Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1595results about How to "Corrosion resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

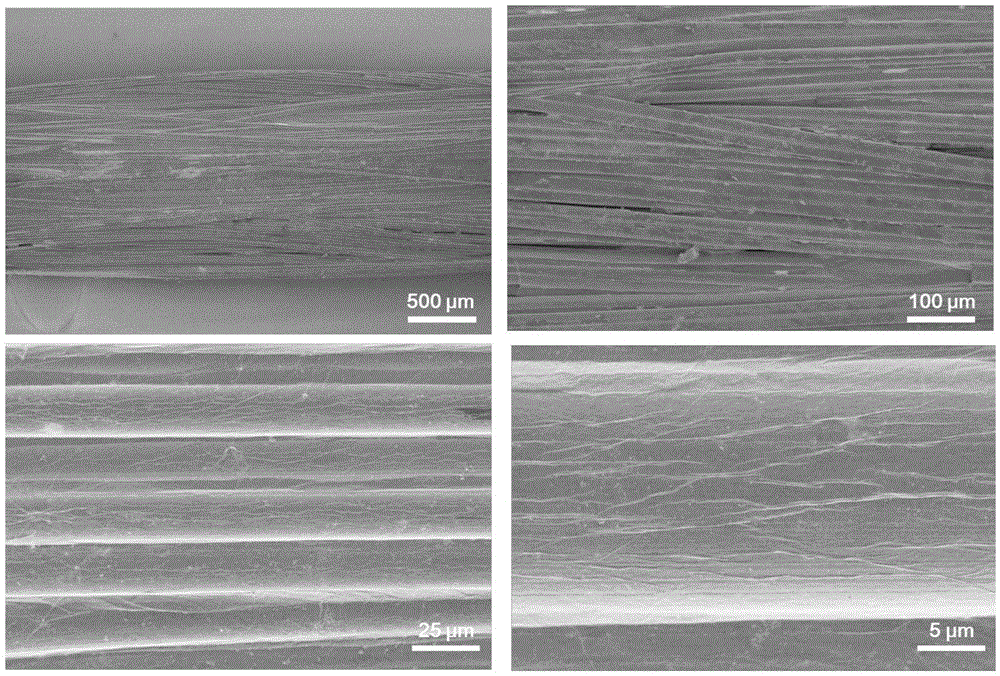

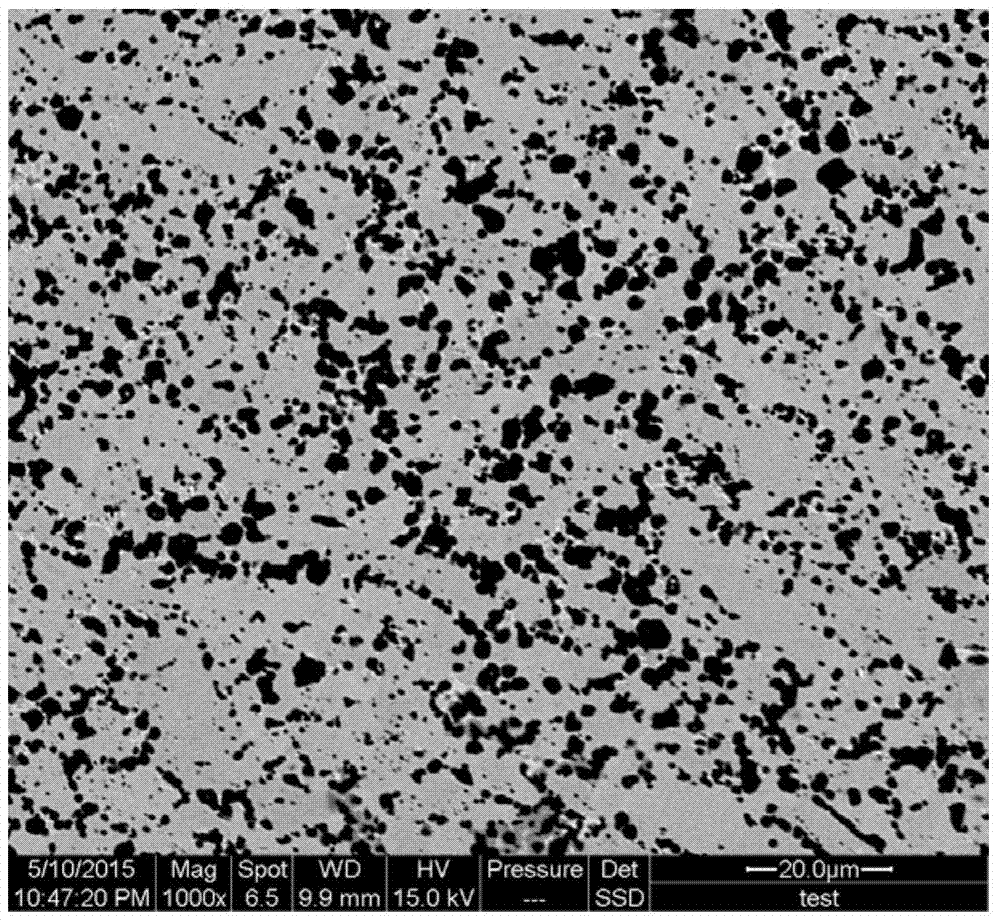

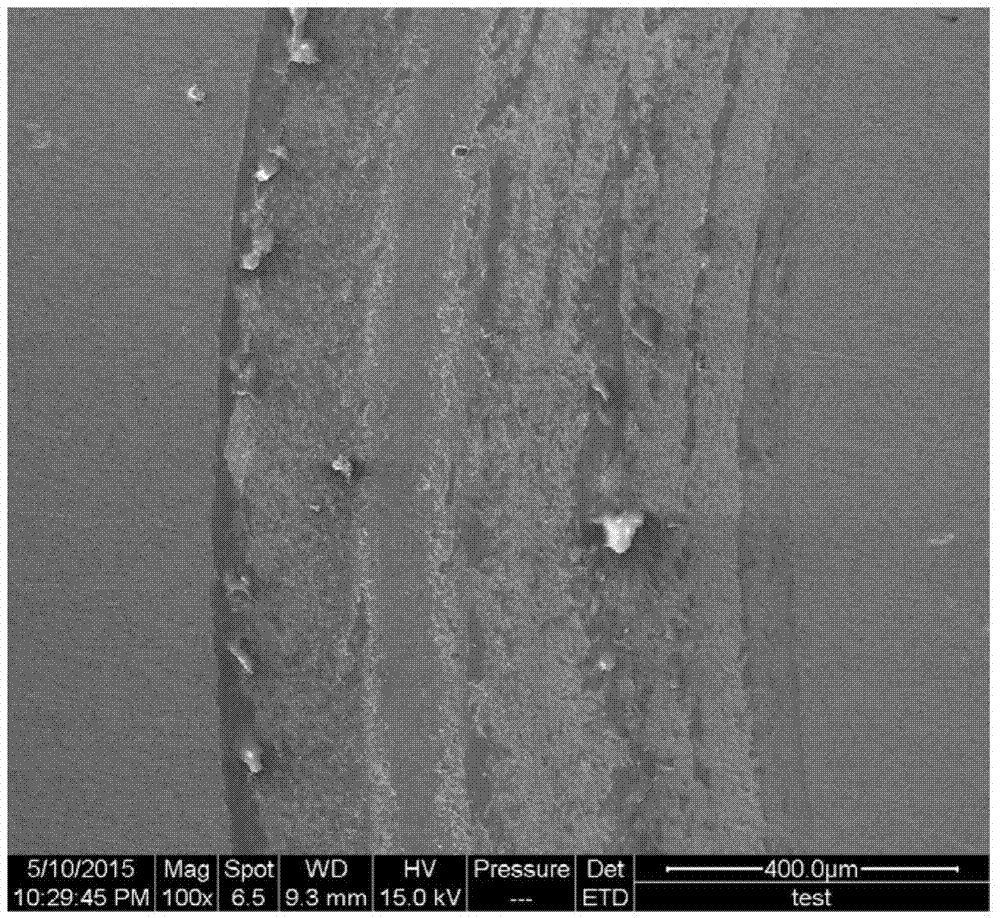

Preparation method of graphene composite conductive fiber

The invention discloses a preparation method of a graphene composite conductive fiber and relates to the technical field of graphene. The method comprises the following steps: processing a common textile polymer fiber with an organic solvent to remove impurities such as an oiling agent on the fiber surface; dipping the textile polymer fiber into an alkali liquor and an oxidized graphene solution, and enabling the fiber surface to fully contact the oxidized graphene; and dipping the dried fiber with an oxidized graphene coating into a solution containing a reducing agent to obtain the graphene composite conductive fiber. By adopting a simple dip coating method, the obtained composite fiber has mechanical property, high temperature resistance and flexibility performance of a traditional high polymer material and also has good conductivity. The method is easy to operate, environment-friendly and convenient to industrialize.

Owner:宁国市龙晟柔性储能材料科技有限公司

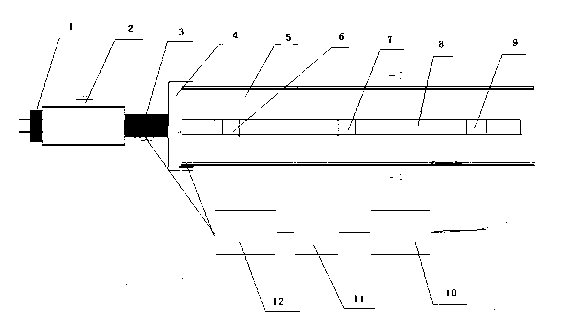

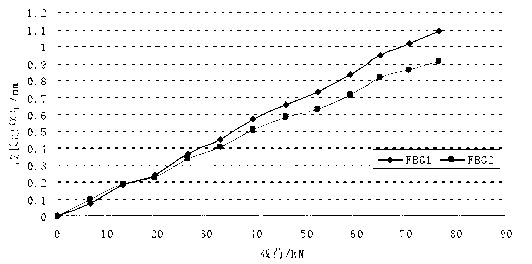

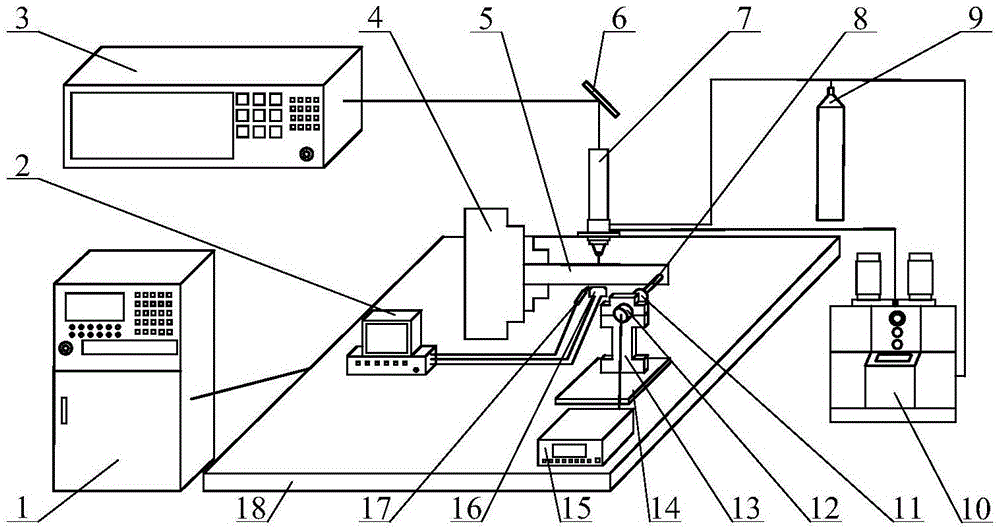

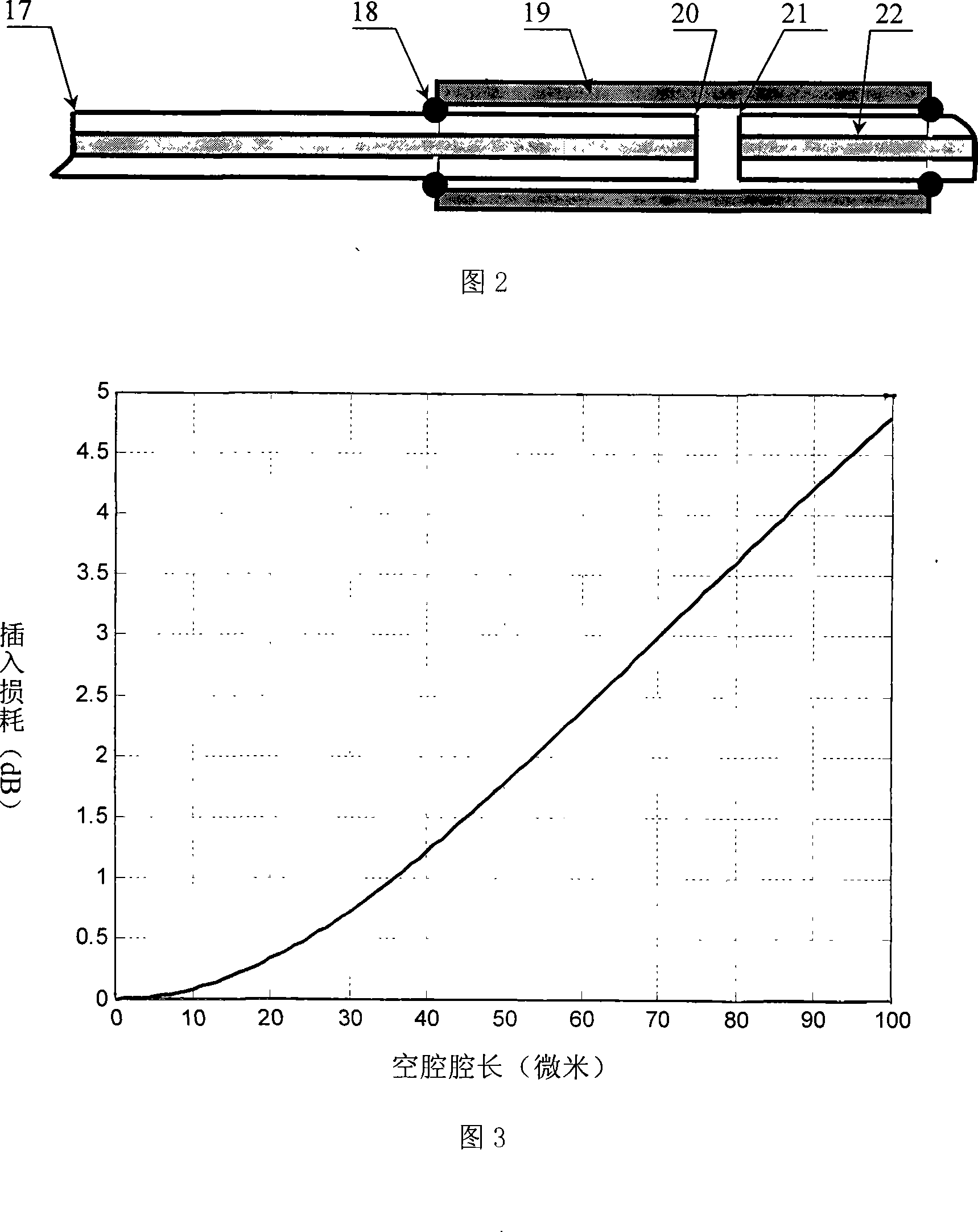

Fiber bragg grating detection system device and method for detecting anchoring force of anchor rod

