Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84 results about "Lead silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead silicate. noun. \ ˈled-\. : any of various salts (as the normal monosilicate PbSiO 3) made by reaction of lead monoxide or a lead salt with silica or a silicate and used chiefly in glass and ceramics and as pigments (as in compounding rubber) — see white lead sense c.

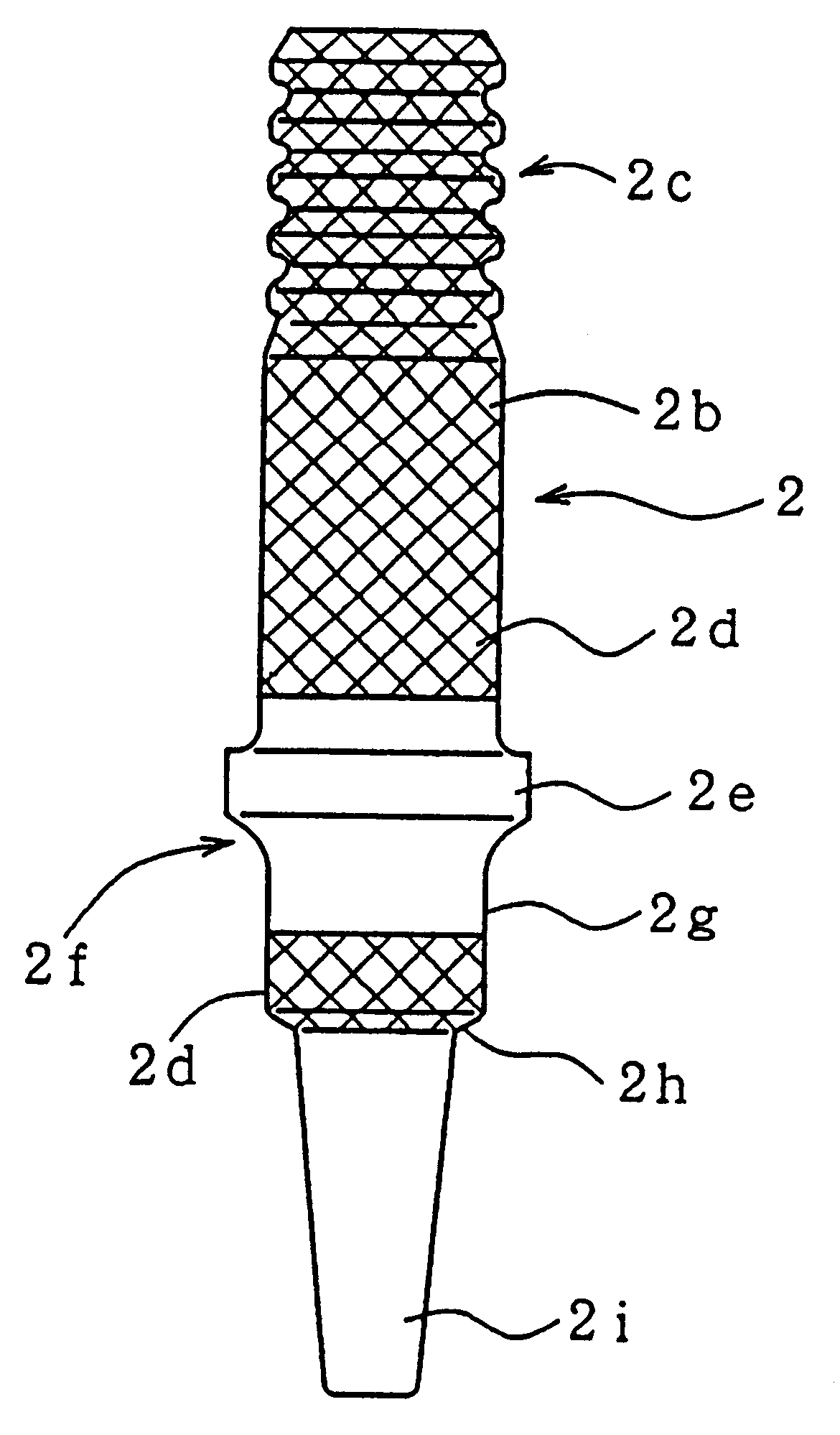

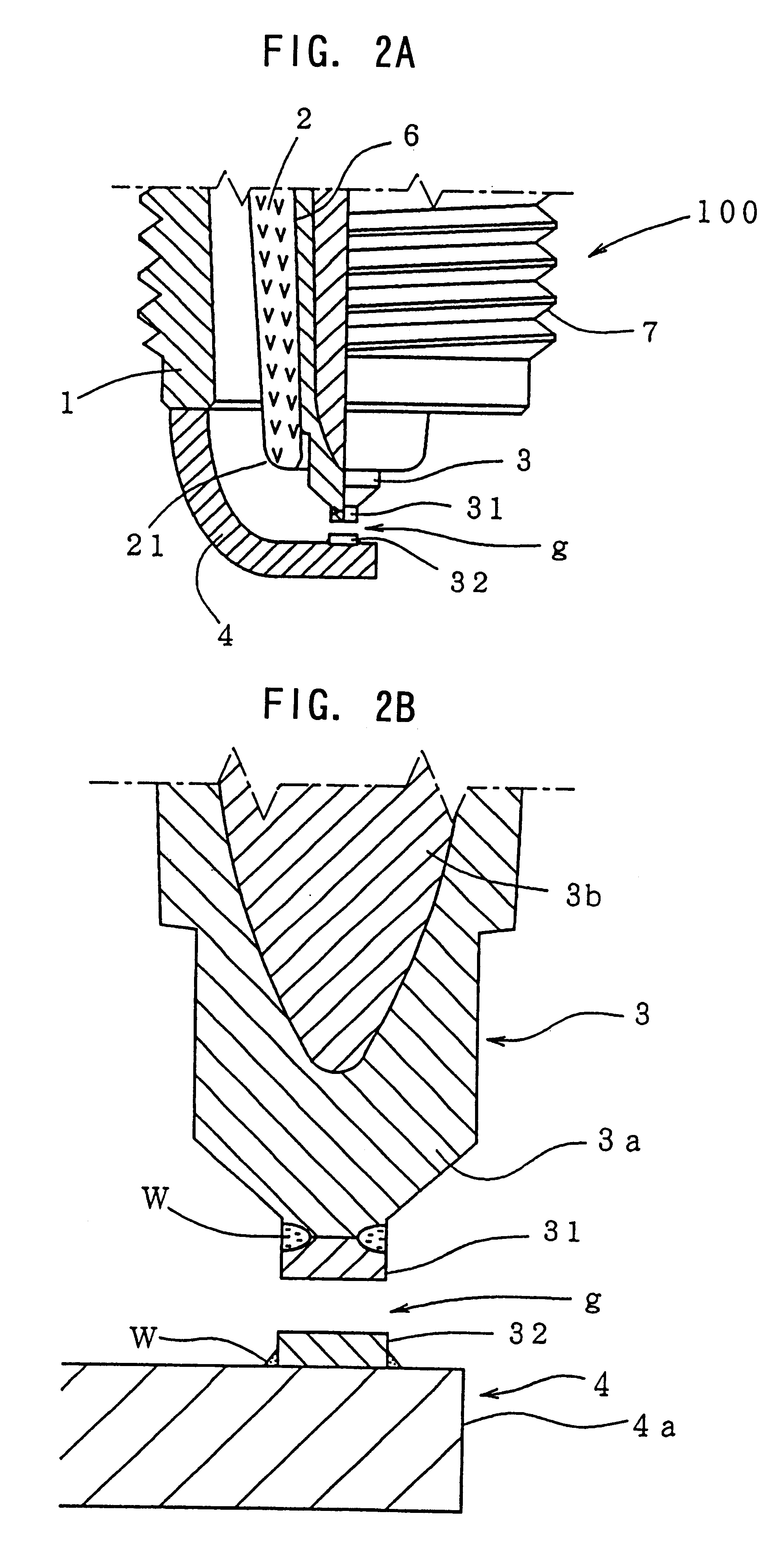

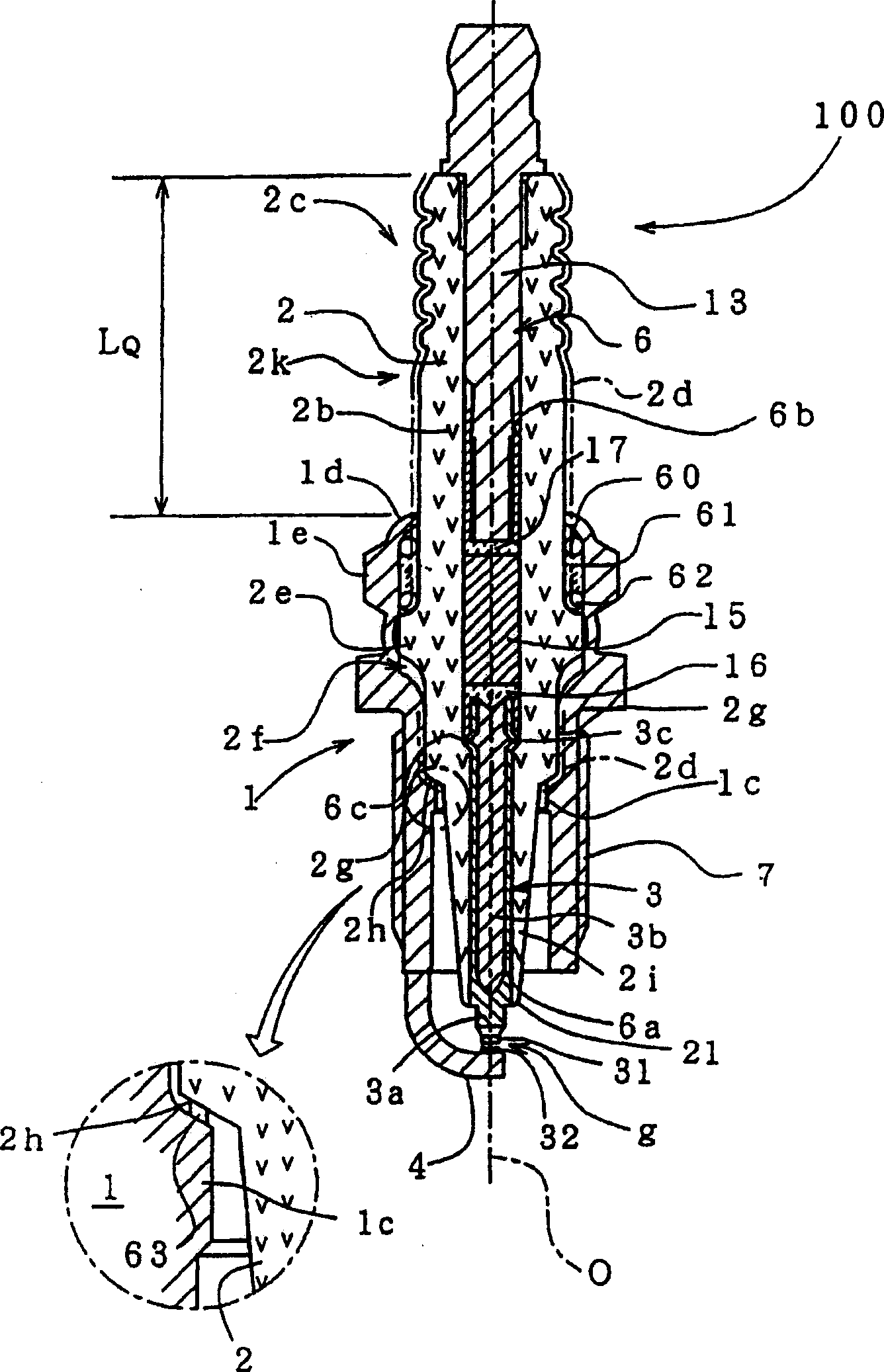

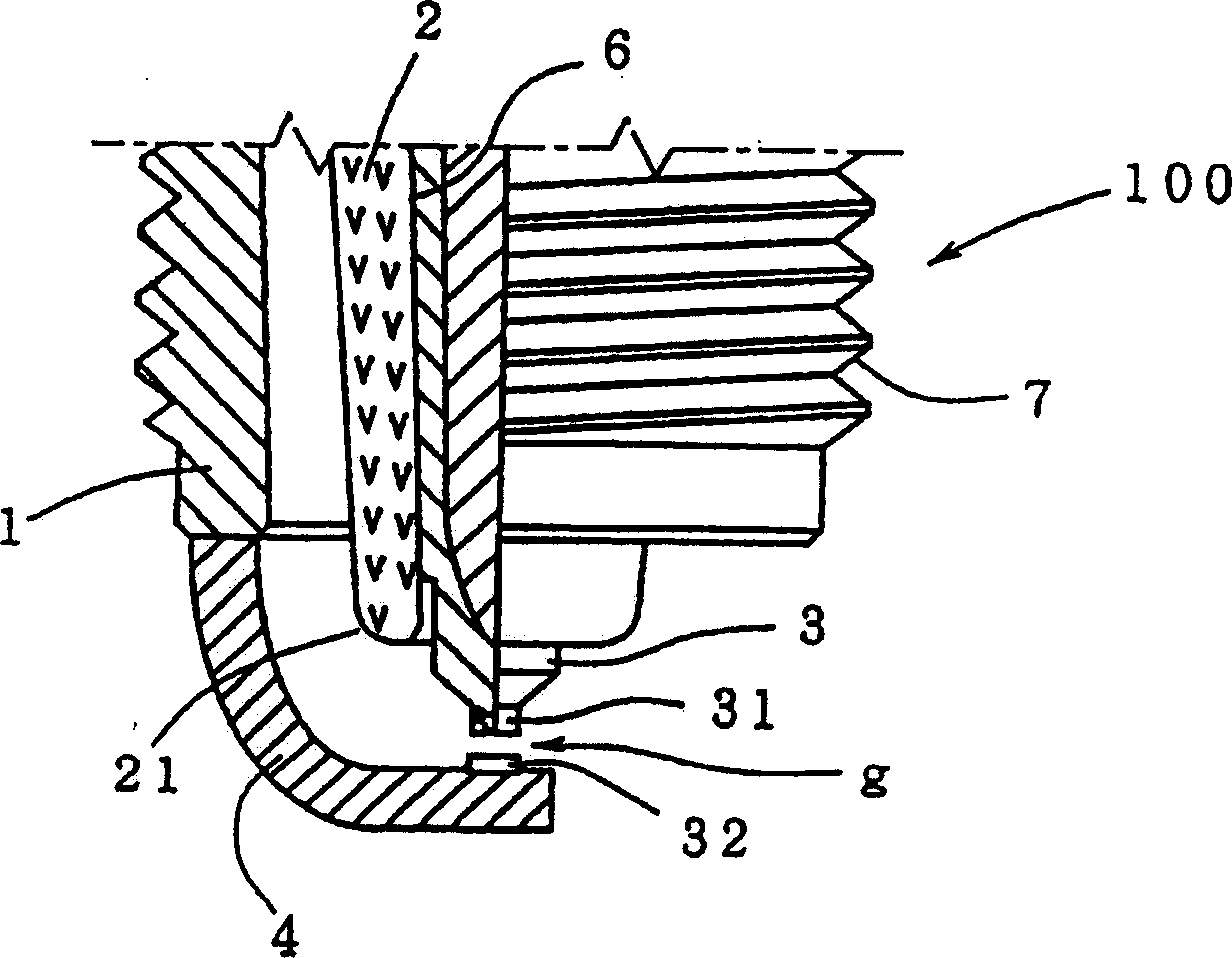

Spark plug and method of manufacturing the same

A glaze layer formed on the surface an alumina-based insulator of a resistor spark plug contains SiO2 (18 to 35% by weight), B2O3 (25 to 40% by weight), ZnO (10 to 25% by weight), BaO (7 to 20% by weight), Na2O (3 to 9% by weight), and K2O (3 to 9% by weight). Since the difference between the coefficients of linear expansion of the glaze and that of the alumina-based insulating material is relatively small, the glaze layer is less susceptible to cracks and the like. Also, since the glaze has a softening point lower than that of conventional lead-silicate-glass-based glaze, the glost-firing temperature can be as low as 800° to 950° C. Therefore, even in the case where glost firing is performed concurrently with a glass sealing step, a center electrode and a terminal metal piece are less susceptible to oxidation. Further, even though the content of the alkali metal component is high, a good insulating performance is obtained so that excellent flashover resistance is attained.

Owner:NGK SPARK PLUG CO LTD

Method for forming a refractive-index-patterned film for use in optical device manufacturing

A process for forming a refractive-index-patterned film for use in optical device manufacturing. The process includes forming a photosensitive lead-silicate-containing film on a substrate (e.g., a silicon, quartz or glass substrate) using, for example, a conventional and inexpensive sol-gel process. A predetermined portion of the lead-silicate-containing film is subsequently exposed to ultra-violet (UV) light through a patterned mask (e.g., a patterned amplitude mask, patterned phase mask or patterned gray scale mask). The UV