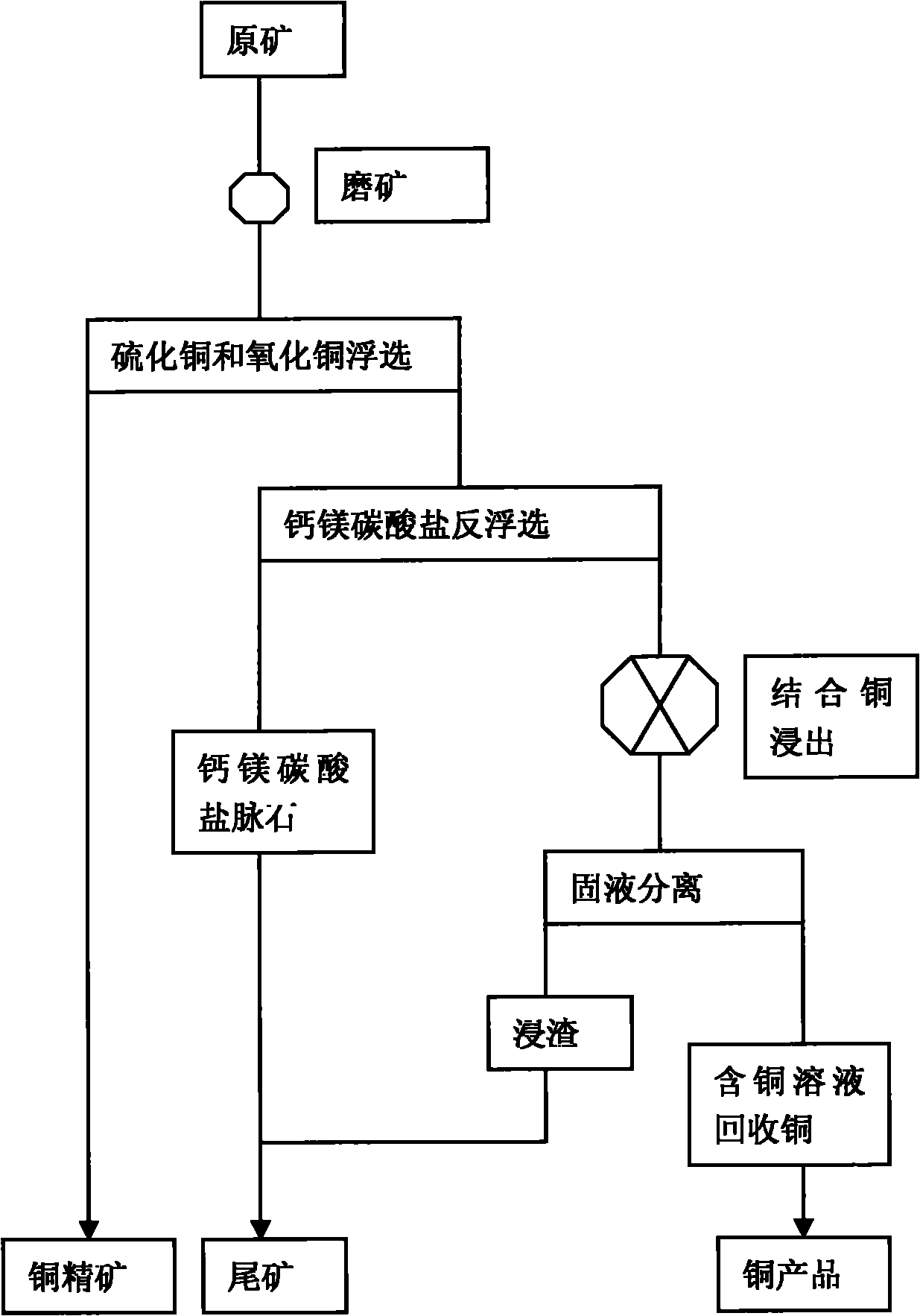

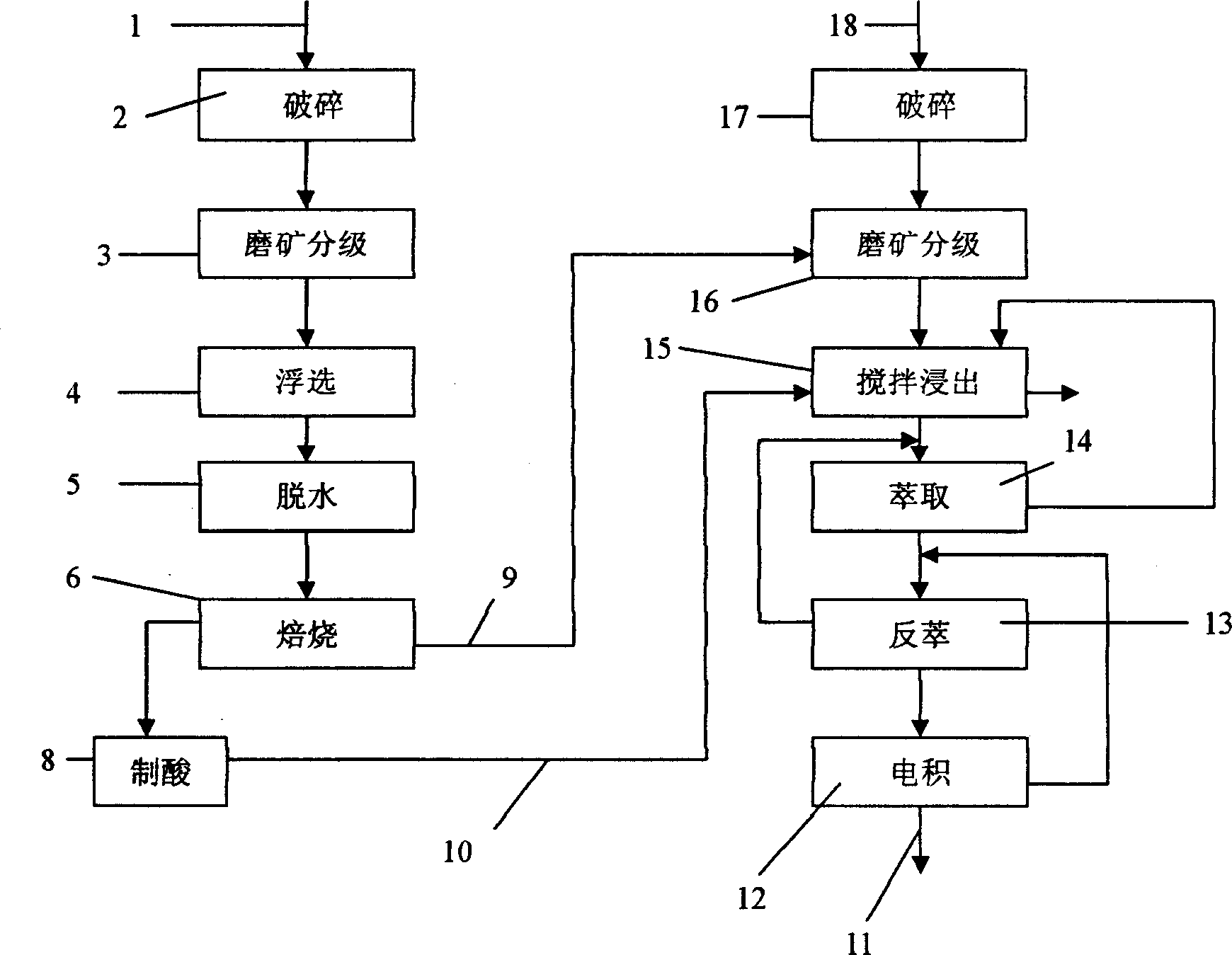

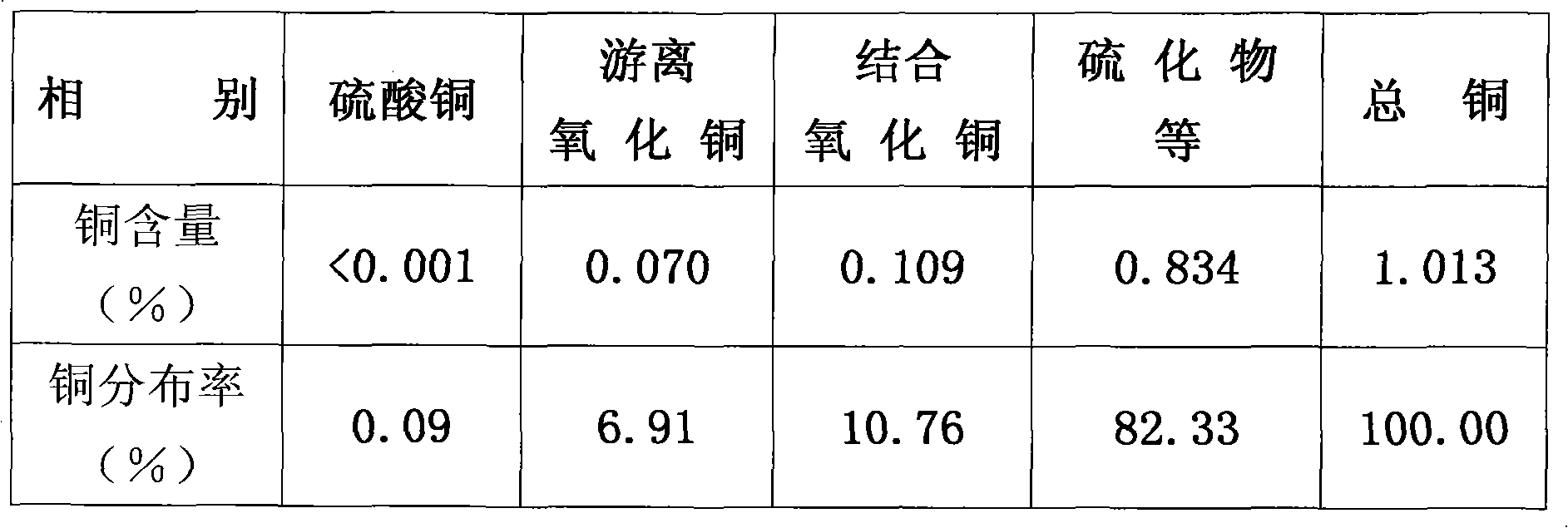

Flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore

ActiveCN101831559AAvoid lostReduce consumptionFlotationProcess efficiency improvementCopper oxideOxygen

The invention relates to a flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore. The flotation and metallurgy method comprises the following steps of: firstly, recovering copper sulfide minerals and free copper oxide minerals in the high-bonding-ratio oxygen-sulfur mixed copper ore with high calcium-magnesium carbonate gangue mineral content by flotation; carrying out reverse flotation on calcium-magnesium carbonate ore in tailings obtained after floatation with fatty acid to obtain middlings containing combined copper and less calcium-magnesium carbonate minerals; then, adding sulphuric acid and stirring to leach out combined copper; and processing a copper-contained solution obtained after solid-liquid separation to obtain a copper product by a metallurgy method. The method combines the flotation and the metallurgy for complementary advantages, efficiently recovers and utilizes high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore resources incapable of being processed at present, lessens the emission of castoff, such as carbon dioxide, magnesium calcium sulfate, and the like and has favorable economic benefits and environmental benefits.

Owner:YUNNAN TIEFENG MINING CHEM NEW TECH CO LTD

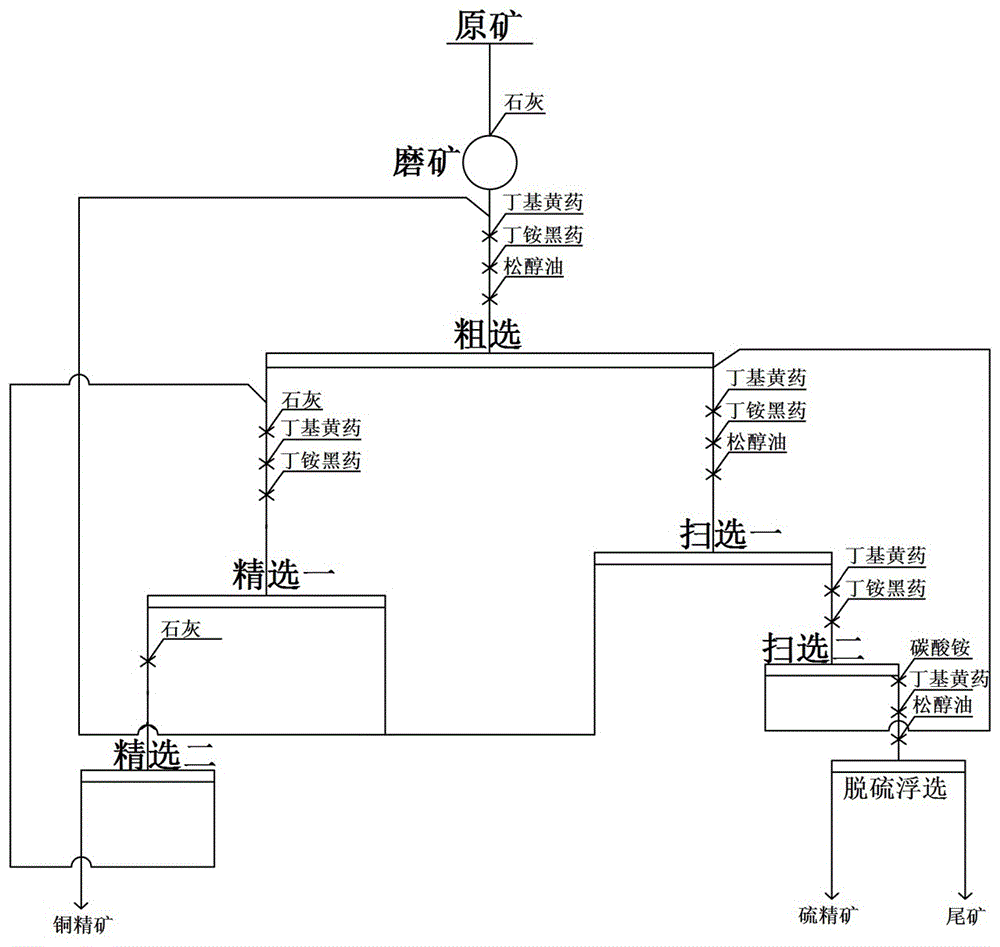

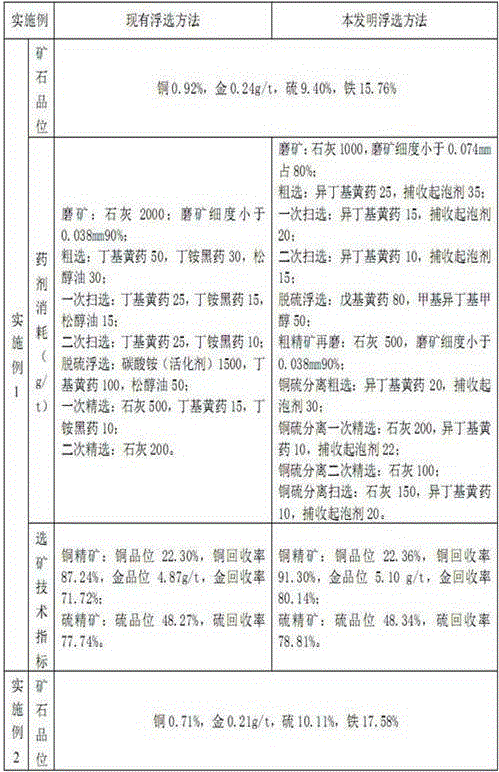

Method for floating high-sulfur gold-bearing copper ore

ActiveCN103691569AEnhanced inhibitory effectImprove beneficiation indexFlotationPropionitrileEthyl group

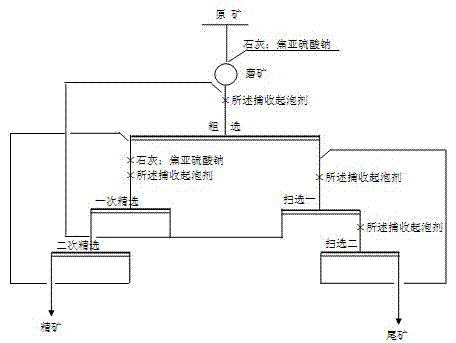

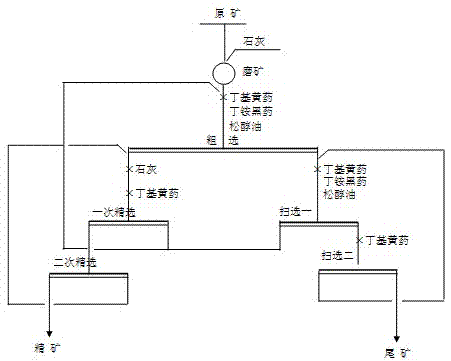

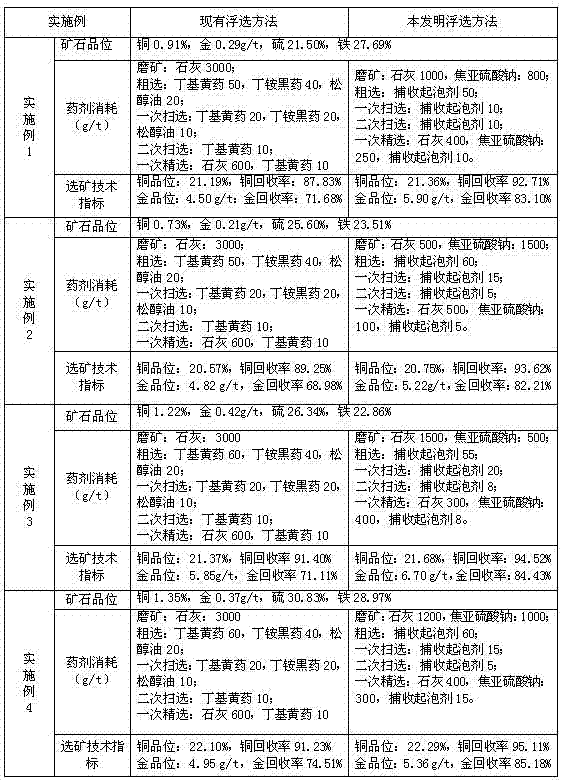

The invention discloses a method for floating high-sulfur gold-bearing copper ore, which aims at solving the problems that the existing beneficiation method is lower in copper and gold recovery rate under high-alkali condition, and problems that xanthate and black powder are adopted as high-sulfur gold-bearing copper ore collecting agents, the collecting power is stronger, the selectivity is poor, the separation difficulty of copper and sulfur can be aggravated and the consumption of inhibitors is increased. The method comprises the steps of by adopting lime and sodium metabisulfite as an ore pulp pH regulator and a pyrite inhibitor, and the mixture of isopropyl xanthogen propionitrile ester, black powder acid and ethyl dithiocarboxyl propionitrile ester according to certain proportion as a collecting foaming agent, carrying out ore grinding, rough concentration, primary scavenging, secondary scavenging, primary concentration, and secondary concentration on a crude ore, thus realizing the high-efficiency recovery on copper and gold in the high-sulfur gold-bearing copper ore. According to the method, through reasonable combination and addition of medicaments, the selective adsorption of the collecting agent on target mineral-copper pyrite and other copper sulfide minerals and gold minerals can be reinforced, and the copper recovery rate and the gold recovery rate can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

