Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Unique artistic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magic star stone glazed brick with surface aventurine effect and preparation method thereof

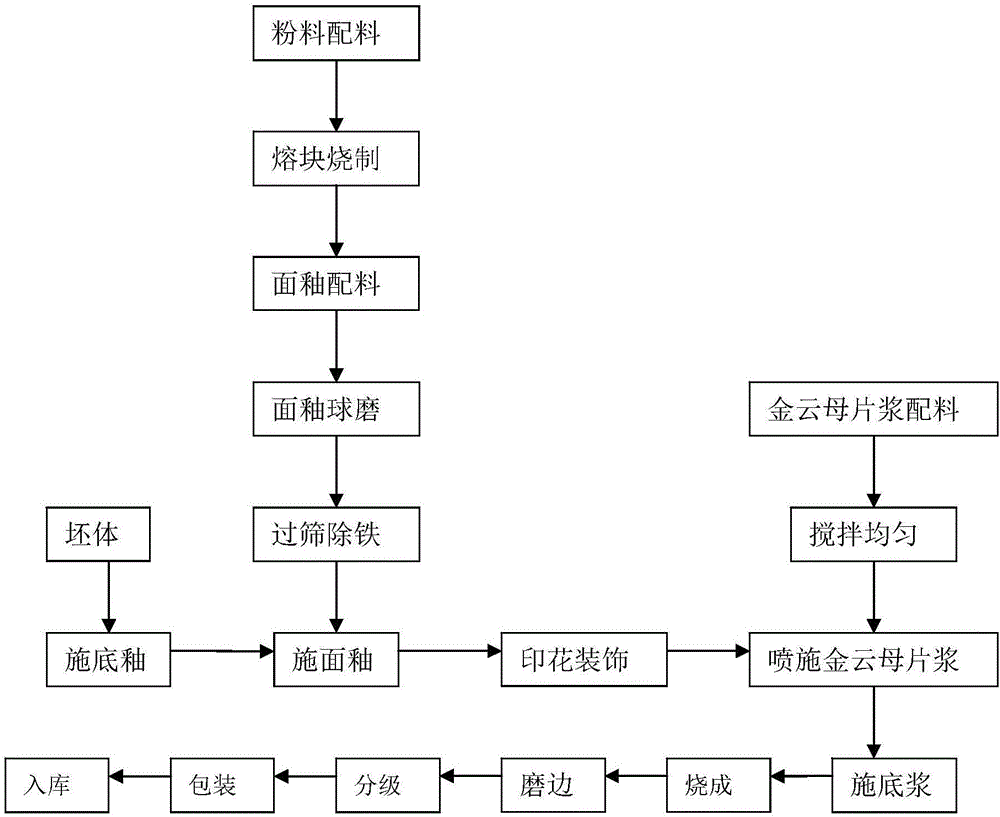

The invention relates to a magic star stone glazed brick with surface aventurine effect, and provides a magic star stone glazed brick with surface aventurine effect and a preparation method thereof. The magic star stone glazed brick comprises a frit, a surface glaze and a gold mica sheet slurry. The magic star stone glazed brick has the advantages that on the basis of not performing major change on the production technology of the existing glazed brick, the formula composition of the frit, the formula composition of the surface glaze, the formula composition of the gold mica sheet slurry, the optimum selection of granularity of gold mica sheet, the glaze applying technique, the slurry applying technique and the like are adjusted and optimized, so that the surface of the prepared magic star stone glazed brick is matte, and the luster of the surface of the product is measured by a WGG60-E4 luster meter and is 8 to 12; under the light radiation condition, the gold mica sheet at the surface of the product, such as mica or hematite small sheets in the aventurine, is glittering, magic and elegant, so that the special decorativeness and artistry are realized; the technique has higher universality, and is suitable for being popularized in industry.

Owner:GUANGDONG WINTO CERAMICS +3

Copper red glaze formula and manufacturing process of copper red glaze porcelain

The invention belongs to the field of ceramic glazes, and in particular relates to a copper red glaze formula and a glazing process thereof, which can be widely applied to art ceramics or household ceramics. The copper red glaze formula comprises the following raw materials in percentage by weight: 40 to 50 percent of feldspar, 15 to 25 percent of quartz, 10 to 15 percent of limestone, 10 to 15 percent of grain ash, 1 to 5 percent of bone ash, 5 to 10 percent of tin, and 0.5 to 1.5 percent of copper. The porcelain prepared by using the copper red glaze is uniform in color and luster and thick in glaze surface; the overall glaze surface is white, and dark red floods from the white glaze surface; the porcelain has a unique artistic effect, and gives the impressions of deepness, steadiness, dignity and elegance.

Owner:福建省太古陶瓷有限责任公司

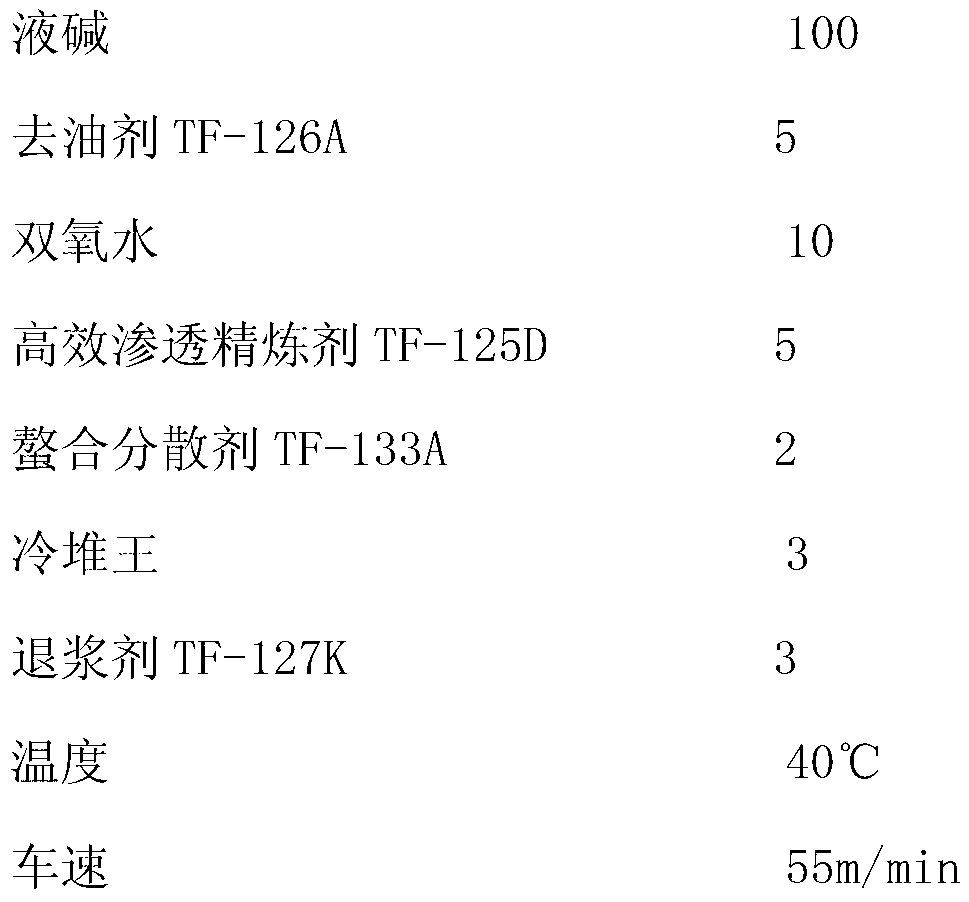

Manufacturing method of polyester-silk interwoven fabrics

The invention discloses a manufacturing method of a polyester-silk interwoven fabric. The manufacturing method comprises the steps of: desizing, splitting, performing nylon yarn fixation, dyeing terylene, soaping, dyeing nylon yarns, soaping, performing secondary fixation, sizing, checking, warehousing and the like. By adopting a newly developed dyeing and finishing process, compared with the original process, the problem that the nylon yarns which are dyed are easily stained, so as to affect the accuracy degree of the color is overcome; the problem of poor spinning color fastness of the traditional polyester silk is also improved; the polyester-silk interwoven fabric is soft in cloth cover, light and thin, plump in color, noble, elegant and glossy, and has super drapability, smooth property, wear resistance and anti-wrinkle property. Advanced cool finishing is adopted, so that the high wearing comfort is provided; and a suit coat made of the polyester-silk interwoven fabric still can bring about touch of cool in hot summer.

Owner:SHENGHONG GRP CO LTD

Lightweight low-temperature fancy golden silk white glazed porcelain and manufacturing process

The invention belongs to the field of ceramic glaze and specifically relates to lightweight low-temperature fancy golden silk white glazed porcelain widely applicable to art ceramics or ceramics for household purpose and a manufacturing process thereof. According to the lightweight low-temperature fancy golden silk white glazed porcelain, by the combination of ground glaze and overglaze, the black galaxy effect is realized. The fired lightweight low-temperature fancy golden silk white glazed porcelain has black ground color, which is covered with golden sand particles. The golden sand particles are polygonal particles when examined under a microscope, and the light-reflecting effect is good. Relative to the black ground color, there is a striking contrast and a unique artistic effect is achieved. In addition, the service life of the lightweight low-temperature fancy golden silk white glazed porcelain is long due to the combination of the ground glaze and overglaze. According to the manufacturing process of the lightweight low-temperature fancy golden silk white glazed porcelain, the effect of the overglaze can be adjusted through the formula and thickness of the ground glaze and overglaze. Then, yield of black galaxy glaze is high, firing temperature is low, energy conservation and environment protection are achieved, and energy consumption is reduced.

