Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

846 results about "Xanthate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Xanthate usually refers to a salt with the formula ROCS⁻₂M⁺ (R = alkyl; M⁺ = Na⁺, K⁺), thus O-esters of dithiocarbonate. The name xanthates is derived from Greek ξανθός xanthos, meaning “yellowish, golden”, and indeed most xanthate salts are yellow. They were discovered and named in 1823 by Danish chemist William Christopher Zeise. These organosulfur compounds are important in two areas: the production of cellophane and related polymers from cellulose and (in mining) for extraction of certain ores. They are also versatile intermediates in organic synthesis. Xanthates also refer to esters of xanthic acid. These esters have the structure ROC(=S)SR′.

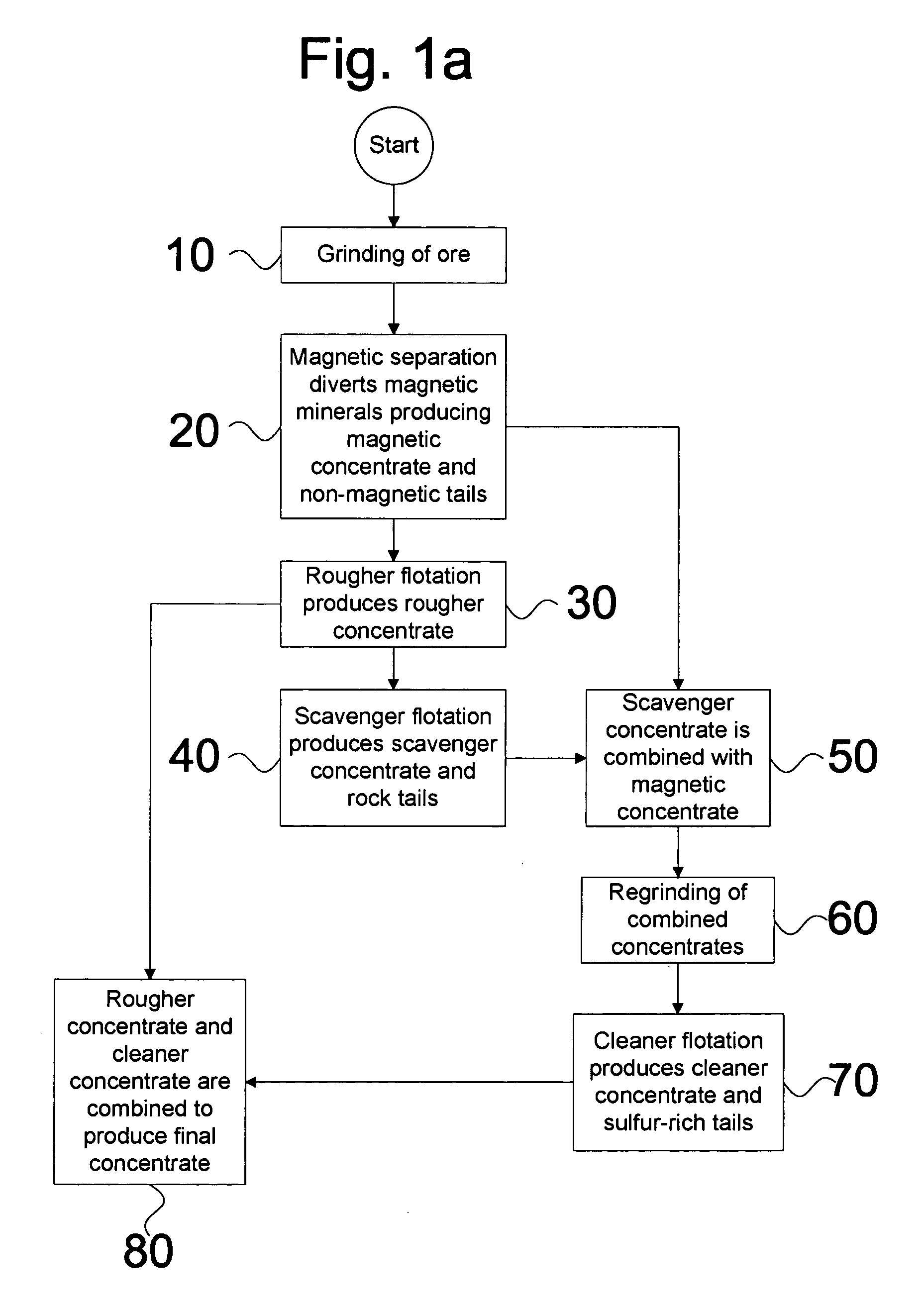

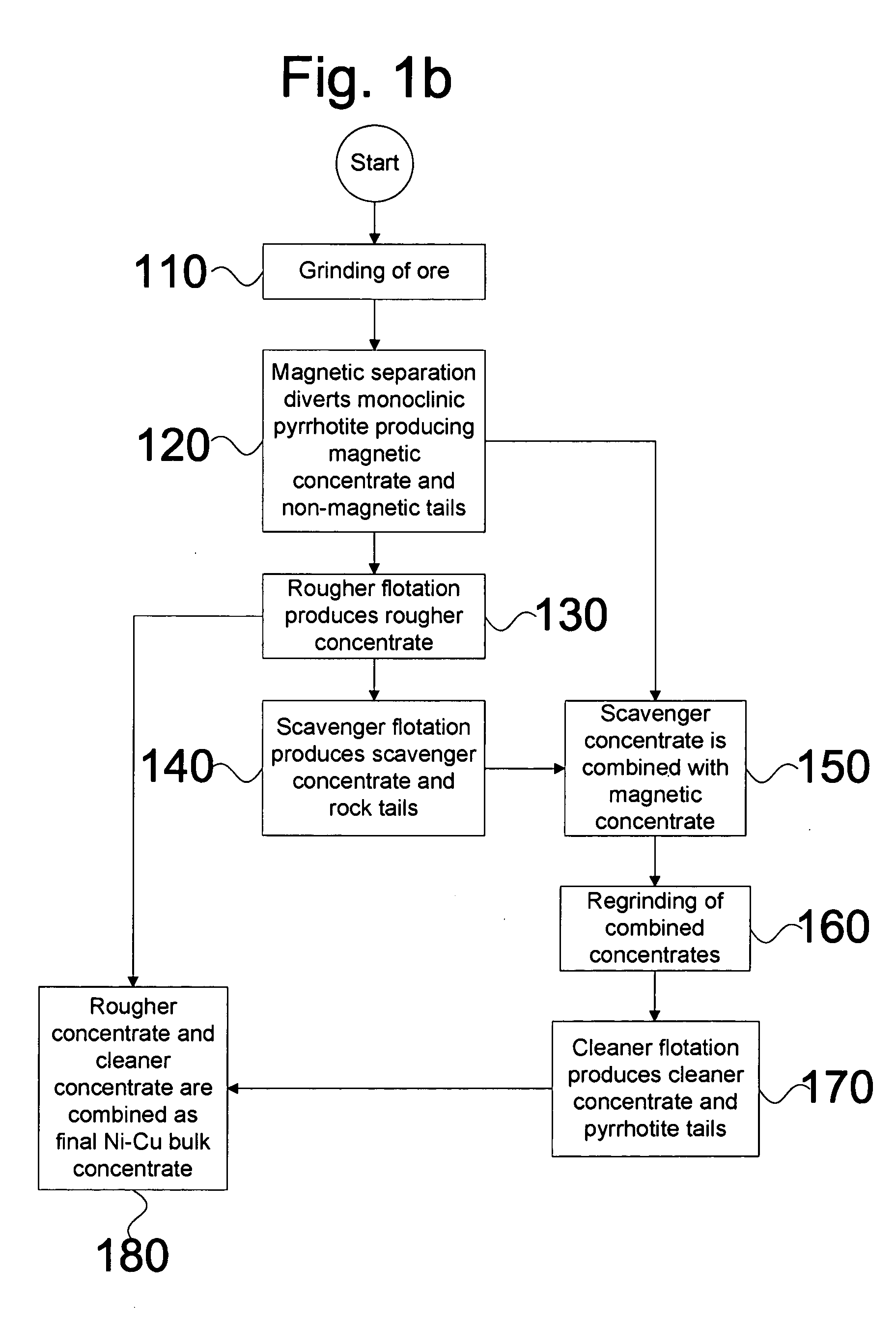

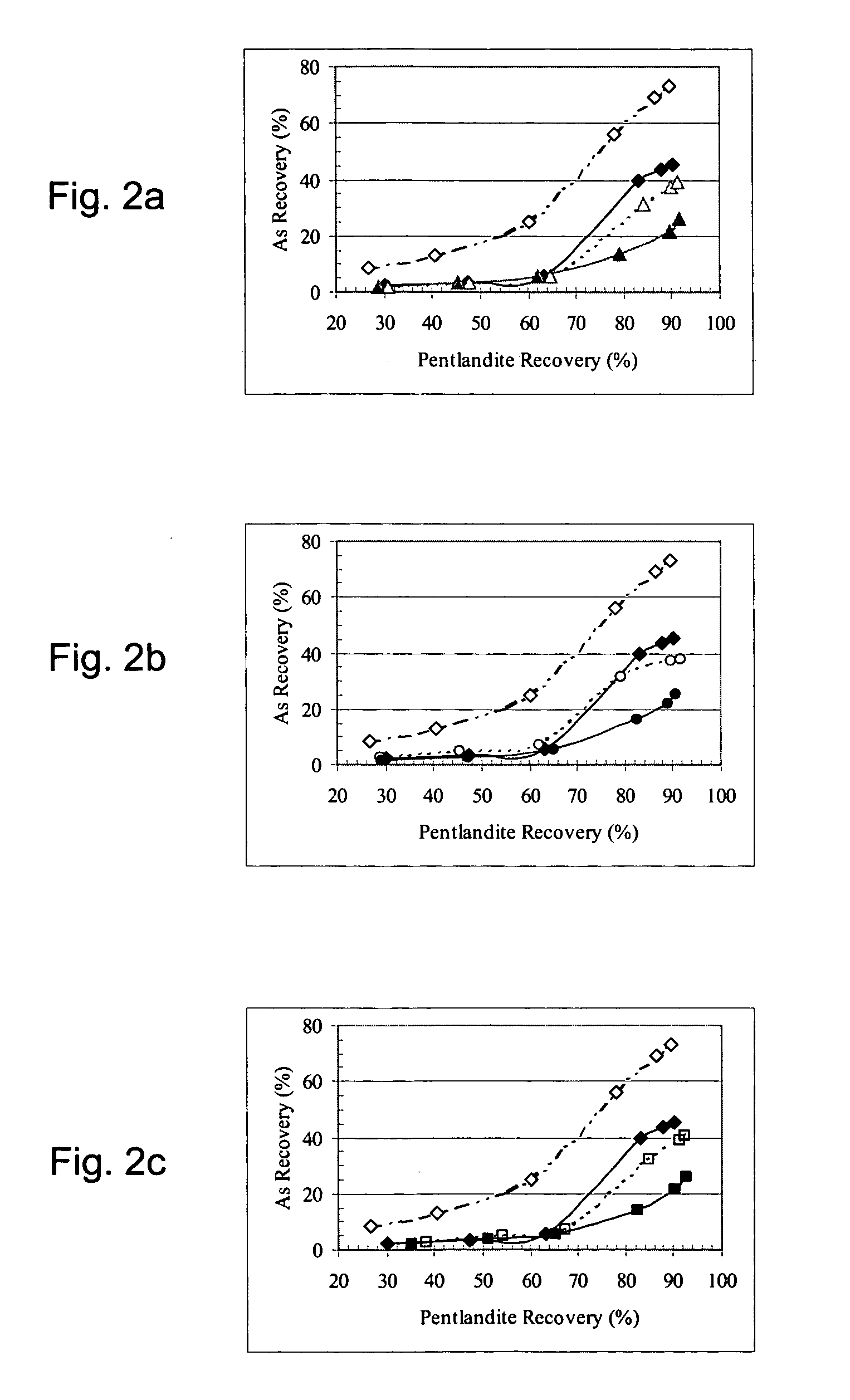

Arsenide depression in flotation of multi-sulfide minerals

A mineral separation process includes wet-grinding the ore to liberation of minerals, oxidizing the slurry using air, hydrogen peroxide or other oxidants and floating the valuable minerals at a pH between about 9.0 and 10.0 with a xanthate as collector, and a combination of a polyamine and a sulfur containing species as depressants for arsenide minerals. This depressant suite effectively depresses the flotation of arsenide minerals with no effect on the flotation of the valuable minerals.

