New stage dissociation-fractional selection flotation process

A new process and dissociation technology, applied in the field of grinding-flotation process of copper sulfide ore, can solve the problems of single agent system, increase of collectors and inhibitors, over-grinding, etc., achieve low environmental pollution, improve High flotation recovery rate and beneficiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The chemical analysis results of the raw copper ore in the following examples are shown in Table 6, and the copper phase analysis is shown in Table 7. It can be seen from Table 6 and Table 7 that the copper ore is a high-sulfur copper ore with a high secondary rate of 28.55%, which is a refractory ore.

[0051] Table 6 Copper ore chemical multi-element analysis / %

[0052] components

Cu

S

Pb

Zn

Au / g·t -1

Ag / g·t -1

content

0.725

16.240

0.184

0.020

0.825

15.520

[0053] Table 7 Copper Phase Analysis / %

[0054] farewell

secondary copper sulfide

free copper oxide

Soluble copper

total copper

content

0.445

0.207

0.038

0.022

0.013

0.725

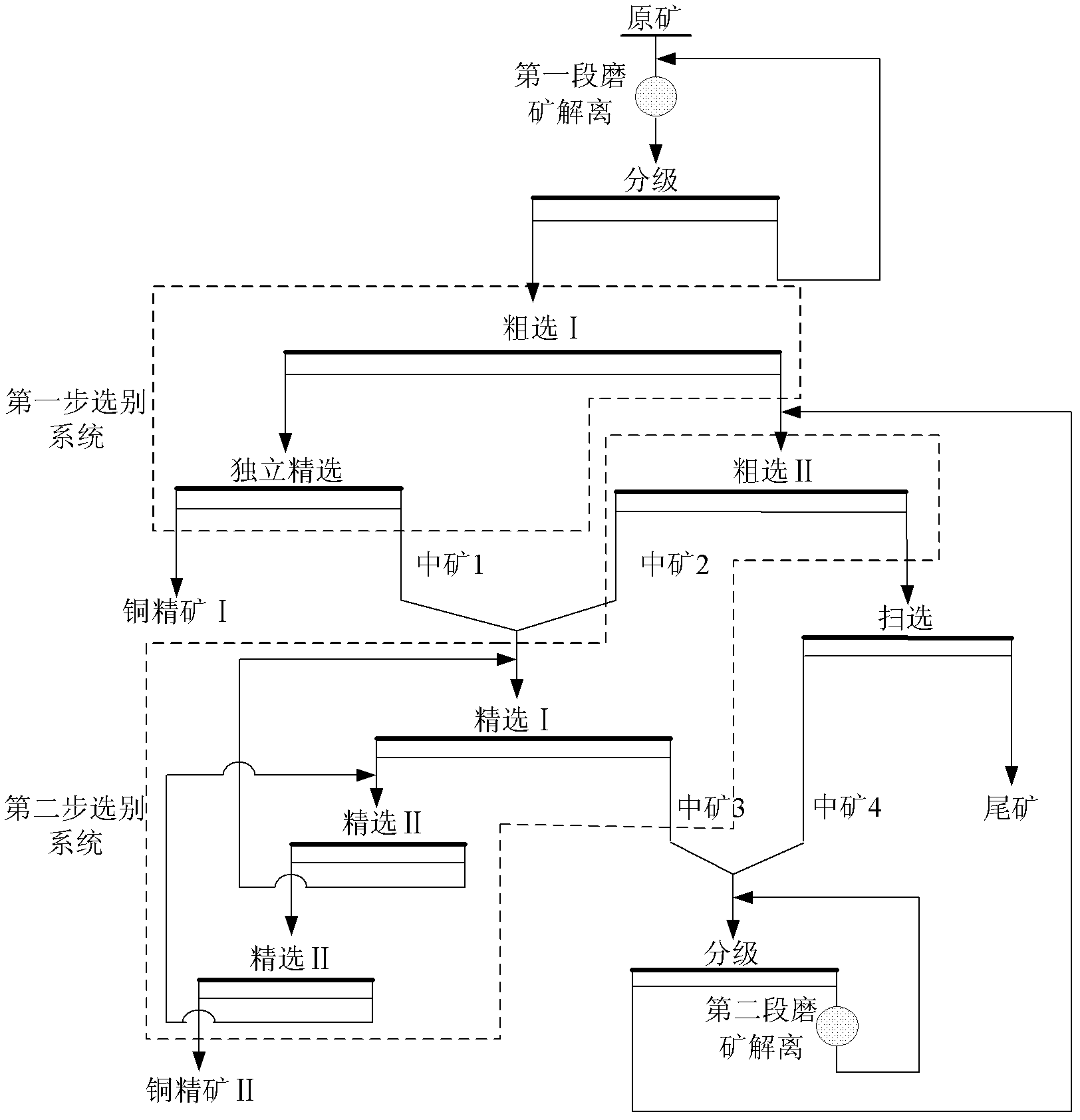

[0055] According to technological process of the present invention figure 2 For the sorting of copper ore, the fineness of the f...