Owner:福建省德化县臻晖陶瓷有限公司

Imitation wood-grain ceramic product and production process thereof

ActiveCN107188528AWith three-dimensional effectReduce manufacturing costCeramic materials productionClaywaresGlazeRed soil

The invention relates to an imitation wood-grain ceramic product and a production process thereof; the imitation wood-grain ceramic product comprises a ceramic body and also comprises a cracked ground glaze layer and a surface glaze layer arranged on the surface of the ceramic body. The imitation wood-grain ceramic product provided herein is totally different from traditional ceramic with smooth glaze, and has unique artistic effect. The cracked ground glaze layer and the surface glaze layer form the natural ceramic body cracked and exposed; as the cracked ground glaze layer is thick, the cracked ground glaze layer is stereoscopic; as the color of the whole ceramic product is adjusted through the surface glaze layer, imitation bark or other rough grains can be achieved. High contents of red soil, clay, gold tailings and other low-price industrial wastes are used as ceramic materials for the imitation wood-grain ceramic product, so that the imitation wood-grain ceramic product has significant environmental value, and has effectively decreased production cost of materials and increased economic benefit and marketing competitiveness.

Owner:德化县如瓷生活文化有限公司

Copper-red glaze and preparation method thereof

The invention relates to copper-red glaze and a preparation method thereof. The copper-red glaze comprises, by weight, 5-10 parts of kaolin, 18-35 parts of quartz, 10-16 parts of calcium phosphate, 15-22 parts of albite, 15-24 parts of potassium feldspar, 2-9 parts of talcum, 1-2 parts of cupric oxalate, 0.5-1.5 parts of tin oxide, 8-16 parts of calcite, 0.5-1.5 parts of zinc oxide and 10-13 parts of borax. The copper-red glaze has the advantages that the glaze is even in color and good in glossiness, and porcelain processed by the copper-red glaze is even in color and thick in glaze, has an unique artistic effect, gives an impression of depth, steadiness, dignity and elegance to people, has a bright red color and is even in glaze color distribution and high in yield.

Owner:崔松伟

Golden stripe tiger skin enameled container and manufacturing technology thereof

ActiveCN106396385AUnique artistic effectHigh economic valueTemperature controlManufacturing technology

The invention belongs to the technical field of ceramic production, and particularly relates to a golden stripe tiger skin enameled container and a manufacturing technology thereof. The golden stripe tiger skin enameled container is prepared from glaze materials comprising feldspar, calcinedtalc, quartz stone, kaoline, violet gold stone, low-temperature fusion cakes, barium carbonate, bone ash, iron sesquioxide, lapis lazuli, mellite and calcium. According to the golden stripe tiger skin enameled container, a burnt glazed surface is black or dark brown integrally, lumpy golden stripes are distributed on the black or dark brown glazed surface, the sizes and density of the stripes are changed according to the shape and the glazing thickness of the enameled container, and the golden stripe tiger skin enameled container has a unique artistic effect. Moreover, a furnace transformation glazing effect is formed by controlling accurate burning, the golden stripe tiger skin enameled container can be industrially produced in a large scale and quickly popularized for temperature control of the golden stripe tiger skin enameled container, and the golden stripe tiger skin enameled container has a relatively high economic value and has relatively high competitive power in the market.

Owner:福建德化县冠晟礼品有限公司

Low-temperature lightweight lime gradient glaze ceramic and production process thereof

The invention belongs to the field of ceramic glaze and in particular relates to a low-temperature lightweight lime gradient glaze ceramic with the advantages of energy saving and environment friendliness and a production process of the low-temperature lightweight lime gradient glaze ceramic. The low-temperature lightweight lime gradient glaze ceramic provided by the invention comprises a lightweight porcelain body and low-temperature lightweight ceramic lime gradient glaze arranged on the lightweight porcelain body. The glaze surface of sintered low-temperature lightweight lime gradient glaze ceramic is alternated with multiple colors of milky white, grey white, light grey and dark grey and is gradually transited and is good in glossiness; gradient directions are different along with the shape change of a green body; the effect of the glaze surface can be adjusted according to formulas and the thicknesses of ground glaze and surface glaze and has a unique artistic effect; besides, green body raw materials of the low-temperature lightweight lime gradient glaze ceramic are selected according to glaze materials; the low-temperature lightweight lime gradient glaze ceramic tightly combines the green body and the glaze and can be sintered at a low sintering temperature at a time; energy saving and environment friendliness are realized, and energy consumption is reduced.

Owner:FUJIAN DEHUA COUNTY HUANGMING CERAMIC

Black gold sand glaze porcelain, and preparation method thereof

The invention belongs to the field of ceramic glaze material, and more specifically relates to a black gold sand glaze porcelain widely applied to the fields of art ceramic or household ceramic, and a preparation method thereof. According to the preparation method, black gold sand effects of the black gold sand glaze porcelain are realized via combination of bottom glaze and surface glaze, the black gold sand glaze porcelain obtained via firing possesses black bottom color, and the black bottom color is covered with golden gold sand particles; under a microscope, the gold sand particles are polygonal particles, light-reflecting effect of the gold sand particles is excellent, striking contrast effect and unique artistic effect are achieved via combination of the black bottom color with the gold sand particles; the bottom glaze and the surface glaze of the black gold sand glaze porcelain are combined firmly; and service life is long. The invention also provides the preparation method of the black gold sand glaze porcelain; the glaze surface effect can be achieved via adjusting the formula and thickness of bottom glaze with surface glaze; black gold sand glaze porcelain finished product ratio is high; firing temperature is low; energy is saved; the preparation method is friendly to the environment; and energy consumption is reduced.