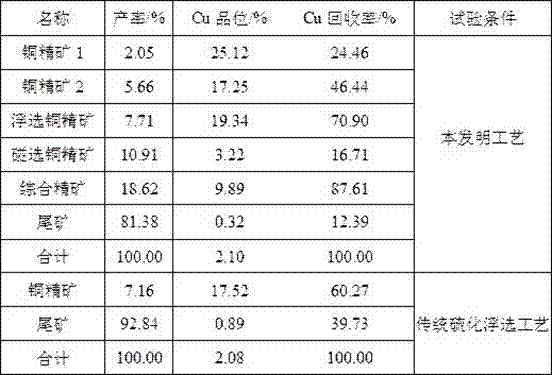

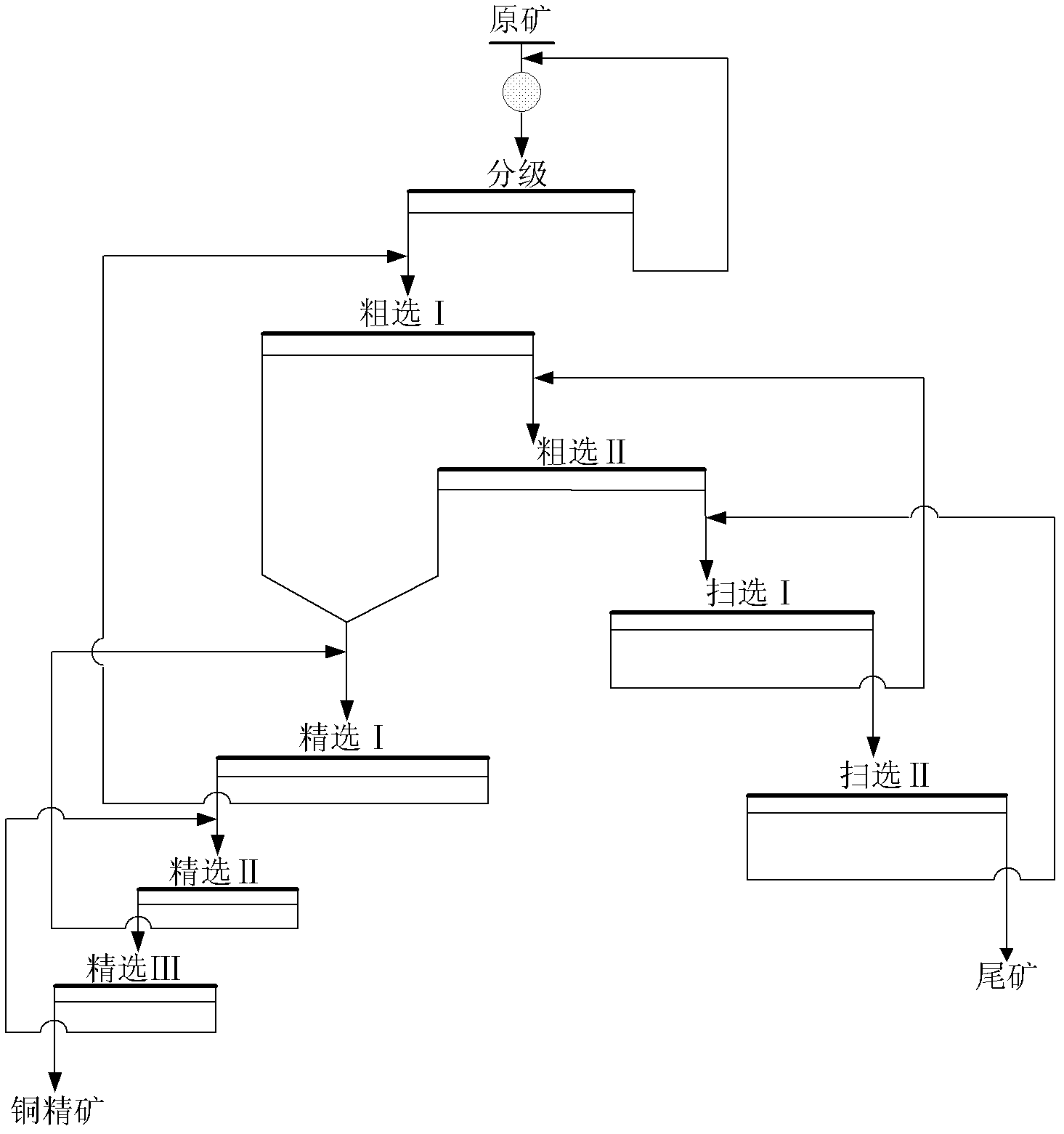

Vulcanization-oxidization mixing copper ore floatation method

InactiveCN101190426AHigh recovery rateImprove concentrate qualityFlotationVulcanizationHydroxamic acid

The invention discloses a sulfurization-oxidation mixed copper mine flotation method, comprising the steps of ore grinding and copper flotation: 20 to 50g / t of pentyl xanthic acid ethyl formate raw ore is added in the grinding process; meanwhile, a pH adjusting agent is added to lead the pH of the mine slurry to keep between 9.5 and 10.5; the invention comprises one time of fast selection, one time of coarse selection, one time of sweeping selection and three times of precise selection; in the fast selection process, 20 to 30g / t of nonyl hydroxamic acid raw ore is added and 20 to 30g / t of frother raw ore is added; in the coarse selection process, 10 to 30g / t of the pentyl xanthic acid ethyl formate raw ore and 10 to 20g / t of the nonyl hydroxamic acid raw ore as well as 10 to 20g / t of the frother raw ore are added; in the sweeping selection process, 10 to 20g / t of the nonyl hydroxamic acid raw ore is added; the pH of the flotation mine pulp is kept between 9.5 and 10.5 and the copper ore is recovered. Compared with the traditional flotation methods of copper sulphide ore and copper oxide ore, the invention improves the flotation efficiency, reduces flotation equipment and energy loss and increases the copper recovery for more than 10%.

Owner:CENT SOUTH UNIV

Method for activating and adjusting mineralized bubbles in vulcanizing flotation process of copper oxide ores

InactiveCN102366731AThe cumulative recovery rate is largeThe cumulative recovery rate increased greatlyFlotationFoaming agentCopper oxide

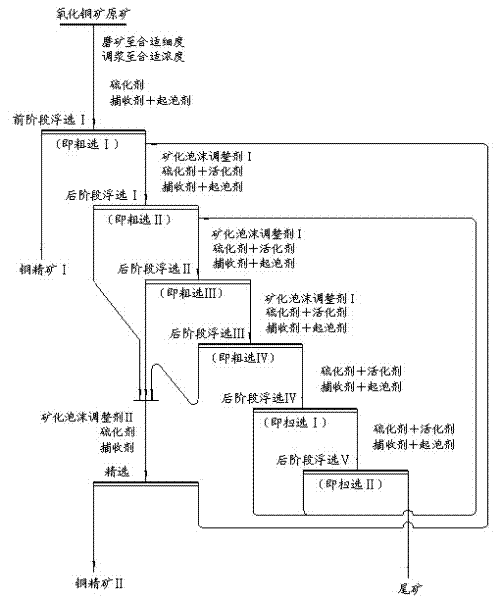

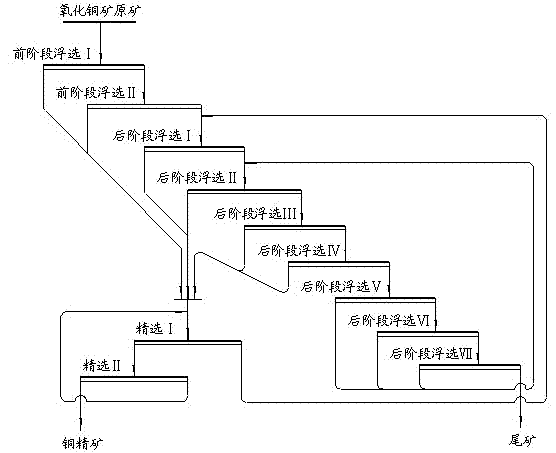

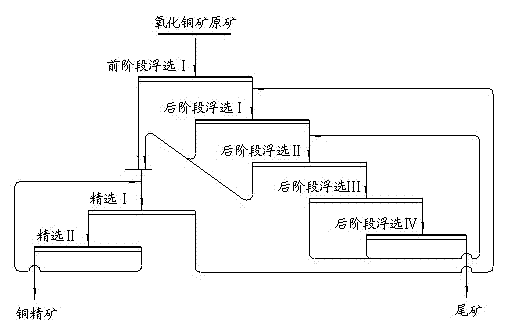

The invention provides a method for activating and adjusting mineralized bubbles in the vulcanizing flotation process of copper oxide ores. The method comprises pre-stage flotation, post-stage flotation and selection; after grinding and mixing, a vulcanizing agent, a collecting agent and a foaming agent are added in each sub-stage of the pre-stage flotation; the mineralized bubble adjusting agent I, a vulcanizing agent, an activating agent, a collecting agent and a foaming agent are added in each sub-stage of the post-stage flotation; and the mineralized bubble adjusting agent II, a vulcanizing agent and a collecting agent are added in each sub-stage of the selection so as to obtain copper concentrate and tailings. The method provided by the invention has the advantages that: the mineralized bubble adjusting agent is correspondingly added when the activating agent is added in the post-stage flotation so as to avoid excessively large bubbles caused by adding the activating agent only, and the production operation is convenient; and compared with the conventional vulcanizing flotation method and conventional activating flotation method, by adopting the medicine adding method and flow structure provided by the invention, the method can improve the recovery rate of copper concentrate by 8-14% while ensuring similar grades of the copper concentrate.

Owner:KUNMING UNIV OF SCI & TECH

Floating method for finely disseminated copper sulfide ores

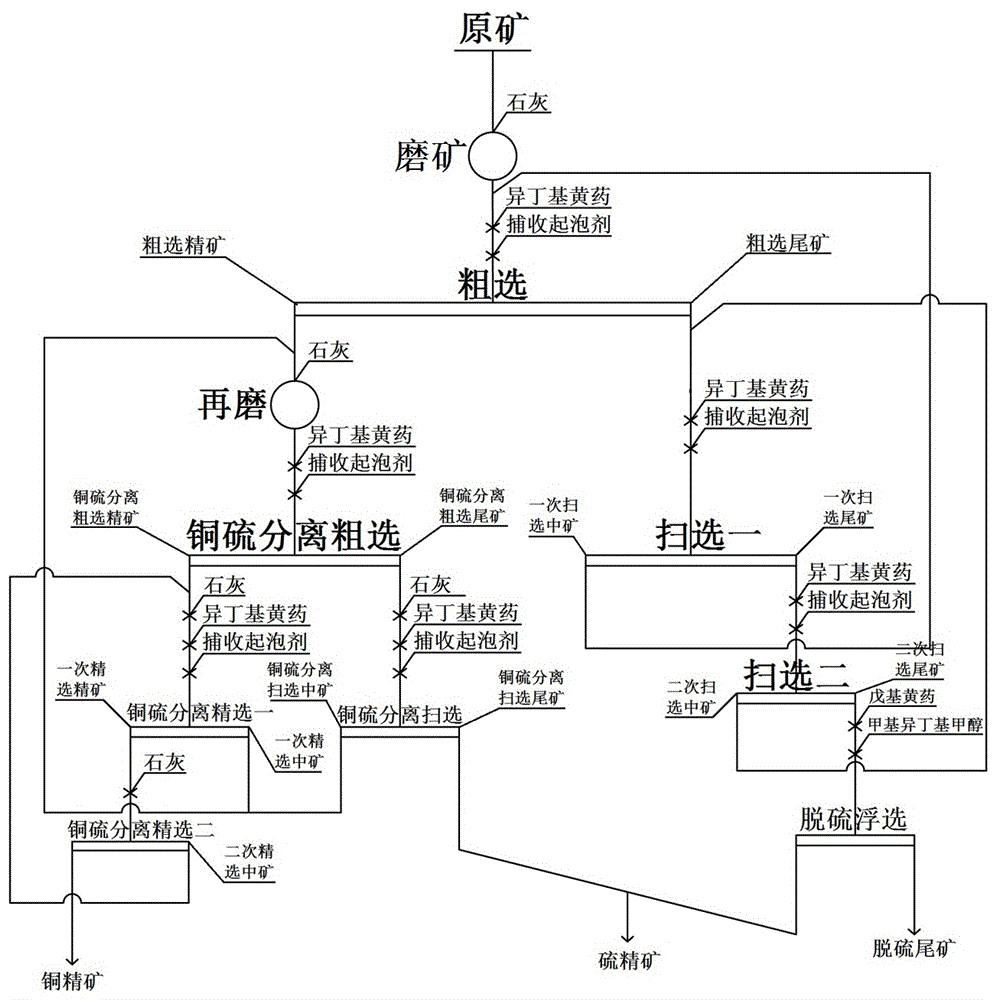

The invention discloses a floating method for finely disseminated copper sulfide ores. The floating method specifically comprises steps such as ore grinding, roughing, roughed concentrate re-grinding, roughed concentrate copper-sulfur separating and floating and roughened tailing scavenging, wherein multi-time concentrating and multi-time scavenging are performed on roughened concentrate and roughened tailings, cyclic ore dressing is performed on ores, and different ore dressing reagents are matched, so that the recovery rate of raw ores is increased. The floating method has the advantages that: by optimizing an ore grinding process and reasonably adding a collecting agent and a collecting-foaming agent, surface characteristics of ores are improved, selective adsorption, on copper sulfide ore particle surfaces such as fine-grained copper pyrite and chalcocite, of the collecting agent is strengthened, and hydrophobic agglomeration is formed, so that the recovery rate of copper concentrate is increased by 3-6% in comparison with that of an existing ore dressing method.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

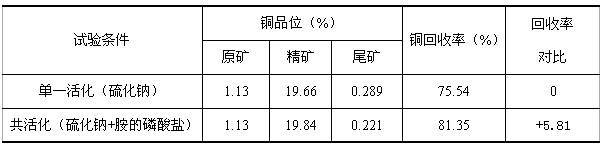

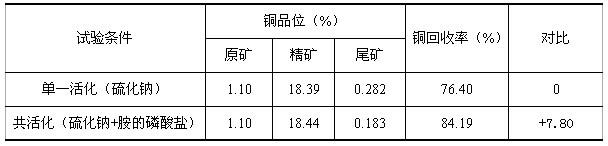

Activation method for flotation process of difficultly processed copper oxide ores

The invention provides an activation method for a flotation process of difficultly processed copper oxide ores. The method comprises the following steps: carrying out wet grinding on copper oxide ores until the mass percentage of the qualified grains with the granularity of 320 mesh is 85-95%, thus obtaining a pulp; adding an activating agent into the pulp, wherein each ton of copper oxide ores are added with 80-200g of the activating agent; and adding sodium sulphide, wherein each tone of the copper oxide ores are added with 1000-2000g of the sodium sulphide; performing activation together; adding 250-400g of conventional collector and 50-80g of foaming agent into one tone of the copper oxide ores, and performing multistage flotation; and producing copper concentrates and tailings via roughing, scavenging and concentrating. The activation effect achieved by the method provided by the invention is better than the effect of conventional activation, and the total use amount of sodium sulphide can be reduced by 10-30%. Compared with the conventional activation flotation, the copper quality of the copper concentrates is slightly increased, and the recovery ratio can be improved by 3-8% by using the activation method provided by the invention.

