Reagent formula used for zinc leaching residue floatation process and application method of reagent formula

A flotation process and zinc leaching slag technology, applied in flotation, solid separation and other directions, to achieve the effect of short process flow, reduced recovery cost and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

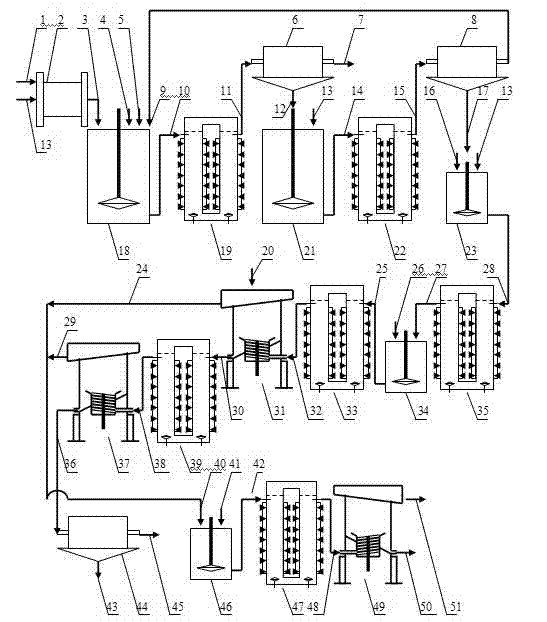

[0025] Embodiment one: An ultrasonic separation and smelting process for treating zinc leaching slag

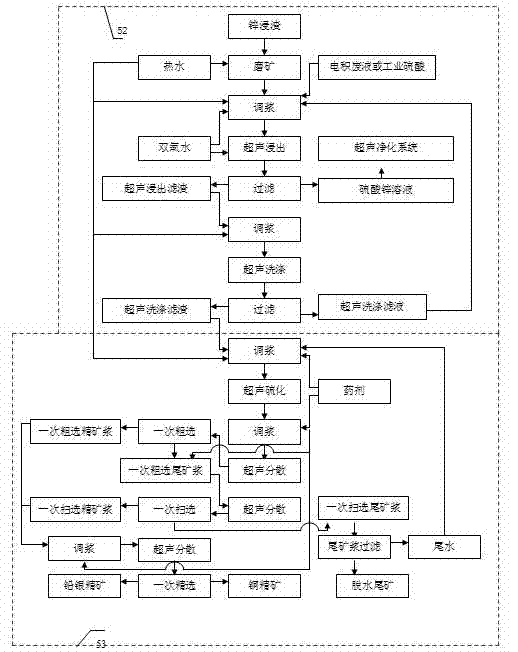

[0026] From figure 1 and 2 It can be seen that the present invention is an ultrasonic separation and smelting process for treating zinc leaching slag. The pre-ultrasonic leaching system 52 is composed of the ore mill 2, the pulping machine 18, the ultrasonic leaching machine 19, the filter 6, the pulping machine 21, the ultrasonic washing machine 22, and the filter 8; the post-ultrasonic flotation system 53 , consisting of pulping machine 23, ultrasonic vulcanizing machine 35, pulping machine 34, ultrasonic dispersing machine 33, inflatable flotation machine 31, ultrasonic dispersing machine 39, inflatable flotation machine 37, pulping machine 46, ultrasonic dispersing machine 47, inflatable Flotation machine 49, filter 44 are made up of. Its technical principle and working process are:

[0027] Zinc leaching slag 1 and hot water 13 are dosed according to a solid-to-liq...

Embodiment 2

[0050] Embodiment two: An ultrasonic separation and smelting process for treating copper-containing zinc leaching slag

[0051] From figure 2 It can be seen that the present invention is an ultrasonic separation and smelting process for treating copper-containing zinc leaching slag, and its engineering design is basically the same as that of Embodiment 1, the difference being that the medicament added in a roughing pre-slurry process In 26, add thiocarbamate (50-200g / t); add thiocarbamate (50-100g / t); Sodium thioglycolate (20-100g / t) is added to the chemical agent 41 added in the slurry mixing process; the first-time selection tailings slurry 50 is copper concentrate, and the copper concentrate is subjected to open-circuit treatment.

[0052] Apply the ultrasonic separation and smelting method of this embodiment to process the zinc leaching residue 1 containing 0.8% copper, obtain ultrasonic washing filter residue 17 containing 2.4% copper in the pre-ultrasonic leaching sy...

Embodiment 3

[0054] Embodiment three: An Ultrasonic Separation and Smelting Process for Treating Silver-Free Zinc Leach Slag

[0055] From figure 2 It can be seen that the present invention is a kind of ultrasonic separation and smelting process that does not contain silver-zinc leaching slag, and its engineering design is basically the same as that of Embodiment 1. The difference is that it does not need to add Y89 and (or ) pentaxanthate. Zinc-lead-silver symbiotic or semi-growth lead-zinc ores are very common in lead-zinc sulfide ore resources, but in the lead-zinc sulfide ores in western Hunan, almost no silver minerals are contained. Among lead-zinc oxide ores, there are also many lead-zinc resources that do not contain silver or contain very little silver. Applying this embodiment to treat silver-free zinc leaching slag is beneficial to saving the cost of chemicals.

[0056] It can be seen from the above examples that the present invention relates to a medicament formulation fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com