InactiveCN102798492AEliminate strain effectsHigh precisionForce measurement by measuring optical property variationSensor arrayFiber

The invention discloses a fiber bragg grating detection system device and method for detecting an anchoring force of an anchor rod. The fiber bragg grating detection system device consists of a fiber bragg grating sensor array, a fiber bragg grating anchor rod dynamometer, a fiber bragg grating demodulator, an optical cable and a computer, wherein the fiber bragg grating anchor rod dynamometer mainly comprises a plurality of fiber bragg grating sensors which are uniformly arranged on an annular elastic body arm and is arranged at the end part of the anchoring end of the anchor rod; meanwhile, the fiber bragg grating sensor array is distributed on a rod body of the anchor rod; the fiber bragg grating sensor array and the fiber bragg grating anchor rod dynamometer are respectively connected with the fiber bragg grating demodulator through the optical cable; and the fiber bragg grating demodulator is connected with the computer. According to the fiber bragg grating detection system device, the real-time detection on the stress of the anchor rod can be realized and the distributed measurement can be realized. The fiber bragg grating detection system device has the advantages of simple structure, convenience in mounting, high detection speed, long-distance monitoring, repeated use and easiness in protection and maintenance, and is widely applied to tunnels and slopes dug for coal mines, metallurgical mines, water conservancy, railways, roads and defense.

Owner:XIAN UNIV OF SCI & TECH

Manufacturing method of ecological fire preventing and heat insulating building material

InactiveCN101618567AImprove insulation effectImprove insulation performanceMixing operation control apparatusCeramic shaping apparatusFiberExpanded clay aggregate

Owner:王建国

High-strength nickel-chromium-silicon-copper alloy material and processing technology thereof

The invention relates to a copper alloy material and a processing technology thereof, in particular to a high-strength nickel-chromium-silicon-copper alloy material and a processing technology thereof. The alloy material has low toxicity and low cost. The alloy material comprises the following components by mass: 2.1-2.9% of Ni, 0.4-0.7% of Cr, 0.3-0.7% of Si, not more than 0.3% of total impurities and the balance of Cu. The processing technology comprises the steps of casting, press processing, high-temperature solution hardening and heat treatment, cold press processing, aging heat treatment and mechanical processing.

Owner:SHENYANG XINGGONG COPPER IND

Method for producing ceramic tile by metallurgical steel slag

The invention discloses a method for producing a ceramic brick by metallurgical steel slag, which comprises the following steps: crushing waste slag after metallurgical steel-making; adding clay, talc, quartz and other materials to the waste slag according to the requirement of formulation property to mold a blank by a dry pressing method through ball milling by a wet method, and powdering by slurry spraying; drying and placing the molded blank into a roller kiln for maturing; and producing the matured product into a finished product through edging, polishing, grading and packaging. The invention can be widely applied in decoration, has the characteristics of environmental production, high strength, corrosion resistance, good decoration effect and so on. The method provided by the invention is simple and feasible, and is beneficial to industrial production.

Owner:GUANGXI OCEANO CERAMICS CO LTD

Thermostable heat-isolating coating and its preparation method

The invention discloses a high-temperature proof insulating paint and making method, which comprises the following parts: 400-500g organic silica resin, 50-100g thermostable dye, 100-200g fill, 80-150 hollow ceramic microball, 30-60g bergmeal, 20-50g potassium titanate whisker, 100-150g solvent and 5-15g adjuvant.

Owner:北京国邦技术发展中心

Method for preparing three-dimensional porous graphene material by solution

InactiveCN102701188AMass production availableAvailable for mass productionGrapheneStretchable electronicsPorous graphene

The invention discloses a method for preparing a three-dimensional porous graphene material by solution. The method comprises the following steps of: immersing a three-dimensional porous template into a graphene oxide solution, and then depositing the graphene oxide on the template to realize three-dimensional assembling of the graphene oxide on the template, and then preparing the three-dimensional porous graphene material containing the template by reduction; removing the template from the three-dimensional porous graphene material containing the template, and then washing to obtain the three-dimensional porous graphene material. The aperture of the three-dimensional porous graphene material can be regulated and controlled by using the templates with different apertures the material prepared by the invention has the advantages of low density, high specific surface area, high heat conductivity, high-temperature resistance, and corrosion resistance; the preparation method is economical and simple and suitable for large-scale production. And the prepared material is applicable to aspects such as catalytic carriers, preparation of flexible conductors, and stretchable electronics.