Owner:INCO

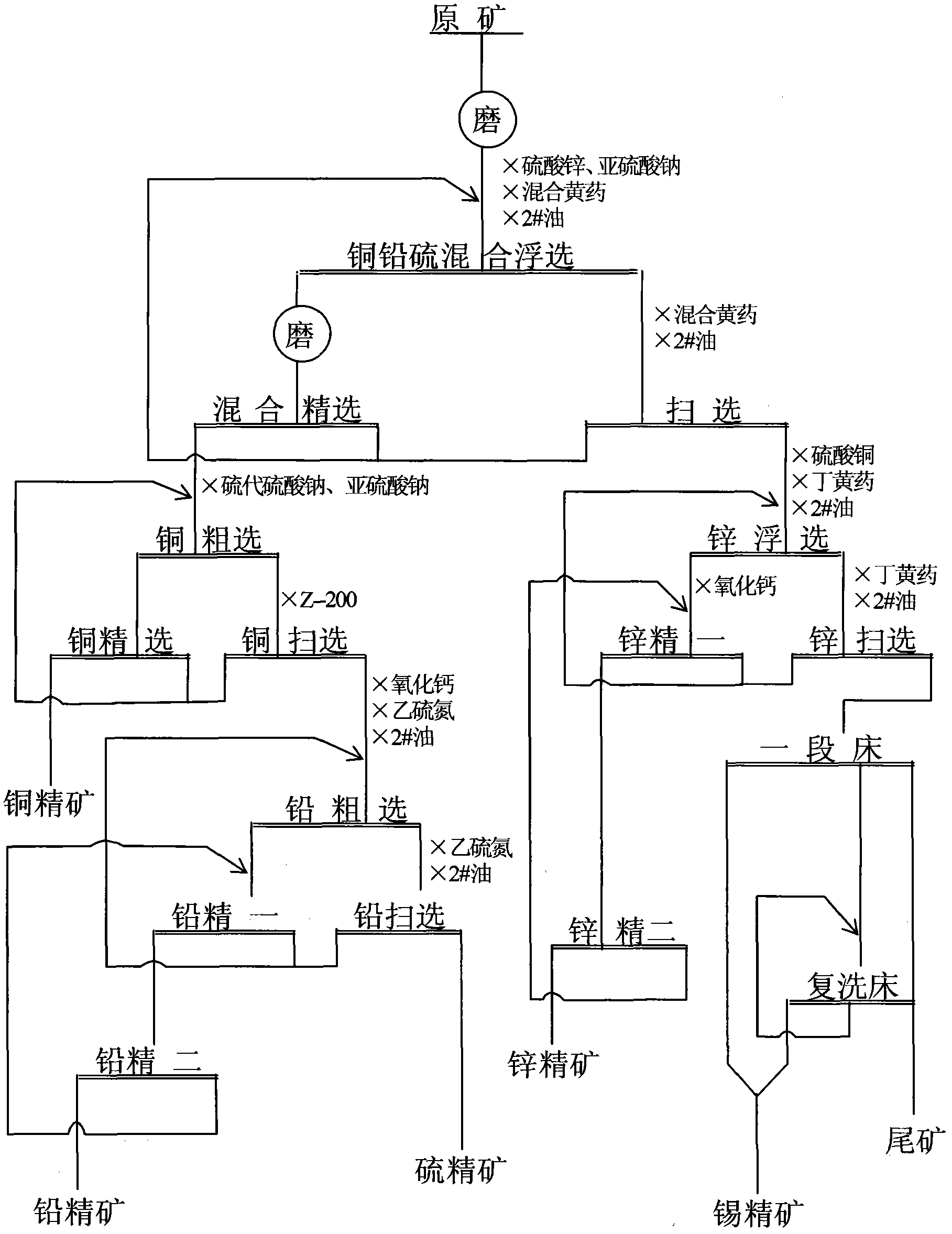

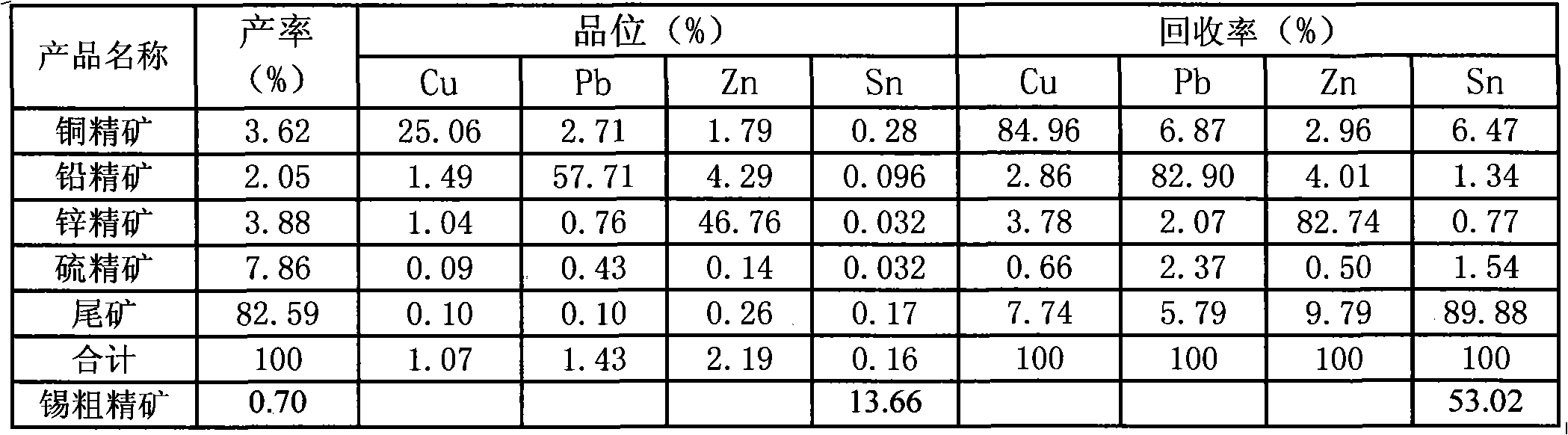

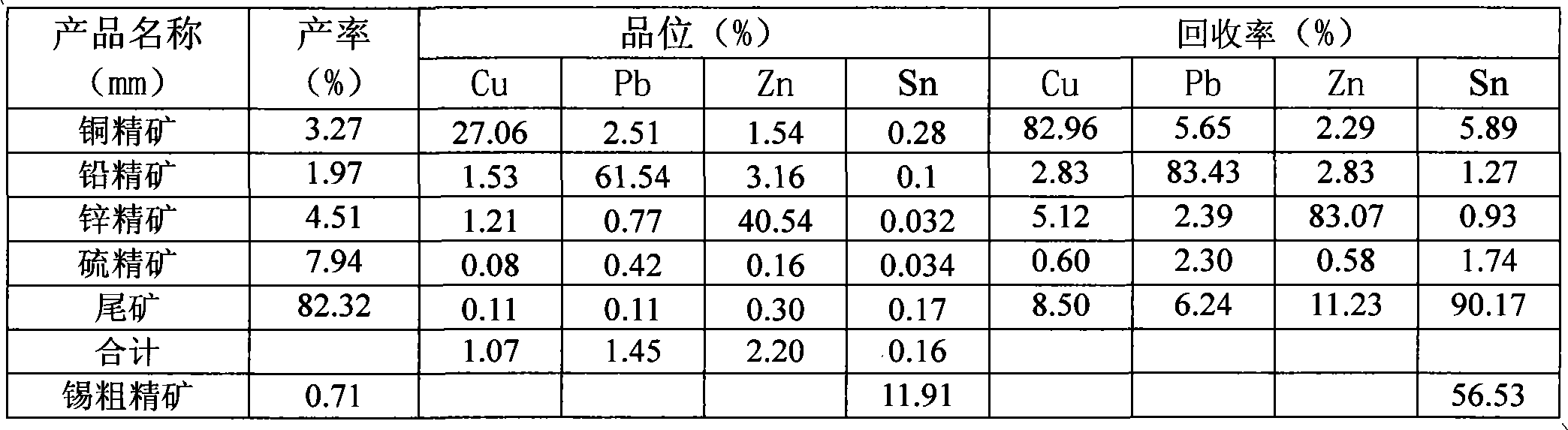

Benification combined method of polymetallic sulphide ore containing copper, lead, zinc and tin

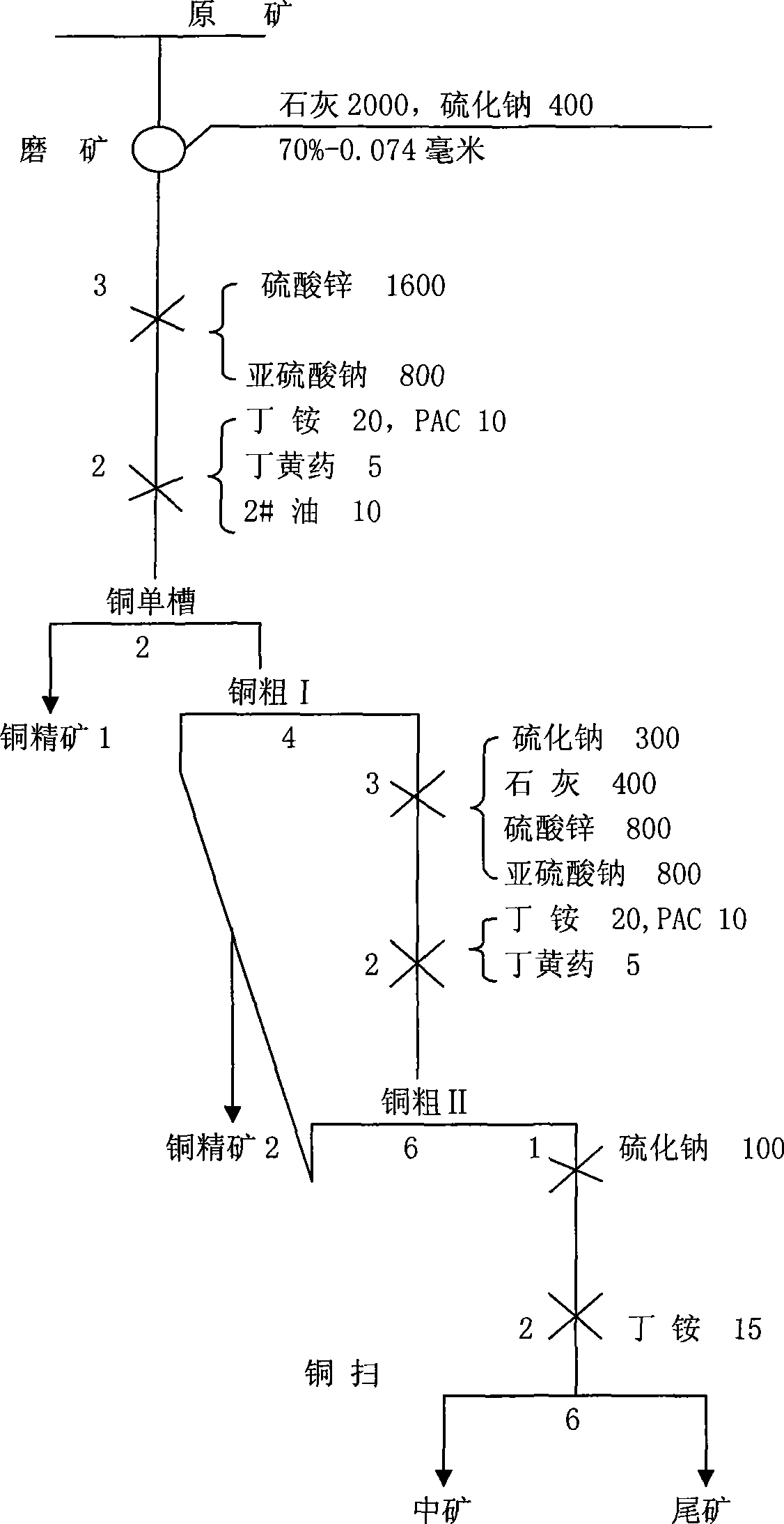

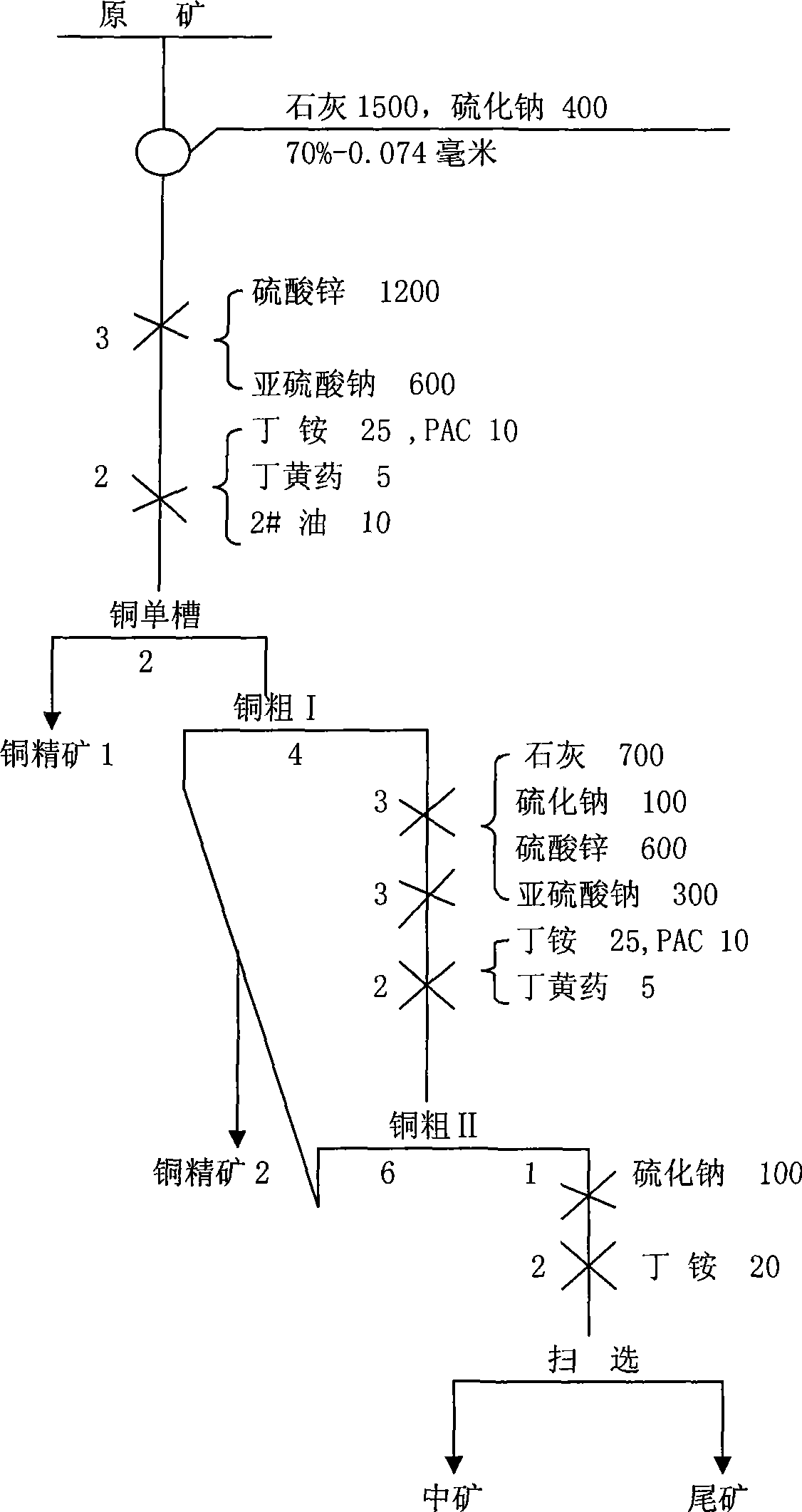

The invention relates to a beneficiation method, in particular to a beneficiation method for separating the polymetallic sulphide ore containing copper, lead, zinc and tin. The method comprises the following steps: (1) carrying out ore grinding on the raw ore before carrying out bulk flotation on copper, lead and sulphur, using diethyl mixed with xanthate as collecting agent of copper and lead mineral, using zinc sulphate and sodium sulfite as inhibitor of zinc mineral; (2) carrying out phase-2 ore grinding and selection; (3) separating copper, lead and sulphur, using sodium sulfite and sodium thiosulfate as the inhibitor of the lead and sulphur mineral, using Z-200 as collecting agent for separation and scavenging and then carrying out lead flotation after the separation and scavenging; (4) carrying out zin flotation on the bulk flotation tailings; and (5) finally, carrying out reselection on the zinc flotation tailings to recover tin. The metalliferous mineral of the invention has the advantages of good separating effect, high metal recovery rate, more complete comprehensive recovery of useful minerals, low cost of medicament, simple method, easy operation and energy conservation.

Owner:云南锡业研究院有限公司研究设计院

Copper-zinc separation beneficiation method

InactiveCN101428250ARaise the gradeRealize zinc suppression and floating copperFlotationSulfite saltSulfate

The invention relates to a copper-zinc separation beneficiation method which comprises the following steps: (1) primary grinding, that is, adopting a combined depressant comprising lime, sodium sulfide, zinc sulfate, and sodium sulfite under the condition that the size and the content of grinding particles are respectively -0.074 mm and 65 to 70 percent; (2) copper rough concentrates regrinding and concentration, that is, selecting out high-quality copper concentrates which contain high-grade copper and silver, but low zinc by adopting single groove speed flotation method and continually using the combined depressant constituted by lime, sodium sulfide, zinc sulfate, and sodium sulfite, so as to realize the zinc depressing and copper flotation; (3) zinc-sulfur separation, that is, using butyl xanthate as a collecting agent to float zinc, obtaining zinc-sulphur bulk concentrate, conducting pulp conditioning by adding lime so as to depress sulfur and float copper and obtain zinc concentrates and partial sulfur concentrates, conducting the iso-flotation on the tailings and further adding the butyl xanthate to conduct flotation and obtain partial sulfur concentrate. The invention has the advantages of adopting the processes of ore blending, primary grinding, copper rough concentrates regrinding and concentration, and zinc-sulphur iso-flotation technological process, thereby better solving the problem that the copper concentrates contain too much zinc or the copper content in the zinc concentrates is over standard.

Owner:杭州建铜集团有限公司

High-efficiency cleaning mineral separation process of complicated sulfuration mine

The invention discloses an efficient and clean beneficiation method of complex sulfide ore. The method includes the following steps: utilizing an activator selected from one of or some of oxalic acid, ammonium carbonate, ammonium bicarbonate, ammonium sulfate, ammonium bisulfate and ferrous sulfate as a combination; utilizing collectors including xanthate collectors, black collectors, white collectors and thionocarbamate collectors; mixing the activator, the collectors and BC; stirring; and performing flotation separation of the sulfide ore to obtain the sulfur concentrate. The inventive beneficiation method has the advantages of high discrimination property, cleanness and non-toxicity; and is suitable for the flotation separation of the complex sulfide ore, particularly the flotation separation of complex sulfide ore containing pyrrhotites and pyrites with fine dissemination size.

Owner:CENT SOUTH UNIV

Technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity

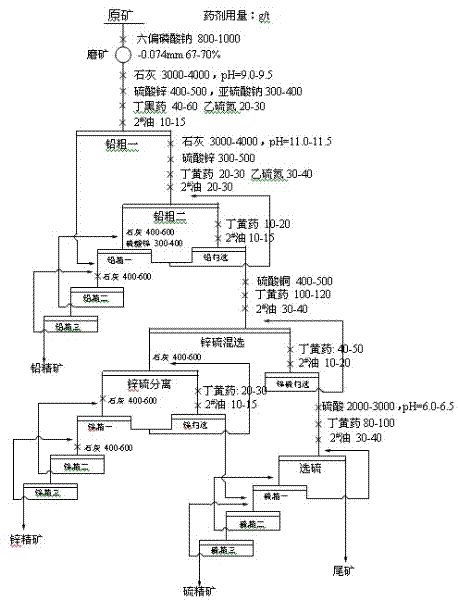

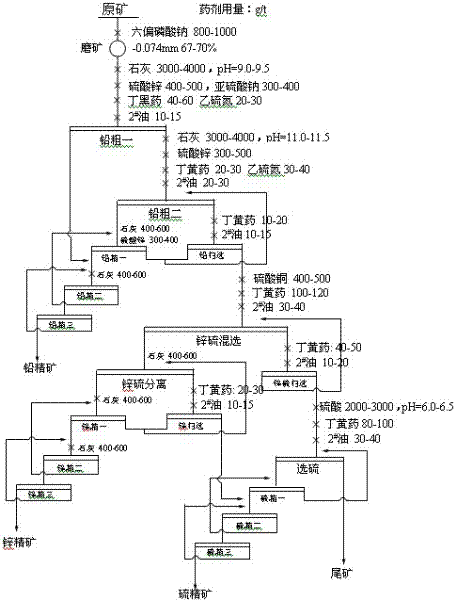

The invention discloses a technology of enhanced-dispersion partial selective and bulk flotation of lead and zinc sulfide ores under low and high alkalinity. During grading of the lead and zinc sulfide ores, sodium hexametahposphate is taken as a dispersion agent and directly added into a ball mill, the ores are ground till the ores with the size of 0.074mm account for 67%-70%, lime is taken as an adjusting agent, zinc sulfate and sodium sulfite are taken as inhibitors, dithiophosphate BA and diethyldithiocarbamate are taken as collectors, and selective flotation of part of lead minerals with good floatability can be performed under low alkalinity; then xanthate and the diethyldithiocarbamate are taken as collectors, and the flotation of the lead minerals is further performed under high alkalinity; copper sulfate is added in lead flotation tailings for activation, butyl xanthate is further taken as the collector for flotation of zinc blende and part of pyrite, and zinc-sulfur separation flotation is further performed on zinc-sulfur mixed concentrate; and sulfuric acid is added in zinc flotation tailings for activation, and the xanthate is taken as the collector for flotation of the remaining pyrite. By adopting the technology, the lead-silver recovery rate can be improved, the using amount of lime and sulfuric acid can be reduced, the circulating amount of middlings can be reduced, the ore dressing cost can be reduced and the grade of the concentrate can be improved.