exposure modifies the refractive index of the predetermined portion, thereby forming a refractive-index-patterned lead-silicate-containing film suitable for use in optical device manufacturing. The use of a photosensitive lead-silicate-containing film enables a relatively large refractive index modification upon exposure to UV light. A vertically tapered waveguide region that includes a substrate with a sloped upper surface protrusion and a refractive-index-patterned lead-silicate-containing film can be formed using the above described process. The refractive-index-patterned lead-silicate film is disposed on the substrate and sloped upper surface protrusion and is, therefore, vertically tapered (i.e., thinned) over the sloped upper surface protrusion. PATENT

Owner:PHOSISTOR TECH

Method for preparing babbitt alloy from residue containing silver of copper anode slime

InactiveCN102312097AEasy to separateLow costProcess efficiency improvementElectrolytic agentAntimony potassium tartrate

The invention relates to a method for preparing a babbitt alloy from residue containing silver of copper anode slime. The method comprises the following steps:1, adding sodium carbonate, powdered carbon and borax according to the mass of the residue containing silver, and uniformly mixing; 2, melting to obtain a crude alloy containing lead; 3, preparing an electrolyte from fluosilicic acid, lead fluorosilicate, stannous oxide and potassium antimonyl tartrate, and adding with gelatin and ethyl naphthol; 4, treating the crude alloy as an anode and a stainless steel plate as a cathode, and taking the cathode plate (the stainless steel plate) and peeling cathode products each 12h; and 5, adding lead, antimony and copper or tin, antimony and copper to the cathode products, and melting to obtain the lead-based or tin-based babbitt alloy. The method which has the advantages of short flow, low cost, and strong practicality and allows the lead-based or tin-based babbitt alloy to be prepared from the residue containing silver of the copper anode slime is especially suitable for anode slime processing in electrolyzing electronic wastes with regenerated copper, and has the characteristics of simple and feasible operation, and high recovery rate of valuable metals.