Owner:HUAZHONG UNIV OF SCI & TECH

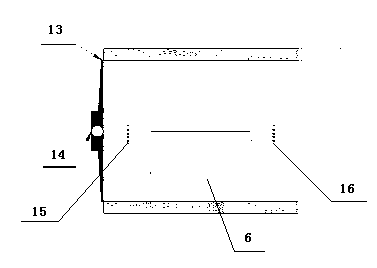

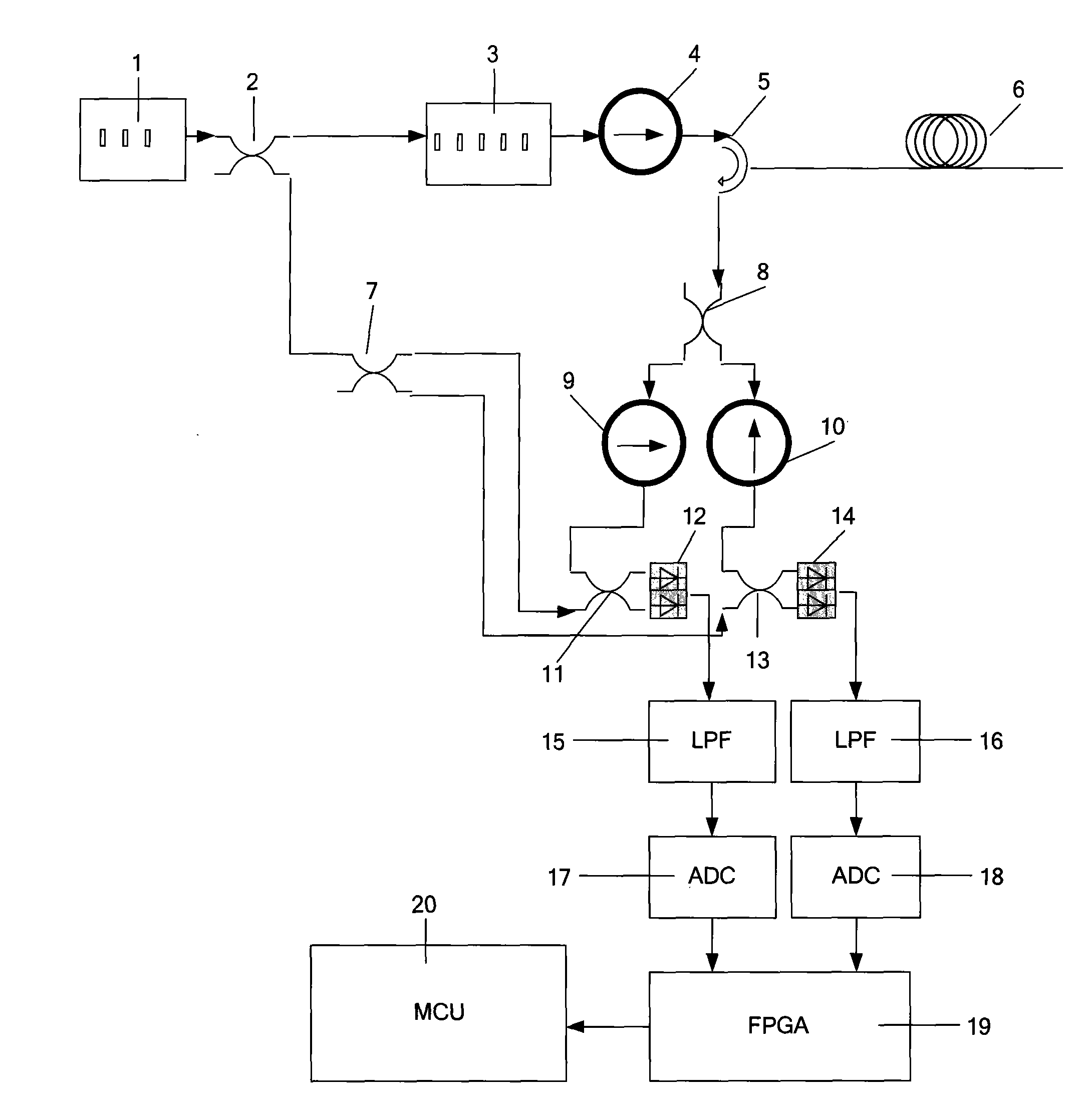

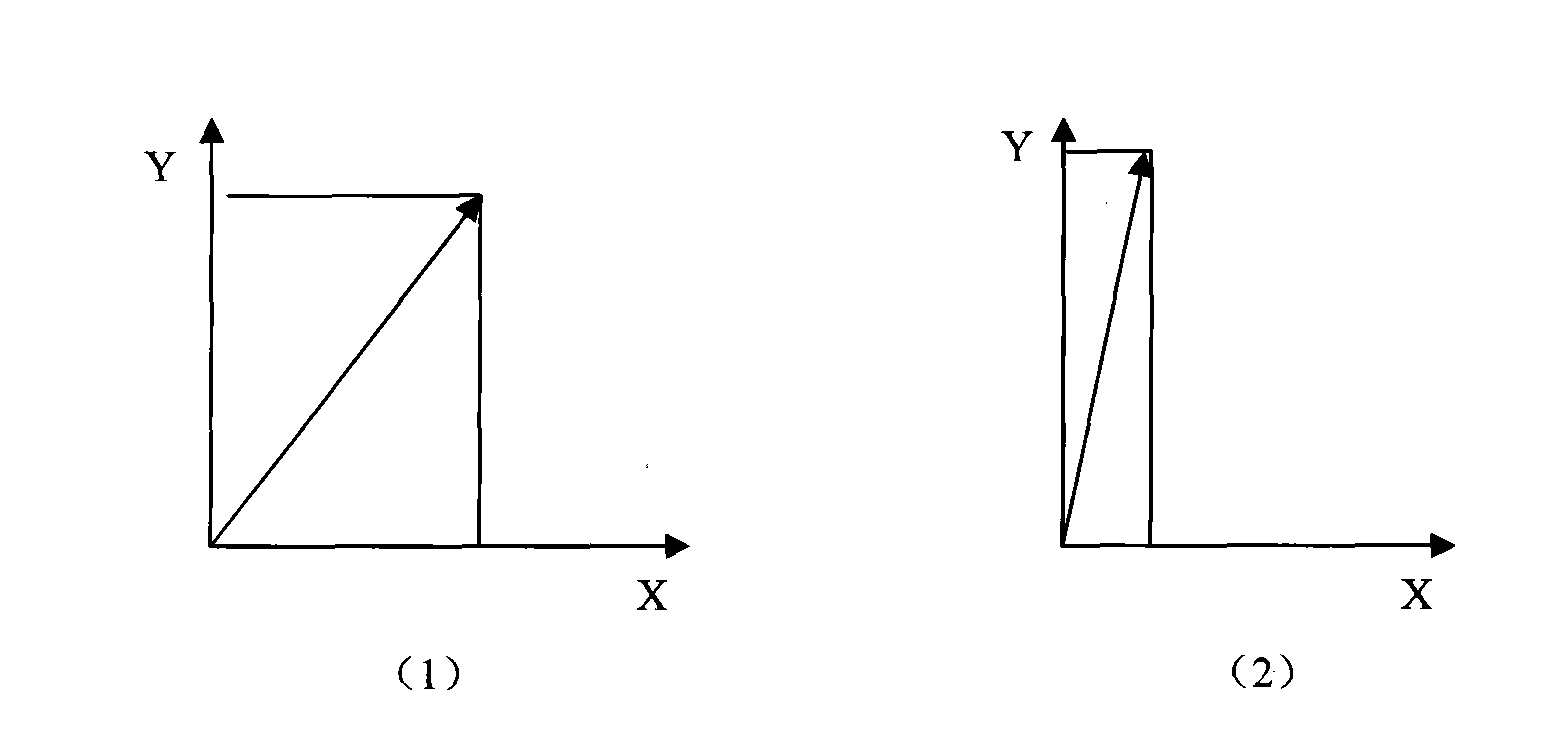

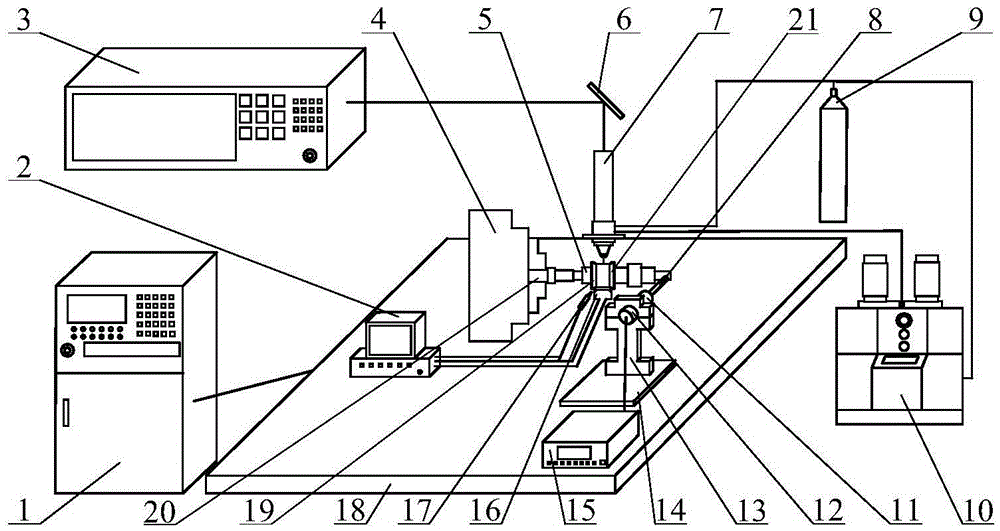

Vibration monitoring structure and method based on optical fiber polarized light time domain reflection sense

InactiveCN101639379AWith anti-electromagnetic interferenceCorrosion resistantSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFrequency spectrumLow-pass filter

The invention relates to a vibration monitoring structure based on optical fiber polarized light time domain reflection sense, comprising a laser (1), a first coupler (2), a second coupler (7), a third coupler (8), a fourth coupler (11), a fifth coupler (13), an acoustic optical modulator (3), a polarizer (4), a circulator (5), a sensing optical fiber (6), a first analyzer (9), a second analyzer (10), a first detector (12), a second detector (14), a first low-pass filter (15), a second low-pass filter (16), a first analog-to-digital converter (17), a second analog-to-digital converter (18), anFPGA (19) and a microprocessor MCU (20); the method comprises the following steps: measuring the changes of the polarization state of each optical fiber section with time according to a plurality ofmeasurements, combining Fourier transformation technology to obtain frequency spectrum information, and analyzing the frequency spectrum information to obtain vibration information. Compared with theprevious method which is adopted by a POTDR system and carries out iteration operation on polarization state, the method has the advantages of simple algorithm and small data operation and greatly reduces monitoring time and cost of the system.

Owner:NANJING UNIV

High-entropy alloy powder for 3D (three-dimensional) printing and method for preparing high-entropy alloy coating by using high-entropy alloy powder

ActiveCN104841930AImprove performanceScientifically optimize the ratioIncreasing energy efficiencySelective laser sinteringHigh entropy alloys

The invention provides high-entropy alloy powder for 3D (three-dimensional) printing and a method for preparing a high-entropy alloy coating by using the high-entropy alloy powder, and belongs to the technical field of coating preparation. By the high-entropy alloy powder, the wear resistance of the existing powder materials for 3D printing is improved. The high-entropy alloy powder is prepared by using the following ingredients in atomic percentage by weight: 16%-25% of Ni, 16%-25% of Co, 16%-25% of Cr, 16%-25% of Ti and 16%-25% of V. The preparation method comprises the following steps of (1) performing ball-mill mixing on raw materials to obtain mixed powder; (2) grinding and cleaning a matrix; and (3) placing the mixed powder in a powder feeder of 3D printing equipment and sintering the mixed powder on the surface of the matrix to form the high-entropy alloy coating by using selective laser. The NiCoCrTiV coating is prepared by selective laser sintering and has the advantages of high hardness, wear resistance, corrosion resistance and the like. The high-entropy alloy powder for 3D printing and the method for preparing the high-entropy alloy coating by using the high-entropy alloy powder can be widely used in the field of 3D printing.

Owner:HARBIN ENG UNIV

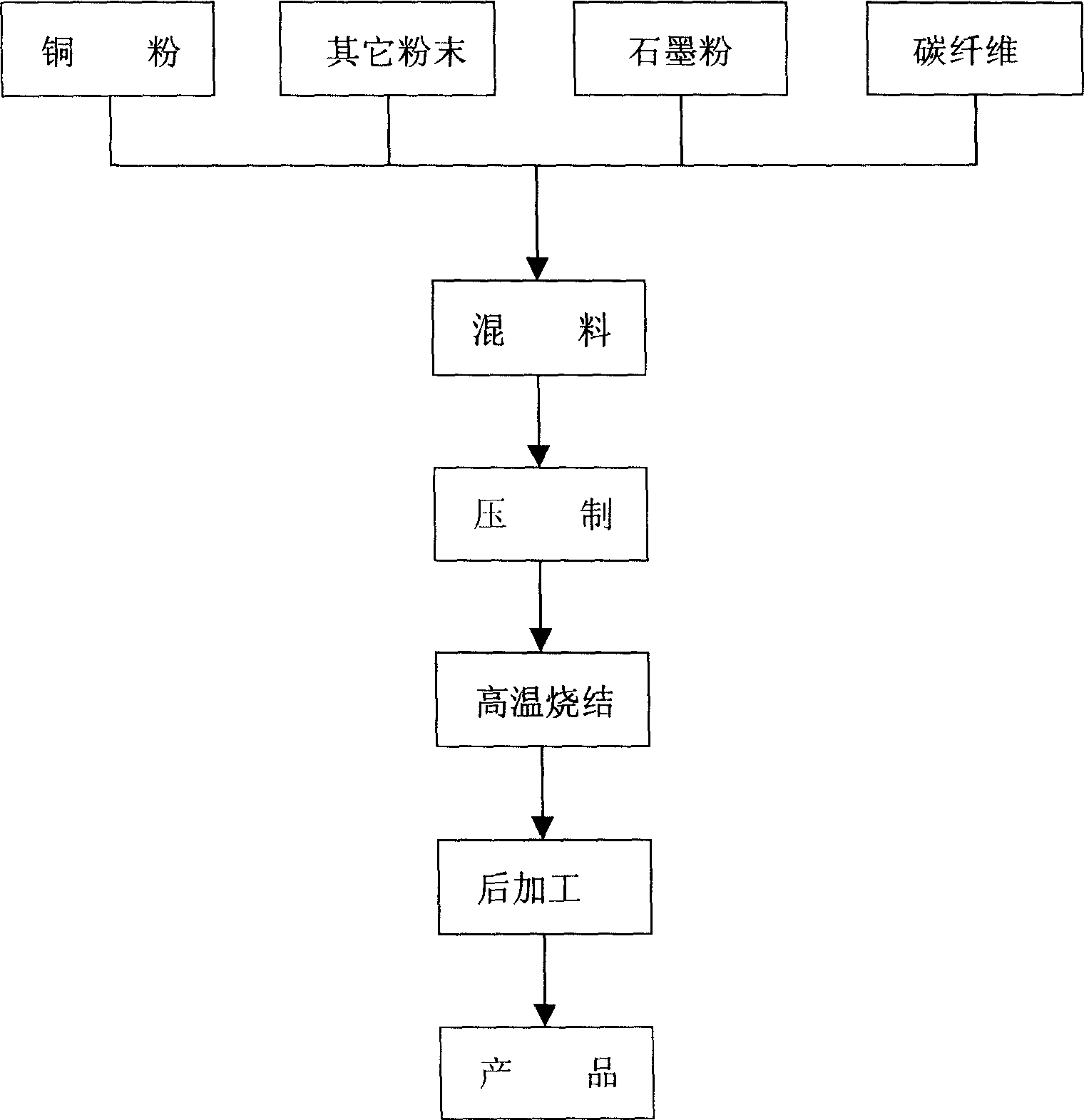

Leadless copper base high temperature self lubricating composite material

InactiveCN1718795AImprove toughnessImprove heat resistanceChemical vapor deposition coatingChemical compositionGraphite

A high-temp self-lubricating non-Pb Cu-base composition has a chemical formula: Ni+C+Sn+Zn+MX+Fe+Cu, where MX is chosen from BN, Si3N4, SiC, Al2O3, TiN, TiC and Cr3 C2 and C is graphite and carbon fibres. It has anti-oxidizing, anti-corrosion and high-temp anti-wear characteristics.

Owner:合肥波林新材料股份有限公司

Inorganic nonmetal composite wave-absorbing material containing graphene nano layer as well as preparation method and application thereof

InactiveCN101823881AHigh temperature resistantCorrosion resistantTemperature resistanceHot isostatic pressing

The invention relates to an inorganic nonmetal composite wave-absorbing material containing a graphene nano layer as well as a preparation method and application thereof. The material comprises the graphene nano layer and inorganic nonmetal, wherein the voltage of the graphene nano layer is 0.1-50 percent of that of the entire inorganic nonmetal composite wave-absorbing material. The preparation method comprises the following steps of: (1) mixing the graphene nano layer and the inorganic nonmetal; and (2) sintering mixed powder of the graphene nano layer and the inorganic nonmetal in as the way of normal pressure, hot pressing, hot isostatic pressing or discharge plasmas, and the like. The material has the characteristics of high temperature resistance, corrosion resistance and good wave absorption performance and improves the wave absorption effect while reducing surface reflection; and the preparation method is simple and suitable for industrialized production.

Owner:DONGHUA UNIV

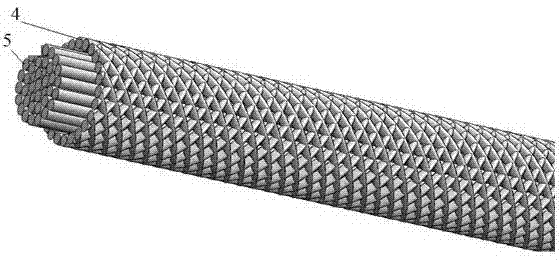

Novel graphite composite grounding material and preparation method thereof

ActiveCN103490180ASolving Corrosion ProblemsIncrease contact areaContact member manufacturingConnection contact member materialYarnCorrosion resistant

The invention discloses a novel graphite composite grounding material and a preparation method thereof. The novel graphite composite grounding material is in the shape of a rope or stranded wire, and comprises a composite graphite yarn inner core and a composite graphite yarn knitted layer wrapped outside the composite graphite yarn inner core, wherein the composite graphite yarn inner core is a composite graphite yarn bundle composed of a plurality of first composite graphite yarns or a single first composite graphite yarn; each first composite graphite yarn is prepared by twisting a first composite graphite belt; the composite graphite yarn knitted layer is prepared by knitting a second composite graphite yarn; and the second composite graphite yarn is prepared by twisting a second composite graphite belt. The graphite composite grounding material disclosed by the invention has the advantages of corrosion resistance, favorable conductivity, high flexibility, low price, precise soil association and the like, and is easy for transportation; since the price is low, artificial theft destroy can be avoided; and the graphite composite grounding material is suitable for the fields of transformer stations, overhead transmission line towers, tall buildings and all other projects in need of electric grounding.