Owner:KUNMING UNIV OF SCI & TECH

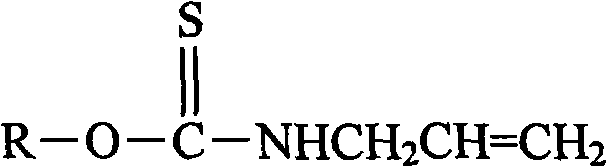

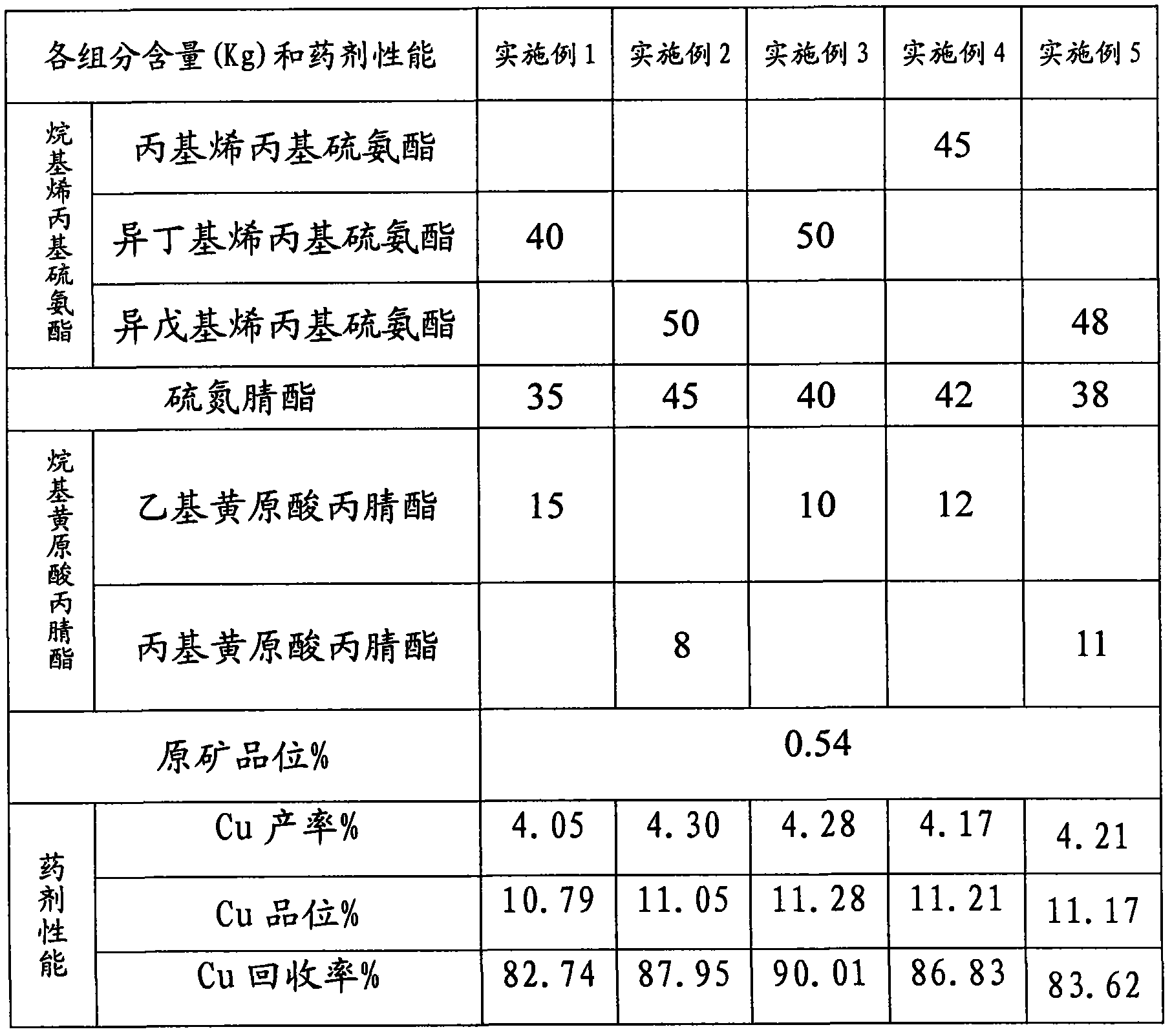

High sulfur copper ore collecting agent

The invention relates to a high sulfur copper ore collecting agent, which is characterized by consisting of the following materials in part by weight: 40 to 50 parts of alkyl allyl thionocarbamate, 35 to 45 parts of sulfur nitrogen nitrile ester and 8 to 15 parts of alkyl xanthonic acid propionitrile ester. The collecting agent has double properties of collecting and foaming, high selectivity and high collecting capacity, can realize high-efficiency separation of copper and sulfur when the pH value is in a range from 7 to 10, can effectively improve the concentrate grade and the recovery rate, and has a wider application range.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Ammonium-amine coupling activation method based on copper mineral sulfurization floatation system

Owner:KUNMING UNIV OF SCI & TECH

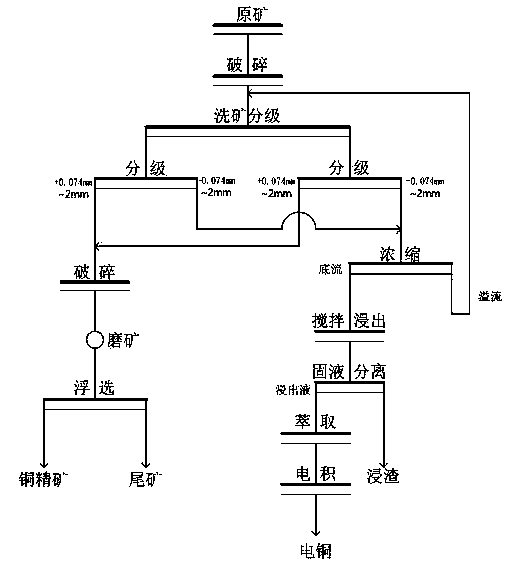

Dressing and smelting method for high-silt content copper oxide ores

InactiveCN103555938AReduce pollutionHigh recovery rateFlotationProcess efficiency improvementPregnant leach solutionFiltration

The invention relates to a dressing and smelting method for high-silt content copper oxide ores, and belongs to the technical field of mineral processing. The method comprises the following steps of crushing and washing the high-silt content copper oxide ores to obtain silt-free coarse-grain ore pulp and silt-free fine-grain ore pulp, and grinding and floating coarse grains to obtain copper concentrates with copper grade of 12-22wt% and tailings by using the prior art; concentrating the fine-grain ore pulp, returning overflow water for washing operation, adding acids to leach base flow after the base flow is concentrated to 30-60wt%, washing filter residues after filtration (solid-liquid separation), and performing extraction and electro-deposition on cleaning fluid obtained by washing and leachate obtained by filtration to prepare electrolytic copper. The method has the characteristics of high recovery rate, low production cost, high adaptability, less environmental pollution and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for extracting copper from mixed copper ores

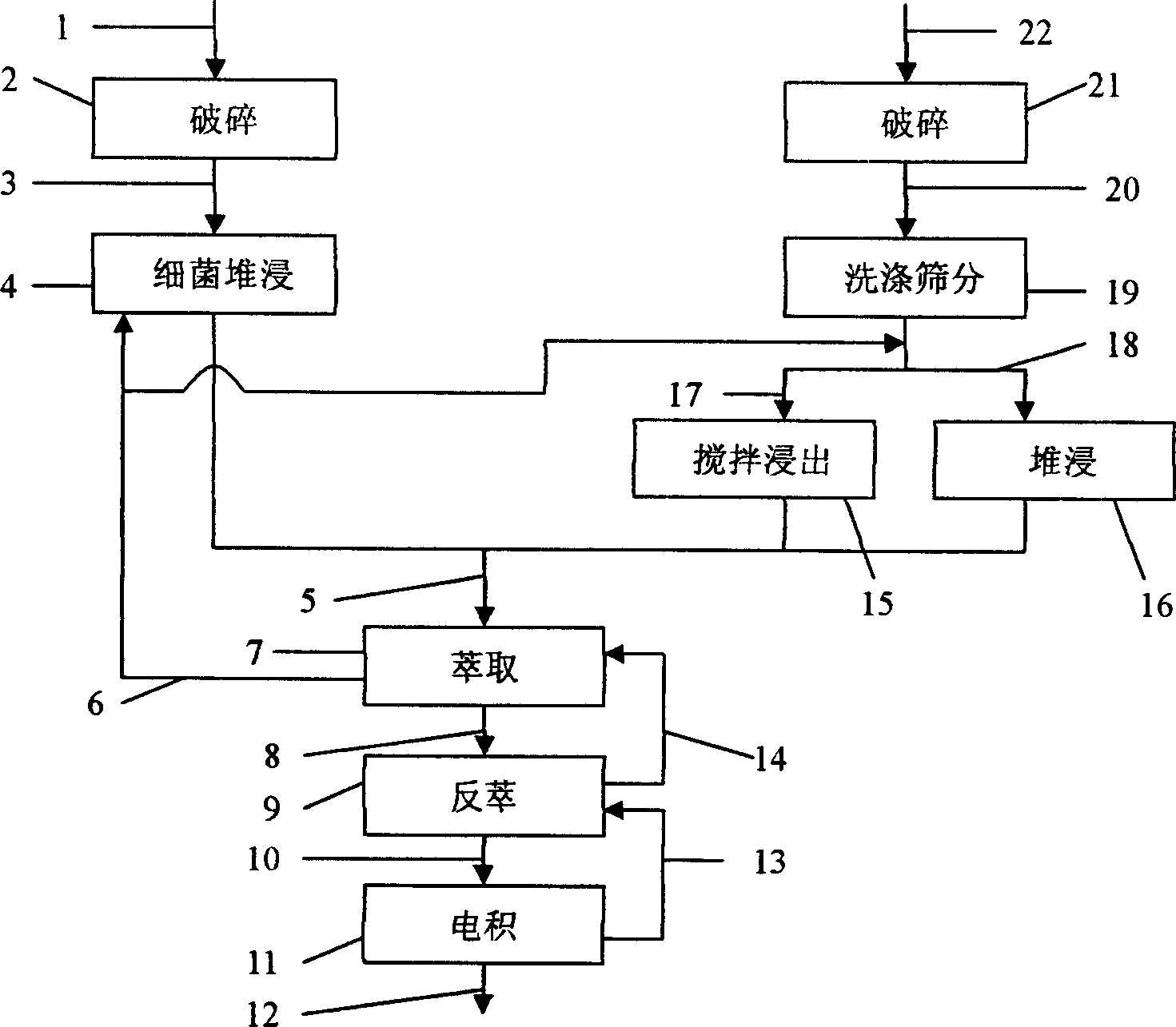

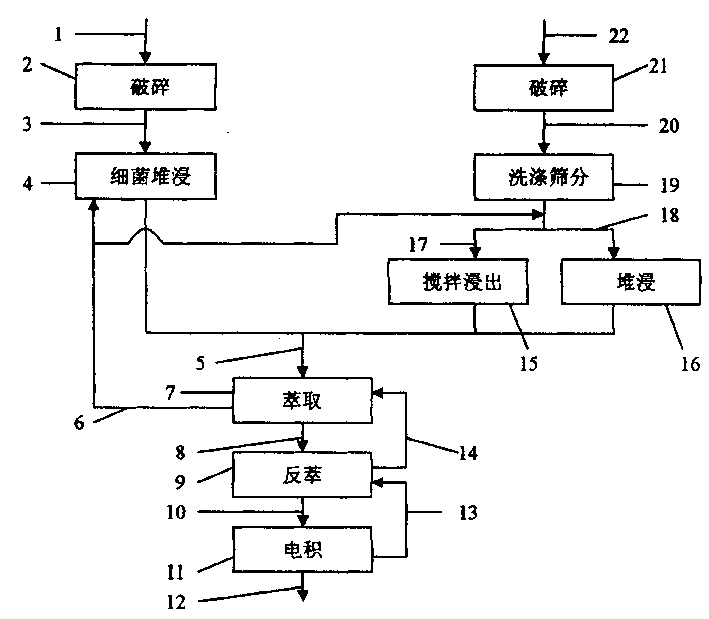

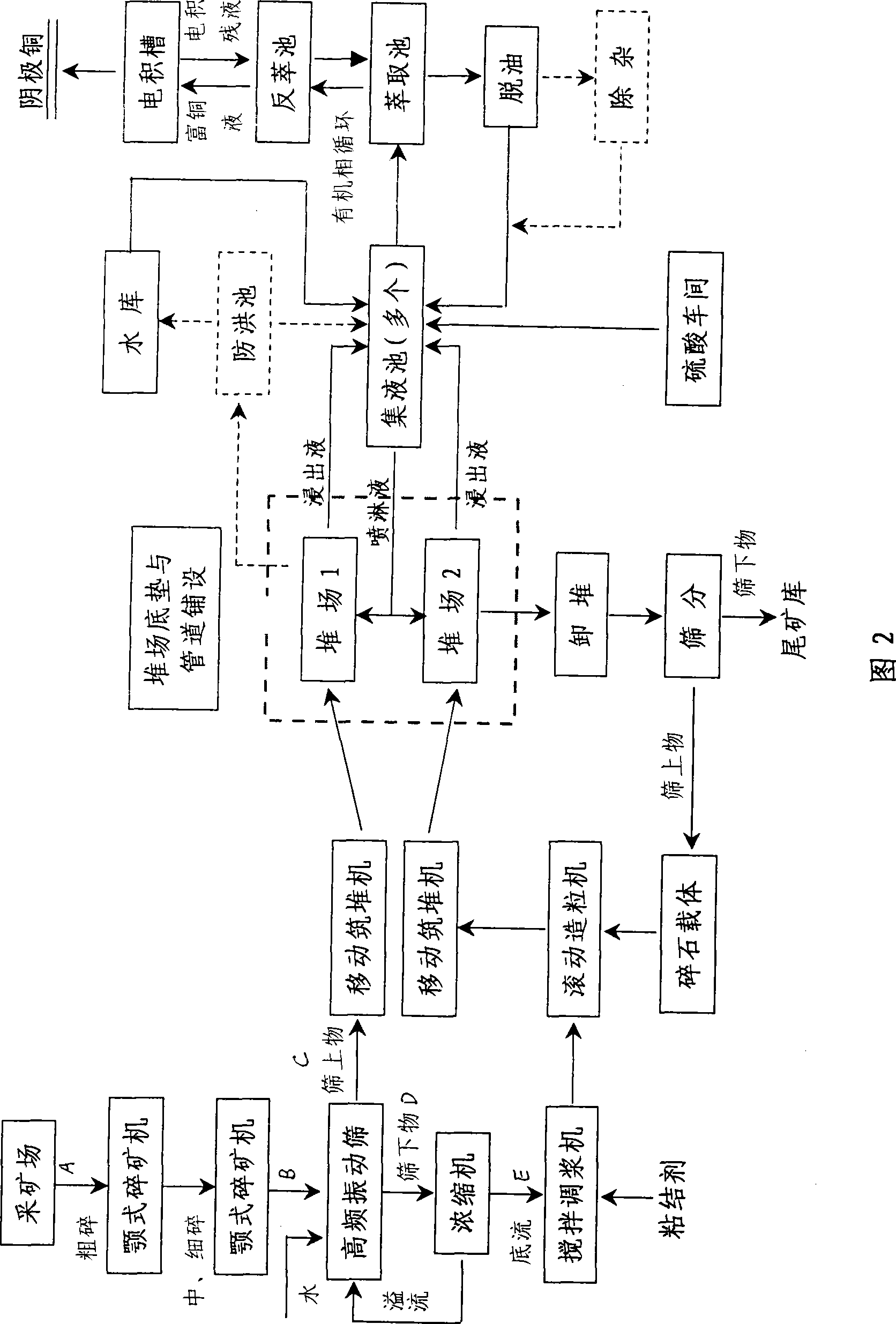

InactiveCN1424413AEasy to stockpileImprove efficiencyProcess efficiency improvementPregnant leach solutionGranularity

A process for extracting copper from the mixture-type copper ore of copper sulfide ore and copper oxide ore includes such steps as respectively cracking, bacterial stacking extracting of one ore, washing, stirring and stacking extracting to another, extracting the extracted liquid, conventional back extracting to carried organic phase, and electrodepositing to obtain high-purity cathode copper. Its advantages are high recovery rate, low cost and no pollution.

Owner:ZIJIN MINING GROUP

Wet processing process of high mud cupric oxide mine at high-cold area

InactiveCN101457299ASolve permeabilitySolve the problem of low copper leaching ratePhotography auxillary processesProcess efficiency improvementSlagCopper oxide

The invention provides a wet copper extraction process used in high mud-content copper oxide ores of cold areas. The process comprises the following steps: crude ores are crushed and sieved, coarse fraction ores are sent to a storage yard for piling, fine fraction ores are sent to an ore washing system for washing and grading; placer ores are sent to the storage yard for the piling after washing the ores, and mud ores are sent to an agitation tank for agitation leaching; leaching solution which is obtained from heap leaching and agitation leaching processes is sent for extraction and stripping; stripping concentration solution is sent to an electrodeposition process, and a qualified cathode copper product is obtained; leached slag from the agitation leaching is neutralized and sent to a tailings reservoir for piling. The process has good permeability, fast copper leaching rate, and greatly improved copper leaching rate and leached copper yield per day by the grading and the heap leaching of the coarse fraction ores; and the copper leaching rate is improved and the ore utilization rate is greatly improved by the agitation leaching of minus 0.074mm size fraction ores. The method is applicable to the development and the application in the wet copper extraction process used in the high mud-content copper oxide ores of the cold areas, solves the difficult technical problems of poor bing permeability and slow copper leaching rate, widens the use range of copper ore resources and improves the comprehensive utilization rate of the copper.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