Owner:广东省资源综合利用研究所

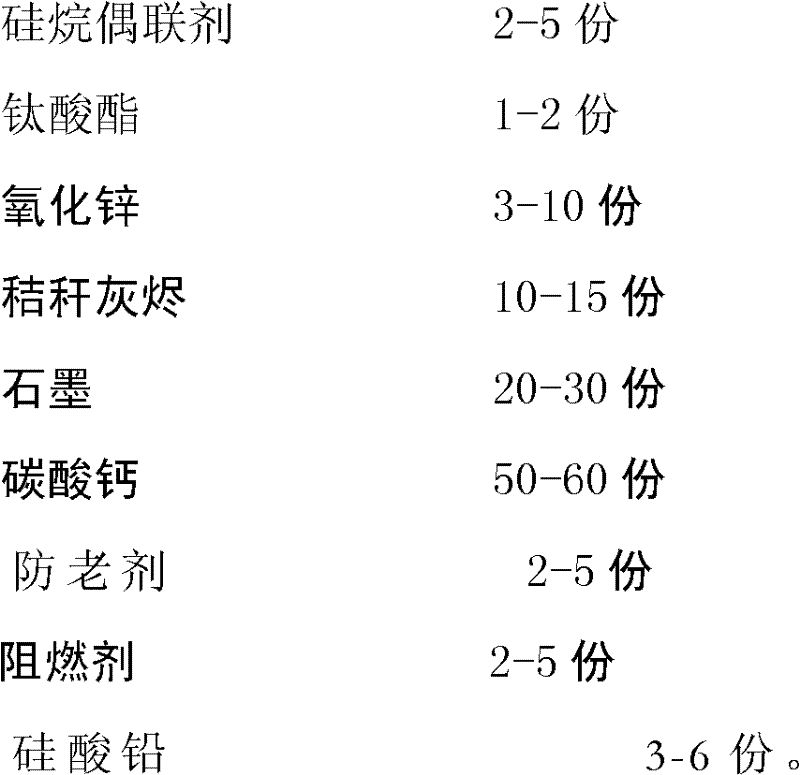

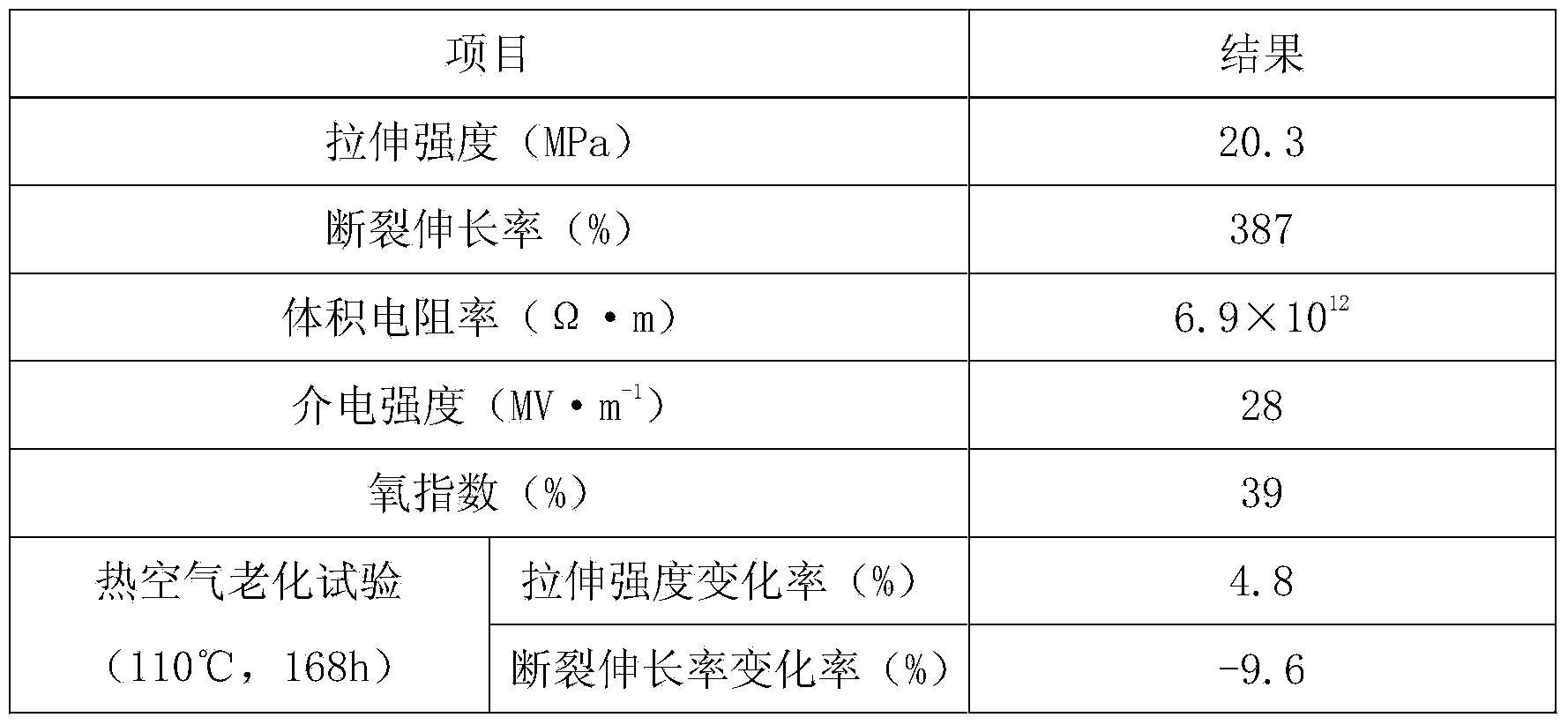

Environment-friendly cable filler and its preparation method

InactiveCN102399401AStable chemical structureGood gelInsulated cablesInsulated conductorsChemical structureSwelling capacity

The invention discloses environment-friendly cable filler and its preparation method. The filler is mainly prepared by mixing the following raw materials in proportion: polyvinyl chloride resin, phenolic resin, polypropylene, triallyl cyanurate, a silane coupling agent, titanate, zinc oxide, straw ash, graphite, calcium carbonate, an antiager, a fire retardant and lead silicate. The environment-friendly cable filler provided in the invention has the advantages of stable chemical structure, indecomposability by microorganism, good gelling performance, high swelling capacity, and can improve electric properties of cables, extend cable service life, and save resources.

Owner:徐州东兴能源有限公司

High-voltage transformer substation cable insulating sheath material and preparation method thereof

ActiveCN103524866ASolve flame retardancySolve the mechanical strengthPlastic/resin/waxes insulatorsInsulated cablesWear resistantFumed silica

The invention discloses a high-voltage transformer substation cable insulating sheath material and a preparation method thereof. The sheath material is prepared from the following raw materials in parts by weight: 60-80 parts of metallocene linear low density polyethylene, 25-35 parts of isotactic polypropylene, 10-15 parts of EVA, 8-12 parts of aluminum hydroxide, 5-10 parts of magnesium hydroxide, 4-8 parts of zinc stannate, 12-18 parts of siliceous rock powder, 4-6 parts of polyethylene wax, 2-3 parts of terephthalic acid zinc, 1-2 parts of magnesium oxide, 3-5 parts of dimethyl silicone oil, 2-3 parts of basic lead silicate, 5-10 parts of triallyl trimellitate, 1-2 parts of gamma-methacryloxy propyl trimethoxyl silane, 15-25 parts of fumed silica, 10-15 parts of active calcium carbonate, 1-2 parts of an antioxidant 168, and 3-5 parts of a composite filler. The sheath material has excellent mechanical strength and abrasion resistance, can effectively improve the wear resistant ability and the impact resistant ability of a cable sheath, moreover, has good flame retardancy, is low in smoke and is halogen-free, effectively solves contradictions among the flame retardancy, the mechanical strength and the abrasion resistance of the sheath material, prolongs the service life of the sheath, and guarantees normal working of a high-voltage transformer substation cable.

Owner:PANJIN GUANGLIDA ELECTRIC

90-degree special temperature selflimiting electric tracing band

InactiveCN101795507AEnhance positive temperature coefficient effectSolve the service lifeHeating element shapesSilicic acidSalicylic acid

The invention discloses a 90-degree special temperature selflimiting electric tracing band, which comprises a conductive core, and a PTC material layer, a polymer insulating inner protective sleeve, an aluminum-magnesium alloy shielding layer and a polymer insulating outer protective sleeve which are covered outside the conductive core in turn, wherein the PTC material is prepared by mixing and melting the following raw material components in part by weight: high-density polyethylene 86-87, carbon black 12-14, tribasic lead sulfate heat stabilizer 0.11-0.13, lead silicate 0.04-0.06, styrenated phenol antioxygen 0.05-0.15, p-tert-butylphenyl salicylate light stabilizer 0.12-0.14 and tribromophenol fire retardant 0.05-0.15. The highest temperature of the band is maintained at 90+ / -5 DEG C, and the band can be used as solar electric tracing band in places with large temperature difference.