Owner:WUHAN HONGMEN ELECTRICAL TECH CO LTD

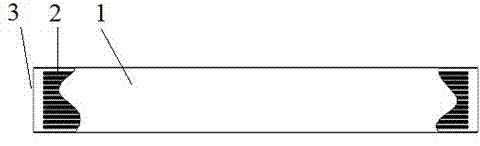

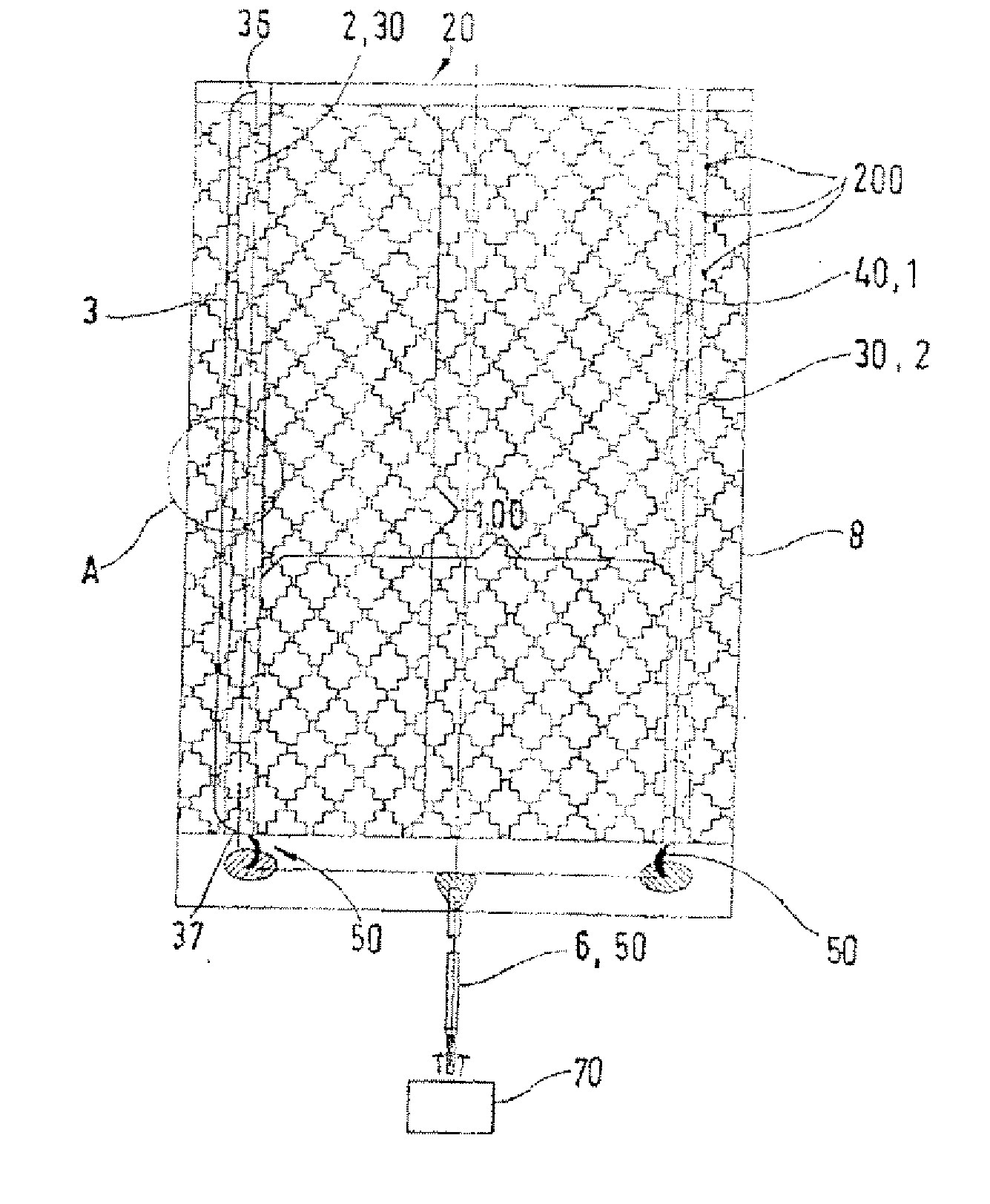

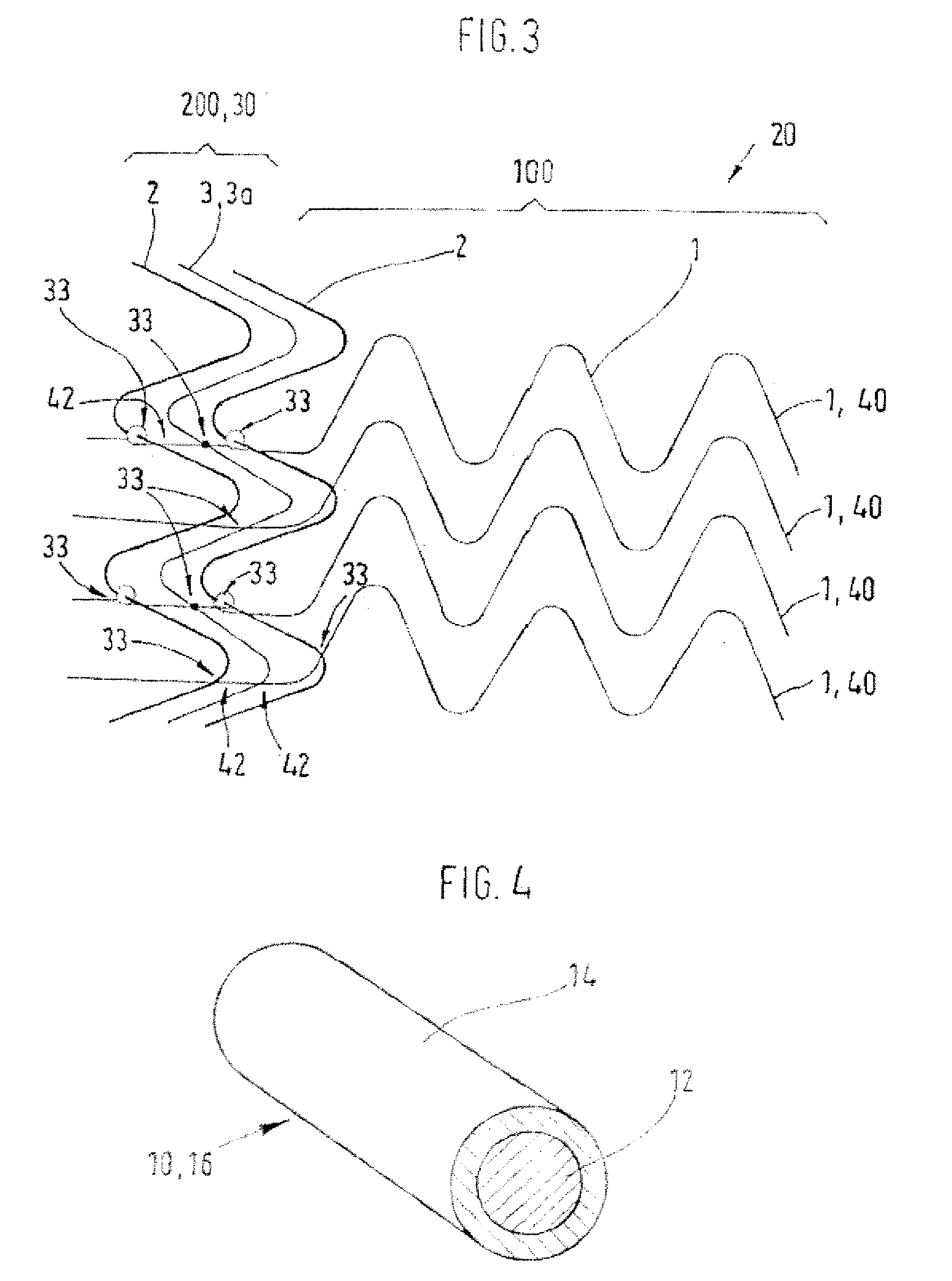

Flat Heating Element

InactiveUS20070278214A1Corrosion-resistantSecure against failure and resistantHeater elementsTransparent/reflecting heating arrangementsElectrical conductorLocal failure

The invention relates to a heating element (20), in particular for heating user contact surfaces of a passenger compartment of a vehicle, comprising at least one heating area (100) wherein at least one electric conductor strand (1), which is used to heat, is arranged, at least one additional conductor strand (2) which is used to feed electric energy into at least one conductor strand (1) which is used to heat the heating area (100), at least one contact area (200) wherein the conductor strand (2), which is used to feed electric energy, is connected in an electrically conductive manner to the at least one conductor strand (1) which is used to heat the heating area (100). According to the invention, at least one additional conductor (3) which forms at least one part of an electrically bridging line which bridges the failure point on a failure point during local failures of at least one of the conductor strands (1, 2), is provided.

Owner:GENTHERM GMBH

Biological protein hair fiber preparation method by dissolving animal hair and cellulose material mixture

InactiveCN1884642AReduce lossesReduce direct lossesConjugated cellulose/protein artificial filamentsCelluloseAdjuvant

The invention discloses a biological protein wool fiber preparing method, which comprises the following steps: blending animal fur and fiber to produce soluble liquid in the ion liquid with positive and negative ion of fusing condition at 100 deg.c and positive ion to form salt; solidifying in the water, carbinol, alcohol, cyanoethyl or (NH4)2SO4 solution; adding adjuvant in the soluble liquid; solidifying in the water, carbinol, alcohol, cyanoethyl or 30 percent (NH4)2SO4 solution; evolving biological protein fur fiber.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for manufacturing aluminium alloy sheet for automobile fuel tank

ActiveCN104294113AStable mechanical propertiesPrecise dimensional tolerancesFuel tankEconomic benefits

The invention provides a method for manufacturing an aluminium alloy sheet for an automobile fuel tank. The method comprises the steps of batching, smelting, refining, grain refining, degassing, filtering, casting, saw-cutting, milling, homogenized heating, hot-rolling, cold-rolling, cleaning, low-temperature stabilized annealing, transverse shearing, edge straightening, board cutting, inspecting and the like. The aluminium alloy sheet for the automobile fuel tank has the advantages of stable mechanical property, precise dimensional tolerance, finish surface and the like. Compared with the present plastic fuel tank, the automobile fuel tank manufactured by the aluminium alloy sheet produced by the method has the advantages of high strength, sun exposure resistance, aging resistance, breakage prevention, environmental protection and the like, and also has the advantages of corrosion resistance, rusting avoidance, light weight, good economic benefits within the product life cycle, high material reutilization ratio and the like in comparison with a copper fuel tank.

Owner:DALISHEN ALUMINUM

Gradient wear-resistant coating and method for preparing same

ActiveCN105543839AImprove wear resistanceHigh temperature resistantSuperimposed coating processWear resistantUltrasonic oscillation

Provided are a gradient wear-resistant coating and a method for preparing the same. Co50+0.15% CeO2 powder, Co50+0.25% CeO2+6% Ni / Wc powder and Co50+0.4% CeO2+12% Ni / WC powder are used for preparing the gradient wear-resistant coating with the structure of a bottom layer, a transition layer and a wear-resistant layer on the surface of a workpiece in a coaxial powder supply manner and a laser cladding manner, and the wear resisting performance of the work surface of a part is improved. An ultrasonic vibration device and a contour tracing electromagnetic induction heating device are adopted in the cladding process. Ultrasonic oscillation of a certain degree is applied to the area close to a cladded area of the workpiece, the grain size of a cladding layer can be remarkably refined, residual stress can be remarkably eliminated, and therefore generated cracks are reduced, and a cladding layer structure with good performance is obtained. The contour tracing electromagnetic induction heating device can be utilized for effectively reducing thermal stress brought by the temperature gradient of the cladding layer and relieving the cracking tendency. According to the technological parameters of the ultrasonic vibration device, the work frequency ranges from 10 kHz to 20 kHz, the maximum output power is 1,000 W, and the pneumatic pressure ranges from 0.3 MPa to 0.6 MPa. According to the technological parameters of the contour tracing electromagnetic induction heating device, the voltage is 380 V, the frequency is 60 Hz, and the heating temperature ranges from 150 DEG C to 1,000 DEG C.

Owner:CHANGCHUN UNIV OF SCI & TECH

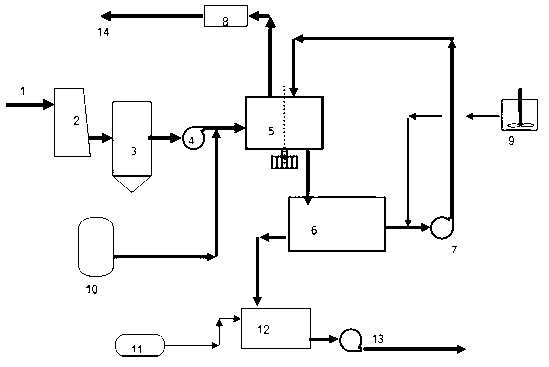

Flue gas dedusting and desulfurization and denitrification craft and special device thereof

The invention discloses a flue gas dedusting, desulfurization and denitrification craft and a special device of the flue gas dedusting, desulfurization and denitrification craft. A mixed glass fiber ceramic bag with double coatings or a polytetrafluoroethylene bag with the double coatings is utilized to dedust. An ultra-gravity bed or a static cyclone is used as an absorbing and washing reactor. A compulsory oxidation and alkali washing manner is adopted by a comprehensive flue gas processing craft for the desulfurization and the denitrification. A dirt catcher is high in dust removal rate, and is high-temperature resisting, and temperature fluctuation in a large scale is resisted. Ultra-fine powder can be removed. According to the ultra-gravity bed as the reactor, reaction and absorbing strength and absorbing efficiency can be greatly improved, and at the same time, size and investment of equipment can be greatly reduced. Modularization combined installation is achieved, occupied space is greatly reduced, and manufacture and installing procedure is easy, fast and convenient.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