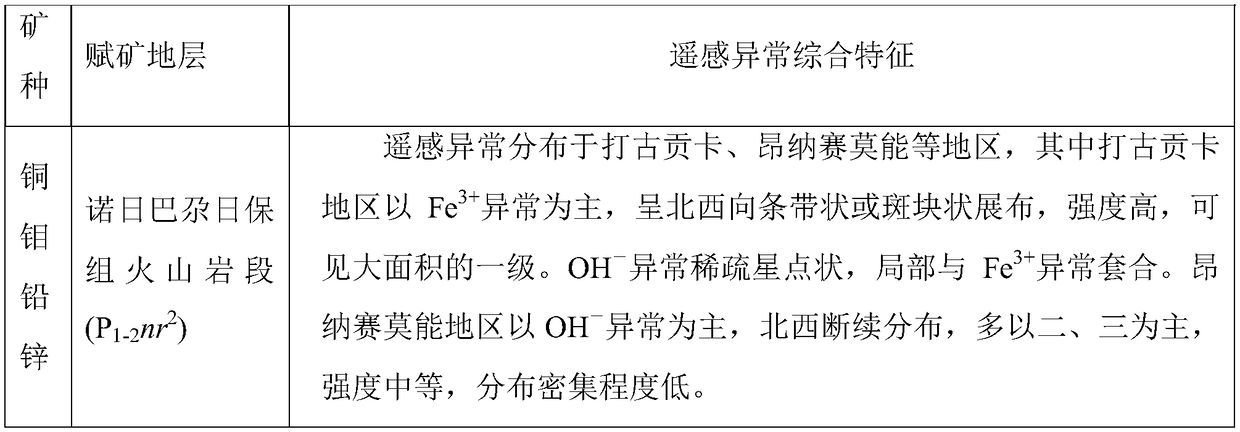

Cenozoic magmatic copper polymetallic ore prospecting method

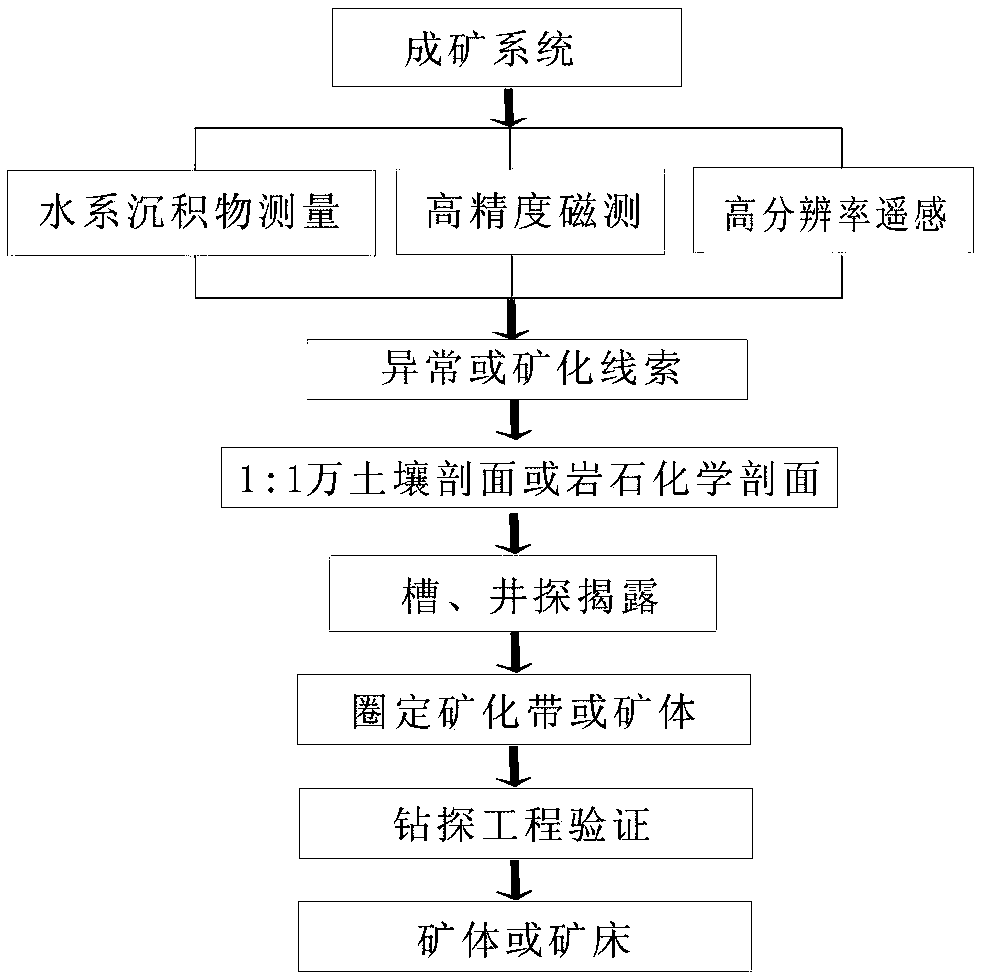

InactiveCN108761564AGreat Prospecting BreakthroughEarth material testingGeological measurementsPetrochemicalCenozoic

The invention discloses a cenozoic magmatic copper polymetallic ore prospecting method. The method comprises the following steps: determining a magmatic zone or an abnormal area (zone) according to magmatic ore deposit and spot output space-time and geological background; preliminarily determining prospecting targets and target classification by virtue of stream sediment measurement; selecting zones having excellent copper mineralization or molybdenum mineralization or excellent abnormality in target classification for performing magnetic survey verification, and determining a first precedencetarget area or a first abnormal area; determining a second precedence target area or a second abnormal area in the first precedence target area or the first abnormal area by adopting high resolutionremote sensing; performing on-the-spot survey inspection on the second precedence target area or the second abnormal area, and finding out a geologic abnormal area (zone) or a mineralization clue area; performing soil profile or petrochemical profile measurement according to 1:10000, and determining the ore-bearing geological body position on the surface and mineralized body features; performing shallow exposure recourse to control the specific location and shape of the mineralized zone or mineralized body by utilizing trenching; and determining the depth grade thickness scale and occurrence conditions of the mineralized body by utilizing drilling, and discovering the metal ore or ore deposit.

Owner:青海省地质调查院

Biological metallurgy mineral leaching microorganism combined bacterium fluid for copper ore and method for recycling metallic copper

InactiveCN101956071ATake advantage ofProtect environmentProcess efficiency improvementEcological environmentSlag

The invention discloses biological metallurgy mineral leaching microorganism combined bacterium fluid for a copper ore and a method for recycling metallic copper. The method comprises the following steps that: mineral leaching microorganisms after adaptive culture, continuous amplification culture and ore pile adaptive culture are combined and used for mineral leaching, and different leaching methods are adopted aiming at the ore of different objects, which comprise a biological metallurgy processing method for lump ores, powder ores, tailings, copper smelting slags and the like; and the obtained qualified leaching solution is used to prepare two products, namely electrolytic copper by an extraction-electrodeposition method and spongy copper by a short stage displacement method. The method has the advantages of suitability for industrial production under different conditions, efficient utilization of low-grade copper ore resources and capacity of effectively protecting the ecological environment of mine areas and achieving a win-win situation of economic benefit and environmental friendliness.

Owner:CENT SOUTH UNIV

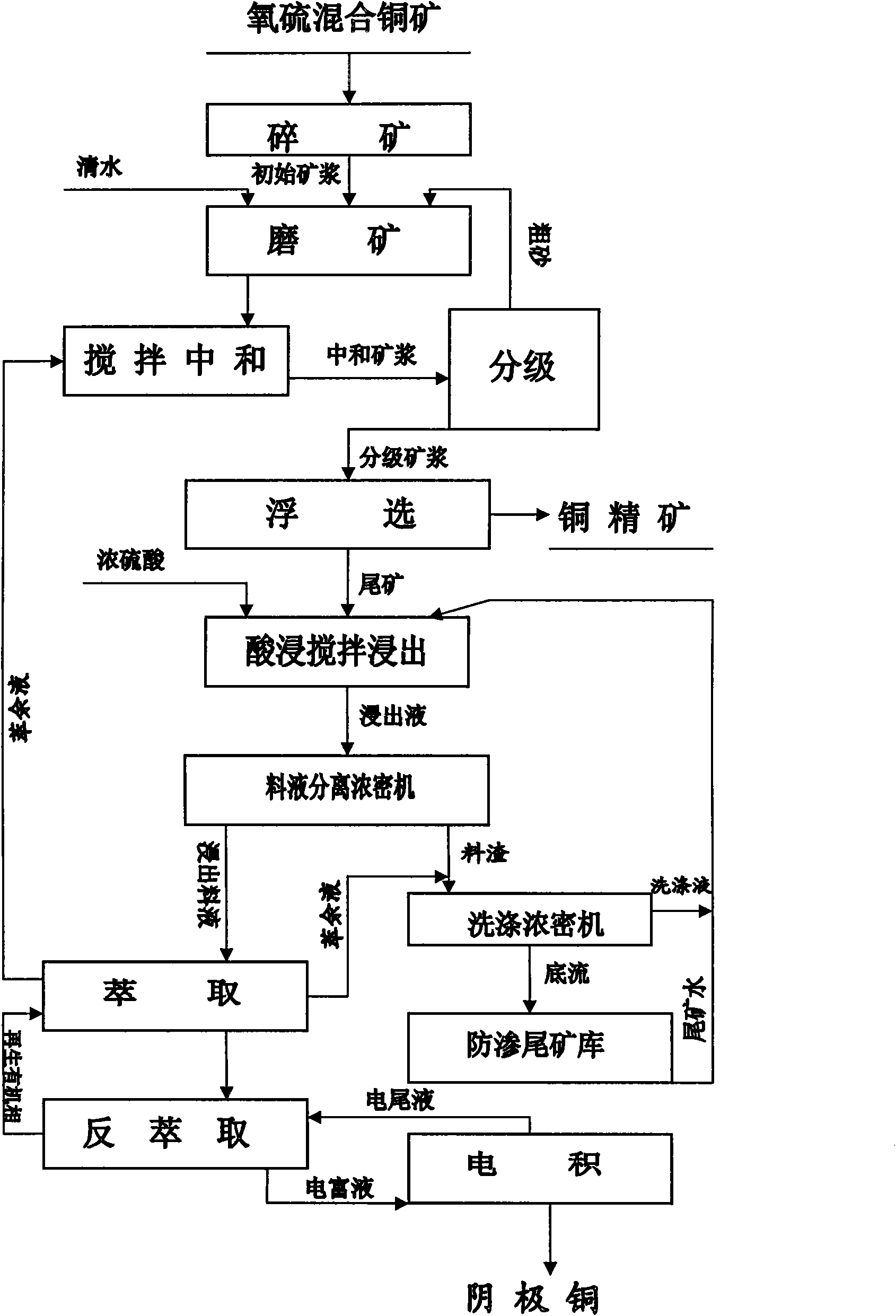

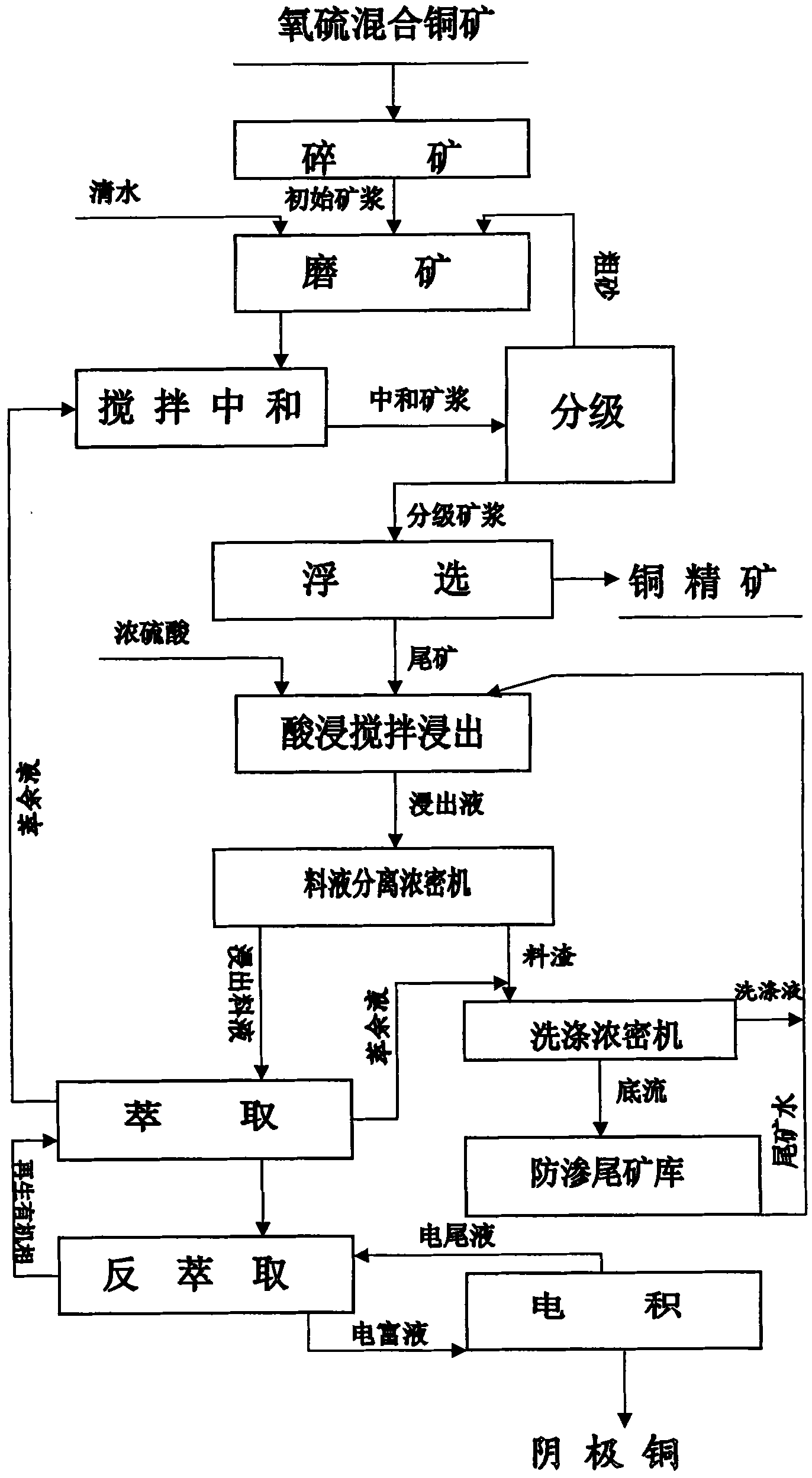

Combined concentration and smelting method for mixed copper ore

The invention discloses a combined concentration and smelting method for mixed copper ore. The method is a flotation-acid leaching combined concentration and smelting method which comprises the following steps of: separating sulphide ore from oxide and sulphide-mixed copper ore with the oxygenation efficiency of 10 to 80 percent to obtain copper ore concentrates; forbidding to add flotation activator Na2S of the copper oxide ore in the flotation, stirring and neutralizing initial ore pulp obtained by ore grinding and obtaining neutralized ore pulp, grading the neutralized ore pulp and obtaining the graded ore pulp, floating the graded ore pulp and obtaining the copper concentrate and tailings; carrying out acid leaching and agitation leaching on the floated tailings directly; and performing extraction electrowinning to obtain the cathode copper. The invention has the advantages that: the recovery rate of the oxide and sulphide-mixed copper ore can be greatly increased and can be increased by 10 to 40 percent generally. The method also has the advantages of saving the investment and production cost of flotation tailings solid-liquid separation process, preventing the copper oxide from entering the copper concentrate, along with simple and efficient process, low consumption of flotation agent, low consumption of process new water, reasonable process and high recovery rate.

Owner:罗光臣

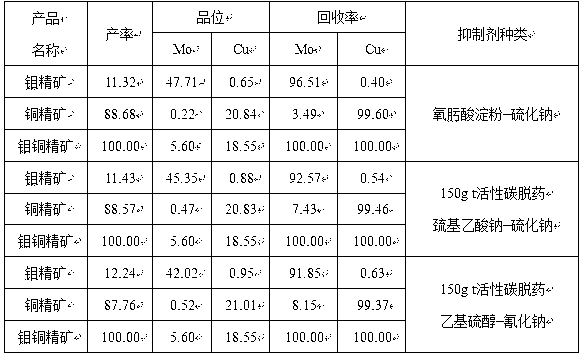

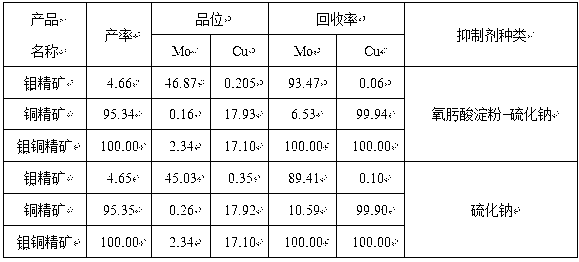

Method for flotation and separation of copper molybdenum sulphide bulk concentrates

The invention discloses a method for flotation and separation of copper molybdenum sulphide bulk concentrates and belongs to the technical field of mineral dressing. The method uses the copper molybdenum sulphide floated bulk concentrates as raw materials, adopts efficient environment-friendly copper ore inhibitor such as hydroxamic acid starch to inhibit copper sulphide ores, performs flotation of molybdenum sulphide ores and performs flotation and separation of copper and molybdenum. Oximido in the hydroxamic acid starch can be combined with active mass points Cu2+ on the surfaces of the copper sulphide ores to produce stable pentabasic chelate rings. Hydroxide radical and other polar radicals in a starch group at the other end of a chelate can be associated with water molecules through hydrogen bonds to enable the copper sulphide ores to be hydrophilic and inhibit the copper sulphide ores. In addition, the enormous hydrophilic water molecules of the hydroxamic acid starch can hide hydrophobic collecting agent molecules absorbed on the surfaces of copper ores, a collecting agent absorbed on the surfaces of the copper ores is not required to be removed, and the flotation and the separation of the copper molybdenum sulphide bulk concentrates do not need mechanical reagent removal or concentrated reagent removal. The hydroxamic acid starch serves as an inhibitor to inhibit the copper ores, sodium sulphide usage can be remarkably decreased, mechanical reagent removal or concentrated reagent removal is not needed, the chemical cost for the separation of the copper and the molybdenum is reduced, copper and molybdenum flotation and separation technological processes are simplified, good separation effect is obtained, and the method is environment-friendly and efficient.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Acid heap leaching process for cupric oxide ore

InactiveCN101435021AImprove the level of comprehensive utilizationReduce pollutionPhotography auxillary processesProcess efficiency improvementPregnant leach solutionClay minerals