Owner:芜湖科阳新材料股份有限公司

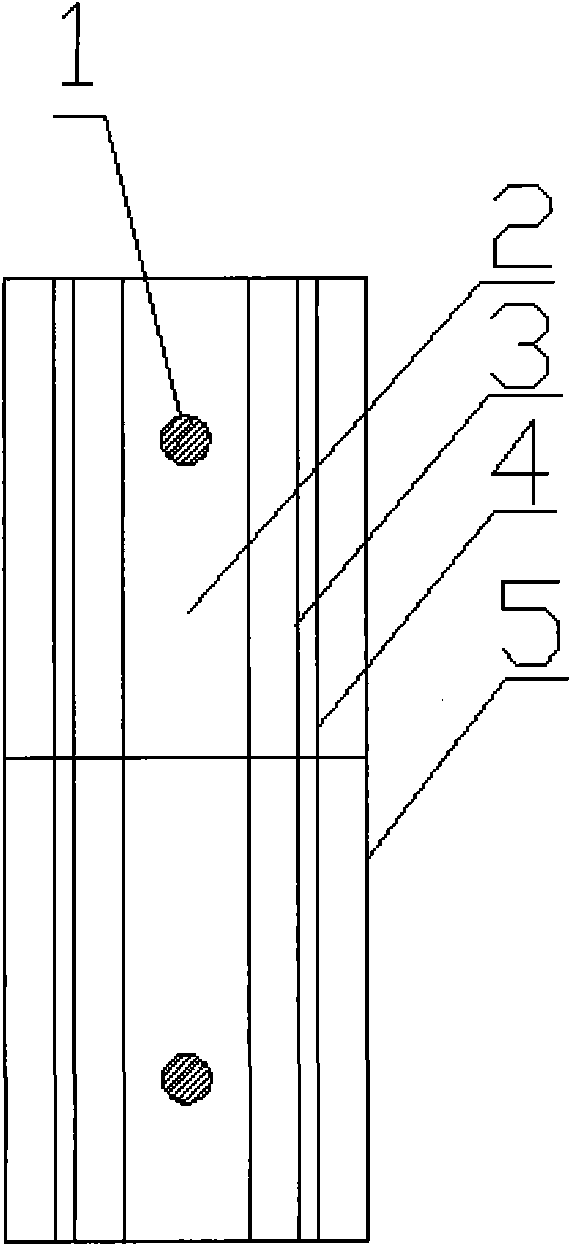

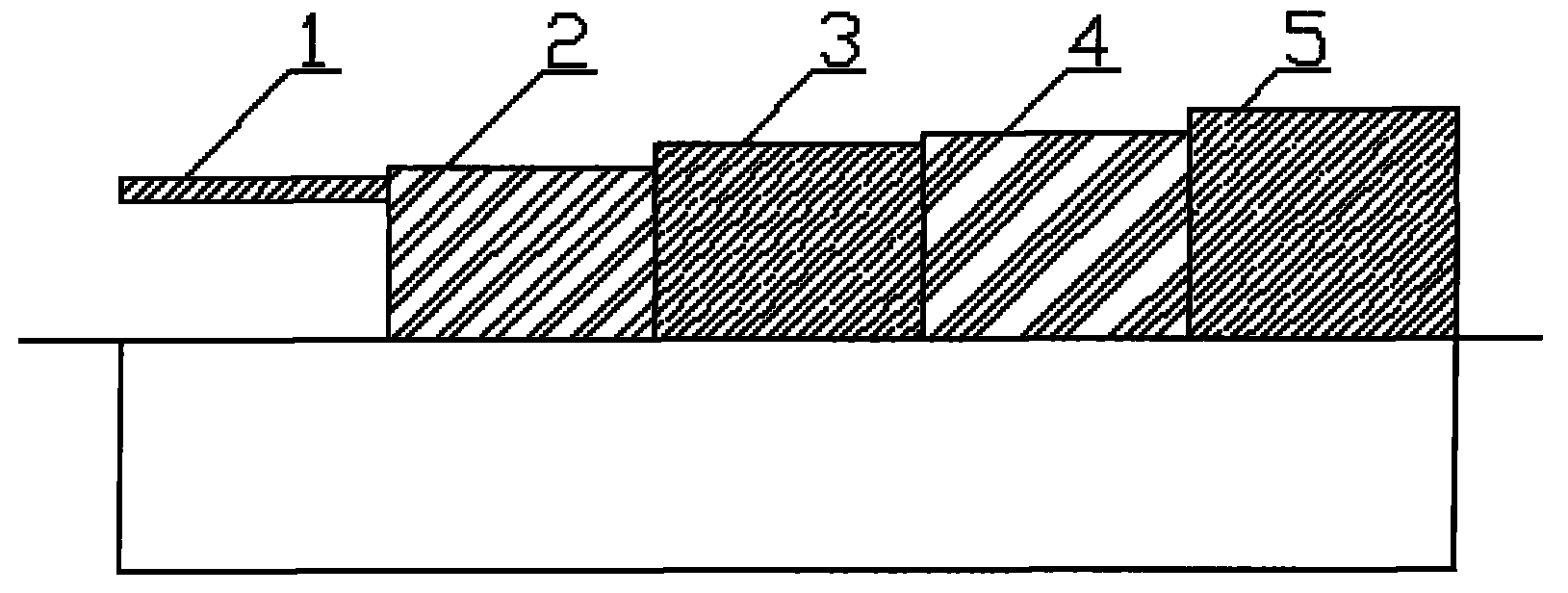

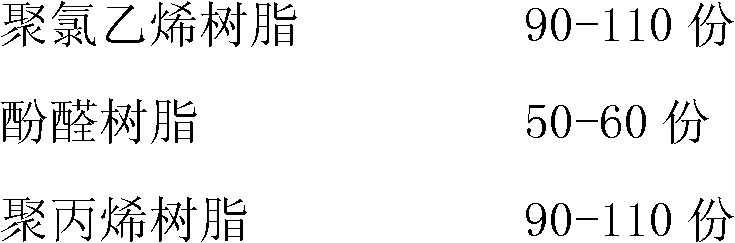

Modified cable filler and preparation method thereof

ActiveCN102585398AStable chemical structureGood gelInsulated cablesInsulated conductorsChemical structurePolymer science

The invention discloses a modified cable filler and a preparation method thereof. The modified cable filler is prepared by mixing raw materials such as polyvinyl chloride (PVC) resin, phenolic resin, polypropylene resin, melamine, a silane coupling agent, titanate, zinc borate, straw ash, attapulgite, glass fibers, graphite, calcium carbonate, a flame retardant and lead silicate in a certain ratio. The modified cable filler has a stable chemical structure and high gel performance and swelling capacity and is not decomposed by microorganisms, the electrical performance of a cable is improved, the service life of the cable is prolonged, and resources are saved.

Owner:安徽塞帕斯电缆材料有限公司

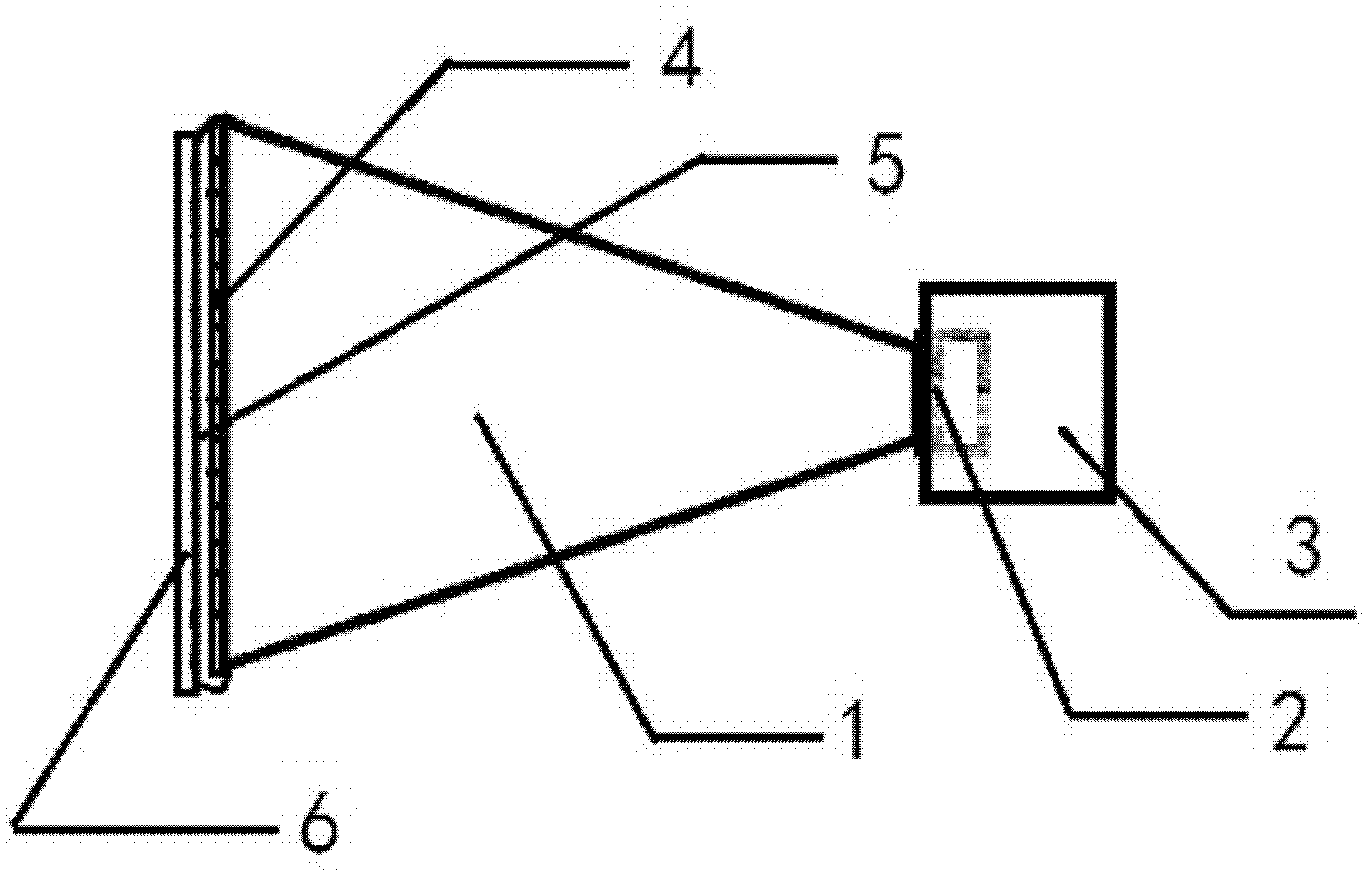

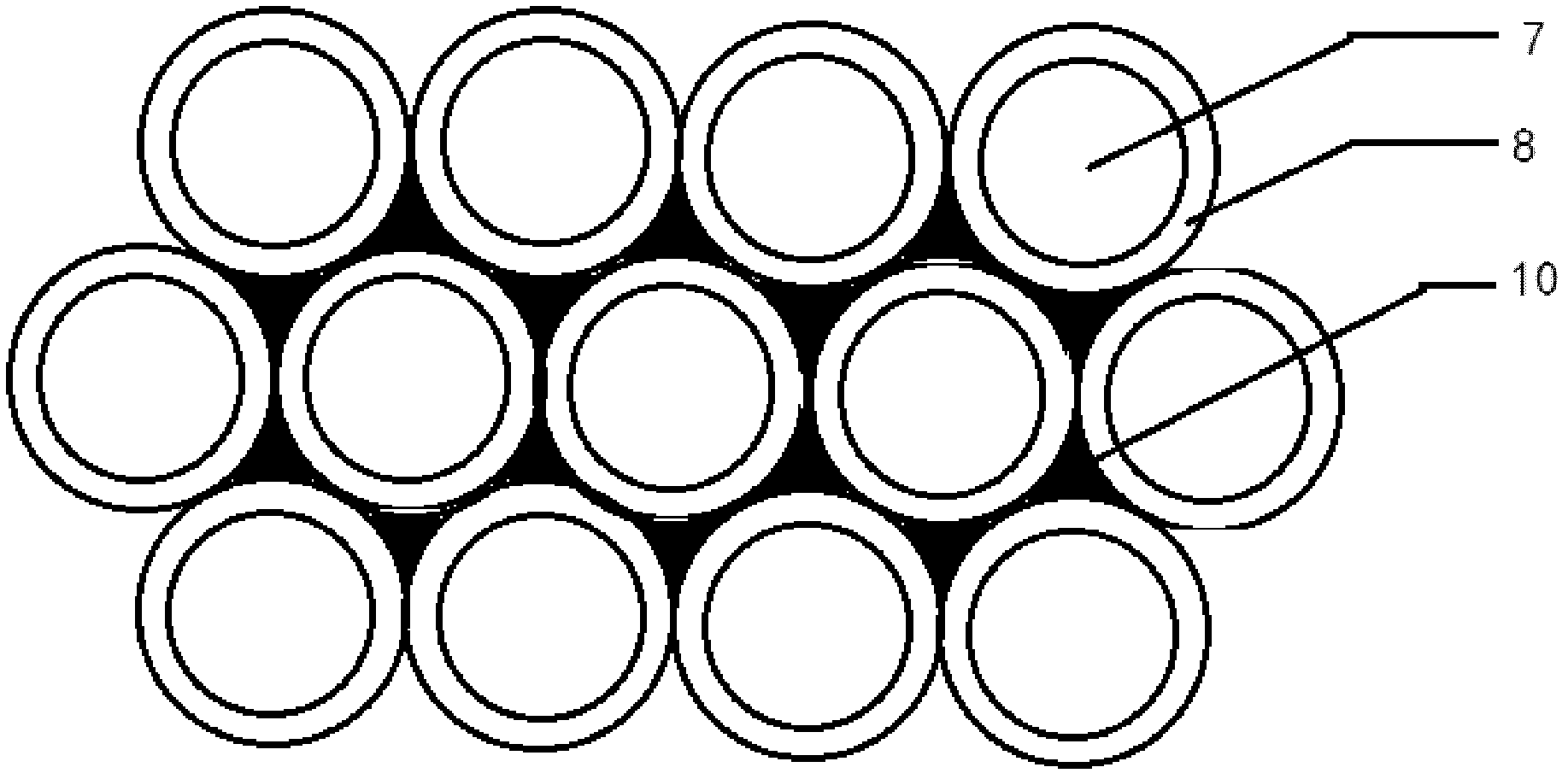

X-ray camera and manufacturing method thereof

InactiveCN102547150AImproved Modulation Transfer FunctionHigh-resolutionTelevision system detailsColor television detailsReduction treatmentRefractive index