Owner:KUNMING UNIV OF SCI & TECH

Beneficiation method for low-grade mixed copper ore containing molybdenum

ActiveCN105435953AReduce mutual inclusionHarvestingFlotationWet separationMineral SourcesLower grade

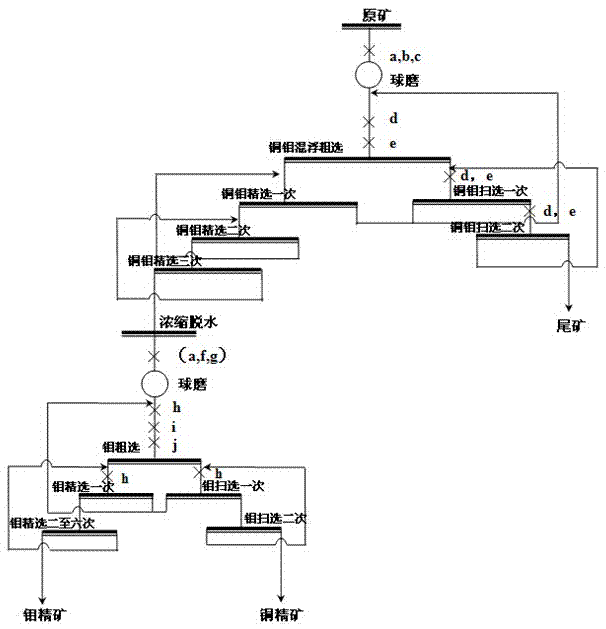

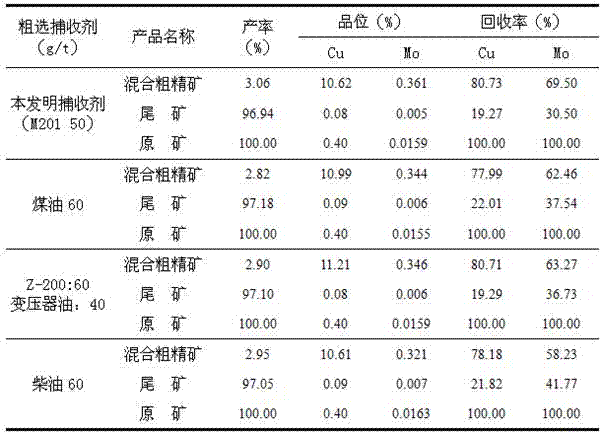

The invention discloses a beneficiation method for low-grade mixed copper ore containing molybdenum. According to the properties and characteristics of the low-grade mixed copper ore containing molybdenum, the copper and molybdenum bulk floatation and re-separation principle technological process is adopted, and high-efficiency concentration of minerals is achieved by using a combination of butyl xanthate and a high-efficiency collector M201 during copper and molybdenum bulk floatation operation; high-efficiency reagent removal of bulk concentrates is achieved through a concentration dewatering and fine grinding method during copper and molybdenum separation operation so that the impact of a large number of reagents existing in copper-lead bulk concentrates on copper and molybdenum separation can be reduced; and moreover, copper minerals are suppressed by means of suppressant F-6, so that separation of copper and molybdenum is effectively realized, and the copper content and molybdenum content of the concentrates are effectively reduced. Meanwhile, in order to stabilize the floatation indexes, the floatation process is optimized for site production, namely, branching and streaming floatation; accordingly, the purpose of comprehensive recovery and utilization of mineral resources is achieved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

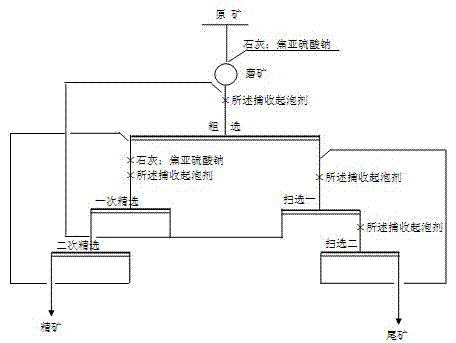

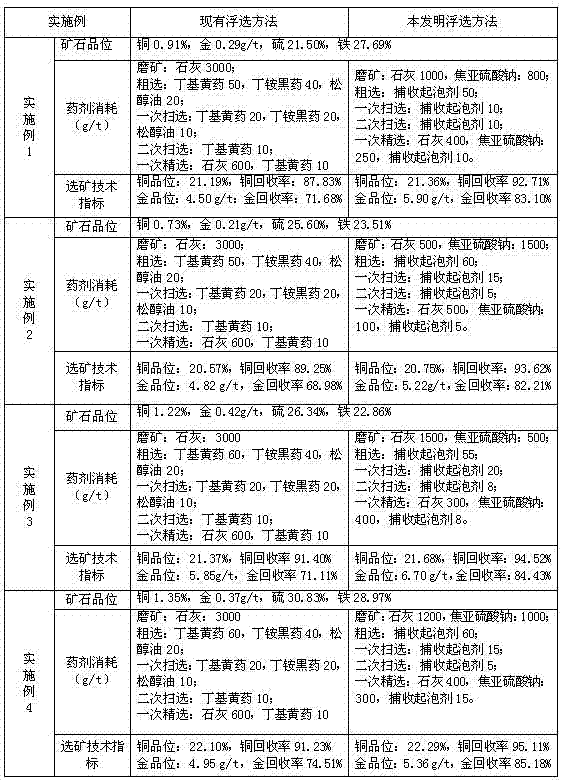

Method for floating high-sulfur gold-bearing copper ore

ActiveCN103691569AEnhanced inhibitory effectImprove beneficiation indexFlotationPropionitrileEthyl group

The invention discloses a method for floating high-sulfur gold-bearing copper ore, which aims at solving the problems that the existing beneficiation method is lower in copper and gold recovery rate under high-alkali condition, and problems that xanthate and black powder are adopted as high-sulfur gold-bearing copper ore collecting agents, the collecting power is stronger, the selectivity is poor, the separation difficulty of copper and sulfur can be aggravated and the consumption of inhibitors is increased. The method comprises the steps of by adopting lime and sodium metabisulfite as an ore pulp pH regulator and a pyrite inhibitor, and the mixture of isopropyl xanthogen propionitrile ester, black powder acid and ethyl dithiocarboxyl propionitrile ester according to certain proportion as a collecting foaming agent, carrying out ore grinding, rough concentration, primary scavenging, secondary scavenging, primary concentration, and secondary concentration on a crude ore, thus realizing the high-efficiency recovery on copper and gold in the high-sulfur gold-bearing copper ore. According to the method, through reasonable combination and addition of medicaments, the selective adsorption of the collecting agent on target mineral-copper pyrite and other copper sulfide minerals and gold minerals can be reinforced, and the copper recovery rate and the gold recovery rate can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

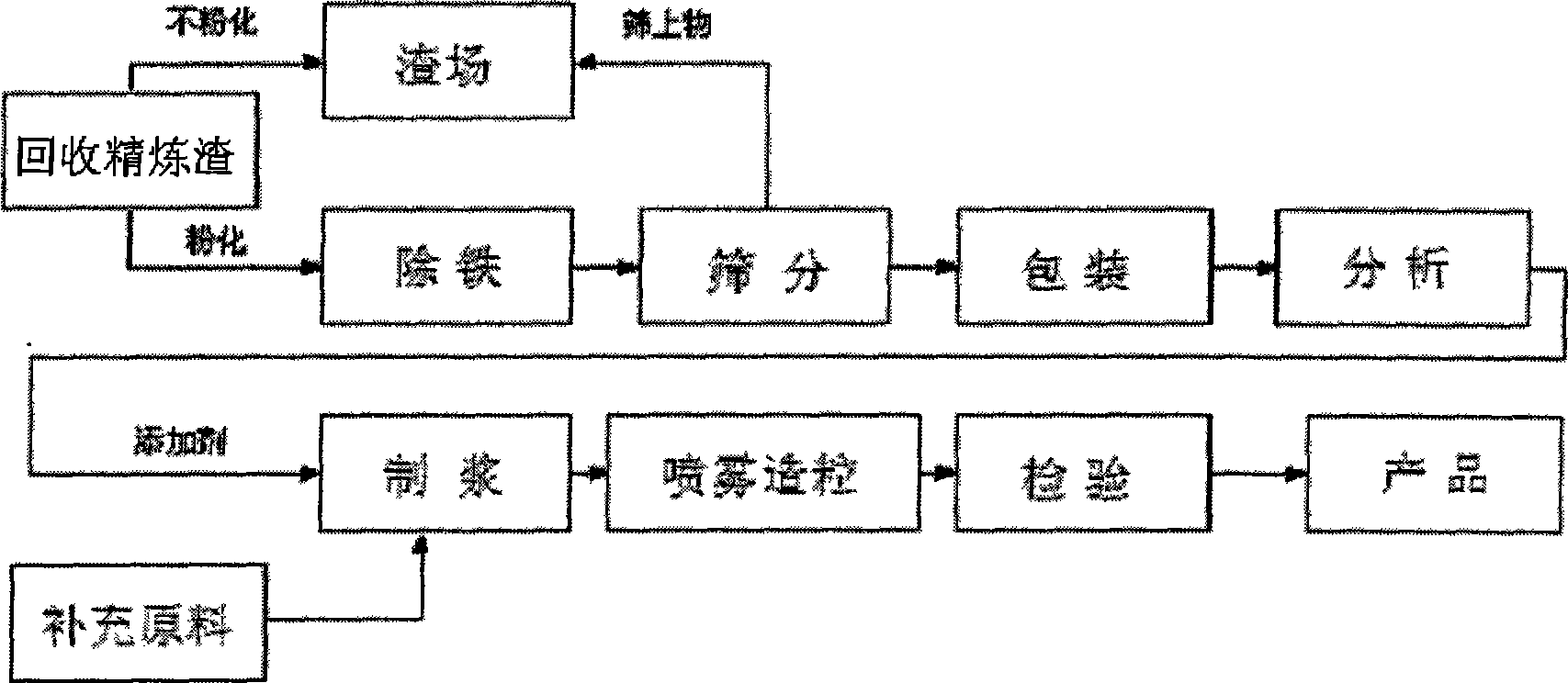

Method for preparing protecting residue from recovery refining slag

The invention relates to a method for preparing protecting slag from recovered refining slag remained in a ladle after continuous casting, which is characterized in that the recovered refining slag is natural cooled down, pulverized, subjected to iron removal and passes a 80-mesh screen; undersize is picked up and subjected to component analysis; according to the target component of the prepared protecting slag, if corresponding amount of natural mineral or fine powder of manually synthesized material containing the lacked components needs to be added, butane radical sodium xanthate and balling bonding agent in the general adding amount are added to prepare pulp with the solid content of between 50 and 70 weight percent, and the pulp is sprayed at the tower top at a hot air temperature of between 550 and 650 DEG C to prepare hollow micro balls. The invention has two characteristics: 1. the method has the simple recycling process, and the materials used to prepared the protecting slag are calculated and added only by the principle of adding what lacks and adding how much lacks, so that the component requirement on the protecting slag preparation is met; and 2. due to high added value of the product, the value of the recovered refining slag can be fully utilized.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

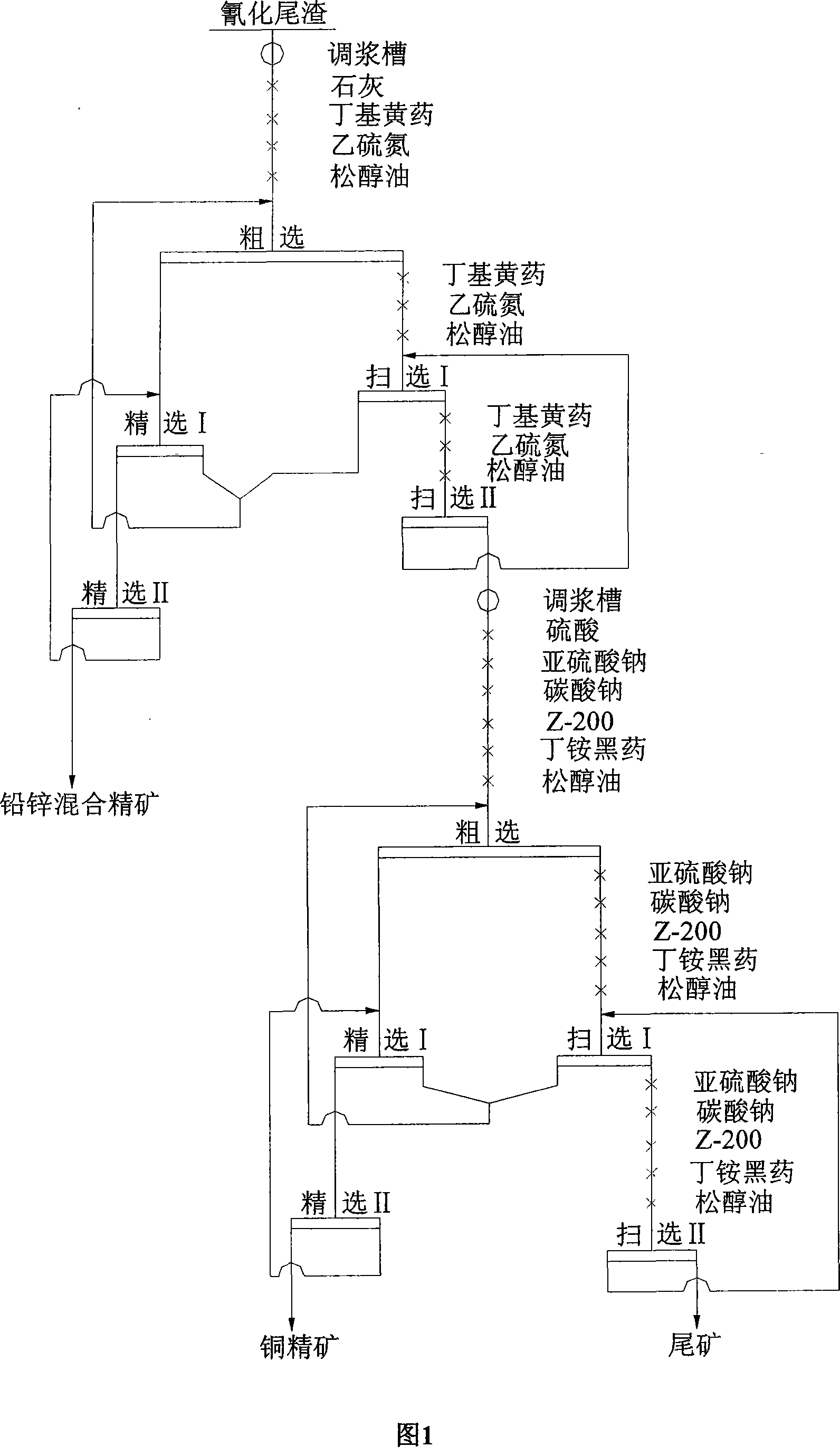

Method for using cyaniding barren solution to float, reclaim and cyaniding copper plumbum and zinc in tailings

A method that cyanide barren solution is used for recovering the copper-lead-zinc from cyanide tailing by means of floatation belongs to the field of nonferrous metal separation. The processing procedures of the method are as following: (1) mashing: the cyanide barren solution is added into the cyanide tailing and stirred to ore slurry, the concentration of which is 35 to 40 per cent; (2) lead-zinc preferential flotation: after being stirred, the ore slurry is put into flotation machine and lime, Ethyl thiocarbamate and Sodium n-butyl xanthate synthetic are added in to the ore slurry. The course of once rough floatation, twice scavenging and twice concentration is processed to recover Zinc and Lead; (3) Cu-S separation: after the tailing of lead and zinc bulk flotation is concentrated, the cyanide barren solution is added into the tailing and the tailing is made into the ore slurry with the concentration of 35 to 40 per cent. And then, the ore slurry is put into the floatation machine and sulfate, sodium sulfite, Z-200 and ammonium butyl aerofloat are added into the tailing. The course of once rough floatation, twice scavenging and twice concentration is processed to recover copper. And the tailing can be for sale as sulfur concentrate; (4) Reuse of separation tailing water: the press filtrate of bulk concentrate, the overflow of thickener, the press filtrate of copper concentrate and the press filtrate of the sulfur concentrate return to the buffer slot of the cyanide barren solution to be used for replacement fluid. The invention has the advantages of good flotation effect, high recovery rate of the copper-lead-zinc and zero discharge of waste water and residue.