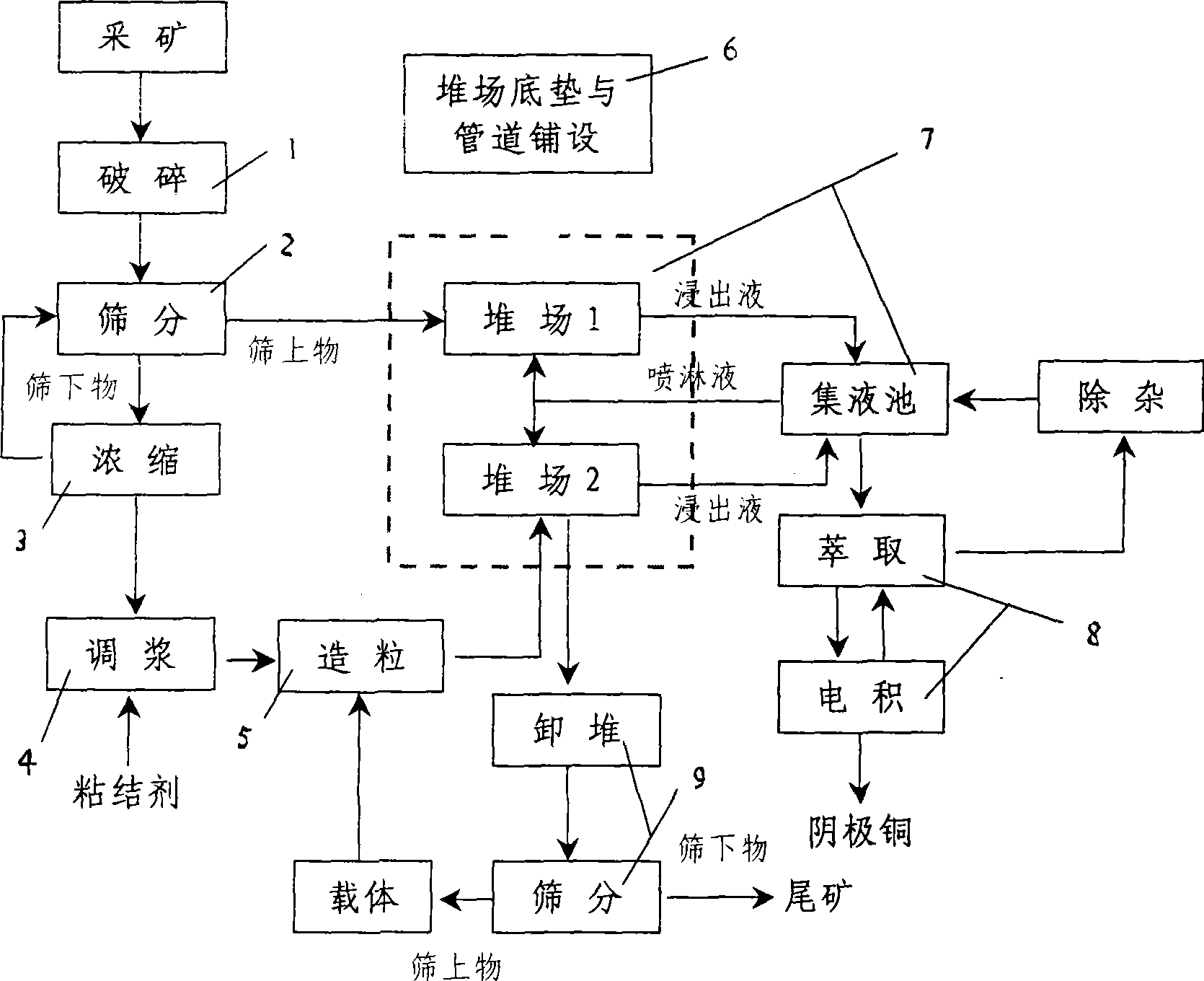

The invention provides a new technique of acid heap leaching of copper oxide ore. The copper oxide ore is crushed and screened, then materials on a screen are carried out conventional acid heap leaching operation and the materials under the screen carry out concentration, size mixing and granulation and then are piled and leached; and leachate rich in copper ions is treated by the procedures of extraction, electrodeposition and the like so as to obtain cathode copper sold on the market. After the materials under the screen are concentrated, a binding agent needs to be added for size mixing; after size mixing, ore pulp and prepared acid-proof gravel with the granularity of 5mm to 25mm are mixed for granulation; in the granulation and heap leaching process, the pile height is 3 to 5m, in the heap leaching process, the concentration of dilute sulphuric acid is 0.1 to 2mol / L, the spraying strength is 0.2 to 0.5L / (min.m<2>) and the leaching period is 1 to 2 months. The technique can fully utilize copper oxide ore resource which is hard to be utilized in the past time, contains a large amount of clay mineral and is easy to argillization, improves the level of comprehensive utilization of mines, saves cost and increases profit. The invention is particularly suitable for being applied to the development of copper ore resources, mainly the copper oxide ore, which are hard to treat in all regions of China, in particular to remote regions of the western highlands.

Owner:有研资源环境技术研究院(北京)有限公司

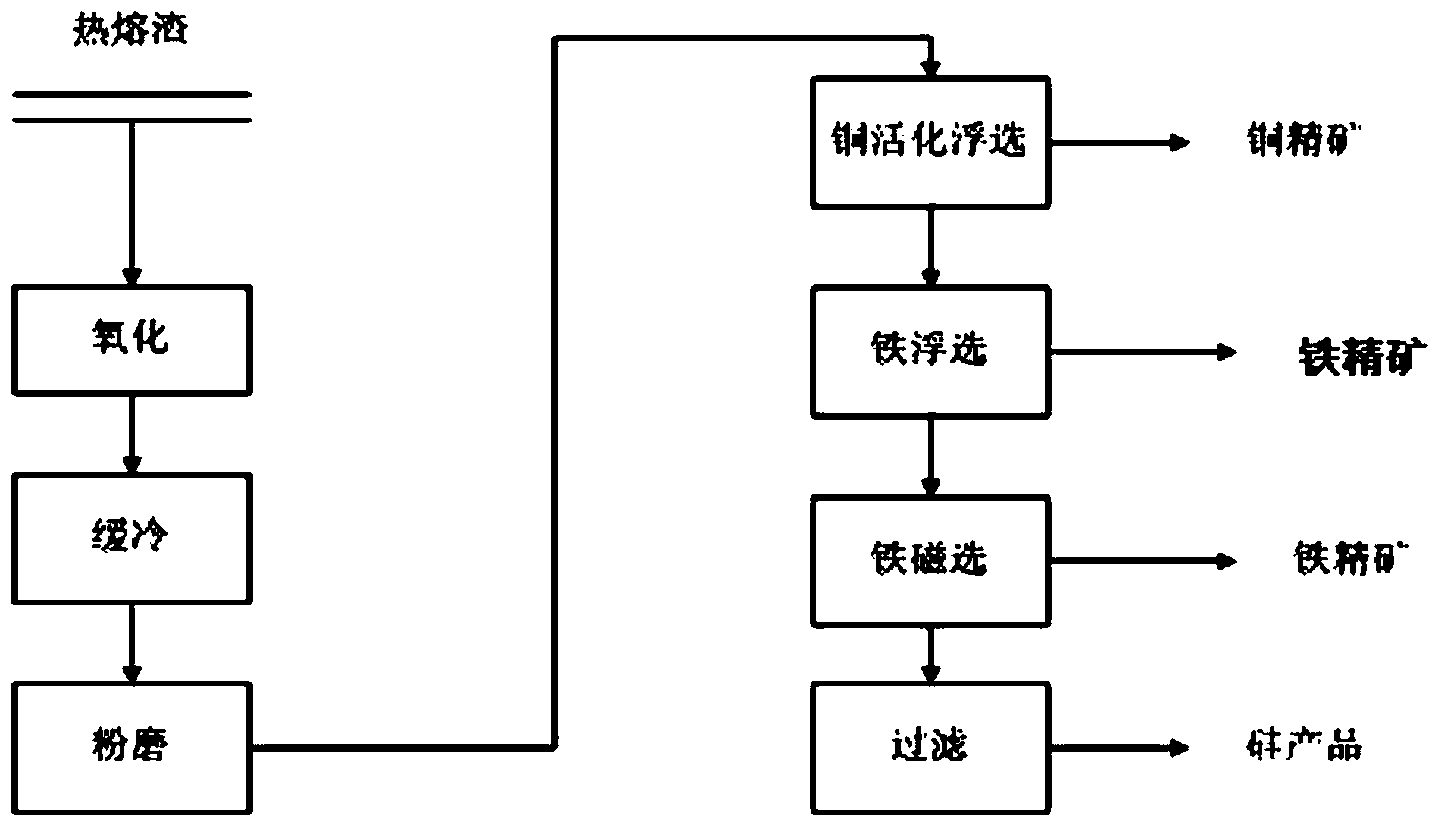

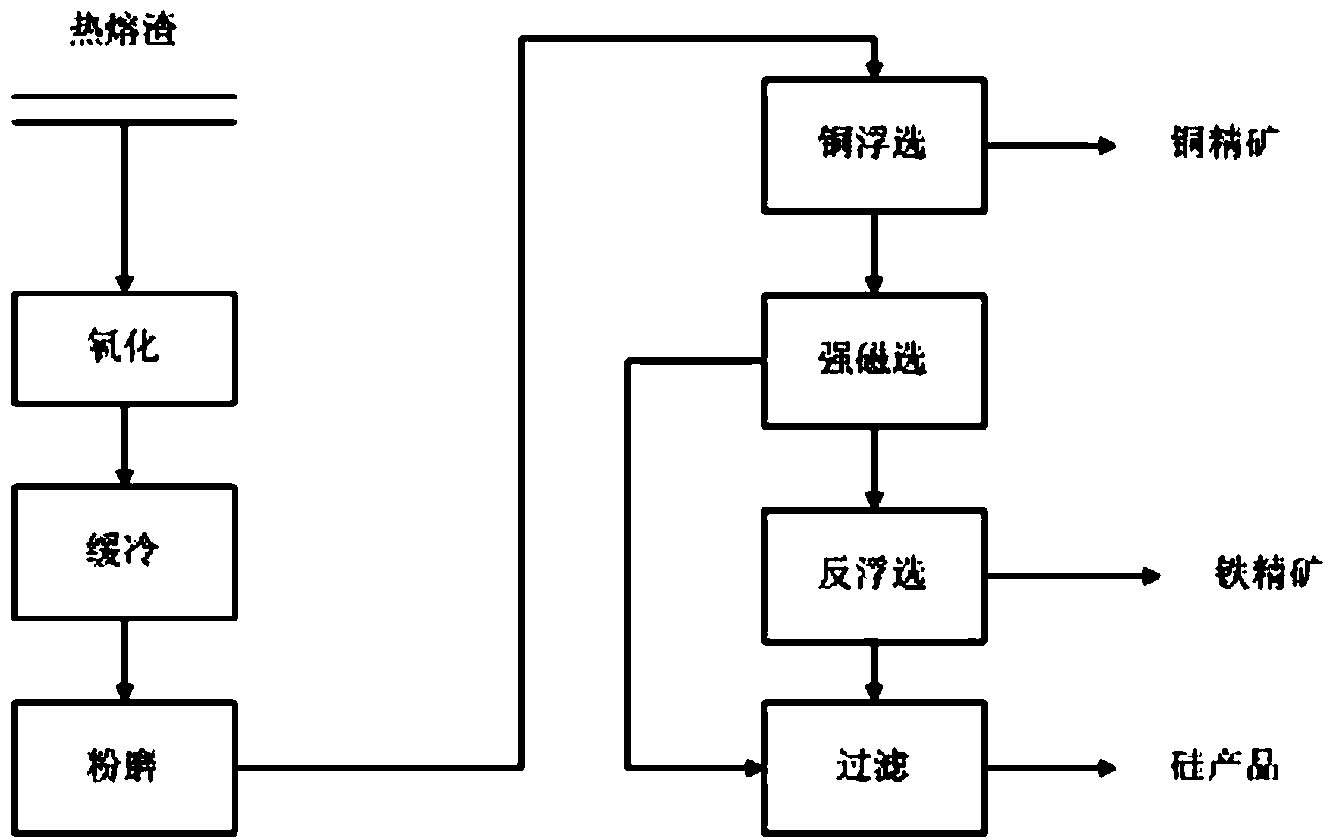

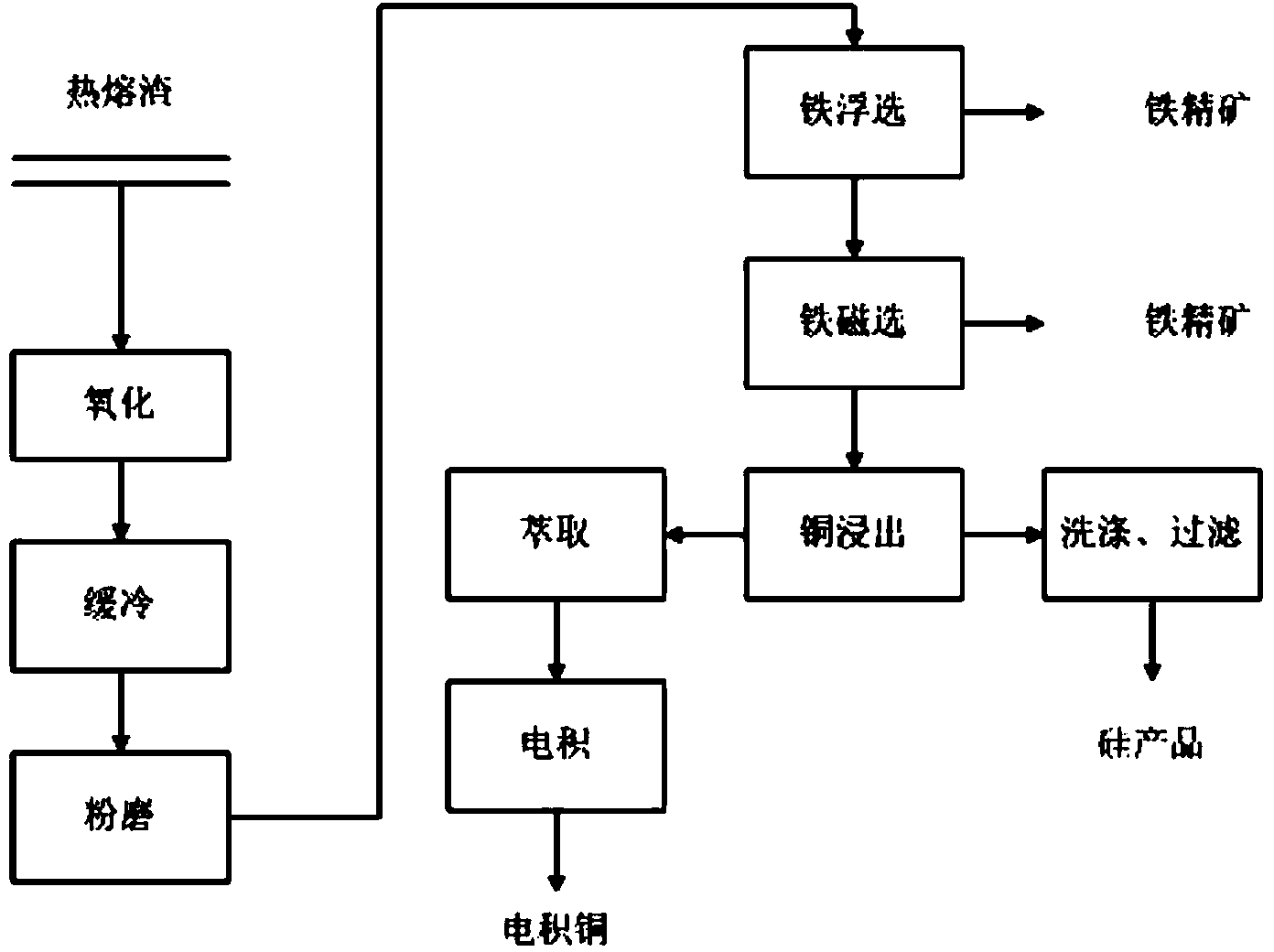

Method for recovering copper, iron and silicon from copper smelting slag

InactiveCN104342561APromote growthMeet the needs of resource processingProcess efficiency improvementSlagCopper oxide

The invention provides a method for recovering copper, iron and silicon from copper smelting slag. The method comprises the following steps: (a) adopting oxygen to oxidize hot copper smelting slag to obtain mixed slag charge, wherein the temperature of the hot copper smelting slag is 1000-1350DEG C, and the mixed slag charge comprises hematite, copper oxide ore and quartz mine, and carrying out slow cooling processing on the mixed slag charge; (b) recovering the hematite from the mixed slag charge subjected to the slow cooling processing in the step (a) through flotation and magnetic separation, receiving a copper-contained product through activation flotation or leaching, and finally filtering tailings subjected to hematite recovery and the copper-contained product to obtain a silicon-contained product. The method provided by the invention has the advantages of short flow, simple technology, easiness in realization and control, wide use range, high practicality and the like and basically meets copper smelting slag resourceful processing requirements of the copper smelting industry. In addition, the method for recovering the copper, the iron and the silicon from the copper smelting slag, which is provided by the invention, does not generate secondary wastes, is free from pollution and has little energy input.