The invention discloses an X-ray camera and a manufacturing method thereof. The X-ray camera is manufactured by coupling a fiber optic taper with a CCD (Charge Coupled Device) or CMOS (Complementary Metal-Oxide-Semiconductor) camera, wherein a needle-like CsI (Cesium Iodide) crystal, a moisture sealer and an aluminium coating or a silicon nitride film are arranged on a big end of the fiber optic taper in order; the fiber optic taper is manufactured by the steps of: sleeving a low-refractive-index cladding on a high-refractive-index core material of an ordinary fiber optic taper, on the basis, sleeving a black glass or lead silicate glass sleeve matching with the fiber optic taper in thermophysical properties, manufacturing a fiber array cylinder according to a front-end process of manufacturing a fiber optic panel, and then drawing the cylinder according to the proportion between the big end and a small end of the fiber optic taper, wherein the fiber optic taper made of the lead silicate glass sleeve requires hydrogen reduction treatment; and after the needle-like CsI crystal, the moisture sealer and the aluminium coating or silicon nitride film are manufactured in order on the big end of the fiber optic taper, the small end of the fiber optic taper is coupled with a light-sensitive surface of the camera by using optical cement. The X-ray camera manufactured in such a way has the minimum pixel reaching 5 micrometers and the resolution ratio being above 301p / mm with good MTF (Modulation Transfer Function).

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

Spark plug

A glaze layer formed on the surface an alumina-based insulator of a resistor spark plug contains SiO2 (18 to 35% by weight), B2O3 (25 to 40% by weight), ZnO (10 to 25% by weight), BaO (7 to 20% by weight), Na2O (3 to 9% by weight), and K2O (3 to 9% by weight). Since the difference between the coefficients of linear expansion of the glaze and that of the alumina-based insulating material is relatively small, the glaze layer is less susceptible to cracks and the like. Also, since the glaze has a softening point lower than that of conventional lead-silicate-glass-based glaze, the glost-firing temperature can be as low as 800 DEG to 950 DEG C. Therefore, even in the case where glost firing is performed concurrently with a glass sealing step, a center electrode and a terminal metal piece are less susceptible to oxidation. Further, even though the content of the alkali metal component is high, a good insulating performance is obtained so that excellent flashover resistance is attained.

Owner:NGK SPARK PLUG CO LTD

Preparation method of light-peach-colored crystal bead blanks

ActiveCN102515532AGood reproducibilityRedox stableGlass pressing apparatusGlass productionAntimony trioxidePotassium carbonate

The invention discloses a preparation method of light-peach-colored crystal bead blanks. Aiming at defects of poor coloring reproducibility, poor product stability, low production efficiency, and unsuitability for continuous tank furnace production of prior art for preparing light-peach-colored crystal bead blanks, the invention provides a light-peach-colored crystal bead blank preparation method with good coloring reproducibility, stable product quality, high production efficiency, and suitability for continuous tank furnace production. According to the light-peach-colored crystal bead blank preparation method, the light-peach-colored crystal bead blanks are prepared from raw materials of, by weight: 50-70 parts of quartz sand, 5-15 parts of soda ash, 7-16 parts of potassium carbonate, 2-9 parts of potassium nitrate, 2-5 parts of boric acid, no more than 45-65 parts of lead silicate, no more than 3 parts of antimony trioxide, no more than 8 parts of cerium oxide, no more than 5 parts of barium carbonate, no more than 10 parts of titanium pigment, no more than 3 parts of zinc oxide, and no more than 15 parts of erbium oxide.

Owner:浙江鑫伟兴水晶有限公司

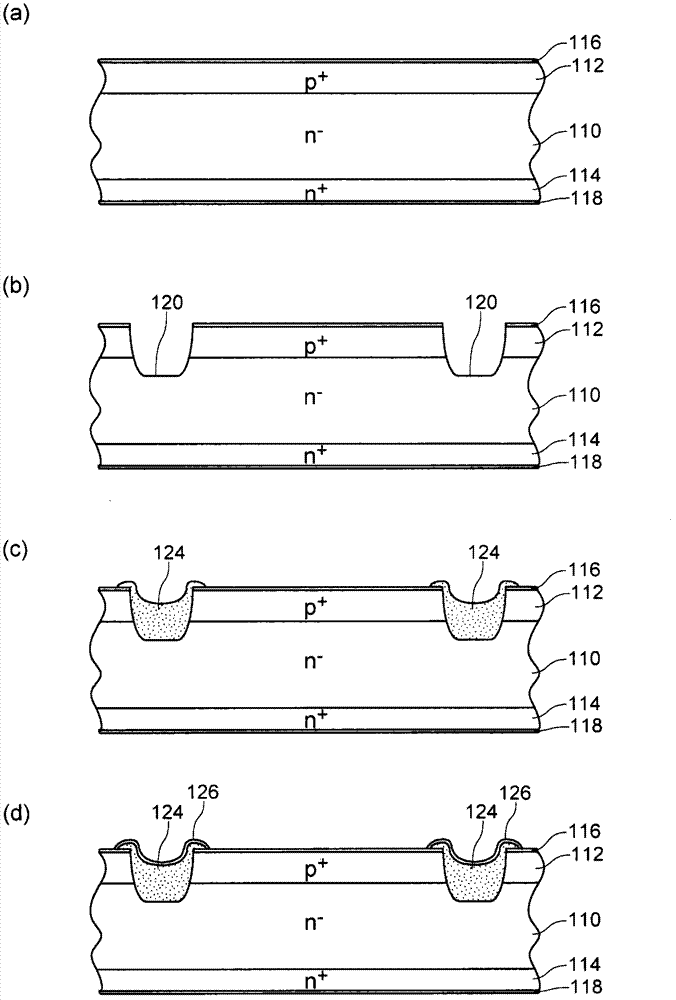

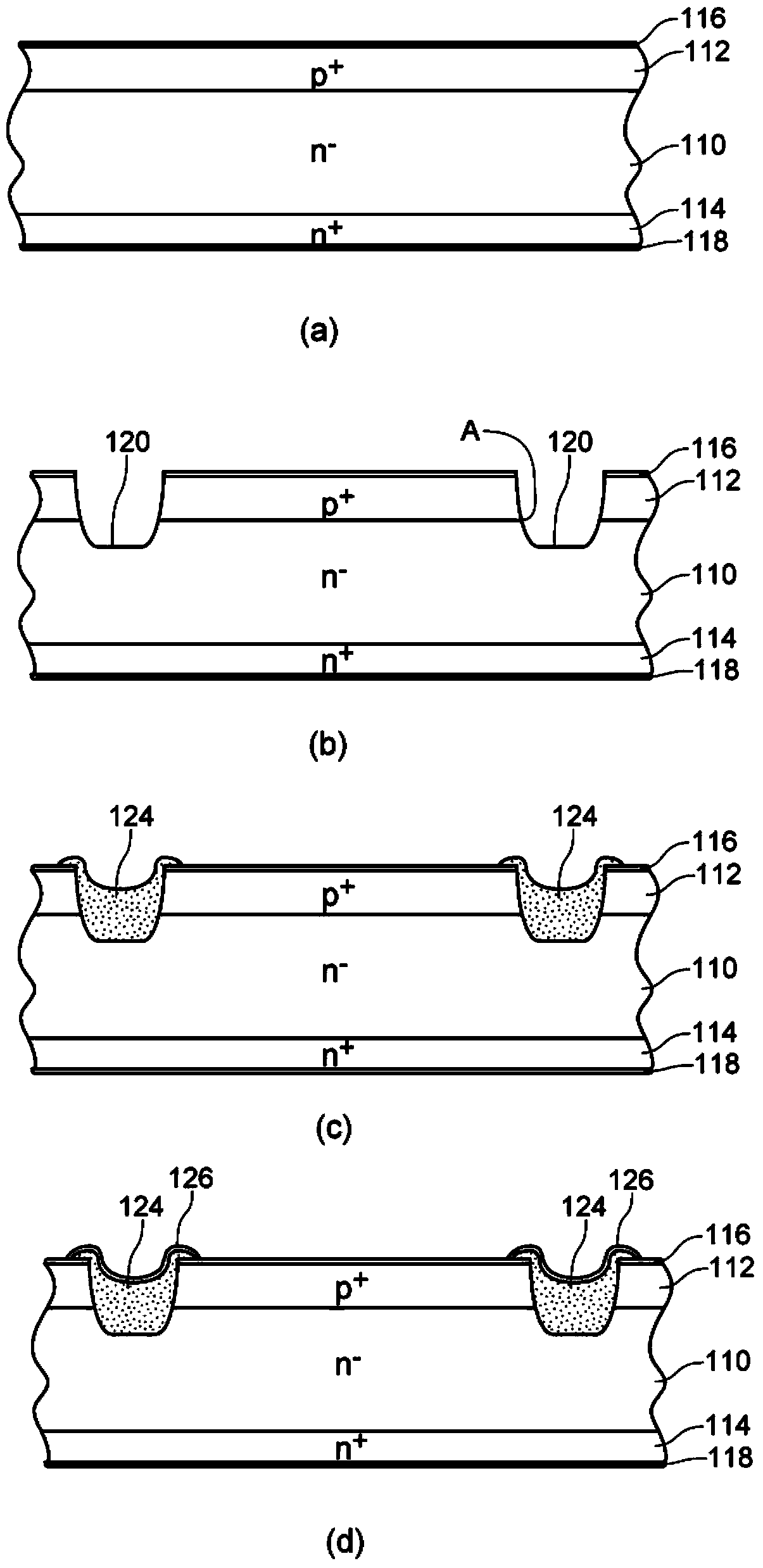

Glass composition for semiconductor junction protection, production method for semiconductor device, and semiconductor device

ActiveCN102781861AWell formedNo loss of insulationSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceHigh pressure

A glass composition for semiconductor junction protection, characterized by including at least SiO2, Al2O3, ZnO, CaO, and 3-10 mol% of B2O3 and by substantially not including Pb, P, As, Sb, Li, Na, or K. It is desirable that the SiO2 content is within the range of 32-48 mol%, the Al2O3 content is within the range of 9-13 mol%, the ZnO content is within the range of 18-28 mol%, the CaO content is within the range of 15-23 mol%, and the B2O3 content is within the range of 3-10 mol%. Production of a semiconductor device having a high pressure-resistance similar to conventional "glass having lead silicate as the main component thereof" and using a glass material not containing lead is possible using this glass composition for semiconductor junction protection.