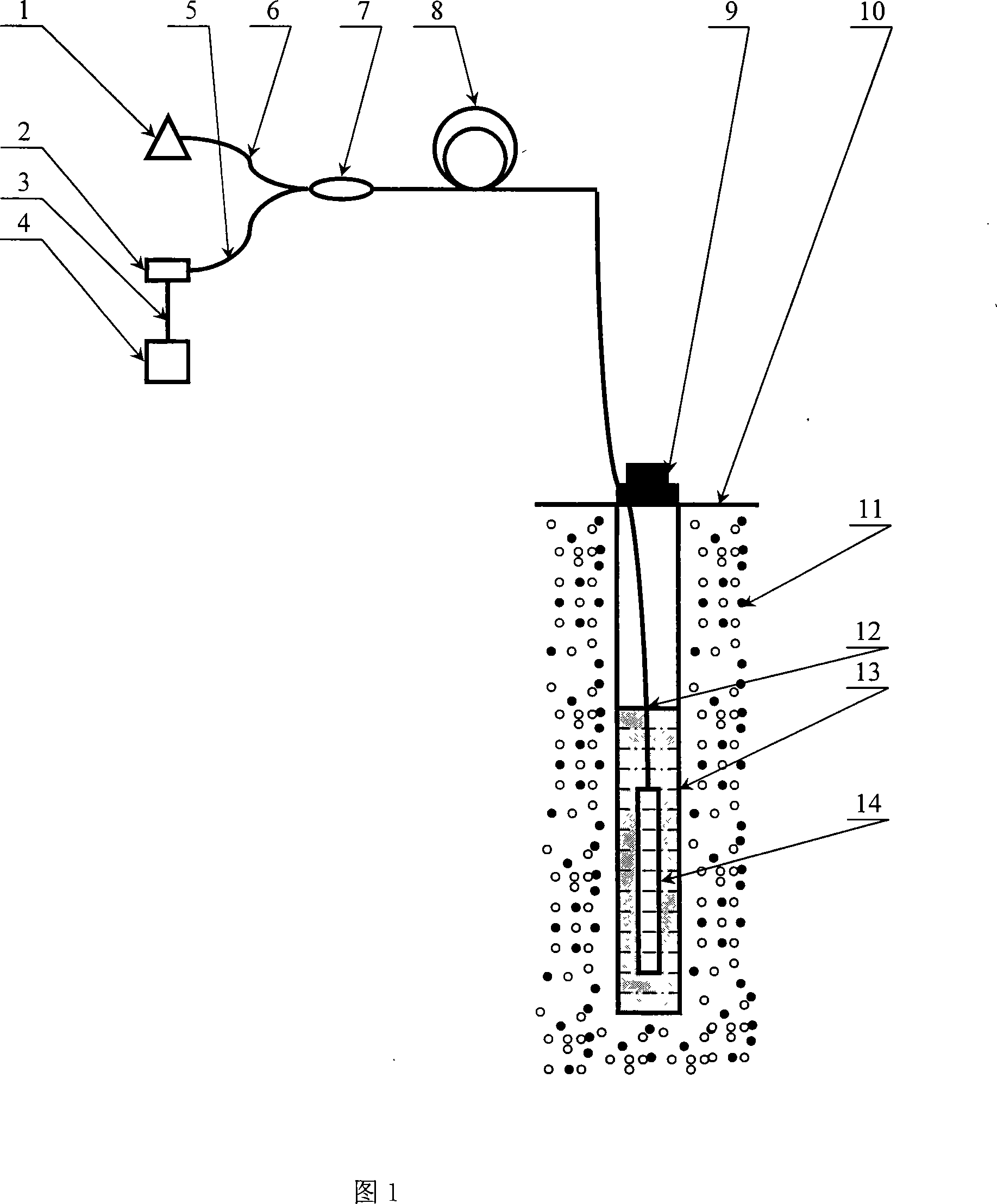

Optical fiber multi-point temperature and pressure measuring method for intelligent well and the device therefor

InactiveCN101187307ASolve stressSolve temperature problemsSurveyConstructionsGratingReflectance spectroscopy

The invention relates to a measuring method and a device for measuring optical fiber multipoint temperature and pressure of an intelligent well, belonging to the technical field of intelligent wells. The measuring method comprises that a plurality of optical fiber temperature sensors and optical fiber pressure sensors are arranged on an optical cable, wherein reversed lights which are reflected by the optical fiber temperature sensors and the optical fiber pressure sensors are respectively transformed into spectroscopic data which is transmitted to a processor, thereby respectively obtaining reflectance spectrums of all sensors, and a wave length value which is relative to the largest reflection rate is used as characteristic parameter of relative temperature sensors, the length of the cavity of each pressure sensor is calculated to be used as characteristic parameter of relative pressure sensors, and then the characteristic parameters of relative temperature and relative pressure sensors are compared with the characteristic parameter calibration curve to gain temperature reading or pressure reading of the optical fiber sensors. The device comprises a broad band light source, a modularized optical spectrometer, a data transmission line, a data processor, a first section optical fiber and a second section optical fiber, a optical fiber coupling, an optical cable, and a two-parameter sensor group of optical fiber temperature and optical fiber pressure. The invention solves the problems of pressure float and temperature crossfire when optical fiber grating technology is applied to a pressure sensor.

Owner:北京蔚蓝仕科技有限公司 +1

Carbon nano tube composite carbon crystal paint and method for preparing carbon crystal electric heating material from same

InactiveCN101914347AStrong far infrared radiationHigh electrothermal conversion efficiencyChemical industryPolyurea/polyurethane coatingsFiberCarbon fibers

The invention discloses a carbon nano tube composite carbon crystal paint and a method for preparing a carbon crystal electric heating material from the same, wherein the carbon crystal composite paint is prepared from carbon nano tubes, modified ball milling short carbon fibers, resin paints, infrared emission powder and the like; and the carbon crystal electric heating material is prepared by spraying or scratching the paint into a film on a planar template (paper base template, plastic template and the like), and compositing with an aging proof high molecular material to obtain the planar electric heating material. The carbon crystal composite paint and the carbon crystal electric heating material have strong far-infrared radiation, high electric heating conversion efficiency, small surface temperature difference, good corrosion resistance, weather resistance and aging resistance and high safety, can be compatible with concrete, can be used as a heating product for buildings, and can also be processed into various electric heating products, such as an electric heating plate, an electric heating carpet, a dry wardrobe, a foot warmer, a food warmer and the like.

Owner:龚亮 +1

Reinforced toughening flame-proof polyolefin resin composition and its preparation method

The invention discloses a flame-proof polyolefin resin component and preparing method in the resin flame resistant modifying domain, which comprises the following parts: a. 9-20% bromine fire retardant with decabran diphenyl ethane or octabromobium ether and heat-stability hexabromide cyclododecane with weight rate at 2: 1-1: 2, b. 3-8% synergic fire retardant with antimony trioxide, c. 3-12% melt resistant melt drip agent with one or more of organic montmorillonite, kaolin and clay.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

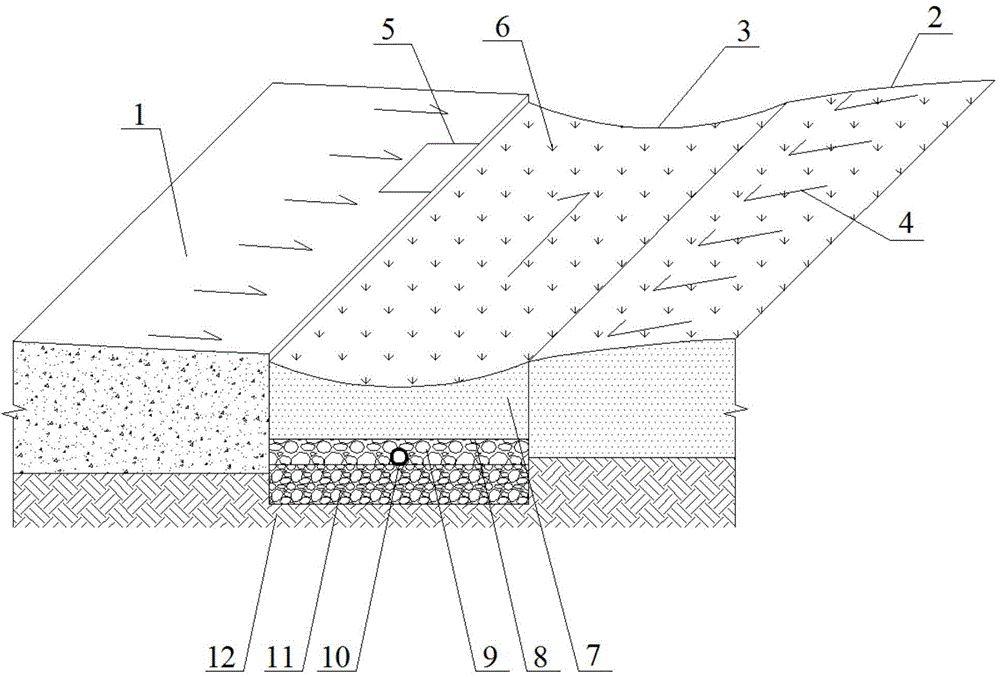

Ecological grass planting trench for cities with rich water resource

ActiveCN104313974AEasy to handleControl non-point source pollutionPaving gutters/kerbsSustainable biological treatmentVegetationRainfall runoff

The invention provides an ecological grass planting trench for cities with rich water resource, which is arranged on one side of a sidewalk road. The ecological grass planting trench sequentially comprises a vegetation layer, a planting soil layer, a building block brick layer, a water permeating and discharging pipe and a gravel layer from top to bottom. The ecological grass planting trench is arranged on one side of the sidewall road and used for collecting rainfall running water on the sidewall road, the pollutants in the running water can be reduced, and a purpose for locally purifying the running water and controlling the pollution of the running water can be achieved; the ecological grass planting trench is arranged between the sidewall road and a green land, so that not only is the landscape not influenced, but also convenience in construction can be realized; the rainfall running water is stopped in the gravel layer and gradually and slowly permeated, finally the water content of the soil of the green land is replenished, the rainfall running water can be completely absorbed and purified, and the water for irrigating the green land can be reduced; the lower end of the water permeating and discharging pipe is connected with a rainy water opening or a rainy water well, the other end of the water permeating and discharging pipe is closed, so that the collected rainfall running water on the sidewalk road can be collected into the rainy water opening or the rainy water well, and a purpose for reducing the rainfall running water and postponing the flood peak can be achieved.

Owner:SHANGHAI JIAO TONG UNIV

Low-cost environment-friendly water glass wood adhesive and preparation method thereof

ActiveCN102863906ARich sourcesLow priceNon-macromolecular adhesive additivesMacromolecular adhesive additivesEmulsionAdhesive

The invention discloses a low-cost environment-friendly water glass wood adhesive which comprises components of 100 parts of water glass with the mass percentage of 30-60%, 10-30 parts of a water-soluble polymer, 90-270 parts of deionized water, 10-50 parts of a high polymer emulsion, 1-5 parts of advanced fatty acid salt and 2-10 parts of an inorganic solidifying agent. Simultaneously, the invention further discloses a preparation method of the water glass wood adhesive. The preparation method includes heating the deionized water, slowly adding the deionized water to the water-soluble polymer, stirring the mixture to obtain a solution, adding the water glass to the solution, evenly stirring the solution to perform an aging reaction, adding the high polymer emulsion and the advanced fatty acid salt after the aging, and preserving heat after stirring at the temperature of 40-80 DEG C; and then cooling the mixture to the temperature of 30-60 DEG C, adding the inorganic solidifying agent, and evenly mixing the mixture to obtain the low-cost environment-friendly water glass wood adhesive. The water glass wood adhesive is stable in performance, simple and easy in preparation process and widely applicable to industrialization production.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Highly-oil-repellenting highly-waterproof seamless polytef expansion sheet materials and preparation method thereof

ActiveCN103158310AReduce weightCorrosion resistantSynthetic resin layered productsFlat articlesLubricationChemical stability

The invention belongs to the technical field of aerospace sealing materials, and particularly discloses highly-oil-repellenting highly-waterproof seamless polytef expansion sheet materials and a preparation method thereof. The preparation method comprises the following steps: mixing materials, performing, pushing and pressing, calendaring, drying, puffing, sizing, thermocompression bonding, surface chemical processing, and the like. The highly-oil-repellenting highly-waterproof seamless polytef expansion sheet materials which are prepared and obtained by the method have good chemical stability, electrical insulating property, and self-lubrication performance, overcome the cold flow property (creepage) of pure polytef sealing materials, cannot become hard or crisp ( good elasticity) with the time, can bear the temperature range of -65 DEG C - +177 DEG C, are applicable to flat seal of various shapes, and are indispensable and important materials in frontier science and modern industries.

Owner:HUZHOU SENNUO FLUORINE MATERIAL TECH

Silk-coating method for PVC/PU coating polyester industrial yarns and device thereof

The invention discloses a silk-coating method for PVC / PU coating polyester industrial yarns and a device thereof. The method comprises the following steps: using polyester industrial yarns as raw materials and a core layer structure; adopting a PVC-coating adhesive as a surface structure; dipping the polyester industrial yarns in the PVC-coating adhesive so that the adhesive is stuck to the silk;extruding the silk; scraping the adhesive; then, winding the silk in a spiral shape and baking; and drying, cooling the dried silk by cold air and coiling so that the coating adhesive is deeply permeated and coated on the core layer structure to form the silk of the coating polyester industrial yarns. The composite silk material has the advantages of high strength, good toughness, corrosion resistance, aging resistance, and the like. A melting point of PVC, PU or PE coating adhesive on the surface is lower than that of core-layer polyester yarns, woven fabrics in a stretching state are baked at high temperature or thermally rolled, shaped and processed, and warp yarns and weft yarns are melted and fused by the coating adhesive so that mesh fabrics are integrally smooth and stiff and meshesare uniform and stable.