Owner:YANGGU XIANGGUANG COPPER

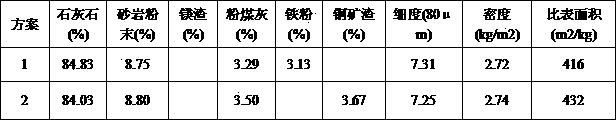

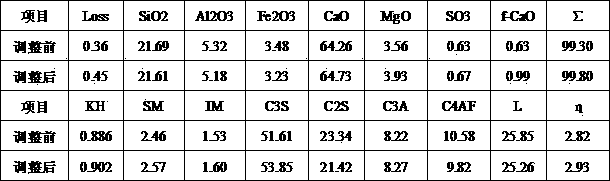

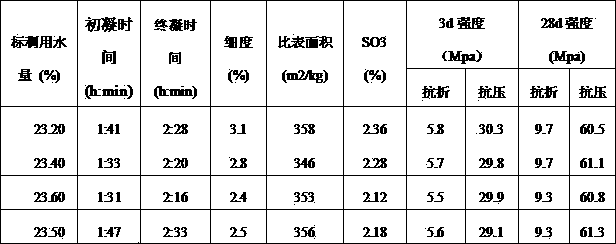

Cement clinker and preparation process thereof

The invention discloses cement clinker and a preparation process thereof, belongs to the technical field of cement and a preparation process thereof, and aims to solve the problem of providing cement clinker prepared by a waste industrial raw material and a process for preparing the cement clinker. The invention adopts a technical scheme as follows: the cement clinker is formed by the following components in percentage by weight: 56.47-80.75% of limestone, 6.37-18.92% of sandstone power, 7.45-20.28% of magnesium slag, 2.36-8.69% of slack coal ash, and 1.54-6.75% of copper ore slag. The preparation process of the cement clinker comprises the following steps: Step I, collecting the limestone, the sandstone power, the magnesium slag, the slack coal ash and the copper ore slag, and mixing the limestone, the sandstone power, the magnesium slag, the slack coal ash and the copper ore slag according to the set weight percent; Step II, drying and grinding the limestone, the sandstone power, the magnesium slag, the slack coal ash and the copper ore slag mixed in the Step I, and obtaining crude material power; Step III, burning the crude material power obtained in the Step II, and obtaining the cement clinker. The preparation process is applied to cement production.

Owner:WEIDUN CEMENT GRP

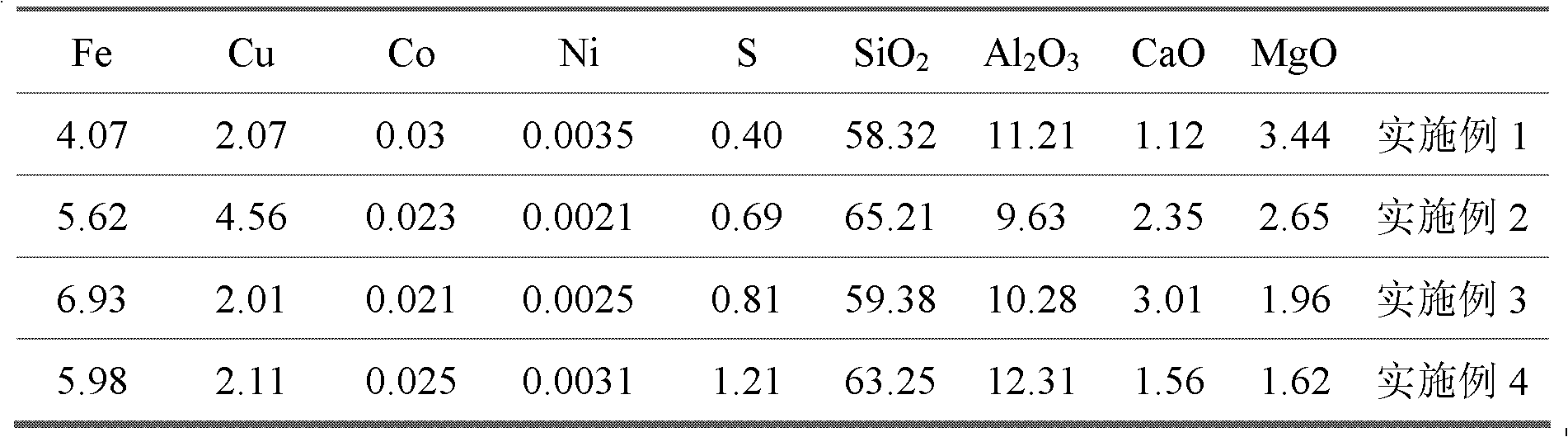

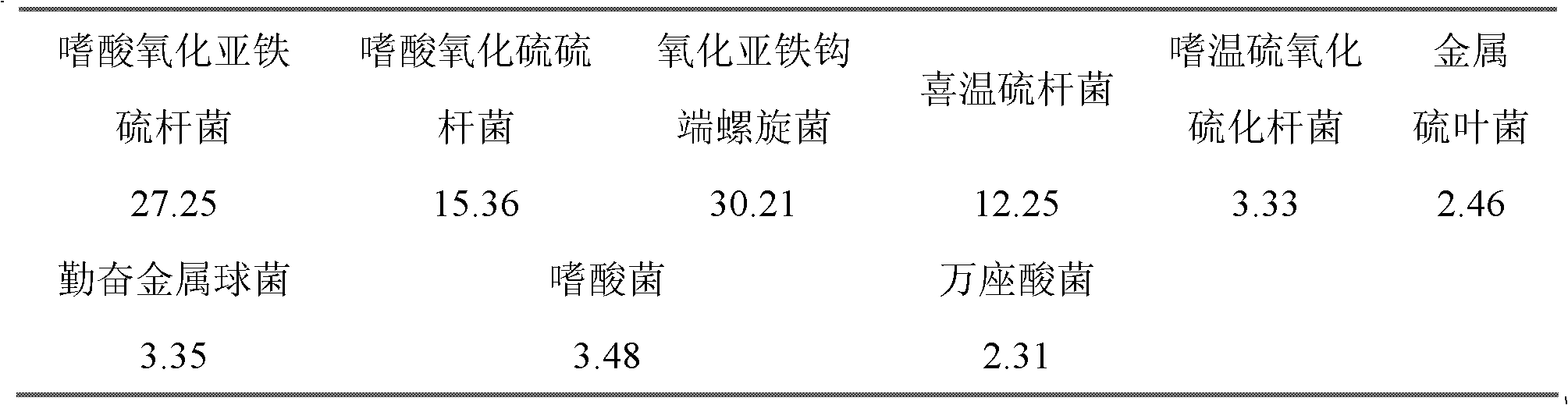

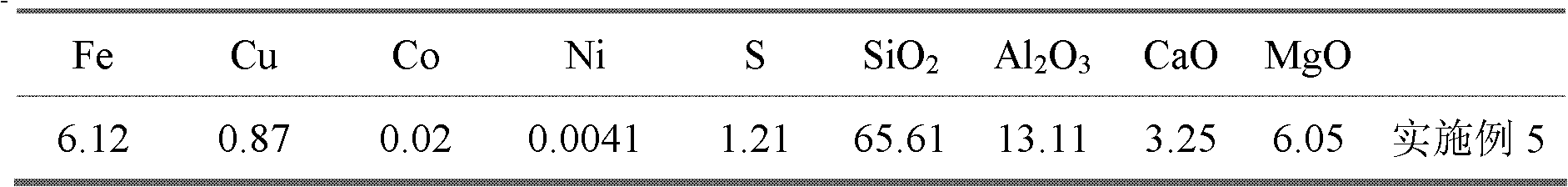

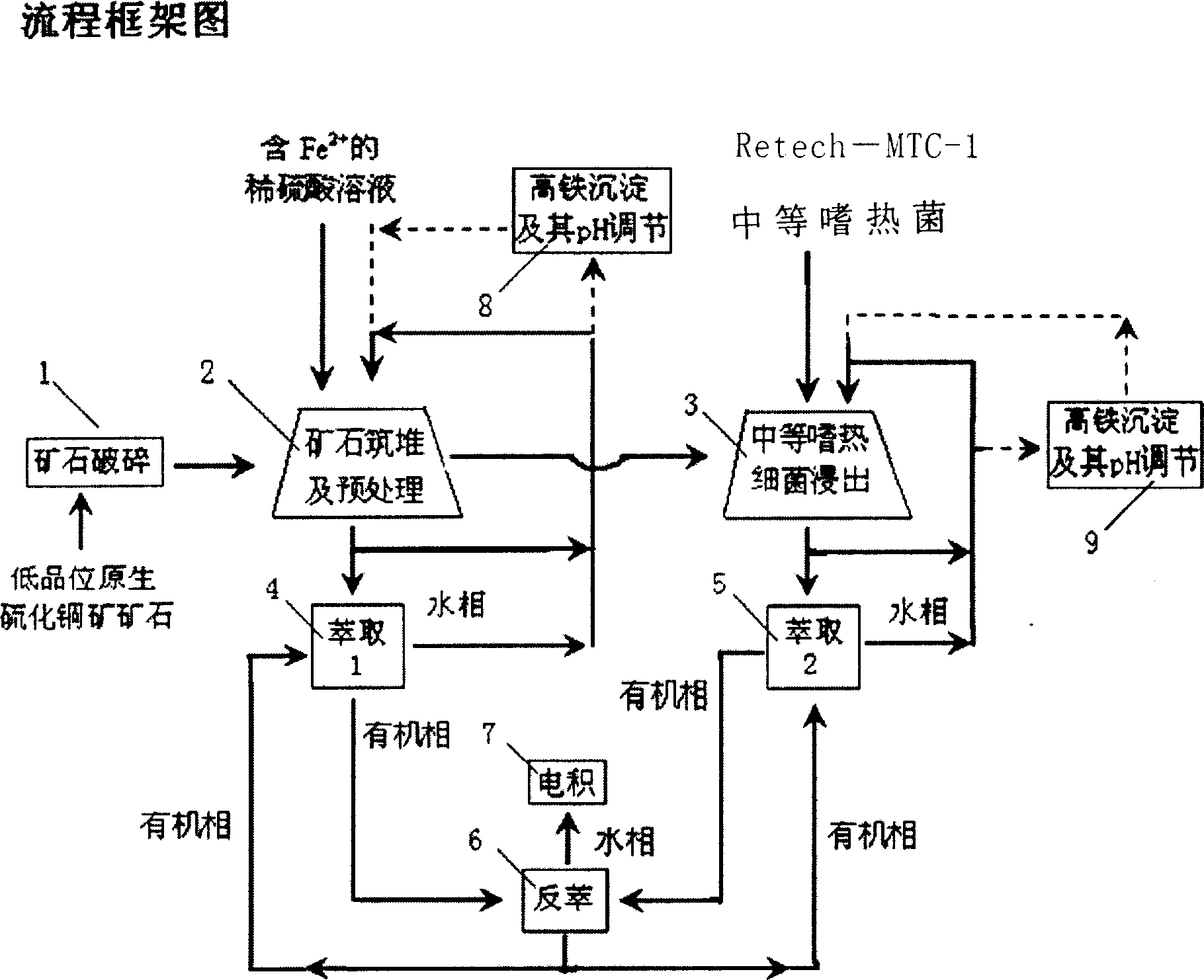

Middle thermophilic bacteria and chemical and biological combined heap leaching technique for low-grade primary copper ore

The invention discloses a chemical and biological combining push soak craft of middle grade thermophile and low-grade primary cupric sulfide ore, which comprises the following steps: utilizing diluted sulfate liquor with Fe2+ ion; pre-processing low-grade primary cupric sulfide ore; choosing domestic middle grade thermophile (Sulfobacillus thermosulfidooxidans Retech-MTC-1) with reinforced sulfur oxidability; leaching primary cupric sulfide ore; reclaiming the copper; extracting leachate in pretreating step; entering organic phase into downstream back extraction process; extracting eligible leachate in middle grade thermophile step; backing the water phase to soaking pile; merging organic phase and the organic phase in pretreating step; entering into downstream back extraction process. This craft possesses short flow process, simple device, low coat and high reclaiming ratio, which can increase the reclaiming ratio of copper.

Owner:有研资源环境技术研究院(北京)有限公司

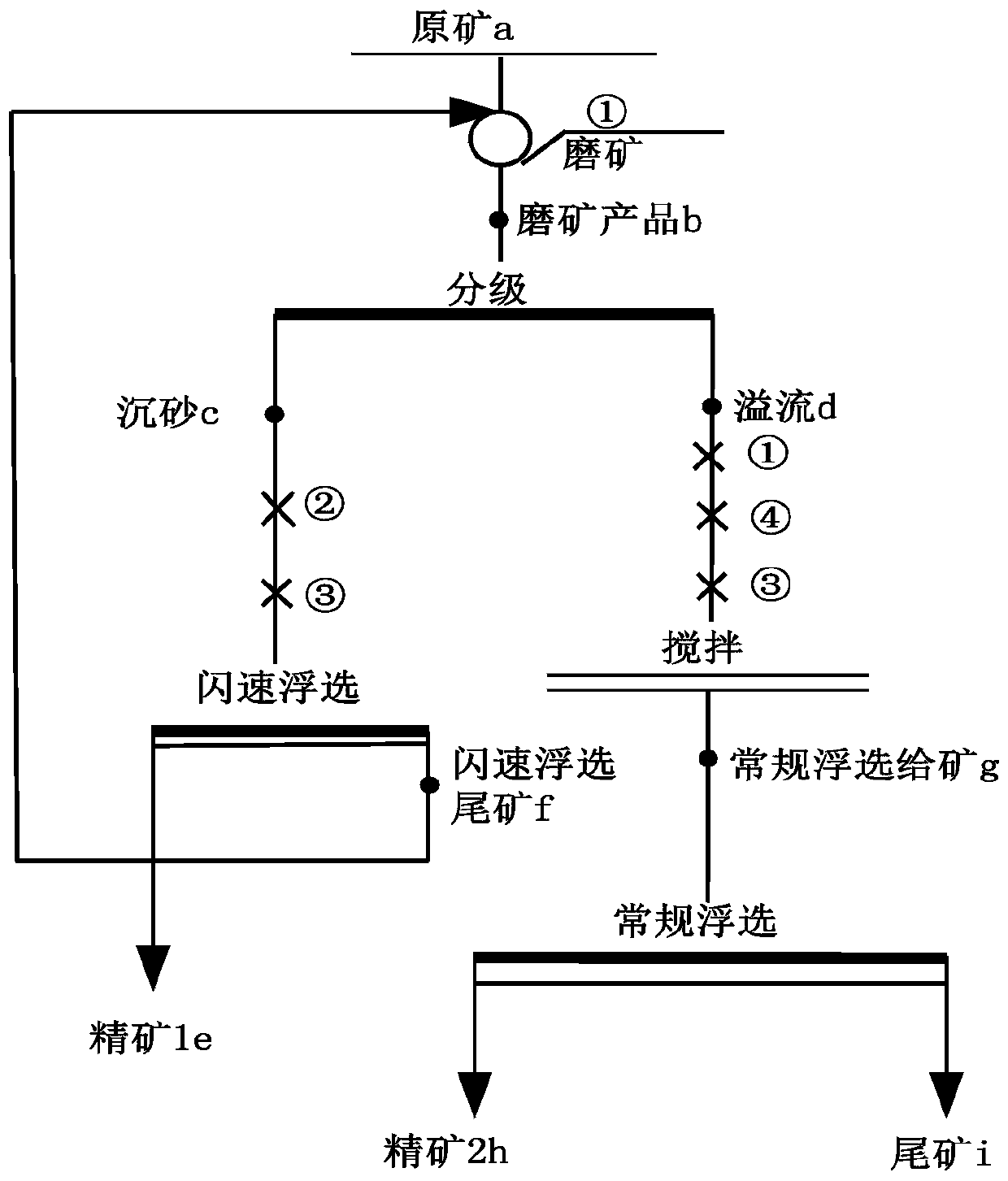

Chalcocite-contained coarse-grain disseminated copper sulfide ore step-by-step ore grinding flotation method

InactiveCN110292984AGuaranteed concentrate gradeGuaranteed RecoveryFlotationWet separationFoaming agentSulfide

The invention relates to a chalcocite-contained coarse-grain disseminated copper sulfide ore step-by-step ore grinding flotation method. According to the chalcocite-contained coarse-grain disseminatedcopper sulfide ore step-by-step ore grinding flotation method, raw ores are subjected to ore grinding and then are graded into two kinds of ore pulp, namely, overflow d and setting sand c to form twoloops to be subjected to flash flotation and conventional flotation correspondingly; during one loop of flash flotation, a high-selectivity collecting agent (2) and a foaming agent (3) are added to the setting sand c ore pulp fed into a single-tank flash flotation machine to be subjected to optimized flotation to obtain a copper concentrate product 1 and flash flotation tailings f; the concentrate grade and the recovery rate of the copper concentrate product 1 can be ensured, ore feeding fluctuation of conventional flotation can be reduced, the stability of the preparation process is improved, and valuable minerals in ores can be recovered as early as possible; during the other loop of conventional flotation, calcium oxide (1), a high-collectivity collecting agent (4) and the foaming agent (3) are added to the overflow d ore pulp to be subjected to stirring and conventional flotation to enable valuable metals such as gold, silver and copper in the overflow d to be enriched into copperconcentrate 2h and remove tailings 1. The chalcocite-contained coarse-grain disseminated copper sulfide ore step-by-step ore grinding flotation method has the advantages of being simple in operation,smooth in process, easy to apply industrially, high in recovery rate, low in production cost, good in comprehensive benefit and the like and is particularly suitable for mineral separation of chalcocite-contained coarse-grain disseminated copper sulfide ores.