Owner:UNIV OF SCI & TECH BEIJING

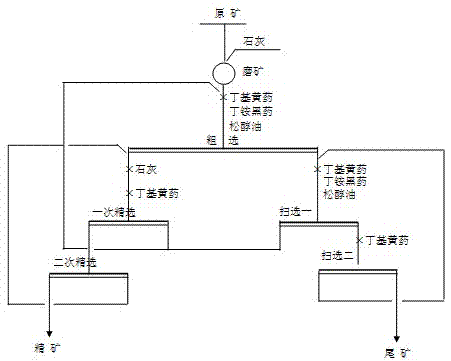

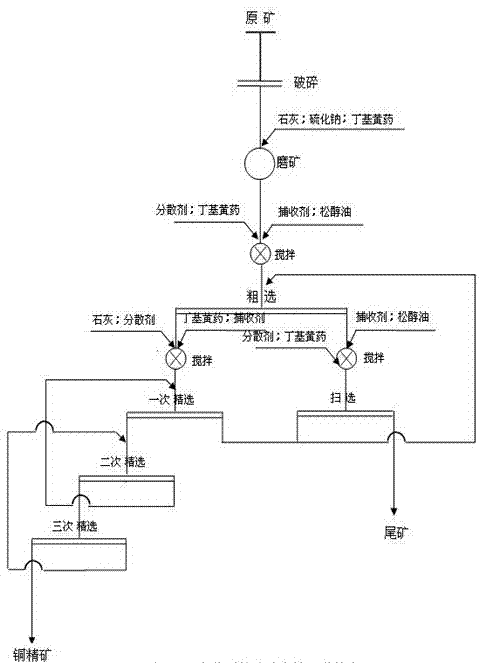

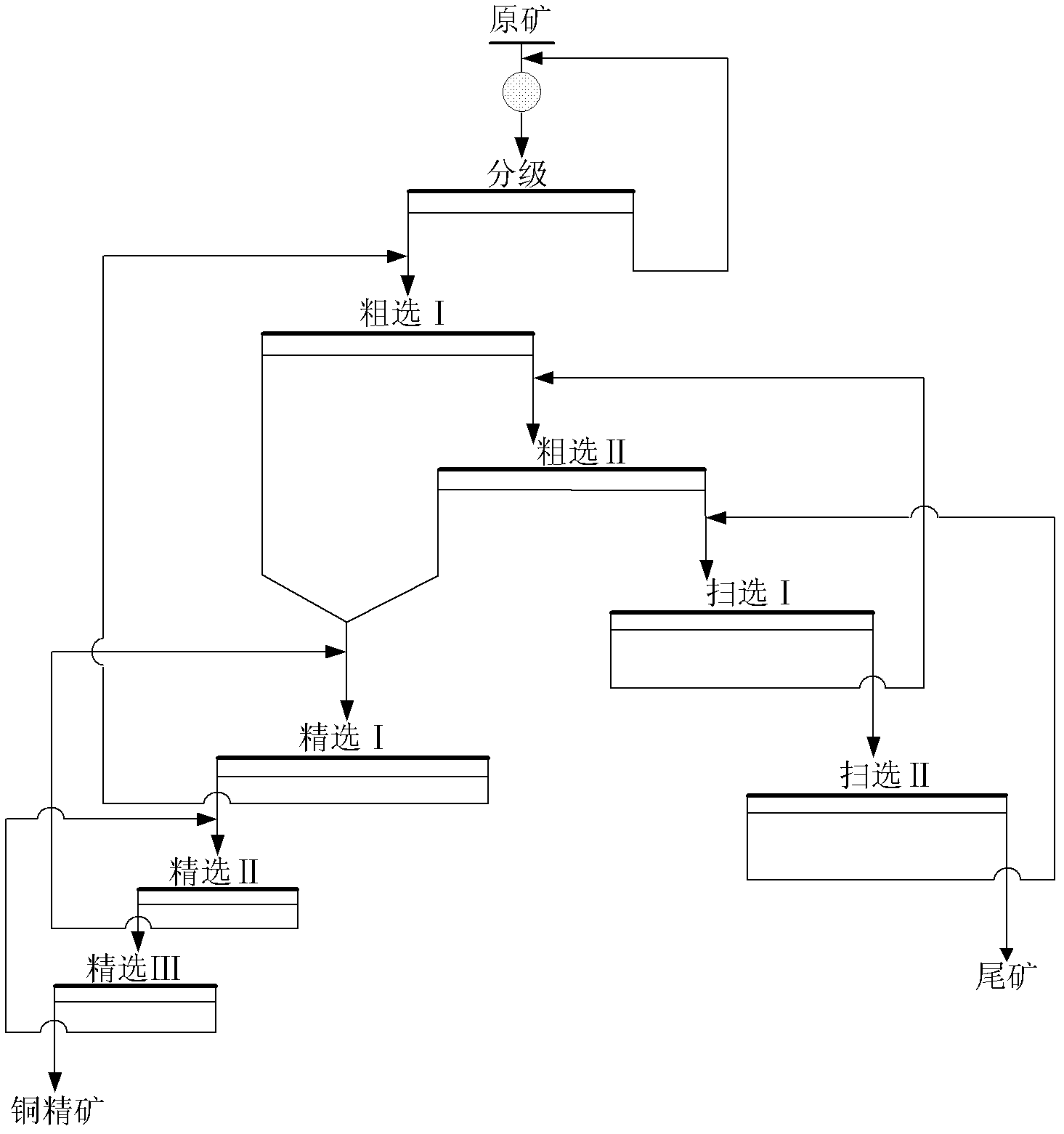

Beneficiation method for copper sulfide ore containing easily-sliming gangue minerals

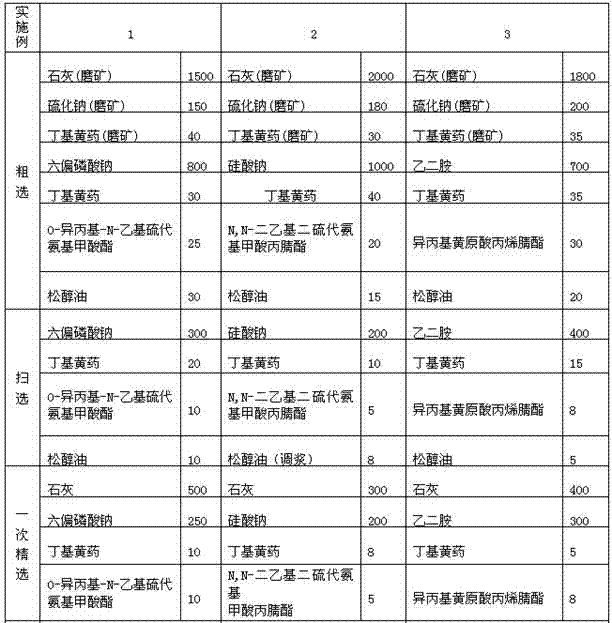

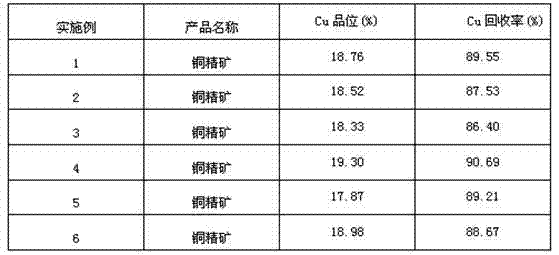

The invention relates to a beneficiation method for copper sulfide ore containing easily-sliming gangue minerals. According to the method, lime is adopted as pH regulator and pyrite depressant of flotation pulp of the copper sulfide ore containing the easily-sliming gangue minerals; sodium sulfide serves as activator of a small number of copper oxide minerals in the ore; sodium hexametaphosphate, sodium silicate or ethylenediamine serves as gangue slurry dispersant; a combination of butyl xanthate and other collectors serves as a collector of copper sulfide minerals; terpernic oil serves as foaming agent. The ore is subjected to primary grinding, primary roughing, primary scavenging and three-time concentration; the ore pulp is subjected to strong stirring and pulp mixing before starting to be subjected to primary roughing, primary scavenging and primary concentration, so that copper contained in the ore is efficiently recovered. According to the method, through reasonable combination and addition of chemicals, the ore grinding and pulp mixing process is strengthened, the adverse influence of gangue slurry on copper sulfide mineral floatation is eliminated, the surface characteristics of copper sulfide minerals are improved, the preferential adsorption of the collector on the surfaces of the copper sulfide minerals is enhanced, and accordingly, compared with a conventional method, the copper grade and the copper recovery rate of copper concentrate are substantially increased.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for preparing novel remover for heavy metal ion and application thereof

The invention provides a method for preparing a novel heavy metal ion remover and an application thereof, and relates to a method for preparing a raw material of the heavy metal ion remover, a process for synthesizing the heavy metal ion remover and an application thereof. The invention is characterized in that the method comprises the following steps that: methenamine and epoxy chloropropane react with carbon bisulfide after the methenamine and the epoxy chloropropane are subject to the cross linking reaction, thereby obtaining a quaternary ammonium salt xanthate chelating agent-the novel heavy metal ion remover. The prepared novel heavy metal ion remover can be used for treating wastewater containing heavy metal ions, and the dosage and the adding process of the novel heavy metal ion remover can be controlled through detecting changes of an oxidation-reduction reaction electrode potential (ORP), thereby achieving the aim of automatically treating the wastewater containing the heavy metal ions with high efficiency.

Owner:陈德琪

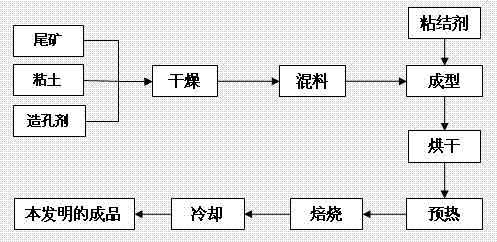

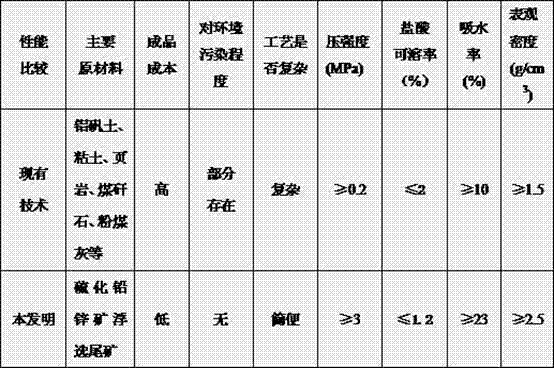

Biological ceramisite filter material made of vulcanized lead zinc ore flotation tailings, and preparation method thereof

InactiveCN103086741AImprove performance qualityLow costSolid waste disposalCeramicwareMining engineeringSulfidation

The invention relates to a biological ceramisite filter material made of vulcanized lead zinc ore flotation tailings. The material is characterized by being prepared from 80-90wt% of vulcanized lead zinc ore flotation tailings, 8-18wt% of clay, 1.5-2.5wt% of pore former and an additional bonder, wherein the pore former is sawdust, bamboo scraps or straws, the bonder is lignin calcium xanthate, sodium carbonate or sodium silicate liquid, and the solid-to-liquid ratio of materials used by the biological ceramisite filter material is (8-12):1. The preparation method comprises the following steps of: weighing based on proportion of main and auxiliary materials; drying; mixing; forming; drying; preheating; roasting; and cooling to prepare a biological ceramisite filter material product made of the vulcanized lead zinc ore flotation tailings. The preparation method is simple and convenient to implement, free from secondary pollution, practical and reliable. The biological ceramisite filter material made of the vulcanized lead zinc ore flotation tailings provided by the invention has the advantages of turning ore waste residue into wealth and greatly lowering the cost of materials, so that the biological ceramisite filter material is a high-quality water treatment agent.