Owner:SHINDENGEN ELECTRIC MFG CO LTD

Resistive glass structures used to shape electric fields in analytical instruments

InactiveUS20080073516A1Reduce resistanceParticle separator tubesIsotope separationGlass structureMass spectrometric

A reflectron lens for a time-of-flight mass spectrometer is disclosed. The reflectron lens includes a glass tube having a conductive surface along the length of the tube. The conductive surface has an electrical resistance gradient along its length. The electrical resistance gradient provides an electric field interior to the tube that varies in strength along the length of the tube when an electric potential is applied to opposing ends of the tube. A mass spectrometer incorporating the reflectron lens, a method of making the reflectron lens, and an apparatus for removing lead from the surface of a lead silicate glass tube are also disclosed.

Owner:LAPRADE BRUCE N

Environment-friendly cable filler and preparation method thereof

InactiveCN102391593AStable chemical structureGood gelInsulated cablesInsulated conductorsChemical structurePolyvinyl chloride

The invention discloses an environment-friendly cable filler and a preparation method thereof. The environment-friendly cable filler is prepared mainly by mixing polrvinyl chloride resin, phenolic resin, polypropylene, triallyl cyanurate, sillicane coupling agent, titanate, zinc oxide, straw ash, graphite, calcium carbonate, anti-aging agent, flame retardant and lead silicate in a certain mixture ratio. The environment-friendly cable filler has the advantages of stable chemical structure, good gelation performance and strong expanding capability, and cannot be decomposed by microorganisms; the electrical performance of a cable is improved; the service life of the cable is prolonged; and the resources are saved.

Owner:安徽金田通信科技实业有限公司

Glass composition for semiconductor junction protection, method for manufacturing semiconductor device, and semiconductor device

ActiveCN104254907AIncrease credibilityLow firing temperatureThyristorSemiconductor/solid-state device detailsAlkaline earth metalDevice material

This glass composition for semiconductor junction protection is a glass composition for semiconductor junction protection for forming a glass layer that protects a pn junction. This glass composition for semiconductor junction protection contains at least ZnO, SiO2, B2O3, Al2O3 and at least two alkaline earth metal oxides selected from among BaO, CaO and MgO, respectively in predetermined amounts, and are composed of fine glass particles that are produced from a melt which is obtained by melting a glass starting material that does not substantially contain Pb, As, Sb, Li, Na and K. This glass composition for semiconductor junction protection does not contain a filler. According to the present invention, a semiconductor device with high reliability can be manufactured using a glass material that does not contain lead. In addition, a layer that is formed of this glass composition for semiconductor junction protection can be fired at a lower firing temperature in comparison to the cases where conventional "glass materials mainly composed of lead silicate" are used, thereby enabling the production of a semiconductor device that has excellent switching characteristics.

Owner:SHINDENGEN ELECTRIC MFG CO LTD

Resistive glass structures used to shape electric fields in analytical instruments

ActiveUS20100090098A1Reduce resistanceStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsElectrical resistance and conductanceReflectron

A reflectron lens for a time-of-flight mass spectrometer and a method of making same are disclosed. The reflectron lens includes a glass tube having a conductive surface along the length of the tube. The conductive surface has an electrical resistance gradient along its length. The electrical resistance gradient provides an electric field interior to the tube that varies in strength along the length of the tube when an electric potential is applied to opposing ends of the tube. A mass spectrometer incorporating the reflectron lens, a method of making the reflectron lens, and an apparatus for removing lead from the surface of a lead silicate glass tube are also disclosed.

Owner:PHOTONIS SCI INC

Preparation method for transparent black crystal ball blank

InactiveCN102515473AGood reproducibilityRedox stableGlass pressing apparatusGlass productionEngineeringPotassium carbonate

The invention discloses a preparation method for a transparent black crystal ball blank, and provides the preparation method for the transparent black crystal ball blank aiming at the defects of low coloring repeatability, product quality and production efficiency in the conventional preparation method for the transparent black crystal ball blank, and the defect that the conventional preparation method for the transparent black crystal ball blank is not suitable for continuous production operation of a tank furnace. By the method, a product is high in coloring repeatability, and stable in quality; and the method is high in production efficiency and suitable for continuous production operation of the tank furnace. According to the preparation method for the transparent black crystal ball blank, the transparent black crystal ball blank is prepared from the following raw materials in part by weight: 50 to 70 parts of quartz sand, 5 to 15 parts of sodium carbonate, 4 to 16 parts of potassium carbonate, 2 to 9 parts of potassium nitrate, 2 to 6 parts of boric acid, less than or equal to 10 parts of lead silicate, less than or equal to 3 parts of aluminum hydroxide, less than or equal to 4 parts of calcium carbonate, less than or equal to 2 parts of lithium carbonate, less than or equal to 5 parts of erbium oxide, less than or equal to 3 parts of chrome oxide green, less than or equal to 3 parts of magnesium carbonate, and less than or equal to 5 parts of nickel oxide.

Owner:ZHEJIANG WEIXING CRYSTAL

Method for preparing peacock blue crystal bead embryo

The invention relates to a method for preparing a peacock blue crystal bead embryo, aiming at the defects of poor coloring reproducibility, unstable product quality, low production efficiency and unsuitability of production work of a continuous tank furnace in the conventional process for preparing the peacock blue crystal bead embryo, and providing the method for preparing the peacock blue crystal bead embryo with good coloring reproducibility, stable product quality, high production efficiency and suitability of production work of the continuous tank furnace. In the method for preparing the peacock blue crystal bead embryo, the peacock blue crystal bead embryo comprises the raw materials in proportions by weight: 50-70 parts of quartz sand, 5-15 parts of soda ash, 2-14 parts of potassium nitrate, 2-8 parts of boracic acid, not more than 10 parts of lead silicate, not more than 3 parts of aluminum hydroxide, not more than 5 parts of calcium carbonate, not more than 1.5 parts of lithium carbonate, not more than 5 parts of barium carbonate, not more than 7 parts of titanium white, not more than 3 parts of magnesium carbonate and not more than 6 parts of copper oxide.

Owner:ZHEJIANG WEIXING CRYSTAL

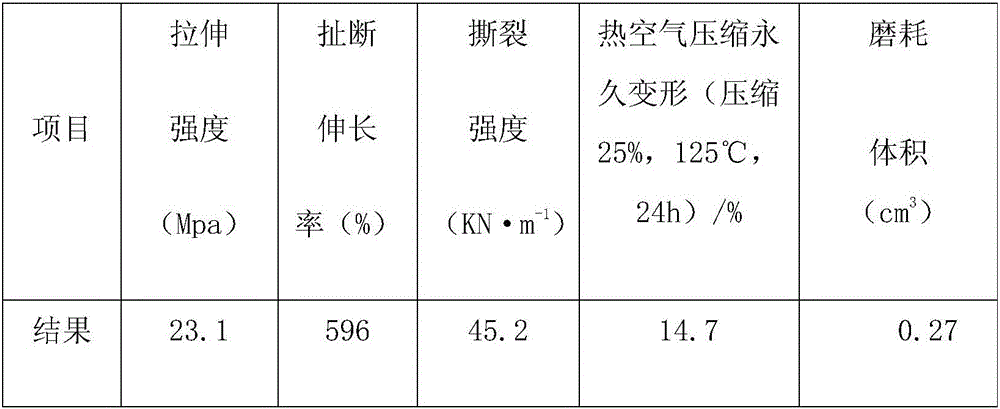

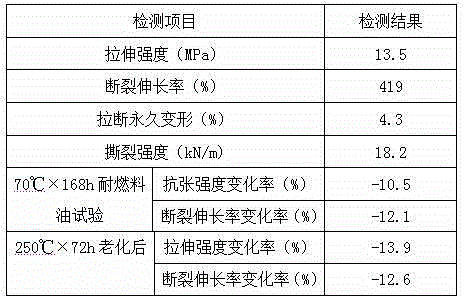

Silicone rubber sealing pad having low permanent compression set value and preparation method thereof

The invention discloses a silicone rubber sealing pad having low permanent compression set value and a preparation method thereof.The silicone rubber sealing pad is prepared from low phenyl silicone rubber, acrylate rubber, isoprene rubber, 4,4'-diamino biphenyl, praseodymium naphthenate, silicon calcium magnesium crystal whiskers, a accelerant DTDM, a accelerant CZ, a accelerant CPB, carbon black N774, carbon black N330, 1,1-bis(tert butyl peroxyl)-3,3,5-trimethyl-cyclohexane, nano palygorskite, cobalt naphthenate, lead silicate white, zinc stearate, vaseline, an antiager 4010 NA, an antiager 2246 and a modifier.The prepared silicone rubber sealing pad has good compressibility and resilience and small permanent compression set, does not produce permanent change when being exposed at higher temperature, can have original mechanical properties of rubber after being put back at the room temperature and meanwhile has excellent abrasion resistance, corrosion resistance, aging resistance and heat resistance and other properties.