Owner:ZIJIN MINING GROUP

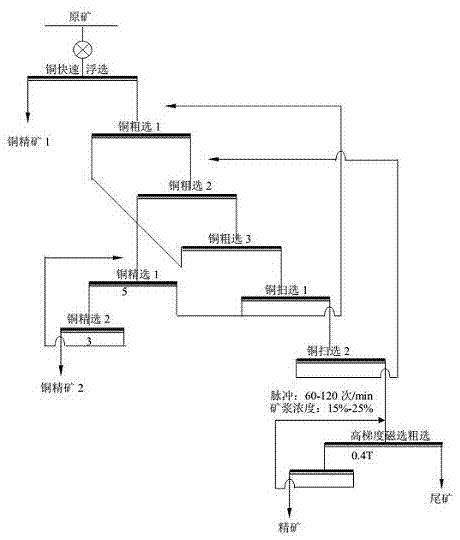

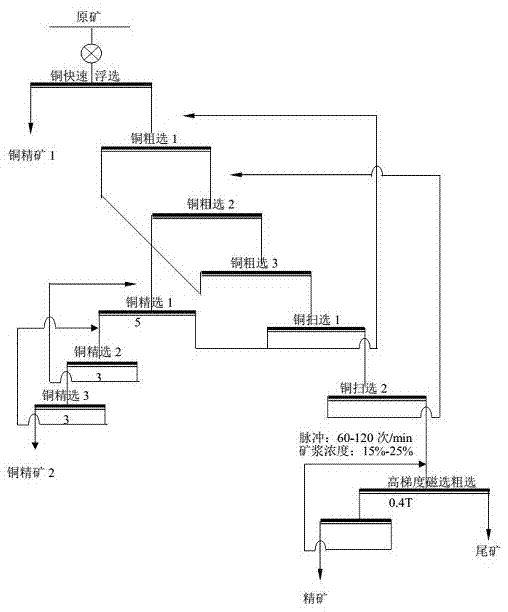

Method for recovering high-pelitic and high-iron copper oxide ore hard to treat

InactiveCN105435952ALight in massLarge specific surface areaWet separationCopper oxideMineral processing

The invention relates to a method for sorting high-pelitic and high-iron copper oxide ore hard to treat, and belongs to the technical field of mineral processing. After being ground, raw copper oxide ore is subjected to rapid flotation, so that a high-grade copper concentrate is obtained; then copper minerals hard to float are separated out through segmented flotation, and a low-grade copper concentrate is obtained; and finally a magnetic concentrate is obtained through high-gradient magnetic separation. Compared with a traditional copper oxide flotation method, the recovery rate of the method is higher by 15%-35%, and interference of mud and iron is avoided. The technological process is stable, high in adaptability, low in production cost, high in copper recovery rate and capable of being industrially implemented.

Owner:HUNAN RES INST FOR NONFERROUS METALS

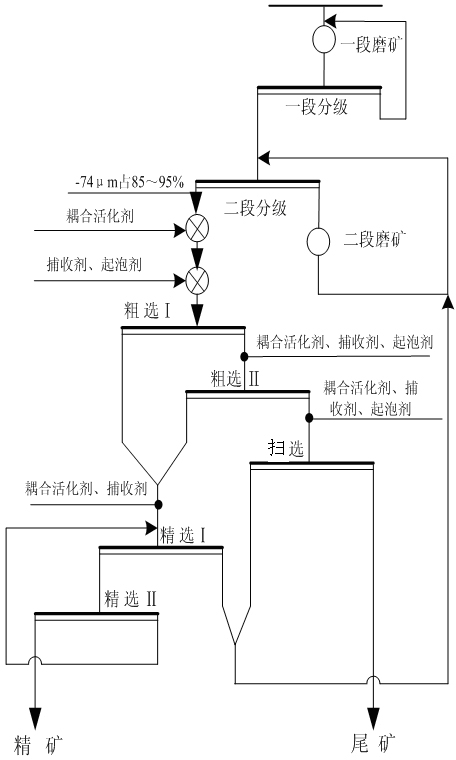

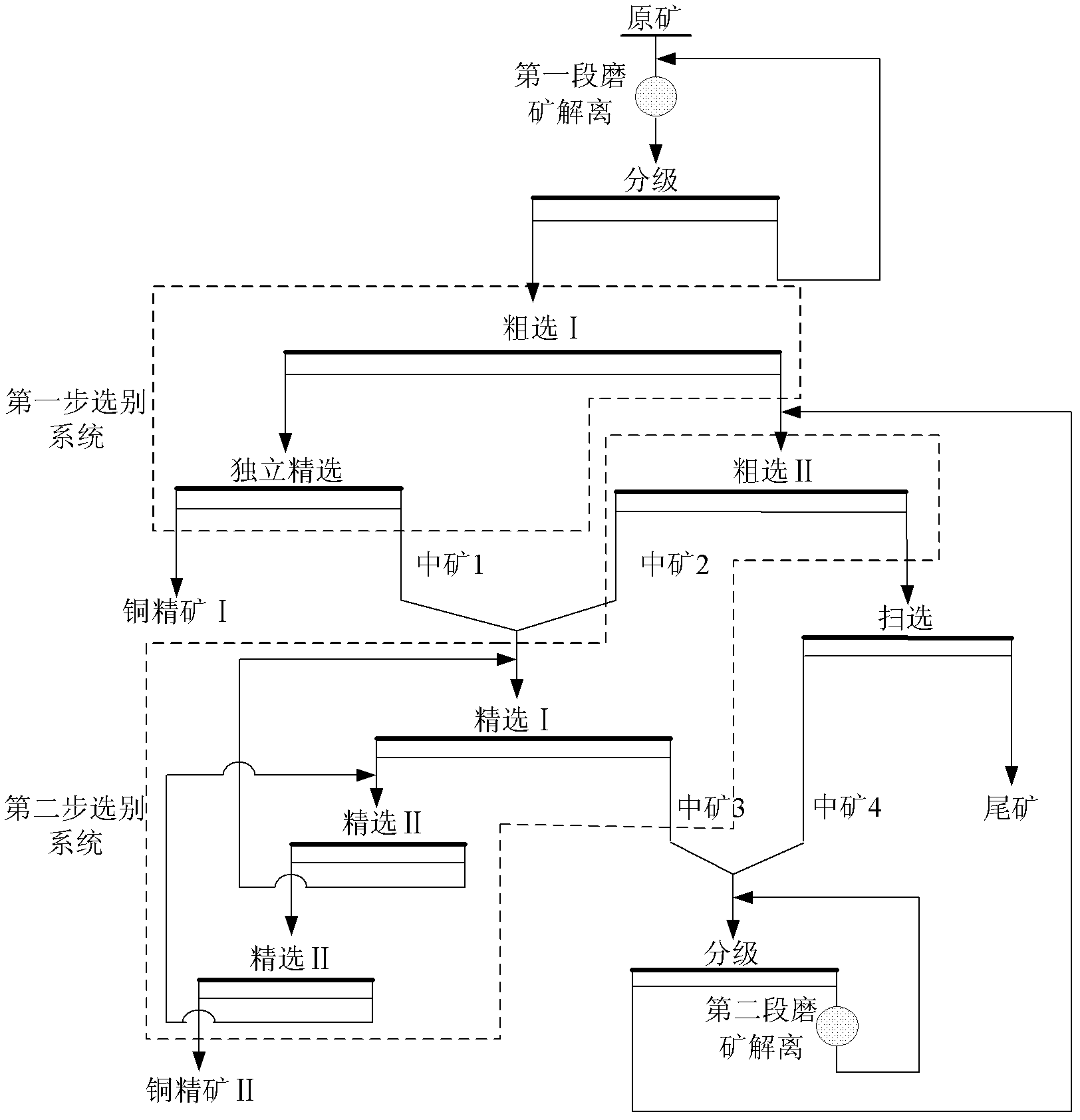

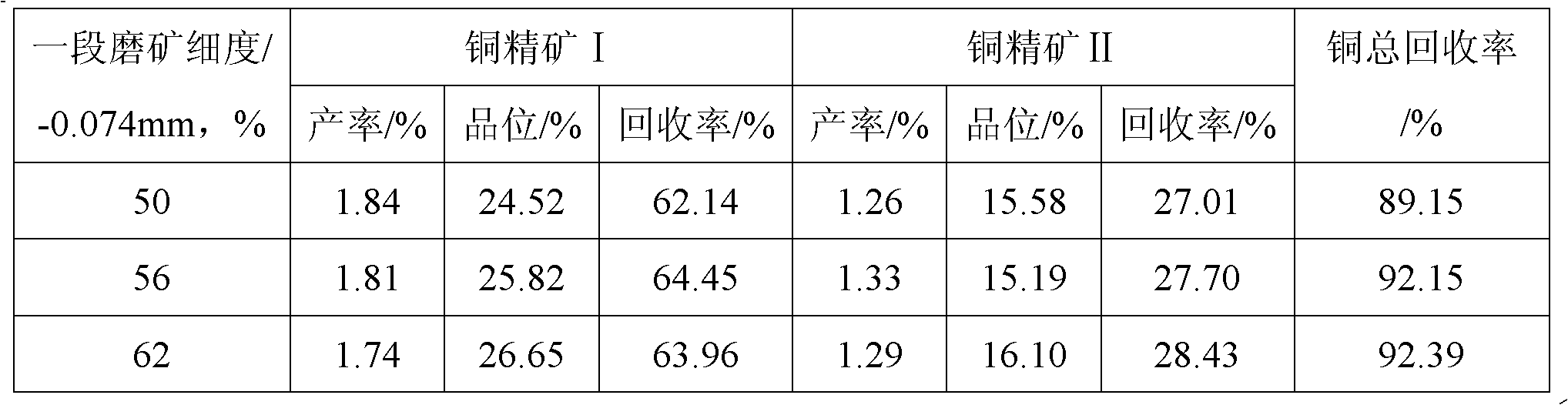

New stage dissociation-fractional selection flotation process

InactiveCN102302969AImprove flotation recoveryReduce pollutionFlotationGrain treatmentsAlkalinitySulfur

The invention relates to a selective grinding-floatation process for copper sulphide ores, particularly relates to a grinding-floatation process for complex copper sulphide ores in which the primary copper content is low, the secondary copper content is high and the secondary copper is accreted with copper oxides and the like, or the sulfide content is high. The process provided by the invention comprises the steps of first-stage ore grinding for dissociation, second-stage ore grinding for dissociation, first-step selection and second-step selection, wherein in the step of first-stage ore grinding for dissociation, ores with grinding fineness of minus 0.074mm are between 50% and 62%; in the step of second-stage ore grinding for dissociation, ores with the grinding fineness of minus 0.074mm are above 90%; in the step of first-step selection, preferential flotation on ores with a low basicity is achieved through taking an chemical agent ester-105 with a high selectivity as a collector; and in the step of second-step selection, the powerful collection of difficult floated copper can be realized by using a chemical agent such as xanthate. By using the process disclosed by the invention, the ore dressing recovery percentage of copper ores is increased, and the ore grinding cost is low, the chemical agent consumption is less, the degree of environmental pollution is low, and the ore dressing efficiency is high.

Owner:JIANGXI UNIV OF SCI & TECH

Method for beneficiating ion-state copper/cobalt/nickel mine of ore

ActiveCN102896037AHigh recovery rateEfficient use ofDifferential sedimentationWet separationCobaltNickel sulphide

The invention belongs to a method for beneficiating copper / cobalt / nickel mine and specifically relates to a method for beneficiating ion-state copper / cobalt / nickel mine of ore; copper ore containing a plenty of ion-state copper / cobalt / nickel in raw ore is beneficiated except copper / cobalt / nickel sulphide; copper / cobalt / nickel sulphide mine can be recycled in a conventional beneficiating and floating method; and the ion-state copper / cobalt / nickel cannot be recycled and is lost in gangue along with the emission of floated gangue. According to the invention, regulating agent and precipitator are added to gangue pulp in a stirring manner after floating the copper / cobalt / nickel sulphide mine; the ion-state copper / cobalt-nickel in mine pulp is reacted with the precipitator so as to generate copper / cobalt / nickel of a compound; the copper / cobalt / nickel is recycled so as to acquire a copper / cobalt / nickel concentrate product in a floating method; compared with conventional flotation, cobalt concentrate recycling rate is increased by 34.01%; and nickel concentrate recycling rate is increased by 31.58%.

Owner:HUNAN HERMES SAFE ENVIRONMENT PROTECTION SCI

Comprehensive treatment method for high-mud content high-combination rate mixed copper ore

The invention provides a comprehensive treatment method for high-mud content high-combination rate mixed copper ore, which comprises the following steps of: grinding the mixed copper ore and roughing copper sulfur so as to obtain copper sulfur ore and tailings; concentrating the copper sulfur ore to obtain the copper ore and middlings; concentrating the copper ore to obtain the copper concentrate, and performing copper rough concentration on the middlings to obtain the copper ore and middlings simultaneously; concentrating the copper ore to obtain the copper concentrate, and performing copper scavenging on the middlings to prepare sulfur concentrate for recovery; performing magnetic separation on the middlings subjected to the copper scavenging so as to obtain magnetic for recovery, and returning the tailings to copper sulfur roughing. In the method, the pyrite (sulfur concentrate) is separated from the copper concentrate successfully in the flotation process for the first time so as to obtain high-quality copper concentrate; meanwhile, a large amount of magnetic pyrite is separated from the middlings subjected to flotation through the magnetic separation step, the iron sulfur content in the middlings is reduced to the greatest degree, the middlings become high-quality sulfur concentrate which can be directly used as raw materials for producing sulfuric acid, the tailings subjected to magnetic separation return to the system for recycled production, and valuable resources are fully recycled.

Owner:YUNNAN DIQING MINING DEV

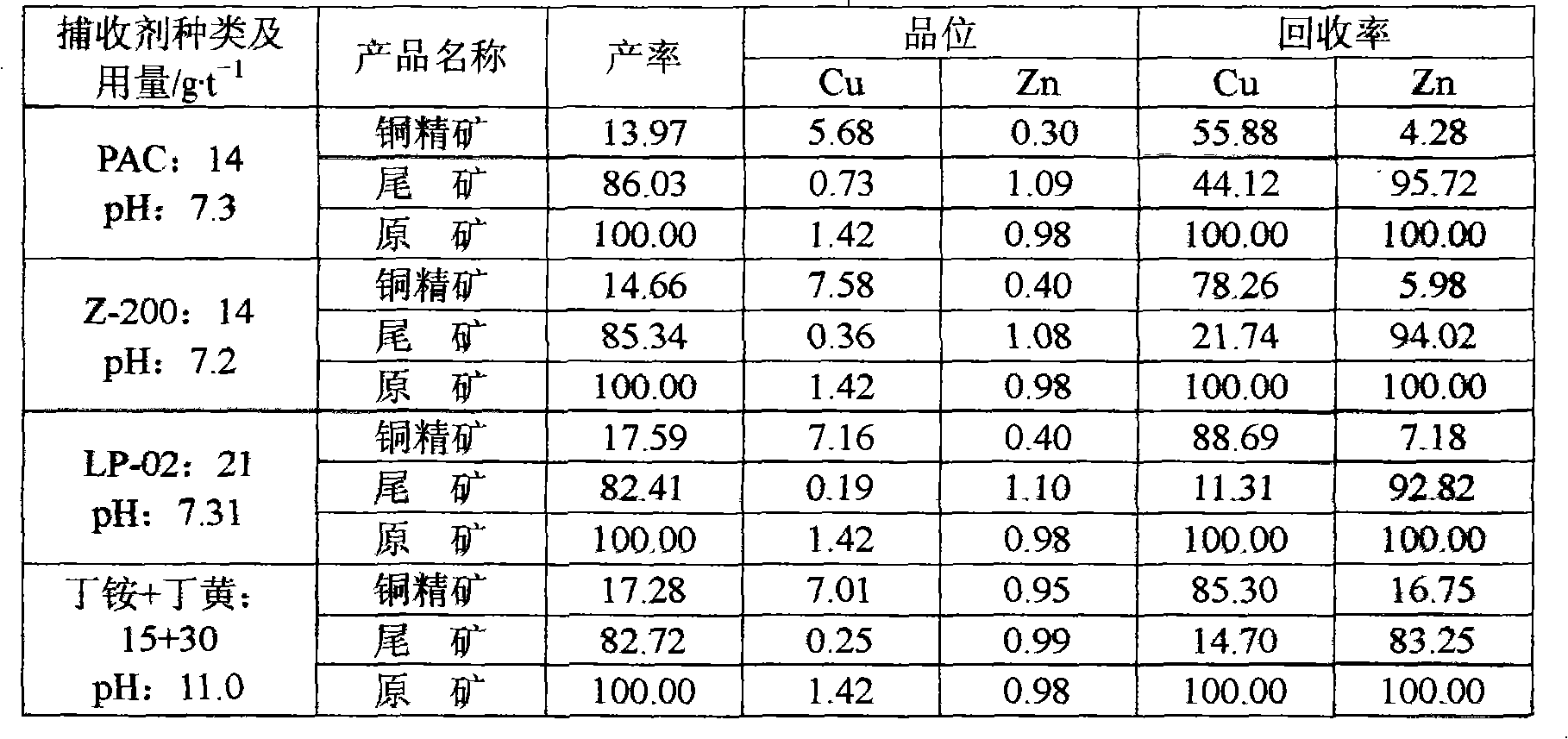

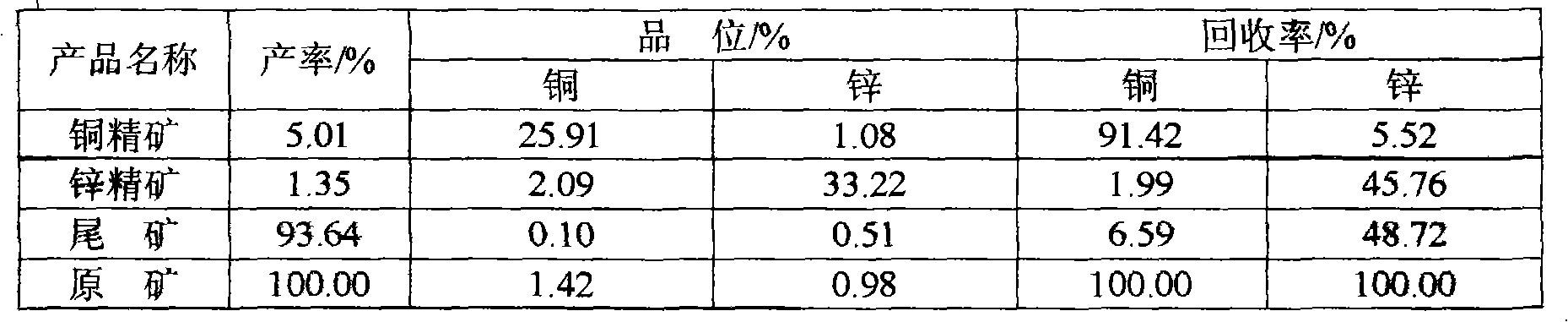

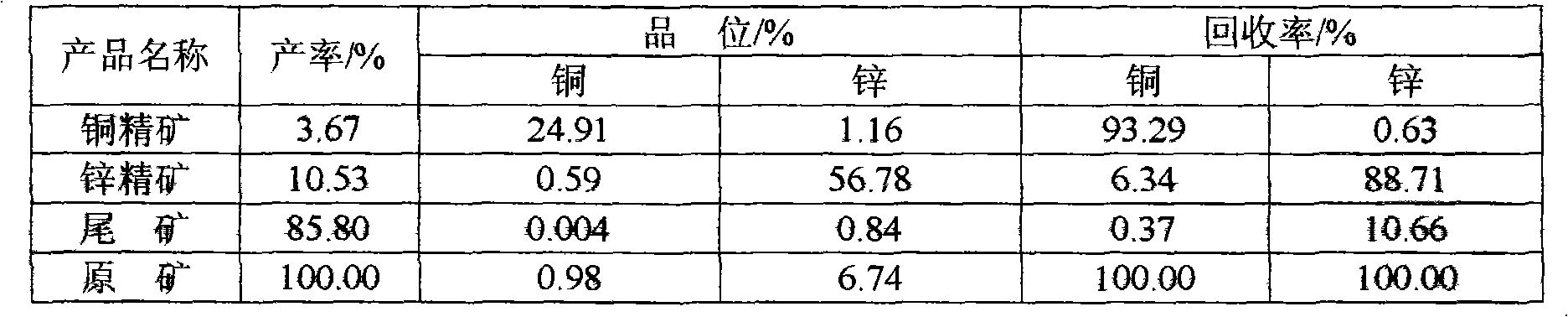

Technique for floatation separation of hard washing copper zinc sulfuration mine

The present invention relates to a floatation separation mineral concentration technology for metal sulfuration mine, especially a technique for floatation separation of hard washing copper zinc sulfuration mine. The copper ore concentrate quality produced by a general copper-zinc differential flotation technique at the present time is low and cost is high. The technique of the invention includes a step of selecting copper and selecting zinc, the copper is floated firstly, the copper and the zinc is separated by using a collecting agent LP-02 with the addition of a combined inhibitor LY-02 under a neutrality condition of the slurry pH value. The technique has a strong adaptability, a stable production target; it is not only used for recovering copper, also improves the quality of the copper and zinc ore concentrate, as well as the copper and zinc recovery rate; the production cost is reduced greatly, the earnings level is improved and it has non environmental pollution.