Owner:FUJIAN QUANZHOU LONGPENG GROUP

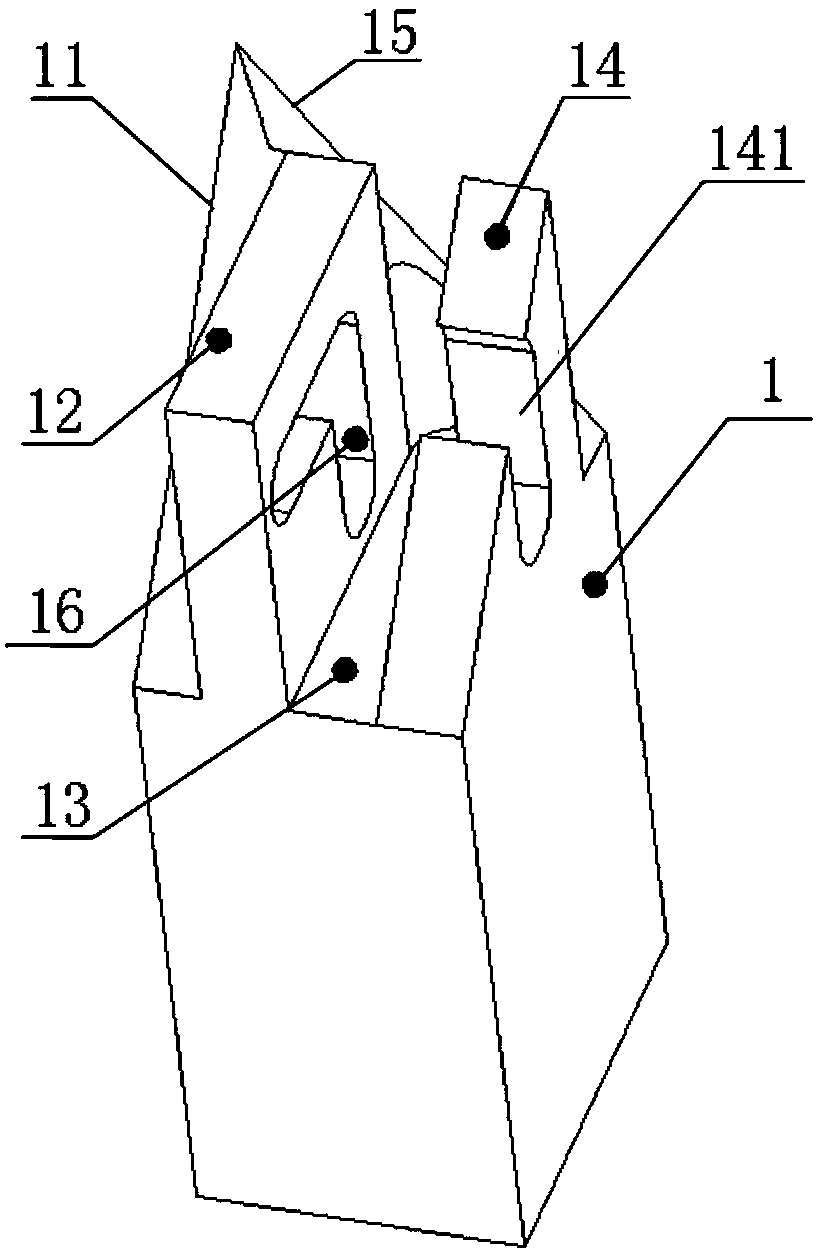

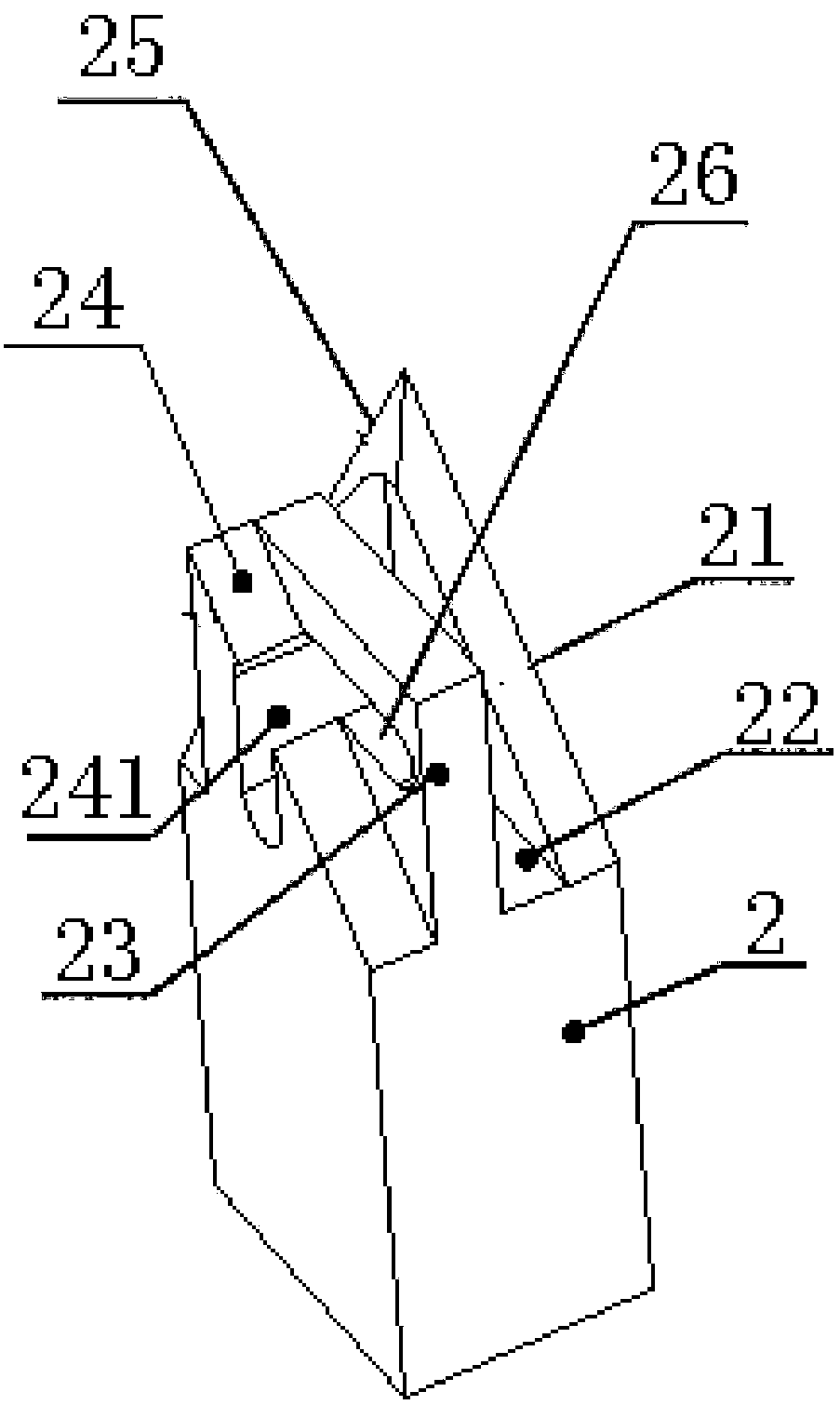

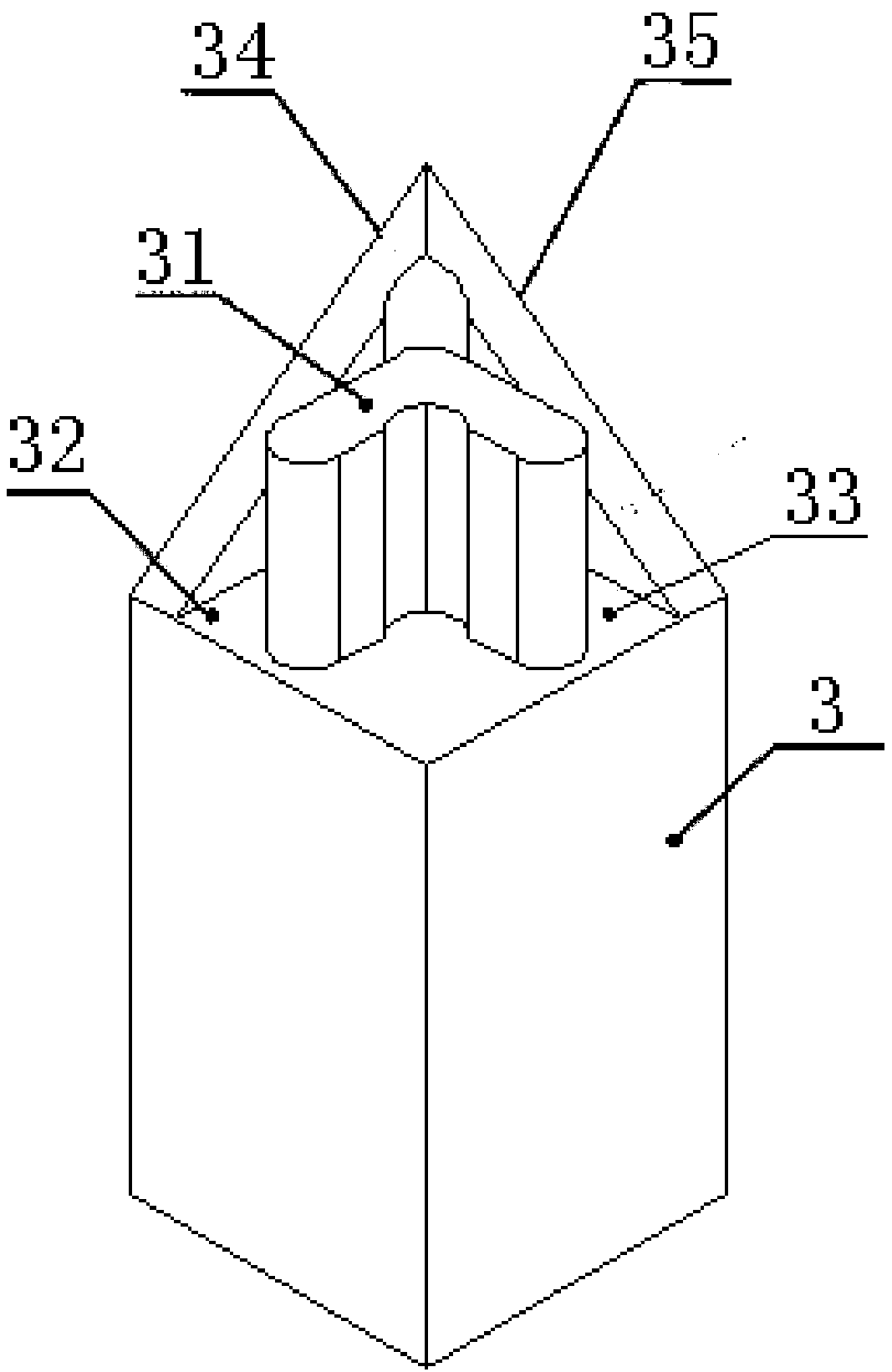

Surface frame tenon

PendingCN108317143AEasy to assembleEasy to disassemble and transportFurniture joiningEdge surfaceFirst insertion

The invention discloses a surface frame tenon. The surface frame tenon comprises a first surface frame tenon, a second surface frame tenon and a third surface frame tenon; and the three are pairwise perpendicular, and are assembled through tenon heads and tenon grooves. The surface frame tenon is characterized in that the first surface frame tenon, the second surface frame tenon and the third surface frame tenon respectively comprise outer edge surface parts and inner tenon head parts; the outer edge surfaces of the first, second and third surface frame tenons are respectively provided with two inclined edges; six inclined edges are pairwise overlapped for dividing a combined turning angle after assembly of the first surface frame tenon, the second surface frame tenon and the third surfaceframe tenon into six angles of 45 degrees; a first insertion hole is formed in the first tenon head of the first surface frame tenon; a second insertion hole is formed in the second tenon head of thesecond surface frame tenon; the first insertion hole and the second insertion hole are overlapped to form a third tenon hole of the third surface frame tenon; and the tenon head of the third surfaceframe tenon is inserted in the third tenon hole from a Y-axle direction to lock the first surface frame tenon and the second surface frame tenon in left and right X-axle directions. Furniture assembled through the structure is flat and beautiful in appearance and unique in artistic effect; and the surface frame tenon is simple and stable in structure, reasonable in design and convenient to machineand assemble.

Owner:苏州铨木智能科技有限公司

Method for glazing and sandblasting surface of sander

The invention relates to a method for forming glazes on the surface of a sander, in particular to a method for glazing and sandblasting the surface of a sander, which solves the problem that the conventional sander has no feasible surface glazing and coloring method. The method comprises the following steps: (1) preparing glaze slurry, which is prepared from the following raw materials in percentage by weight: 26 to 34 percent of feldspar, 6 to 10 percent of calcium carbonate, 4 to 6 percent of barium carbonate, 11 to 17 percent of quartz, 4 to 6 percent of processed talc, 4 to 8 percent of calcite, 20 to 28 percent of elutriated pure loess and 5 to 11 percent of high-temperature ceramic pigment; then adding carboxymethyl cellulose accounting for 0.1 percent of the weight sum of the raw materials into the raw materials; crushing all the glaze slurry raw materials, deironing, then adding water into the raw materials, and controlling the specific gravity value to reach 1.5 to 1.6 grams per milliliter by controlling the added water quantity; (2) spraying the glaze slurry to the surface of a blank evenly by adopting a spraying device to form granular glazes; and (3) firing the blank. The method fills the blank that the sander has no surface glazing and sandblasting method, so the sander originally only having practical value has more artistic appreciation and collection values.

Owner:张宏亮

Production method of portoro glaze ceramic

The invention relates to the technical field of ceramic production, in particular to portoro glaze and a production method of ceramic with a light emperador glaze effect. The portoro glaze is characterized by comprising black ground glaze and portoro glaze, a special raw material formula is selected, unique glazing and firing processes are used according to characteristics of glaze, the fired portoro glaze ceramic has a basic black tone on the surface, has golden yellow grains intermittently and uniformly distributed in a stripe shape like bright yellow golden flowers scattered on black satin,gives people sense of steadiness and nobleness, has unique decoration and artistic effects and can be used as a creation carrier of home decoration and artwork, so that use of natural stone can be reduced, the production cost can be reduced, stone resources can be saved, and the portoro glaze ceramic has positive social and economic benefits.