Owner:HOHAI UNIV

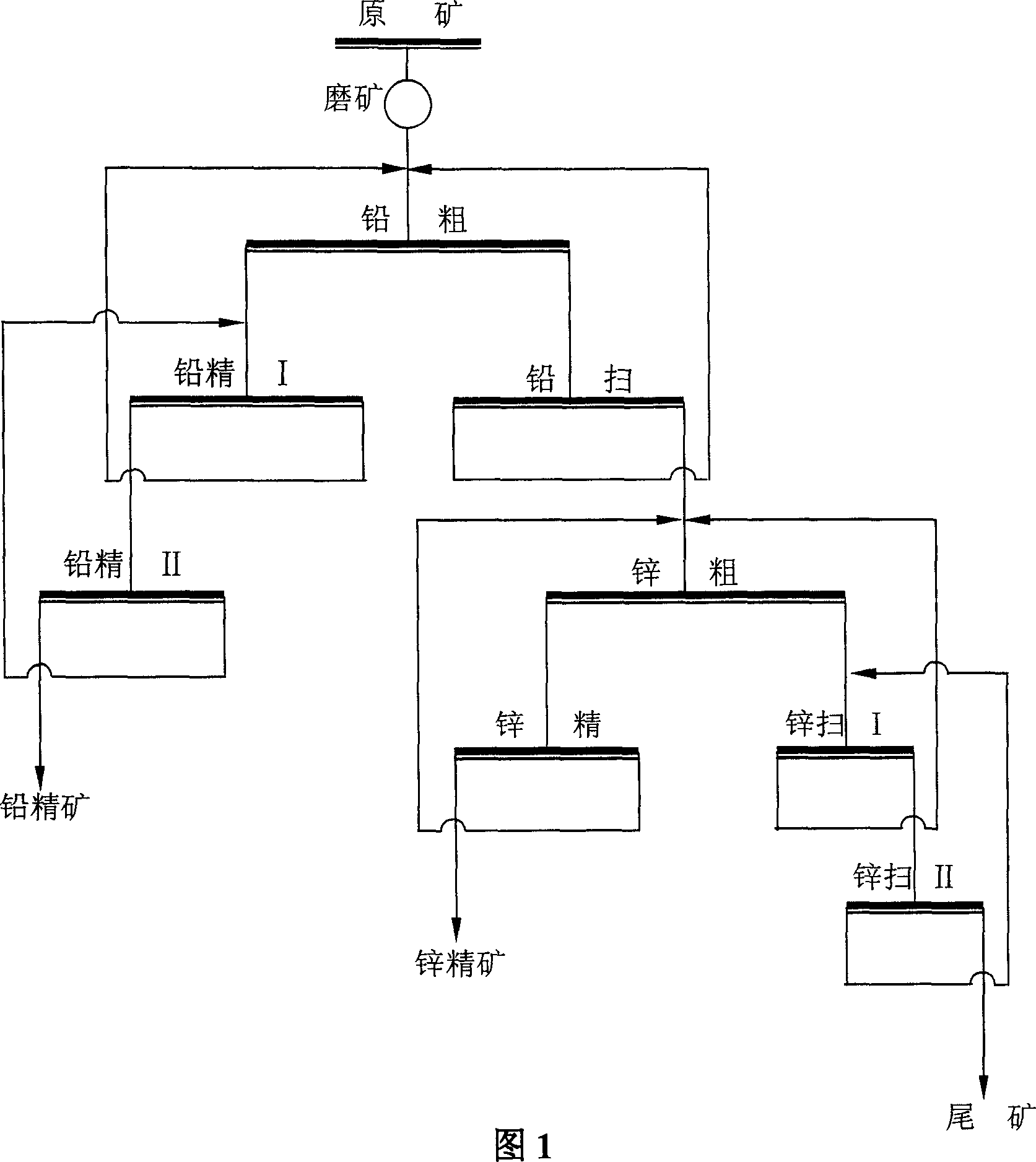

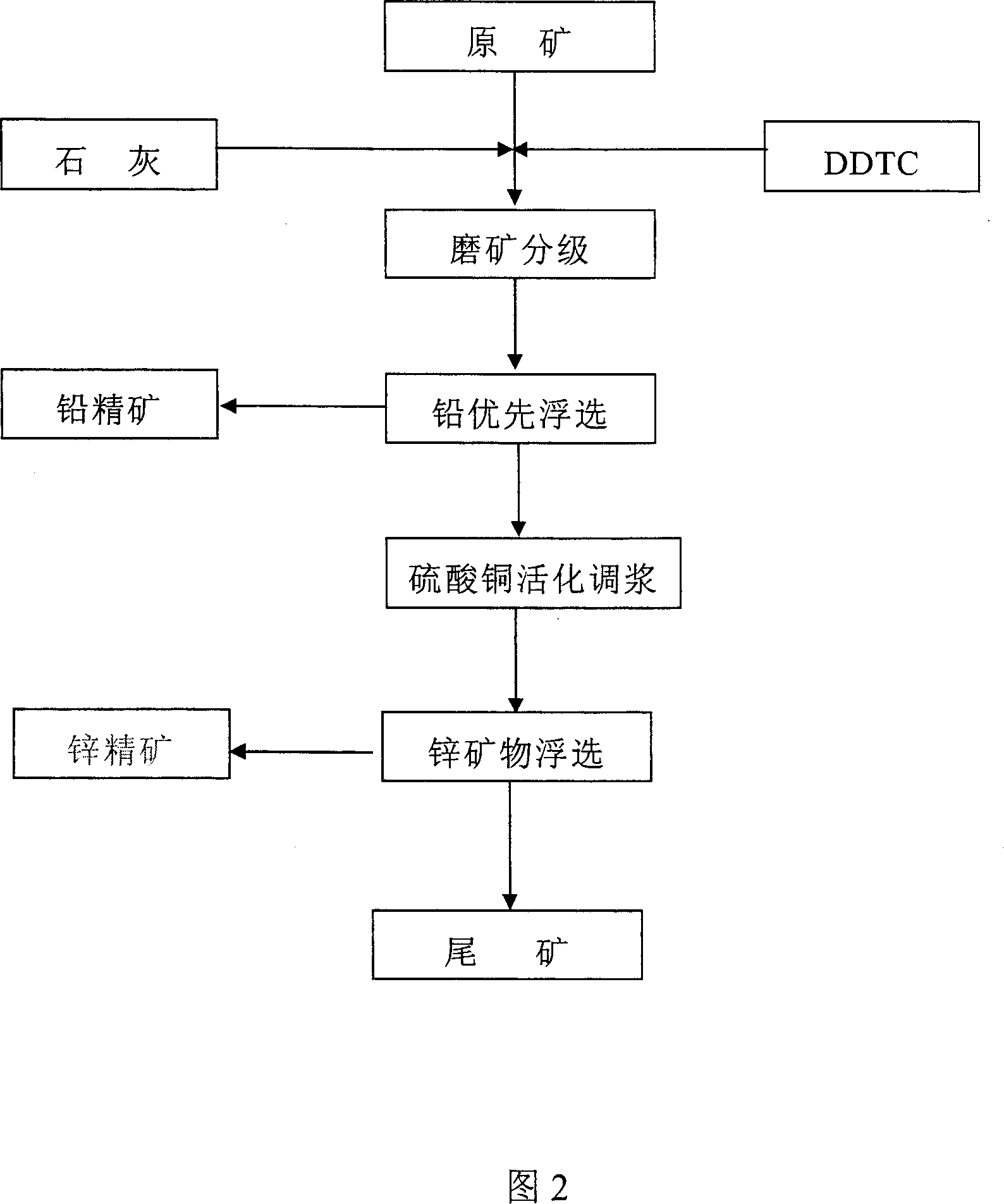

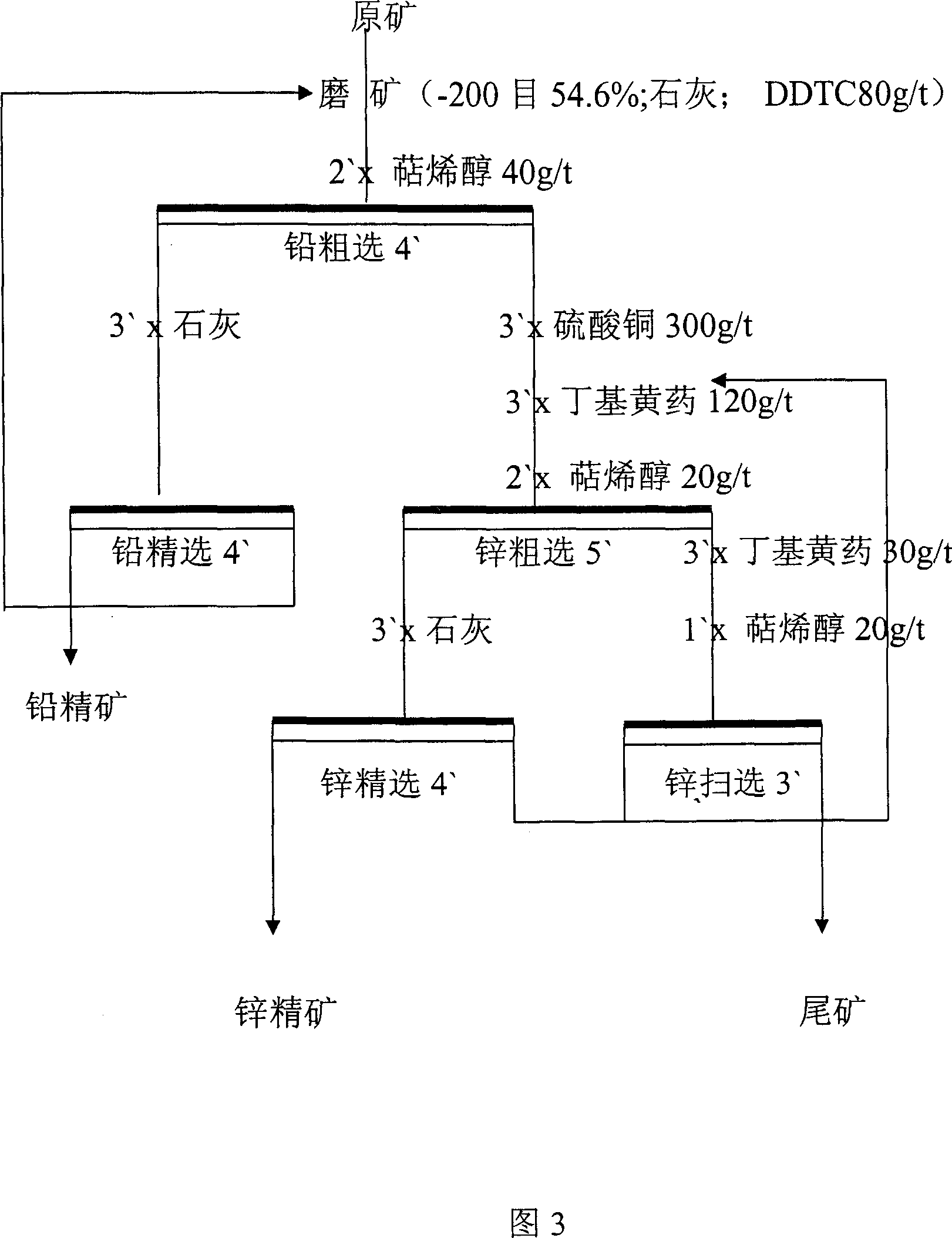

Process for increasing complicated sulfurized-lead-zinc ore dressing recovery rate

The present invention is green process of recovering complicated lead-zinc sulfide ore in high recovering rate. The technological process adopts lime to form high alkalinity and maintain the original potential of lead-zinc sulfide slurry during ore grinding floatation, sodium diethyl dithioamino formate as the selective lead mineral collecting agent, copper sulfate as the sphalerite activating agent and butyl xanthate as the zinc mineral collecting agent for optimized successive fast floatation. The present invention has raised recovering rate, low chemical consumption, simple technological process and low production cost.

Owner:青海西部矿业科技有限公司

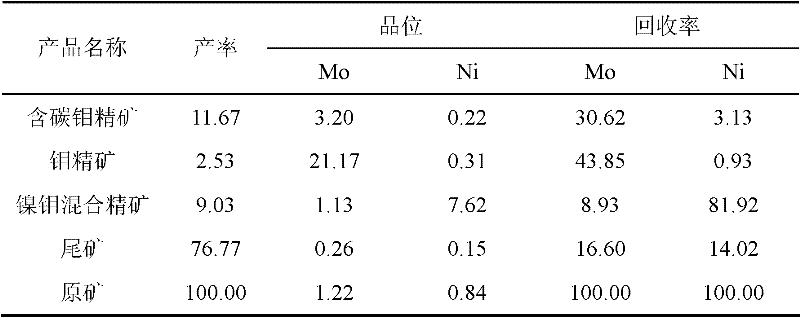

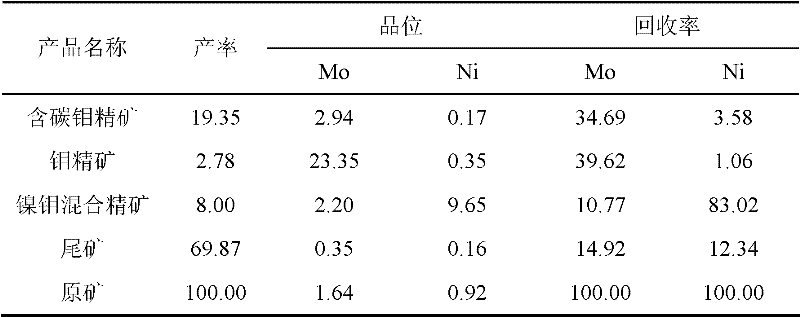

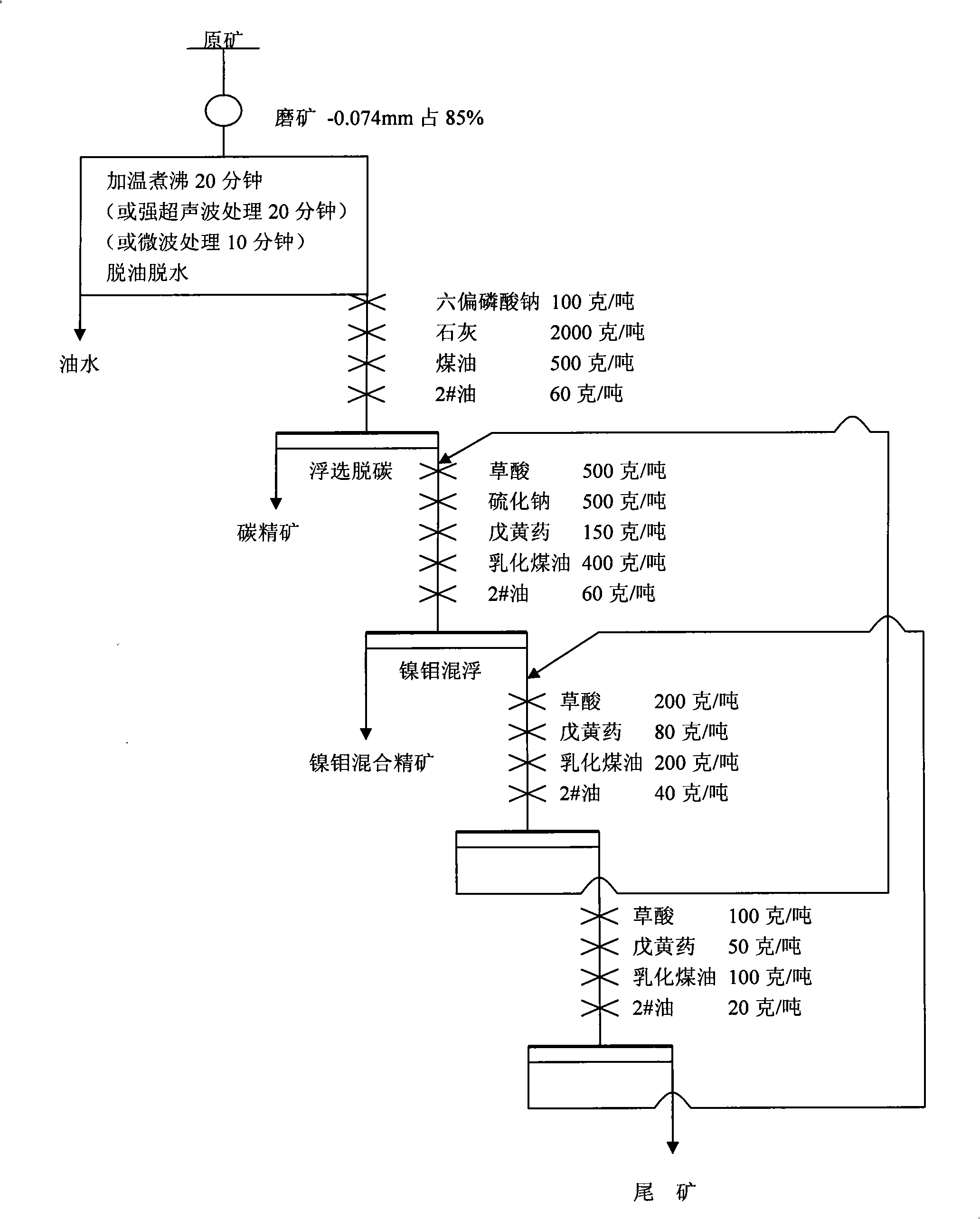

Method for high-efficiency floatation and separation of molybdenum and nickel and recovery of molybdenum and nickel from high carbon nickel-molybdenum ore to obtain molybdenum concentrate and nickel-molybdenum bulk concentrate

The invention discloses a method for high-efficiency floatation and separation of molybdenum and nickel and recovery of molybdenum and nickel from high carbon nickel-molybdenum ore to obtain molybdenum concentrate and nickel-molybdenum bulk concentrate. The method comprises the following steps of: selecting raw ore; grinding the ore; performing floatation to remove carbon; performing floatation of molybdenum preferably; and performing nickel-molybdenum bulk floatation, wherein in the step of performing carbon removal floatation, an ore dressing reagent of methyl isobutyl carbinol (MIBC) is used as a carbon substance foaming agent and collector, and water glass and lime are used as a dispersing agent and an ore pulp regulator; in the step of performing floatation of molybdenum preferably, emulsified kerosene is used as a collector for molybdenum mineral, terpenic oil is used as a foaming agent, carboxy methylated cellulose (CMC) is used as an inhibitor for carbonic matters and gangue, and Na2SO3 and lime are used as an inhibitor for nickel mineral and pentlandite; and in the step of performing nickel-molybdenum bulk floatation, ore dressing reagents of butyl xanthate and diethyldithiocarbamate are used as a collector for nickel-molybdenum mineral, terpenic oil is used as a foaming agent, CuSO4 is used to activate the nickel mineral, and sulfuric acid is used as a regulator to regulate the pH value of the ore pulp so as to induce the floatation of the nickel and the molybdenum. In the method, the metallic mineral separating effect is good, the recovery rates of metals are high, and the process flow is easy to control and has high repeatability.

Owner:HUNAN RES INST FOR NONFERROUS METALS

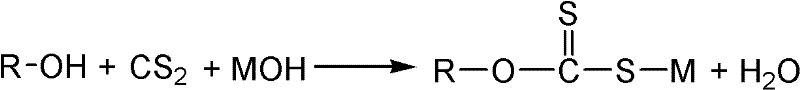

Method for synthesizing xanthate

ActiveCN102690218AReduce volatile lossGood dispersionOrganic chemistryDistillationPotassium hydroxide

Disclosed is a method for synthesizing xanthate, relating to a synthetic process of a flotation collector of metal mines. The invention provides a method for synthesizing xanthate with high yield and good quality. The xanthate of the invention is prepared by adopting the technical solution that raw materials comprise alcohol, carbon disulfide, and caustic alkali with a molar ratio of 1:3-9:1-1.1, wherein the caustic alkali is sodium hydroxide or potassium hydroxide, and the xanthate which is known as Huangyao is prepared by reacting the raw materials for 0.5-8 hours at a temperature ranged from 10 DEG C to 70 DEG C. The invention further discloses methods for recycling a carbon disulfide solvent. The first method comprises filtering materials from a reactor under the protection of nitrogen, and carrying out reduced pressure distillation on the obtained filter cake to acquire a xanthate product with high purity and a carbon disulfide solvent. A Filter liquor and the recycled carbon disulfide can be cycledly utilized. The second method comprises first carrying out an atmospheric distillation on materials from the reactor at a temperature ranged from 50 DEG C to 90 DEG C to recover most of the carbon disulfide, and then carrying out reduced pressure distillation to recover the rest of the carbon disulfide and acquire a xanthate product with high purity at the same time.

Owner:CENT SOUTH UNIV

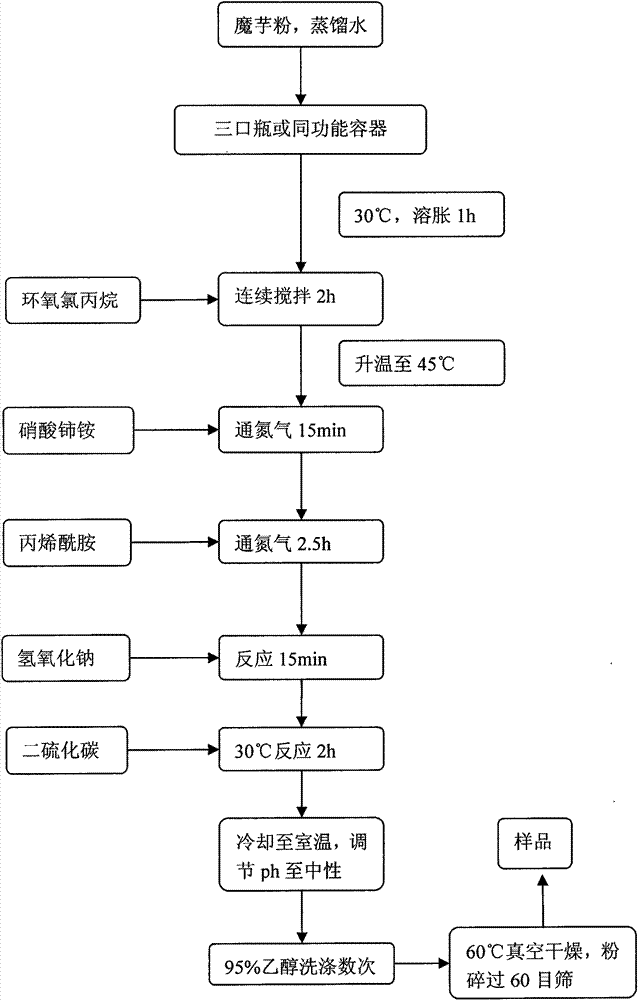

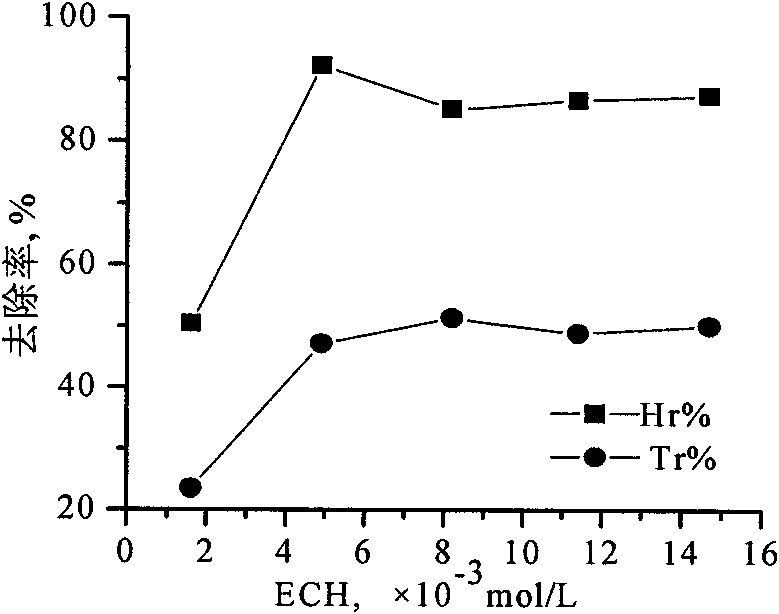

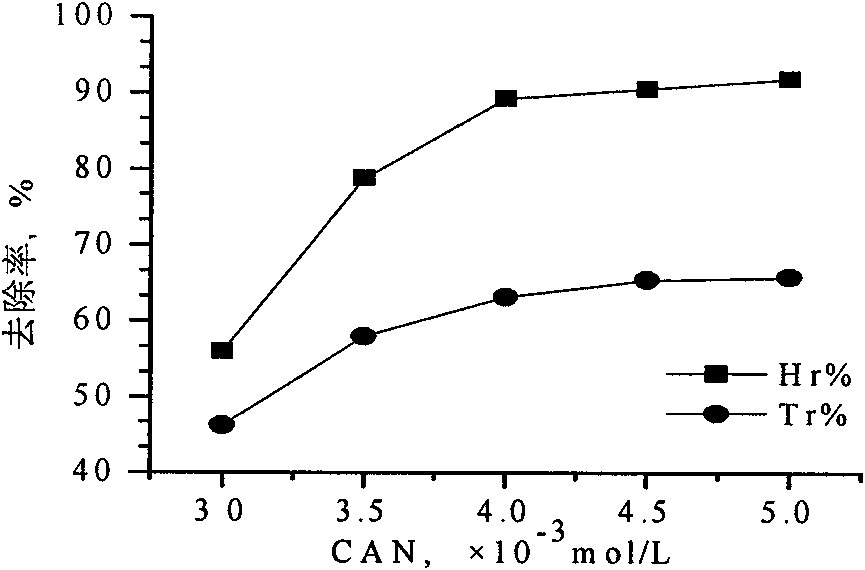

Preparation method and application of polymeric flocculant

InactiveCN102952238ABroad application spaceOvercome defectsWater/sewage treatment by flocculation/precipitationDesorptionCROCUS SATIVUS FLOWER

The invention belongs to the technical field of polymeric flocculant synthesis, and concretely relates to a preparation and an application of a flocculant suitable for sewage treatment. The flocculant can be used for the sewage treatment field. The preparation of the flocculant is characterized in that a final product which is konjak grafted xanthate is obtained through an epichlorohydrin crosslinking-acrylamide grafting-xanthation three-step process carried out on konjak powder which is a raw material. The preparation method of the flocculant concretely comprises the following steps: adding the konjak powder and distilled water into a three-necked bottle having a stirring and condensing device to form a reaction system; adding epichlorohydrin to the reaction system, and continuously stirring; adjusting the temperature of the reaction system under the protection of nitrogen, and adding ceric ammonium nitrate to the reaction system; adding acrylamide; adding sodium hydroxide and carbon disulfide to make reaction products be saffron in color; and adjusting the pH of the obtained reaction product solution to 7, repeatedly washing with ethanol, carrying out vacuum dying of crude products, crushing, and sieving to obtain the polymeric flocculant. The first regeneration desorption rate of the polymeric flocculant can reach 96%, and the copper ion removal rate of the polymeric flocculant can reach above 80%.