Owner:绍兴顺金纺织窗材有限公司

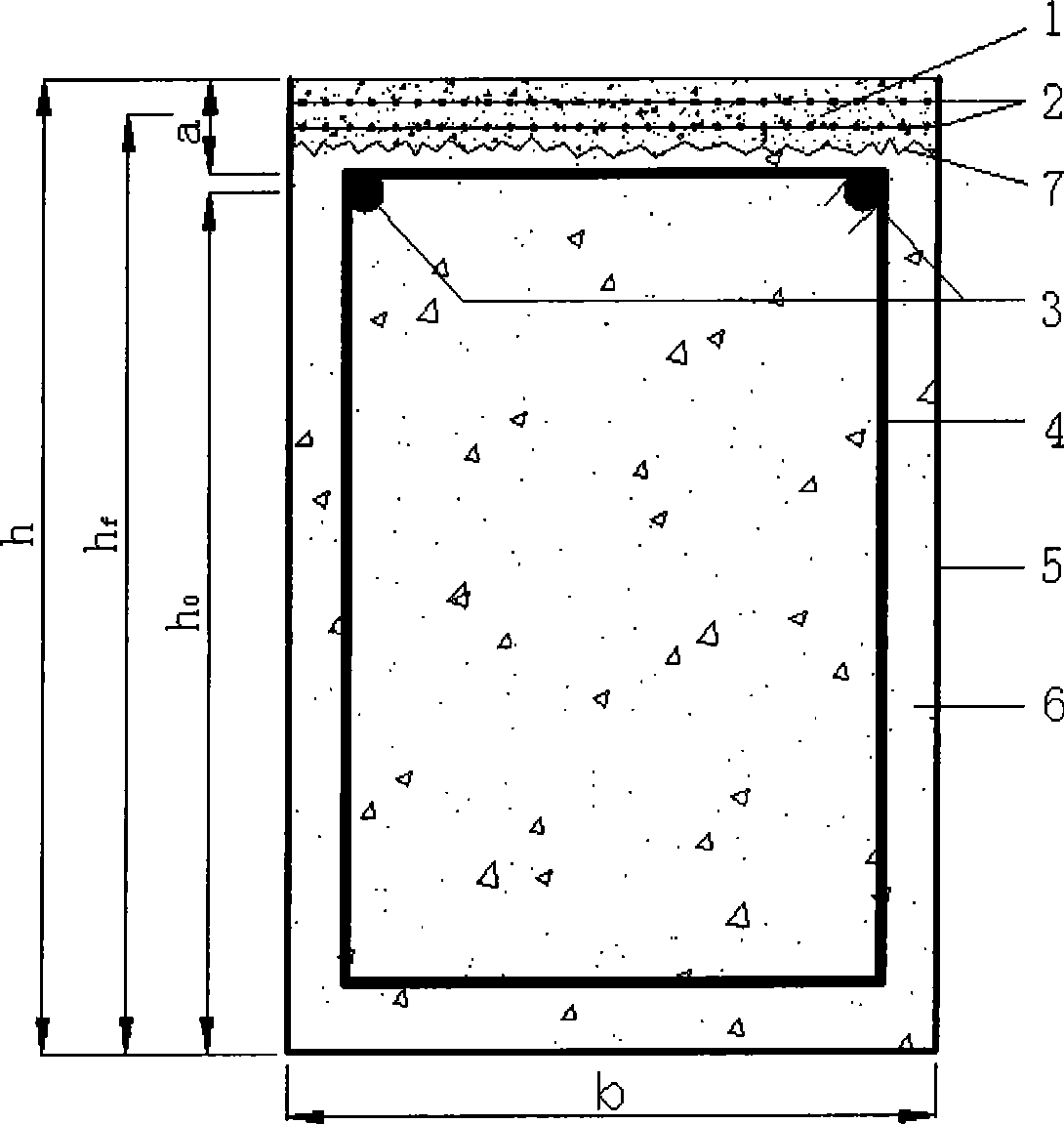

Construction structure for textile reinforced composite reinforced bar concrete and manufacturing method thereof

InactiveCN101481930AHigh strengthLimit or improve cracksSolid waste managementBuilding reinforcementsFiberRebar corrosion

The invention belongs to the technical field of concrete reinforcement, relating to utilizing fiber mesh grids to enhance the concrete strength. The arrangement of structural reinforcing steel, the thickness of concrete protective layers of main stress ribs and the grade of the concrete strength of the invention are designed according to the design criterion of a reinforced concrete structure. The invention is characterized in that before the initial setting of the concrete, fine concrete and the fiber mesh grids are cast on the outer side of the stretched and drawn area of the structure or the external surface of a large-scale integral structure, the total thickness of the fiber mesh grids and the fine concrete ranges from 10mm to 20mm, concrete with equal thickness of external surfaces are replaced, and the fiber mesh grids are evenly distributed in the fine concrete. The grid type or the plate type structure of the invention can adopt the structure of replacing partial reinforcing steel with the fiber mesh grids. The invention can effectively control cracks and solve the problems of concrete cracking and reinforcing steel corrosion, and has the advantages of firm bonding of the boundary surfaces of the fine concrete and the concrete, light self weight, low production cost, corrosion resistance, safe and durable usage, etc.

Owner:DALIAN UNIV OF TECH

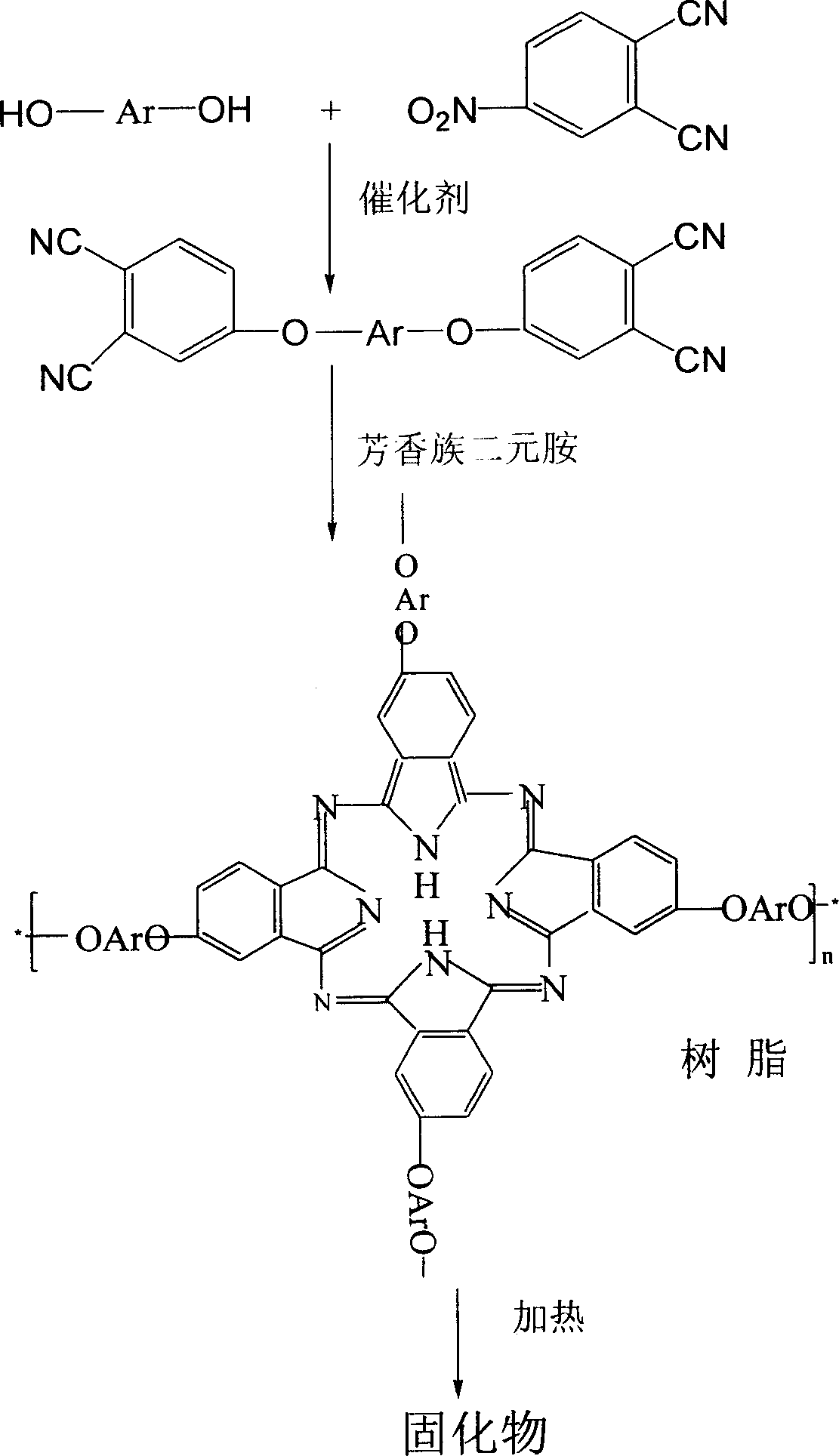

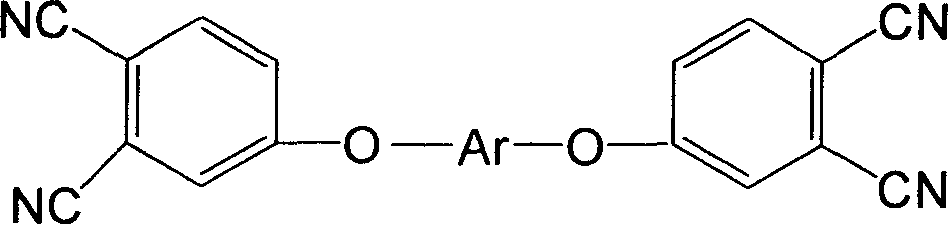

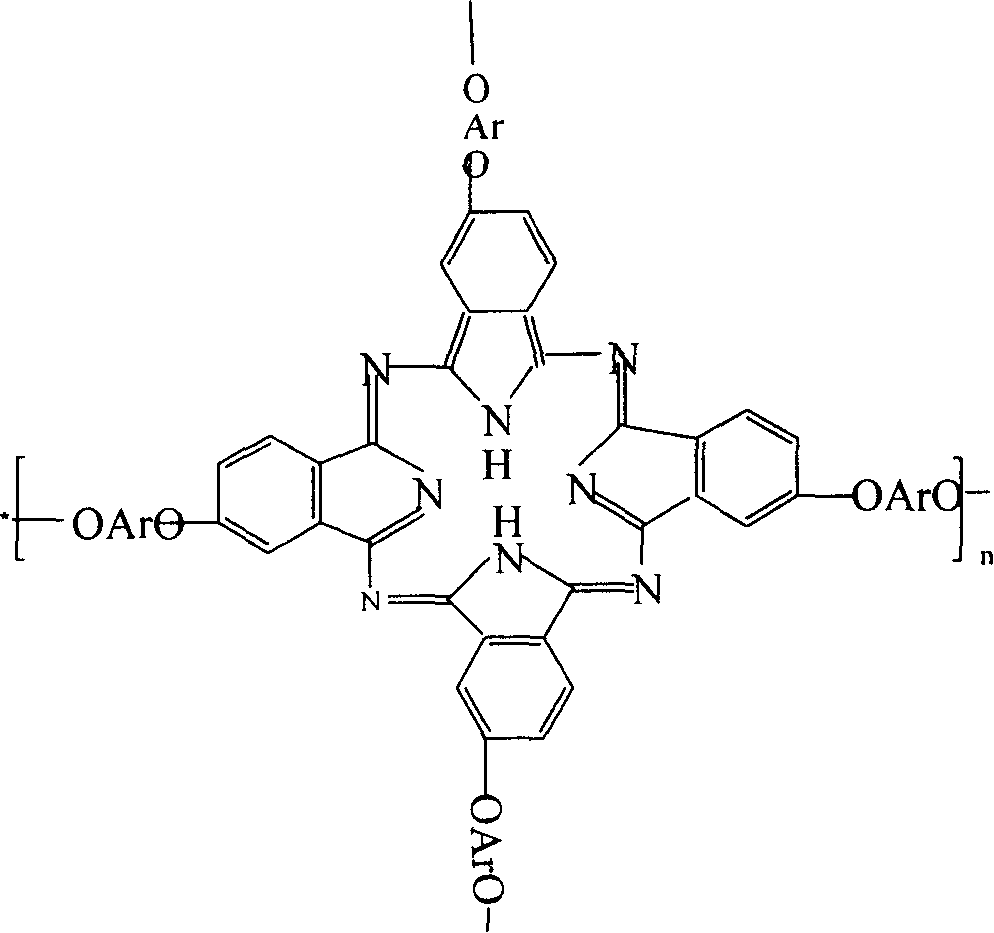

Double end-group phthalonitrile, resin, condensate and its preparation method and uses

ActiveCN1876615ARegulatory and Control StructuresTuning and Controlling PerformanceOrganic chemistryPolymer scienceEnd-group

The invention belongs to the high molecular synthetic material field. The invention relates the double-end phthalonitrile, resin, condensate, which are made by phthalonitrile, and preparing method. The invention uses 4-nitro-o-phthalonitrile and dihydric phenol as reaction integral to get double-end phthalonitrile. The double-end phthalonitrile and diamine are used to react in aromatic amine solution at 140-200Deg.C to get phthalonitrile resin which possesses phthalocyanine ring structure. The resin is cured at 220-280Deg.C, then carried out heat treatment at 320-370Deg.C to get phthalocyanine condensate which possesses high heat stability. The invention has the advantages of good heat stability and fire-retardancy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