Owner:ANHUI JINGYI GLASS MACHINERY

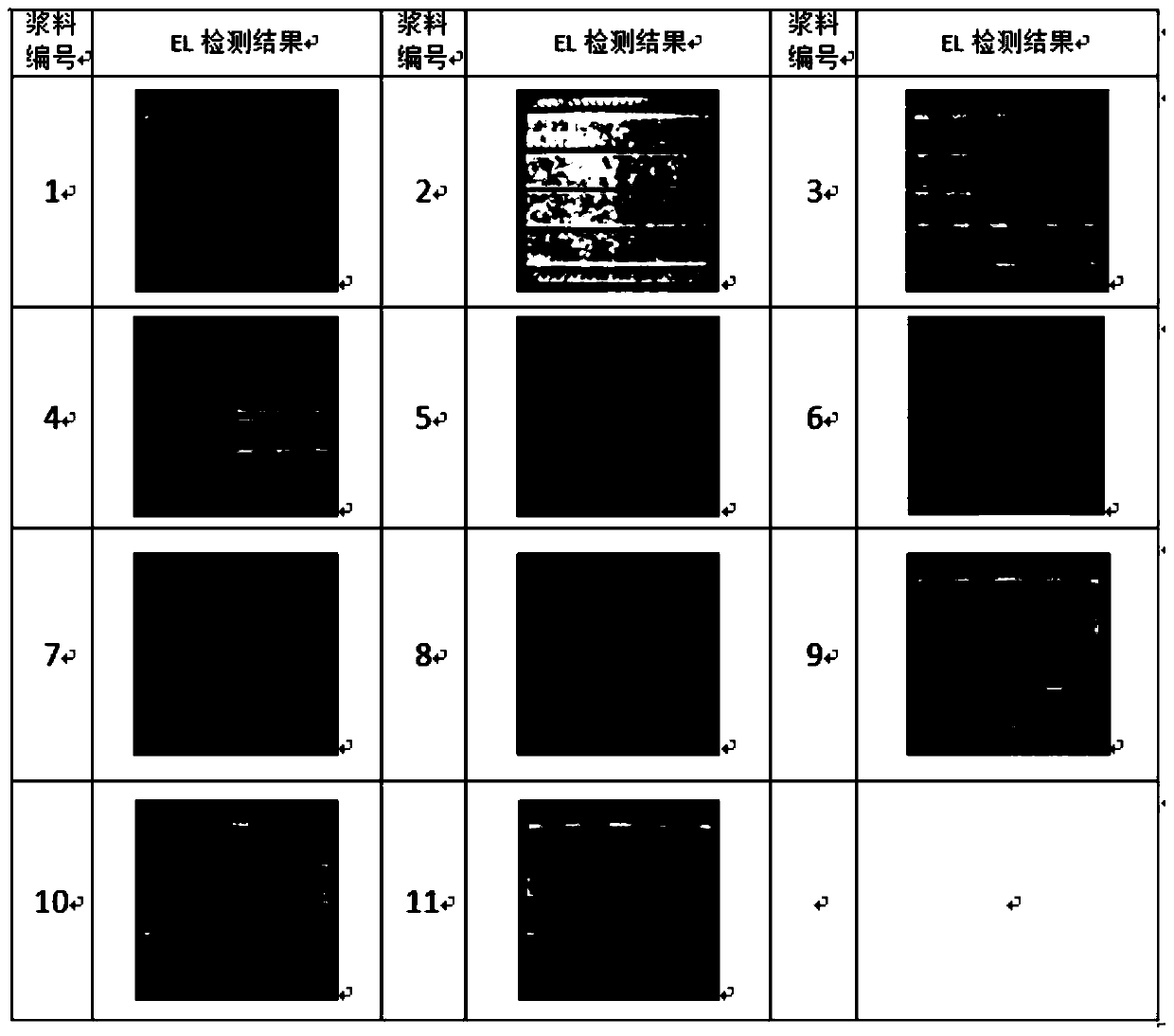

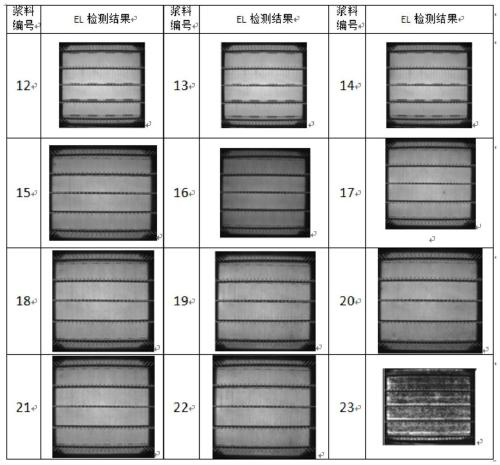

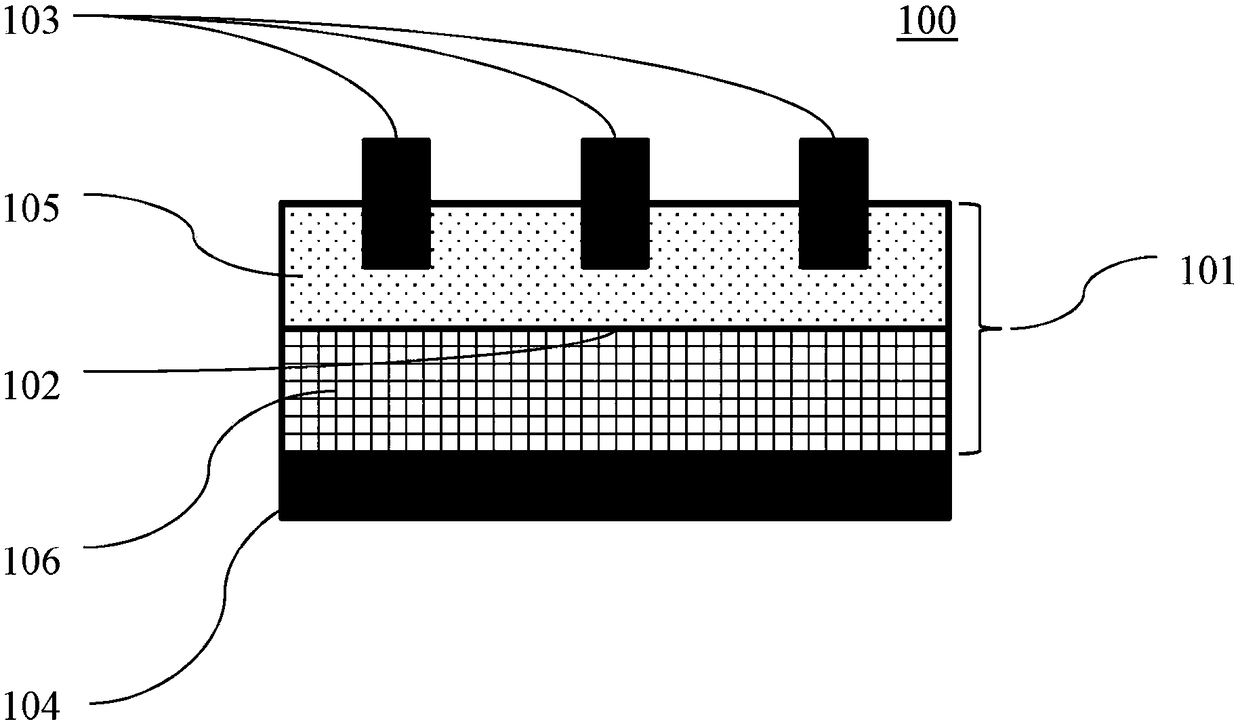

Solar cell conductive paste, frit and solar cell

ActiveCN111599506AEL detection is normalHigh bonding strengthNon-conductive material with dispersed conductive materialPhotovoltaic energy generationConductive pasteFrit

The invention discloses solar cell conductive paste, which comprises conductive powder, mixed glass and an organic phase, wherein the mixed glass comprises the following two types of glass components:the first type of glass is selected from at least one of tellurium-based glass which does not contain lead, zinc and silicon and takes tellurium, bismuth and lithium as essential components, and thesecond type of glass is at least one selected from lead silicate glass which takes lead, silicon and vanadium as essential components and does not contain tellurium and bismuth. The invention also provides frit and a solar cell. The solar cell prepared from the conductive paste is normal in EL detection, high in cell efficiency and excellent in bonding strength.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD

Preparation method for light blue crystal bead blanks

InactiveCN102503127AGood reproducibilityStable redox balanceGlass pressing apparatusGlass productionPotassiumAntimony trioxide

The invention discloses a preparation method for light blue crystal bead blanks. The preparation method for light blue crystal bead blanks aims to overcome shortcomings that existing preparation process for light blue crystal bead blanks is poor in coloring reproducibility, low in production efficiency and unsuitable for production operation of a continuous tan furnace, and the quality of products is unstable. The preparation method for light blue crystal bead blanks is fine in coloring reproducibility, high in production efficiency and applicable to production operation of a continuous furnace tank, and the quality of products is stable. In the preparation method for light blue crystal bead blanks, raw materials of the light blue crystal bead blanks include, by weight ratio, from 50 to 70 parts of quartz sand, from 3 to 15 parts of soda, from 4 to 16 parts of potassium carbonate, from 2 to 9 parts of potassium nitride, from 1 to 5 parts of boric acid, equal to or lower than 14 parts of lead silicate, equal to or lower than 3 parts of antimony trioxide, equal to or lower than 10 parts of barium carbonate, equal to or lower than 5 parts of titanium dioxide, equal to or lower than 3 parts of zinc oxide and equal to or lower than 2 parts of cobalt oxide.

Owner:ZHEJIANG WEIXING CRYSTAL

High-strength heat-resistant glass micro-bead for reflective film and preparation method thereof

The invention discloses a high-strength heat-resistant glass micro-bead for a reflective film and a preparation method thereof. The high-strength heat-resistant glass micro-bead for the reflective film is prepared by using the following raw materials in parts by weight: 38 to 49 parts of quartz powder, 24 to 37 parts of staurolite, 17 to 33 parts of phenacite, 22 to 34 parts of fluorite, 9 to 17 parts of carbon nano-tube, 12 to 18 parts of hafnium boride, 10 to 15 parts of lead silicate, 24 to 36 parts of steel slag micro-powder, 20 to 30 parts of kyanite tailing, 8 to 14 parts of potassium pyrosulfate, 5 to 10 parts of sodium carbonate, 10 to 15 parts of cerium carbonate and 6 to 12 parts of additive. By using staurolite, phenacite, steel slag micro-powder, kyanite tailing and the like as main raw materials, the advantages of each component are fully exploited and the high temperature resistance of the glass micro-bead can be obviously improved; by adding carbon nano-tube, hafnium boride, lead silicate and cerium carbonate, the thermal stability and the high temperature resistance of the glass micro-bead can also be improved, and the glass micro-bead is enabled to still have higher mechanical strength and better optical performance under high temperature conditions, and the glass micro-bead prepared by the invention has higher mechanical strength and a better reflective effect, can resist high temperature of 1380 DEG C and is applicable to part of reflective film production which has higher requirements on temperature.

Owner:HEFEI DINGLIANG OPTICAL TECH

Silver-lead-silicate glass for electroconductive paste composition

An electroconductive paste composition including metallic particles, glass frit including lead oxide, silicon dioxide, and silver or a silver-containing compound, and an organic vehicle is provided. The invention also provides a solar cell produced by applying the electroconductive paste according to the invention to a silicon wafer and firing the silicon wafer. The invention further provides a solar cell module comprising electrically interconnected solar cells according to the invention. The invention also provides a method of producing a solar cell, including the steps of providing a silicon wafer having a front surface and a back surface, applying an electroconductive paste according to the invention to the silicon wafer, and firing the silicon wafer.