Owner:HUAZHONG AGRI UNIV

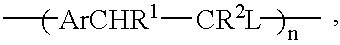

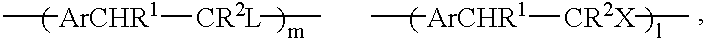

Conjugated copolymers for use in luminescent devices

InactiveUS6423428B1Electroluminescent light sourcesSynthetic resin layered productsLeaving groupCarboxylic salt

A process for the preparation of a conjugated poly(arylene vinylene) copolymer for use in a luminescent device, which comprises: (1) providing a precursor polymer comprising units of general formulain which Ar is substituted or unsubstituted arylene, L is a leaving group, R1 and R2 are each independently H, alkyl, alkoxy, aryl or an electron-withdrawing group, and n is an integer; (2) reacting the precursor polymer with a reactant comprising a carboxylate, an aldehyde, a ketone, a sulphonate, a thioate, a disulphide, a xanthate, an amine, a pyridine, a hydrazide, a phenoxide, an alcohol with a boiling point above 100° C., or a derivative thereof, under substitution conditions whereby a proportion of the leaving groups are substituted to form a substituted precursor copolymer comprising units of general formulain which Ar, R1, R2 and L are defined above, X is a substituent group from the reactant, l and m are independently integers; and (3) converting the substituted precursor copolymer to a conjungated poly(arylene vinylene) copolymer by elimination of the leaving groups from the substituted precursor copolymer.

Owner:CAMBRIDGE DISPLAY TECH LTD

Ore dressing method for removing pyrrhotite from iron ore

InactiveCN104069937AEnhanced harvesting capacityGood beneficiation effectFlotationWet separationChemical mixturesIronstone

The invention discloses an ore dressing method for removing pyrrhotite from iron ore. The ore dressing method for removing the pyrrhotite from the iron ore includes that performing crushing, ore grinding, grading and low intensity magnetic separation techniques to obtain low intensity magnetic concentrate, wherein the TFE grade of the low intensity magnetic concentrate is more than or equal to 65.0%, and the low intensity magnetic concentrate comprises 0.5-1.4% of S; carrying out reverse flotation roughing and reverse flotation selection on the low intensity magnetic concentrate to obtain low-pyrite concentrate with less than 0.15% of S. Weighted by the dry ore amount for the reverse flotation, the reverse flotation roughing chemical comprises (1) pH regulating agent, to be specific, 800-1200 g / t of sulfuric acid; (2) activating agent, to be specific, 80-150 g / t of copper sulfate; (3) collecting agent, to be specific, 250-400 g / t of iso-butyl xanthate and 150-250 g / t of butyl dithiophosphate; (4) foaming agent, to be specific, 30-70 g / t of 2# oil. The ore dressing method for removing the pyrrhotite from the iron ore uses the butyl dithiophosphate and butyl xanthate or iso-butyl xanthate to form sulfur content reducing chemical mixture, the molecular arrangement between the chemical micelles is improved to form a synergistic effect, the chemical is good for mineralizing and adsorbing, the hydrophobicity and the floating speed are properly reinforced, and the sulfur content of the iron concentrate is reduced to less than or equal to 0.03-0.15%. The ore dressing method for removing the pyrrhotite from the iron ore is especially suitable for removing the pyrrhotite from the iron ore with pyrrhotite through reverse flotation.

Owner:马钢集团设计研究院有限责任公司 +1

High iron pelitization wulfenite floatation method

The high iron slimed wulfenite floating process adopts sodium hexametaphosphate as dispersant, sodium hydroxide as ore pulp pH regulator, sodium sulfide for sulfurizing and deleading, copper sulfate as activator, kerosene as water repellent, isoamyl xanthate as wulfenite collector and 2# oil as foaming agent. The process can float to recover wulfenite with high iron content and serious sliming effectively. When the raw ore has Mo content of 0.5-0.76 %, Mo concentrate obtained through once coarse separation and four times of fine separation has Mo content of13-16.8 % and recovery rate up to 71-76 %.

Owner:GUANGXI UNIV

High-efficiency ore sorting technique for nickel-molybdenum mineral

The invention provides a high-efficiency beneficiation technology of NiMo minerals. The technical proposal of the invention is that: a strong physical field is introduced to preprocess and decarbonize minerals, such as a thermodynamic field, an intense ultrasonic wave field or a microwave field, etc., and after adding high-efficiency activating agents to activating Ni and Mo, kerosene or xanthate is used for collection. 0.5 to 2 percent of low grade NiMo minerals are processed by the technology of the invention to obtain NiMo mixed concentrate with the NiMo grade of 5 to 8 percent and a recovery rate of more than 75 percent, which fully satisfies the requirement of metallurgical materials in a united flow of the beneficiation and metallurgy, thus providing a new way for NiMo mineral resources in China refractory black rock series.

Owner:CENT SOUTH UNIV

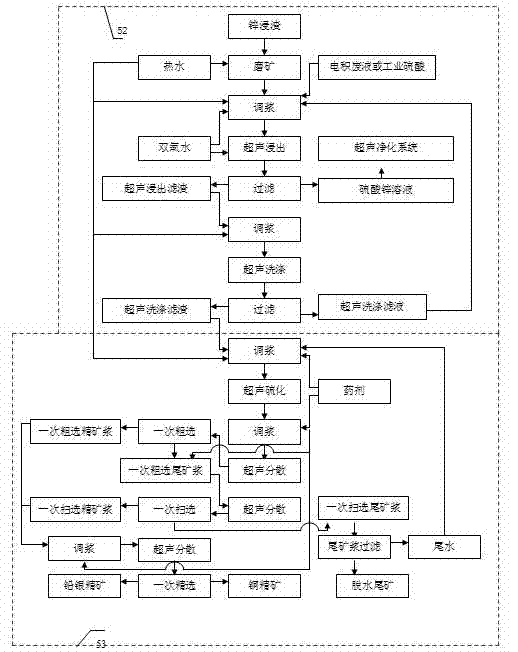

Reagent formula used for zinc leaching residue floatation process and application method of reagent formula

The invention relates to a reagent formula used for a zinc leaching residue floatation process and an application method of the reagent formula. The reagent is a floatation reagent which is added into floatation processes such as sulfurizing, rough floatation, scavenging and concentration. The reagent formula is characterized in that 1) one or two of sodium sulphide and sodium hydrosulfide are added into a sulfurizing process as a sulfurizing reagent; 2) in the rough floatation process, N,N-sodium diethyldithiocarbamate, butyl ammonium black powder and 25# black powder are added as lead mineral collecting agents, Y89 and (or) pentyl xanthate are added as silver mineral collecting agent(s); 3) in a scavenging process, one or two of sodium sulphide and sodium hydrosulfide are added as the sulfutizing agent(s), N,N-sodium diethyldithiocarbamate, butyl ammonium black powder and 25# black powder are added as the lead mineral collecting agents, and the Y89 and (or) pentyl xanthate are added as the silver mineral collecting agent(s); and 4) carboxymethylcellulose is added as a gangue inhibiting agent in a concentration process. After applying the reagent formula disclosed by the invention, by adopting one-time rougher floatation, one-time scavenging and one-time concentration, lead yield can reach up to more than 95% and lead tail run can reach 0.1-0.2%.

Owner:XINGMIN TECH ZHUZHOU

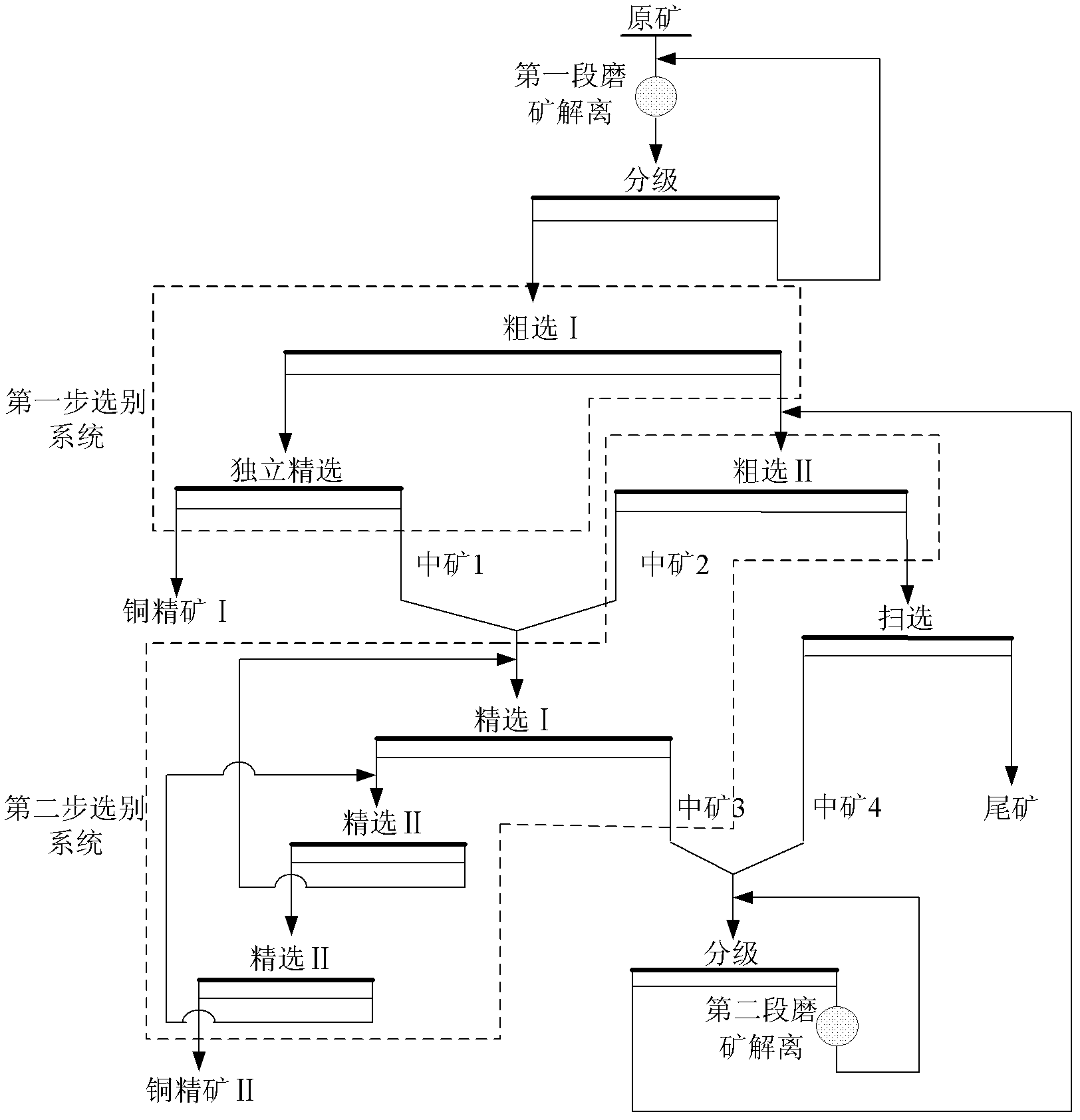

New stage dissociation-fractional selection flotation process

InactiveCN102302969AImprove flotation recoveryReduce pollutionFlotationGrain treatmentsAlkalinitySulfur

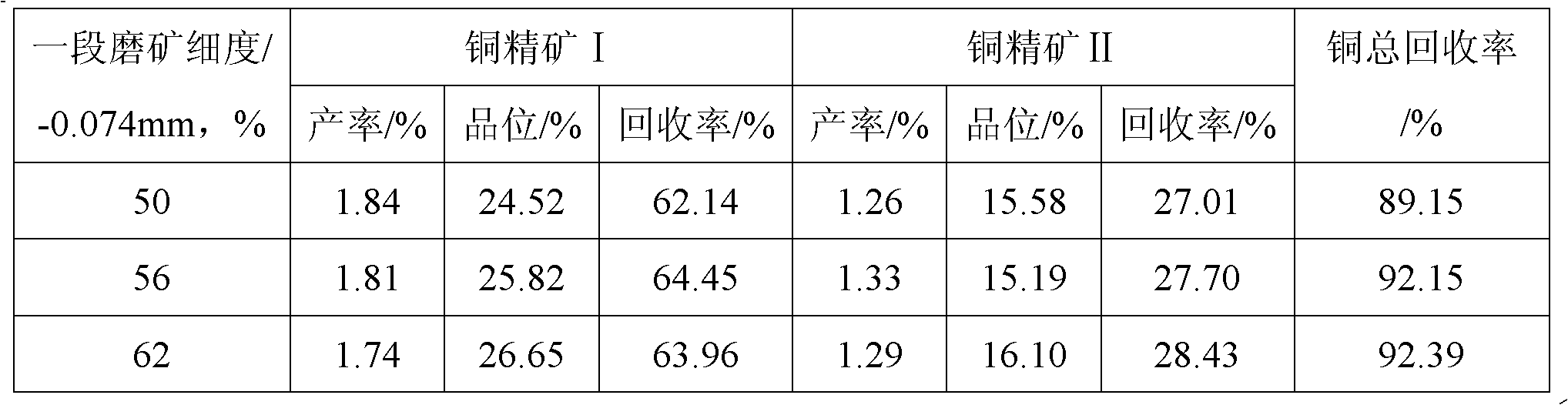

The invention relates to a selective grinding-floatation process for copper sulphide ores, particularly relates to a grinding-floatation process for complex copper sulphide ores in which the primary copper content is low, the secondary copper content is high and the secondary copper is accreted with copper oxides and the like, or the sulfide content is high. The process provided by the invention comprises the steps of first-stage ore grinding for dissociation, second-stage ore grinding for dissociation, first-step selection and second-step selection, wherein in the step of first-stage ore grinding for dissociation, ores with grinding fineness of minus 0.074mm are between 50% and 62%; in the step of second-stage ore grinding for dissociation, ores with the grinding fineness of minus 0.074mm are above 90%; in the step of first-step selection, preferential flotation on ores with a low basicity is achieved through taking an chemical agent ester-105 with a high selectivity as a collector; and in the step of second-step selection, the powerful collection of difficult floated copper can be realized by using a chemical agent such as xanthate. By using the process disclosed by the invention, the ore dressing recovery percentage of copper ores is increased, and the ore grinding cost is low, the chemical agent consumption is less, the degree of environmental pollution is low, and the ore dressing efficiency is high.