Owner:FUJIAN DEHUA LONGNAN CERAMICS CO LTD

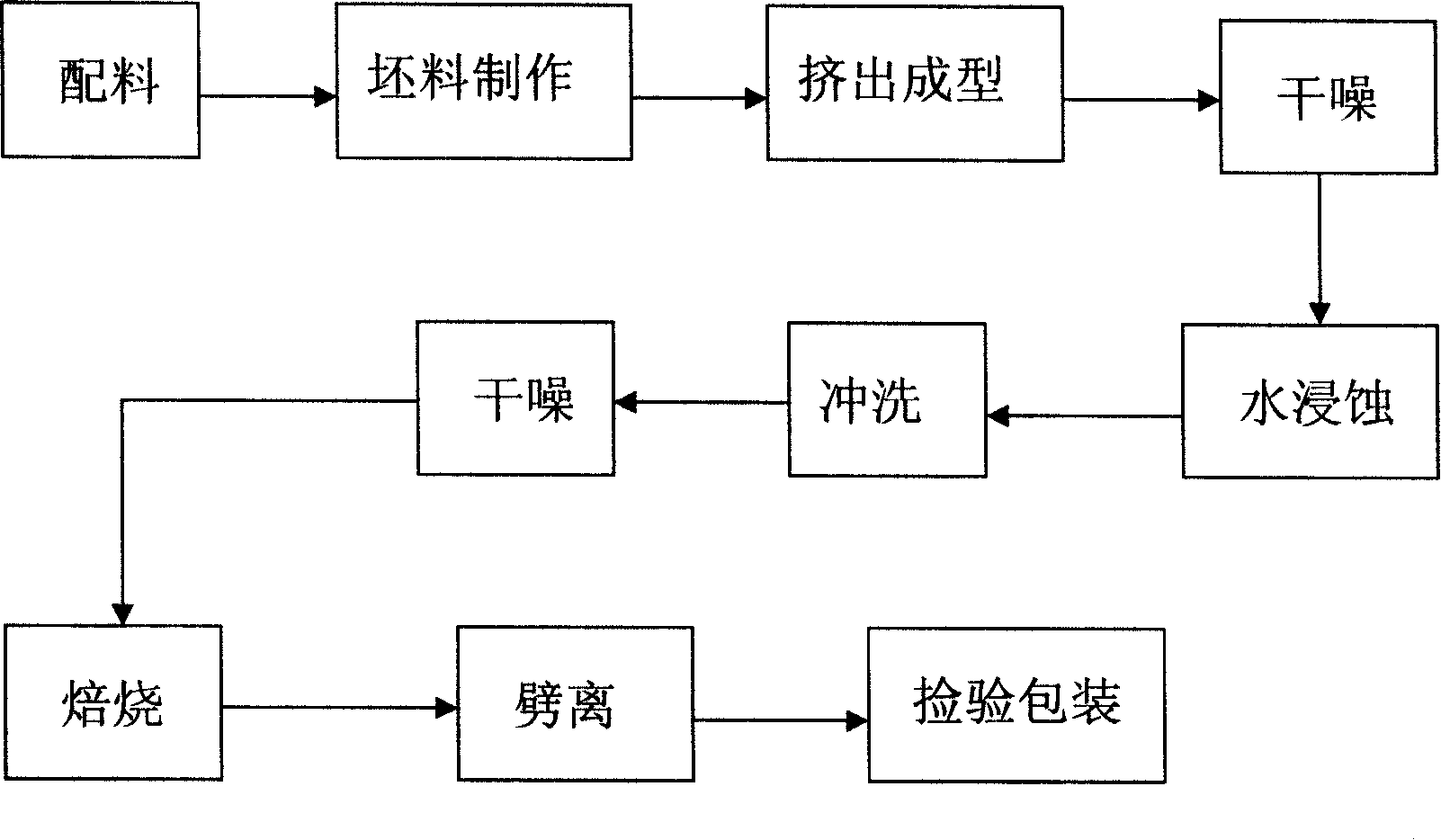

Natural water erosion face ceramic decoration split tile and its production method

InactiveCN101173552AUnique artistic effectSatisfy the pursuit of natureCovering/liningsSidewalk pavingsAdobeBrick

The invention relates to a ceramic decorative detached brick with natural water erosion surface, comprising an adobe made of same or different colored blanks, the brick surface is water erosion surface, namely a plurality of rugged pits or cambered surfaces or natural round pitting surfaces different depth generated due to water immersion and erosion are arranged on the surface of the brick. Compared with the prior detached brick, the production method is characterized in that the water erosion and flushing process are added between the drying process and the calcination process, the drying process is as follow: immersing the dry adobe surface of detached brick under water 1 to 3mm for 1 to 10 minutes, when the immersed part fully softened, washing the brick surface with fresh water, thus a plurality of rugged pits or cambered surfaces or water erosion surfaces with the depth of 0.1 to 3mm are formed on the brick surface, then calcining the adobe after drying. The surface of the brick produced with the method has smooth rugged pits which are similar to the stone surface eroded or flushed by water, and appears the unique artistic effect; furthermore, the brick surface has no scratch; the appearance is beautiful, and the brick body is higher in strength and more corrosion resistant.

Owner:柳州市奋进建筑材料有限责任公司

Preparation method of glaze isolated color-printed chinaware

The invention relates to a preparation method of glaze isolated color-printed chinaware, which belongs to the technical field of ceramic preparation. The preparation method comprises the following steps: preparing basic glaze powder, surface layer glaze, bottom layer glaze and a chinaware clay body, performing color printing on the surface of the mud clay body by using a transfer color printing machine conventionally used by ceramics for daily use and using the bottom layer glaze to obtain a pattern composed of strips, drying, manually glazing the color-printed and oven-dried product, storing the glazed product in a cool and dry place for 8-16 hours, and burning the glazed product in a kiln to obtain the glaze isolated color-printed chinaware. The product prepared by using the preparation method of the invention has a slightly concaved-convexed and colored pattern on the surface thereof, and has a good three-dimensional effect; the glaze isolated color-printed chinaware has regular appearance and smooth glaze, and the strip-like motif pattern in the glaze is clear; and the method has high efficiency and low cost.

Owner:GUANGDONG SITONG GROUP

Application of PVC (Polyvinyl Chloride) expansion sheet to printmaking

InactiveCN102689563AModerate surface hardnessModerate hardnessDecorative surface effectsSpecial ornamental structuresArtistic renderingPolyvinyl chloride

The invention relates to application of a PVC (Polyvinyl Chloride) expansion sheet to printmaking, and mainly solves the problems of complex processes, time consumption, labor consumption and high cost by applying the conventional material to printmaking existing in the prior art. The application of the PVC expansion sheet to printmaking comprises the following steps of: 1, creating a draft; 2, checking the draft or transferring a pattern to the PVC expansion sheet; 3, performing plate making: engraving or scribing along the draft on the PVC expansion sheet by using an engraving knife or a sharp instrument, wherein the engraving depth range is over 1.5 mm; positive scribing is that convex lines show the appearance, negative scribing is that concave lines show the appearance; and engraving concave lines on the plate plane; 4, printing: after positive scribing of the convex lines, rolling ink to print a white-ground black-line image; and after negative scribing of the concave lines, rolling ink to print a black-ground white-line image. The hardness of the PVC expansion sheet in the application of the PVC expansion sheet to printmaking is moderate and low in cost, and is concise in printmaking process, time-saving, labor-saving, high in efficiency and good in artistic effect.

Owner:冯亚发

Antiqued copper craft ceramic and manufacturing process thereof

ActiveCN106396408AIncrease brightnessUnique artistic effectClaywaresCopper oxideAmmonium metavanadate

The invention belongs to the technical field of ceramic production, and in particular relates to an antiqued copper craft ceramic and a manufacturing process of the antiqued copper craft ceramic. The antiqued copper craft ceramic comprises a ceramic body and antiqued copper glazes arranged on the ceramic body, wherein the antiqued copper glazes comprise the raw materials of lead silicate, quartz, purple stone, graphite, copper oxide, a low-temperature frit, zirconium silicate powder, kaolin, lithium carbonate, ferric oxide, nickel oxide, ammonium metavanadate and manganese dioxide. By adopting the antiqued copper craft ceramic, a fired glaze surface can appropriately promote the brightness of the glaze surface along with the increase of combustion temperature, the colors from dark bronze to bright copper can be obtained through adjusting the glazing thickness and firing temperature according to creation needs, so that the antiqued copper craft ceramic has a unique artistic effect. In addition, the invention provides a temperature control for the antiqued copper craft ceramic, so that the batch industrial production and rapid popularization can be realized, and economic values are higher, and the competitiveness of the antiqued copper craft ceramic in the market is higher.

Owner:福建省德化佳诚陶瓷有限公司

Ice blue wood leaf lacquer cup and preparation method thereof

The invention relates to the technical field of ceramic manufacturing, in particular to an ice blue wood leaf lacquer cup and a preparation method thereof. The iced blue wood leaf lacquer cup comprises a cup blank, and further comprises a brown glaze layer, a blade, a phosphor powder layer, an iced blue glaze layer and a lacquer layer which are sequentially arranged outside the cup blank. The surface of the ice blue wood leaf lacquer cup is grey black; the blade is dark blue or light blue, and is clear in texture and distinct from the cup body; clear, bright and unique effects are achieved; the outer wall of the cup is decorated with lacquer, the colorful colors of the lacquer correspond to those of the ice blue blade, and the unique artistic effect is achieved. In addition, a process forprecisely controlling firing of the ice blue wood leaf lacquer cup is provided, and the success rate of firing can be increased.