Embodiment 2

[0063] The chemical analysis results of the raw copper ore in the following examples are shown in Table 10, and the copper phase analysis is shown in Table 11. The sulfur content of this ore is 1.84%, which is relatively low, and it is a low-sulfur ore with high primary copper content and low secondary rate. It is an easy-to-select ore.

[0064] Table 10 Analysis results of raw ore multi-element chemical composition / %

[0065] components

Cu

S

Fe

SiO 2

al 2 o 3

CaO

MgO

Au / g·t -1

Ag / g·t -1

content

0.646

1.84

37.54

22.40

1.58

14.02

4.32

0.28

2.7

[0066] Table 11 Raw ore copper phase analysis / %

[0067] farewell

secondary copper sulfide

total copper

content

0.615

0.020

0.011

0.646

share

95.20

3.10

1.70

100

[0068] Process acc...

Embodiment 3

[0074] The copper ore of the following examples is the same as the raw ore of Example two.

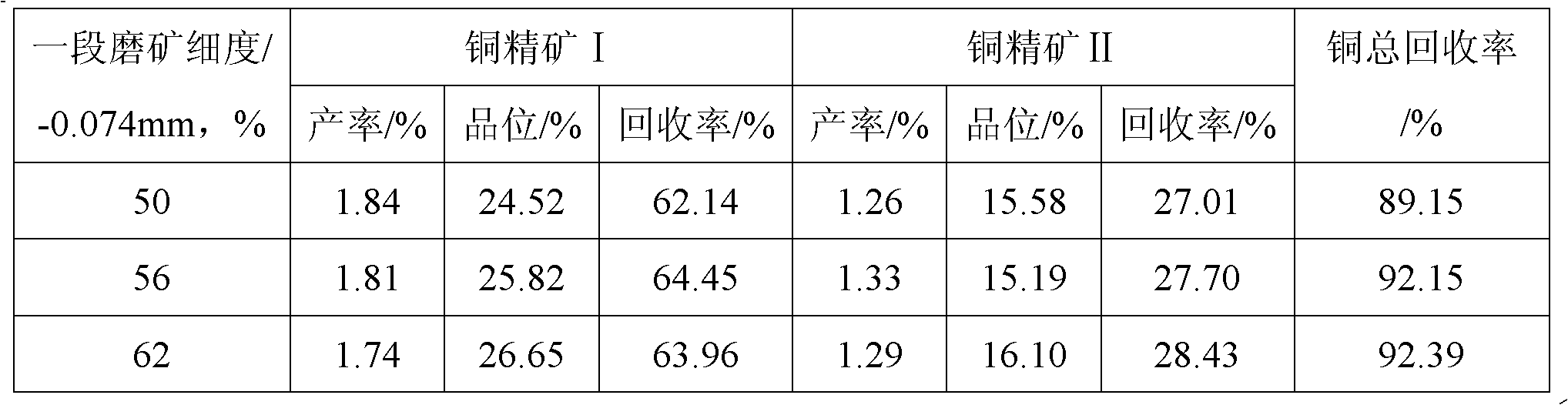

[0075] Process according to the invention figure 2 For the sorting of copper ore, the fineness of the first stage grinding is -0.074mm 50%, and the fineness of the second stage grinding is -0.074%90%. The amount of ester agents used in the first stage of rough selection is 30g / t, 2# oil 20g / t, lime 500g / t in the independent selection stage, 40g / t of xanthate agents and 15g / t of 2# oil are added in the second stage of rough selection. The medicine added by the selection is gradually halved. The closed circuit test results are shown in Table 13.

[0076] Table 13 Example 3 closed-circuit test results

[0077]

[0078] It can be seen from Table 13 that when the ore is selected by the new process, when the first-stage grinding and the second-stage grinding take the lower limit fineness of 50% and 90%, the copper recovery rate is 82.28%, which shows that the new process is more adapt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com