Owner:JIANGXI UNIV OF SCI & TECH

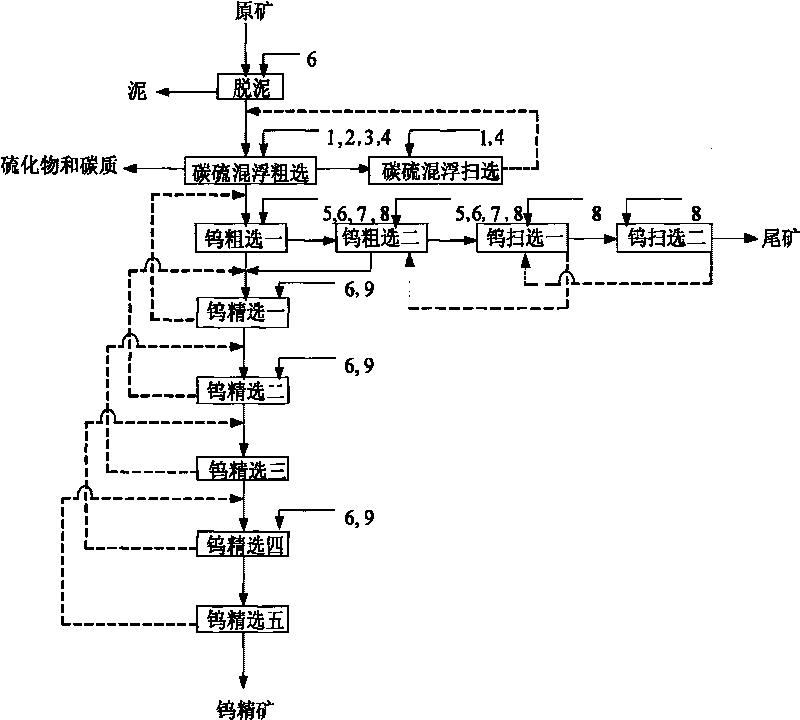

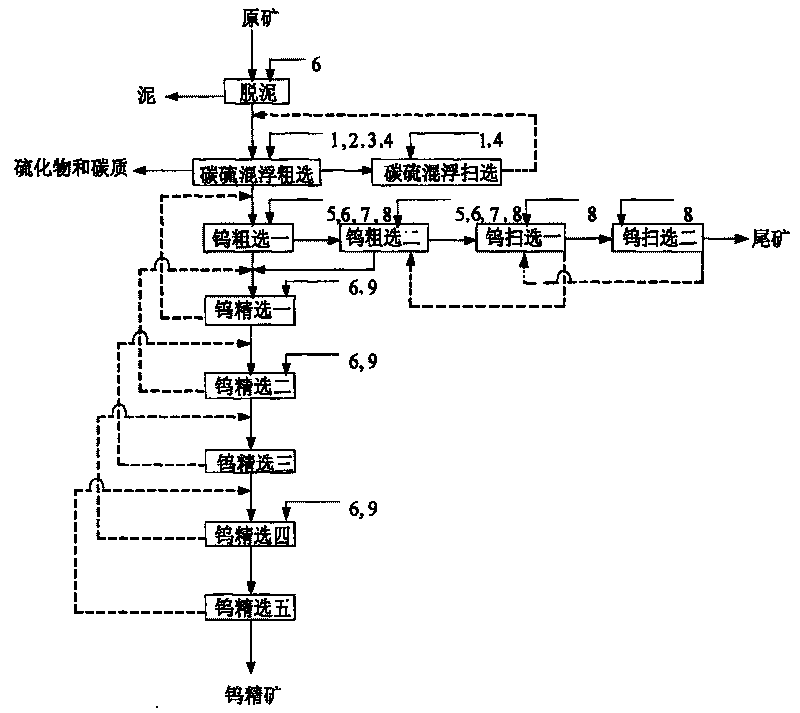

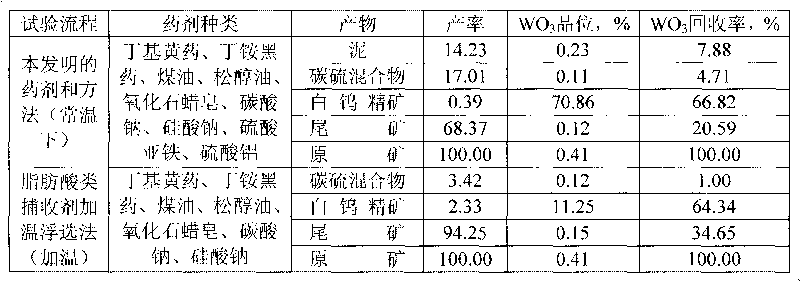

Beneficiation reagent and method for separating scheelite from complex tungsten ore

The invention relates to a beneficiation reagent and a method for separating scheelite from complex tungsten ore; the beneficiation reagent adopts oxidized paraffin soap, kerosene, butyl xanthate, dithiophosphate BA as collectors, adopts sodium carbonate as modifier and terpenic oil as foaming agent, and also adopts one or the combination of Sodium silicate and ferrous sulfate or aluminum sulfate as inhibitor; the method employing the beneficiation reagent for separating scheelite from complex tungsten ore includes: desliming in normal temperature, carbon-sulfide bulk rough floatation, secondary tungsten rough floatation and quintic tungsten concentration, so tailings and tungsten concentrate product are obtained; besides, the invention has the advantages of high sorting efficiency, high yield rate, wide reagent resource, low price, low cost and dosage, simple and reliable process, easy operation and normal temperature working, and is particularly applicable to the beneficiation application of complex tungsten ores.

Owner:ZIJIN MINING GROUP

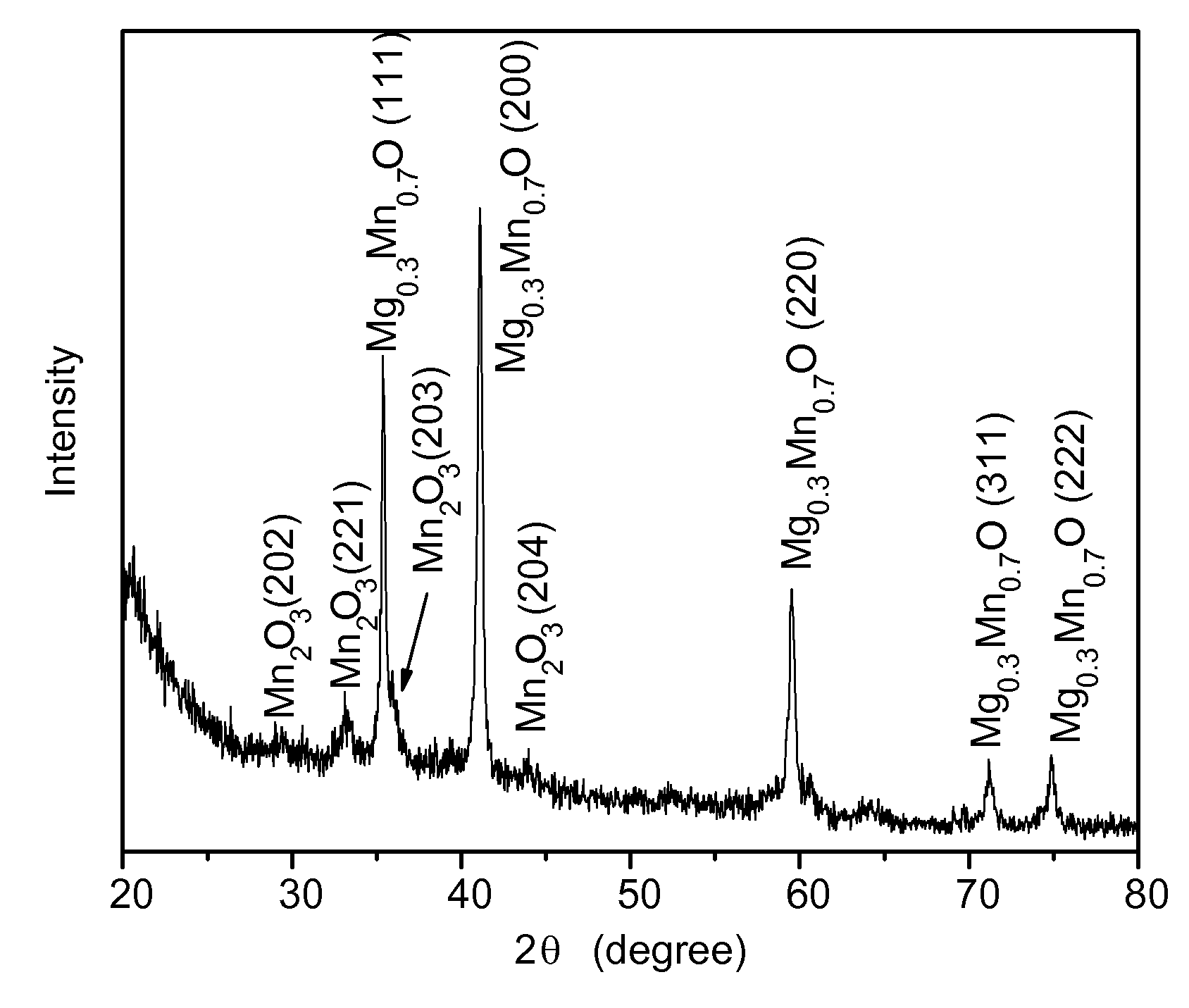

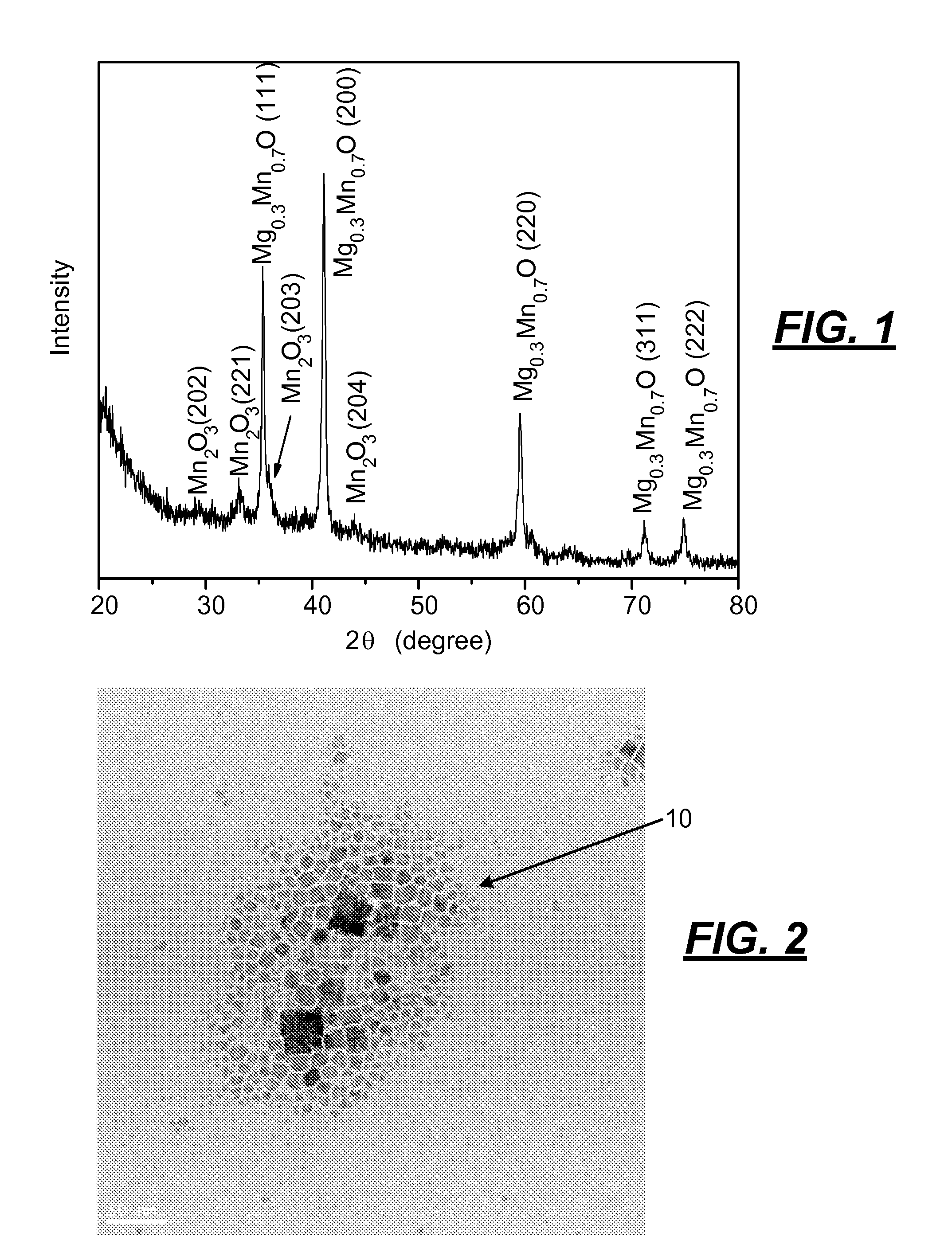

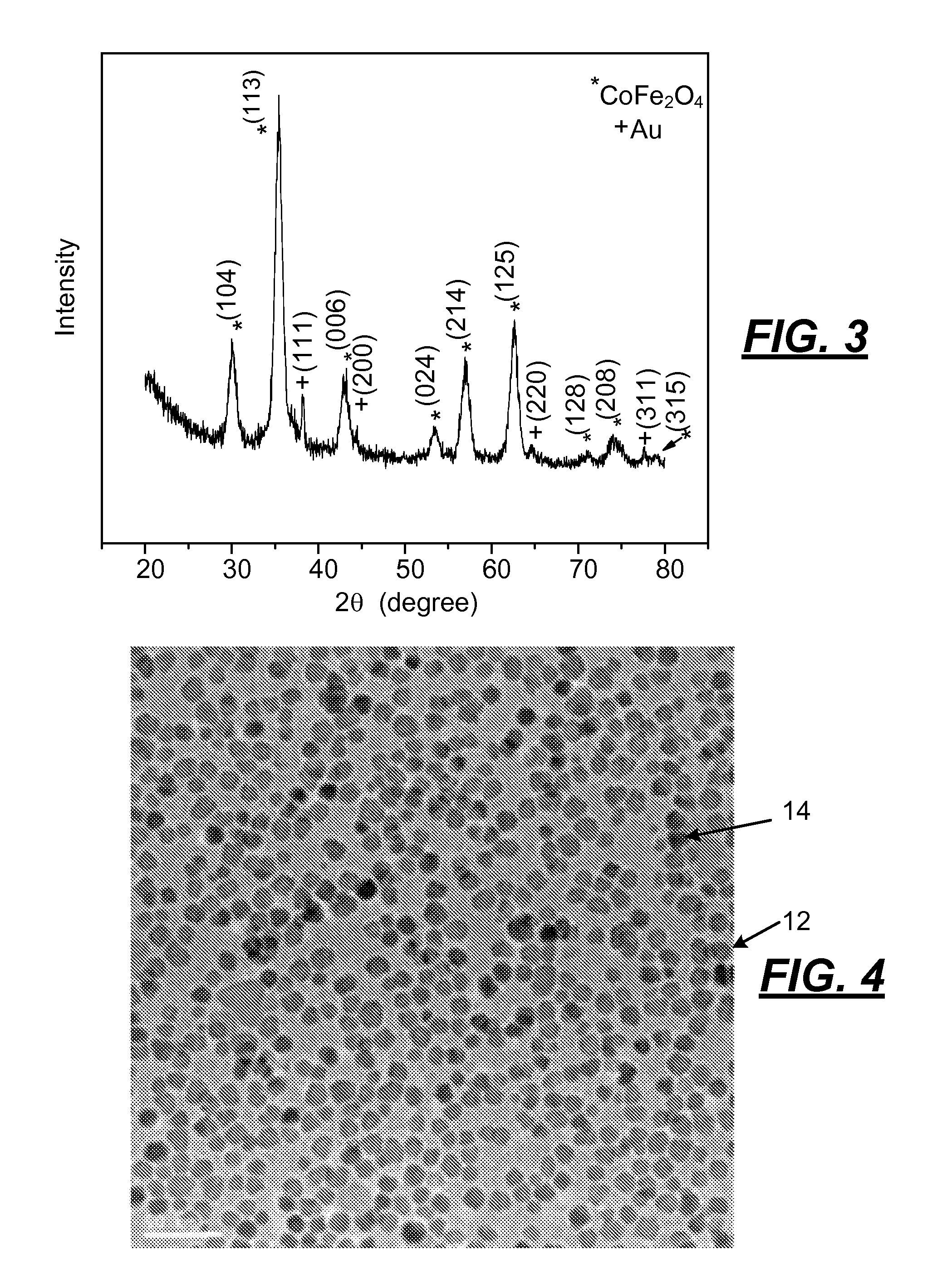

Methods for making metal-containing nanoparticles of controlled size and shape

InactiveUS20080164141A1Low costUniform size distributionMaterial nanotechnologyOxide/hydroxide preparationStoichiometryXanthate

A method for producing metal-containing nanoparticles. The method includes combining a metal organic compound selected from metal acetates, metal acetyl acetonates, and metal xanthates with an amine to provide a solution of metal organic compound in the amine. The solution is then irradiated with a high frequency radiation source to provide metal nanoparticles having the formula (Aa)m(Bb)nXx, wherein each of A and B is selected from a metal, X is selected from the group consisting of oxygen, sulfur, selenium, phosphorus, halogen, and hydroxide, subscripts a, b, and x represent compositional stoichiometry, and each of m and n is greater than or equal to zero, with the proviso that at least one of m and n is greater than zero.

Owner:AFTON CHEMICAL +1

Method for producing wood pulp sponge

The invention discloses a method for producing wood pulp sponge. The method is as follows: using wood pulp as the main raw material, soaking, squeezing, yellowing, gluing, mixing, foam forming and washing with water to obtain the biodegradable wood cellulose sponge product, wherein (a) soaking process: adding sodium hydroxide and wood pulp into a dip vat in a mixing manner to prepare wood pulp; (b) squeezing process: placing the soaked wood pulp into a presser to obtain compressed alkali cellulose blocks; (c) yellowing process: smashing the alkali cellulose blocks after standing into particles or small lumps of alkali cellulose using a mill, and introducing an excess ratio of carbon disulfide gas for yellowing reaction; (d) gluing process: putting xanthate and additional wood pulp, bamboo pulp and water into a kneader for mixing to prepare a gluing material; (e) mixing process: mixing the gluing material with sodium sulfate crystals and toner ribbon to prepare a heat foaming sponge mixture; (f) foam forming process: preparing sponge blocks using the sponge mixture.