Owner:林荣献

Formula and manufacturing process of glazing-free white series marbling imitative porcelain

The invention belongs to the field of porcelain manufacturing and specifically relates to a formula and a manufacturing process of glazing-free white series marbling imitative porcelain. By using quartz, chinastone, Zhangzhou soil, bentonite, talc, kaolin and iron powder as raw materials, the unpolished white series marbling imitative porcelain is prepared by virtue of a production process with reasonable formula and proper control. The surface of the porcelain is cinerous and black flecks are uniformly distributed on the surface. As the outer layer of the porcelain is not glazed, a coarse particle face is formed. The marbling-imitative porcelain prepared by the formula and the method is similar to unpolished marbles in color, decorative patterns and texture and has a unique artistic effect. In addition, the raw materials of the glazing-free white series marbling imitative porcelain are simple and the glazing-free white series marbling imitative porcelain is simple in manufacturing process and low in production cost.

Owner:FUJIAN DEHUA YOUSHENG CERAMICS

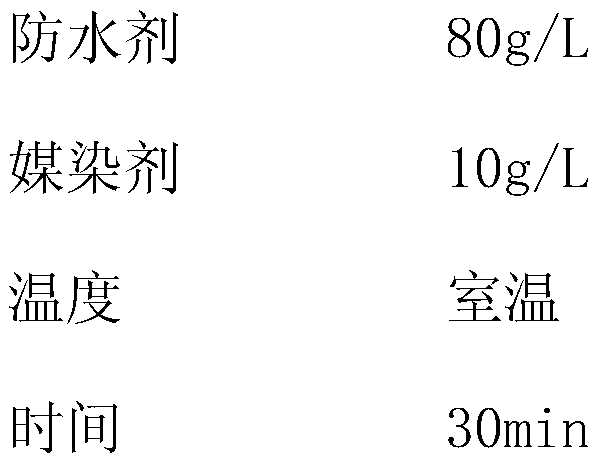

Rubbing-first-bandhnu-then production method of silk plants

The invention discloses a rubbing-first-bandhnu-then production method of silk plants.The method includes the following steps: collecting leaves, roots, flowers, stems and fruits of plants according to patterns and colors; soaking the above materials into mixed liquid of a waterproof agent and a mordant; soaking a silk fabric into an acetic acid solution; sticking the plants on the fabric with scotch tape according to patterns; rolling the silk fabric into rolls and tying up the silk fabric; steaming and coloring; removing leaves; baking; imprinting the patterns; painting the leaves and stems;washing with water and drying.The roots, stems, leaves, petals and fruits of the plants are used as patterns; before rubbing, the roots, stems, leaves, petals of the plants are soaked into the mixedliquid of the waterproof agent and the mordant with a certain concentration; textures and colors of the plants are imprinted on the silk fabric soaked in the acetic acid solution with high-temperaturesteaming; baking and high-temperature baking are performed, so that the rubbed patterns have the effect of resisting water, the phenomenon that paint is not painted on the rubbed patterns during a subsequent bandhnu coloring process is ensured, and shapes, textures and saturation of the patterns are ensured.

Owner:IANGSU COLLEGE OF ENG & TECH

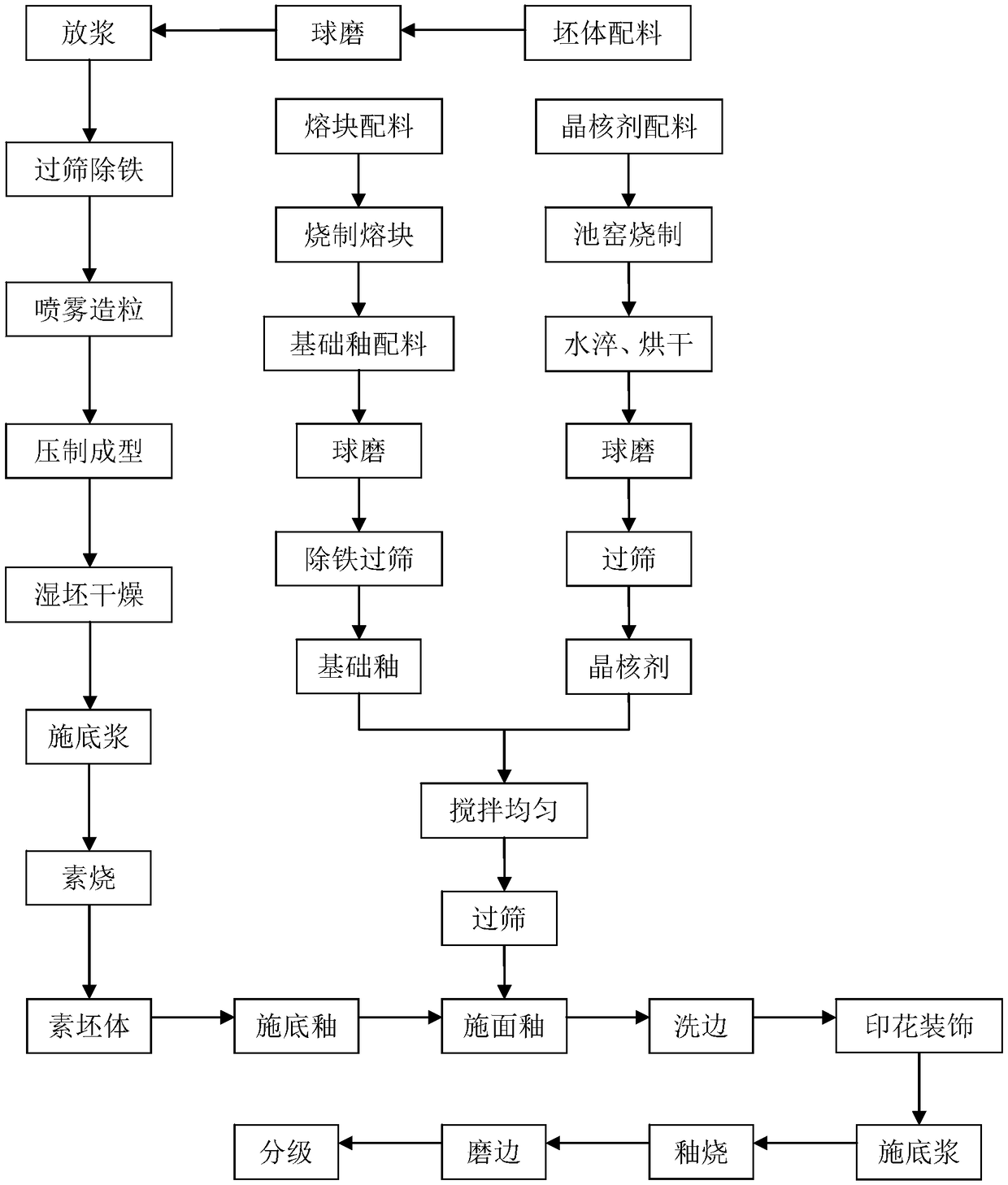

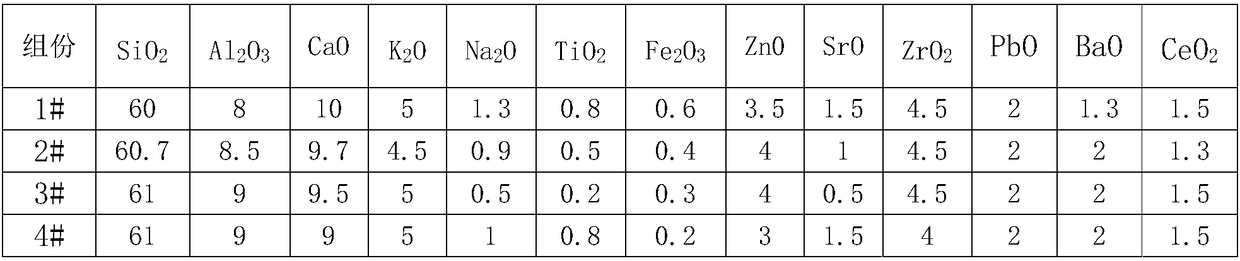

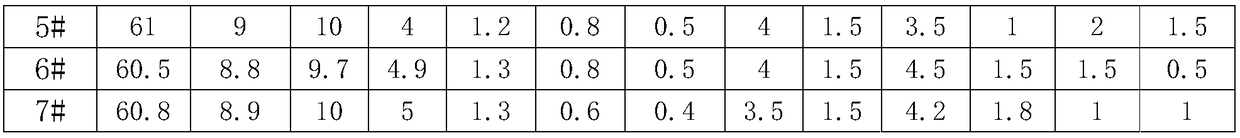

Crystalline glazed tile capable of durably producing negative ions and preparation method thereof

The invention provides a crystalline glazed tile capable of durably producing negative ions and a preparation method thereof. In the invention, without significant change on a production process of glazed tiles in the prior art, the method mainly pays attention to formulas and compositions of a frit, a basic glaze, a nucleation agent and a surface glaze, fineness of the basic glaze and the nucleation agent, and optimization on a sintering process and the like, so that a large number of silver crystals, in the size of a rice grain, are formed on the surface of the glaze tiles, wherein the crystals emit a bright silver light under irradiation by oblique light or lamp light, while the glaze base surrounding the crystals are matte, so that the whole tile looks like a starry night. In addition,there are a plurality of photo-catalytic semiconductor microcrystalline mineral, which cannot be seen by naked eyes, such as SrTiO3 and CaO.TiO2, in the surface glaze, wherein the minerals can be reacted with oxygen in air to generate oxygen negative ions durably, quantity of the inductively generated negative ions in air reaching 538 / s*cm<2>. The product is a decorative material which integratesdecorative and artistic properties and health-functional effects.