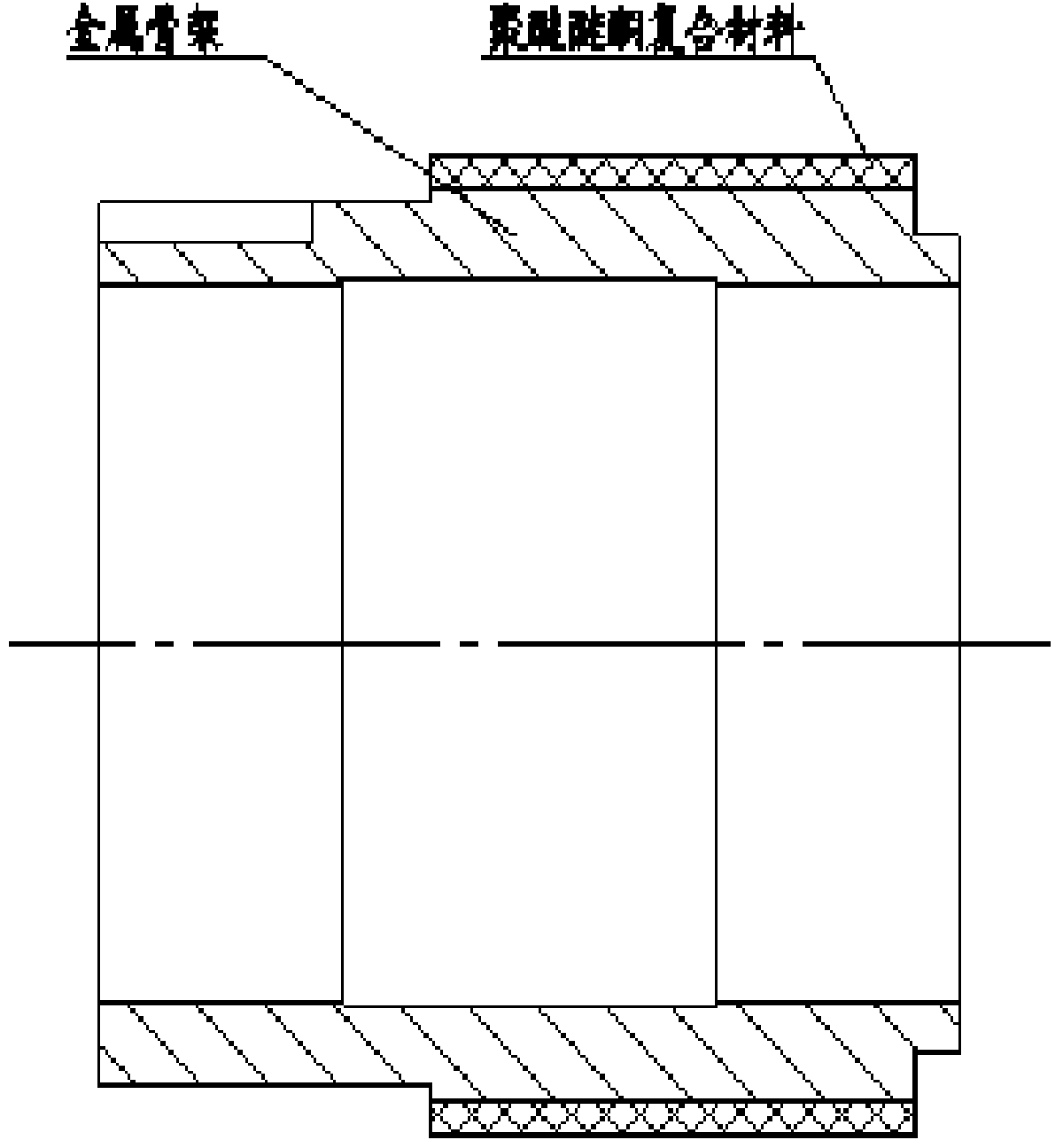

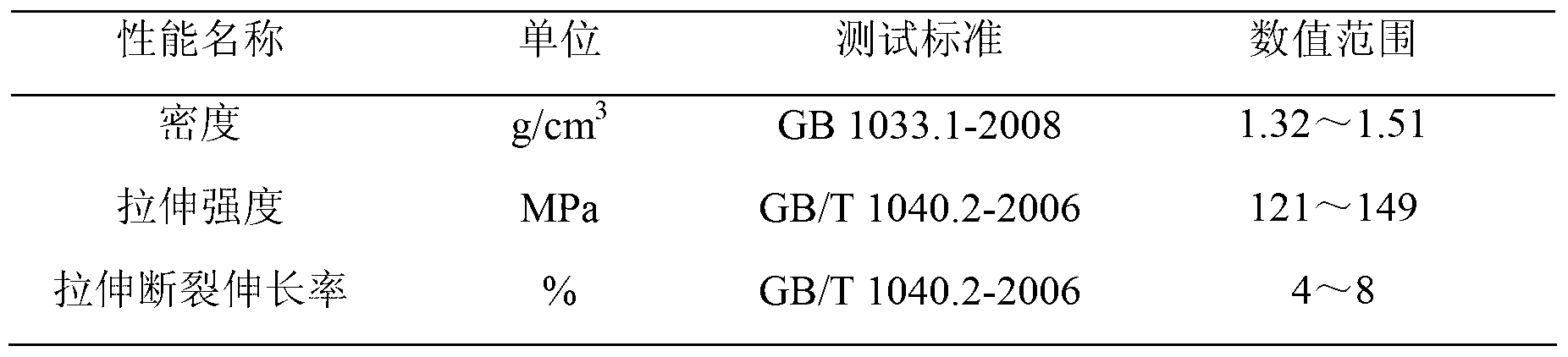

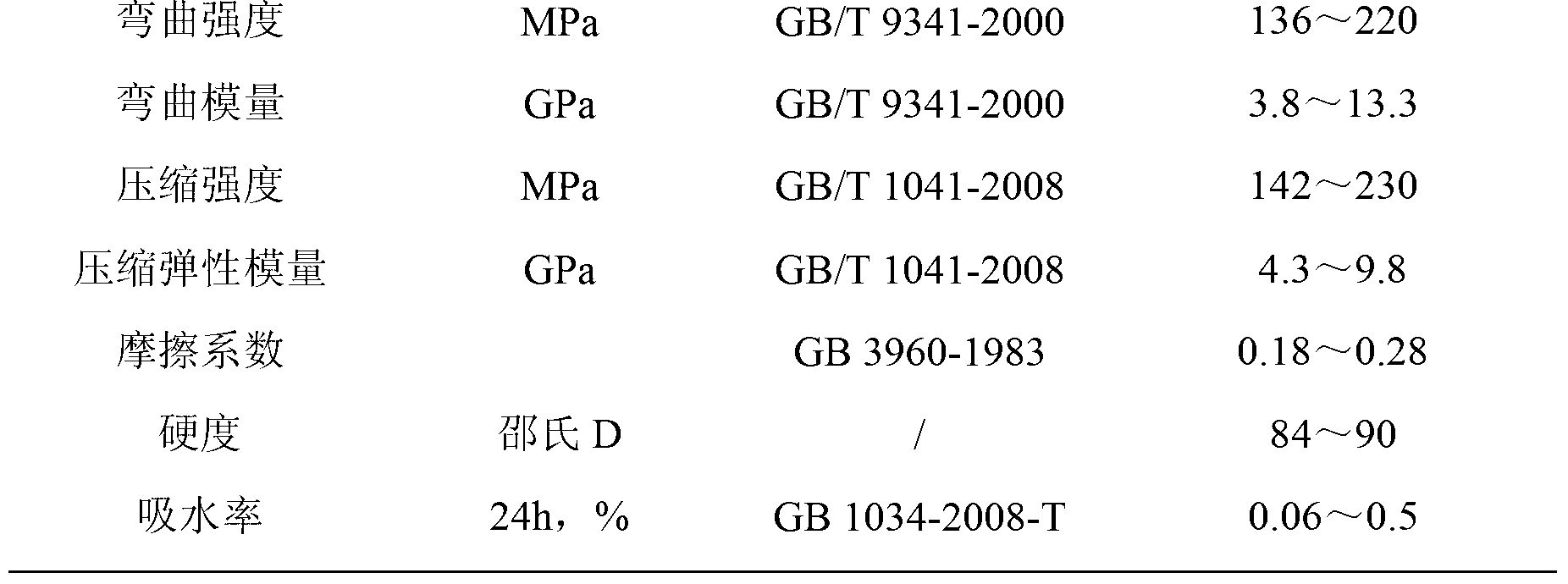

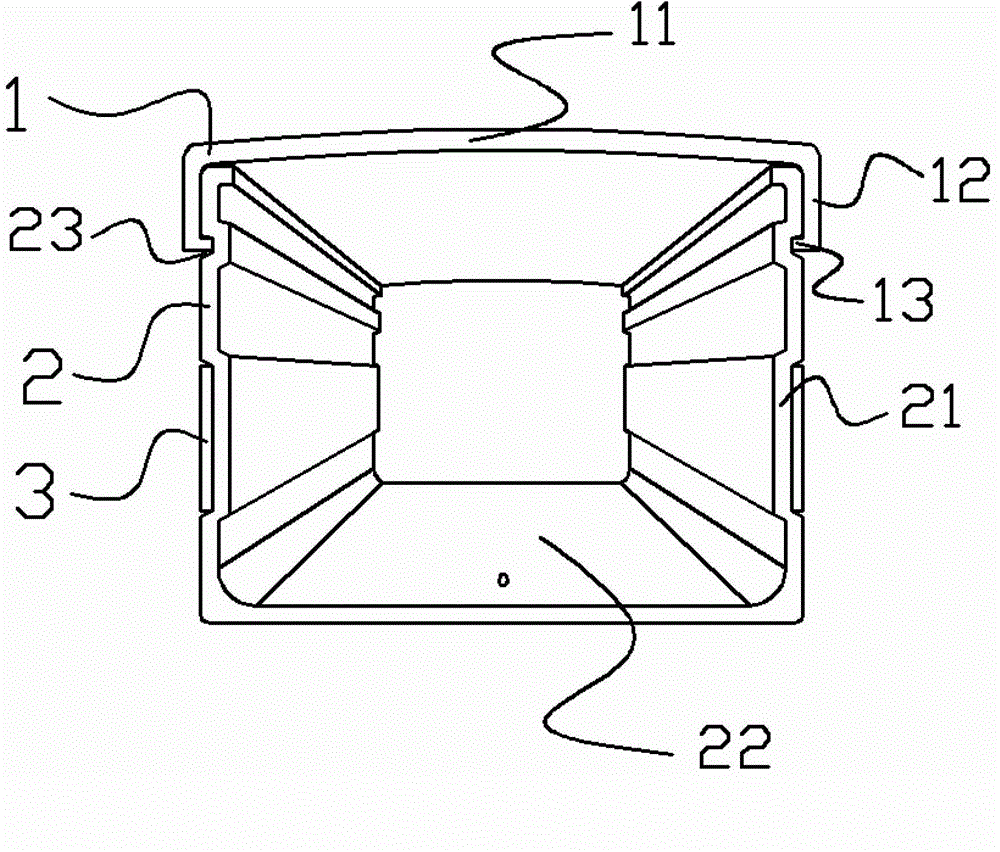

Wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material

The invention discloses a wear-resistant, high-strength and light-weight poly (ether-ether-ketone) composite material. The poly (ether-ether-ketone) composite material comprises the following raw materials in parts by weight: 71-83 parts by weight of poly (ether-ether-ketone) resin, 5-10 parts by weight of suspension polytetrafluoroethylene resin, 7-12 parts by weight of carbon fiber powder and 5-7 parts by weight of aluminum oxide powder, as well as a silane coupling agent with the adding quantity of 0.8-1.5% of the weight of the aluminum oxide powder. The poly (ether-ether-ketone) composite material disclosed by the invention has the performance characteristics of wear resistance, high strength, self-lubrication, light weight, corrosion resistance and the like, is used for replacing a hard alloy and a metal framework to assemble a novel sliding bearing, effectively reduces the cost and weight of a bearing product (the weight is reduced by 30%) under the situation of meeting the requirements for service life, and can obviously reduce the power consumption and noise of a pump and achieve the purposes of saving energy and reducing consumption.