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

Glass composition for semiconductor junction protection, method for manufacturing semiconductor device, and semiconductor device

ActiveCN103890919AImprove pressure resistanceExcellent forward characteristicsSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceAlkaline earth oxides

A glass composition for semiconductor junction protection, which contains at least SiO2, B2O3, Al2O3, ZnO and at least two alkaline earth metal oxides selected from among CaO, MgO and BaO, but does not substantially contain Pb, As, Sb, Li, Na and K. This glass composition for semiconductor junction protection has an average linear expansion coefficient within the range from 3.33 10-6 to 4.13 10-6 for the temperature range from 50 DEG C to 550 DEG C. A glass composition for semiconductor junction protection of the present invention enables the production of a semiconductor device having high withstand voltage with use of a glass material that contains no lead as in the cases where conventional ''glass materials that are mainly composed of lead silicate'' are used.

Owner:SHINDENGEN ELECTRIC MFG CO LTD

Preparation method for modena crystal bead blank

ActiveCN102674694AGood reproducibilityStable redox balanceGlass pressing apparatusGlass productionAluminium hydroxidePotassium carbonate

The invention discloses a preparation method for a modena crystal bead blank. The invention provides a preparation method, which has the advantages of good coloring reproducibility, stable product quality and high production efficiency and can be suitable for the production operation of a continuous tank furnace, for a modena crystal bead blank by aiming at the defects of poor coloring reproducibility, unstable product quality, low production efficiency and inadequacy for the production operation of a continuous tank furnace of the traditional technology for preparing the modena crystal bead blank. According to the preparation method for a modena crystal bead blank, the modena crystal bead blank is prepared from the following raw materials in parts by weight: 50-70 parts of quartz sand, 5-15 parts of soda ash, 4-16 parts of potassium carbonate, 2-9 parts of nitrate of potash, 2-6 parts of boric acid, 4.5-6 parts of potassium permanganate, less than or equal to 10 parts of lead silicate, less than or equal to 7 parts of aluminium hydroxide, less than or equal to 3 parts of calcium carbonate, less than or equal to 1 part of lithium carbonate and less than or equal to 3 parts of magnesium carbonate.

Owner:浙江鑫伟兴水晶有限公司

Oil resistant silicone rubber material and preparation method thereof

The invention discloses an oil resistant silicone rubber material and a preparation method thereof. The material consists of the following raw materials by weight: 75-95 parts of methyl vinyl trifluoropropyl silicone rubber, 40-60 parts of polyethylene naphthalate, 4-8 parts of dihydroxy polydimethylsiloxane, 5-10 parts of nano titanium boride, 3-6 parts of methyl silicone oil, 2-3 parts of aluminum naphthenate, 4-6 parts of lead silicate white, 2-3 parts of triphenylmethane triisocyanate, 10-15 parts of precipitated barium sulfate, 3-6 parts of candelilla wax, 5-10 parts of hydroxyl terminated liquid nitrile rubber, 2-3 parts of dibenzoylquinone dioxime, 1.5-2.5 parts of N,N'-1,3-phenylene bismaleimide, 1-2 parts of polytrimethyldihydroquinoline, 0.5-1.5 parts of TNPP and 3-5 parts of an additive. The silicon rubber material provided by the invention has the advantages of good oil resistant performance, heat resistance, high mechanical strength, tear resistance and aging resistance, can work in the oil medium for a long time, is not easy to age, and has long service life, good processing performance, low cost and broad application prospects.

Owner:天长市荣盛有机硅科技有限公司

Antiqued copper craft ceramic and manufacturing process thereof

ActiveCN106396408AIncrease brightnessUnique artistic effectClaywaresCopper oxideAmmonium metavanadate

The invention belongs to the technical field of ceramic production, and in particular relates to an antiqued copper craft ceramic and a manufacturing process of the antiqued copper craft ceramic. The antiqued copper craft ceramic comprises a ceramic body and antiqued copper glazes arranged on the ceramic body, wherein the antiqued copper glazes comprise the raw materials of lead silicate, quartz, purple stone, graphite, copper oxide, a low-temperature frit, zirconium silicate powder, kaolin, lithium carbonate, ferric oxide, nickel oxide, ammonium metavanadate and manganese dioxide. By adopting the antiqued copper craft ceramic, a fired glaze surface can appropriately promote the brightness of the glaze surface along with the increase of combustion temperature, the colors from dark bronze to bright copper can be obtained through adjusting the glazing thickness and firing temperature according to creation needs, so that the antiqued copper craft ceramic has a unique artistic effect. In addition, the invention provides a temperature control for the antiqued copper craft ceramic, so that the batch industrial production and rapid popularization can be realized, and economic values are higher, and the competitiveness of the antiqued copper craft ceramic in the market is higher.

Owner:福建省德化佳诚陶瓷有限公司

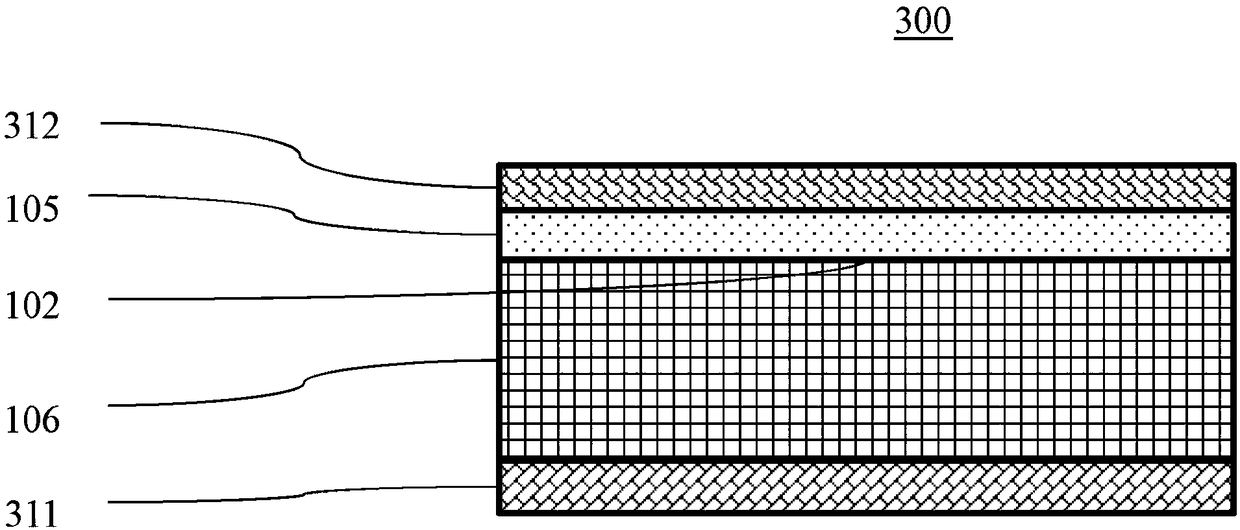

Halogenide containing glasses in metallization pastes for silicon solar cells

InactiveCN108883965ANon-conductive material with dispersed conductive materialPhotovoltaic energy generationParticulatesElectrical battery

In general, the invention relates to a paste comprising : i) silver particles; ii) a particulate lead-silicate glass comprising iia) at least one oxide of silicon; iib) at least one oxide of lead; iic) at least one chloride; iid) optionally at least one further oxide being different from components iia) and iib); iii) an organic vehicle. The invention also relates to a solar cell precursor, to a process for the preparation of a solar cell, to a solar cell obtainable by this process, to a module comprising such a solar cell and to the use of a particulate lead-silicate glass as a component in asilver paste that can be used for the formation of an electrode.

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

Composite heat-insulating heat-preserving material

InactiveCN106866055AMeet thermal insulation requirementsImprove insulation effectBasalt fiberLead silicate

The invention discloses a composite heat-insulating heat-preserving material. The heat-preserving material is prepared from a solid feedstock and a thickening and water retention agent, wherein the solid feedstock is prepared from the ingredients in parts by weight: 28 parts of staple lead silicate fibers, 12 parts of staple basalt fibers, 4 parts of basalt fiber powder, 6 parts of floating beads, 13 parts of perlite powder, 9 parts of sodium oxide and 20 parts of cement 425#. The composite heat-insulating heat-preserving material disclosed by the invention is excellent in heat-insulating heat-preserving performance, is non-toxic, odorless, pollution-free and non-irritating and has class-A incombustible fireproof performance; and during construction, the composite heat-insulating heat-preserving material can be prepared into paste through being added with water and then is directly smeared to the surface of a building, so that the construction is simple and easy.

Owner:JIZHOU SHENGDA ENERGY SAVING BUILDING MATERIALS

Conductive paste, solar cell prepared from conductive paste and manufacturing method

ActiveCN111902881AEL performance test is normalImprove efficiencyFinal product manufactureNon-conductive material with dispersed conductive materialConductive pasteOhmic contact

The invention discloses a conductive paste for forming a surface electrode of a solar cell. The conductive paste comprises conductive powder, mixed glass and an organic phase, wherein the mixed glasscomprises the following two types of glass components: the first type of glass is at least one selected from tellurium-based glass which does not substantially contain lead and takes tellurium bismuthlithium as an essential component; the second type of glass is at least one kind of glass selected from lead silicate-based glasses that contain lead and silicon as essential components and that do not substantially contain tellurium. The invention also provides a solar cell prepared by printing the conductive paste into a surface electrode and a manufacturing method of the solar cell. A solar cell prepared from the conductive paste is good in EL performance detection, excellent in cell ohmic contact, high in cell efficiency, high in stability and strong in adhesive force, and the bonding performance is considered while the stability and the ohmic contact are improved.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD

High-impact-resistance automobile nylon composite and preparation method thereof

The invention discloses a high-impact-resistance automobile nylon composite and a preparation method thereof. The high-impact-resistance automobile nylon composite is prepared from the following raw materials by weight: 40 to 60 parts of nylon 12, 30 to 50 parts of nylon 6, 25 to 35 parts of poly(butyleneadipate-co-terephthalate), 15 to 20 parts of methacryIate-butadiene-styrene copolymer, 18 to 24 parts of spinel powder, 12 to 16 parts of boron mud, 10 to 15 parts of aluminum titanate fiber, 6 to 12 parts of cork powder, 1.5 to 2.5 parts of tetraisopropyl di(dioctylphosphate) titanate, 10 to 15 parts of C5 petroleum resin, 2 to 3 parts of magnesium oxide, 1.5 to 2.5 parts of calcium benzoate, 4 to 8 parts of coal tar pitch, 10 to 15 parts of octodecyl acyl tributyl citrate, 8 to 14 parts of dicyclohexyl phthalate, 2 to 3 parts of basic lead silicate, 1 to 2 parts of barium stearate, 1 to 2 parts of zinc stearate, 15 to 20 parts of modified kaolin and 1.5 to 2.5 parts of an antioxidant 3010. The nylon composite provided by the invention has greatly improved notch impact strength while maintaining high tensile strength and bending strength and has excellent shock resistance.

Owner:ANHUI ANLAN MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com