Owner:GUANGDONG WINTO CERAMICS +3

Medium-temperature transmutation stained paper and preparation method thereof and ceramic provided with medium-temperature transmutation stained paper

ActiveCN106676973ASimple production processOvercoming controllabilitySpecial visual effect coatingsCoatings with pigmentsSesquioxidePrinting ink

The invention relates to the technical field of ceramic products, and in particular relates to medium-temperature transmutation stained paper and a preparation method thereof and a ceramic provided with the medium-temperature transmutation stained paper. The medium-temperature transmutation stained paper comprises stained paper bottom, and a printing material layer and a cover layer which are successively arranged on the stained paper bottom, wherein the printing material layer is proportioned by 15-35% printing ink and the balance of a dry power raw material; the dry power comprises kaolin, feldspar, quartz, iron sesquioxide, titanium dioxide, stannic oxide and pigments. The medium-temperature transmutation stained paper is used for decorating a ceramic utensil. The medium-temperature transmutation stained paper achieves a transmutation effect through the stained paper and can solve the technical problem that the conventional transmutation effect cannot be controlled and quantitative production cannot be performed. In addition, a production process for producing and preparing the ceramic product with the medium-temperature transmutation stained paper is simple. Through detection, no lead and cadmium are dissolved out, so that the medium-temperature transmutation stained paper is safe to use and attractive in appearance and has a unique artistic effect.

Owner:福建省德化云水窑陶瓷有限公司

Sapphire blue glaze porcelain with gold-thread and iron-wire crackle network and preparation method of sapphire blue glaze porcelain

ActiveCN106116695AUnique artistic effectImprove the decorative effectCeramic materials productionClaywaresPyrophylliteDolomite

The invention provides sapphire blue glaze porcelain with a gold-thread and iron-wire crackle network and a preparation method of the sapphire blue glaze porcelain. According to the sapphire blue glaze porcelain with the gold-thread and iron-wire crackle network, a preform body of the sapphire blue glaze porcelain with the gold-thread and iron-wire crackle network is prepared from red earth, waste glass, dolomite, sodium tripolyphosphate, wollastonite, feldspar and pyrophyllite; a glaze material is prepared from expansive soil, feldspar, quartz, copper carbonate, lithium carbonate and yellow soil. According to the sapphire blue glaze porcelain with the gold-thread and iron-wire crackle network, formulae of the preform body and the glaze material are changed respectively, a unique firing method is combined, so that the porcelain obtained after firing has a very high decorative effect different from a traditional glaze effect and is particularly suitable for being used as a home decorative ornament and artware, and a prepared product has a unique artistic effect and a high additional value; besides, compared with traditional cracked glaze, the sapphire blue glaze porcelain with the gold-thread and iron-wire crackle network has the advantage that the preform body and the glaze material both utilize low-price raw materials, is fired at low temperature, fuel-saving, energy-saving and environment-friendly and has positive social and economic benefits.

Owner:福建省德化县嘉发陶瓷有限公司

Low-temperature bubble glaze ceramic and preparation process thereof

InactiveCN110937813AAchieve recyclingReduce consumptionCeramic materials productionClaywaresFritCeramic glaze

The invention belongs to the field of ceramic products, and particularly relates to a low-temperature bubble glaze ceramic and a preparation process thereof. The low-temperature bubble glaze ceramic comprises a low-temperature ceramic blank body and low-temperature bubble glaze arranged on the surface of the low-temperature ceramic blank body. The low-temperature bubble glaze comprises the following raw material components: waste glass, a carbonate, a fluxing agent, a high-expansion low-temperature frit, a metal oxide and a cooling agent. The invention provides the low-temperature bubble glazeand a preparation process thereof. A ceramic glaze surface with a brand-new effect is provided, bubbles with irregular sizes are formed in the glaze surface, and bubbles are formed by low-temperaturefiring. According to the low-temperature bubble glaze, waste glass and other waste raw materials are utilized, the firing temperature is low, recovery of solid wastes is achieved, energy consumptionis reduced, emission is reduced, energy conservation and environmental protection are achieved, the glaze effect is obviously different from that of ceramic glaze of a traditional glaze, and the low-temperature bubble glaze has unique artistry and attractiveness.

Owner:福建省德化县合和陶瓷技术开发有限公司

Pearl frosted glaze ceramic prepared from waste ceramics and preparation process thereof

ActiveCN109592991AHigh glossUnique artistic effectCeramic materials productionClaywaresFritEconomic benefits

The invention relates to the technical field of production of ceramics and particularly relates to pearl frosted glaze ceramic prepared from waste ceramics and a preparation process thereof. The pearlfrosted glaze ceramic prepared from waste ceramics comprises a ceramic blank body and pearl frosted glaze. According to the pearl frosted glaze prepared from the waste ceramics, the raw materials such as the waste ceramics and low-temperature titanium glaze frits are introduced and are used as glaze materials; one-time glazing and one-time firing and molding are achieved; the process problems ofrepeated glazing and repeated firing of the conventional frosted glaze are solved; after the ceramics are fired and molded, the formed bulges are high in frosted texture, high in glaze surface glossiness and special in artistic effect; the pearl frosted glaze is low-temperature fired glaze ceramic; a low-temperature rapid firing process is used; the low-temperature titanium glaze frits are introduced into the glaze materials, the glaze surface is high in glossiness and has pearly glossiness. The pearl frosted glaze ceramic provides a novel field of application of the waste ceramics, has positive significance to promotion of development of ceramic products, and has positive economic benefits.