Owner:NINGBO NECO SPONGE TECHONOLOGY CO LTD

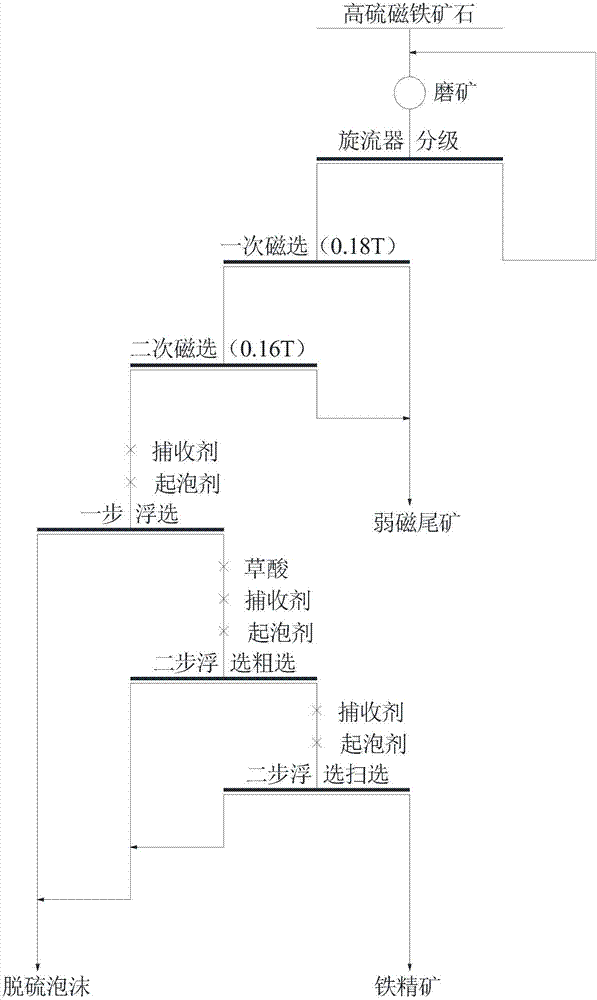

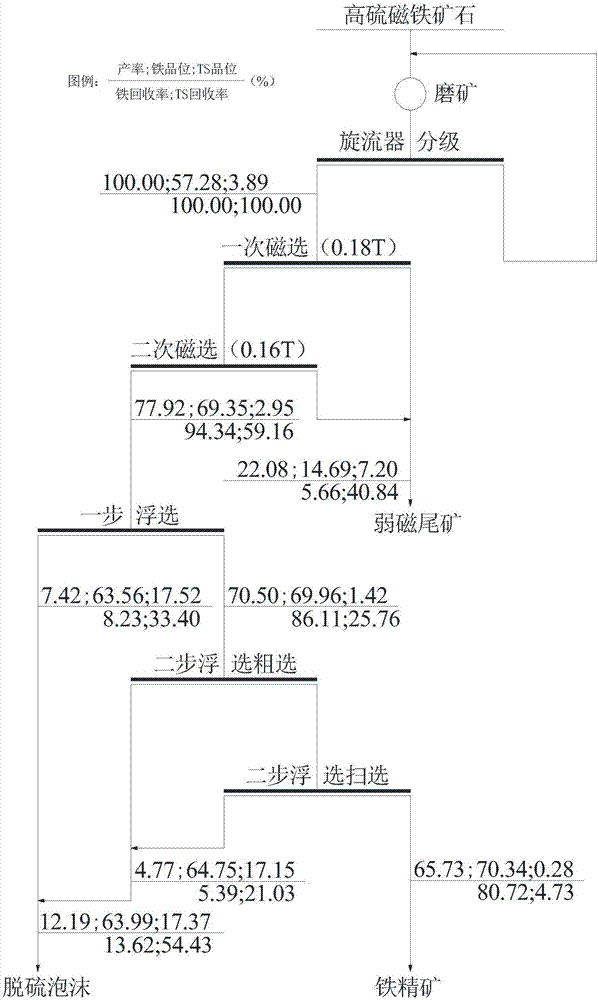

Beneficiation method for high sulphur magnetite containing pyrrhotite and pyrite

The invention discloses a beneficiation method for high sulphur magnetite containing pyrrhotite and pyrite. The method is used for beneficiation of the high sulphur magnetite with the grade of raw ore TFe being 56%-60% and the content of TS being 3.5%-4.2%. The method comprises the following technological steps that (1) the high sulphur magnetite is subjected to grinding and grading-low-intensity magnetic separation operation; (2) the pyrite is removed through primary flotation, specifically, butyl xanthate is used as a collecting agent for the pyrite, and 2#oil serves as a foaming agent; and (3) the pyrrhotite is removed through secondary flotation, specifically, primary roughing and primary scavenging are adopted, oxalic acid is used as a pH value regulator and an activating agent of the pyrrhotite, the butyl xanthate serves as a collecting agent of the pyrrhotite, and the 2#oil serves as the foaming agent. The beneficiation method has the advantages that the grade of iron ore concentrate TFe is high, the content of a harmful impurity S is low, production is stable, and safety and high efficiency are achieved, so that safety risks are reduced; and the oxalic acid (solid) is adopted to replace concentrated sulfuric acid to serve as the pH value regulator and the activating agent of the pyrrhotite, operation is simple and easy in the production process, and the safer and more reliable effect is achieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Floatation wastewater biological treatment process

ActiveCN105800796AShort reaction timeMaintenance freeWater treatment compoundsBiological water/sewage treatmentMetaboliteMetallic sulfide

The invention provides a floatation wastewater biological treatment process which comprises an adjusting buffer tank, a xanthate degradation tank and a sulfate reduction tank, wherein a xanthate degradation bacterium and a sulfate reduction bacterium are adopted to treat floatation wastewater; a sulfur source and a carbon source are provided for the sulfate reduction bacterium through metabolite of the xanthate degradation bacterium; sulfur ions can be generated from metabolism of the sulfate reduction bacterium; the sulfur ions can be reacted with heavy metal ions in the flotation wastewater so as to generate metal sulfide precipitate. The floatation wastewater biological treatment process has the advantages that through synergism of the xanthate degradation bacterium and the sulfate reduction bacterium, degradation of a beneficiation reagent xanthate in the flotation wastewater can be achieved, valent resources in the flotation wastewater can be recycled, and resource recycling can be achieved.

Owner:KUNMING UNIV OF SCI & TECH

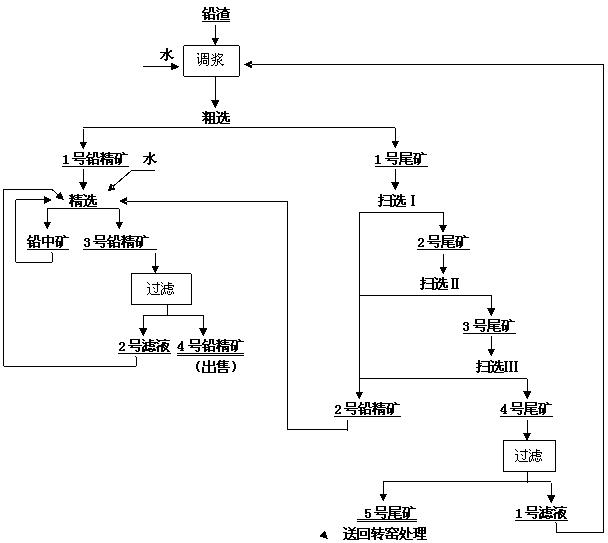

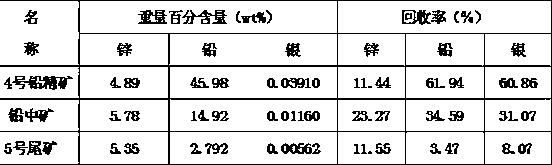

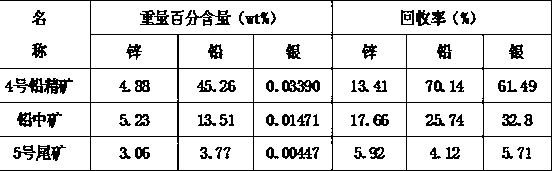

Method for comprehensively recovering lead and silver from lead slag

The invention relates to a method for comprehensively recovering lead and silver from lead slag. The lead slag produced in an electric zinc factory serves as the raw material and mainly contains 10-18wt% of lead, 7-10wt% of zinc and 0.01-0.02wt% of silver. The flotation process of one roughing, three times of scavenging and one cleaning is adopted, lead in the lead slag is selected in flotation mode, silver enters lead concentrate, tailings enter a rotary kiln for volatilizing, and further the remained valuable metals in the lead slag are recovered. During flotation, sodium carbonate serves as regulators, sodium sulfide serves as vulcanizers, zinc sulfate serves as inhibitors, and butyl amine aerofloat, butyl xanthate and diethyldithiocarbamate serve as collecting agents. Lead recovery rate can reach 95-97%, and silver recovery rate can reach 90-95%.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

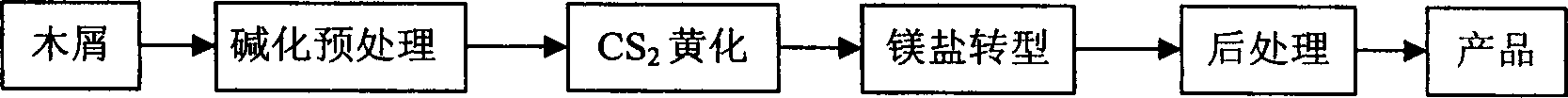

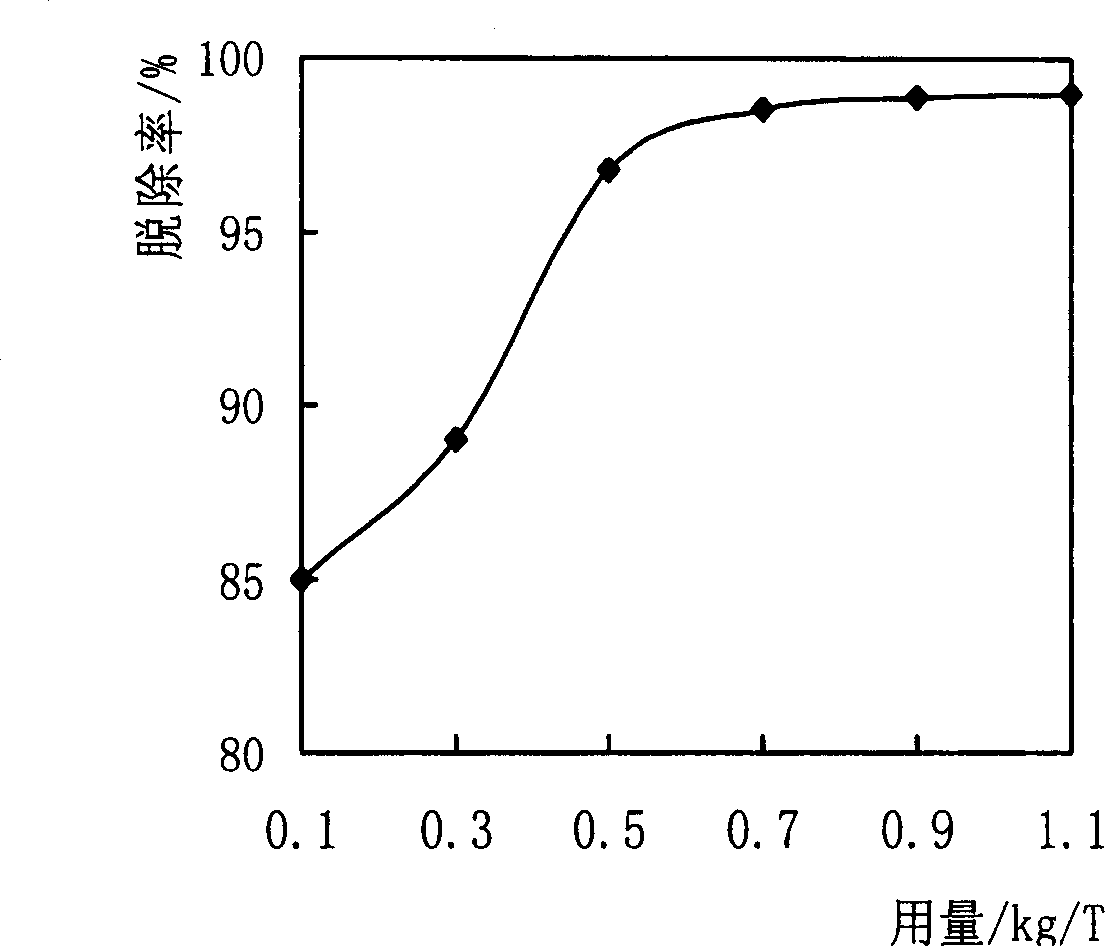

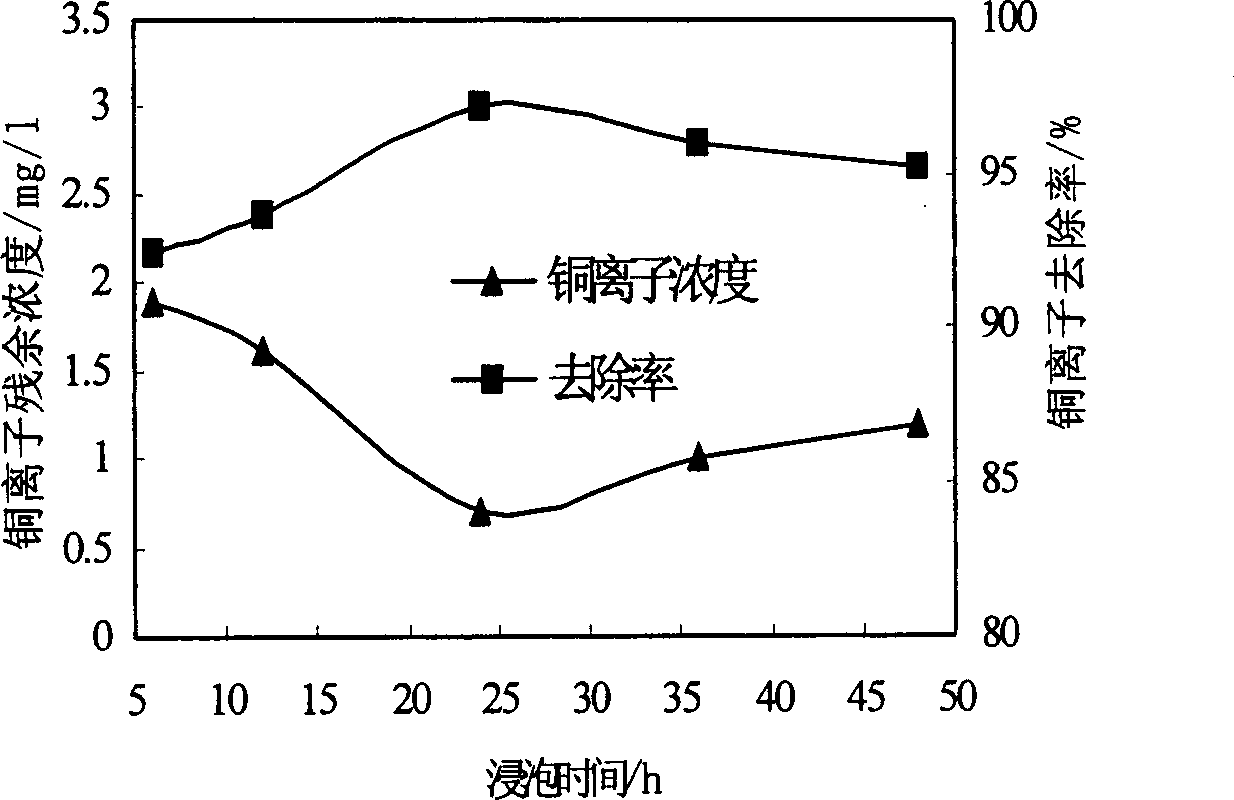

Method for producing sawdust xanthogenate using sawdust and for treating heavy metal waste water using it

InactiveCN1775751AImprove stabilityTo achieve the purpose of treating heavy metal wastewaterOrganic chemistryMultistage water/sewage treatmentFiberWater use

The invention provides a xanthate produced by bits of wood and a method for processing heavy metal waste water by it, belonging to the technical fields of medicament and heavy metal waste water processing. Its producing method: screening the bits of dry wood with a sieve of an aperture 1mm-0.8mm; soaking the screened bits of dry wood in NaOH solution of a mass concentration 10%-30%, press ¿Cfiltering and dehydrating to obtain basified fiber; adding CS2 into the solution for reacting; making conversion reaction by soluble magnesium salt, adding dilute magnesium salt solution, alcohol and acetone, pump-filtering, press-drying and drying to obtain thexanthate. The method for processing heavy metal waste water: taking the waste water containing heavy metallic ions, blending, filtering and dehydrating. The advantages of the invention: by thexanthate, the removal ratio of heave metal is up to 95%.

Owner:UNIV OF SCI & TECH BEIJING

Manufacturing method for degradable sponge product

A manufacturing method for a degradable sponge product comprises the following steps: soaking, squeezing, yellowing, sticking, mixing, carrying out foam molding, washing, and preparing the degradable sponge product prepared from wood cellulose, wherein a), in the soaking process, two raw materials of sodium hydroxide and mixed pulp are mixed together in a dip vat; b) in the squeezing process, the soaked size is compressed to obtain an alkali cellulose block; c) in the yellowing process, carbon disulfide gas is introduced in the alkali cellulose block for yellowing to obtain xanthate; d) in the sticking process, xanthate, bamboo pulp, wood pulp and water are added in a kneading machine to be mixed to prepare an adhesive material; e) in the mixing process, the adhesive material, a sodium sulfate crystal and a toner ribbon are mixed to prepare a sponge mixture capable of being heated and foamed; f) in the foaming process, the sponge mixture is electrified, heated and coagulated to manufacture a sponge block.

Owner:NINGBO NECO SPONGE TECHONOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com