Owner:西部矿业集团科技发展有限公司

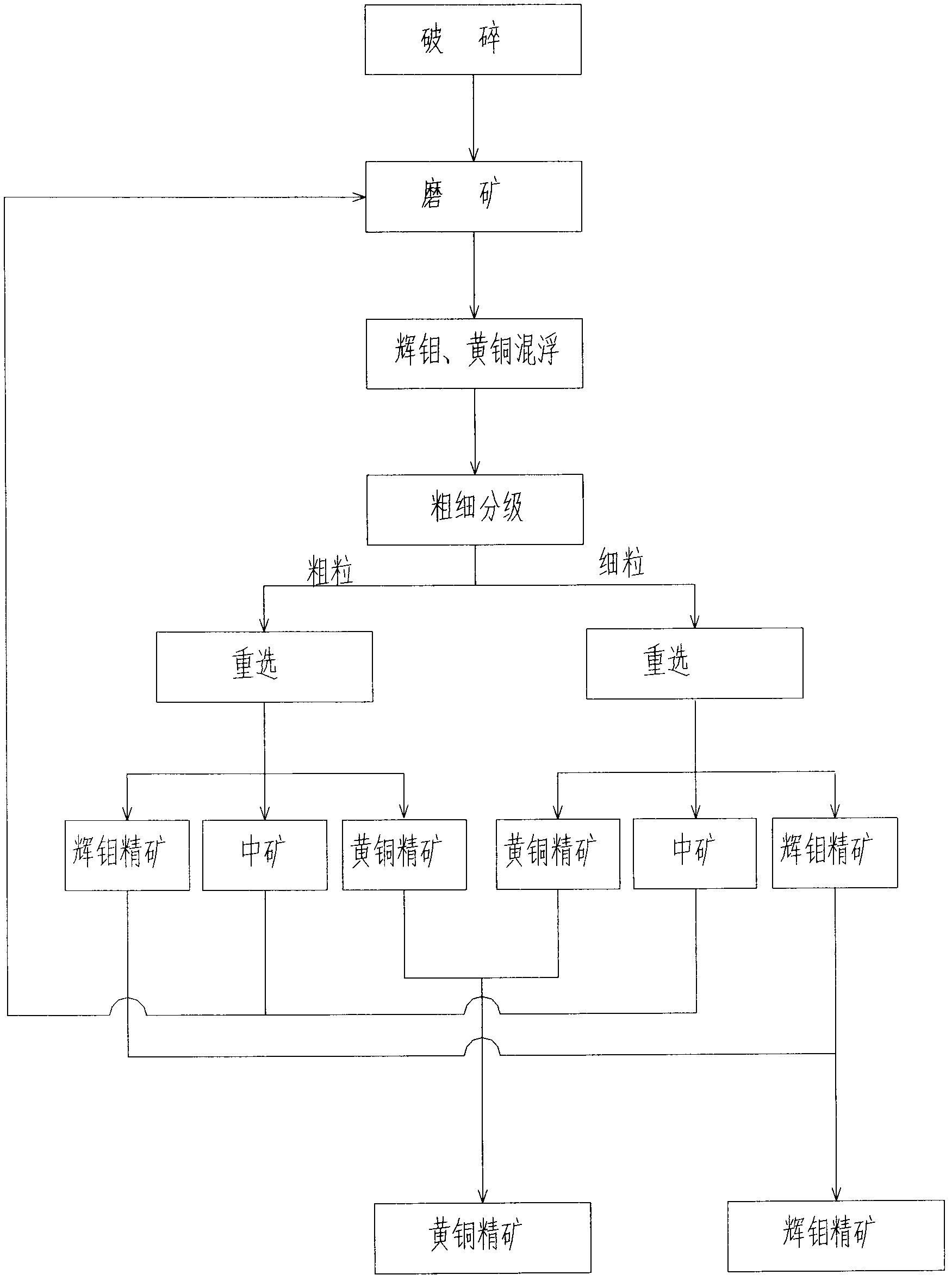

Method for separating bright molybdenum and brass in refractory molybdenum copper sulphide ore

InactiveCN102824954ALow recovery rateHigh recovery rateFlotationWet separationChalcopyriteRefractory

The invention discloses a method for separating bright molybdenum and brass in refractory molybdenum copper sulphide ore. According to the method, primordial bright molybdenum and brass ore are used as raw materials and are subject to general floatation after being crushed and ground, thereby enriching bright molybdenum and brass; the bright molybdenum and brass are subject to thickness grading in order to separate out coarse and fine products, the coarse particle portion and the fine particle portion are respectively subject to table re-separation in order to separate bright molybdenum and brass, thereby obtaining the qualified bright molybdenum and brass ore concentrate, mixed intermediate ore of bright molybdenum ore and brass ore, and qualified brass ore; the mixed intermediate ore is returned back to the re-grinding technique and introduced into the circulating system, thereby realizing the separation of the refractory bright molybdenum and brass. The technique has the following advantages that the disadvantages of greatly increased cost caused by the addition of a large amount of inhibitors in the common separation of bright molybdenum and brass for inhibiting the brass ore and the removing of the regents when brass is recovered from the tailings, in particular the disadvantages of the reduction of recovering ratio of the bright molybdenum particularly the brass when a large amount of brass ore inhibitors are existent in the water system, and the environmental impact due to the need of reagents in the common floating separation, are avoided.

Owner:北京华夏建龙矿业科技有限公司

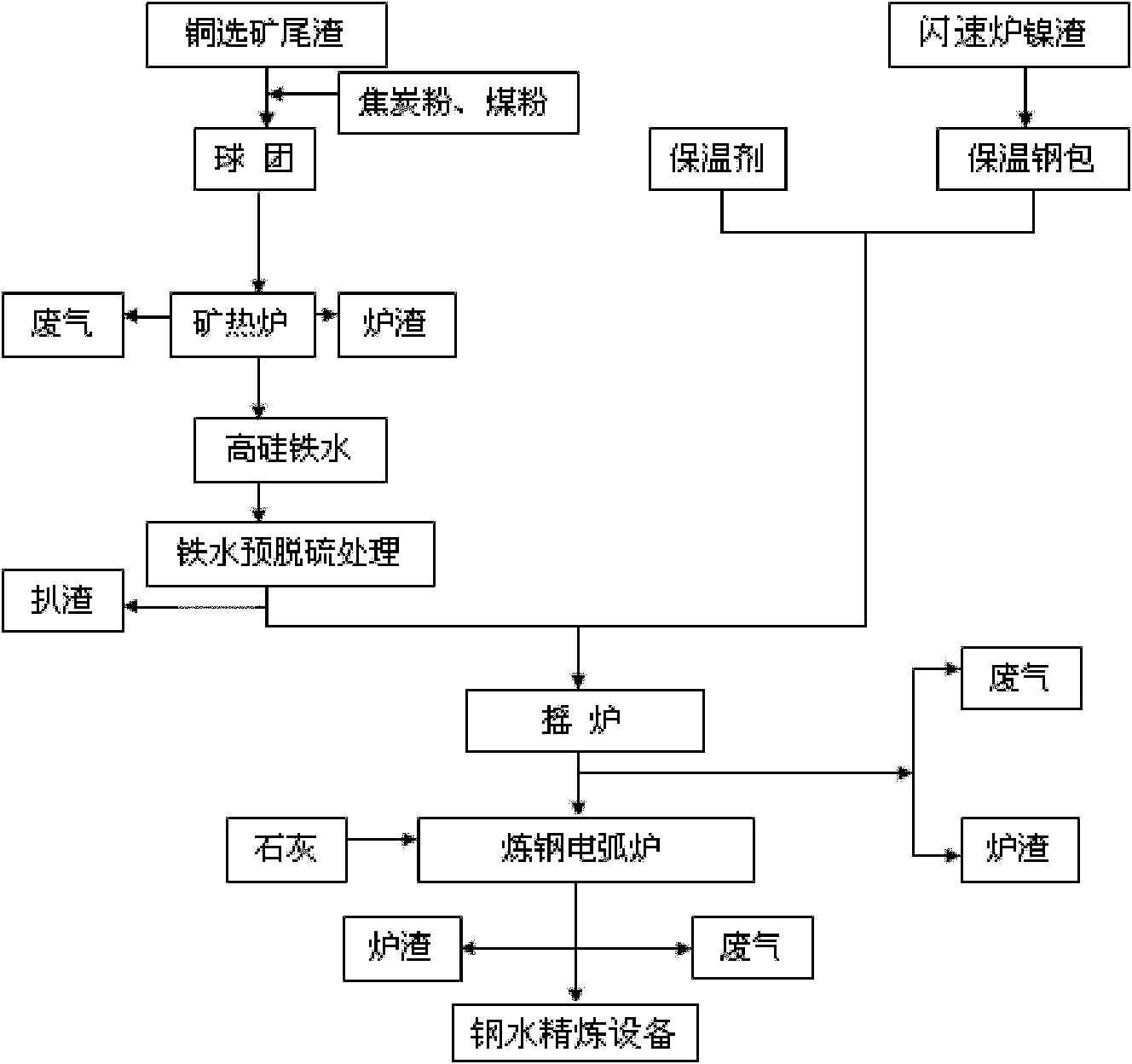

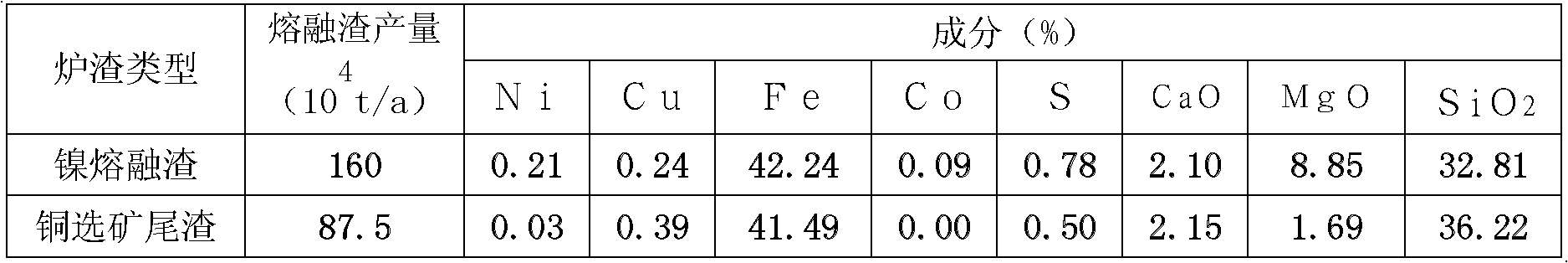

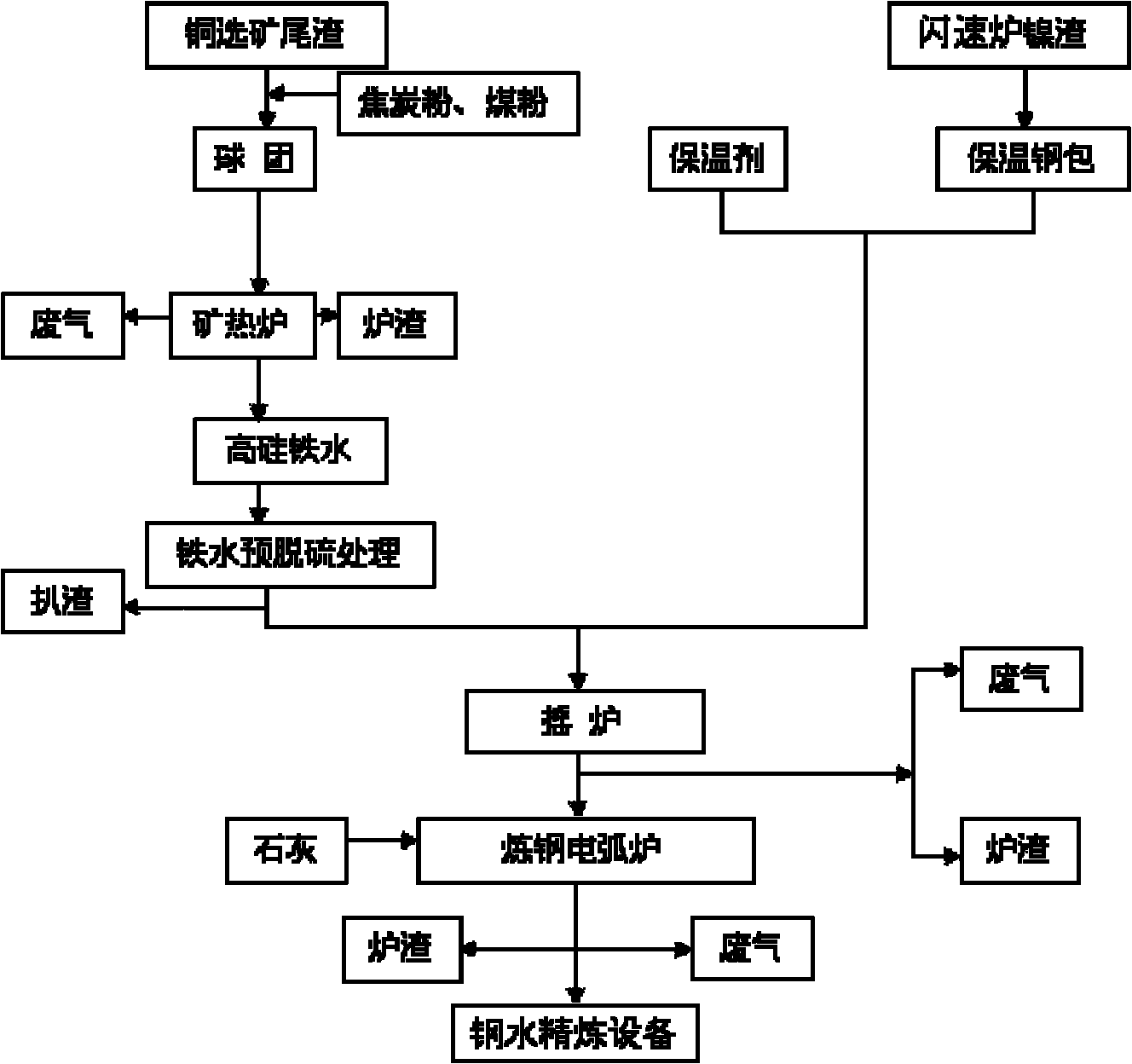

Iron extracting and steelmaking process for comprehensively treating copper ore tailing and nickel molten slag

InactiveCN102051428AGood reduction kinetics conditionsImprove smelting efficiencySteelmakingProcess equipment

The invention discloses an iron extracting and steelmaking process for treating copper ore tailing and nickel molten slag by an ore heating furnace, a shaking furnace, a steelmaking electric arc furnace and a refining furnace. The iron extracting and steelmaking process comprises the following steps of: (1) uniformly mixing copper ore tailing and a carbonaceous reducing agent and granulating into pellet lump ore; (2) charging the pellet lump ore into the ore heating furnace and smelting to obtain silicon-contained molten iron; (3) desulfurating and deslagging the silicon-contained molten iron to obtain low-sulphur-silicon molten iron or confirming whether sulphur is removed according to the sulphur content of the silicon-contained molten iron; (4) transporting the nickel molten slag to an iron extracting station in a heat preserving way; (5) charging the nickel molten slag into the shaking furnace, adding lime and low-sulphur-silicon molten iron, mixing and stirring to obtain reduced molten iron; and (6) conveying the reduced molten iron into the electric arc furnace and adding lime for desulfurating, decarbonizing and dephosphorizing to obtain molten steel. The process reasonably utilizes the components of the copper ore tailing, fully recovers valuable metals in the copper ore tailing and the nickel molten slag, achieves the aim of comprehensive utilization, has reasonable design, is convenient for mastering and construction and is suitable for industrialized application.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com