Owner:FUJIAN QUANZHOU SHUNMEI GROUP

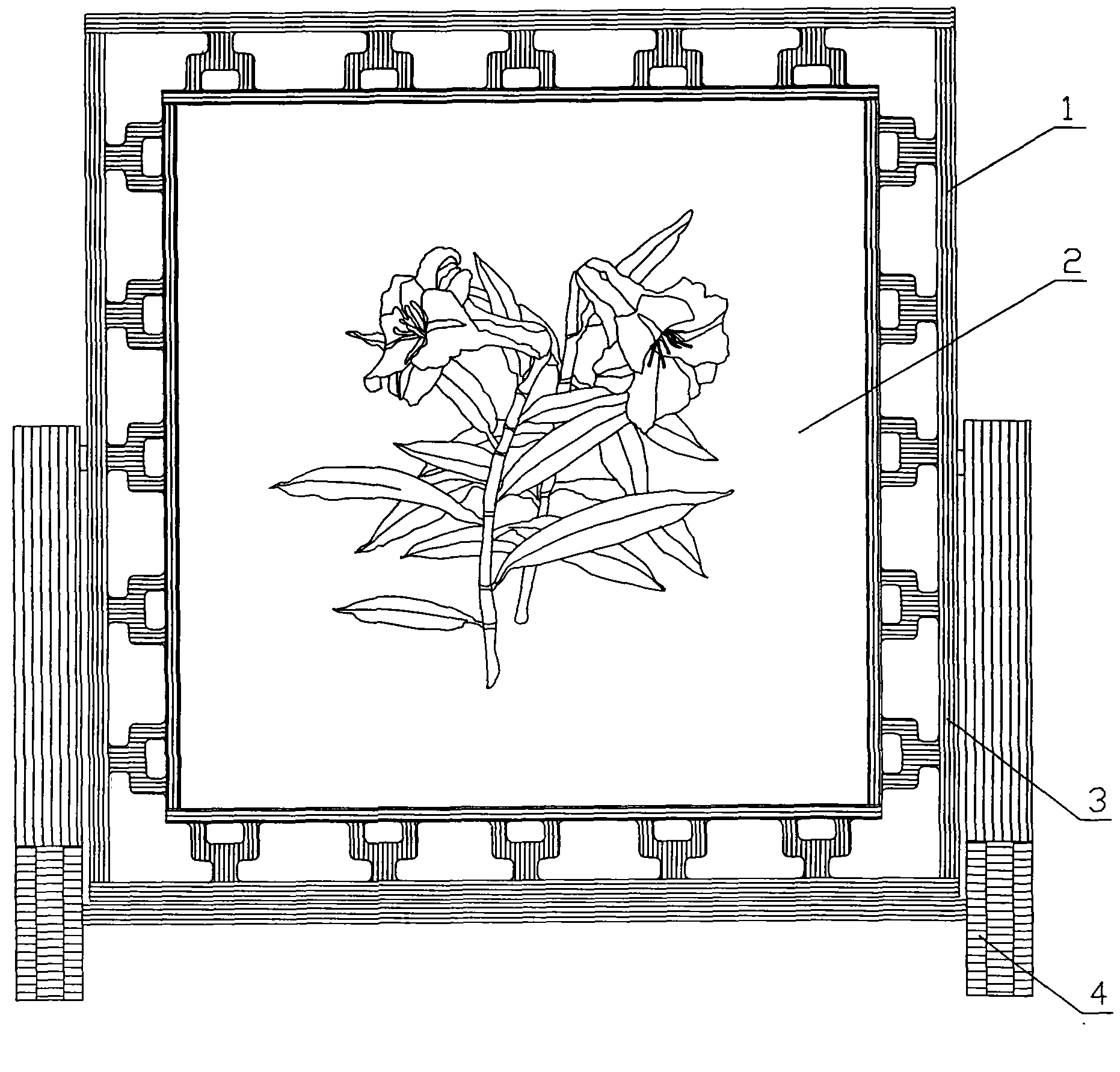

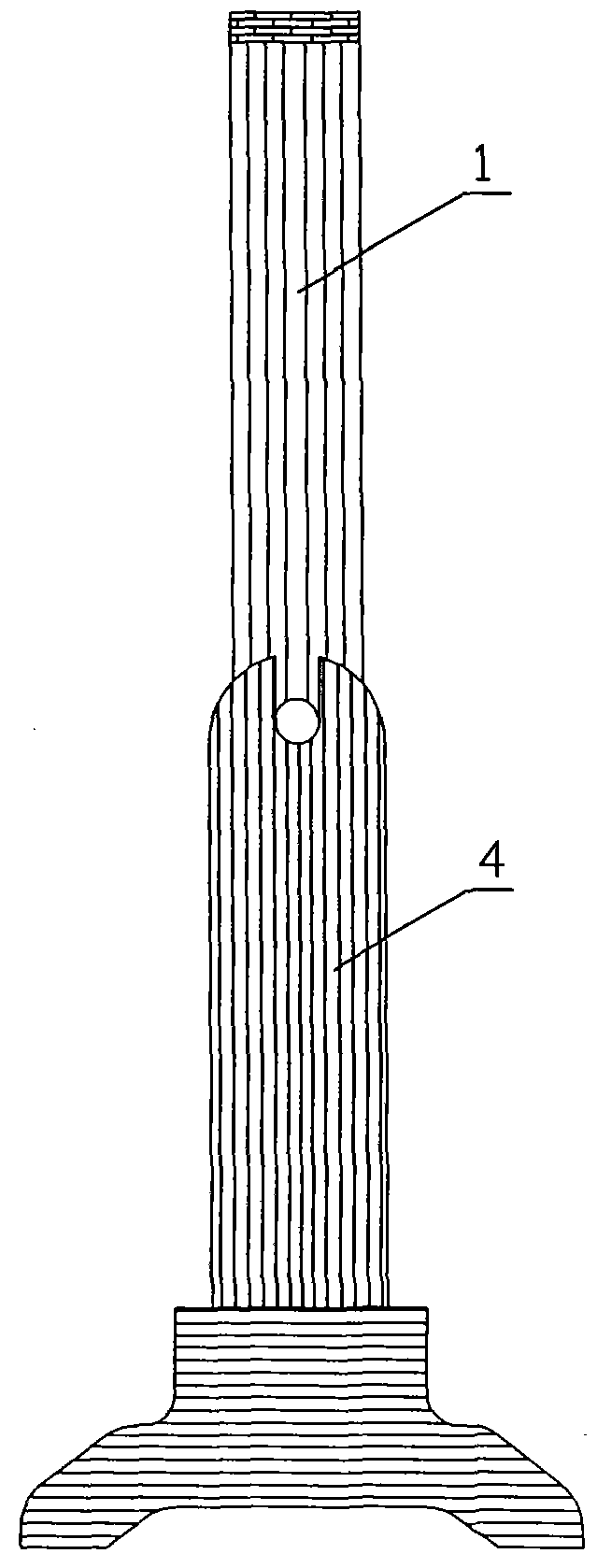

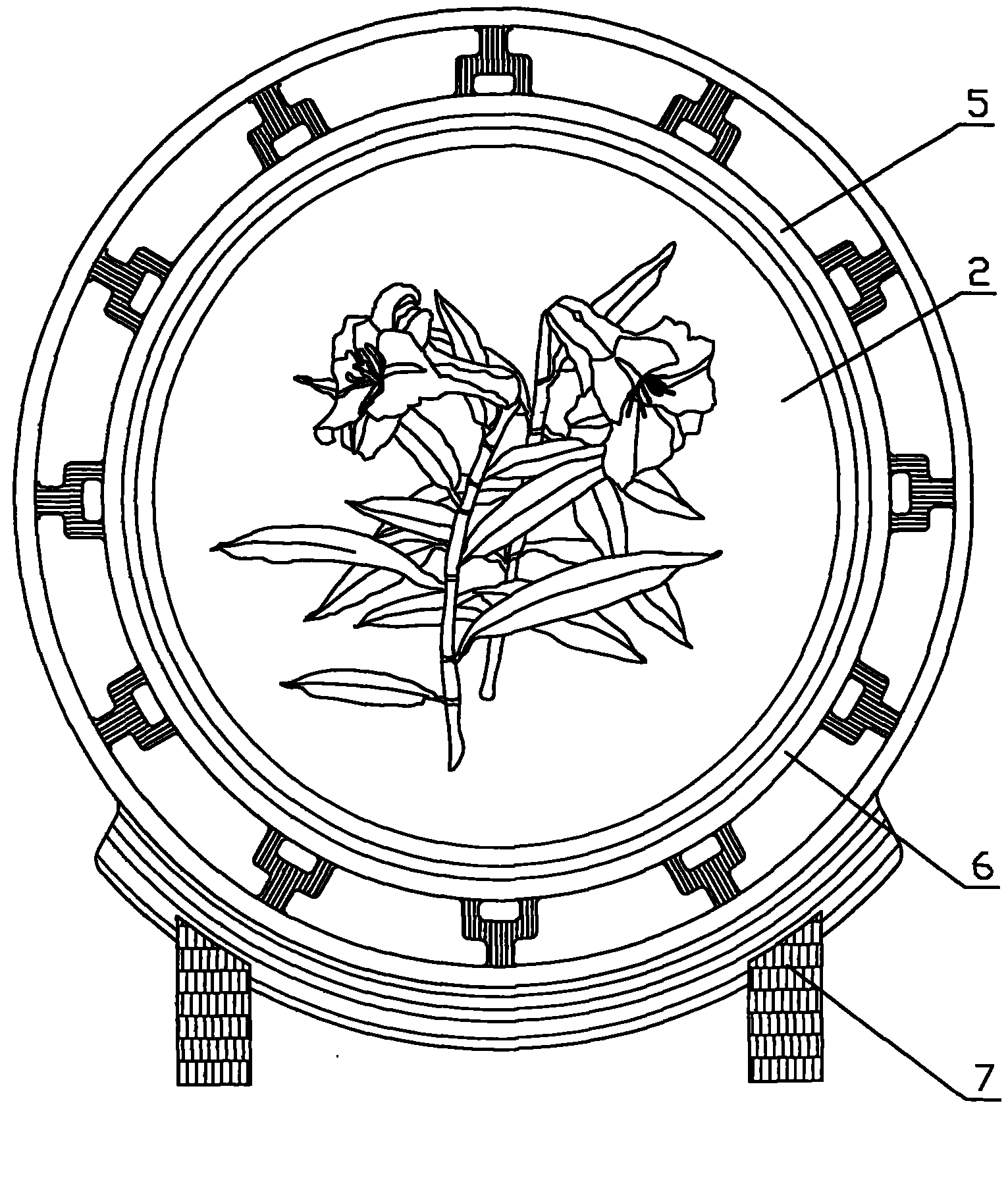

Screen frame made from bamboo materials

InactiveCN104068694AImprove regenerative abilityHas an ecological functionScreensEngineeringSocial function

The invention discloses a screen frame made from bamboo materials. The screen frame is prepared from a bamboo integrated material, wherein the bamboo integrated material may be prepared by longitudinally flatly-paving, stacking and pressing bamboo pieces, or prepared by longitudinally and laterally flatly-splicing, stacking and pressing bamboo pieces or prepared by longitudinally packing and pressing bamboo filaments, and the screen frame is provided with a picture core; the picture core may be a bamboo stereograph or a bamboo charcoal plate picture or Suzhou embroidery or Guangdong embroidery or Sichuan embroidery or Hunan embroidery or a silk painting or a bamboo skin burnt picture. The screen frame has the beneficial effects that bamboo is high in regeneration capacity, and has ecological functions, economic functions and social functions; the bamboo materials are convenient to get, abundant in texture, plain in colour and lustre, high in visual impact force and prominent in artistic effect; the screen frame is the perfect combination of bamboo culture, ecological culture and traditional culture, and opens up the new field of art.

Owner:董婉君

White ground black fancy glazed porcelain and preparation method thereof

White-ground black fancy glazed porcelain comprises a green body, engobe, black fancy glaze and protection glaze, the engobe is prepared from the following raw materials: dolomite, borax, clam meal, talc, anorthite, bentonite and wollastonite; and according to the fired vitreous enamel, white serves as the ground color, the black floral patterns are formed on the surface of the ground color, the black floral patterns and the ground color form a distinct contrast, the expressive force of the black floral patterns is greatly improved, and the white-ground black fancy glazed porcelain has a unique artistic effect so as to meet more market requirements.

Owner:福建省德化县奇丽工艺有限公司

Composite dry granules for ceramic tile production and ceramic tile

The invention relates to the field of ceramic tile production, and provides composite dry granules for ceramic tile production and a ceramic tile, which are used for improving the quality of ceramic products. The invention provides a composite dry granule for ceramic tile production. The composite dry granule comprises 45 to 52 percent of SiO2, 13 to 15 percent of Al2O3, 0.2 to 0.5 percent of Fe2O3, 0 to 0.02 percent of TiO2, 12 to 15 percent of CaO, 5 to 7 percent of MgO, 0.5 to 1.5 percent of K2O, 1 to 1.5 percent of Na2O, 1 to 4 percent of B2O3, 3 to 5 percent of ZrO2, 1 to 5 percent of BaO, 1 to 4 percent of F and 3 to 5 percent of NiO2. The dry particles can achieve multiple effects, and have color and surface texture. The dry particles are used for decorating the product, and the effect is better than that of special ink spraying. The characteristics of high hardness, corrosion resistance, compression resistance, impact resistance, less dust staining, no radiation and the like are realized.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