Owner:HEFEI GENERAL MACHINERY RES INST

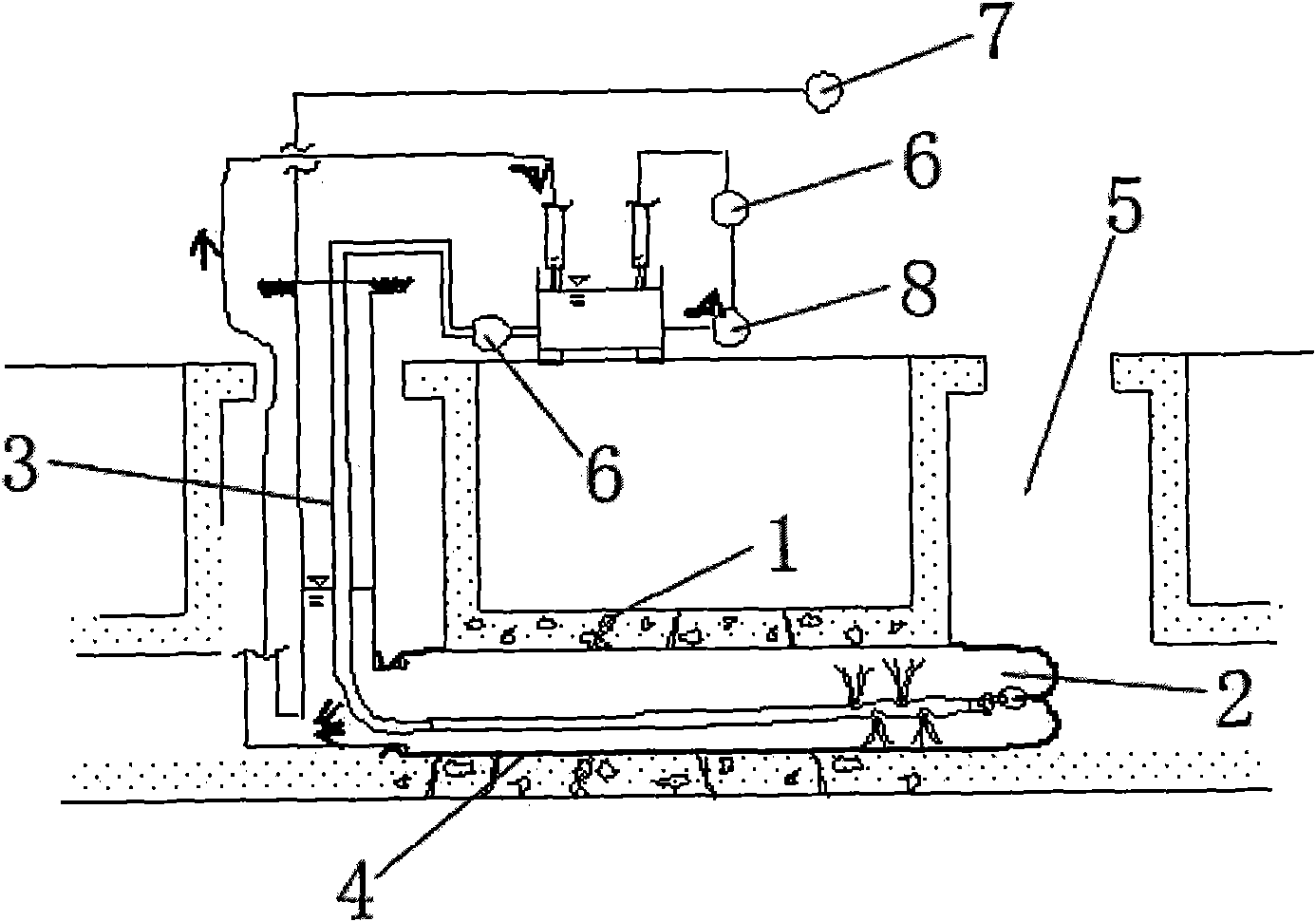

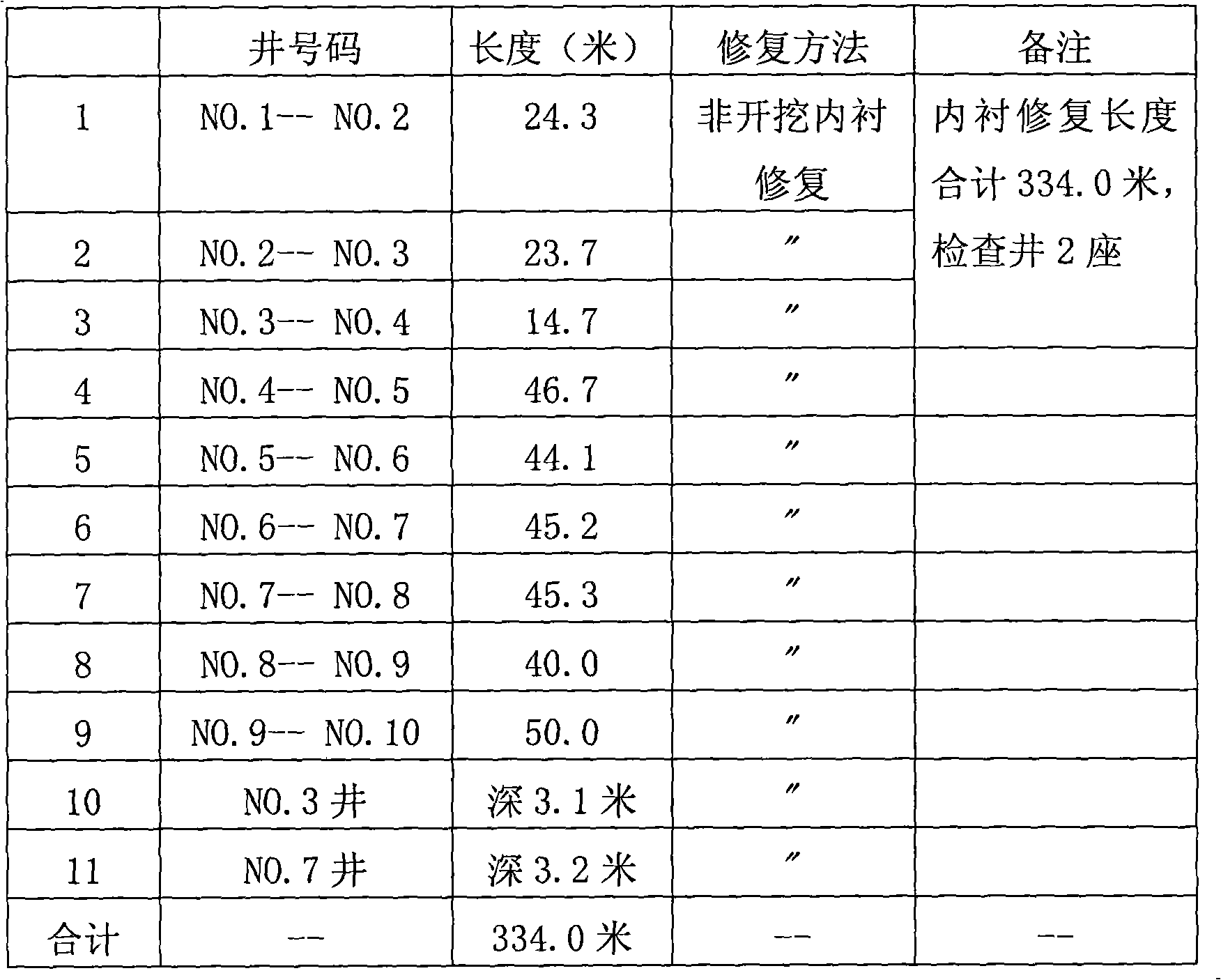

Method for repairing underground pipeline without digging

InactiveCN101649944AShort construction timeSolving Temporary Drainage ProblemsPipe elementsWarm waterSewage

The invention relates to a method for repairing an underground pipeline without digging, which comprises the following steps: (1) blocking and cleaning an old sewage pipeline needing repair and usingclosed circuit TV system (CCTV) equipment to detect the inner part of the pipeline; (2) delivering a waterproof barrel-shaped auxiliary lining hose pipe into the pipeline and injecting thermosetting resin to form a resin hose pipe; (3) turning over and inserting the resin hose pipe and a warm water delivery pipe for heating into the waterproof barrel-shaped auxiliary lining hose pipe; (4) expanding the resin hose pipe with water and compressed air so that the resin hose pipe is tightly attached to the inner wall of an old pipe, circularly heating by warm water and hardening and molding the thermosetting resin hose pipe so that the inner wall of the old pipe forms a new lining pipe with high strength; (5) opening pipe openings at both ends of the new lining pipe by cutting to smooth the pipeline; and (6) cutting at the extending positions of the pipe openings of the new lining pipe, which are positioned in the well wall of a check well. The method can prevent leakage, protect the pipe openings, prevent the thermosetting resin injected into the lining hose pipe from being mixed with underground water and prevent a poor phenomenon of lining material part hardening.

Owner:管丽环境技术(上海)有限公司 +1

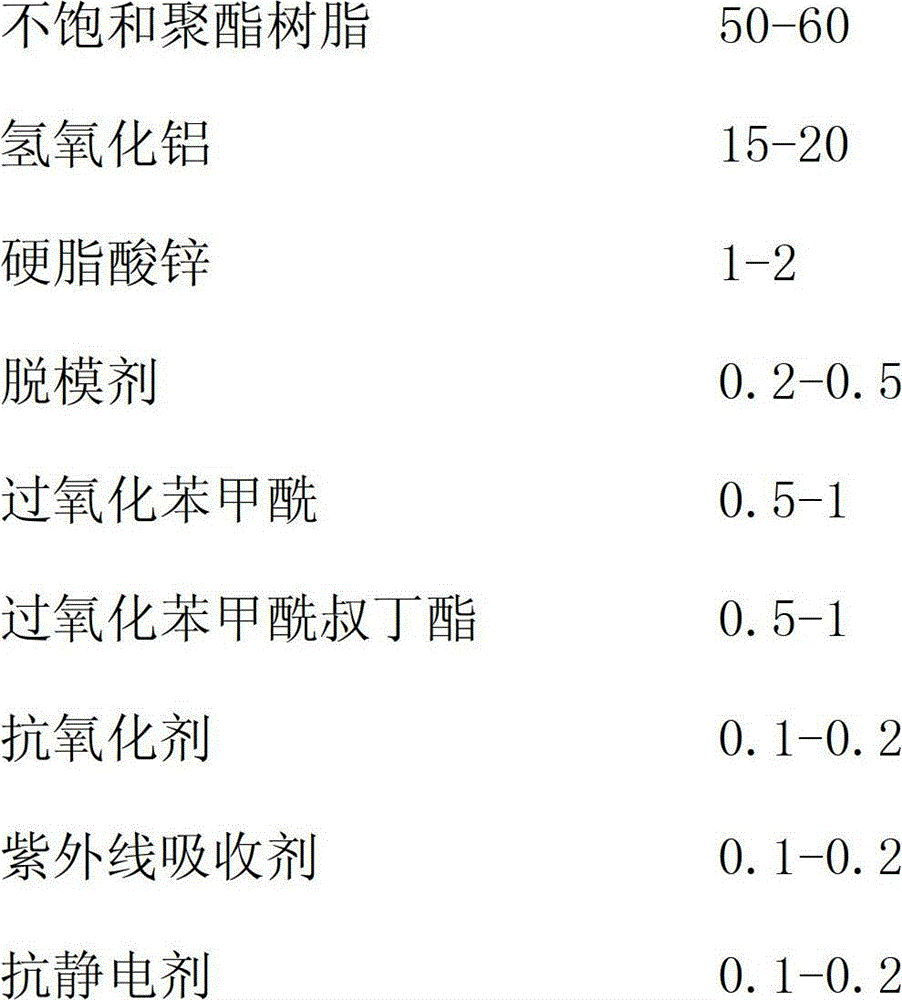

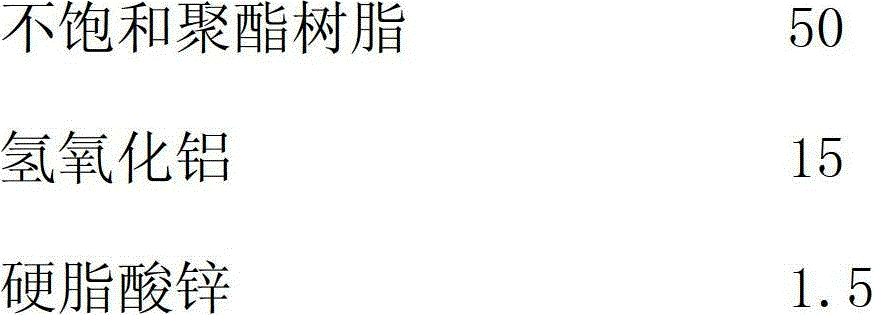

Glass fiber reinforced plastic curing agent composition and glass fiber reinforced plastic composite material prepared by same as well as cable trough

ActiveCN102977574AGood anti-aging performanceHigh strengthElectrical apparatusGlass fiberBenzoyl peroxide

The invention discloses a glass fiber reinforced plastic curing agent composition and a glass fiber reinforced plastic composite material prepared by the same as well as a cable trough. The glass fiber reinforced plastic curing agent composition is formed by the following components in parts by weight: 50-60 parts of unsaturated polyester resin, 15-20 parts of aluminum hydroxide, 1-2 parts of zinc stearate, 0.2-0.5 part of de-molding agent, 0.5-1 part of benzoyl peroxide, 0.5-1 part of benzoyl peroxide tert-butyl ester, 0.1-0.2 part of antioxidant, 0.1-0.2 part of ultraviolet absorbent, and 0.1-0.2 part of antistatic agent. A glass fiber reinforced plastic material is prepared by an extruding and molding process. The glass fiber reinforced plastic material prepared by the curing agent composition disclosed by the invention is low in production cost, has light weight and high strength, and has good weather resistance even under an extreme hygrothermal environment.

Owner:ELECTRICITY AFFAIR ENG COMPANY OF CHINA RAILWAY NO 8 ENG GRP

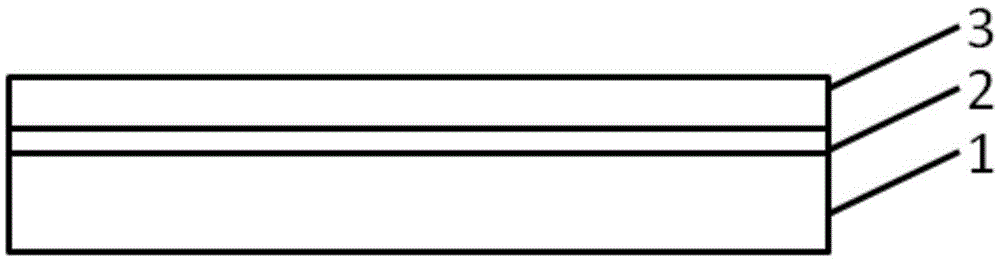

Graphene-doping conductive polymer modified metal bipolar plate of proton exchange membrane fuel cell and preparation method of metal bipolar plate

ActiveCN105552399ADoes not affect other performanceLow corrosion current densityFinal product manufactureCollectors/separatorsConductive polymerPre treatment

The invention relates to a graphene-doping conductive polymer modified metal bipolar plate of a proton exchange membrane fuel cell and a preparation method of the metal bipolar plate, belonging to the technical field of a fuel cell. The bipolar plate comprises a metal plate, a polarity oxide film layer and a graphene-doping conductive polymer film layer, wherein the polarity oxide film layer covers the surface of the metal plate, the graphene-doping conductive polymer film layer covers the surface of the polarity oxide film layer, and the thickness of the graphene-doping conductive polymer film layer is 0.005-0.3 millimeter, the thickness of the polarity oxide film layer is 5-30 nanometers, and the thickness of the metal plate is 0.1-2 millimeters. A graphene-doping conductive polymer film is deposited on the surface of a stainless steel plate after preprocessing by an electrochemical synthesis method, the metal bipolar plate prepared according to the invention has the advantages of relatively low contact resistance, low corrosion current density and high bonding firmness of the metal substrate and the conductive polymer film, moreover, the method is simple, the processing cost is low, and mass production can be achieved.

Owner:HUBEI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com