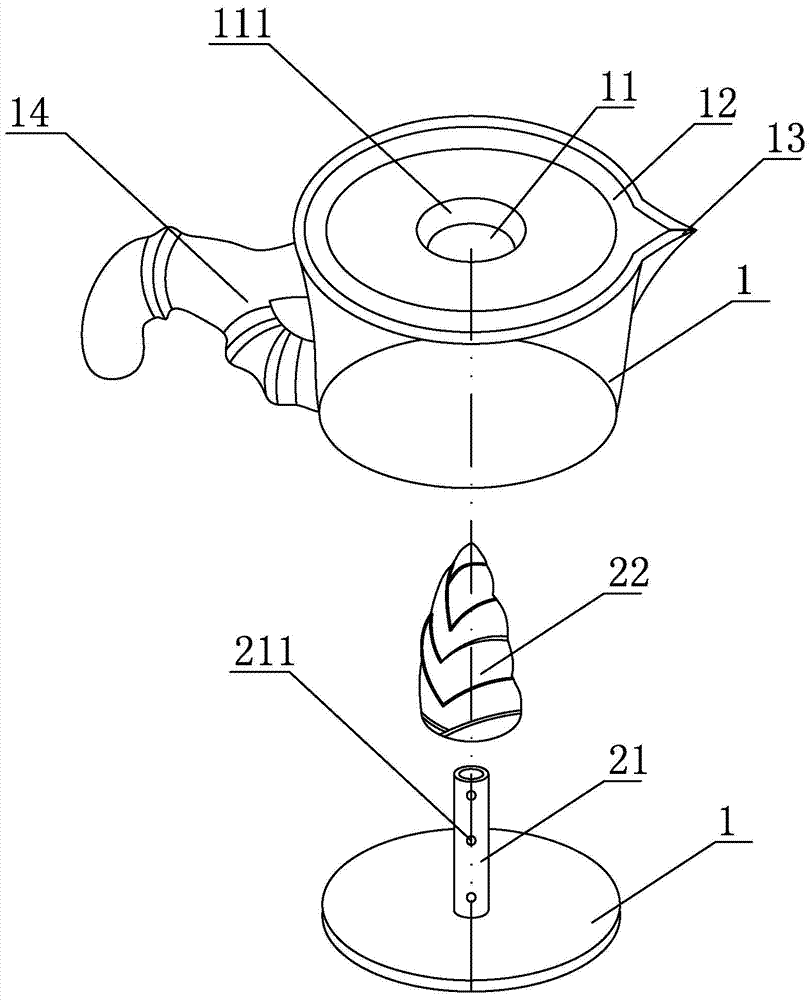

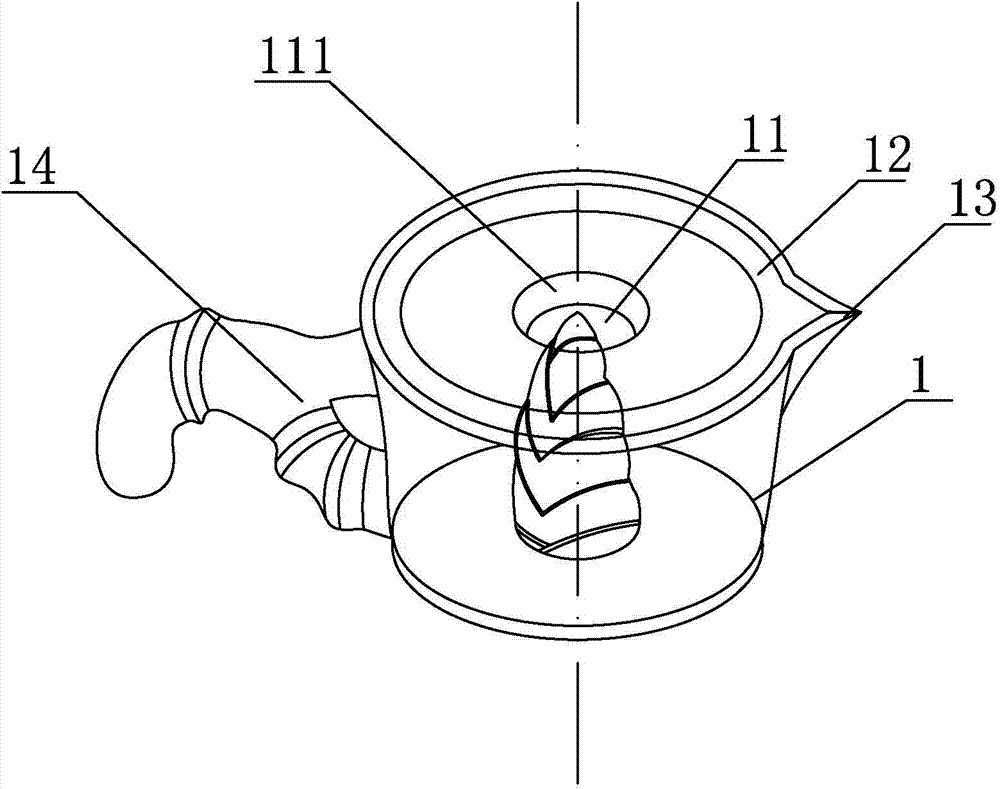

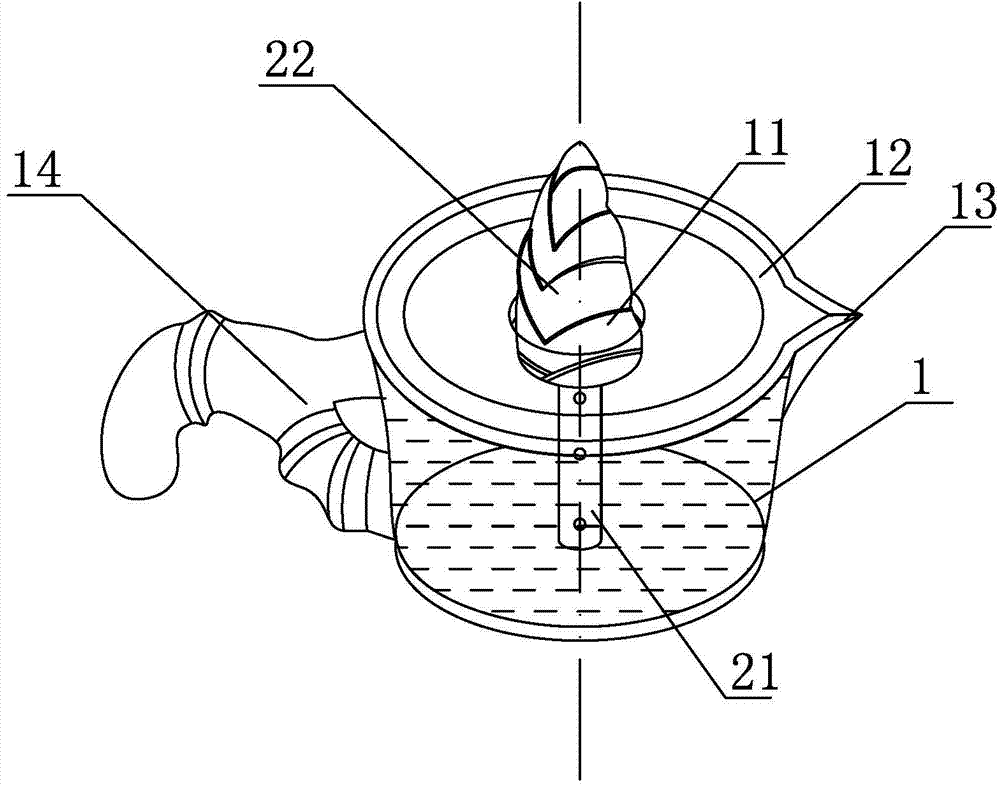

Interesting justice cup and preparation method thereof

The invention relates to the technical field of tea sets, in particular to a justice cup combining high practicability, artistry and interestingness and a preparation method of the justice cup. The interesting justice cup comprises a closed cup body, wherein the cup body is provided with a water inlet hole and a water outlet nozzle, and the water inlet hole is formed in the top face of the cup body. The interesting justice cup further comprises a water inlet hole closing device arranged in the cup body. The water inlet hole closing device comprises a guide rod and a porcelain carving capable of floating on a water surface. The guide rod is connected to the bottom face of the cup body and is coaxial with the water inlet hole. The porcelain carving is of a hollow structure and is arranged on the guide rod in a liftable and sleeving mode. The porcelain carving is of a big-end-down conical structure. The diameter of the upper end of the porcelain carving is smaller than the diameter of the water inlet hole, and the diameter of the lower end of the porcelain carving is larger than the diameter of the water inlet hole. According to the interesting justice cup, the structure completely different from a traditional justice cup structure is adopted, the practicability, interestingness and artistry of the justice cup are integrated, the shape is unique, and the production process is simple.

Owner:福建省德化县唐丰陶瓷有限公司

Manufacturing method of low-temperature colorful gulch-gold decal paper and manufacturing process with decal paper products

ActiveCN106274105ALower firing temperatureEasy to useSpecial paperSynthetic resin layered productsSocial benefitsRadiance

The invention relates to the technical field of low-temperature decal paper, in particular to a manufacturing method of low-temperature colorful gulch-gold decal paper and a manufacturing process with decal paper products. PVC serves as a raw material, and the manufacturing method of the low-temperature colorful gulch-gold decal paper includes the steps of dyeing, smashing, paste manufacturing, printing, film sealing and the like. The decal paper manufactured through the manufacturing method of the low-temperature colorful gulch-gold decal paper can achieve a gulch-gold effect on a base body, and multiple colors are mixed on the surface of the decal paper; due to the fact that part of particles have metallic luster and can achieve a metal reflecting effect and the reflecting effect of the particles has multiple angles, the surface of the decal paper seems like gulch gold, starry radiance glitters, and a special decoration effect is achieved for the base body. The low-temperature colorful gulch-gold decal paper is wide in application range, can be suitable for multiple base bodies and safe in use, and has a special artistic effect; the adopted materials are environmentally friendly, and the low-temperature colorful gulch-gold decal paper is low in firing temperature, can effectively save energy, and has positive economic and social benefits.

Owner:德化县新佳兴印刷有限公司

Cooper mural production method

InactiveCN103317948AThe picture is harmonious and unifiedUnique artistic effectSpecial ornamental structuresCopper foilWood plank

The present invention discloses a cooper mural production method, which comprises the following steps: S1, pressing a mural pattern on one surface of a wood plate; S2, padding copper foil on the wood plate surface pressed with the mural pattern, and beating the copper foil until the mural pattern completely appears on the copper foil; S3, liquefying a filler, and pouring the filler onto the back surface of the copper foil obtained in the step S2 to fill; S4, adhering a metal or a non-metal liner plate on the back surface of the copper foil; and S5, carrying out a polishing treatment on the cooper foil surface pressed with the mural pattern. According to the cooper mural production method, production of the pattern on the thin cooper foil, filling on the back surface of the cooper foil, liner plate adding, the polishing treatment on the cooper foil surface and other process steps are performed to produce the relief printing mural, the picture is harmony and united, an artistic effect is unique, characteristics of robustness and durability are provided, a new approach adopting a handicraft product as a building material is developed, and people life is enriched.

Owner:阚曙彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com